Compound liquid fertilizer with high suspension degree, and preparation method and application thereof

A composite liquid, high suspension technology, applied in the application, fertilizer mixture, fertilization device and other directions, can solve the problems of low nutrient content of suspended fertilizer, poor stability and suspension, easy precipitation, etc., to enhance the lasting suspension and stability, Good fluidity and stability, excellent effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]1) Fully pulverize macronutrient and micronutrient fertilizers and pass through a 20-mesh sieve to obtain fertilizers with a particle size of 0.85mm;

[0039] 2) Pour 353 parts of urea, 472 parts of ammonium nitrate and 175 parts of water into the mixer, control the temperature at 45°C, and keep stirring for 35 minutes to obtain a 32% nitrogen solution;

[0040] 3) Dissolve 11 parts of sodium alginate, 1 part of syrup, 5 parts of xanthan gum, 1 part of diatomaceous earth, 2 parts of sepiolite and 240 parts of tap water at 50°C and fully stir to obtain suspension I;

[0041] 4) In step 3), add 800 parts of the nitrogen solution prepared in step 2), 120 parts of potassium dihydrogen phosphate, 100 parts of potassium nitrate, 10 parts of boric acid and 10 parts of EDTA-Zn, and fully dissolve to obtain a suspended I-composite Fat;

[0042] 5) Adjust the temperature of the suspended I-compound fertilizer in step 4) to 20°C, add 0.5 parts of sodium naphthalene acetate, 0.5 pa...

Embodiment 2

[0044] 1) Same as step 1) in Example 1;

[0045] 2) Same as step 2) in Example 1;

[0046] 3) Fully stir and dissolve 4 parts of sodium alginate, 7 parts of syrup, 1 part of chitosan, 1 part of diatomaceous earth, 1 part of attapulgite and 241 parts of tap water at 60°C to obtain suspension I;

[0047] 4) In step 3), add 880 parts of the nitrogen solution prepared in step 2), 120 parts of potassium dihydrogen phosphate, 132 parts of potassium chloride, 100 parts of ammonium dihydrogen phosphate, and 20 parts of boric acid, fully dissolve, and obtain suspension I - compound fertilizer;

[0048] 5) Adjust the temperature of the suspended I-compound fertilizer in step 4) to 30°C, add 0.5 parts of sodium naphthalene acetate, 0.5 parts of DA-6, 0.5 parts of gibberellin, 1 part of Span, 1 part of methanol, and 2 parts of coconut Oleamide Betaine. Mix well, add 3 parts of carboxymethylcellulose and 4 parts of sodium hydroxyethyl cellulose, keep stirring, and bottle it after 90 min...

Embodiment 3

[0050] 1) Same as step 1) in Example 1;

[0051] 2) Same as step 2) in Example 1;

[0052] 3) Fully stir and dissolve 6 parts of syrup, 2 parts of chitosan, 1 part of sodium bentonite and 251 parts of tap water at 55°C to obtain suspension I;

[0053] 4) In step 3), add 460 parts of the nitrogen solution prepared in step 2), 140 parts of potassium dihydrogen phosphate, 201 parts of potassium nitrate, 160 parts of ammonium dihydrogen phosphate, and 20 parts of EDTA-Zn, fully dissolve and obtain a suspension I - compound fertilizer;

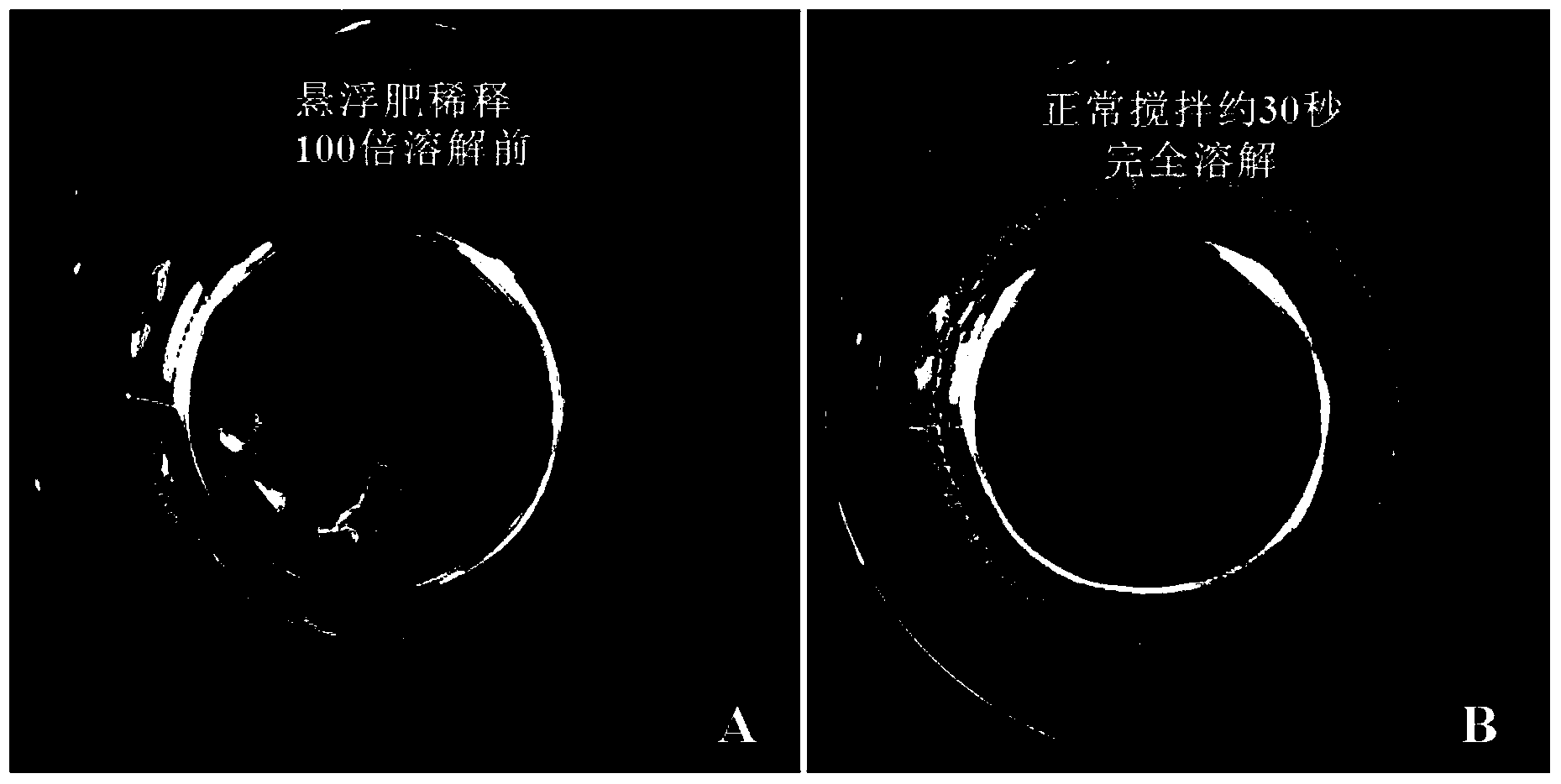

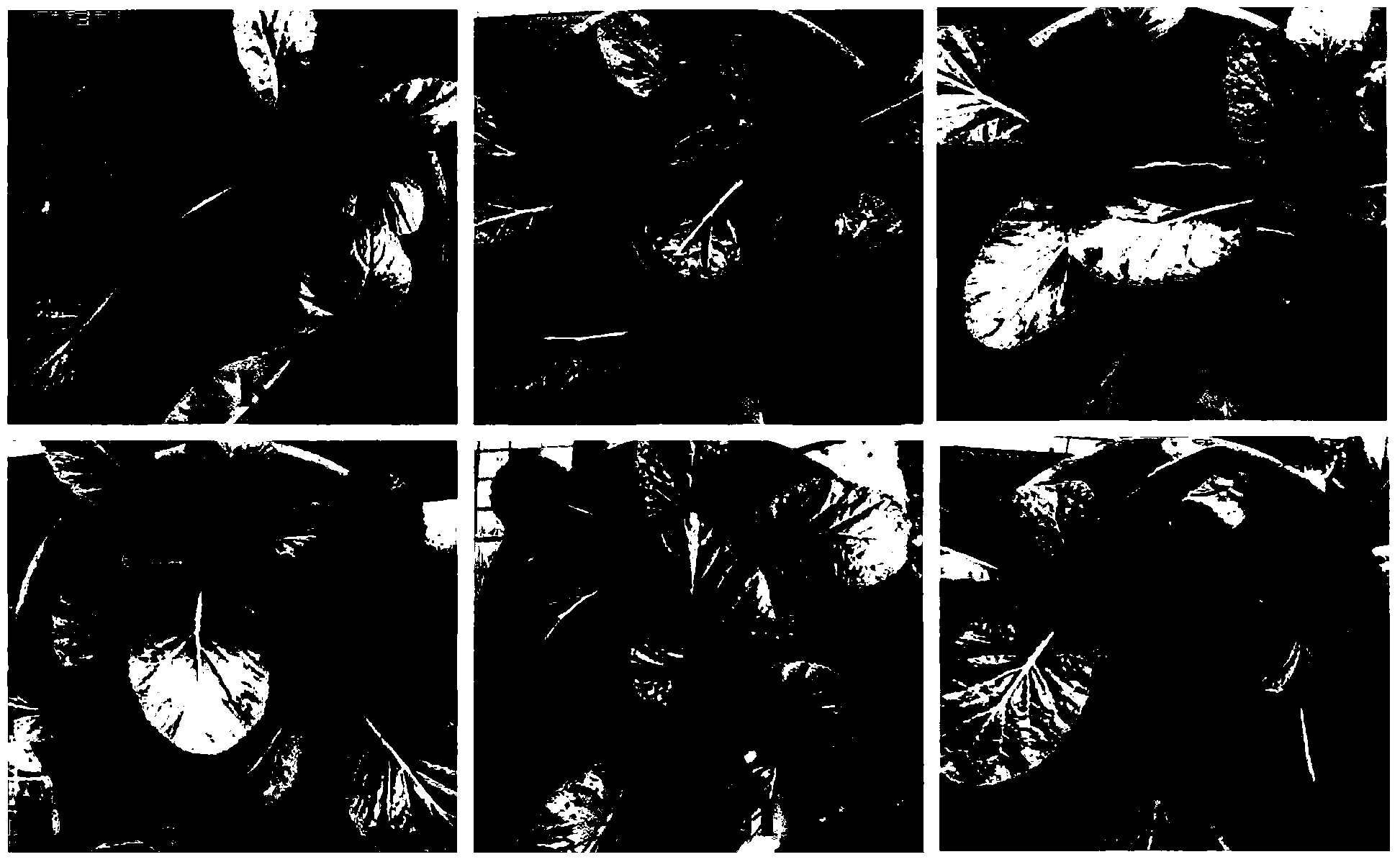

[0054] 5) Adjust the temperature of the suspended I-compound fertilizer in step 4) to 28°C, add 0.5 parts of DA-6, 0.5 parts of brassinolide, 0.5 parts of triacontanol, 2 parts of glycerin, 1 part of ethanol, 1 Parts of alkylphenol polyoxyethylene ether. Fully stir and mix, add 10 parts of hydroxypropyl methylcellulose, keep stirring, after 60 minutes, bottle it, and obtain the high-suspension compound liquid fertilizer III (such as figure 1 A-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com