Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2700results about "Insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

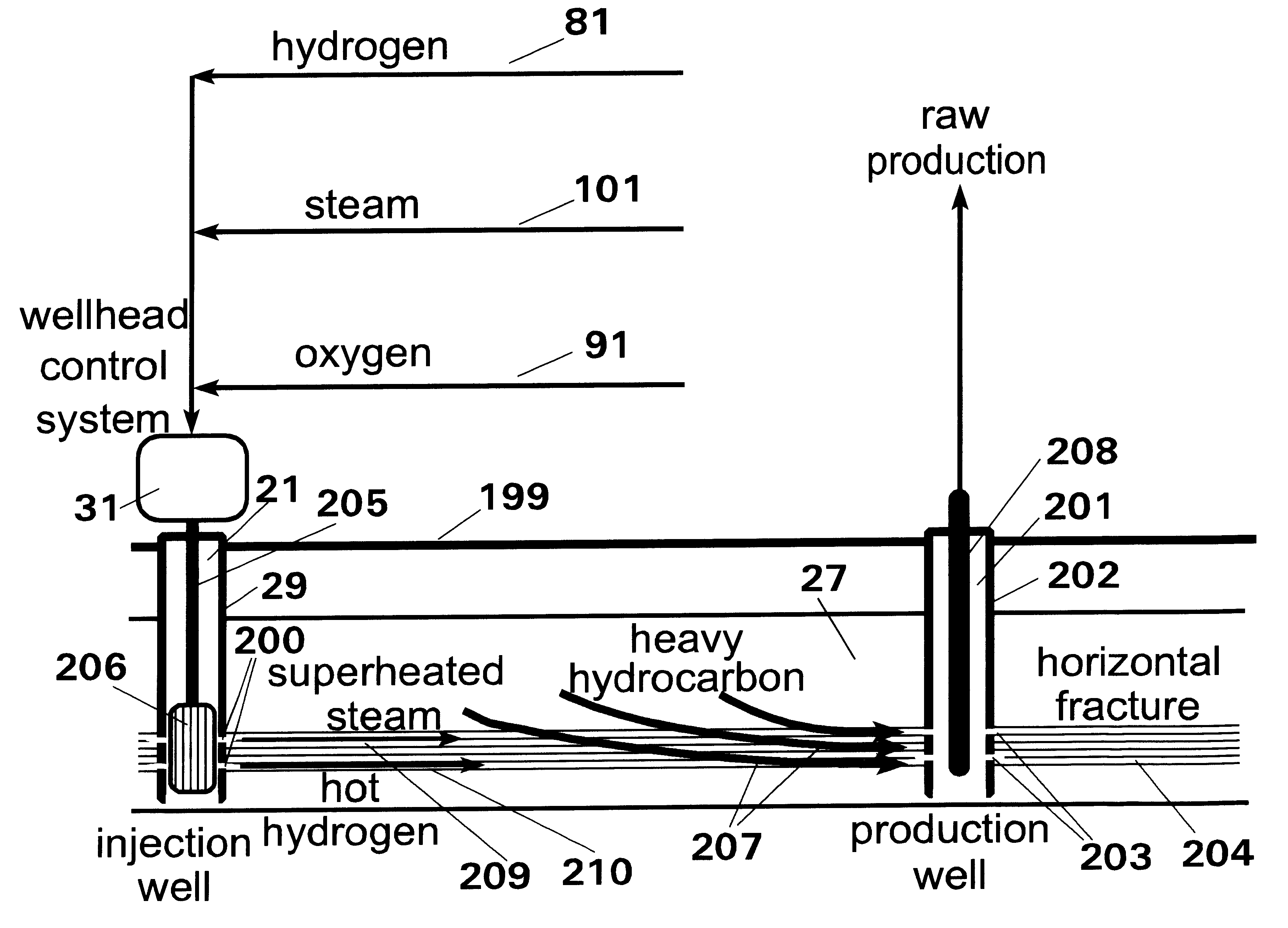

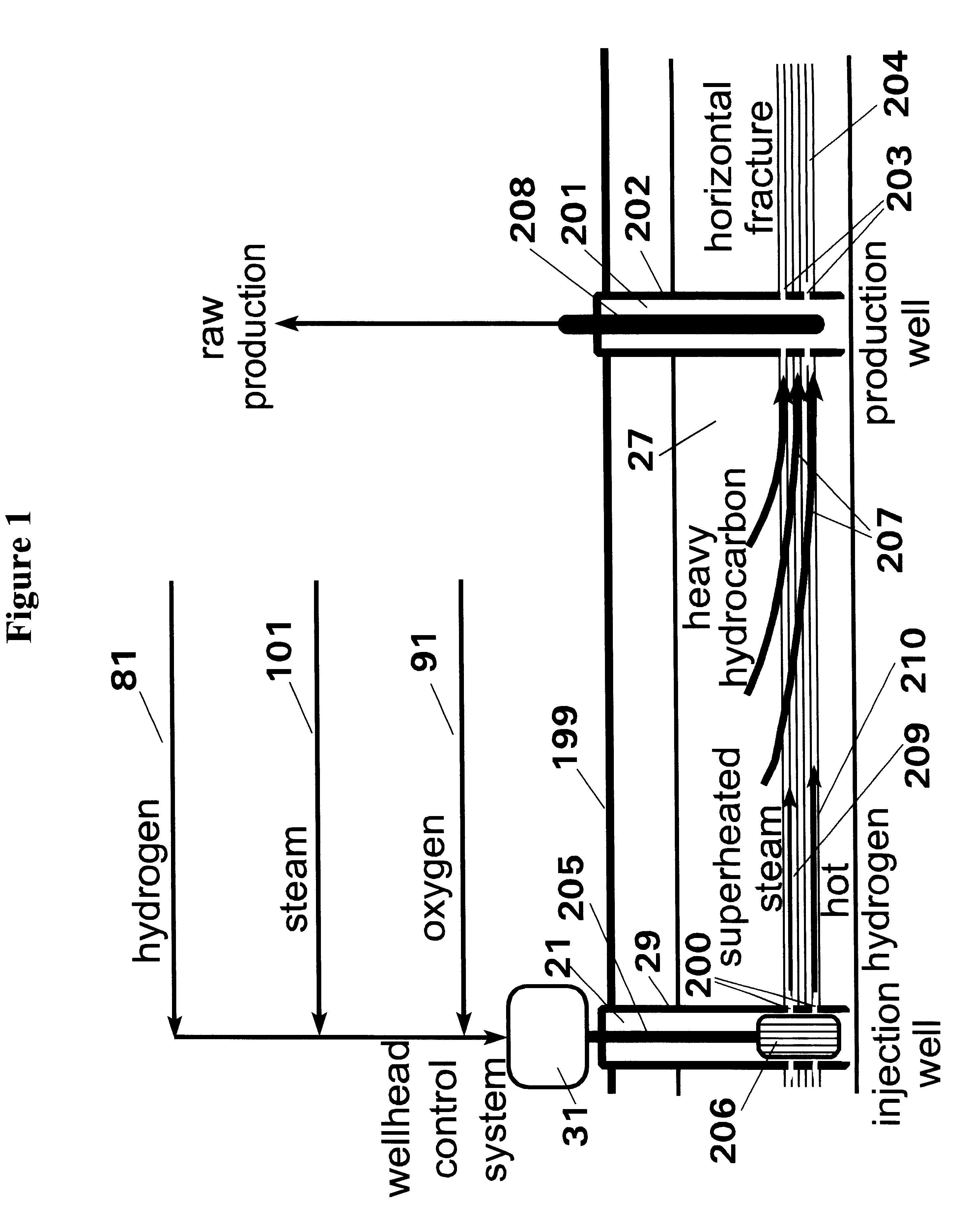

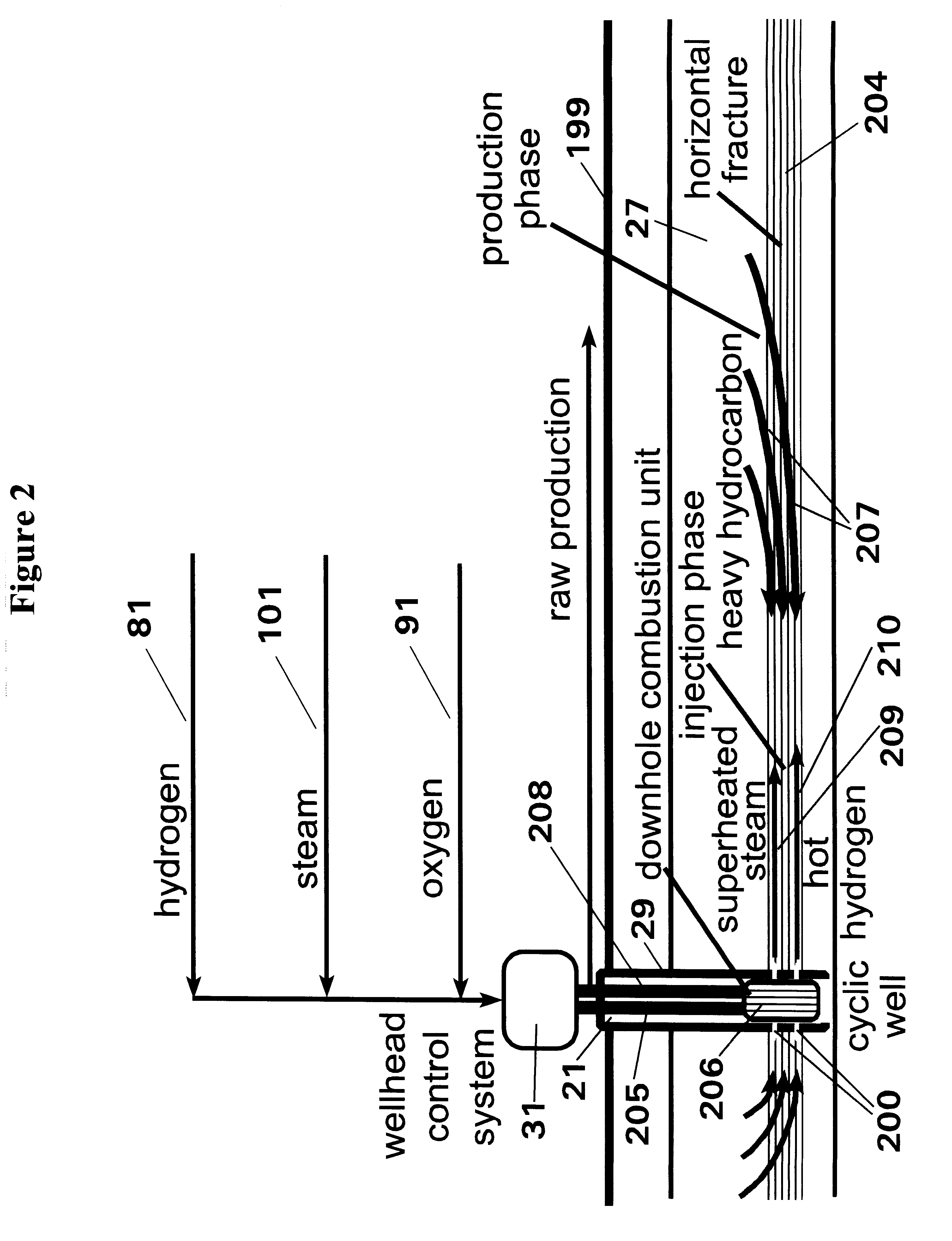

Inventor

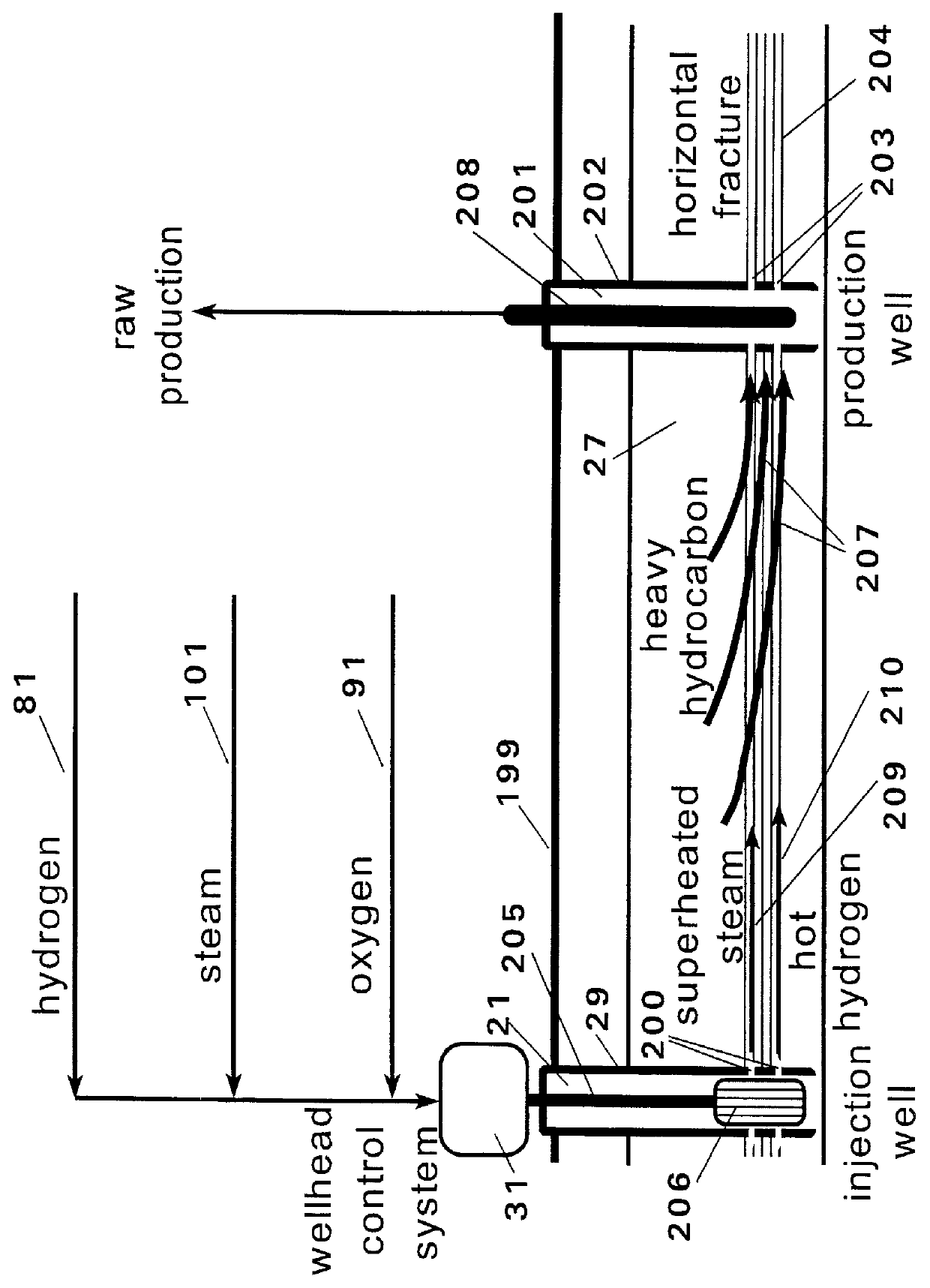

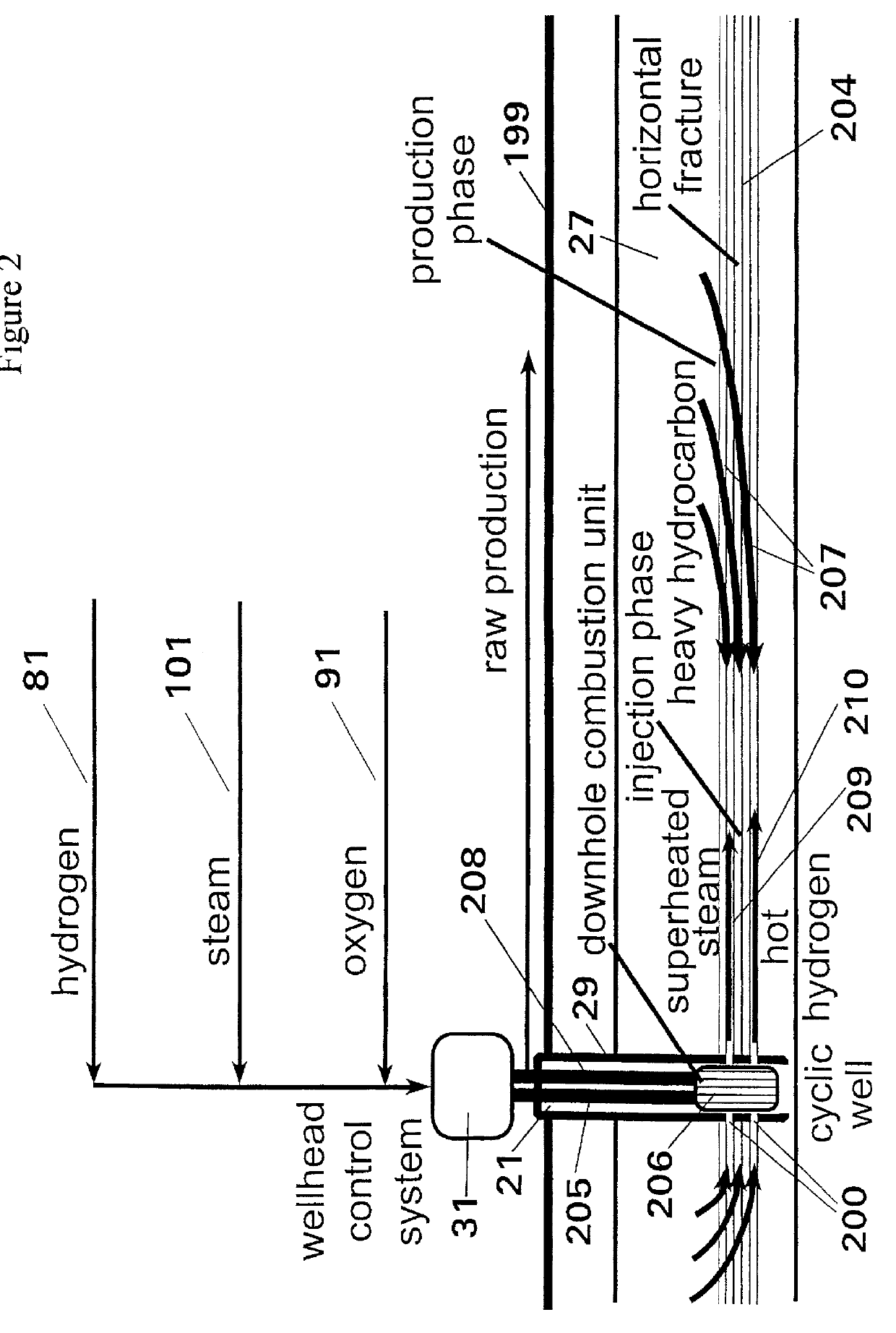

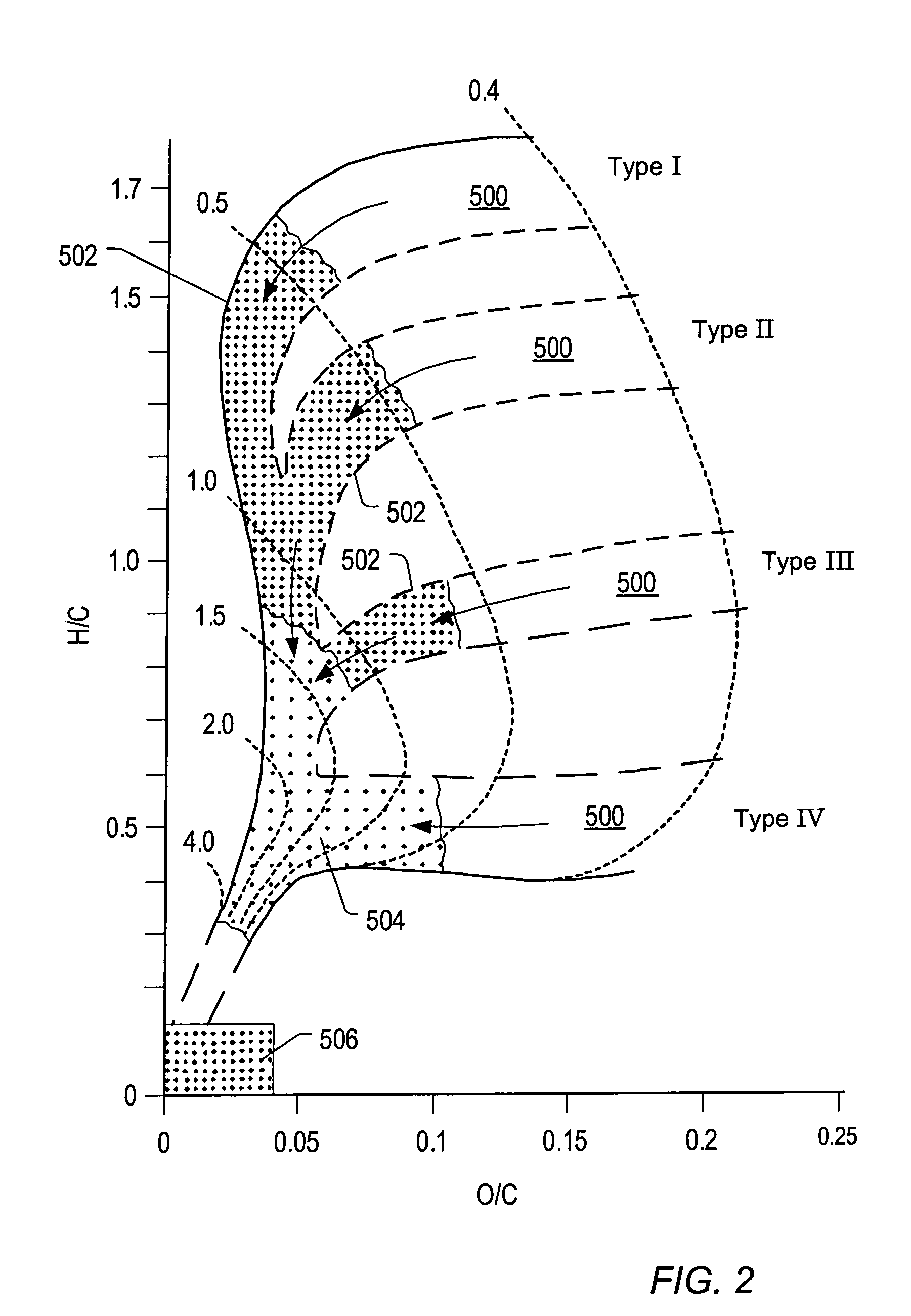

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

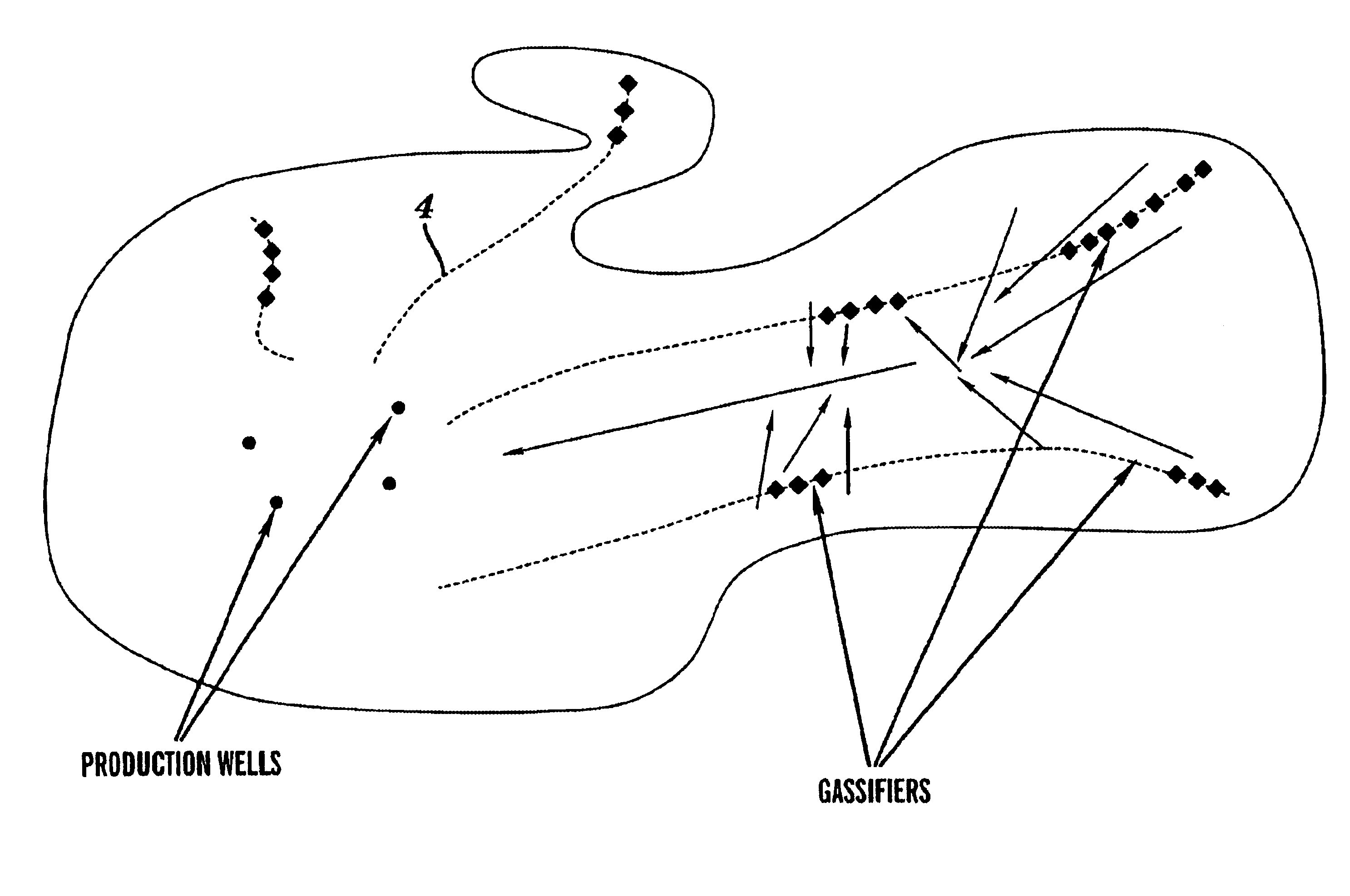

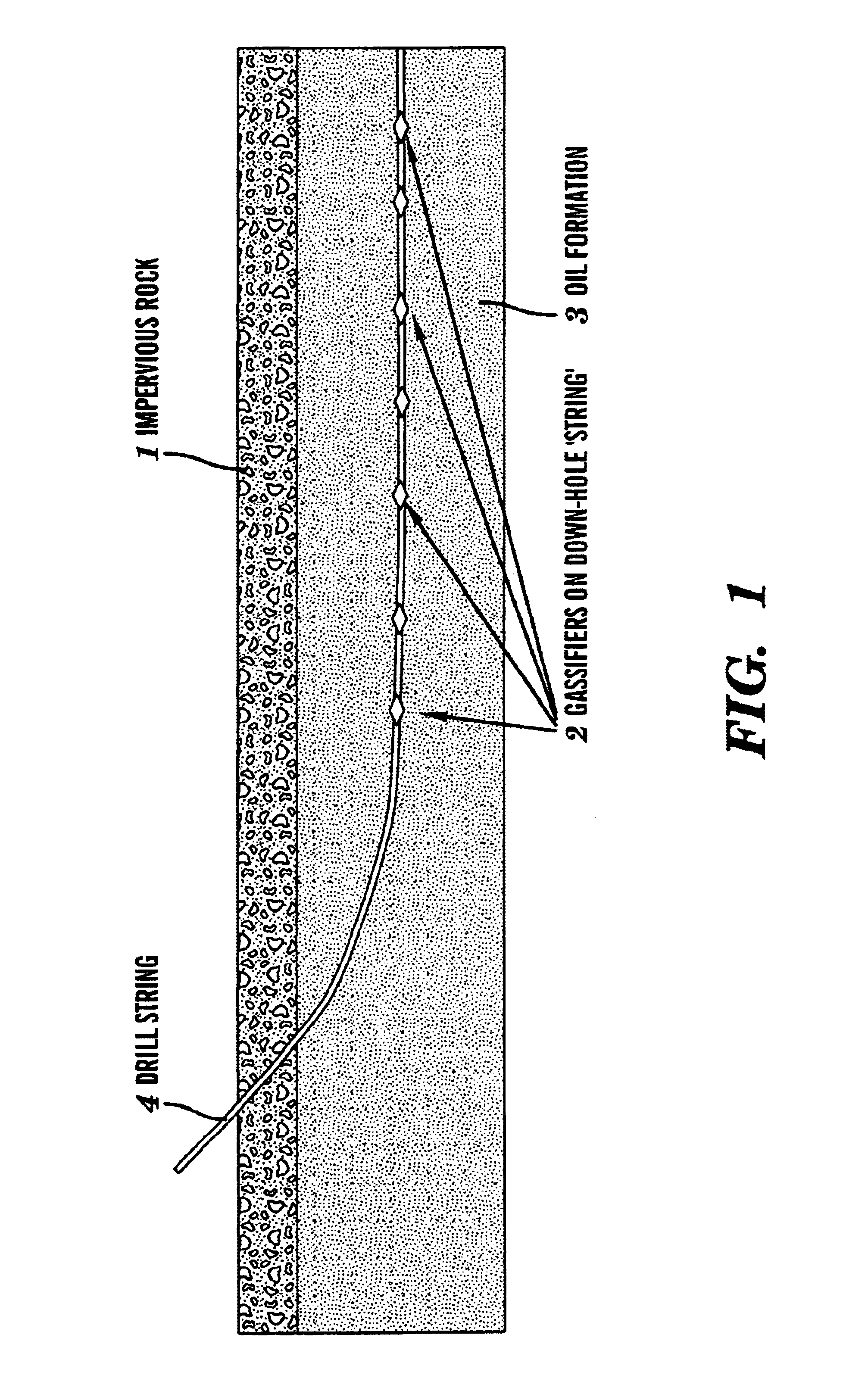

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more injection and production boreholes, which may include horizontal boreholes, or a cyclic operation whereby both injection and production occur in the same boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing or related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

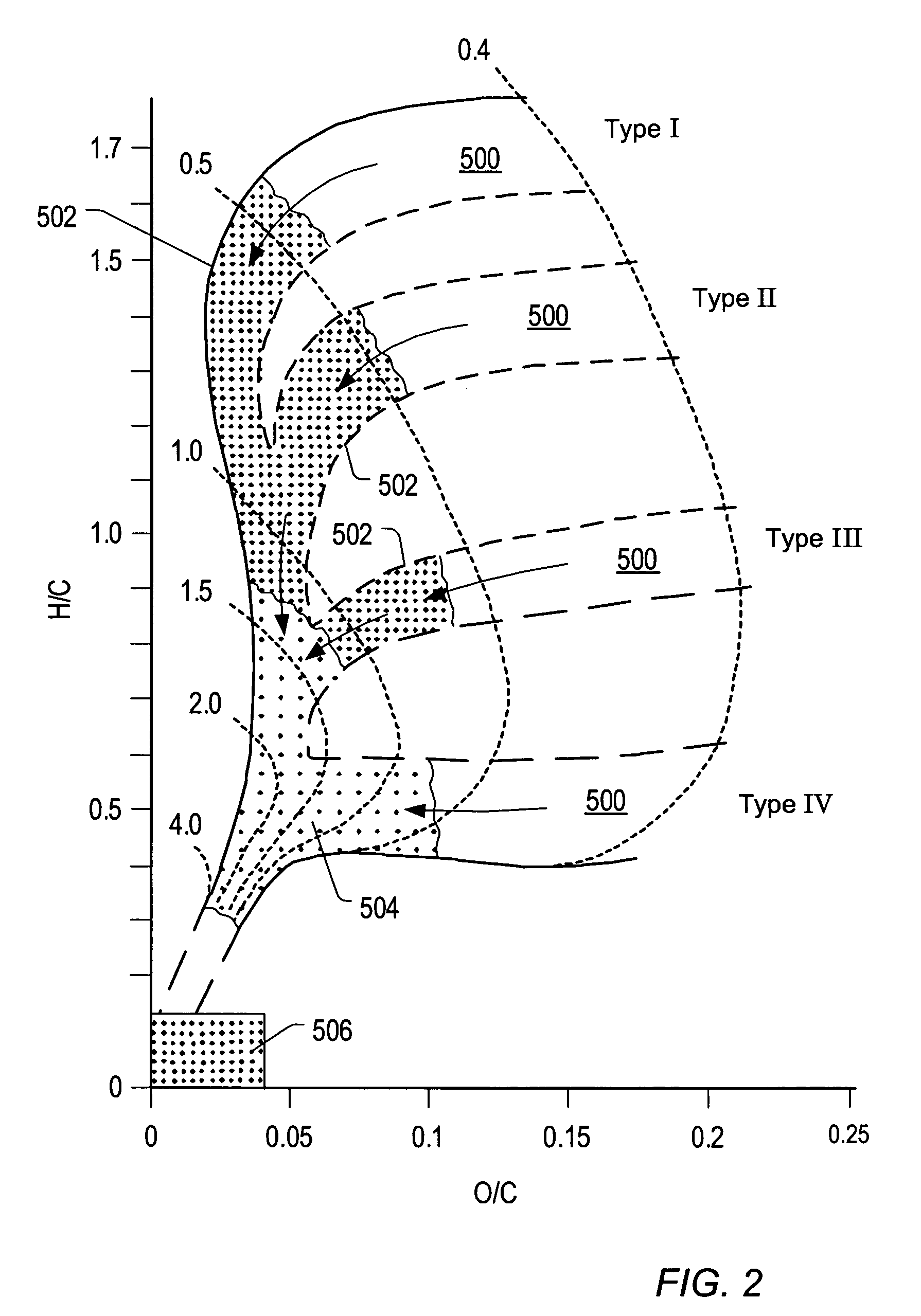

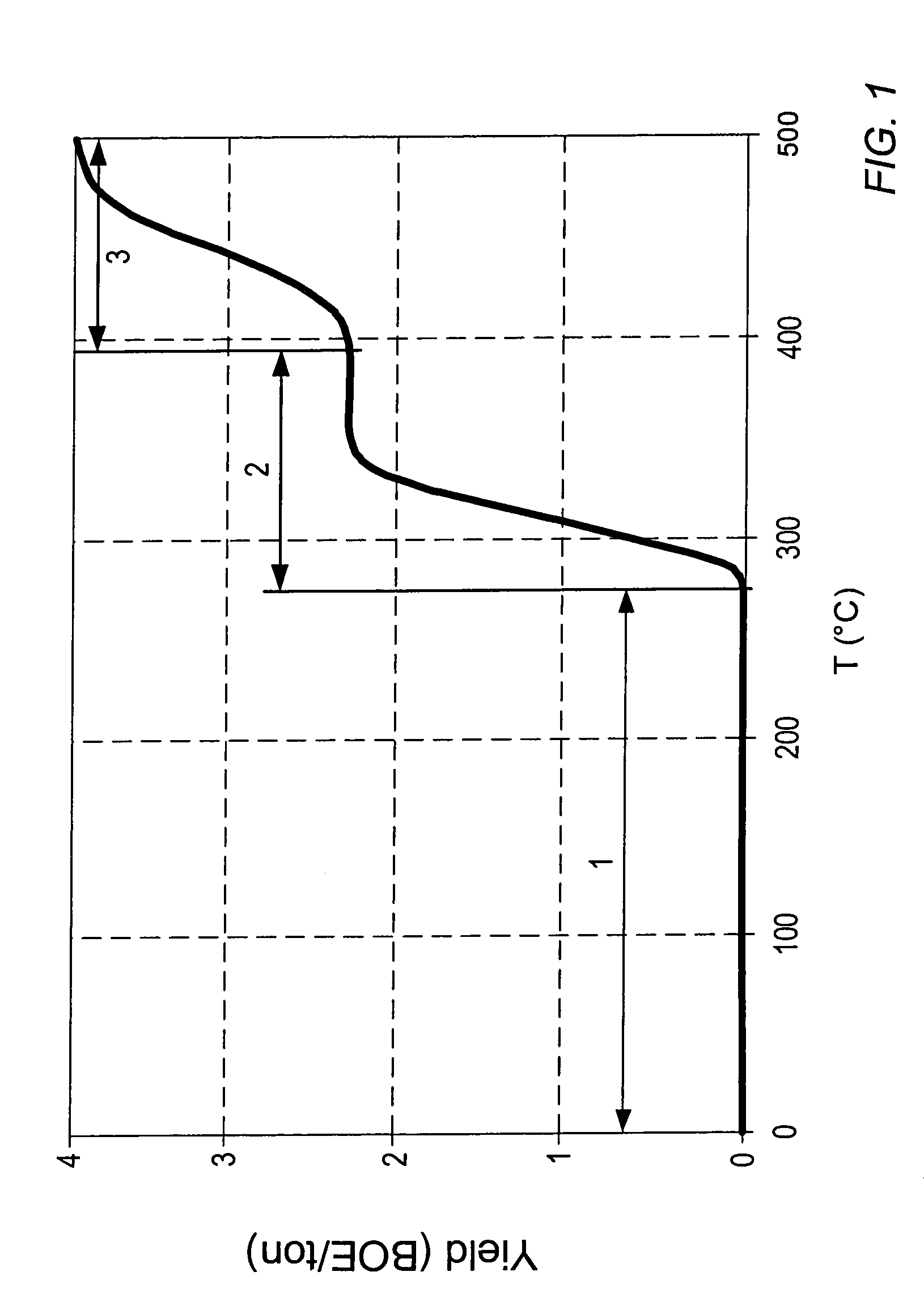

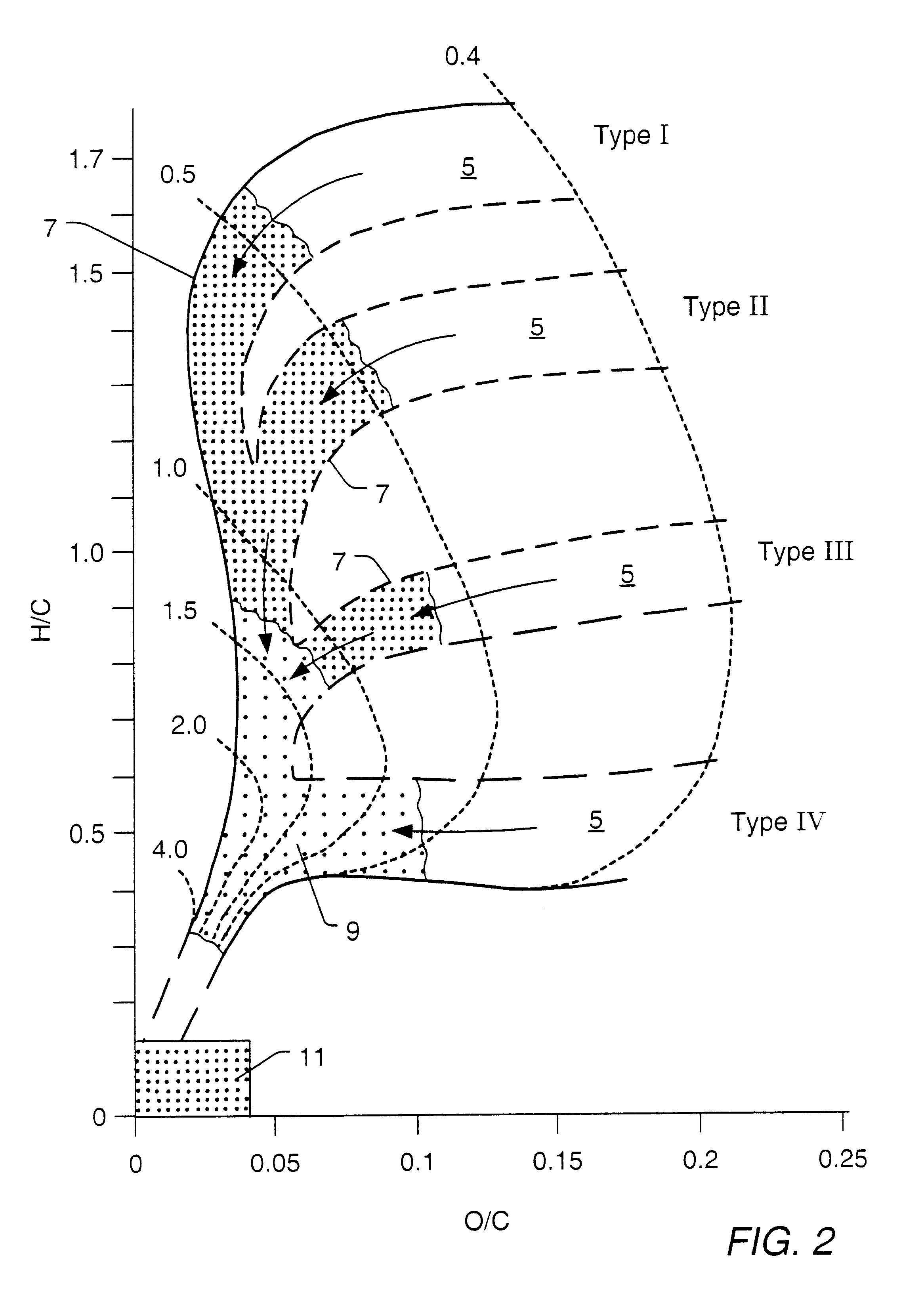

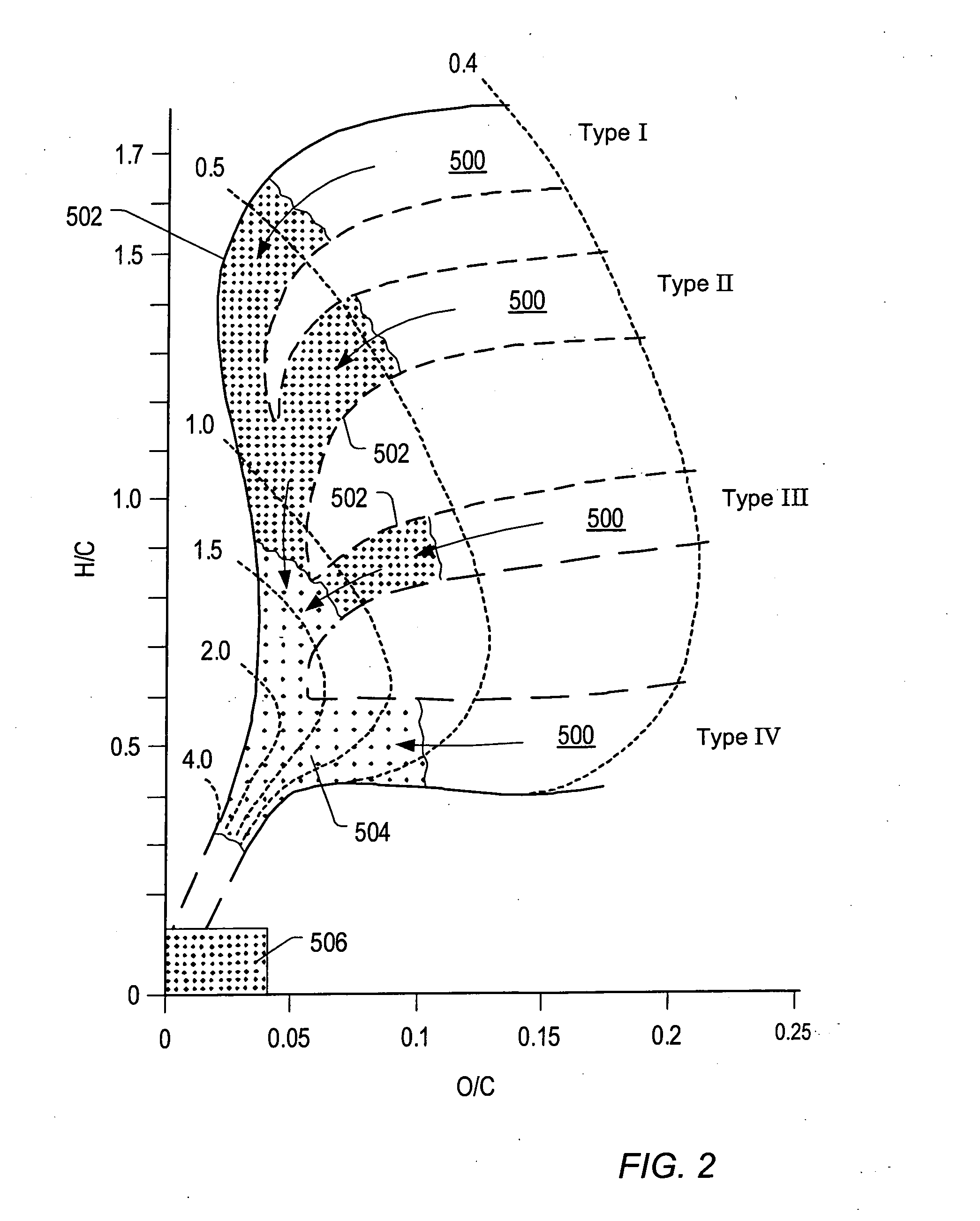

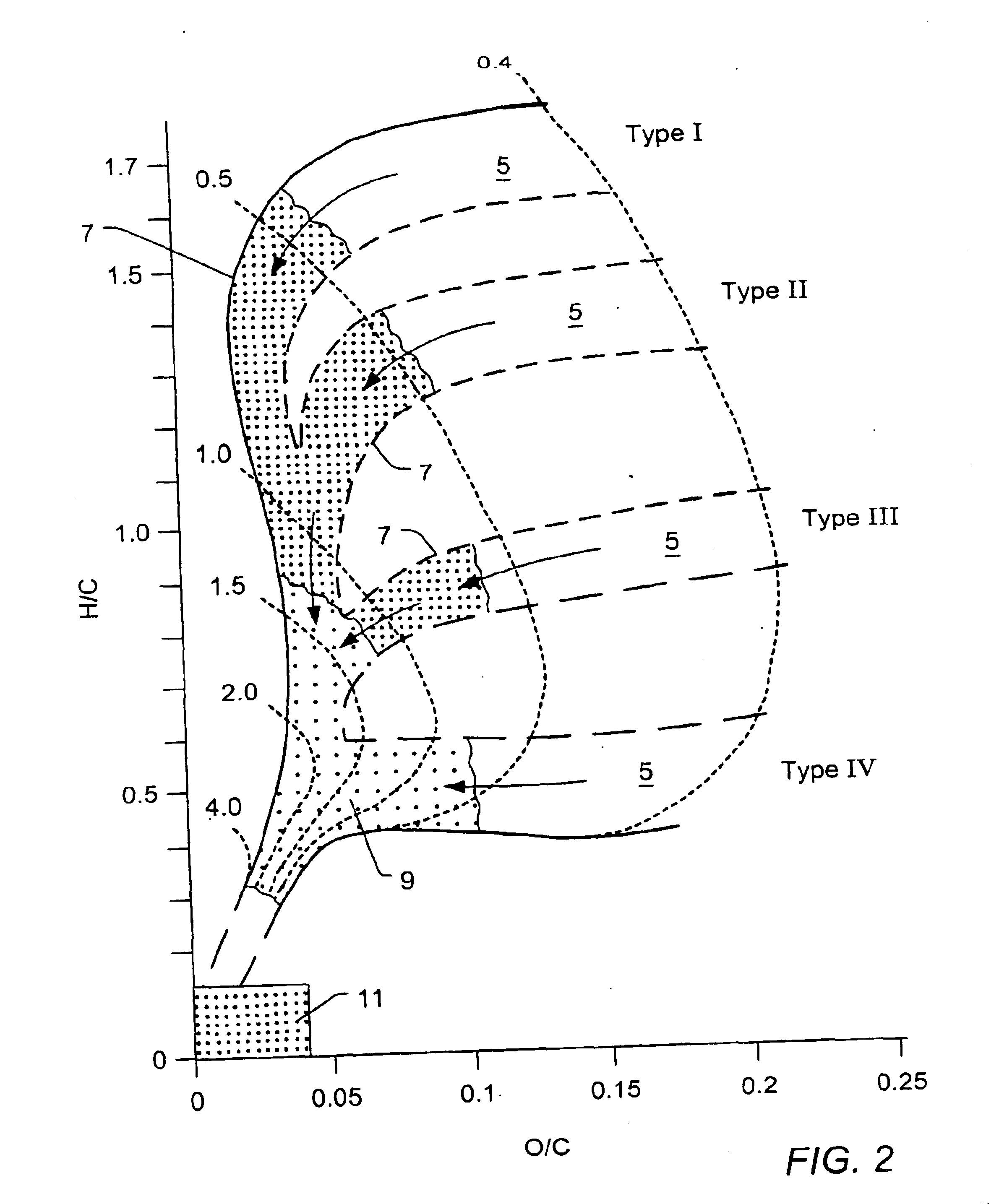

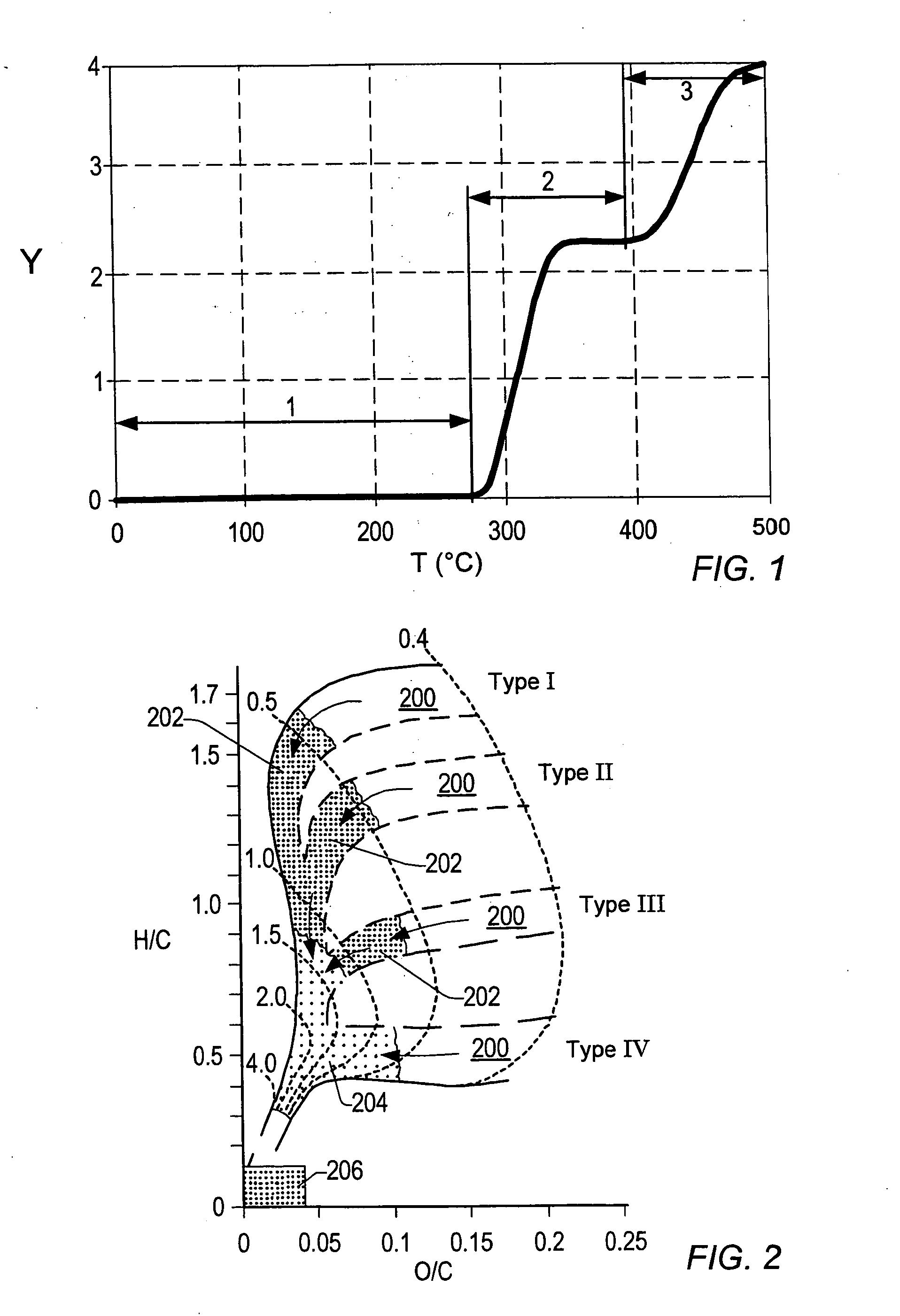

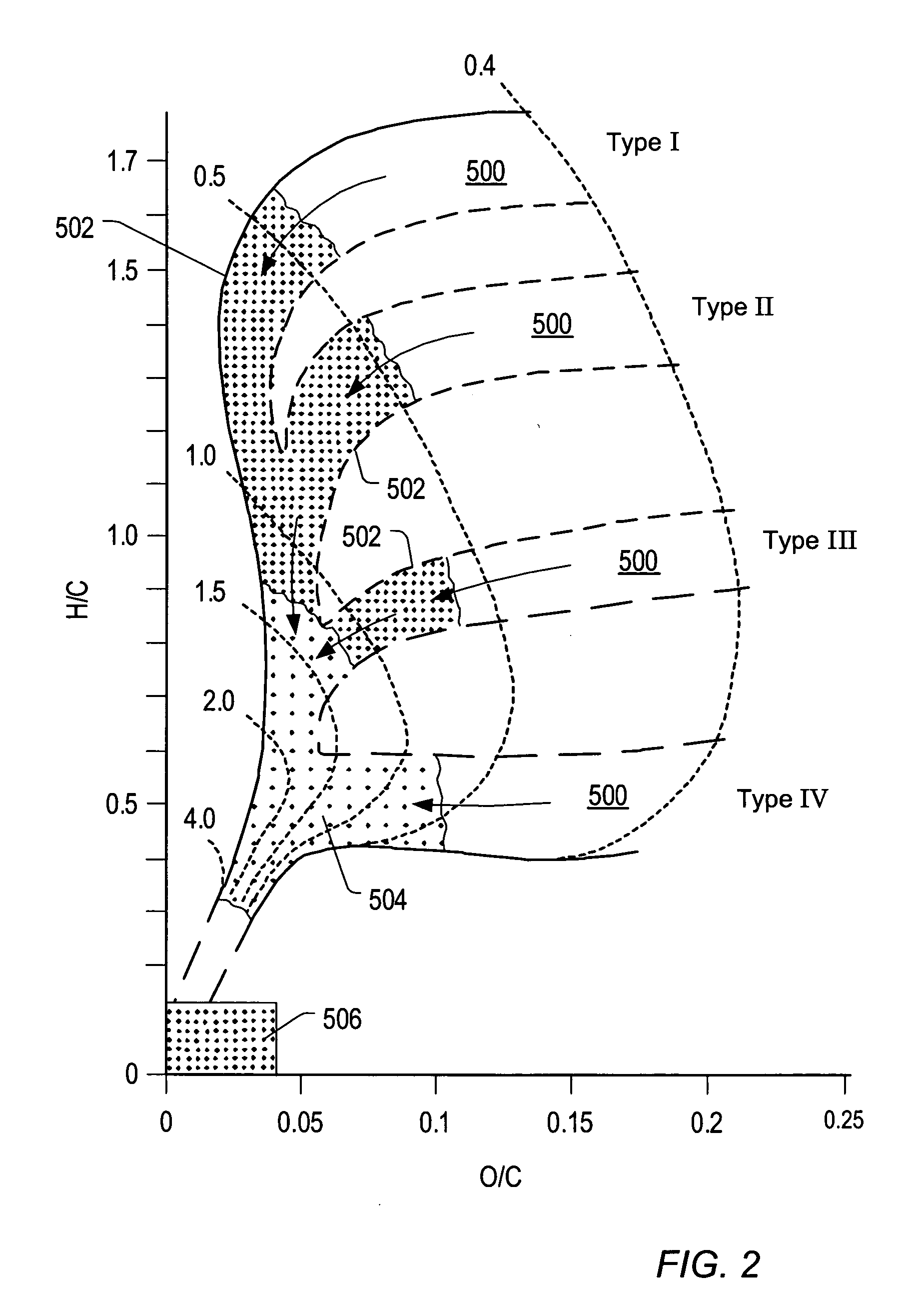

Thermal processes for subsurface formations

A process may include providing heat from one or more heaters to at least a portion of a subsurface formation. Heat may transfer from one or more heaters to a part of a formation. In some embodiments, heat from the one or more heat sources may pyrolyze at least some hydrocarbons in a part of a subsurface formation. Hydrocarbons and / or other products may be produced from a subsurface formation. Certain embodiments describe apparatus, methods, and / or processes used in treating a subsurface or hydrocarbon containing formation.

Owner:SHELL OIL CO

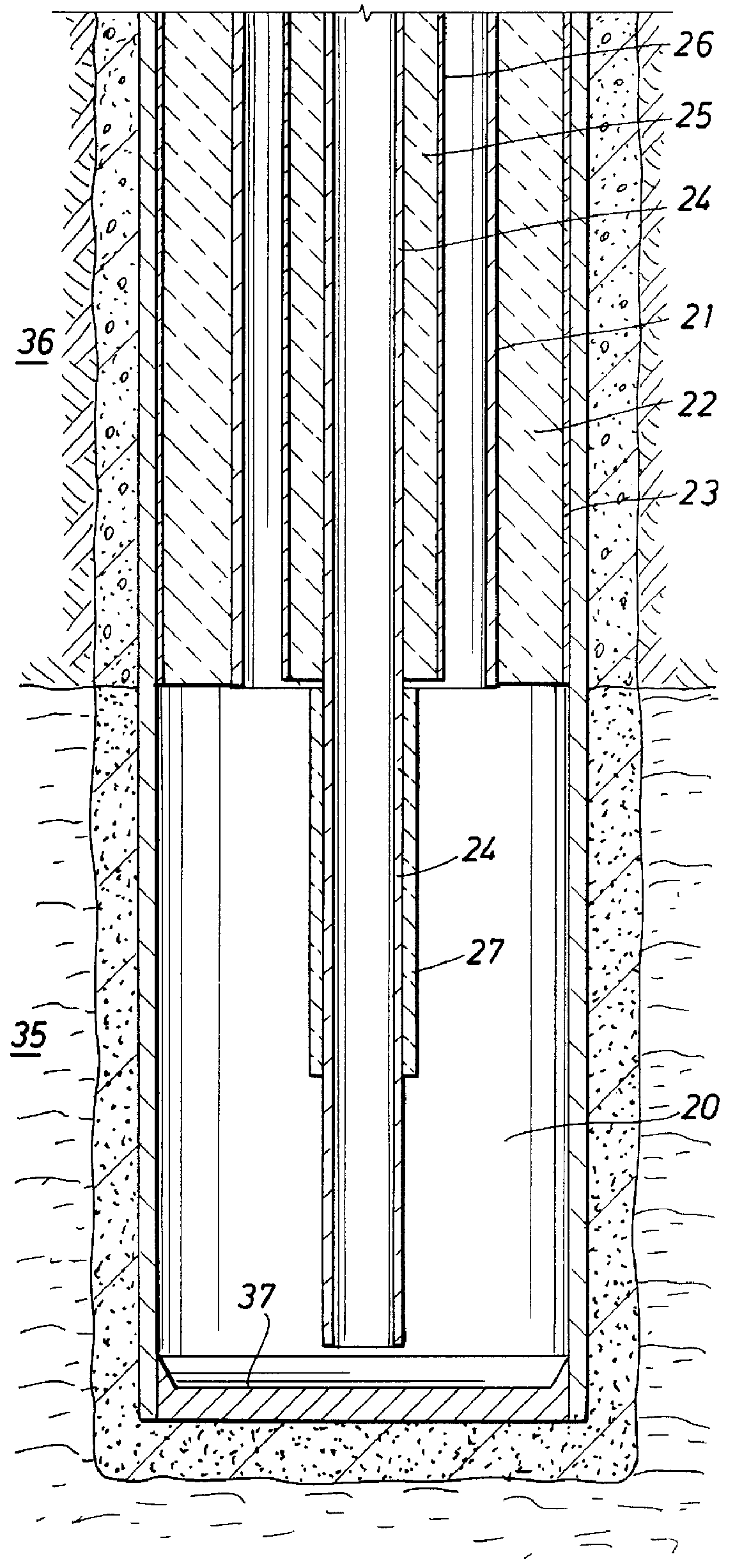

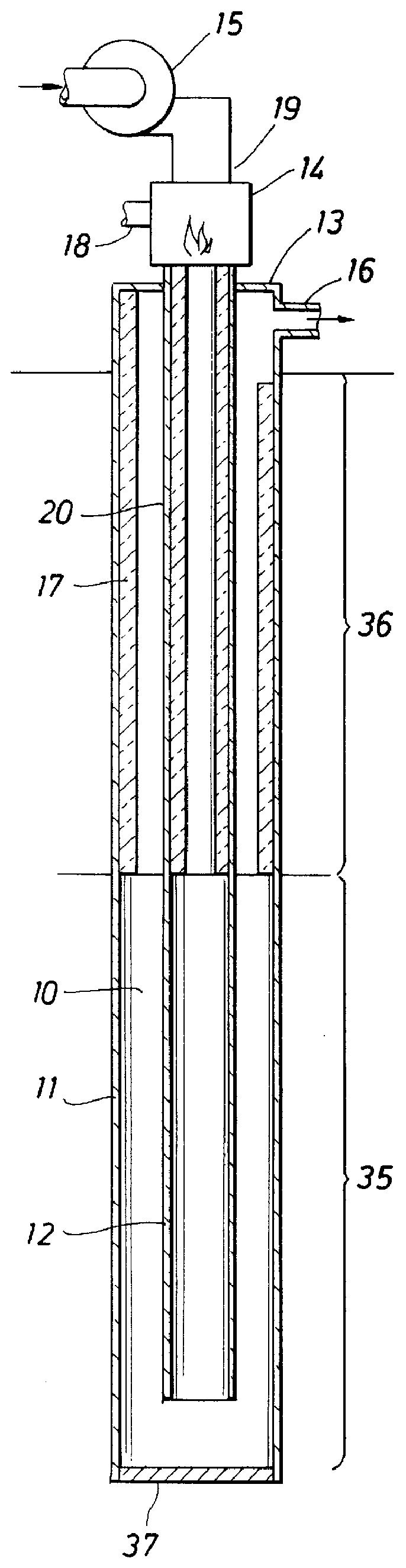

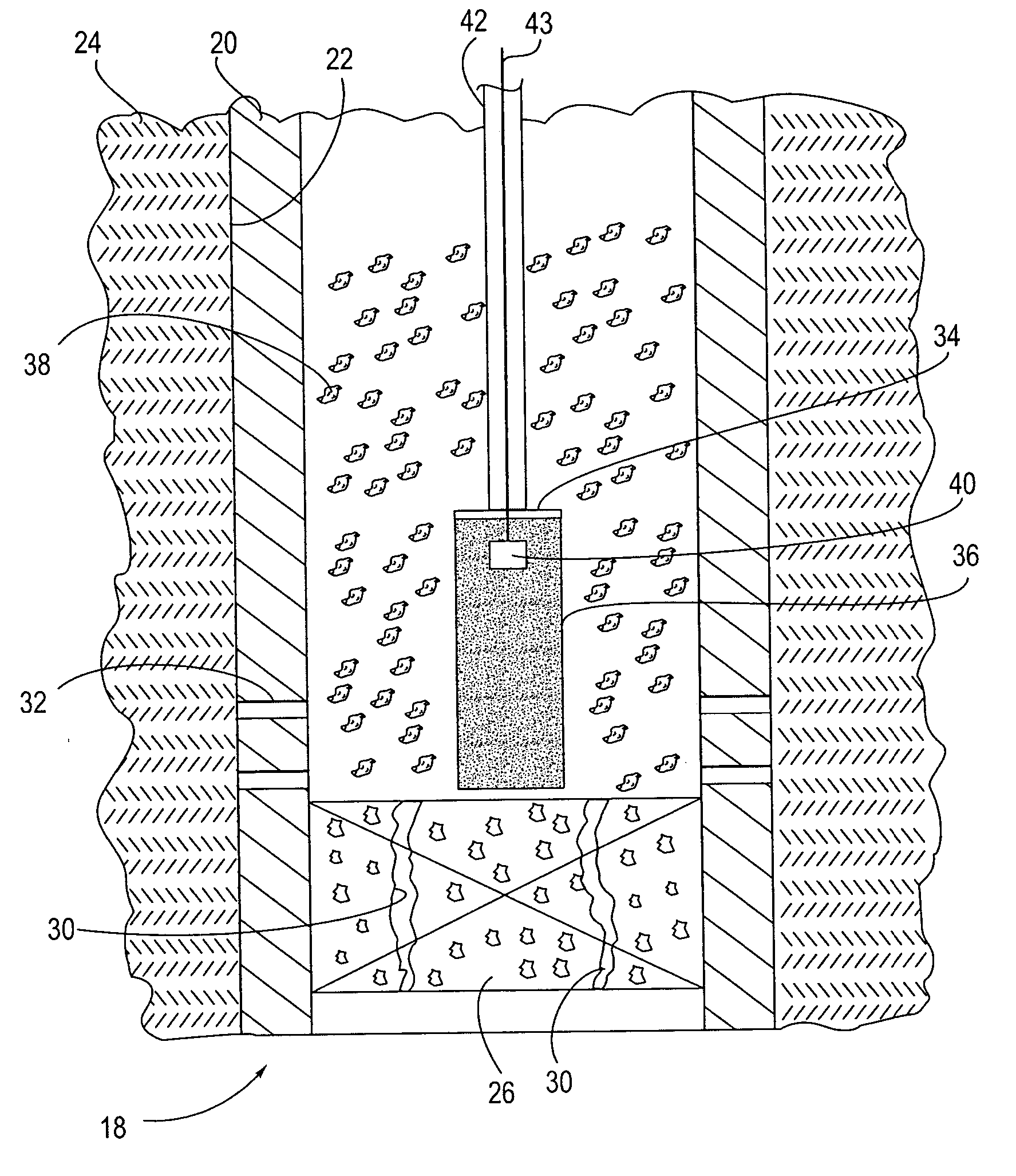

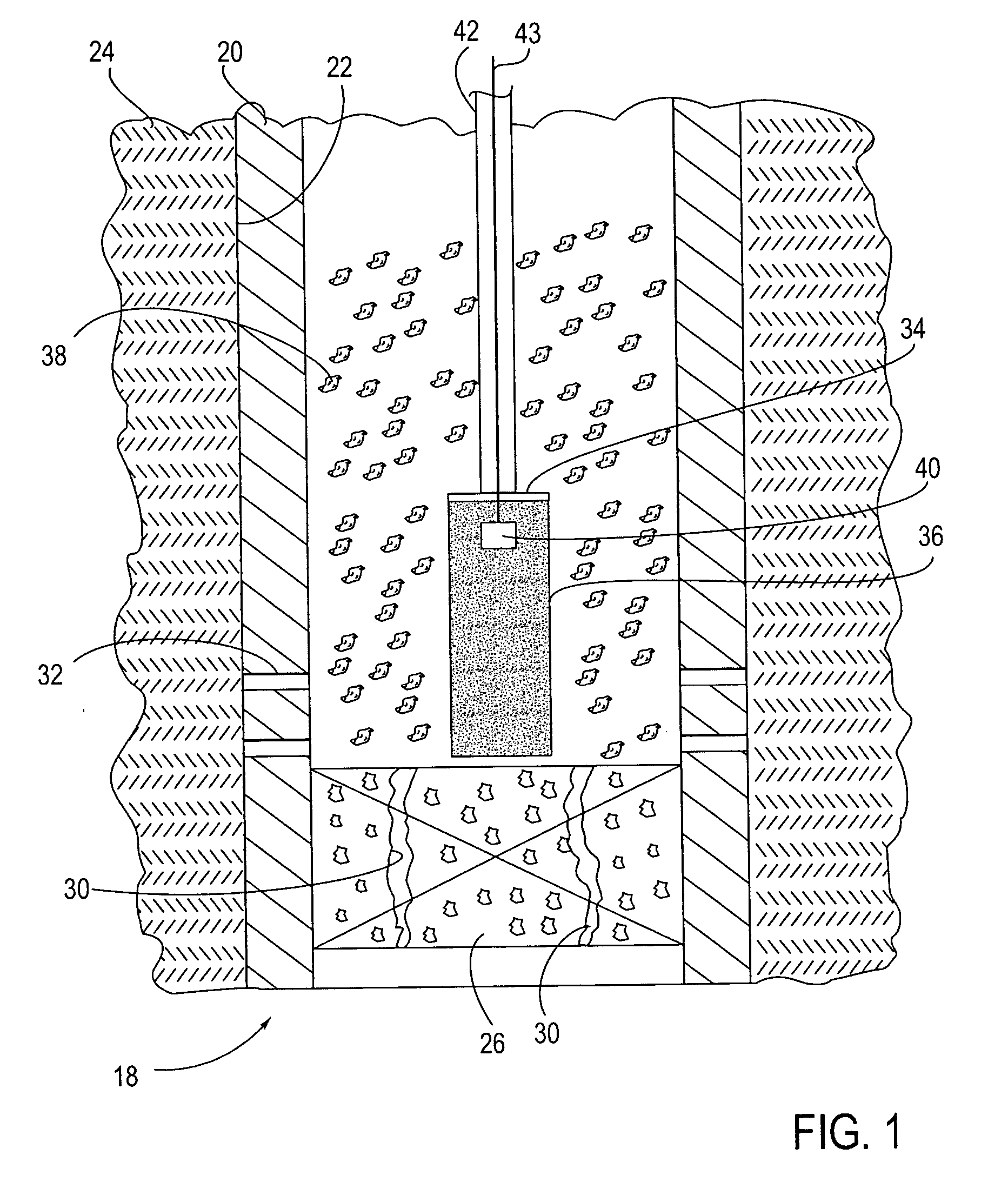

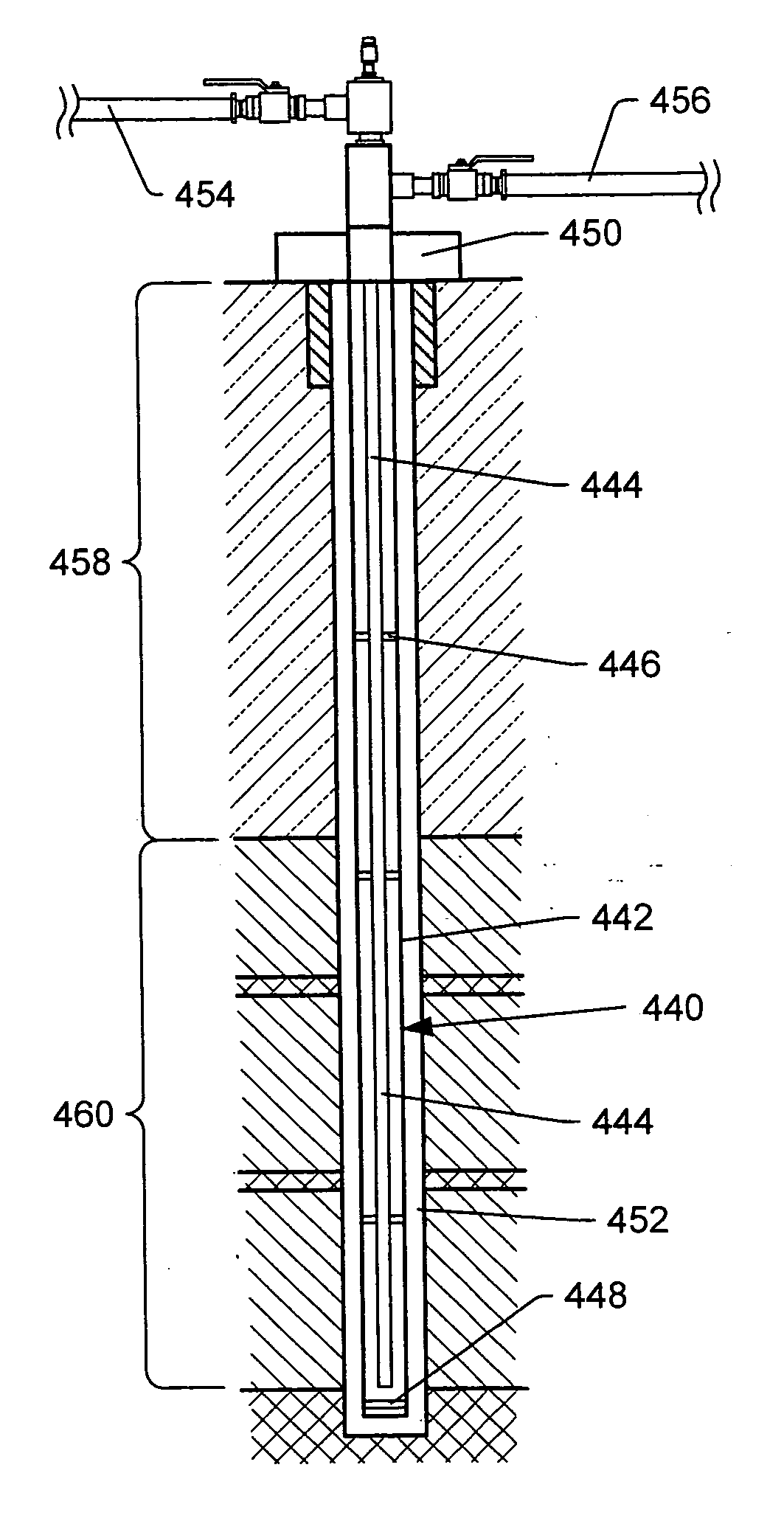

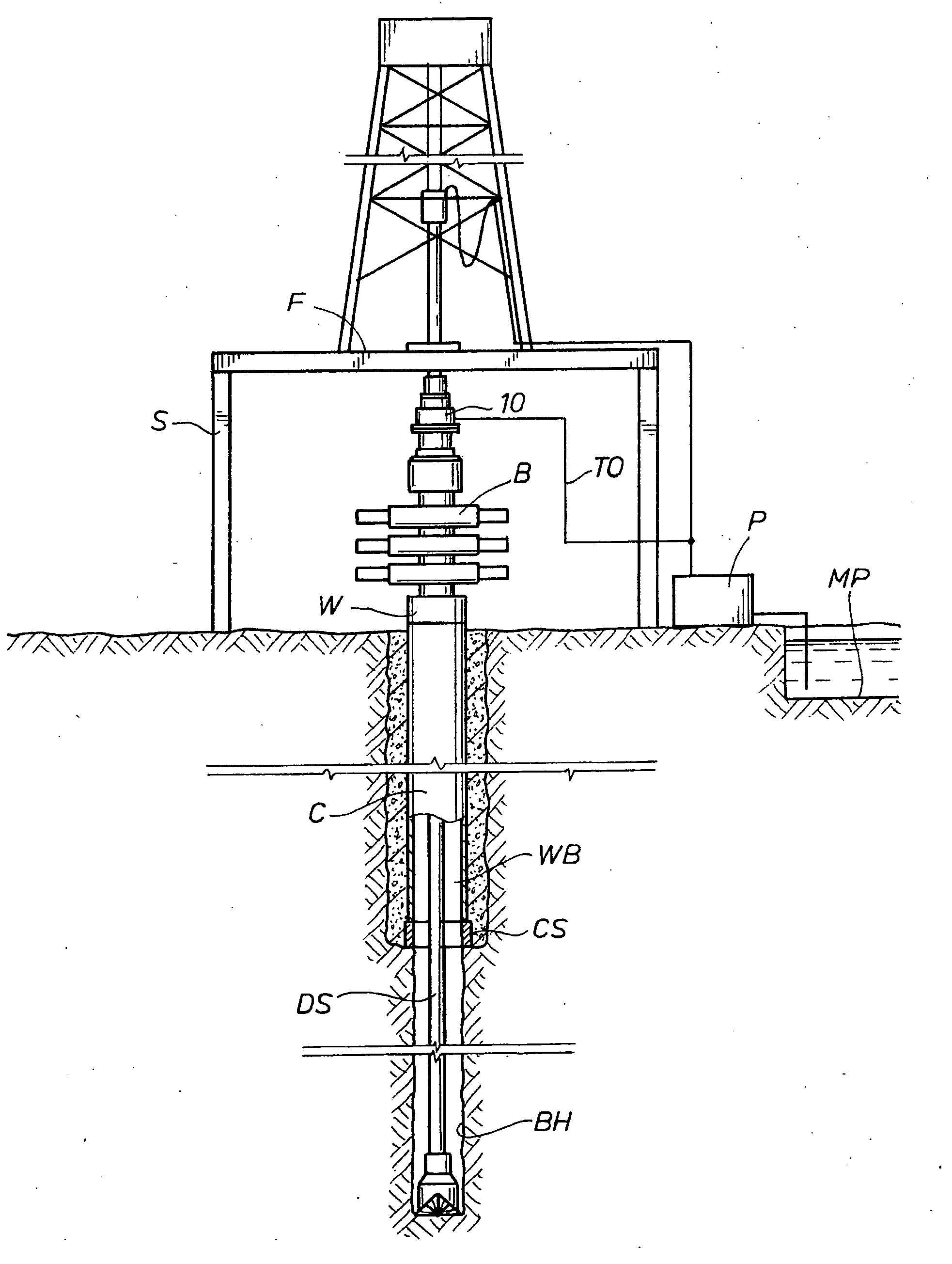

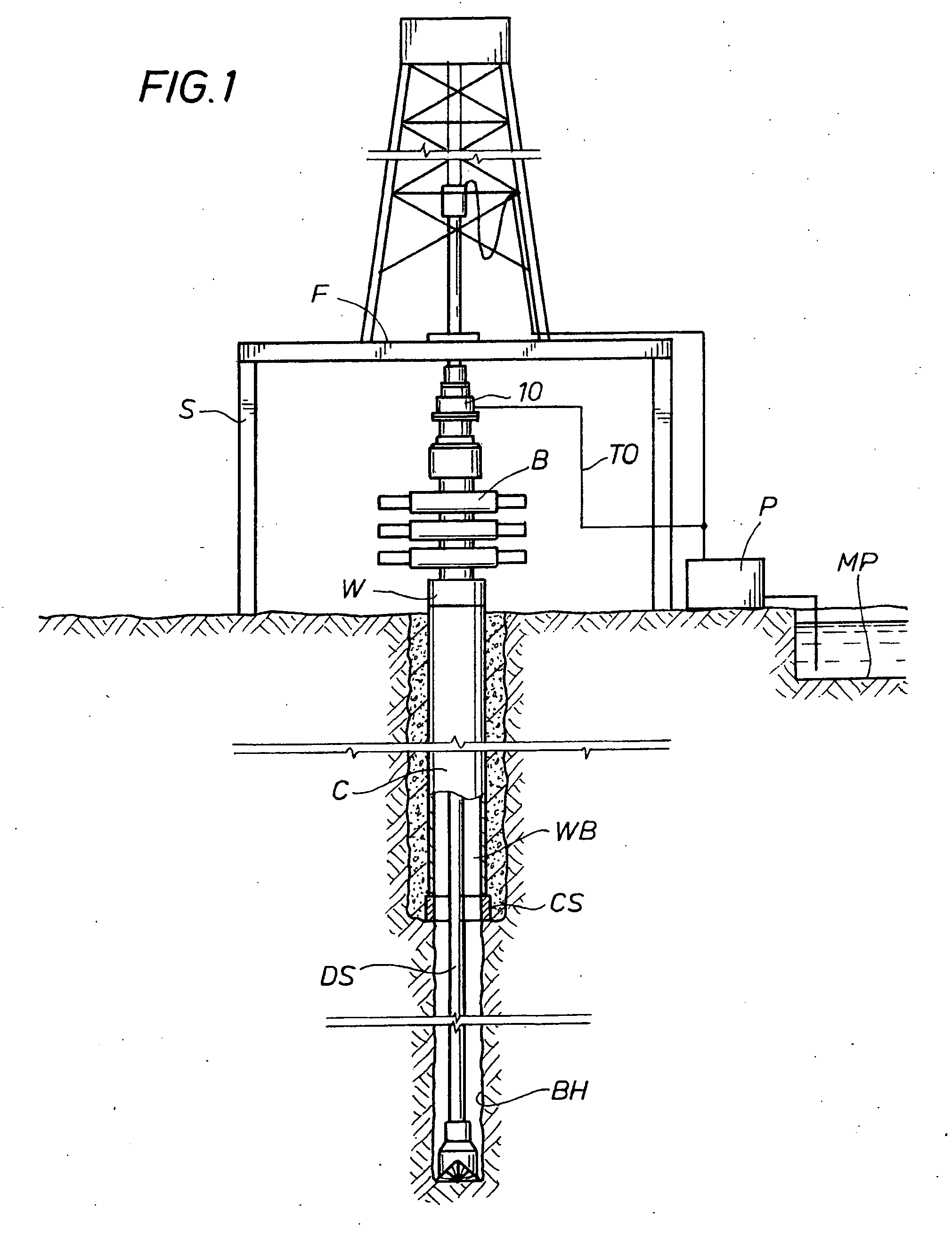

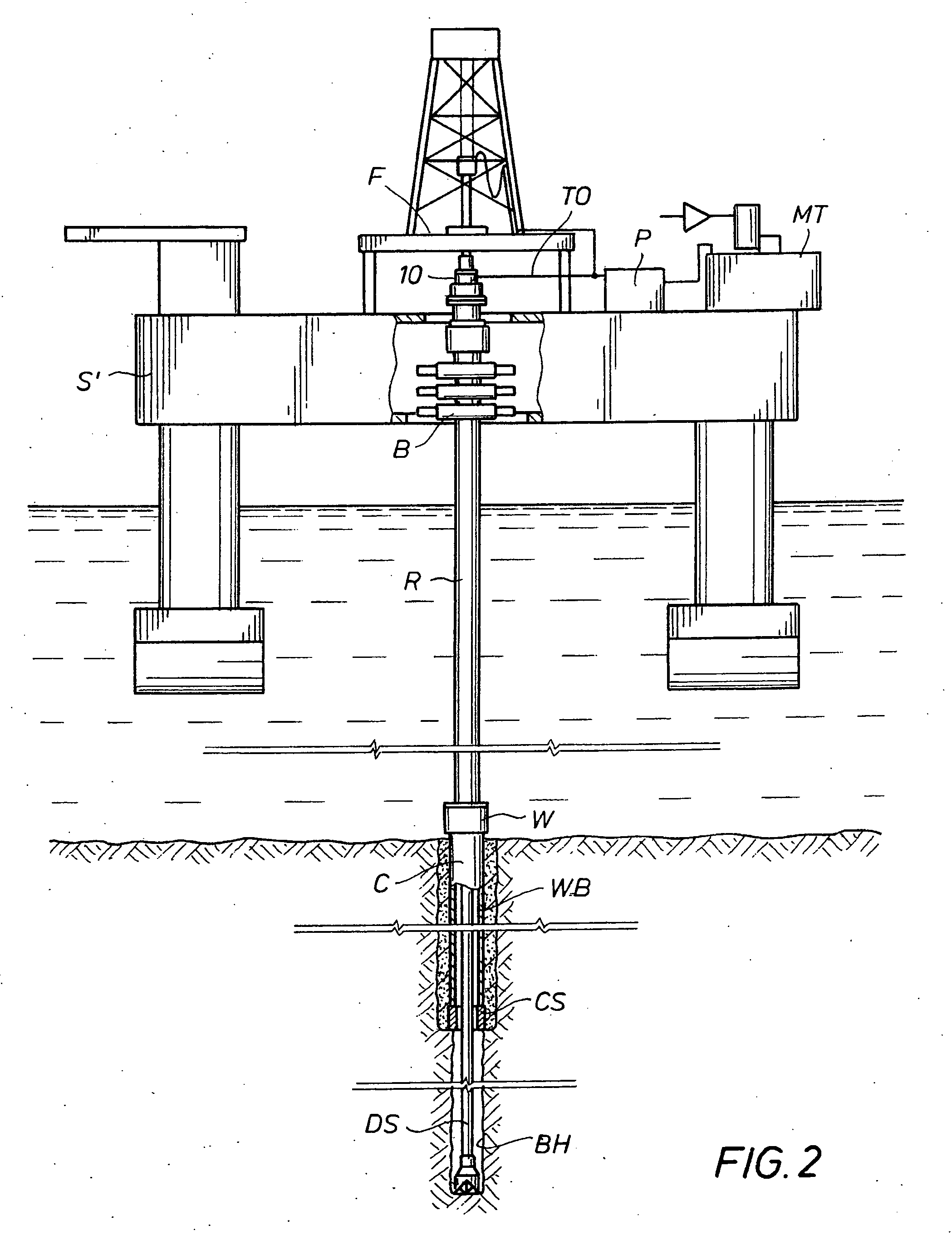

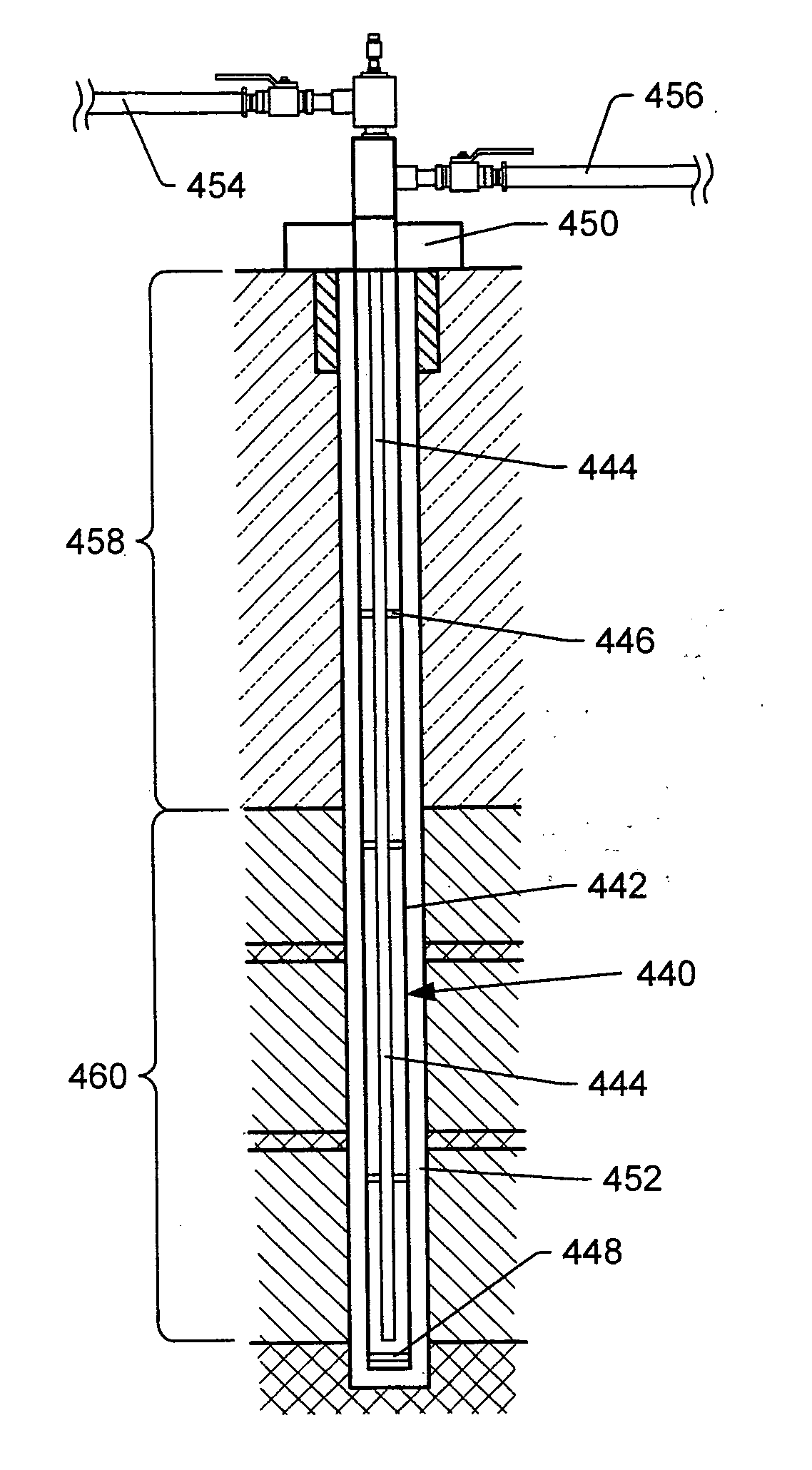

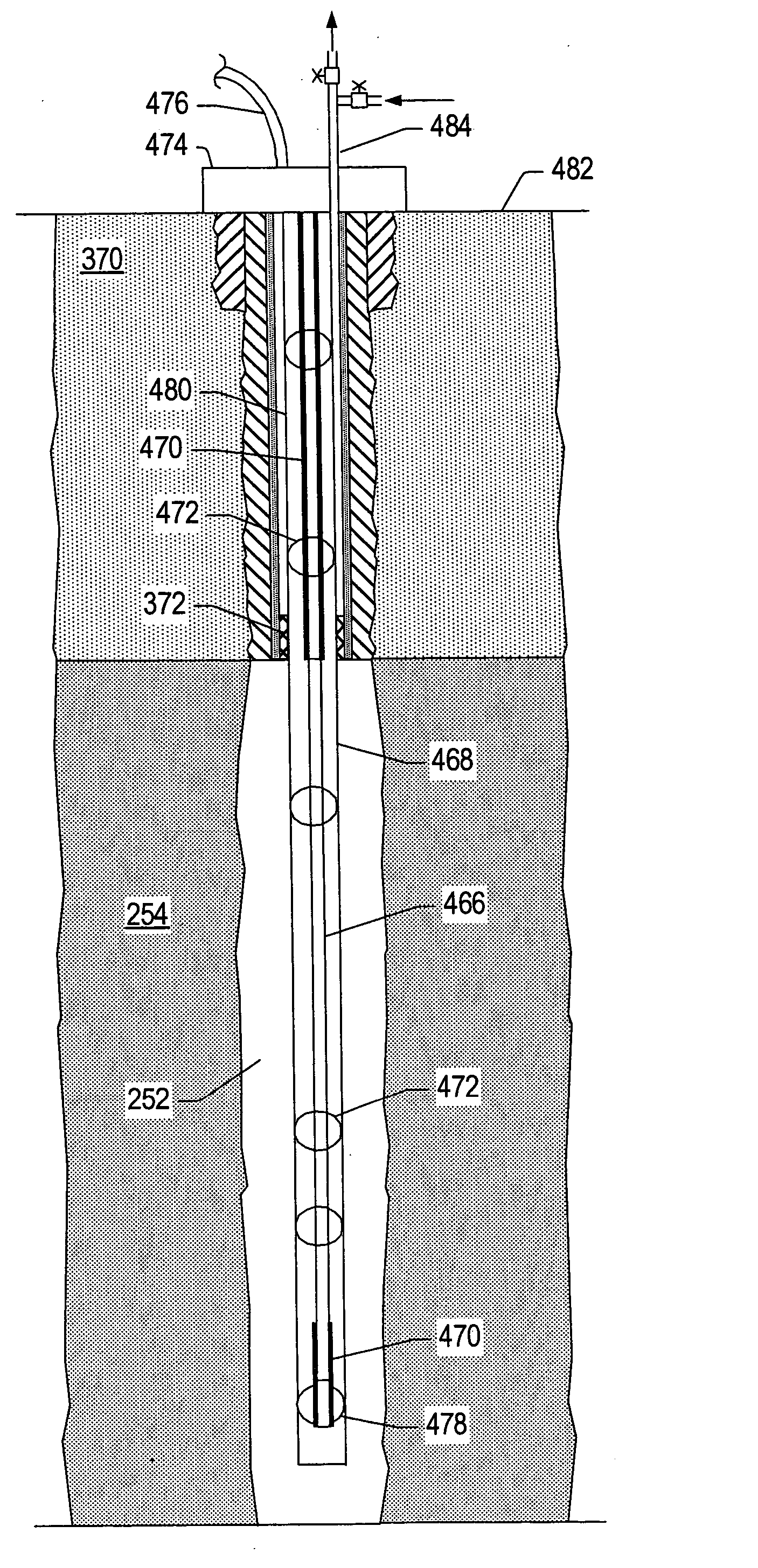

Heater well method and apparatus

InactiveUS6079499AImprove efficiencyImprove completenessInsulationFluid removalGeomorphologyWellbore

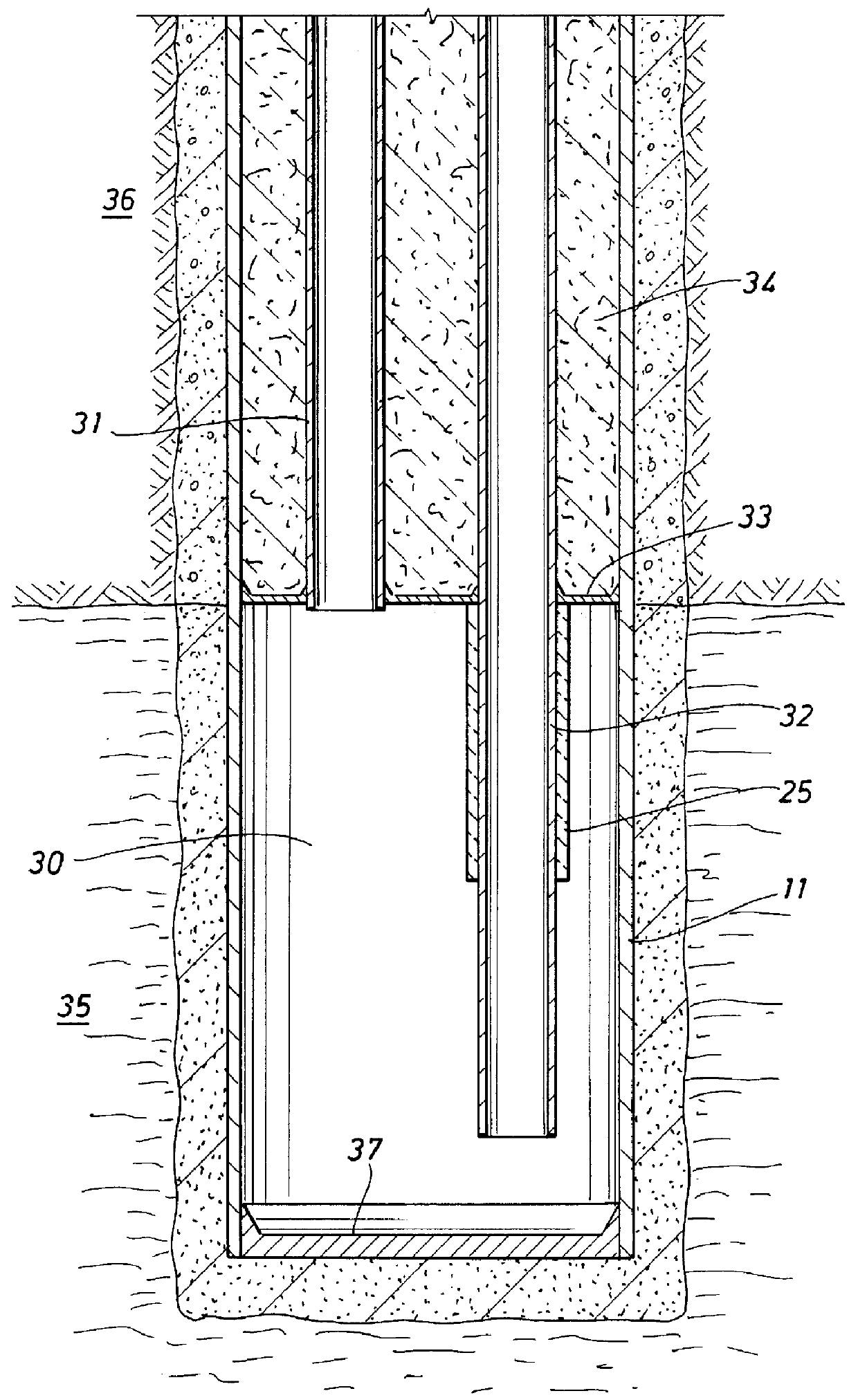

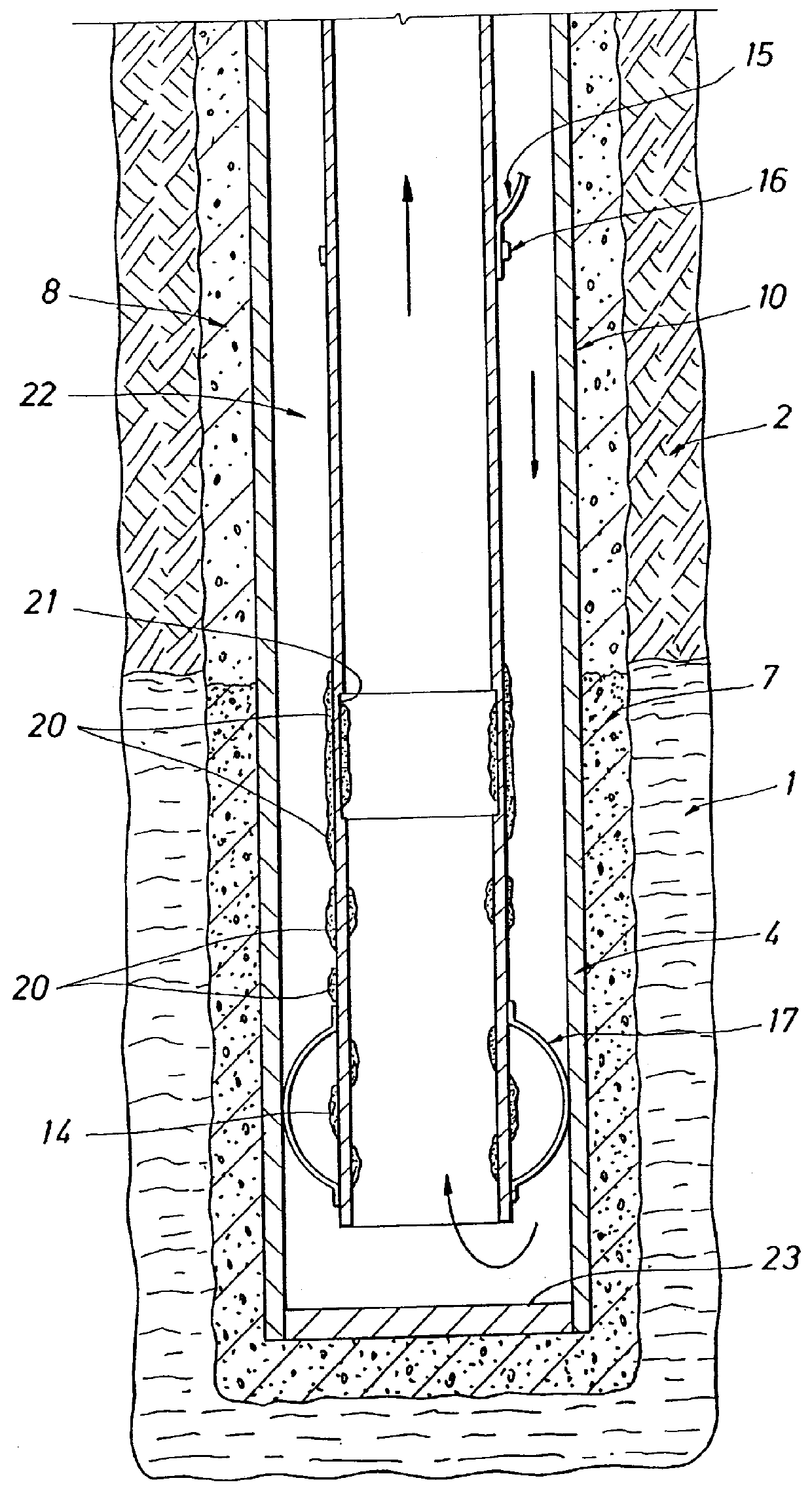

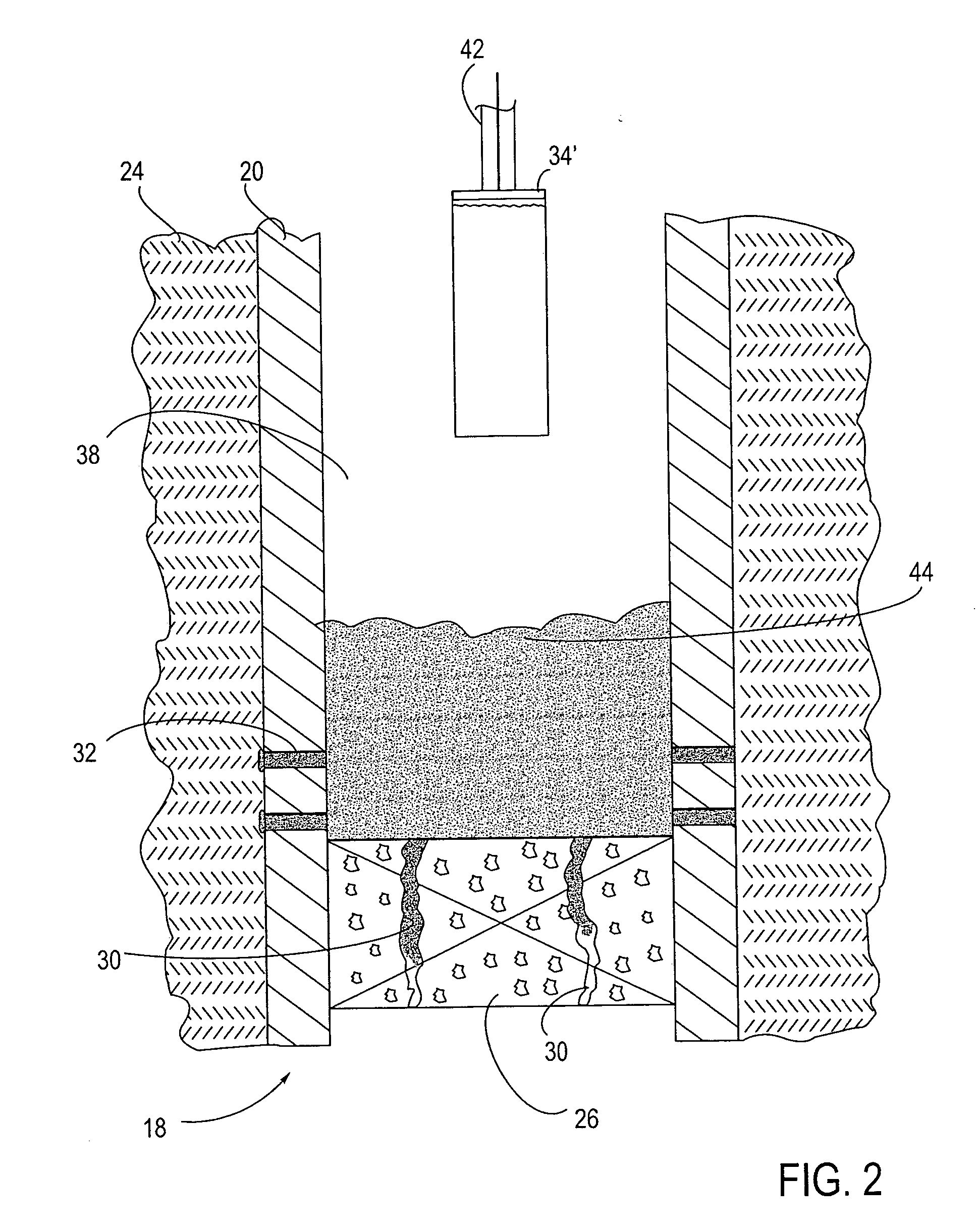

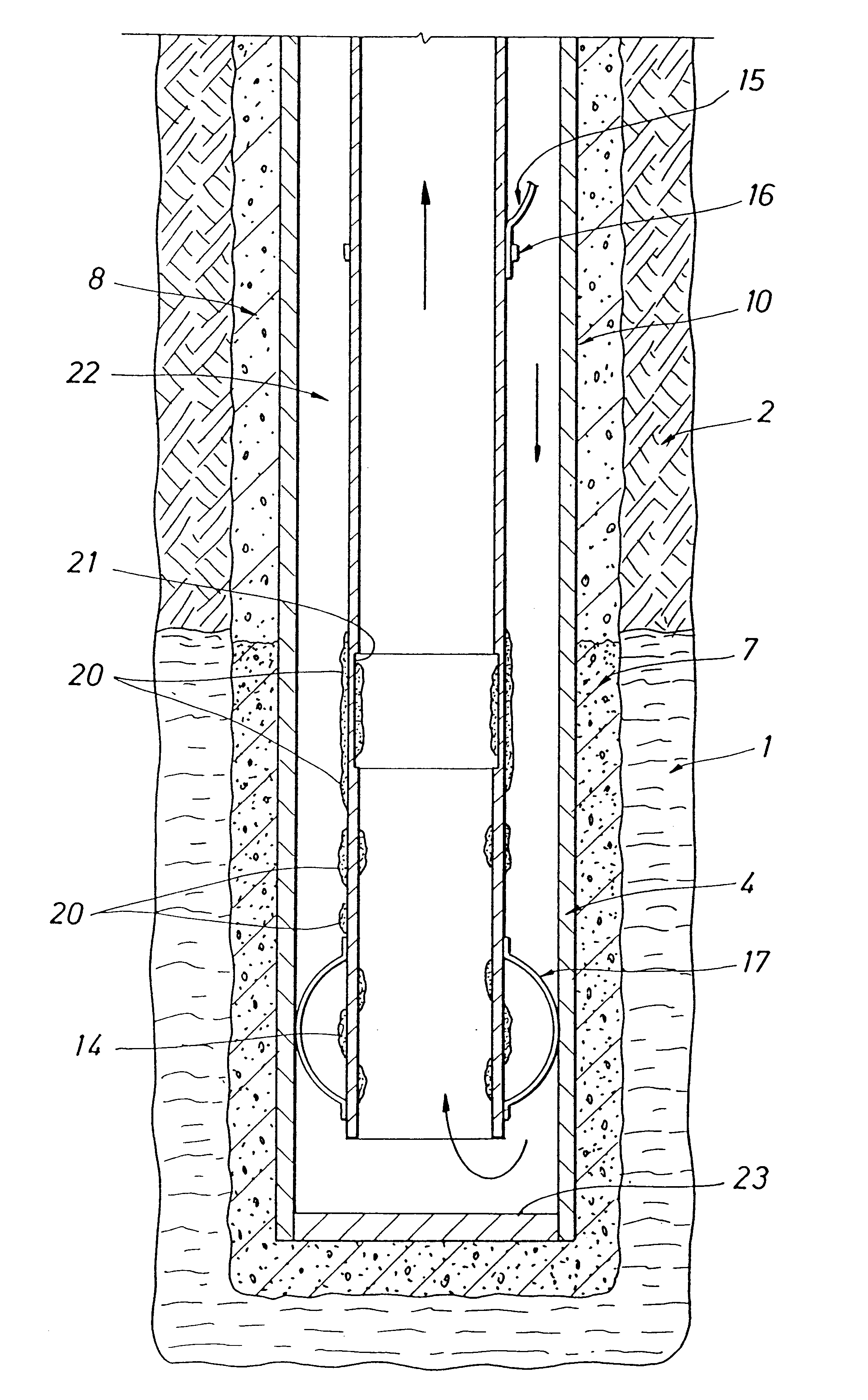

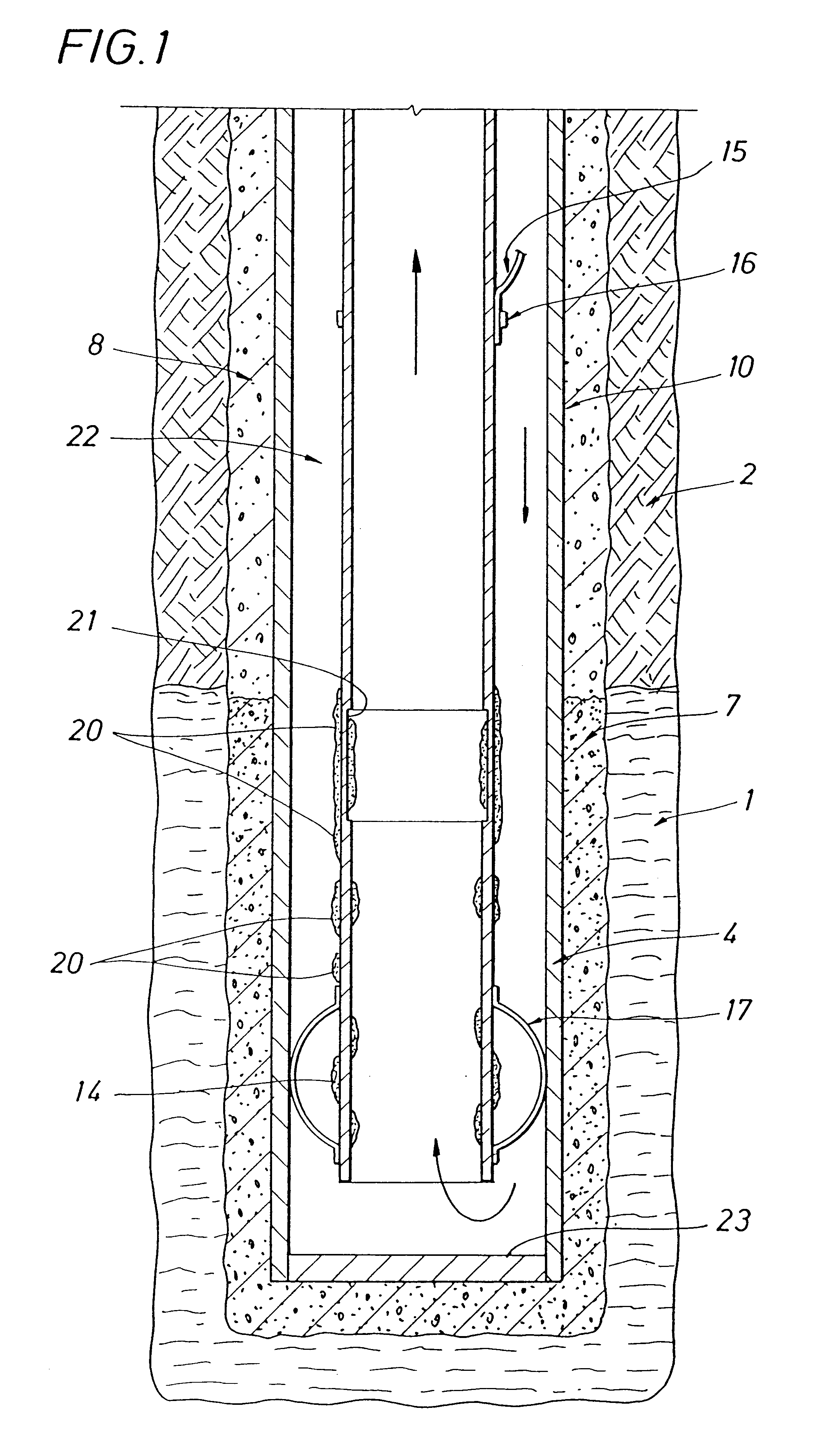

A method and apparatus is disclosed for heating of formations using fired heaters. The method includes the steps of: providing a wellbore within the formation to be heated, the wellbore comprising a casing within the formation to be heated, a tubular defining, in the inside of the tubular, a flowpath for hot gases from the surface to a point in the wellbore near the bottom of the formation to be heated, and a volume between the tubular and the casing providing a flowpath for hot gases from near the bottom of the formation to be heated to the top of the formation to be heated, wherein the flowpaths are in communication with each other near the bottom of the formation to be heated and the volume between the casing and the tubular at the top of the formation to be heated is in communication with a point above the surface, and insulation for a portion of the length of the wellbore within the formation to be heated between the flowpath for hot gases from the surface to the point in the wellbore near the bottom of the formation to be heated and the flowpath for hot gases from near the bottom of the formation to be heated to the surface; and supplying a flow of hot gases to the flowpath for hot gases from the surface to a point in the wellbore near the bottom of the formation to be heated.

Owner:SHELL OIL CO

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

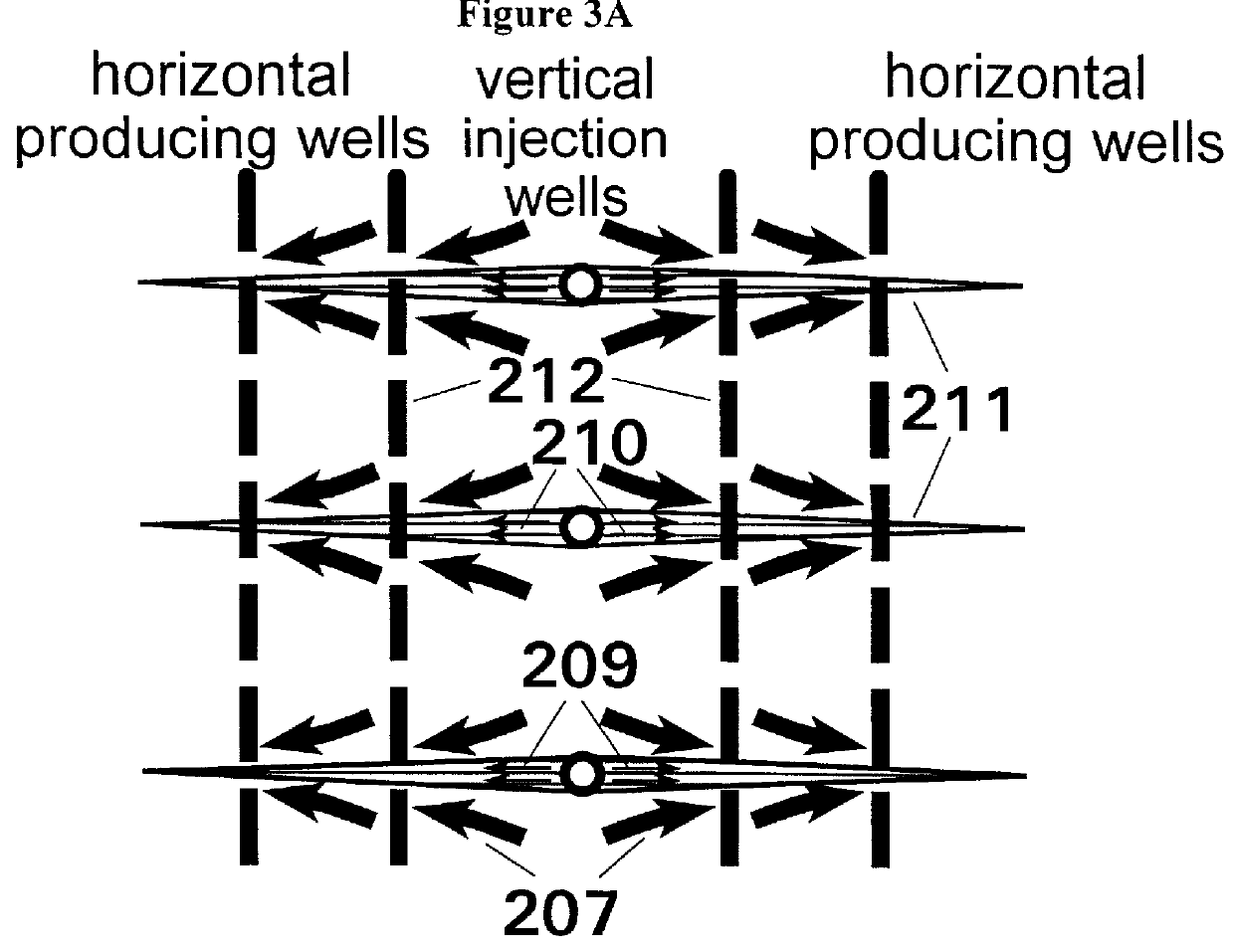

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more vertical injection boreholes and one or more vertical production boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes, or a cyclic operation whereby both injection and production occur in the same vertical boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing, multiple horizontal boreholes extending from vertical boreholes, or other related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

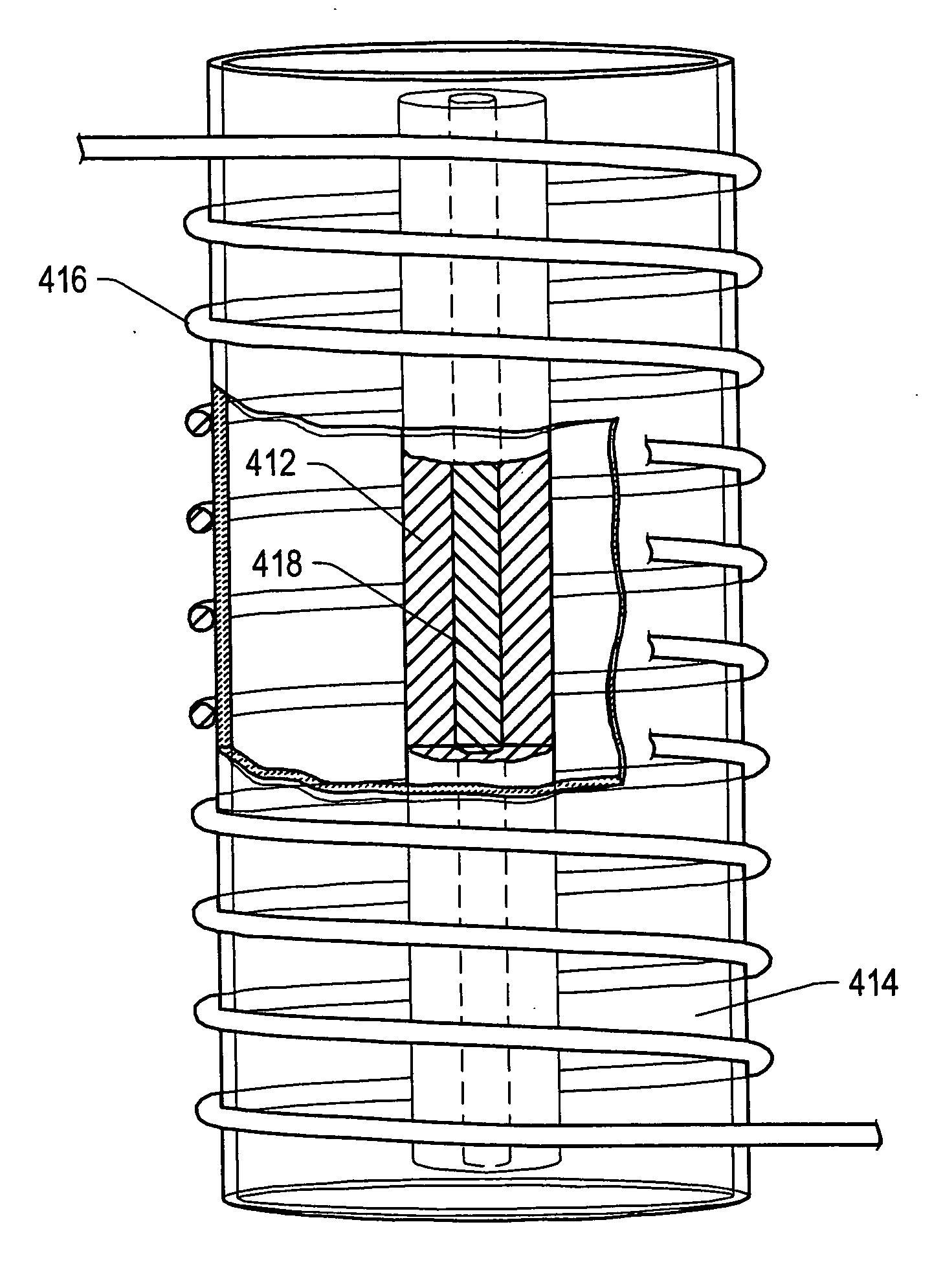

Flameless combustor

InactiveUS6019172AEasy to igniteImprove the level ofApparel holdersInsulationCombustorCombustion chamber

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

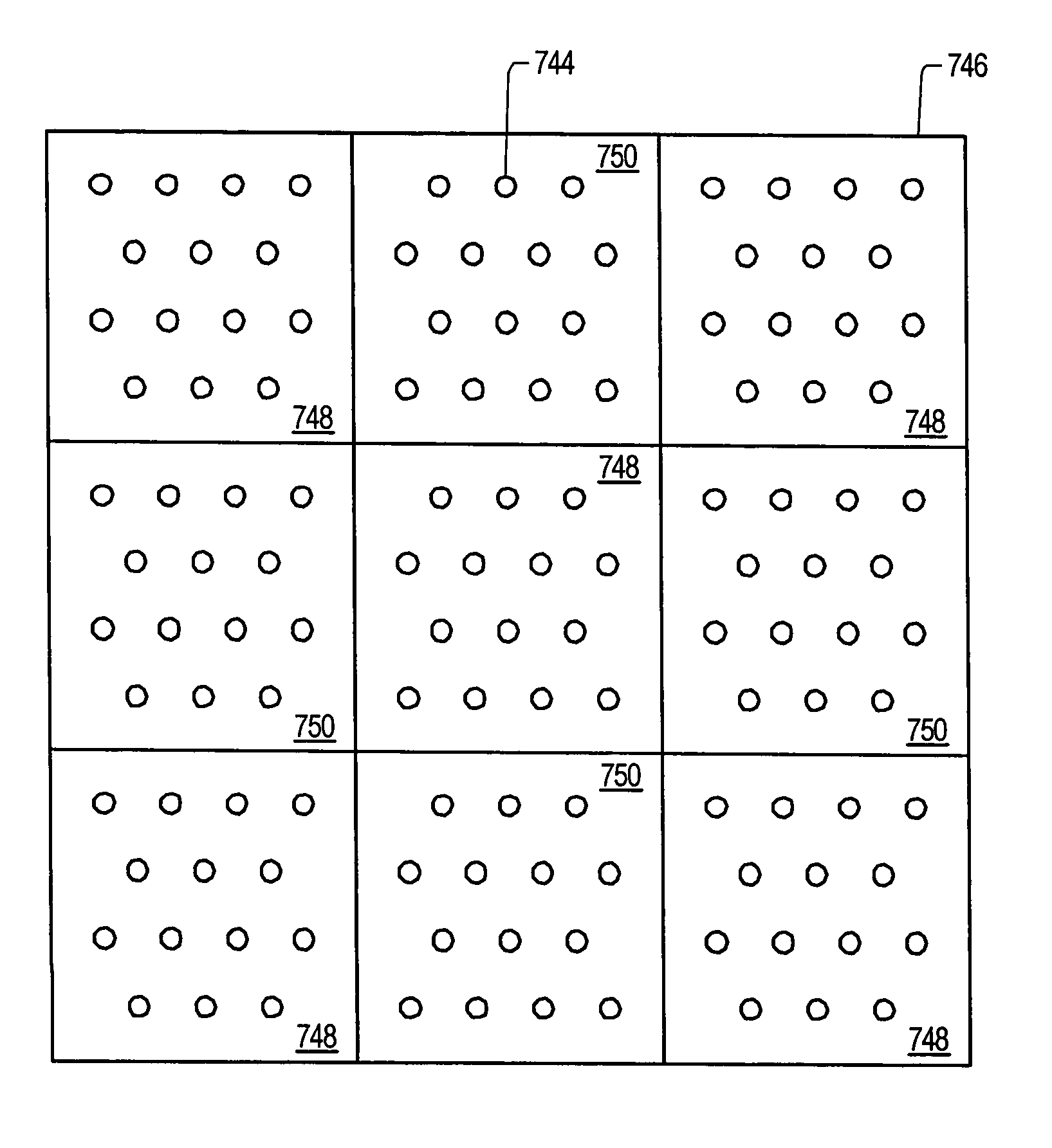

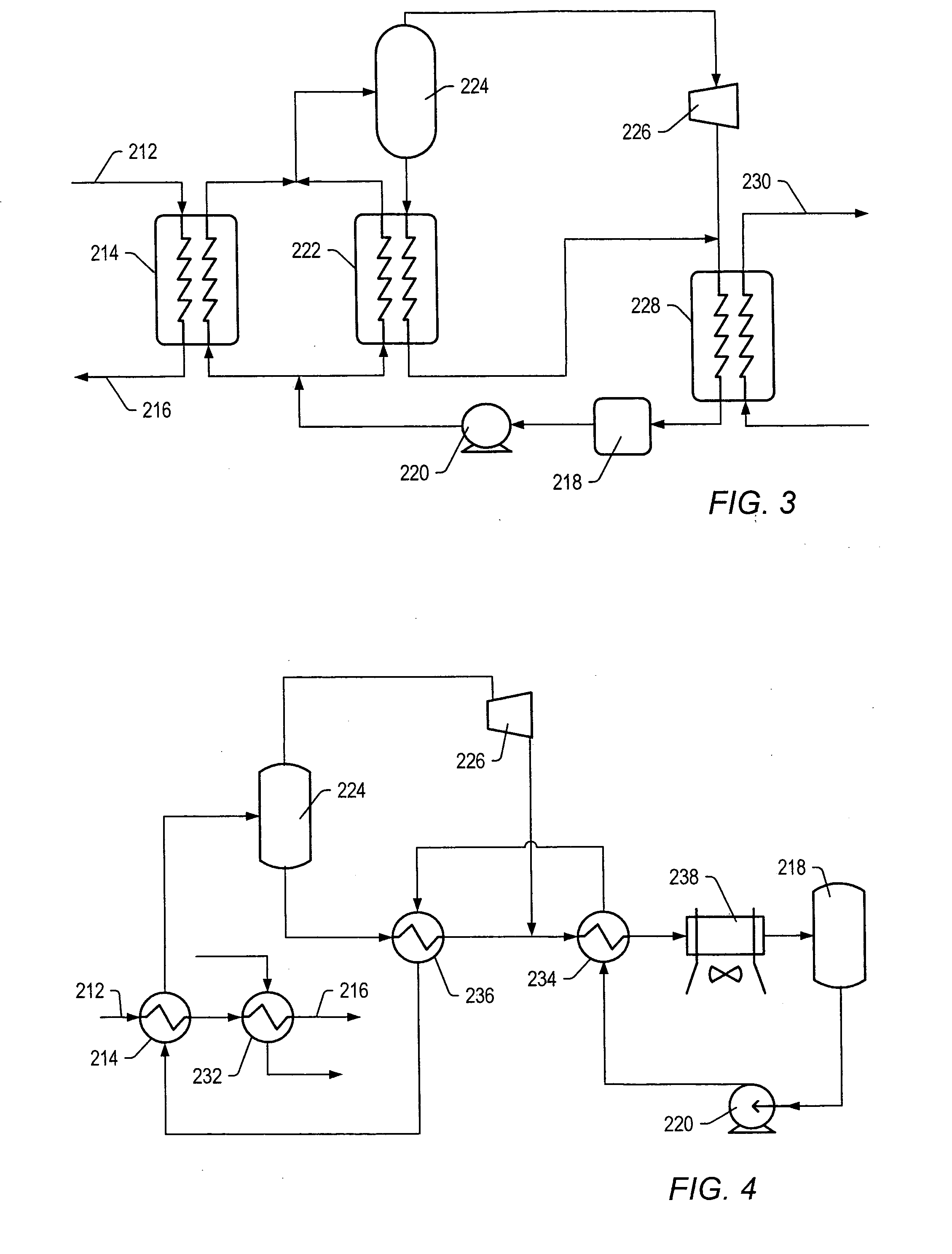

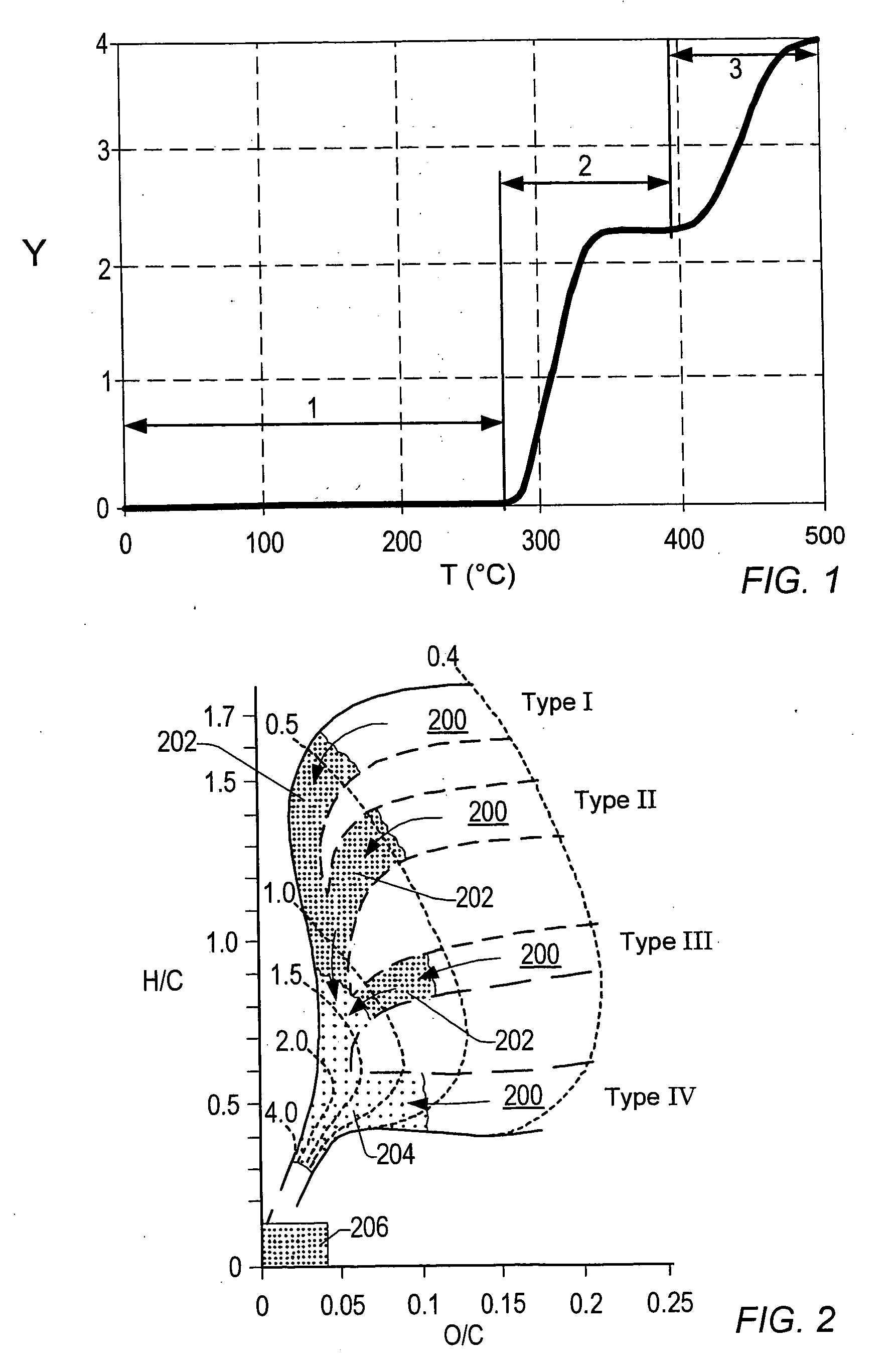

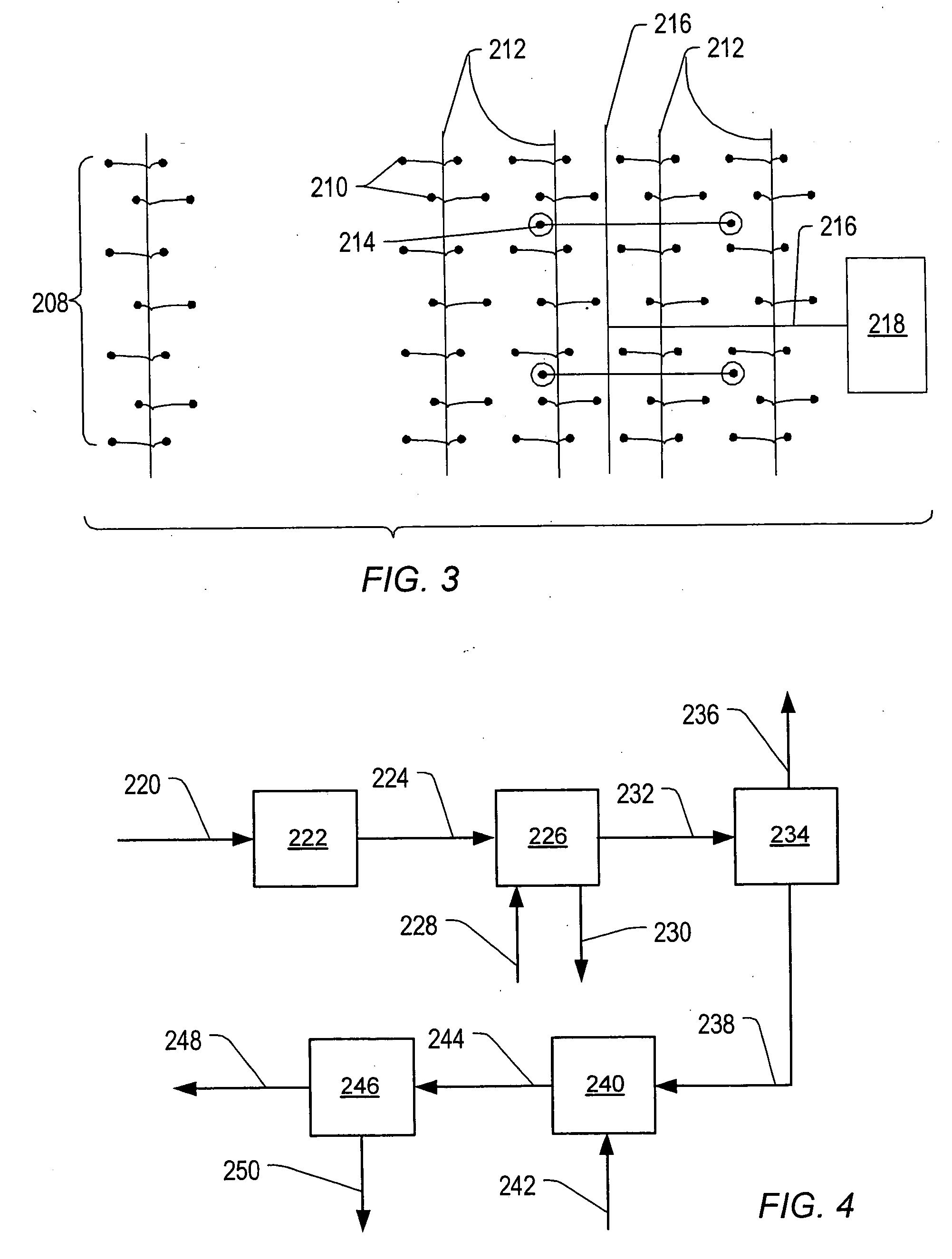

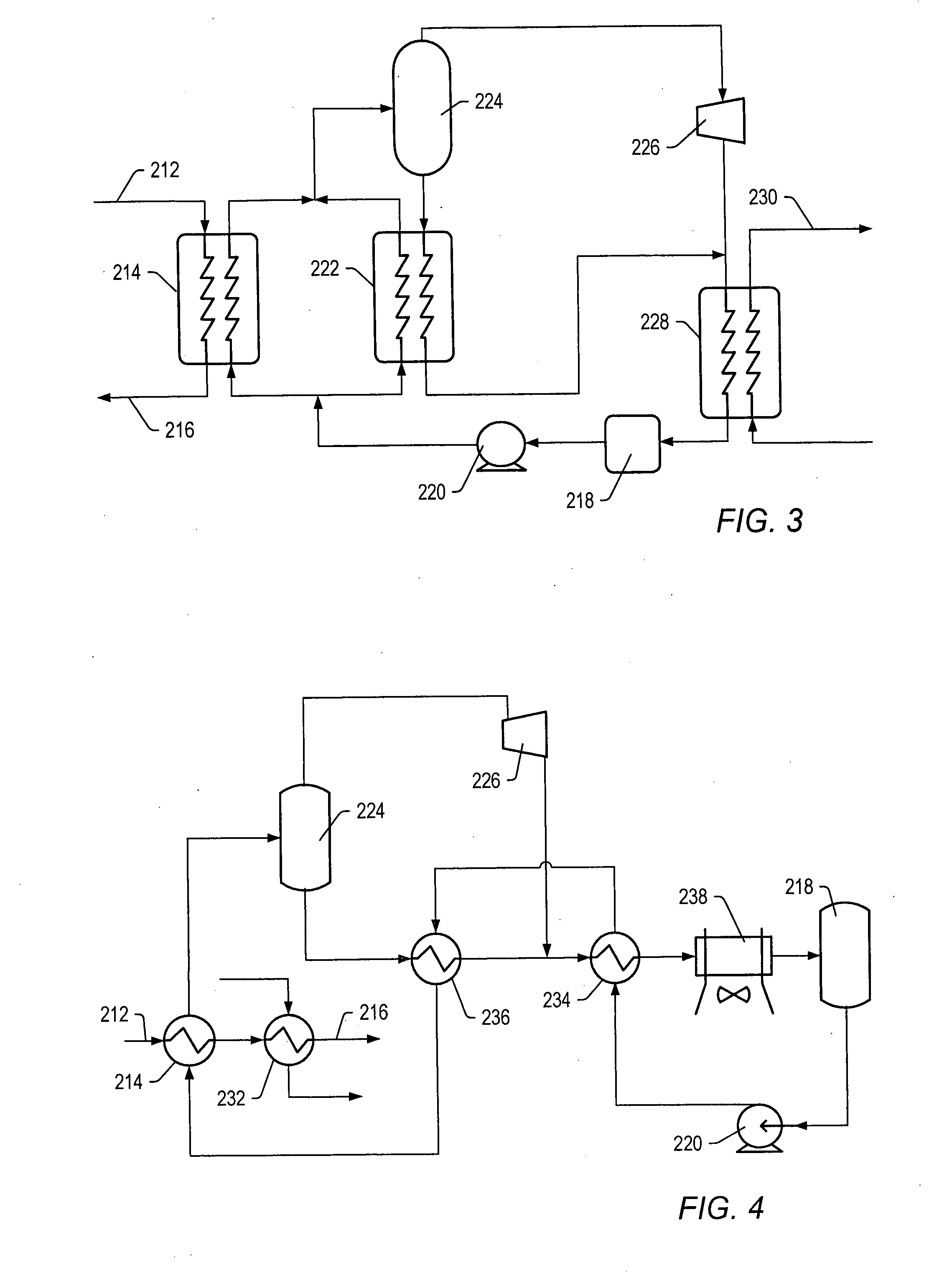

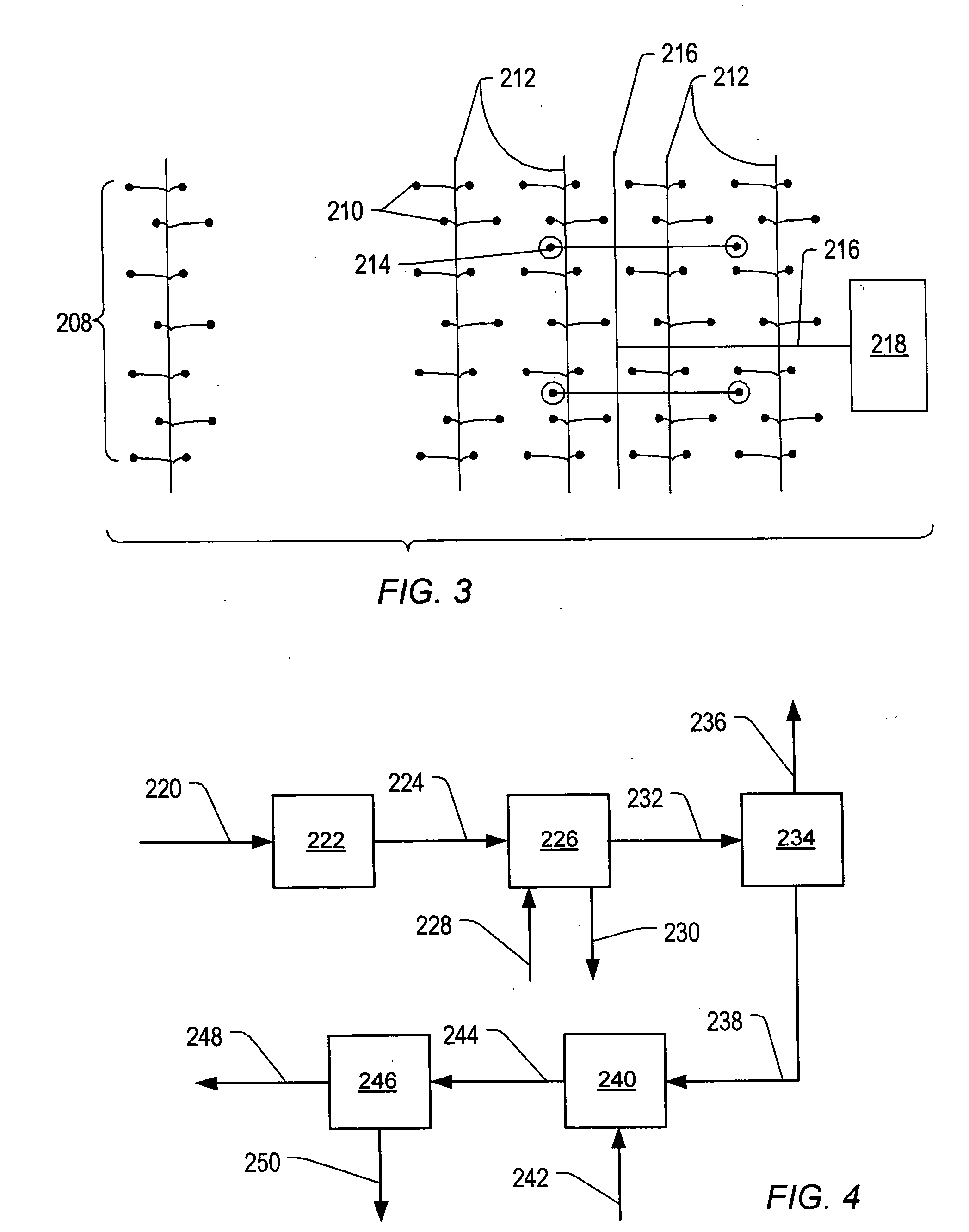

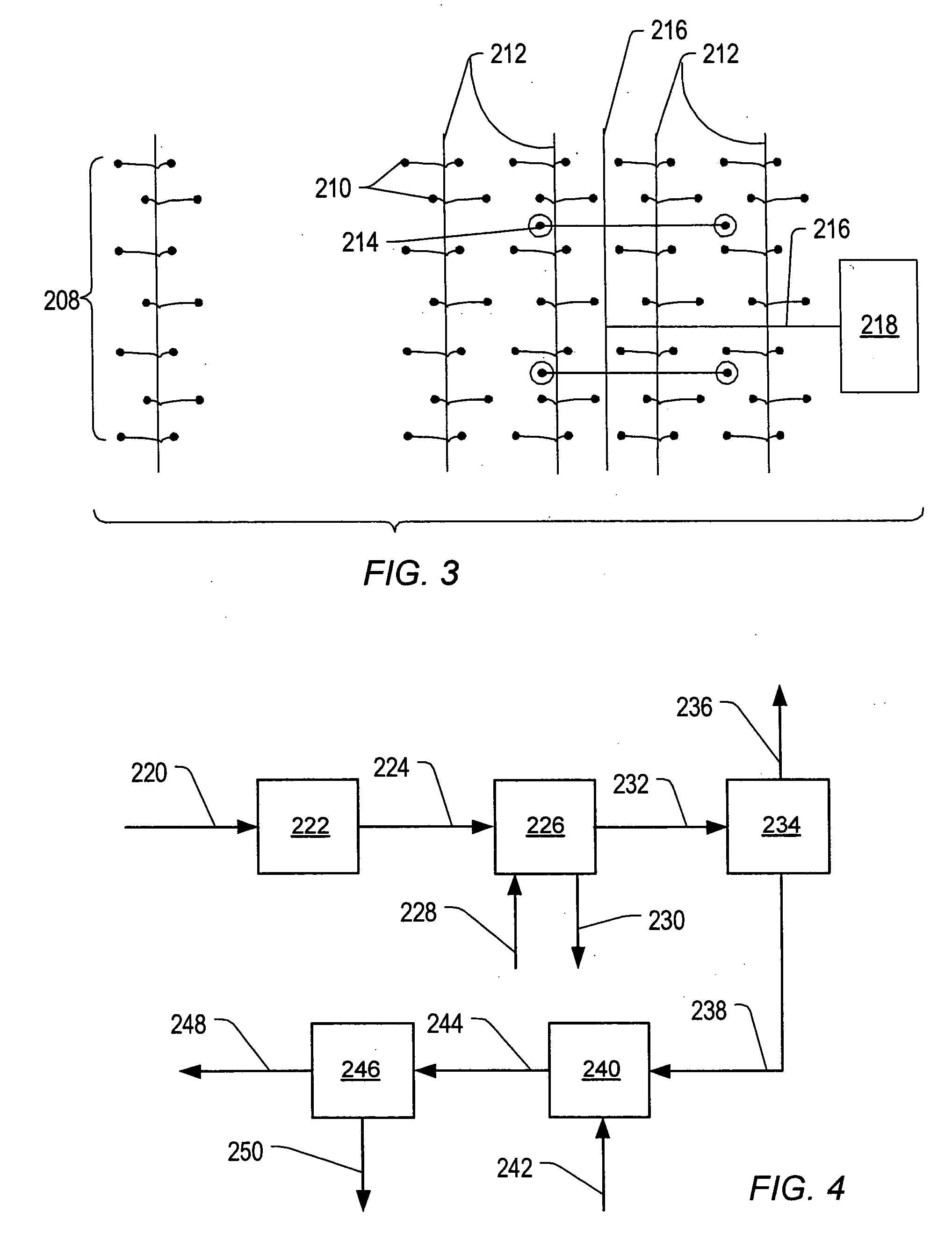

Staged and/or patterned heating during in situ thermal processing of a hydrocarbon containing formation

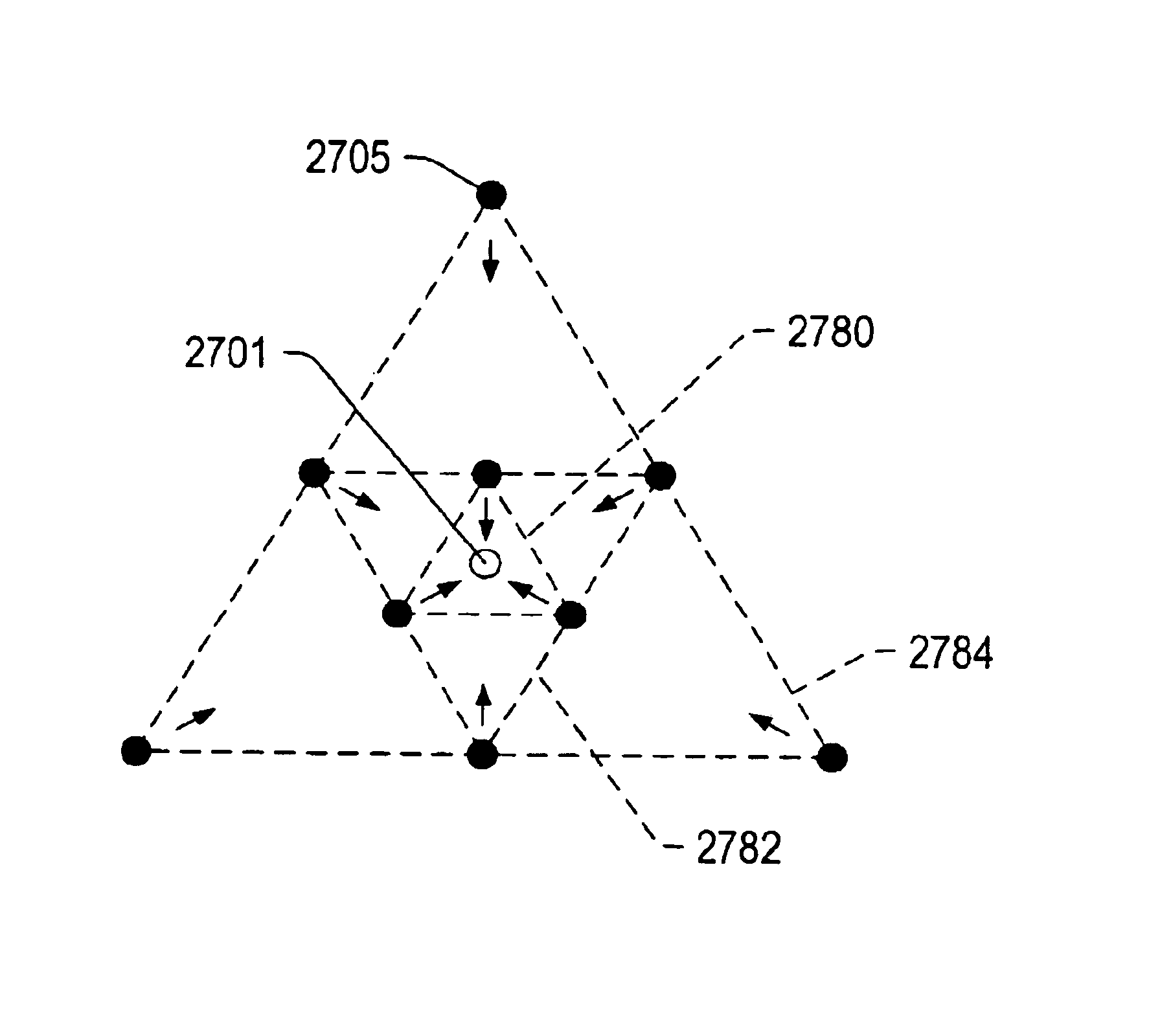

A method for treating a hydrocarbon containing formation is described. The method for treating a hydrocarbon containing formation may include heating a first volume of the formation using a first set of heaters. A second volume of the formation may be heated using a second set of heaters. The first volume may be spaced apart from the second volume by a third volume of the formation. The first volume, second volume, and / or third volume may be sized, shaped, and / or located to inhibit deformation of subsurface equipment caused by geomechanical motion of the formation during heating.

Owner:SHELL OIL CO

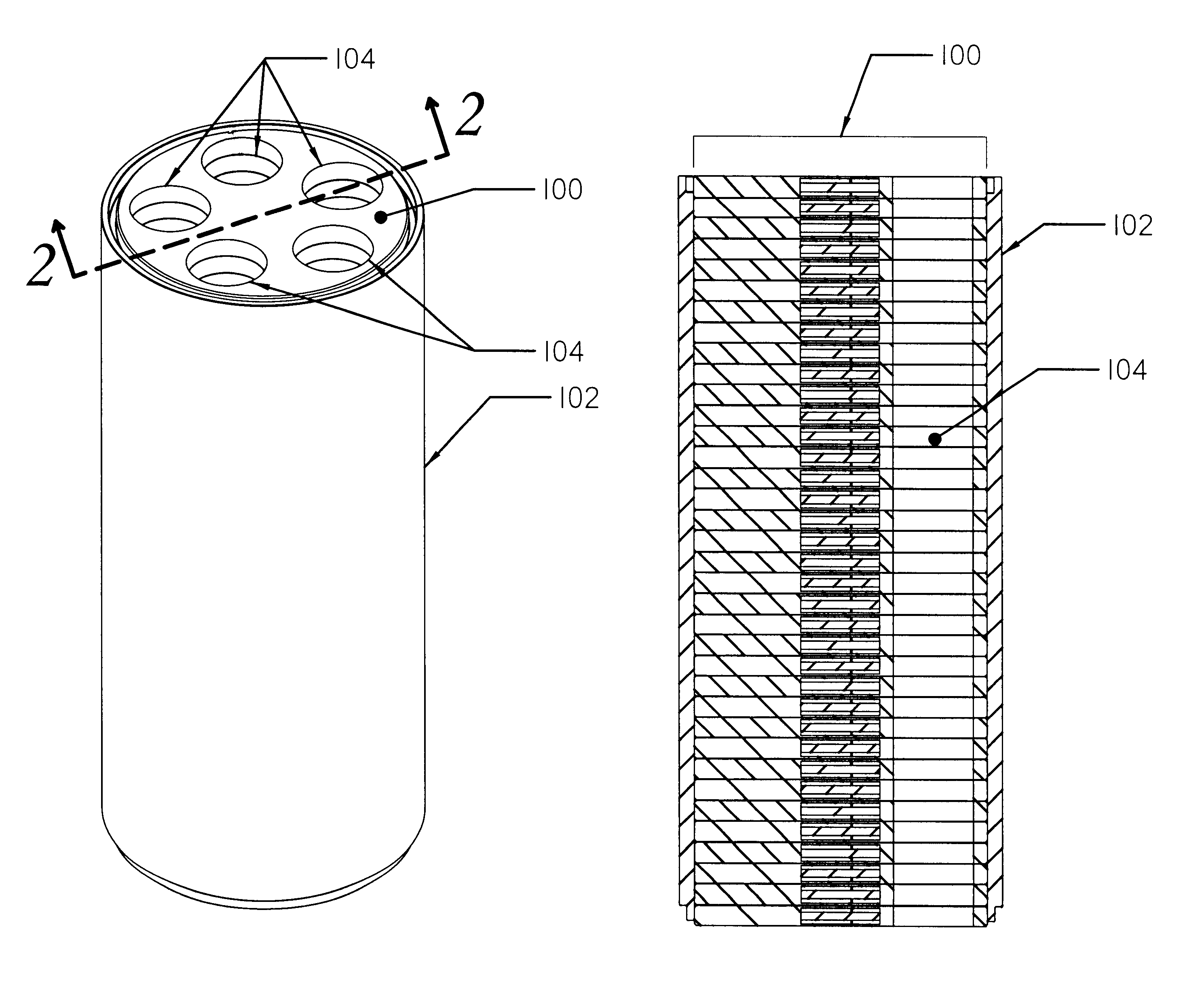

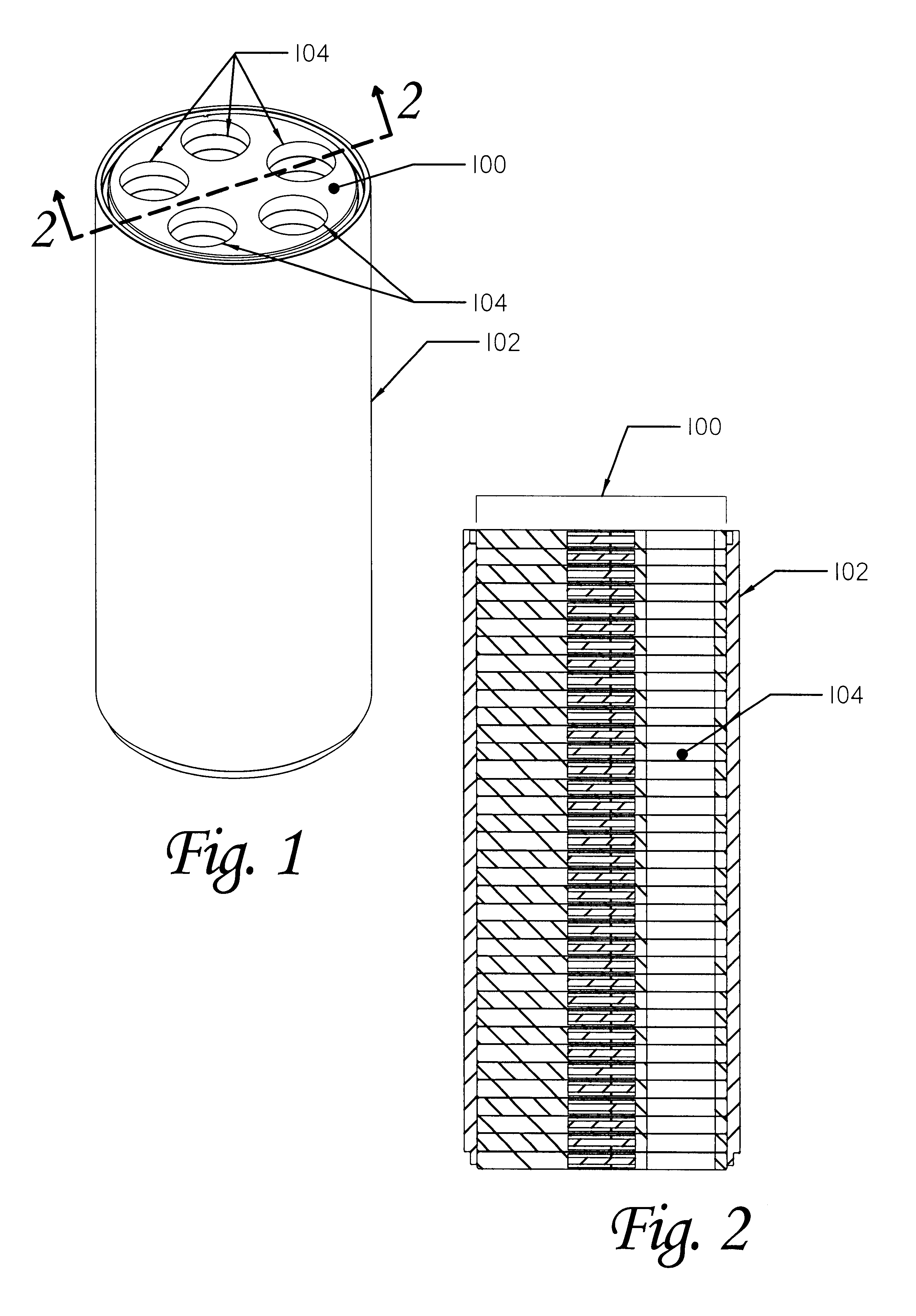

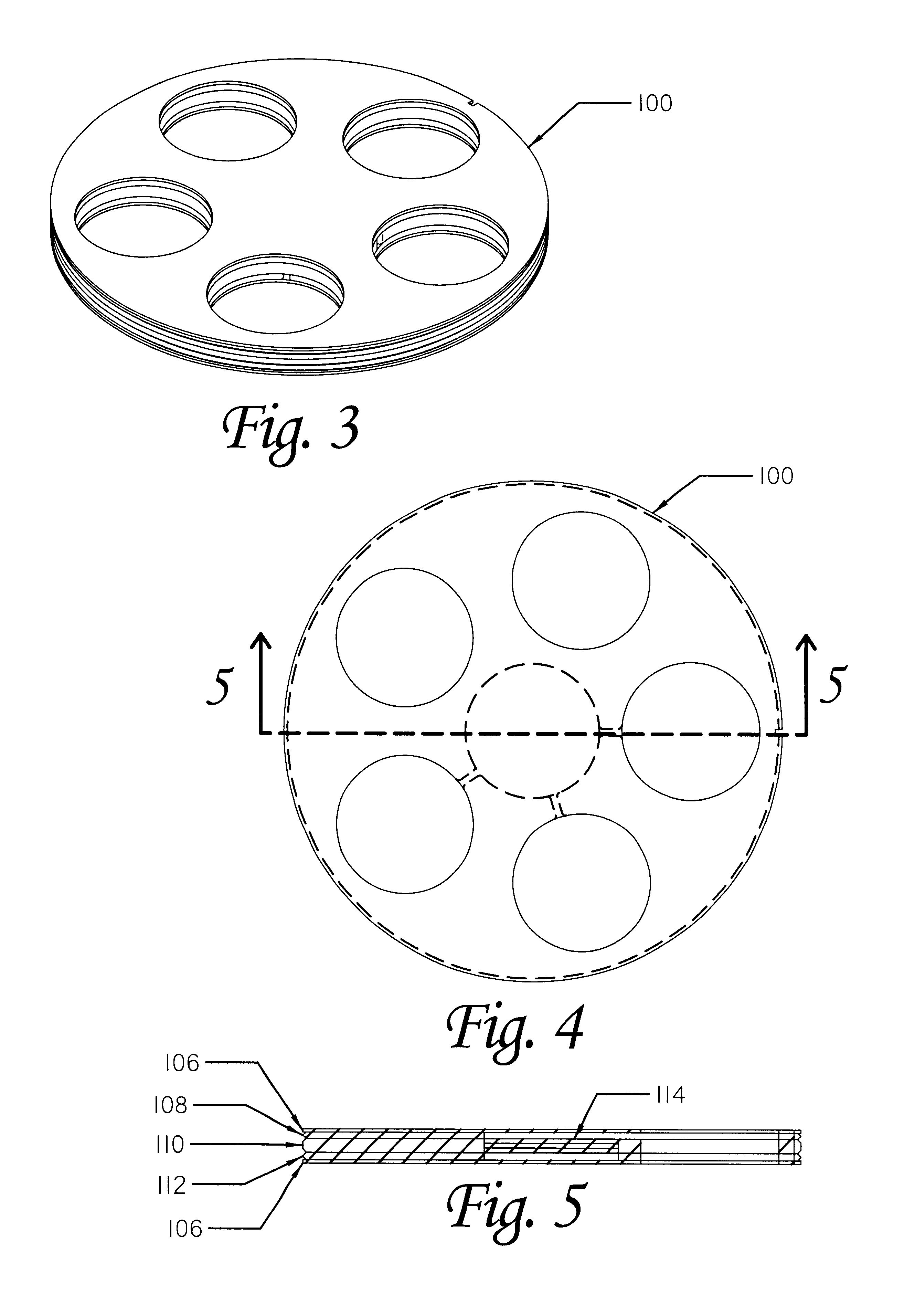

Apparatus and method for heating subterranean formations using fuel cells

InactiveUS6684948B1Eliminate needAvoid inefficiencyFuel cell heat exchangeFuel cells groupingElectricityFuel cells

A fuel cell based subterranean heater for mineral extraction, in situ decontamination, or other applications. The fuel cells are preferably stacked within a casing which is then inserted into a hole bored, or otherwise formed, into the formation to be heated. Conduits within the casing, and preferably formed by adjacent, aligned holes formed through the plates of the individual fuel cells supply fuel and air and extract exhaust gases. An optional manifold is used to span the overburden without applying heat to it directly. The manifold may also function as a heat exchanger between incoming and exhaust gases. Preferably the fuel cell is fueled by gases produced by the formation and also generates electricity which is available for use or export.

Owner:IEP TECH INC

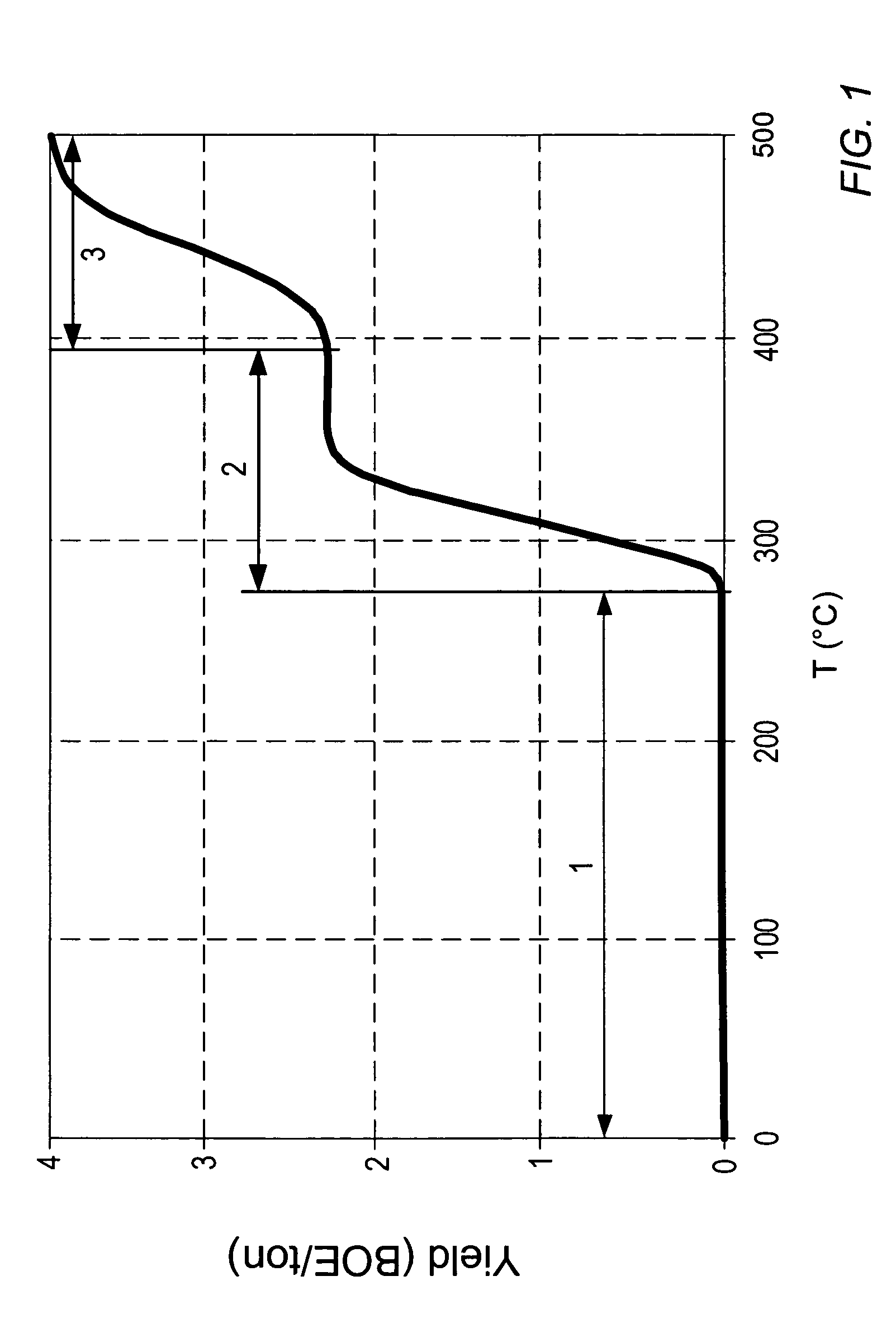

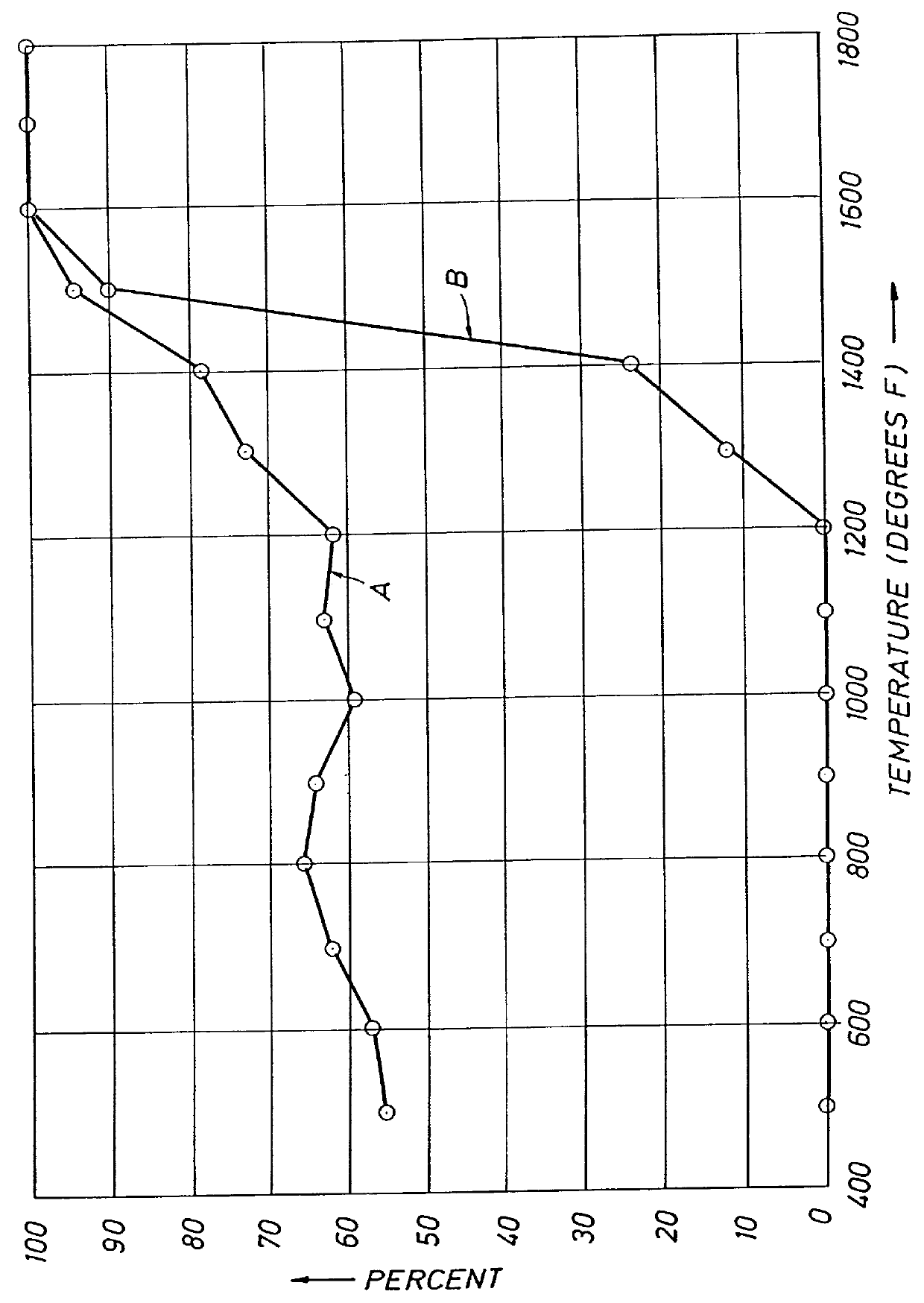

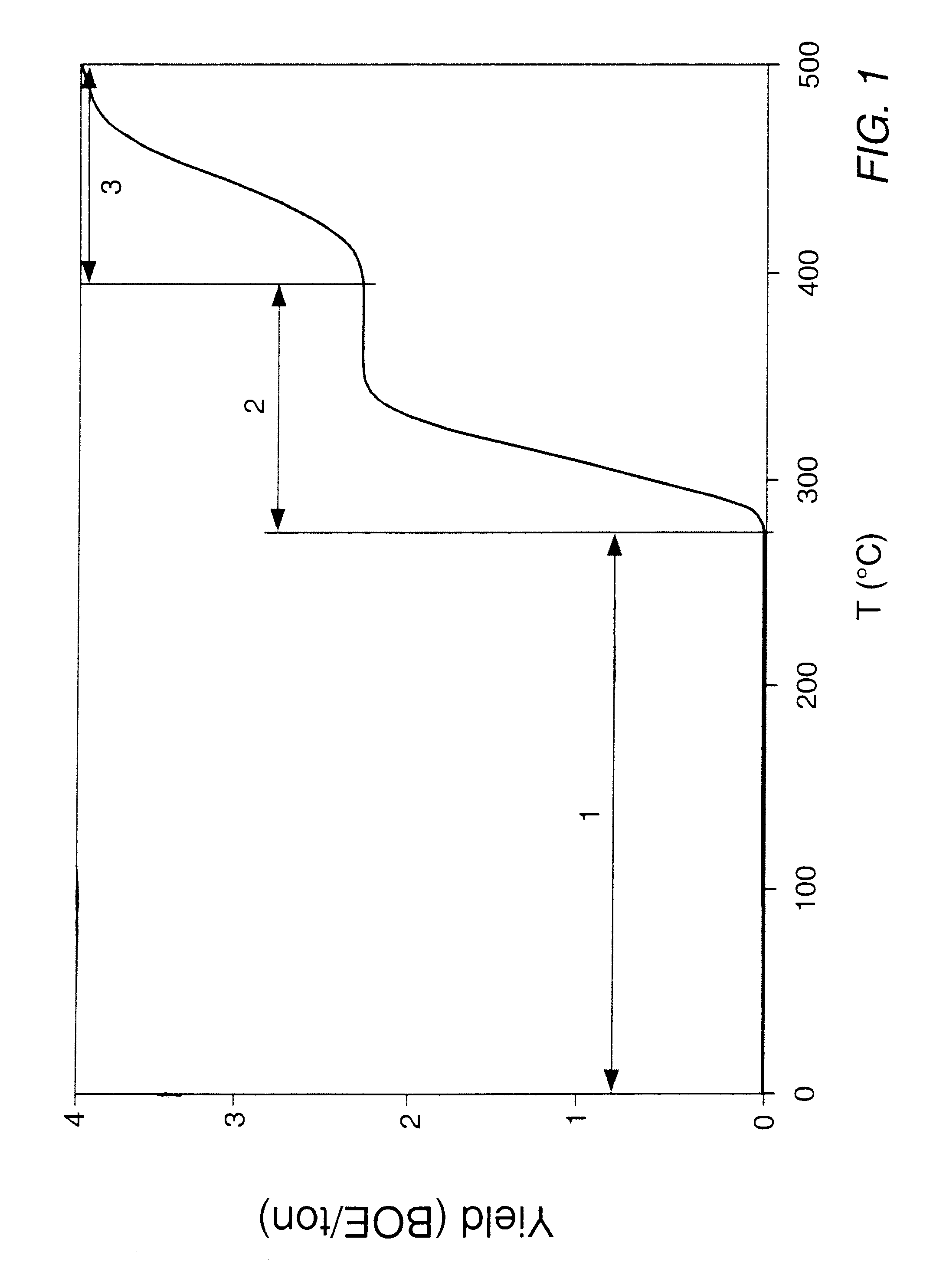

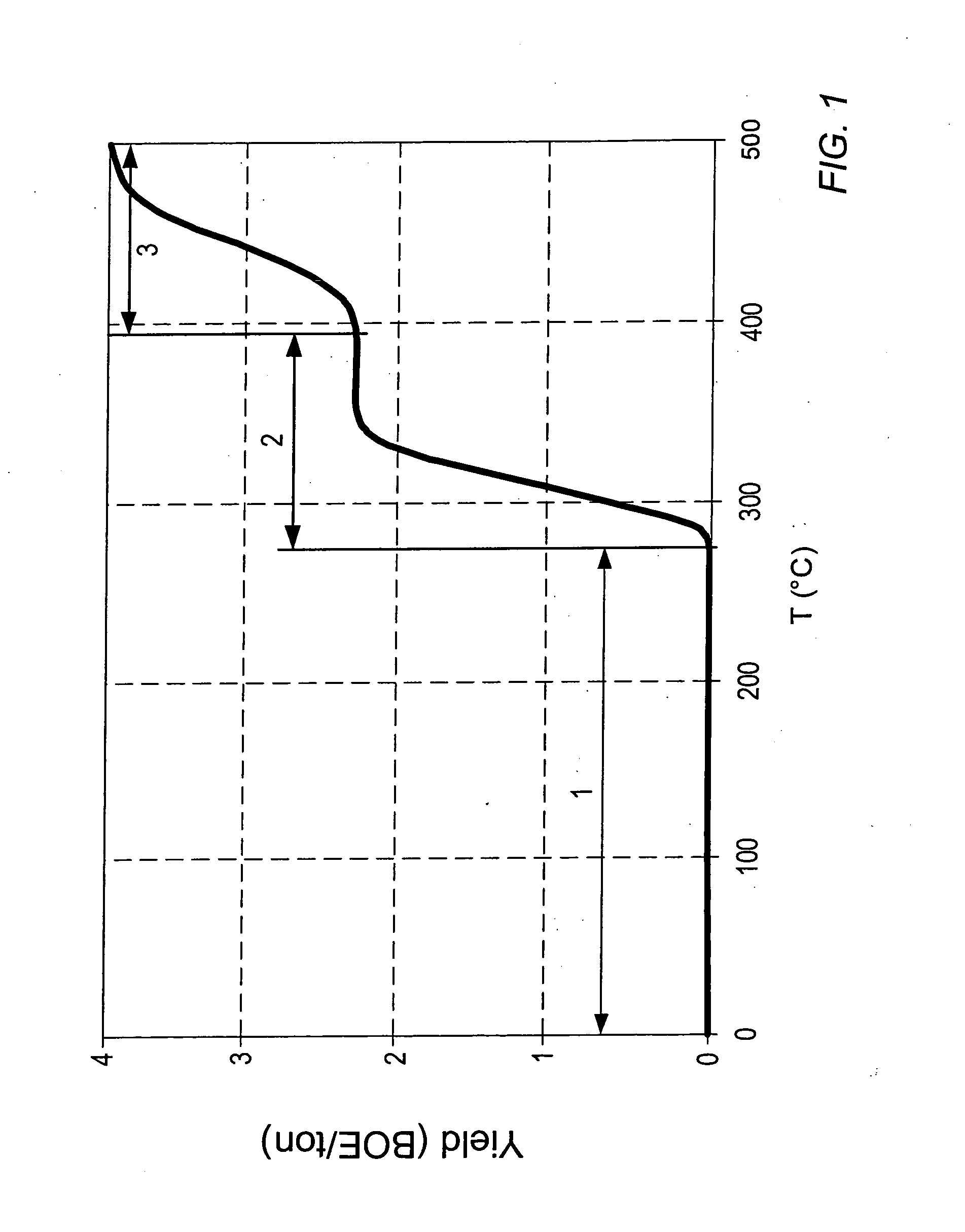

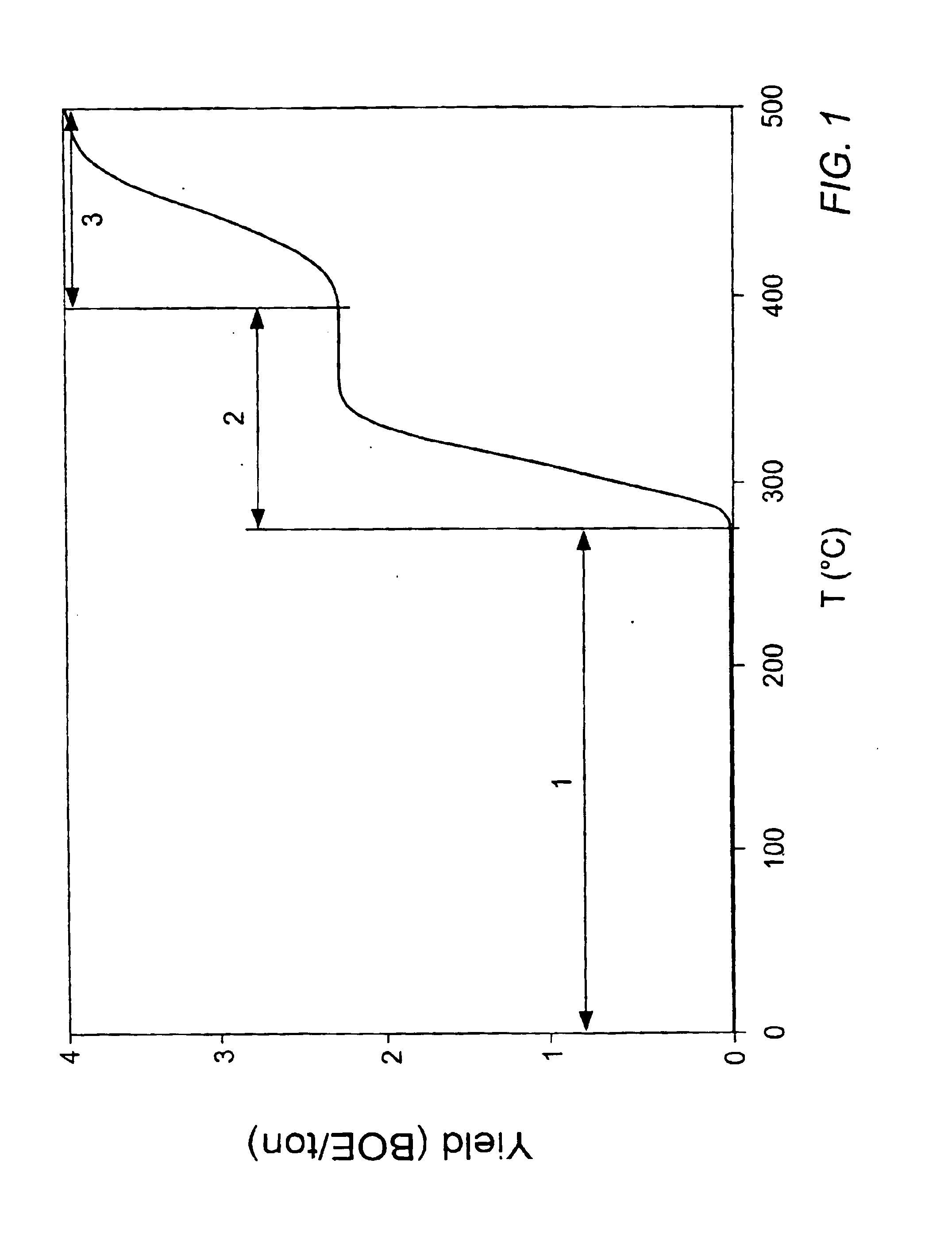

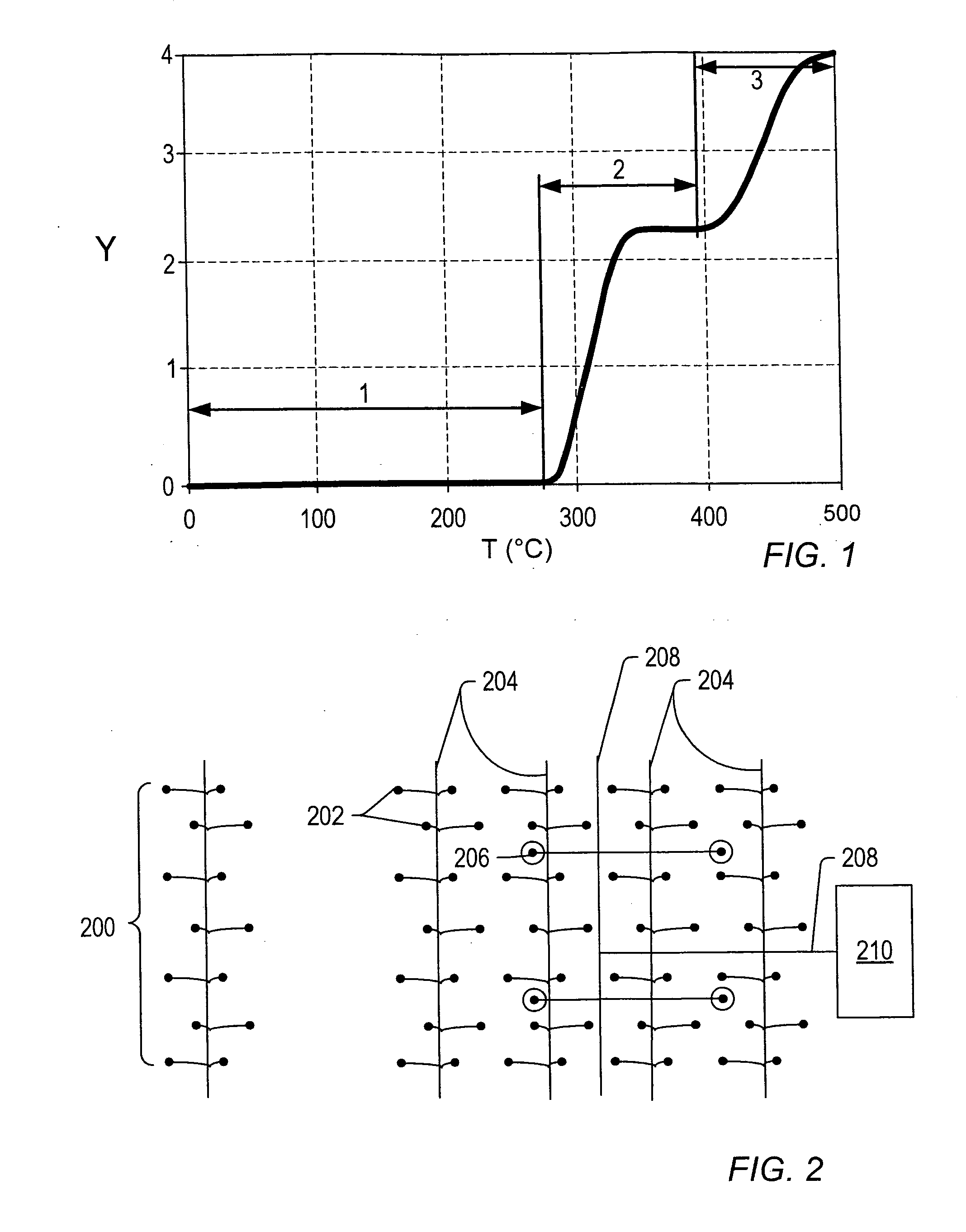

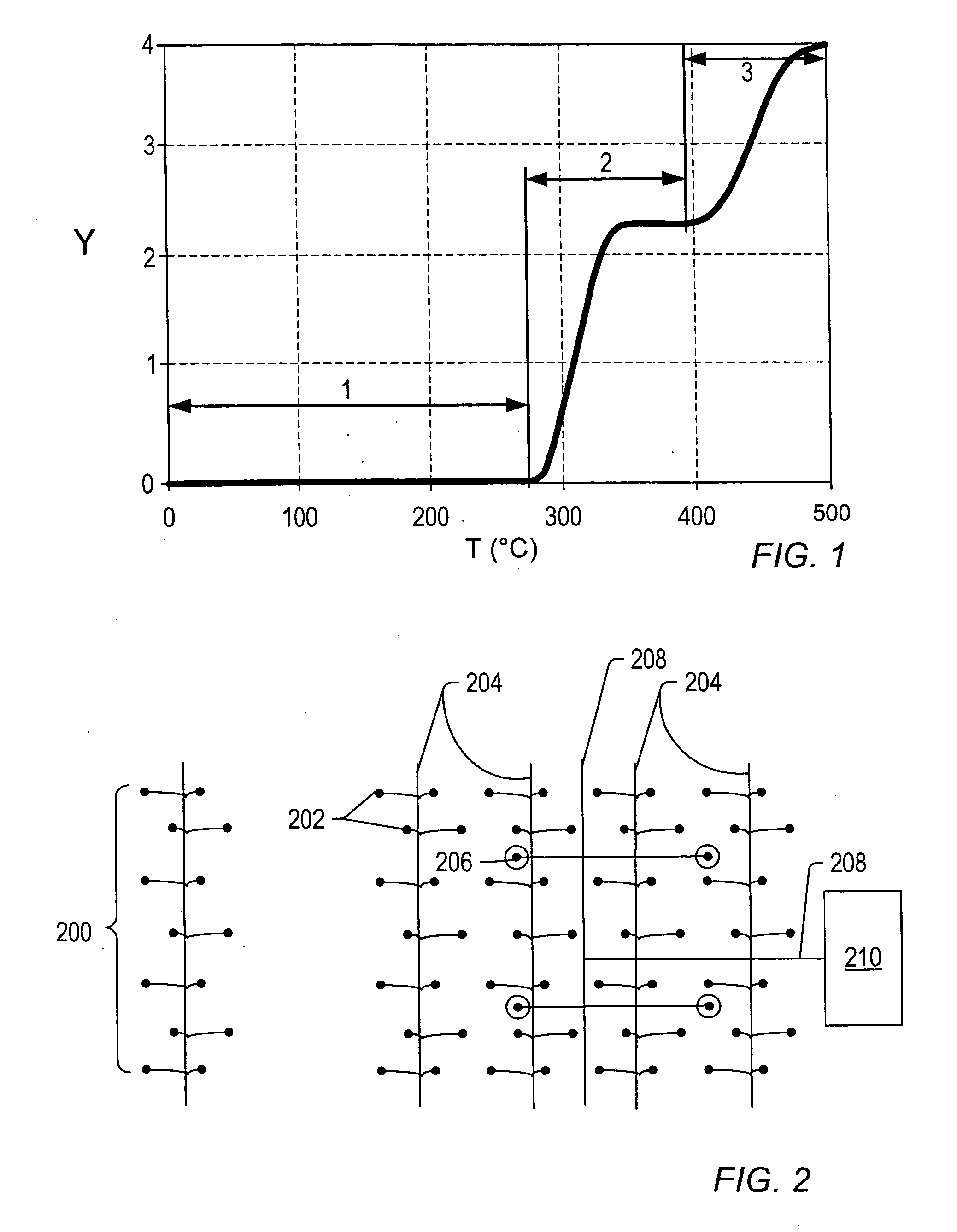

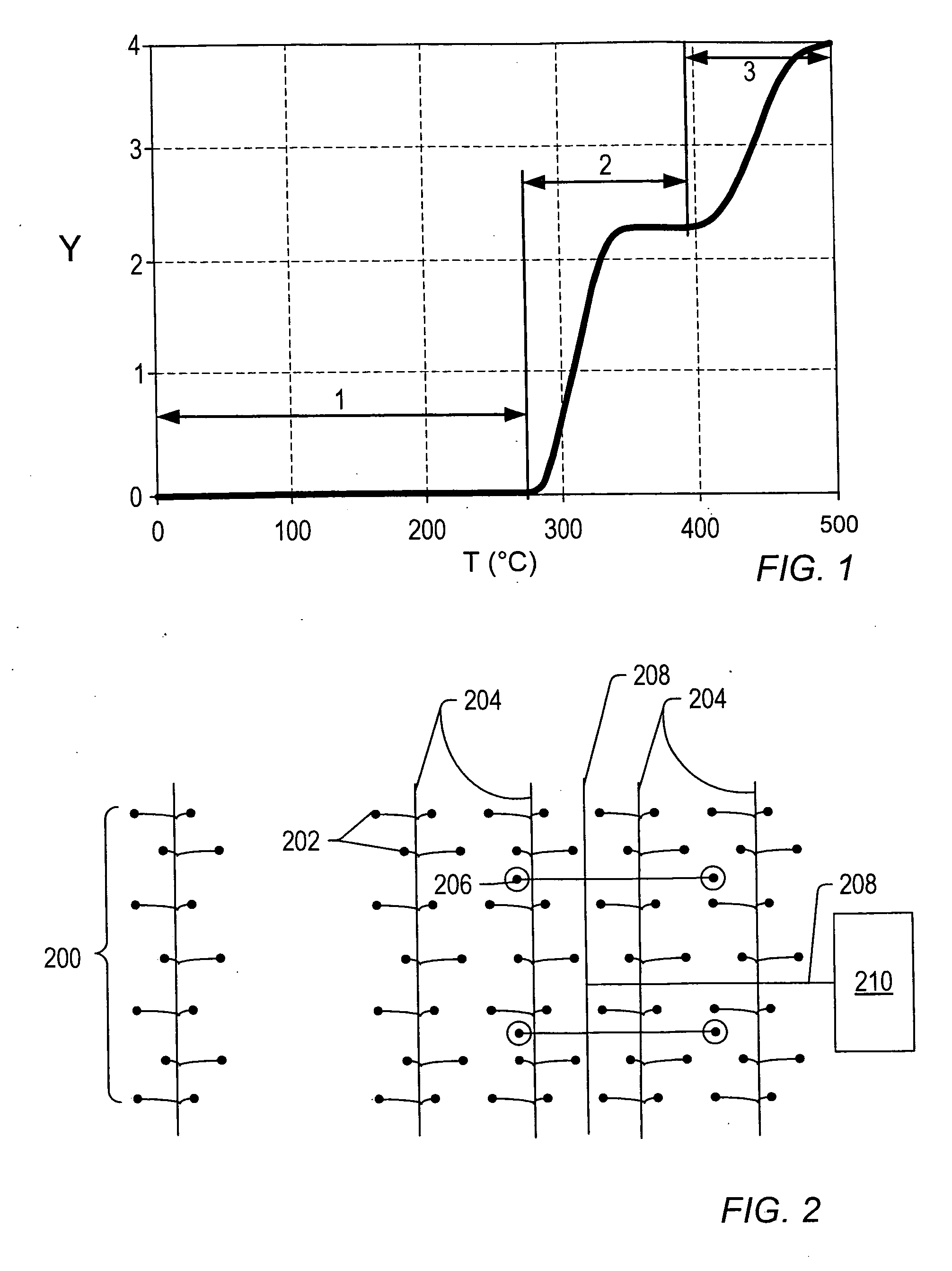

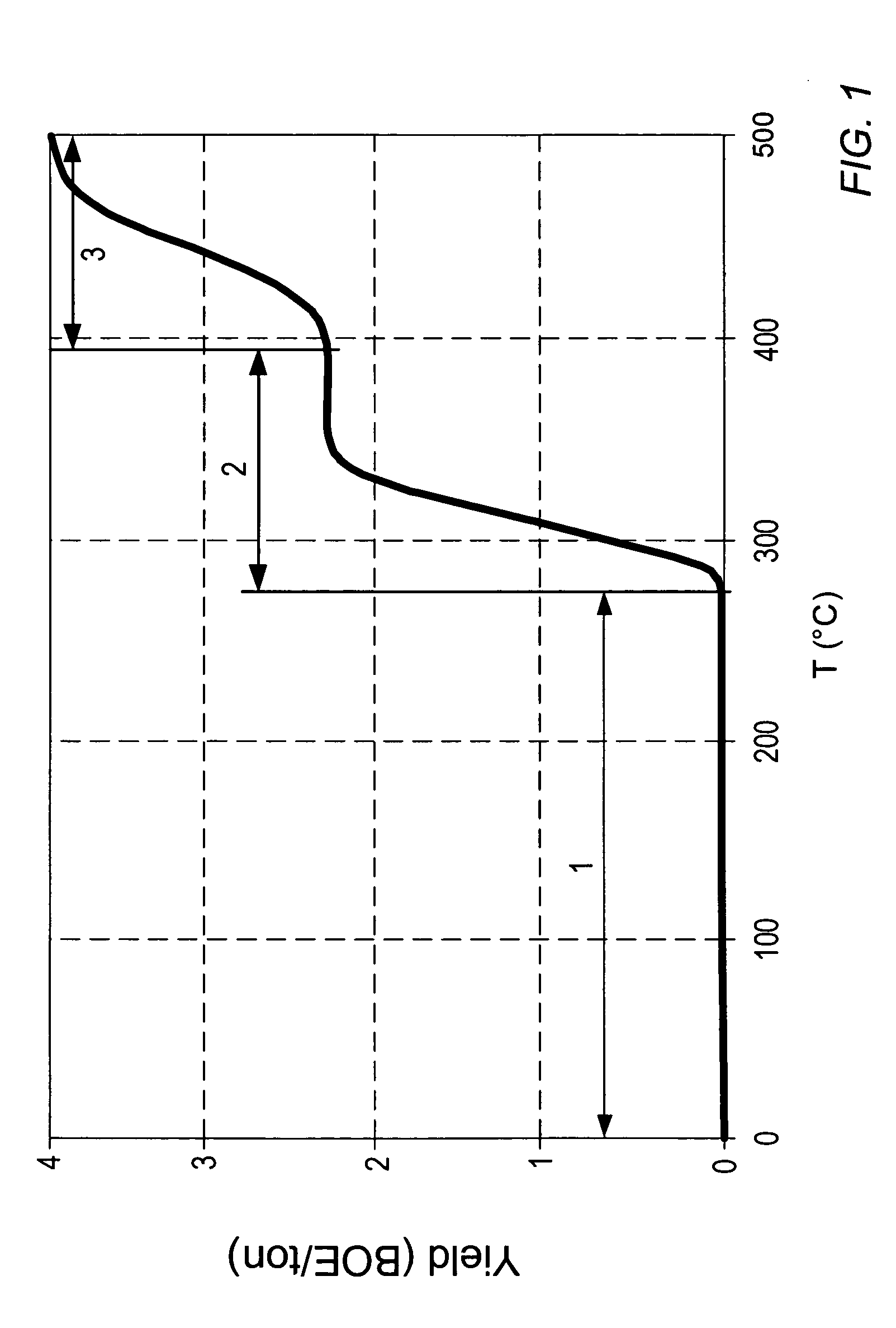

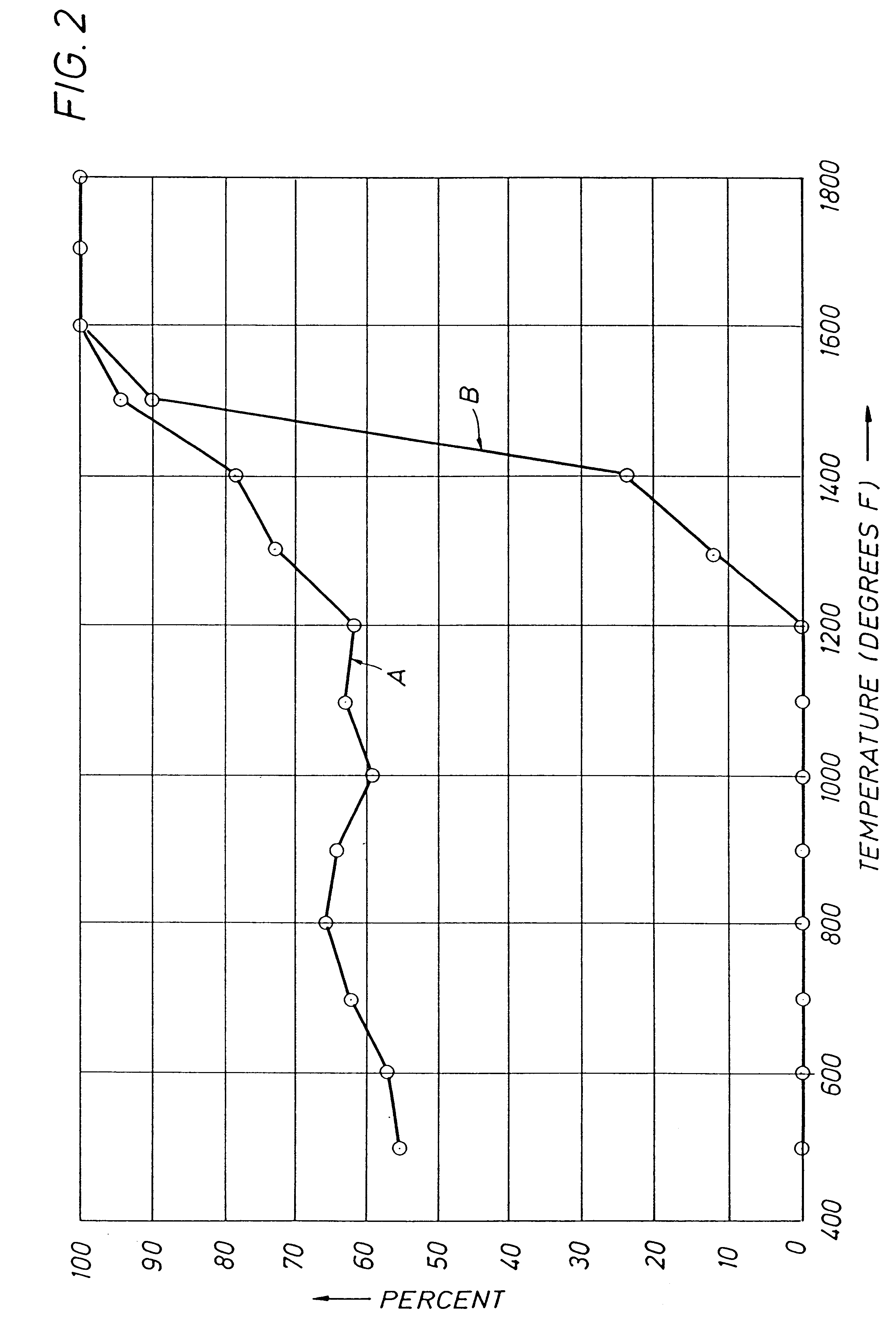

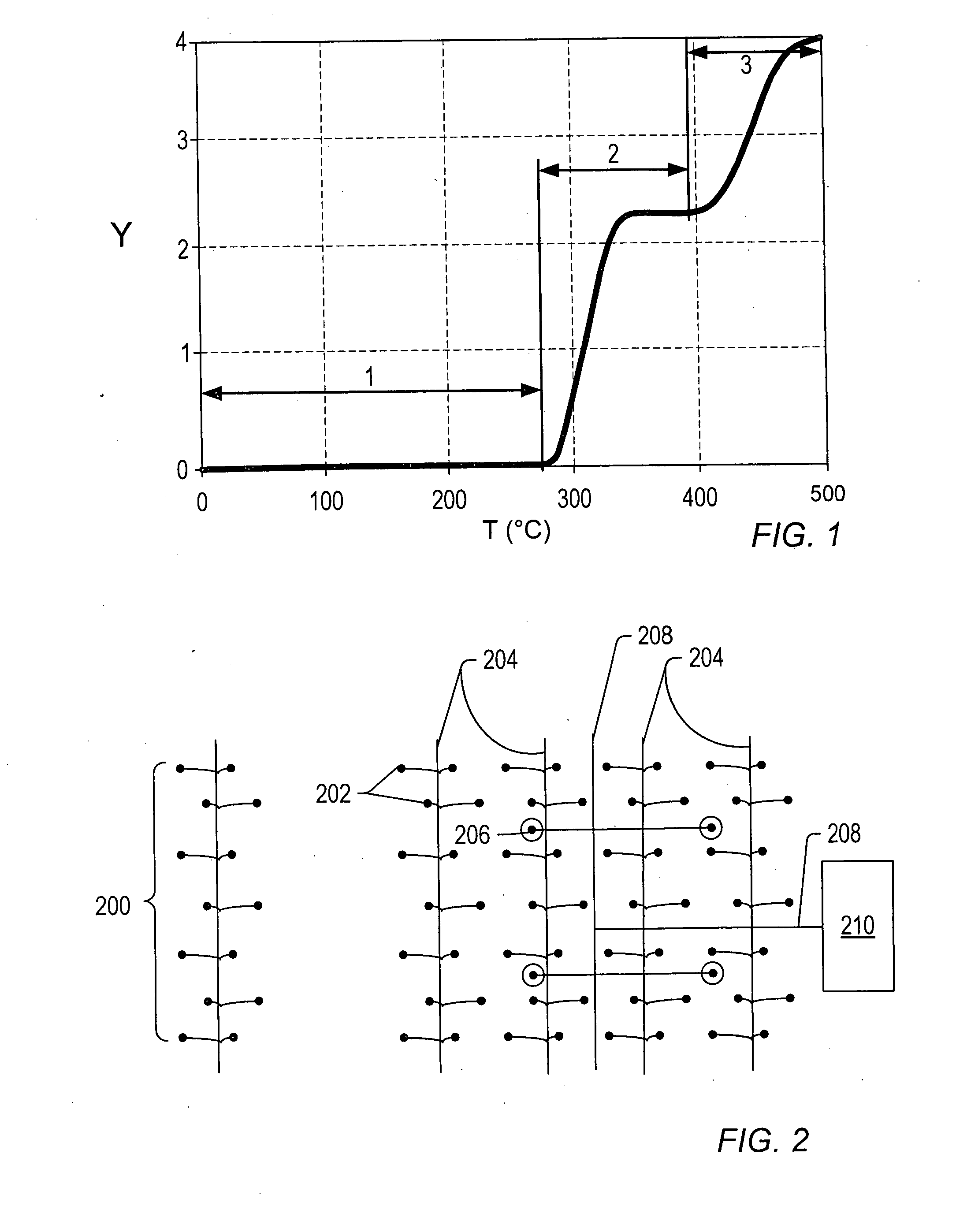

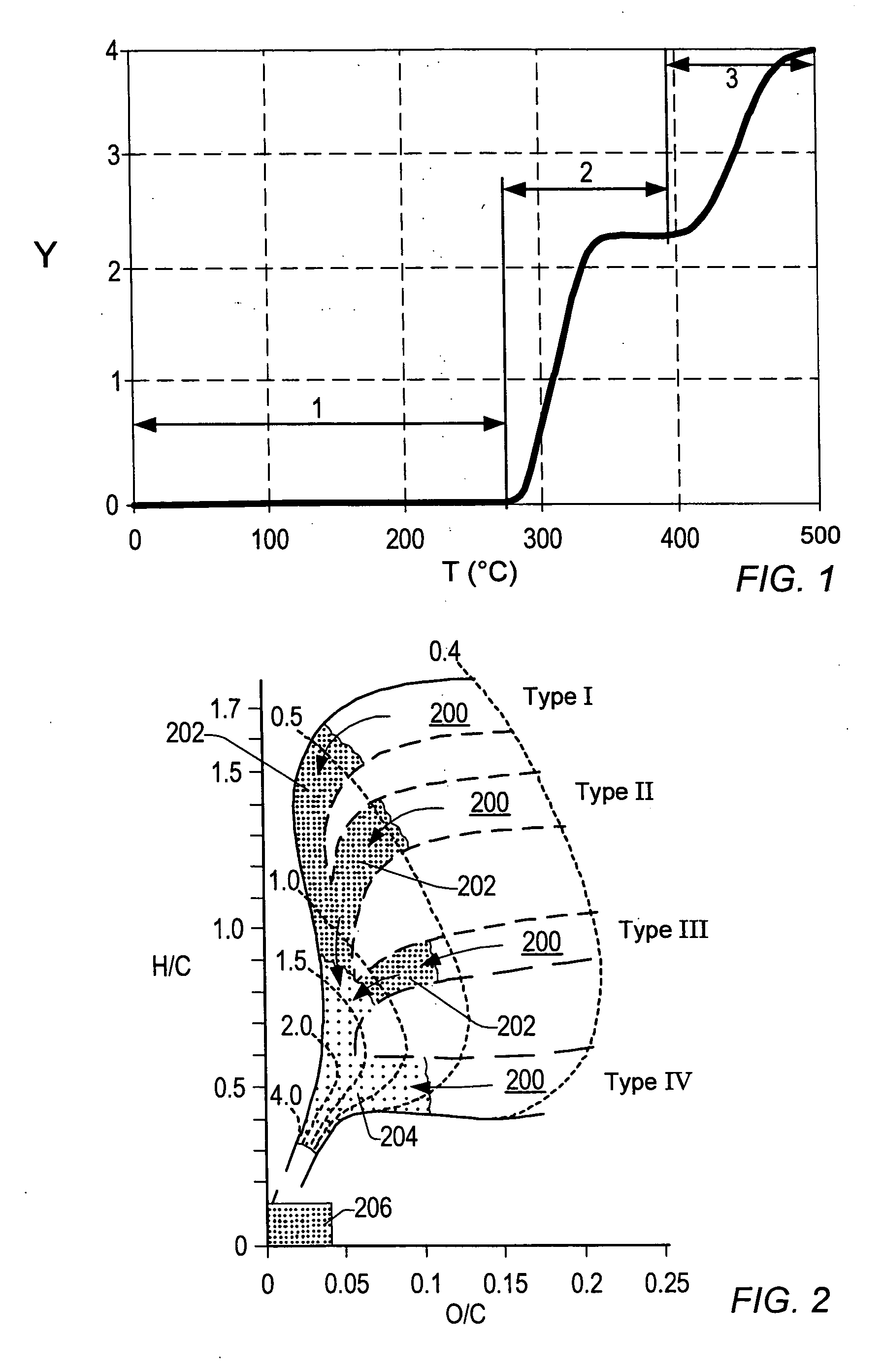

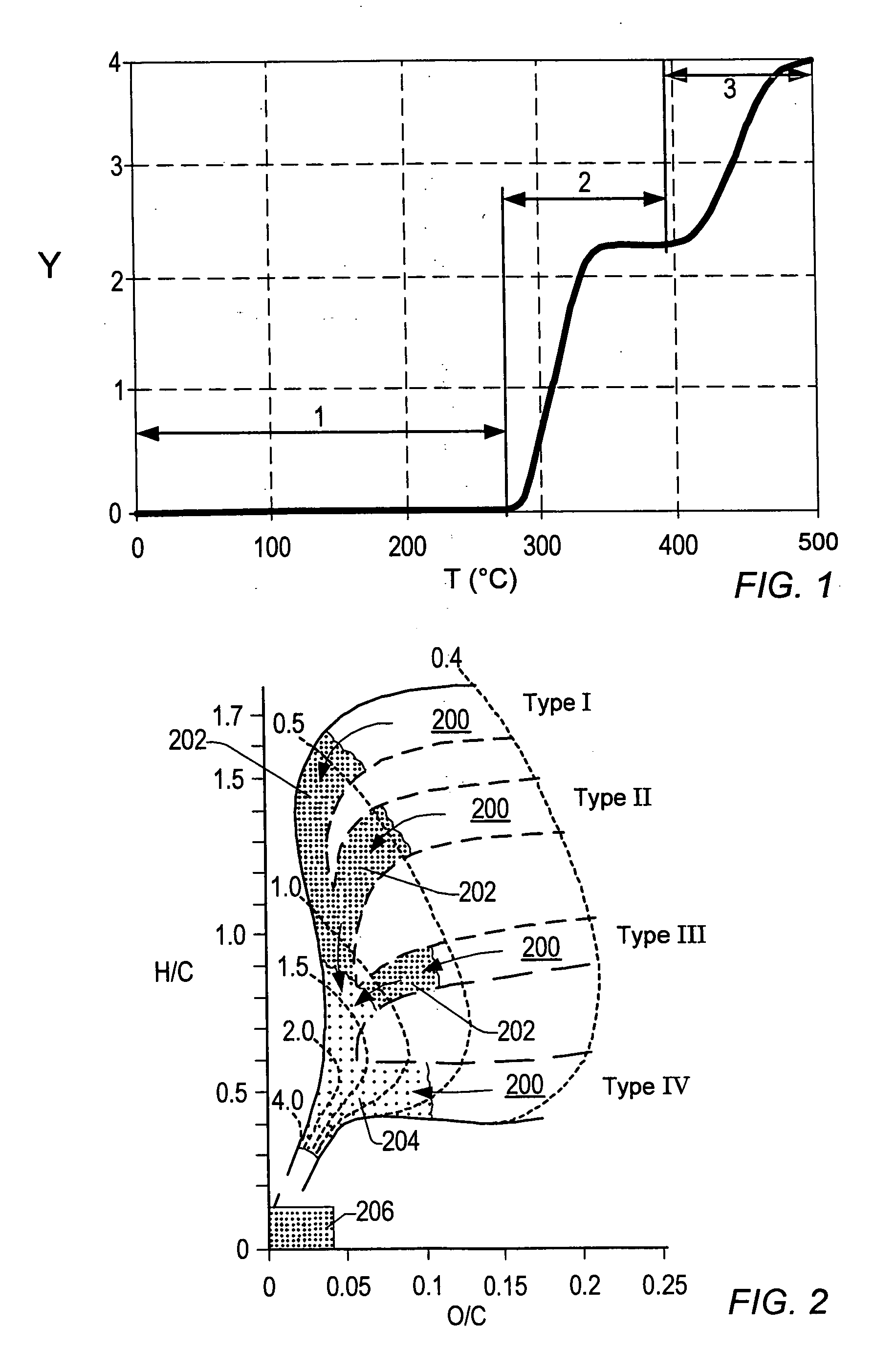

In situ thermal processing of a hydrocarbon containing formation using a controlled heating rate

InactiveUS6745837B2High calorific valueImprove the heating effectSurveyCombustion processFormation fluidHeat energy

A hydrocarbon containing formation may be treated using an in situ thermal process. A mixture of hydrocarbons, H.sub.2, and / or other formation fluids may be produced from the formation. Heat may be applied to the formation to raise a temperature of a portion of the formation to a pyrolysis temperature. A heating rate to a selected volume of the formation may be controlled by altering an amount of heating energy per day that is provided to the selected volume.

Owner:SALAMANDER SOLUTIONS INC

Variable frequency temperature limited heaters

InactiveUS20050006097A1Avoid deformationReduce heatThermal drillingInsulationElectrical resistance and conductancePower flow

A heater system may include an alternating current supply and an electrical conductor. Alternating current may be applied to one or more electrical conductors at a frequency between about 100 Hz and about 1000 Hz. The electrical conductors may be located in a formation. The electrical conductors may resistively heat upon application of the alternating electrical current. At least one of the electrical conductors may include an electrically resistive ferromagnetic material. The electrical conductor may provide a reduced amount of heat above or near a selected temperature. Heat may transfer from the electrical conductor to a part of formation.

Owner:SHELL OIL CO

Method and apparatus for repair of wells utilizing meltable repair materials and exothermic reactants as heating agents

A method and apparatus are described for creating a fluid seal in a subterranean well structure having a fluid seal defect. The method comprises introducing a meltable repair material proximate a structure in a subterranean well which has a fluid seal defect or enhanced seal capacity is required or it is desired to temporarily or permanently hydraulically isolate a portion the well or strengthen the structural integrity of well tubulars or tubular hangers. Exothermic reactant materials are located proximate the meltable repair material. The exothermic reactant material is ignited or an exothermic reaction otherwise initiated which supplies heat to and melts the meltable repair material into a molten mass. The molten mass flows and solidifies across the structure and the fluid seal defect to effect a fluid seal in the subterranean well structure or the structural integrity is enhanced. Examples of preferred exothermic reactant materials include thermite, thermate, fusible chemical reactants such as ammonium chloride and sodium nitrate, and oxidizers and accompanying hydrocarbon based fuels. Examples of preferred meltable repair materials include solder or brazing materials and eutectic metals which expand upon cooling and solidifying from a molten state.

Owner:CHEVROU USA INC

In situ thermal processing of a coal formation to increase a permeability/porosity of the formation

InactiveUS6866097B2Reduce the temperatureHigh strengthSurveyCombustion processPorosityInitial permeability

Owner:SHELL OIL CO

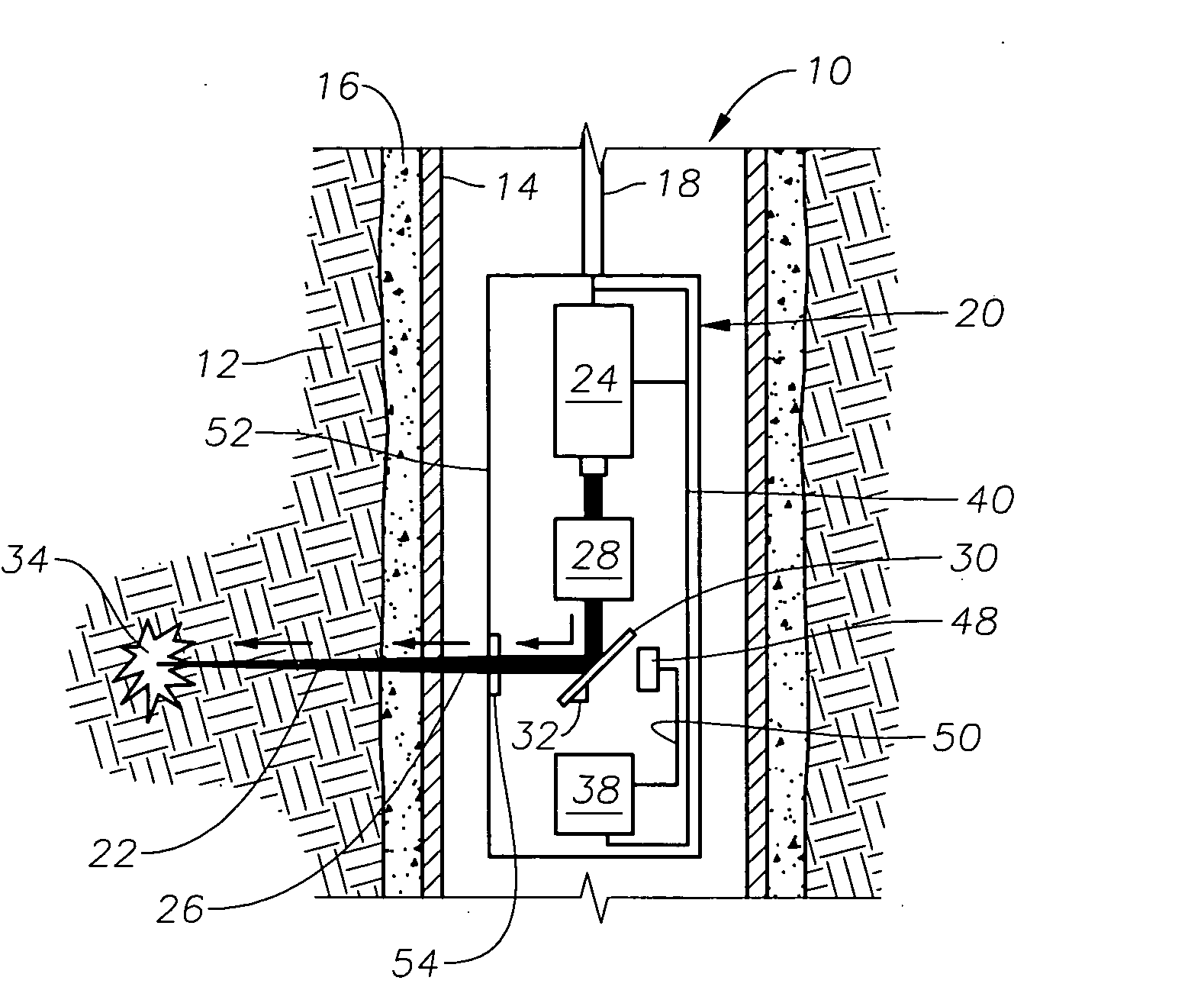

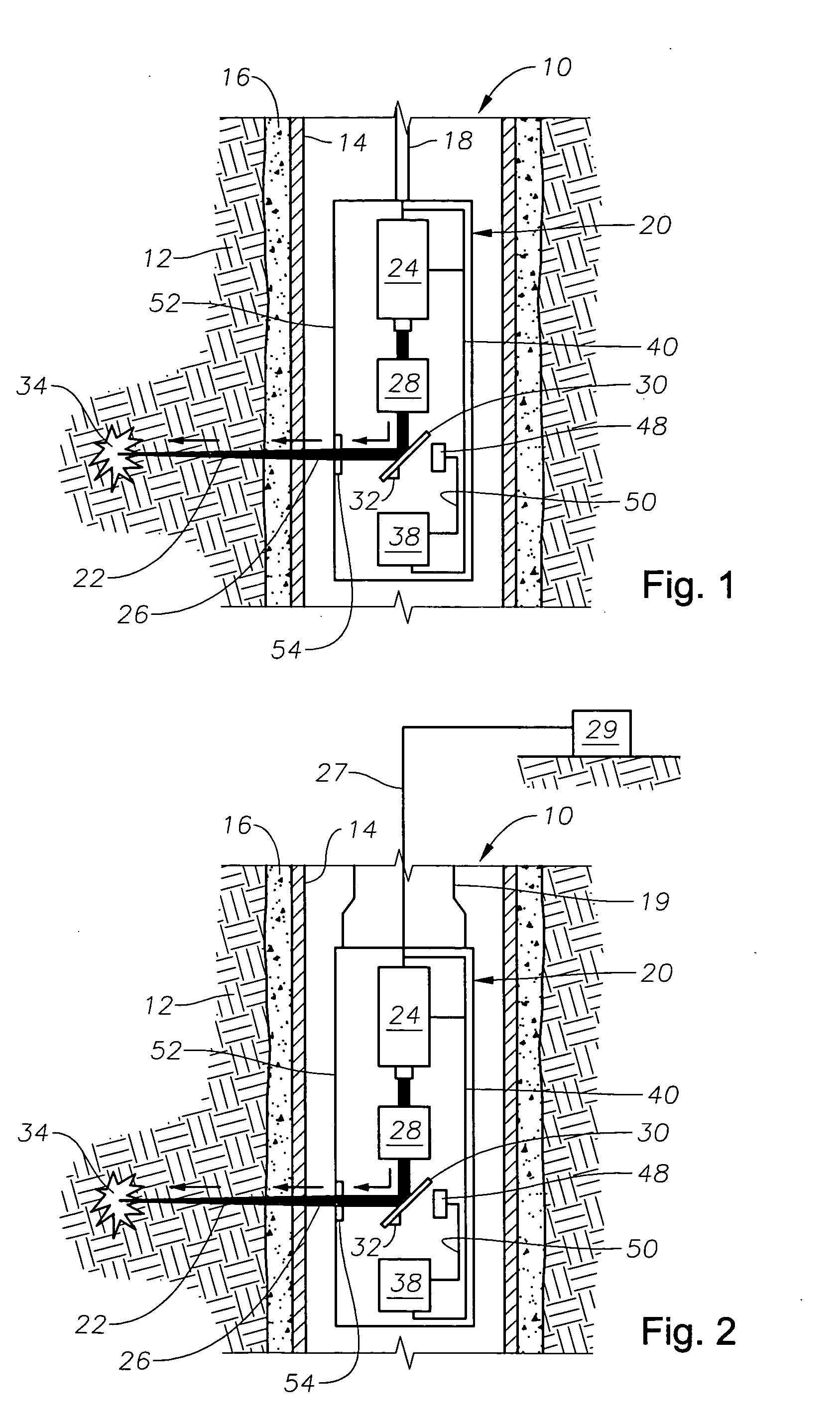

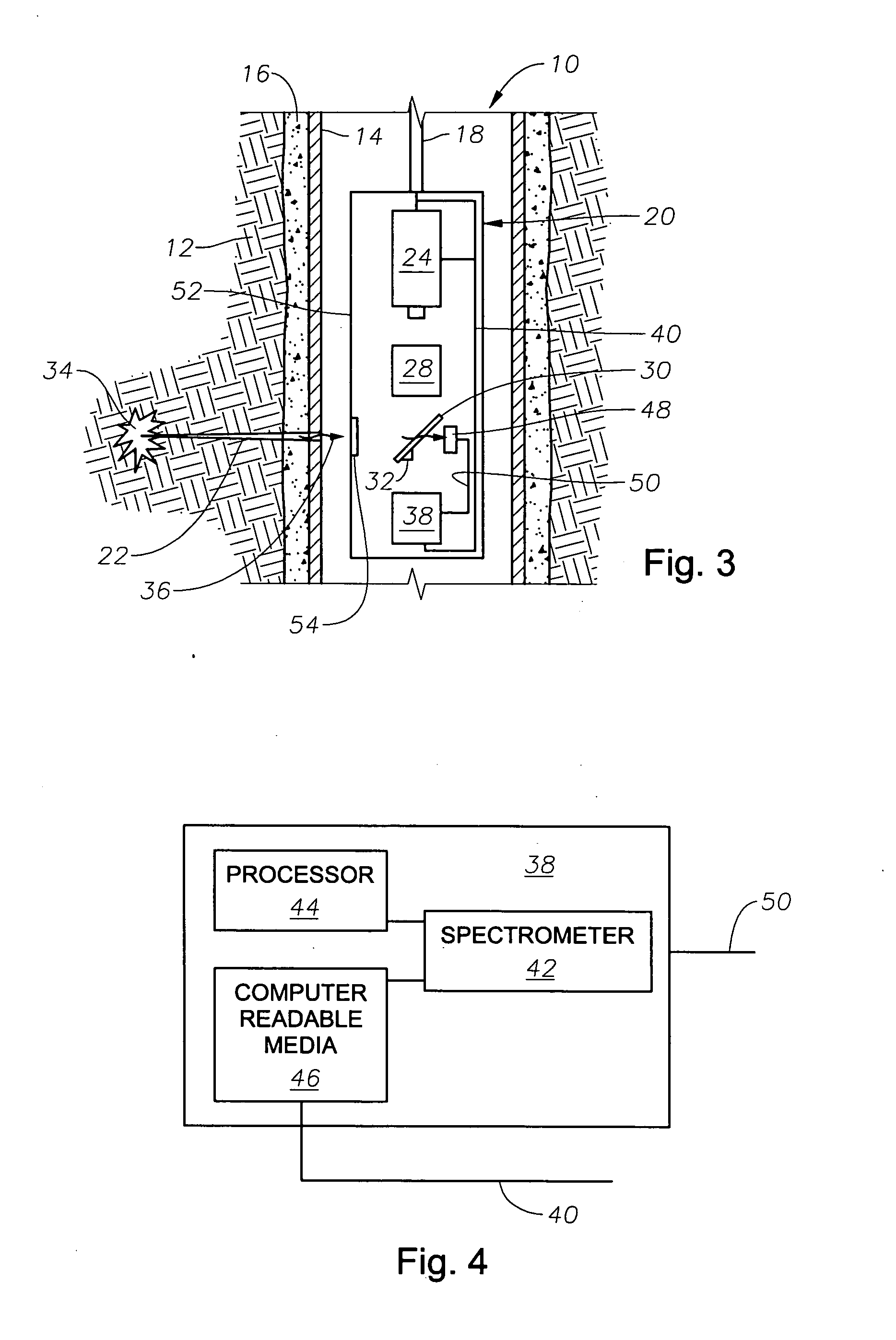

Drilling, perforating and formation analysis

ActiveUS20060102343A1Easy to useImprove breathabilitySpectrum investigationConstructionsMaterial removalWell drilling

A system and method of drilling and / or perforating uses a laser beam to remove material, such as to perforate the casing, cement and formation or drill a well bore. The system and method can further or alternately encompass material analysis that can be performed without removing the material from the well bore. The analysis can be performed apart from or in connection with drilling operations and / or perforating the casing, cement and formation. The analysis can be used in a feed back loop to adjust material removal, adjust material analysis, determine the location of future material removal, and for other uses.

Owner:HALLIBURTON ENERGY SERVICES INC

Subsurface heaters with low sulfidation rates

Owner:SHELL OIL CO

Temperature limited heaters with high power factors

Certain embodiments provide a heater. The heater includes a ferromagnetic member. The heater also includes an electrical conductor electrically coupled to the ferromagnetic member. The electrical conductor is configured to conduct a majority of time-varying electrical current passing through the heater at about 25° C. The heater is configured to provide a first heat output below the Curie temperature of the ferromagnetic member. The heater is configured to automatically provide a second heat output approximately at and above the Curie temperature of the ferromagnetic member. The second heat output is reduced compared to the first heat output.

Owner:SHELL OIL CO

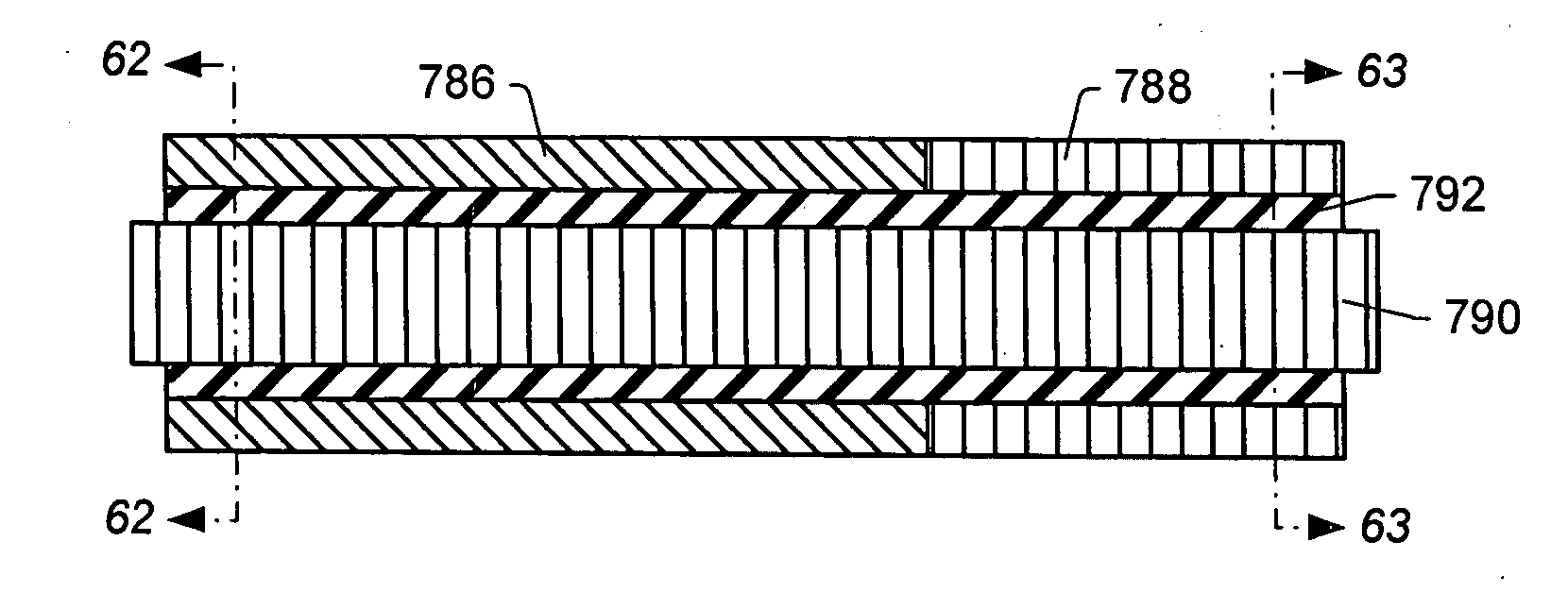

Subsurface electrical heaters using nitride insulation

Certain embodiments provide a heating system configurable to heat a subsurface formation. The system includes an electrical conductor configured to generate an electrically resistive heat output during application of electrical current to the electrical conductor. An electrical insulator at least partially surrounds the electrical conductor. The electrical insulator includes a nitride. A sheath at least partially surrounds the electrical insulator.

Owner:SHELL OIL CO

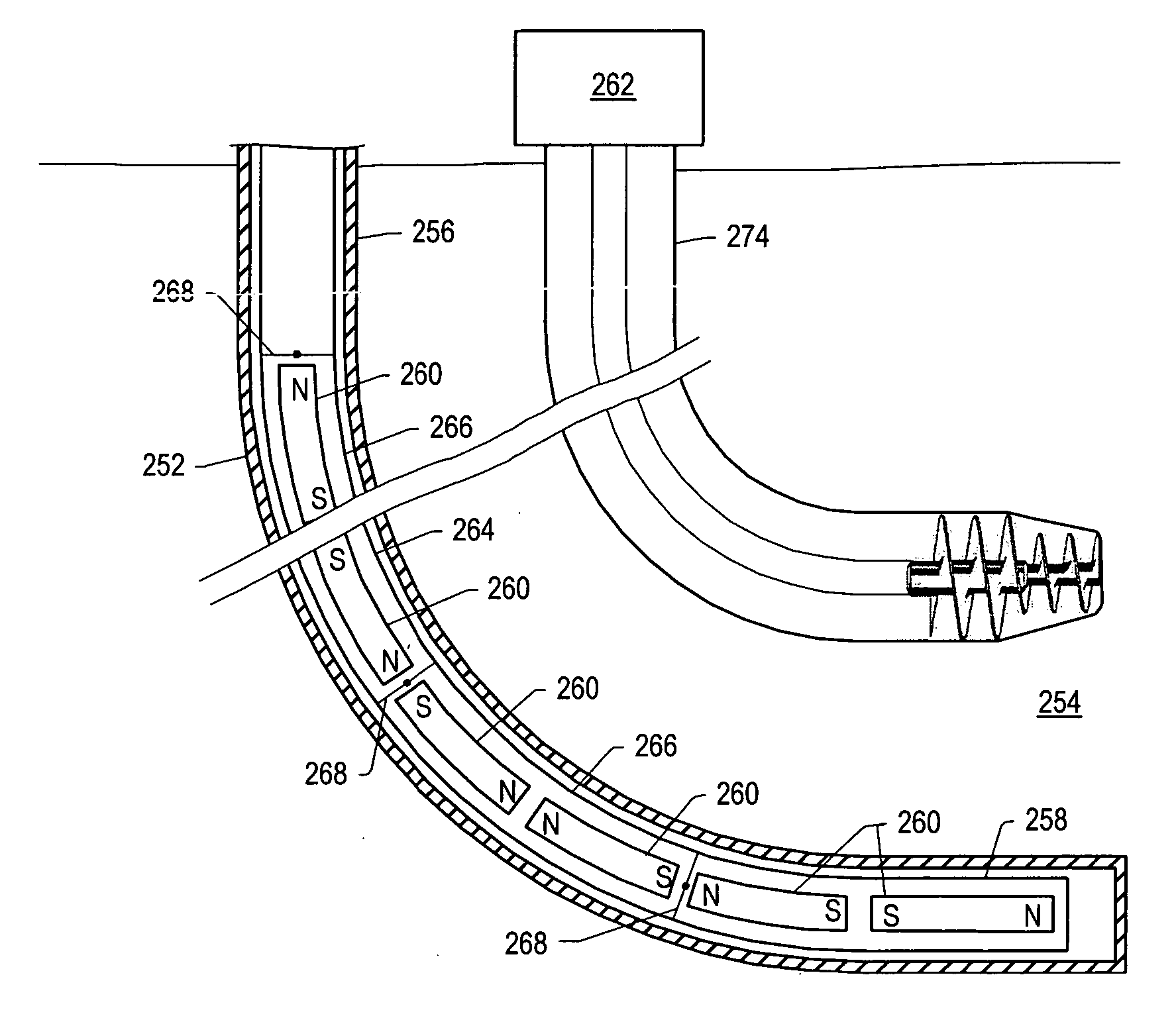

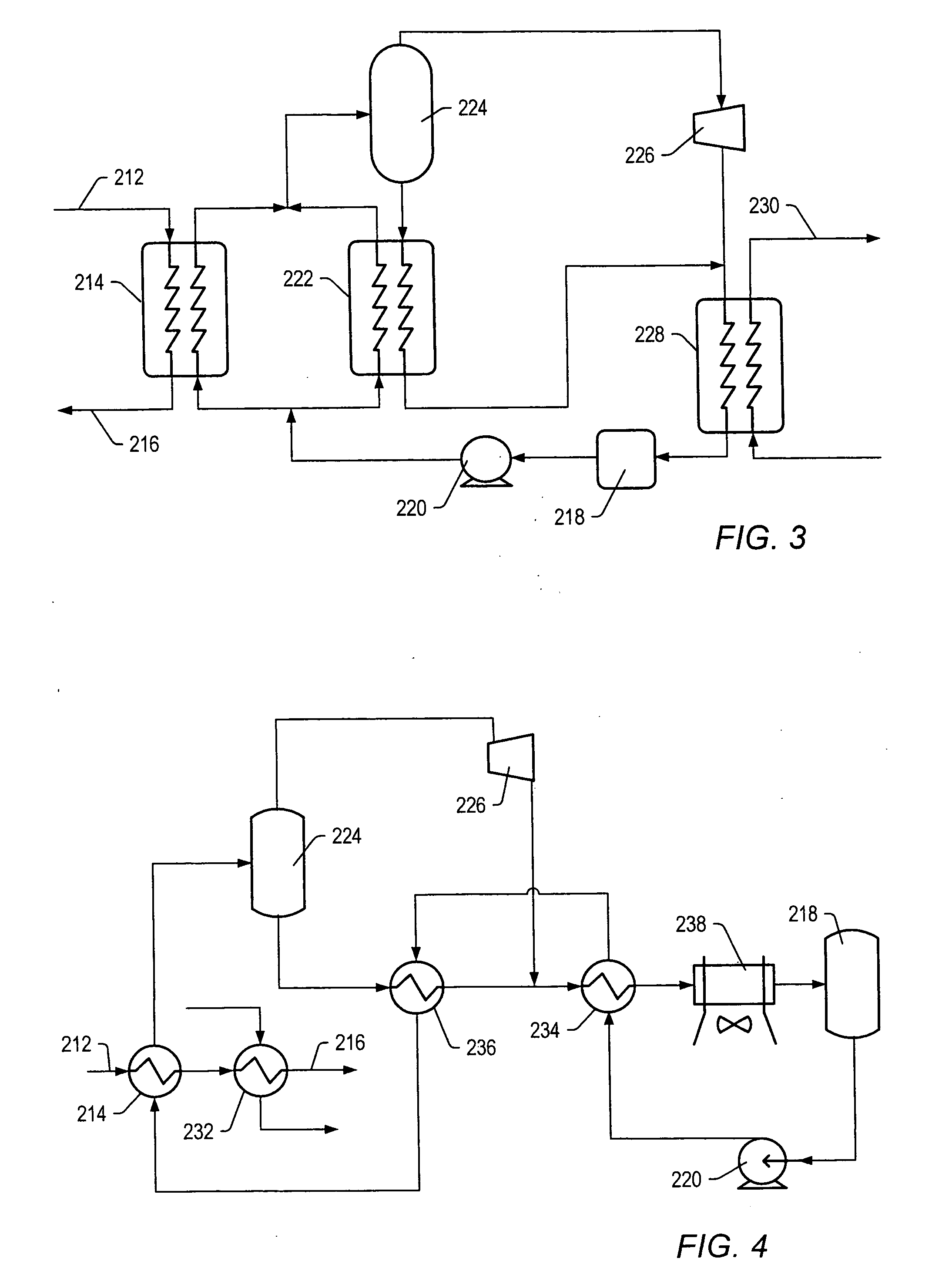

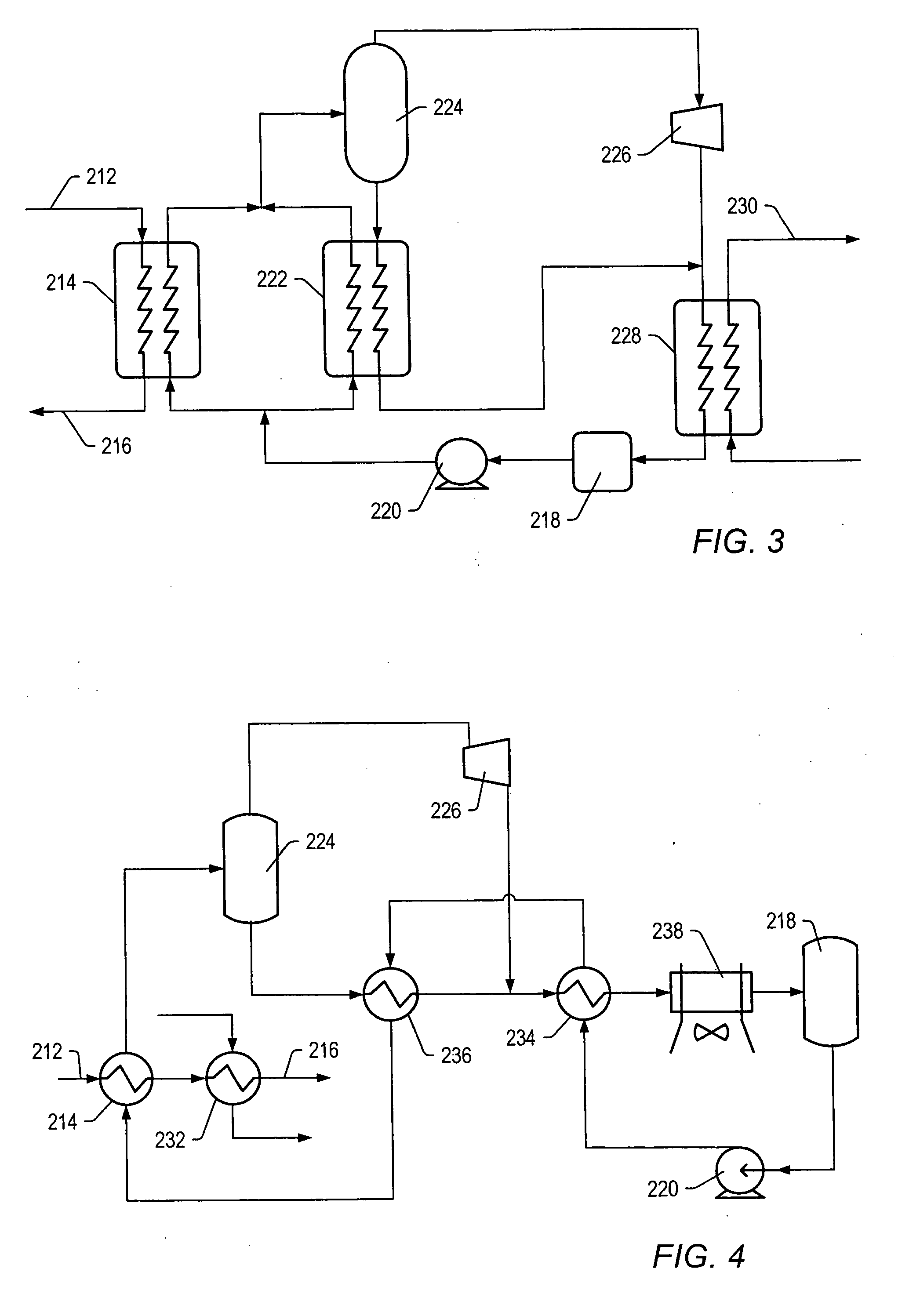

Cogeneration systems and processes for treating hydrocarbon containing formations

InactiveUS20070095536A1Thermal non-catalytic crackingCatalytic crackingElectricityNuclear engineering

A system for treating a hydrocarbon containing formation includes a steam and electricity cogeneration facility. At least one injection well is located in a first portion of the formation. The injection well provides steam from the steam and electricity cogeneration facility to the first portion of the formation. At least one production well is located in the first portion of the formation. The production well in the first portion produces first hydrocarbons. At least one electrical heater is located in a second portion of the formation. At least one of the electrical heaters is powered by electricity from the steam and electricity cogeneration facility. At least one production well is located in the second portion of the formation. The production well in the second portion produces second hydrocarbons. The steam and electricity cogeneration facility uses the first hydrocarbons and / or the second hydrocarbons to generate electricity.

Owner:SHELL OIL CO

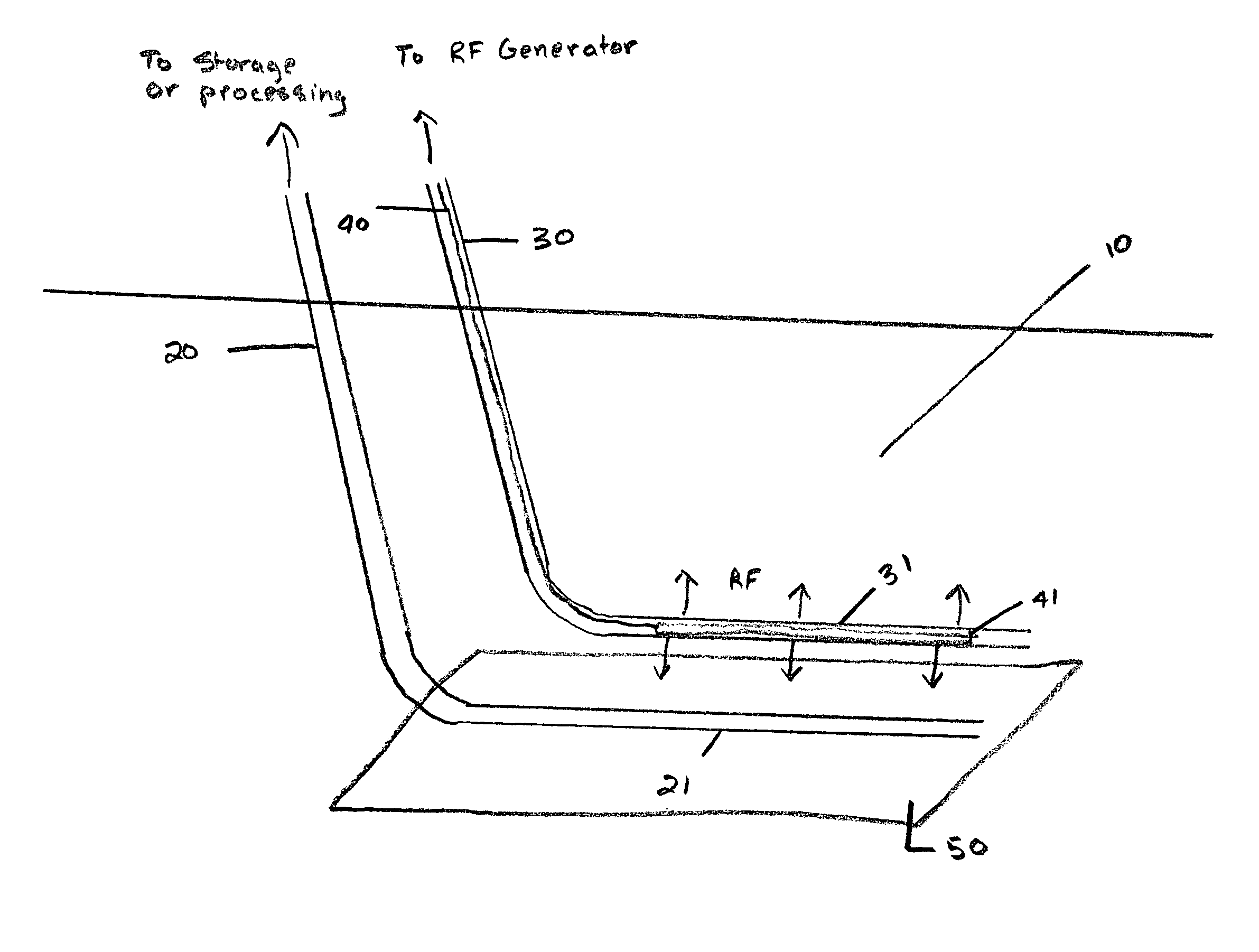

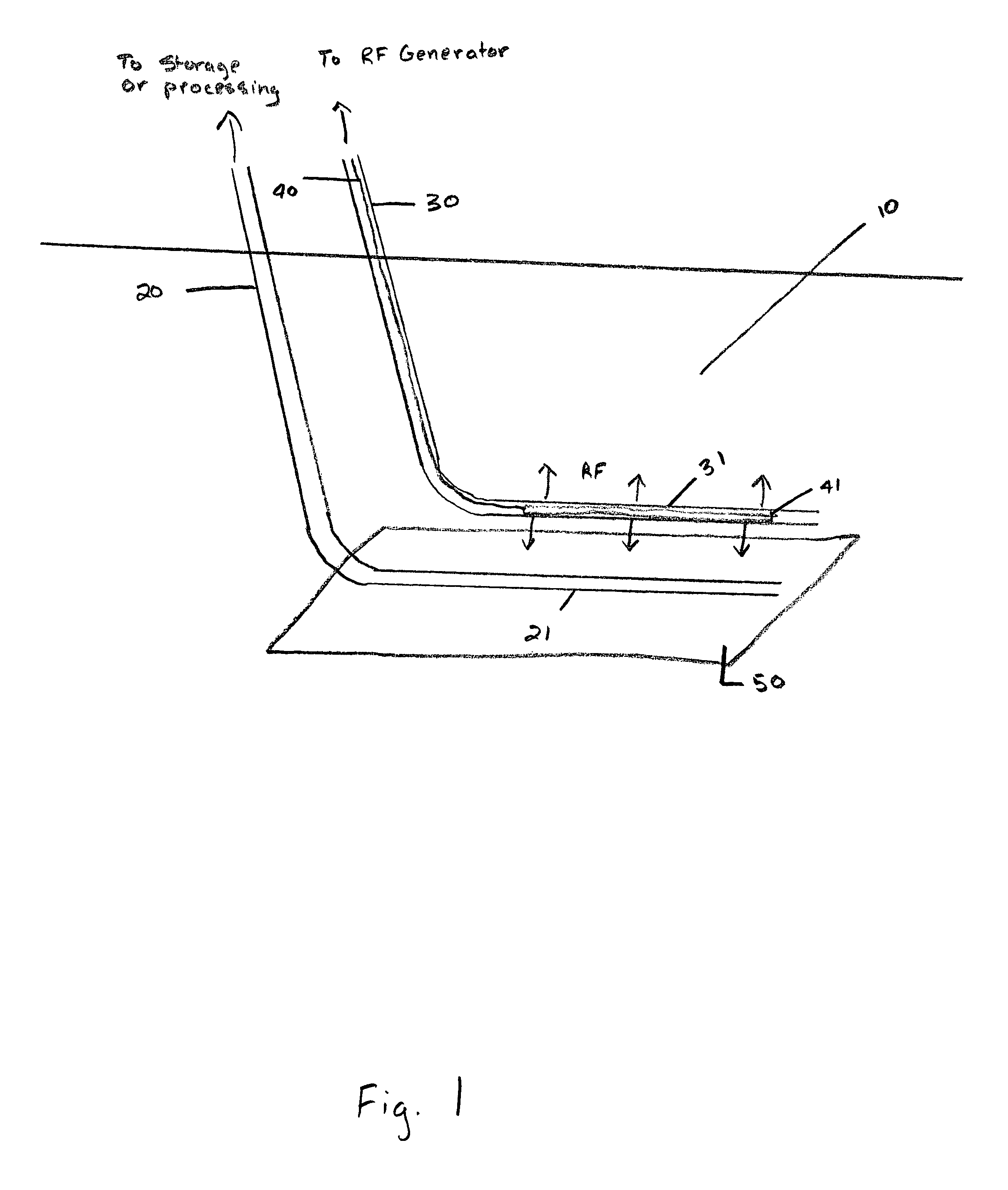

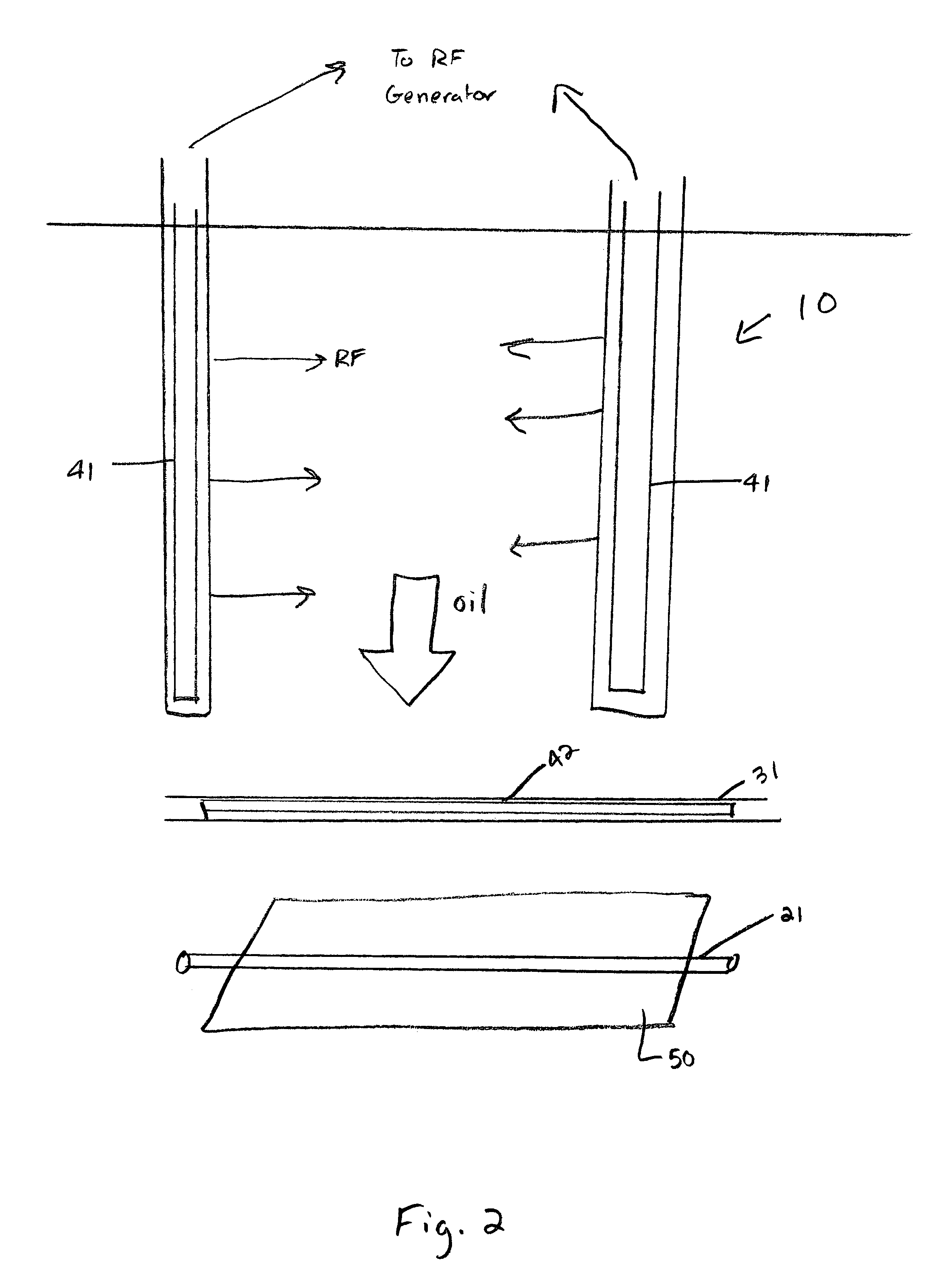

Method and apparatus for in-situ radiofrequency assisted gravity drainage of oil (RAGD)

InactiveUS7441597B2Promote recoveryEnhanced overall recoveryInsulationFluid removalHeavy crude oilFuel oil

The present invention relates generally to the use of radiofrequency energy to heat heavy crude oil or both heavy crude oil and subsurface water in situ, thereby enhancing the recovery and handling of such oil. The present invention further relates to methods for applying radiofrequency energy to heavy oils in the reservoir to promote in situ upgrading to facilitate recovery. This invention also relates to systems to apply radiofrequency energy to heavy oils in situ.

Owner:KSN ENERGIES

Drilling with a high pressure rotating control device

ActiveUS20110024195A1Operational securityHigh safety factorSurveyDrilling rodsWell drillingControl system

A Drill-To-The-Limit (DTTL) drilling method variant to Managed Pressure Drilling (MPD) applies constant surface backpressure, whether the mud is circulating (choke valve open) or not (choke valve closed). Because of the constant application of surface backpressure, the DTTL method can use lighter mud weight that still has the cutting carrying ability to keep the borehole clean. The DTTL method identifies the weakest component of the pressure containment system, such as the fracture pressure of the formation or the casing shoe leak off test (LOT). With a higher pressure rated RCD, such as 5,000 psi (34,474 kPa) dynamic or working pressure and 10,000 psi (68,948 kPa) static pressure, the limitation will generally be the fracture pressure of the formation or the LOT. In the DTTL method, since surface backpressure is constantly applied, the pore pressure limitation of the conventional drilling window can be disregarded in developing the fluid and drilling programs. Using the DTTL method a deeper wellbore can be drilled with larger resulting end tubulars, such as casings and production liners, than had been capable with conventional MPD applications.

Owner:WEATHERFORD TECH HLDG LLC

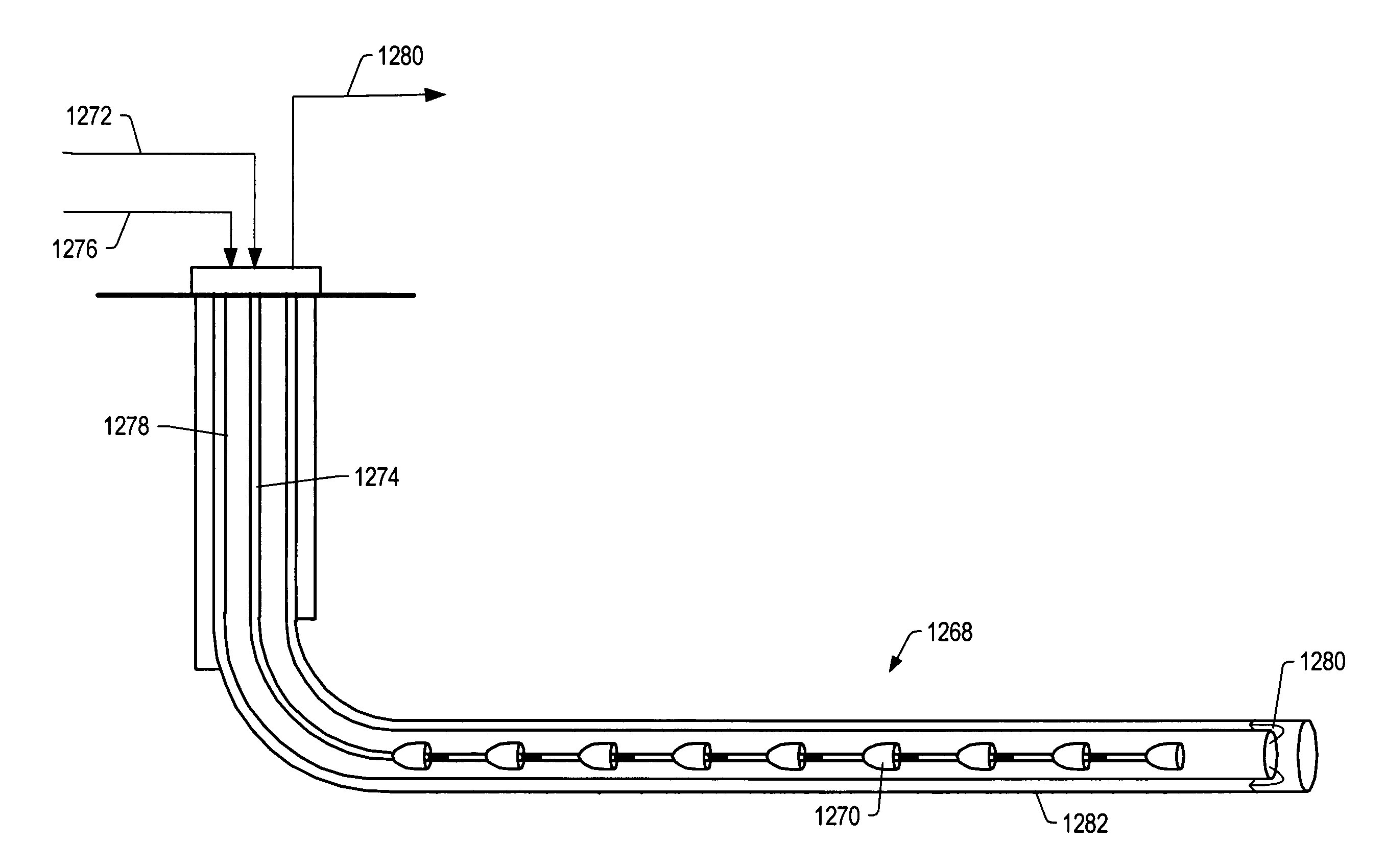

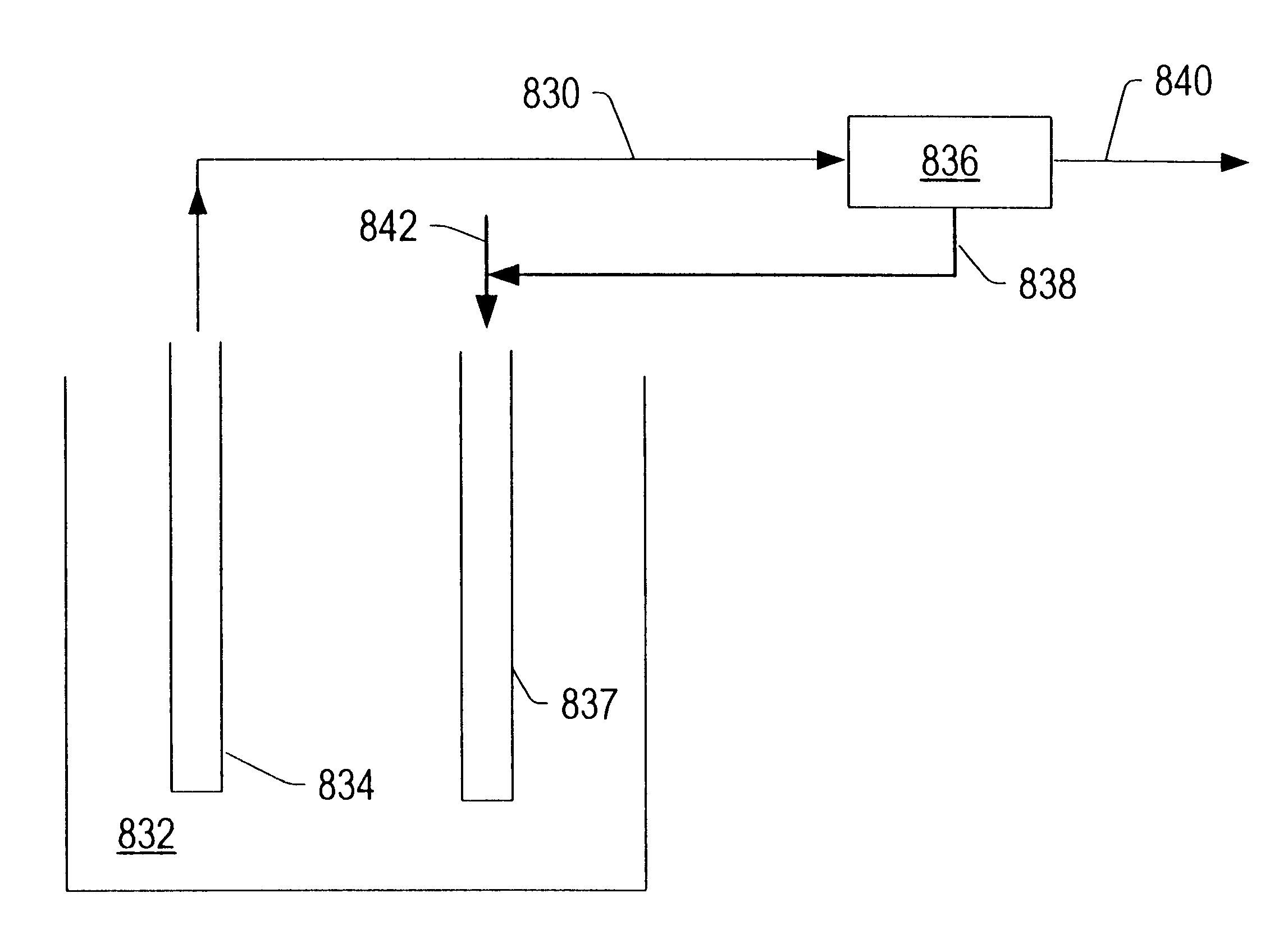

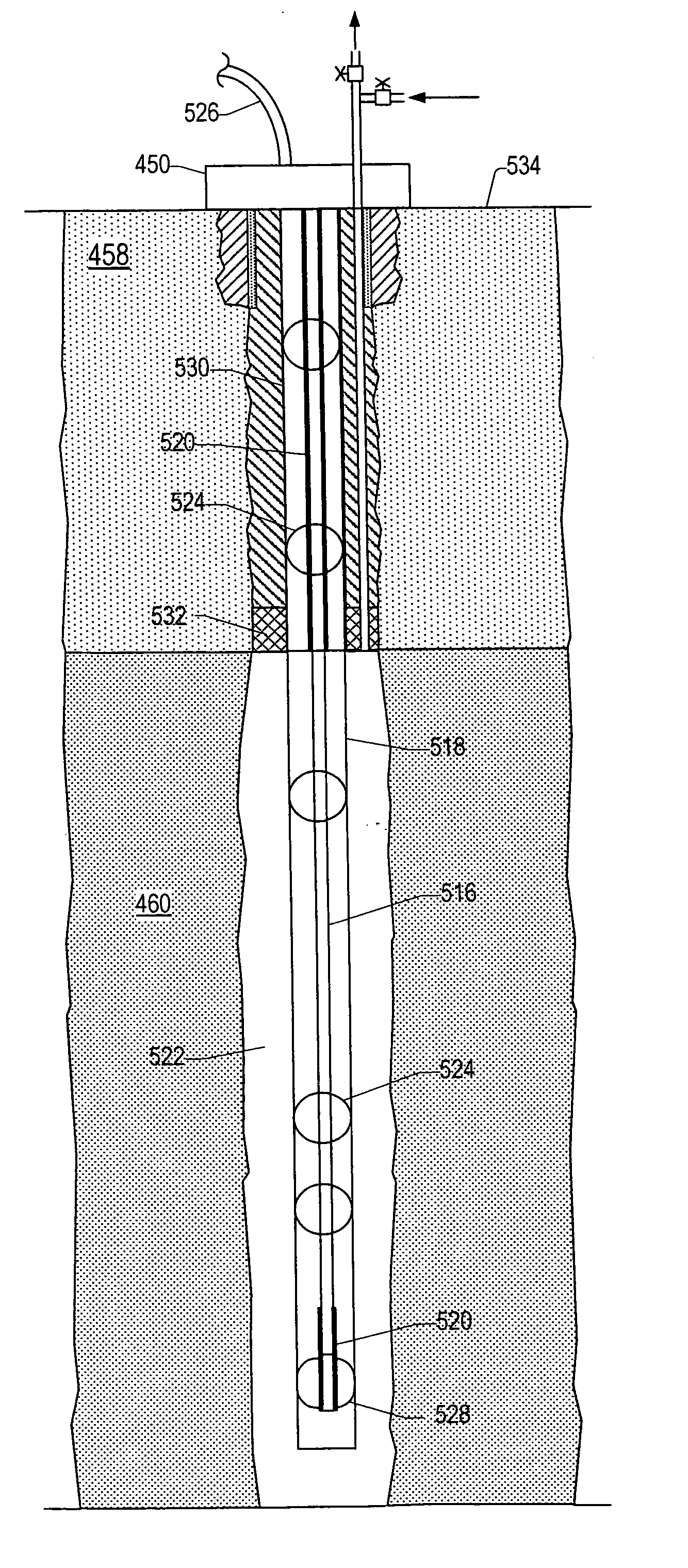

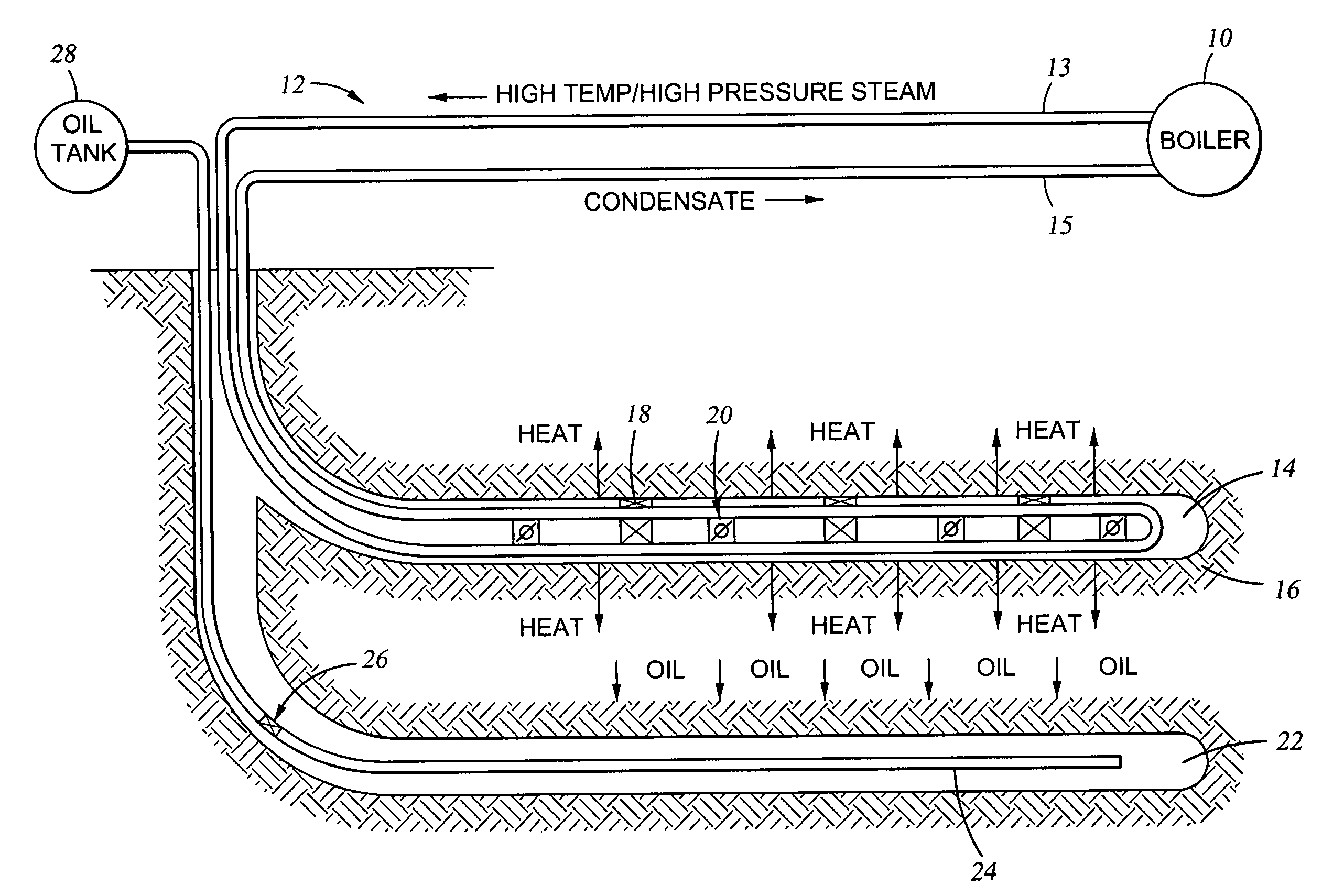

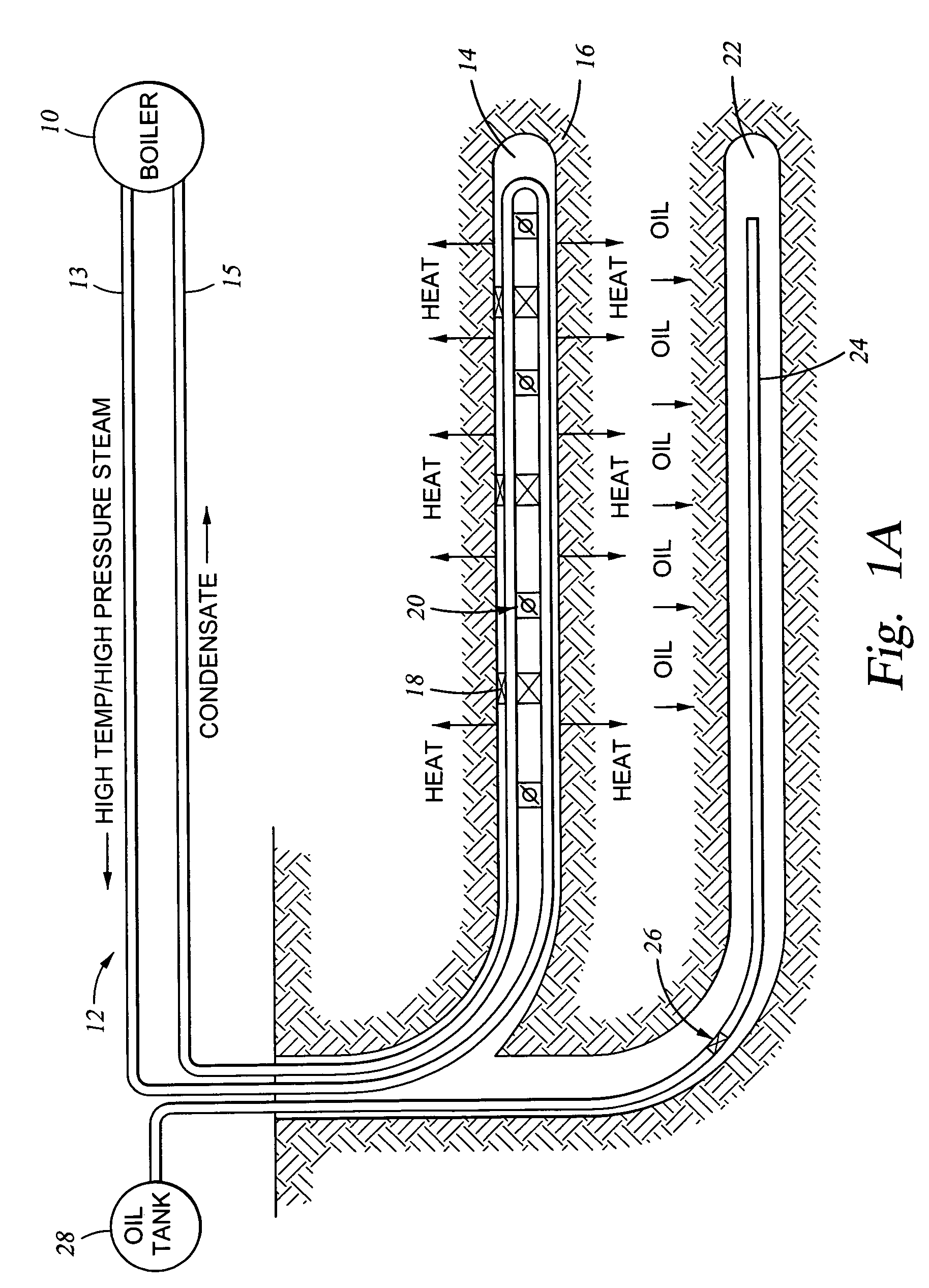

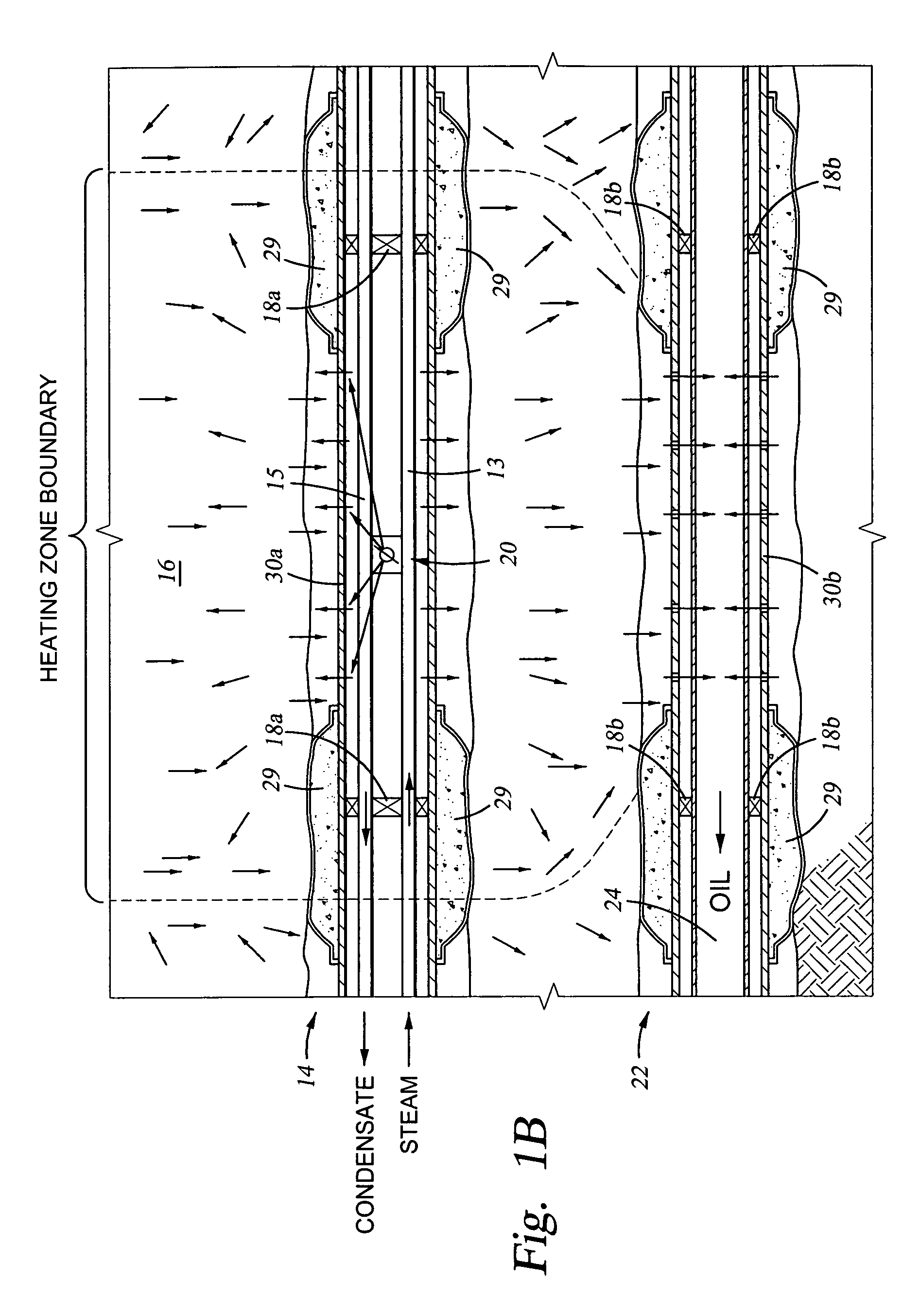

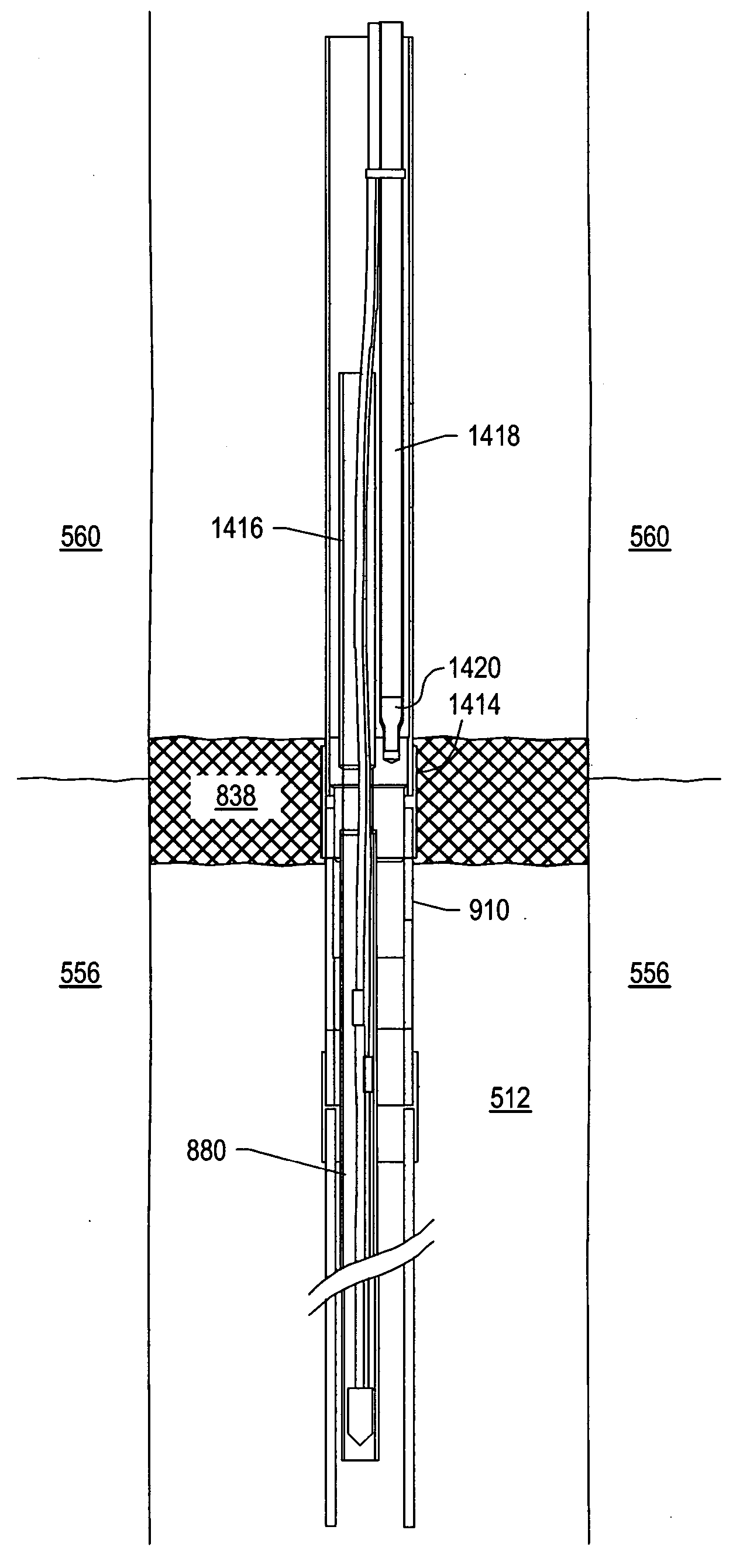

Loop systems and methods of using the same for conveying and distributing thermal energy into a wellbore

Systems and methods are provided for treating a wellbore using a loop system to heat oil in a subterranean formation contacted by the wellbore. The loop system comprises a loop that conveys a fluid (e.g., steam) down the wellbore via a injection conduit and returns fluid (e.g., condensate) from the wellbore via a return conduit. A portion of the fluid in the loop system may be injected into the subterranean formation using one or more valves disposed in the loop system. Alternatively, only heat and not fluid may be transferred from the loop system into the subterranean formation. The fluid returned from the wellbore may be re-heated and re-conveyed by the loop system into the wellbore. Heating the oil residing in the subterranean formation reduces the viscosity of the oil so that it may be recovered more easily.

Owner:HALLIBURTON ENERGY SERVICES INC

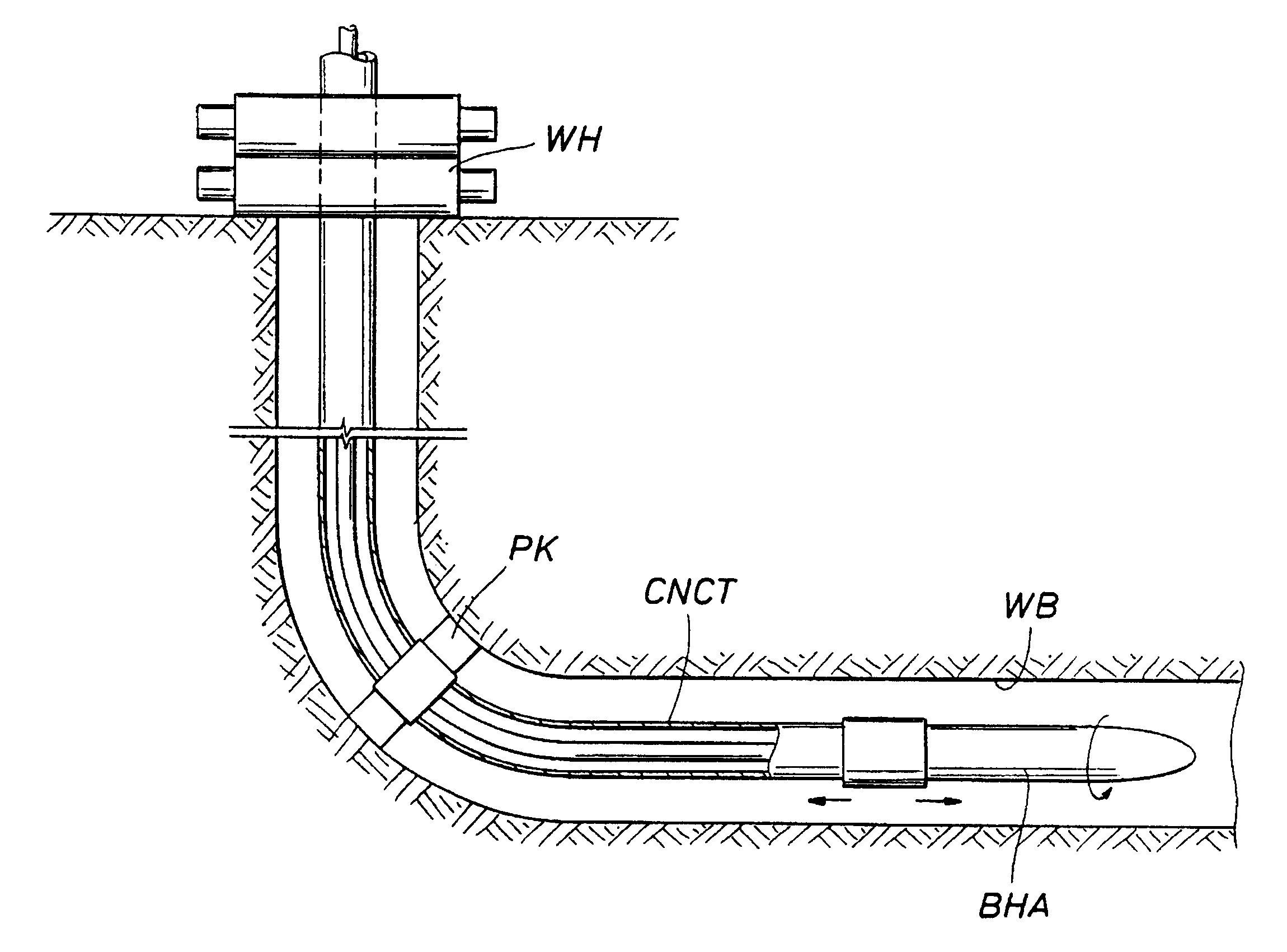

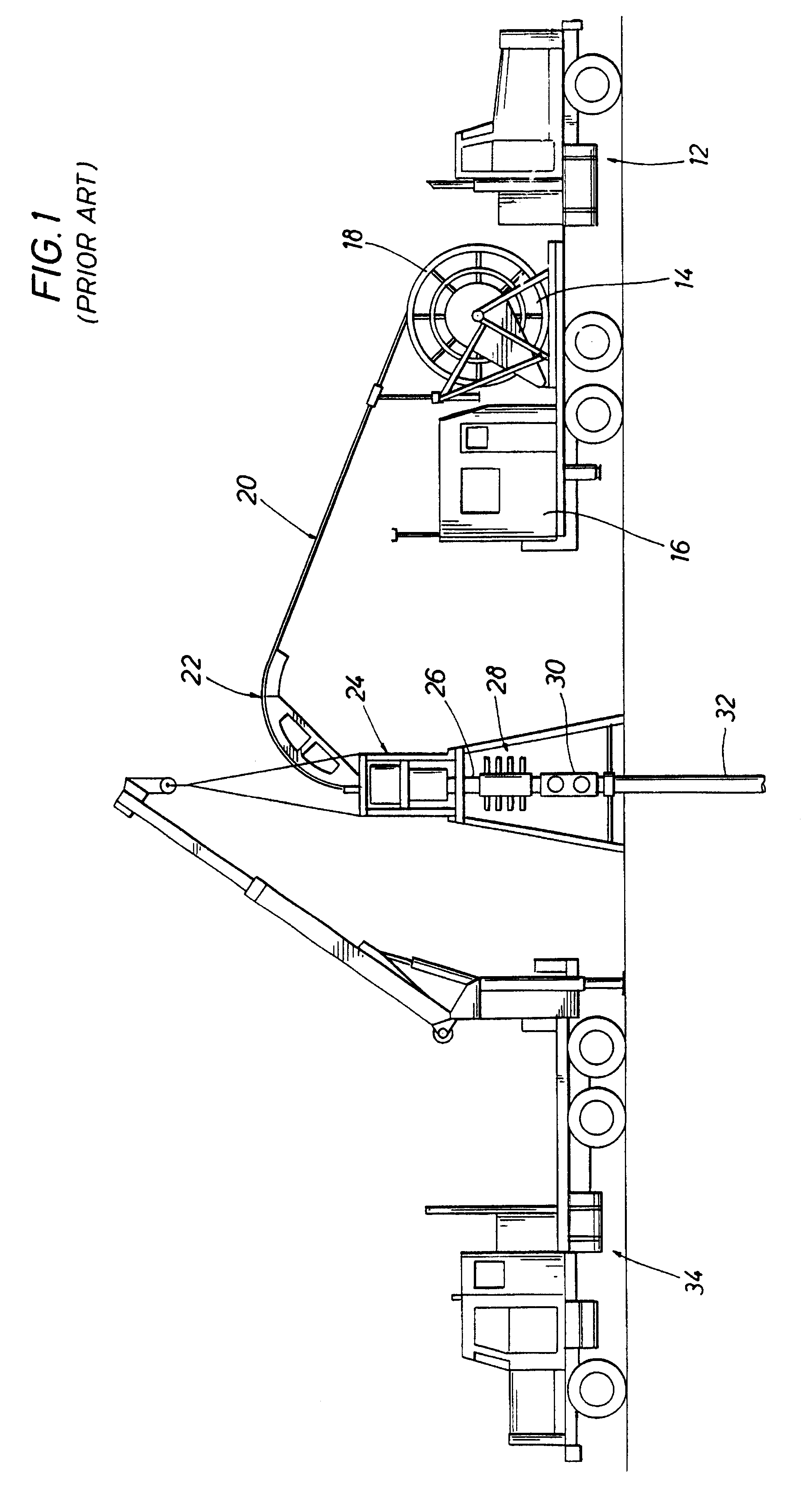

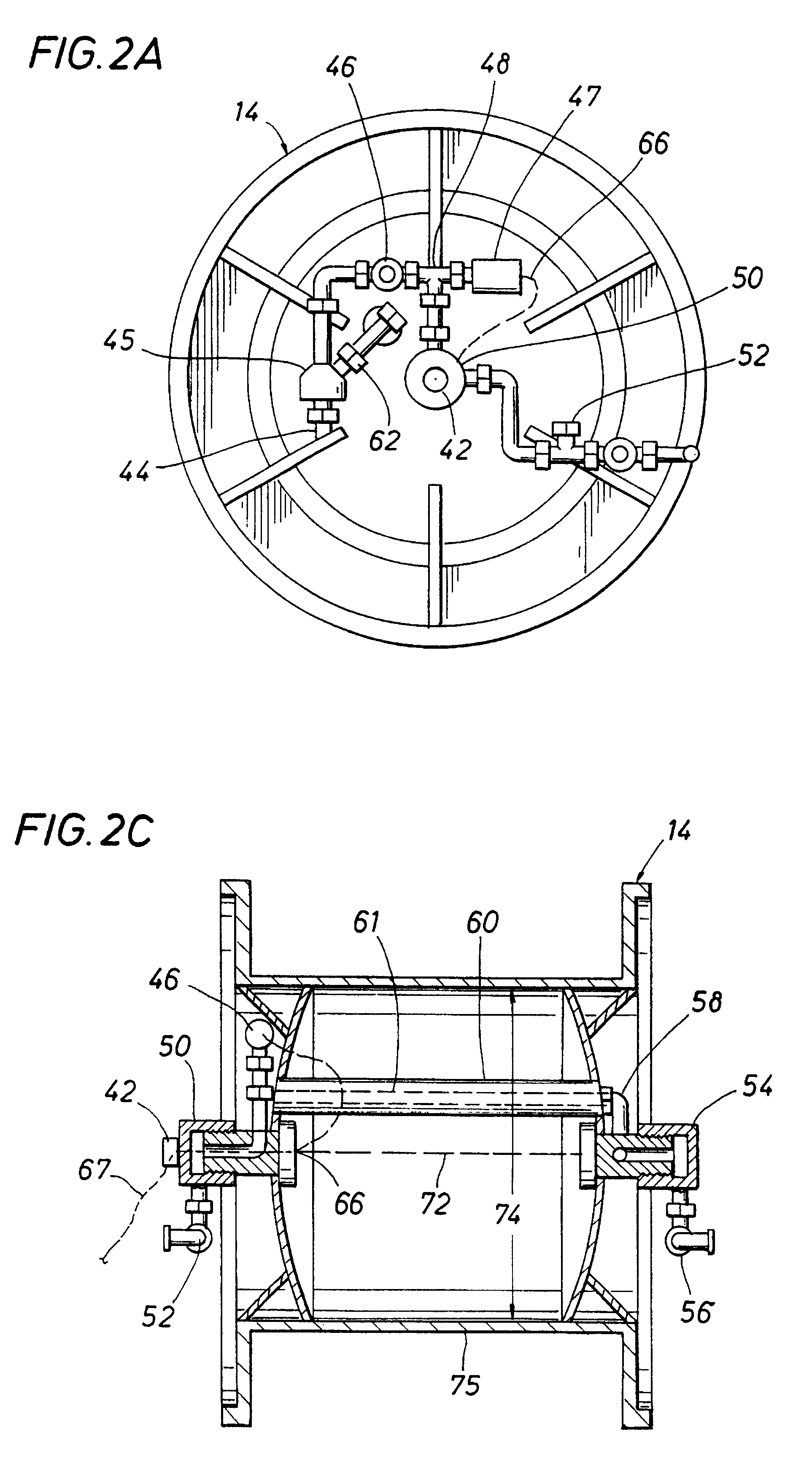

Method and apparatus using coiled-in-coiled tubing

Method and apparatus for performing well operations, such as measuring or forming or testing or treating or the like, and combinations of the above operations, including the use of coiled-in-coiled tubing (CCT) connected to a bottomhole assembly package (BHA), such that the assembly is in communication with both fluid conduits (80 and 82) defined by the coiled-in-coiled tubing.

Owner:BJ SERVICES CO

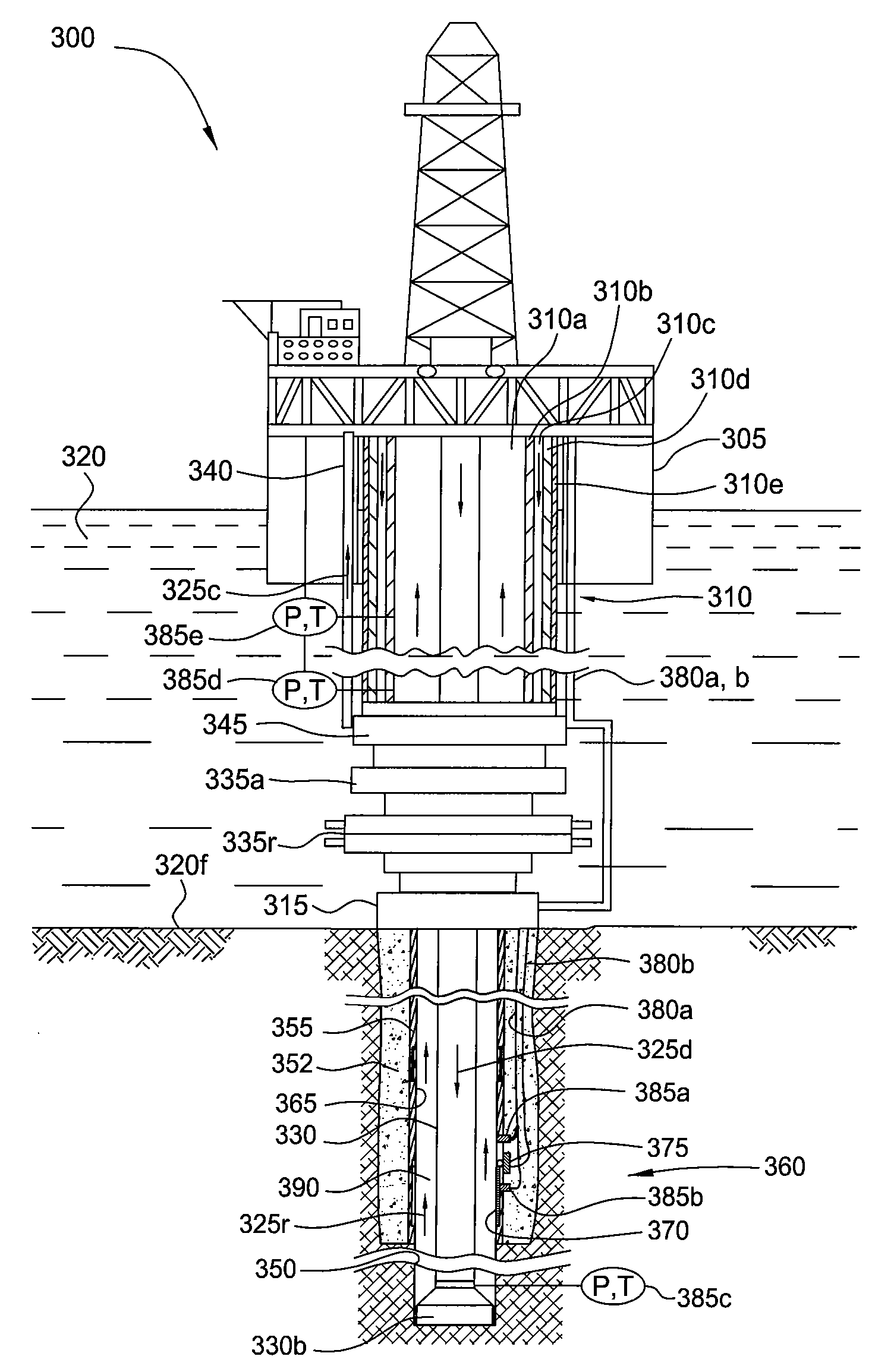

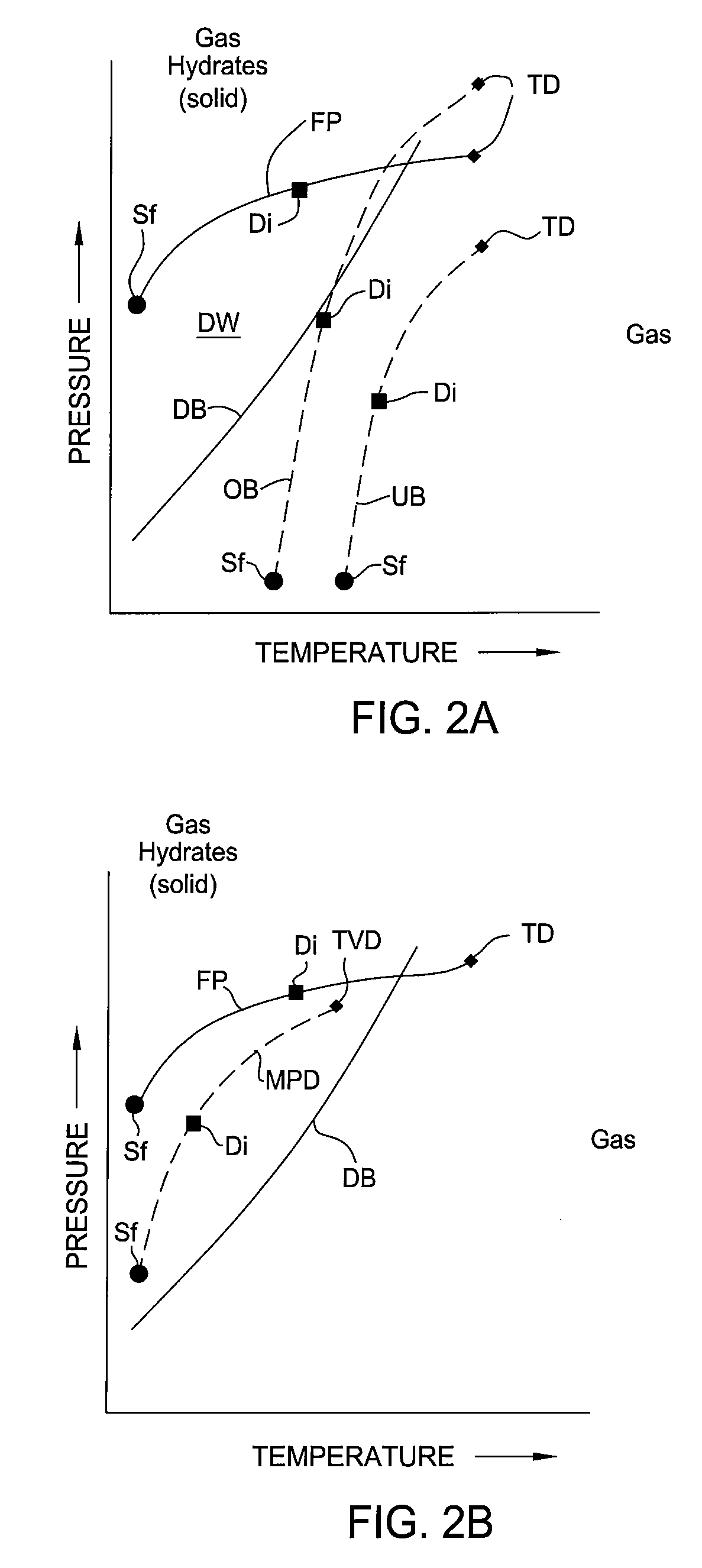

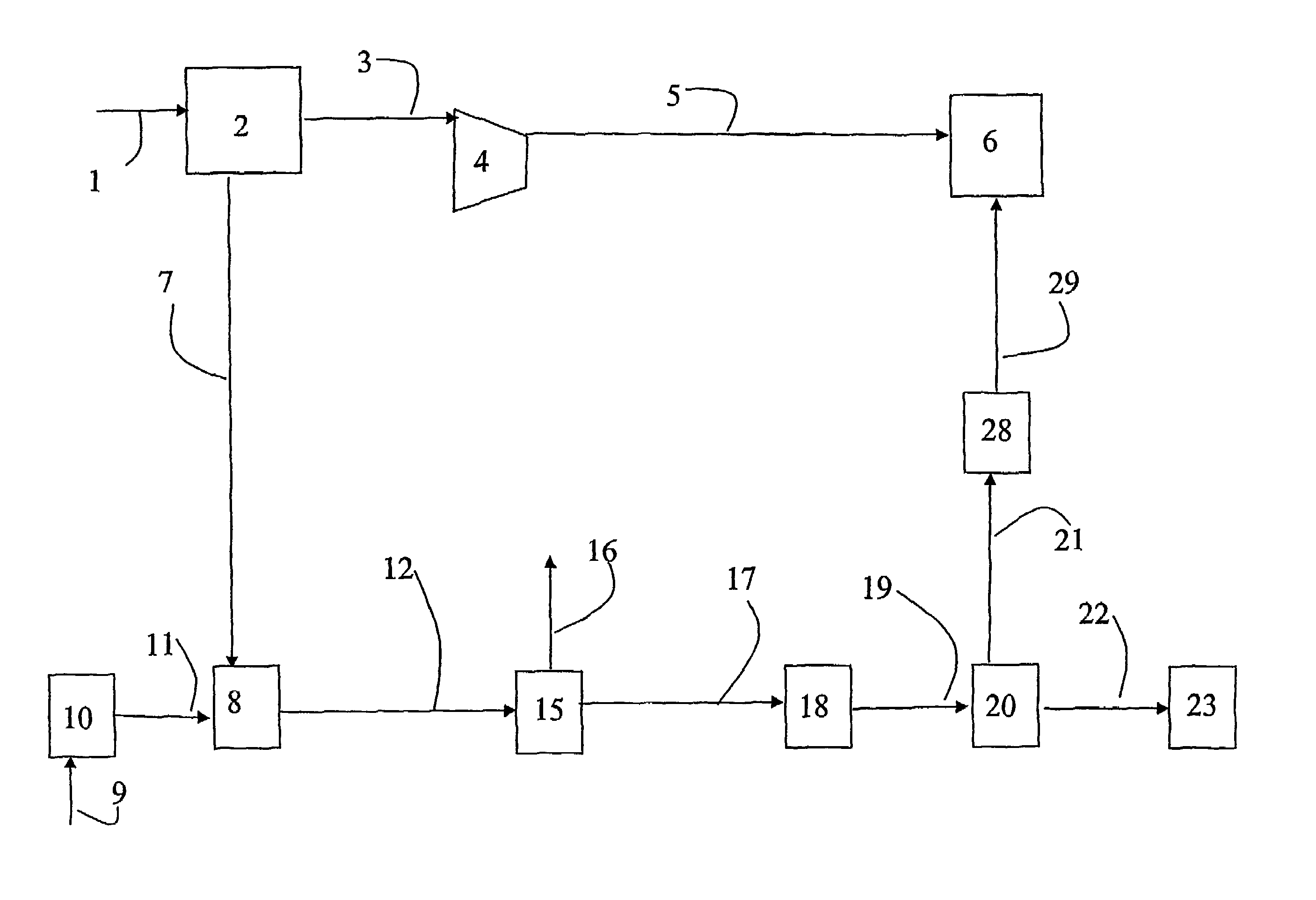

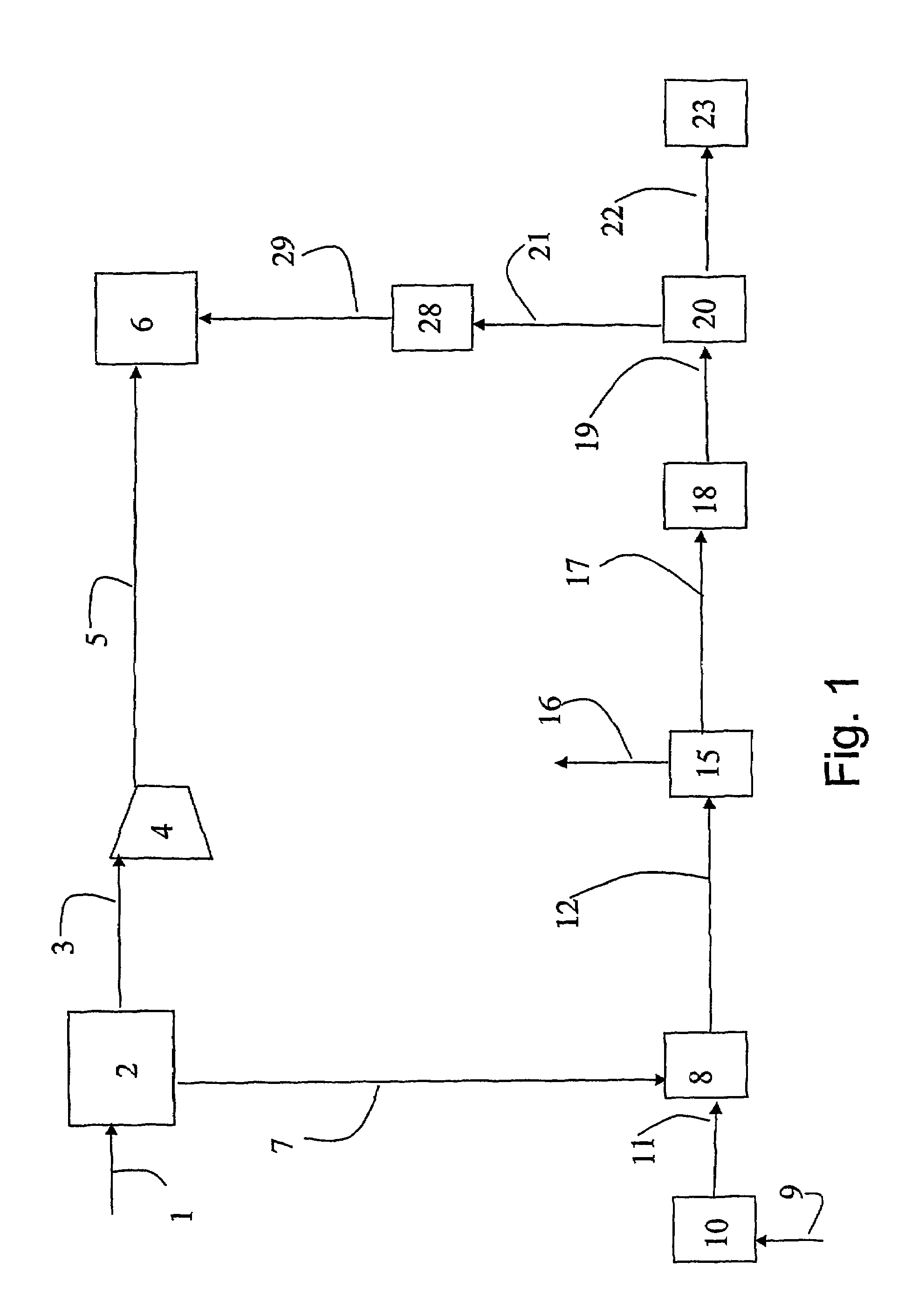

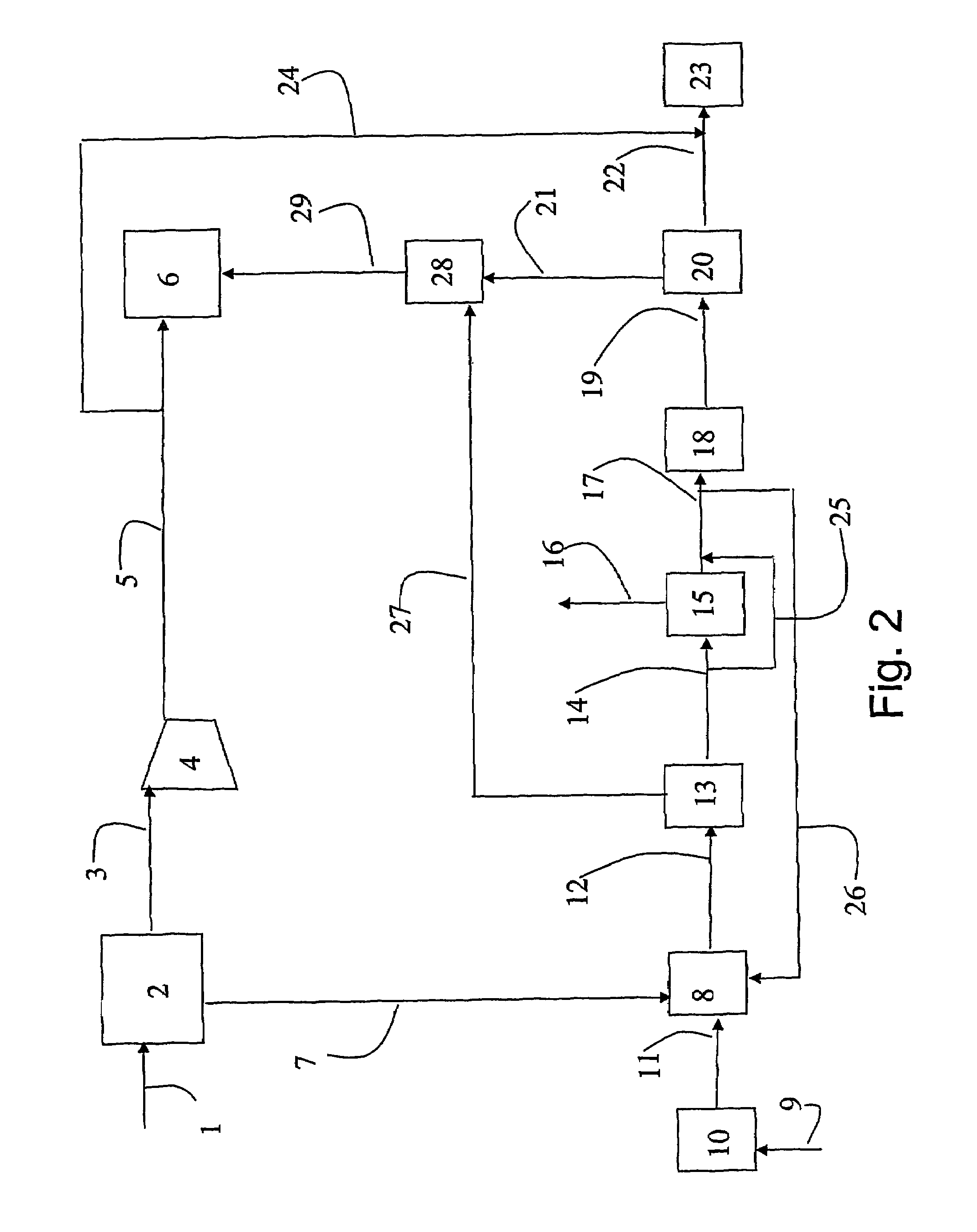

Managed pressure and/or temperature drilling system and method

The present invention relates to a managed pressure and / or temperature drilling system (300) and method. In one embodiment, a method for drilling a wellbore into a gas hydrates formation is disclosed. The method includes drilling the wellbore into the gas hydrates formation; returning gas hydrates cuttings to a surface of the wellbore and / or a drilling rig while controlling a temperature and / or a pressure of the cuttings to prevent or control disassociation of the hydrates cuttings.

Owner:WEATHERFORD TECH HLDG LLC

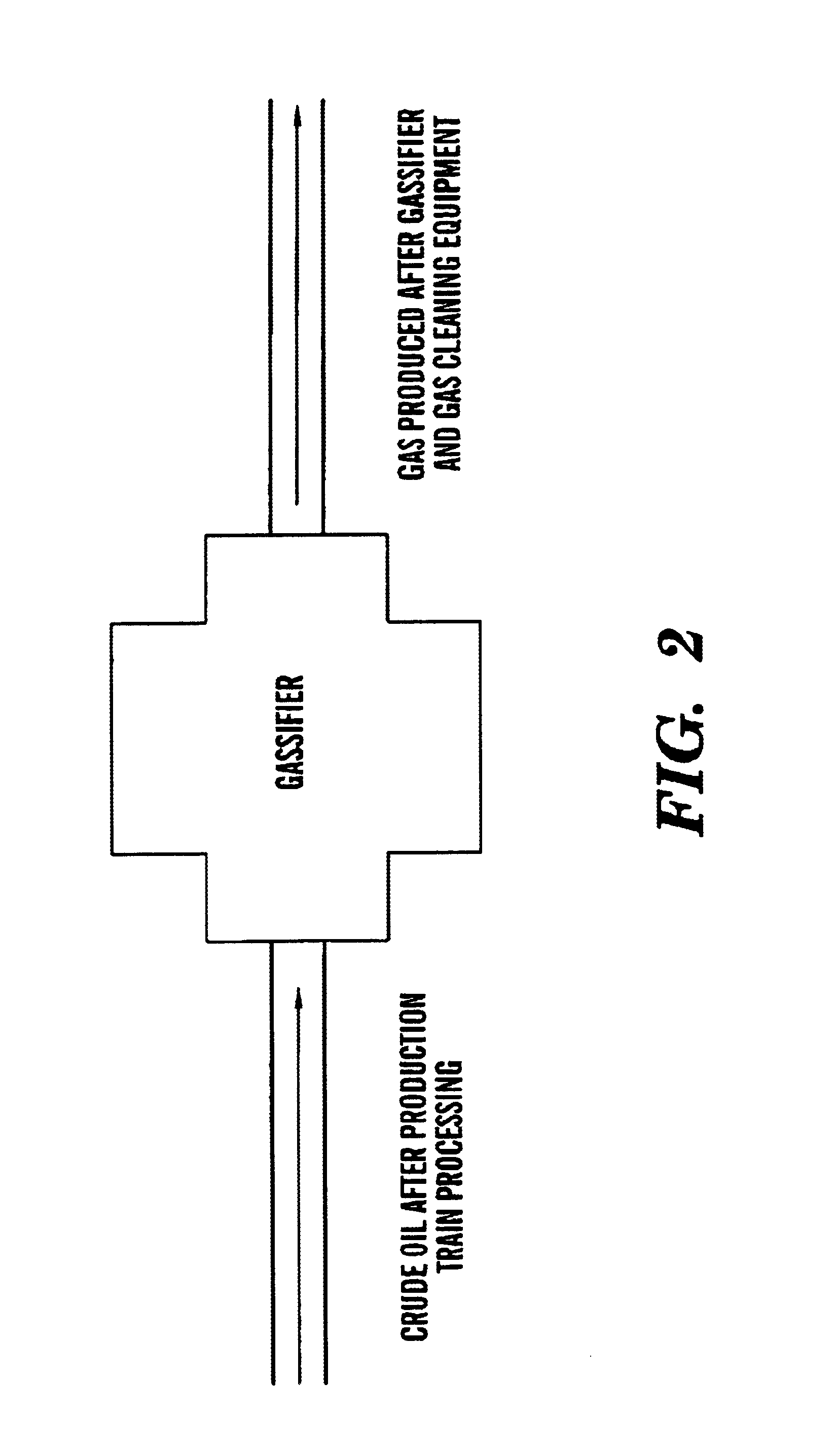

Plant and a method for increased oil recovery

Owner:DEN NORSKE STATS OLJESELSKAP AS

Solution mining dawsonite from hydrocarbon containing formations with a chelating agent

A method for treating an oil shale formation comprising dawsonite includes providing heat from one or more heaters to the formation to heat the formation. Hydrocarbon fluids are produced from the formation. At least some dawsonite in the formation is decomposed with the provided heat. A chelating agent is provided to the formation to dissolve at least some dawsonite decomposition products. The dissolved dawsonite decomposition products are produced from the formation.

Owner:SHELL OIL CO

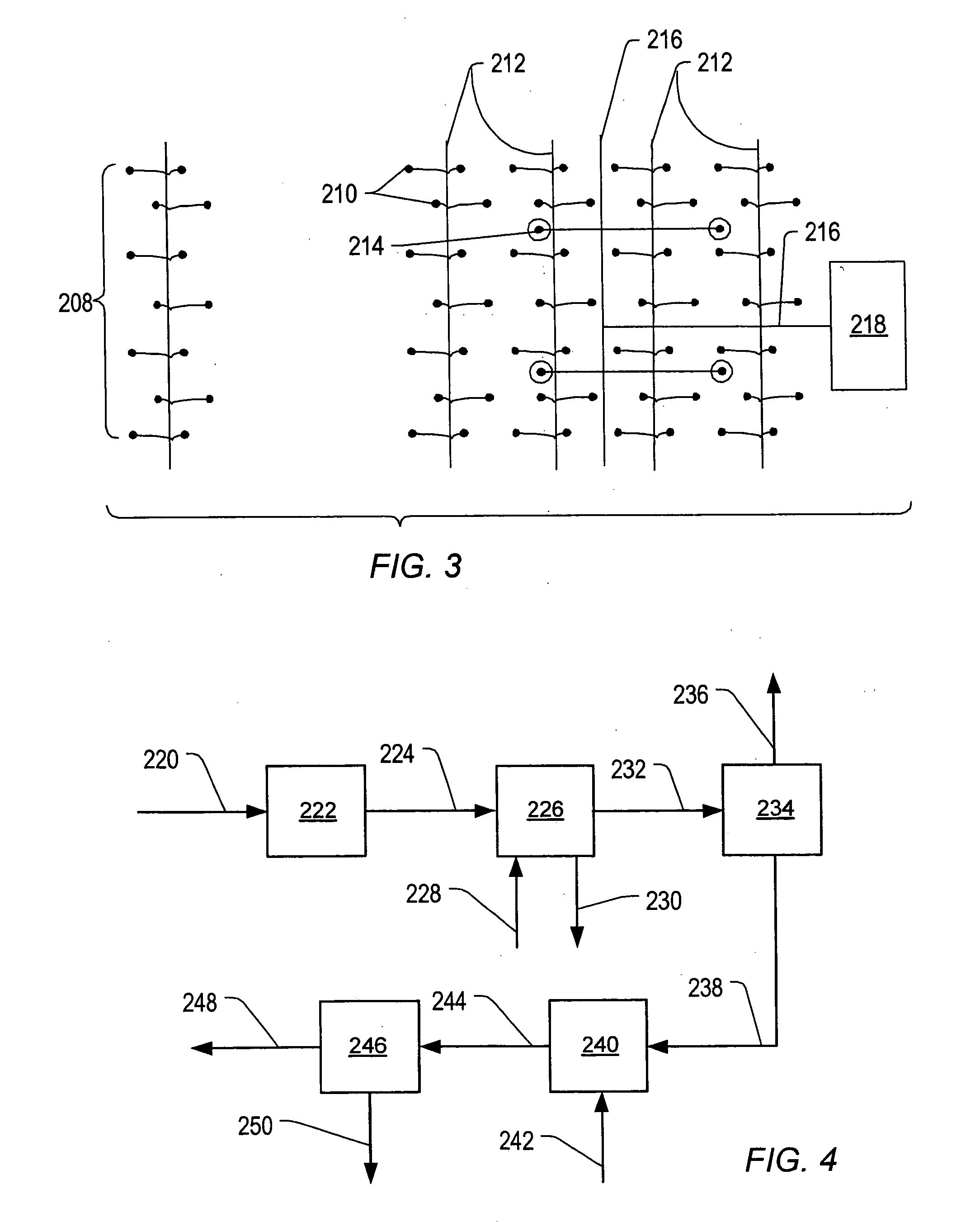

Thermal processes for subsurface formations

InactiveUS20050051327A1Reduce heatMaintaining separation distanceSurveyConstructionsGeophysicsHydrocarbon

A process may include providing heat from one or more heaters to at least a portion of a subsurface formation. Heat may transfer from one or more heaters to a part of a formation. In some embodiments, heat from the one or more heat sources may pyrolyze at least some hydrocarbons in a part of a subsurface formation. Hydrocarbons and / or other products may be produced from a subsurface formation. Certain embodiments describe apparatus, methods, and / or processes used in treating a subsurface or hydrocarbon containing formation.

Owner:SHELL OIL CO

Gas and oil production

A process for in situ gasification of mineral oil in a subterranean formation comprises running a tool having a controllable thermal device therein from a surface production facility down to the subterranean formation, bringing said tool into operational proximity with the mineral oil in said subterranean formation, and activating the tool to operate the thermal device within a predetermined temperature range to generate gases or oily vapours from said mineral oil, which permits either an enhanced oil recovery (EOR) method with reduced water contamination, or a gas production process (GPP) which is useful in reducing environmental risks normally associated with transport of crude oil.

Owner:SCOTOIL SERVICES

Method for ignition of flameless combustor

InactiveUS6269882B1Easy to igniteImprove the level ofApparel holdersIncandescent ignitionCombustorCombustion chamber

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

Non-ferromagnetic overburden casing

Systems, methods, and heaters for treating a subsurface formation are described herein. At least one system for electrically insulating an overburden portion of a heater wellbore is described. The system may include a heater wellbore located in a subsurface formation and an electrically insulating casing located in the overburden portion of the heater wellbore. The casing may include at least one non-ferromagnetic material such that ferromagnetic effects are inhibited in the casing.

Owner:SHELL OIL CO

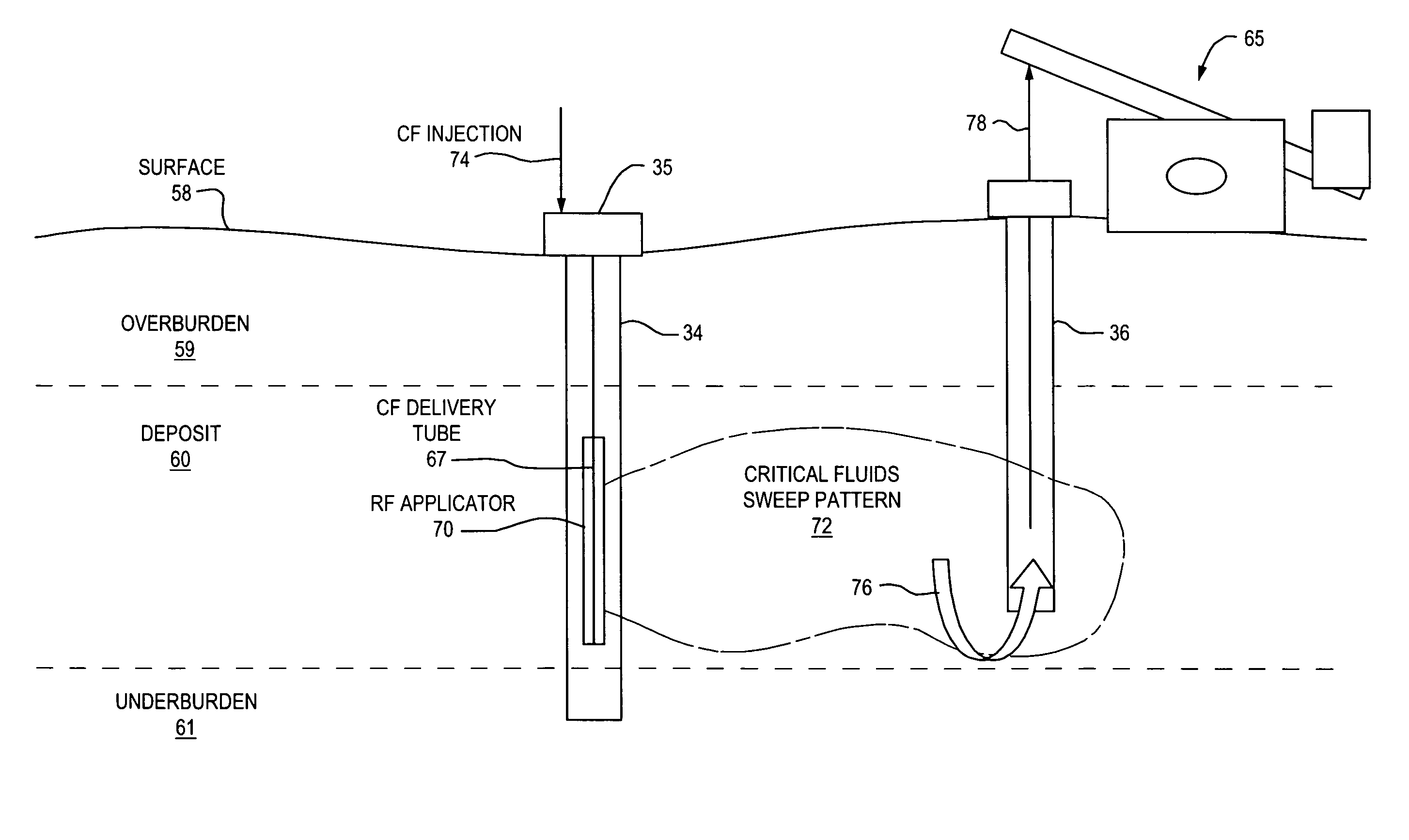

Method and apparatus for capture and sequester of carbon dioxide and extraction of energy from large land masses during and after extraction of hydrocarbon fuels or contaminants using energy and critical fluids

ActiveUS7562708B2Reduce energy consumptionMinimal pollutionSurveyOther gas emission reduction technologiesClosed loopUltra fine

A closed loop system for increasing yield, reducing post process pollution, reducing energy consumed during and after extraction of fuels or contaminants in formations and for sequestering of carbon dioxide C02 from various sources is converted to a critical fluid for use as a flushing and cooling medium. Electrical energy heats a hydrocarbon rich formation resulting in the extraction of hot fluids which are fed to heat exchangers, gas / liquid separator, and steam turbine whereby oil, electric power, carbon dioxide and methane are produced for reuse in the system or for external use. Further, a method for sequestering of carbon dioxide in a formation comprises the steps of injecting CO2 into the reservoir, flushing with cool pressurized CO2 for heat removal, infiltrating with ultra-fine low density suspended catalyst particles of dry sodium hydroxide in CO2, pumping water moistened CO2 into the reservoir to activate the catalysts, binding the CO2 with reacting materials and capping the reservoir.

Owner:RAYTHEON CO

Temperature limited heaters with thermally conductive fluid used to heat subsurface formations

InactiveUS20050269090A1Improve thermal conductivityThermal drillingInsulationEngineeringElectrical current

Certain embodiments provide a system including a heater. The heater includes one or more electrical conductors. The heater is configured to generate a heat output during application of electrical current to the heater. The heater includes a ferromagnetic material. A conduit at least partially surrounds the heater. A fluid is located in a space between the heater and the conduit. The fluid has a higher thermal conductivity than air at standard temperature and pressure (STP) (0° C. and 101.325 kPa). The system is configured to provide (a) a first heat output below a selected temperature when time-varying electrical current is applied to the heater, and (b) a second heat output near or above the selected temperature when time-varying electrical current is applied to the heater.

Owner:SHELL OIL CO

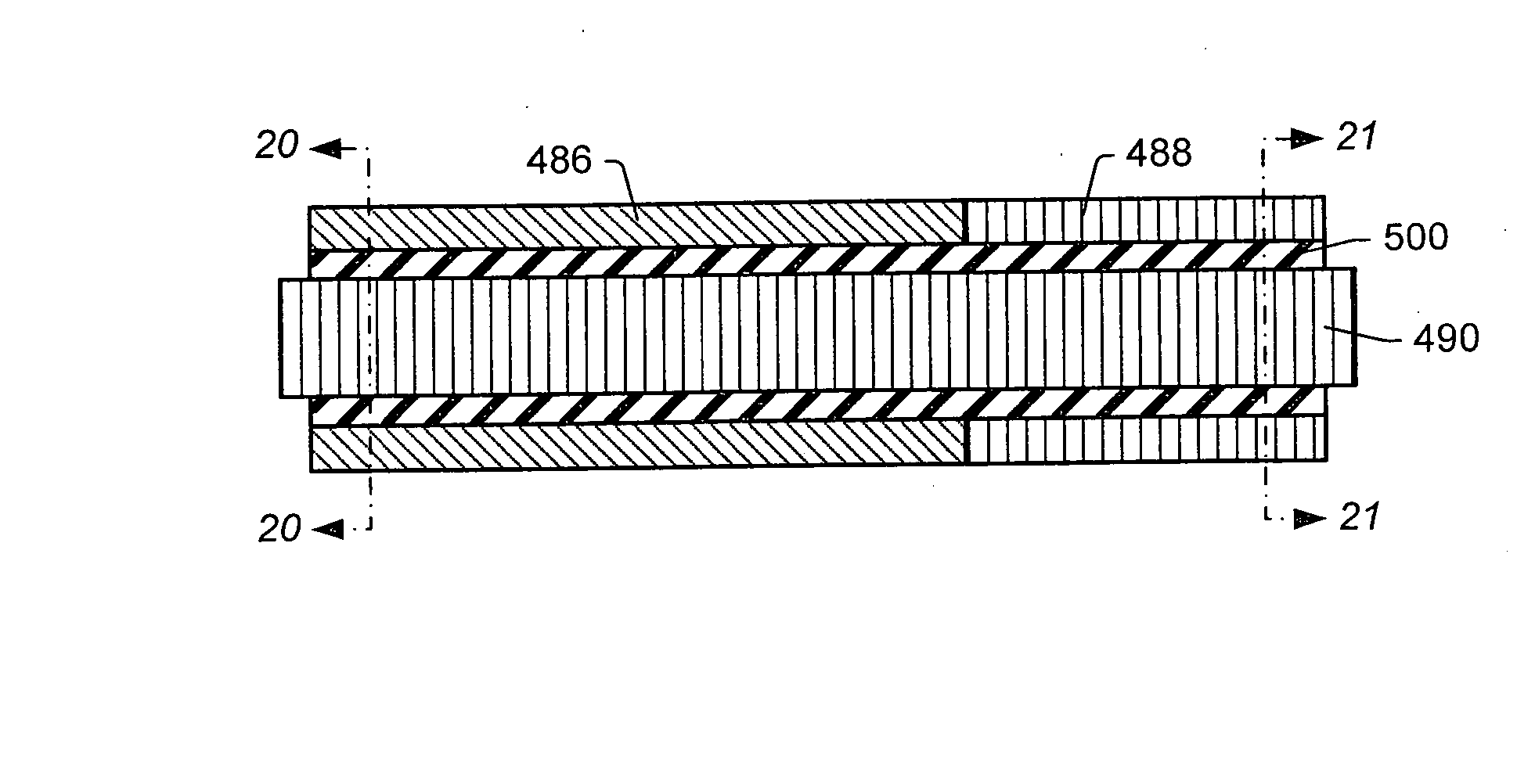

Triaxial temperature limited heater

InactiveUS20050269094A1InsulationFluid removalElectrical resistance and conductanceElectrical conductor

Certain embodiments provide a heater. The heater includes an inner electrical conductor. A heater section at least partially surrounds the inner electrical conductor. The heater section is configured to generate an electrically resistive heat output during application of time-varying electrical current to the heater section. The heater section includes ferromagnetic material. An outer electrical conductor at least partially surrounds the heater section. An applied time-varying electrical current is configured to propagate through the inner electrical conductor and the outer electrical conductor in substantially the same direction. The applied time-varying electrical current is configured to propagate through the heater section in a substantially opposite direction. The heater provides a first heat output when time-varying electrical current is applied to the heater below a selected temperature, and a second heat output approximately at and above the selected temperature during use. The second heat output is reduced compared to the first heat output.

Owner:SHELL OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com