Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21661results about How to "High recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

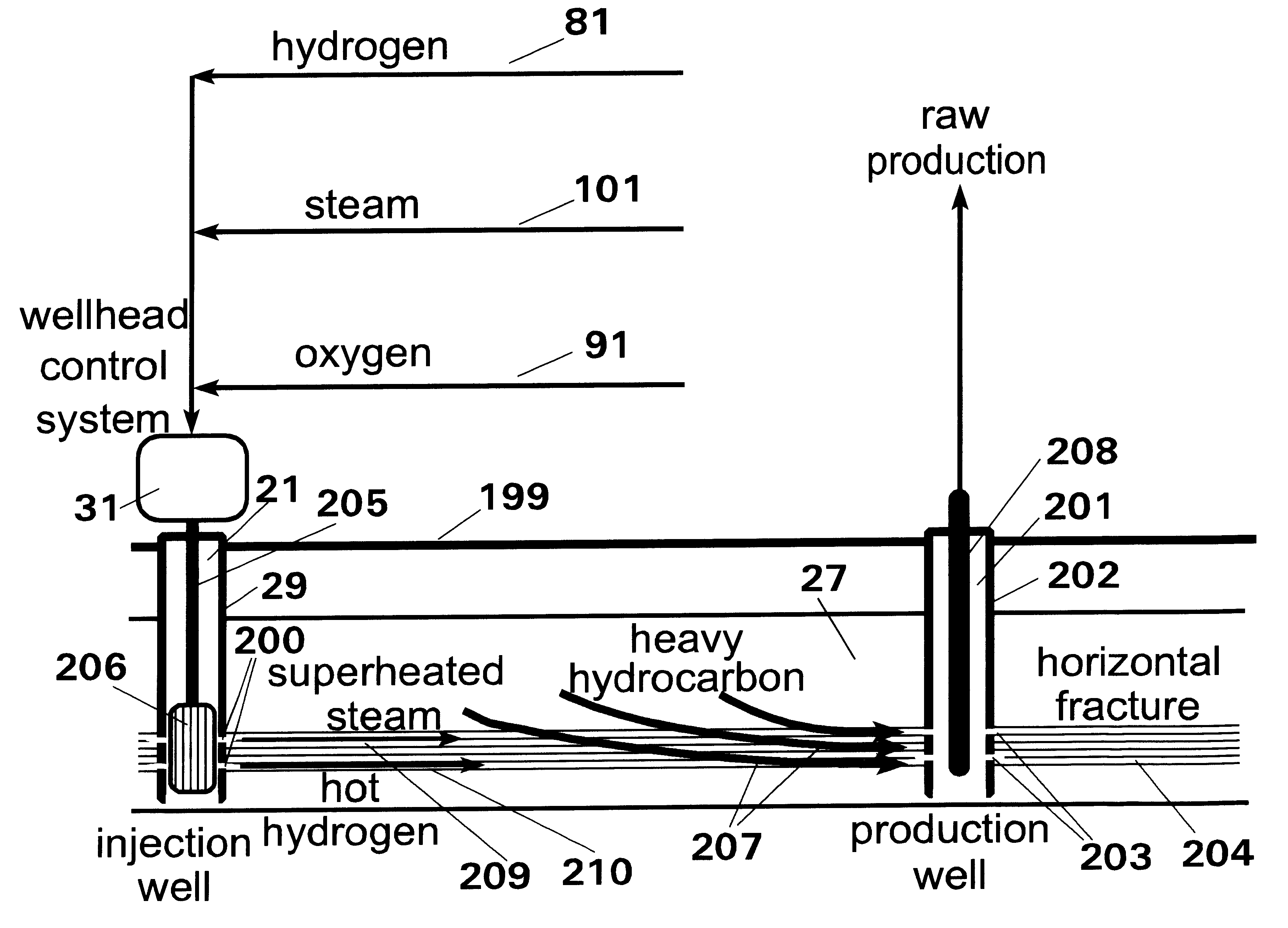

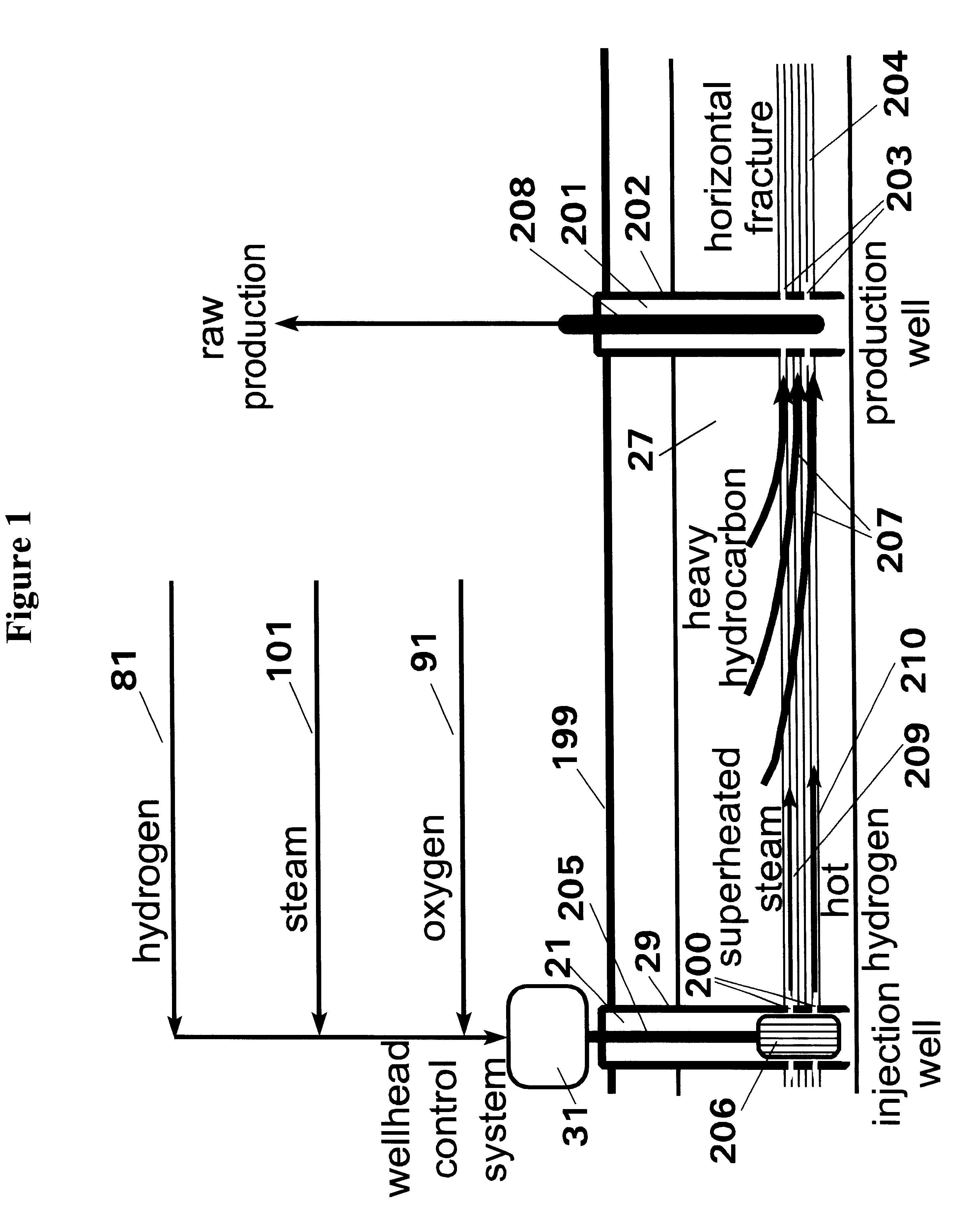

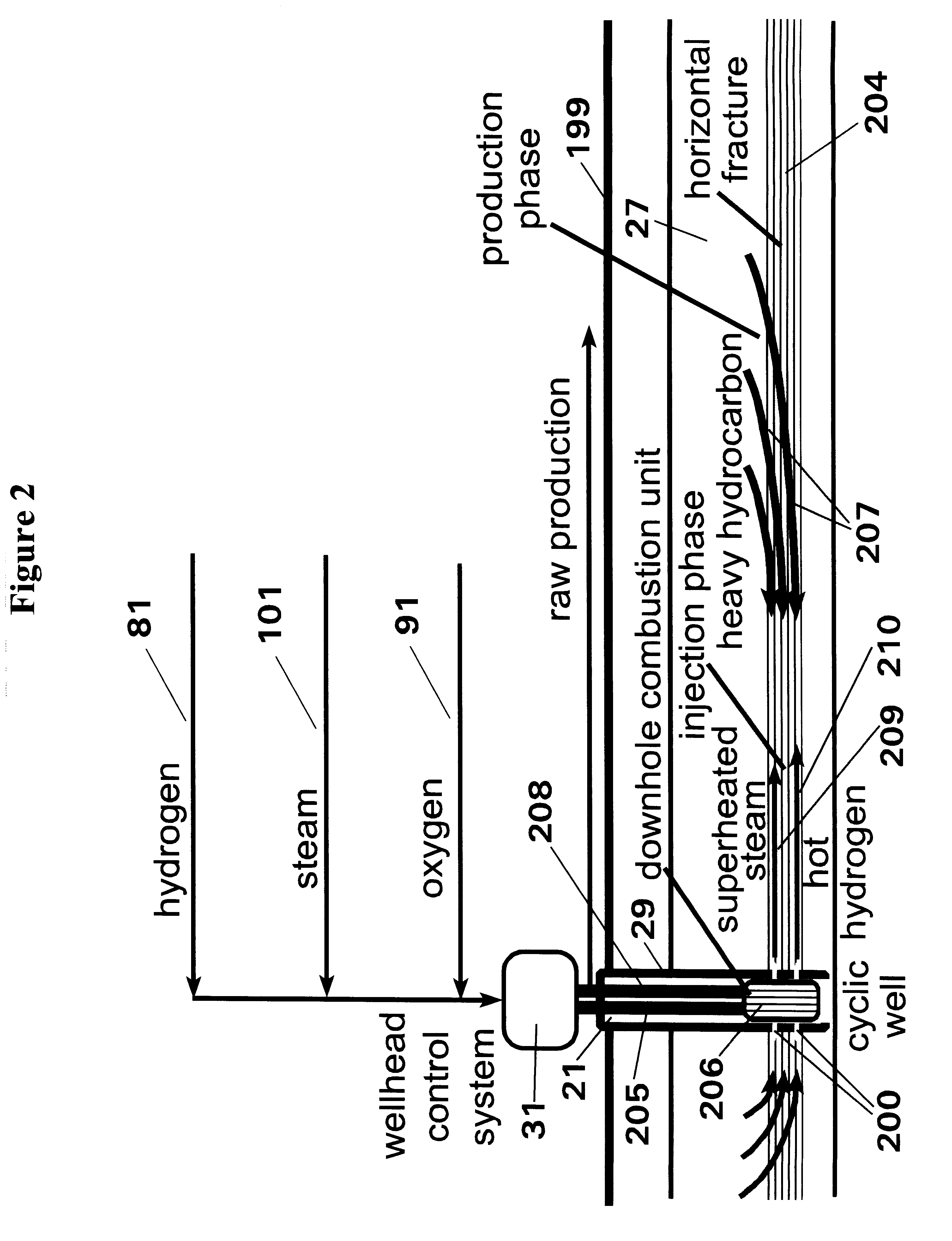

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more vertical injection boreholes and one or more vertical production boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes, or a cyclic operation whereby both injection and production occur in the same vertical boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing, multiple horizontal boreholes extending from vertical boreholes, or other related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

Protein purification

InactiveUS7074404B2High recovery ratePeptide/protein ingredientsSerum immunoglobulinsIon chromatographyMulti pollutant

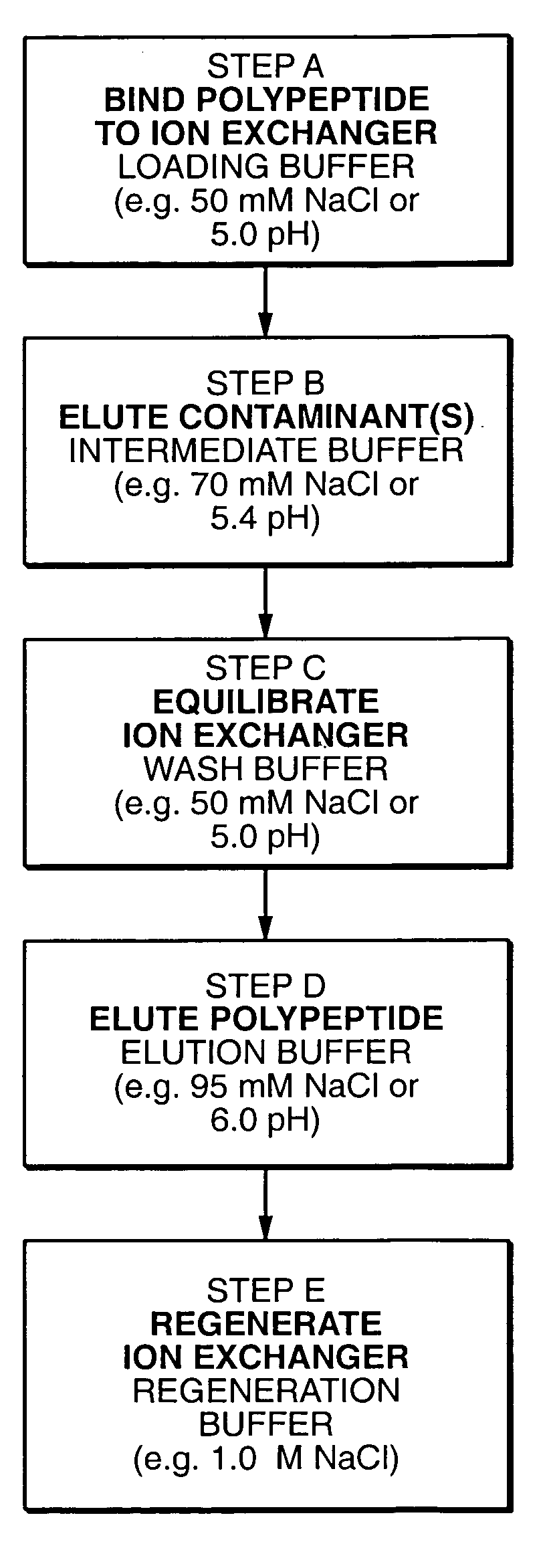

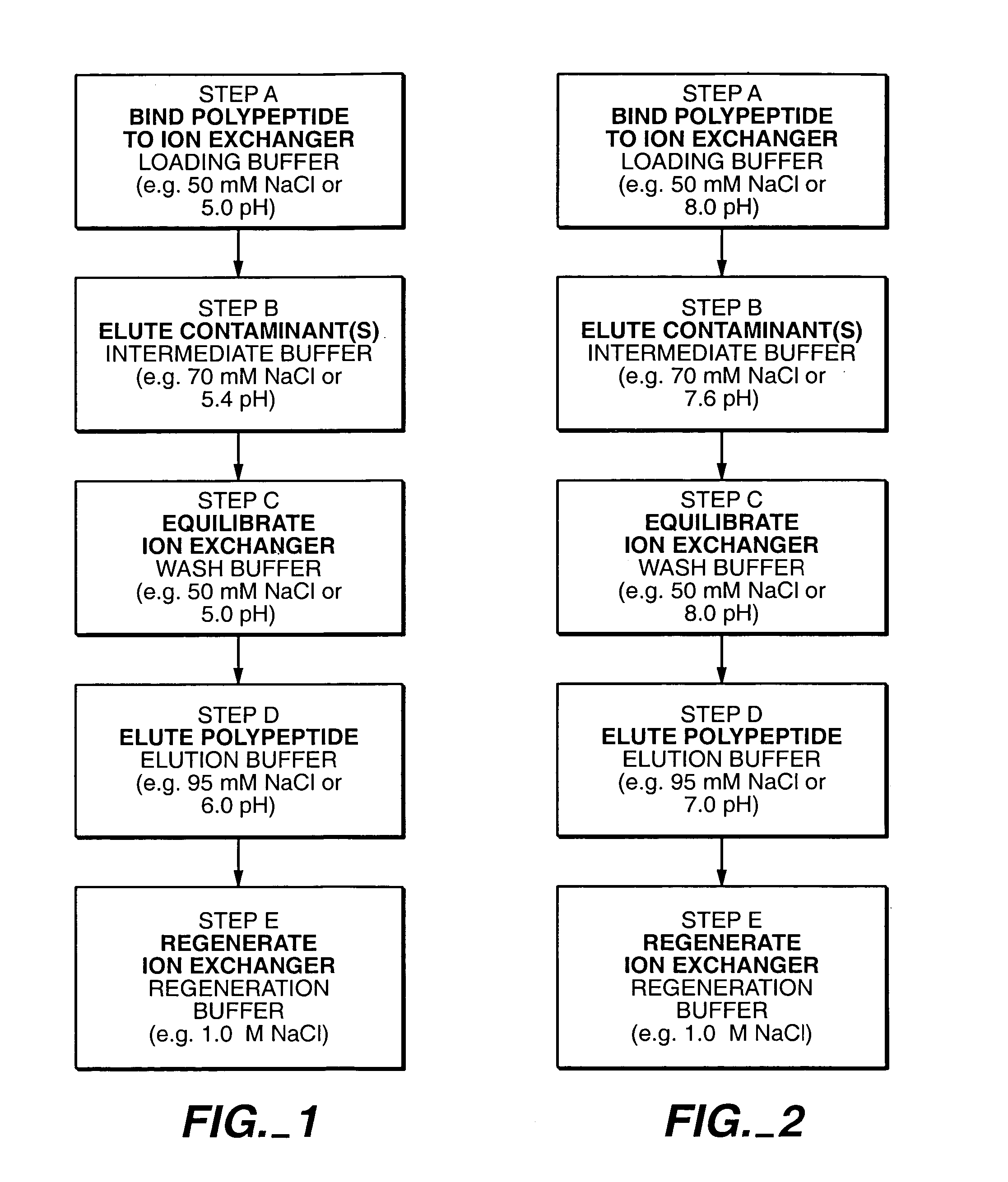

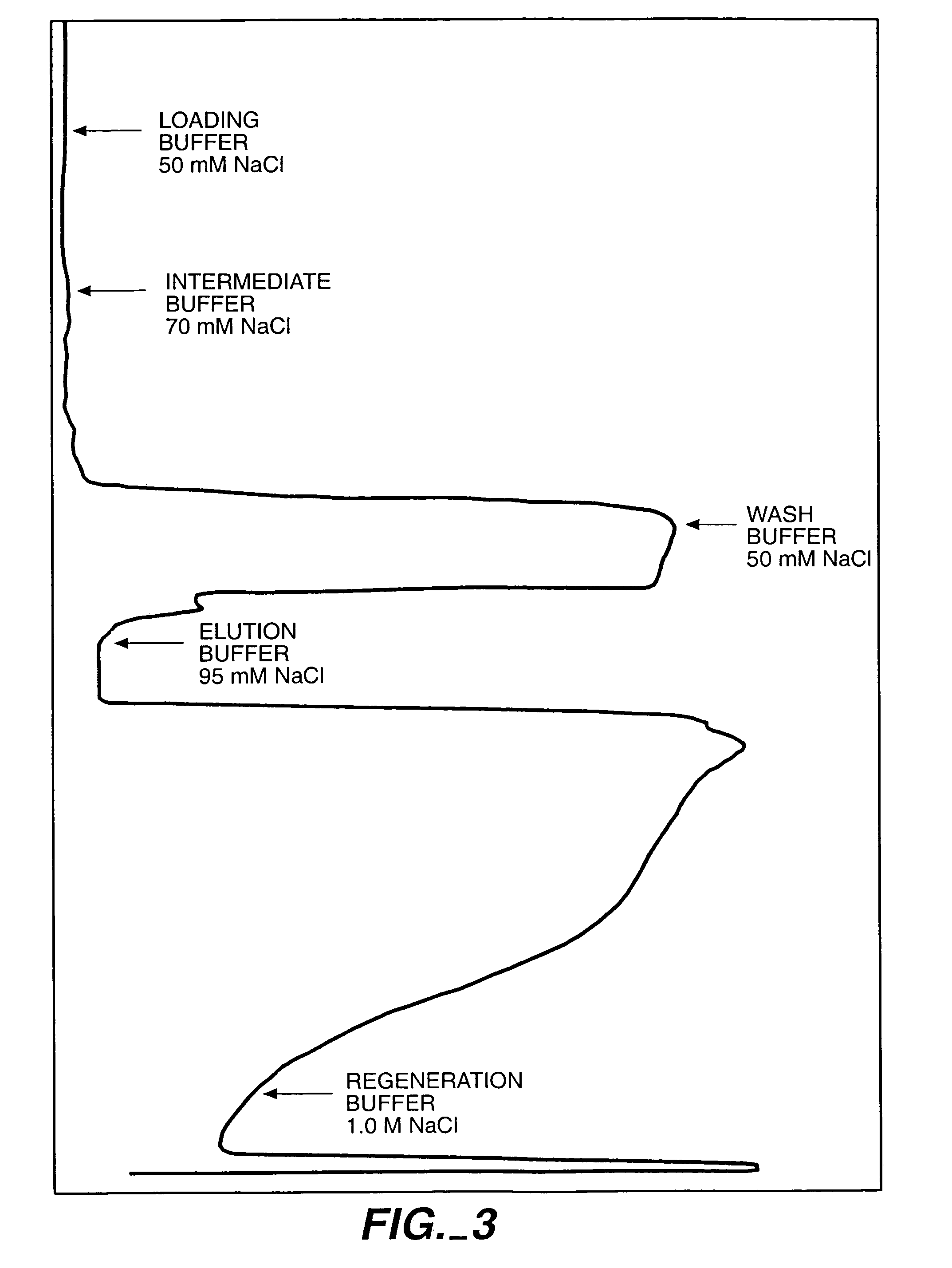

A method for purifying a polypeptide by ion exchange chromatography is described which involves changing the conductivity and / or pH of buffers in order to resolve a polypeptide of interest from one or more contaminants.

Owner:GENENTECH INC

Metallurgical V-N microalloying and compound deoxidation cored wire

A metallurgical V-N microalloying and compound deoxidation cored wire contains a core wire and a cladding steel belt. The technical key point of the cored wire is as follows: the core wire of the cored wire consists of a vanadium-increasing agent, a nitrogen-increasing agent and a deoxidizing nitrogen-fixing agent of which particle sizes are less than 6mm, wherein the vanadium-increasing agent is ferrovanadium, nitrided ferrovanadium or vanadium pentoxide; the nitrogen-increasing agent is ferrosilicon nitride, silicomanganese nitride, ferromanganese nitride, ferrochromium nitride, silicon nitride, aluminum nitride or calcium cyanamide; and the deoxidizing nitrogen-fixing agent contains one or more of aluminum, calcium, magnesium and barium, and can also contain one or more of titanium, zirconium, niobium, manganese, chromium, silicon, carbon and iron. By adopting the cored wire, the V / N ratio of steel can get closer to the optimal proportion, the enhancing function of vanadium can be utilized furthest, vanadium resources can be saved, the recovery rate of nitrogen is high, the nitrogen content is stable, the compound deoxidation function can also be realized, the V-N microalloying cost can be reduced and the quality of steel can be increased.

Owner:侯巍 +2

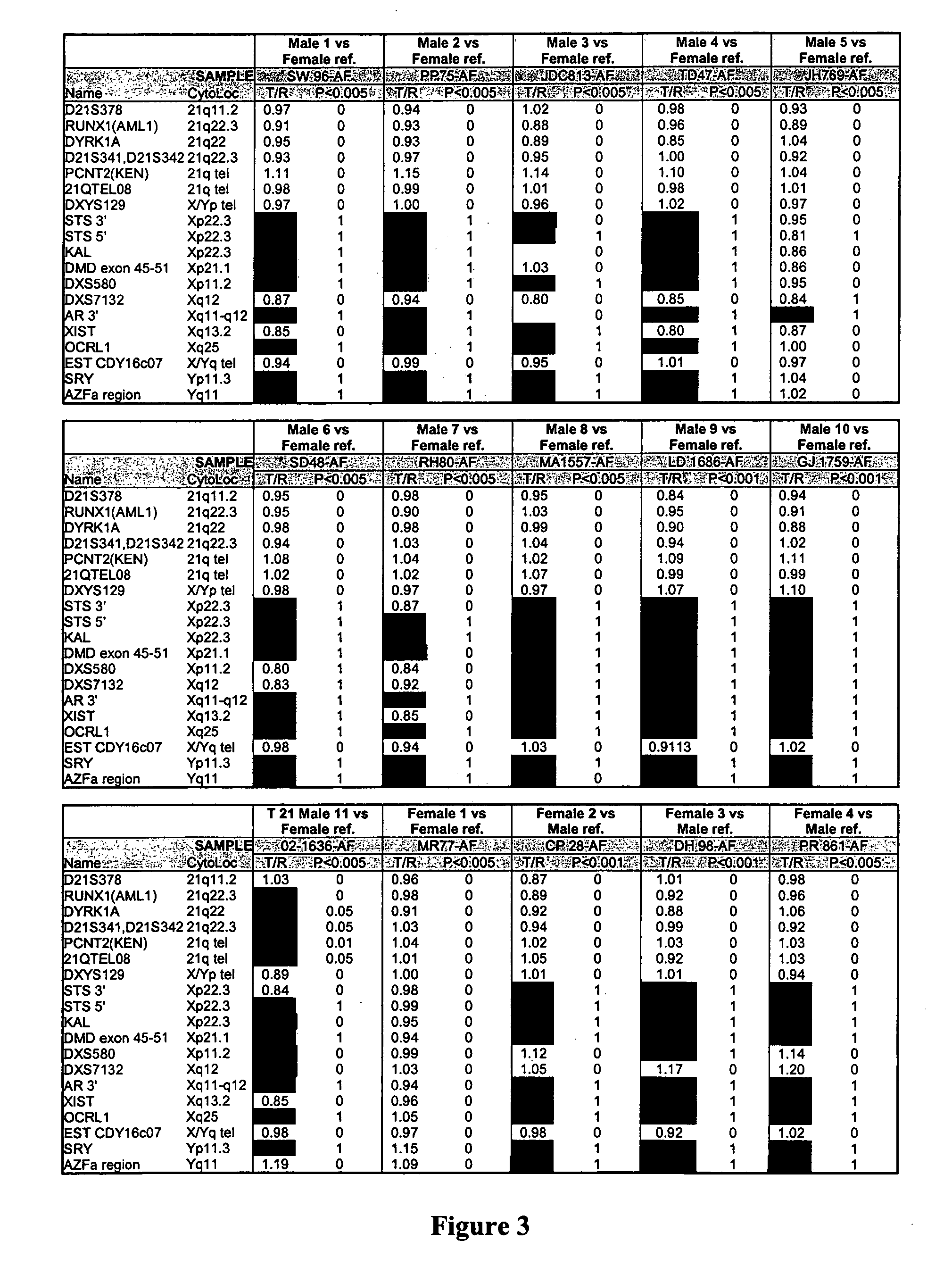

Prenatal diagnosis using cell-free fetal DNA in amniotic fluid

InactiveUS20070111233A1Improved and rapid methodHigh recovery rateSugar derivativesMicrobiological testing/measurementCell-free fetal DNAAmniotic fluid

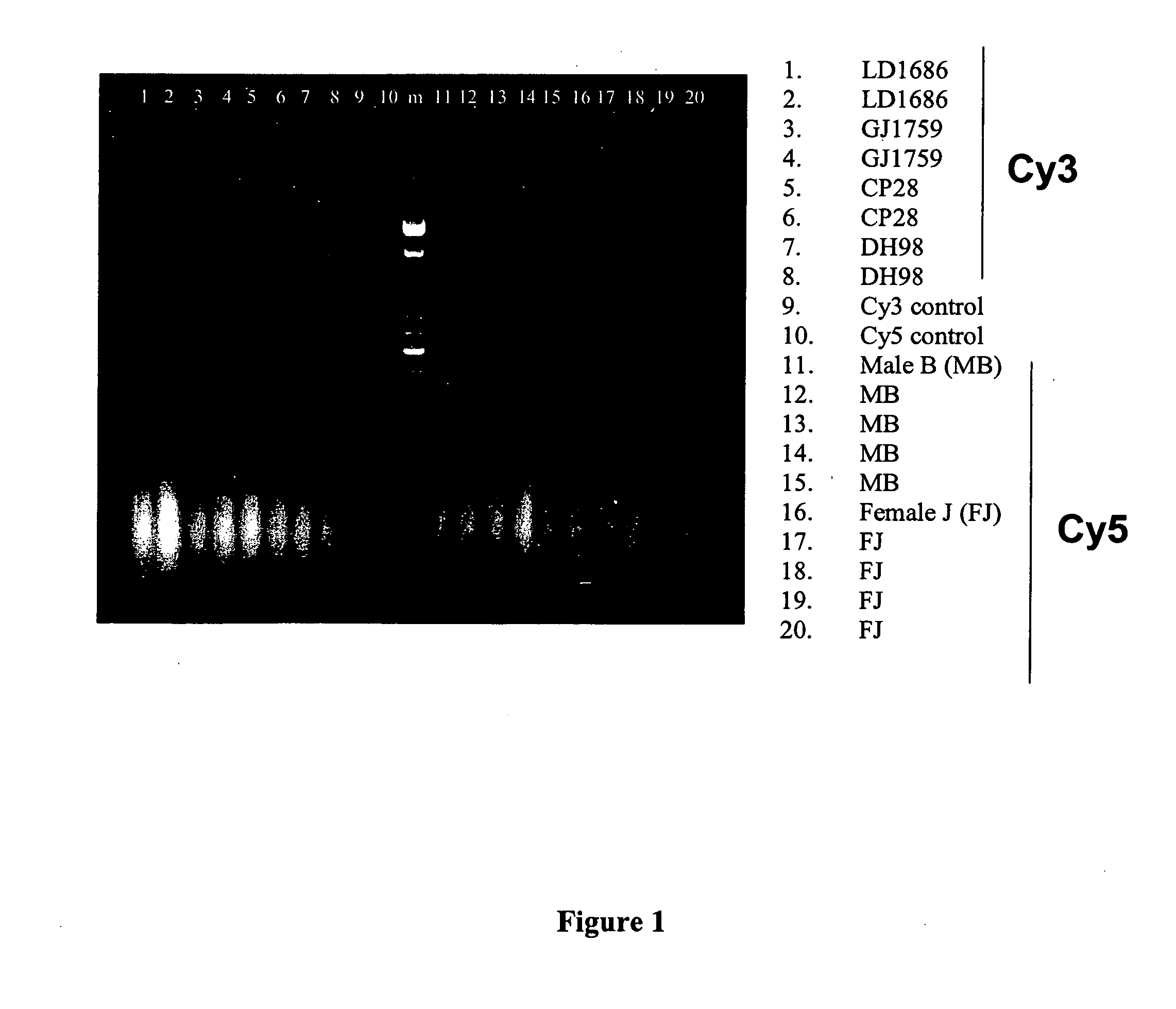

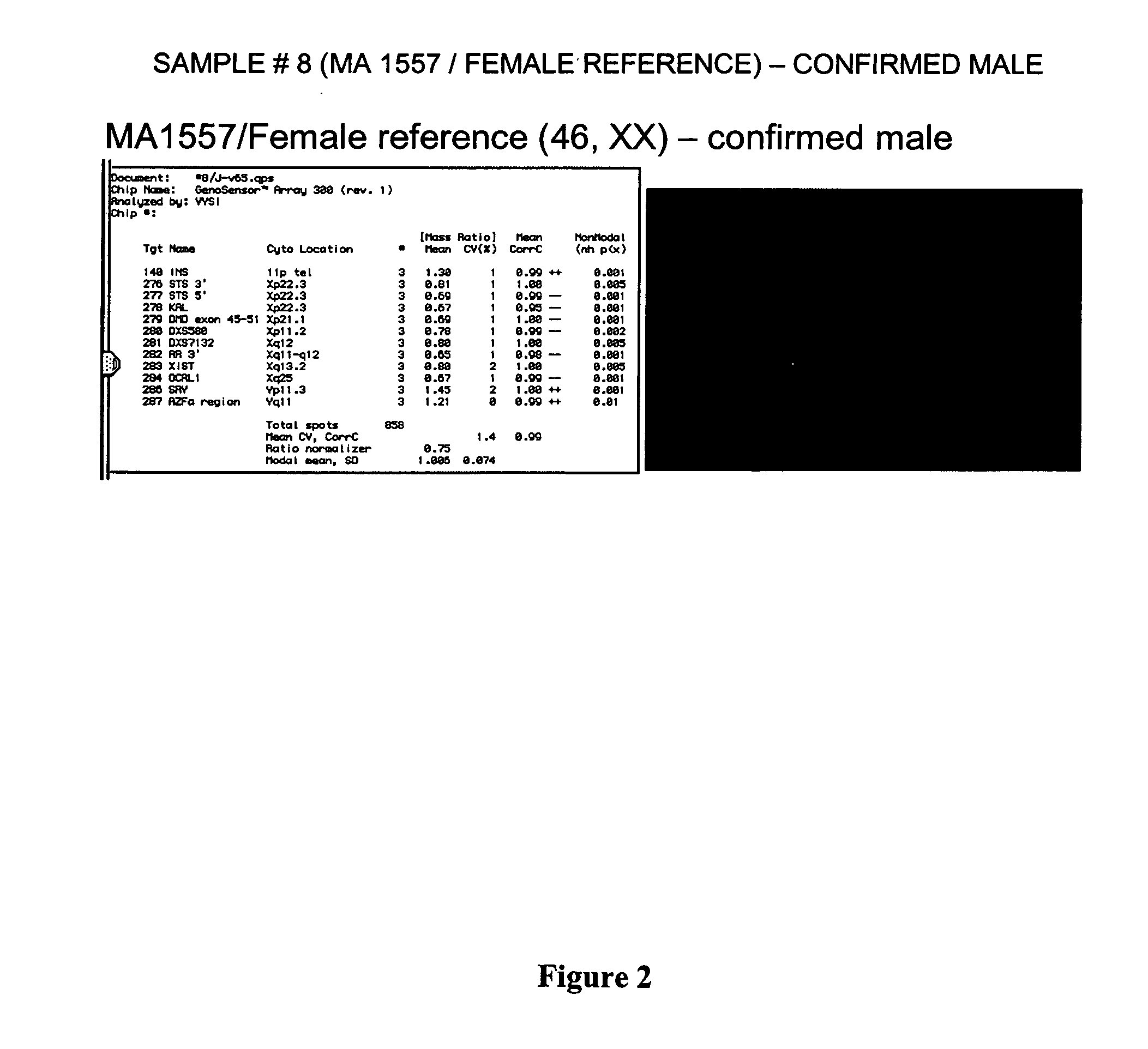

The present invention relates to improved methods of prenatal diagnosis, screening, monitoring and / or testing. The inventive methods include the analysis by array-based hybridization of cell-free fetal DNA isolated from amniotic fluid. In addition to allowing the prenatal diagnosis of a variety of diseases and conditions, and the assessment of fetal characteristics such as fetal sex and chromosomal abnormalities, the new inventive methods provide substantially more information about the fetal genome in less time than it takes to perform a conventional metaphase karyotype analysis. In particular, the enhanced molecular karyotype methods provided by the present invention allow the detection of chromosomal aberrations that are not often detected prenatally such as microdeletions, microduplications and subtelomeric rearrangements. Also provided are improved methods of extraction of fetal DNA from amniotic fluid.

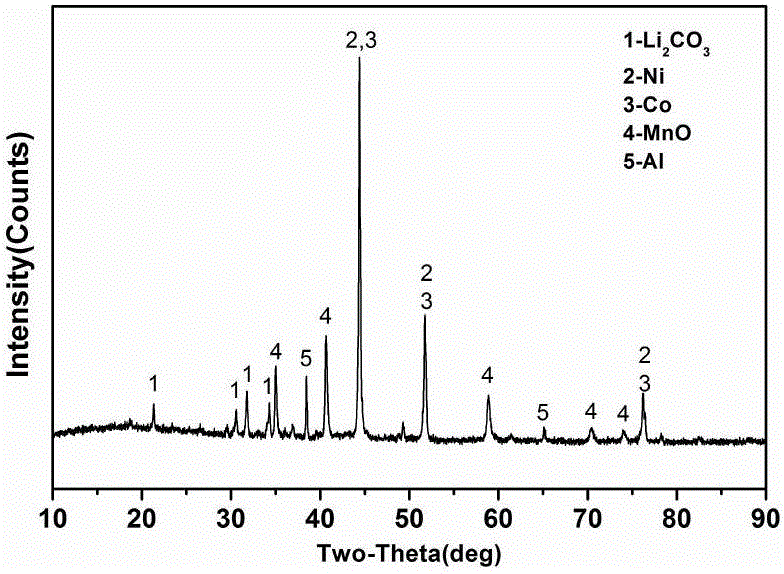

Method for comprehensively recovering valuable metals from waste lithium-ion battery material

ActiveCN106129511AEfficient recyclingHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementManganeseAmmonia

The invention discloses a method for comprehensively recovering valuable metals from a waste lithium-ion battery material. The method is characterized by comprising the steps of mixing a waste lithium-ion battery positive electrode material with a reducing agent, or mixing simply crushed whole battery with a carbon reducing agent; carrying out reducing roasting treatment at the temperature of 500-750 DEG C; firstly carbonizing and leaching a roasted product through CO2 to obtain a lithium bicarbonate water solution for preparing an Li2CO3 product; and leaching valuable elements of cobalt, nickel, manganese and the like from liquid leached residues through oxidation acid leaching or oxidation ammonia leaching, carrying out extracting and purifying and then preparing the corresponding compound product. The method is simple in technology and short in flow; the reagent cost is low; and valuable metal elements of lithium, the cobalt, the nickel, the manganese and the like in the waste lithium-ion battery material can be efficiently recovered.

Owner:GUANGDONG GUANGHUA SCI TECH

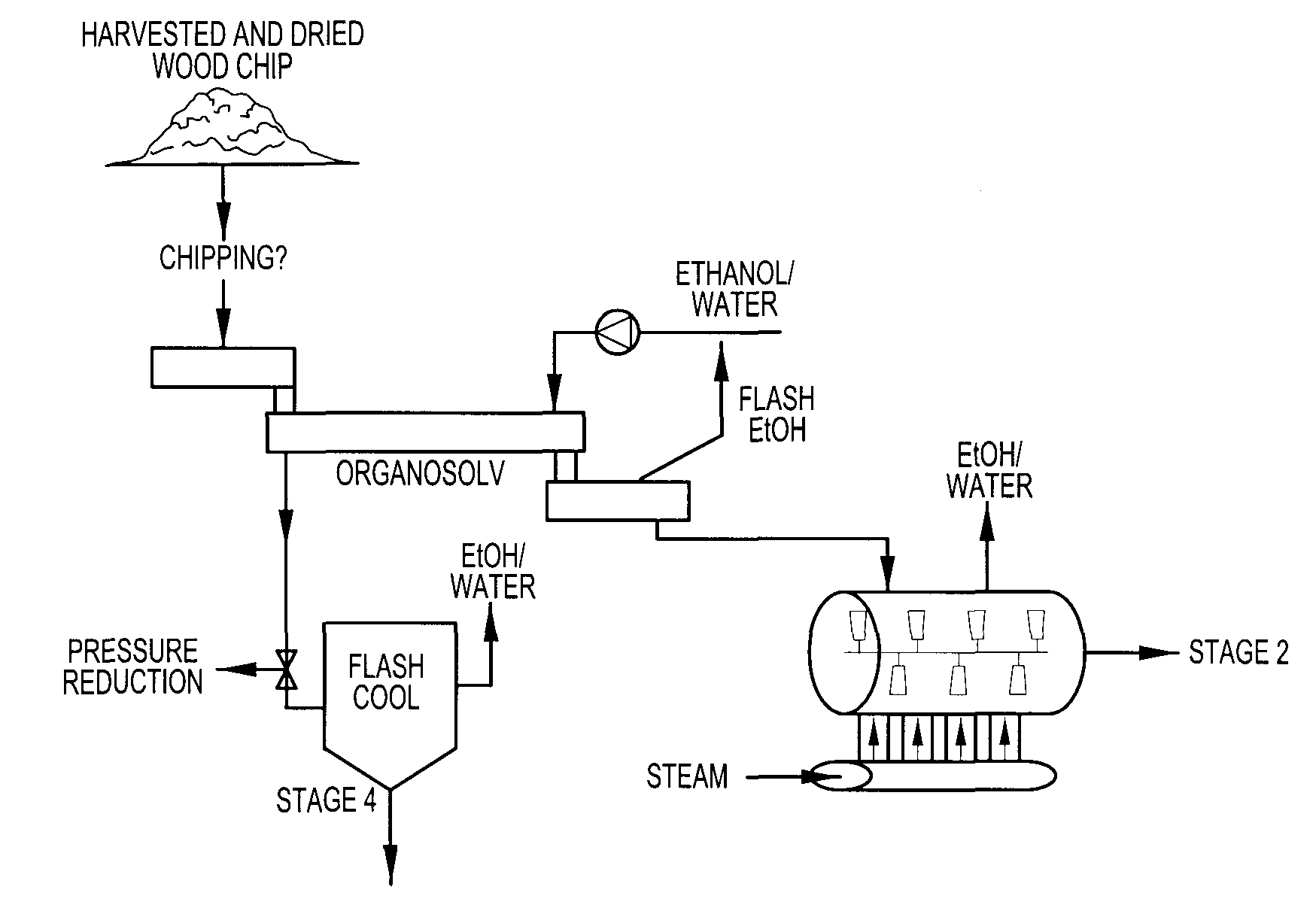

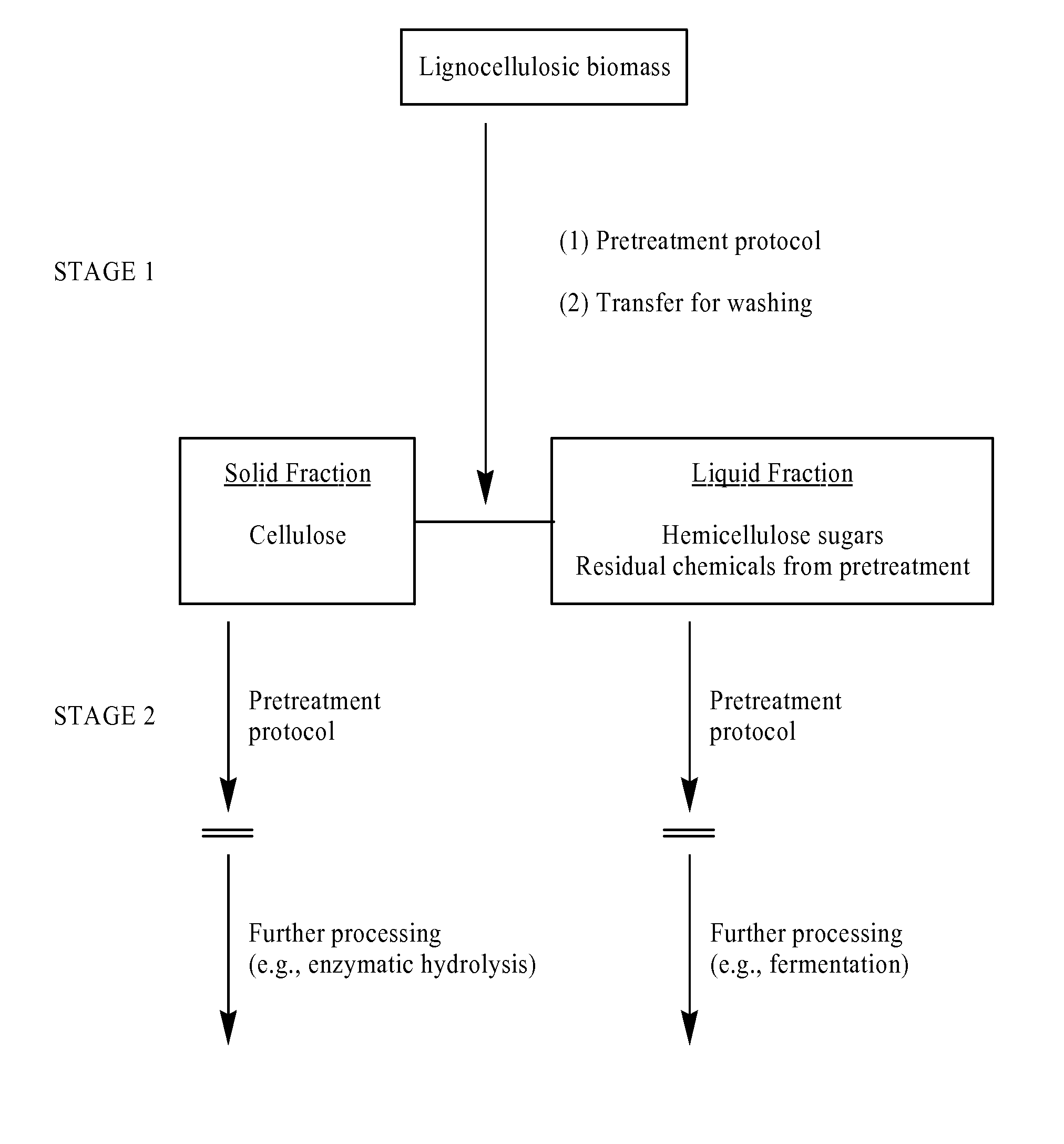

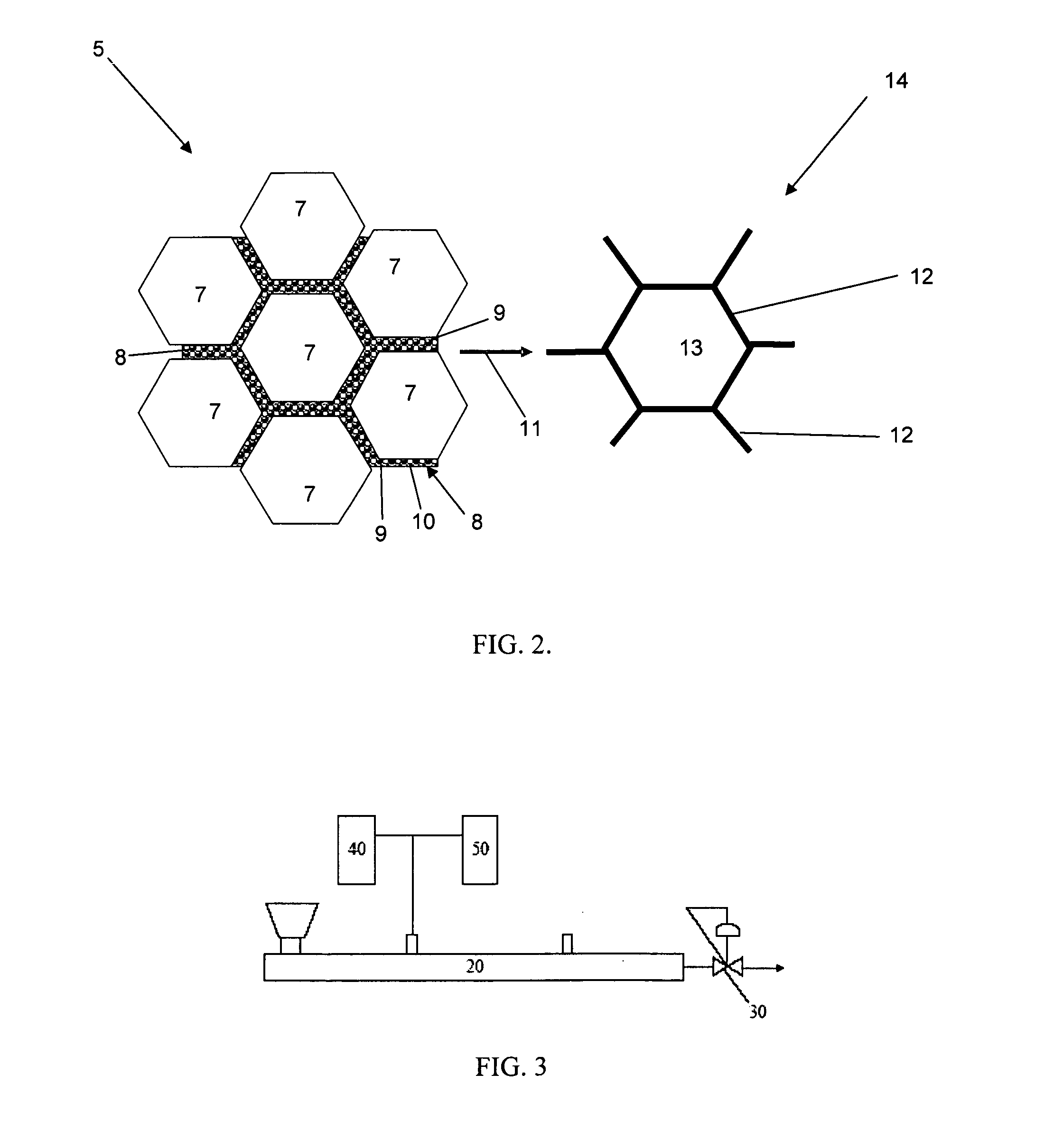

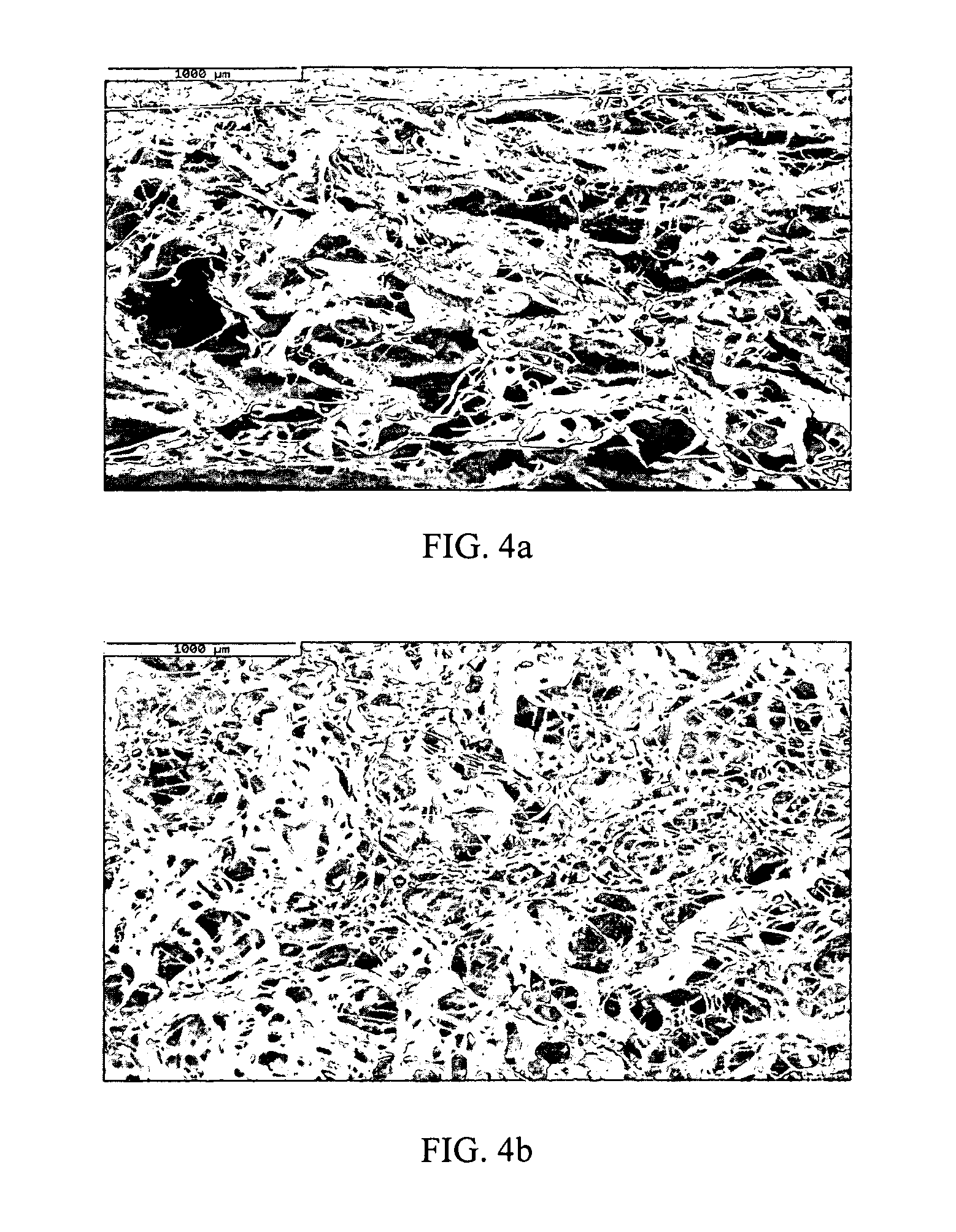

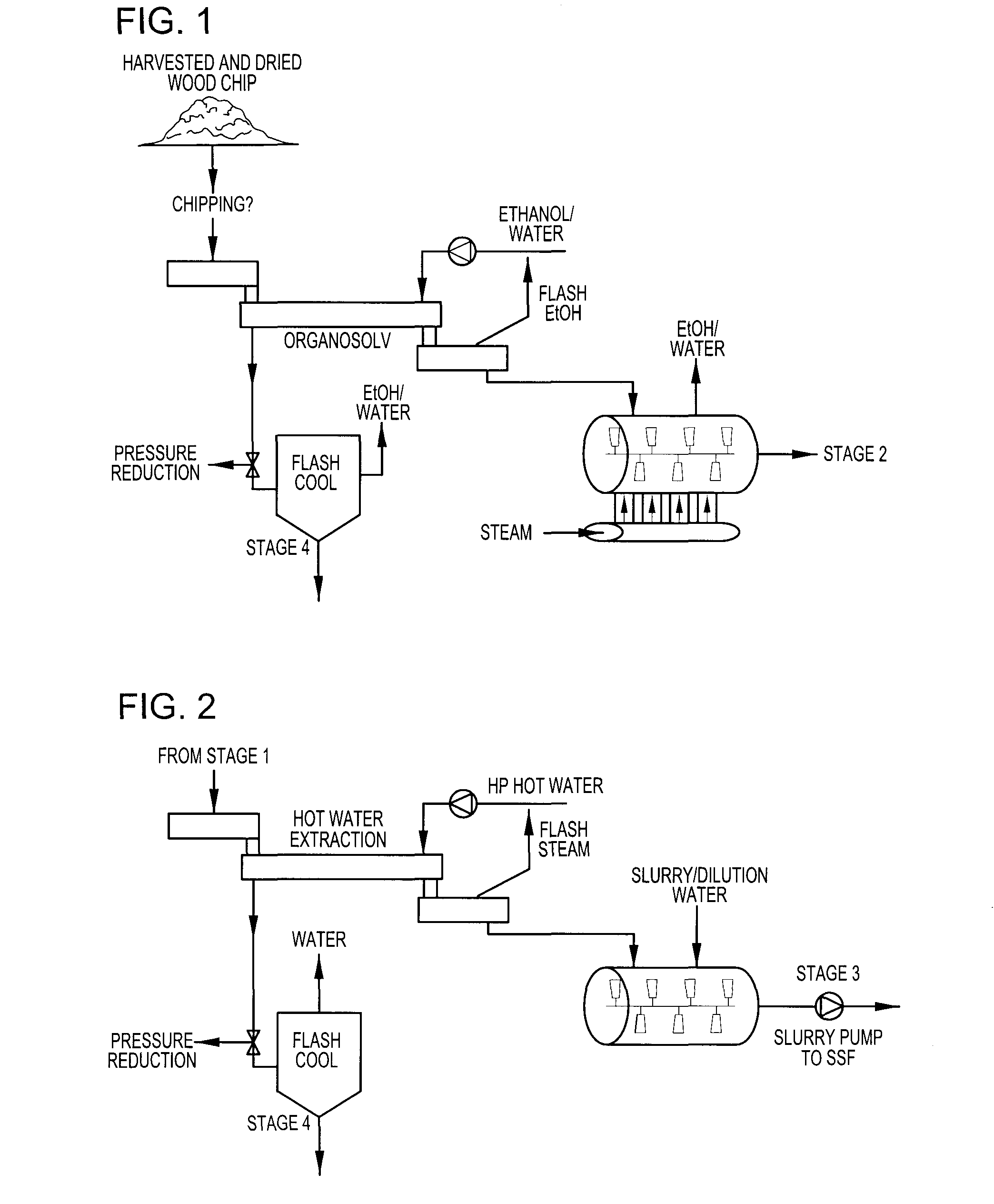

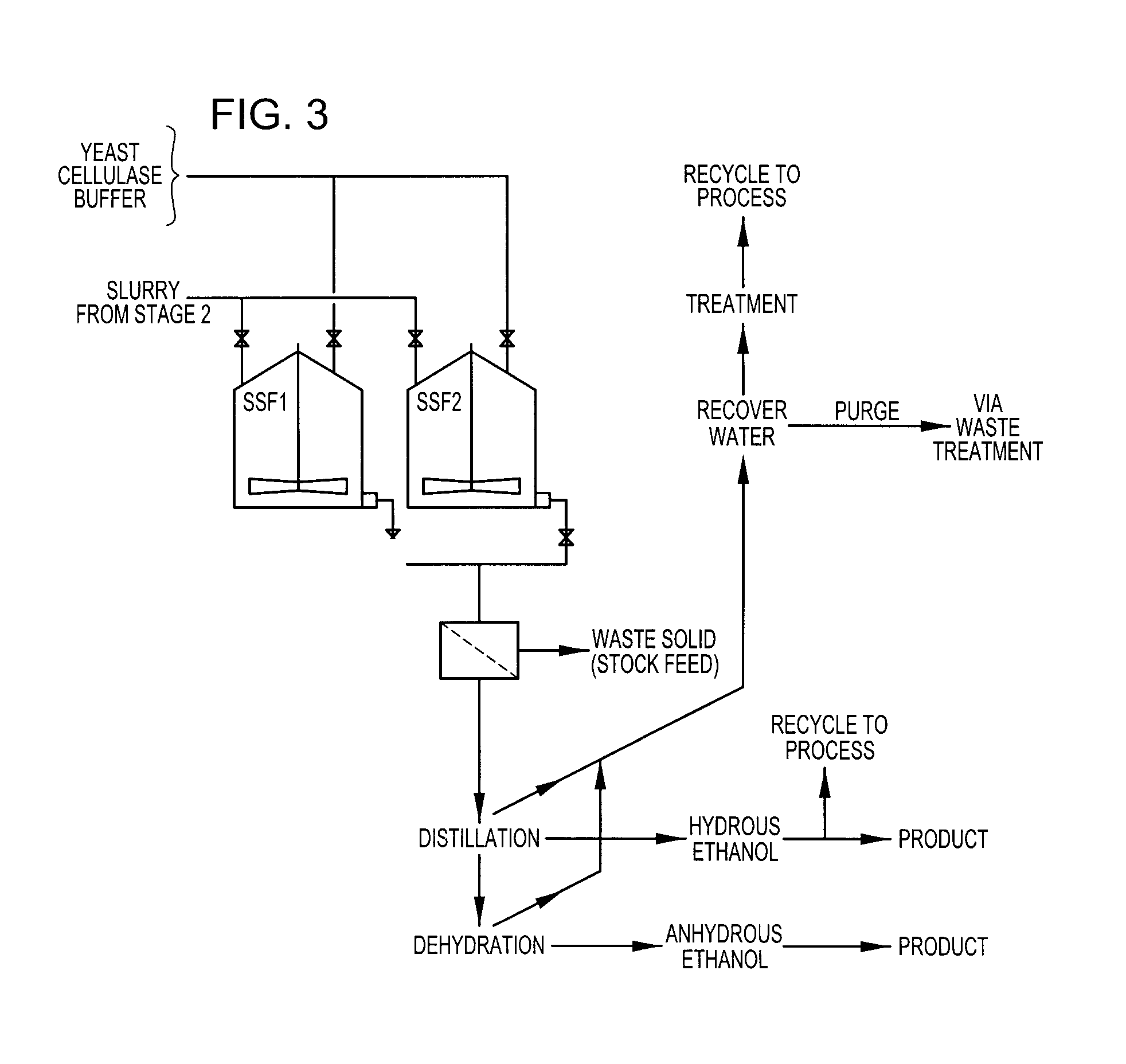

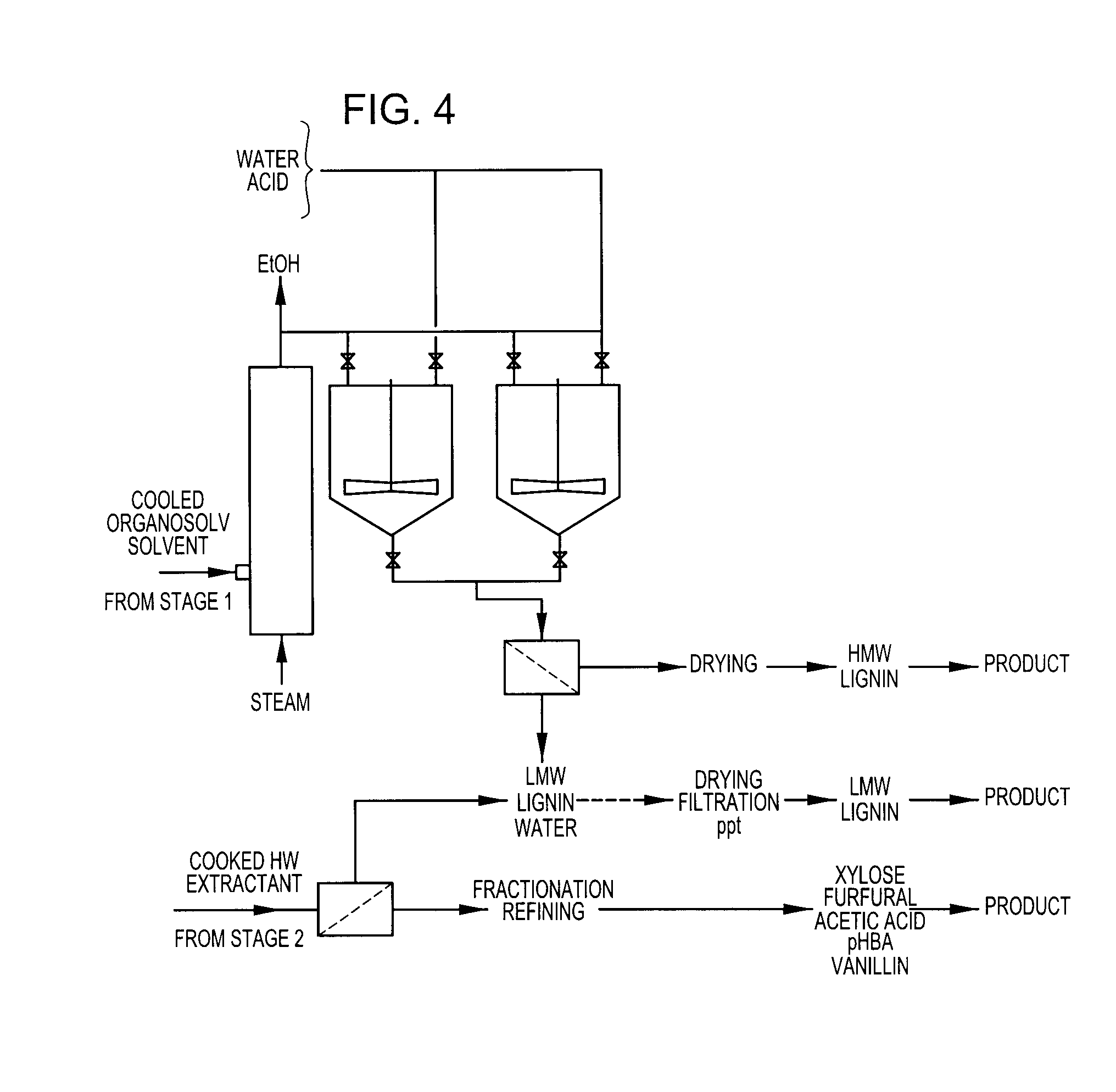

Process for the production of biofuel from plant materials

InactiveUS20070259412A1Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseBiofuel

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

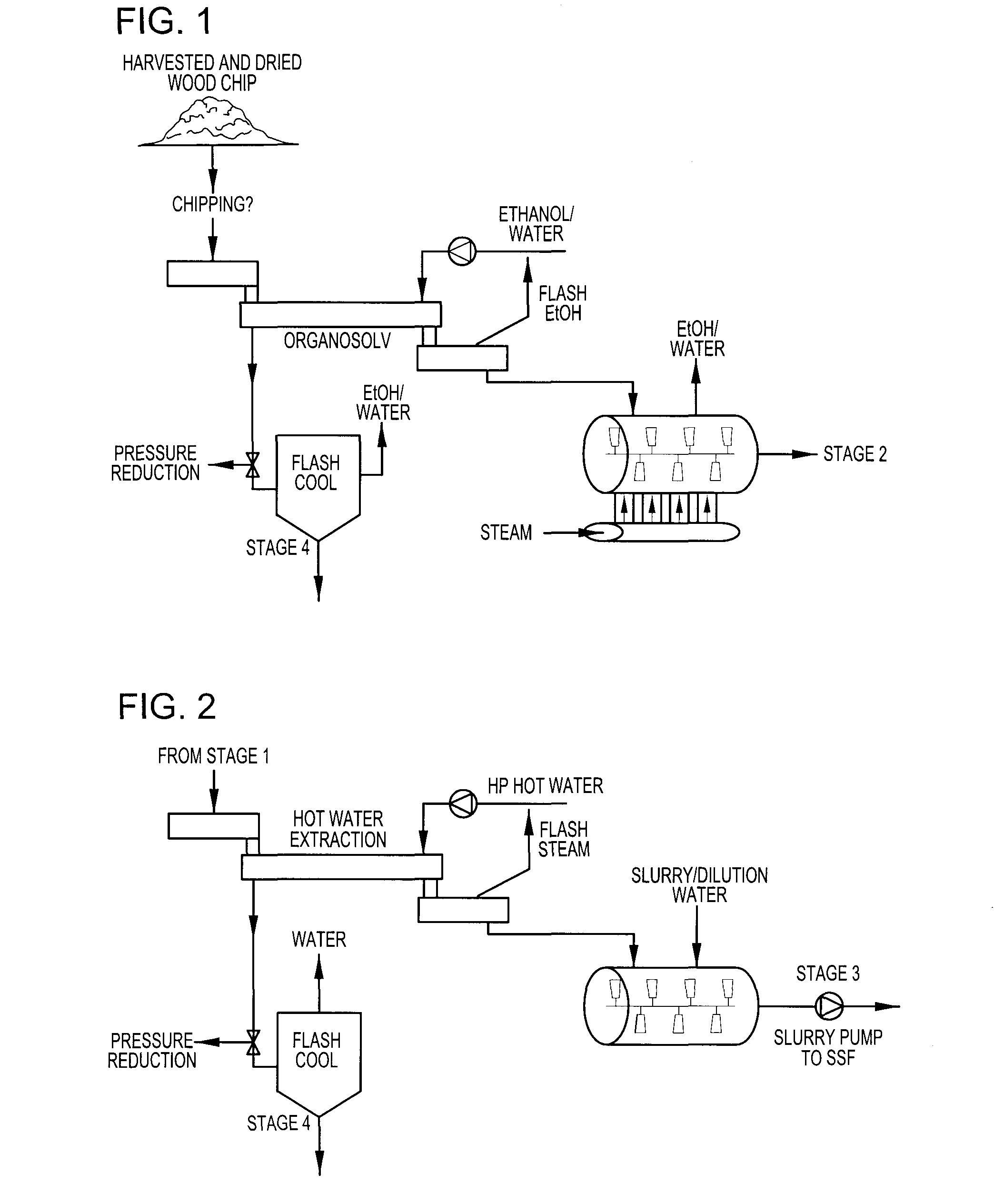

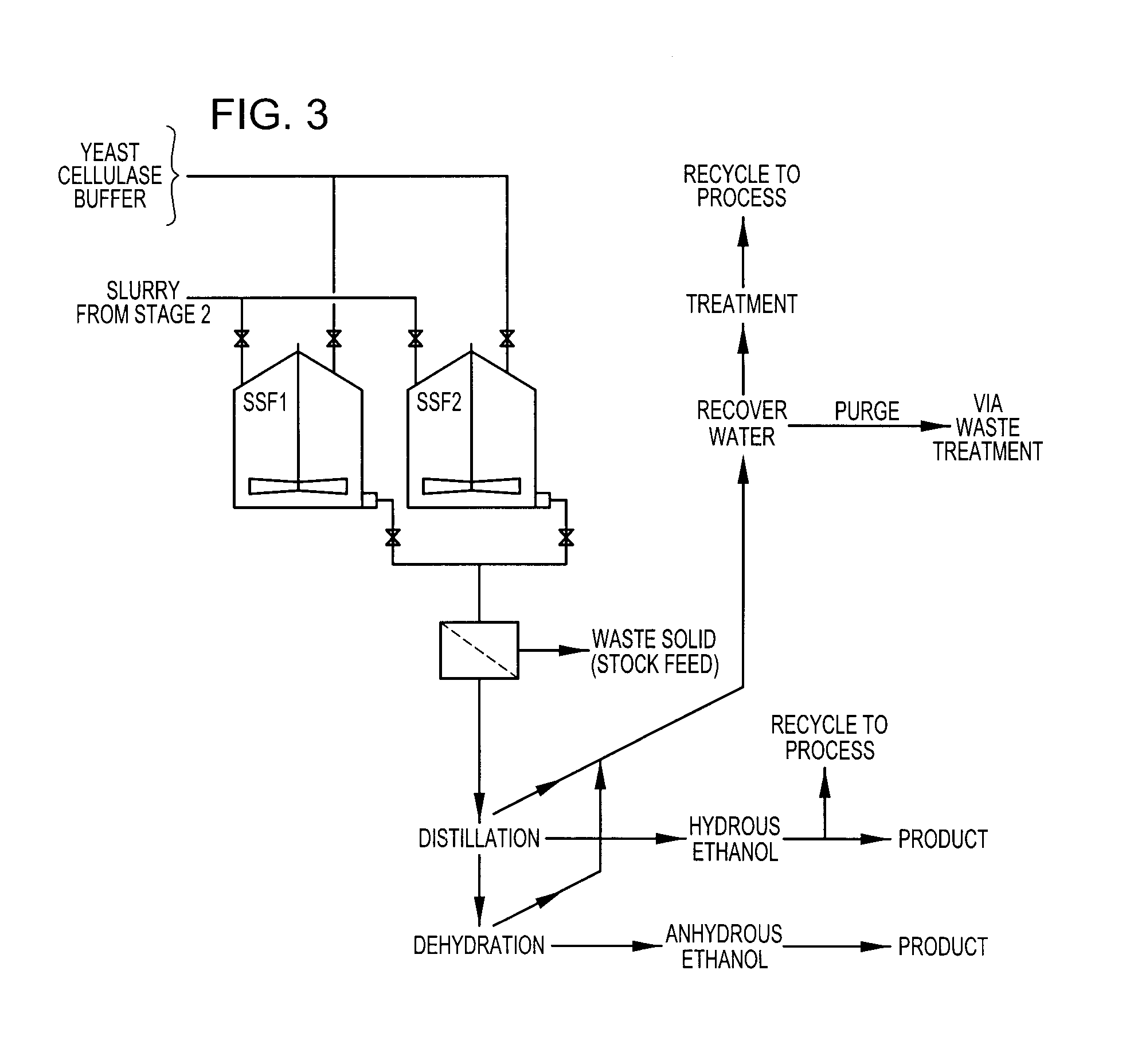

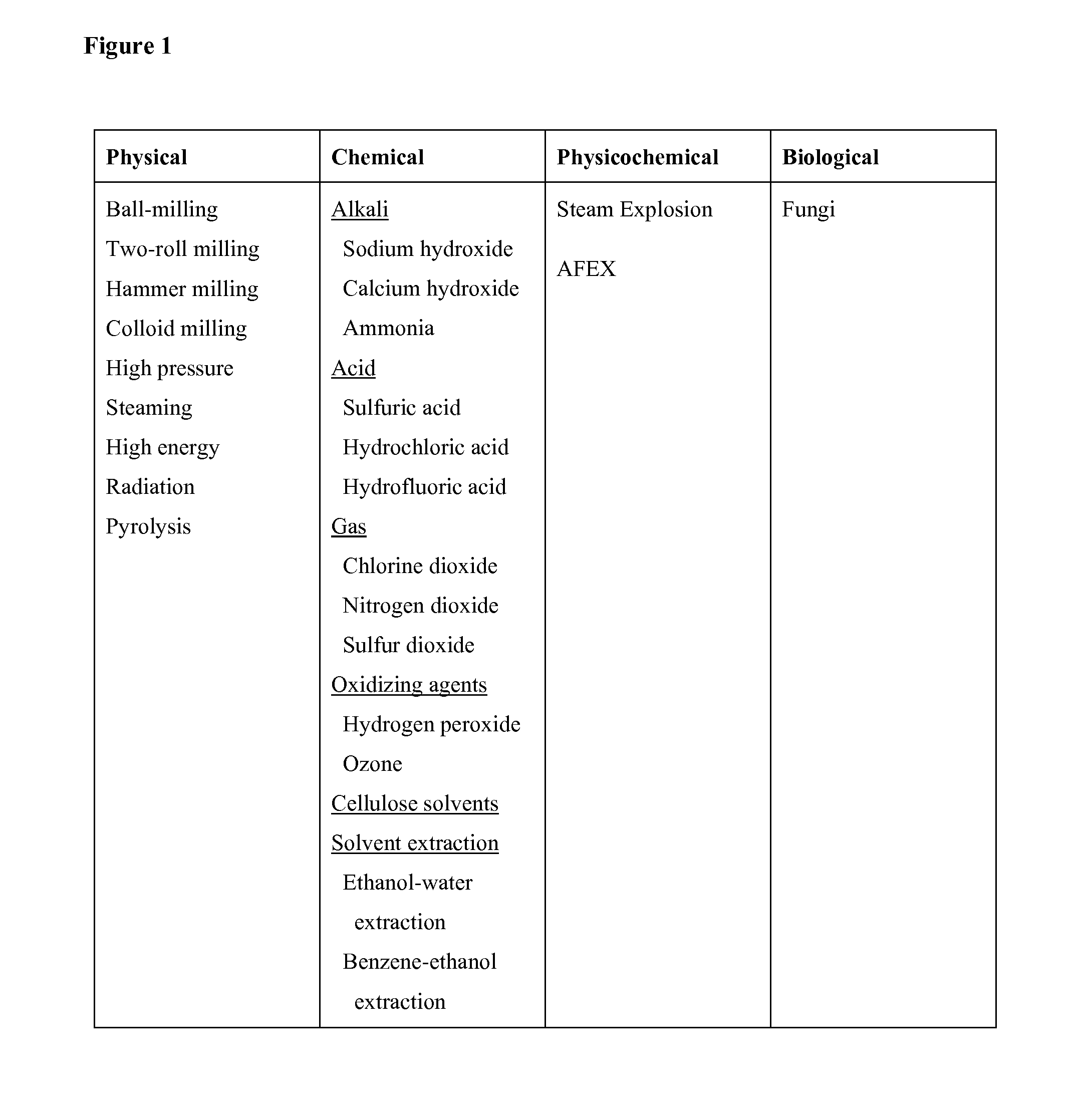

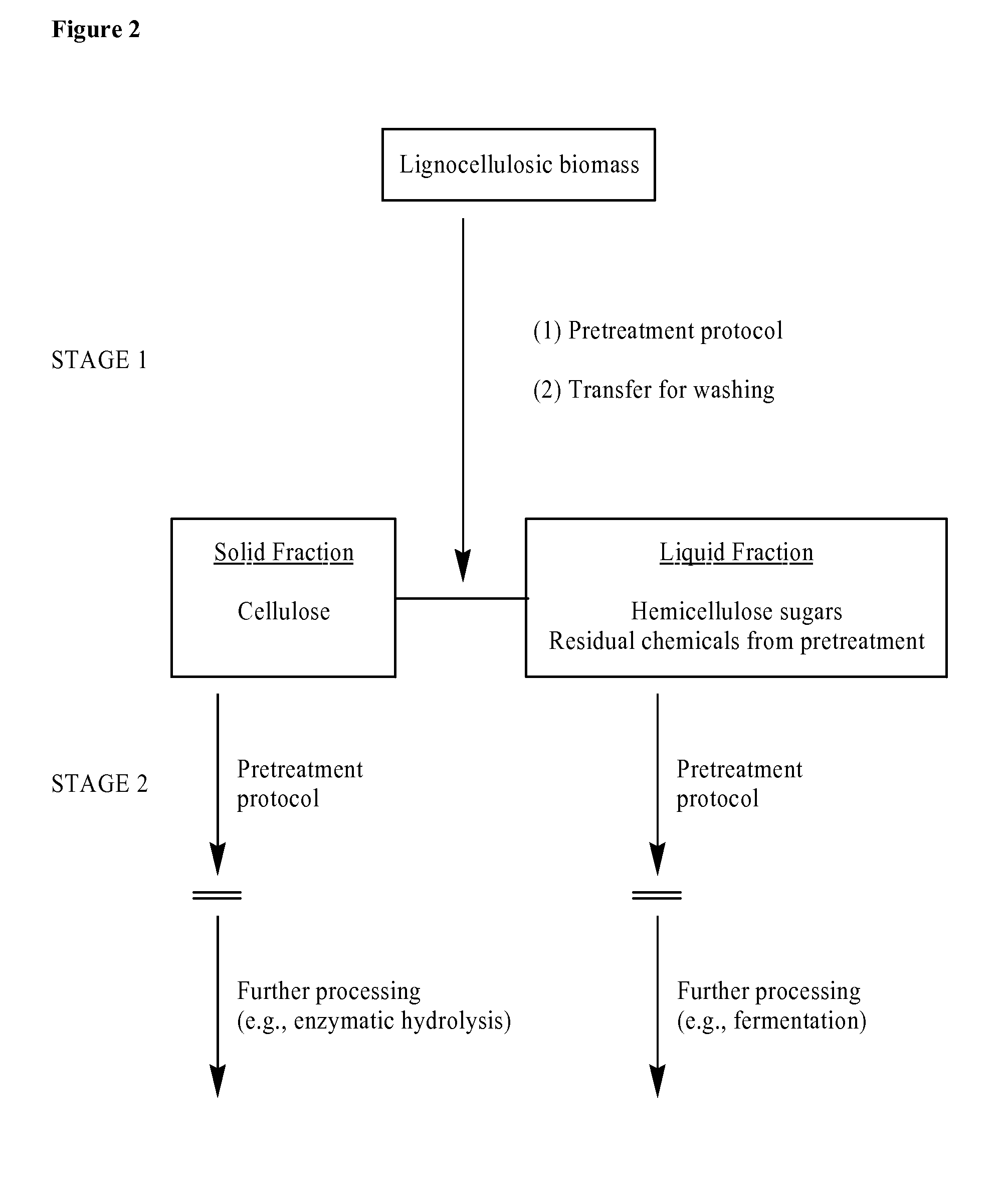

Two-stage method for pretreatment of lignocellulosic biomass

InactiveUS20100279361A1Reduce decreaseMaximize efficiencyOrganic compound preparationFood processingCelluloseFiber

One aspect of the invention relates to a process, comprising treating lignocellulosic biomass according to a first pretreatment protocol, thereby generating a first product mixture; separating the first product mixture into a first plurality of fractions; and treating at least one fraction of said first plurality of fractions according to a second pretreatment protocol, thereby generating a second product mixture. In one embodiment, the lignocellulosic biomass is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugarcane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp protocol protocol fiber, paper sludge, sawdust, hardwood, softwood, and combinations thereof.

Owner:MASCOMA CORPORATION

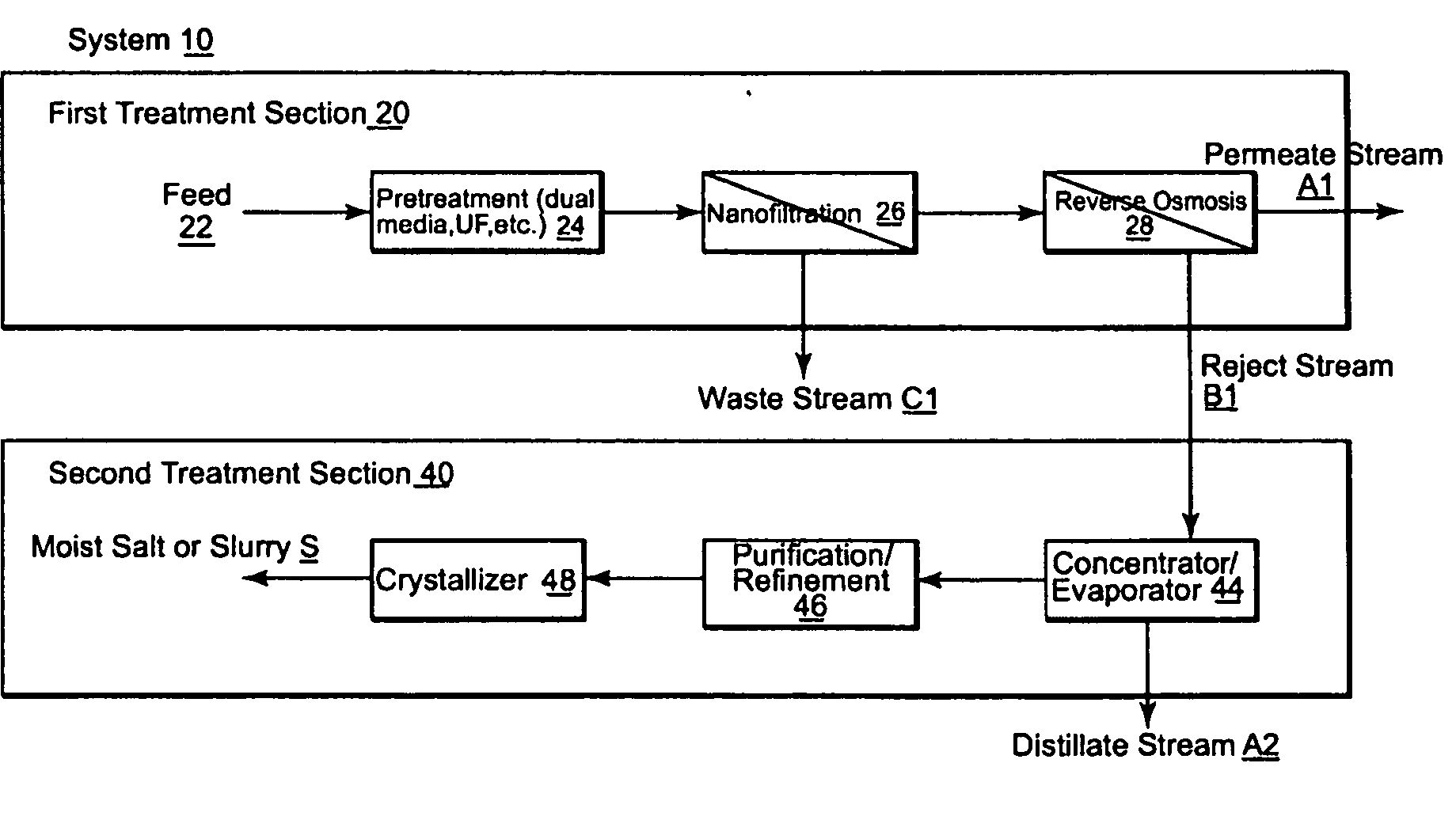

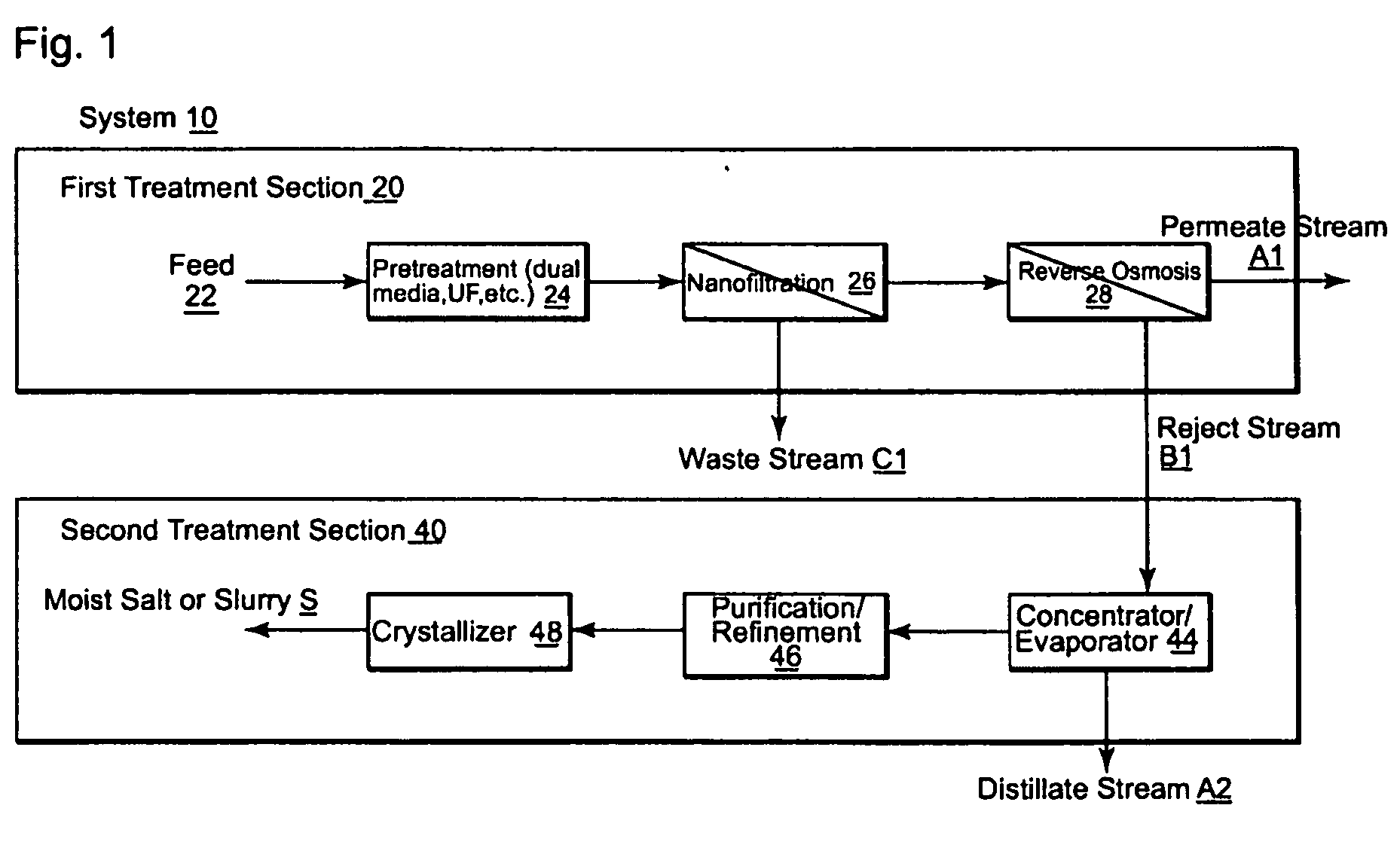

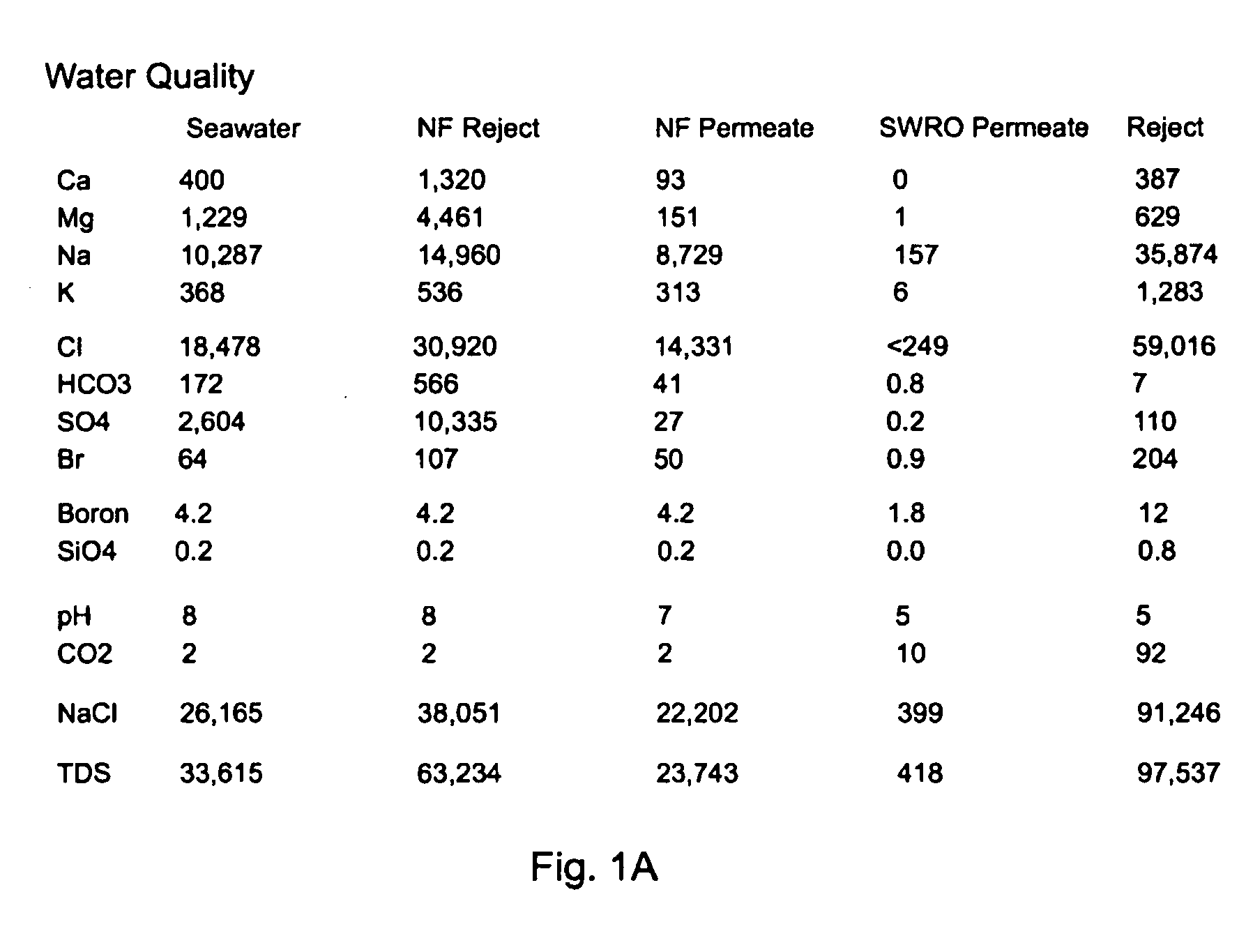

Water desalination plant and system for the production of pure water and salt

InactiveUS20100163471A1Large industrial capacitySimplified and cost-effective processSludge treatmentGeneral water supply conservationWater desalinationTotal dissolved solids

The present invention discloses a desalination plant that operates with a sea water or brackish water feed and produces a concentrated and selectively improved salt reject stream and a pure water permeate stream from a first treatment section that is arranged to produce primarily water at high recovery using membrane desalination processes. The reject stream from the first treatment line has a component distribution that is substantially reduced in native di- and polyvalent scaling ions, essentially depleted of sulfate, has substantially higher total dissolved solids than a traditional sea water reverse osmosis reject, yet is suitable for thermal treatment processes. The system may be enhanced by monovalent salt components. The unit may be integrated with a second treatment section, in which the first reject stream is further concentrated, purified, and processed to produce a high purity salt product.

Owner:GENERAL ELECTRIC CO

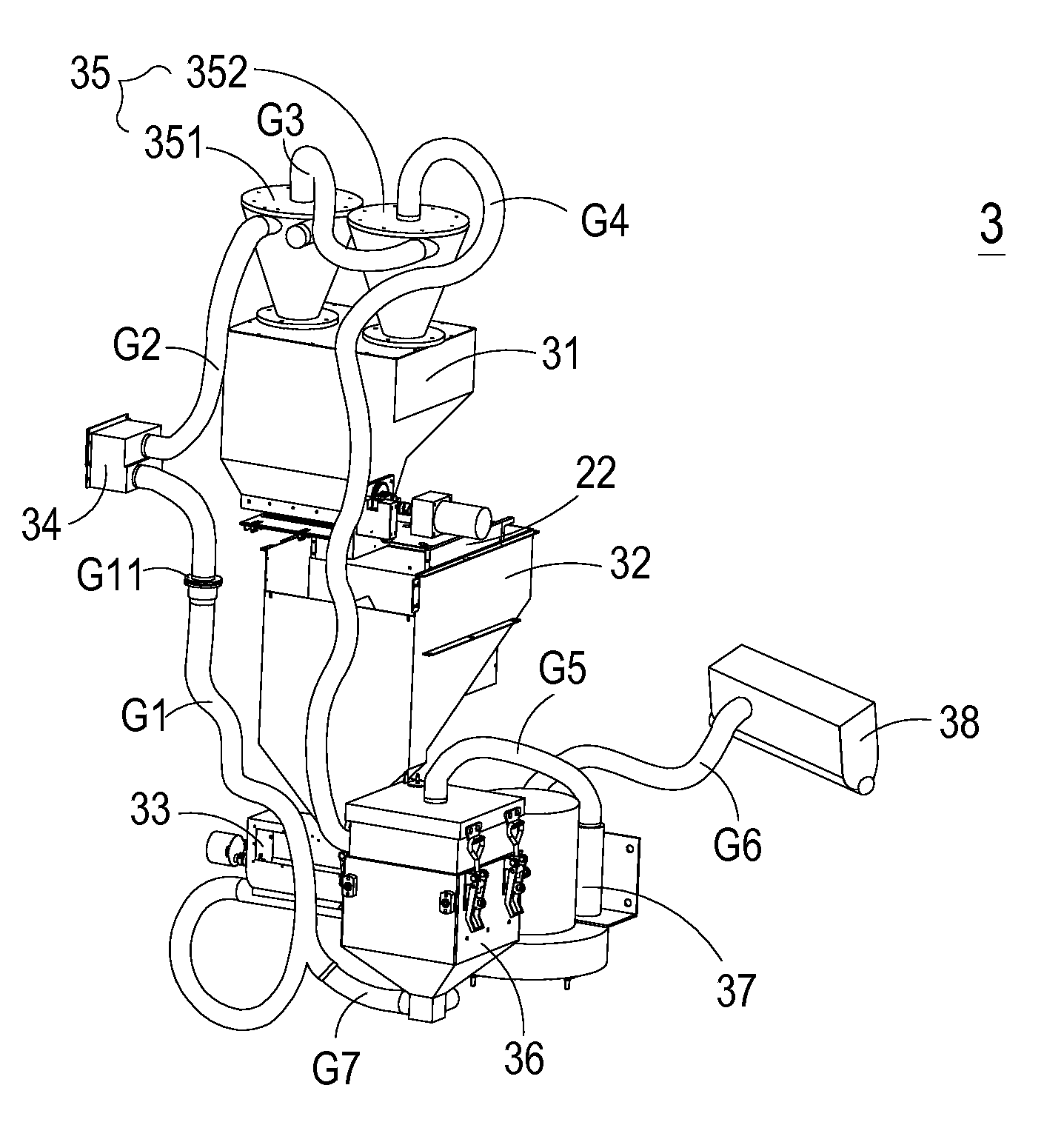

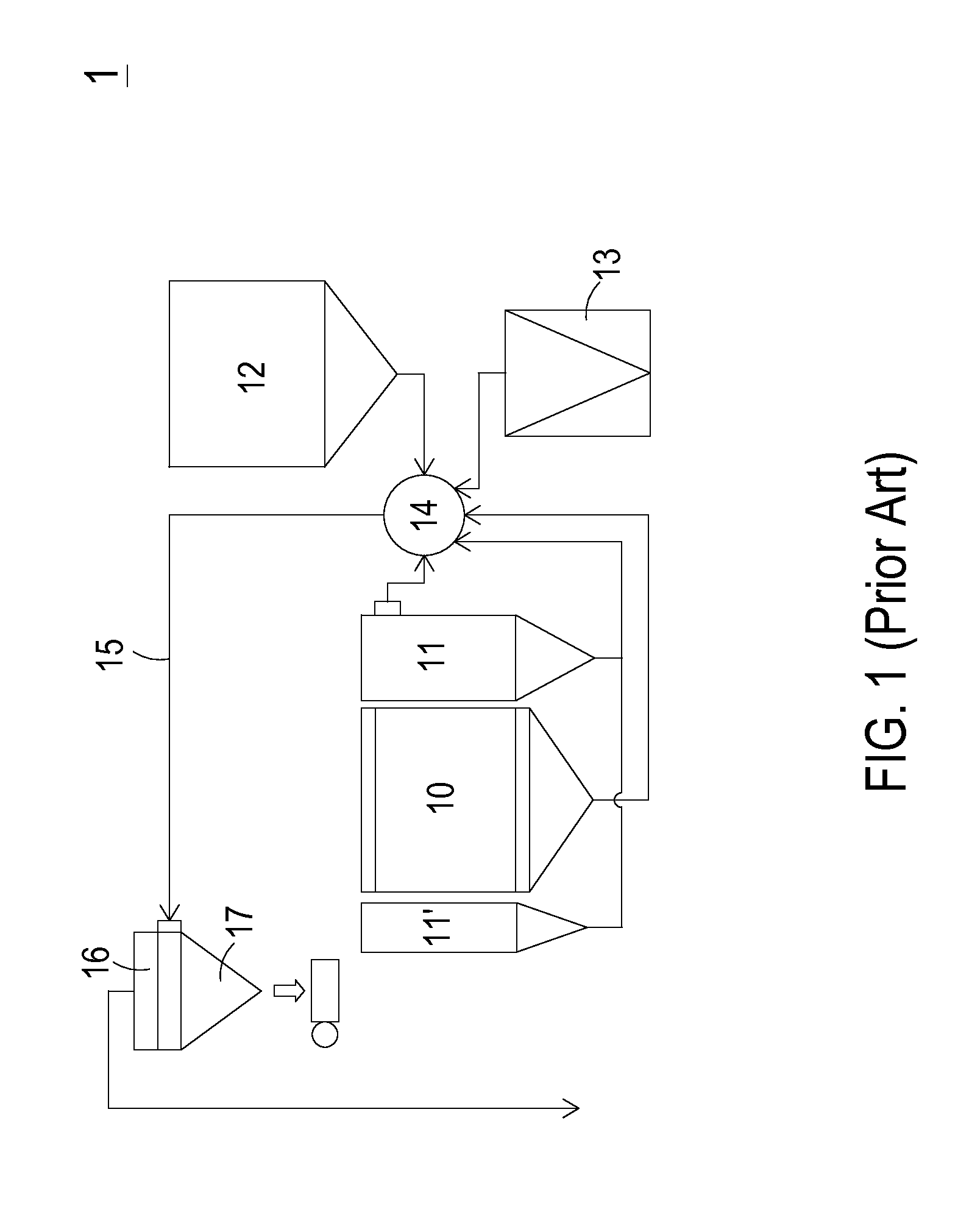

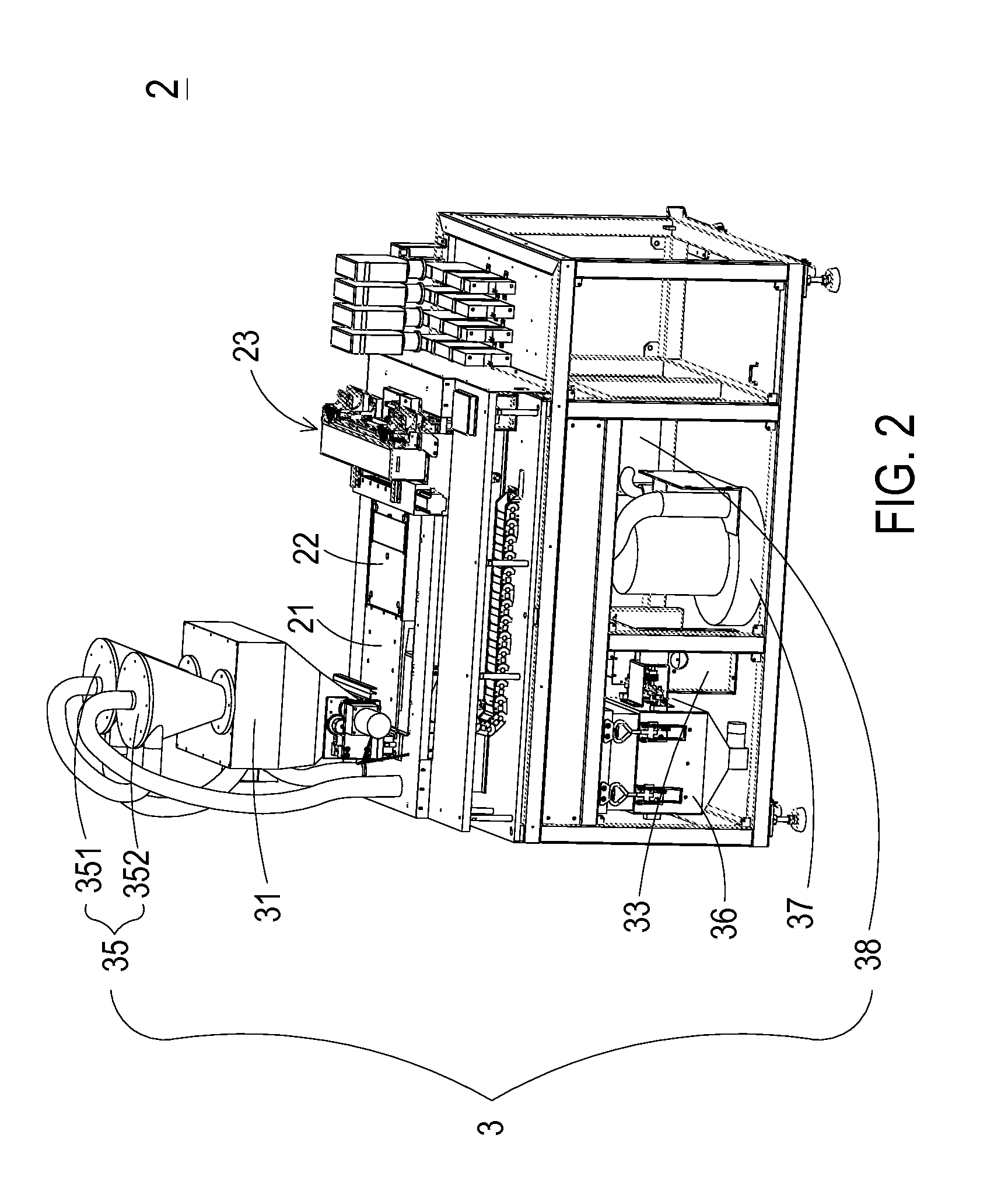

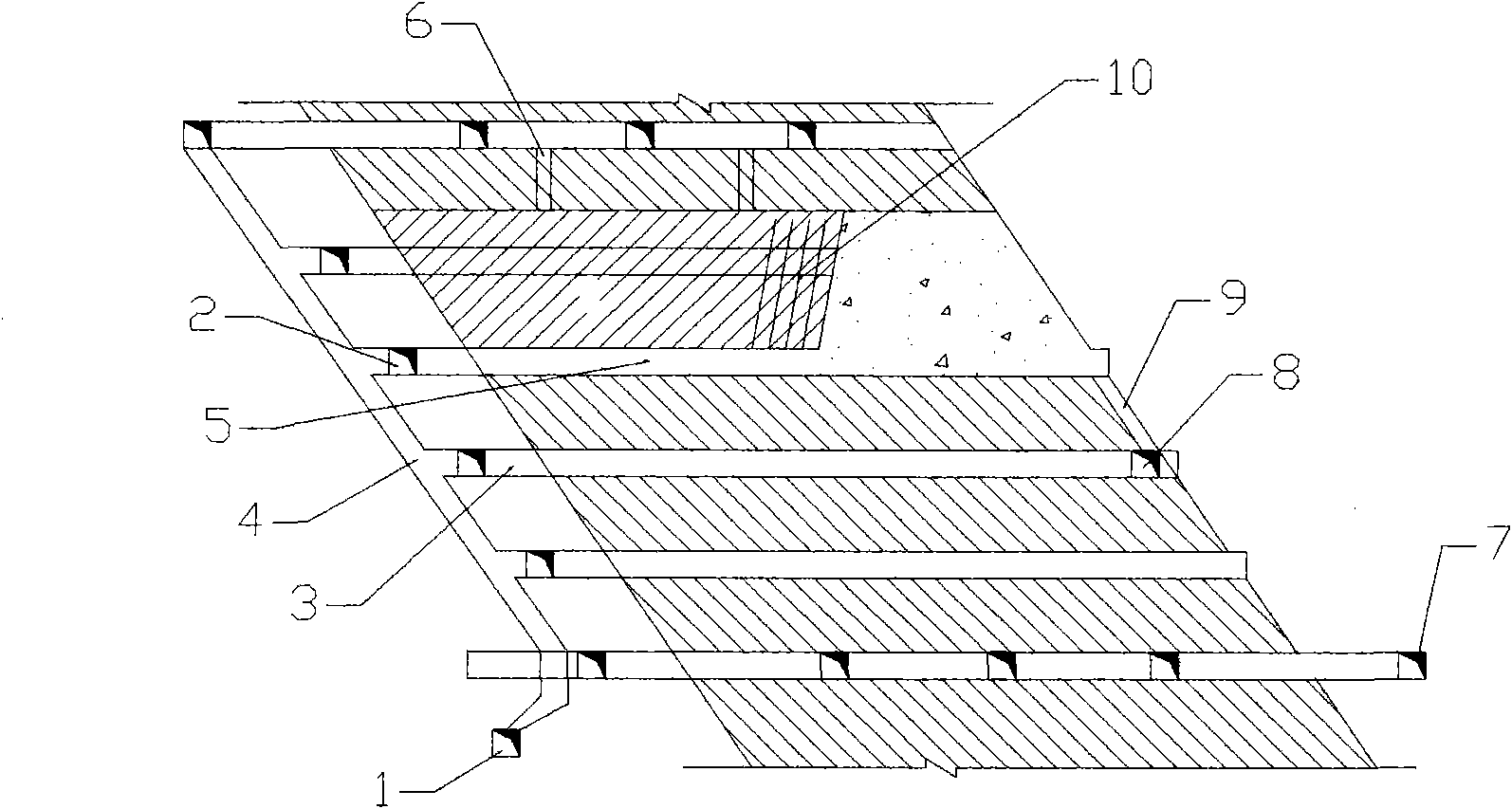

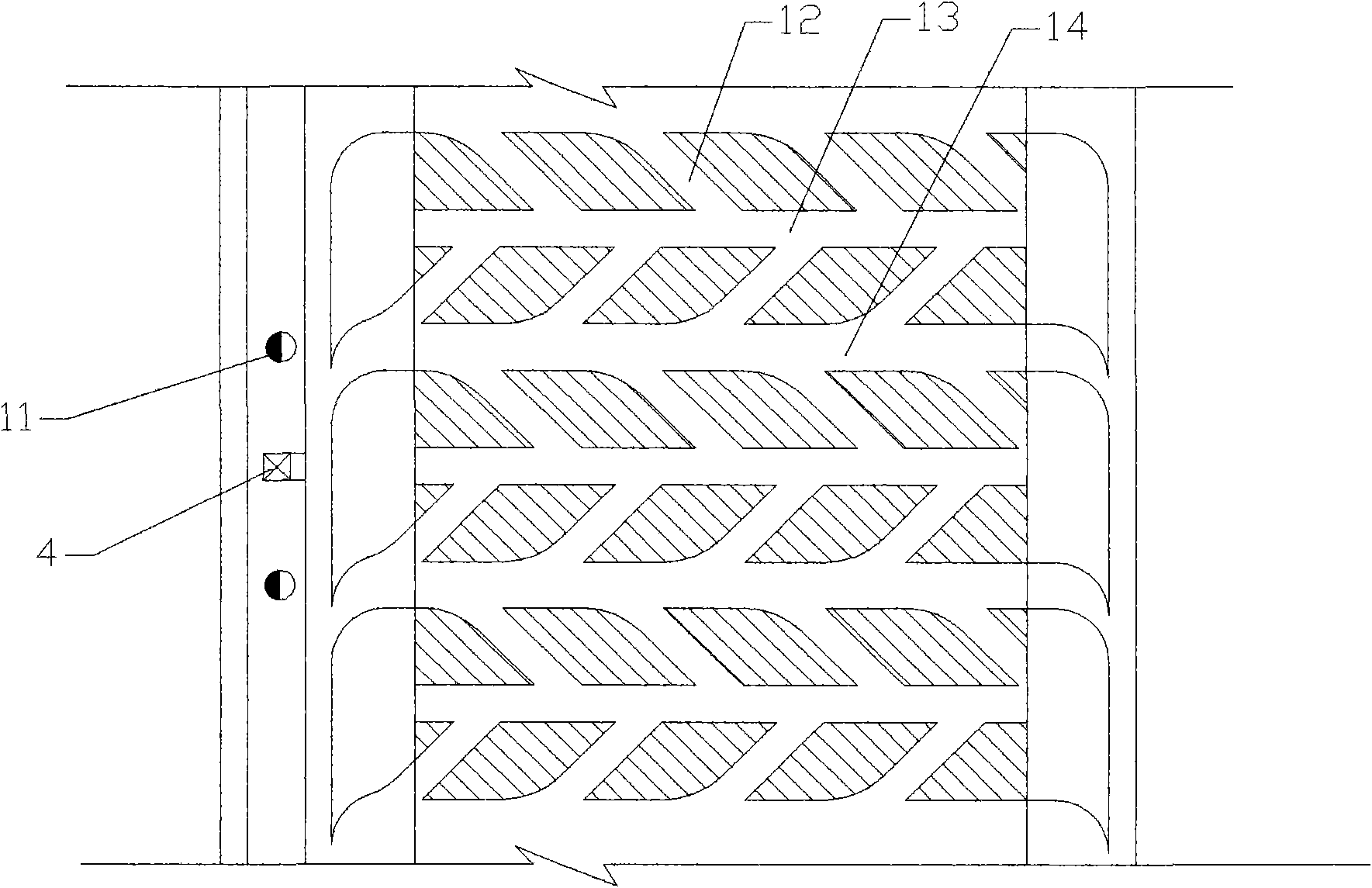

Powder recycling system

ActiveUS20150298397A1More user-friendlyCost-effectiveAdditive manufacturing apparatusGas current separationParticulatesPressure generation

A powder recycling system includes a powder feeder, a remaining powder collector, a bridge breaker, a block powder filter, a cyclone separator, a particulate filter cleaner, an air pressure generation device and an electrostatic precipitator. The powder feeder provides a construction powder to a construction platform. The remaining powder collector for collects the remaining powder. The cyclone separator is used to separate the large-size powdery particles and the small-size powdery particles of the remaining powder from each other through a rotating gaseous stream. The large-size powdery particles fall down to the powder feeder due to gravity, and the small-size powdery particles of the remaining powder is removed from the rotating gaseous stream and transmitted to the particulate filter cleaner. After the small-size powdery particles of the remaining powder are filtered by the particulate filter cleaner, the suspended small-size powdery particles are transmitted to the electrostatic precipitator.

Owner:MICROJET TECH

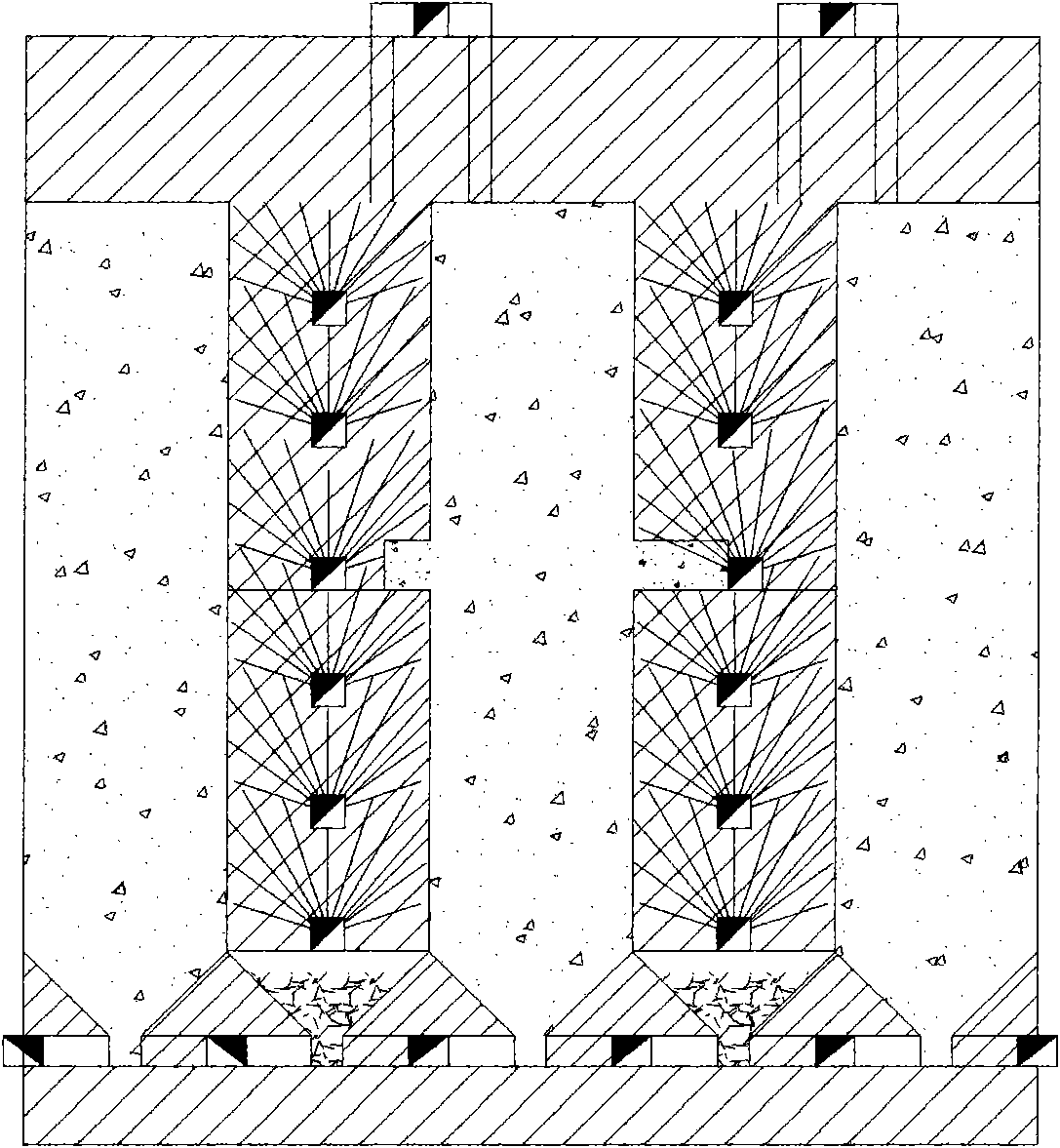

Sublevel shrinkage caving stage open stope afterwards filling mining method

InactiveCN101881169ALarge amount of filling at one timeIncrease production capacityUnderground miningSurface miningEarth surfaceComputer science

The invention discloses a sublevel shrinkage caving stage open afterwards filling mining method. In the earlier stage of stoping, caved ores are utilized to support surrounding rocks on a top tray, and in the later stage of stoping, a goaf area is filled with fillers to control ground pressure so as to achieve safe and efficient mining. Ore blocks are mined in two steps, mining blocks in step two are stoped after the mining blocks in step one are stoped and filled. After the ores are completely let out, the goaf area is filled with the fillers to control the ground pressure. Because the stoping modes of sublevel ore caving, sublevel shrinkage, final ore drawing and empty area afterwards filling are adopted, the mining method has large one-time filling amount and low cost; the method adopts middle-deep hole drilling and blasting and carry scraper ore removal, and the device has high level and large production capacity; the method has the advantages of large production capacity of the sublevel caving method and the stage open stope method, high recovery rate of the filling method, and earth surface protection; the safety is good, and drilling, ore removal and other operations are all carried out in a sublevel drilling and ore removal approach roadway; and the ores can be removed in advance, and the ores can be removed partially after the first sublevel is ready.

Owner:NORTHEASTERN UNIV +1

Process for producing sodium sulfate and sodium chloride in Na2SO4-NaCl-H2O system

InactiveCN1944256AIncrease profitReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal halide purificationInorganic saltsSeparation technology

The process of producing sodium sulfate and sodium chloride in a Na2SO4-NaCl-H2O system belongs to the field of mixed inorganic solution evaporating separation technology. Mixed solution of sodium sulfate and sodium chloride as material is first evaporated and then separated to obtain sodium sulfate, sodium chloride and evaporated mother liquor; the evaporated mother liquor is low temperature evaporated and separated to obtain sodium chloride and salt-making mother liquor; and the salt-making mother liquor is evaporated and separated to obtain sodium sulfate and saltpeter-making mother liquor. The present invention has the features of high main and side product quality, high material adaptability, low cost, low cost, no waste draining, etc.

Owner:CHINA LIGHT IND INT ENG CO LTD +1

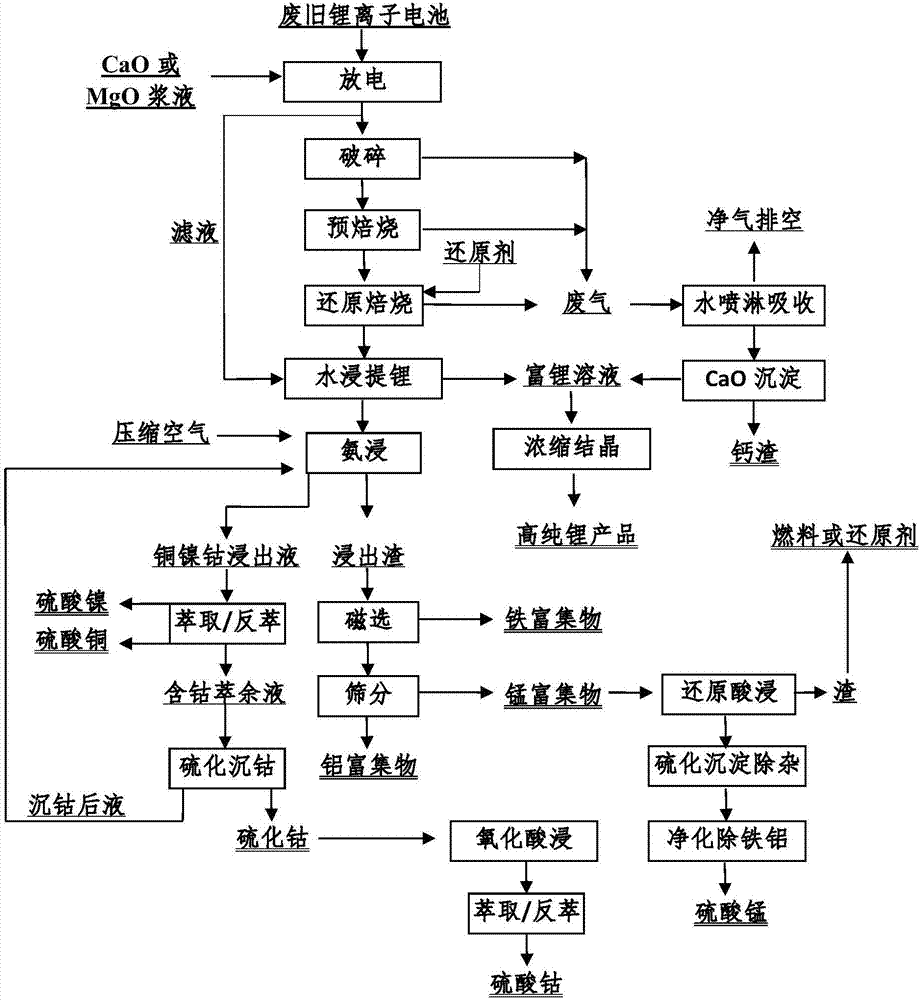

Method for comprehensively recycling valuable metals from spent lithium ion battery

ActiveCN107017443AThe pre-processing process is simpleHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementVulcanizationSlag

The invention discloses a method for comprehensively recycling valuable metals from a spent lithium ion battery. The method comprises the following steps: carrying out electric discharge treatment on a spent battery, crushing, pre-roasting at 300-400 DEG C, adding a reducing agent, and carrying out reduction roasting at 450-700 DEG C; carrying out water extraction and evaporative crystallization on fine aggregates obtained through the reduction roasting, so as to obtain a high-purity lithium product, leaching copper, nickel and cobalt from leached slag and roasted lump materials by virtue of ammonia oxide, carrying out magnetic separation and sieving on ammonia leaching slag so as to obtain iron and aluminum enriched products, and carrying out reduction acid leaching, purification and edulcoration on sieved products, so as to obtain a high-purity manganese sulfate solution; and carrying out extraction and selective reverse extraction on ammonia leaching liquid, so as to obtain a high-purity nickel sulfate solution and a high-purity copper sulfate solution, and carrying out vulcanization cobalt precipitation, oxidation acid leaching and extraction purification on raffinate, so as to obtain a high-purity cobalt sulfate solution. The method is high in extraction rate of valuable metals and applicable to the treatment of multiple waste lithium ion battery raw materials and efficient utilization of multiple elements, and sorting is not required.

Owner:GUANGDONG GUANGHUA SCI TECH

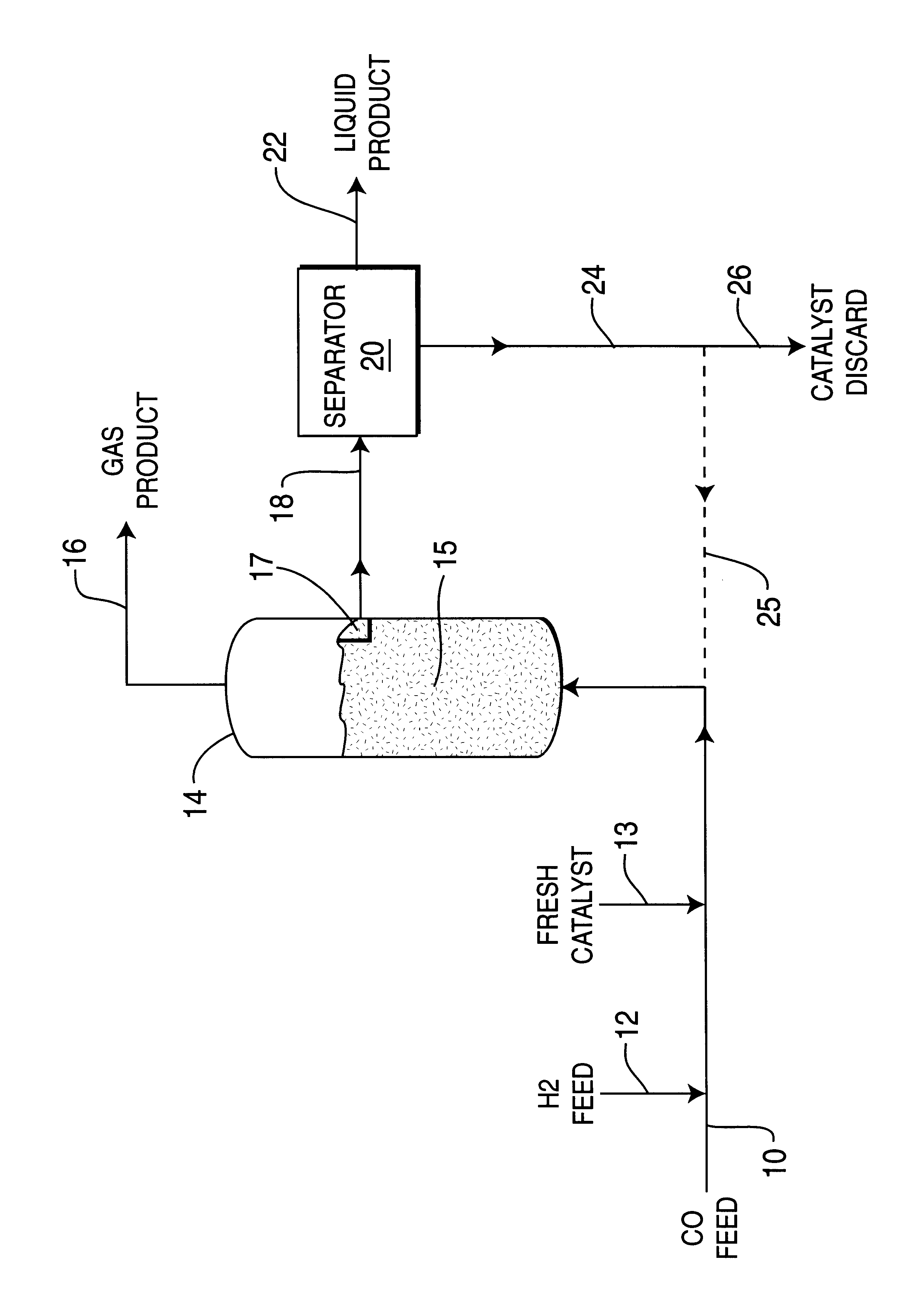

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS6277895B1High particle strengthGood attristion resistanceHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size, 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy pulverized particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen and to provide the smaller size skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-350° C. temperature, 0.5-3.0 mPa pressure and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:INST OF COAL CHEM ICCCHINESE ACADEMY OF SCI +1

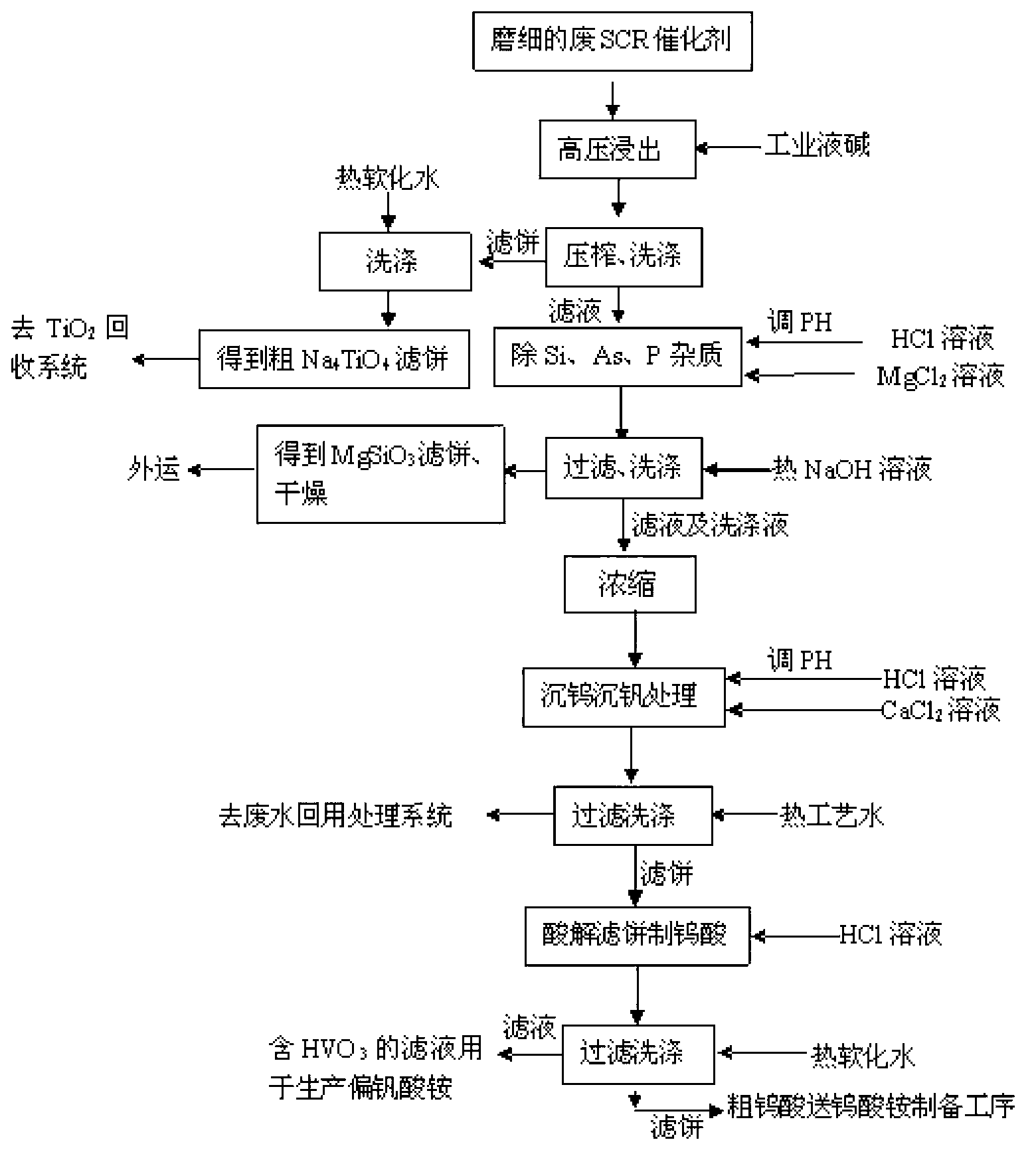

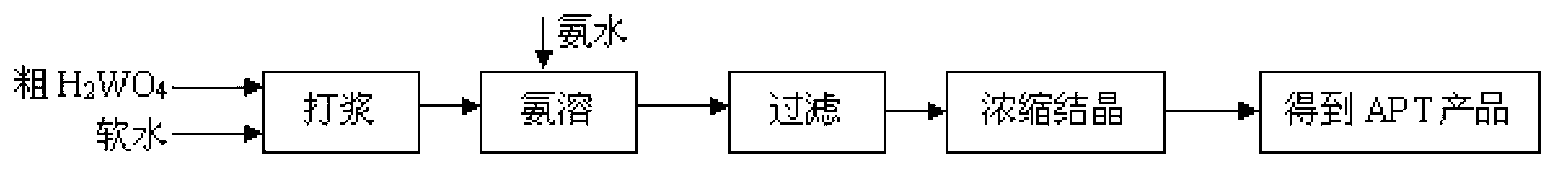

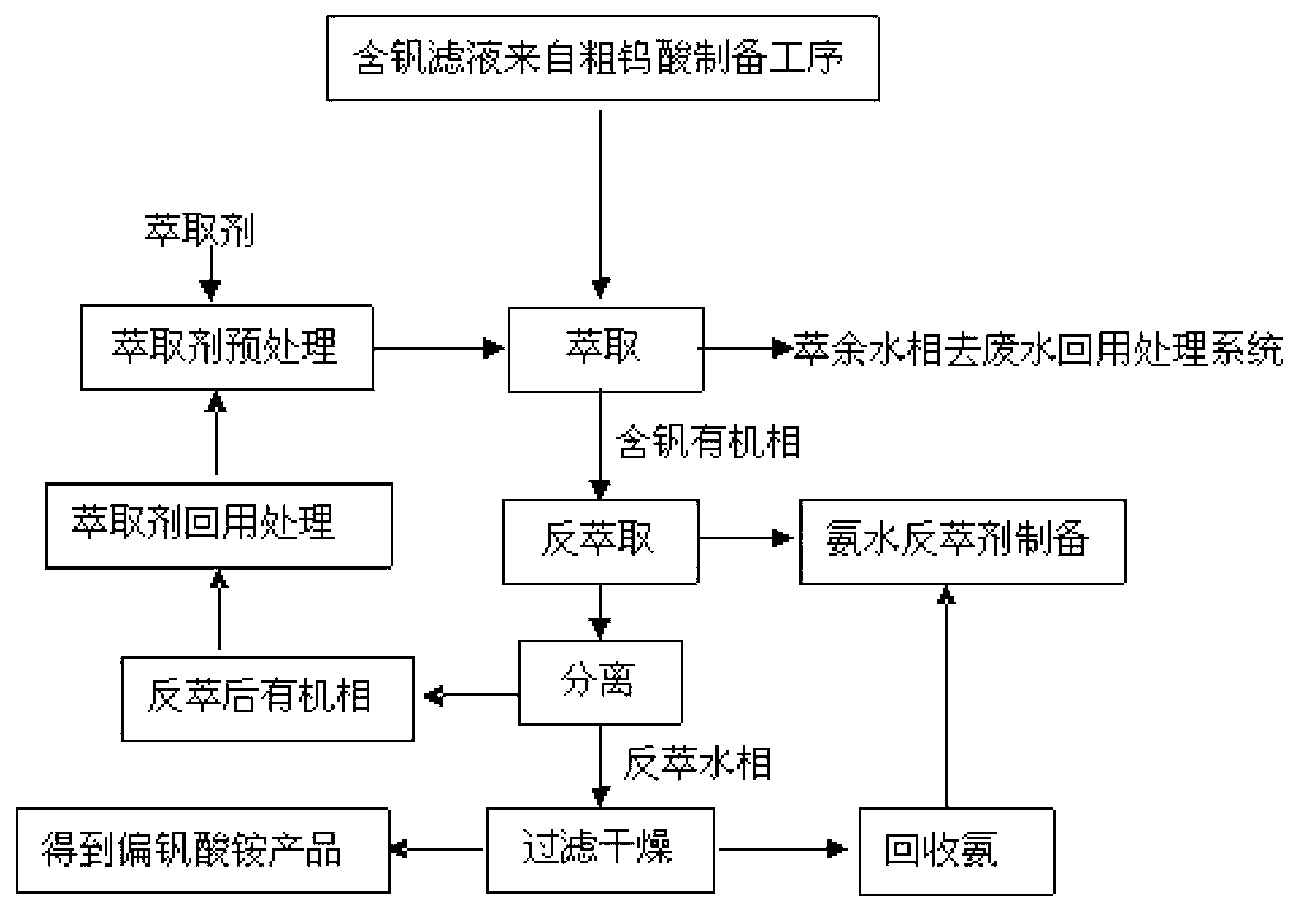

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

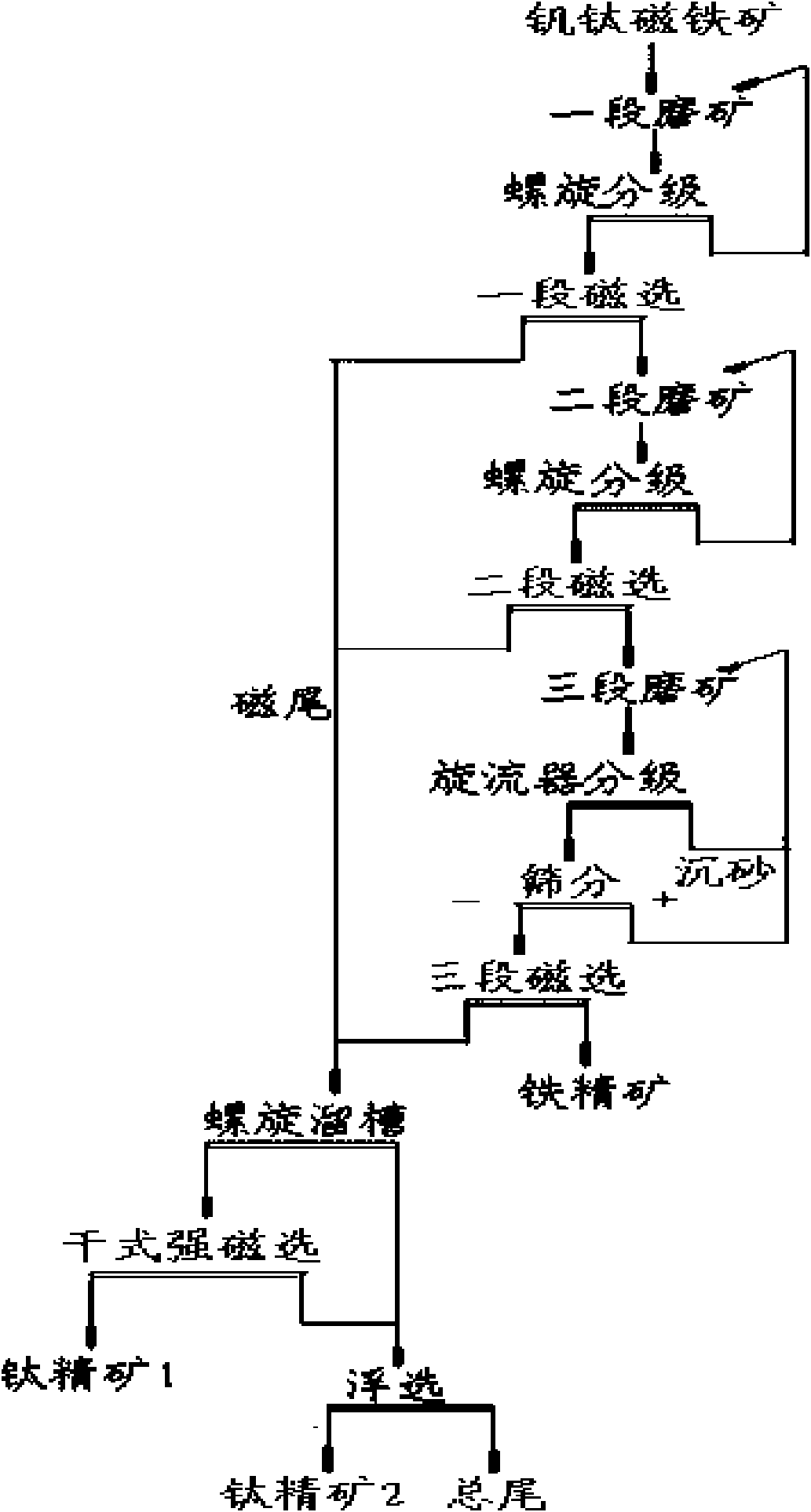

Vanadium titano-magnetite screen method

ActiveCN101564707AQuality improvementHigh recovery rateFlotationMagnetic separationMagnetiteMaterials science

The invention relates to a screen method for vanadium titano-magnetite with high quality, belonging to the ore screen field. The method adopts three stage-grinding and stage-concentration process for magnetic separation, wherein the field intensity of one-stage magnetic separation is 3000-4000 Gs; the field intensity of two-stage magnetic separation is 1800-2200 Gs; and the field intensity of three-stage magnetic separation is 1300-1700 Gs. The recovery rate of the screened iron ore concentrate and the titanium ore concentrate is high and the screened cost of the screened iron ore concentrate and the titanium ore concentrate is low, thus providing a new selection for the low grade vanadium titano-magnetite resource and having a broad application prospect.

Owner:四川安宁铁钛股份有限公司

Fibrillated polyolefin foam

ActiveUS20080076844A1Improve heat resistanceLow compression setAbsorbent padsBandagesThermoplasticFiber

A method for generating a thermoplastic foam from an aqueous dispersion, the aqueous dispersion comprising a thermoplastic resin, water, and a dispersion stabilizing agent, the method including: adding at least one froth stabilizing surfactant to the aqueous dispersion to form a mixture; adding a fiber to the mixture; and frothing the mixture to create a froth, removing at least a portion of the water in the froth to create a foam, wherein the foam generated has a non-cellular fibrillated morphology. In another aspect, embodiments disclosed herein relate to a foam having a thermoplastic-based, fibrillated, non-cellular structure, wherein the foam has an average density of about 0.02 g / cm3 to about 0.07 g / cm3. In certain embodiments, the foam may be used in an absorbent article.

Owner:DOW GLOBAL TECH LLC

Integrated processing of plant biomass

InactiveUS7649086B2Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseWoody plant

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

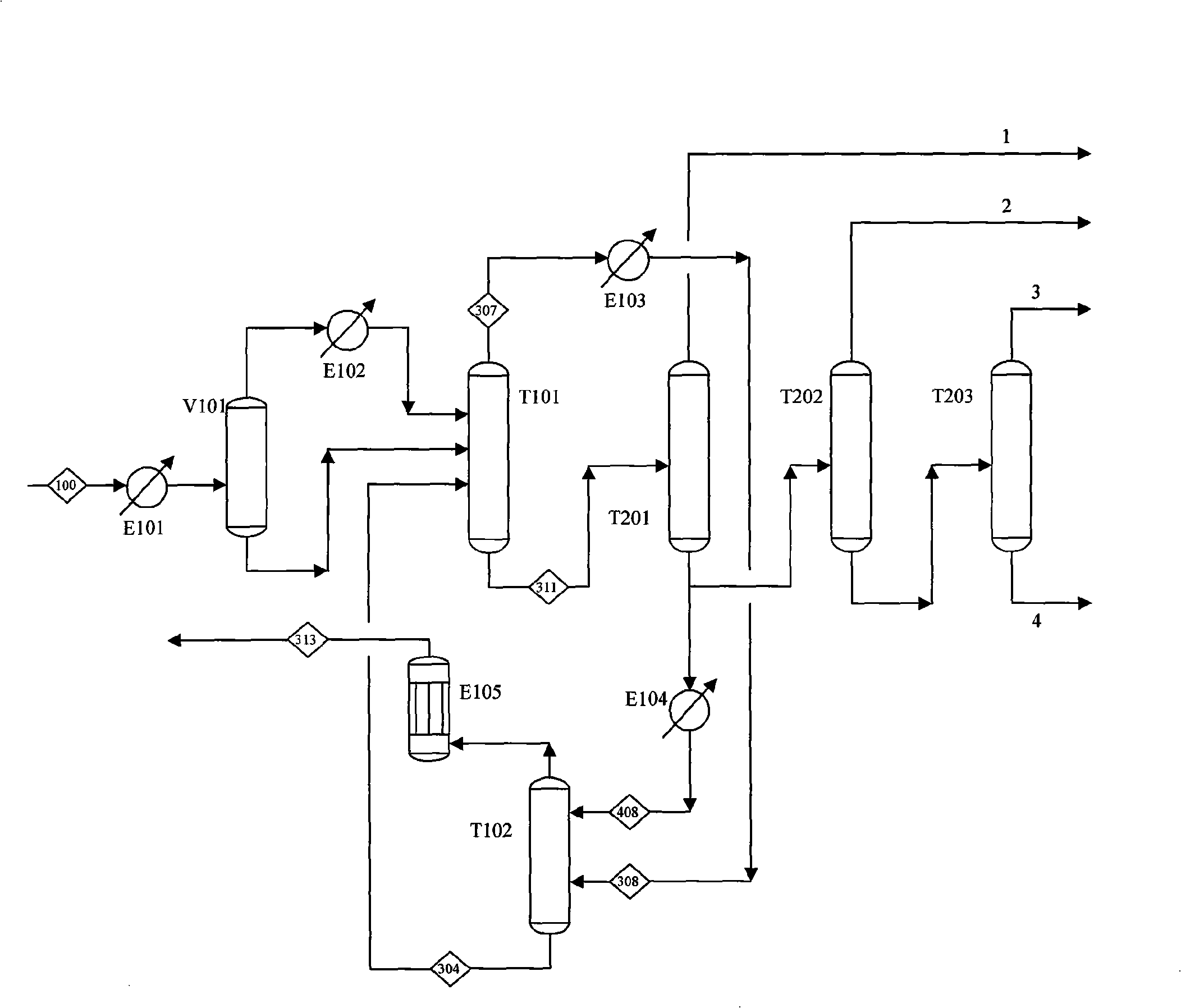

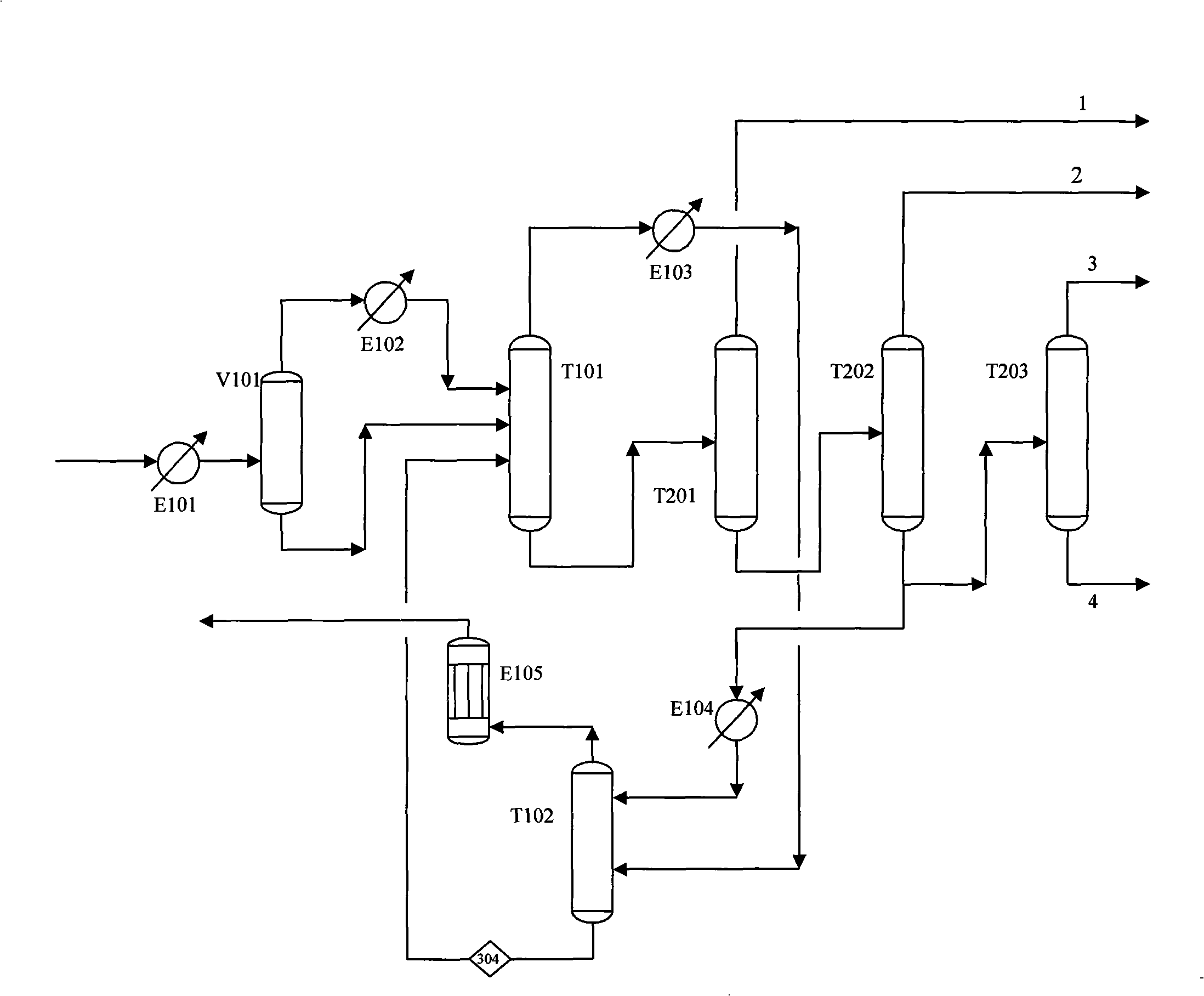

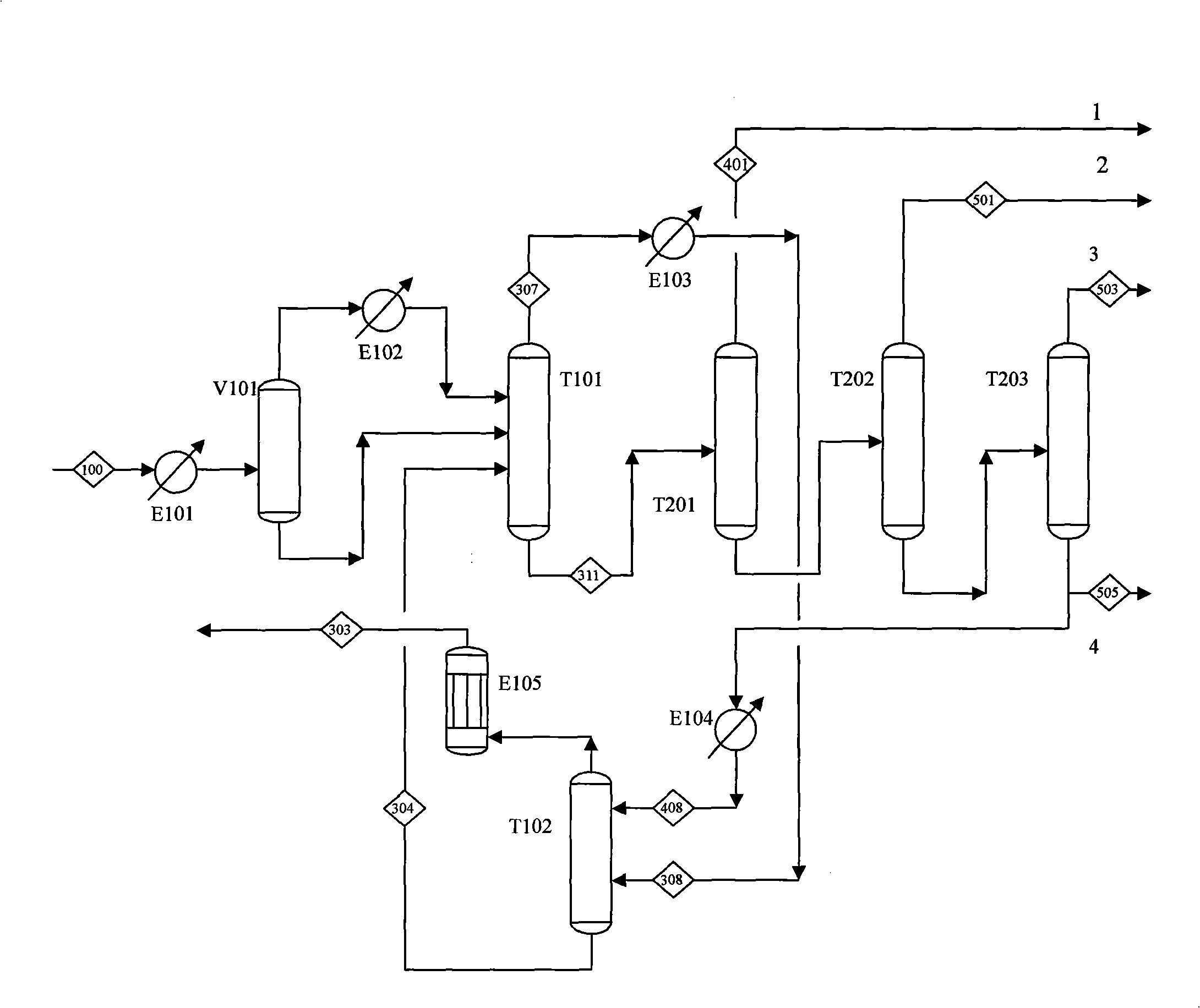

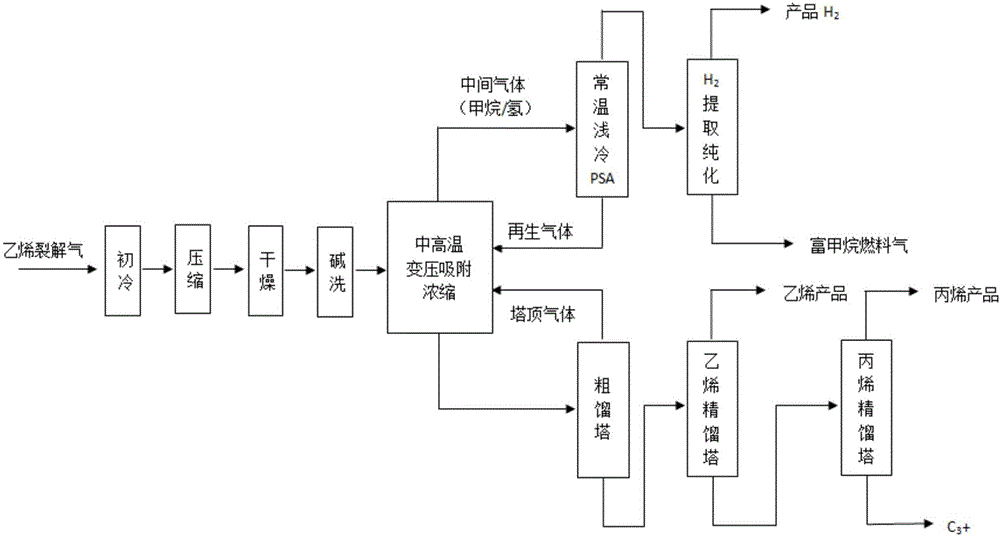

Non-copious cooling lower carbon number hydrocarbons separation method containing light gas

ActiveCN101353286AHigh ethylene contentHigh recovery rateFractional condensation purification/separationHydrocarbonsCarbon numberProduct gas

The invention relates to a separation method for non-cryogenic low-carbon hydrocarbon containing light gases. The method comprise the steps as follows: (1) pre-treated gas at the outlet of a reactor is cooled to the temperature of 10-37 DEG C and sent to a pre-cutting tower; (2) a product at the top of the pre-cutting tower is cooled and sent to an absorption tower, and C2 hydrocarbons in the product at the top of the pre-cutting tower are absorbed by an absorbent consisting of C3, C4, C5 or the mixture of hydrocarbons thereof; and (3) tower kettle products of the pre-cutting tower are sent to a deethanizing column for clearly cutting the C2 and the C3 to obtain C2 distillate at the top of the tower; the tower kettle products are C3 and heavier components. Compared with the prior art, the method has the advantages of lower investment, lower energy consumption, higher recycling rate of materials, simpler operation, less maintenance workload, reliable operation, etc.

Owner:WISON ENG

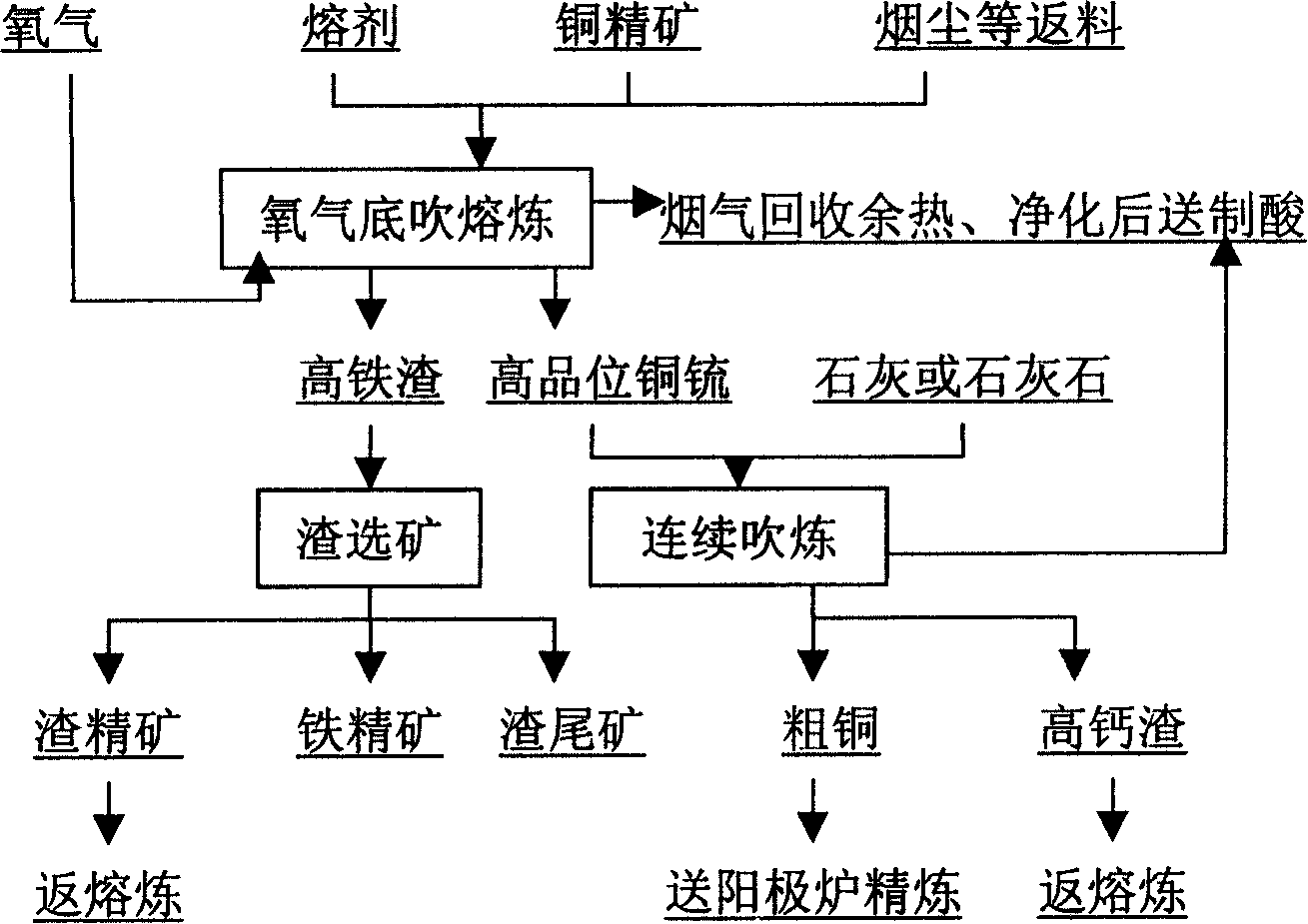

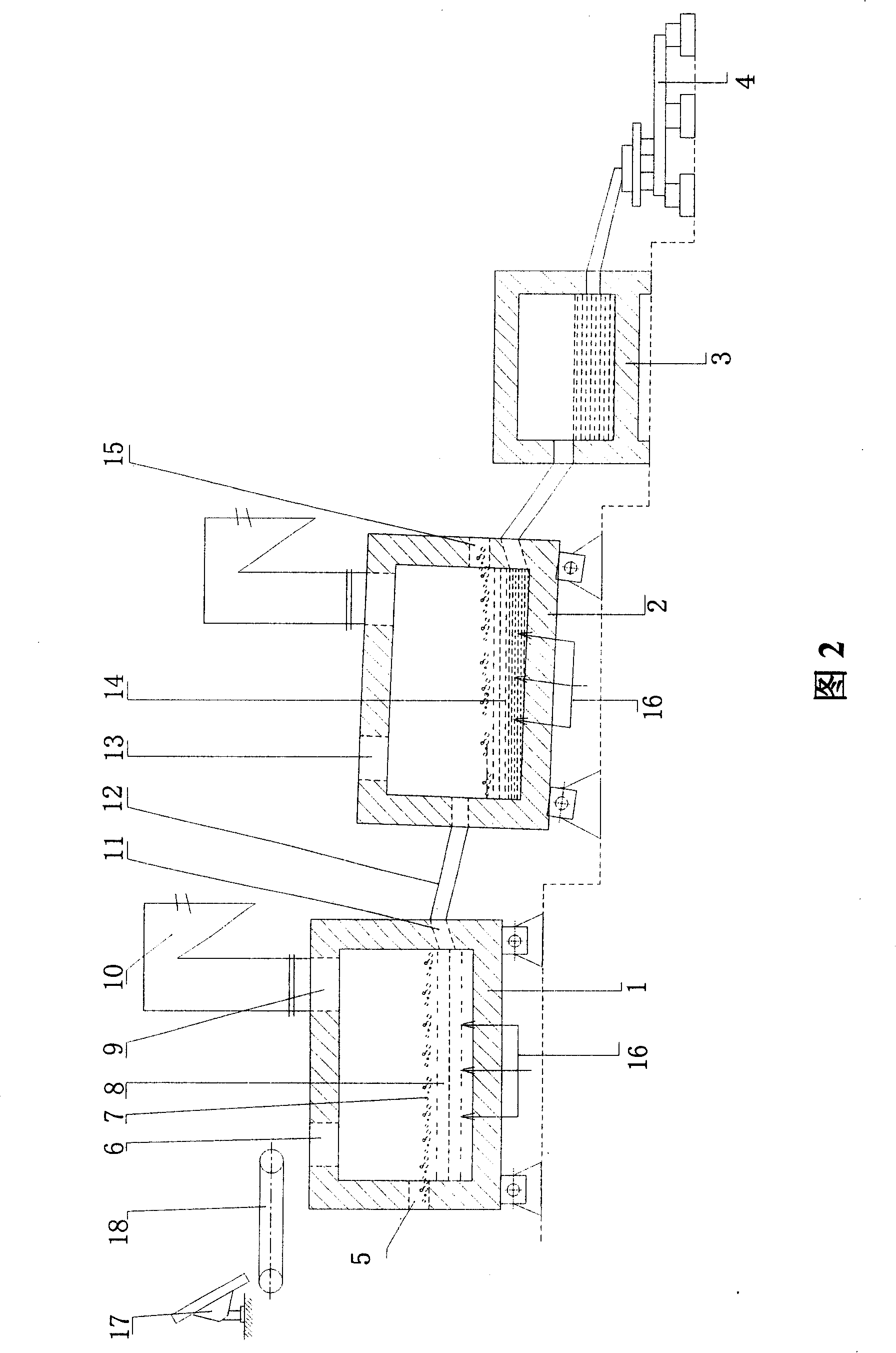

Technique for continuously smelting copper by employing oxygen bottom converter and device thereof

ActiveCN101165196AReduce loadHigh smelting yieldProcess efficiency improvementAutomatic controlSmelting process

The present invention relates to continuous copper-smelting oxygen bottom blowing furnace process and apparatus. The continuous copper-smelting process includes smelting high grade copper matte in an oxygen bottom blowing furnace, smelting coarse copper product with the high grade copper matte in one other bottom blowing furnace, producing high iron slag, dressing the furnace slag to obtain copper concentrate and returning to smelting furnace, separating out iron concentrate product and obtaining tailings. The process has short flow path, low investment, low power consumption, low cost, environment friendship and other advantages.

Owner:CHINA ENFI ENGINEERING CORPORATION

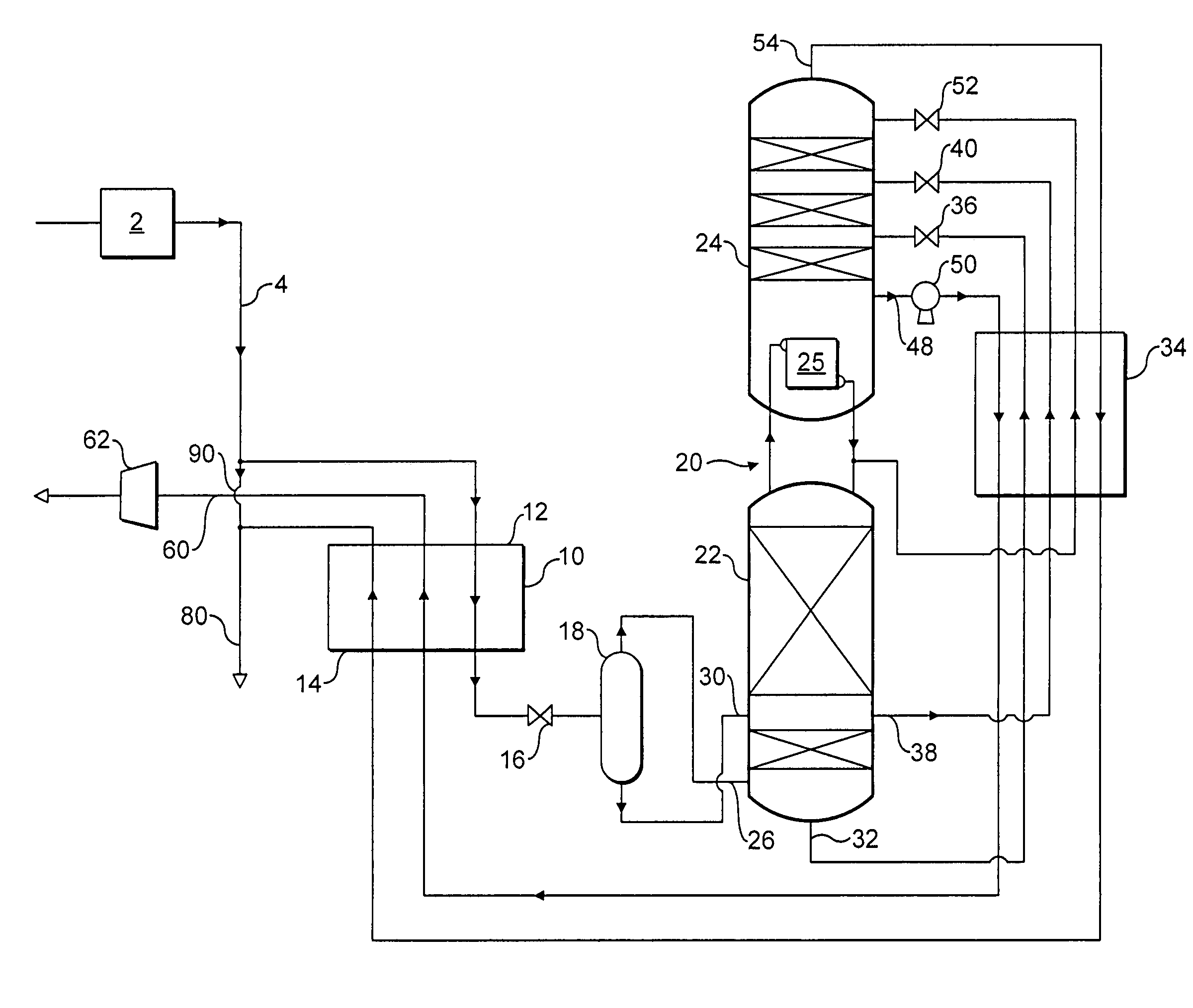

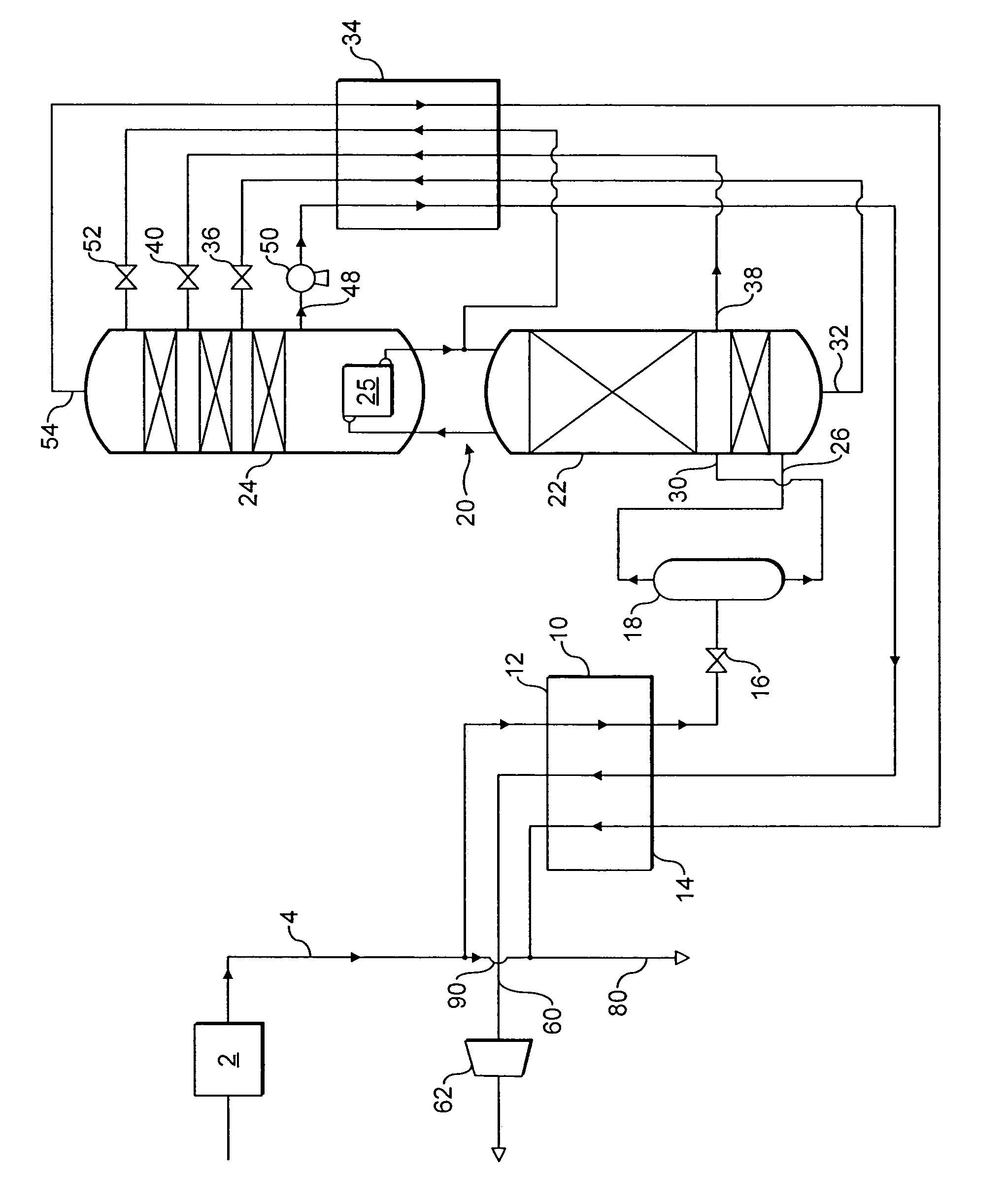

Nitrogen rejection method and apparatus

Nitrogen is rejected from a feed natural gas stream comprising methane and nitrogen so as to form a primary methane product. The mole fraction of nitrogen in the feed natural gas increases over a period of time. The feed natural gas stream is cooled in a main heat exchanger and is rectified in a double rectification column. A primary product methane stream and a secondary nitrogen-enriched product stream are withdrawn from the rectification column. The secondary nitrogen-enriched product stream has a mole fraction of methane at or above a chosen minimum value when the said mole fraction of nitrogen is at a minimum. When the said mole fraction of nitrogen rises to a value at which the mole fraction of methane in the secondary nitrogen-enriched product stream falls below the chosen minimum, a part of the feed gas is introduced through conduit into the secondary nitrogen-enriched product stream so as to restore its mole fraction of methane to the chosen minimum value or a value thereabove.

Owner:THE BOC GRP PLC

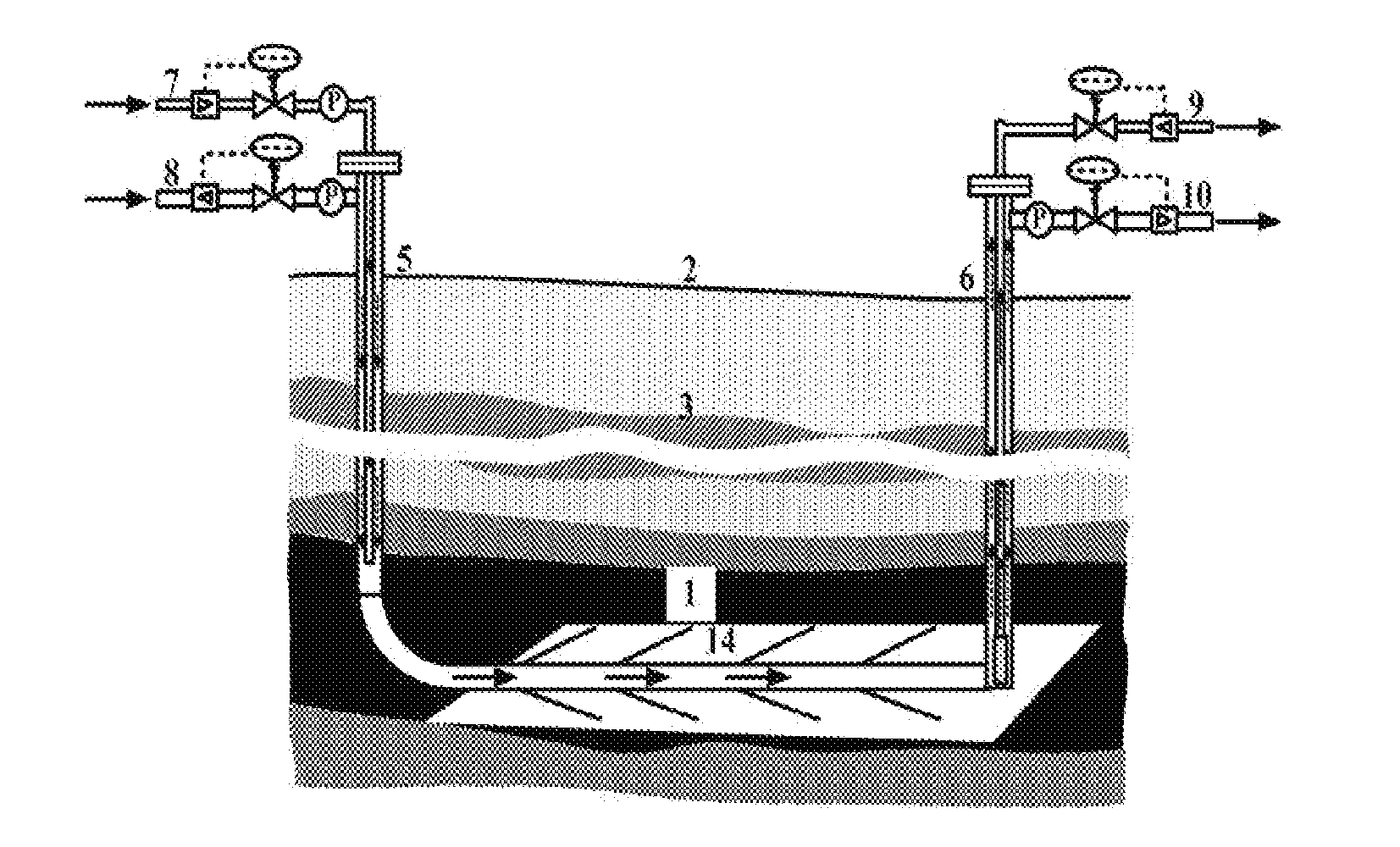

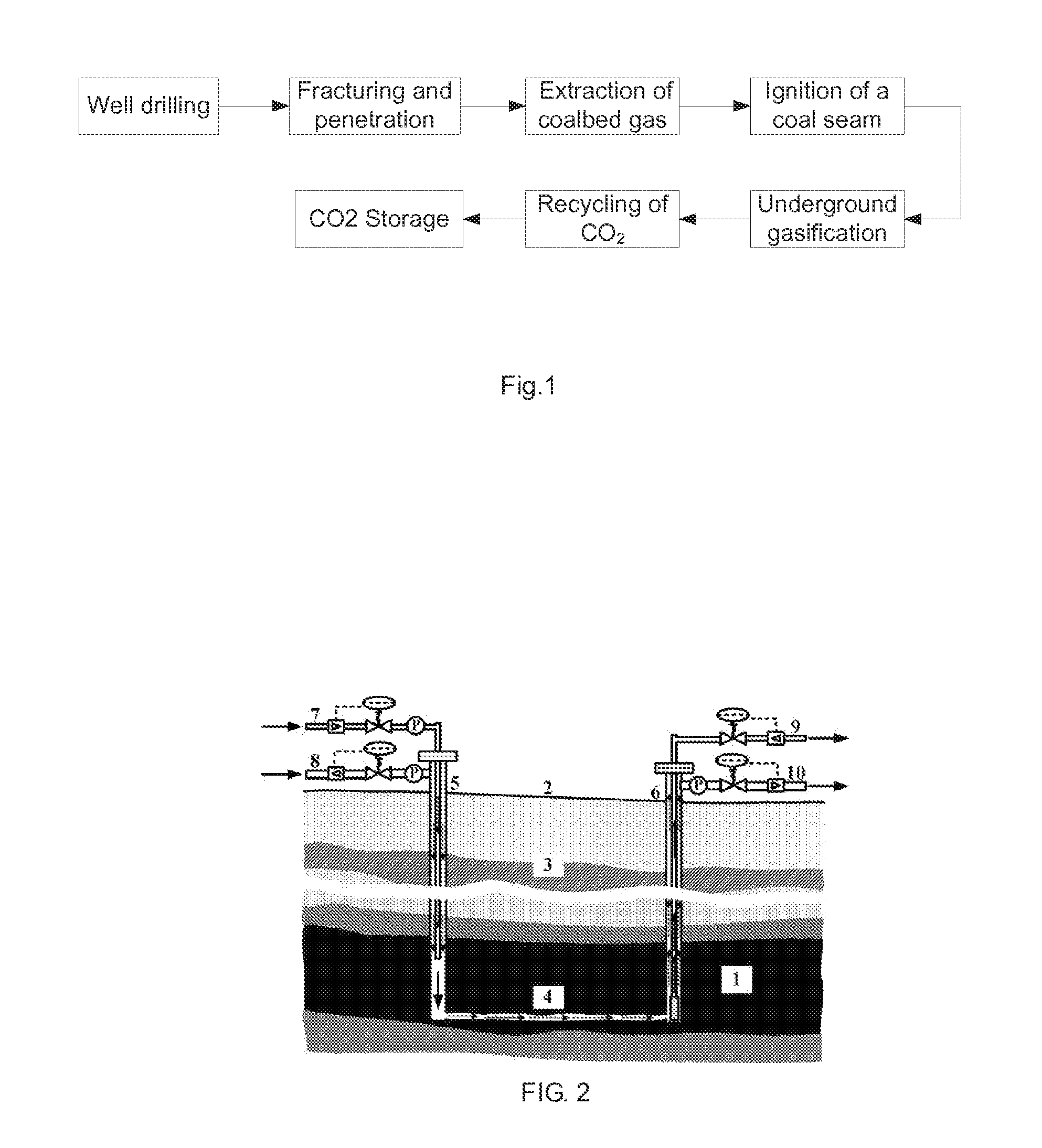

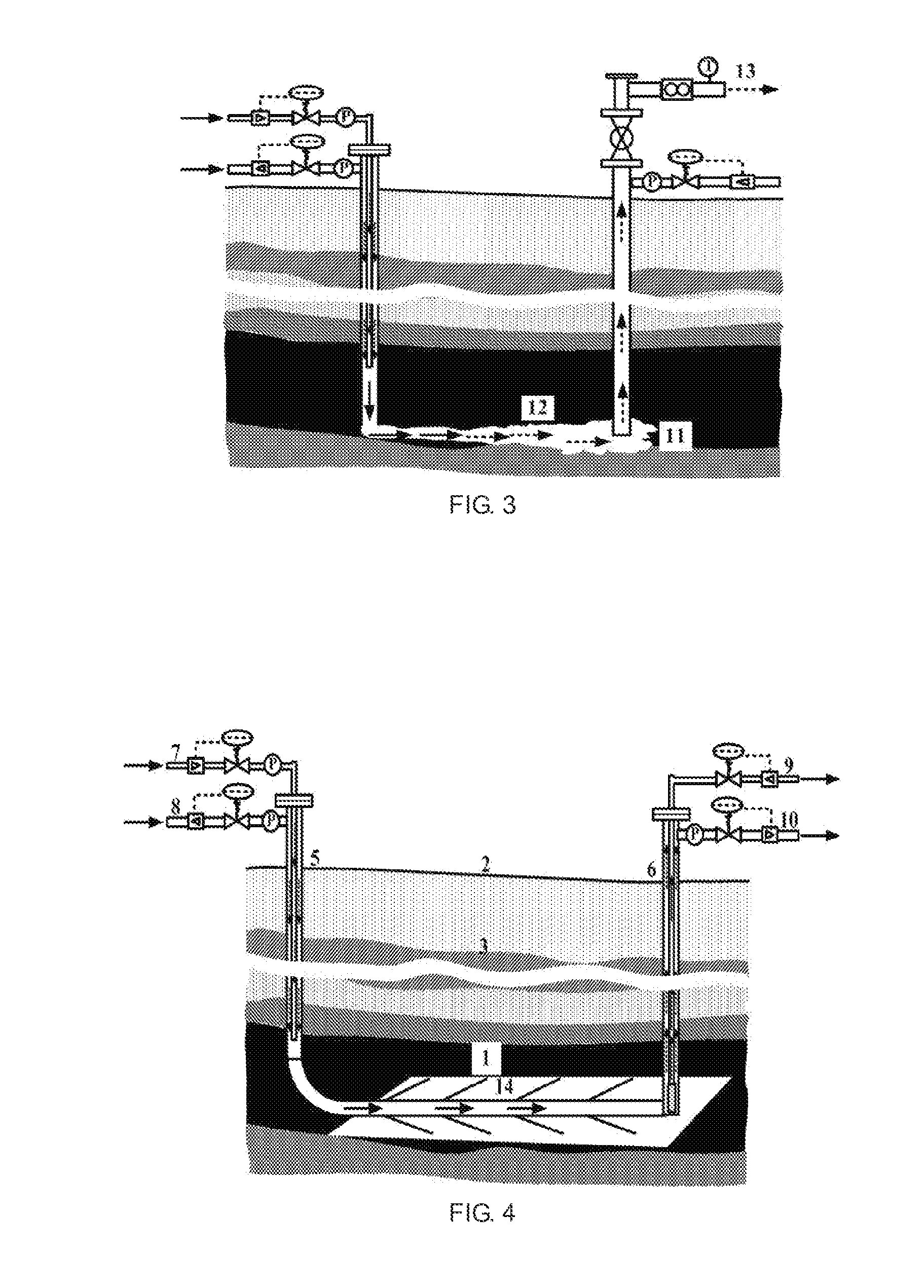

Method for joint-mining of coalbed gas and coal

InactiveUS20150247385A1Increase ratingsImprove breathabilityArtificial islandsFluid removalWell drillingProcess engineering

Provided is a method for joint-mining of coalbed gas and coal. The method comprises: a well-drilling step; a fracturing and penetration step; a coalbed gas extraction step: an ignition step, and an underground gasification step. The method combines an underground coal gasification technology and a coalbed gas extraction technology, not only allows for utilization of the high temperature of underground gasification to heat a coalbed. thus increasing the permeability of a coal seam. and increasing the recovery rate of the coalbed gas, but also allows for utilization of the coalbed gas to perform the drilling and the fracturing and penetration processes, thus increasing the efficiency of underground coal gasification for mining.

Owner:ENN COAL GASIFICATION MINING

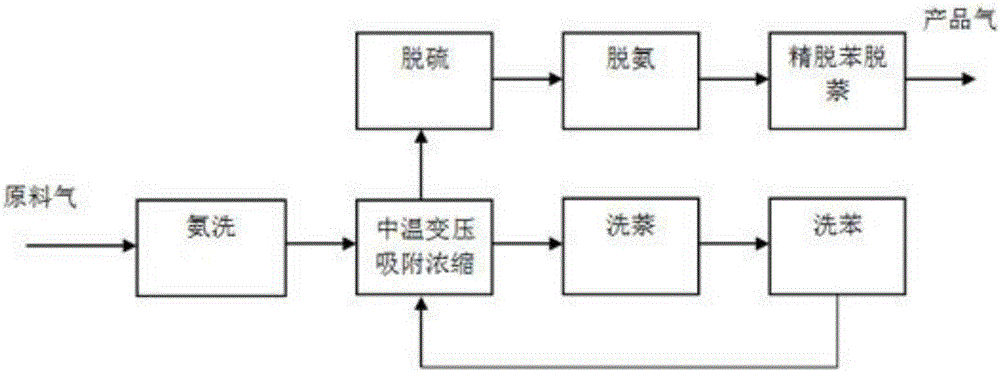

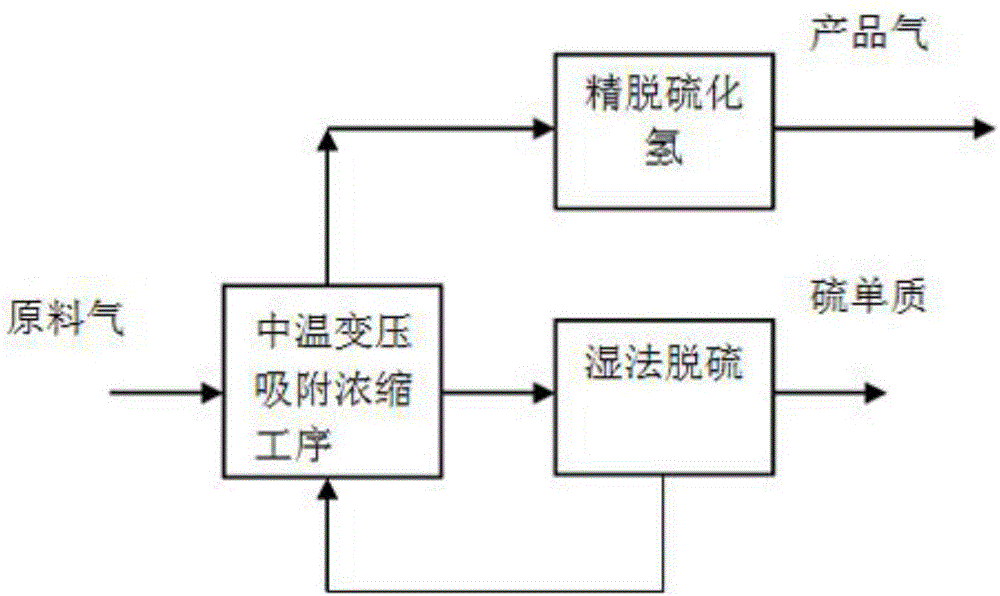

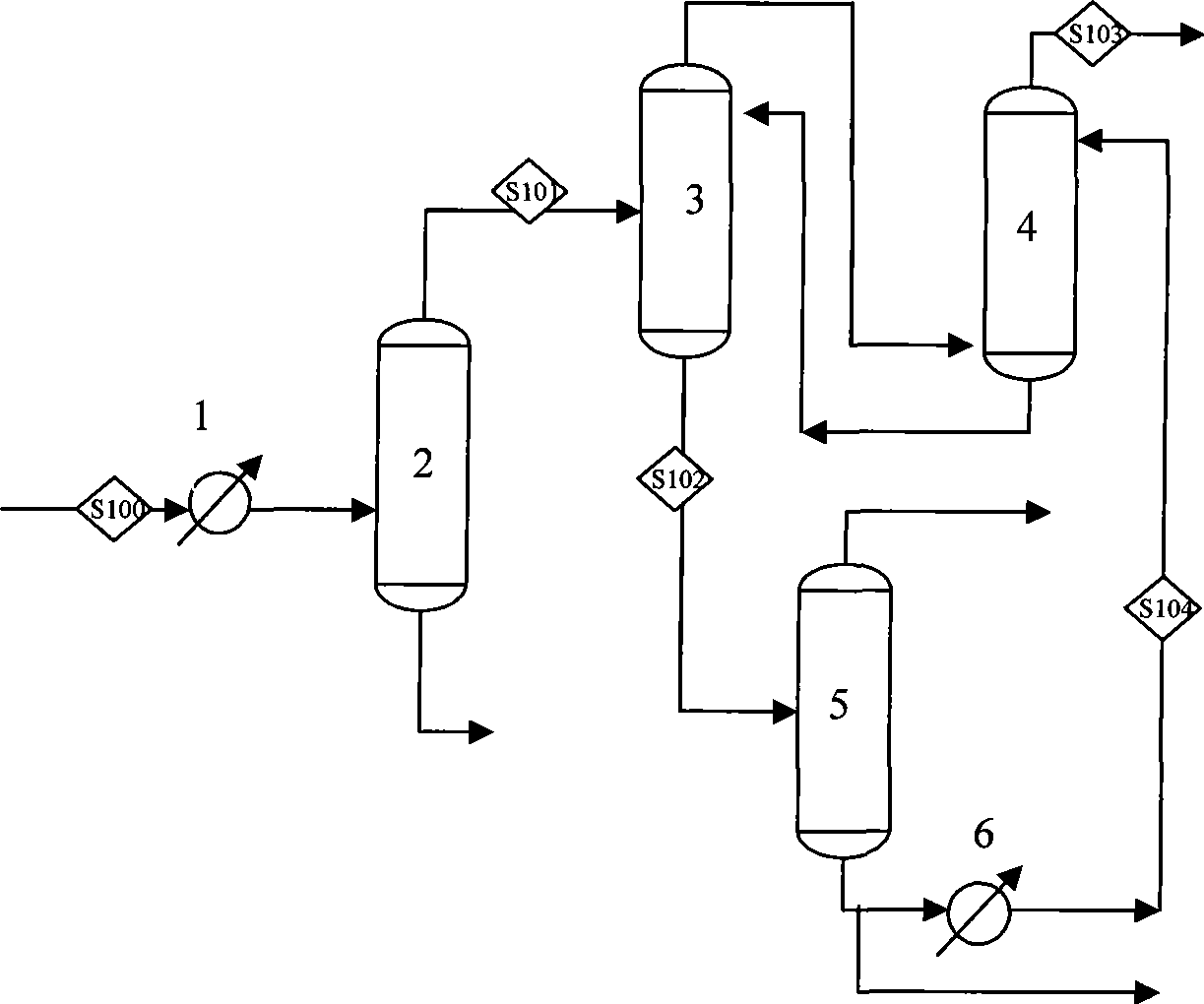

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

Separation method for light hydrocarbon products in MTO/MTP reaction products

InactiveCN101367697AHigh recovery rateLess investmentDistillation purification/separationHydrocarbon from oxygen organic compoundsChemistryProduct gas

The invention relates to a method of separating light hydrocarbon product from MTO / MTP reaction product. The steps of the method comprise: pretreating and sending the MTO / MTP reaction product to a deethanizer for the clean separation of C2 / C3; sending gas phase on the top of the deethanizer to an absorption-distillation tower which uses rich absorbent from an oil absorption tower for absorption. The bottom product of the deethanizer enters into a subsequent separating system. The top production of the absorption-distillation tower is cooled and then is sent to the oil absorption tower. The oil absorption tower takes ethane as poor absorbent to separate ethylene from the top product of the absorption-distillation tower. Other light gas is discharged from the top. The bottom product serves as the rich absorbent and returns to the absorption-distillation tower. The bottom product of the absorption-distillation tower goes into an ethylene tower. Bottom ethane components serve as the poor absorbent and go into the oil absorption tower after cooling. Compared with the prior art, the invention has the advantages of less investment and high material recovery rate.

Owner:WISON ENG

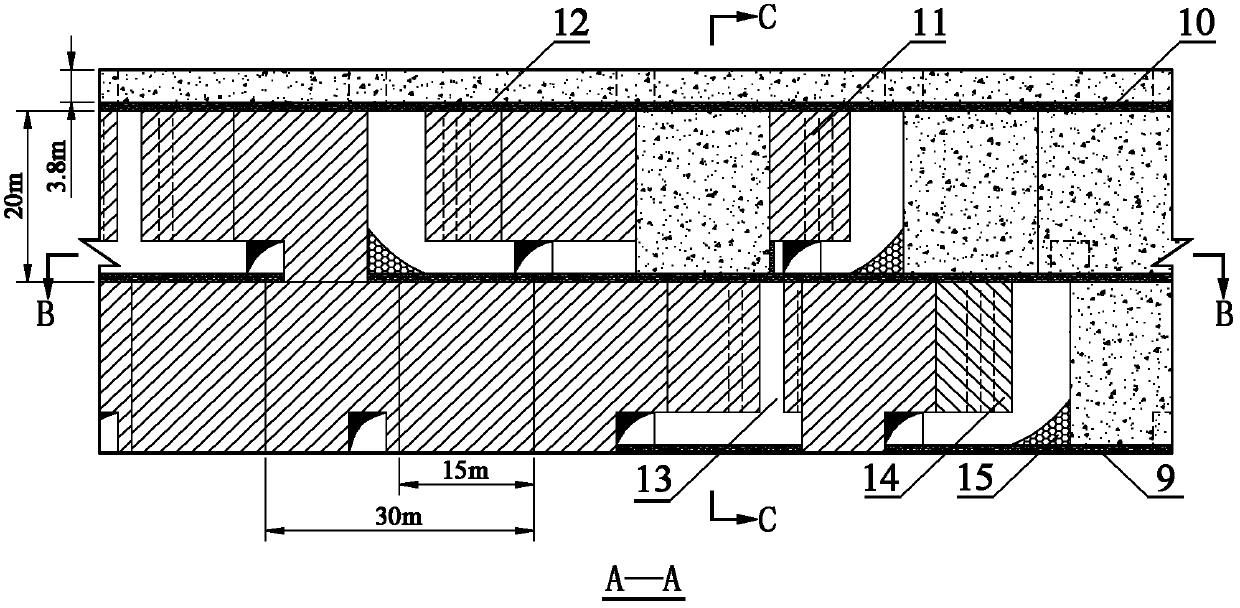

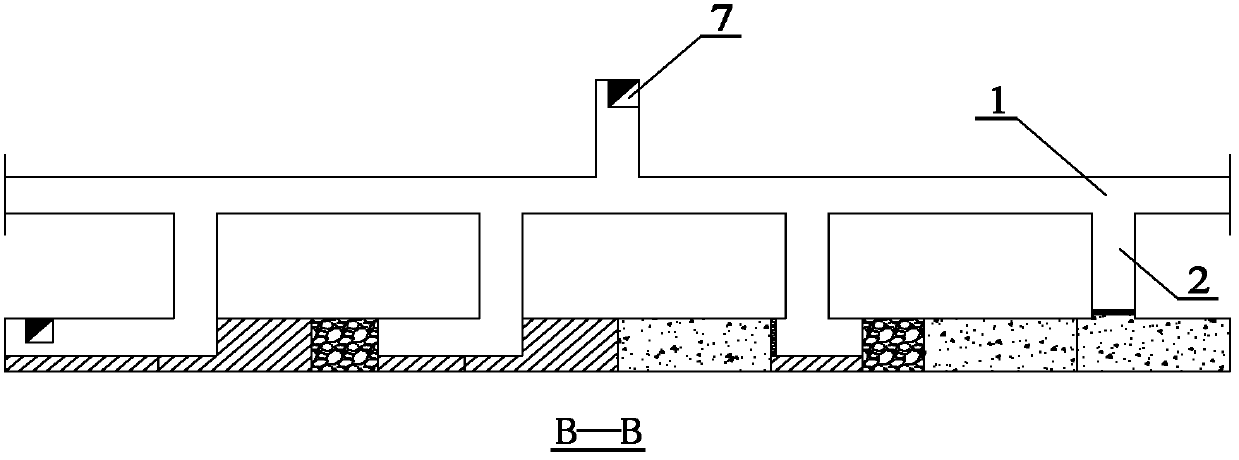

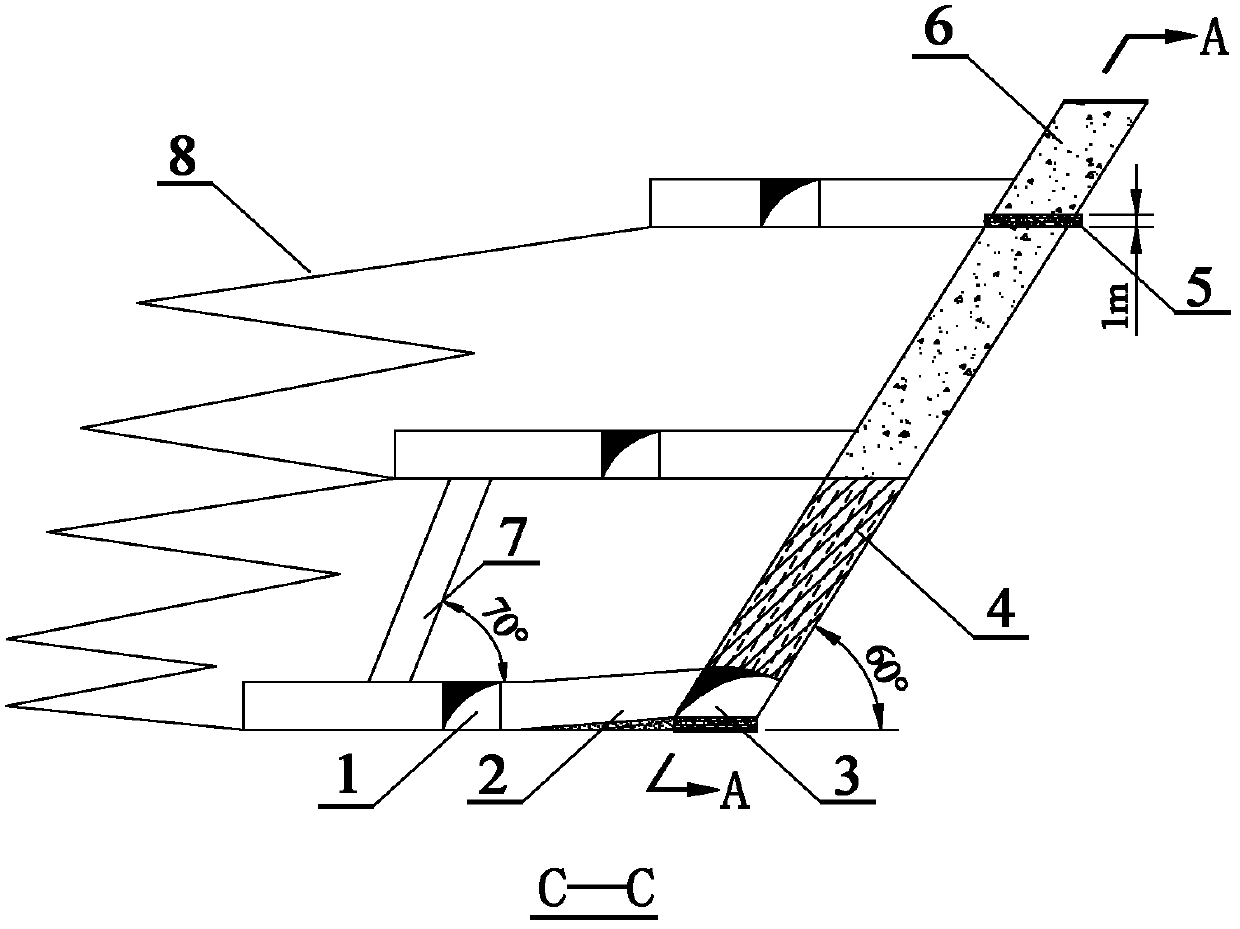

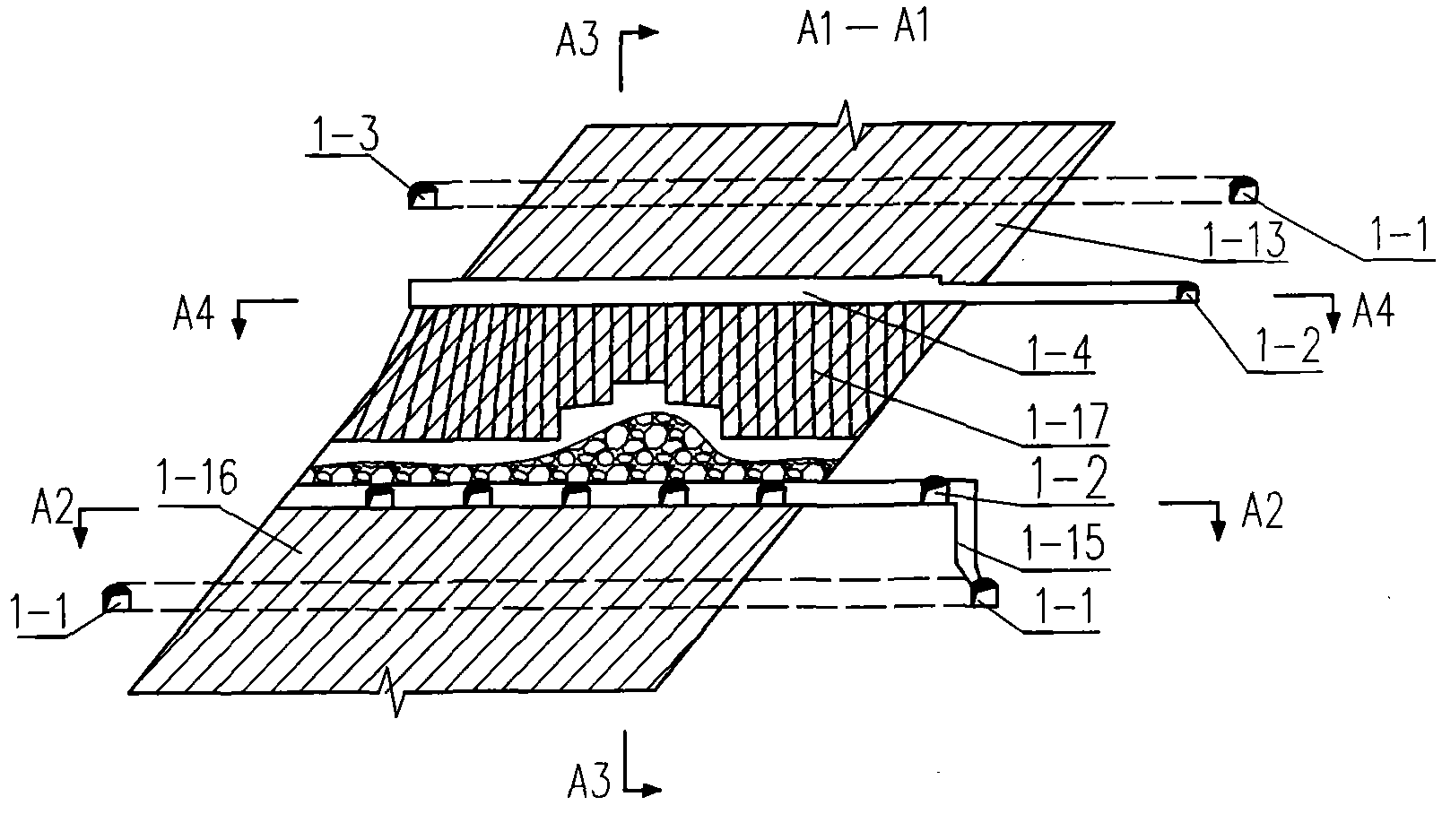

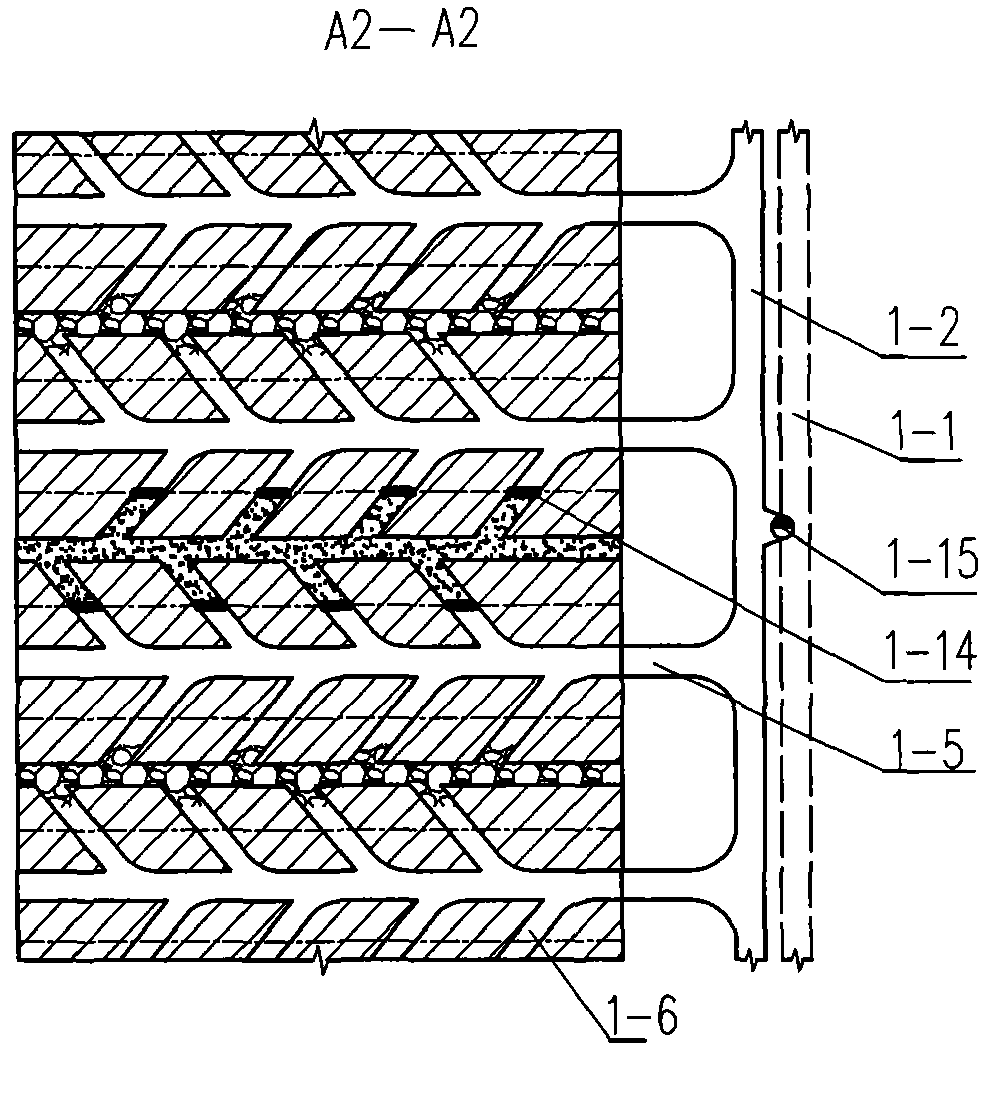

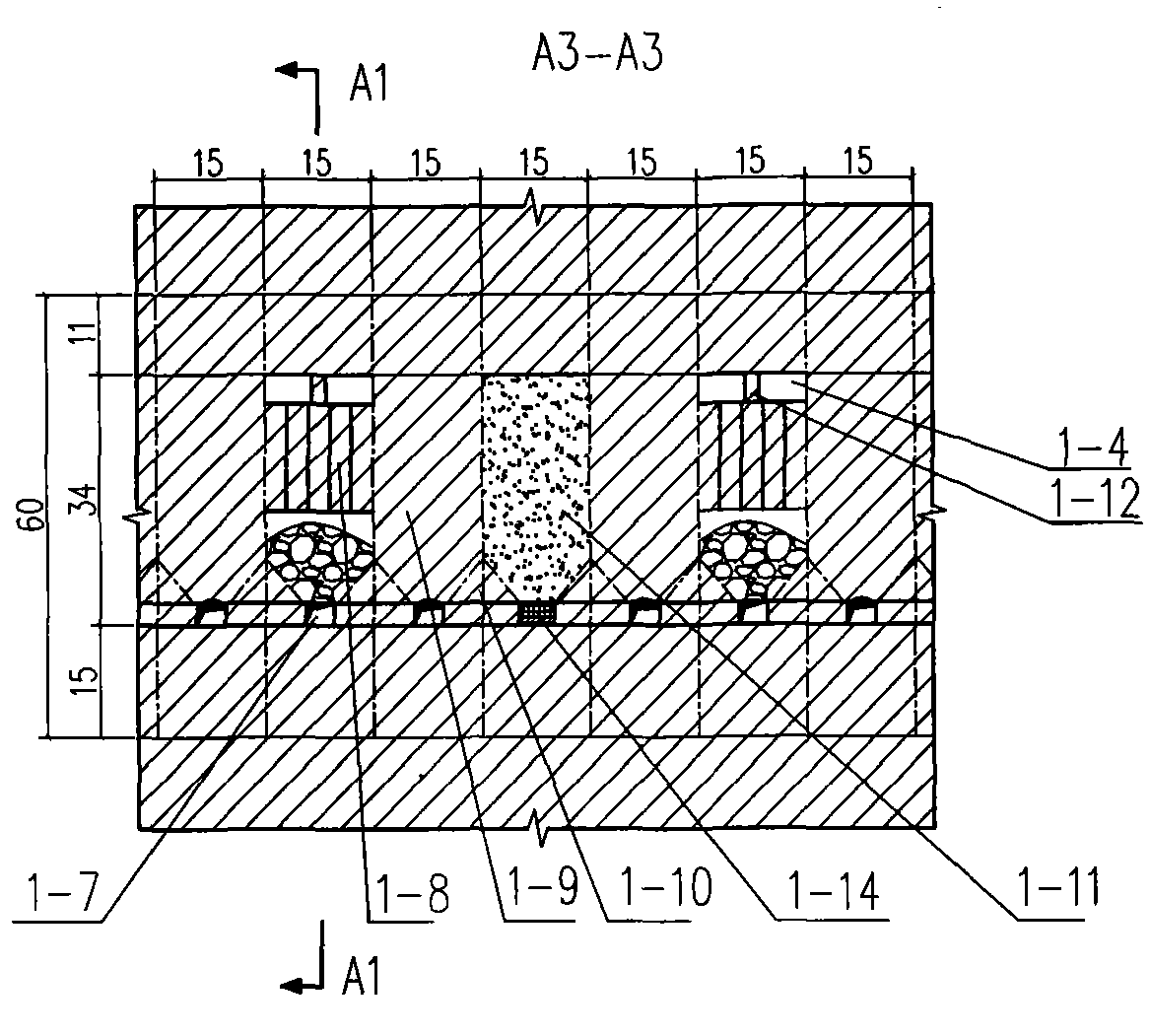

Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

InactiveCN102606159AImprove efficiencyImprove securityUnderground miningTunnel/mines ventillationRoom and pillar miningReinforced concrete

The invention discloses a medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method which comprises the following steps: dividing chamber jambs along the trend of an ore body; adopting a rail-less mining aligning system; pre-constructing a high-strength reinforced concrete artificial top in a segmented drilling lane; adopting a stoping sequence from up to down; performing drilling and blasting ore removal on the ore body through the segmented drilling lane at bottom; adopting medium-length hole drilling and remotely controlling a scraper to discharge ore; after finishing the mining of the chamber, utilizing concrete tailings to perform cemented filling; after finishing the mining of the jambs, utilizing concrete tailings or pure tailings to perform cemented filling; after completely stoping the mine chamber in the frame under the protection of the concrete artificial top, starting to stope the jamb adjacent to the segment, and meanwhile stoping the corresponding mine chamber in the frame of the next segment, and then stoping the corresponding jamb of the next segment; and after completely mining the chamber jamb in the middle segment, immediately turning towards the lower middle segment for stoping. The method provided by the invention has the advantages that the safety for mining the heavy-pitch medium thick crushed or ultra-crushed ore body is high, the resource depletion loss rate is low, the mechanical degree is high, the production capacity is high, and the like.

Owner:CENT SOUTH UNIV +1

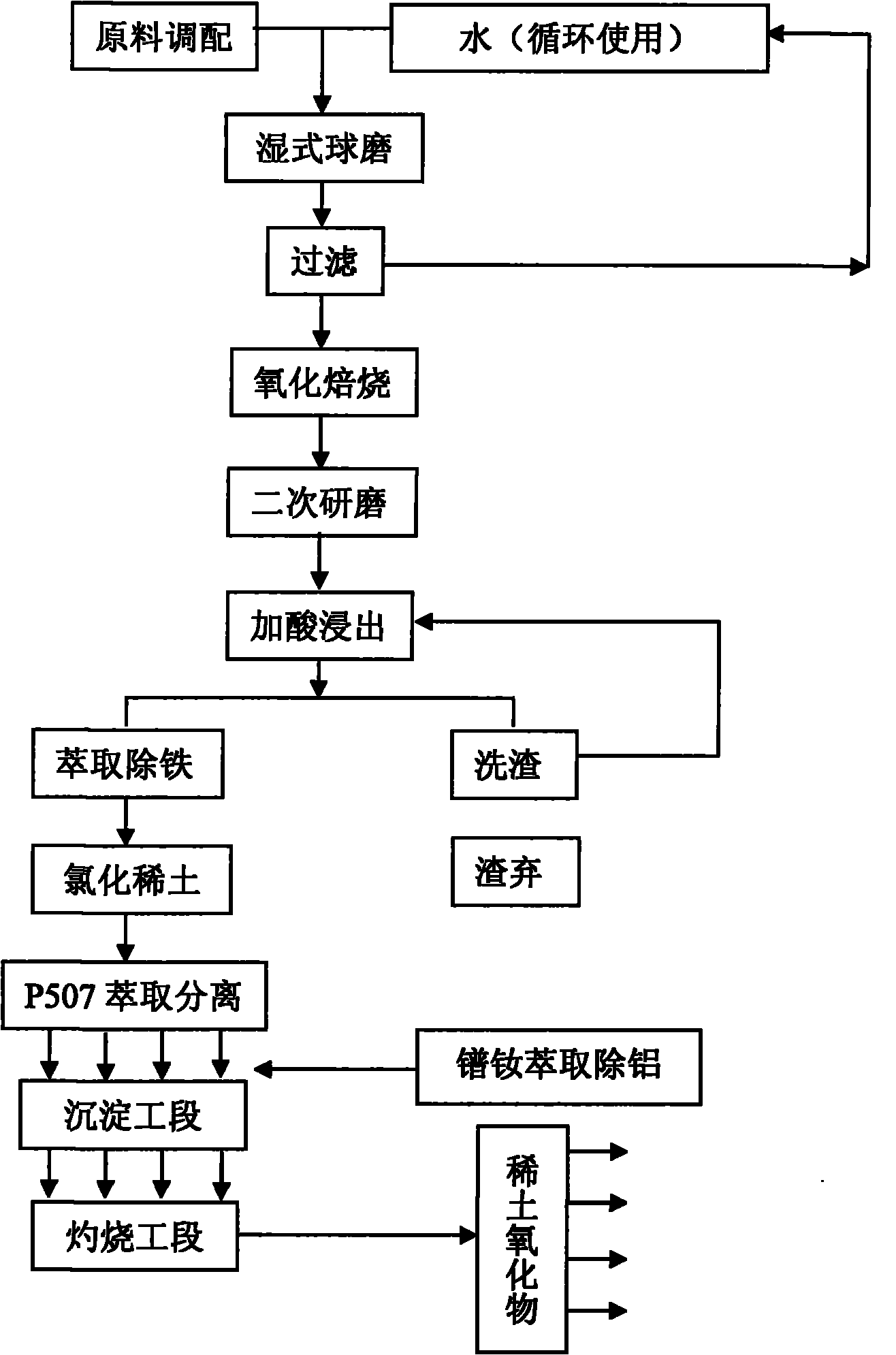

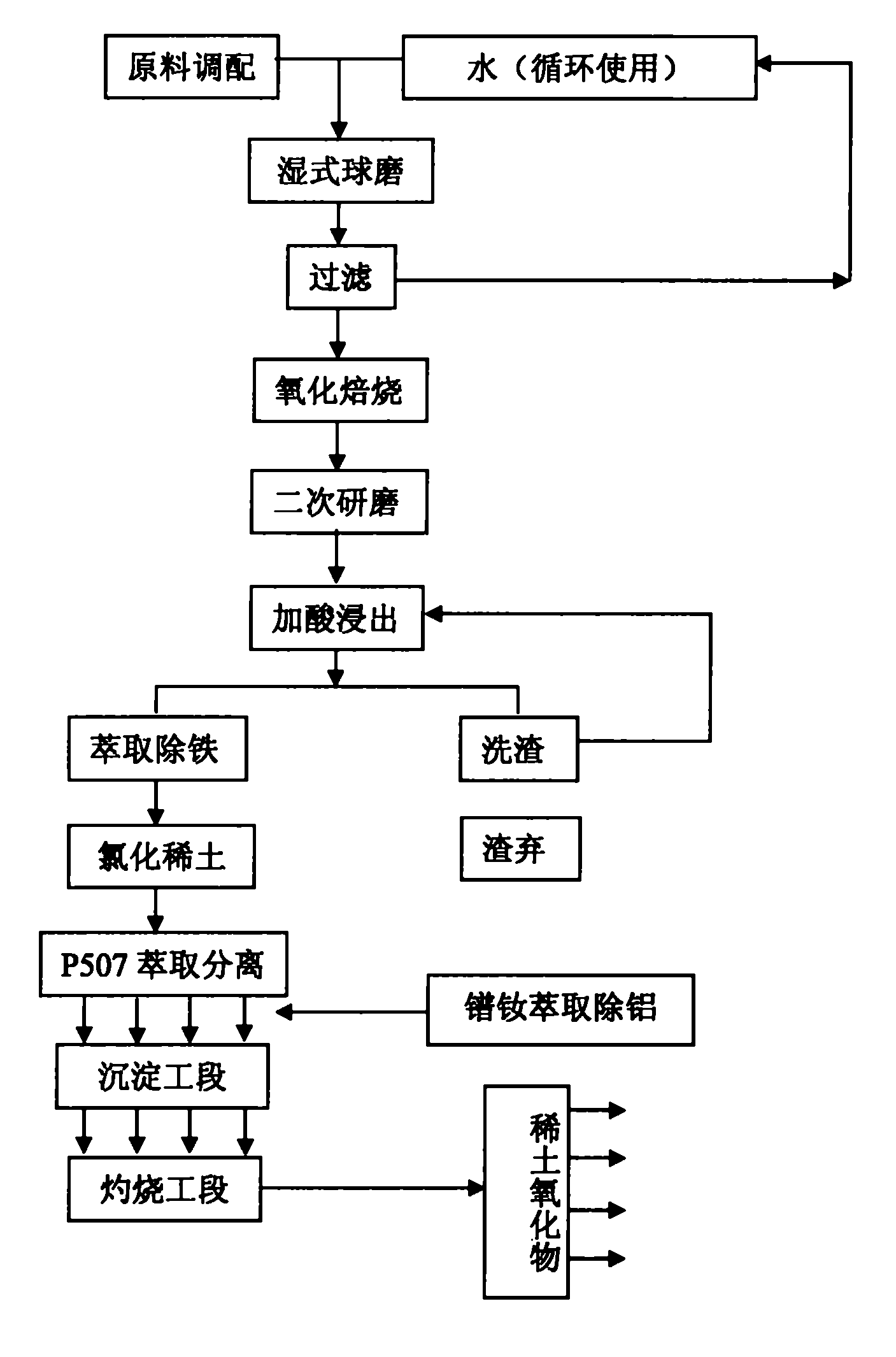

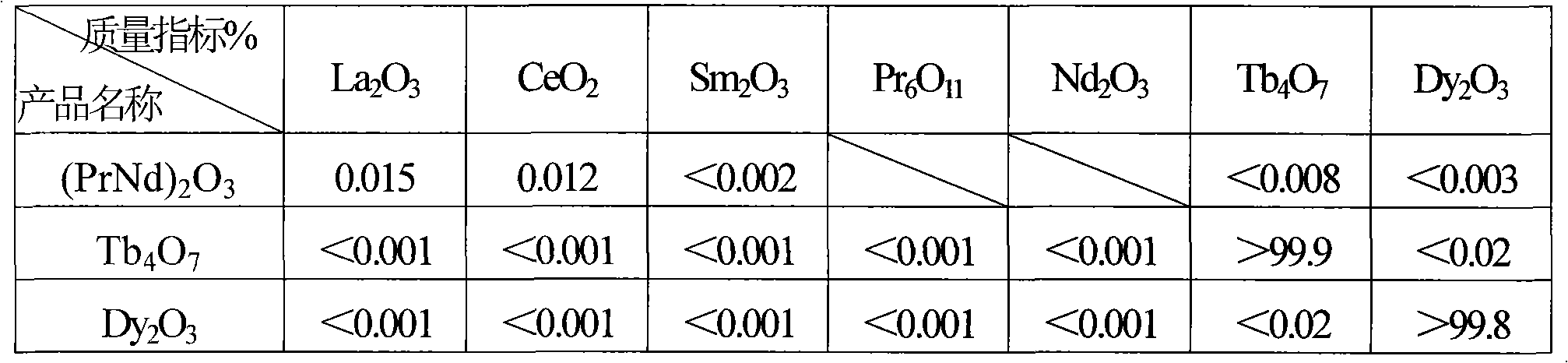

Method for recovering rare earth elements from neodymium-iron-boron wastes

InactiveCN102011020AHigh recovery rateImprove use valueProcess efficiency improvementMischmetalRare-earth element

The invention discloses a method for recovering rare earth elements from neodymium-iron-boron wastes, which comprises the steps of: mixing the neodymium-iron-boron wastes with water and then grinding; oxidizing the ground neodymium-iron-boron wastes; carrying out the secondary grinding for oxidation products; leaching by adding acid; separating solid from liquid; extracting to remove iron; chloridizing rare earth; separating the rare earth by extraction; extracting to remove aluminum; sedimenting; and firing. The method applied to recovery of the rare earth has the beneficial effects that the rare earth recovery rate is increased by 5-8%; the use value of the recovered rare earth is improved so that the production cost of further processing is reduced; the problem of puree fused salt in the electrolysis of single rare earth is solved, and the electrolytic efficiency of the rare earth metal during electrolysis is improved and energy consumption is effectively reduced; and the contents of non rare earth metals, such as C, S, O and the like are reduced.

Owner:BAOTOU XIJUN RARE EARTH

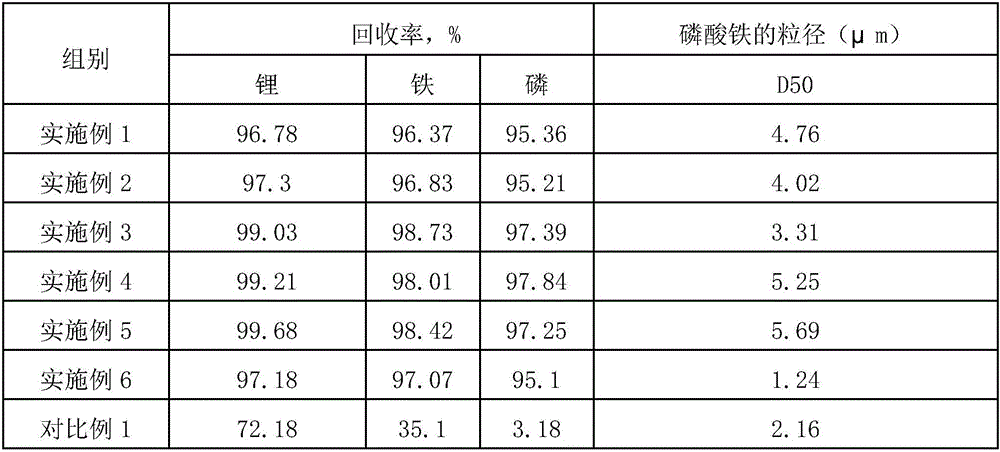

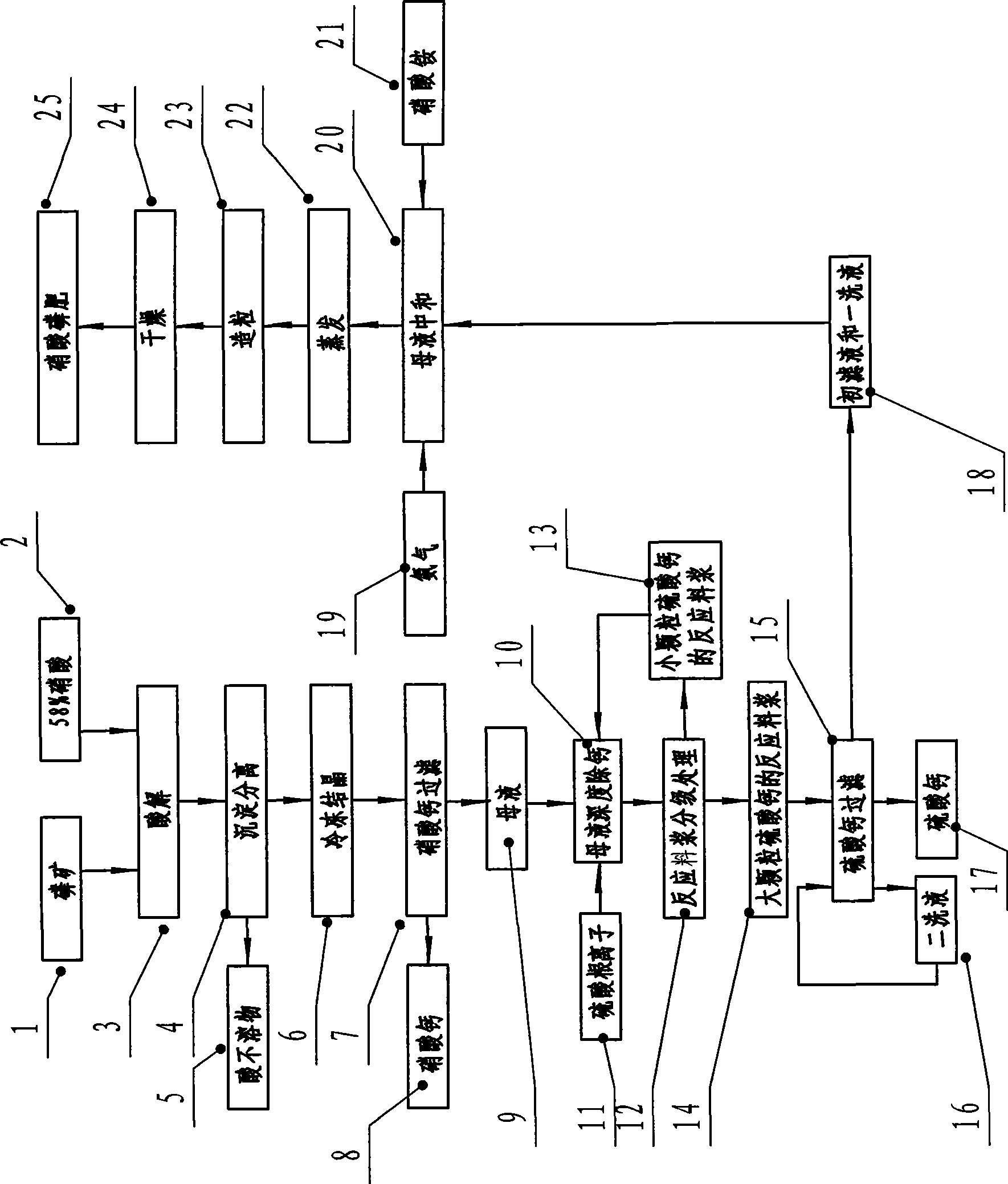

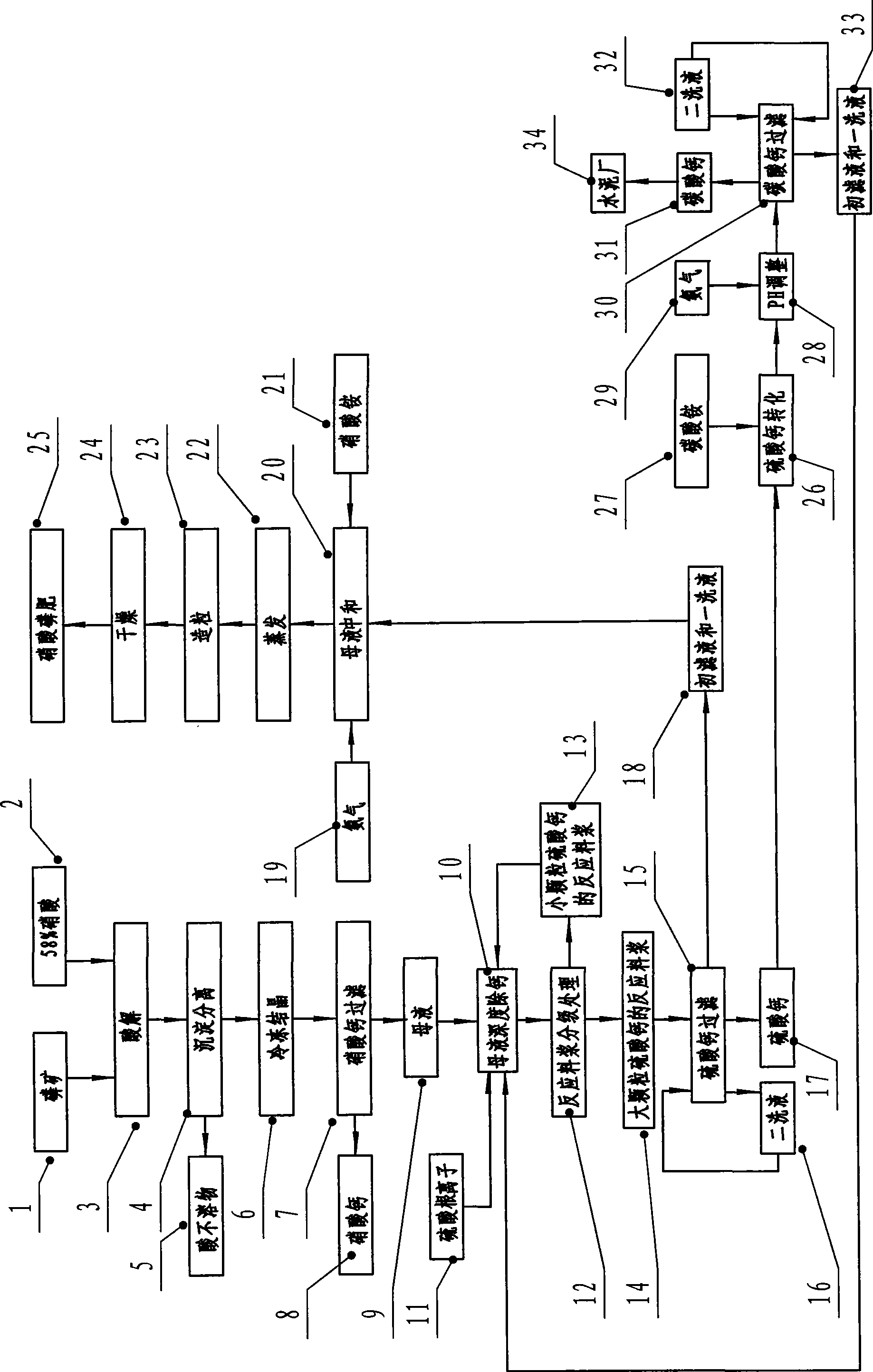

Method for recovering waste/used lithium iron phosphate positive-pole material by acid leaching method

ActiveCN106684485AHigh recovery rateLow impurity contentWaste accumulators reclaimingBattery recyclingLithium electrodePhosphate

The invention belongs to the technical field of recovery of lithium-ion batteries and particularly relates to a method for recovering a waste / used lithium iron phosphate positive-pole material by an acid leaching method. The method provided by the invention comprises the following steps: (a) carrying out acid leaching: adding acid into the lithium iron phosphate positive-pole material for acid leaching so as to obtain a suspension, and carrying out filtration, so as to obtain filtrate; (b) carrying out oxidation: adjusting the pH value of the filtrate obtained in the step (a) to be smaller than 1, and adding an oxidant into the filtrate to oxidate ferrous ions in the filtrate into ferric ions, so as to obtain a mixed solution; (c) carrying out separation: adjusting the pH value of the mixed solution obtained in the step (b) to be 1.5 to 4, carrying out a reaction for 1 to 3 hours at the temperature of 60 DEG C to 95 DEG C so as to produce ferric phosphate precipitates, and carrying out filtrating and washing, thereby obtaining lithium-containing filtrate and ferric phosphate. The method provided by the invention is simple in process, continuous in cycle, low in cost and easy to industrialize and is environmentally friendly; the recovery rate of Li, Fe and P reaches 95% or more, subsequent prepared FePO4 is low in impurity content, the particle size is 1 to 6 microns, is uniform and is narrow in distribution, and the morphology is controllable, so that the FePO4 is battery-grade ferric phosphate.

Owner:TIANQI LITHIUM CORP

Technological process for producing high concentration nitric-phosphate fertilizer

The invention discloses a technique method for producing high-concentration nitric phosphate, which comprises the following steps of: adding nitric acid into phosphorus ore for acidolysis, depositing and separating acid non-soluble substance, freezing and crystallizing calcium nitrate, filtering the calcium nitrate, neutralizing the mother liquid, vaporization, pelleting and drying. The invention is characterized in that: a step of thoroughly removing the calcium of the mother liquid is arranged between the steps of filtering the calcium nitrate, and neutralizing the mother liquid. The steps comprise the following steps of: I) thoroughly removing the calcium of the mother liquid and adding sulfuric acid or ammonium sulfate; the calcium ions and the sulfate ions in the mother liquid generate dihydrate calcium sulfate crystal; II) the grading processing of reaction slurry: employing a grading device to carry out grading processing to the reaction slurry; returning the reaction slurry provided with small grain calcium sulfate to the mother liquid for thoroughly removing the calcium, and feeding the reaction slurry provided with large grain calcium sulfate to the calcium sulfate for filtering; and III) filtering and washing the filtering reaction slurry of calcium sulfate by a filter, feeding the primary filtrate and the primary lavage fluid into the working procedure of neutralizing, and returning the secondary lavage fluid to the filter. The invention has the advantage of using middle-low quality phosphorite to prepare the high-concentration nitric phosphate.

Owner:TIANJI COAL CHEM IND GROUP +1

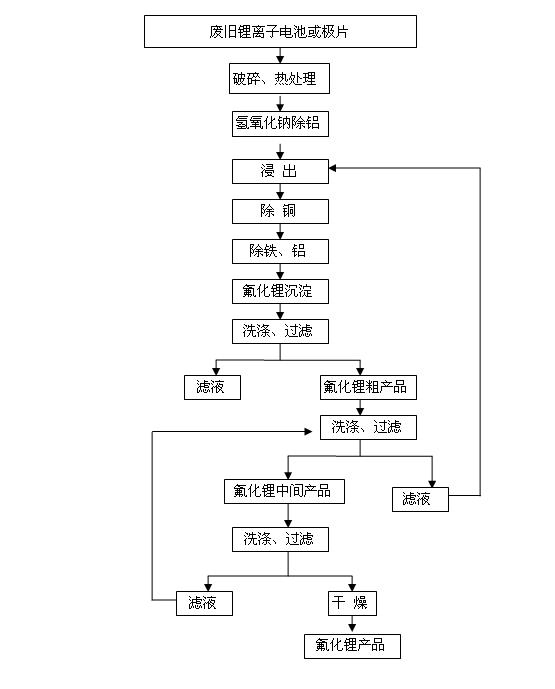

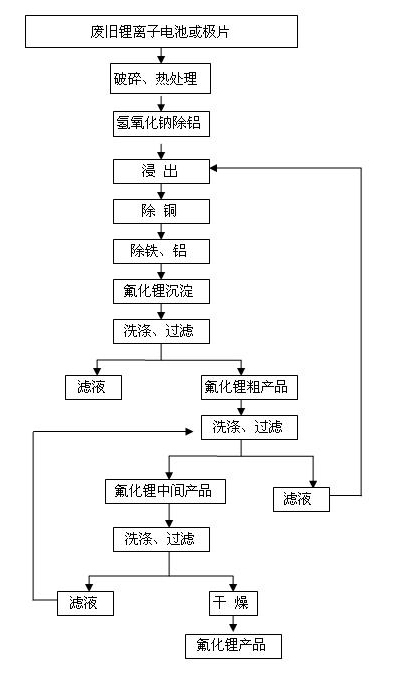

Method for recovering lithium from waste lithium ion battery and waste pole piece

ActiveCN101942569AHigh recovery rateEffectively realize comprehensive recyclingProcess efficiency improvementPhysical chemistryLithium-ion battery

The invention discloses a method for recovering lithium from a waste lithium ion battery and a waste pole piece. The method comprises the following steps of: (1) crushing the waste lithium ion battery or the waste pole piece by using a crusher, placing the crushed material in a high-temperature furnace and removing an adhesive from the crushed material by thermal processing to obtain powder; (2) removing aluminum from the powder by dissolving the aluminum in sodium hydroxide solution and filtering the solution to obtain low-aluminum filter mud; (3) leaching the low-aluminum filter mud with acid and a reducing agent to obtain lixivium; (4) removing impurities such as iron, copper, aluminum and the like from the lixivium by a chemical method; (5) precipitating lithium in the lixivium with fluorine salt to obtain a lithium fluoride rough product; (6) washing the lithium fluoride rough product, filtering and drying to obtain a lithium fluoride product; and (7) returning filtrate obtained after the lithium fluoride rough product is washed to the step (3) for processing. By the method of the invention, the lithium fluoride product has purity of over 98.0 percent and the primary recoveryrate of lithium is between 75 and 92 percent; and the method of the invention has the advantages of simple process, low cost, easy industrial production and high economic benefit.

Owner:HUNAN BRUNP RECYCLING TECH

Unsupported catalyst and preparation method thereof

ActiveCN101255356ALarge specific surface areaImprove hydrogenation activityRefining to eliminate hetero atomsUreaCatalytic hydrogenation

Disclosed are a unsupported catalyst for deeply hydrofinishing of intermediate distillate and method for making the same, particularly a catalyst particle with nanometer pore and relatively high specific surface area obtained by urea melt reaction. The most outstanding technical feature of the invention is that by adopting synthesis technique of urea melt reaction, metal is free of loss, prepared metal composite has nanometer pore and relatively high specific surface area, and could provide abundant catalytic hydrogenation activity bits, and the inventive catalyst has much higher catalytic hydrogenation activity comparing with conventional supported catalyst because of this. Meanwhile, the invention is simple in process, easy to operate, fast in reaction, suitable for industrial production.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for filling and mining after ore caving

ActiveCN102587916AReduce impact damageImprove work efficiencyUnderground miningSurface miningSpelunkingMineral Sources

The invention discloses a method for filling and mining after ore caving, which includes the following steps: exploiting; mining quasi work; cutting work: including excavation of mine collection trench and patio cutting, cutting a patio at one end portion of a rock drilling chamber, cutting the patio by using a vertical deep hole ore falling stage chamber method, and enabling patio cutting to provide sufficient compensation space for actual mining; chamber extraction work: constructing a downward blasthole in the rock drilling chamber, filling and blasting, one-time blasting charging at the entire middle section height of the blasthole, and enabling blasting to adopt one-time lateral blasting and ore removal; filling and maintaining: closing all outlets communicated with a lower mine of the empty area, burying strainer pipes, leading in filling pipelines from the upper portion of the chamber, and filling and maintaining the chamber; and pillar recovery: recovering pillars after filling and maintaining the chamber, and the pillar recovery is the same as the chamber extraction work. The method for filling and mining after ore caving is high in recovery rate of mineral resources, small in blasting impact effect, low in cost and high in production efficiency.

Owner:金建工程设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com