Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1143results about "Alkali metal halide purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conversion of petroleum residua to methane

InactiveUS6955695B2Eliminate needReduce usageThermal non-catalytic crackingElectrolysis componentsParticulatesGas phase

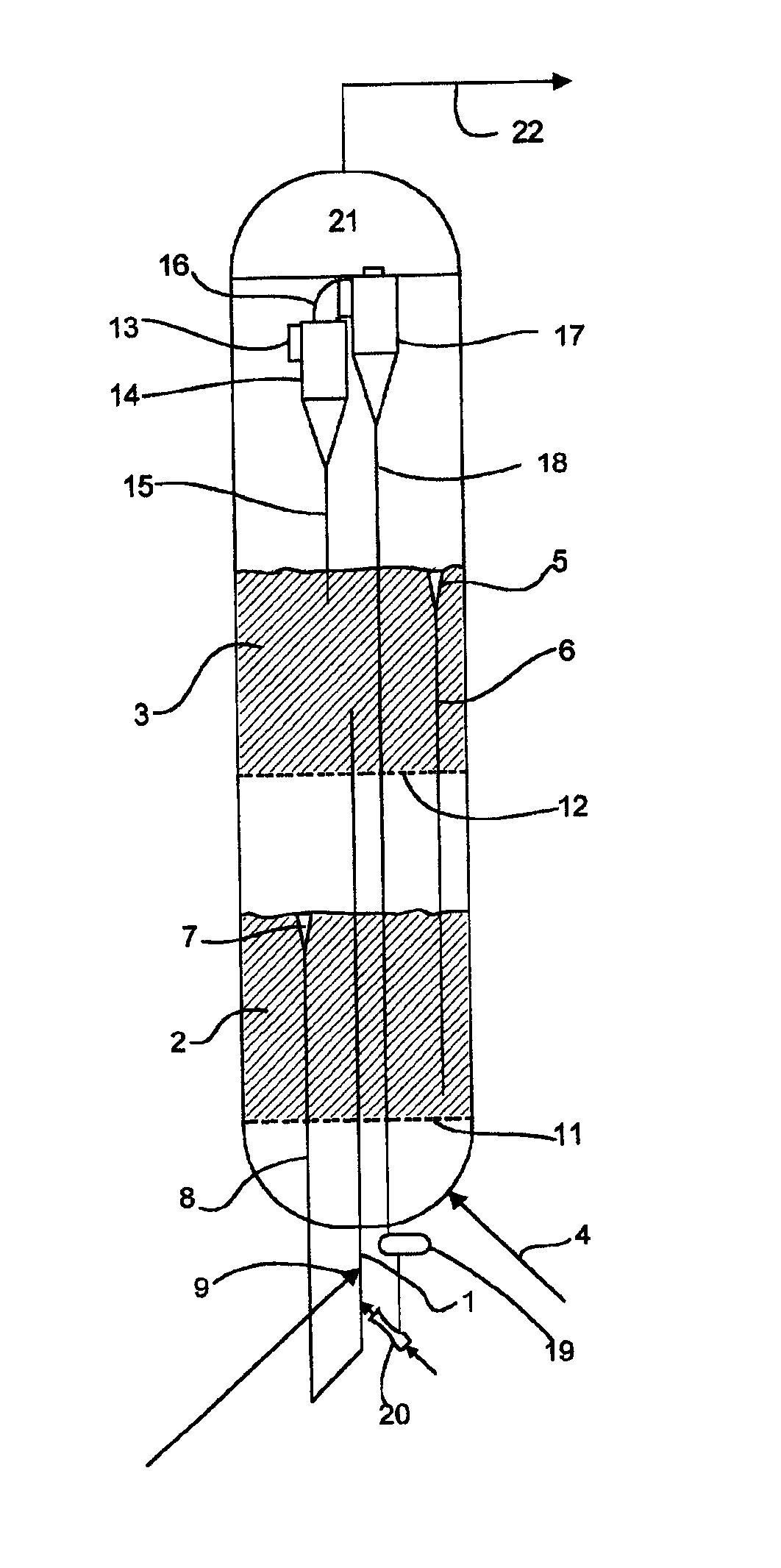

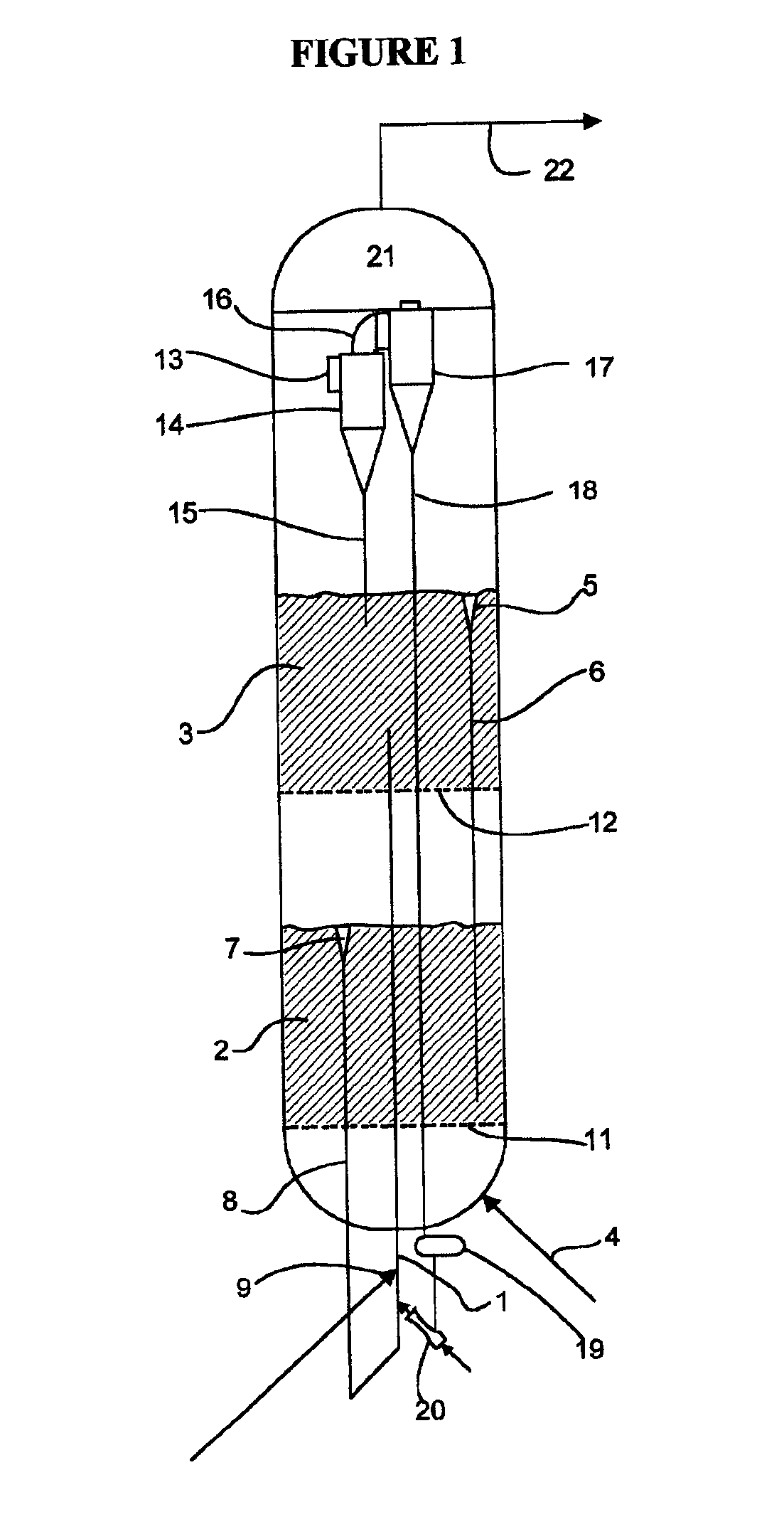

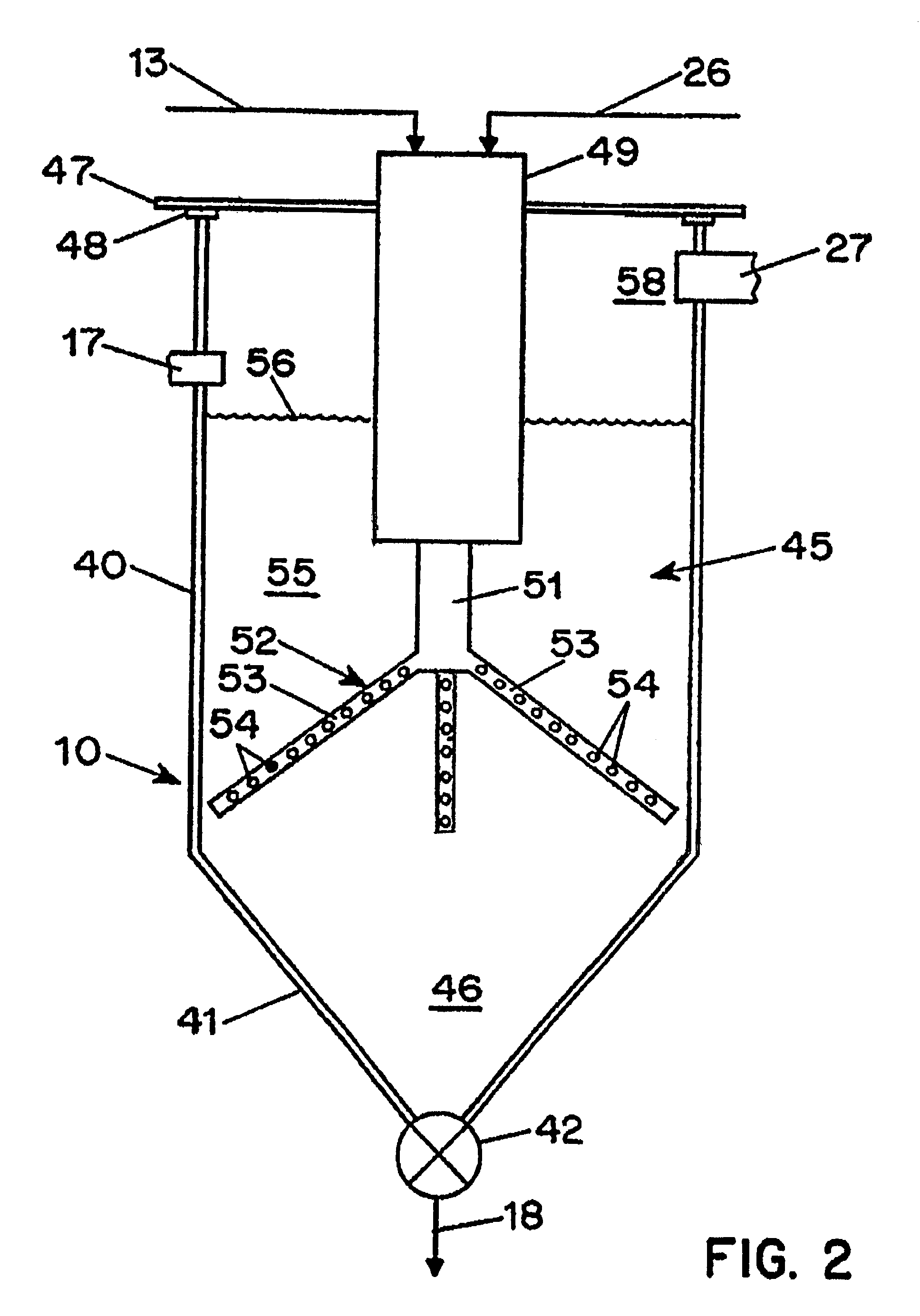

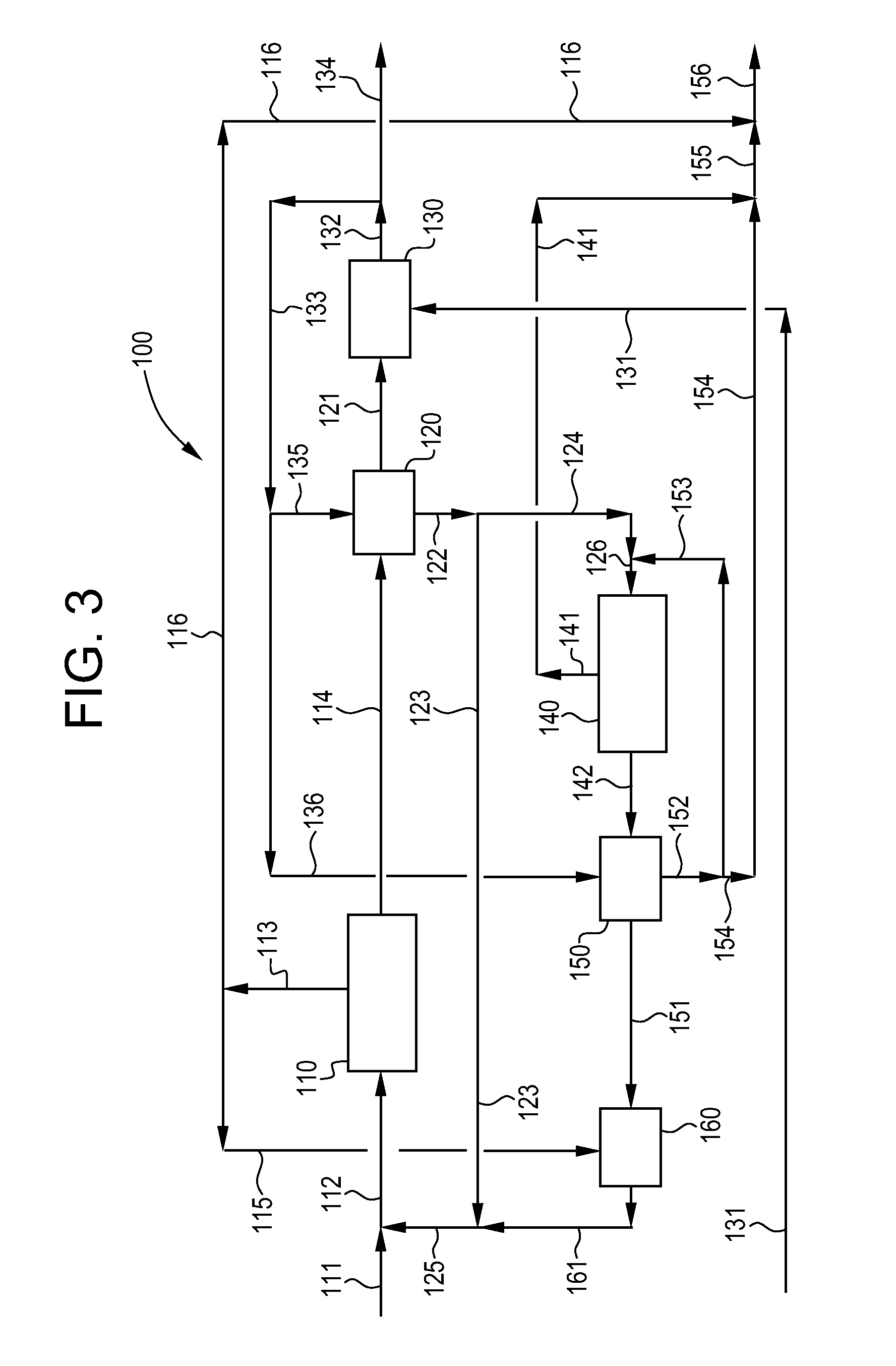

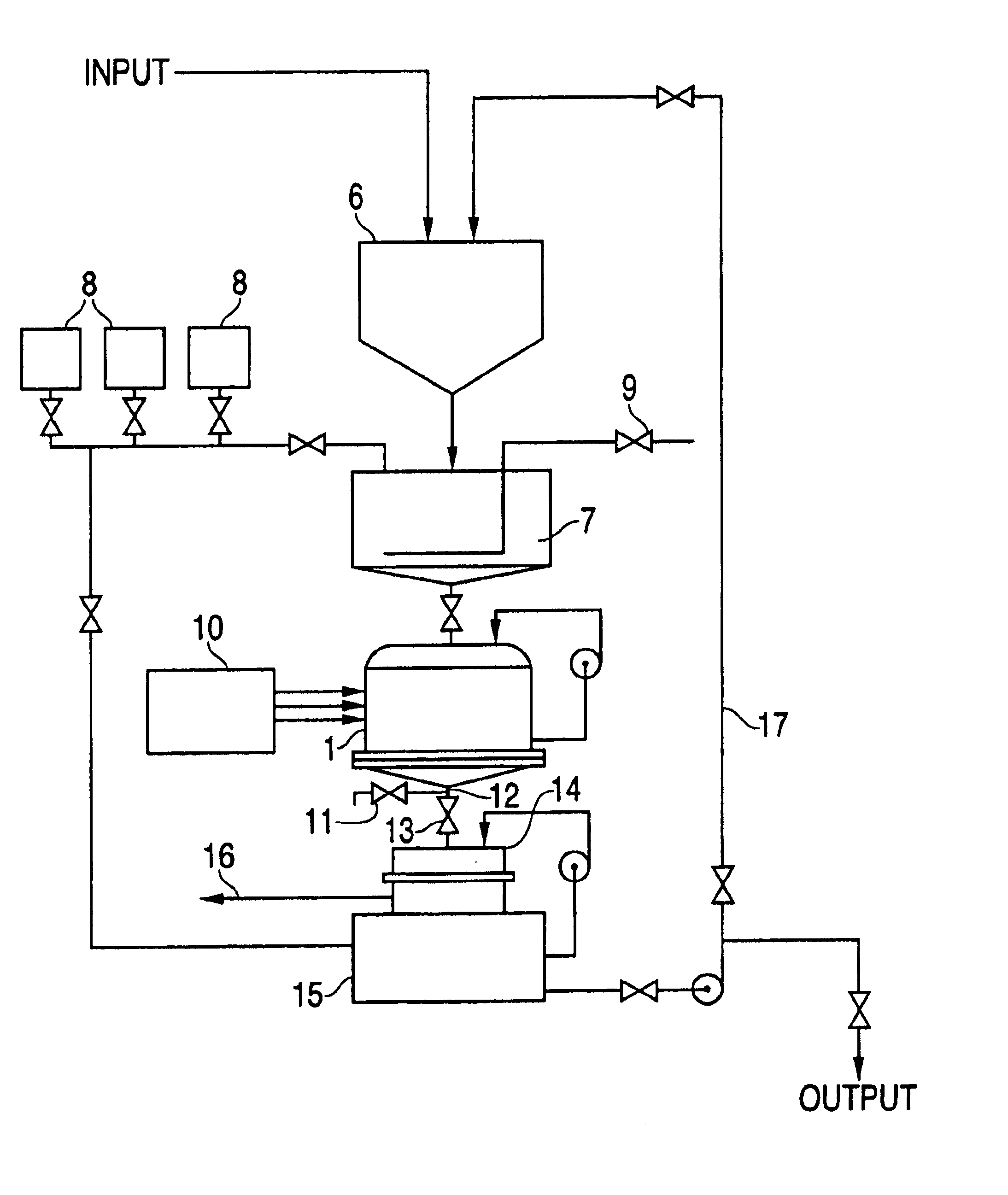

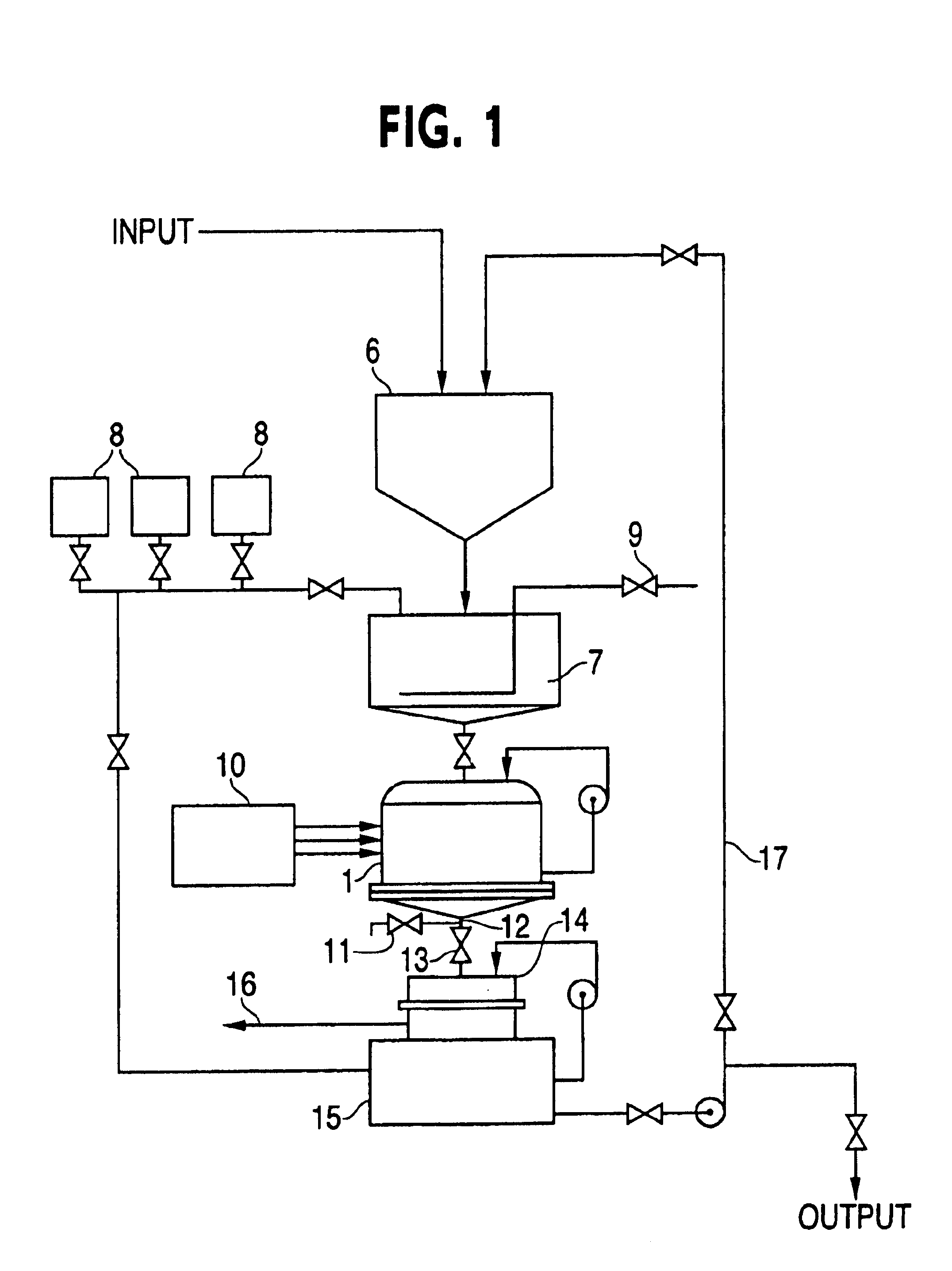

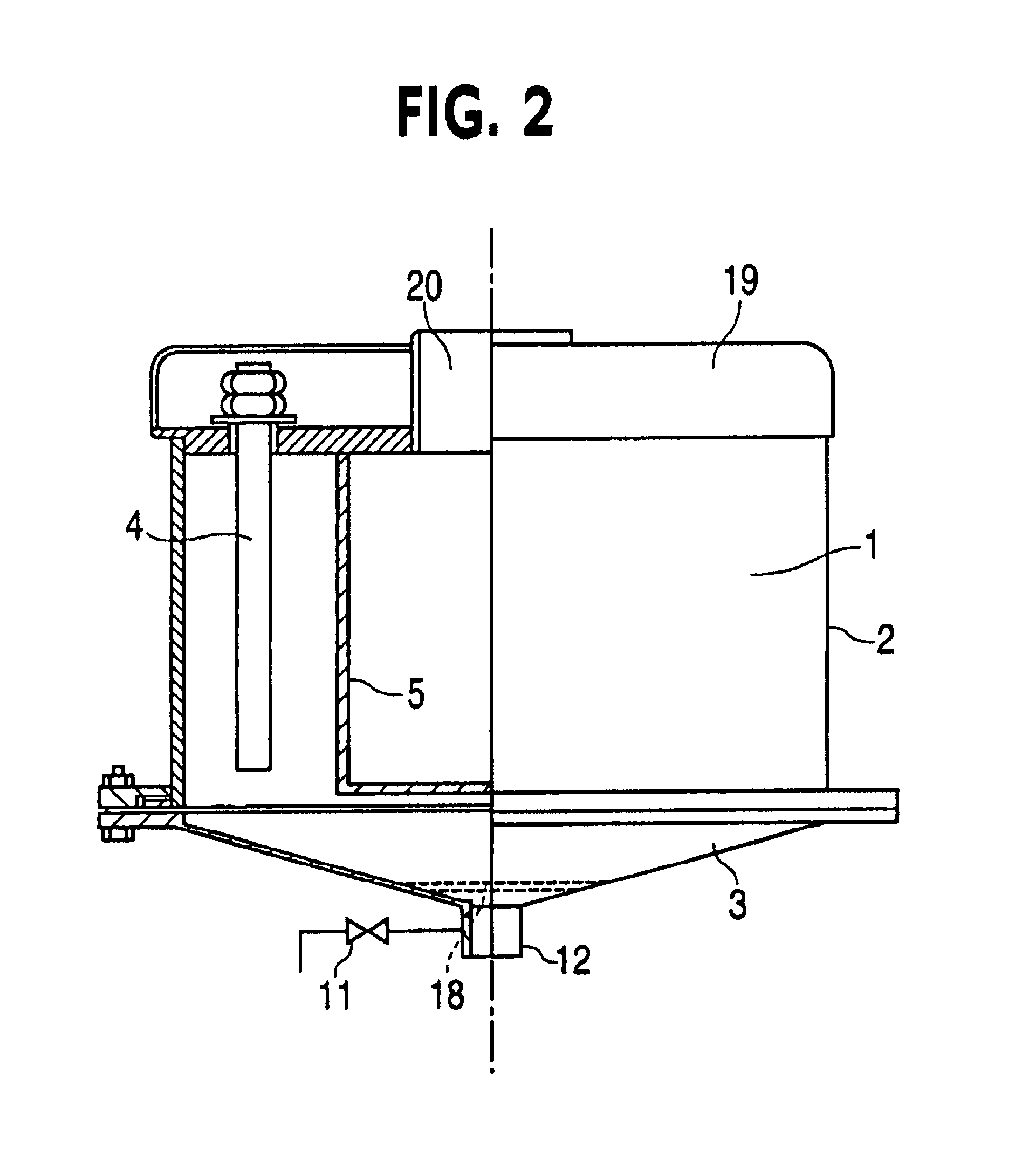

This invention discloses improvements on previous inventions for catalytic conversion of coal and steam to methane. The disclosed improvements permit conversion of petroleum residua or heavy crude petroleum to methane and carbon dioxide such that nearly all of the heating value of the converted hydrocarbons is recovered as heating value of the product methane. The liquid feed is distributed over a fluidized solid particulate catalyst containing alkali metal and carbon as petroleum coke at elevated temperature and pressure from the lower stage and transported to the upper stage of a two-stage reactor. Particulate solids containing carbon and alkali metal are circulated between the two stages. Superheated steam and recycled hydrogen and carbon monoxide are fed to the lower stage, fluidizing the particulate solids and gasifying some of the carbon. The gas phase from the lower stage passes through the upper stage, completing the reaction of the gas phase.

Owner:PETRO2020

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169448A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesPhysical chemistryAlkali metal

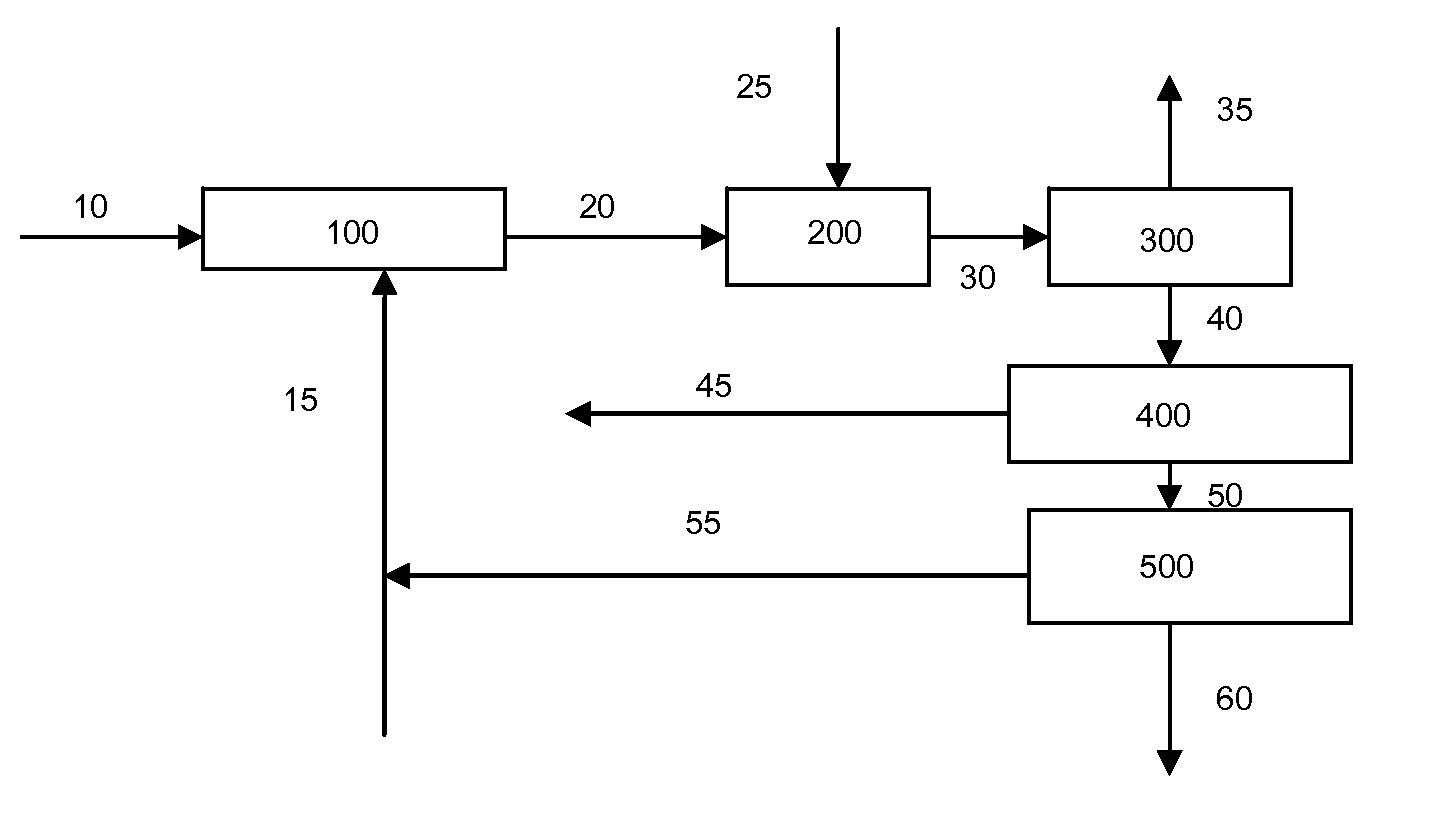

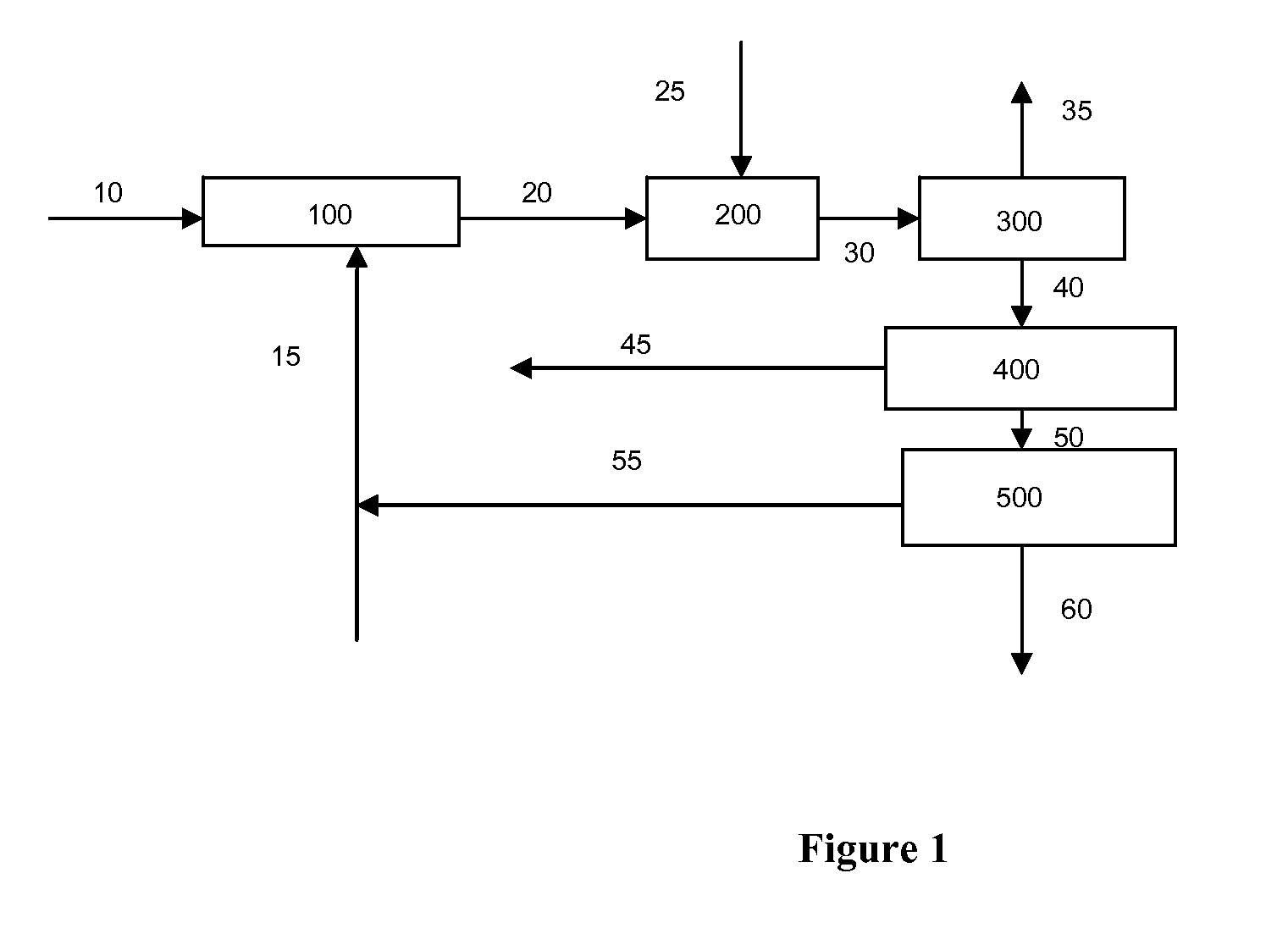

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Process for producing sodium sulfate and sodium chloride in Na2SO4-NaCl-H2O system

InactiveCN1944256AIncrease profitReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal halide purificationInorganic saltsSeparation technology

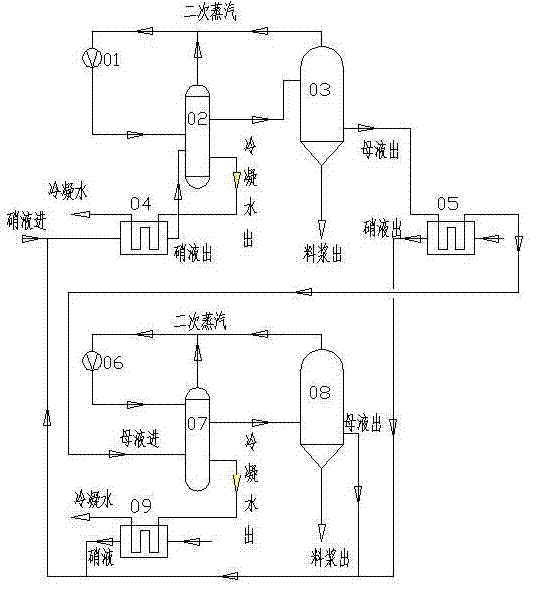

The process of producing sodium sulfate and sodium chloride in a Na2SO4-NaCl-H2O system belongs to the field of mixed inorganic solution evaporating separation technology. Mixed solution of sodium sulfate and sodium chloride as material is first evaporated and then separated to obtain sodium sulfate, sodium chloride and evaporated mother liquor; the evaporated mother liquor is low temperature evaporated and separated to obtain sodium chloride and salt-making mother liquor; and the salt-making mother liquor is evaporated and separated to obtain sodium sulfate and saltpeter-making mother liquor. The present invention has the features of high main and side product quality, high material adaptability, low cost, low cost, no waste draining, etc.

Owner:CHINA LIGHT IND INT ENG CO LTD +1

Process and apparatus for the treatment of saline water

InactiveUS20060196836A1Reduce ZLD costReduce loadWaste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

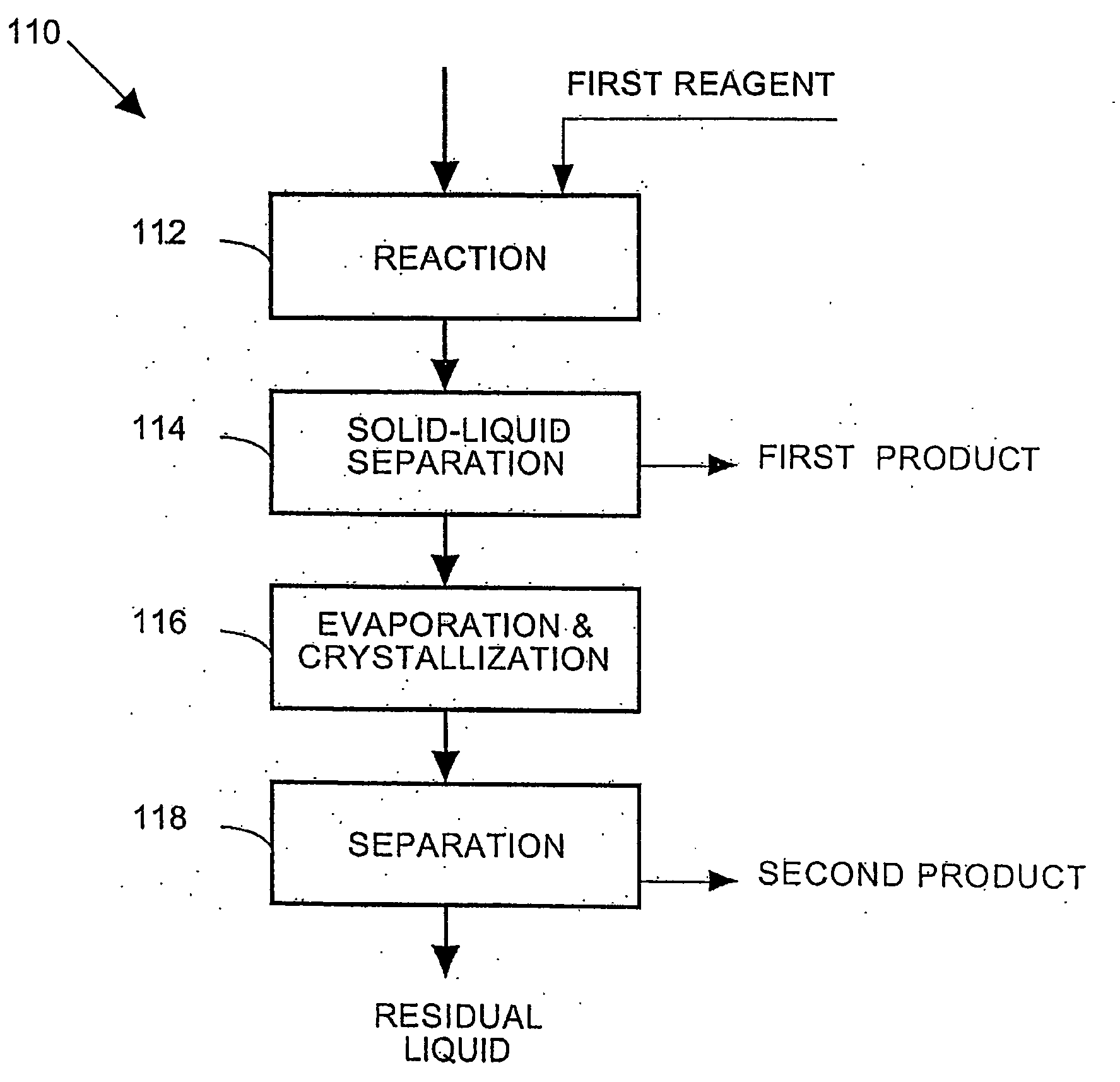

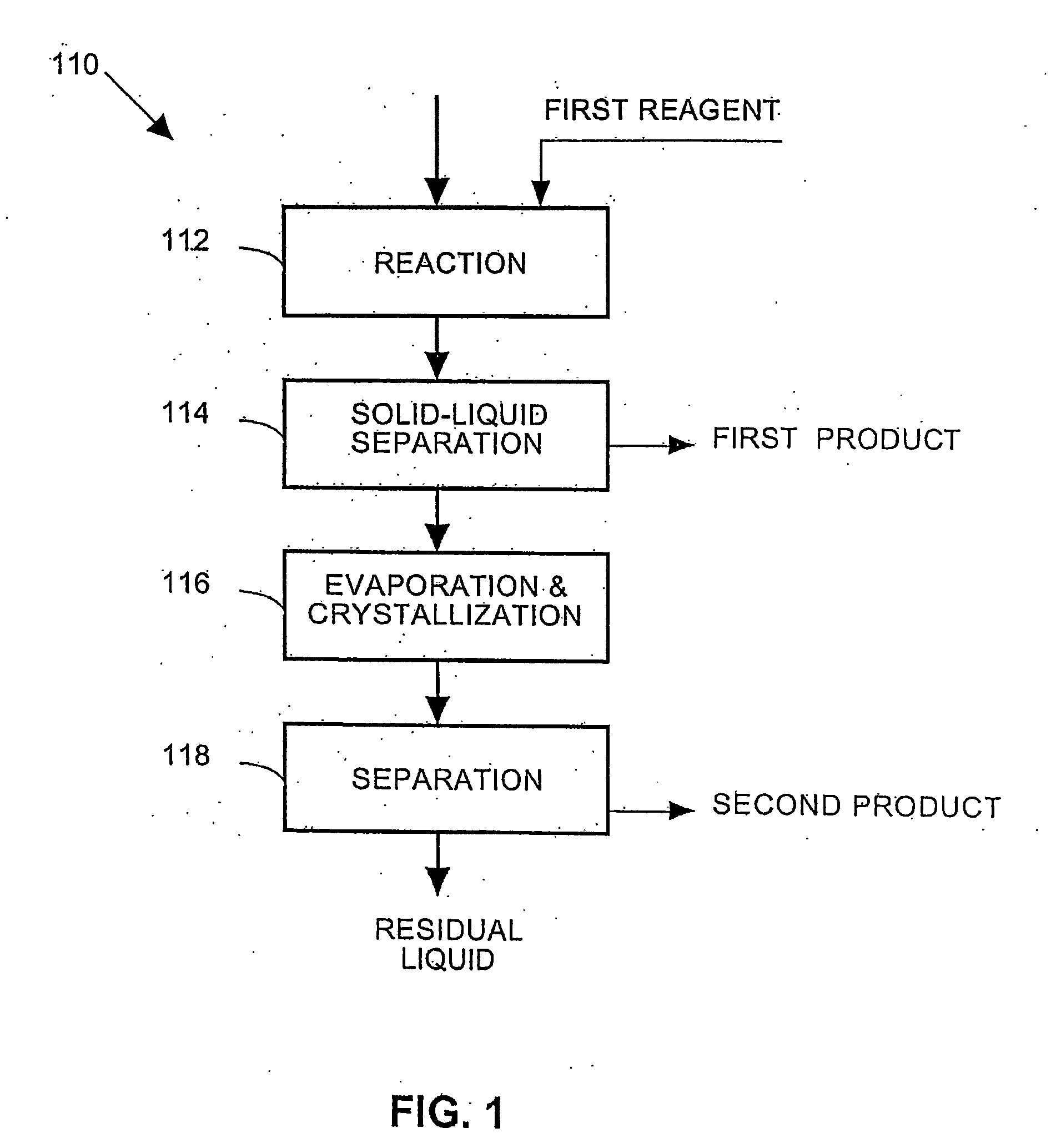

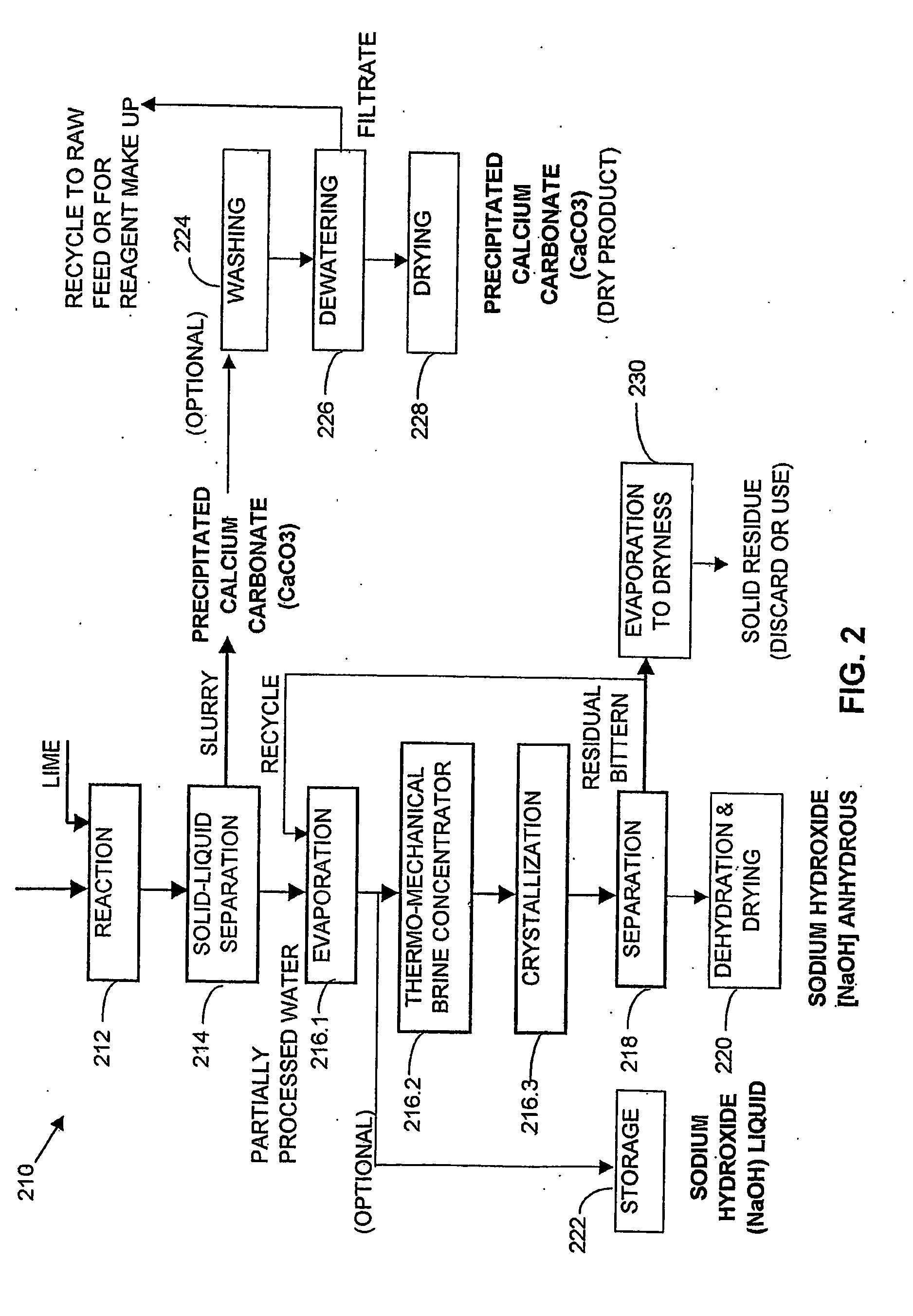

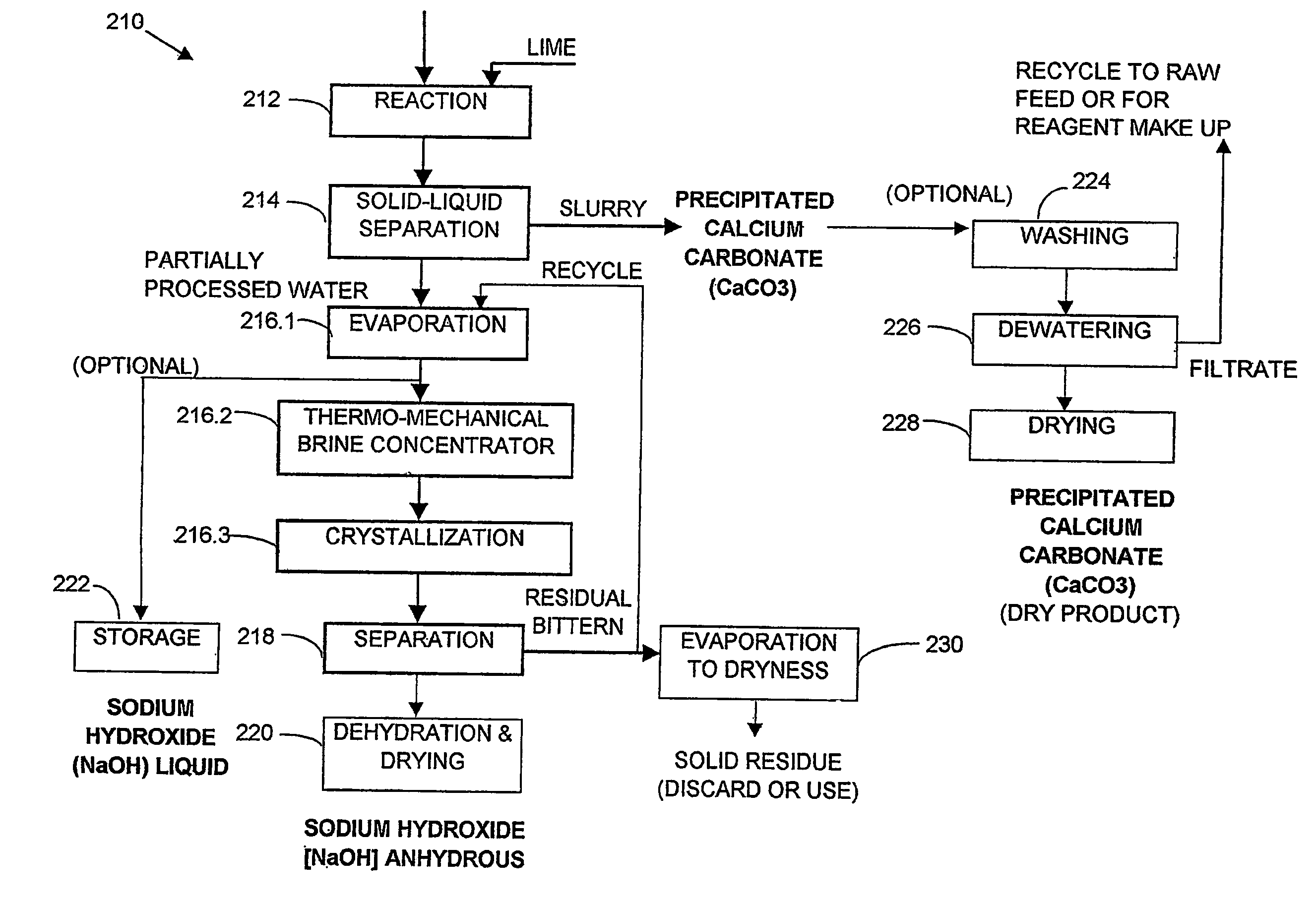

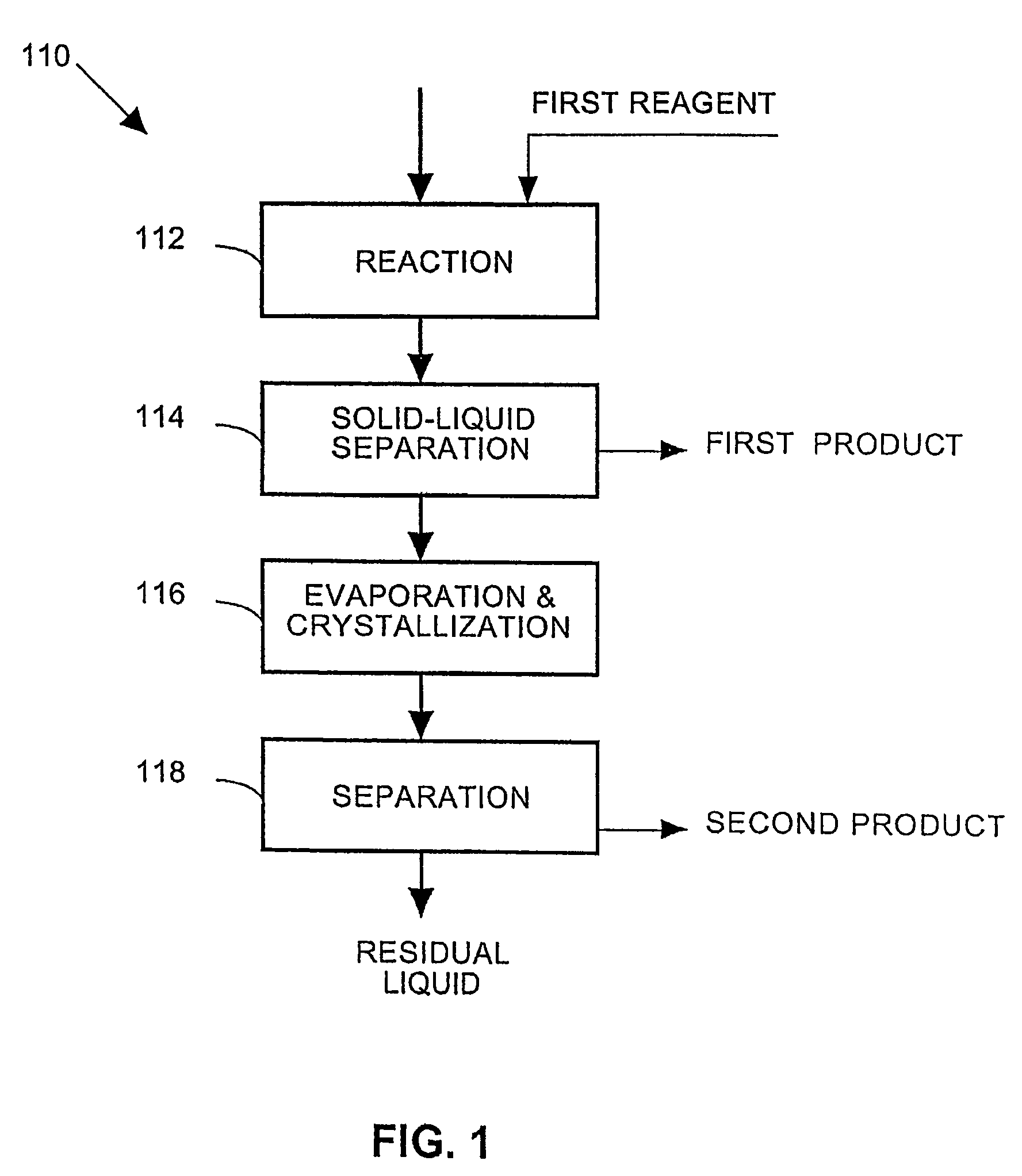

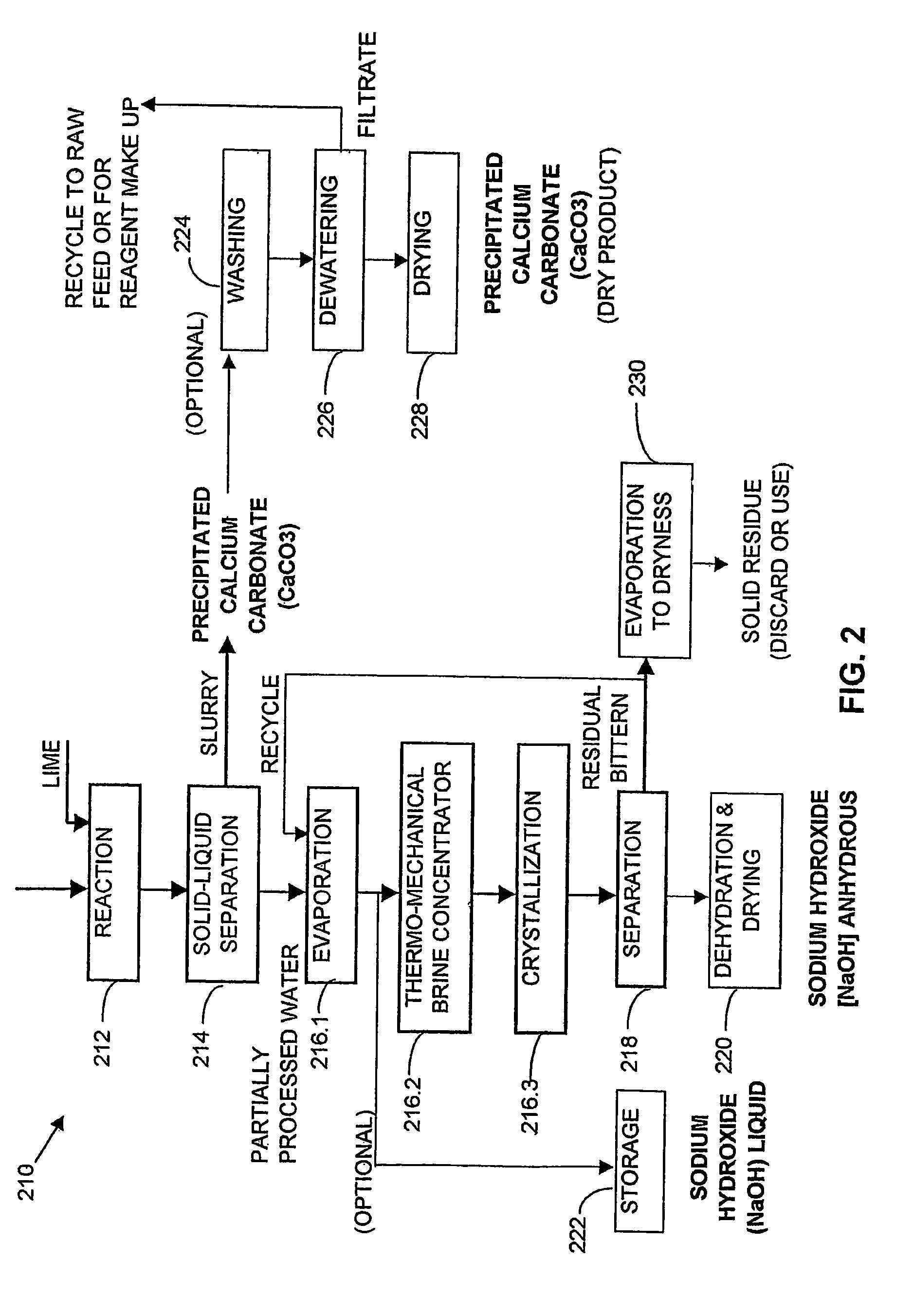

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

Recovery of common salt and marine chemicals from brine

InactiveUS6776972B2High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

Process for the treatment of saline water

InactiveUS7595001B2Waste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

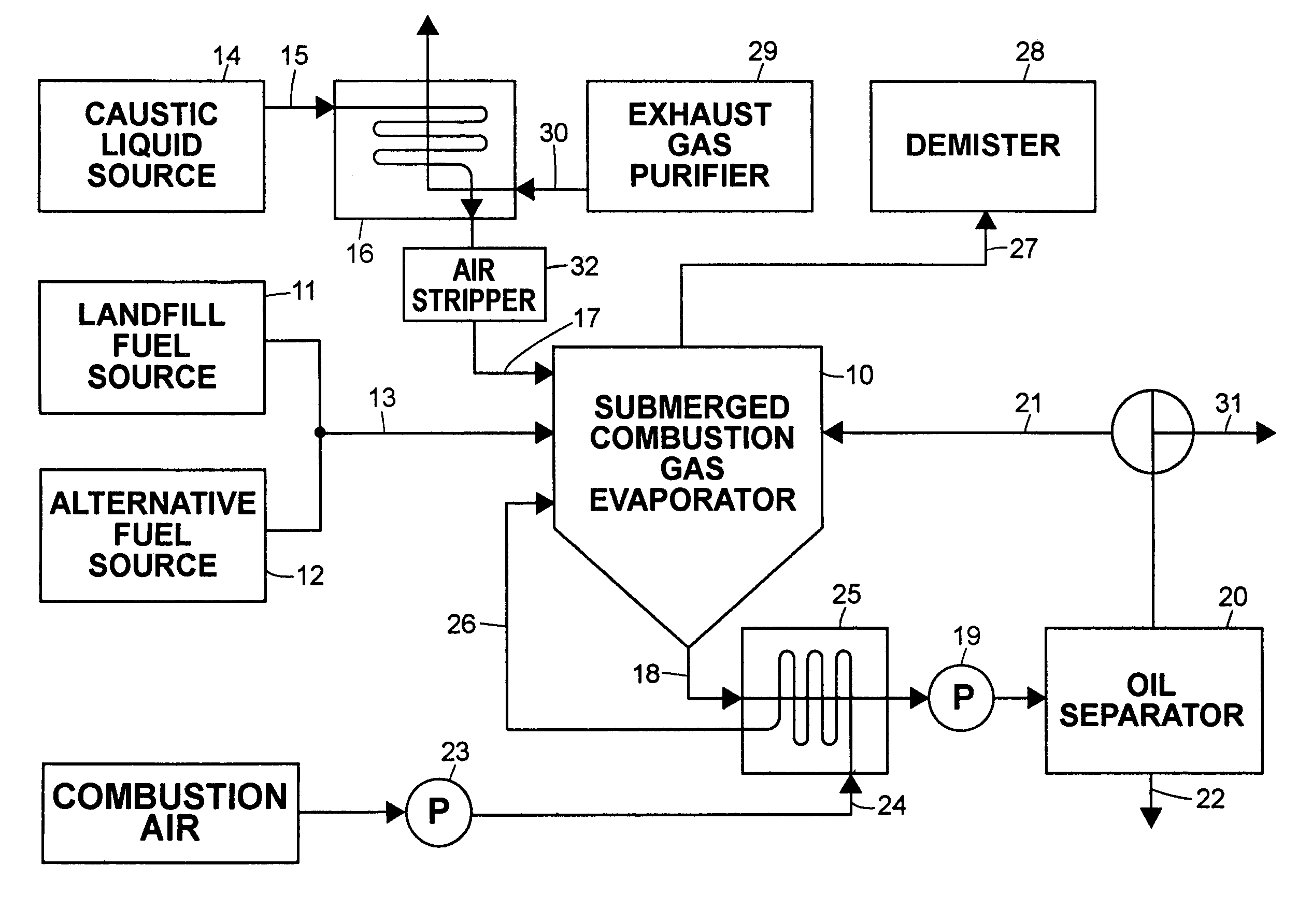

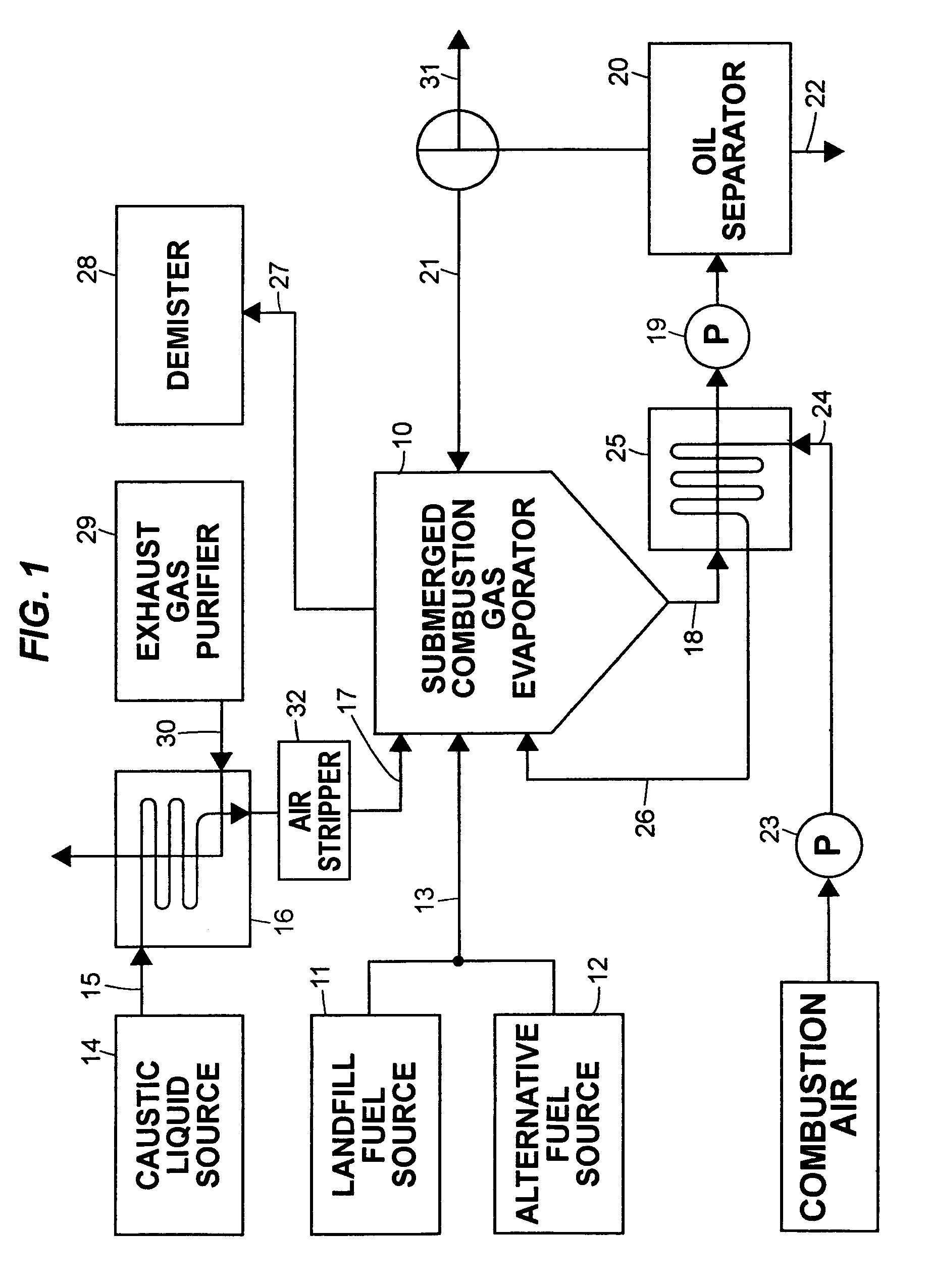

Treatment of spent caustic refinery effluents

InactiveUS7214290B2Avoid spreadingDrying using combination processesLiquid degasificationLiquid wasteCombustion

In the methods for treatment of caustic effluents described in the specification, a spent caustic refinery effluent is supplied to a submerged combustion gas evaporator in which hot combustion gas containing carbon dioxide is injected into the caustic liquid to concentrate the liquid and convert a hydroxide constituent to a carbonate. Where the caustic effluent is from a petroleum refinery, oil in the waste liquid is separated from the aqueous constituent before, during or after concentration.

Owner:GEI LIQUID SOLUTIONS +1

Application of MVR (mechanical vapor recompression) crystallizing evaporator in sodium sulfate and sodium chloride separation technology

InactiveCN103172088AImprove thermal efficiencyReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal chloridesPhysical chemistryExhaust fumes

The invention discloses an industrial application of an MVR (mechanical vapor recompression) crystallizing evaporator technology in the production of sodium sulfate and sodium chloride in Huaian, Jiangsu, and relates to an improvement of a salt and sodium sulfate coproduction evaporation technology, belonging to the technical field of chemical three-waste treatment and utilization, and in particular to an application of an MVR crystallizing evaporator in a sodium sulfate and sodium chloride separation technology. The application is mainly technically characterized in that sodium sulfate liquid is concentrated by the MVR crystallizing evaporator, the sodium sulfate is produced at high temperature, and the sodium chloride is produced at low temperature. According to the invention, the mechanical re-compressed vapor is evaporated, concentrated and crystallized at 90-100 DEG C to obtain sodium sulfate, and the re-compressed vapor at a low temperature of 55 DEG C is concentrated and crystallized to obtain sodium chloride. According to the invention, the application of the MVR technology to the concentration of sodium sulfate liquid is realized, the sodium sulfate is produced at high temperature, and sodium chloride is produced at low temperature. The application disclosed by the invention is an environmental protection project which saves energy, reduces emission and avoids waste gas, waste water and waste residue.

Owner:NAFINE CHEMICAL INDUSTRY GROUP CO LTD

Recovery of common salt and marine chemicals from brine

InactiveUS20030080066A1High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

Brine purification

InactiveUS20100219372A1Increase contentLower levelTreatment using aerobic processesIsotope separationSaline waterCarbon adsorption

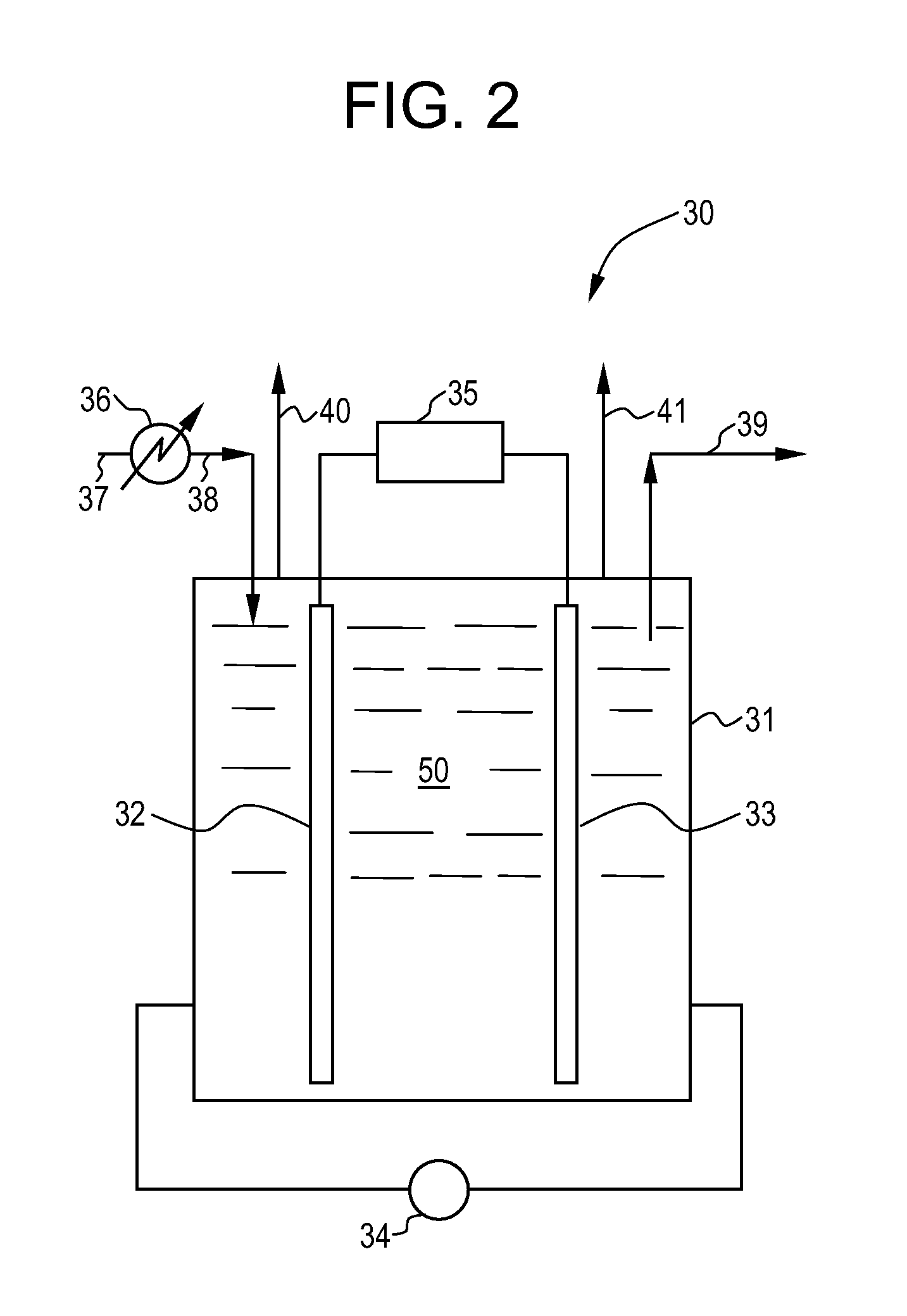

Process and apparatus for reducing organic content of brine comprising subjecting a brine solution to at least two purification treatments selected from electrochemical treatment, chlorinolysis, or other chemical oxidation treatment, carbon adsorption, extraction, biological treatment and chrystallizing treatment; wherein the organic content of purified brine is sufficiently low to enable sense of the purified brine in an industrial process.

Owner:DOW GLOBAL TECH LLC

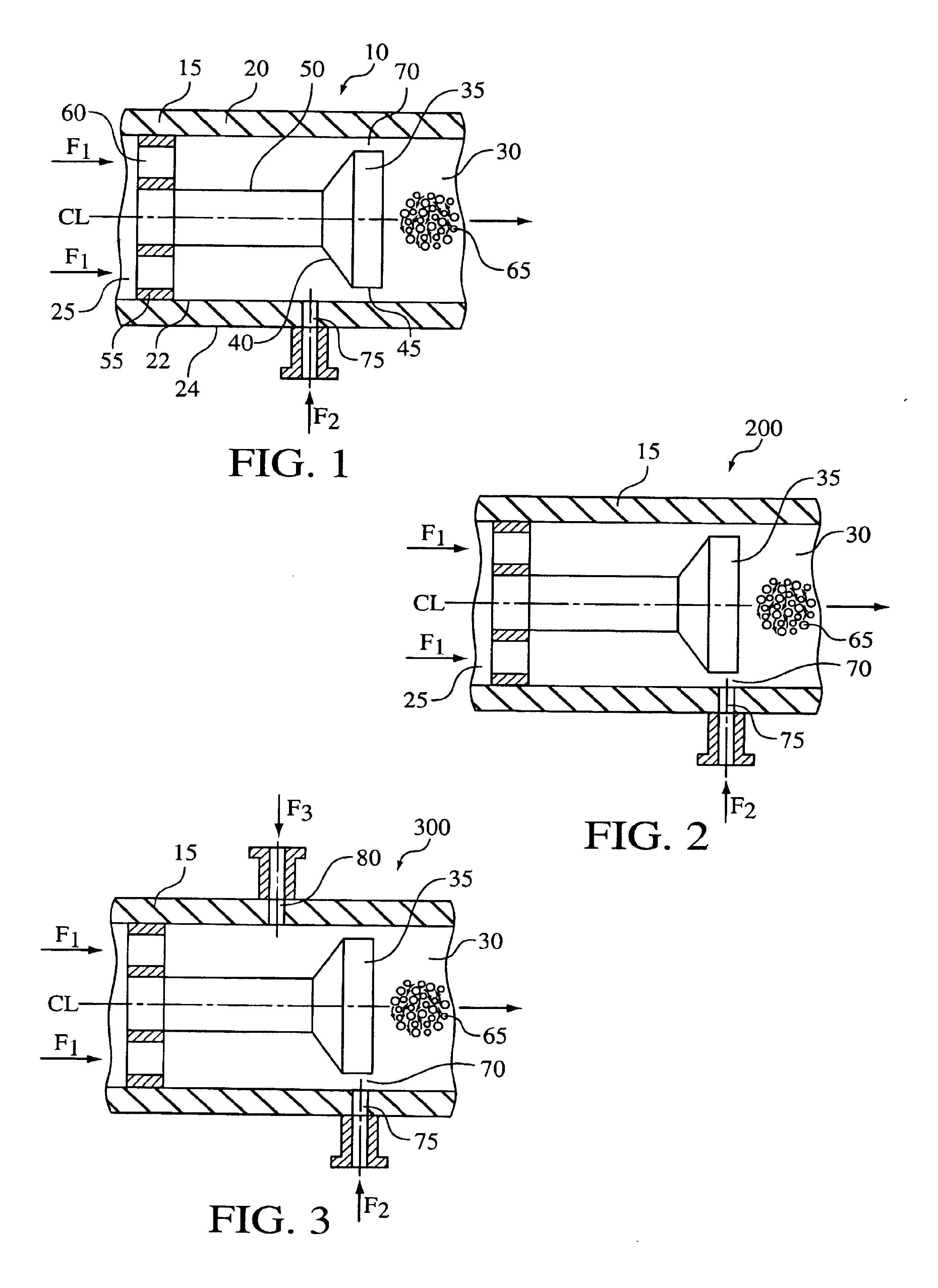

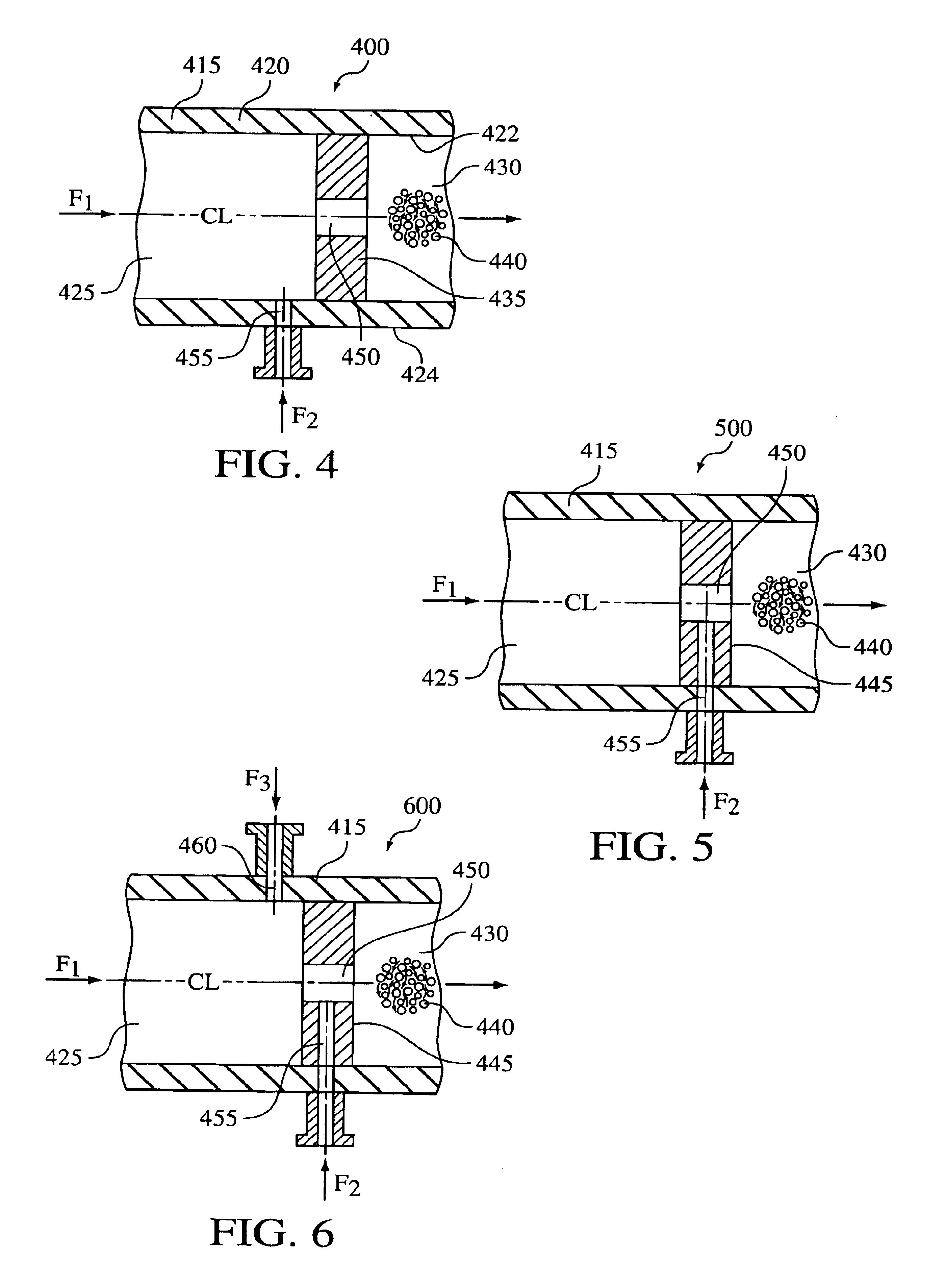

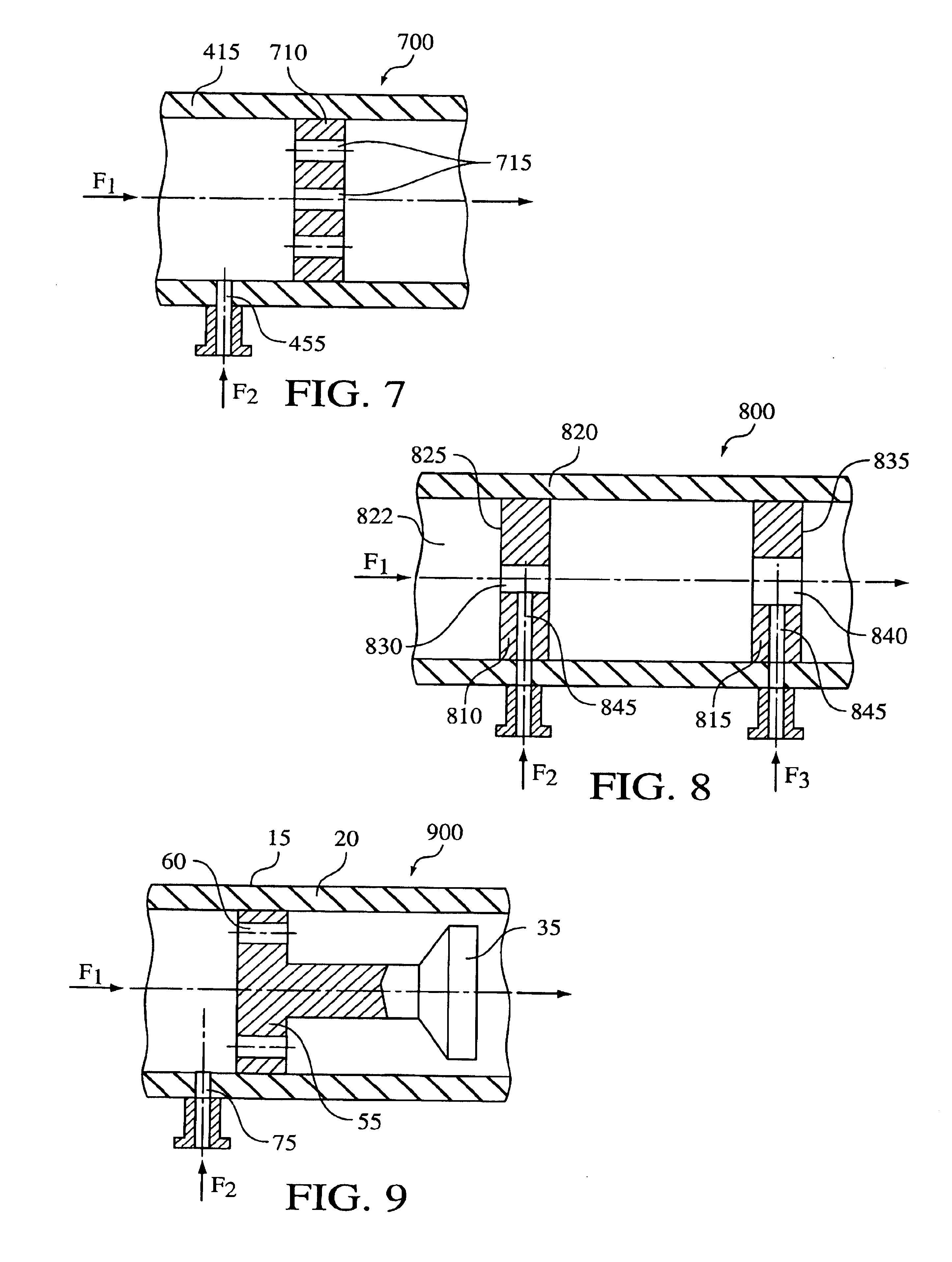

Hydrodynamic cavitation crystallization process

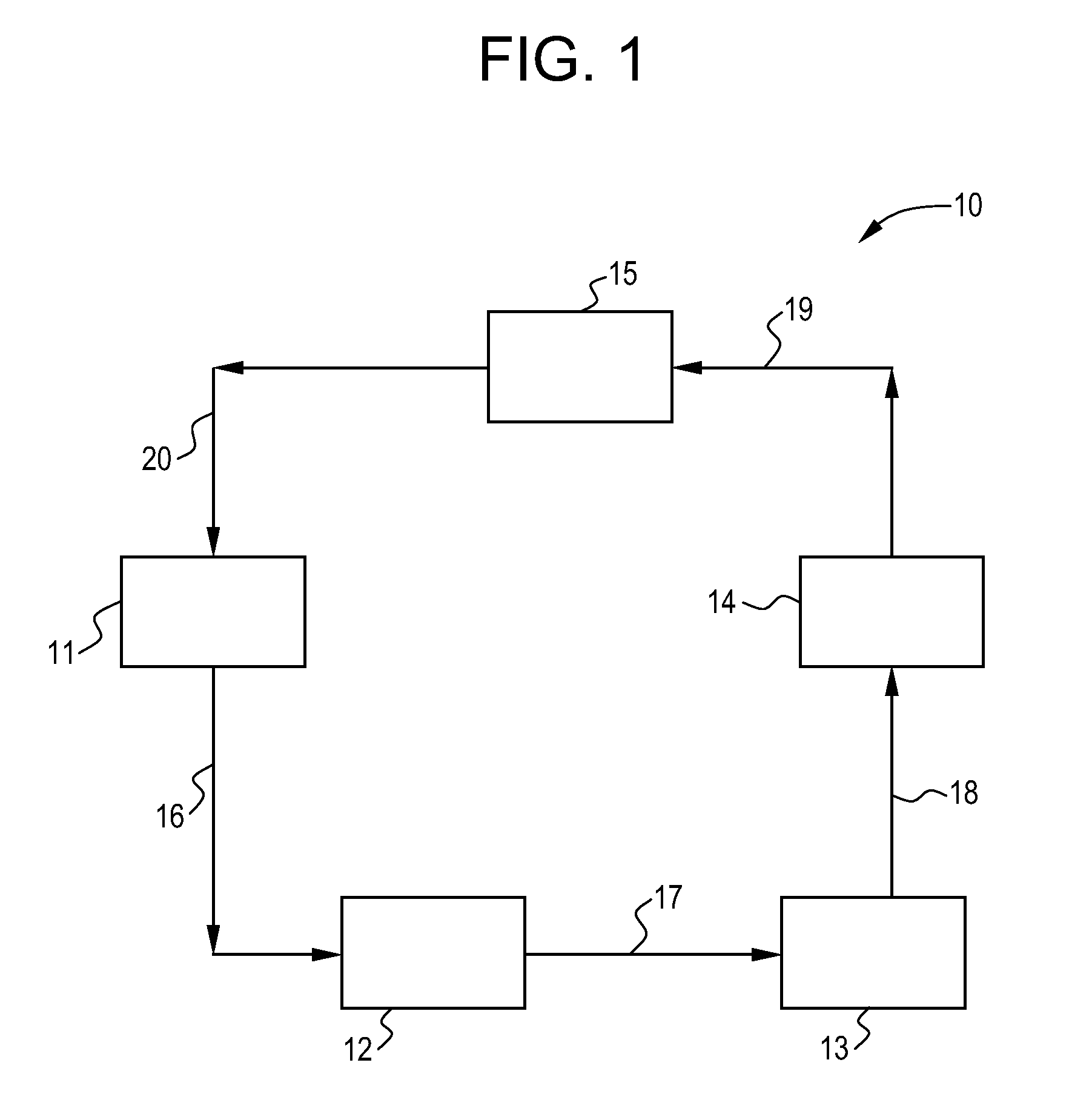

A device and process for crystallizing a compound using hydrodynamic cavitation comprising the steps of mixing at least one stream of a solution of such compound to be crystallized with at least one stream of an anti-solvent and passing the mixed streams at an elevated pressure through a local constriction of flow to create hydrodynamic cavitation thereby causing nucleation and the direct production of crystals.

Owner:ARISDYNE STSTEMS INC

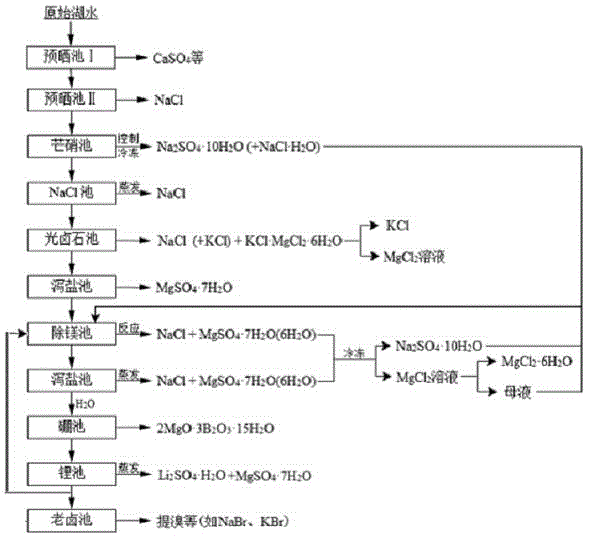

Clean production process of plateau sulfate type boron-lithium salt lake brine

InactiveCN102910652AHigh purityReduce the ratio of magnesium to lithiumChemical industryAlkali metal halide purificationHydration reactionSylvinite

The invention relates to a clean production process of plateau sulfate type boron-lithium salt lake brine. The process comprises the following steps of: (1) arranging a pre-airing pond, a mirabilite pond, a NaCl pond, a carnallite pond, an epsom salt pond I, a magnesium removing pond, an epsom salt pond II, a boron pond, a lithium pond and an old brine pond; (2) controlling the sodium ion concentration in plateau sulfate type boron-lithium salt lake brine, precipitating mirabilite out in winter to obtain brine A, naturally evaporating the brine A, and salting out to obtain brine B; (3) naturally evaporating the brine B, and precipitating sylvine and carnallite out in sequence to obtain brine C; (4) naturally evaporating the brine C, precipitating an epsom salt out, and performing solid-liquid separation to obtain brine D and a solid A; (5) blending the brine D with mirabilite, removing magnesium to obtain brine E, and naturally evaporating brine E to obtain brine F and a solid B; (6) performing a hydration reaction on brine F, naturally evaporating, and precipitating reservoir water / inderite and brine G out; and (7) evaporating brine G or refrigerating for precipitating lithium sulfate, and processing the lithium sulfate into a corresponding product. The process has the advantages of comprehensive utilization of natural energy, saving in energy and environment friendliness.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

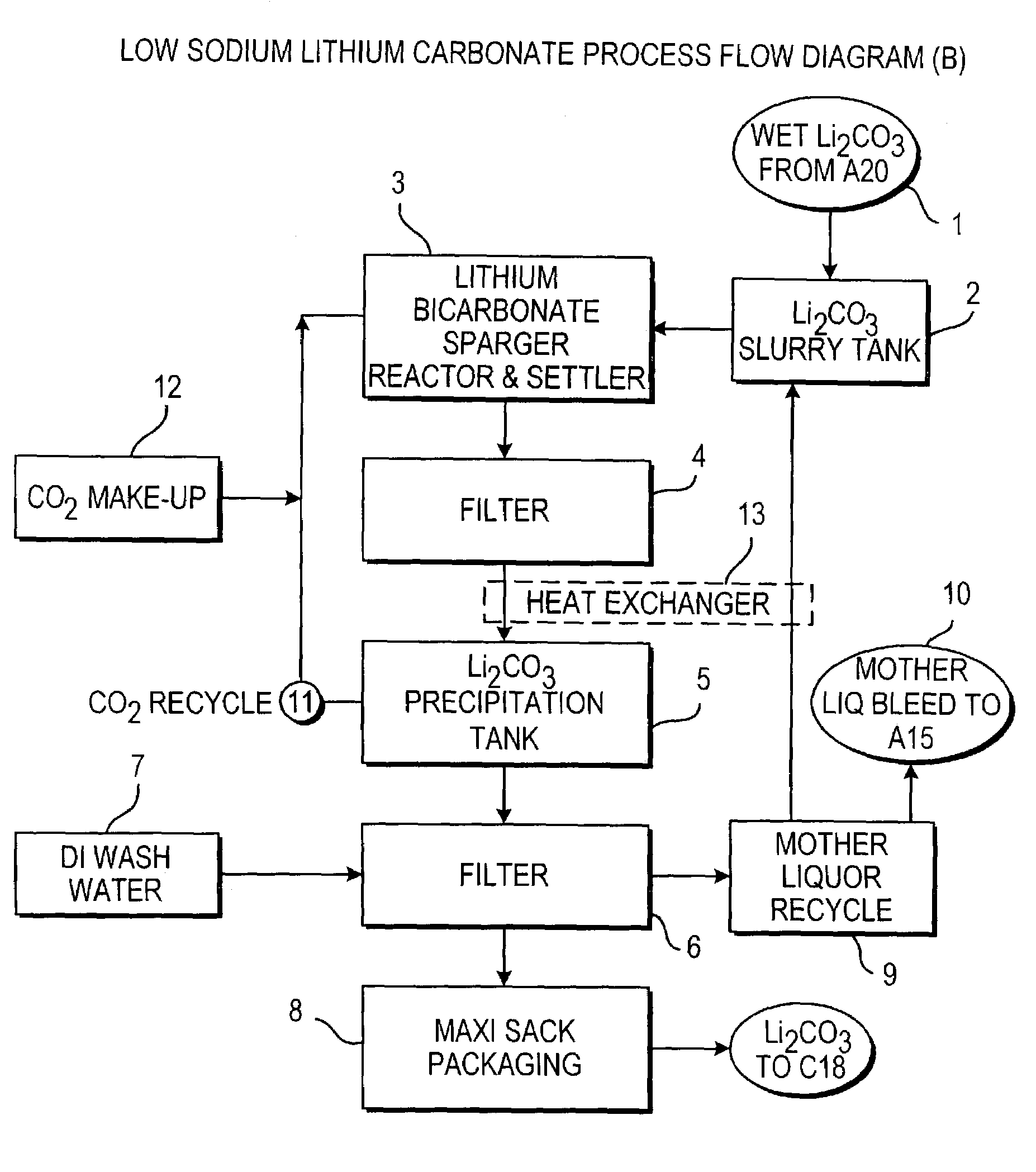

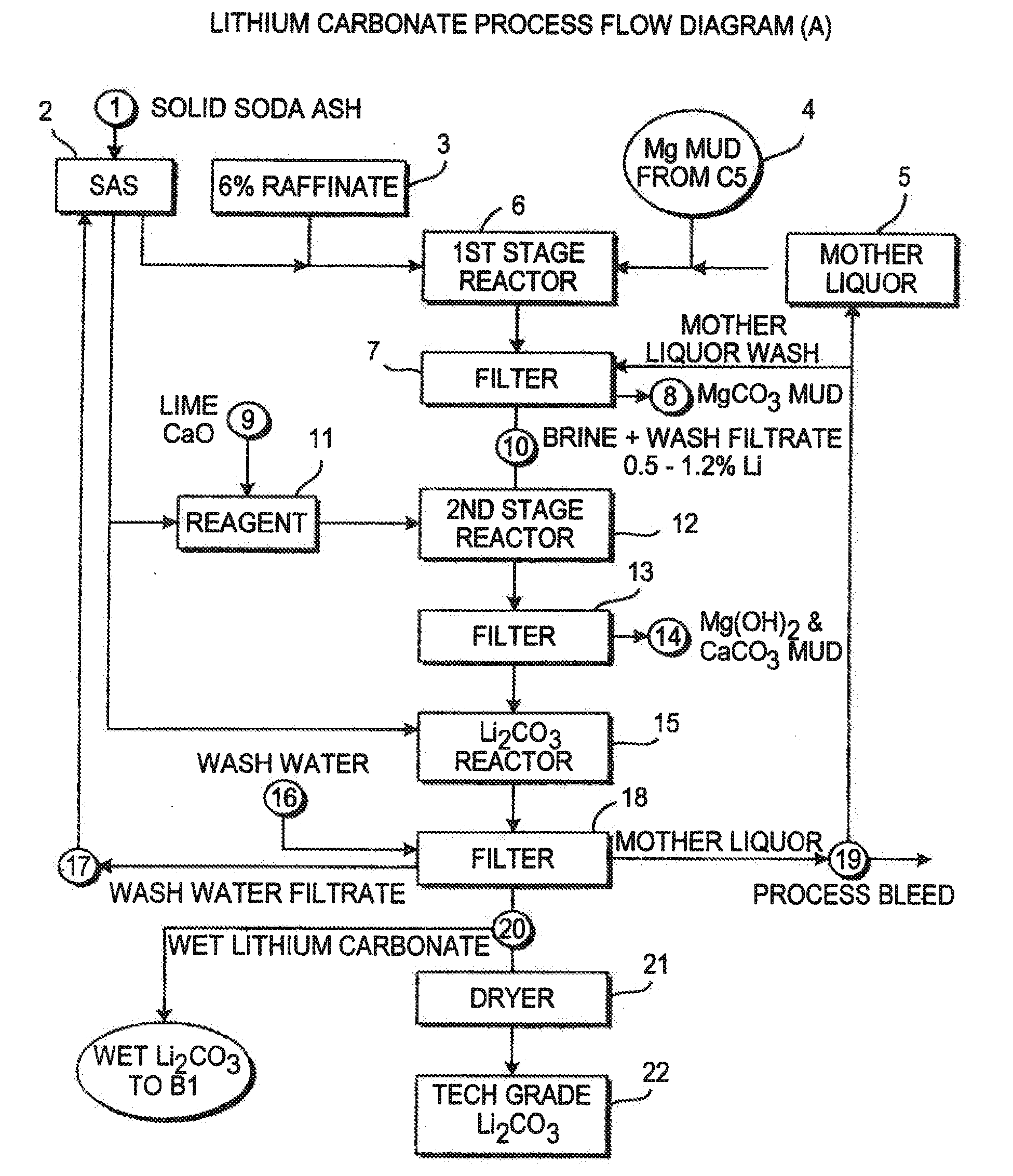

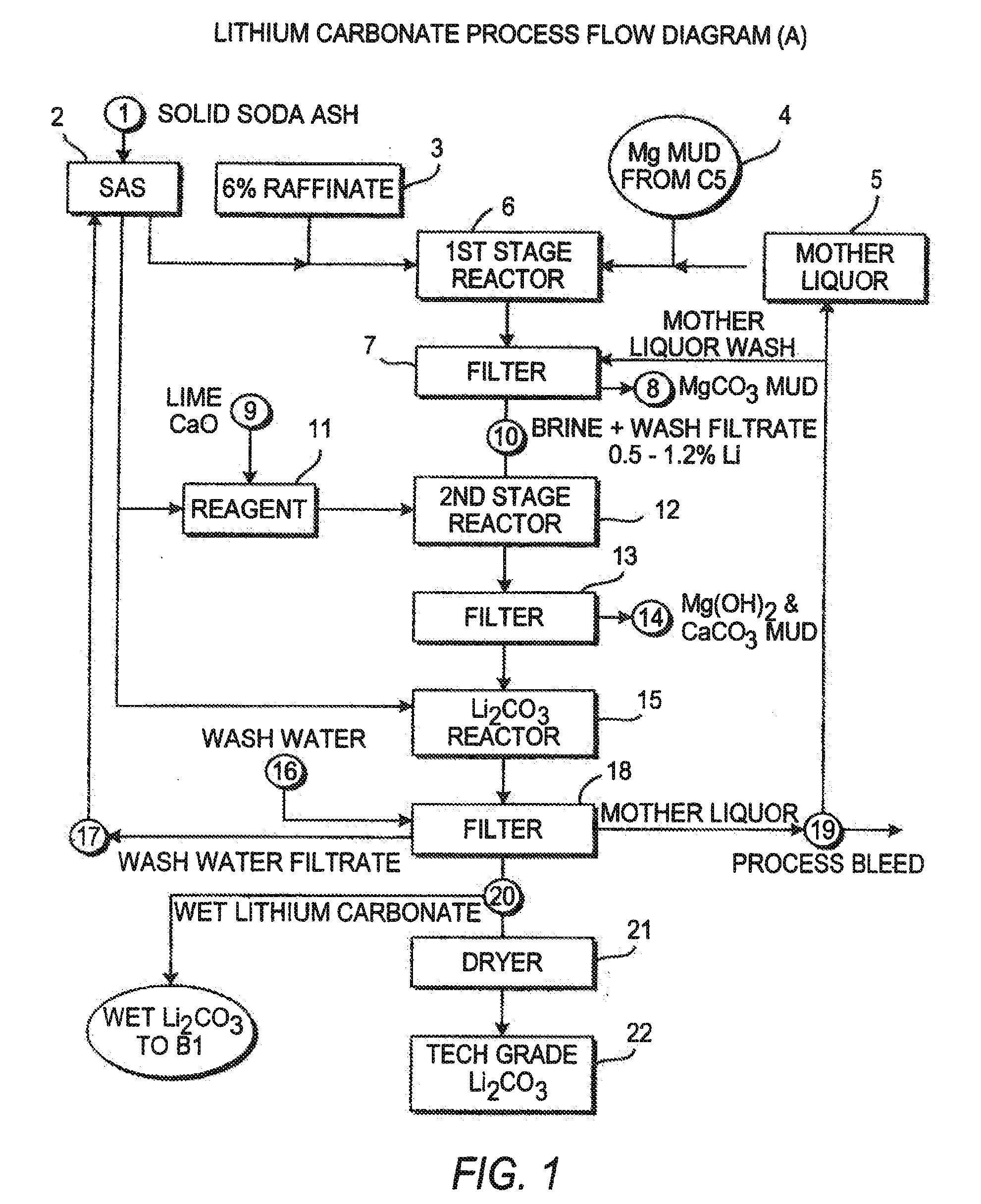

Production of lithium compounds directly from lithium containing brines

InactiveUS7157065B2Reduce in quantityPromote absorptionCalcium/strontium/barium carbonatesChemical/physical/physico-chemical processesSlurryLithium compound

A continuous process for directly preparing high purity lithium carbonate from lithium containing brines by preparing a brine containing about 6.0 wt % lithium and further containing other ions naturally occurring in brines; adding mother liquor containing carbonate to precipitate magnesium; adding a solution of CaO and sodium carbonate to remove calcium and any residual magnesium; precipitating lithium carbonate from the purified brine by adding soda ash solution; filtering to obtain solid lithium carbonate; preparing an aqueous slurry of the lithium carbonate and introducing carbon dioxide gas at a temperature from at least minus 10 to +40° C.; passing the lithium bicarbonate solution through a filter to clarify the solution; introducing said filtered lithium bicarbonate solution into a reactor and adjusting the temperature of the solution to from 60–100° C. to precipitate ultra-pure lithium carbonate.

Owner:ROCKWOOD LITHIUM INC

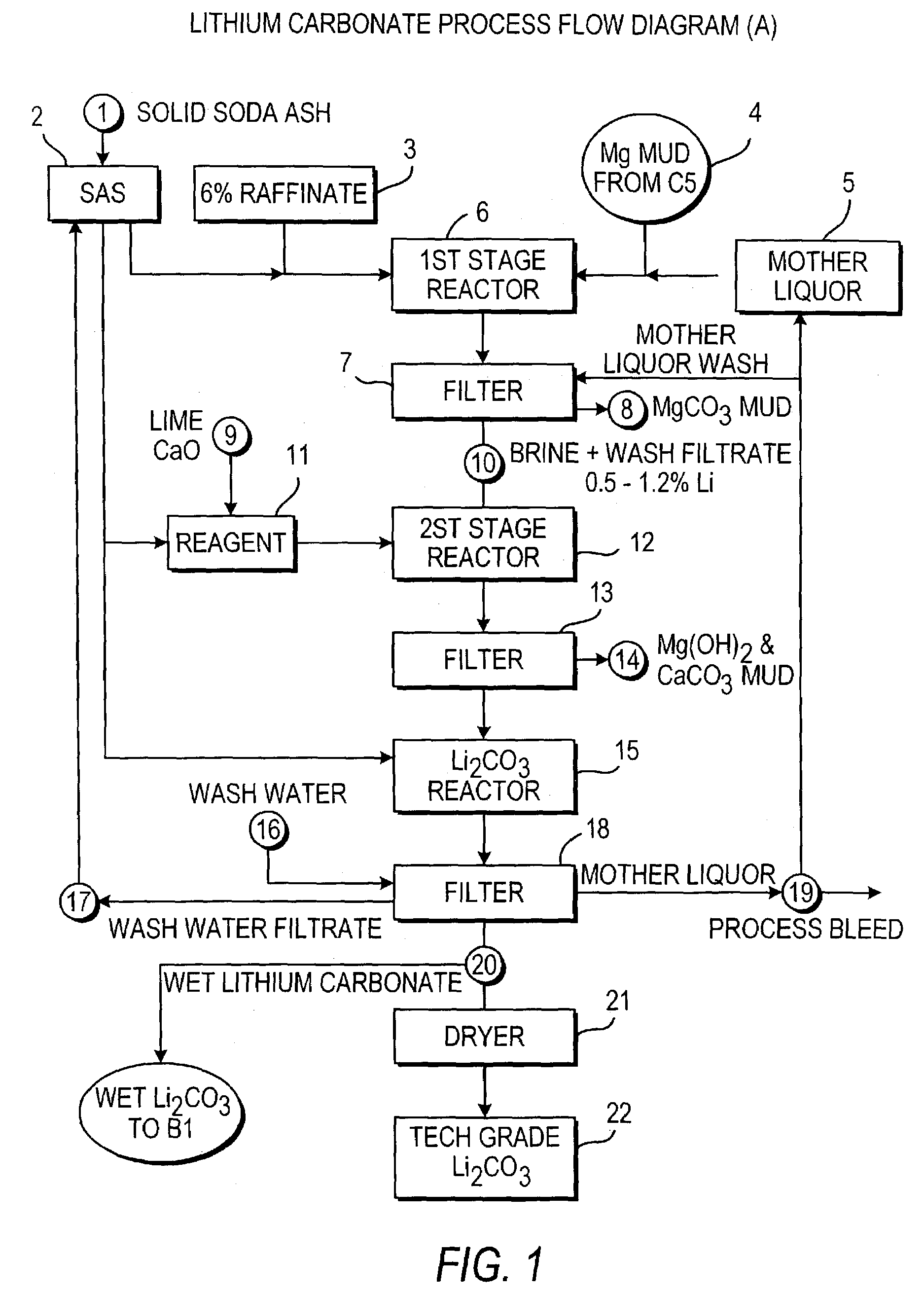

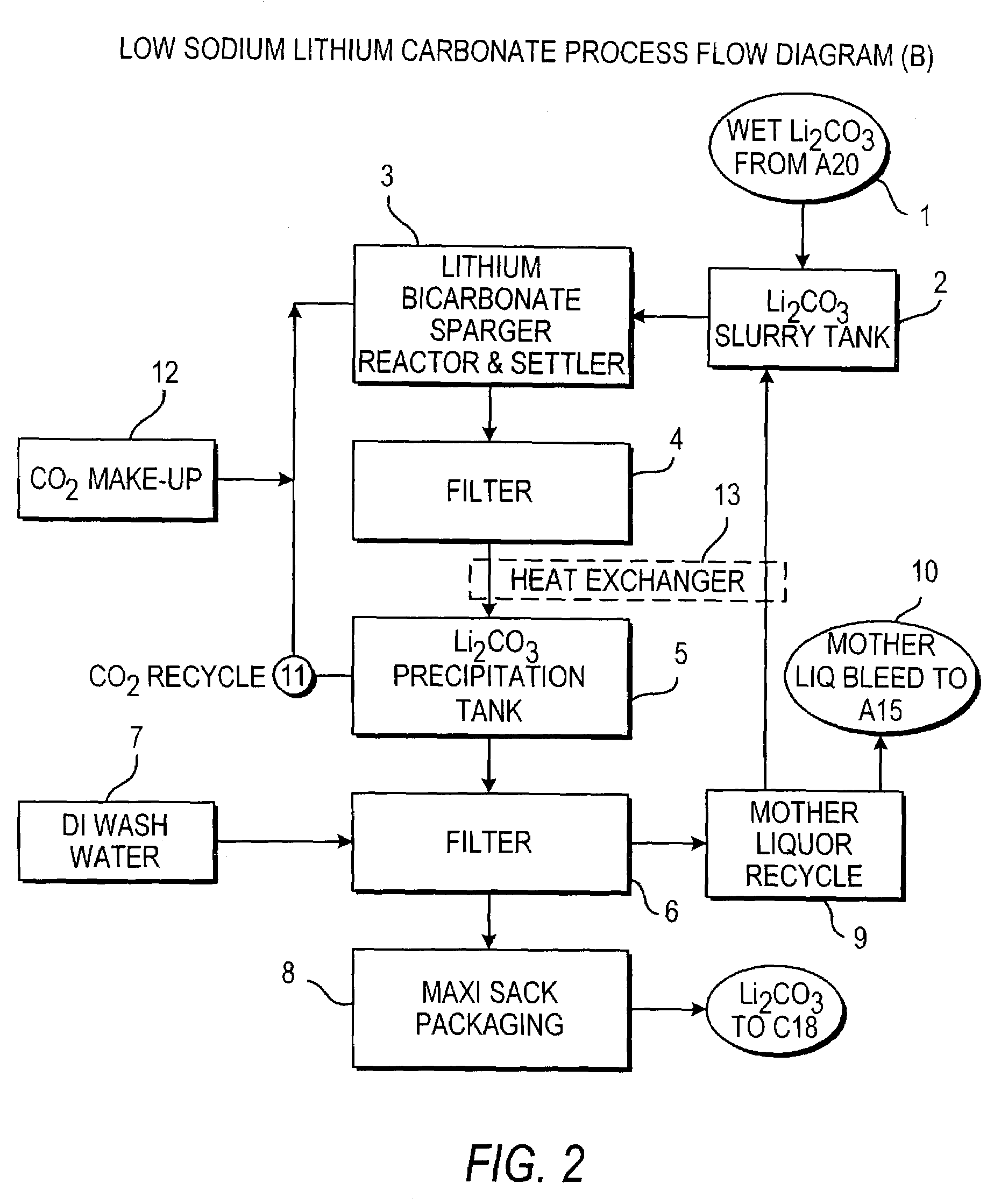

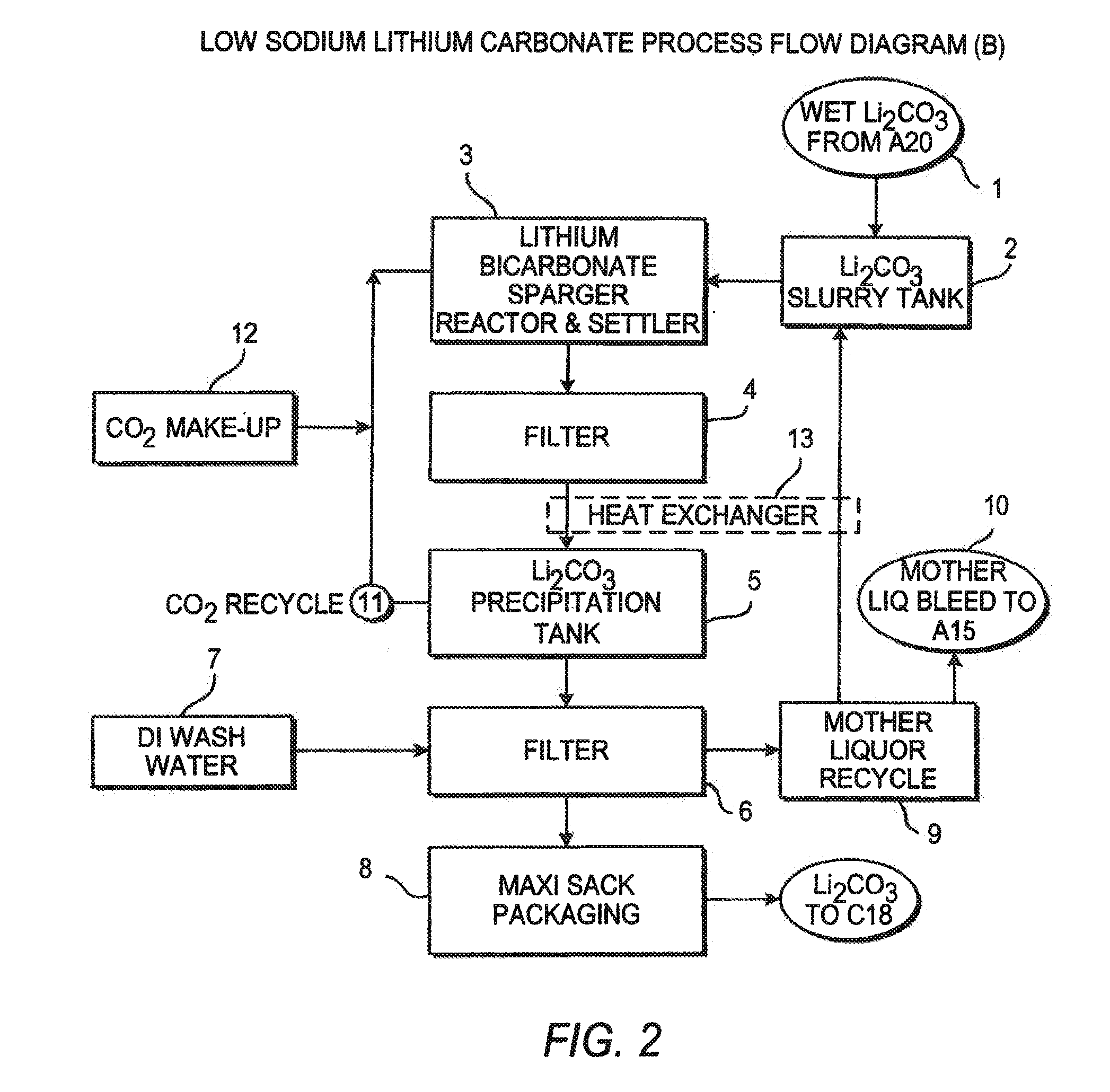

Production of lithium compounds directly from lithium containing brines

InactiveUS20110123427A1Reduce in quantityPromote absorptionVarying alkali metal carbonate water contentRubidium/caesium/francium compoundsLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

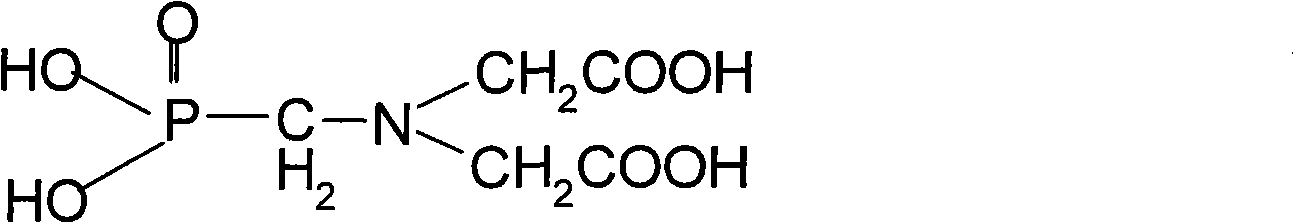

Comprehensive processing method of N-phosphonomethyliminodiacelic acid mother liquor

ActiveCN101348266AHigh degree of automationReduce energy consumptionElectrolysis componentsGroup 5/15 element organic compoundsElectrolysisFiltration

The invention relates to a process for comprehensively treating a mother liquor containing sodium chloride, obtained by the synthesis of an IDA line n-(phosphonomethyl)iminodiacetic acid. The treated sodium chloride meet the quality requirement for producing caustic soda by electrolysis, in particular, the concrete treatment steps comprises: an n-(phosphonomethyl)iminodiacetic acid, an n-(phosphonomethyl)iminodiacetic acid homolog and a dense liquid richly concentrated on the inner side of the film of the sodium filtration film condensed mother liquor are used to recover the n-(phosphonomethyl)iminodiacetic acid, and coarse sodium chloride is obtained by the dehydration crystallization of a weak liquor; the coarse sodium chloride is treated to obtain refined sodium chloride which can be directly used for producing caustic soda by electrolysis. By the comprehensive treatment method of the invention, the n-(phosphonomethyl)iminodiacetic acid of the n-(phosphonomethyl)iminodiacetic acid mother liquor can be effectively recovered, the by-product sodium chloride in the waste water can be fully utilized, thereby thoroughly meeting the requirements on economy, energy conservation and environmental protection.

Owner:JIANGSU YANGNONG CHEM +1

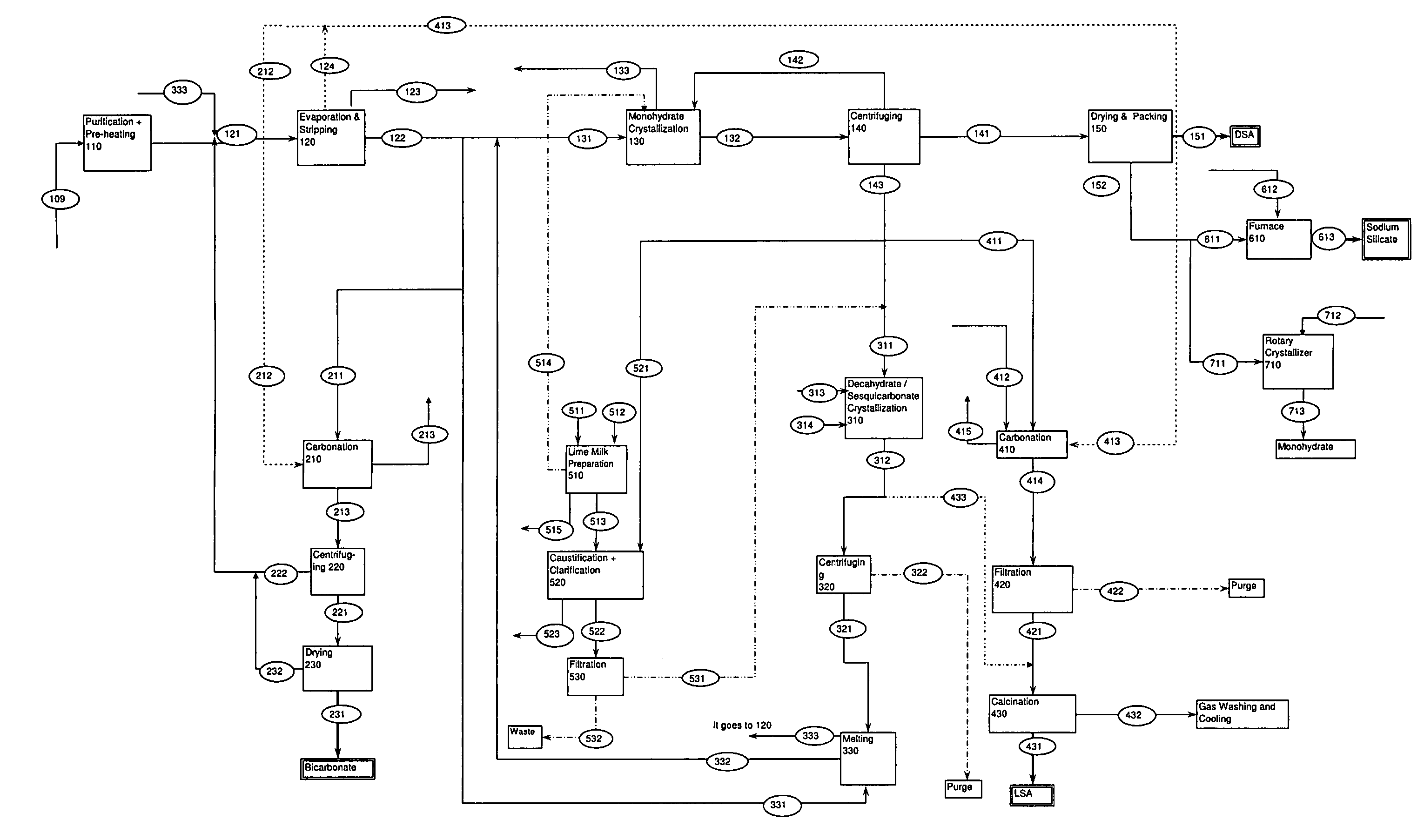

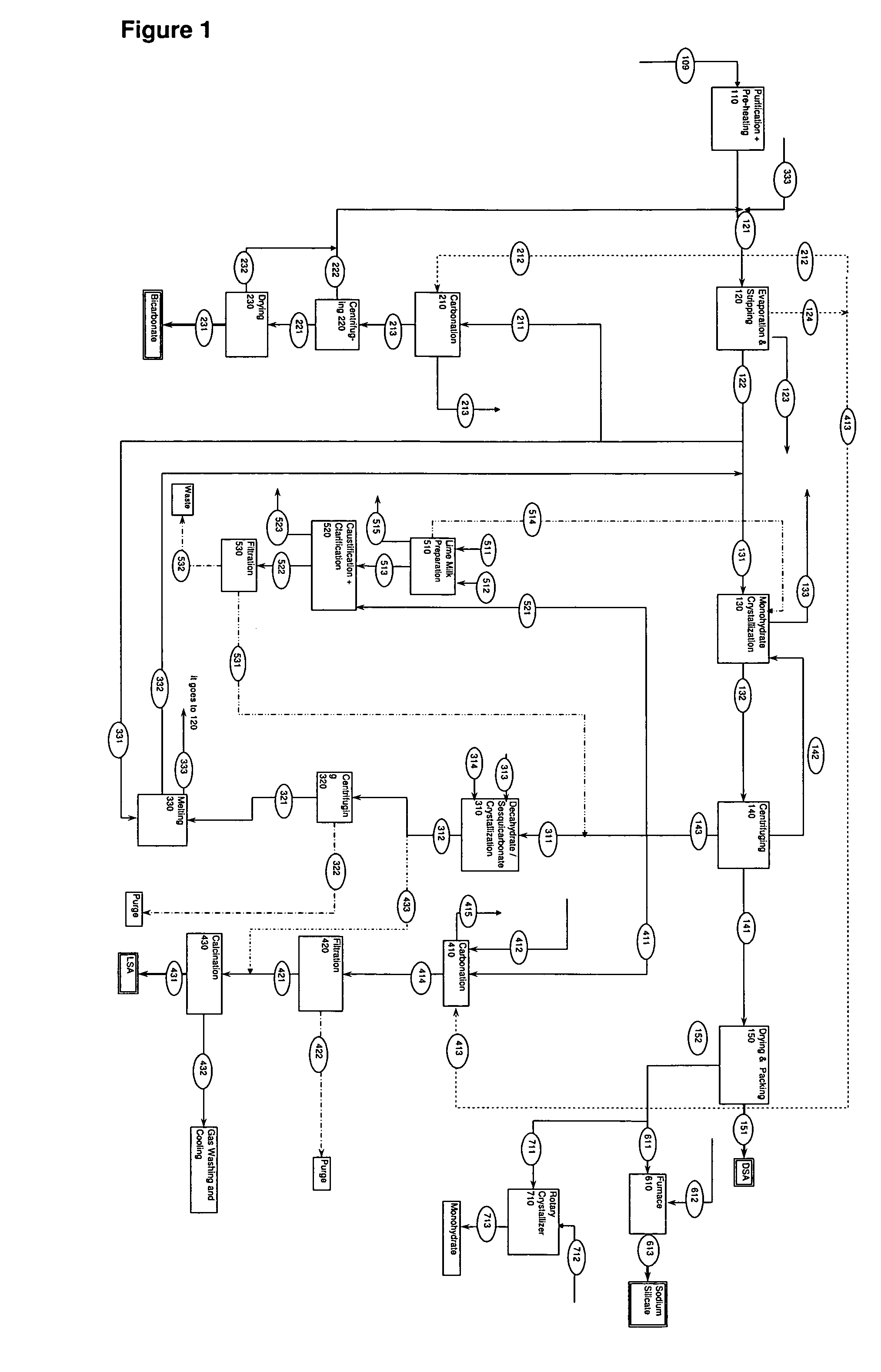

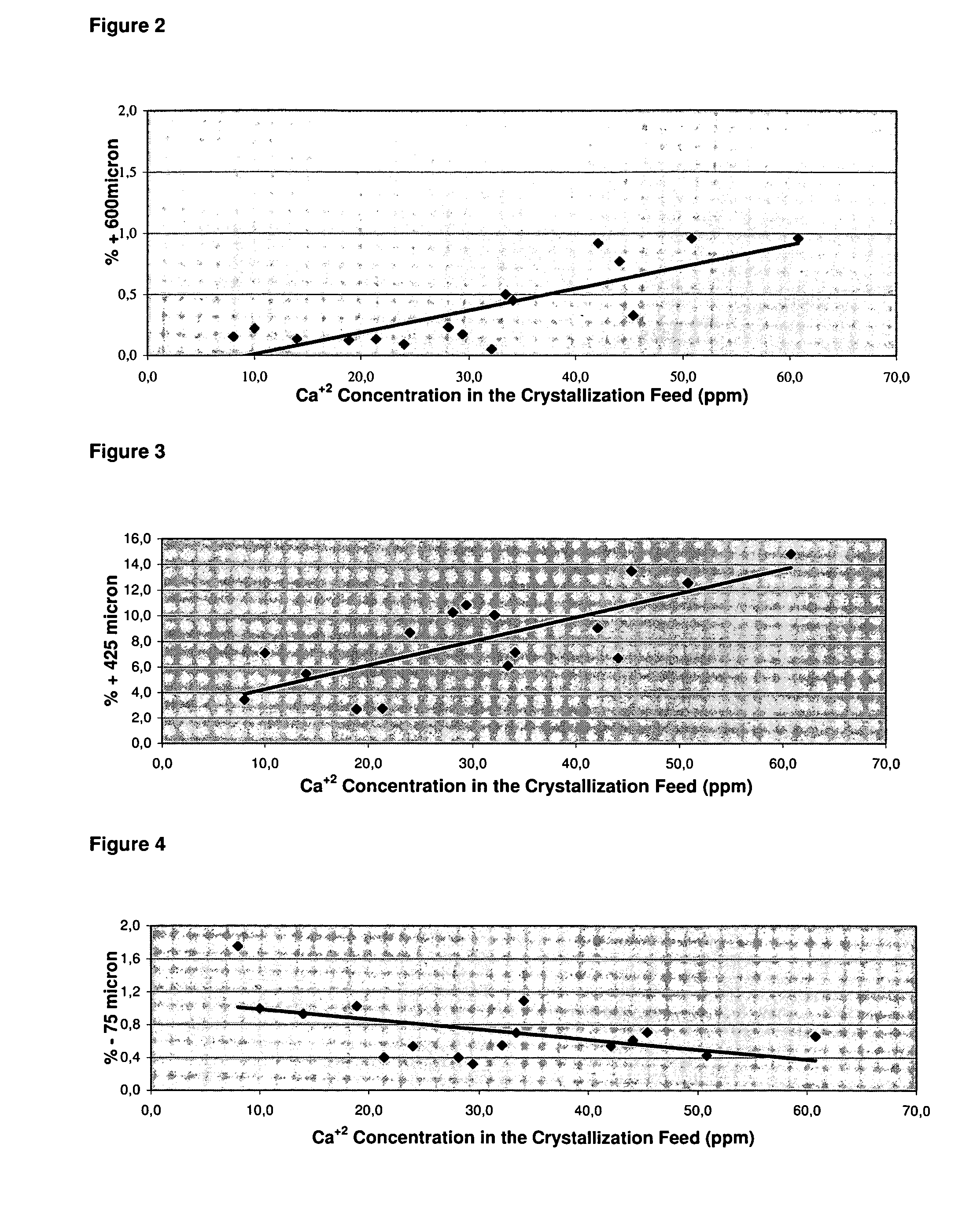

Process for production of dense soda, light soda, sodium bicarbonate and sodium silicate from solutions containing bicarbonate

ActiveUS7507388B2Processing requirementLow production costCrystallization separationAlkali metal silicatesSodium bicarbonateEvaporation

A process related to sodium chemicals production, including the processing of bicarbonate containing solutions obtained by solution mining of trona, nahcolite or wegscheiderite reserves and the lake waters containing bicarbonates, includes the steps of purification, evaporation-decarbonation, crystallization, centrifuging, and drying.

Owner:ETI SODA URETIM PAZARLAMA NAKLIYAT & ELEKTRIK URETIM SANAYI & TICARET A S

Method for recycling impurity salts generated in industrial wastewater treatment

ActiveCN106745076AEasy to handleWide operating conditionsCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesHigh concentrationSulfate radicals

The invention provides a method for recycling impurity salts generated in industrial wastewater treatment. The method comprises the following steps: (1) calcining impurity salts generated in an industrial wastewater treatment process, cooling, dissolving in pure water, and obtaining a high-concentration sodium chloride solution; (2) performing solid-liquid separation, and removing residual organisms in the solution; (3) successively removing sulfate radicals and calcium ions, adjusting the pH of the solution to neutral, and obtaining a high-purity sodium chloride solution; and (4) crystallizing the high-purity sodium chloride solution obtained in step (3), obtaining a sodium chloride crystal product, and washing to obtain the high-purity sodium chloride crystal product. By adopting the method, the effective treatment and recycling of impurity salts generated in the industrial wastewater zero emission process of electric power, petroleum chemistry, coal chemistry and the like; moreover, the method is simple in treatment process and moderate in operation conditions, and is a high-efficiency and stable impurity salt recycling method; and a final product sodium chloride is high in recycling rate and purity.

Owner:DATANG INT CHEM TECH RESINST

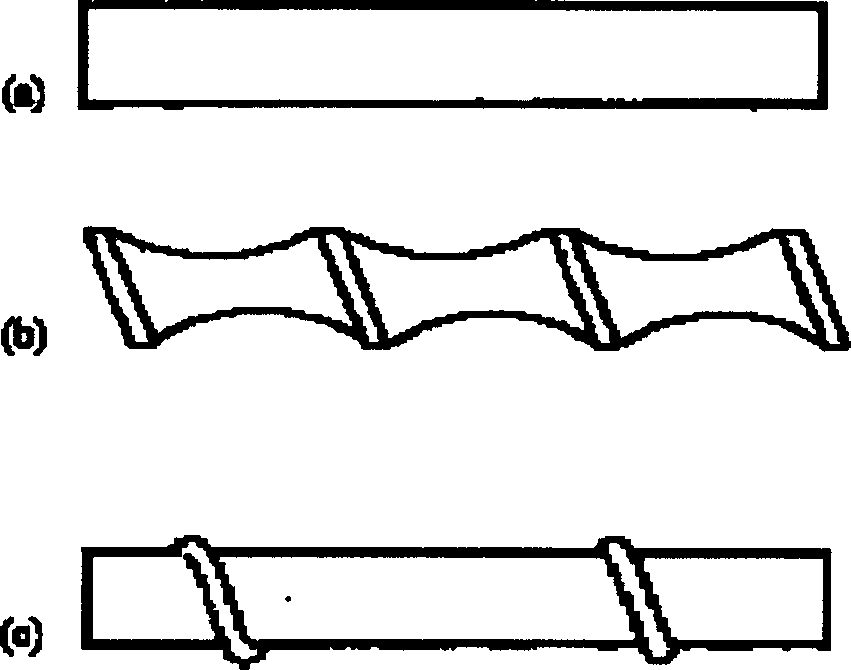

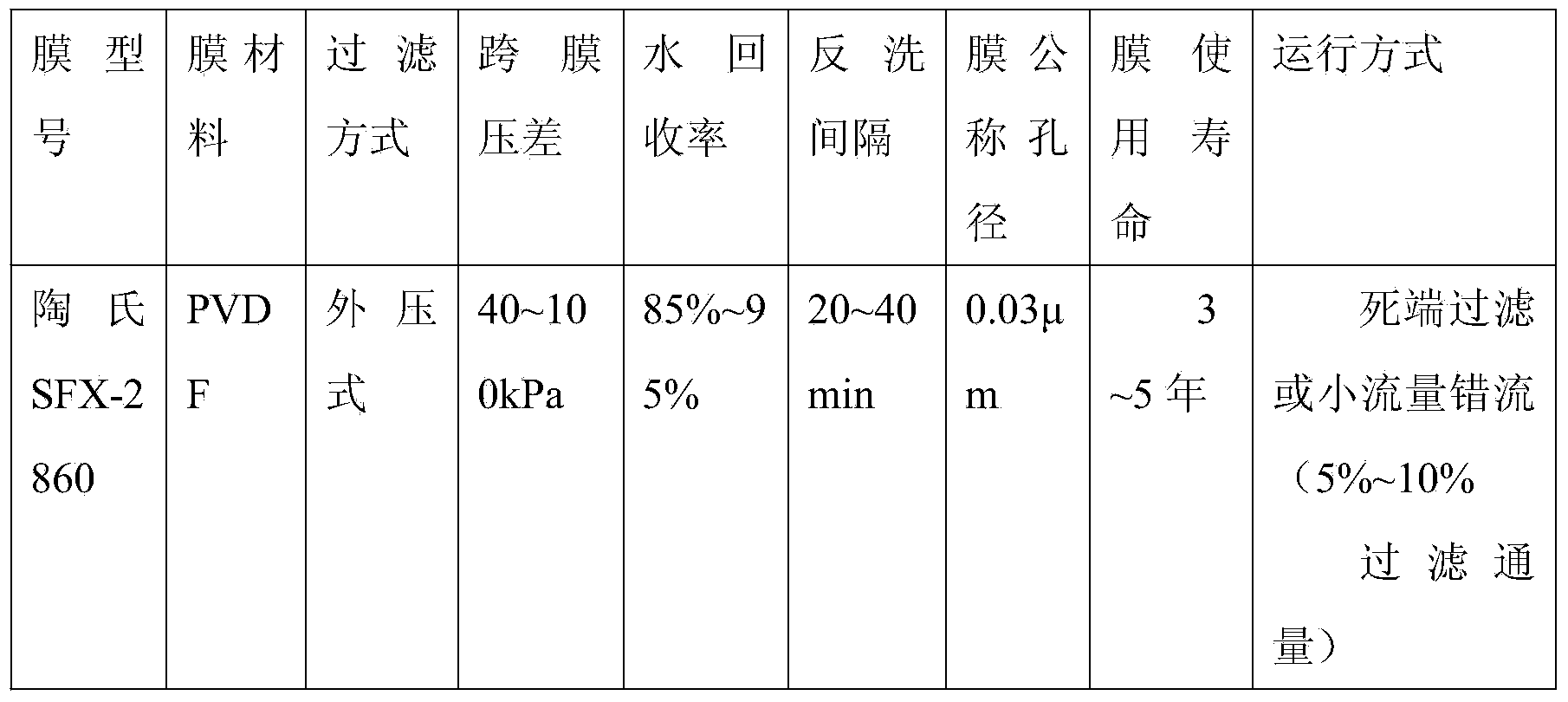

Method of refining salt by membrane filtration

ActiveCN1868878AReduce processing loadImprove permeabilitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisIon exchangeCross-flow filtration

A membrane filter process for refining saline includes such steps as dissolving salt to obtain saturated solution, adding sodium hydroxide, sodium carbonate and barium chloride, reaction to generate magnesium hydroxide, calcium carbonate and barium sulfate, adding coagulating precipitant and oxidant for pre-treating, adsorbing and depositing to remove magnesium hydroxide colloid and part of particles, cross-flow filtering by inorganic membrane, and ion exchange.

Owner:JIANGSU JIUWU HITECH

Method for producing high-quality sodium fluoride from fluorine-containing wastewater as raw material

ActiveCN106830012ARecovery rateRecycling rate due toAlkali metal fluoridesAlkali metal halide purificationNuclear chemistryPrecipitation

The invention discloses a method for producing high-quality sodium fluoride from fluorine-containing wastewater as a raw material. The method comprises the following steps: directly adding excessive sodium carbonate into the fluorine-containing wastewater to completely crystallize and separate fluorine in the solution in a mode of sodium fluoride, or firstly, adding amino into the fluorine-containing wastewater so as to obtain an ammonium fluoride solution, or firstly, precipitating and enriching the fluorine in the fluorine-containing wastewater, secondly, converting a precipitated and enriched product into an ammonium fluoride solution by using an ammonium salt solution, adding excessive sodium carbonate into the ammonium fluoride solution to completely crystal and separate the fluorine in the mode of sodium fluoride, and filtering so as to obtain sodium fluoride filter cakes and a post fluorine precipitation liquid; and washing the sodium fluoride filter cakes by using the ammonium fluoride solution, drying so as to obtain a high-quality sodium fluoride product of which the purity is up to 99.25% or greater, crystallizing the post fluorine precipitation liquid to recycle sodium carbonate in the post fluorine precipitation liquid, further desalting a sodium carbonate crystallization mother liquid, and recycling reclaimed water. The method has the advantages of being simple and convenient to operate, high in fluorine recycling rate, low in production cost, good in sodium fluoride product quality, free of fluorine-containing waste and the like.

Owner:CENT SOUTH UNIV

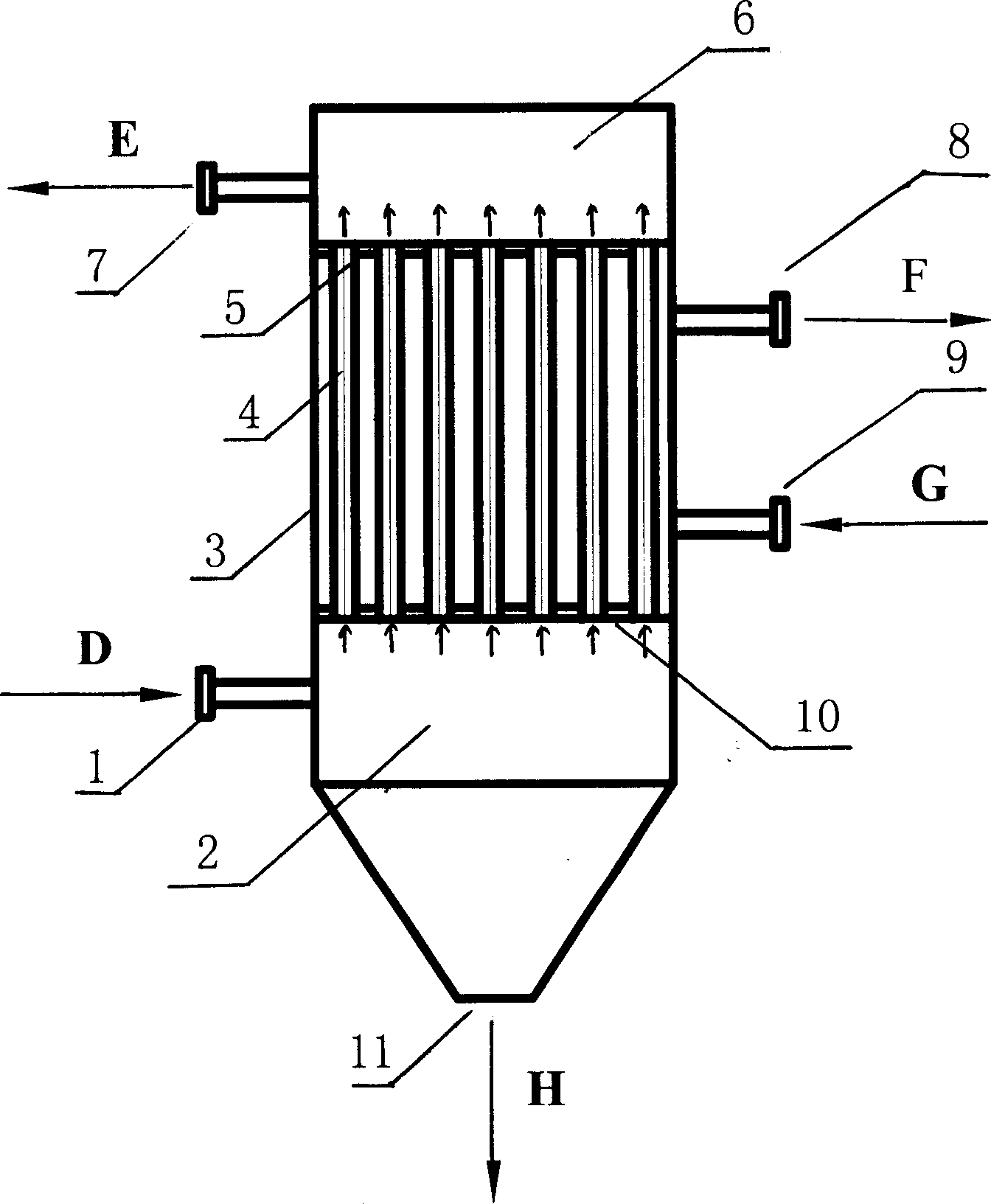

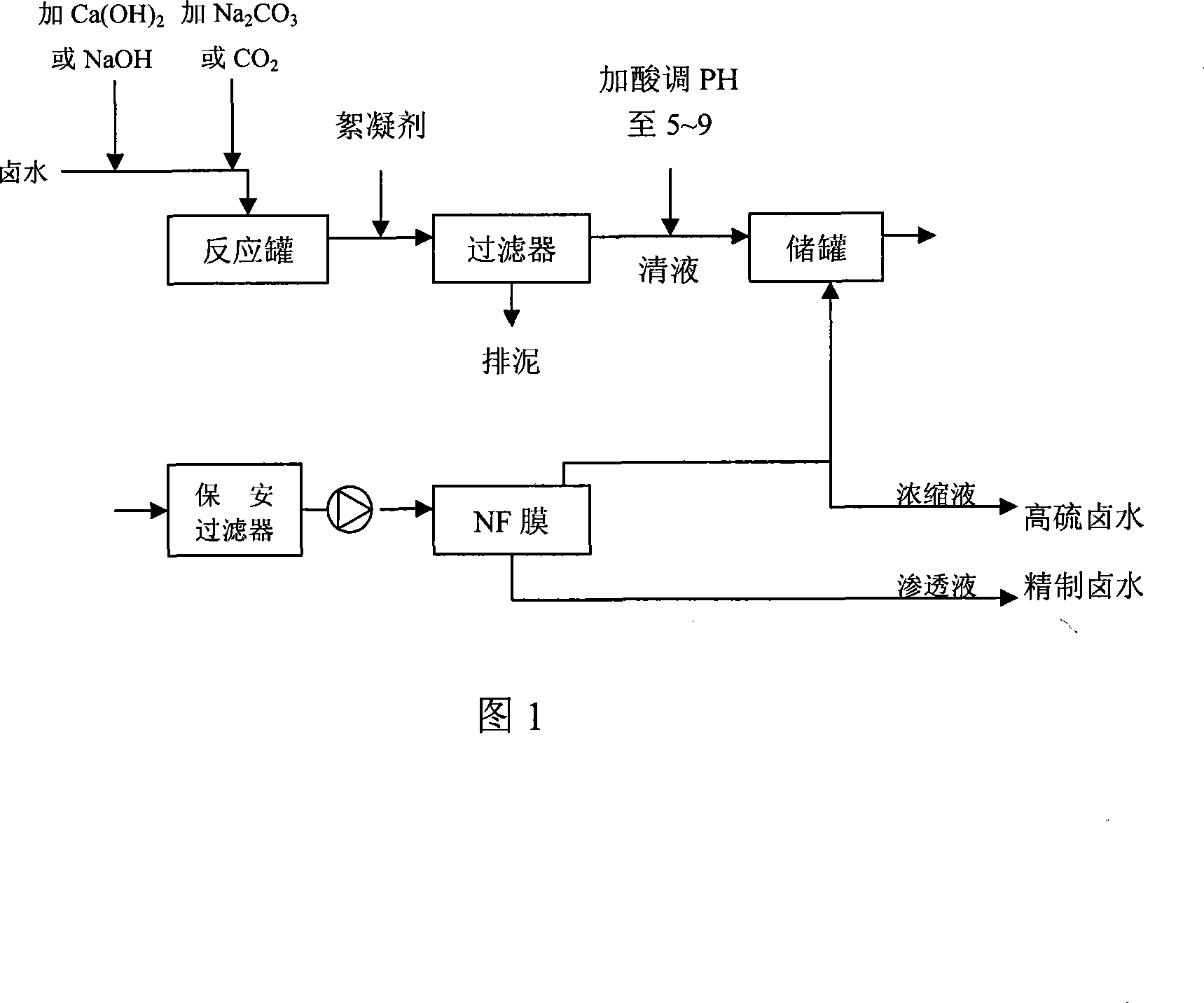

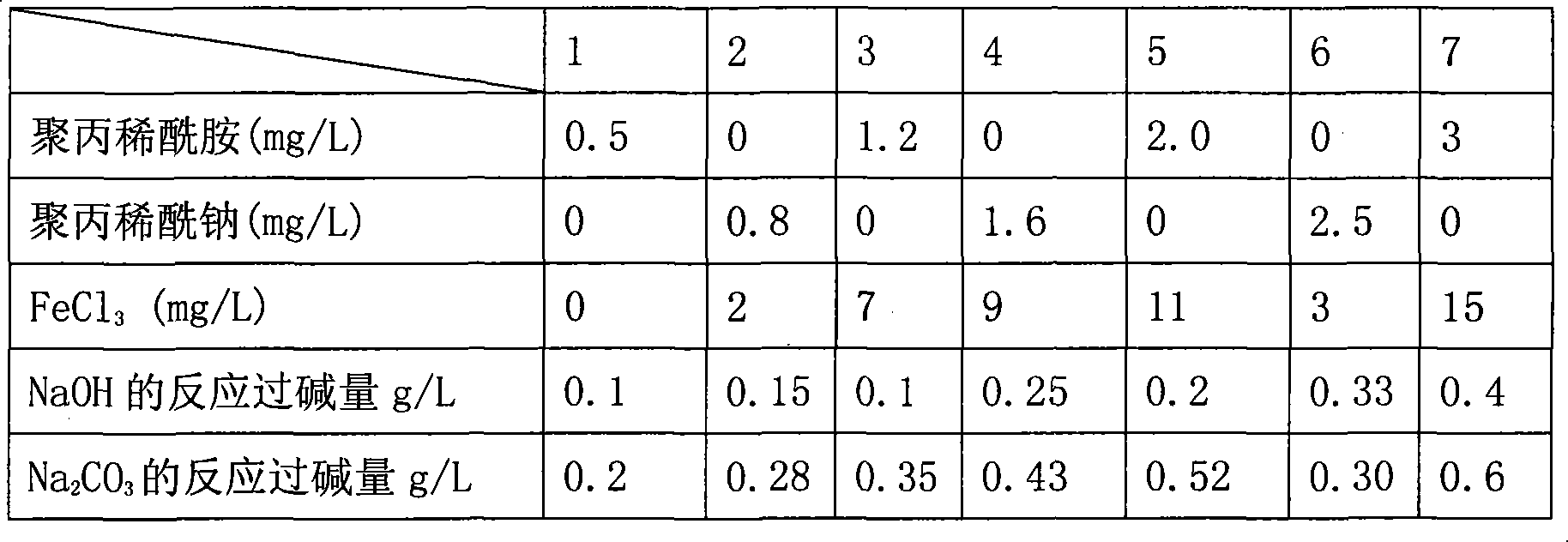

Advanced treatment technique for brine

ActiveCN101214975AReduce pollutionGuaranteed brine qualityAlkali metal chloridesAlkali metal halide purificationSaline waterHigh concentration

The invention discloses a process of advanced treatment of brine, which is characterized by pretreating brine to enable the concentration of Ca2+, Mg2+ and SS to be smaller than 1.0mg / L, then adjusting the pH value of the brine to 5.0-9.0 and filtering by using a filtering unit of nano filter films. In the process of treatment of brine, multivalent ions and Na2SO4 are separated from saline water by employing the nano filter films, wherein the saline water with high concentration of Na2SO4 is used to produce solid NaCl and Na2SO4, and refined brine with low concentration of Na2SO4 is directly supplied for chlor-alkali plants to use. Then Na2SO4 can be recycled as a resource without consuming BaCl2, brine purification systems are saved, and affection of Ba2+ upon ionic membranes is eliminated.

Owner:SHANGHAI CN WATER

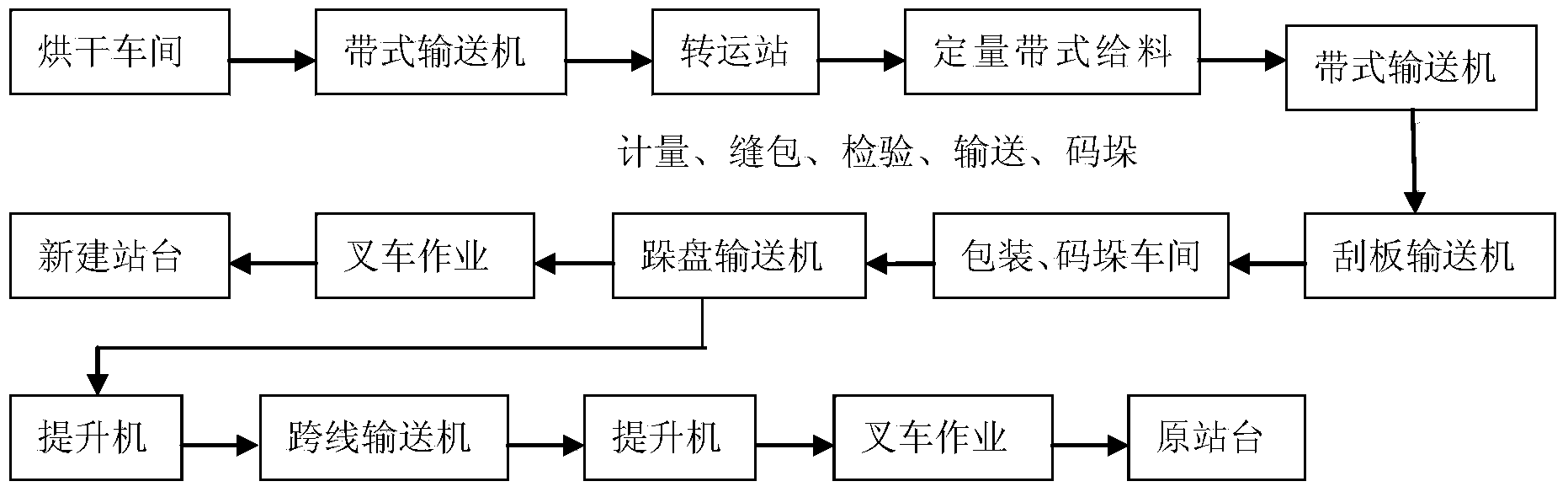

High-grade potassium chloride production system and method thereof

ActiveCN104058427ARaise the gradeReduce dosageAlkali metal chloridesAlkali metal halide purificationChemistryLow sodium

The invention discloses a high-grade potassium chloride production system and a method thereof. The system comprises a raw ore screening and concentrating system, a size mixing system, a floatation system, a low sodium concentration and dehalogenation system, a cold crystallization and thick potassium screening system, a thick potassium concentration and dehalogenation system, a refined potassium washing and dehalogenation system, a piling and filtering storage stock ground system, a breaking and conveying system and a drying cooling, packing, stacking and line crossing conveying system, and all the systems are sequentially connected and are arranged in a three-dimensional mode. Materials enter a next system in a self-flowing mode. An automatic dosing, automatic water adding and dehalogenation device is adopted, a spiral screen type centrifugal machine is used for replacing a horizontal belt type filter, and other technology improvements are adopted, so that the potassium chloride grade is improved to 98 percent from 95 percent, the piling and filtering technology is adopted in the system so that the natural gas using amount can be saved, production operation is convenient, and equipment operation is stable.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

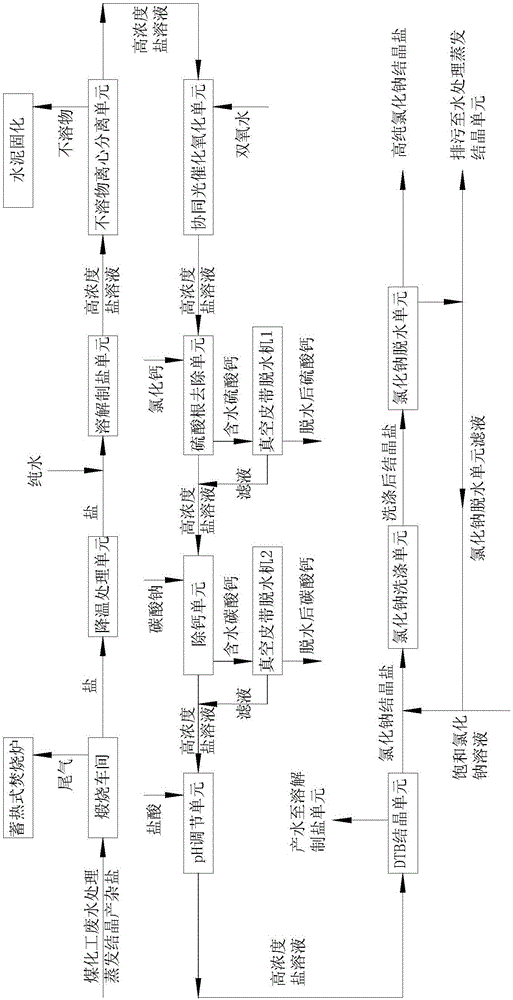

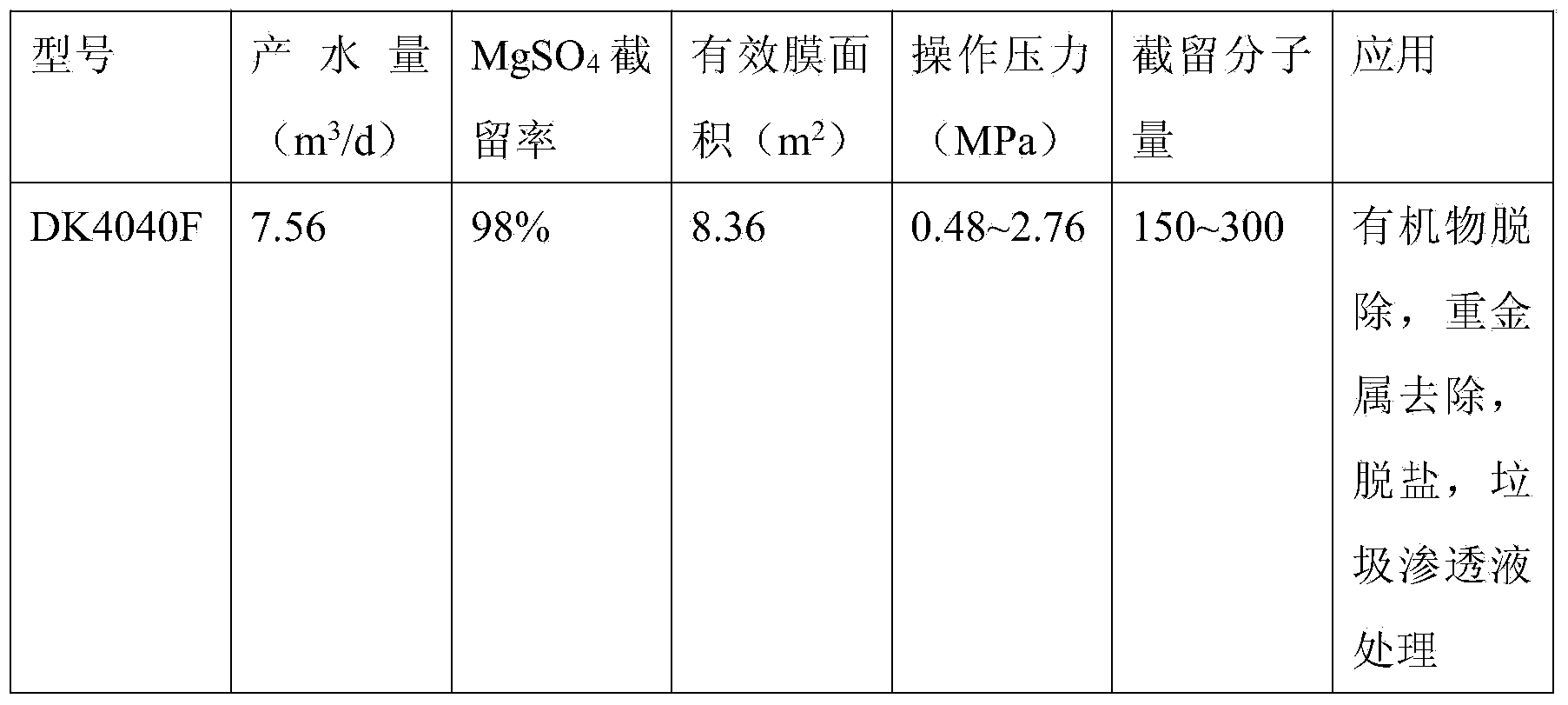

Method for preparing industrial salt through separation, evaporation and crystallization of coal chemical strong brine

ActiveCN104071808AWill not cause accumulationTake advantage ofAlkali metal chloridesAlkali metal halide purificationFiltrationUltrafiltration

The invention relates to a method for preparing industrial salt with coal chemical strong brine, particularly to a method for preparing the industrial salt through separation, evaporation and crystallization of the coal chemical strong brine, and aims to solve the problems that secondary pollution exists and resources are not recycled in existing coal chemical strong brine treatment processes. The method comprises the steps as follows: 1, adding lime milk, a coagulant and a magnesium agent into the coal chemical strong brine, and feeding the coal chemical strong brine into a clarifying tank or a coagulative precipitation tank for chemical precipitation treatment; 2, adjusting the pH; 3, performing ultra-filtration treatment; 4, performing nano-filtration treatment; 5, performing single-effect evaporating crystallization or quadruple-effect evaporating crystallization to obtain the industrial salt. The method is used for treating the coal chemical strong brine and preparing the industrial salt from the coal chemical strong brine.

Owner:中煤西安设计工程有限责任公司

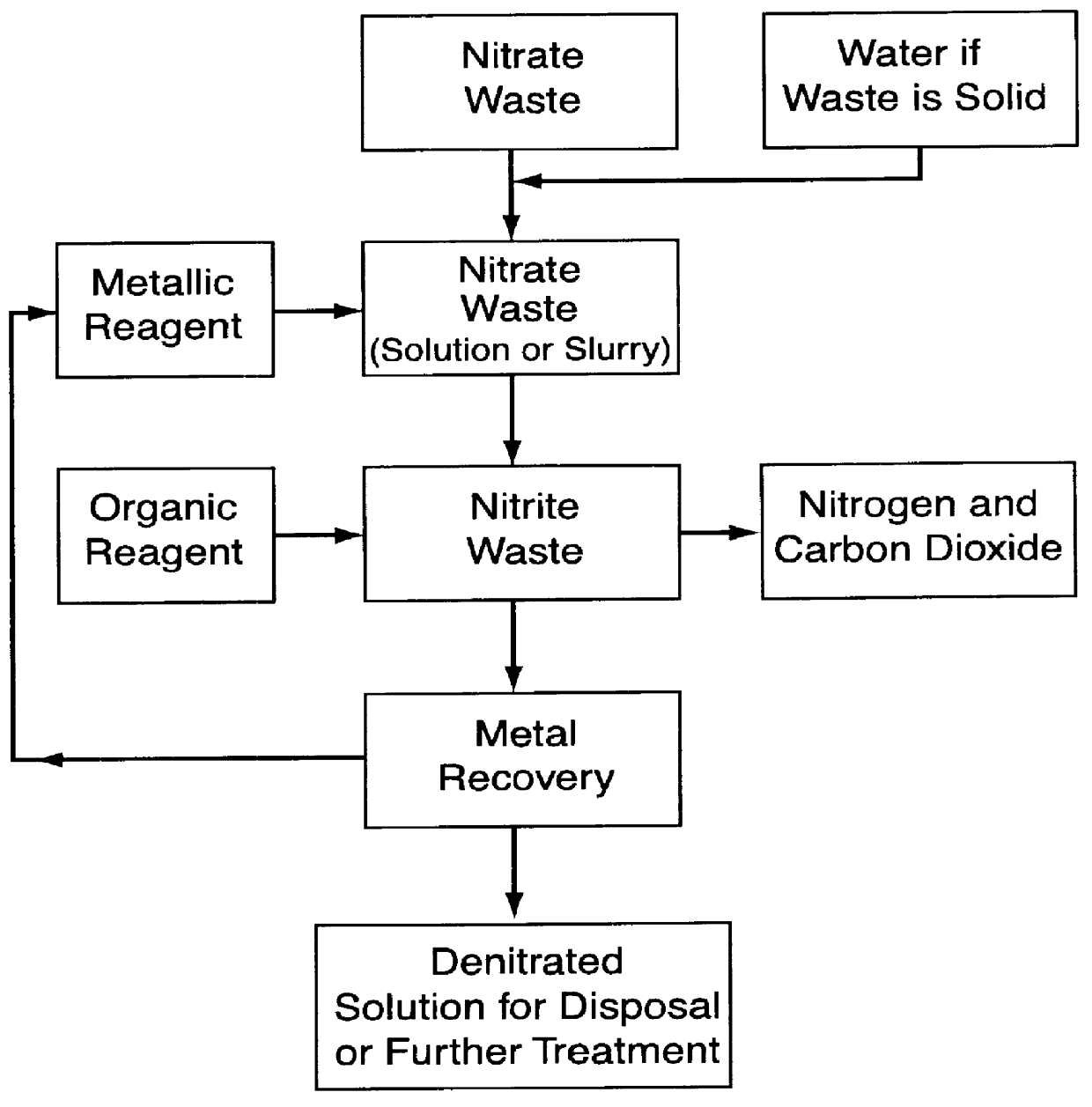

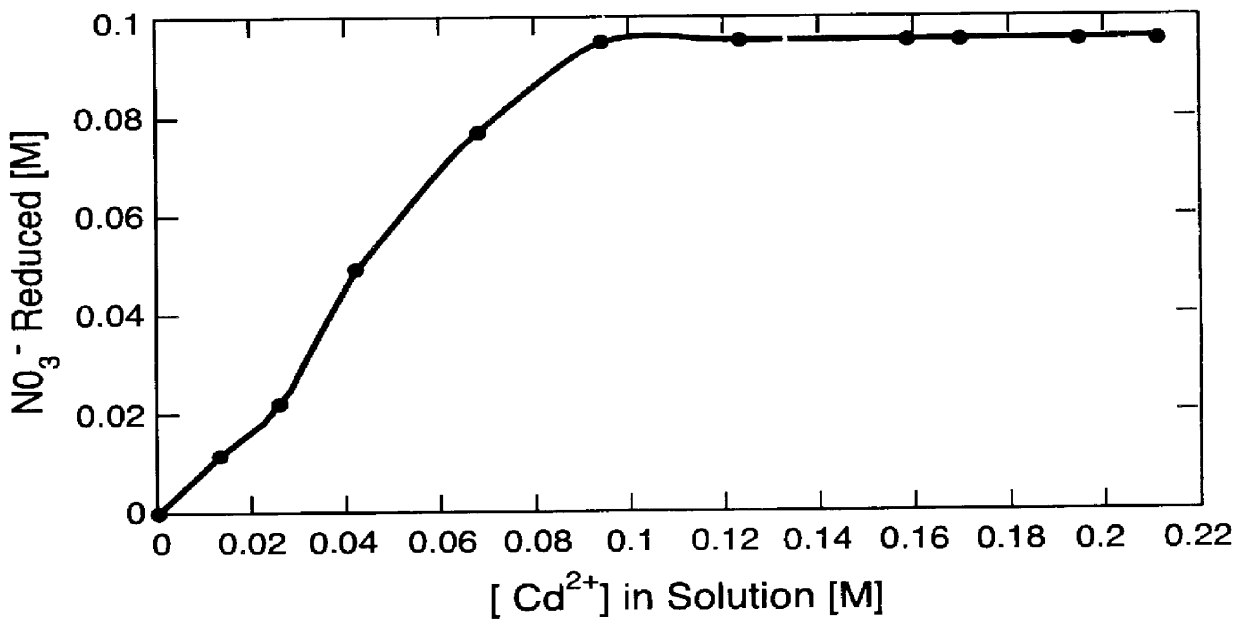

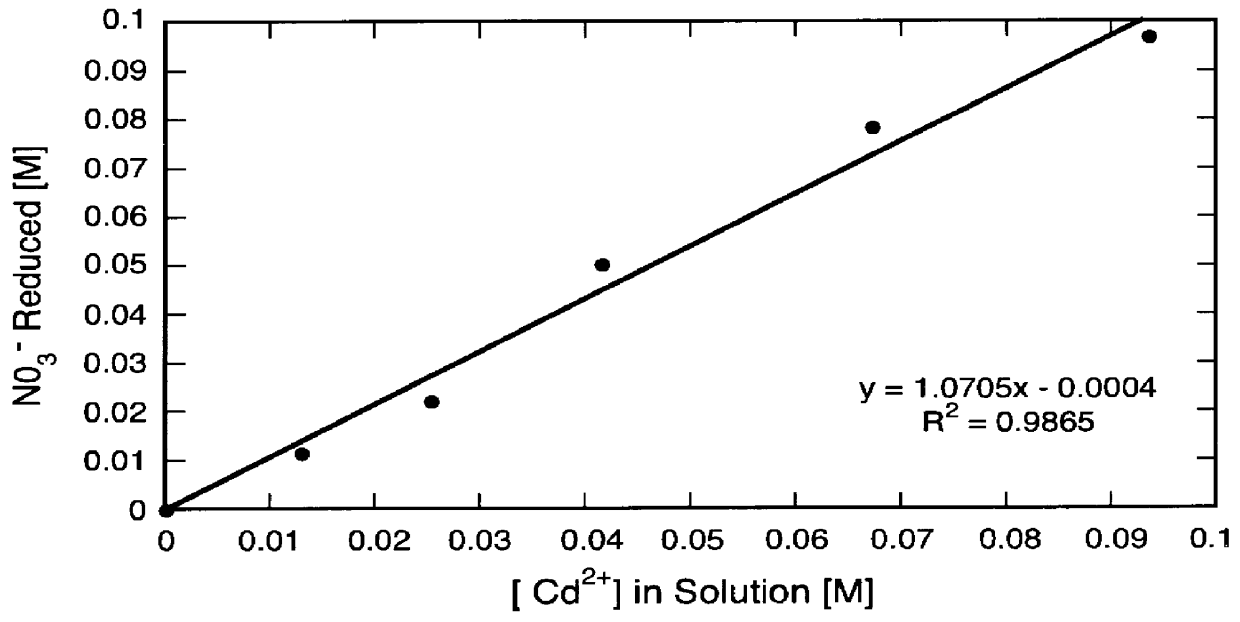

Nitrate reduction

InactiveUS6030520APhotography auxillary processesFrom normal temperature solutionsNitriteMetal catalyst

Nitrates are reduced to nitrogen gas by contacting the nitrates with a metal to reduce the nitrates to nitrites which are then contacted with an amide to produce nitrogen and carbon dioxide or acid anions which can be released to the atmosphere. Minor amounts of metal catalysts can be useful in the reduction of the nitrates to nitrites. Metal salts which are formed can be treated electrochemically to recover the metals.

Owner:LOS ALAMOS NATIONAL SECURITY

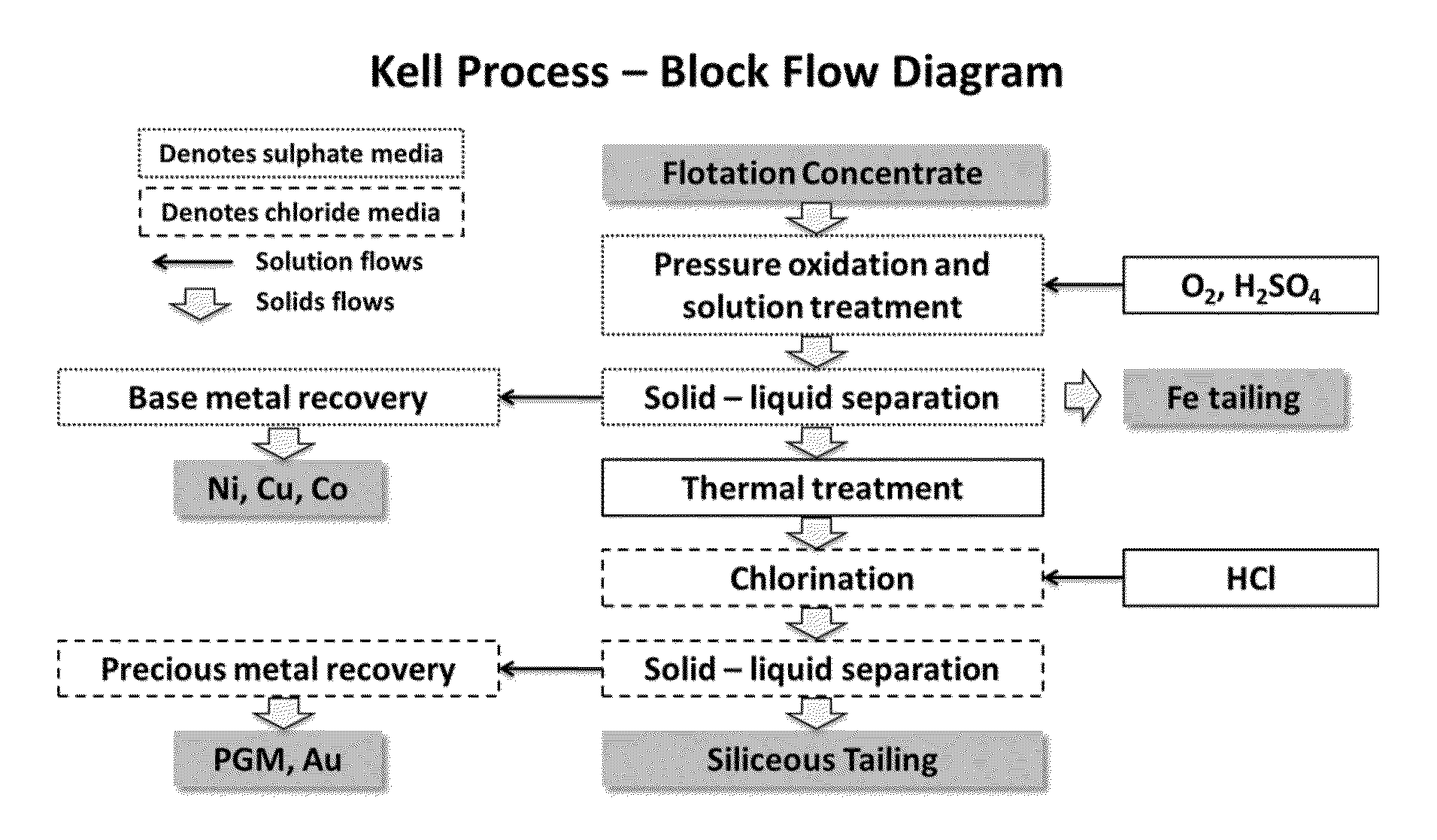

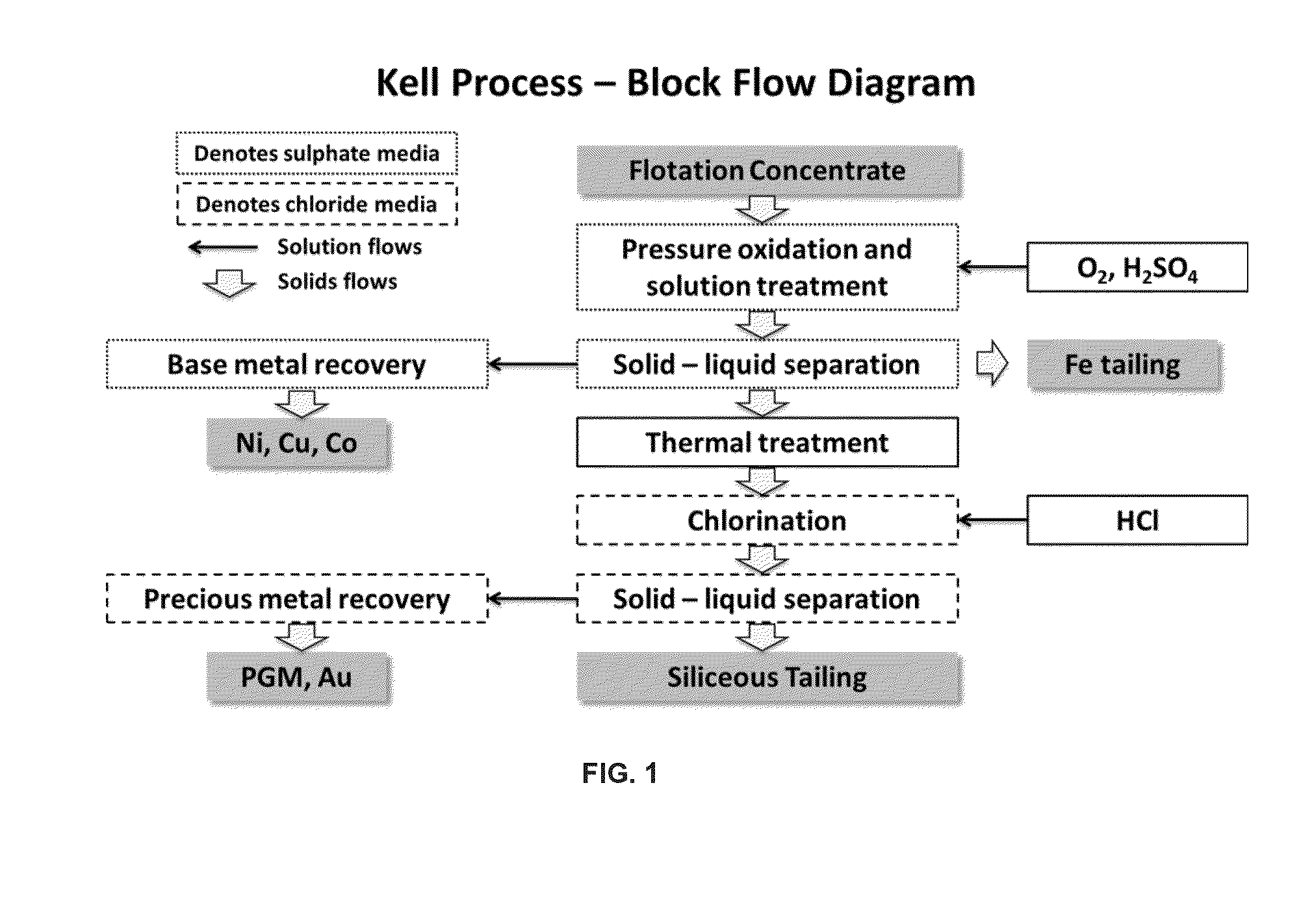

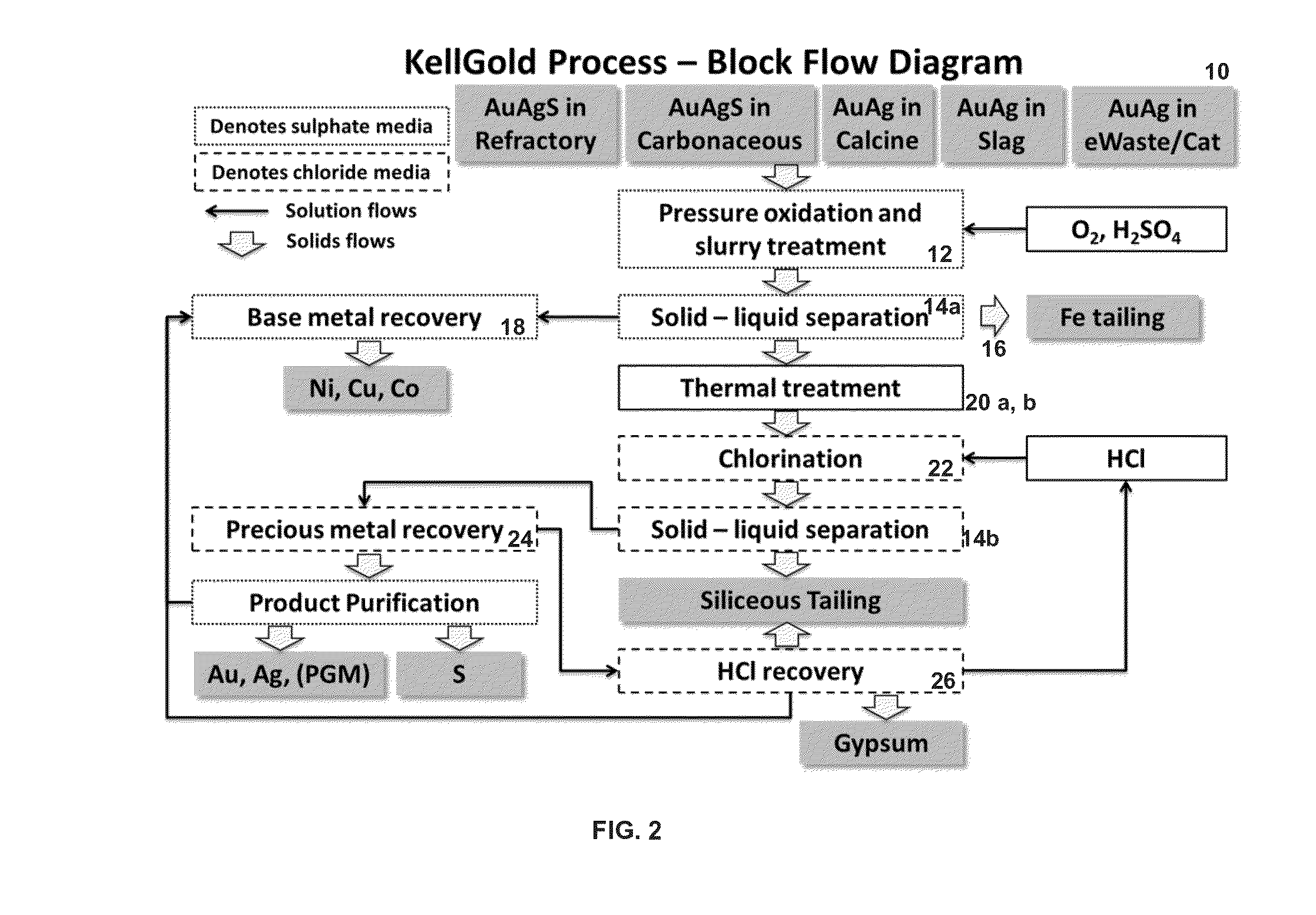

Treatment process for extraction of precious, base and rare elements

ActiveUS20160145714A1Low recovery ratePolycrystalline material growthChlorine/hydrogen-chloride purificationTrace elementRefractory

This invention describes a hydrometallurgical process for the recovery and separation of valuable elements, in particular gold and silver, from a feed material comprising a refractory, intractable or otherwise poorly responding to conventional treatment routes ores, concentrates and other materials. In particular, the process is a process integrated into one or more existing value element extraction processes.

Owner:LIFEZONE

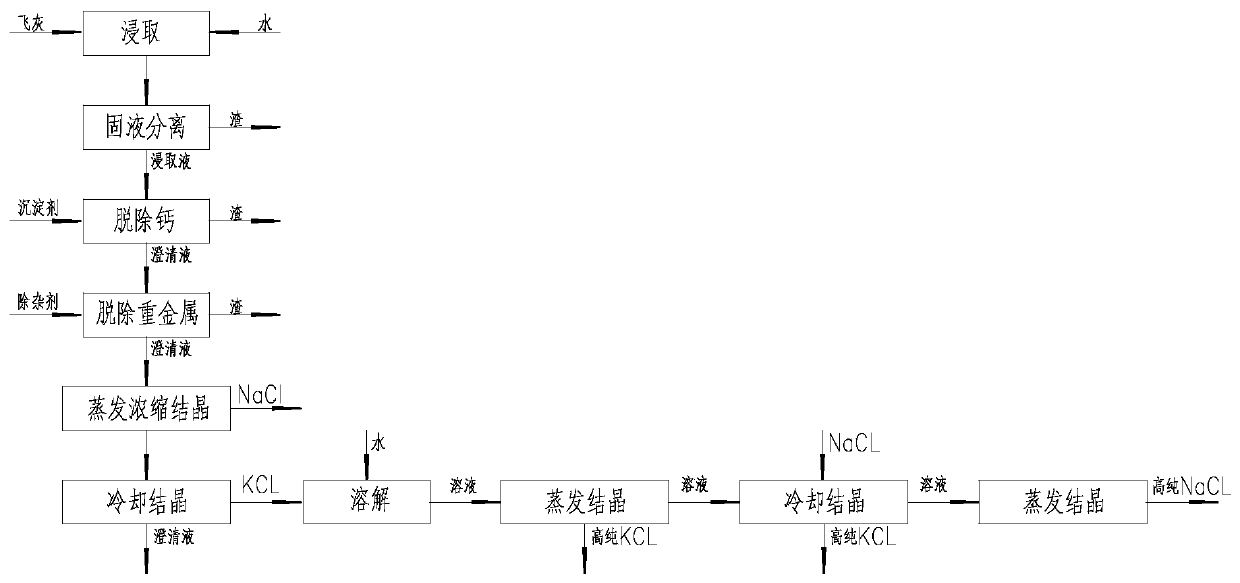

Method for producing potassium salt and sodium salt by using waste incineration fly ash

ActiveCN110040748AHigh purityEfficient use ofAlkali metal halide purificationTechnical gradeSodium salt

The invention discloses a method for producing potassium salt and sodium salt by using waste incineration fly ash, comprising the following steps: extracting waste incineration fly ash with water to obtain an extract; removing calcium ions and heavy metal impurities in the extract, and adjusting the pH of the solution to 6-8; heating and evaporating to concentrate the solution obtained in the previous step until crystallization, immediately filtering to obtain crystals sodium chloride, and naturally cooling the filtrate to room temperature for crystallization to obtain crystals crude potassiumchloride; dissolving the crude potassium chloride in water with a mass ratio of the crude potassium chloride to water is 1:1-1:1.9, heating and evaporating the solution until crystallization, and immediately separating the solid and liquid to get crystals pure potassium chloride and filtrate; and supplementing sodium chloride into the filtrate obtained in the previous step, cooling for crystallization, and filtering to obtain crystals pure potassium chloride. The invention can separate sodium salt and potassium salt in fly ash washing wastewater, and obtain high purity or industrial grade ofsodium chloride and potassium chloride crystals.

Owner:SINOMA INT ENG

Method and device for electroextraction of heavy metals from technological solutions and wastewater

InactiveUS6887368B2Reduced heavy metal levelLess energy consumptionFrom normal temperature solutionsLiquid separation by electricityConductive materialsMaterials science

The basic principles of the method for heavy metals electroextraction from technological solutions and wastewater includes pretreating to remove Chromium-6 and high concentrations of heavy metals and periodically treating in a six-electrode bipolar cylindrical electroreactor made of non-conducting material to achieve lower accepted levels of impurities. Six cylindrical steel electrodes form two triode stacks and are fed with three-phase alternating current of commercial frequency (50-60 Hz), which can be pulsed. Each phase of the three-phase current is connected to three electrodes of one triode stack or in parallel to two triode stacks. The parallel connection of three-phase current to two triode stacks is performed so that the same phase of the three phase current is connected in parallel with each two opposite electrodes of six electrodes located along the periphery, or with two adjacent electrodes. A bipolar stationary aluminum electrode is situated in the inter-electrode space. In one of the embodiments, the bipolar electrode is made of a perforated heat-resistant plastic container filled with secondary aluminum and duralumin scrap. In another embodiment, the bipolar electrode of aluminum or duralumin scrap may be made without a perforated container and is placed in the inter-electrode space as a bulk scrap. In this case, to prevent shorts, each of six steel electrodes is placed in isolated perforated plastic shell with holes of 5 mm in diameter. Non-ferrous metals are extracted in a form of ferrite-chromites, and aluminates as well as hydroxyl salts deposited in the inter-electrode space without electrolysis deposits on electrodes. Deposits are separated from solution by known methods of filtration.

Owner:URAL PROCESS ENG +2

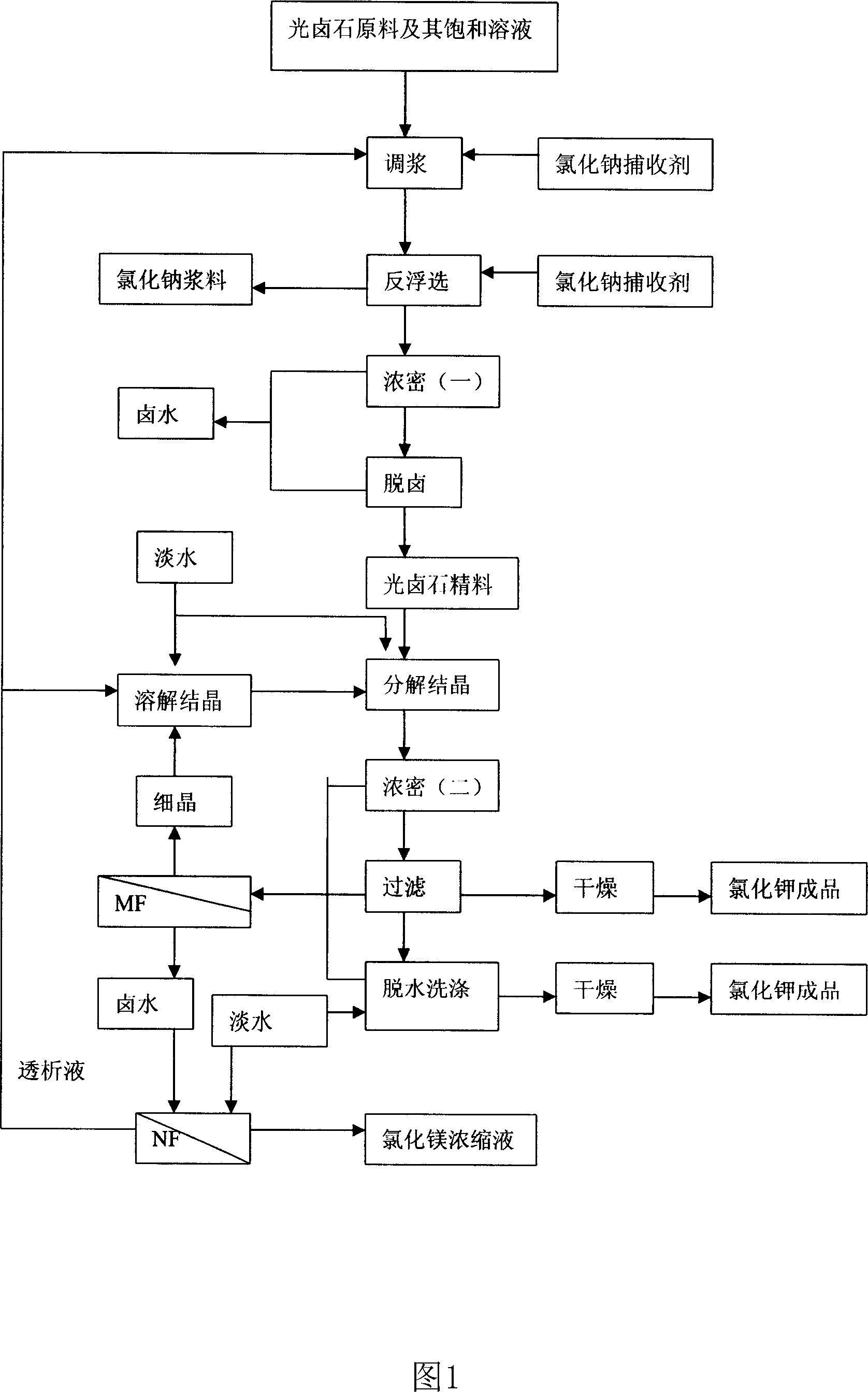

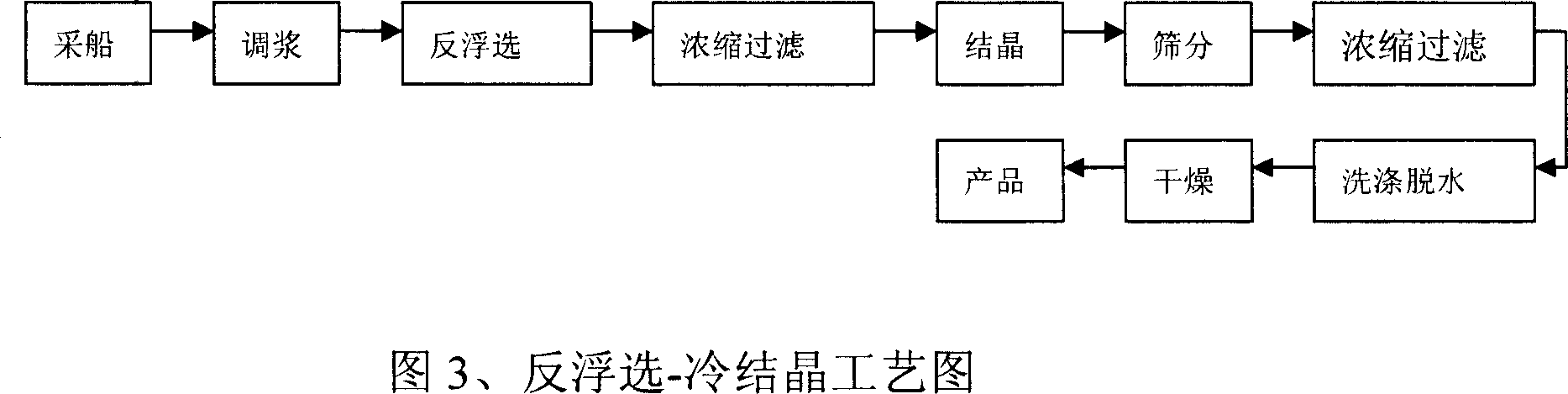

Reverse floatation-cold crystallization process for producing potassium chloride

InactiveCN101066769ALarge particlesQuality improvementAlkali metal chloridesAlkali metal halide purificationGranularityFresh water

The reverse floatation and cold crystallization process for producing potassium chloride includes the following four steps: 1. reverse floatation to prepare low sodium carnallite; 2. decomposing low sodium carnallite in fresh water, crystallizing, centrifugally filtering and drying to prepare potassium chloride product; 3. microporous membrane filtering to recover fine potassium chloride crystal, dissolving, returning to potassium chloride crystallizer for secondary crystallization to prepare potassium chloride; and 4. returning the bittern for reuse. The process has potassium chloride yield up to 80 %, great potassium chloride crystal granularity and high product quality, and is suitable for industrial production.

Owner:陈颖

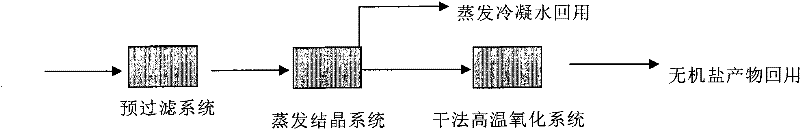

Method for recovering organic effluent brine

InactiveCN102633398AIncrease expansionIncrease its valueElectrolysis componentsMultistage water/sewage treatmentFiltrationEvaporation

The invention discloses a method for recovering organic effluent brine. The method comprises the following steps: introducing organic effluent brine containing inorganic salts and organic matter into a prefiltration system, an evaporation crystallization system and a dry-method high temperature oxidation reaction system, after filtration, evaporation, and oxidation treatment, allowing the obtained inorganic salt product to be dissolved to become saturated brine, wherein the total organic carbon TOC is less than 10 ppm. With the method of the invention, more than 90% of water and inorganic salts can be recovered, and the zero discharge standard for waste water is basically reached; the recovery rate for the recycling of organic effluent brine is effectively increased; and great benefits are generated for environment protection and resource recovery; additionally, the obtained inorganic salt product can be used as an industrial raw material for recycling in ionic membrane electrolytic devices.

Owner:凯膜过滤技术(上海)有限公司

Production method of chemical reagent potassium chloride

InactiveCN105668591AHigh recovery rateHigh purityAlkali metal chloridesAlkali metal halide purificationFiltrationPotassium

The invention discloses a production method of the chemical reagent potassium chloride, which comprises: (1) raw ore screening; (2) slurry mixing; (3) flotation; (4) low-sodium concentration and dehalogenation; Crystallization and screening of crude potassium; (6) concentration and dehalogenation of crude potassium; (7) washing and centrifugal dehydration; (8) re-dissolving; (9) two-stage filtration; (10) re-crystallization; (11) dehydration and separation. The process of the present invention not only increases the recovery rate of potassium chloride to over 62%, but also effectively removes soluble impurities and insoluble matter in the crude potassium chloride product with a purity of 95%, thereby increasing the purity of the potassium chloride product to over 99%. The process of the invention can be operated continuously, has no pollution to the environment, and is easy to realize industrialization.

Owner:SHANGHAI GUANCHUN FINE CHEM TECH CO LTD

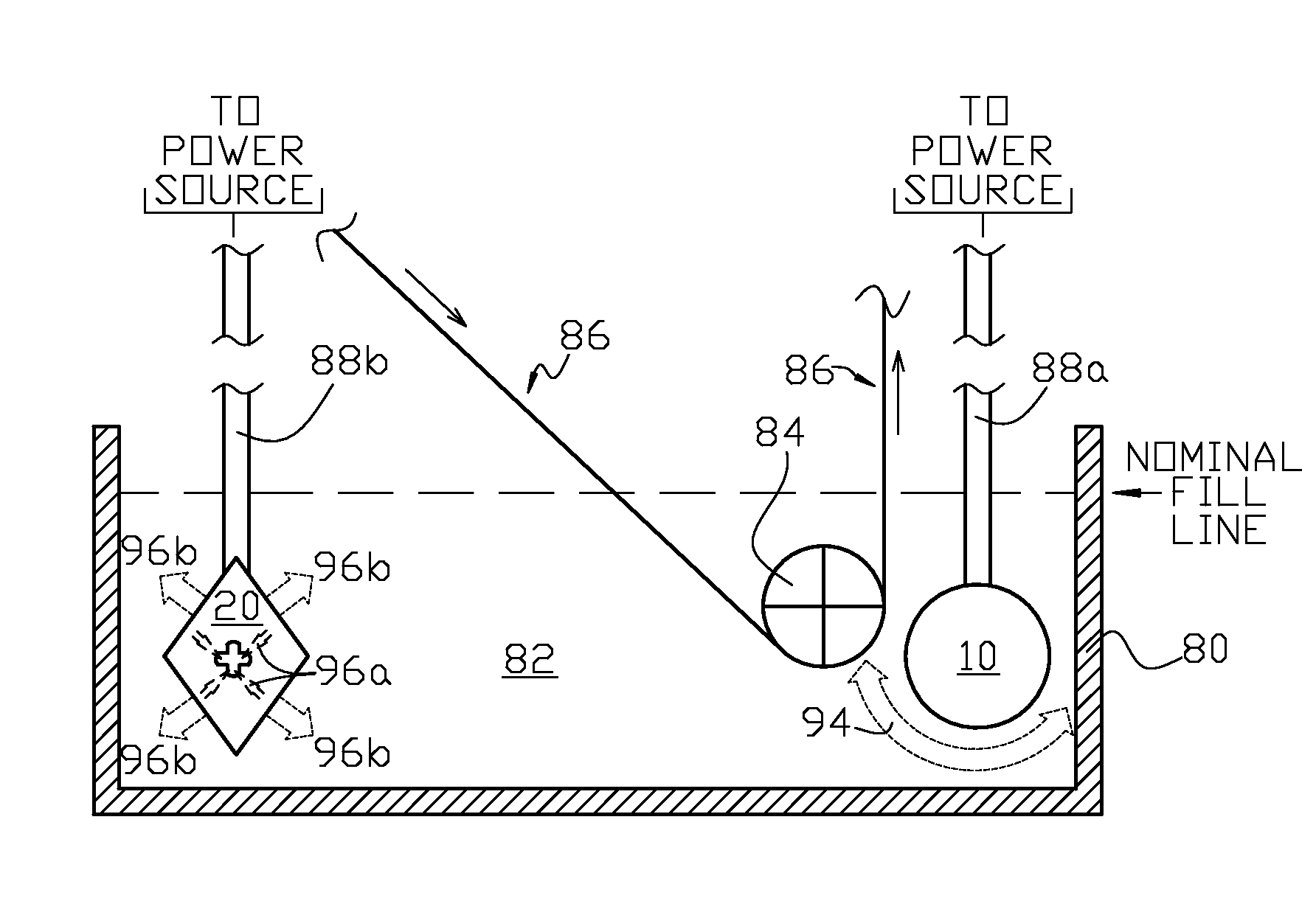

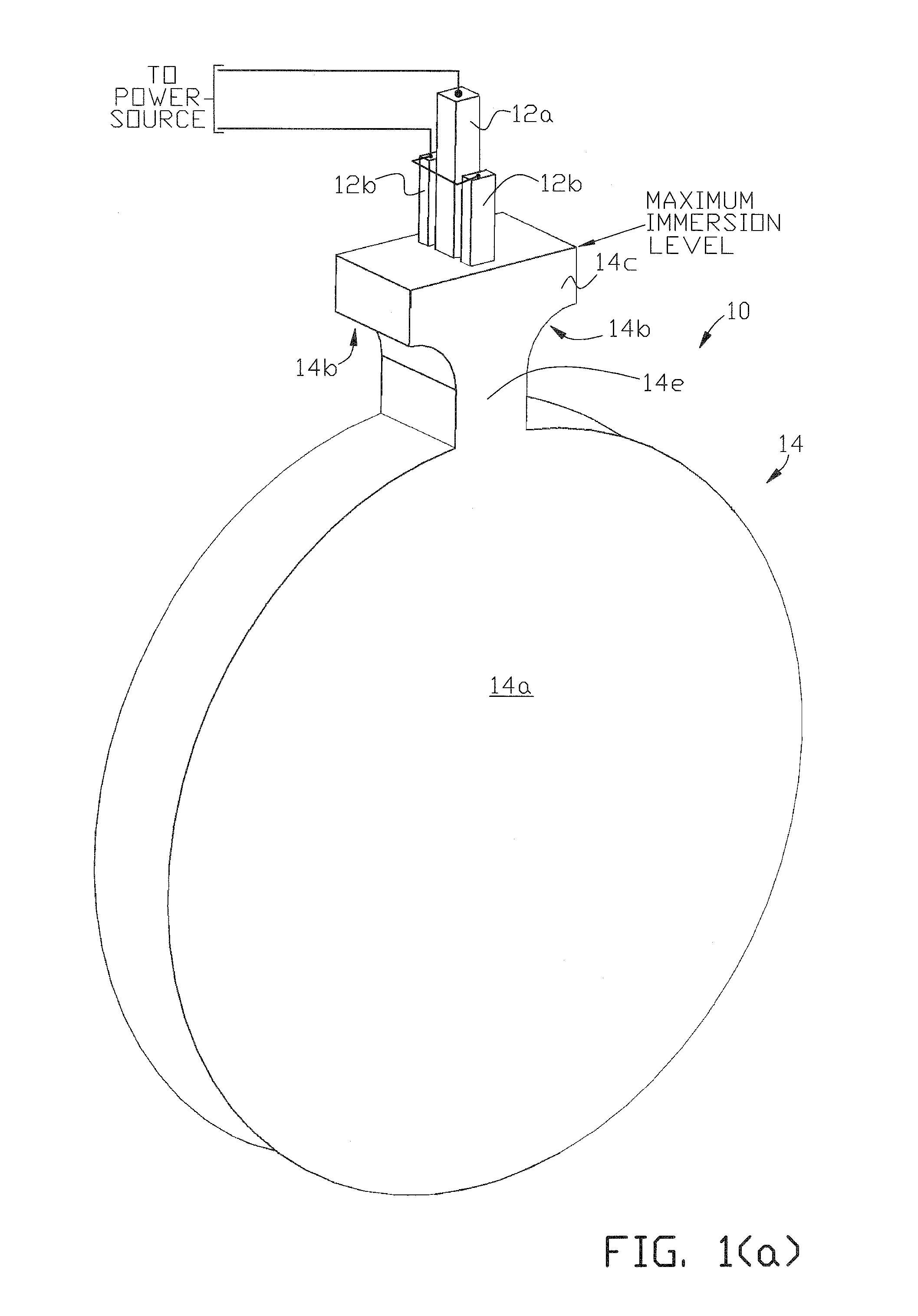

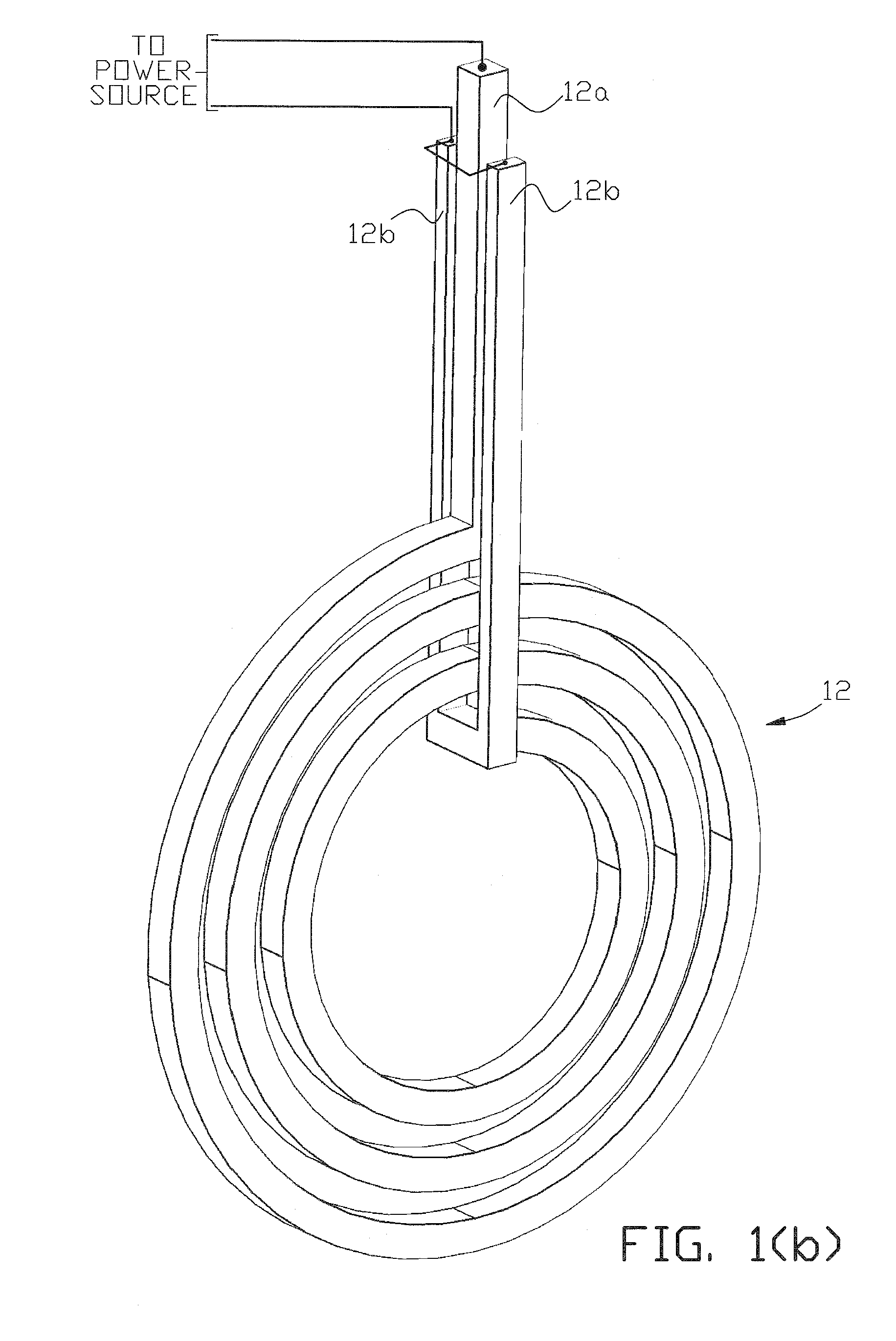

Electric Induction Heating and Stirring of an Electrically Conductive Material in a Containment Vessel

ActiveUS20110011750A1Furnaces without endless coreFrom normal temperature solutionsRefractoryElectrically conductive

Apparatus and method are provided for electric induction heating and / or stirring of a molten electrically conductive composition in a containment vessel with the apparatus being removably insertable in the molten composition. An induction coil embedded in refractory or a coating is submerged in the composition and used to heat and / or stir the molten composition either externally or internally to the refractory or coating.

Owner:INDUCTOTHERM INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com