Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

175 results about "Salt pond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

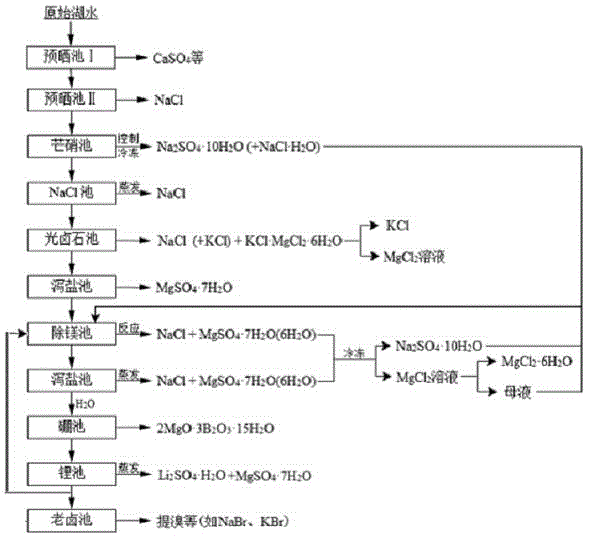

Clean production process of plateau sulfate type boron-lithium salt lake brine

InactiveCN102910652AHigh purityReduce the ratio of magnesium to lithiumChemical industryAlkali metal halide purificationHydration reactionSylvinite

The invention relates to a clean production process of plateau sulfate type boron-lithium salt lake brine. The process comprises the following steps of: (1) arranging a pre-airing pond, a mirabilite pond, a NaCl pond, a carnallite pond, an epsom salt pond I, a magnesium removing pond, an epsom salt pond II, a boron pond, a lithium pond and an old brine pond; (2) controlling the sodium ion concentration in plateau sulfate type boron-lithium salt lake brine, precipitating mirabilite out in winter to obtain brine A, naturally evaporating the brine A, and salting out to obtain brine B; (3) naturally evaporating the brine B, and precipitating sylvine and carnallite out in sequence to obtain brine C; (4) naturally evaporating the brine C, precipitating an epsom salt out, and performing solid-liquid separation to obtain brine D and a solid A; (5) blending the brine D with mirabilite, removing magnesium to obtain brine E, and naturally evaporating brine E to obtain brine F and a solid B; (6) performing a hydration reaction on brine F, naturally evaporating, and precipitating reservoir water / inderite and brine G out; and (7) evaporating brine G or refrigerating for precipitating lithium sulfate, and processing the lithium sulfate into a corresponding product. The process has the advantages of comprehensive utilization of natural energy, saving in energy and environment friendliness.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

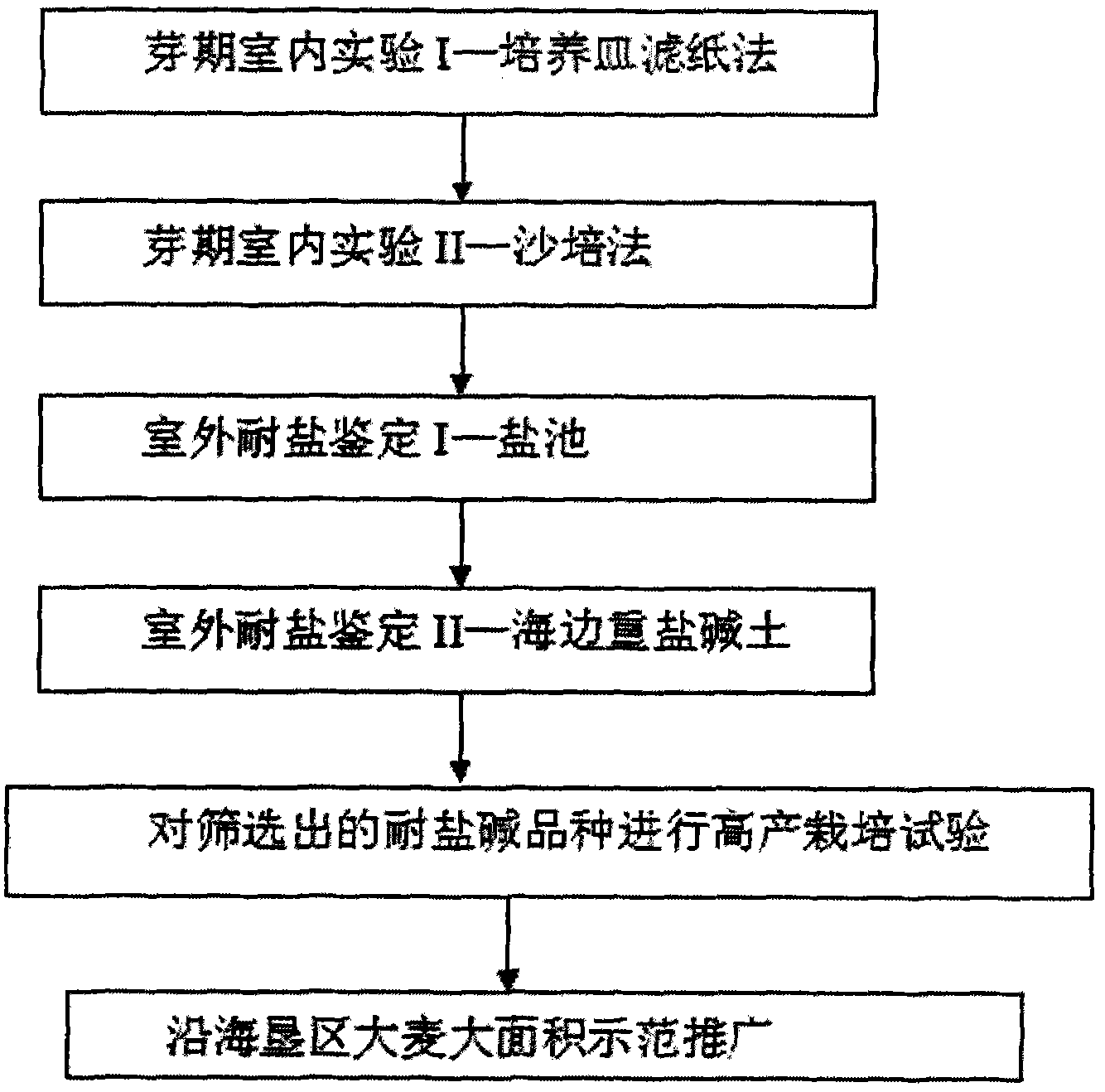

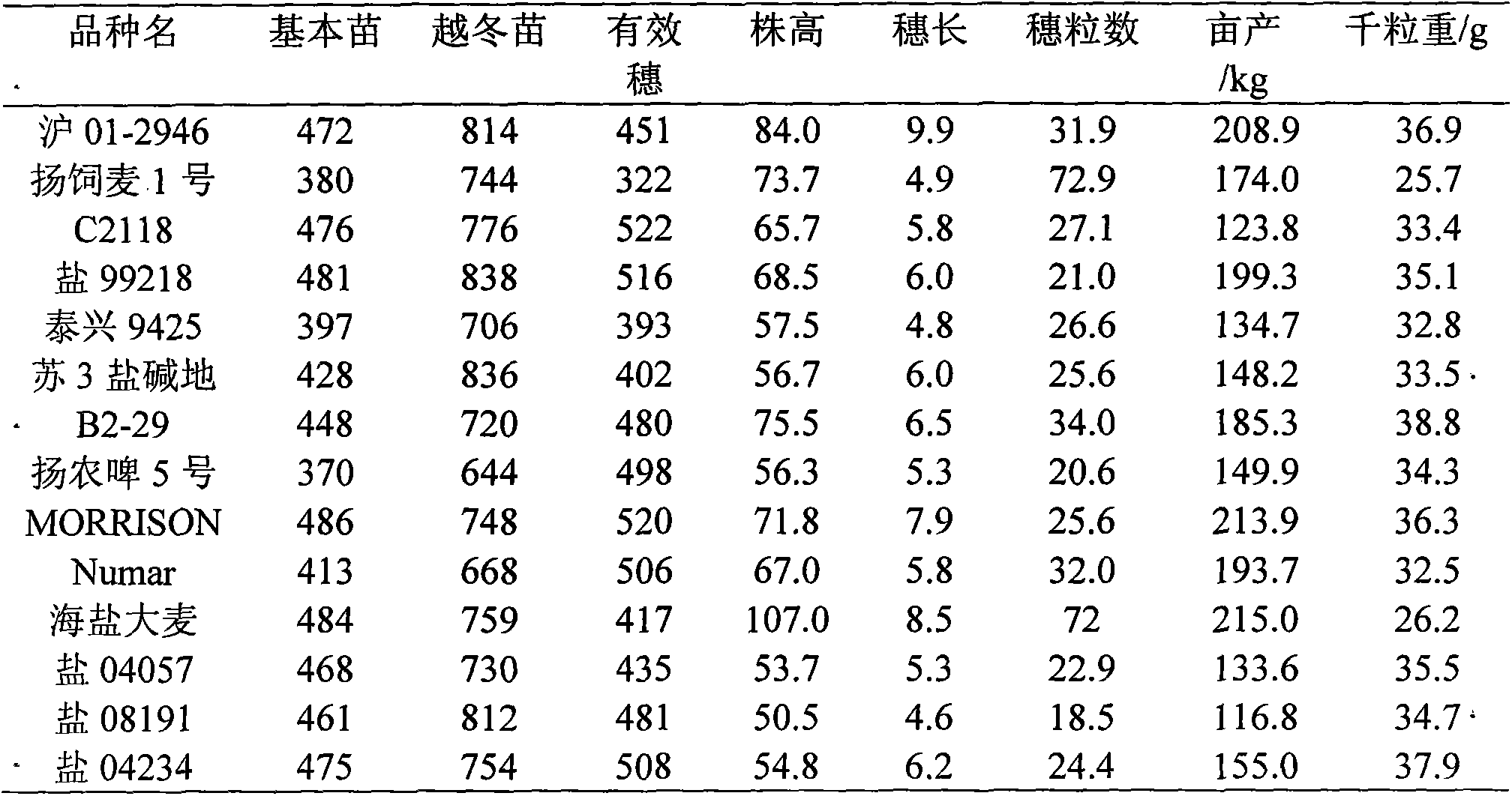

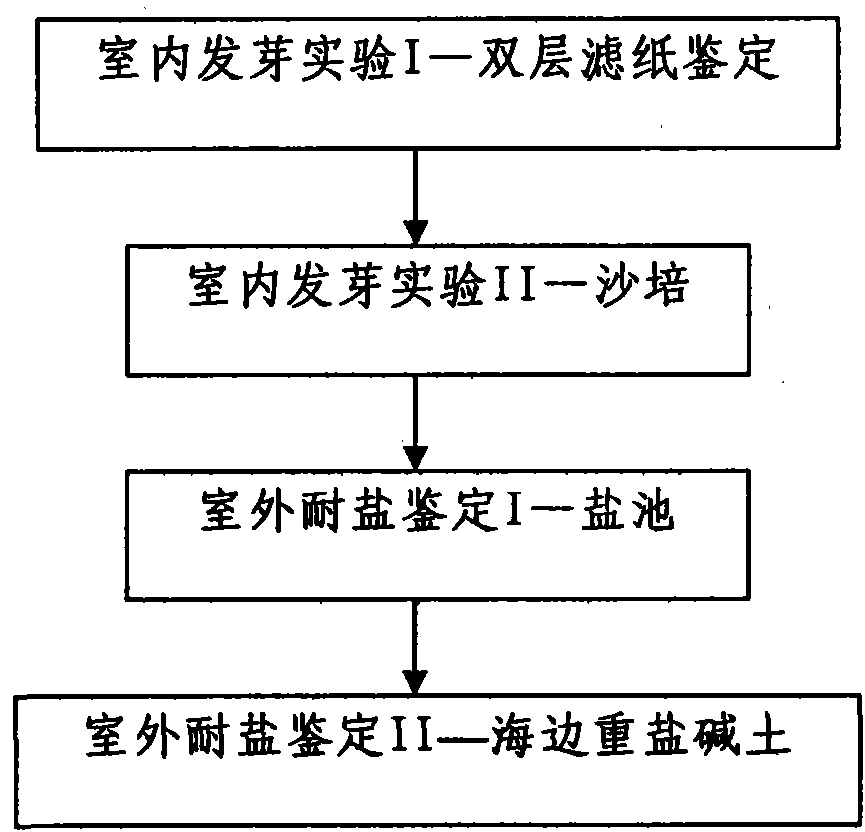

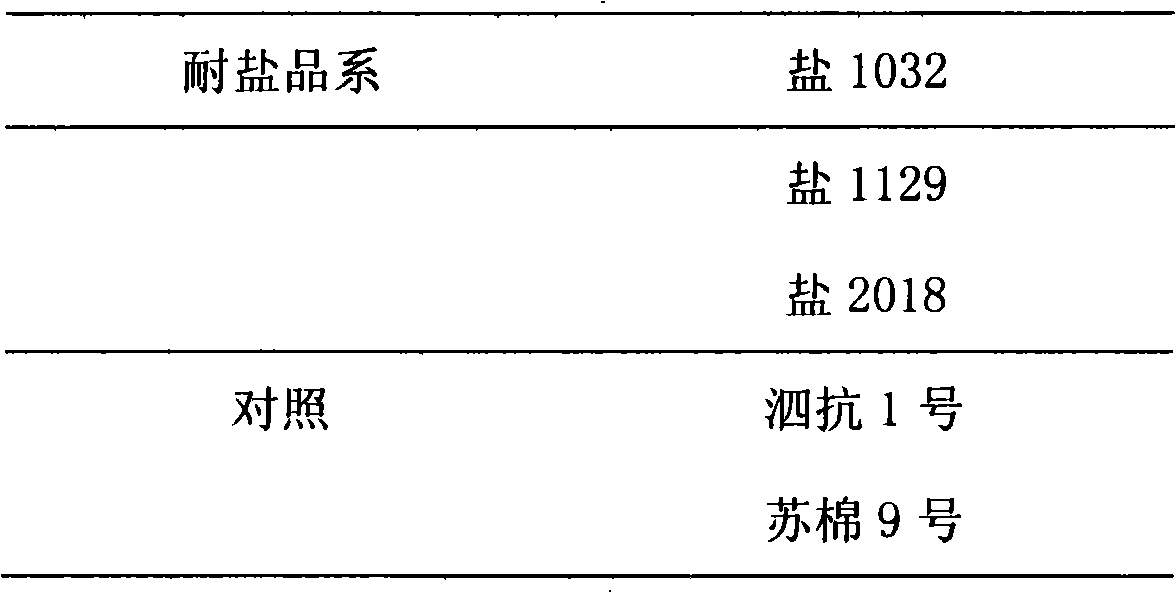

Saline-alkaline tolerant germplasm screening and high-yield cultivating method of barley

InactiveCN103828713AEfficient detectionStable detectionCultivating equipmentsHorticulture methodsAlkali soilHordeum vulgare

The invention discloses a saline-alkaline tolerant germplasm screening and high-yield cultivating method of barley. Laboratory experiments and outdoor experiments are combined for performing saline-alkaline tolerant germplasm screening; the laboratory experiments include germinating experiment and sand culture physiological experiment in a seedling stage, the outdoor experiments include outdoor saline-alkaline tolerance identification experiment of a salt pond and coastal field identification experiment; the cultivating method comprises the steps of film coverage, fresh water salt pressing and moisture making, and carrying out experiments under different sowing times, fertilizers and densities. The method can comprehensively identify and screen saline-alkaline tolerant characteristics of barley in a barley germination period, in a seedling stage and in an adult-plant stage by use of filter paper, sand, the salt pond and seaside heavy saline-alkali soil, and can stably and comprehensively detect the saline-alkaline tolerance of the barley in a high-efficiency manner, and can formulate the relevant high-yield culture technique for the saline-alkali soil.

Owner:JIANGSU COASTAL AREA AGRI SCI RES INST

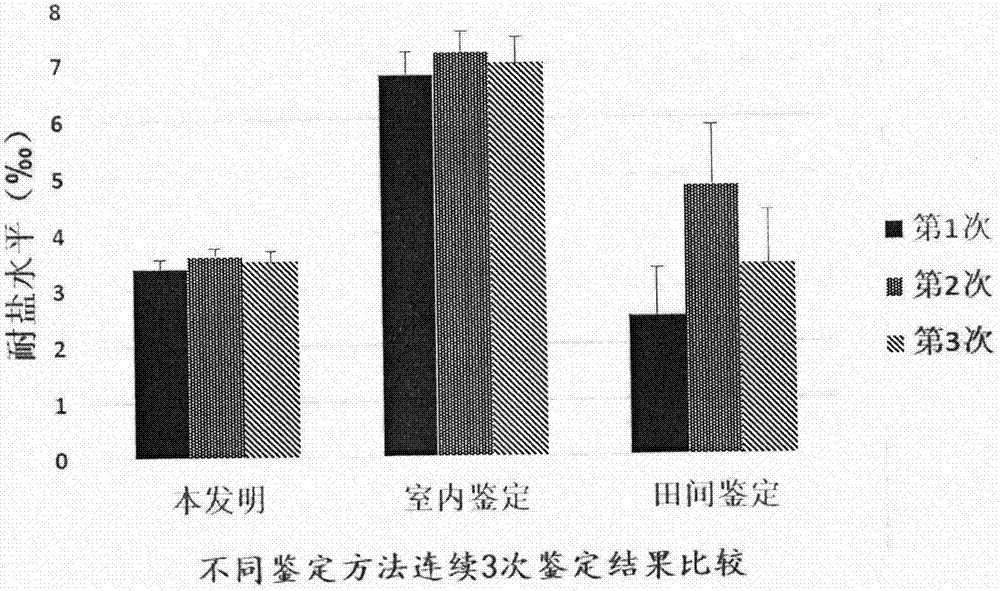

Rice-variety salt-tolerance evaluating method

The invention relates to a rice-variety salt-tolerance evaluating method and belongs to the technical field of plant breeding. The invention provides an identifying and evaluating method for a rice-variety salt-tolerance system, i.e., the salt tolerance of rice varieties is comprehensively evaluated under the same salt concentration and different salt concentrations at three salt sensitive periods, i.e. the budding and seedling period, the tillering stage and the booting stage of rice respectively at a laboratory, a manually-simulated salt pond and a saline soil field by adopting a total biomass-measuring method according to salt-tolerance indexes (the total biomass dry-weight specific-value percent of the rice varieties in a saline environment and a saltless environment). Compared with laboratory assessment in the prior art, the rice-variety salt-tolerance evaluating method has stronger practical effects and can be more directly applied to the planting of the rice varieties.

Owner:JIANGSU COASTAL AREA AGRI SCI RES INST

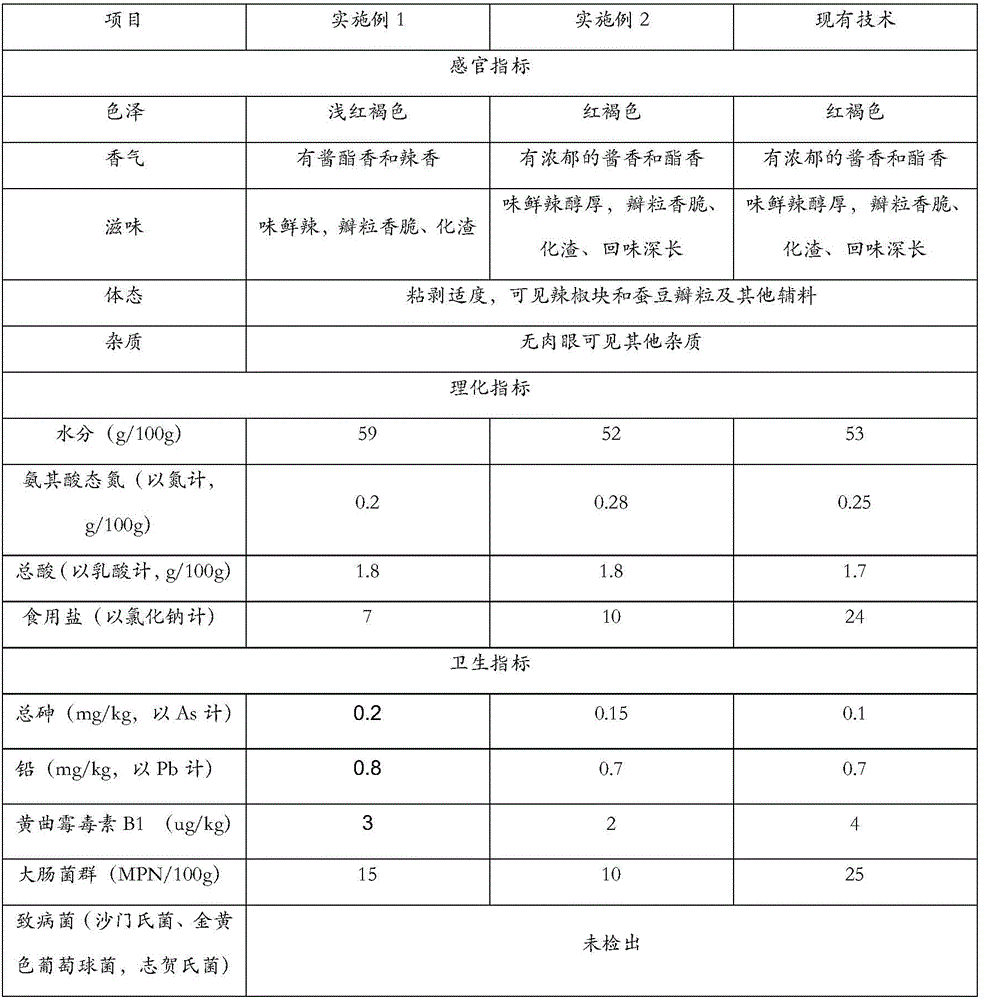

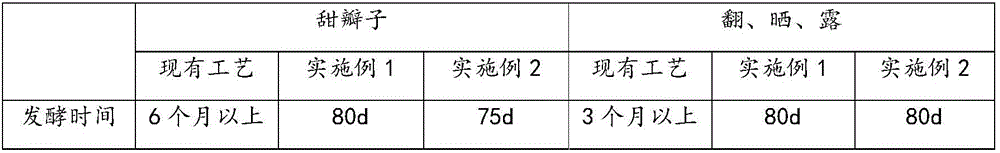

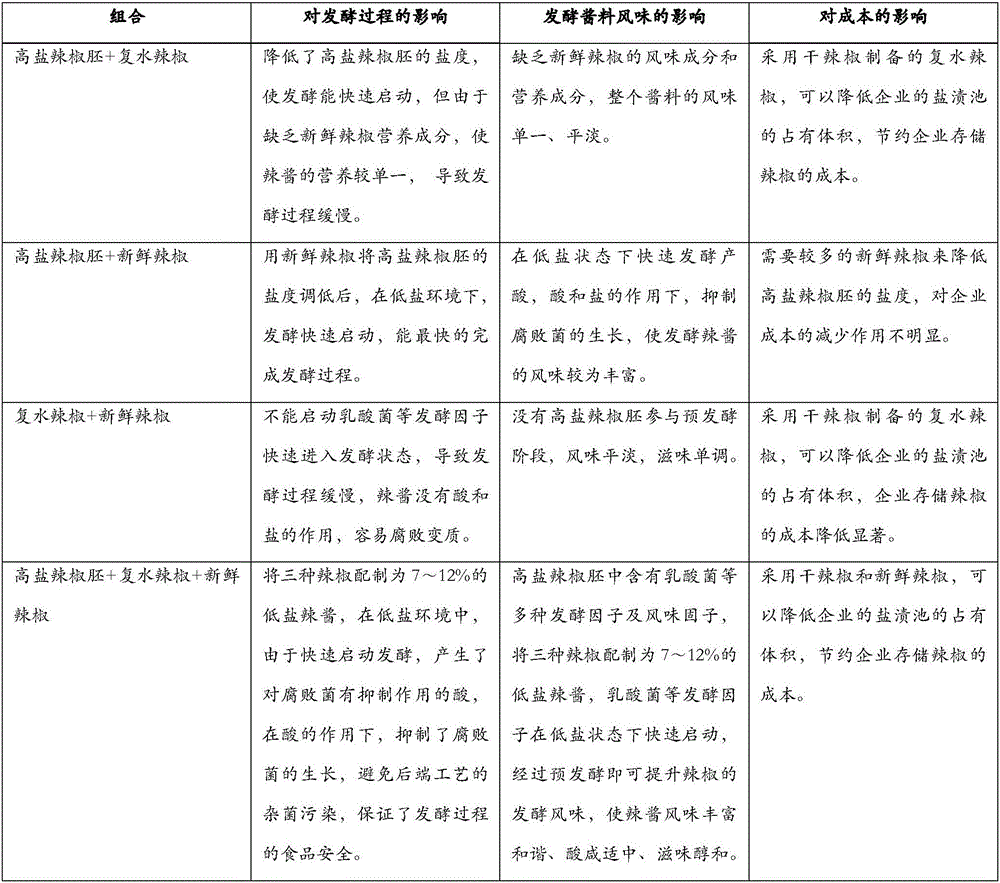

Low-salt quick fermentation technology of Pixian thick broad-bean sauce

ActiveCN106690073ABoosts Fermented FlavorAdd flavorFood preservationFood ingredient for microbe protectionPutrefying bacteriaFlavor

The invention belongs to the field of foods, and particularly relates to a low-salt quick fermentation technology of Pixian thick broad-bean sauce. The technology comprises the following steps of (1) making low-salt fermented hot pepper blanks; (2) making sweet fermented broad beans; and (3) making the low-salt Pixian thick broad-bean sauce: mixing the low-salt fermented hot pepper blanks with the fermented broad beans in a ratio of the low-salt fermented hot pepper blanks to the sweet fermented broad beans being 9 to 1 to obtain a low-salt sauce, putting the low-salt sauce in a sealed fermenting tank or a sealed fermenting jar, adopting a two-stage fermentation technology comprising stirring the sauce, drying the sauce in the sun and allowing the sauce to stand at night for natural fermentation to obtain the low-salt Pixian thick broad-bean sauce, and then subjecting the low-salt Pixian thick broad-bean sauce to a pasteurization technology so as to obtain the finished product of the low-salt Pixian thick broad-bean sauce. According to the technology disclosed by the invention, pre-fermentation is performed, so that the fermentation flavor of the hot peppers can be promoted, and the salinity can also be reduced; under the effects of acid and salt, the growth of putrefying bacteria can be restrained, and pollution caused by infectious microbes in subsequent processes can be avoided; in addition, dried hot peppers and fresh hot peppers are adopted, so that the occupied volume of salting ponds of enterprises can be reduced, and the cost of the enterprises for storing the hot peppers can be reduced; and the fresh hot peppers are added, so that the table salt in the high-salt hot pepper blanks can be diluted, the flavor of the fresh hot peppers can also be increased, and the mouth feel of the sauce can be enriched.

Owner:SICHUAN ACAD OF FOOD & FERMENTATION INDS

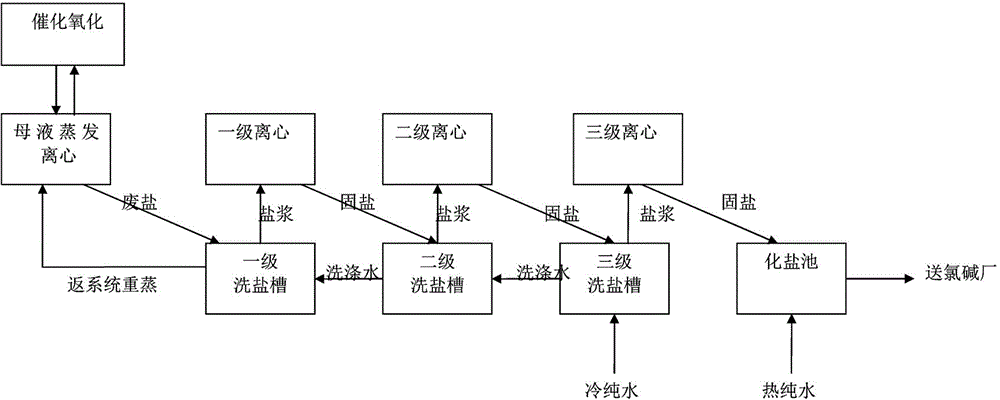

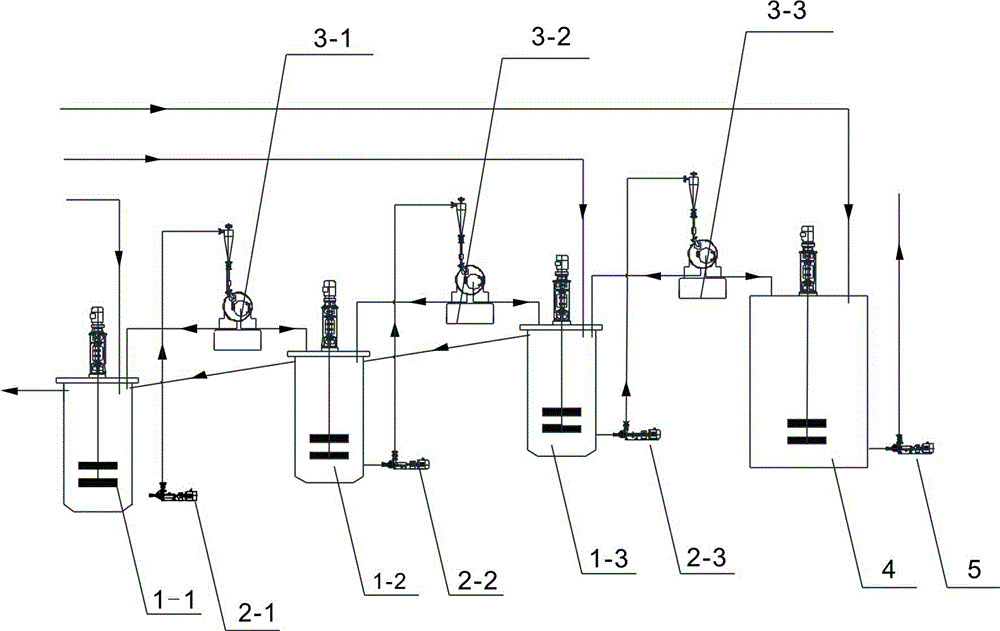

Purification device and purification process for waste salt in by-product of glyphosate

ActiveCN104098113AAchieve reuseSolve the narrow scope of useAlkali metal halide purificationMelting tankSaline water

The invention relates to a purification device of waste salt in a by-product of plyphosate. A first-stage salt cleaning tank is connected with a first-stage slurry pump through route pipelines first, then the first-stage slurry pump is connected with a first-stage centrifuge; the first-stage centrifuge is connected with a second-stage salt cleaning tank through the route pipelines; after three stages of circulating connection of the salt cleaning tanks, the slurry pumps and the centrifuges, a three-stage centrifuge is connected with a salt melting tank through the route pipelines, and the salt melting tank is connected with a salt water delivery pump. The waste salt from an evaporation system is conveyed to the first-stage salt cleaning tank, and mixed with water obtained from the centrifuge of the previous stage to obtain salt slurry with the solid content rate of 25%; after being uniformly stirred, the salt slurry is pumped into the first-stage centrifuge utilizing the first-stage slurry pump; the centrifuged solid salt is conveyed to the second-stage salt cleaning tank, and the salt cleaning water returns to the second-stage salt cleaning tank. The purified refined salt cleaned through three stages adopting the same method has the solid content rate of 60-70%; through the adoption of the process, waste salt is converted into raw materials capable of being used in the downstream chlor-alkali industry, and improves the economic benefit of waste salt treatment; meanwhile, in virtue of great raw material demand in the chlor-alkali industry, the defects of narrow application range and small demand for the conventional waste salt are completely overcome.

Owner:HUBEI TAISHENG CHEM

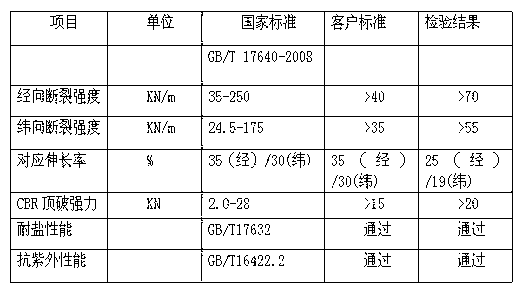

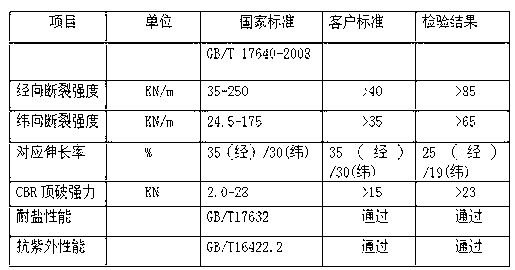

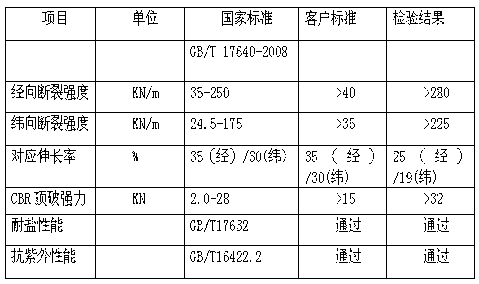

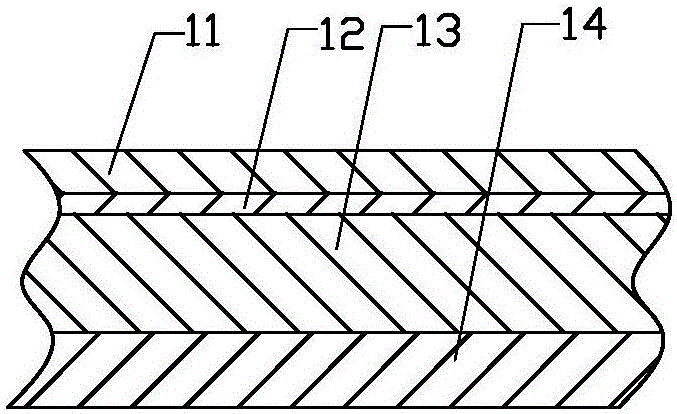

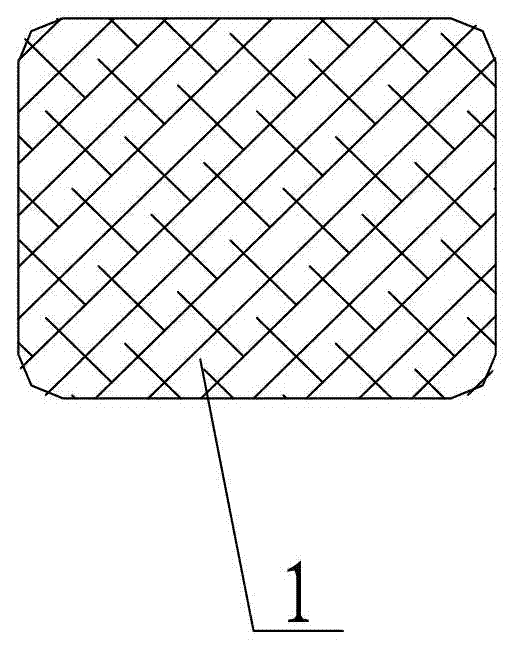

Composite impermeable cloth for salt pond and preparation method thereof

InactiveCN103287004AHigh strengthImprove acid resistanceFibre typesSynthetic resin layered productsPolyesterPolyvinyl chloride

The invention discloses composite impermeable cloth for a salt pond. The composite impermeable cloth consists of polyester industrial cloth, a polyvinyl chloride rubber modified films and pasty polyvinyl chloride coatings, wherein the pasty polyvinyl chloride coatings are adhered to two surfaces of the polyester industrial cloth; the polyvinyl chloride rubber modified films are attached to two sides surfaces of each pasty polyvinyl chloride coating through pressurization. The invention also provides a method for preparing the composite impermeable cloth for the salt pond. The method comprises the following steps: infiltrating and coating the pasty polyvinyl chloride coatings on the polyester industrial cloth, plastifying the polyester industrial cloth coated with the pasty polyvinyl chloride coatings at the high temperature of 180-240 DEG C, attaching the rubber modified films to the two side surfaces of a semi-finished product, and the like.

Owner:HUBEI JINLONG NEW MATERIALS

Method for treating and improving saline and alkaline land

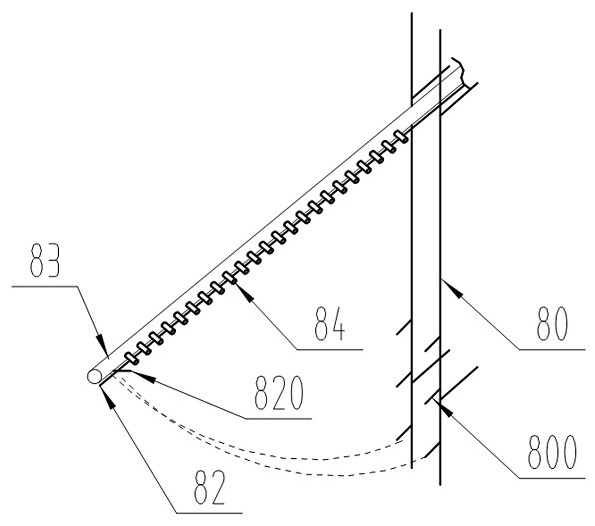

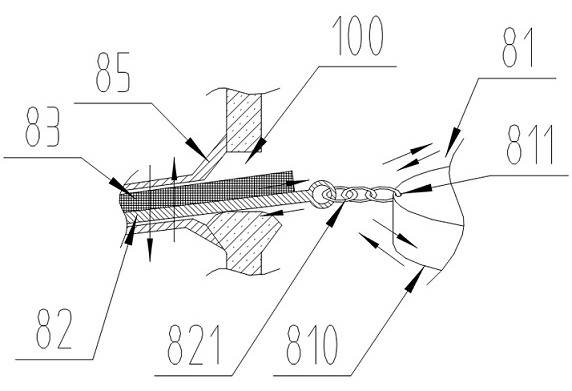

The invention relates to the technical field of washing devices, in particular to a method for treating and improving saline and alkaline land. The method comprises the following steps: plowing the saline and alkaline land, evenly spreading plowed saline and alkaline soil to be flat so as to obtain a saline and alkaline soil layer, and arranging a salt pond on the saline and alkaline soil layer, (2) laying a first salt insulating layer on the surface of the saline and alkaline soil layer, (3) laying a plurality of main water soaker hoses in a parallel mode on the surface of the first salt insulating layer in an inclined mode, and one end, lower in position, of each soaker hose is communicated with the salt pond, (4) covering the main soaker hoses with a second salt insulating layer, (5) laying a soil replacement layer on the second salt insulating layer. Compared with the prior art, the method has the advantages of being low in cost, simple in technology, strong in maneuverability, and the like.

Owner:SUZHOU GOLD MANTIS GREEN LANDSCAPE LIMITED

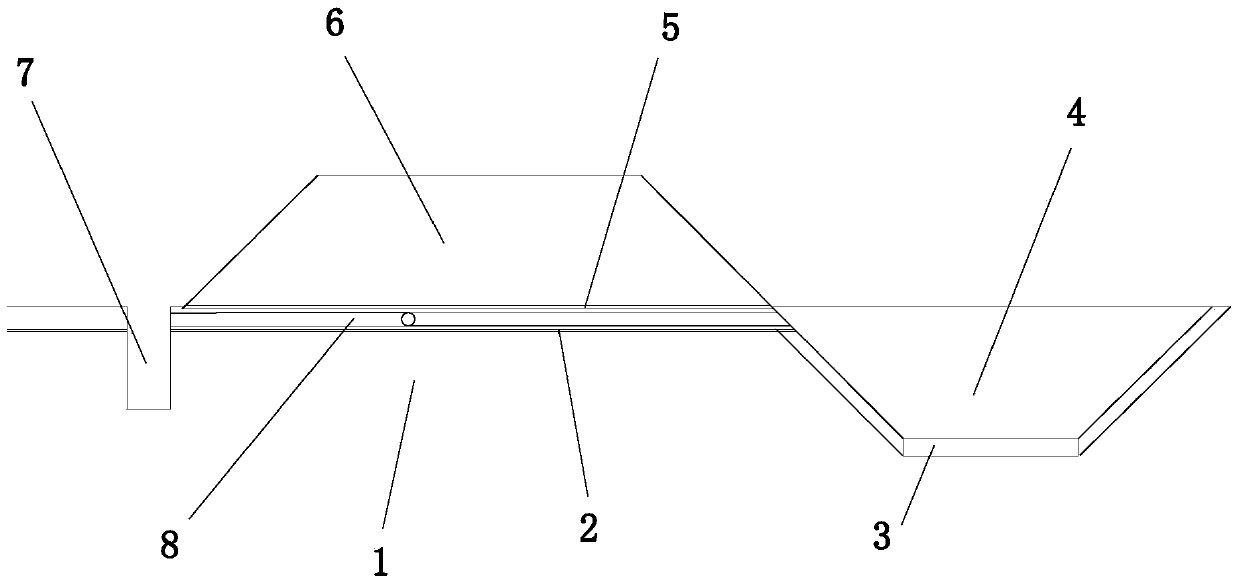

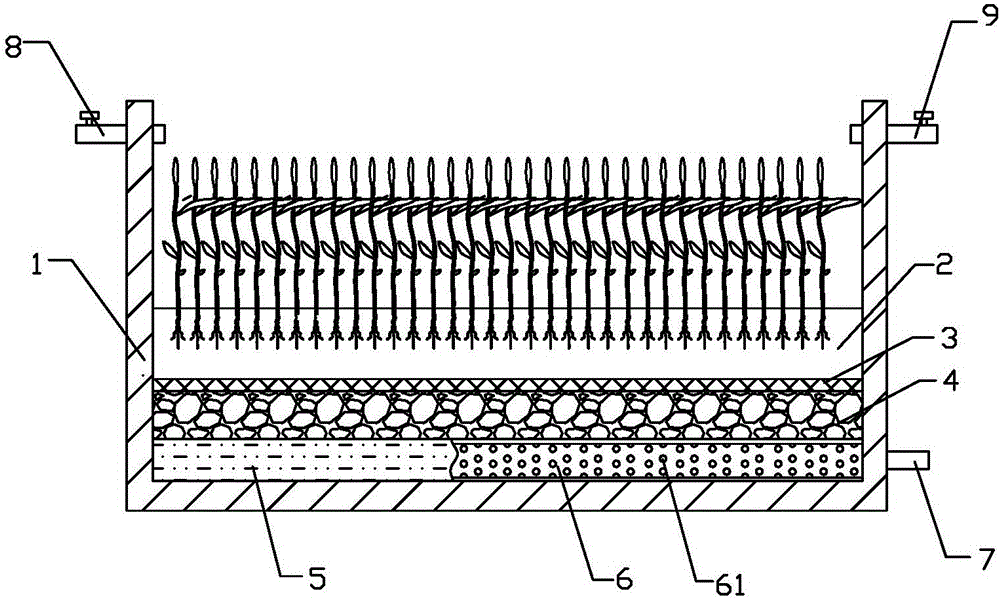

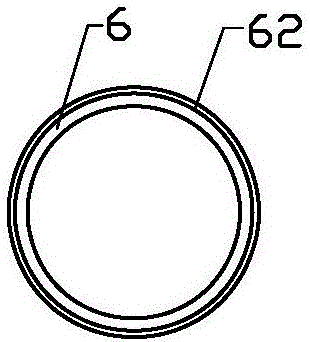

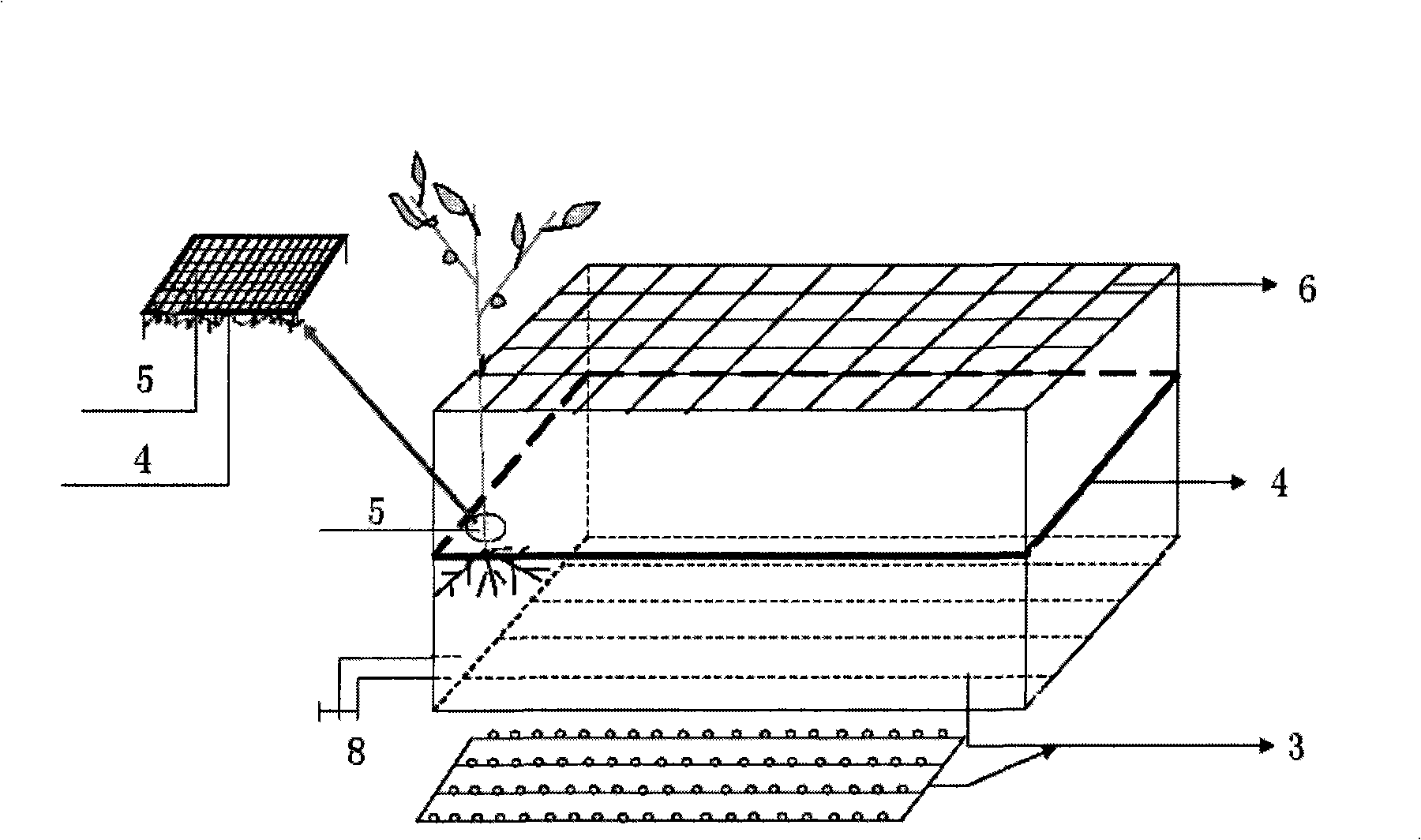

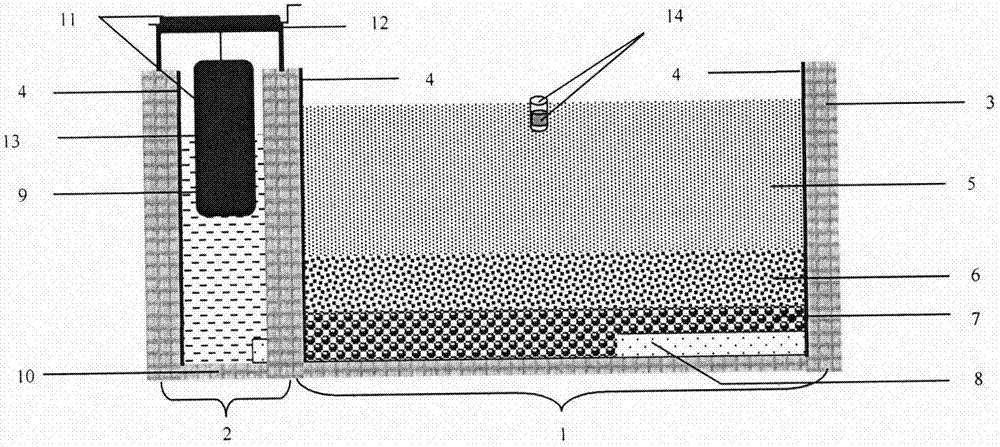

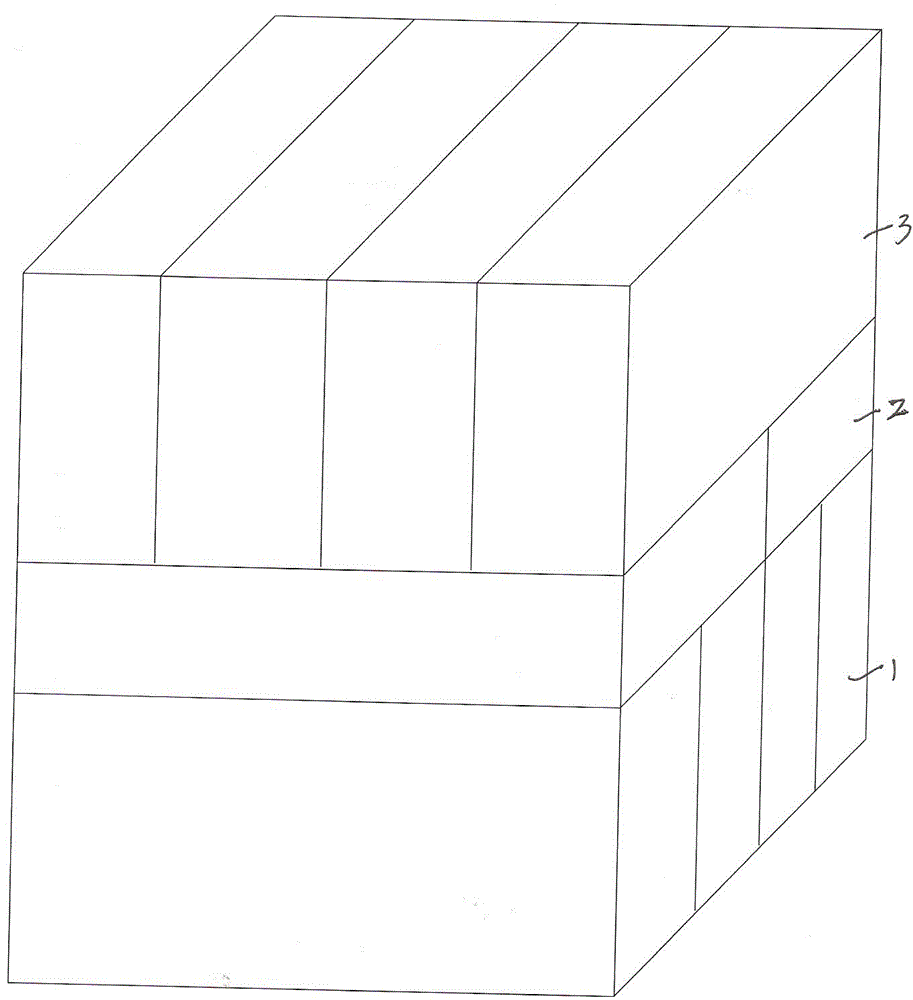

Salt pond for identifying saline-alkaline tolerance in rice and method of using same

InactiveCN106212141AHigh precisionDefine salt toleranceReceptacle cultivationWater-setting substance layered productStructure of the EarthPhacus

The invention discloses a salt pond for identifying saline-alkaline tolerance in rice and a method of using the same. The salt pond structurally comprises a salt pond base that contains a tillable layer, a gravel layer and a medium sand layer sequentially from top to bottom, a filter mesh that supports the tillable layer is provided between the tillable layer and the gravel layer, a seepage pipe is arranged in the medium sand layer, one end of the seepage pipe is connected with an outer drain outlet of the salt pond base, the seepage pipe is evenly provided with a plurality of seeping holes, the seepage pipe is covered with nonwoven to prevent fine sand from entering the seeping holes and blocking the seeping holes, one side of the upper portion of the salt pond base is provided with a water inlet, and the other side of the upper portion of the salt pond base is provided with a water outlet correspondingly. The salt pond is used for identifying saline-alkaline tolerance of rice in natural saline-alkaline soil with different salinity levels under different development stages, and the identification of saline-alkaline tolerance in rice is more precise.

Owner:SHANDONG RICE RES INST

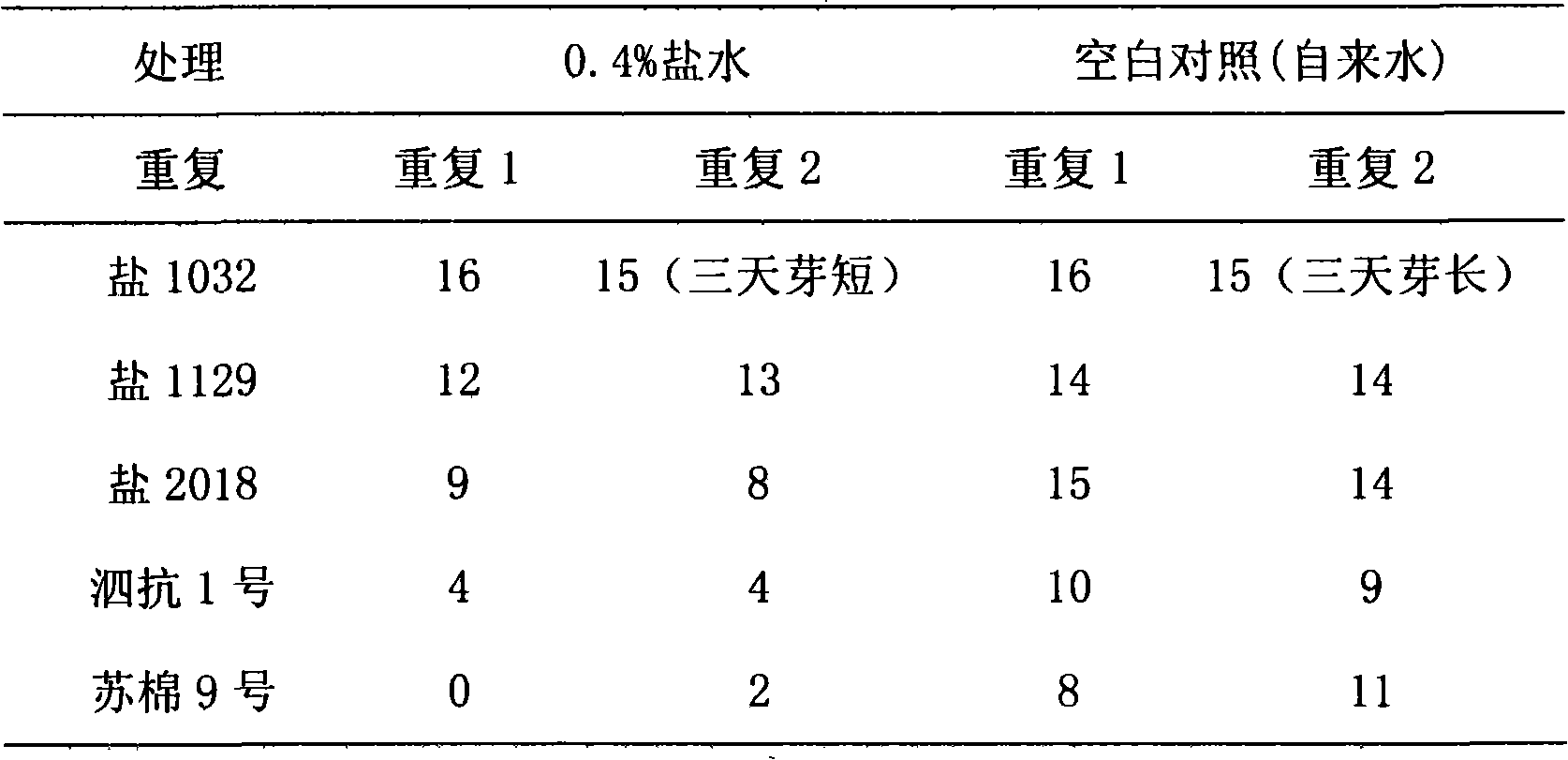

Method for identifying quality of cotton salt-tolerant seeds

InactiveCN102172118AWeather/light/corrosion resistanceSeed and root treatmentAgricultural scienceSalt-tolerant crops

The invention discloses a method for identifying quality of cotton salt-tolerant seeds. Salt-tolerant seeds are screened by adopting an indoor experiment and an outdoor experiment, wherein the indoor experiment comprises an indoor germination experiment I and / or an indoor germination experiment II; and the outdoor experiment comprises outdoor salt-tolerance identification I and / or outdoor salt-tolerance identification II. In the invention, the salt-tolerance character of cotton is integrally identified and evaluated by adopting double-layered filter papers, sand, salt ponds and heavy alkali-salinity soils by the seaside. The salt-tolerance in the germination stage, the seedling stage and the plant-forming stage of cotton can be identified and evaluated. The salt-tolerance of cotton is detected roundly and stably with high efficiency and high throughout. The integral identification and evaluation of multi-stage, multi-place and multi-level can be performed for the salt-tolerance of crops which are controlled by complicated quantitative inheritance genes and greatly influenced by external environment.

Owner:JIANGSU COASTAL AREA AGRI SCI RES INST

Method for removing ammoniasoda process calcined soda waste residue chloride ion

InactiveCN101780464AEasy to removeImprove adsorption capacityWaste processingSolid waste disposalIndustrial waste waterReclaimed water

The invention discloses a method for removing ammoniasoda process calcined soda waste residue chloride ion, which comprises the steps: mixing ammoniasoda process calcined soda waste residue and recycled water of a sewage treatment plant and / or industrial waste water containing a certain amount of organic matter, separating solid and liquid and then washing filter cakes, thus achieving the purpose of removing the ammoniasoda process calcined soda waste residue chloride ion. The method uses recycled water of the sewage treatment plant and / or industrial waste water as washing water, has the advantages of simple process, low cost and the like; the ammoniasoda process calcined soda waste residue without the chloride ion can be used for producing building materials such as cement and the like; and the washing water can be directly discharged into sea or discharged into a salt pond for solar salt, thus having both the environmental benefit and economic benefit.

Owner:SHANDONG HAIHUA GRP CO LTD

Device and brine solution for fast appraising salinity and alkalinity resistance of tree

InactiveCN101294943AAvoid influenceSolve the impactMaterial analysisDipotassium hydrogen phosphatePhosphoric acid

The invention relates to a device and salt solution used for fast identifying the characteristic of salinity-alkalinity tolerance of trees, belonging to the agriculture and forestry technical field; the device of the invention comprises a rain proof shed, a salt pond, an aerator pipe, a floating plate carrier, a non-woven fabric, a fixed net side, an air pump, a water outlet, a drainage ditch and a wastewater disposal basin in sequence; wherein, the salt pond holds salt solution and the weight percentage of the composition of the salt solution is: 0.007 percent to 0.031 percent of calcium nitrate, 0.007 percent to 0.030 percent of dipotassium hydrogen phosphate, 0.003 percent to 0.018 percent of magnesium sulfate, 0.00004 percent to 0.009 percent of sodium chloride and sodium hydroxide and the rest of distilled water; the device and salt solution of the invention provide good environment for the growth of plants, have simple structure, easy operation, convenient maintenance, little one-time investment, low operating cost, high level of precision of ion concentration in the salt solution, faster identifying speed, wide application range and stronger practicability and direction.

Owner:SHANGHAI JIAO TONG UNIV

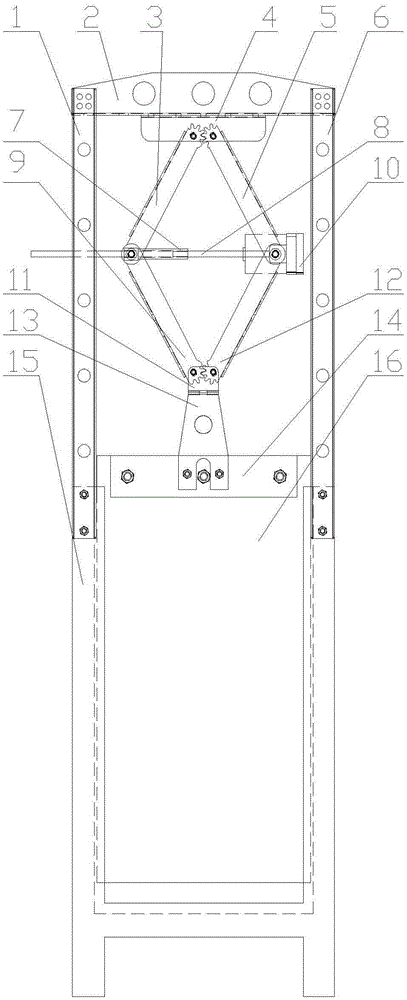

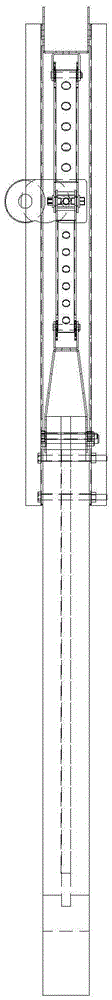

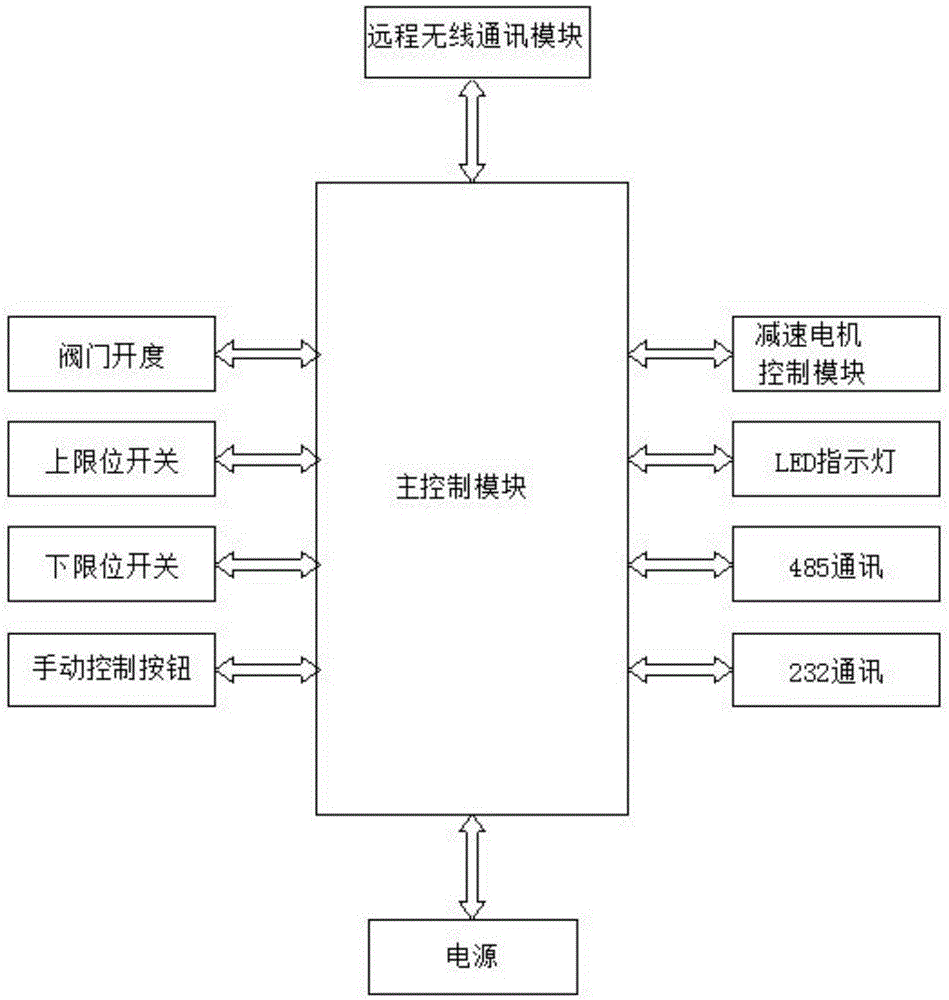

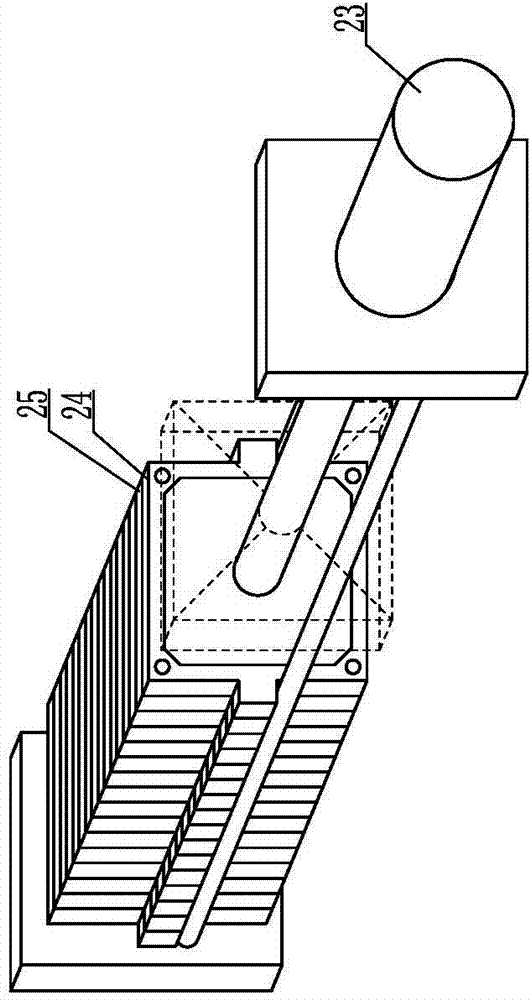

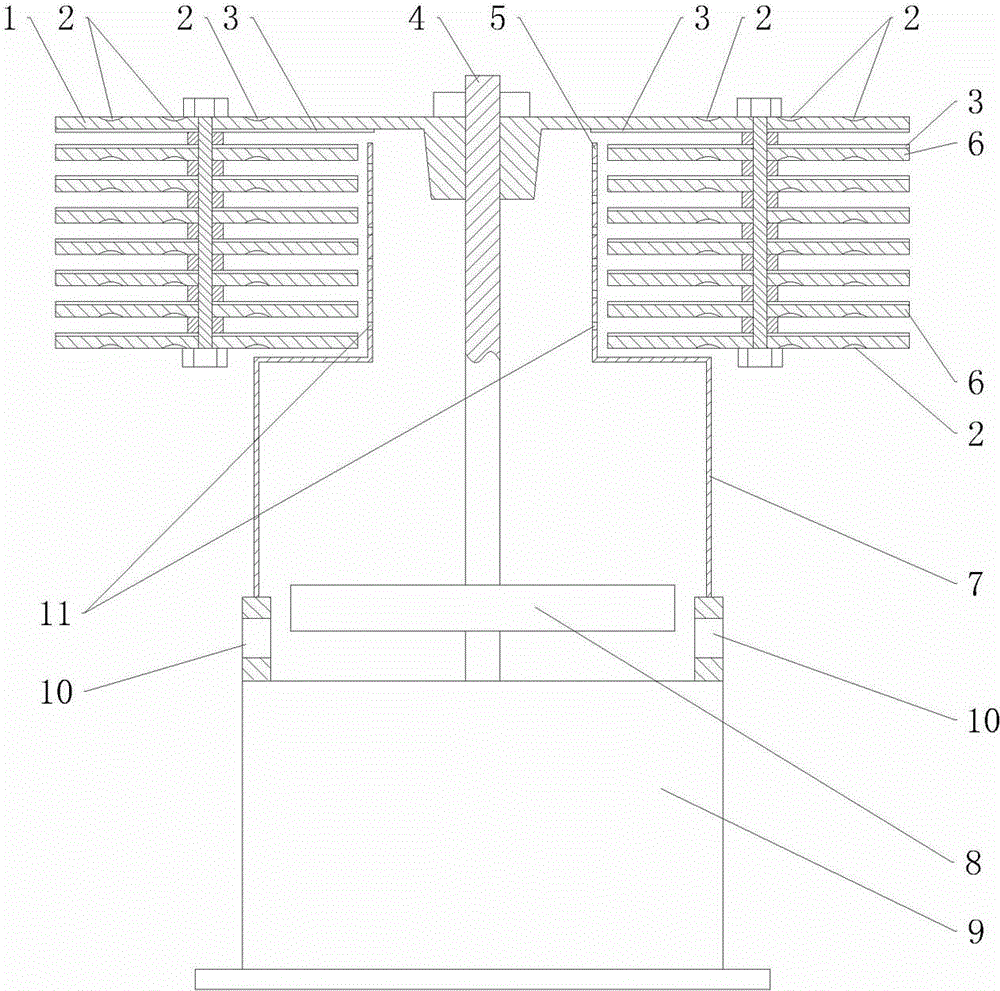

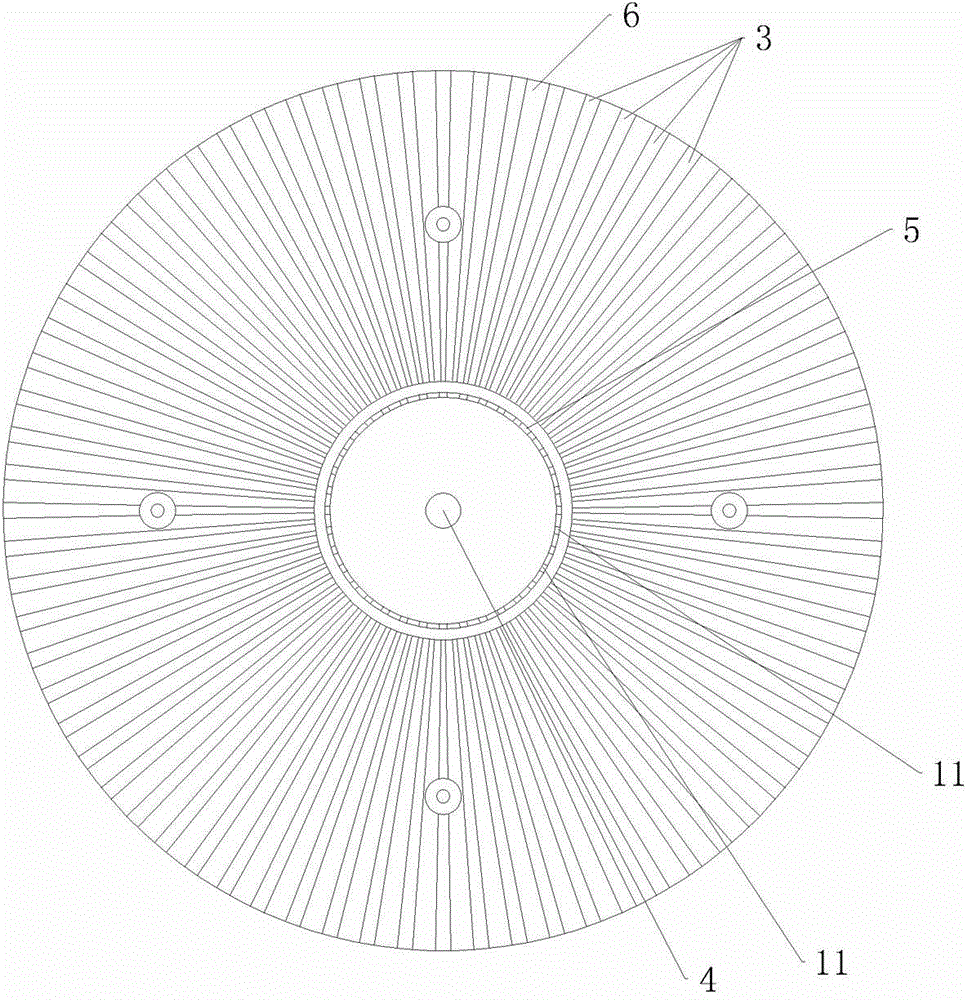

Lifting mechanism for remote control electric gate of salt pond

ActiveCN105387225ARealize automatic liftingNo manual operationOperating means/releasing devices for valvesSlide valveRemote controlSalt pond

The invention relates to a lifting mechanism for a remote control electric gate of a salt pond. The lifting mechanism for the remote control electric gate of the salt pond is characterized in that the lifting mechanism comprises a steel gate frame, a lifting mechanism body and a control unit, wherein the steel gate frame, the lifting mechanism body and the control unit are installed on a wooden gate unit; the wooden gate unit comprises a wooden gate frame, a wooden gate plate and a gate plate cross beam; the steel gate frame is fixedly connected to the upper portion of the wooden gate frame; the lifting mechanism body is installed on the steel gate frame; the upper portion of the wooden gate plate and the gate plate cross beam are fixedly installed; the two sides of the wooden gate plate are installed in the wooden gate frame in a guiding mode; the upper portion of the wooden gate plate is connected with the lifting mechanism body through the gate plate cross beam and is driven by the lifting mechanism body to go up and down in the wooden gate frame; the lifting mechanism body is controlled by the control unit. According to the lifting mechanism for the remote control electric gate of the salt pond, the design is scientific and reasonable; the remote control of the gate of the salt pond can be achieved; the lifting mechanism has the advantages of being stable in structure, smooth in operation, easy to control and long in service life, is especially suitable for severe environments of the salt pond, and has good application prospects.

Owner:TIANJIN BOYADA TECH

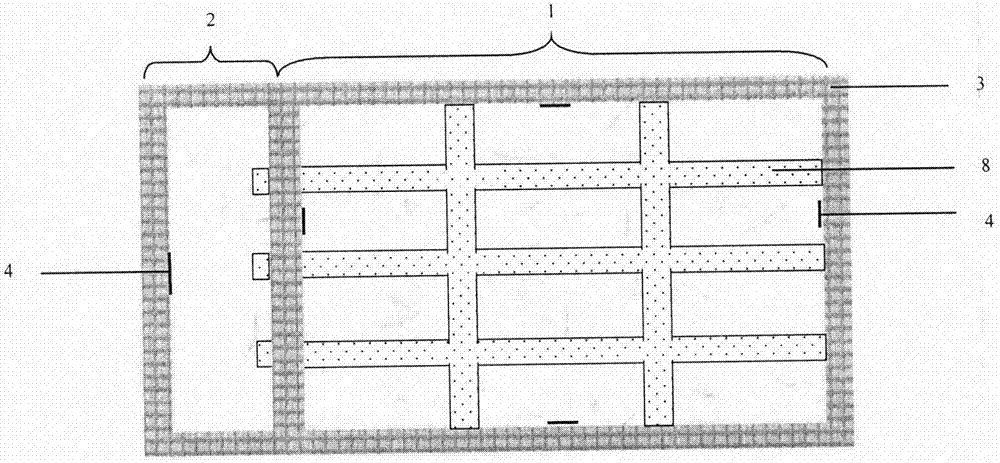

Plant salt tolerance identification pond and use method thereof

ActiveCN107114103ASimulated coercionObjective and Accurate Evaluation of Salt ToleranceHorticulture methodsSaline waterHalotolerance

The invention discloses a plant salt tolerance identification pond and a use method thereof. The plant salt tolerance identification pond structurally comprises a salt tolerance identification pond and a salinity regulating pond. The salt tolerance identification pond internally comprises a saline soil layer, a sand layer, a stone layer and a water seepage pipeline from top to bottom. A water level observation pipe is arranged on the top of the saline soil layer, saline water is contained in the salinity regulating pond, and a water level regulating device is arranged above the salinity regulating pond. Graduated scales with the minimum scale of 0.5 mm are marked in the pond walls of the salt tolerance identification pond and the salinity regulating pond. The saline water can be formed by diluting seawater or extracting saline-alkali soil or is manually prepared. The use method of the plant salt tolerance identification pond includes the steps of salt tolerance identification pond land leveling and plastic film mulching, salinity regulating pond saline water adding, plant material preparation, soil salinity regulating and keeping and salt damage evaluation. The defects that an existing salt pond is uncontrollable in soil salt content and poor in stability are overcome, and the accuracy of a plant salt tolerance qualification test is improved.

Owner:JIANGSU COASTAL AREA AGRI SCI RES INST +1

Photo-thermal plate for accelerating salt manufacture by means of brine evaporation and method for applying photo-thermal plate

PendingCN109354097APrevent infiltrationTo achieve the effect of salt resistanceGeneral water supply conservationSeawater treatmentInsulation layerBiochemical engineering

The invention discloses a photo-thermal plate for accelerating salt manufacture by means of brine evaporation and a method for applying the photo-thermal plate. The photo-thermal plate comprises a first hydrosol layer, a heat-insulation layer, a buoyancy material and a salt pond. A first hydrophobic layer is arranged on the upper side of the first hydrosol layer, and a black light absorption material is arranged on the lower side of the first hydrosol layer; a second hydrophobic layer is arranged on the upper side of the heat-insulation layer and is adhered with the black light absorption material via a second hydrosol layer, and a water absorption sheet is arranged on the lower side of the heat-insulation layer; a plurality of groups of through holes are uniformly formed in the surfaces of the buoyancy material, and a photo-thermal plate body floats on the salt pond. The photo-thermal plate for accelerating salt manufacture by means of brine evaporation and the method have the advantages that the second hydrophobic layer can prevent brine from being permeated into materials, salt which is dissolved out by means of brine evaporation is difficult to adhered to the surfaces of the materials, and accordingly salt-resistant effects of the materials can be realized; absorbers can be separated from water bodies by the aid of the hydrophobic properties of the materials, only the surface brine is heated, the brine can be quickly evaporated, the salt manufacture periods can be shortened to a great extent, and accordingly the salt manufacture quantities can be increased.

Owner:江苏金羿射日新材料科技有限公司

Preparation method of salted chilli

InactiveCN101744204APure taste and rich aromaStrong flavorClimate change adaptationFood preparationSaline waterSalt pond

The invention discloses a preparation method of salted chilli, which includes the following steps: (1) material selection: weighing salt and chilli on weigh proportion of 20-30:90-110; (2) salting: pouring the salt and the chilli into an empty pond for salting; (3) sealing and pressurizing: flat pressing the chilli in the salt pond through a bamboo or wooden plate, and putting a stone on the bamboo or wooden plate to press and seal the chilli in the salt pond; (4) cyclic pouring by period: in the first month after the chilli is soaked in the pond, pumping the brine once a week and pouring thebrine from the surface of the chilli; one month after the chilli is soaked in the pond, pumping the brine once a month and pouring the brine from the surface of the chilli; and two months late, taking the chilli out of the pond. In this way, the salted chilli can be ready. The salted chilli prepared through this method is of pure taste and rich aroma and has distinctive feature no matter the salted chilli is used as hot pot seasoning or be used as auxiliary material in other seasonings.

Owner:GUIZHOU XUYANG FOOD GROUP

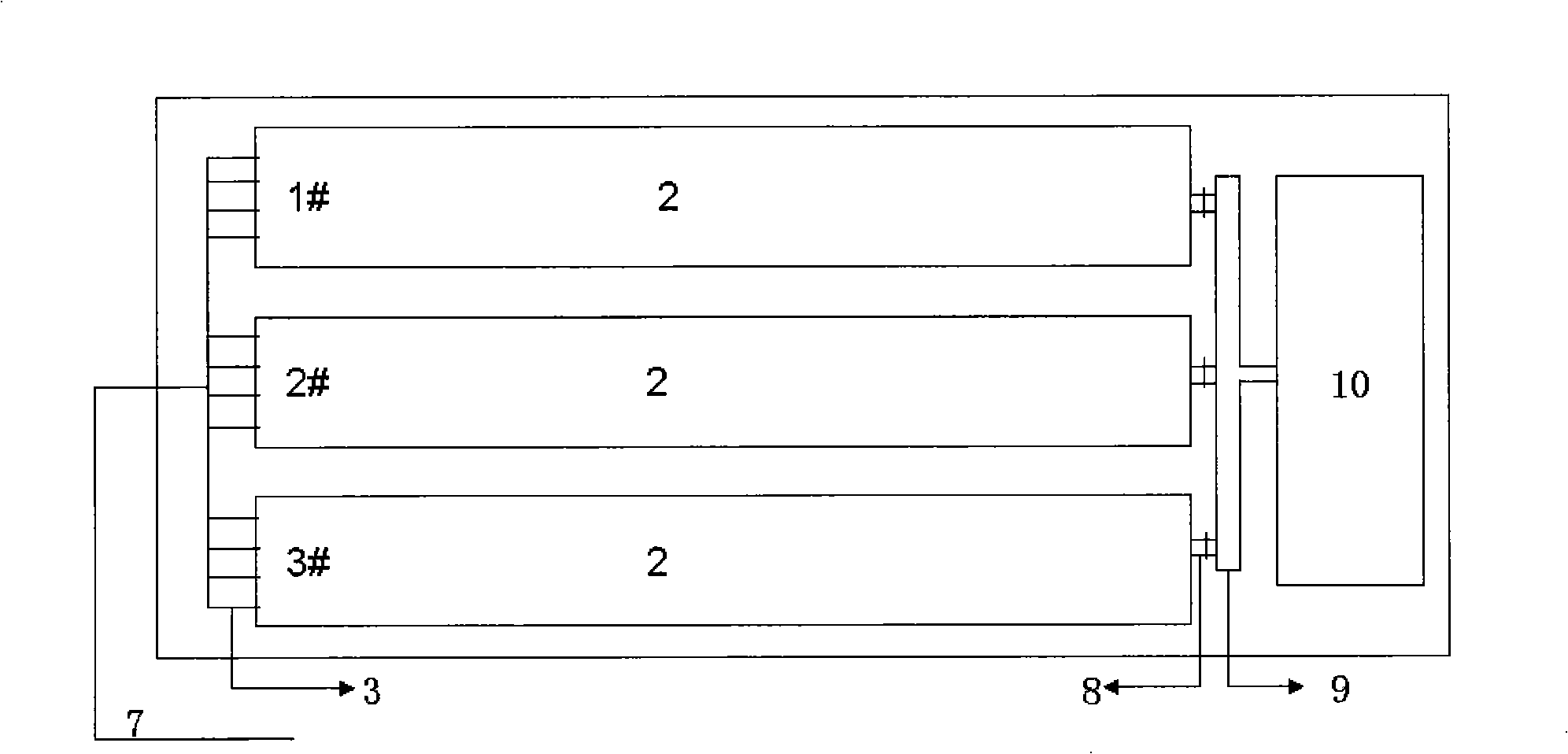

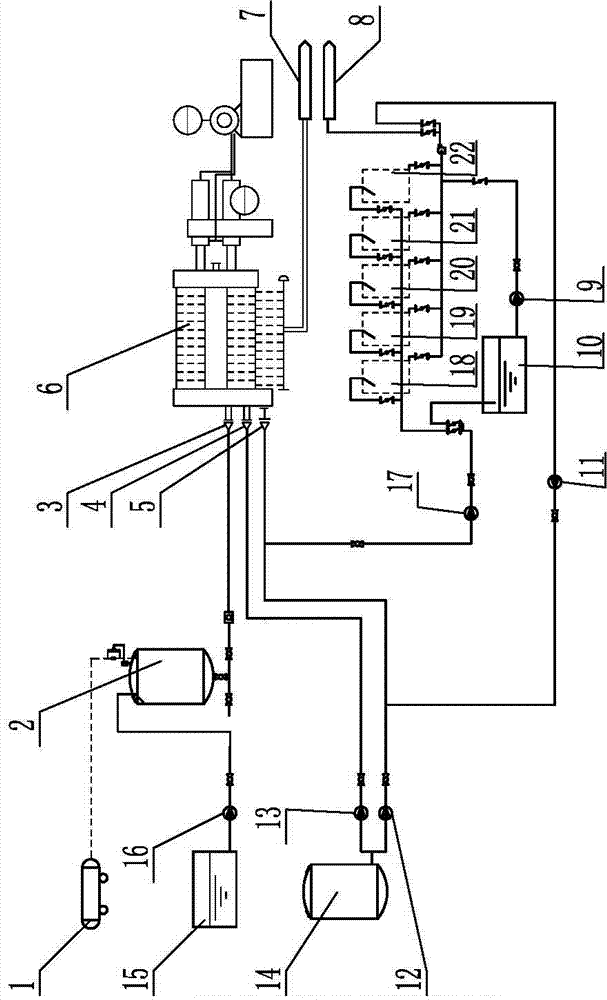

Performance test device of forward osmosis membrane

ActiveCN103736397AReduce areaGuaranteed uniformitySemi-permeable membranesHigh concentrationEngineering

The invention discloses a device for evaluating performance of a forward osmosis membrane. The device comprises a raw material liquid tank, a feed liquid pool, a forward osmosis membrane component, a draw solution pool, a high-concentration salt pond and a delivery tank, wherein a check valve and an overflow pipe are arranged on an overflow tank of the pool; an aeration pipe is arranged at the bottom; the forward osmosis membrane component comprises a shell; a forward osmosis membrane is arranged inside the shell, and divides the shell into upper and lower lattices, which respectively are a draw solution chamber and a feed liquid chamber; the draw solution chamber is put into a magnetic stirrer; a water inlet / outlet of the draw solution pool is connected with the draw solution chamber of the forward osmosis membrane component; a probe of a conductivity controller is put into the pool; the water outlet of the high-concentration salt pond is connected with the water inlet of the draw solution pool through a pipeline with a strong brine pump; opening and closing of the strong brine pump are controlled by a conductivity meter; the delivery tank is put on an electric scale. The device disclosed by the invention is small in volume, simple and easy to operate, stable in test result, small in required area of the forward osmosis membrane, wide in application range, and applicable to test of the forward osmosis membranes with kinds of sources.

Owner:JIANGNAN UNIV

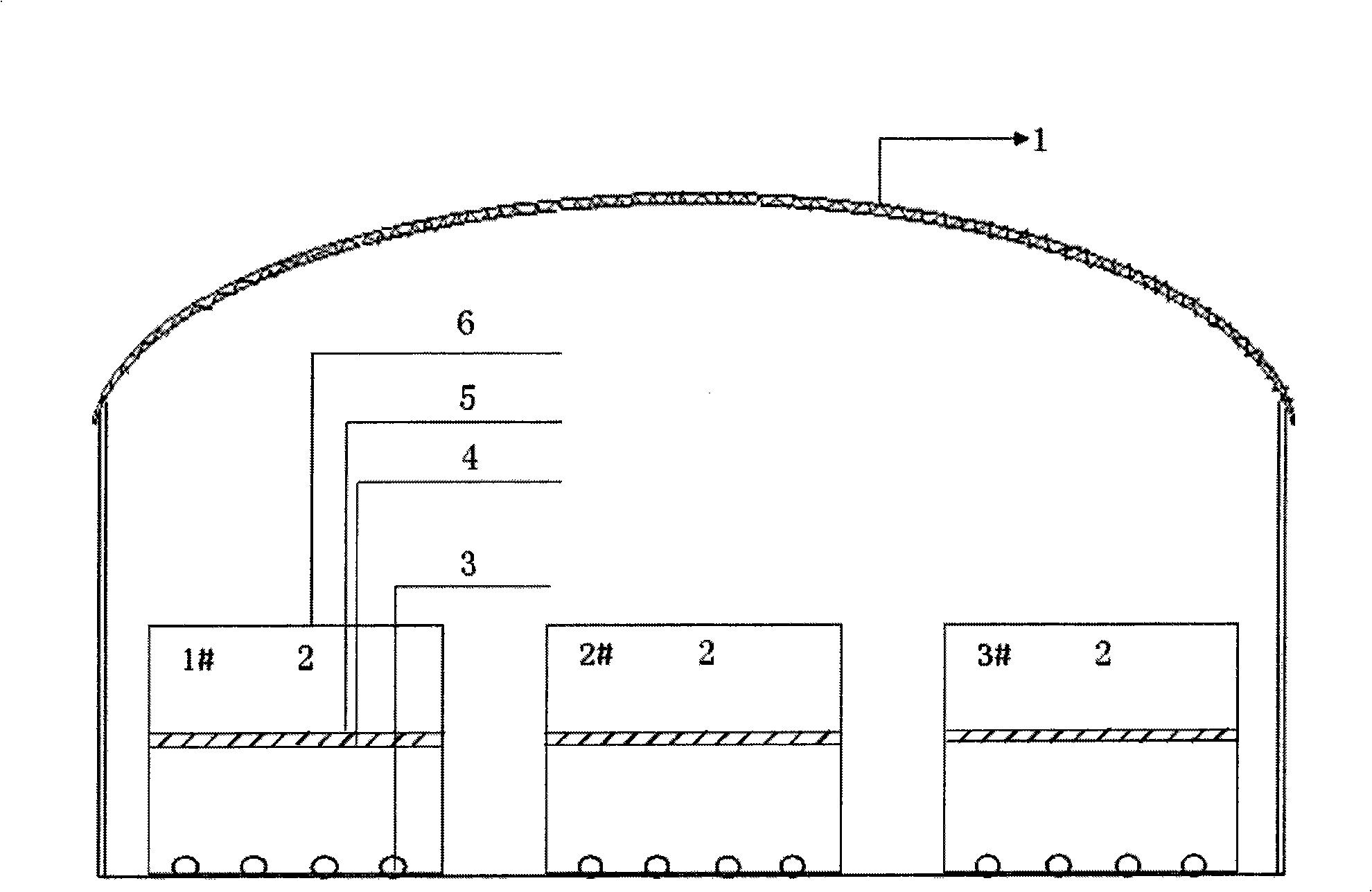

Salt pond for experiment of plant seedlings

InactiveCN102972230AGood experimental stabilityReduce distractionsReceptacle cultivationBrickEngineering

The invention discloses a salt pond for an experiment of plant seedlings. Two parallel salt ponds are arranged in each plastic shed with an actual width of 6m, clay common brick bodies are arranged on the inner wall around each salt pond and comprise three layers of bricks from bottom to top, the inner surfaces of the brick bodies and the surfaces of the bottoms of the salt ponds are covered with black film flat spreading layers; and mixed soil of saline soil and common soil, with the thickness of 25cm, is placed in each salt pond, and salt contents of the mixed soil in the salt ponds are respectively 0.01 percent, 0.2 percent, 0.3 percent, 0.4 percent, 0.5 percent or 0.6 percent. The salt ponds has good experiment stability, can obtain one batch of representative data; and the experiment can be carried out around the year, and is little interfered by outside conditions. The salt pond is especially suitable for the experiment of seedlings with the heights of below 1m.

Owner:张健

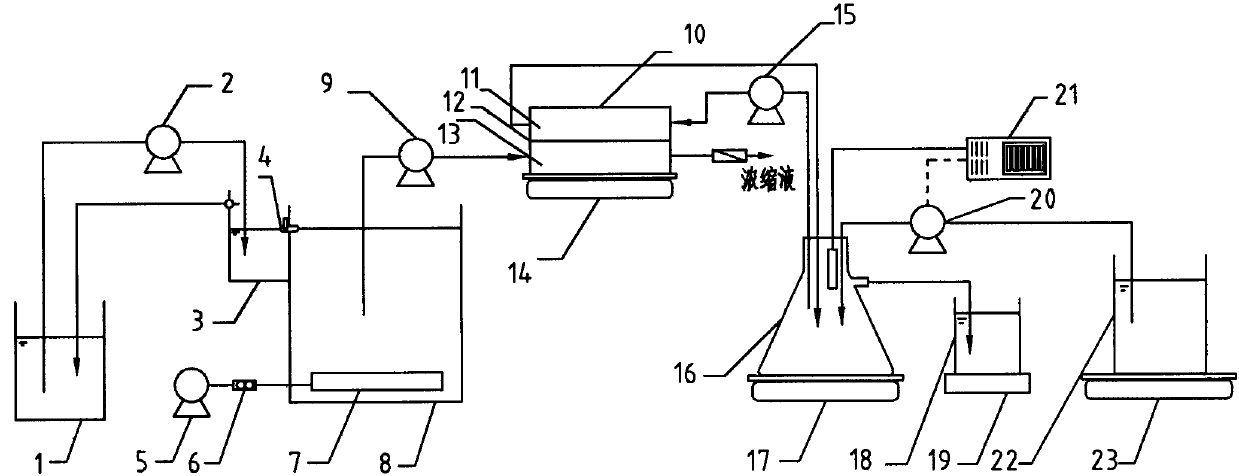

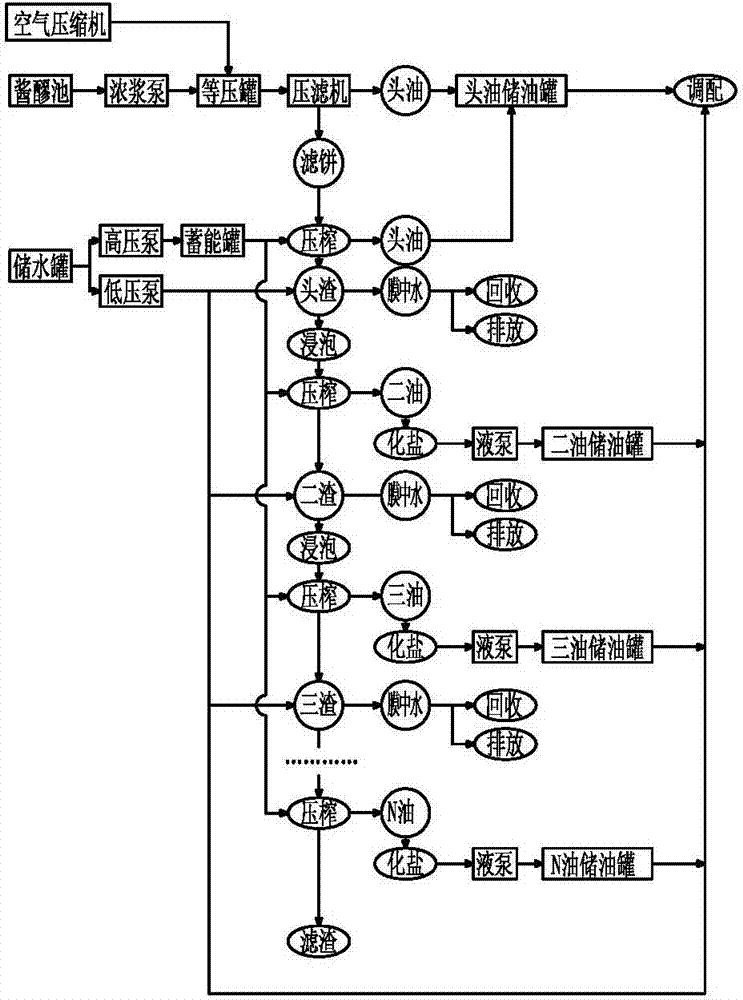

Squeezing system and squeezing process for high-salt liquid sauce

ActiveCN104757502ALess stickyReduce particle damage and other phenomenaFood preparationWater storageWater storage tank

The invention provides a squeezing system and squeezing process for a high-salt liquid sauce, belonging to the field of squeezing of sauces. The squeezing system is characterized by comprising a sauce mash squeezing system, a pneumatic system and a water-circulating pipe system, wherein the sauce mash squeezing system is connected with a feed inlet of an isobaric tank through an underflow pump, a discharge outlet of the isobaric tank is connected with a feed inlet of a membrane plate-type filter press, discharge outlets of the membrane plate-type filter press are separately connected with a salt dissolving pond and an oil storage tank, the salt dissolving pond is connected with the oil storage tank through a material pump, an air compressor of the pneumatic system is connected with the air inlet of the isobaric tank, water storage tanks of the water-circulating pipe system are separately connected with a high-pressure pump and a low-pressure pump, the high-pressure pump is connected with a membrane plate water filling port of the membrane plate-type filter press, and the low-pressure pump is connected with the discharge outlet of the membrane plate-type filter press. The squeezing system provided by the invention needs low investment; the squeezing process is excellent; high production efficiency and high crude oil removal quality are obtained; and labor intensity of workers is low.

Owner:山东玉兔食品股份有限公司

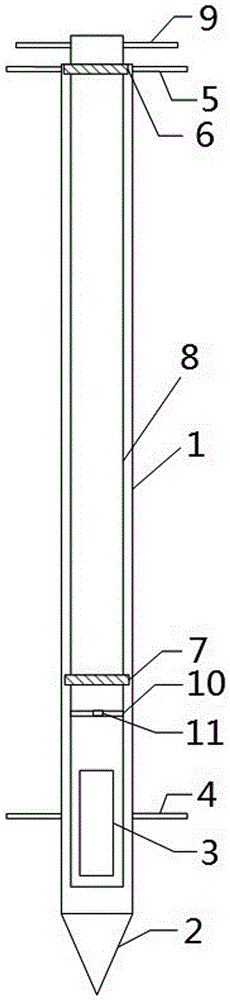

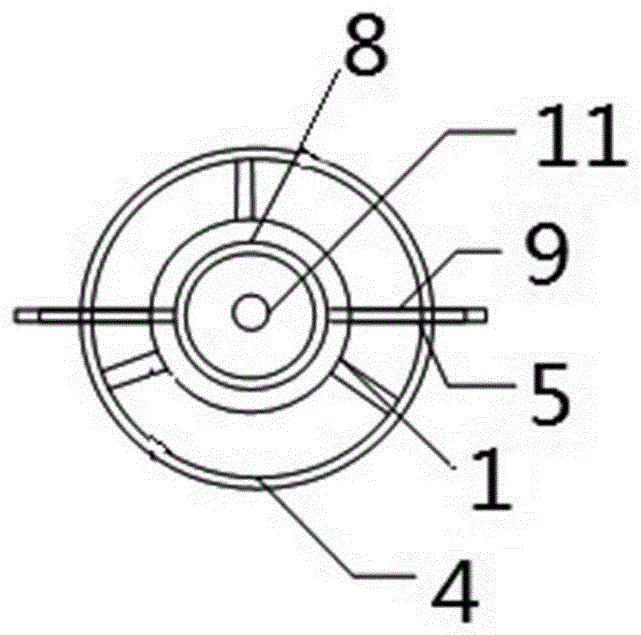

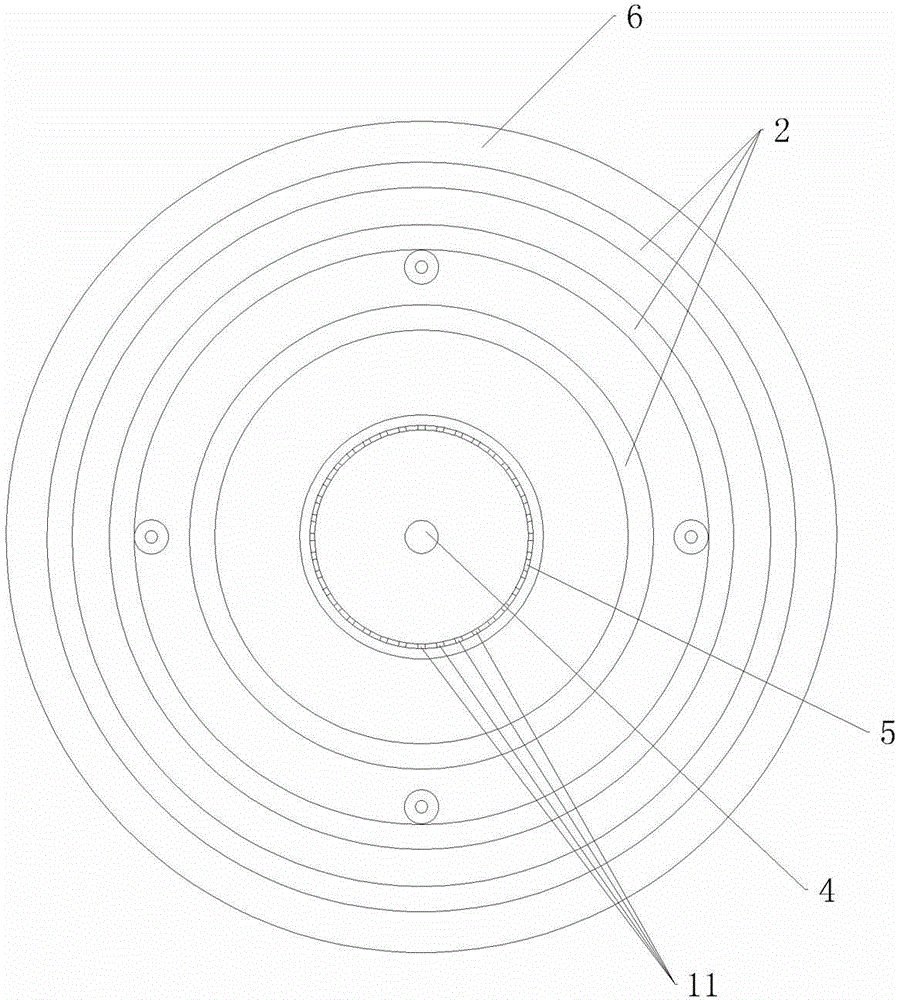

Rotary type solid-liquid surface sediment sampling device and use method thereof

The invention belongs to a brine solid-liquid two-phase fidelity sampling device. The device comprises a rotating rod, wherein a rotating rod handle is arranged at the upper end of the rotating rod; an outer connecting tube is arranged on the periphery of the lower part of the rotating rod; the lower end of the rotating rod is connected with a rotary connecting shaft; a handle is arranged at the upper end of the outer connecting tube; an outer barrel is arranged at the lower end of the outer connecting tube; an end cover is arranged at the upper part of the outer barrel; a liquid sampler is arranged below the end cover; a solid sampler is arranged below the liquid sampler; a bottom plate is arranged below the solid sampler. The device can accurately perform undisturbed fidelity collection on a solid sample and a liquid sample at a solid-liquid interface in a salt pond, and reliable basis is provided for research of sample data analysis of the salt pond.

Owner:SDIC XINJIANG LUOBUPO POTASH CO LTD +1

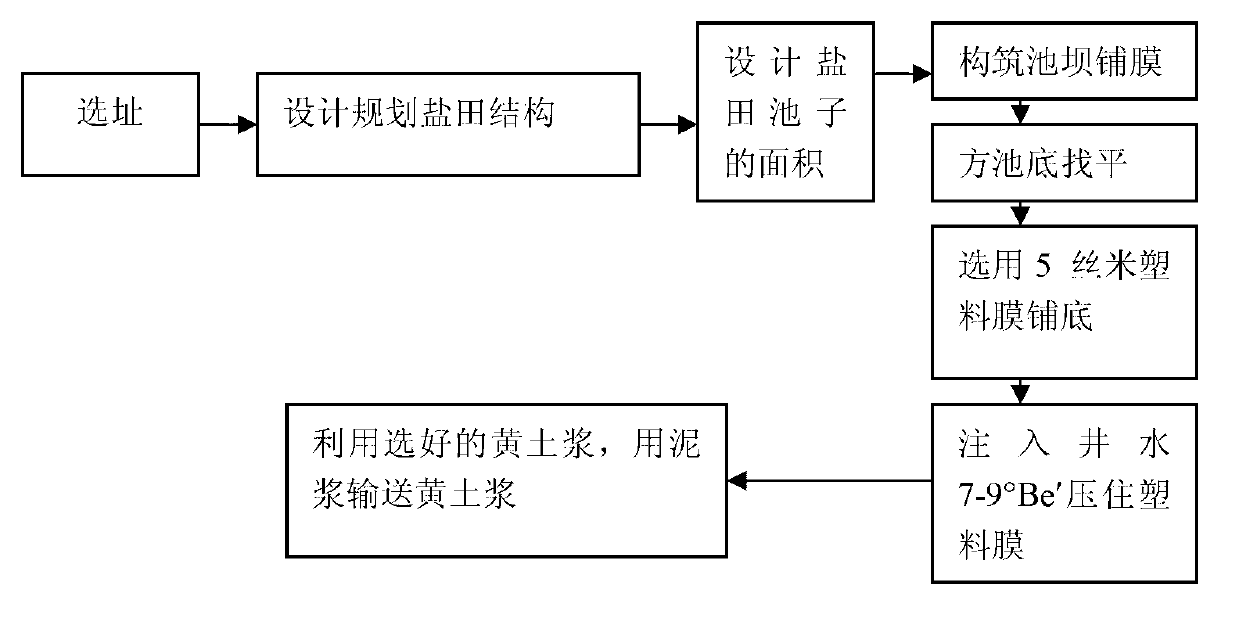

Method for rapidly building anti-seepage salt pond

The invention relates to a method for rapidly building an anti-seepage salt pond, which comprises the steps of constructing a pond dam, carrying out leveling and film laying on the bottom of the pond, injecting water and filling loess slurry, and finishing a loess slurry pool plate, and the like. In the method disclosed by the invention, the step of constructing a pond dam can be implemented by using underground loess locally produced in Laizhou Bay, but in traditional processes, clay must be used in the construction of pond dams, the application of clay has more and more obvious shortcomings, one shortcoming is shown in the aspects of trouble transportation and high cost, and another shortcoming is that the clay can be subjected to water seepage, thereby causing the waste of brine; due to the application of a polyethylene plastic film, in the process of salt manufacturing, brine is separated from the bottom of the pond through the plastic film, so that a water seepage phenomenon can be prevented; and through adopting the way, in the process of salt manufacturing, the application amount of brine is reduced by 50%. The method is simple in operation, and compared with traditional processes, the cost is reduced by 20%, and the beach building time is reduced by about 75%.

Owner:莱州诚源盐化有限公司

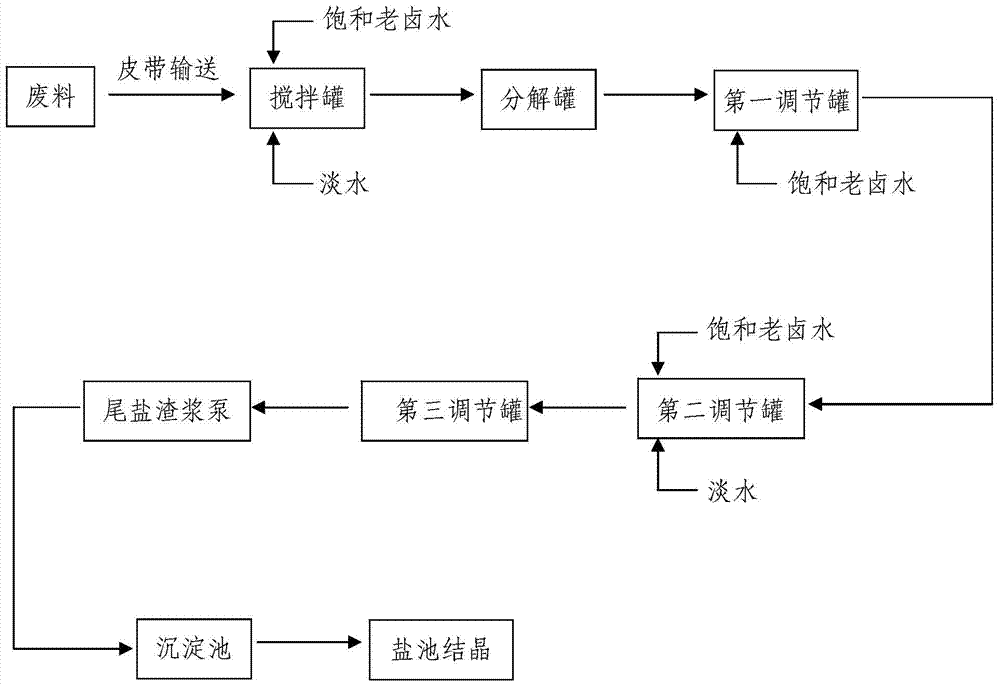

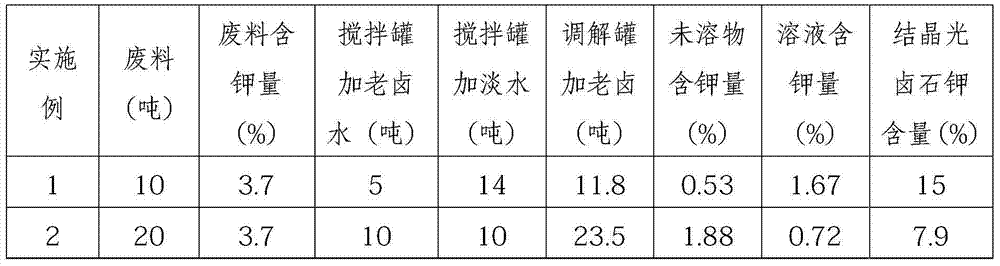

Method for extracting and recycling residual potassium chloride from salt-lake tail salt and waste carnallite

ActiveCN104743580ASimple processReduce energy consumptionAlkali metal halide purificationSalt lakeChloride

The invention relates to a method for extracting and recycling residual potassium chloride from salt-lake tail salt and waste carnallite. The method comprises the following steps: mixing to-be-recycled waste, aged saturated brine and fresh water to obtain a waste-dissolved solution, adding aged saturated brine at least once to adjust the baume degree of the waste-dissolved solution, and keeping the baume degree of the waste-dissolved solution within a preset range in such a way that the waste-dissolved solution is introduced into a salt pond and then crystallized to form carnallite. According to the method, high-quality carnallite with the potassium content great than or equal to 15% can be obtained through the technical processes such as batching, decomposing, allocating, mixing, clarifying and crystallizing. The method for extracting and recycling residual potassium chloride from salt-lake tail salt and waste carnallite can be used for effectively recycling residual potassium from the waste and has the advantages of low cost, high efficiency, reduction of resource waste and the like; and a great amount of potassium chloride can be refined from the high-quality carnallite by a flotation technology.

Owner:陈杰

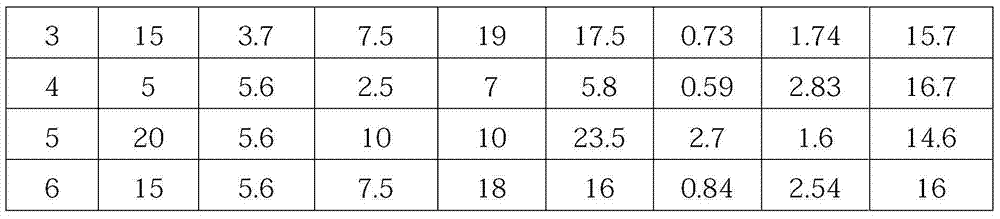

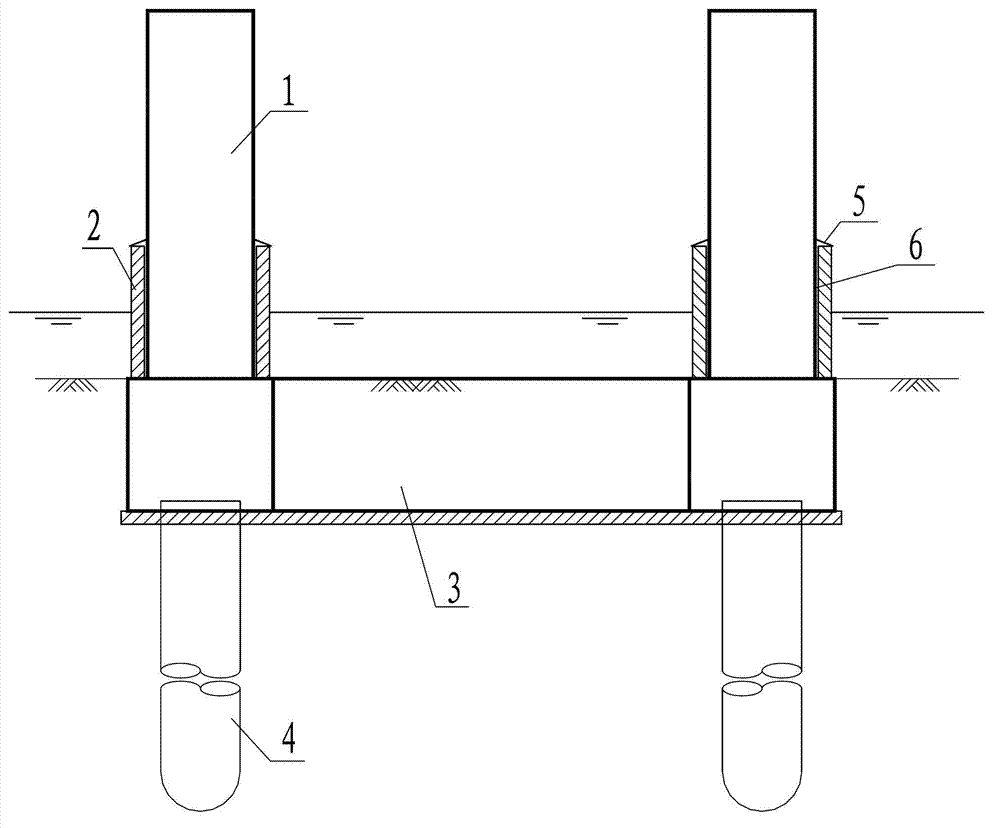

Multifunctional offshore wind power structure

PendingCN113137338ACompact and reasonable structureAbundant resourcesGeneral water supply conservationSeawater treatmentEnvironmental engineeringOffshore wind power

Owner:FOSHAN DIANJIAN ELECTRICAL EQUIP CO LTD

Preparation method of yellow pepper blank

The invention discloses a preparation method of a low-salt yellow pepper blank. The preparation method comprises the following steps: slicing or sectioning fresh yellow pepper materials, adding salt water after mixing with white grape wine, kiwi fruit granules, saussurea involucrata fruit granules and solid salt, further mixing uniformly and obtaining raw materials of the yellow pepper blank; salting the raw materials of the yellow pepper blank by adopting underground salting, putting the raw materials of the yellow pepper blank into a pond body of a salting pond, spraying edible alcohol on the surfaces of the raw materials of the yellow pepper blank, closing a pond cover to seal the inner part of the pond body, pressing and placing a heavy object on the pond cover, and salting to obtain the low-salt yellow pepper blank. The preparation method is simple and can meet large-scale industrial production. The prepared low-salt yellow pepper blank has the advantages that the sour flavor is mild, the taste is delicious and fresh, the salinity is palatable, the fragrance is strong, the color is golden yellow, the color is bright, the quality guarantee period of the low-salt yellow pepper blank is 3 years i the sealed state, and the application requirement can be met.

Owner:衡东兴薇三樟黄贡农产品有限公司

Pump-type liquid atomizing drying device

InactiveCN104014138AAccelerated evaporative dryingReduce consumptionEvaporation by sprayingImpellerSludge

The invention provides a pump-type liquid atomizing drying device. The pump-type liquid atomizing drying device comprises a lower shell, wherein the lower shell is provided with a water inlet, a motor is fixedly connected in the lower shell, and the pump-type liquid atomizing drying device is characterized in that the upper end of the lower shell is connected with a cylindrical upper shell, the upper shell is communicated with the lower shell, an output shaft of the motor is connected with an impeller and an upper flywheel, the lower part of the upper flywheel is sequentially connected with a plurality of ring-shaped lower flywheels, the upper flywheel is fixedly connected with the output shaft, the surface of each lower flywheel and / or the upper flywheel is provided with atomizing teeth, and the side wall of the upper shell is provided with a plurality of water injection holes corresponding to a centrifugal atomizing device. By adopting the pump-type liquid atomizing drying device, under the condition that little energy is consumed, a great amount of different liquids and liquid contained solid particles can be atomized and dried, the application range is wide, the evaporation drying of the liquids can be greatly improved by atomizing the liquids and greatly absorbing the heat in the air, the energy consumption is low, and the pump-type liquid atomizing drying device can be widely applied to the fields of air curing of salt in salt ponds, preparation of milk powder, the sludge drying, and the like.

Owner:贾会荣 +1

Process for removing sodium chloride from salt mud produced in chlor-alkali production

InactiveCN109534703AReduce saltSalt (NaCl) reductionWater/sewage treatment by centrifugal separationSludge treatmentMass ratioPolyacrylamide

The invention discloses a process for removing sodium chloride from salt mud produced in chlor-alkali production, and belongs to the technical field of environmental protection control. The process ischaracterized by comprising the process steps: (1) 0.3%-1.3% by mass of polyacrylamide is added into a salt-mud-containing salt solution, the salt mud and the salt solution are separated through an automatic centrifugal separator, and the salt mud is transferred into a salt washing pool; (2) water is added into the salt mud in the salt washing pool to stir and wash, wherein the mass ratio of thesalt mud to the water in the salt washing pool is (12 to 15):(83 to 86); (3) the mixture is conveyed to a plate-and-frame filter press to be subjected to filter pressing, and liquid obtained through filter pressing is directly discharged, wherein the filter pressing pressure is 0.75-0.85 MPa, and the filter pressing time is 120-150 min; and (4) the salt mud after filter pressing is used as a cement production raw material or used for plant cultivation. The sodium chloride in the salt mud can be completely removed in a washed mode, thus the salt (NaCl) content in the salt mud is decreased to be1% or below, the waste discharge pressure is reduced, and clean production of the chlor-alkali industry is achieved.

Owner:胥敏一 +2

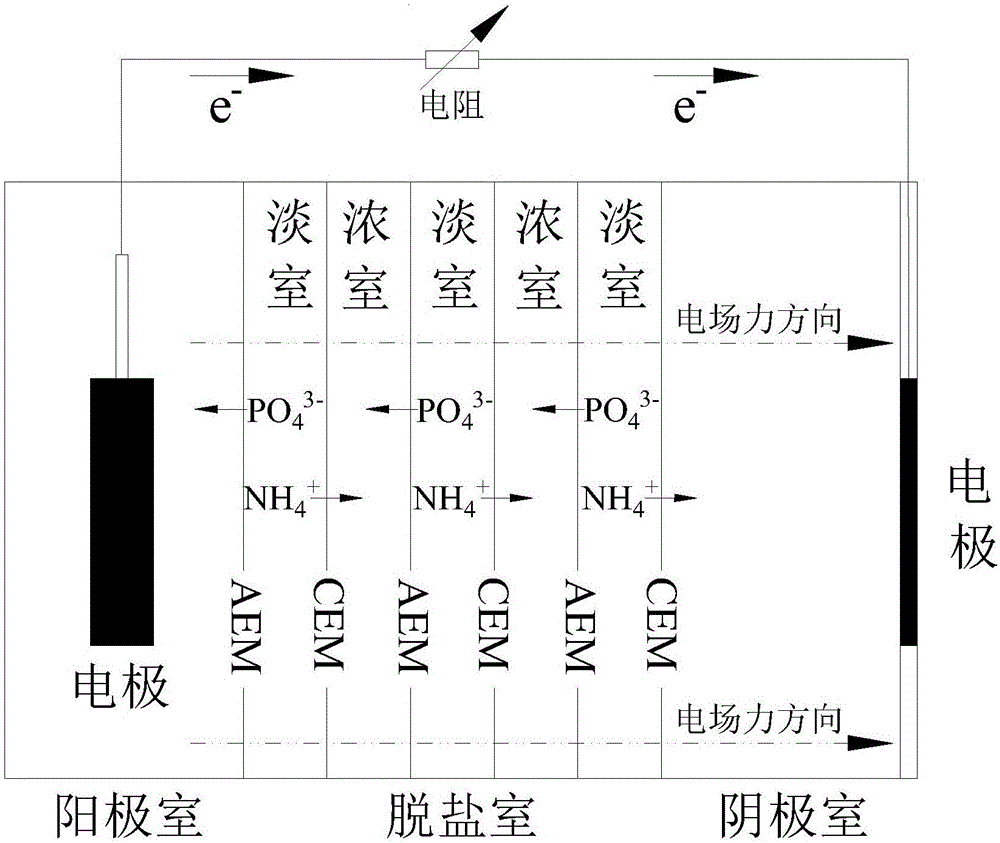

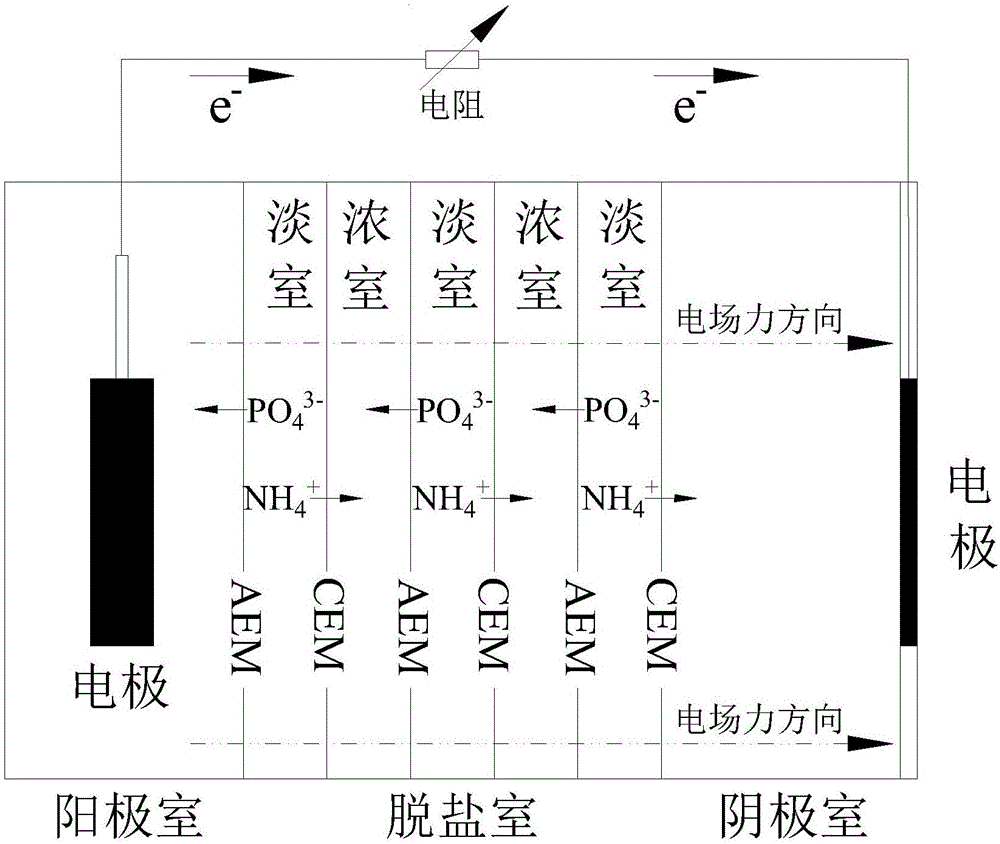

Denitrification method of ammonia-nitrogen wastewater and microbial desalination tank

InactiveCN106630113AHigh removal rateTreatment by combined electrochemical biological processesSpecific water treatment objectivesPhosphateDesalination

The invention provides a denitrification method of ammonia-nitrogen wastewater and a microbial desalination tank. The microbial desalination tank comprises a shell, an outer circuit, an anode chamber, a cathode chamber and a desalination chamber, wherein the anode chamber, the cathode chamber and the desalination chamber are arranged in the shell. The denitrification method includes: adding human manure liquid into the anode chamber inoculated with anaerobic sludge; adding phosphate buffer into the cathode chamber; allowing the ammonia-nitrogen wastewater to enter the microbial desalination tank from the desalination chamber so as to remove ammonia and nitrogen. The denitrification method using the ammonia-nitrogen wastewater has the advantages that the ammonia and the nitrogen can be removed efficiently by adding a small amount of phosphate buffer, electric energy generated in an electrochemical system can also be recycled during denitrification, and the removing rate of the ammonia and the nitrogen in the ammonia-nitrogen wastewater reaches up to 93%.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

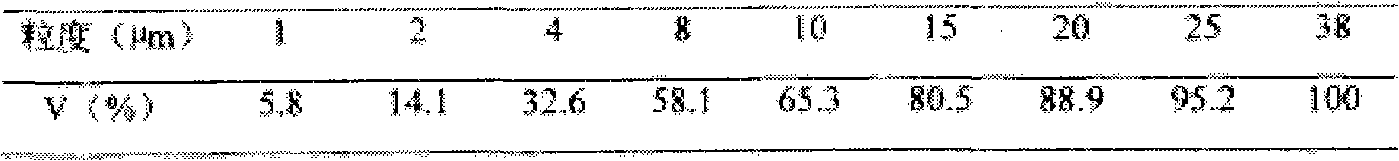

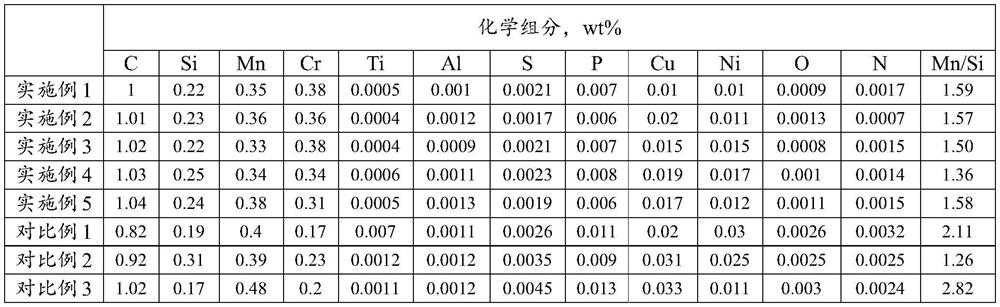

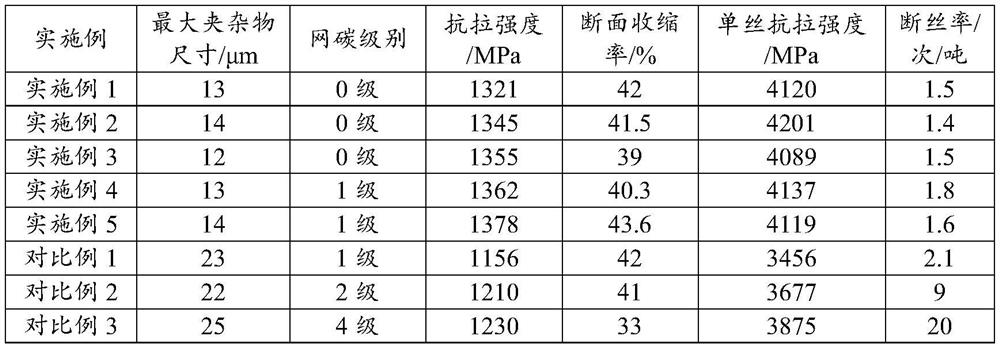

102-grade steel cord, 102-grade cord steel wire rod and production method of 102-grade cord steel wire rod

The invention discloses a 102-grade steel cord, a 102-grade steel cord steel wire rod and a production method of the 102-grade steel cord steel wire rod. The production method comprises the following steps: in a steel smelting stage, smelting molten steel of which the size of inclusions is less than or equal to 15 microns; in the blank casting stage, the center carbon segregation value of a continuous casting blank is smaller than or equal to 1.05, and C in a segregation area is smaller than or equal to 1.09%; a cogging stage; in the rolling stage, the rolled wire rod comprises the following chemical components in percentage by mass: 1.00-1.04% of C, 0.2-0.3% of Si, 0.3-0.4% of Mn, 0.3-0.4% of Cr, less than or equal to 0.0020% of Al, less than or equal to 0.0006% of Ti, less than or equal to 0.003% of S, less than or equal to 0.008% of P, less than or equal to 0.03% of Cu, less than or equal to 0.02% of Ni, less than or equal to 0.0015% of O, less than or equal to 0.0030% of N and the balance of Fe and other inevitable impurities; wherein the content of Mn and the content of Si meet the condition that Mn / Si is equal to 1.3-1.6; a temperature control cooling stage; and in the salt bath heat treatment stage, the wire rod subjected to temperature control cooling is heated in a salt bath heating furnace and then sent to a salt pond to be rapidly cooled, the temperature in the salt bath heating furnace ranges from 960 DEG C to 980 DEG C, the temperature of molten salt ranges from 520 DEG C to 540 DEG C, and the wiring speed of the wire rod ranges from 10 m / min to 12 m / min. According to the invention, the problems of limited strength and easy wire breakage during drawing caused by high carbon content of the tire cord steel are solved.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +2

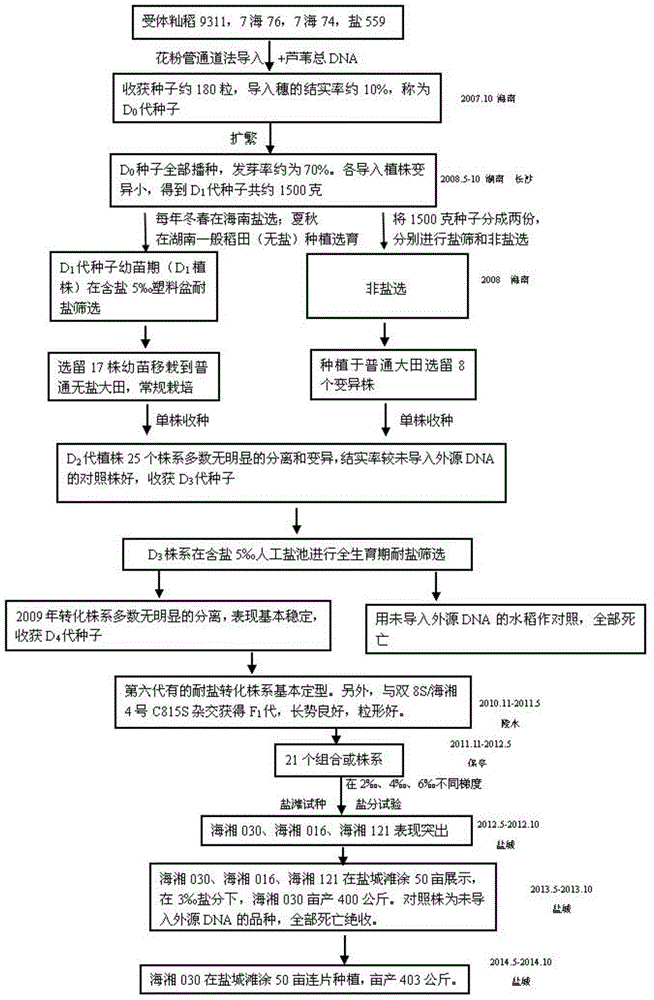

Method for cultivating salt-tolerant rice by using pollen-tube pathway transformation technology

InactiveCN104531764AImport method newNew screening methodMicroinjection basedPlant genotype modificationBiotechnologySalt Tolerant Plants

The present invention discloses a method for cultivating salt-tolerant rice by using a pollen-tube pathway transformation technology. The method comprises: (1) extracting bulrush leaf DNA; (2) transforming the exogenous DNA into acceptor rice; (3) carrying out pot screening at a germination period; (4) carrying out artificial salt pond screening and big field breeding; and (5) planting the stable strain in the salt marsh field. According to the present invention, the pollen-tube pathway technology is utilized to transfer the total DNA of the halophyte into the ordinary rice, such that the transferring of the super-distant genetic material is achieved, the tissue culture process is eliminated, a variety of unpredictable adverse effects possibly produced during the plant tissue culture process are avoided, multiple genes can be simultaneously imported, and the molecular breeding of the salt-tolerant plants can be achieved.

Owner:林栖凤 +3

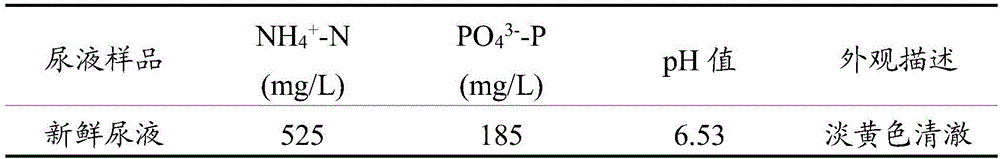

Method for synchronously treating human manure and urine and microbial desalting tank

ActiveCN106315993AReduce removal rateHigh removal rateTreatment by combined electrochemical biological processesBiological treatment apparatusMicroorganismPhosphate ion

The invention provides a method for synchronously treating human manure and urine. The method comprises the following steps: carrying out ammoniomagnesium phosphate crystallization pretreatment on human urine to obtain a crystallization pretreatment solution; and carrying out denitrification and dephosphorization treatment on the crystallization pretreatment solution and human manure by a microbial desalting tank, wherein the mass ratio of the magnesium ions in the ammoniomagnesium phosphate crystallization pretreatment process to the phosphate ions in the urine is (0.9-2):1. The method provided by the invention can treat ammonia nitrogen and phosphates in the human urine only by adding a small amount of magnesium ions. The experimental result on the method provided by the invention shows that the maximum removal rate for ammonia nitrogen in the urine can reach 94.4%, and the maximum removal rate for phosphates can reach 99%.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Bridge pier column under high-concentration salt solution corrosion environment

InactiveCN103194961AAvoid destructionEnsure safetyBridge structural detailsHigh concentrationEngineering

The invention discloses a bridge pier column under a high-concentration salt solution corrosion environment. The bridge pier column comprises a pier column body arranged on a bearing platform. A column boot is arranged on the periphery of the pier column body within a range from the top surface of the bearing platform to above the maximum water level of a salt pond, gaps are reserved between the column boot and the pier column body, sealant is filled in the gaps, and a rainproof cover fixed on the pier column body is arranged at the top of the column boot. The rainproof cover is provided with a slope surface with a high inner edge and a low outer edge, and the outer diameter of the rainproof cover is larger than that of the column boot. The column boot and the rainproof cover serve as anti-corrosive protecting members of the pier column, high-concentration salt solution is isolated to avoid corroding the pier column, damage of a main body structure is avoided, main body structure safety is guaranteed, service life of the bridge pier column is prolonged, and later-period maintenance difficulty of the bridge pier column is reduced. The column boot is of a concrete structure and is convenient to construct, later-period maintenance workload is small, and engineering comprehensive fabricating cost is low. The column boot is not engaged in structure stress, quake-proof plastic hinge design difficulty of the bridge pier column is reduced, and the bridge pier column is easy to maintain especially after destruction of earthquake action.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com