Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1429results about "Waste processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

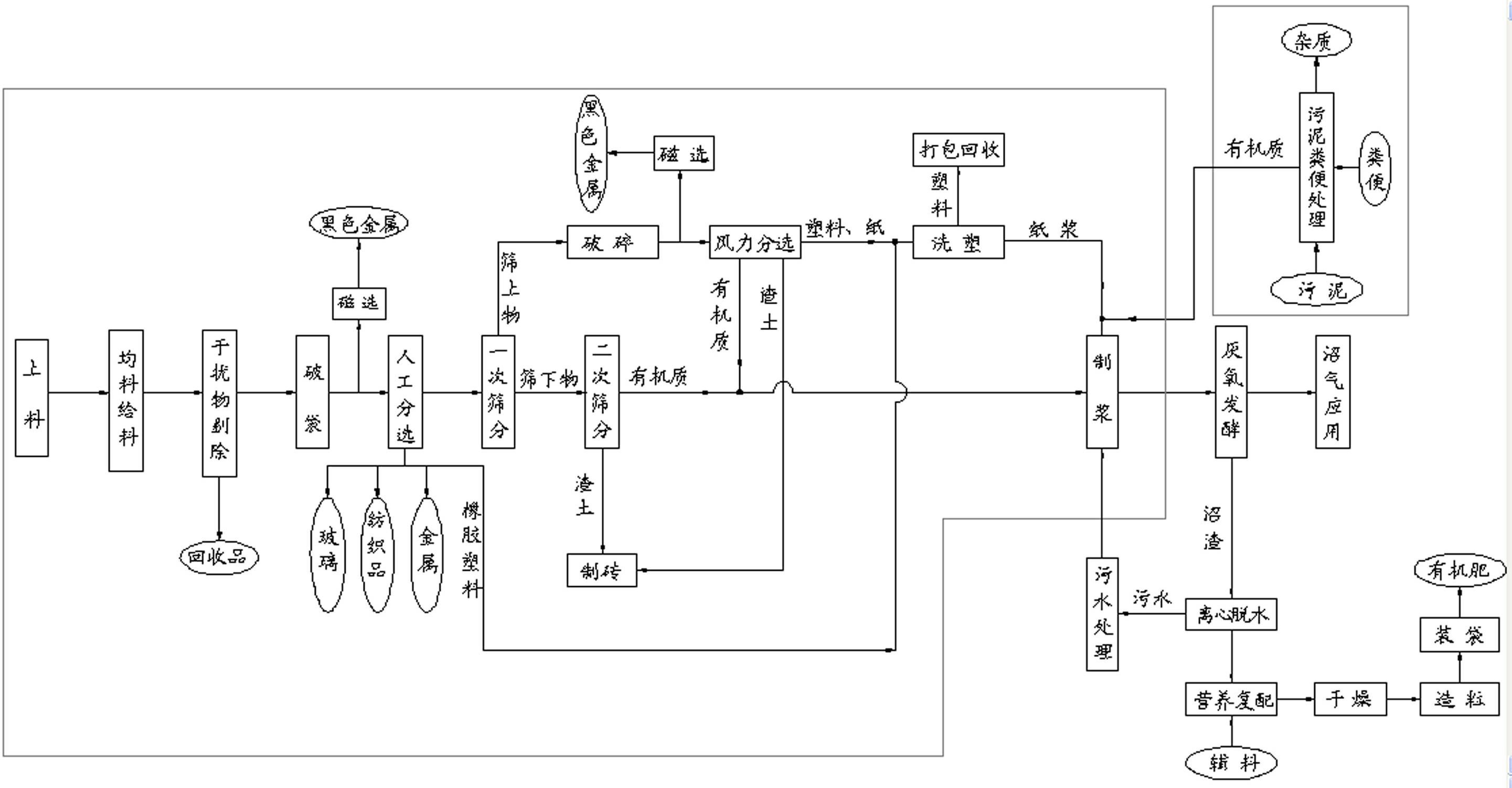

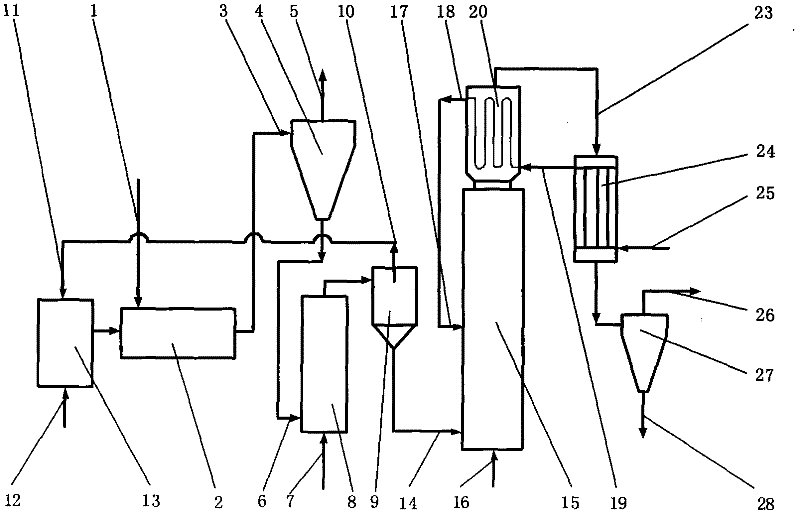

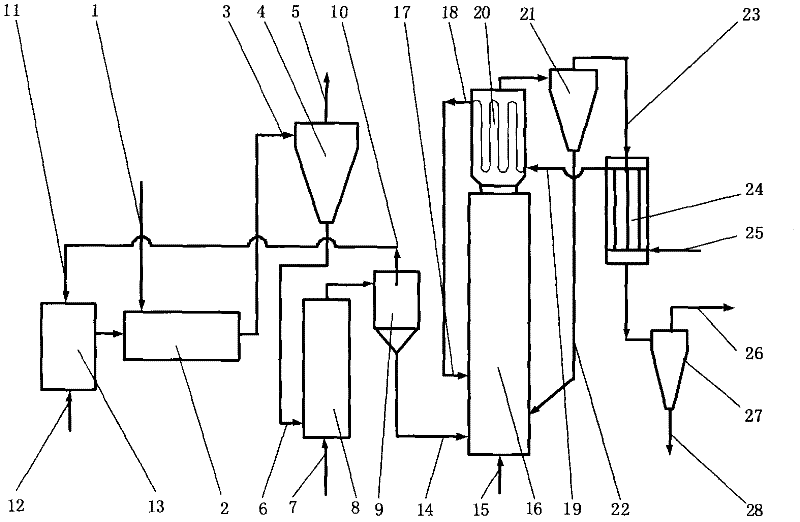

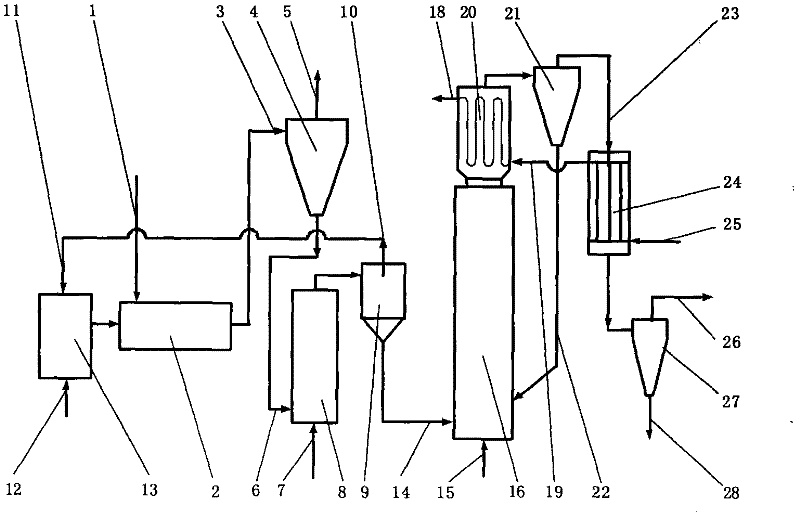

Comprehensive treating system for domestic wastes

InactiveCN102527701AIncrease productionImprove qualityBio-organic fraction processingWaste processingSludgeOrganic manure

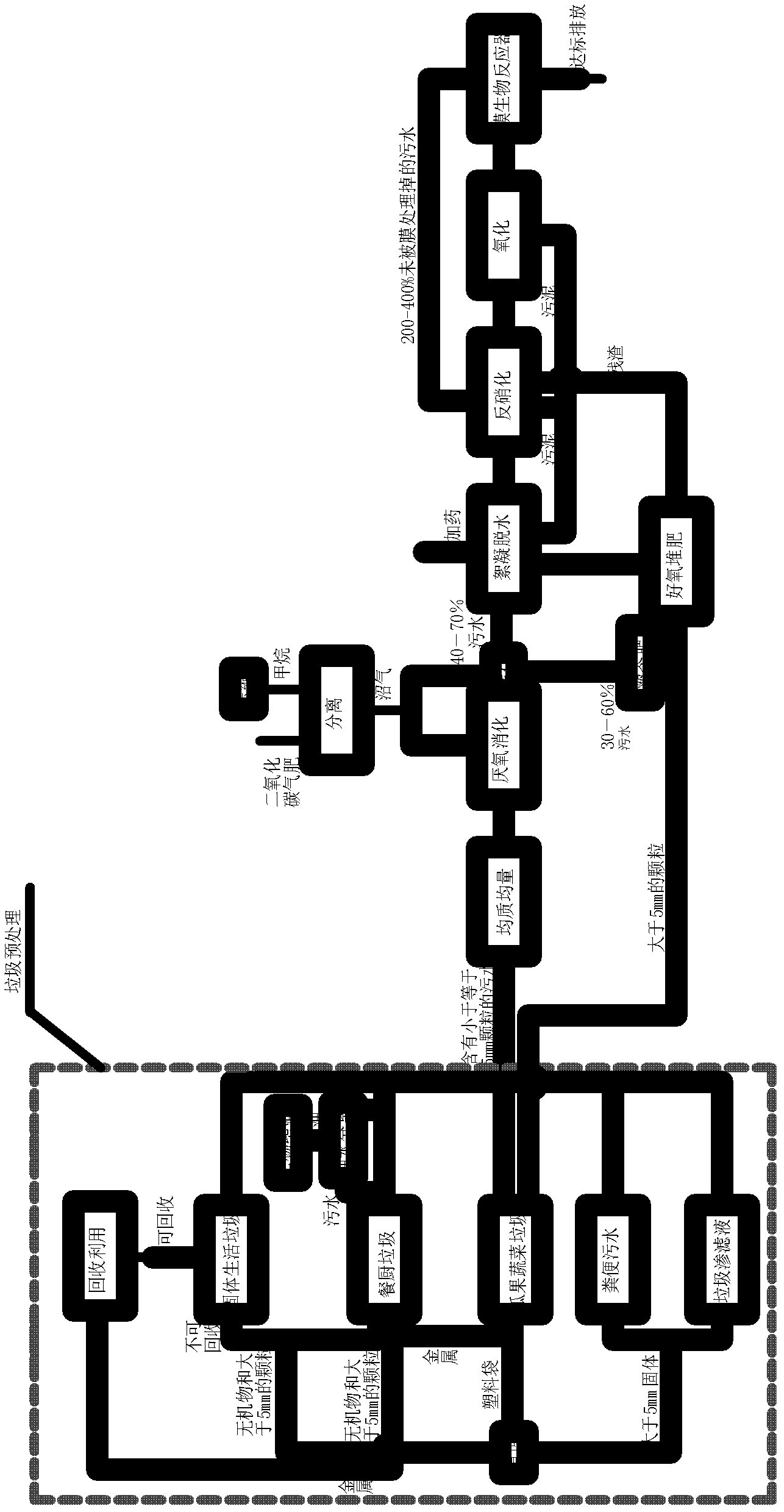

The invention discloses a comprehensive treating system for domestic wastes. Reutilizing comprehensive treatment for mixed wastes is realized by the system according to a comprehensive sorting technology and a combined anaerobic fermentation technology, wherein the advanced sorting techniques, such as, crushing, magnetic separating, sieving, air classifying, and the like, are adopted in the comprehensive sorting technology; reutilized products, such as metal, plastics, organic matters, and the like, are screened out; the screened organic matters are prepared into slurry together with sludge and excrements and are then subjected to the combined anaerobic fermentation; the reutilized products, such as methane, organic fertilizer, and the like, can be produced under the action of anaerobic fermentation; and after the methane is purified, the methane is used for generating power, domestic fuel or vehicle-mounted fuel. According to the technology, the intensified treatment for organic wastes, such as domestic wastes, sludge, excrements, kitchen wastes, and the like, can be realized. The comprehensive treating system is high in mechanical and automated degree. Compared with the prior art, the comprehensive treating system has the advantages of simplification, effectiveness, less labor power, and the like.

Owner:BEIJING HAOHAI TIANJI TECH +1

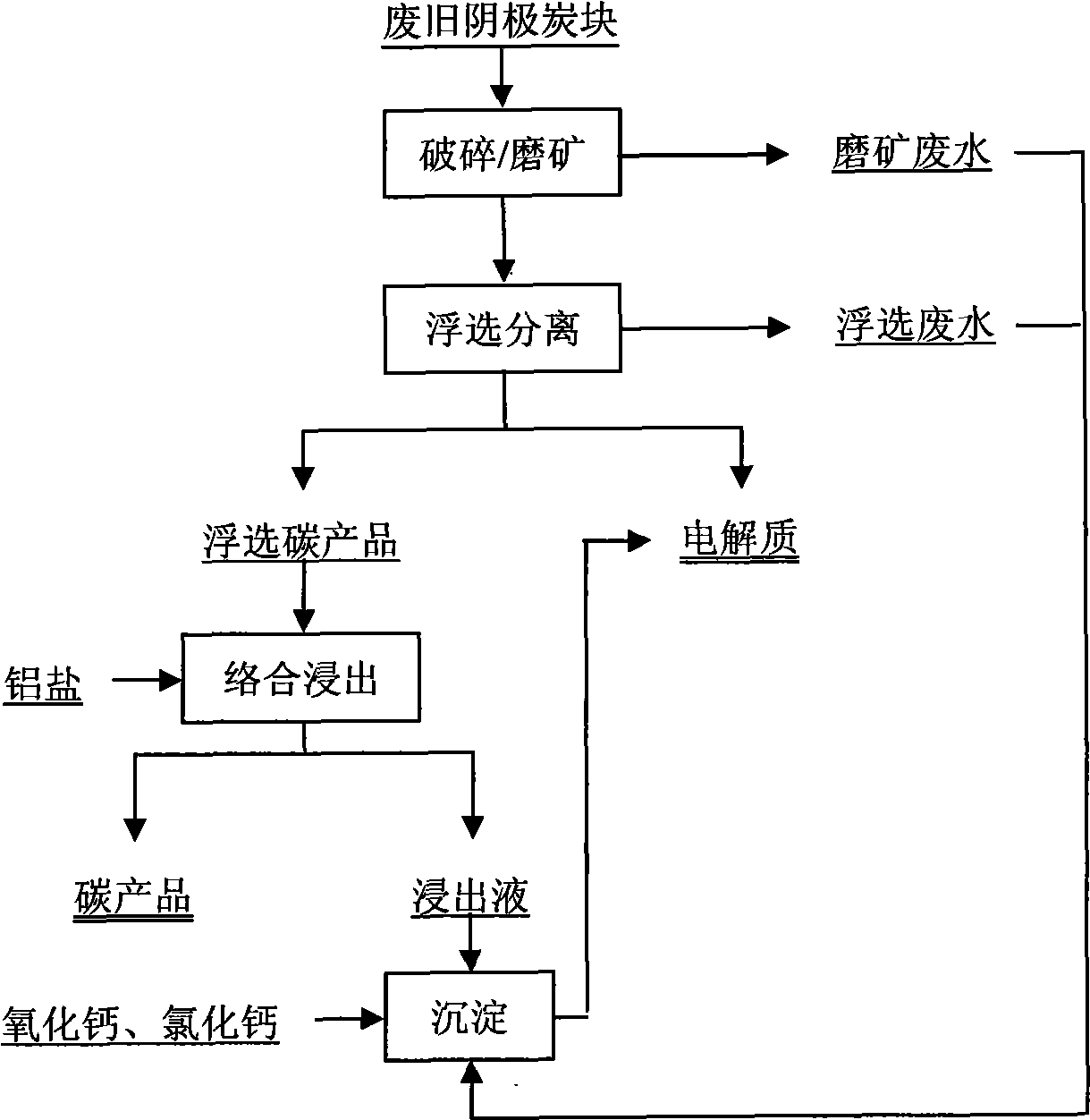

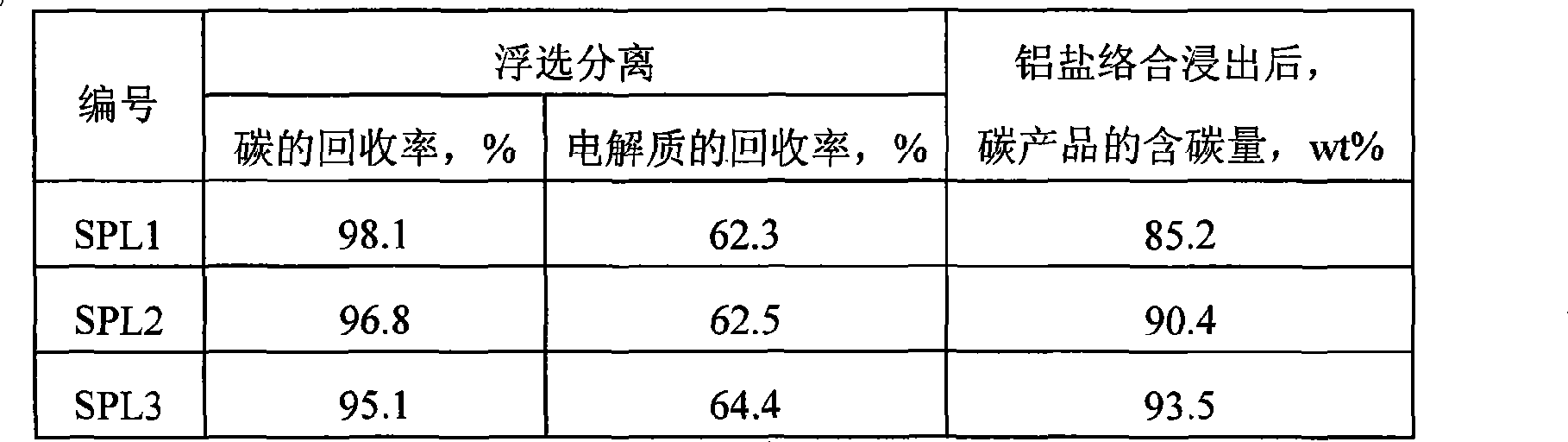

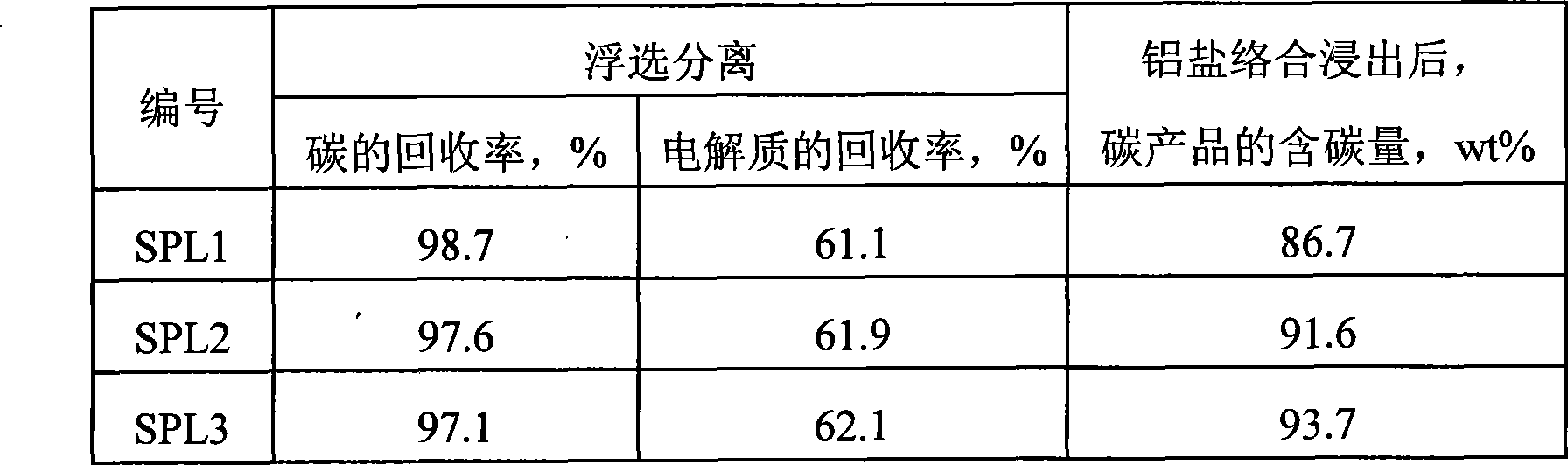

Method for electrolyzing waste and old cathode carbon block by comprehensive utilization of aluminum

ActiveCN101480658ARealize flotation separationHigh carbon contentFluoride preparationWaste processingPregnant leach solutionHigh carbon

The invention relates to a method for comprehensively using aluminium to electrolyze a waste cathode carbon block, which belongs to the technical field of environment protection and comprises the following steps: crushing and grinding the waste cathode carbon block; adjusting the concentration and the PH value of ore slurry after the grinding, then using floatation equipment to carry out floatation treatment, and separating electrolyte and carbon which are contained in the waste cathode carbon block; using an aluminium salt solution to soak for extracting the electrolyte contained in a carbon product obtained from the floatation, and further improving the grade of a high-carbon product; mixing the grinding waste water, the floatation waste water and the soaking solution, and adding CaO and CaCl2 to precipitate and recover aluminium and fluothane in the mixture. The method for comprehensively using aluminium to electrolyze a waste cathode carbon block has simple operating condition, low energy consumption, high recovery ratio of valuable substances and good application prospect.

Owner:NORTHEASTERN UNIV

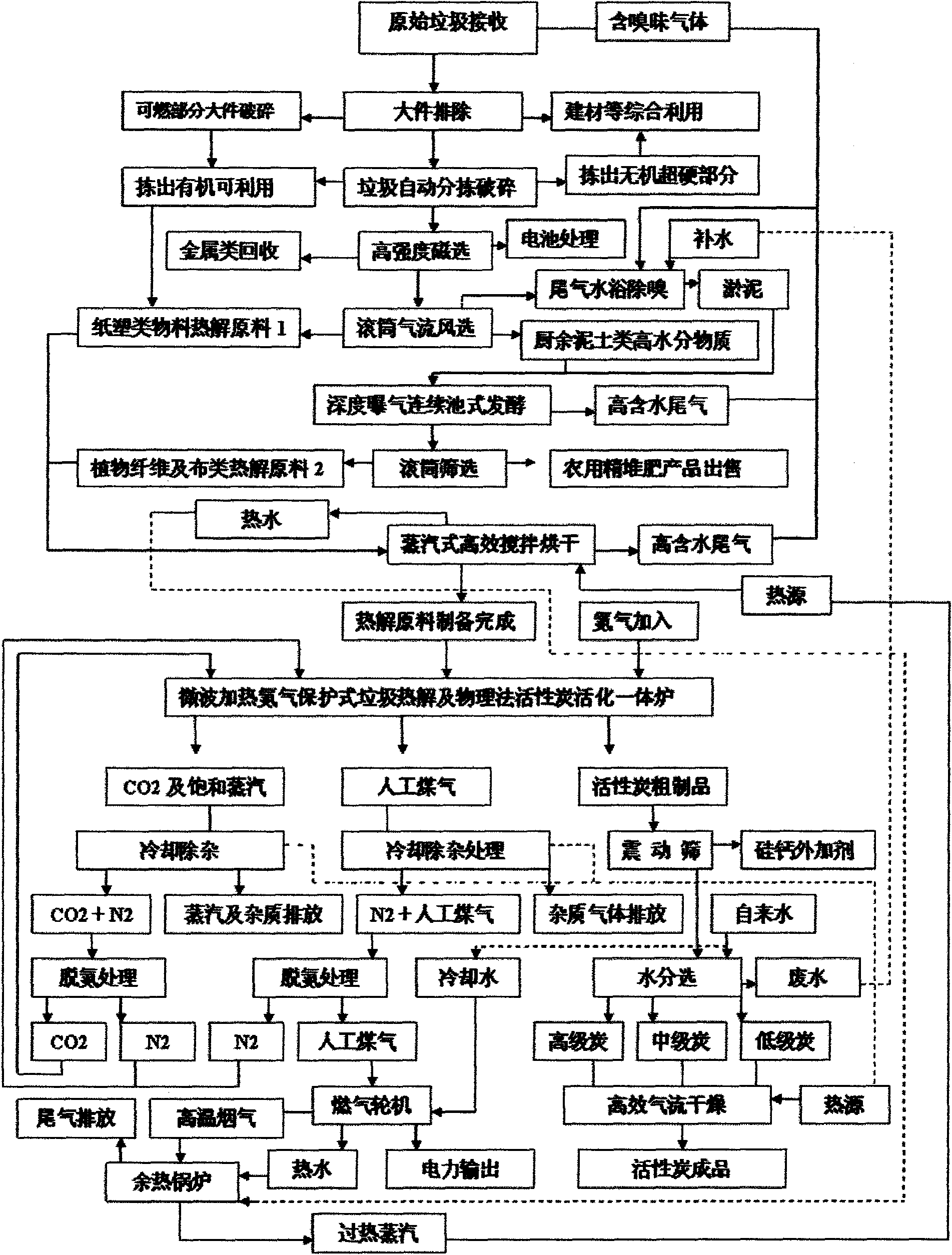

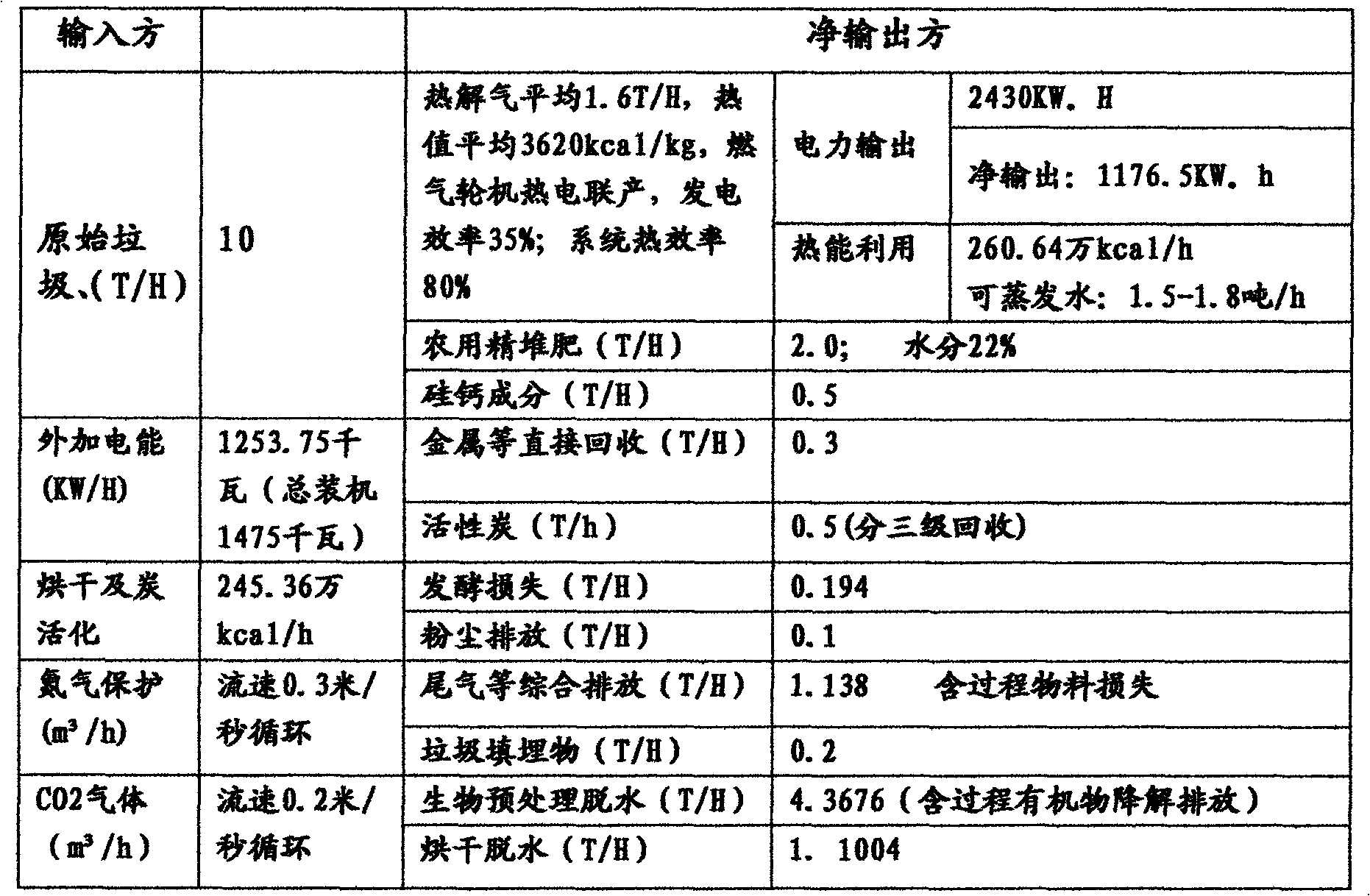

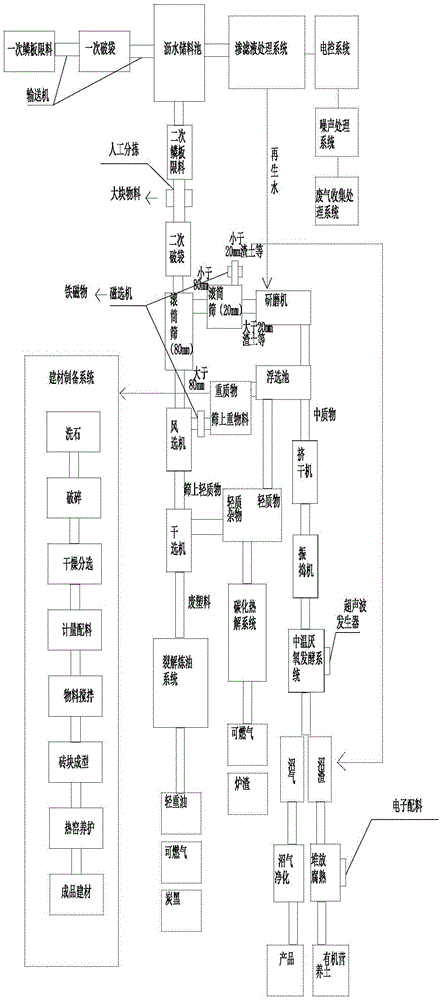

Technological method of comprehensive utilization of separation and pyrolysis treatment of garbage

InactiveCN101618392AAchieve harmless disposal rateReduce energy consumptionDrying solid materials with heatCarbon compoundsEvaporationOxygen

The invention relates to a technological method of comprehensive utilization of separation and pyrolysis treatment of garbage, which solves the problem of comprehensive utilization of separation pretreatment and pyrolysis gas in the process of separation treatment of garbage. The method comprises the following steps: separating and crushing the garbage for secondary classification; classifying the available components in the garbage into three classes, wherein the first class comprises paper, plastic and the like which are used as pyrolysis raw materials 1, the second class comprises the mixture of soil, kitchen wastes and the like, and the third class comprises the mixture of rag, fresh branches, vines and the like; chopping the mixture of the third class, and mixing the chopped mixture of the third class with the mixture of the second class; treating the mixture of the second class and the mixture of the third class by aerobic fermentation, and using penetrant for direct back-spraying and evaporation in high-temperature regions; treating the obtained product by secondary sieving to obtain pyrolysis raw materials 2; mixing and drying the pyrolysis raw materials 1 and the pyrolysis raw materials 2; condensing the generated steam to obtain hot water which back flows into a waste heat boiler of a power generating system to be used as supplemental water; commercializing and recovering the pyrolysis raw materials; and burning the obtained combustible gas for power generation. The invention has the advantages of high recovery rate, low energy consumption and no pollution caused by discharge.

Owner:SHEN ZHEN A MART IND

Method for jointly treating different garbage

ActiveCN102531295ASave processing powerProportional balanceBio-organic fraction processingWaste processingFlocculationBiodiesel

The invention discloses a method for jointly treating different garbage. In the implementation process, different garbage is subjected to pretreatment, homogenization, anaerobic digestion, flocculation dewatering, denitrification, oxidation treatment, membrane bioreactor treatment, aerobic composting and biodiesel production, treated sewage can reach the third grade Standard of Water Pollutants Discharge of DB11 / 307-2005, the process flow is greatly shortened, the cost is reduced, and methane generated in the treatment process and the recovered waste oil are subjected to deep processing to beutilized as green energy.

Owner:北京昊业怡生科技有限公司

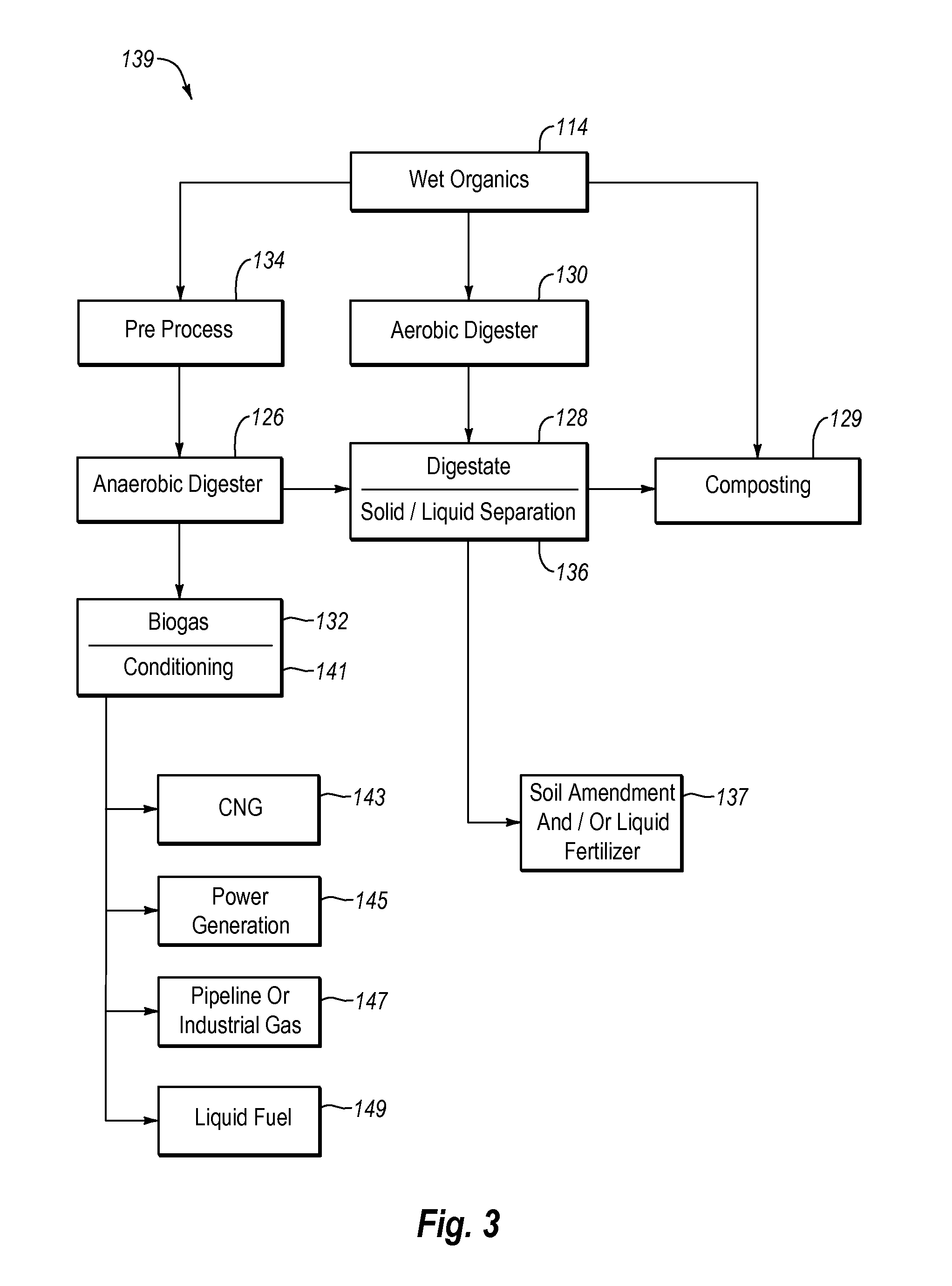

Systems and methods for processing mixed solid waste

ActiveUS20120190102A1Efficient extractionMaximize efficiencyInternal combustion piston enginesWaste processingEnvironmental chemistry

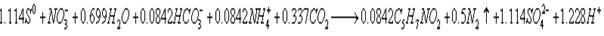

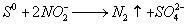

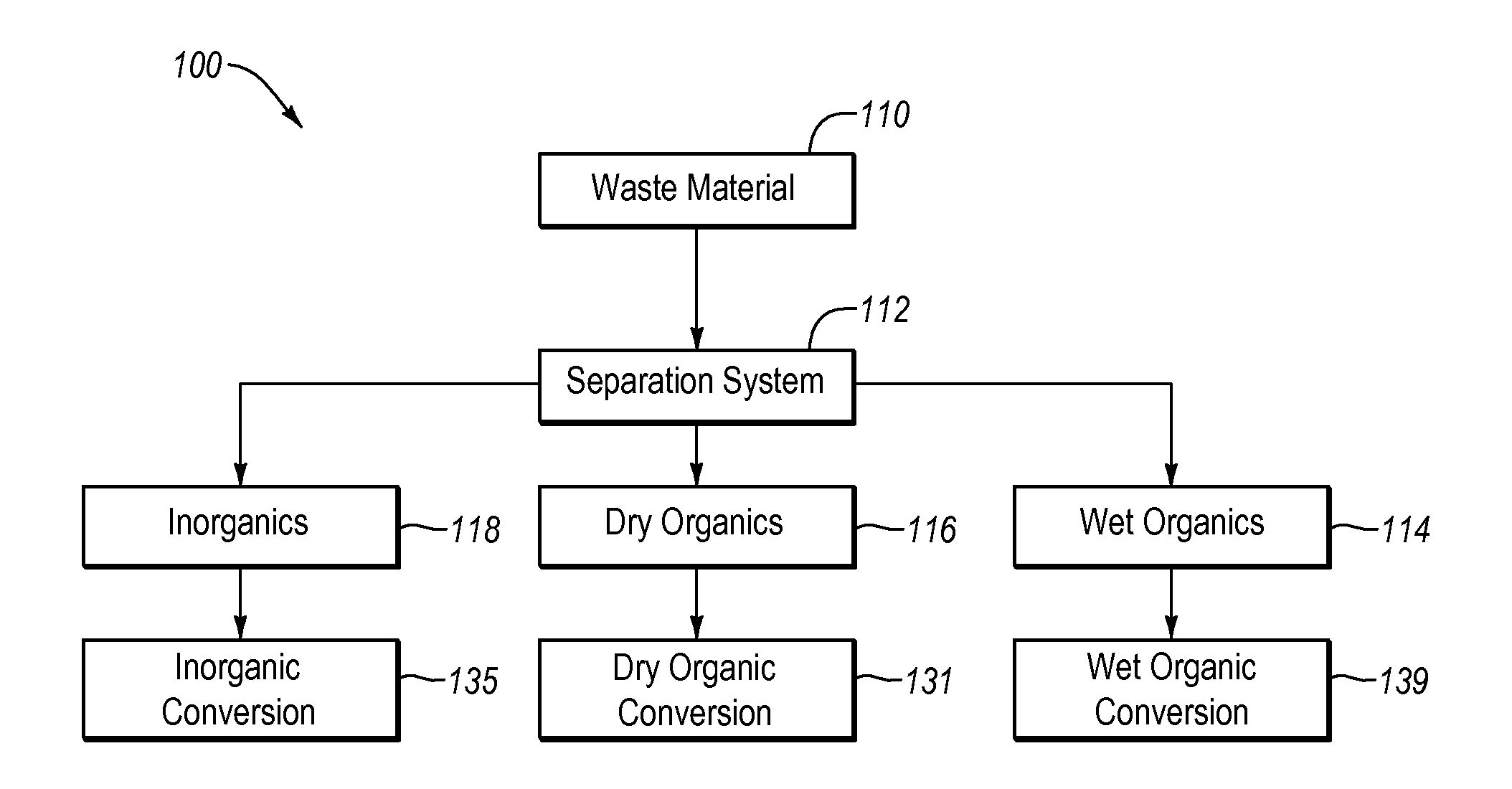

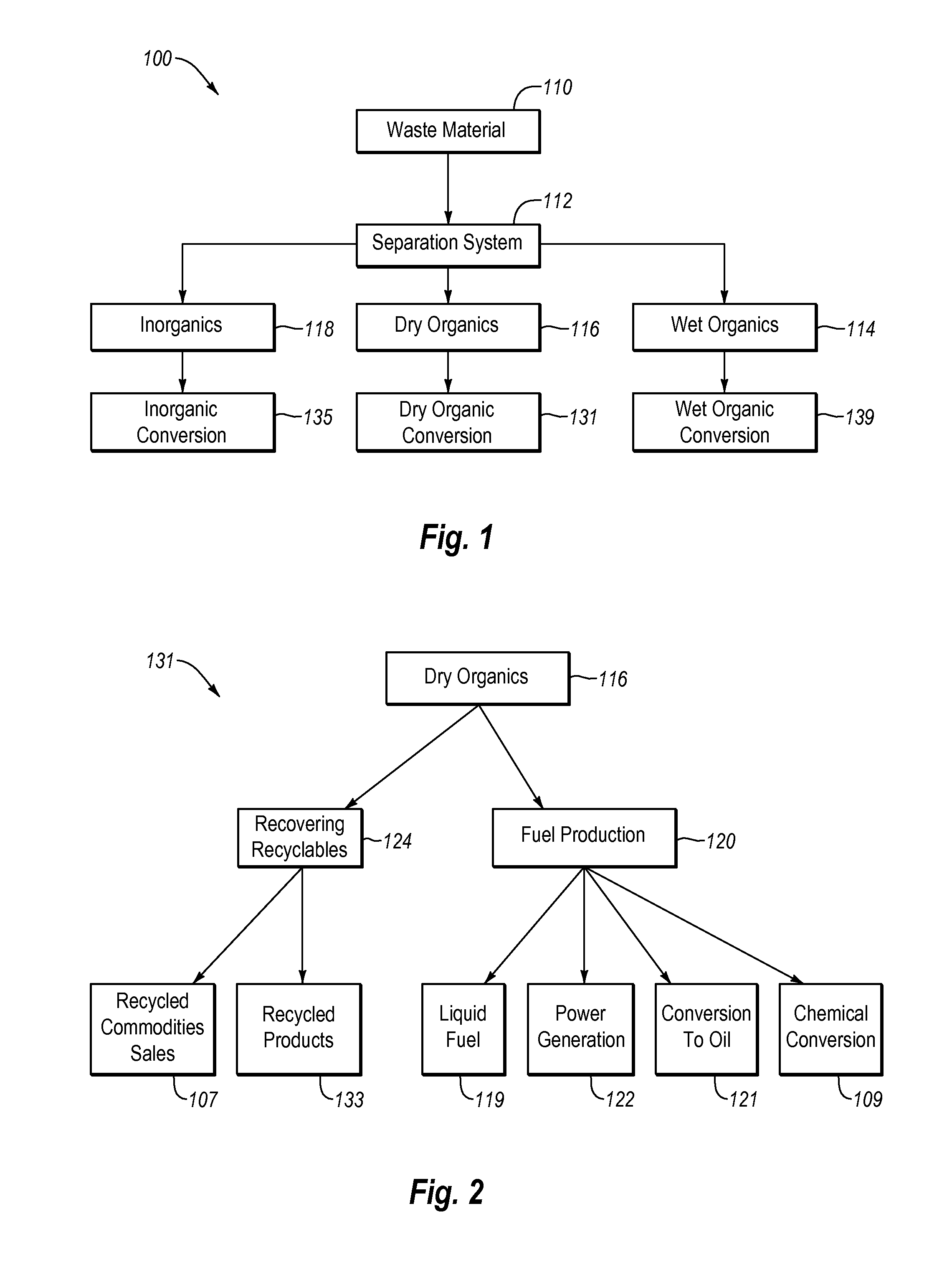

Solid waste that includes a mixture of wet organic material and dry organic material can be are separated using mechanical separation to produce a wet organic stream enriched in wet organics and a dry organic stream enriched in dry organics. The separated wet organic stream and dry organic stream are separately converted to renewable or recyclable products using different conversion techniques particularly suited for the separated wet and dry organic streams.

Owner:UPLAND ROAD IP HOLDCO LLC +2

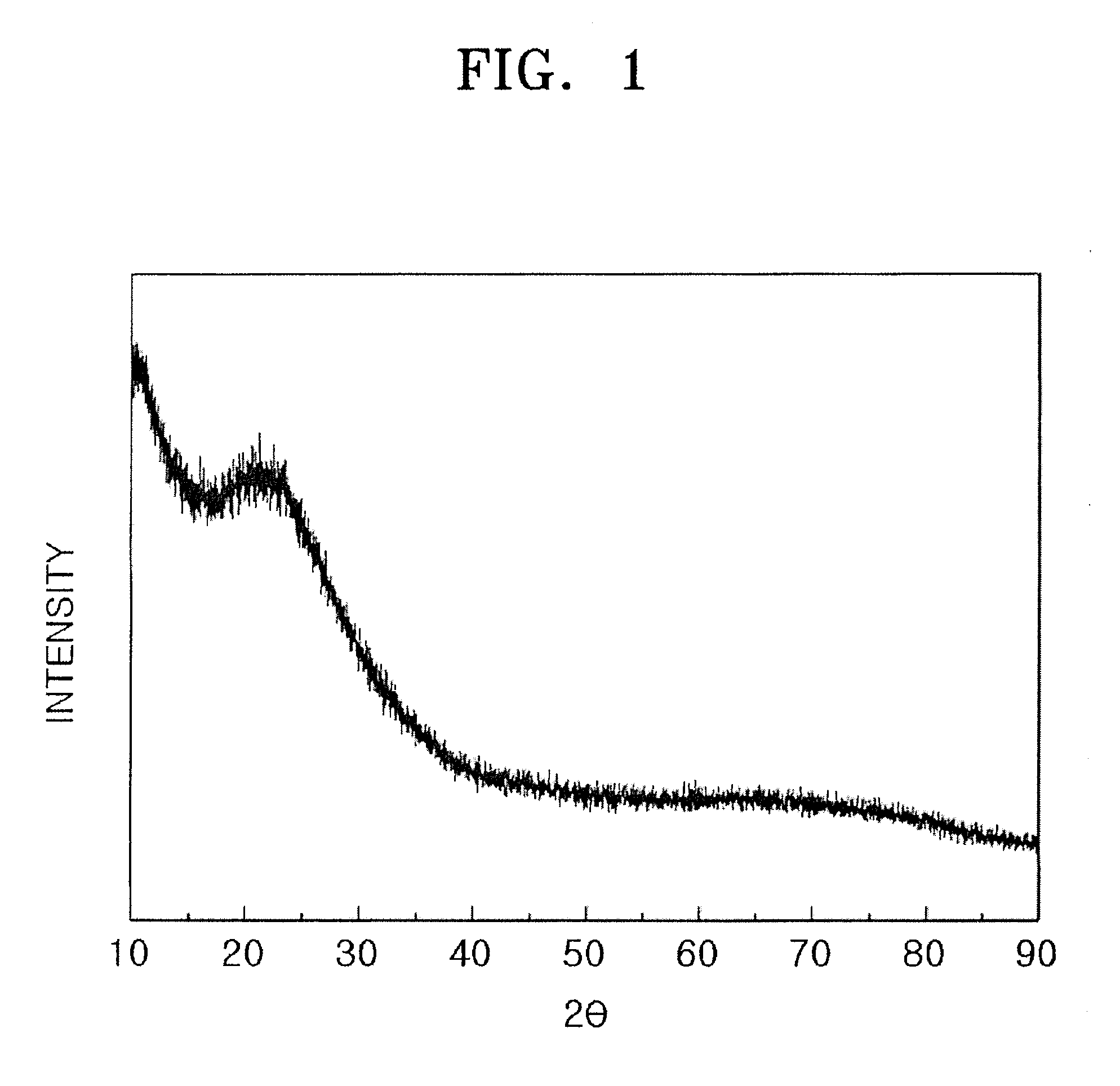

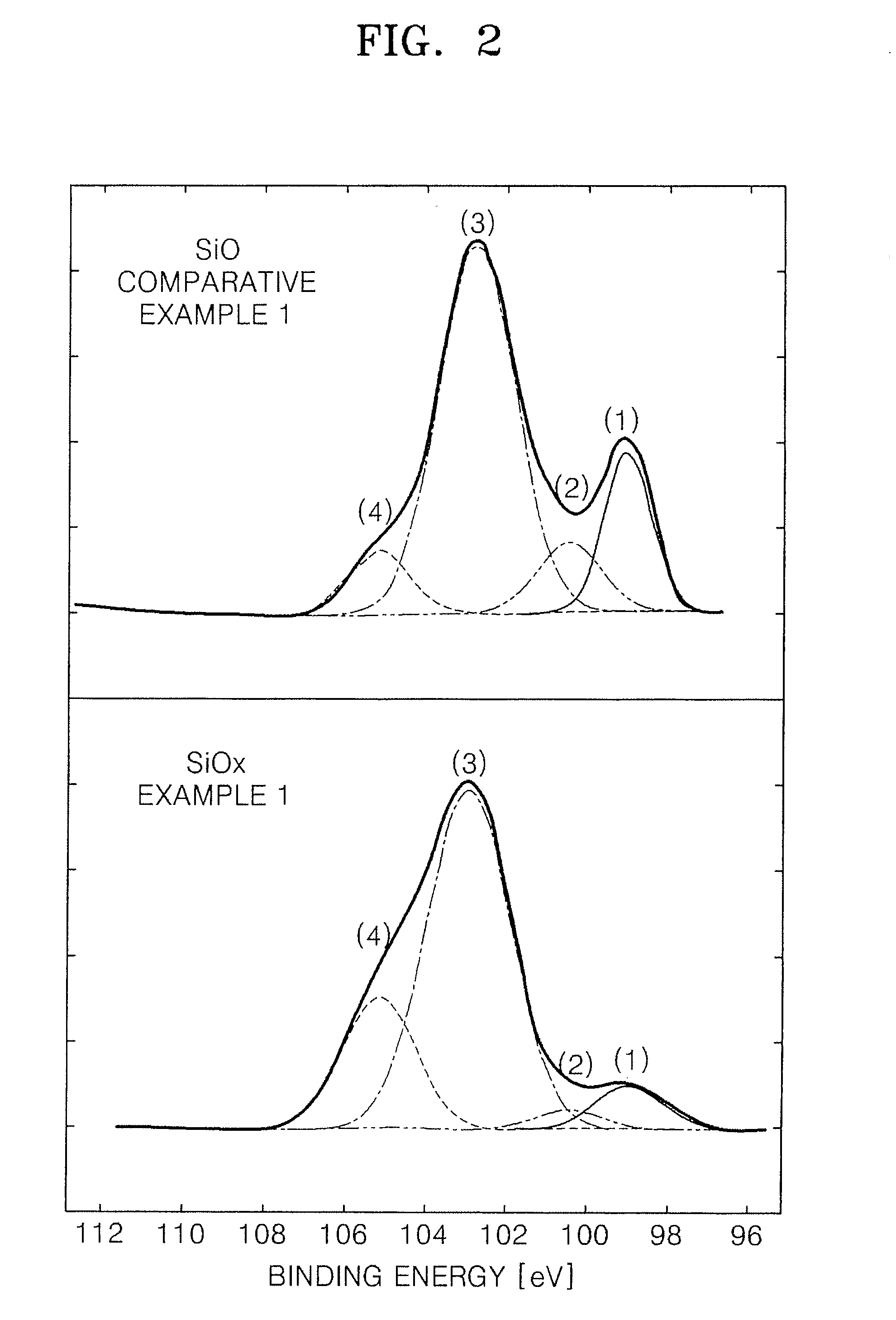

Anode active material, method of preparing the same, and anode and lithium battery containing the material

ActiveUS20080166634A1Improving initial chargeImprove discharge efficiencyBio-organic fraction processingSilicaFull width at half maximumX-ray

Silicon oxide based composite anode active materials including amorphous silicon oxides are provided. In one embodiment, the amorphous silicon oxide is represented by SiOx (where 0<x<2), has a binding energy of about 103 to about 106 eV, a silicon peak with a full width at half maximum (FWHM) ranging from about 1.6 to about 2.4 as measured by X-ray photoelectron spectrometry, and an atomic percentage of silicon greater than or equal to about 10 as calculated from an area of the silicon peak. The anode active material is a composite anode active material obtained by sintering hydrogen silsesquioxane (HSQ). Anodes and lithium batteries including the anode active material exhibit improved charge and discharge characteristics.

Owner:SAMSUNG SDI CO LTD

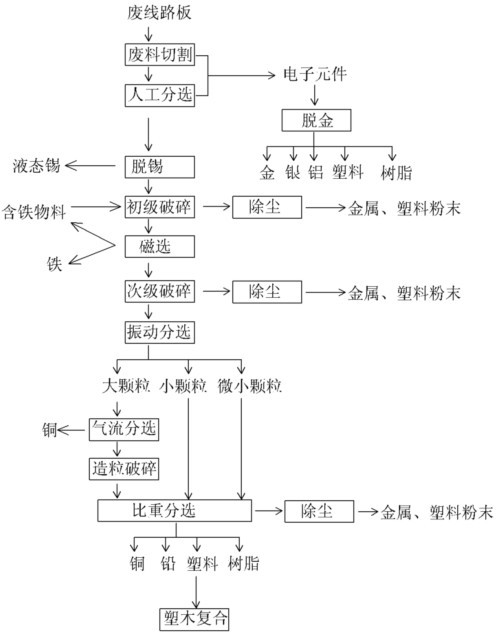

Recycling processing technology for waste circuit board

ActiveCN102671916ARealize recyclingEfficient separationWaste processingSolid waste disposalSpecific gravityScrap

The invention discloses a recycling processing technology for a waste circuit board and relates to the recycling processing technology for waste resources. The recycling processing technology comprises the following steps of: cutting wastes; manually separating; removing gold; removing tin; primarily crushing; magnetically separating; secondarily crushing; separating by vibrating; separating through airflow; crushing pellets; separating according to specific gravity; compounding plastic and wood; and lastly, respectively recycling the matters, such as gold, silver, aluminum, iron, tin, copper, lead, plastic and resins, thereby reusing the matters. The recycling processing technology has the advantages that: (1) the flow line production operation is realized, the degree of automation is high and the yield is high; (2) compared with the traditional processing method, the recycling processing technology effectively reduces the emission of toxic gas and water and improves the environmental protection index; and (3) various matters in the waste circuit board are more effectively separated, the noble metal is recycled, the recycling of resources is realized, the mineral resource exploitation and wood felling are indirectly reduced, and the energy consumption and pollution during the processes of mineral resource exploitation and metallurgy processing are reduced.

Owner:NINGBO HUILONG MACHINERY CO LTD

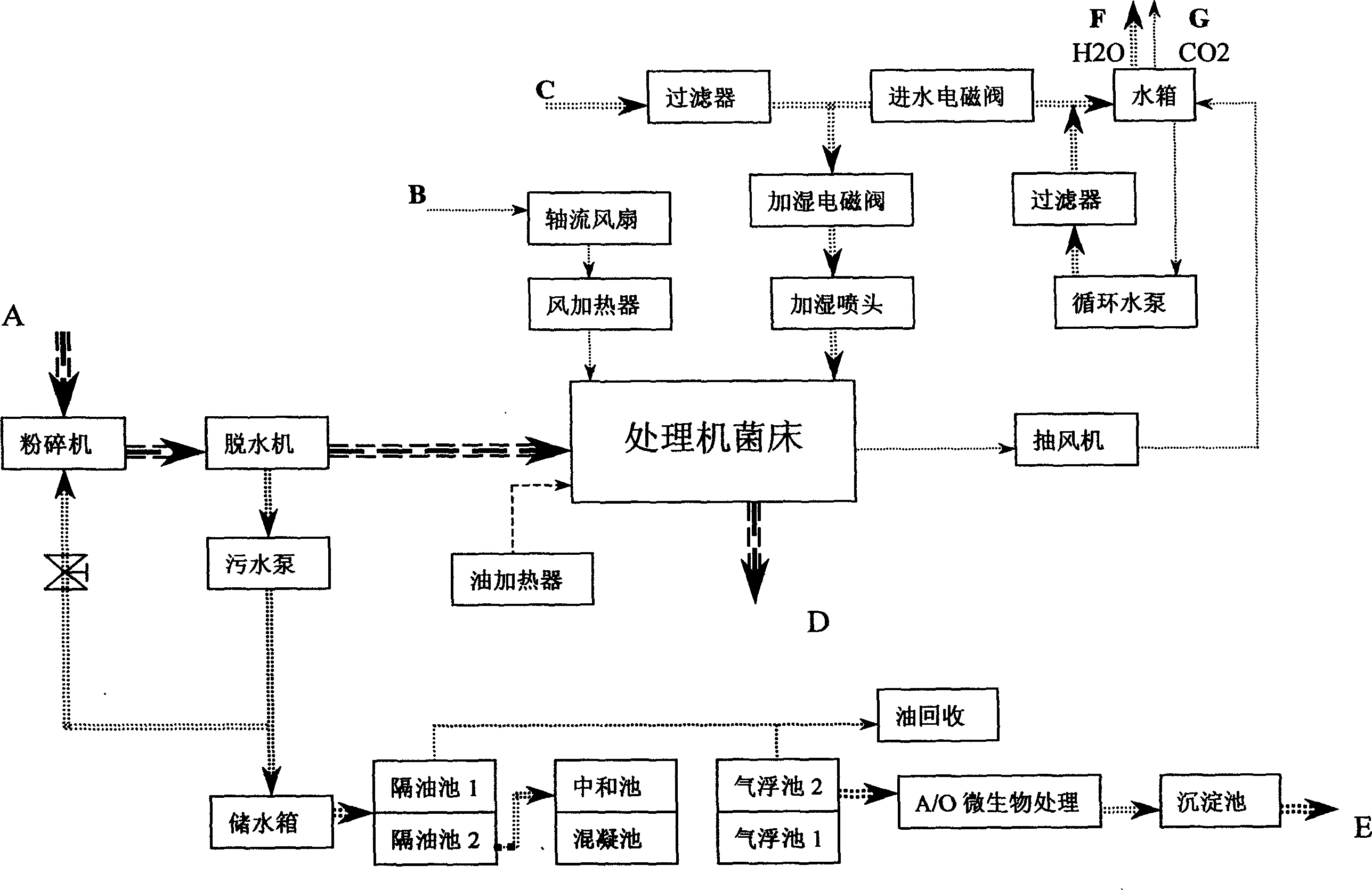

Biological treatment for organic garbage from dining room and kitchen

InactiveCN1480267AIncrease microbial throughputGenerate-in-placeSludge treatmentWaste processingSewageOil water

A biologic process for treating the organic garbage coming from kitchen includes breaking, dewatering, microbial treating, processing tail gas to generate Co2, separating oil from water, and treating sewage. Its advantages are high effect and no secondary pollution.

Owner:陈建乐

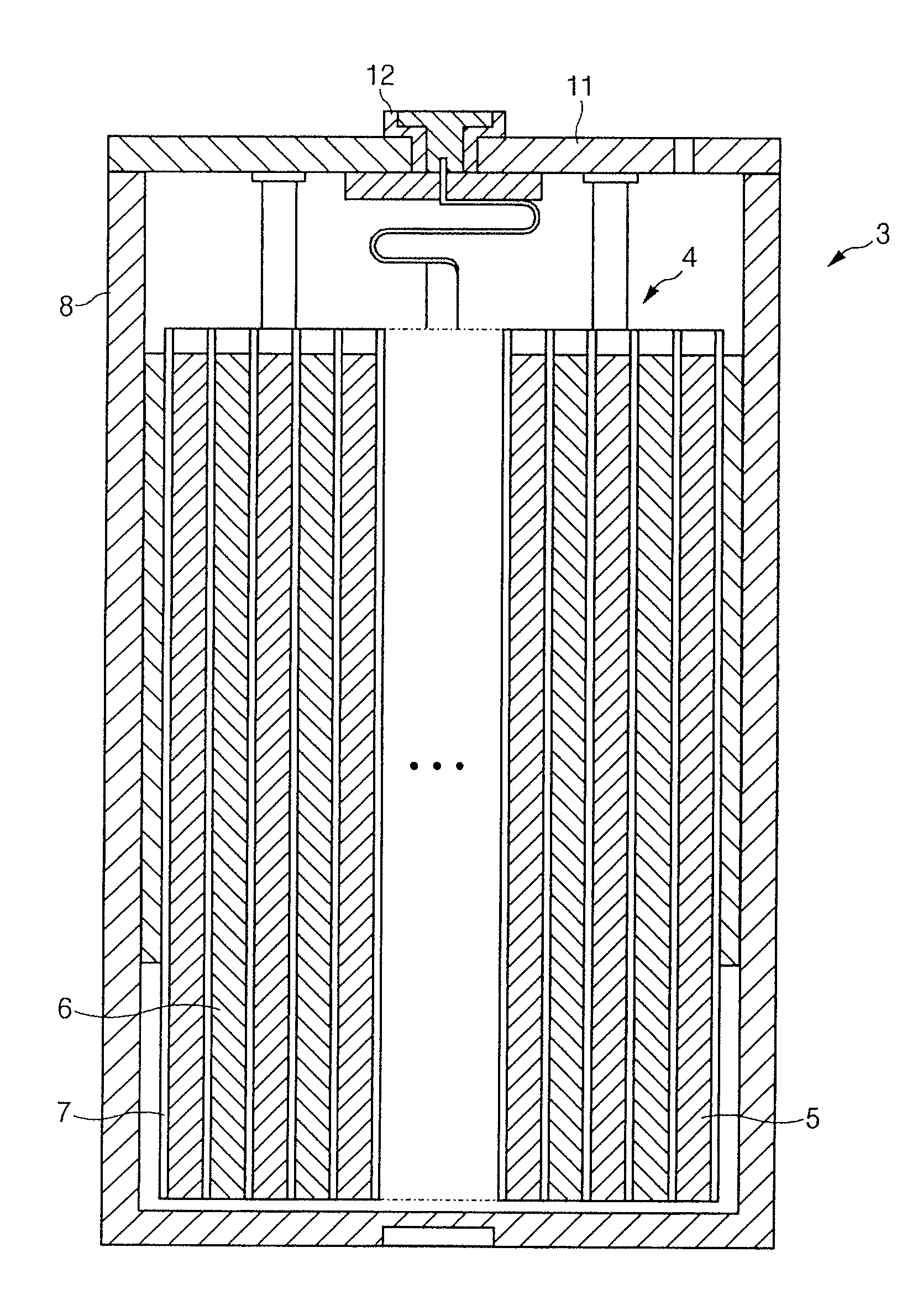

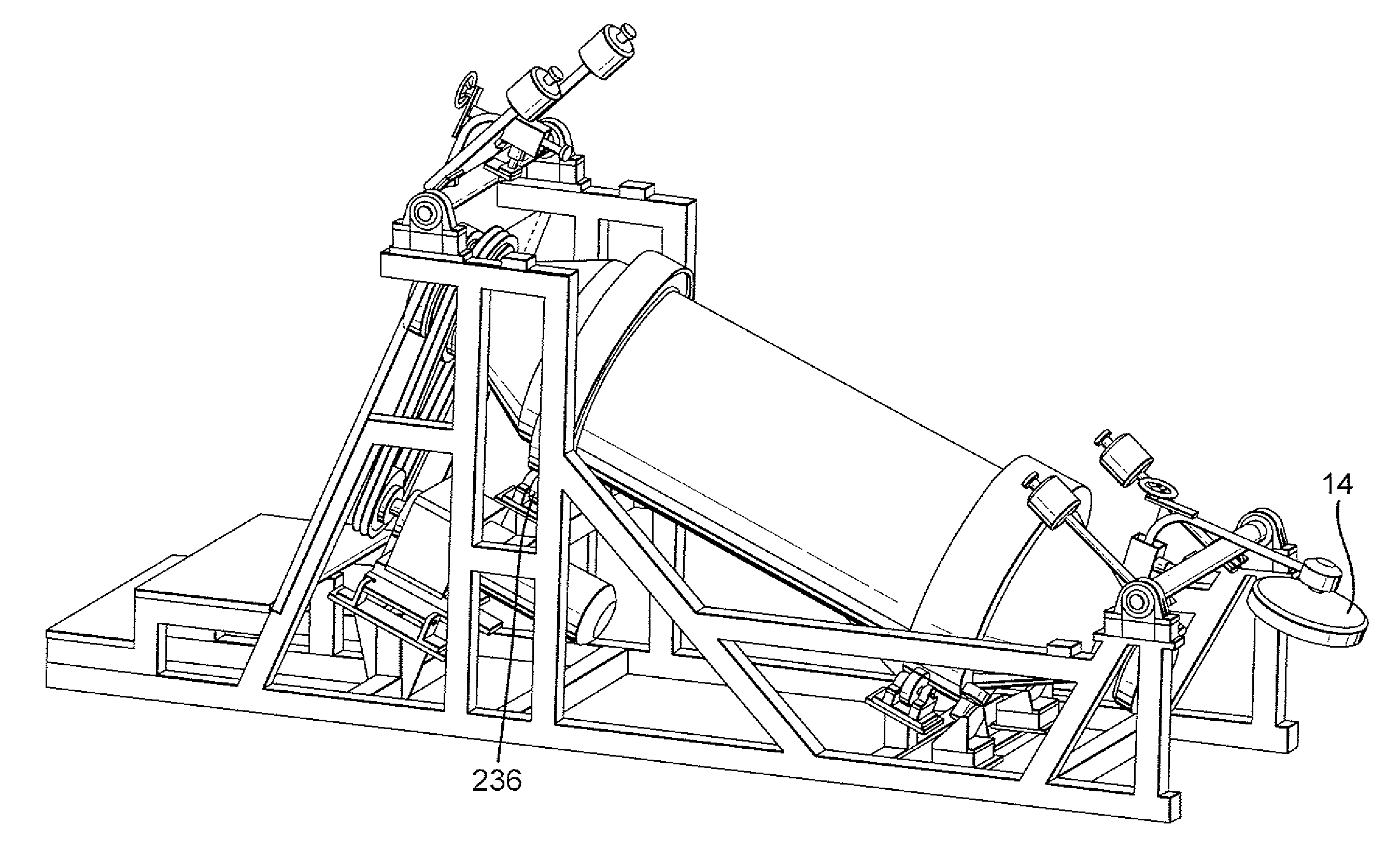

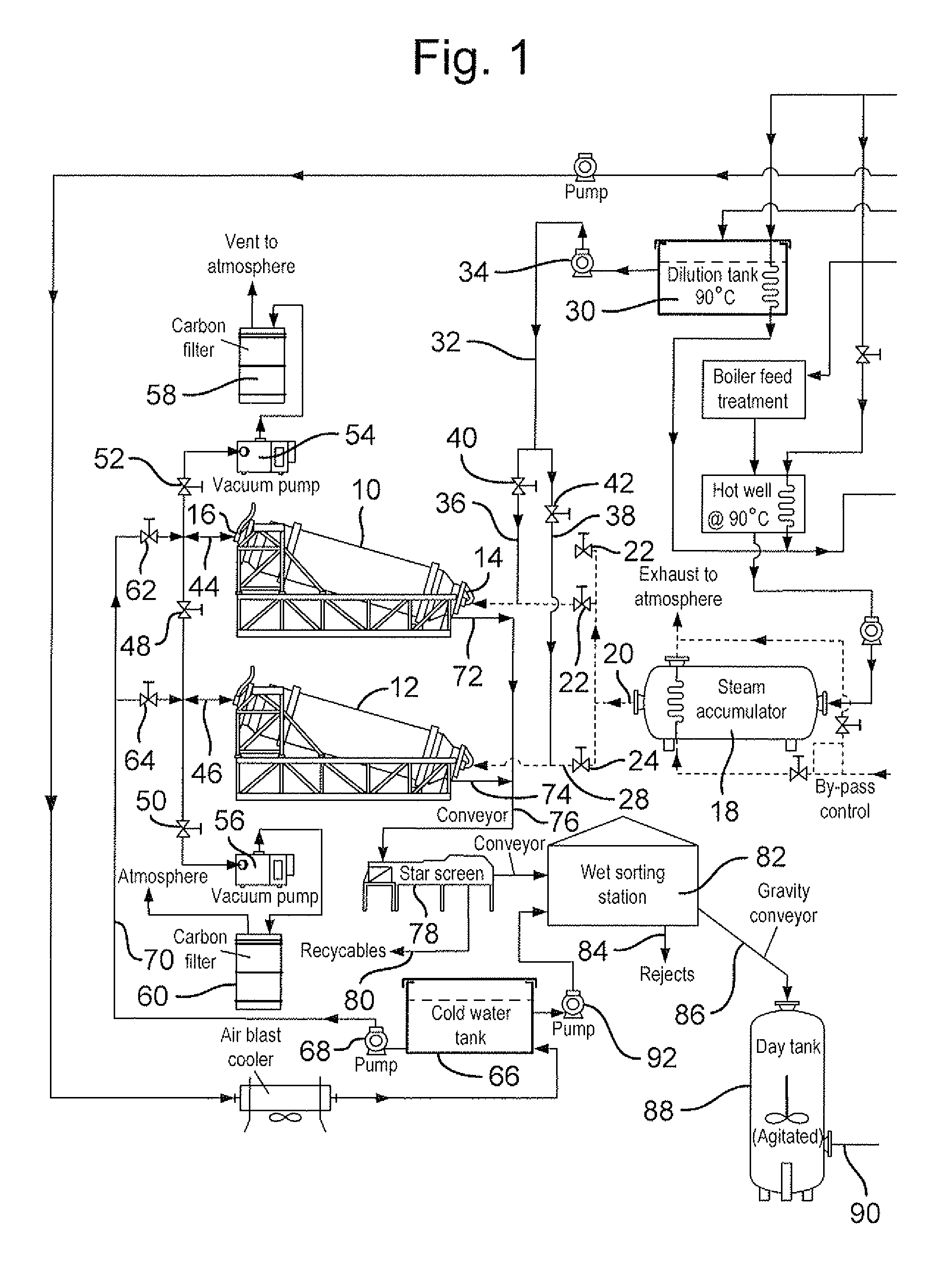

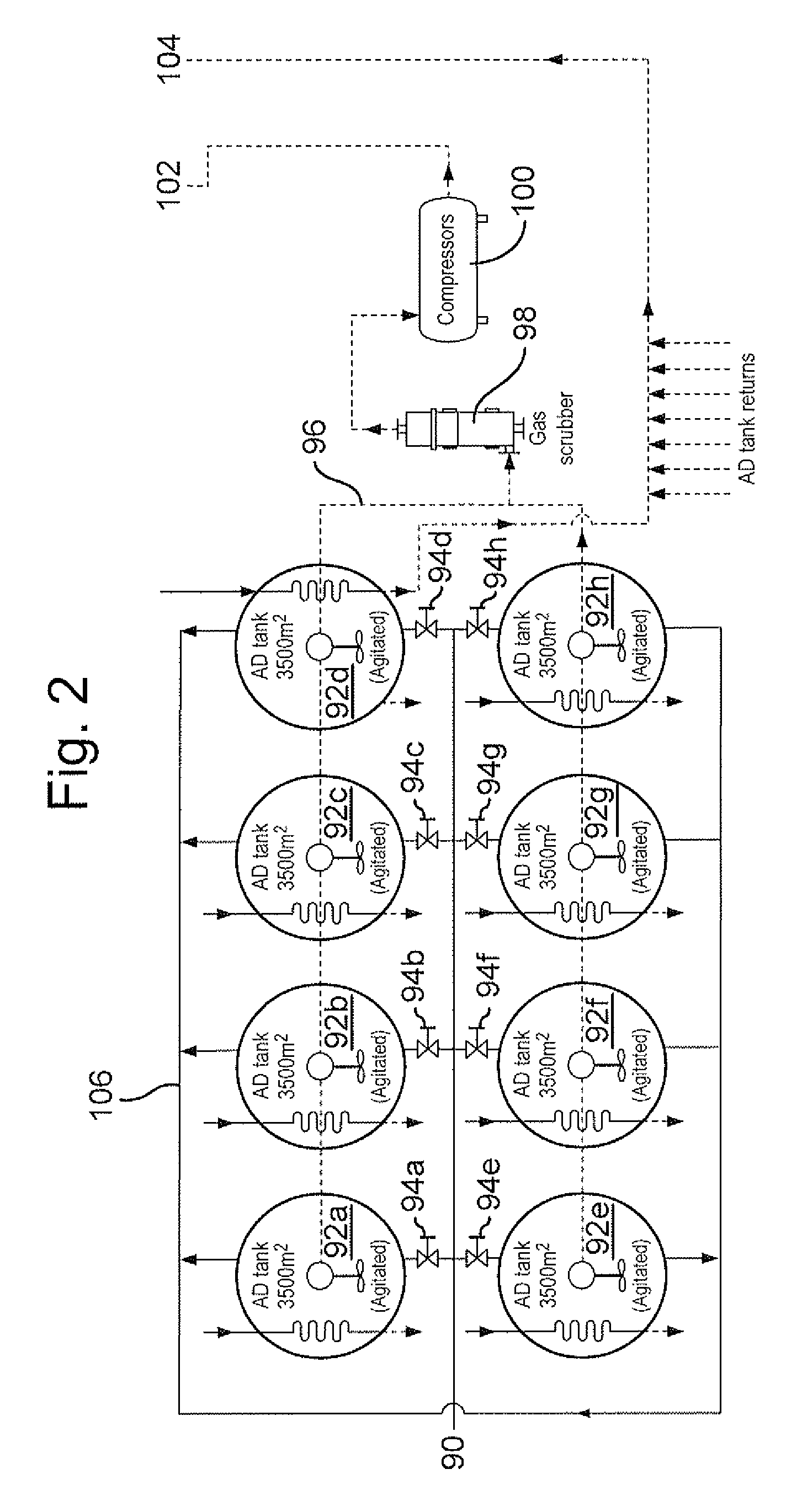

Apparatus and process for treating waste

ActiveUS20130029394A1Easy to separateEliminate needBioreactor/fermenter combinationsBiological substance pretreatmentsDigestionInternal combustion engine

A method for treating municipal solid waste and other waste is provided which comprises: introducing said waste into a rotary autoclave which is downwardly inclined towards its discharge end and has a door at the discharge end; and injecting steam through said door into said autoclave to treat the load. A method is also provided for treating waste, comprising steam autoclaving the waste, anaerobically digesting an organic-rich fraction of the autoclaved waste, recovering methane-containing gas from anaerobic digestion, internally combusting the methane-containing gas to generate power and exhaust gas, and generating steam for autoclaving using the waste heat. A plant for treating the waste may comprise at least one autoclave for steam treating the waste, at least one anaerobic digestion tank for digesting an organic-rich fraction of the autoclaved waste, a recovery system for recovering methane-containing gas from the or each digestion tank, at least one internal combustion engine for combusting the methane-containing gas and generating power, and a steam generator fed with combustion gas from the internal combustion engine for generating and accumulating steam for supply to said at least one autoclave. Also provided is a method of treating waste material in a rotary autoclave, which comprises: loading the waste material into a top opening of the autoclave whilst rotating the autoclave in a first direction in which screw flights within the autoclave convey the waste forwardly along a downwardly inclined body of the autoclave towards a base of the autoclave; rotating the autoclave in a second direction opposite to the first direction so as to establish a circulation of the loaded material between the upper and lower ends of the autoclave to facilitate vacuum and / or steam treatment thereof; and monitoring the load imparted by the autoclave adjacent upper and lower ends thereof during the reverse rotation, increase of the load adjacent the upper end of the autoclave providing an indication of effective load circulation. A door structure for a commercial-scale autoclave based on a castellated door and a locking ring with lock blocks of inwardly facing U-structure is also provided.

Owner:AEROTHERMAL GROUP

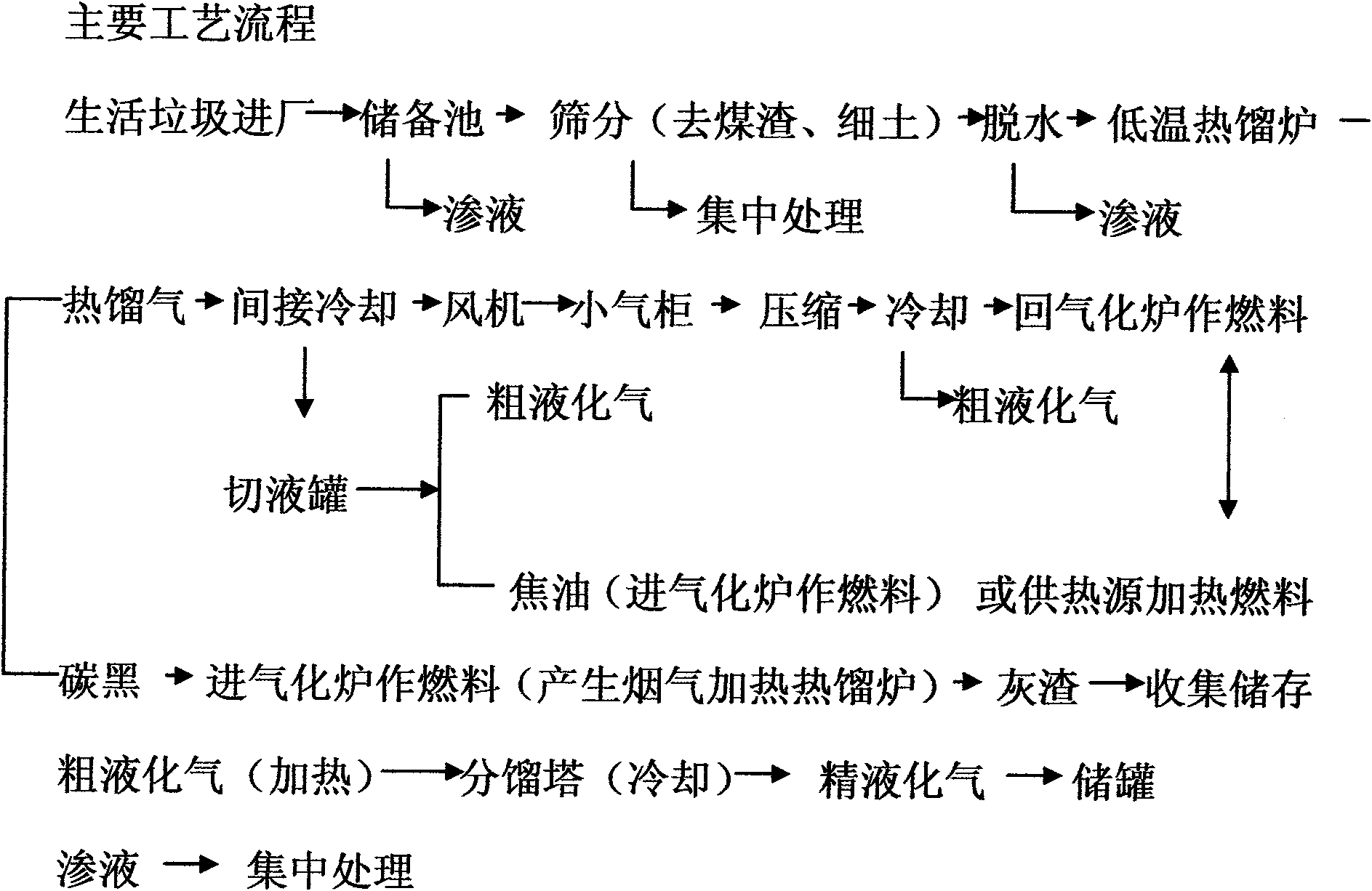

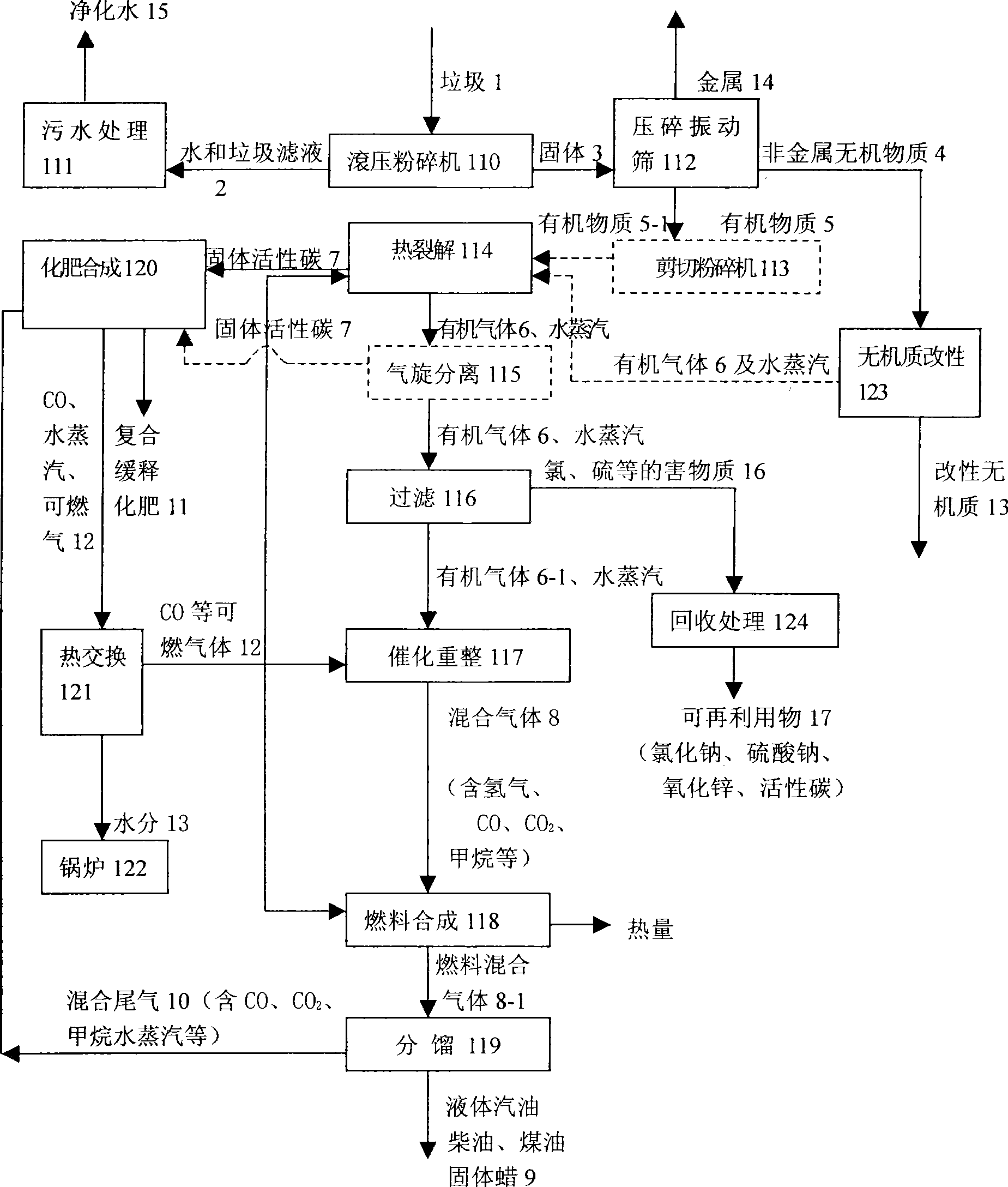

Energy sources regeneration of urban domestic garbage and non-waste comprehensive utilization processing technique

InactiveCN101433904AEffective generationAchieve conversionWaste processingSolid waste disposalFiltrationFuel oil

The invention relates to a manufacturing technique for energy regeneration and non-waste comprehensive utilization of municipal domestic waste, which is characterized by comprising the steps of waste classification, pretreatment and treatment of nonmetallic inorganic substances, schizolysis, filtration and reforming of organic substances, synthesis of fuel oil and treatment of organic substance byproducts. The manufacturing technique completely treats waste, has no secondary pollution during the whole treatment, and really realizes complete conversion and utilization of the waste. When the technology is used for treating organic substance waste and so on, including organic substance parts of the municipal domestic waste and various animal and plant waste, not only the environmental problem caused by the municipal domestic waste and the waste problem of the waste can be solved but also energy and slow release fertilizer which returns to earth can be efficiently generated, so that green circulation of renewable energy resources is realized. The applied proposal has reasonable energy consumption in the whole process, has no pollution, has controllable products, high output value and stable and reliable sources of raw materials, and realizes sustainable development.

Owner:深圳开普蓝生能源环保有限公司

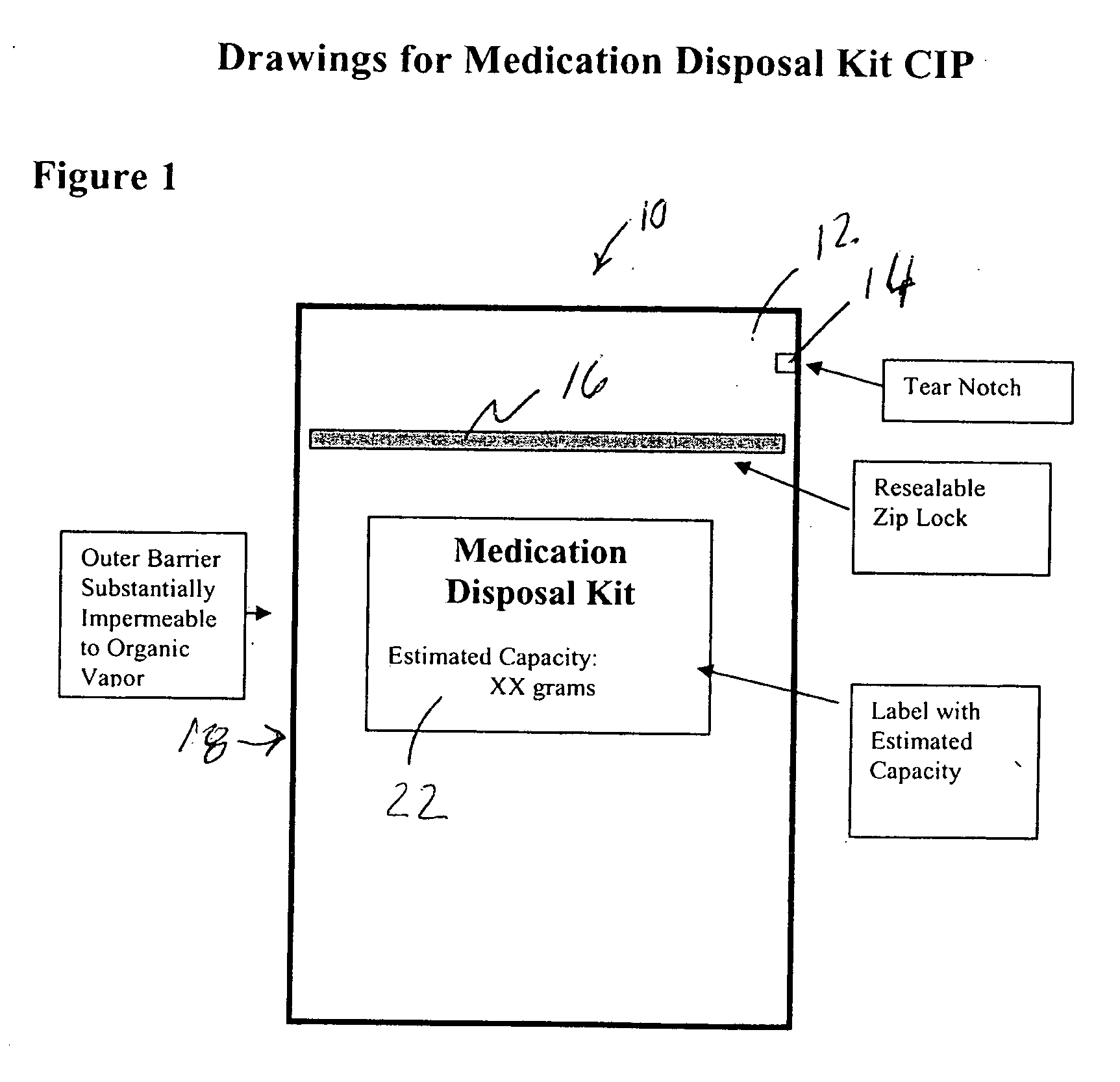

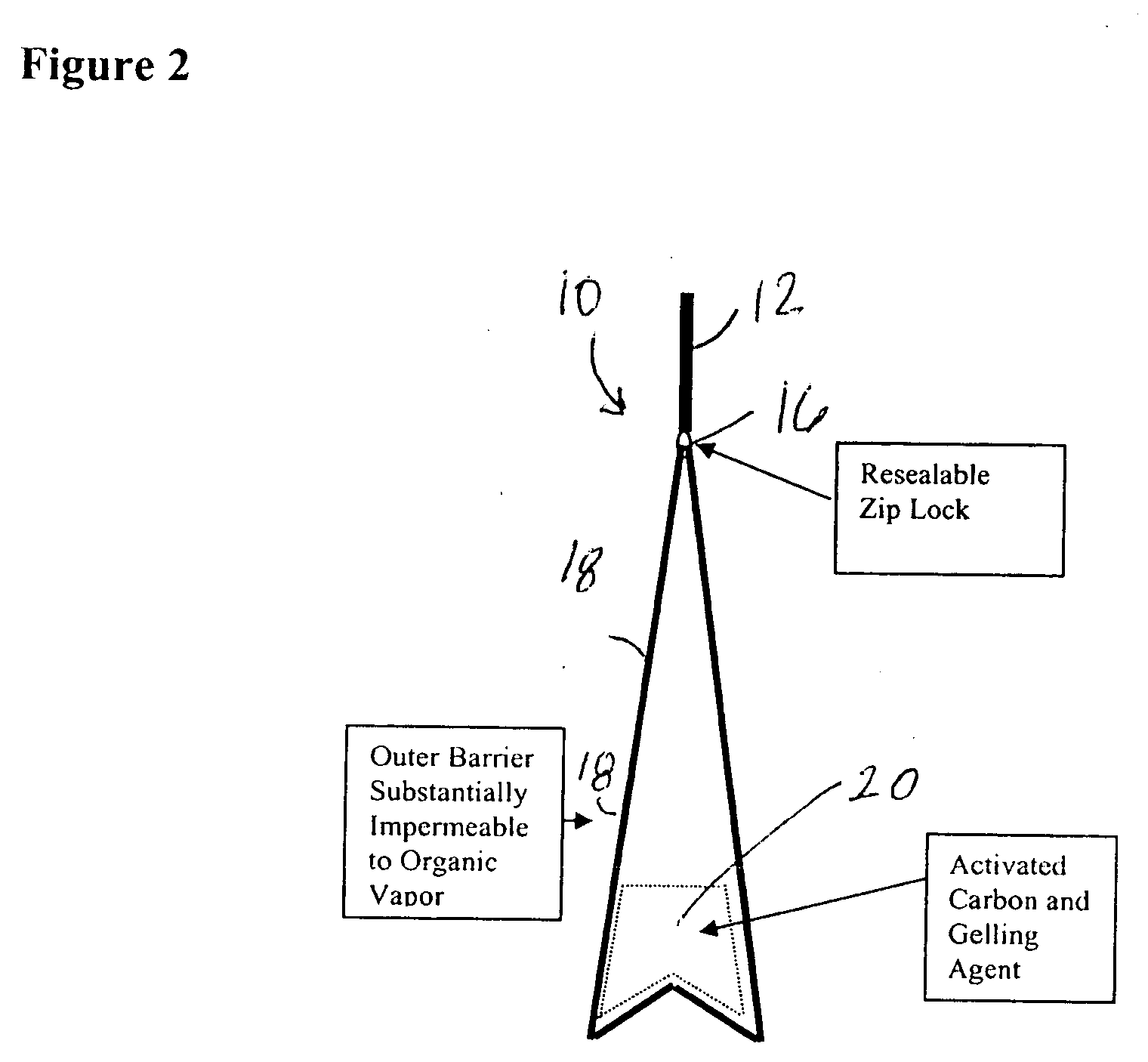

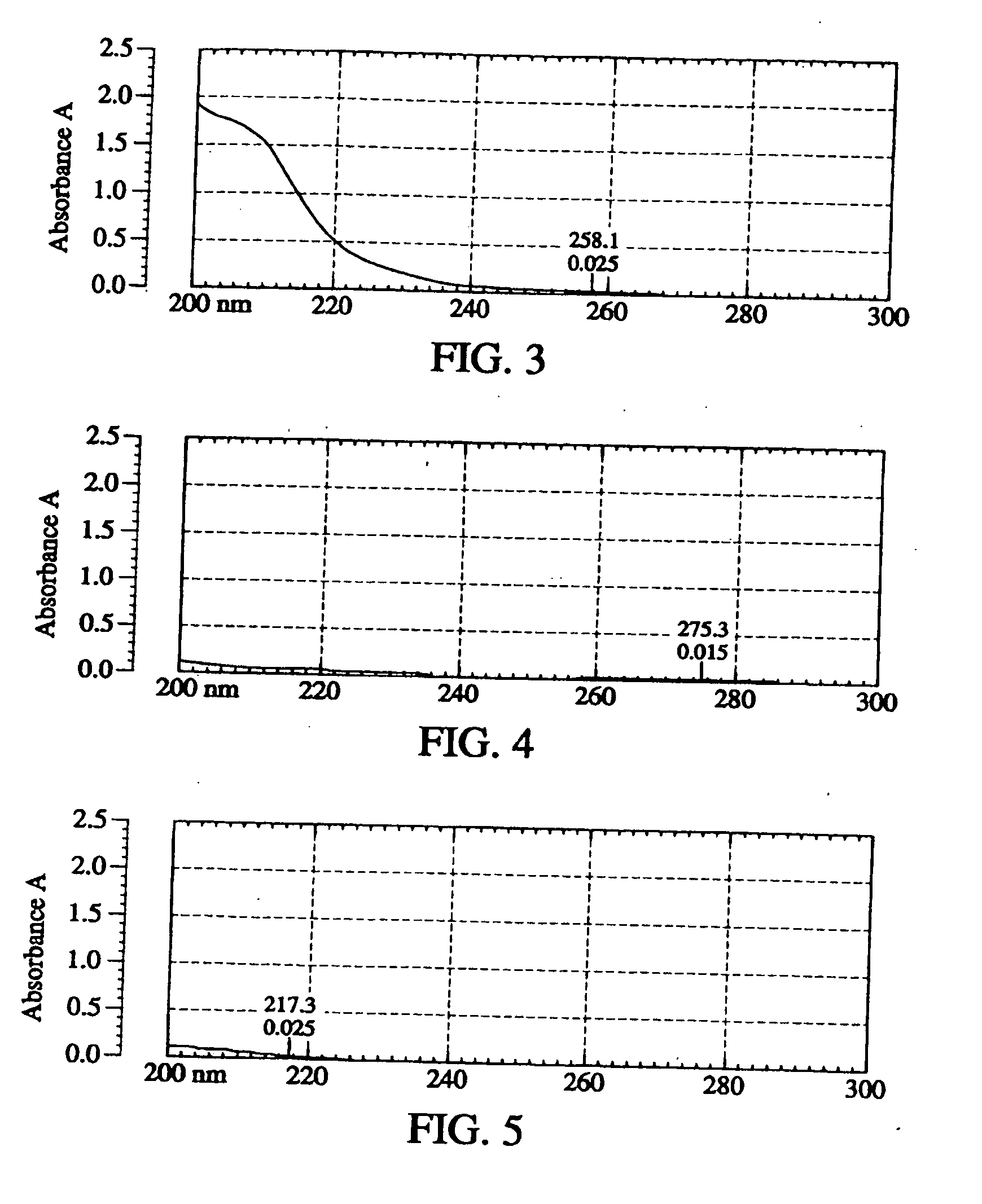

Medication disposal system

ActiveUS20090180936A1Reducing potential substance abuseReducing environmental contaminationPowder deliveryOrganic active ingredientsActivated carbonEnvironmental health

The potential for environmental release of unused and expired medications is reduced by the provision of a system and method for combining the unused or expired medication with an amount of activated carbon as part of a disposal procedure.

Owner:VERDE ENVIRONMENTAL TECH INC

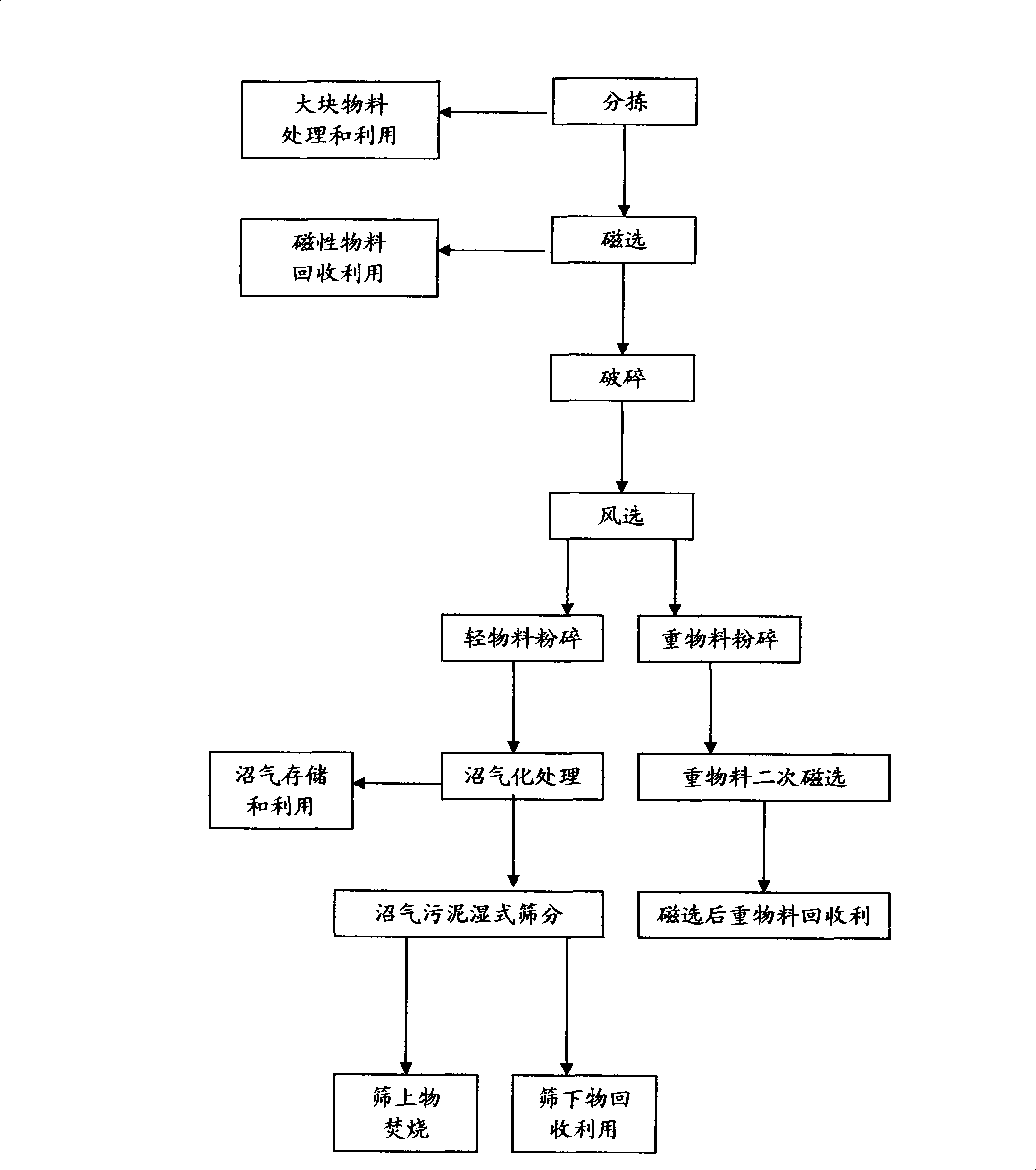

Consumer waste reutilization method

InactiveCN101259479AImprove stabilityReduce pollutionWaste processingSolid waste disposalBurn treatmentSludge

The invention relates to a recycling method for living garbage which comprises the steps: (1) separating: recoverable materials of big blocks and other materials are sorted out; (2) magnetic separation: magnetic materials like an iron block, etc., are separated; (3) cracking: the garbage materials after being separated are cracked to a granularity that is suitable for a subsequent treatment; (4) air separation: heavy materials and light materials are separated; (5) cracking of the heavy materials; (6) secondary magnetic separation of the heavy materials; (7) recycling of the heavy materials after magnetic separation; (8) cracking of the light materials; (9) firedamp treatment of the light materials; (10) firedamp storage; (11) screening of the firedamp mud; (12) burning treatment of the matters on the screen of the firedamp mud screen and (13) recycling of the matters under the screen of the firedamp mud screen, etc. The recycling method is mainly used for treating the living garbage and can better make use of the materials and energies in the garbage to simplify the treatment process and reduce the treatment cost and the pollution to environment.

Owner:BEIJING HENGYECUN S&T

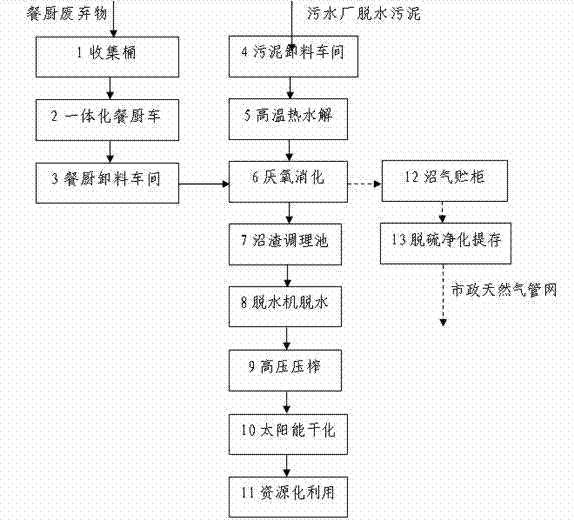

Cooperative treating method of kitchen waste and sludge of sewage plant

InactiveCN106964633AReduce the impactAvoid pollutionSludge treatment by de-watering/drying/thickeningWaste processingSolar dryingSewage

The invention discloses a cooperative treating method of kitchen waste and sludge of a sewage plant. The method comprises the following steps that A, a kitchen waste source is pretreated; B, the sludge is subjected to high-temperature hydrolysis cooperating with anaerobic digestion; C, biogas residues are dehydrated and pressed; and D, drying treatment is conducted to obtain finished products. The cooperative treating method has the advantages that after the comprehensive treating processes that the kitchen waste source is pretreated, the sludge is subjected to high-temperature hydrolysis cooperating with anaerobic digestion, the biogas residues are dehydrated through a dehydrator and pressed directly through a high-pressure filter press and subjected to solar drying, stabilization, harmlessness and reduction of the sludge can be achieved, and meanwhile waste is changed into treasures, specifically, available biogas and garden greening soil and forest land are produced.

Owner:江苏泓润生物质能科技有限公司

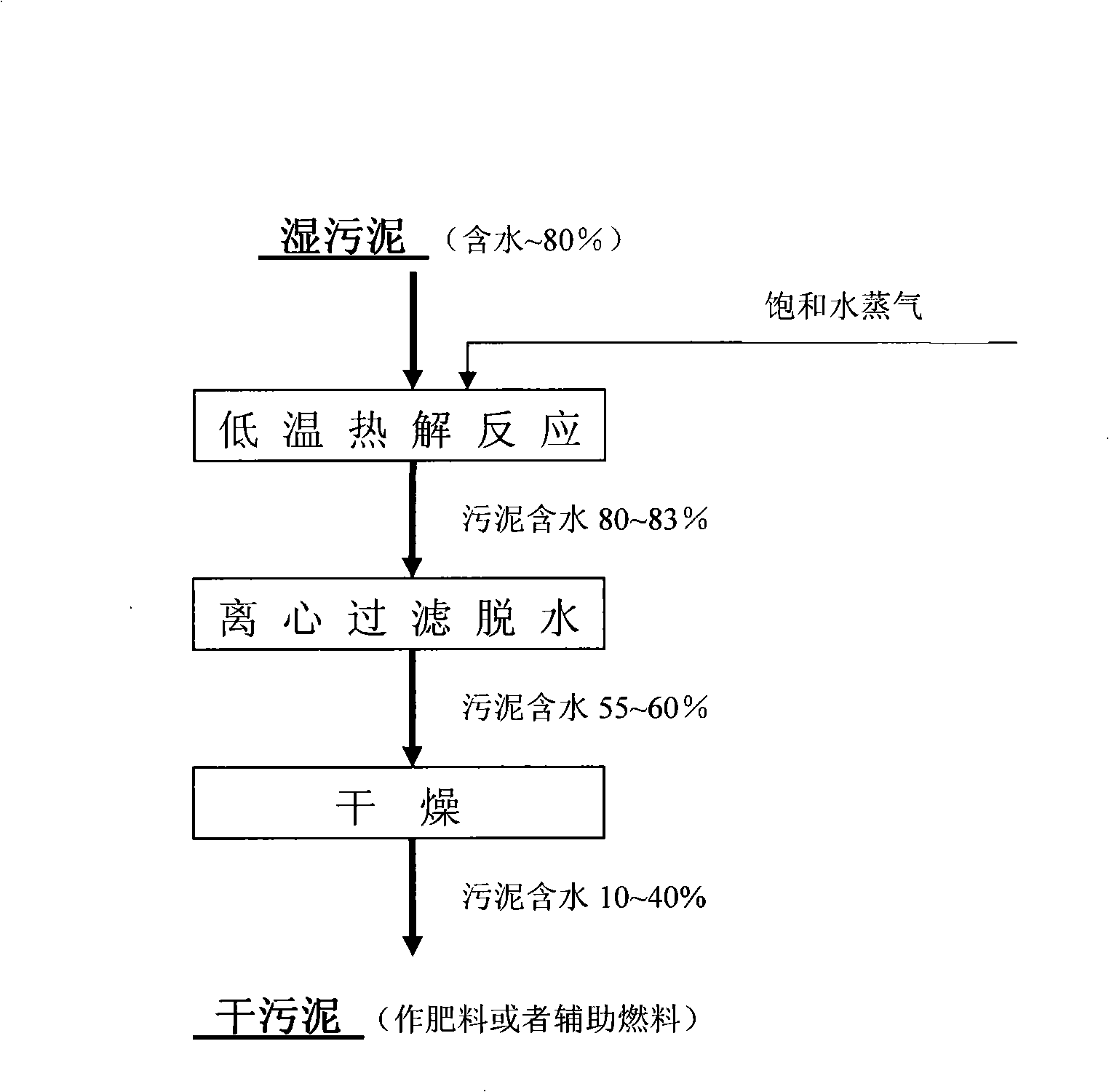

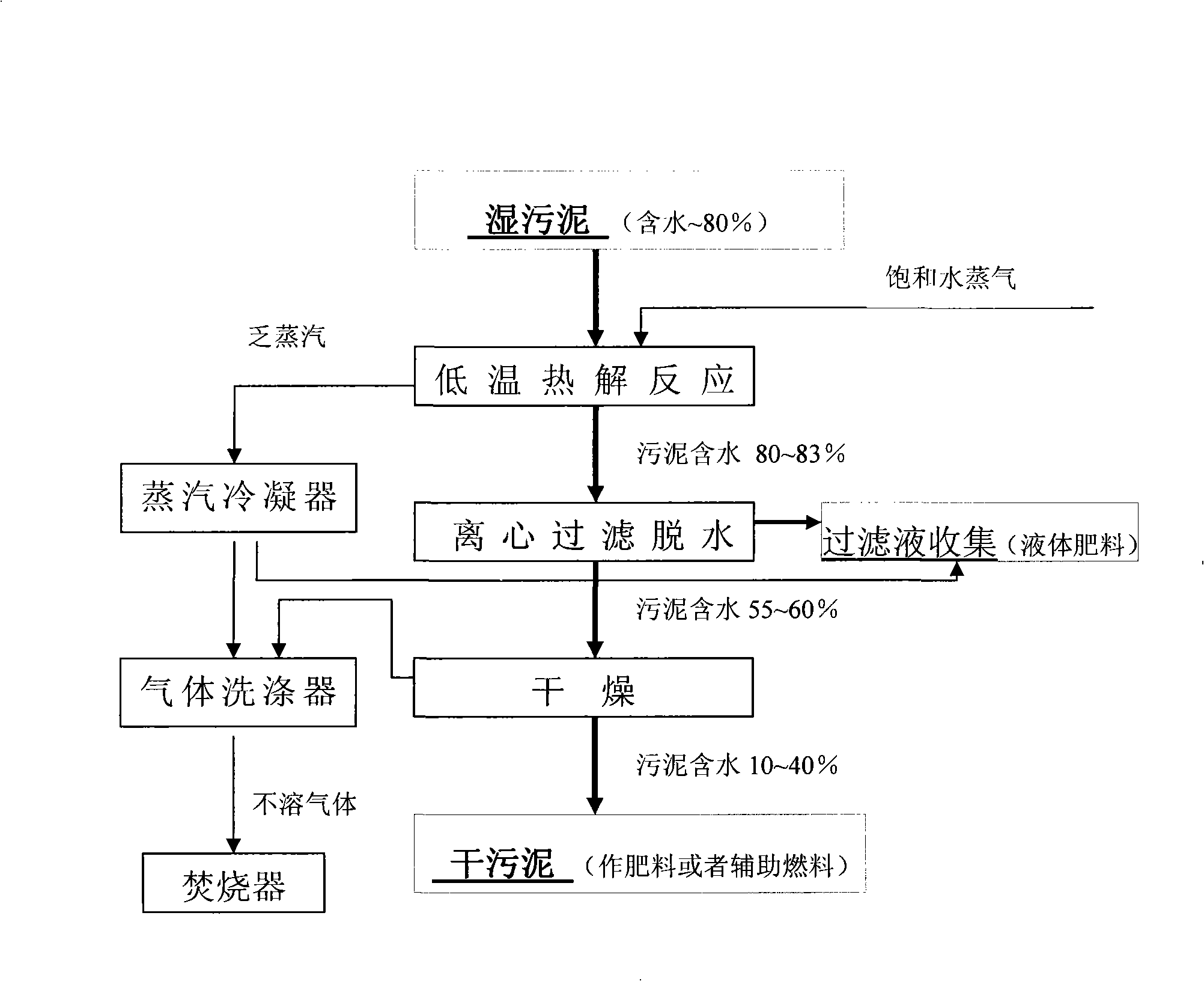

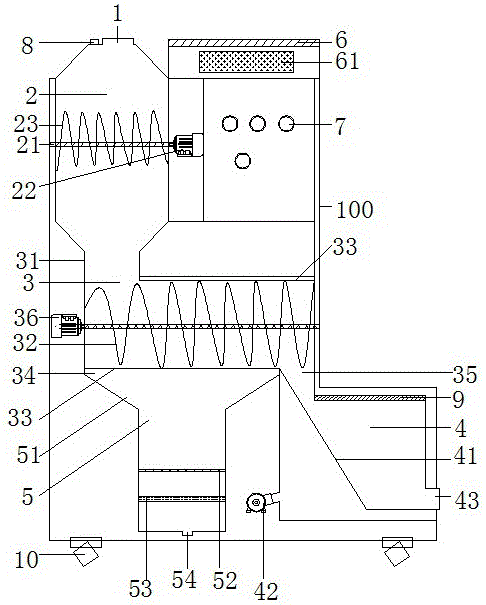

System and process for anhydration treatment of wet sludge

ActiveCN101289267AAvoid it happening againNo odorSludge treatment by de-watering/drying/thickeningWaste processingResource utilizationSludge

The invention relates to a wet sludge anhydration treatment system which comprises a low-temperature pyrolysis reaction device which is used for carrying out the low-temperature pyrolysis reaction of wet sludge and saturated water vapor to convert macromolecular organics in the wet sludge into low-molecular organics, a spiral centrifugal filtering device which is used for carrying out centrifugal filtering and dehydration to the wet sludge after the pyrolysis in a mechanical separation manner so as to obtain semi-dry sludge with the water content of 55 percent to 60 percent, and a drying device which is used for drying and removing the water in the semi-dry sludge after the filtering and hydration so as to obtain dried-sludge solid fuel with the water content of 10 percent to 40 percent. Meanwhile, the invention also relates to a wet sludge anhydration treatment technology by adopting the treatment system. The system and the technology of the invention can solve the problem of renewable resource of sludge in a method of environment protection, energy saving, high resource utilization and low operating cost.

Owner:SHENZHEN ECO SOLUTION TECH CORP

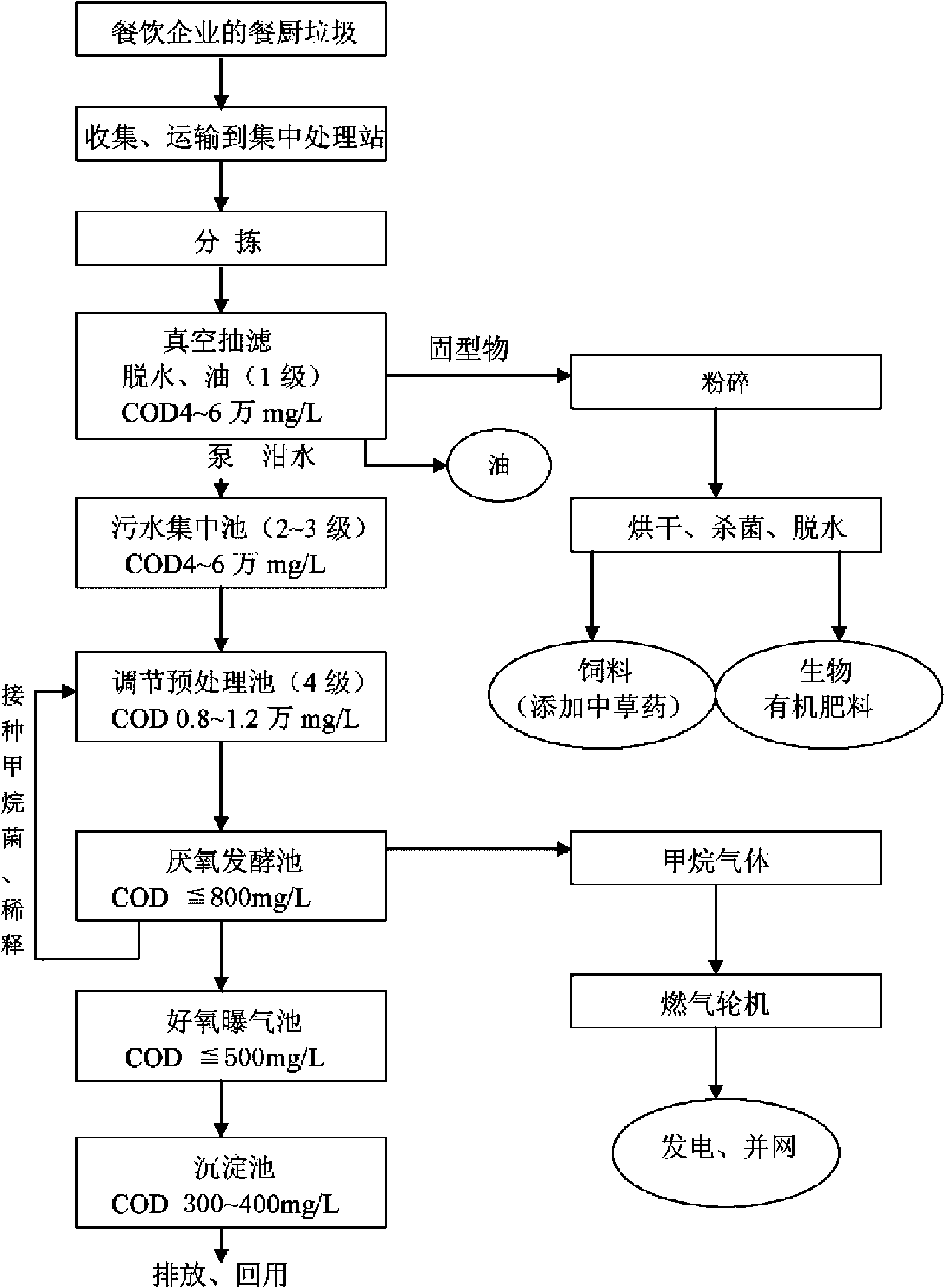

Processing method for changing restaurant and kitchen garbage into resource without environmental pollution

InactiveCN101274860AAvoid wastingEnergizeBio-organic fraction processingWaste processingThermal energyAnaerobic bacteria

The invention relates to a treating method for energy regeneration, resource recovery and pollution free of restaurant garbage, which comprises the steps that separated liquid material is pumped into a swage concentrating pool; then the concentrated liquid material is discharged into a regulating and pretreating pool, in which methane bacteria are inoculated; the pretreated liquid material is discharged into an anaerobic fermentation pool, in which anaerobic bacteria groups are added so that methane gas is generated and the overflowing liquid material from the anaerobic fermentation pool is led to enter an aerobic aerated pool for aerobic reaction; the liquid material after the aerobic reaction is discharged into a sedimentation tank for sedimentation. In the comprehensive utilization of 'swill', the disposing method of the invention carries out anaerobic fermentation and aerobic aerated biochemical treatment to transform part of the energy in the swill into bio-energy which is then transformed into heat energy and finally into electrical energy that is connected with power grid for use. The separated solid material is smashed, dried, sterilized, dehydrated and then added with Chinese herbal medicine to be processed into Chinese herbal medicine compound feeds and fertilizers; meanwhile, the treatment of energy regeneration, resource recovery and pollution free of restaurant garbage for restaurant garbage is realized.

Owner:WUXI KELUN SCI & TECH DEV

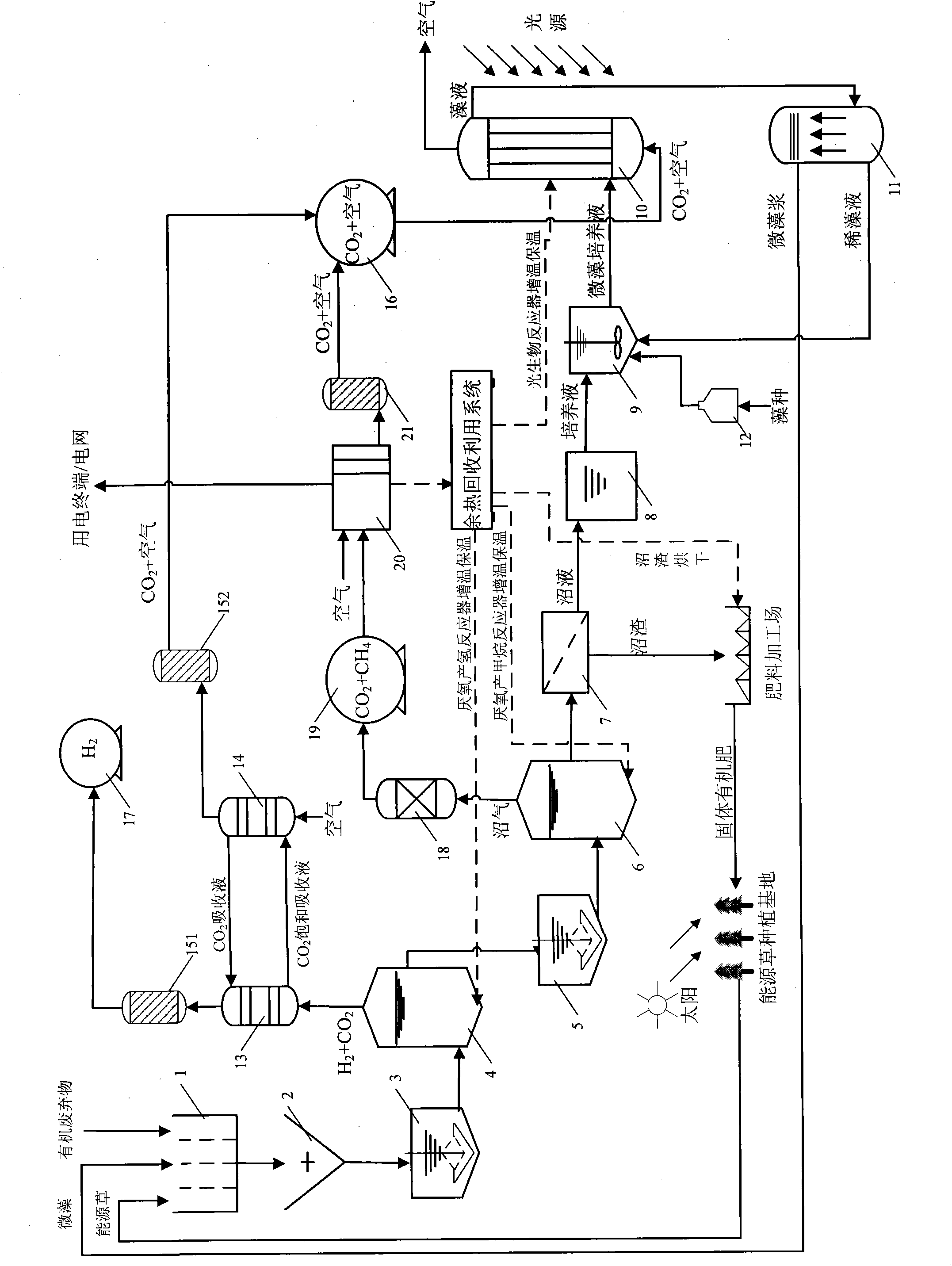

Energy utilization system of organic wastes with zero emission of carbon dioxide

ActiveCN101920258ARealize processingEliminate pollutionWaste processingSolid waste disposalSludgeCo2 absorption

The invention provides an energy utilization system of organic wastes with zero emission of carbon dioxide, which organically combines anaerobic fermentation hydrogen production, methane fermentation, CO2 absorption, microalgae fixation CO2, biogas liquid treatment and energy grass planting. The system is suitable for treating various types of organic wastes, can be applied to the treatment of agricultural organic wastes, industrial organic wastes, domestic organic wastes, slurry and the like, and the industries, such as new energy development. Through the application of the invention, the specific application demonstration of recycling economy can be carried out, clean energy is obtained while eliminating environmental pollution, no greenhouse gas emits in the process, and the triple effects of wastes treatment, production of clean and renewable energy sources and reduction of carbon dioxide emission can be realized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Kitchen waste treatment device

InactiveCN106673719AEasy to handleTurn waste into treasureWaste processingTransportation and packagingOil waterWaste treatment

The invention discloses a kitchen waste treatment device, which comprises a waste feeding hole, a crushing chamber, a solid-liquid separation chamber, a solid treatment chamber and a liquid treatment chamber, wherein the crushing chamber comprises a crushing rotating shaft and a crushing motor; a plurality of crushing knives are evenly distributed on the crushing motor; the solid-liquid separation chamber comprises a separation chamber inlet, a spiral dehydrator, a filter net, a liquid outlet, a solid outlet and a separation motor; the solid treatment chamber comprises an inclined drying net and a fan; the liquid treatment chamber comprises a liquid inlet, an oil-water separation layer, a purification layer and a water outlet; a solar panel is arranged at the top of the waste treatment device and is connected with a storage battery; and the crushing motor, the separation motor and the fan are connected with the storage battery through a wire. The kitchen waste treatment device has the beneficial effects that the structure is reasonable, the operation is convenient, the recycling of kitchen waste is facilitated and the environment is protected.

Owner:石芮巾

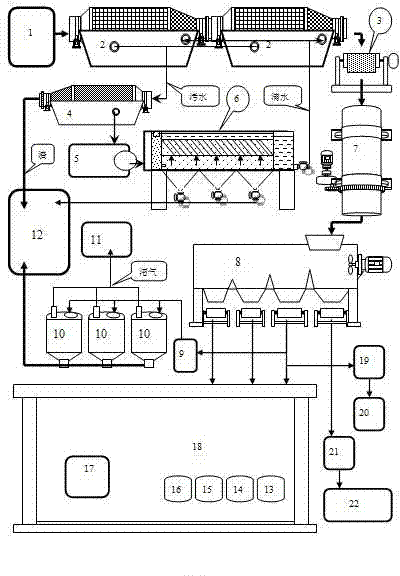

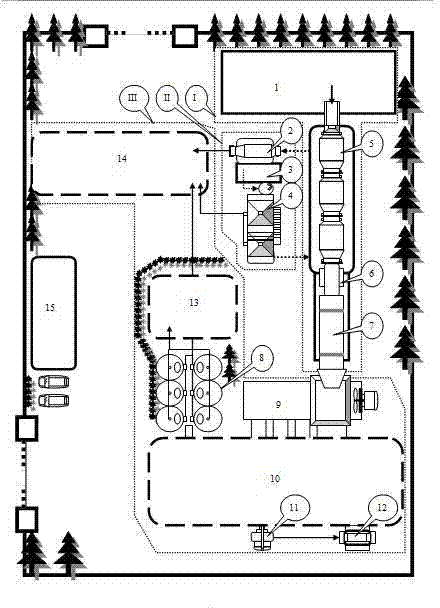

Water washing garbage cleaning production treatment method

InactiveCN102896135ANo emissionsEasy dischargeBio-organic fraction processingWaste processingRefuse DisposalsFermentation

The invention relates to a water washing garbage treatment method, wherein a purpose of the invention is to achieve urban garbage resource comprehensive utilization. According to the method, urban garbage is cleaned by using a running water washing manner, processes of dehydration, drying, winnowing, ??fine sorting and the like are performed, and classification centralization comprehensive utilization is performed; the water washing garbage sewage is treated through a sewage purifier to be rapidly recycled; and the production process adopts a cleaning production process, and no secondary pollution is generated. According to the present invention, the integrated design comprises water washing garbage sorting classification, fertilizer production through organic matter fermentation, heat supply through combustible combustion, a biogas engineering technology, a sewage treatment system and a plurality of mature application technologies; the urban garbage is adopted as a new urban mineral resource, and a water washing garbage resource comprehensive utilization workshop is established in a garbage landfill collection field so as to eliminate garbage pollution hazards; and sustainable development of large-scale garbage treatment industry is promoted, high economic benefits, social benefits and environmental benefits are generated, and good benefits are provided for humans.

Owner:唐义龙

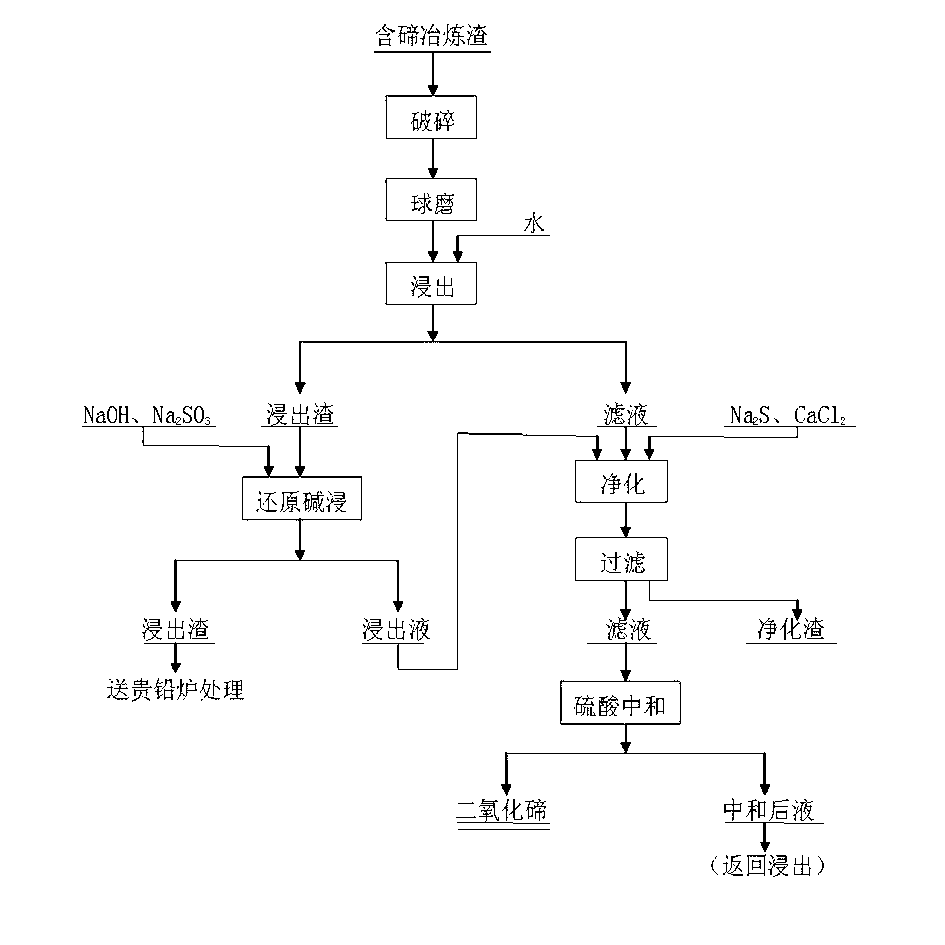

Technology for extracting tellurium dioxide from tellurium-containing smelting slag

ActiveCN102992280AImprove leaching rateReduce dosageWaste processingSolid waste disposalSlagMaterials science

The invention relates to a technology for extracting tellurium dioxide from tellurium-containing smelting slag. The technology comprises the following steps: ball-milling tellurium slag, leaching by water, carrying out reduction alkali leaching, vulcanizing, carrying out silicon removal purification, and neutralizing to precipitate tellurium. The method has the advantages of tellurium leaching rate improvement, reduction of the alkali application amount in the leaching operation, and production cost reduction. The method is characterized in that sodium hydrosulphite is adopted as a transition agent to transit insoluble high-valence tellurium to low-valence tellurium, so the leaching rate leaching rate is increased. The total tellurium leaching rate can reach above 90% under a suitable technological condition; and after recovering tellurium through neutralizing, the TeO2 grade of the smelting slag can reach above 50%, and the content of tellurium in the waste liquid obtained after the neutralizing is 0.1-0.3g / L. The method also has the advantages of further enrichment of copper, lead, bismuth, antimony and precious metals in the leaching slag, realization of the resource reuse, production cost reduction, and energy saving, and is of great importance to the resource recovery and the environmental protection.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

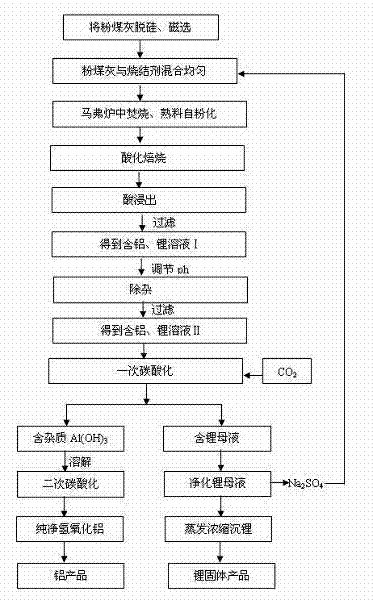

Technical method for comprehensively extracting aluminum and lithium from coal ash through acid process

The invention provides a technical method for comprehensively extracting aluminum and lithium from coal ash through an acid process. The method is characterized by comprising the following technological steps which are carried out in sequence: (A) desiliconizing and magnetically separating; (B) thermally processing; (C) acidizing and roasting; (D) leaching; (E) removing residues; (F) carbonizing, and precipitating aluminum; (G) purifying lithium mother liquor; and (H) evaporating, concentrating and precipitating lithium. The method has the advantages that the silicon, iron, aluminum and lithium are sequentially extracted from the industrial coal ash, so that the waste is turned into treasure, the cost of the raw materials is reduced, the technological operation is simple and convenient, and the comprehensive extracting rate of aluminum source and lithium resources can be maximized; and the method is an ideal method for comprehensively extracting aluminum and lithium from the coal ash through the acid process.

Owner:HEBEI UNIV OF ENG

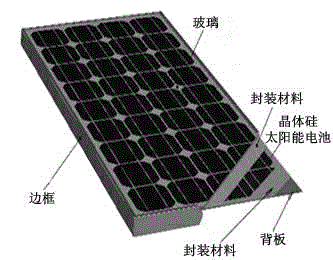

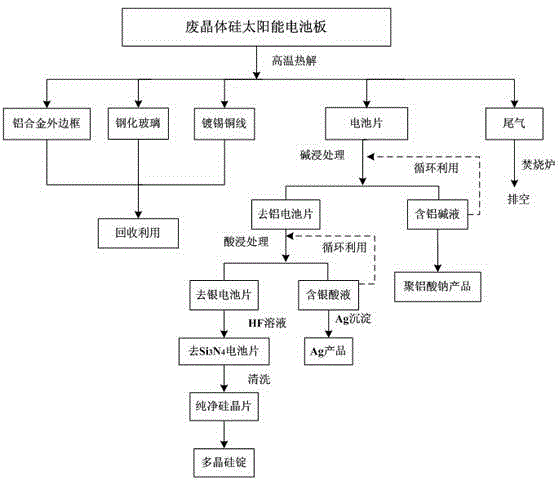

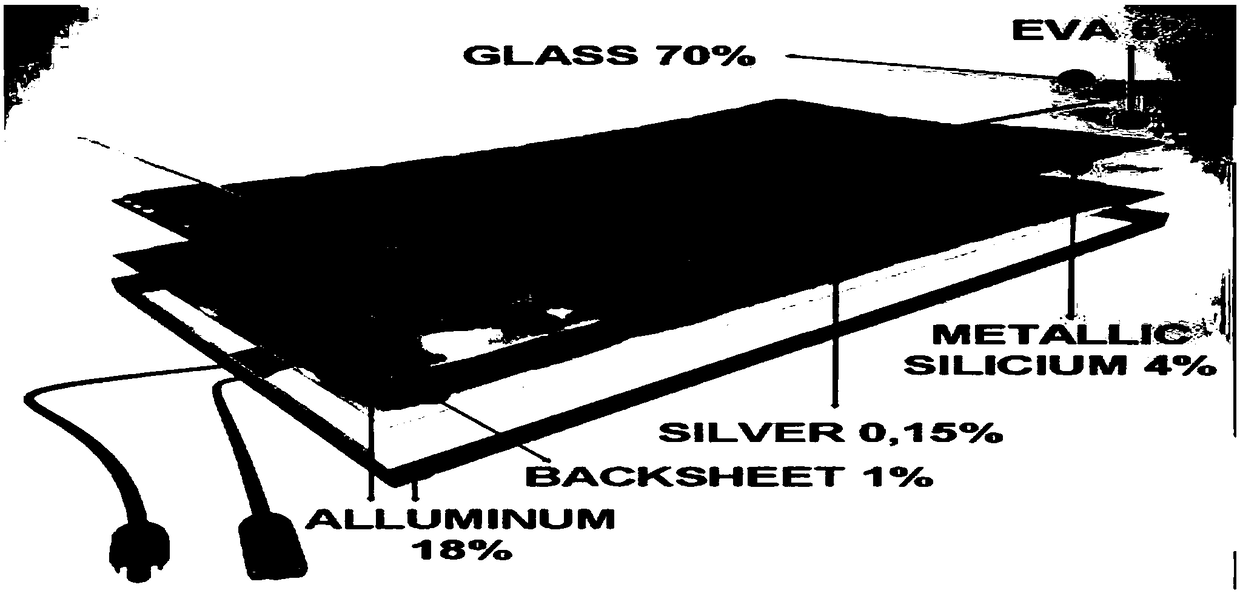

Waste crystalline silicon solar cell panel disassembling and recovering method

ActiveCN103978021AIncrease added valueRealize sorting and recyclingWaste processingSolid waste disposalWaferingPhysical chemistry

The invention discloses a waste crystalline silicon solar cell panel disassembling and recovering method. The method can realize the classification recovery of aluminum frames, toughened glass, silicon wafers, aluminum, silver and copper of waste crystalline silicon solar cell panels. The method adopts a heat treatment technology and a chemical technology combination technique to realize the frame and glass recovery of the waste crystalline silicon solar cell panels, the silicon wafer separation, and the valuable metal and silicon wafer recovery. The method has the advantages of recovery treatment difficulty reduction, tail gas harmlessness realization, secondary pollution control and environment protection; and an alkali dipping treatment and acid dipping treatment solution can be recycled, so the reagent consumption is reduced, the waste acid and waste alkali generation amount is reduced, and the final waste treatment cost is reduced.

Owner:刘景洋

Dismantling method of scrapped photovoltaic module

ActiveCN109092842AEnvironmentally friendly and economical dismantlingSimple structureWaste processingSolid waste disposalNon-ferrous metalAluminium

Owner:CHANGZHOU RUISAI ENVIRONMENTAL PROTECTION TECH CO LTD

Quick biological drying method for household garbage

InactiveCN101899348AImprove environmental conditionsImprove degradation conditionsWaste processingSolid waste disposalEnergy recoveryOxygen

The invention relates to a quick biological drying method for household garbage. The method comprises the following steps of: uniformly mixing the household garbage from which large impurities are screened out, a biological drying product of the garbage and broken straw, and stacking the mixture in a groove-type compost reactor; covering bundled straw cushions on the garbage surface; supplying enough oxygen to aerobic microorganisms by a timed ventilation method; and after the temperature of the stack reaches a high-temperature section (more than 55 DEG C), adopting a stack temperature feedback ventilation method to evaporate moisture by fully using heat generated by metabolism of the aerobic microorganisms, and bringing out steam by using sufficient ventilation flow to realize quick drying of the garbage. The dried garbage is separated and recycled or transported to an incineration plant for energy recovery. The method improves a lower heat value of the dried garbage by 100 percent and a separation rate by 140 percent, obviously improves household garbage incineration and separation recycling values, and can be widely applied to drying treatment of household garbage which contains 65 to 50 percent of moisture and in which biodegradable organisms account for 50 to 35 weight percent of dry matters.

Owner:TONGJI UNIV

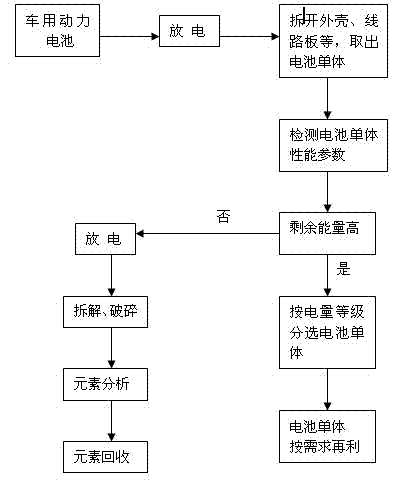

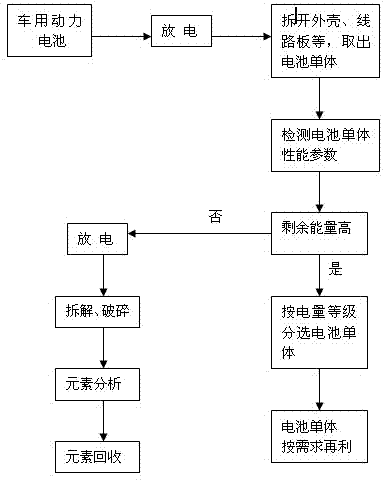

Method for recovering power cells for new energy vehicles

ActiveCN102347520ARealize cascade utilizationAvoid wastingWaste processingSolid waste disposalPower batteryElectrical battery

The invention discloses a method for recovering power cells for new energy vehicles. The method comprises the following steps of: (1) discharging the expired power cells for removing the remaining energy of the power cells to ensure that the subsequent processes can be performed safely; (2) initially partitioning; (3) detecting and classifying the performance parameters of single batteries; (4) disassembling the useless single batteries to take out the positive and negative pole pieces thereof; (5) performing elemental analysis on the obtained positive and negative pole pieces, based on the result of elemental analysis, determining the mixing amount of different batches of raw materials according to the contents of the elements and the proportion of each major element of a target product, and extracting the metal elements by hydrometallurgy to prepare the target product; and (6) sorting the employable single batteries by a battery sorter according to the residual capacitance of the single batteries, grading and classifying based on the capacitance, and then applying to products according to actual requirements.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

Processing method of cellulose industrial biomass waste and process device thereof

ActiveCN102311742AWide adaptabilityOvercome the disadvantages of difficult continuous processingWaste processingCarbon compoundsCellulosePorous carbon

The invention discloses a processing method and a process device of cellulose industrial biomass wastes, and the method comprises the following steps: feeding raw materials into a drying system continuously, supplying heat by high-temperature flue gas from the combustion of volatile matter precipitated in pyrolysis and carbonization so as to dry the raw materials; allowing the dried raw materials to enter a carbonization reactor for pyrolysis and carbonization, delivering the intermediate products of pyrolysis and carbonization to a riser reactor, preparing porous carbon-based adsorption functional material (namely active carbon), syngas (or called biomass gas), or steam under the action of an oxidative medium and an activator, or an oxidative medium and an gasifying agent, or an oxidative medium. The steam required by the system is prepared by the activated or gasified high-temperature gas-solid products through heat exchange, which can increase the energy recovery efficiency of the process; the process adopts a continuous running mode with complete self-heating, and realizes the high-value conversion of cellulose industrial biomass wastes.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for recovering crystalline silicon cell plate in double-glass solar cell assembly with PVB interbed

The invention discloses a method for recovering a crystalline silicon cell plate in a double-glass solar cell assembly with a PVB interbed under the condition of no damage to a crystalline silicon cell. The recovering method comprises the following steps of: placing the double-glass solar cell assembly with the PVB interbed on a supporting frame; heating; thermal insulating; after the PVB interbed is molten completely or partially, removing an upper layer of glass from the assembly; cooling the assembly the upper layer of glass of which is removed; placing the assembly into a solvent for soaking and enabling the crystalline silicon cell plate to separate from PVB glue; taking out the cell plate; washing; and drying to obtain the reusable crystalline silicon cell plate.

Owner:WUJIANG GOLDEN GLASS TECH

Household garbage fine separation and complete recycling comprehensive treatment process

InactiveCN105665410ARealize resourcesHarmlessWaste processingSolid waste disposalSoil organic matterLitter

The invention discloses a household garbage fine separation and complete recycling comprehensive treatment process and relates to a process for treating household garbage. According to the household garbage fine separation and complete recycling comprehensive treatment process, urban household garbage which is collected in a centralized manner can be recycled in a plurality of manners and enters all recycling systems, a plurality of products are produced and returned to the urban for use, and recycling, maximum reduction and harmlessness of the household garbage are truly and completely achieved. The household garbage fine separation and complete recycling comprehensive treatment process comprises following steps of bag breaking, leaching and material storage of the household garbage; separating, wherein waste plastic, unrecyclable combustible materials, organic matter, inert inorganic matter and ferromagnetic matter are separated out; treatment of the separated matter; collecting and treating of garbage leachate and waste water; collecting and treating of waste gas or bad smell; and treating of the noise.

Owner:BEIJING ZHENGSHI ENVIRONMENTAL PROTECTION ENG CO LTD

Method for recycling crystalline silicon solar cell module

InactiveCN105618461AEffective recyclingGood energy saving and environmental protection effectWaste processingSolid waste disposalCross-linkEconomic benefits

The invention discloses a method for recycling a crystalline silicon solar cell module. The method includes the following specific technological steps that firstly, an aluminum frame and a junction box of a solar cell panel are demounted in a mechanical demounting manner; secondly, a cutting device is used for cutting off a peripheral edge rubber sealing strip of the solar cell panel with the aluminum frame and the junction box being demounted; thirdly, the cutting device is used for separating ultra-white glass, an EVA film, a battery piece, a backboard film, and a backboard of the solar cell panel with the peripheral edge rubber sealing strip being removed; fourthly, the separated battery piece and cross-linked EVA are dissolved in a solvent, so that a solar cell chip is separated; and fifthly, the solar cell chip is treated through a chemical method, and therefore a silicon material and silver powder are obtained. By means of design of the technological steps, crystalline silicon solar cell module resources can be effectively recycled, the energy-saving and environment-friendly effects are good, and social and economic benefits are good.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

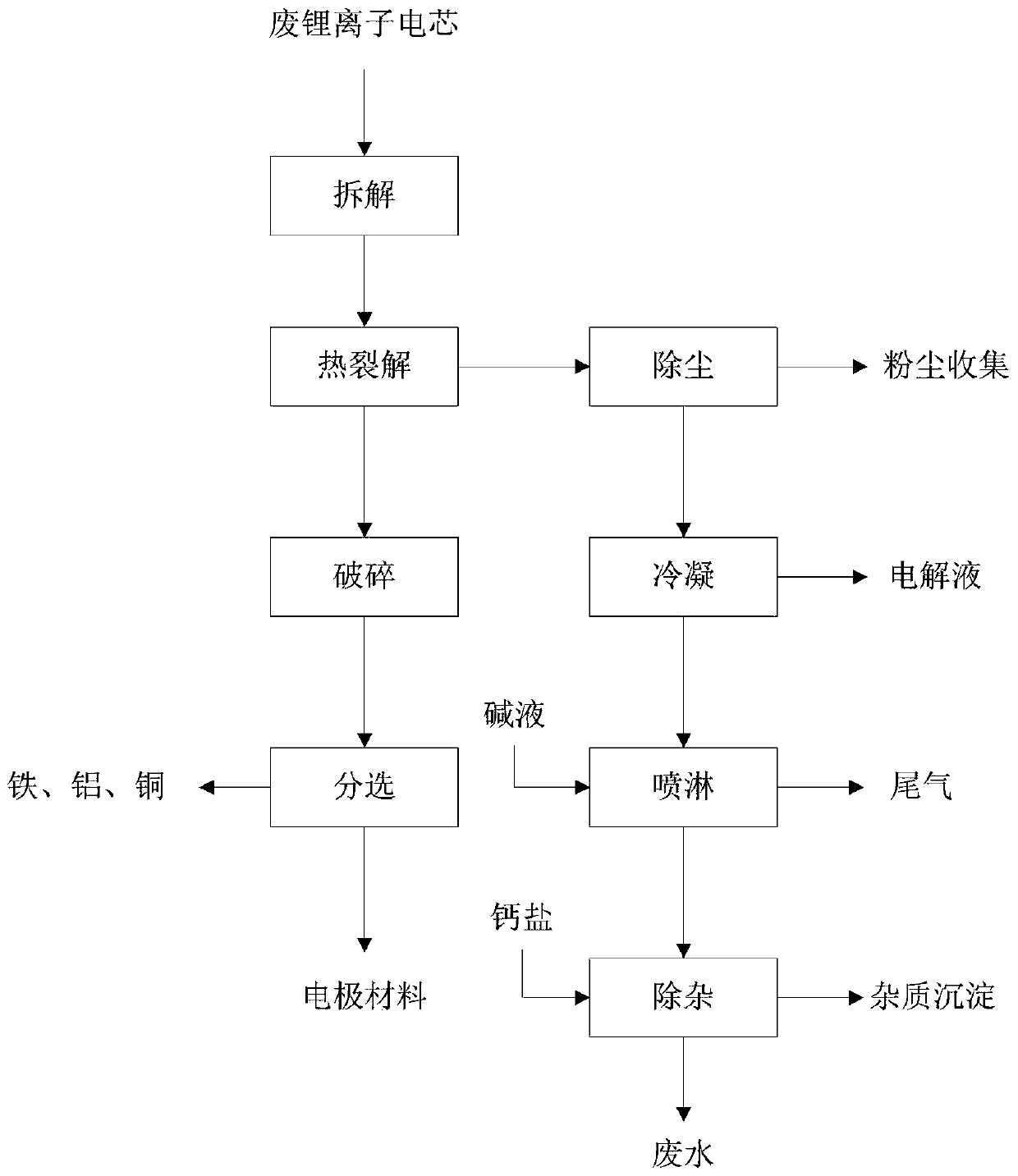

Method for recovering electrolyte in waste lithium ion battery

InactiveCN110534834ASafe recyclingEfficient recyclingWaste processingSolid waste disposalElectrolytic agentElectrical battery

The invention discloses a method for recovering an electrolyte in a waste lithium ion battery. The method comprises the steps that the single cell of the waste lithium ion battery after discharging isdisassembled; thermal cracking treatment is carried out at 300 to 500 DEG C, wherein the pyrolysis time is 0.5 to 1.5h; the solid material after thermal cracking is pulverized, sorted and recovered to acquire an electrode material, iron, aluminum and copper powder; the thermally cracked gas is first dedusted and then condensed to recover the condensed electrolyte; and the condensed gas is discharged after being leached with an alkaline solution. According to the method provided by the invention, the electrolyte is recovered, and the fluorine content of the discharged gas is reduced to below the emission standard to meet the requirement of environmental protection treatment.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

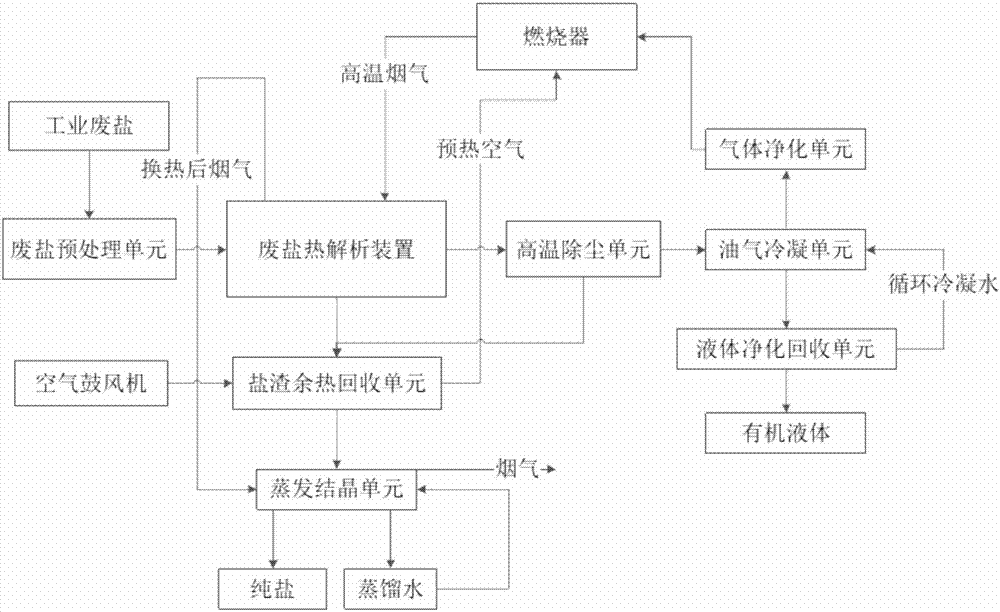

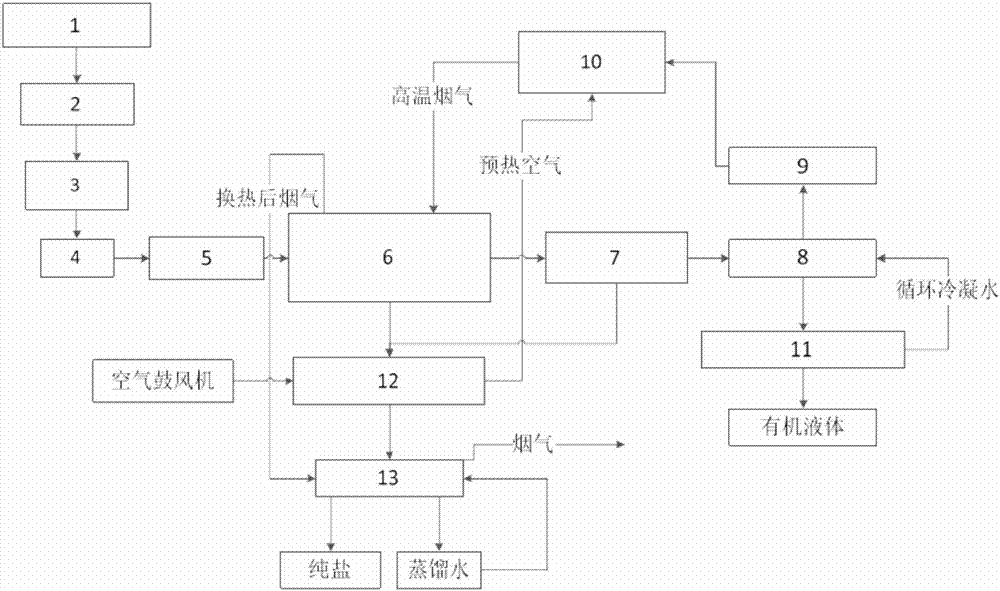

Industrial waste salt system and method

The invention belongs to the technical field of environmental protection, and particularly relates to an industrial waste salt system and method. The industrial waste salt system comprises a waste salt pretreatment unit, a waste salt thermal analysis device, a high temperature dust removal unit, an oil and gas condensing unit, a gas purification unit, a liquid purification and recovery unit, a burner, an evaporation and crystallization unit, and a salt slag waste heat recovery unit. The industrial waste salt system and method is complete in harmless treatment, high in resource recovery rate, and low in treatment energy consumption, and the recovery rate of the waste salt after the treatment of the system can reach 80%.

Owner:BEIJING BIOTECHINA ENVIRONMENT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com