Processing method of cellulose industrial biomass waste and process device thereof

A processing method and industrially produced technology, applied in the field of biomass resource utilization, can solve the problems of low attention, lack of high-value utilization methods, etc., and achieve good adsorption performance and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The biomass waste used in the cellulose industrial biomass waste processing method provided in this example is distiller's grains, a by-product of the solid-state fermentation process, with a moisture content of 55-65%. The content is 66-74%, the fixed carbon content is 15-20%, and the ash content is 10-15%.

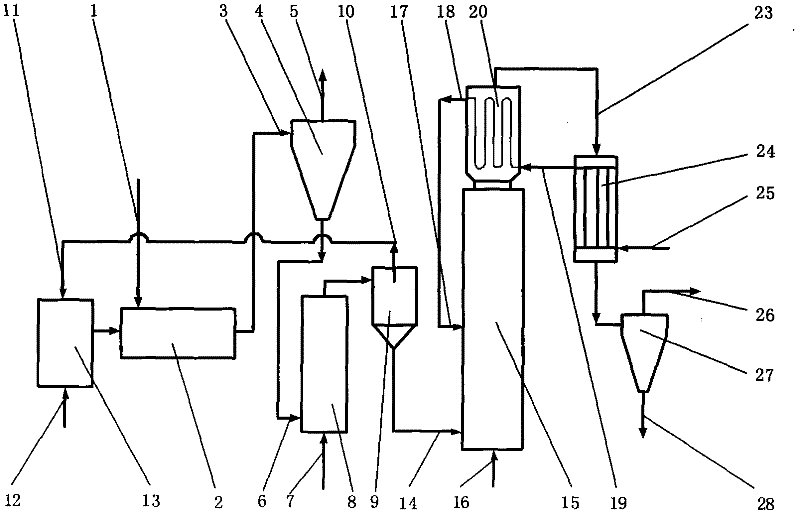

[0055] The process operation of its riser reactor adopts the mode of activation reaction, and the process method is to prepare porous carbon material as the target product. The process flow is as follows figure 1 As shown, wherein, the reference signs are as follows:

[0056] 1 raw material inlet 2 dryer

[0057] 3 Gas-solid separator inlet 4 Dry raw material gas-solid separator

[0058] 5 Gas phase outlet of separator 6 Raw material inlet of carbonization reactor

[0059] 7 Carbonization reactor air inlet 8 Carbonization reactor

[0060] 9 carbonized product separator 10 volatile matter outlet

[0061] 11 Gas inlet 12 Hot blast stove tuyeres

[0062] 13 Hot...

Embodiment 2

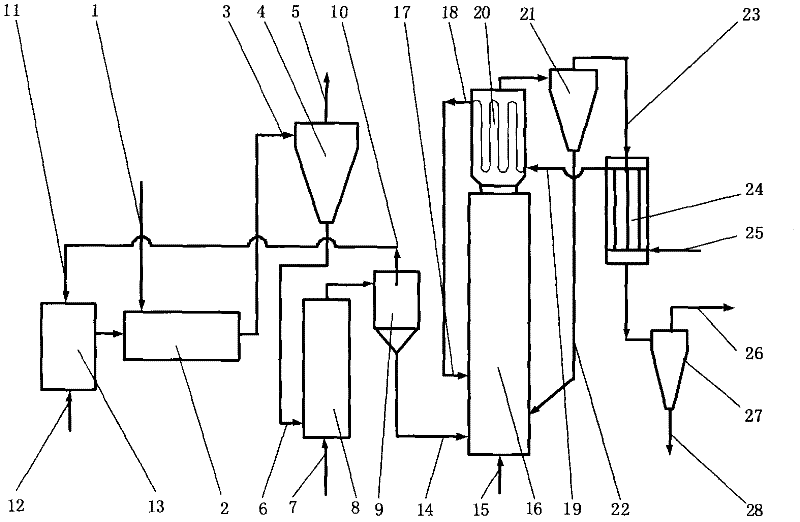

[0084] The processing method of the cellulose industrial biomass waste implemented by the present invention does not need to change the technological process of the unit equipment, only needs to adjust its operating conditions, and can flexibly switch the target product of the processing method, and its technological process is as follows figure 2 shown. The difference between this example and Example 1 is that the treatment mode of the pyrolysis carbonization intermediate product is to blow oxidative medium and gasification agent into the riser reactor, so that the pyrolysis carbonization intermediate product is in the oxidative medium and gasification agent. The gasification reaction occurs under the combined action of the gas, and the synthesis gas (that is, biomass gas) is prepared. The oxidizing medium used in the process is oxygen, the temperature of the system is maintained at 1000-1200 ° C, and the gasification agent used is water vapor.

Embodiment 3

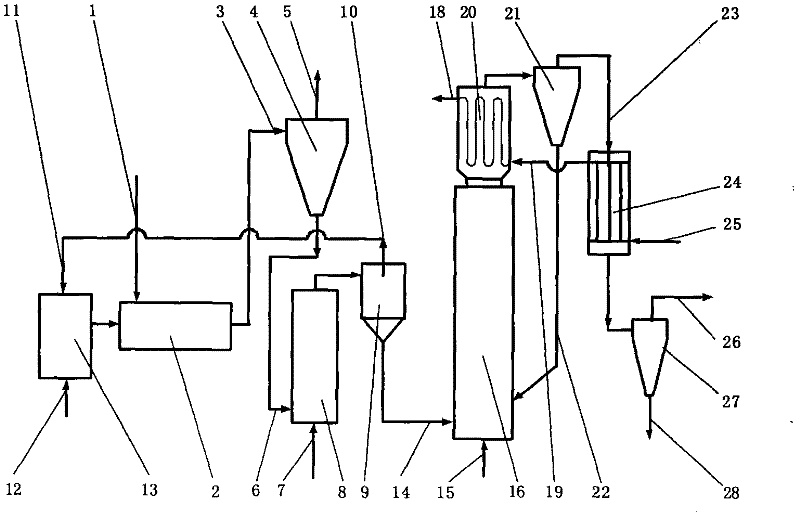

[0086] Another treatment mode of the pyrolysis carbonization intermediate product in this embodiment is to completely burn the pyrolysis carbonization intermediate product by blowing an oxidizing medium into the riser reactor, and the temperature of the generated flue gas is 800-1000°C. It is used to prepare steam for external supply, and its technological process is as attached image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com