Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

970 results about "Waste processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

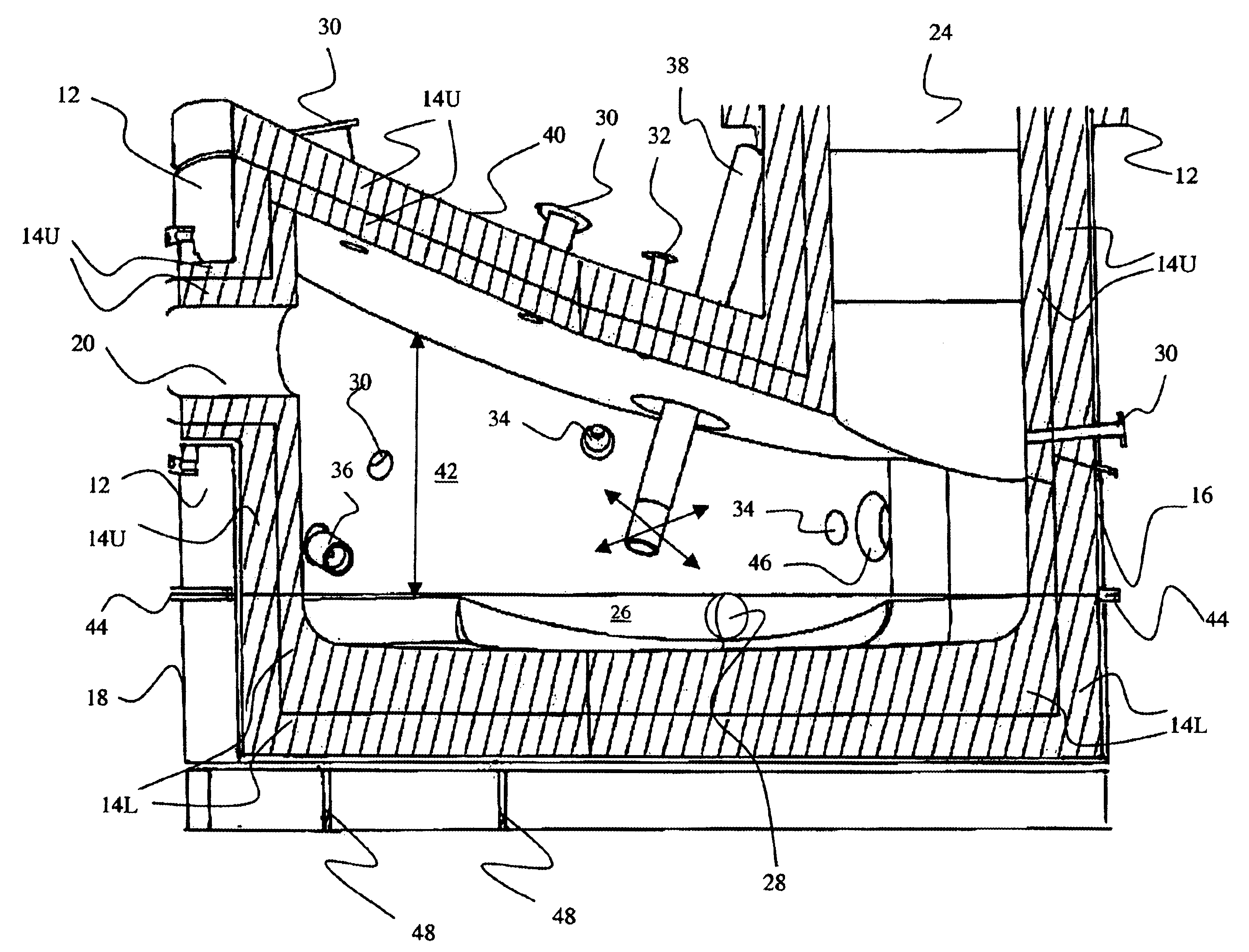

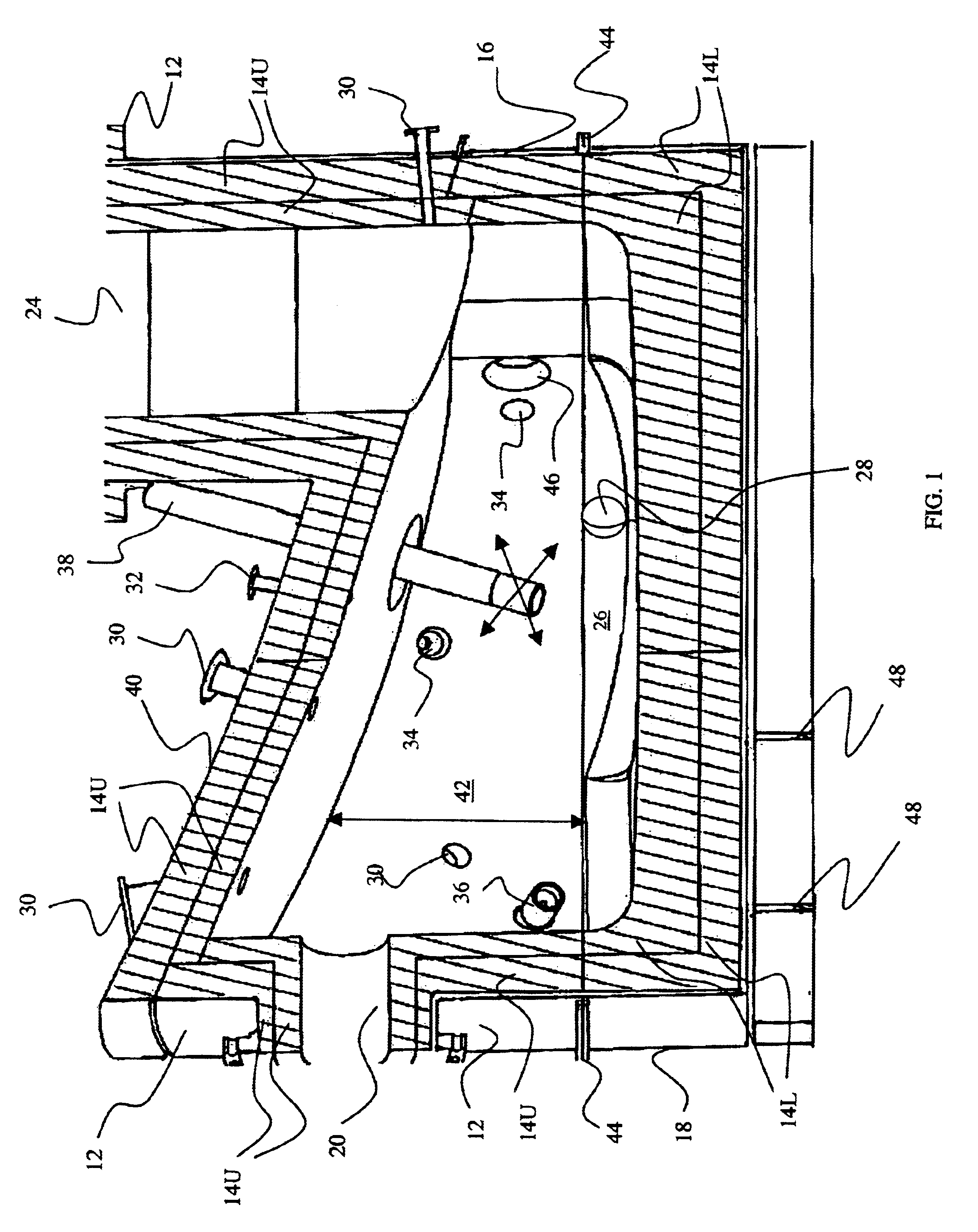

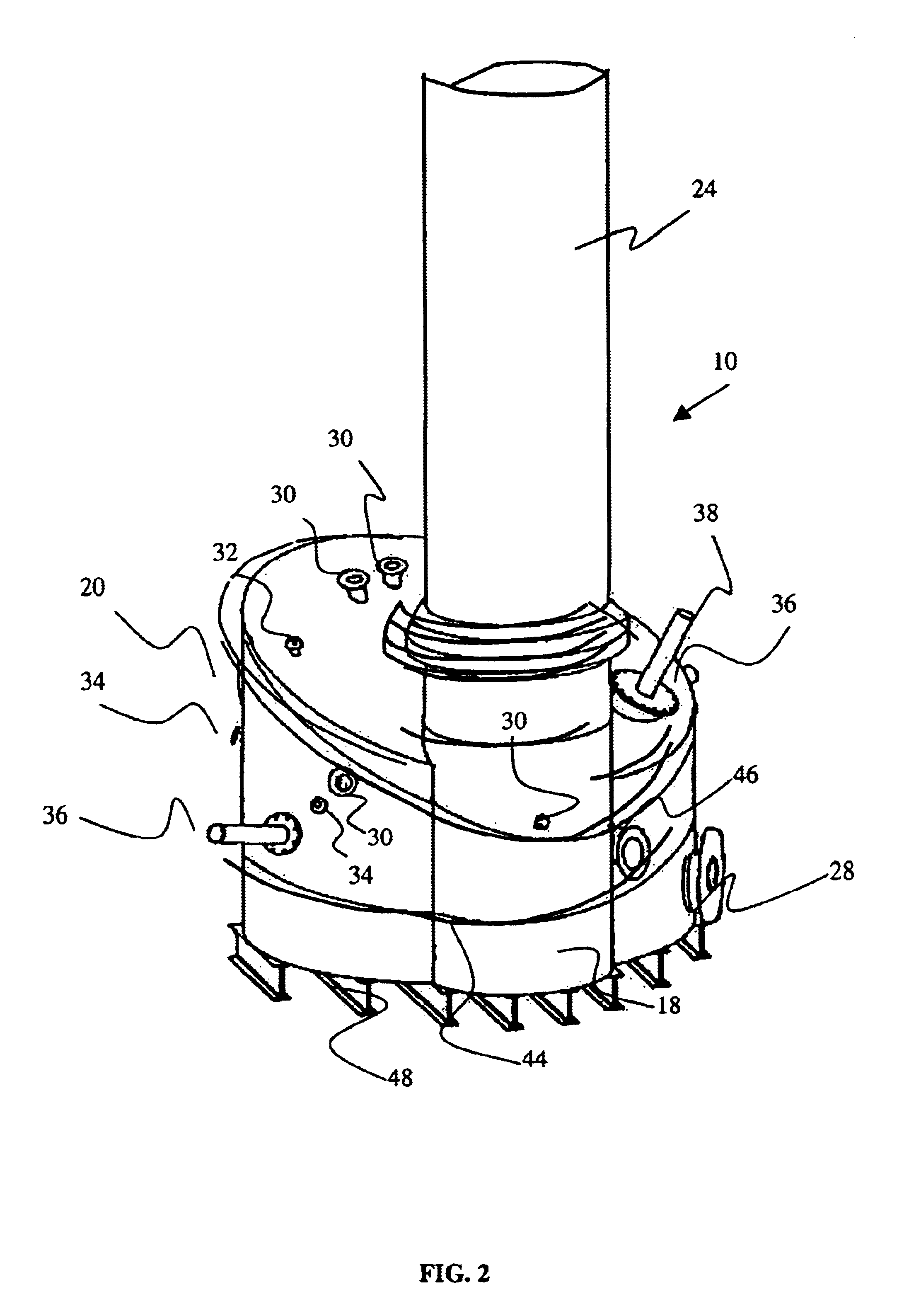

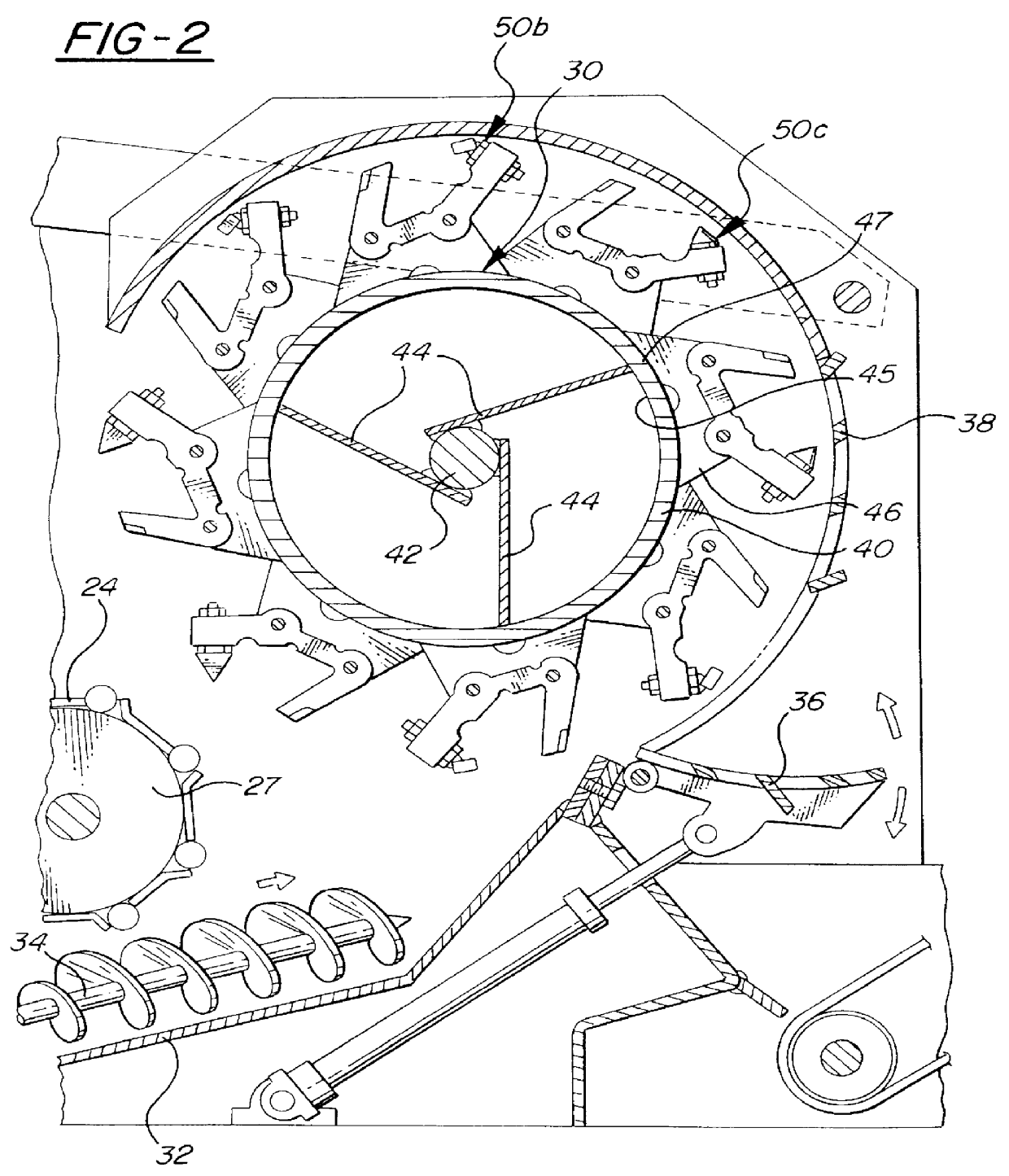

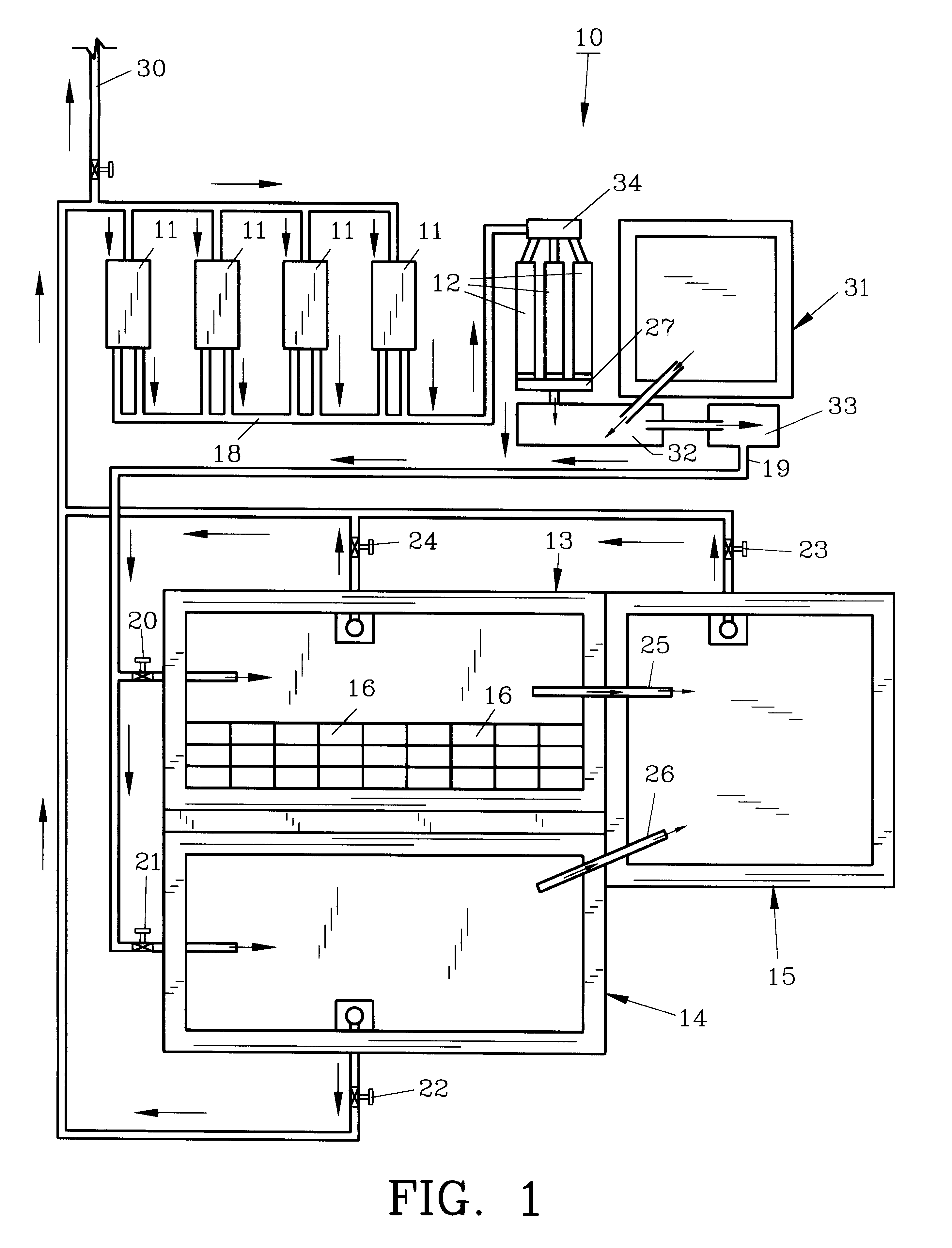

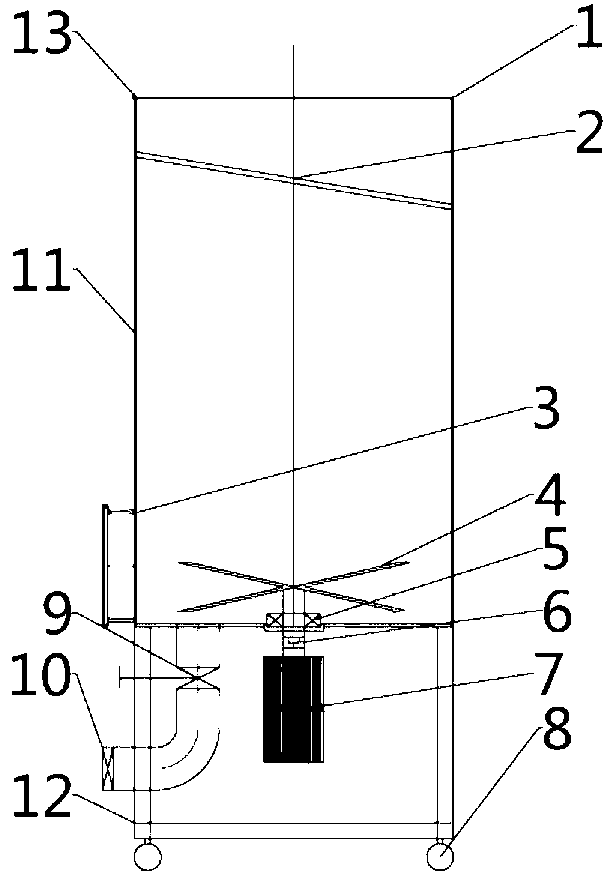

Multiple plasma generator hazardous waste processing system

A waste processing system is provided herein which entails the use of at least one fixed-position plasma arc generator for primary processing and at least one moveable plasma arc generator for secondary processing assistance and / or final conditioning of the slag prior to exit from the reactor vessel. This optimum processing environment is provided by control of reactor vessel configuration and real time control of processing characteristics to ensure maximum processing efficiency.

Owner:PLASCO ENERGY GROUP INC

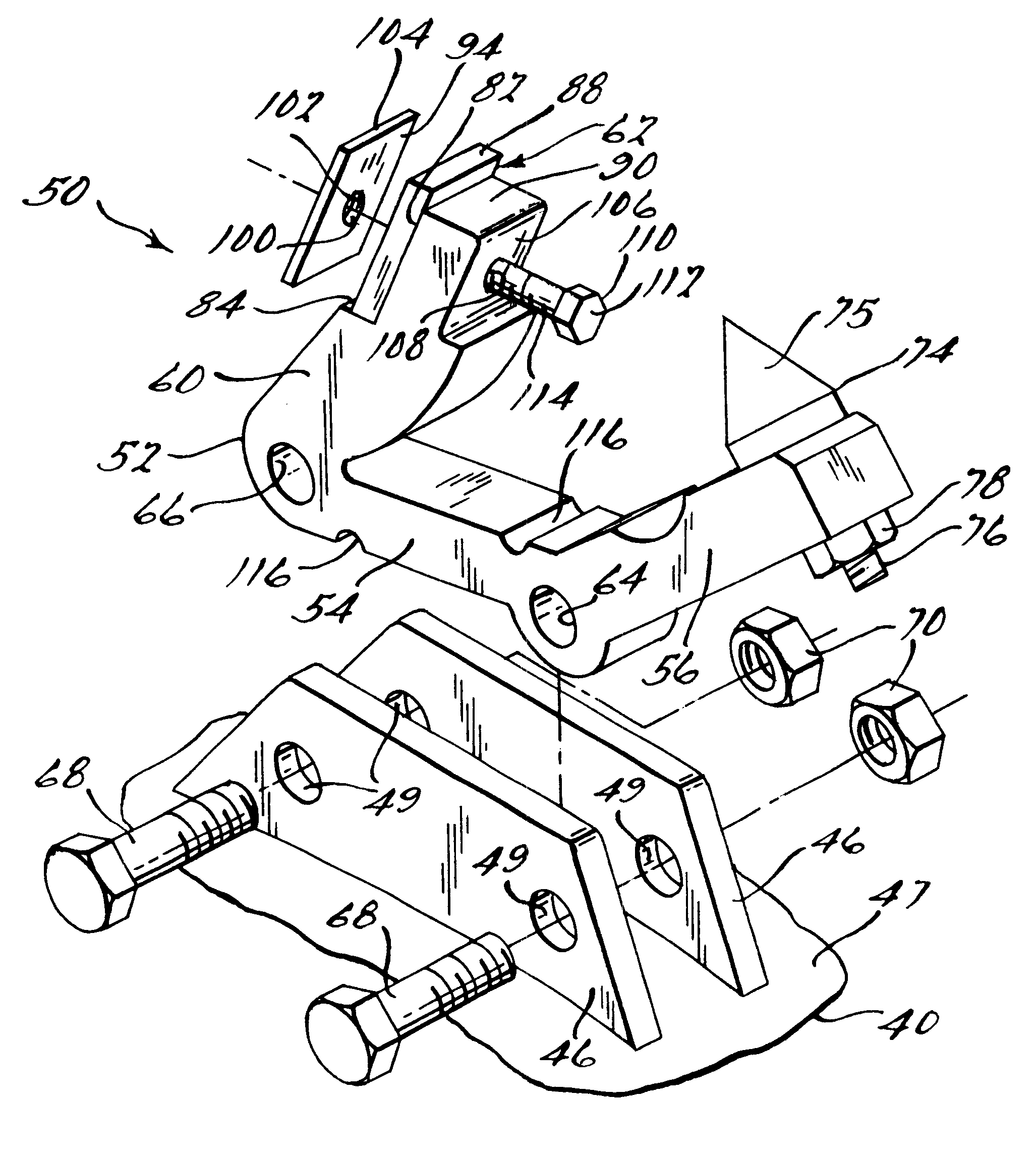

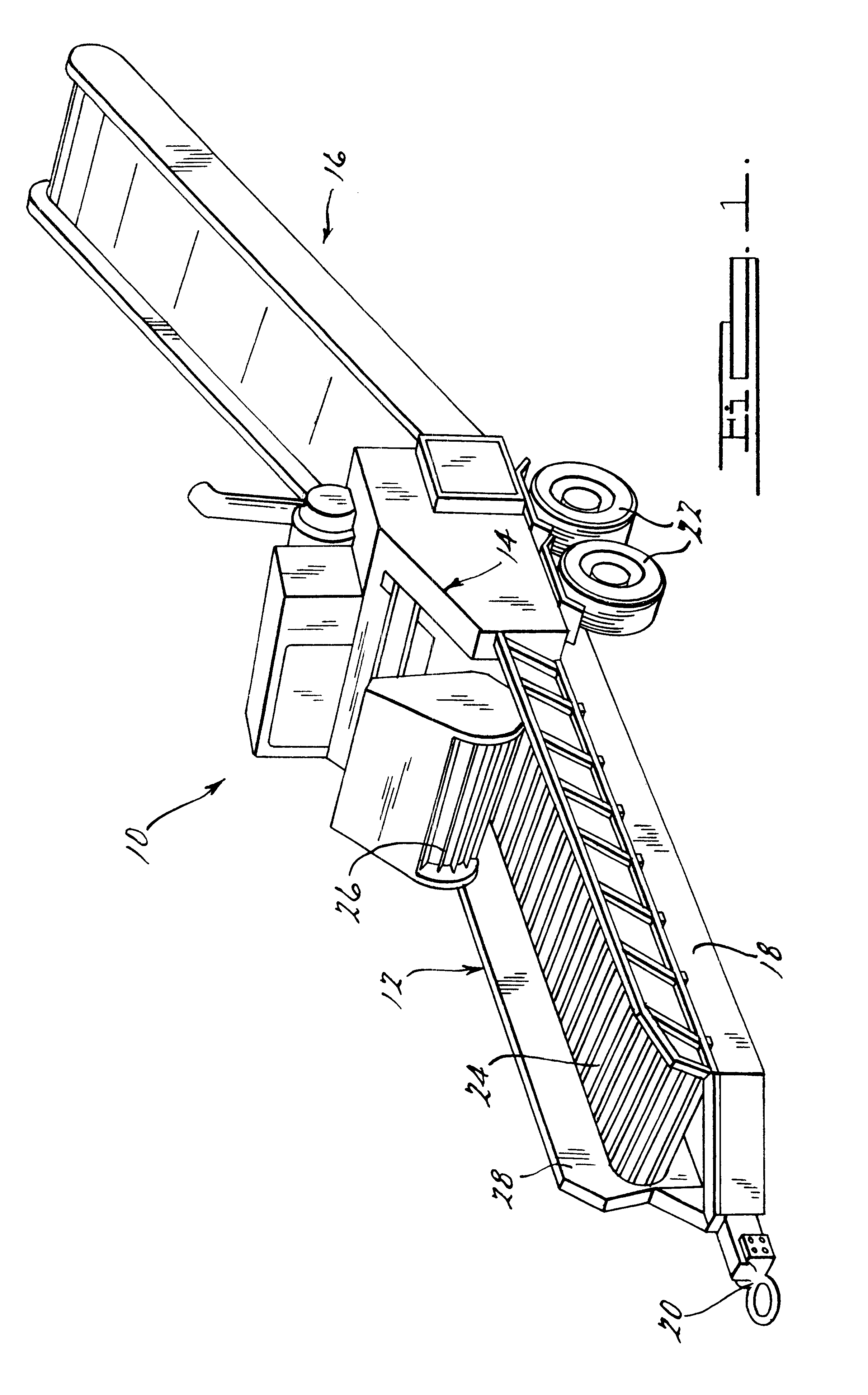

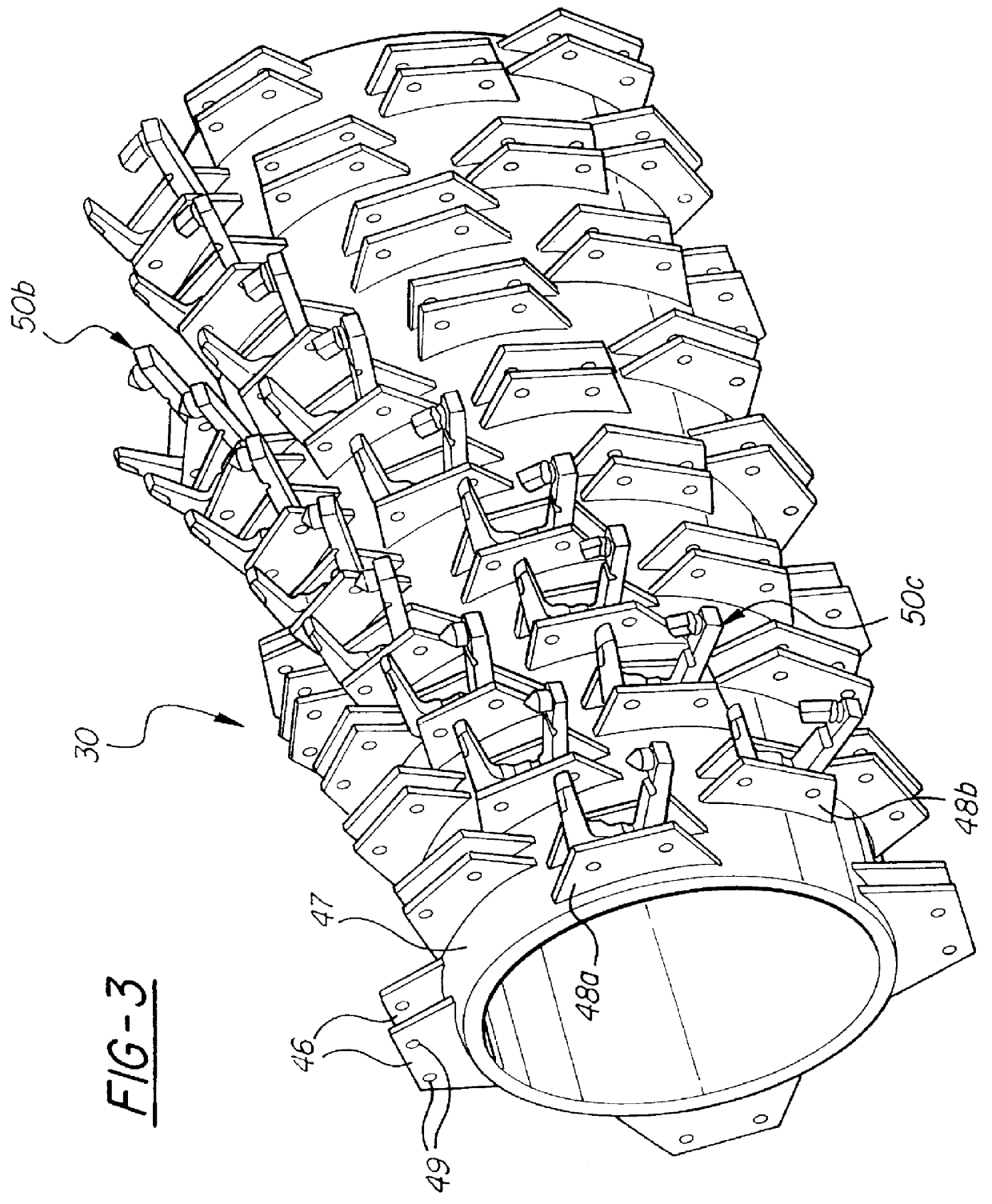

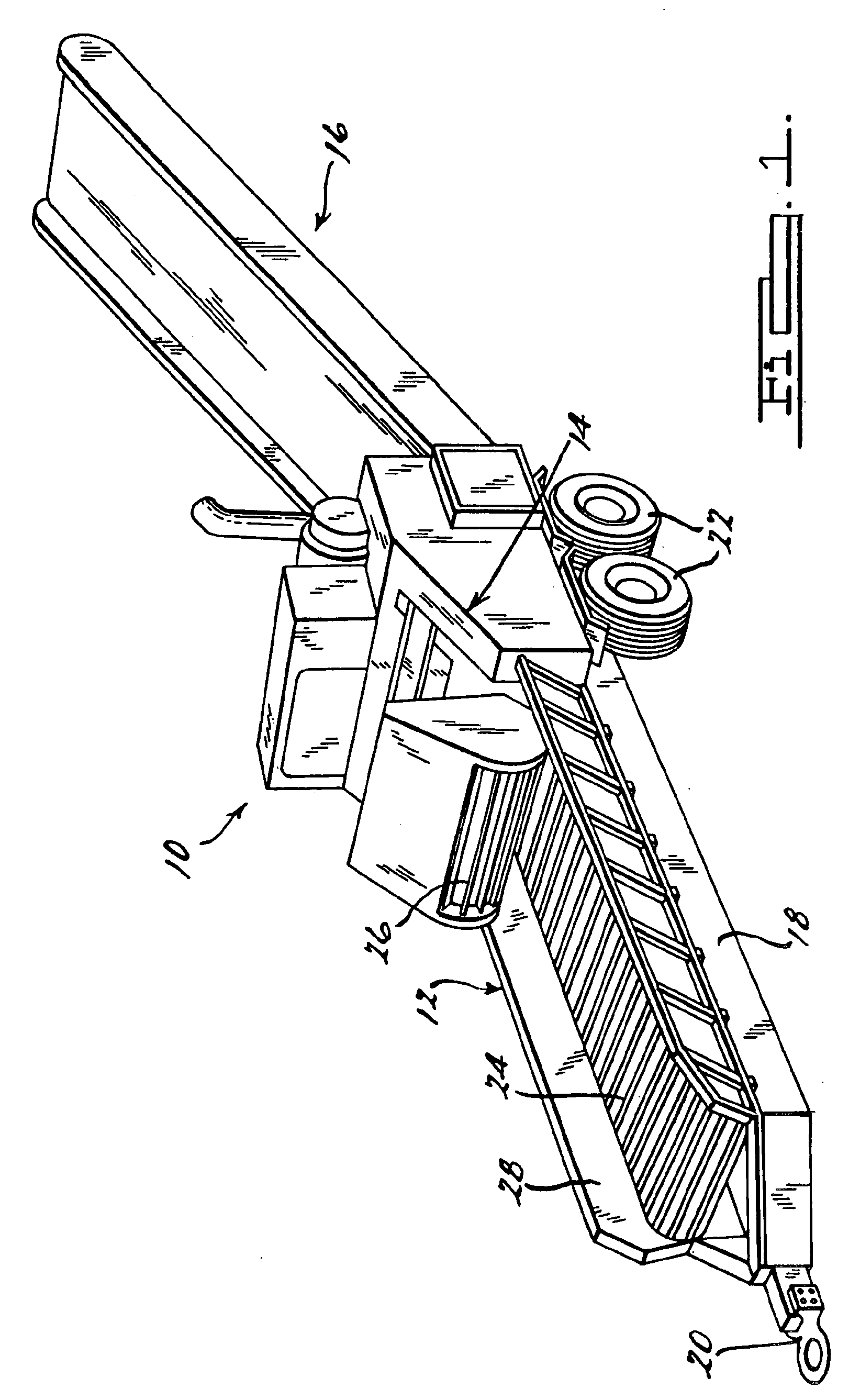

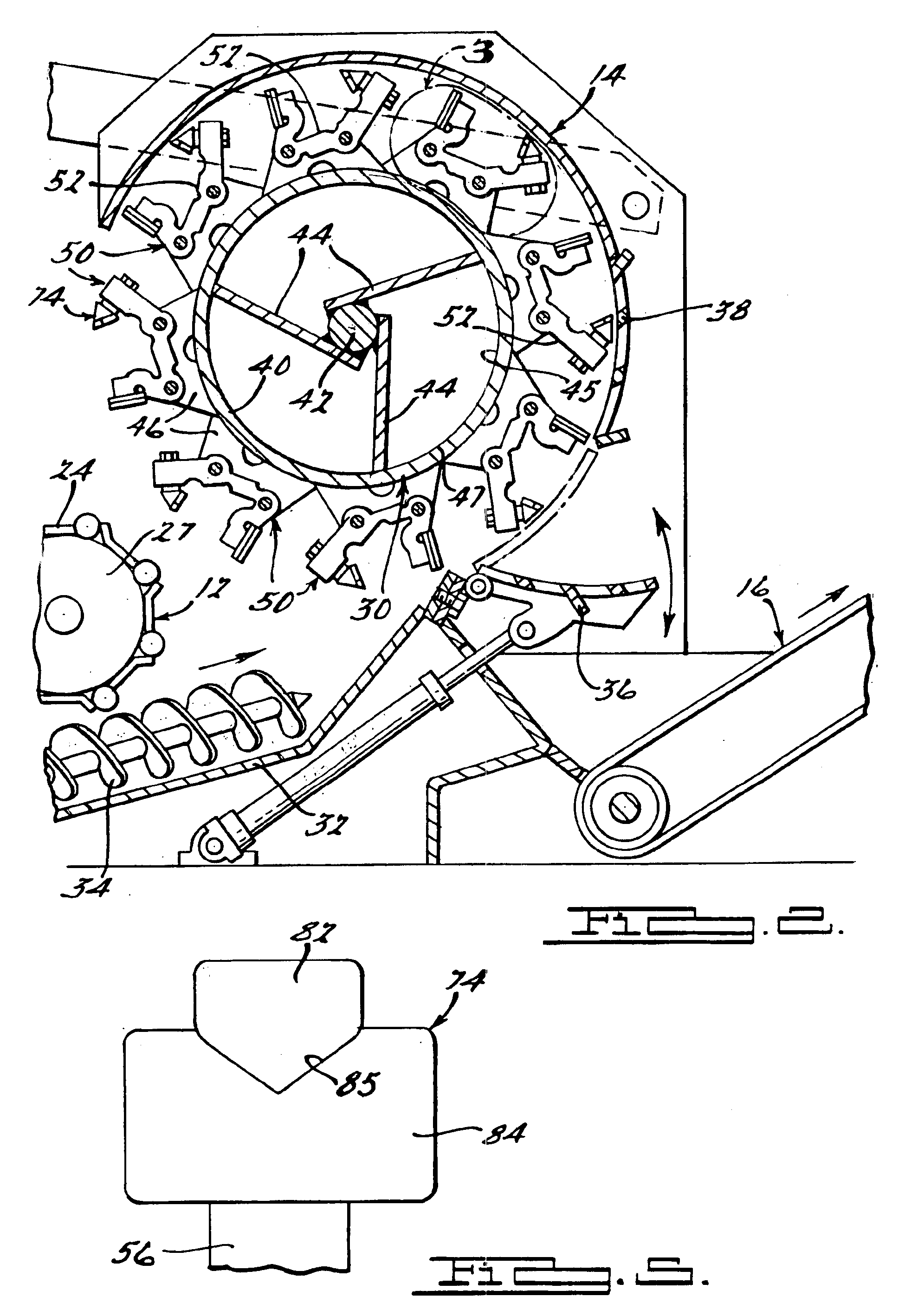

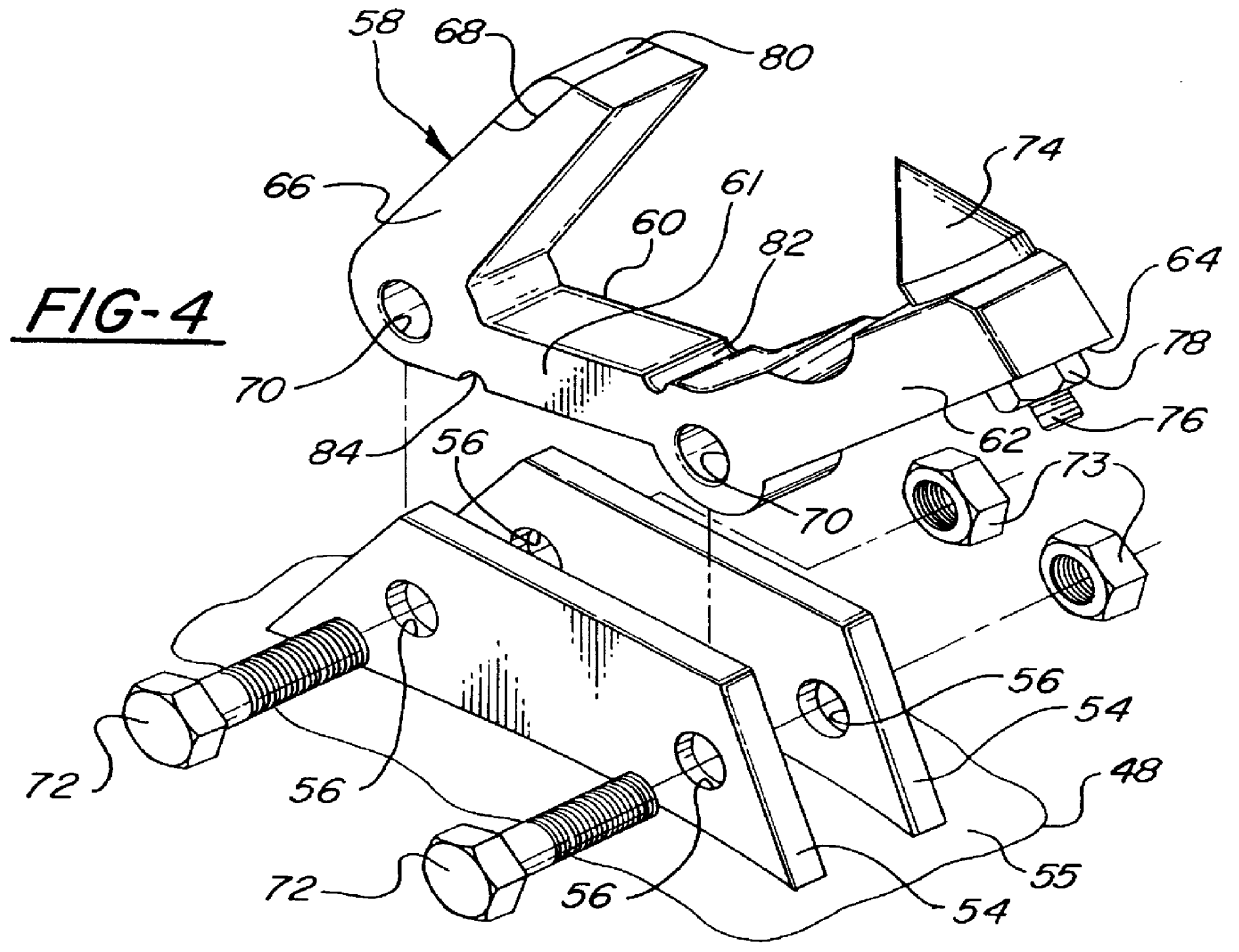

Replaceable raker assembly for processing tool of waste processing machine

A replaceable raker assembly for a processing tool of a waste processing machine includes a tool holder for attachment to a rotor assembly of the waste processing machine. The replaceable raker assembly also includes a raker removably attached to the tool holder to rake reduced waste material.

Owner:SMORACY

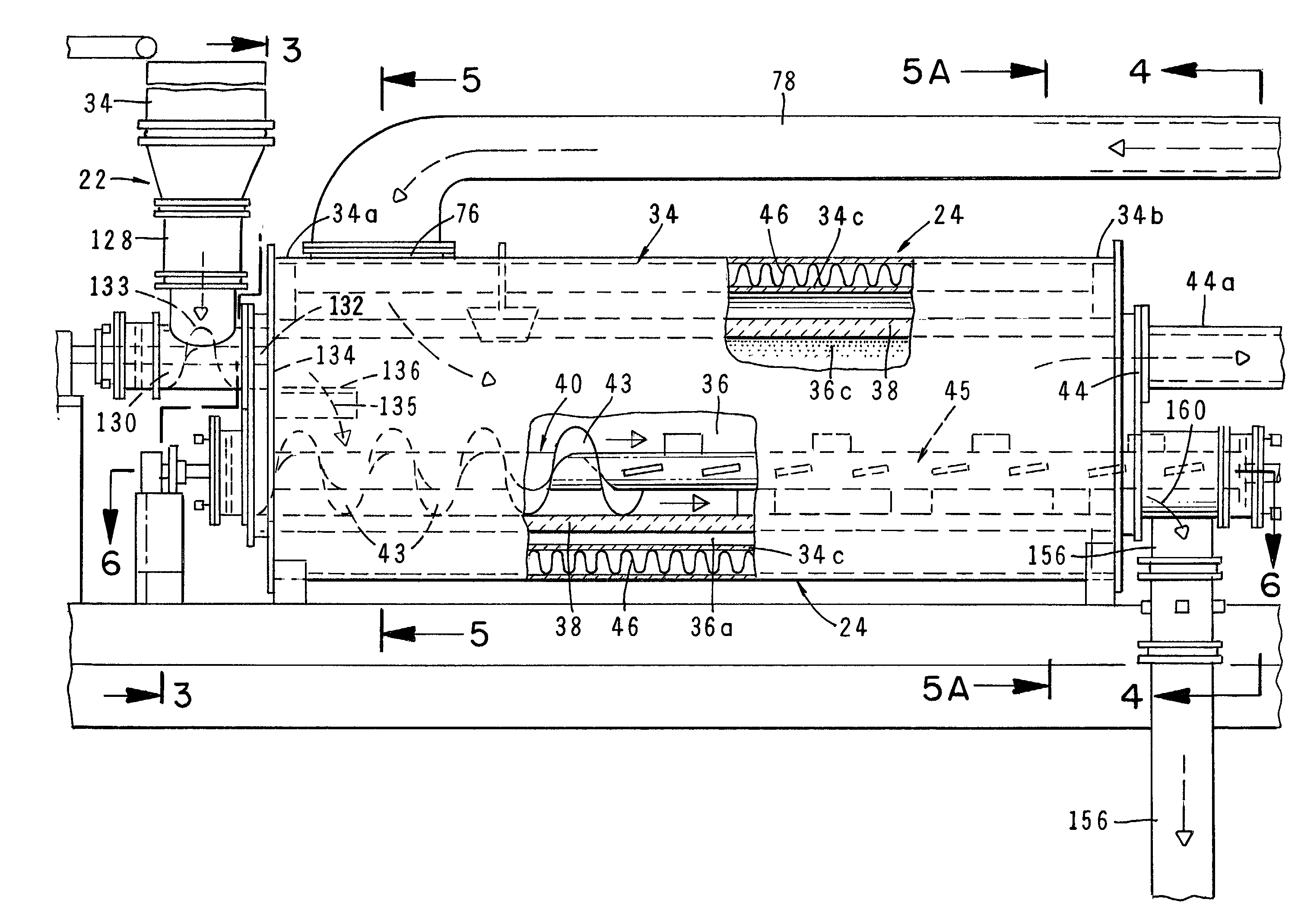

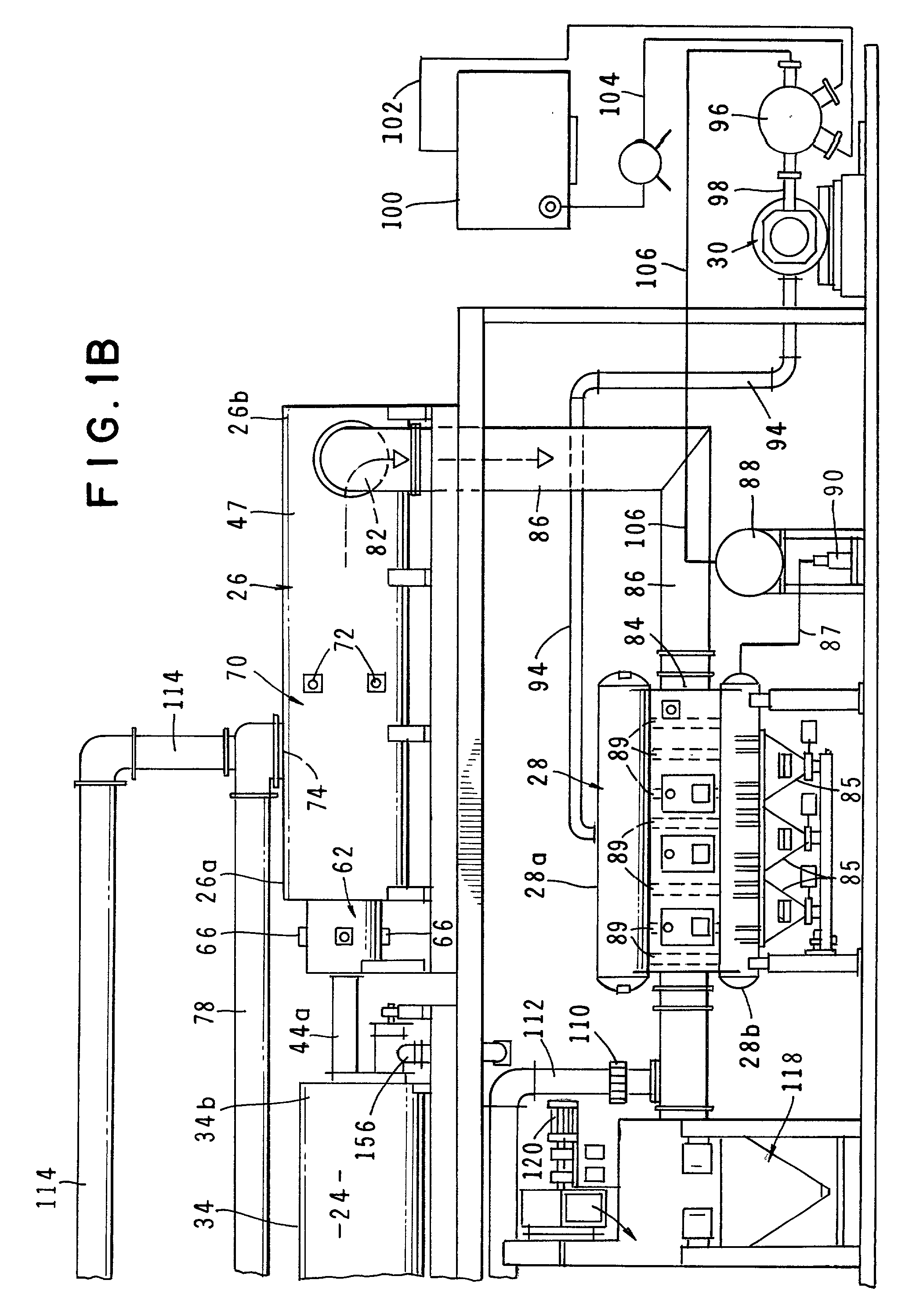

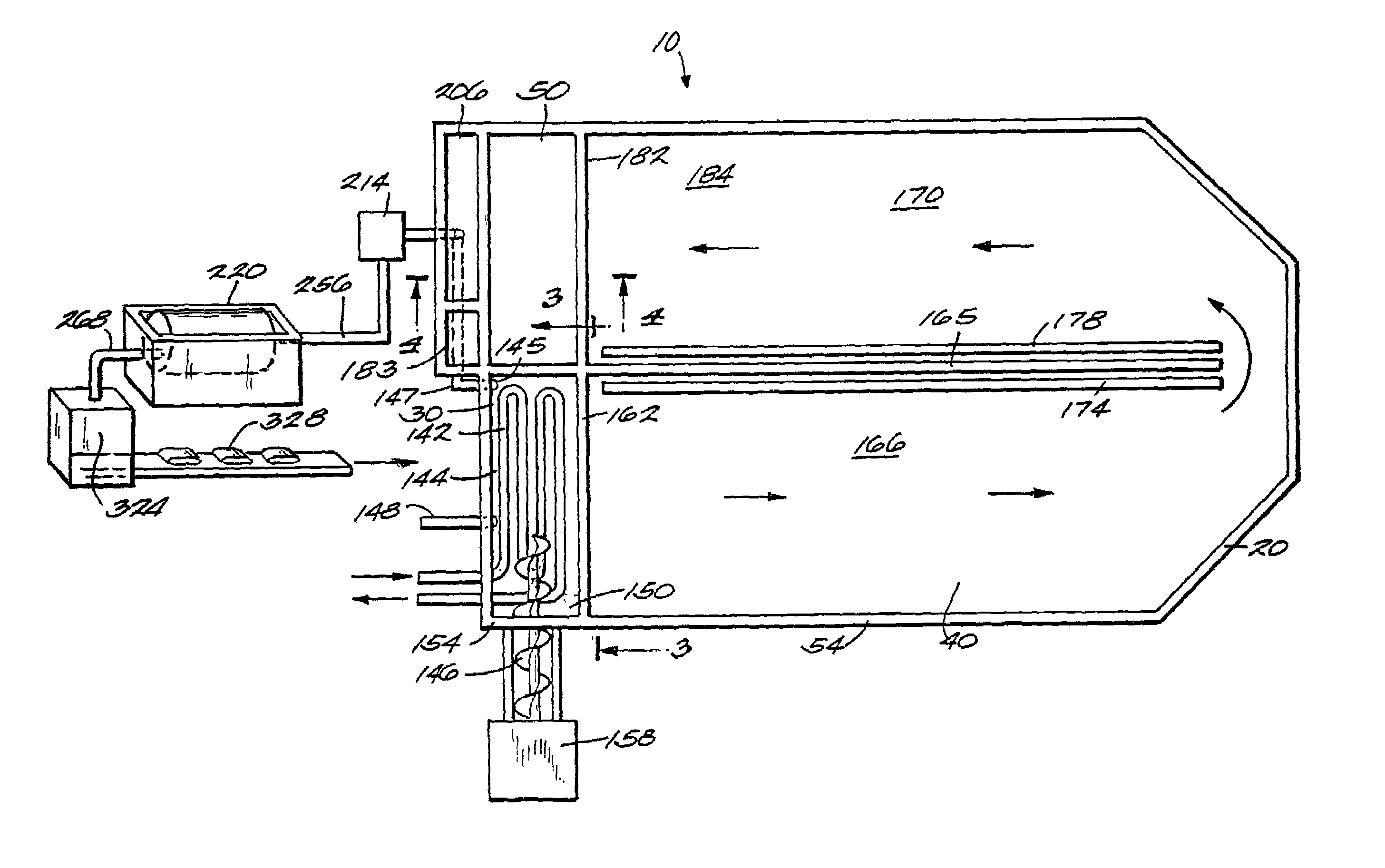

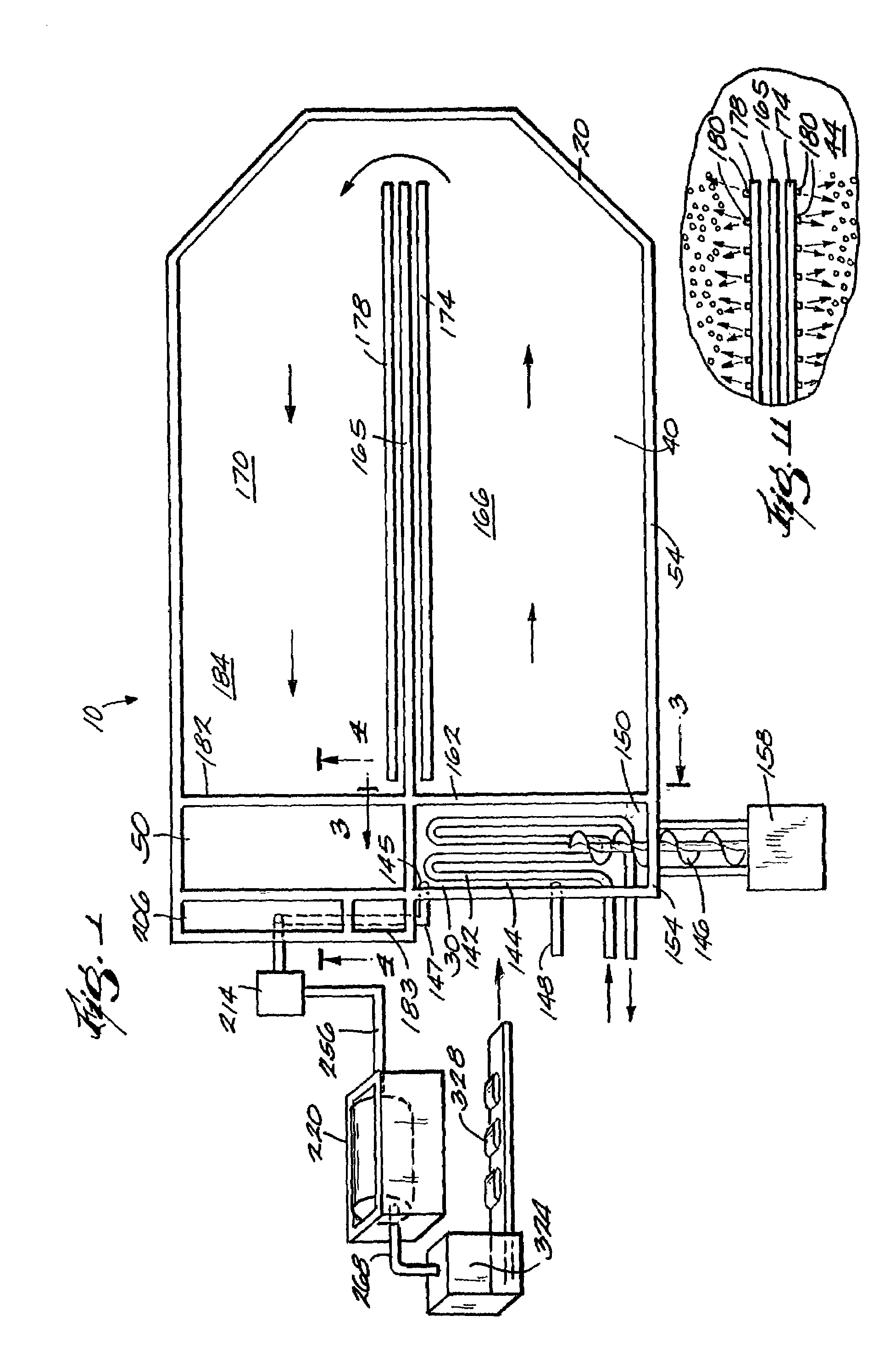

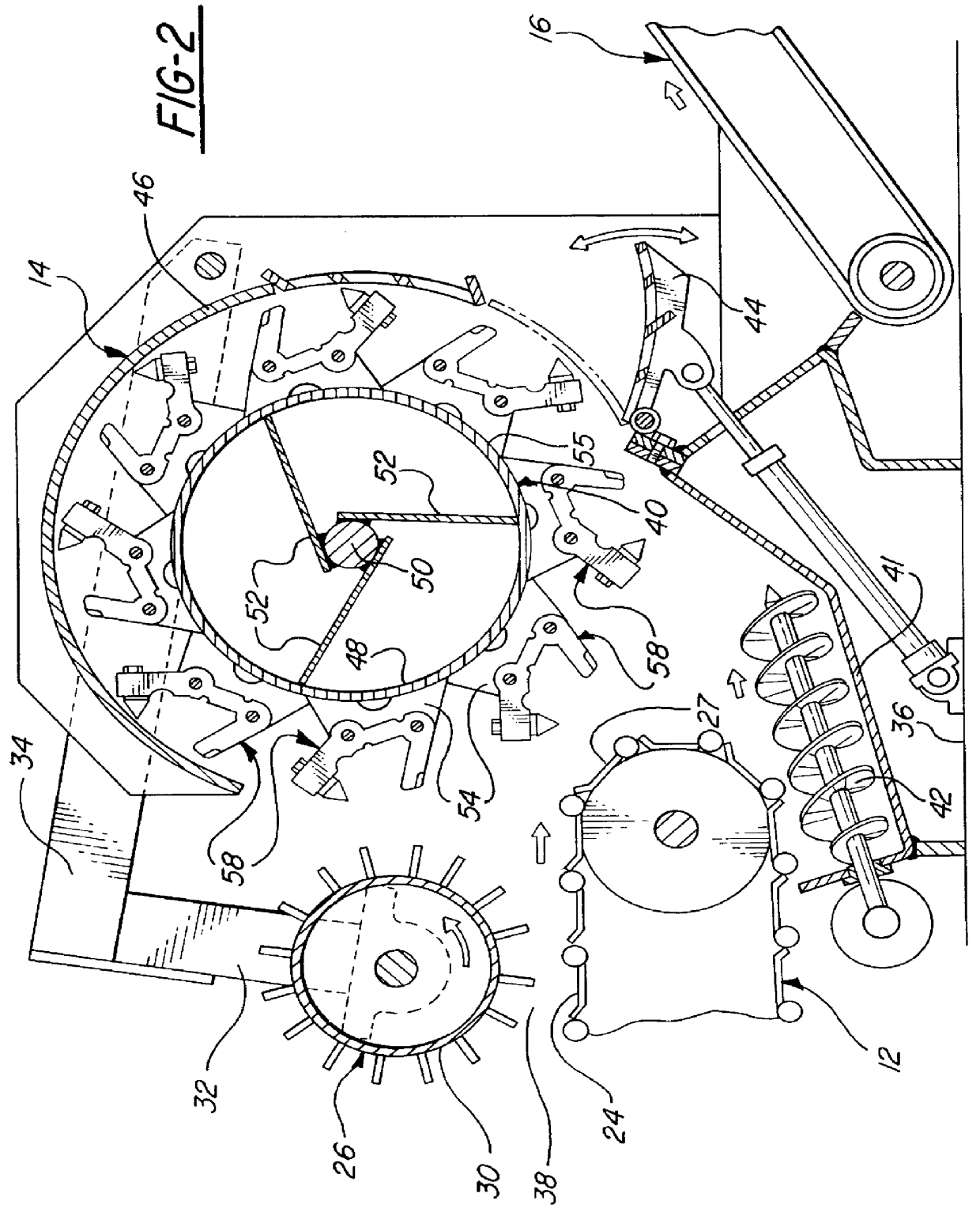

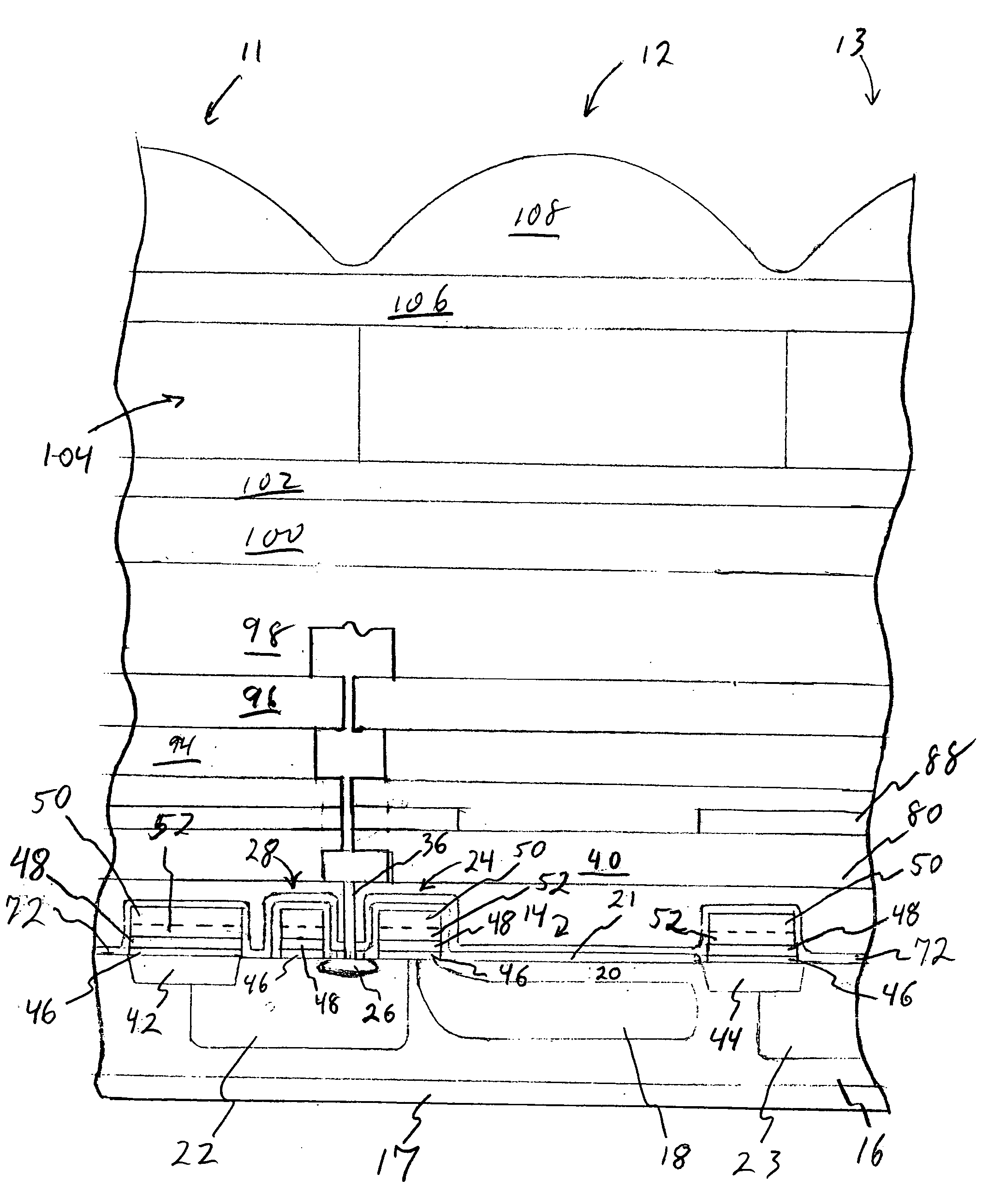

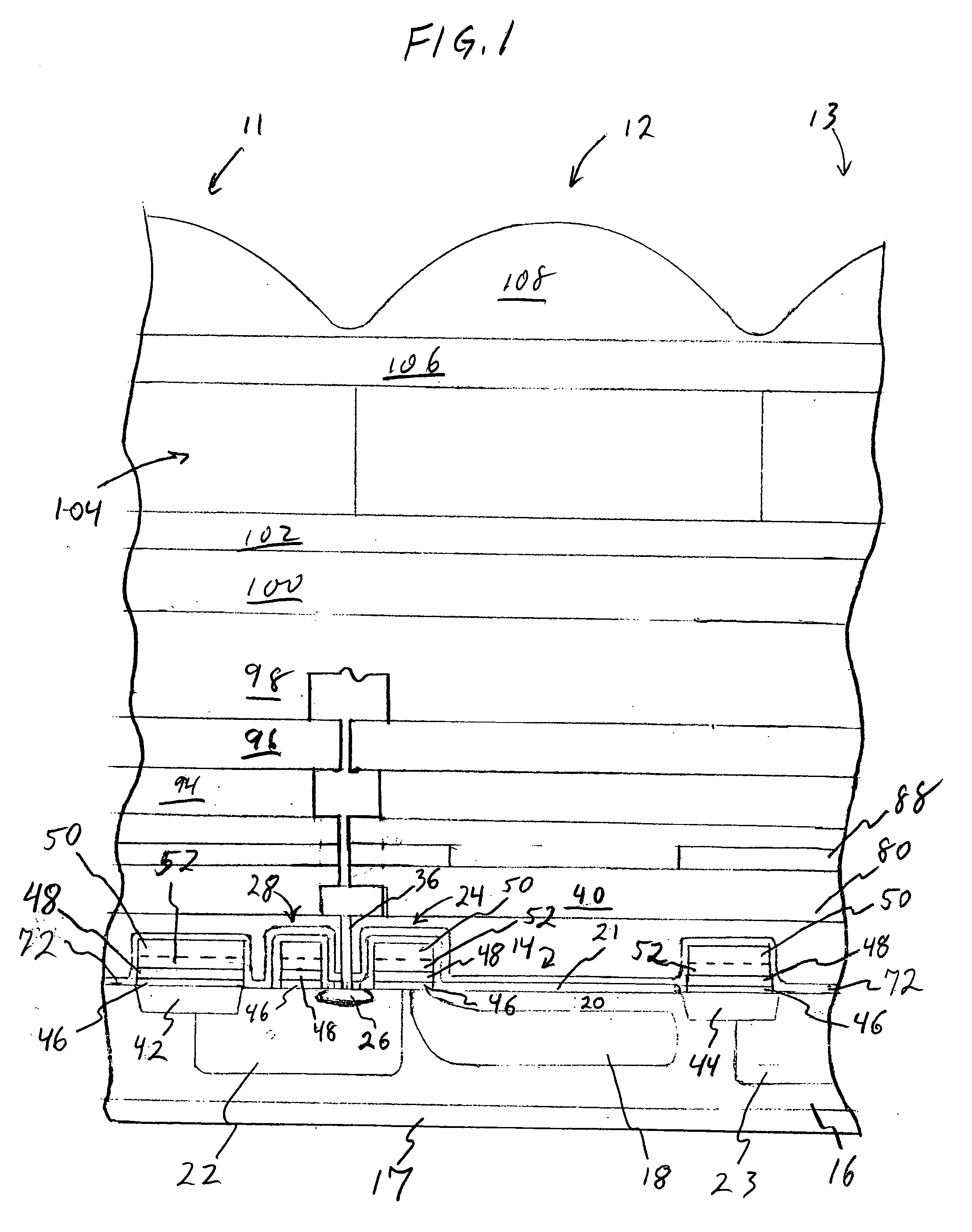

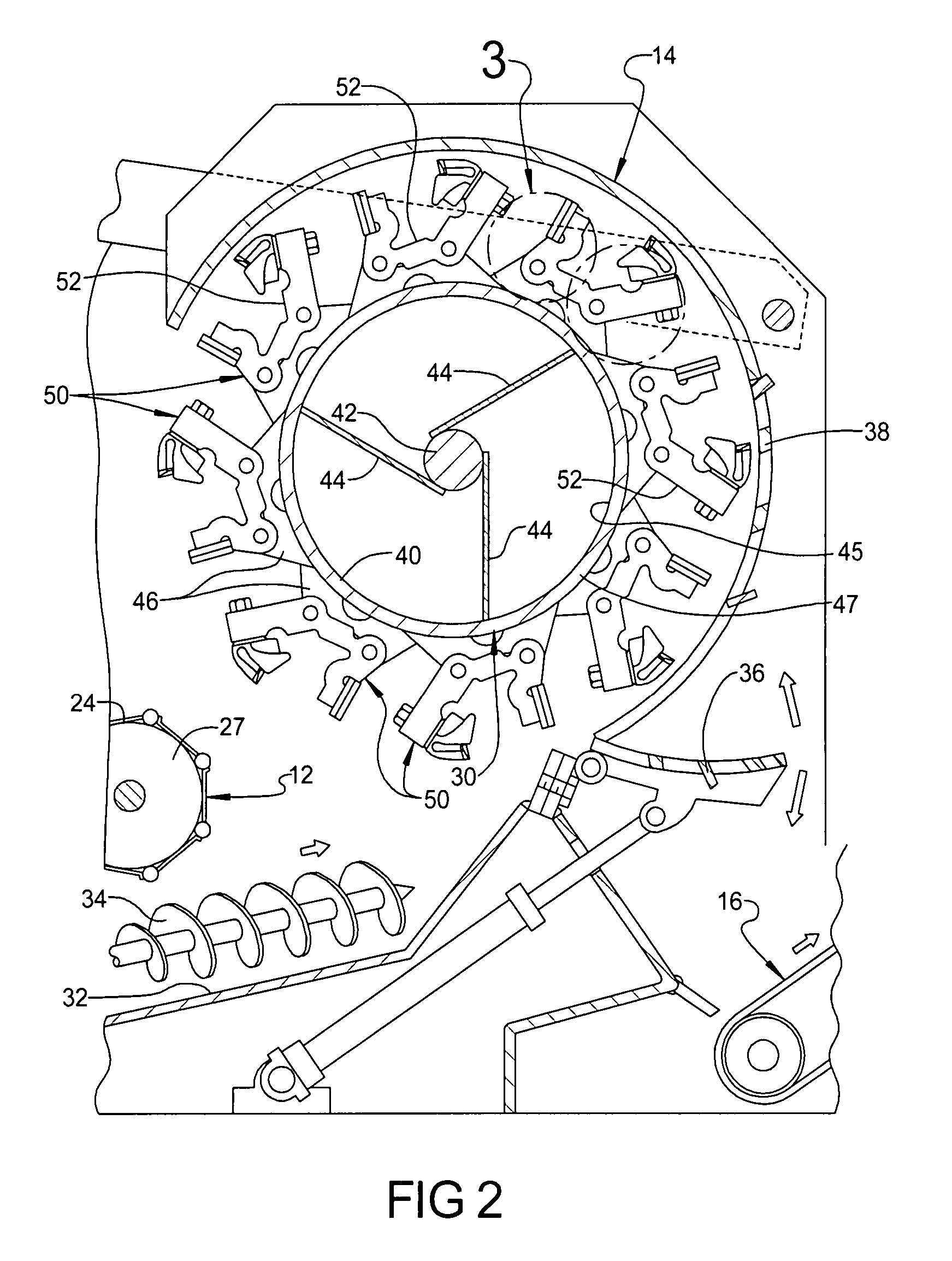

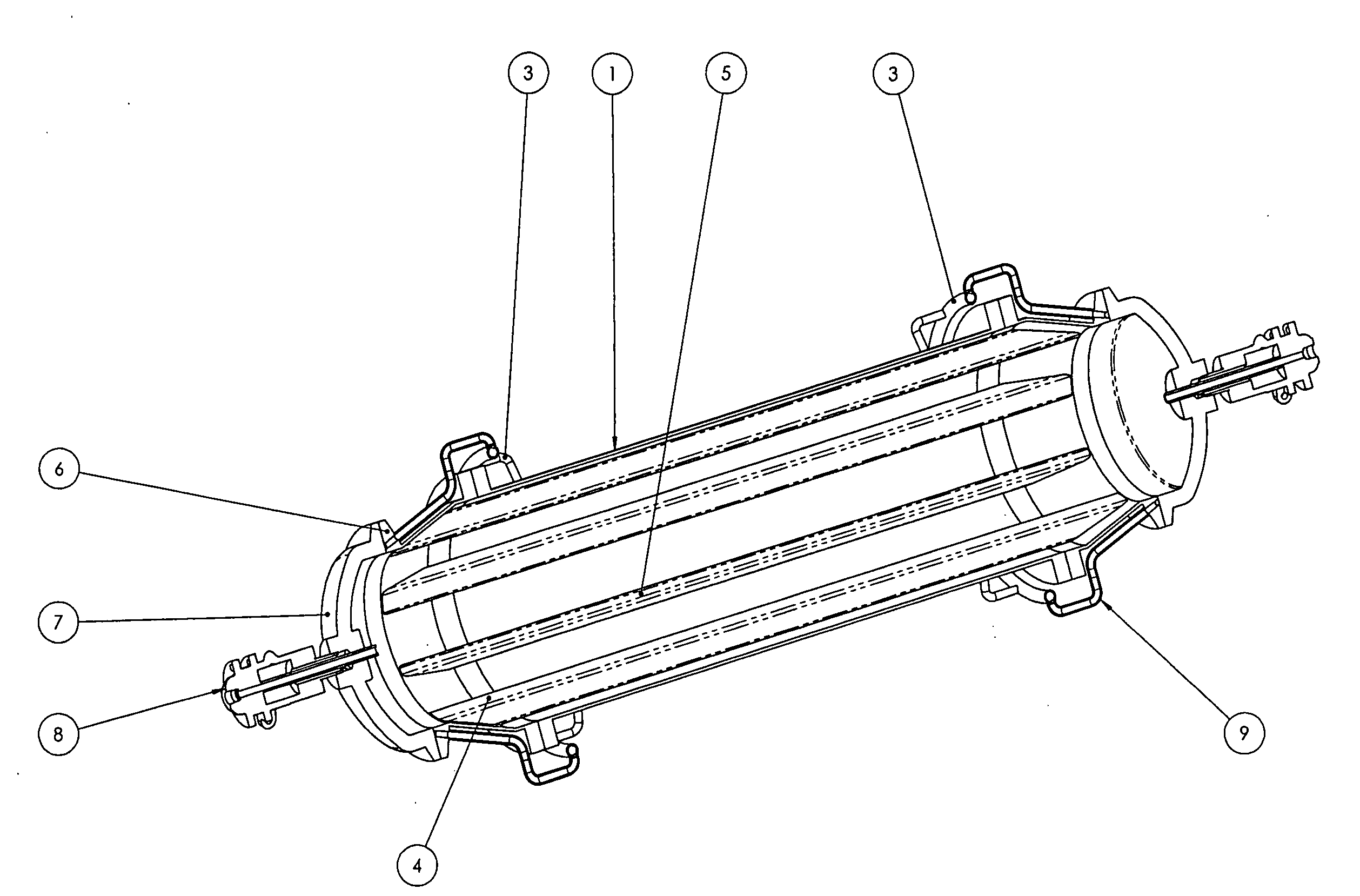

Method and apparatus for treatment of waste

InactiveUS20020195031A1Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

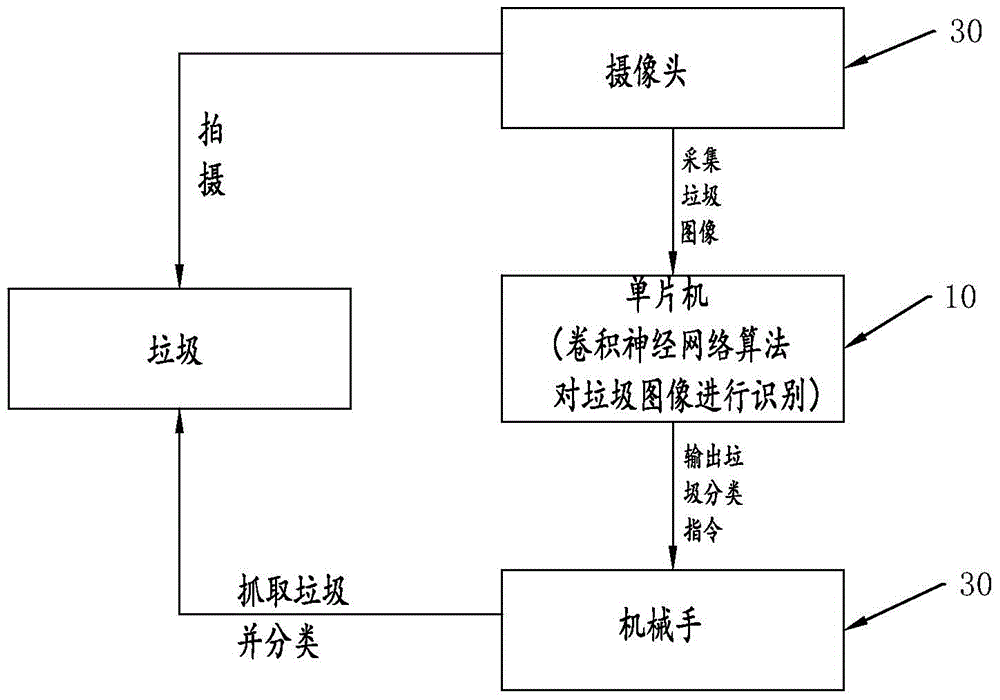

Waste classification robot based on image recognition technology

InactiveCN105772407AImprove processing efficiencyReduce training parametersCharacter and pattern recognitionSortingSocial benefitsMicrocontroller

The invention discloses a waste classification robot based on an image recognition technology. The waste classification robot based on the image recognition technology comprises a single-chip microcomputer, a manipulator and a camera, wherein actions of the manipulator are controlled by the single-chip microcomputer; the camera is used for shooting images of waste and inputting the images into the single-chip microcomputer for classification calculation after preprocessing the images; the single-chip microcomputer recognizes the images of waste through a convolutional neural network algorithm, and outputs a classification instruction to the manipulator; and the manipulator grabs different kinds of waste according to the classification instruction and places the waste to specific positions so that waste classification can be achieved. Automatic waste classification is conducted by combination with the manipulator, so that the waste processing efficiency is greatly improved, and the social benefit of a clean and comfortable living environment is brought.

Owner:耿春茂

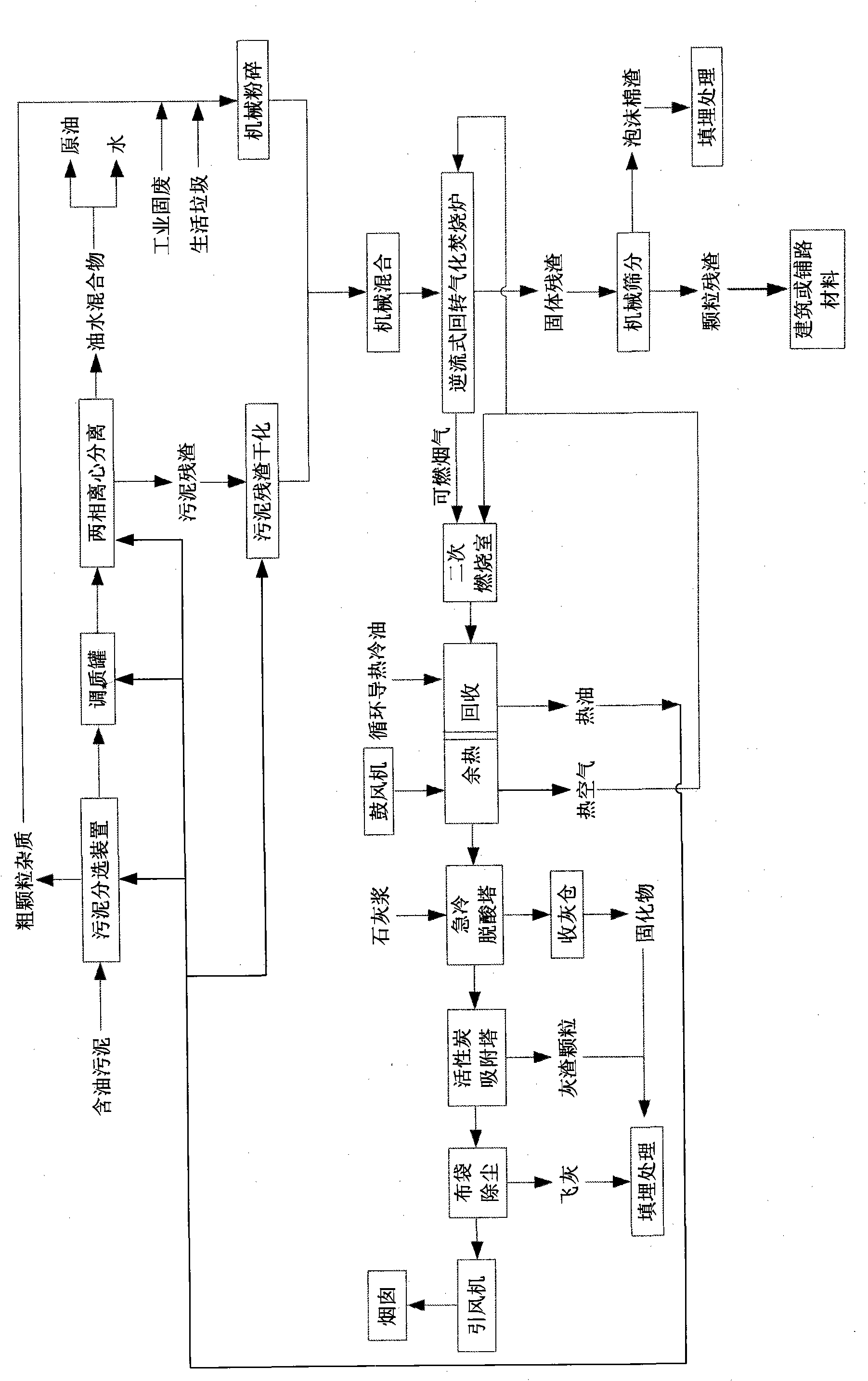

Combined treatment method for oilfield solid waste

InactiveCN101963358AHigh recovery rateLess investmentIncinerator apparatusCombustion chamberOil sludge

The invention provides a new combined treatment process for oilfield solid waste (oil sludge, industrial solid waste and household garbage). In the process, liquid-solid separation is performed on the oil sludge of an oilfield by adopting a conditioning-centrifugal separation process; the separated liquid enters oil-water separation equipment constructed on the oilfield for recovering crude oil; the oil recovery rate is up to 65 to 90 percent; after drying separated solid residue, the separated solid residue and pre-crushed industrial solid waste and household garbage are mixed and enter a countercurrent-type rotary gasification incinerator; combustible components in the oilfield solid waste are decomposed and gasified into combustible gases which are combusted partially in the incinerator; the combustible gases are combusted completely in a secondary combustion chamber; high-temperature smoke gas afterheat is recovered by a conduction oil afterheat boiler and air preheating equipment; and low-temperature smoke gas of which the afterheat is recovered is harmlessly exhausted after being treated by a sharp-quenching deacidification tower, an activated carbon adsorption tower and a bag-type dust remover. The process realizes the purposes of decrement, harmlessness and resources of oilfield solid waste treatment.

Owner:KUNMING UNIV OF SCI & TECH

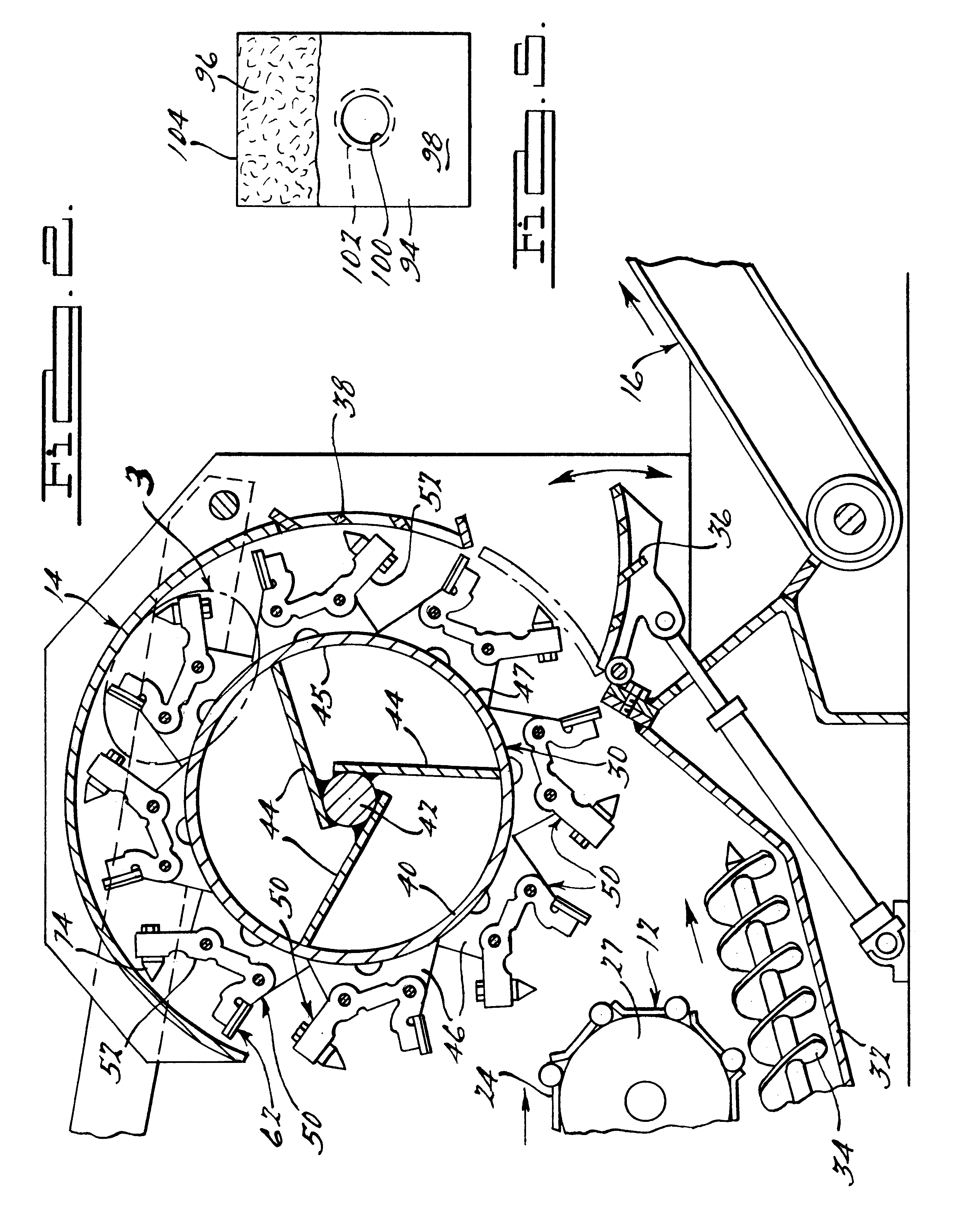

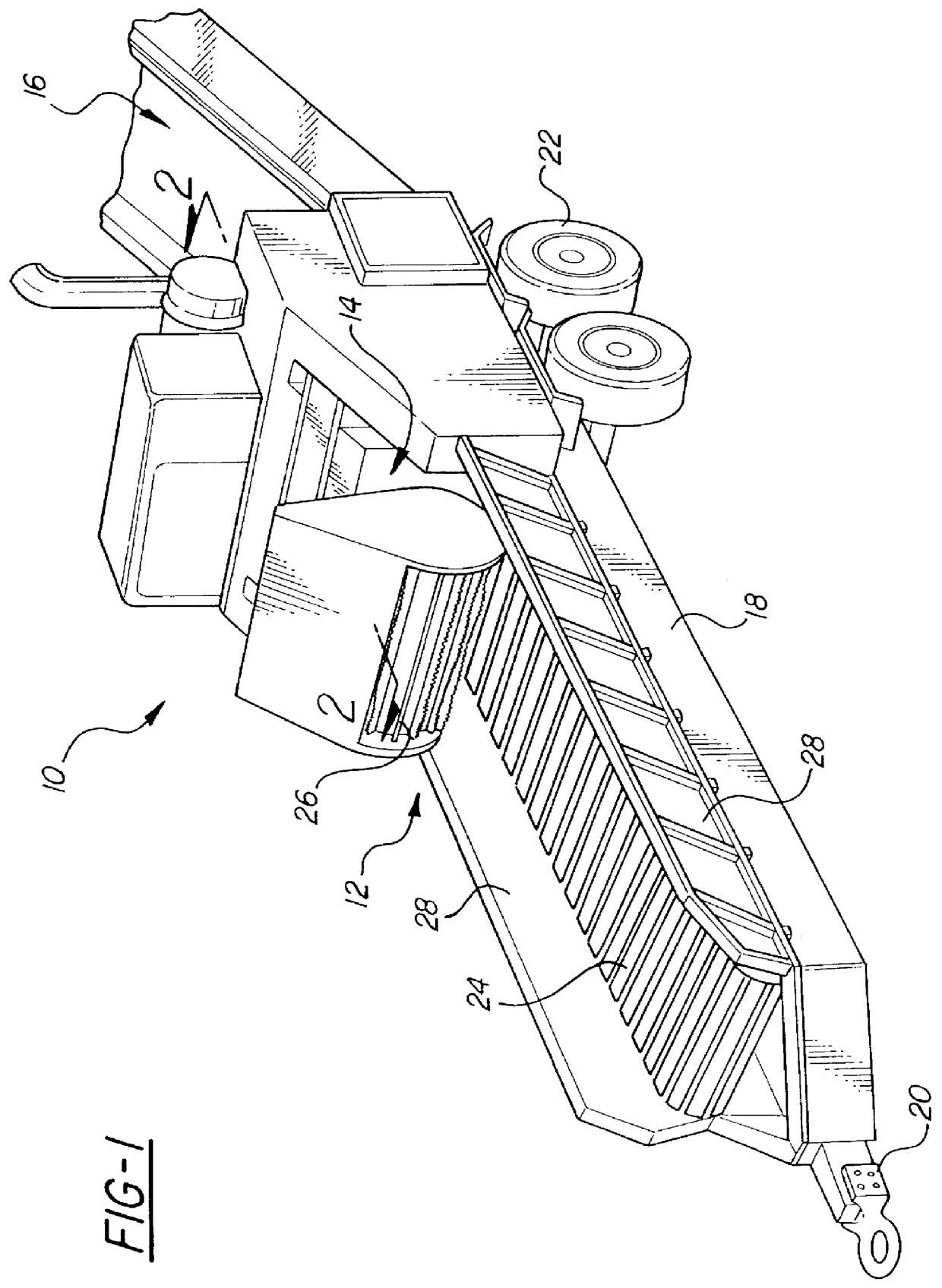

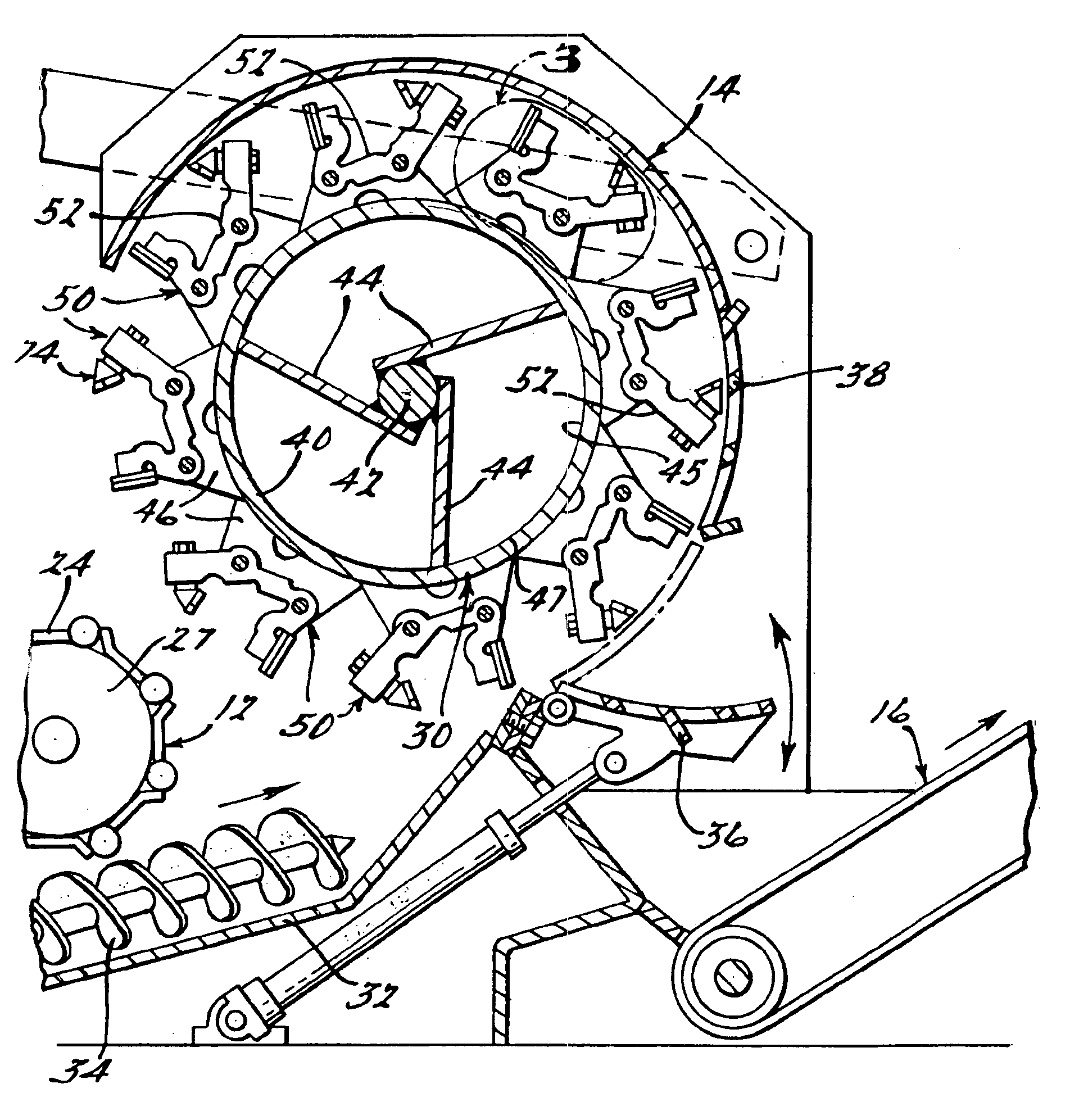

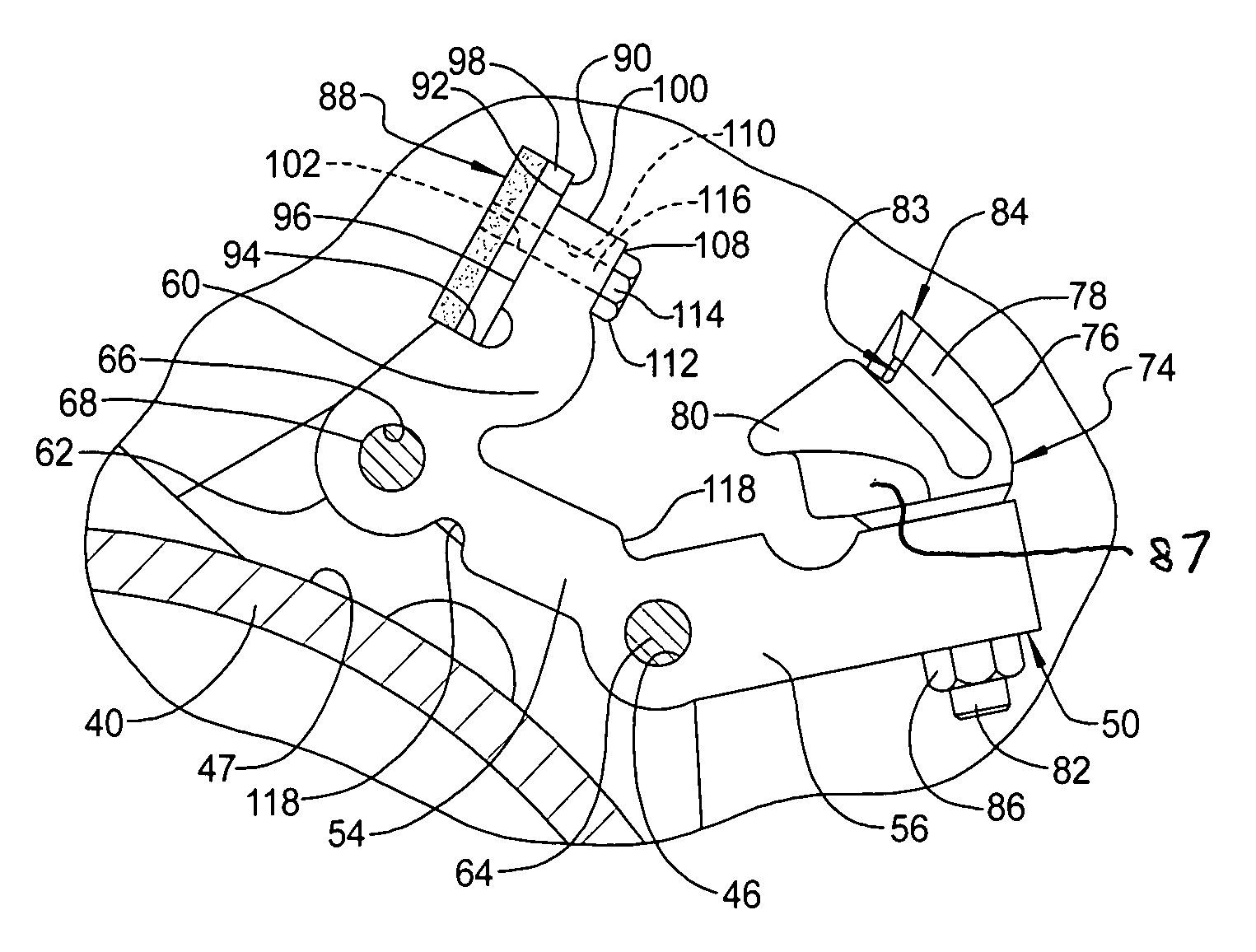

Rotor assembly for a waste processing machine

A rotor assembly for a waste processing machine includes a rotor and a plurality of processing tools mounted to the rotor. The processing tools are a combination of at least two different tools to provide aggressive intake of waste material and aggressive output of reduced waste material.

Owner:SMORACY

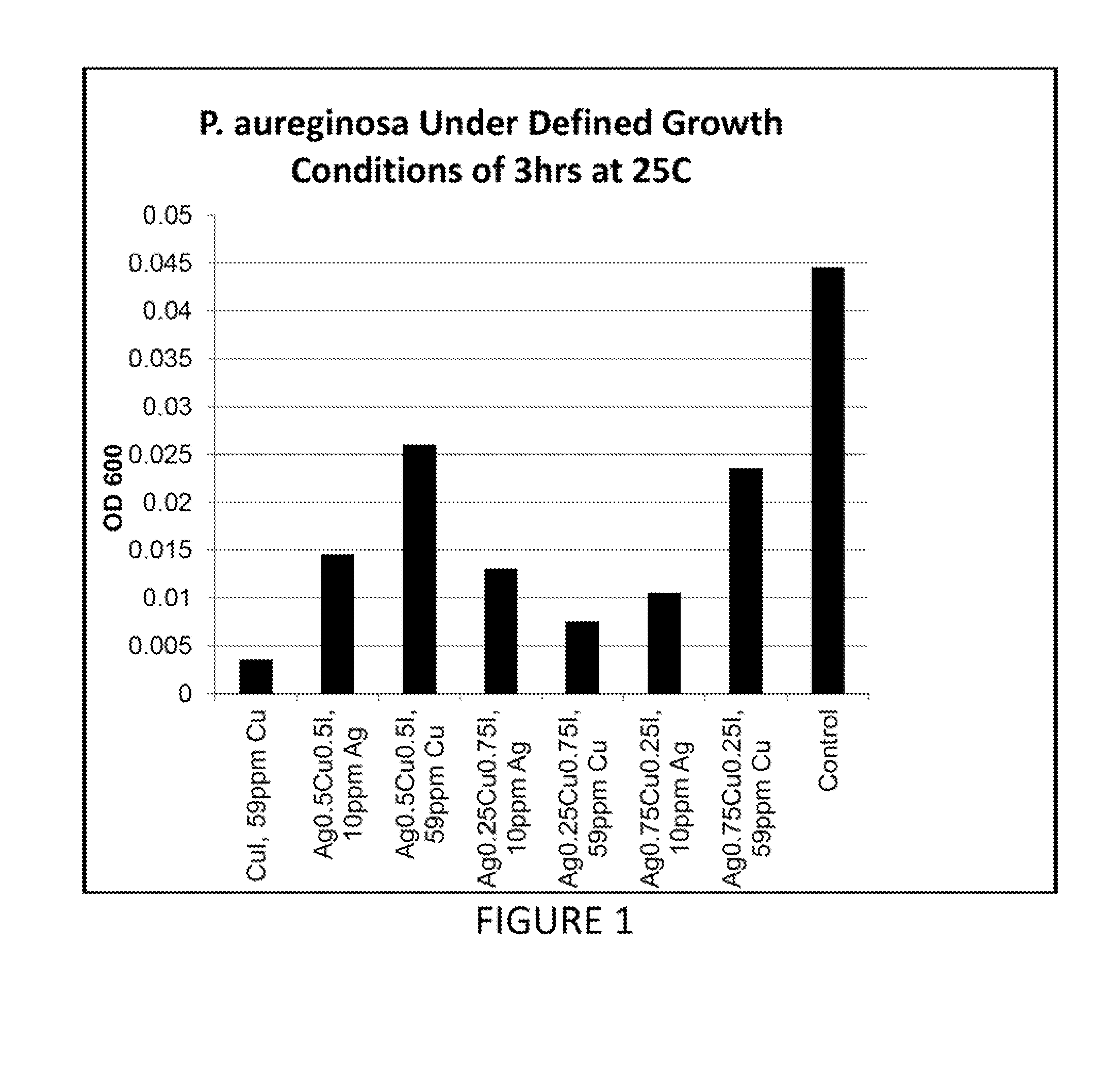

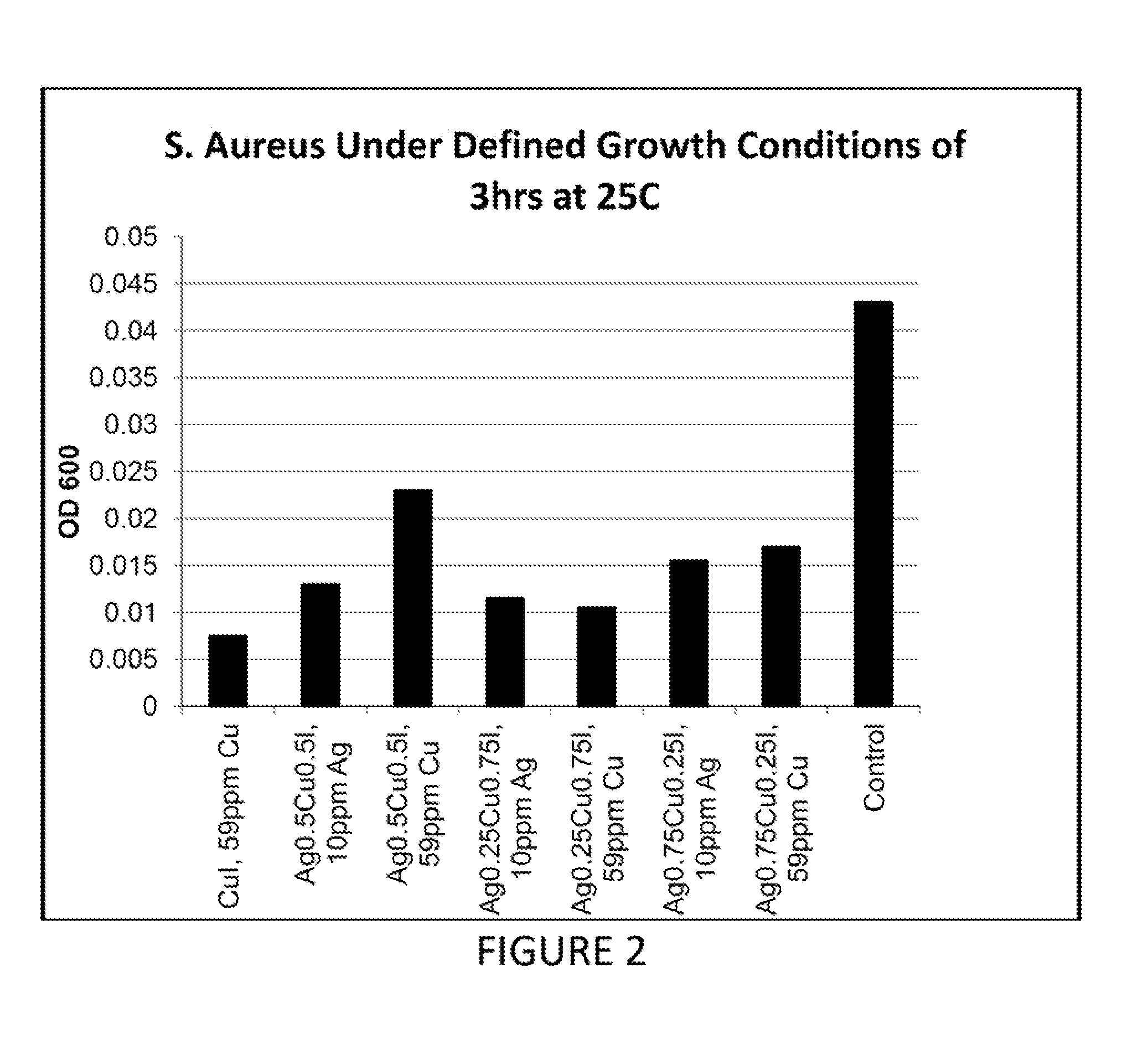

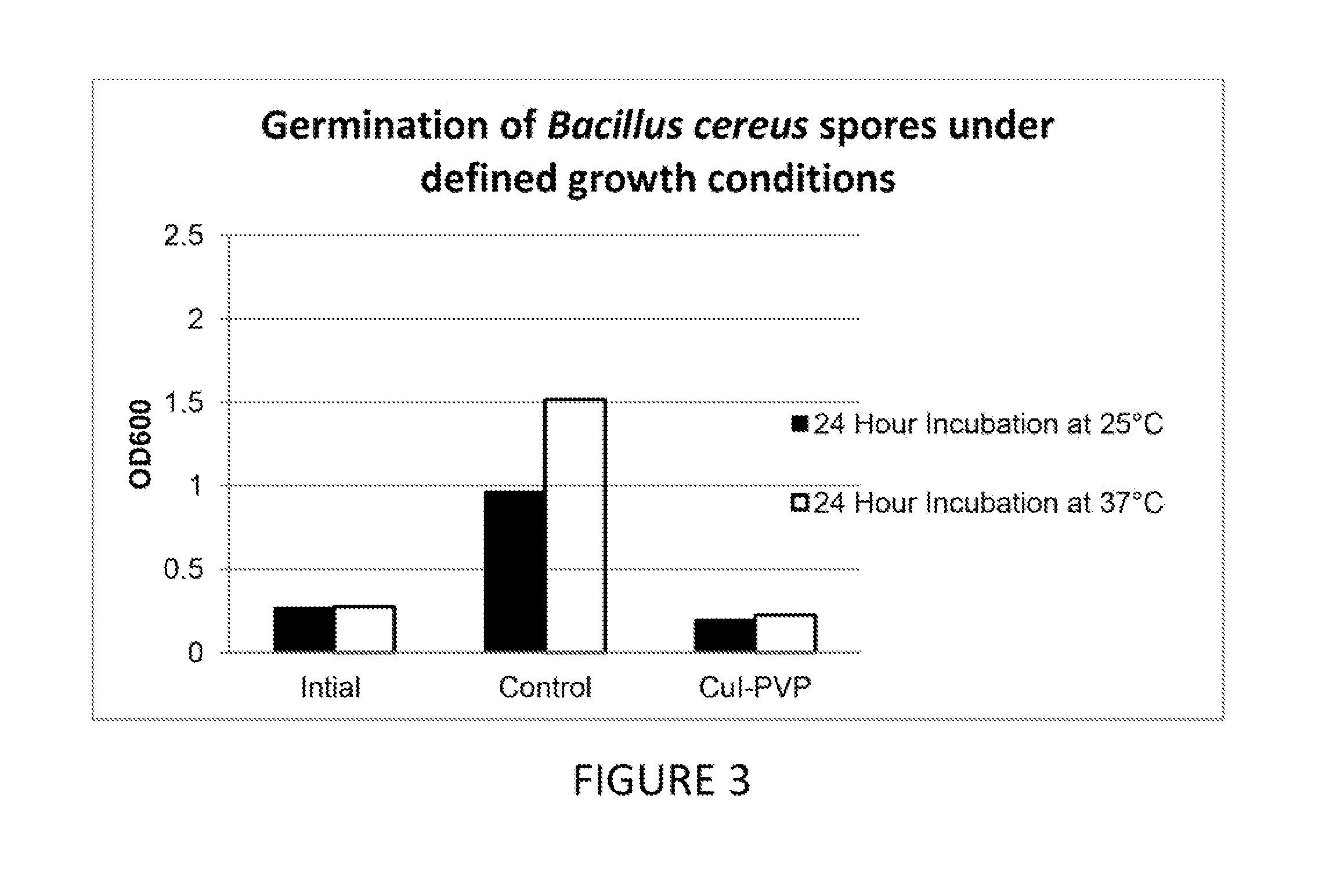

Antimicrobial compositions for use in products for petroleum extraction, personal care, wound care and other applications

ActiveUS20140271757A1Improve viabilityProvide benefitsBiocideCosmetic preparationsSolubilityPersonal care

Compositions having antimicrobial activity contain surface functionalized particles comprising an inorganic copper salt which has low water solubility. These types of inorganic salts may also be introduced in porous particles to yield antimicrobial compositions. The compositions may optionally comprise additional antimicrobial agents, salts with high water solubility, organic acids, salts of organic acids and their esters. The compositions may be added to various fluids used in the petroleum extraction industry, or used as coatings on components used in this industry. These antimicrobial materials may be used for reducing both anaerobic and aerobic bacteria and are also useful for reducing corrosion of ferrous components caused by anaerobic bacteria. Although such compositions may be used for any antimicrobial application, and some of the other important uses of these compositions are in wound care, personal care and waste processing.

Owner:AGIENIC

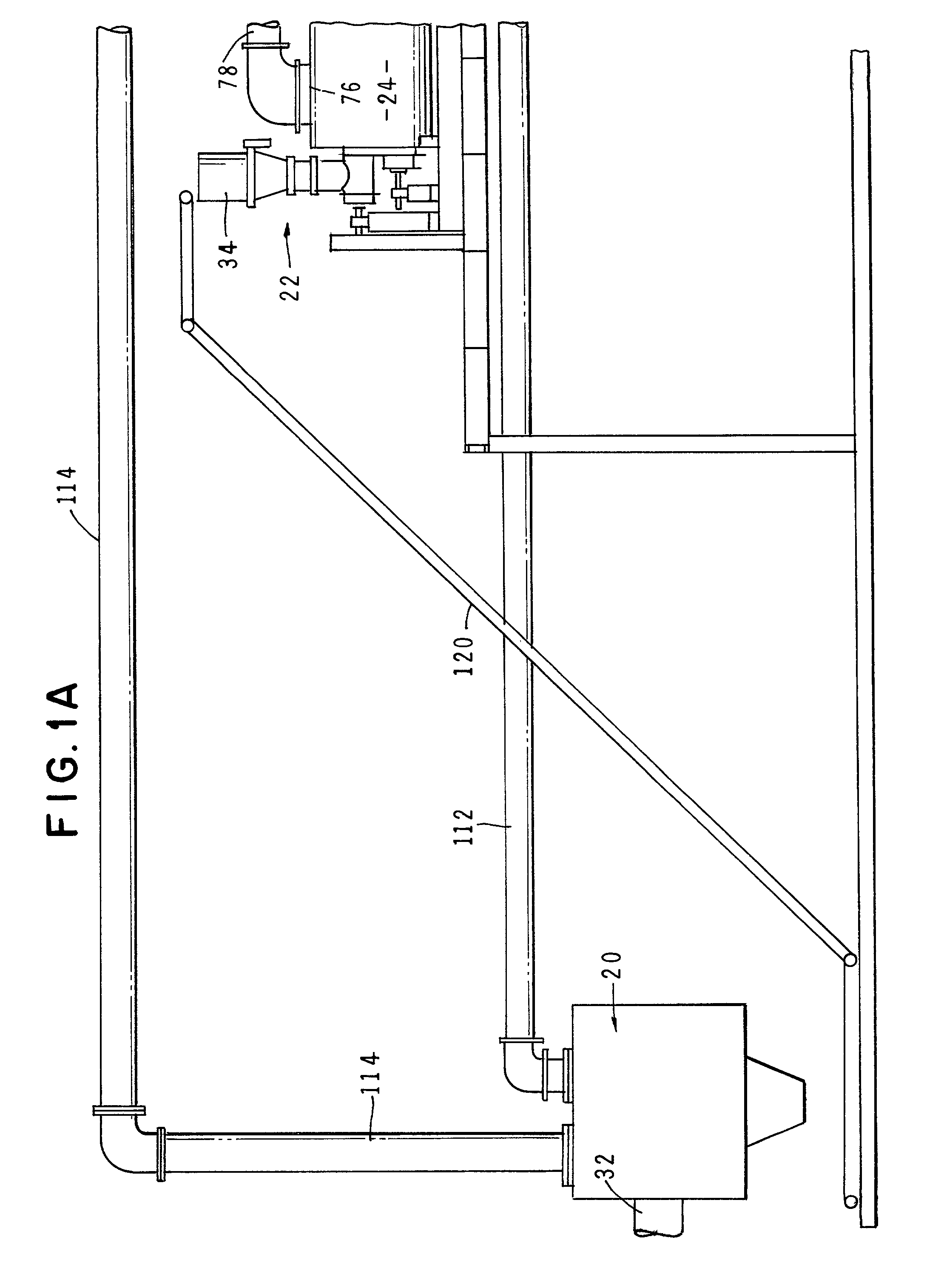

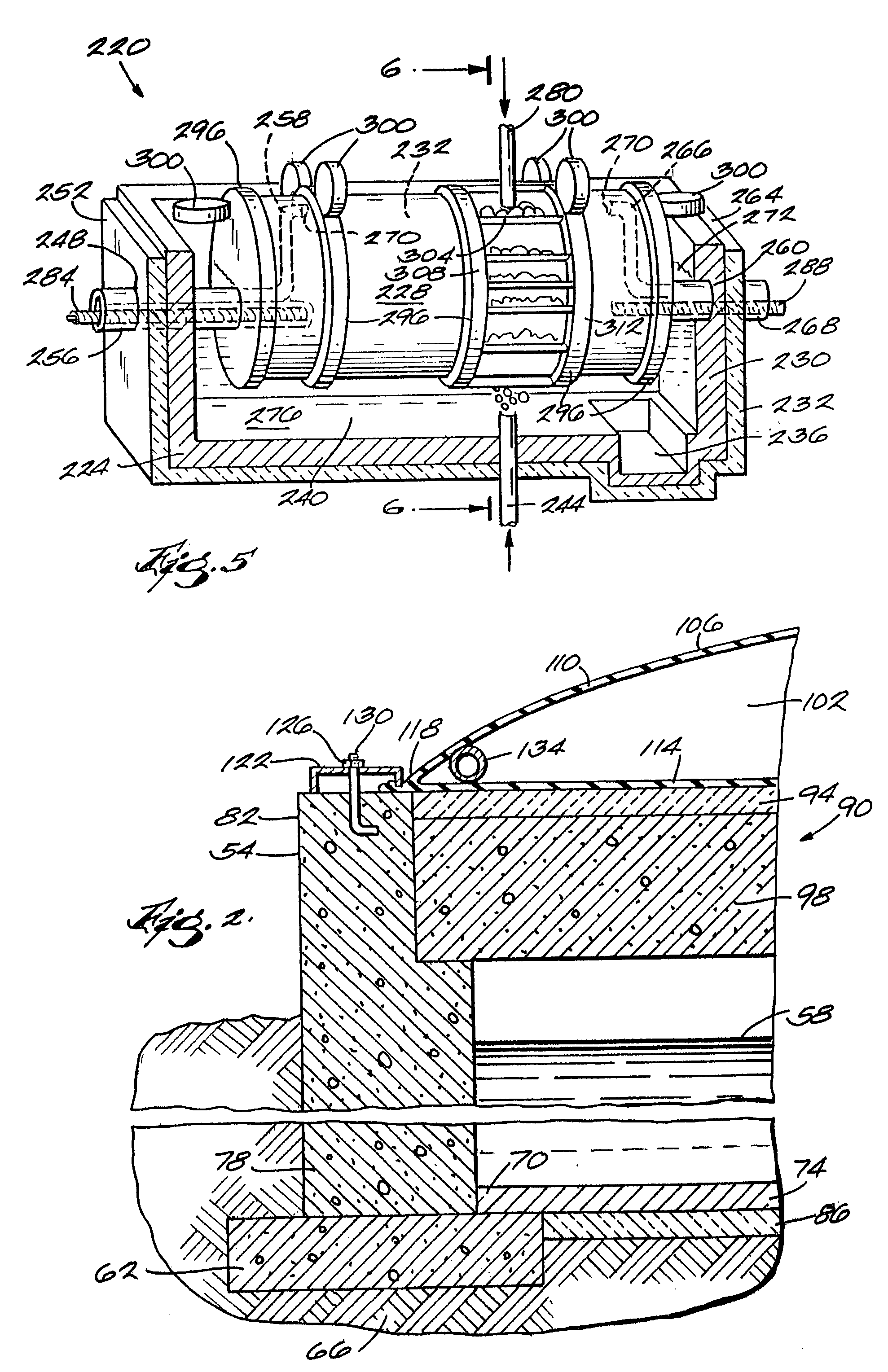

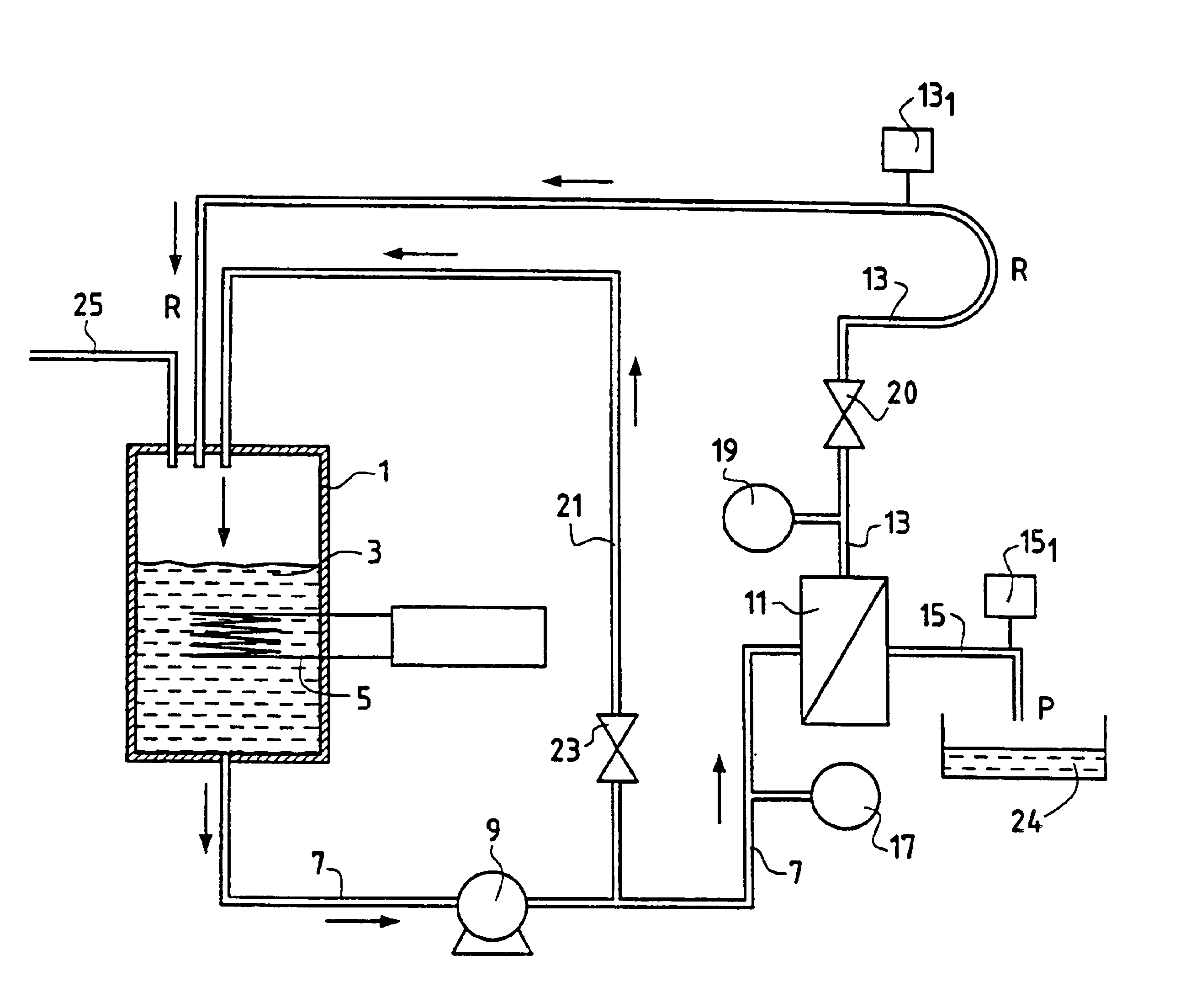

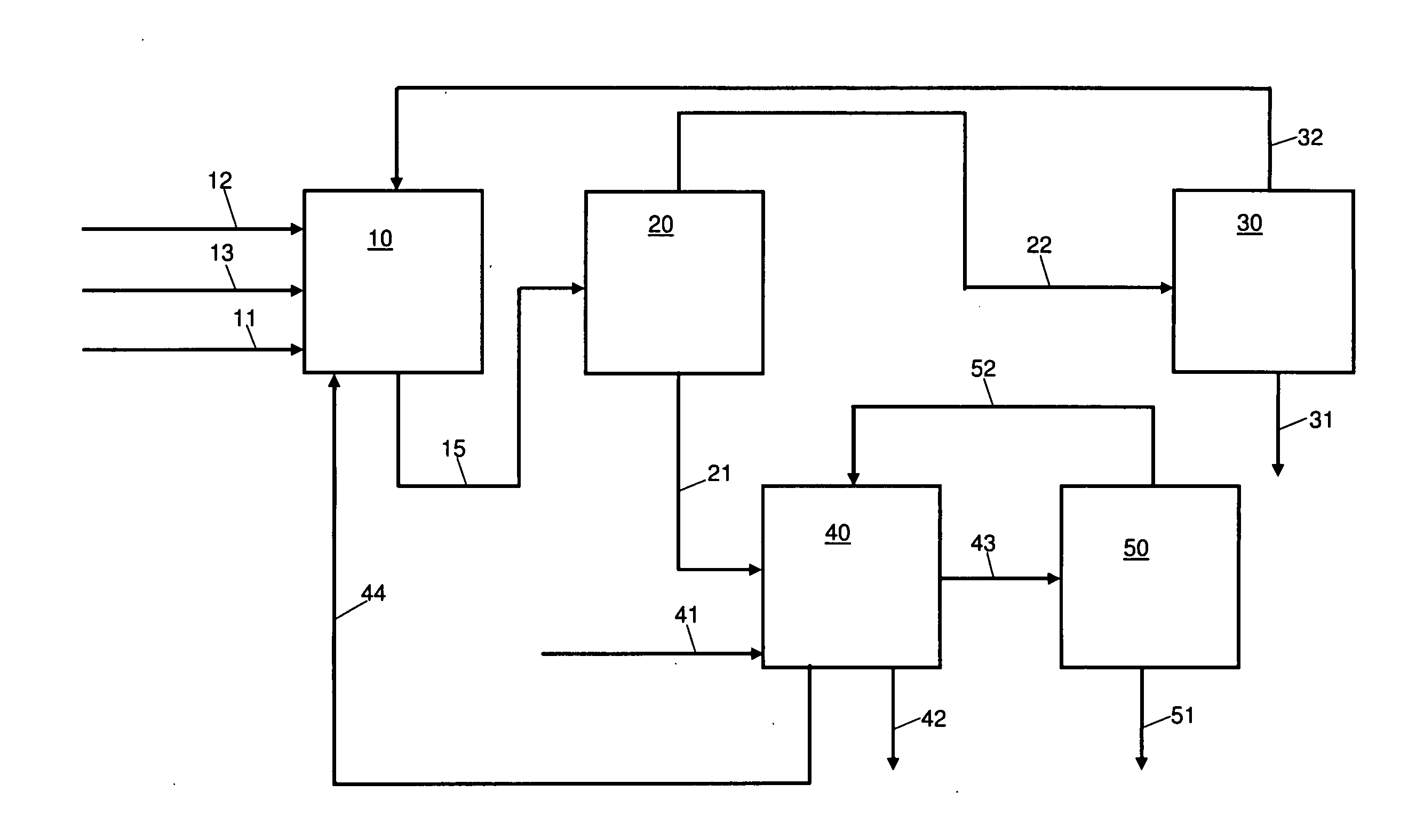

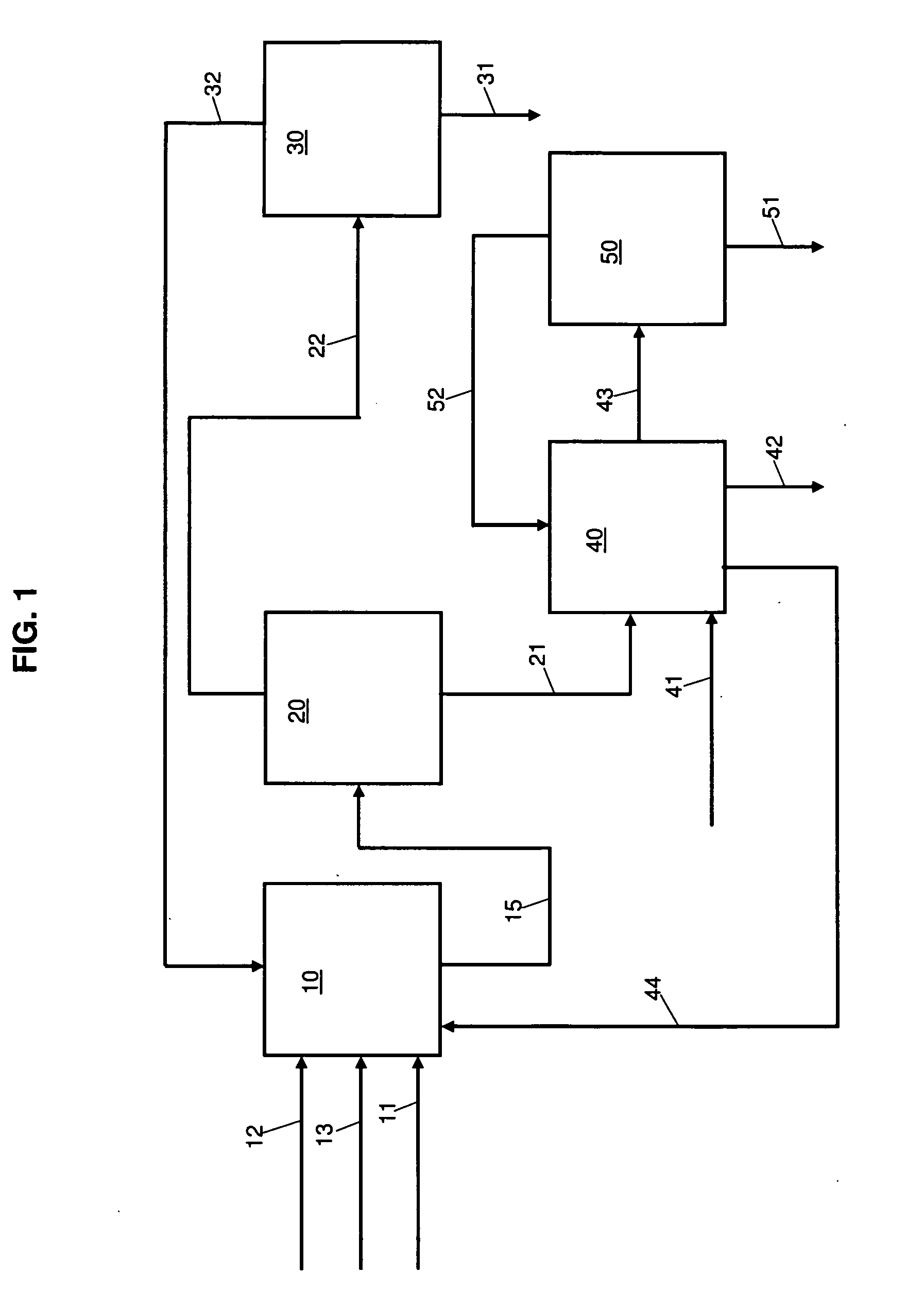

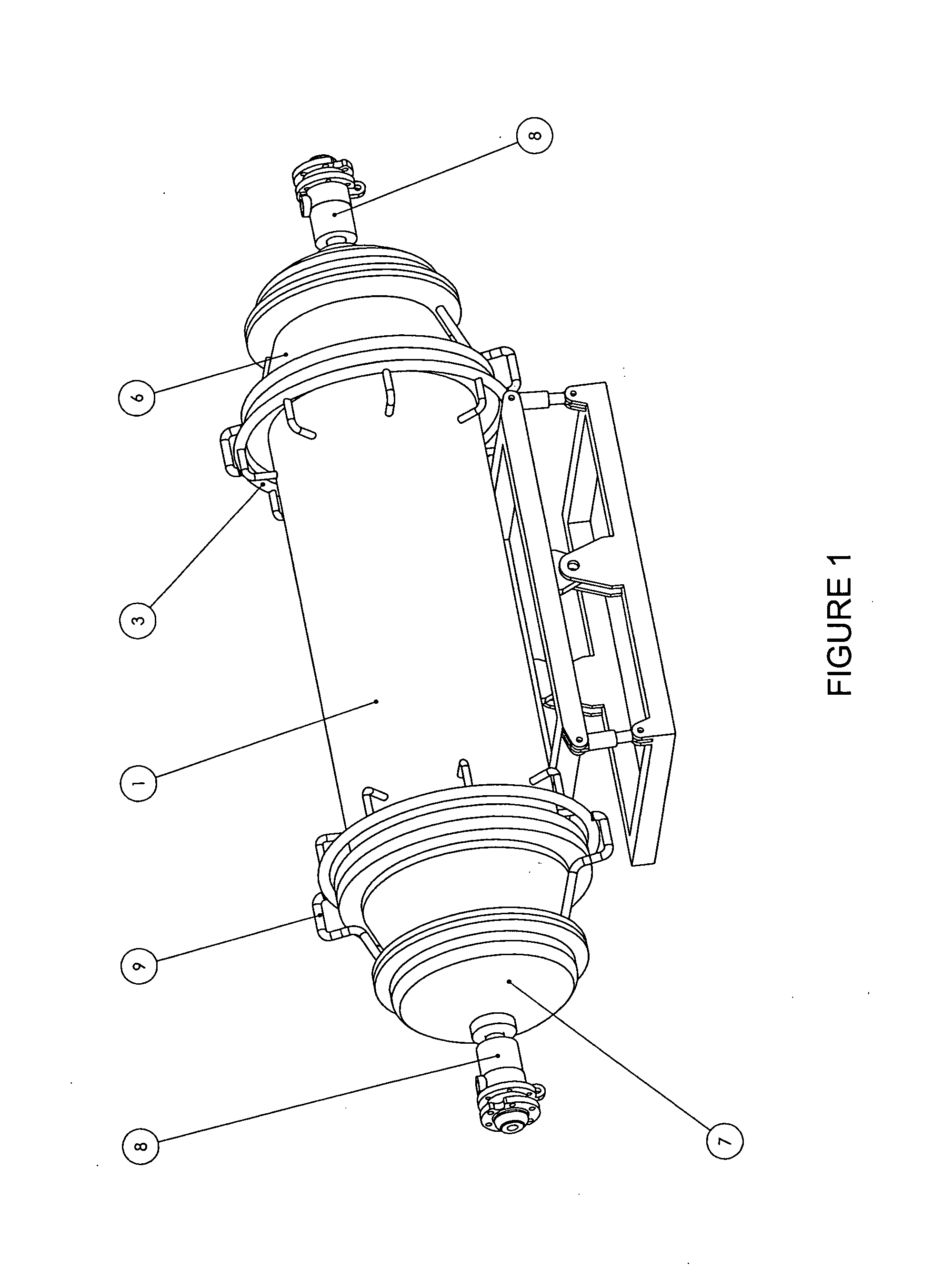

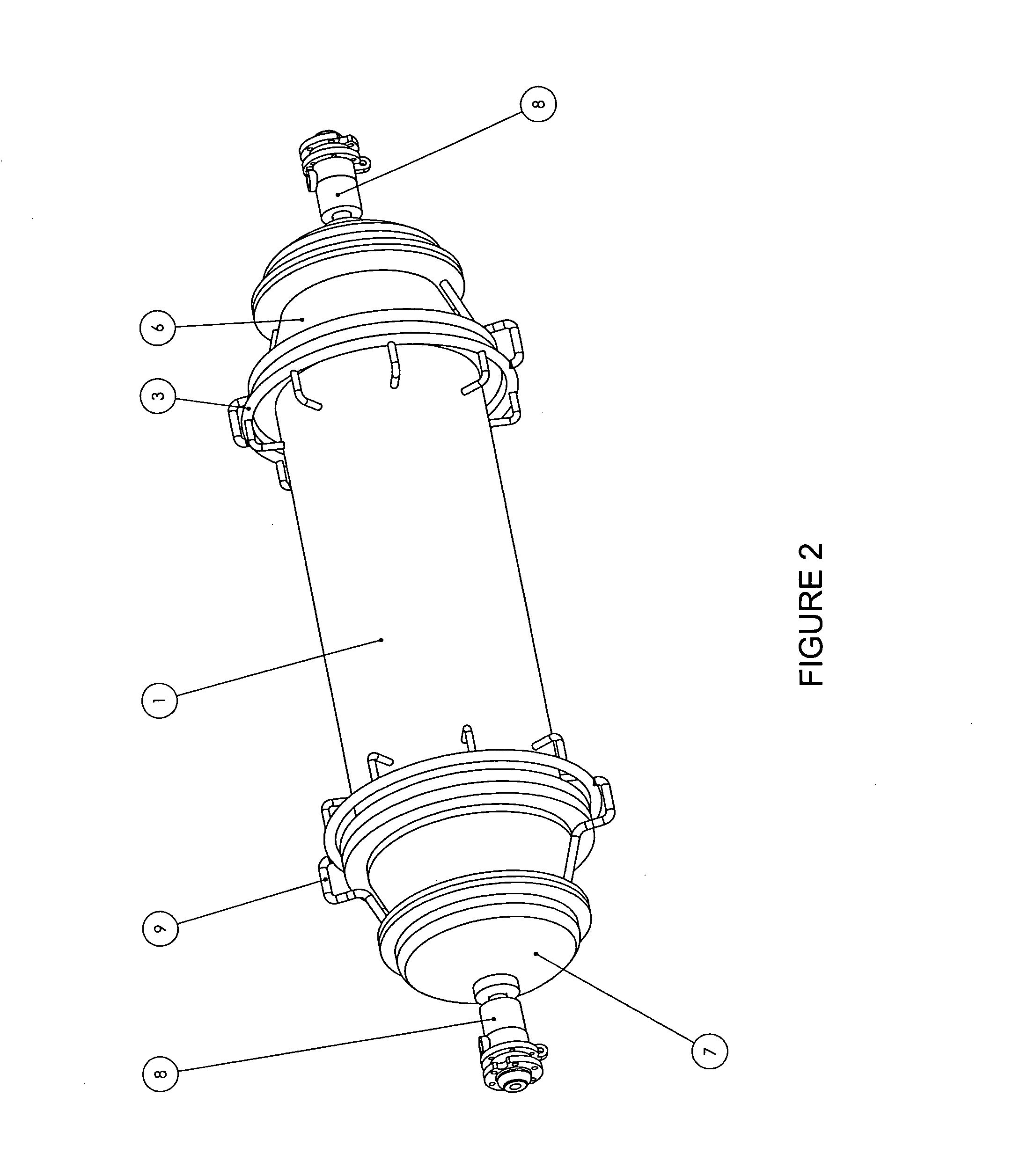

Method and apparatus for solids processing

InactiveUS7078229B2Minimize end waste productMaximize energy efficiencyBioreactor/fermenter combinationsBio-organic fraction processingWaste processingProcess engineering

This invention provides a waste-processing system capable of processing high-solids wastes such as manure. This invention provides a compact U-shaped digester that allows for recycling of activated sludge to improve the efficiency of the process. Efficiency is also improved through a sludge heating design that creates a current in the digester and efficiently heats the sludge. A composter is provided to further process the sludge through aerobic digestion to create usable fertilizer. Finally, one embodiment provides a turbine that is fueled by biological gases from the digester to generate heat and electricity to be used by the system.

Owner:DVO LICENSING

Multi-functional tool assembly for processing tool of waste processing machine

A multi-functional tool assembly for a processing tool of a waste processing machine includes a tool holder for attachment to a rotor assembly of the waste processing machine. The multi-functional tool assembly also includes a multi-functional tool attached to the tool holder to reduce waste material and to aggressively output the reduced waste material from the rotor assembly of the waste processing machine.

Owner:BANDIT IND

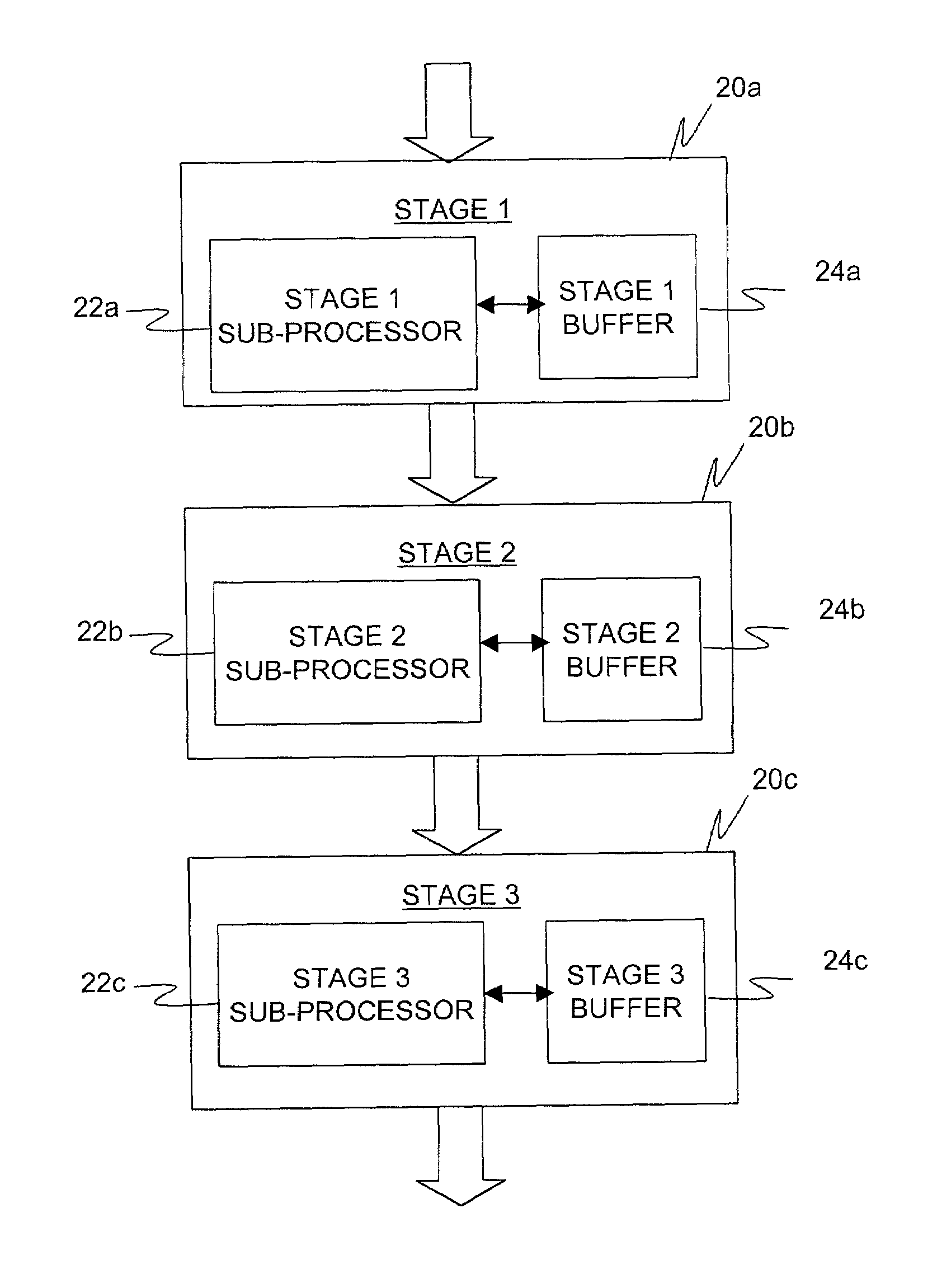

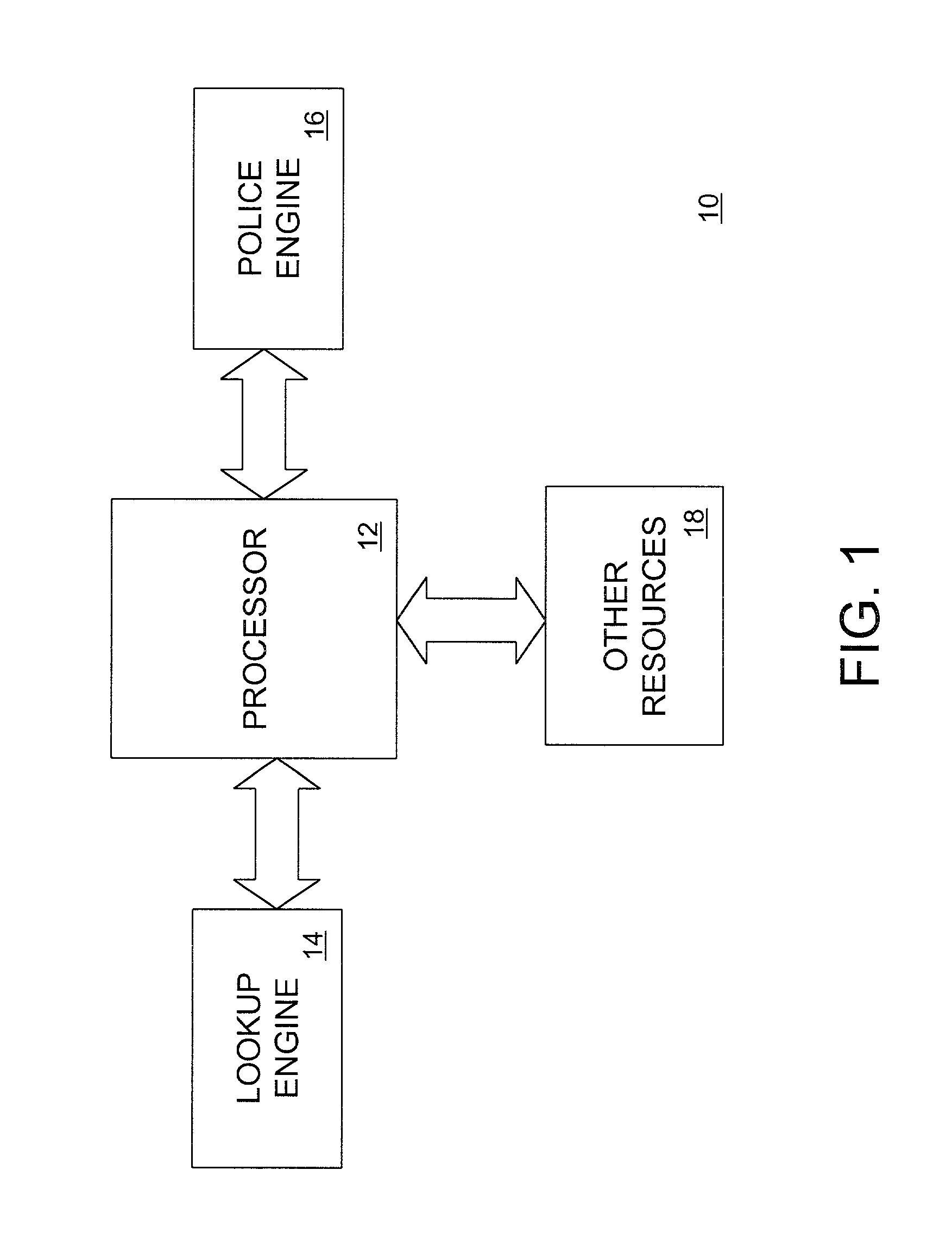

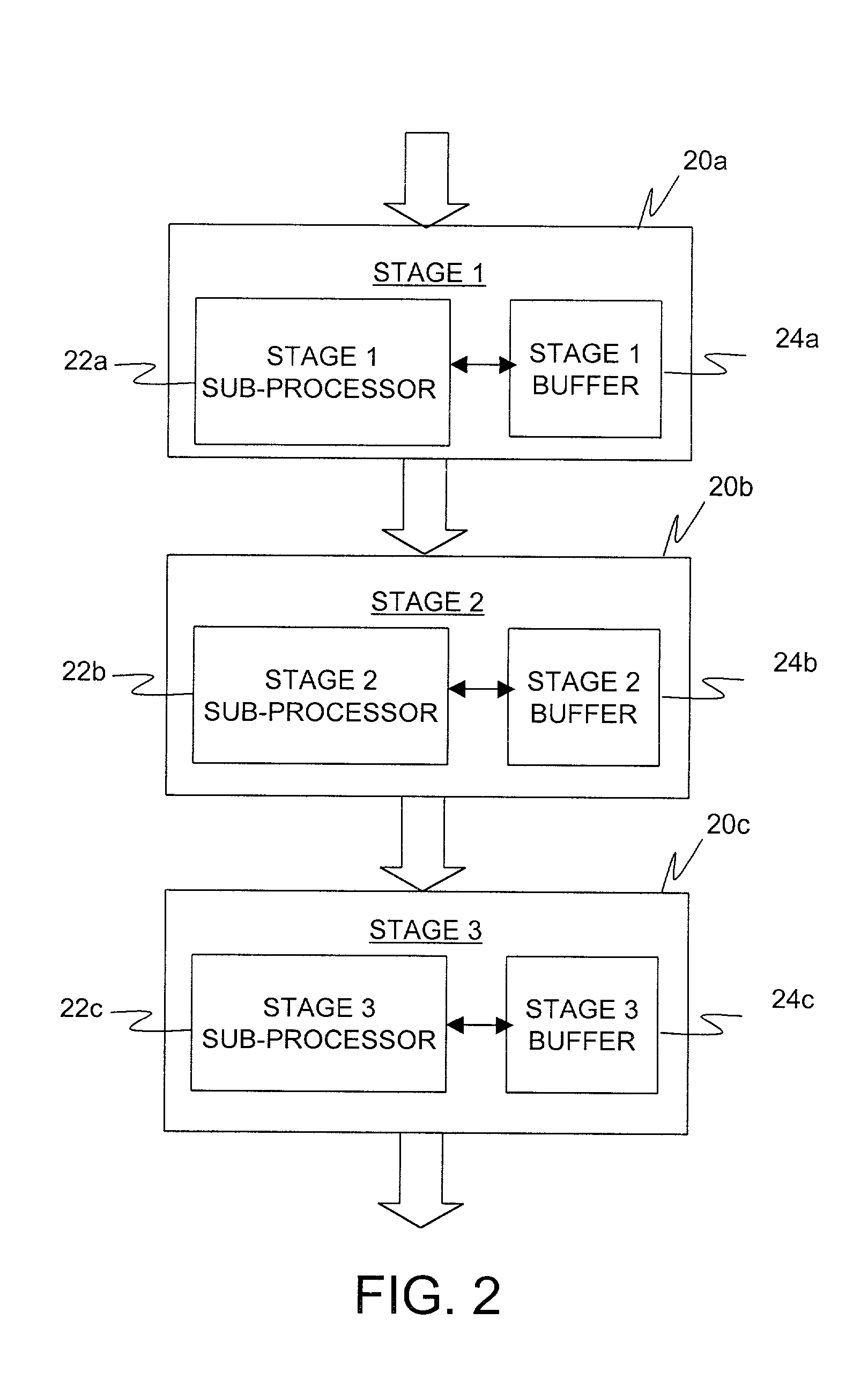

Non-blocking, multi-context pipelined processor

ActiveUS7080238B2Improve throughputImprove processing efficiencyData switching by path configurationConcurrent instruction executionWaste processingConditional branch

A packet processor whose processing capabilities are optimized by concurrently processing multiple packets within various pipelined stages. At each stage, multiple packets are processed via an internally pipelined sub-processor. In one embodiment, the packets are processed in a round robin fashion. When a particular packet is done processing at a particular stage, it may pass another packet whose processing is not complete, and move to a next stage. In another embodiment, a packet is processed until a conditional branch instruction or any other instruction causing a potential stall is encountered. If such an instruction is encountered, a next available packet is selected and processed instead of wasting processing cycles during the stall, or proceeding with the processing of the current packet based on a predicted result. The sub-processor resumes processing of the packet once the stall is over.

Owner:ALCATEL INTERNETWORKING PE

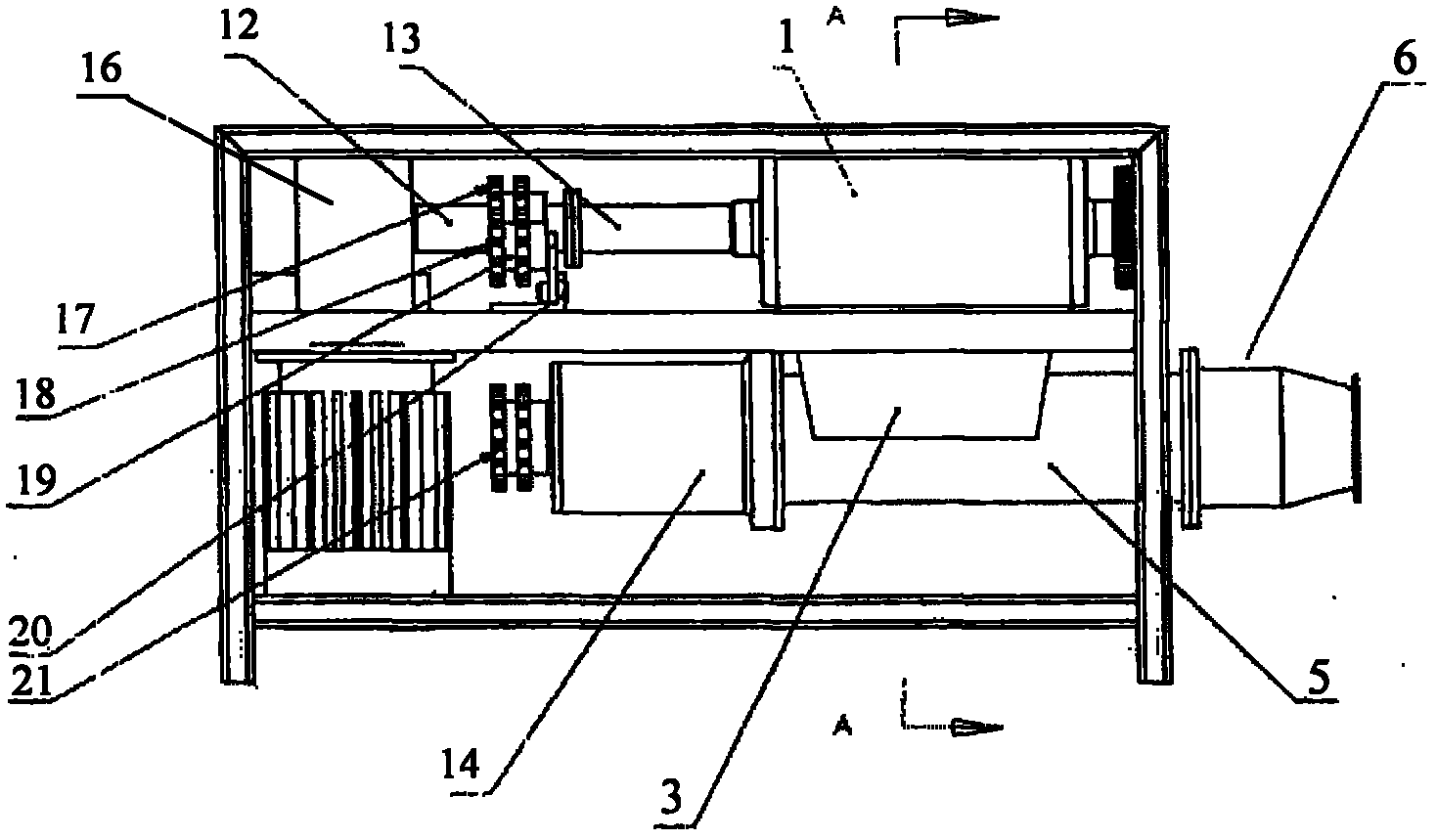

Building waste processing device and working method thereof

InactiveCN107661791ASmooth and smooth feedingSmooth and smooth crushing processMagnetic separationGrain treatmentsWaste processingArchitectural engineering

The invention discloses a building waste processing device and a working method thereof. The building waste processing device comprises a base, a material lifting device and a crushing cavity, whereinthe material lifting device is vertically arranged on the upper side of the left end of the base, and the crushing cavity is located right above the base and is adjacently connected to the material lifting device; and the material lifting device comprises a vertical lifting cylinder, a lifting rotating shaft, a driving motor and a spiral lifting fin, the lifting rotating shaft is arranged in theaxle center of the lifting cylinder, the driving motor is connected to the top end of the lifting rotating shaft and is fixedly mounted at the top of the lifting cylinder, the spiral lifting fin is welded to the outer part of the lifting rotating shaft, a feeding hopper is connected to the bottom of the left side of the lifting cylinder in a penetration manner, a downward-inclined material conveying pipeline is arranged at the top end of the right side of the lifting cylinder in a penetration manner, a discharging end of the material conveying pipeline deeply penetrates into the crushing cavity, and a fixed shaft crushing roll and a movable shaft crushing roll are mounted in the crushing cavity in parallel. According to the building waste processing device, the working efficiency can be effectively improved, the feeding and crushing processes of the material can be relatively smooth and steady, and the labor and the time are saved; and the building waste processing device is simple andreasonable in structure, convenient to use, practical and efficient.

Owner:陈彬

Break-away processing tool for a waste processing machine

A break-away processing tool for a waste processing machine includes a tool holder, at least one fastener for attaching the tool holder to a rotor assembly of the waste processing machine and a structure for allowing breakage of the tool holder in a controlled manner such that broken pieces of the tool holder remains attached to the rotor assembly by the fastener.

Owner:SMORACY

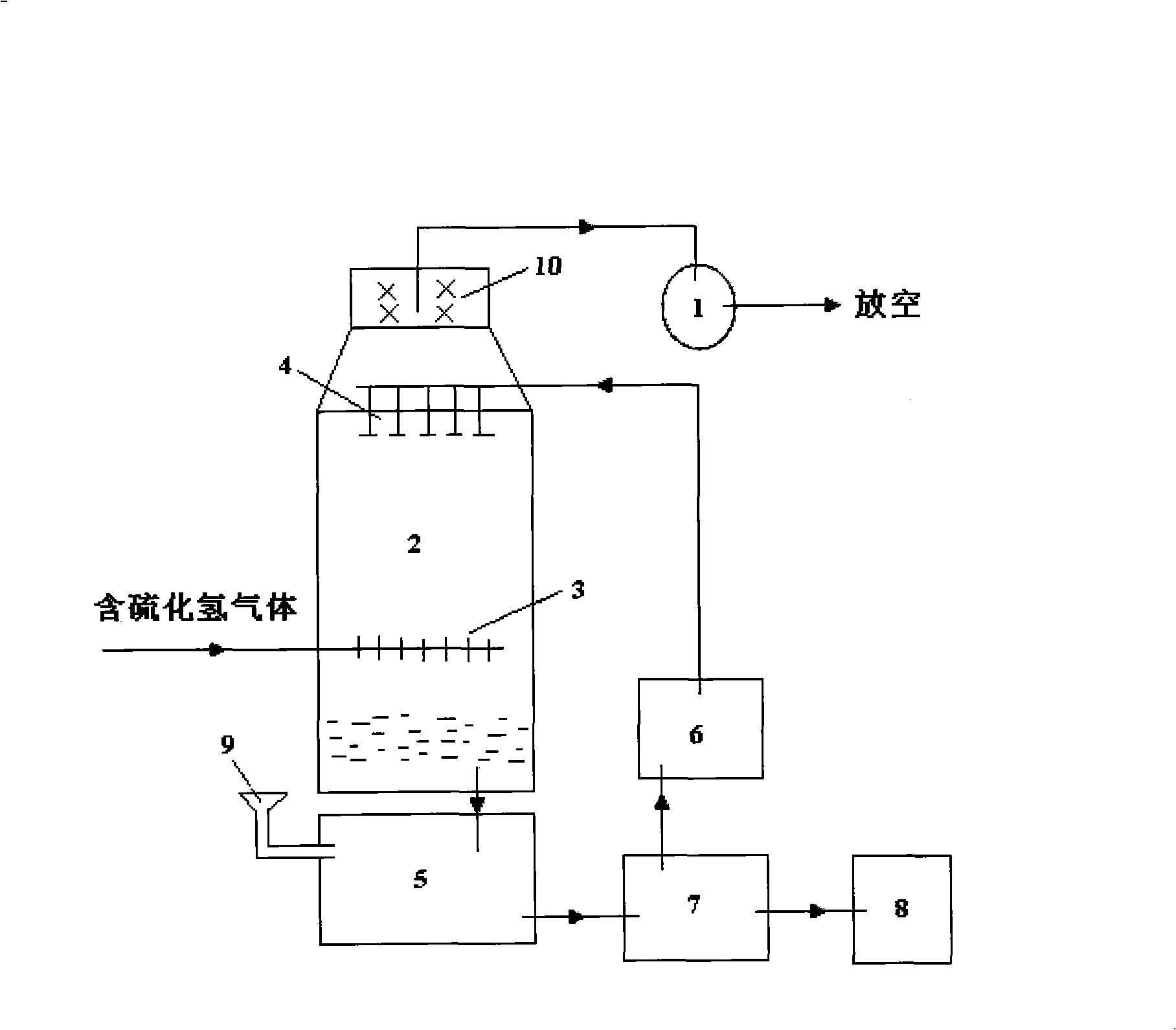

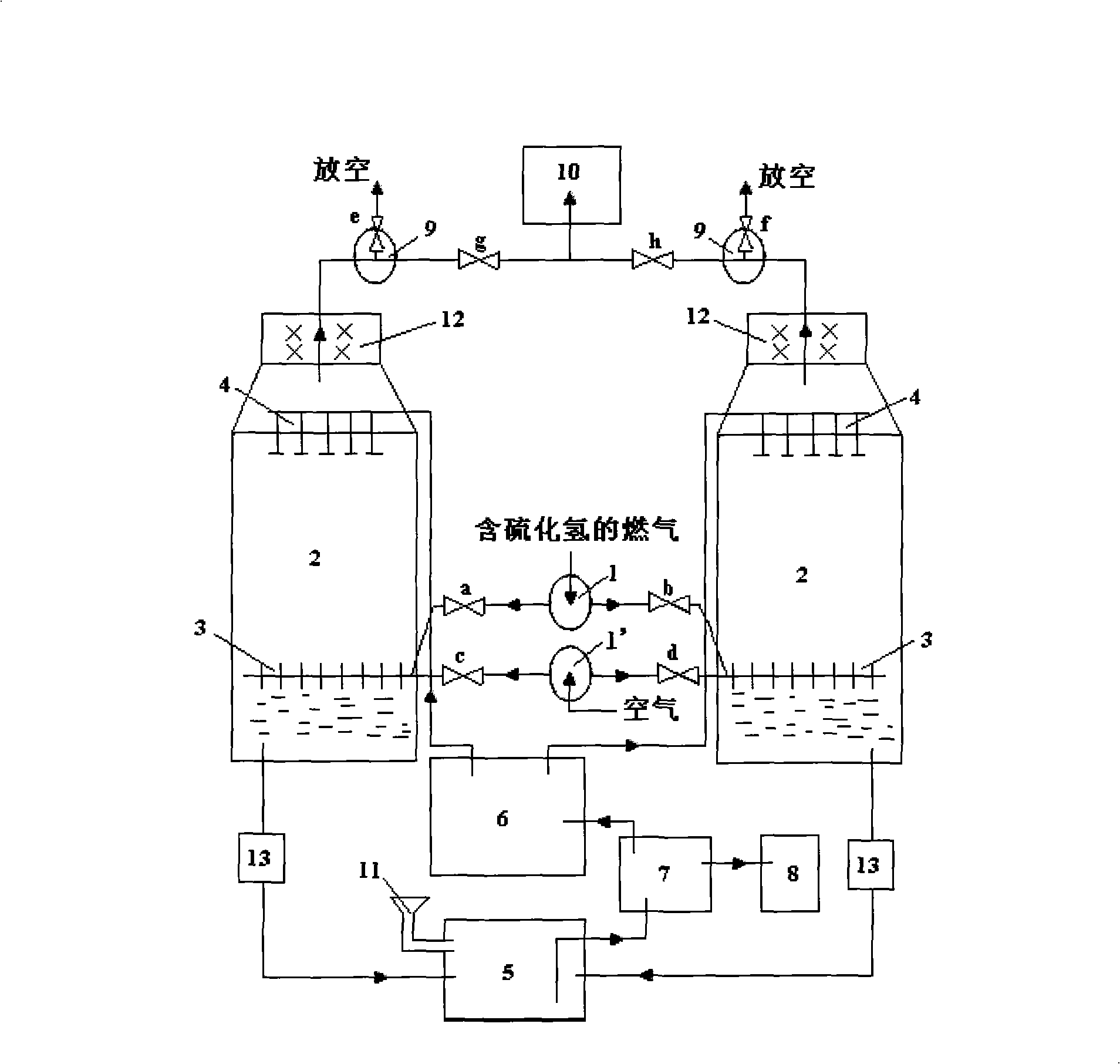

Method and device for removing hydrogen sulfide from gas containing hydrogen sulfide and recovering sulfer using catalytic oxidation

InactiveCN101327396AHigh removal and purification efficiencyFast conversionOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationEthylenediamineCatalytic oxidation

The present invention discloses a method for removing the hydrogen sulfide from the gas containing the hydrogen sulfide and for recycling the sulfur element with the catalytic oxidation effect, and discloses a device thereof. A catalytic oxidation system consisting of iron ion and ethylenediamine tetracetic acid is used, so that the hydrogen sulfide is transformed to the sulfur element so as to be removed from the air stream containing the hydrogen sulfide; the hydrogen sulfide removing rate reaches 99.9 percent. The method of the present invention not only can be used for removing the hydrogen sulfide in the gas from the manure processing field, the urban living garbage transshipping station, the public toilet, the sewage treatment plant, the solid waste processing field, the oil refining plant and the animal dead-body sanitary processing field, but also can be used for removing the hydrogen sulfide in the fuel gases such as the marsh gas, the land-filling gas, the natural gas, etc. During the treatment process, except the useful sulfur element is produced, no other product that influences the environment is produced.

Owner:深圳龙澄高科技环保股份有限公司

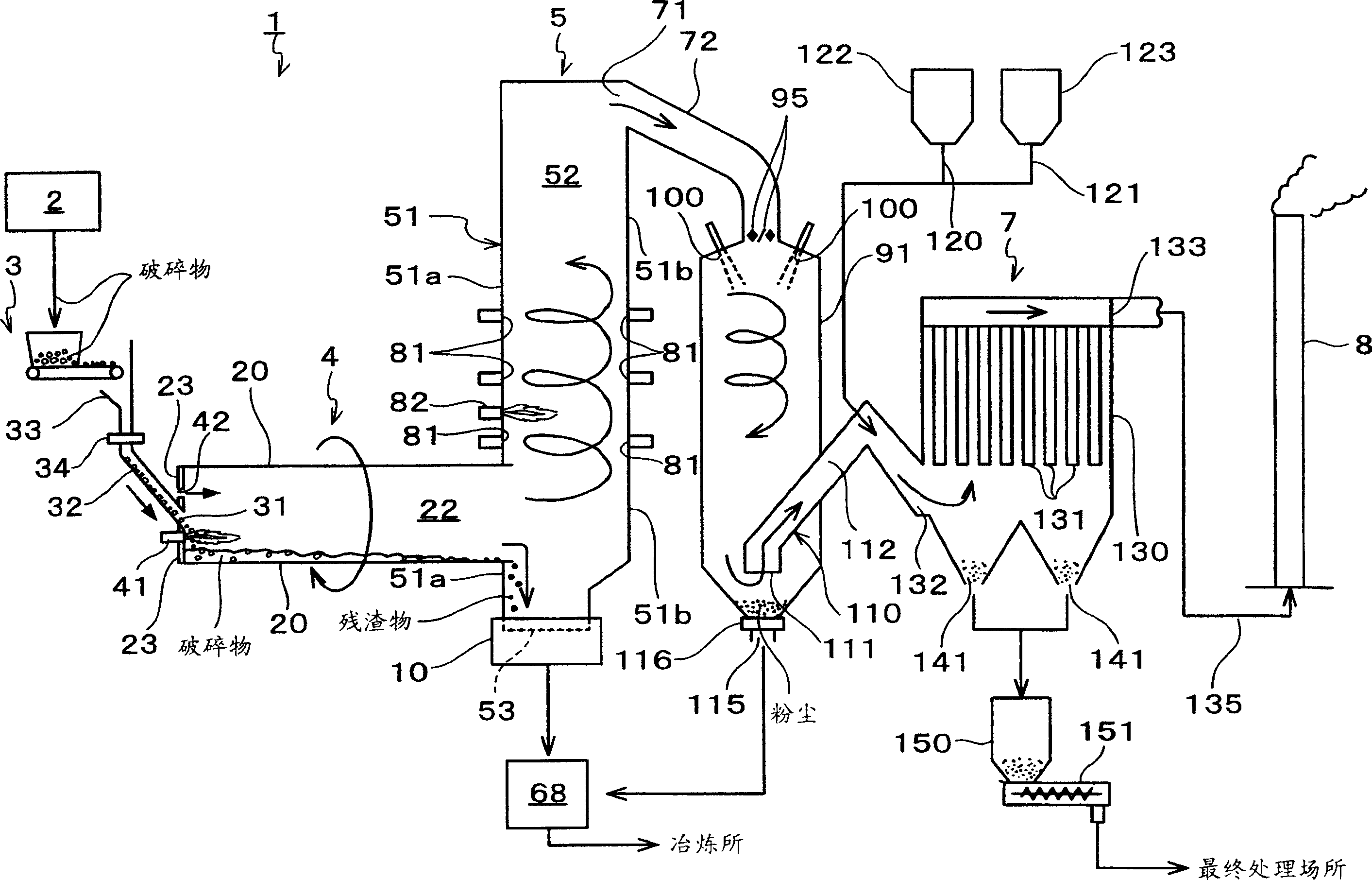

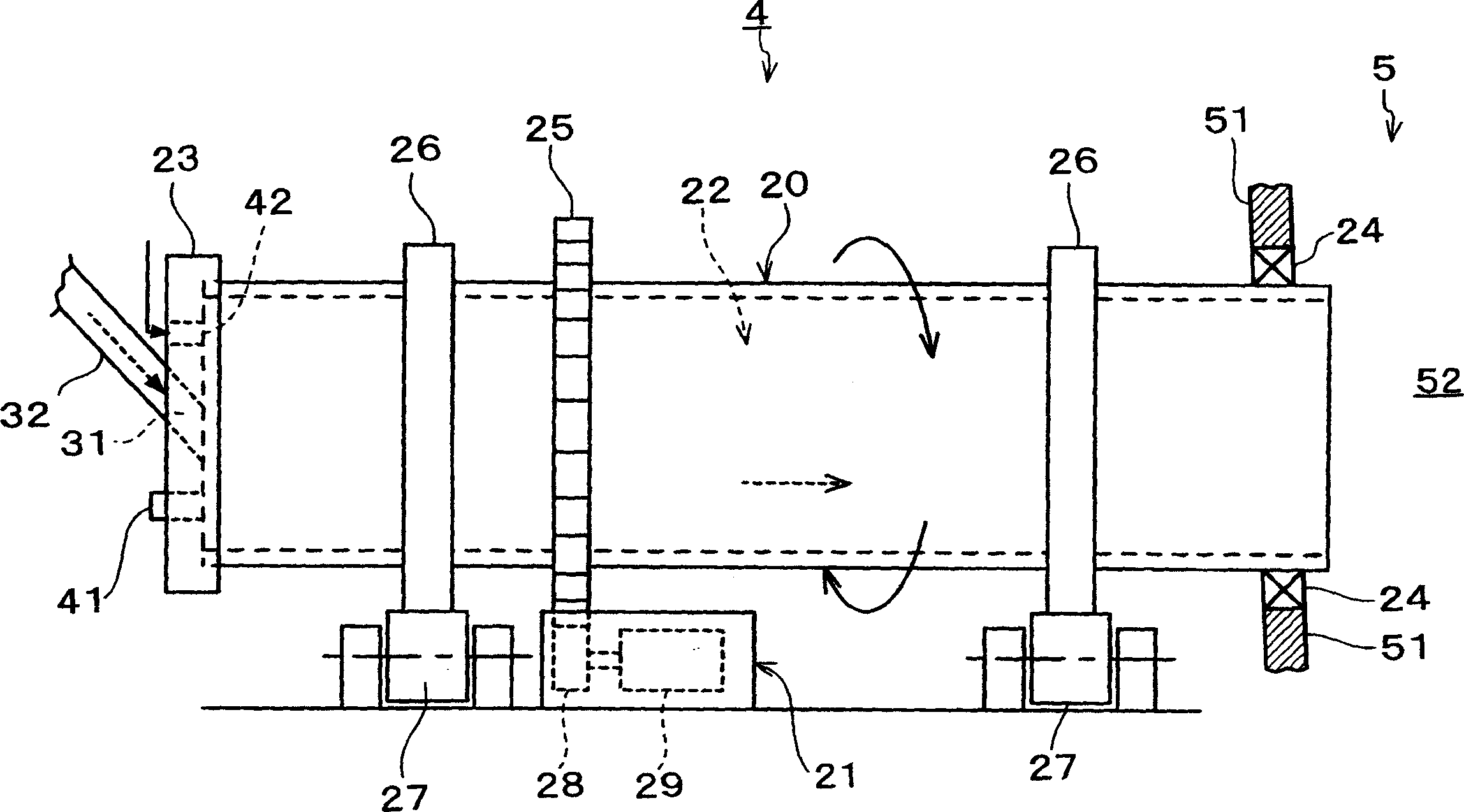

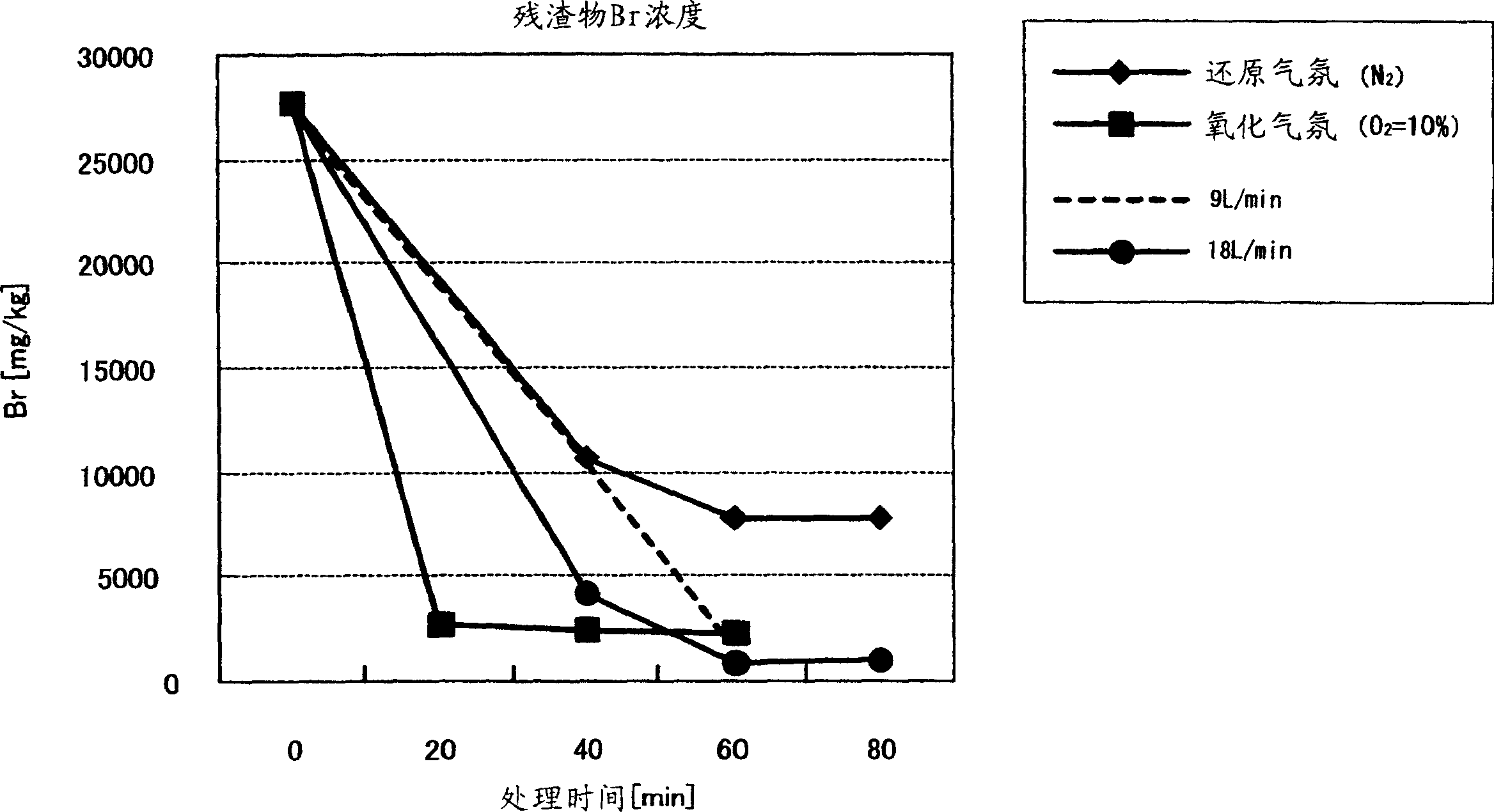

Castoff processing method and system

ActiveCN1834537AEfficient combustionEfficient gasificationProcess efficiency improvementIncinerator apparatusWaste processingHazardous substance

The invention relates to a waste processing method and a waste processing system which can avoid discharging harmful material as dioxins and effectively attain the slag of value metal. Wherein, the method for recycling value metal comprises: burning the waste, recycling the slag that containing value metal, and fully burning generated gas , and cooling said burning gas with the cooling speed that avoiding generating dioxins. With said method, the invention can gasify the resin component in the waste via burning waste, to obtain the slag of value metal in short time.

Owner:DOWA METALS & MINING CO LTD

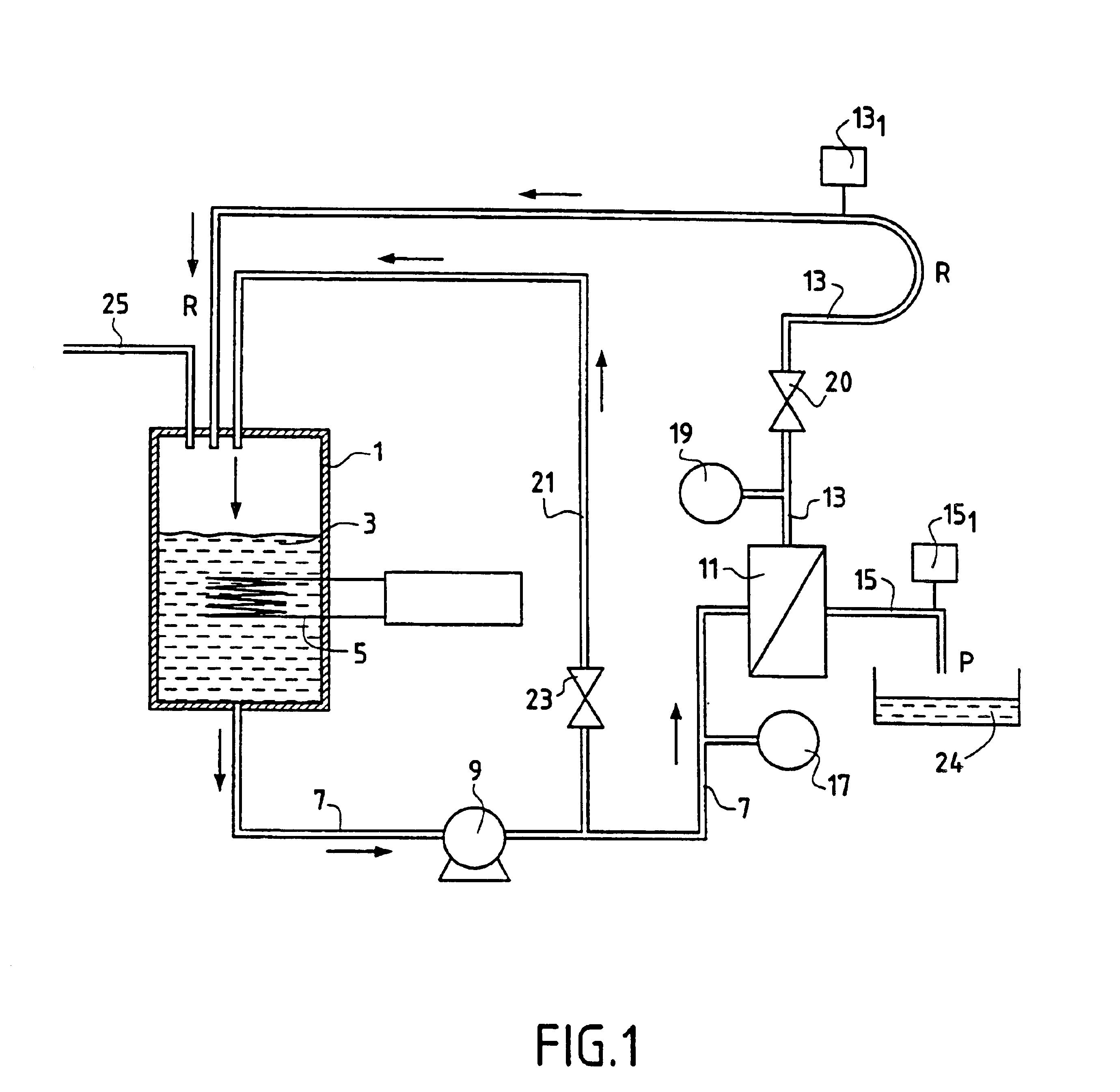

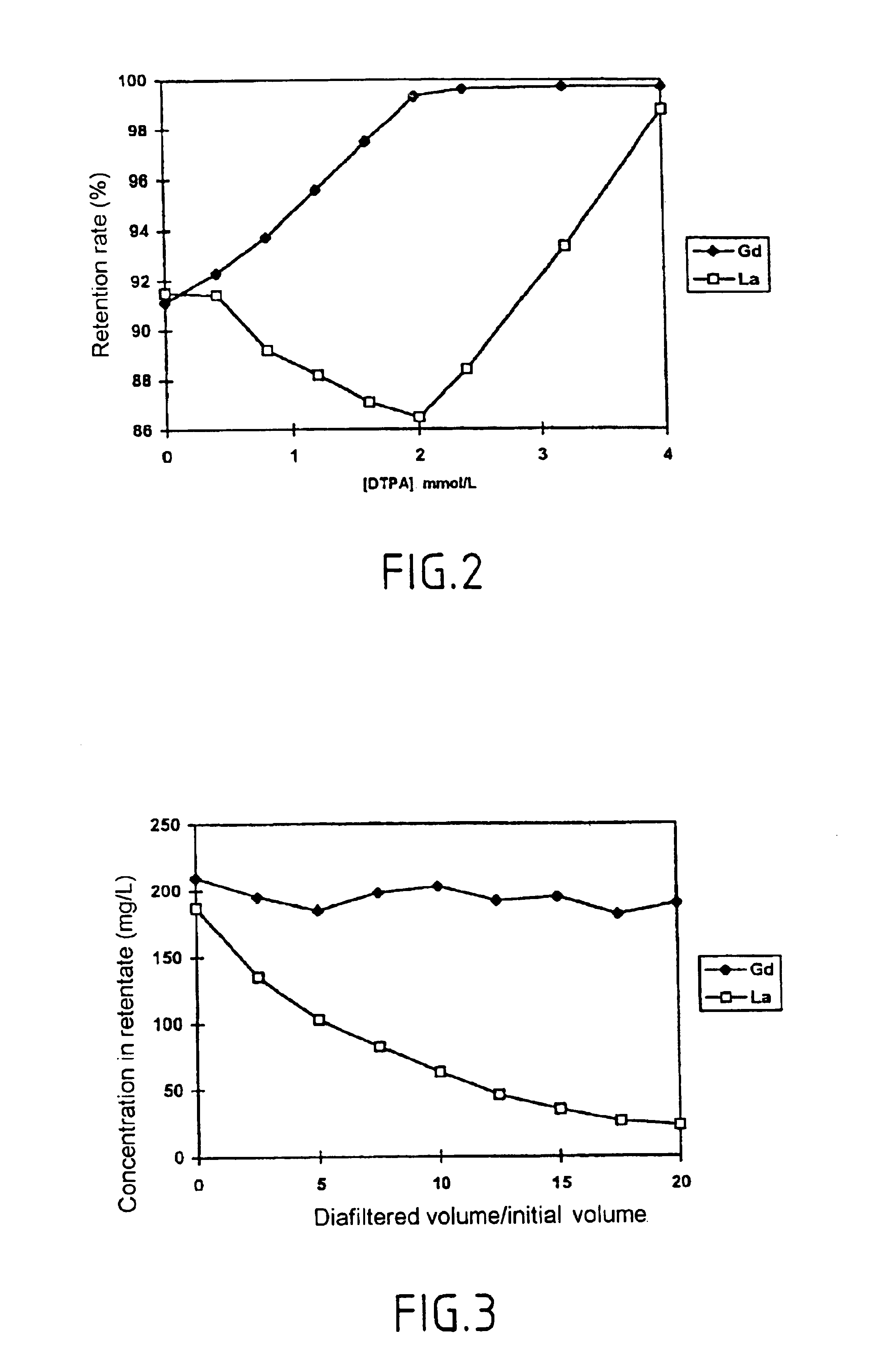

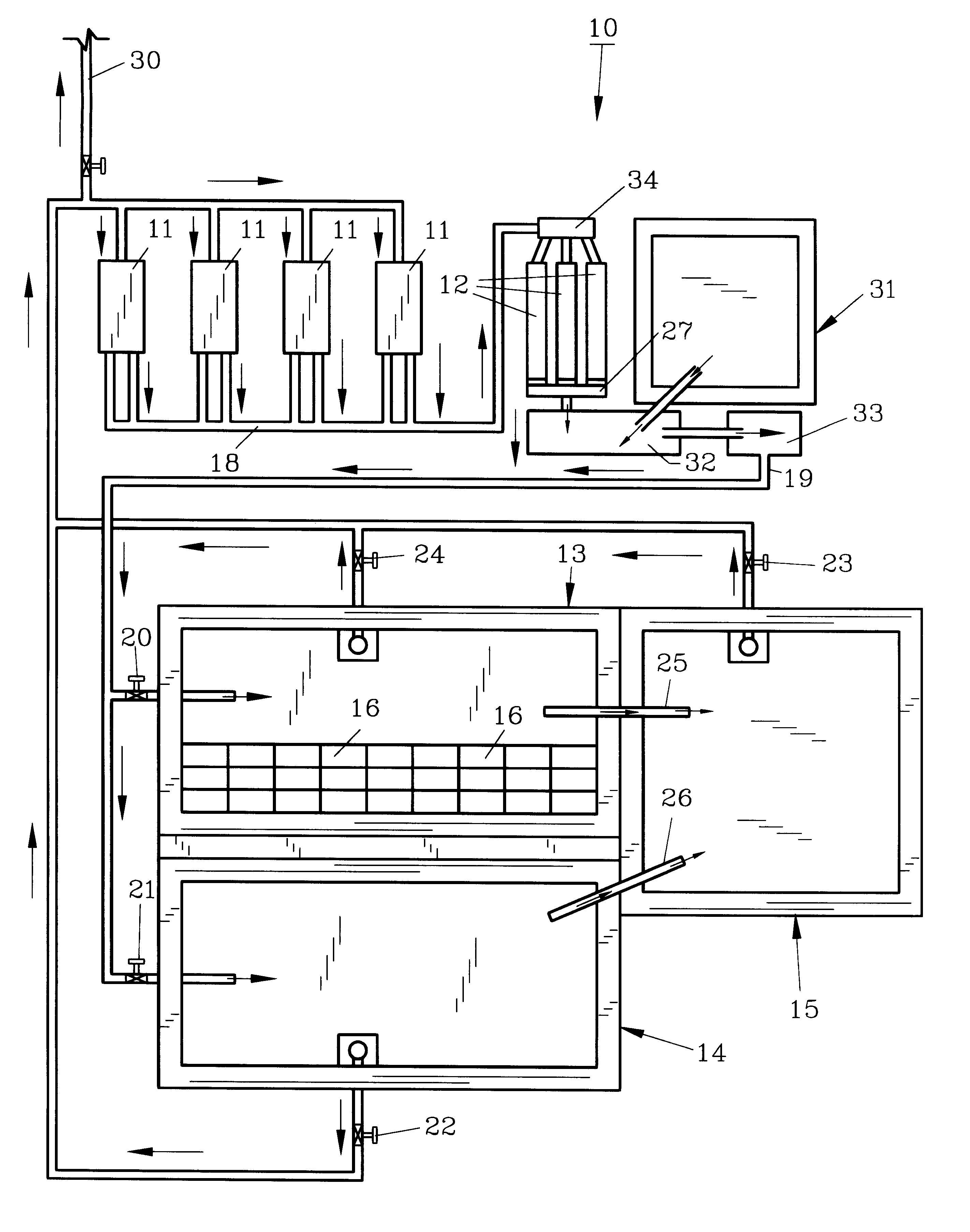

Method for separating in an aqueous medium lanthanides and/or actinides by combined complexing-nanofiltration, and novel complexing agents therefor

InactiveUS6843917B1Easy to implementEasily degradableMembranesOrganic chemistryWaste processingLanthanide

The invention relates to the separation of lanthanides and actinides by nanofiltration complexation. The object of the invention is to satisfy the existing need for a simple, efficient and economical technique for separating lanthanides and actinides. This object is achieved by a process consisting of using ligands of the polyamino acid type, such as EDTA or DTPA, for complexing lanthanides and / or actinides before separating them by nanofiltration. The invention further relates to novel polyamino acid ligands incorporating ligand structures additional to EDTA and DTPA. Application to the production of rare earths or nuclear waste processing, especially to recycling operations carried out on spent nuclear fuels is also discussed.

Owner:UNIV CLAUDE BERNARD LYON 1 +1

Hog waste processing apparatus and method

InactiveUS6207057B1Prevent escapeEfficient processingTreatment using aerobic processesWaste water treatment from animal husbandryWaste processingExcess fluids

A hog waste processing apparatus is comprised of standard hog barns which are fluidly connected to separators. The separators are fluidly connected to a pair of reactor cells. The reactor cells are filled with EcoBlocks to increase the surface area upon which biological reactions occur. Excess fluid from the reactor cells drains into a polishing cell which recycles the water to flush the barns. A method is also affiliated with the apparatus. The method comprises flushing the barns with water once a week to remove animal waste to the separators. Once a month the separator being used is allowed to completely dry and the solid waste is removed to a storage area for further drying and shipment.

Owner:TIRE RECYCLERS

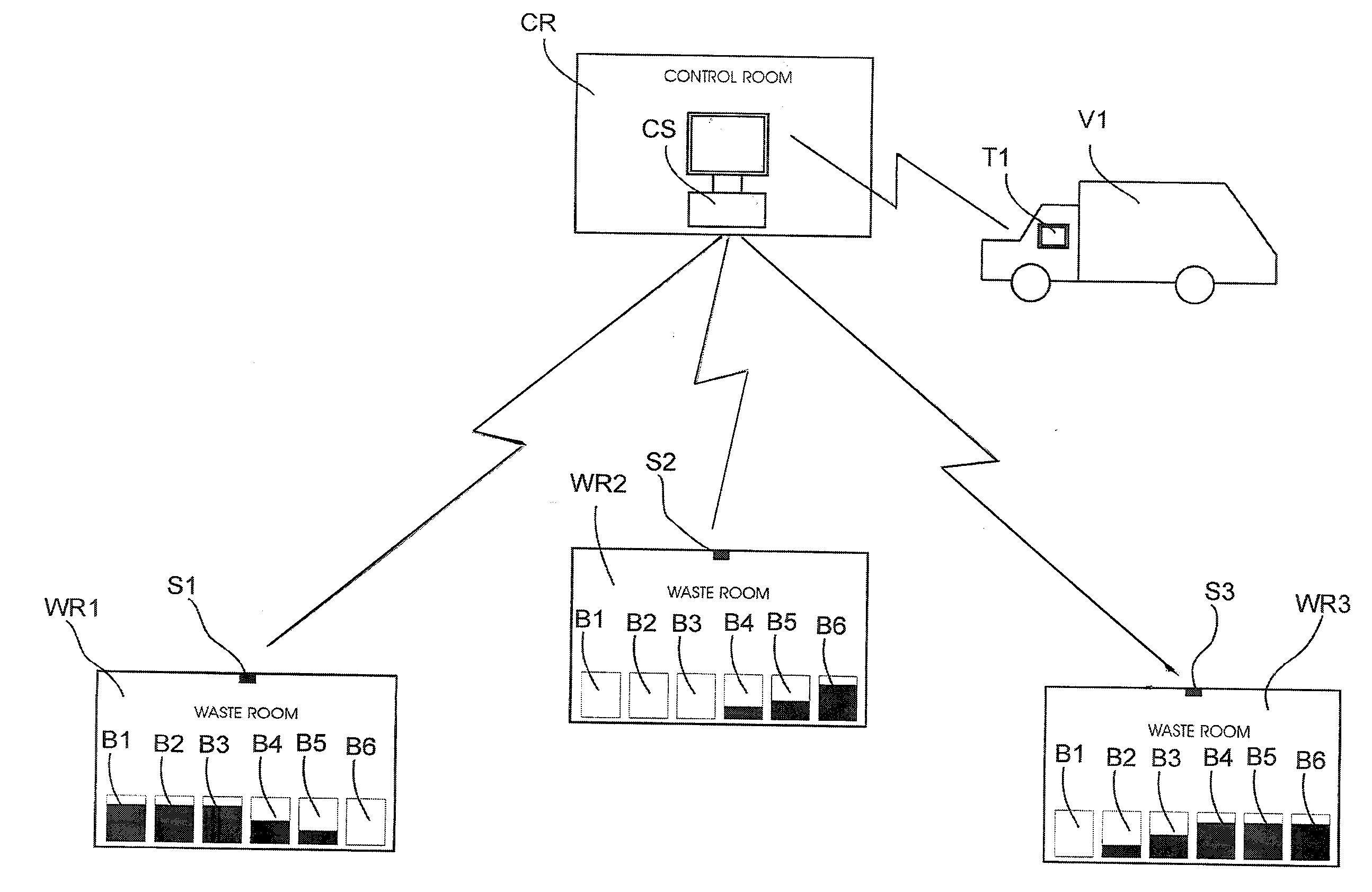

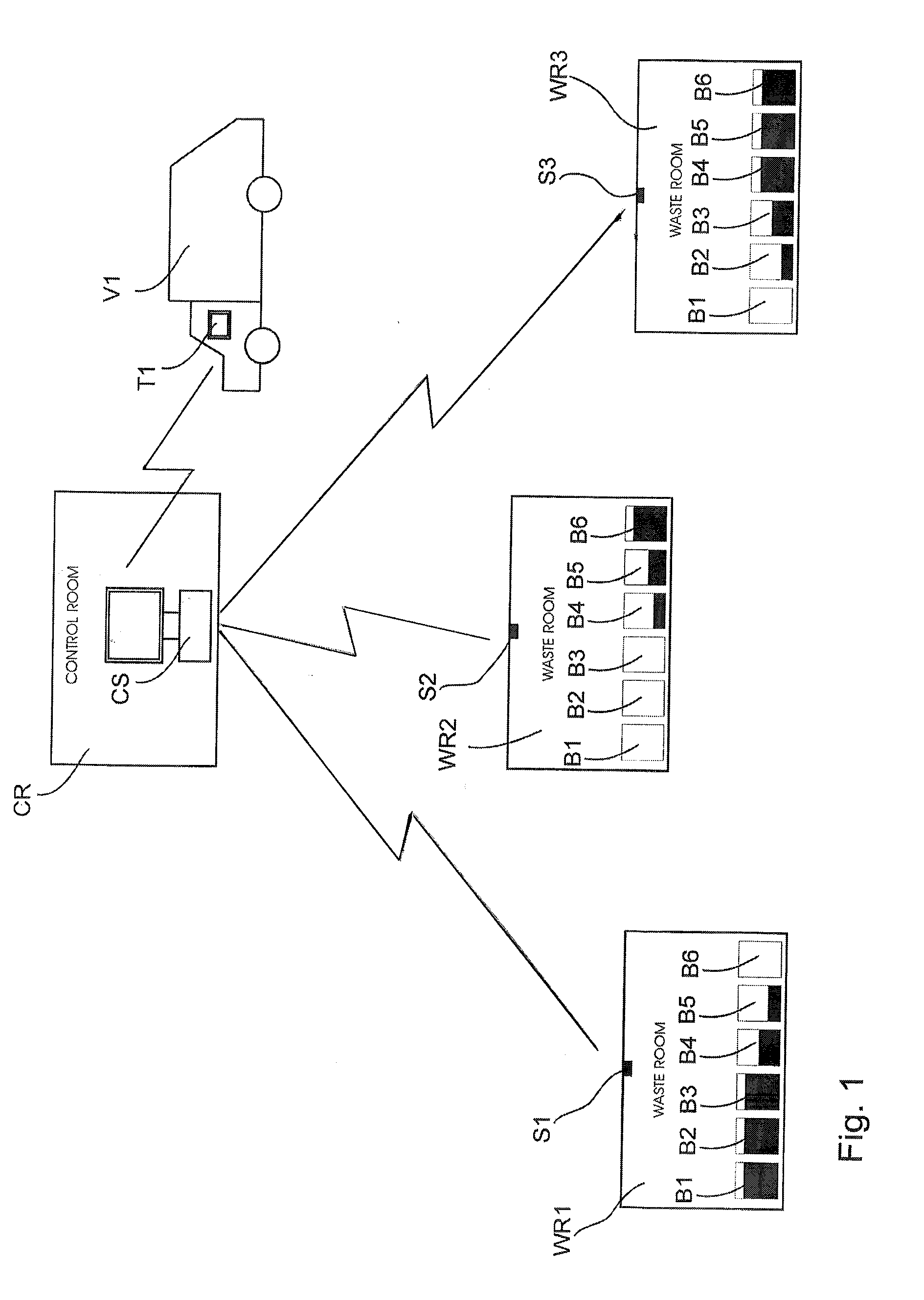

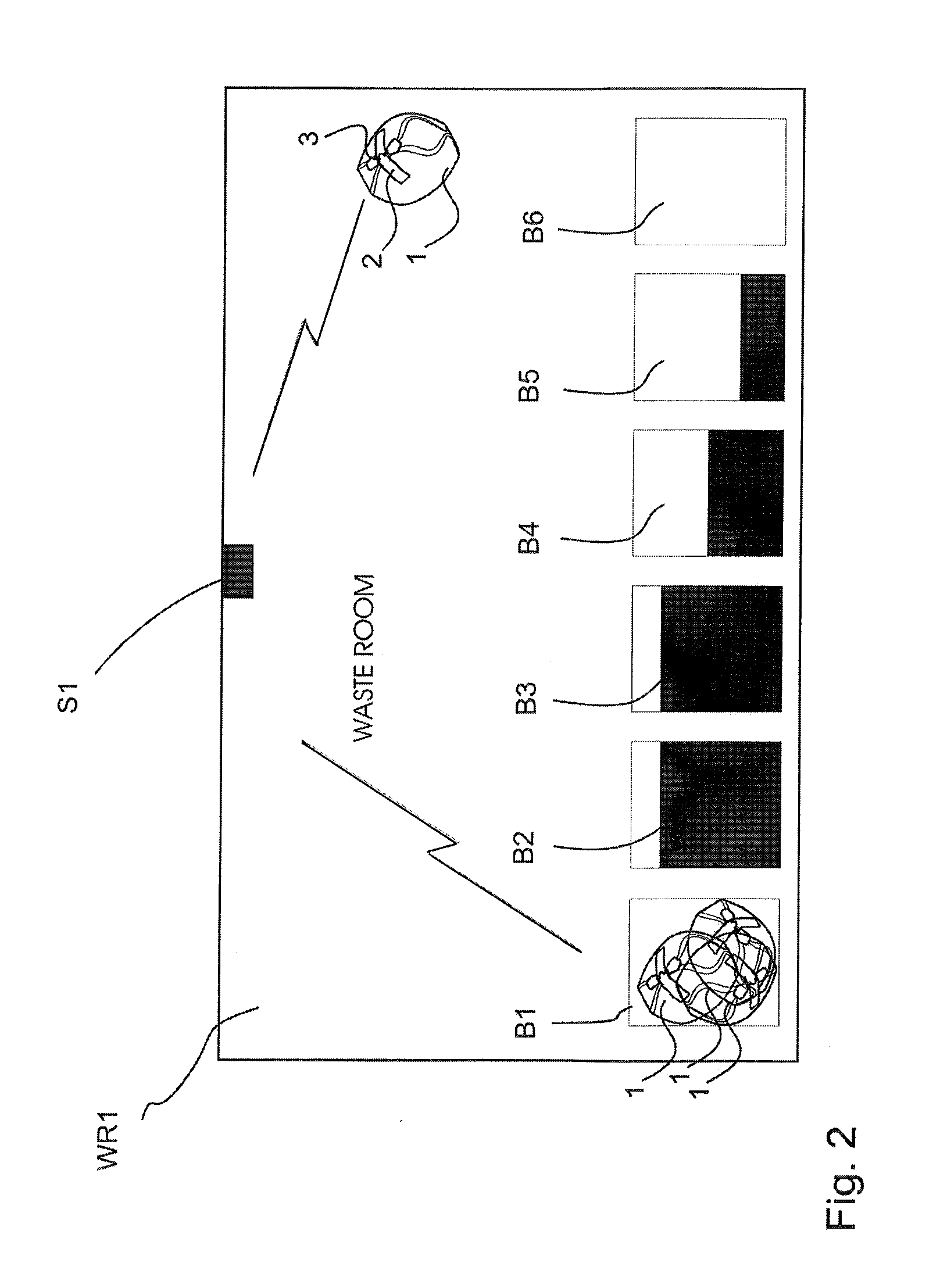

Waste handling system and method

ActiveUS20120010746A1EffectiveEasy to useSustainable waste treatmentData processing applicationsTransport systemHandling system

Method in a waste handling system, in which waste or recyclable material is transported in carrier bags, bags or sacks (1) to a disposal point, such as to a waste bin of a waste room (WR1, WR2, WR3), and from there onwards by a transport vehicle for further processing. An RFID identifier (3) is used in connection with the carrier bag, bag, sack (1) or corresponding used in waste transport, preferably a closing means (2) that is provided with an RFID identifier (3) is used in closing, or as verification of the closing of, the carrier bag, bag, sack (1) or corresponding, and in which method a sensor (S1, S2, S3) is arranged in connection with, or in the proximity of, a disposal point, such as a waste room (WR1, WR2, WR3), of the waste system, the information read from the RFID identifier of which sensor is transmitted to a control unit (CS), which is fitted to control the waste transport system, or a part of it, on the basis of the information given by the RFID identifier. The invention also relates to a waste transport system.

Owner:MARICAP OY

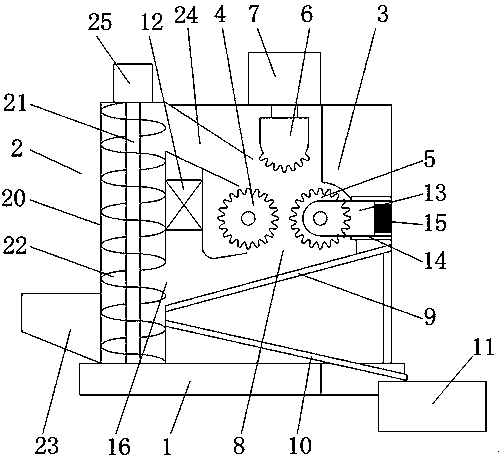

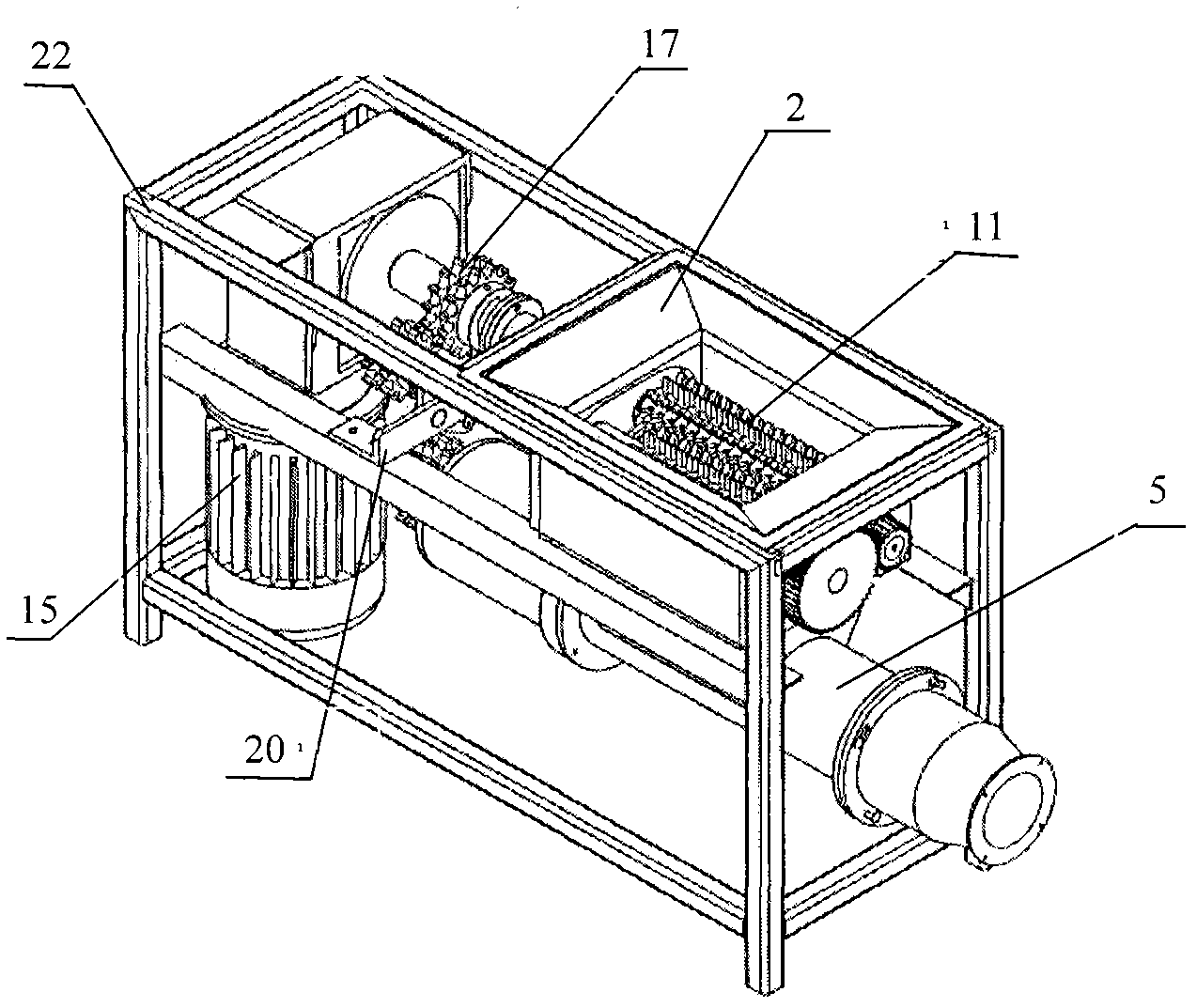

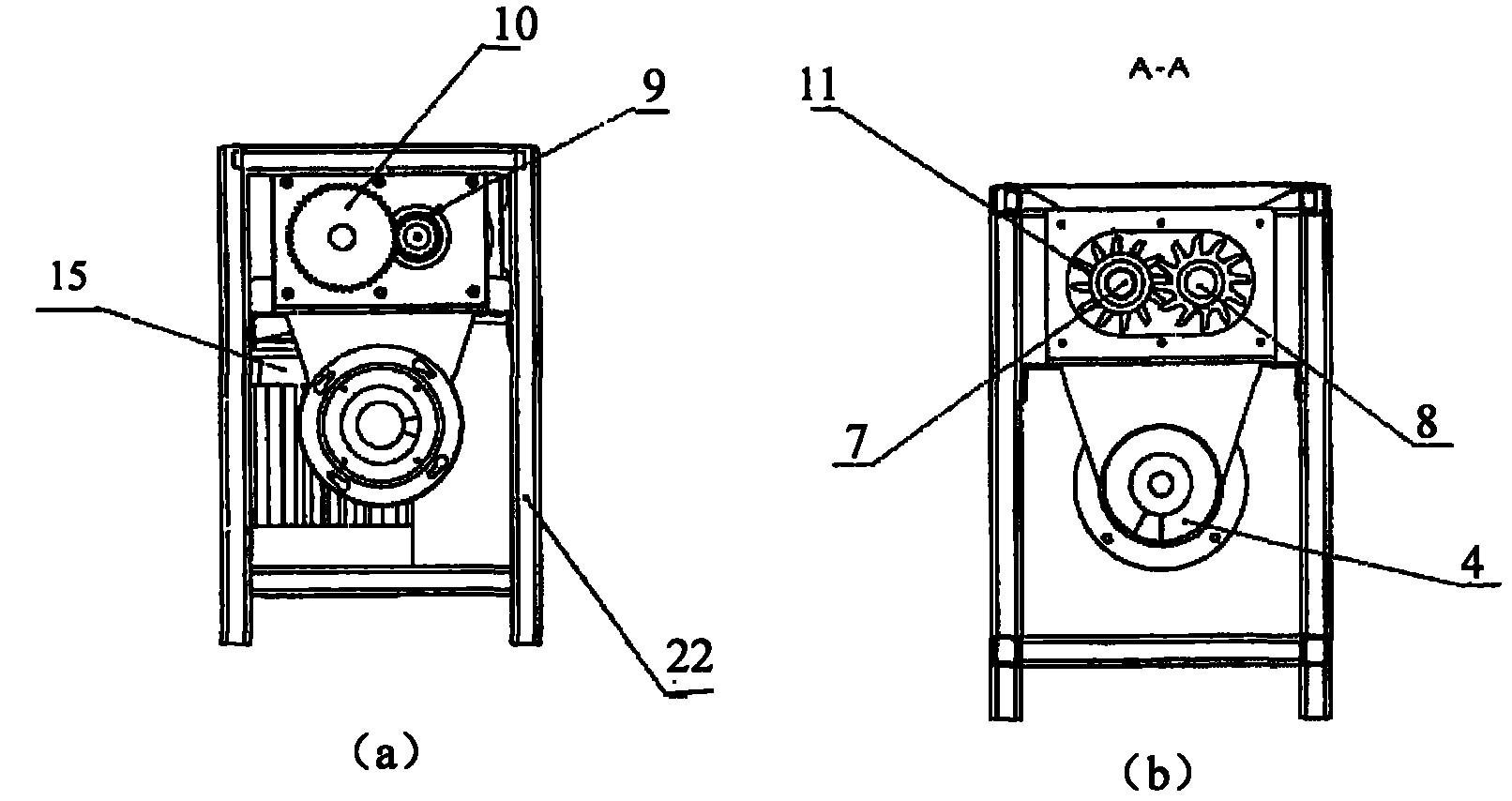

Kitchen waste crushing and squeezing processor

The invention belongs to the field of environmental protection, and relates to a waste processing device, in particular to a kitchen waste crushing and squeezing processor. In order to overcome the defect of the lack of special kitchen waste processing equipment in the prior art, the invention provides a kitchen waste crushing and squeezing processor. The kitchen waste crushing and squeezing processor comprises a crushing part and a squeezing and dewatering part, wherein the crushing part comprises a roll type crushing mechanism, the roll type crushing mechanism comprises a driving shaft and a driven shaft, gears are arranged on the driving shaft and the driven shaft respectively, each gear comprises a gear ring and a gasket, gear teeth are arranged on the gear ring, the cutting gap between tooth surfaces of adjacent gears is 0.5mm, and the cutting gap between tip-shaped tops of the gear teeth and the gaskets is 0.5mm. The kitchen waste crushing and squeezing processor integrates crushing, squeezing and dewatering, and can be used for efficiently processing kitchen waste.

Owner:邢征

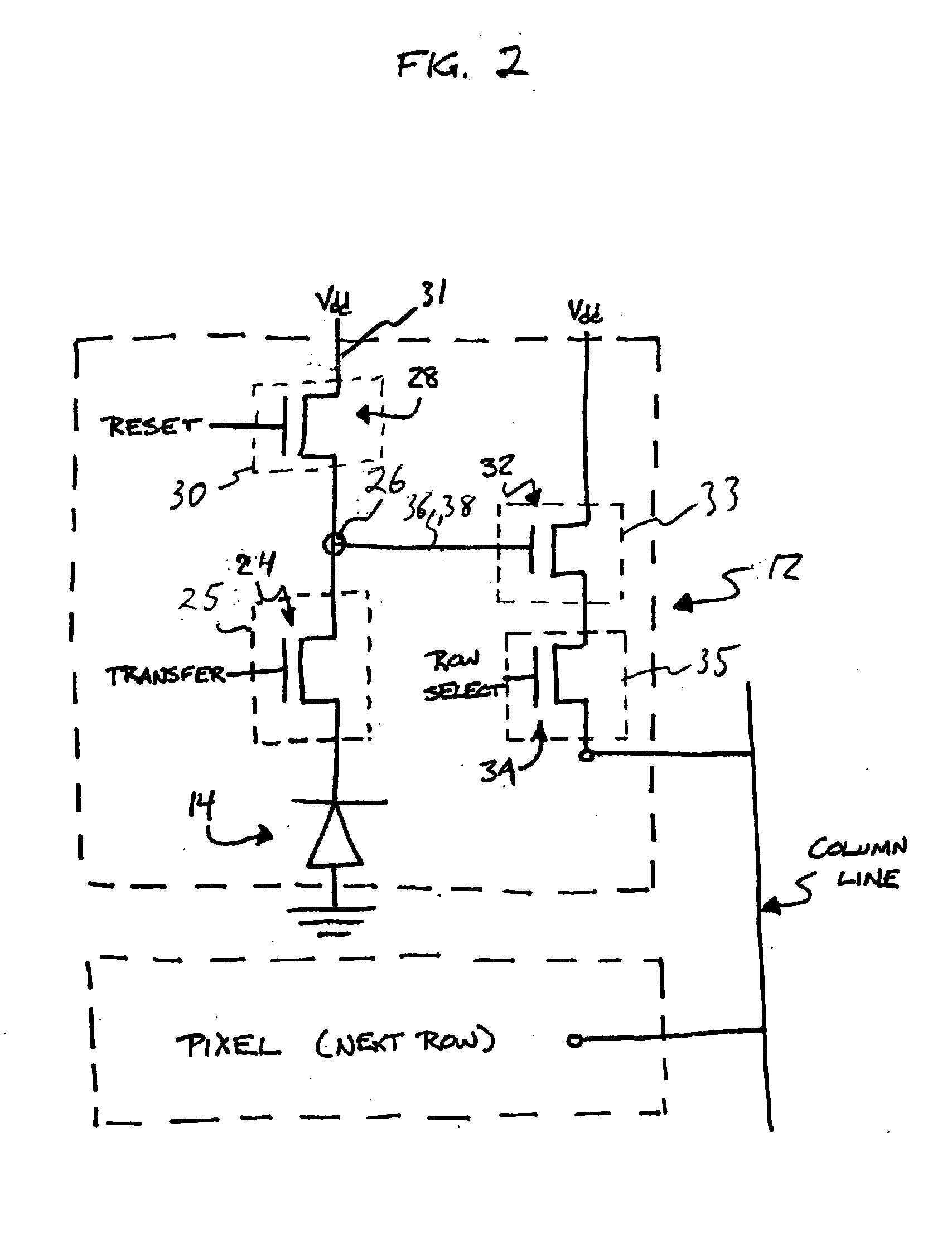

Method and structure to reduce optical crosstalk in a solid state imager

ActiveUS20060197169A1More compact pixel constructionSolid-state devicesRadiation controlled devicesWaste processingEngineering

Methods and structures to reduce optical crosstalk in solid state imager arrays. Sections of pixel material layers that previously would have been etched away and disposed of as waste during fabrication are left as conserved sections. These conserved sections are used to amend the properties and performance of the imager array. In the resulting structure, the conserved sections absorb incident light. The patterned portions of conserved material provide additional light shielding for array pixels.

Owner:MICRON TECH INC

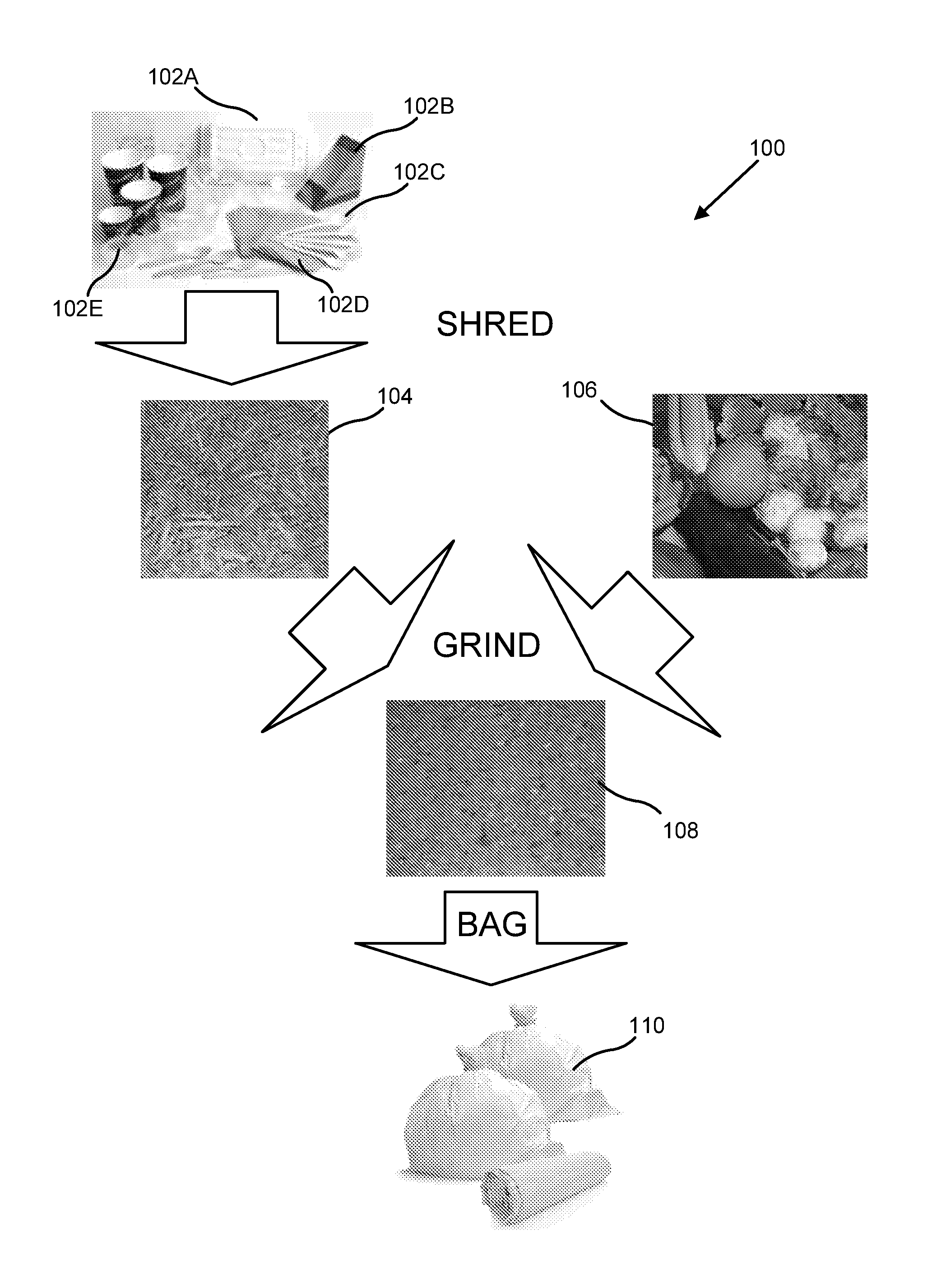

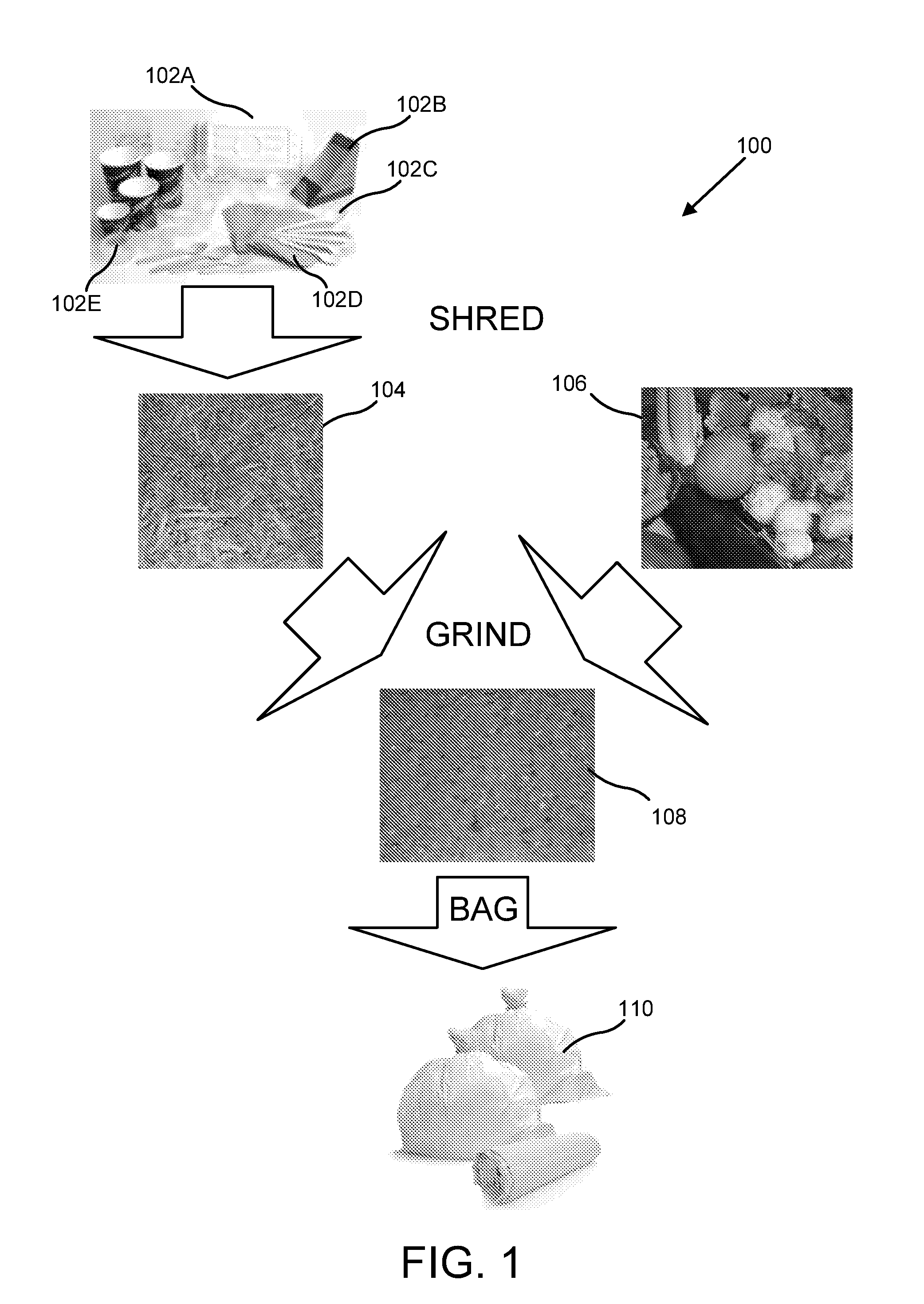

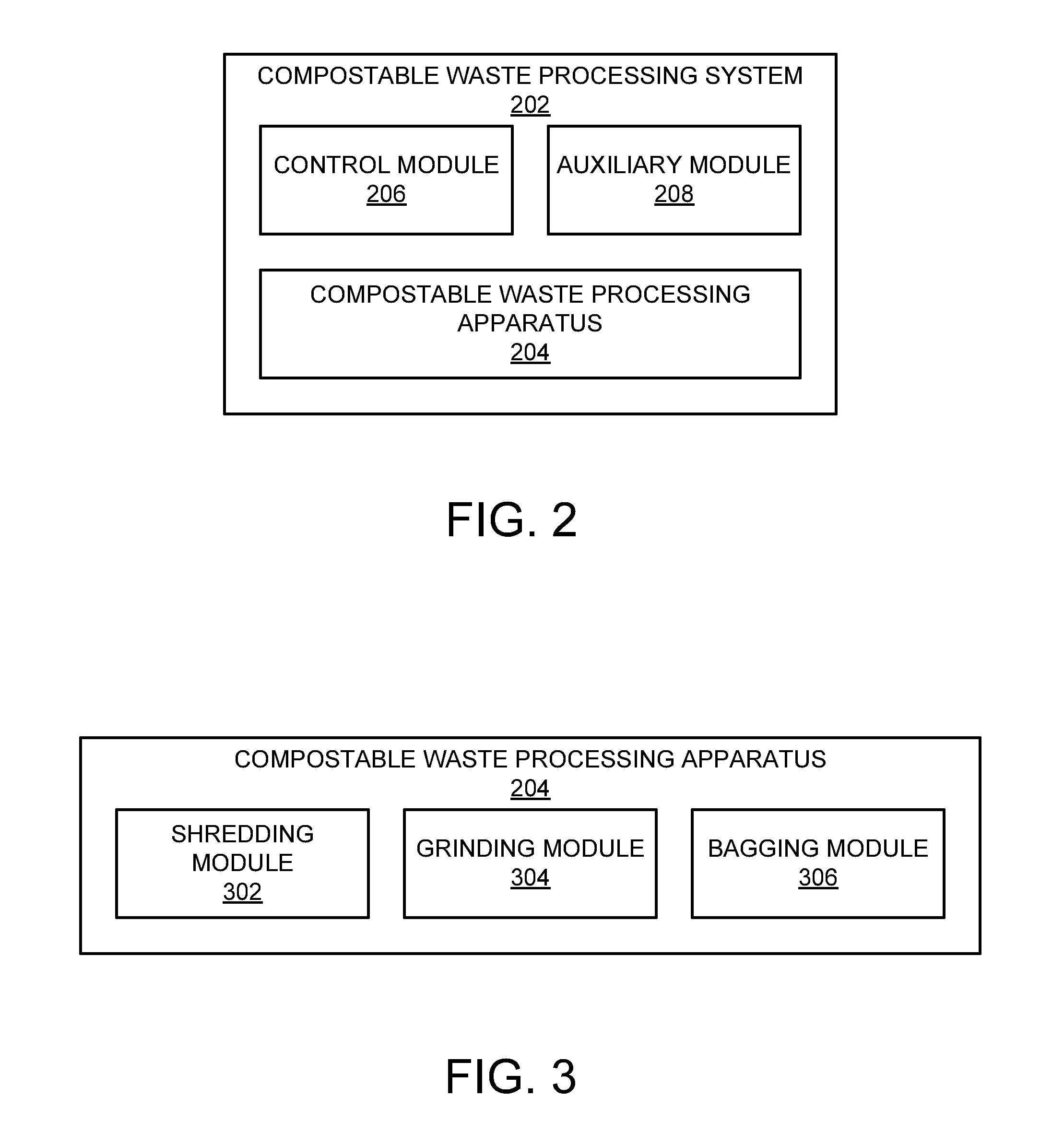

Apparatus, system, and method for compostable waste processing

InactiveUS20110101137A1Overcomes shortcomingLower the volumeProductsBio-organic fraction processingParticulatesWaste processing

An apparatus, system, and method to process compostable waste. The apparatus includes a shredding module, a grinding module, and a bagging module. The shredding module may operate to shred non-food compostable waste into shredded waste. The grinding module may operate to combine the shredded waste with food waste into combined waste, add water to the combined waste if an insufficient moisture condition exists for further processing, and grind the combined waste into particulate waste. The bagging module may operate to bag the particulate waste into a compostable bag.

Owner:LANGSTON JODY

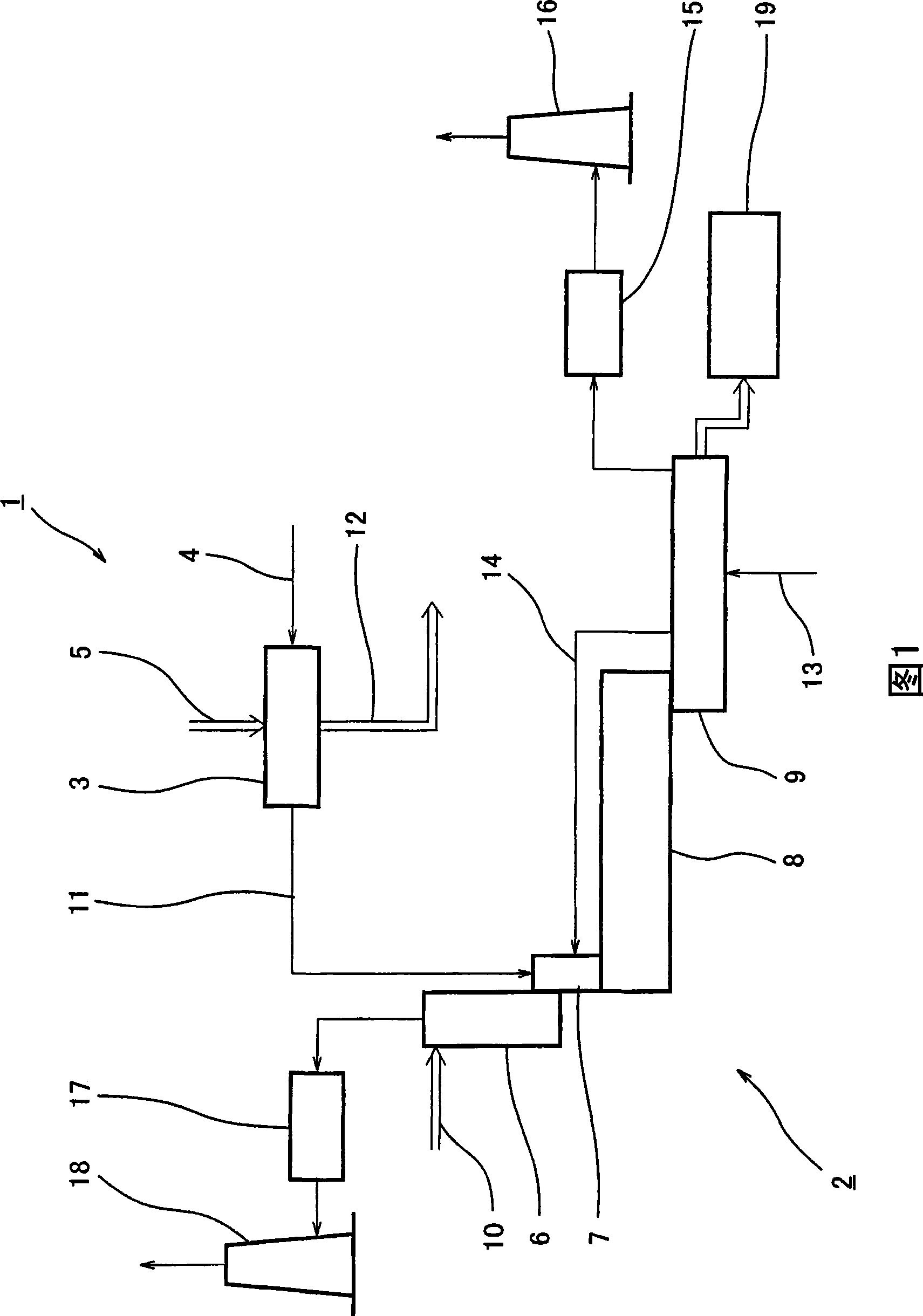

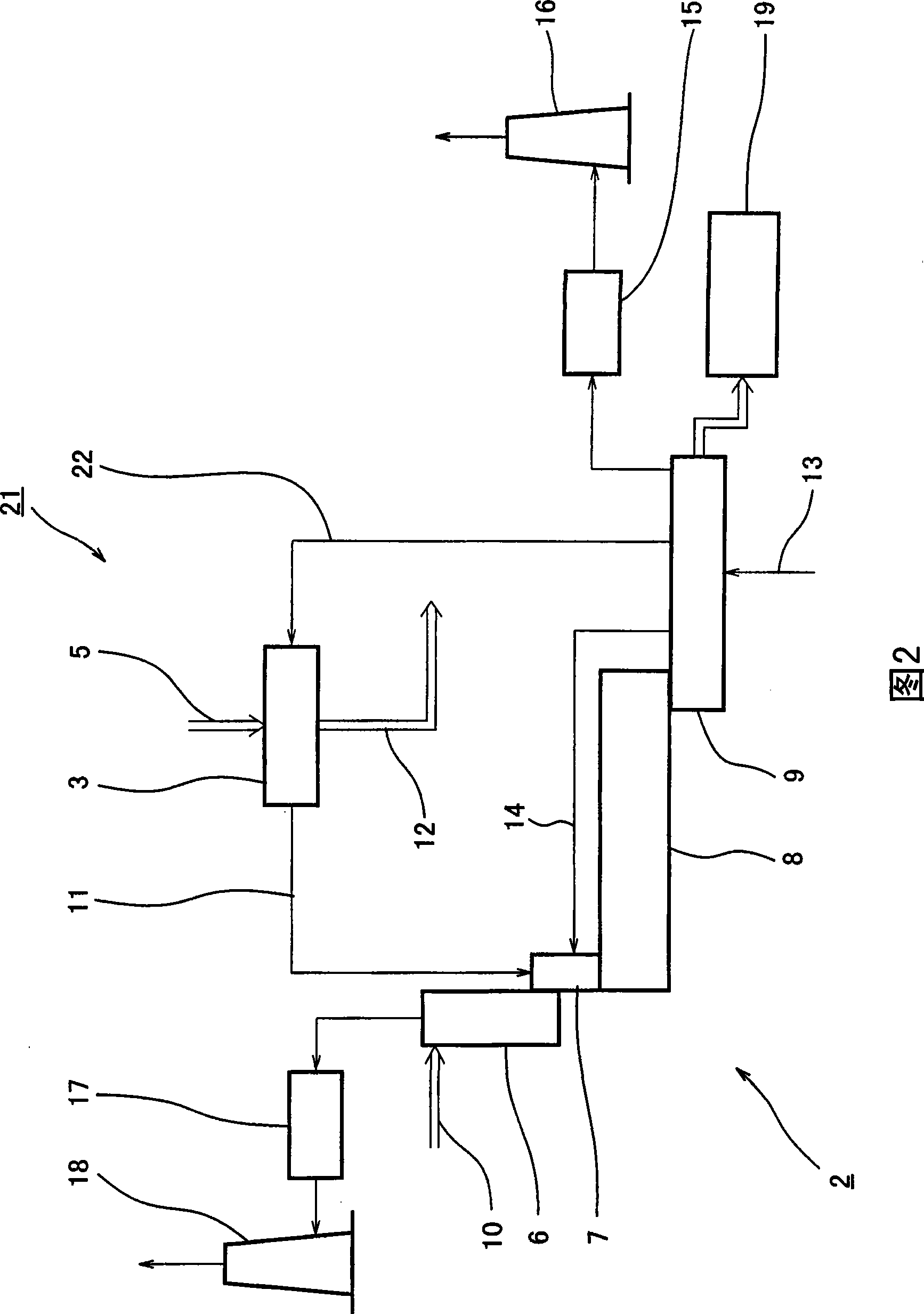

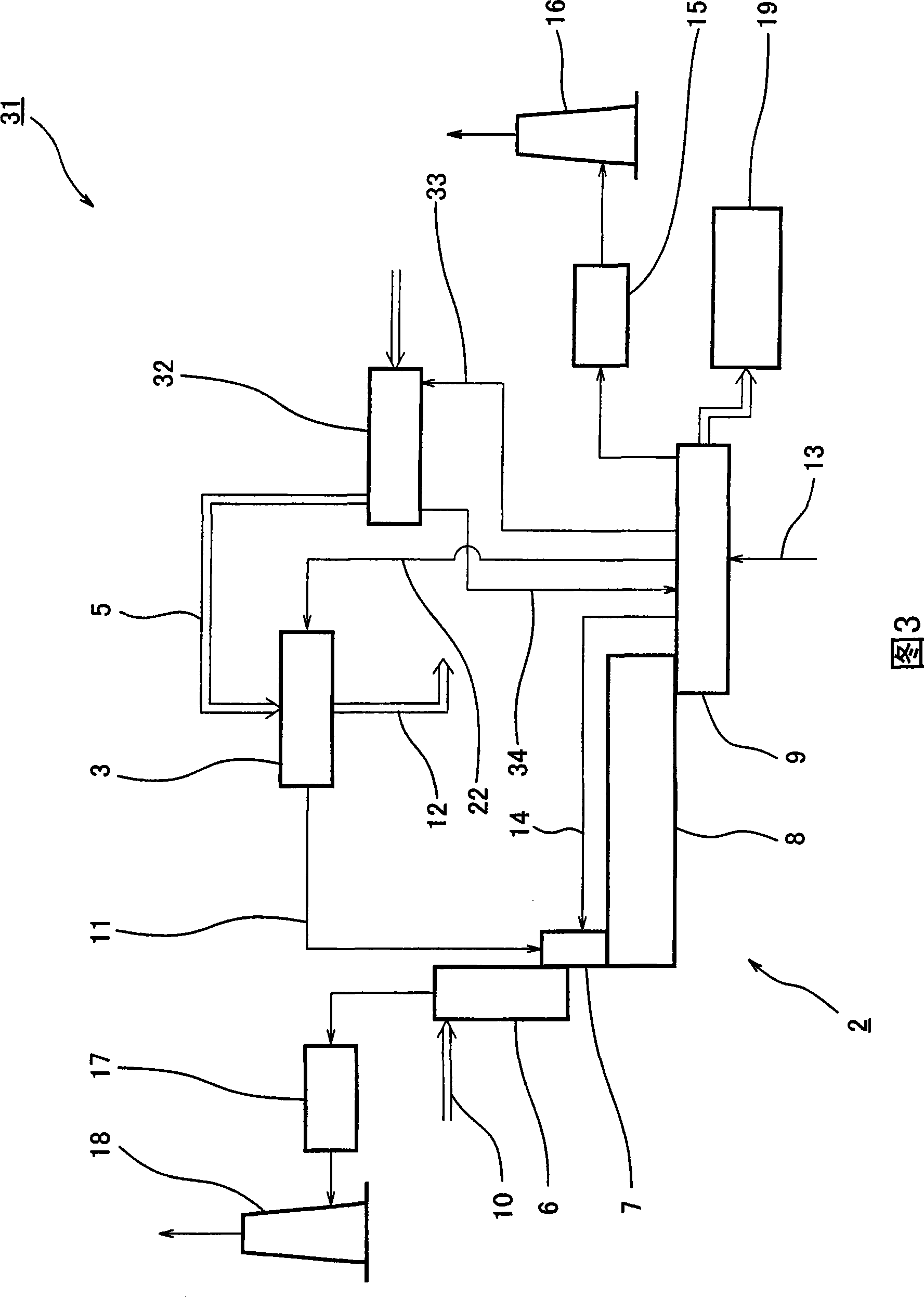

Apparatus and method for processing wastes

InactiveCN101434461AEfficient use ofLow costClinker productionSpecial form destructive distillationWaste processingProcess engineering

The invention provides waste processing equipment which is expected for improving utilization of heat energy and lowering equipment cost by means of a cement manufacturing process. The method for solving the problems is the waste processing equipment of the invention which is provided with a gasifier (3) for heating the waste and enabling the waste to generate thermal decomposition gas, a preheater (6) for preheating cement stone of cement manufacturing complete plant (2), a calcinator (7), a welding furnace (8), and a clinker cooler (9), and a gas delivery passage (11) for delivering particle-shaped carbon and ash and pyrolytic eumatolytic gas generated from the gasifier (3) to at least one of the calcinator (7) and the welding furnace (8).

Owner:KAWASAKI HEAVY IND LTD +3

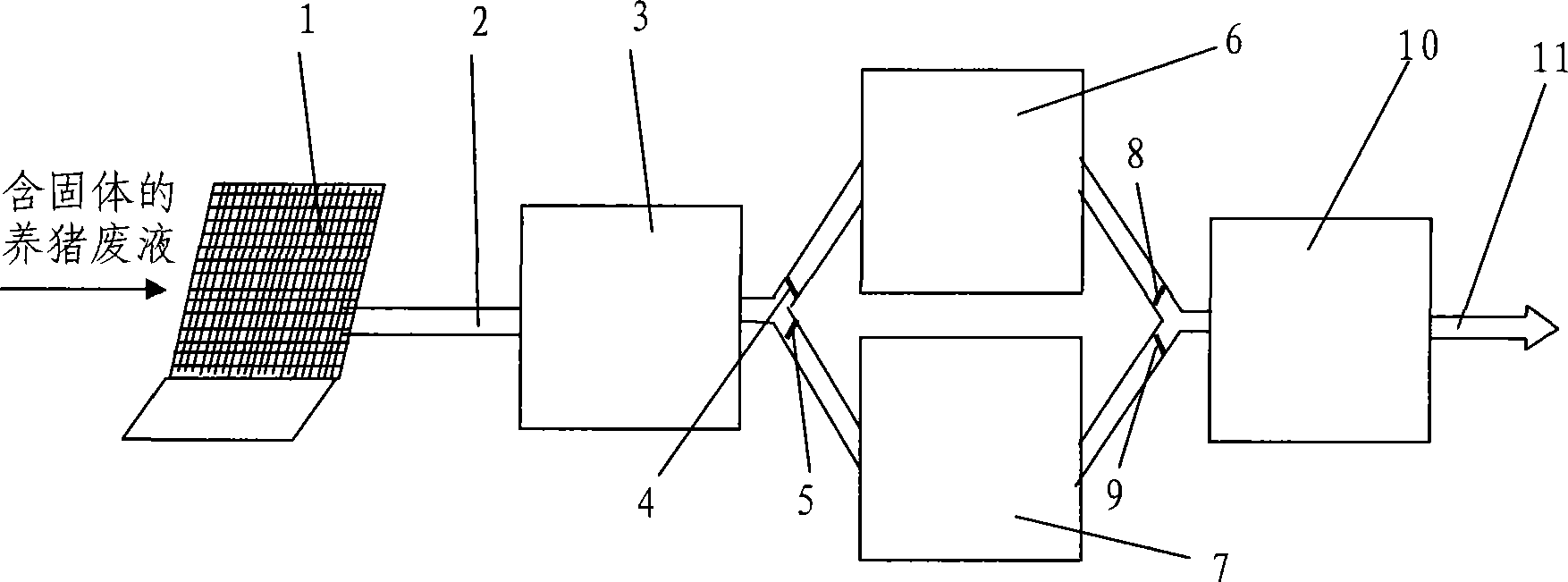

Purification treatment method and apparatus for pig raising waste liquid

InactiveCN101481180ASimple processEasy to implementClimate change adaptationExcrement fertilisersPig farmsWaste processing

The invention relates to waste processing, in particular to a method and a device for purifying waste liquid from pig cultivation, which solves the problem that the waste liquid of pig cultivation pollutes the environment. After solid and liquid waste generated by pig cultivation is separated, absorption, filtration and automatic purification technology is used for enabling the separated waste liquid from pig cultivation to enter into a first absorption pool for first absorption and filtration, then filtrated liquid enters an automatic purification depositing pool for purification depositing processing and then a second absorption pool for second absorption and filtration processing, and lastly, the processed waste water reaches the standard and is discharged. The device for purifying waste liquid from pig cultivation comprises a first absorption and filtration pool, an automatic purification depositing pool and a second absorption and filtration pool which are sequentially communicated, wherein filtration material is arranged in the absorption and filtration pools, and the filtration material is only one or a plurality of layers of furnace slag, crop stems, zeolite and gravel. The invention has simple technology, low cost and easy application, and is suitable for the purification and the standard discharge of the waste liquid from family type pig farms or small pig farms.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

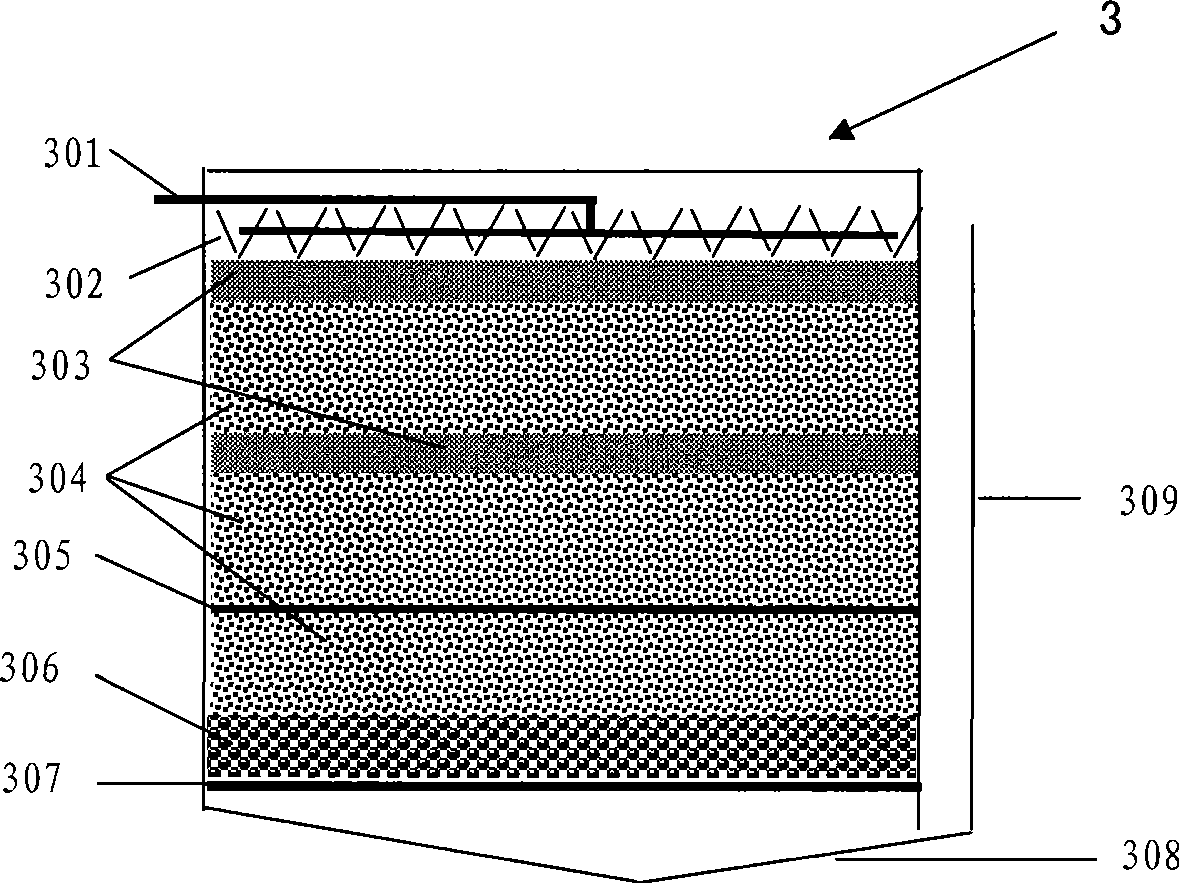

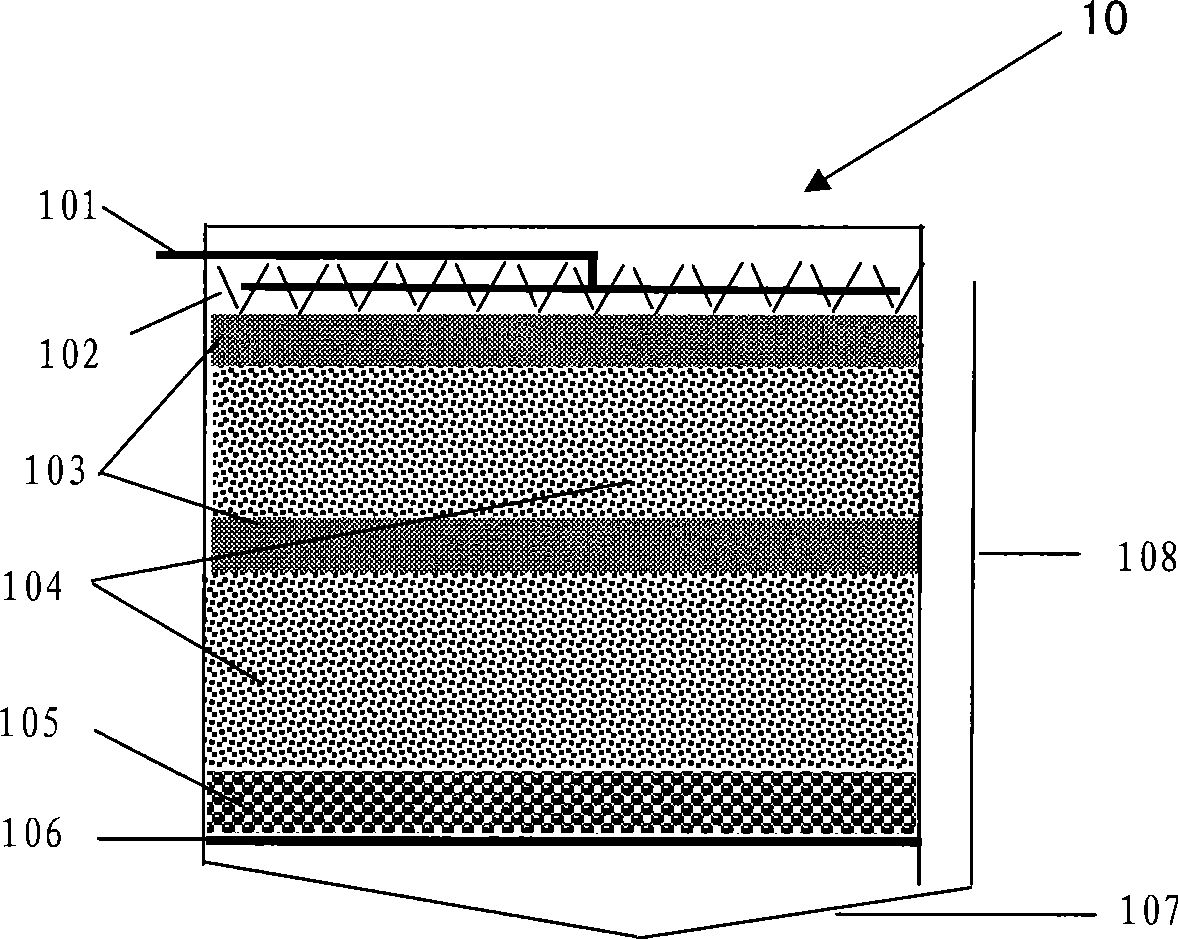

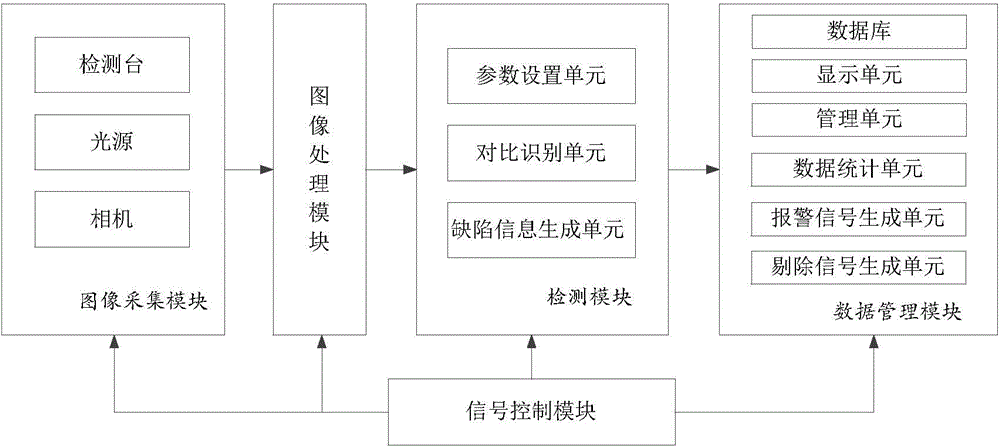

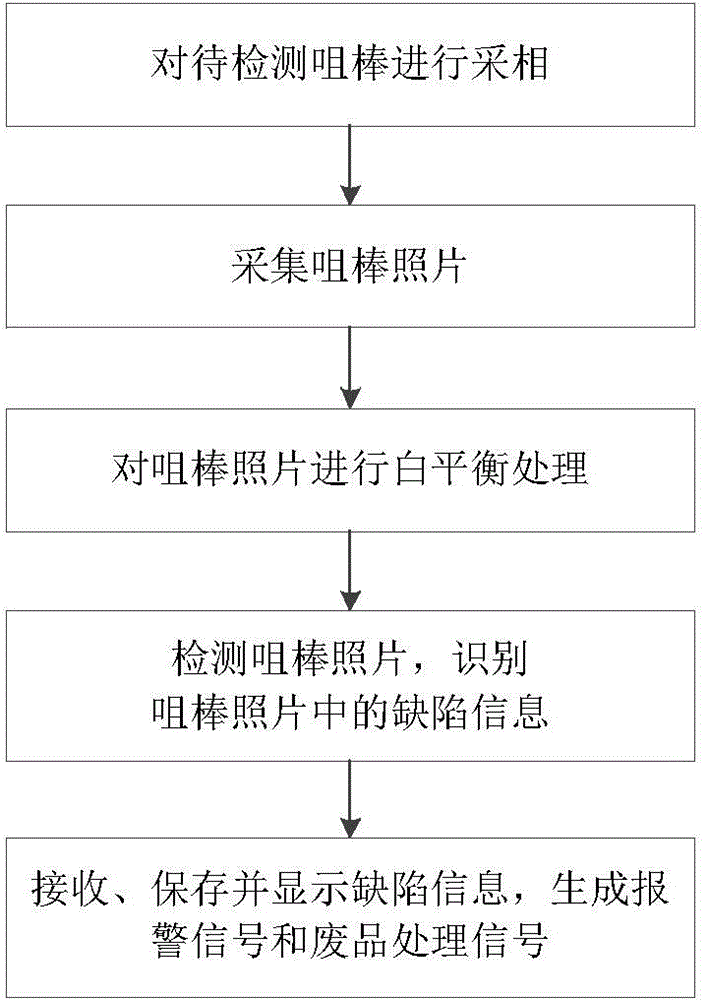

Visual detection system and method for filter

ActiveCN104807829AReliable test resultsTest results are stableOptically investigating flaws/contaminationControl signalVisual perception

The invention relates to a visual detection system and method for a filter. The visual detection system comprises an image acquisition module, an image processing module, a detection module, a data management module and a signal control module, wherein the image acquisition module is used for photo sampling of a filter to be detected; the image processing module is used for performing white balance treatment on the filter photos; the detection module is used for selecting a qualified filter photo as a standard sample and comparing the standard sample with other filter photos to identify product defect types; the data management module is used for receiving, storing and displaying defect information, and meanwhile, generating a warning signal and a waste processing signal; the signal control module is used for input and output control of signals, signal filtering and denoising and / or abnormal signal interference screening. As a machine is adopted for detection, not only is the labor intensity of workers reduced, but also the detection speed and the detection precision are high, the detected products are reliable in quality, and quality management of cigarette material plants is greatly assisted.

Owner:WUHAN EASY VIEW SCI & TECH CO LTD +1

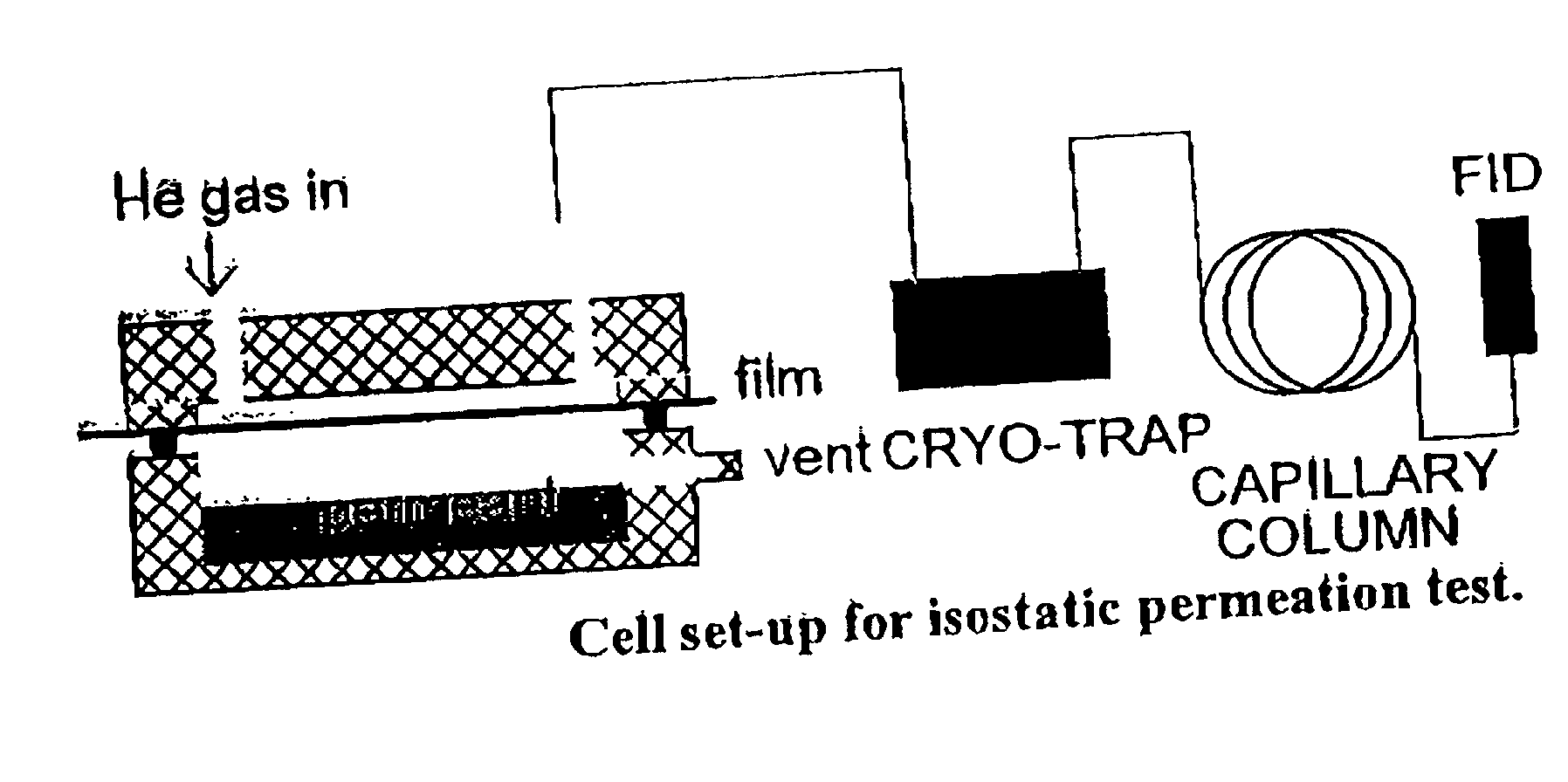

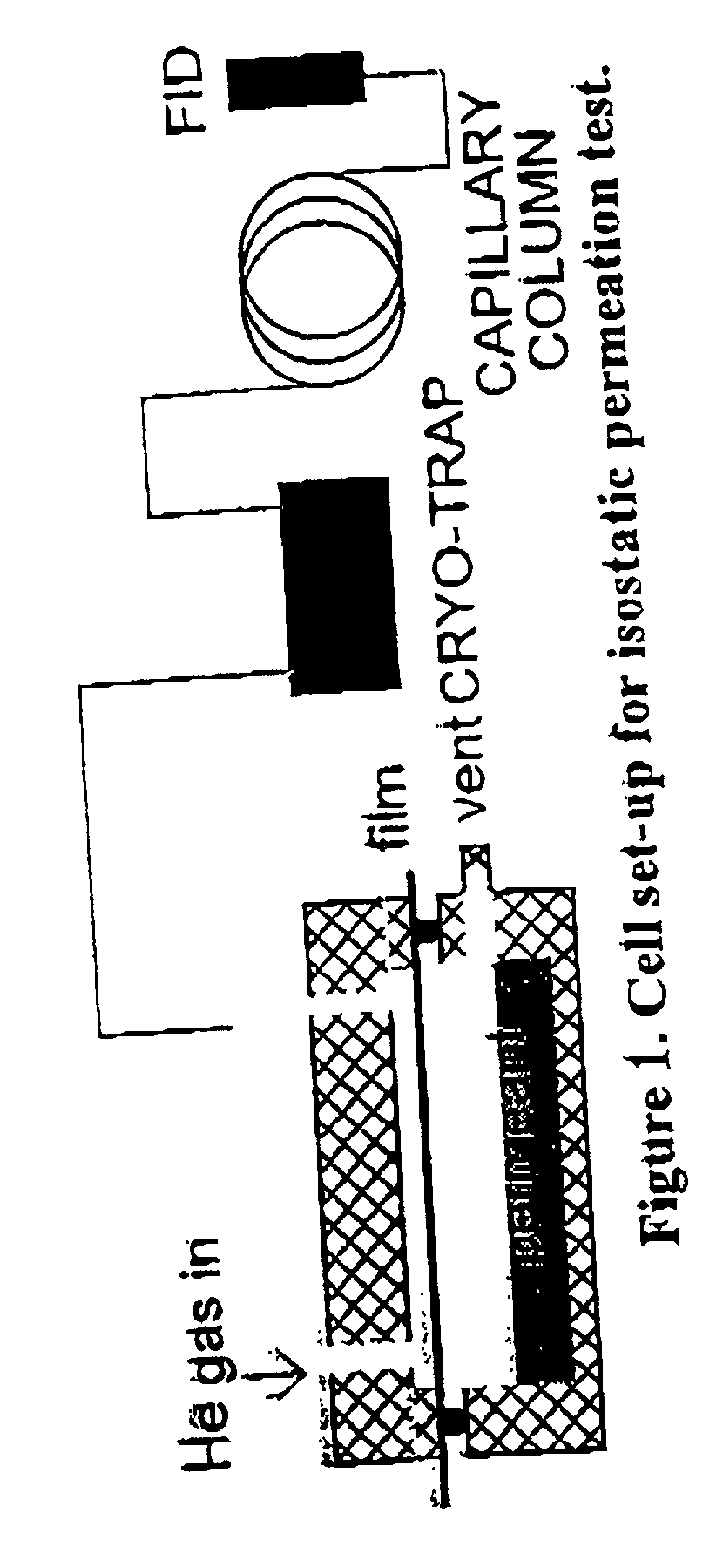

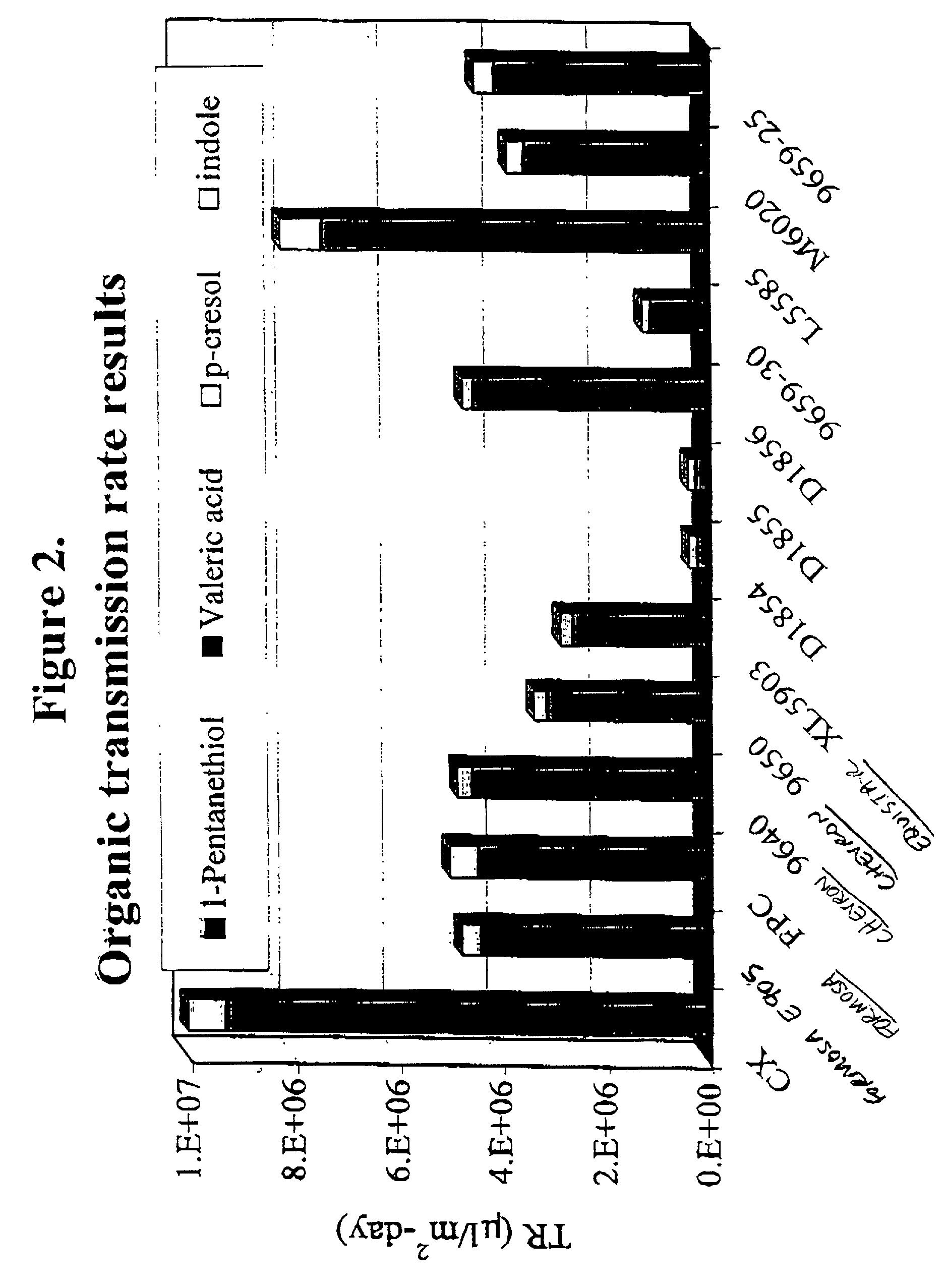

Odor control cassette

InactiveUS20030131569A1Reduce odorInexpensive and easy to manufactureRefuse receptaclesContainer/bottle contructionHigh-density polyethyleneEngineering

A film is provided for use in a cassette. Preferably, the cassette is used in a waste disposal system. The film is a high density polyethylene film resin having both a low melt index and a high density, thereby providing improved odor control capabilities and enhanced tear strength and assembly strength.

Owner:PLAYTEX PROD INC

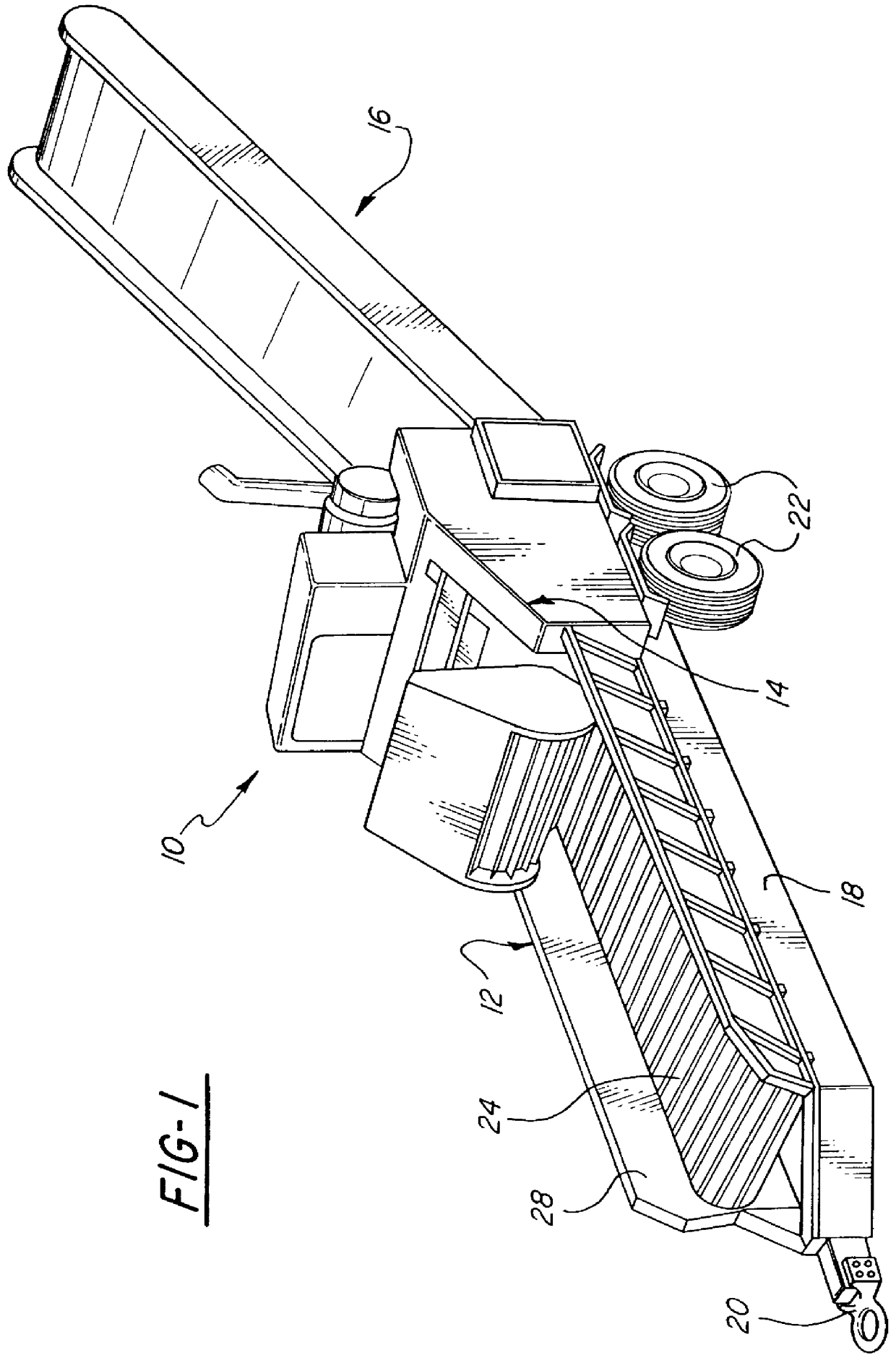

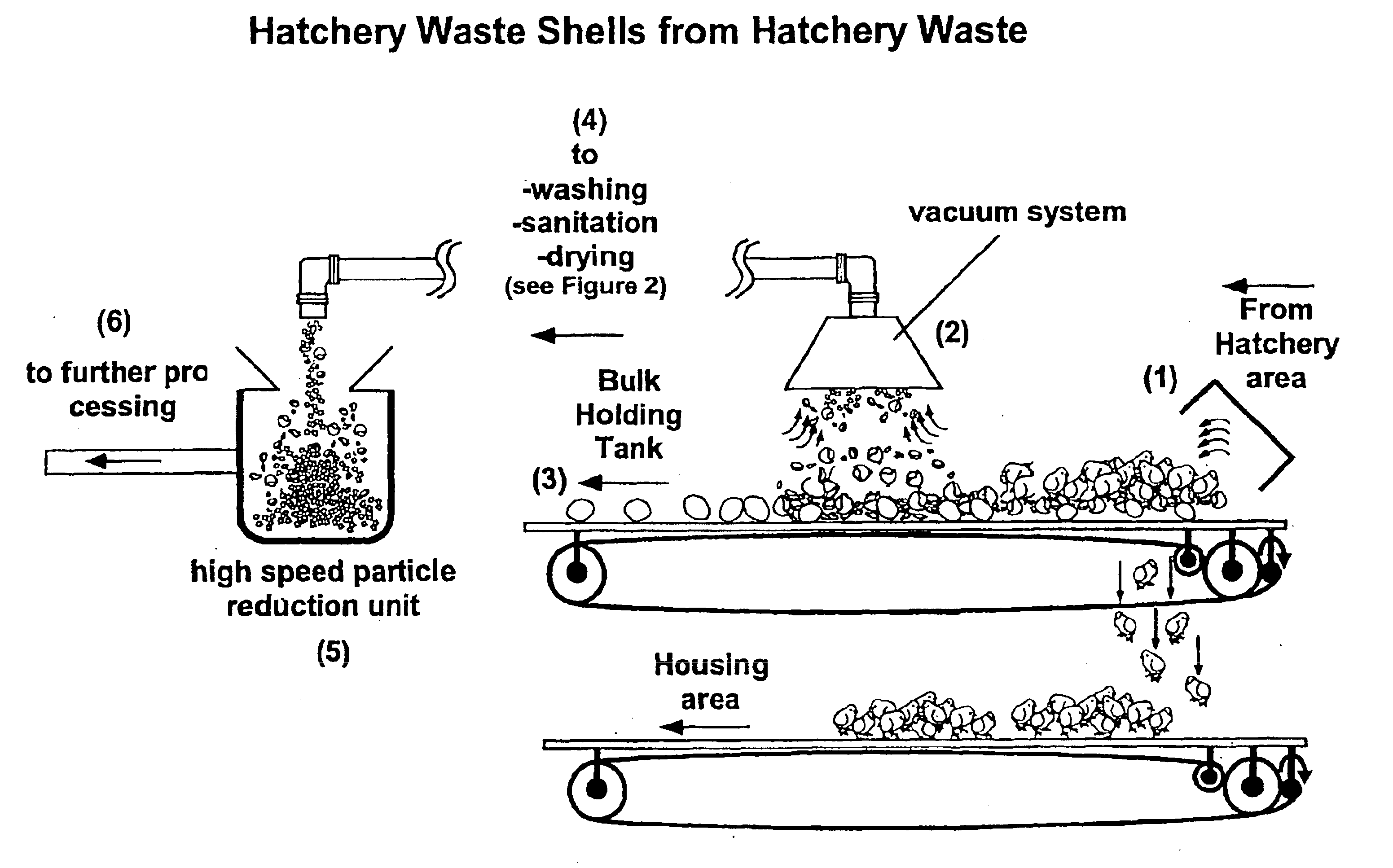

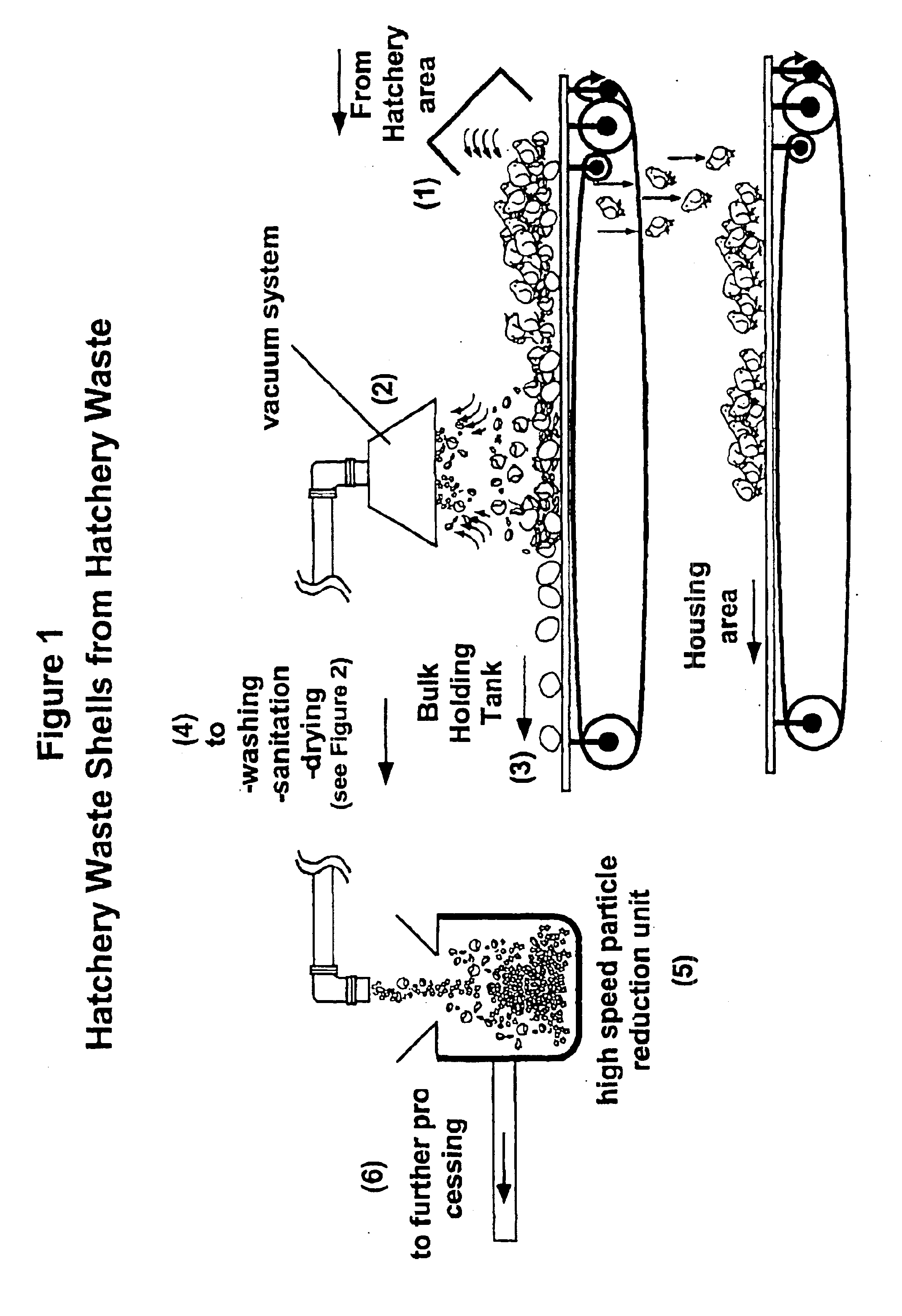

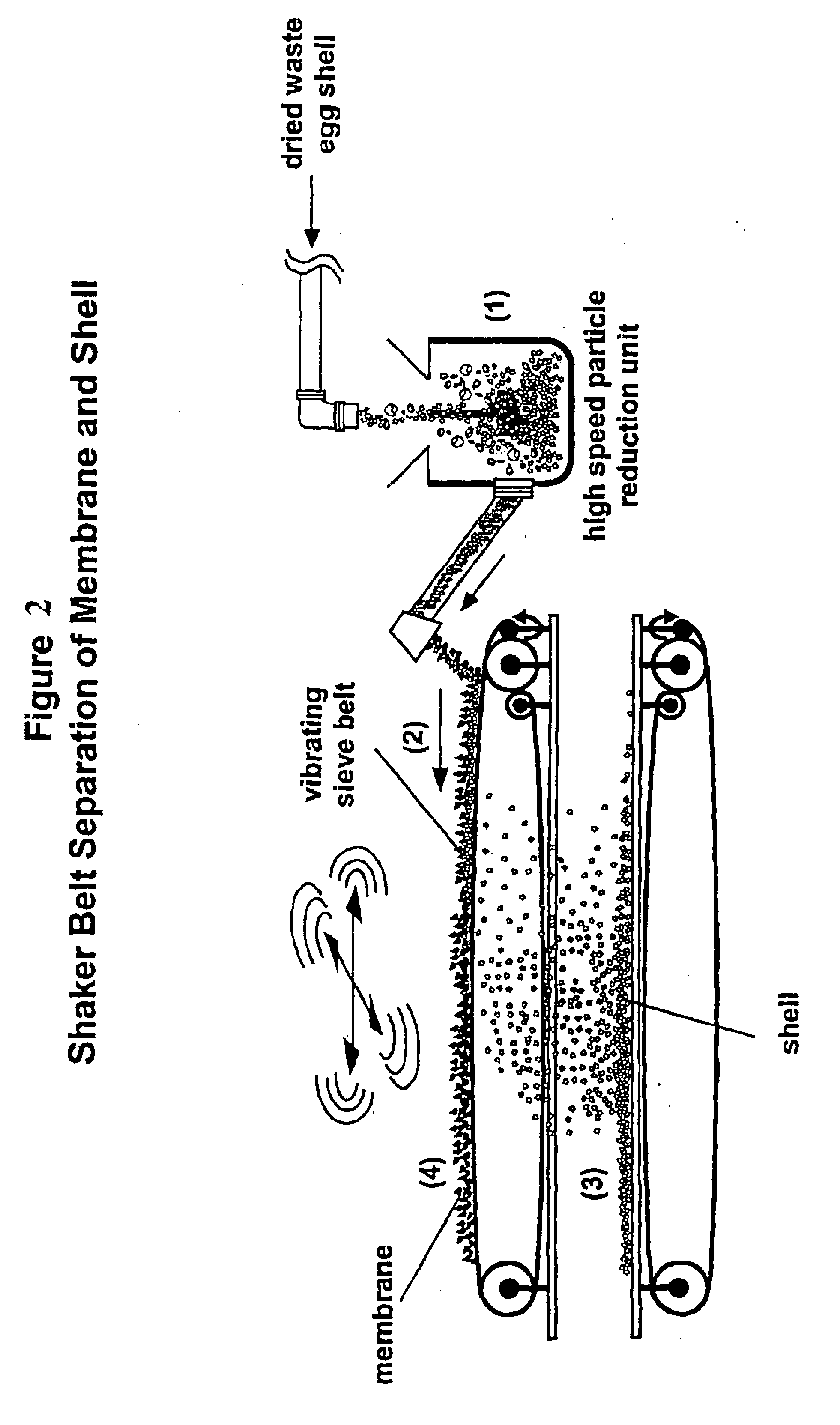

Hatchery eggshell waste processing method and device

InactiveUS6899294B2Reduce environmental impactEconomic benefitVitamin food ingredientsPeptide/protein ingredientsWaste processingEggshell

A method and apparatus for separating the organic membrane portion of waste egg shells from the hard inorganic mineral portion thereof, so that each can be used or further processed as desired, thereby addressing the environmental and economic issues associated with disposing of waste egg shells. The membrane and shell are separated by first processing waste eggshells so as to yield small waste eggshell particles. During this processing, the waste eggshell particles are at least slightly abraded, whereby the linking structure between the membrane and shell is at least partially disrupted. Thereafter, the waste eggshell particles are conveyed to a device, which isolates the two components based on their size and weight differences. The methods listed above can provide products from the eggshell waste including precipitated calcium carbonate, membrane, protein, amino acids, collagen and other important components.

Owner:PENN STATE RES FOUND

Asphalt production from solvent deasphalting bottoms

ActiveUS20090301931A1Minimizing conventional waste handling demandEliminate wasteWorking-up pitch/asphalt/bitumen by selective extractionWorking-up tarEffective solutionDesorption

A cost-effective solution is provided for eliminating refinery process waste, including spent catalytic and non-catalytic adsorbent materials, as well as adsorbate process reject materials derived from desorption, while minimizing conventional waste handling demands. An asphalt composition includes asphalt and spent adsorbent material from a solvent deasphalting unit. The asphalt can comprise asphaltic material obtained from a solvent deasphalting unit, and spent adsorbent material in the asphalt composition was previously utilized in the solvent deasphalting unit. The asphalt composition can also include process reject materials.

Owner:SAUDI ARABIAN OIL CO

Multi-functional tool assembly for processing tool of material processing machine

InactiveUS7726594B2Reduce materialReduce shear forceGas current separationCocoaWaste processingReduction drive

Owner:SMORACY

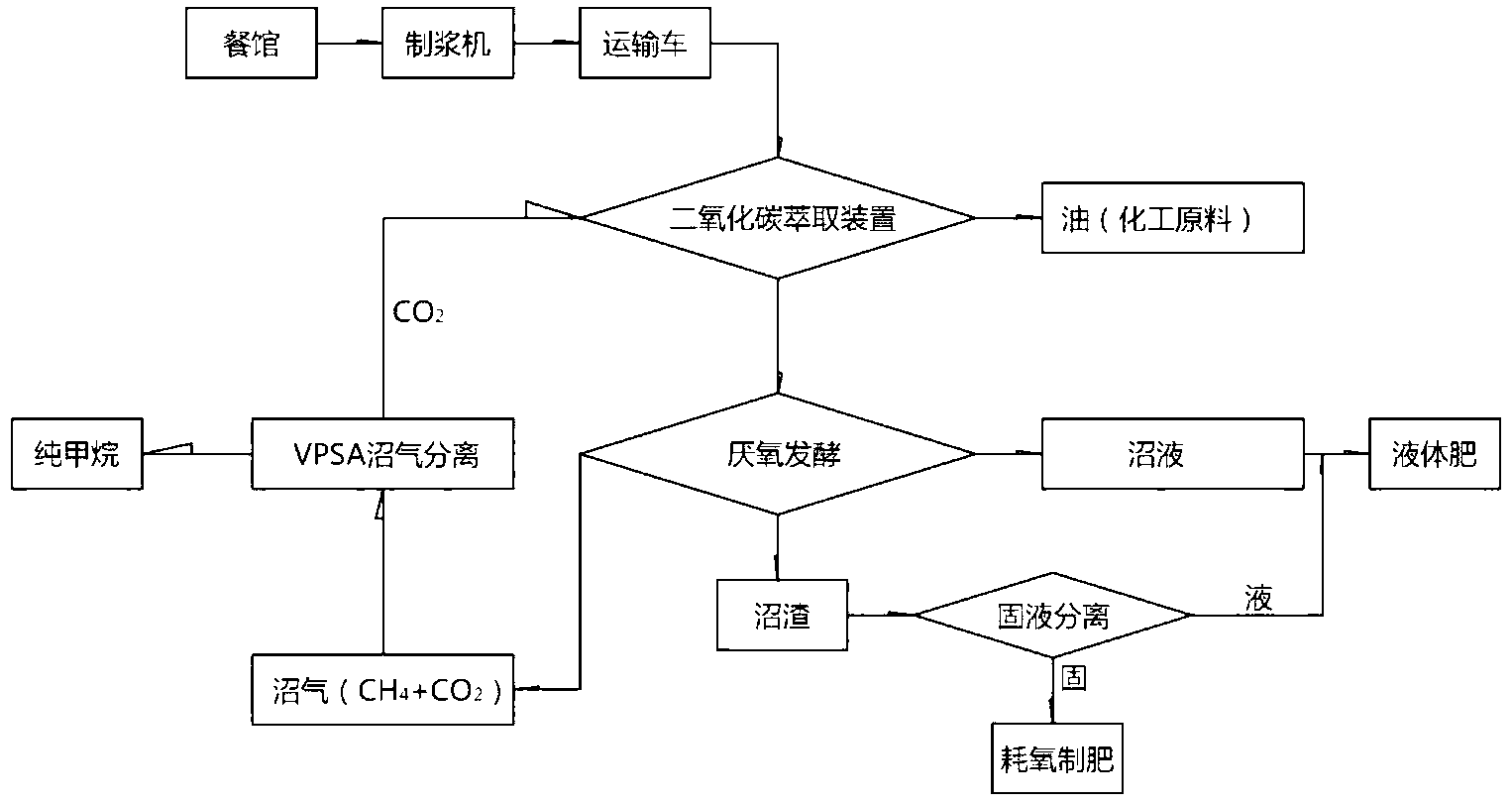

Kitchen waste processing method

ActiveCN103056145AIncrease productivityAvoid secondary pollutionWaste processingSolid waste disposalOil and greaseWaste processing

The invention relates to the field of kitchen waste processing, in particular to a kitchen waste processing method which comprises the following steps that: 1) materials easy to smash in kitchen waste is separated through a pulping machine in a restaurant, and waste grout is prepared; 2) the waste grout is inputted into a feeding tank through a pumping tank truck to be fermented; 3) the fermented waste grout is extracted to obtain oil through a CO2 supercritical method in an extraction tank, and non oil materials enter into a fermentation system to carry out anaerobic fermentation to obtain biogas; and 4) methane and CO2 are obtained through separation and purification from the biogas through a gas separation device. According to the kitchen waste processing method, the yield of the oil and the gases is high, intermediate products produced in the processing process can be recycled, biogas residues obtained through the separation can be used for making fertilizers, obtained products of the kitchen waste processing is prevented from causing secondary environment pollution, and environment protection is benefited.

Owner:北京时代桃源环境科技股份有限公司

Waste treatment autoclave to provide for steam - assisted drying

InactiveUS20100135851A1Efficient regenerationWaste processingTransportation and packagingSteam pressureSteam condensation

An autoclave system provides a means of sterilizing municipal solid waste, hydrolyzing many of its components, and preparing the material for post-autoclave automated separations. The present apparatus provides a means of drying the solid waste in the vessel, while conserving the energy used to dry the vessel. Non-contact steam is recovered through separations of steam and water, with condensate steam pressure regenerated by mechanical vapor recompression and condensate water returned to the boiler / steam generator. Heat transfer to combustion air, by heat transfer via heat pump to generate additional steam, and / or by mechanical vapor recompression recovers the latent heat of loose contact steam condensate. The process design provides for in-vessel drying while reducing the energy cost of operating a waste autoclave, as compared to the current art.

Owner:ESTECH

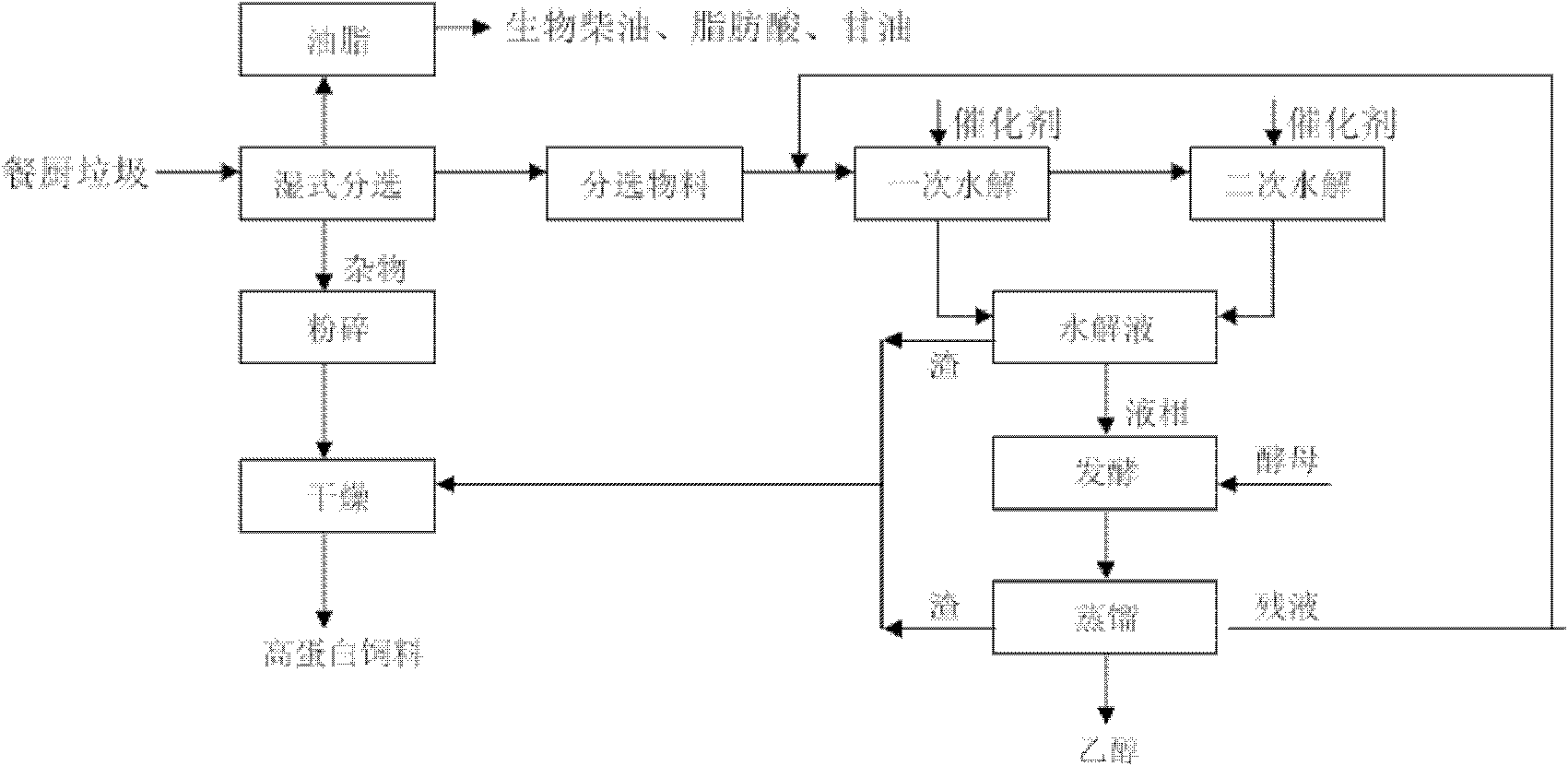

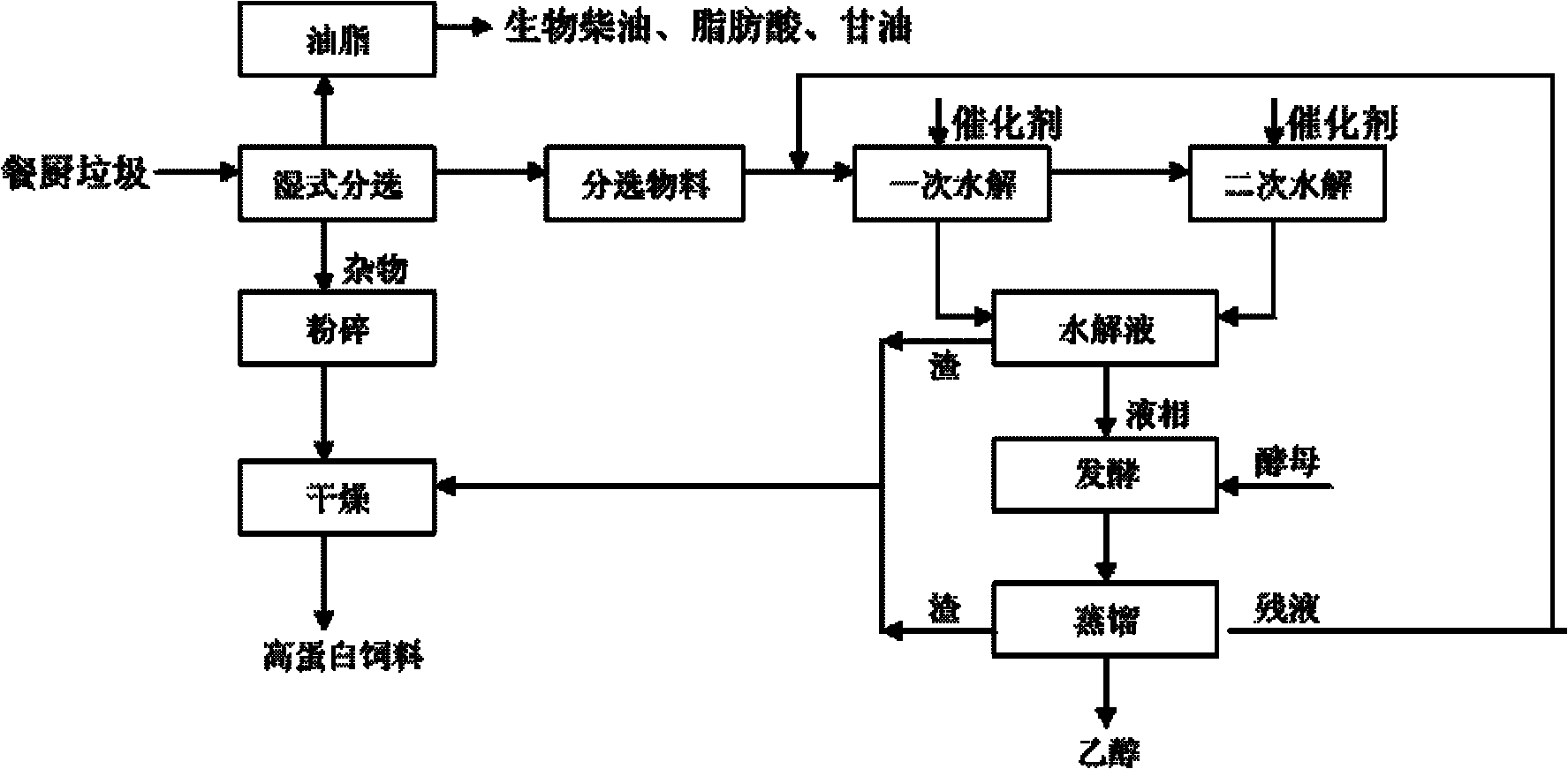

Recycling method for cleaning and processing kitchen waste

InactiveCN101890423AIncrease the degree of hydrolysisCompletely hydrolyzedFatty oils/acids recovery from wasteSolid waste disposalOil and greaseOperational costs

The invention relates to a waste processing method, in particular to relate to a recycling method for cleaning and processing kitchen waste and comprising the following steps: sorting, separating and recovering grease, performing secondary hydrolysis on materials after grease separation and recovery, further fermenting hydrolysis liquid and preparing solid residue obtained by sorting, hydrolysis and fermentation into feed. The invention has the following beneficial effects: economic and reasonable technologies suitable for industrialized application are adopted, thus greatly lowering processing cost; regenerative recycled products can be prepared with wide application and high additional value; and the production process is clean and environment-friendly, closed cycle of materials can be realized, secondary pollutants are prevented, and the recycled products have wide application, low operation cost and high economic benefit.

Owner:武汉市金书环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com