Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

24604results about "Optically investigating flaws/contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

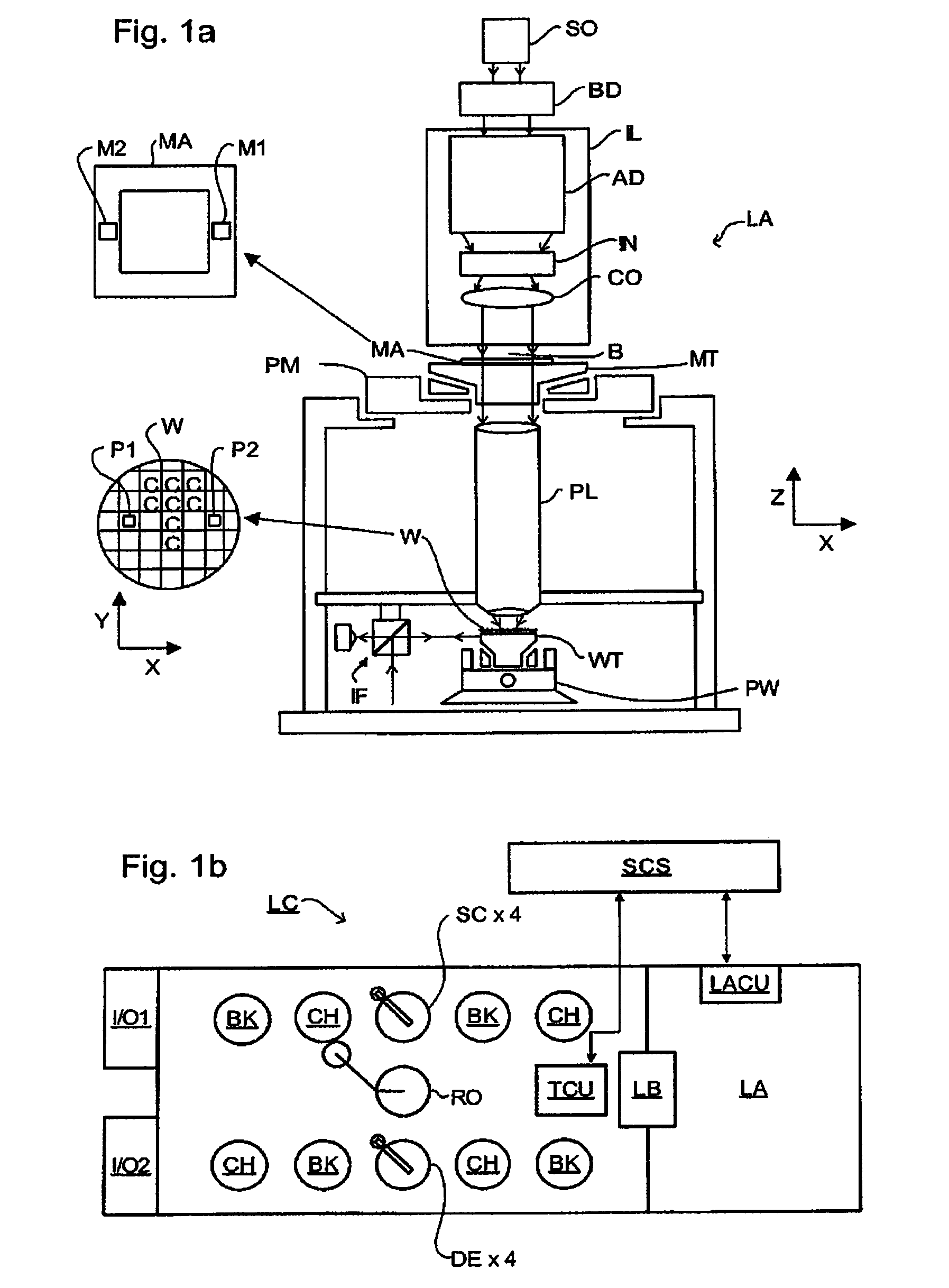

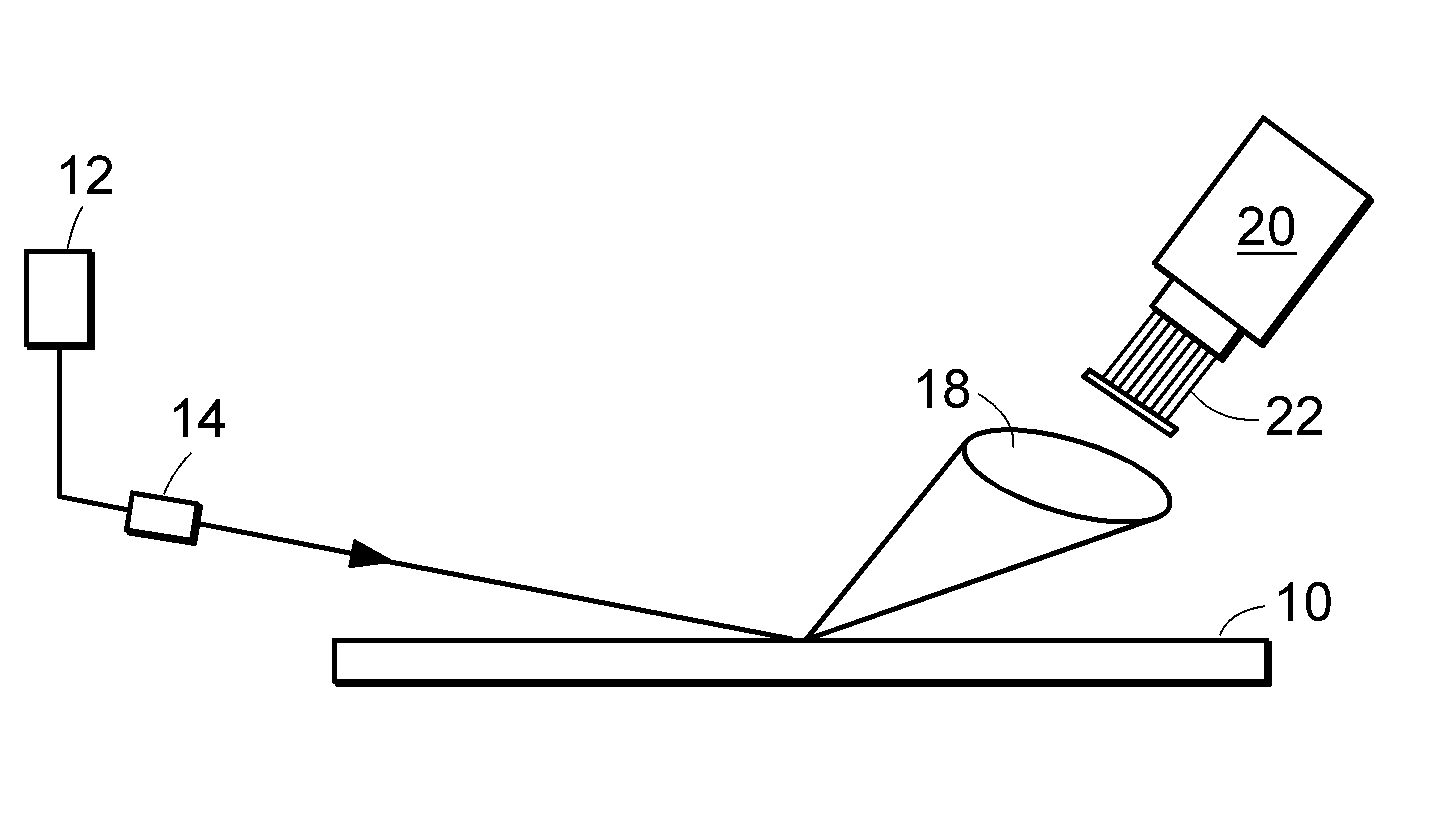

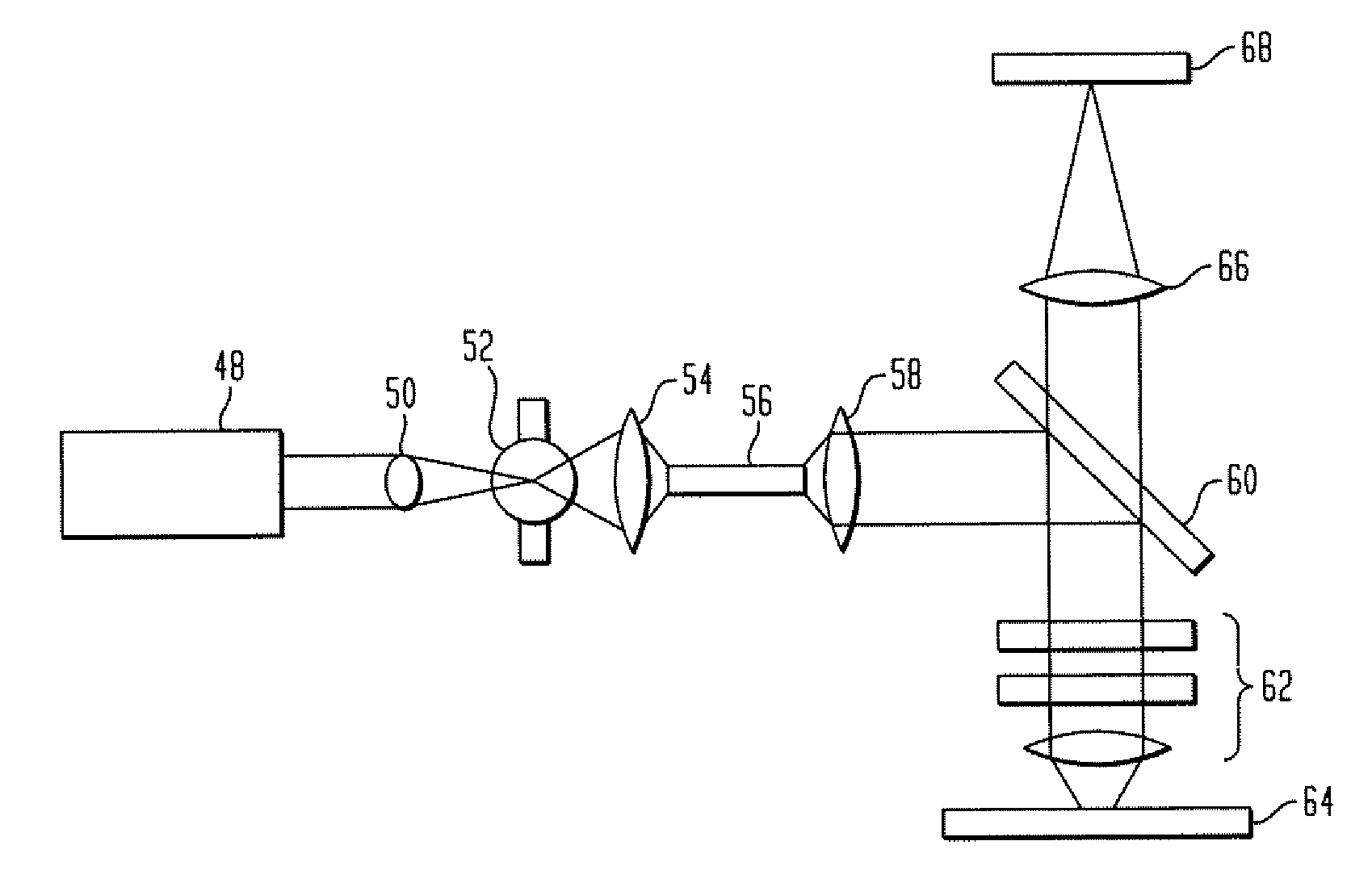

Methods and Scatterometers, Lithographic Systems, and Lithographic Processing Cells

ActiveUS20110027704A1Scattering properties measurementsSemiconductor/solid-state device manufacturingScatterometerEngineering

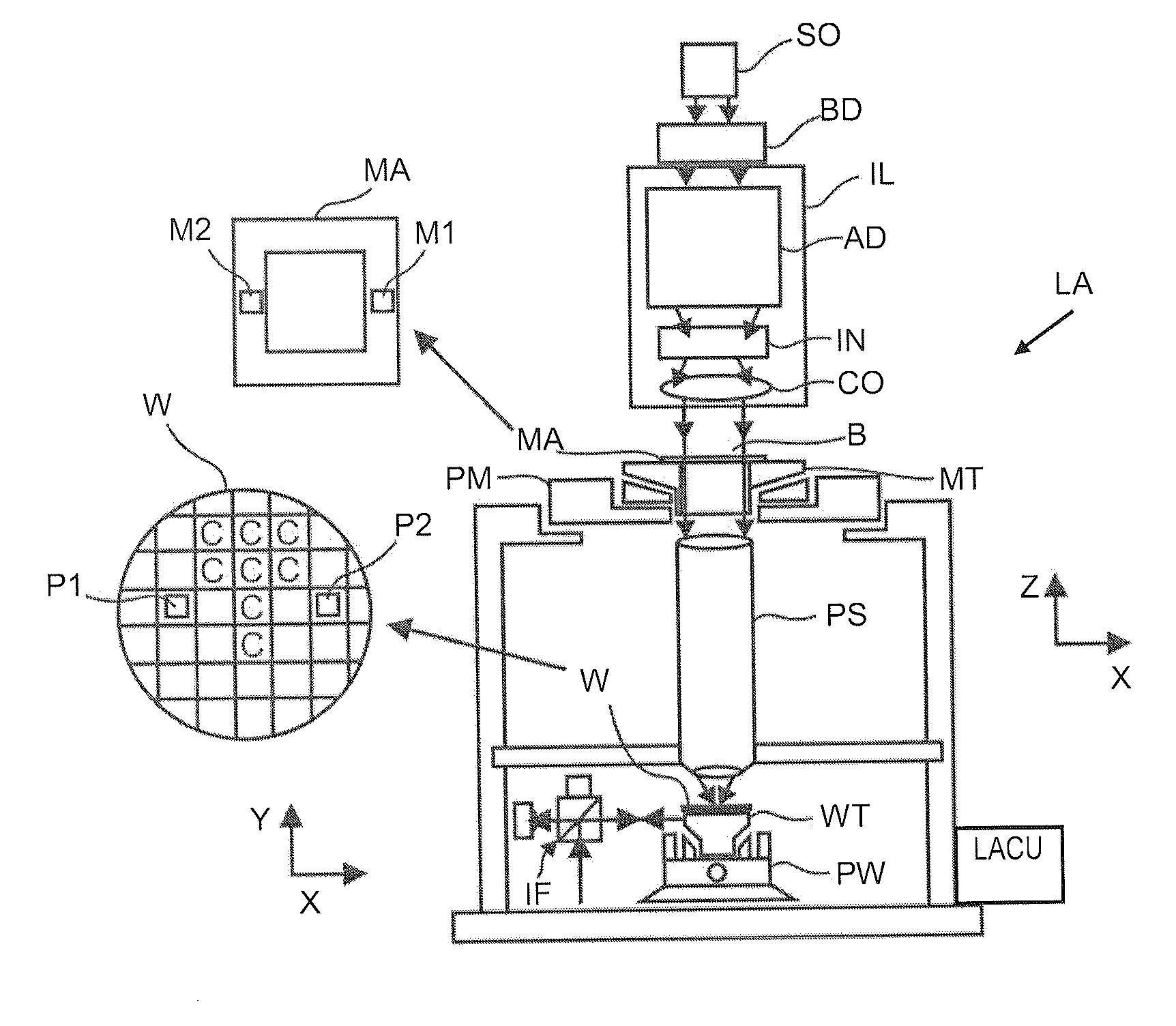

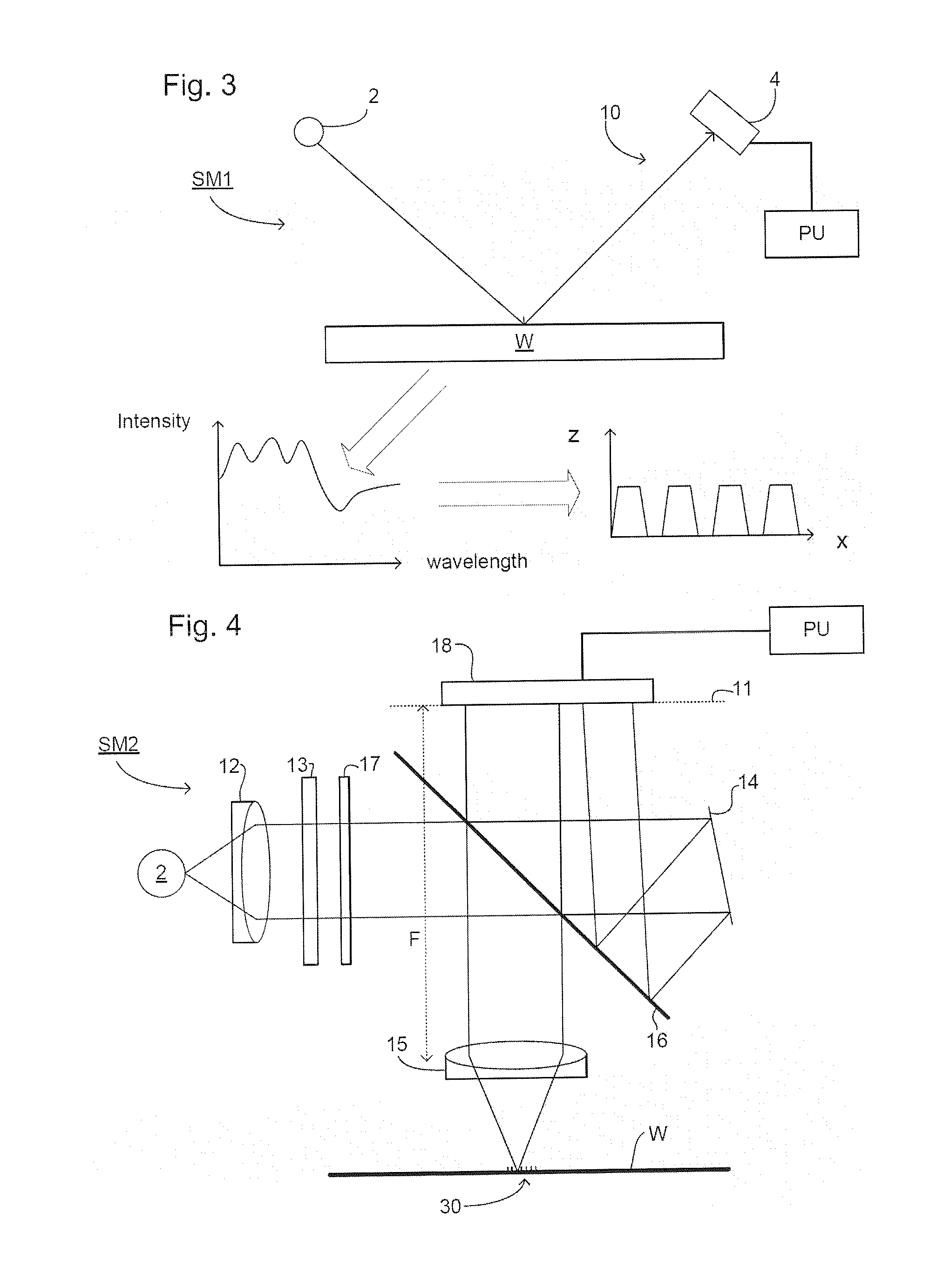

In a method of determining the focus of a lithographic apparatus used in a lithographic process on a substrate, the lithographic process is used to form a structure on the substrate, the structure having at least one feature which has an asymmetry in the printed profile which varies as a function of the focus of the lithographic apparatus on the substrate. A first image of the periodic structure is formed and detected while illuminating the structure with a first beam of radiation. The first image is formed using a first part of non-zero order diffracted radiation. A second image of the periodic structure is foamed and detected while illuminating the structure with a second beam of radiation. The second image is formed using a second part of the non-zero order diffracted radiation which is symmetrically opposite to the first part in a diffraction spectrum. The ratio of the intensities of the measured first and second portions of the spectra is determined and used to determine the asymmetry in the profile of the periodic structure and / or to provide an indication of the focus on the substrate. In the same instrument, an intensity variation across the detected portion is determined as a measure of process-induced variation across the structure. A region of the structure with unwanted process variation can be identified and excluded from a measurement of the structure.

Owner:ASML NETHERLANDS BV

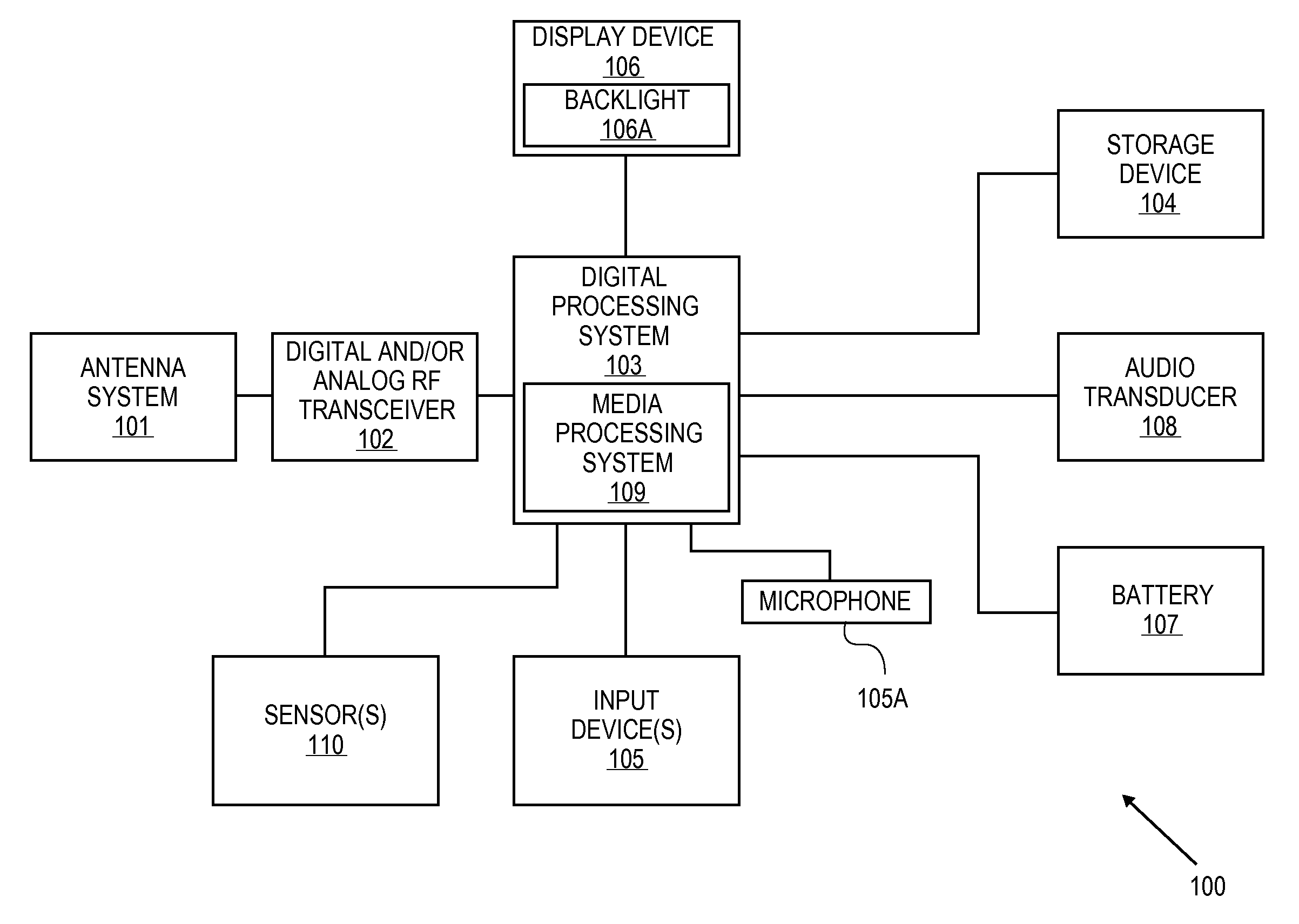

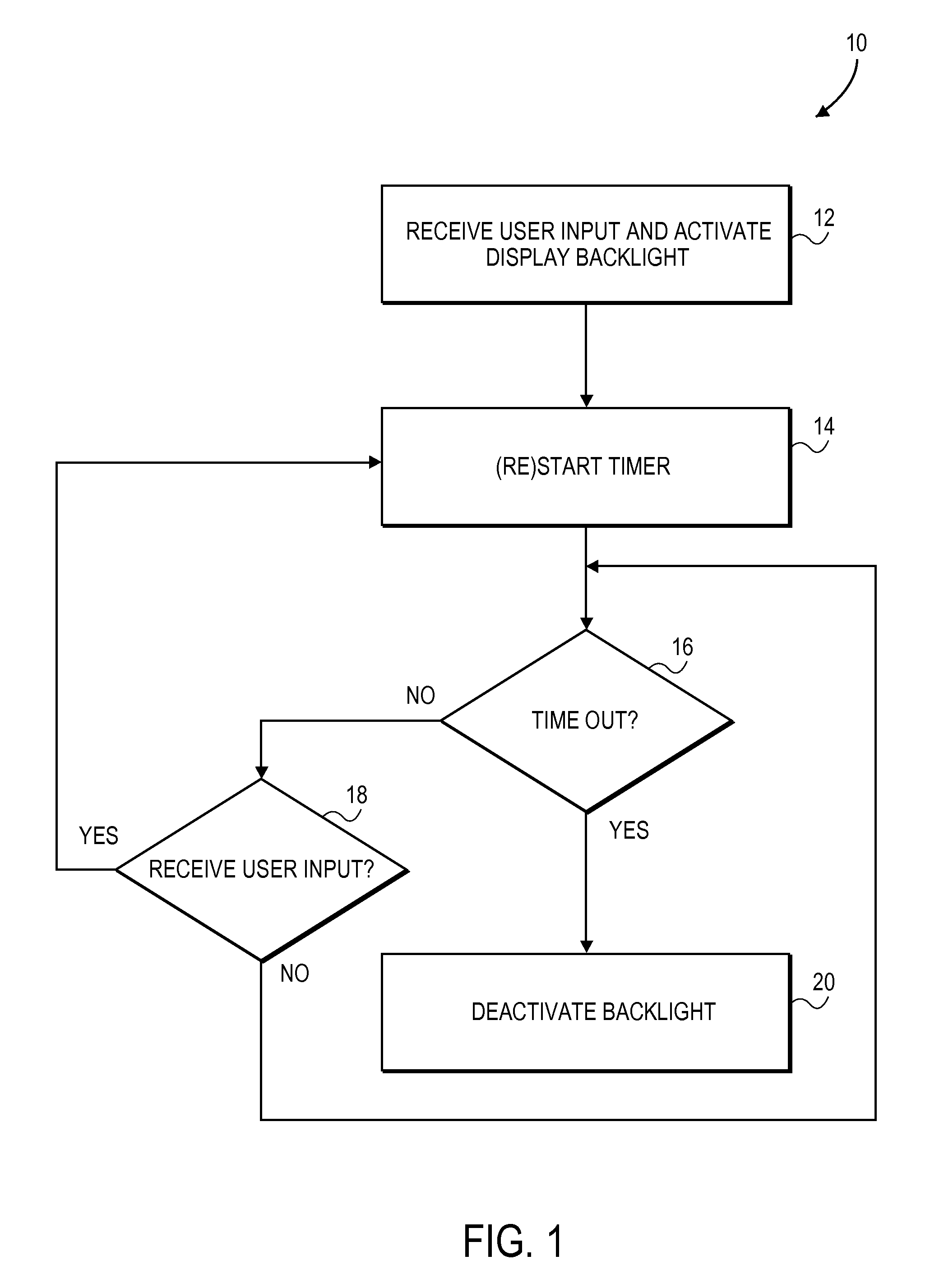

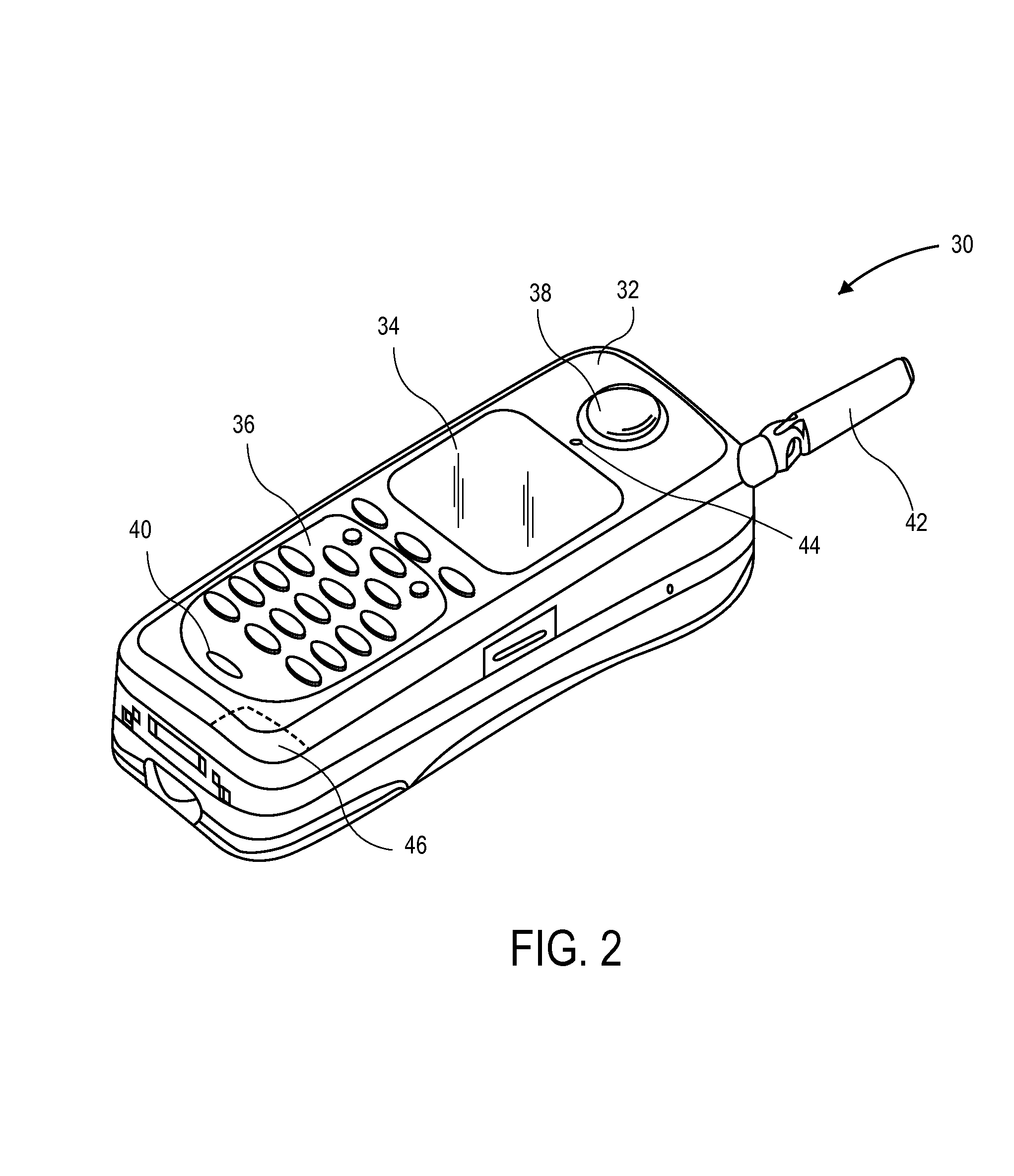

Automated response to and sensing of user activity in portable devices

ActiveUS7633076B2Input/output for user-computer interactionGain controlComputer scienceEquipment state

Owner:APPLE INC

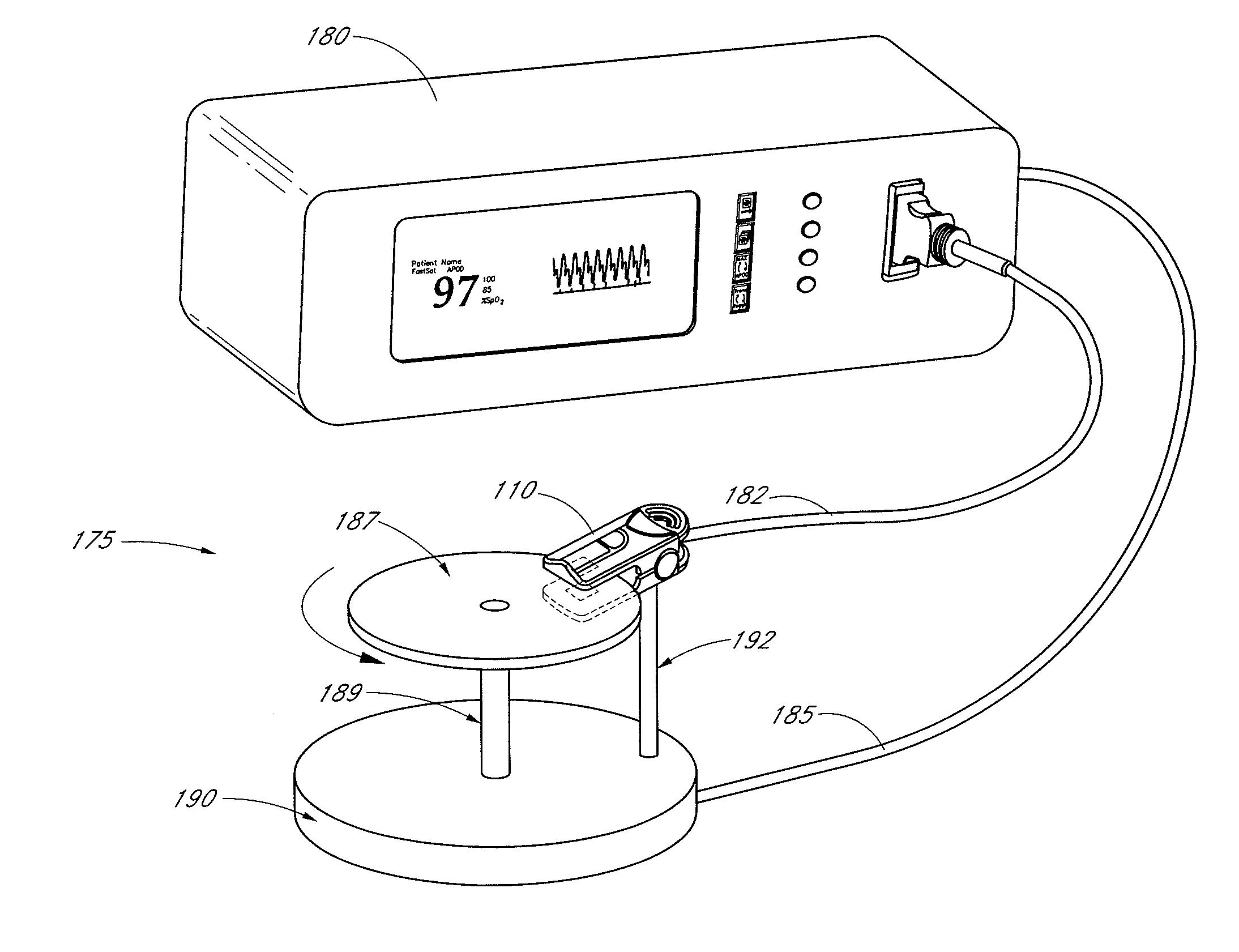

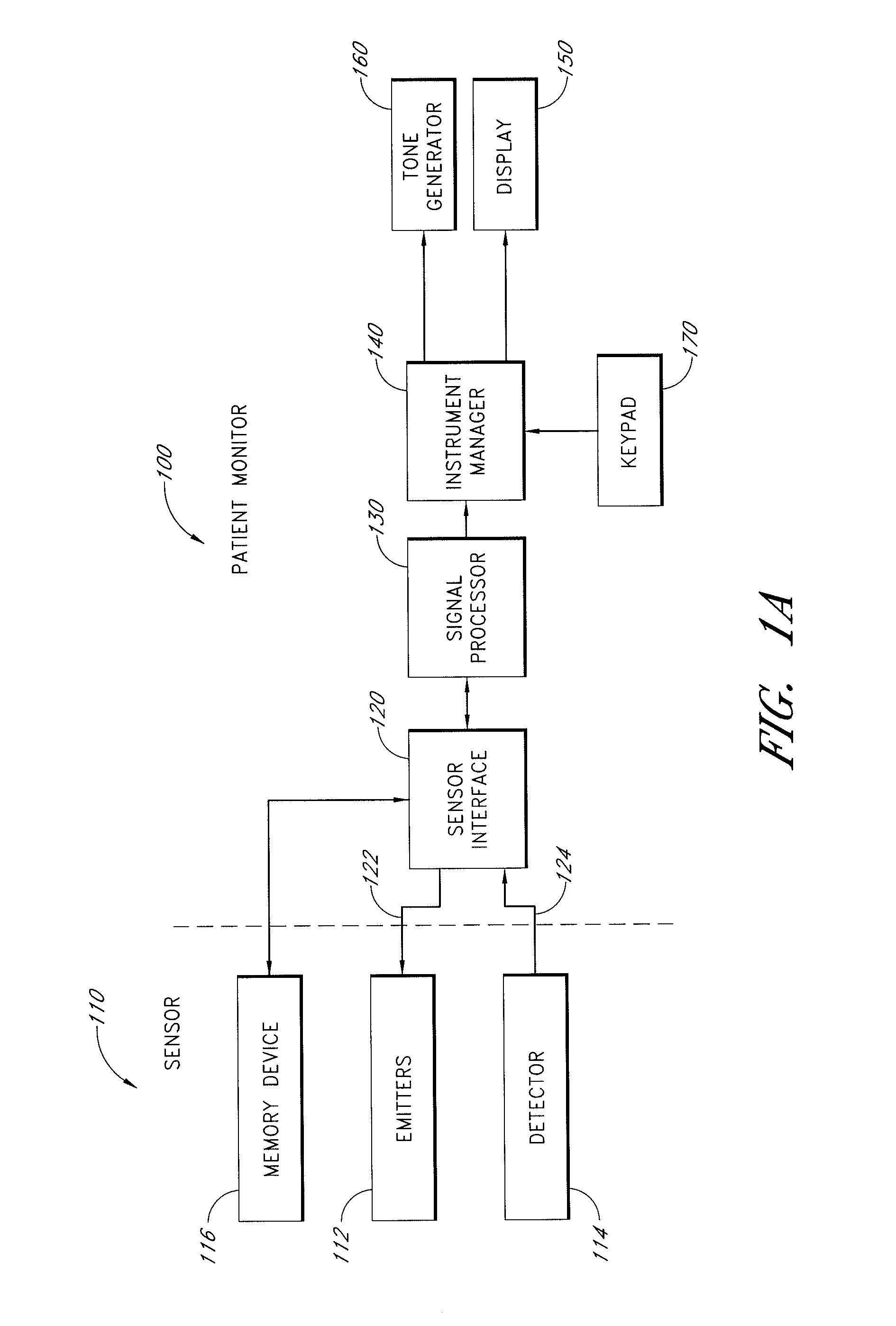

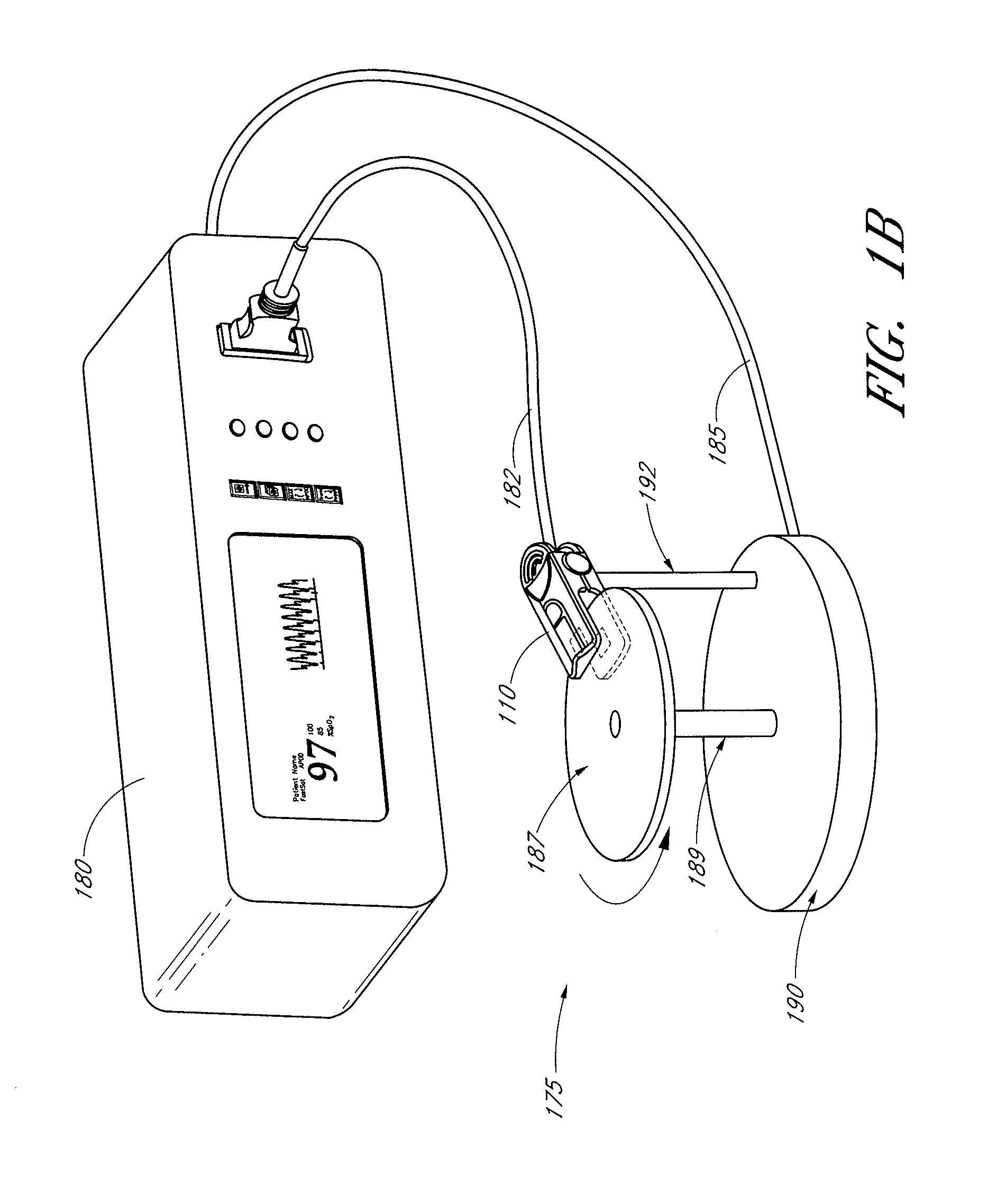

Non-invasive sensor calibration device

ActiveUS8418524B2Reliable timeMaterial analysis by electric/magnetic meansOptically investigating flaws/contaminationNon invasiveAcoustics

Owner:JPMORGAN CHASE BANK NA

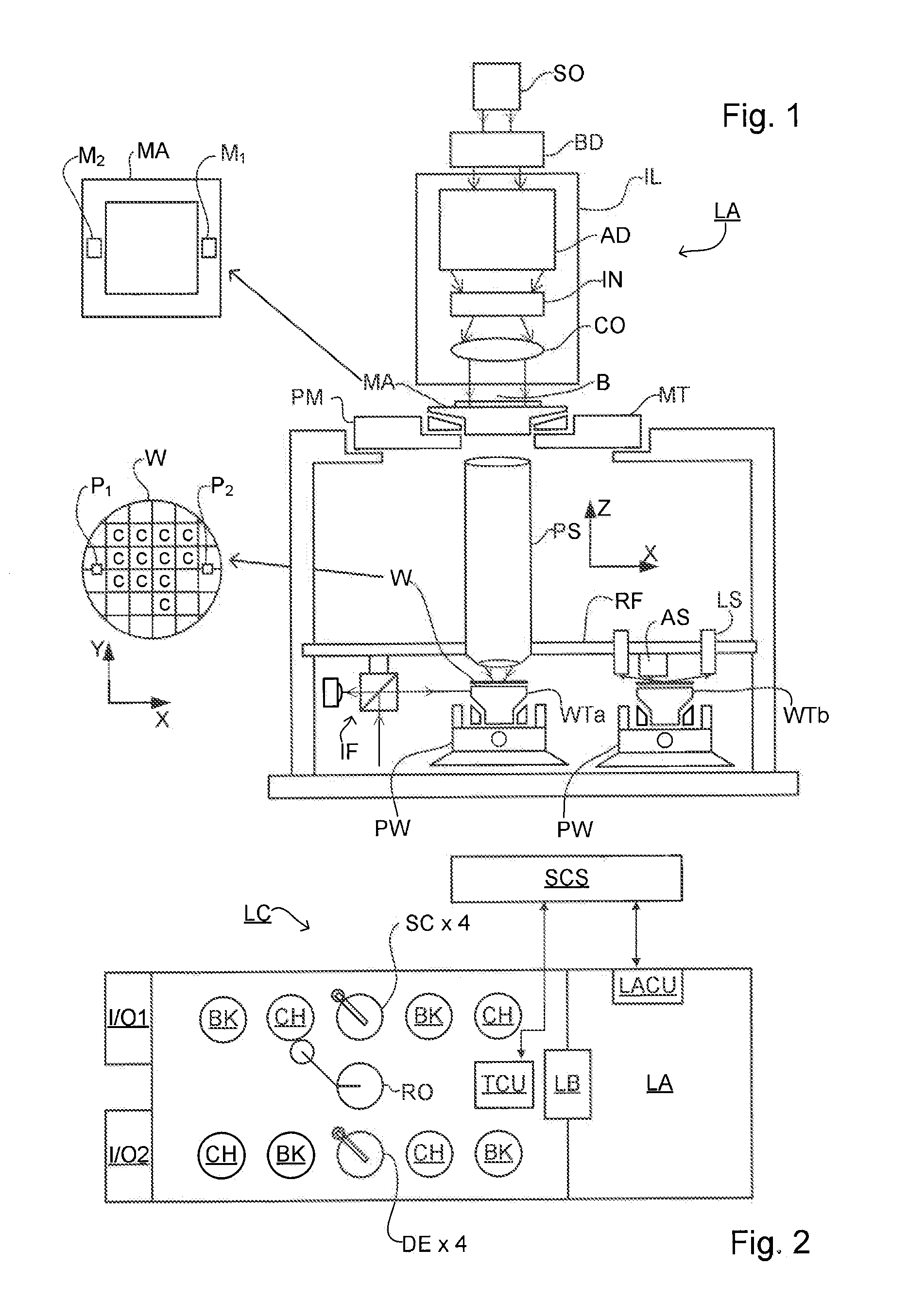

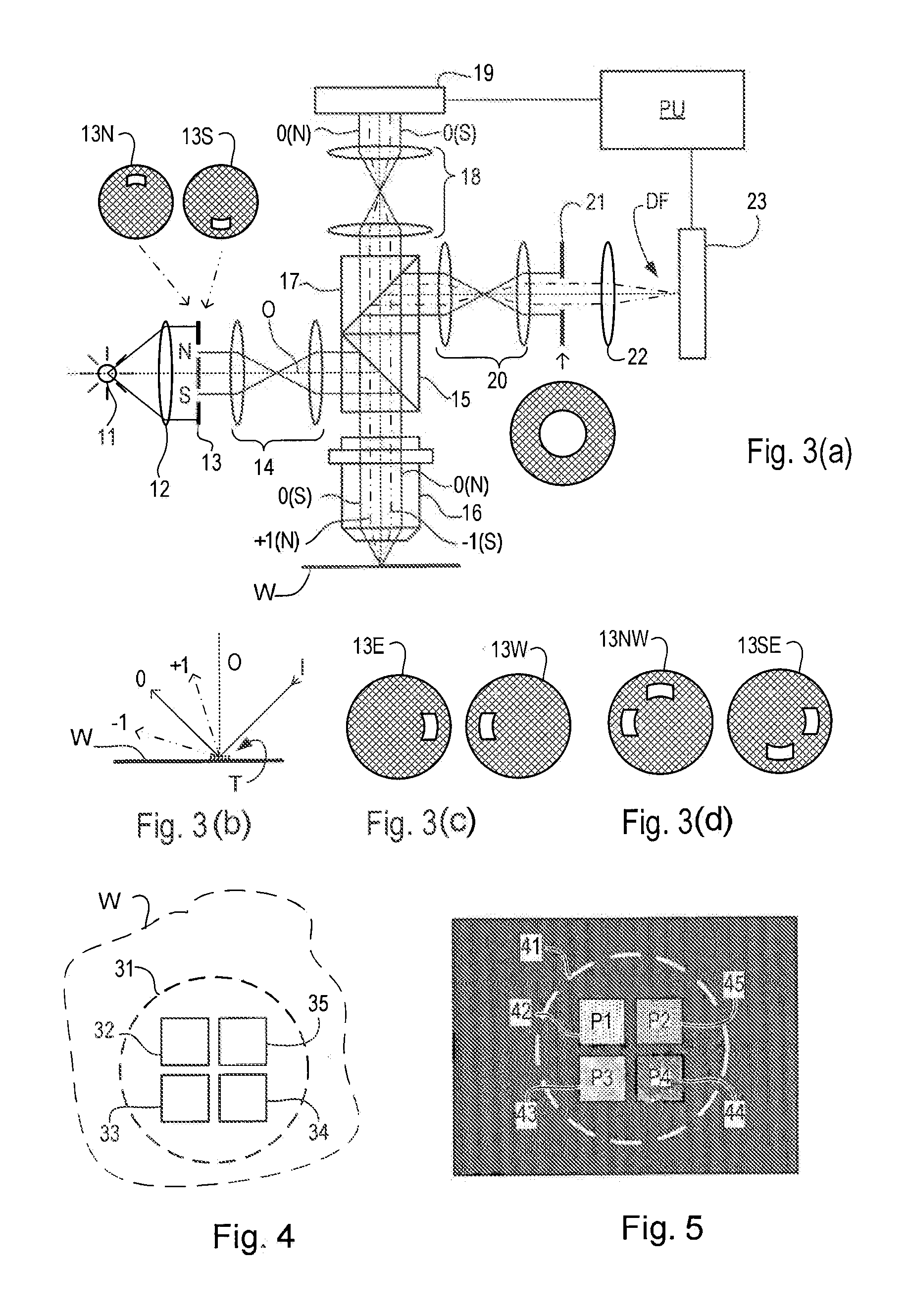

Metrology Method and Apparatus, and Device Manufacturing Method

ActiveUS20120242970A1Improve accuracyImprove throughputPhotomechanical apparatusOptically investigating flaws/contaminationMetrologyGrating

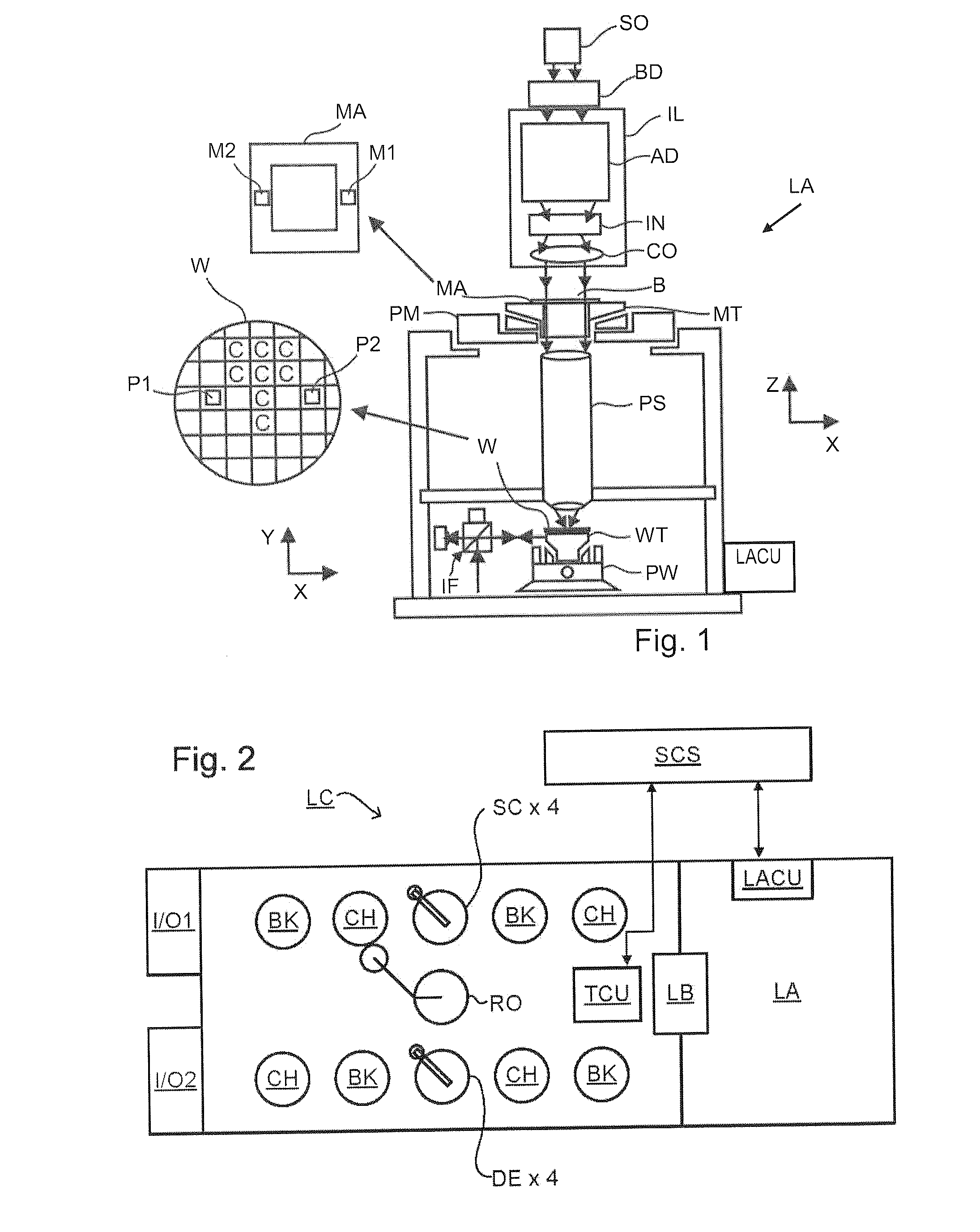

Methods are disclosed for measuring target structures formed by a lithographic process on a substrate. A grating or other structure within the target is smaller than an illumination spot and field of view of a measurement optical system. The position of an image of the component structure varies between measurements, and a first type of correction is applied to reduce the influence on the measured intensities, caused by differences in the optical path to and from different positions. A plurality of structures may be imaged simultaneously within the field of view of the optical system, and each corrected for its respective position. The measurements may comprise first and second images of the same target under different modes of illumination and / or imaging, for example in a dark field metrology application. A second type of correction may be applied to reduce the influence of asymmetry between the first and second modes of illumination or imaging, for example to permit a more accurate overly measurement in a semiconductor device manufacturing process.

Owner:ASML NETHERLANDS BV

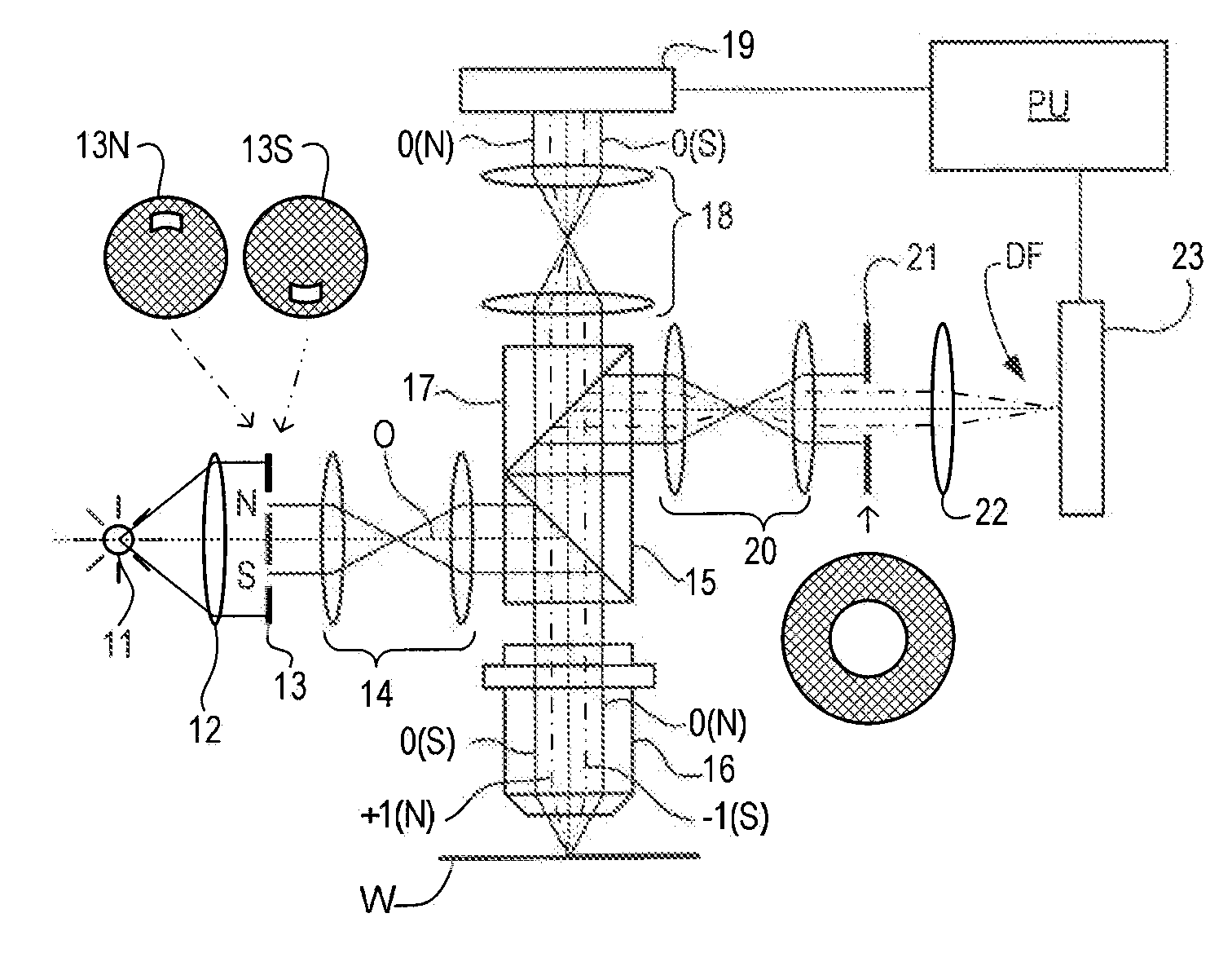

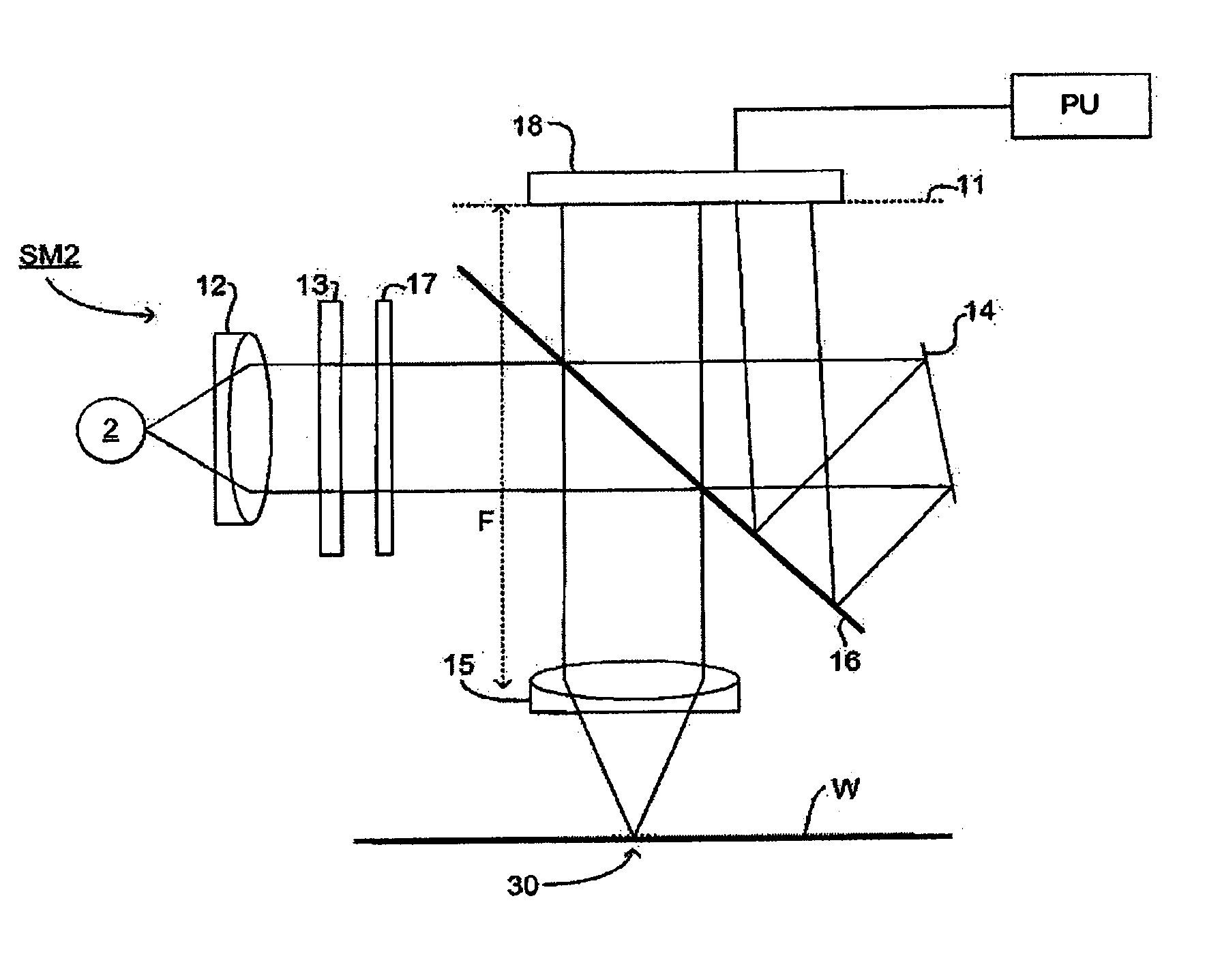

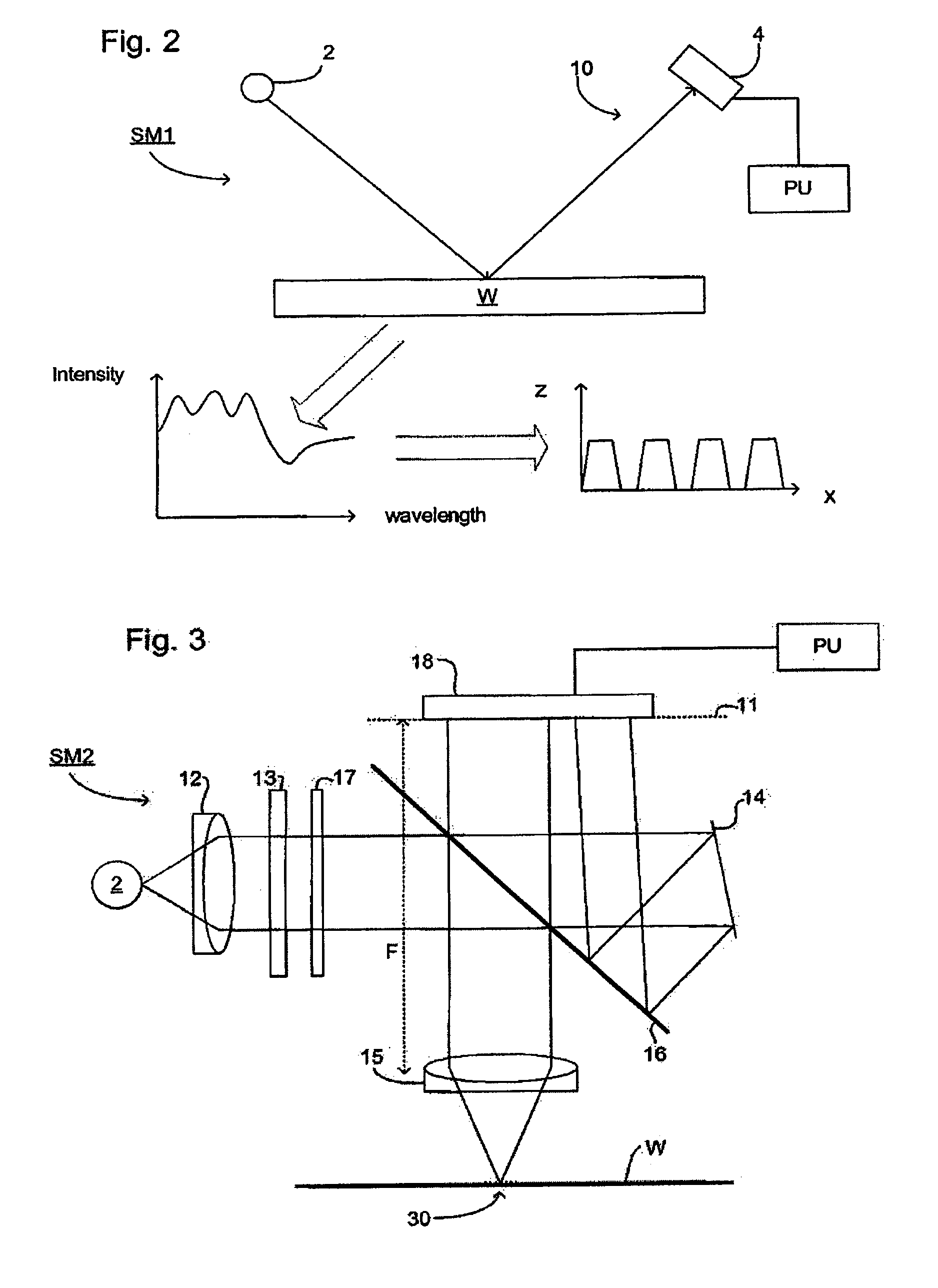

Inspection Method and Apparatus, Lithographic Apparatus, Lithographic Processing Cell and Device Manufacturing Method

ActiveUS20100007863A1Small targetRadiation pyrometrySpectrum investigationHigh numerical aperturePupil

An apparatus and method to determine a property of a substrate by measuring, in the pupil plane of a high numerical aperture lens, an angle-resolved spectrum as a result of radiation being reflected off the substrate. The property may be angle and wavelength dependent. The radiation that is reflected off the substrate is radially polarized.

Owner:ASML NETHERLANDS BV

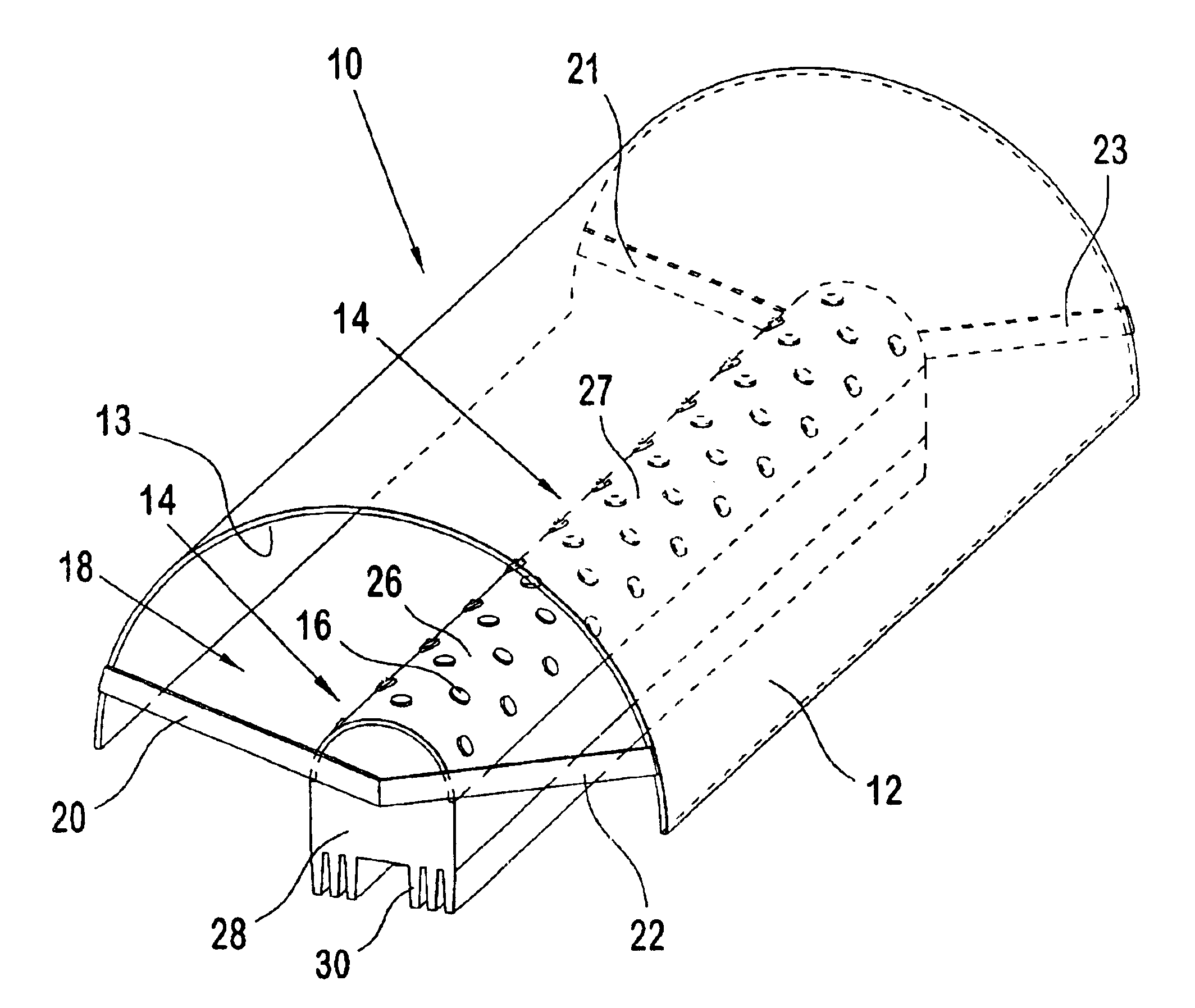

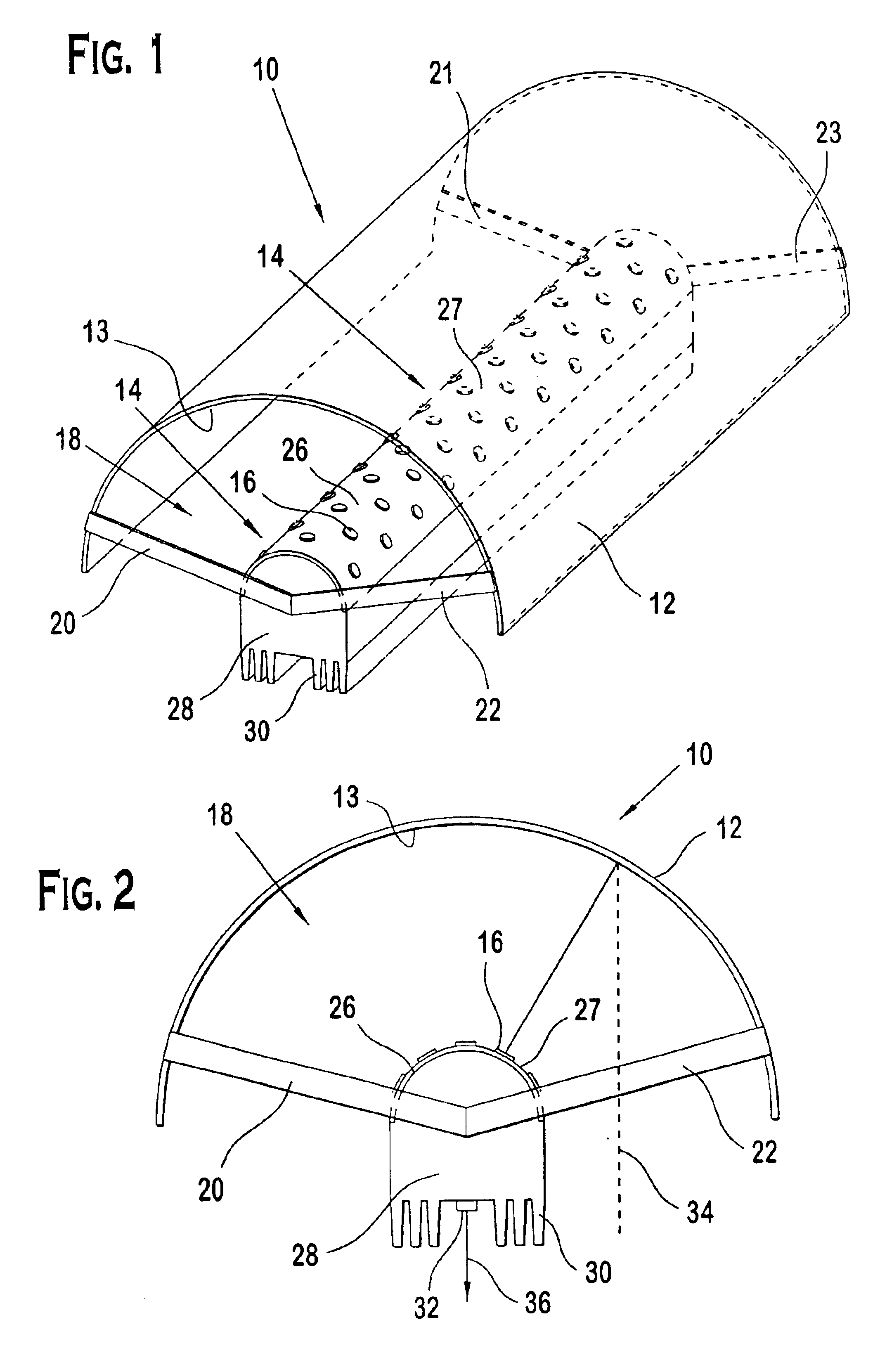

Integrating LED illumination system for machine vision systems

InactiveUS6871993B2Efficiently focusPoint-like light sourcePortable electric lightingLed arrayOptoelectronics

A system for focusing light on an illumination area. The system includes a reflector having a focusing reflective surface and a focal region and an LED array having a plurality of LEDs located within the focal region. Each of the plurality of LEDs in the LED array is positioned to emit light toward the focusing reflective surface. The focusing reflective surface reflects light from each of the plurality of LEDs of the LED array toward the illumination area.

Owner:DATALOGIC AUTOMATION

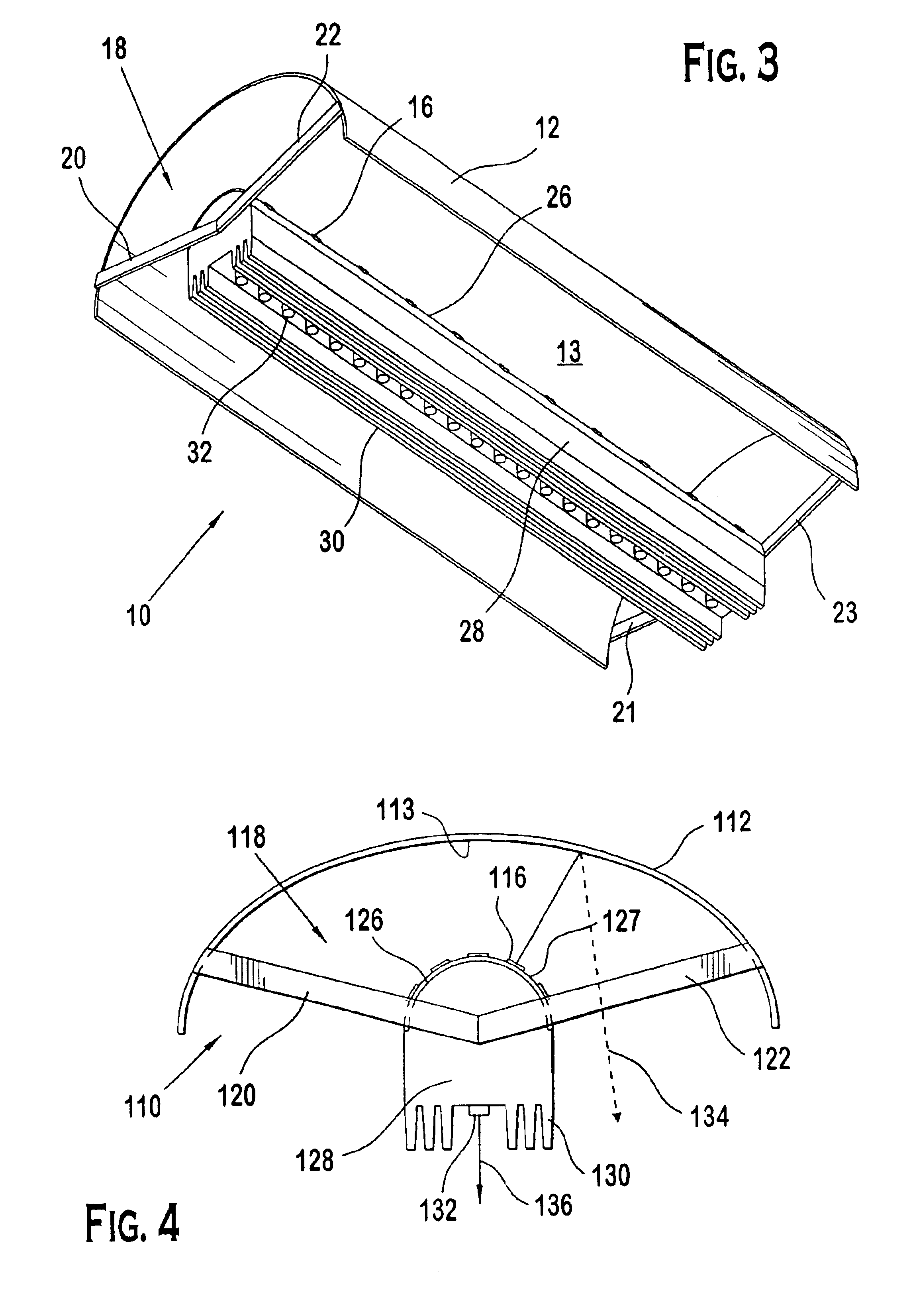

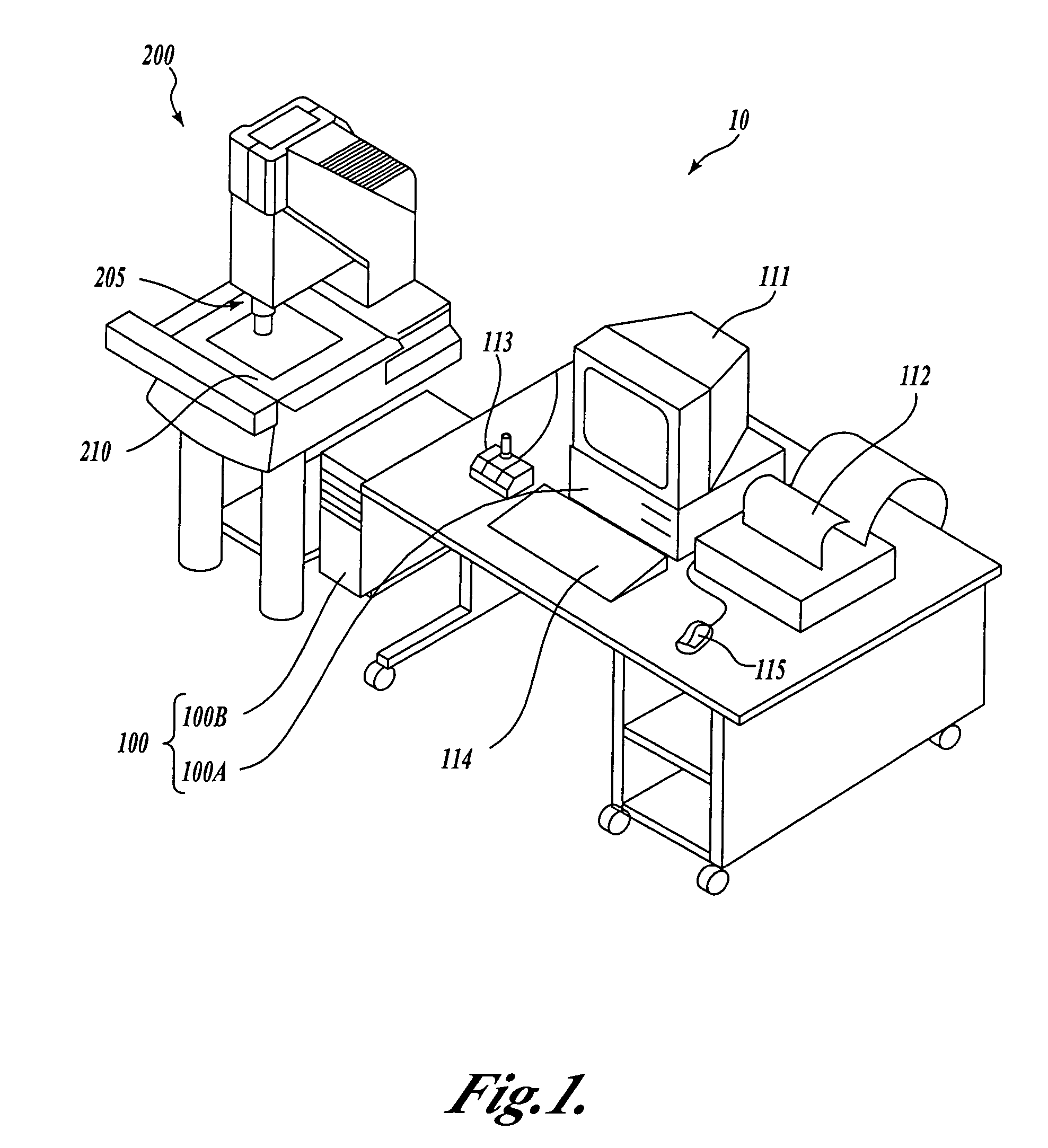

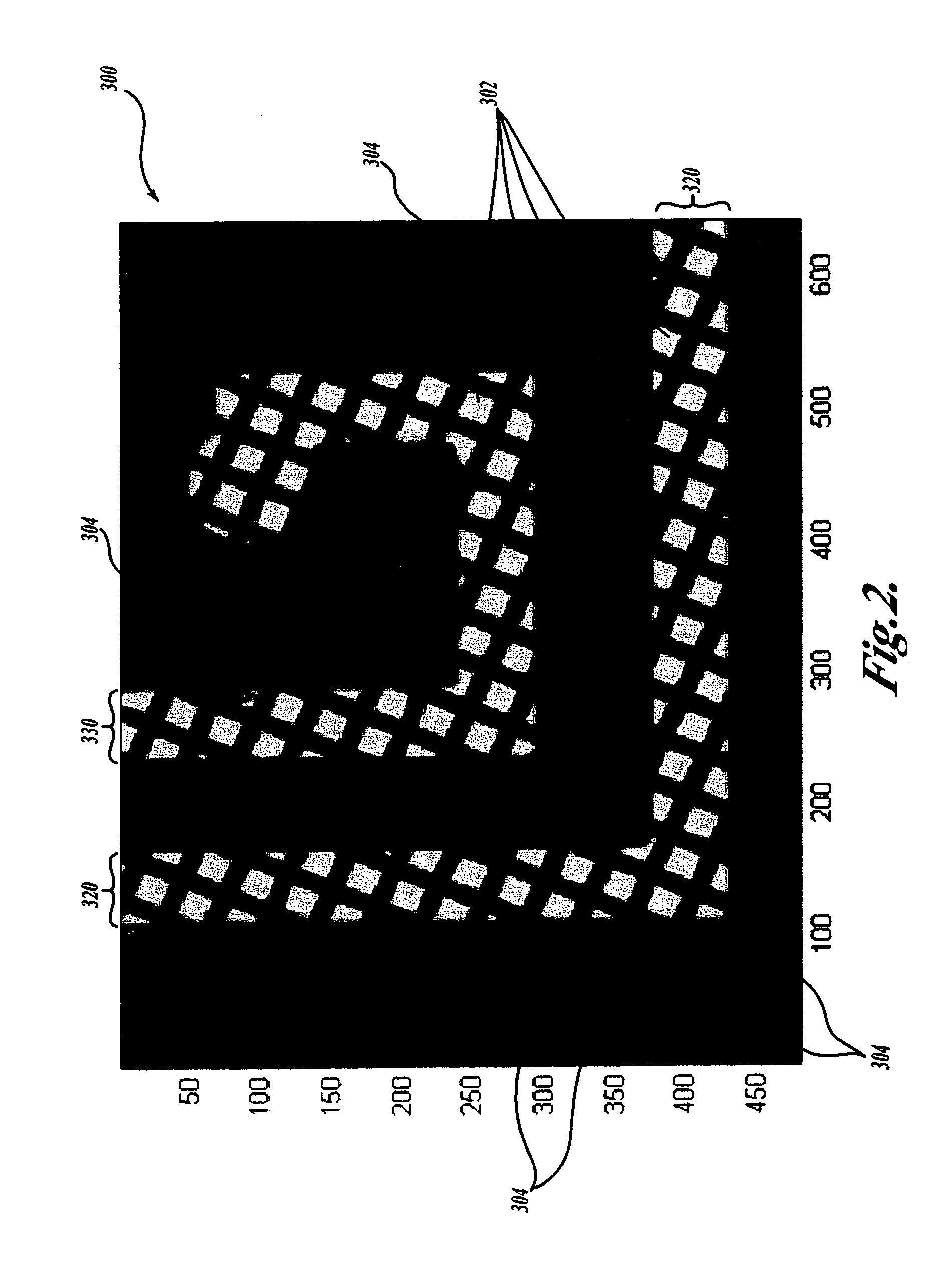

System and method for excluding extraneous features from inspection operations performed by a machine vision inspection system

ActiveUS7324682B2Easy to useVariation in spacingImage enhancementImage analysisMachine visionImaging Feature

Systems and methods are provided for excluding extraneous image features from inspection operations in a machine vision inspection system. The method identifies extraneous features that are close to image features to be inspected. No image modifications are performed on the “non-excluded” image features to be inspected. A video tool region of interest provided by a user interface of the vision system can encompass both the feature to be inspected and the extraneous features, making the video tool easy to use. The extraneous feature excluding operations are concentrated in the region of interest. The user interface for the video tool may operate similarly whether there are extraneous features in the region of interest, or not. The invention is of particular use when inspecting flat panel display screen masks having occluded features that are to be inspected.

Owner:MITUTOYO CORP

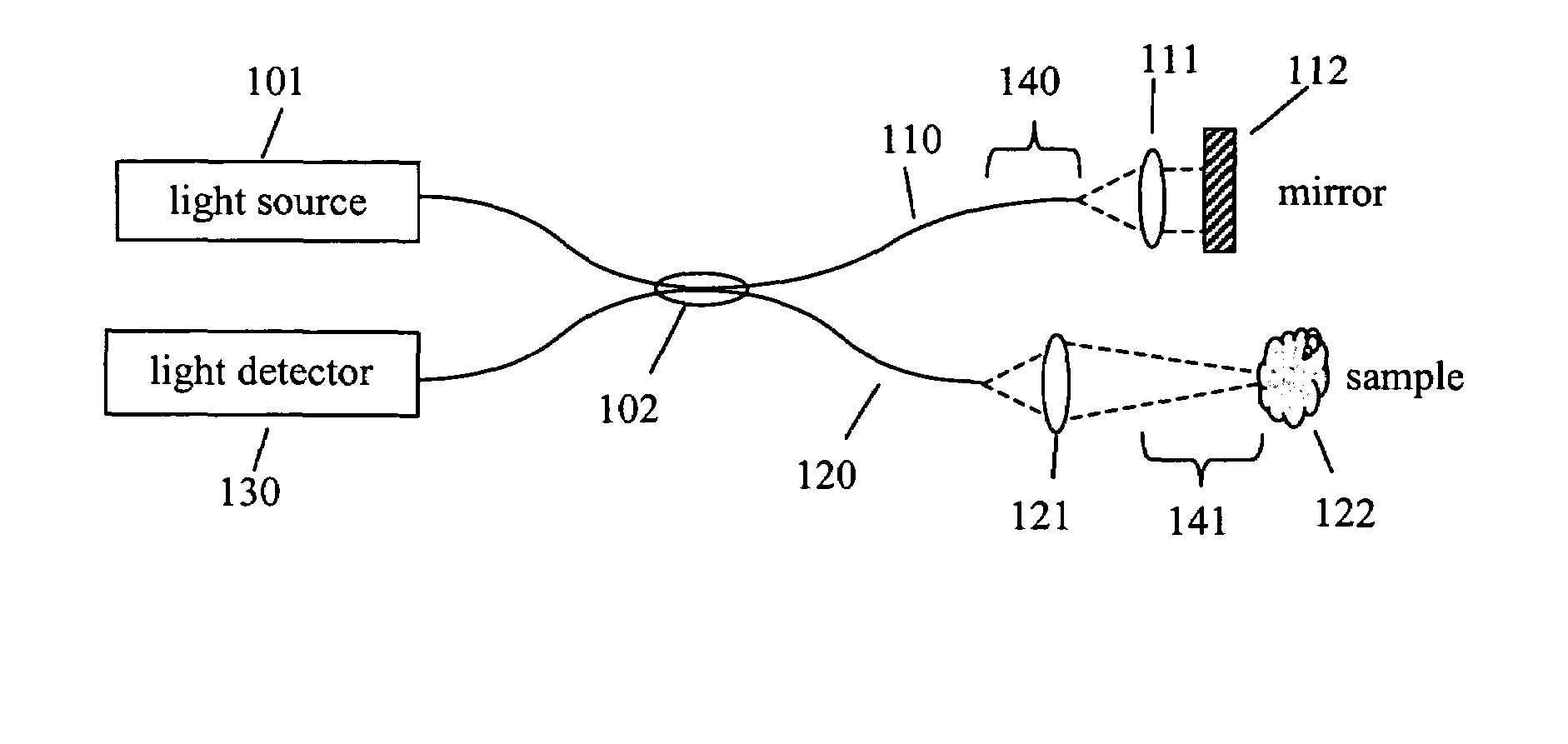

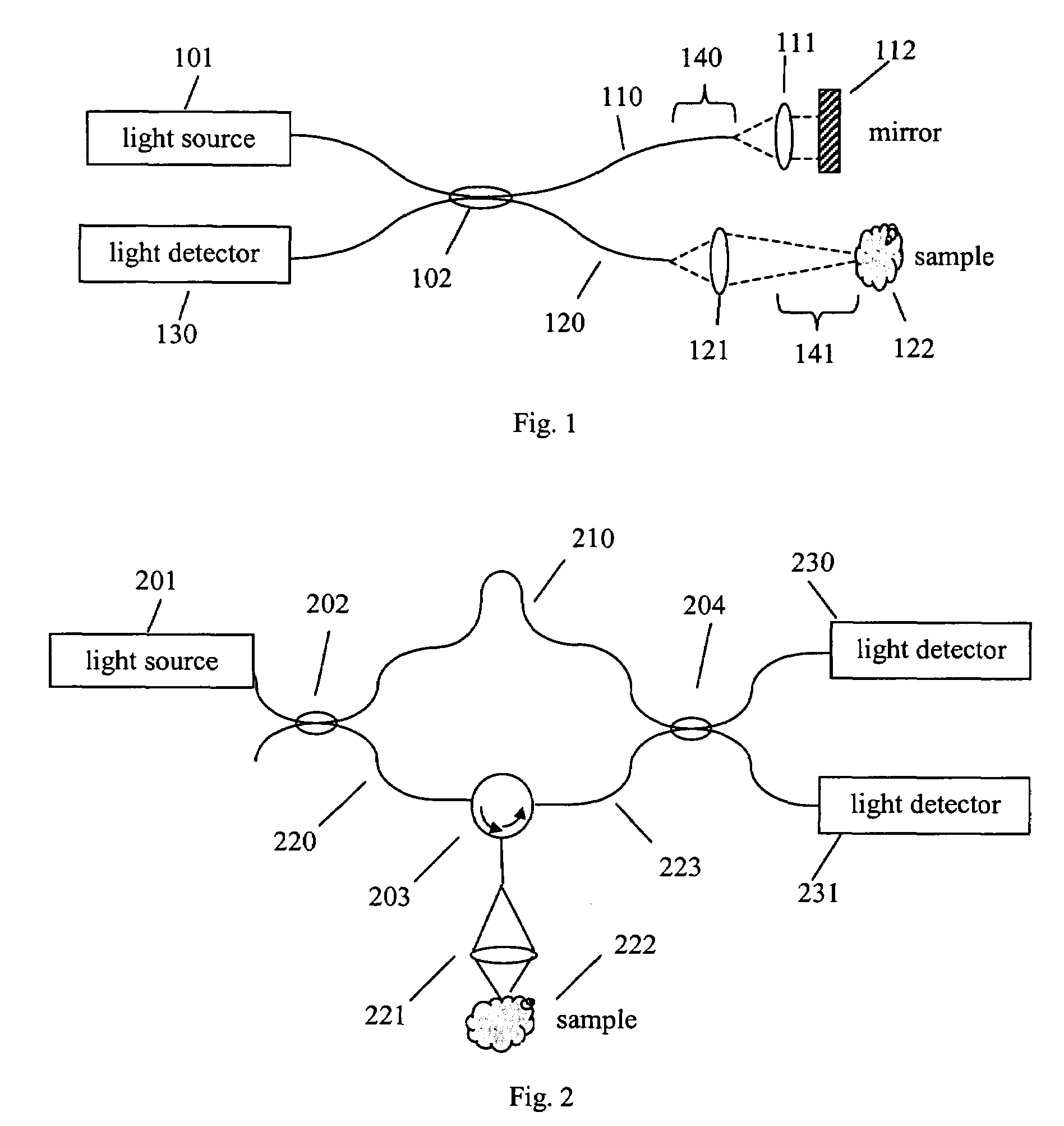

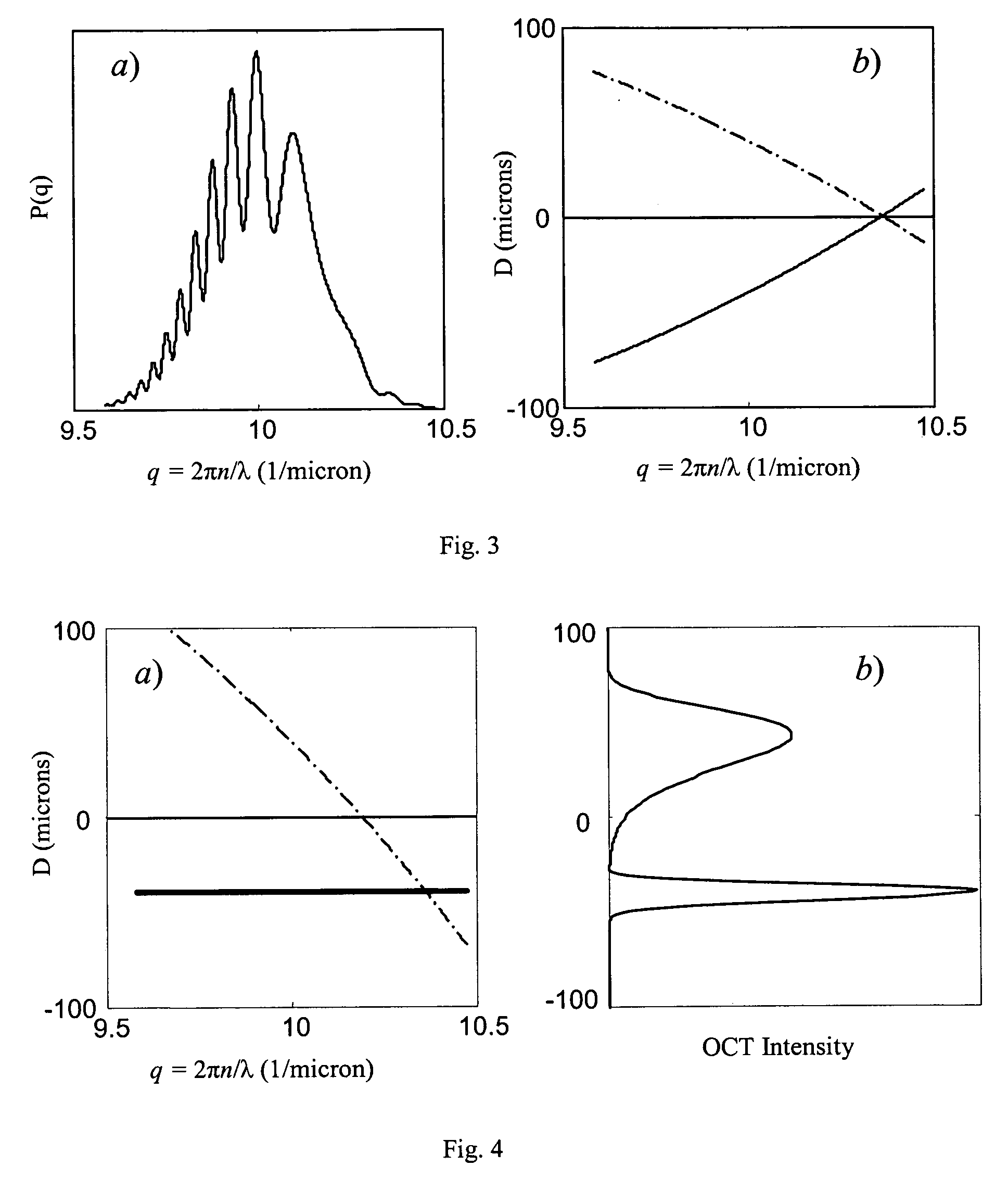

Method to suppress artifacts in frequency-domain optical coherence tomography

ActiveUS7330270B2Radiation pyrometryMaterial analysis using wave/particle radiationFrequency domain optical coherence tomographySignificant difference

One embodiment of the present invention is a method for suppressing artifacts in frequency-domain OCT images, which method includes (a) providing sample and reference paths with a significant difference in their chromatic dispersion (b) correcting for the effects of the mismatch in chromatic dispersion, for the purpose of making artifacts in the OCT image readily distinguishable from the desired image.

Owner:CARL ZEISS MEDITEC INC

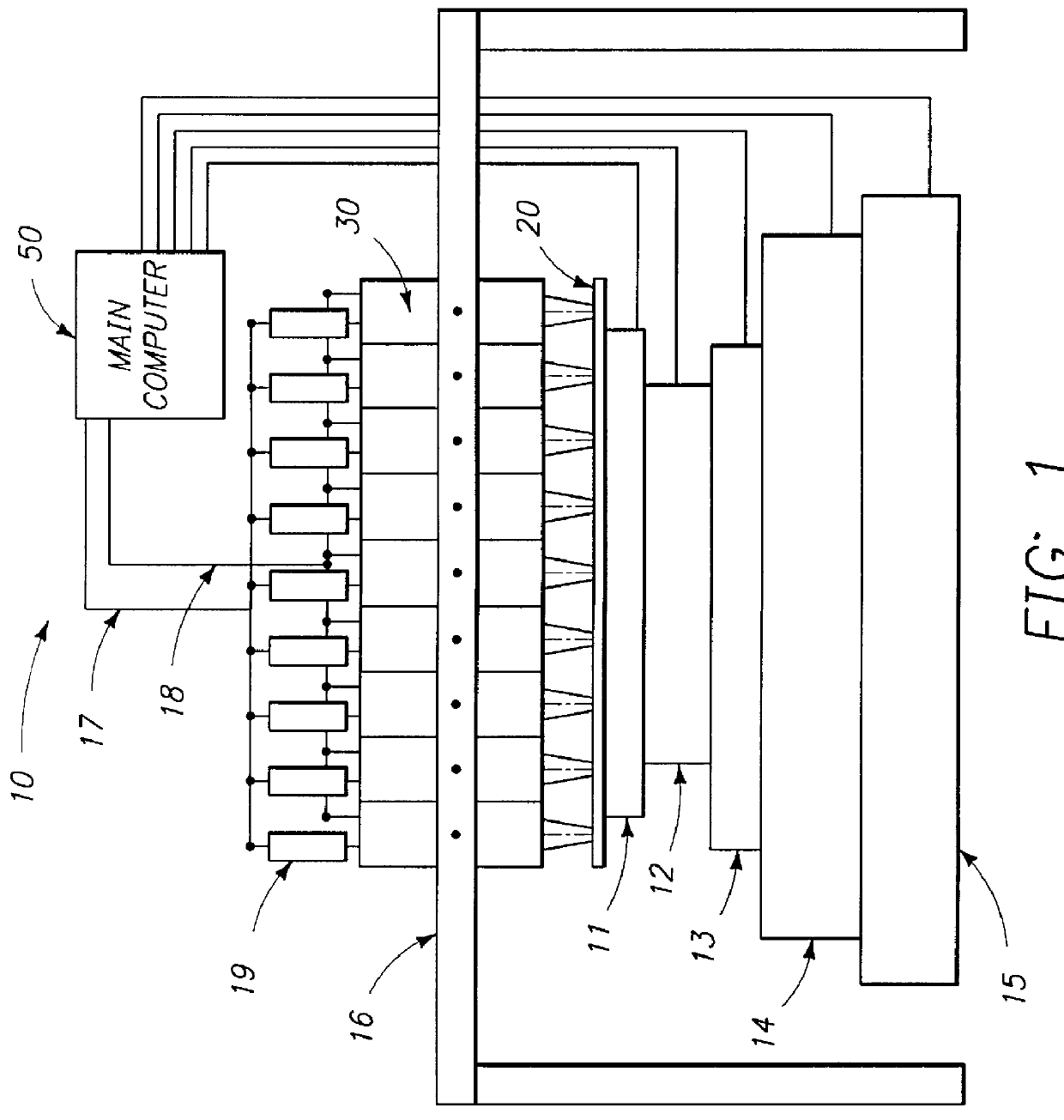

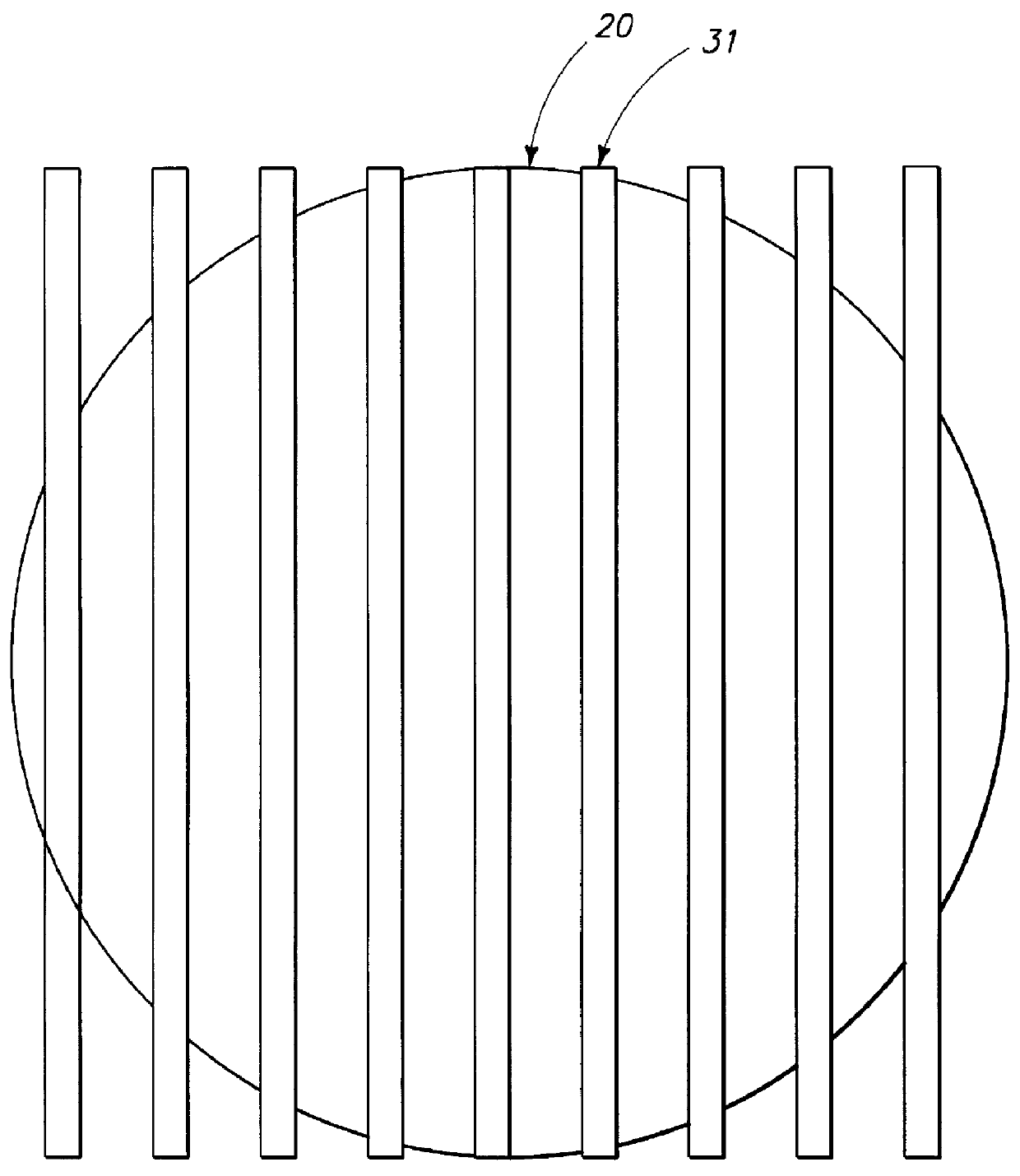

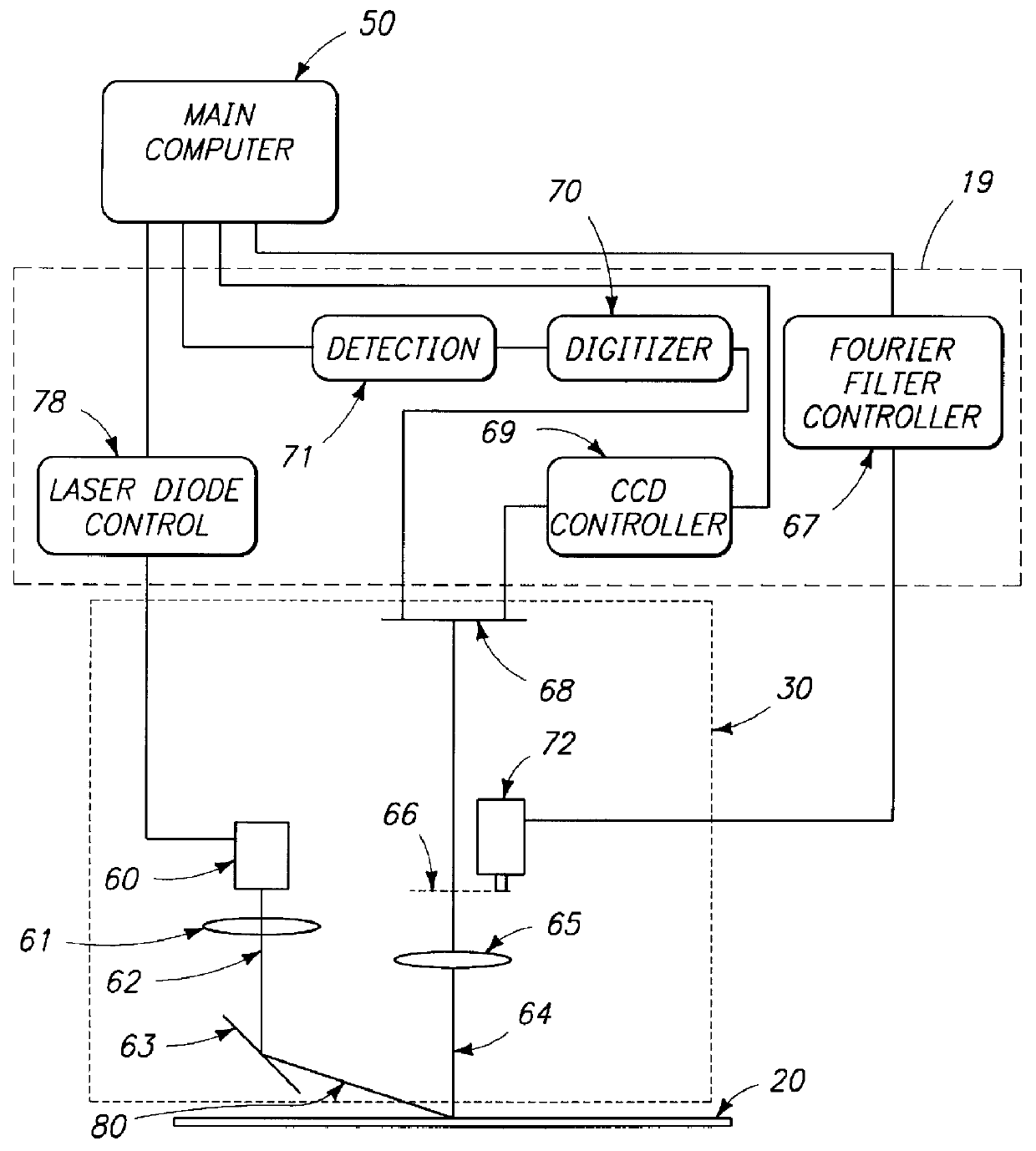

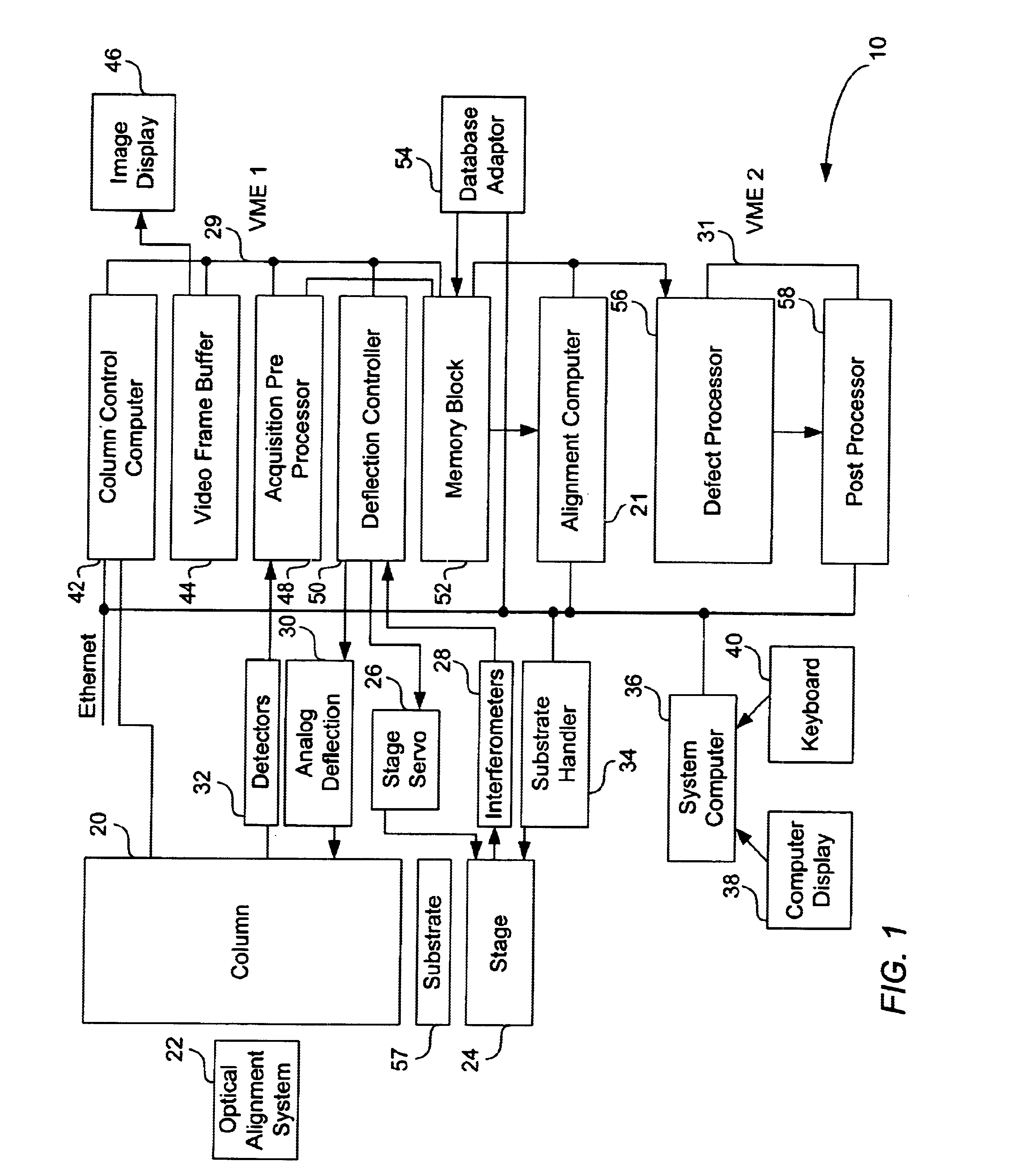

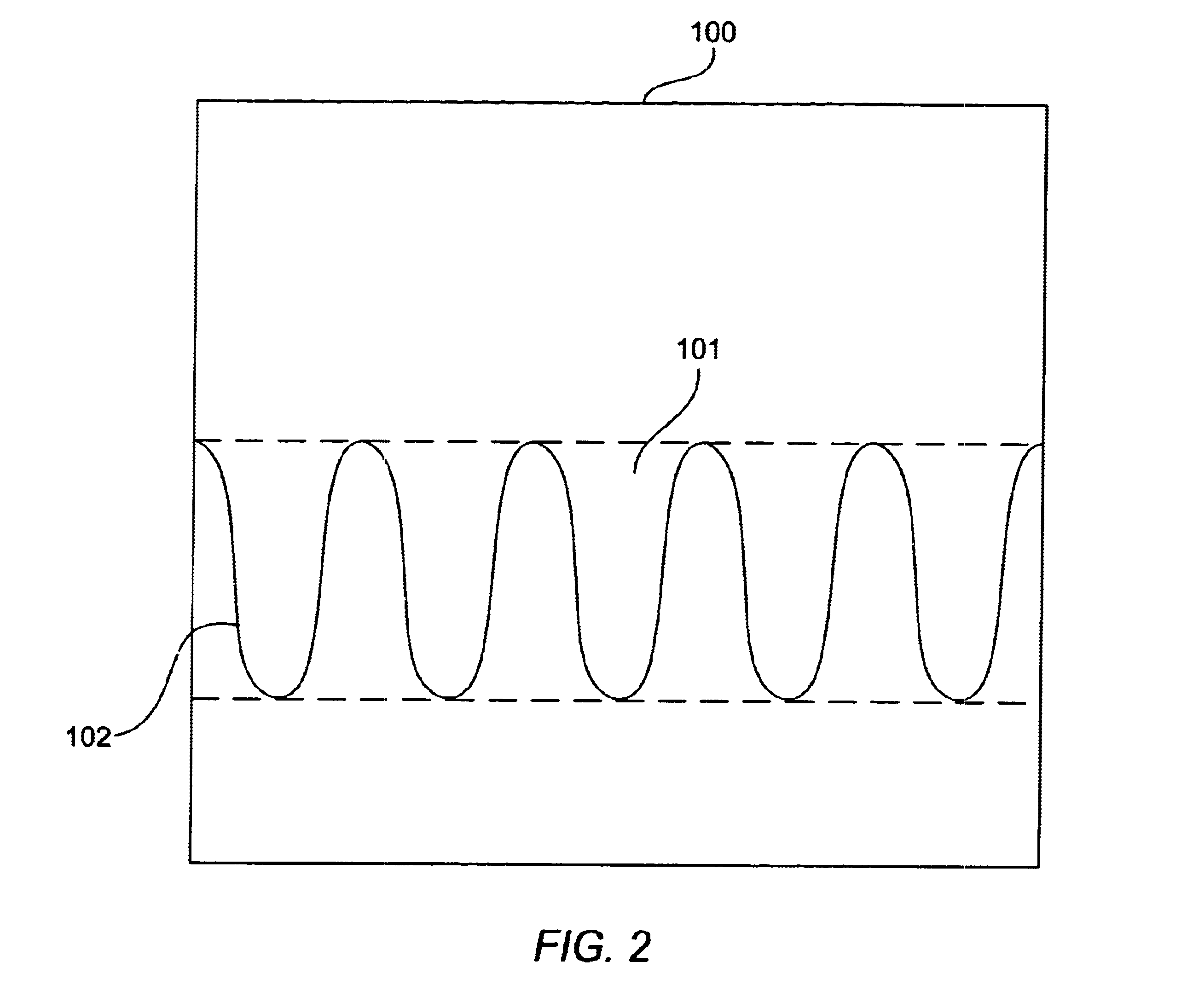

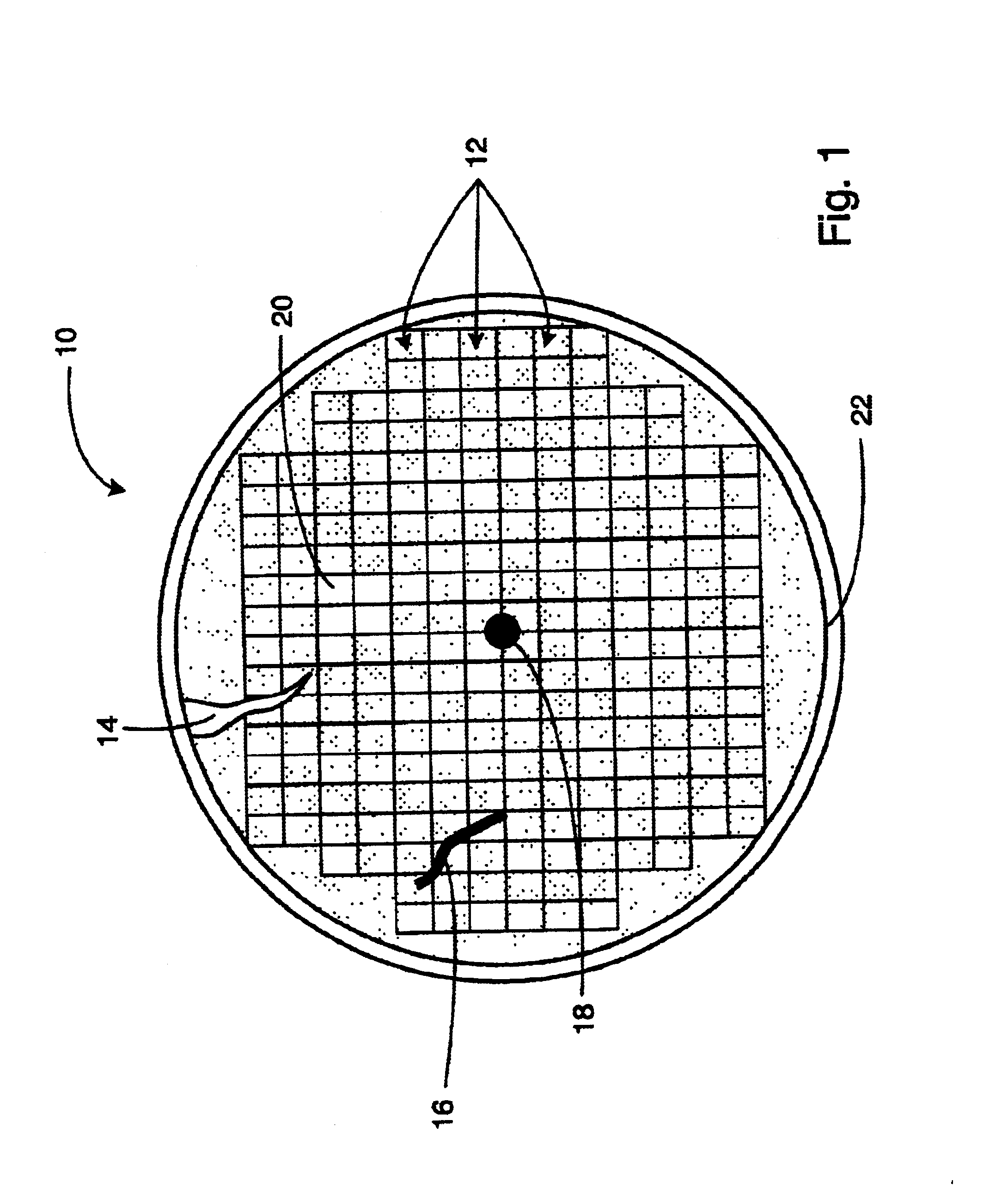

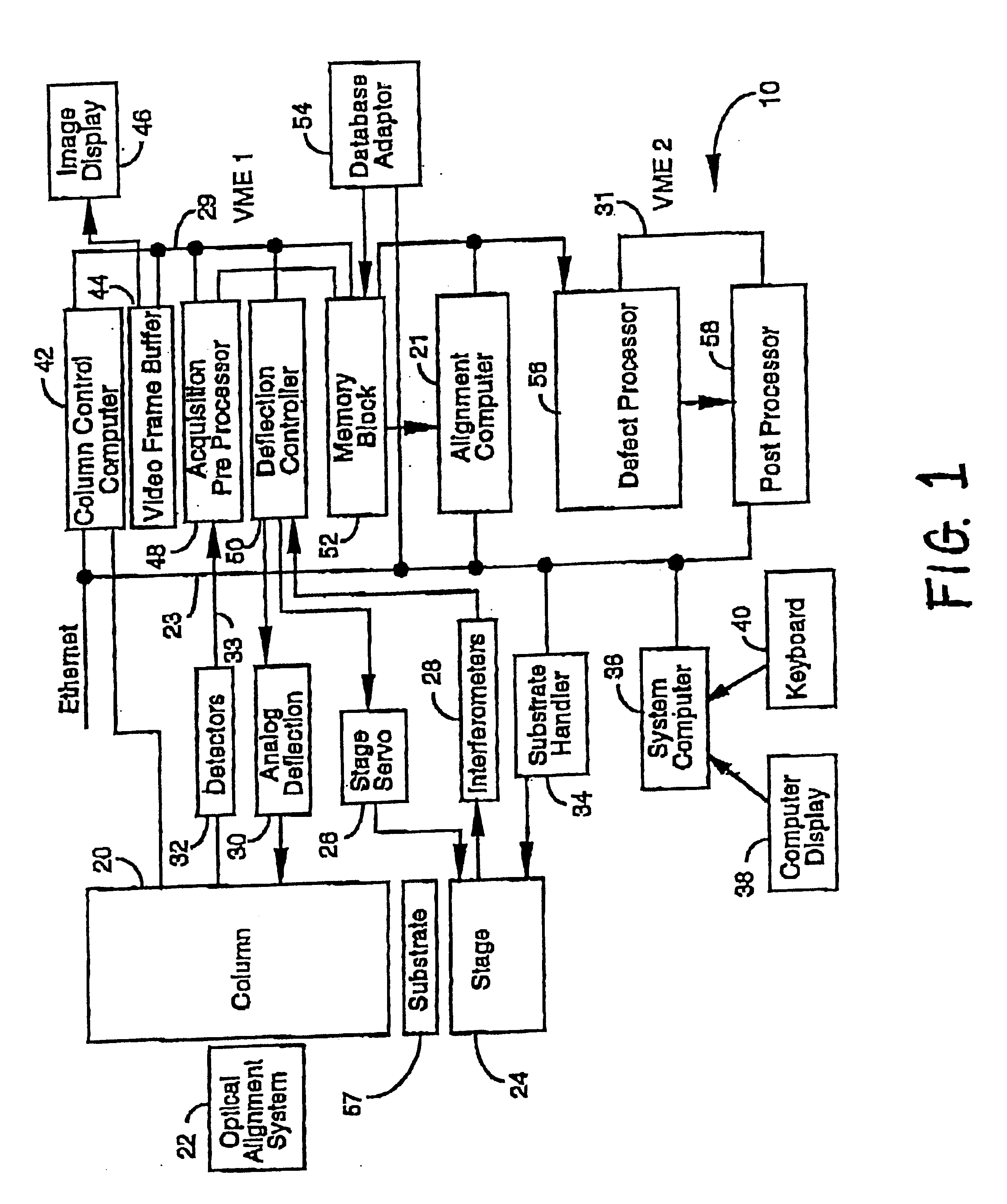

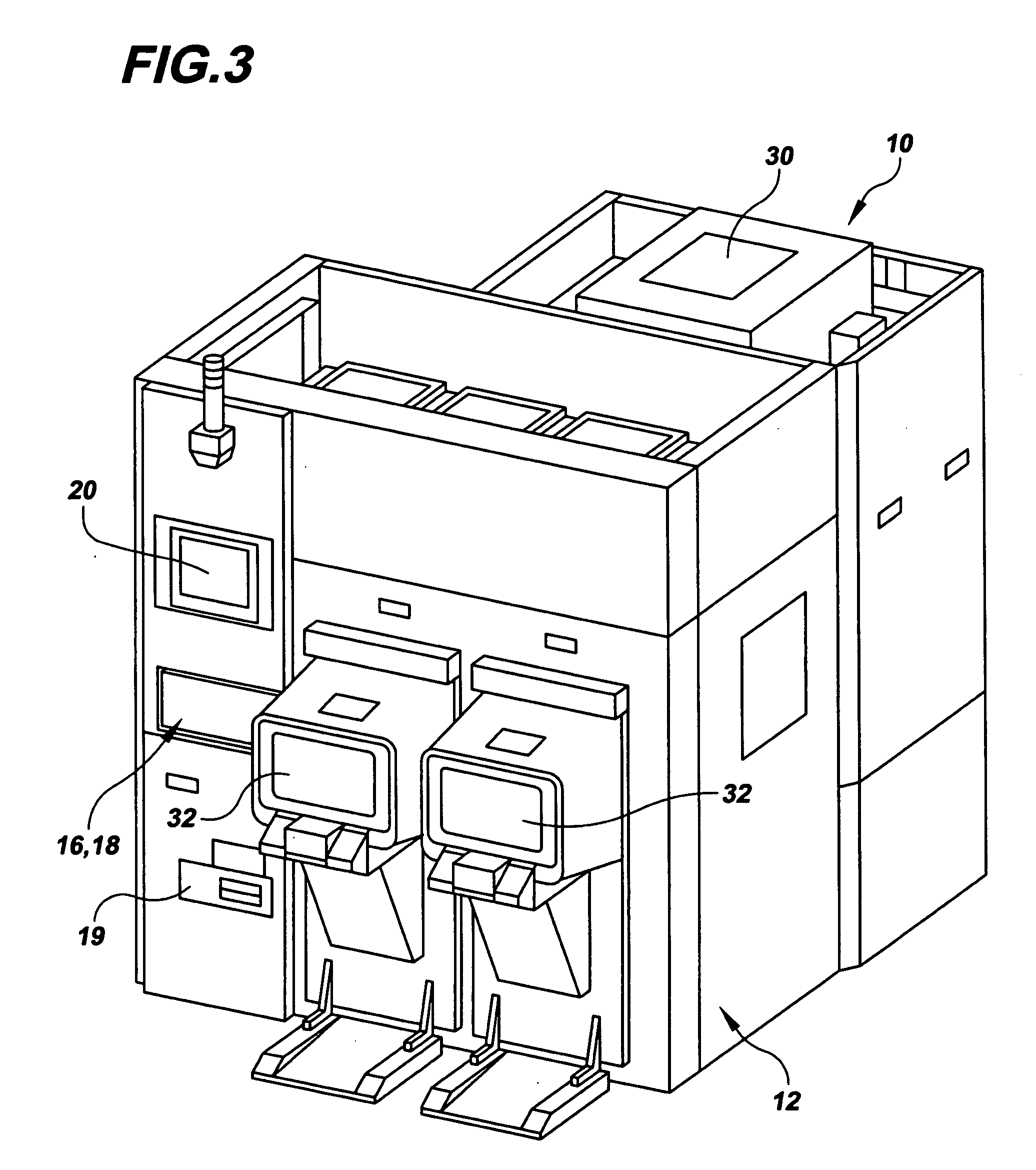

System and method for inspecting semiconductor wafers

InactiveUS6020957ALow costFaster throughputSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingGratingImage subtraction

A method for inspecting semiconductor wafers is provided in which a plurality of independent, low-cost, optical-inspection subsystems are packaged and integrated to simultaneously perform parallel inspections of portions of the wafer, the wafer location relative to the inspection being controlled so that the entire wafer is imaged by the system of optical subsystems in a raster-scan mode. A monochromatic coherent-light source illuminates the wafer surface. A darkfield-optical system collects scattered light and filters patterns produced by valid periodic wafer structures using Fourier filtering. The filtered light is processed by general purpose digital-signal processors. Image subtraction methods are used to detect wafer defects, which are reported to a main computer to aid in statistical process control, particularly for manufacturing equipment.

Owner:KLA TENCOR CORP

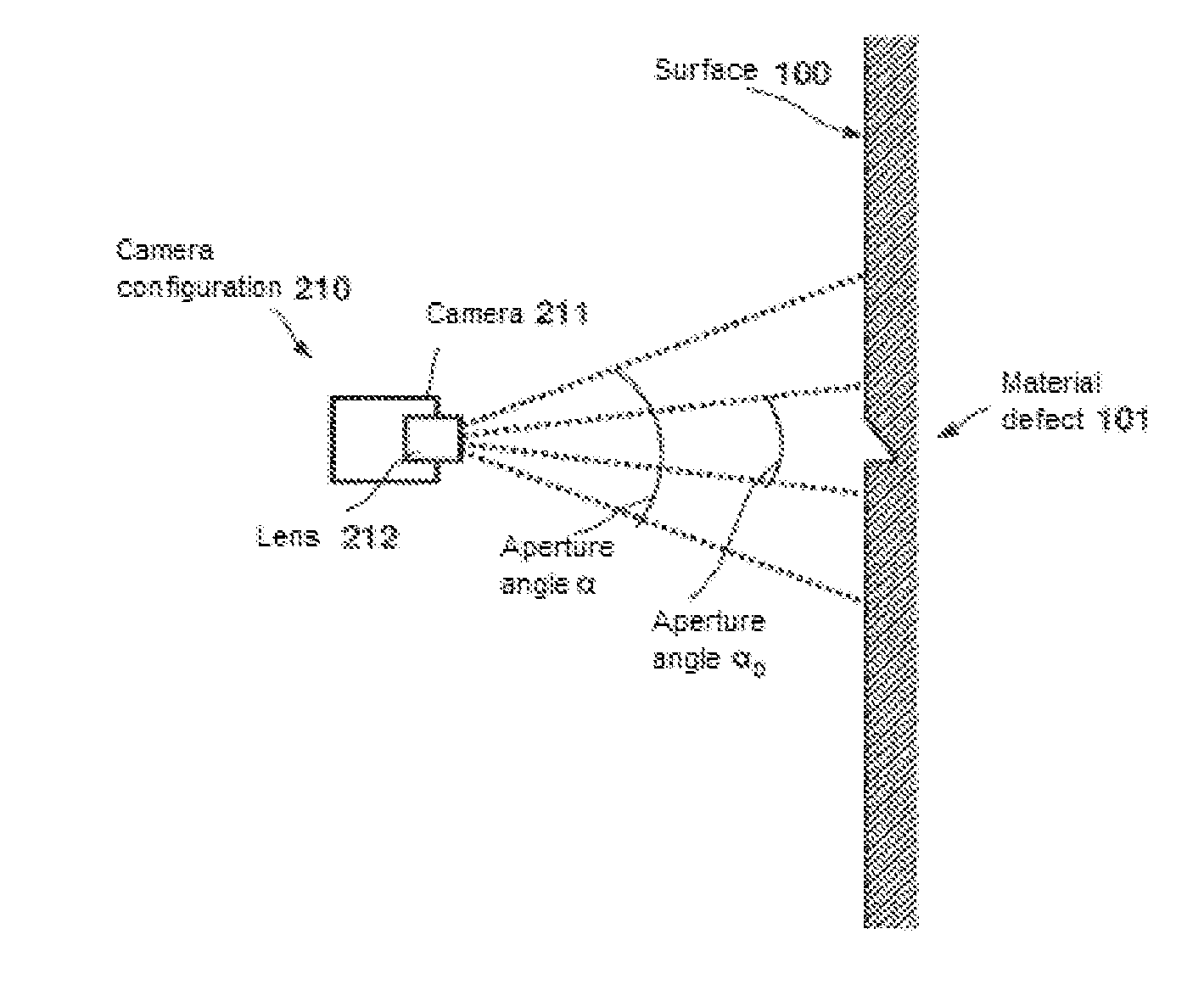

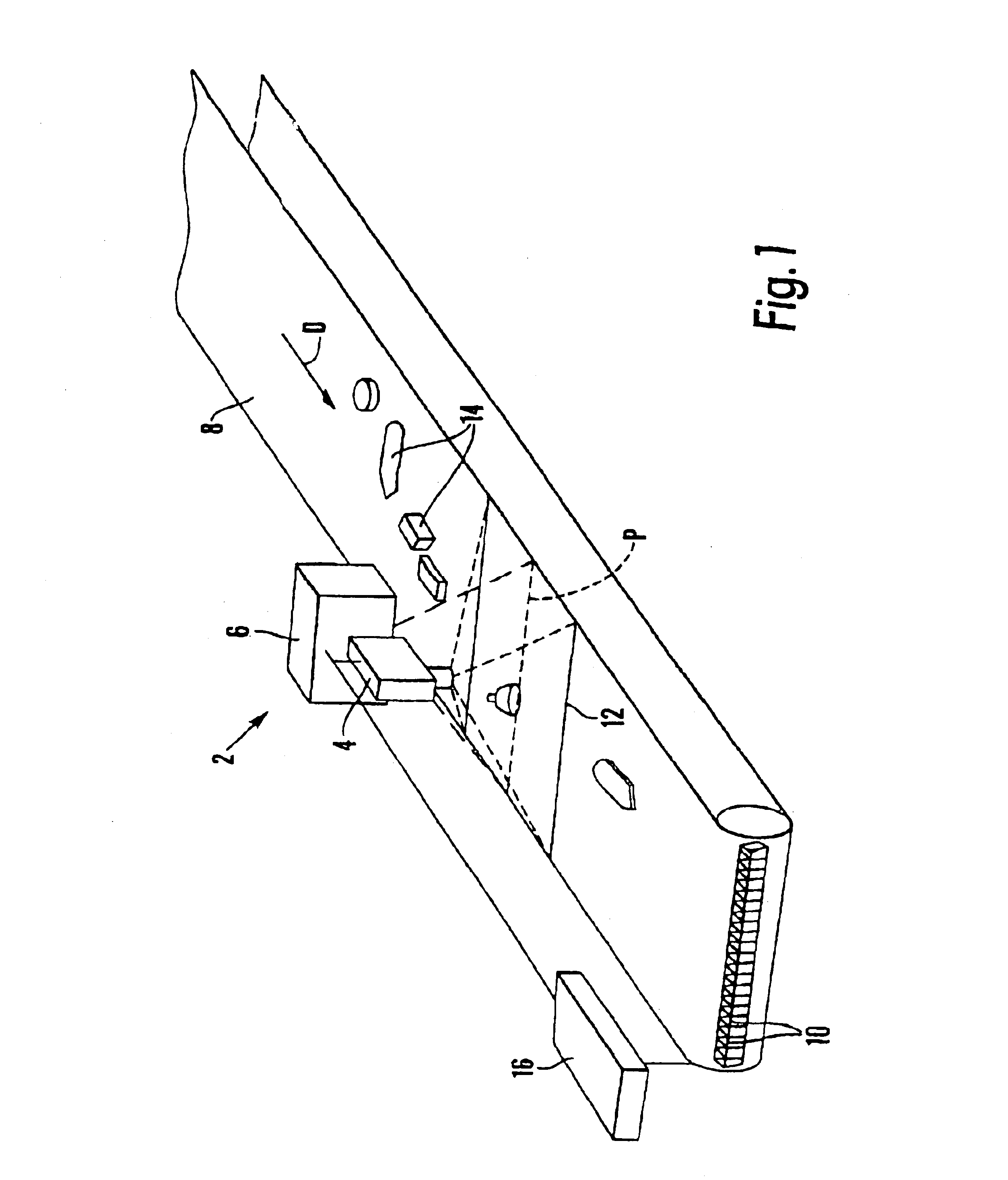

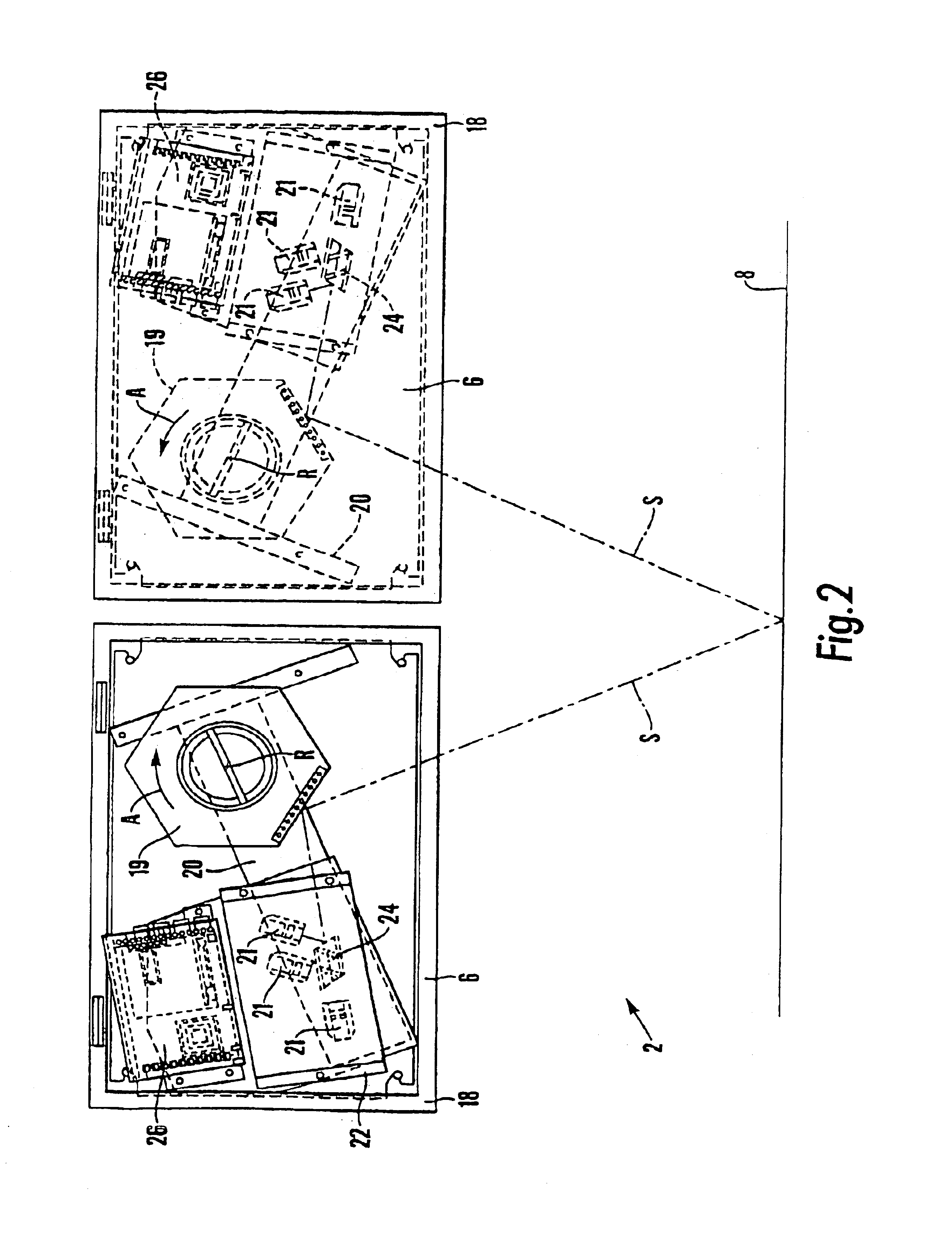

Method and System for Inspecting a Surface Area for Material Defects

ActiveUS20140168420A1Reduce associated effortReduce security risksPicture taking arrangementsColor television detailsMaterial defectEngineering

A camera assembly arranged on an unmanned and autonomously navigating aerial vehicle is employed to inspect a surface area of for material defects. The vehicle is automatically flown to the surface area from a launch site, wherein it can fly around obstacles using automatic obstacle detection and avoidance methods. A relative position of the aerial vehicle with respect to the surface area with the aid of a position sensor is continuously measured and a sequence of images of the surface area is recorded. Between the individual images, the aerial vehicle is moved along a flight path overlapping image details of the surface area. The images of the sequence are composed into an overall image of the surface area to allow for the surface area to be inspected for defects and the location of defects to be ascertained on the basis of the overall image.

Owner:EADS DEUT GMBH

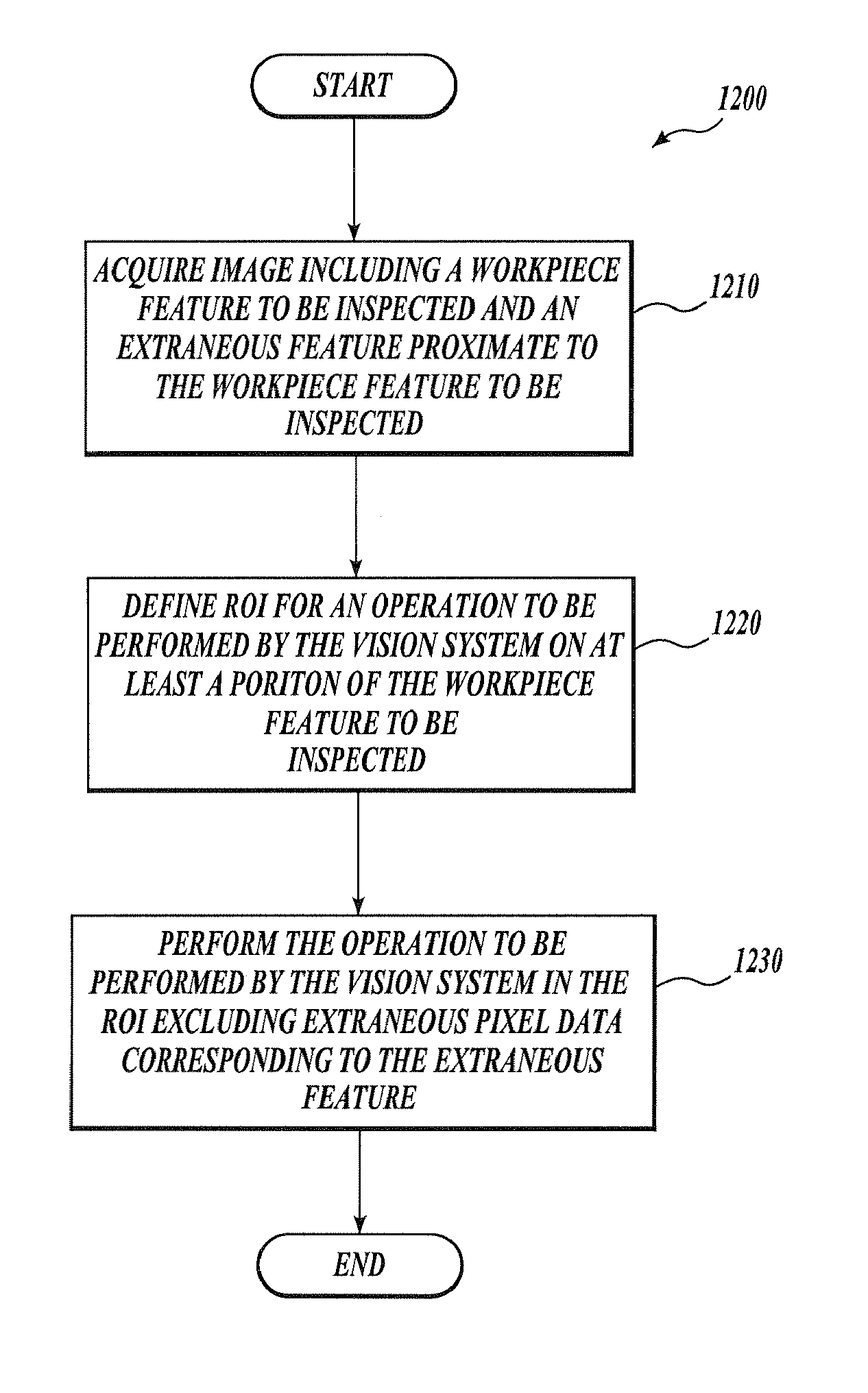

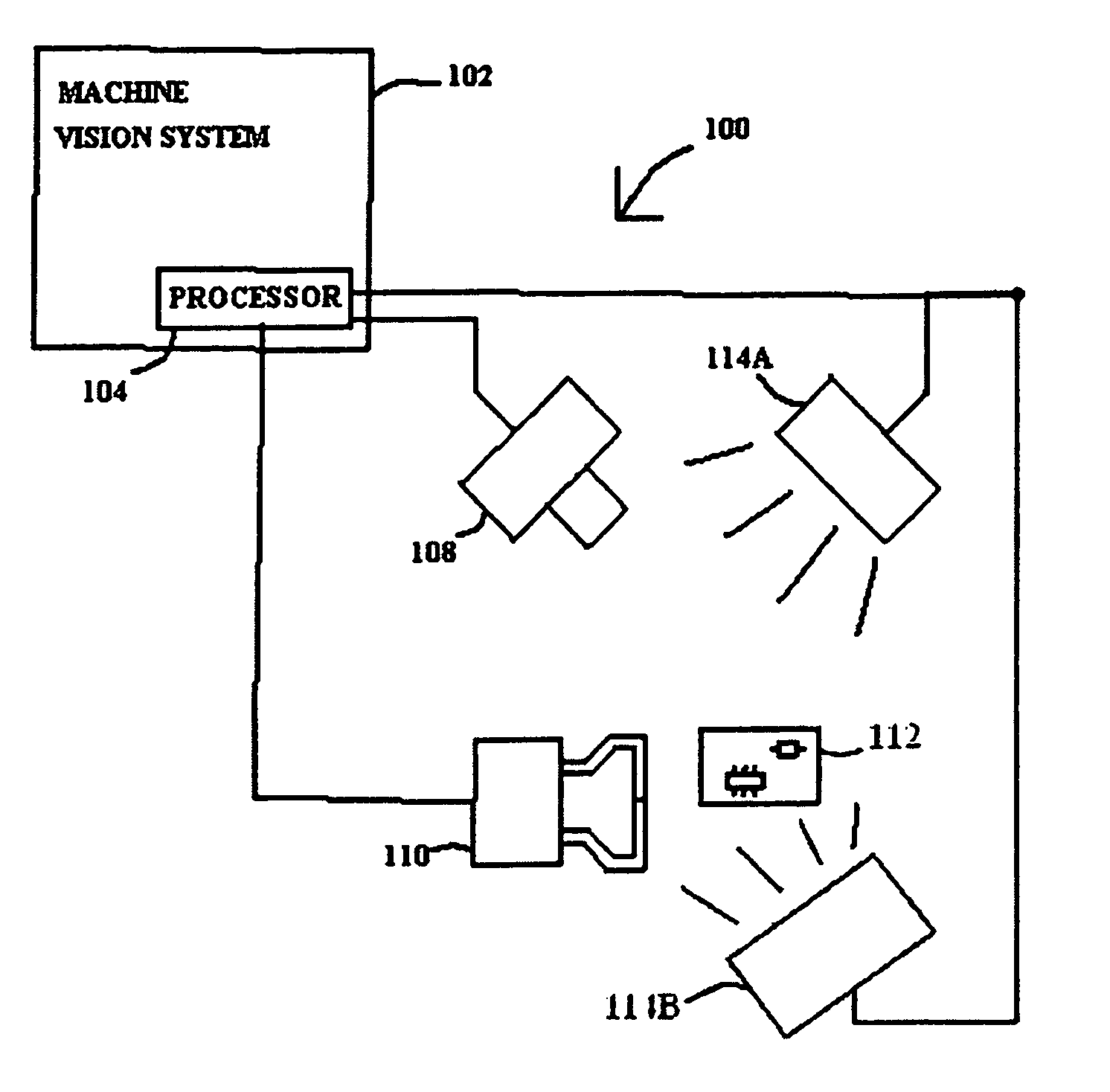

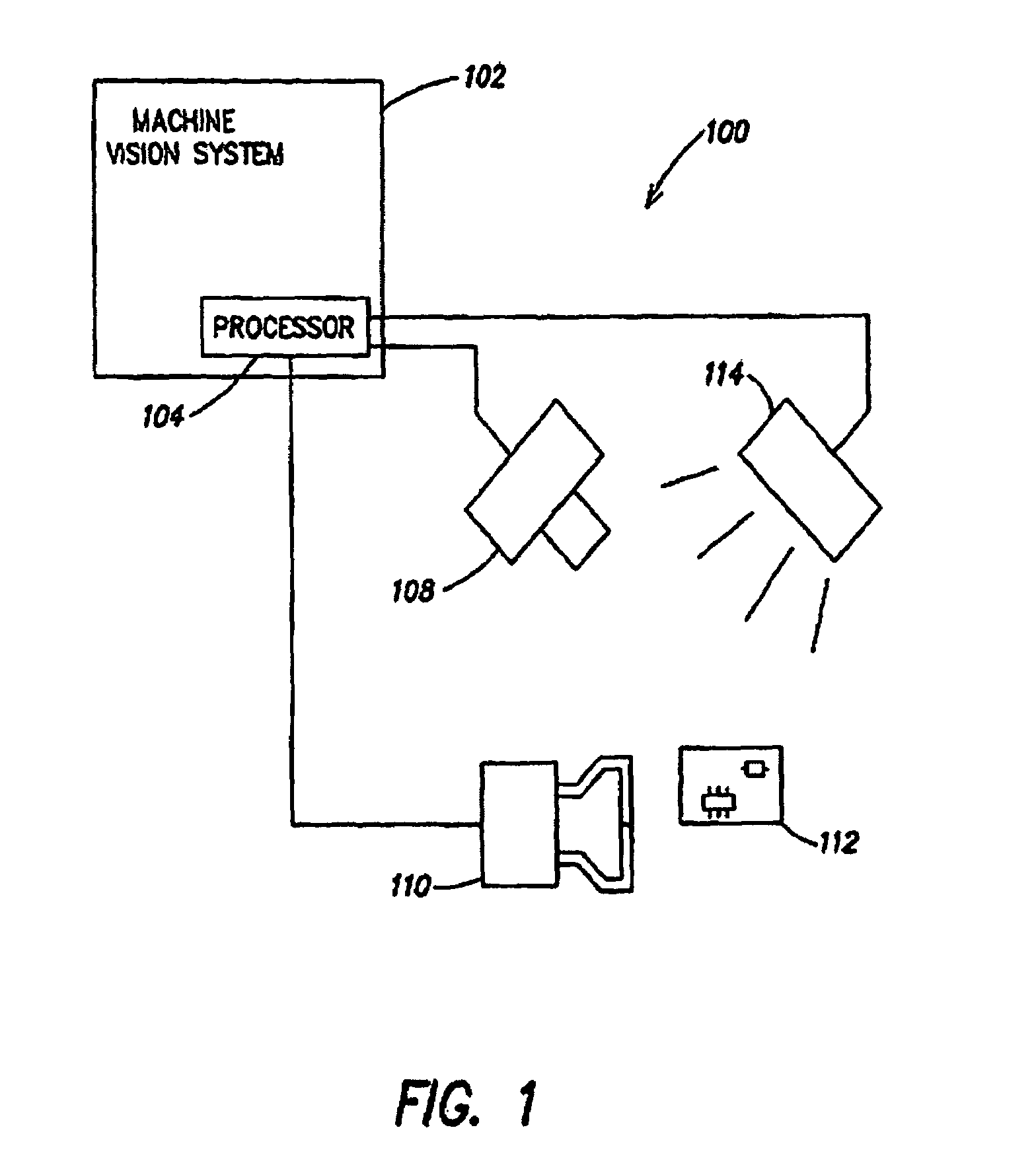

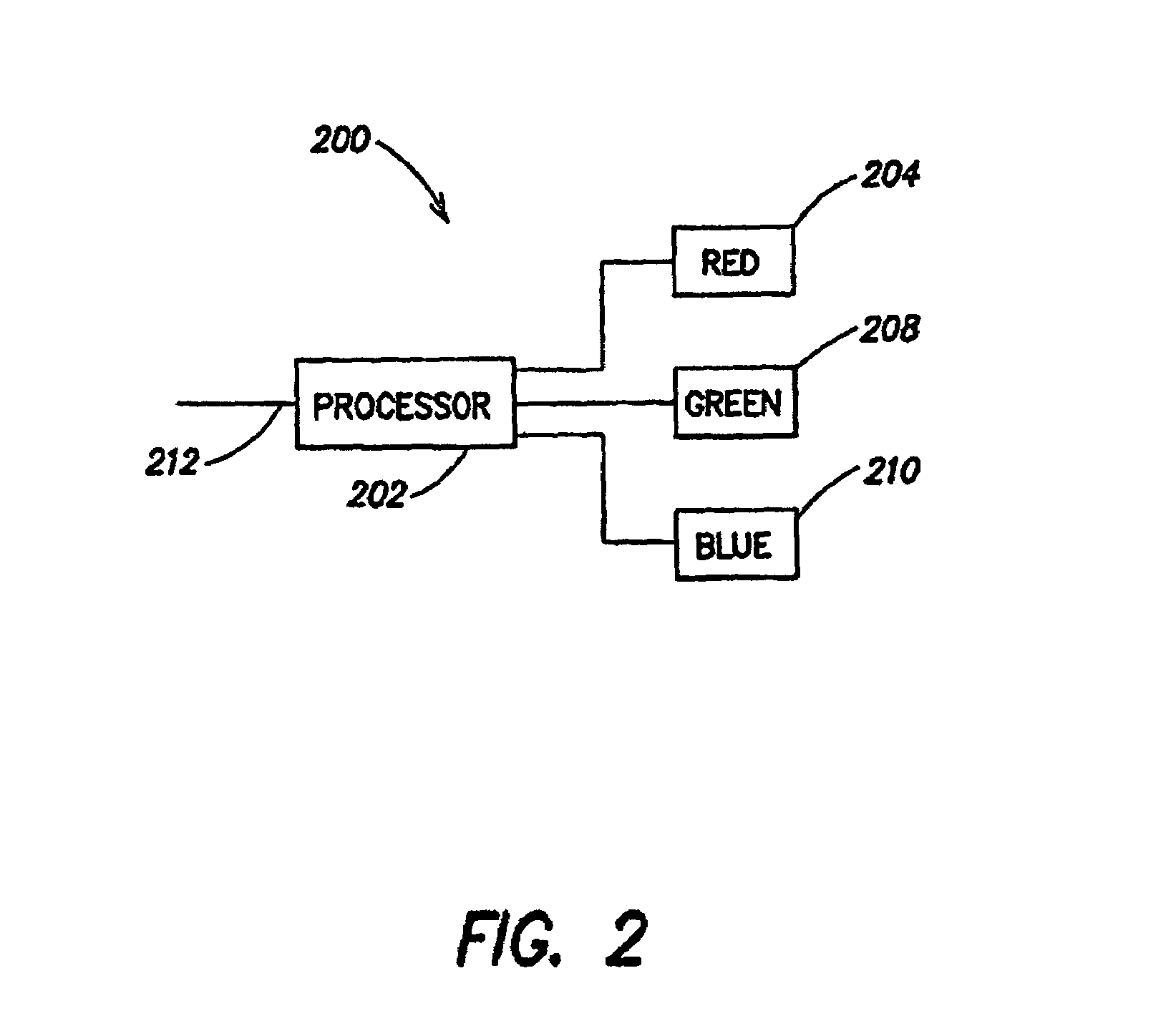

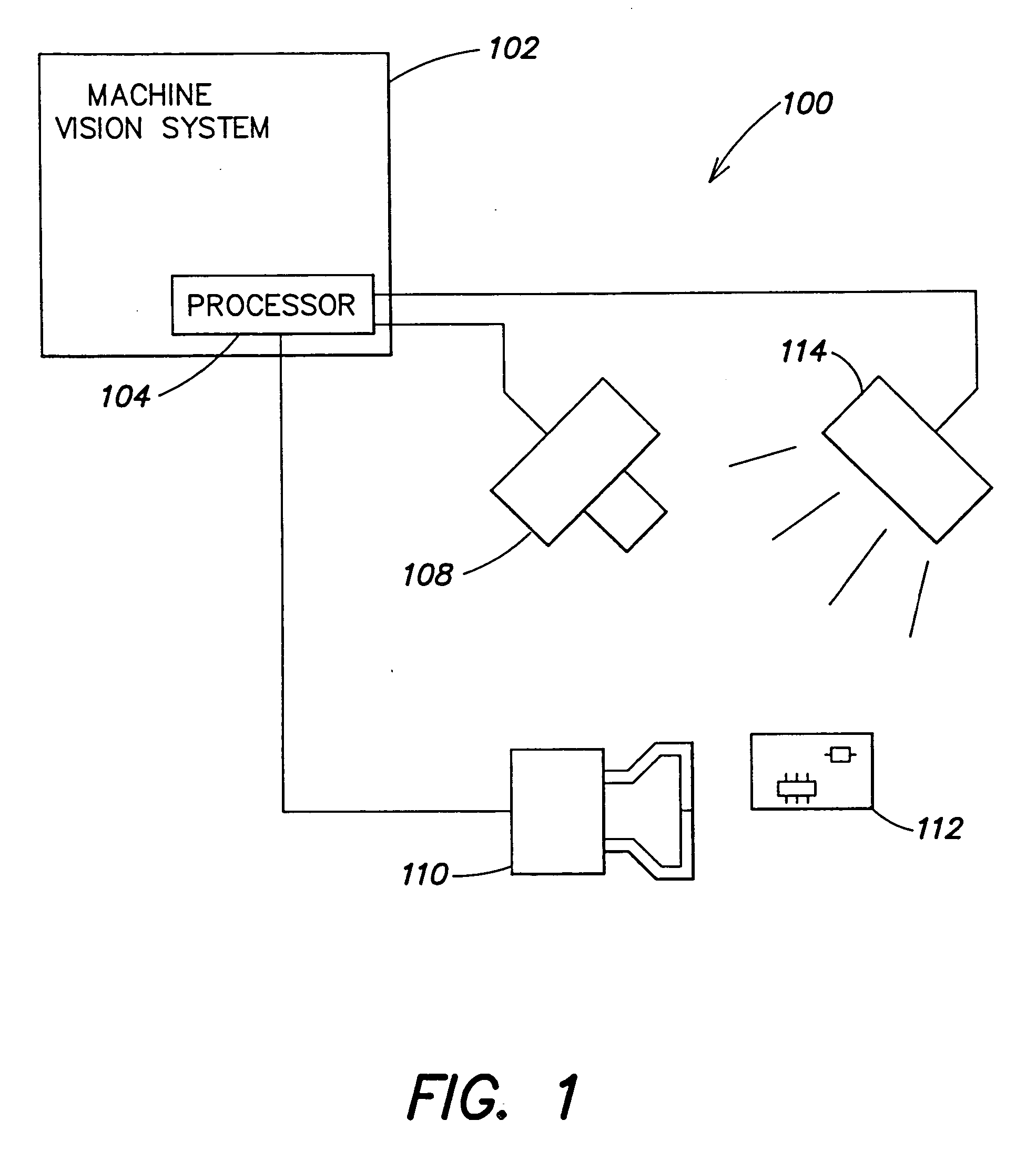

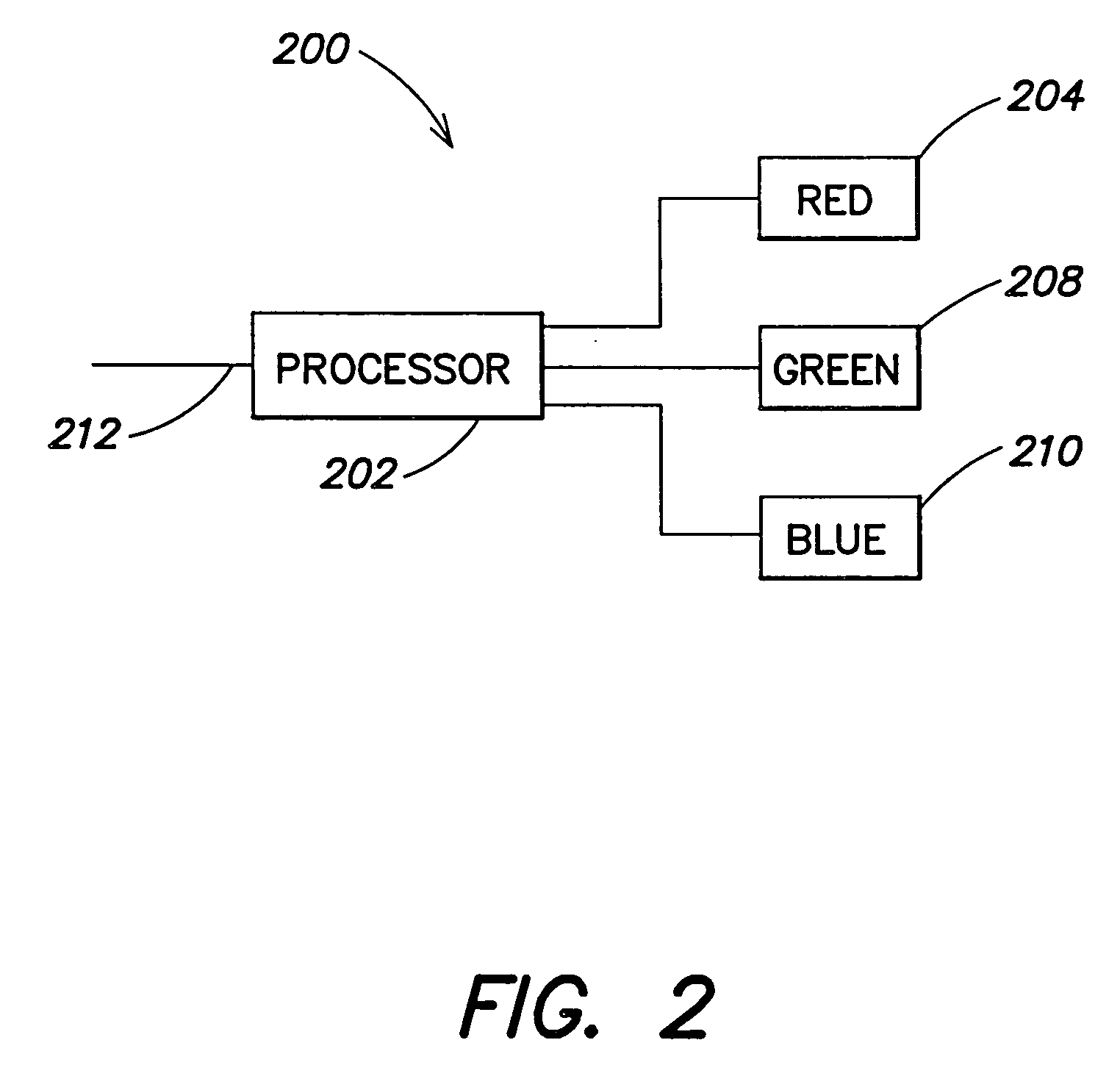

Systems and methods for providing illumination in machine vision systems

InactiveUS7042172B2Photoelectric discharge tubesElectric light circuit arrangementOphthalmologyLighting system

A lighting system associated with a machine vision system. The machine vision system may direct lighting control commands to the lighting system to change the illumination conditions provided to an object. A vision system may also be provided and associated with the machine vision system such that the vision system views and captures an image(s) of the object when lit by the lighting system. The machine vision system may direct the lighting system to change the illumination conditions and then capture the image.

Owner:SIGNIFY NORTH AMERICA CORP

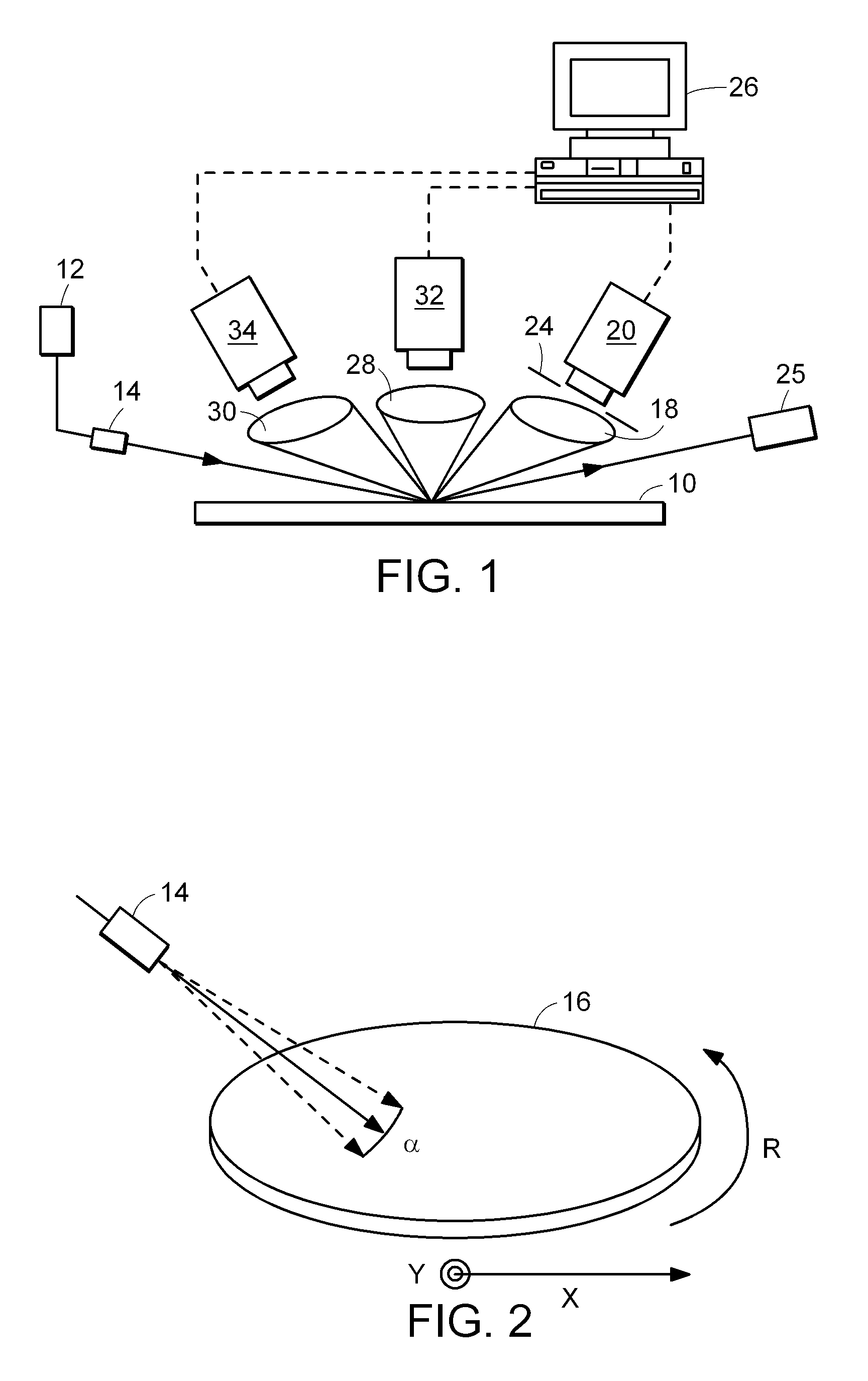

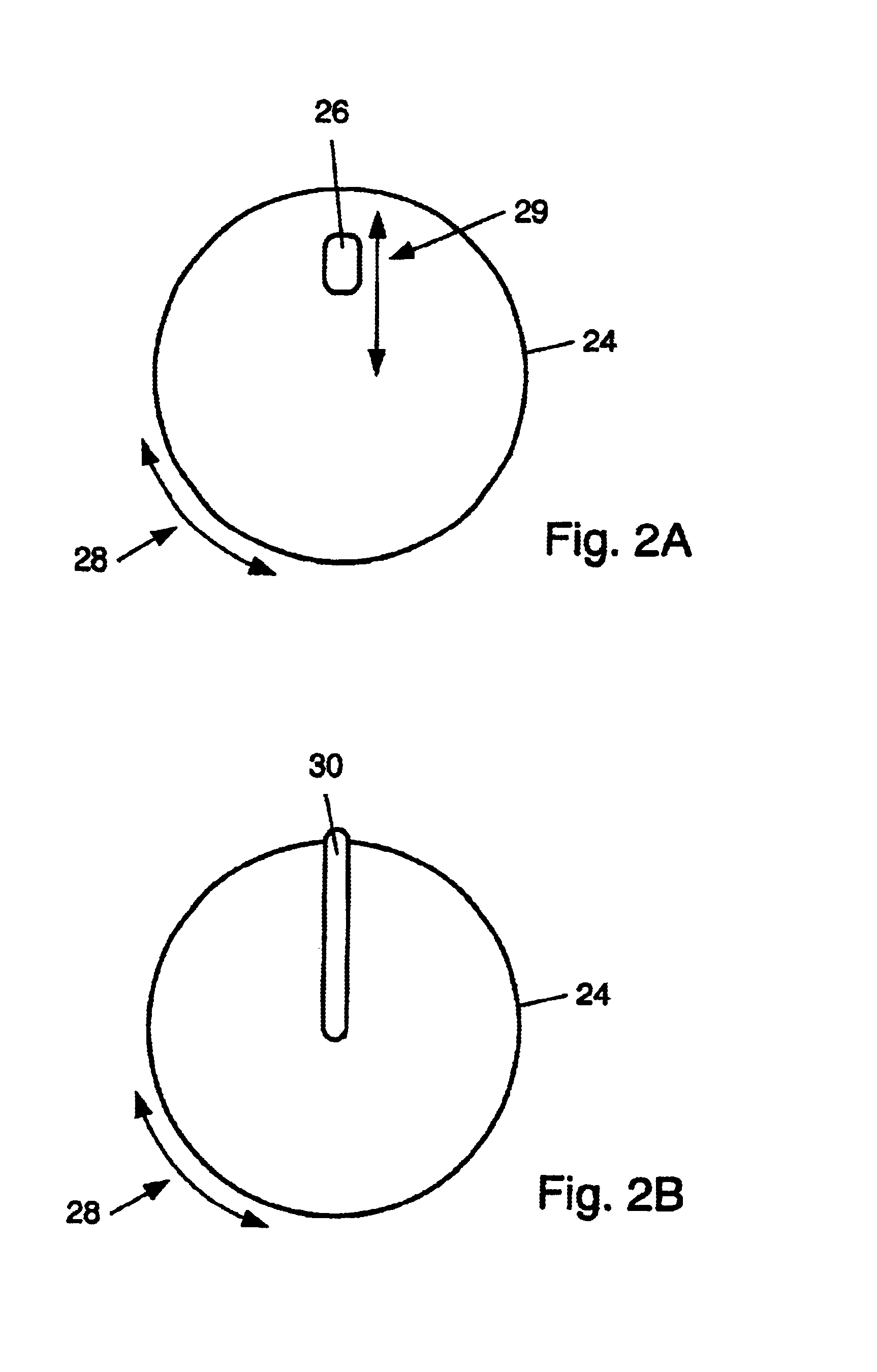

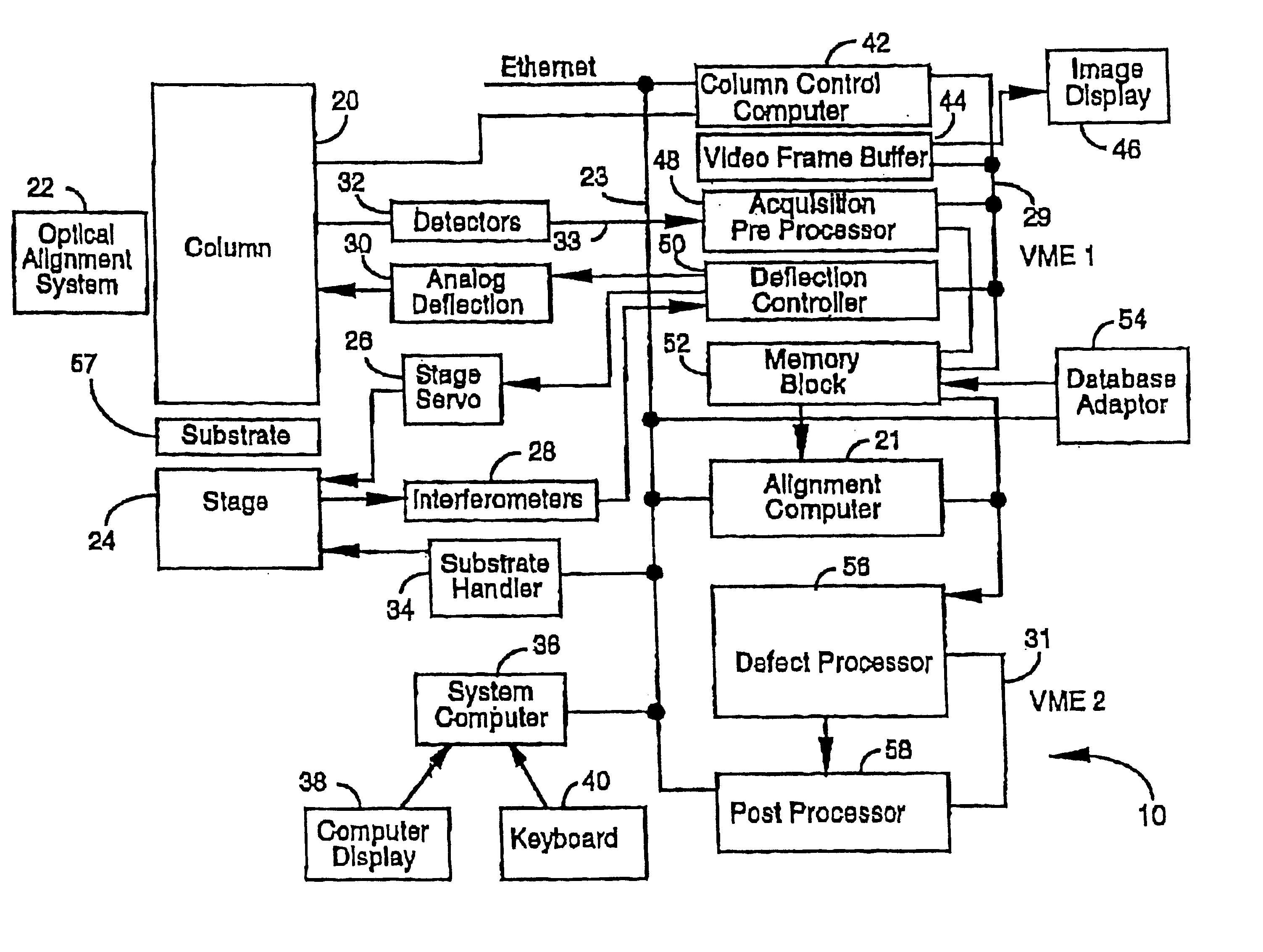

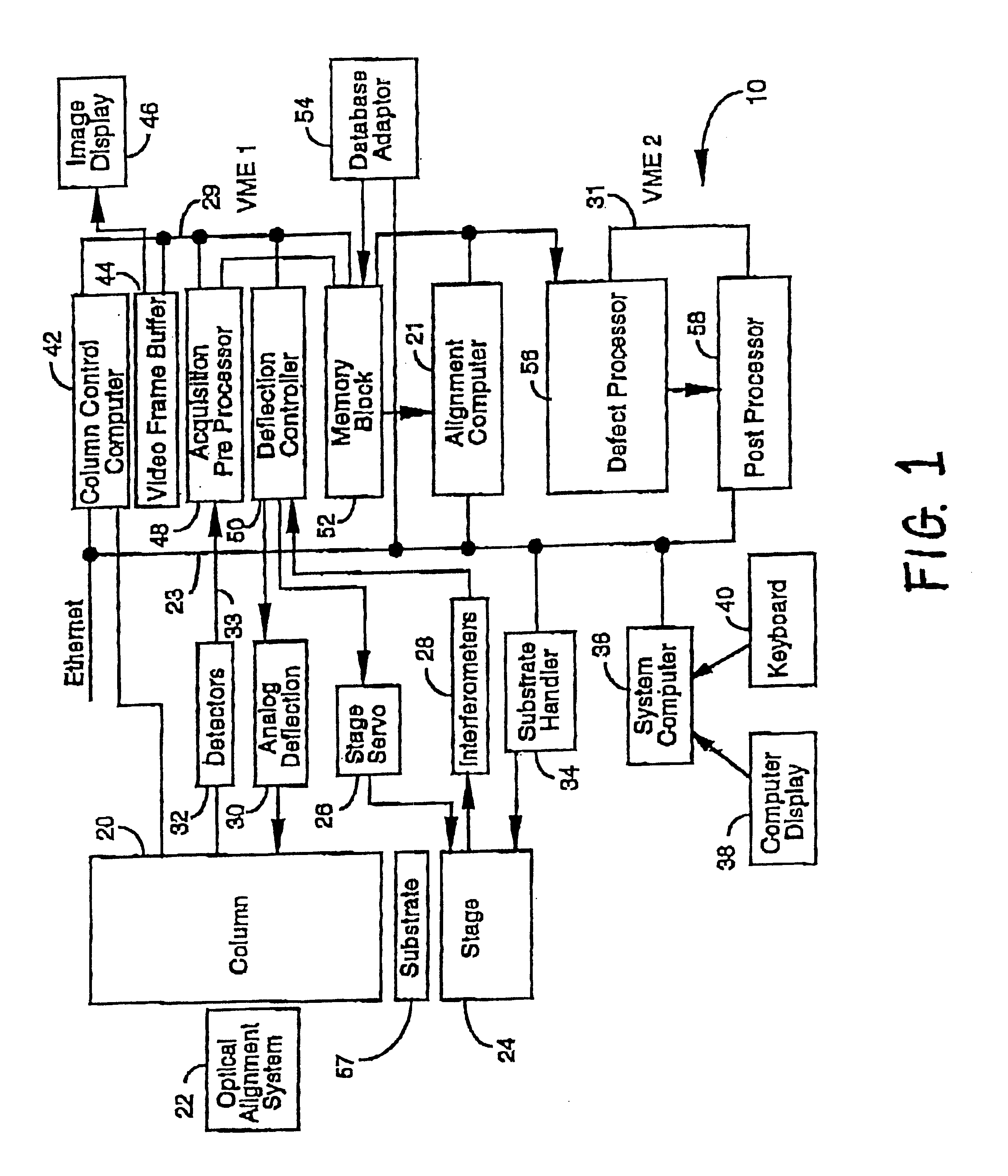

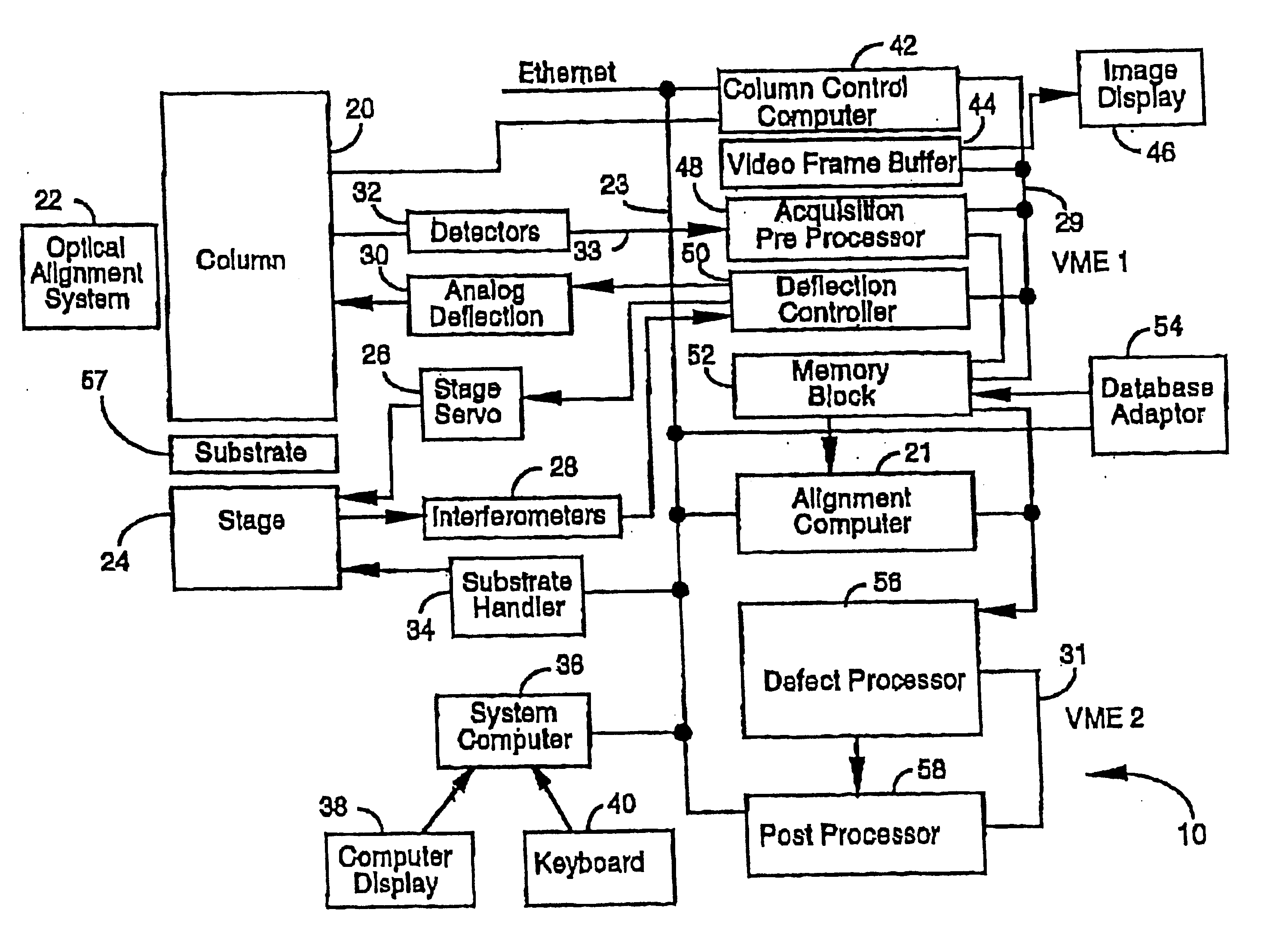

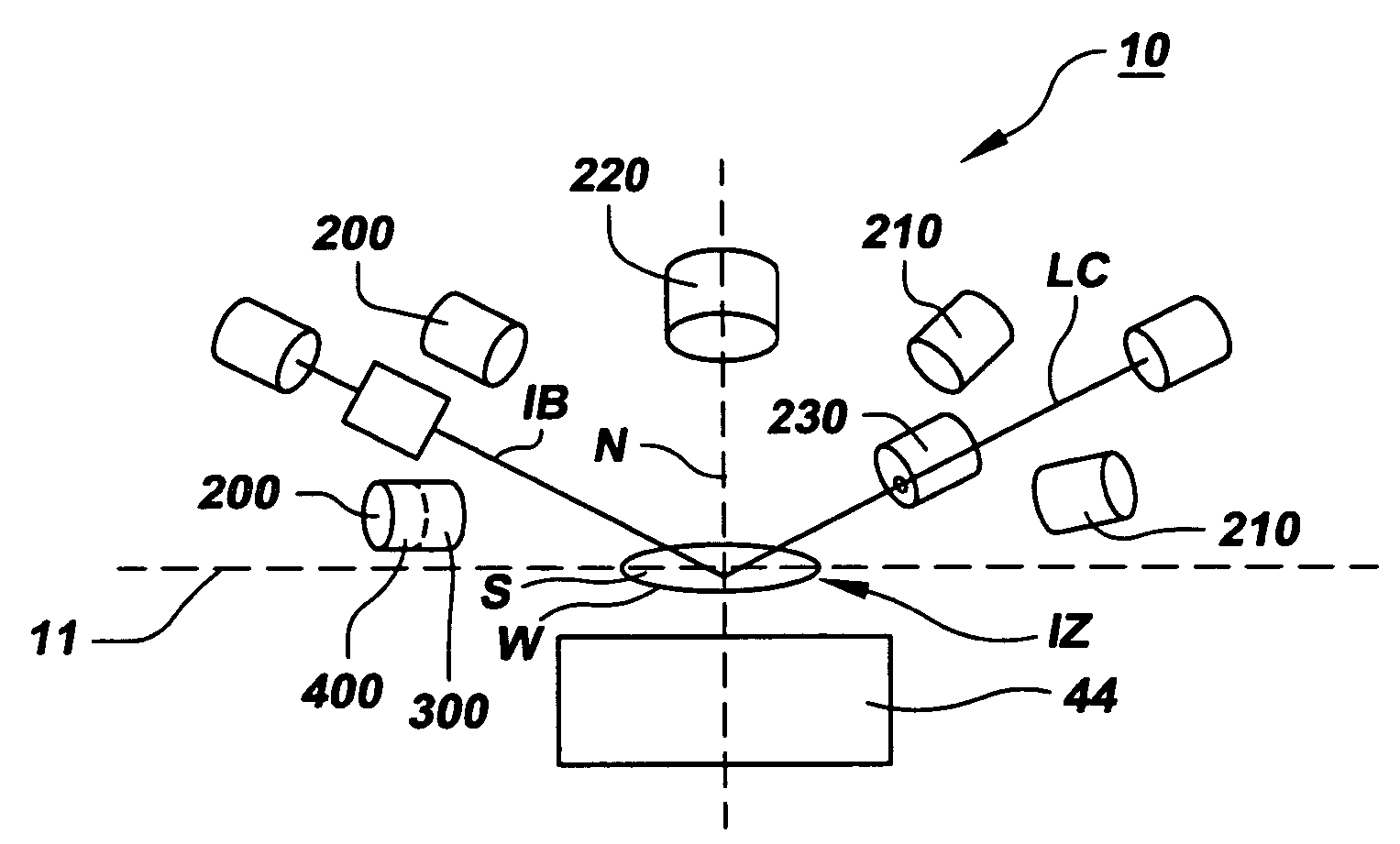

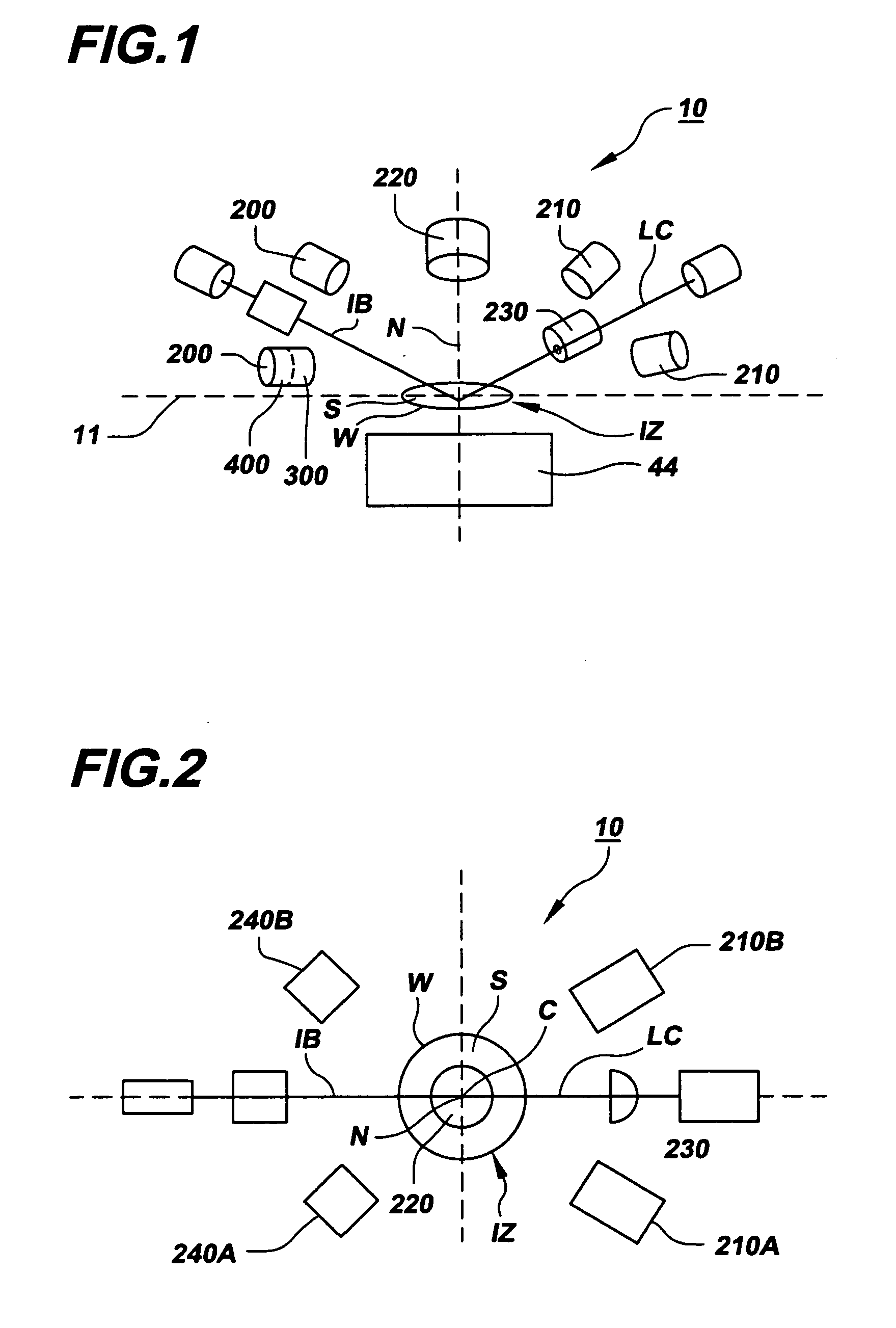

Systems for inspection of patterned or unpatterned wafers and other specimen

ActiveUS7068363B2Scattering properties measurementsOptically investigating flaws/contaminationLighting systemLight scattering

Systems for inspection of patterned and unpatterned wafers are provided. One system includes an illumination system configured to illuminate the specimen. The system also includes a collector configured to collect light scattered from the specimen. In addition, the system includes a segmented detector configured to separately detect different portions of the light such that azimuthal and polar angular information about the different portions of light is preserved. The detector may also be configured to produce signals representative of the different portions of the light. The system may also include a processor configured to detect defects on the specimen from the signals. In another embodiment, the system may include a stage that is configured to rotate and translate the specimen. In one such embodiment, the system may also include an illumination system configured to scan the specimen in a wide scan path during rotation and translation of the specimen.

Owner:KLA TENCOR TECH CORP

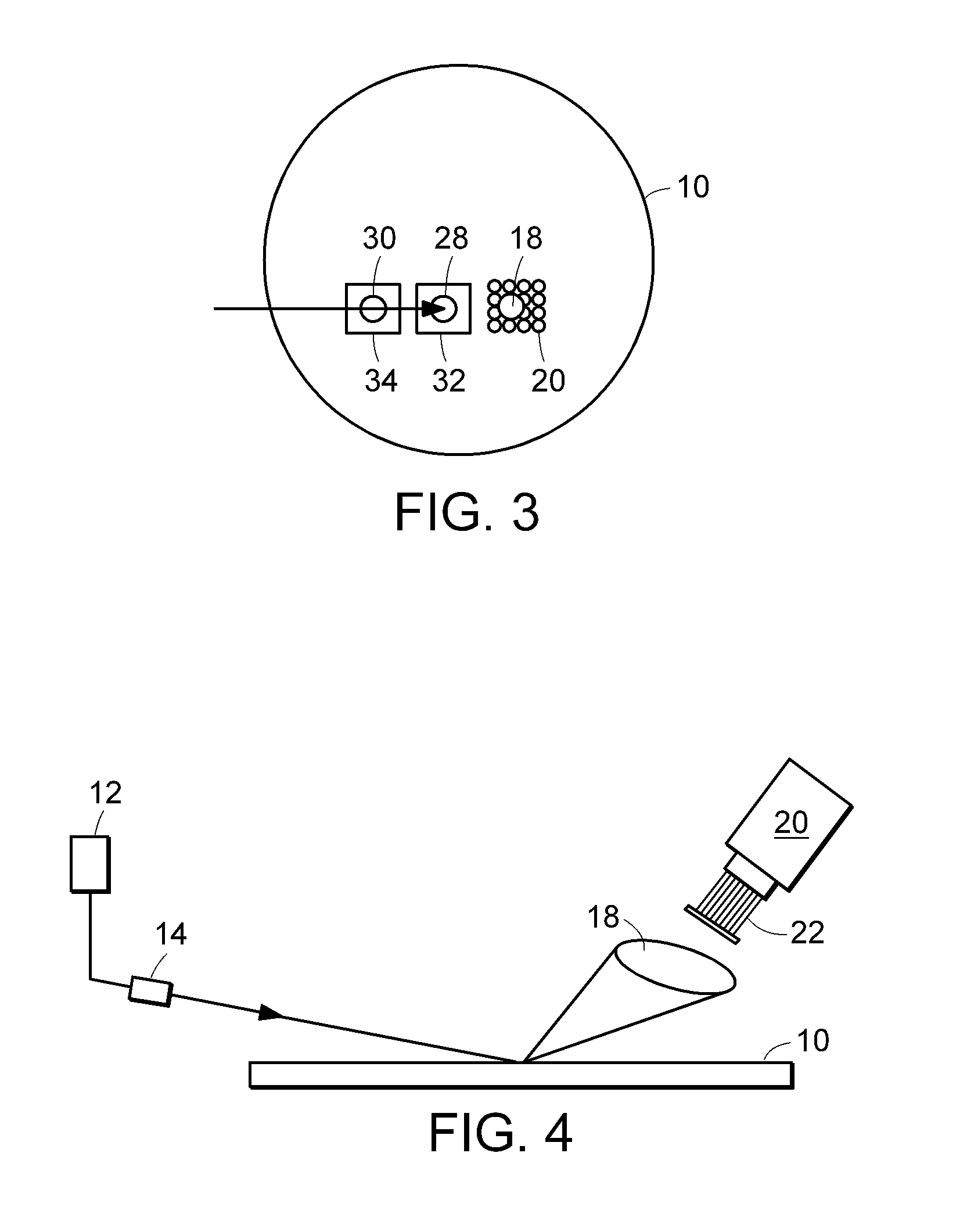

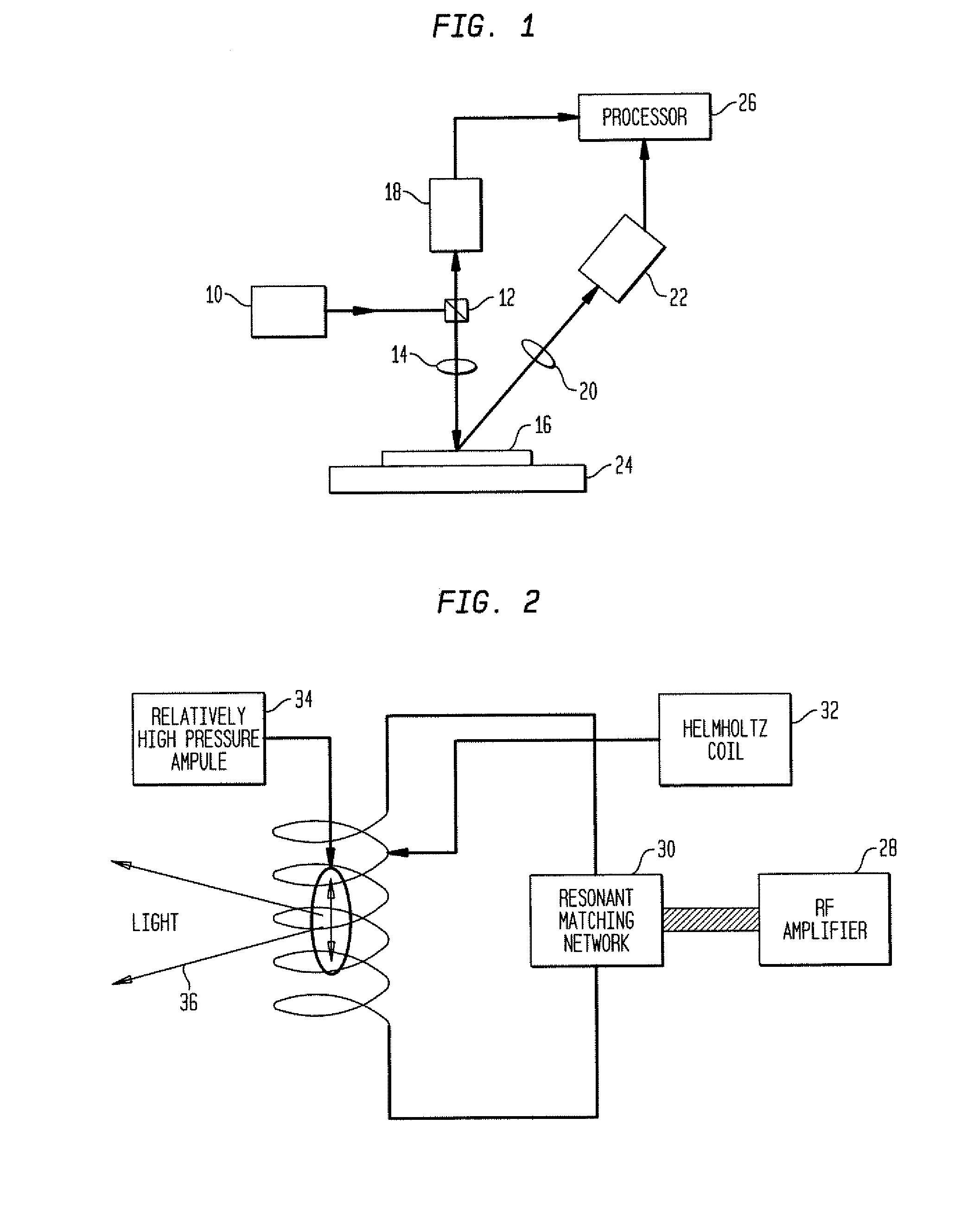

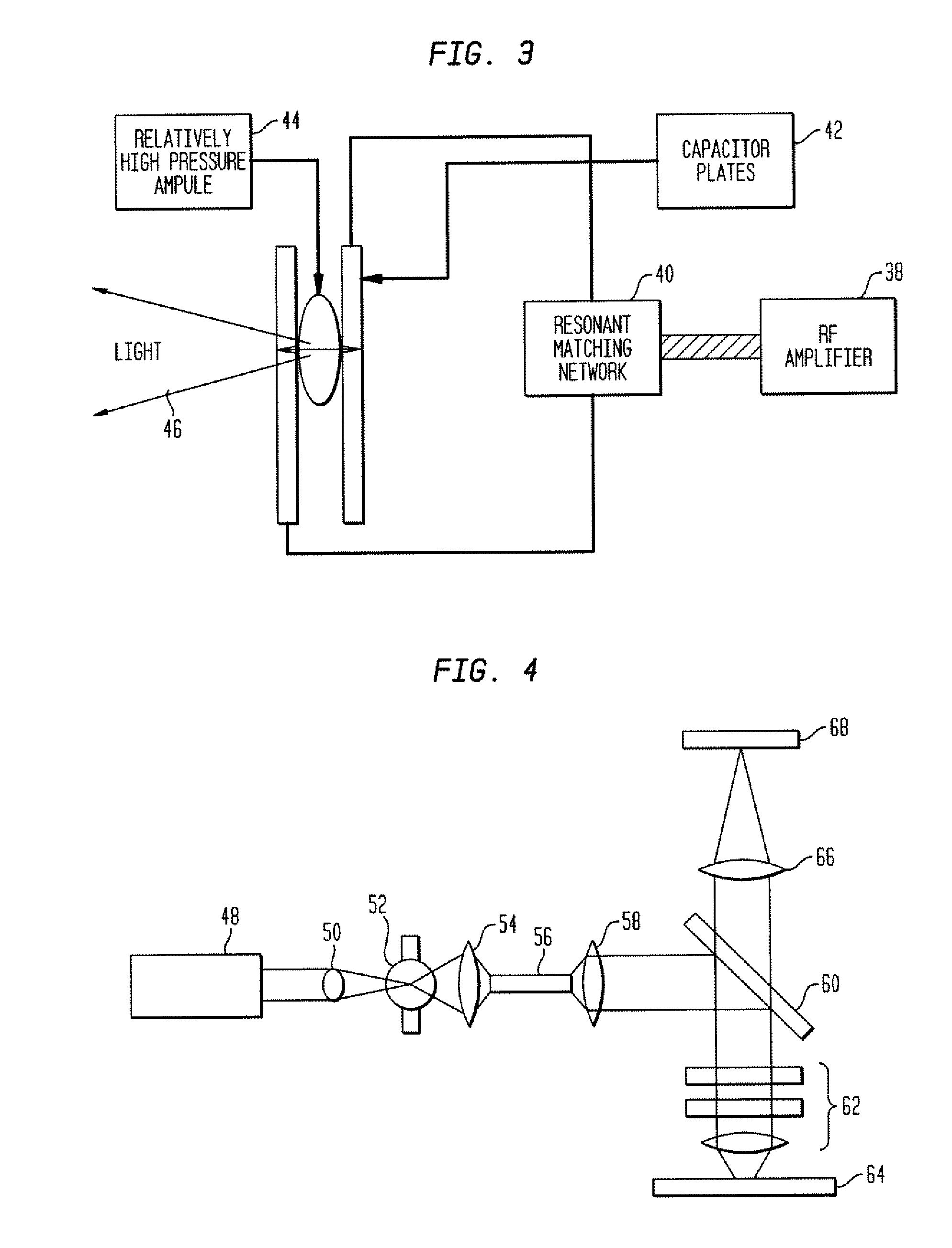

Methods and systems for providing illumination of a specimen for a process performed on the specimen

ActiveUS7705331B1Improve isolationConvenient lightingMaterial analysis using wave/particle radiationPhotomechanical apparatusElectrodeless lampLaser

Methods and systems for providing illumination of a specimen for a process performed on the specimen are provided. One system configured to provide illumination of a specimen for a process performed on the specimen includes a laser configured to generate excitation light. The system also includes focusing optics configured to focus the excitation light to a plasma in an electrodeless lamp such that the plasma generates light. The system is also configured such that the light illuminates the specimen during the process.

Owner:KLA TENCOR TECH CORP

Stepper type test structures and methods for inspection of semiconductor integrated circuits

InactiveUS6633174B1Reduce pressureNanotechSemiconductor/solid-state device testing/measurementEngineeringSemiconductor

Disclosed is a method of inspecting a sample. The method includes moving to a first field associated with a first group of test structures. The first group of test structures are partially within the first field. The method further includes scanning the first field to determine whether there are any defects present within the first group of test structures. When it is determined that there are defects within the first group of test structures, the method further includes repeatedly stepping to areas and scanning such areas so as to determine a specific defect location within the first group of test structures. A suitable test structure for performing this method is also disclosed.< / PTEXT>

Owner:KLA TENCOR TECH CORP

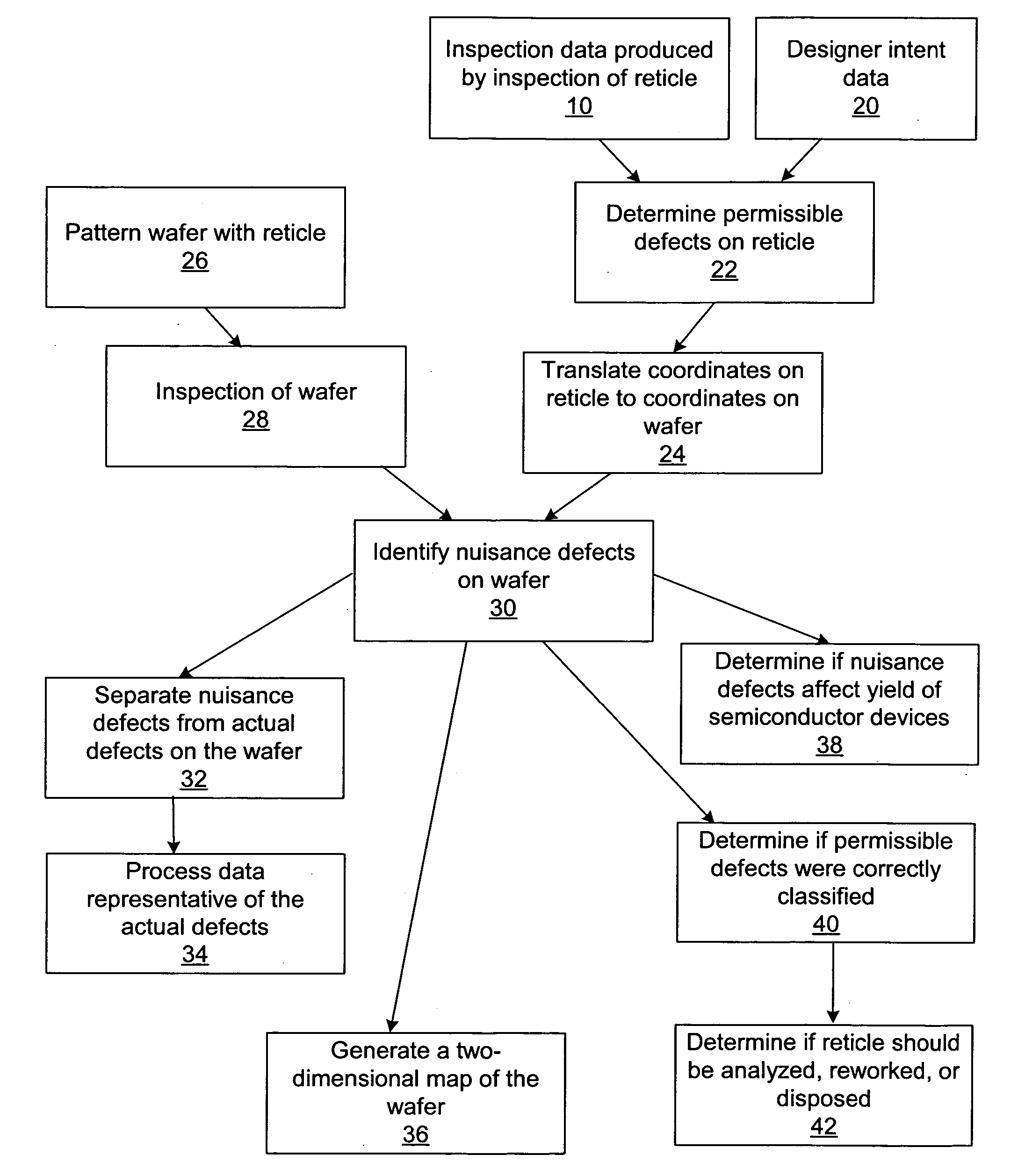

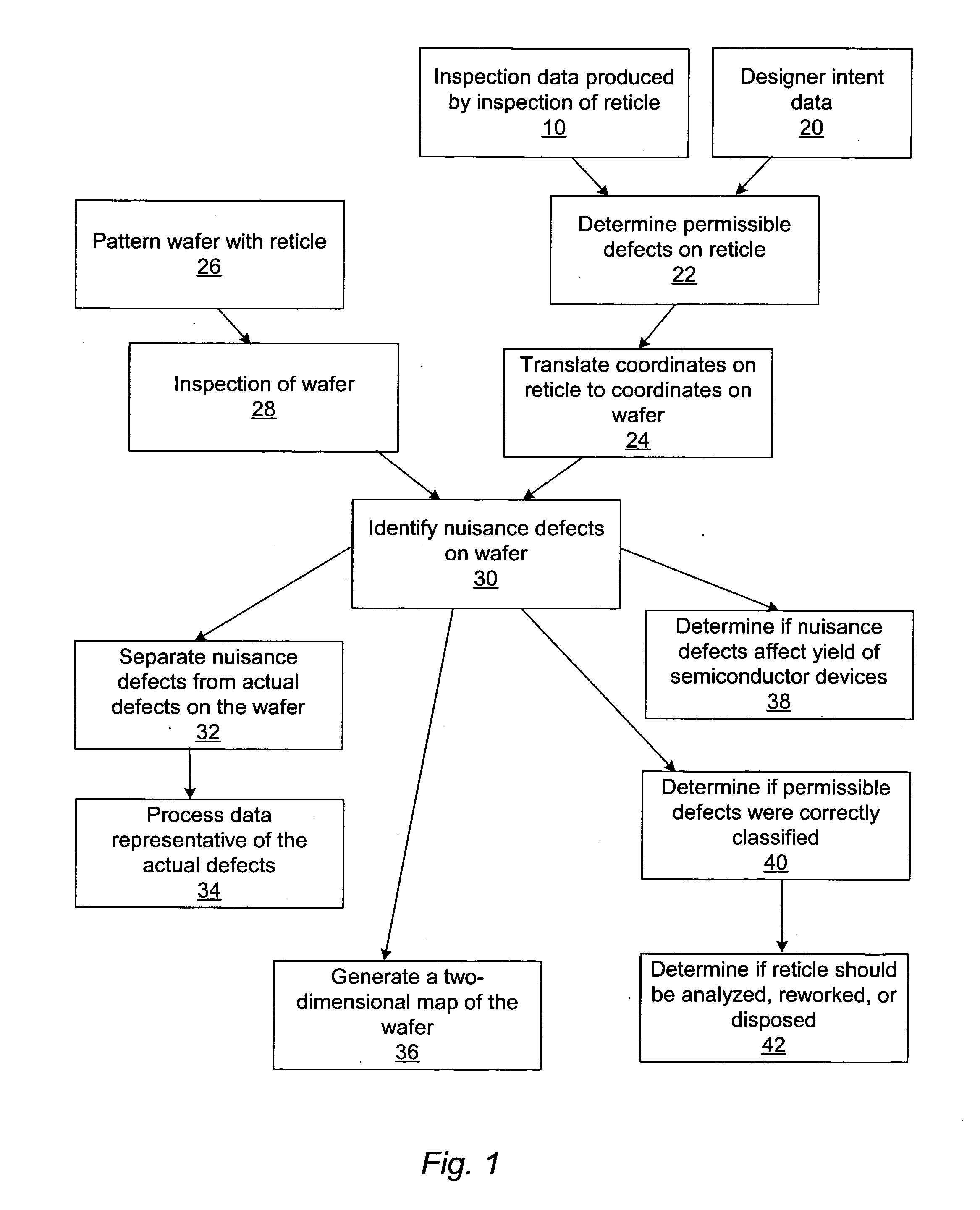

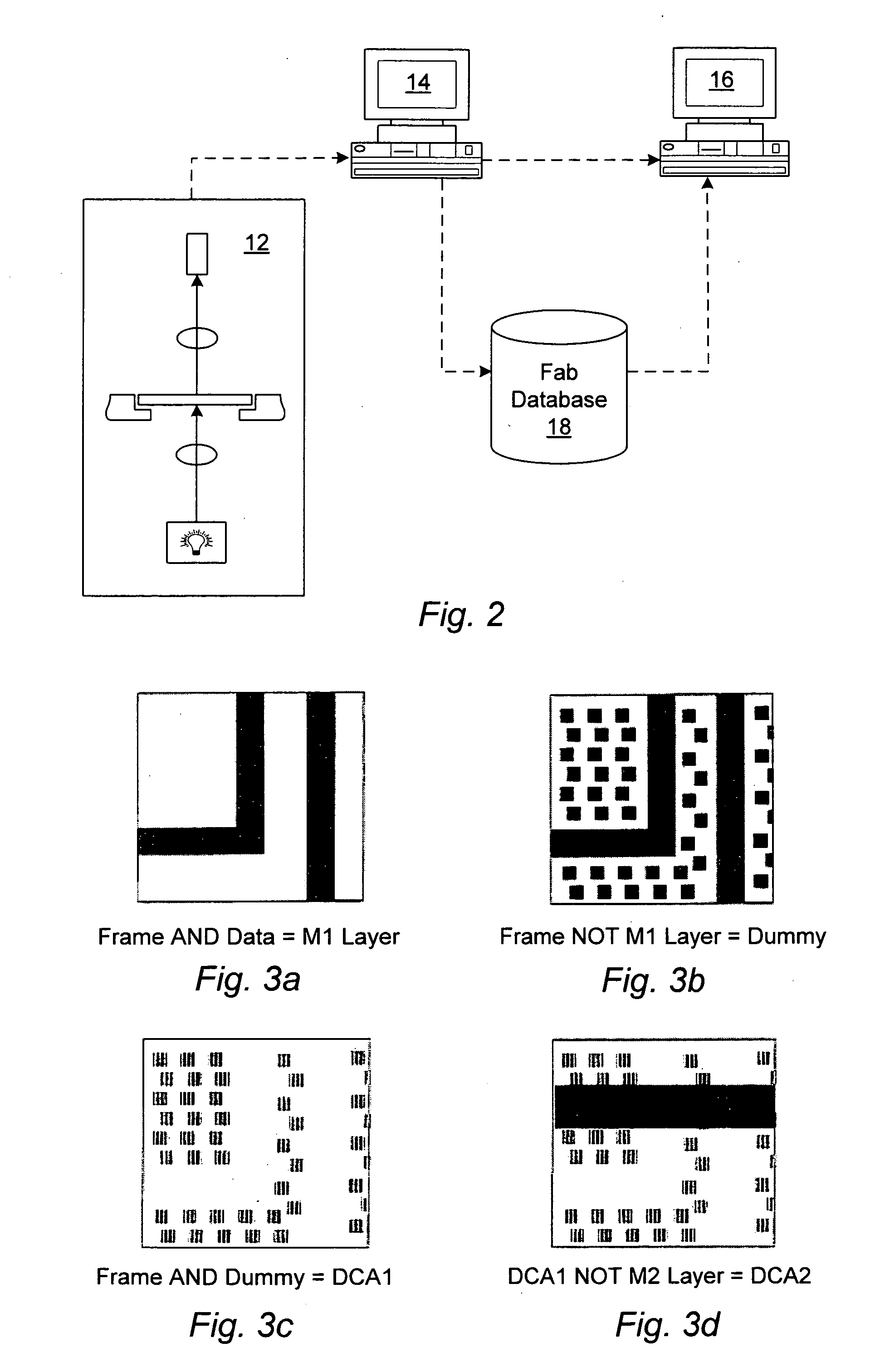

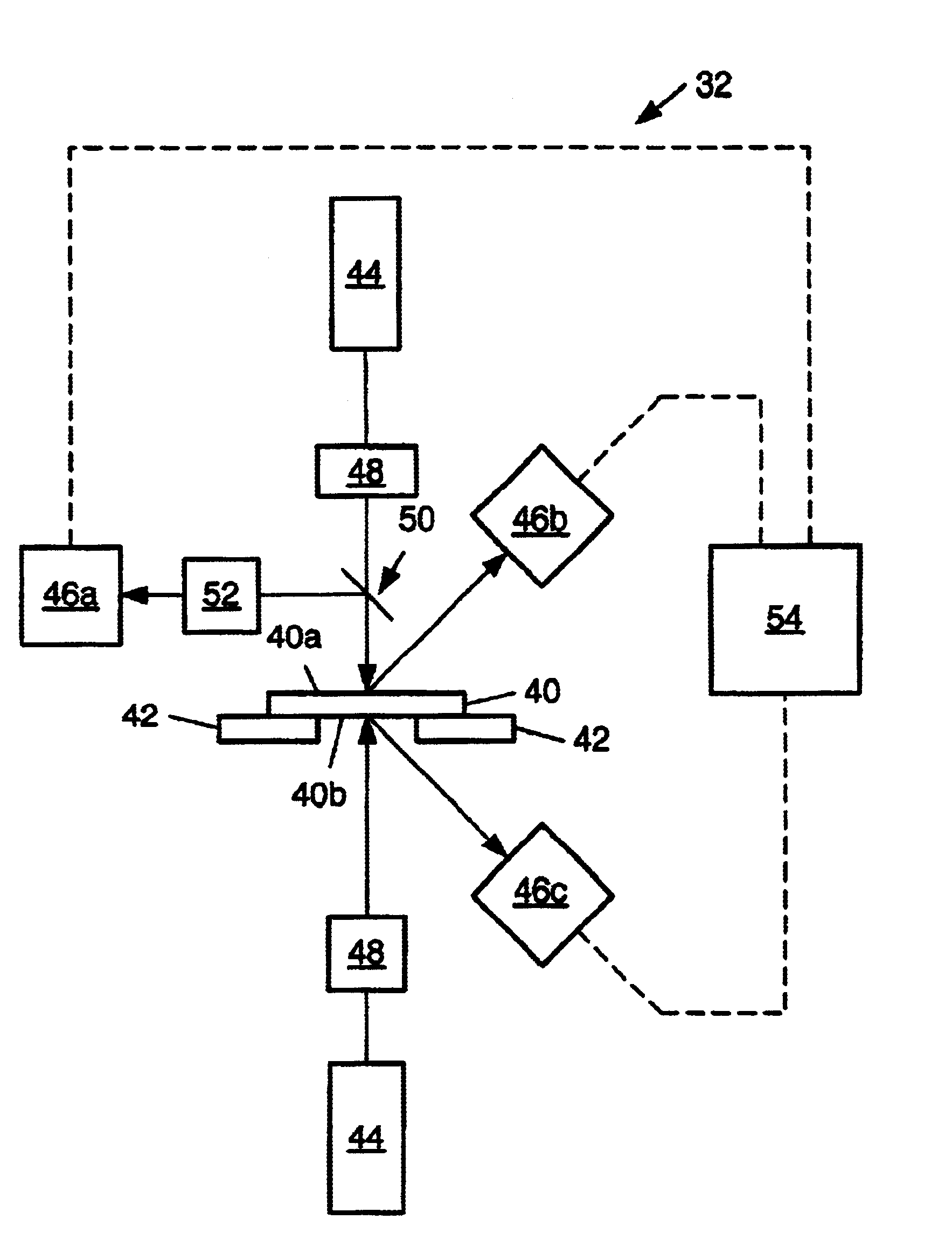

Methods and systems for inspection of wafers and reticles using designer intent data

Methods and systems for inspection of wafers and reticles using designer intent data are provided. One computer-implemented method includes identifying nuisance defects on a wafer based on inspection data produced by inspection of a reticle, which is used to form a pattern on the wafer prior to inspection of the wafer. Another computer-implemented method includes detecting defects on a wafer by analyzing data generated by inspection of the wafer in combination with data representative of a reticle, which includes designations identifying different types of portions of the reticle. An additional computer-implemented method includes determining a property of a manufacturing process used to process a wafer based on defects that alter a characteristic of a device formed on the wafer. Further computer-implemented methods include altering or simulating one or more characteristics of a design of an integrated circuit based on data generated by inspection of a wafer.

Owner:KLA TENCOR TECH CORP

Methods and systems for determining a critical dimension and overlay of a specimen

InactiveUS6891627B1Speed up the processShorten the timeSemiconductor/solid-state device testing/measurementElectric discharge tubesMeasurement deviceEngineering

Methods and systems for monitoring semiconductor fabrication processes are provided. A system may include a stage configured to support a specimen and coupled to a measurement device. The measurement device may include an illumination system and a detection system. The illumination system and the detection system may be configured such that the system may be configured to determine multiple properties of the specimen. For example, the system may be configured to determine multiple properties of a specimen including, but not limited to, critical dimension and overlay misregistration. In this manner, a measurement device may perform multiple optical and / or non-optical metrology and / or inspection techniques.

Owner:KLA CORP

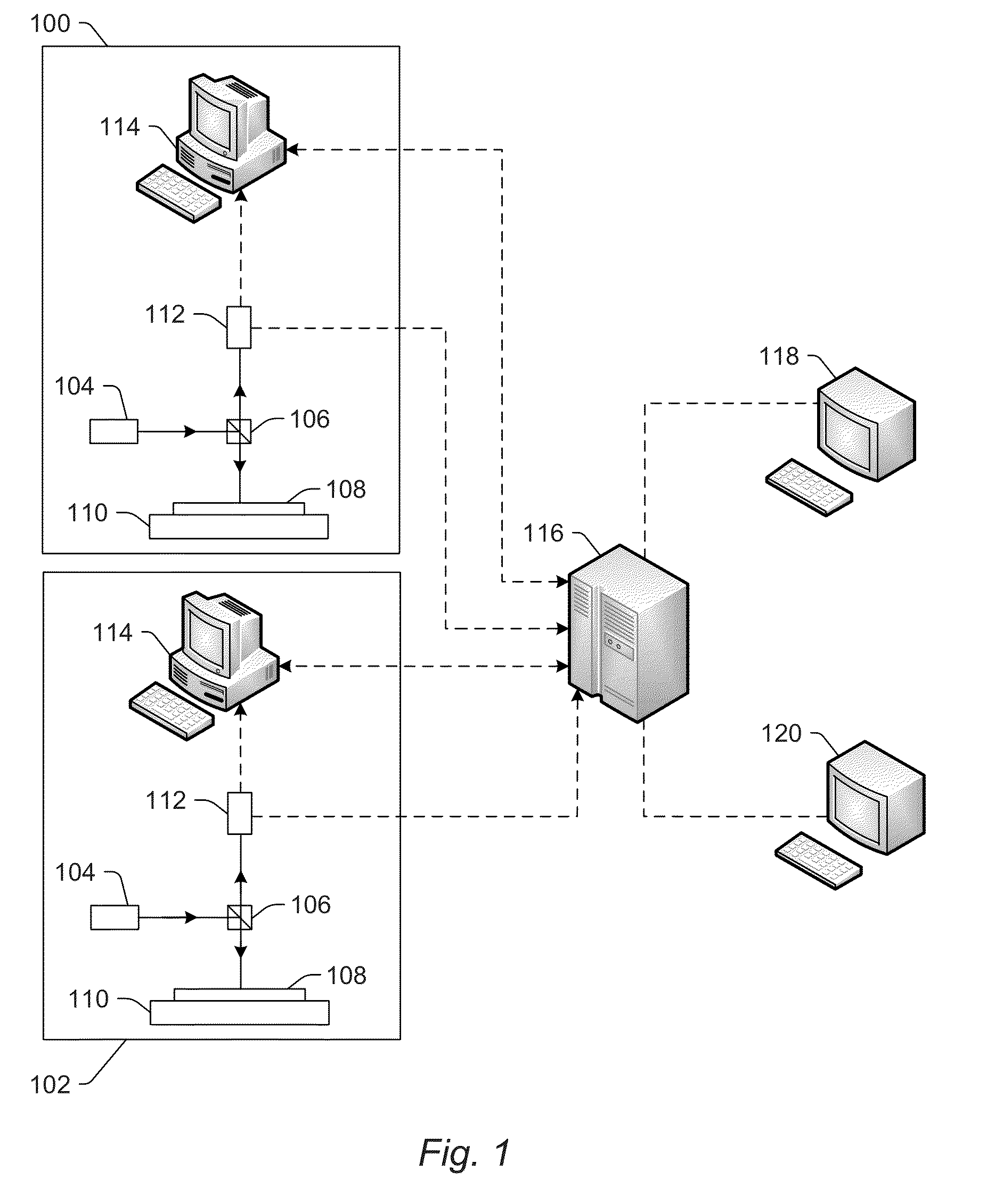

Generalized virtual inspector

Generalized virtual inspectors are provided. One system includes two or more actual systems configured to perform one or more processes on specimen(s) while the specimen(s) are disposed within the actual systems. The system also includes one or more virtual systems coupled to the actual systems to thereby receive output generated by the actual systems and to send information to the actual systems. The virtual system(s) are configured to perform one or more functions using at least some of the output received from the actual systems. The virtual system(s) are not capable of having the specimen(s) disposed therein.

Owner:KLA CORP

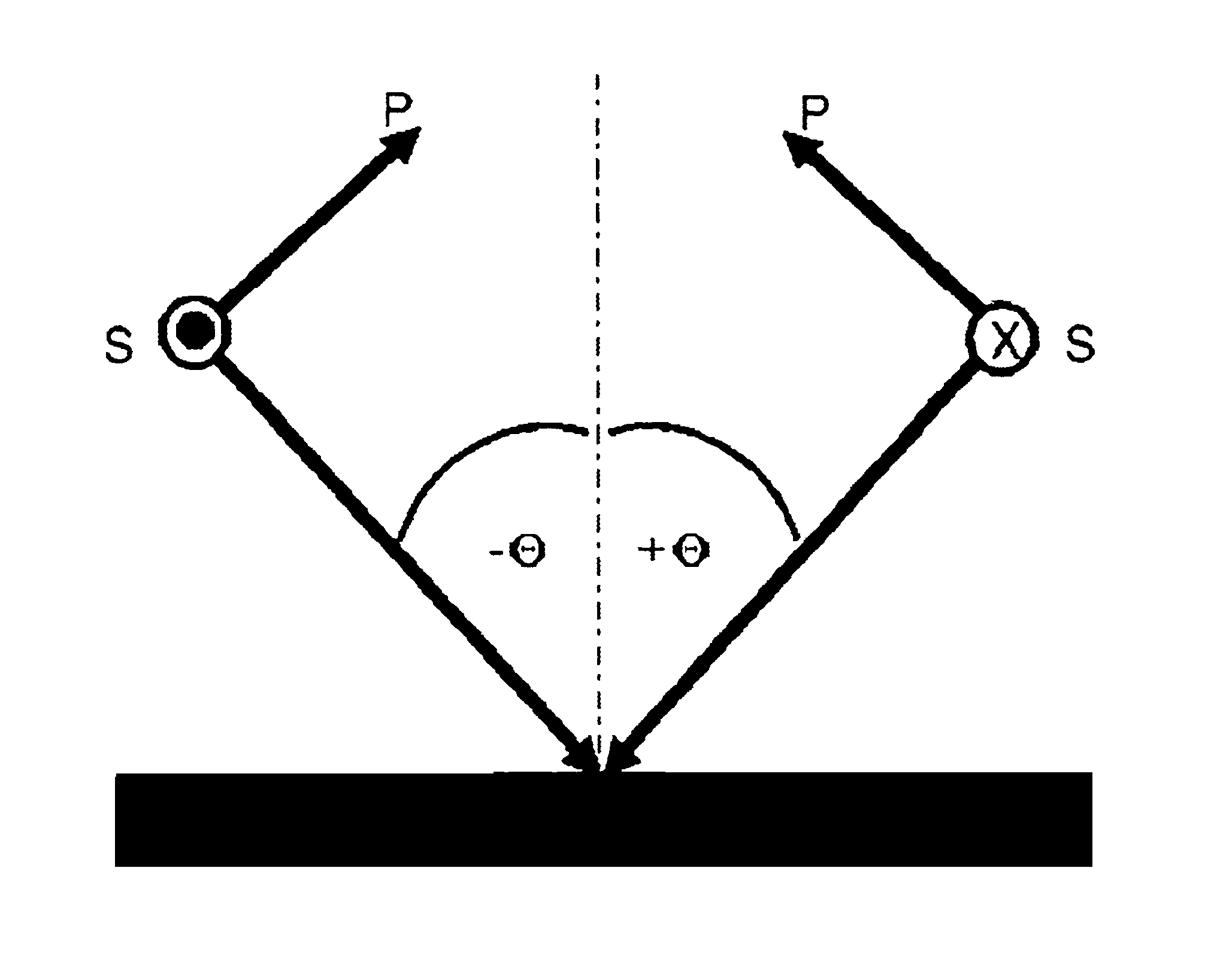

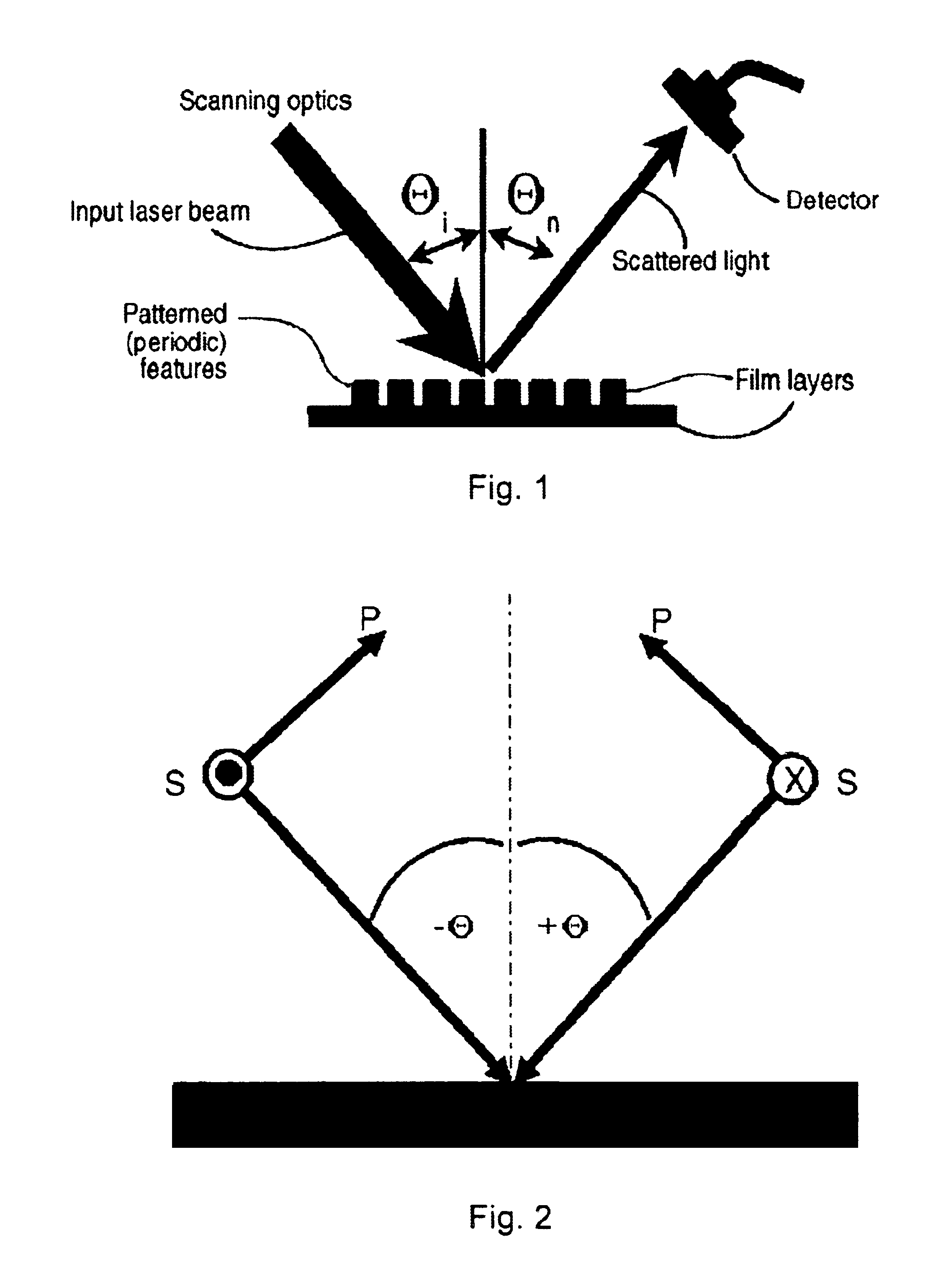

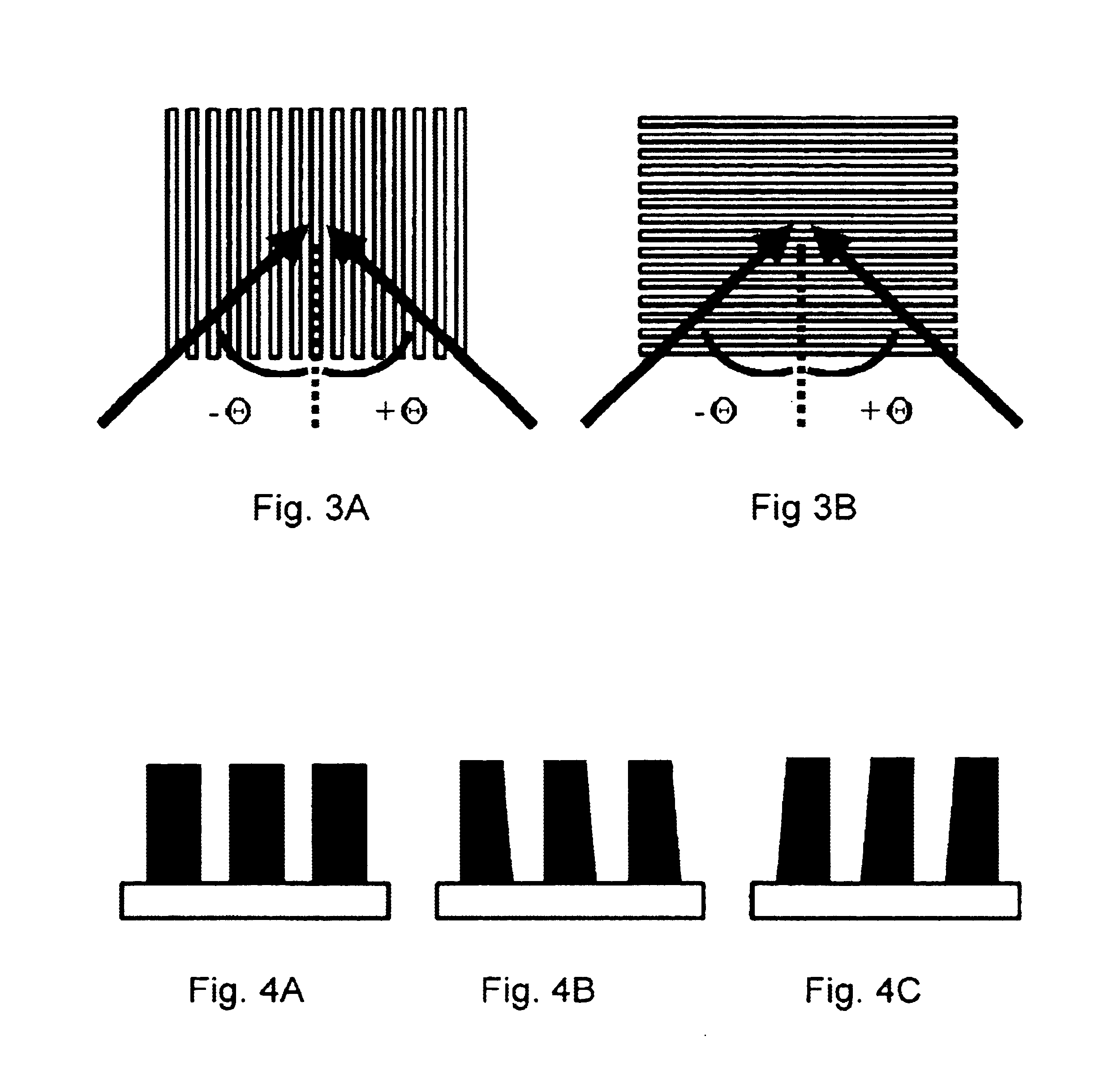

Line profile asymmetry measurement using scatterometry

InactiveUS6856408B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingScatterometerLength wave

A method of and apparatus for measuring line profile asymmetries in microelectronic devices comprising directing light at an array of microelectronic features of a microelectronic device, detecting light scattered back from the array comprising either or both of one or more angles of reflection and one or more wavelengths, and comparing one or more characteristics of the back-scattered light by examining data from complementary angles of reflection or performing a model comparison.

Owner:ONTO INNOVATION INC

Systems and methods for providing illumination in machine vision systems

InactiveUS20040113568A1Photoelectric discharge tubesElectric light circuit arrangementEffect lightEngineering

A lighting system associated with a machine vision system. The machine vision system may direct lighting control commands to the lighting system to change the illumination conditions provided to an object. A vision system may also be provided and associated with the machine vision system such that the vision system views and captures an image(s) of the object when lit by the lighting system. The machine vision system may direct the lighting system to change the illumination conditions and then capture the image.

Owner:SIGNIFY NORTH AMERICA CORP

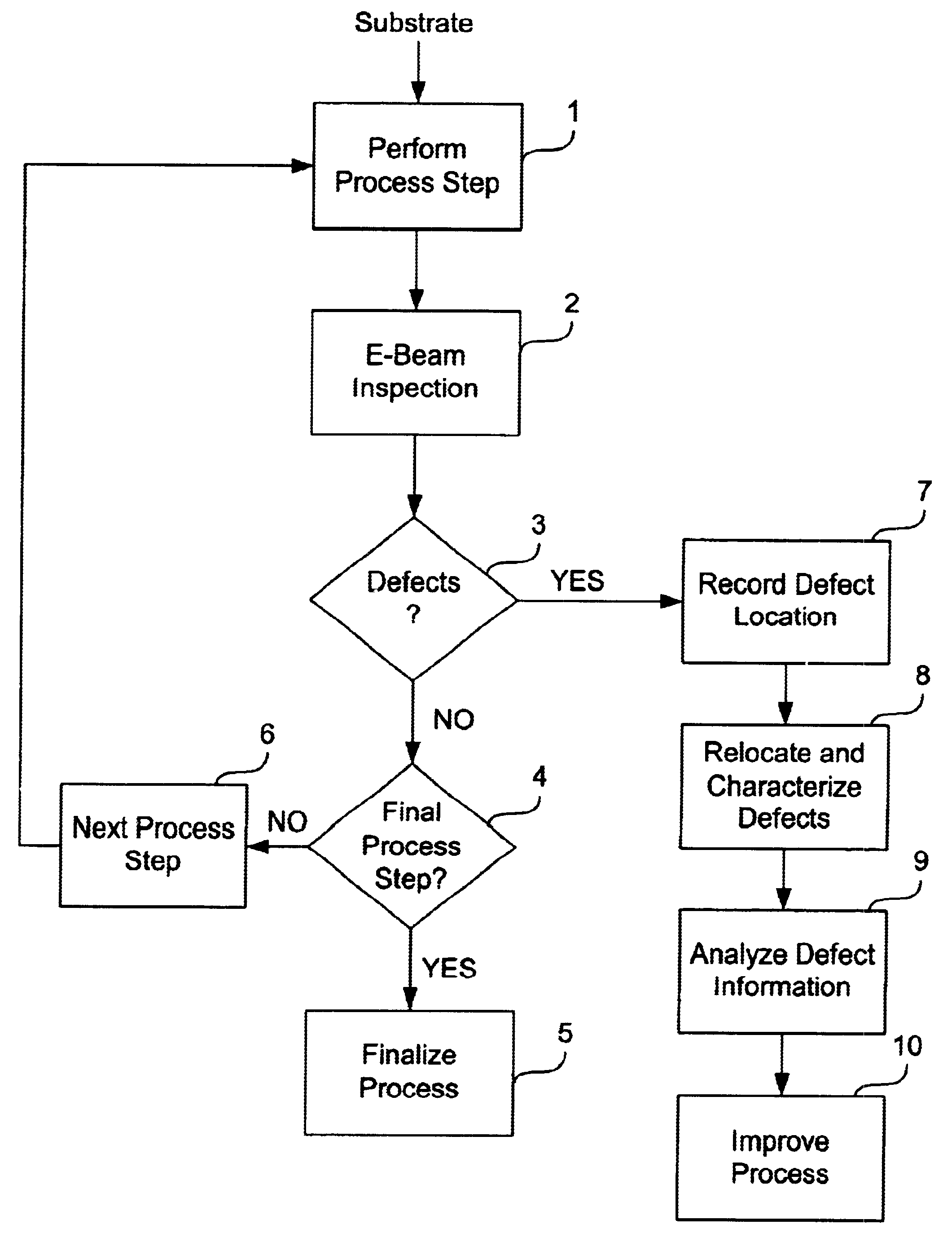

Methods and apparatus for optimizing semiconductor inspection tools

InactiveUS6433561B1Reduce pressureSemiconductor/solid-state device testing/measurementElectric discharge tubesEngineeringVoltage contrast

Disclosed is a method of inspecting a sample. At least a portion of the sample is illuminated. Signals received from the illuminated portion are detected, and the detected signals are processed to find defects present on the sample. The processing of the detected signals is optimized, at least in part, based upon results obtained from voltage contrast testing. In one implementation, the illumination is an optical illumination. In another embodiment, the processing comprises automated defect classification, and setup of the automated classification is optimized using the results obtained from voltage contrast testing. In another implementation, the results relate to a probability that a feature present on the sample represents an electrical defect.

Owner:KLA TENCOR TECH CORP

Inspectable buried test structures and methods for inspecting the same

InactiveUS6509197B1Easily dry-etchedEasy to processSemiconductor/solid-state device testing/measurementElectric discharge tubesVoltage contrastSemiconductor

Disclosed is a semiconductor die having a lower test structure formed in a lower metal layer of the semiconductor die. The lower conductive test structure has a first end and a second end. The first end is coupled to a predetermined voltage level. The semiconductor die also includes an insulating layer formed over the lower metal layer. The die further includes an upper test structure formed in an upper metal layer of the semiconductor die. The upper conductive test structure is coupled with the second end of the lower conductive test structure. The upper metal layer is formed over the insulating layer. In a specific implementation, the first end of the lower test structure is coupled to ground. In another embodiment, the semiconductor die also includes a substrate and a first via coupled between the first end of the lower test structure and the substrate. In yet another aspect, the lower test structure is an extended metal line, and the upper test structure is a voltage contrast element. Methods for inspecting and fabricating such semiconductor die are also disclosed.

Owner:KLA TENCOR CORP

System and method for signal processing for a workpiece surface inspection system

ActiveUS20060181700A1High sensitivityImprove reliabilityImage enhancementImage analysisBeam sourceData acquisition

A surface inspection system, as well as related components and methods, are provided. The surface inspection system includes a beam source subsystem, a beam scanning subsystem, a workpiece movement subsystem, an optical collection and detection subsystem, and a processing subsystem. The signal processing subsystem comprises a series of data acquisition nodes, each dedicated to a collection detection module and a plurality of data reduction nodes, made available on a peer to peer basis to each data acquisition nodes. Improved methods for detecting signal in the presence of noise are also provided.

Owner:ADE CORPORATION

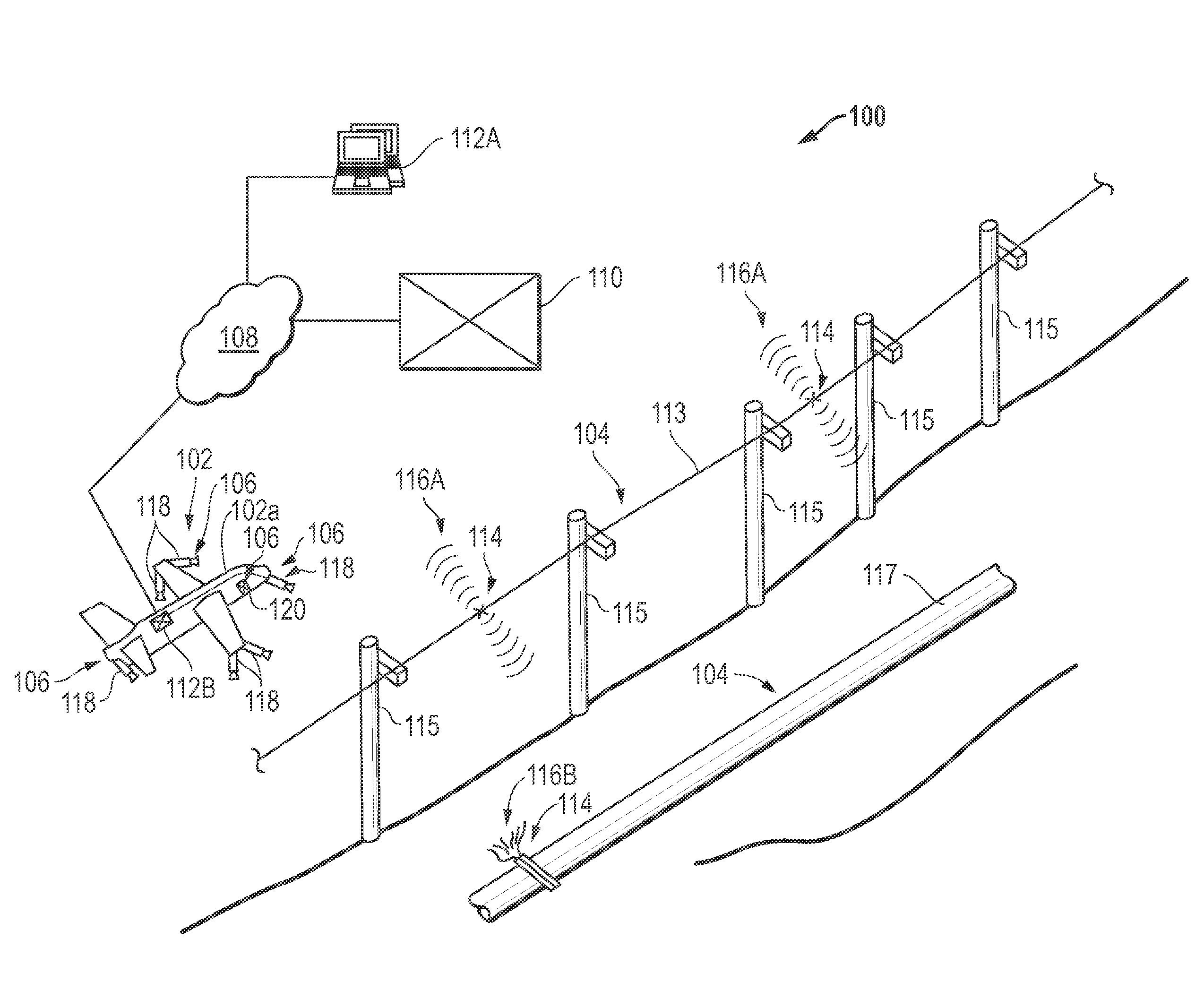

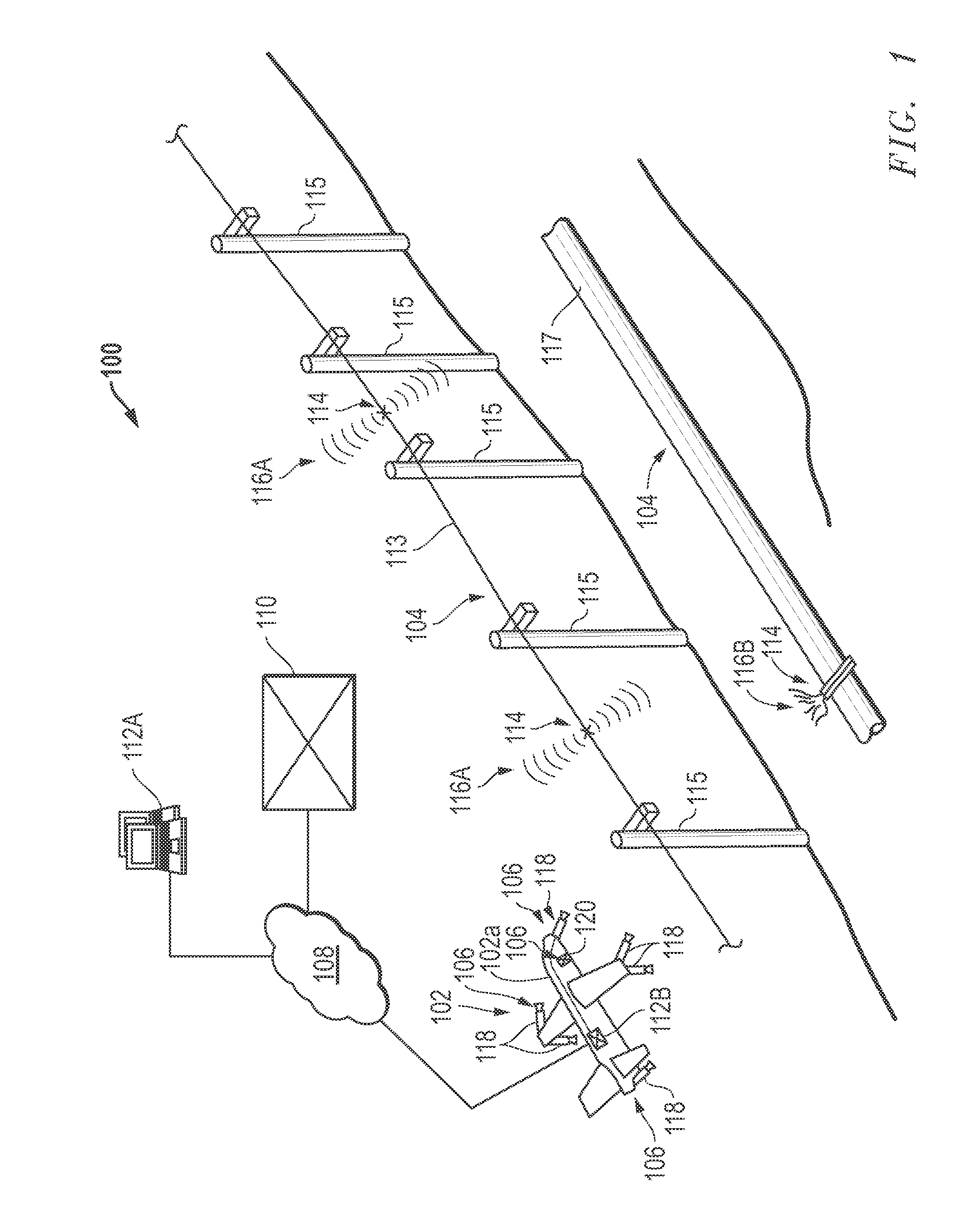

Aerial Inspection System(s) and Method(s)

An aerial inspection system has at least one transmission line, an aerial vehicle, and a detection device coupled to the aerial vehicle. The detection device is configured to detect a condition of the transmission line as the aerial vehicle flies across the transmission line. The aerial vehicle may be in the form of a drone.

Owner:QUANTA ASSOC

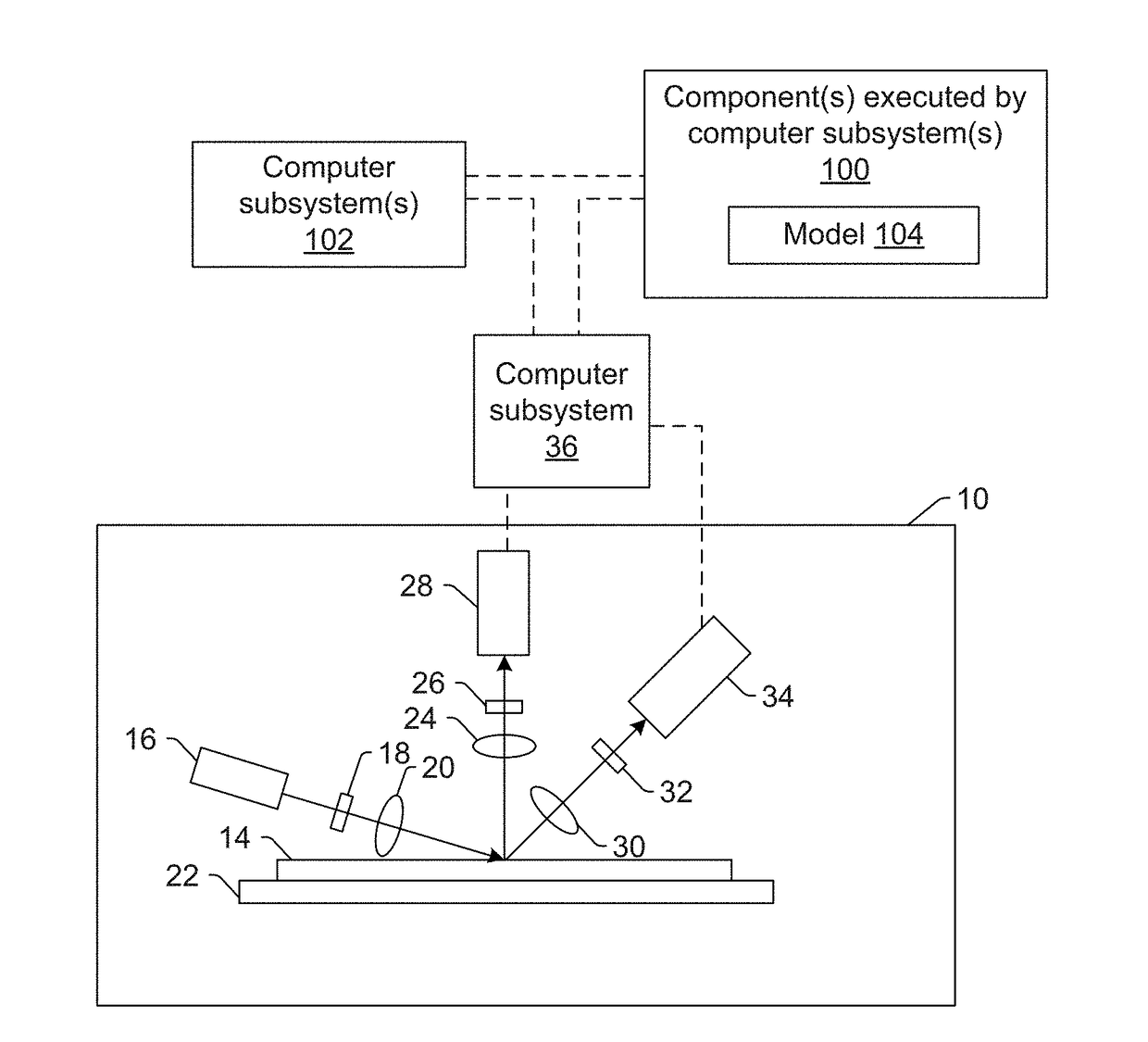

Generating high resolution images from low resolution images for semiconductor applications

Methods and systems for generating a high resolution image for a specimen from one or more low resolution images of the specimen are provided. One system includes one or more computer subsystems configured for acquiring one or more low resolution images of a specimen. The system also includes one or more components executed by the one or more computer subsystems. The one or more components include a model that includes one or more first layers configured for generating a representation of the one or more low resolution images. The model also includes one or more second layers configured for generating a high resolution image of the specimen from the representation of the one or more low resolution images.

Owner:KLA TENCOR TECH CORP

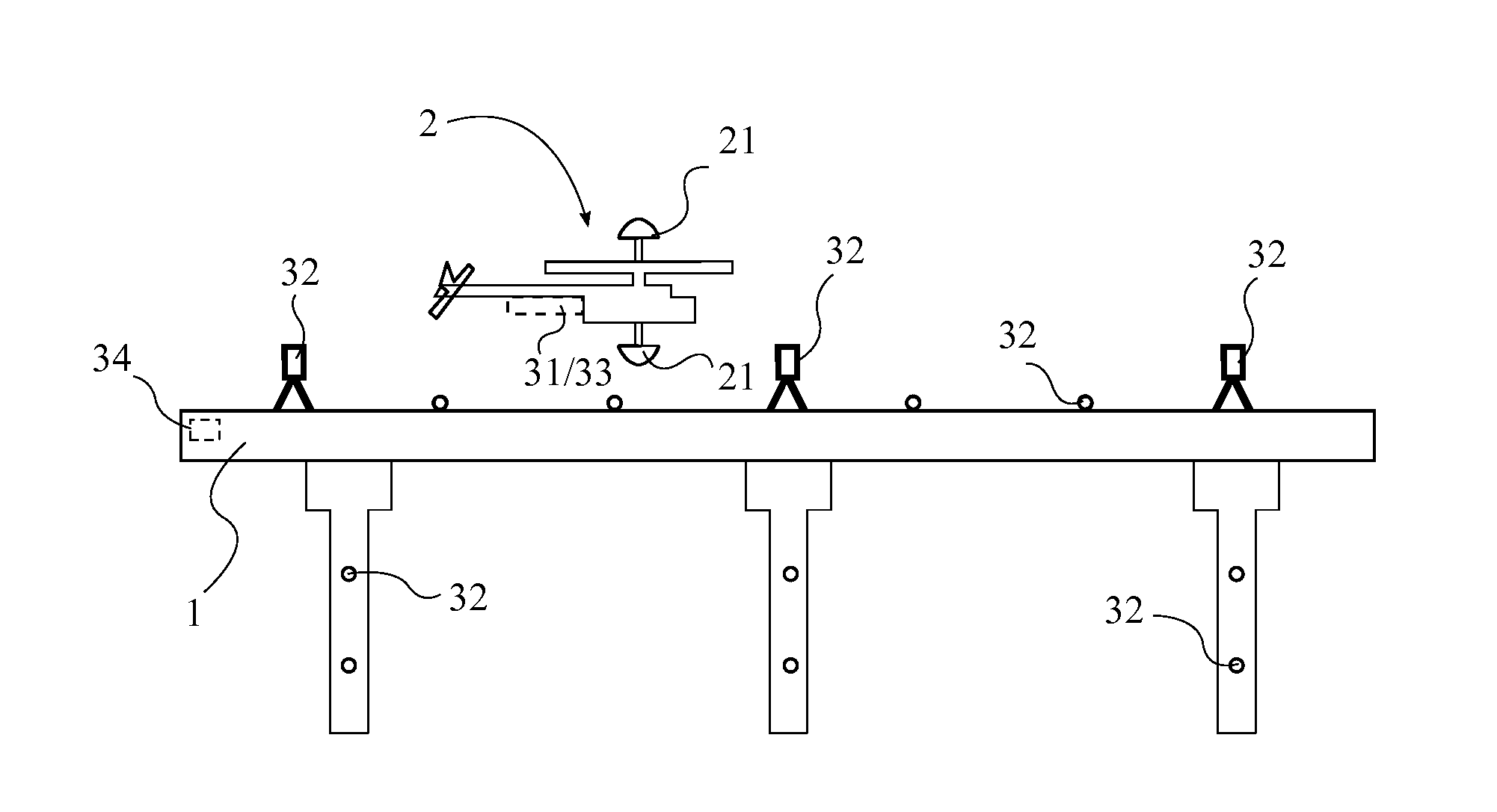

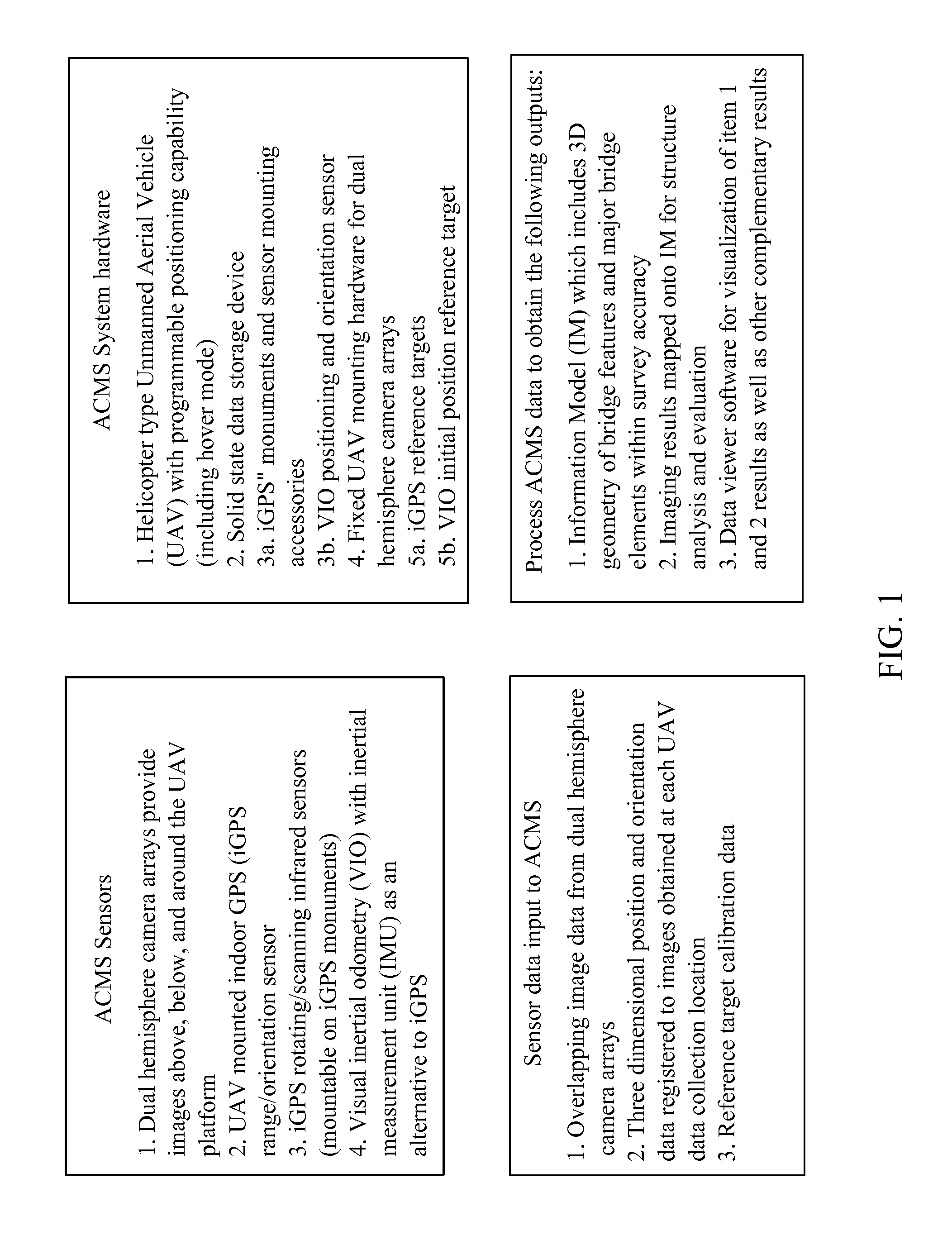

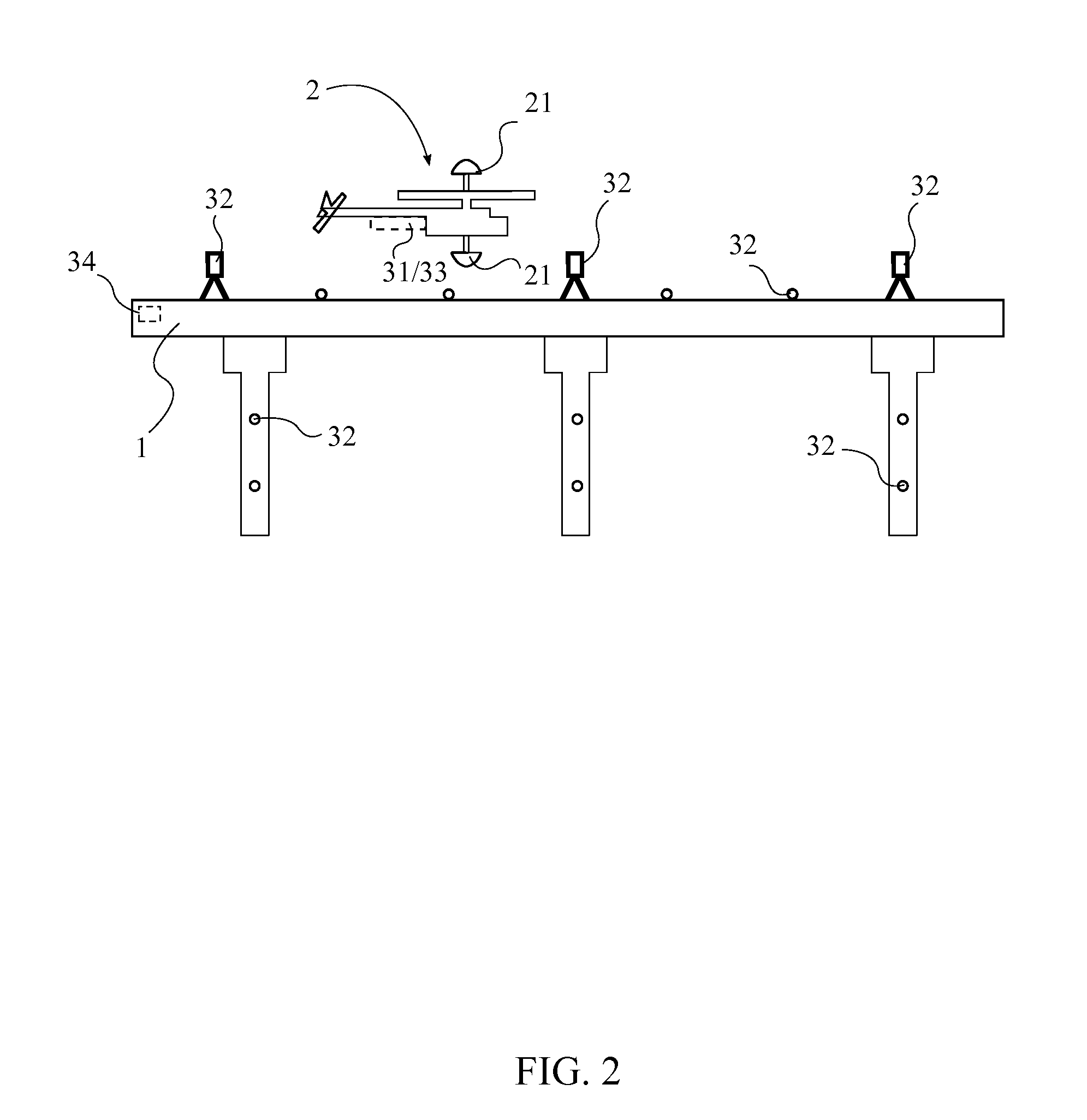

System and Method of Automated Civil Infrastructure Metrology for Inspection, Analysis, and Information Modeling

A system and method of automated civil infrastructure metrology for inspection, analysis, and information modeling utilizes an unmanned aerial vehicle (UAV) equipped with a position tracking system and digital cameras to capture a plurality of images of a structure to be inspected. The UAV is flown in a scan pattern around the structure while continually capturing images of the structure while position and orientation data is also recorded and linked for each of the images. Image processing and pattern recognition software algorithms are used to analyze the images and create an information model of the structure which is then used to carry out a virtual inspection of the structure in a three dimensional software environment.

Owner:SCOTT MICHAEL L

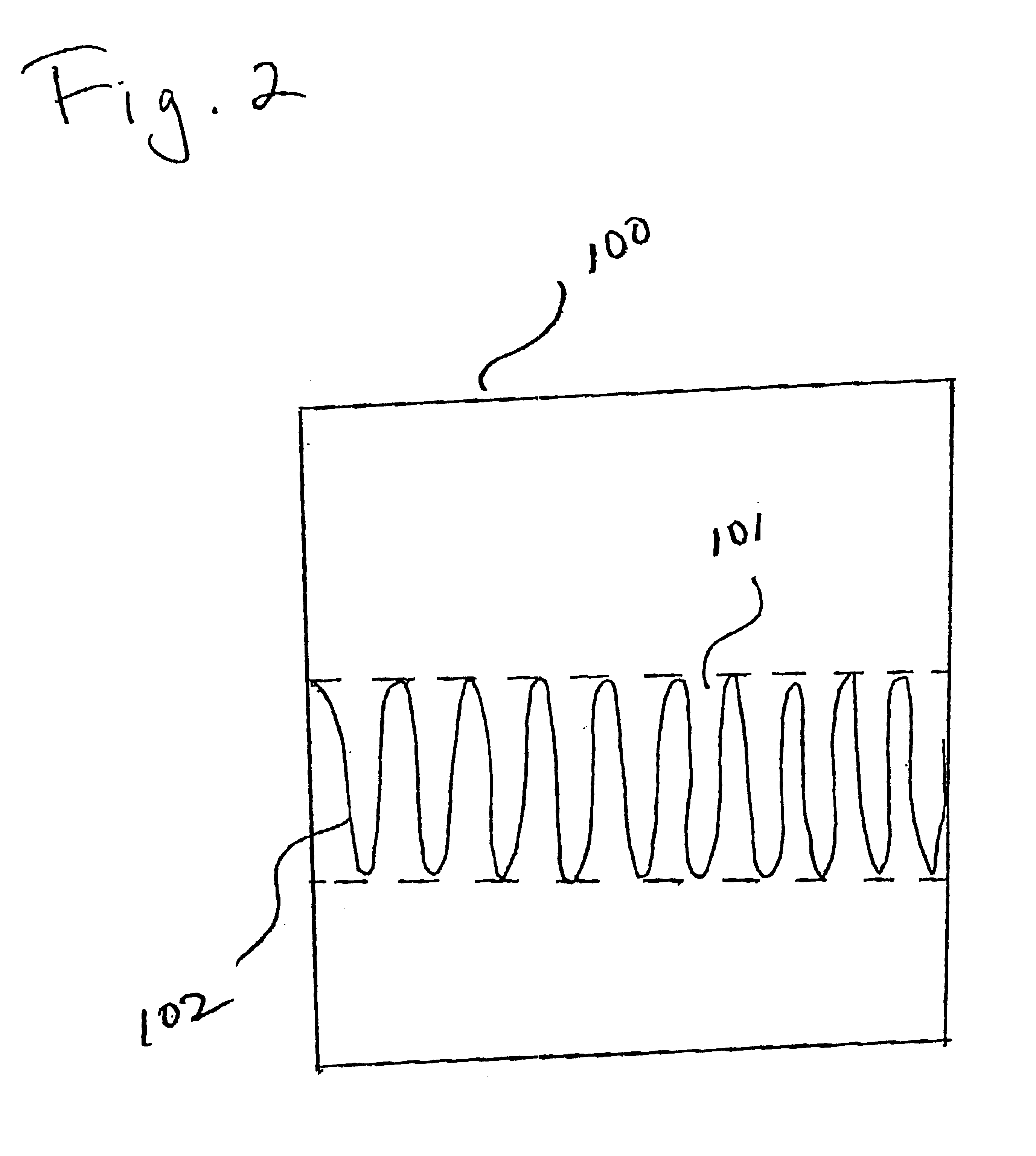

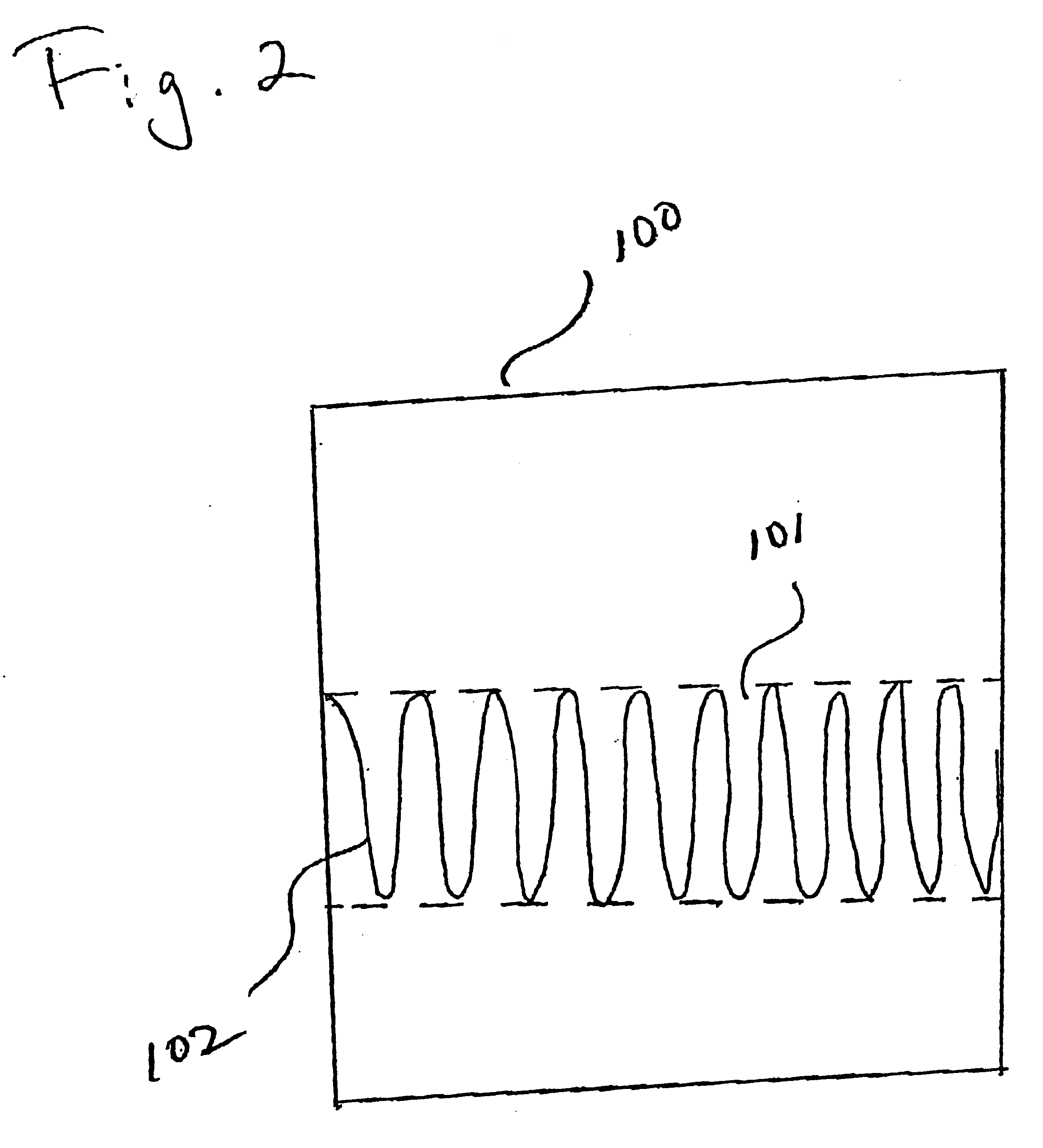

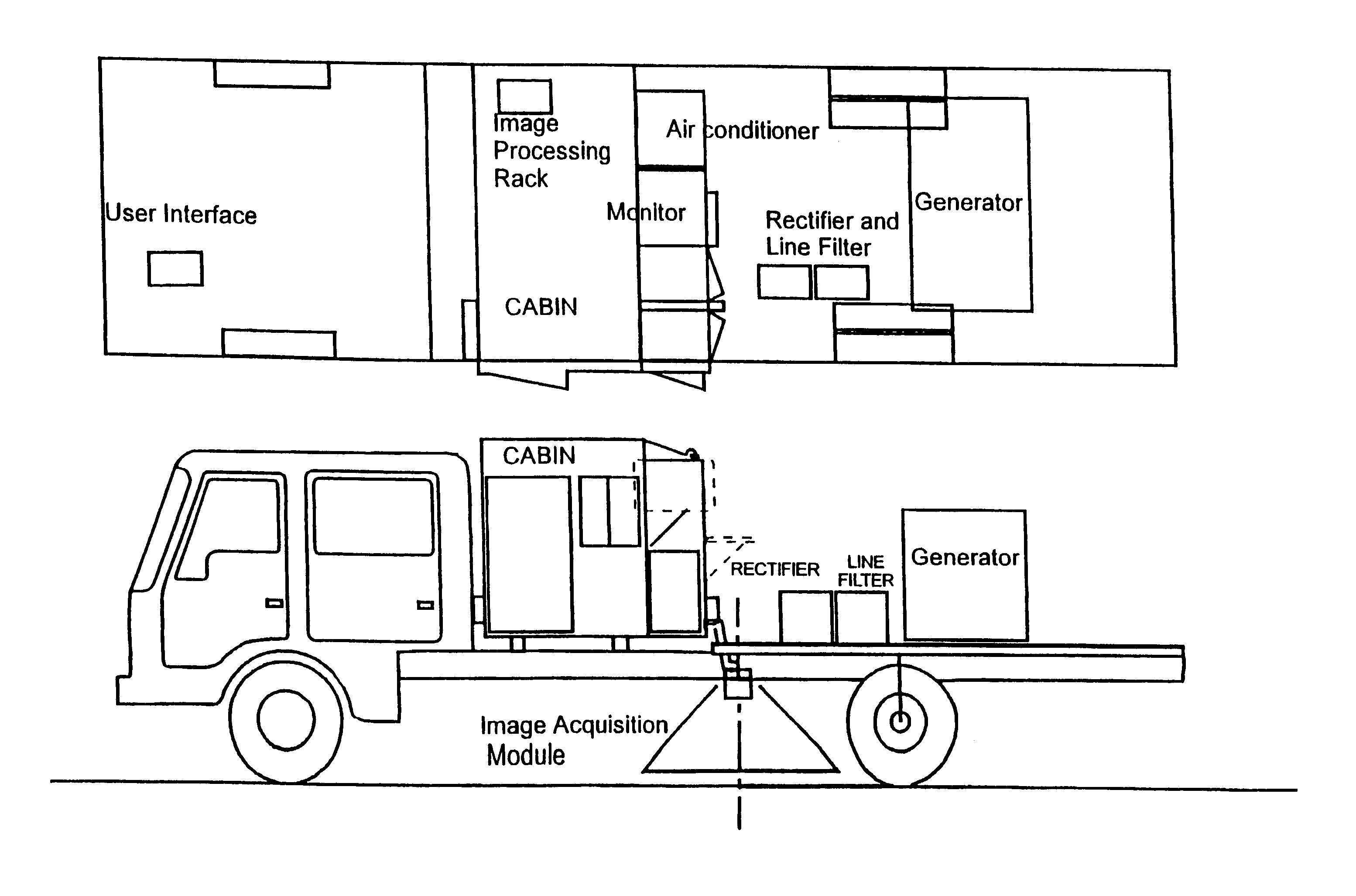

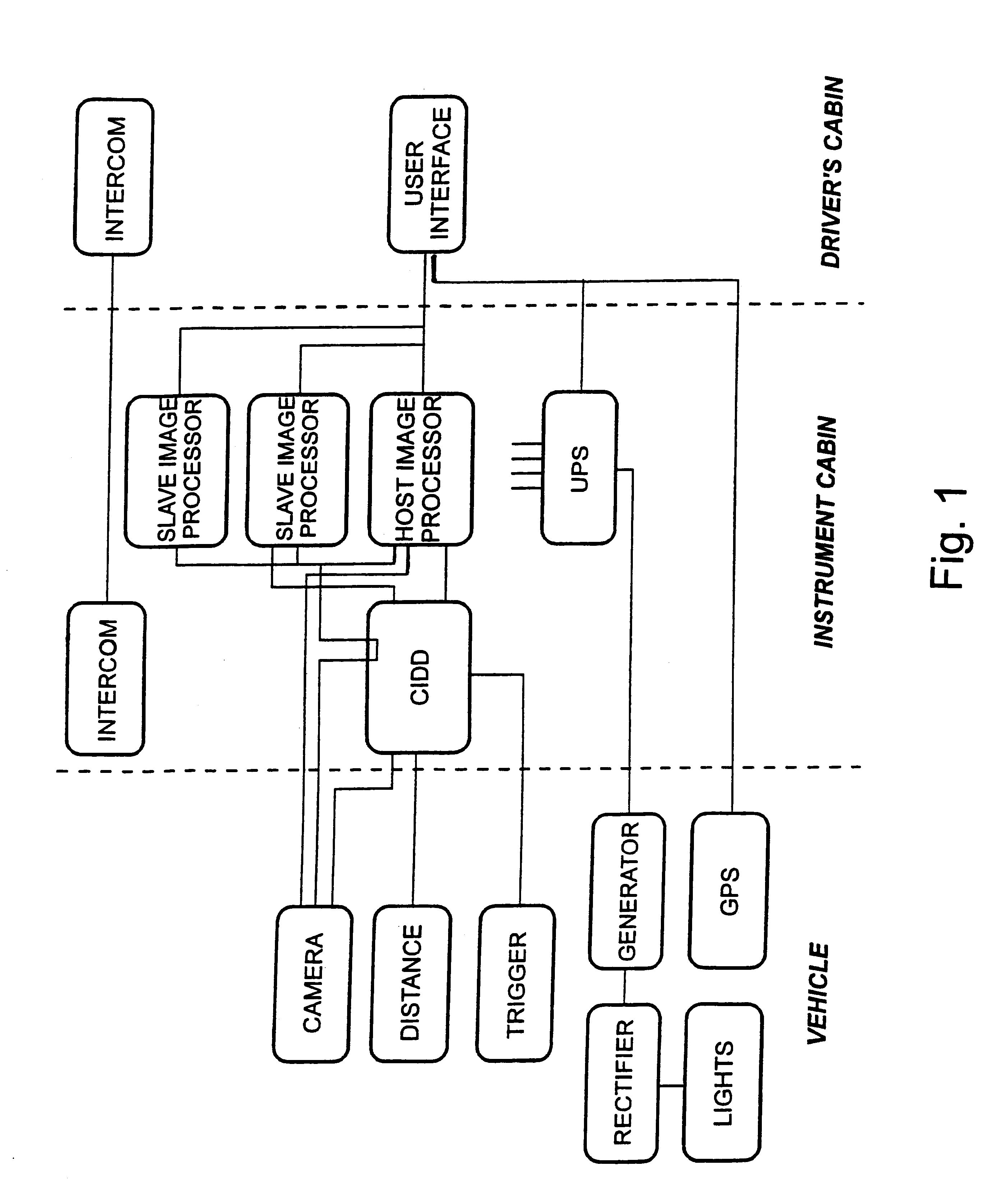

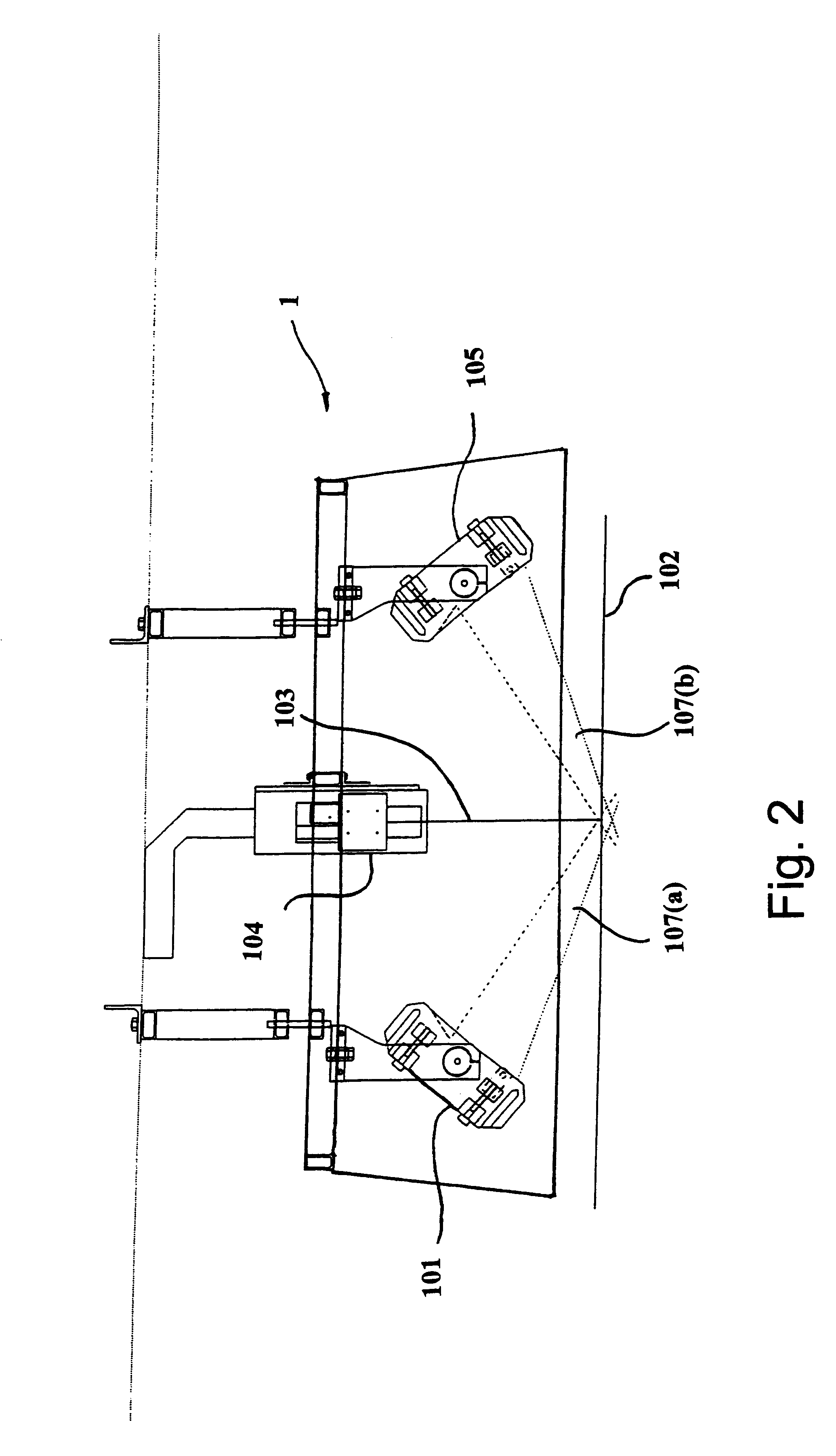

Road pavement deterioration inspection system

InactiveUS6615648B1Reduce the risk of injuryReduce transferDigital computer detailsMeasurement arrangements for variableRoad surfaceDigital camera

A system for acquiring, processing, storing, analyzing and reporting data relating to the condition of a road or other pavement surface (102) in real time. The system includes a digital camera (104) mounted on a vehicle and positioned relative to a pavement surface (102) so as to capture images of the pavement surface (102) while the camera (104) is moving relative to the surface (102). The system also includes an illumination assembly (100) to illuminate the region from which an image is taken and an interface between the digital camera (104) and at least one computer. The system also includes a processor in the computer for processing the images to detect and classify cracks and other pavement surface (102) features.

Owner:COMMONWEALTH SCI & IND RES ORG +1

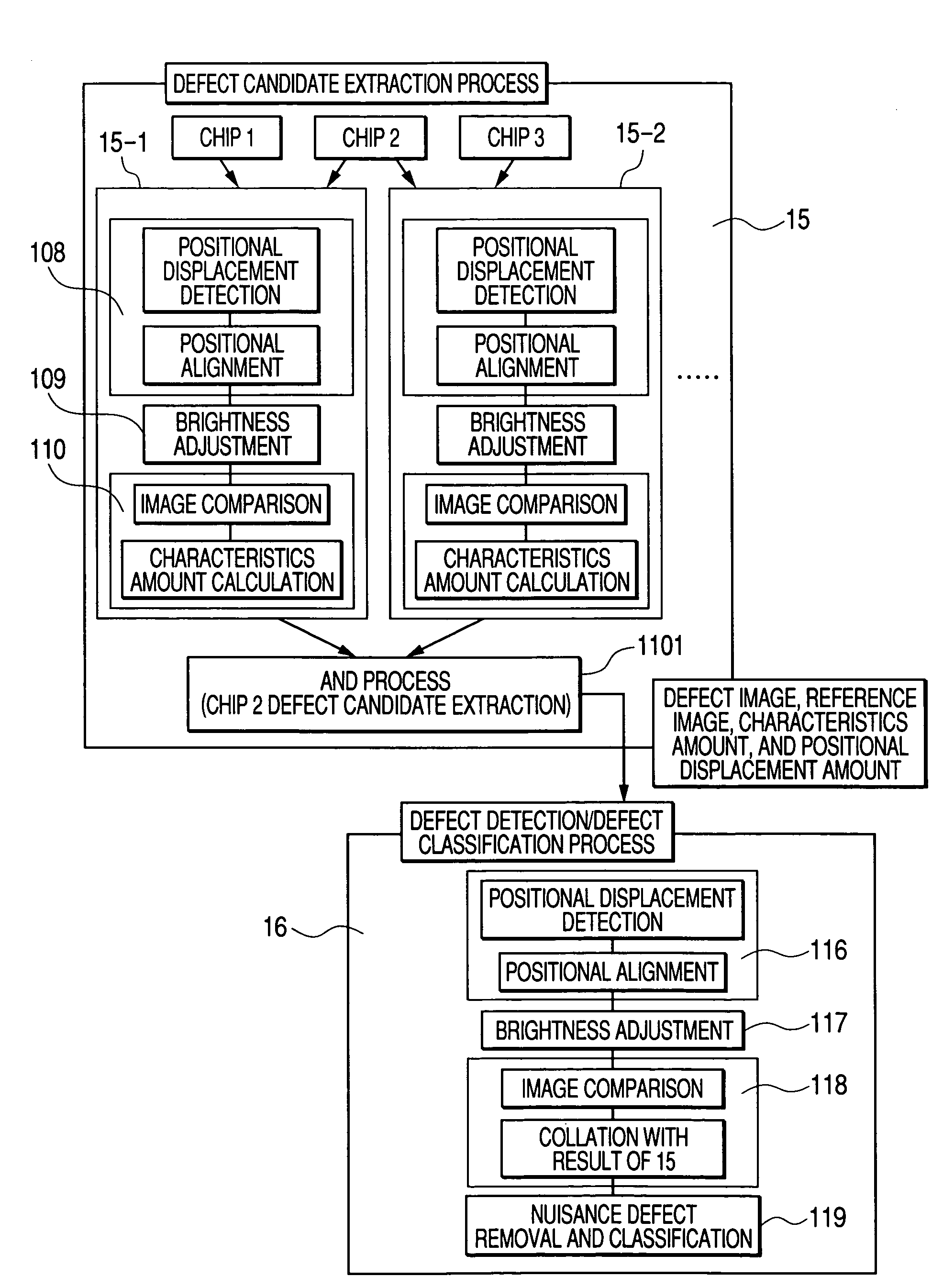

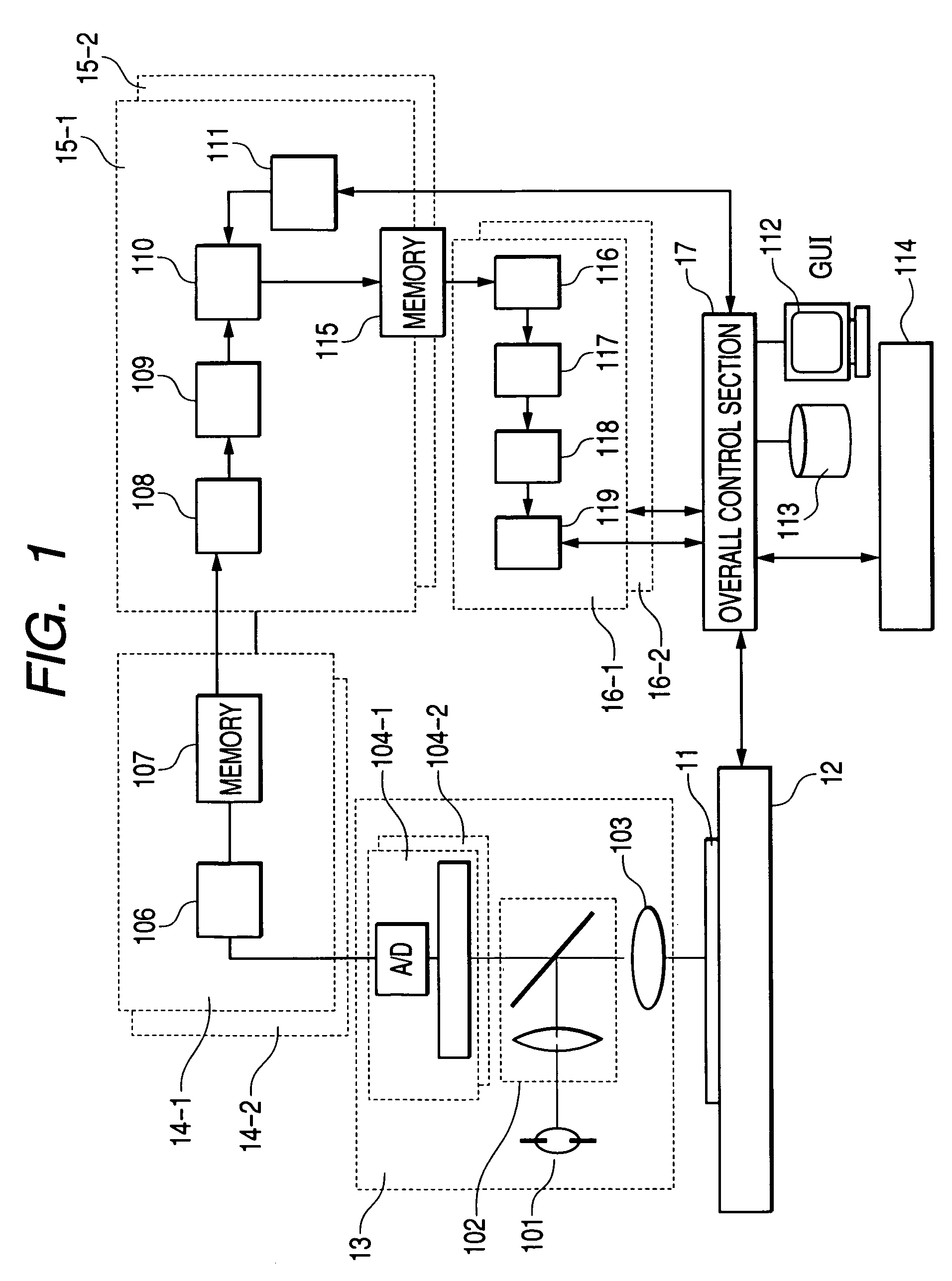

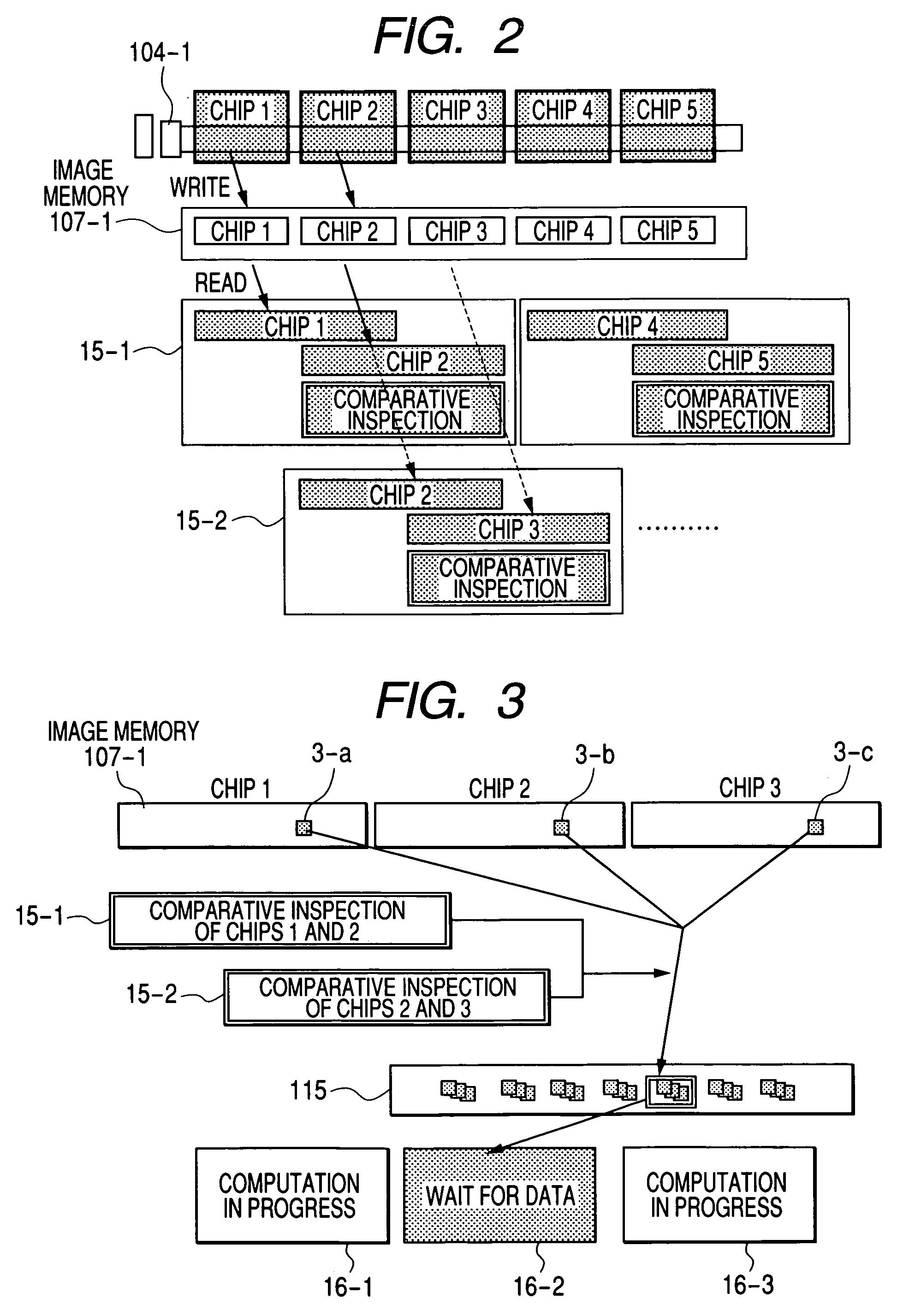

Method and apparatus for inspecting pattern defects

InactiveUS7388979B2High sensitivityIncrease speedImage enhancementImage analysisPattern recognitionComputer graphics (images)

The present invention relates to a pattern defect inspection method and apparatus that reveal ultramicroscopic defects on an inspection target in which ultramicroscopic circuit patterns are formed, and inspect the defects with high sensitivity and at a high speed. The present invention provides a pattern inspection apparatus for comparing the images of corresponding areas of two formed patterns that should be identical with each other, and judging any mismatched image area as a defect. The pattern inspection apparatus includes means for performing an image comparison process on a plurality of areas in a parallel manner. Further, the pattern inspection apparatus also includes means for converting the gradation of the image signals of compared images in each of a plurality of different processes. Therefore, the present invention can properly detect defects even if the same patterns of compared images differ in brightness.

Owner:HITACHI HIGH-TECH CORP

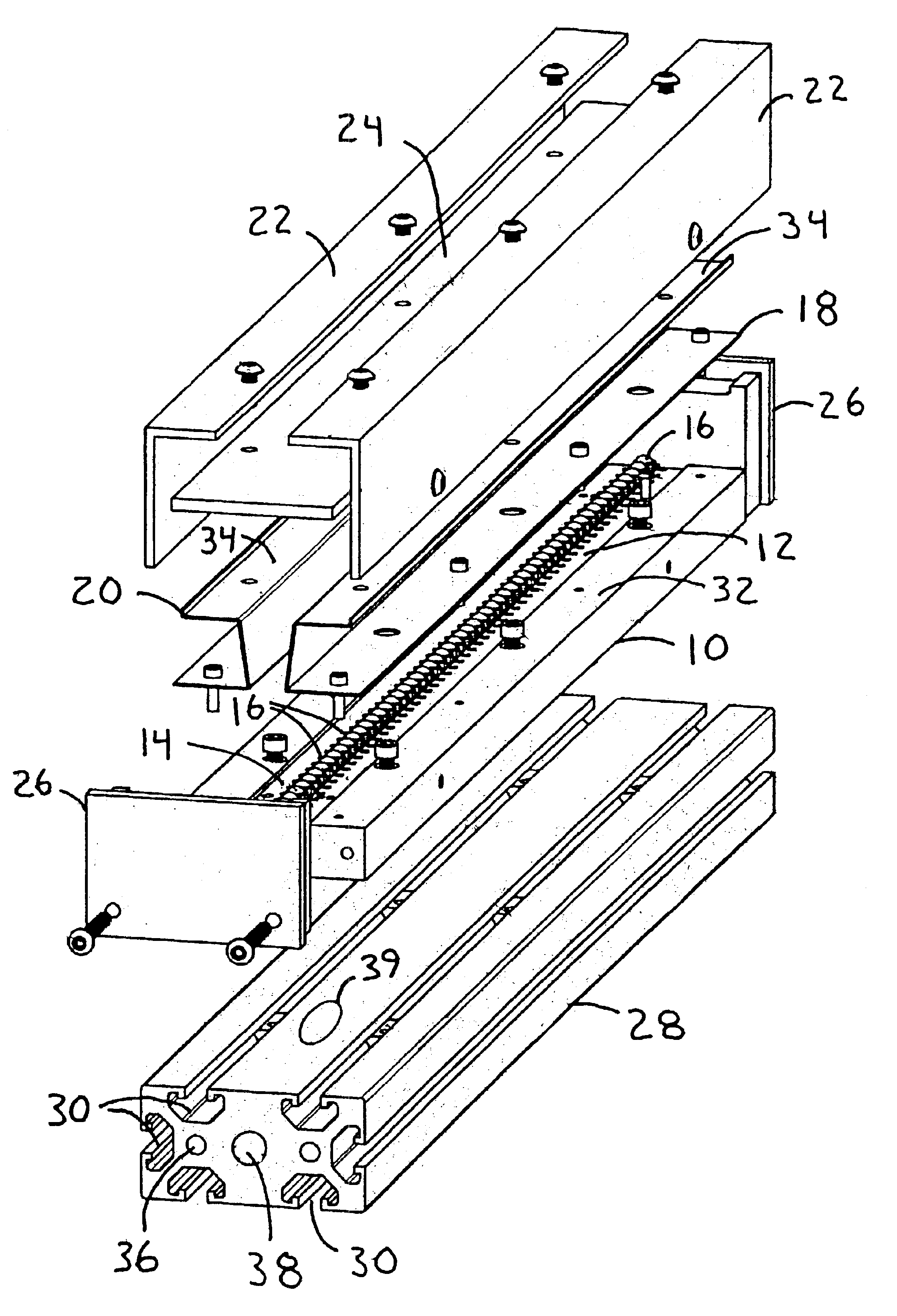

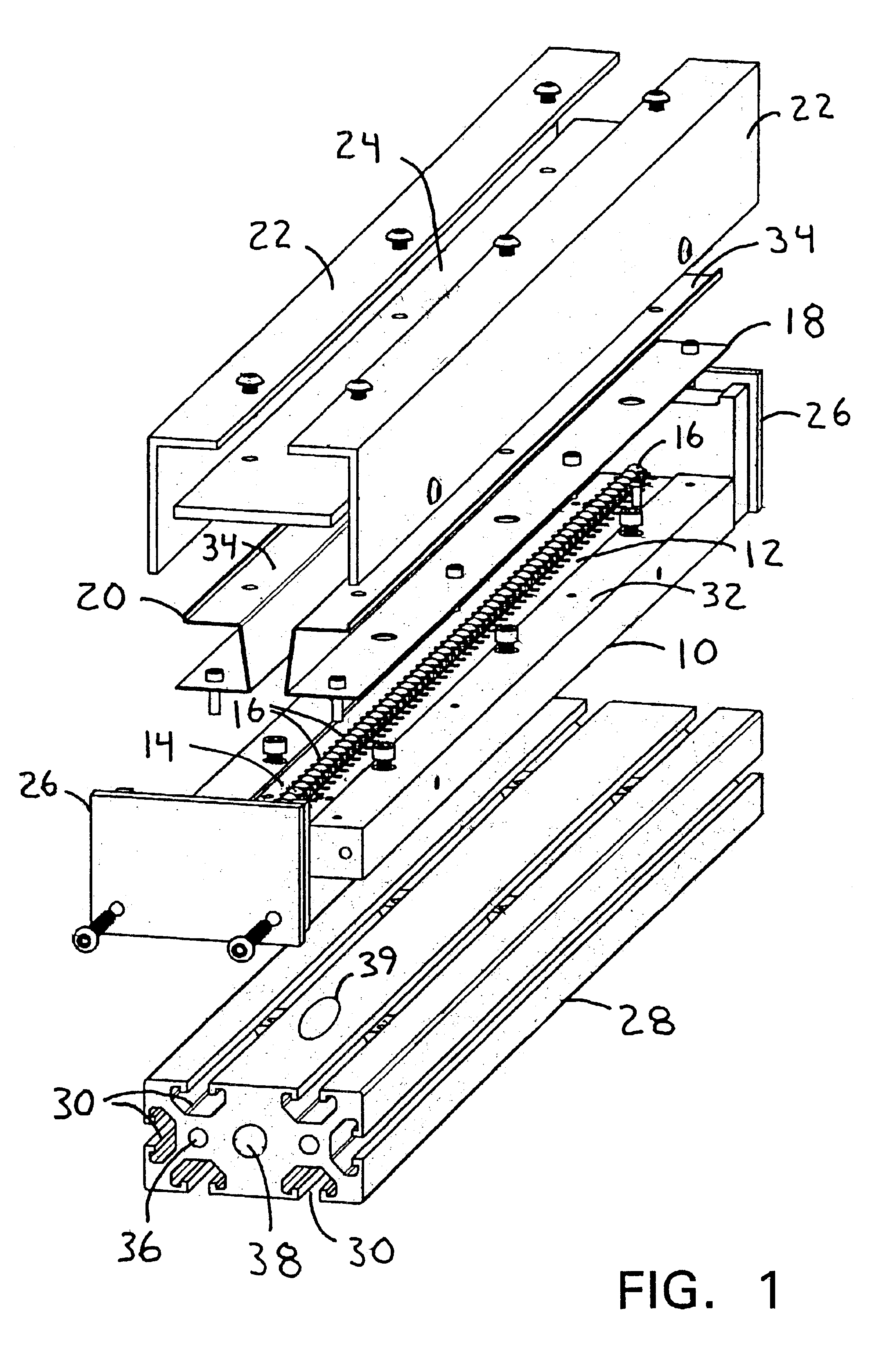

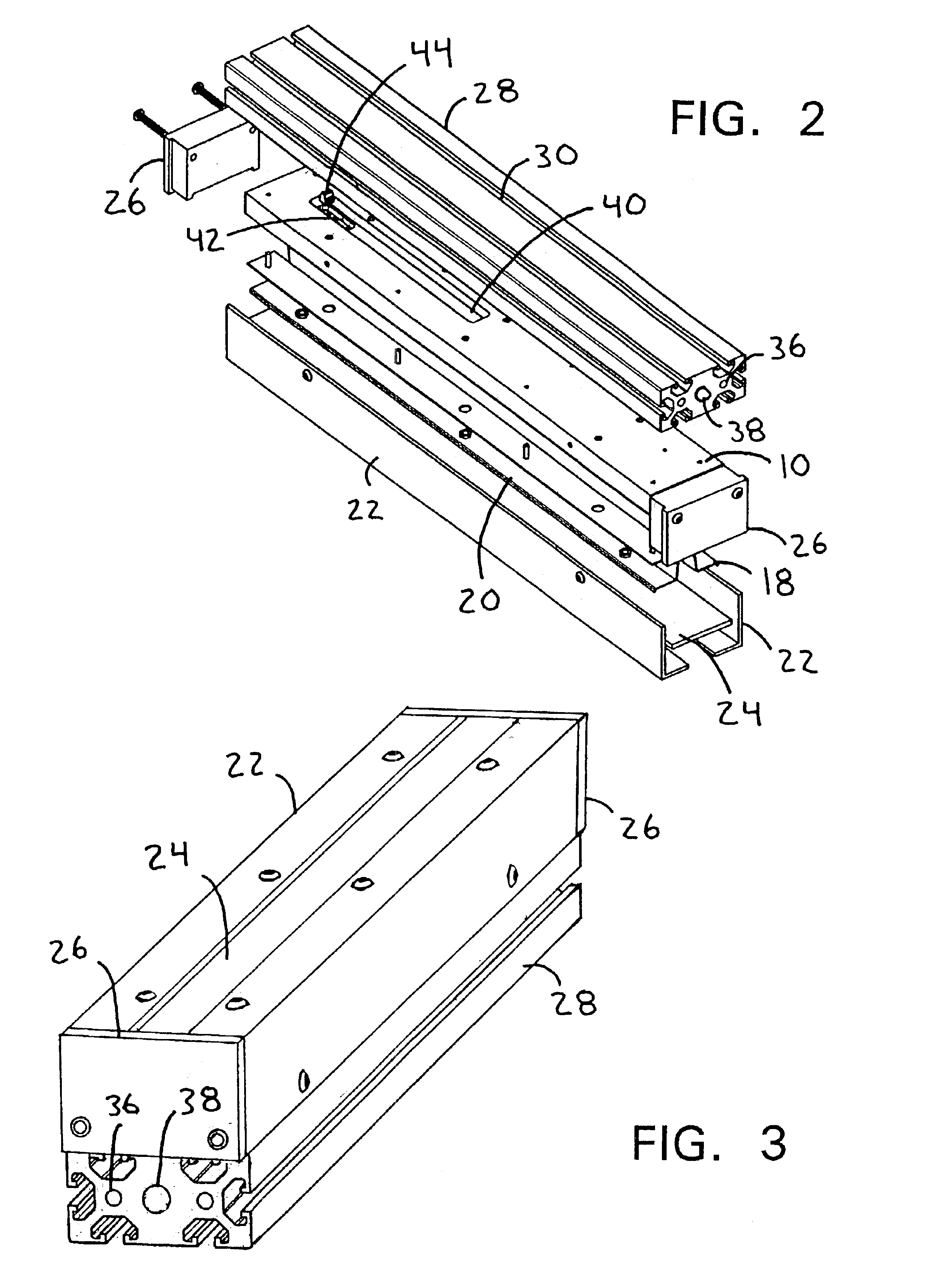

Extensible linear light emitting diode illumination source

InactiveUS6880952B2Avoid catastrophic failureImprove reliabilityMechanical apparatusLighting support devicesPower cableDirect illumination

A compact, energy-efficient extensible illumination source combines the reliability advantages of light emitting diodes (LEDs) with the brightness of conventional lighting. High reliability of the LEDs provides trouble-free operation over a long hour lifetime. This high-output light source can be used in direct lighting applications or for backlighting for translucent materials. The illumination source includes LED printed wire board segments that may be configured to form a light line of any length. The segments are mounted on a inner mounting base which also serves as a first stage heat sink for the LEDs. The illumination source includes a linear mirror for reflecting radiant energy away from the LEDs to produce a uniform linear illumination pattern. A window provides mechanical protection for the LEDs and may be used for diffusing or filtering light from the LEDs. An integral base in contact with the inner mounting base also serves as a heat sink and provides structural support for the illumination source. The integral base further includes channels and cavities for cooling the illumination source and for housing power cables.

Owner:WINTRISS ENG

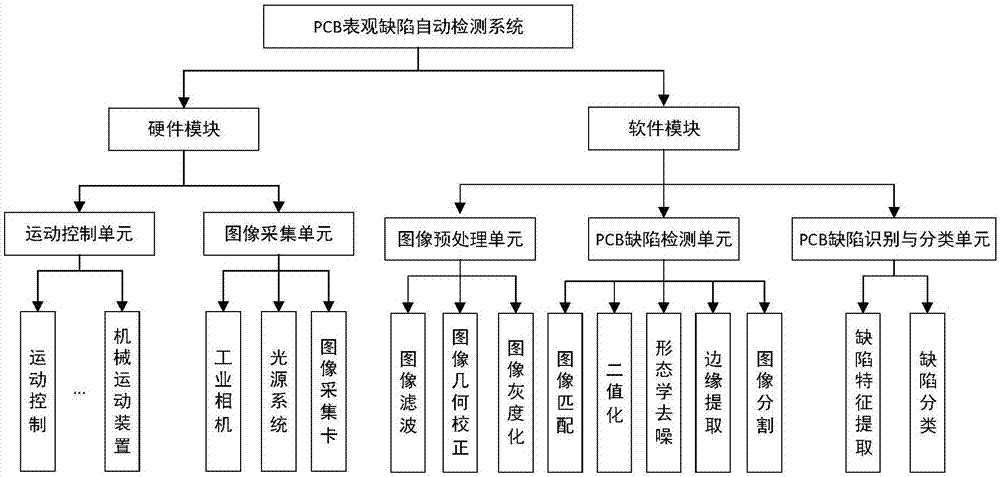

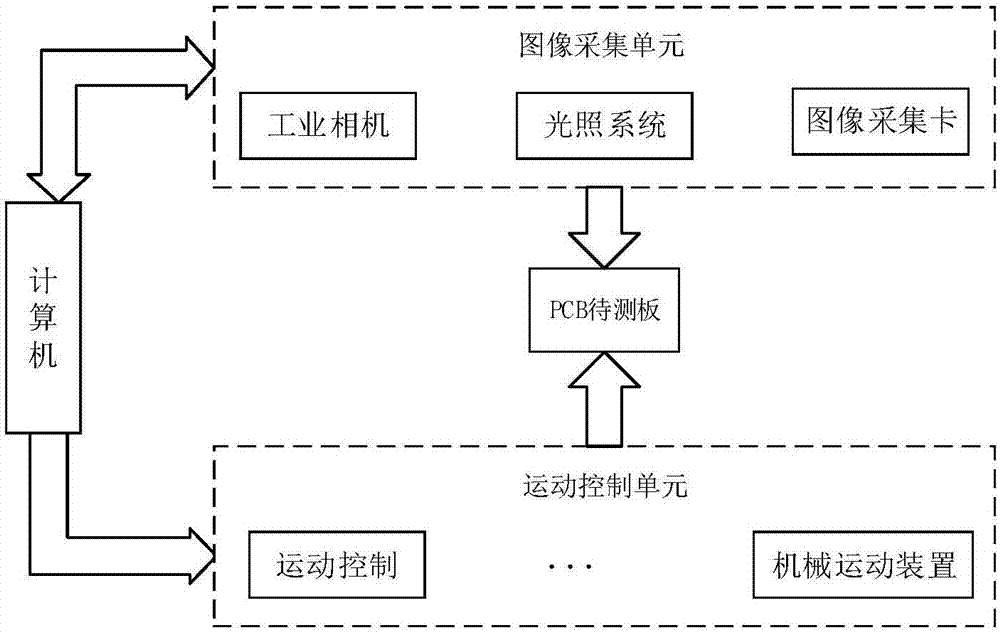

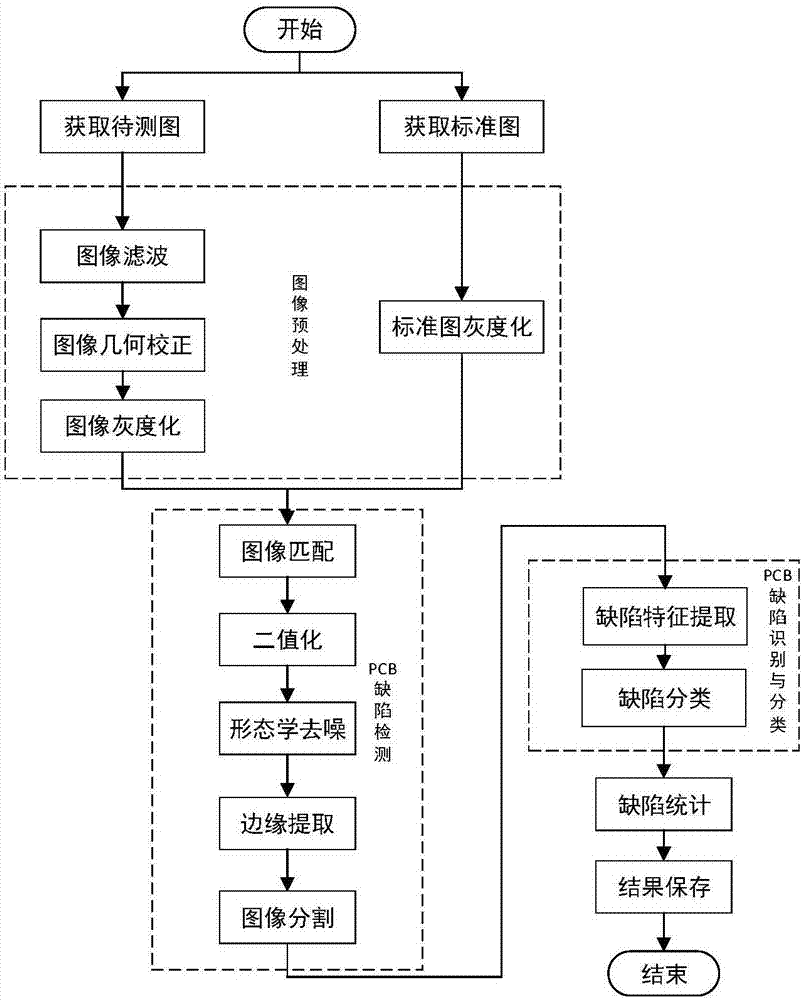

PCB apparent defect automatic detection system and method based on image

InactiveCN107389701AImprove detection efficiencyReduce false detection rateImage enhancementImage analysisMovement controlAutomatic testing

The invention provides a PCB apparent defect automatic detection system and method based on an image and aims at solving the problems that detection efficiency is low and misjudgment rate is high. The method comprises the following steps: firstly transmitting a to-be-detected PCB to a specified position by virtue of a motion control unit; acquiring an image of the to-be-detected PCB by utilizing image acquisition equipment such as an image acquisition card and an industrial camera; then sequentially carrying out a series of operation such as image preprocessing, PCB defect detection and PCB defect identification and classification on the acquired image, so that PCB defect automatic detection is completed; and finally realizing real-time automatic sorting of an unqualified PCB and timely reporting a defect position and a defect analysis result to an operator. The system and method which are provided by the invention can automatically detect the PCB defect and identify the defect type to a great extent, and false detection rate is reduced, so that enterprise cost is reduced, and the system and method which are provided by the invention have stronger practicability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

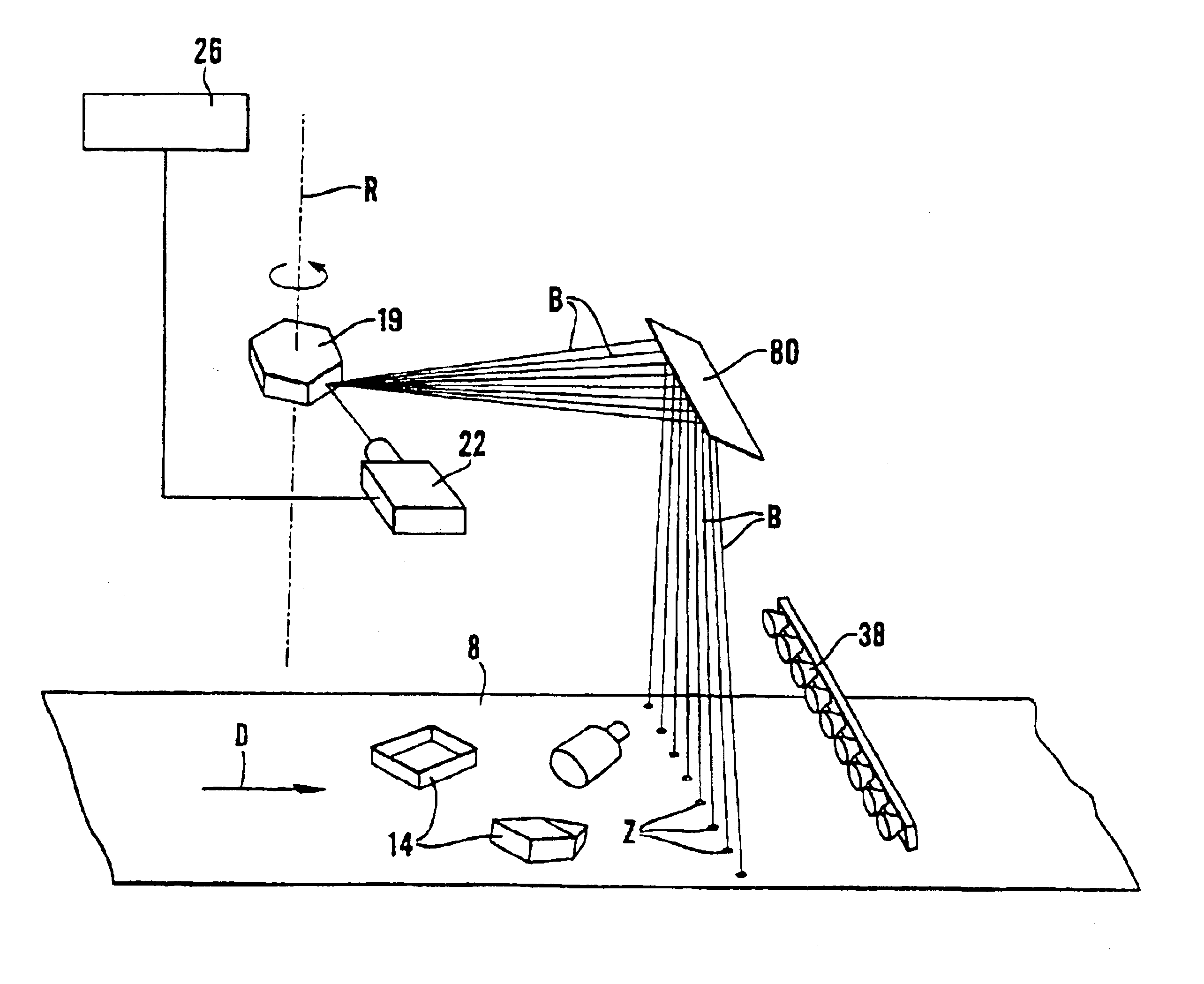

Inspection of matter

InactiveUS6914678B1Variation is detectedHigh separation rateInvestigating moving fluids/granular solidsScattering properties measurementsPlane mirrorLight beam

Apparatus for automatically inspecting a stream of matter comprises lamps which emit a detection medium, such as IR or visible light, to be active at the matter, a rotary polygonal mirror which receives from a multiplicity of detection zones at the matter detection medium which has been varied by variations in the matter, an optical detection device which receives the varied medium by reflection from the mirror, to detect a plurality of wavelengths of the varied medium substantially simultaneously, and to generate detection data in respect of that plurality of wavelengths substantially simultaneously and in dependence upon the variations in the medium, and a microprocessor which obtains the detection data from the device. The beams of the varied medium which are received at the device and emanate from the zones travel along respective paths from the matter to the mirror 9 which paths converge continuously with respect to each other from the matter to the mirror. Those paths may extend to the mirror indirectly by way of at least one planar mirror, or directly to the mirror, in which latter case the axis of the mirror would be substantially parallel to the direction of advance of the matter.

Owner:TITECH VISIONSORT

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com