Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29422results about "Microlithography exposure apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Particle-optical projection system

ActiveUS7388217B2Minimize distortionCompensation deviationElectric discharge tubesNanoinformaticsOptical axisProjection system

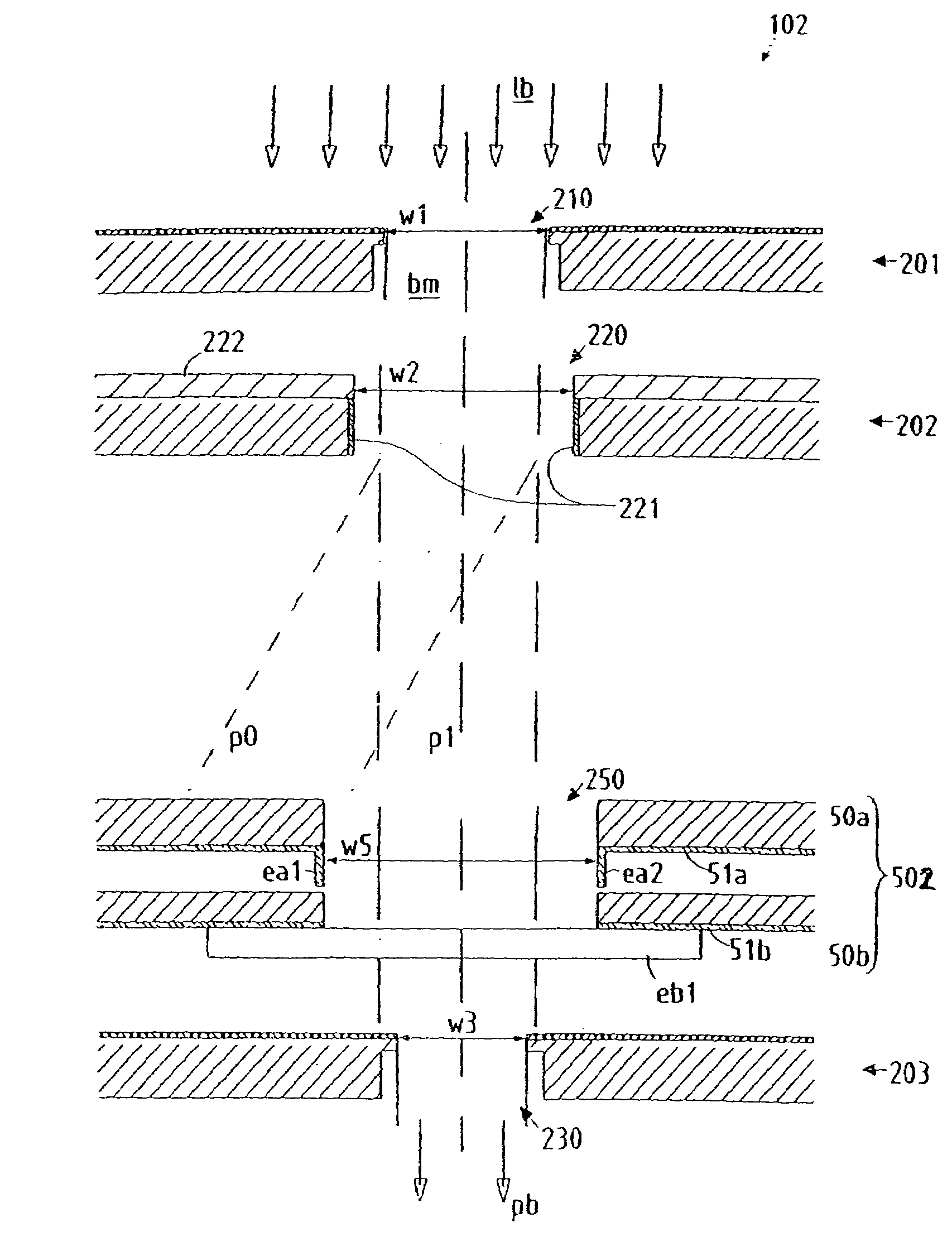

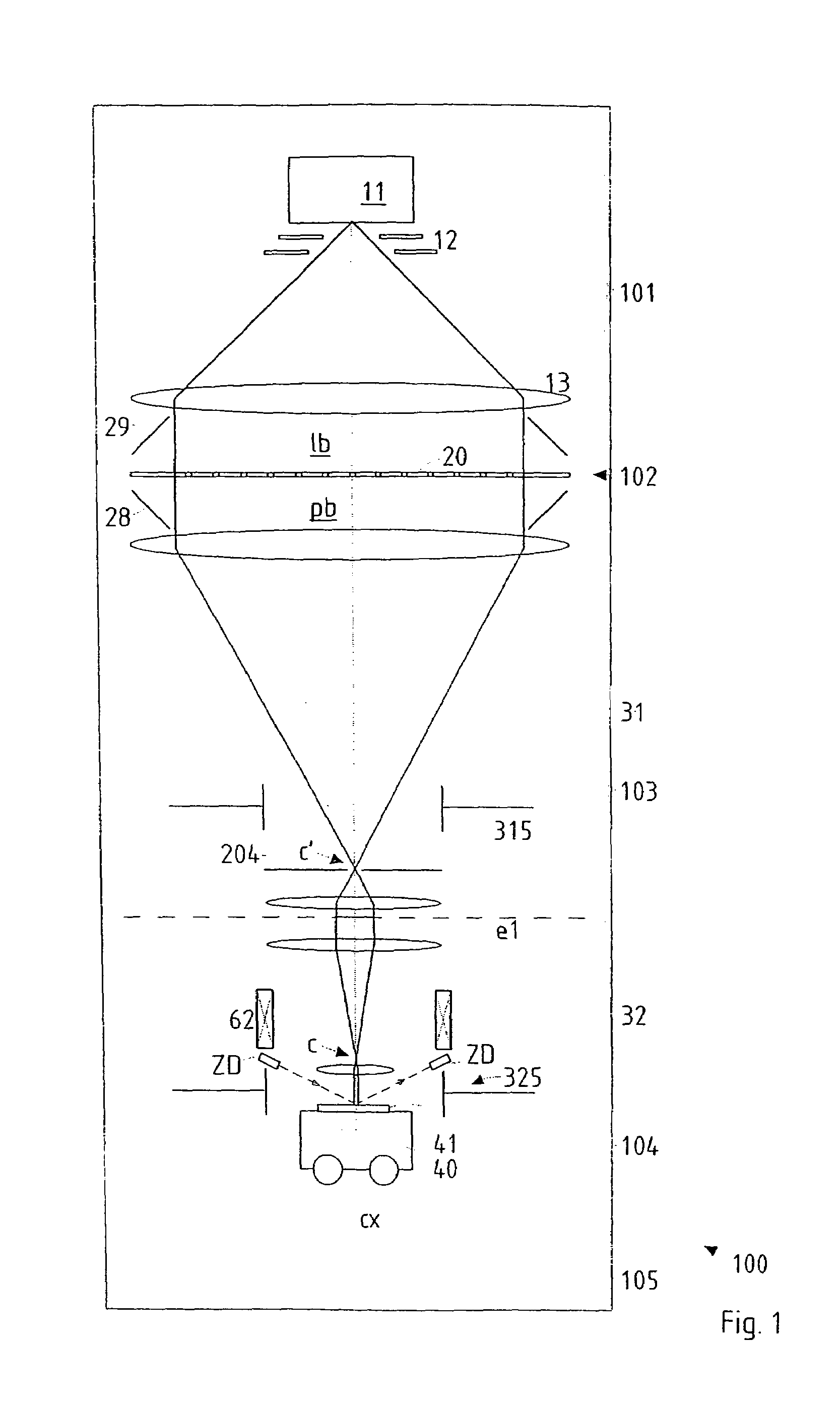

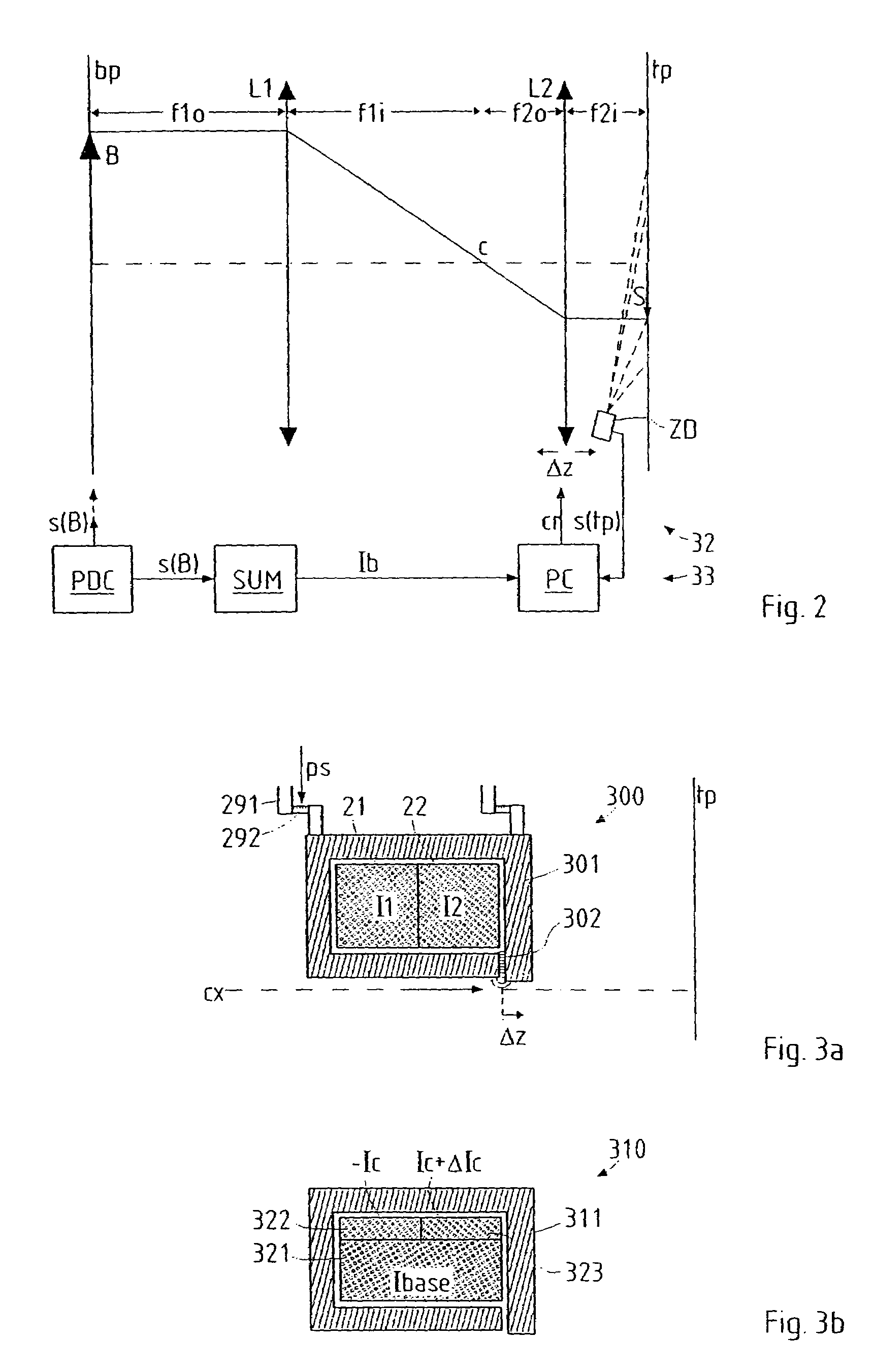

In a particle-optical projection system a pattern is imaged onto a target by means of energetic electrically charged particles. The pattern is represented in a patterned beam of said charged particles emerging from the object plane through at least one cross-over; it is imaged into an image with a given size and distortion. To compensate for the Z-deviation of the image position from the actual positioning of the target (Z denotes an axial coordinate substantially parallel to the optical axis), without changing the size of the image, the system includes a position detector for measuring the Z-position of several locations of the target, and a controller for calculating modifications of selected lens parameters of the final particle-optical lens and controlling said lens parameters according to said modifications.

Owner:IMS NANOFABTION

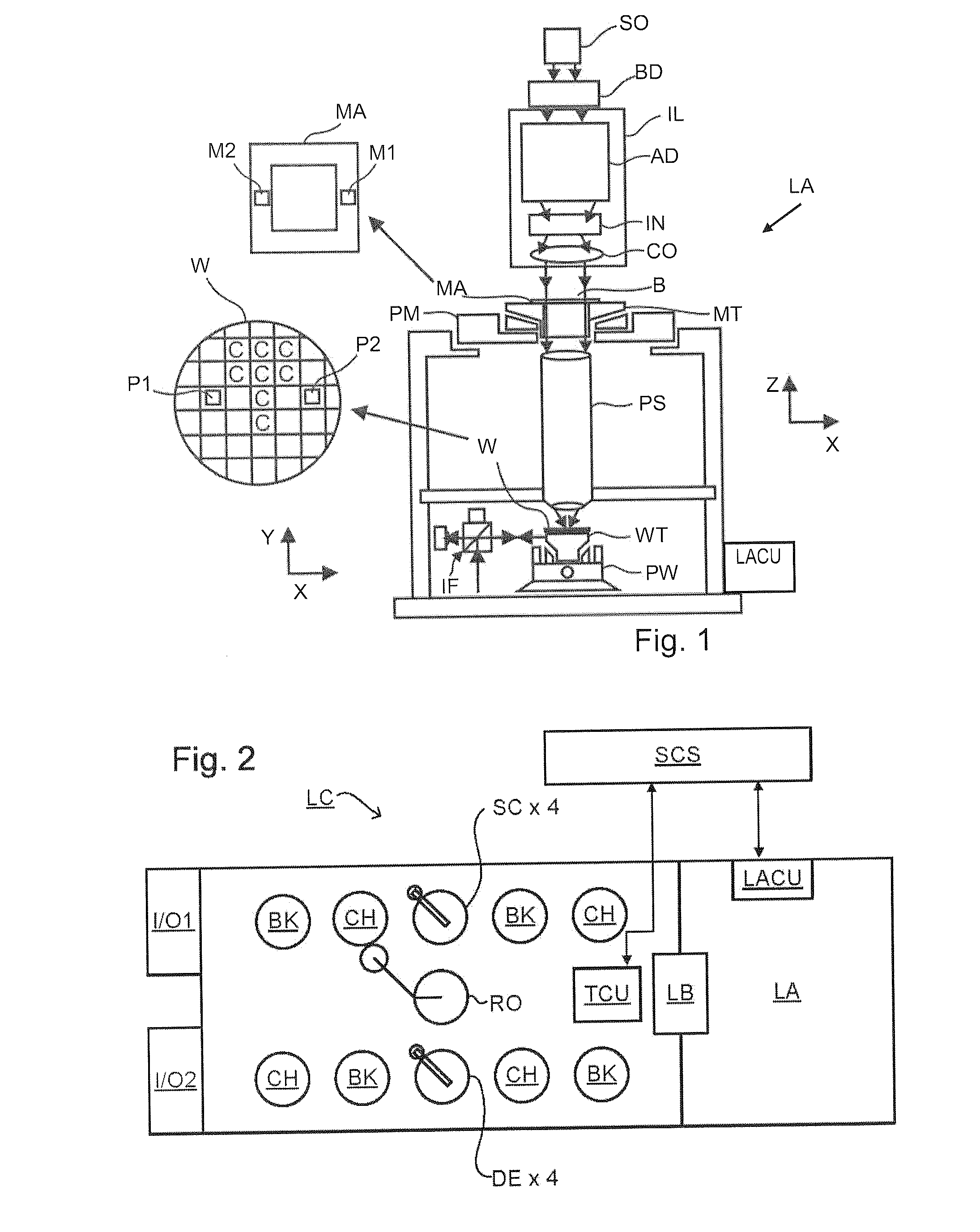

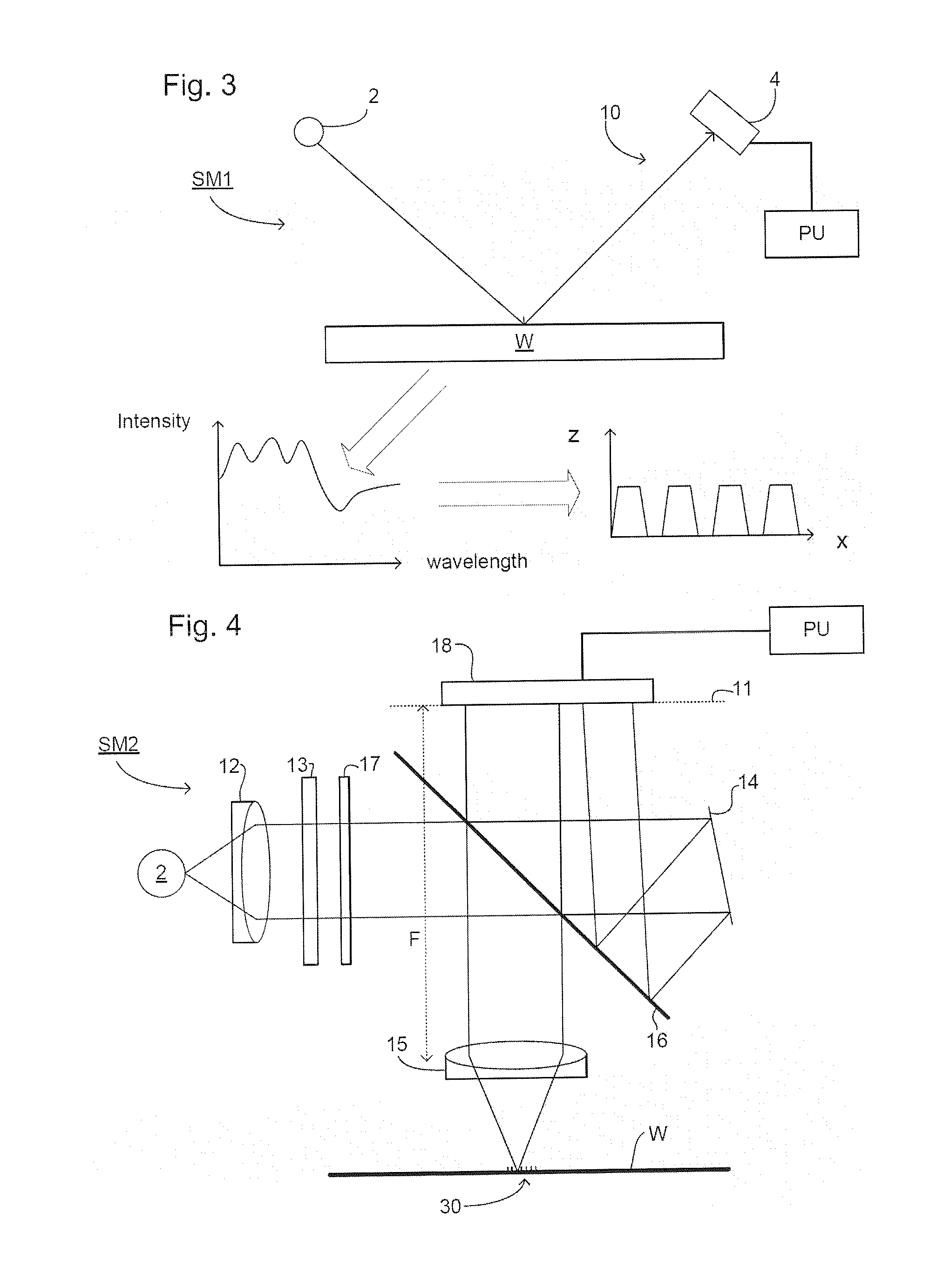

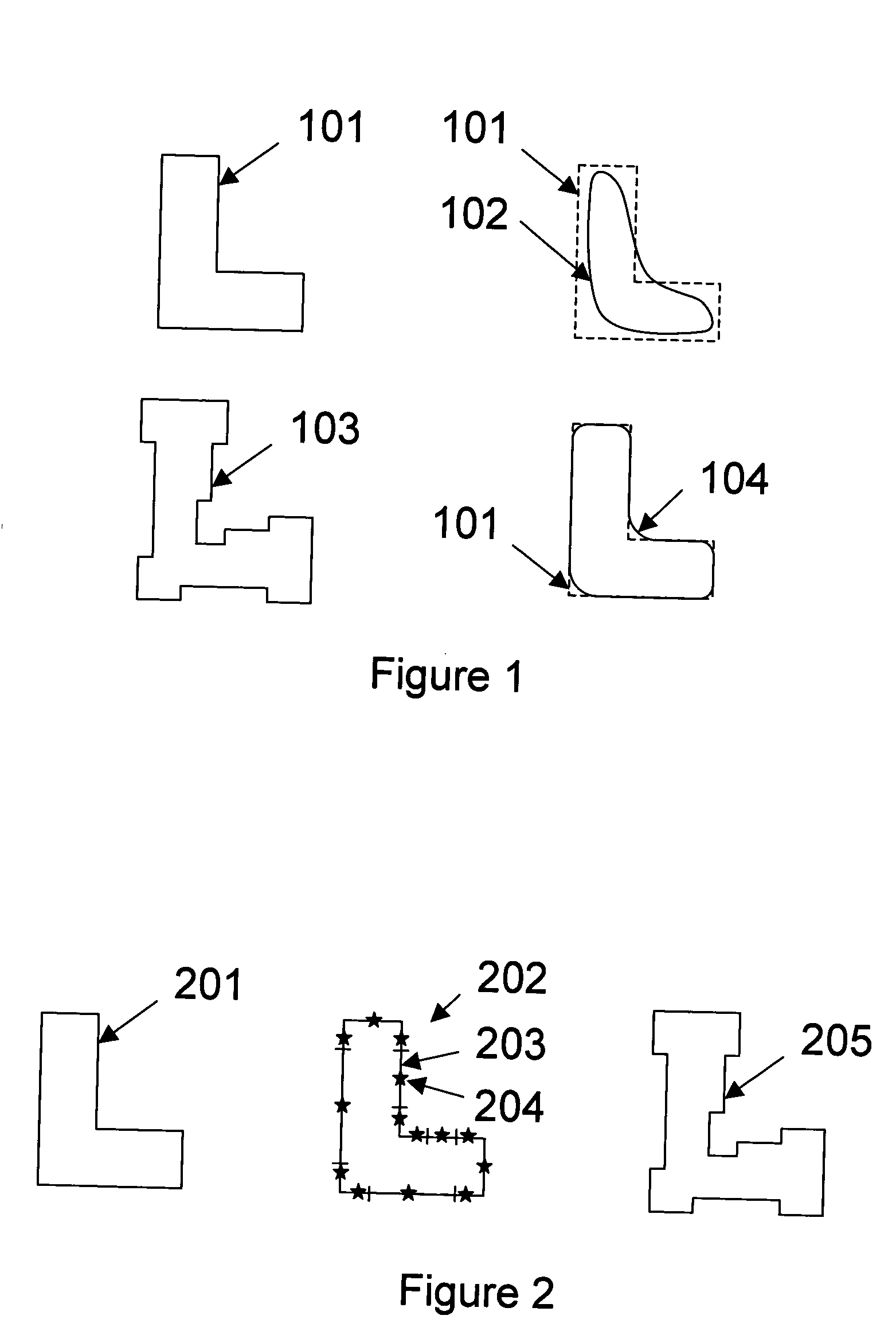

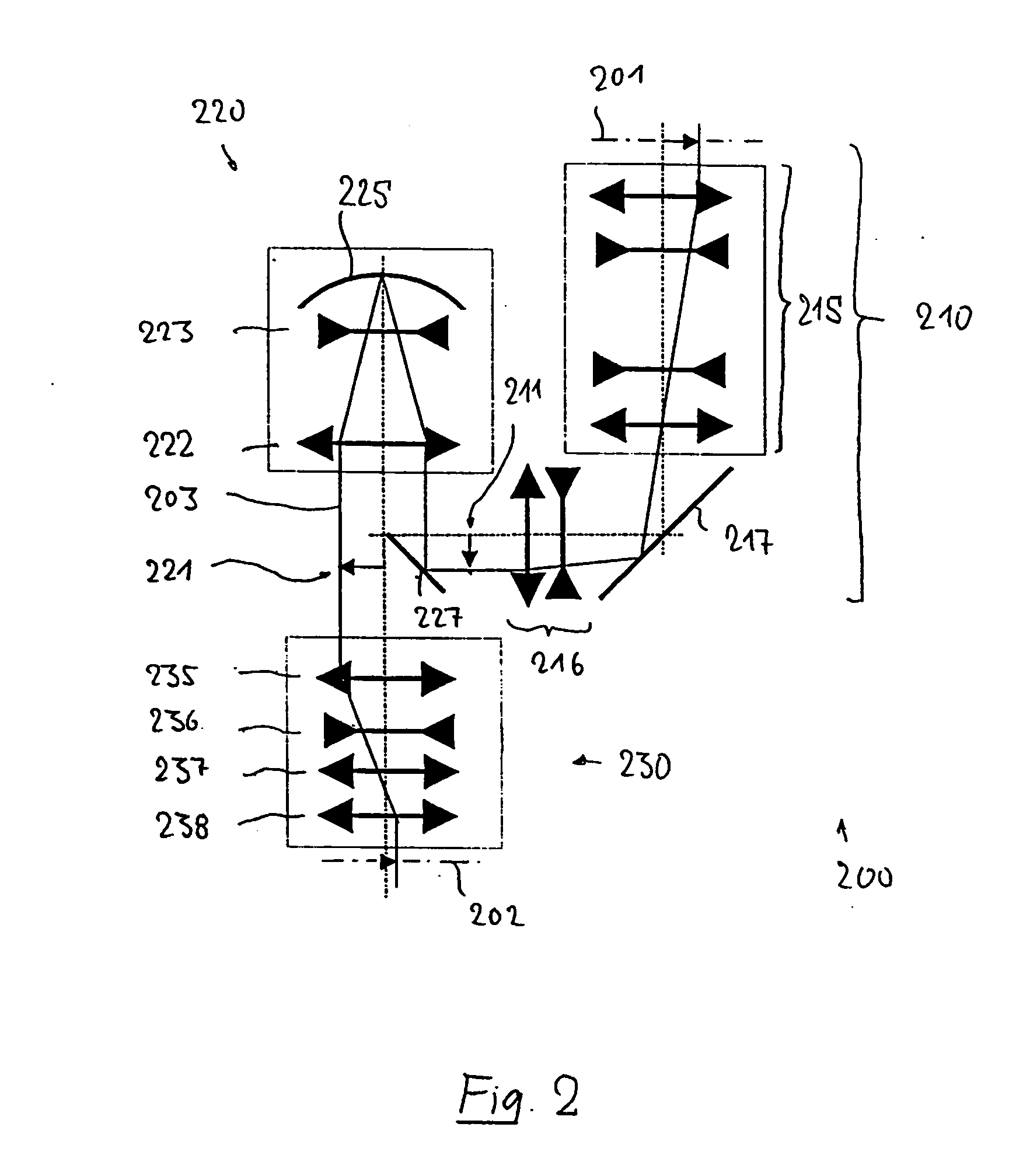

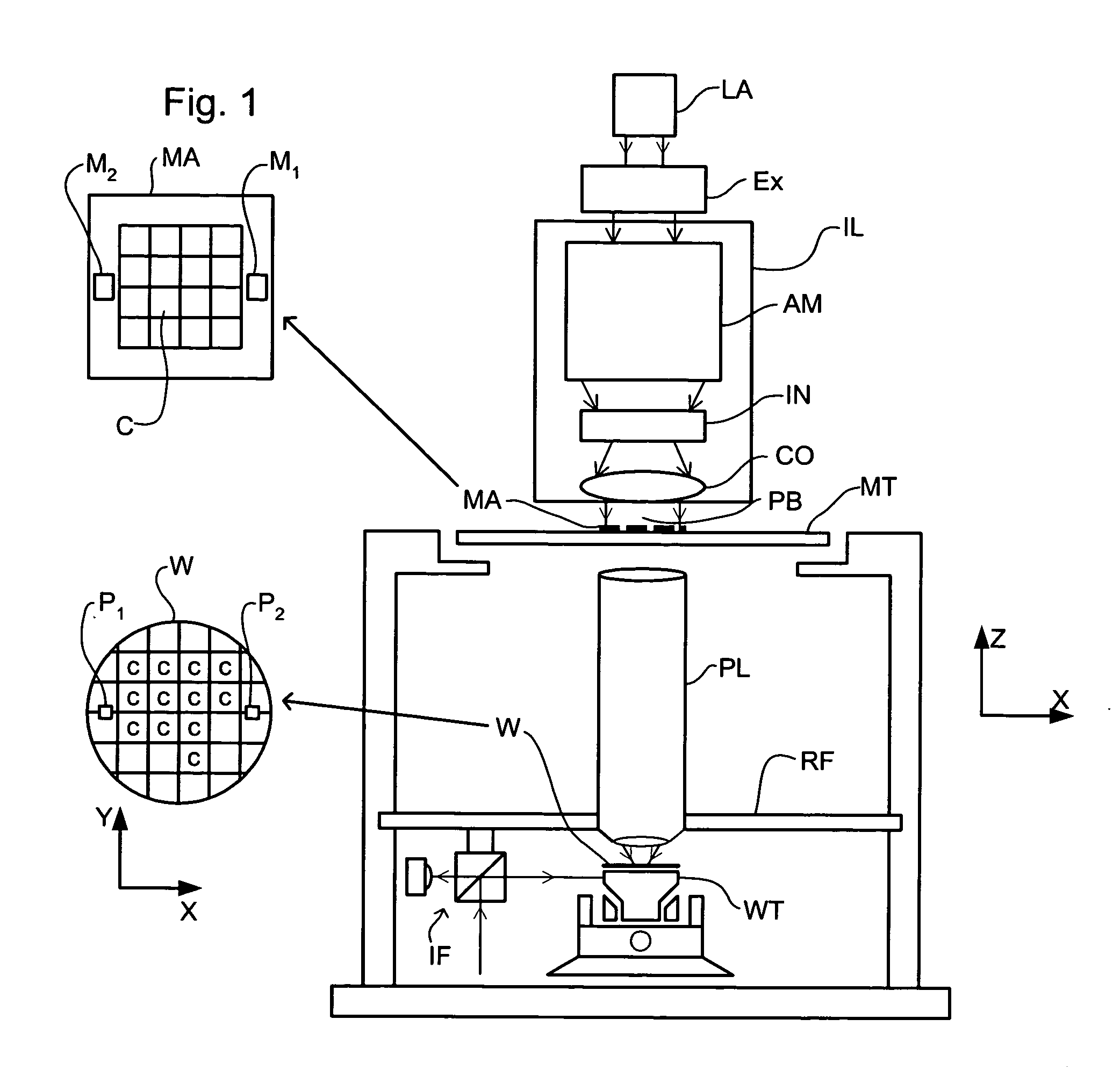

Methods and Scatterometers, Lithographic Systems, and Lithographic Processing Cells

ActiveUS20110027704A1Scattering properties measurementsSemiconductor/solid-state device manufacturingScatterometerEngineering

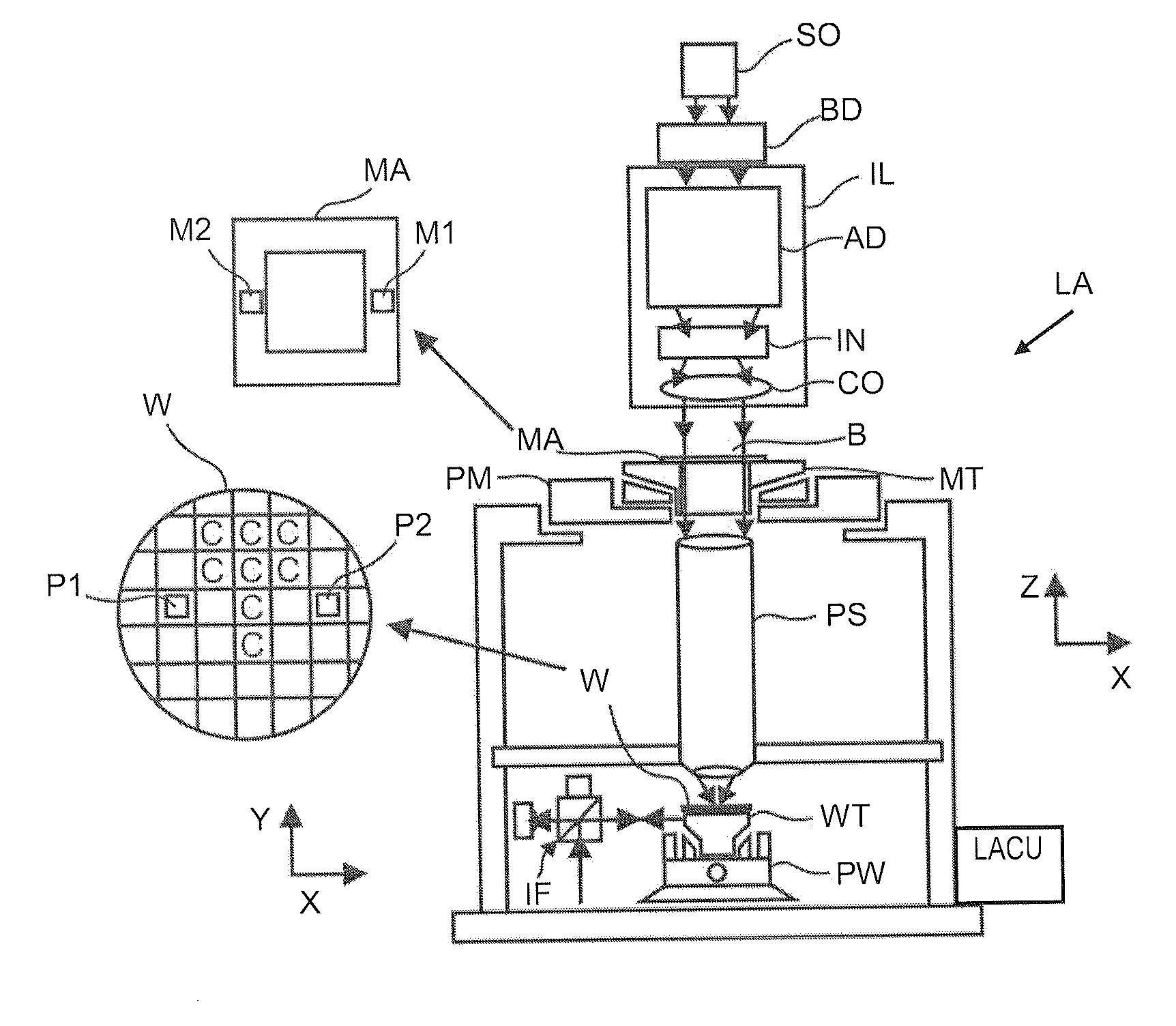

In a method of determining the focus of a lithographic apparatus used in a lithographic process on a substrate, the lithographic process is used to form a structure on the substrate, the structure having at least one feature which has an asymmetry in the printed profile which varies as a function of the focus of the lithographic apparatus on the substrate. A first image of the periodic structure is formed and detected while illuminating the structure with a first beam of radiation. The first image is formed using a first part of non-zero order diffracted radiation. A second image of the periodic structure is foamed and detected while illuminating the structure with a second beam of radiation. The second image is formed using a second part of the non-zero order diffracted radiation which is symmetrically opposite to the first part in a diffraction spectrum. The ratio of the intensities of the measured first and second portions of the spectra is determined and used to determine the asymmetry in the profile of the periodic structure and / or to provide an indication of the focus on the substrate. In the same instrument, an intensity variation across the detected portion is determined as a measure of process-induced variation across the structure. A region of the structure with unwanted process variation can be identified and excluded from a measurement of the structure.

Owner:ASML NETHERLANDS BV

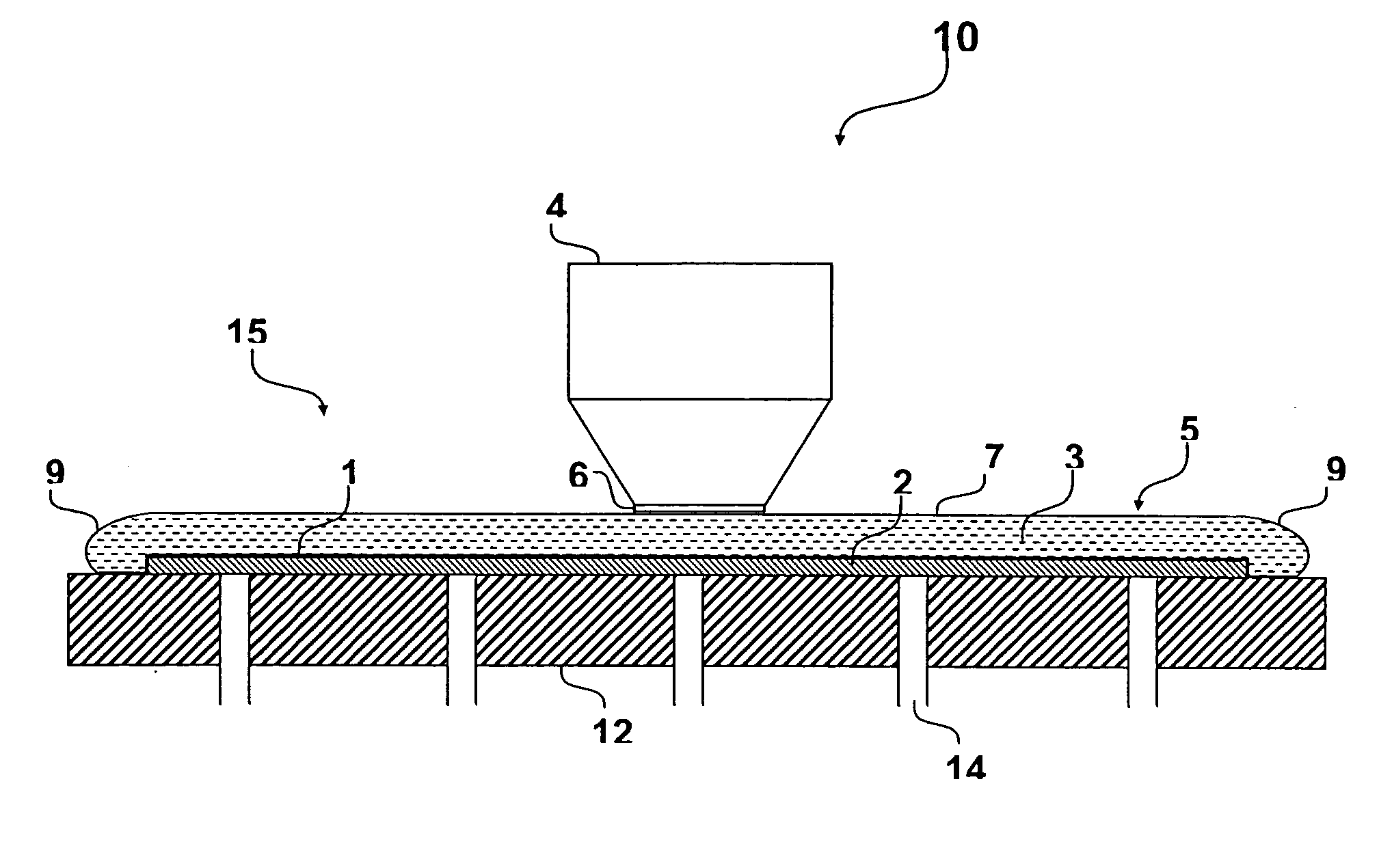

Method and system for drying a substrate

ActiveUS20050046934A1Good pattern uniformityImprove uniformityMicroscopesPhotomechanical exposure apparatusCooking & bakingThin membrane

A method and system is described for drying a thin film on a substrate following liquid immersion lithography. Drying the thin film to remove immersion fluid from the thin film is performed prior to baking the thin film, thereby reducing the likely hood for interaction of immersion fluid with the baking process. This interaction has been shown to cause non-uniformity in critical dimension for the pattern formed in the thin film following the developing process.

Owner:TOKYO ELECTRON LTD

Gradient immersion lithography

InactiveUS20050094116A1Increase the angle of incidenceReduce reflectionRadiation applicationsSemiconductor/solid-state device manufacturingRefractive indexProjection system

In a lithographic projection apparatus, a space between an optical element of a projection system is filled with a first fluid and a second fluid separated by a translucent plate. The first and second fluids have first and second indices of refraction, respectively, that are different from one another. The first fluid is provided in a space between a substrate and the translucent plate and preferably has an index of refraction similar to the index of refraction of the substrate. The second fluid is provided in a space between the translucent plate and the optical element and preferably has an index of refraction similar to the index of refraction of the optical element. The translucent plate has a third index of refraction between the first and second indices of refraction. The third index of refraction may be equal to the first index of refraction or the second index of refraction. A device manufacturing method includes filling a space between the optical element and the substrate with at least two fluids having different indices of refraction.

Owner:ASML NETHERLANDS BV

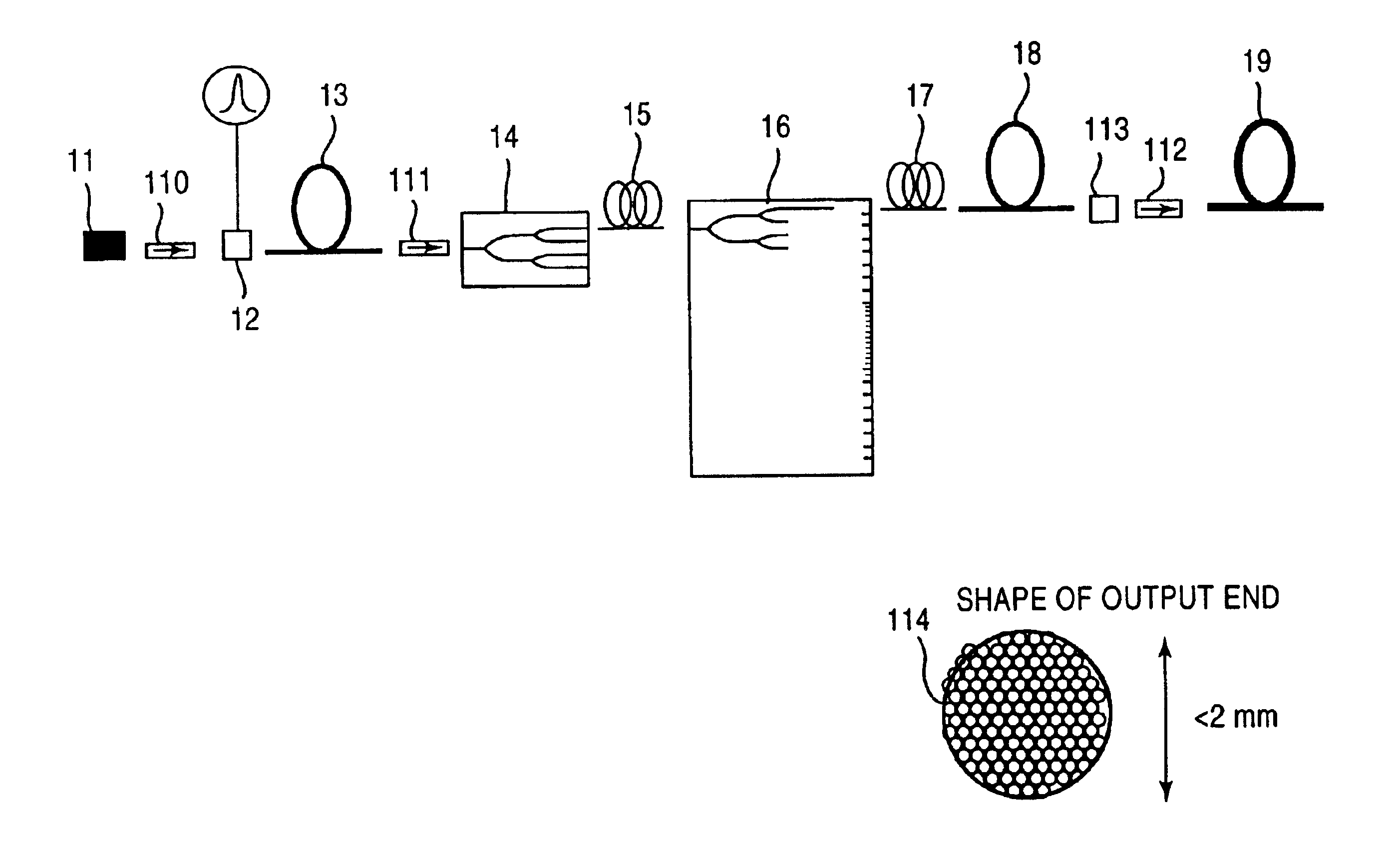

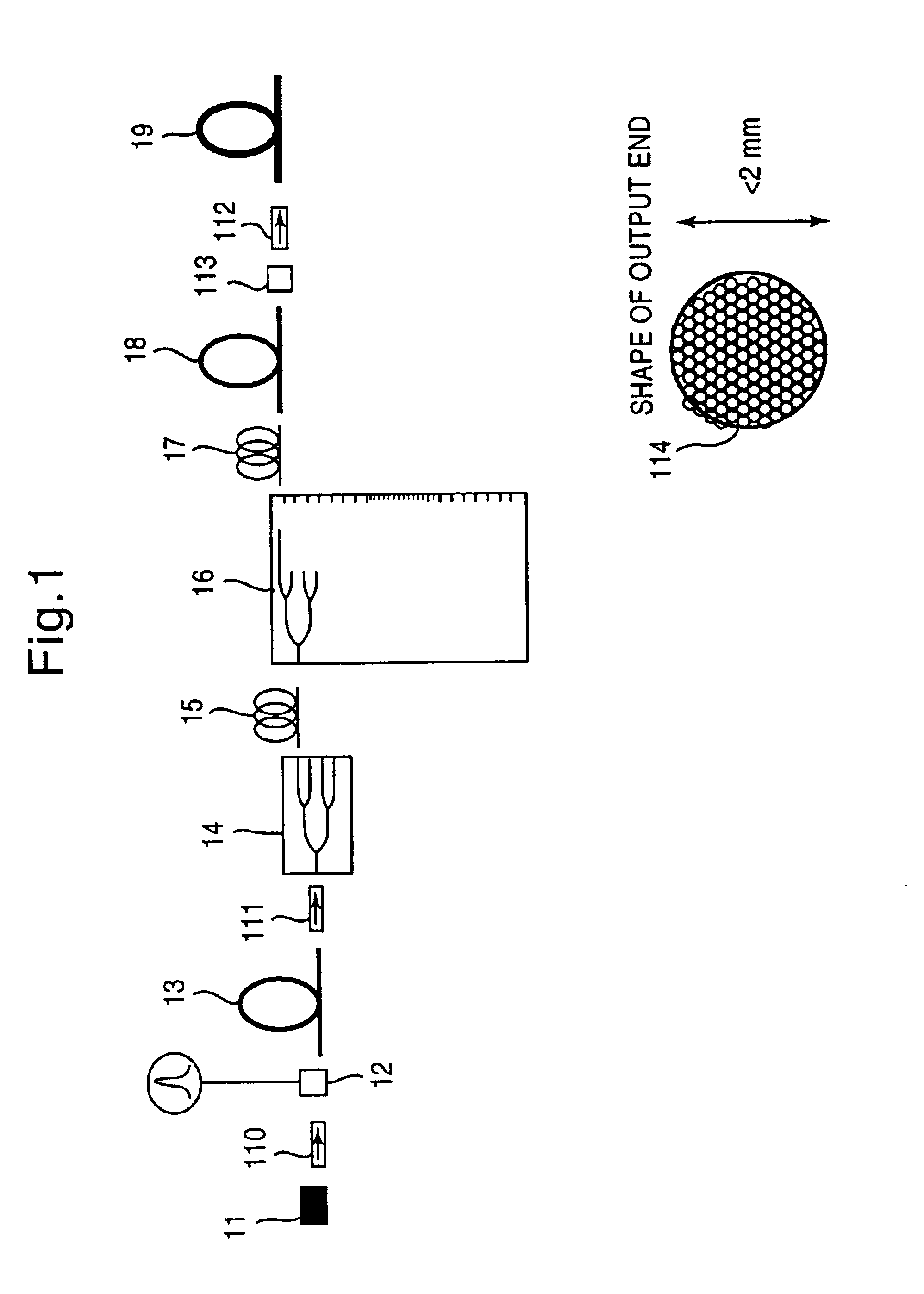

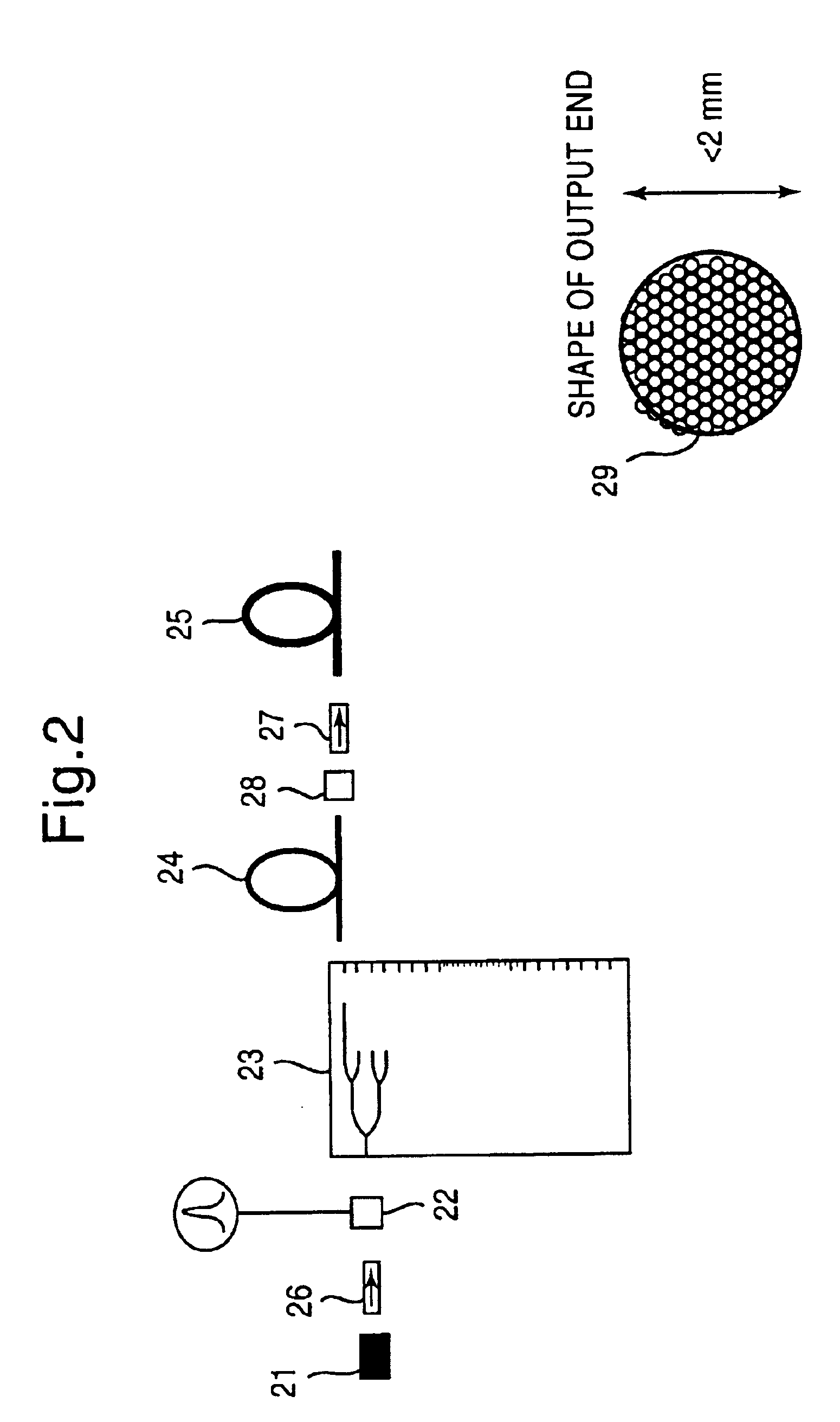

Ultraviolet laser apparatus and exposure apparatus using same

InactiveUS7023610B2Easy to getReduce spatial coherenceLaser using scattering effectsLaser arrangementsFiberUltraviolet lights

An ultraviolet laser apparatus having a single-wavelength oscillating laser generating laser light between an infrared band and a visible band, an optical amplifier for amplifying the laser light, and a wavelength converting portion converting the amplified laser light into ultraviolet light using a non-linear optical crystal. An exposure apparatus transfers a pattern image of a mask onto a substrate and includes a light source having a laser apparatus emitting laser light having a single wavelength, a first fiber optical amplifier for amplifying the laser light, a light dividing device for dividing or branching the amplified laser light into plural lights, and second fiber optical amplifiers for amplifying the plural divided or branched lights, respectively, and a transmission optical system for transmitting the laser light emitted from the light source to the exposure apparatus.

Owner:NIKON CORP

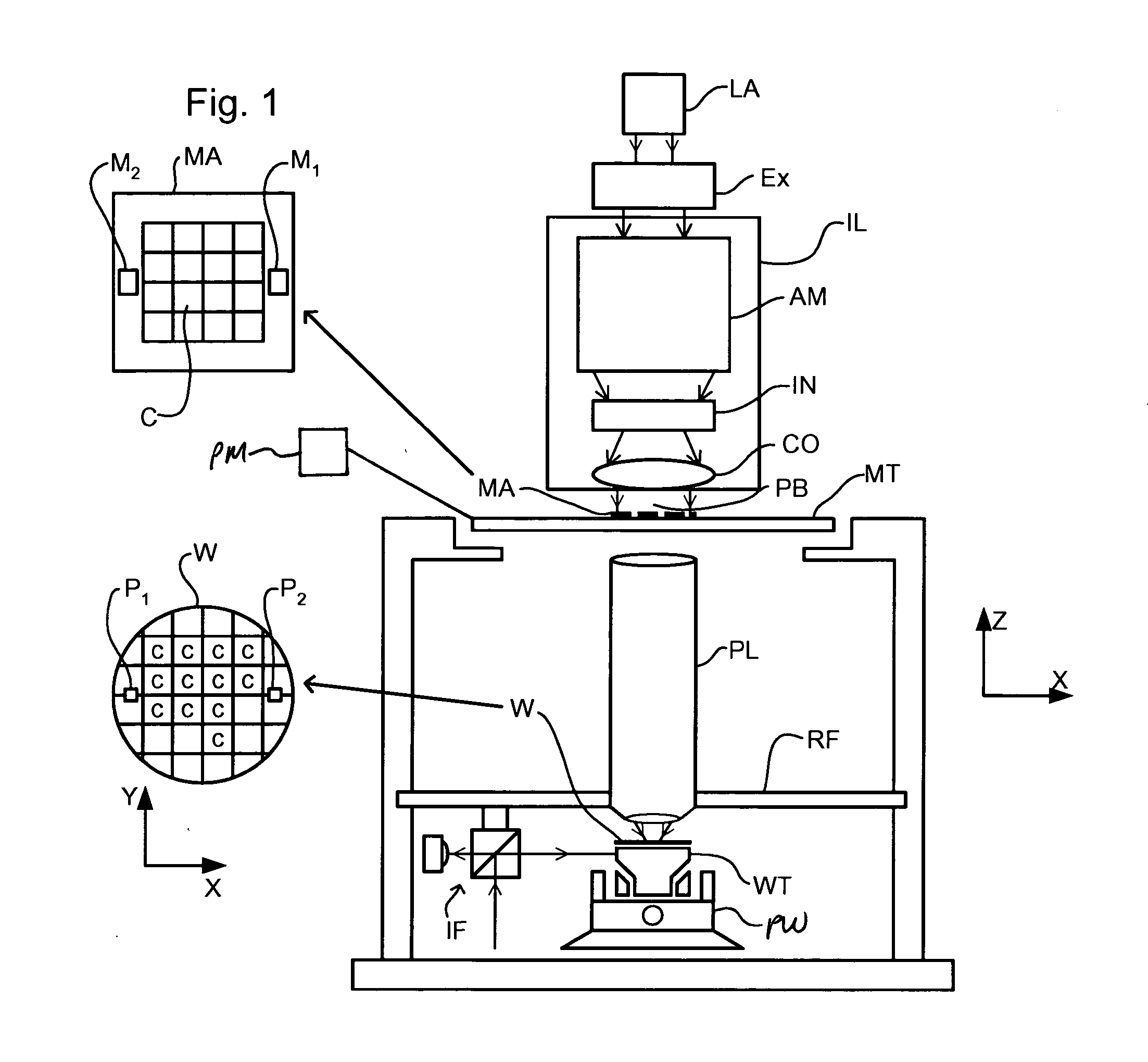

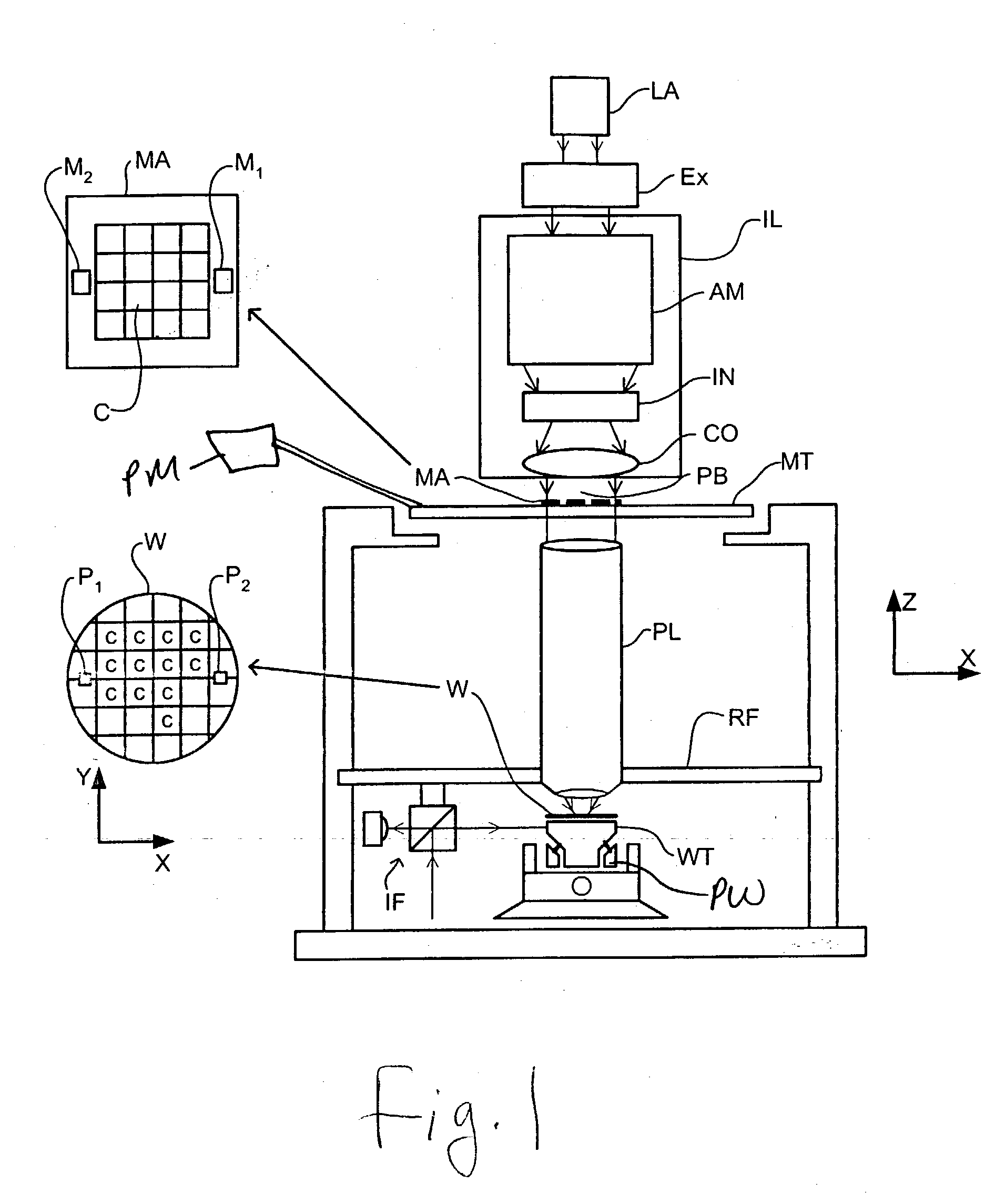

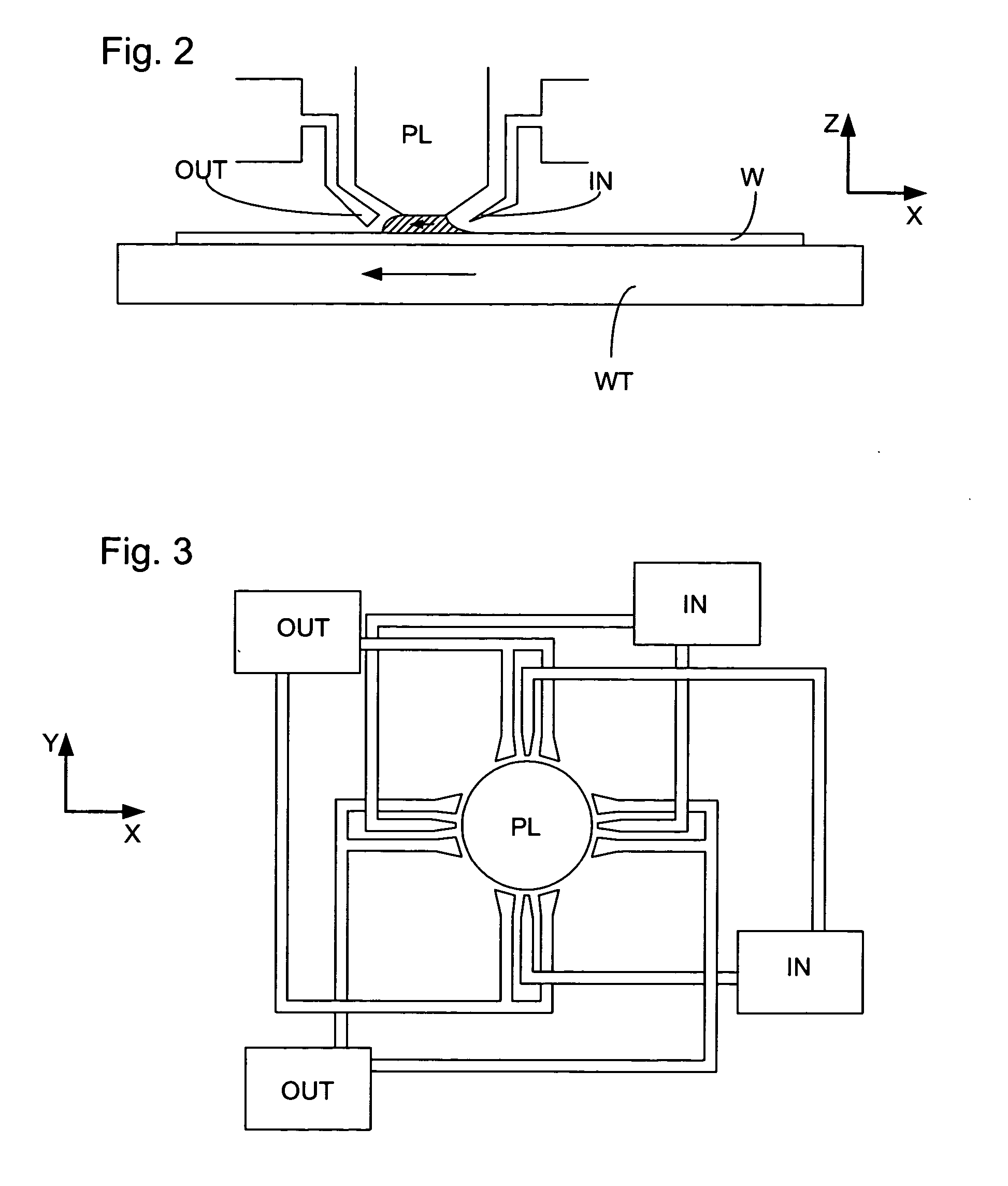

Lithographic apparatus and device manufacturing method

ActiveUS20050007569A1Reduce decreaseResidue reductionServomotor componentsSemiconductor/solid-state device manufacturingControl systemEngineering

In a lithographic apparatus, a localized area of the substrate surface under a projection system is immersed in liquid. The height of a liquid supply system above the surface of the substrate can be varied using actuators. A control system uses feedforward or feedback control with input of the surface height of the substrate to maintain the liquid supply system at a predetermined height above the surface of the substrate.

Owner:ASML NETHERLANDS BV

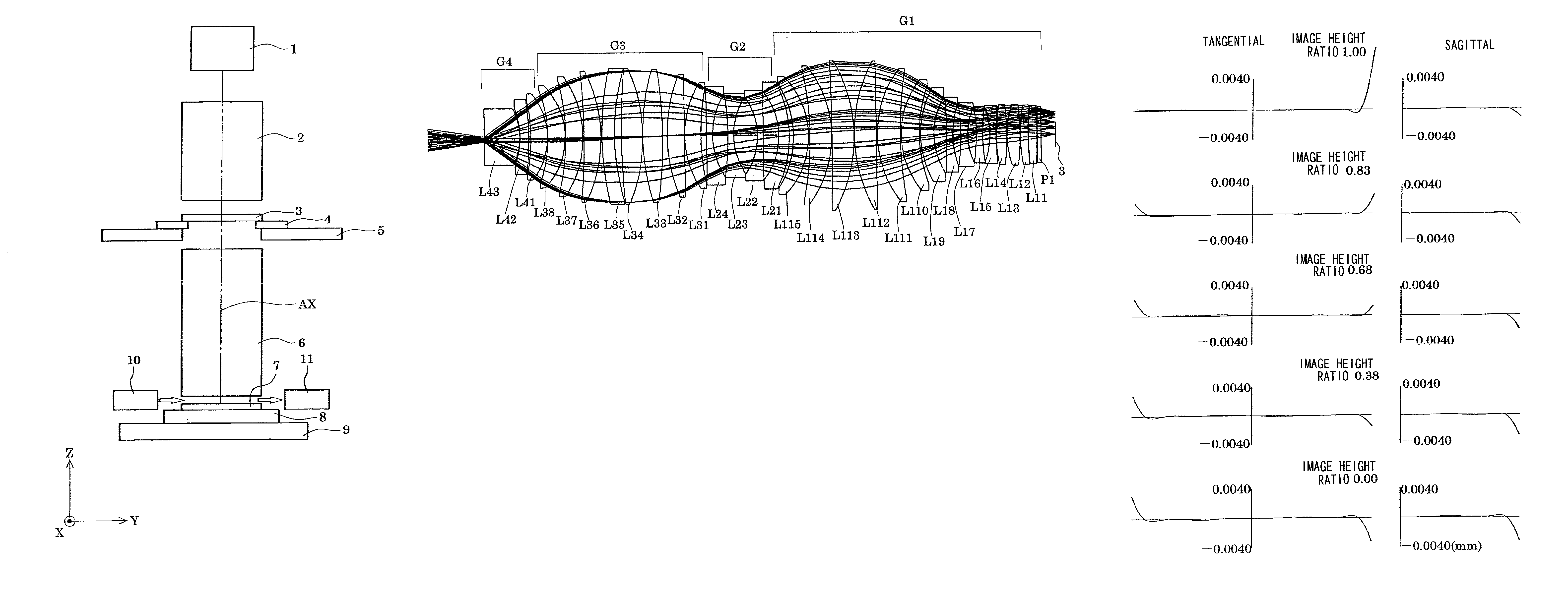

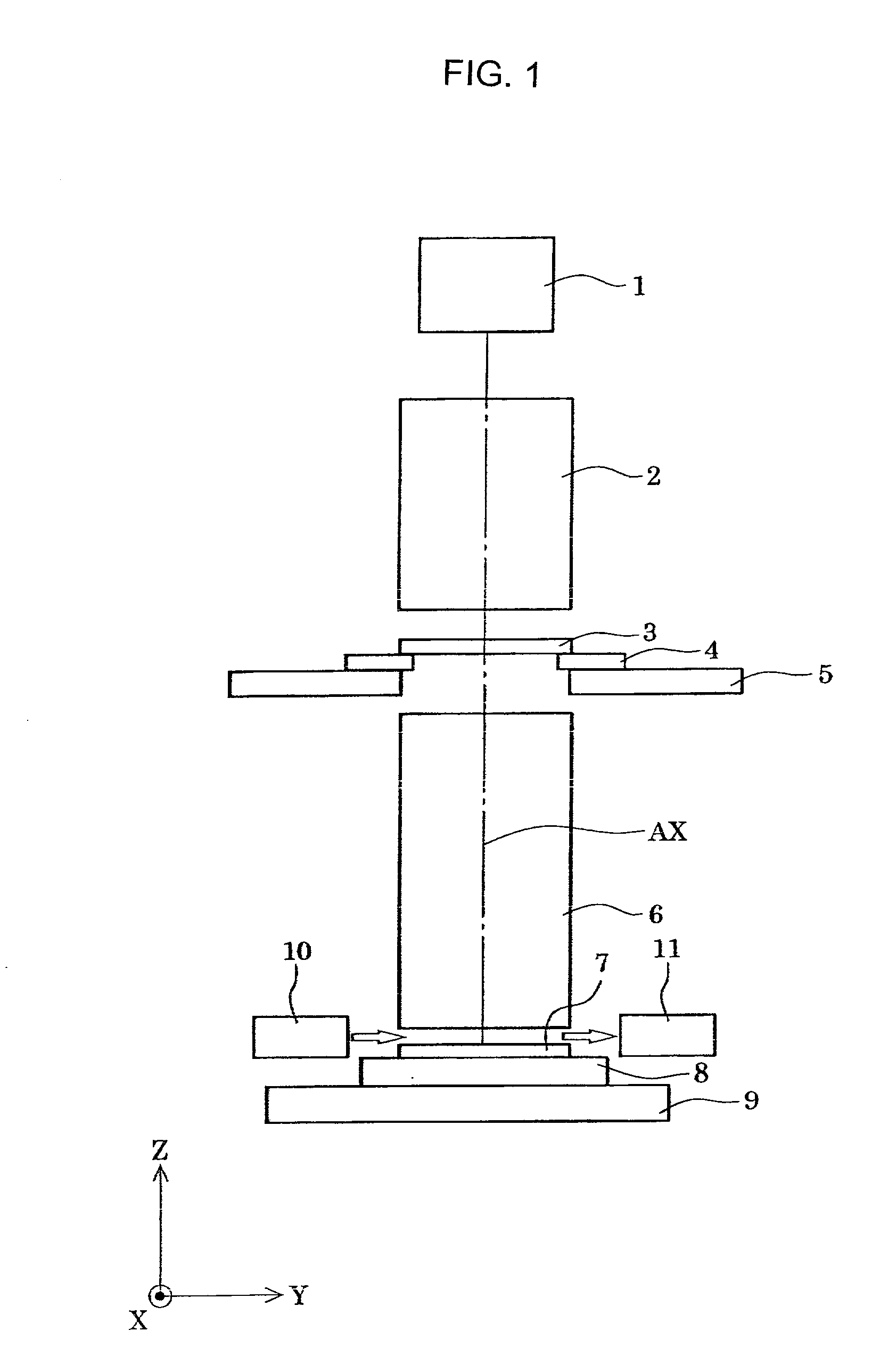

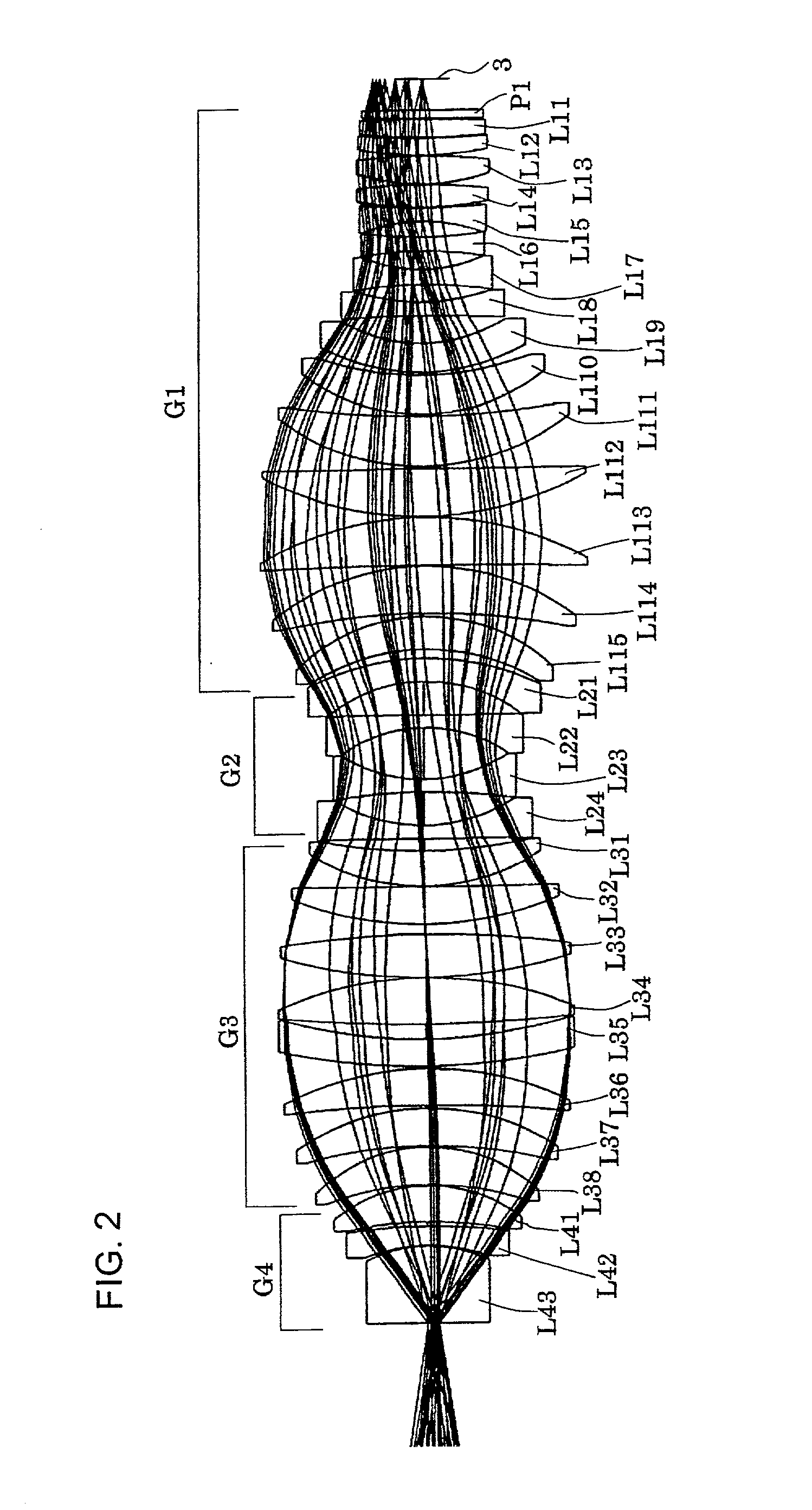

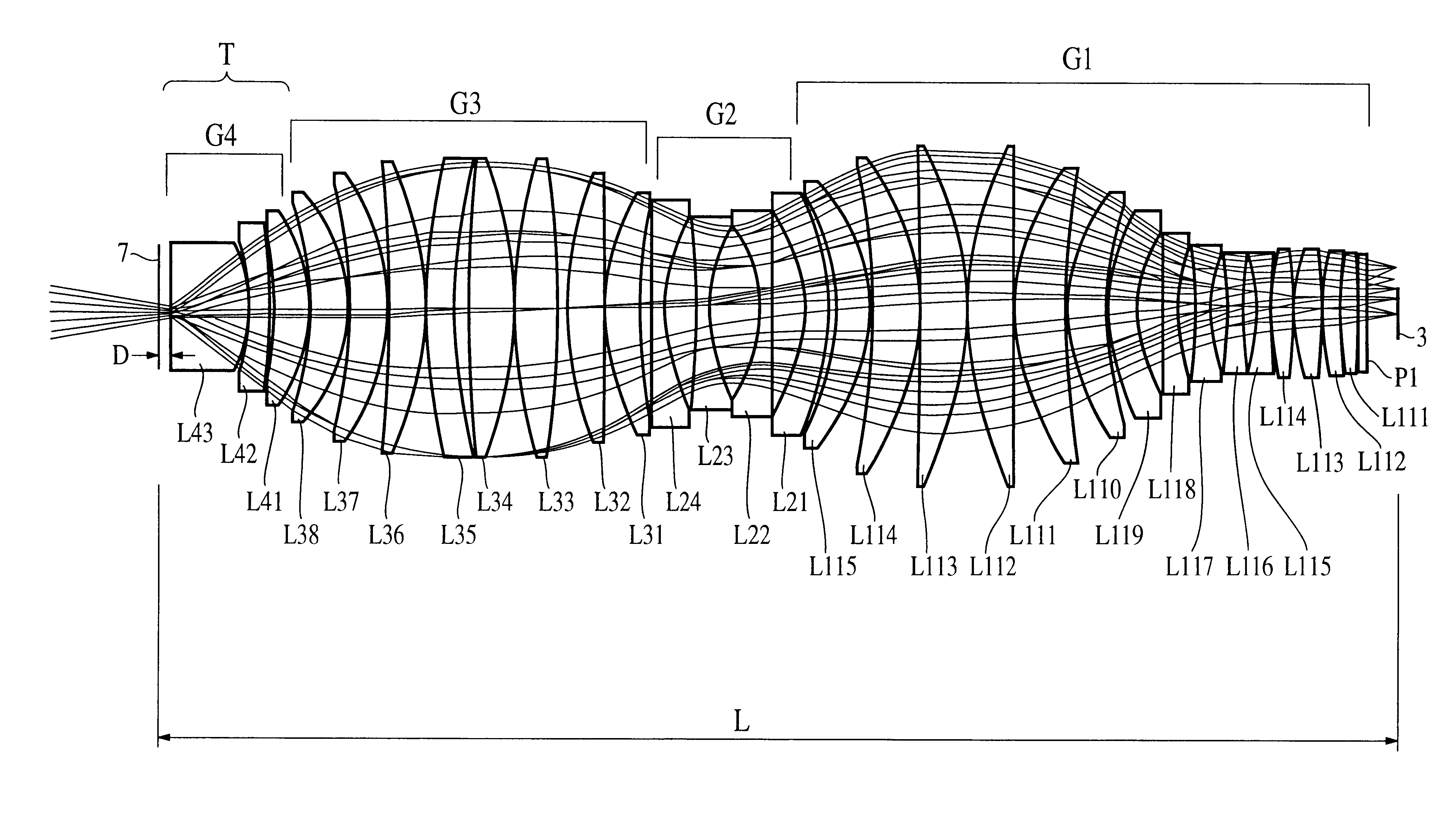

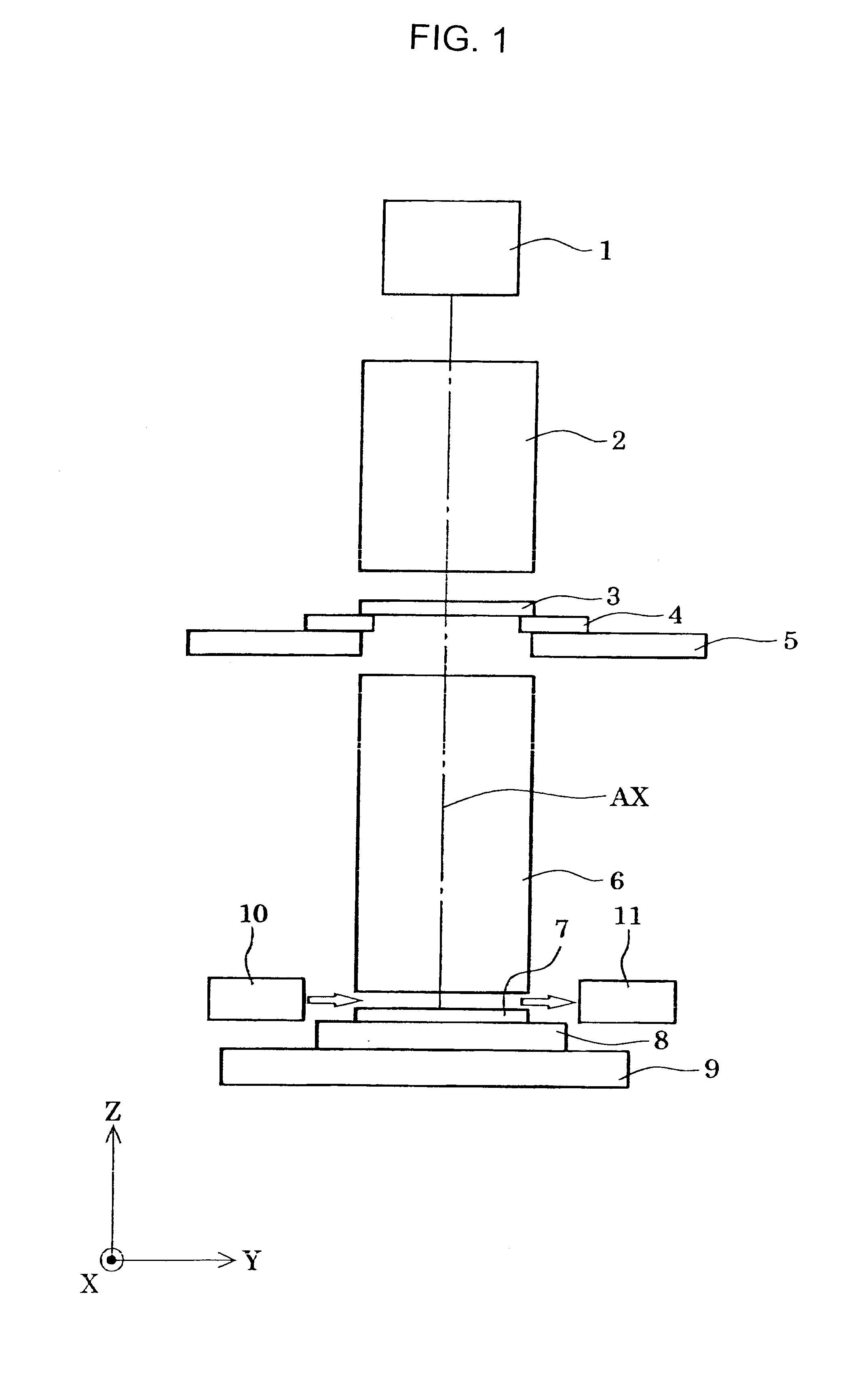

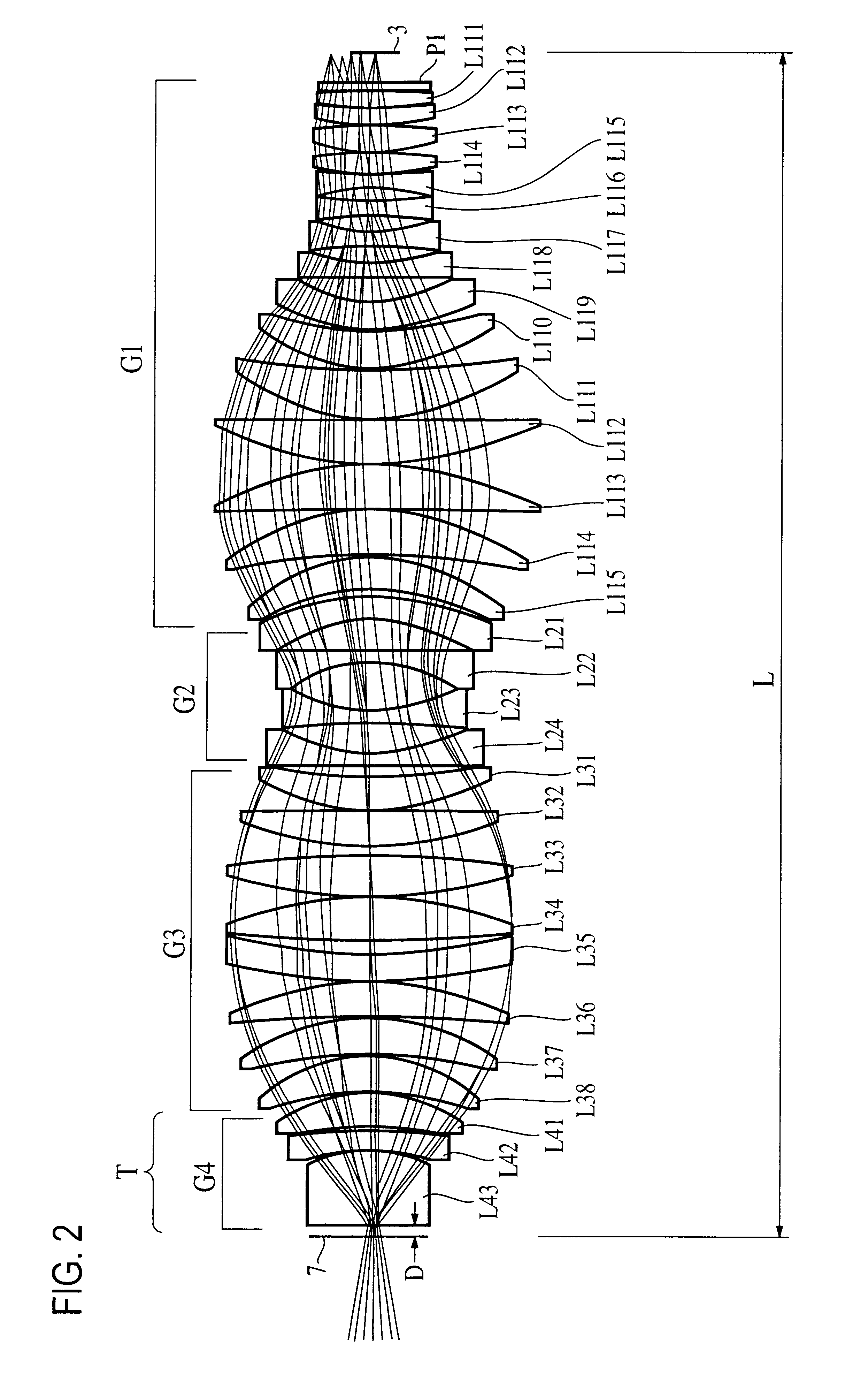

Projection optical system and exposure apparatus having the projection optical system

InactiveUS20030030916A1Avoid stickingPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical axisLength wave

A projection optical system according to the present invention whose image side numerical aperture is greater than or equal to 0.75, and which forms an image of a first object upon a second object using light of a predetermined wavelength less than or equal to 300 nm, comprises: a first lens group G1 of positive refractive power; a second lens group G2 of negative refractive power; a third lens group G3 of positive refractive power; and a fourth lens group G4 of positive refractive power, and: the first lens group G1, the second lens group G2, the third lens group G3 and the fourth lens group G4 are arranged in order from a side of the first object; and a distance D in mm along an optical axis between an optical surface of the fourth lens group G4 closest to the second object, and the second object, satisfies a condition of 0.1<D<5.

Owner:NIKON CORP

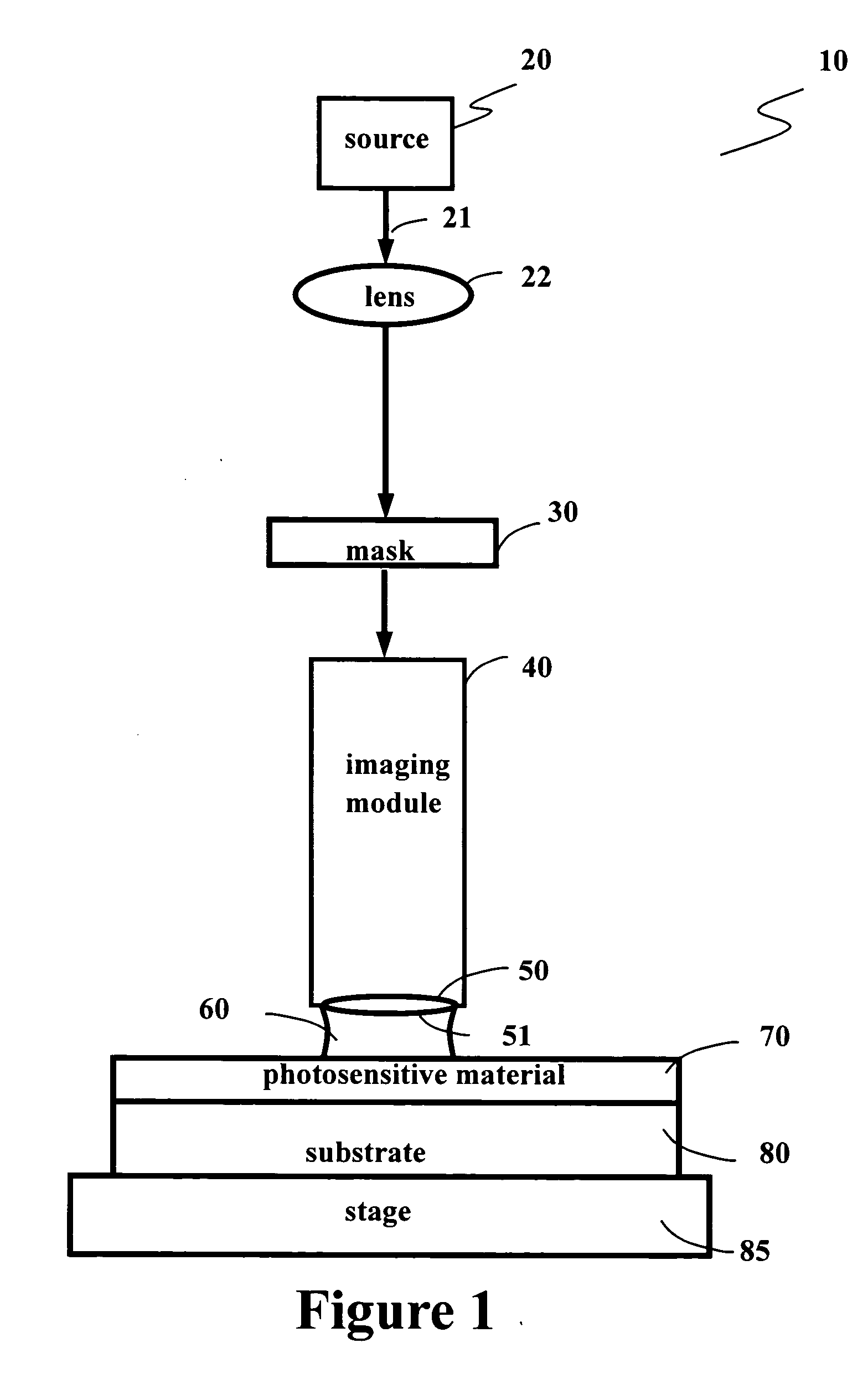

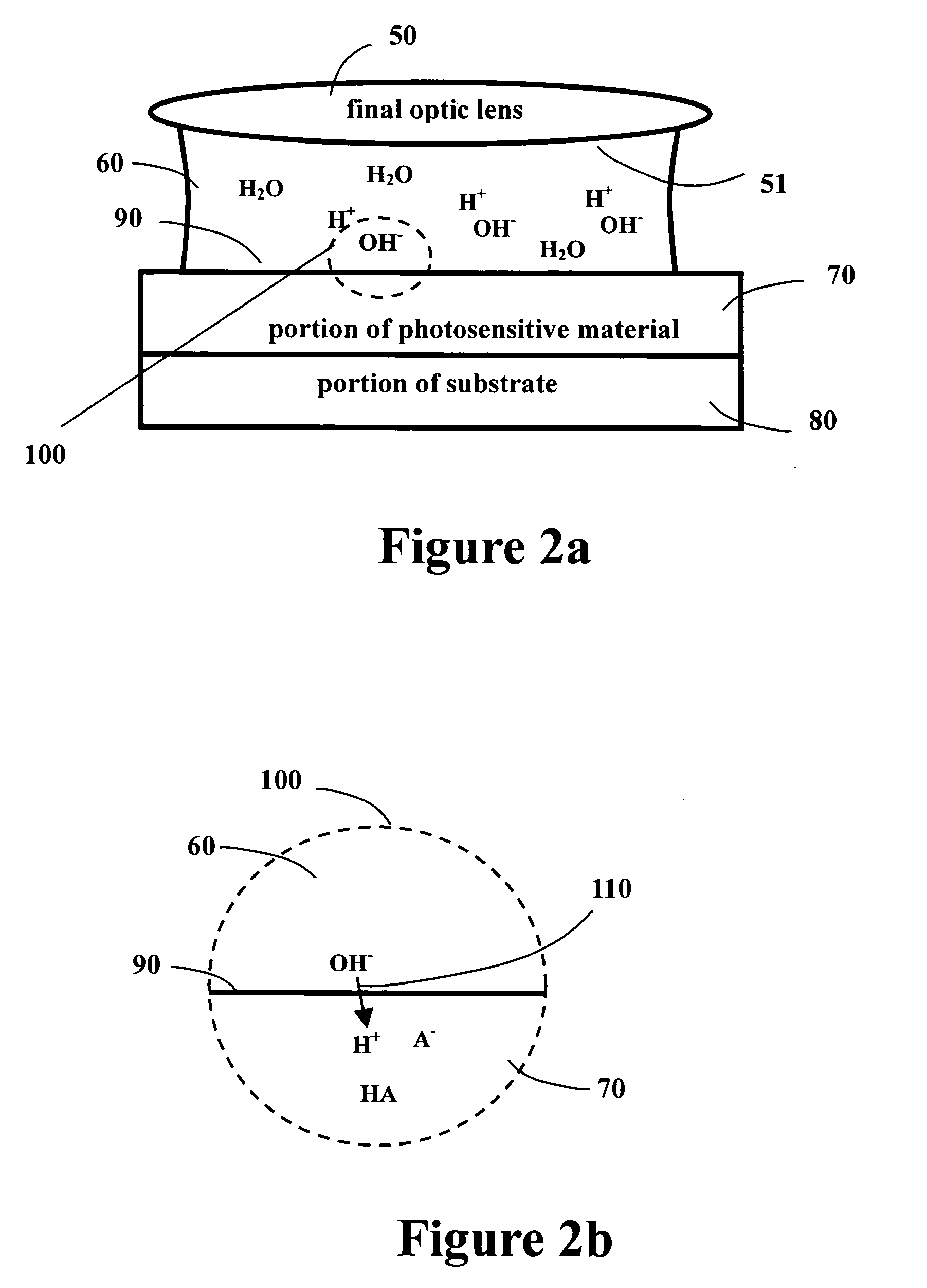

Immersion fluid for immersion Lithography, and method of performing immersion lithography

ActiveUS20050036183A1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusSemiconductor structureOptical surface

An immersion lithographic system 10 comprises an optical surface 51, an immersion fluid 60 with a pH less than 7 contacting at least a portion of the optical surface, and a semiconductor structure 80 having a topmost photoresist layer 70 wherein a portion of the photoresist is in contact with the immersion fluid. Further, a method for illuminating a semiconductor structure 80 having a topmost photoresist layer 70 comprising the steps of: introducing an immersion fluid 60 into a space between an optical surface 51 and the photoresist layer wherein the immersion fluid has a pH of less than 7, and directing light preferably with a wavelength of less than 450 nm through the immersion fluid and onto the photoresist.

Owner:TAIWAN SEMICON MFG CO LTD

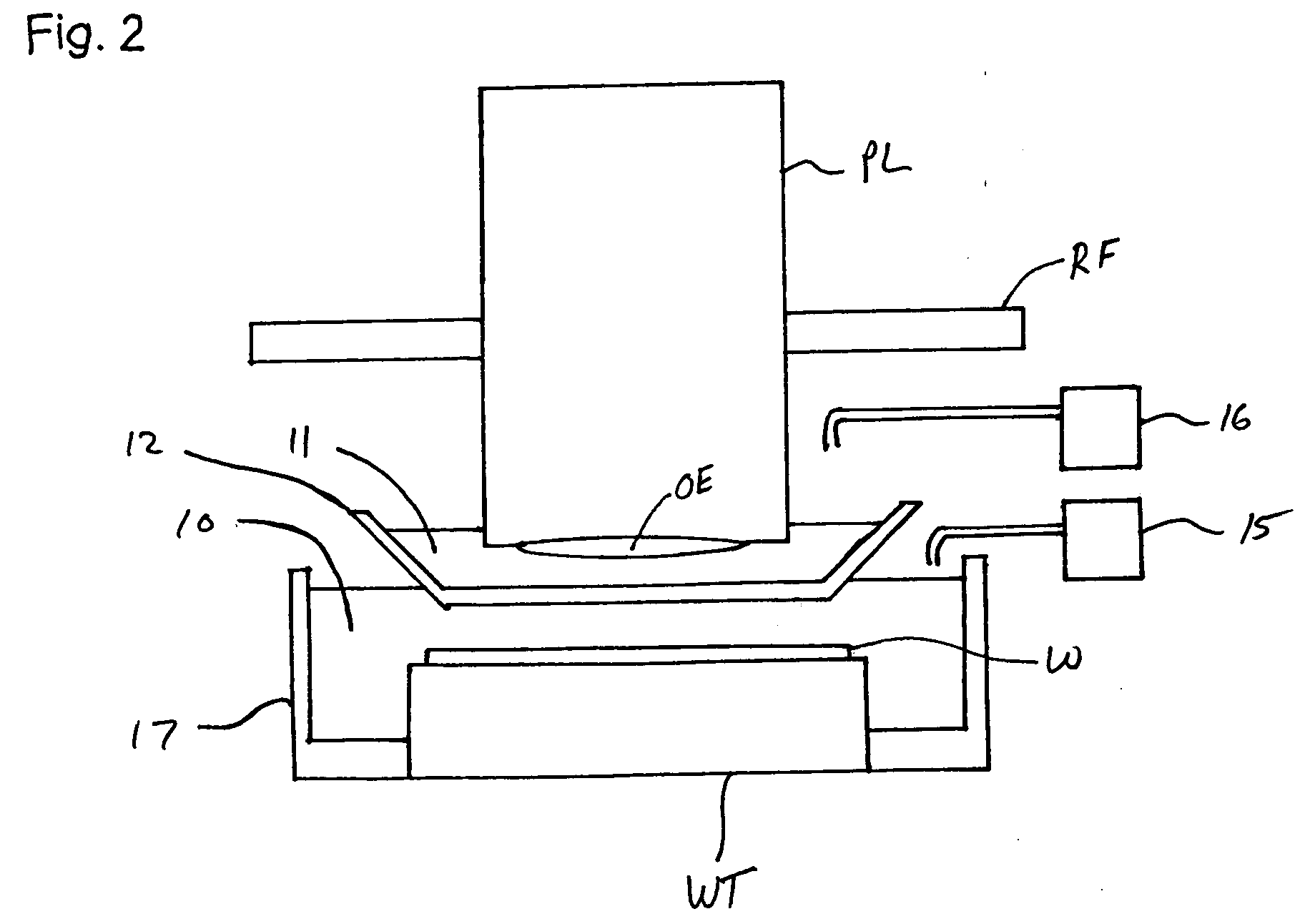

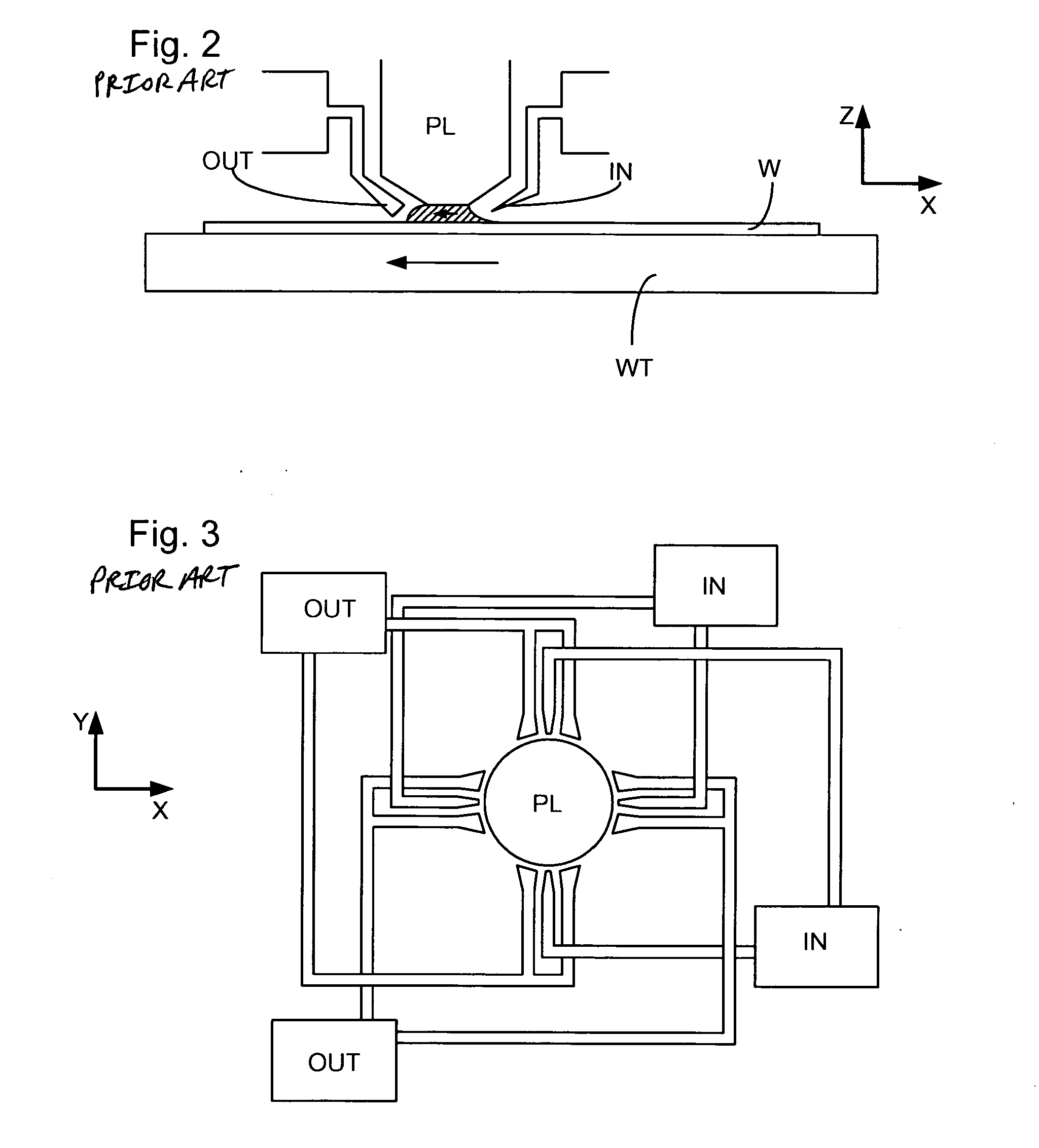

Exposure apparatus and device manufacturing method

InactiveUS20050259234A1Pressure of waterRaise transfer toSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringElectrical and Electronics engineering

Liquid is supplied by a supply mechanism to a space between a lens and a wafer via a supply nozzle on one side of the lens, and the liquid is recovered by a recovery mechanism via a recovery pipe on the other side of the lens. When the supply and the recovery of the liquid are performed in parallel, a predetermined amount of liquid (exchanged at all times) is held between the lens and the substrate on the stage. Accordingly, when exposure (pattern transfer on the substrate) is performed in this state, an immersion method is applied and a pattern is transferred with good precision onto the substrate. In addition, in the case the liquid leaks out from under the lower edge of a peripheral wall, the liquid that could not be recovered is recovered by an auxiliary recovery mechanism via a slit. And, by such operations, the substrate is freed from the residual liquid on the substrate.

Owner:NIKON CORP

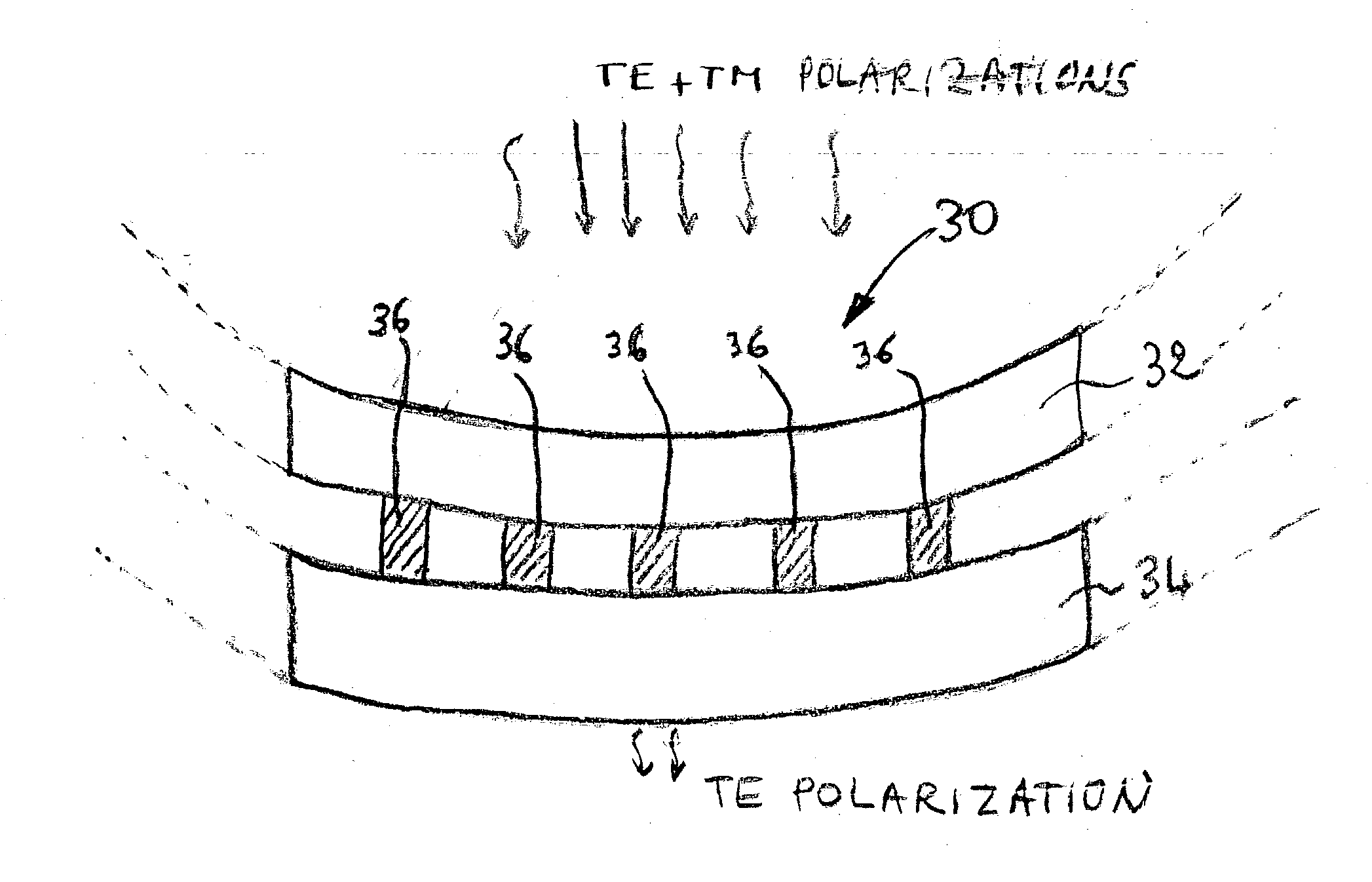

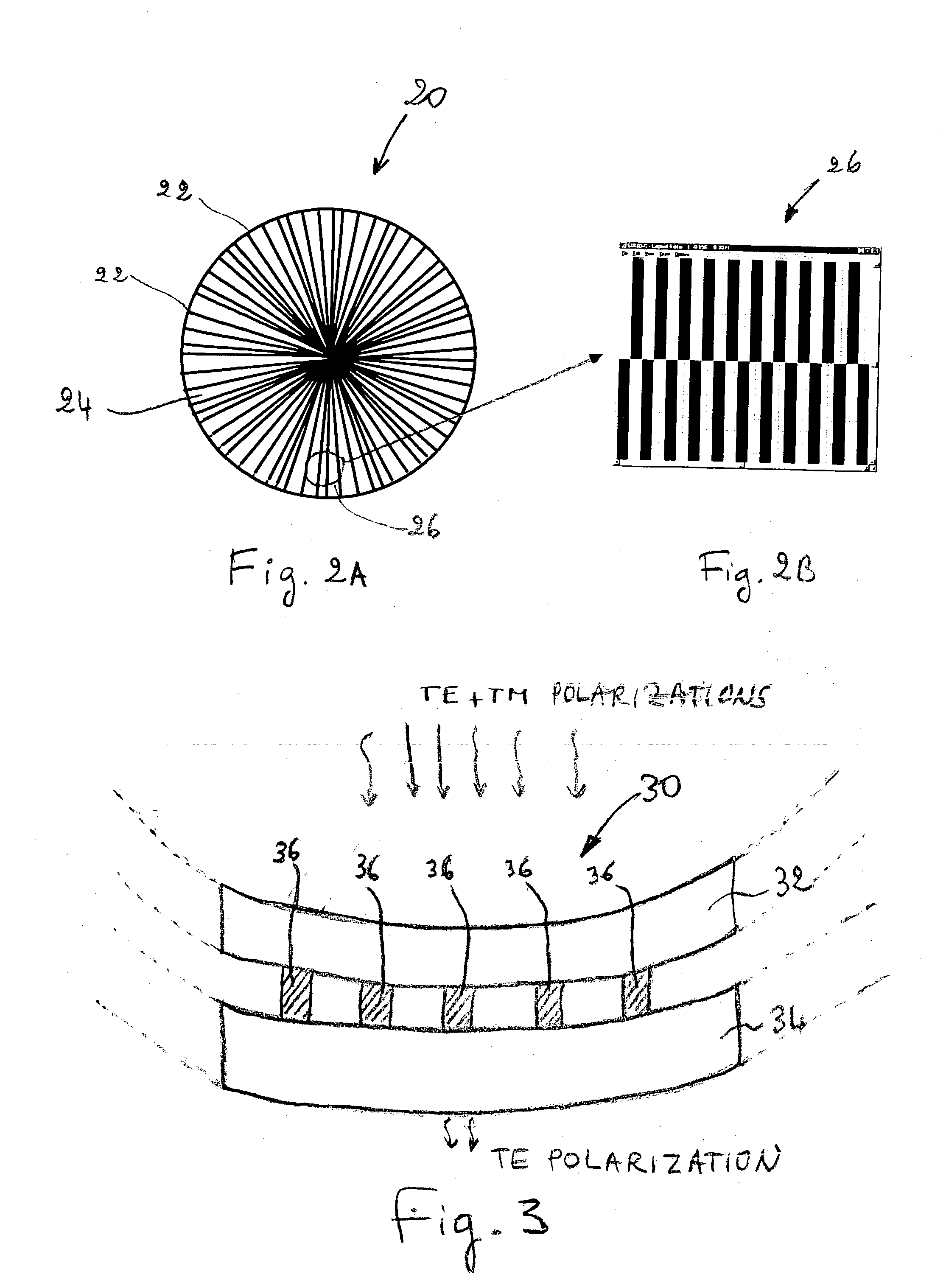

Stationary and dynamic radial transverse electric polarizer for high numerical aperture systems

InactiveUS20040169924A1Polarising elementsSemiconductor/solid-state device manufacturingHigh numerical apertureClassical mechanics

A radial transverse electric polarizer device is provided. The device includes a first layer of material having a first refractive index, a second layer of material having a second refractive index, and a plurality of elongated elements azimuthally and periodically spaced apart, and disposed between the first layer and the second layer. The plurality of elongated elements interact with electromagnetic waves of radiation to transmit transverse electric polarization of electromagnetic waves of radiation. One aspect of the invention is, for example, to use such polarizer device in a lithographic projection apparatus to increase imaging resolution. Another aspect is to provide a device manufacturing method including polarizing a beam of radiation in a transverse electric polarization.

Owner:ASML NETHERLANDS BV

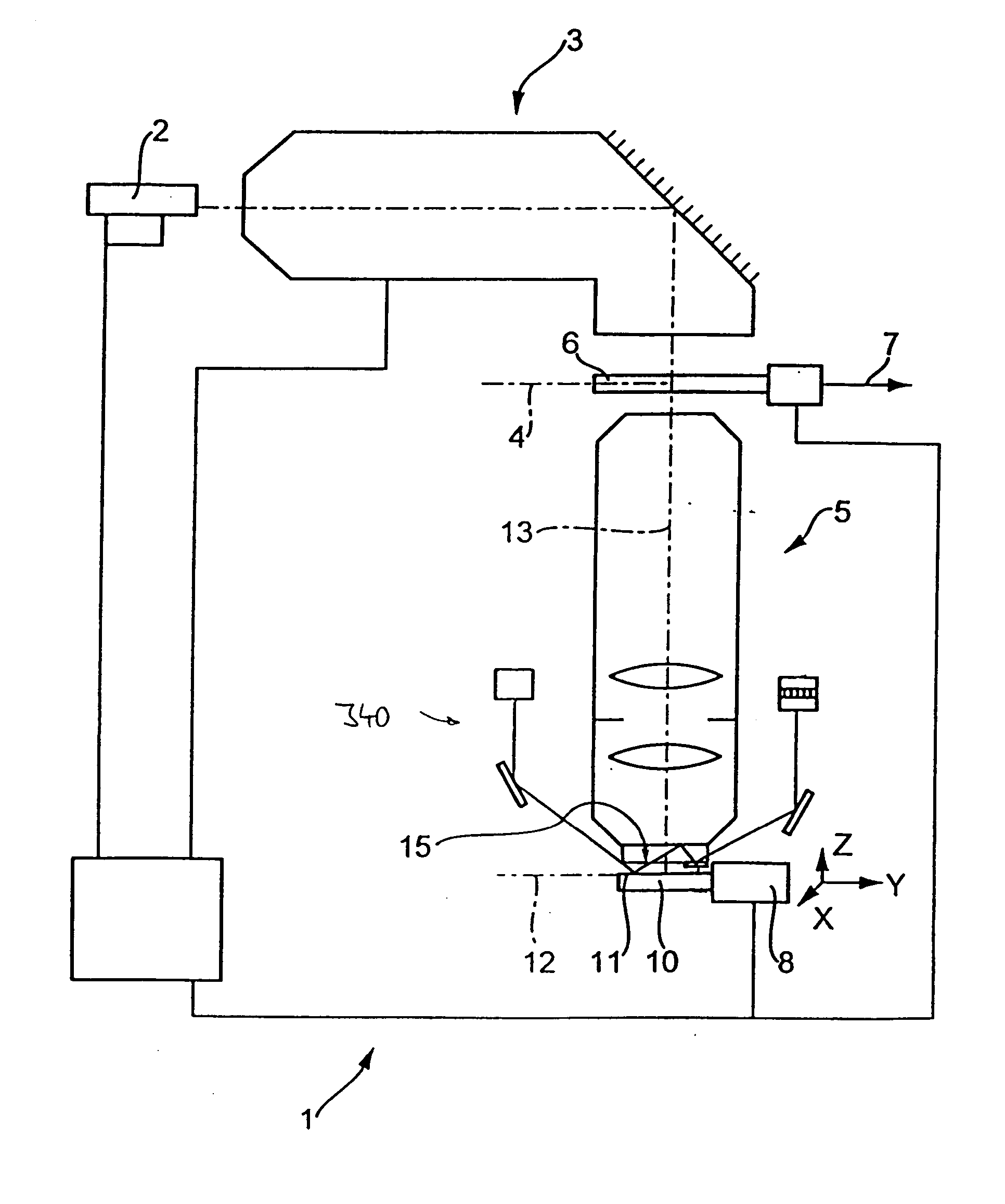

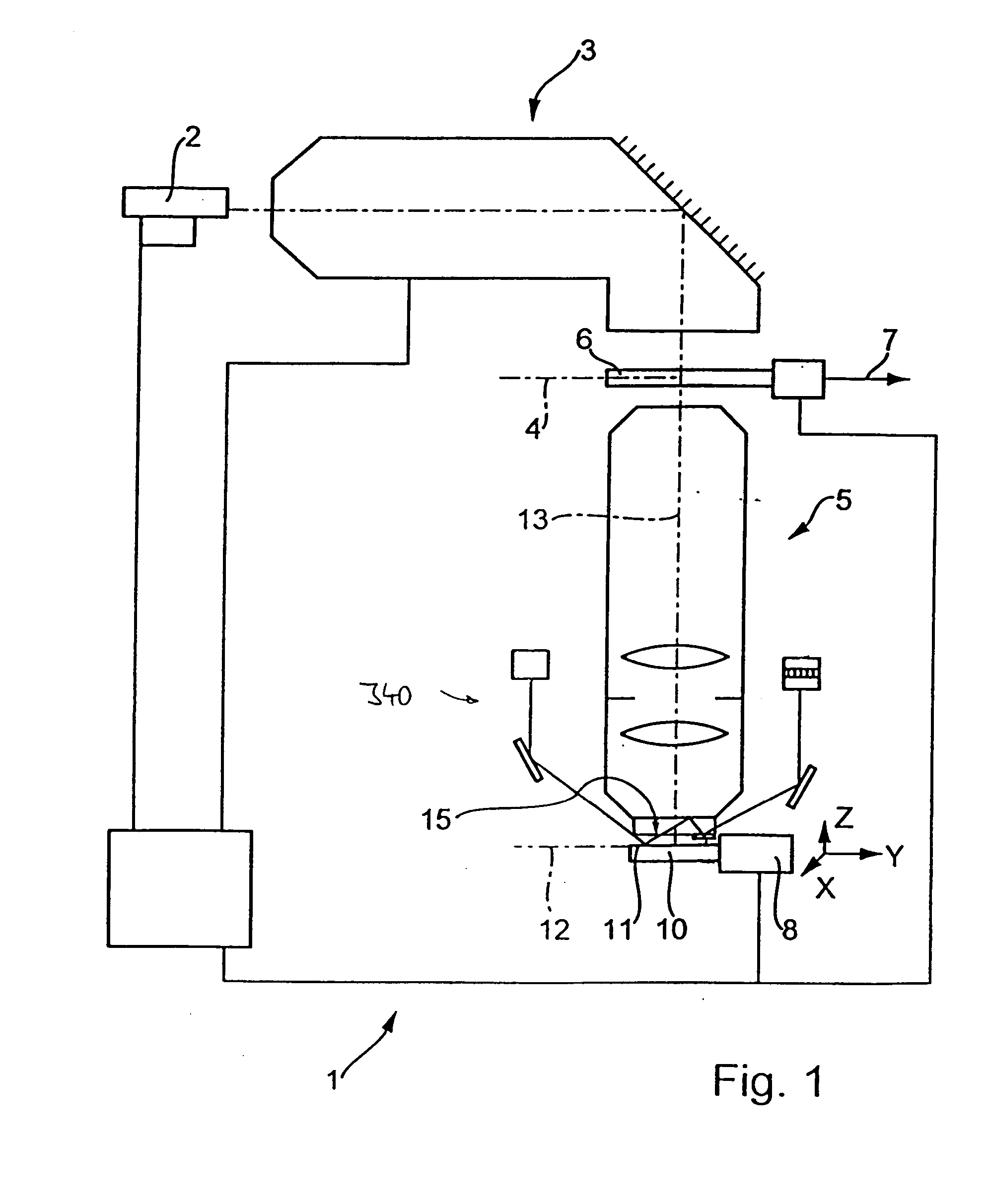

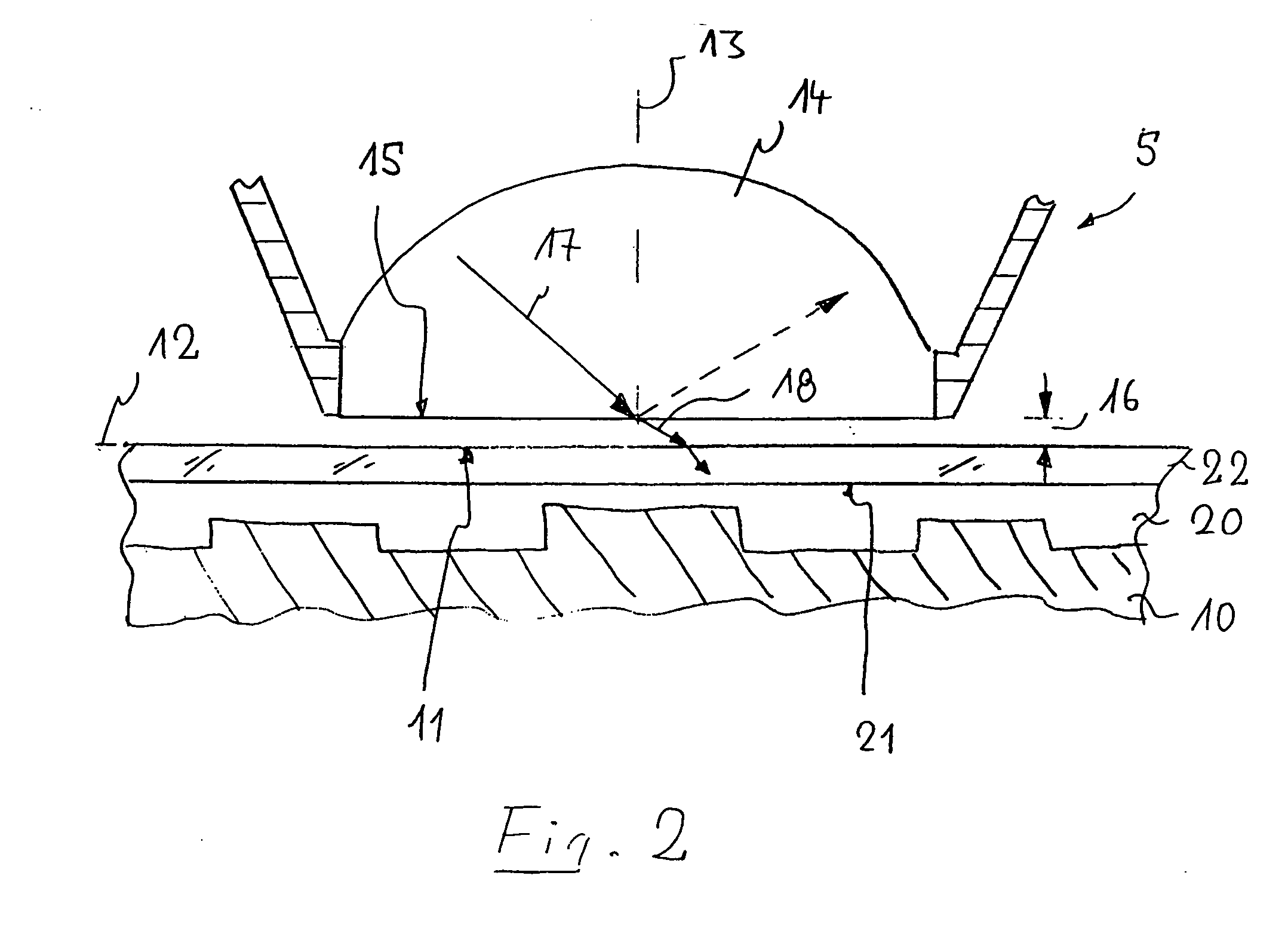

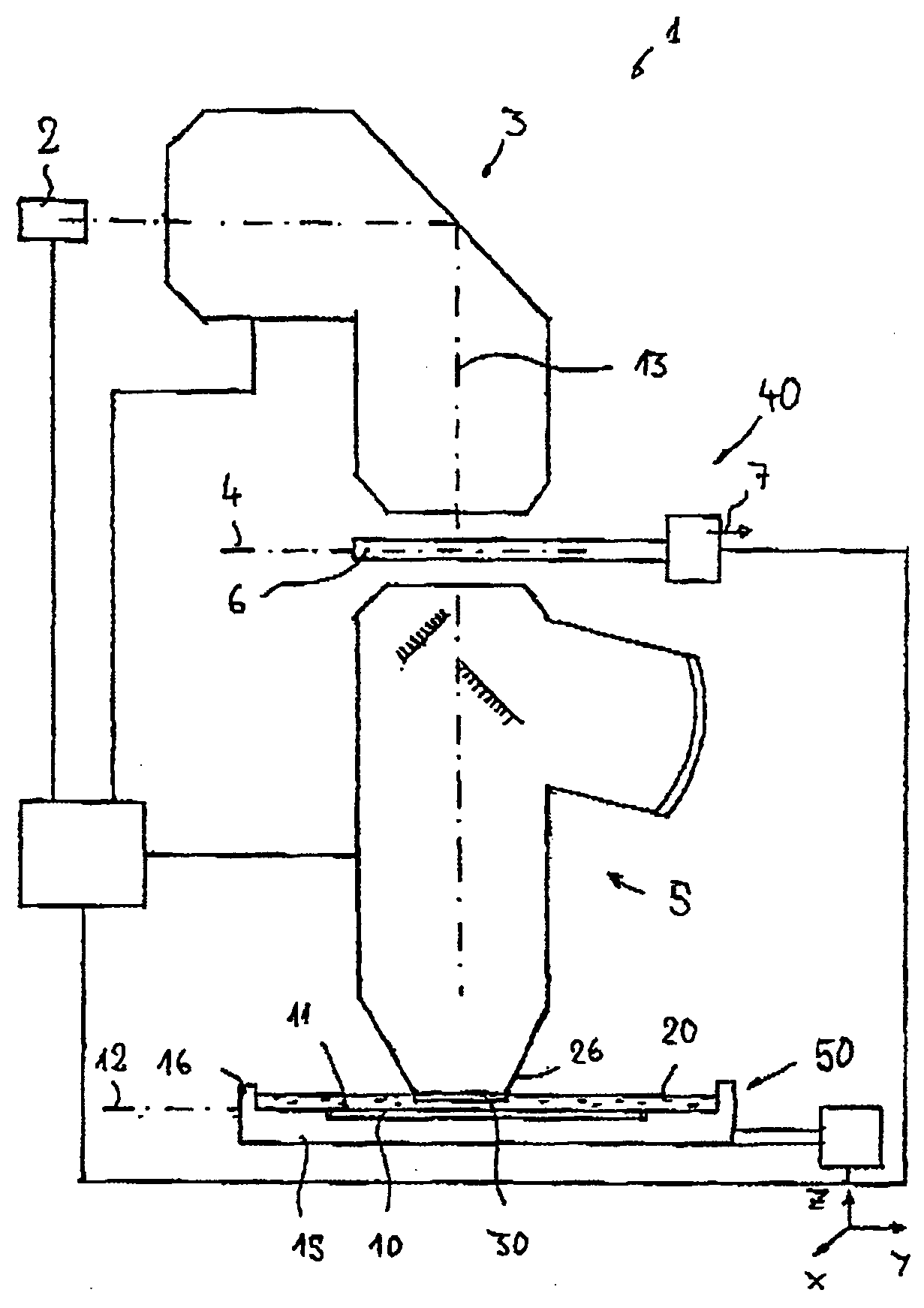

Projection exposure method and projection exposure system

InactiveUS20050030506A1Avoid defocusing errorProvides adequateNanoinformaticsMaterial analysis by optical meansLithographic artistHigh numerical aperture

In a method for manufacturing semiconductor devices and other finely structured parts, a projection objective (5) is used in order to project the image of a pattern arranged in the object plane of the projection objective onto a photosensitive substrate which is arranged in the region of the image plane (12) of the projection objective. In this case, there is set between an exit surface (15), assigned to the projection objective, for exposing light and an incoupling surface (11), assigned to the substrate, for exposing light a small finite working distance (16) which is at least temporarily smaller in size and exposure time interval than a maximum extent of an optical near field of the light emerging from the exit surface. As a result, projection objectives with very high numerical apertures in the region of NA>0.8 or more can be rendered useful for contactless projection lithography.

Owner:CARL ZEISS SMT GMBH

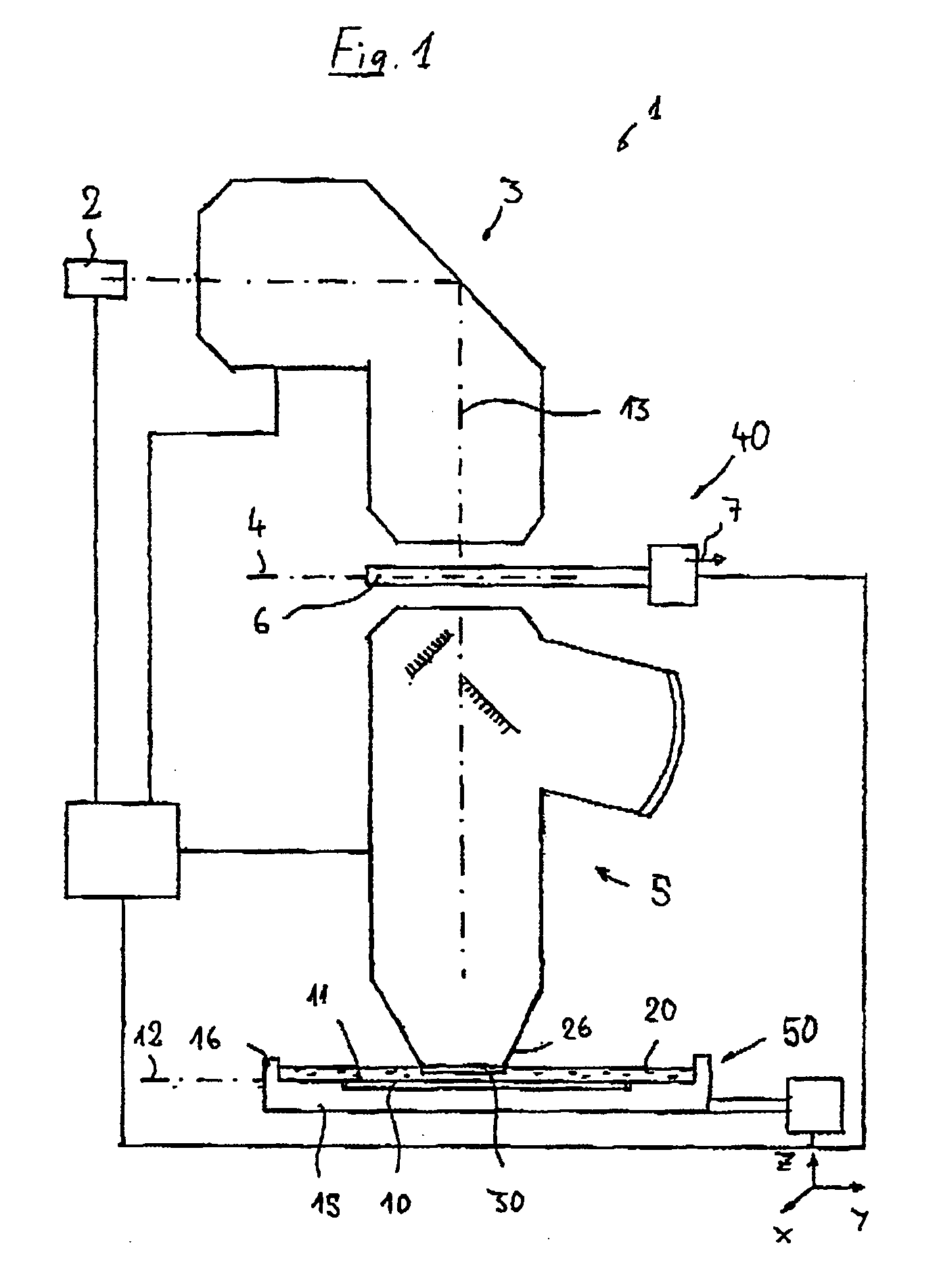

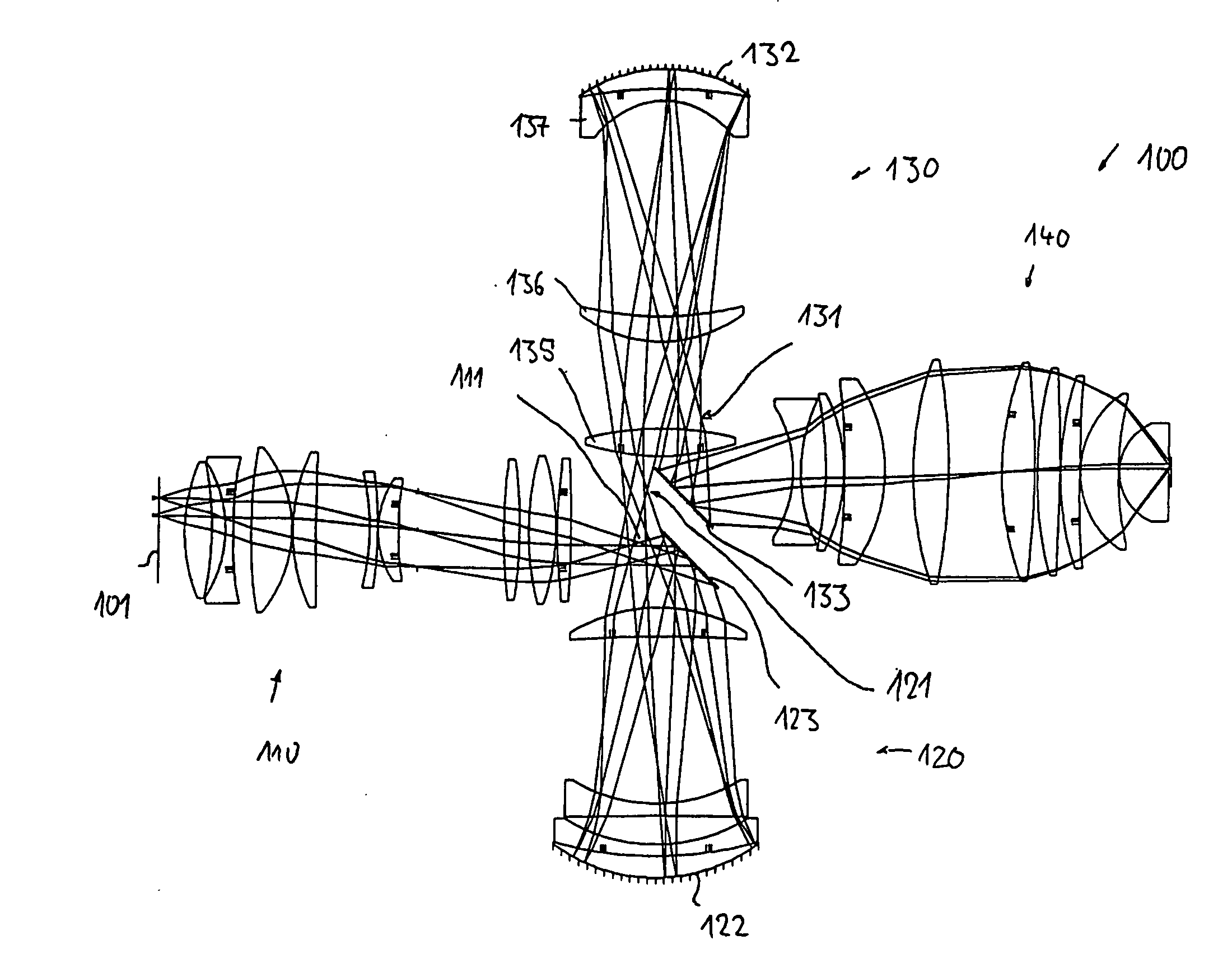

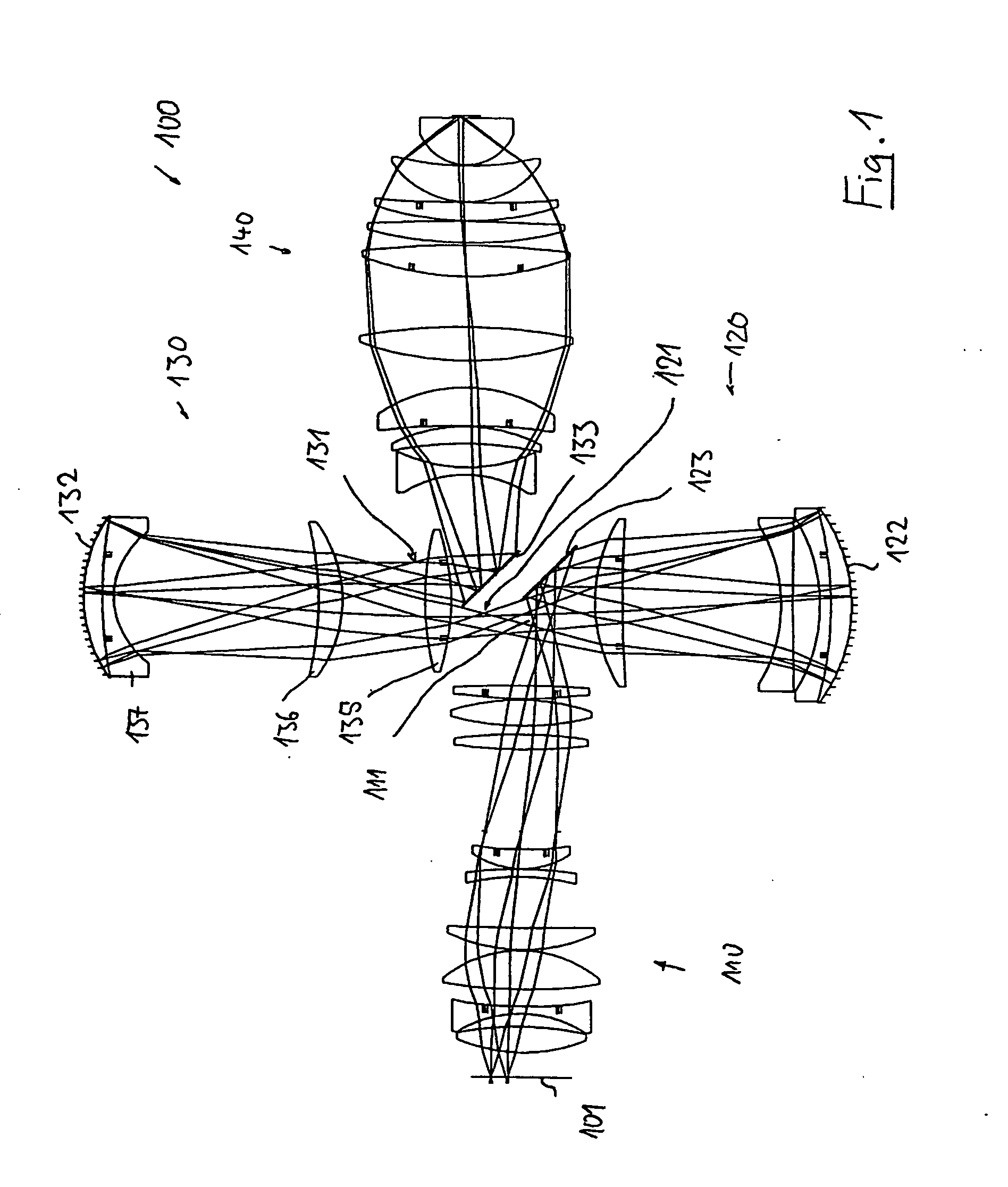

Catadioptric projection objective with geometric beam splitting

InactiveUS20050117224A1Good engineering qualityEasy to installMicroscopesPhotomechanical exposure apparatusIntermediate imageOptical axis

A catadioptric projection objective is used to project a pattern arranged in an object plane of the projection objective into an image plane of the projection objective with the formation of at least one real intermediate image and has an image-side numerical aperture NA>0.7. The projection objective comprises an optical axis and at least one catadioptric objective part that comprises a concave mirror and a first folding mirror. There are a first beam section running from the object plane to the concave mirror and a second beam section running from the concave mirror to the image plane. The first folding mirror is arranged with reference to the concave mirror in such a way that one of the beam sections is folded at the first folding mirror and the other beam section passes the first folding mirror without vignetting, the first beam section and the second beam section crossing one another in a cross-over region.

Owner:CARL ZEISS SMT GMBH

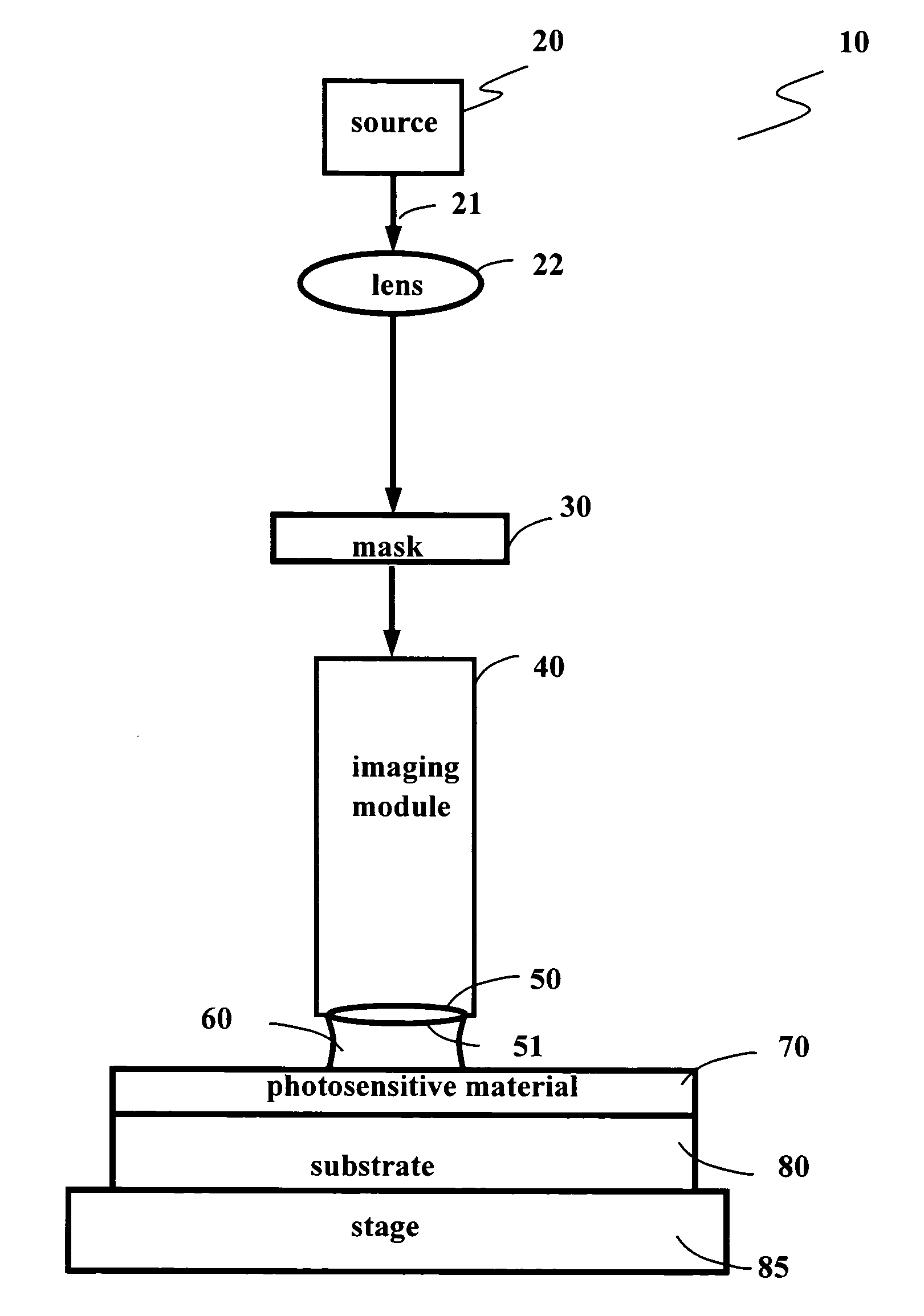

Lithography apparatus for manufacture of integrated circuits

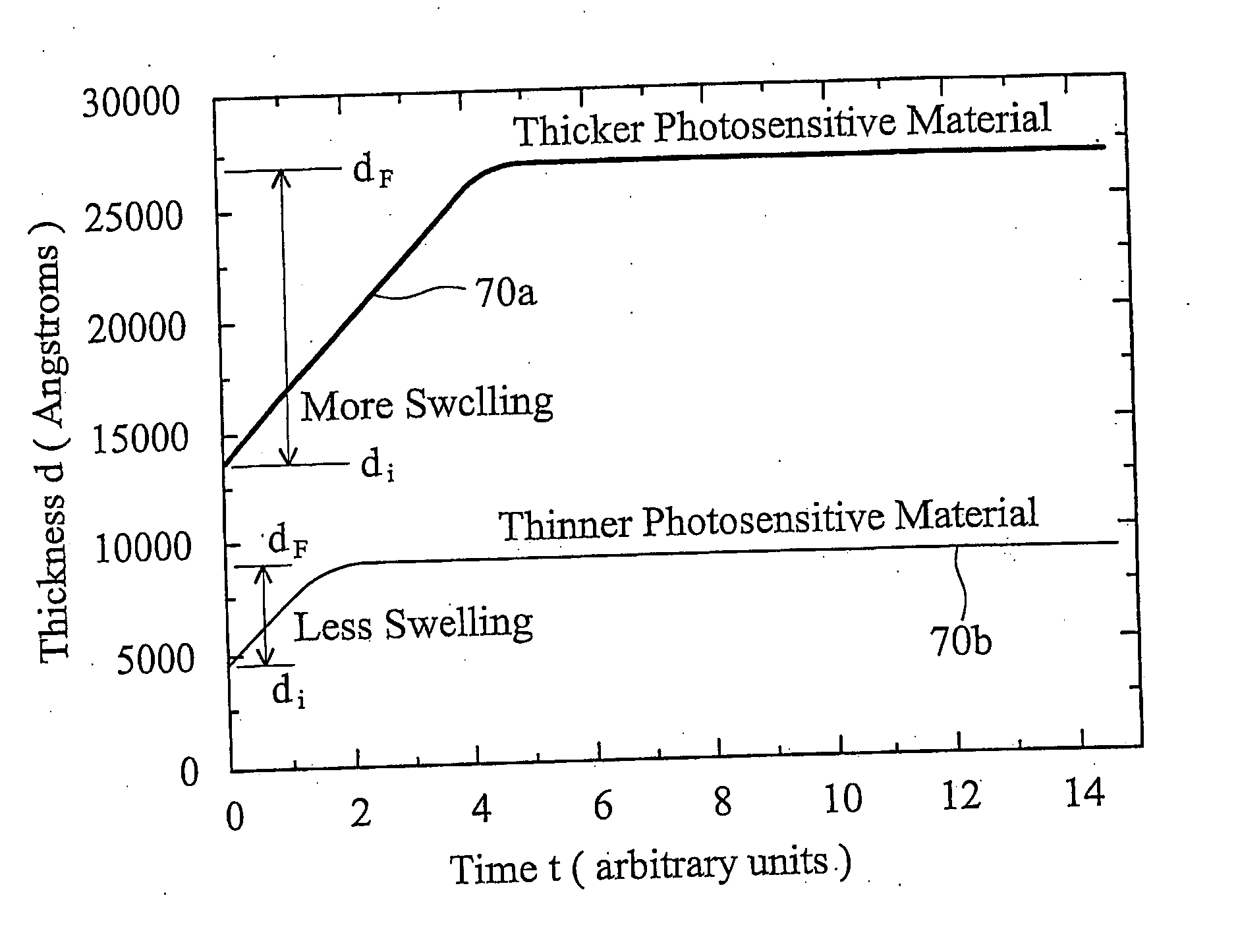

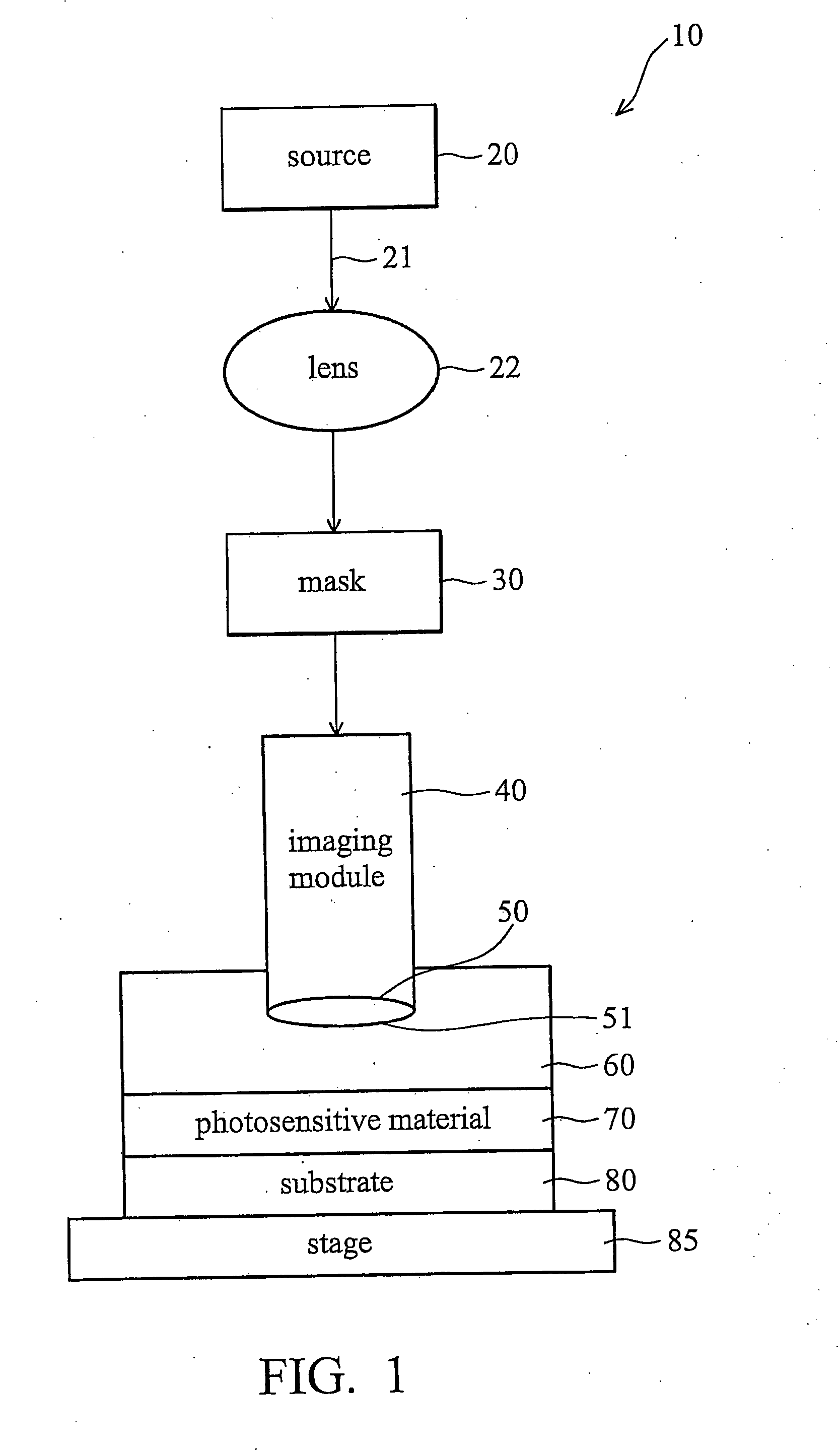

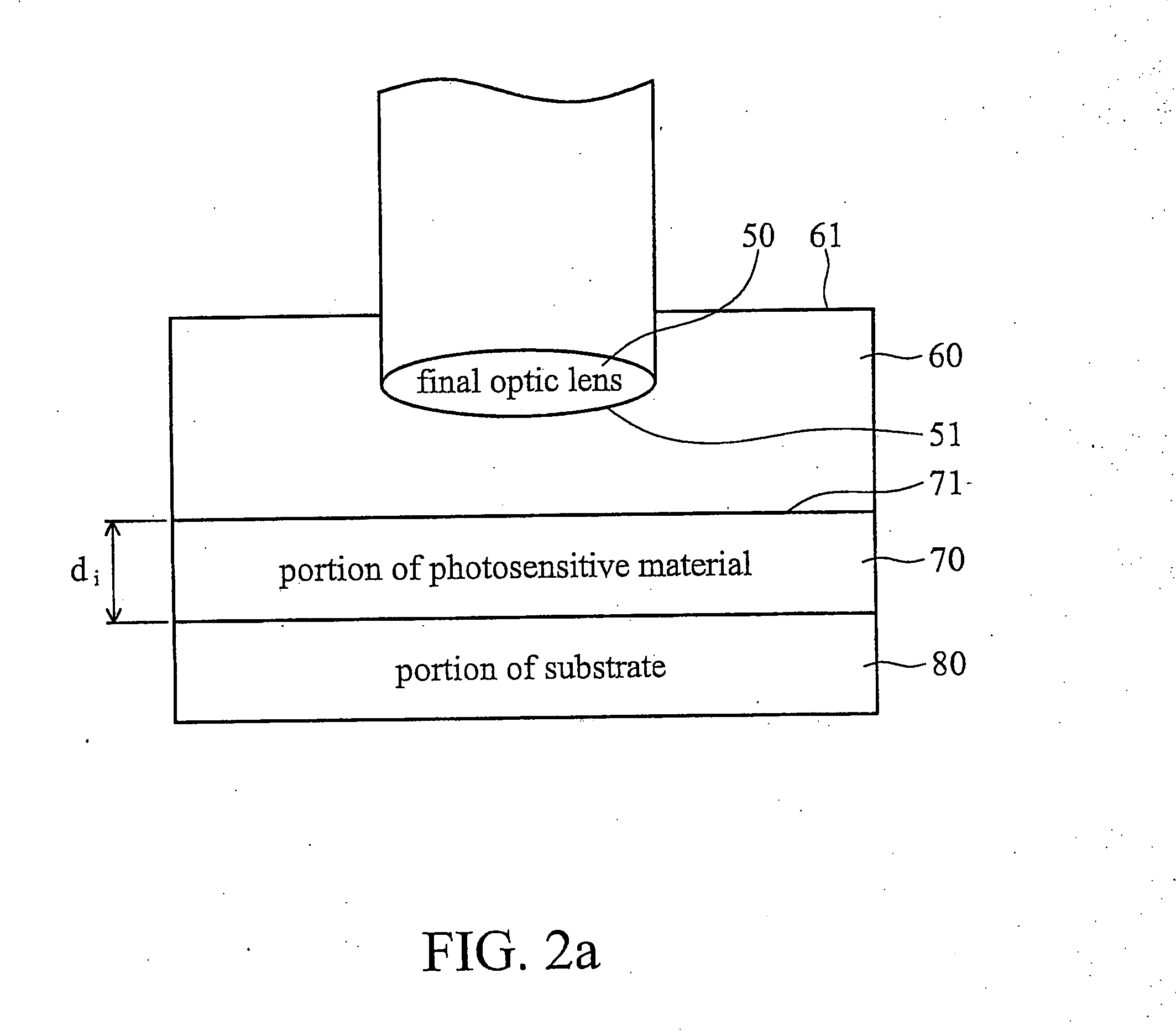

ActiveUS20050036184A1Limit amount of swellingSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLithographic artistSemiconductor structure

An immersion lithographic system 10 comprises an optical surface 51, an immersion fluid 60 contacting at least a portion of the optical surface, and a semiconductor structure 80 having a topmost photoresist layer 70 having a thickness of less than about 5000 angstroms, wherein a portion of the photoresist is in contact with the immersion fluid. Further, a method for illuminating a semiconductor structure 80 having a topmost photoresist layer 70 with a thickness of less than about 5000 angstroms, comprising introducing an immersion fluid 60 into a space between an optical surface 51 and the photoresist layer, and directing light preferably with a wavelength of less than about 450 nm through the immersion fluid and onto the photoresist.

Owner:TAIWAN SEMICON MFG CO LTD

Method and device for immersion lithography

InactiveUS20050073670A1Reduce decreasePhotomechanical exposure apparatusMicrolithography exposure apparatusElectromagnetic radiationImage plane

The present invention relates to an immersion lithographic system for patterning a work piece arranged at an image plane and covered at least partly with a layer sensitive to electromagnetic radiation. Said system comprising a source emitting electromagnetic radiation onto an object plane, a mask, adapted to receive and modulate said electromagnetic radiation at said object plane and to relay said electromagnetic radiation toward said work piece, and an immersion medium contacting at least a portion of a final lens of said lithographic system and a portion of said work piece, wherein an area of said contacting is restricted by capillary forces. The invention further relates to a method for patterning a workpiece.

Owner:MICRONIC LASER SYST AB

Contact printing using a magnified mask image

InactiveUS20050068639A1Avoid stickingPhotomechanical exposure apparatusMicrolithography exposure apparatusRefractive indexOff-axis illumination

Improvements in the fabrication of integrated circuits are driven by the decrease of the size of the features printed on the wafers. Current lithography techniques limits have been extended through the use of phase-shifting masks, off-axis illumination, and proximity effect correction. More recently, liquid immersion lithography has been proposed as a way to extend even further the limits of optical lithography. This invention described a methodology based on contact printing using a projection lens to define the image of the mask onto the wafer. As the imaging is performed in a solid material, larger refractive indices can be obtained and the resolution of the imaging system can be increased.

Owner:APPLIED MATERIALS INC

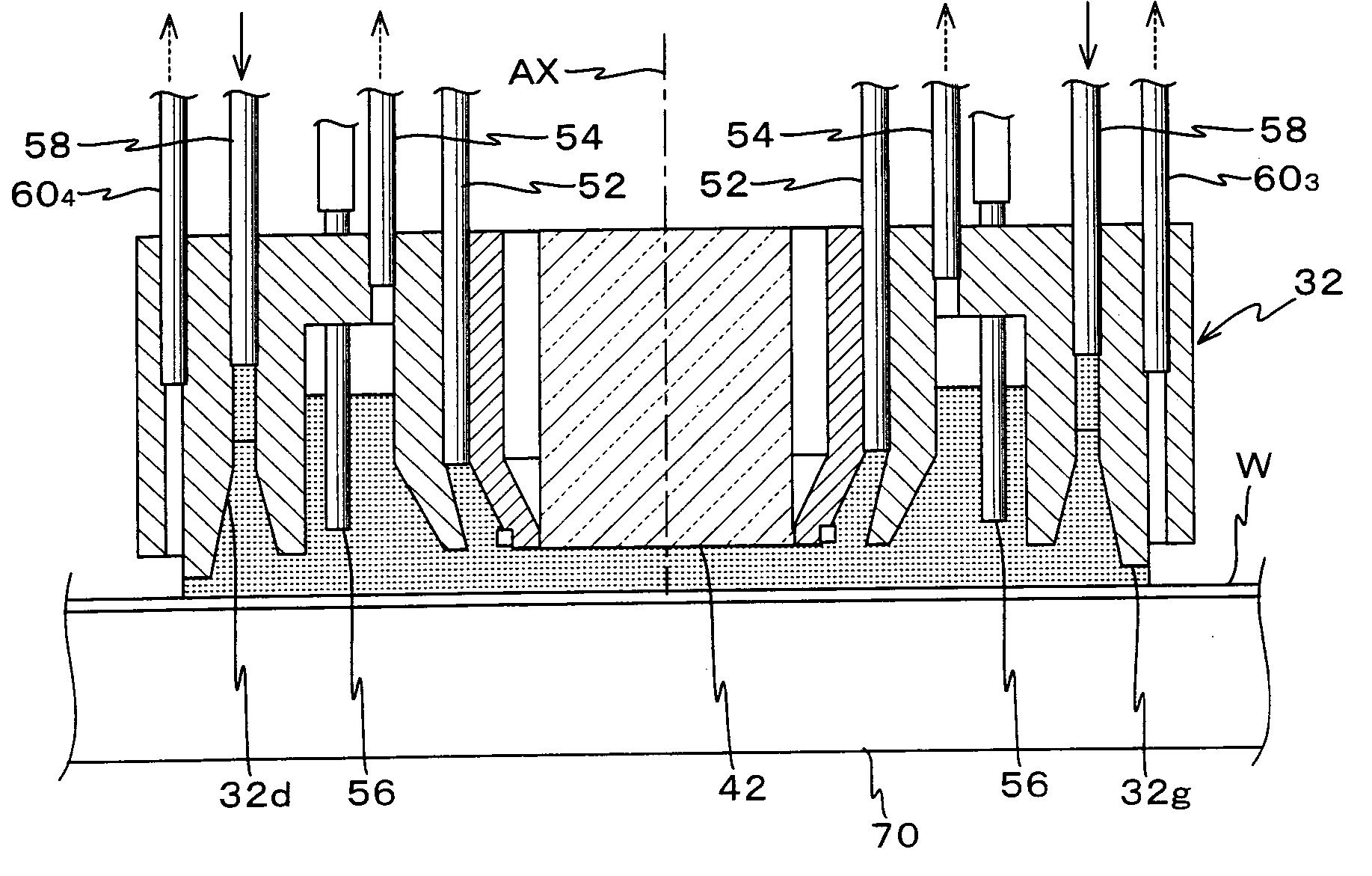

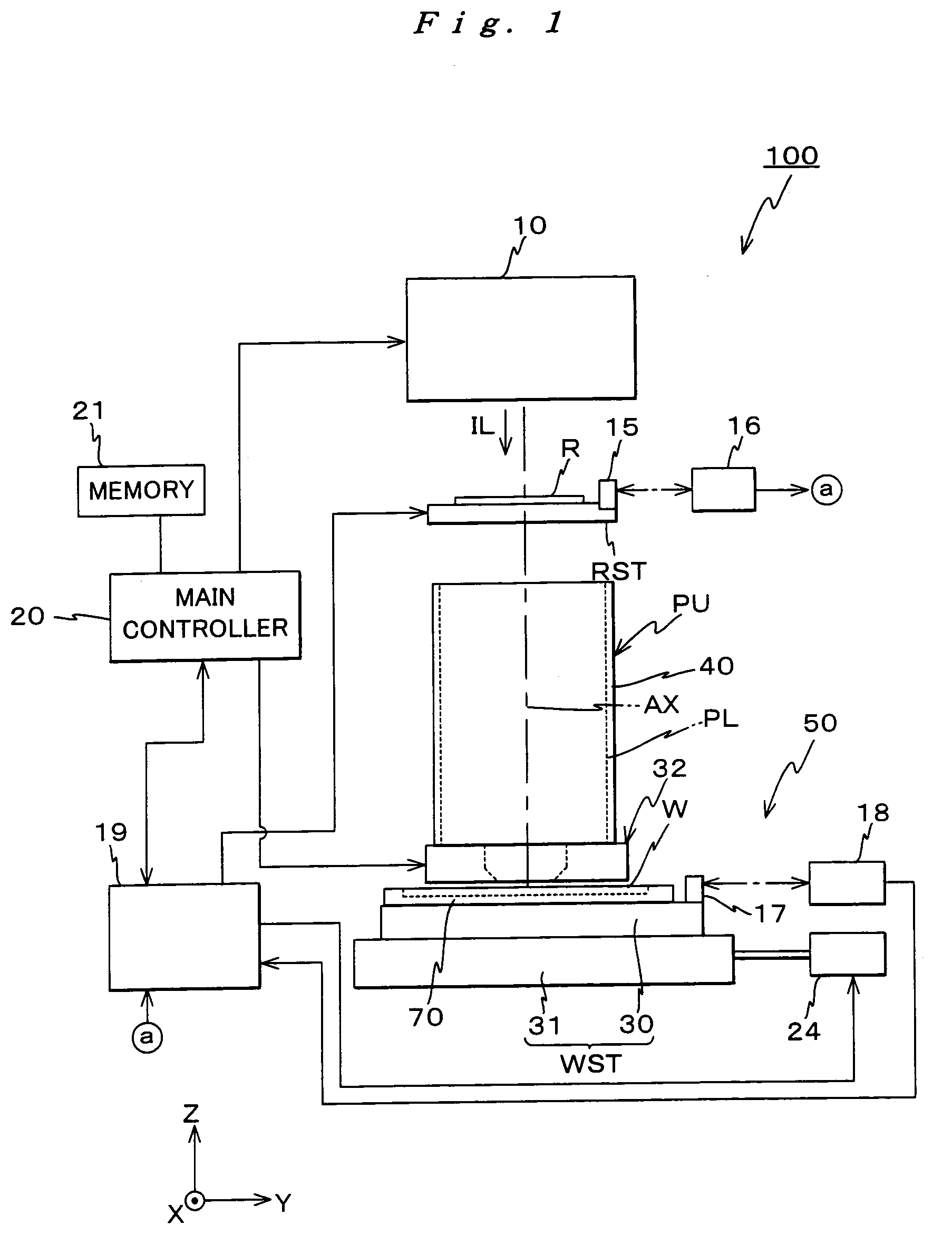

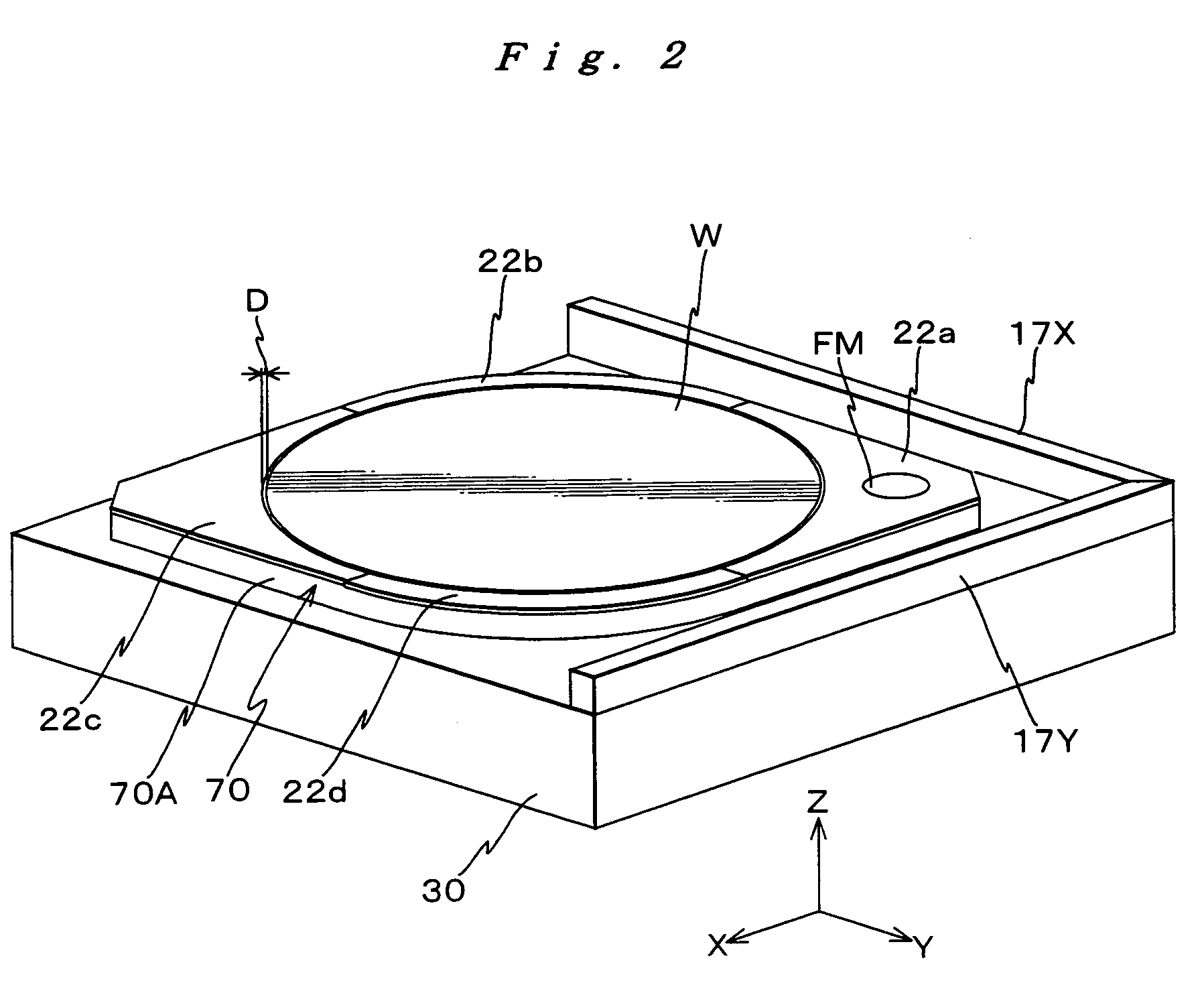

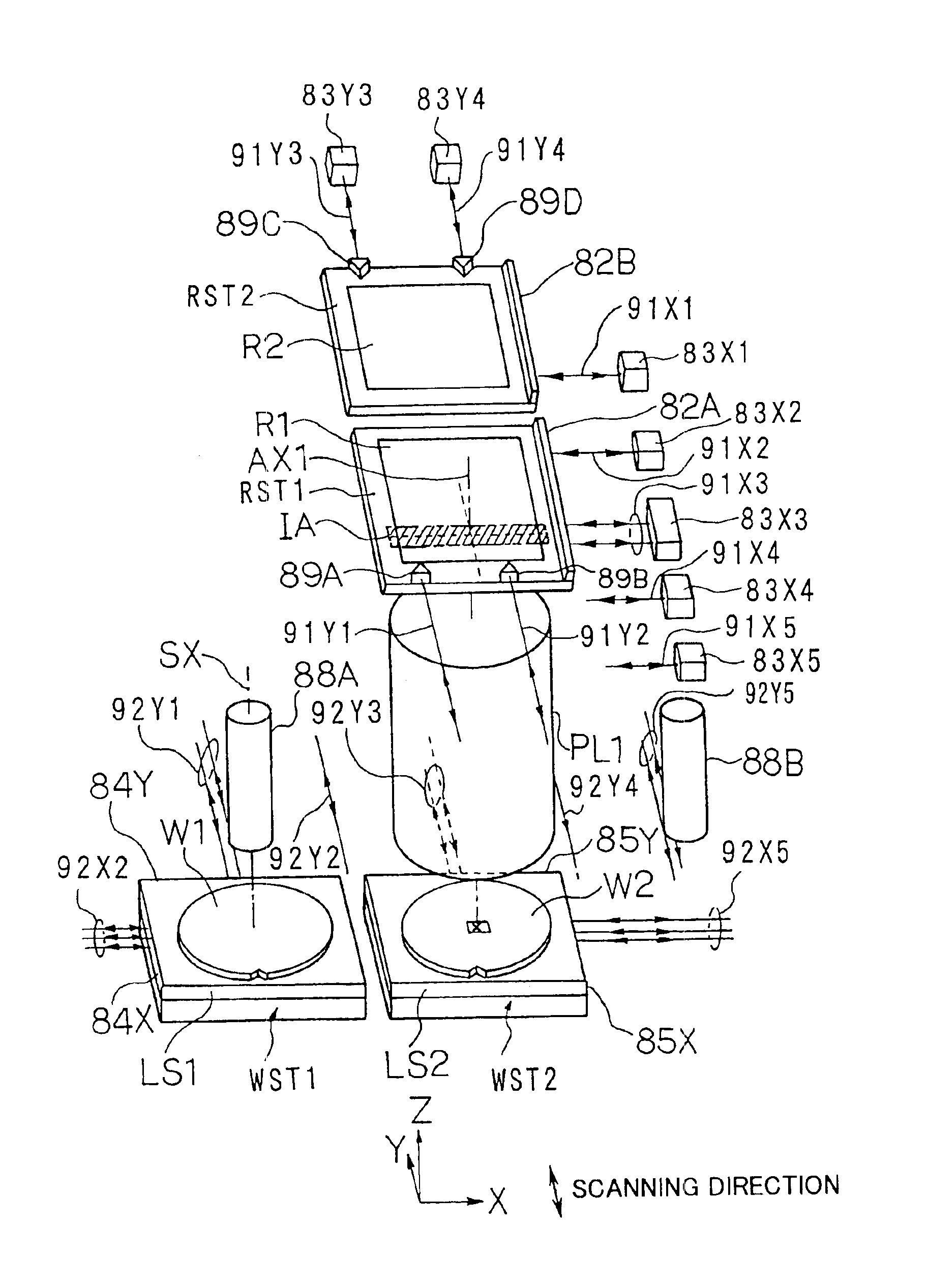

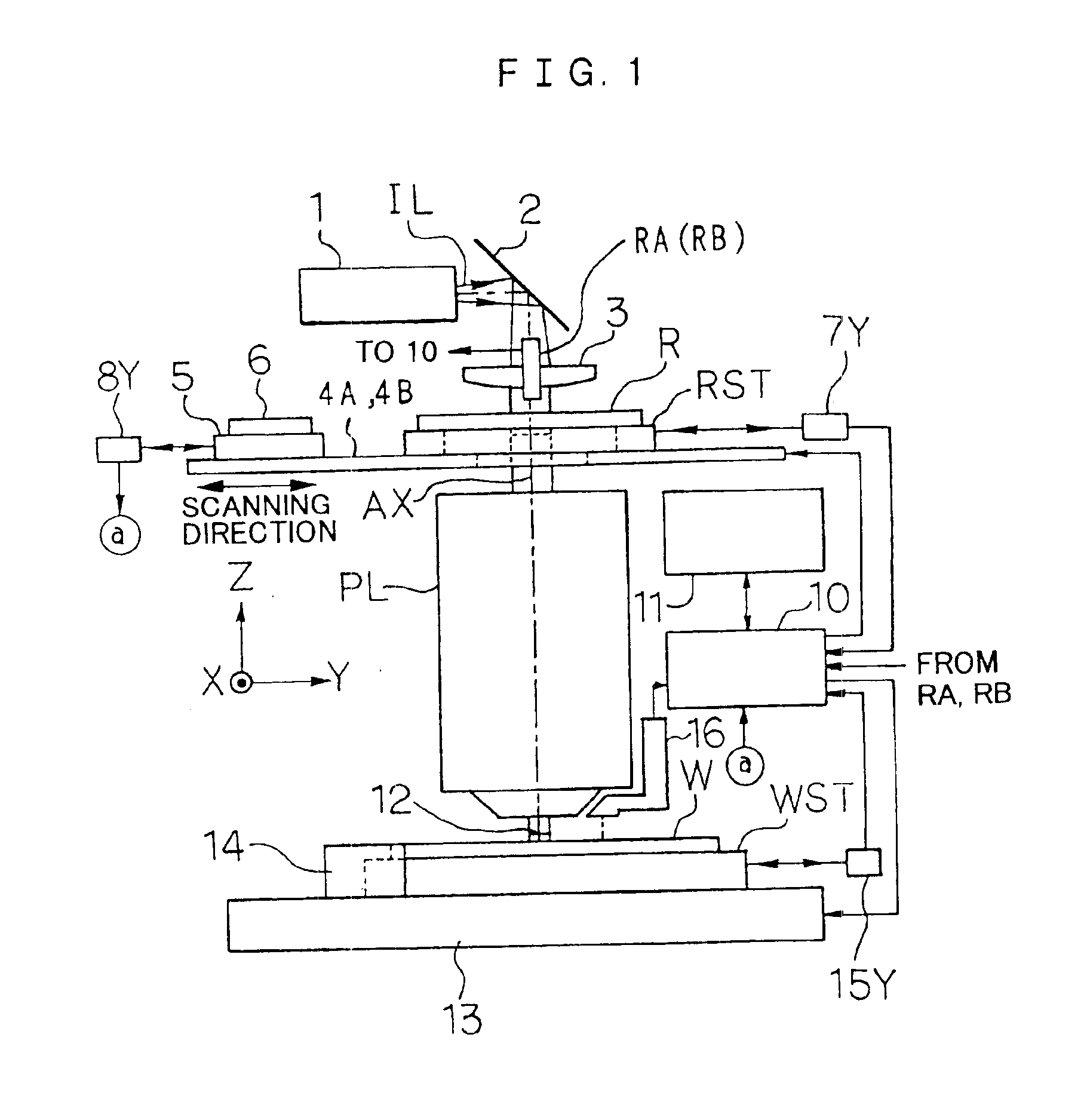

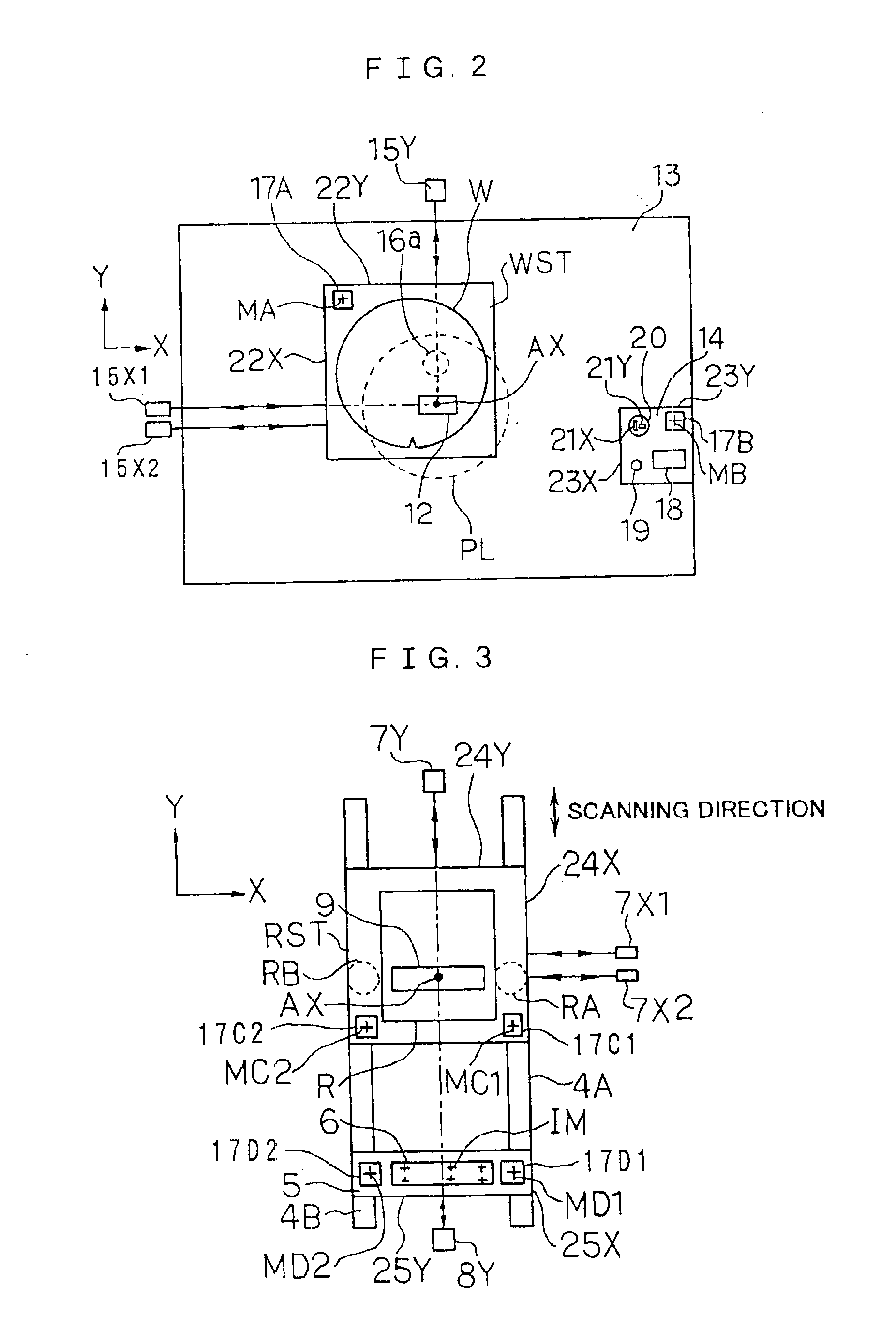

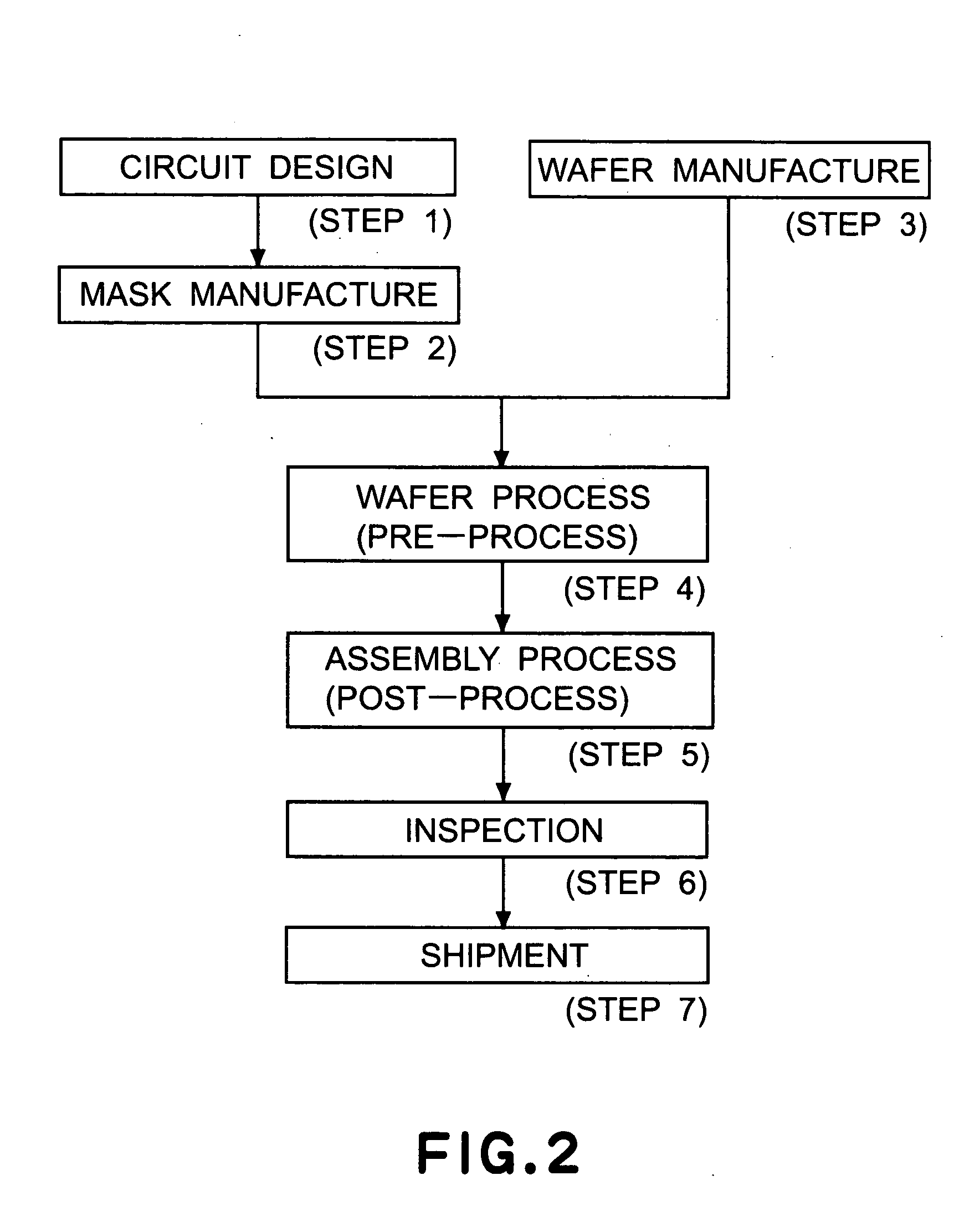

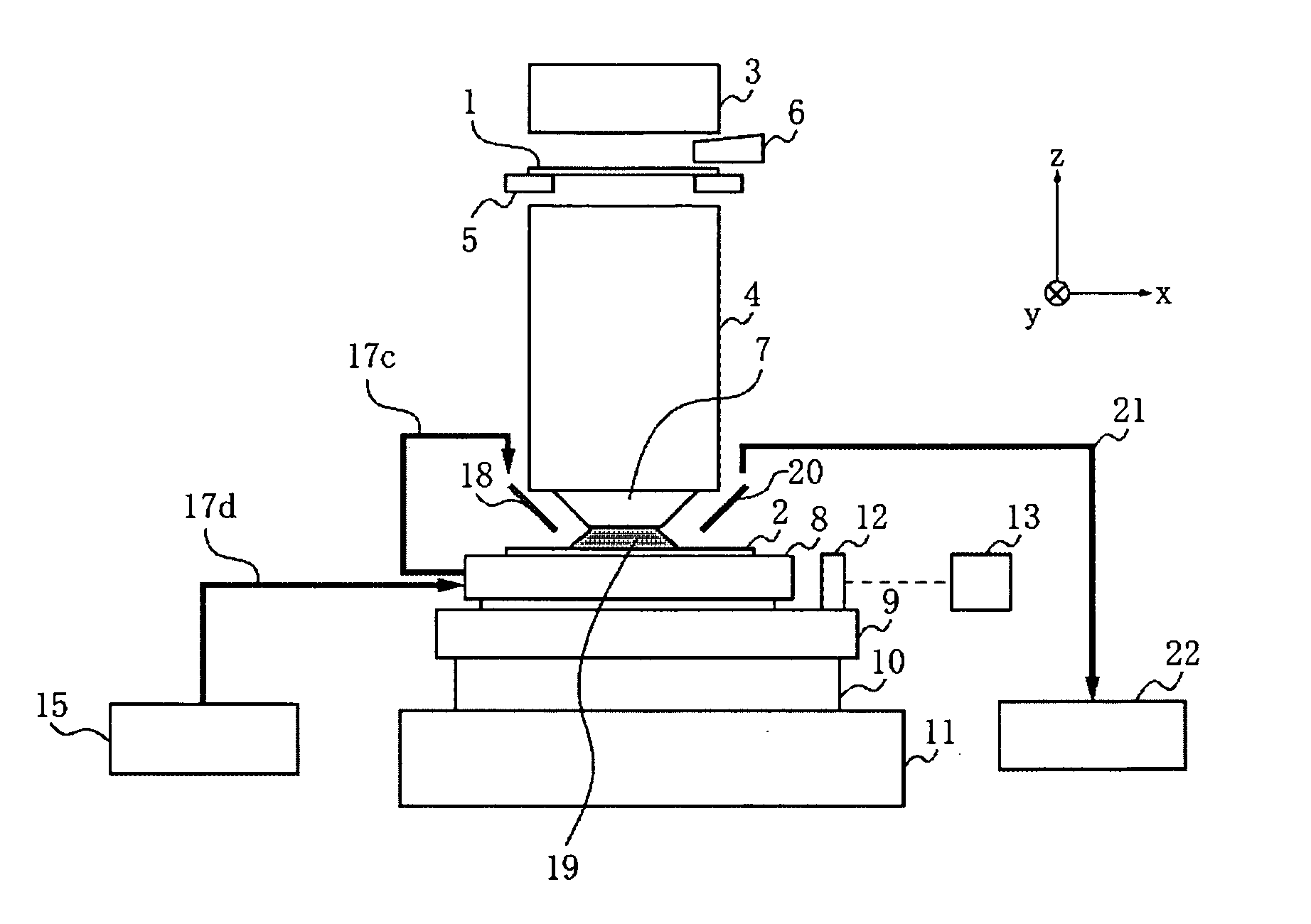

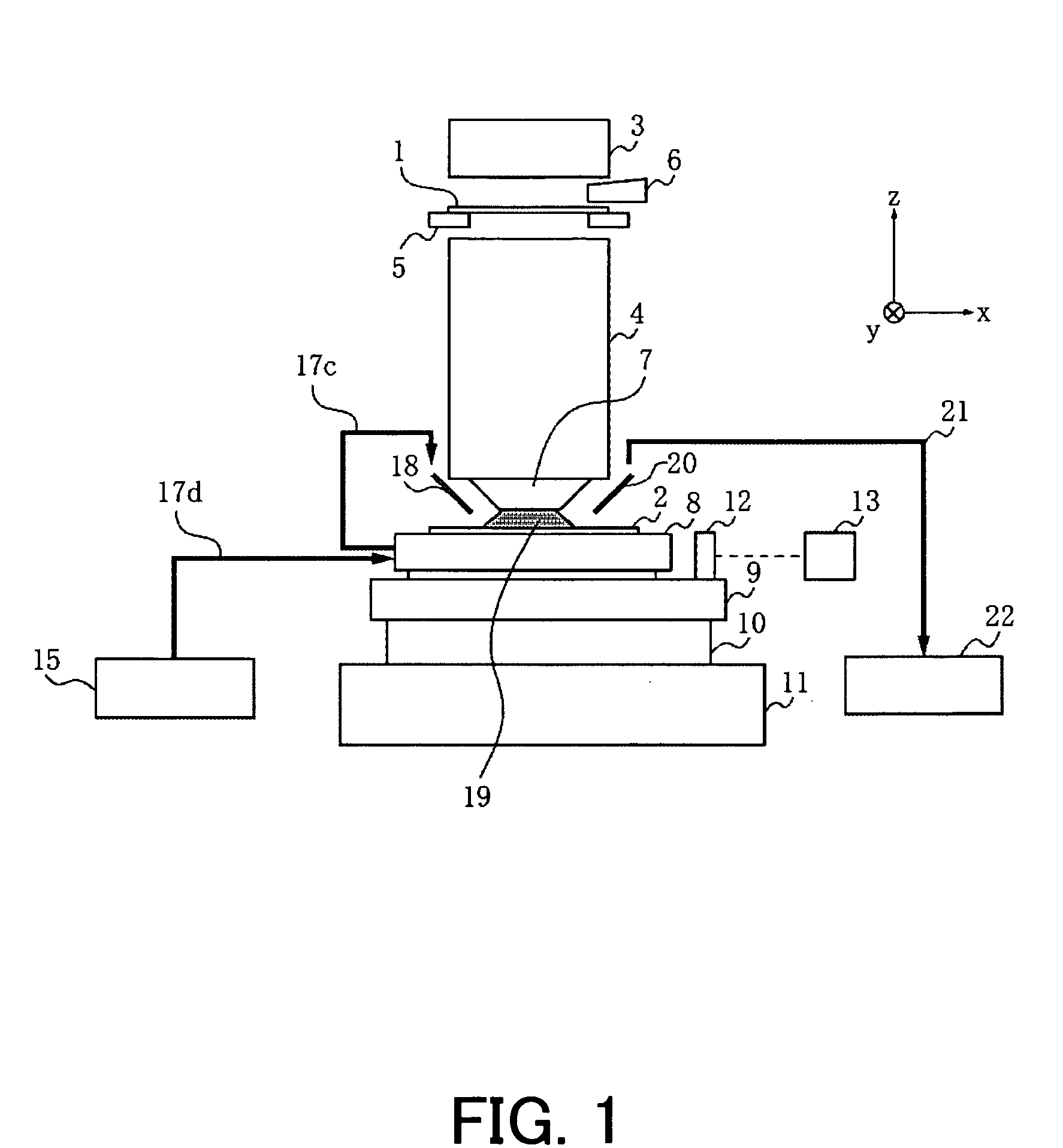

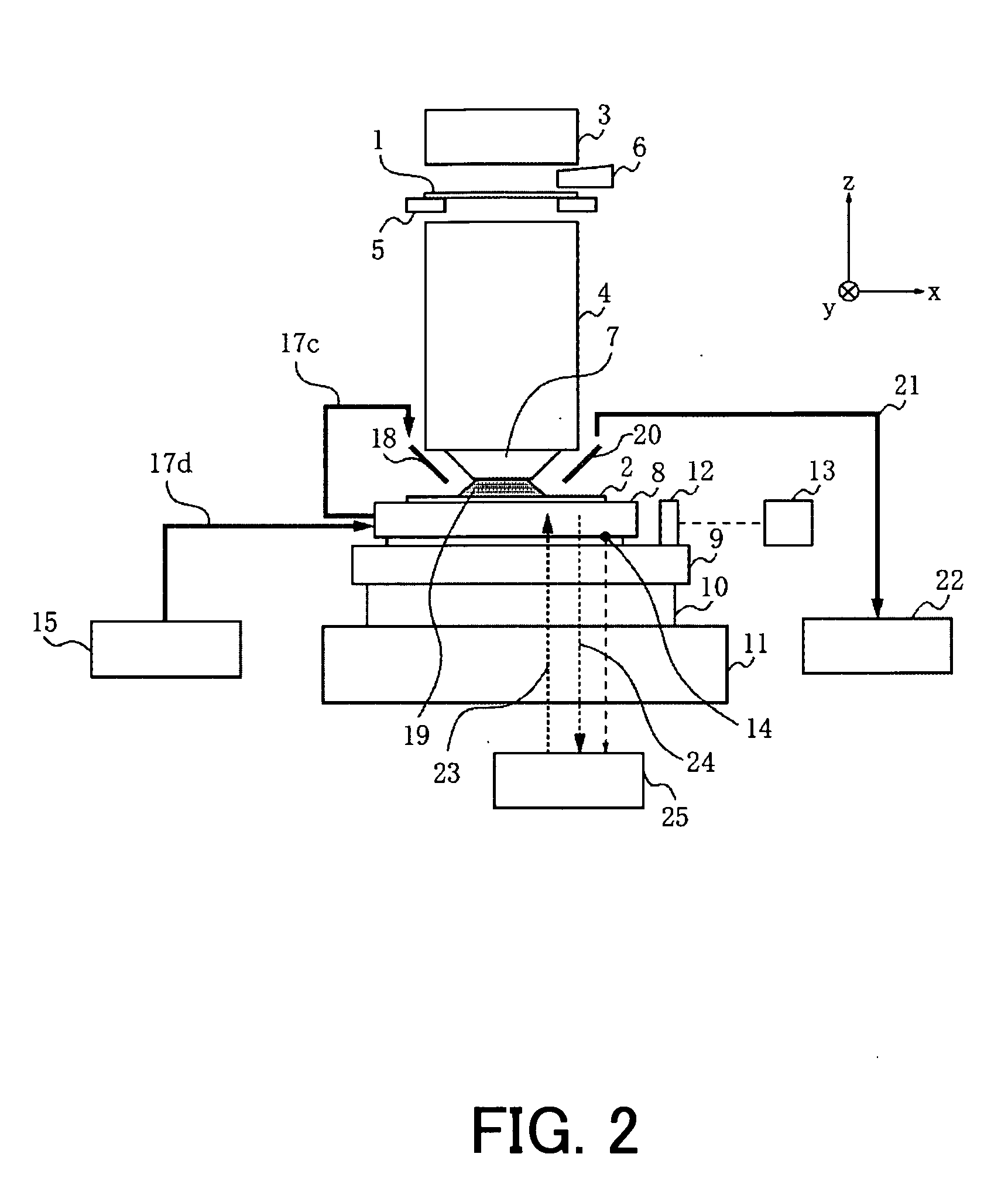

Stage device and exposure apparatus

InactiveUS6897963B1Increase speedImprove throughputSemiconductor/solid-state device manufacturingUsing optical meansLaser beamsSemiconductor

A stage device suitable for exposure apparatus used to produce semiconductor devices, is movable in an area wider than the measurement area of interferometer for position measurement, and is capable of measuring the position with high precision. When a movable stage moves from the position where the laser beams from laser interferometers are not applied into the measurement area of the laser interferometer, the position of reference mark is measured by a wafer alignment sensor, and the measurement value measured by the laser interferometer is corrected based on the results of the measurement by the wafer alignment sensor. When another movable stage enters the measurement area of the laser interferometer, the position of the reference mark is similarly measured by a wafer alignment sensor, and the measurement value measured by the laser interferometer is corrected based on the results of the measurement by the wafer alignment sensor.

Owner:NIKON CORP

Catadioptric projection objective

ActiveUS20050190435A1High image side numerical apertureSmall amountSemiconductor/solid-state device manufacturingMicroscopesIntermediate imageHigh numerical aperture

A catadioptric projection objective for imaging a pattern provided in an object plane of the projection objective onto an image plane of the projection objective comprises: a first objective part for imaging the pattern provided in the object plane into a first intermediate image; a second objective part for imaging the first intermediate imaging into a second intermediate image; a third objective part for imaging the second intermediate imaging directly onto the image plane; wherein a first concave mirror having a first continuous mirror surface and at least one second concave mirror having a second continuous mirror surface are arranged upstream of the second intermediate image; pupil surfaces are formed between the object plane and the first intermediate image, between the first and the second intermediate image and between the second intermediate image and the image plane; and all concave mirrors are arranged optically remote from a pupil surface. The system has potential for very high numerical apertures at moderate lens material mass consumption.

Owner:CARL ZEISS SMT GMBH

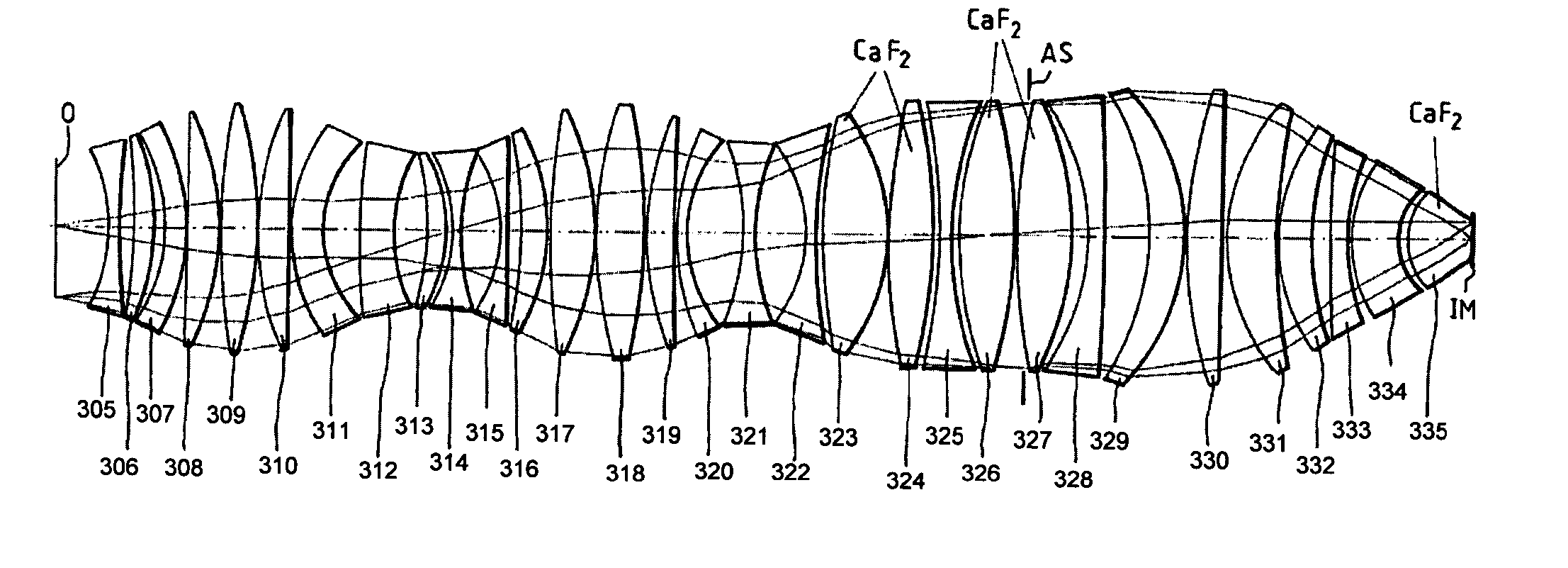

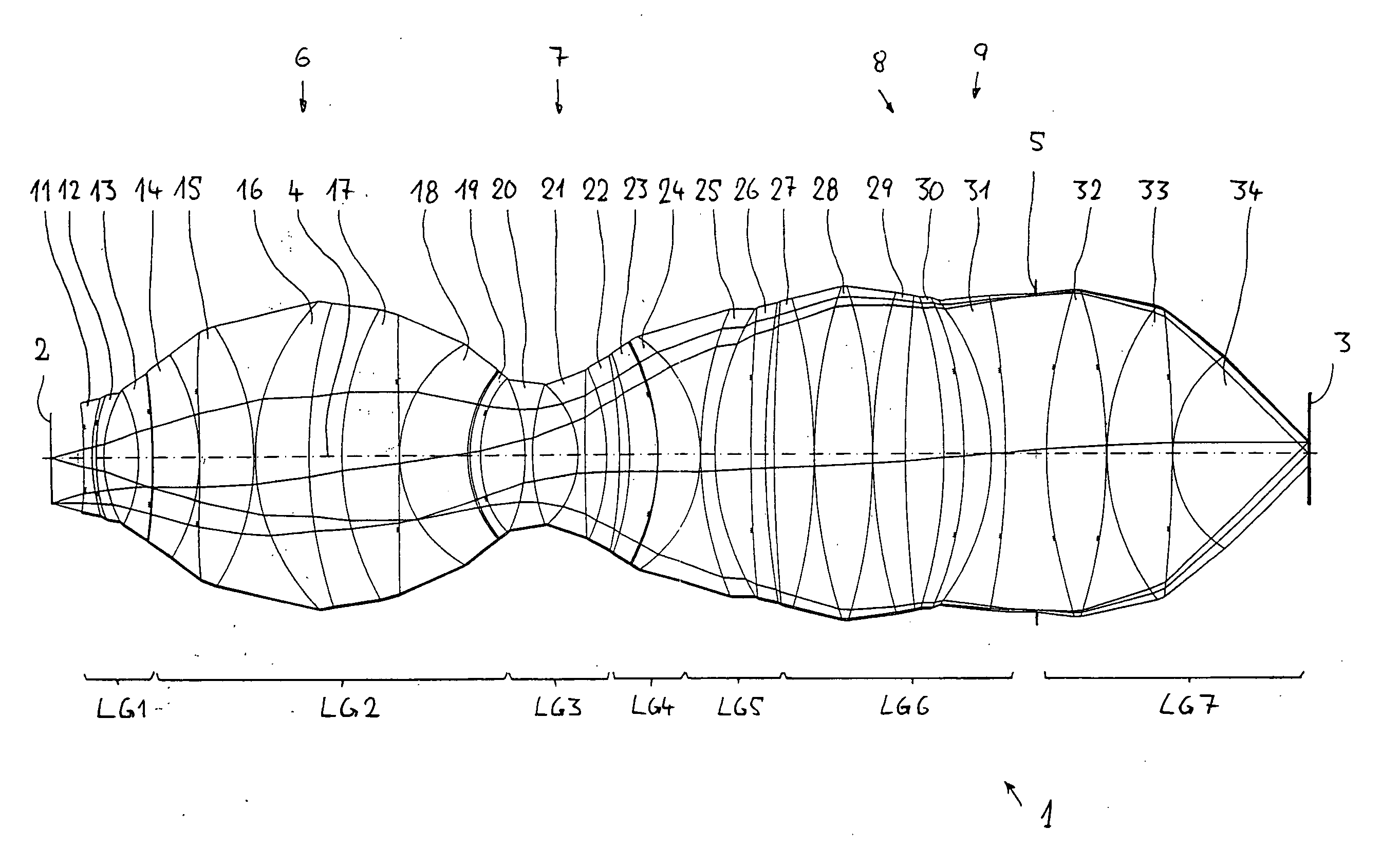

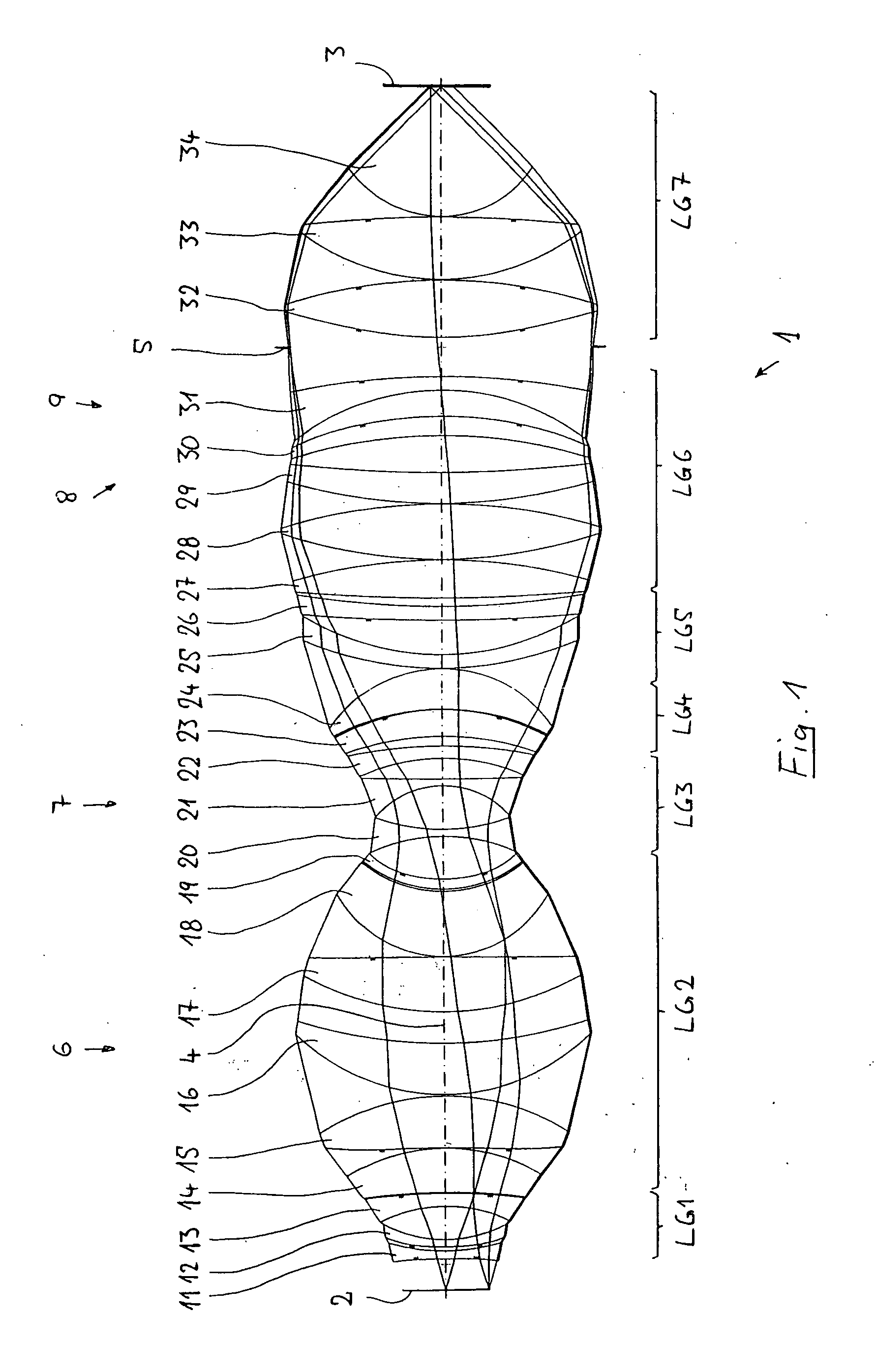

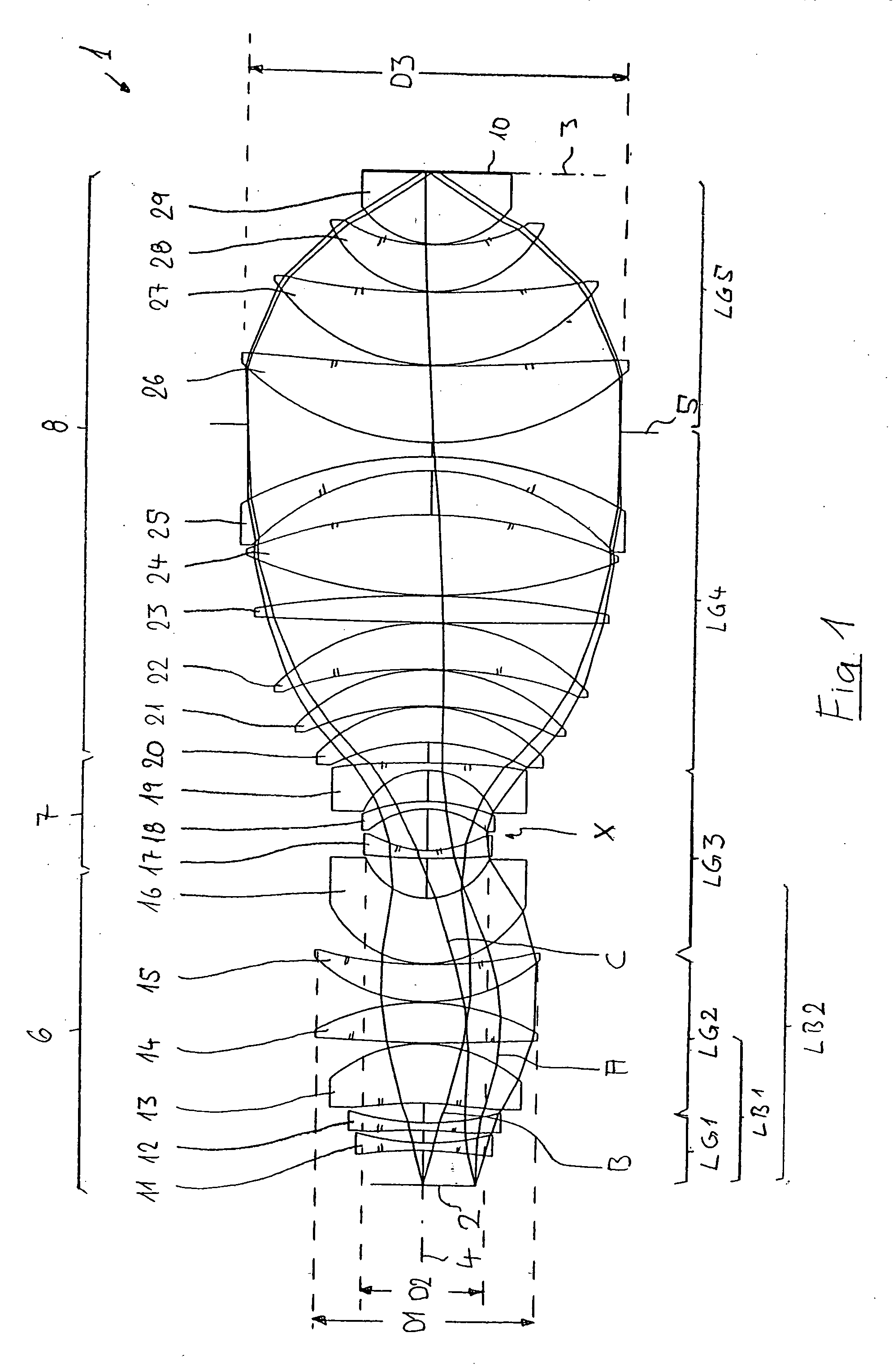

Very high-aperture projection objective

InactiveUS20050141098A1Guaranteed true stateIncrease the number ofSemiconductor/solid-state device manufacturingMicroscopesSpherical shapedOptic system

A very high-aperture, purely refractive projection objective having a multiplicity of optical elements has a system diaphragm (5) arranged at a spacing in front of the image plane. The optical element next to the image plane (3) of the projection objective is a planoconvex lens (34) having a substantially spherical entrance surface and a substantially flat exit surface. The planoconvex lens has a diameter that is at least 50% of the diaphragm diameter of the system diaphragm (5). It is preferred to arrange only positive lenses (32, 33, 34) between the system diaphragm (5) and image plane (3). The optical system permits imaging in the case of very high apertures of NA≧0.85, if appropriate of NA≧1.

Owner:CARL ZEISS SMT GMBH

Liquid immersion type exposure apparatus

InactiveUS20050134817A1Reduce productionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLiquid mediumEngineering

Disclosed is a liquid immersion type exposure apparatus which is applicable not only to a liquid immersion exposure apparatus of the type that an exposure substrate as a whole is immersed in a liquid vessel but also to a liquid immersion exposure apparatus of the type that a liquid medium is held in a portion between the exposure substrate and a termination end portion of a projection optical system, and by which production of bubbles can be reduced without interference with exposure. In one preferred from, a degassing system for removing a gas dissolved in the liquid is provided in a liquid medium supplying path and / or a liquid medium collecting path, by which production of bubbles is reduced sufficiently.

Owner:CANON KK

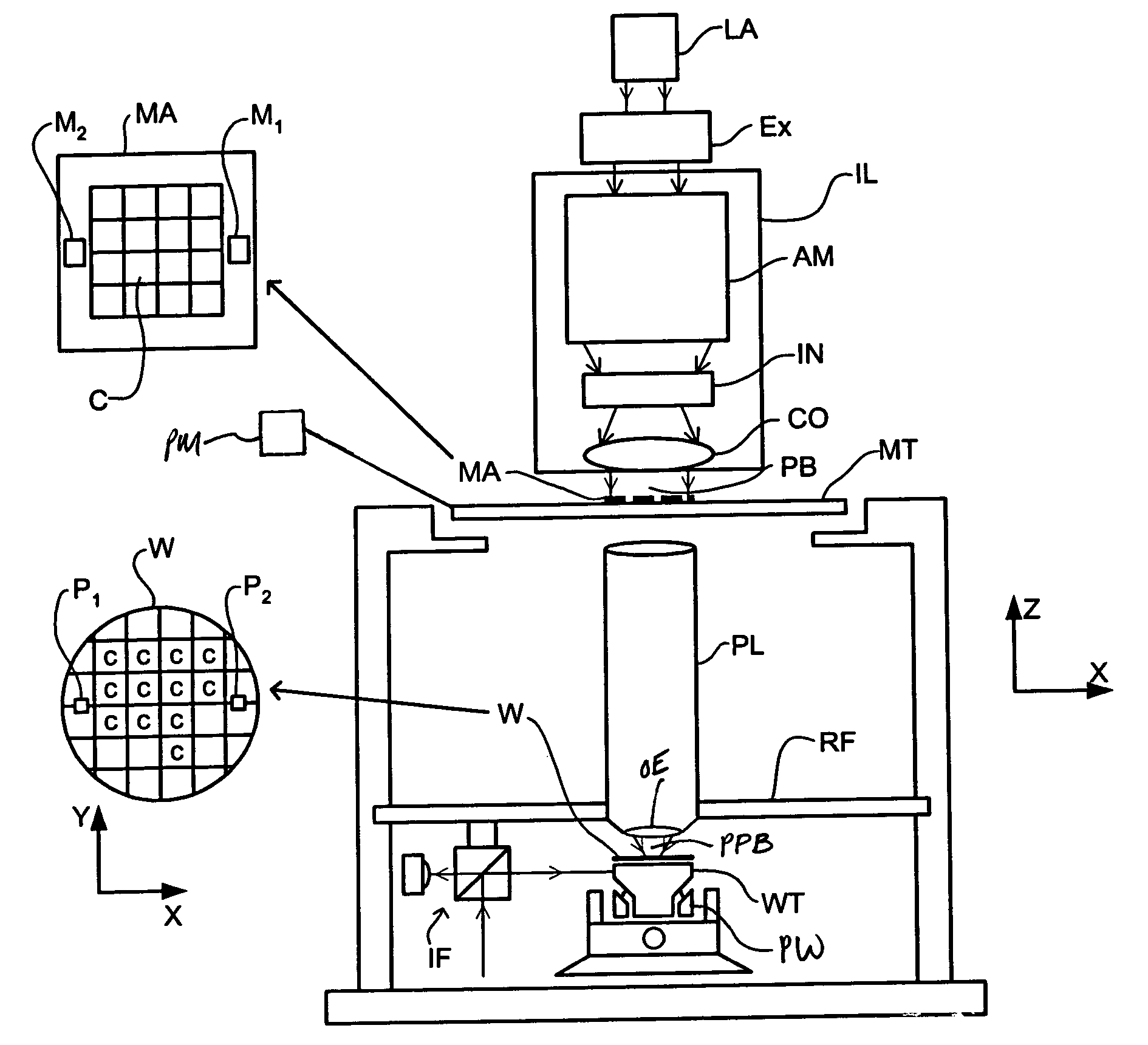

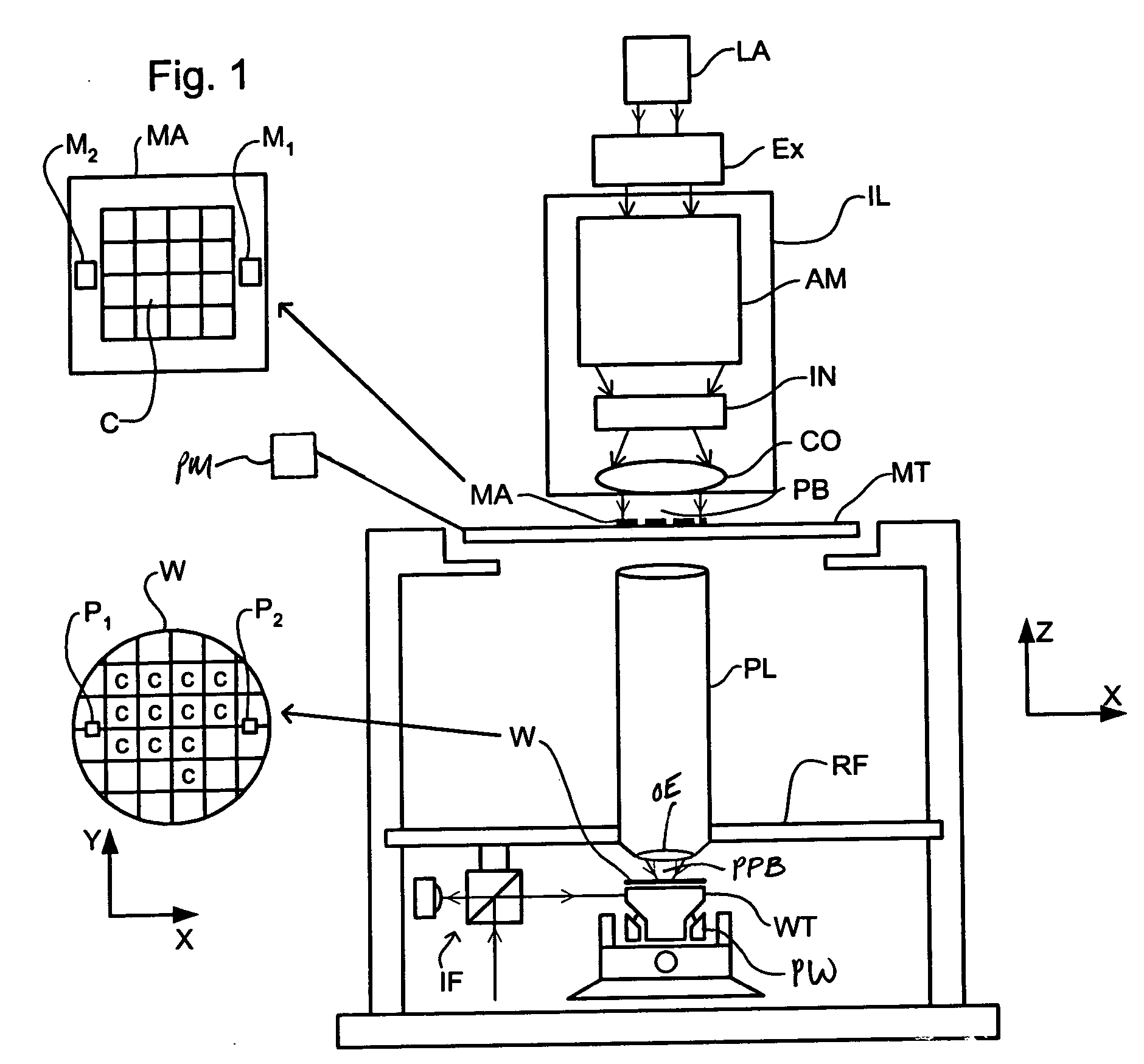

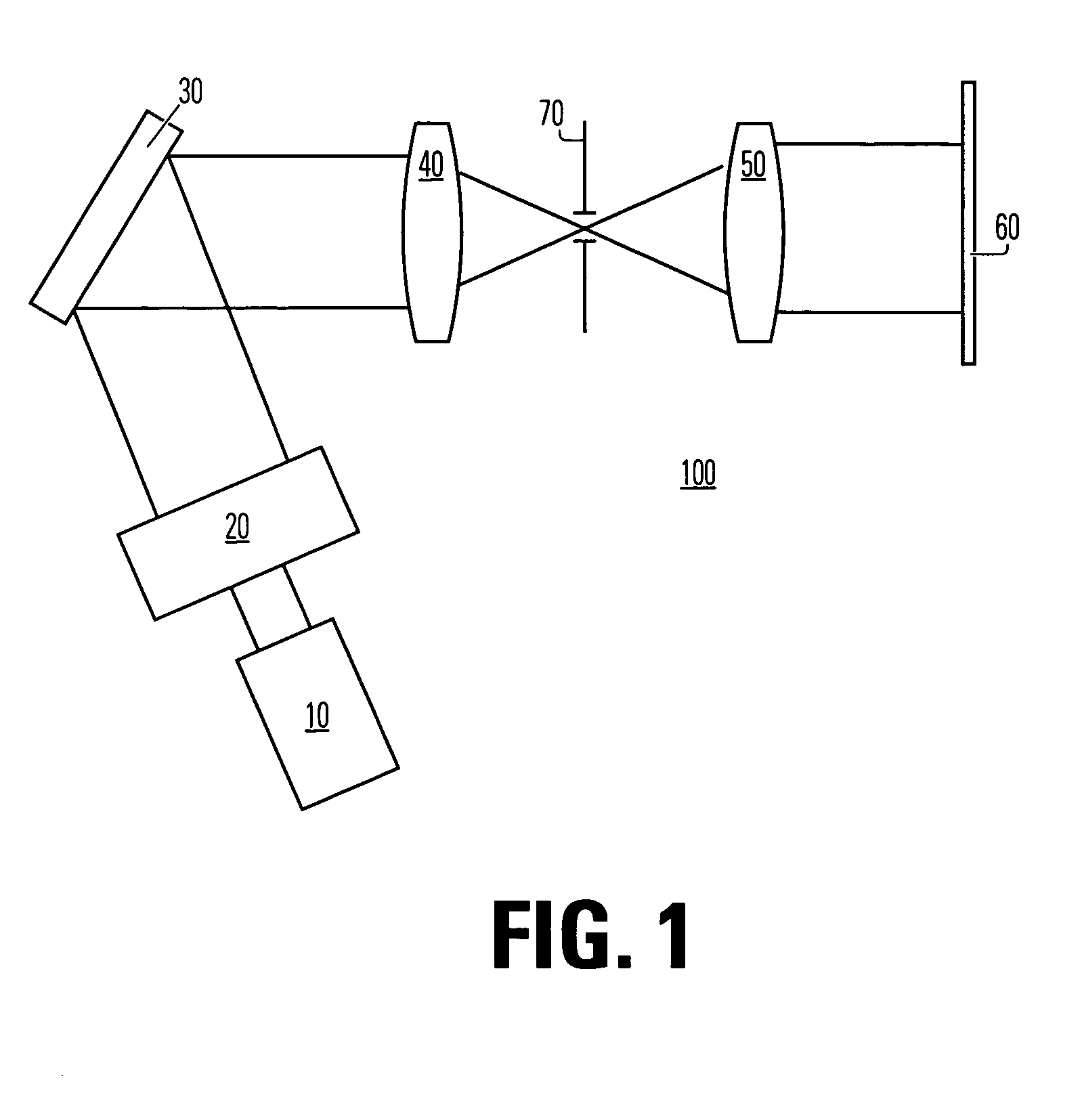

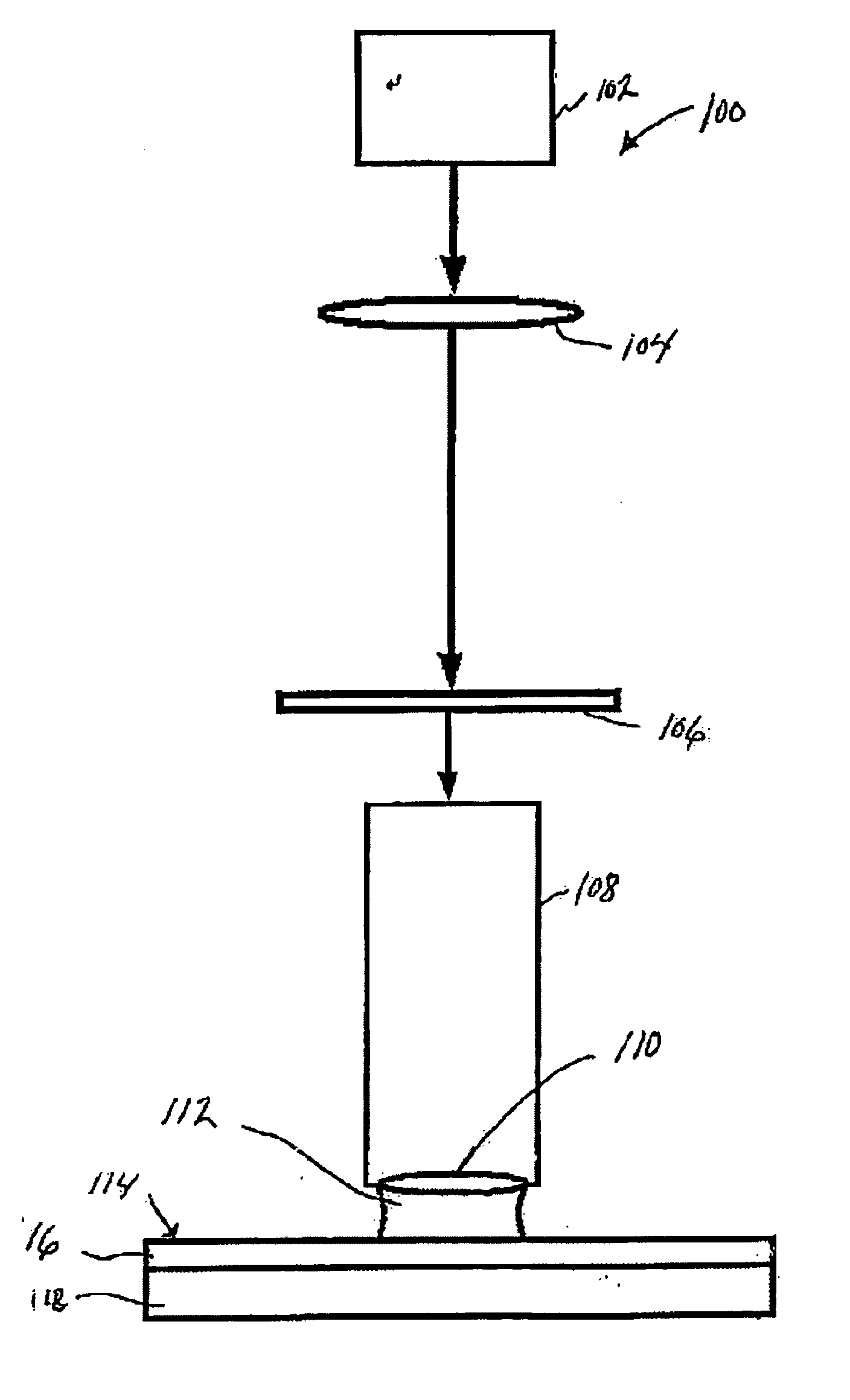

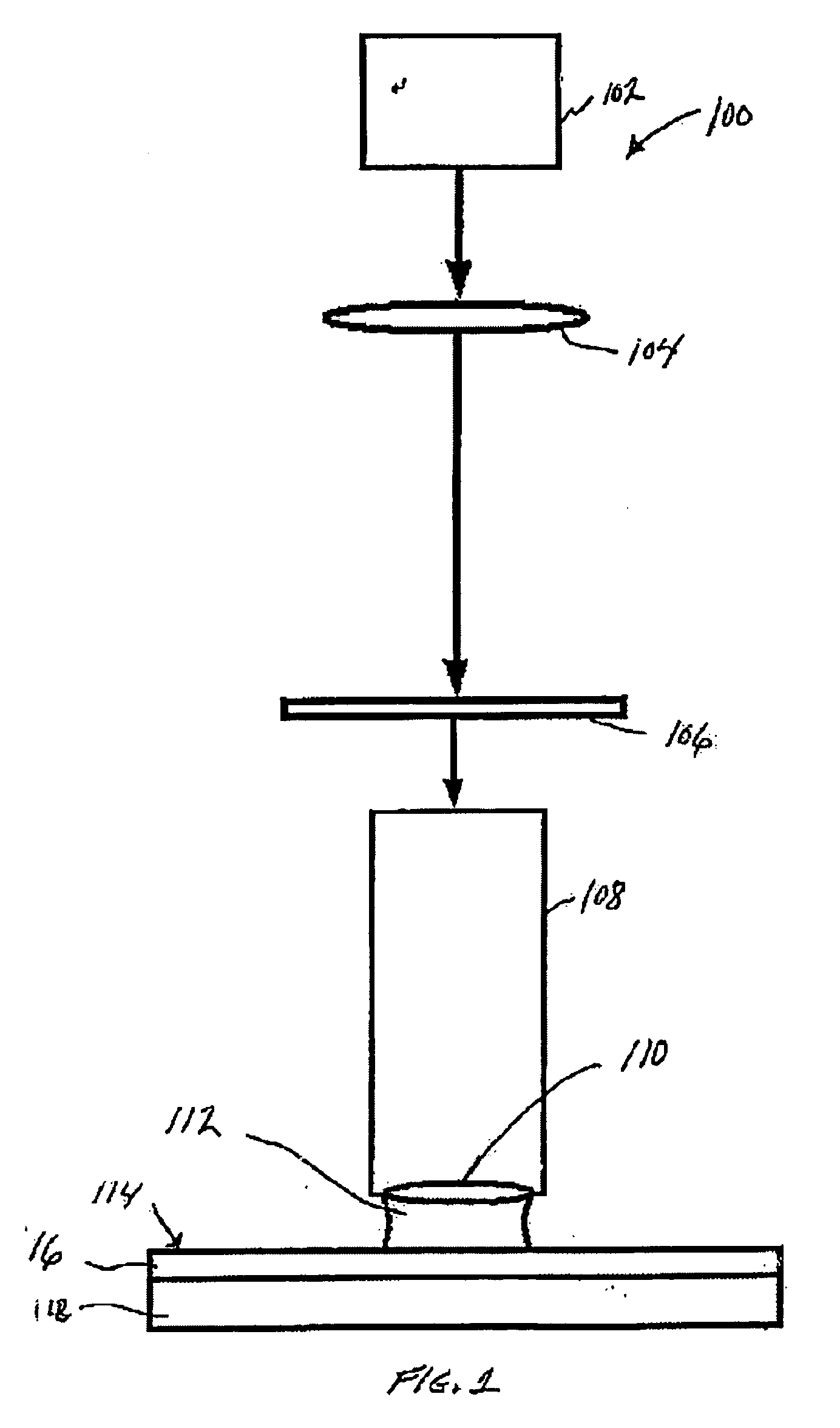

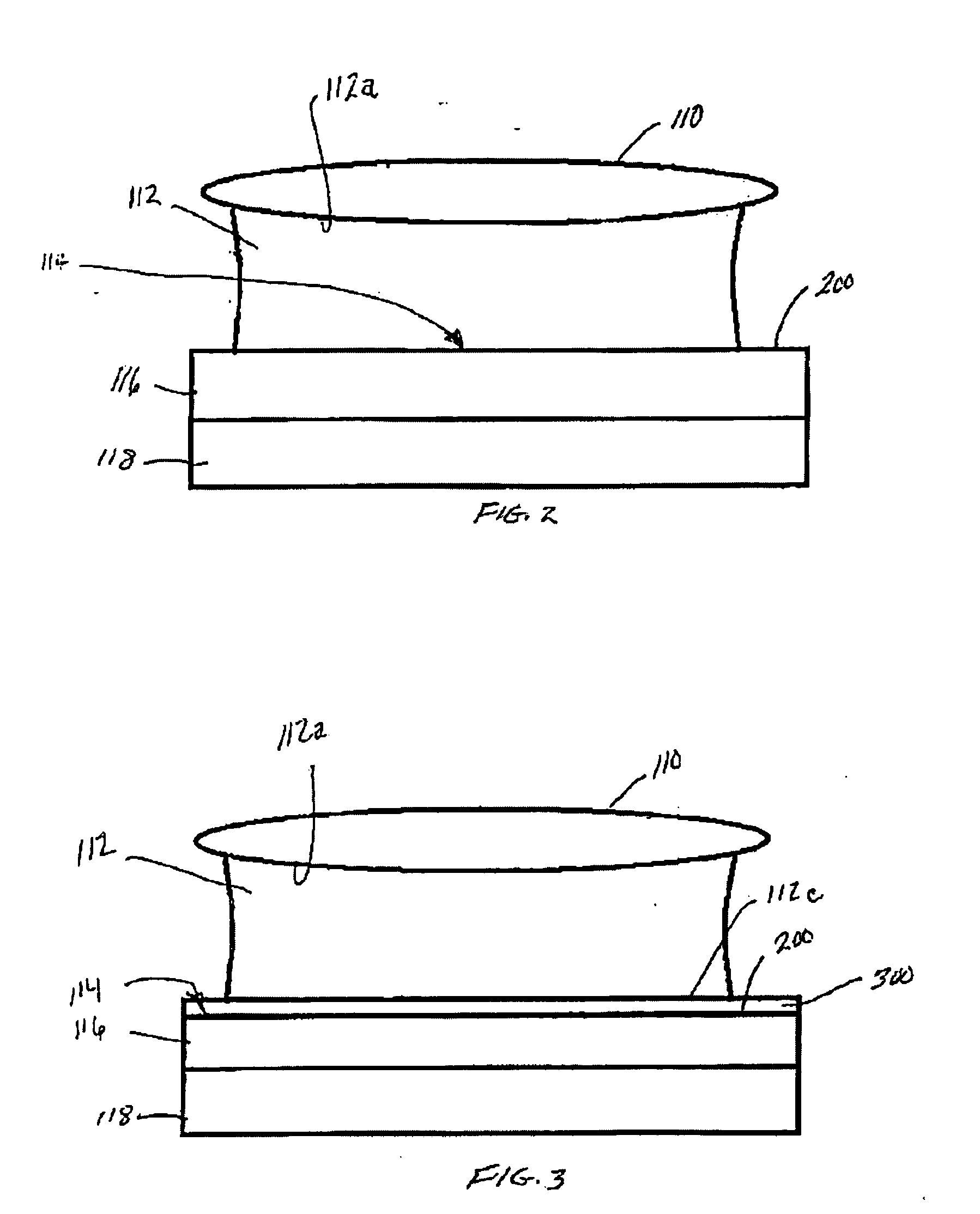

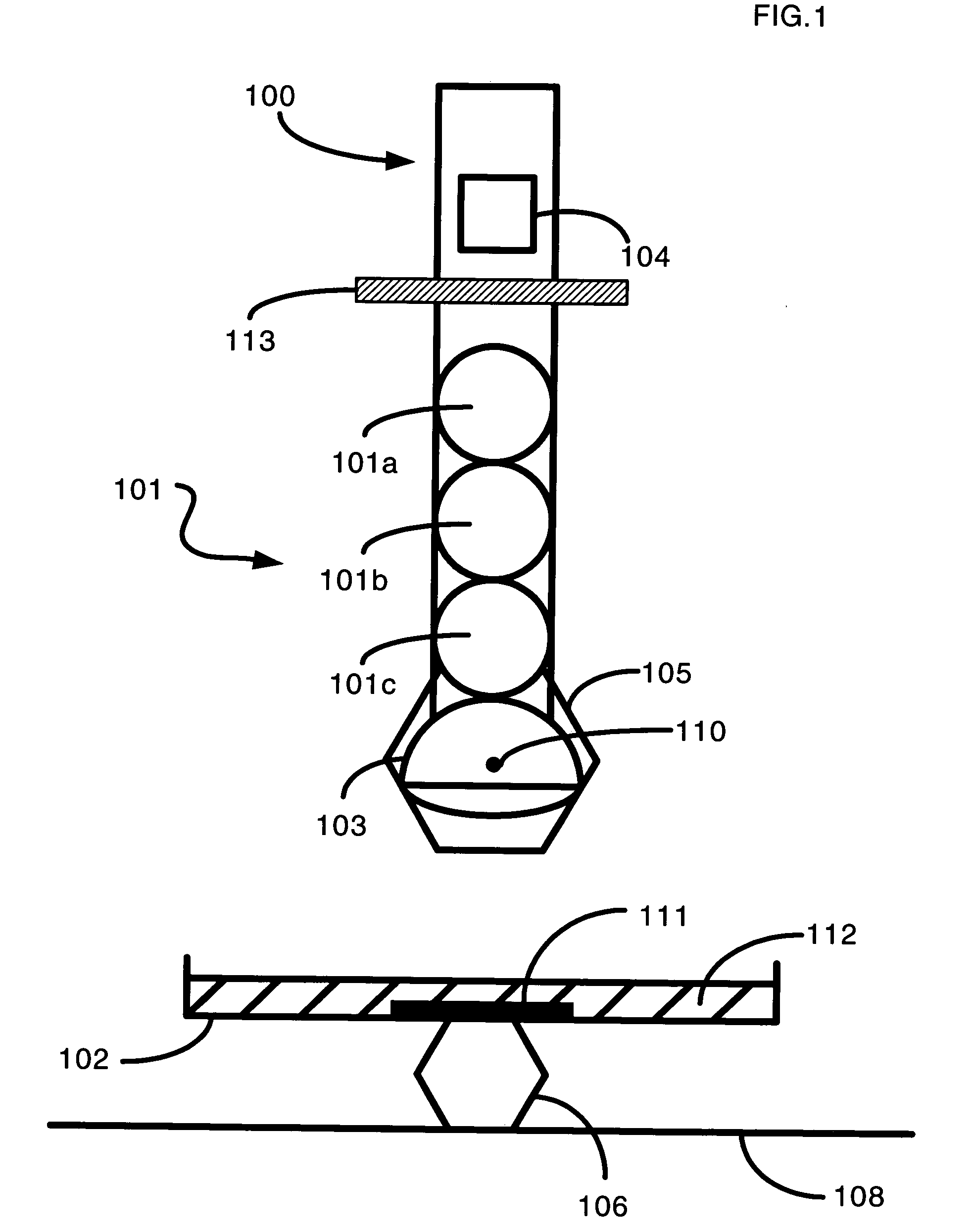

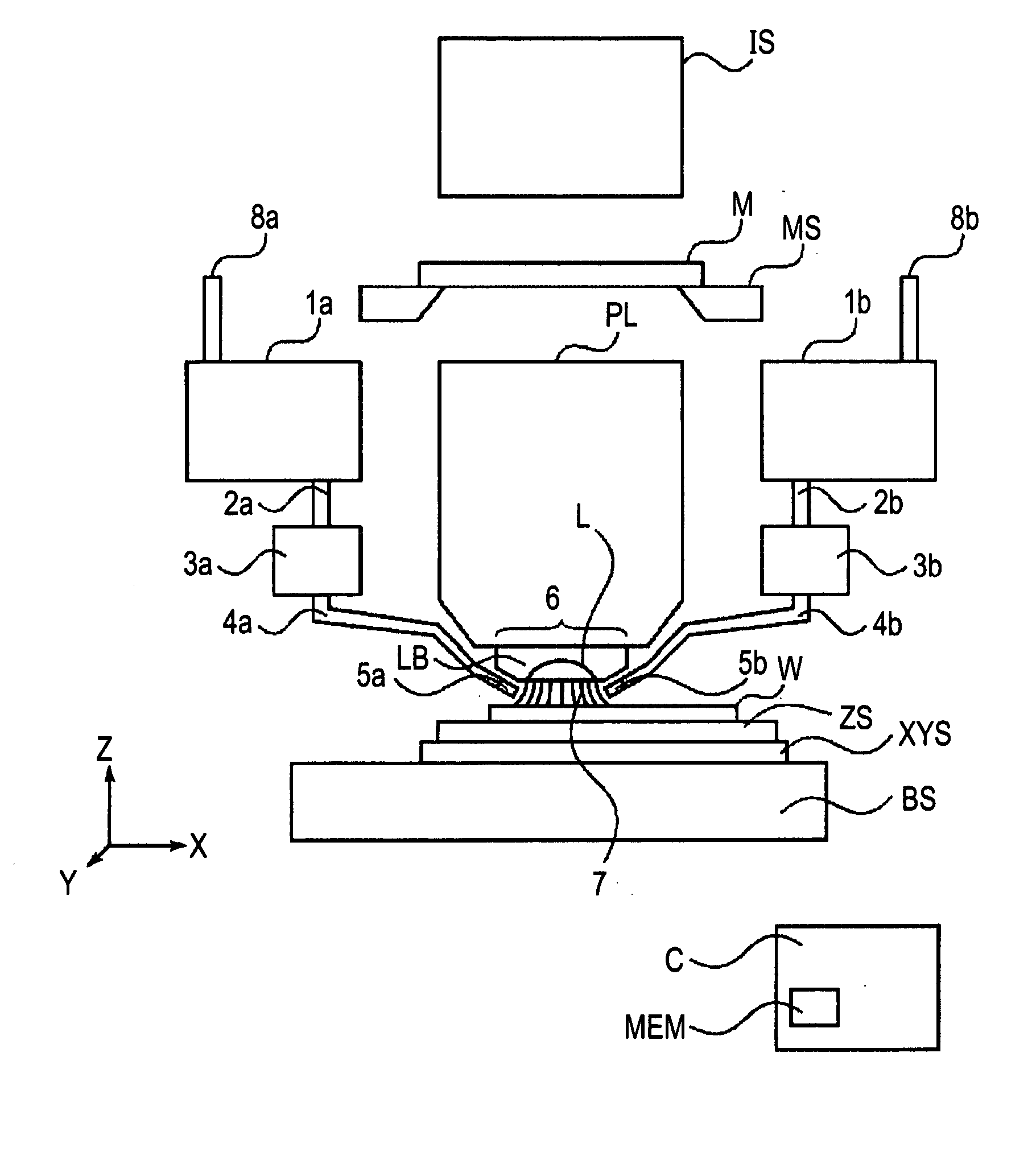

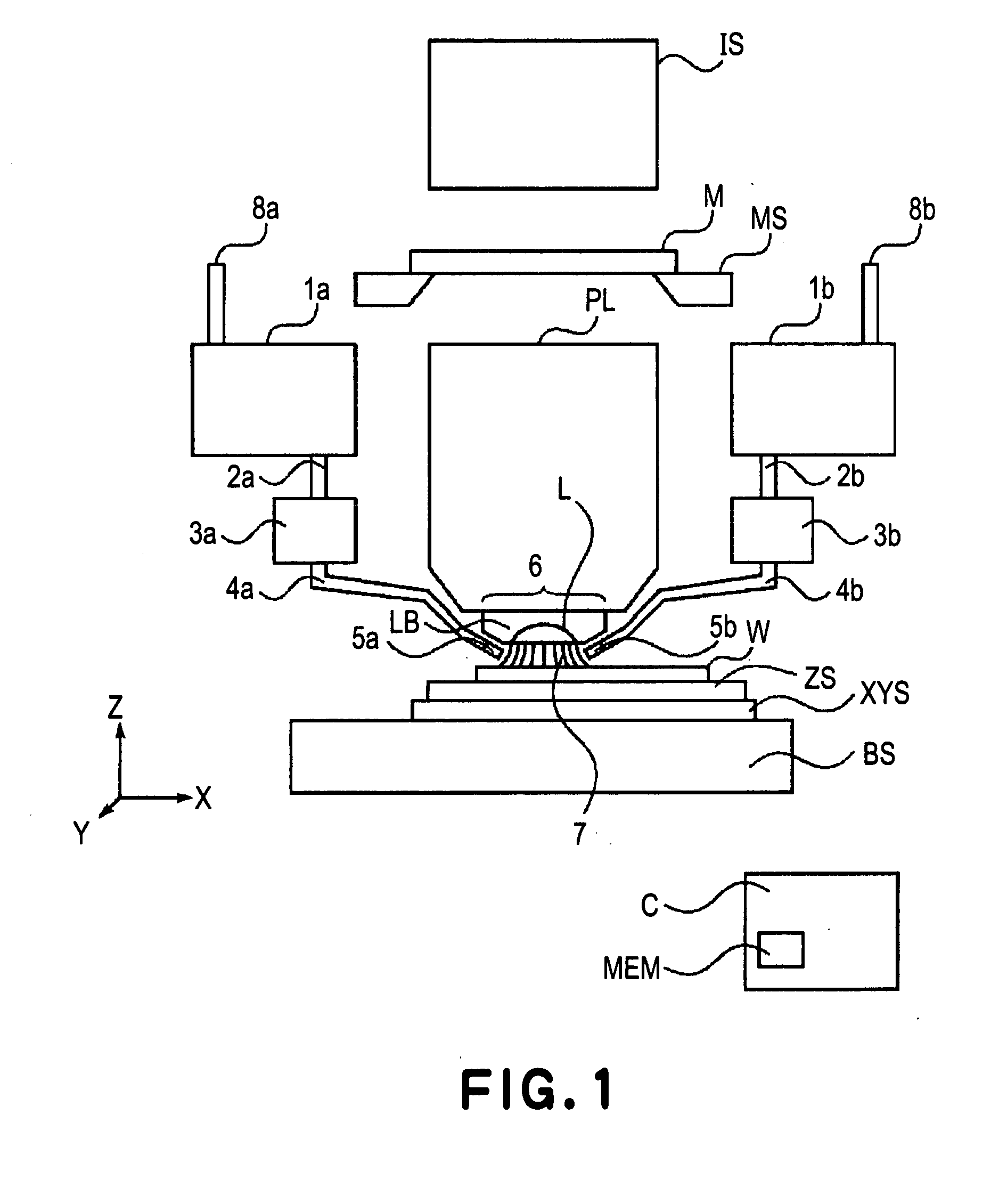

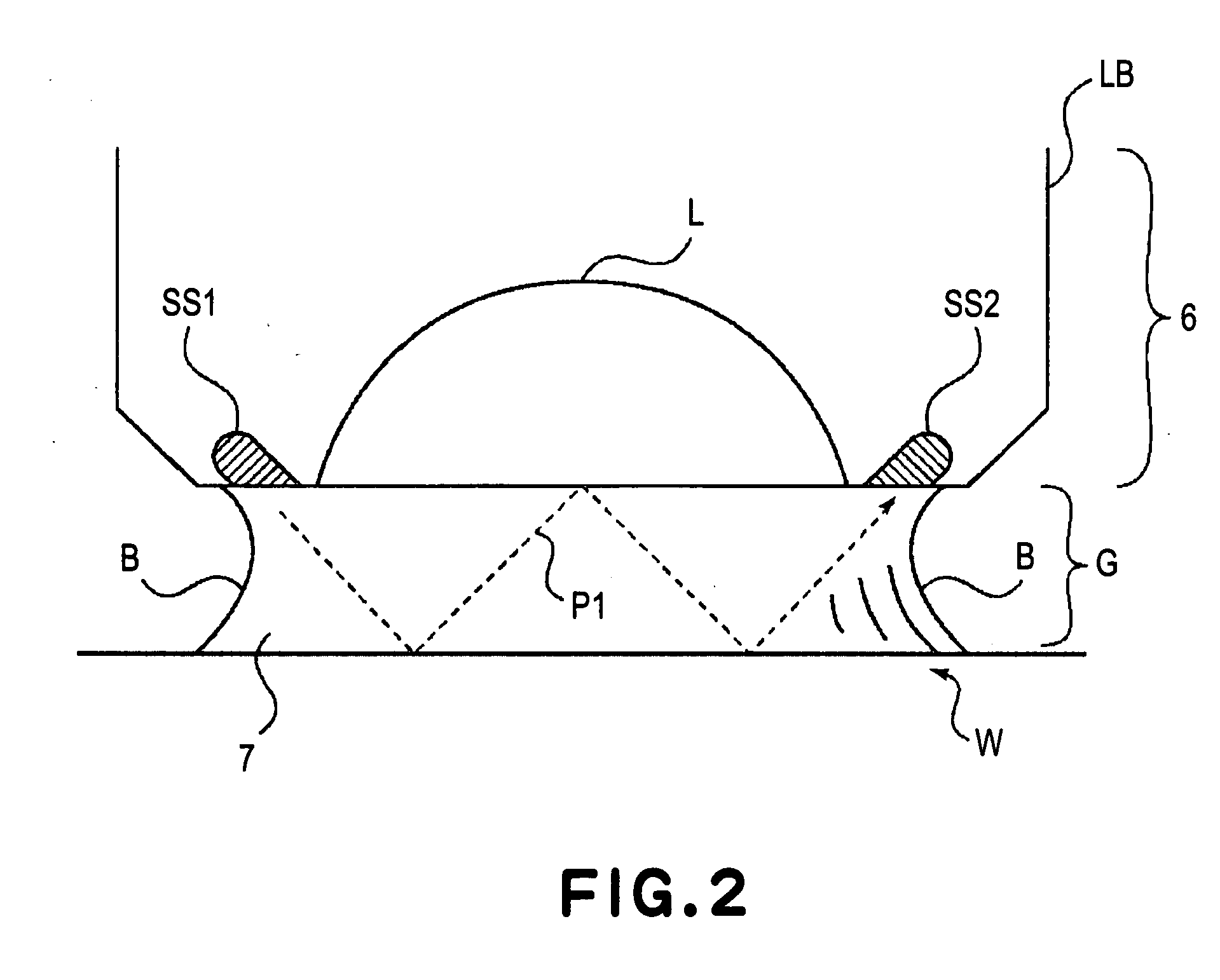

Method and system for immersion lithography

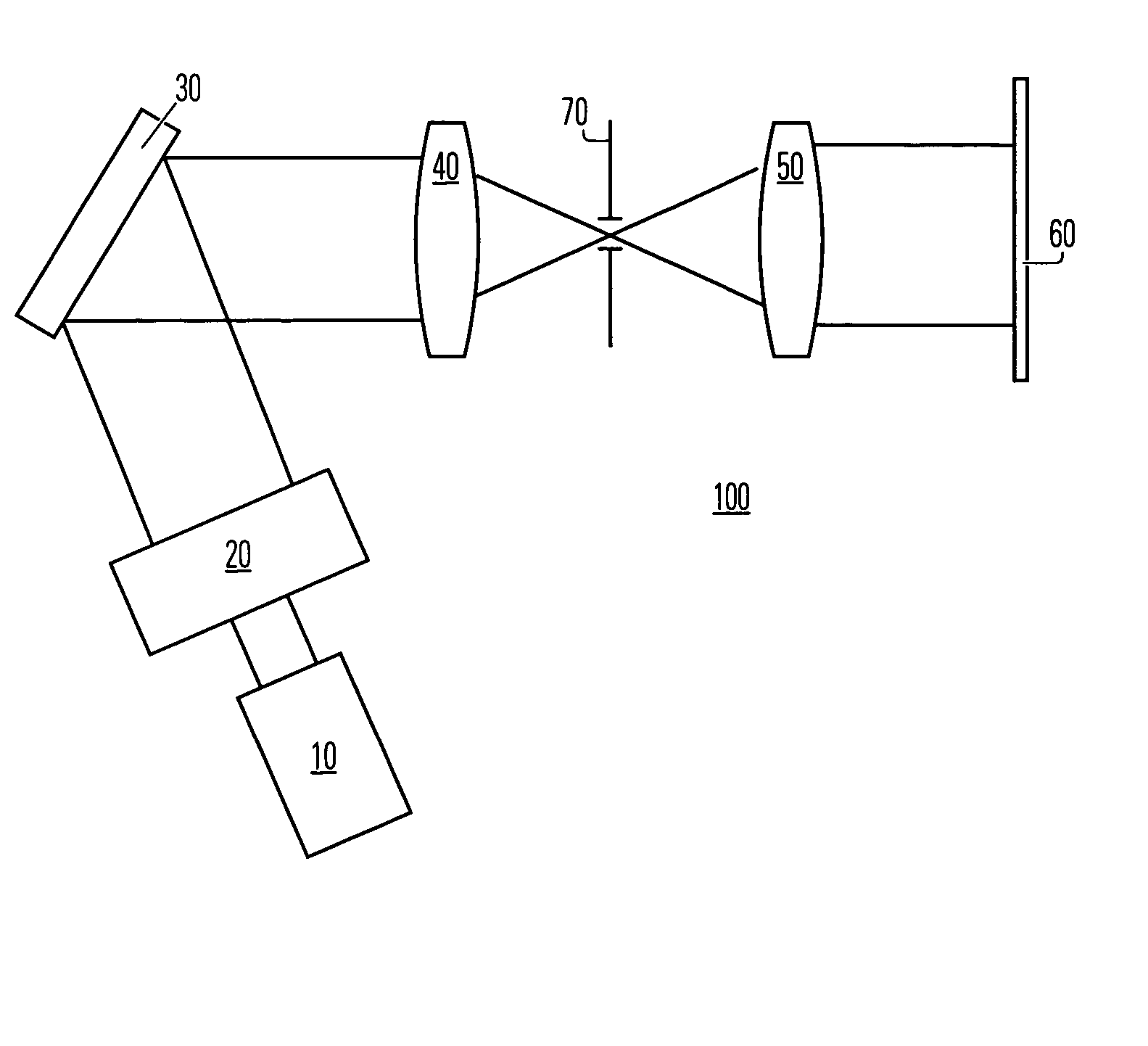

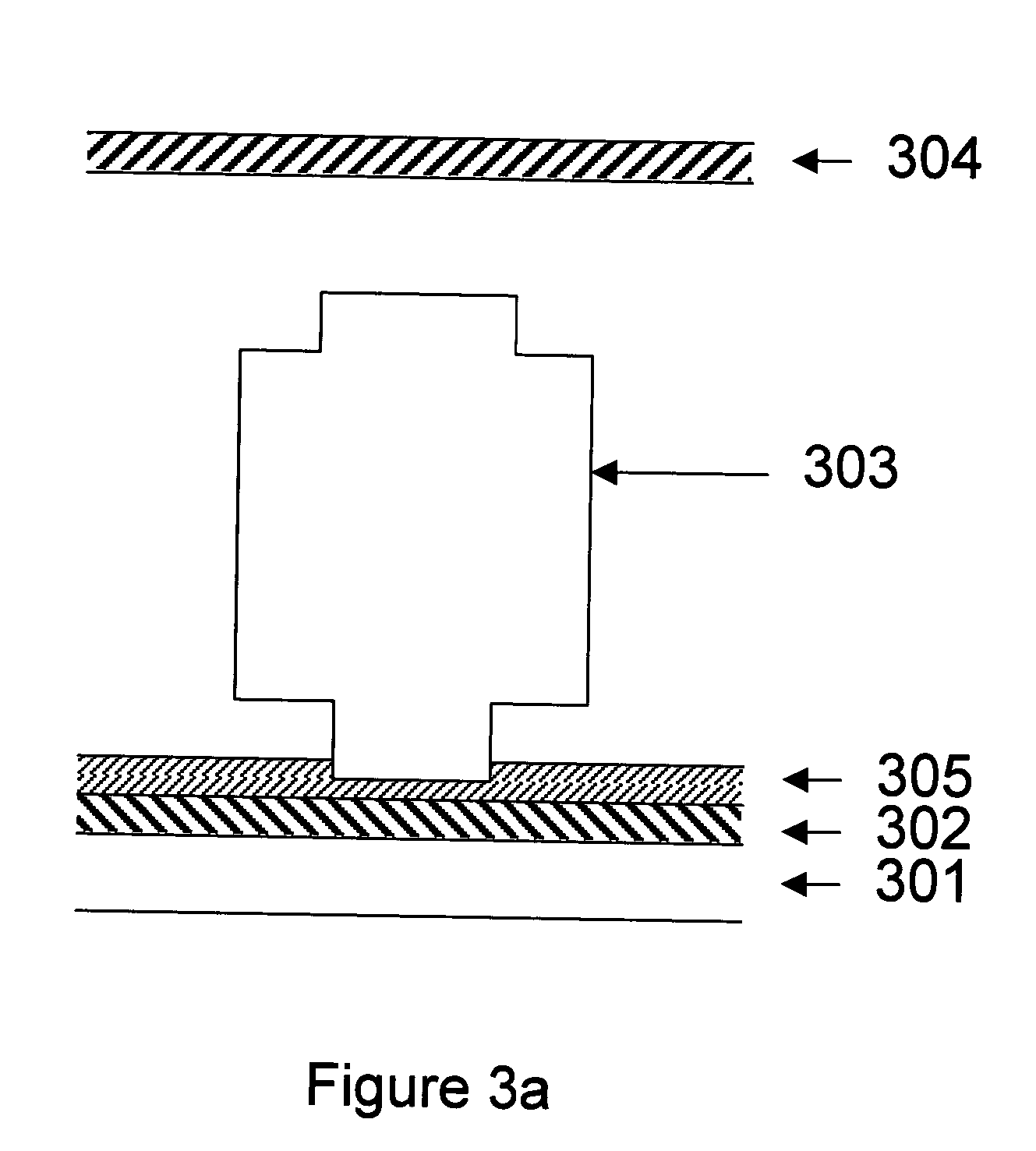

InactiveUS20050147920A1Avoid interactionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusImmersion lithographyLight sensitive

A system (100) and method for immersion lithography is disclosed in which an immersion medium (112) interfaces with a proximal lens (110) that focuses a patterned light beam on a light sensitive material (116), wherein the light sensitive material (116) is covered by a protective film (300) that interfaces with the immersion medium (112).

Owner:TAIWAN SEMICON MFG CO LTD

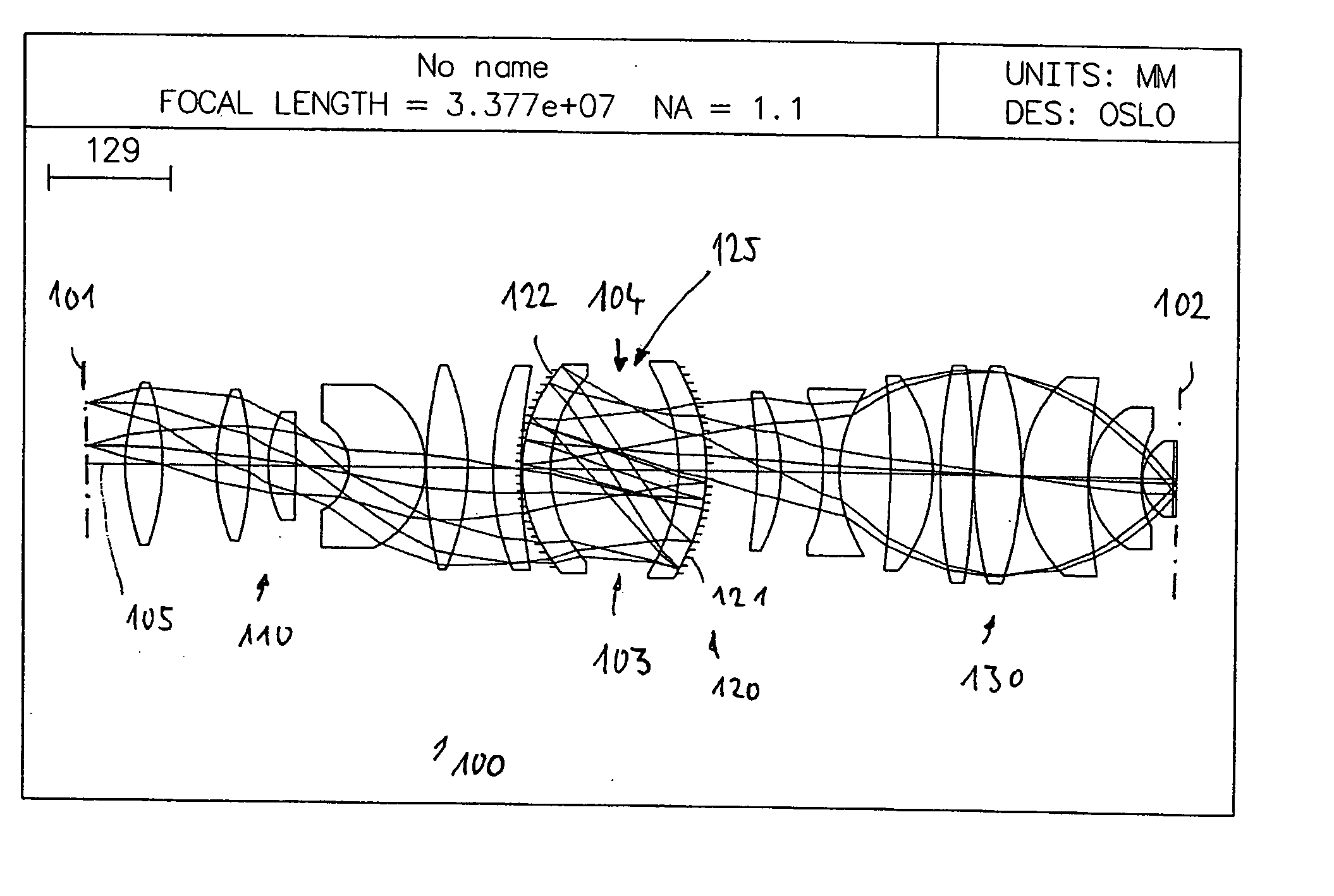

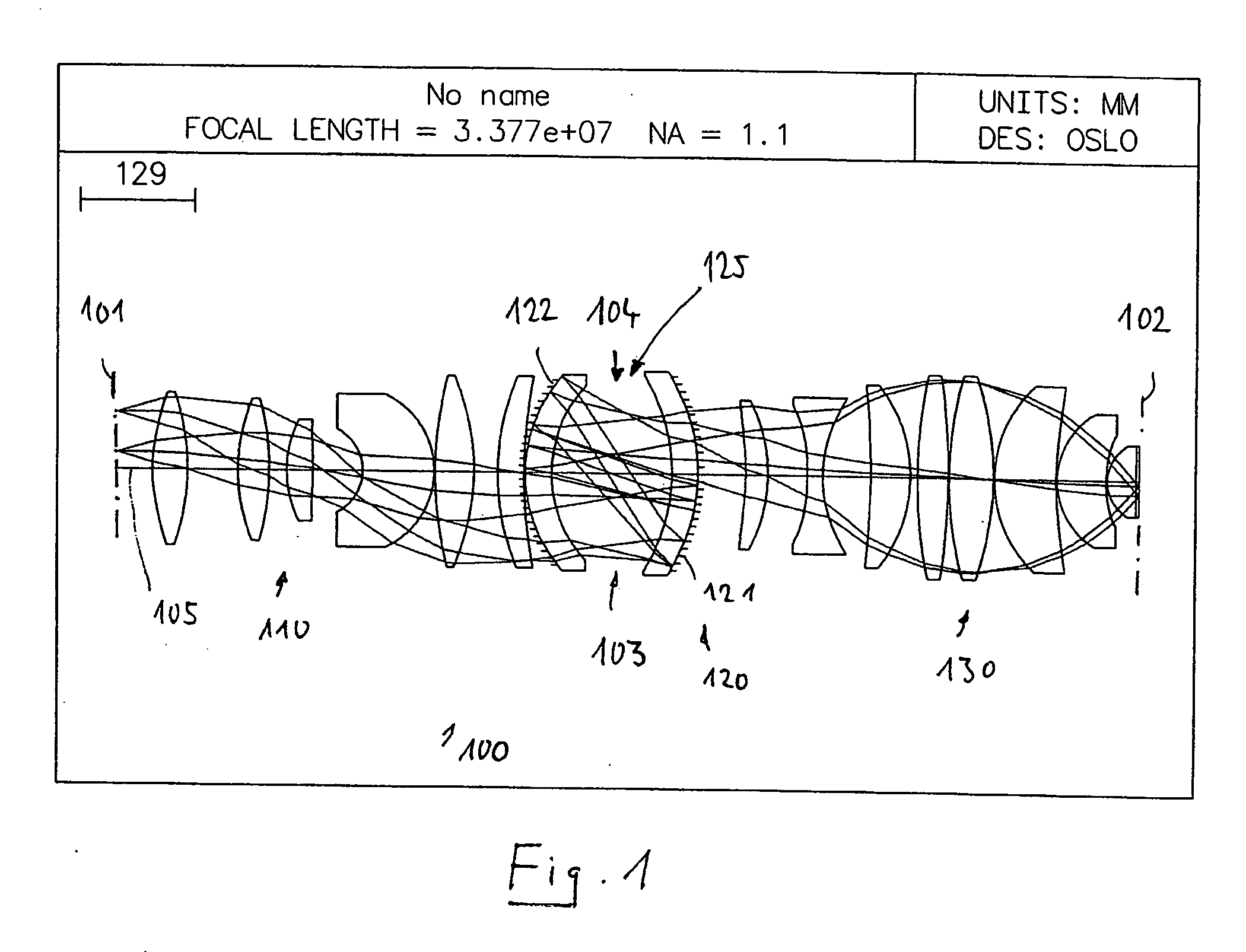

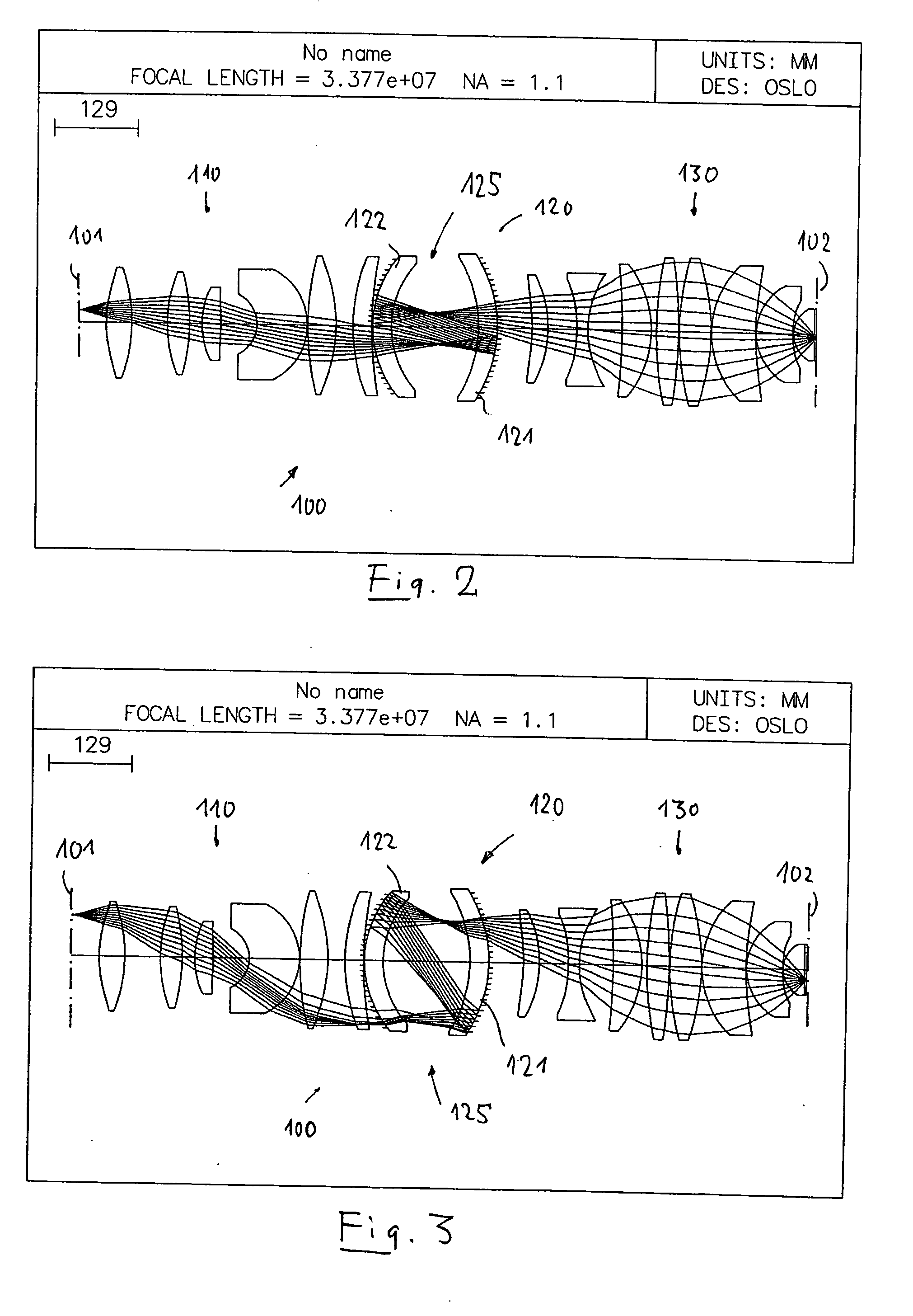

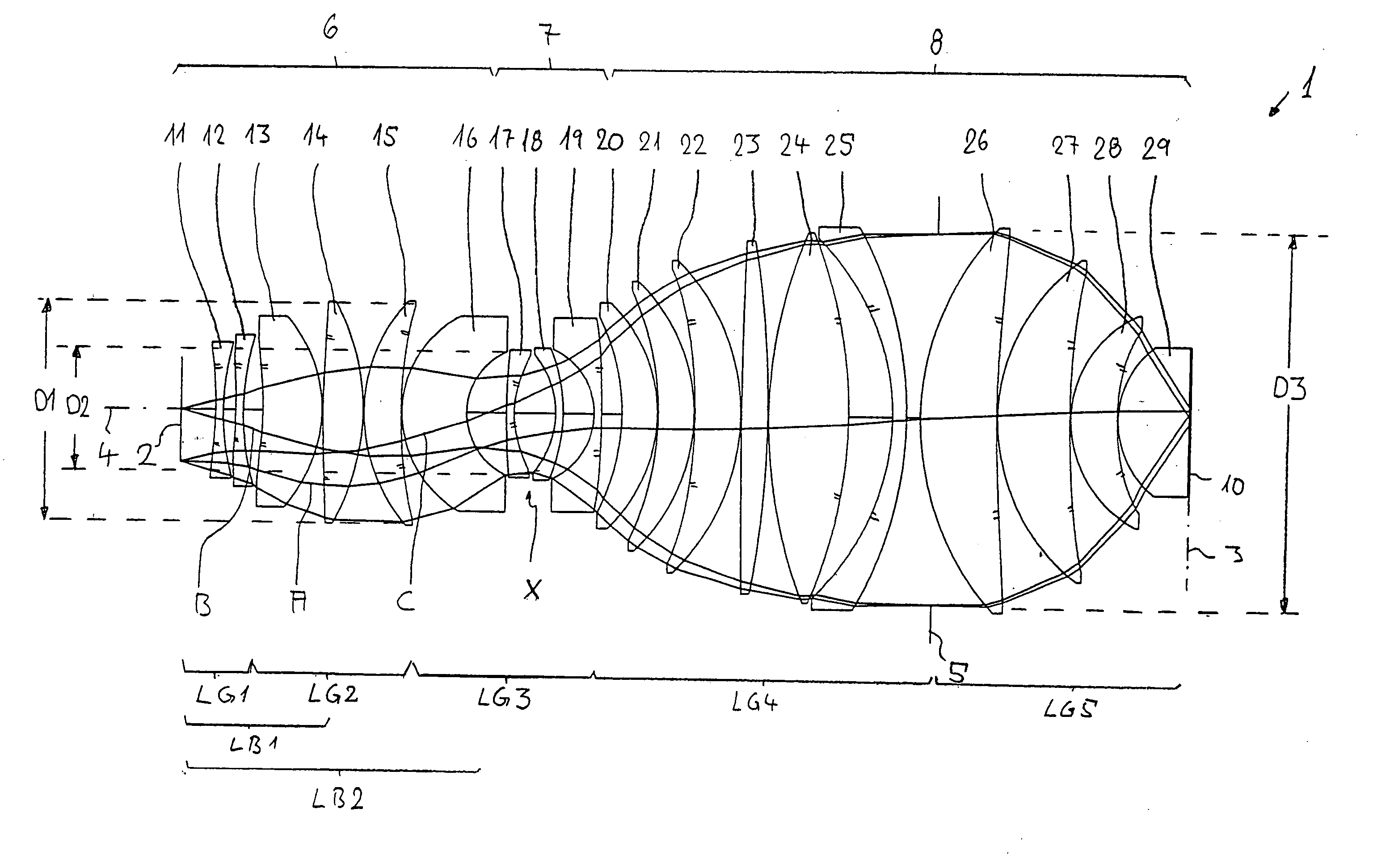

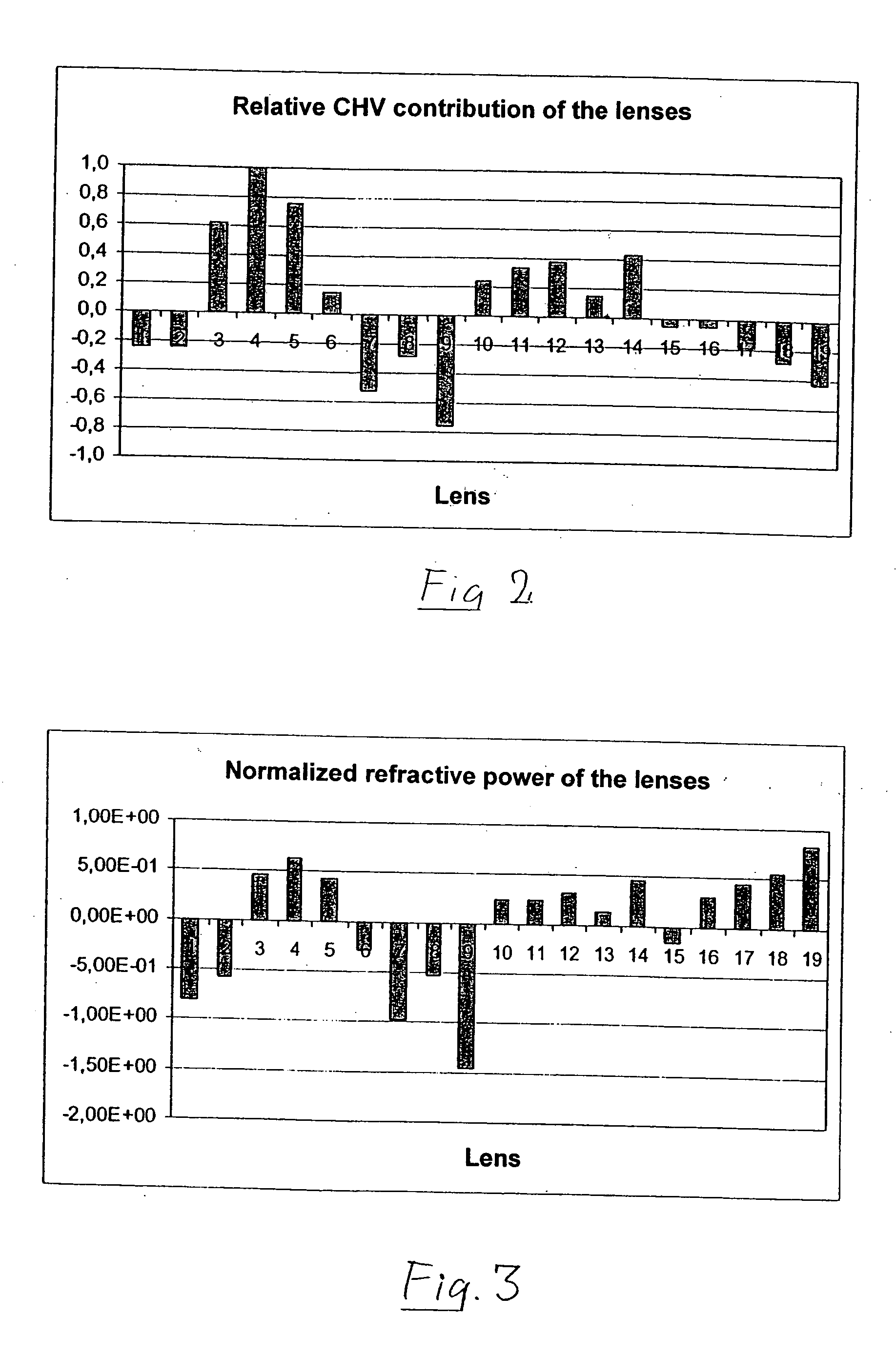

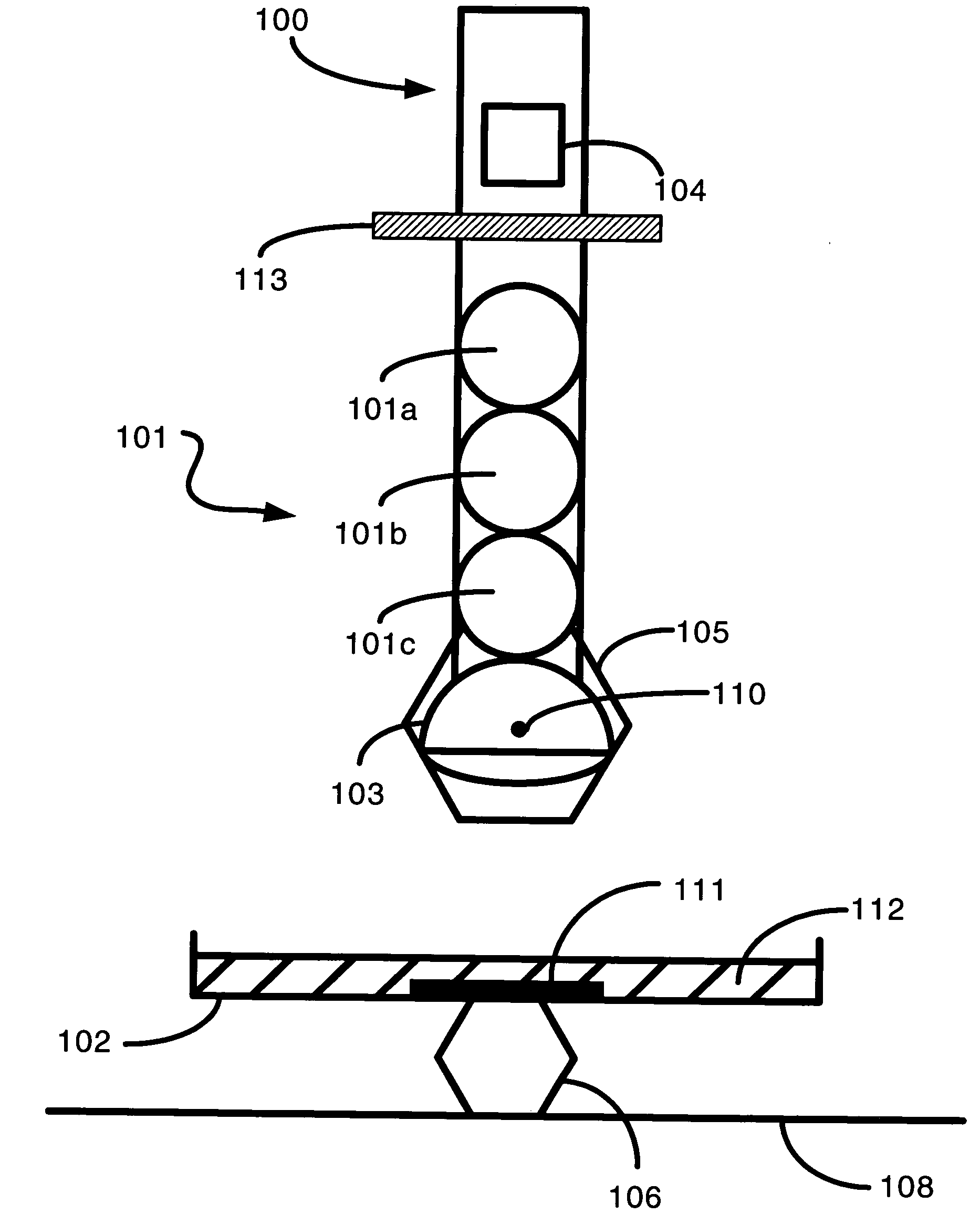

Refractive projection objective for immersion lithography

InactiveUS20050190455A1Small sizeGood correction stateMicroscopesPhotomechanical exposure apparatusHigh numerical apertureOptoelectronics

A purely refractive projection objective suitable for immersion microlithography is designed as a single-waist system with five lens groups, in the case of which a first lens group with negative refractive power, a second lens group with positive refractive power, a third lens group with negative refractive power, a fourth lens group with positive refractive power and a fifth lens group with positive refractive power are provided. A constriction site of narrowest constriction of the beam bundle lies in the region of the waist. A waist distance AT exists between the object plane and the constriction site X. The condition AT / L≦0.4 holds for a distance ratio AT / L between the waist distance AT and an object-image distance L of the projection objective. Embodiments of inventive projection objectives reach very high numerical apertures NA>1.1 in conjunction with a large image field and are distinguished by a compact overall size and good correction of the lateral chromatic aberration.

Owner:CARL ZEISS SMT GMBH

Moving lens for immersion optical lithography

InactiveUS20050145803A1Reduce turbulenceReduces air bubbleMaterial analysis using wave/particle radiationPhotometryLithographic artistImage resolution

An apparatus for immersion optical lithography having a lens capable of relative movement in synchrony with a horizontal motion of a semiconductor wafer in a liquid environment where the synchronous motion of the lens apparatus and semiconductor wafer advantageously reduces the turbulence and air bubbles associated with a liquid environment. The relative motions of the lens and semiconductor wafer are substantially the same as the scanning process occurs resulting in optimal image resolution with minimal air bubbles, turbulence, and disruption of the liquid environment.

Owner:IBM CORP

Liquid immersion type exposure apparatus

InactiveUS20050030497A1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOptics

Disclosed is a liquid immersion type exposure apparatus specifically arranged to maintain a liquid film between an exposure substrate and a terminal end portion of a projection optical system. In one preferred form, the liquid immersion type exposure apparatus includes a projection optical system for projecting a pattern of a mask onto a substrate, a liquid film forming system for forming a liquid film in a predetermined region between the projection optical system and the substrate, and a sensor for detecting disappearance of at least a portion of the liquid film in the predetermined region.

Owner:CANON KK

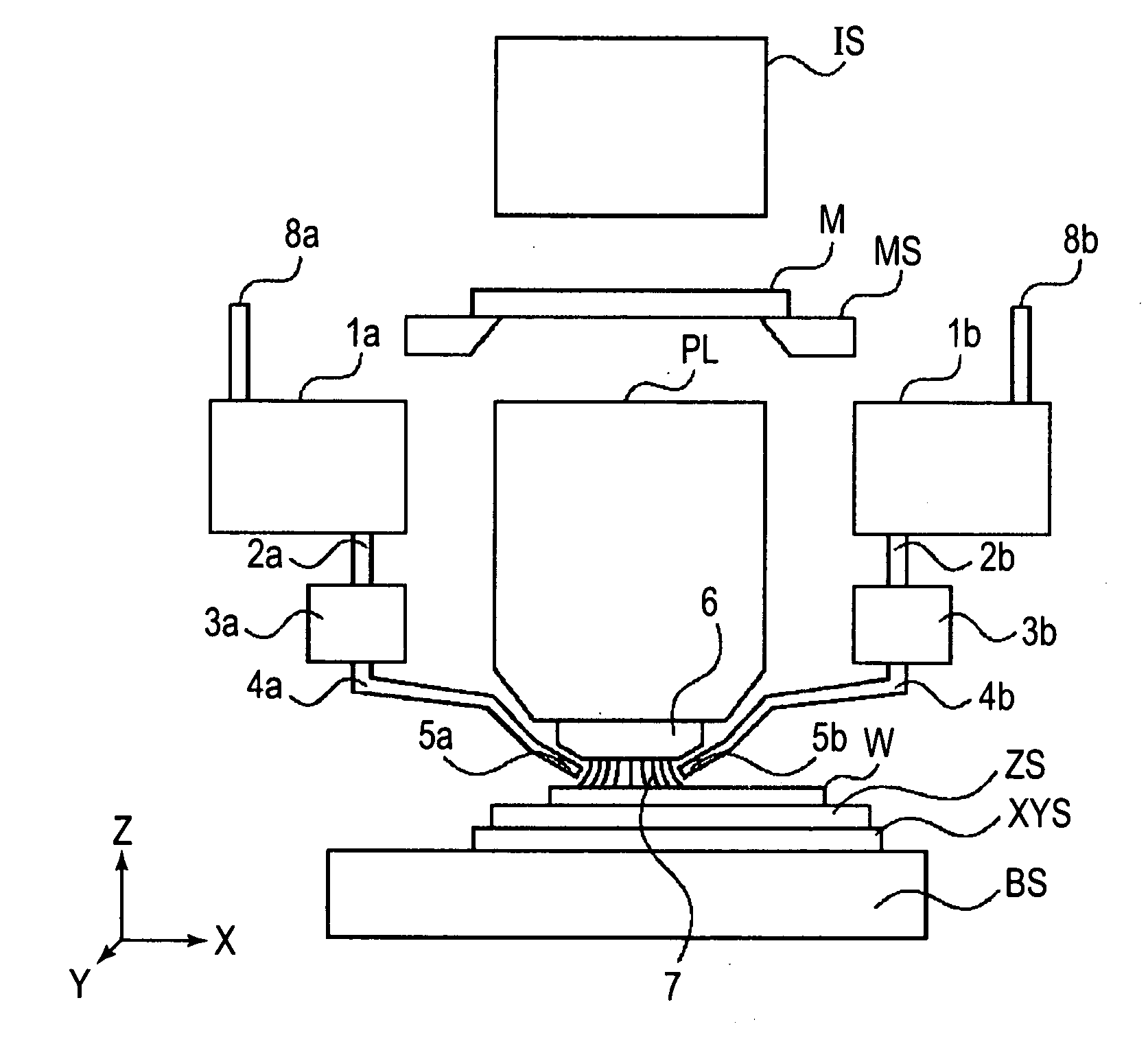

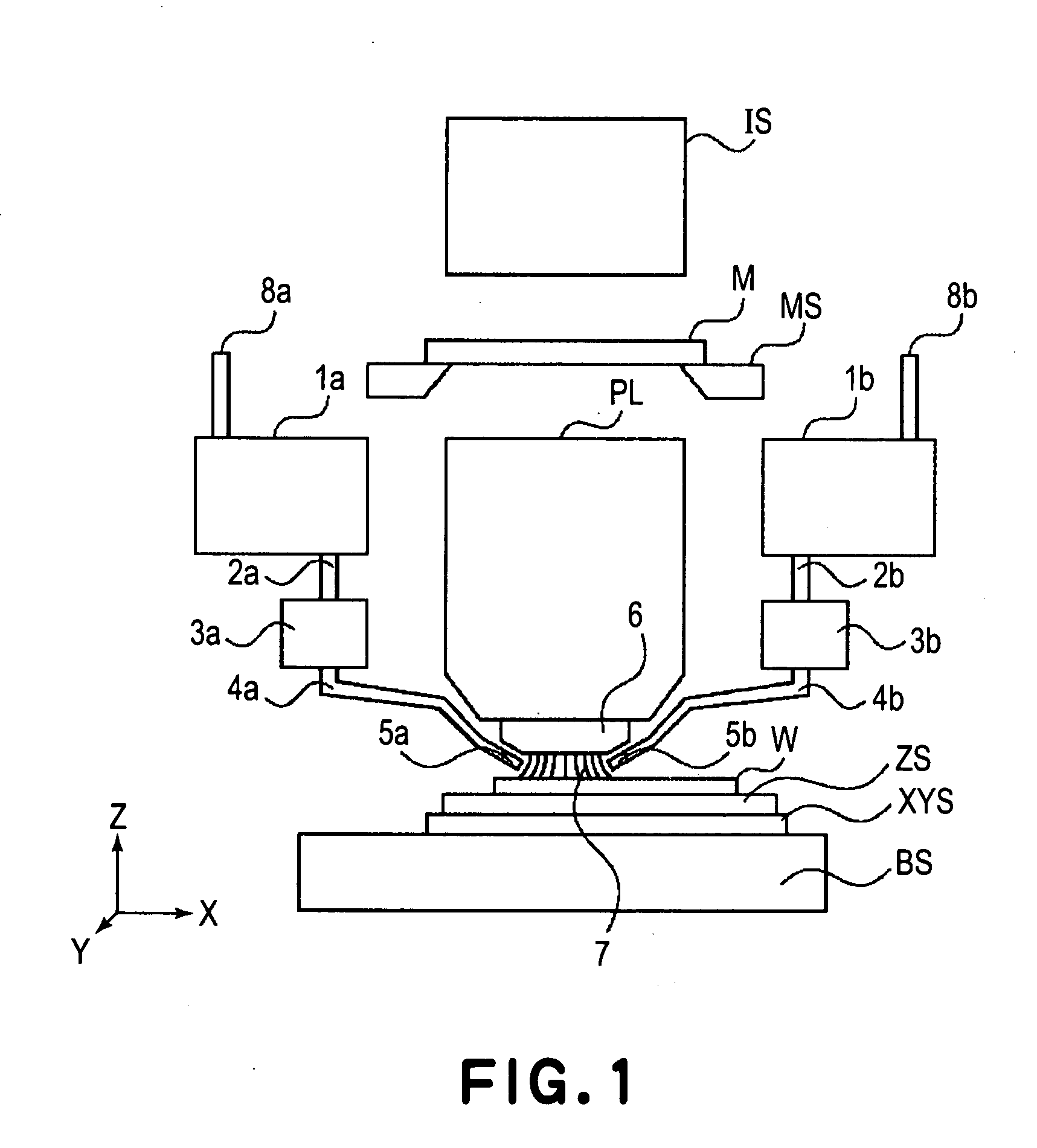

Exposure apparatus and device manufacturing method

InactiveUS20050146695A1Reduce thermal strainSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusBiomedical engineeringFluid supply

An exposure apparatus includes a projection optical system for projecting a pattern of a mask onto a substrate, a holder for holding the substrate and having a first channel for the fluid to flow, and a fluid supply unit for supplying the fluid from the first channel of the holder to at least part of a space between the projection optical system and the substrate, the exposure apparatus exposing the substrate via the projection optical system and the fluid.

Owner:CANON KK

Catadioptric projection objective with geometric beam splitting

InactiveUS20050185269A1Easy to correctCorrect chromatic aberrationMicroscopesPhotomechanical exposure apparatusIntermediate imageBeam splitting

A catadioptric projection objective for imaging a pattern arranged on the object plane of the projection objective, on the image plane of the projection objective, comprising: a first objective part for imaging an object field in a first real intermediate image; a second objective part for producing a second real intermediate image with the radiation coming from the first objective part; and a third objective part for imaging the second real intermediate image on the image plane; wherein at least one of the objective parts is a catadioptric objective part with a concave mirror, and at least one of the objective parts is a refractive objective part and a folding mirror is arranged within this refractive objective part in such a way that a field lens is arranged between the folding mirror and an intermediate image which is closest to the folding mirror.

Owner:CARL ZEISS SMT GMBH

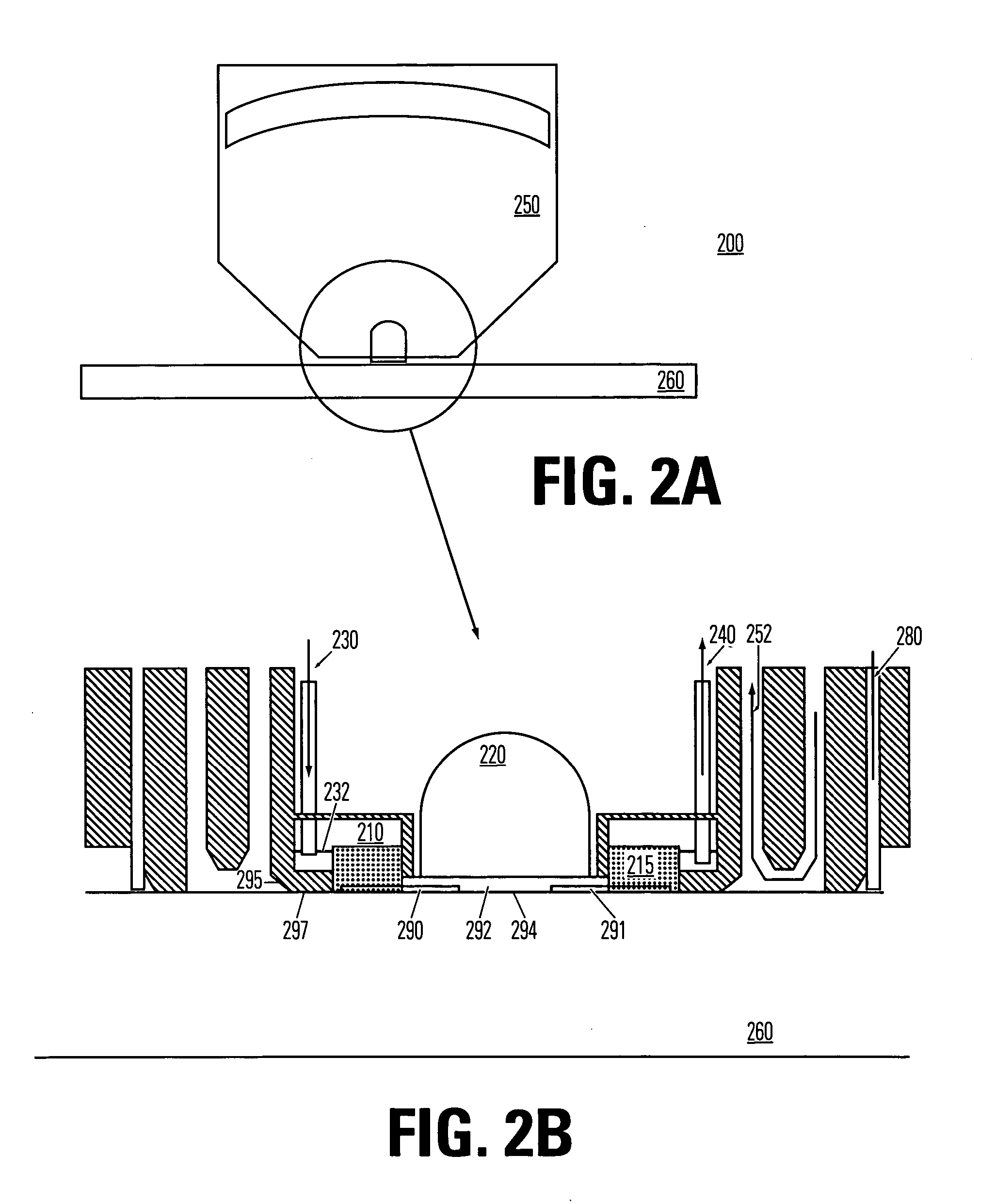

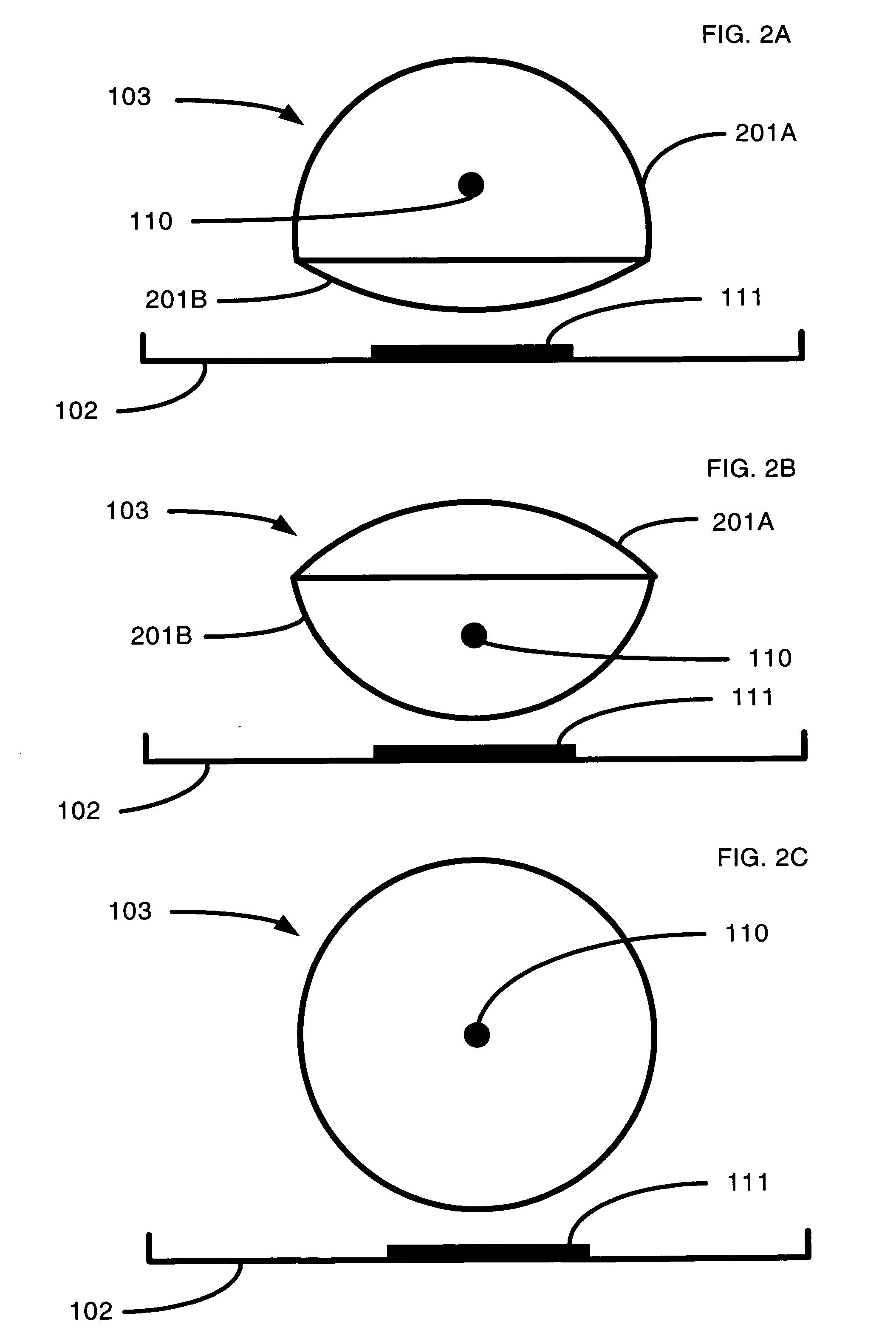

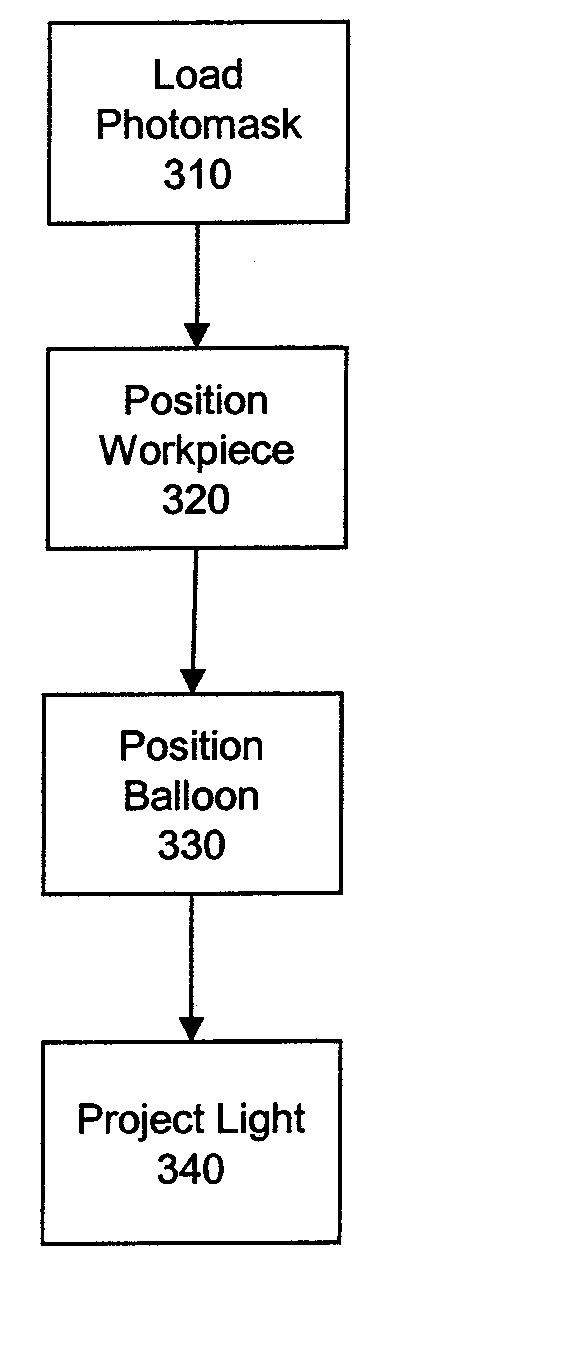

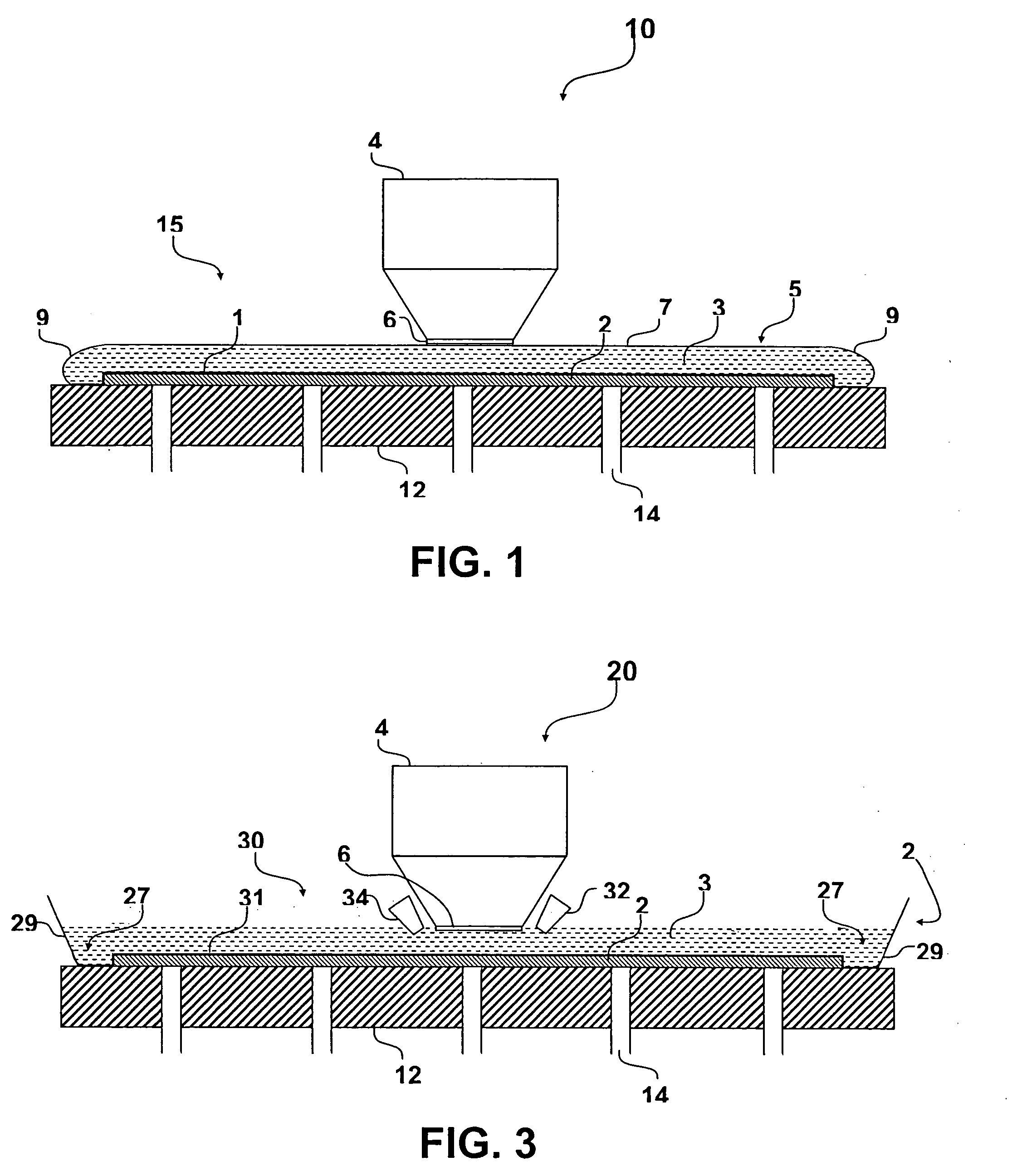

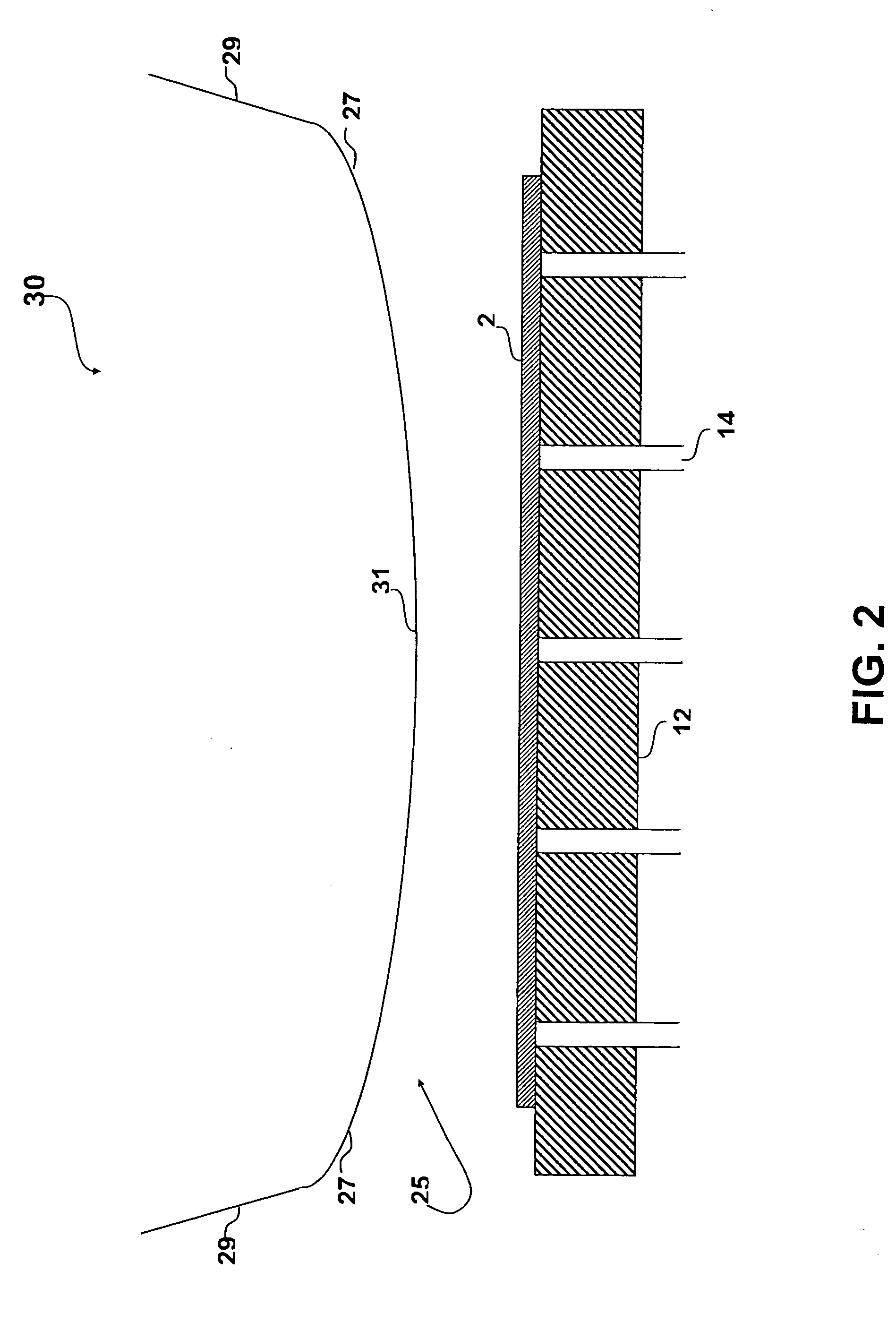

Liquid-filled balloons for immersion lithography

ActiveUS20050158673A1Suitable optical propertyPhotoprinting processesSemiconductor/solid-state device manufacturingOptical propertySemiconductor structure

A liquid-filled balloon may be positioned between a workpiece, such as a semiconductor structure covered with a photoresist, and a lithography light source. The balloon includes a thin membrane that exhibits good optical and physical properties. Liquid contained in the balloon also exhibits good optical properties, including a refractive index higher than that of air. Light from the lithography light source passes through a mask, through a top layer of the balloon membrane, through the contained liquid, through a bottom layer of the balloon membrane, and onto the workpiece where it alters portions of the photoresist. As the liquid has a low absorption and a higher refractive index than air, the liquid-filled balloon system enhances resolution. Thus, the balloon provides optical benefits of liquid immersion without the complications of maintaining a liquid between (and in contact with) a lithographic light source mechanism and workpiece.

Owner:TWITTER INC

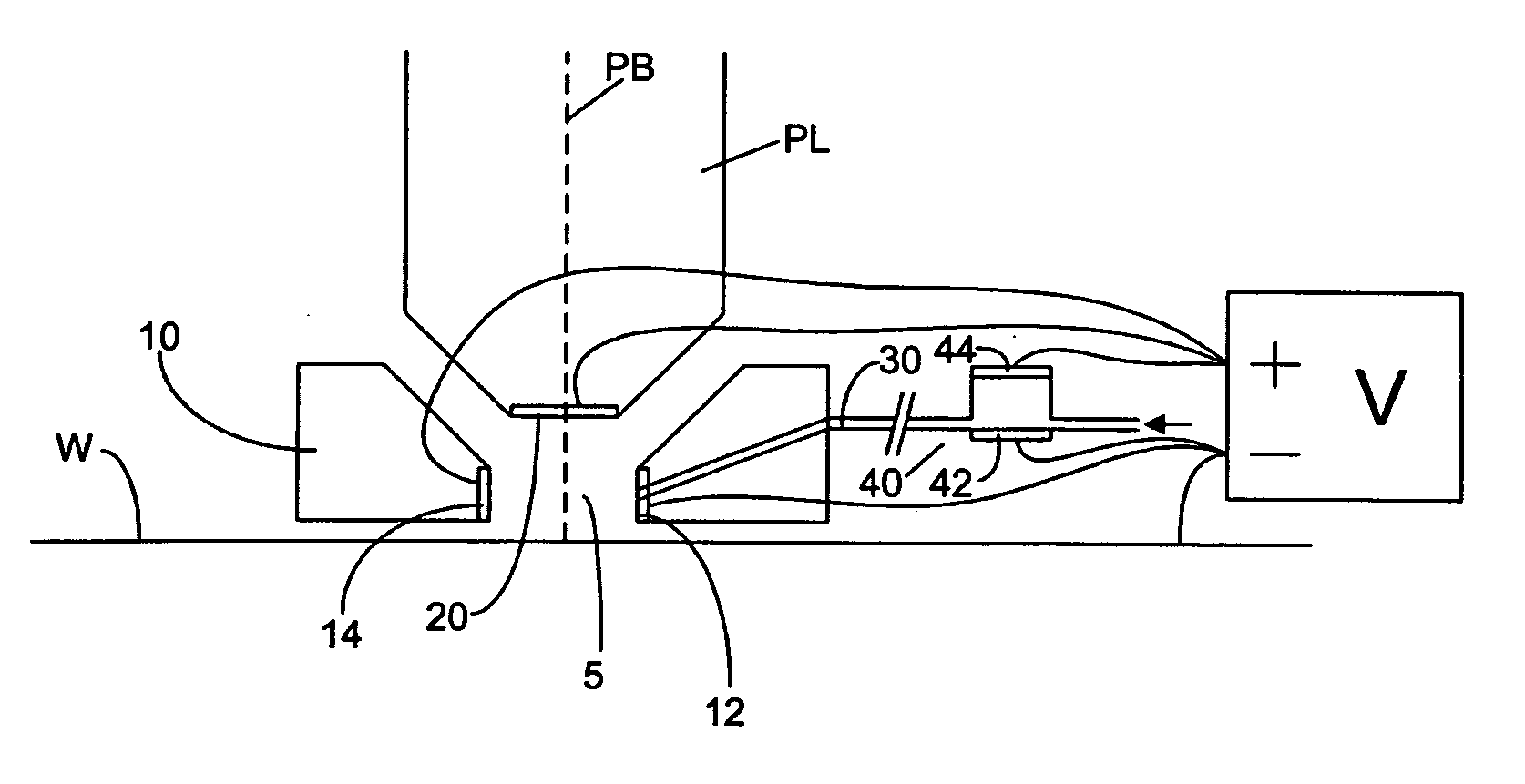

Lithographic apparatus and device manufacturing method

ActiveUS20050174549A1Reduce the impactReduce impactSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusVoltage generatorPotential difference

An immersion lithographic apparatus includes a voltage generator or power source that applies a potential difference to an object in contact with the immersion liquid such that bubbles and / or particles in the immersion liquid are either attracted or repelled from that object due to the electrokinetic potential of the surface of the bubble in the immersion liquid.

Owner:ASML NETHERLANDS BV

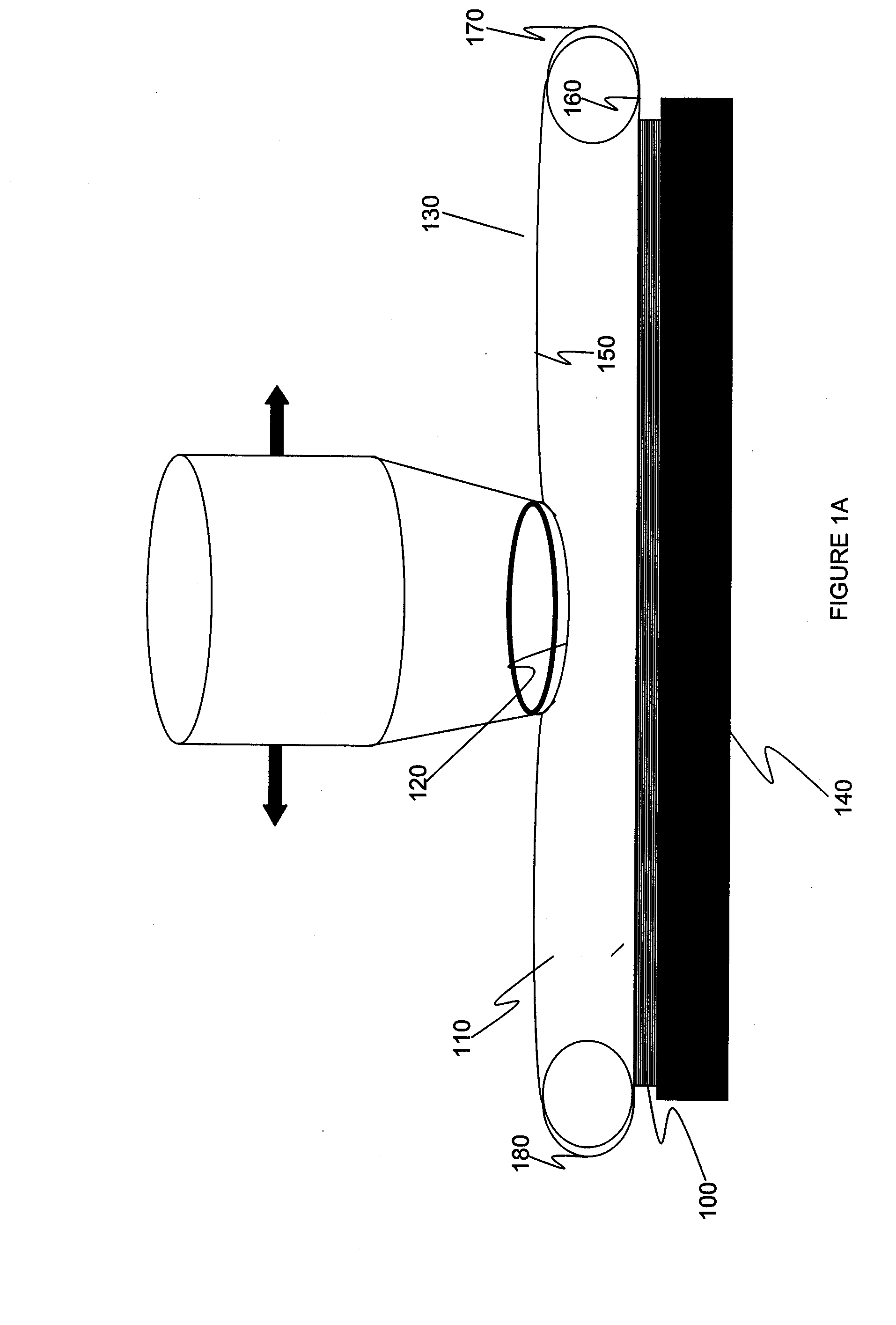

System and apparatus for photolithography

InactiveUS20050213061A1Photomechanical exposure apparatusMicrolithography exposure apparatusEngineeringMechanical engineering

A photolithographic apparatus, system and method employing an improved refractive medium. The photolithographic apparatus may be used in an immersion lithography system for projecting light onto a workpiece such as a semiconductor wafer. In one embodiment, the photolithographic apparatus includes a container containing a transparent fluid. The fluid container is positioned between a lens element and the wafer. The container is further characterized as having a substantially flexible and transparent bottom membrane contacting an upper surface of the wafer and overlapping at least one side edge of the wafer such that a fluid filled skirt is formed extending beyond the edges of the wafer.

Owner:IBM CORP

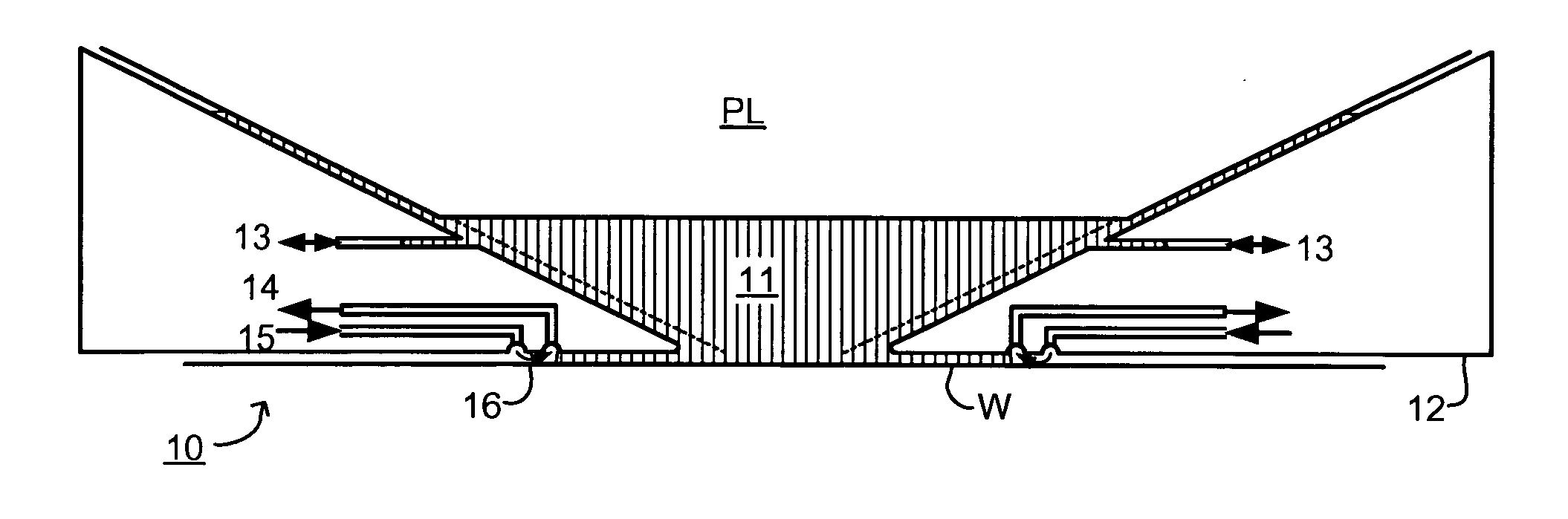

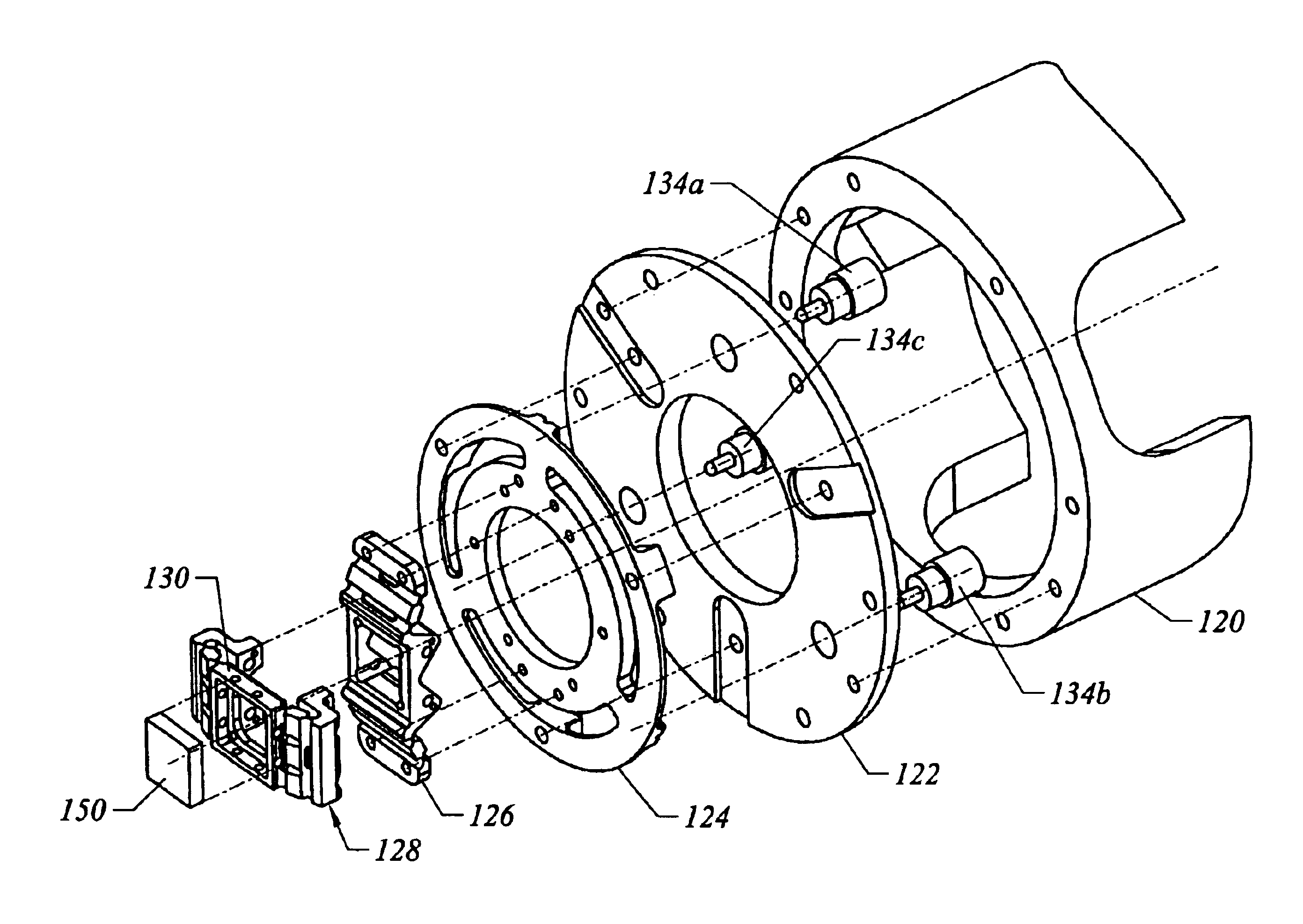

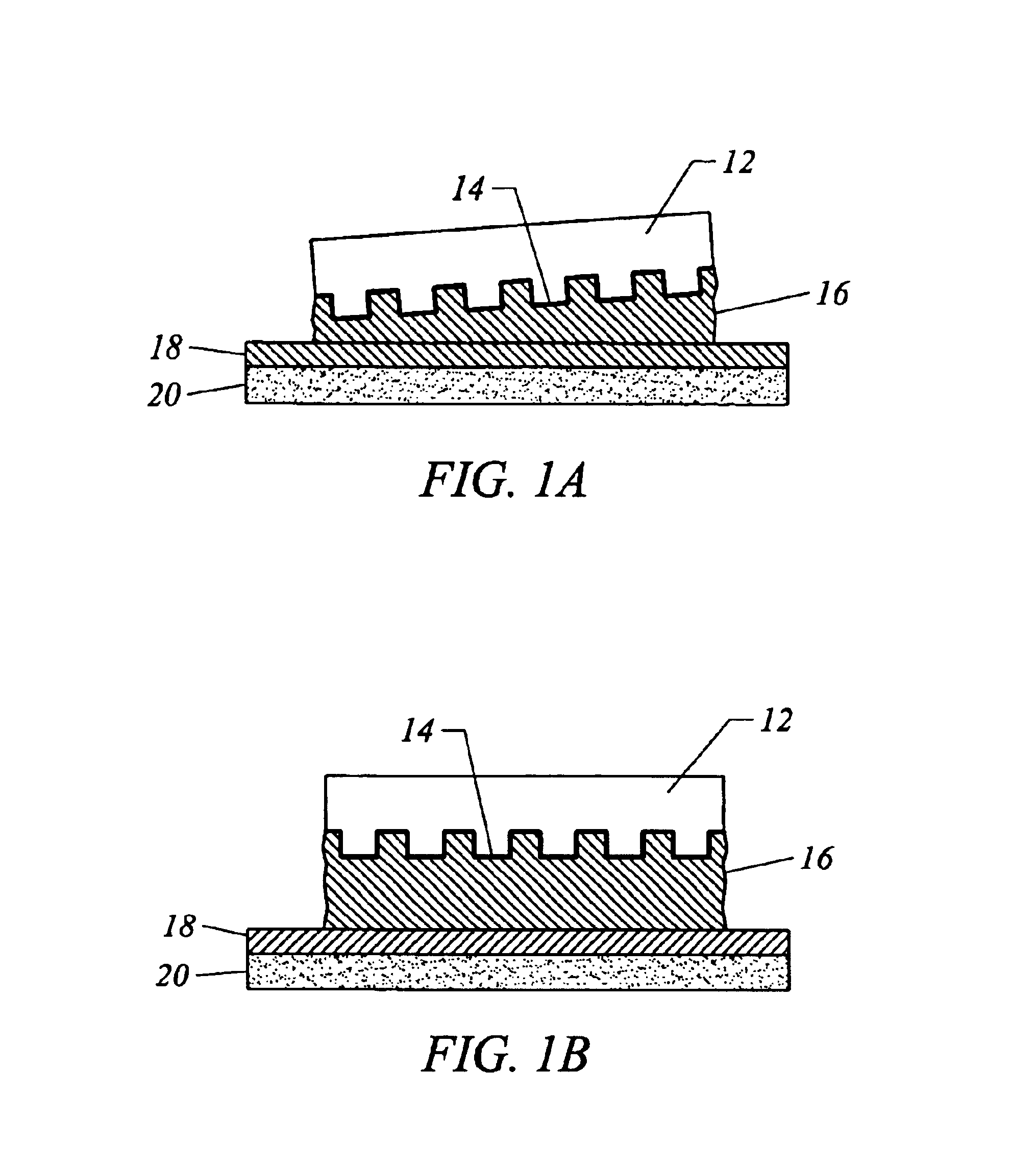

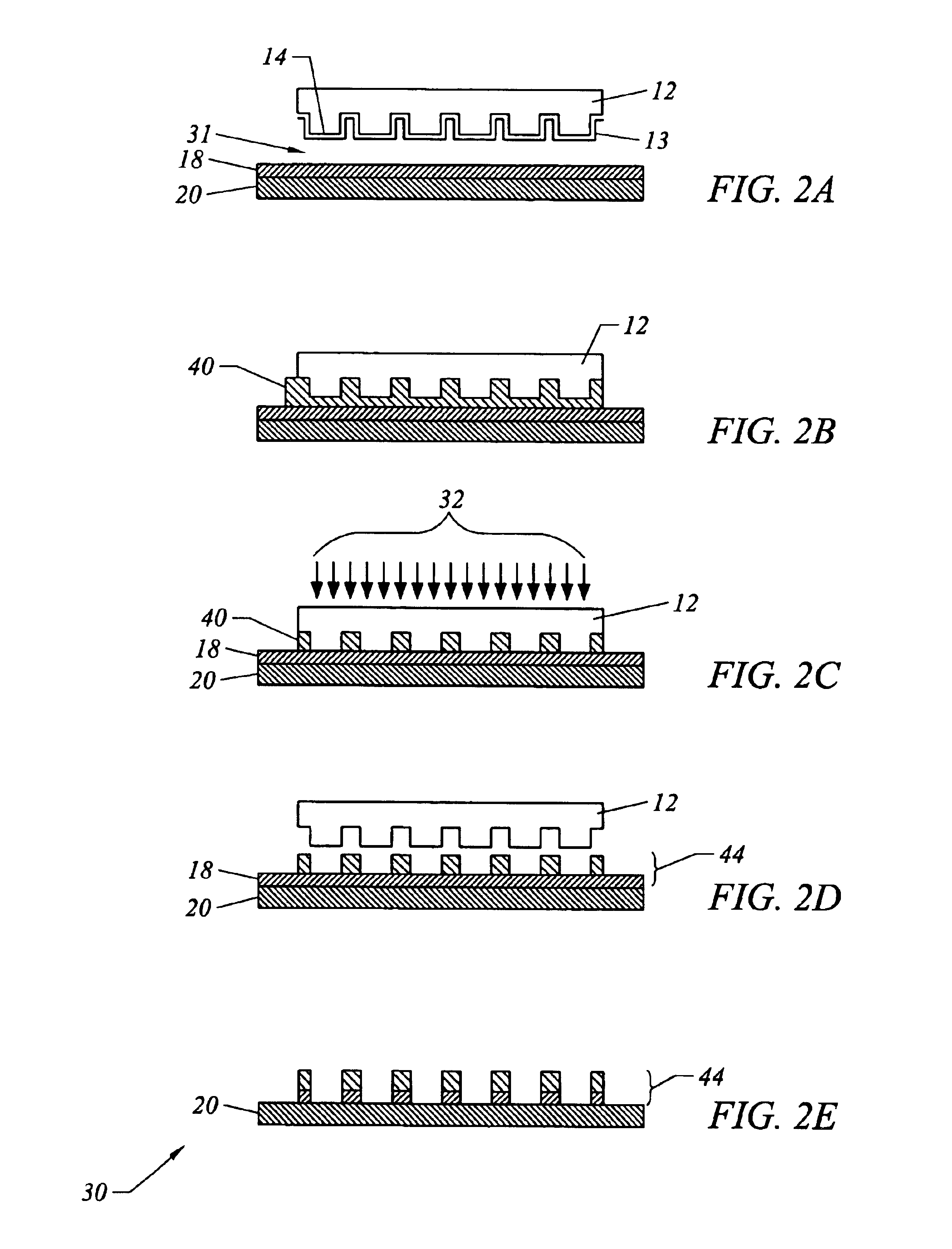

High precision orientation alignment and gap control stages for imprint lithography processes

InactiveUS6873087B1Achieve separationPiezoelectric/electrostriction/magnetostriction machinesNanoinformaticsLithography processEngineering

Processes and associated devices for high precision positioning of a template an substrate during imprint lithography includes a calibration system with a course calibration stage and a fine orientation stage capable of maintaining a uniform gap between the template and substrate. The fine orientation stage includes a pair of flexure members having flexure joints for motion about a pivot point intersected by first and second orientation axes. Actuators lengthen or shorten to expand or contract the flexure members. Separation of the template is achieved using a peel-and-pull method that avoids destruction of imprinted features from the substrate.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

Projection optical system and exposure apparatus having the projection optical system

InactiveUS6633365B2Avoid stickingPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical axisLength wave

A projection optical system according to the present invention whose image side numerical aperture is greater than or equal to 0.75, and which forms an image of a first object upon a second object using light of a predetermined wavelength less than or equal to 300 nm, comprises: a first lens group G<HIL><PDAT>1 < / BOLD><PDAT>of positive refractive power; a second lens group G<HIL><PDAT>2 < / BOLD><PDAT>of negative refractive power; a third lens group G<HIL><PDAT>3 < / BOLD><PDAT>of positive refractive power; and a fourth lens group G<HIL><PDAT>4 < / BOLD><PDAT>of positive refractive power, and: the first lens group G<HIL><PDAT>1, < / BOLD><PDAT>the second lens group G<HIL><PDAT>2, < / BOLD><PDAT>the third lens group G<HIL><PDAT>3 < / BOLD><PDAT>and the fourth lens group G<HIL><PDAT>4 < / BOLD><PDAT>are arranged in order from a side of the first object; and a distance D in mm along an optical axis between an optical surface of the fourth lens group G<HIL><PDAT>4 < / BOLD><PDAT>closest to the second object, and the second object, satisfies a condition of 0.1<D<5.

Owner:NIKON CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com