Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31085 results about "Laser beams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

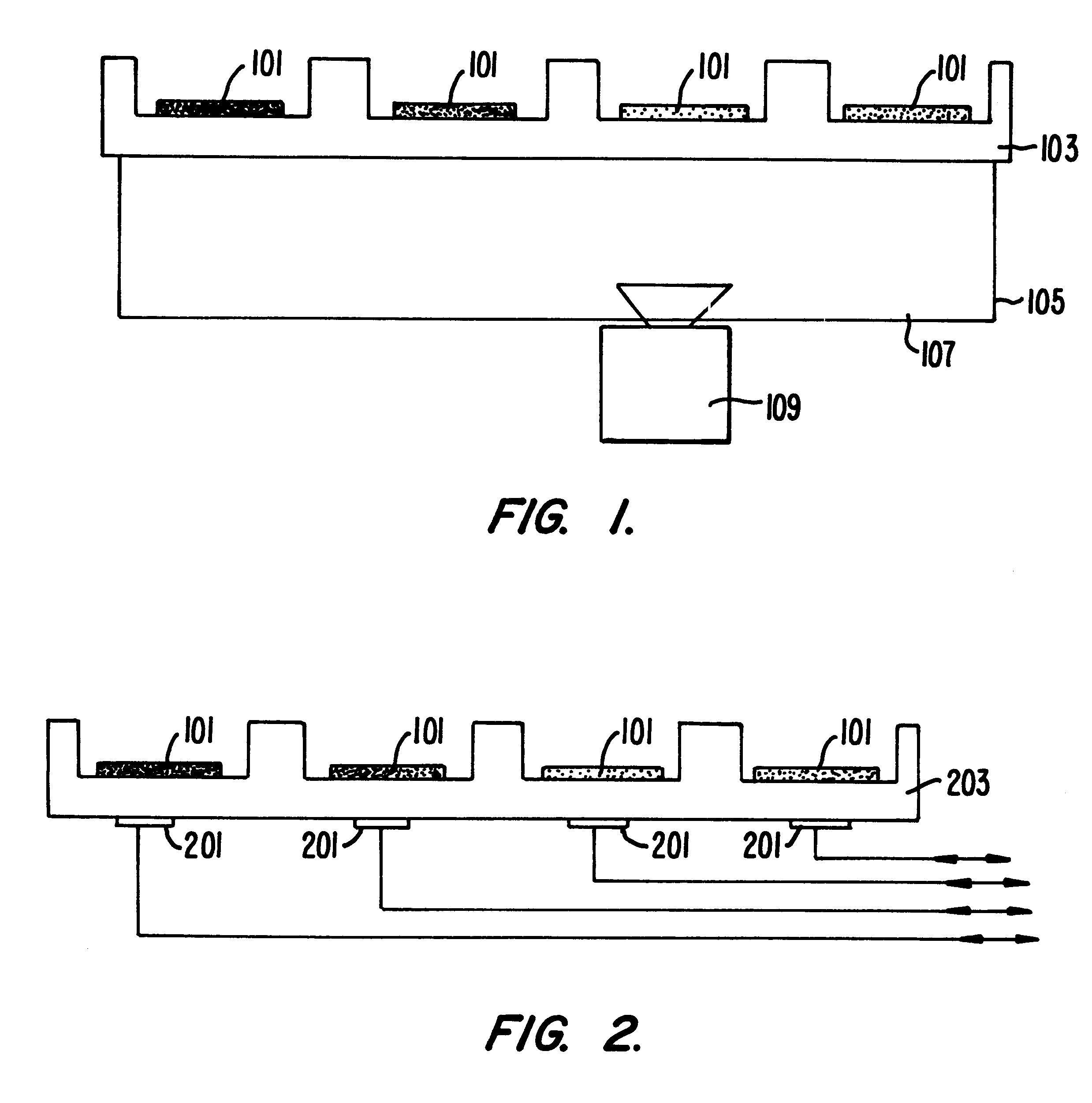

Bar code symbol reading system employing an extremely elongated laser scanning beam capable of reading poor and damaged quality bar code symbols with improved levels of performance

ActiveUS8376233B2Increase reflectionOptimized laser beam characteristicsTelevision system scanning detailsCharacter and pattern recognitionLaser scanningLight beam

Owner:METROLOGIC INSTR

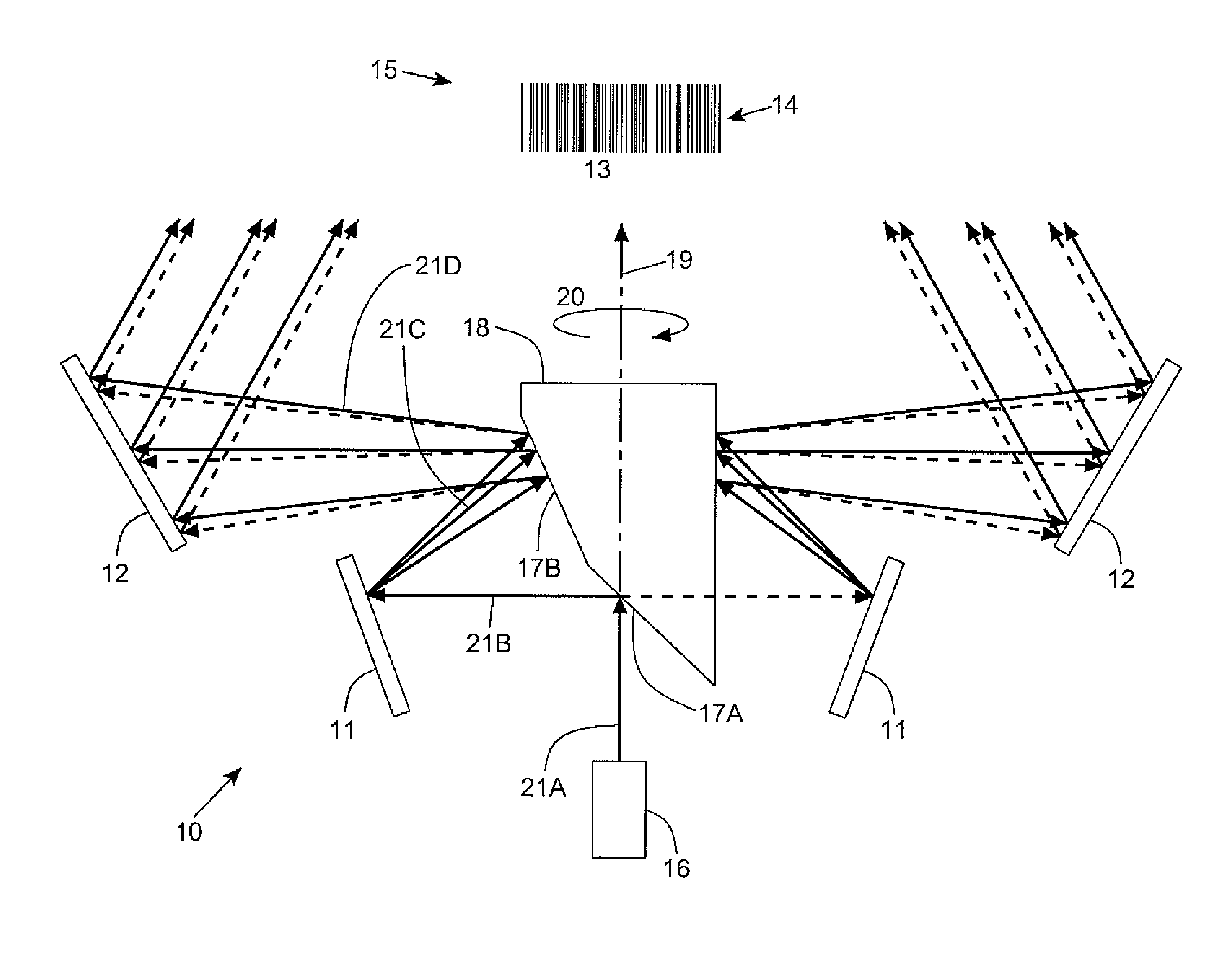

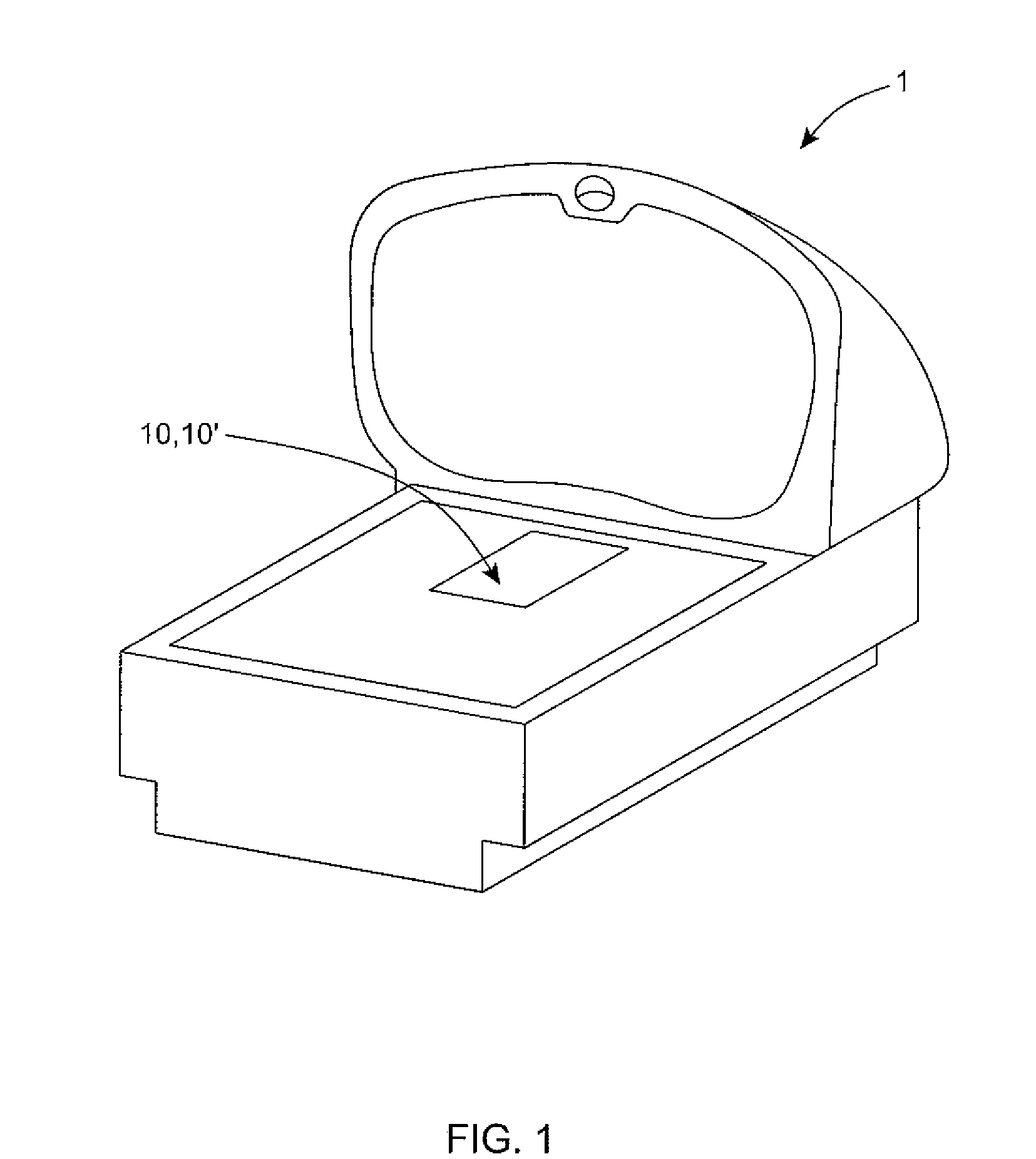

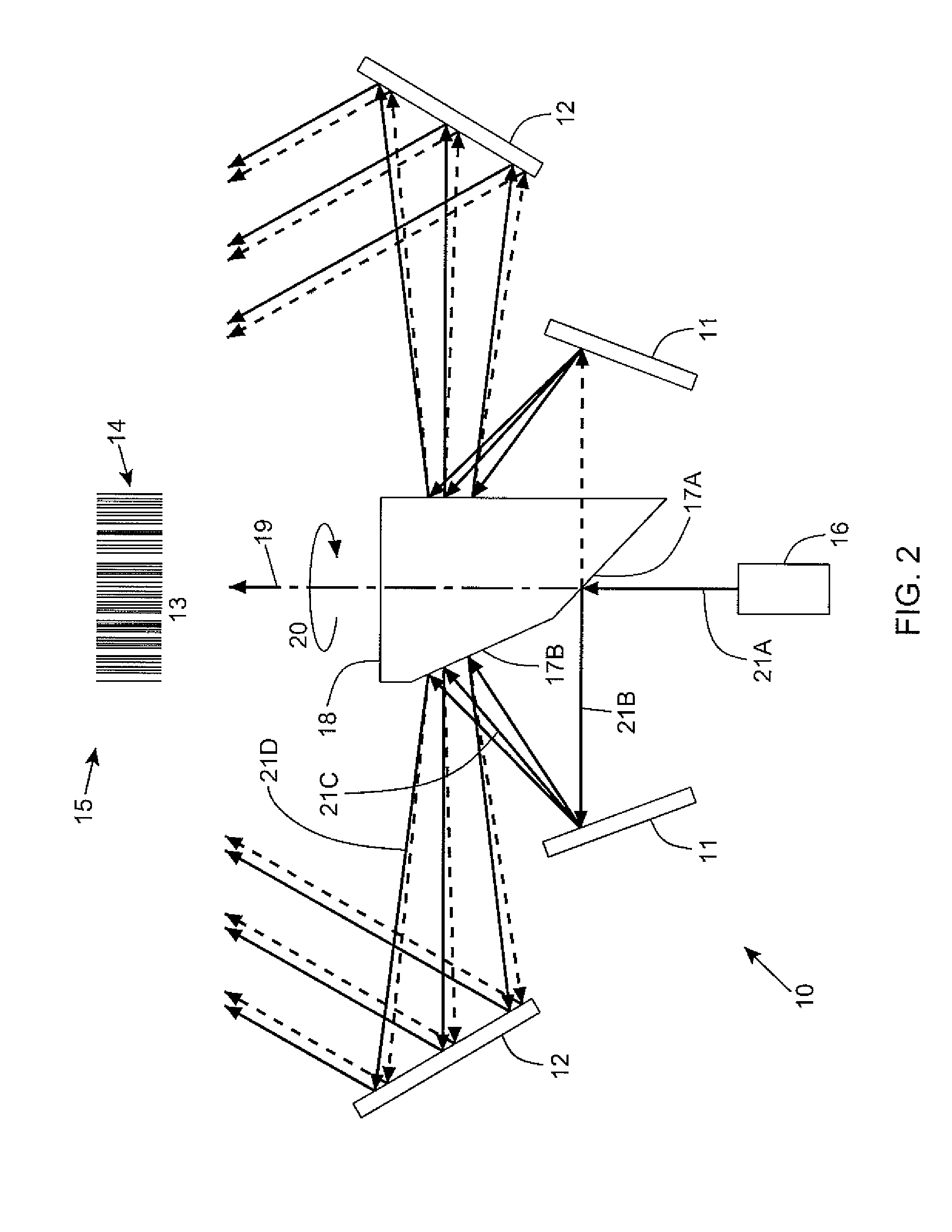

Laser scanning assembly having an improved scan angle-multiplication factor

InactiveUS8408469B2Increase multipleUniform collectionMirrorsBeam/ray focussing/reflecting arrangementsRotational axisAcute angle

A laser scanning system for generating a laser scanning pattern in a scanning field, while amplifying the scan-angle multiplication factor of rotating mirrors employed therein. The laser scanning system employs rotatable laser scanning assembly having an axis of rotation and first and second rotating mirrors with normal vectors that are coplanar with each other and said rotational axis, and which form an acute angle substantially less than 90 degrees so as to provide a laser scanning assembly with a scan angle multiplication factor that is greater than 2.0. A cluster of stationary mirrors mounted about the first and second rotating mirrors, for sweeping a laser beam off the cluster of stationary mirrors after a laser beam has been reflected off the first rotating mirror, then reflected off the second rotating mirror, and then directed outwardly towards an array of pattern mirrors, so as to generate a resultant laser scanning pattern within the scanning field.

Owner:METROLOGIC INSTR INC

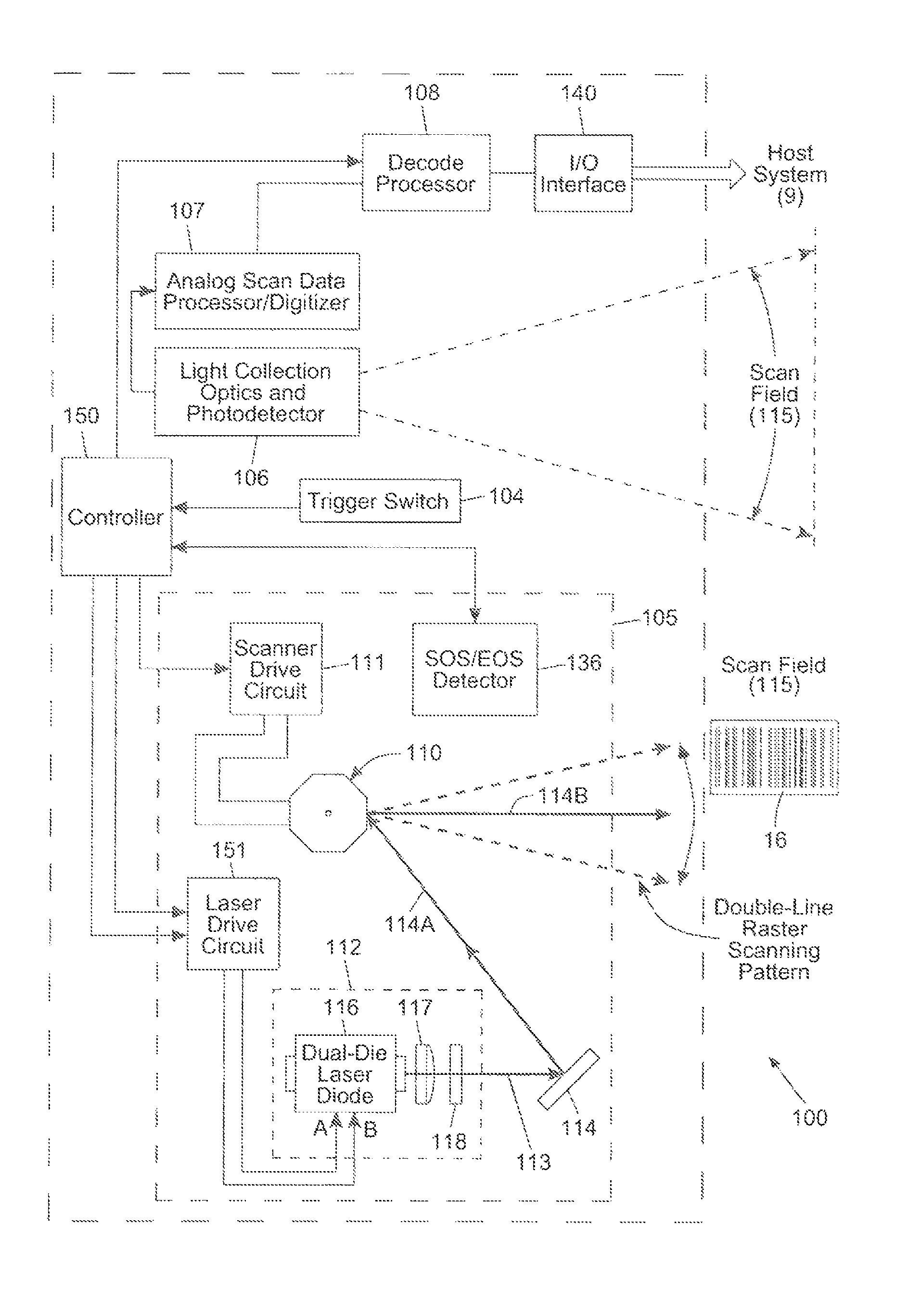

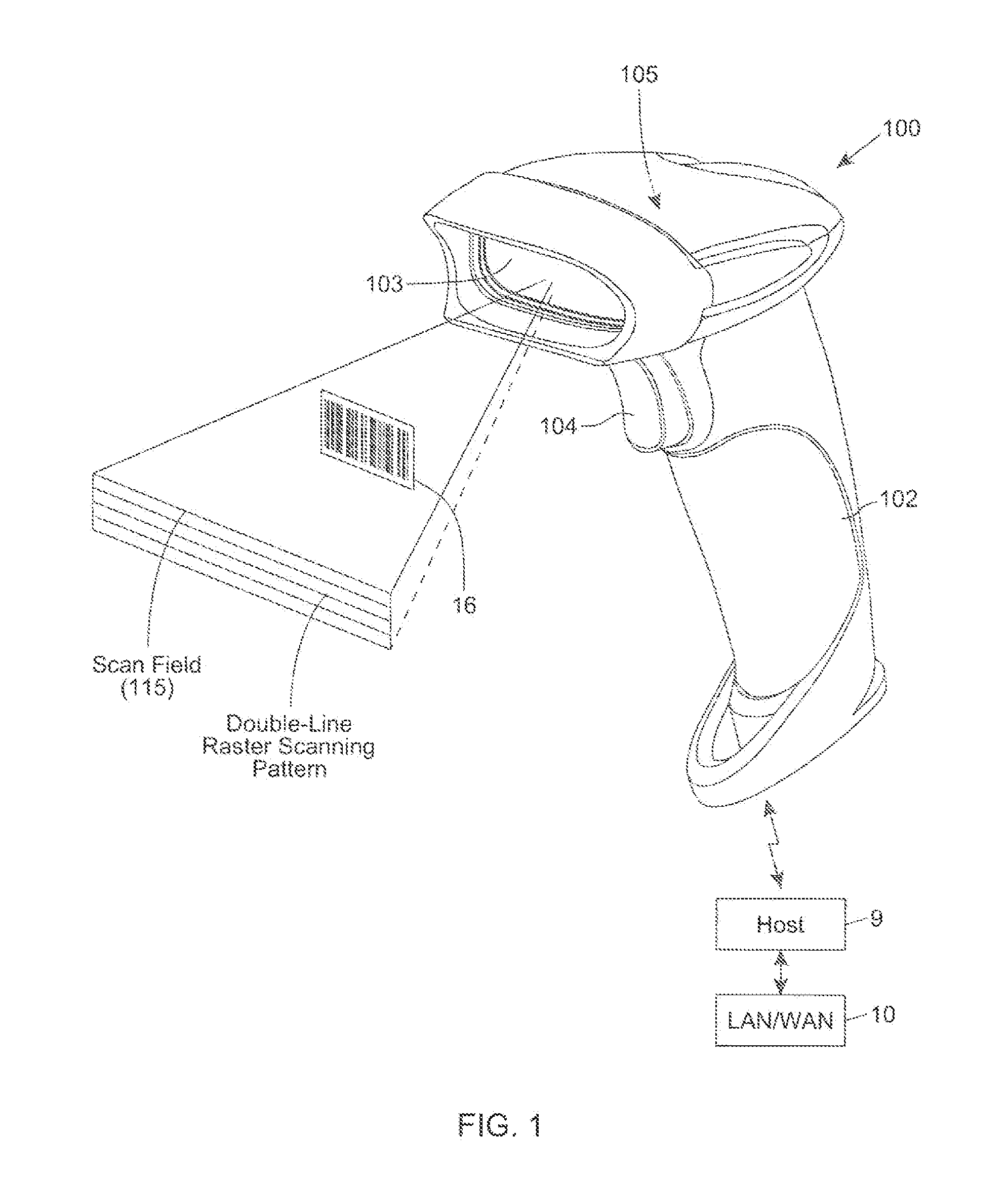

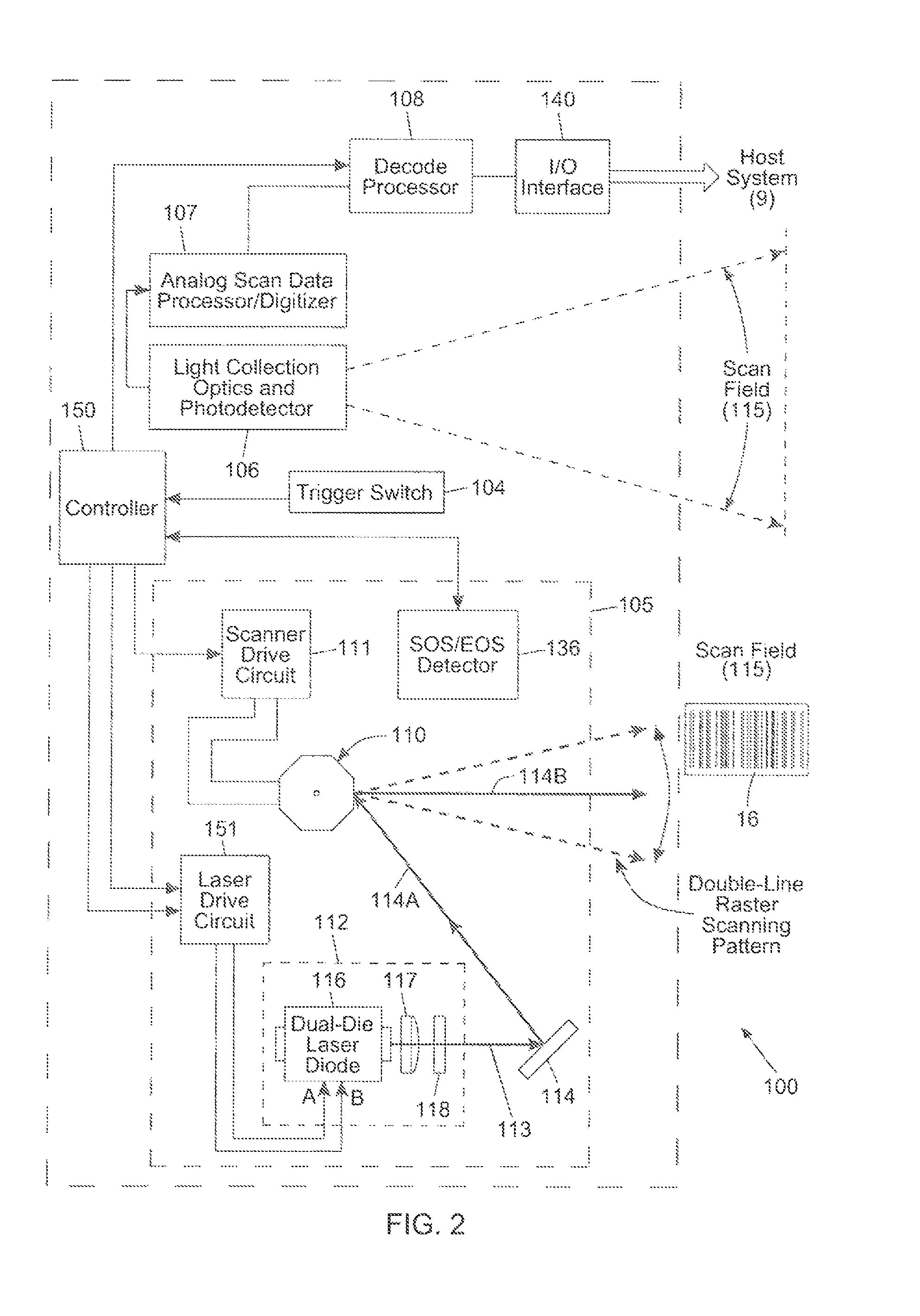

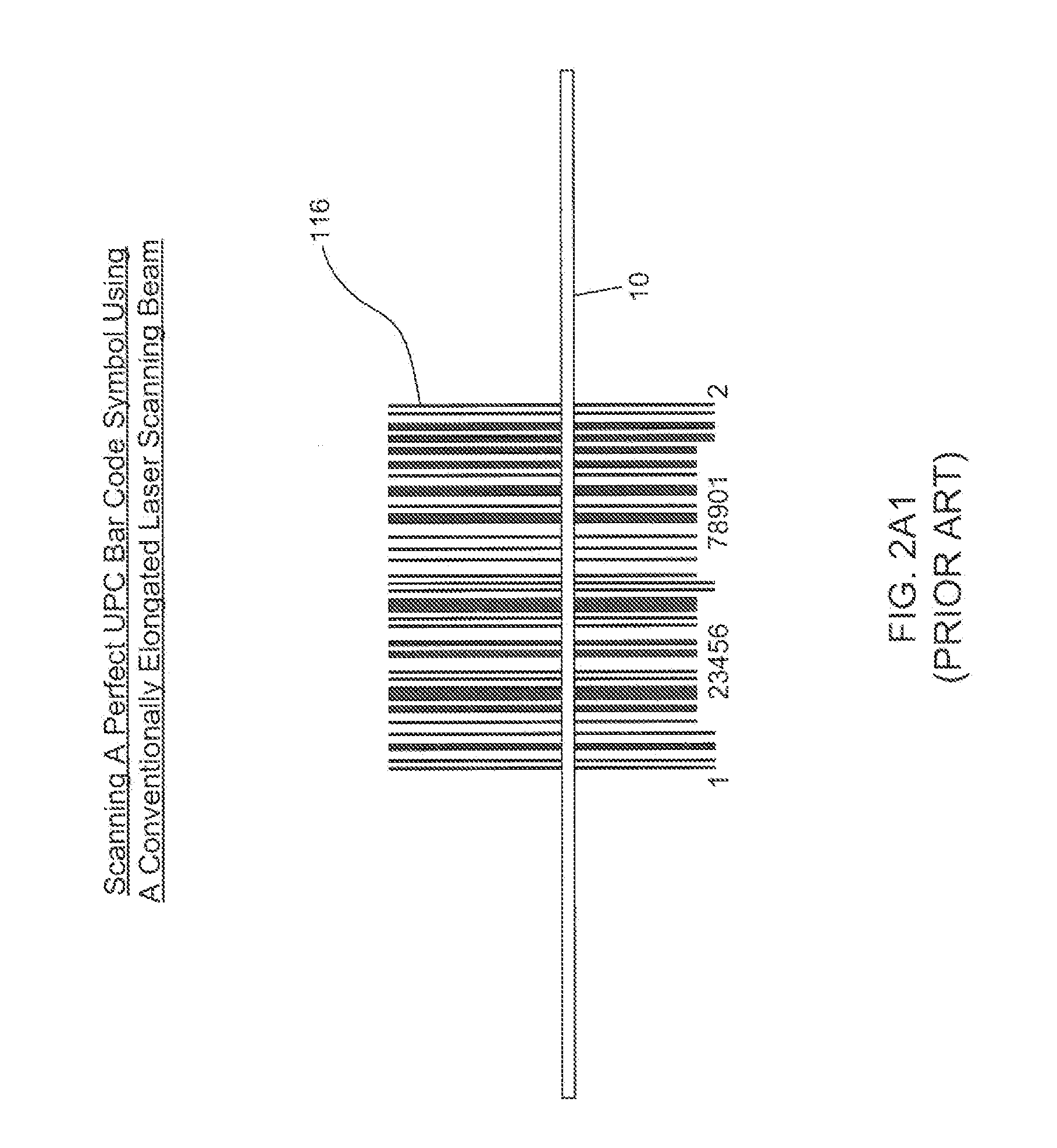

Method of and apparatus for multiplying raster scanning lines by modulating a multi-cavity laser diode

ActiveUS8678285B2Improve featuresHigh densityCharacter and pattern recognitionSensing by electromagnetic radiationGratingLaser scanning

A method of and apparatus for generating a multiple raster-type scanning pattern by modulating a multi-cavity laser diode in such a way that it sequentially generates different laser beams synchronously during different laser scanning cycles, while the output laser beams are directed incident upon a rotating polygonal laser scanning element. The system does not require additional moving parts beyond the rotating polygon scanning element so as to reduce complexity and simplify construction of the laser scanning mechanism.

Owner:METROLOGIC INSTR INC

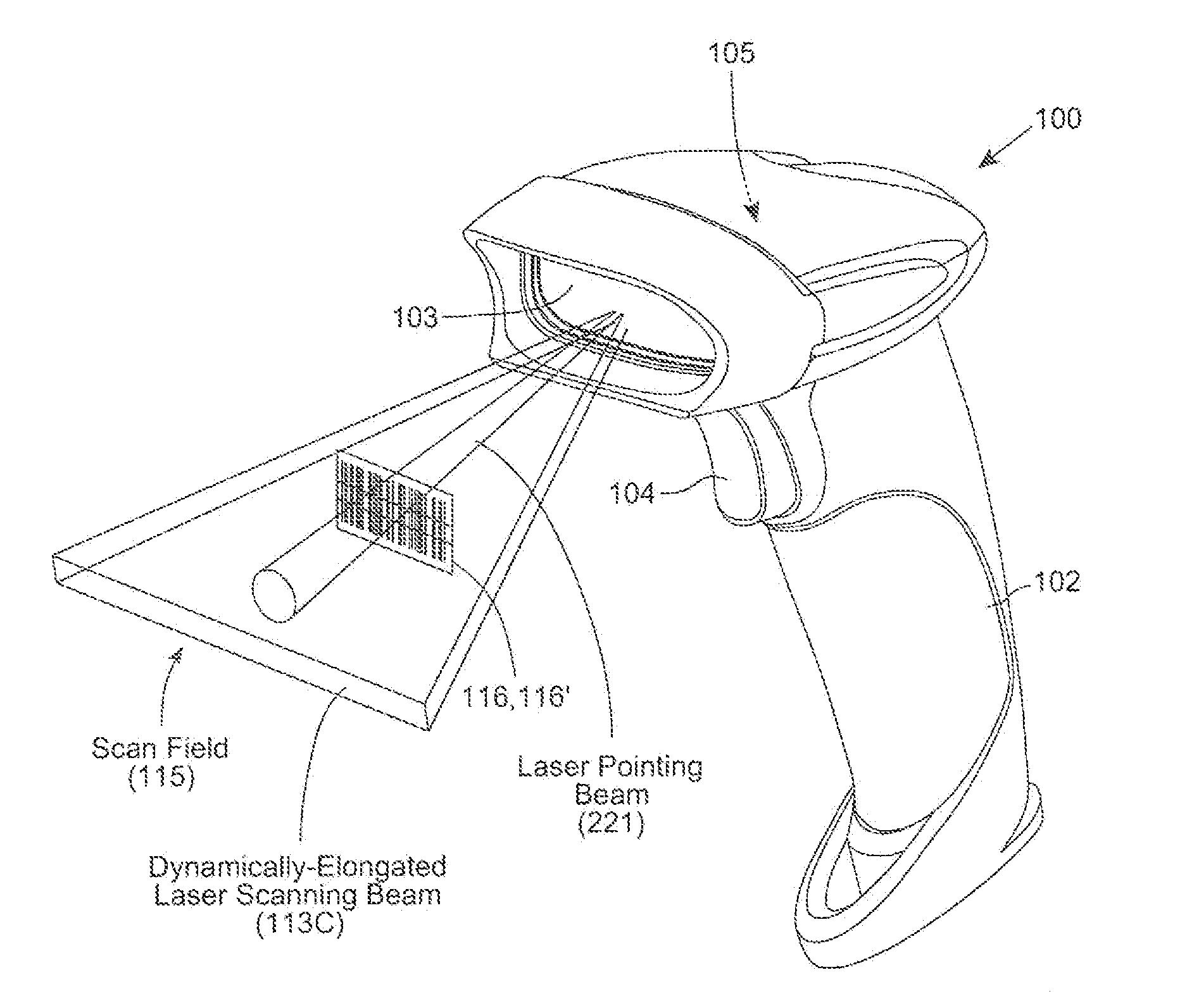

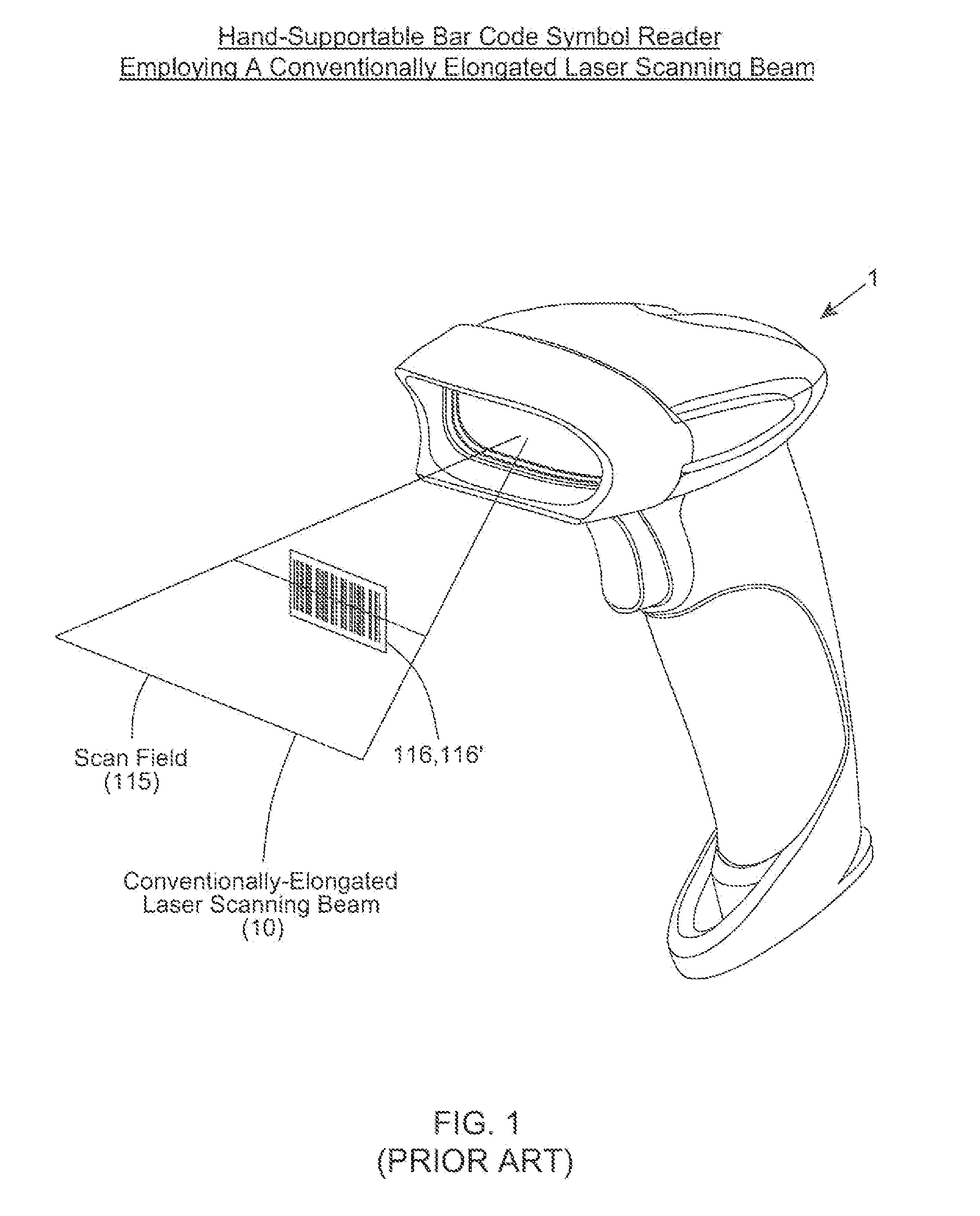

Code symbol reading system employing dynamically-elongated laser scanning beams for improved levels of performance

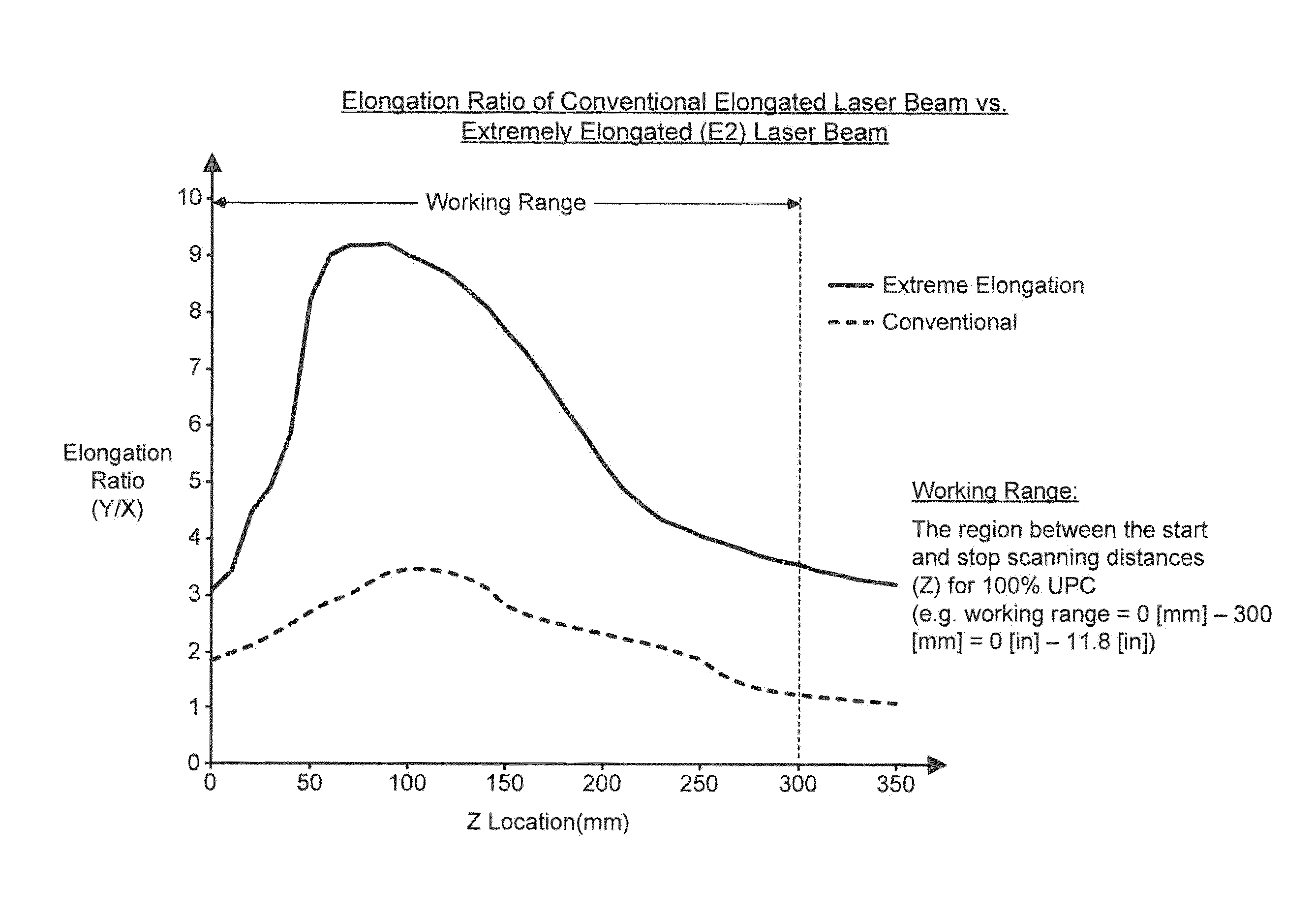

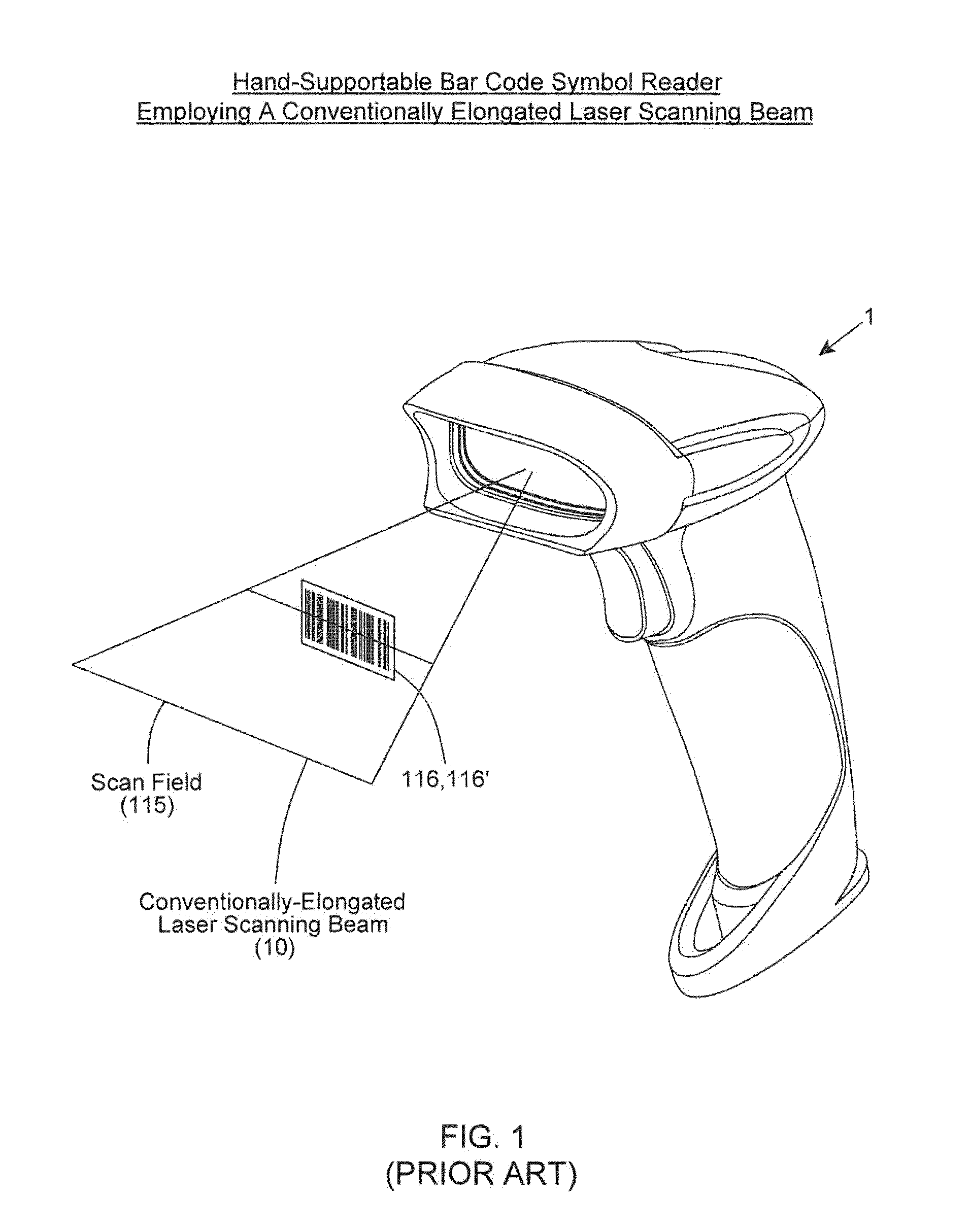

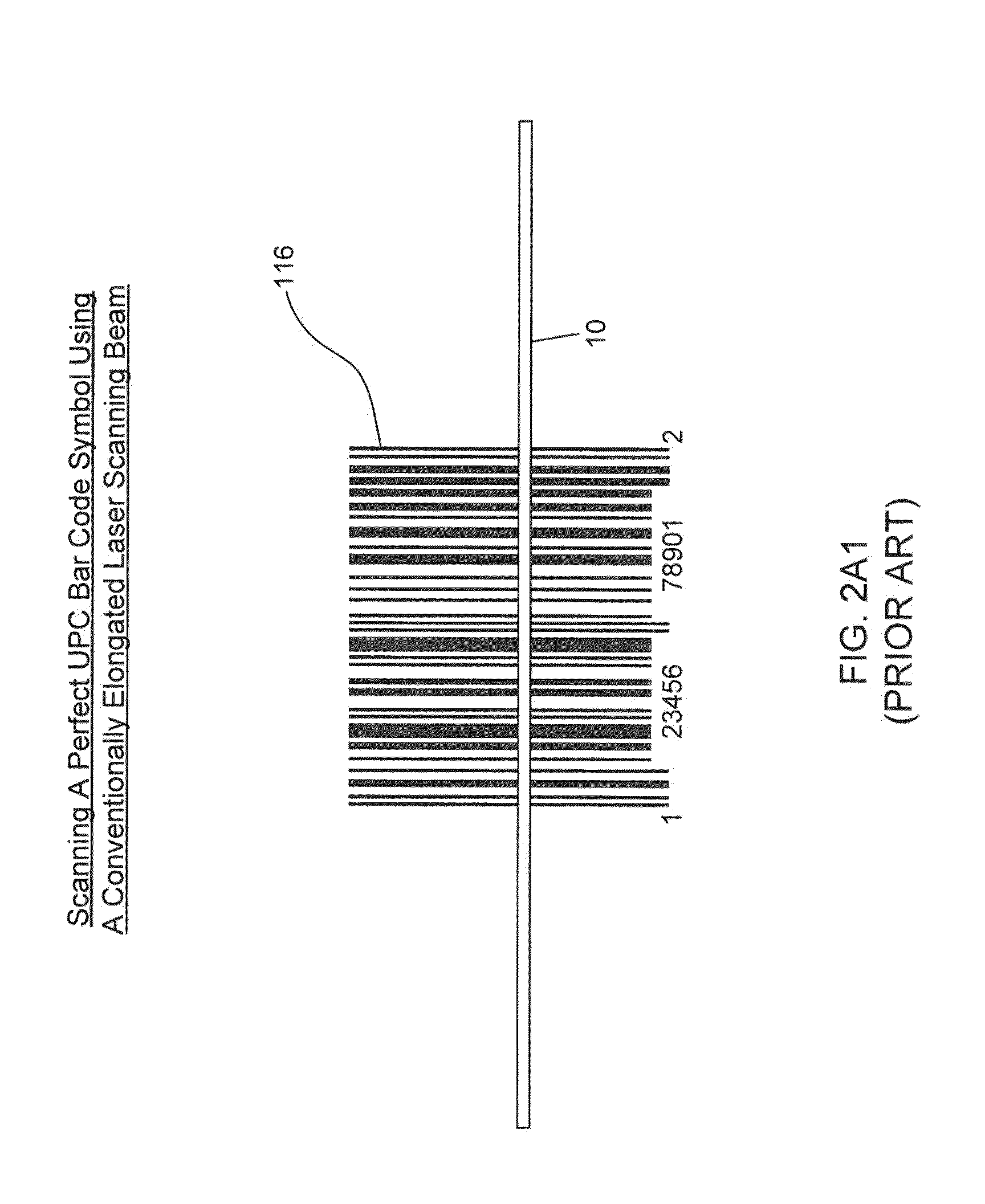

InactiveUS20130043312A1Improve signal-to-noise ratioAverage out defectsCharacter and pattern recognitionSensing by electromagnetic radiationLight beamLaser scanning

A laser scanning bar code symbol reading system for scanning and reading poor quality and damaged bar code symbols in flexible operating conditions. The system includes a housing having a light transmission window; a dynamically-elongated laser beam production module, including a multi-cavity visible laser diode (VLD), for producing a dynamically-elongated laser beam having (i) a direction of propagation extending along a z reference direction, (ii) a height dimension being indicated by the y reference direction, and (iii) a width dimension being indicated by the x reference direction, where x, y and z directions are orthogonal to each other. Each dynamically-elongated laser beam is characterized by an elongation ratio (ER) that is defined as Y / X where, for any point within the working range of the laser scanning bar code symbol reading system, extending along the z direction, (i) Y indicates the beam height of the dynamically-elongated laser beam measured in the Y reference direction, (ii) X indicates the beam width of the dynamically-elongated laser beam measured in the X reference direction, and (iii) the beam height (Y) and the laser beam width (X) are measured at 1 / e2 intensity clip level. A laser scanning mechanism is provided for scanning the dynamically-elongated laser beam out the light transmission window and across a scanning field defined external to the housing, in which a bar code symbol is present for scanning by the dynamically-elongated laser scanning beam.

Owner:METROLOGIC INSTR

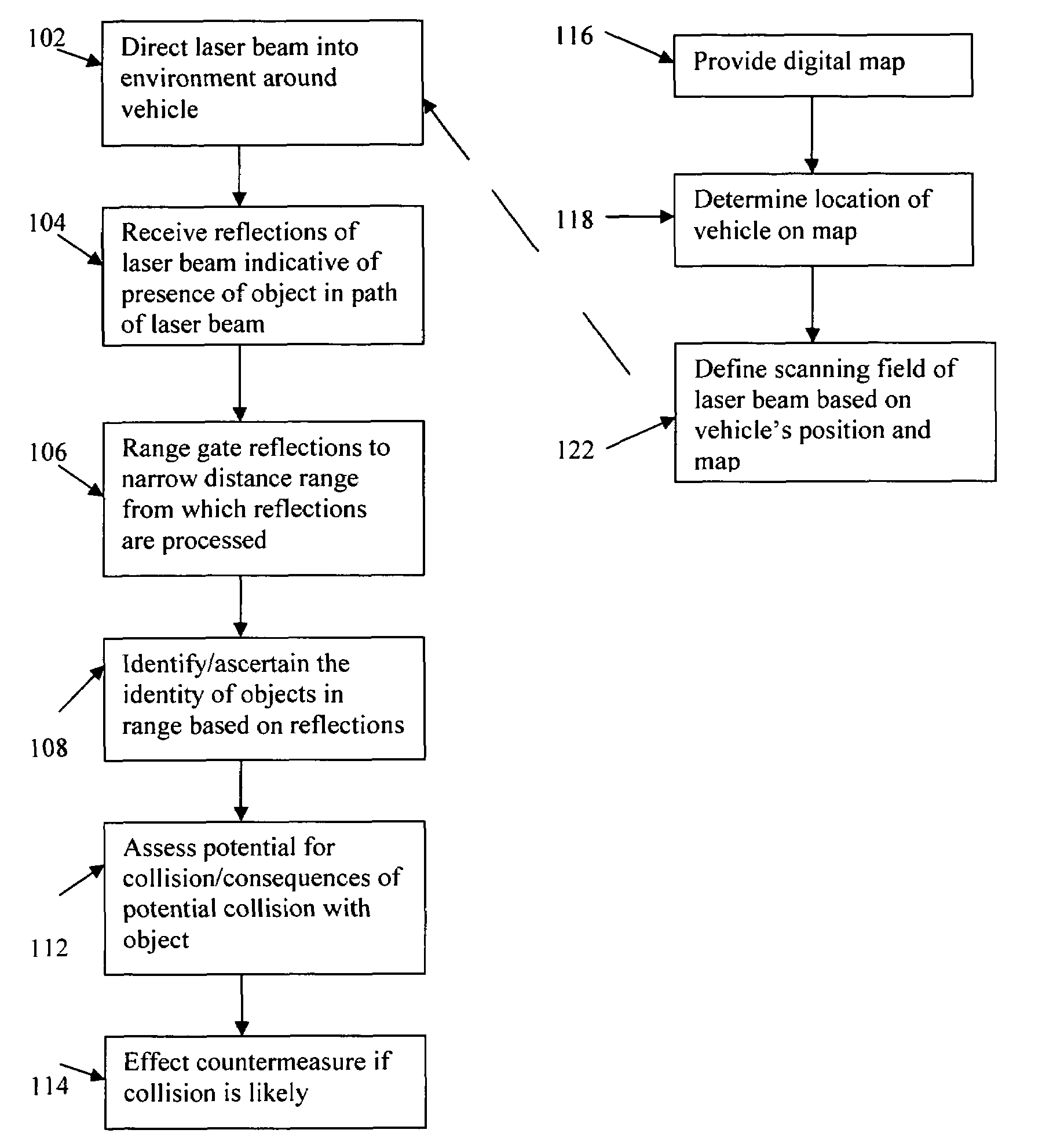

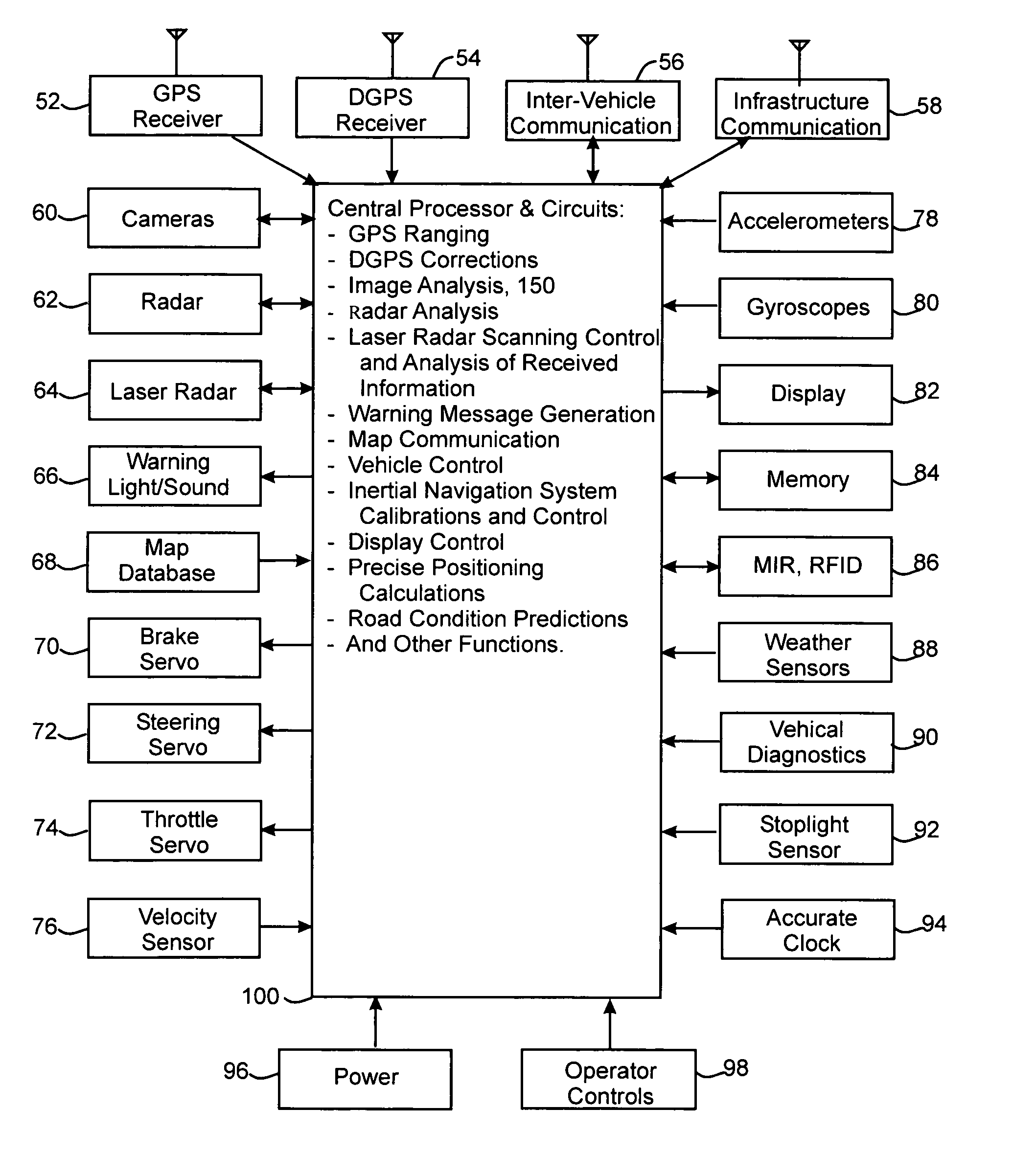

Method and system for detecting objects external to a vehicle

InactiveUS7202776B2Avoid collisionVehicle seatsInstruments for road network navigationRange gateLaser beams

Method and system for obtaining information about objects in the environment outside of and around a vehicle and preventing collisions involving the vehicle includes directing a laser beam from the vehicle into the environment, receiving from an object in the path of the laser beam a reflection of the laser beam at a location on the vehicle, and analyzing the received laser beam reflections to obtain information about the object from which the laser beam is being reflected. Analysis of the laser beam reflections preferably entails range gating the received laser beam reflections to limit analysis of the received laser beam reflections to only those received from an object within a defined (distance) range such that objects at distances within the range are isolated from surrounding objects.

Owner:AMERICAN VEHICULAR SCI

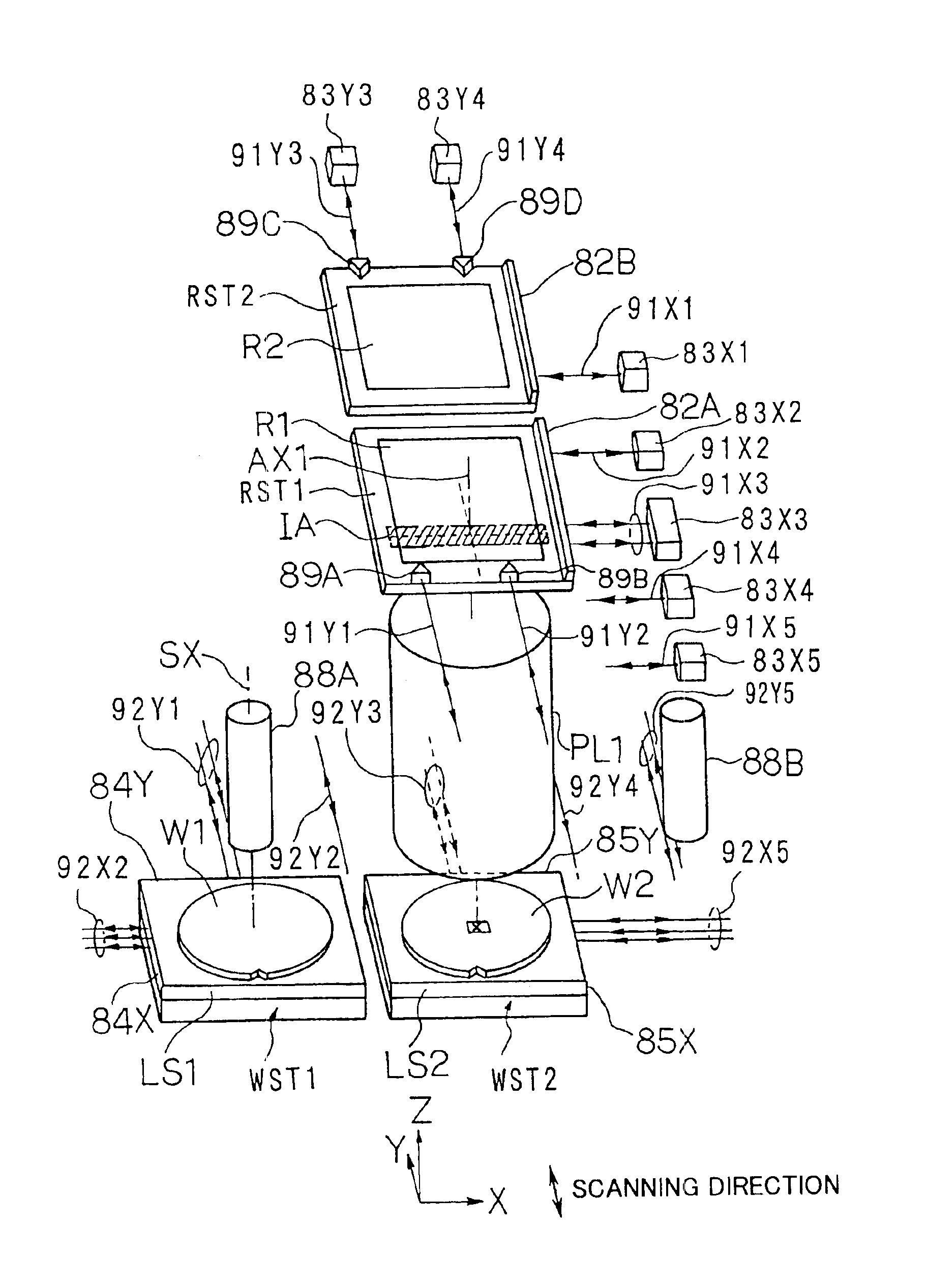

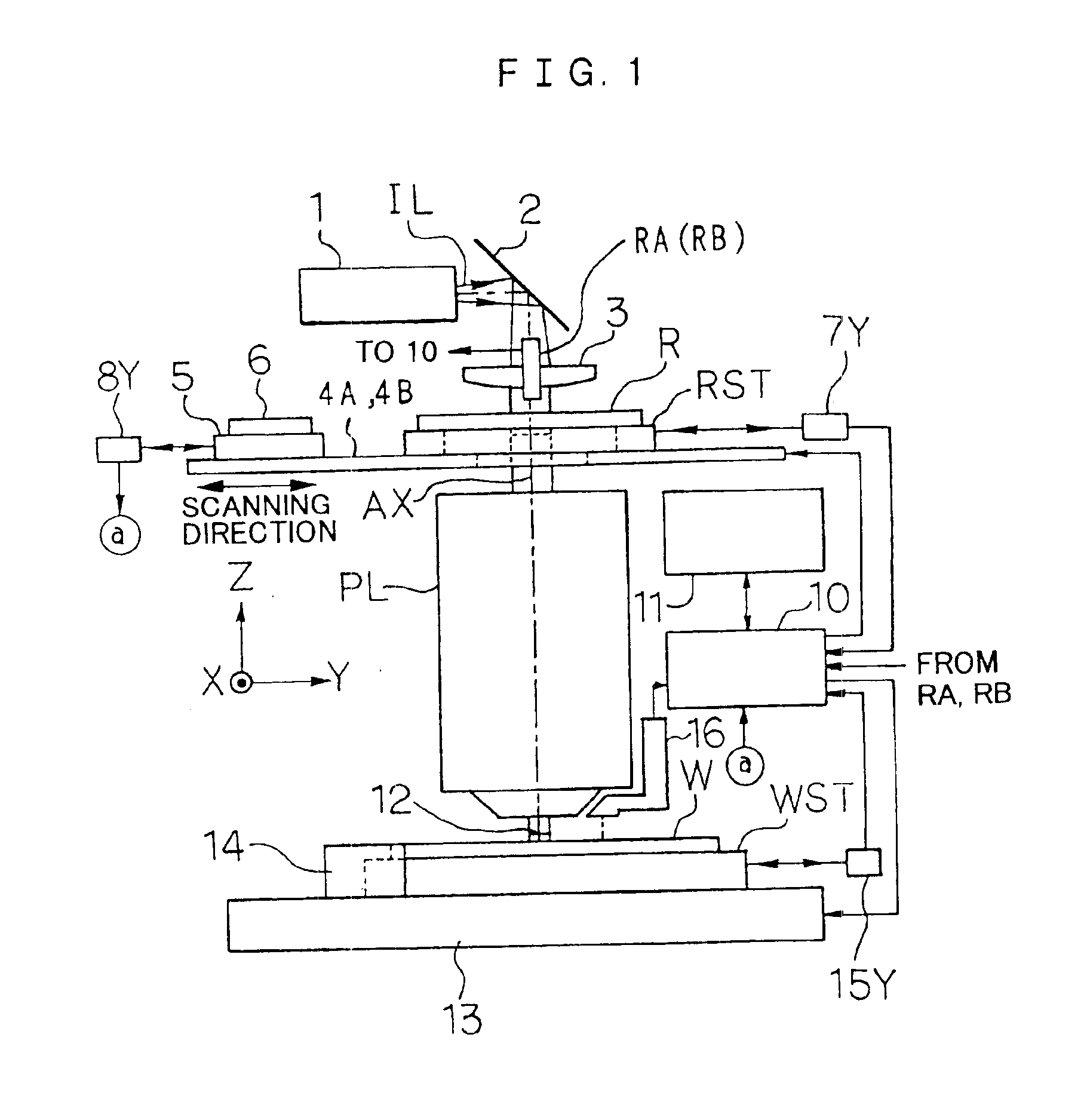

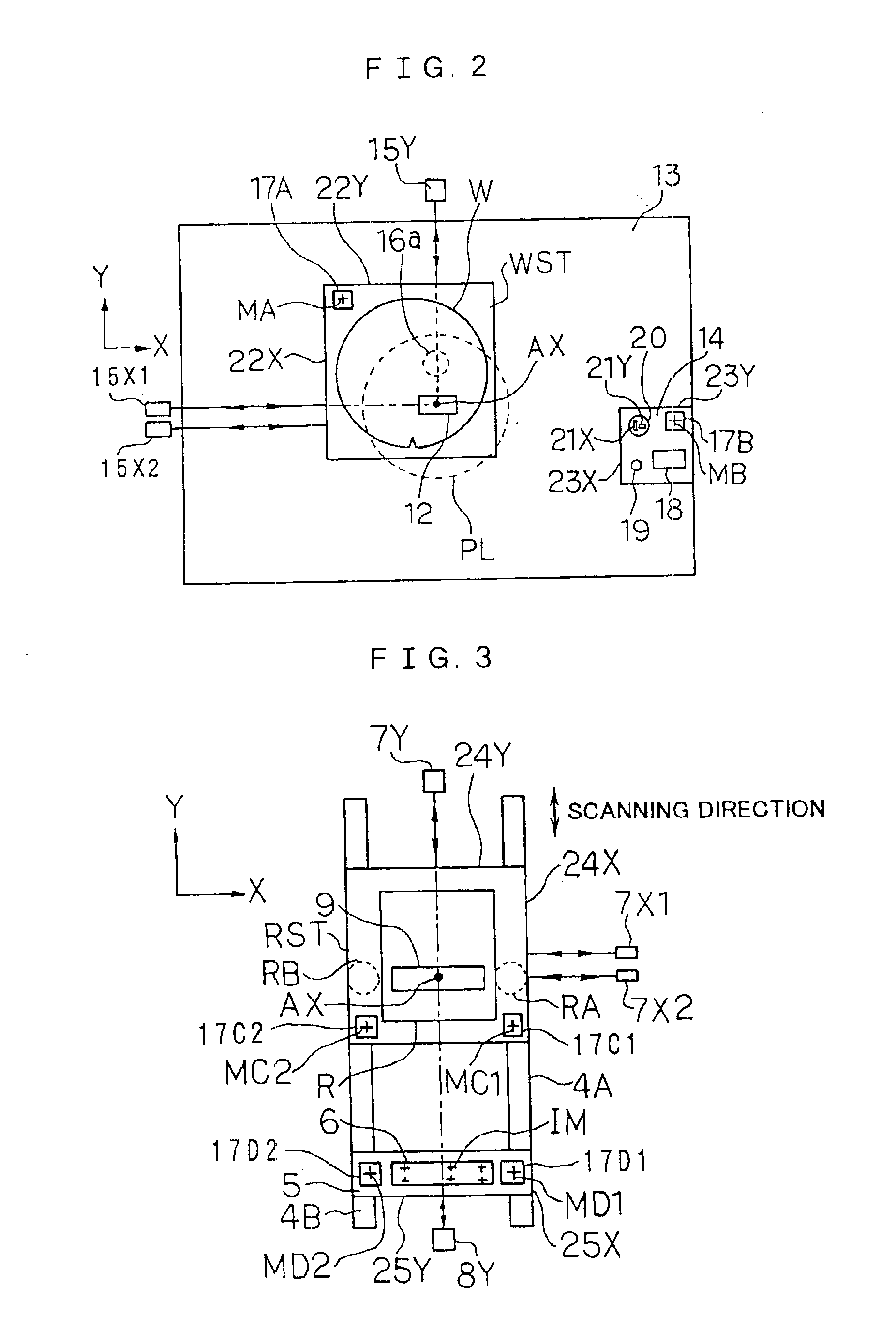

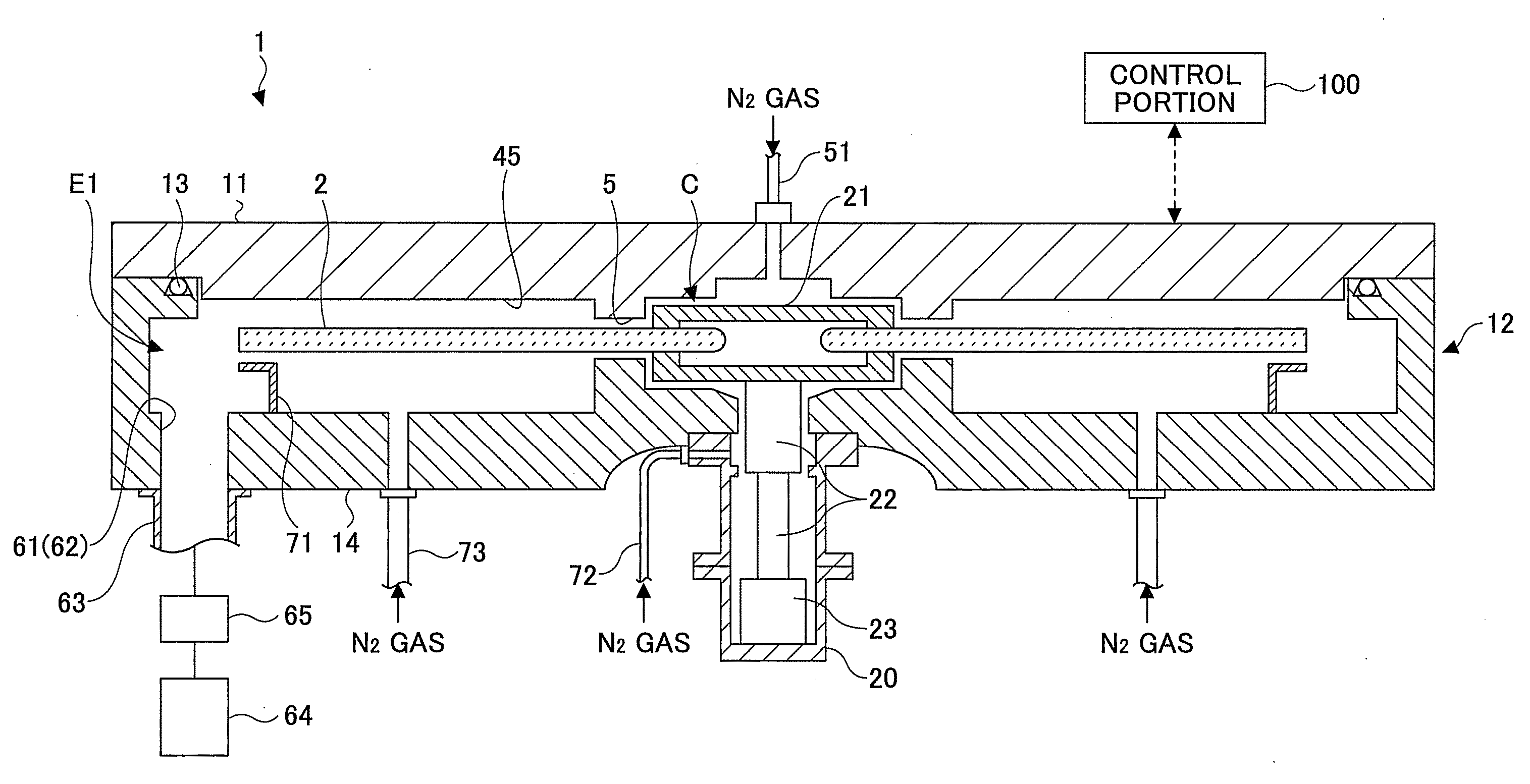

Stage device and exposure apparatus

InactiveUS6897963B1Increase speedImprove throughputSemiconductor/solid-state device manufacturingUsing optical meansLaser beamsSemiconductor

A stage device suitable for exposure apparatus used to produce semiconductor devices, is movable in an area wider than the measurement area of interferometer for position measurement, and is capable of measuring the position with high precision. When a movable stage moves from the position where the laser beams from laser interferometers are not applied into the measurement area of the laser interferometer, the position of reference mark is measured by a wafer alignment sensor, and the measurement value measured by the laser interferometer is corrected based on the results of the measurement by the wafer alignment sensor. When another movable stage enters the measurement area of the laser interferometer, the position of the reference mark is similarly measured by a wafer alignment sensor, and the measurement value measured by the laser interferometer is corrected based on the results of the measurement by the wafer alignment sensor.

Owner:NIKON CORP

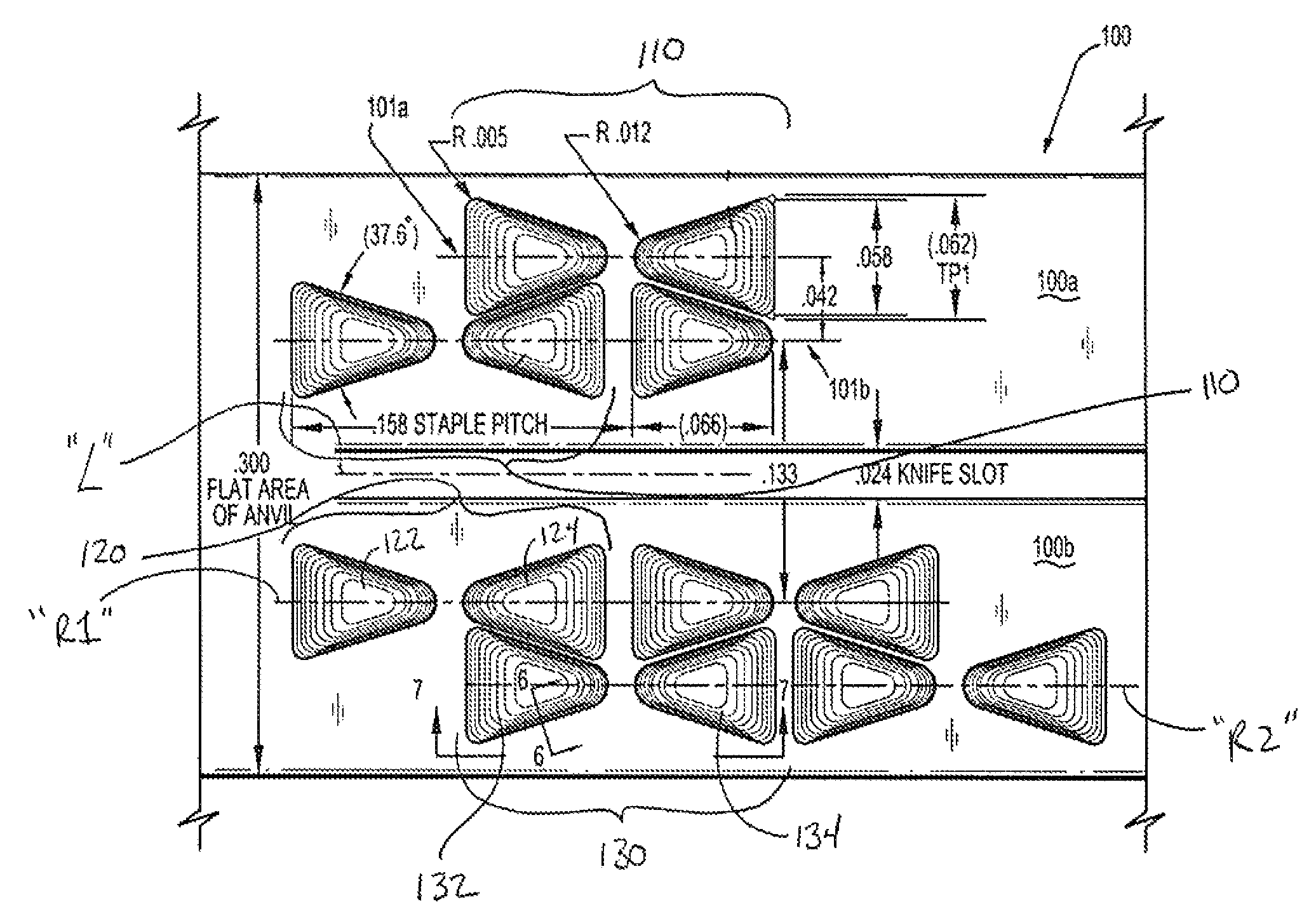

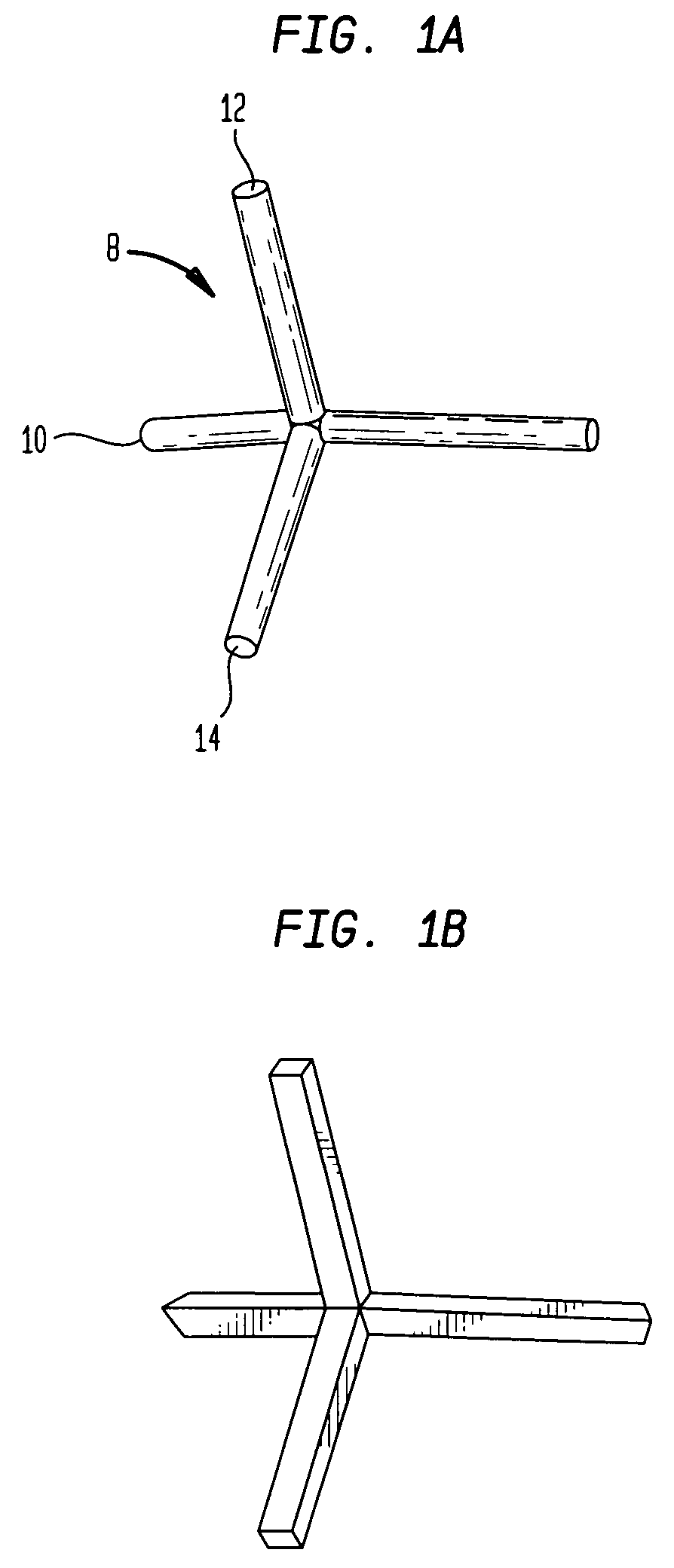

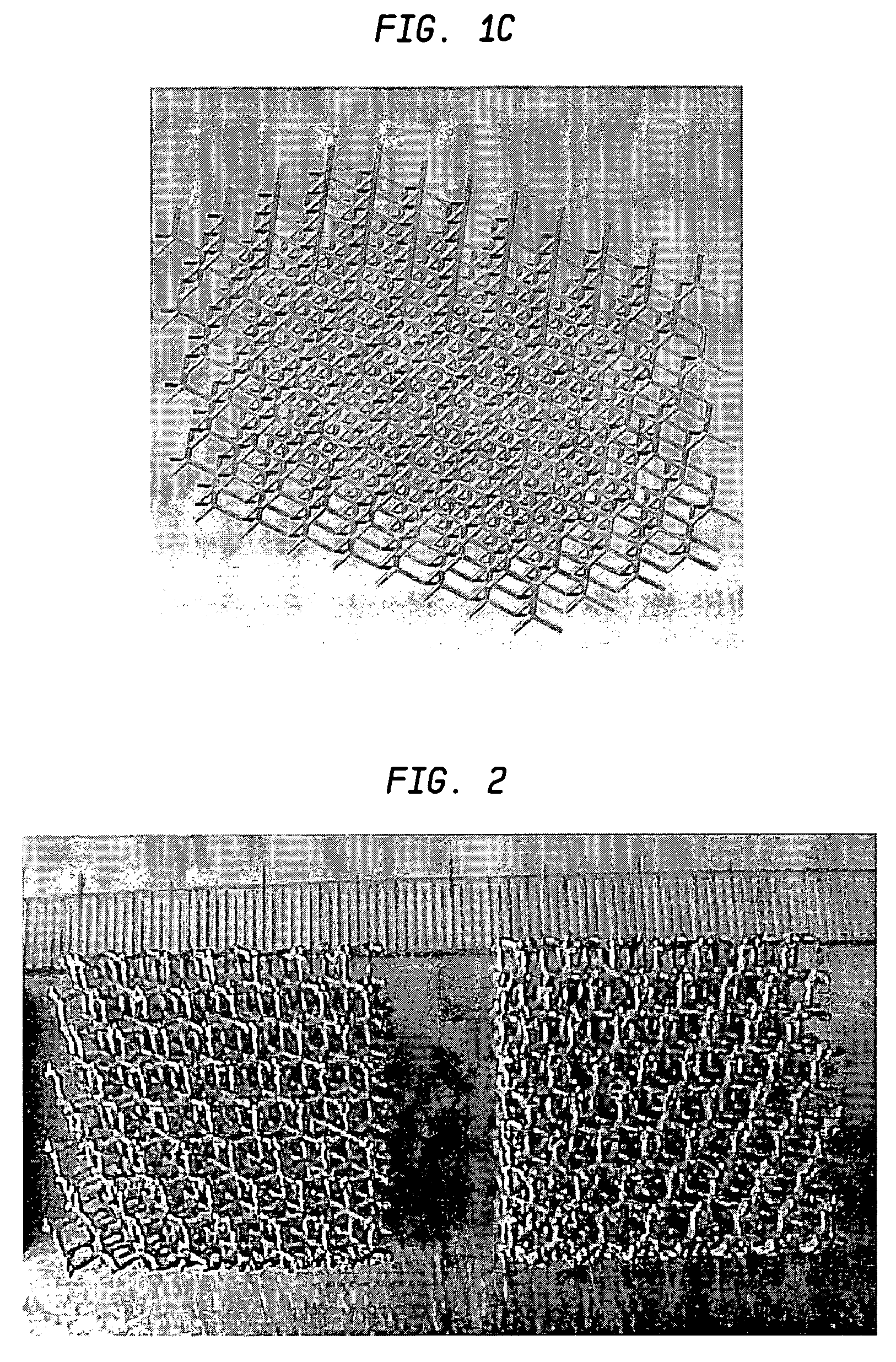

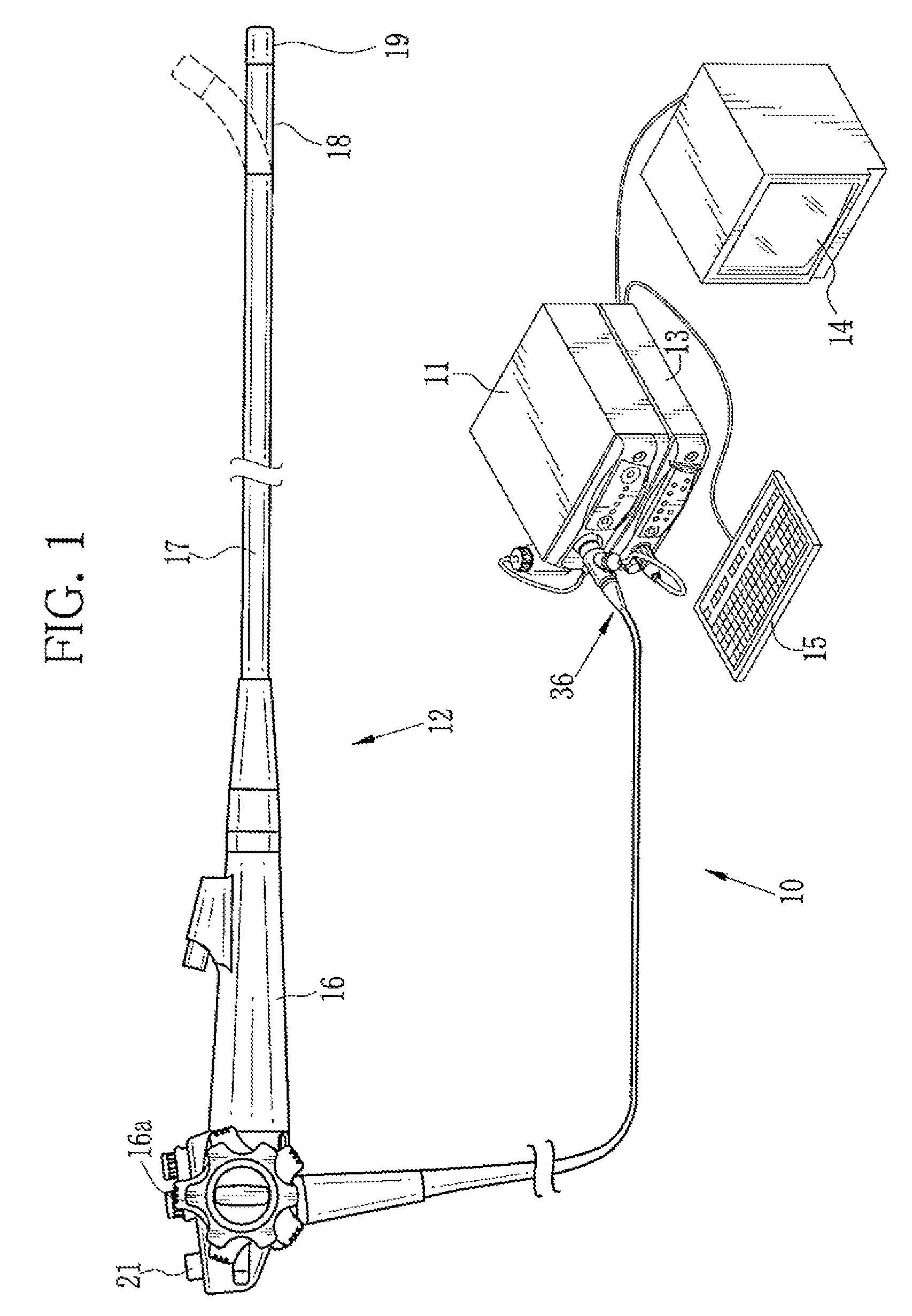

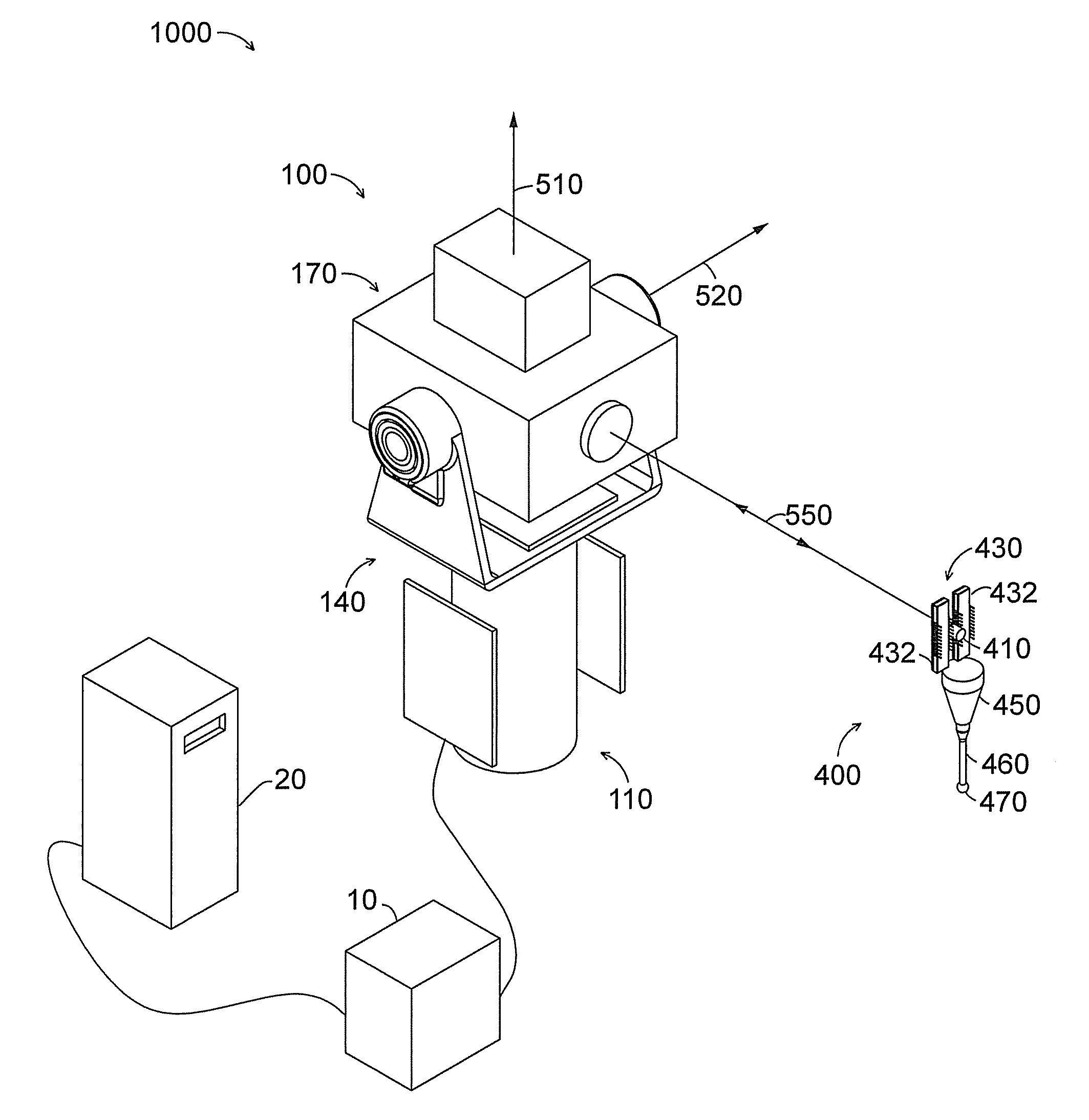

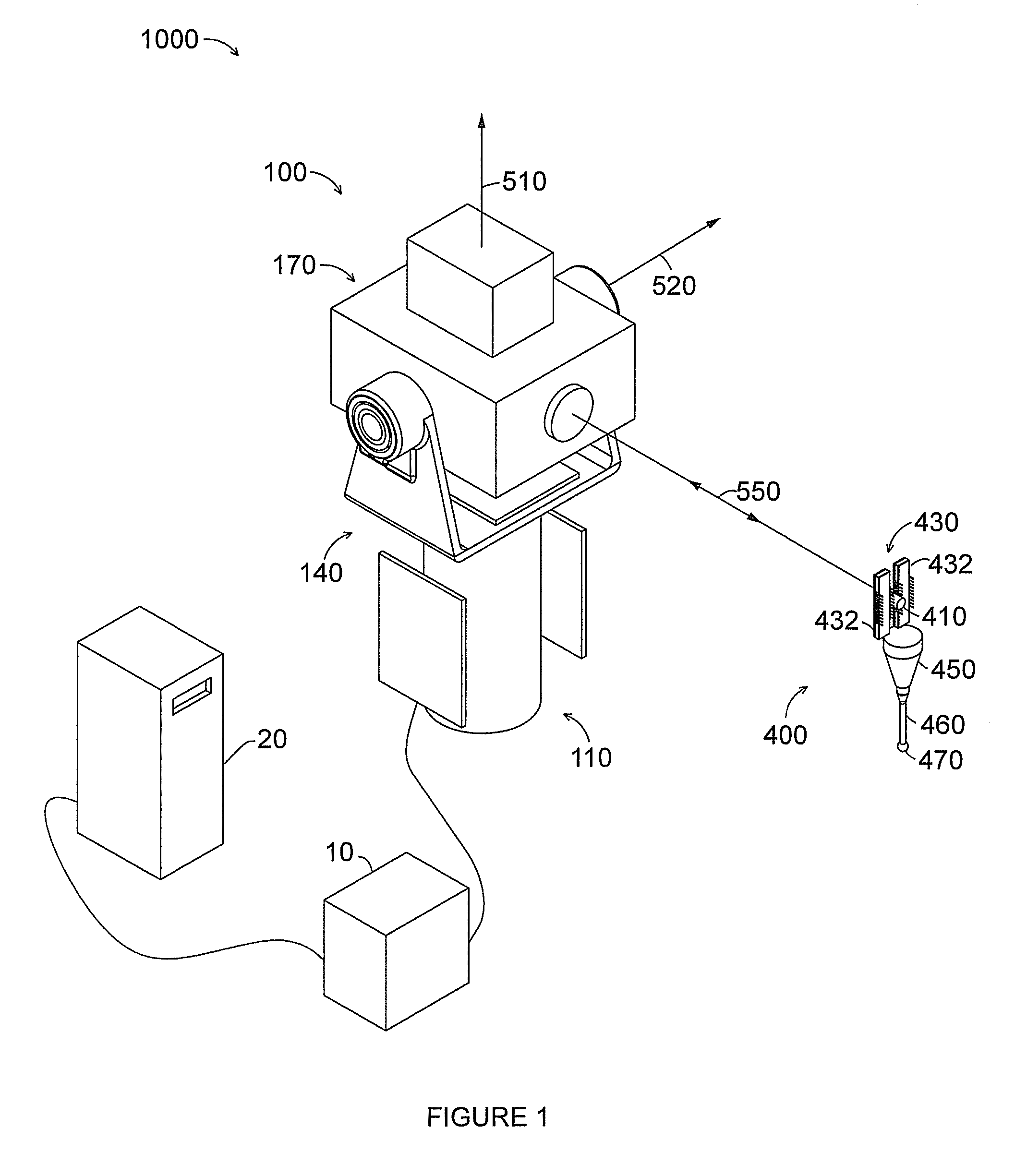

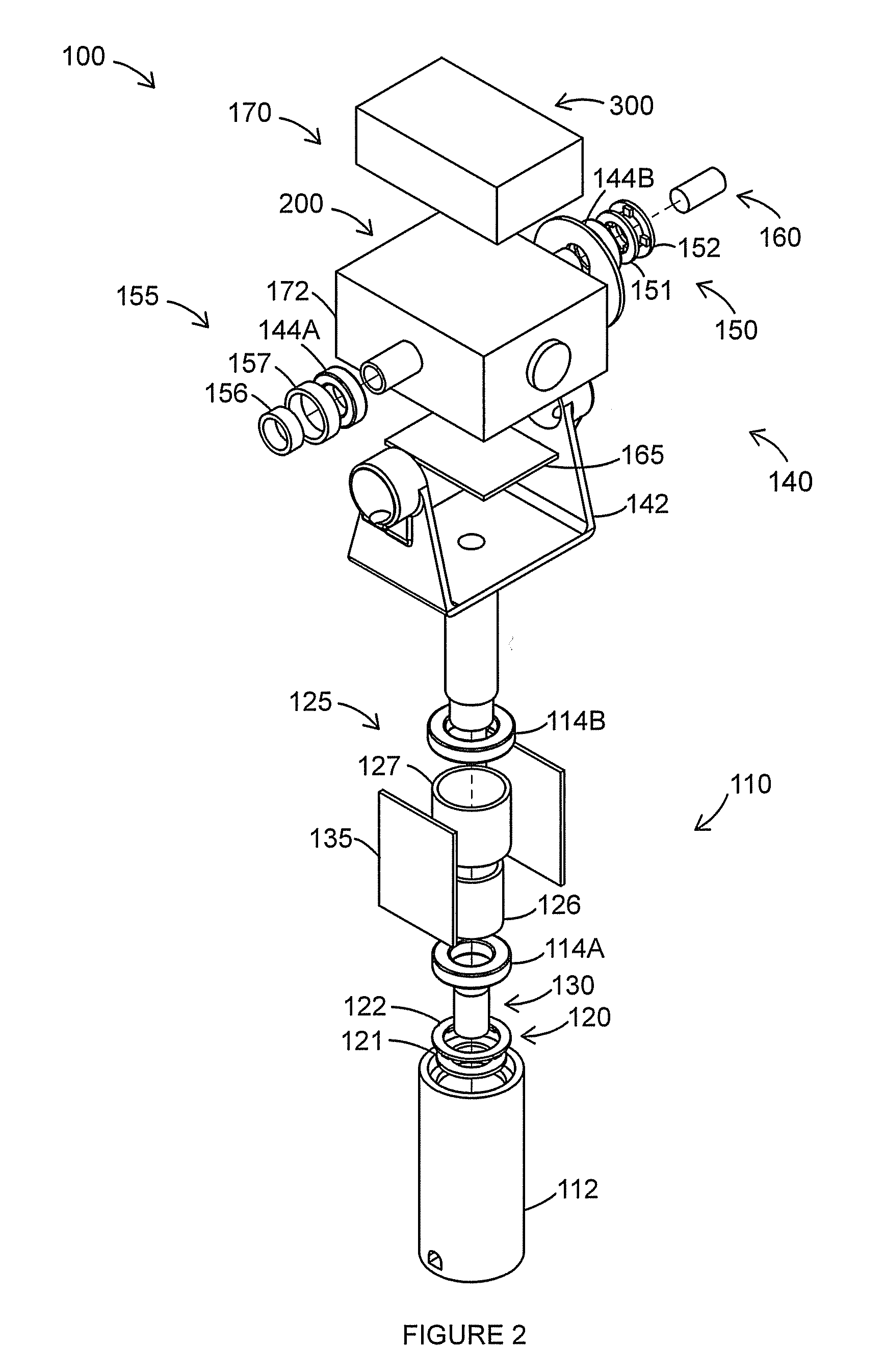

Method for forming staple pockets of a surgical stapler

A system and method for forming a staple pocket, e.g., on the anvil portion of a surgical stapler device. A laser-machining system may include a laser-emitting device that is configured to emit a laser beam or beams for forming staple pockets on the anvil of a surgical stapler. The staple pockets of an anvil may be formed successively or simultaneously. The anvil of the surgical stapler is mounted in a mounting mechanism so as to control its movement, and the laser-emitting device is controlled by a control module, which may control any aspect of the laser-machining operation, e.g., the intensity of the laser beam, the movement of the laser-emitting device relative to the anvil, etc. The control module may be a processor that includes software that provides instructions for the operation of the control module, and may be programmable by a user for inputting parameters, e.g., shape, arrangement, etc., corresponding to the staple pockets.

Owner:TYCO HEALTHCARE GRP LP

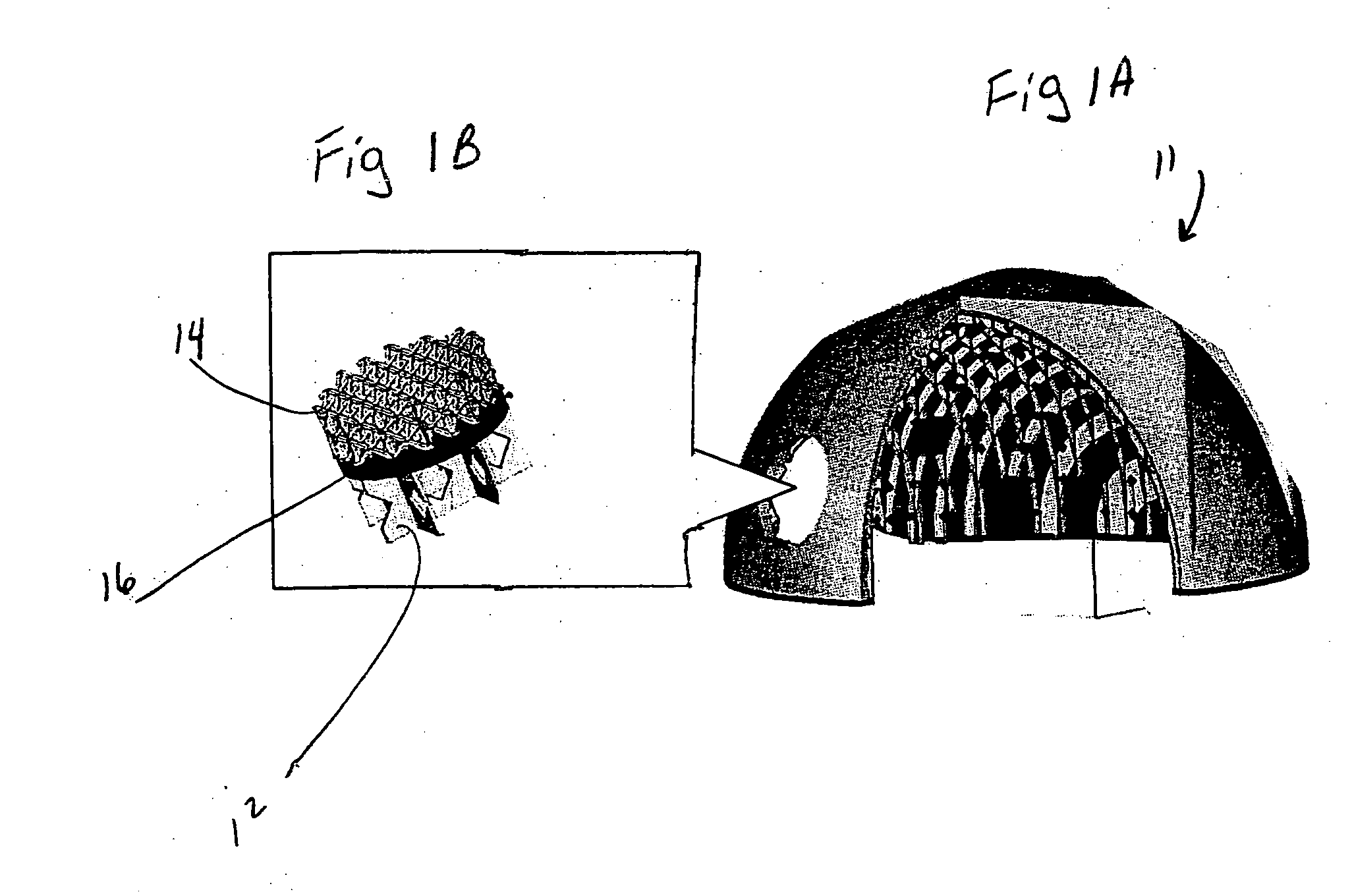

Laser-produced porous structure

The present invention disclosed a method of producing a three-dimensional porous tissue in-growth structure. The method includes the steps of depositing a first layer of metal powder and scanning the first layer of metal powder with a laser beam to form a portion of a plurality of predetermined unit cells. Depositing at least one additional layer of metal powder onto a previous layer and repeating the step of scanning a laser beam for at least one of the additional layers in order to continuing forming the predetermined unit cells. The method further includes continuing the depositing and scanning steps to form a medical implant.

Owner:UNIV OF LIVERPOOL +1

Surgical tools for laser marking and laser cutting

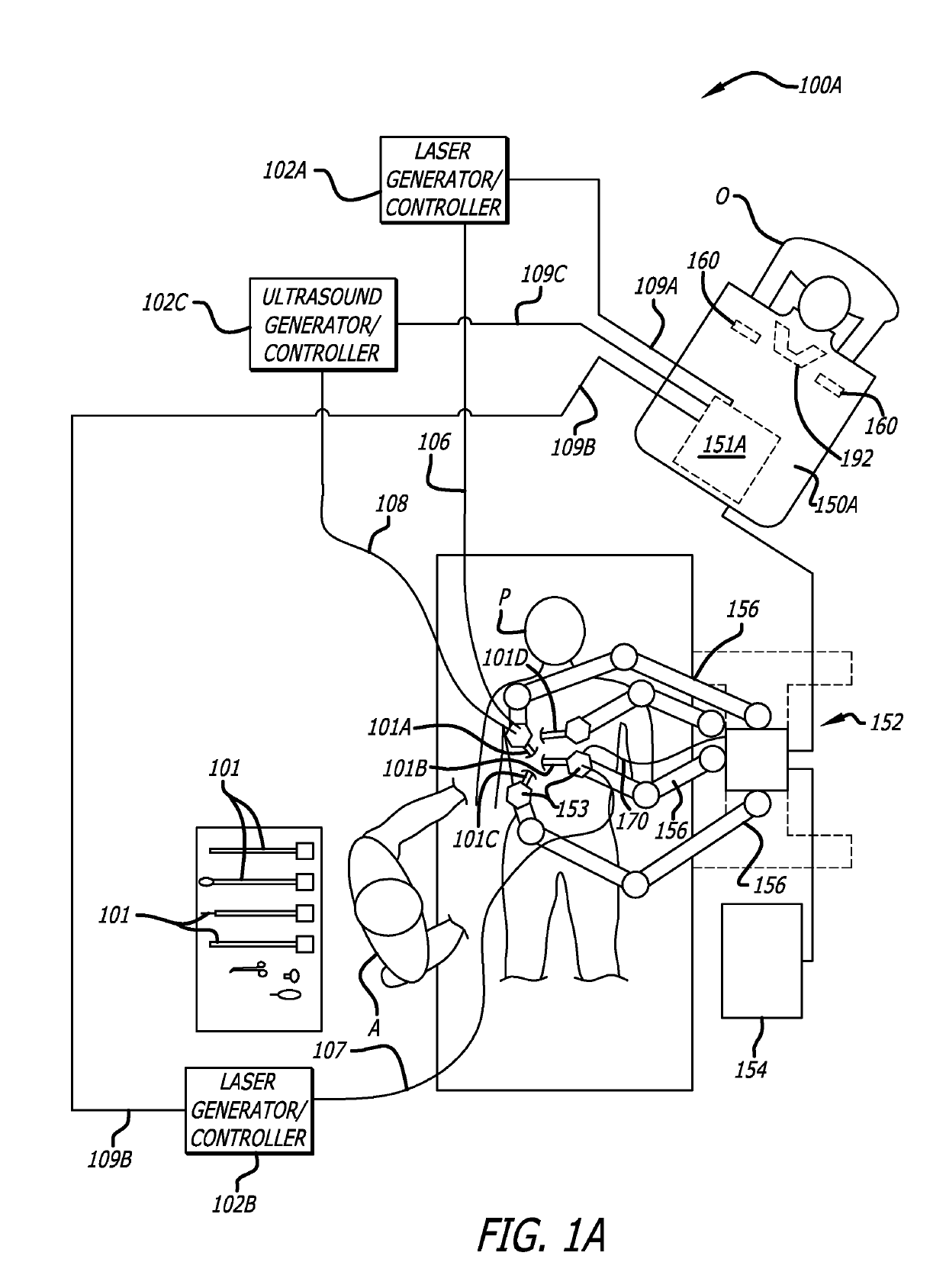

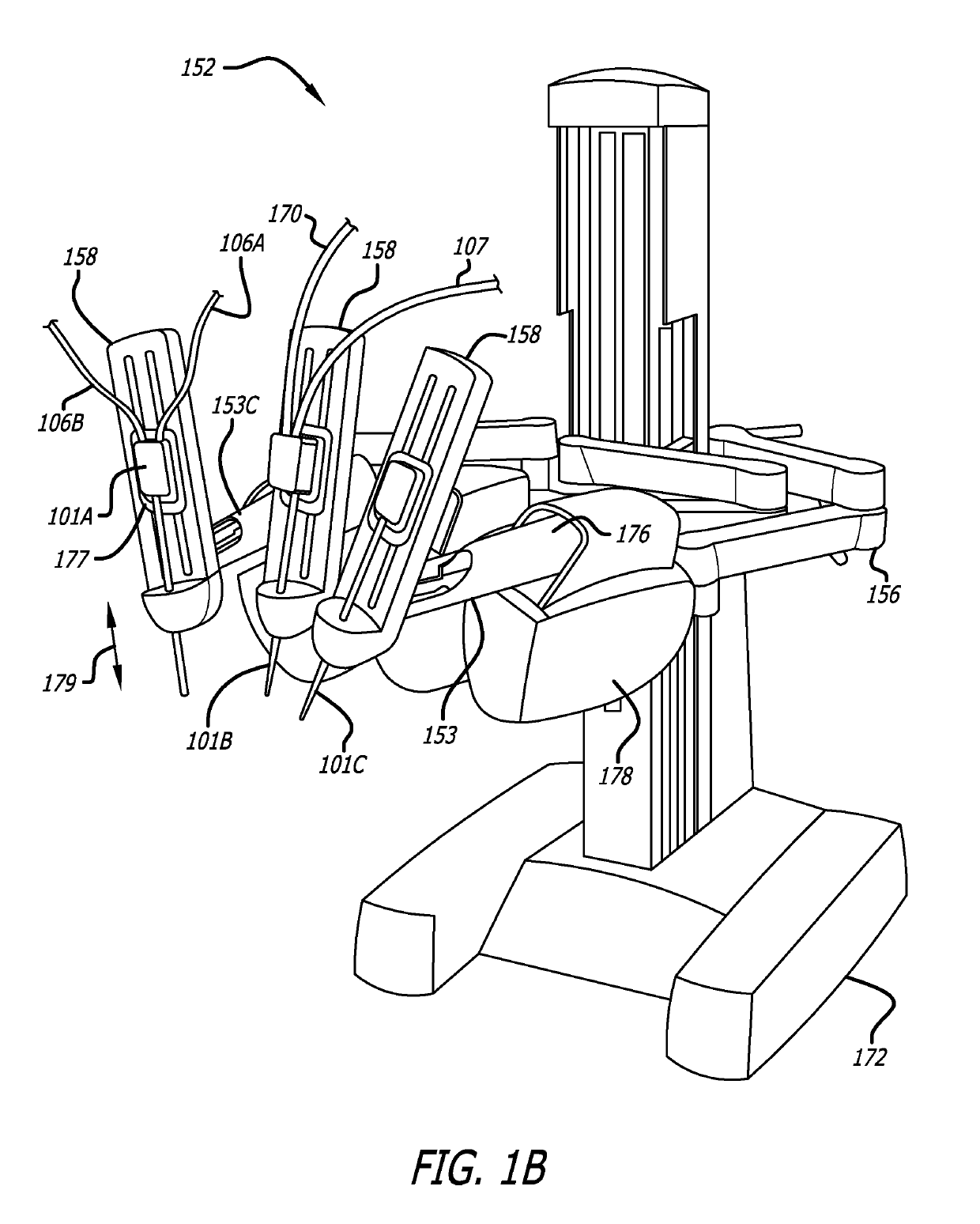

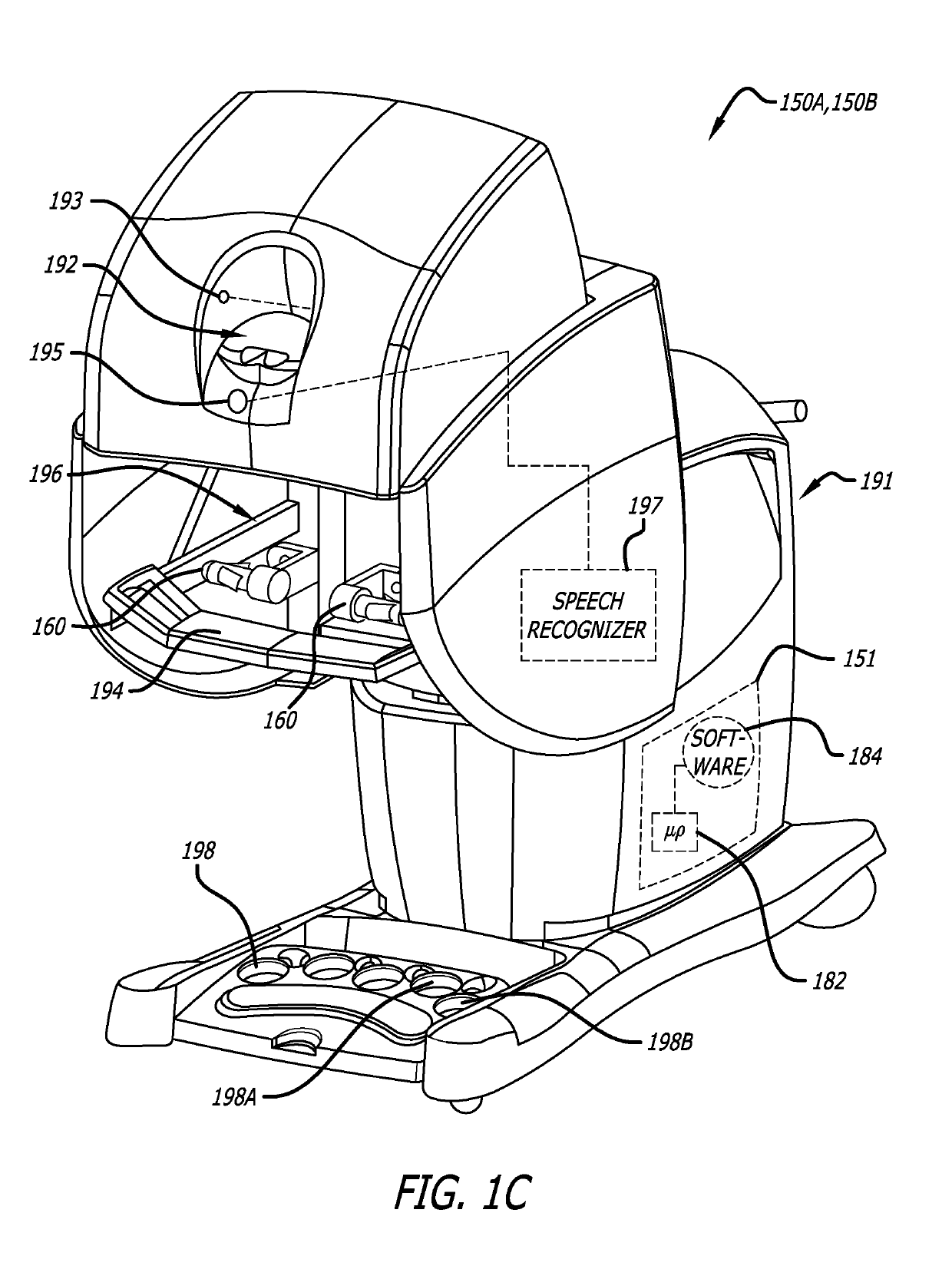

ActiveUS10368838B2Ultrasonic/sonic/infrasonic diagnosticsSurgical instrument detailsRobotic armDisplay device

In one embodiment of the invention, a robotic surgical system includes a combined laser imaging robotic surgical tool, a control console, and a laser generator / controller. The tool is mounted to a first robotic arm of a patient side cart. The tool has a wristed joint and an end effector coupled together. The end effector has a laser-emitting device to direct a laser beam onto tissue in a surgical site and an image-capturing device to capture images of the tissue in the surgical site. The control console, in communication with the tool, receives the captured images of tissue in the surgical site and displays the captured images on a display device to a user. The laser generator / controller is coupled to the tool and the control console to control the emission of the laser beam onto tissue of the surgical site.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Method and system for detecting objects external to a vehicle

InactiveUS20050134440A1Avoid collisionAvoid and minimize effectVehicle seatsInstruments for road network navigationRange gateLaser beams

Method and system for obtaining information about objects in the environment outside of and around a vehicle and preventing collisions involving the vehicle includes directing a laser beam from the vehicle into the environment, receiving from an object in the path of the laser beam a reflection of the laser beam at a location on the vehicle, and analyzing the received laser beam reflections to obtain information about the object from which the laser beam is being reflected. Analysis of the laser beam reflections preferably entails range gating the received laser beam reflections to limit analysis of the received laser beam reflections to only those received from an object within a defined (distance) range such that objects at distances within the range are isolated from surrounding objects.

Owner:AMERICAN VEHICULAR SCI

Laser ablation process and apparatus

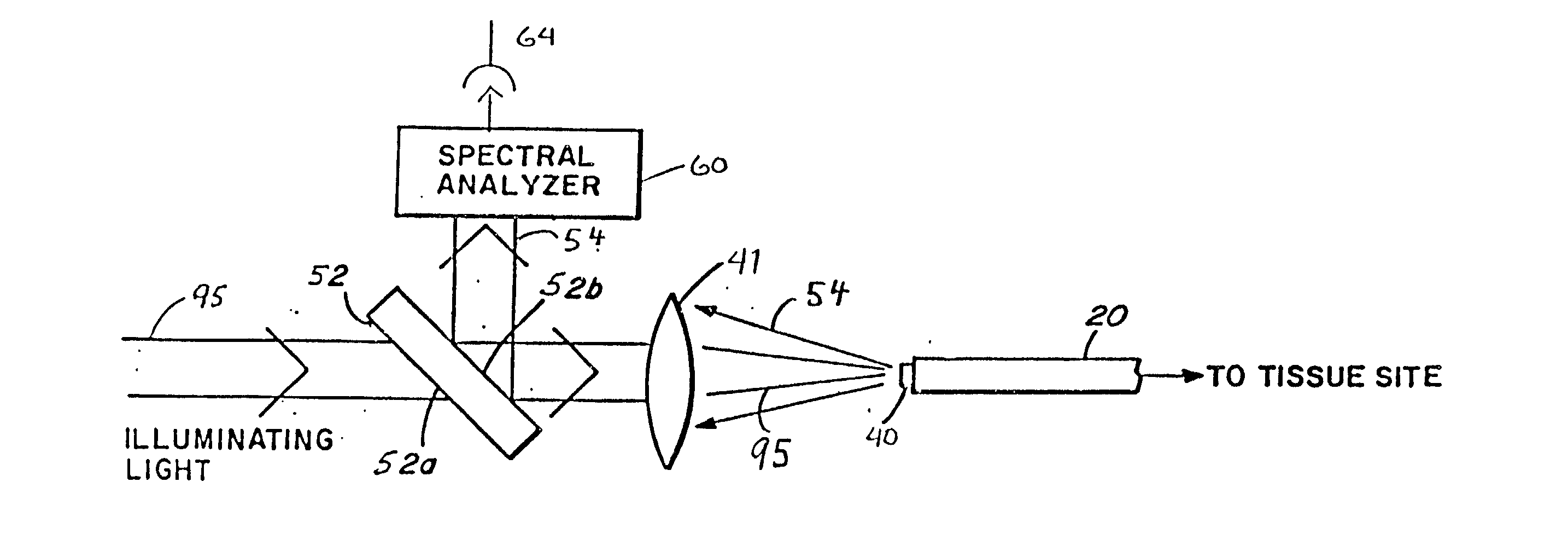

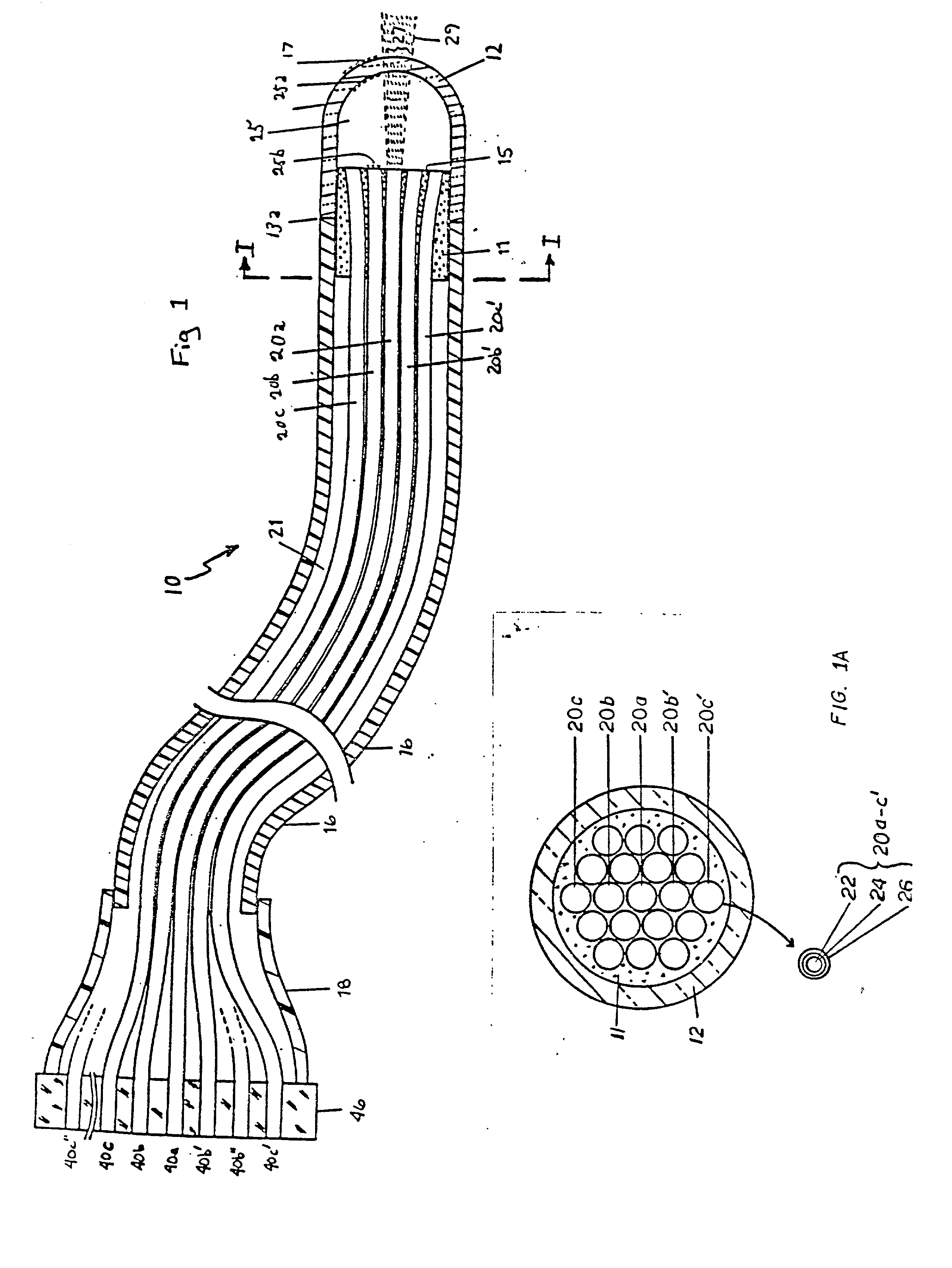

InactiveUS20020045811A1Reduce Fresnel reflectionMaximize transmitted lightControlling energy of instrumentDiagnostics using spectroscopyFiberLaser light

A laser catheter is disclosed wherein optical fibers carrying laser light are mounted in a catheter for insertion into an artery to provide controlled delivery of a laser beam for percutaneous intravascular laser treatment of atherosclerotic disease. A transparent protective shield is provided at the distal end of the catheter for mechanically diplacing intravascular blood and protecting the fibers from the intravascular contents, as well as protecting the patient in the event of failure of the fiber optics. Multiple optical fibers allow the selection of tissue that is to be removed. A computer controlled system automatically aligns fibers with the laser and controls exposure time. Spectroscopic diagnostics determine what tissue is to be removed.

Owner:KITTRELL CARTER +2

Method and apparatus for detecting a wafer's posture on a susceptor

InactiveUS20030042419A1Improve accuracyControl quantityRadiation pyrometryMaterial analysis by optical meansWaferingSusceptor

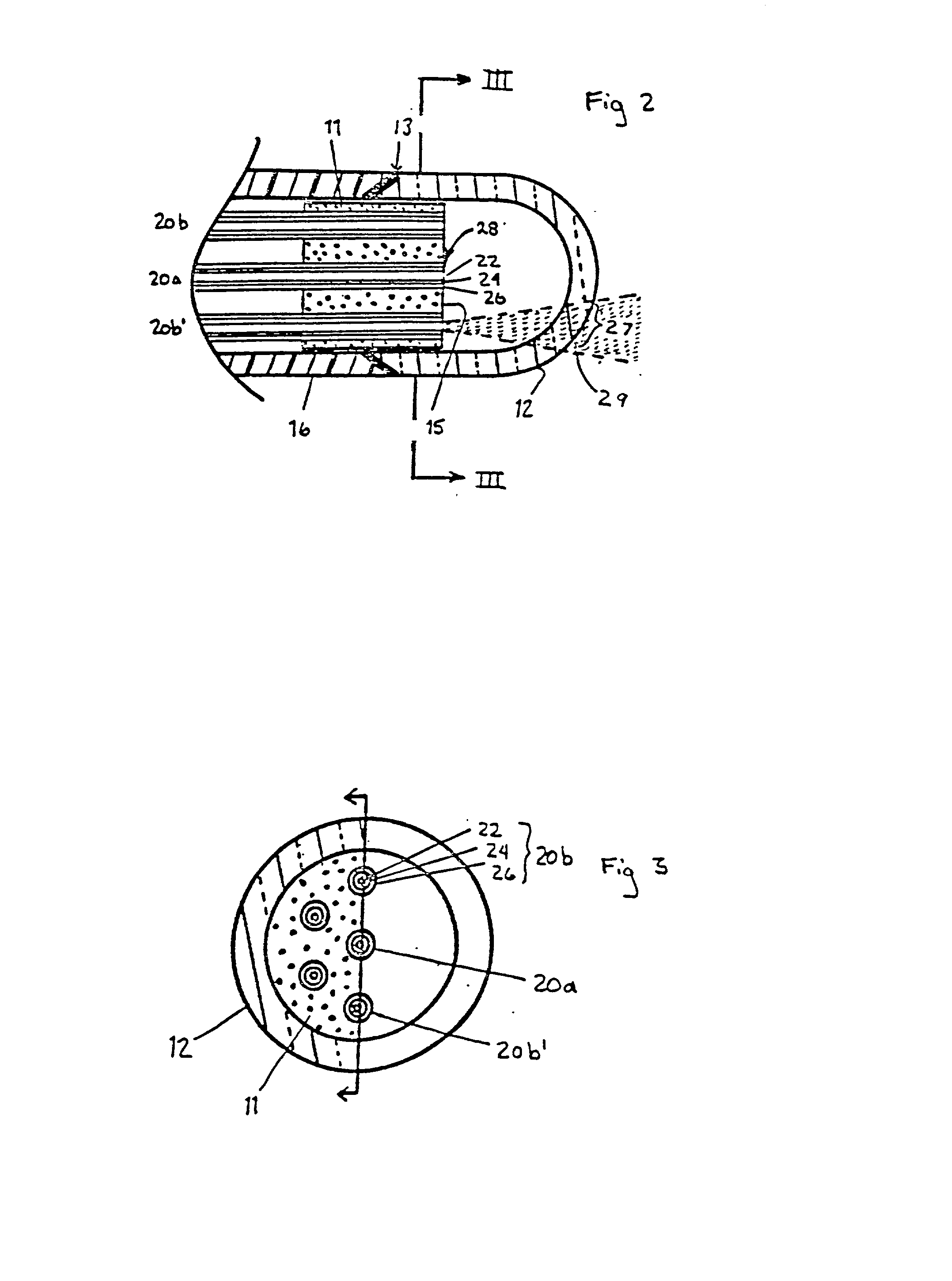

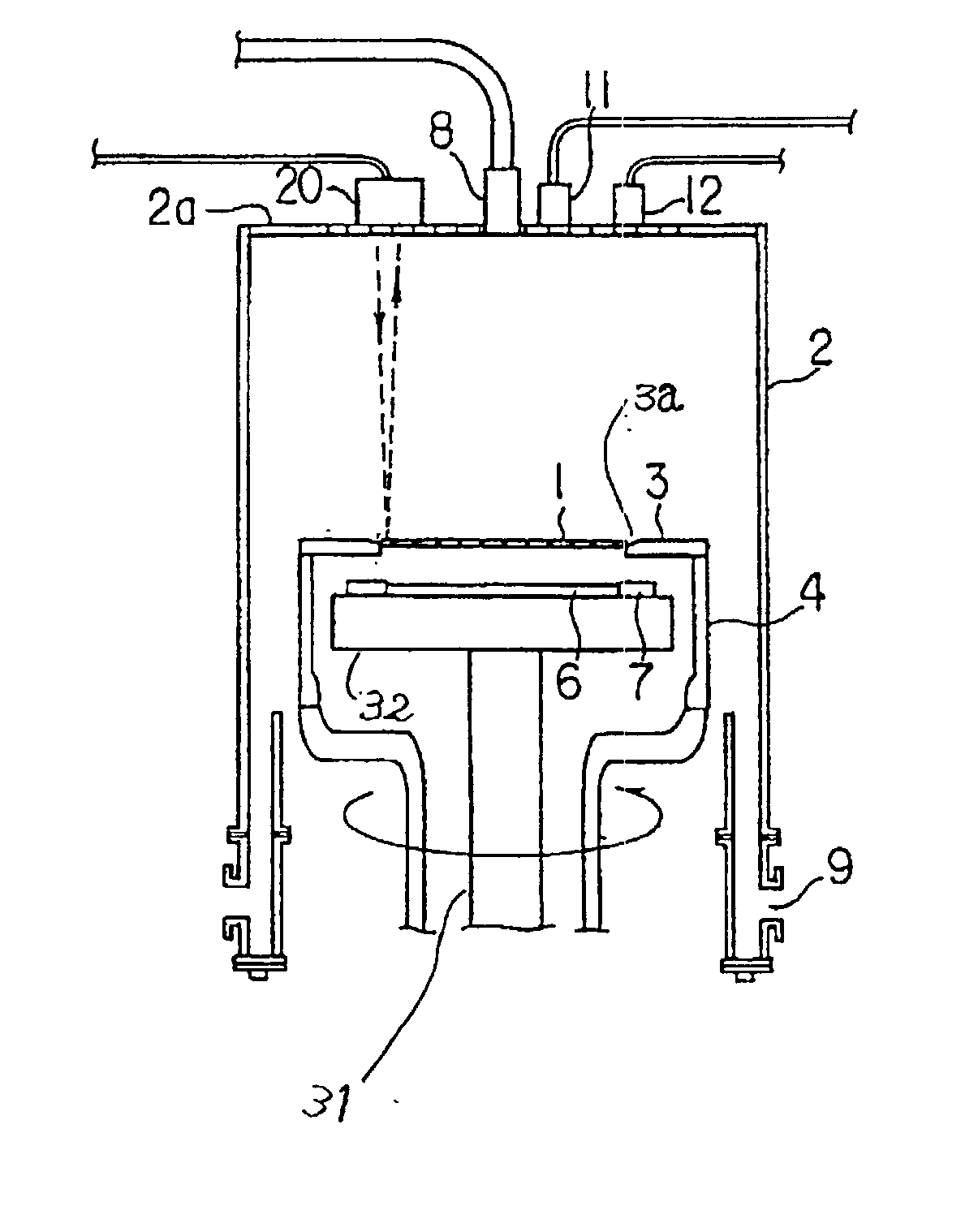

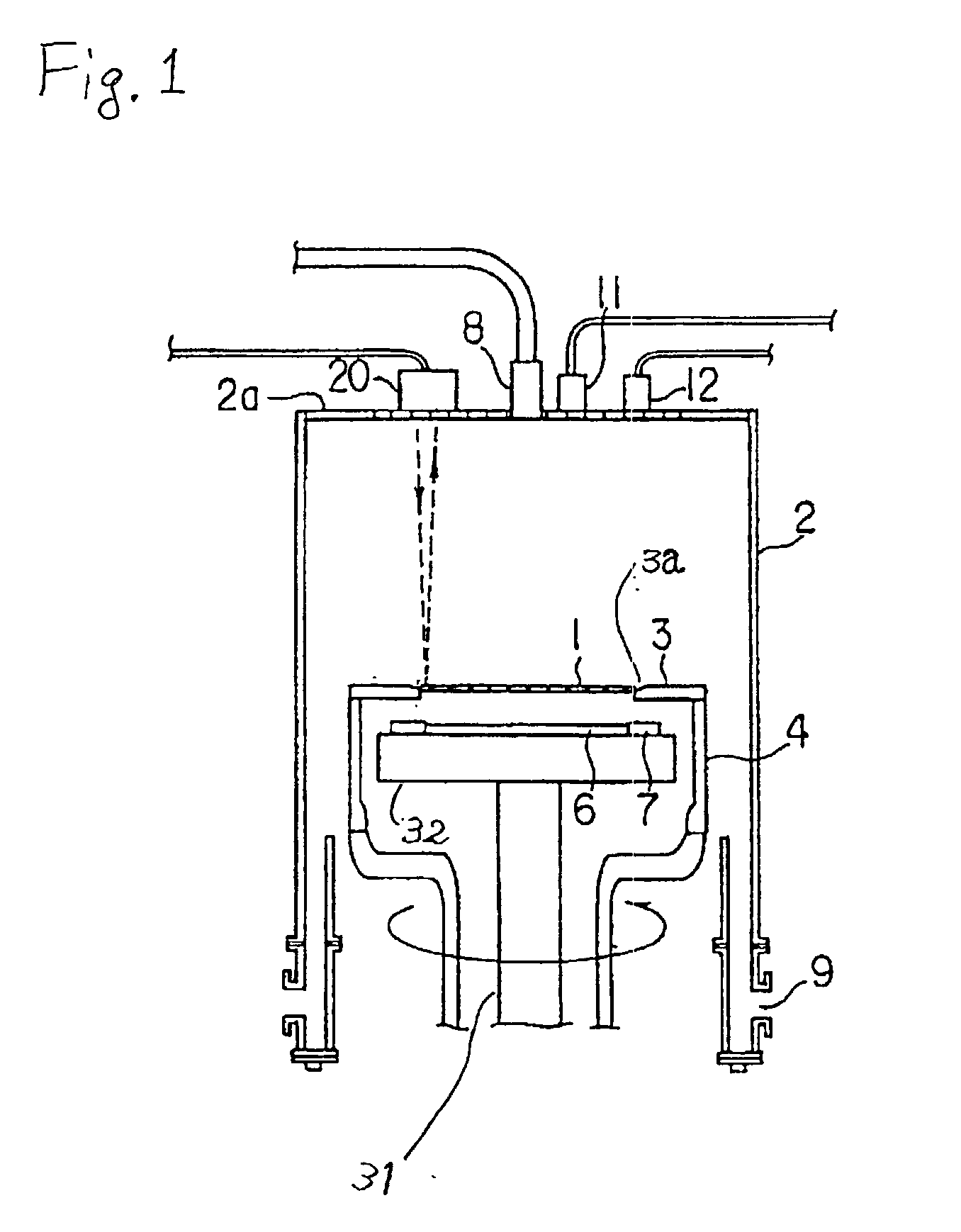

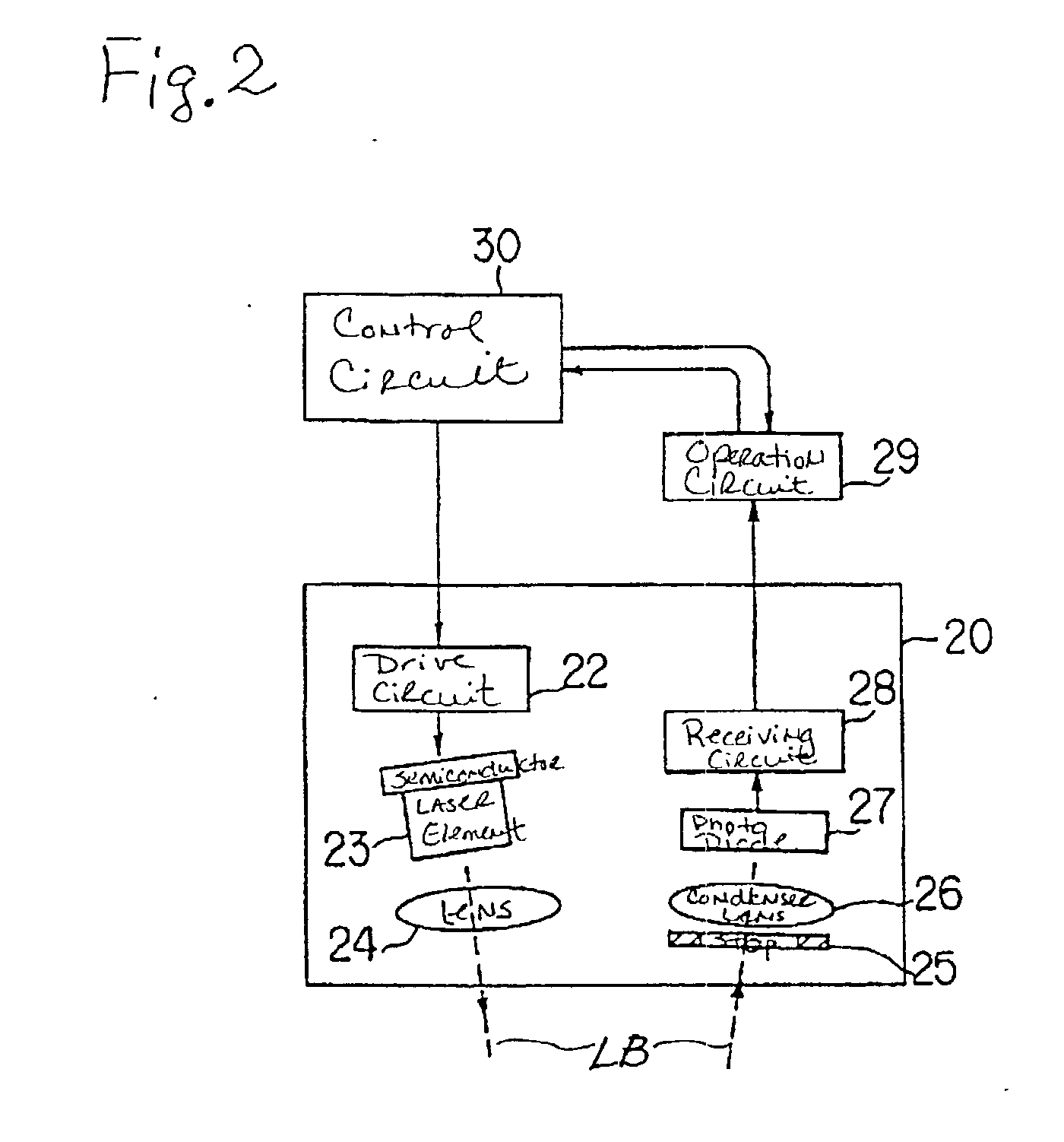

An apparatus used for an epitaxial vapor growing arrangement and for detecting whether a wafer is properly seated within a susceptor contained therein. The apparatus includes a semiconductor laser element that generates a laser beam which irradiates the wafer's surface. The apparatus, further, includes a combination of a stop mechanism, a condenser lens and a photo diode, which detects the laser beam reflected from the wafer surface and an operation circuit, which determines the wafer's posture on the susceptor. During operation, the reflected laser beam focuses on a receiving surface of the photo diode through the condenser lens. The operation circuit then compares the output signal from the photo diode with a preset reference value for discriminating the slope of the wafer.

Owner:TOSHIBA MASCH CO LTD

Laser-produced porous surface

ActiveUS20070142914A1Promote bone ingrowthGood stiffness characteristicsAdditive manufacturing apparatusMolten spray coatingLight beamMetal powder

A method of forming an implant having a porous tissue ingrowth structure and a bearing support structure. The method includes depositing a first layer of a metal powder onto a substrate, scanning a laser beam over the powder so as to sinter the metal powder at predetermined locations, depositing at least one layer of the metal powder onto the first layer and repeating the scanning of the laser beam.

Owner:UNIV OF LIVERPOOL +1

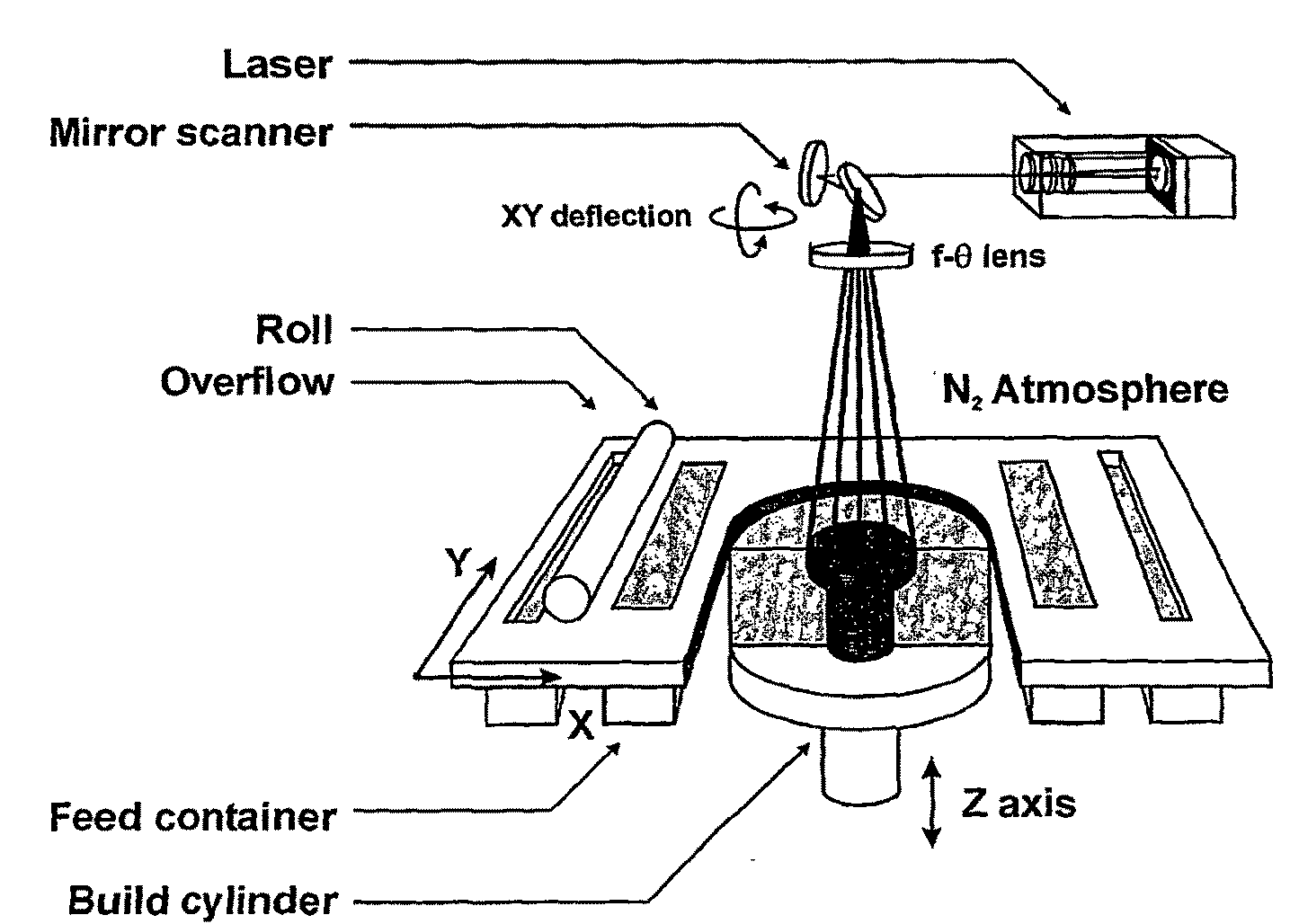

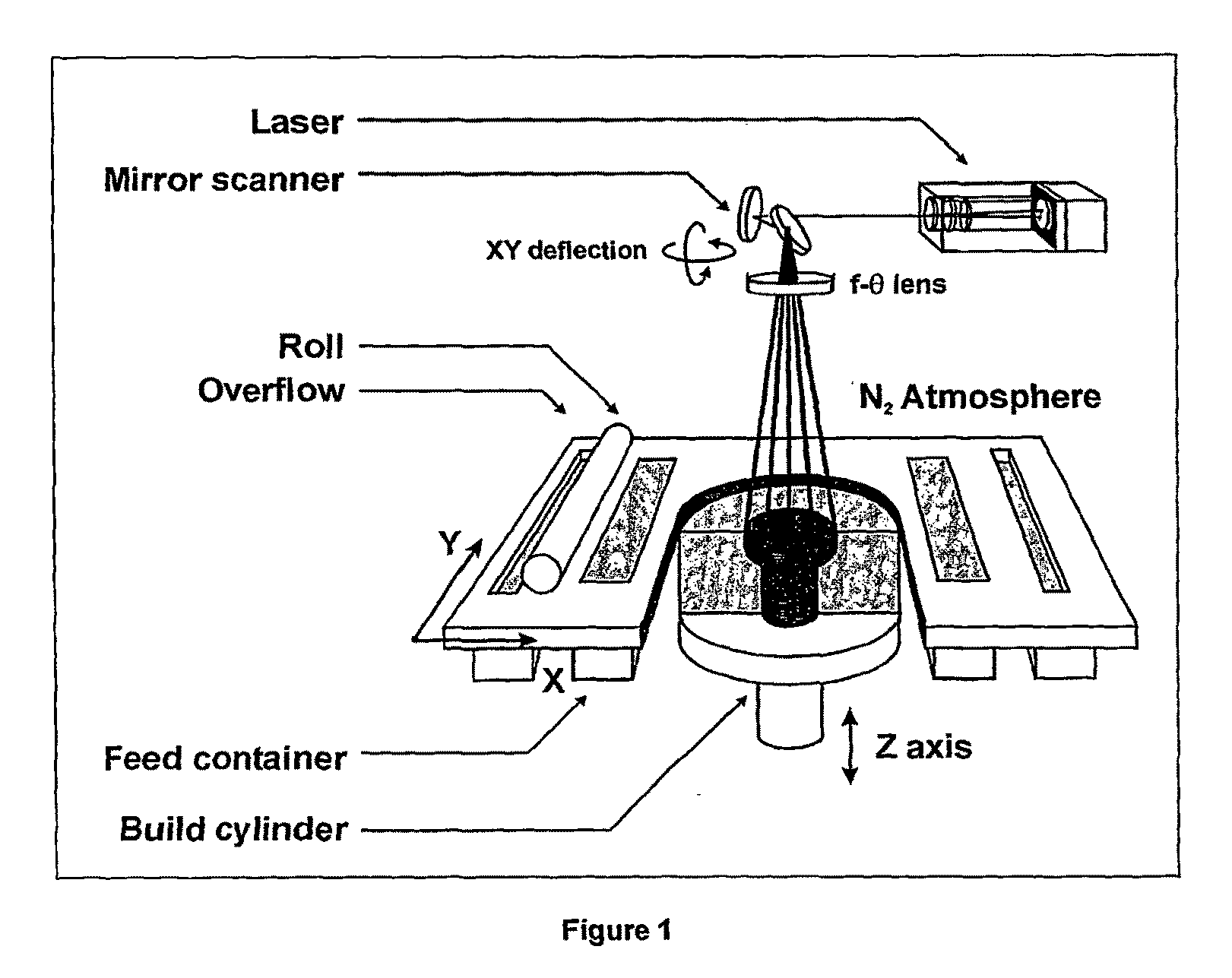

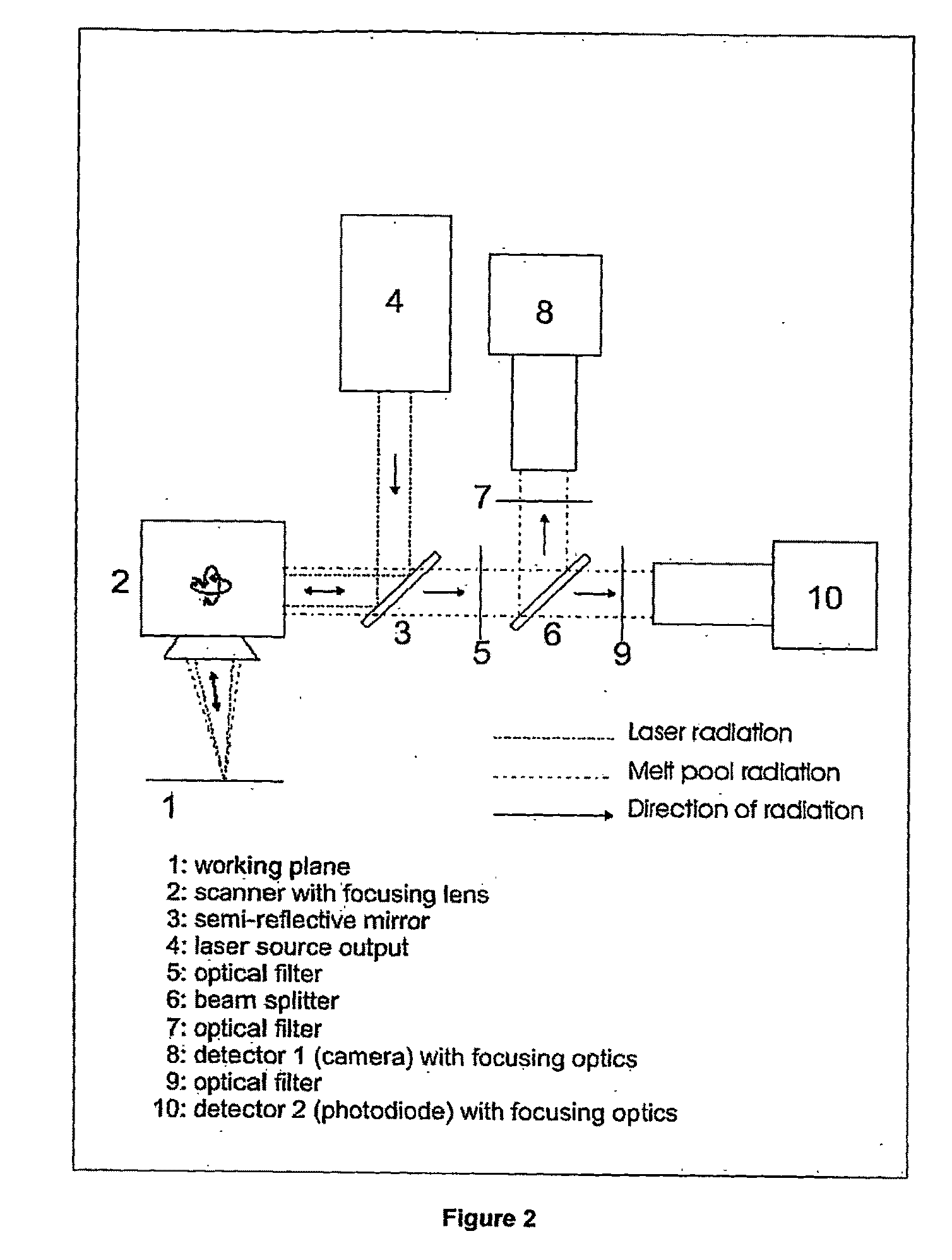

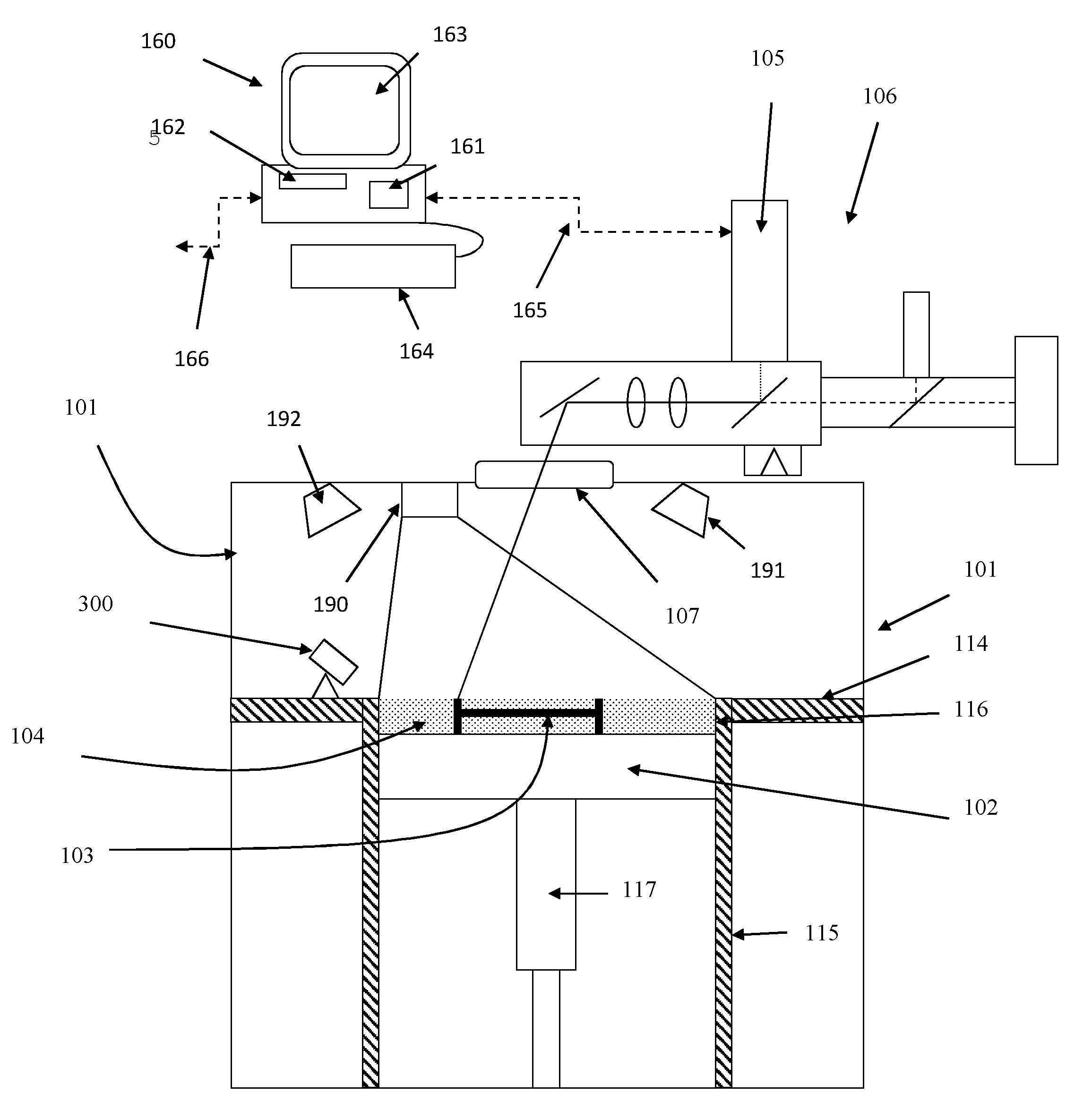

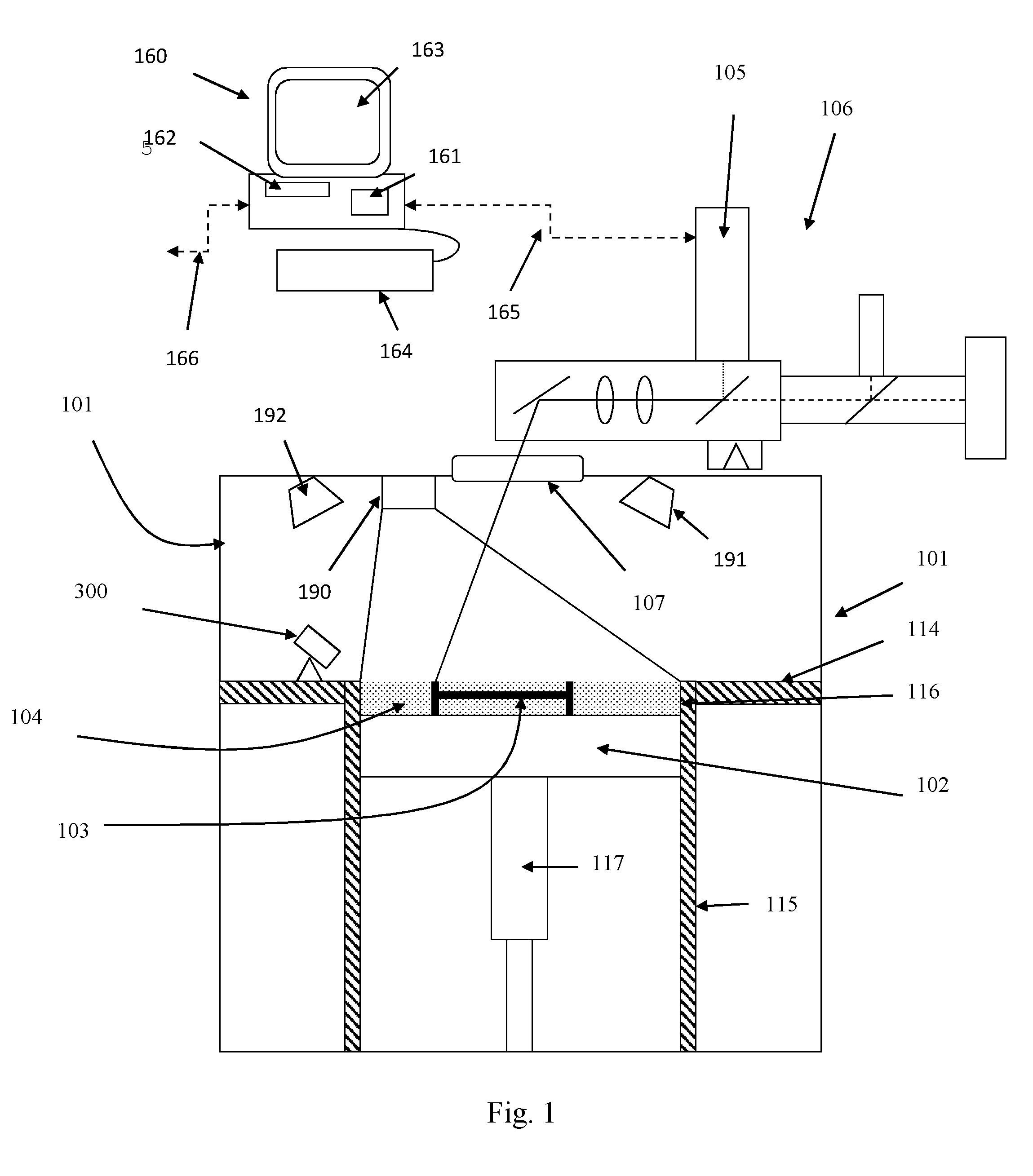

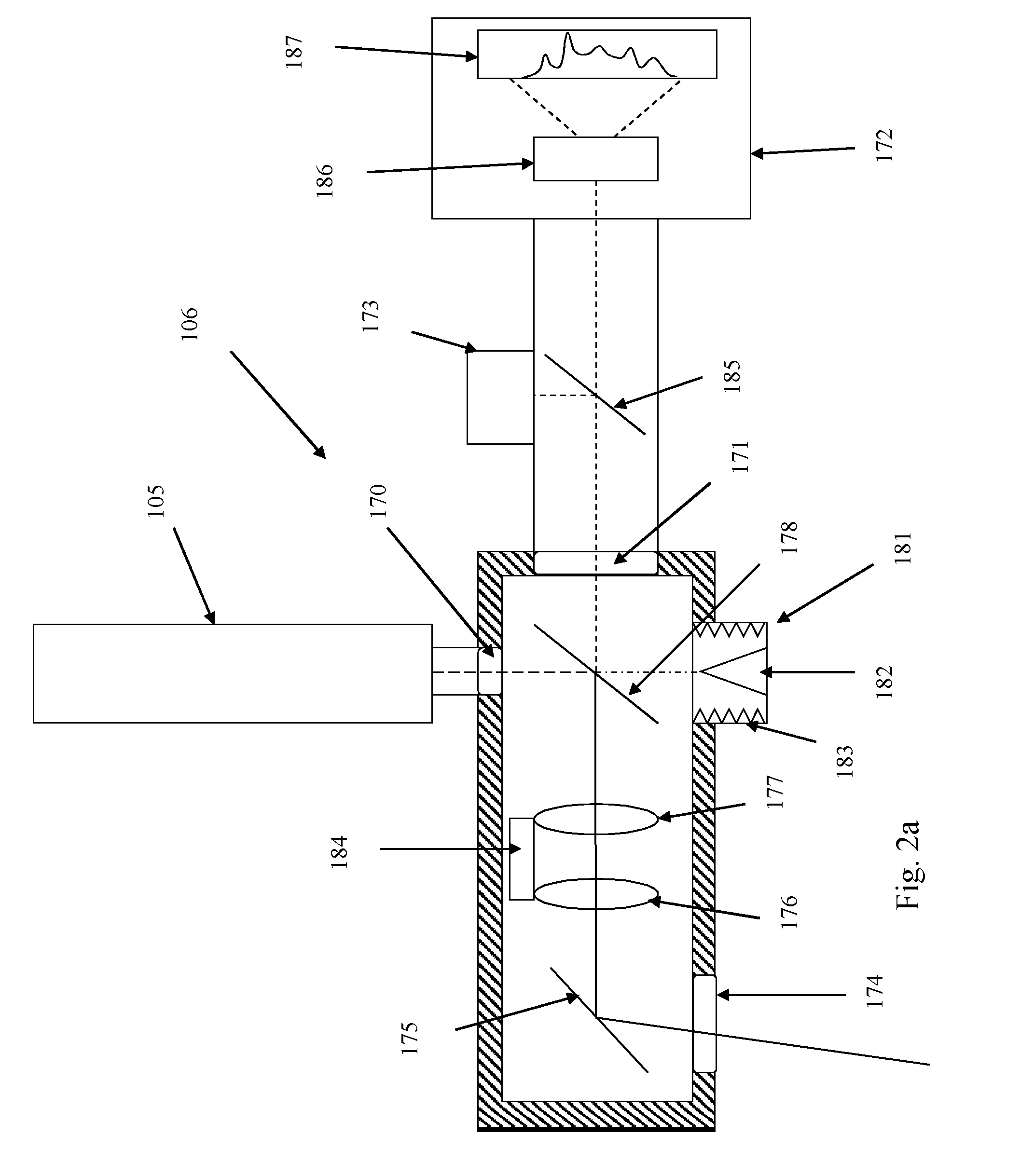

Procedure and apparatus for in-situ monitoring and feedback control of selective laser powder processing

InactiveUS20090206065A1Quality improvementReduce spectral distortionAdditive manufacturing apparatusIncreasing energy efficiencyControl systemFeedback controller

The present invention relates to a method and a device to monitor and control the Selective Laser Powder Processing. A Selective Laser Powder Processing device comprising a feedback controller to improve the stability of the Selective Laser Powder Processing process is presented. A signal reflecting a geometric quantity of the melt zone is used in the feedback controller to adjust the scanning parameters (e.g. laser power, laser spot size, scanning velocity, . . . ) of the laser beam (4) in order to maintain the geometric quantity of the melt zone at a constant level. The signal reflecting the geometric quantity of the melt zone can also be displayed in order to monitor the Selective Laser Powder Processing process. The present invention allows for the production of three-dimensional objects from powder material and improves the state of the art by compensating variations of the border conditions (e.g. local heat conduction rate) by a feedback control system based on a geometric quantity of the melt zone resulting in e.g. a lower amount of dross material when overhang planes are scanned.

Owner:KRUTH JEAN PIERRE +1

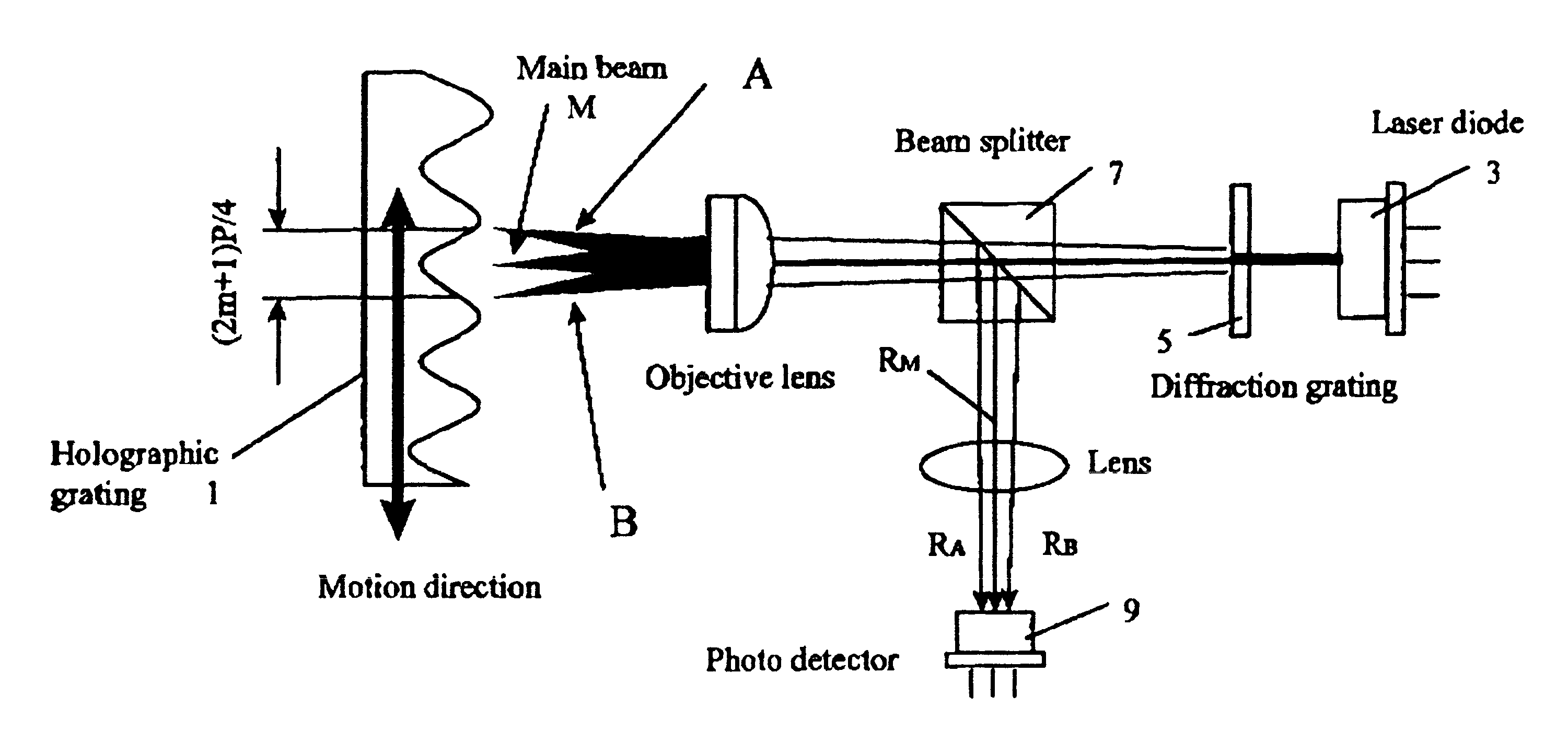

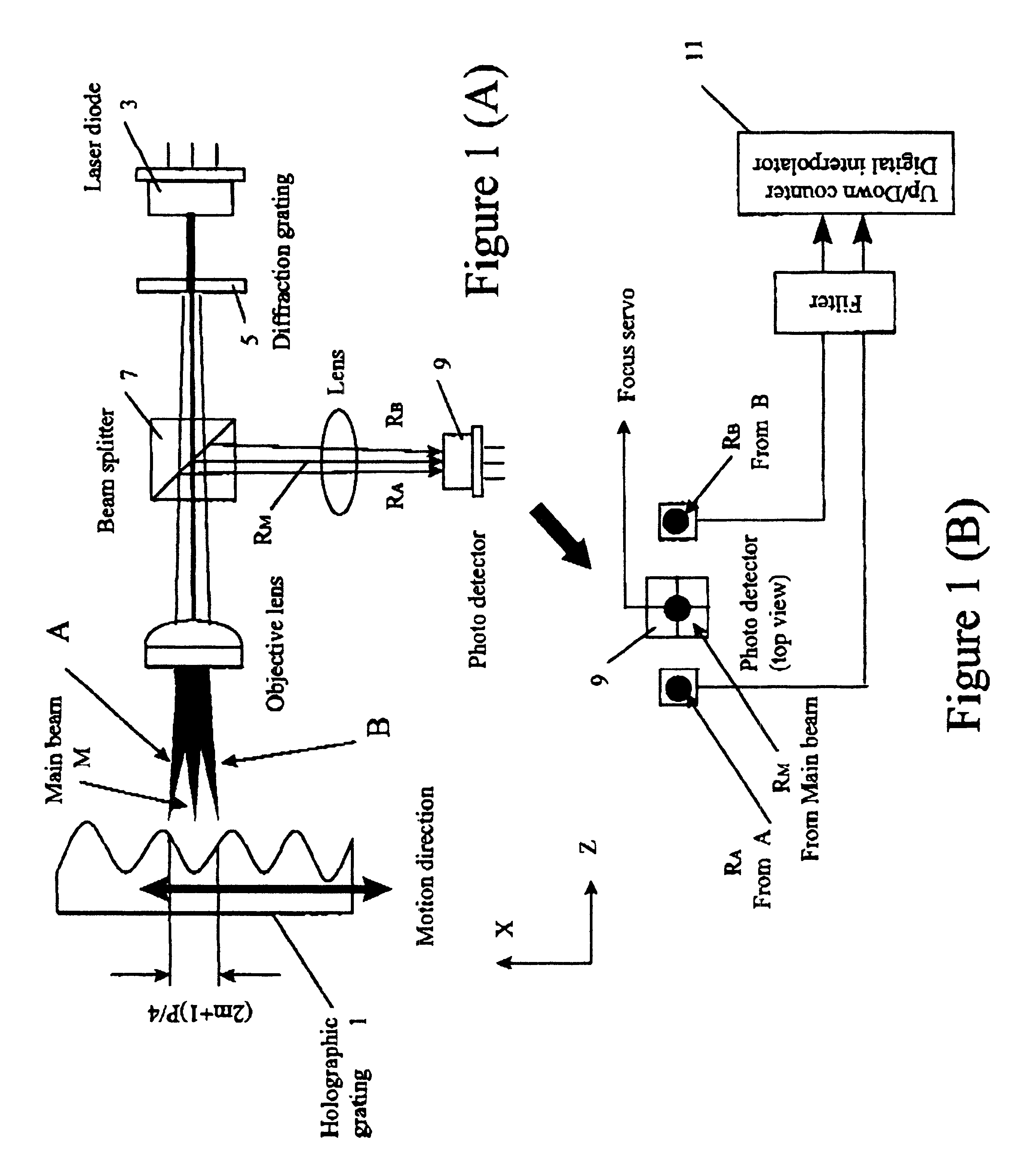

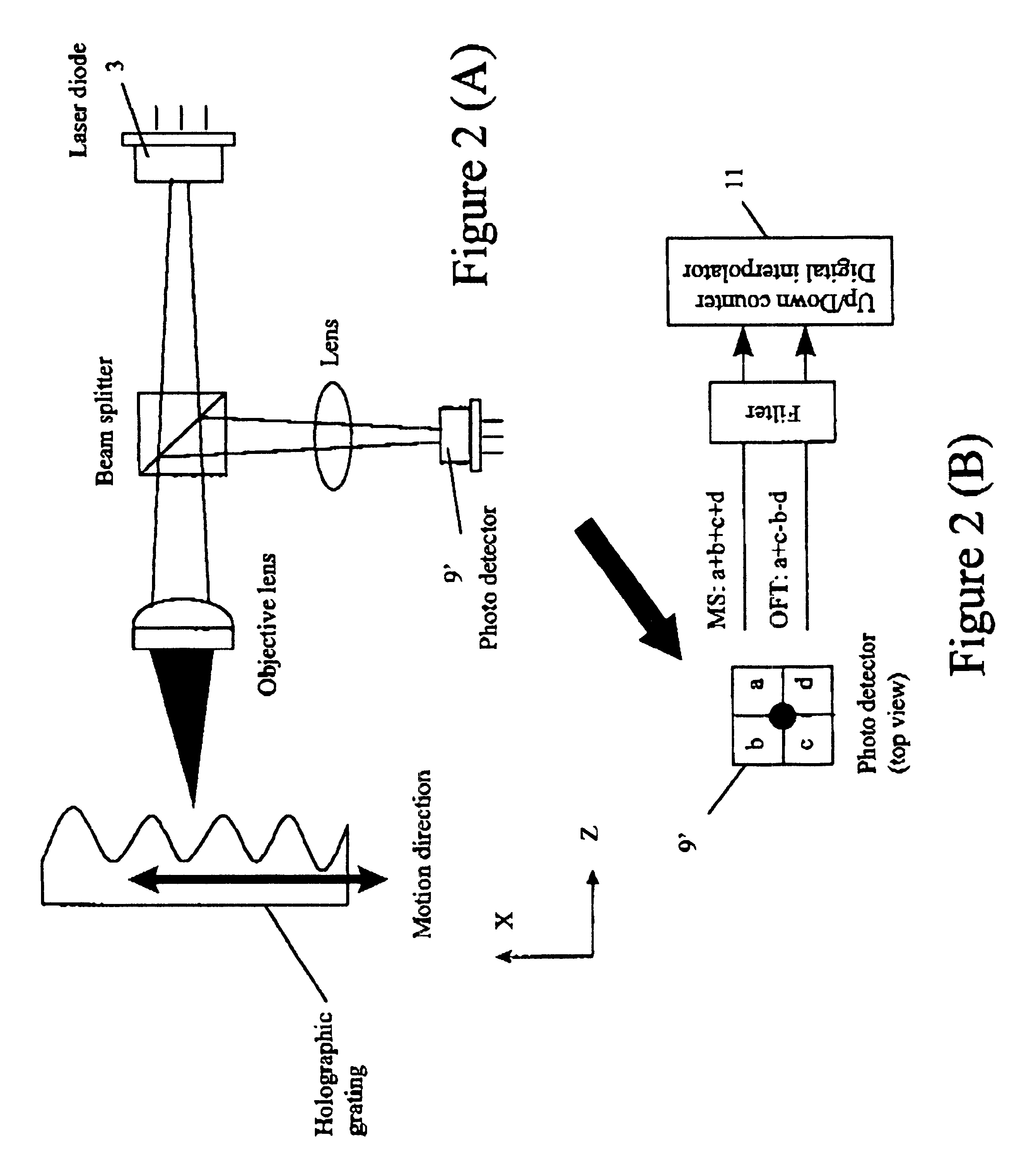

Method of and apparatus for real-time continual nanometer scale position measurement by beam probing as by laser beams and the like of atomic and other undulating surfaces such as gratings or the like relatively moving with respect to the probing beams

InactiveUS6639686B1Improved position sensing responseImprove operationNanoopticsInstrumental componentsGratingLight beam

An improved method of and apparatus for real-time continual nanometer scale position measurement by beam probing as by laser beams and the like, both fixed and oscillating or scanning, over an atomic and other undulating surface such as gratings or the like, relatively moving with respect to the probing beams; and providing, where desired, increased detection speeds, improved positioning sensing response, freedom from or relaxed requirements of strict control on probing oscillation amplitude, and multi-dimensional position measurement with focused beam probes and the like.

Owner:NANOWAVE

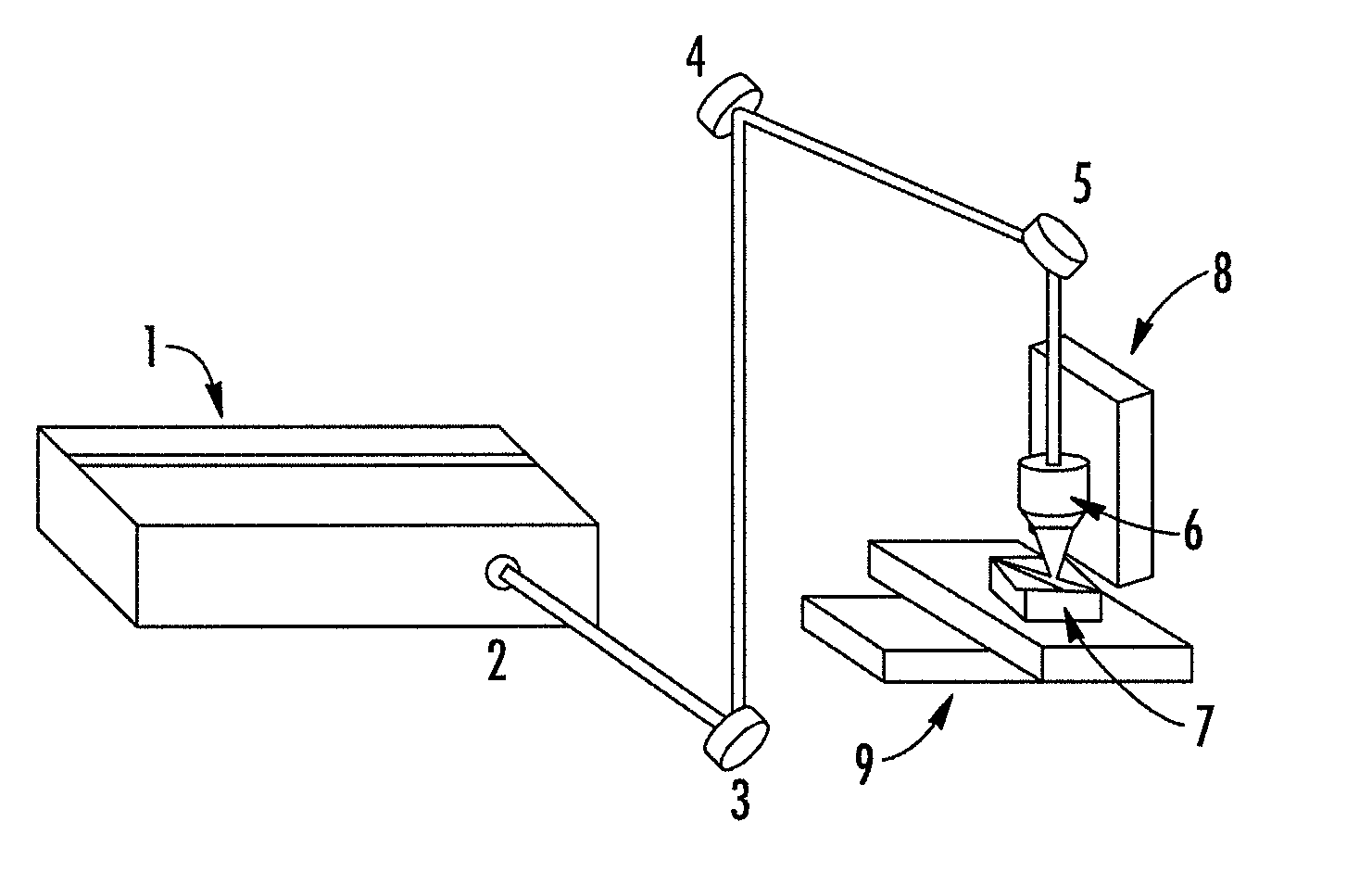

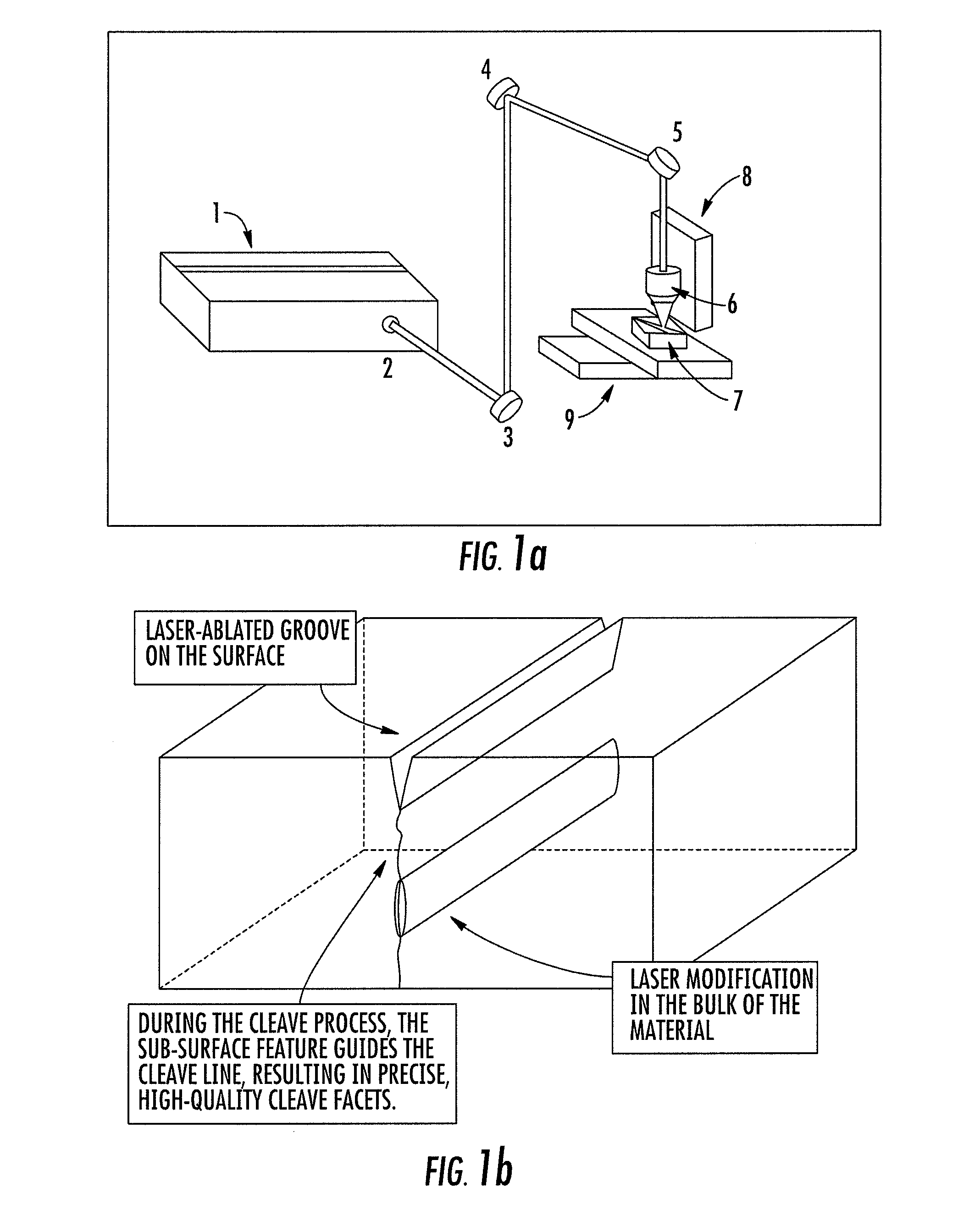

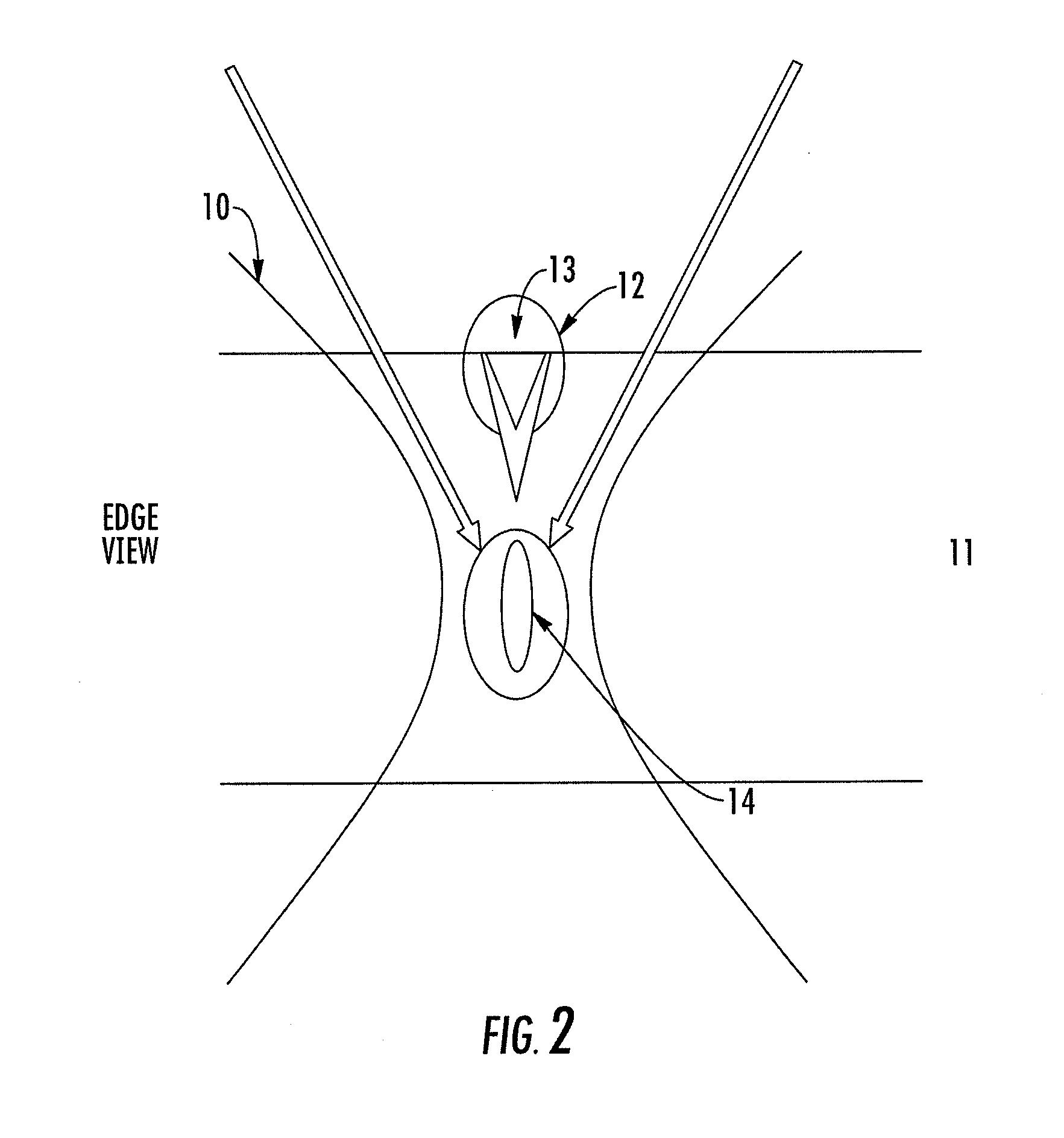

Transparent material processing with an ultrashort pulse laser

InactiveUS20100025387A1Reduce quality problemsPoor precisionSemiconductor/solid-state device manufacturingFine working devicesLight beamOptoelectronics

Methods, devices, and systems for ultrashort pulse laser processing of optically transparent materials are disclosed, with example applications in scribing, marking, welding, and joining. For example, ultrashort laser pulses create scribe features with one pass of the laser beam across the material, with at least one of the scribe features being formed below the surface of the material. Slightly modifying the ultrashort pulse laser processing conditions produces sub-surface marks. When properly arranged, these marks are clearly visible with correctly aligned illumination. Reflective marks may also be formed with control of laser parameters. A transparent material other than glass may be utilized. A method for welding transparent materials uses ultrashort laser pulses to create a bond through localized heating. In some embodiments of transparent material processing, a multifocus beam generator simultaneously forms multiple beam waists spaced depthwise relative to the transparent material, thereby increasing processing speed.

Owner:IMRA AMERICA

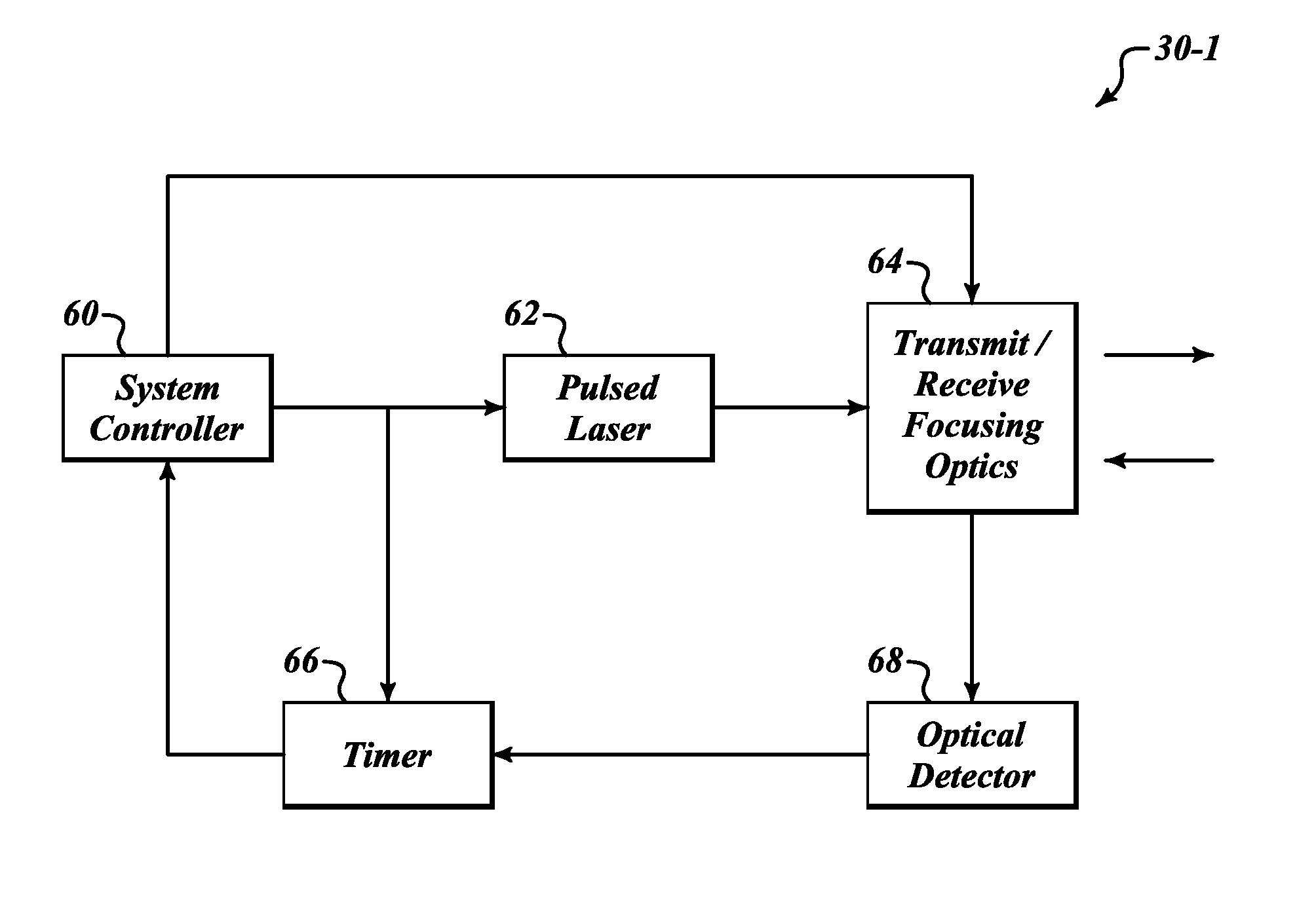

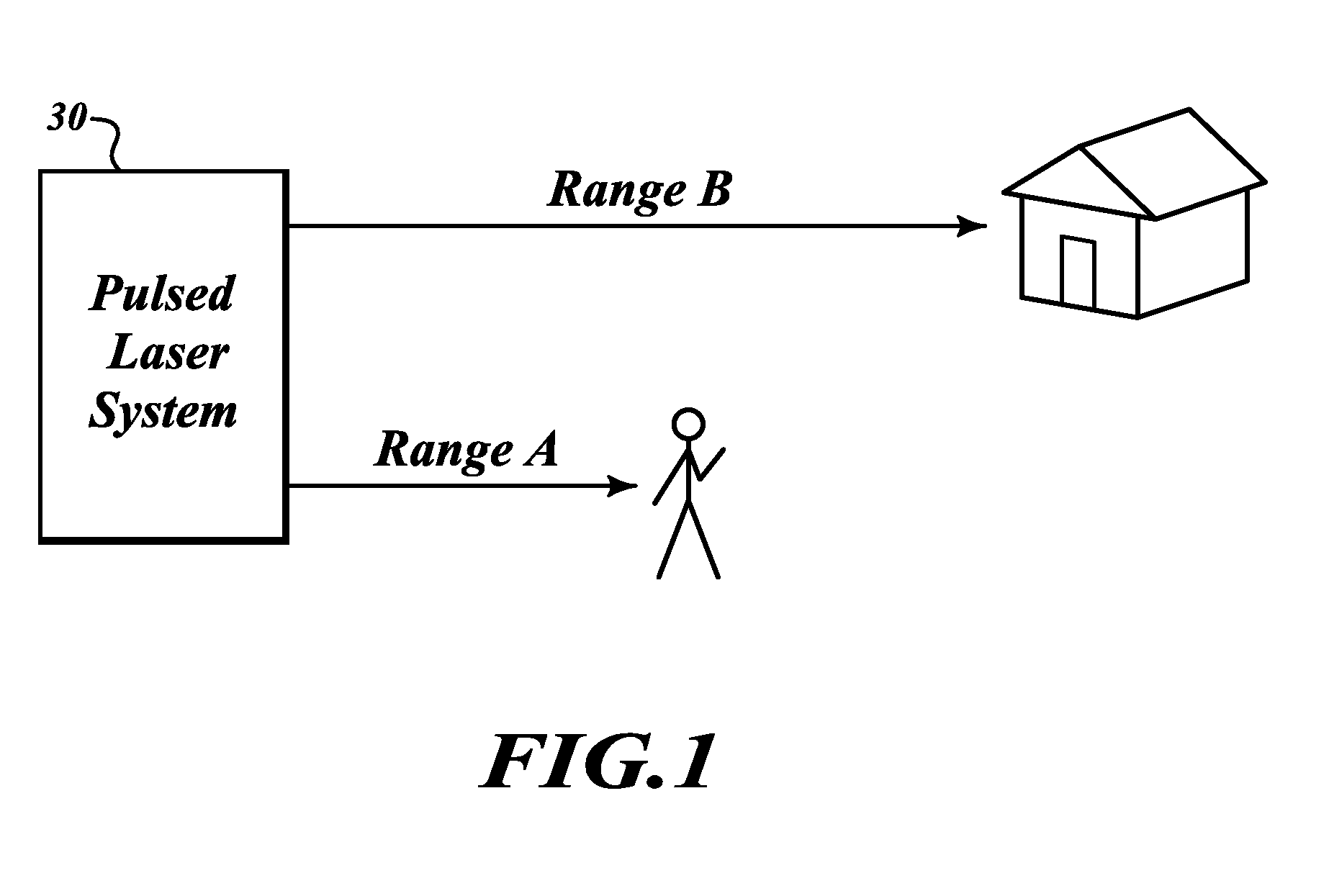

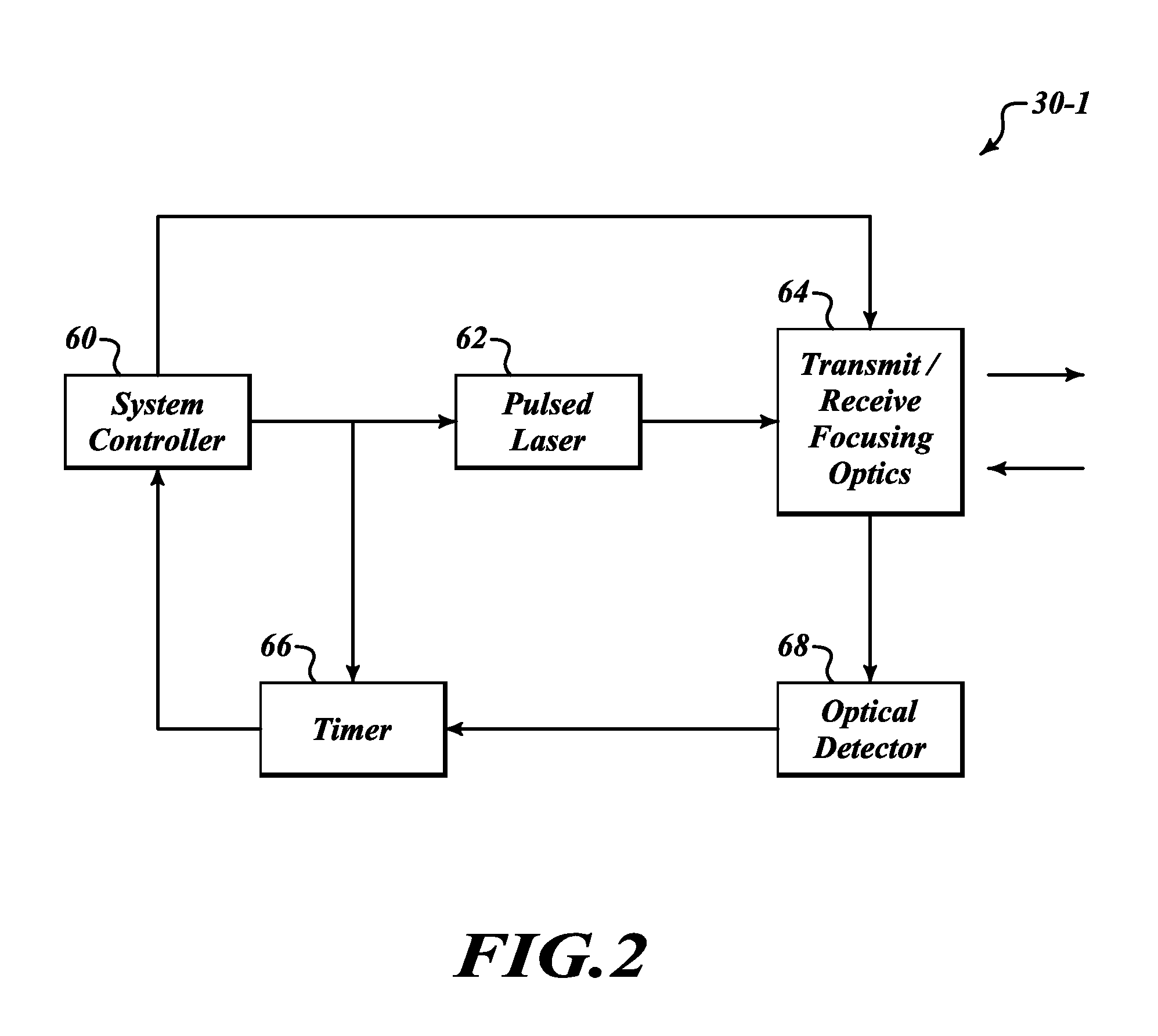

Systems and methods for safe laser imaging, detection and ranging (LIDAR) operation

InactiveUS20090273770A1Realize automatic adjustmentOptical rangefindersElectromagnetic wave reradiationLaser imagingField of view

A Laser Imaging, Detection and Ranging (LIDAR) system that automatically adjusts laser output so that no eye damage occurs to human targets. In one example, a component automatically measures range to targets in a field of view and determines the closest targets based on the measured range. A laser device outputs a laser beam and a controller adjusts one of pulse repetition frequency, power, or pulse duration of the laser device based on the measured range of the closest target in order to comply with a predefined eye safety model.

Owner:HONEYWELL INT INC

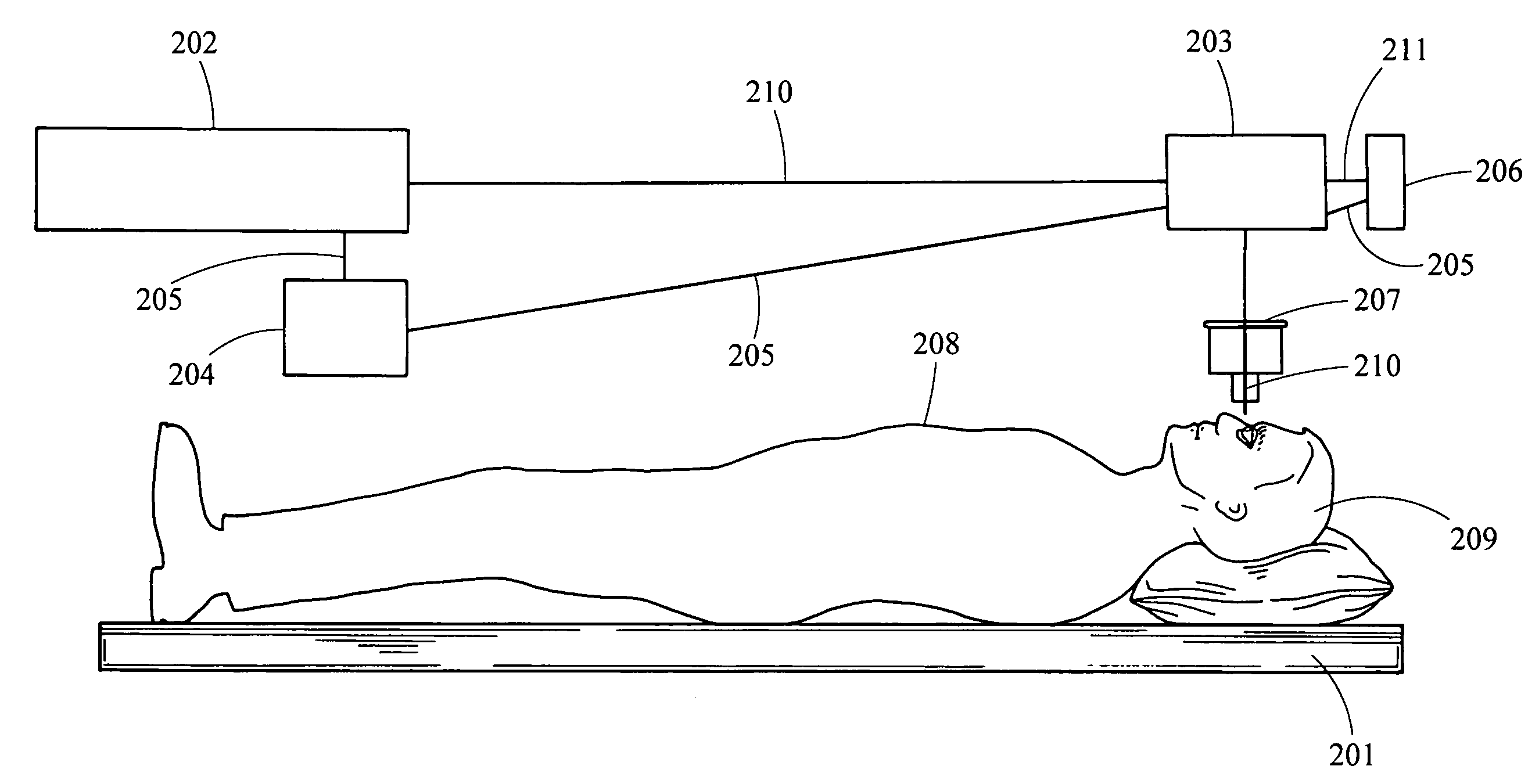

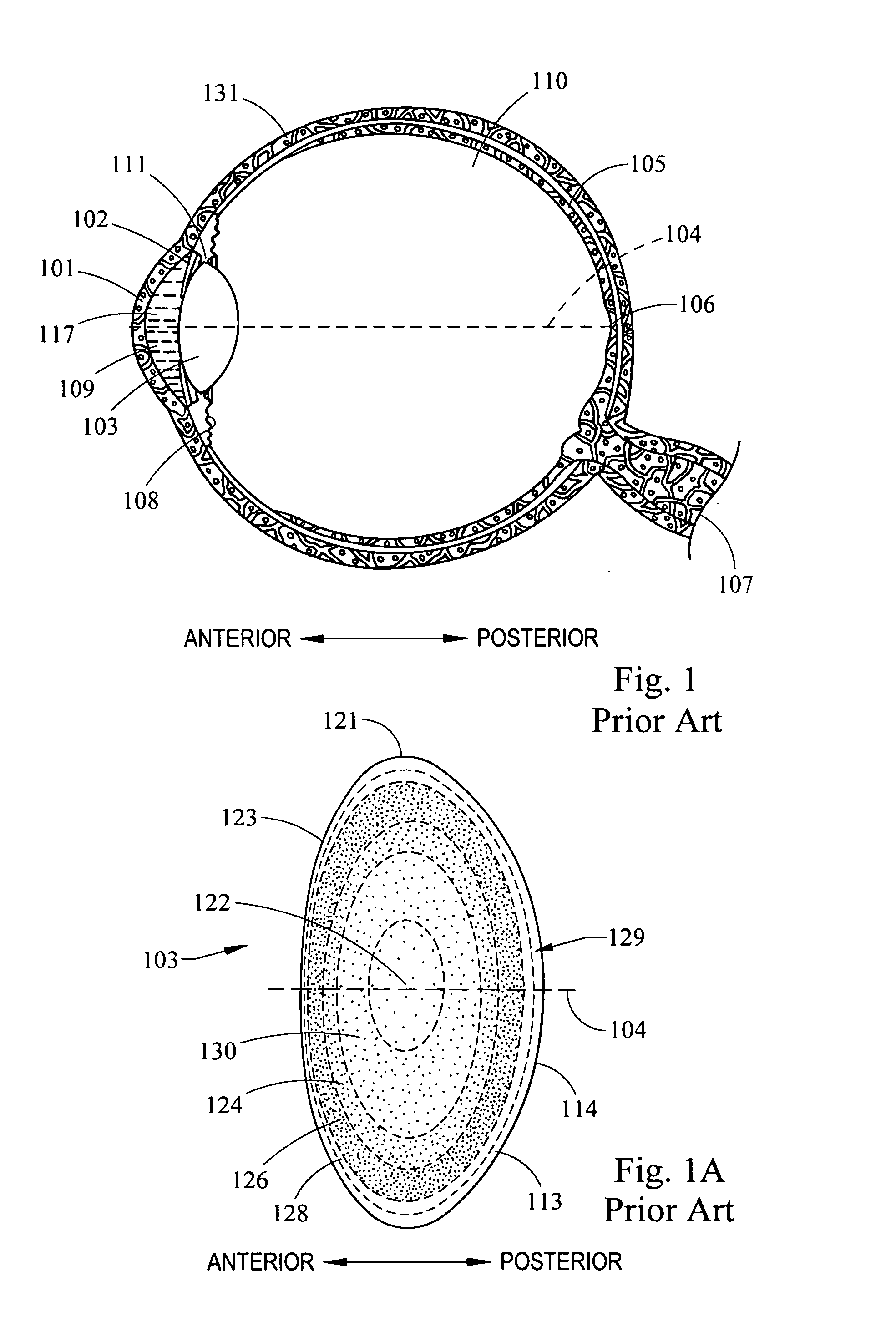

System and method for providing the shaped structural weakening of the human lens with a laser

ActiveUS8262646B2Increase amplitudeImprove errorLaser surgeryDiagnosticsRefractive errorLens materials

A system and method for increasing the amplitude of accommodation and / or changing the refractive power of lens material of a natural crystalline lens is provided. Generally, there is provided methods and systems for delivering a laser beam to a lens of an eye in a plurality of sectional patterns results in the shaped structural weakening of the lens. There is also provided a method and system for determining adjustments to refractive errors in the lens of an eye relating to the treatment of presbyopia. The change to refractive error can be a predicted error or an actual error that has been determined.

Owner:LENSAR LLC

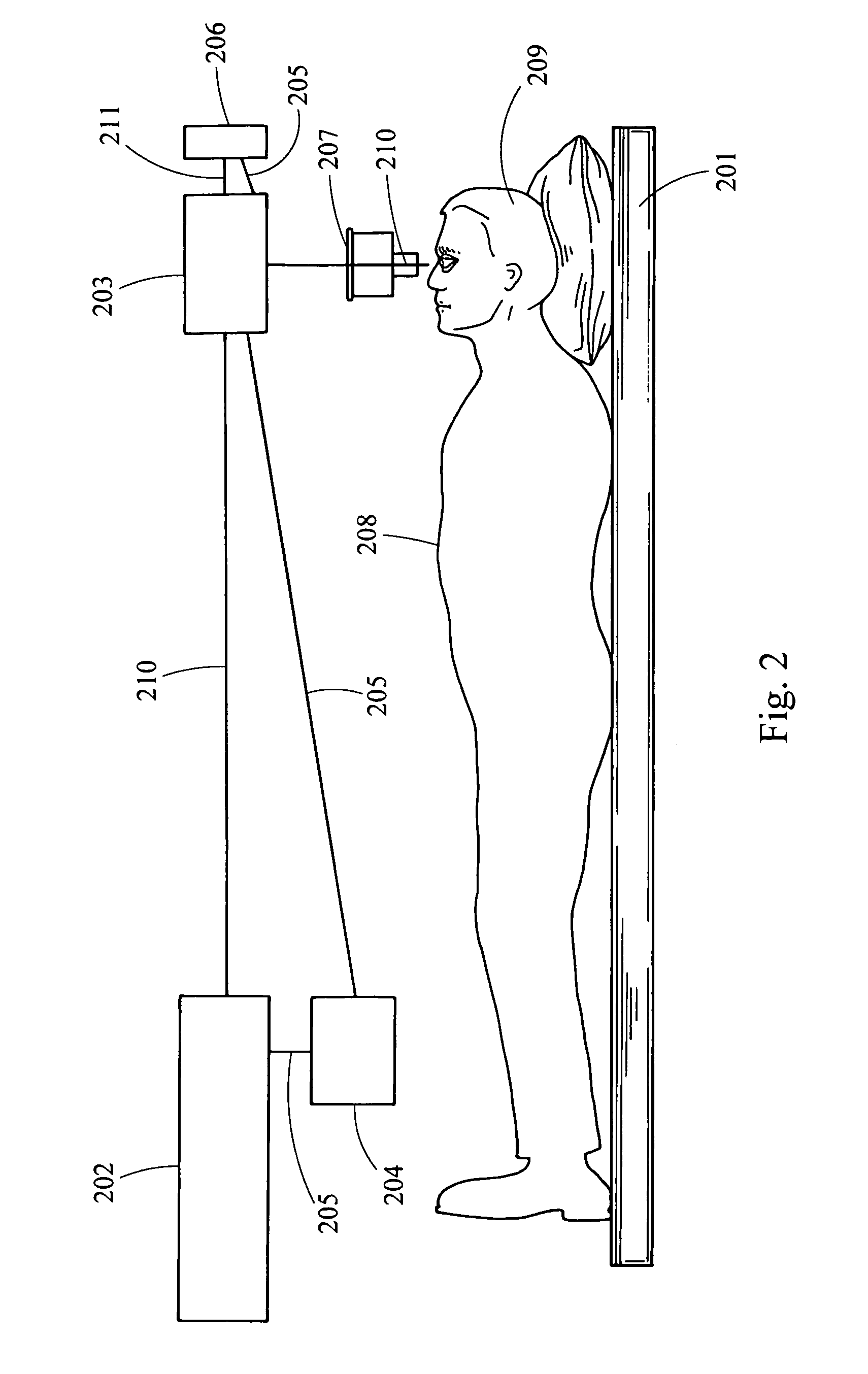

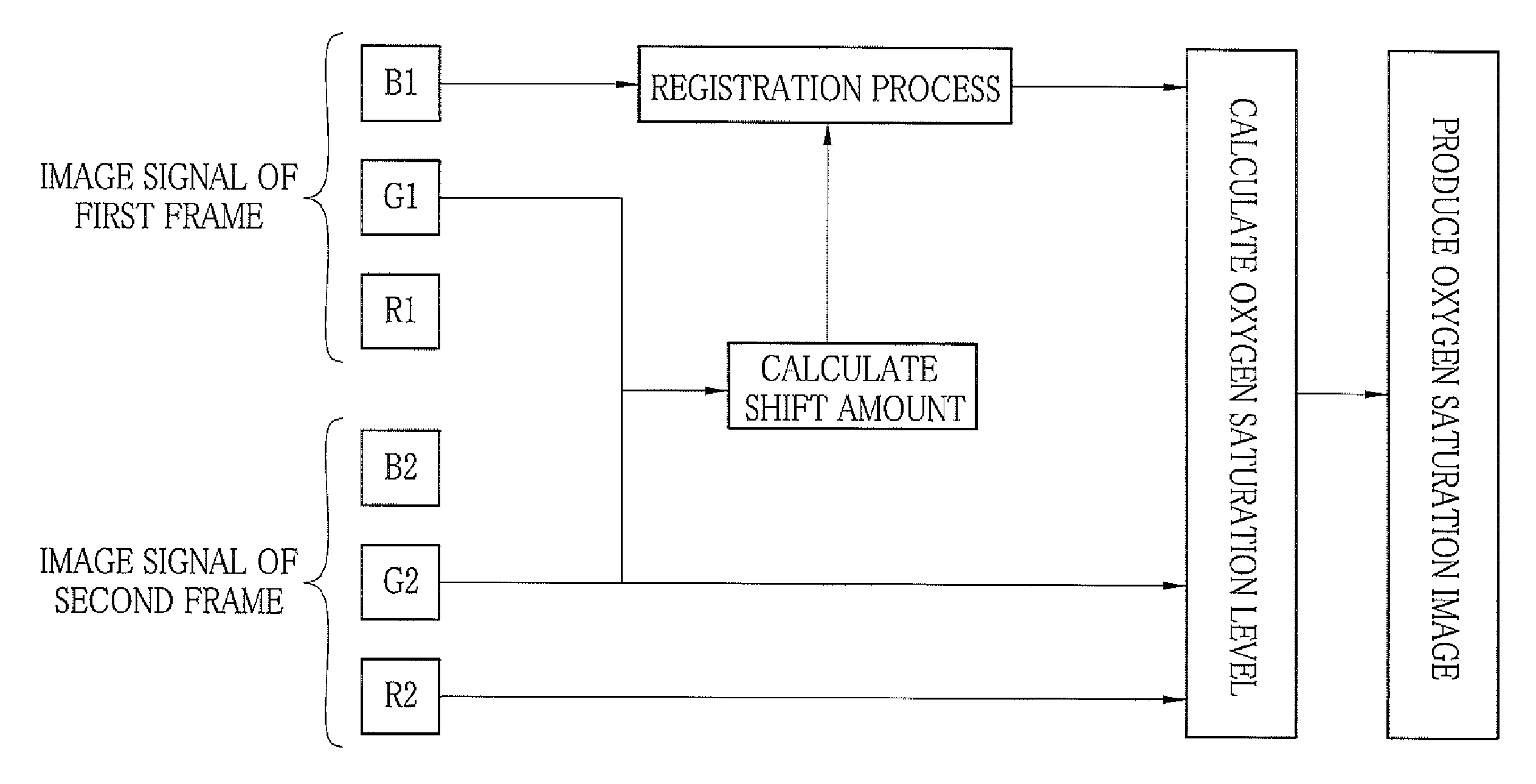

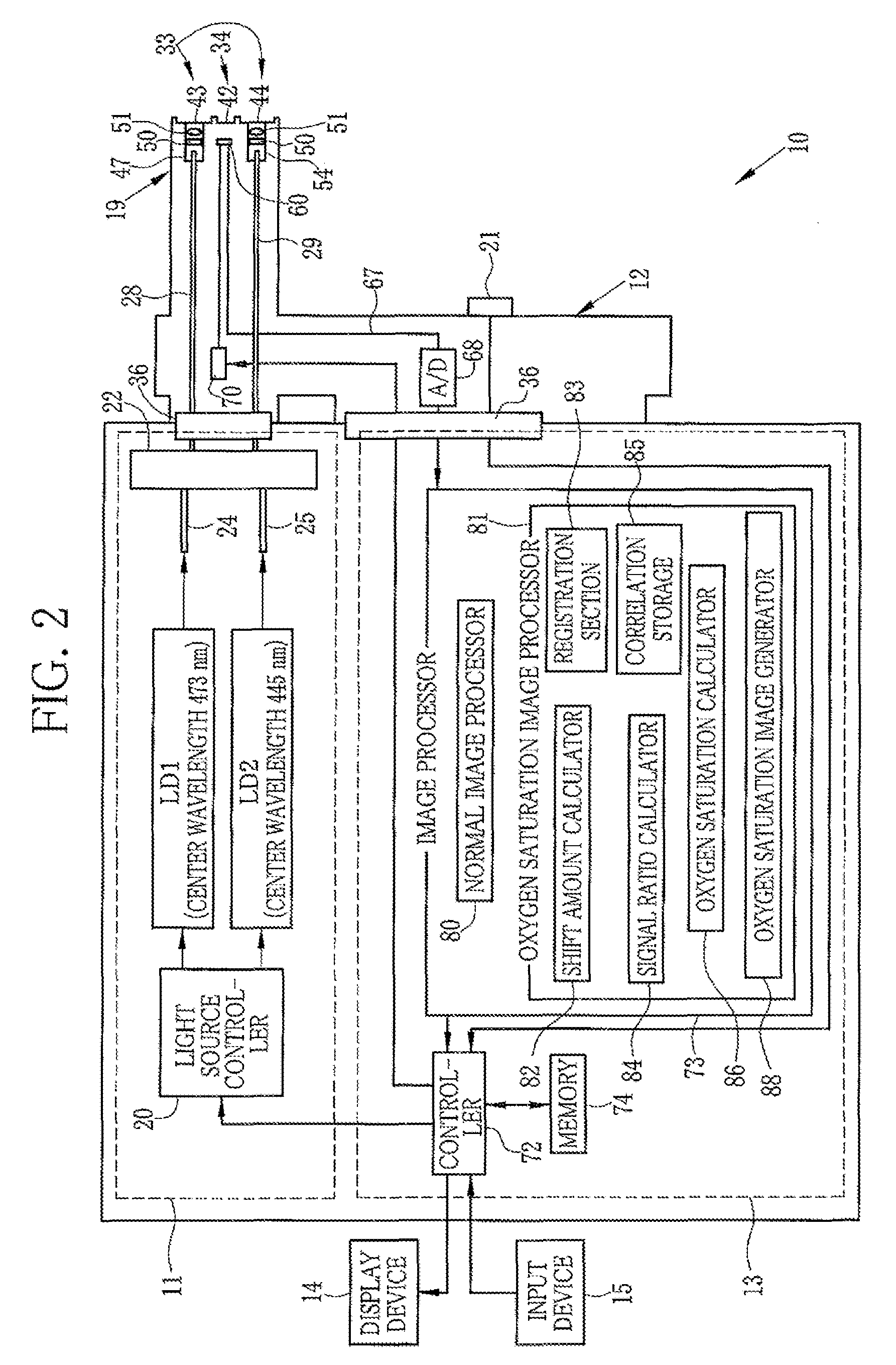

Endoscope system, processor device thereof, and image producing method

First and second white light is generated by excitations of phosphors with first and second laser beams having center wavelengths of 473 nm and 445 nm, respectively. The first and second white light is applied, in respective frames, sequentially to a region of interest in a subject. A color image sensor images the region of interest in the each frame. Based on a shift amount, calculated from green signals of first and second frames, between images, an image of a blue signal of the first frame is moved to be aligned with an image of a green signal and an image of a red signal of the second frame. After the alignment, an oxygen saturation image representing an oxygen saturation level of hemoglobin in blood is produced from the blue signal of the first frame and green and red signals of the second frame.

Owner:FUJIFILM CORP

Optical phased array lidar system and method of using same

A lidar-based system and method are used for the solid state beamforming and steering of laser beams using optical phased array (OPA) photonic integrated circuits (PICs) and the detection of laser beams using photodetectors. Transmitter and receiver electronics, power management electronics, control electronics, data conversion electronics and processing electronics are also included in the system and used in the method.Laser pulses beamformed by the OPA PIC reflect from objects in the field of view (FOV) of said OPA, and are detected by a detector or a set of detectors.A lidar system includes at least one lidar, and any subset and any number of complementary sensors, data processing / communication / storage modules, and a balance of system for supplying power, protecting, connecting, and mounting the components of said system.Direct correlation between the 3D point cloud generated by the lidar and the color images captured by an RGB (Red, Green, Blue) video camera can be achieved by using an optical beam splitter that sends optical signals simultaneously to both sensors.A lidar system may contain a plurality of lidar sensors, a lidar sensor may contain a plurality of optical transmitters, and an optical transmitter may contain a plurality of OPA PICs.

Owner:QUANERGY SOLUTIONS INC

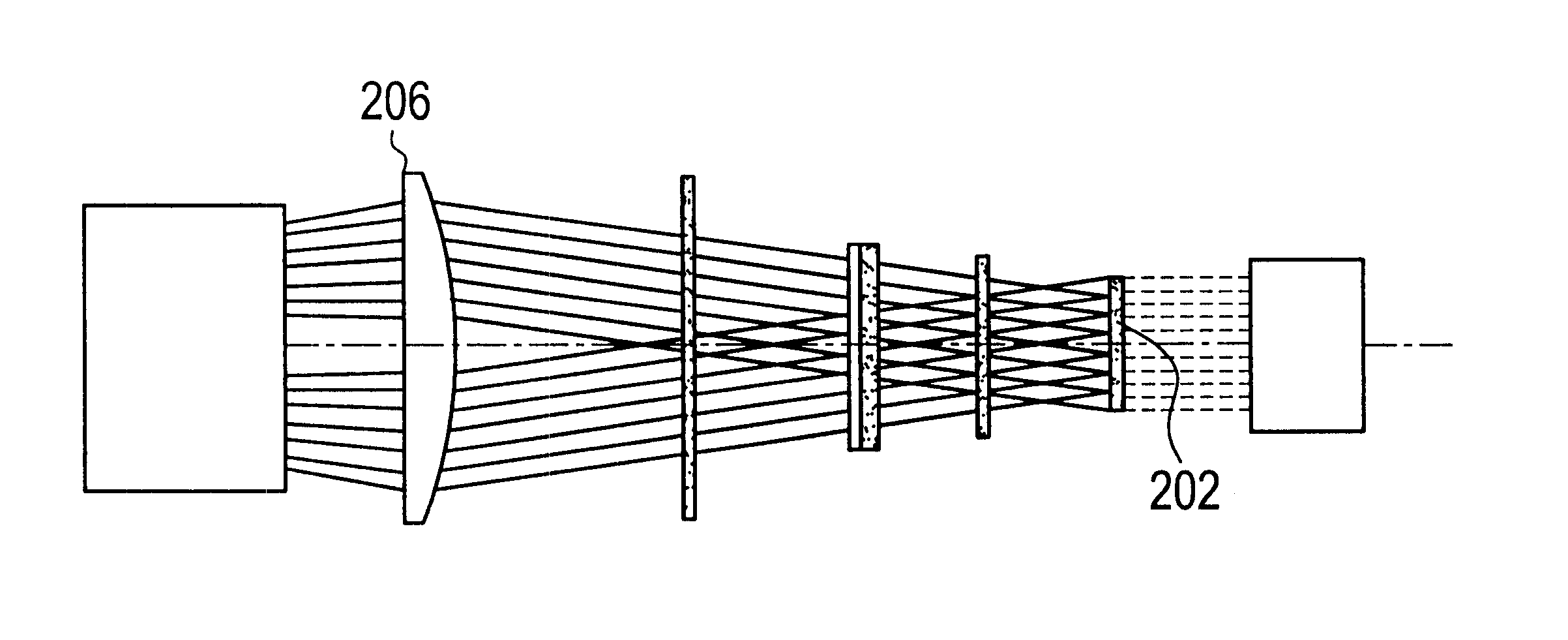

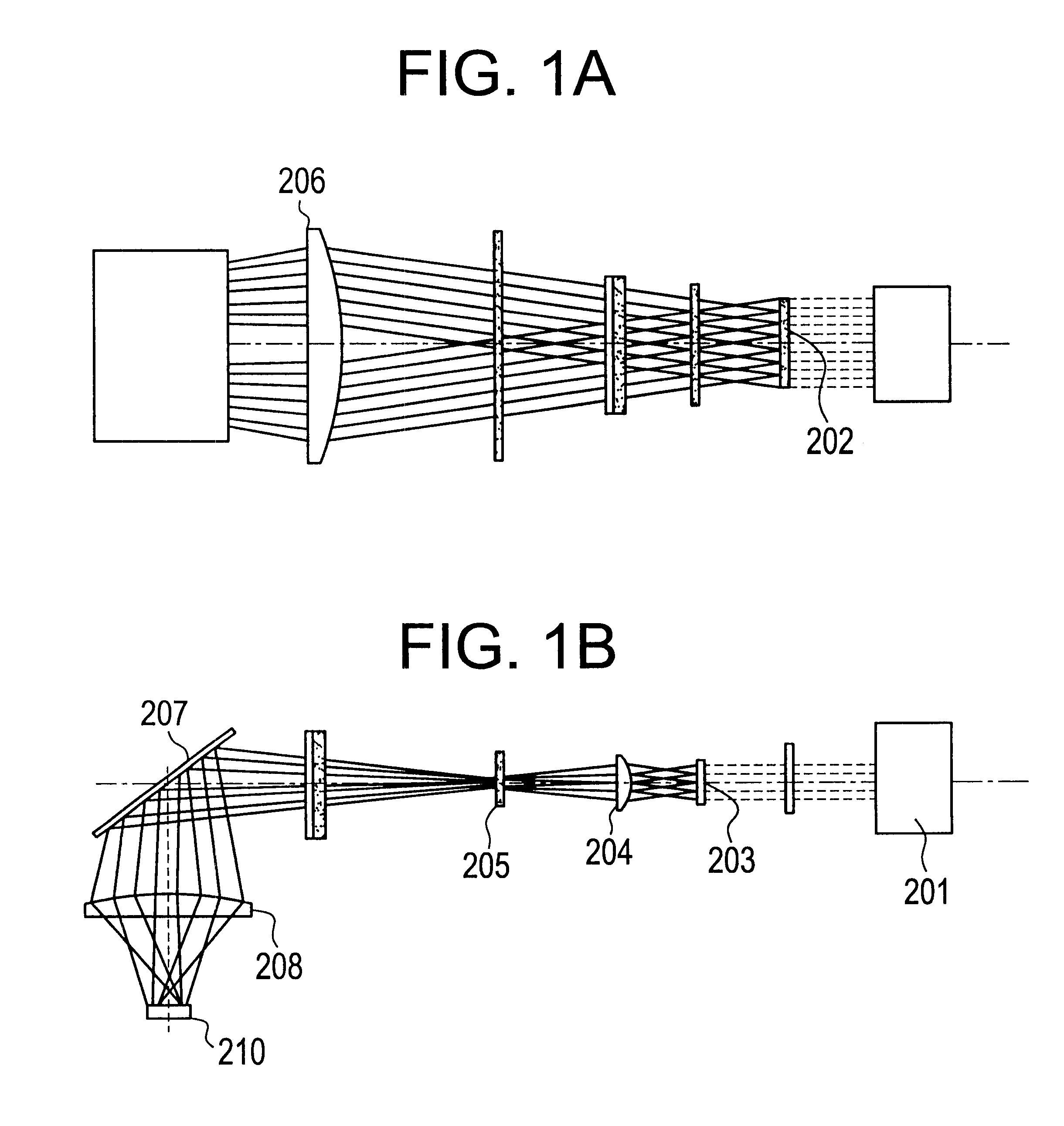

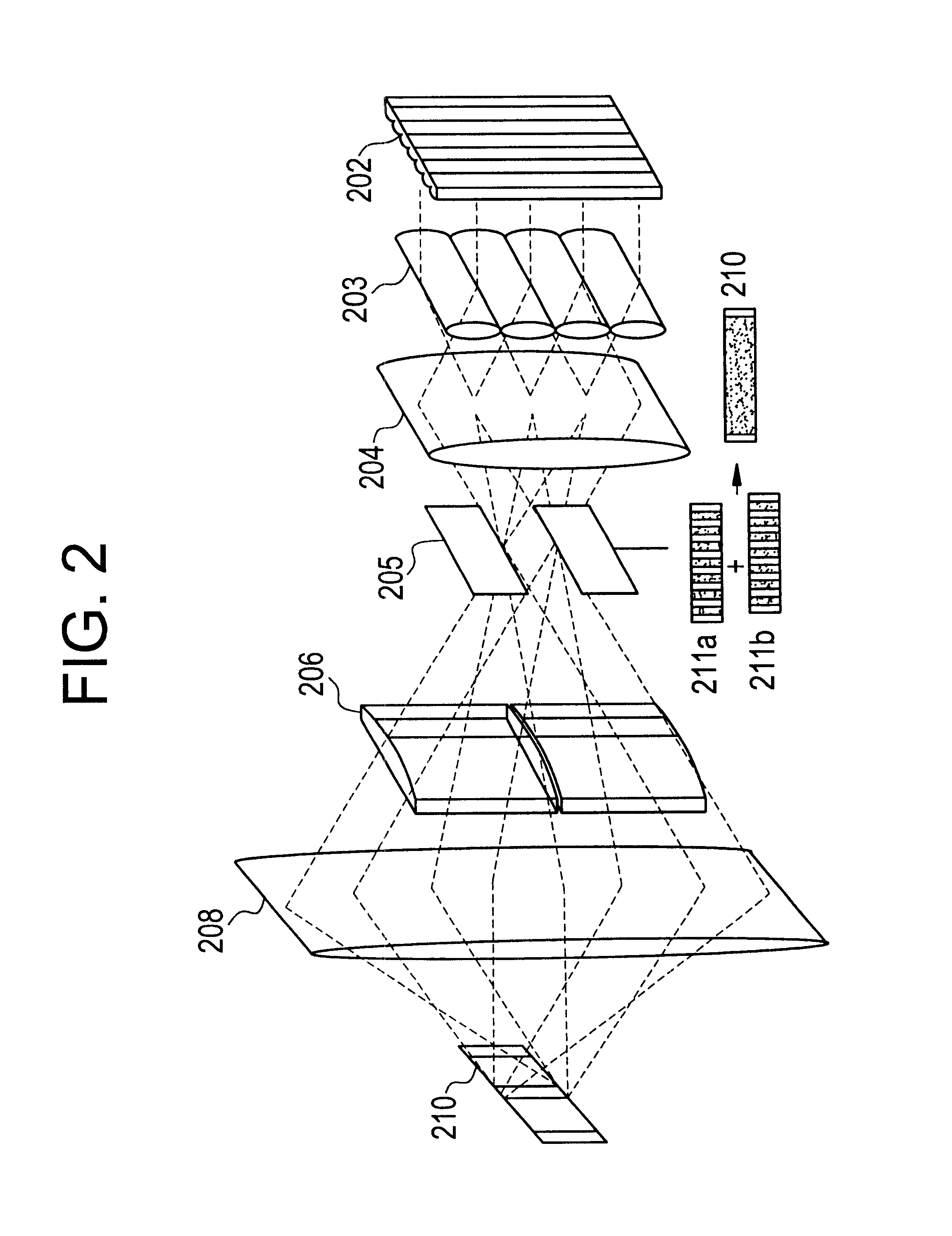

Beam homogenizer and laser irradiation apparatus

InactiveUS6393042B1Semiconductor/solid-state device manufacturingOptical resonator shape and constructionLight beamOptoelectronics

There is provided a beam homogenizer which can unify the energy distribution of a linear laser beam in a longitudinal direction. In the beam homogenizer including cylindrical lens groups for dividing a beam, and a cylindrical lens and a cylindrical lens group for condensing the divided beams, the phases, in the longitudinal direction, of linear beams passing through individual cylindrical lenses of the cylindrical lens group for condensing the divided beams are shifted, and then, the beams are synthesized, so that the intensity of interference fringes of the linear beam on a surface to be irradiated is made uniform.

Owner:SEMICON ENERGY LAB CO LTD

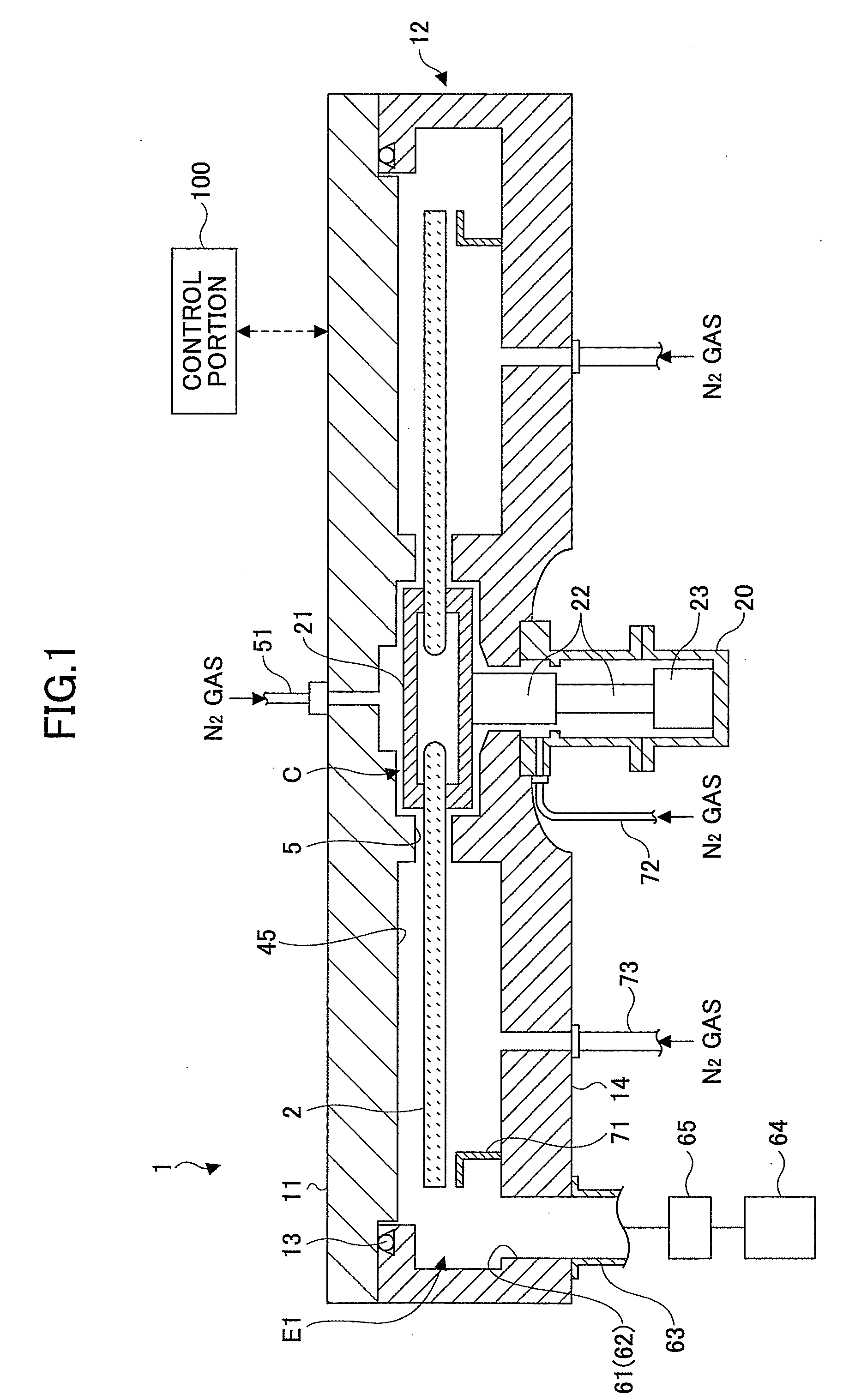

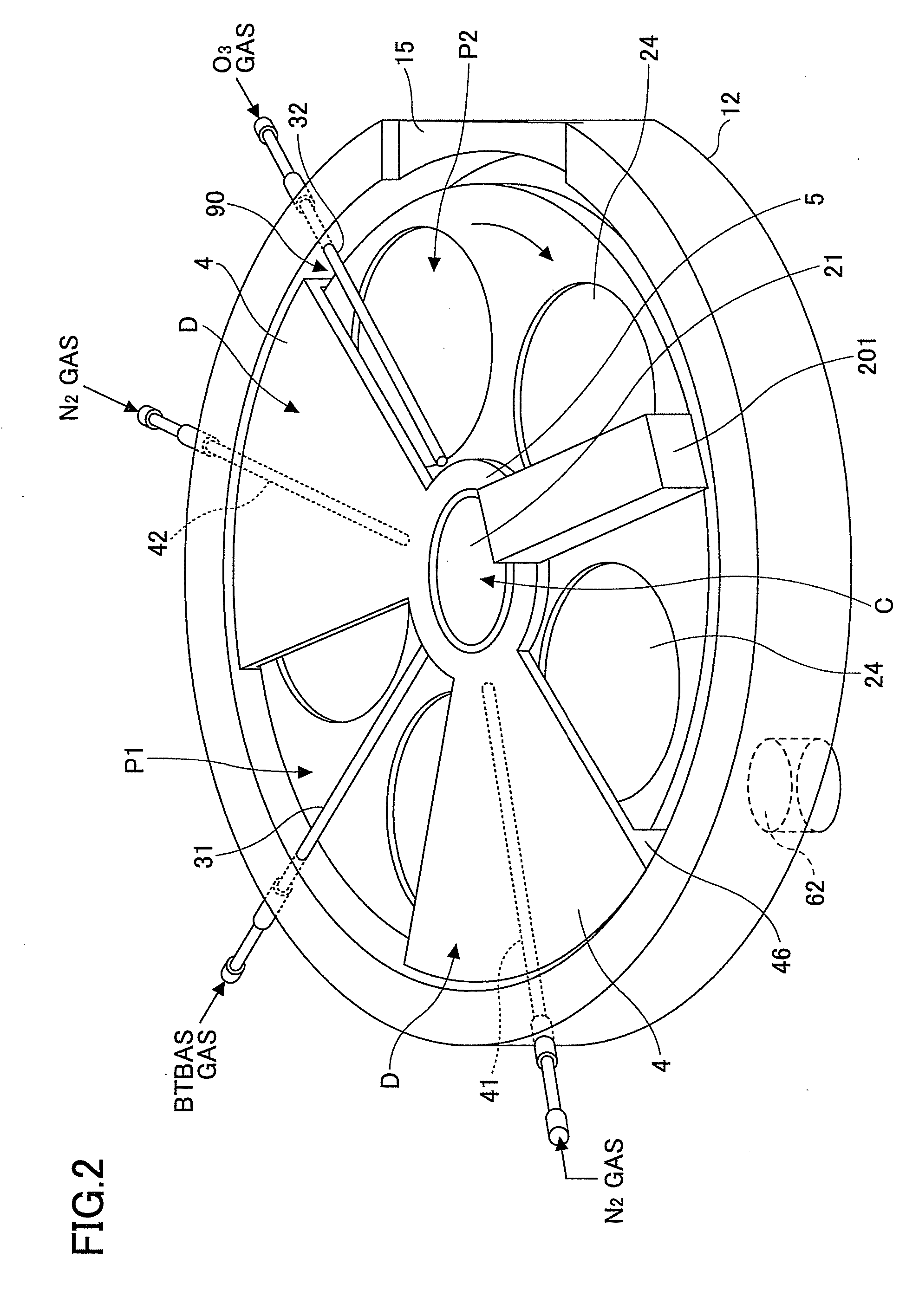

Film deposition apparatus, film deposition method, and storage medium

In a film deposition apparatus where bis (tertiary-butylamino) silane (BTBAS) gas is adsorbed on a wafer and then O3 gas is adsorbed on the wafer so that the BTBAS gas is oxidized by the O3 gas thereby depositing a silicon oxide film by rotating a turntable on which the wafer is placed, a laser beam irradiation portion is provided that is capable of irradiating a laser beam to an area spanning from one edge to another edge of a substrate receiving area of the turntable along a direction from an inner side to an outer side of the table.

Owner:TOKYO ELECTRON LTD

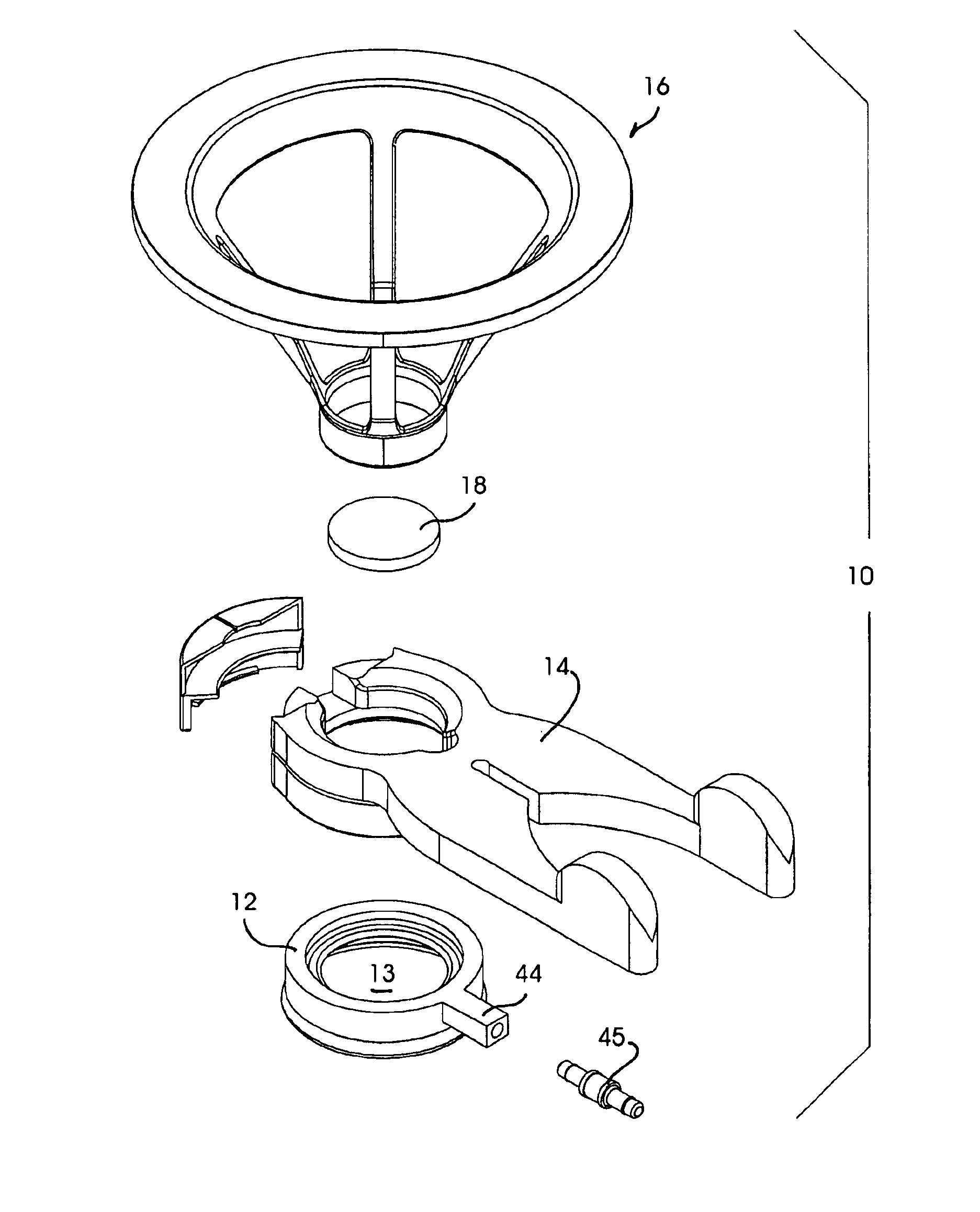

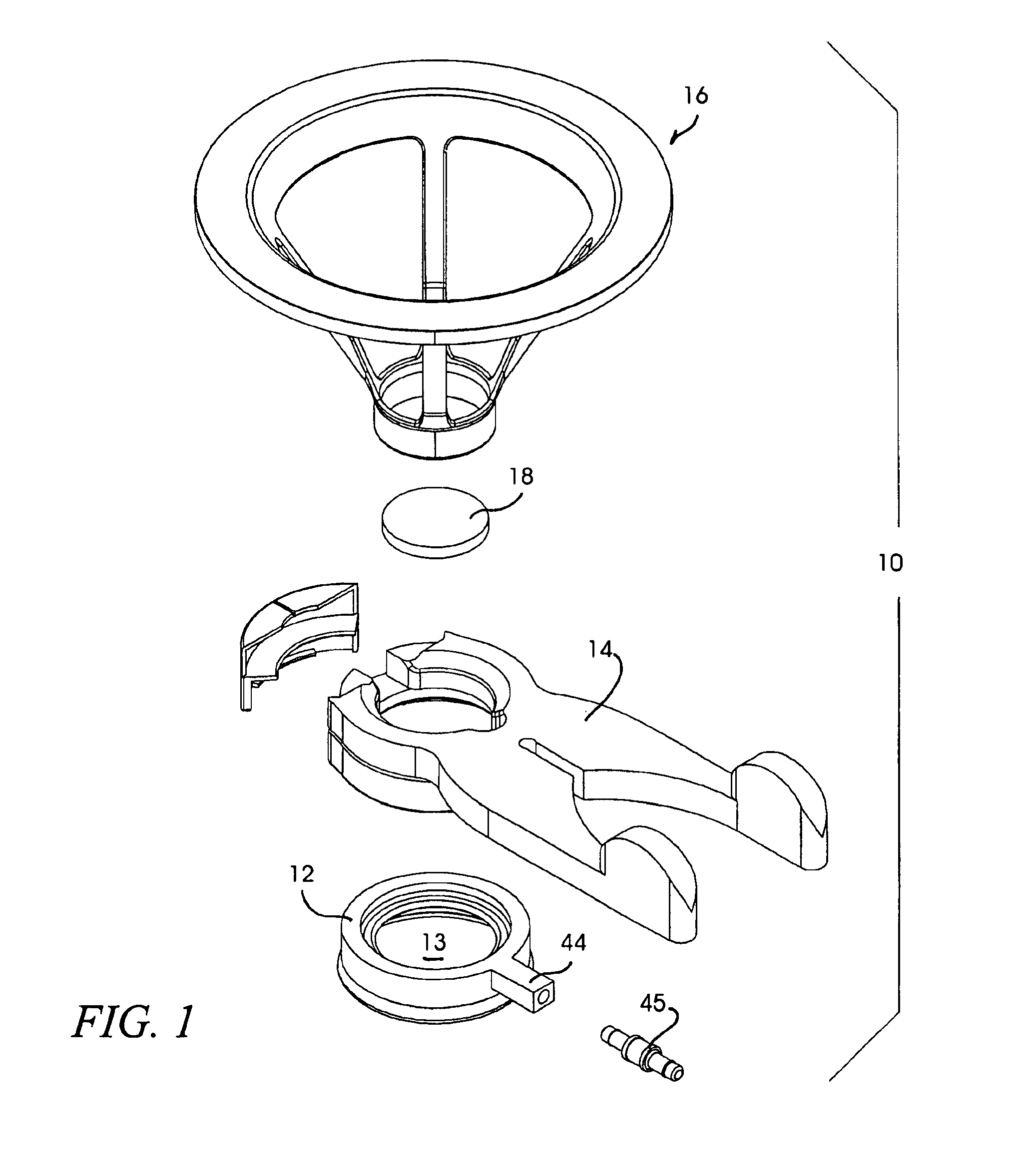

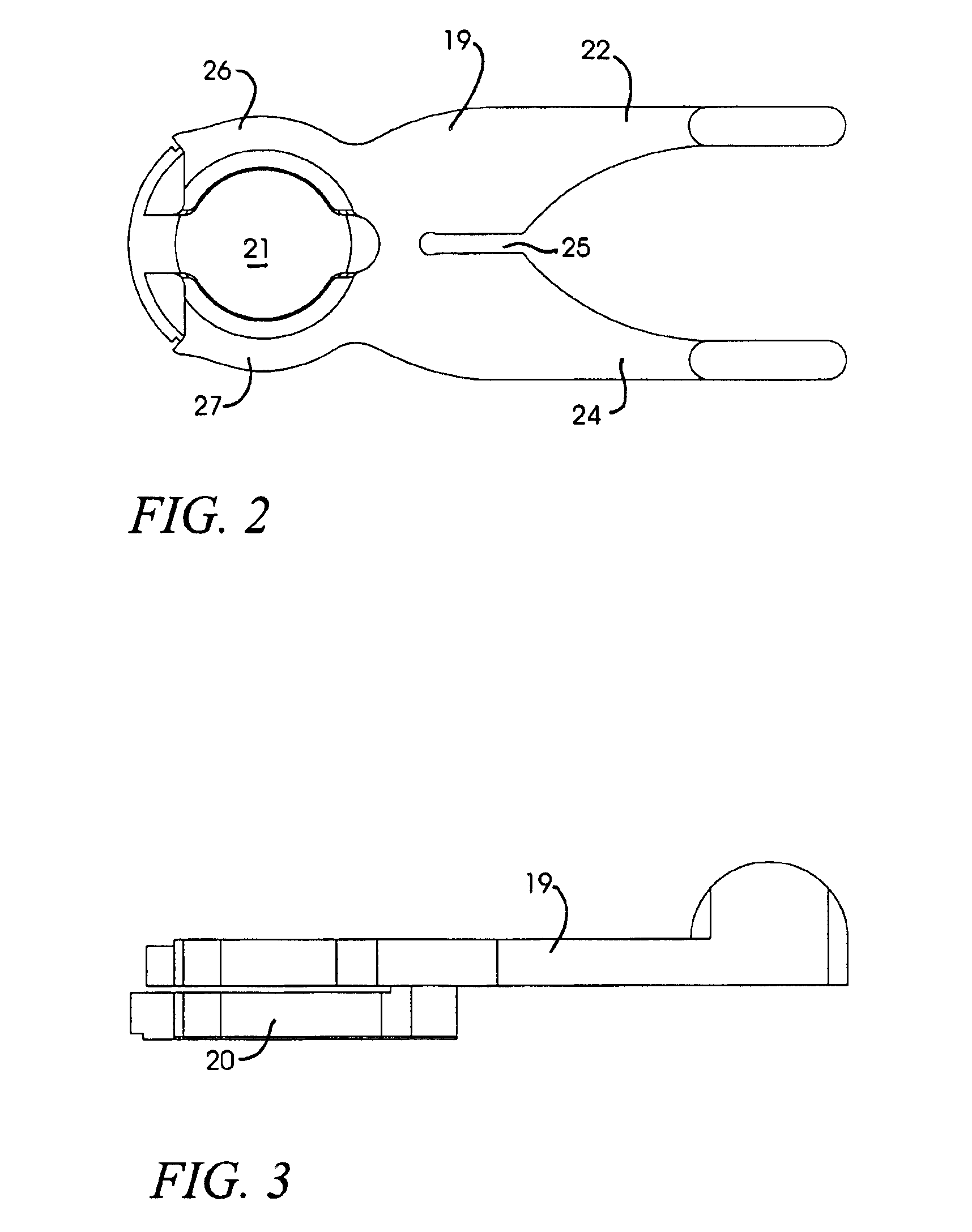

Ocular fixation and stabilization device for ophthalmic surgical applications

InactiveUS6863667B2Position stabilityLaser surgerySurgical instrument detailsEye laser surgeryCorneal surface

A disposable stabilization and applanation device for reconfiguring the cornea of an eye for ophthalmic laser surgery, includes an applanation lens that is disposed in a particular spatial position with respect to an incident laser beam. The applanation lens is inserted into the central opening of an attachment ring and applanates the eye in response to pressure from a lens cone. The attachment ring is coupled to the eye and includes a skirt which surrounds the applanation lens and extends outwardly therefrom to define a chamber. The skirt is formed with a groove which defines a suction channel between the attachment ring skirt and the corneal surface of an eye. A vacuum source is connected and fluid communication with the suction channel and is selectively activated to create a partial vacuum in the channel.

Owner:AMO DEVMENT

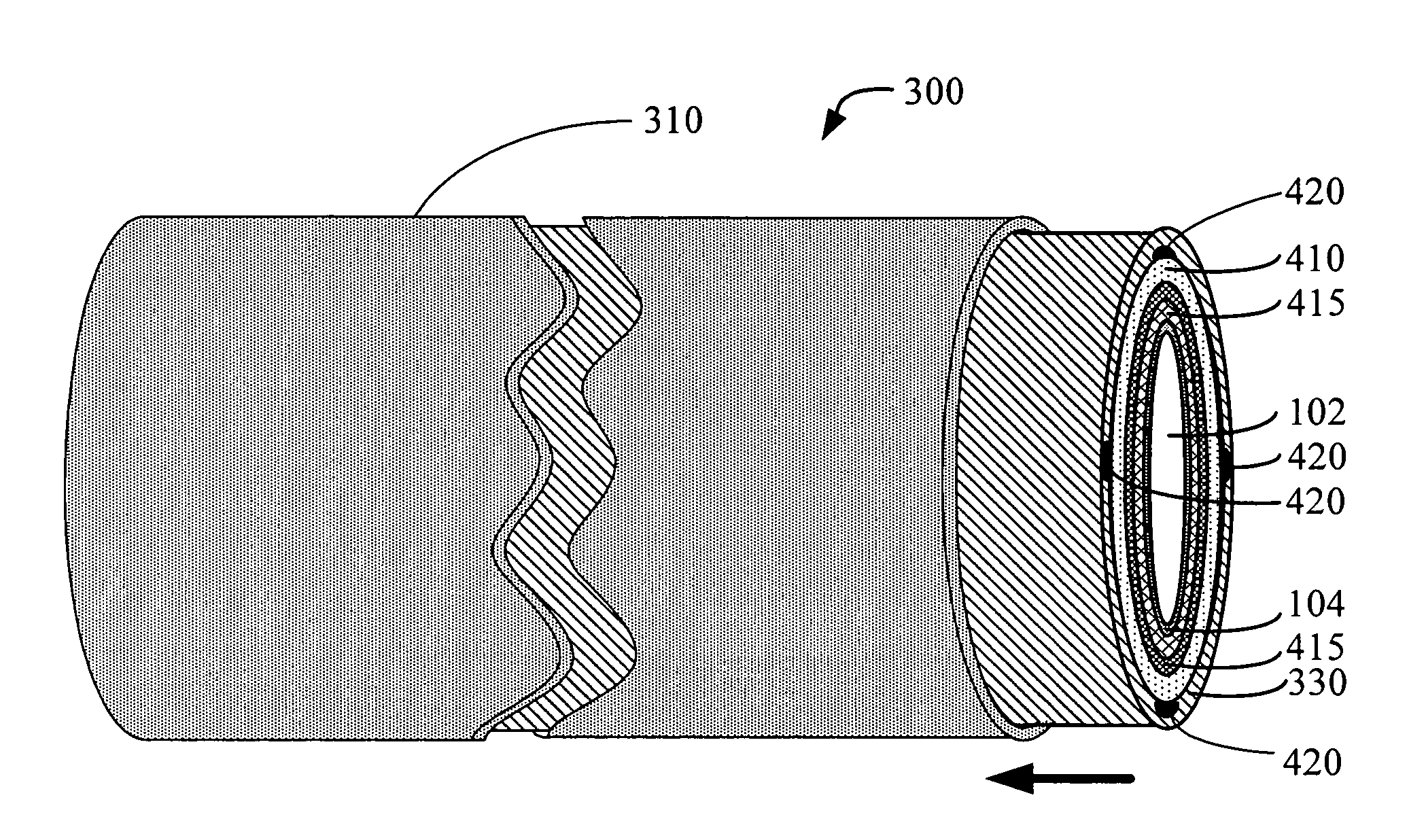

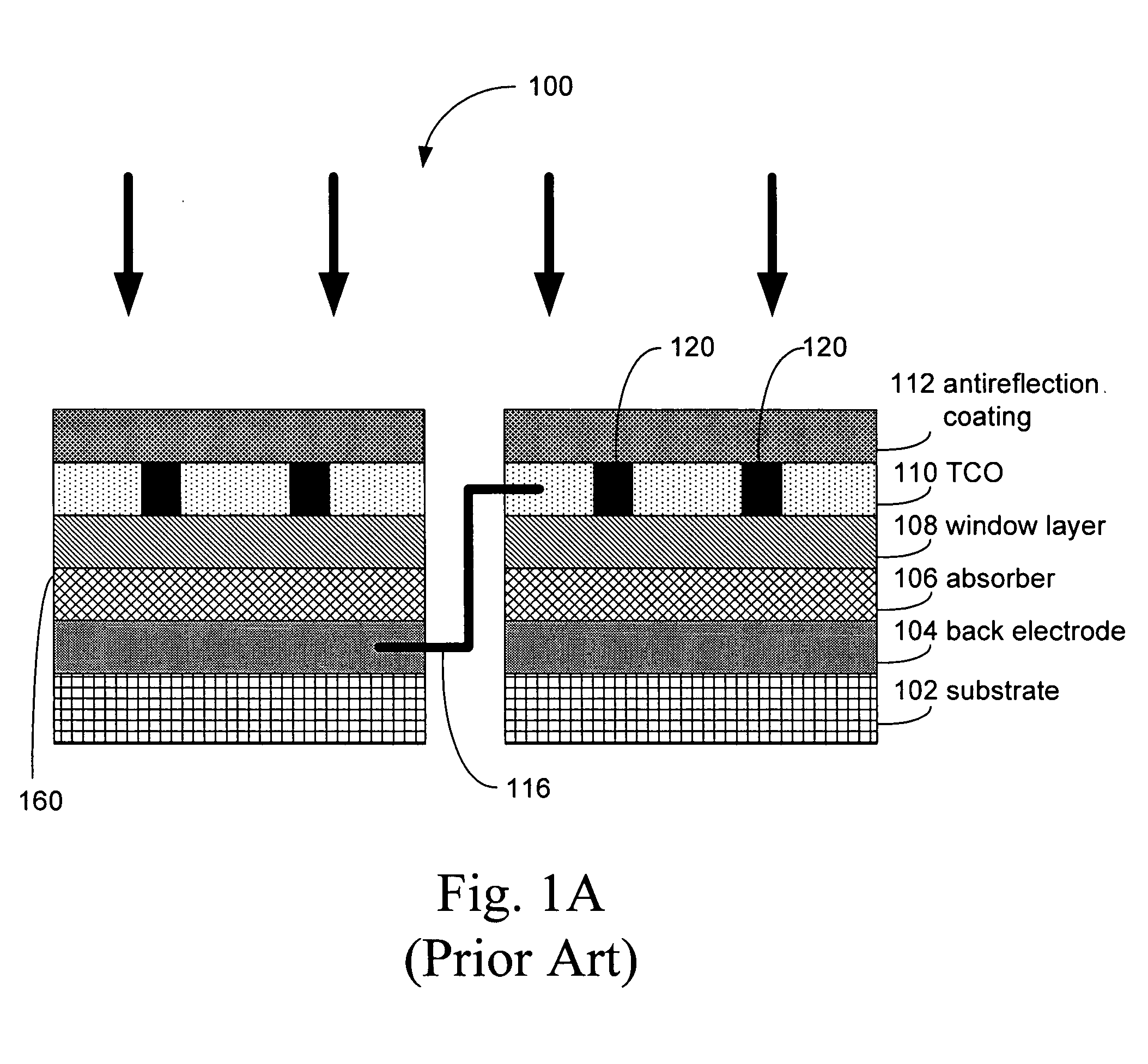

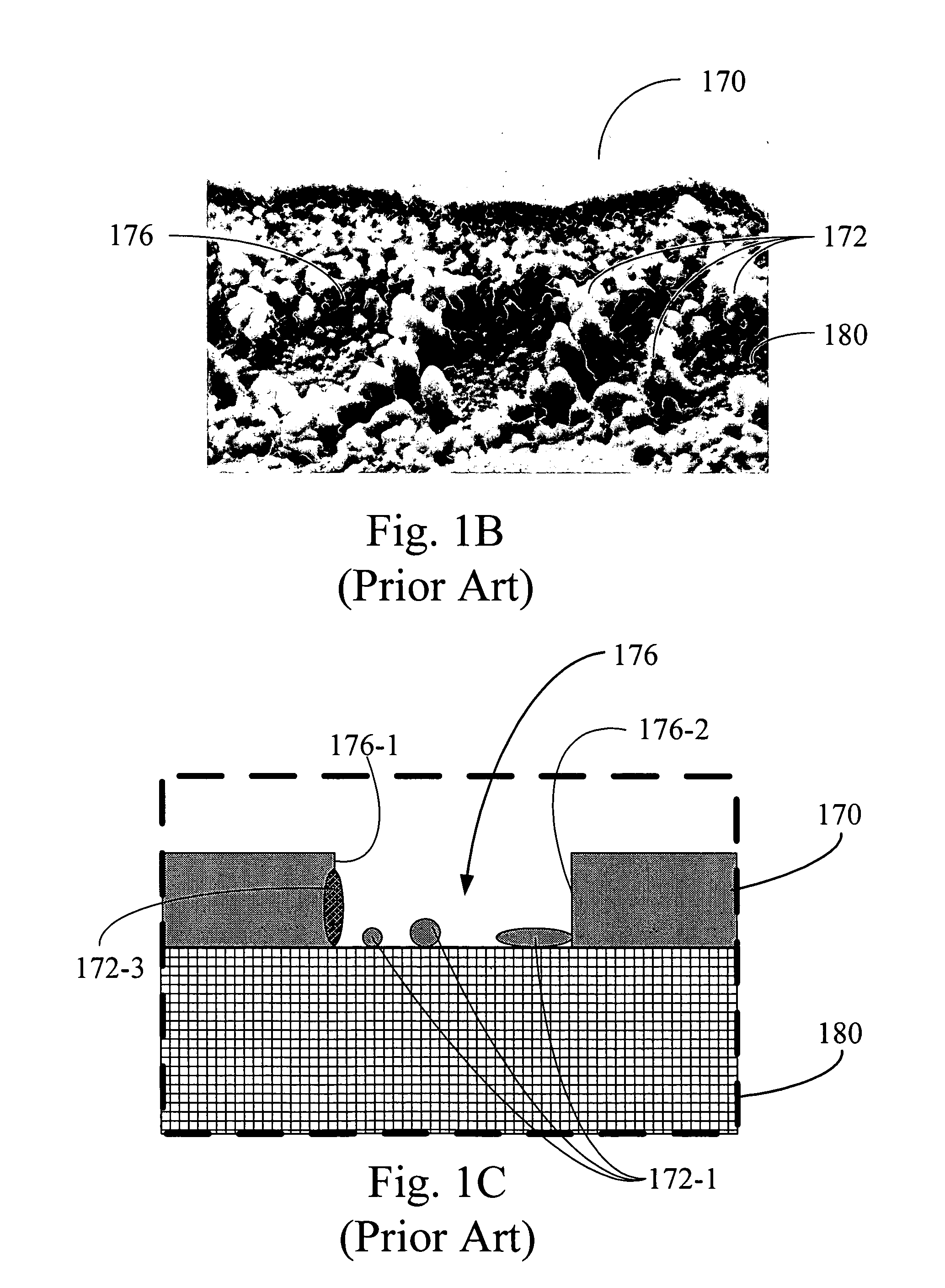

Laser scribing apparatus, systems, and methods

InactiveUS20080029152A1Final product manufactureWelding/soldering/cutting articlesLaser scribingEngineering

Apparatus, systems, and methods for forming a photovoltaic cell from a common layer on a substrate are provided. A first pass is made with a first laser beam over an area on the common layer. The first pass forms a groove in the common layer. The first pass forms within the common layer a first edge and a second edge. The first edge is separated from the second edge by the groove. The groove provides a first level of electrical isolation between the first edge and the second edge. A second pass is made with a second laser beam over approximately the same area on the common layer. The second pass provides a second level of electrical isolation between the first edge and the second edge. The second level of electrical isolation is greater than the first level of electrical isolation.

Owner:SOLYNDRA

Semiconductor laser device

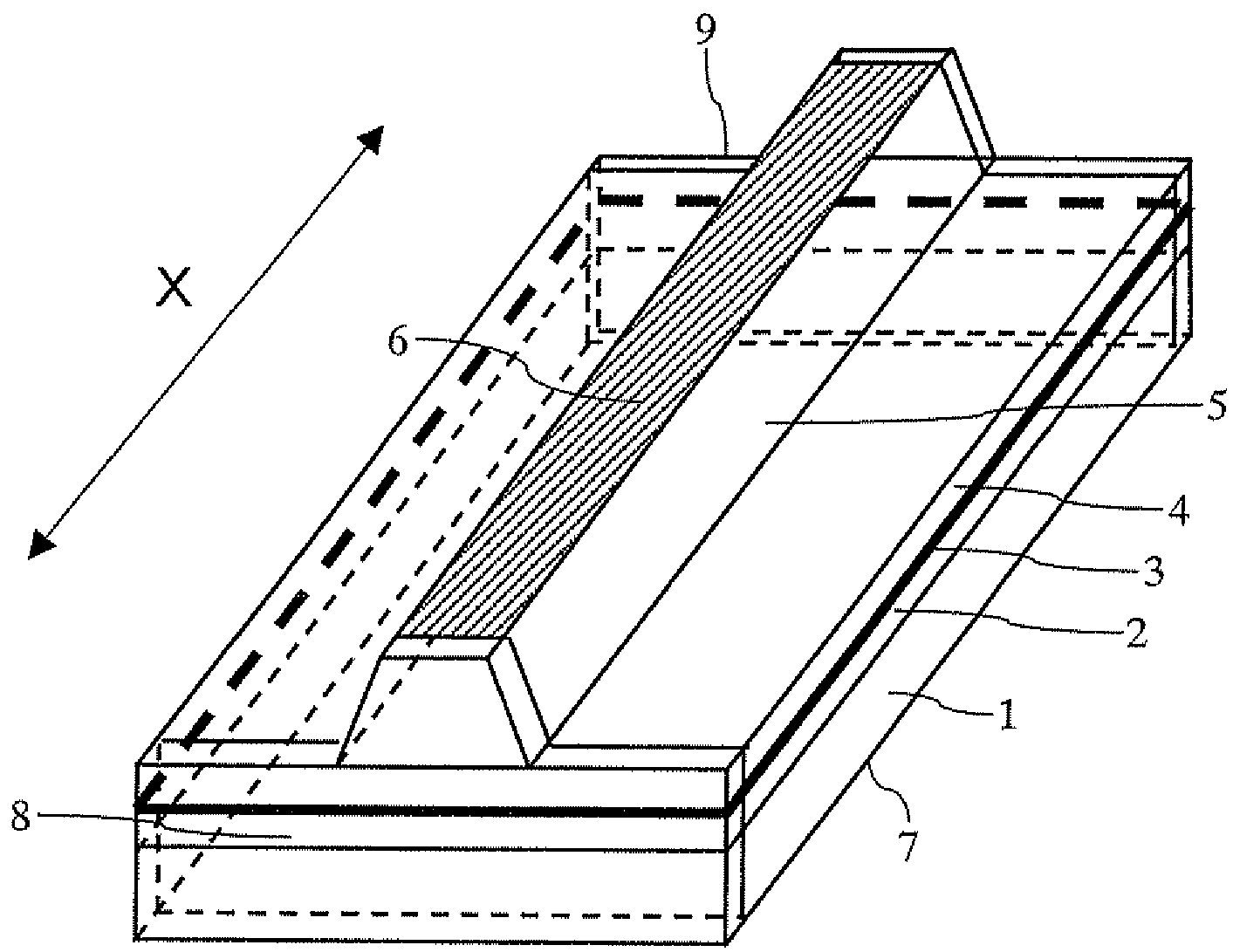

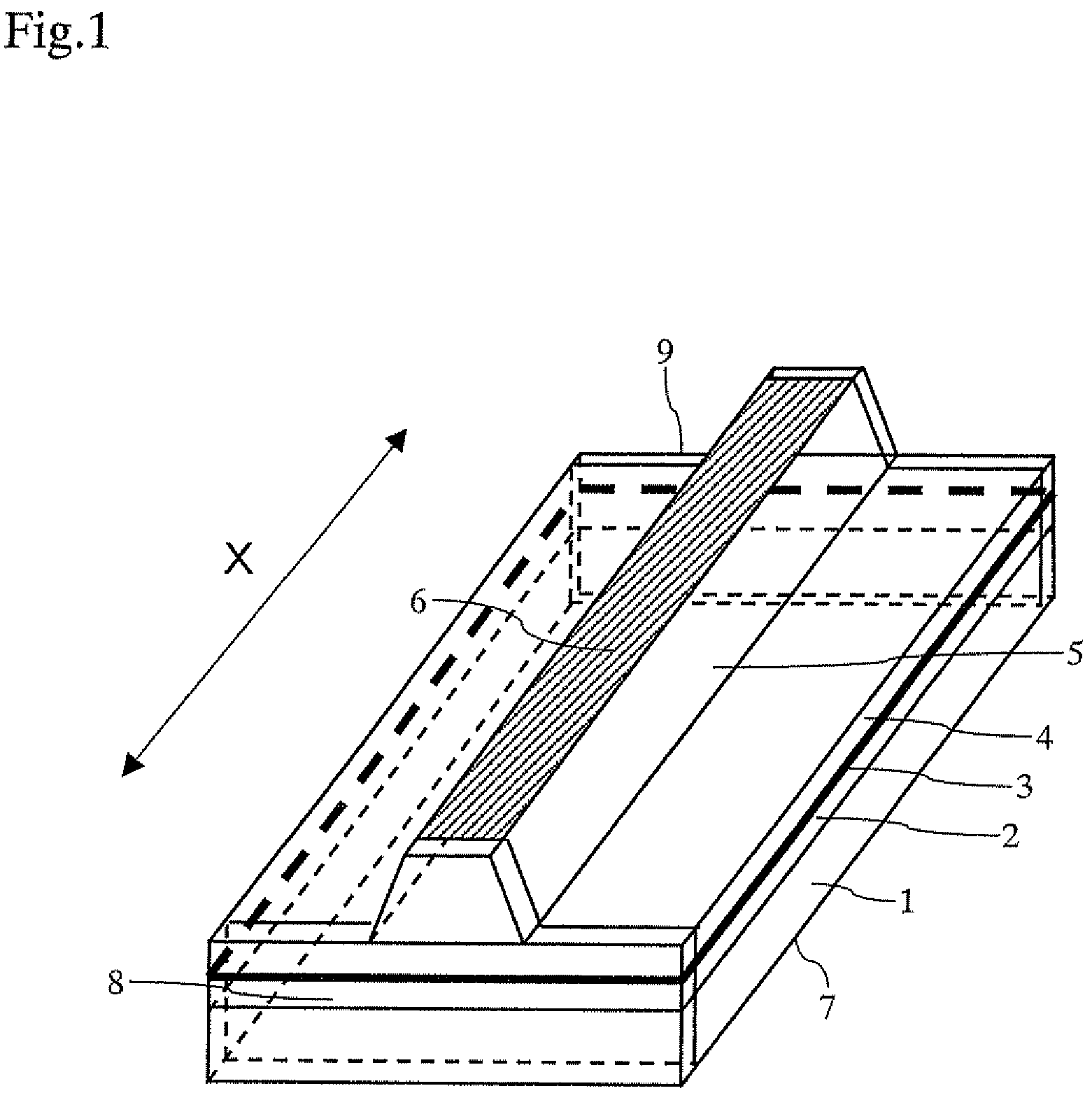

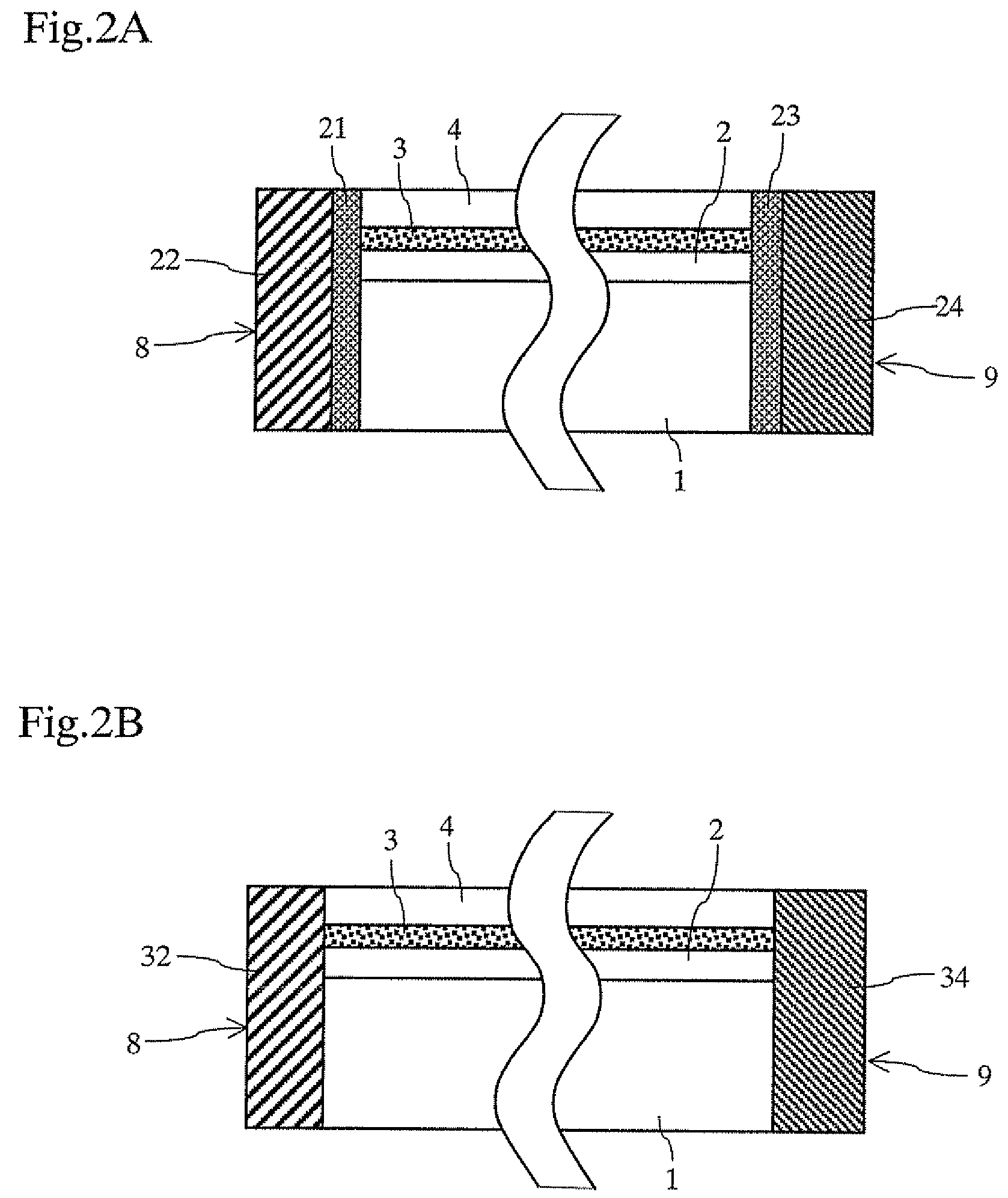

A semiconductor laser device includes a cavity extending in a propagation direction of a laser beam (X-direction). A front facet is on one end of the cavity through which the laser beam is emitted. A rear facet is on the other end of the cavity. Further, an adhesive layer and a coating film are on the front facet, and an adhesive layer and a coating film are on the rear facet. The adhesive layers preferably have a thickness of 10 nm or less and preferably include an anodic oxide film of one of Al, Ti, Nb, Zr, Ta, Si, and Hf.

Owner:MITSUBISHI ELECTRIC CORP

Device and method for measuring six degrees of freedom

InactiveUS20100128259A1Angle measurementBeacon systems using electromagnetic wavesLight beamDegrees of freedom

A laser tracker system for measuring six degrees of freedom may include a main optics assembly structured to emit a first laser beam, a pattern projector assembly structured to emit a second laser beam shaped into a two-dimensional pattern, and a target. The target may include a retroreflector and a position sensor assembly. A center of symmetry of the retroreflector may be provided on a different plane than a plane of the position sensor assembly. A method of measuring orientation of a target may include illuminating the target with a laser beam comprising a two-dimensional pattern, recording a position of the two-dimensional pattern on a position sensor assembly to create a measured signature value of the two-dimensional pattern, and calculating an orientation of the target based on the measured signature value.

Owner:FARO TECH INC

Additive manufacturing apparatus and method

ActiveUS20160236279A1Sufficient reflectivityAdditive manufacturing apparatusSpectrum investigationManufactured apparatusFeedback control

This invention concerns a laser solidification apparatus for building objects by layerwise solidification of powder material. The apparatus including a build chamber containing a build platform, a device for depositing layers of powder material on to the build platform, an optical unit for directing a laser beam to selectively solidify areas of each powder layer and a spectrometer for detecting characteristic radiation emitted by plasma formed during solidification of the powder by the laser beam. The invention also relates to a spectrometer for detecting characteristic radiation generated by interaction of the metal with the or a further laser beam. The spectra recorded using the spectrometer may be used for feedback control during the solidification process.

Owner:RENISHAW PLC

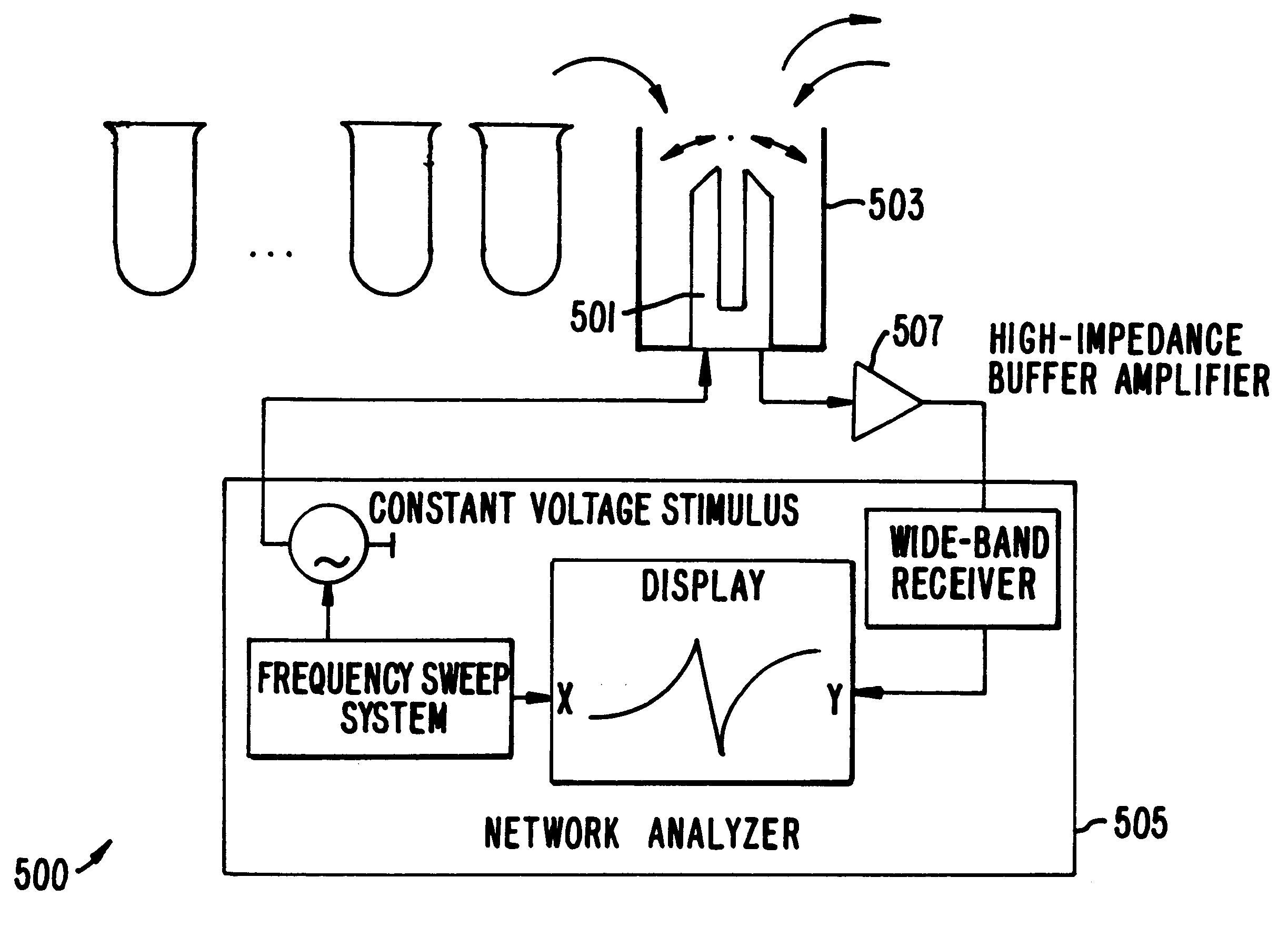

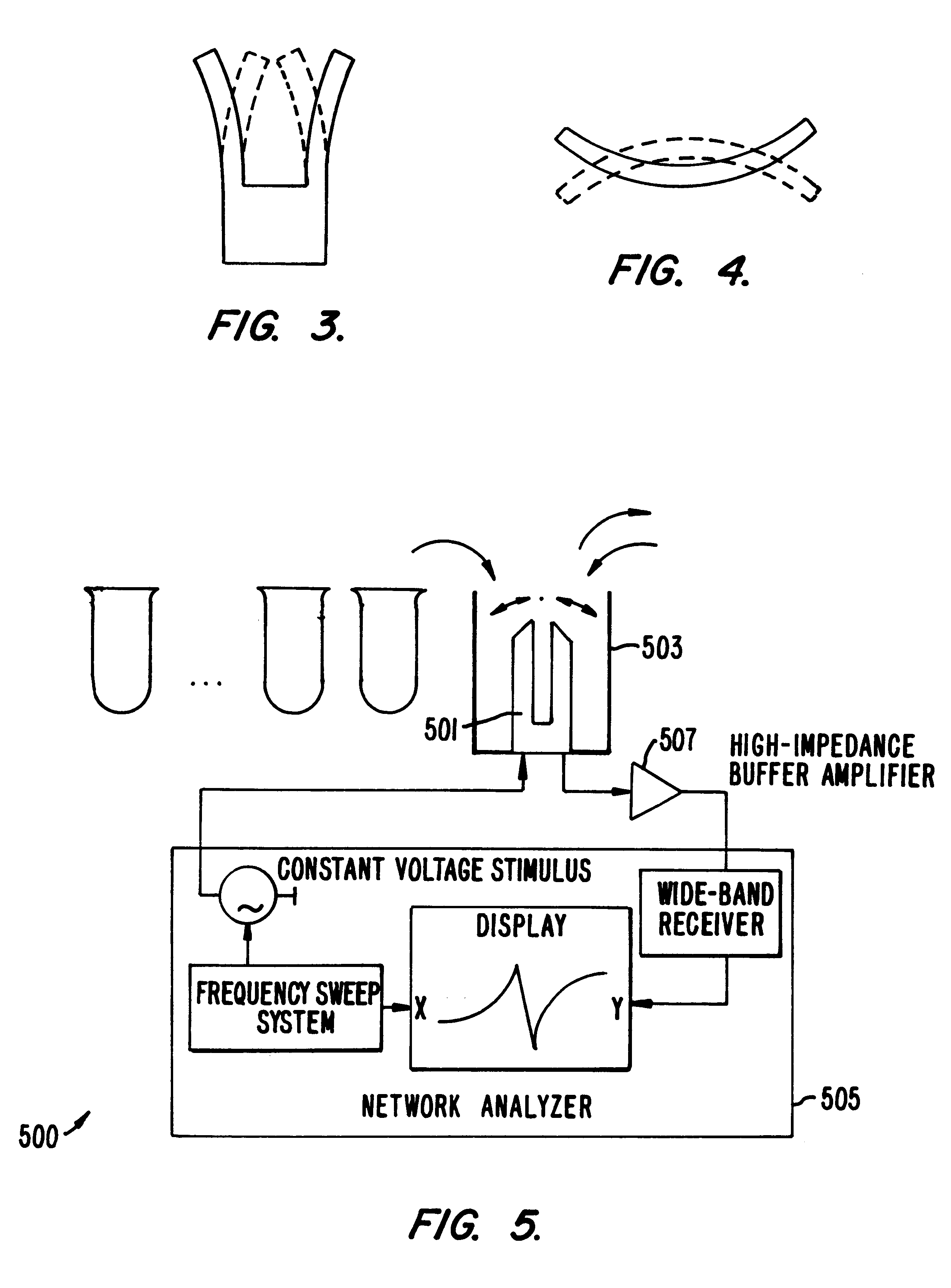

Systems and methods for characterization of materials and combinatorial libraries with mechanical oscillators

InactiveUS6182499B1Optical radiation measurementMaterial nanotechnologySonificationVisual perception

Methods and apparatus for screening diverse arrays of materials are provided. In one aspect, systems and methods are provided for imaging a library of materials using ultrasonic imaging techniques. The system includes one or more devices for exciting an element of the library such that acoustic waves are propagated through, and from, the element. The acoustic waves propagated from the element are detected and processed to yield a visual image of the library element. The acoustic wave data can also be processed to obtain information about the elastic properties of the library element. In another aspect, systems and methods are provided for generating acoustic waves in a tank filled with a coupling liquid. The library of materials is then placed in the tank and the surface of the coupling liquid is scanned with a laser beam. The structure of the liquid surface disturbed by the acoustic wave is recorded, the recorded disturbance being representative of the physical structure of the library. In another aspect of the invention, a mechanical resonator is used to evaluate various properties (e.g., molecular weight, viscosity, specific weight, elasticity, dielectric constant, conductivity, etc.) of the individual liquid elements of a library of materials. The resonator is designed to ineffectively excite acoustic waves. The frequency response of the resonator is measured for the liquid element under test, preferably as a function of time. By calibrating the resonator to a set of standard liquids with known properties, the properties of the unknown liquid can be determined. An array of library elements can be characterized by a single scanning transducer or by using an array of transducers corresponding to the array of library elements. Alternatively, multiple resonators of differing design may be used to evaluate each element of a library of elements, thus providing improved dynamic range and sensitivity.

Owner:FREESLATE

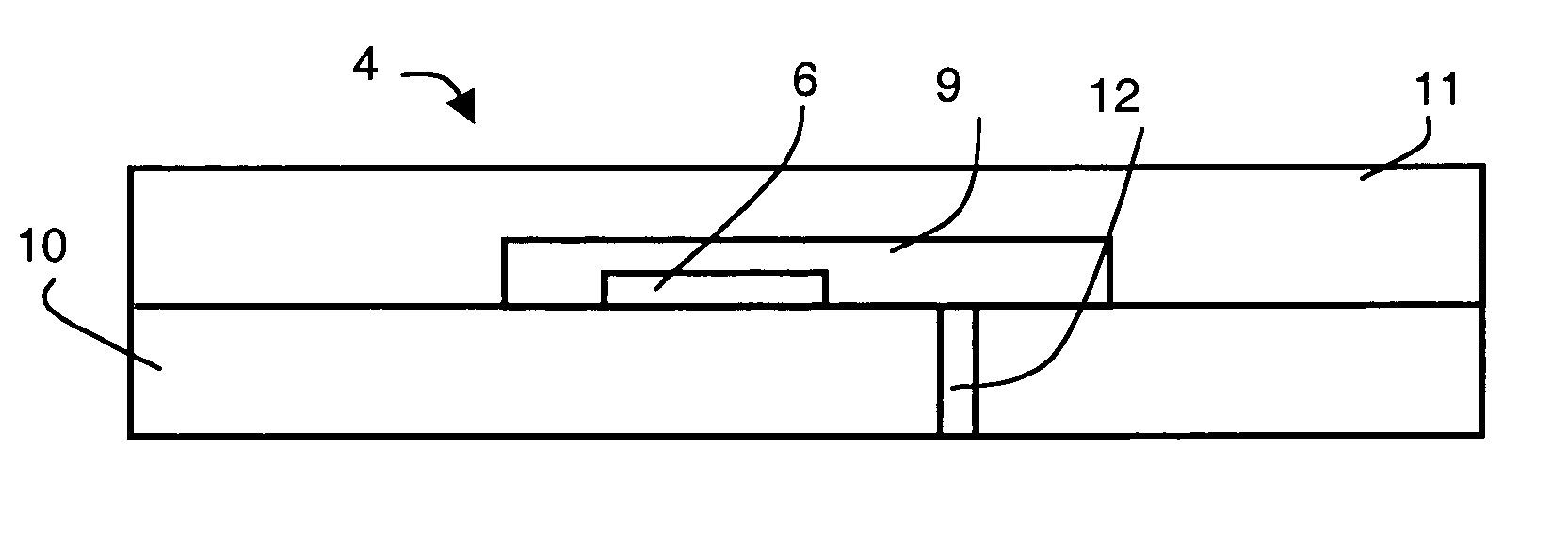

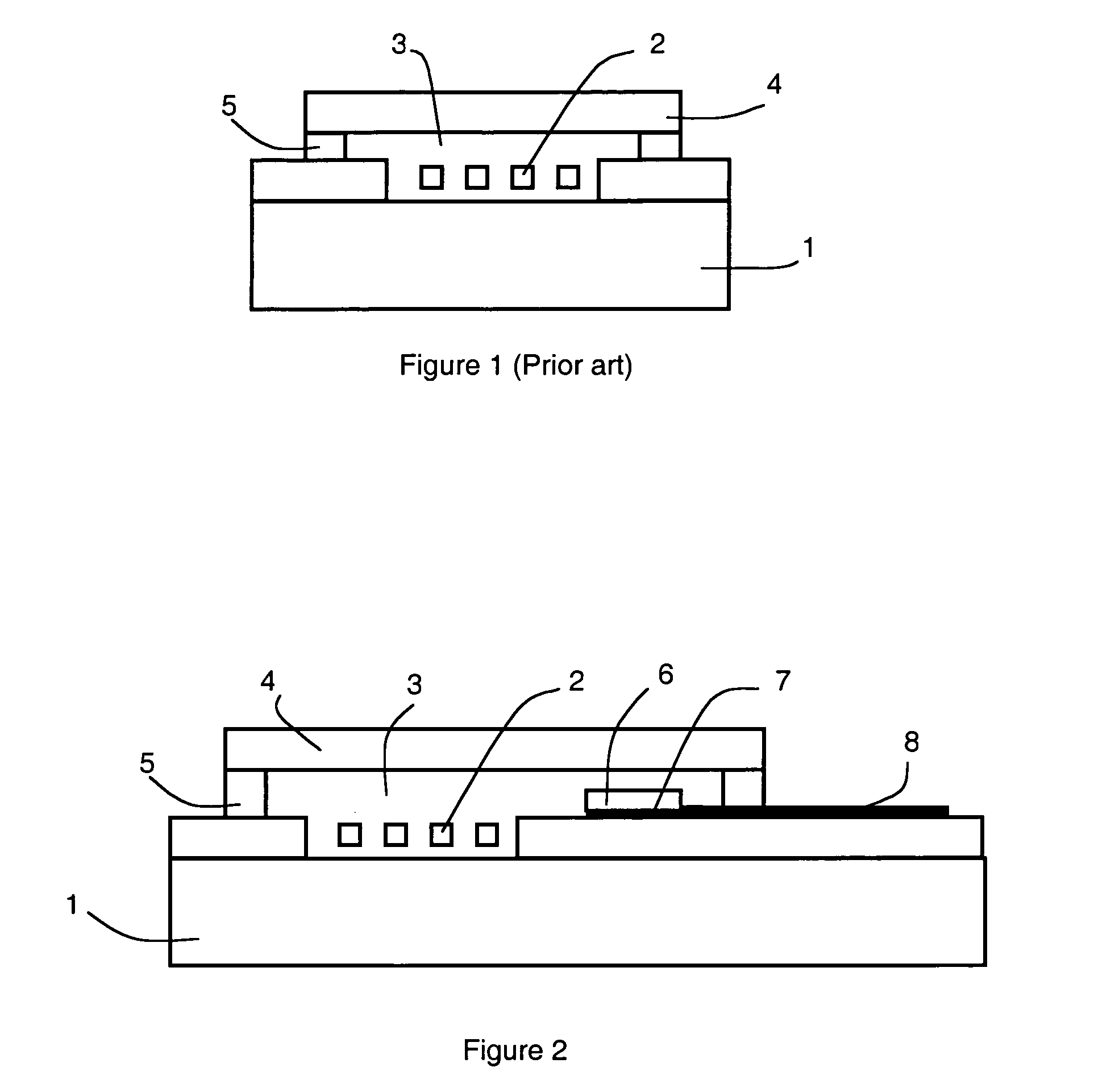

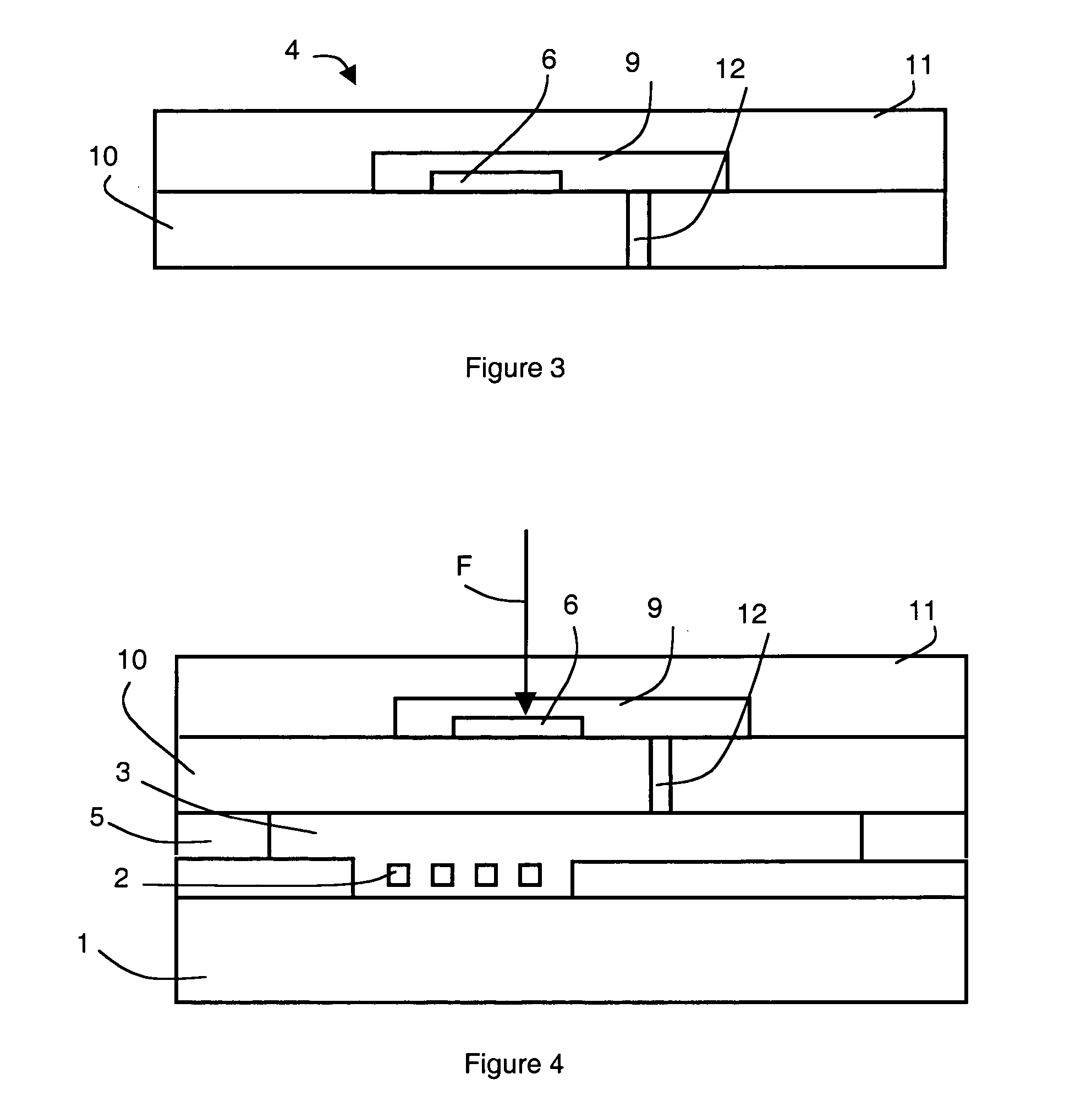

Integrated electromechanical microstructure comprising pressure adjusting means in a sealed cavity and pressure adjustment process

ActiveUS20040080035A1Simple processEasy to controlSemiconductor/solid-state device detailsSolid-state devicesCombustionEngineering

The integrated electromechanical microstructure comprises a base substrate and a cavity closed by a protective cover. Means for adjusting the pressure in the cavity after the protective cover has been sealed comprise at least one element made of pyrotechnic material combustion whereof releases gas into the cavity. The pressure in the cavity can thus be adjusted independently from the sealing process. Selective ignition of the elements made of pyrotechnic material can be achieved by heating electrical resistors or by laser beams coming from outside the microstructure and directed selectively towards the elements made of pyrotechnic material through a transparent zone of the protective cover.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

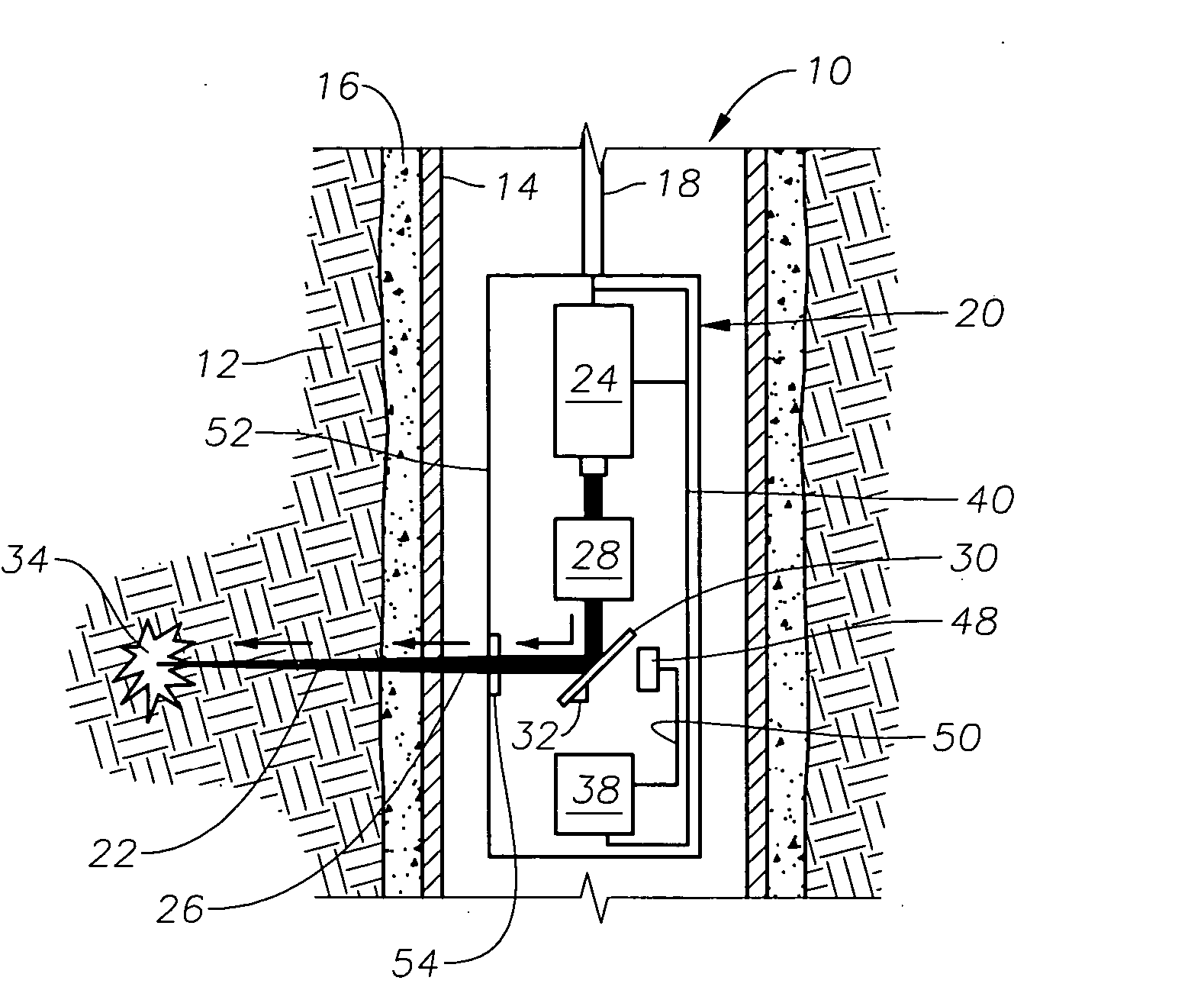

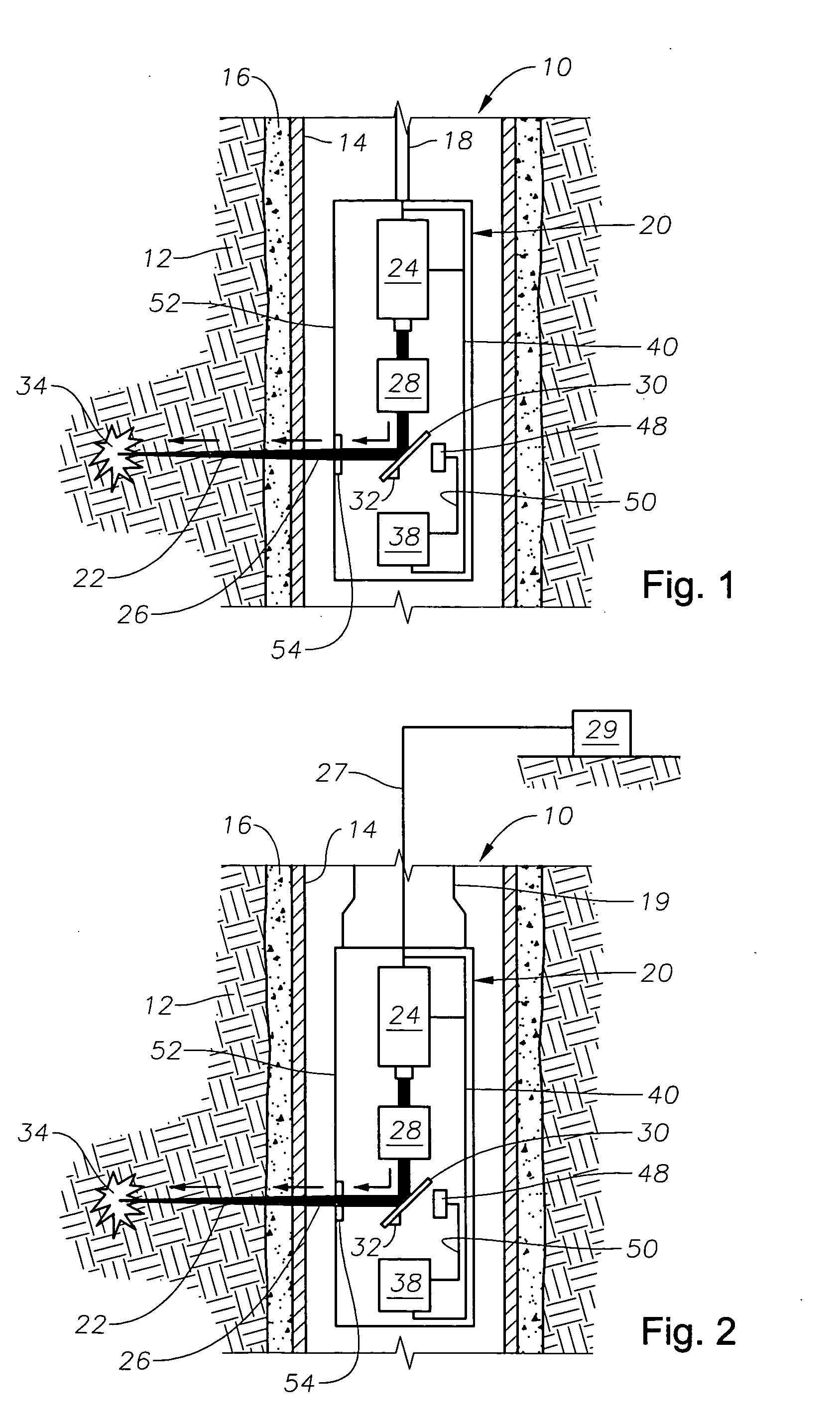

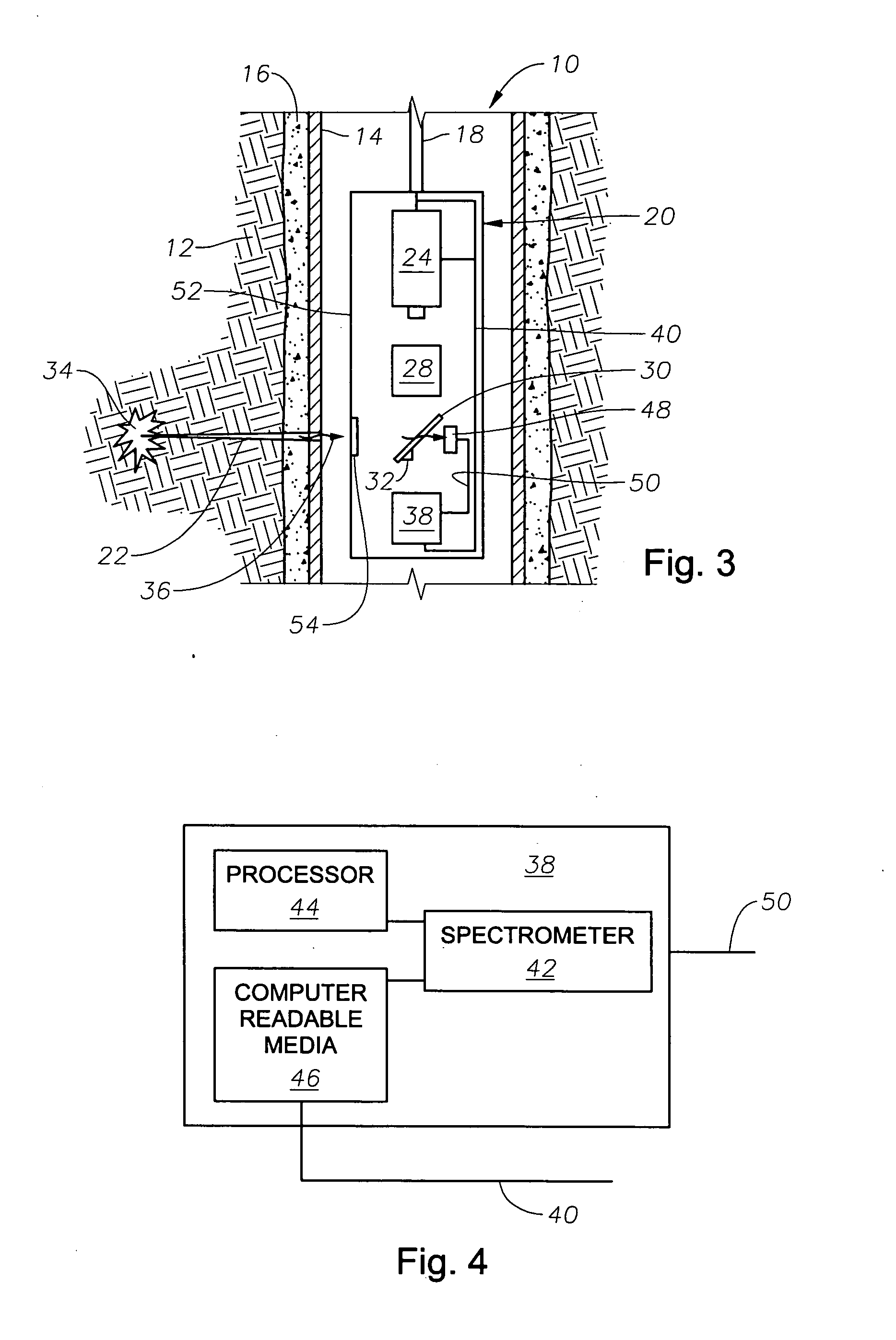

Drilling, perforating and formation analysis

ActiveUS20060102343A1Easy to useImprove breathabilitySpectrum investigationConstructionsMaterial removalWell drilling

A system and method of drilling and / or perforating uses a laser beam to remove material, such as to perforate the casing, cement and formation or drill a well bore. The system and method can further or alternately encompass material analysis that can be performed without removing the material from the well bore. The analysis can be performed apart from or in connection with drilling operations and / or perforating the casing, cement and formation. The analysis can be used in a feed back loop to adjust material removal, adjust material analysis, determine the location of future material removal, and for other uses.

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com