Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1786 results about "Susceptor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

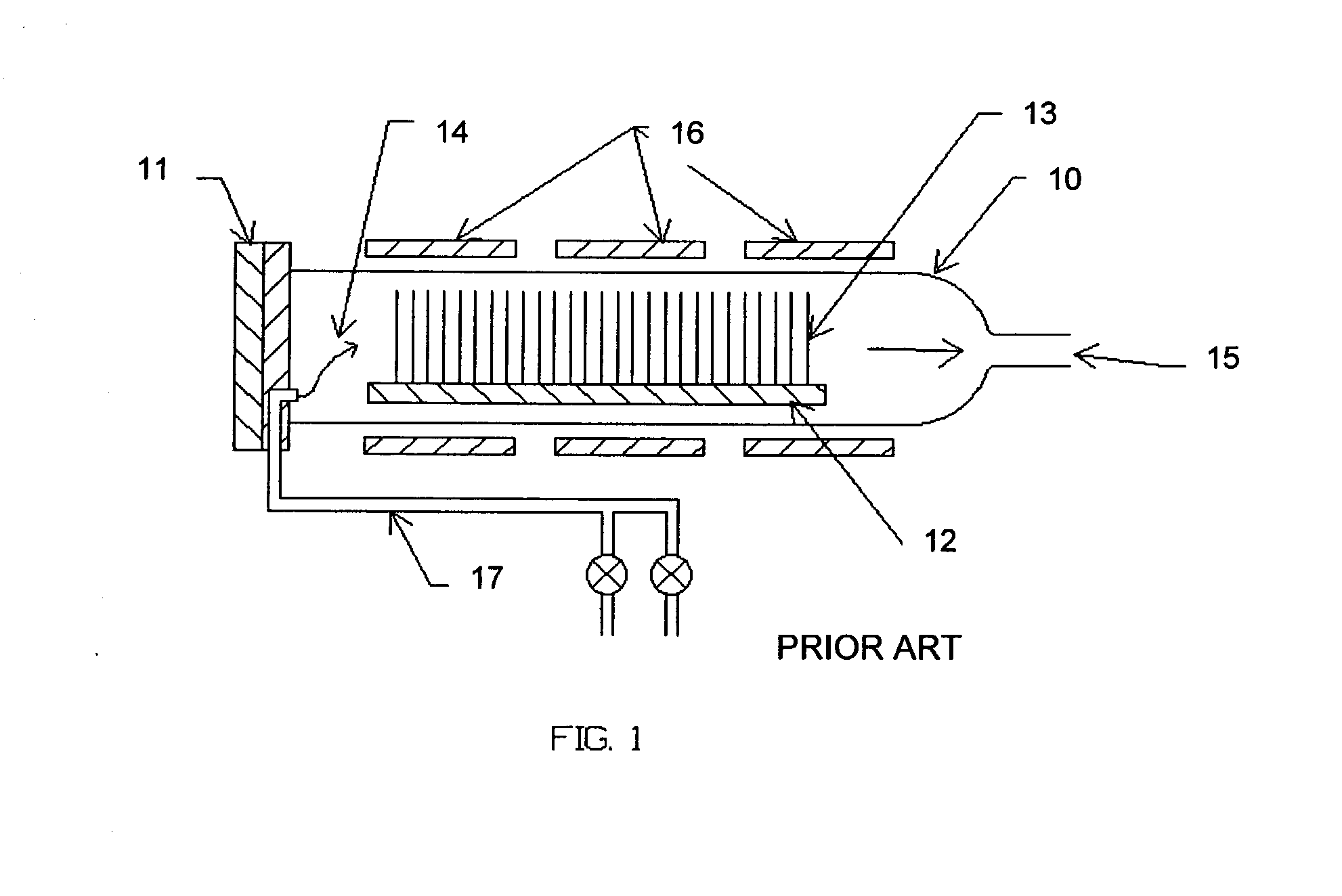

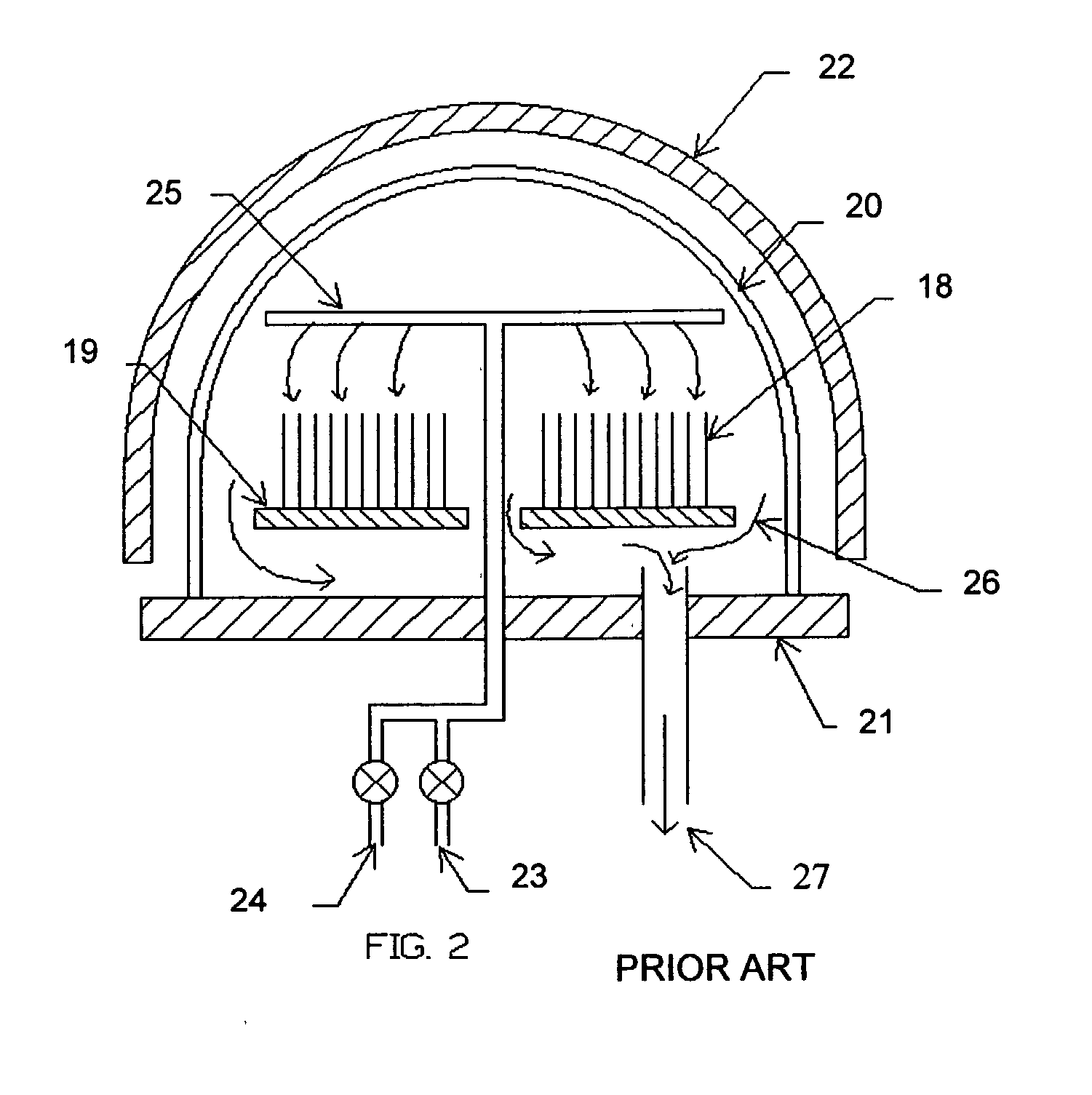

Susceptor is a material used for its ability to absorb electromagnetic energy and convert it to heat (which is sometimes designed to be re-emitted as infrared thermal radiation). The electromagnetic energy is typically radiofrequency or microwave radiation used in industrial heating processes, and also in microwave cooking. The name is derived from susceptance, an electrical property of materials that measures their tendency to convert electromagnetic energy to heat.

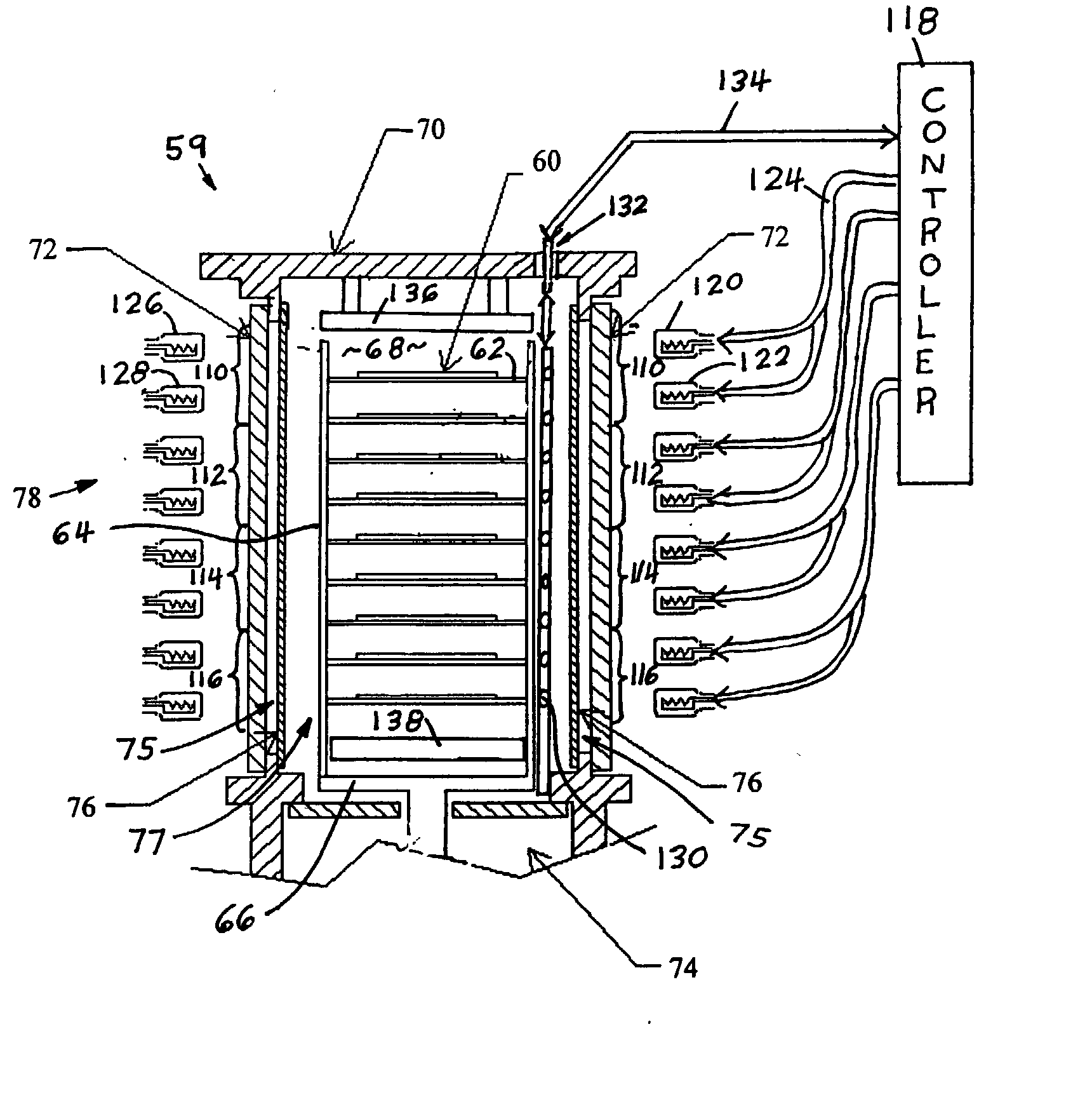

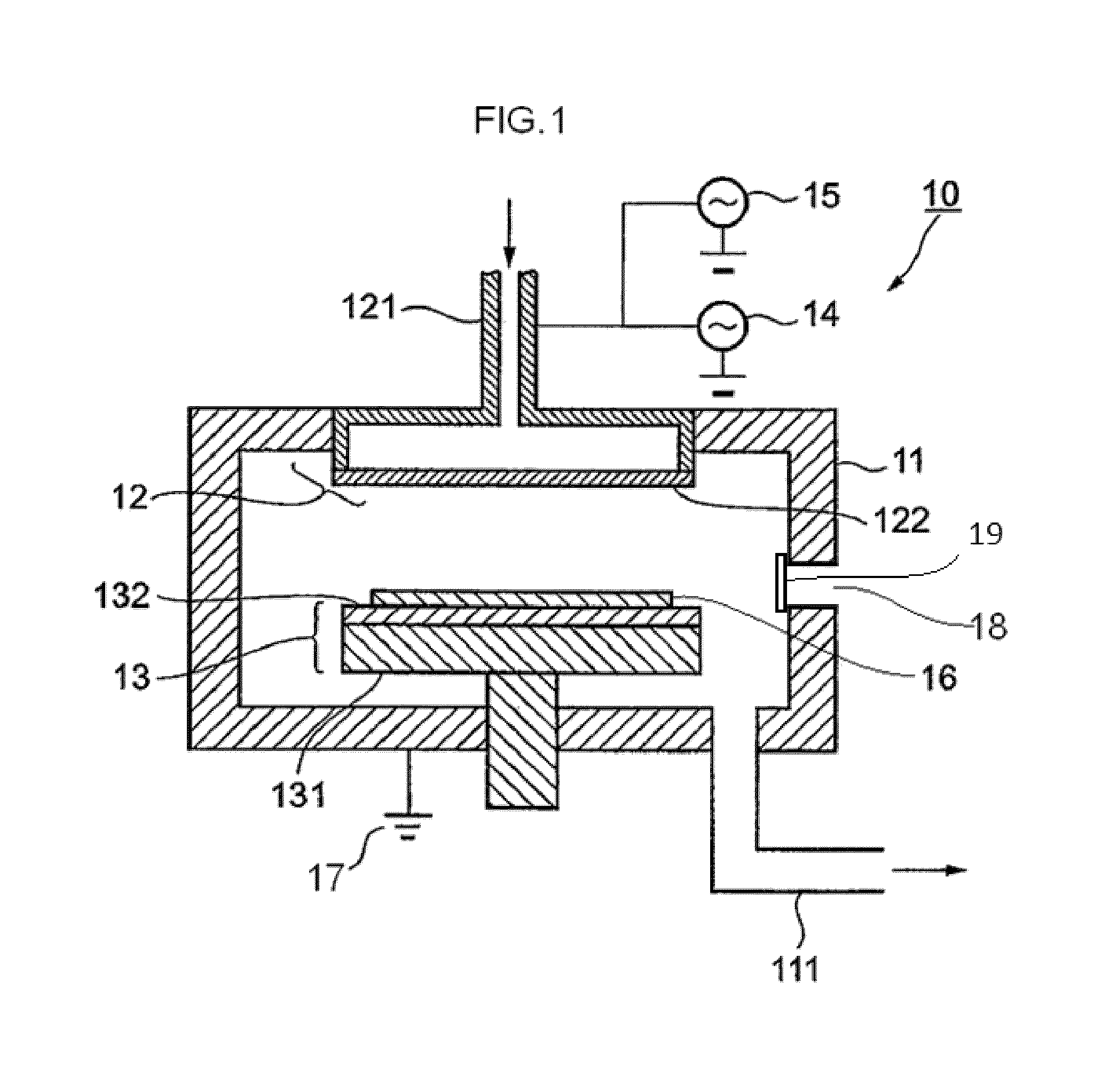

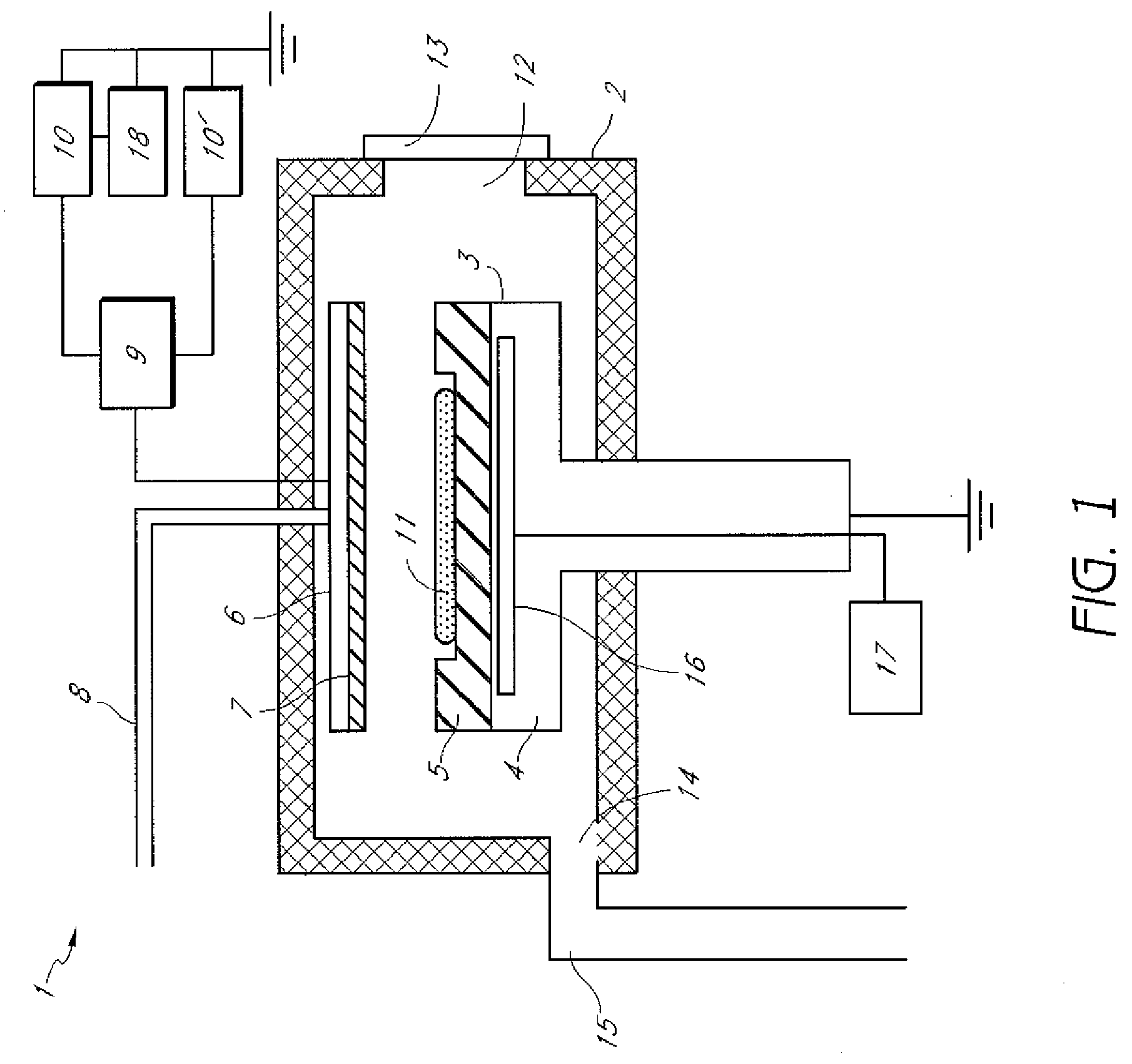

High rate deposition at low pressures in a small batch reactor

InactiveUS20030049372A1Increase ratingsRapid and uniform deposition of materialElectric discharge tubesSemiconductor/solid-state device manufacturingHigh rateSusceptor

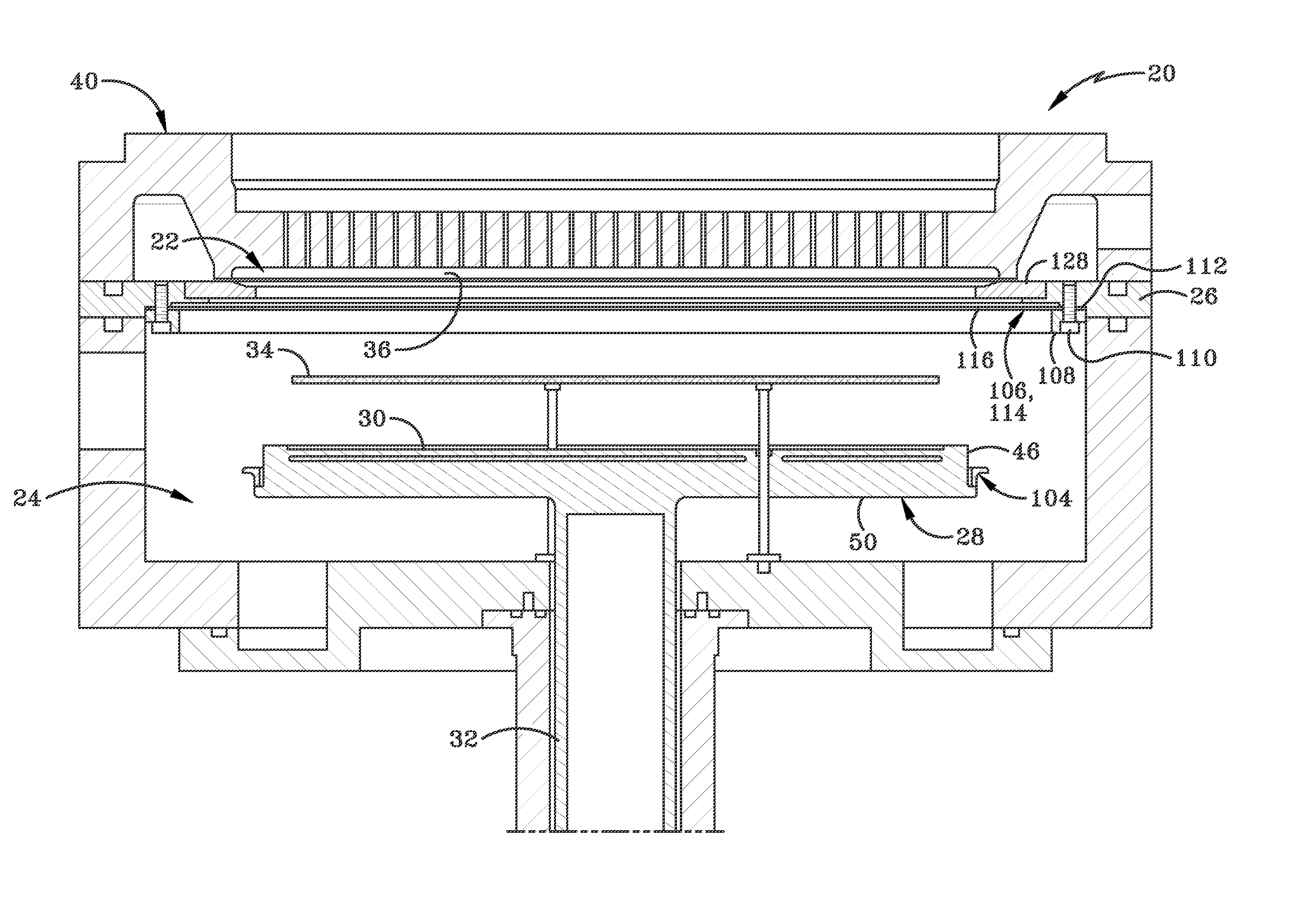

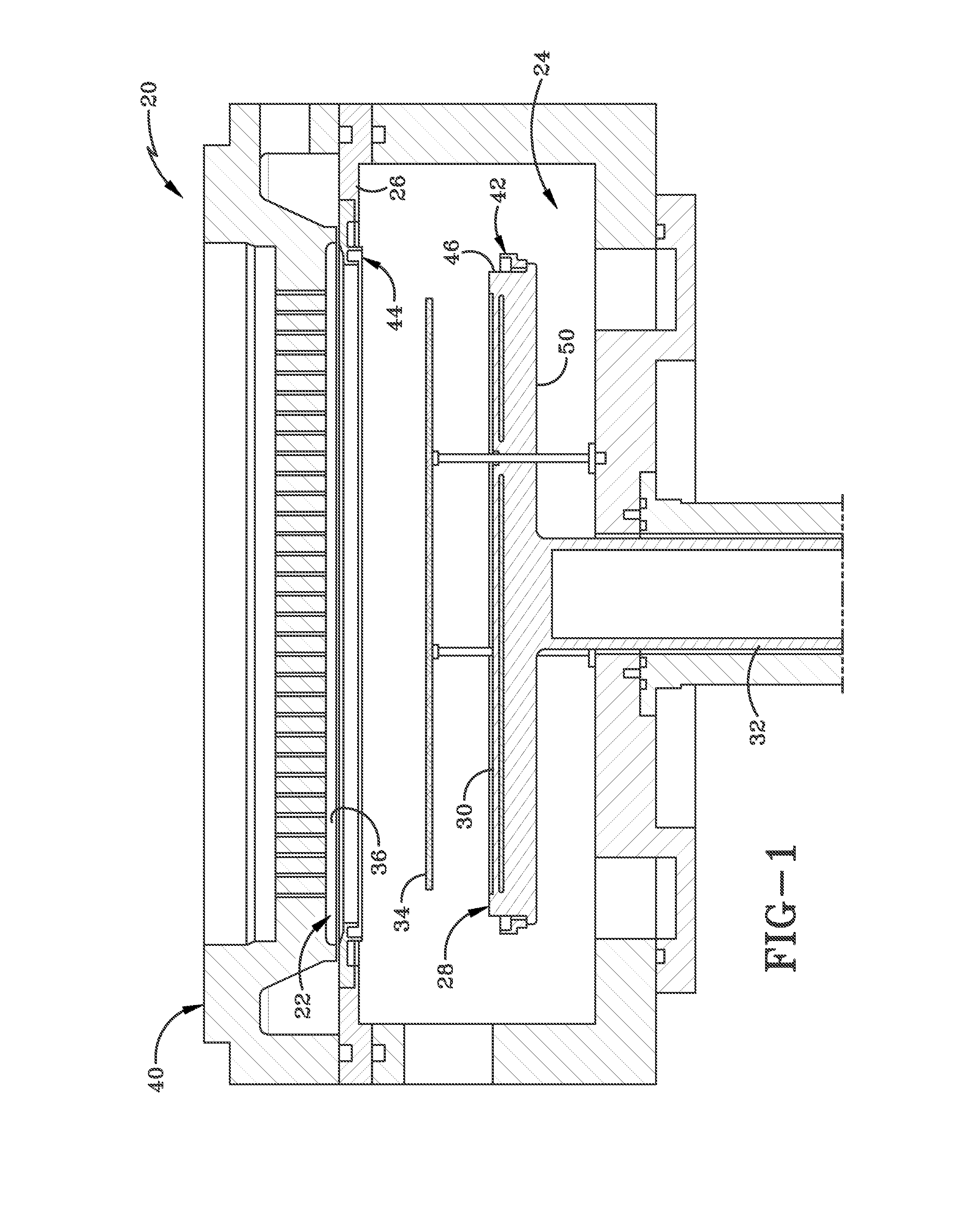

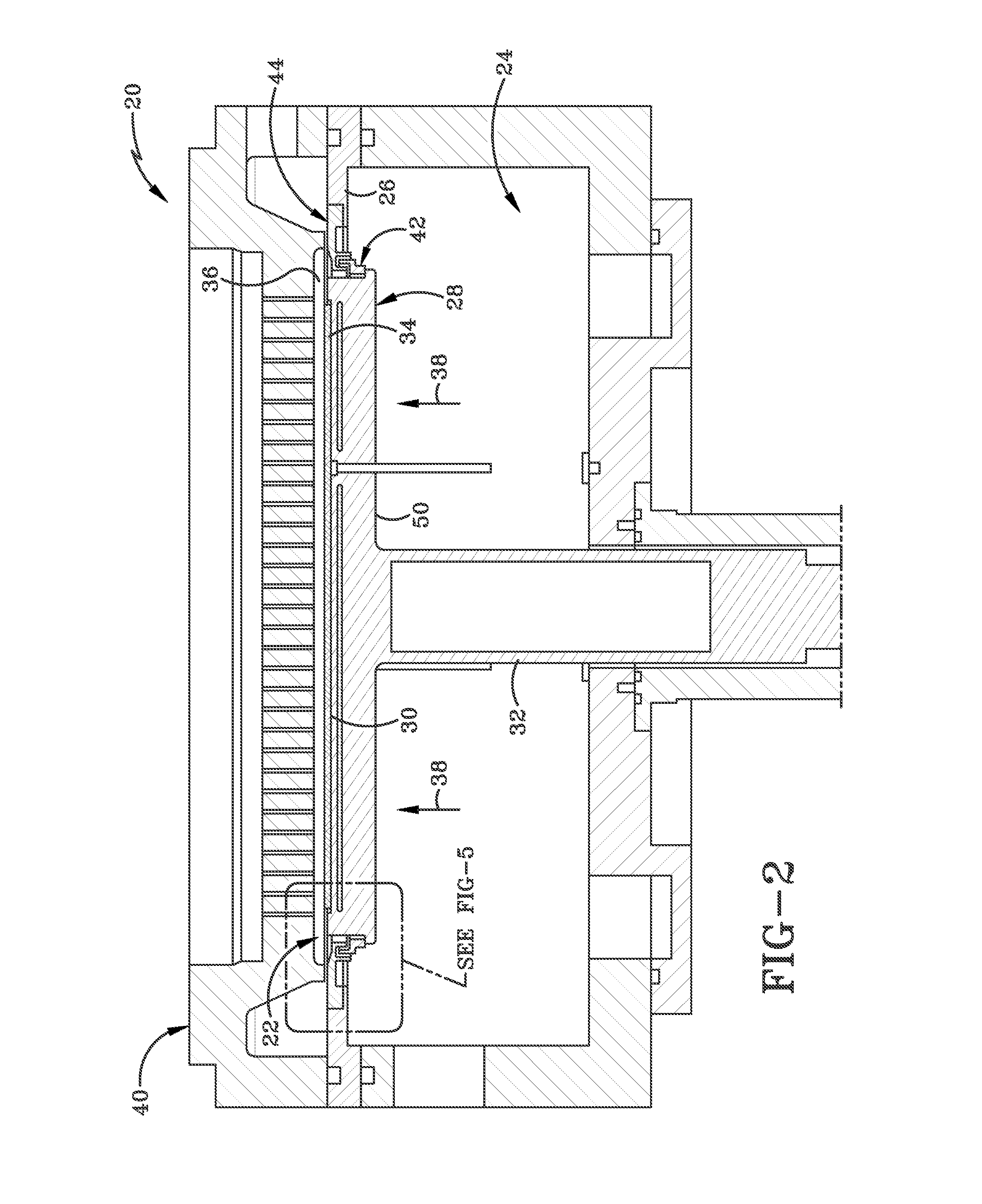

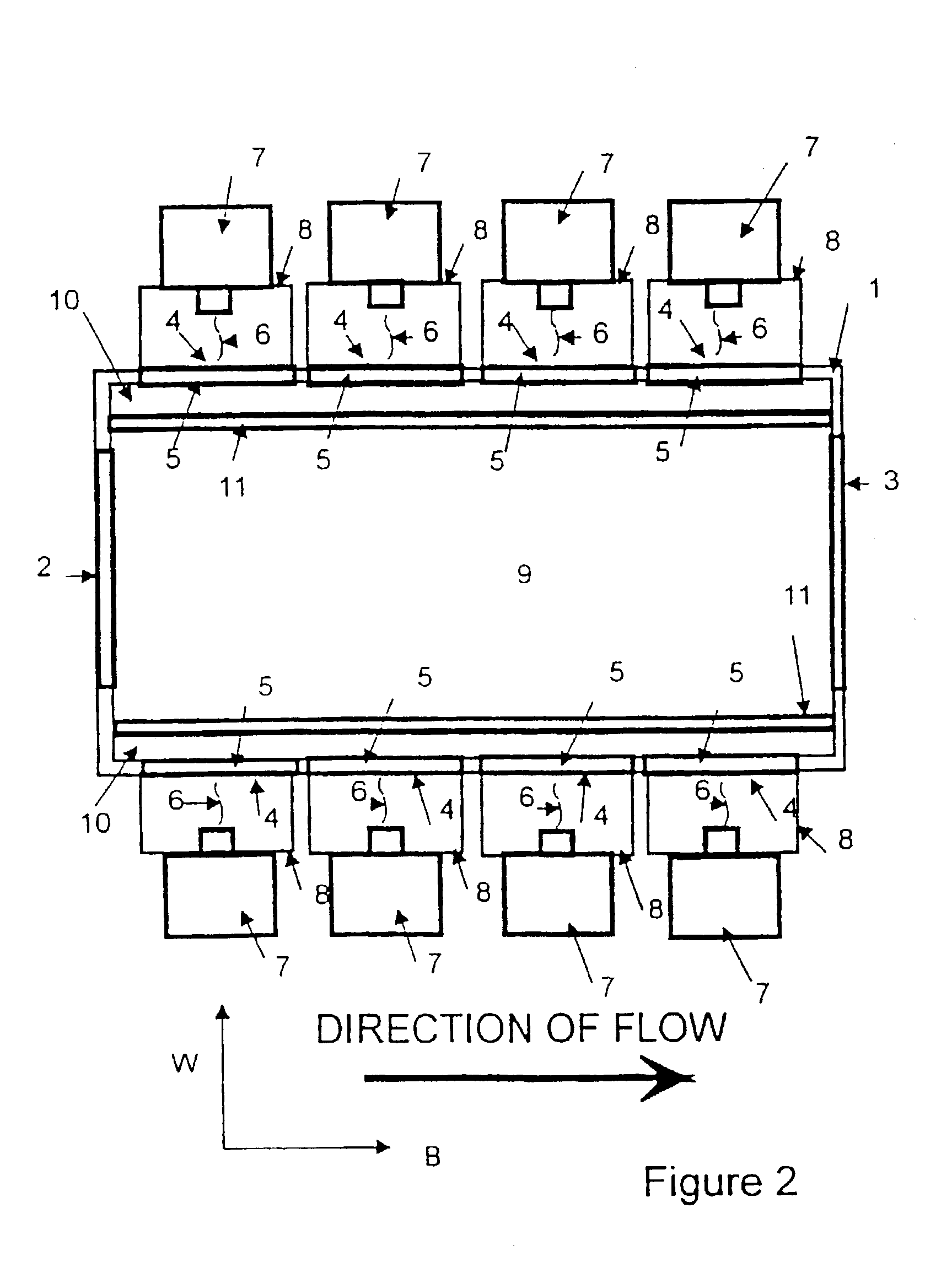

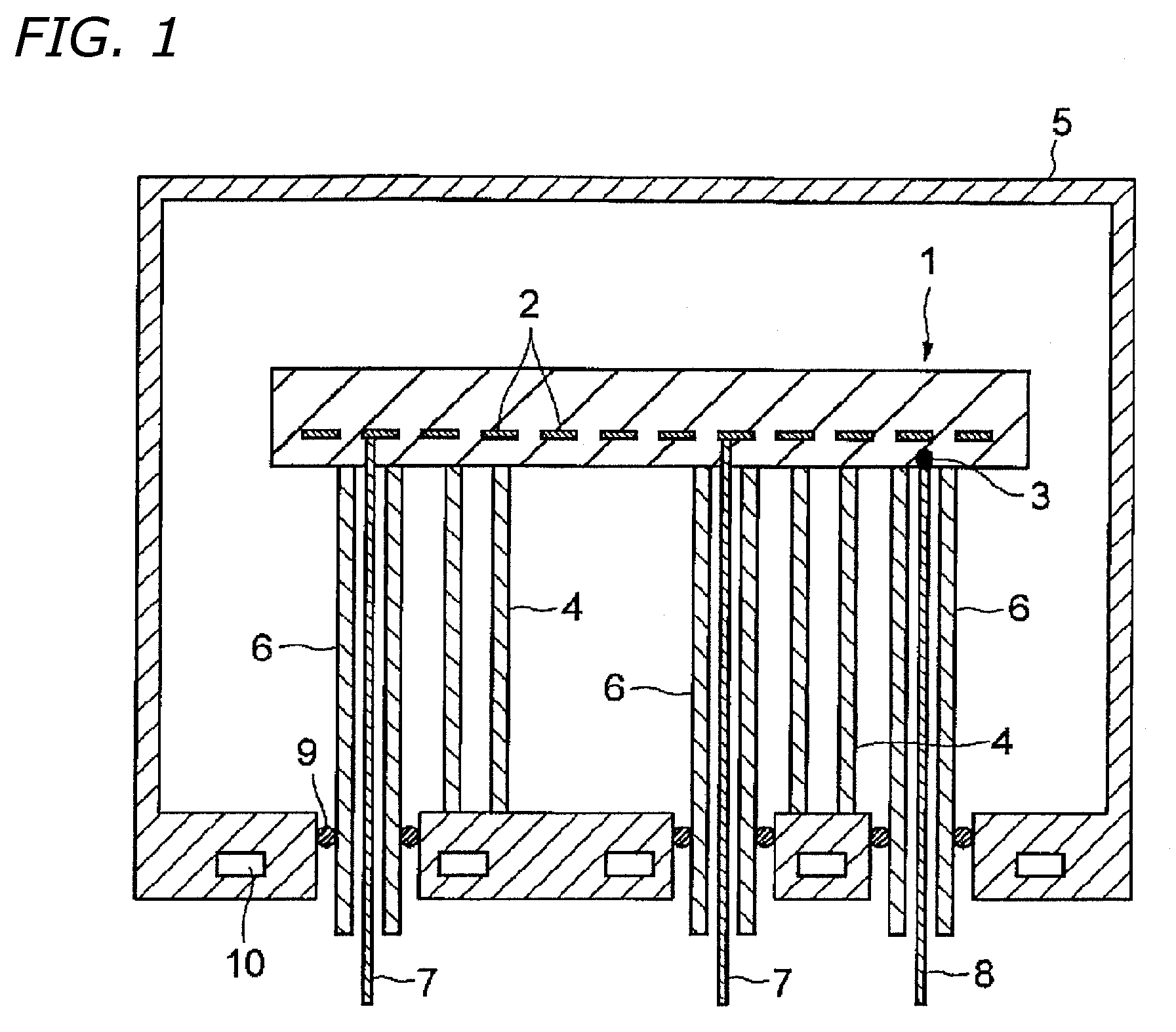

A chemical vapor deposition reactor including a wafer boat with a vertical stack of horizontally oriented susceptors serving as thermal plates and each having pins extending upward for suspending a wafer between a pair of susceptors. Reactant gas injector and exhaust apparatus are positioned to concentrate a forceful supply of reactant gas across each wafer at a speed in excess of 10 cm / sec. The pressure is held in the range of 0.1 to 5,000 mTorr. The forceful gas flow avoids gas depletion effects, thinning the boundary layer and resulting in faster delivery of reactants to substrate surfaces, resulting in surface rate reaction limited operation. A plurality of individually controllable heaters are spaced vertically around the sides of the boat. Temperature sensors monitor the temperature along the boat height and provide input to a controller for adjusting the heater drive to optimize the temperature uniformity.

Owner:APPLIED MATERIALS INC

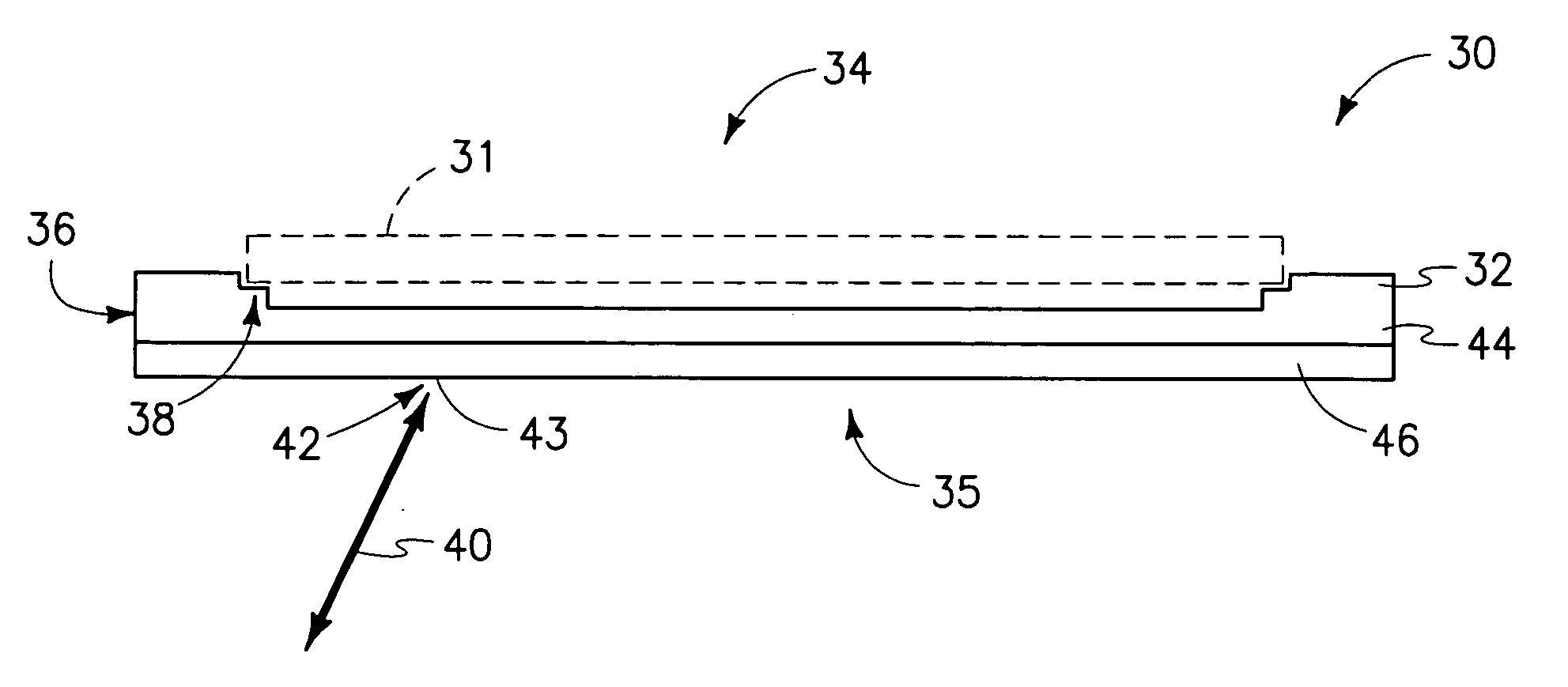

Substrate susceptors for receiving semiconductor substrates to be deposited upon and methods of depositing materials over semiconductor substrates

In one implementation, a substrate susceptor for receiving a semiconductor substrate for selective epitaxial silicon-comprising depositing thereon, where the depositing comprises measuring emissivity of the susceptor from at least one susceptor location in a non-contacting manner, includes a body having a front substrate receiving side, a back side, and a peripheral edge. At least one susceptor location from which emissivity is to be measured is received on at least one of the front substrate receiving side, the back side, and the edge. Such at least one susceptor location comprises an outermost surface comprising a material upon which selective epitaxial silicon will not deposit upon during selective epitaxial silicon depositing on a semiconductor substrate received by the susceptor for at least an initial thickness of epitaxial silicon depositing on said substrate. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

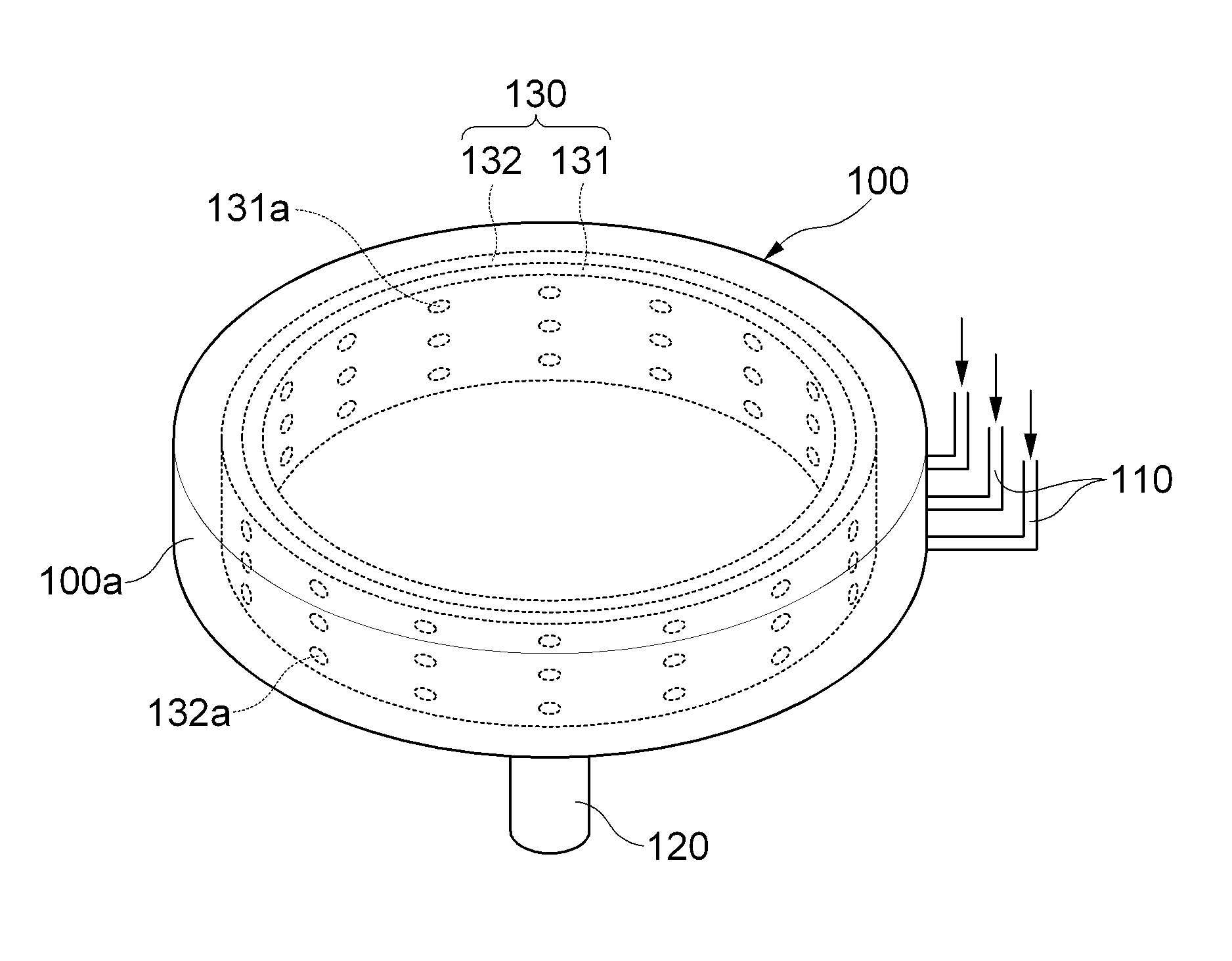

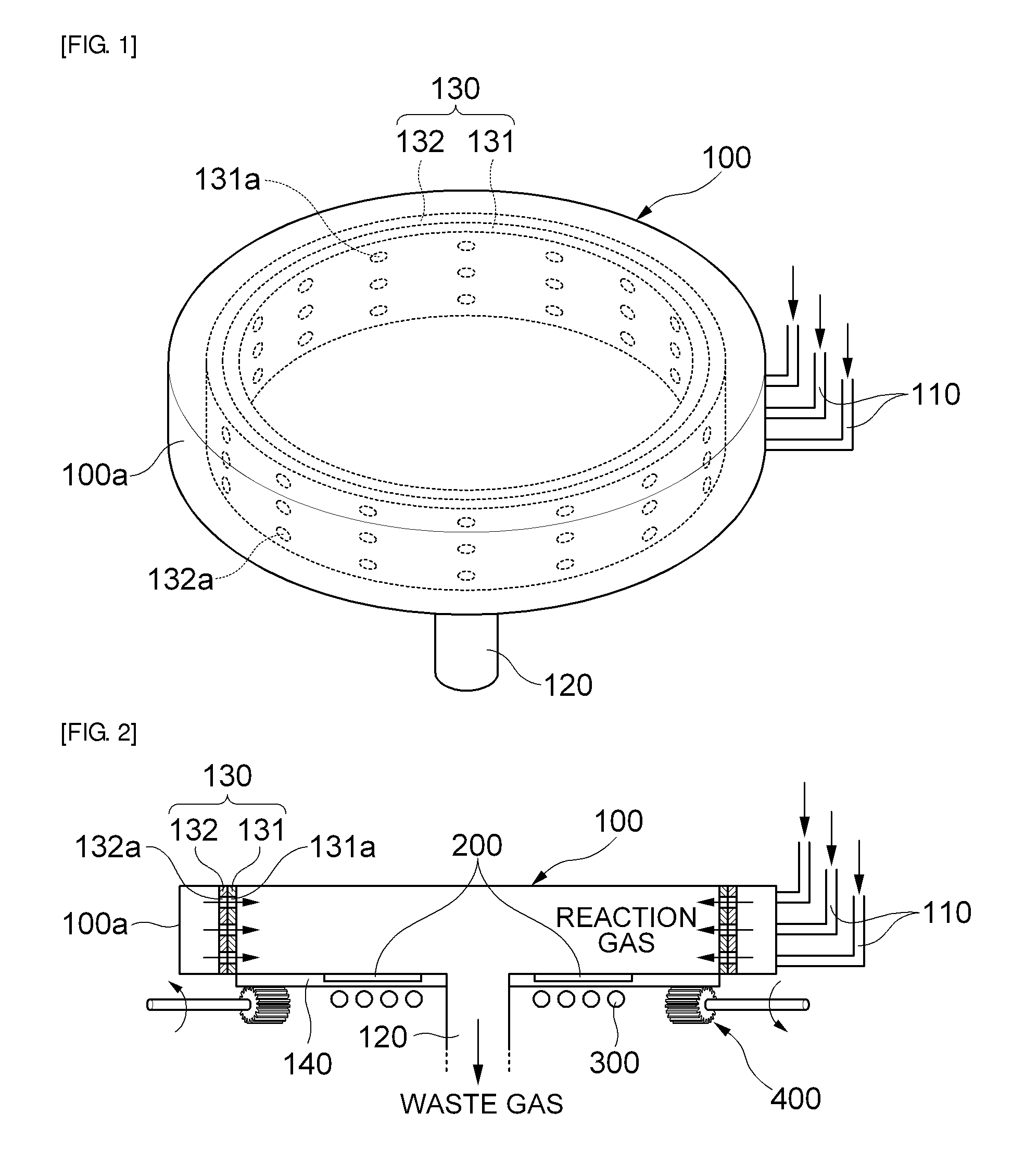

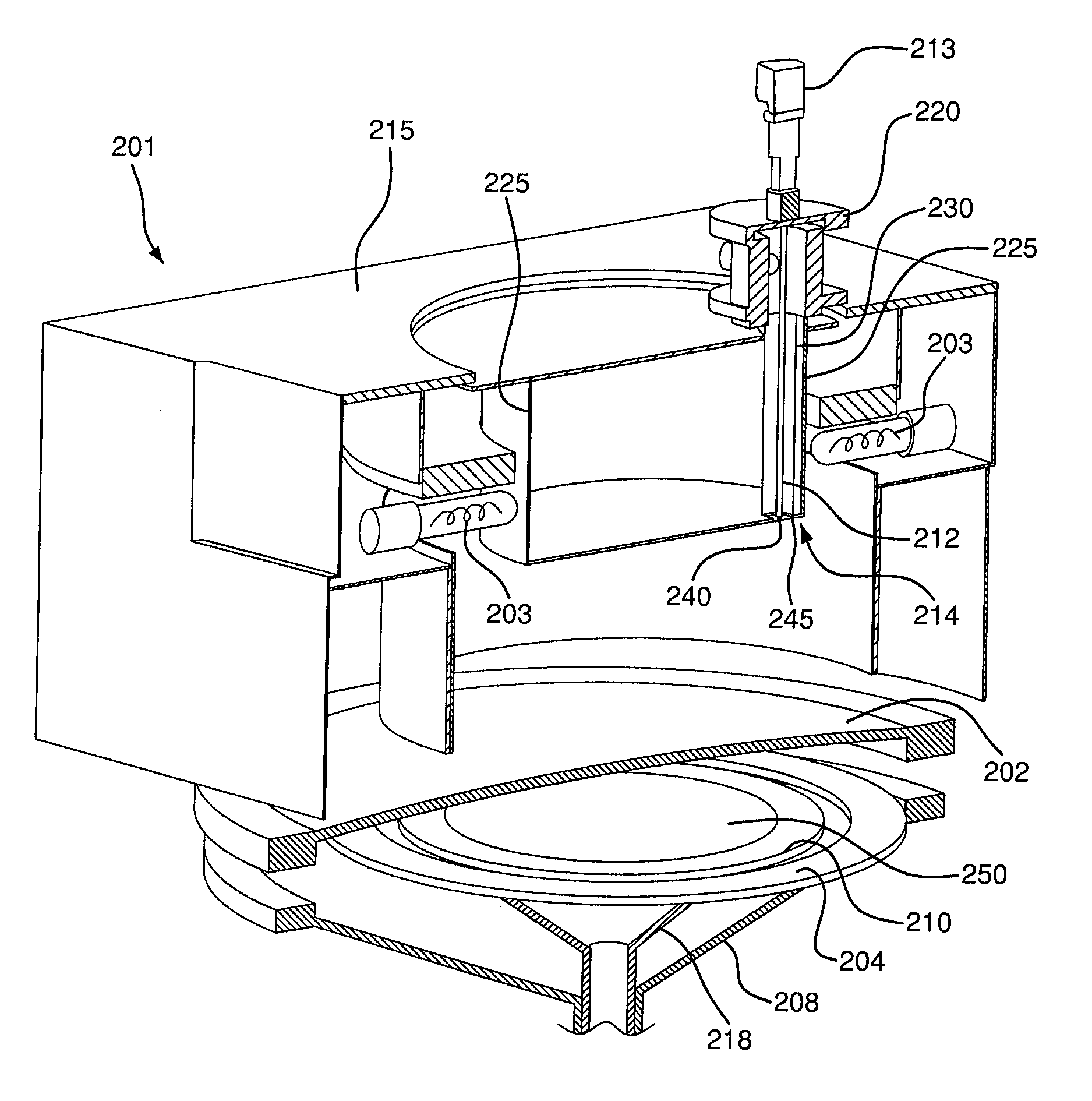

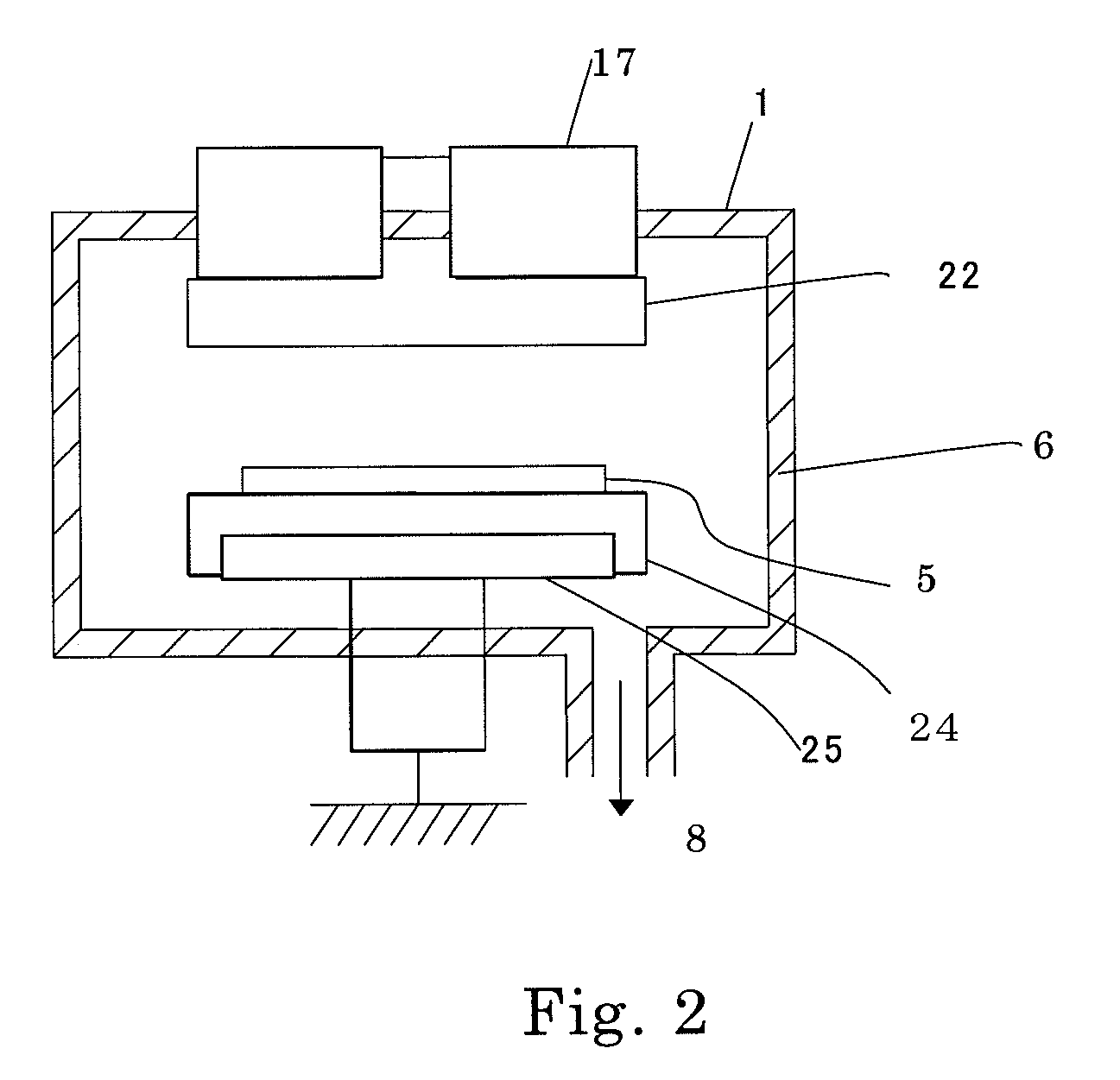

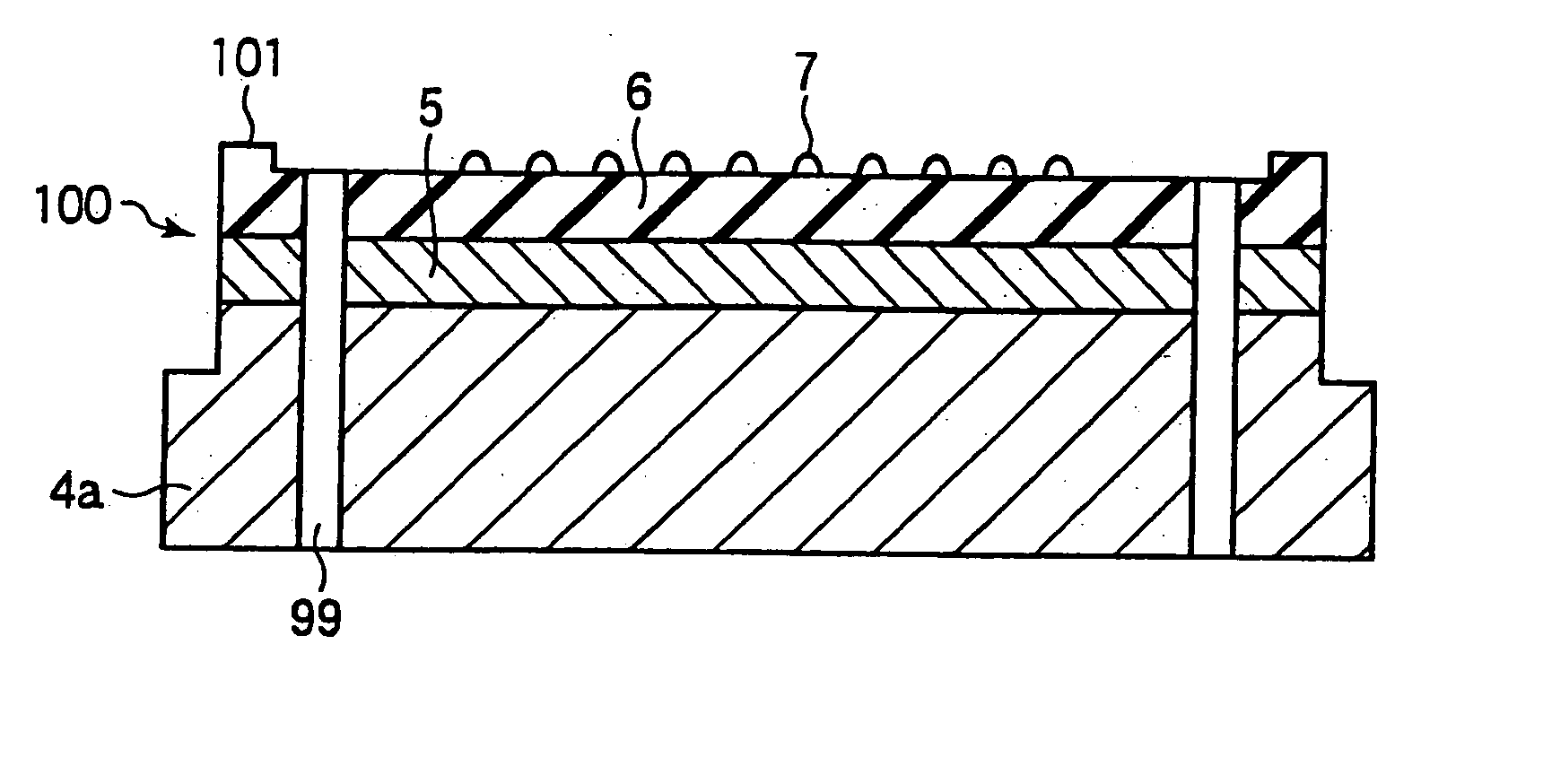

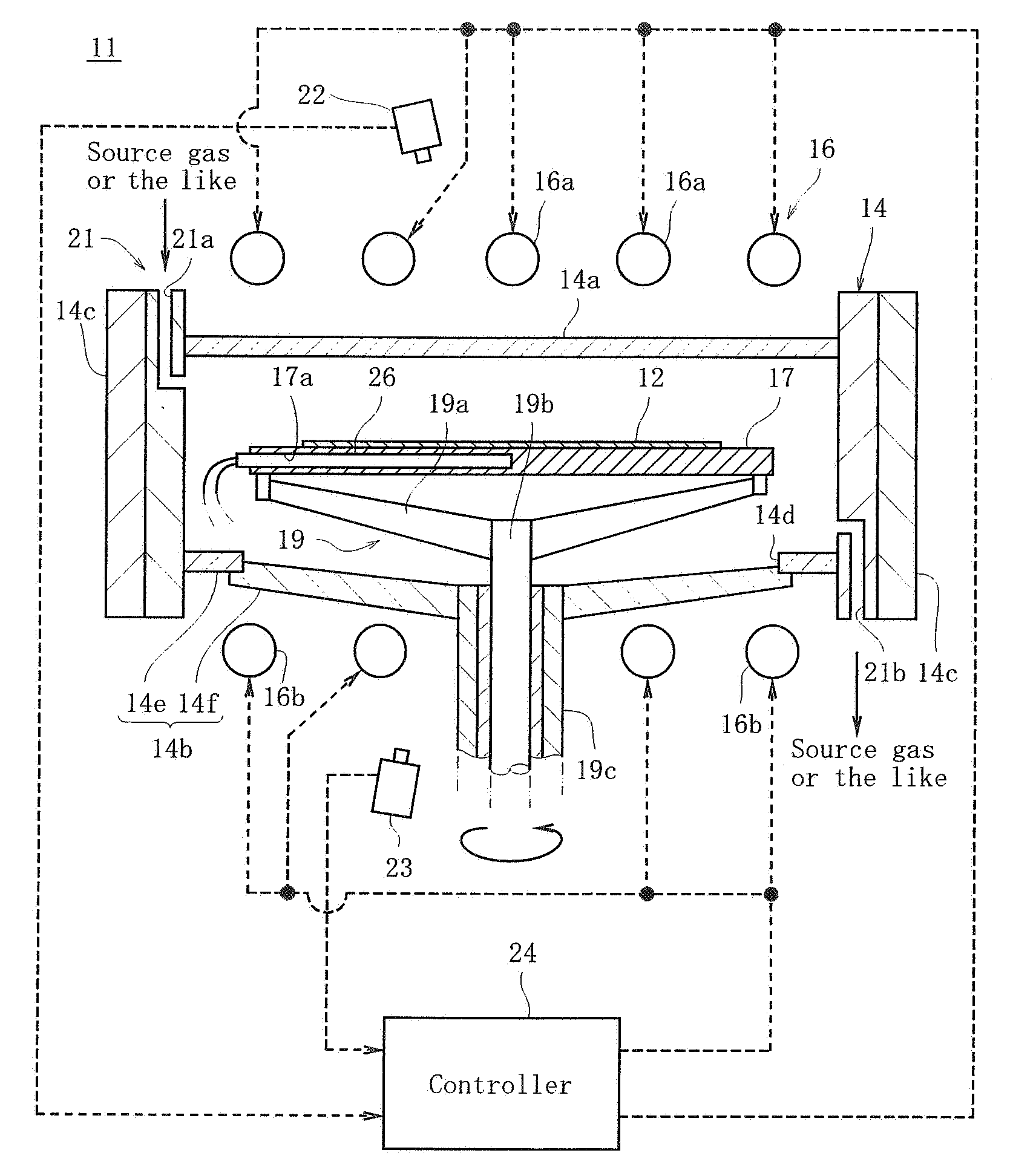

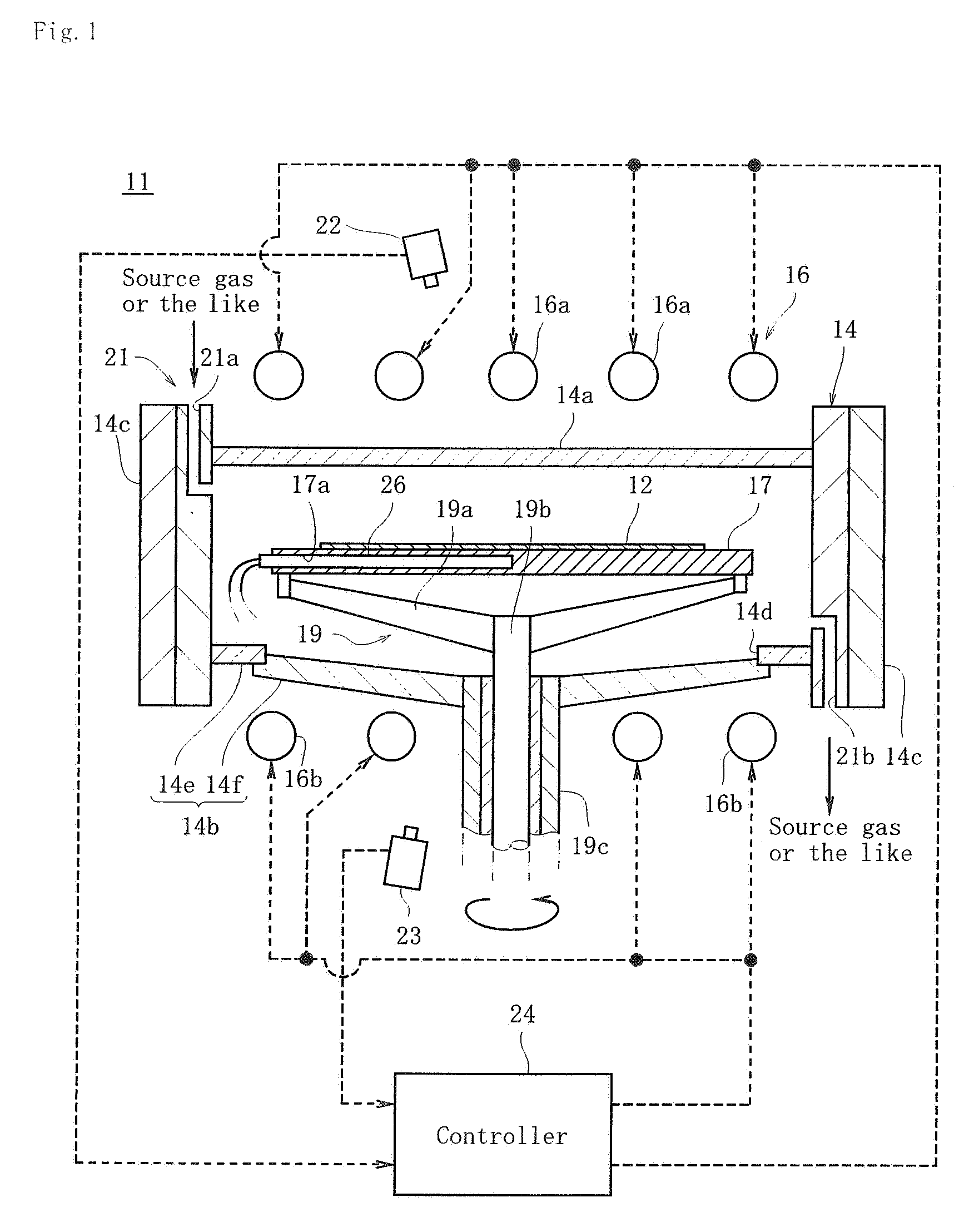

Chemical vapor deposition apparatus

InactiveUS7749326B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorChemical vapor deposition

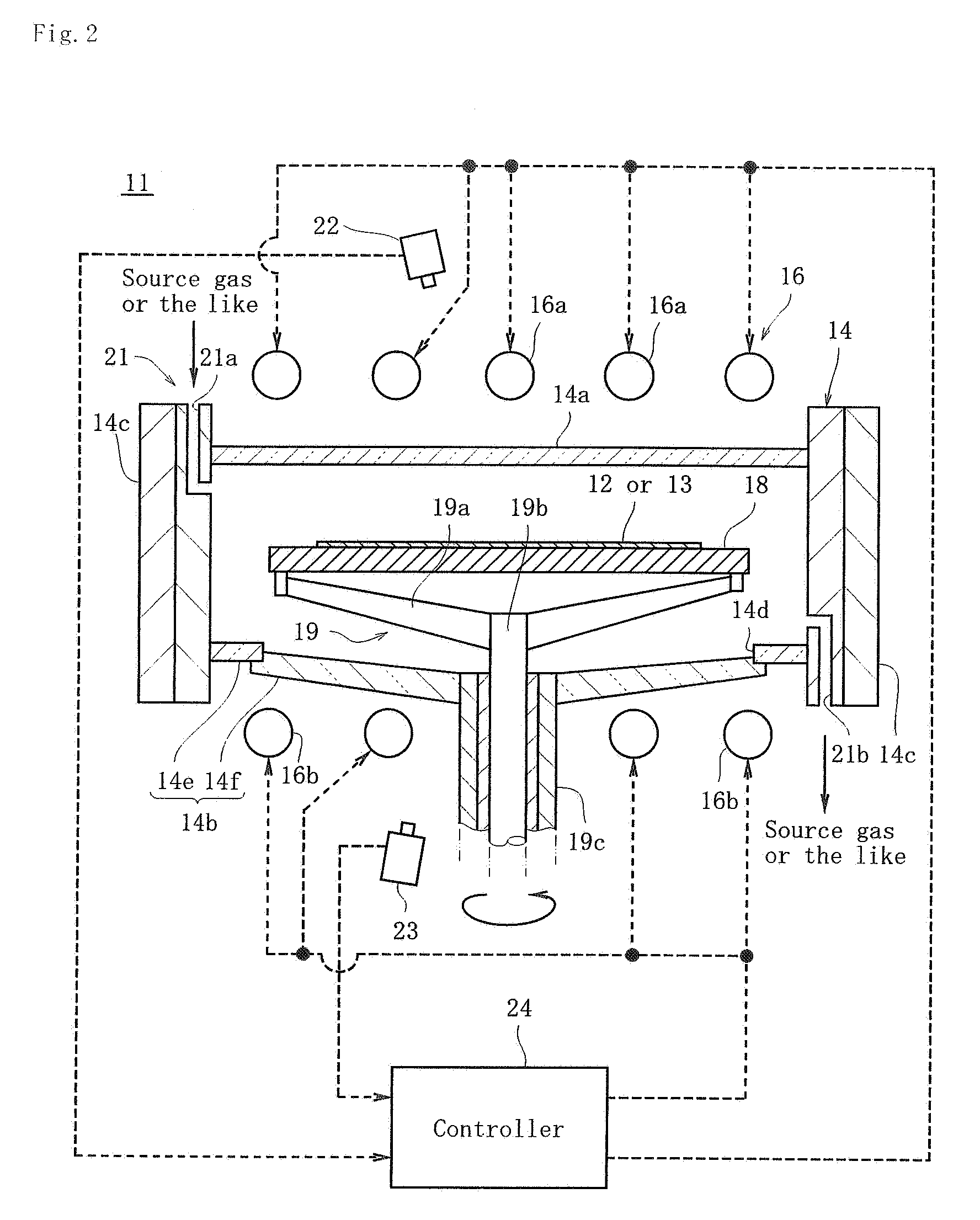

Provided is a chemical vapor deposition apparatus including a reaction chamber; a susceptor that is provided in the reaction chamber and has a plurality of wafers mounted thereon; a rotation driving unit that rotates the susceptor; a gas inlet that is provided in the reaction chamber and introduces reaction gas into the reaction chamber from the outside of the reaction chamber; a gas outlet that is provided in the reaction chamber and discharges the reaction gas, of which the reaction is finished, from the inside of the reaction chamber along the rotation-axis direction of the susceptor; and a variable gas-flow adjusting unit that is provided between the gas inlet and the gas outlet and is formed by superimposing a plurality of gas jetting plates having a plurality of holes.

Owner:SAMSUNG ELECTRONICS CO LTD

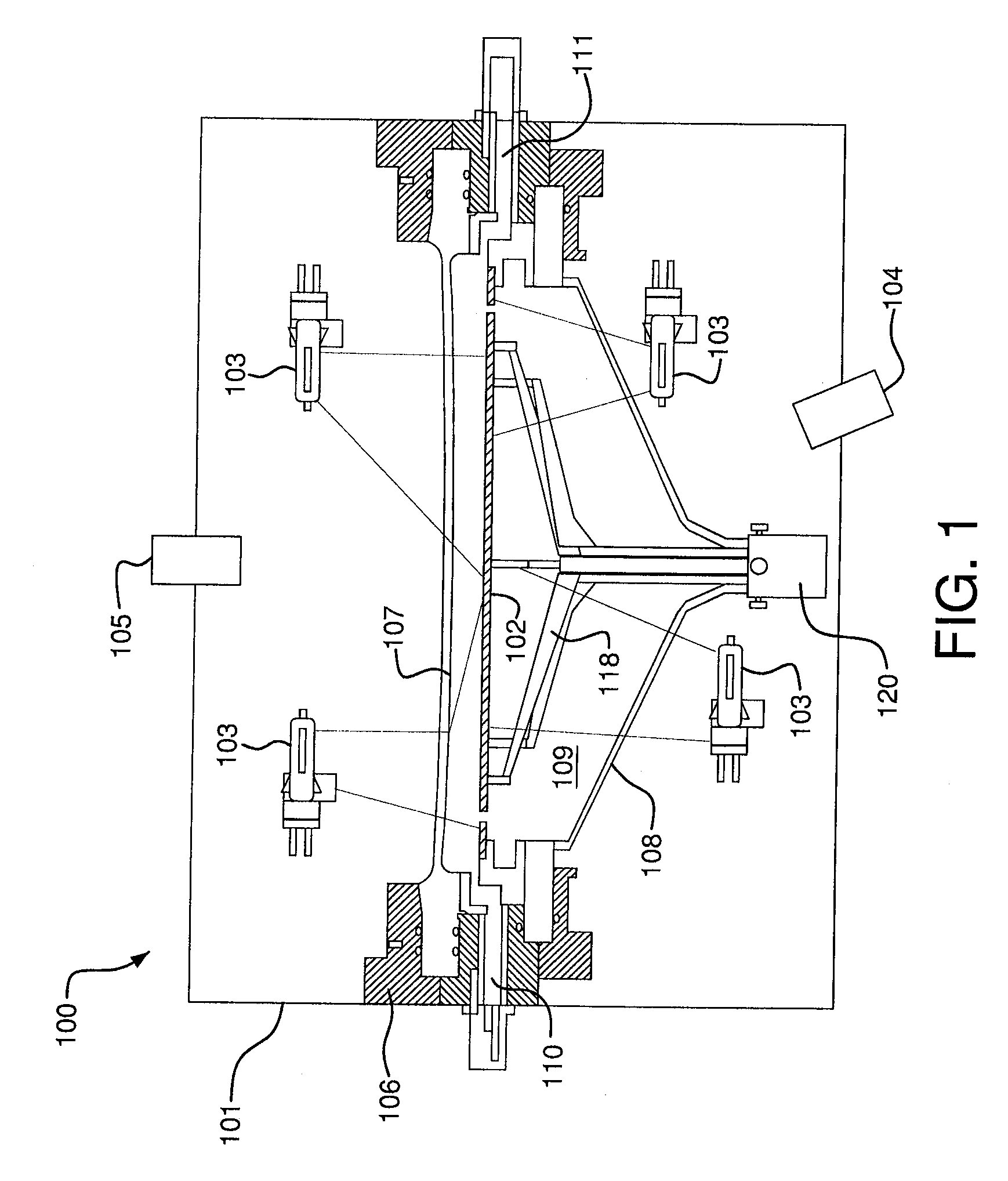

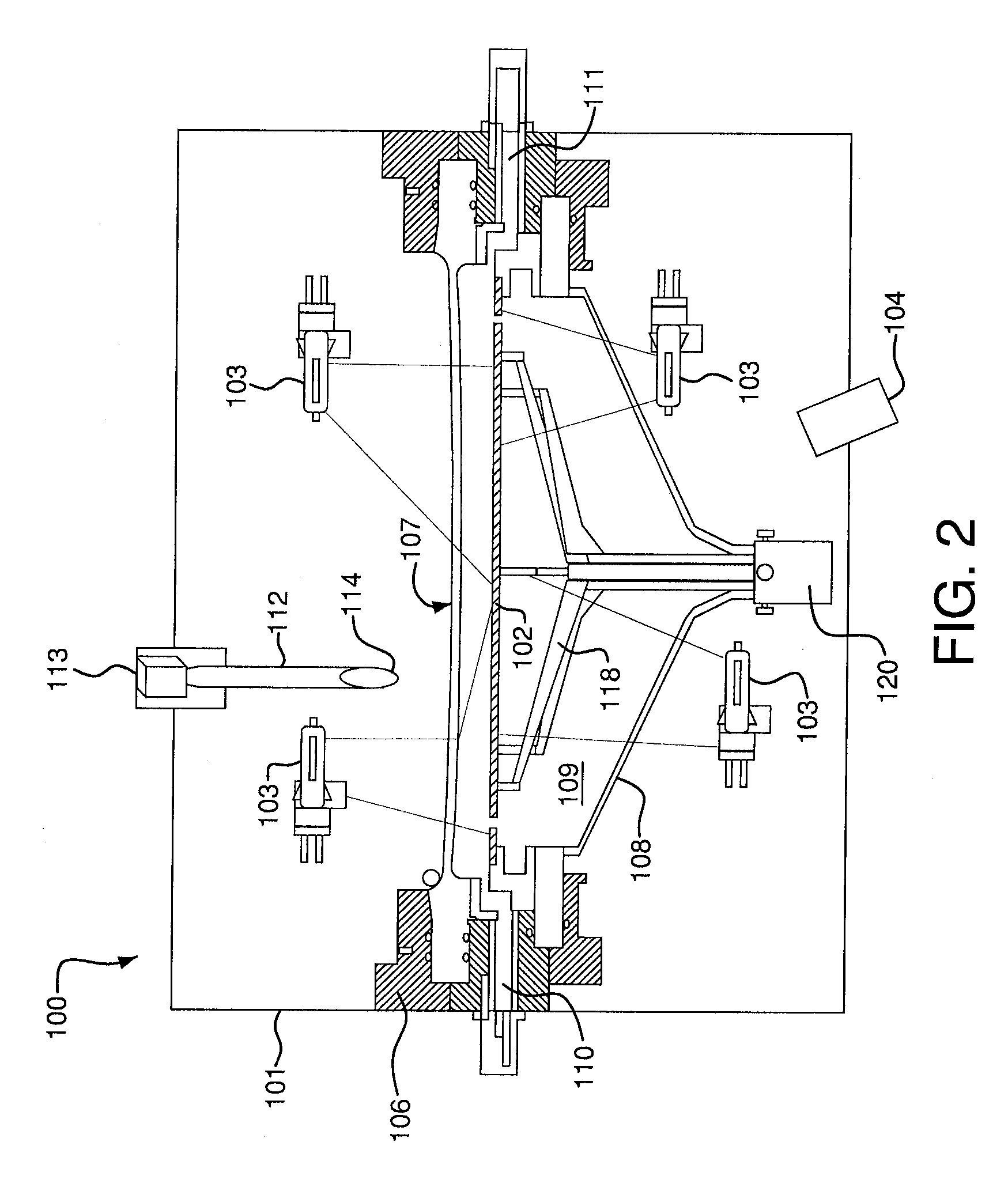

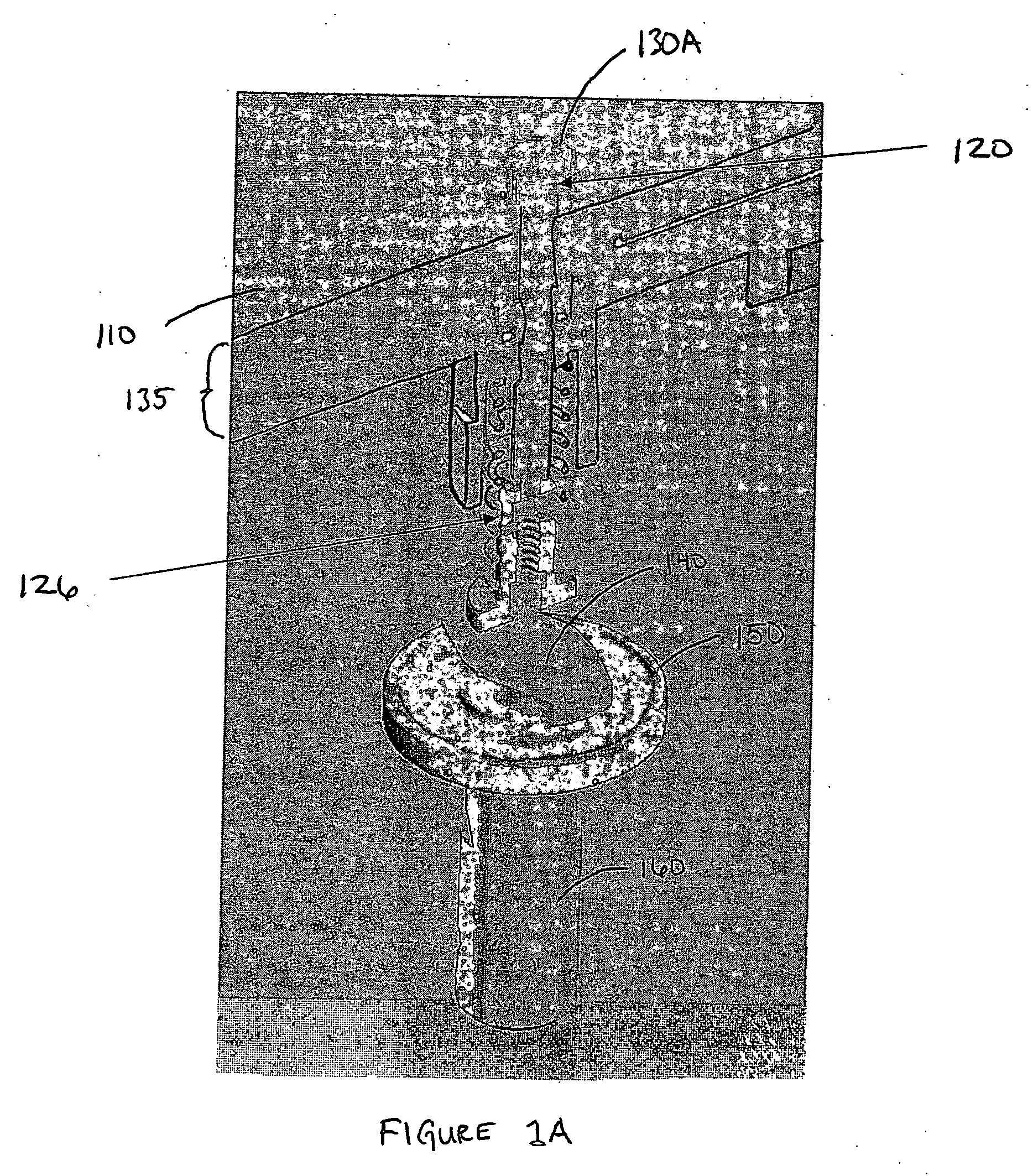

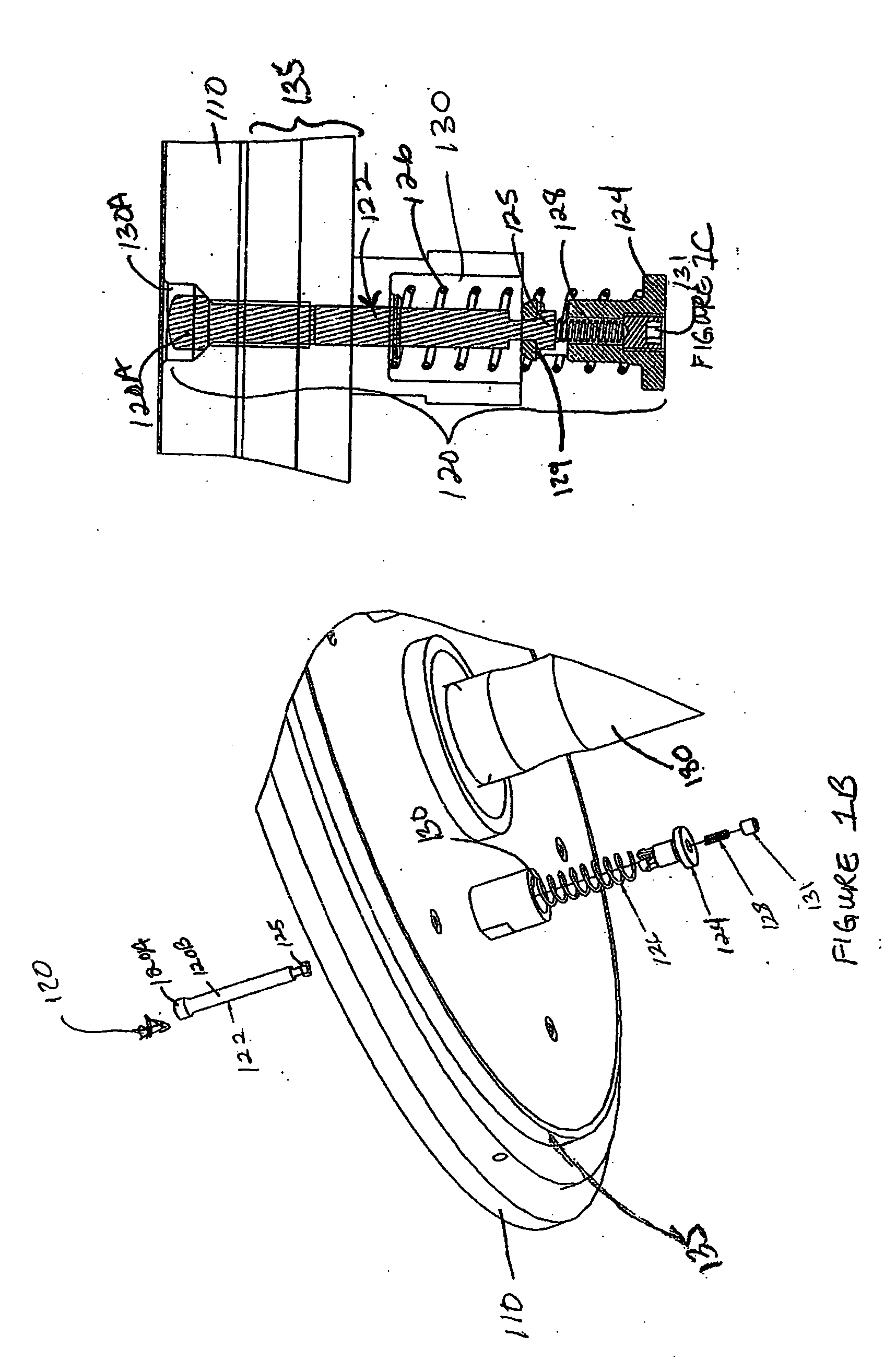

Semiconductor process chamber vision and monitoring system

A system for monitoring a process inside a high temperature semiconductor process chamber by capturing images is disclosed. Images are captured through a borescope by a camera. The borescope is protected from high temperatures by a reflective sheath and an Infrared (IR) cut-off filter. Images can be viewed on a monitor and can be recorded by a video recording device. Images can also be processed by a machine vision system. The system can monitor the susceptor and a substrate on the susceptor and surrounding structures. Deviations from preferred geometries of the substrate and deviations from preferred positions of susceptor and the substrate can be detected. Actions based on the detections of deviations can be taken to improve the performance of the process. Illumination of a substrate by a laser for detecting deviations in substrate geometry and position is also disclosed.

Owner:APPLIED MATERIALS INC

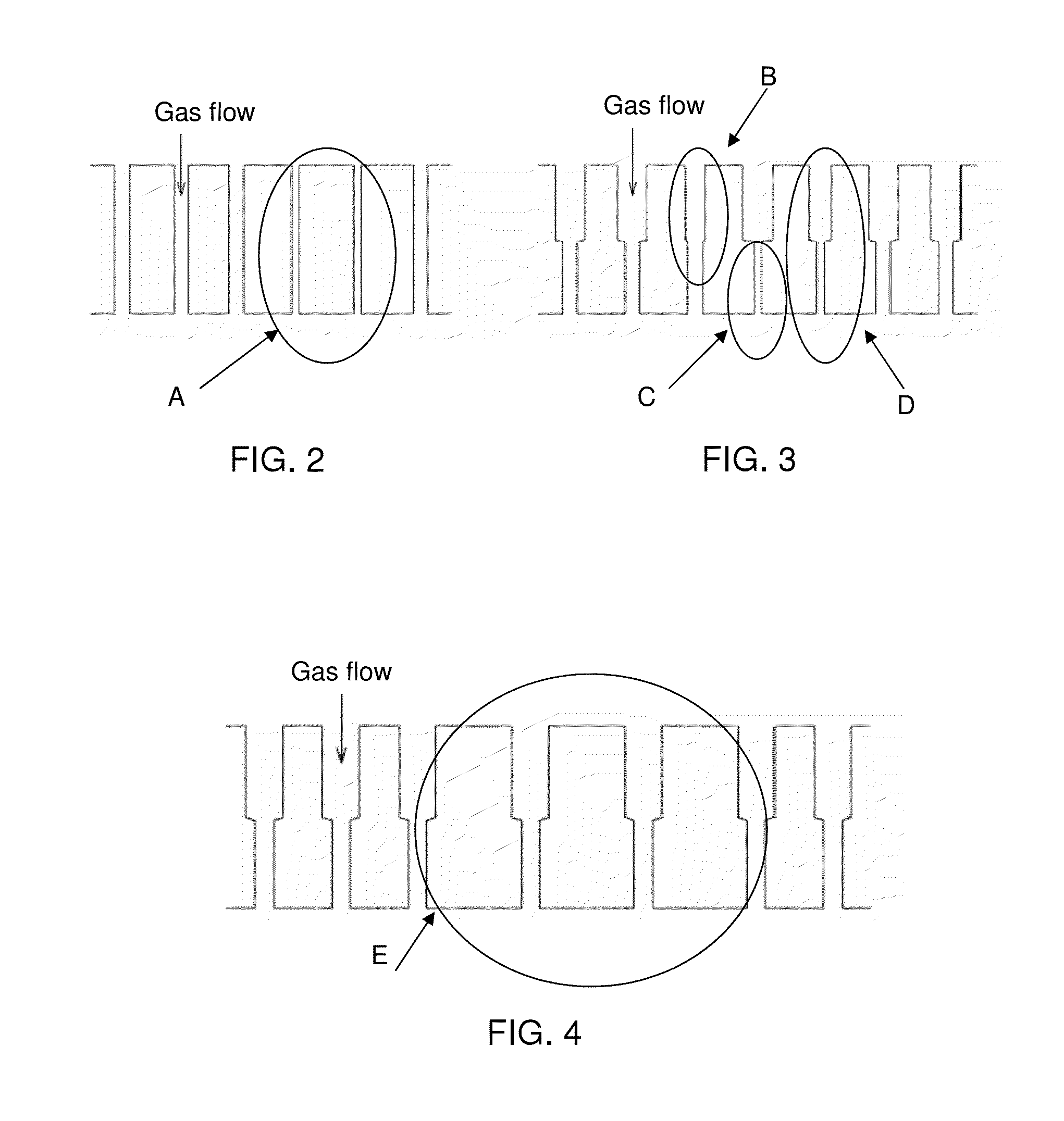

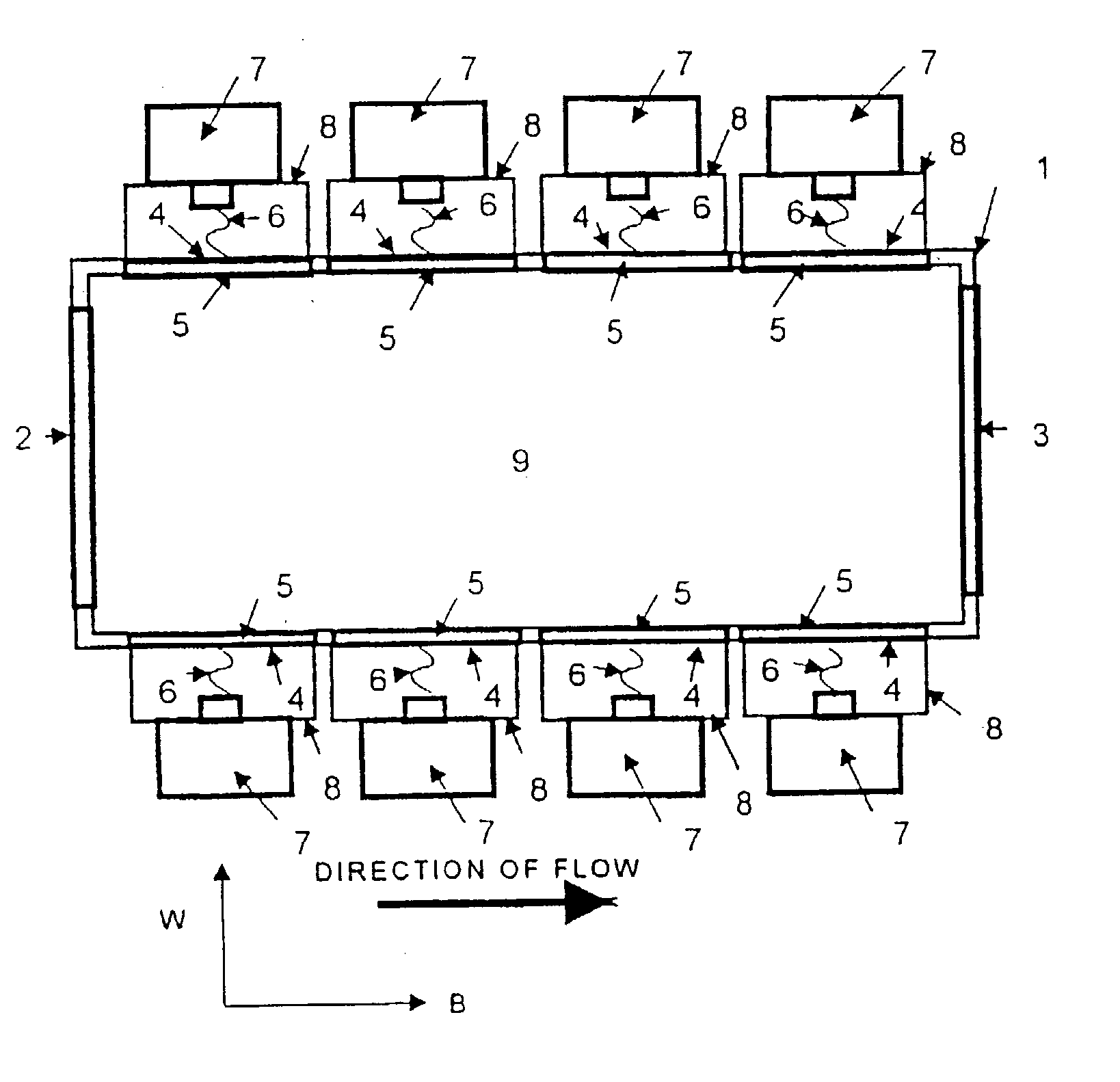

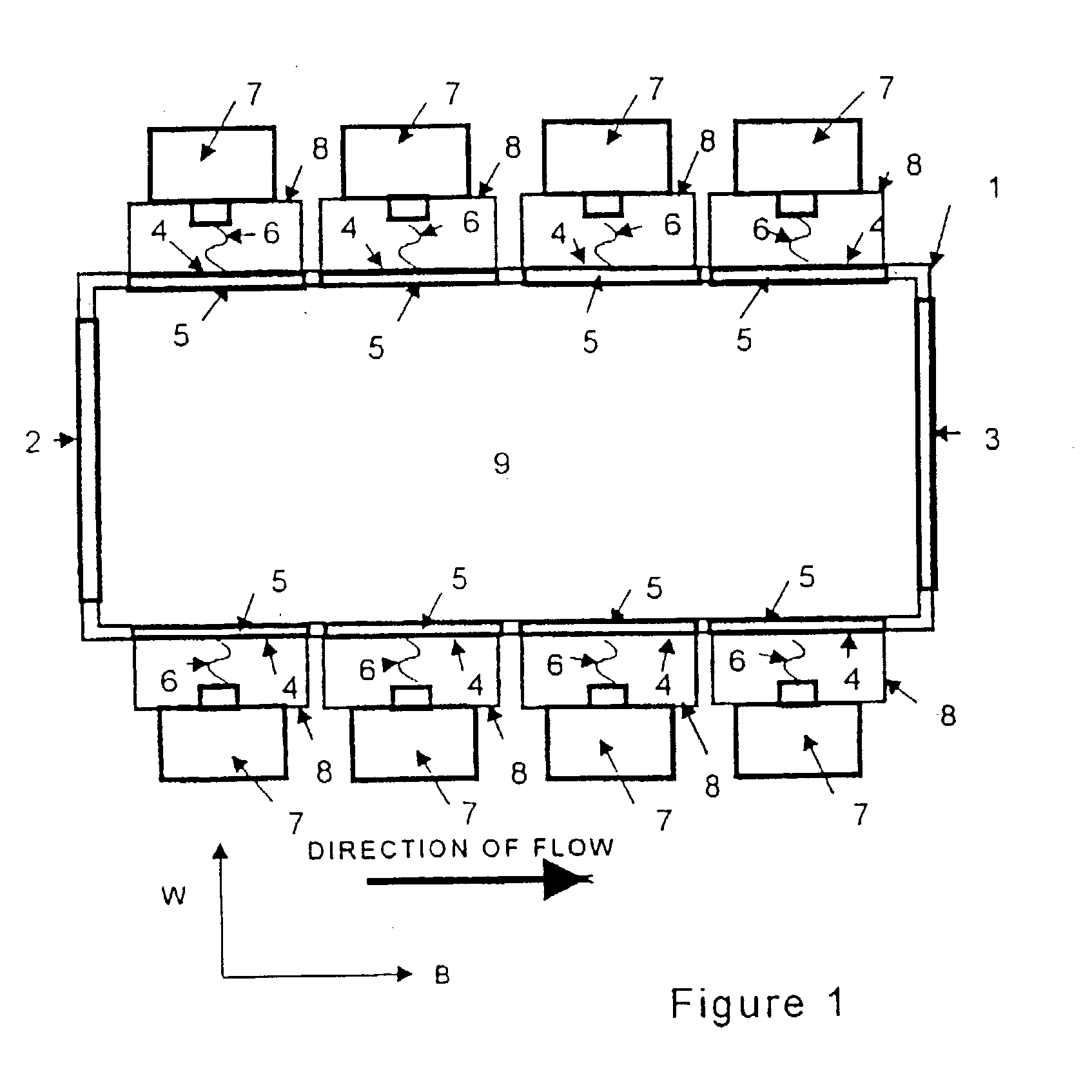

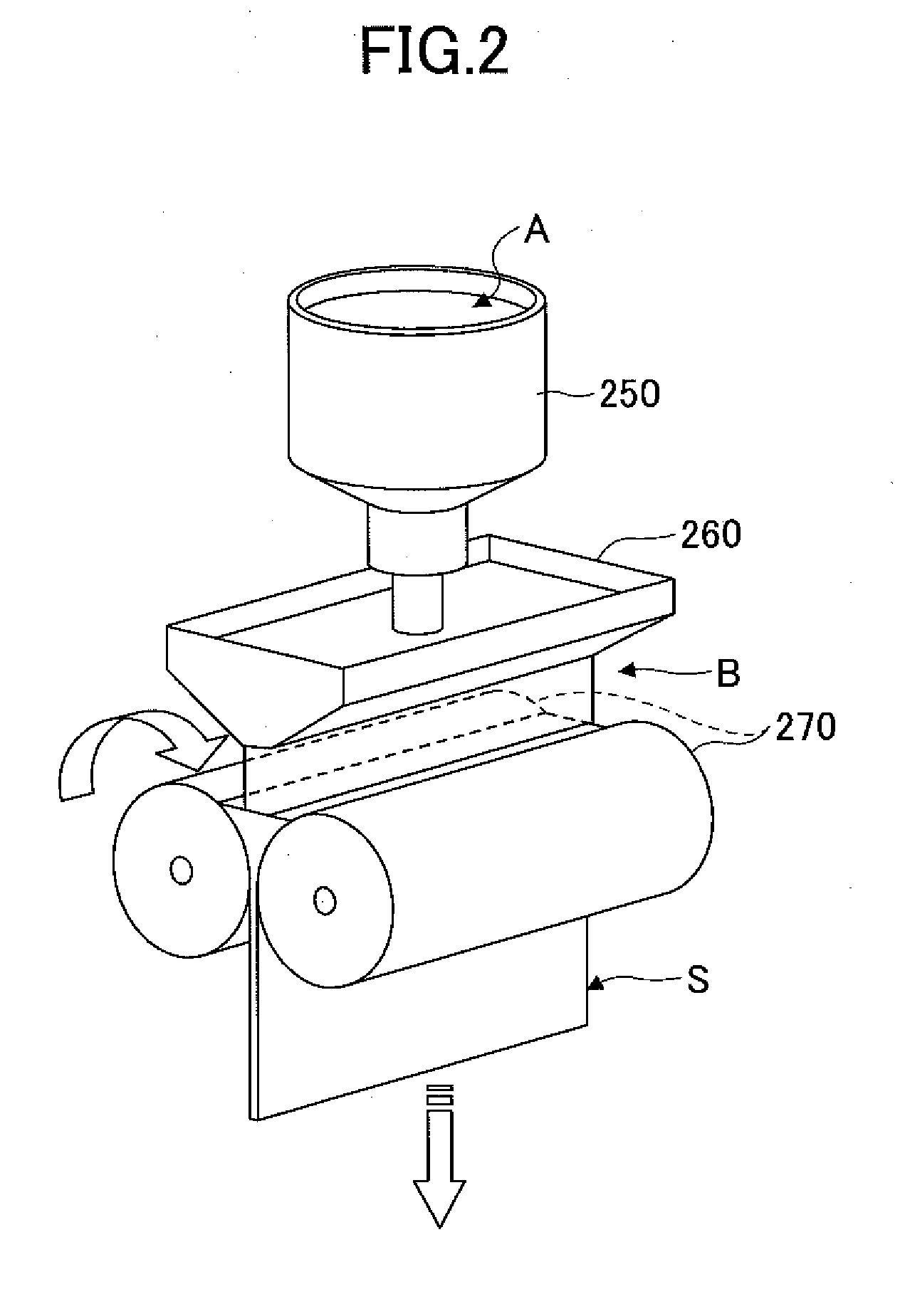

Metal organic chemical vapor deposition equipment

InactiveUS20080006208A1Uniform film thicknessImprove formation efficiencyAfter-treatment apparatusFrom chemically reactive gasesSusceptorProduct gas

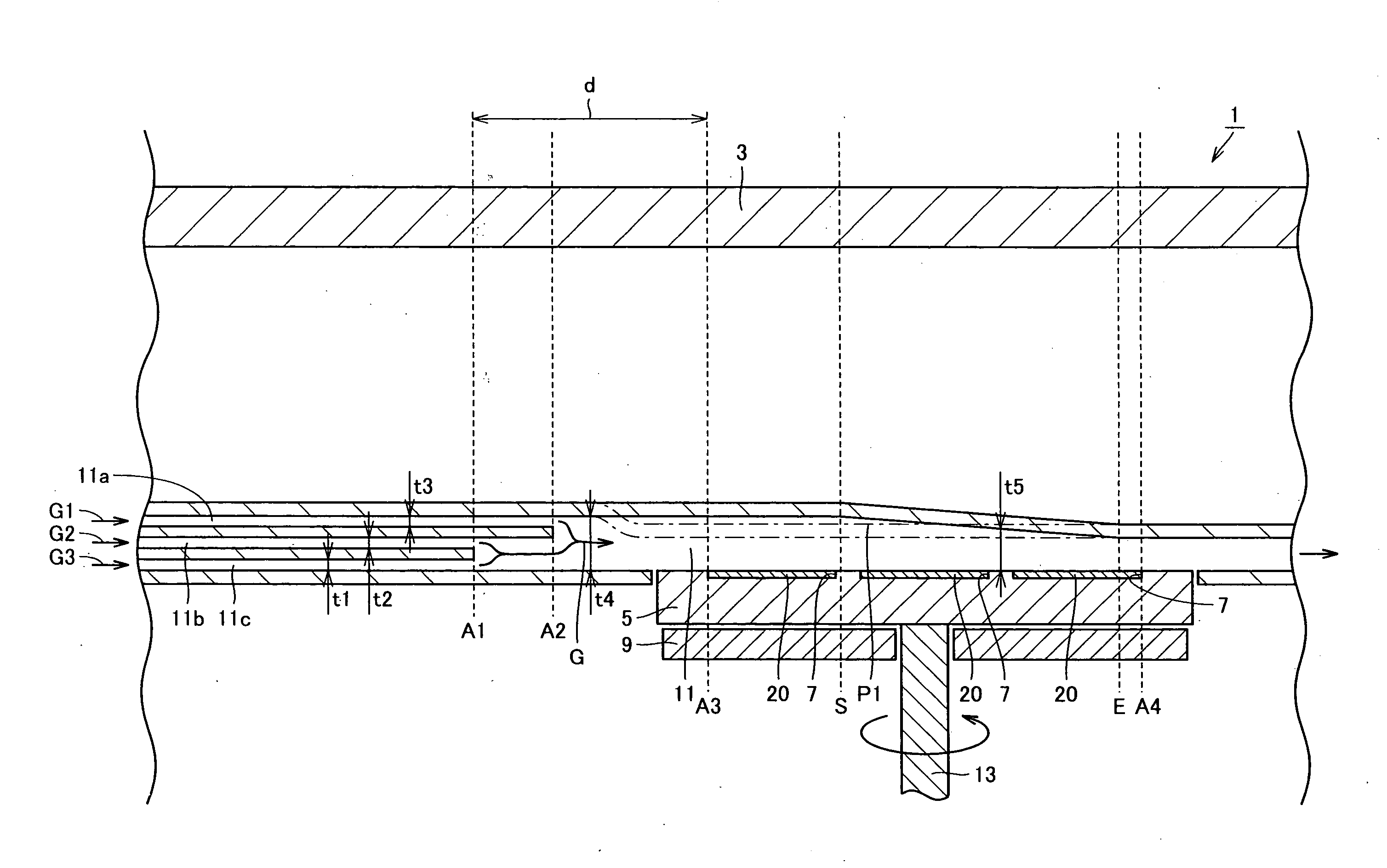

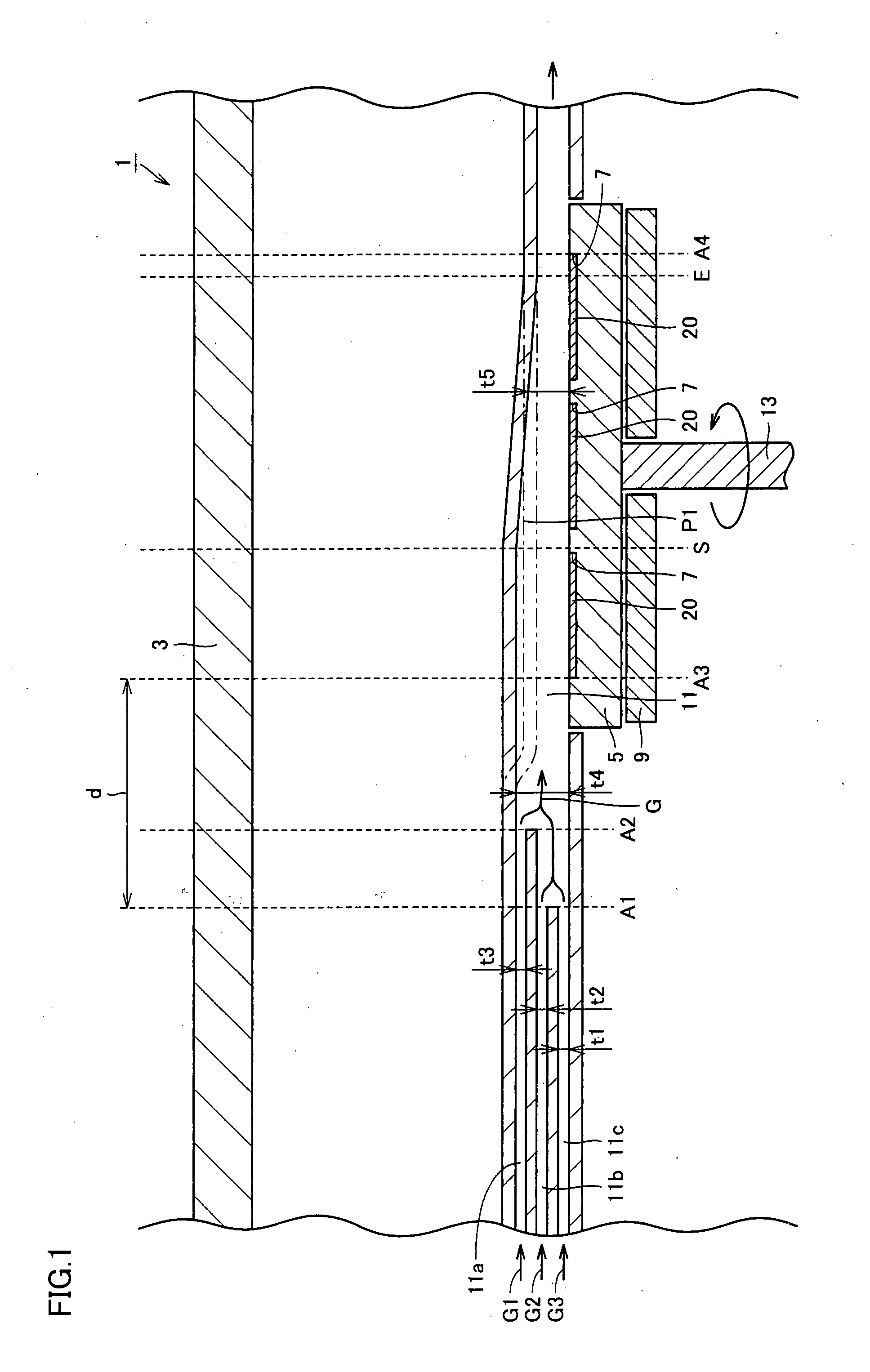

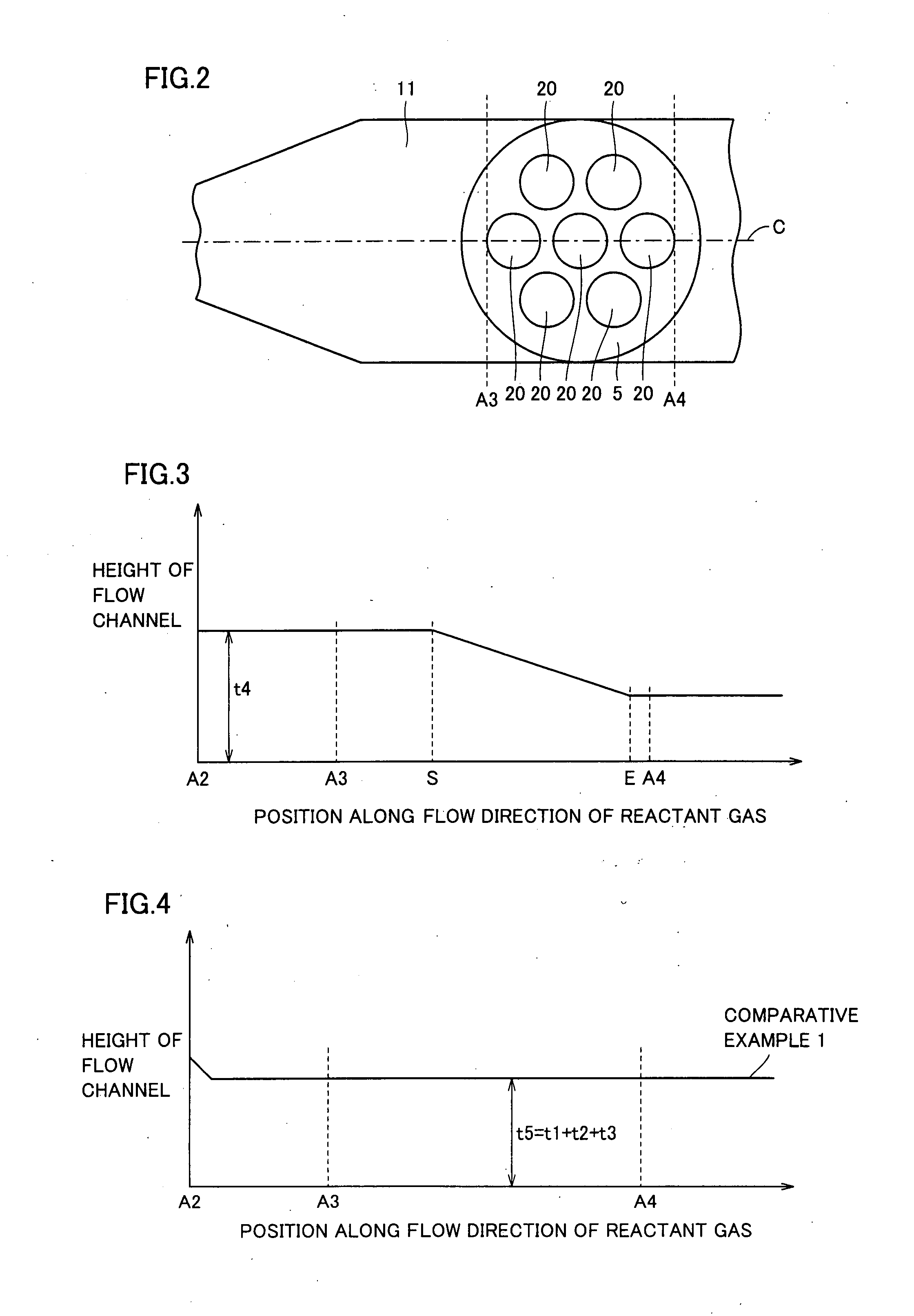

Metal organic chemical vapor deposition equipment is metal organic chemical vapor deposition equipment for forming a film on a substrate by using a reactant gas, and includes a susceptor heating the substrate and having a holding surface for holding the substrate, and a flow channel for introducing the reactant gas to the substrate. The susceptor is rotatable with the holding surface kept facing an inner portion of the flow channel, and a height of the flow channel along a flow direction of the reactant gas is kept constant from a position to a position, and is monotonically decreased from the position to the downstream side. It is thereby possible to improve film formation efficiency while allowing the formed film to have a uniform thickness.

Owner:SUMITOMO ELECTRIC IND LTD

Susceptor device

InactiveUS7678197B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTemperature controlSusceptor

A susceptor device comprises a base body, an electrostatic absorbing inner electrode which is disposed on a bottom surface of the base body, a power supplying terminal, an insulating sprayed layer which coats the electrostatic absorbing inner electrode and a connecting section for the power supplying terminal and the electrostatic absorbing inner electrode, and a temperature controlling section. The insulating sprayed layer and the temperature controlling section are attached together unitarily via the bonding agent layer. The flange of the base body fits to a notched section of the temperature controlling section such that the electrostatic absorbing inner electrode, insulating sprayed layer, and the bonding agent layer should be sealed from thereoutside. It is possible to form a thin supporting plate and improve controllability for temperature on the plate sample and transparency for the plasma.

Owner:SUMITOMO OSAKA CEMENT CO LTD

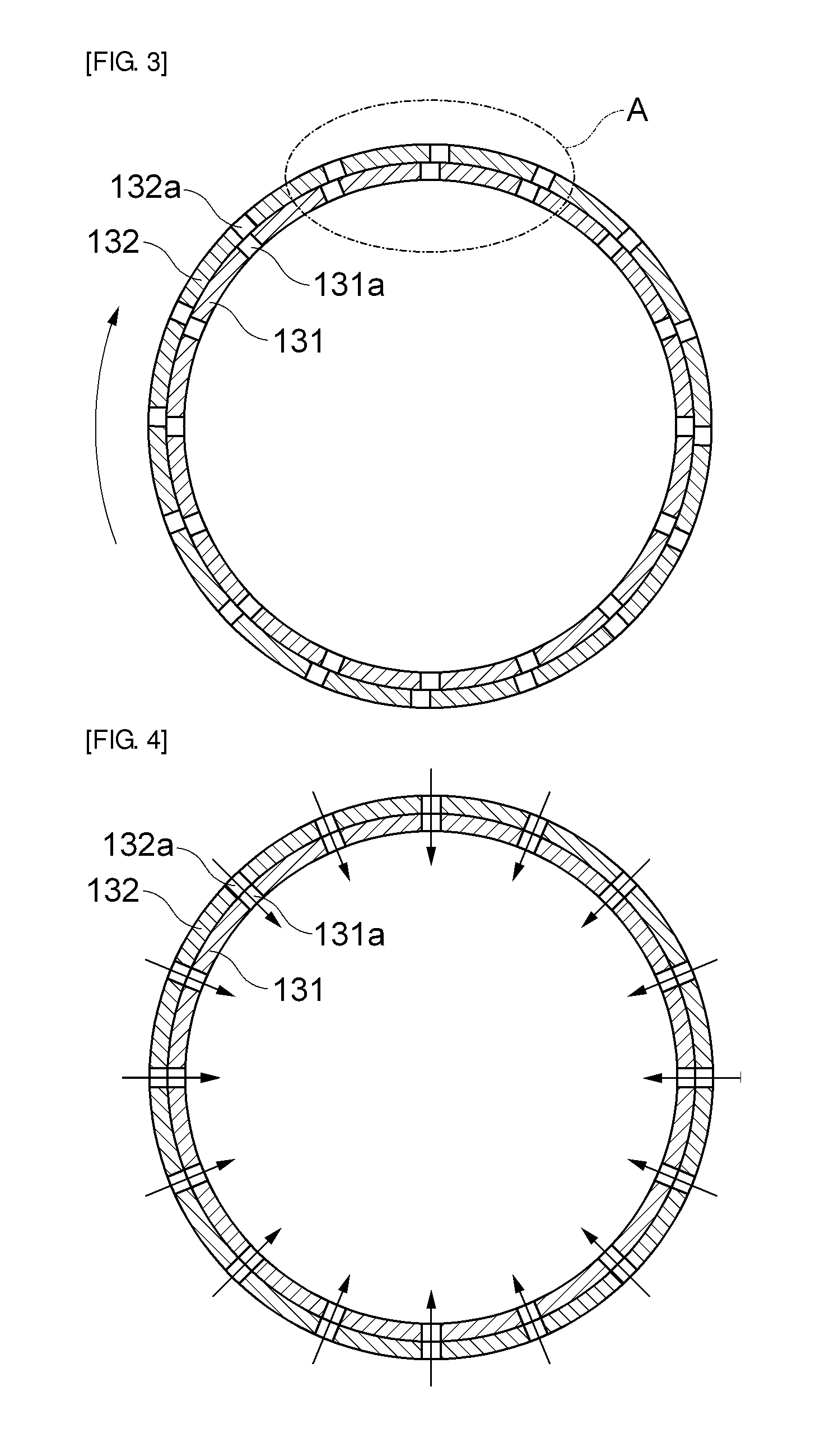

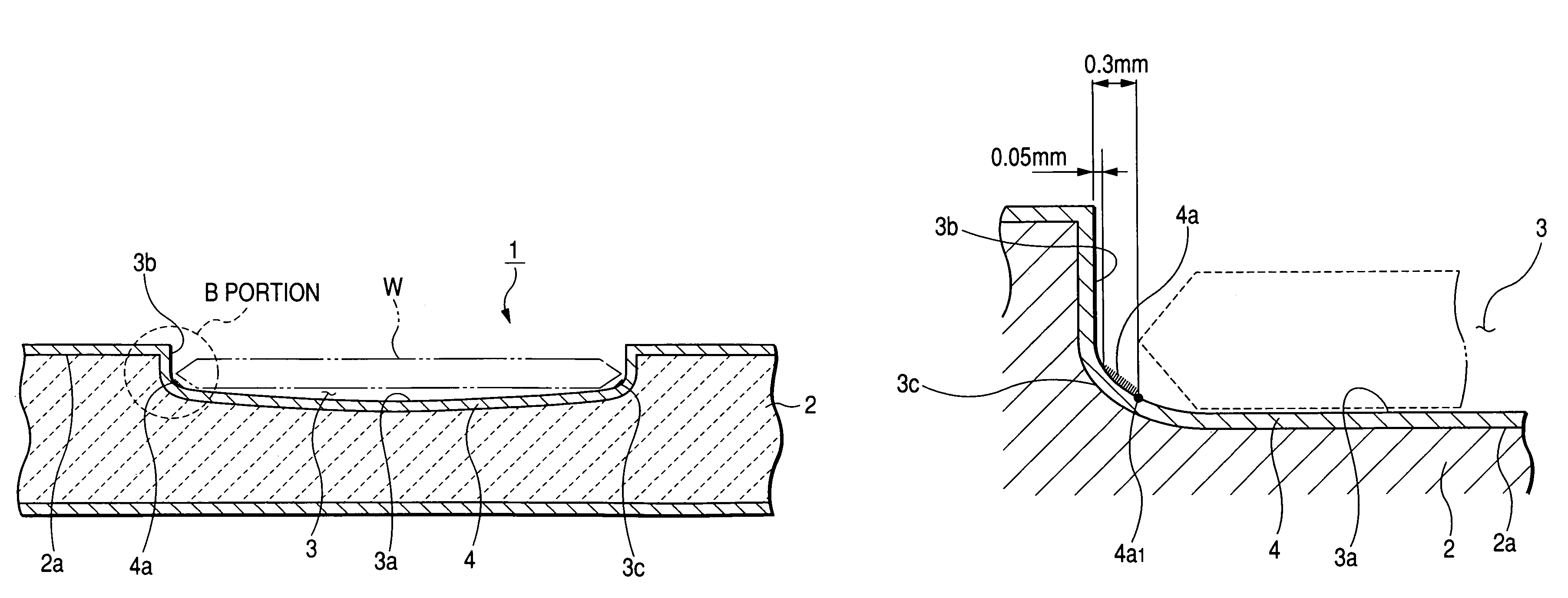

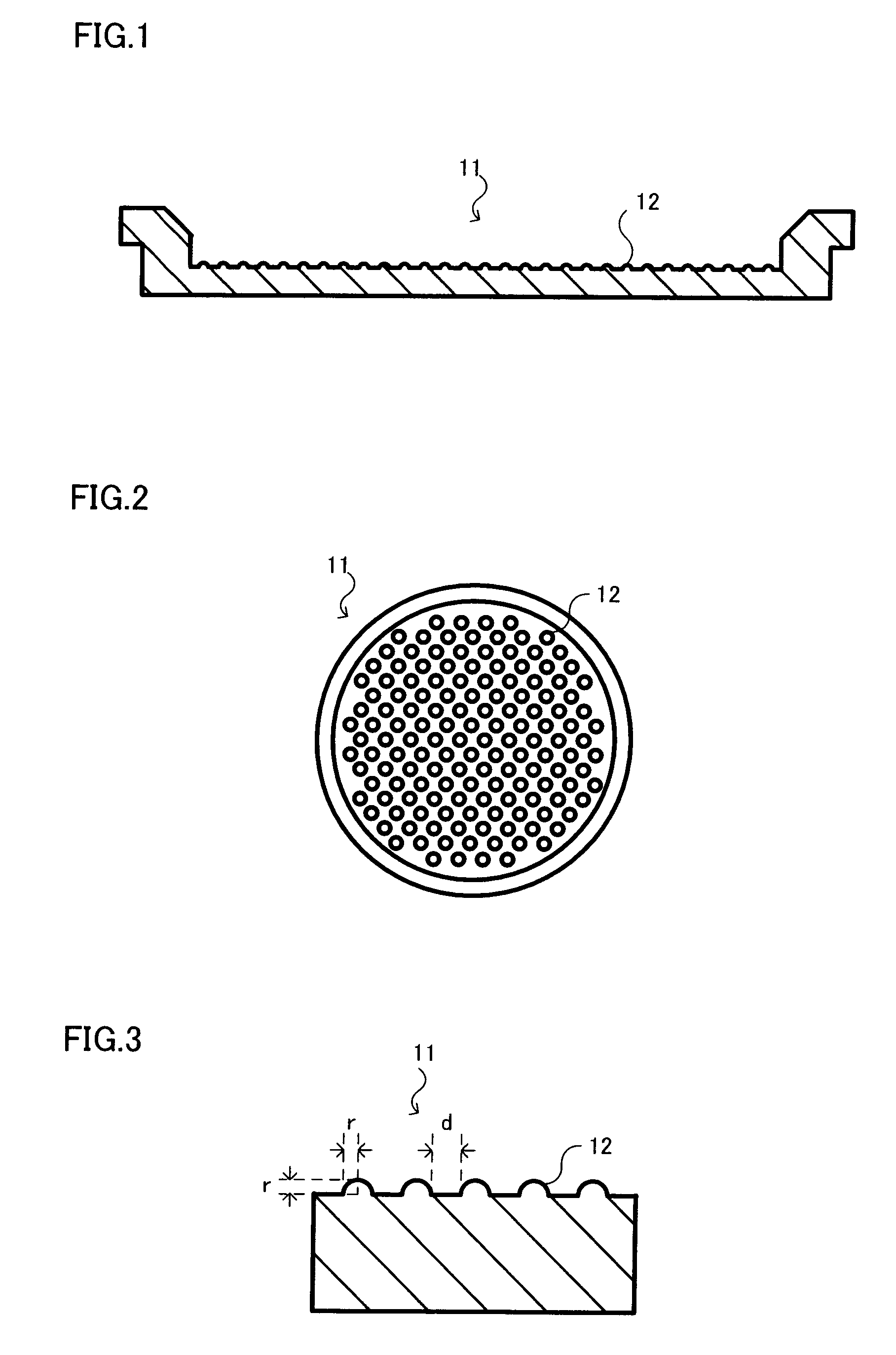

Susceptor

ActiveUS7393418B2Stably holdUnified performanceLiquid surface applicatorsDiffusion/dopingSusceptorSurface roughness

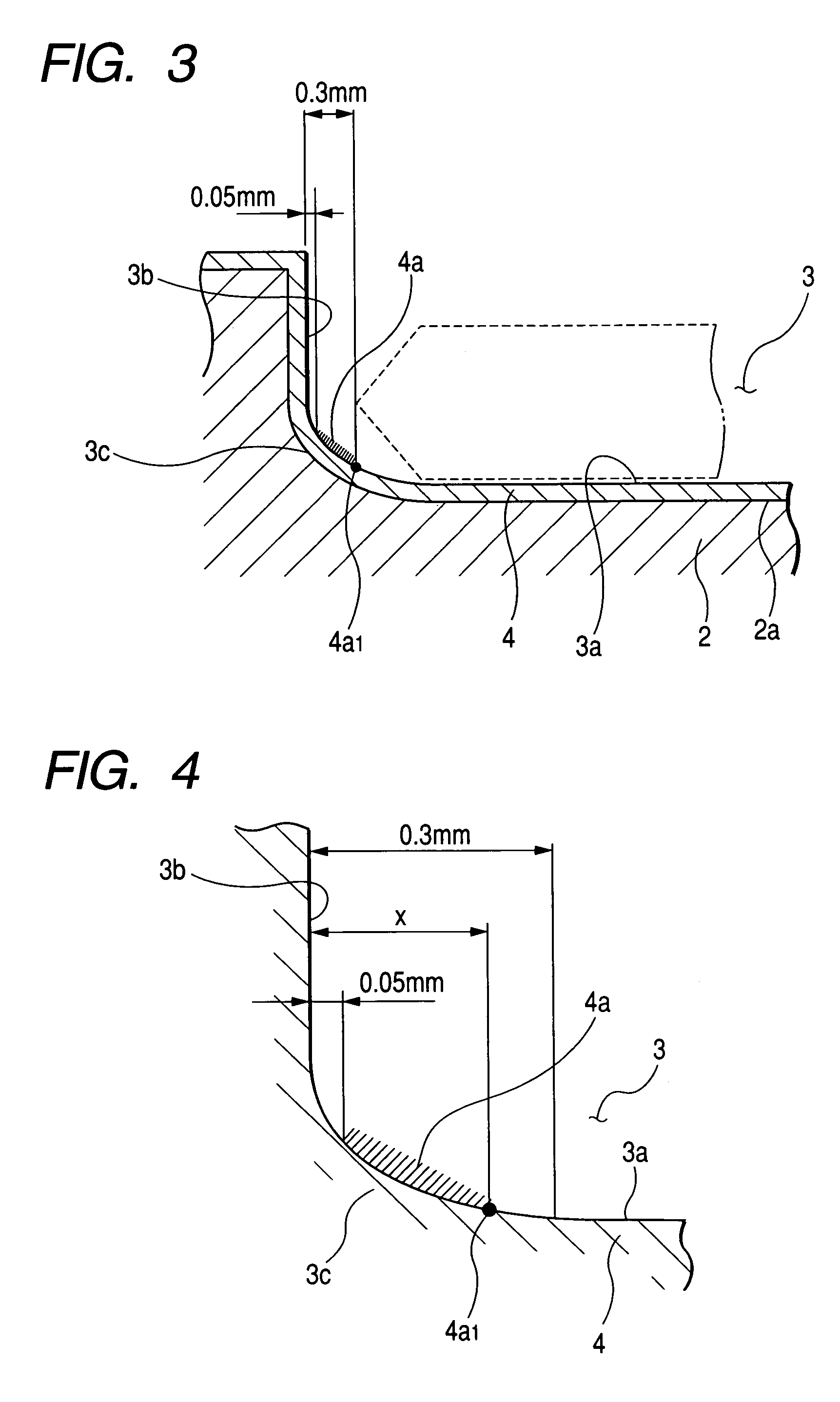

A susceptor at least a surface thereof being coated with SiC, includes a recess where an wafer is mounted, the recess having an round portion disposed on a lower portion of an outer circumferential portion of the recess, a ring-shaped SiC crystal growth surface portion provided within the round portion in a range of 0.05 mm or more and 0.3 mm or less defined from an outer circumference vertical portion of the recess and a contact portion, where the susceptor contacts with the wafer on the recess, having a surface roughness Ra in a range of 0.5 μm or more and 3 μm or less.

Owner:COORSTEK INC

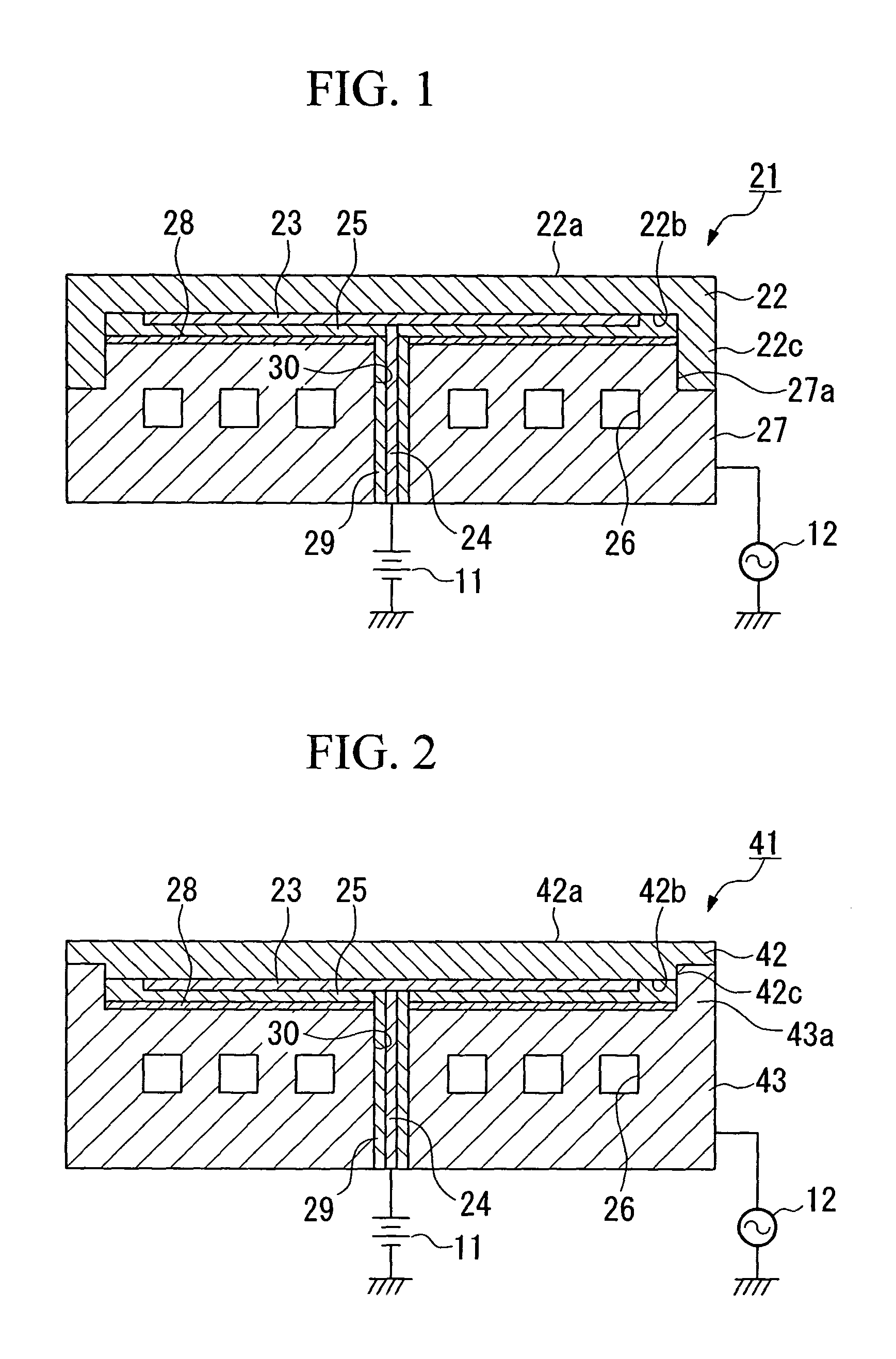

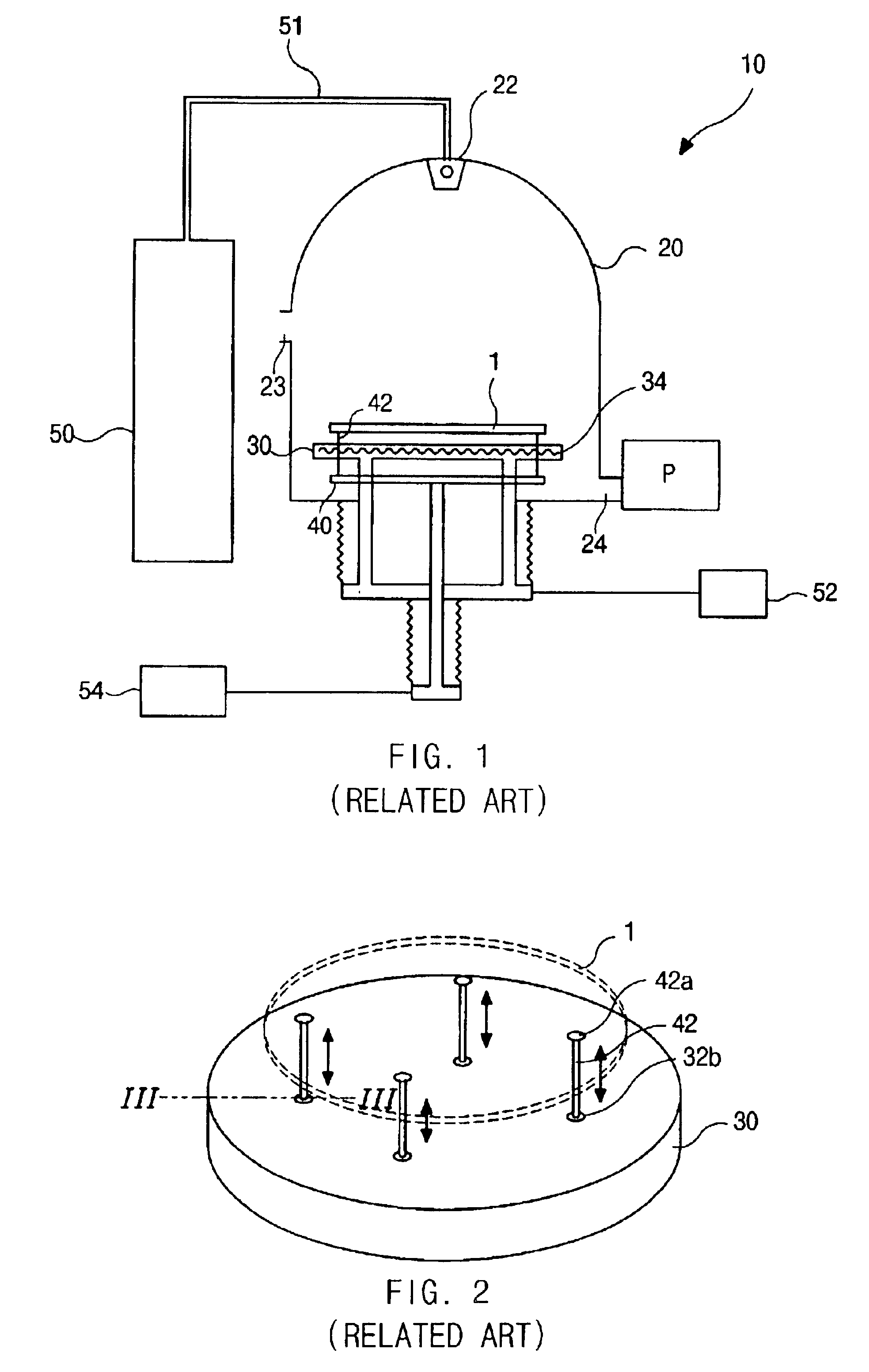

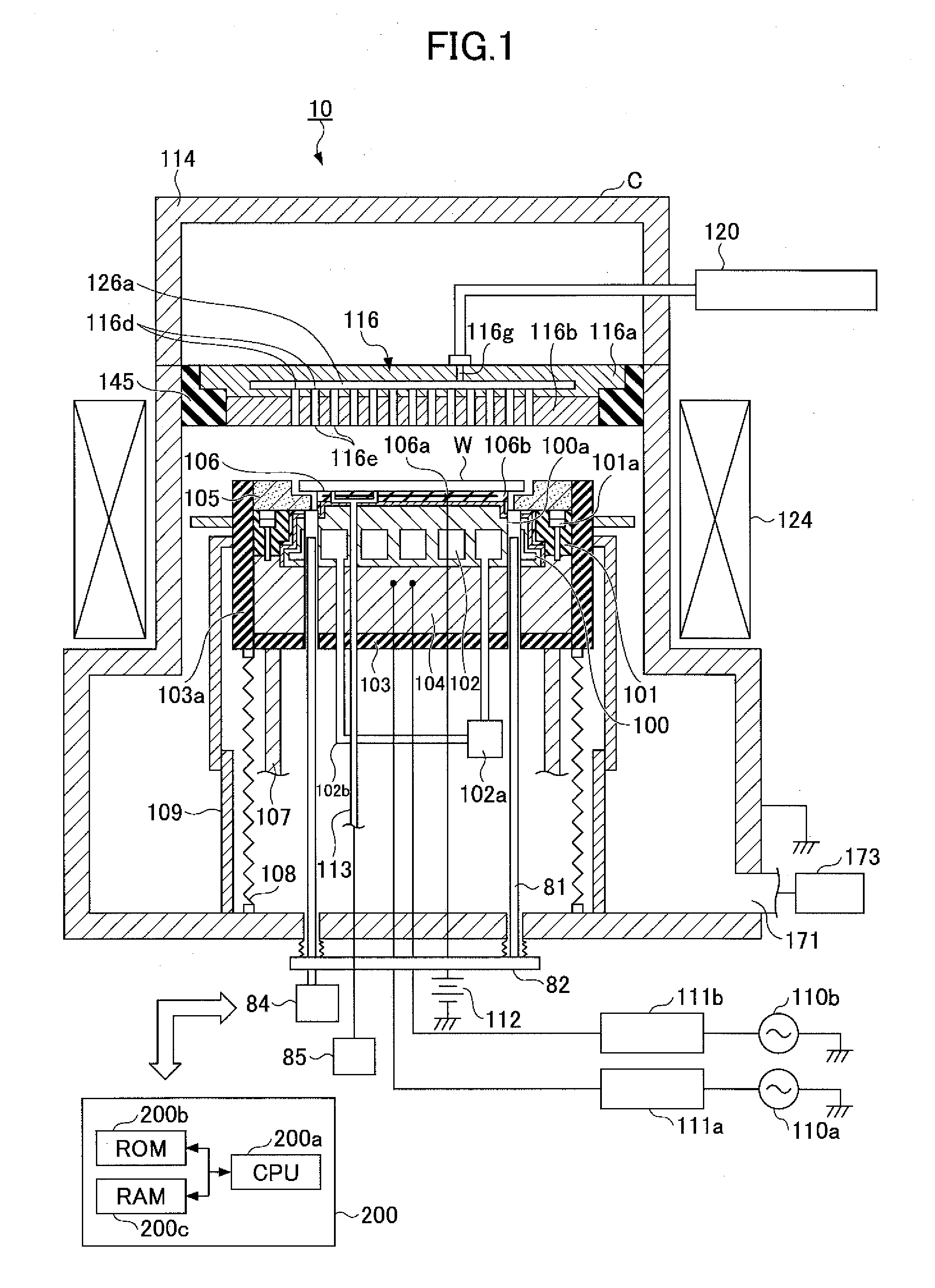

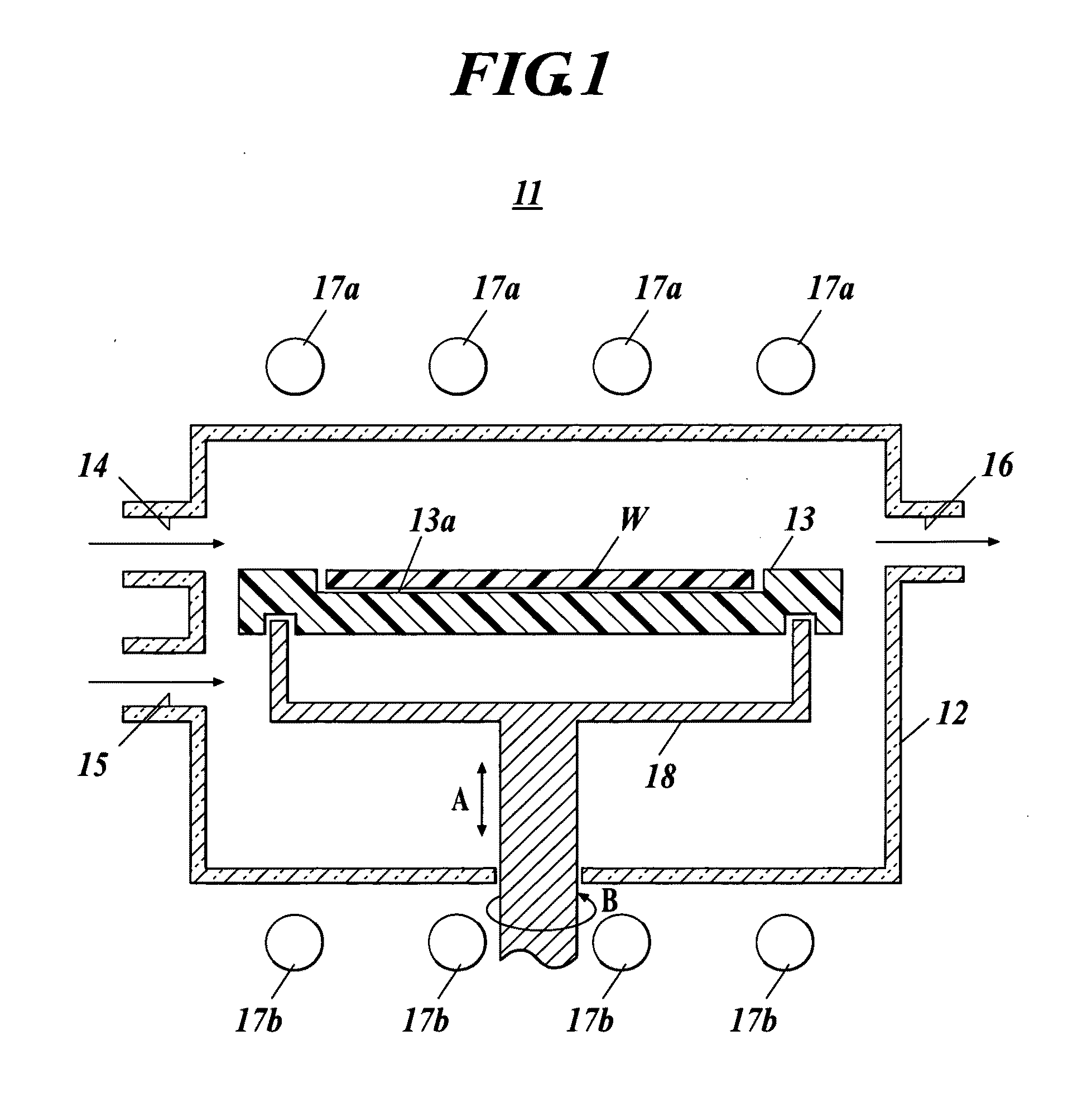

Processing apparatus for object to be processed and processing method using same

InactiveUS20050034674A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorEngineering

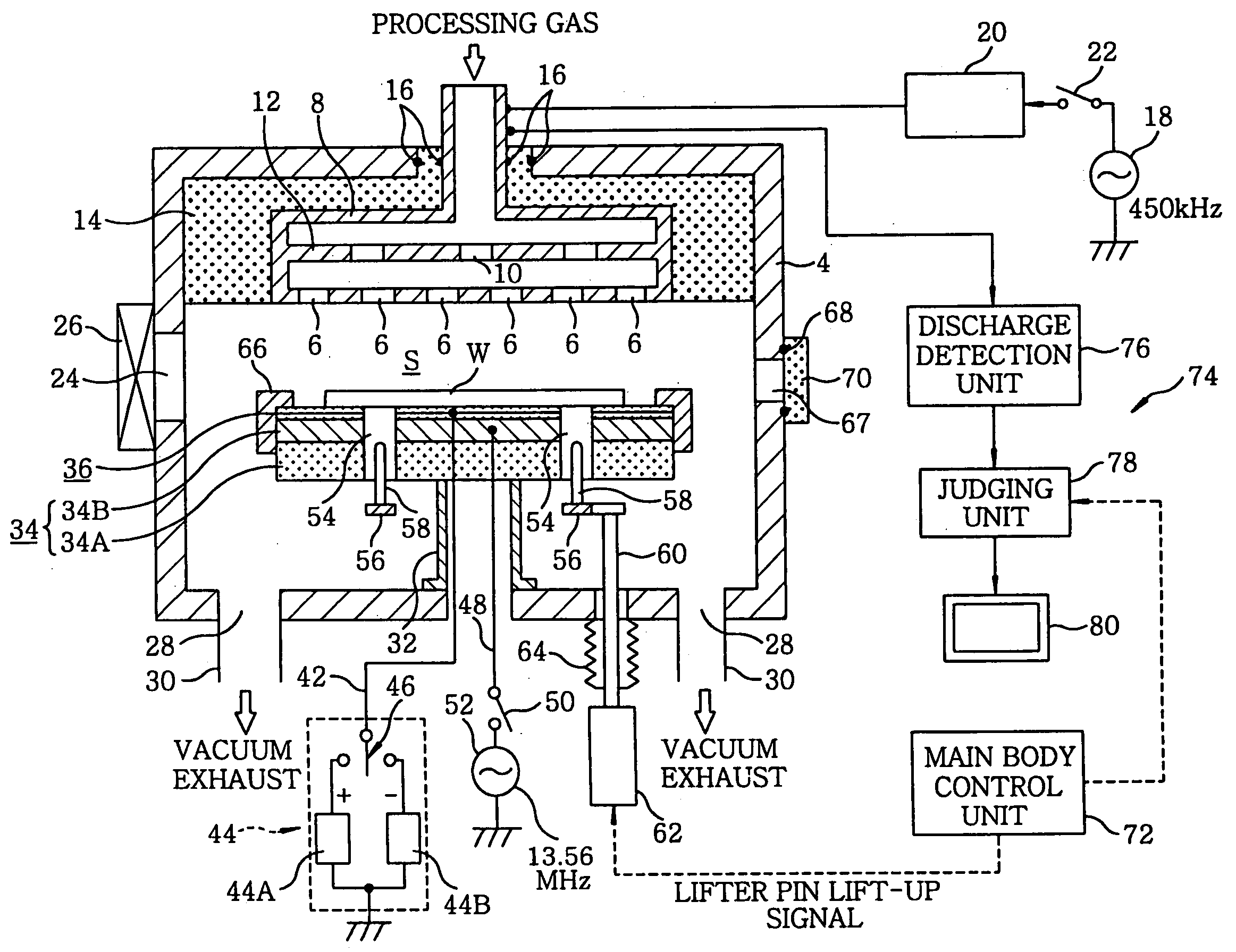

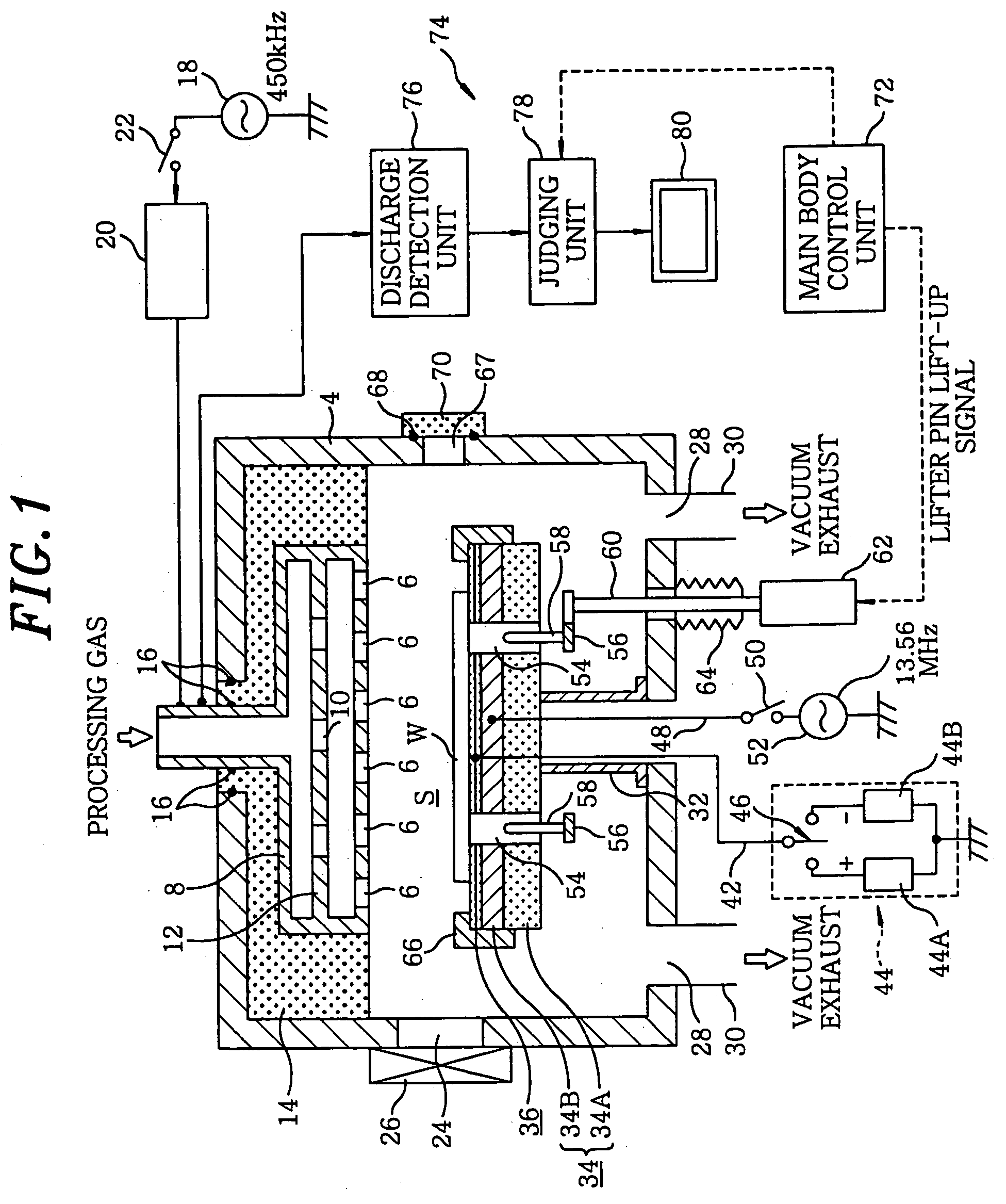

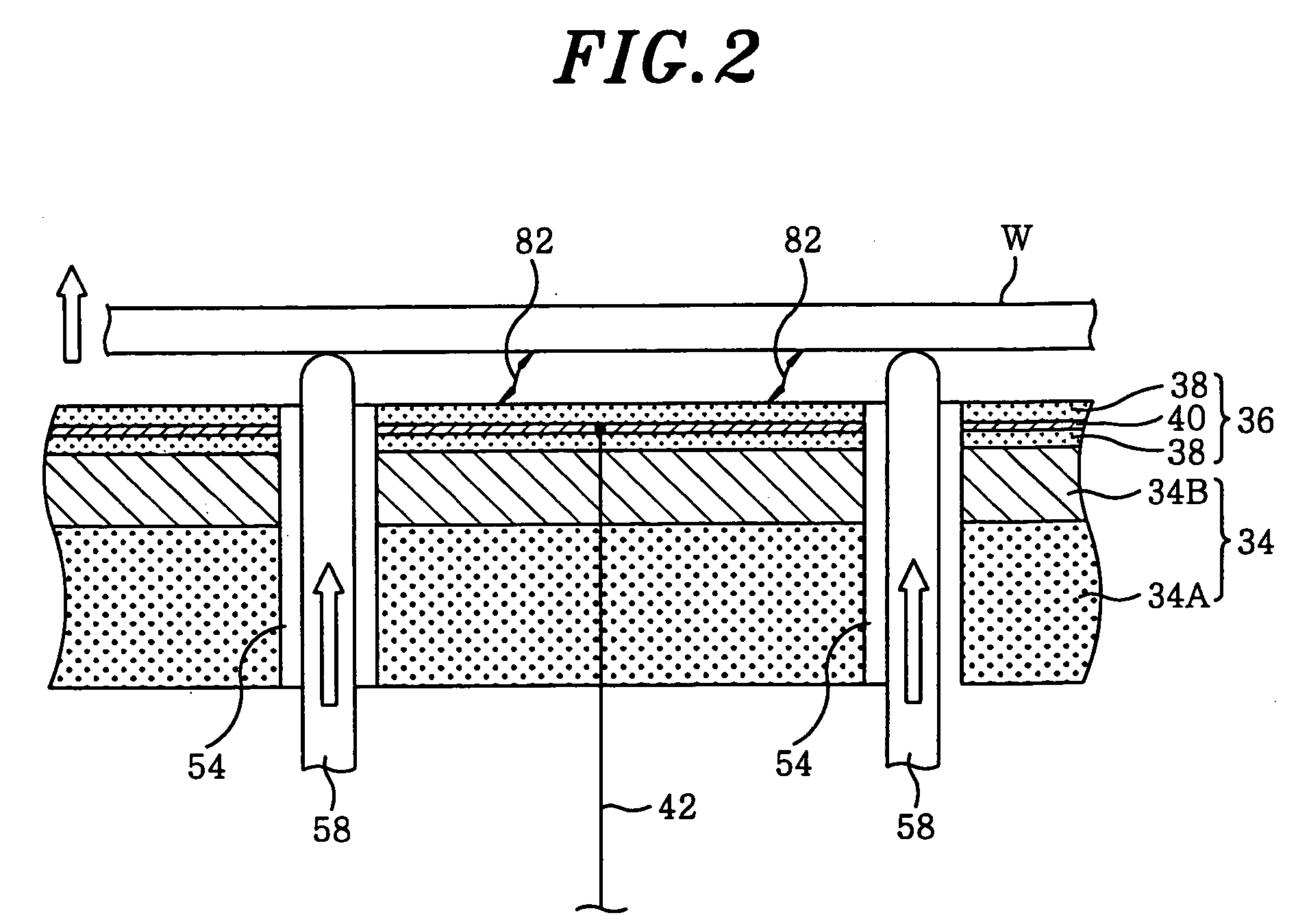

A processing apparatus includes a processing vessel; a susceptor installed in the processing vessel and having an electrostatic chuck for attracting and holding an object to be processed; lifter pins, elevatably installed with respect to the susceptor, for separating the object from the susceptor; and a jump-up detection device for detecting whether or not the object jumps up from the susceptor when the object is lifted up to be separated therefrom by the lifter pins, wherein the jump-up detection device has a discharge detection unit for detecting at least one of a discharge current and a discharge voltage generated between the object and the susceptor when the object is separated from the susceptor; and a judging unit for judging whether or not the object jumps up based on a detection result of the discharge detection unit.

Owner:TOKYO ELECTRON LTD

Chamber sealing member

ActiveUS20130129577A1Semiconductor/solid-state device manufacturingChemical/physical/physico-chemical processesSusceptorMechanical engineering

A reaction chamber including an upper region for processing a substrate, a lower region for loading a substrate, a susceptor movable within the reaction chamber, a first sealing member positioned on a perimeter of the susceptor, a second sealing member positioned between the upper region and the lower region, wherein the first and second sealing members are selectively engaged with one another to limit communication between the upper region and the lower region.

Owner:ASM IP HLDG BV

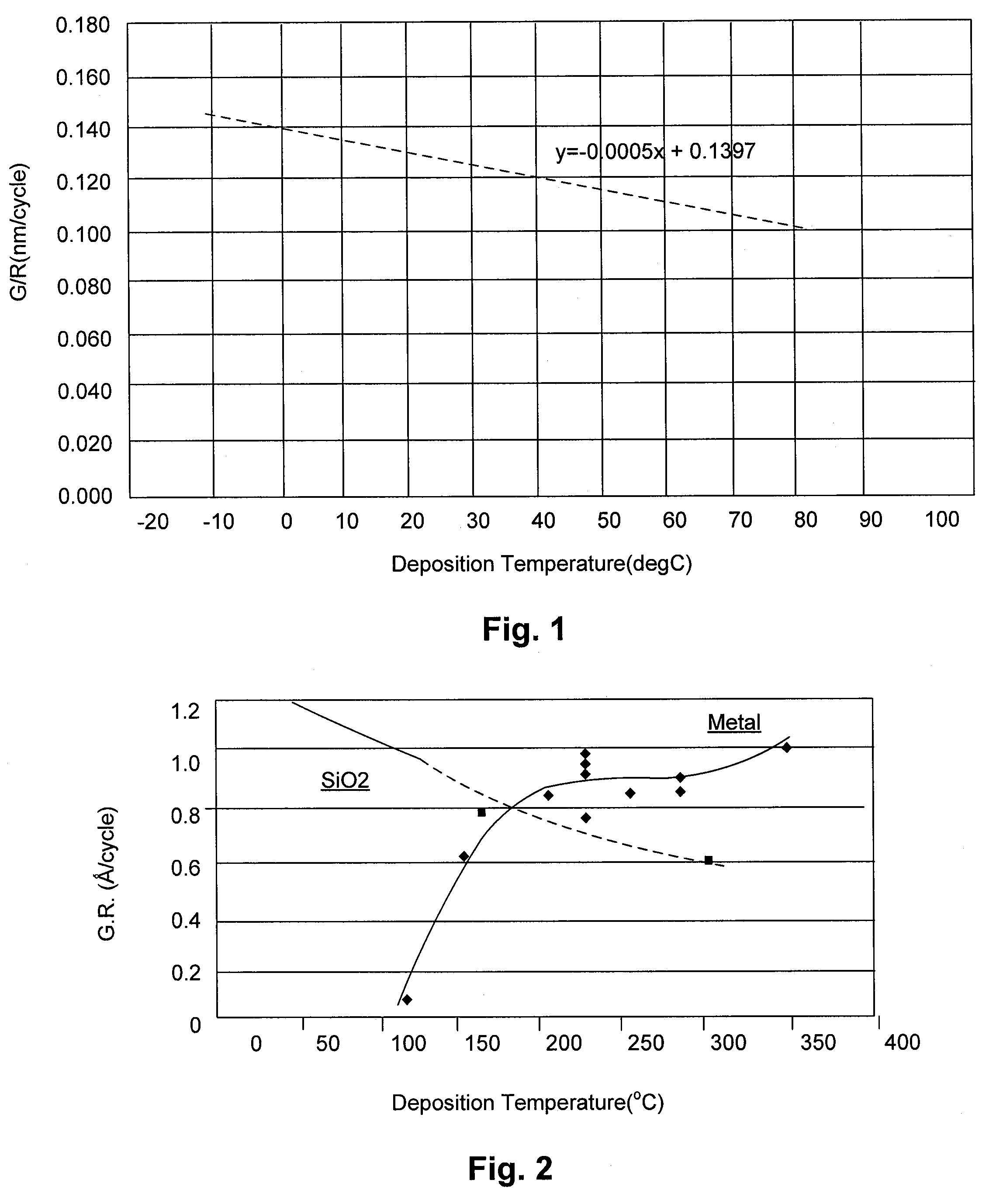

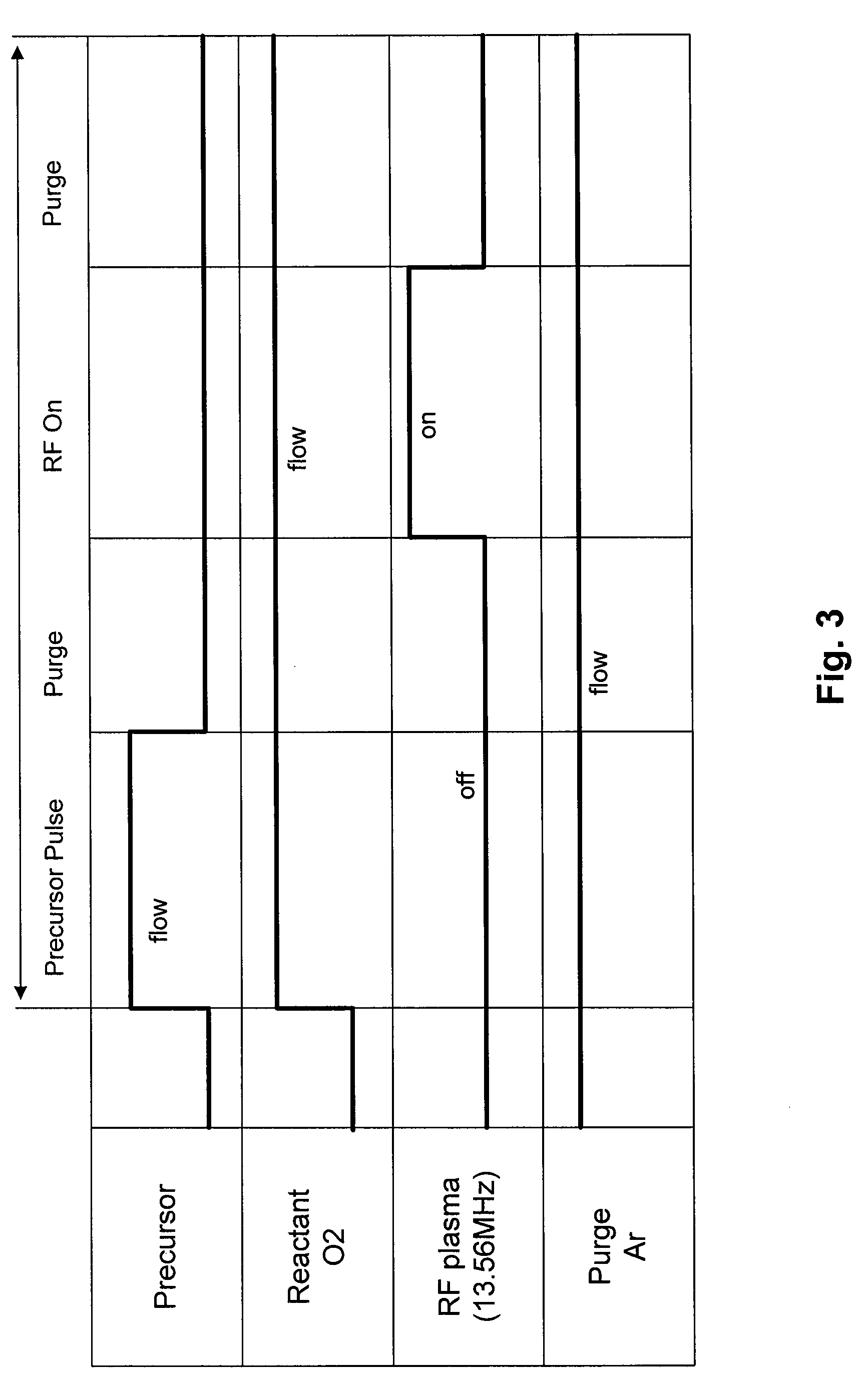

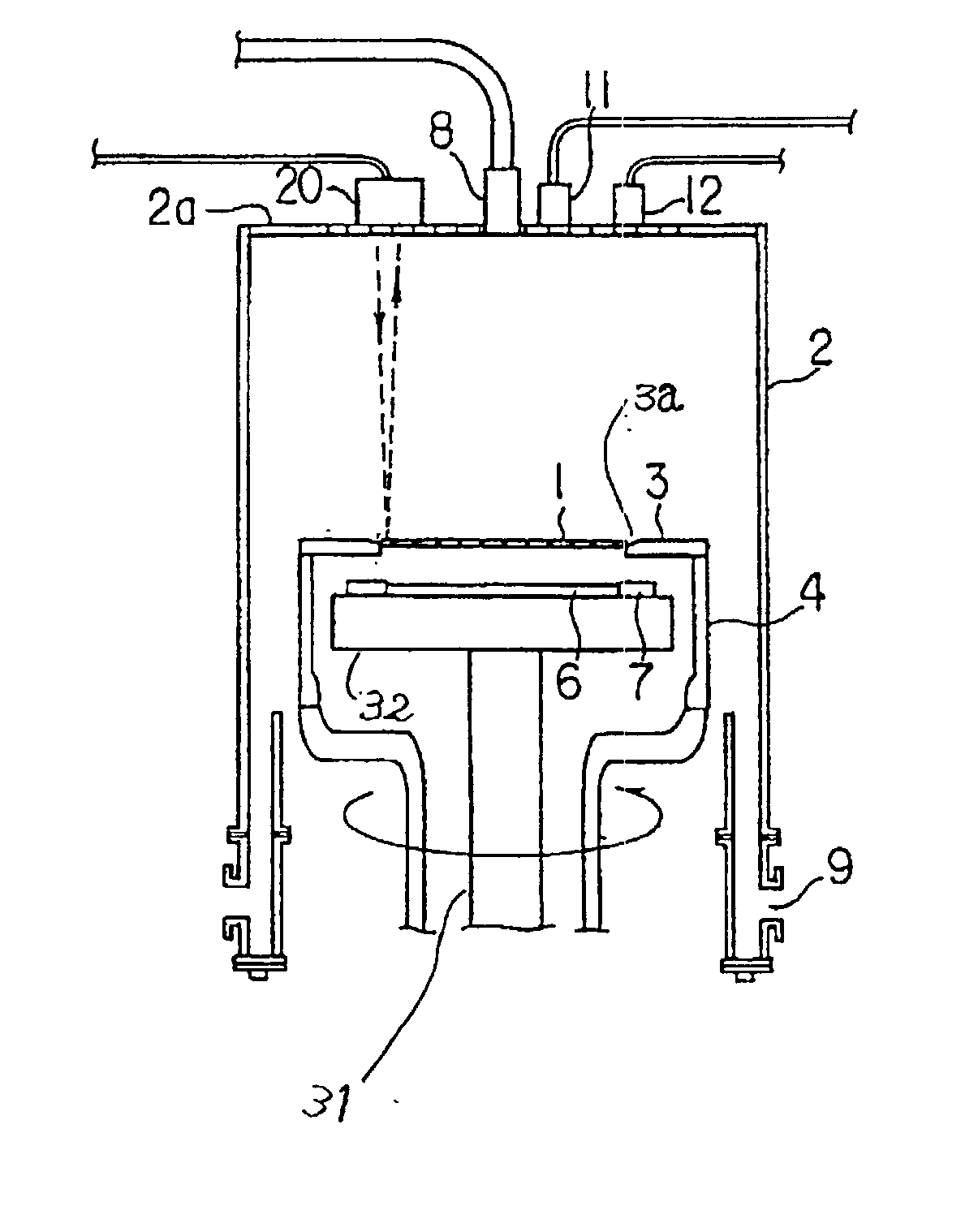

Method of depositing silicon oxide film by plasma enhanced atomic layer deposition at low temperature

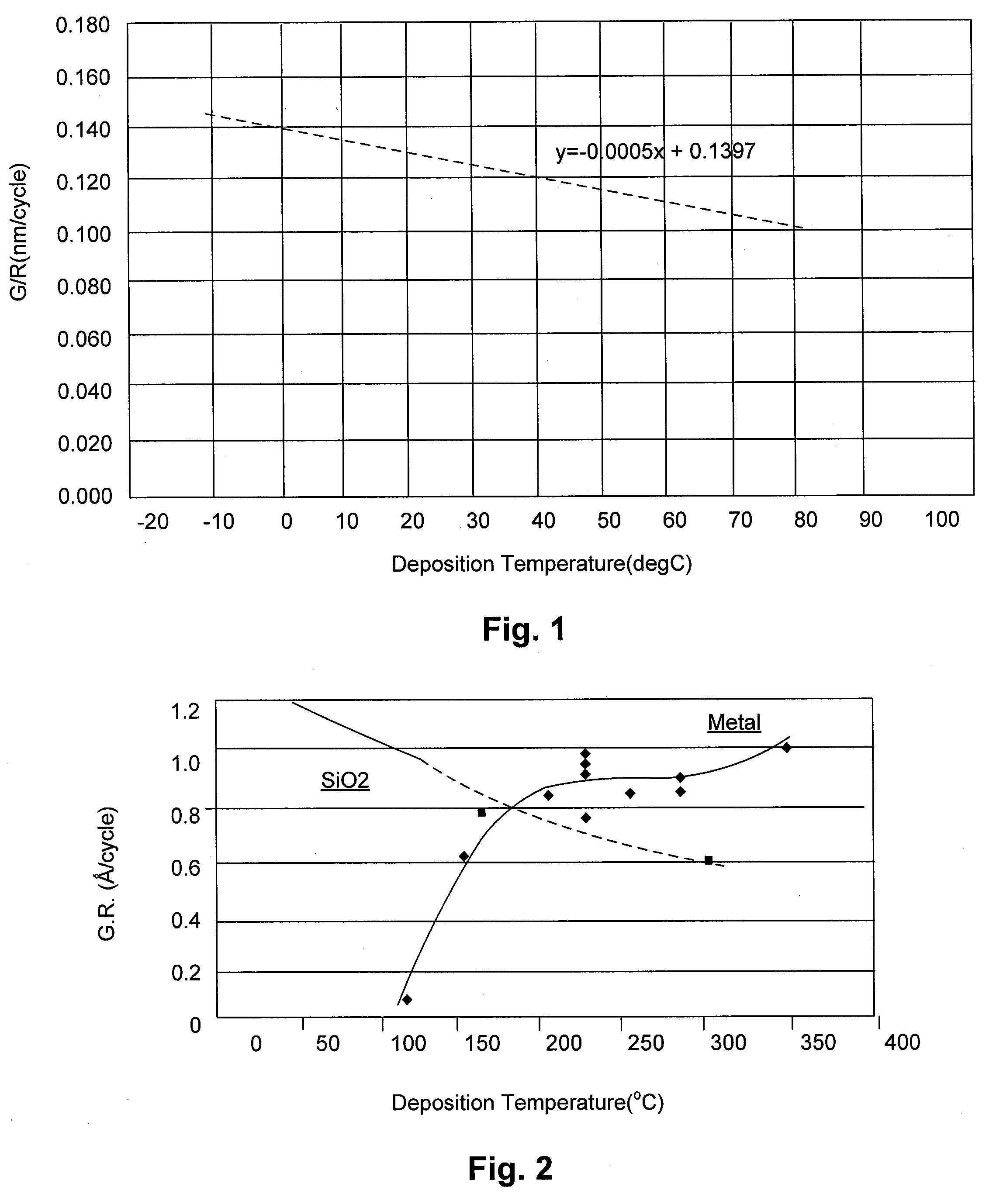

ActiveUS8197915B2Increase deposition rateInhibition is effectiveSemiconductor/solid-state device manufacturingPhotosensitive material processingResistDeposition temperature

Owner:ASM JAPAN

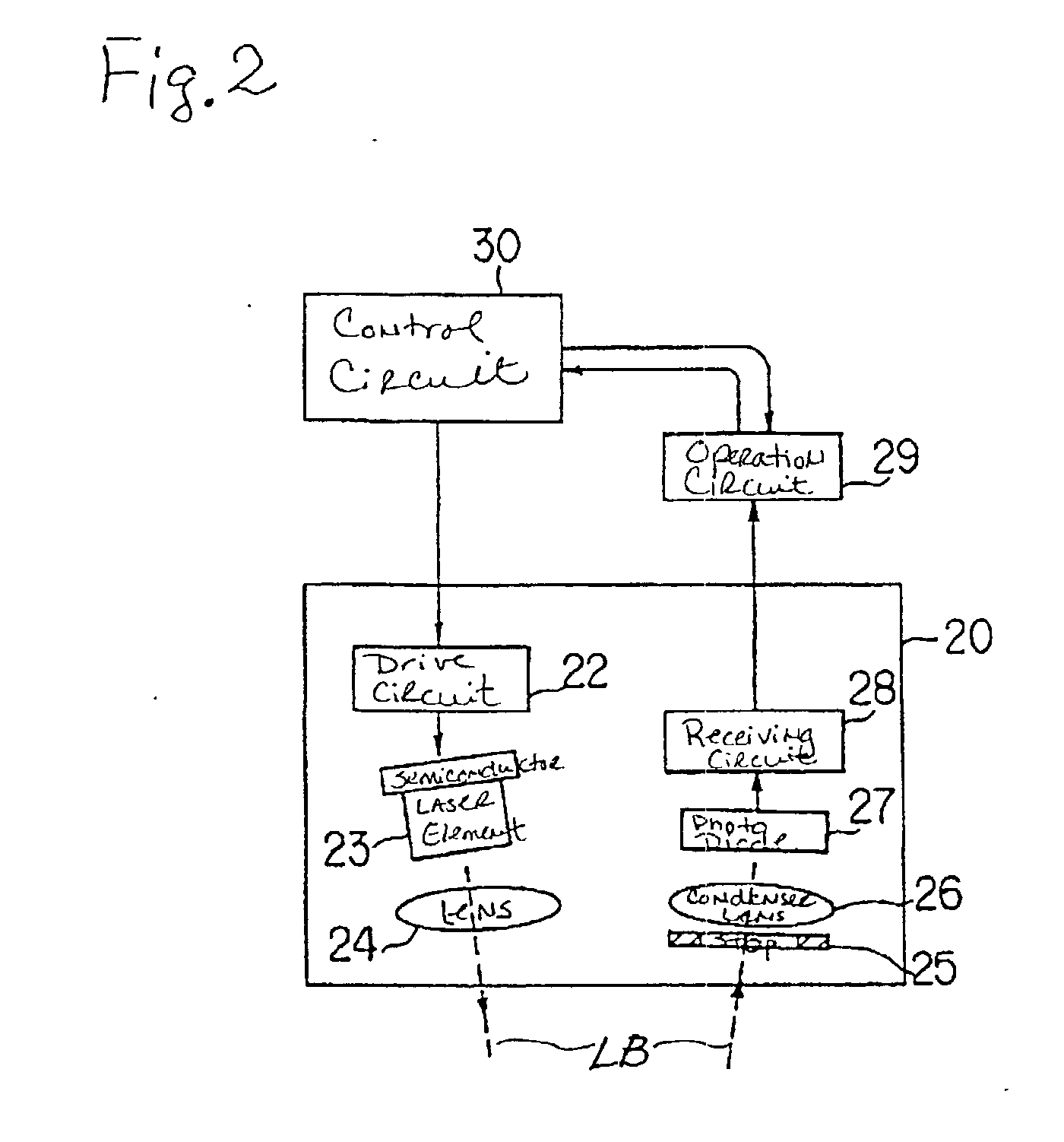

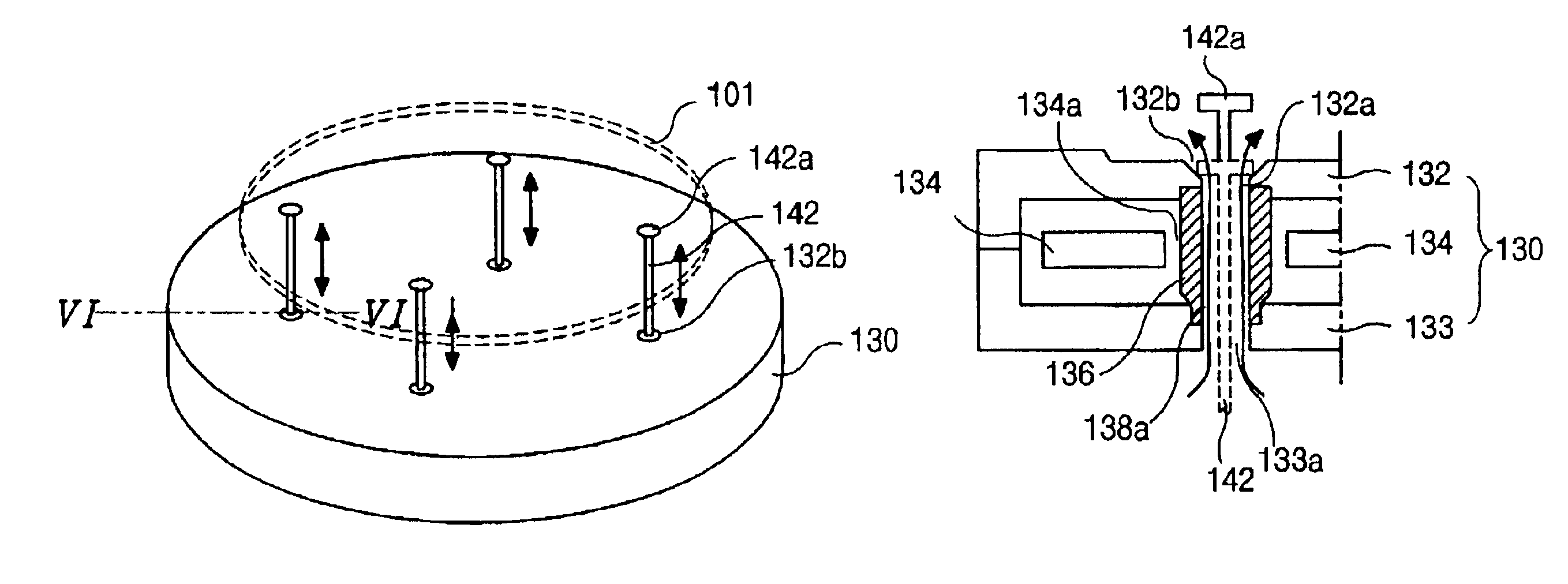

Method and apparatus for detecting a wafer's posture on a susceptor

InactiveUS20030042419A1Improve accuracyControl quantityRadiation pyrometryMaterial analysis by optical meansWaferingSusceptor

An apparatus used for an epitaxial vapor growing arrangement and for detecting whether a wafer is properly seated within a susceptor contained therein. The apparatus includes a semiconductor laser element that generates a laser beam which irradiates the wafer's surface. The apparatus, further, includes a combination of a stop mechanism, a condenser lens and a photo diode, which detects the laser beam reflected from the wafer surface and an operation circuit, which determines the wafer's posture on the susceptor. During operation, the reflected laser beam focuses on a receiving surface of the photo diode through the condenser lens. The operation circuit then compares the output signal from the photo diode with a preset reference value for discriminating the slope of the wafer.

Owner:TOSHIBA MASCH CO LTD

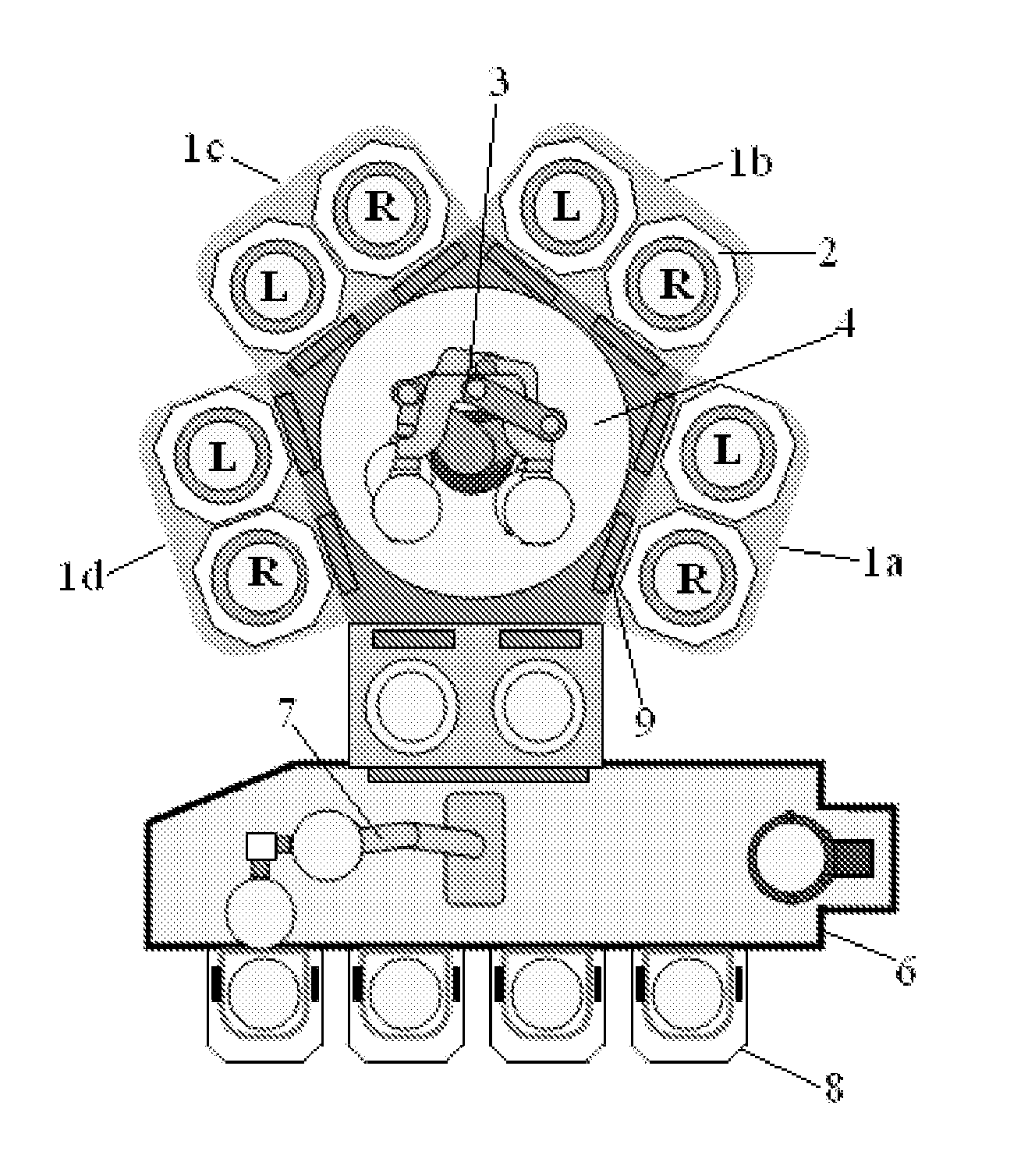

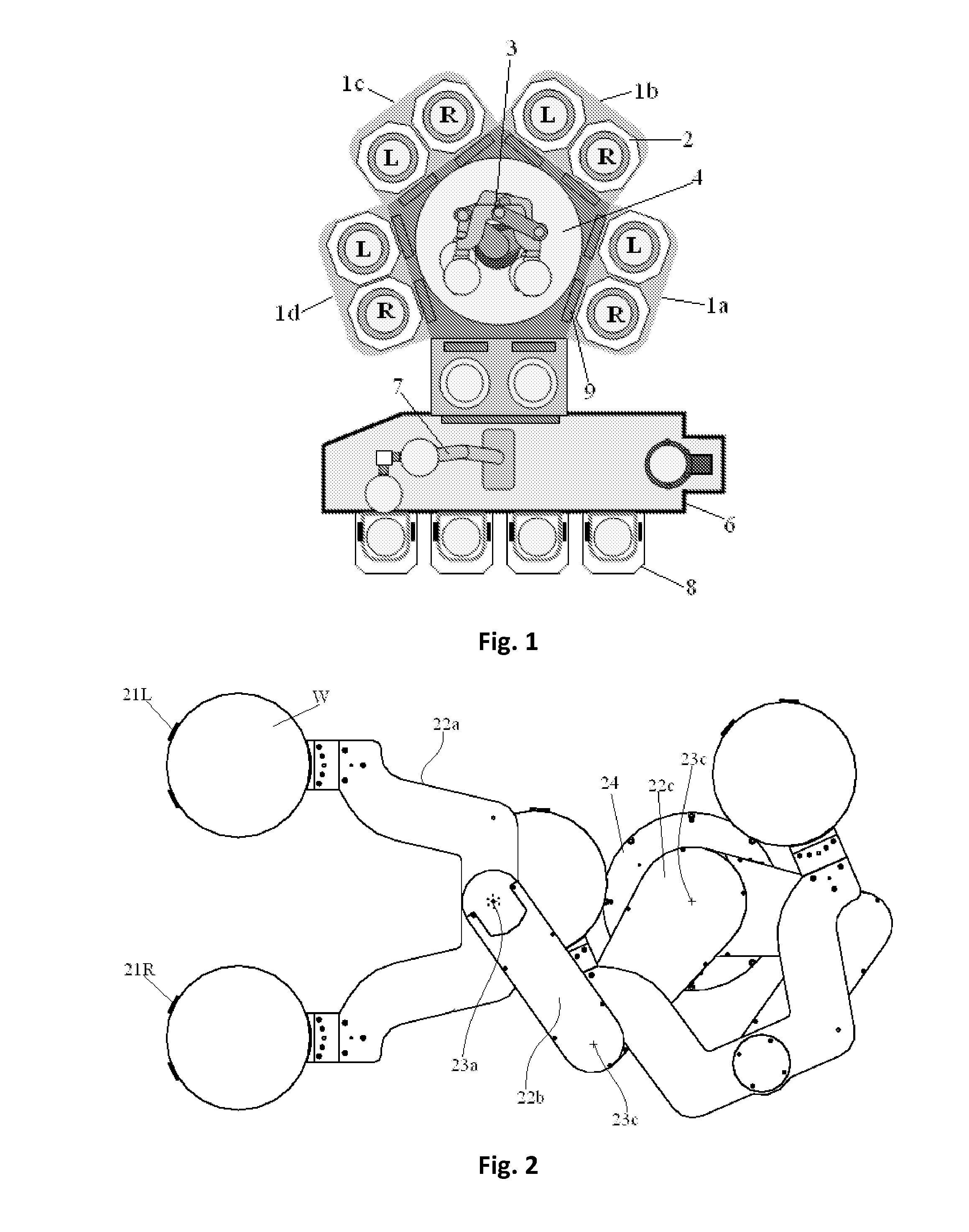

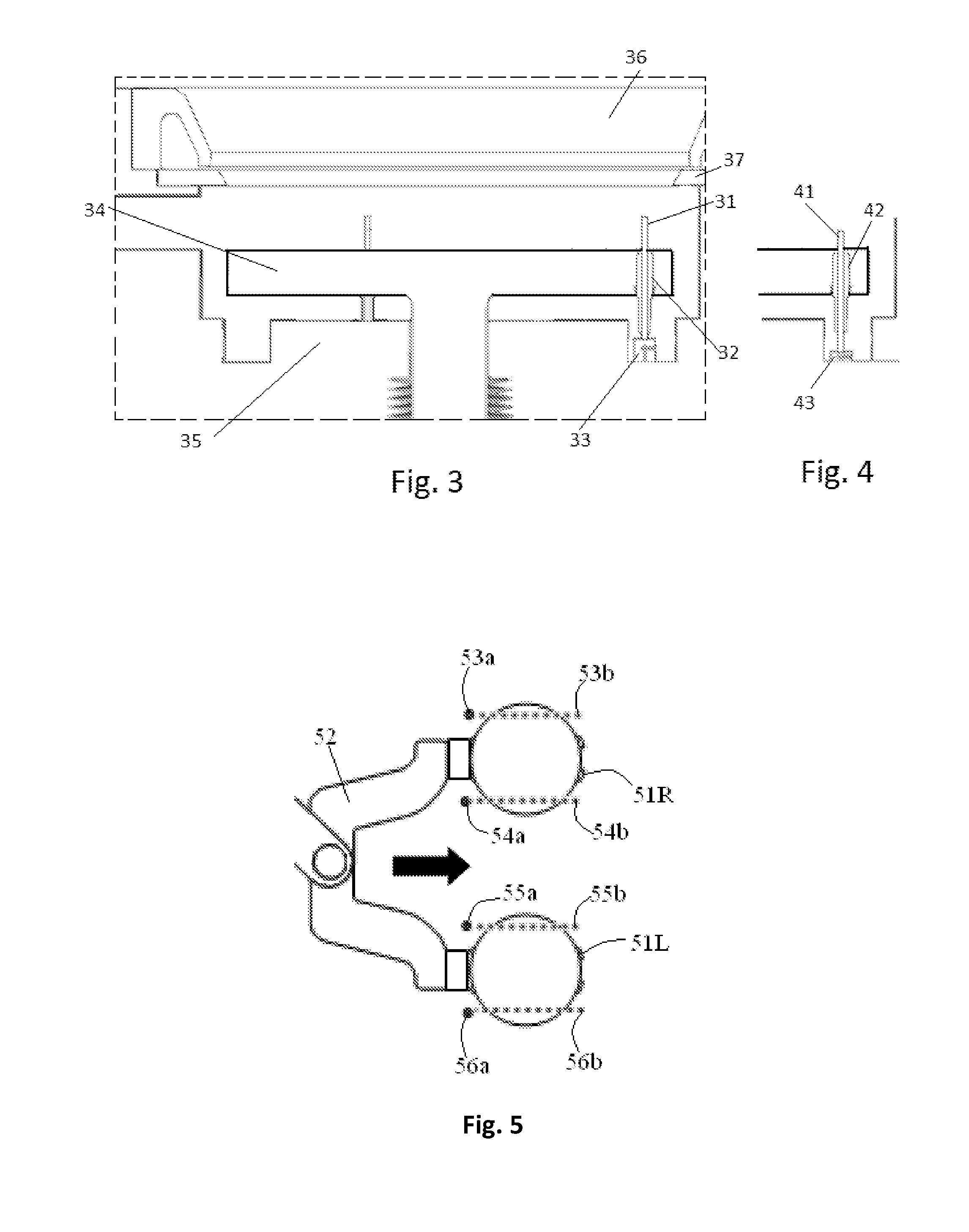

Method for Positioning Wafers in Multiple Wafer Transport

ActiveUS20120325148A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingWaferingSusceptor

A method for positioning wafers in dual wafer transport, includes: simultaneously moving first and second wafers placed on first and second end-effectors to positions over lift pins protruding from first and second susceptors, respectively; and correcting the positions of the first and second wafers without moving any of the lift pins relative to the respective susceptors or without moving the lift pins relative to each other, wherein when the first and second wafers are moved to the respective positions, the distance between the first wafer and tips of the lift pins of the first susceptor is substantially smaller than the distance between the second wafer and tips of the lift pins of the second susceptor.

Owner:ASM JAPAN

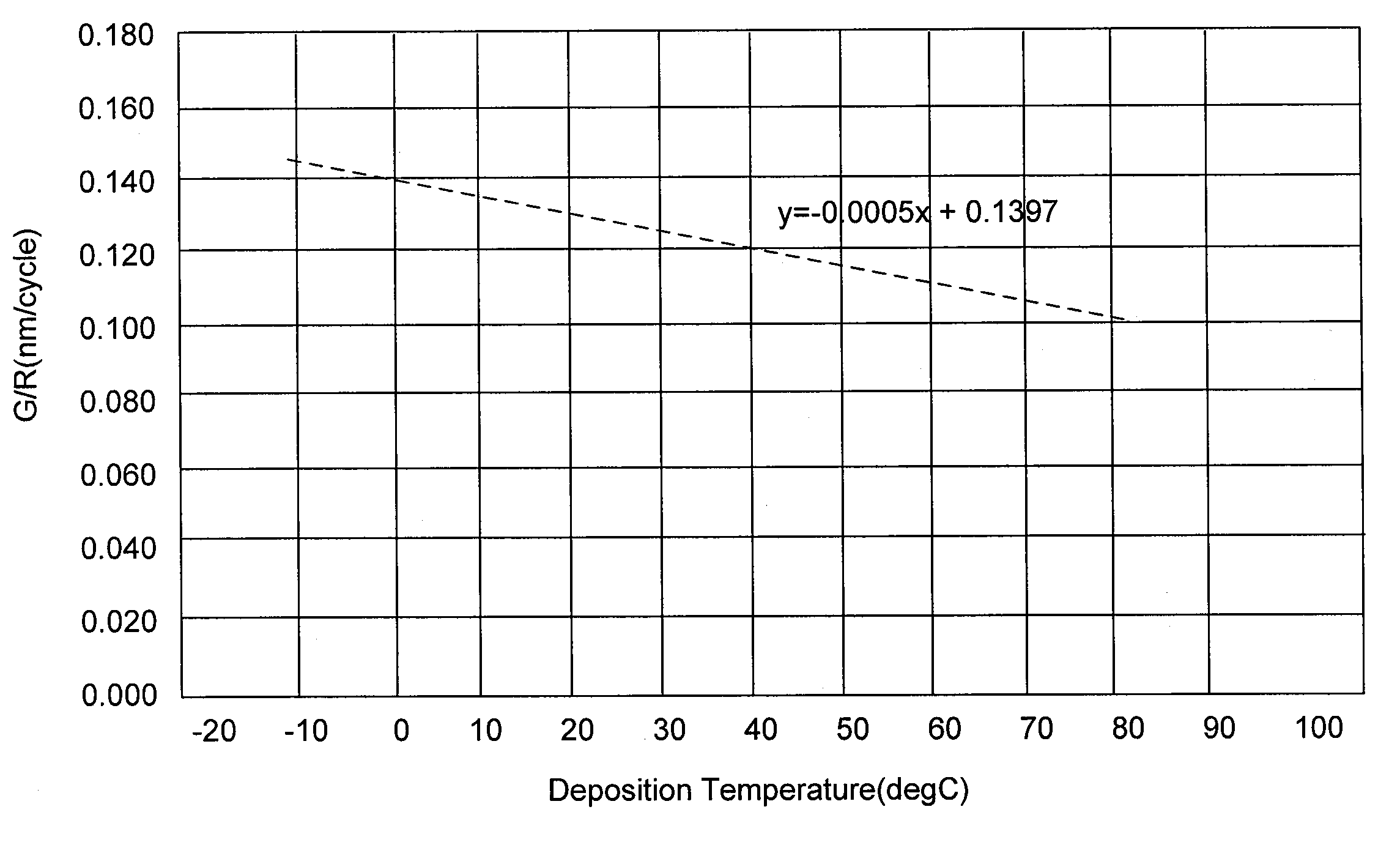

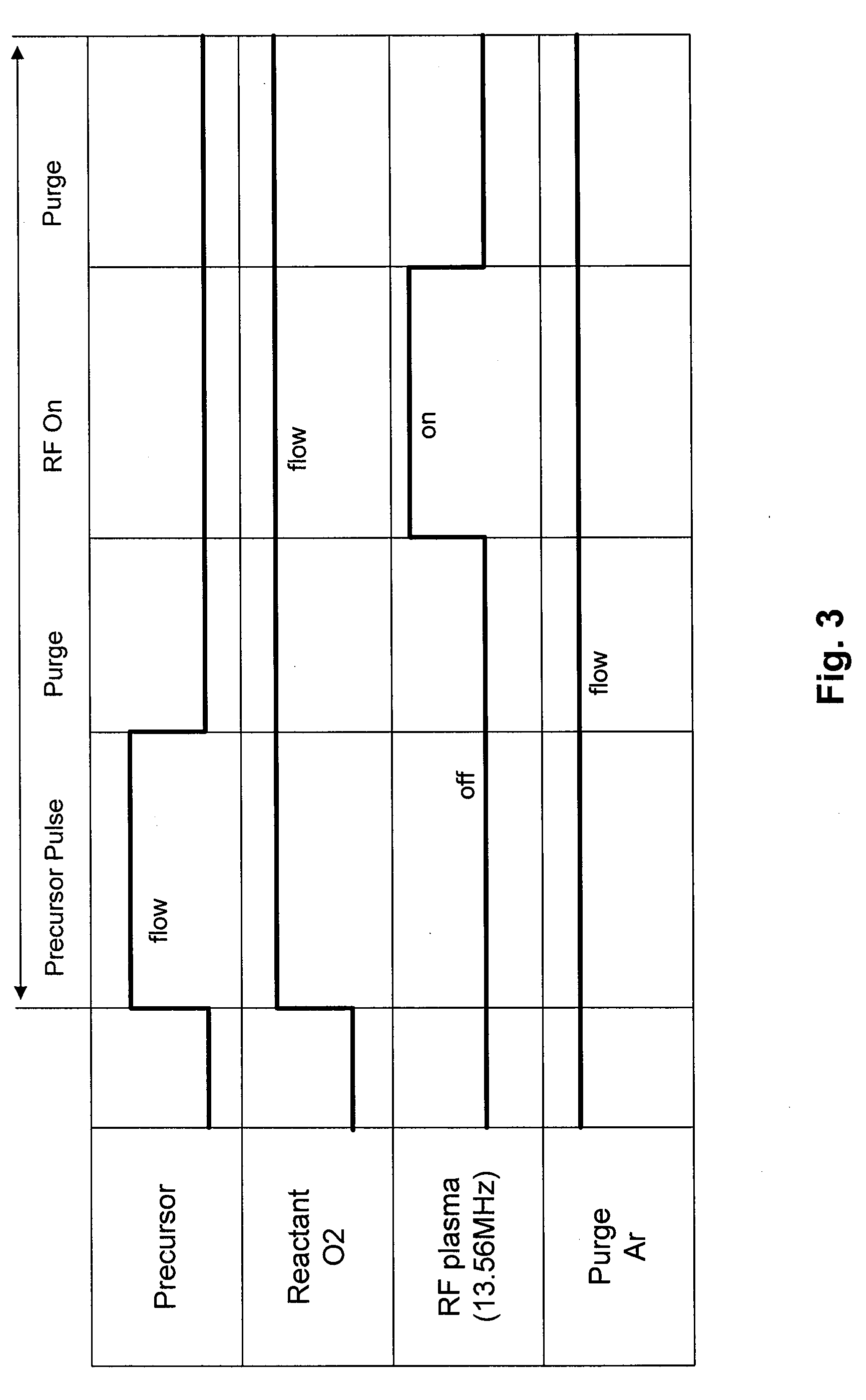

Method of Depositing Silicon Oxide Film by Plasma Enhanced Atomic Layer Deposition at Low Temperature

ActiveUS20100255218A1Increase deposition rateInhibition is effectiveLiquid surface applicatorsSemiconductor/solid-state device manufacturingResistDeposition temperature

A method of depositing a silicon oxide film on a resist pattern or etched lines formed on a substrate by plasma enhanced atomic layer deposition (PEALD) includes: providing a substrate on which a resist pattern or etched lines are formed in a PEALD reactor; controlling a temperature of a susceptor on which the substrate is placed at less than 50° C. as a deposition temperature; introducing a silicon-containing precursor and an oxygen-supplying reactant to the PEALD reactor and applying RF power therein in a cycle, while the deposition temperature is controlled substantially or nearly at a constant temperature of less than 50° C., thereby depositing a silicon oxide atomic layer on the resist pattern or etched lines; and repeating the cycle multiple times substantially or nearly at the constant temperature to deposit a silicon oxide atomic film on the resist pattern or etched lines.

Owner:ASM JAPAN

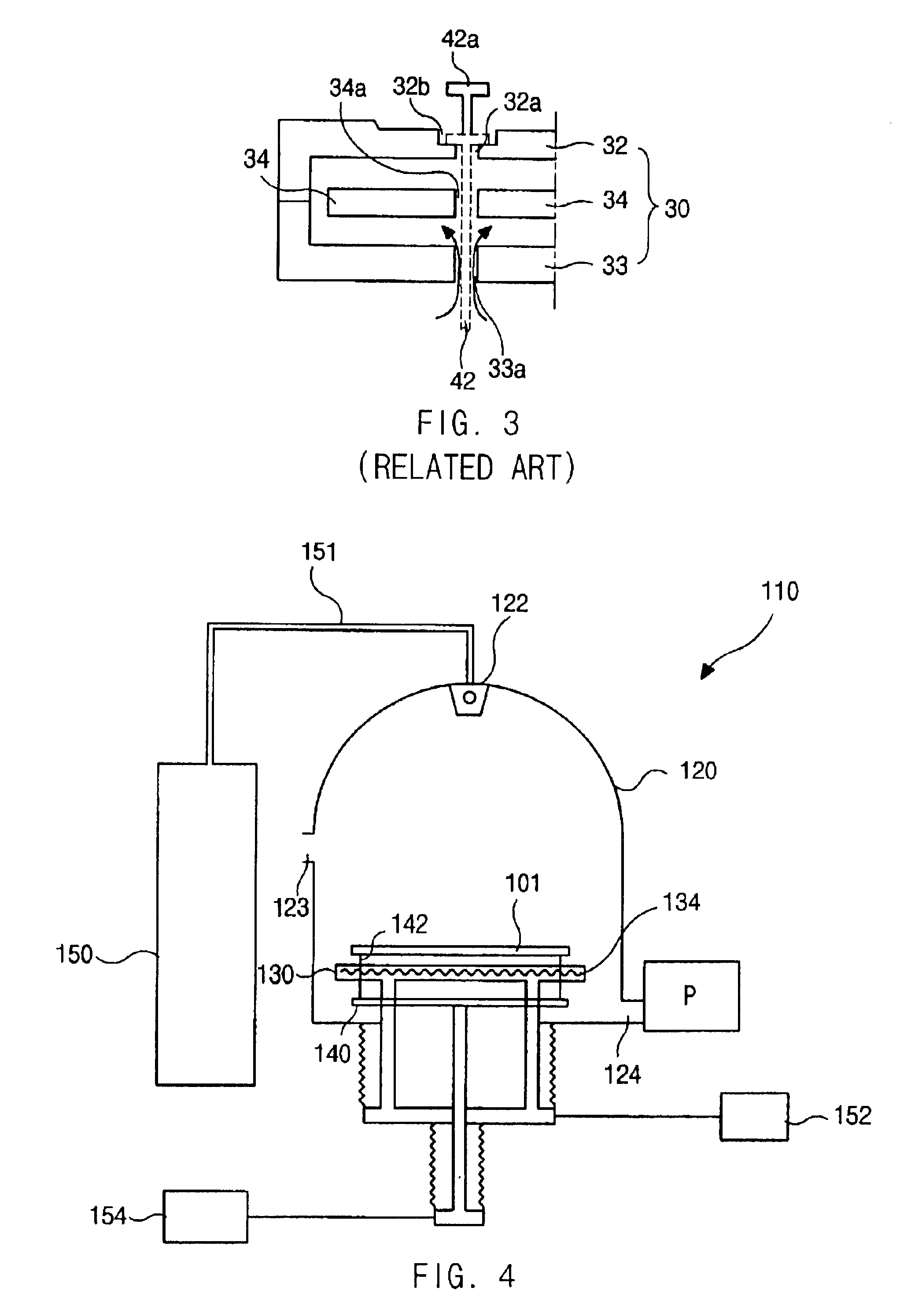

Susceptor of apparatus for manufacturing semiconductor device

InactiveUS6884319B2Prevent oxidationAvoid spaceCellsVacuum evaporation coatingSusceptorBiomedical engineering

A susceptor of an apparatus for manufacturing a semiconductor device includes a first part having a first lift pin hole, a second part combined with the first part and forming a space with the first part, wherein the second part has a second lift pin hole corresponding to the first lift pin hole, a heater disposed in the space, wherein the heater has a third lift pin hole corresponding to the first and second lift pin holes, a lift pin tube inserted in the first, second and third lift pin holes, wherein the lift pin tube is combined with the first and second part thereby preventing air from going into the space, and a lift pin passing through the lift pin tube.

Owner:JUSUNG ENG

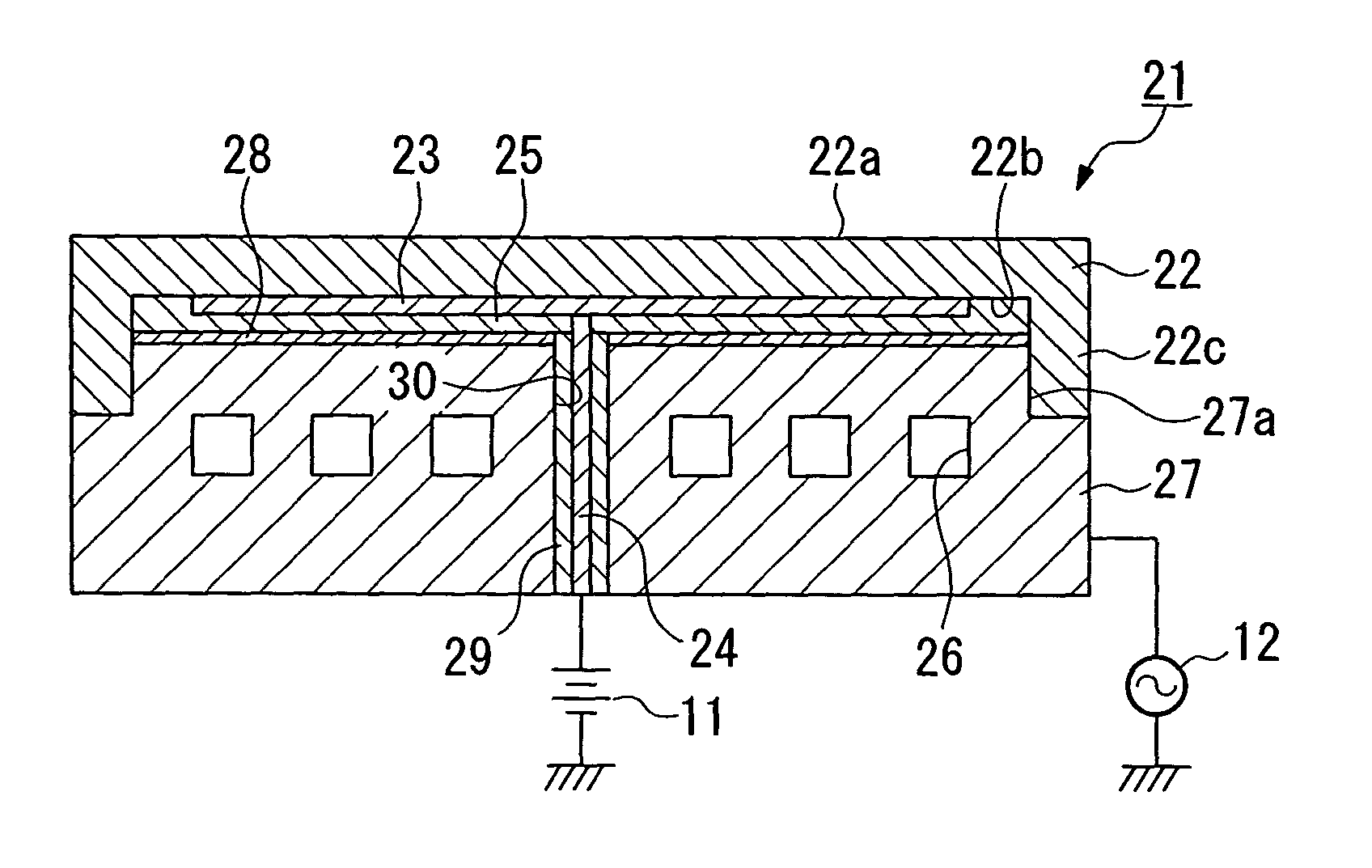

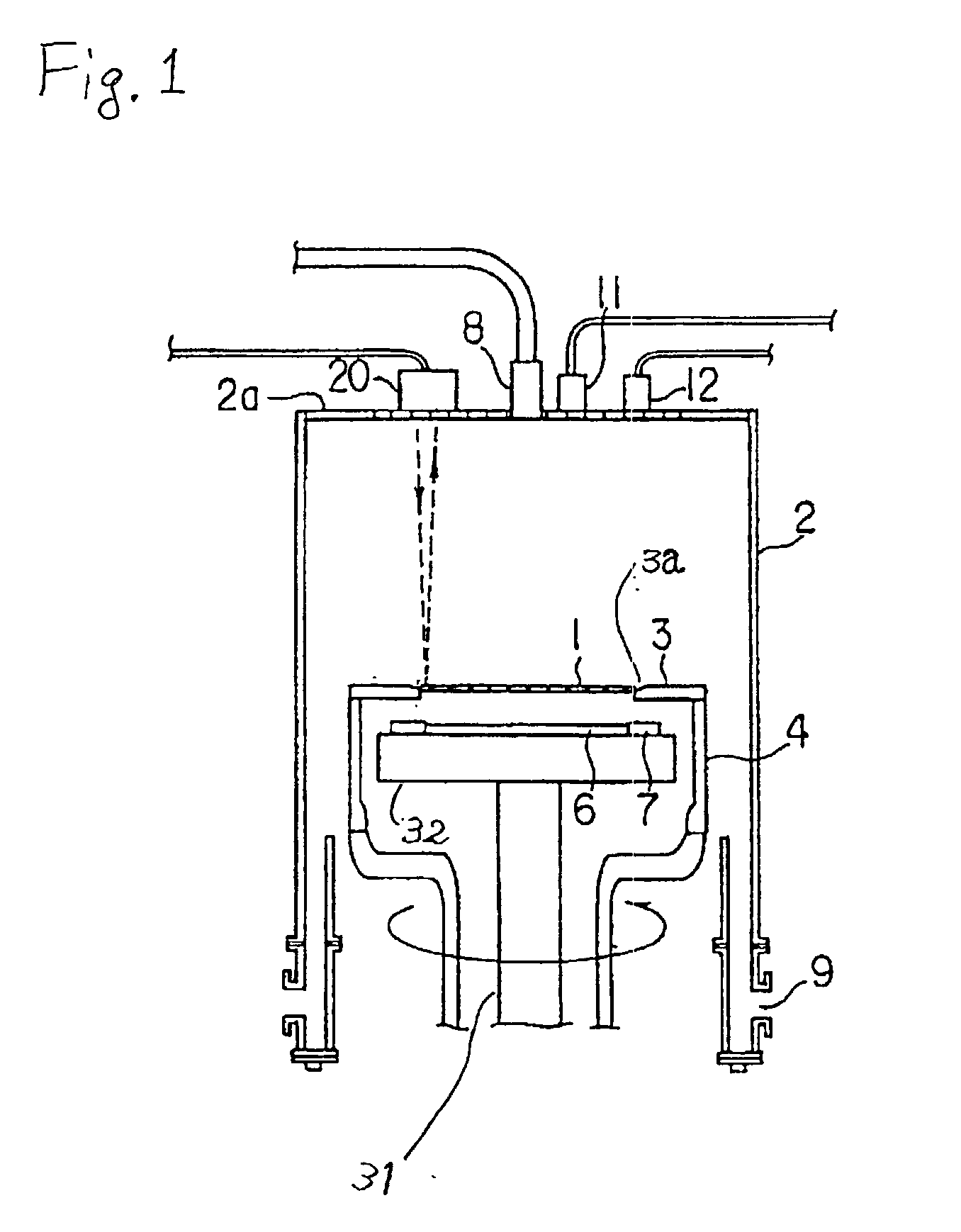

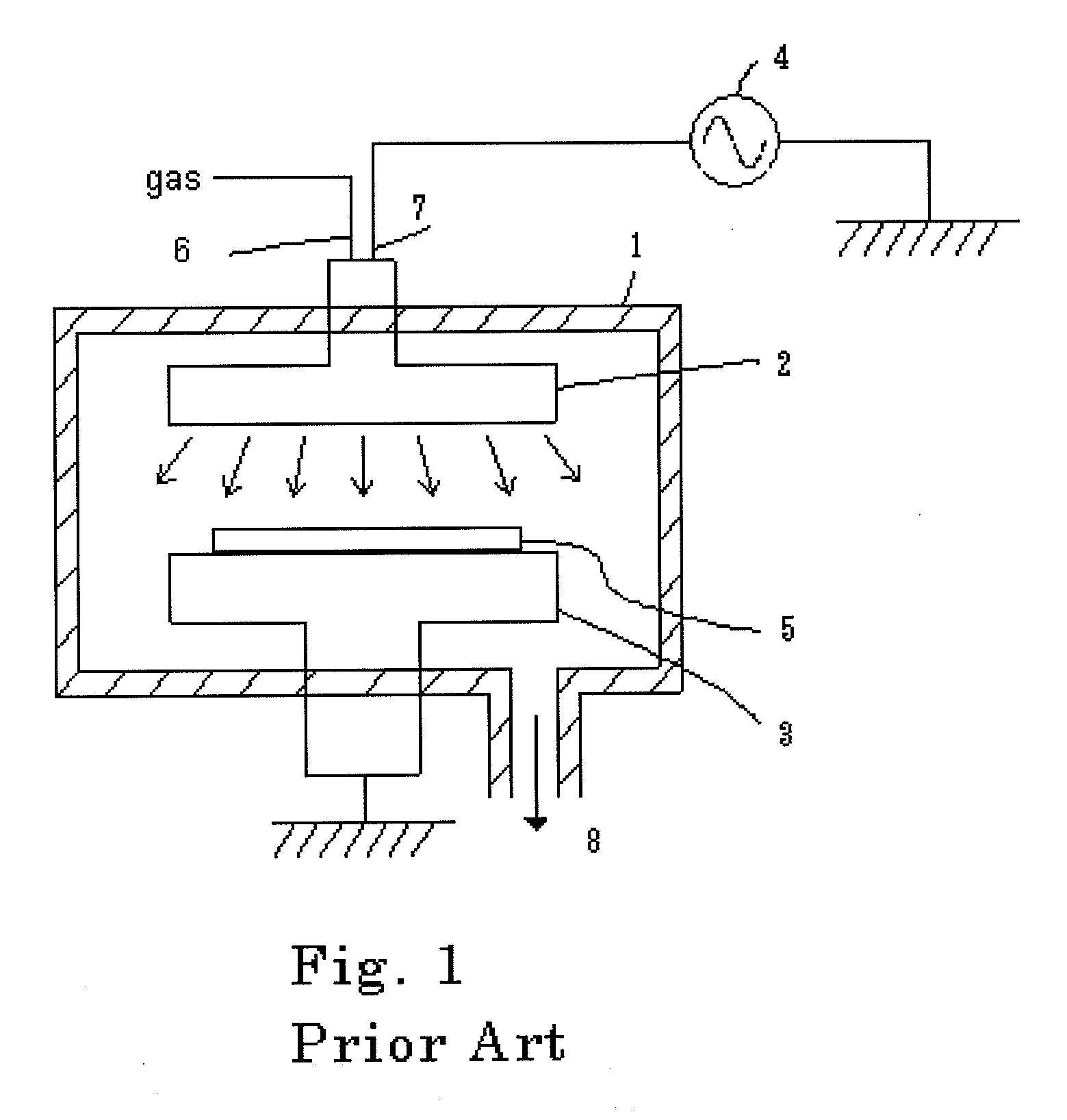

Plasma CVD apparatus having non-metal susceptor

InactiveUS20080299326A1Avoid Metal ContaminationConcerning long-term stabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorMetallurgy

A plasma CVD apparatus includes: a cooling susceptor for placing a substrate thereon and serving as an electrode; and a shower plate for introducing gas toward the susceptor via multiple throughholes formed therein. The shower plate serves as an electrode and is disposed in parallel to the susceptor. The cooling susceptor is made of a ceramic material provided with a cooling fluid flow path for passing a cooling fluid therethrough.

Owner:ASM JAPAN

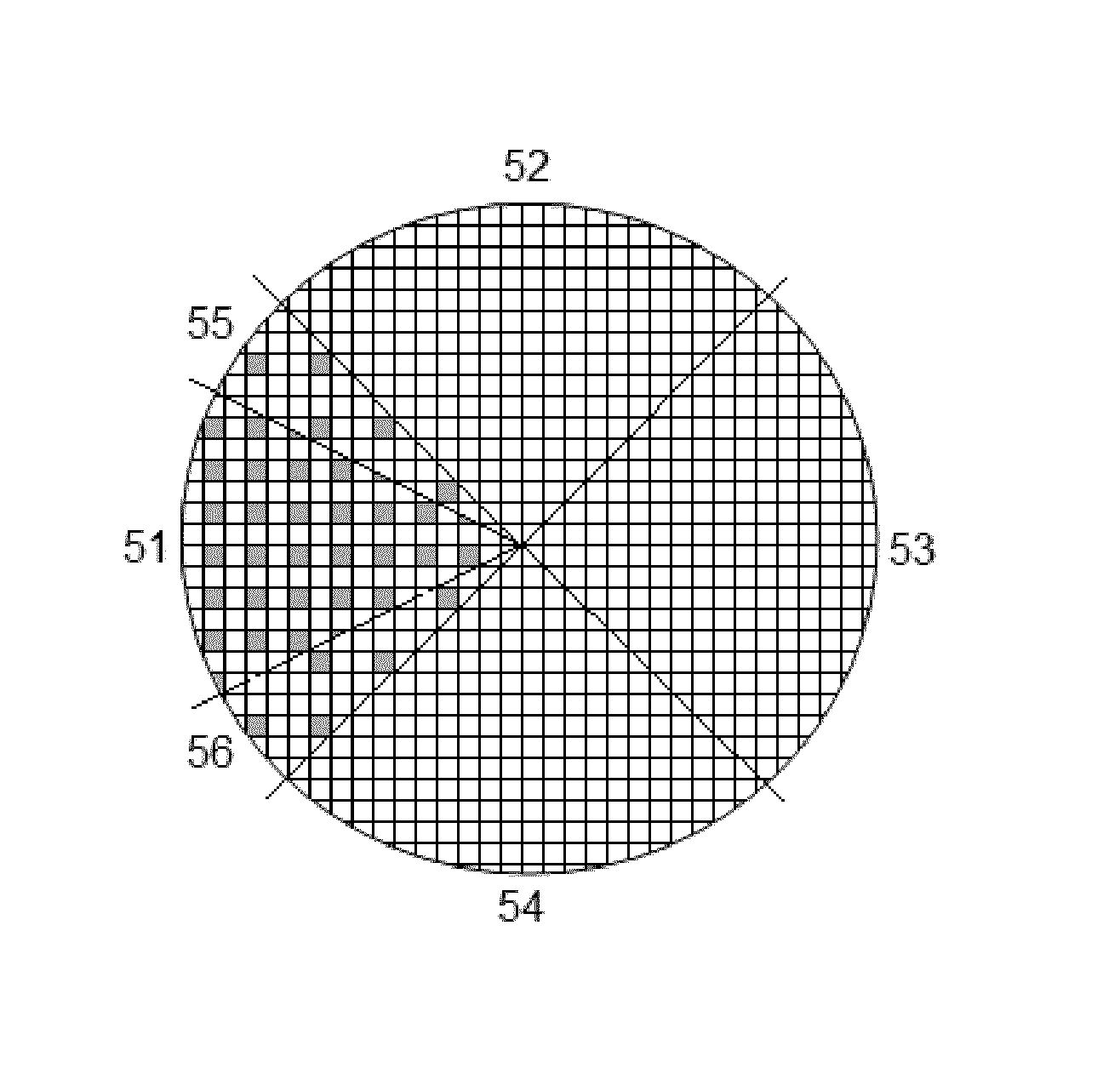

Shower plate having different aperture dimensions and/or distributions

ActiveUS8845806B2Improve uniformityUniform propertyElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorMechanical engineering

A shower plate is adapted to be attached to the showerhead and includes a front surface adapted to face the susceptor; and a rear surface opposite to the front surface. The shower plate has multiple apertures each extending from the rear surface to the front surface for passing gas therethrough in this direction, and the shower plate has at least one quadrant section defined by radii, wherein the one quadrant section has an opening ratio of a total volume of openings of all the apertures distributed in the section to a total volume of the one quadrant section, which opening ratio is substantially smaller than an opening ratio of another quadrant section of the shower plate.

Owner:ASM JAPAN

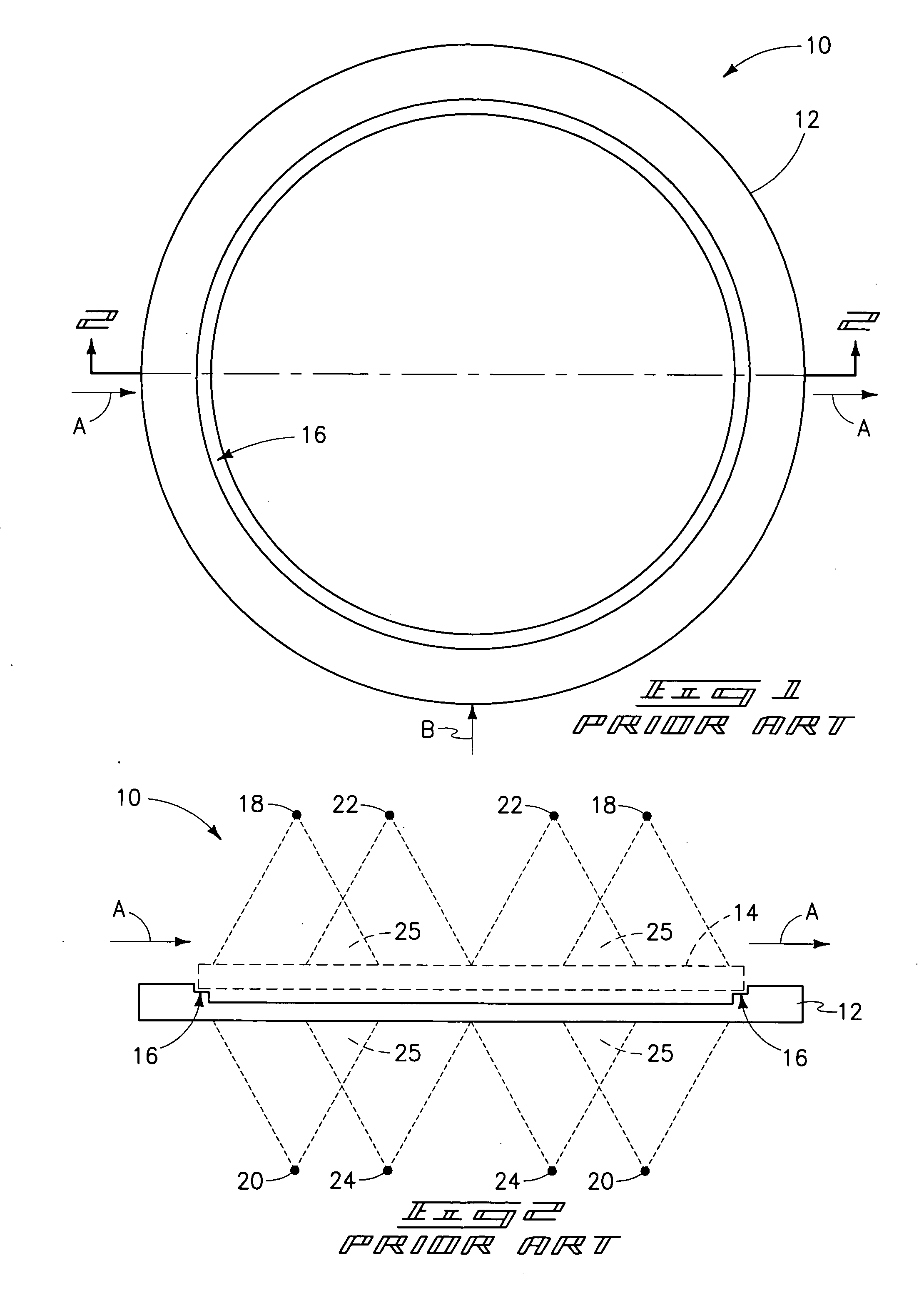

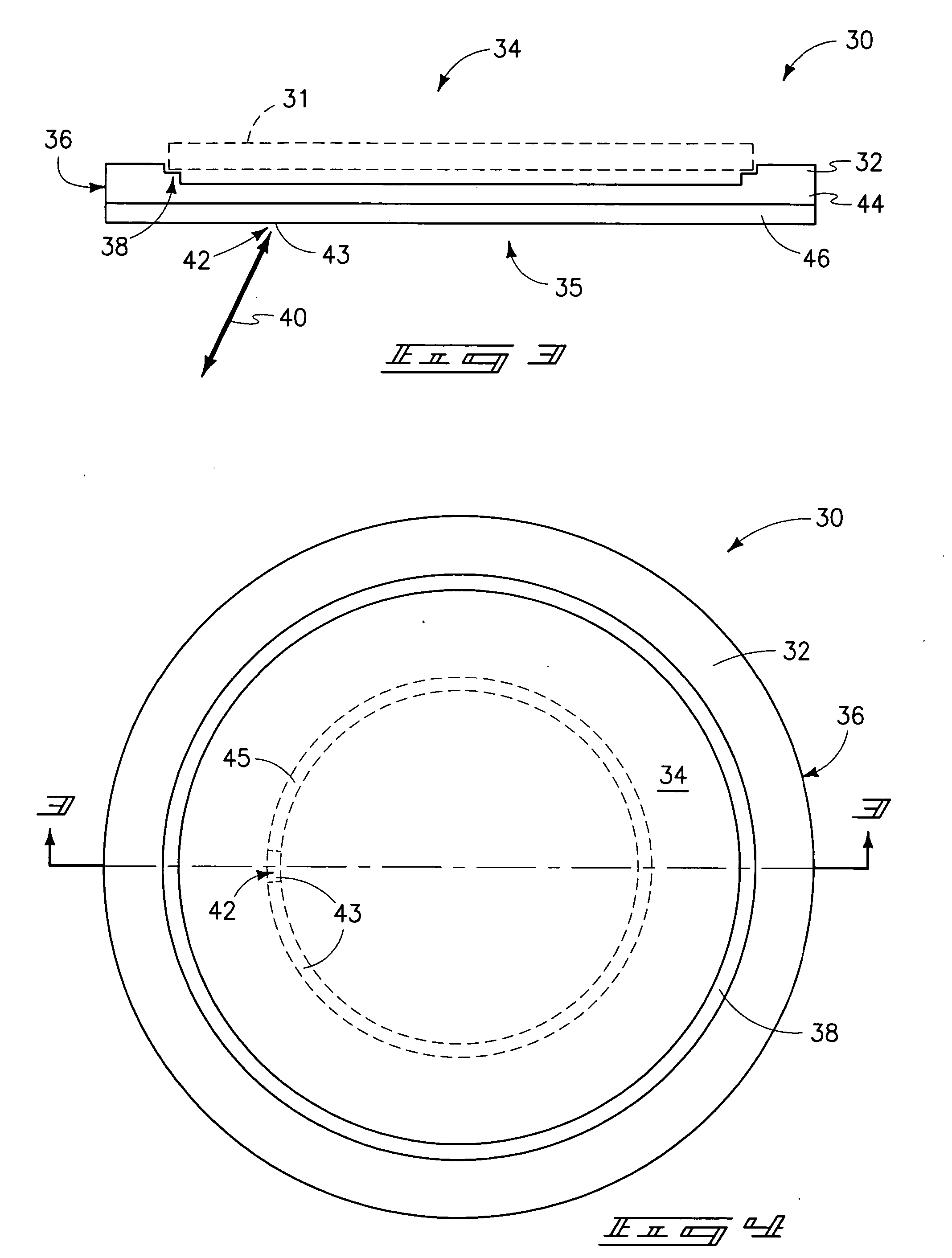

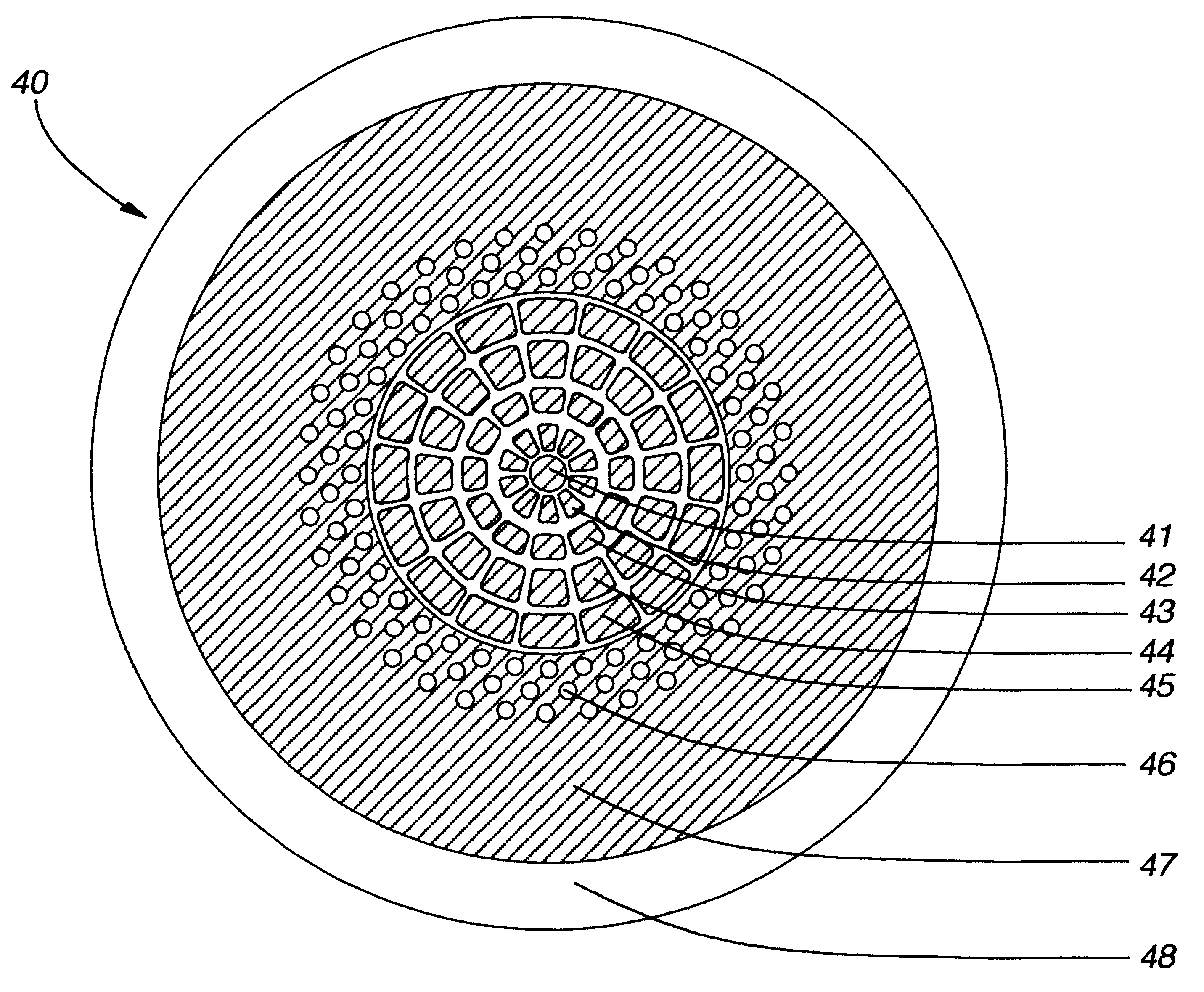

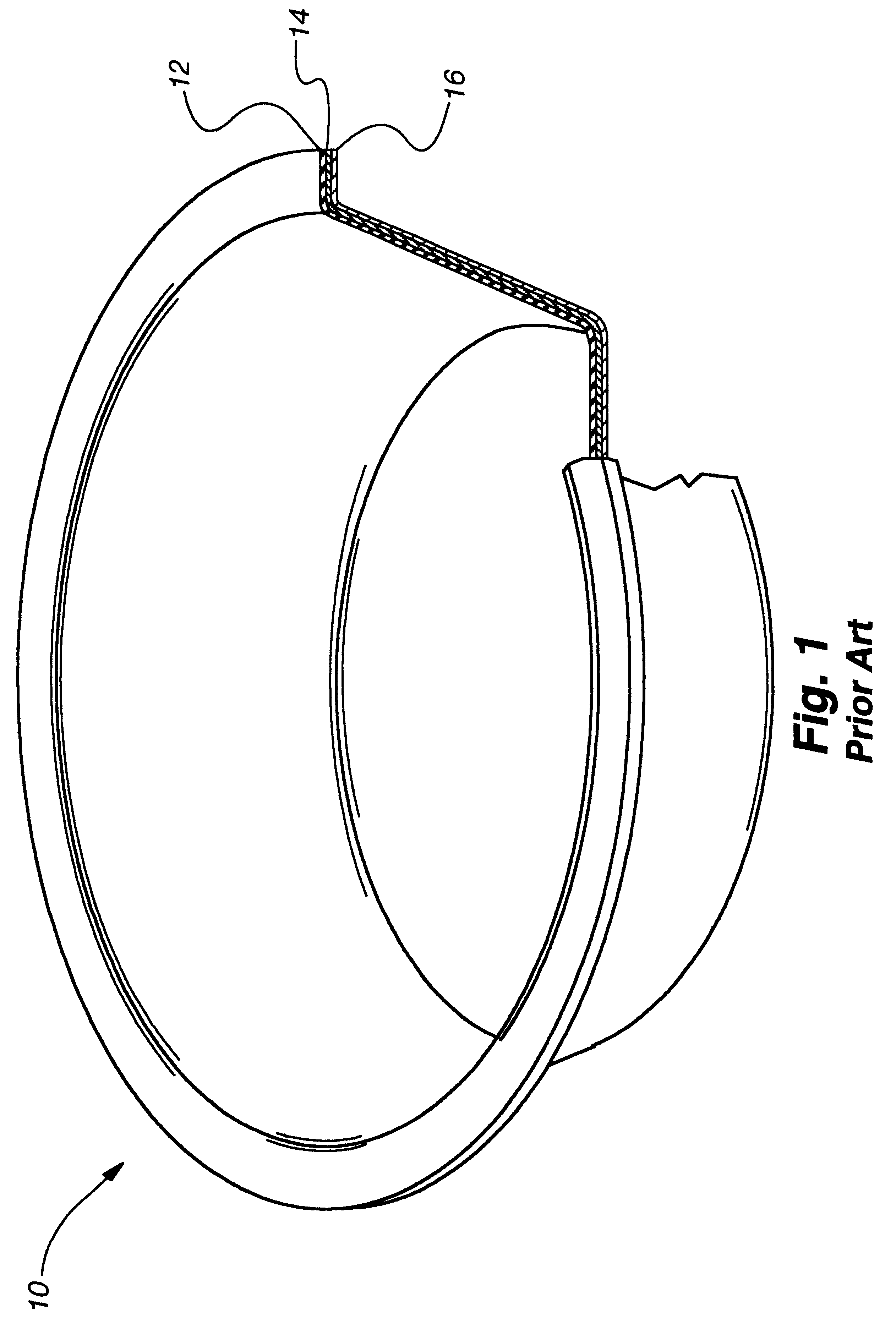

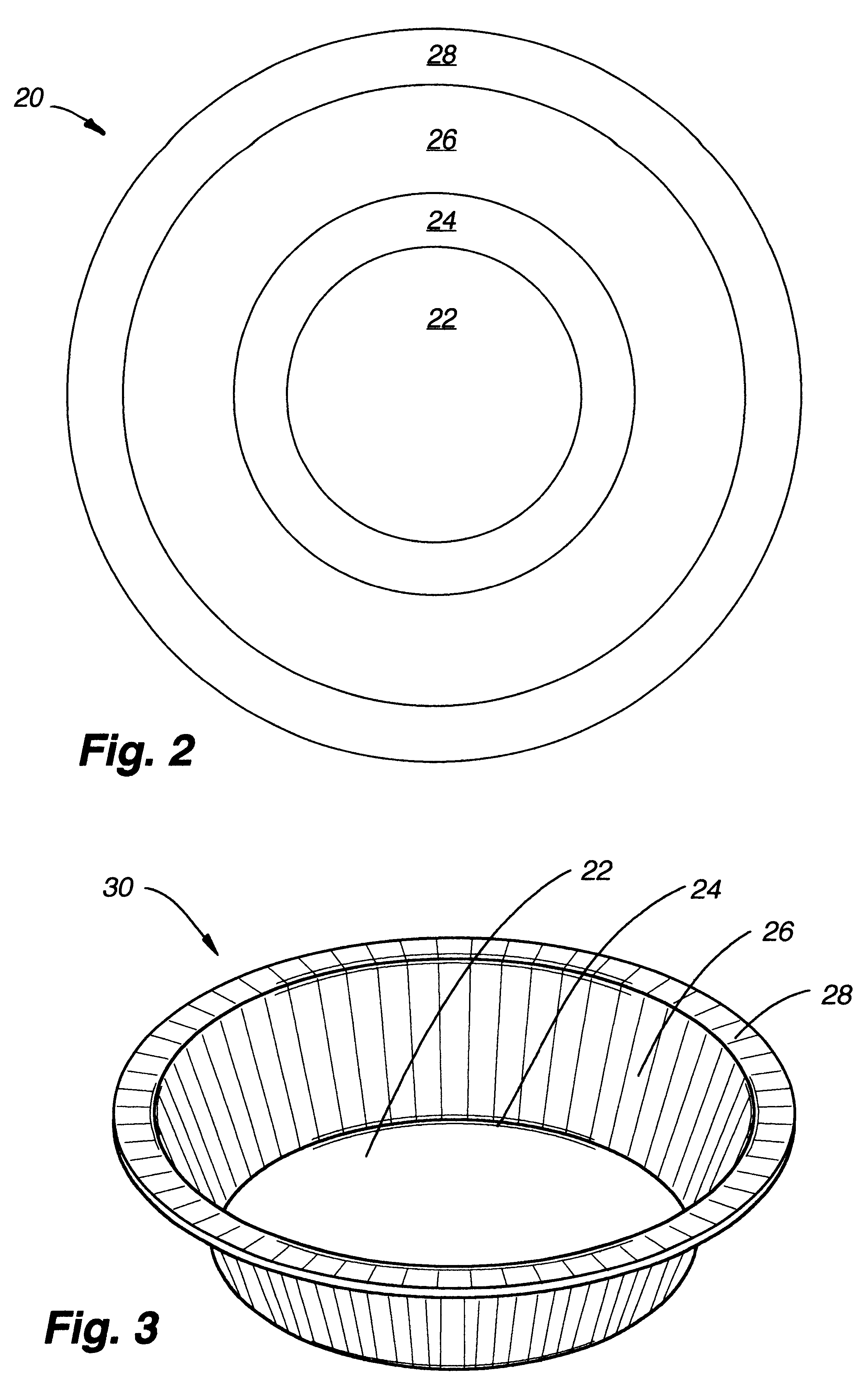

Patterned microwave susceptor element and microwave container incorporating same

A container has a patterned susceptor region in the bottom, a fold region between the bottom and the sidewall of the container, a sidewall region, and a flange region that forms a flange or lip of the container. The patterned susceptor region includes arrangements of microwave-interactive features disposed generally along respective close plane curves, which reduces overheating and increases the filling temperature of the food product. The fold region contains microwave transparent features that minimize de-lamination of the container in the folded region, and also create a generally transmissive area in the vicinity of the heel of the food product to improve the cooking thereof. The sidewall region shields the periphery of the food product so that it is not overcooked while promoting an appropriate degree of pie dough shell browning. The flange area is transmissive to promote an appropriate degree of cooking of the food product crust.

Owner:GRAPHIC PACKAGING INT

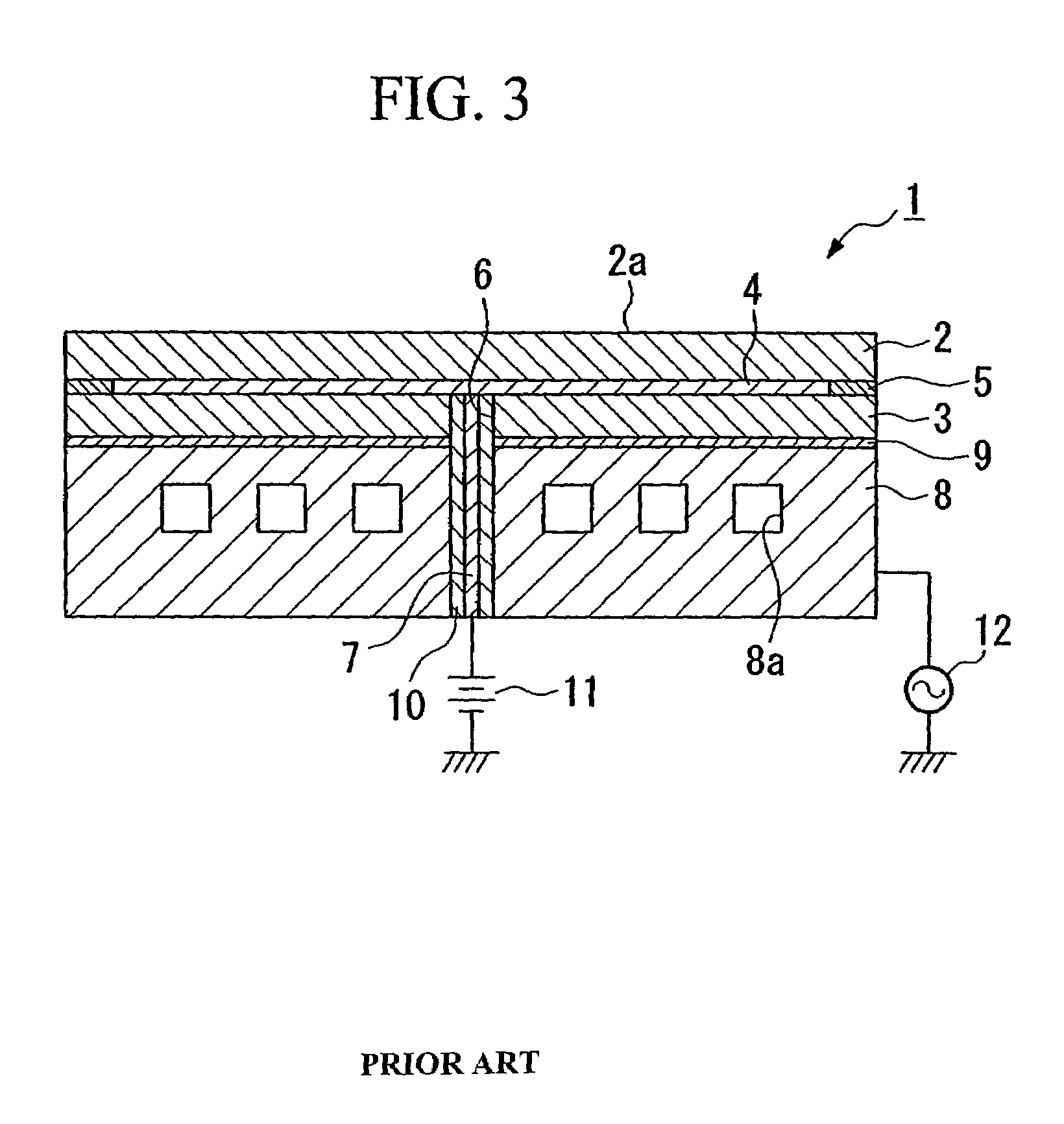

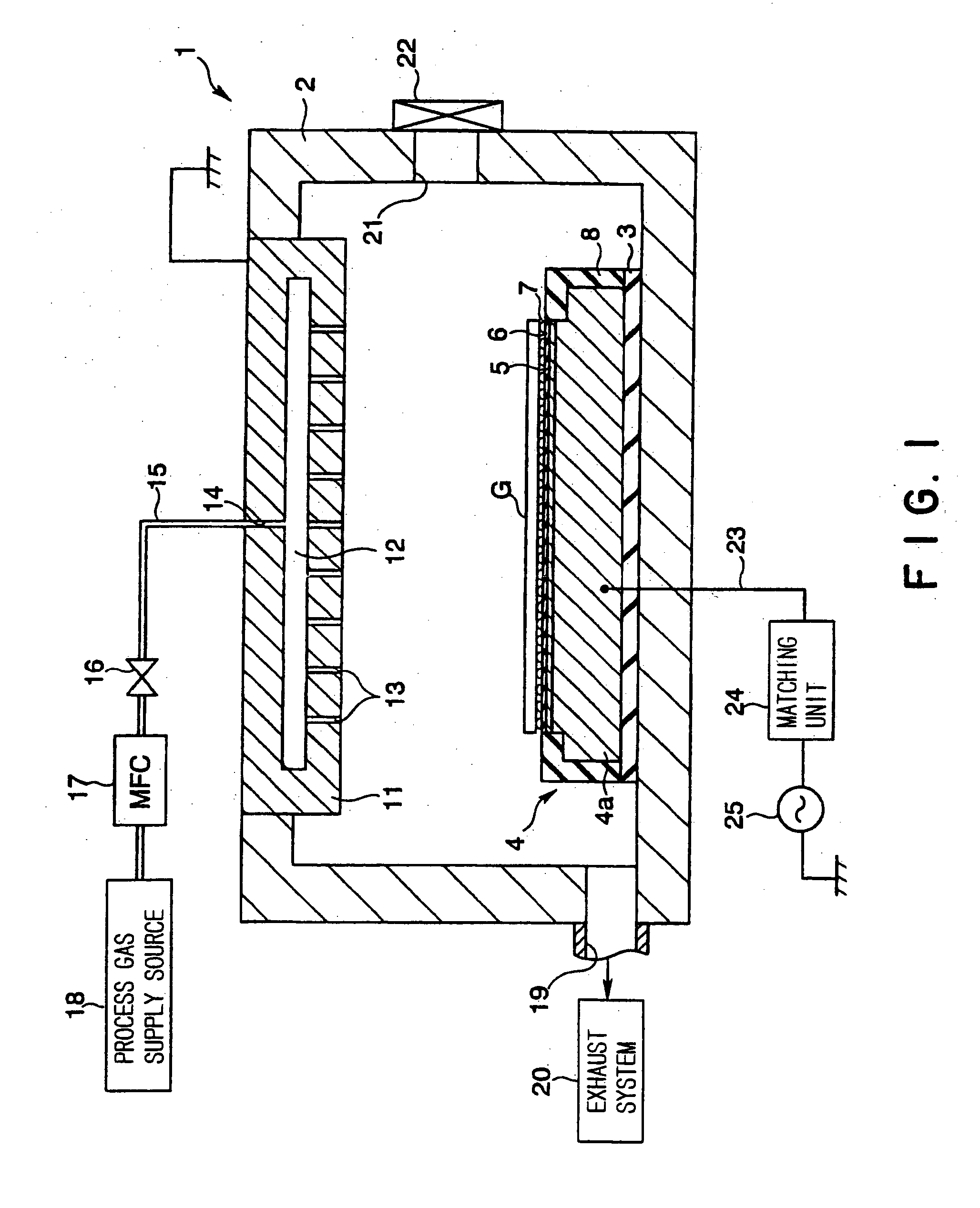

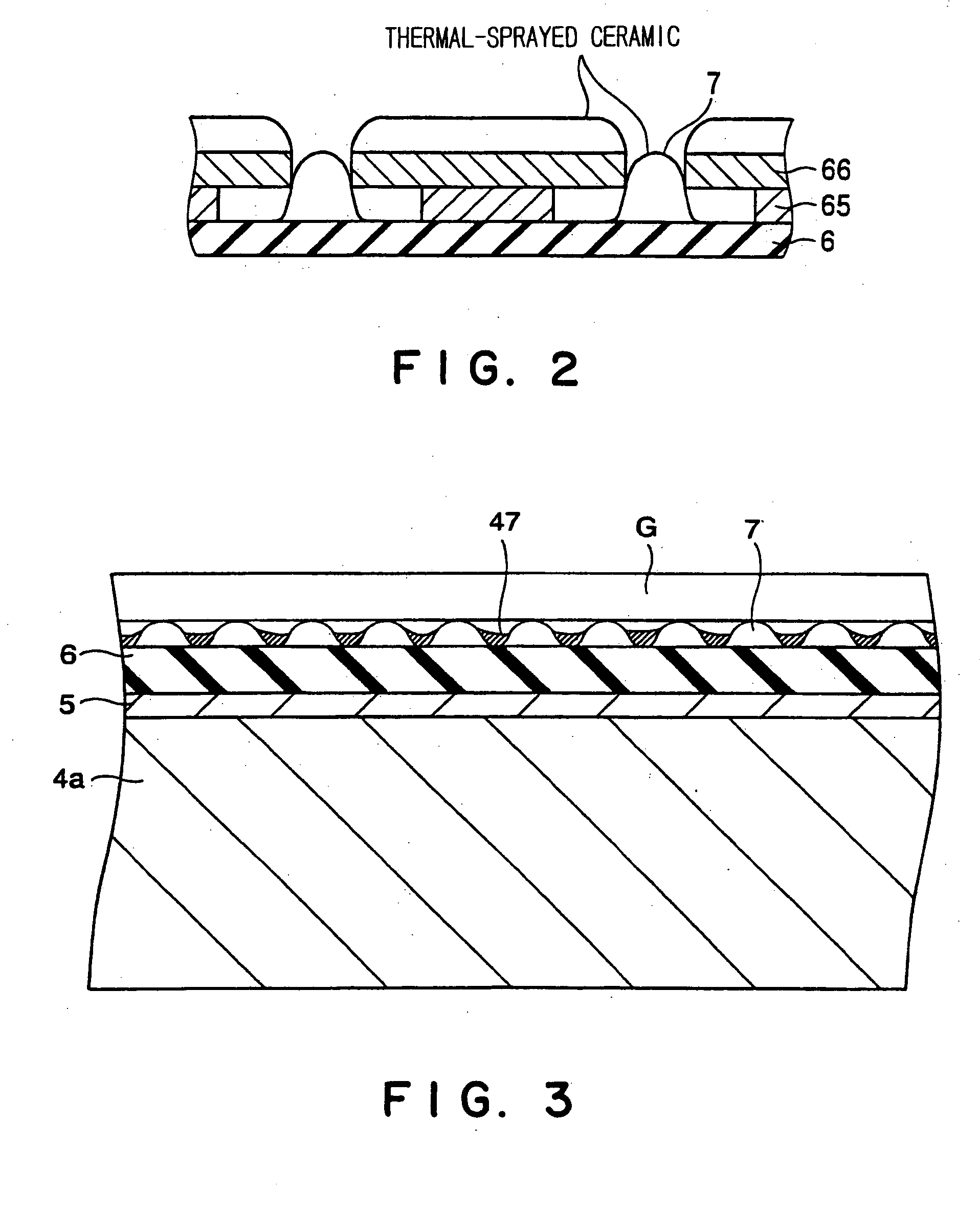

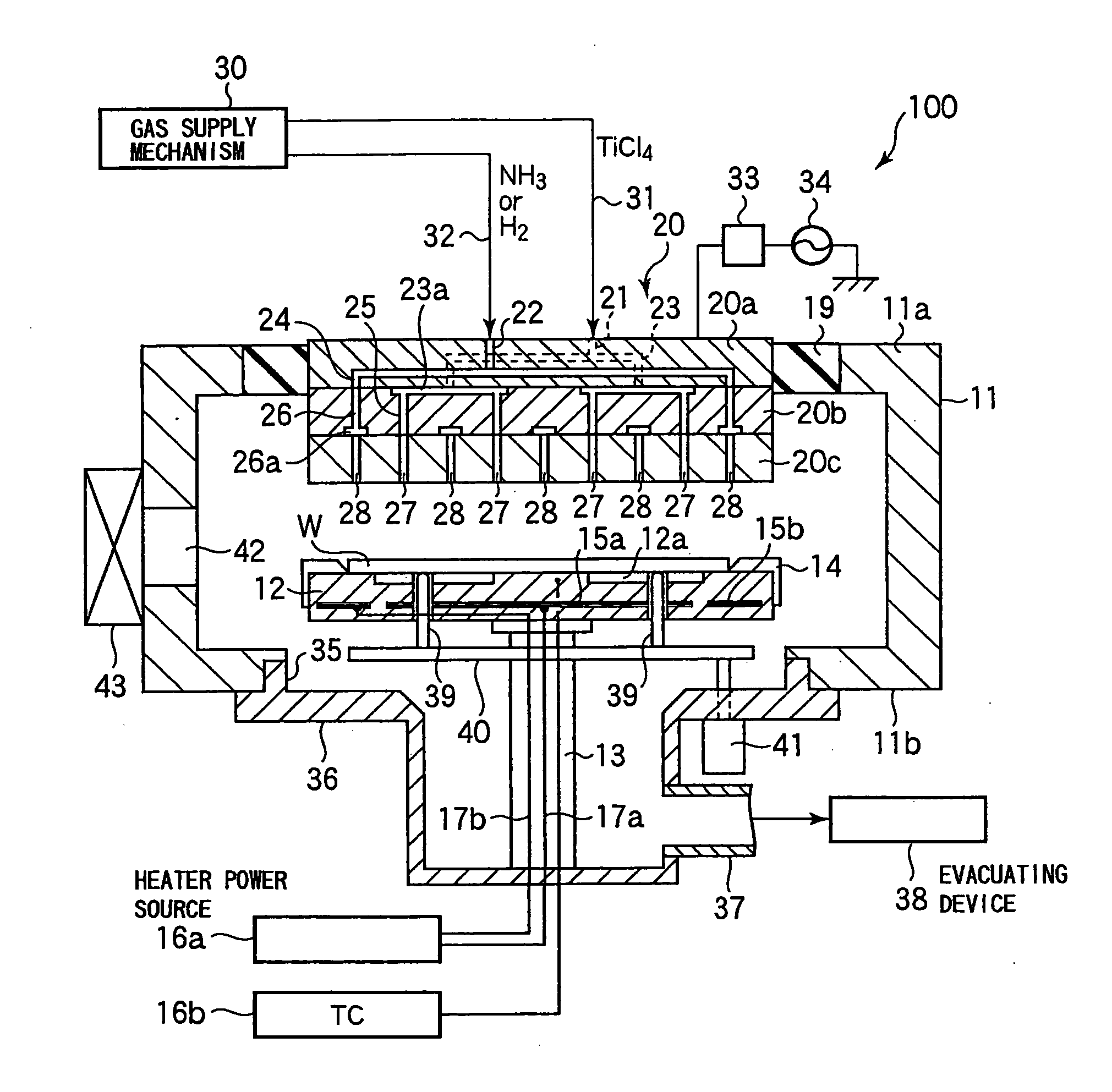

Substrate supporting table, method for producing same, and processing system

InactiveUS20050120962A1Avoid processing irregularityAvoid formingSleeve/socket jointsElectric discharge tubesSusceptorThermal spraying

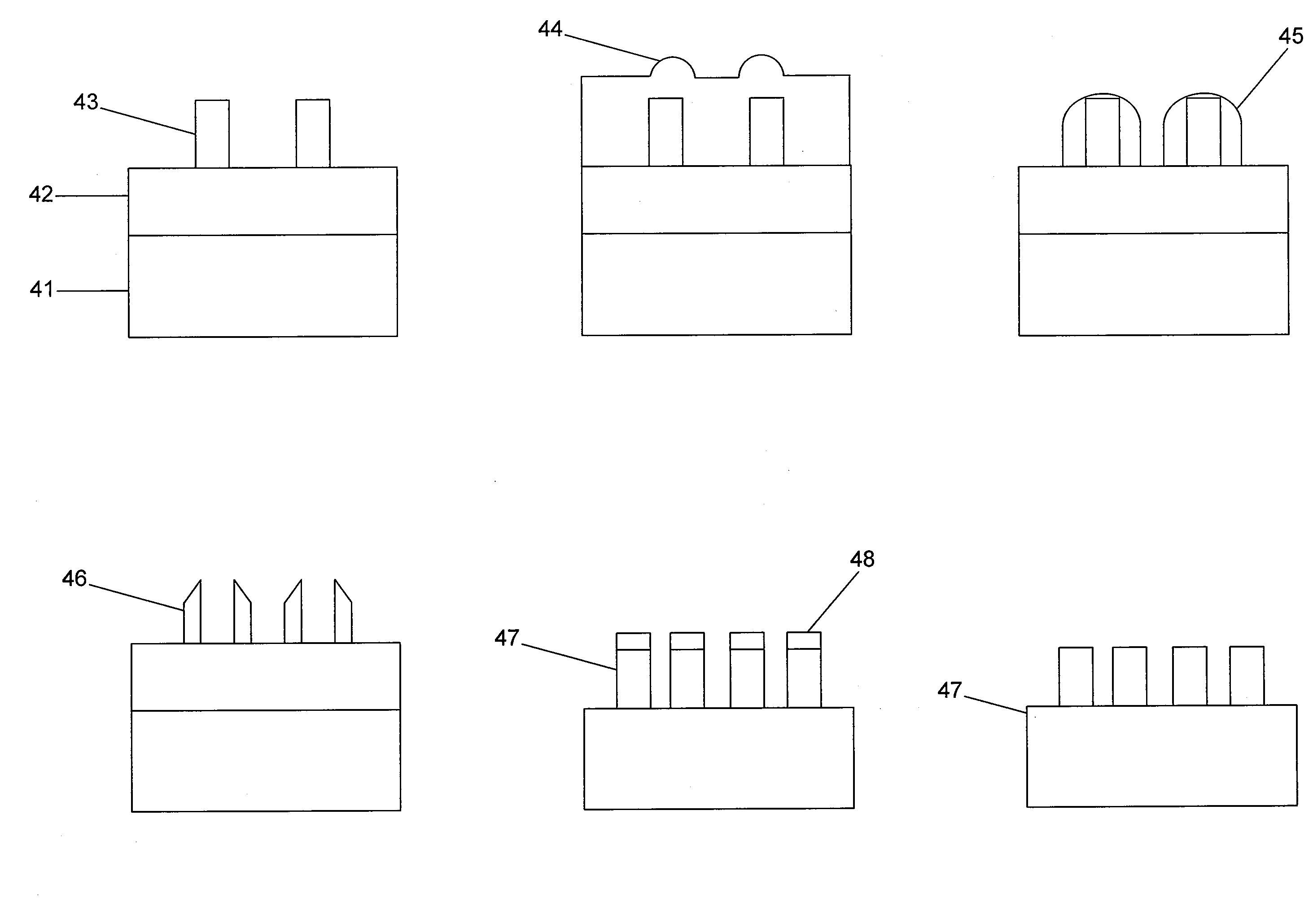

A plasma processing system has a susceptor, provided in a processing vessel, for supporting thereon a substrate. A process gas is supplied into the processing vessel to produce the plasma of the process gas. The susceptor has a dielectric film formed on a base, and a plurality of protrusions formed on the film. The protrusions of the susceptor are formed by thermal-spraying a ceramic onto the dielectric film via an aperture plate having a plurality of circular apertures.

Owner:USHIODA JOICHI +3

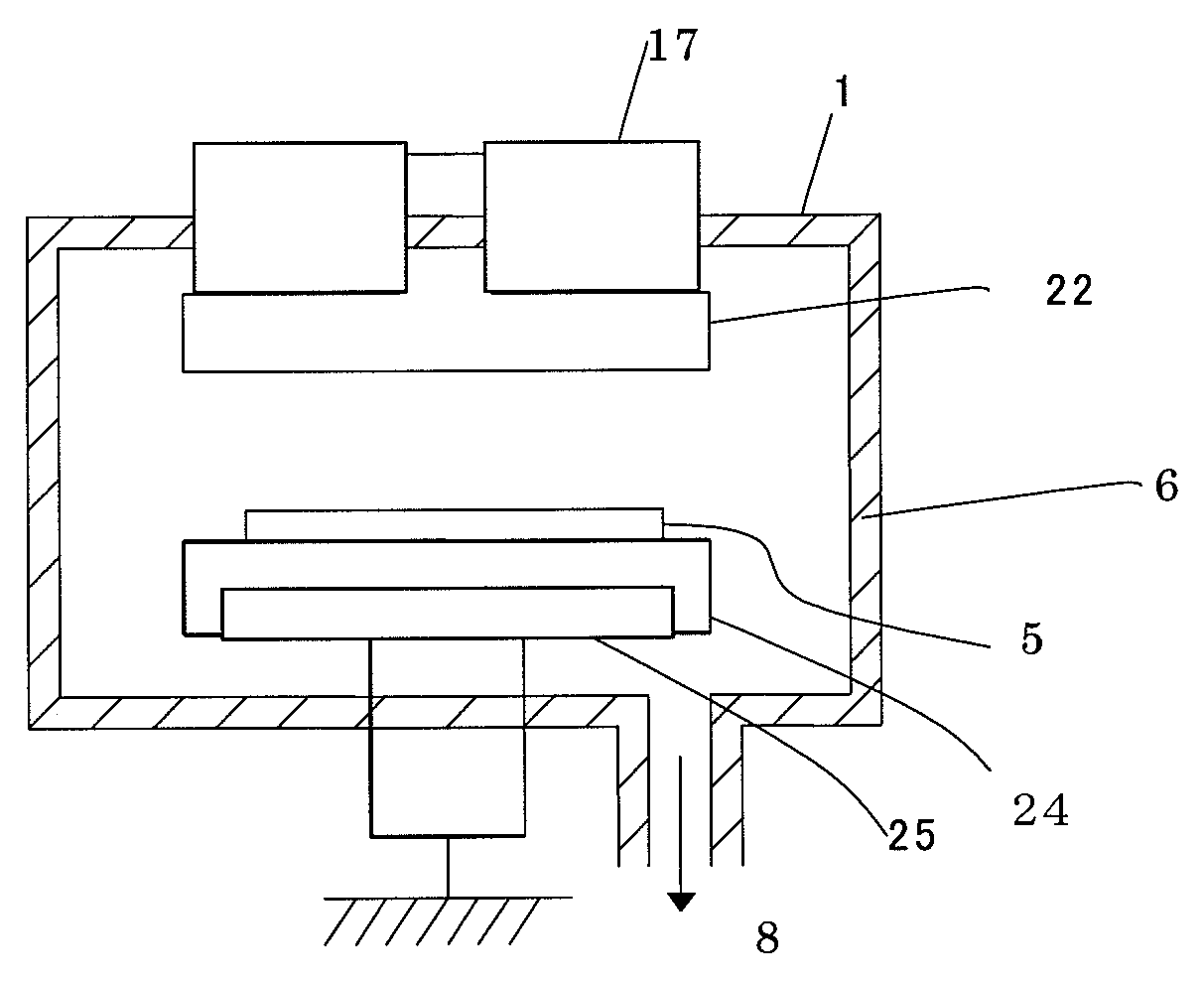

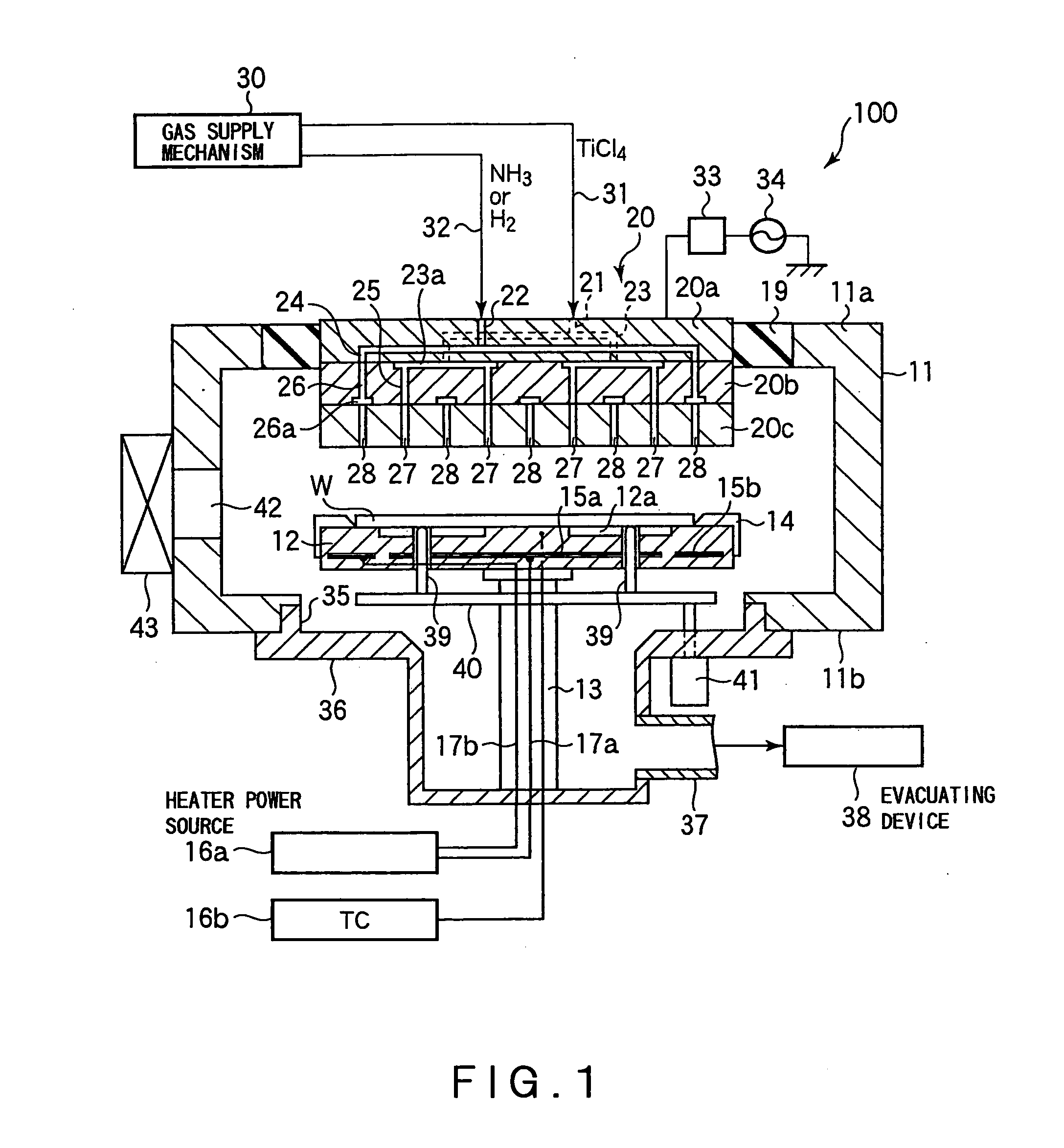

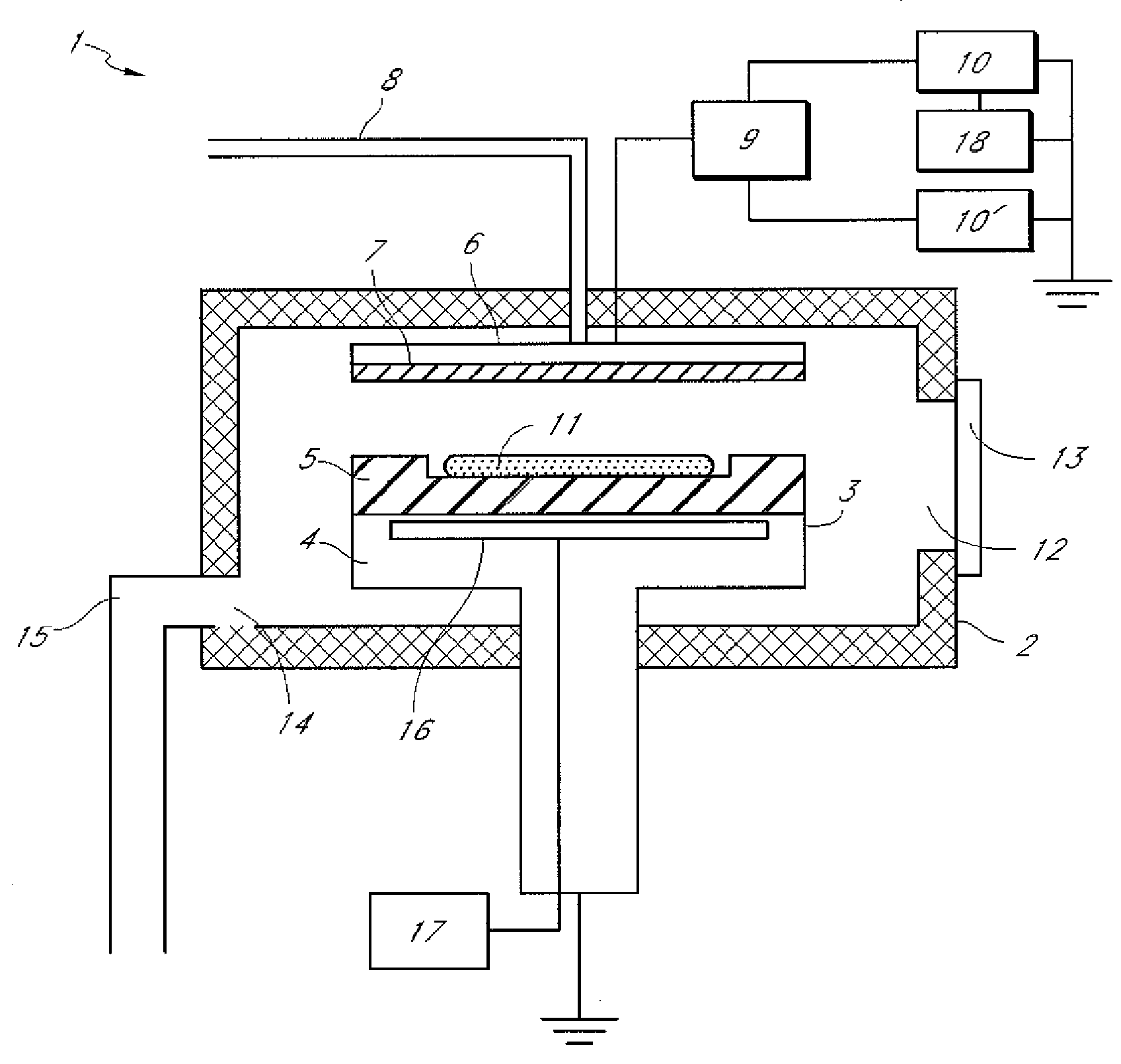

Substrate Processing Apparatus and Substrate Mount Table Used in the Apparatus

InactiveUS20100162956A1Achieving temperature uniformityEliminate the effects ofElectric discharge tubesSemiconductor/solid-state device manufacturingInternal pressureSusceptor

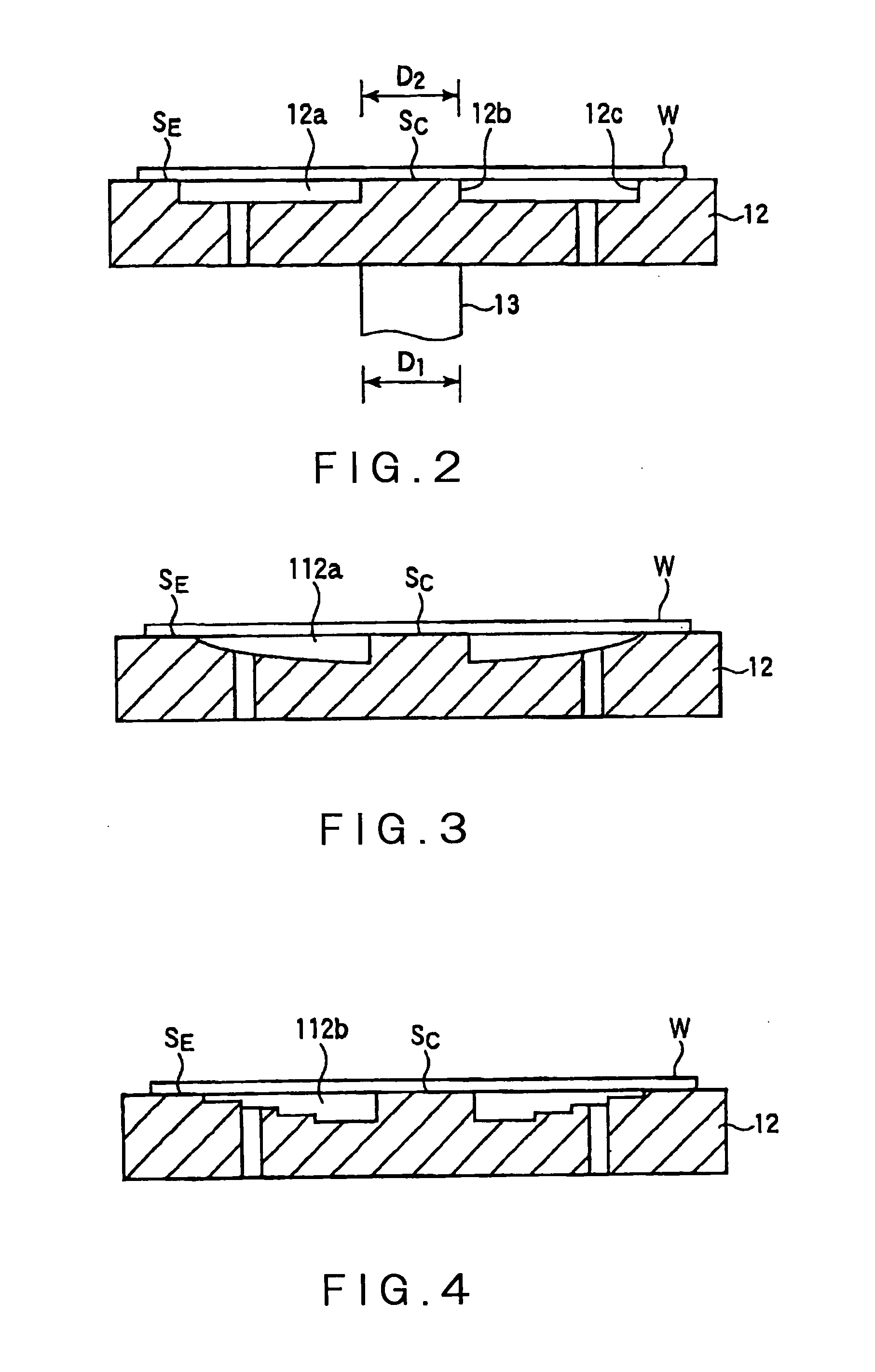

Disclosed is a susceptor which achieves uniform temperature distribution of a wafer placed on the susceptor, and also disclosed is a substrate processing apparatus provided with the susceptor. An annular recess 12a is formed in an intermediate portion between the central portion and the peripheral portion of a wafer support surface of the susceptor 12. Due to the provision of the recess, the substrate heating effect by thermal radiation from the susceptor is suppressed in the intermediate portion. The geometrical dimension of the recess is determined taking the chamber internal pressure into consideration.

Owner:TOKYO ELECTRON LTD

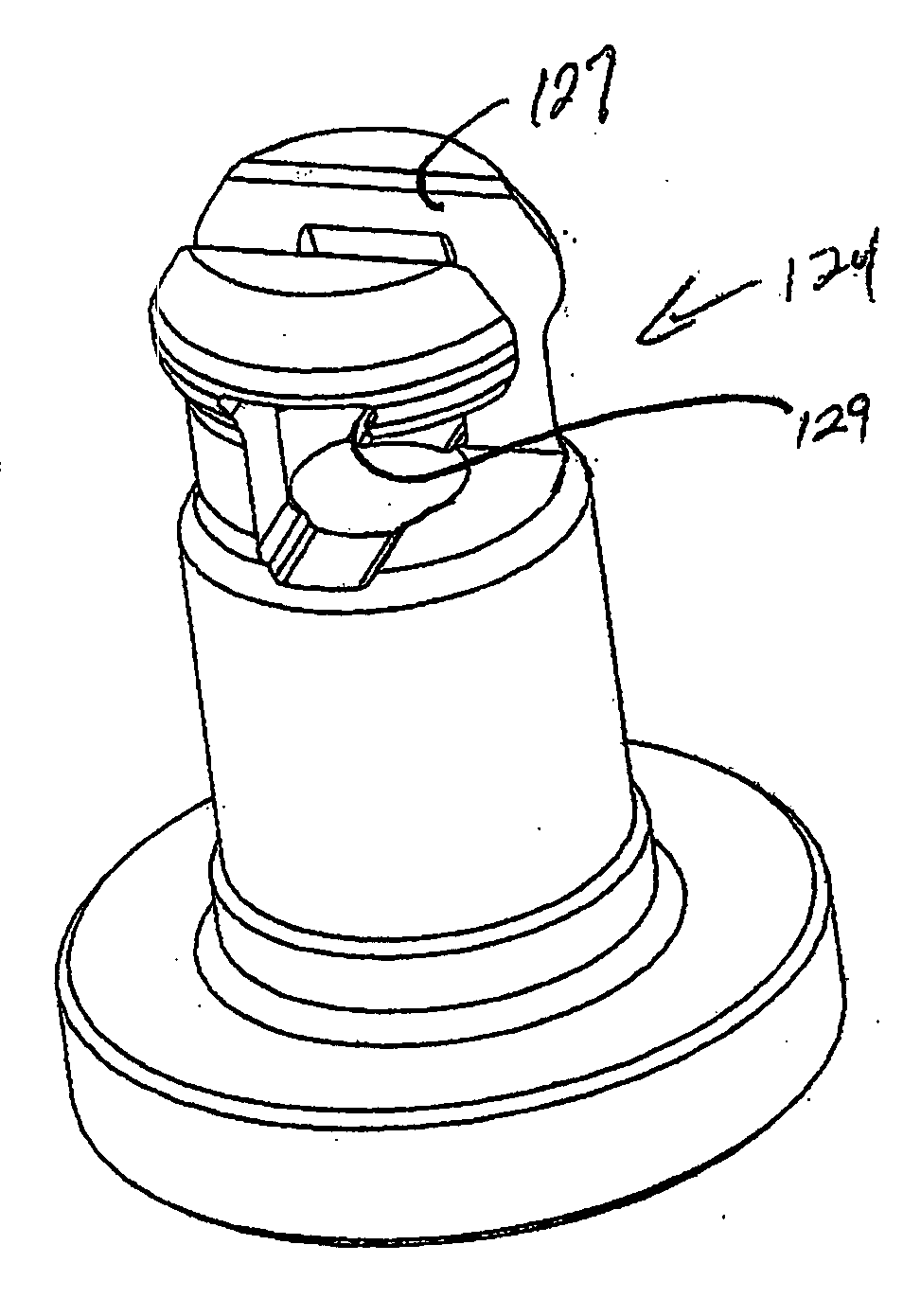

Wafer support pin assembly

InactiveUS20060156981A1After-treatment apparatusSemiconductor/solid-state device manufacturingSusceptorFast release

A semiconductor wafer support pin assembly. A susceptor has at least three support pins configured to raise a wafer above the top surface of the susceptor. Each support pin includes and upper pin and a lower pin, which lock together by means of a quick-release mechanism in the form of a bayonet mount. The upper pin is made of a non-metallic material, such as polybenzimidazole. The susceptor is driven up and down by a lifting mechanism, driven by an electric motor or pneumatic cylinder. The susceptor moves up and down, relative to the support pins.

Owner:ASM AMERICA INC

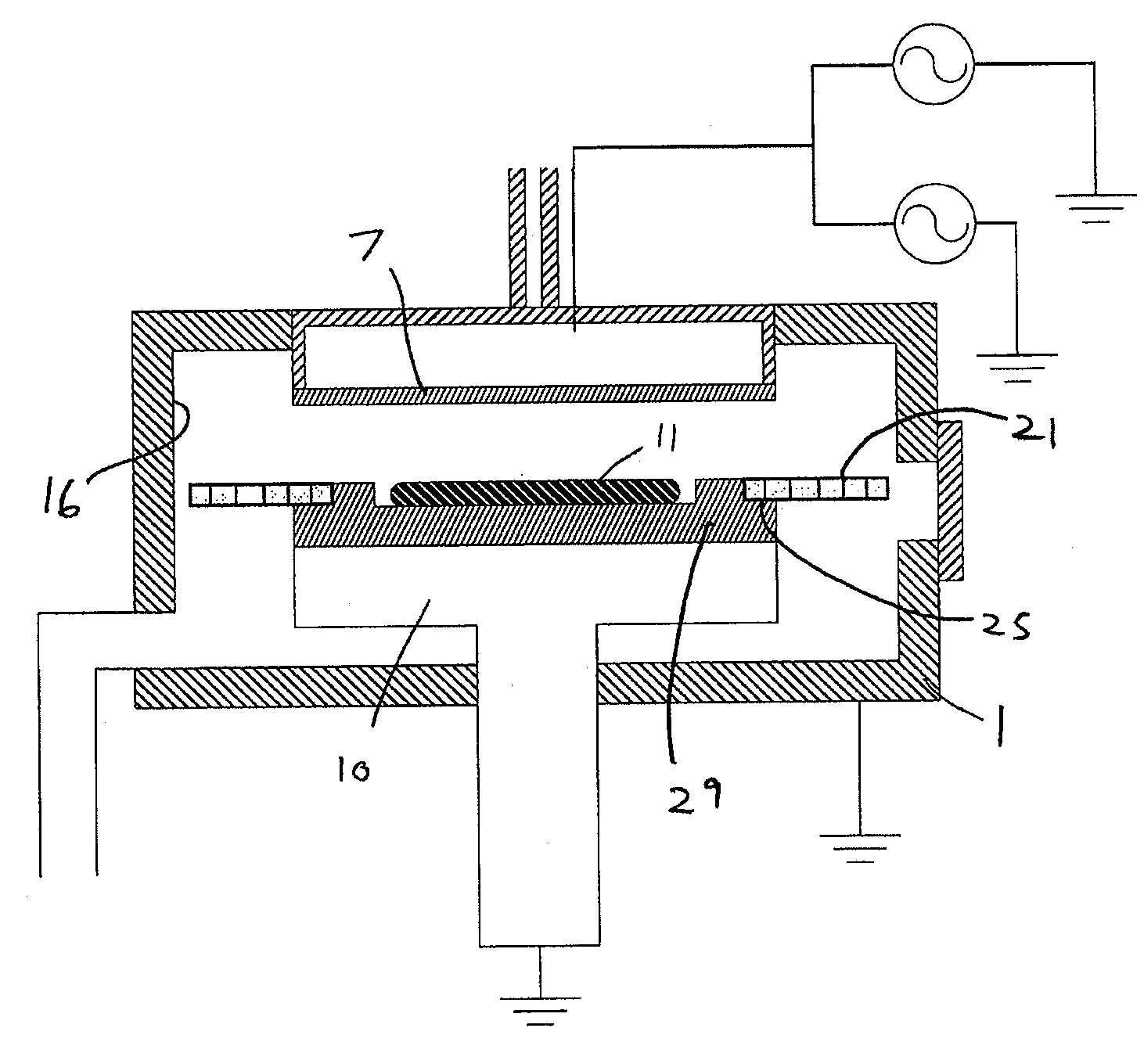

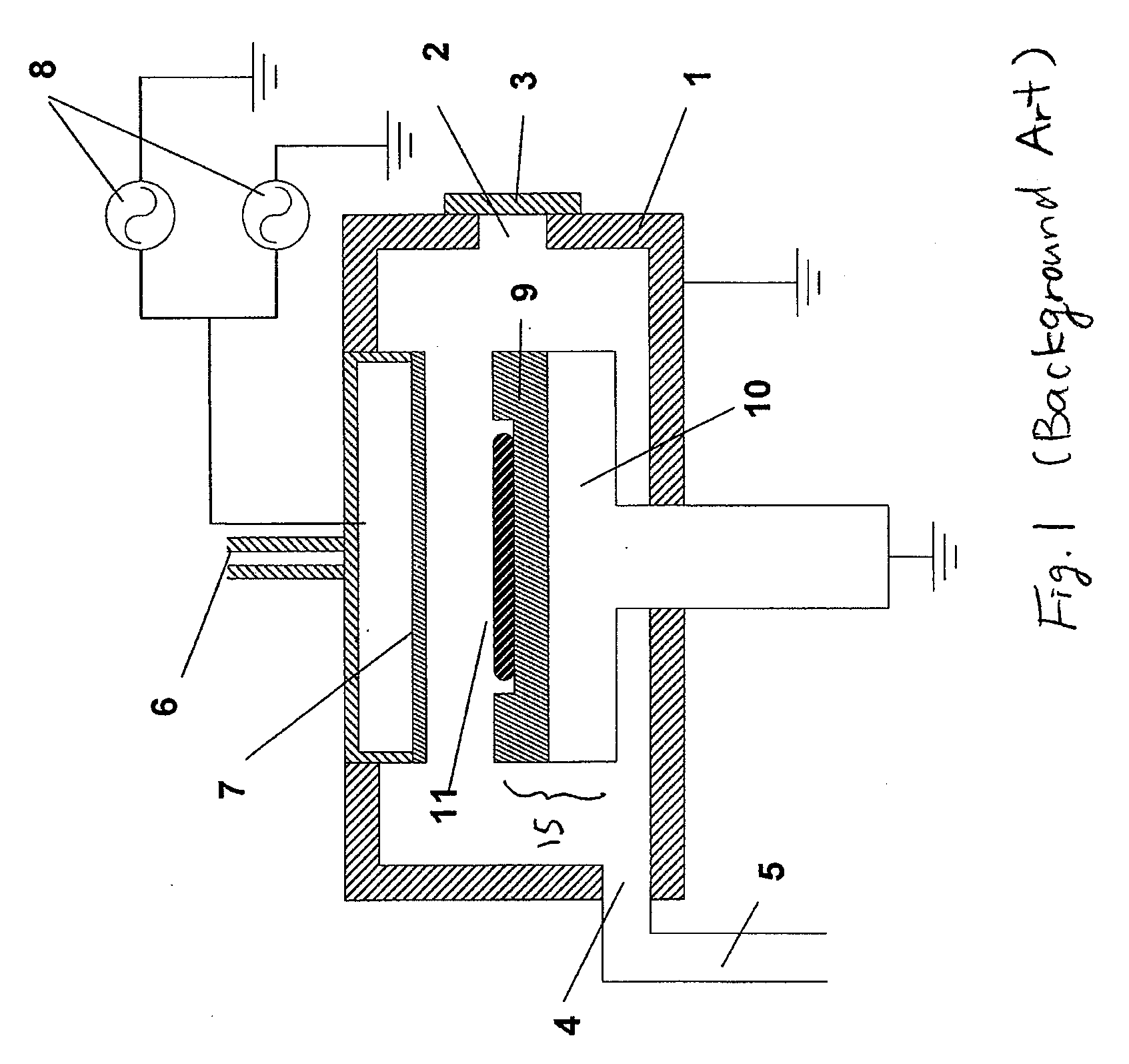

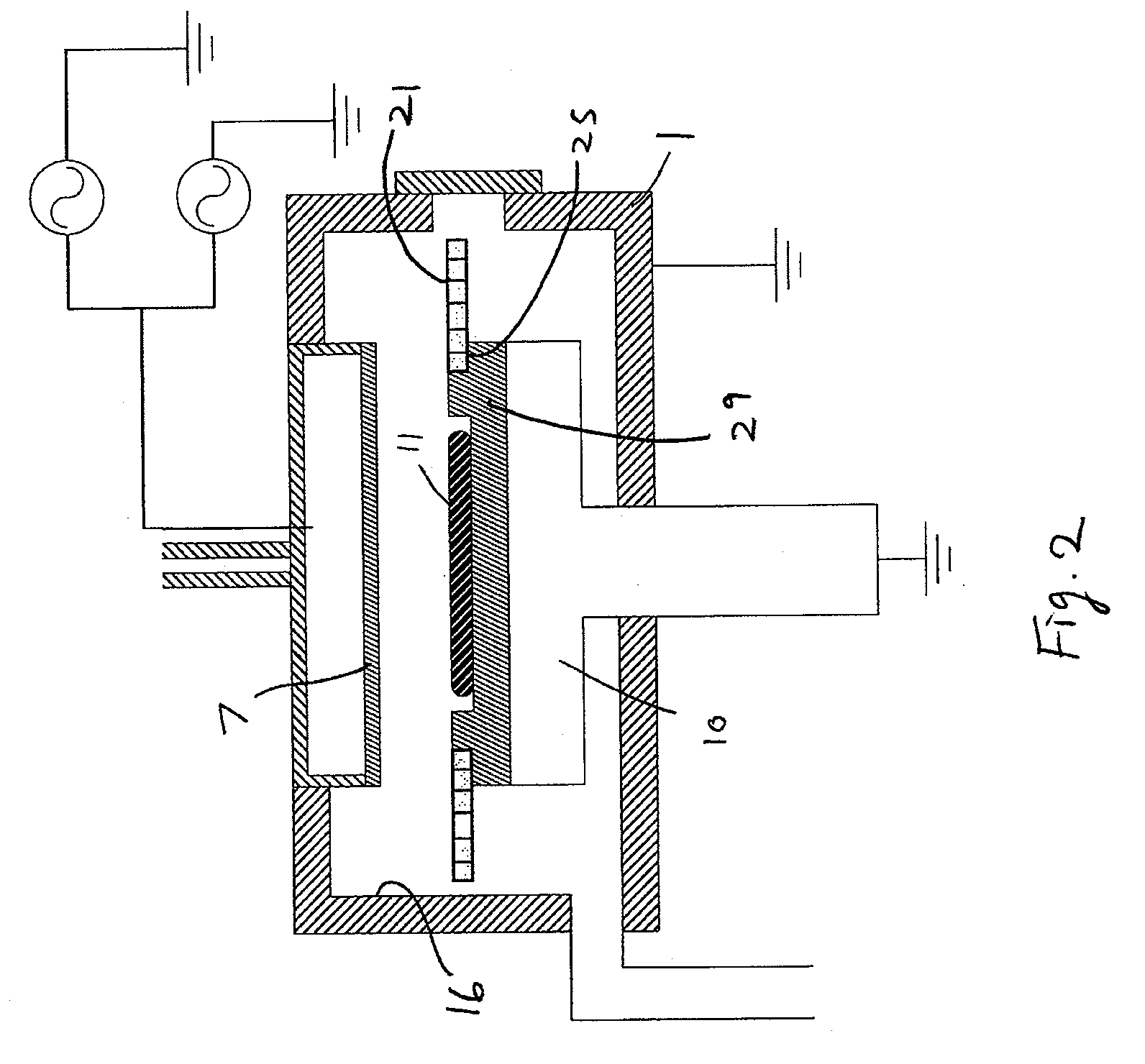

Plasma CVD apparatus equipped with plasma blocking insulation plate

InactiveUS20070266945A1Floating potentialControl areaElectric discharge tubesChemical vapor deposition coatingSusceptorEngineering

A plasma CVD apparatus for forming a thin film on a substrate includes: a vacuum chamber; an upper electrode; a susceptor as a lower electrode; and a ring-shaped insulation plate disposed in a gap between the susceptor and an inner wall of the chamber in the vicinity of or in contact with the susceptor to minimize a floating potential charged on the substrate while processing the substrate.

Owner:ASM JAPAN

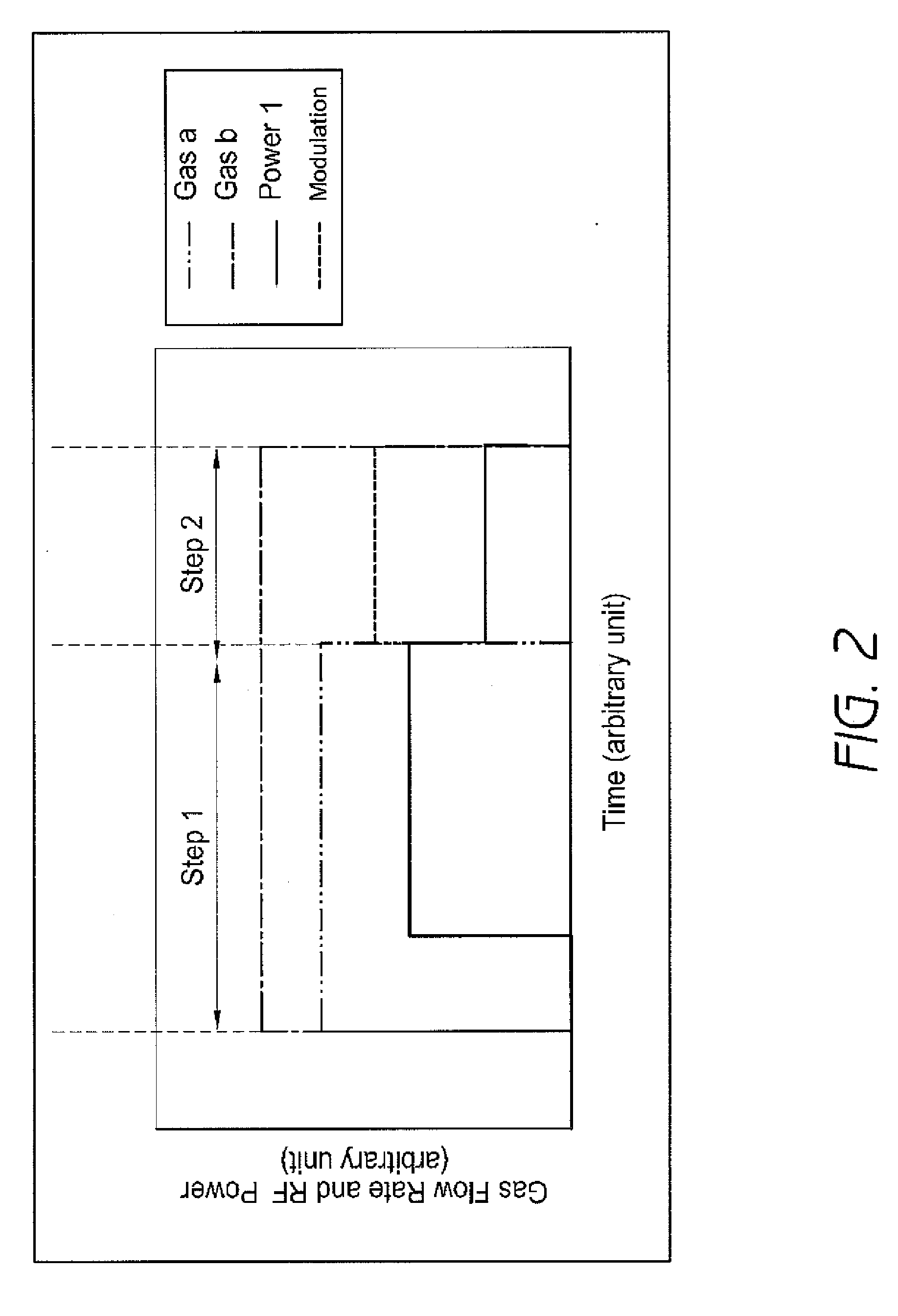

Method of plasma treatment using amplitude-modulated RF power

ActiveUS20090136683A1Reduce floating potentialSufficient voltageElectric discharge tubesVacuum evaporation coatingSusceptorForming gas

A method for processing a substrate by plasma CVD includes: (i) forming a film on a substrate placed on a susceptor by applying RF power between the susceptor and a shower plate in the presence of a film-forming gas in a reactor; and (ii) upon completion of step (i), without unloading the substrate, applying amplitude-modulated RF power between the susceptor and the shower plate in the absence of a film-forming gas but in the presence of a non-film-forming gas to reduce a floating potential of the substrate.

Owner:ASM JAPAN

Electromagnetic susceptors with coatings for artificial dielectric systems and devices

InactiveUS20030226840A1Enhanced radiationLow dielectric constantGas treatmentMethane captureChemical treatmentSusceptor

A coated susceptor of electromagnetic energy for chemical processing made of a matrix material that surrounds a non-matrix material that is made from a material that is different from the matrix material, in which the matrix material is constructed of material having lower dielectric losses compared to the non-matrix material, the non-matrix material initially absorbs electromagnetic energy applied to the electromagnetic susceptor to a greater extent than the matrix material, the non-matrix material produces subsequent heat in the matrix material, and the surface of the susceptor is coated with a material that interacts with applied electromagnetic energy of at least one frequency and initially absorbs electromagnetic energy and produces heat.

Owner:DALTON ROBERT C

Temperature gauge and ceramic susceptor in which it is utilized

InactiveUS7090394B2Shorten the timeEasy to replaceThermometer detailsThermometers using electric/magnetic elementsSusceptorMetallurgy

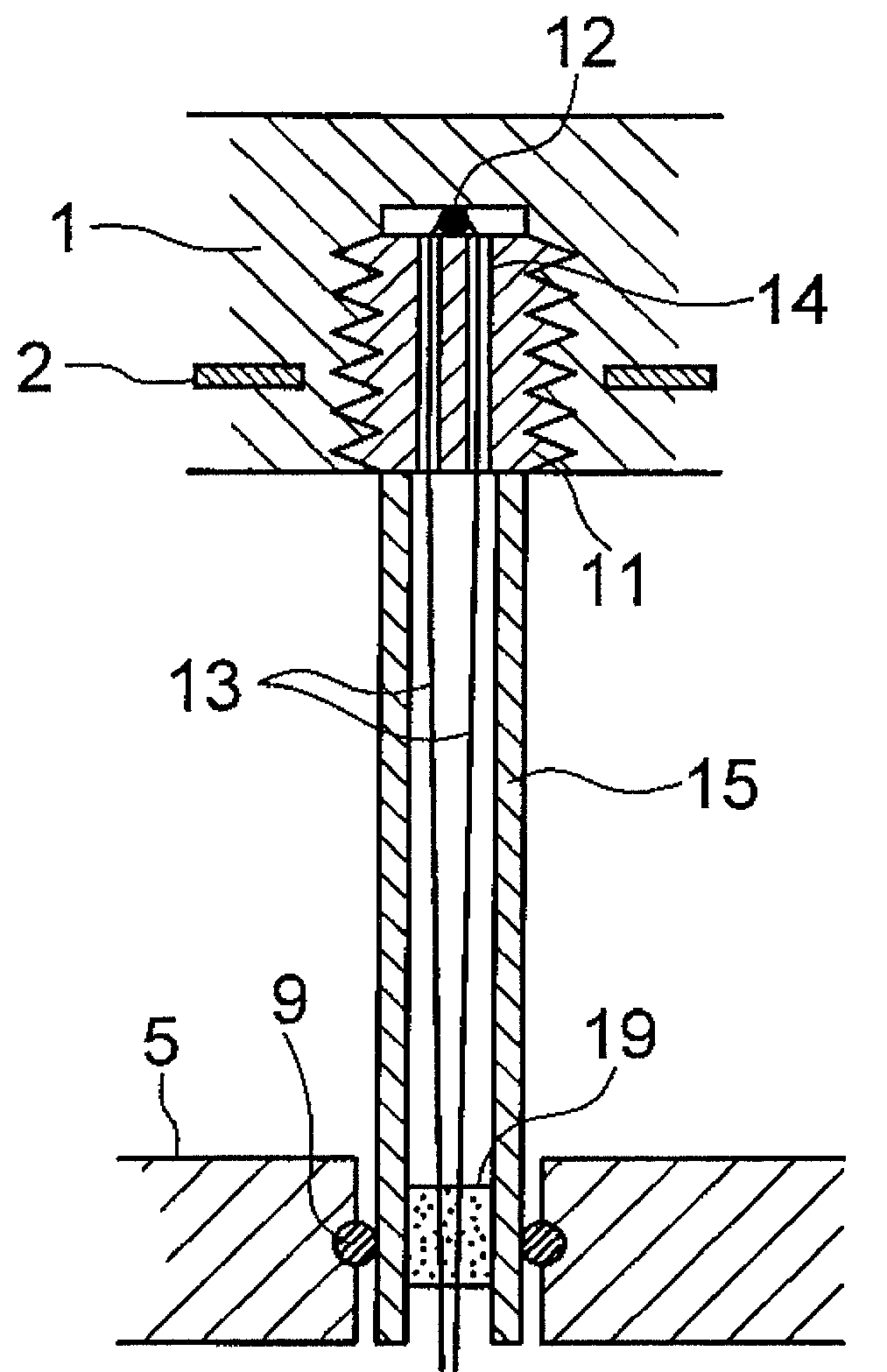

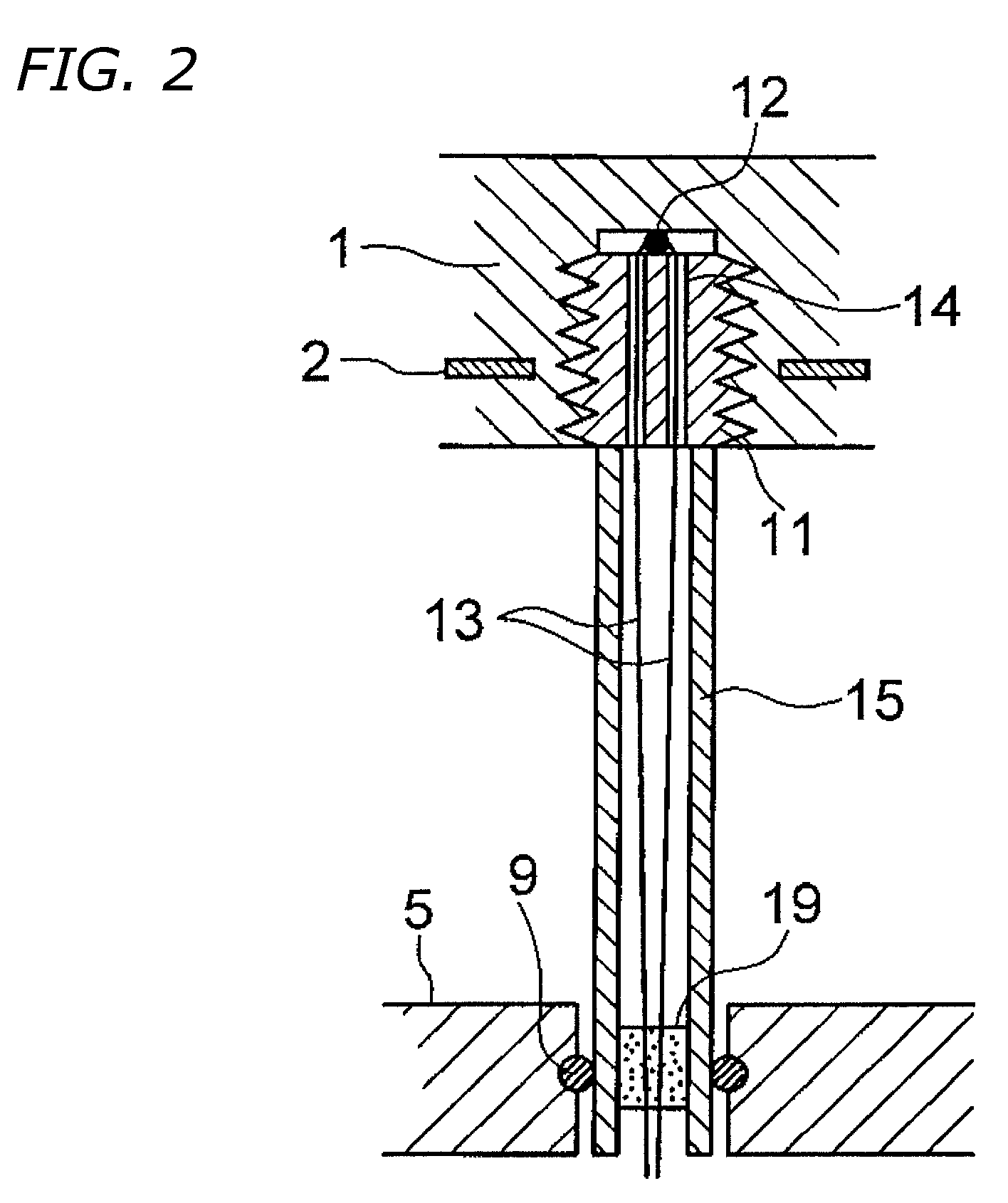

Temperature gauge, and ceramic susceptors and semiconductor manufacturing equipment utilizing the temperature gauge, in which the thermocouple may be easily replaced even if damaged, and in which heat from the temperature-gauging site is readily transmitted to the temperature-gauging contact, shortening time until the measurement temperature stabilizes. A temperature-gauging contact (12) in the tip of the thermocouple contacts, in an exposed-as-it-is state, a temperature-gauging site on a ceramic susceptor (1), and by means of a circular cylindrical-shaped retaining member (11) screwed into female threads in the ceramic susceptor (1) is detachably pressed upon and retained against the ceramic susceptor. Thermocouple lead lines (13), passing through a through-hole (14) in the retaining member (11), stretch from one end face to the other end face thereof. The retaining member may be provided with a flange having threaded holes and screwlocked into female screws in the ceramic susceptor.

Owner:SUMITOMO ELECTRIC IND LTD

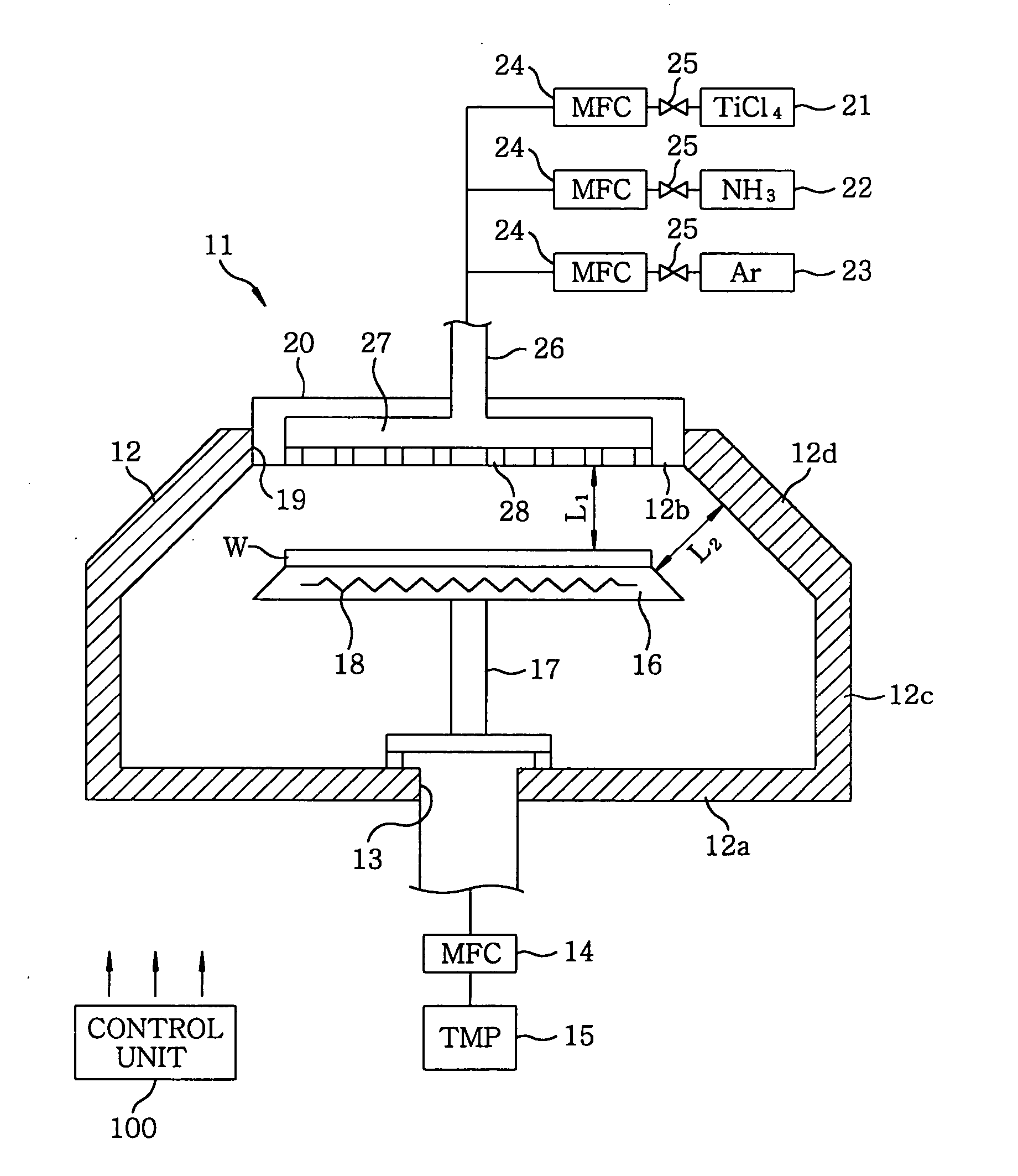

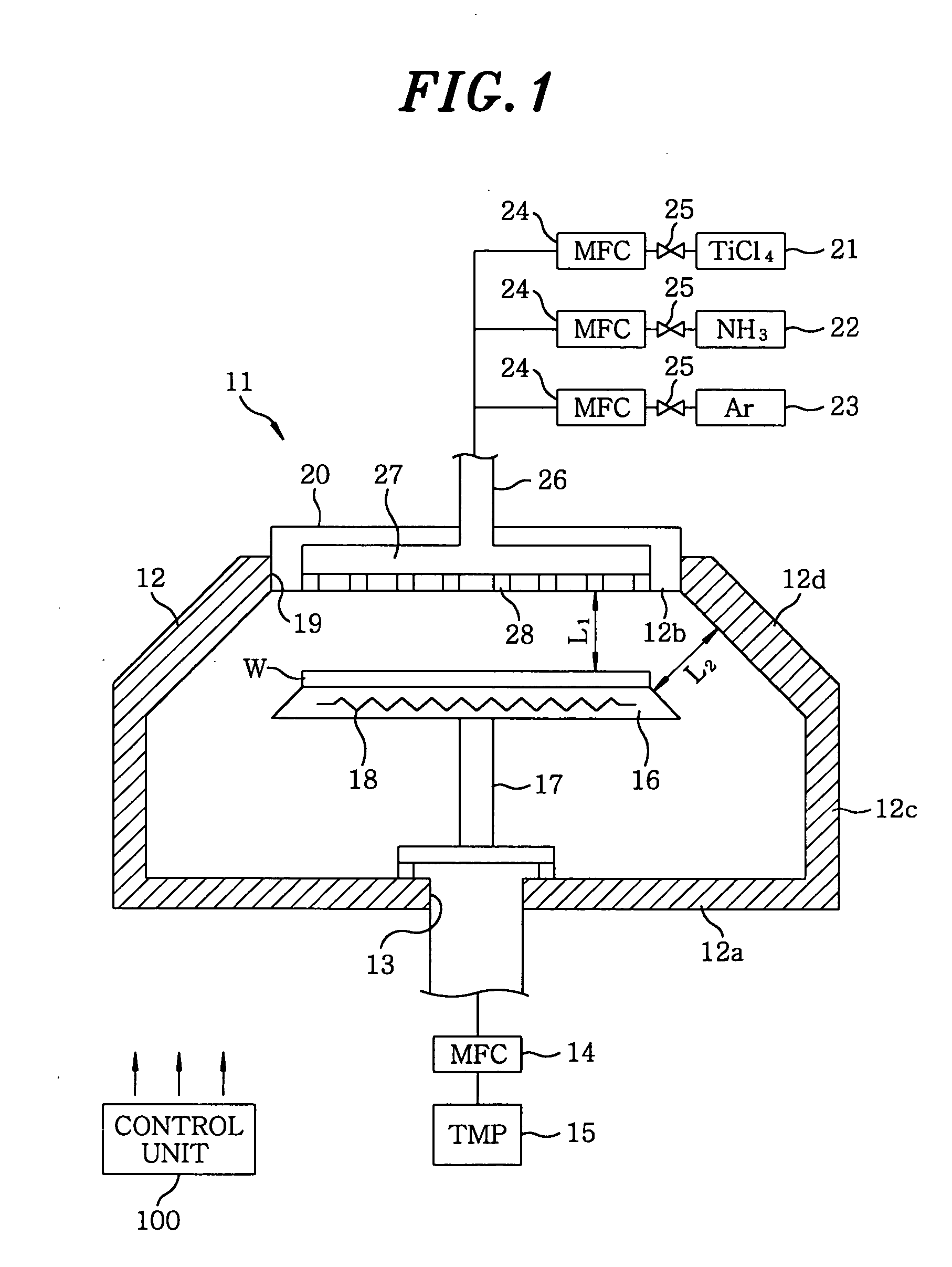

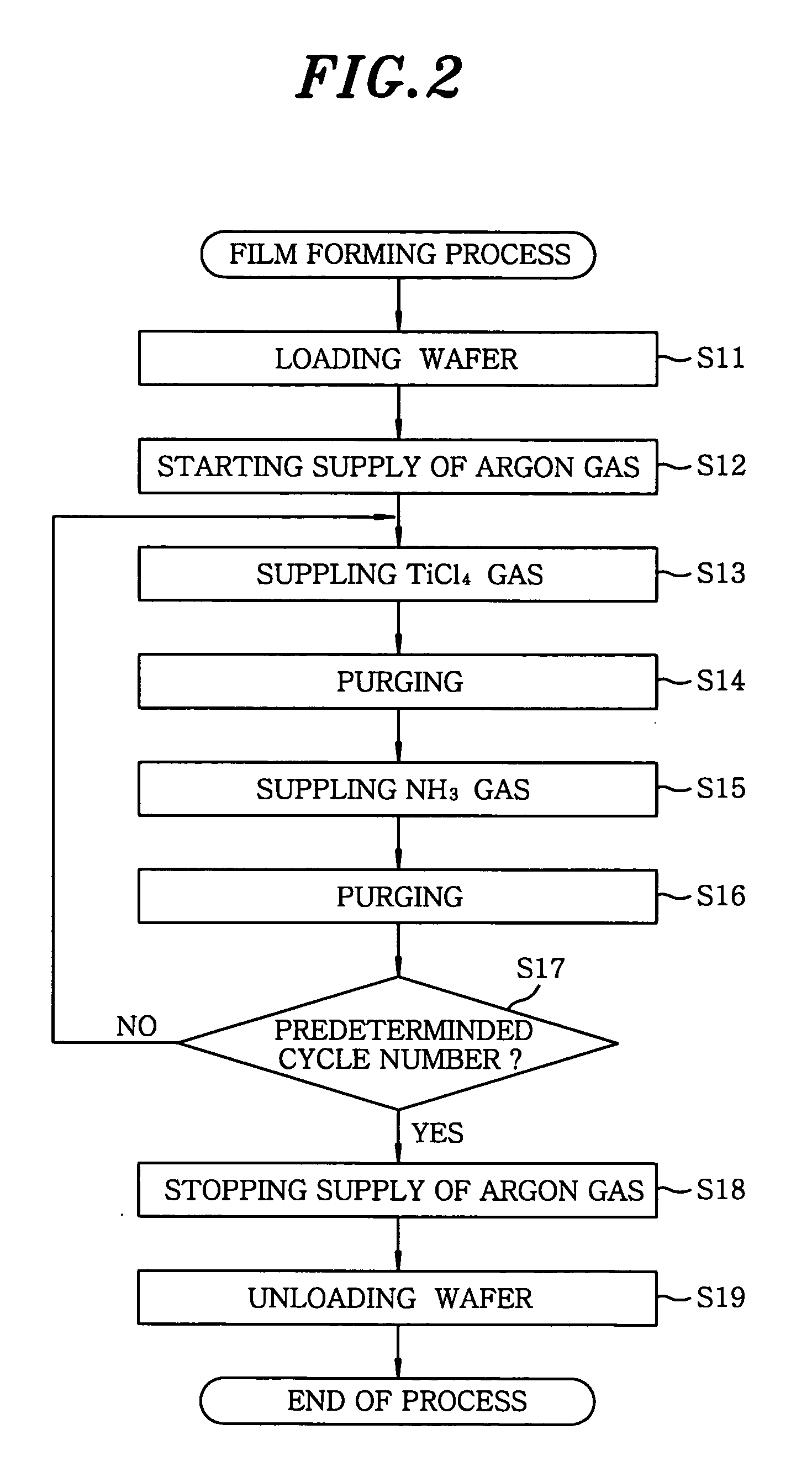

Processing device and processing method

InactiveUS20050211167A1Increase speedHigh productSemiconductor/solid-state device manufacturingFrom chemically reactive gasesSusceptorEngineering

The ceiling surface (12b) of a chamber (12) is substantially entirely formed with a gas supply port (19). Further, the gas supply port (19) has shower head (20) fitted therein. The peripheral edge of the ceiling surface (12b) has connected thereto a second side wall (12d) forming an angle greater than 90 degrees with ceiling surface (12b). Further, the side surface of a susceptor (16) is formed such that it forms an angle greater than 90 degrees with a mounting surface for a wafer (W) and is substantially parallel with the second side wall (12d) of the chamber (12). Further, the susceptor (16) is disposed such that the distance (L2) between its side surface and the second side wall (12d) is greater than the distance (L1) between the shower head (20) and the wafer (W).

Owner:TOKYO ELECTRON LTD

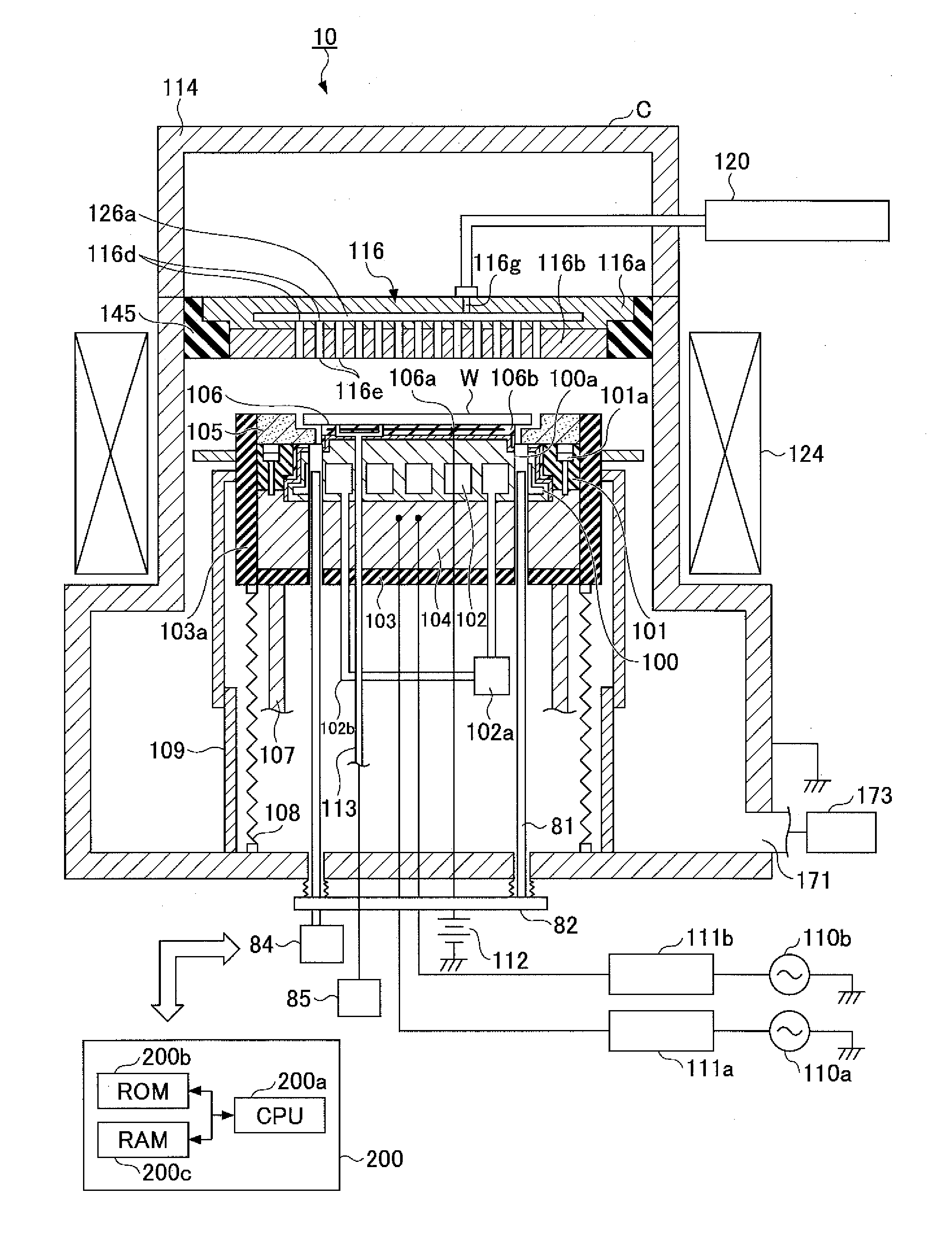

Substrate processing apparatus and susceptor

ActiveUS20140202386A1Increase temperatureLiquid surface applicatorsMolten spray coatingHigh frequency powerSusceptor

A substrate processing apparatus includes a chamber, a susceptor to receive a substrate and provided in the chamber, a gas supply source to supply a predetermined gas into the chamber, and a high frequency power source to treat the substrate by plasma. The susceptor includes a first ceramics base member including a flow passage to let a coolant pass through, a first conductive layer formed on a principal surface and a side surface on a substrate receiving side of the first ceramics base member, and an electrostatic chuck stacked on the first conductive layer and configured to electrostatically attract the wafer received thereon. A volume of the flow passage is equal to or more than a volume of the first ceramics base member. The high frequency power source is configured to supply high frequency power to the first conductive layer.

Owner:TOKYO ELECTRON LTD

Temperature Control Method of Epitaxial Growth Apparatus

ActiveUS20070062439A1Quality improvementPrevent slippingPolycrystalline material growthThermometer testing/calibrationTemperature controlSusceptor

An object of the invention is to calibrate an upper pyrometer for indirectly measuring a substrate temperature at the time of epitaxial growth in a comparatively short time and with accuracy to thereby improve the quality of an epitaxial substrate. After calibrating an upper pyrometer by a thermocouple mounted to a temperature calibrating susceptor, a measured value of a lower pyrometer is adjusted to a calibrated value of the upper pyrometer. Then, a correlation line between substrate temperature indirectly measured by the upper pyrometer at the time of epitaxial growth onto a sample substrate and haze of a sample substrate measured immediately after epitaxial growth is set to indirectly measure a substrate temperature by the upper pyrometer at the time of epitaxial growth onto a mass-production substrate. Moreover, substrate temperature at the time of epitaxial growth onto the mass-production substrate is estimated by applying the haze of the mass-production substrate measured immediately after epitaxial growth to the correlation line and then a measured temperature of the upper pyrometer is adjusted to the estimated temperature.

Owner:SUMCO CORP

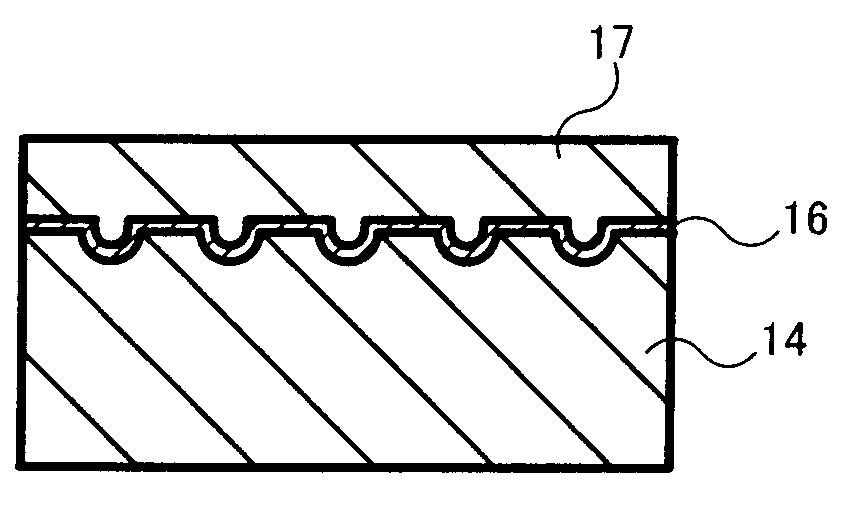

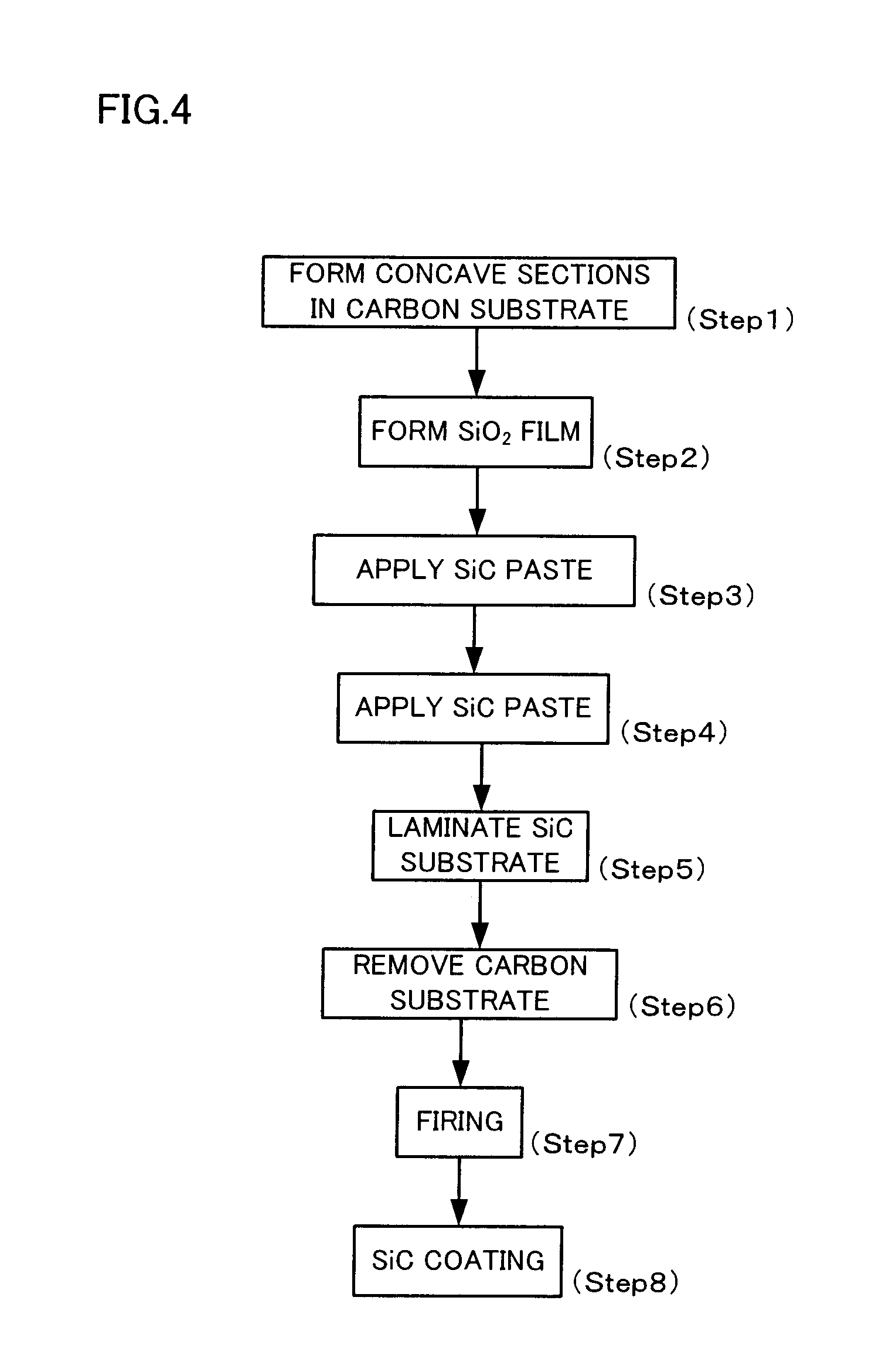

Method for manufacturing susceptor

ActiveUS20100163524A1Decorative surface effectsSemiconductor/solid-state device manufacturingSusceptorMetallurgy

A method for manufacturing a susceptor includes: forming a concave pattern in a surface of a substrate to be processed; applying a SiC paste containing a SiC powder and a sintering agent to the surface of the substrate to be processed to fill the concave pattern to form a SiC coating layer; laminating a SiC substrate on the SiC coating layer; and firing the SiC coating layer to form a SiC layer having at least one convex section on the surface of the SiC substrate.

Owner:NUFLARE TECH INC

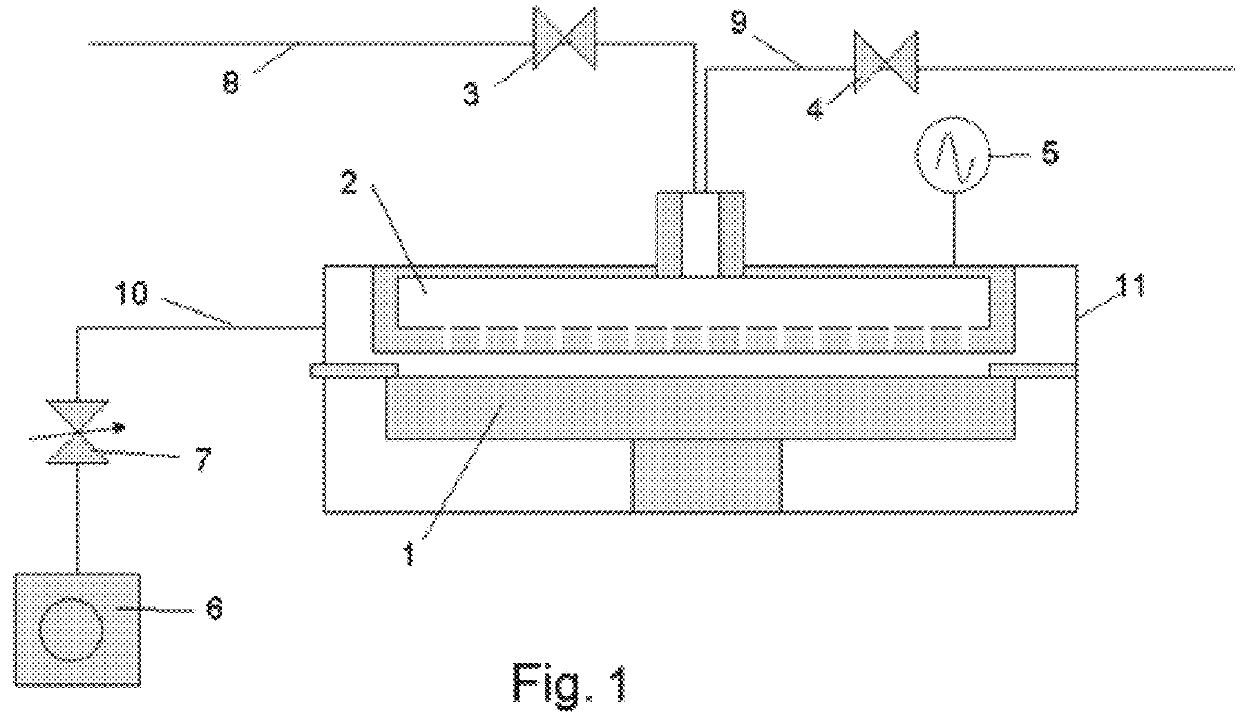

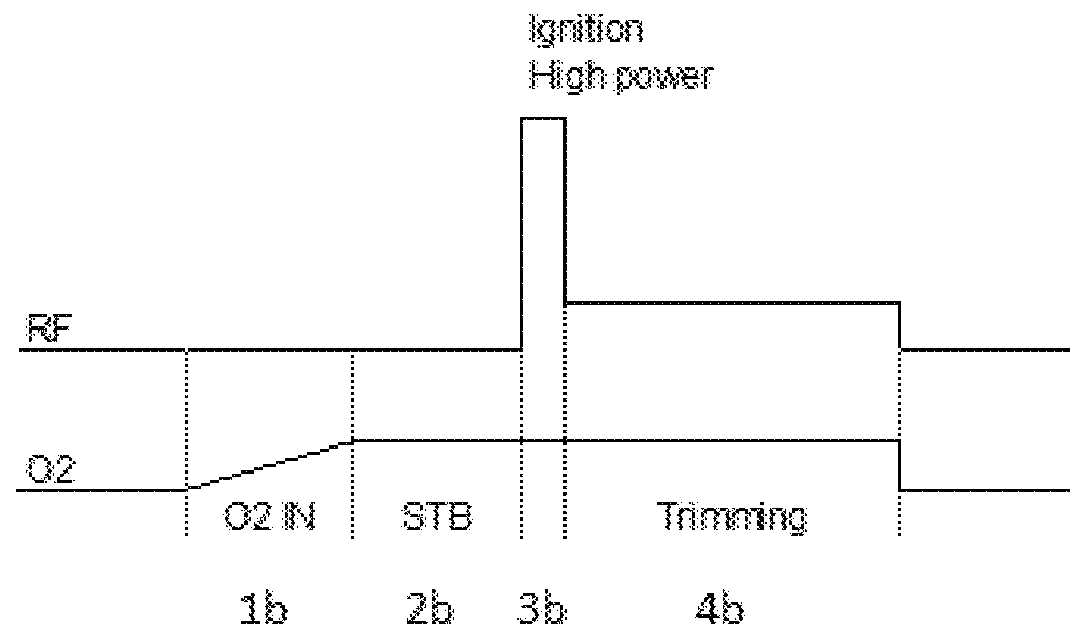

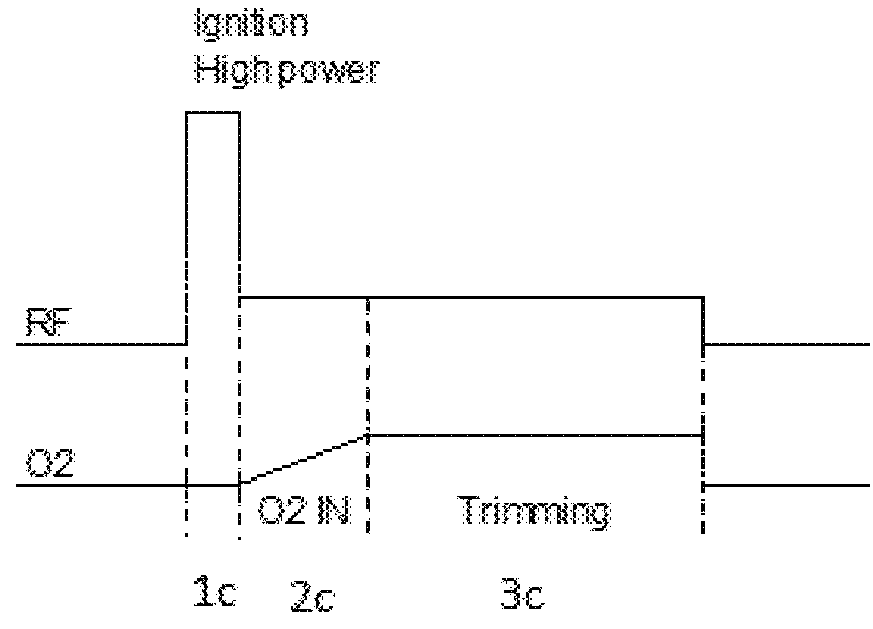

Method for trimming carbon-containing film at reduced trimming rate

ActiveUS9343308B2Reduce rateEasy to handleElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorThin membrane

Owner:ASM IP HLDG BV

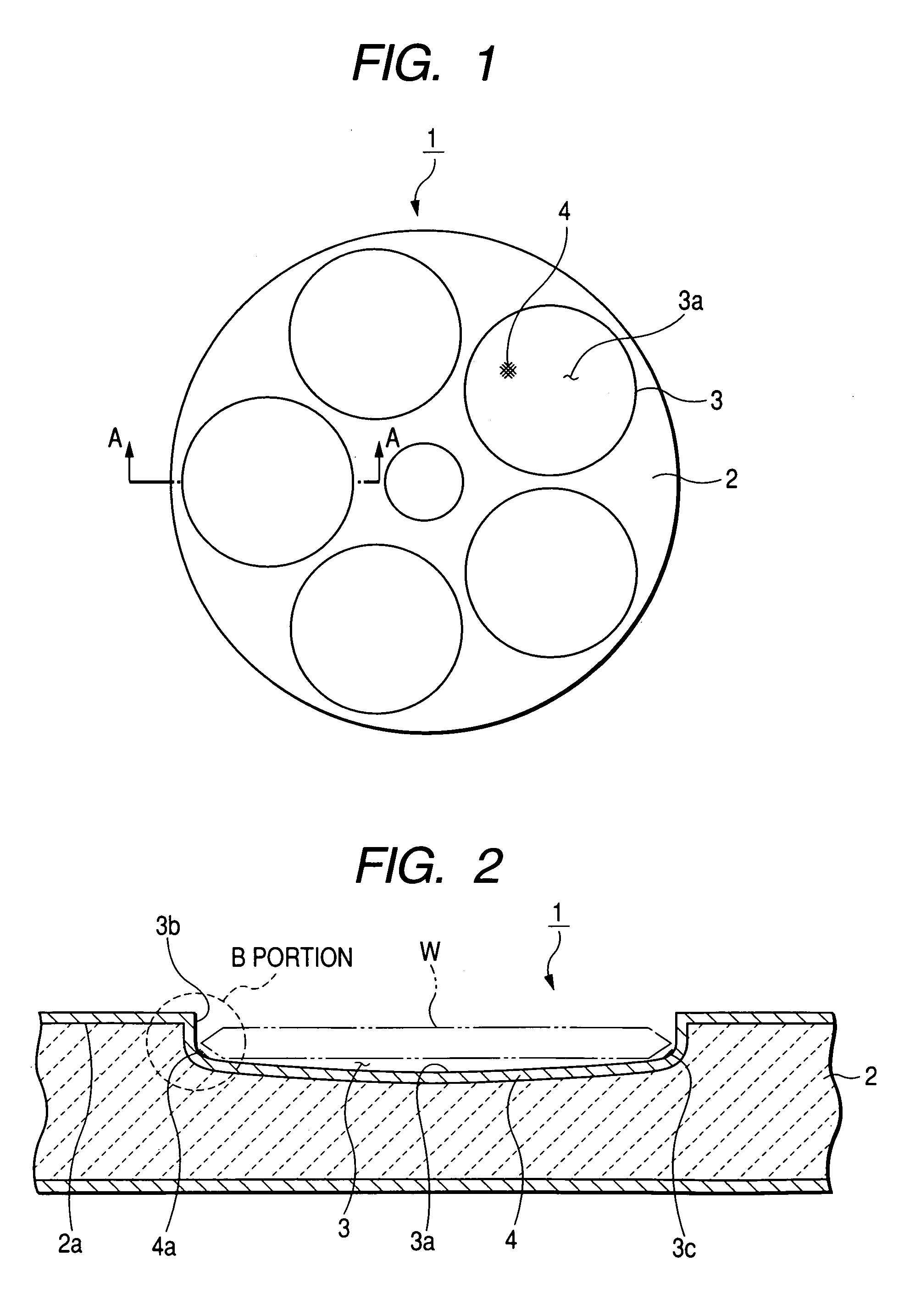

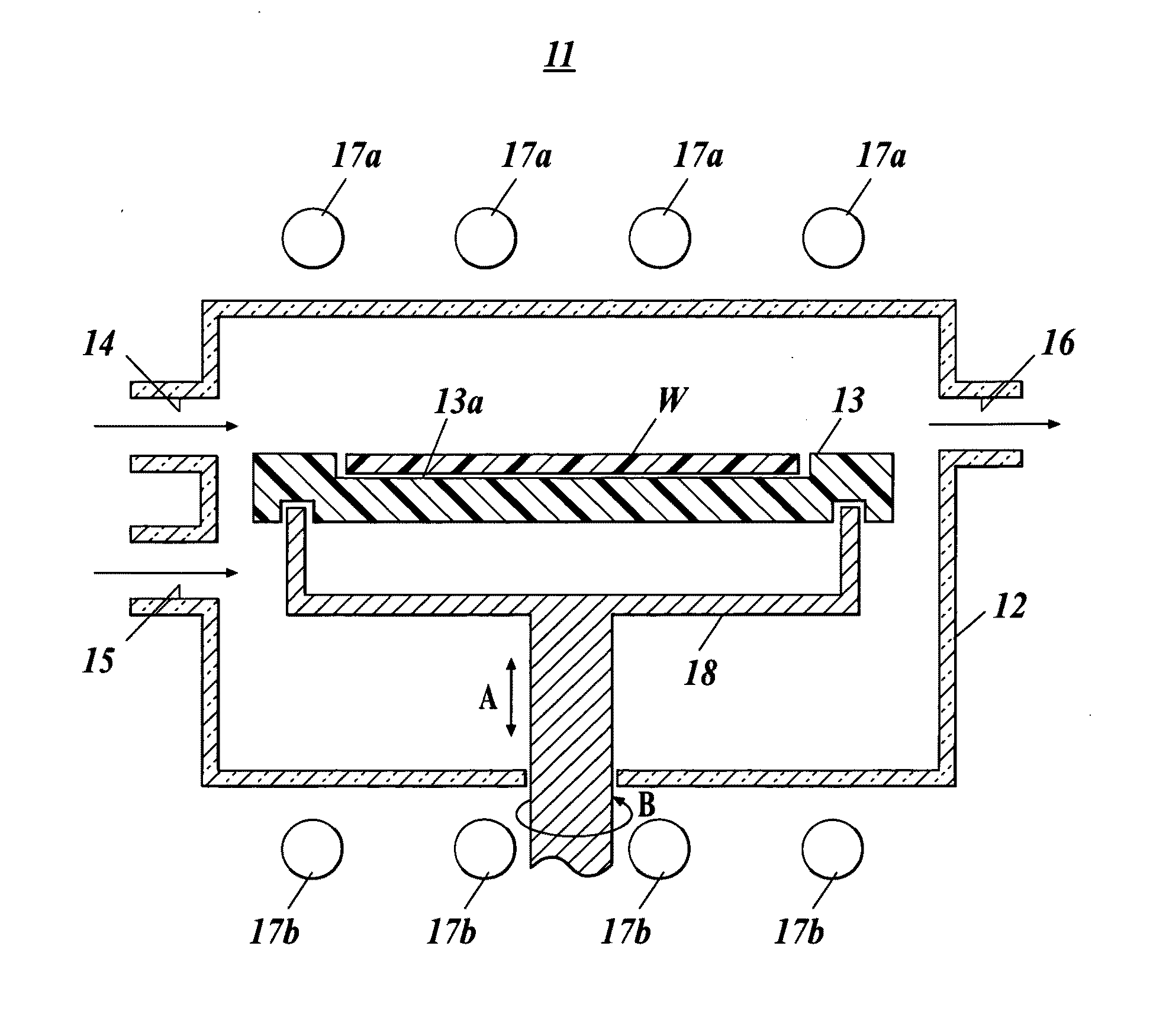

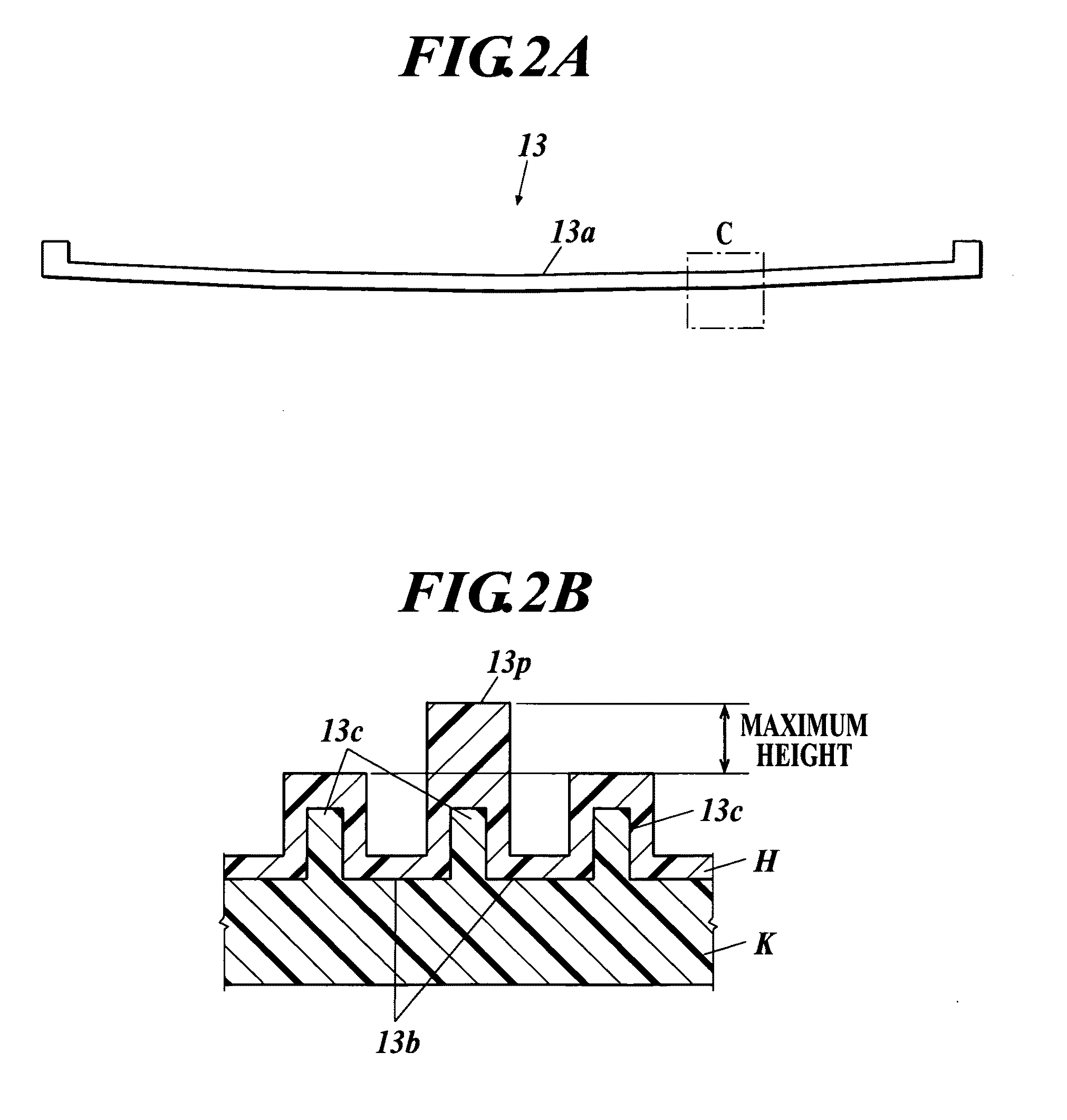

Susceptor and method for manufacturing silicon epitaxial wafer

ActiveUS20100129990A1Avoid stickingPolycrystalline material growthLiquid surface applicatorsSusceptorWafering

Provided is a susceptor 13 for manufacturing an epitaxial wafer, comprising a mesh-like groove 13b on a mount face on which a silicon substrate W is to be mounted, wherein a coating H of silicon carbide is formed on the mount face, and the coating has a surface roughness of 1 μm or more in centerline average roughness Ra and a maximum height of a protrusion 13p generated in forming the coating H of 5 μm or less. Thus, defects such as warping and slip as well as adhesion of the silicon substrate to the susceptor are prevented.

Owner:SHIN-ETSU HANDOTAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com