Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

155 results about "Borescope" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A borescope (occasionally called a boroscope, though this spelling is nonstandard) is an optical device consisting of a rigid or flexible tube with an eyepiece or display on one end, an objective lens or camera on the other linked together by an optical or electrical system in between. The optical system in some instances is surrounded by optical fibers used for illumination of the remote object. An internal image of the illuminated object is formed by the objective lens and magnified by the eyepiece which presents it to the viewer's eye.

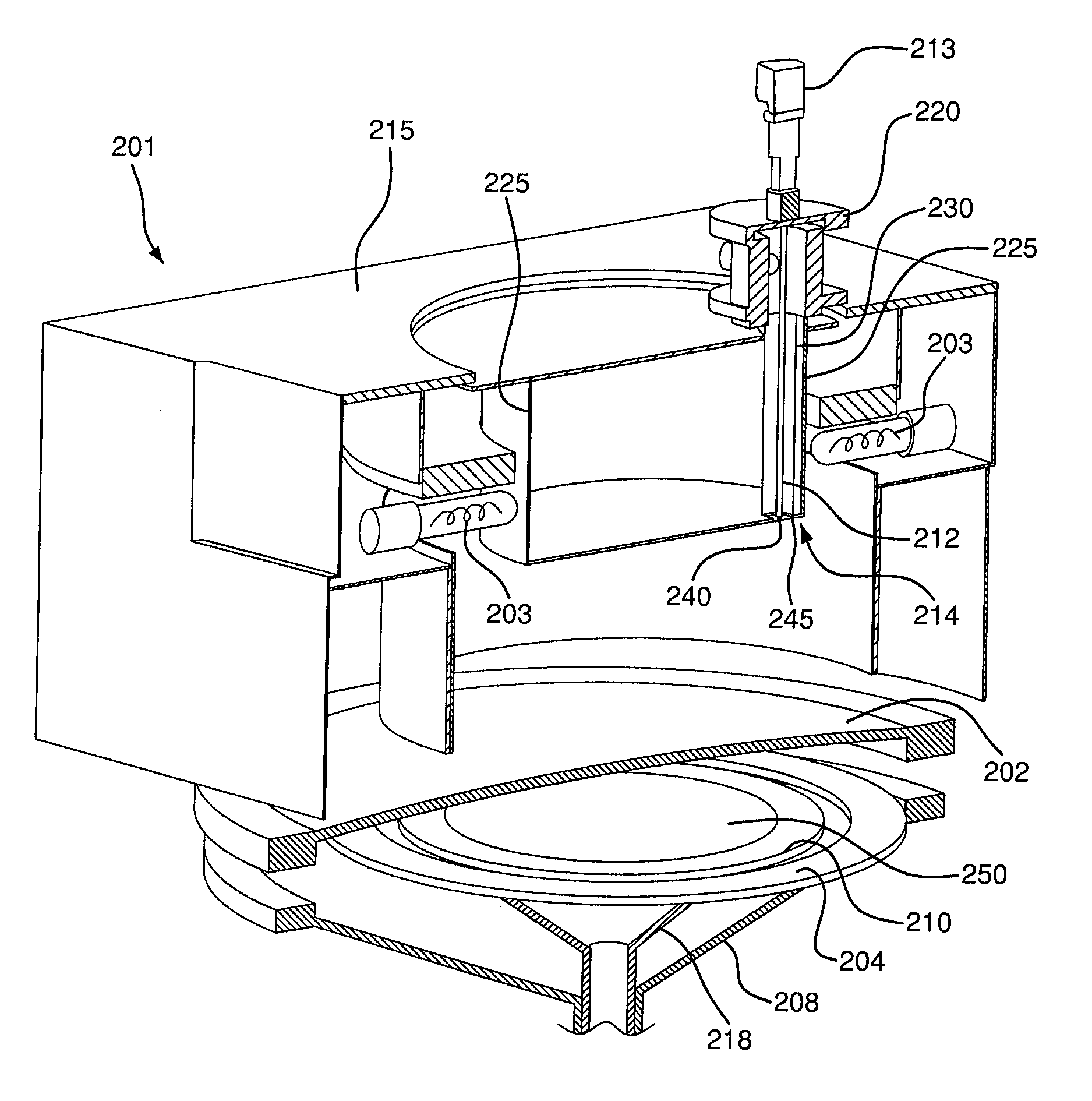

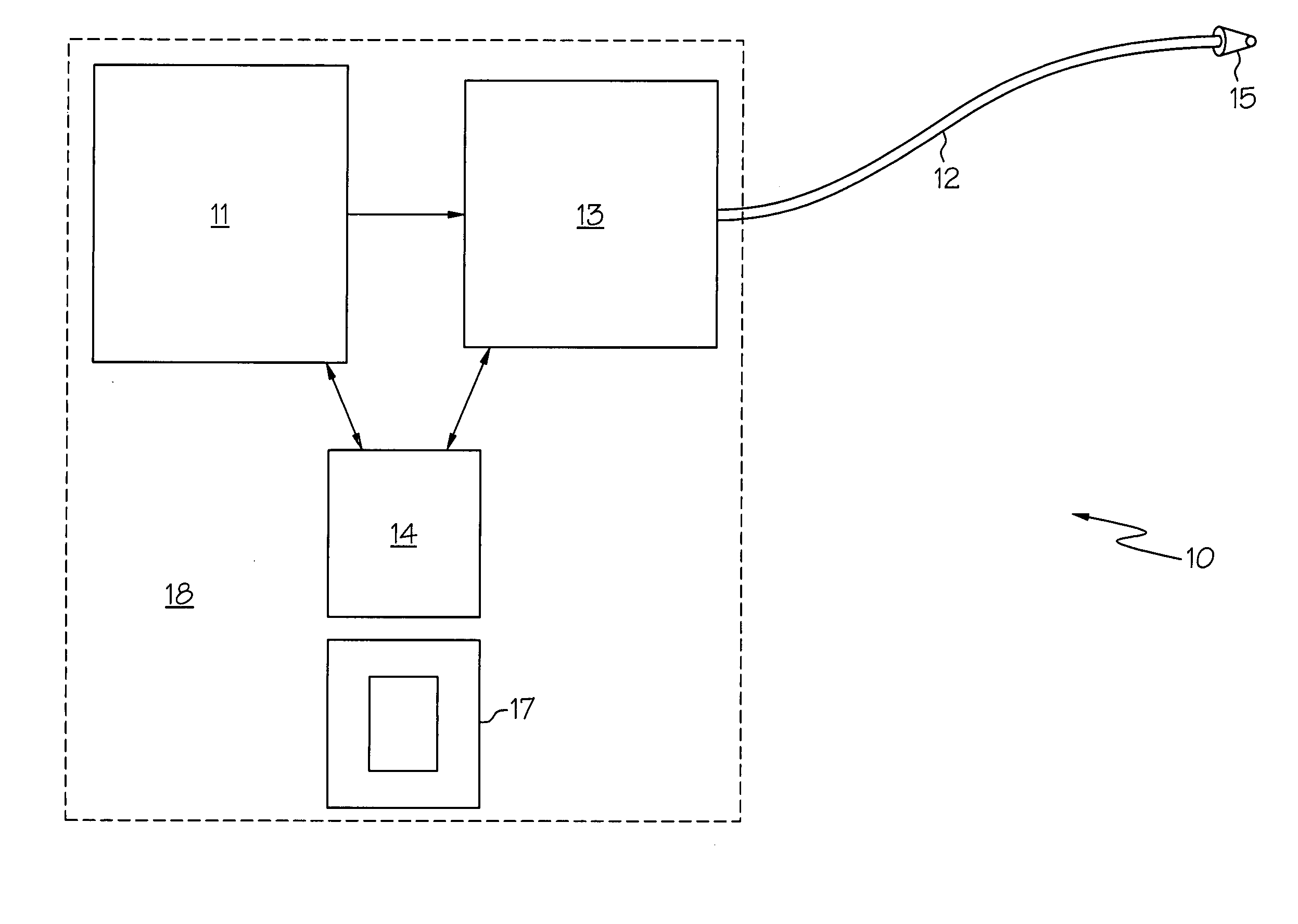

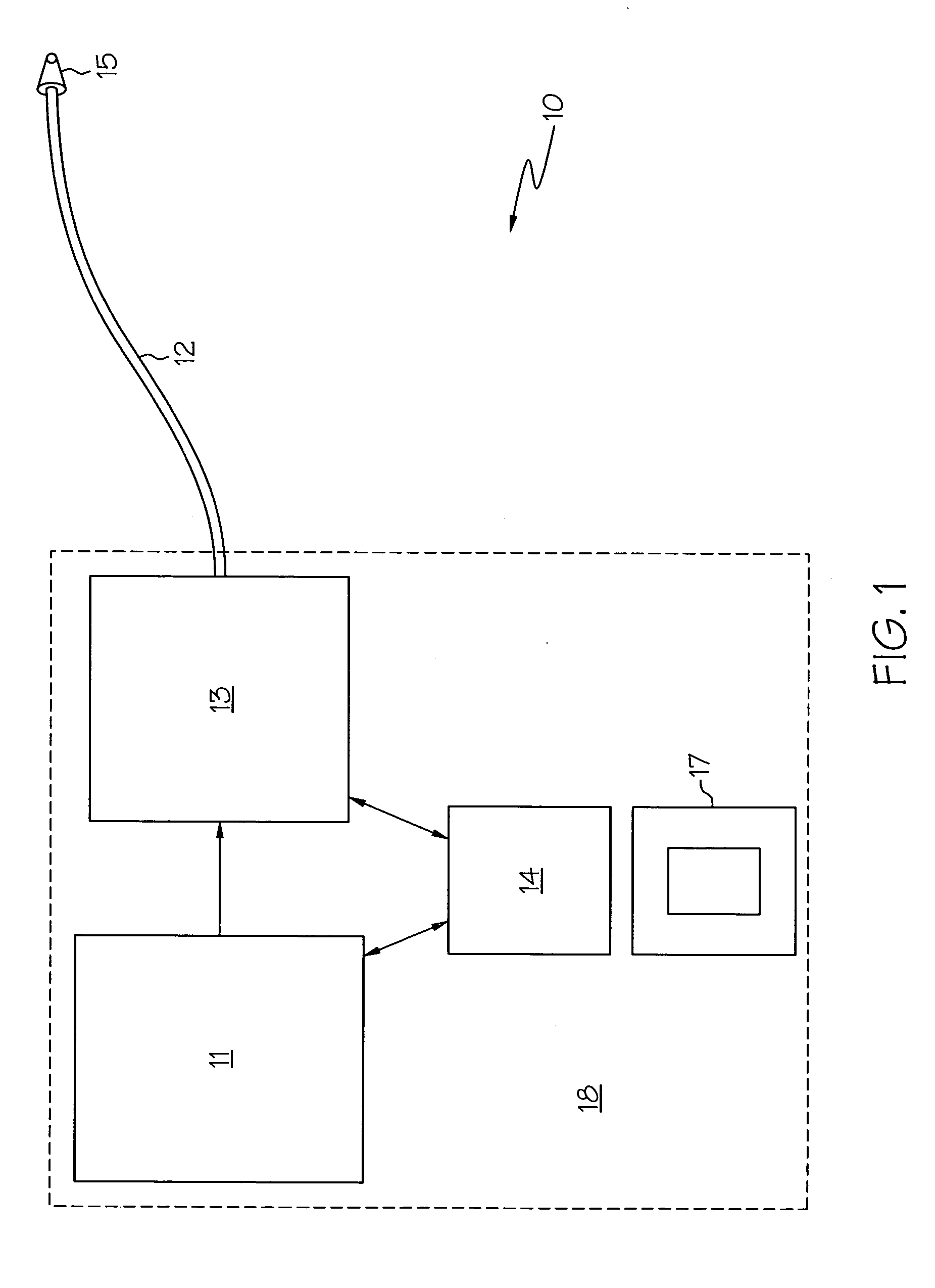

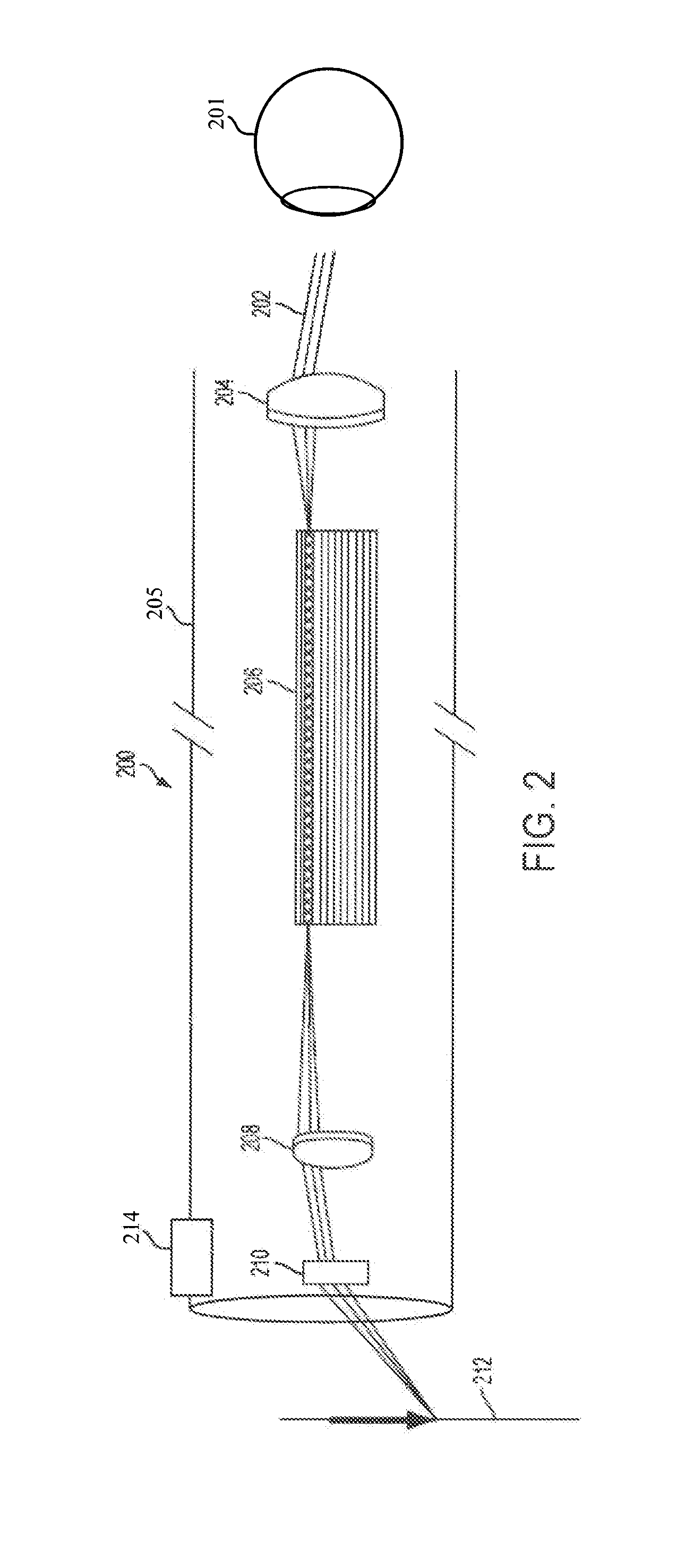

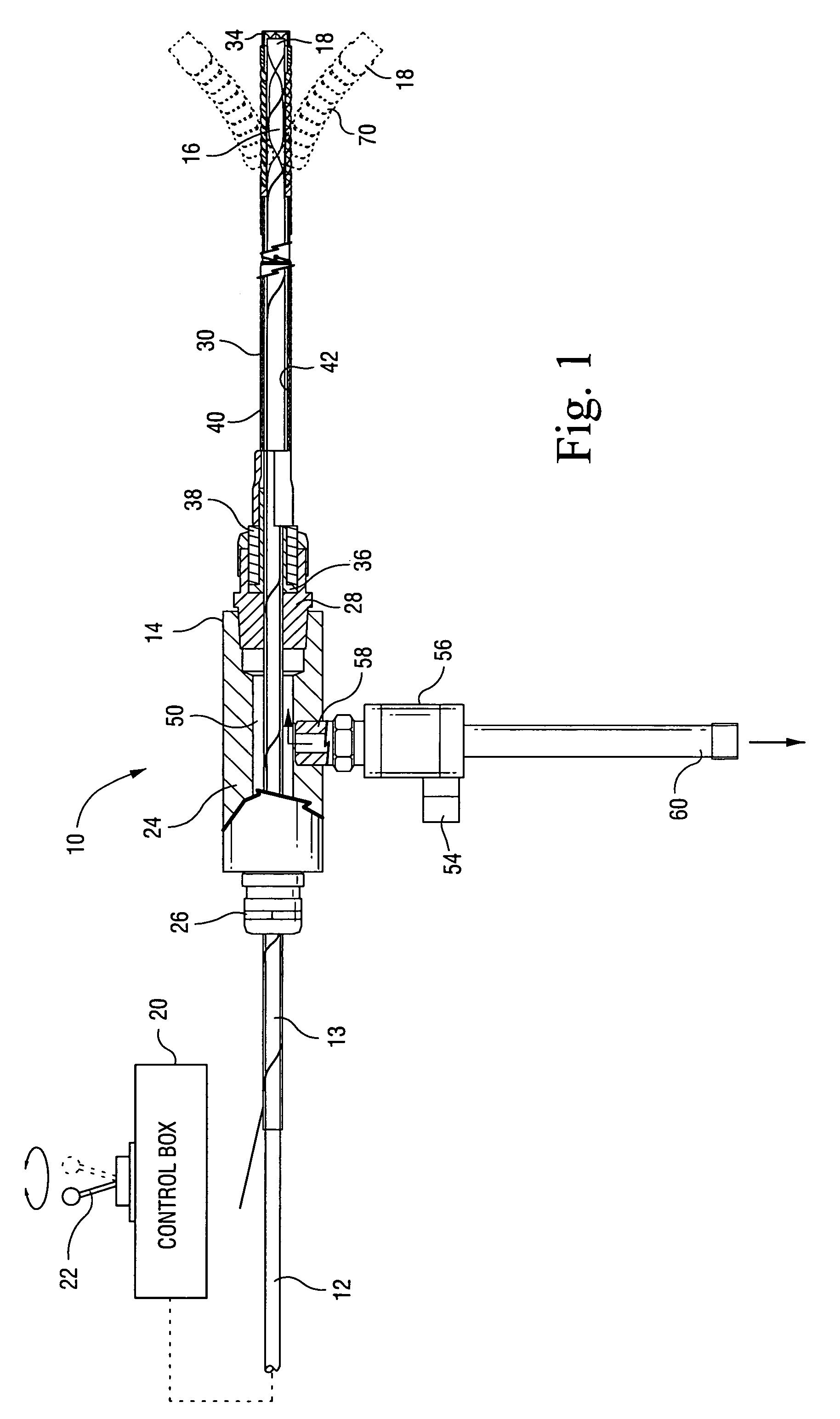

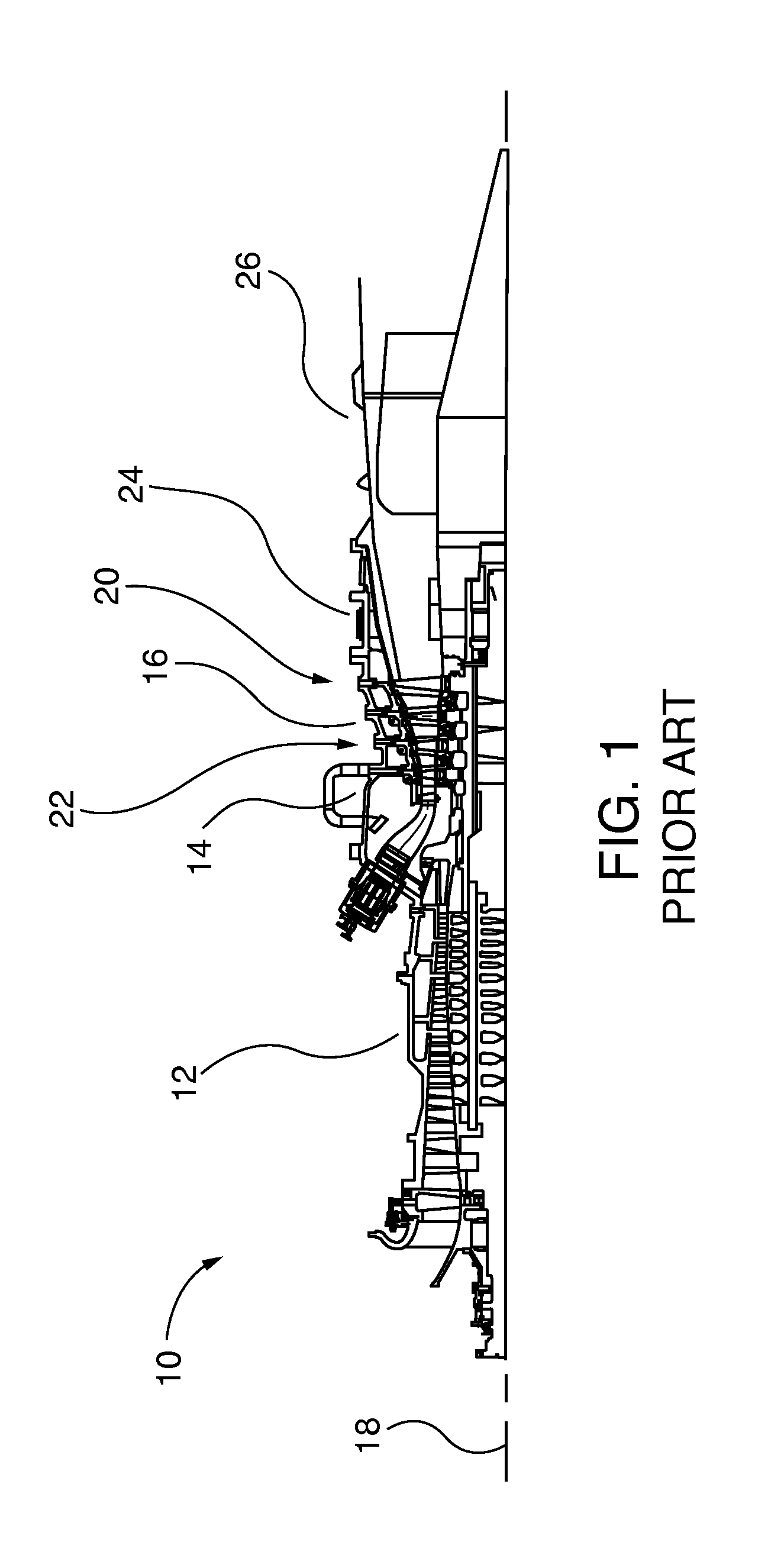

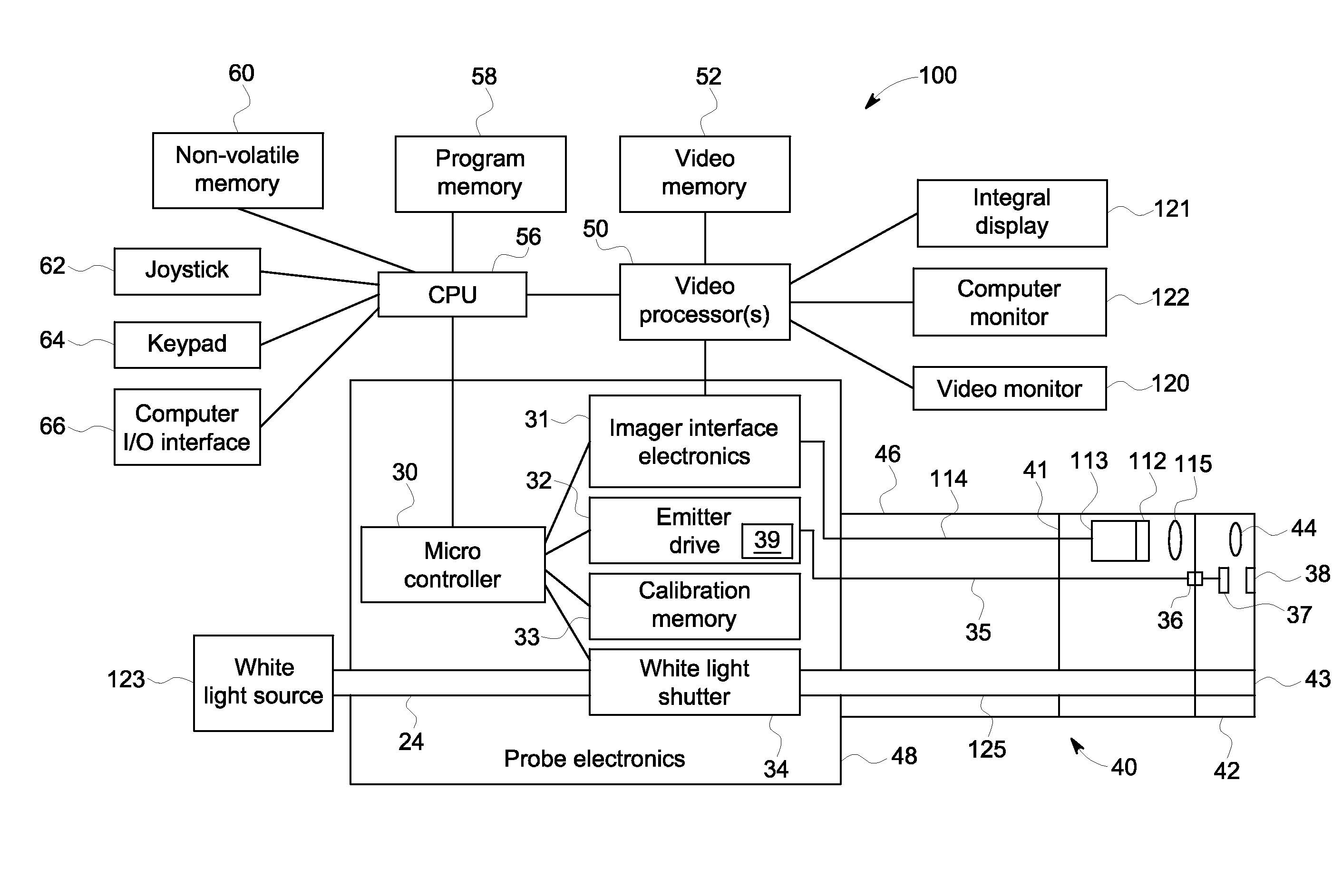

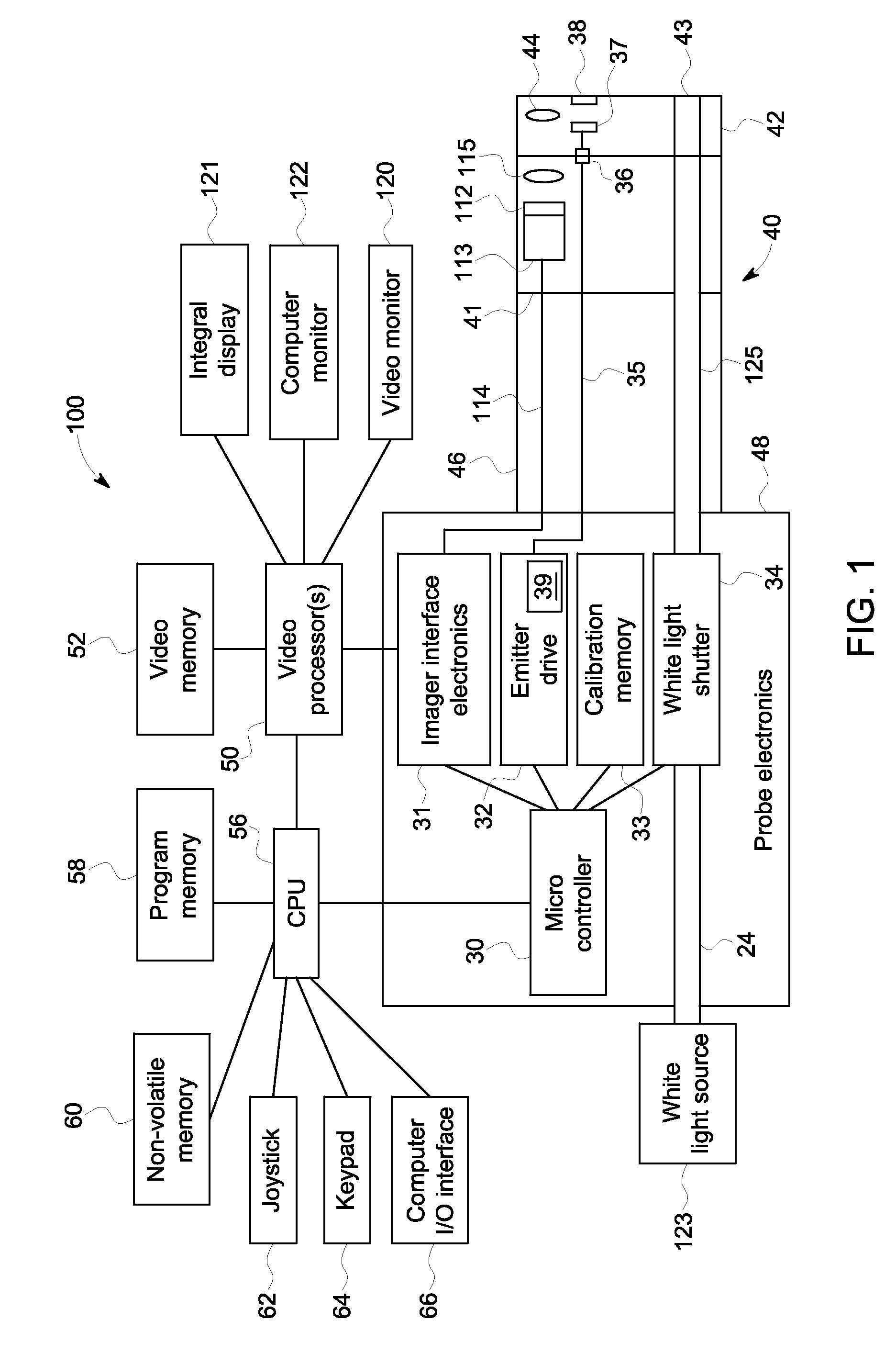

Semiconductor process chamber vision and monitoring system

A system for monitoring a process inside a high temperature semiconductor process chamber by capturing images is disclosed. Images are captured through a borescope by a camera. The borescope is protected from high temperatures by a reflective sheath and an Infrared (IR) cut-off filter. Images can be viewed on a monitor and can be recorded by a video recording device. Images can also be processed by a machine vision system. The system can monitor the susceptor and a substrate on the susceptor and surrounding structures. Deviations from preferred geometries of the substrate and deviations from preferred positions of susceptor and the substrate can be detected. Actions based on the detections of deviations can be taken to improve the performance of the process. Illumination of a substrate by a laser for detecting deviations in substrate geometry and position is also disclosed.

Owner:APPLIED MATERIALS INC

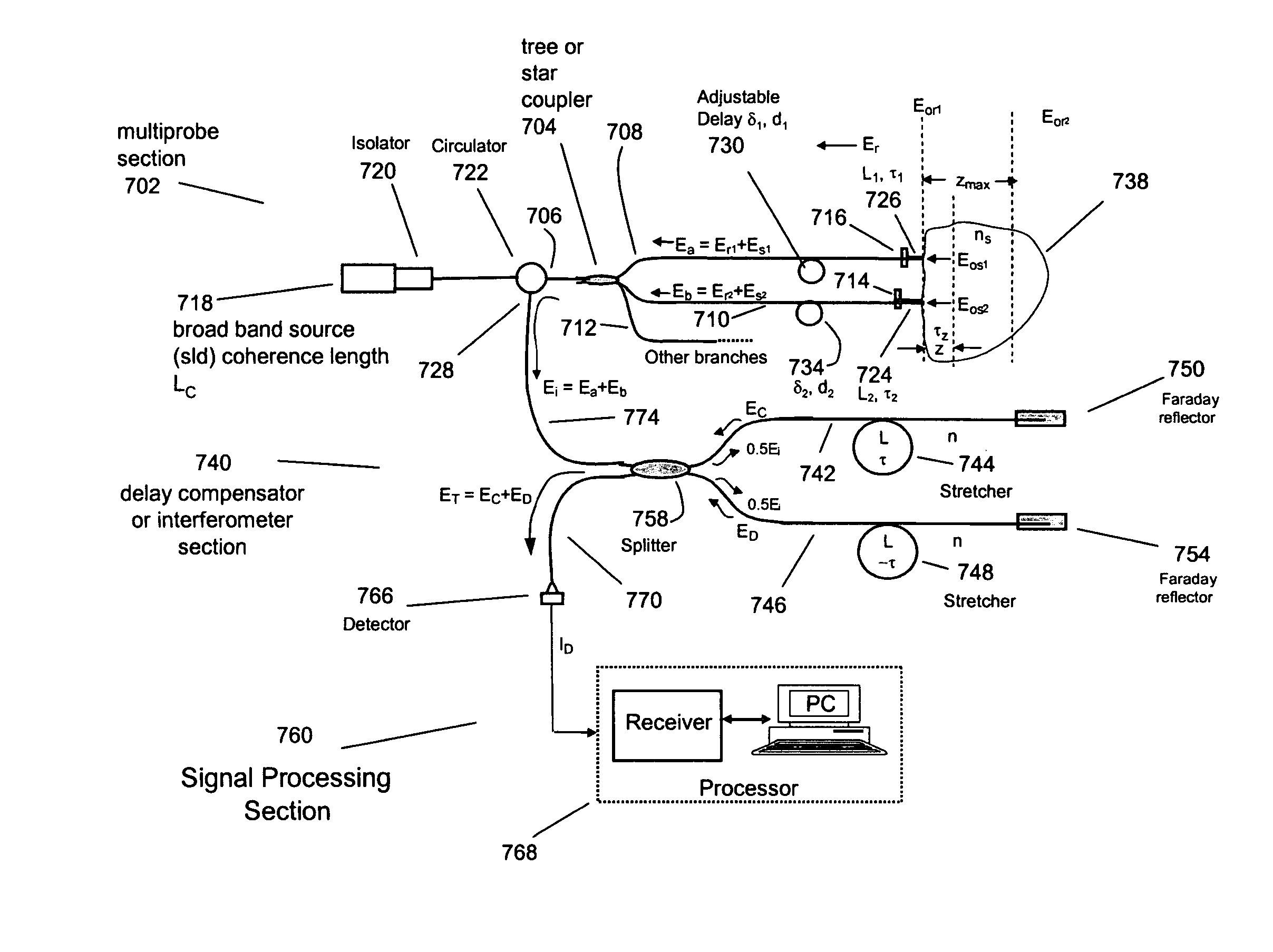

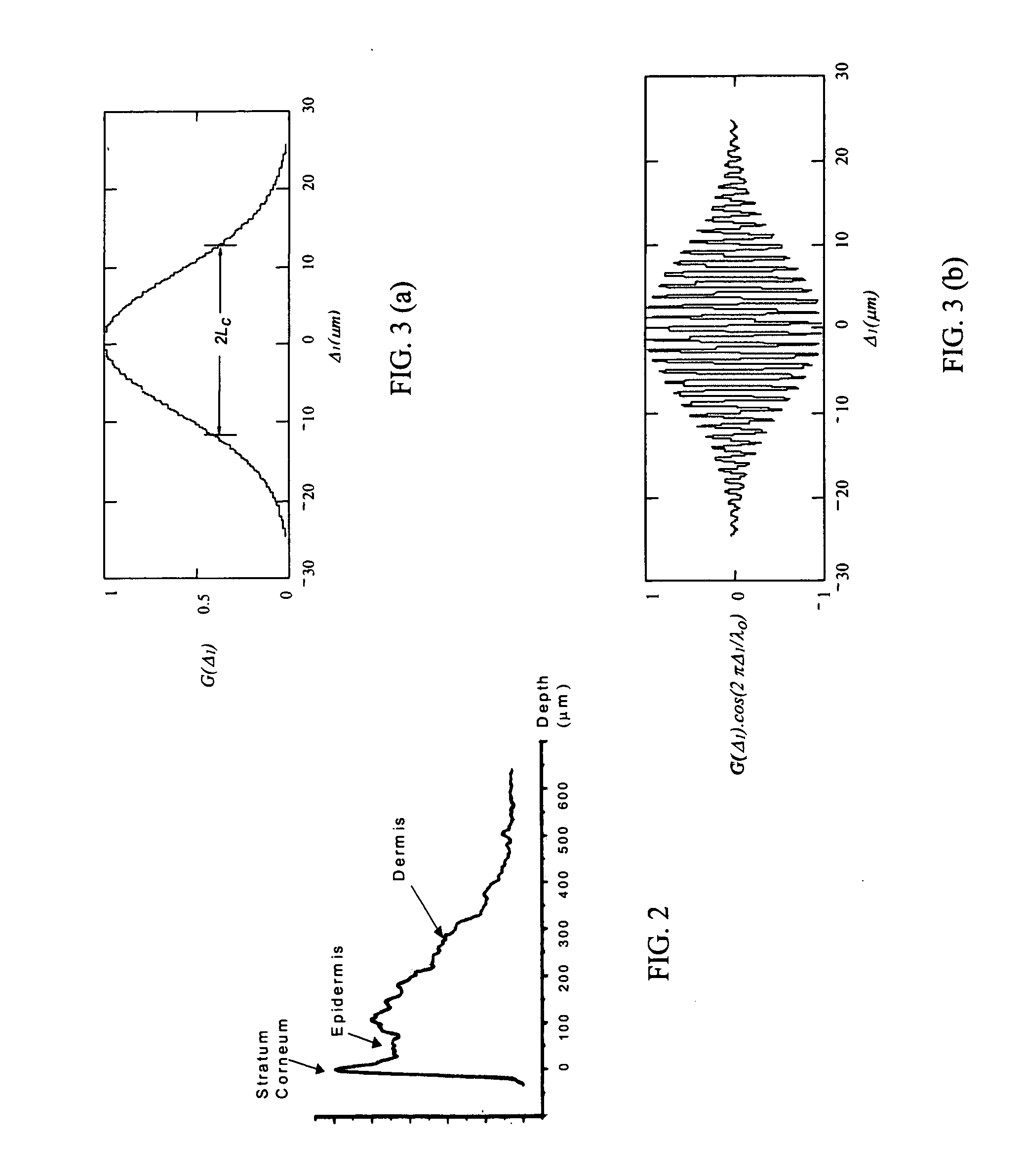

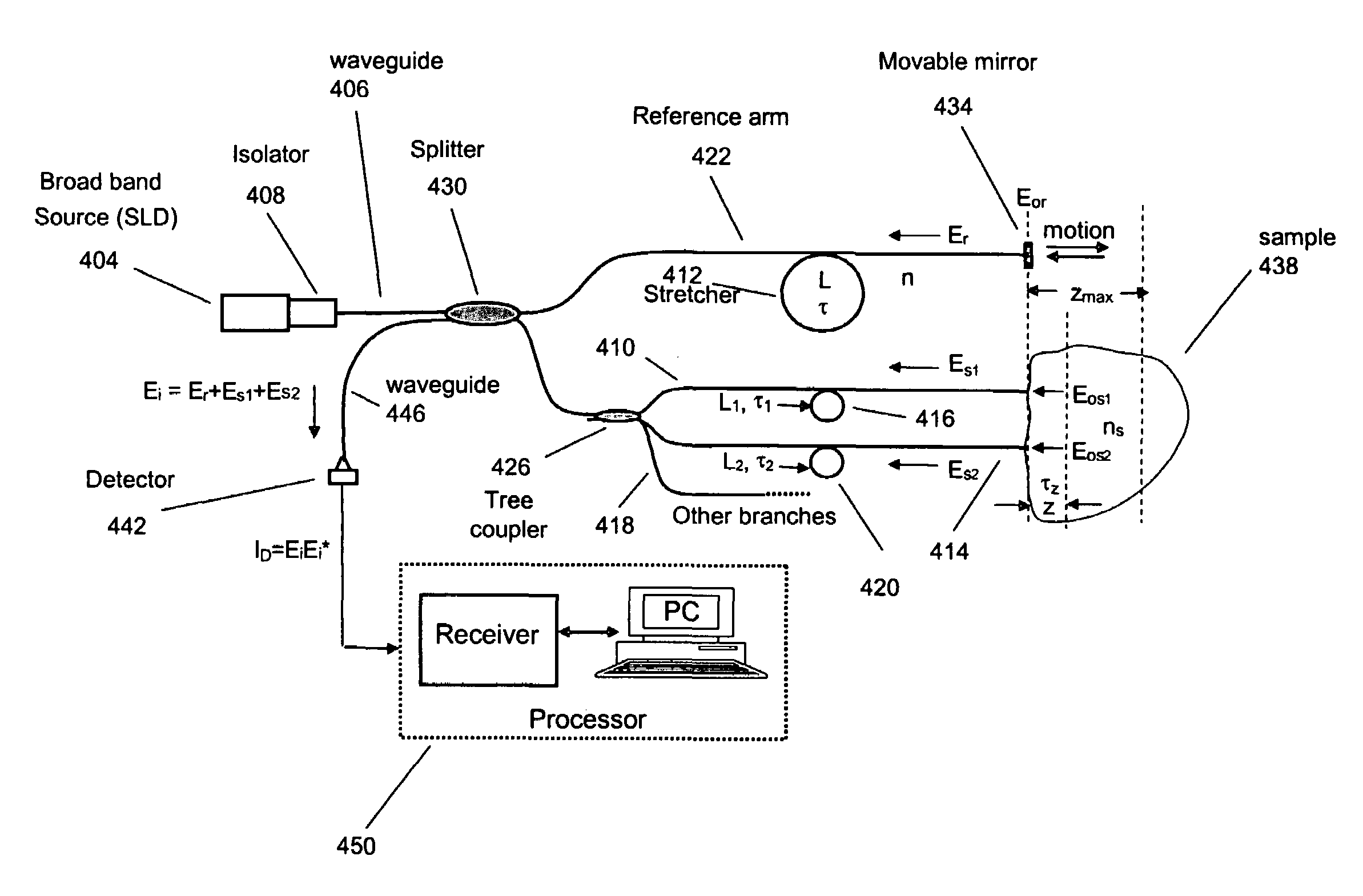

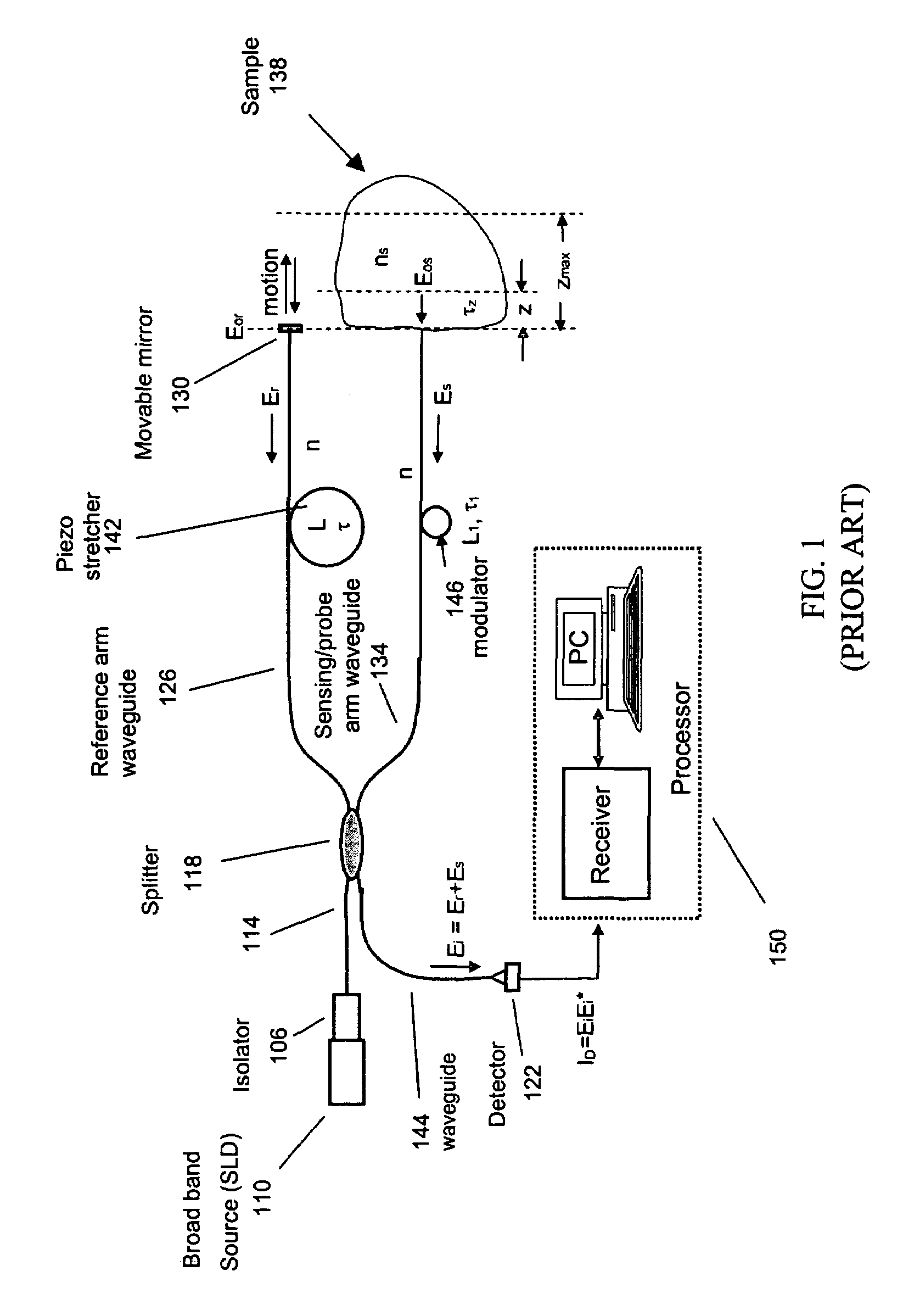

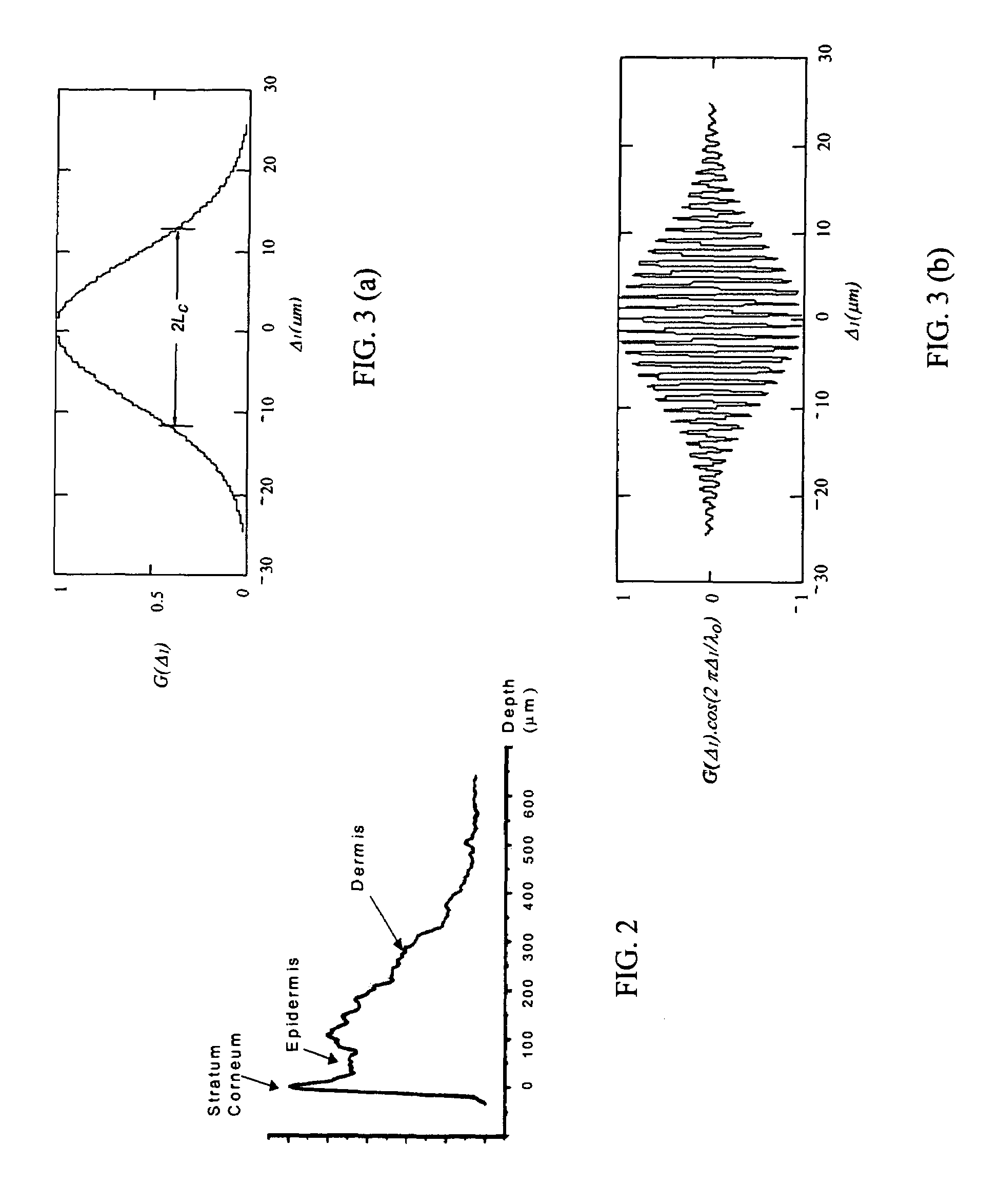

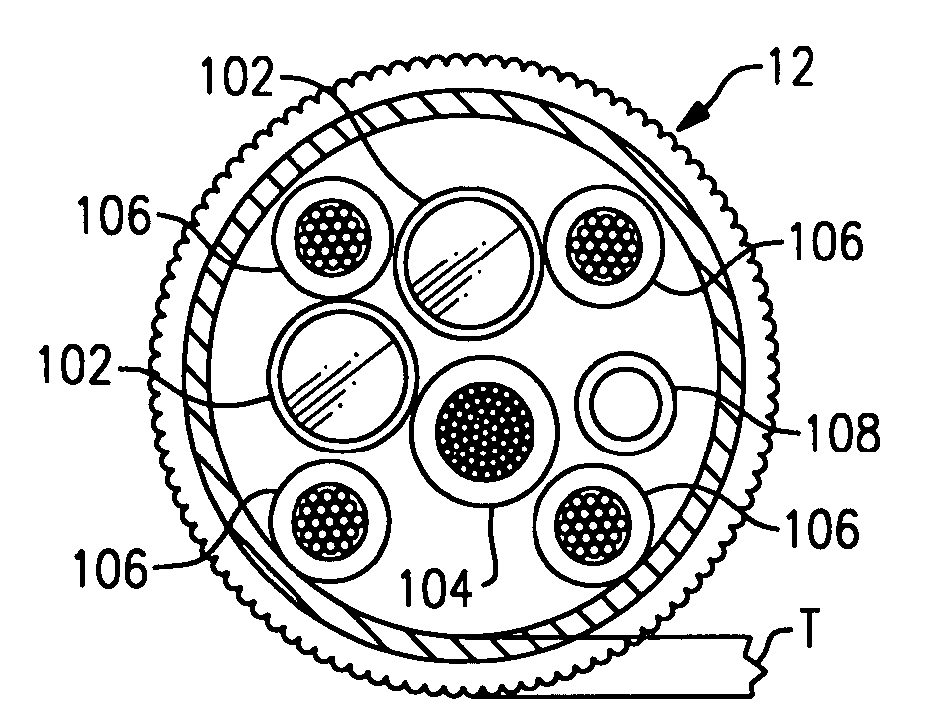

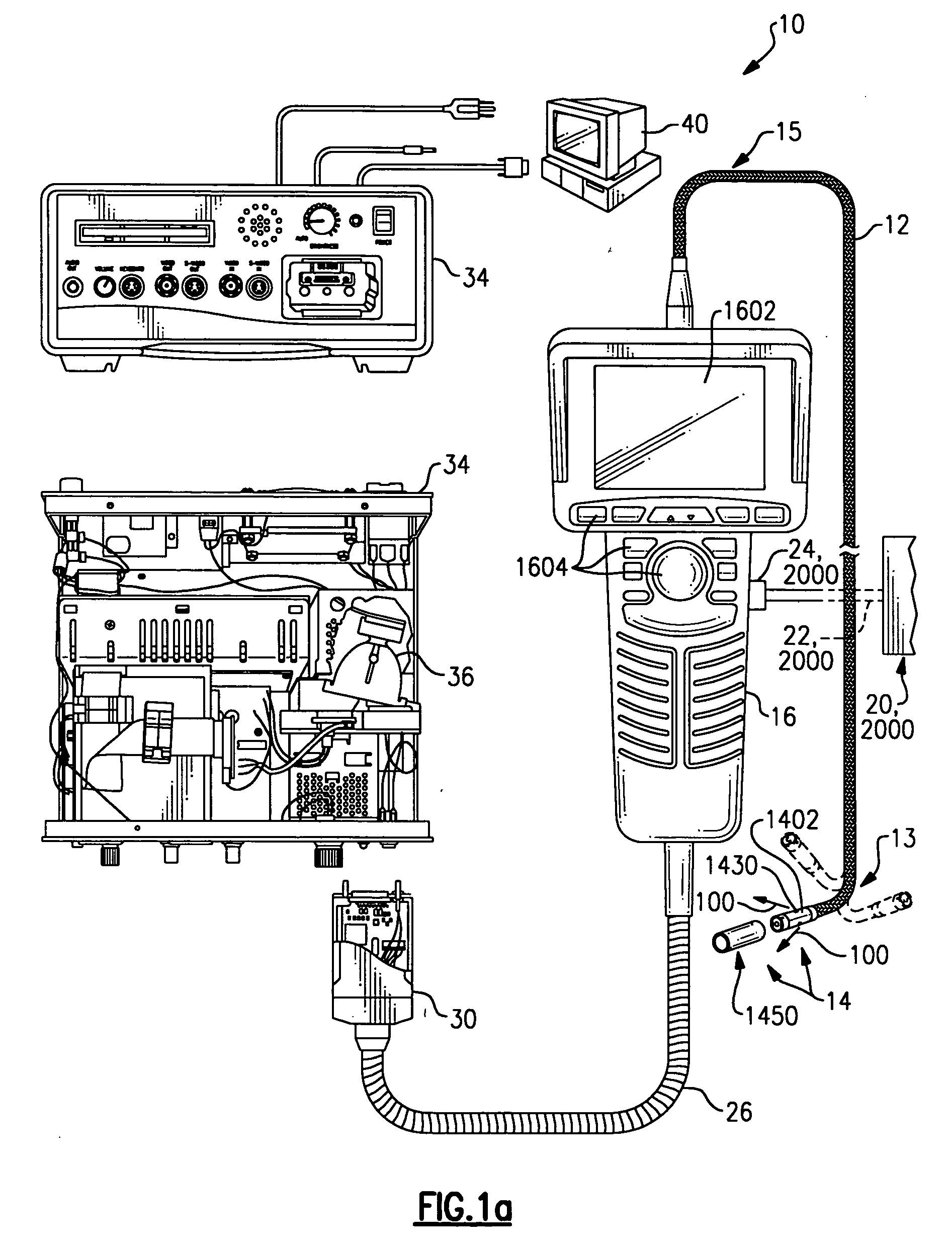

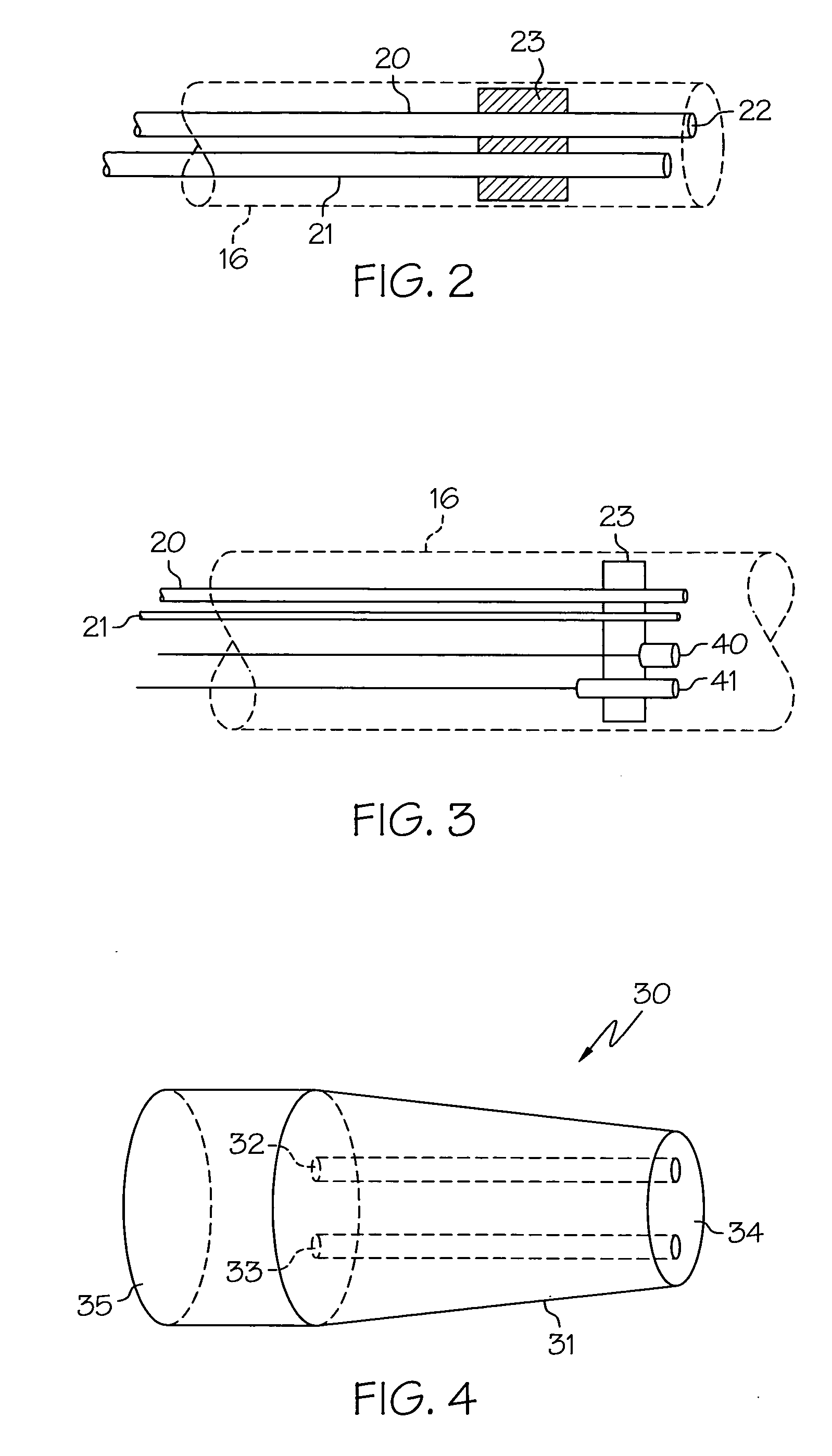

Single trace multi-channel low coherence interferometric sensor

InactiveUS20060103850A1Shorten the timeQuick identificationCatheterDiagnostic recording/measuringInterferometric sensorBorescope

Interferometers and autocorrelator based sensors are disclosed that are configured to have multiple sample arms which can be scanned and the backscattered low coherence source light from a sample resolved in a single sweep of one or more variable delays of the sensor. Borescopes and catheters capable of scanning multiple sections or areas of materials and tissues using these sensors are described.

Owner:MEDEIKON

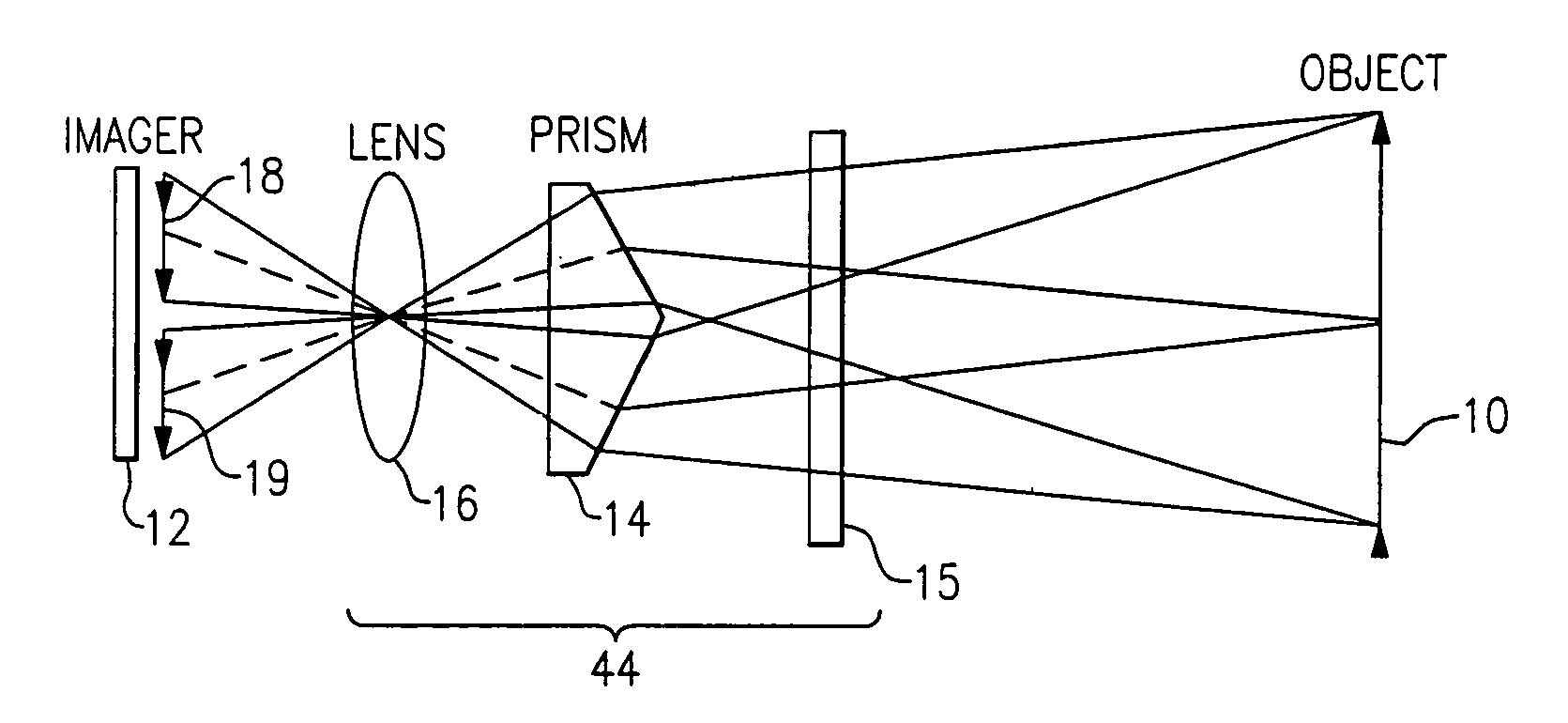

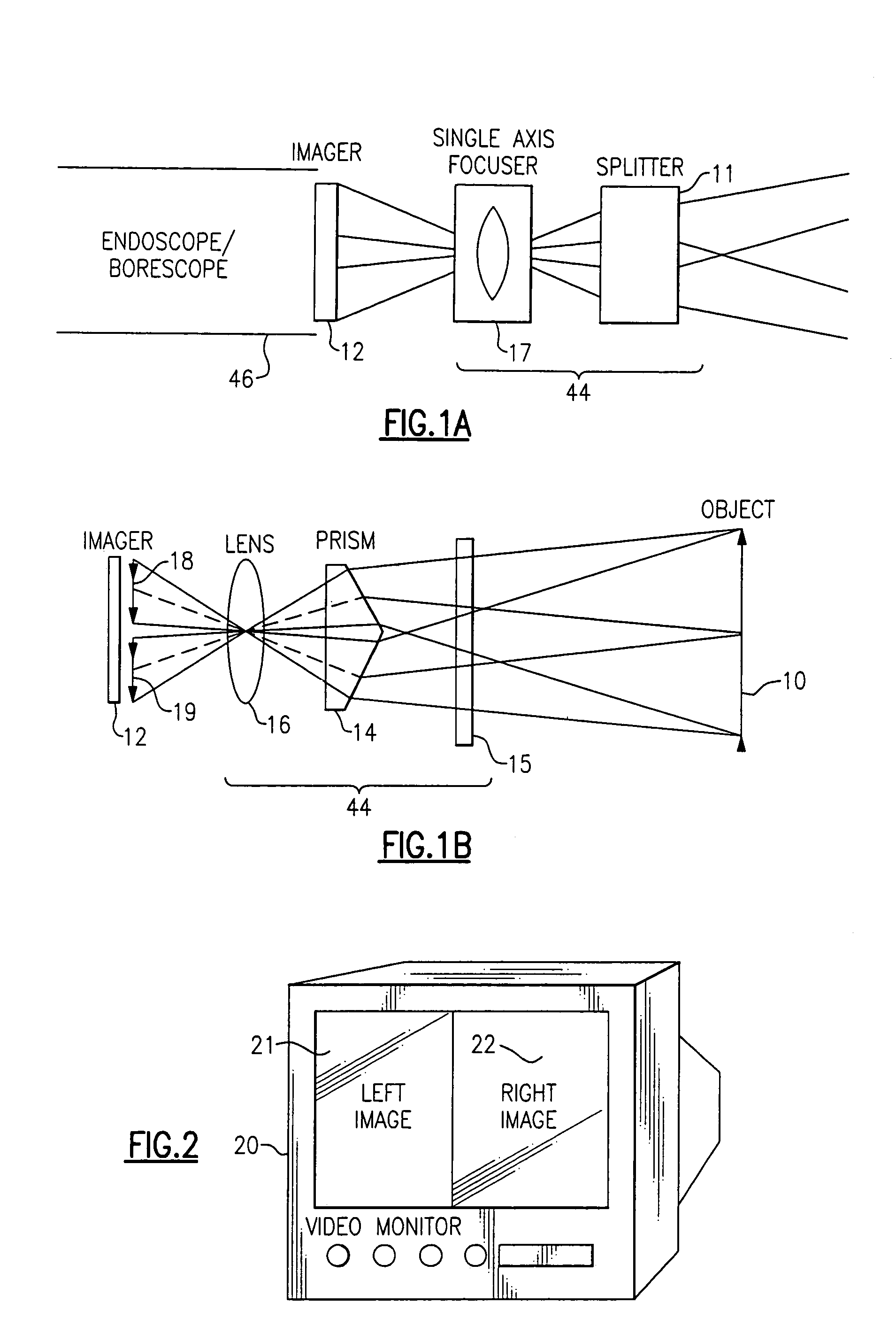

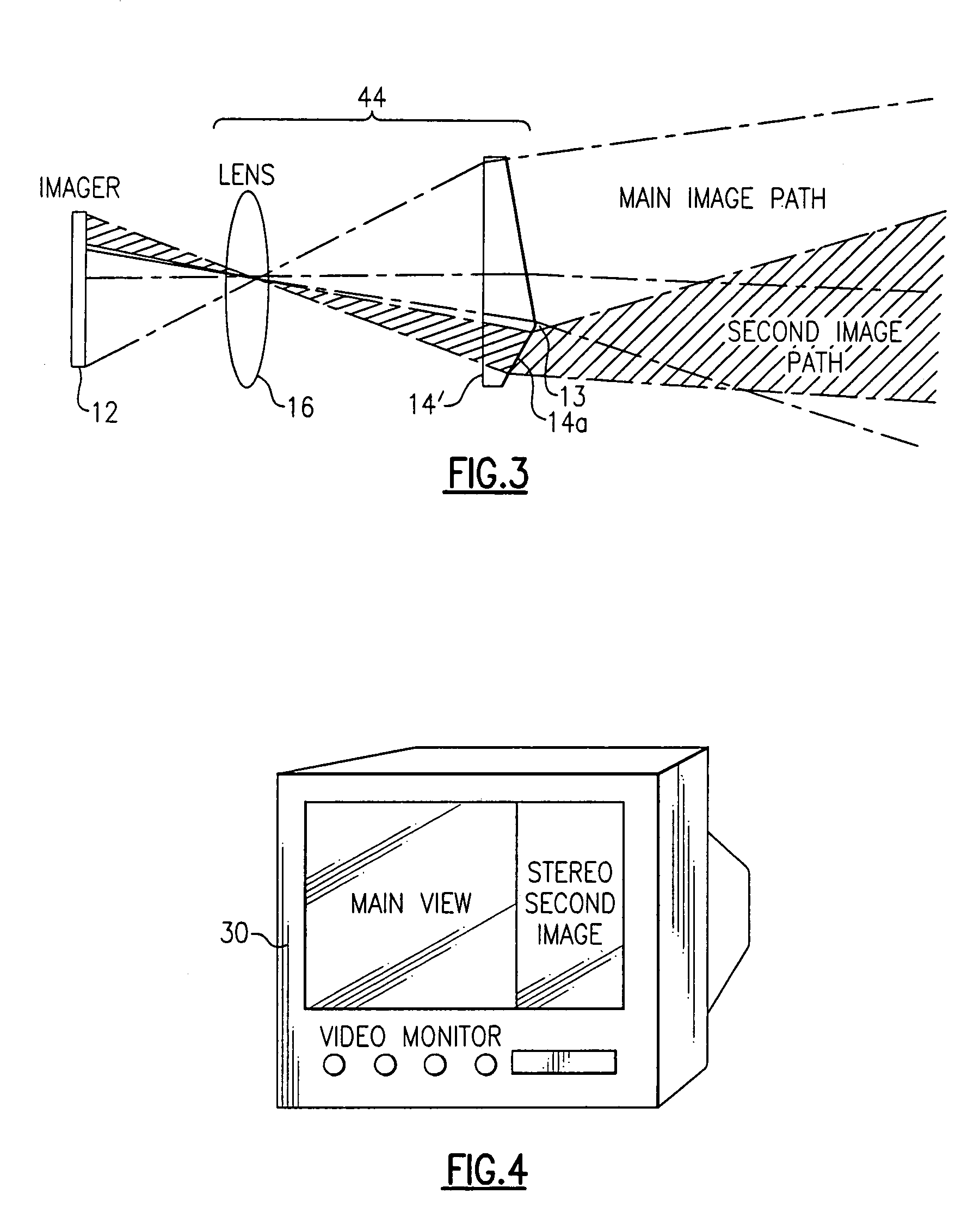

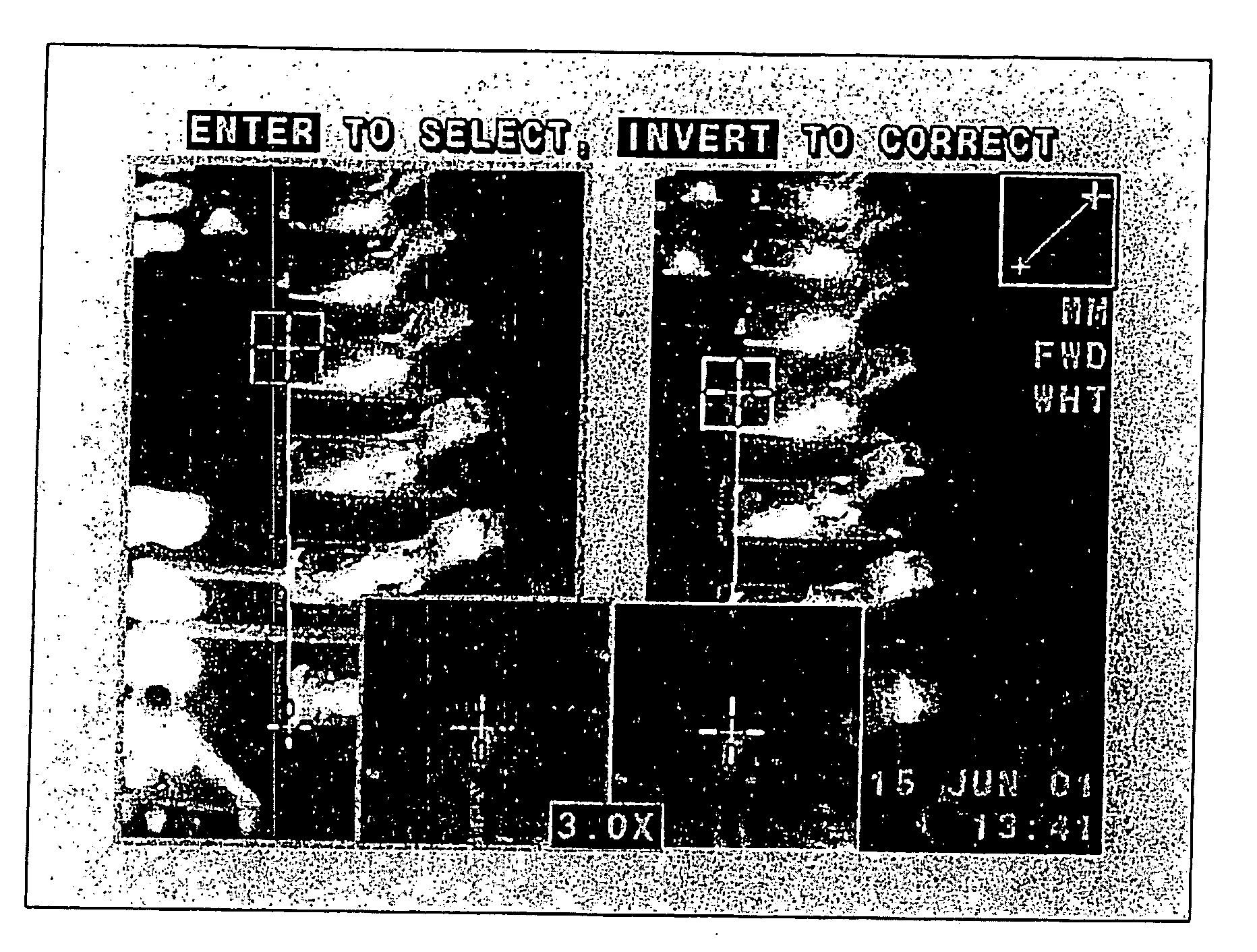

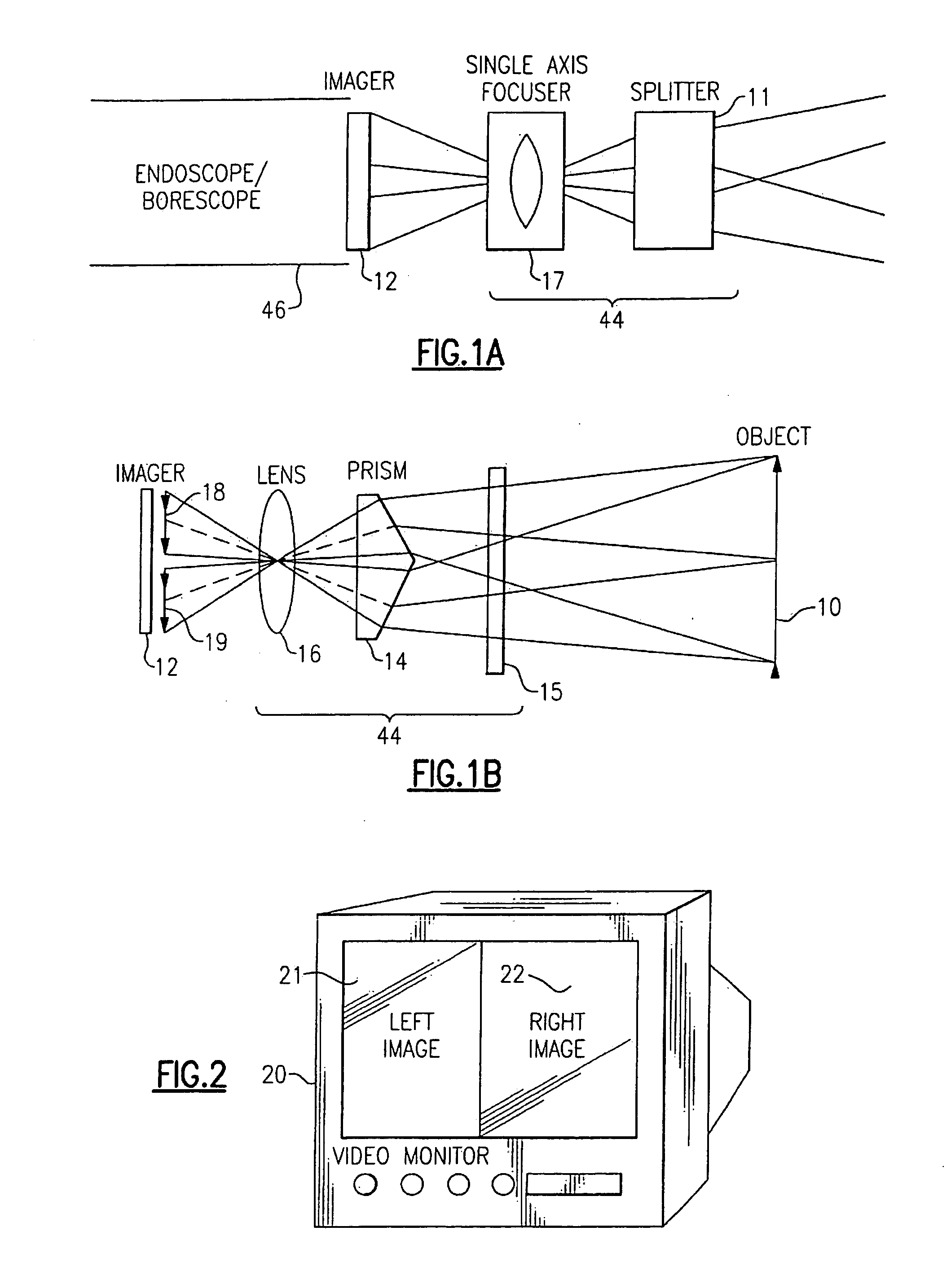

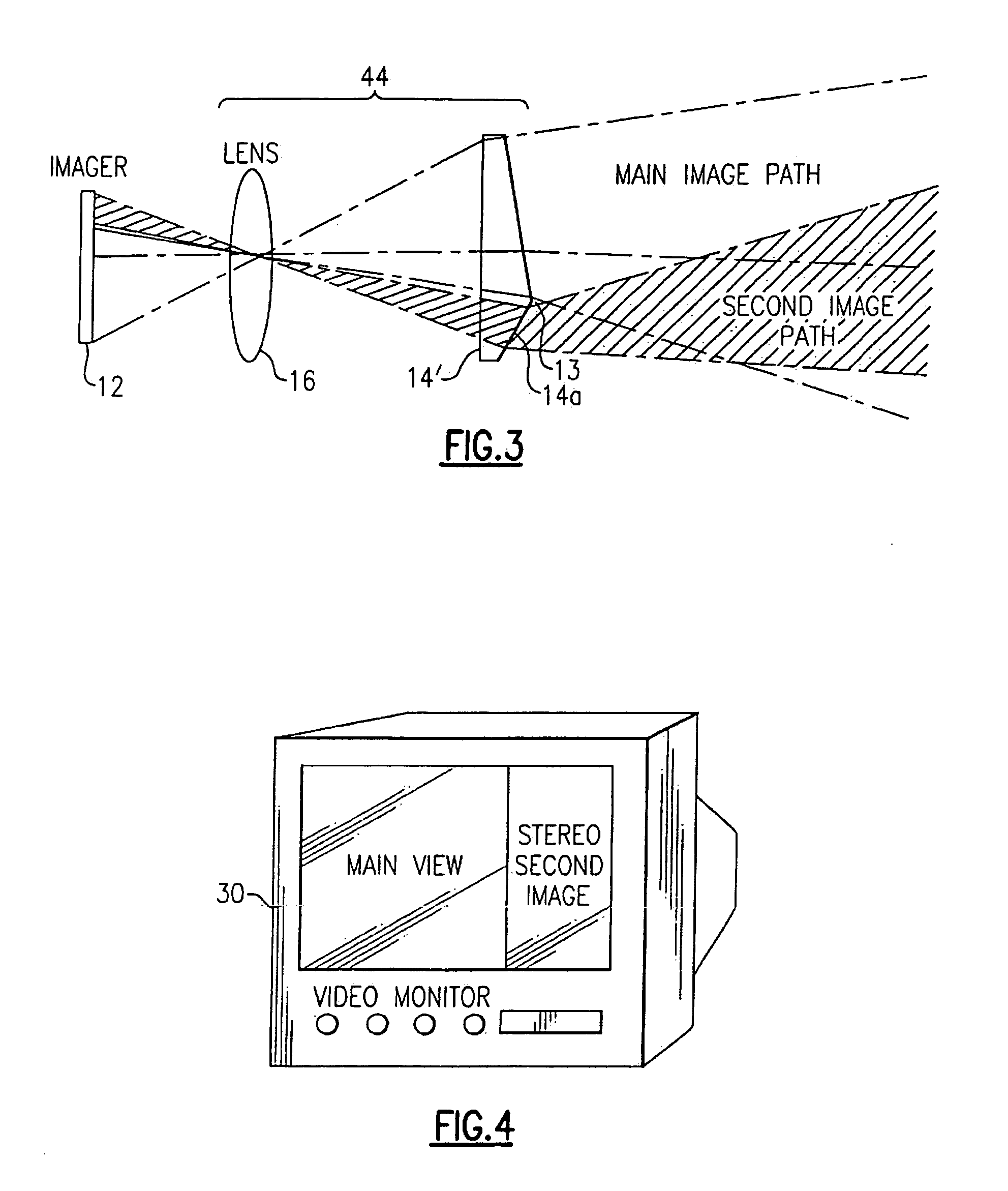

Stereo-measurement borescope with 3-D viewing

Two stereo images are created by splitting a single image into two images using a field of view dividing splitter. The two images can be displayed side by side so that they can be viewed directly using stereopticon technology, heads-up display, or other 3-D display technology, or they can be separated for individual eye viewing. The two images focus on one imager such that the right image appears on the right side of the monitor and the left image appears on the left side of the monitor. The view of the images is aimed to converge at a given object distance such that the views overlap 100% at the object distance. Measurement is done with at least one onscreen cursor.

Owner:GE INSPECTION TECH LP

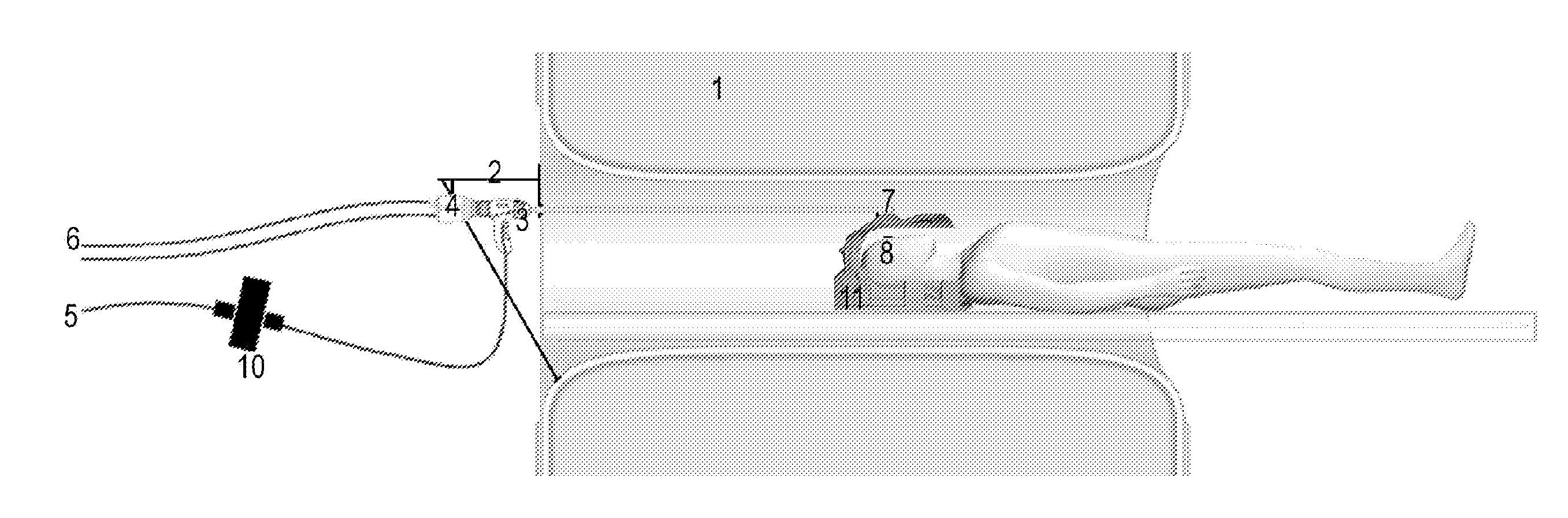

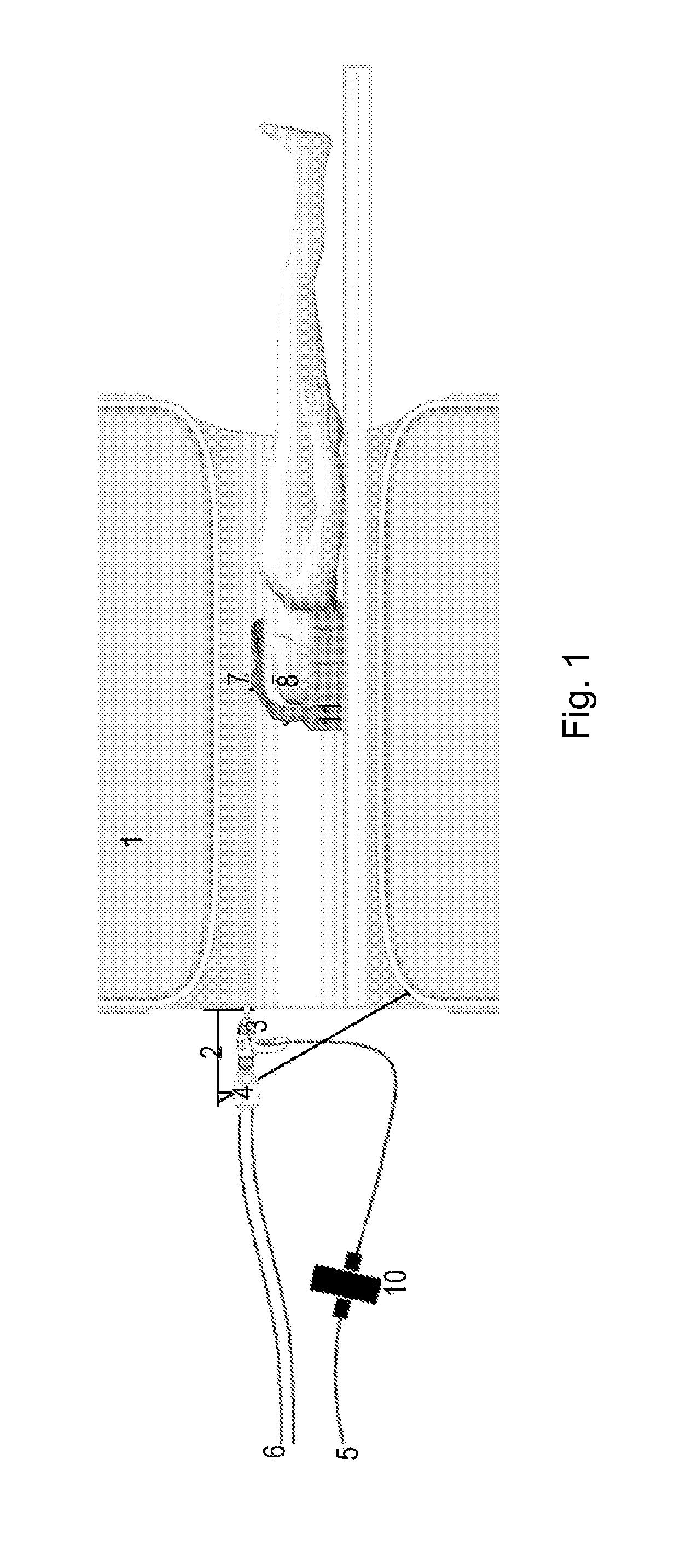

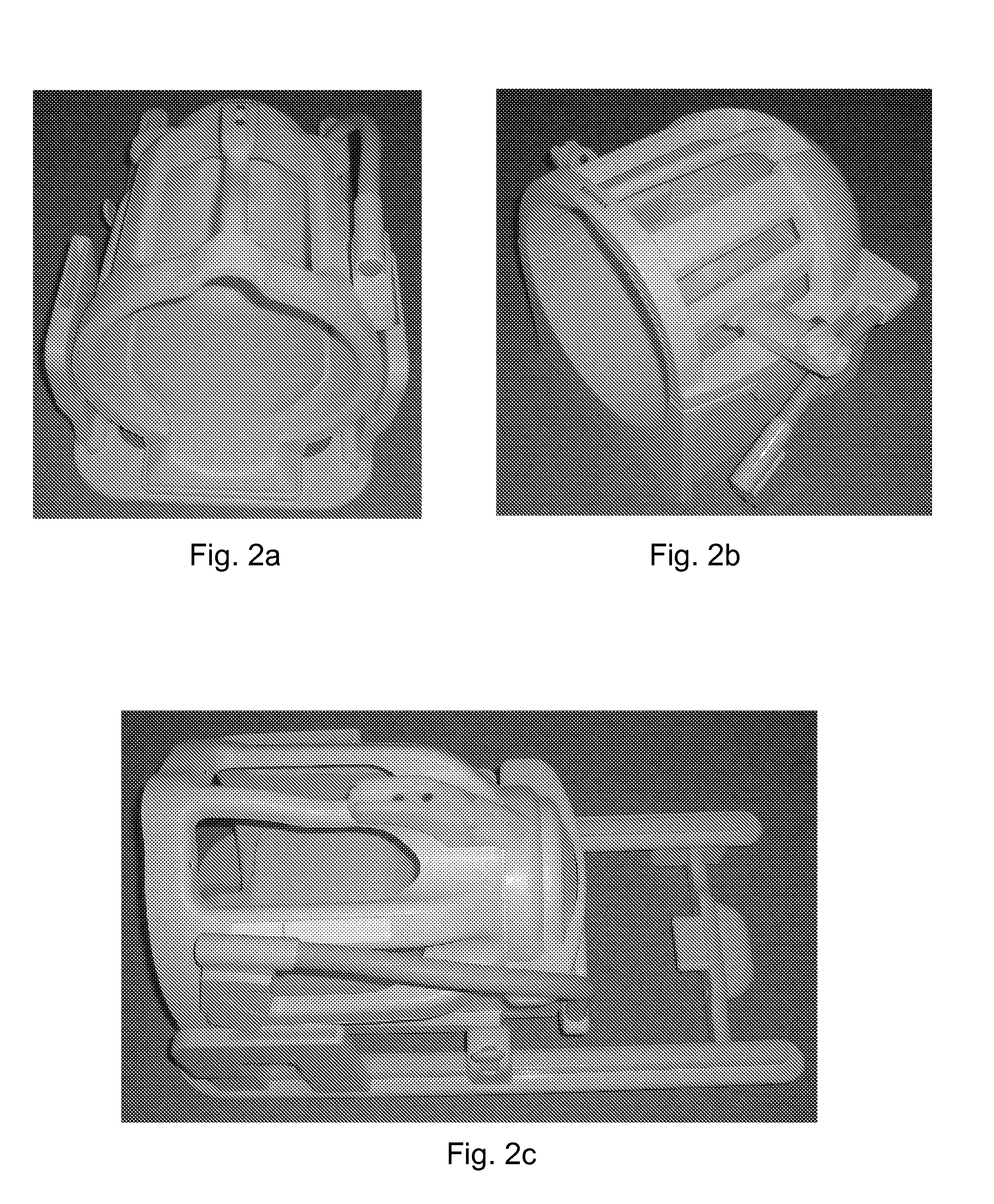

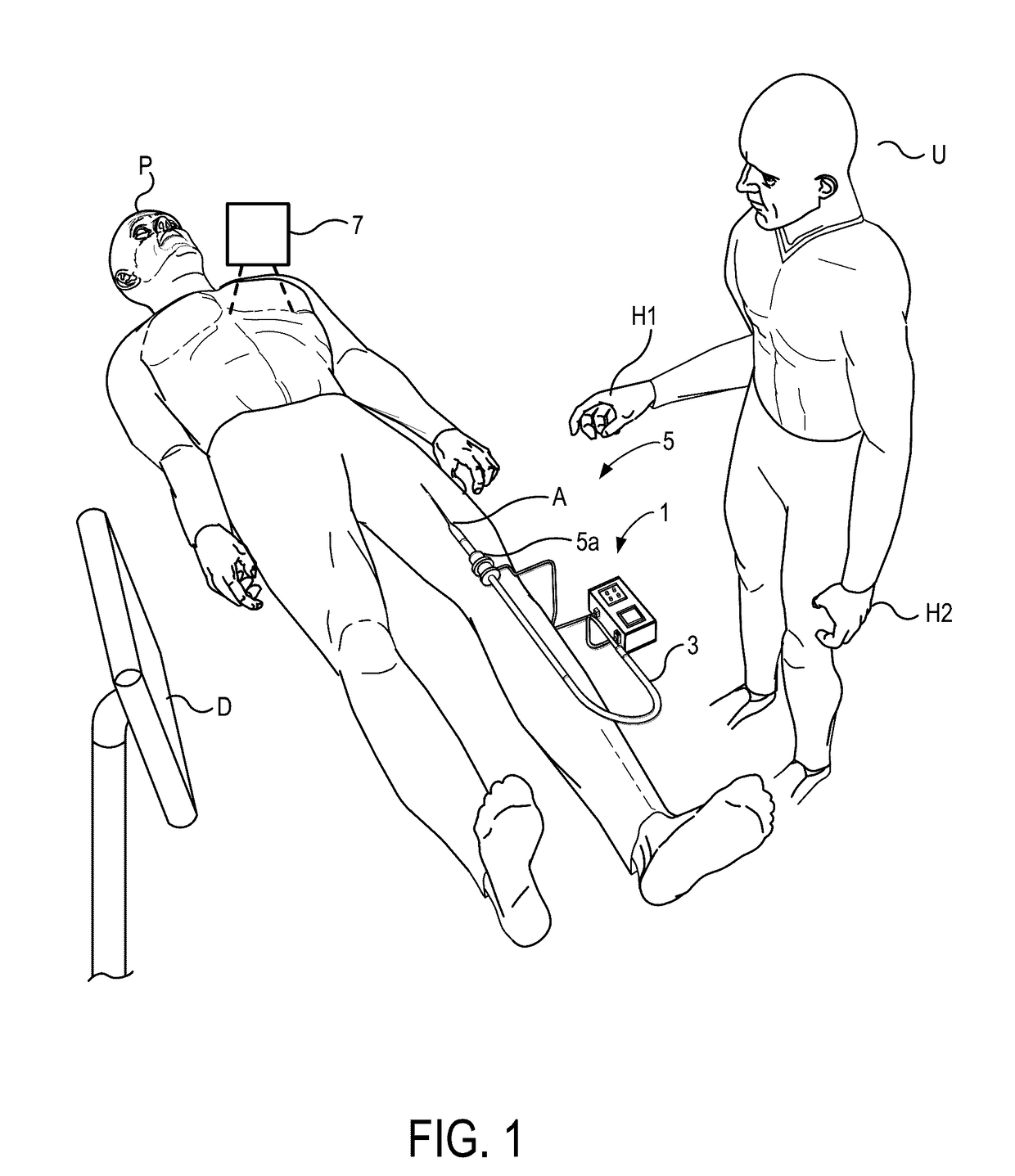

Optical motion tracking of an object

InactiveUS20130093866A1Limited resolutionIncrease heightMagnetic measurementsColor television detailsImaging processingObject motion

The present invention relates to a system and a method for monitoring / tracking the movement of an object in a location which is difficult to access, such as the movement of a patient in a clinical MRI scanner. This is achieved by an optical motion tracking system for determining the movement of an object at least partly located in a volume of difficult access and / or at least partly located in an electromagnetic field, said system comprising a borescope for imaging a pattern on the object or a surface part of the object with a camera, said pattern or surface part located adjacent to a distal end of the borescope and said camera attached to a proximal end of said borescope, and image processing means for calculating the movement of said pattern or surface part relative to the distal end of the borescope based on a plurality of frames / images captured by the camera. The invention further relates to the use of a borescope for motion tracking of an object and a marker plate suitable for use in the motion tracking system.

Owner:RIGSHOSPITALET

Single trace multi-channel low coherence interferometric sensor

Interferometers and autocorrelator based sensors are disclosed that are configured to have multiple sample arms which can be scanned and the backscattered low coherence source light from a sample resolved in a single sweep of one or more variable delays of the sensor. Borescopes and catheters capable of scanning multiple sections or areas of materials and tissues using these sensors are described.

Owner:MEDEIKON

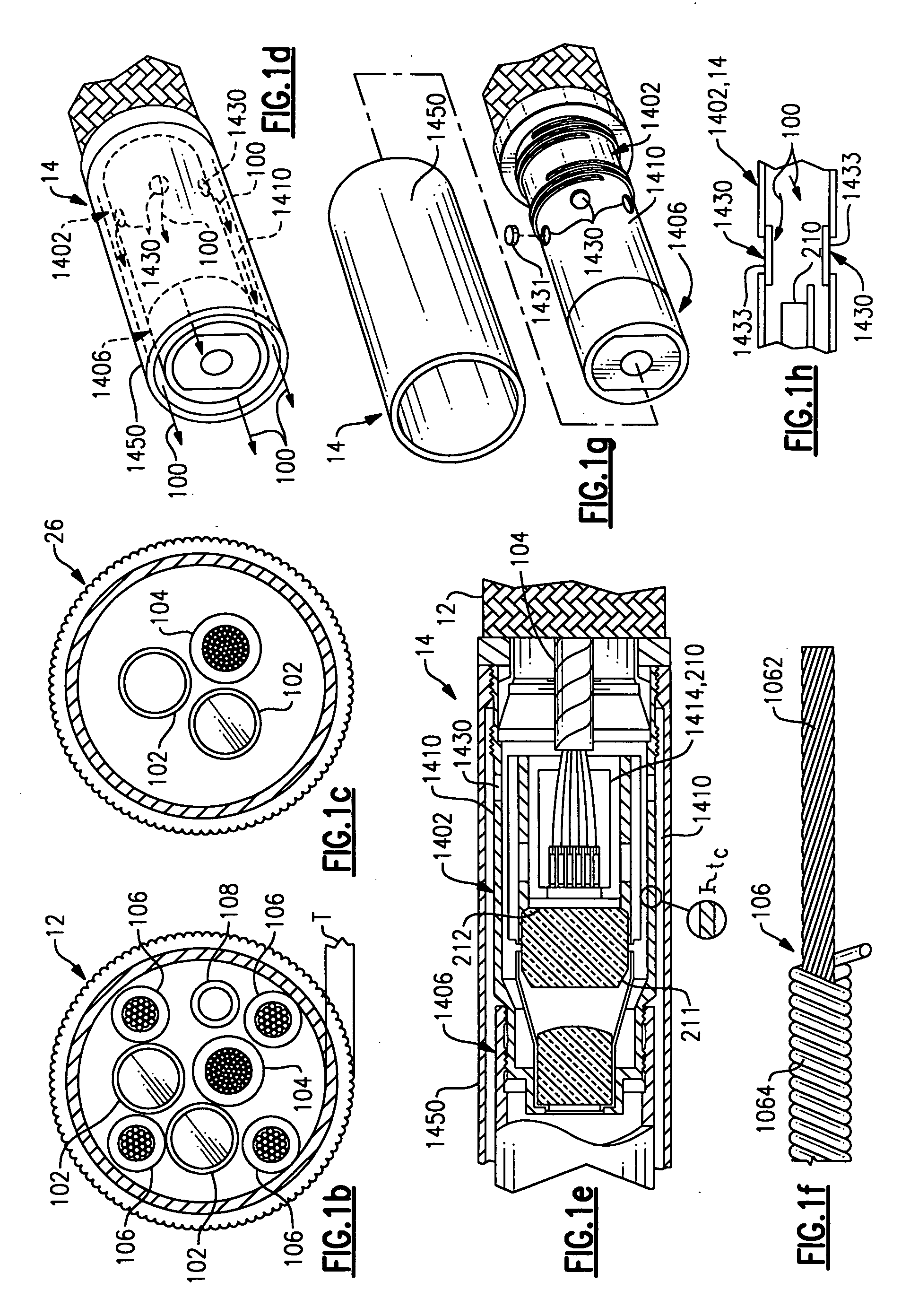

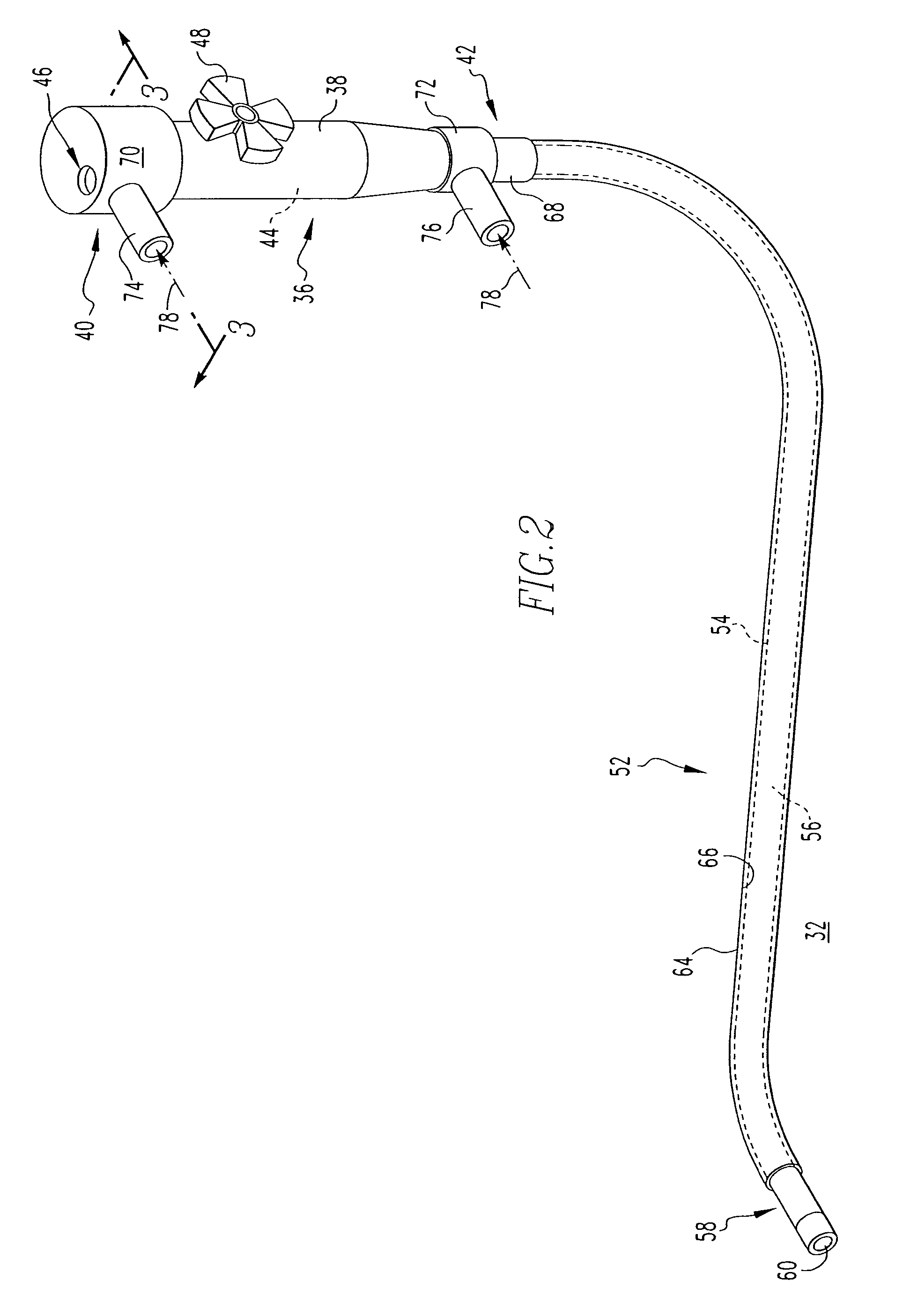

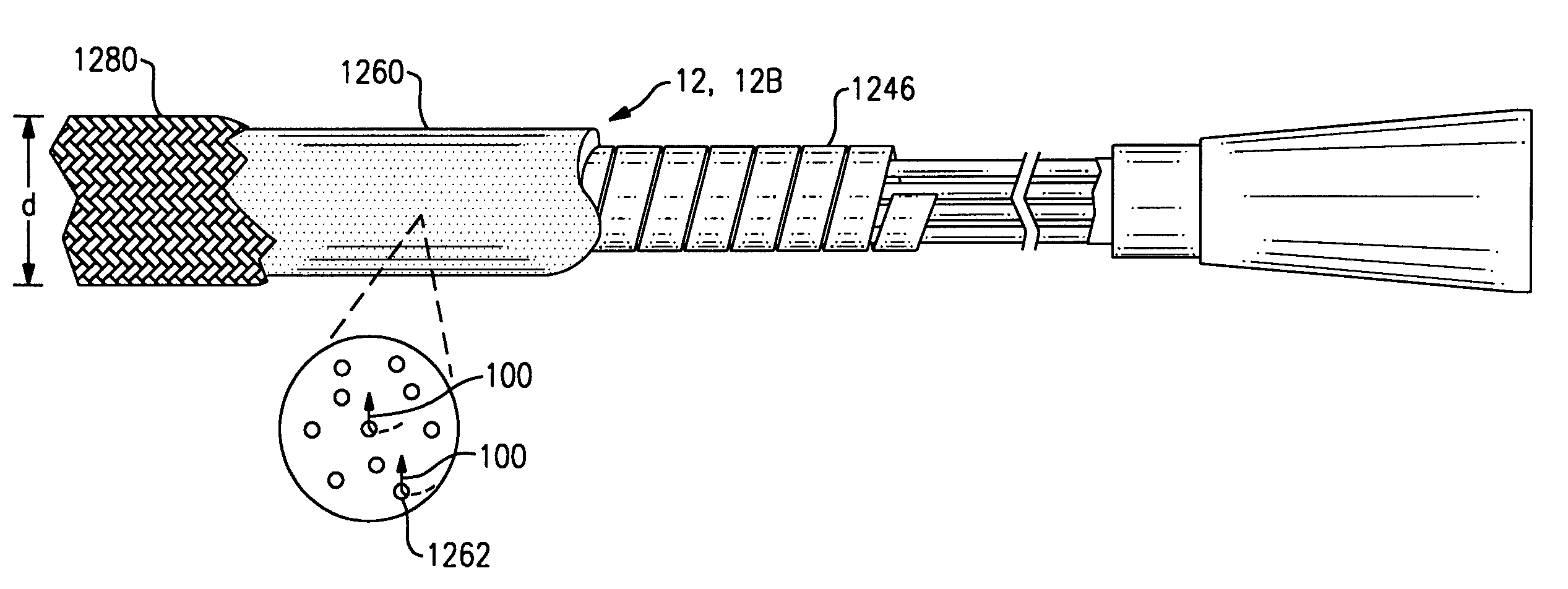

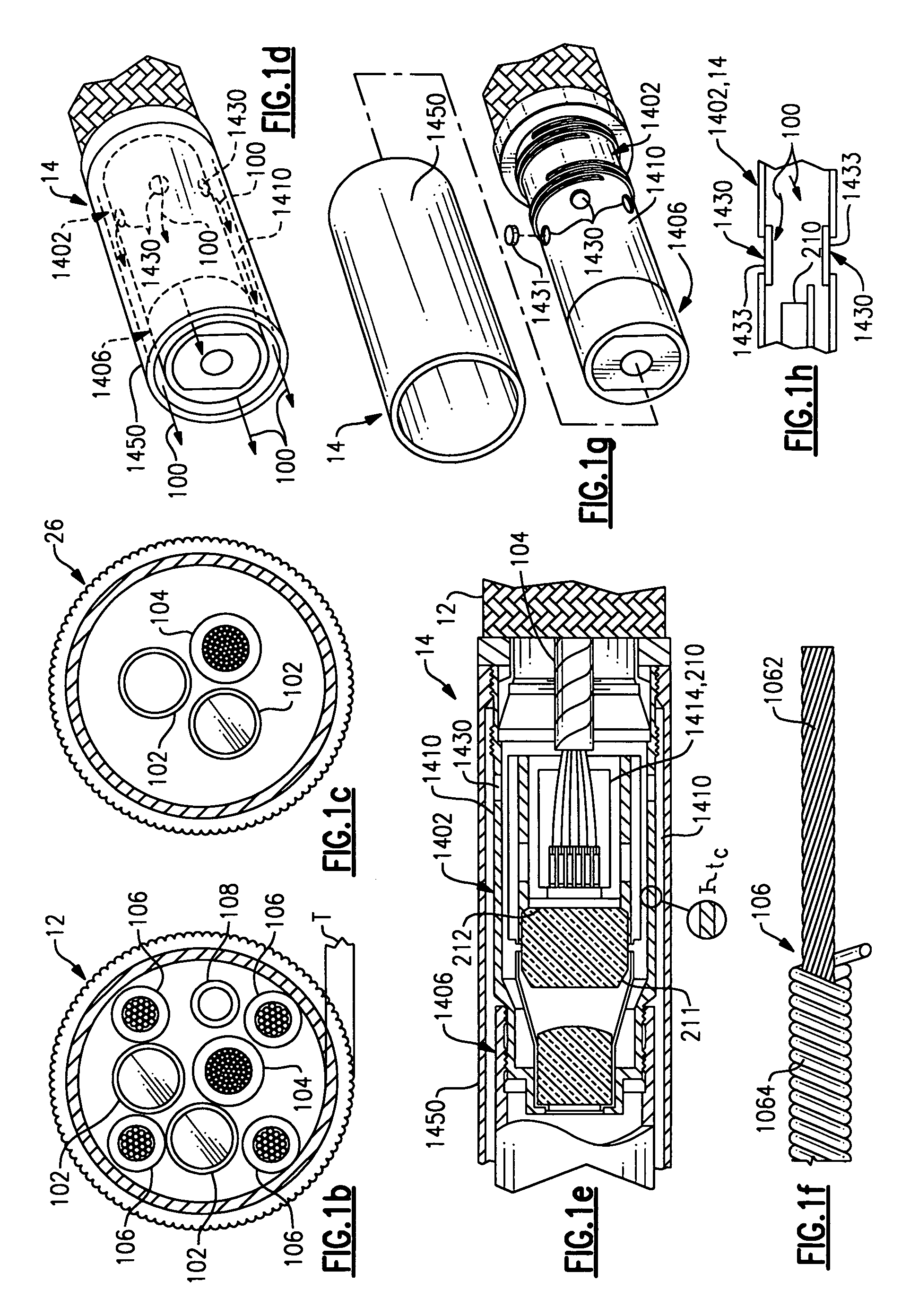

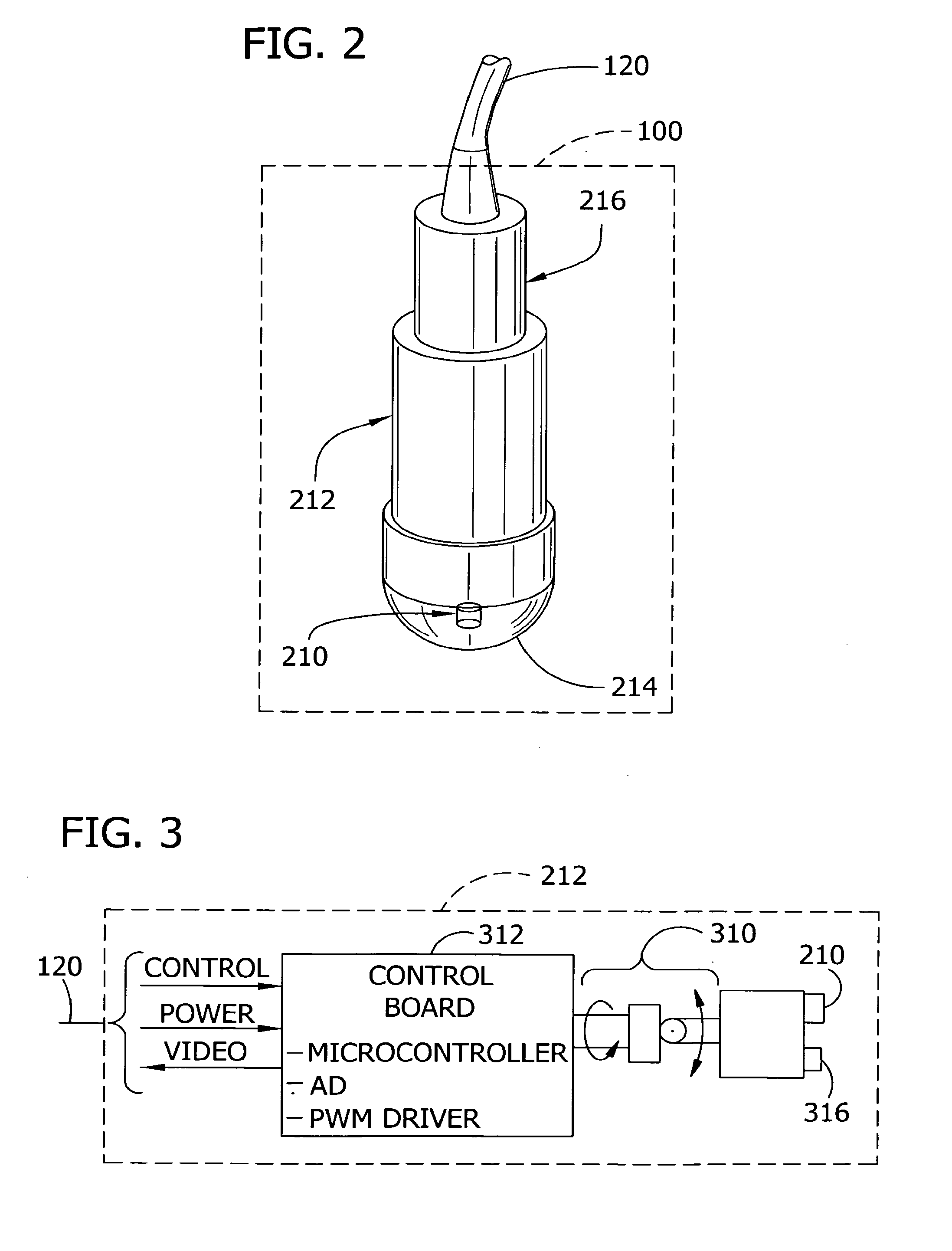

Borescope comprising fluid supply system

InactiveUS20050281520A1Avoid enteringMinimize temperature lossSurgeryEndoscopesBorescopeBiomedical engineering

A borescope device having an insertion tube, a camera head assembly, and a fluid supply system. The camera assembly includes through holes allowing fluid escape. The fluid supply system is controllable to force fluid through the through holes. The fluid supply system may be actuated to cool the camera head assembly.

Owner:GE INSPECTION TECH LP

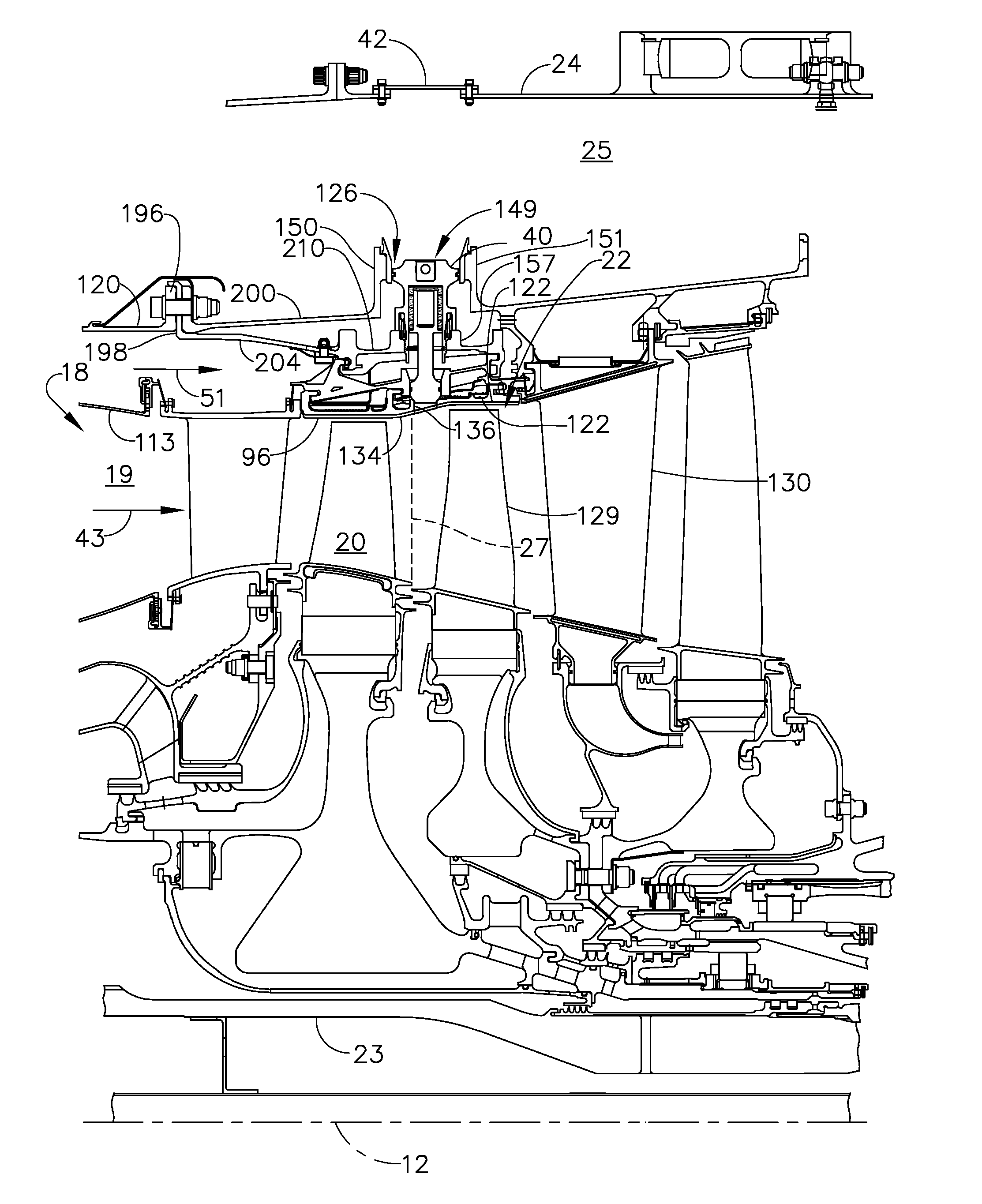

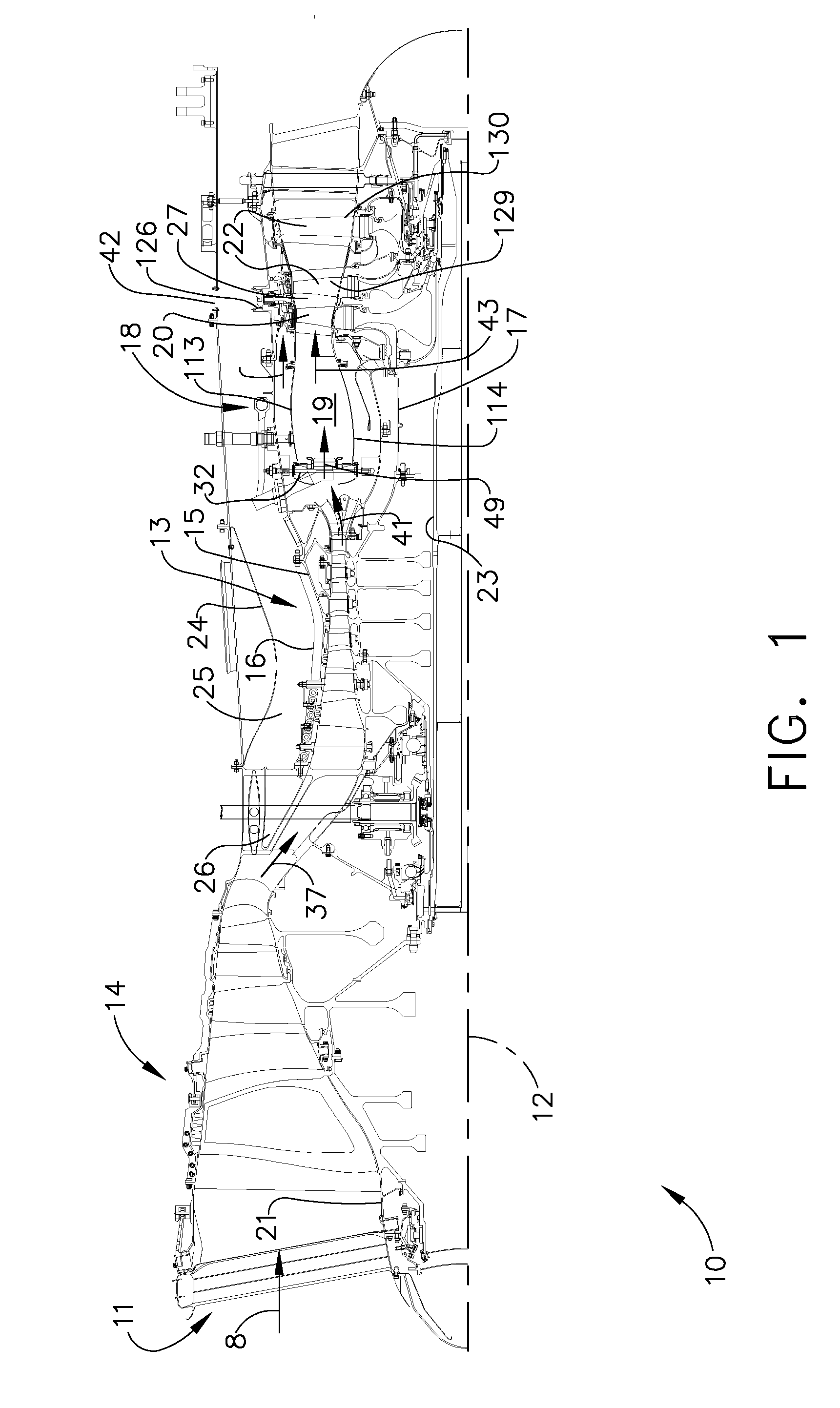

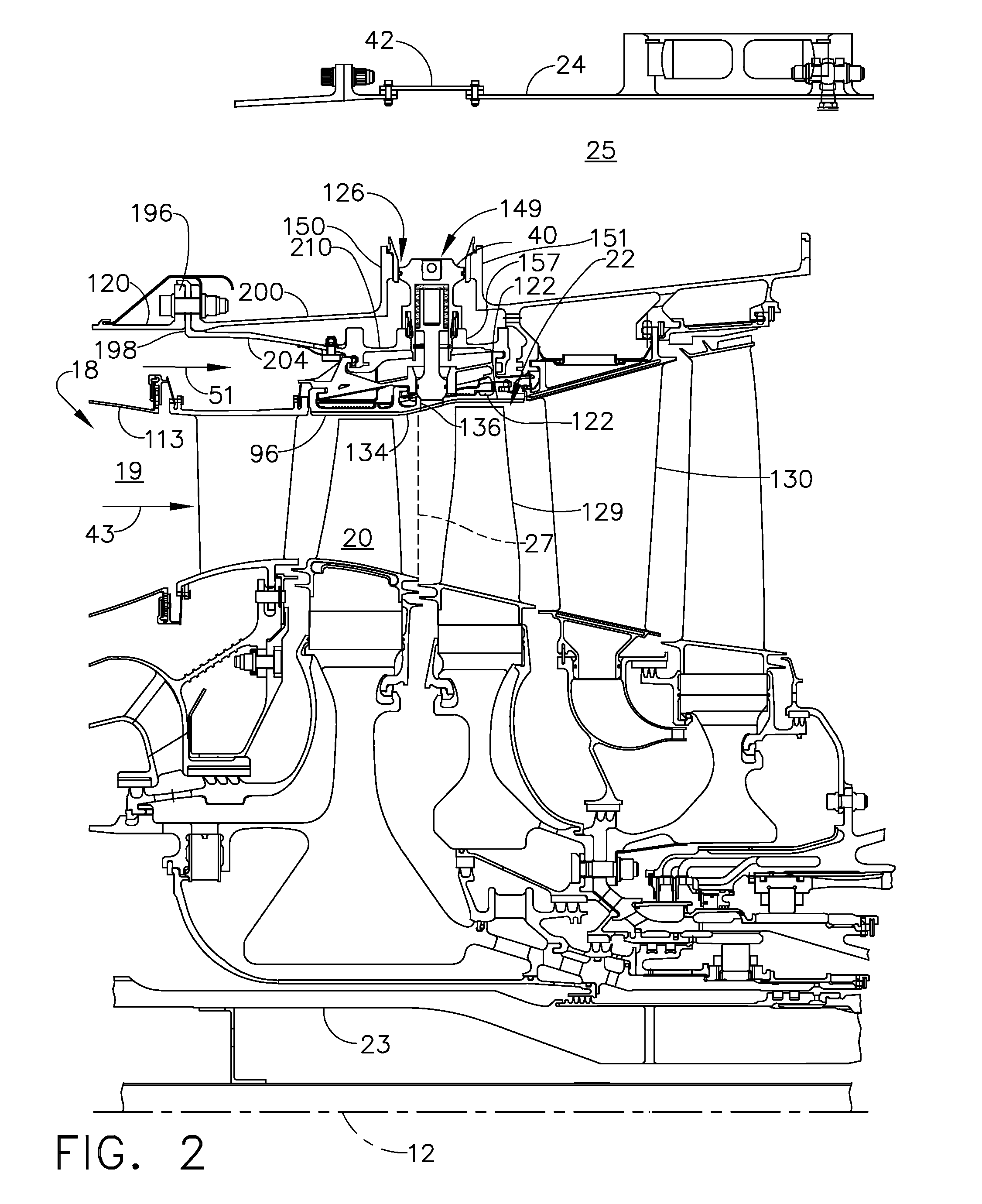

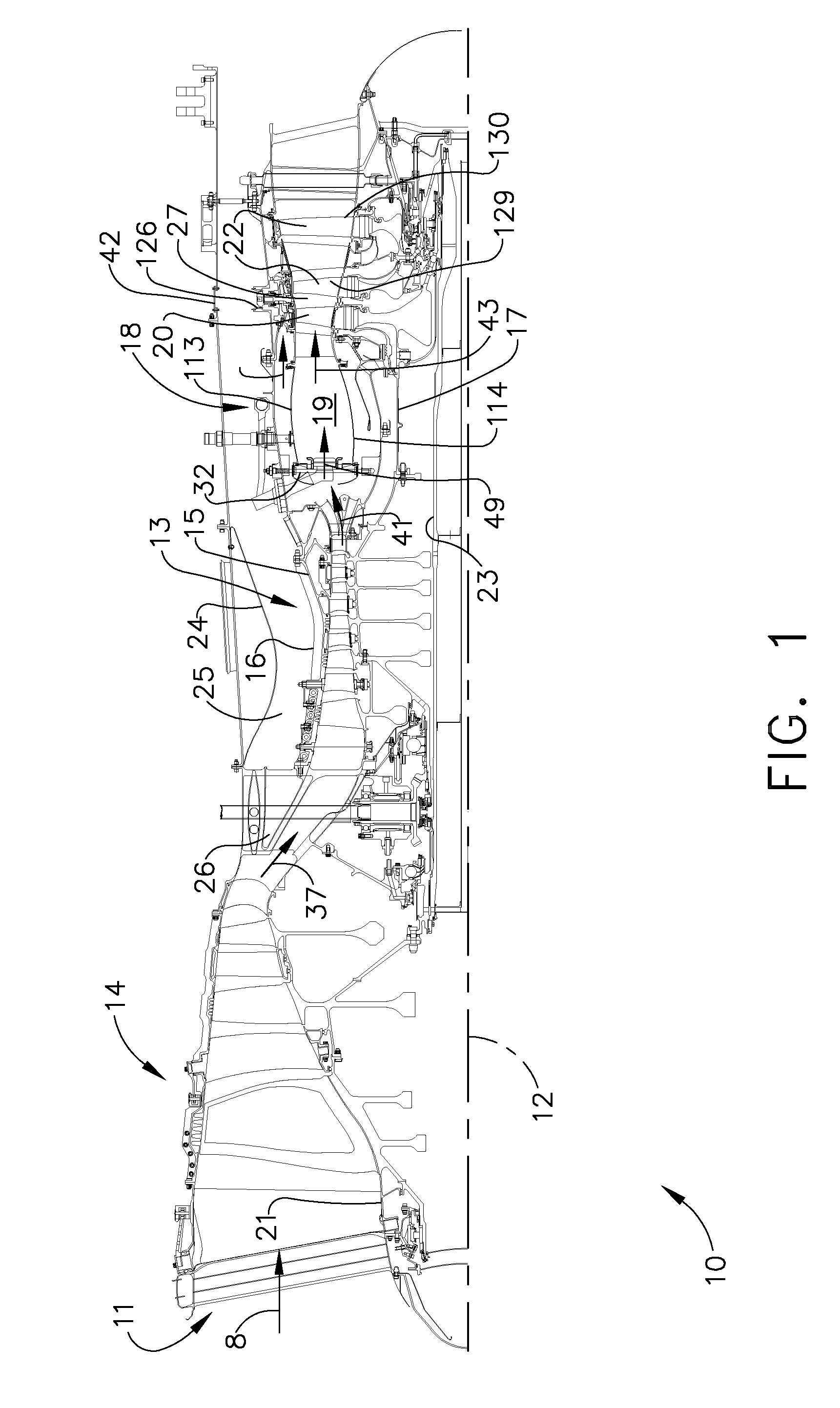

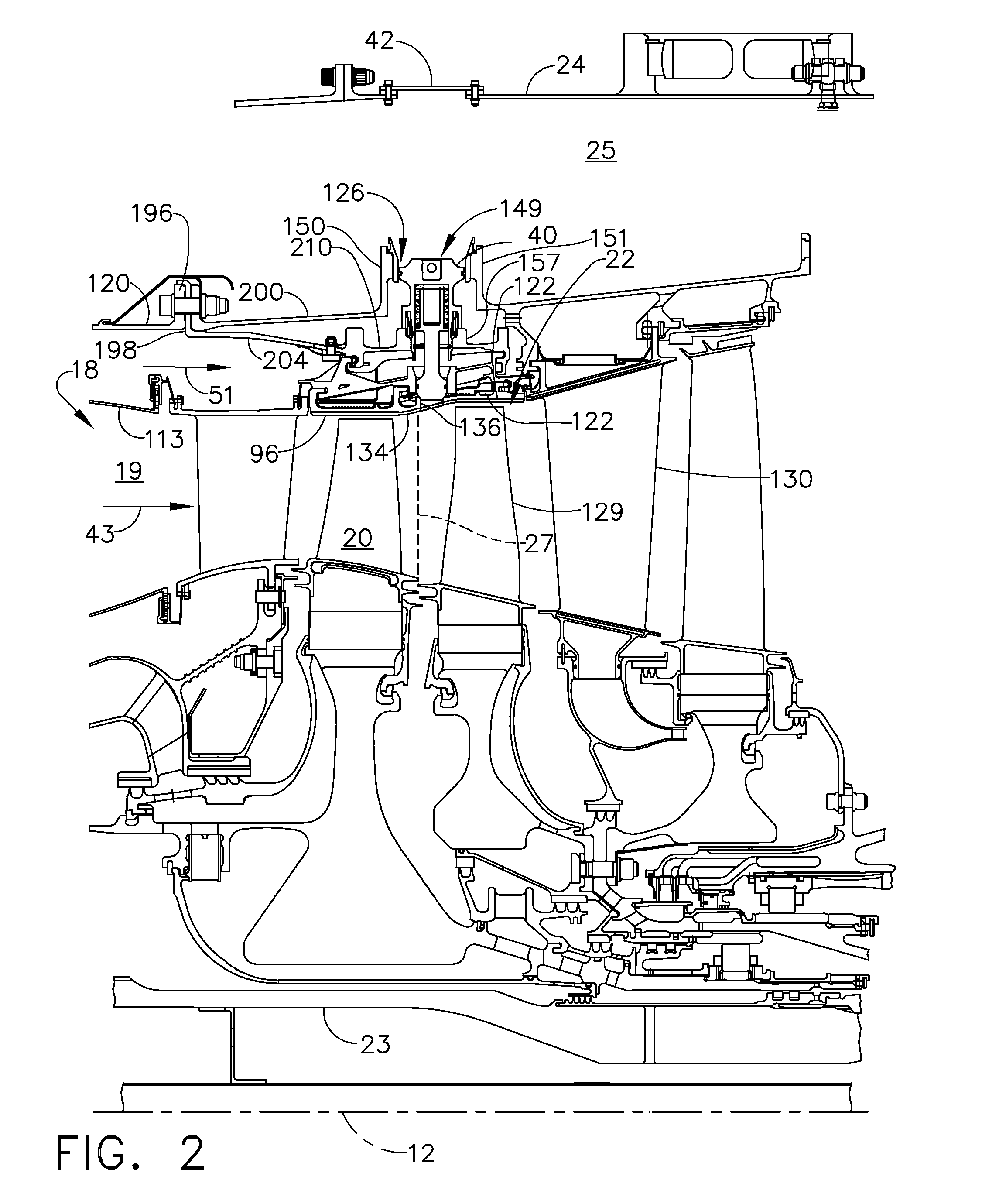

Repair of turbines on wing

The present invention provides an apparatus for repairing turbine blades of a gas turbine engine by a laser welding operation. The method uses a miniaturized laser and related apparatus. The miniaturized laser is fed through a borescope access hole to a desired location such as a high pressure turbine blade. The laser is then powered and manipulated so as to perform the desired welding operation. Filler material may also be provided in situ to accomplish the welding procedure. The method realizes a significant cost savings to the vehicle operator in that repairs can be accomplished without the need to remove the engine or disassemble the engine.

Owner:HONEYWELL INT INC

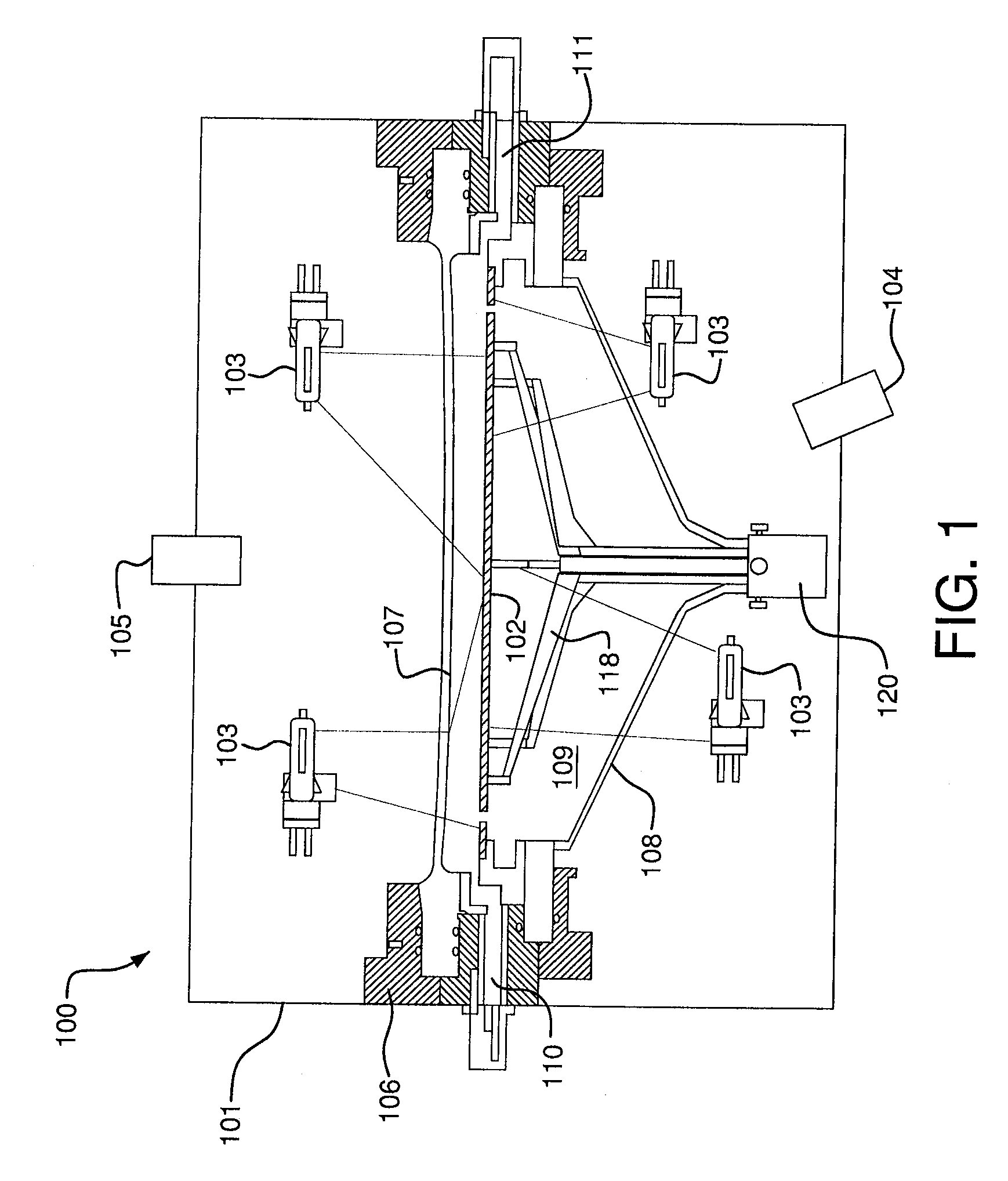

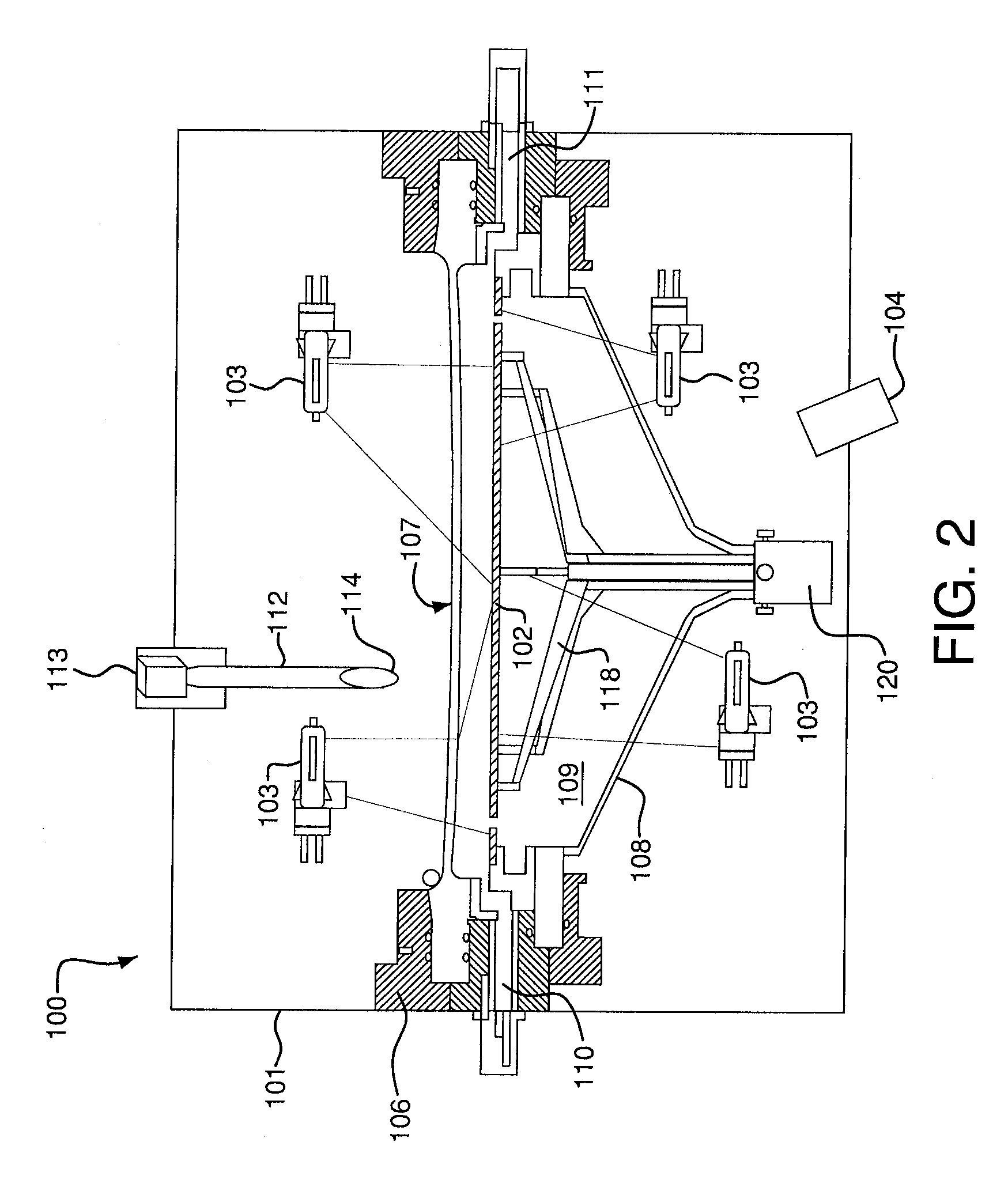

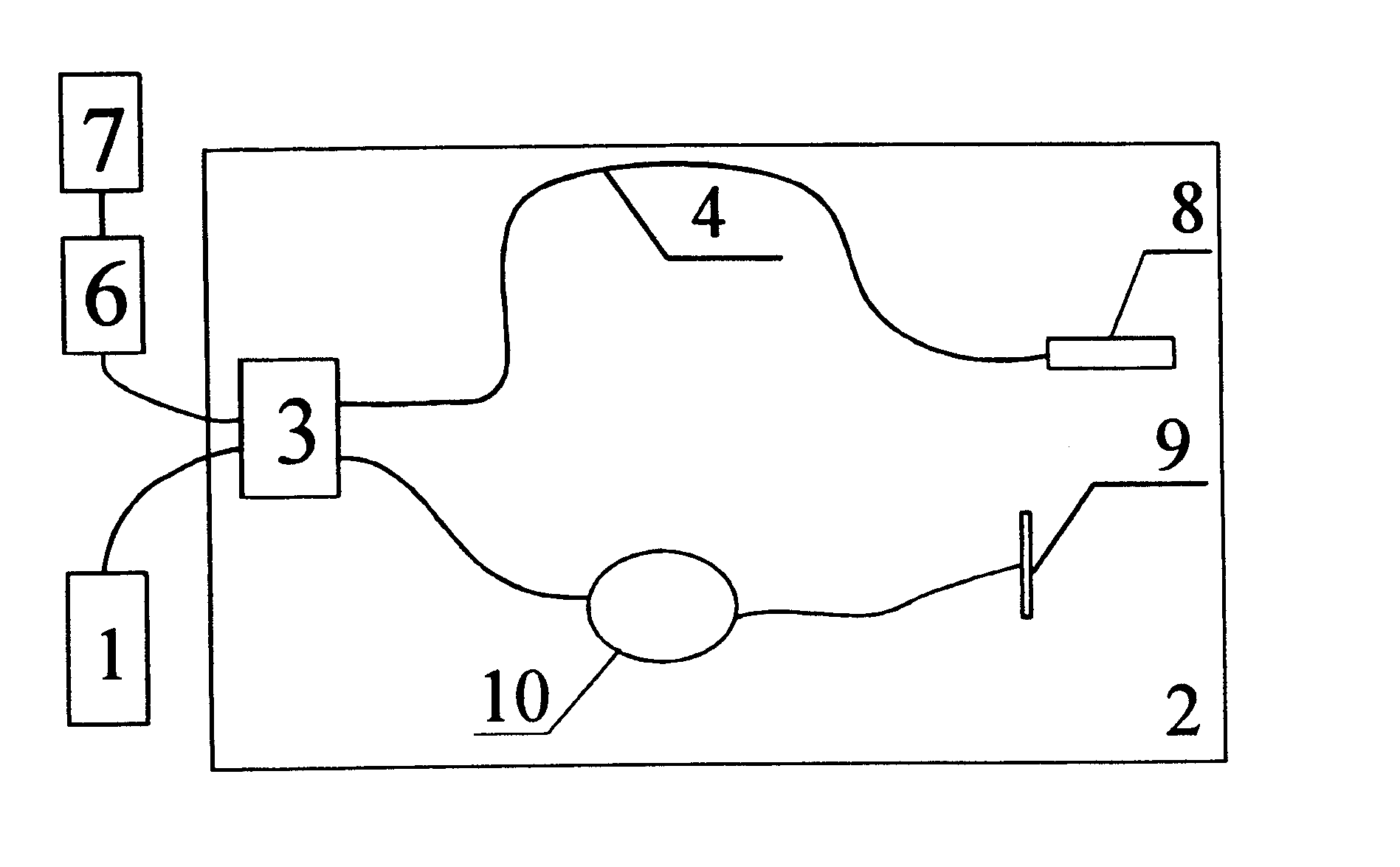

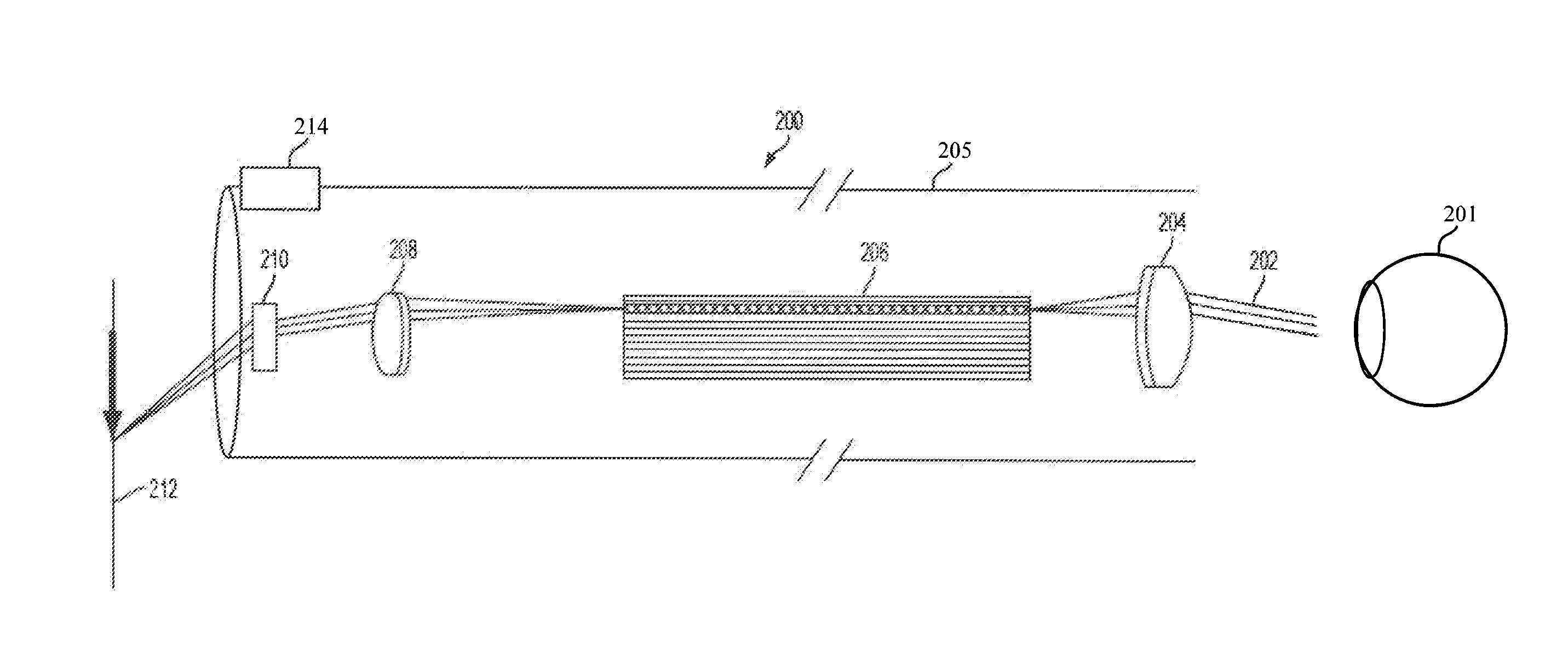

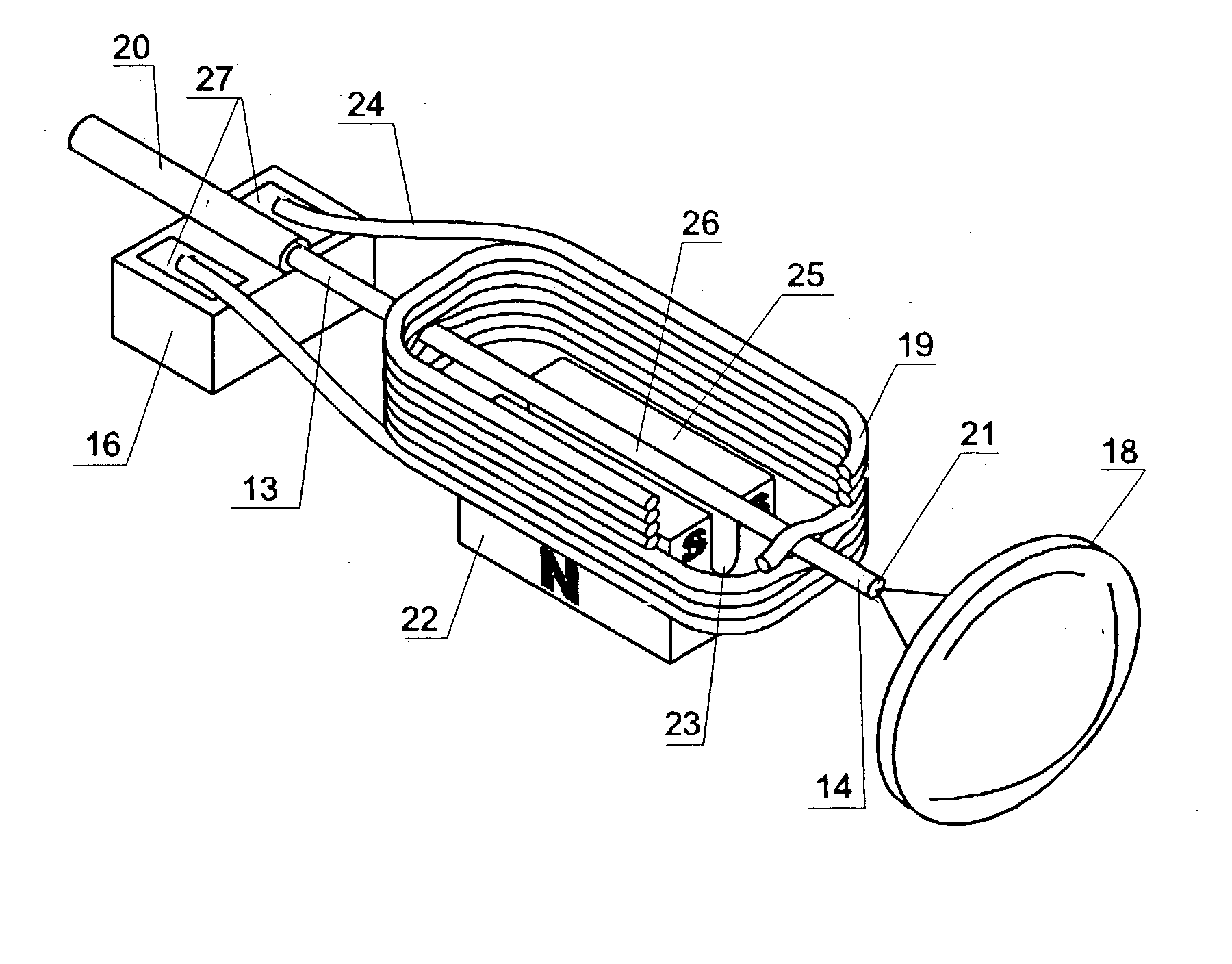

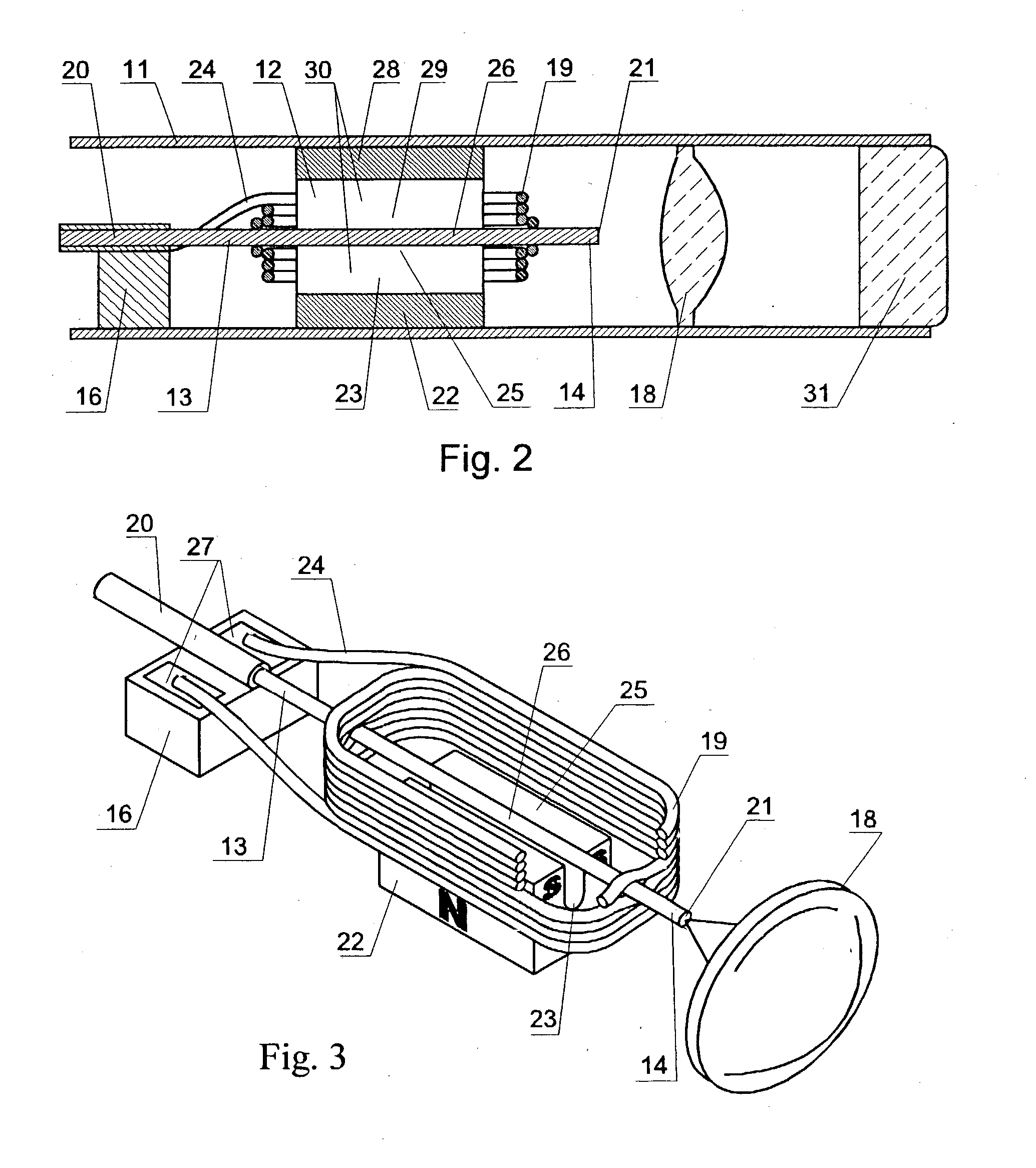

Optical coherence tomography apparatus, optical fiber lateral scanner and method for studying biological tissues in vivo

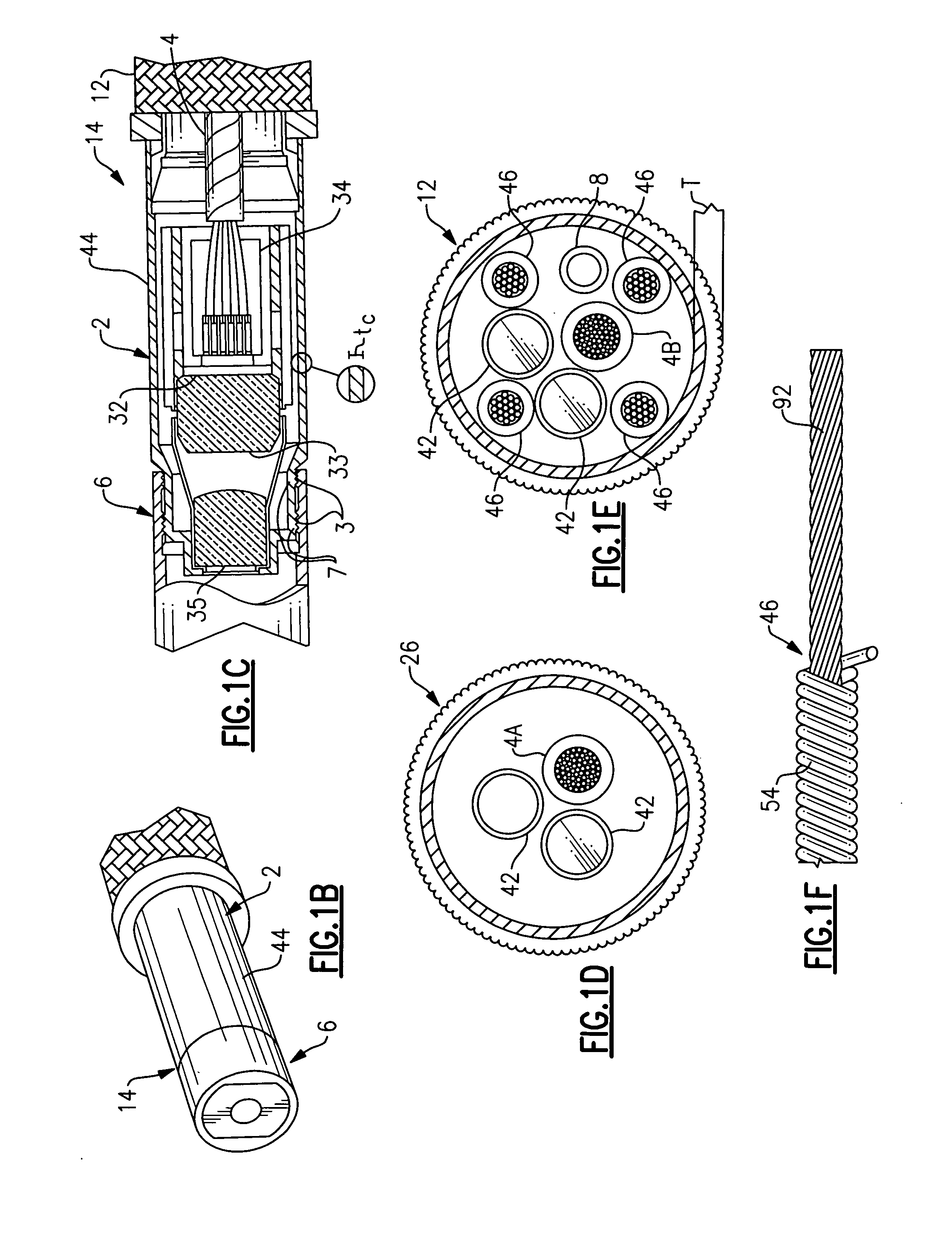

InactiveUS6608684B1Data augmentationIncrease spaceInterferometersSurgeryElectrical conductorBasal membrane

The present invention relates to the analysis of the internal structures of objects using optical means. According to the invention there were designed an apparatus suited for optical coherence tomography (OCT), an optical fiber lateral scanner (15), which is a part of said apparatus and is incorporated into an optical fiber probe (8), and a method for studying biological tissue in vivo, which allows for making a diagnostics of the biological tissue under, study on basis of the state of the basal membrane (46). The moving part of lateral scanner (15) of sampling arm (4) of interferometer (2) is arranged comprising a current conductor (19), which envelopes a magnetic system (17) in the area of one of its poles (25) and an optical fiber (13), which is rigidly fastened to current conductor (19), whereas optical fiber (13) serves as a flexible cantilever, allowing to miniaturize the optical fiber probe (8). Constructing magnetic system (17) as two permanent magnets (22, 28) which are aligned at their analogous poles (25, 29), and placing optical fiber (13) in a throughhole (30), the throughhole (30) being formed by the facing grooves made in said analogous poles (25, 29) of permanent magnets (22, 28), ensure optimization of the design of optical fiber probe (8), the body (11) of said optical fiber probe (8) having limited dimensions. Optical fiber probe (8) is placed at the distal end of an instrumental channel of an endoscope or borescope. Studying of biological tissue in vivo with the aid of the developed apparatus allows for non-invasive diagnostics of biological tissue on basis of the state of basal membrane (46).

Owner:IMALUX CORP

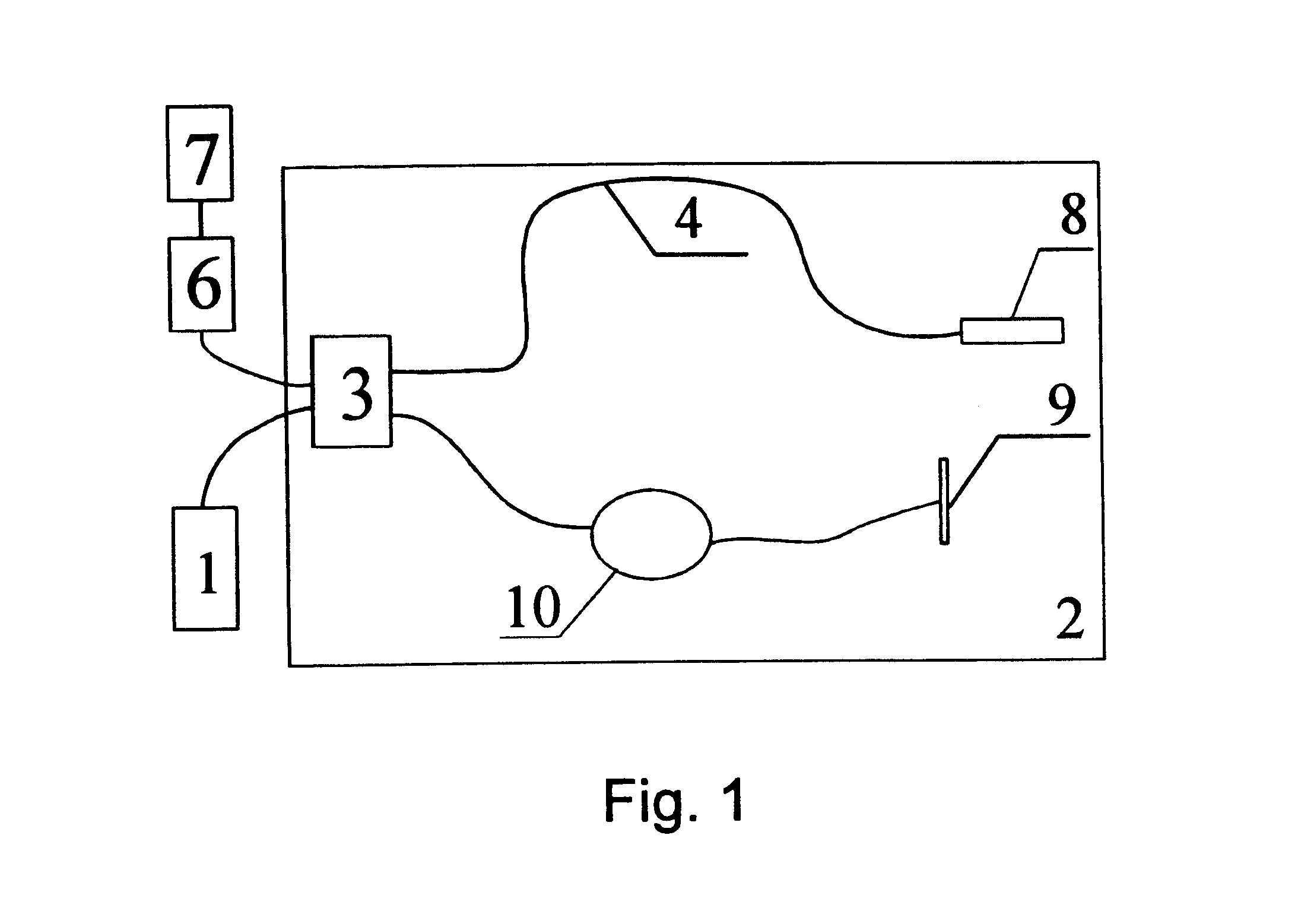

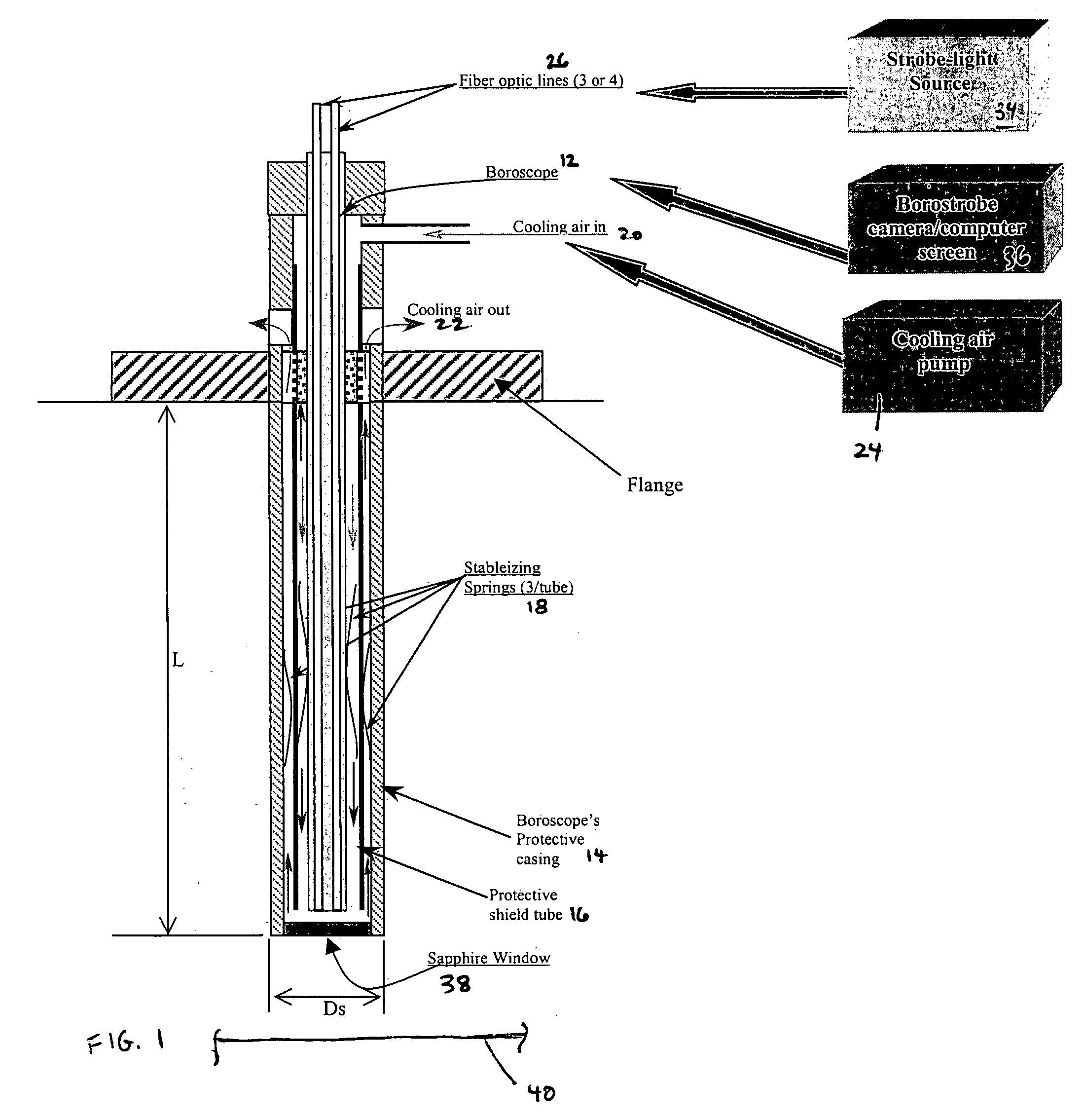

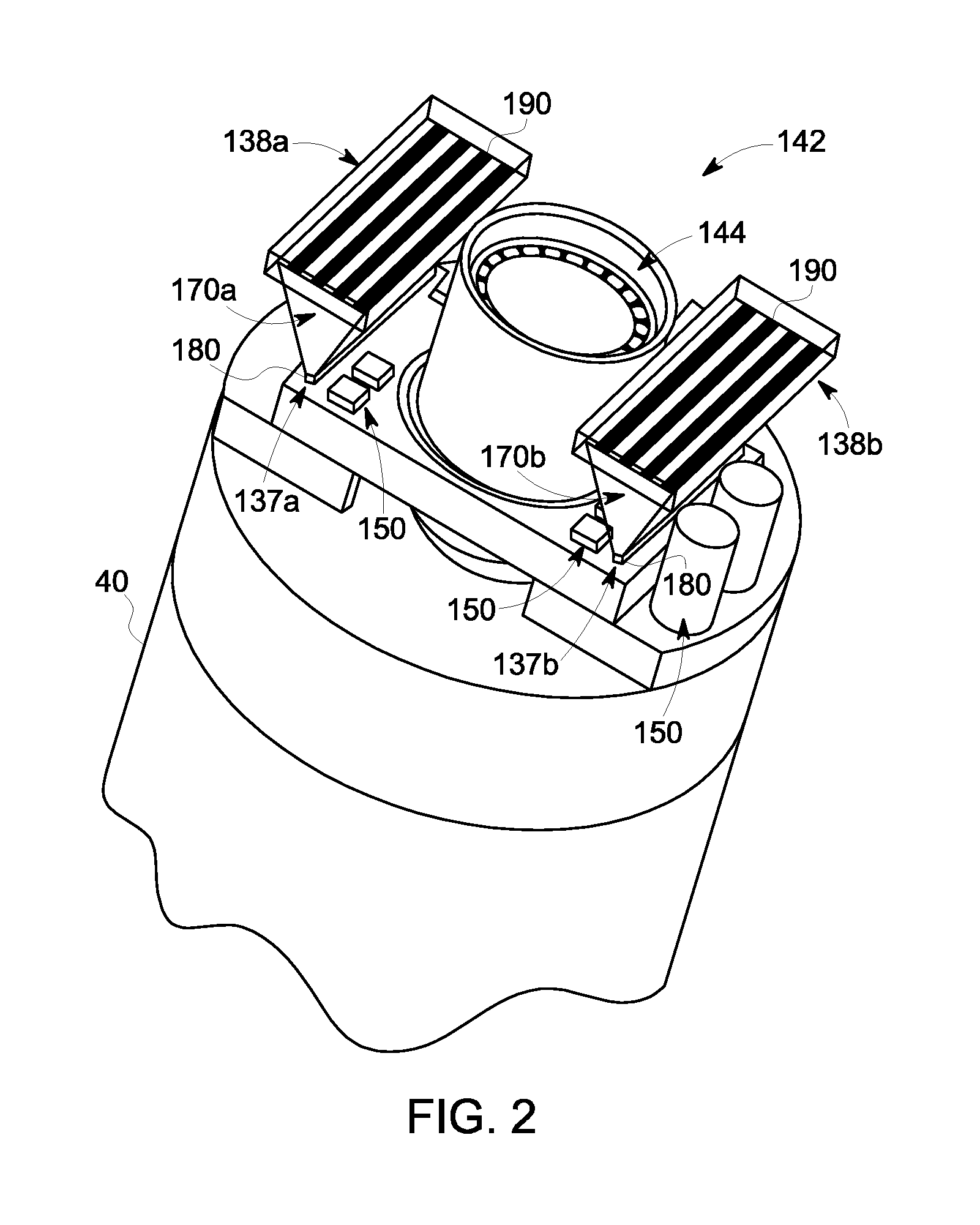

Borescope assembly for detecting a condition of a rotating part

A borescope assembly is suitable for detecting a condition of a rotating part. The assembly includes a borescope disposed in a borescope housing and including structure that relays an image to an image viewer. A plurality of fiber optic lines are disposed in the borescope housing, and a strobe light source is coupled with the fiber optic lines. An image processor is coupled with the image viewer. With this structure, the condition of a rotating part can be detected without stopping the part.

Owner:GENERAL ELECTRIC CO

Stereo-measurement borescope with 3-D viewing

Two stereo images are created by splitting a single image into two images using a field of view dividing splitter. The two images can be displayed side by side so that they can be viewed directly using stereopticon technology, heads-up display, or other 3-D display technology, or they can be separated for individual eye viewing. The two images focus on one imager such that the right image appears on the right side of the monitor and the left image appears on the left side of the monitor. The view of the images is aimed to converge at a given object distance such that the views overlap 100% at the object distance. Measurement is done with at least one onscreen cursor.

Owner:GE INSPECTION TECH LP

Variable Power Endoscope Based On Liquid Lens Technology

An endoscope realized as either a borescope or a fiberscope including one or more fluid filled lenses is described. In an embodiment, the optical power of the fluid filled lenses may be adjusted to adjust the focal length associated with the endoscope. Thus, variable working distances are allowable while maintaining focus on an object in front of the endoscope. The endoscope may include a distance sensor, which is used to determine a distance between the endoscope and a sample. A processor may compare the measured distance to the current optical power of the one or more sealed fluid filled lenses. The processor may transmit signals to one or more actuators coupled to one or more sealed fluid filed lenses to change the optical power of the one or more sealed fluid filled lenses based on the comparison.

Owner:ADLENS BEACON INC

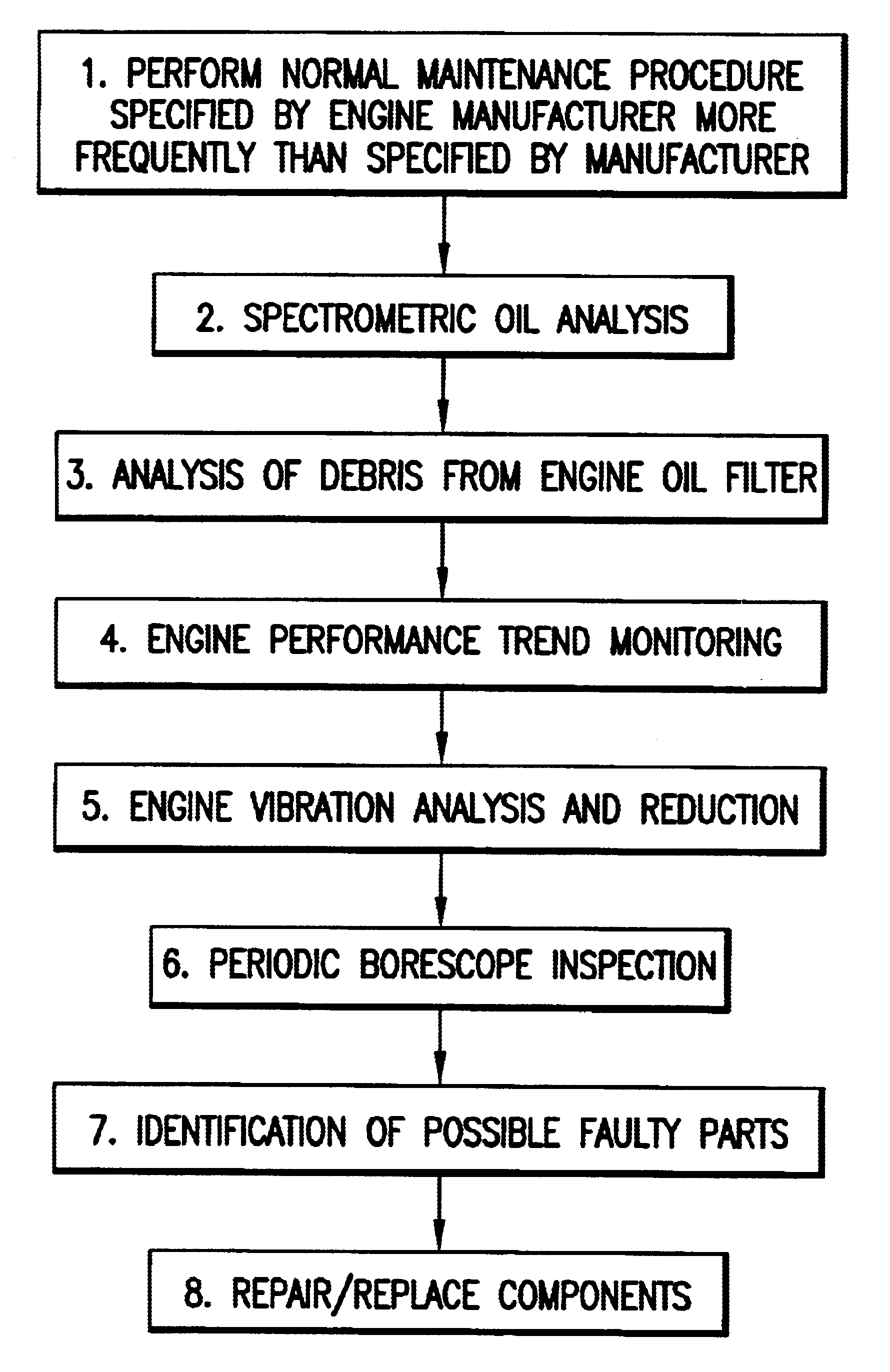

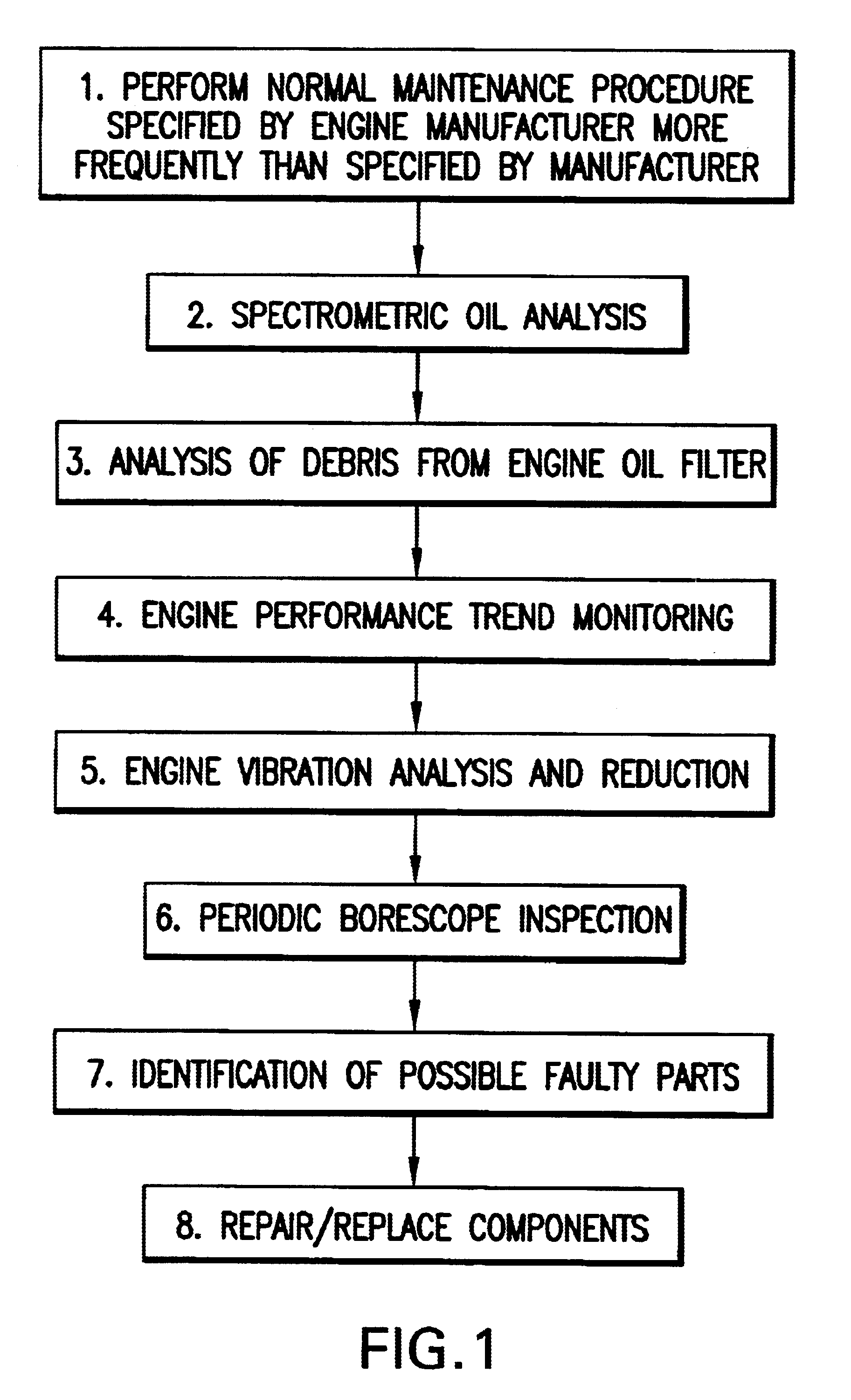

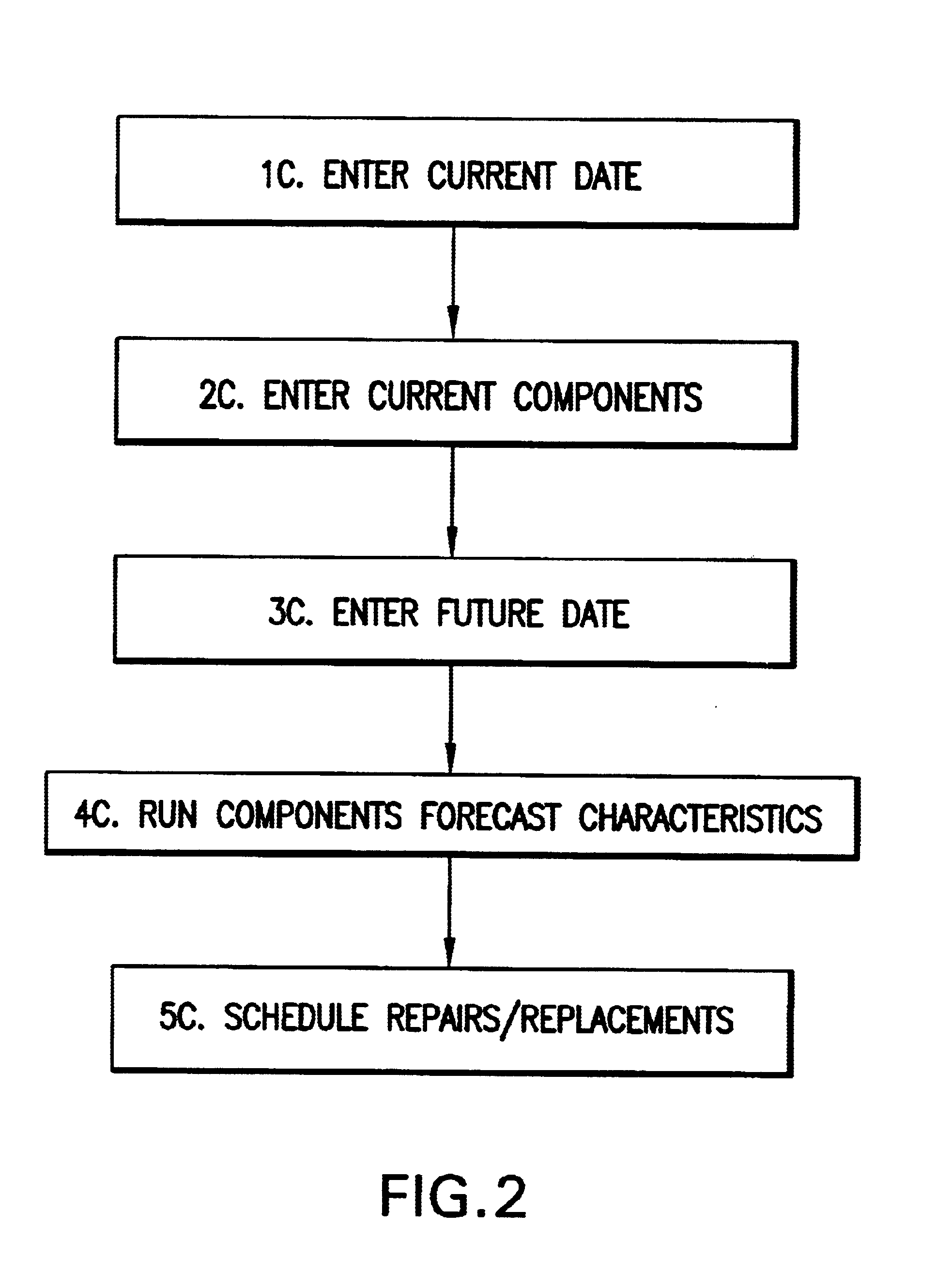

Aircraft engine reliability business model

A business model algorithm for maintaining aircraft engines in reliable and safe operating condition without the necessity of performing major engine overhaul in which engine manufacturers' maintenance procedures are enhanced and performed more frequently and supplemented by engine trend analysis, engine oil analysis, engine vibration analysis, borescope inspection and computer algorithm forecasting to identify, repair, and / or replace engine components without necessity of major engine overhaul.

Owner:BANGERT BARRY +1

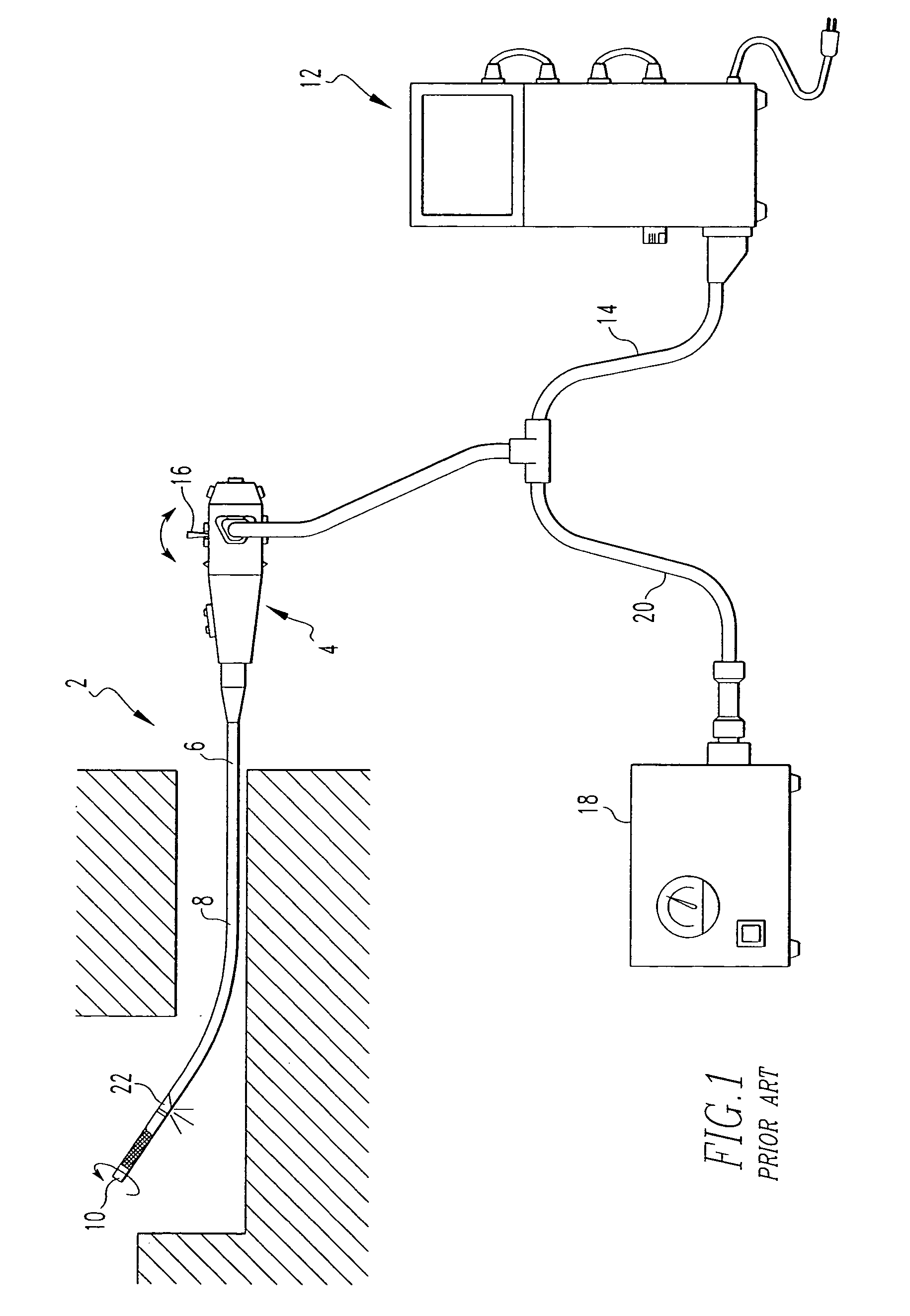

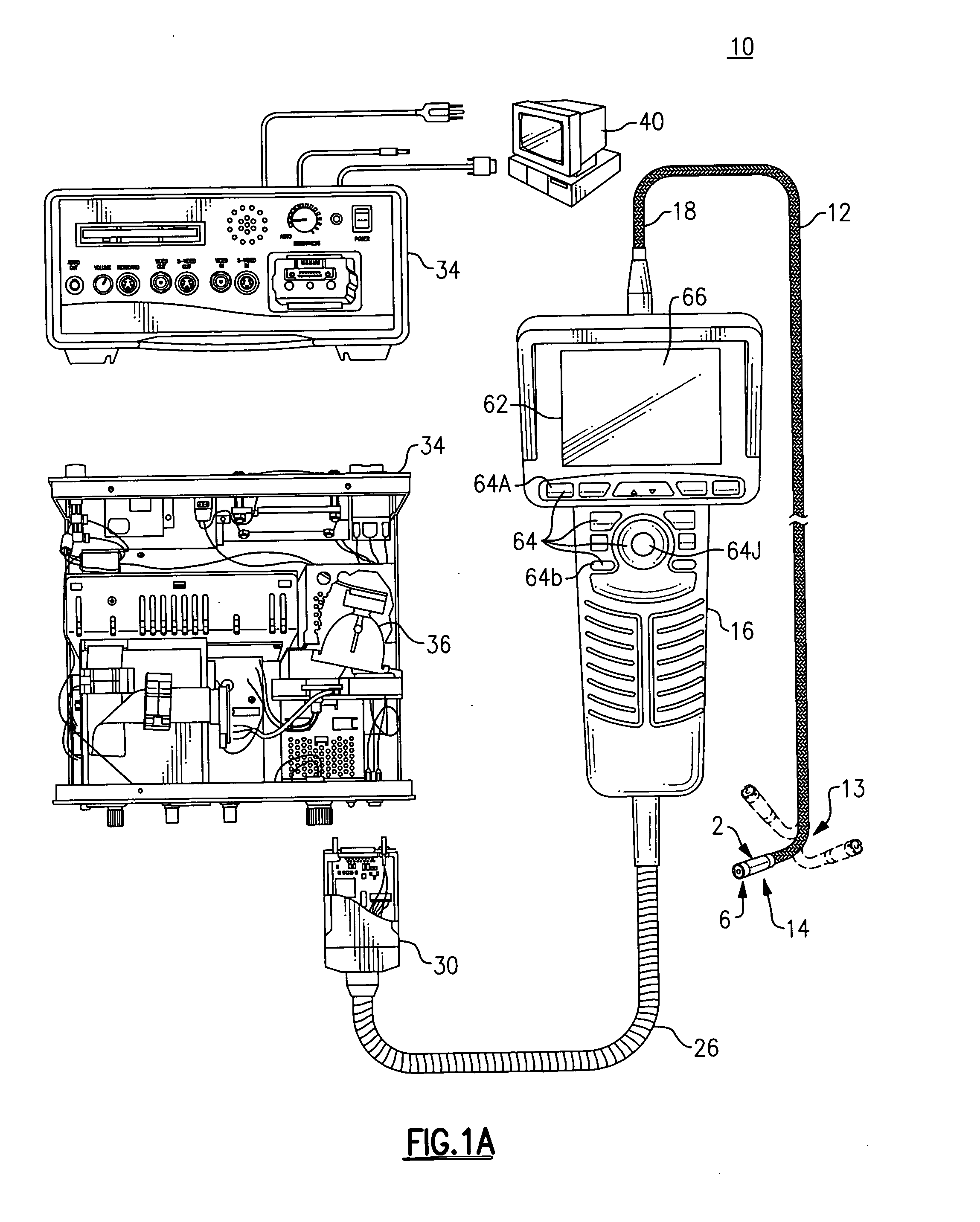

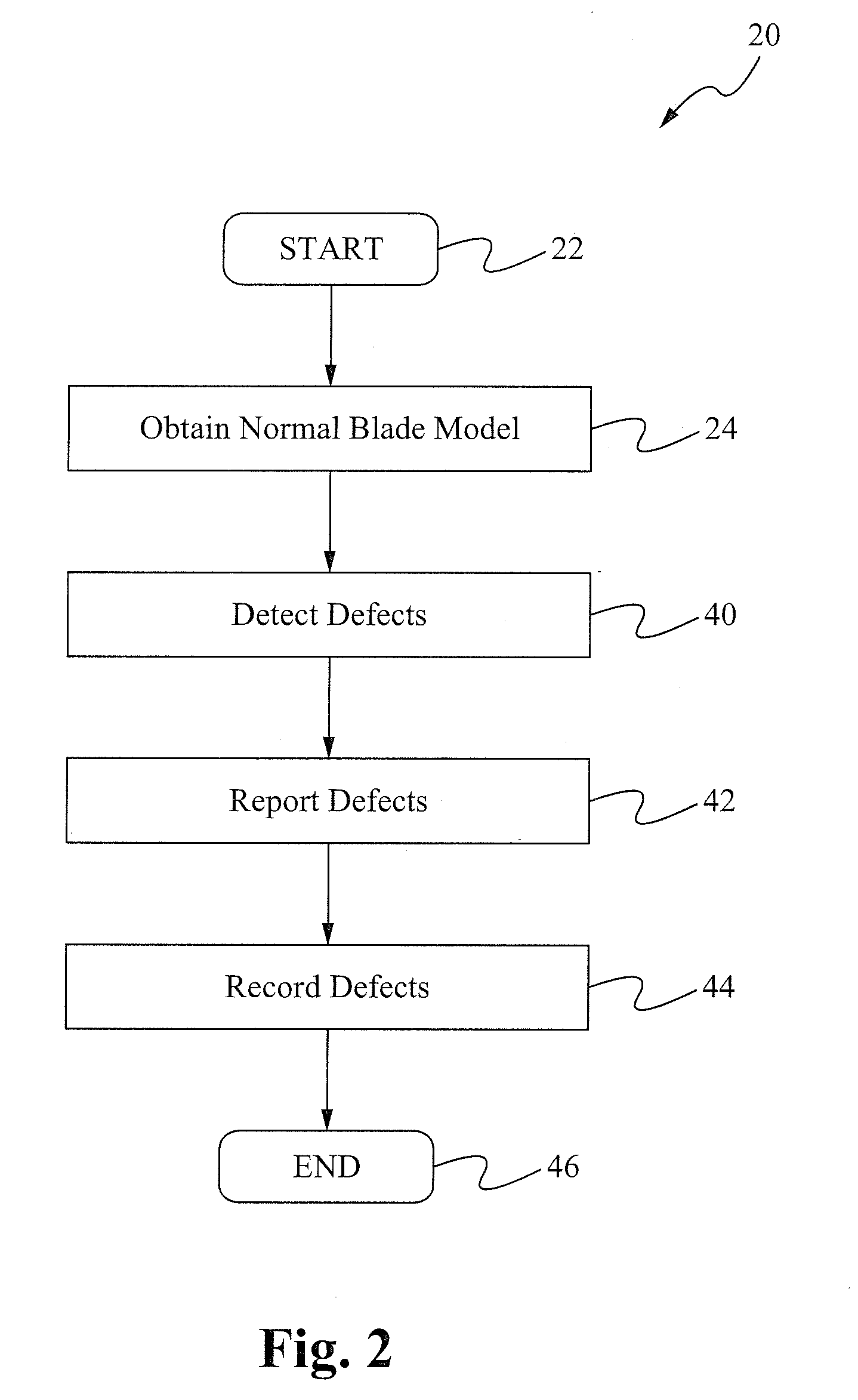

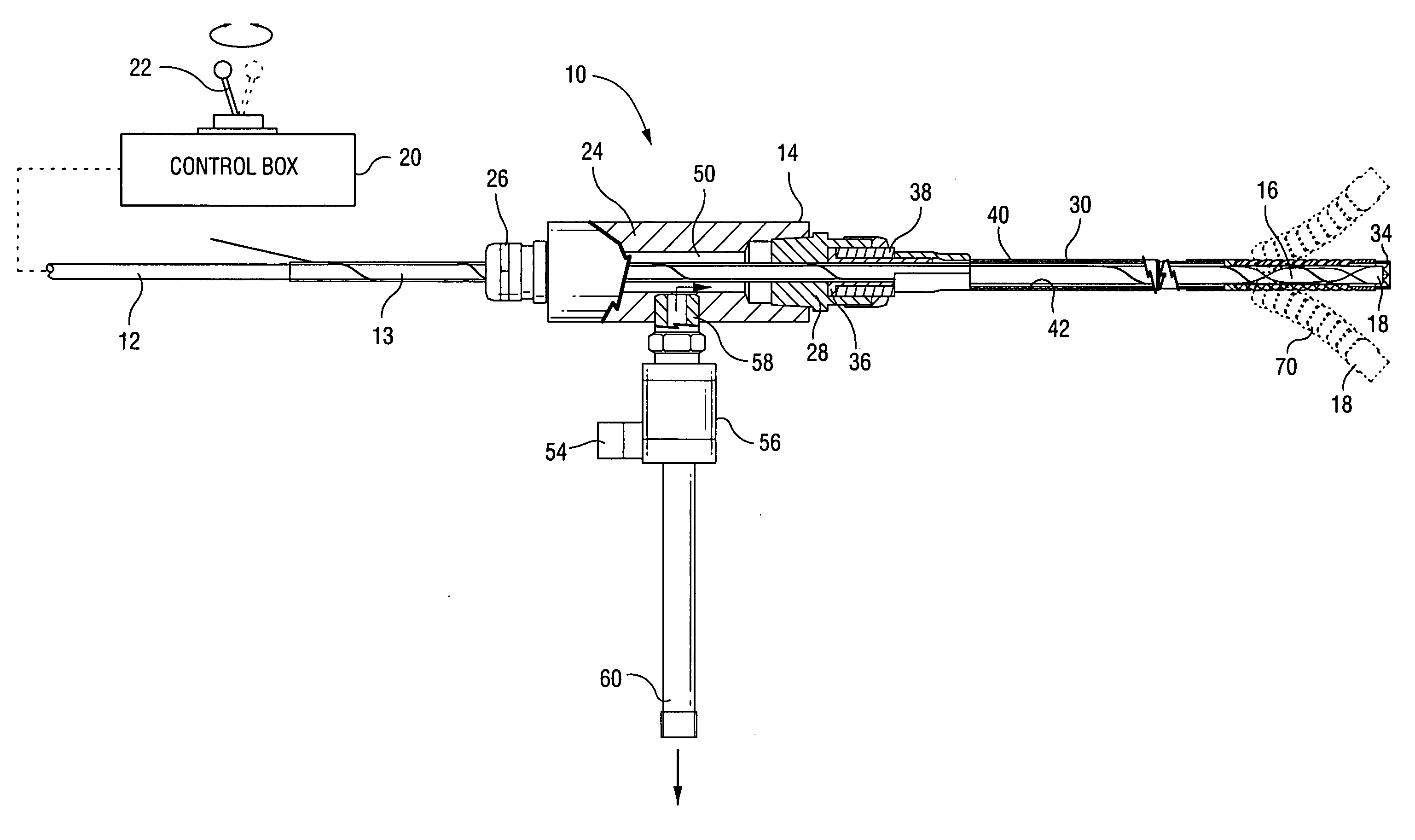

High-temperature inspection device and cooling apparatus therefor

ActiveUS7121098B2Eliminating a lengthy and expensive cooling down timeCompression machinesEndoscopesCombustionVisual inspection

An inspection system includes a cooling apparatus for conducting visual inspections within operating temperature environments, such as, for example, the interior of a combustion turbine shortly after shut down. The cooling apparatus provides cooling for an inspection probe such as a video borescope. The cooling apparatus includes an articulating guide tube having a control portion, an elongate flexible portion and an articulating section. The video borescope is inserted down through the articulating guide tube. A thermal protective sleeve surrounds and thermally insulates a portion of the articulating guide tube. Vortex coolers circulate cooled, compressed air within the cooling apparatus, thereby maintaining a cool video borescope operating temperature.

Owner:SIEMENS ENERGY INC

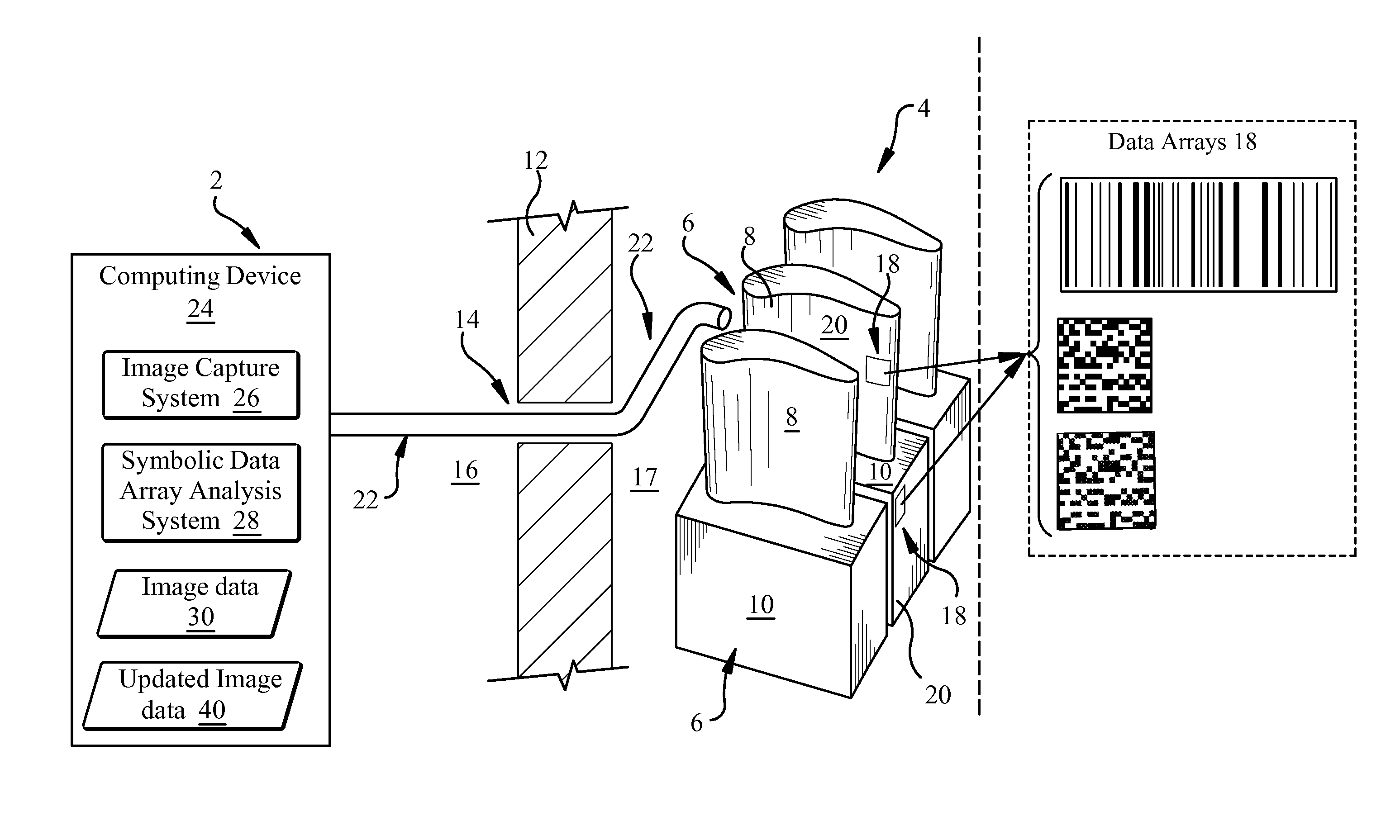

Turbomachine component monitoring system and method

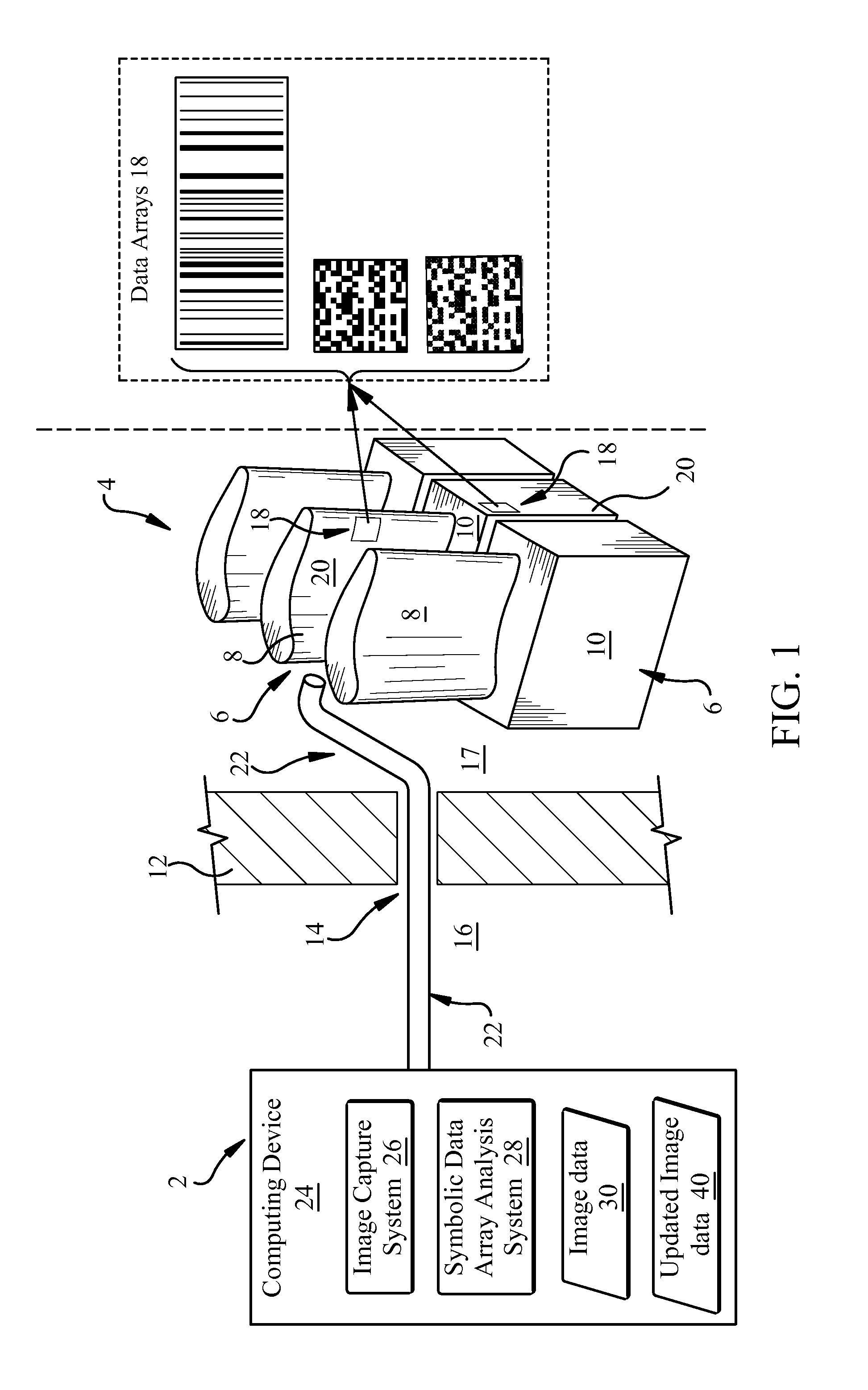

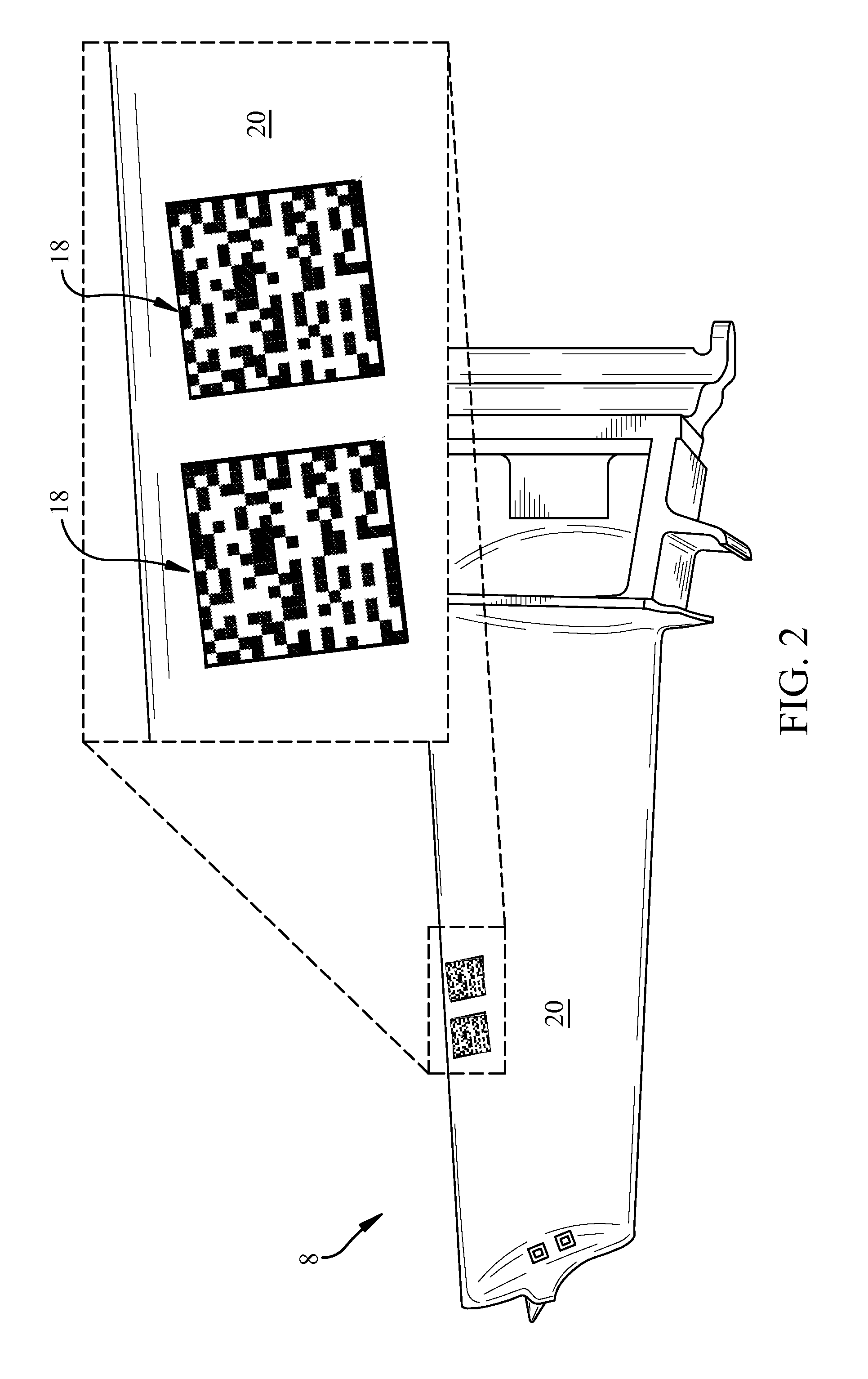

Various embodiments include approaches for monitoring turbomachine components. In various particular embodiments, a system for monitoring a component within a turbomachine includes: a borescope probe sized to pass through an opening in the turbomachine, the borescope probe for detecting a symbolic data array on the component within the turbomachine; and at least one computing device operably coupled to the borescope probe, the at least one computing device configured to: obtain image data about the symbolic data array from the borescope probe; evaluate the image data to determine whether the image data is compatible with a symbolic data array analysis program; and analyze the image data using the symbolic data array analysis program in response to determining the image data is compatible with the symbolic data array analysis program.

Owner:GENERAL ELECTRIC CO

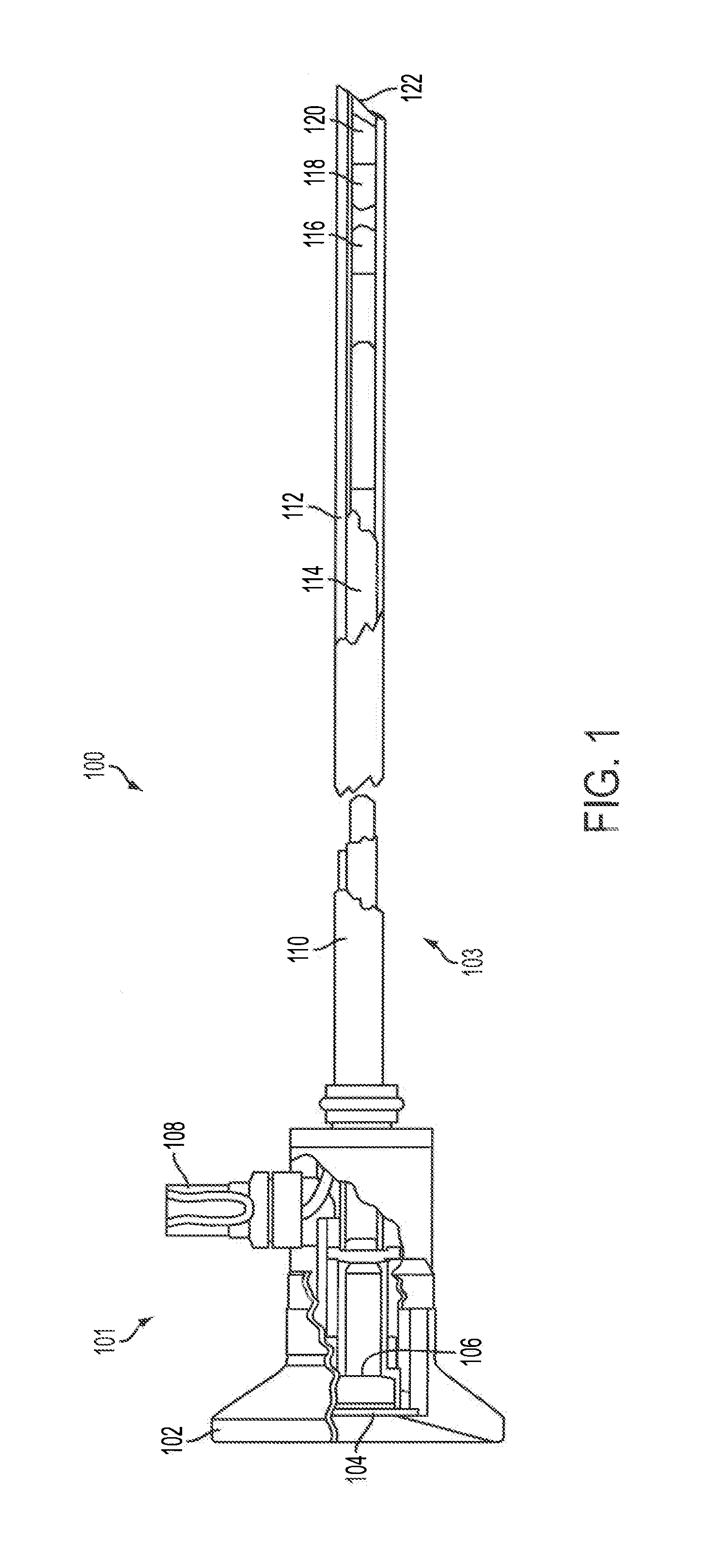

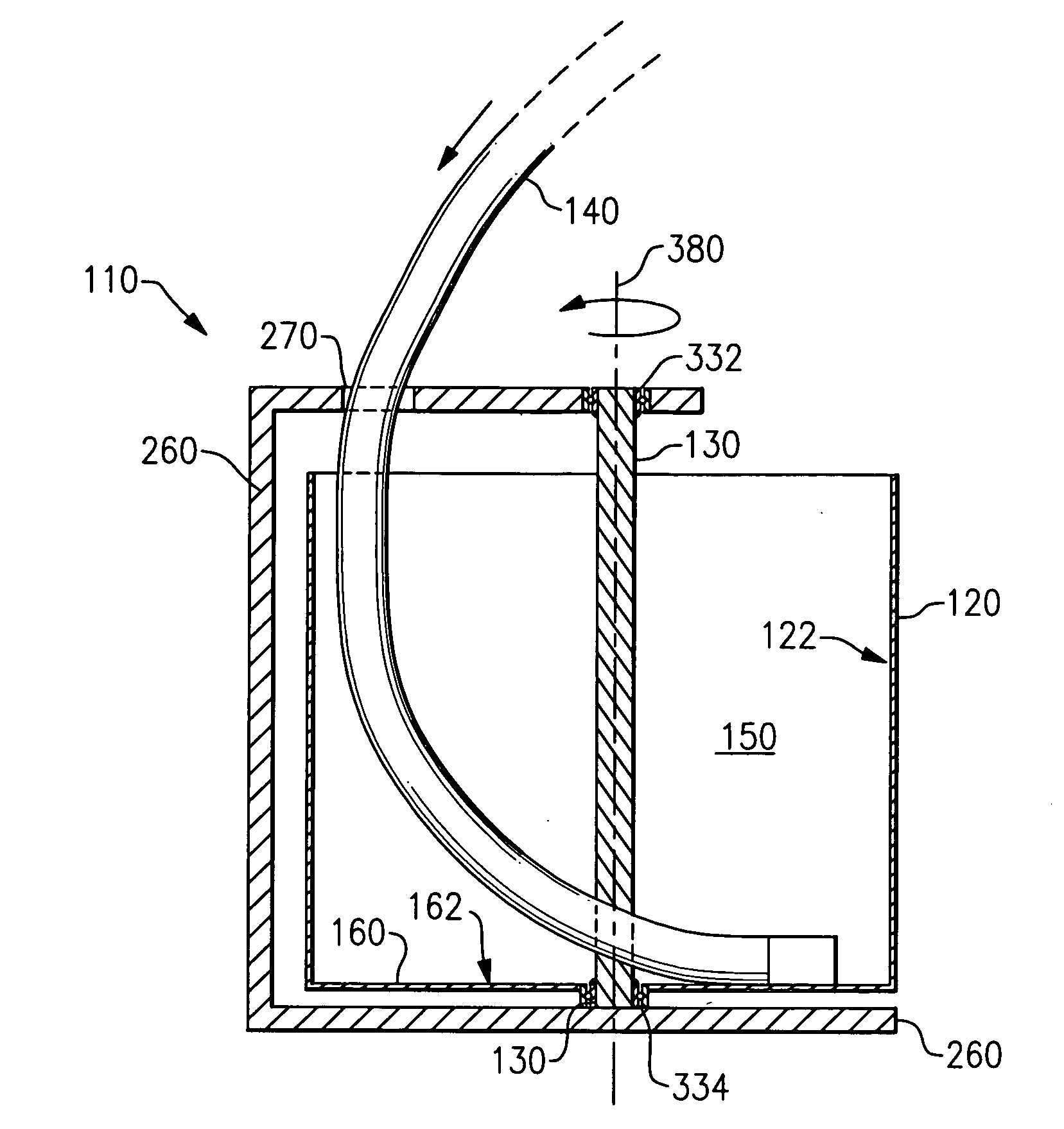

Insertion tube storage carousel

An apparatus for storing at least one elongated and flexible object, such as an insertion tube that functions as a portion of an endoscope or a borescope device. The apparatus includes a rotating storage carousel having a base and a peripheral barrier. An elongated and flexible object, such as an insertion tube, is stored along the inner side of the peripheral barrier and the base. The storage cavity of the carousel rotates while accepting the transfer of the elongated and flexible object for storage.

Owner:GE INSPECTION TECH LP

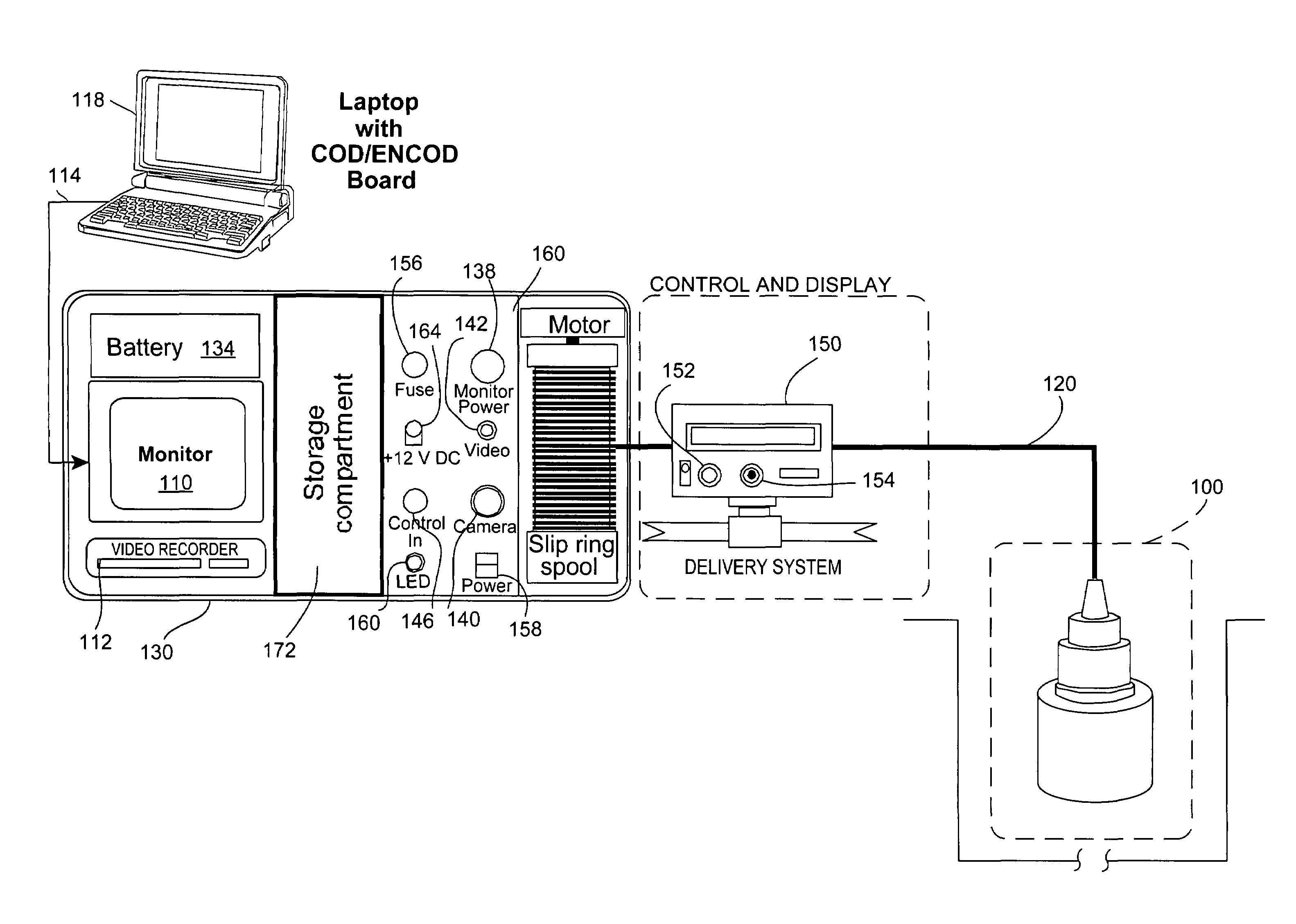

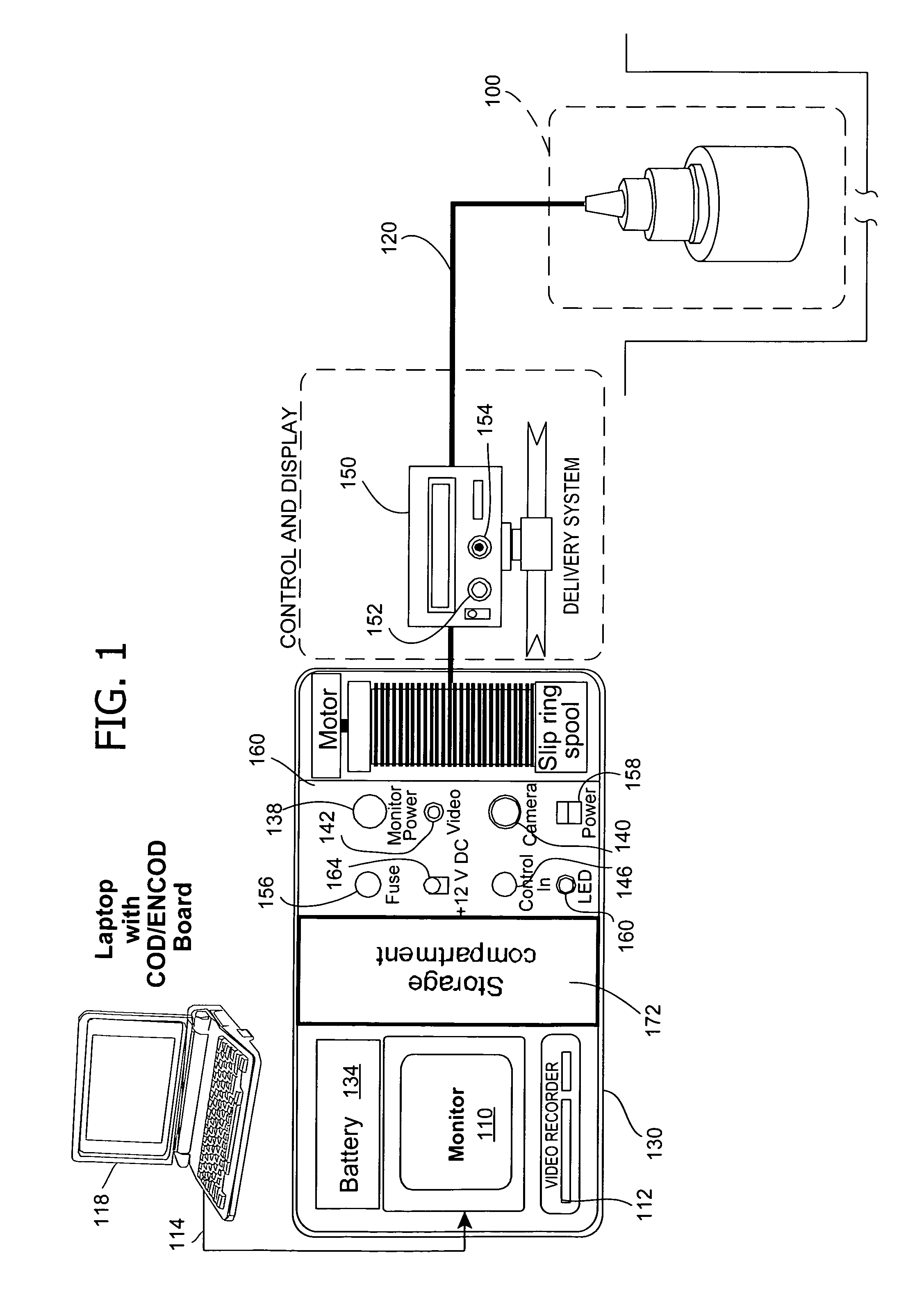

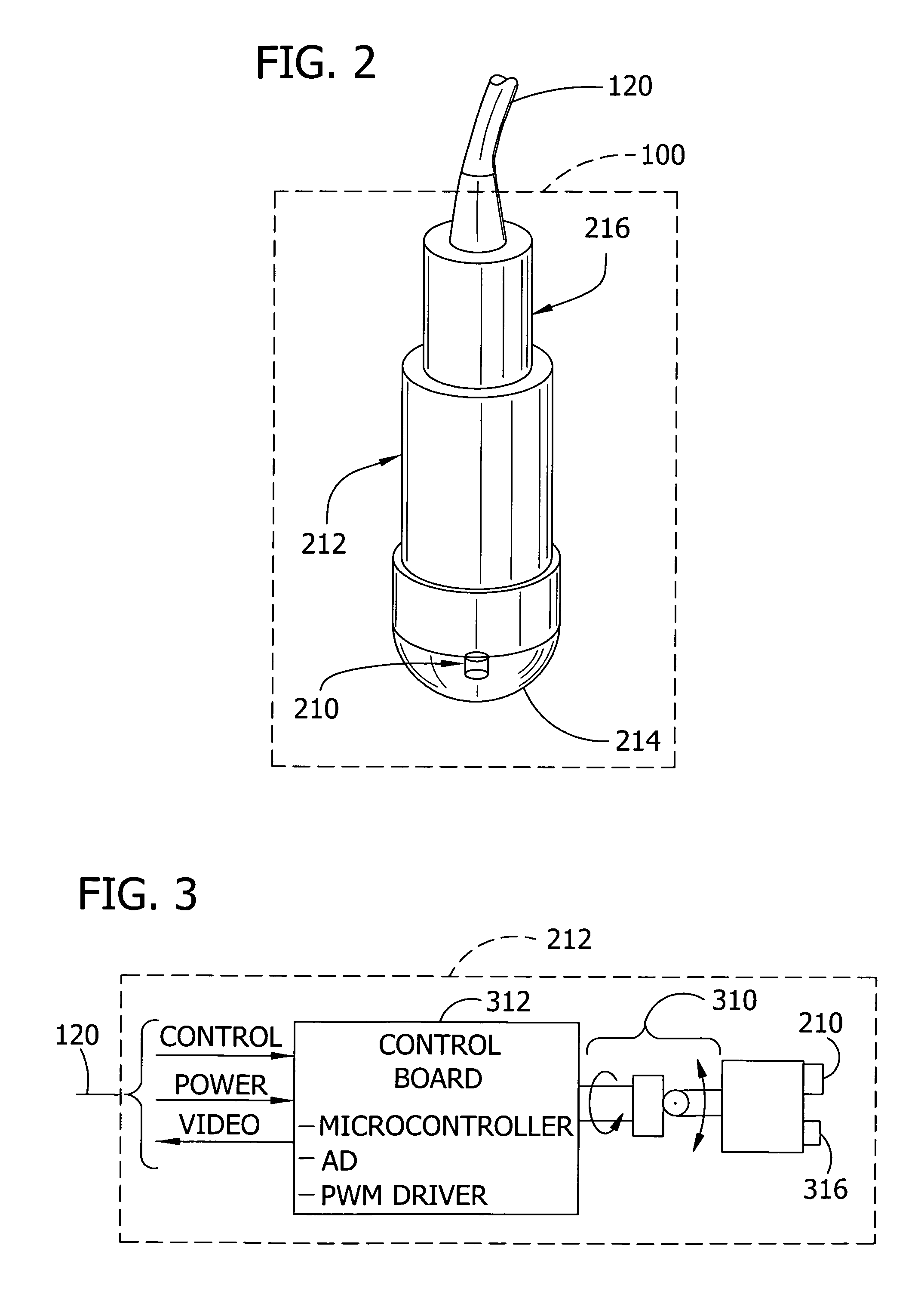

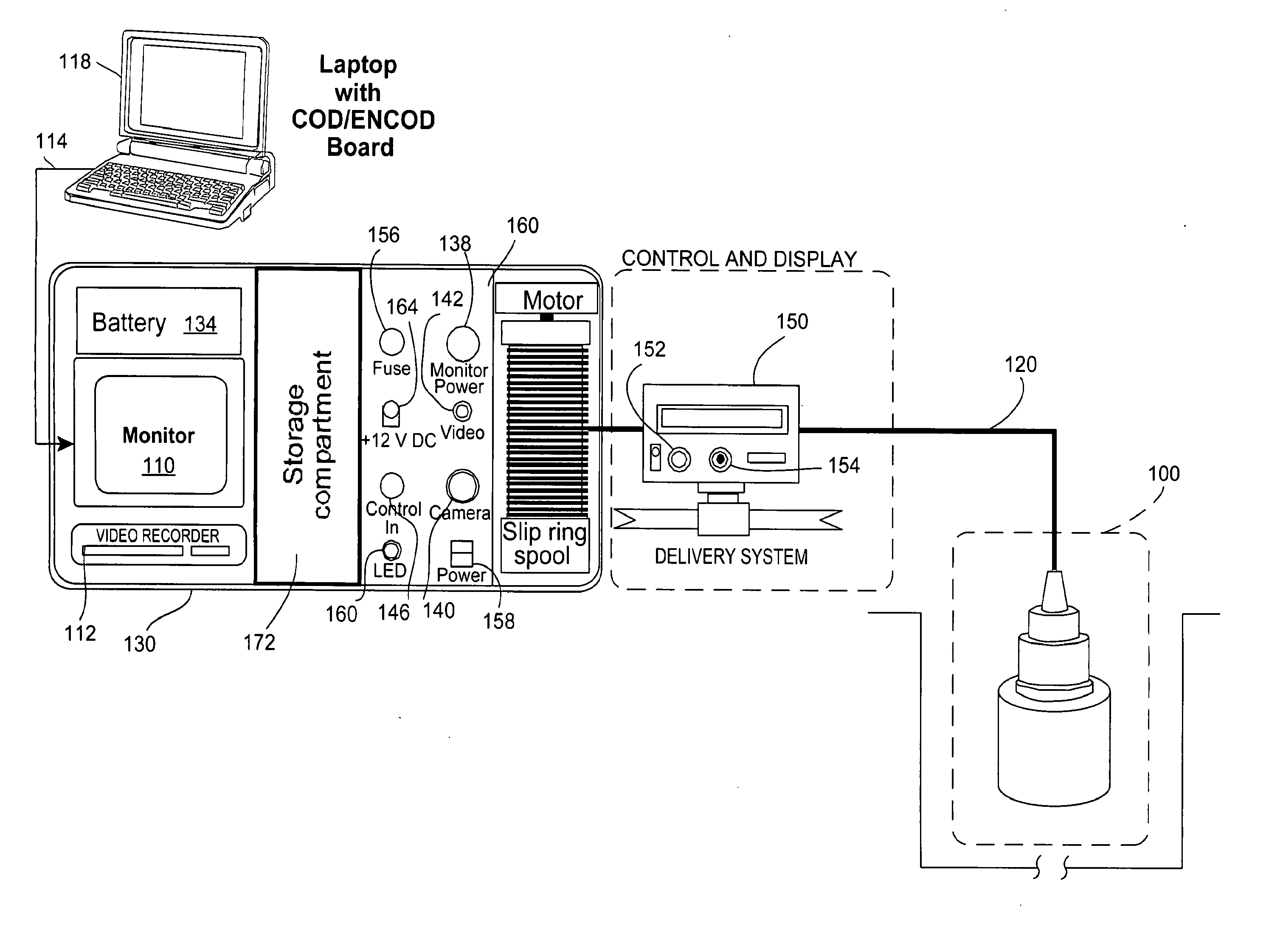

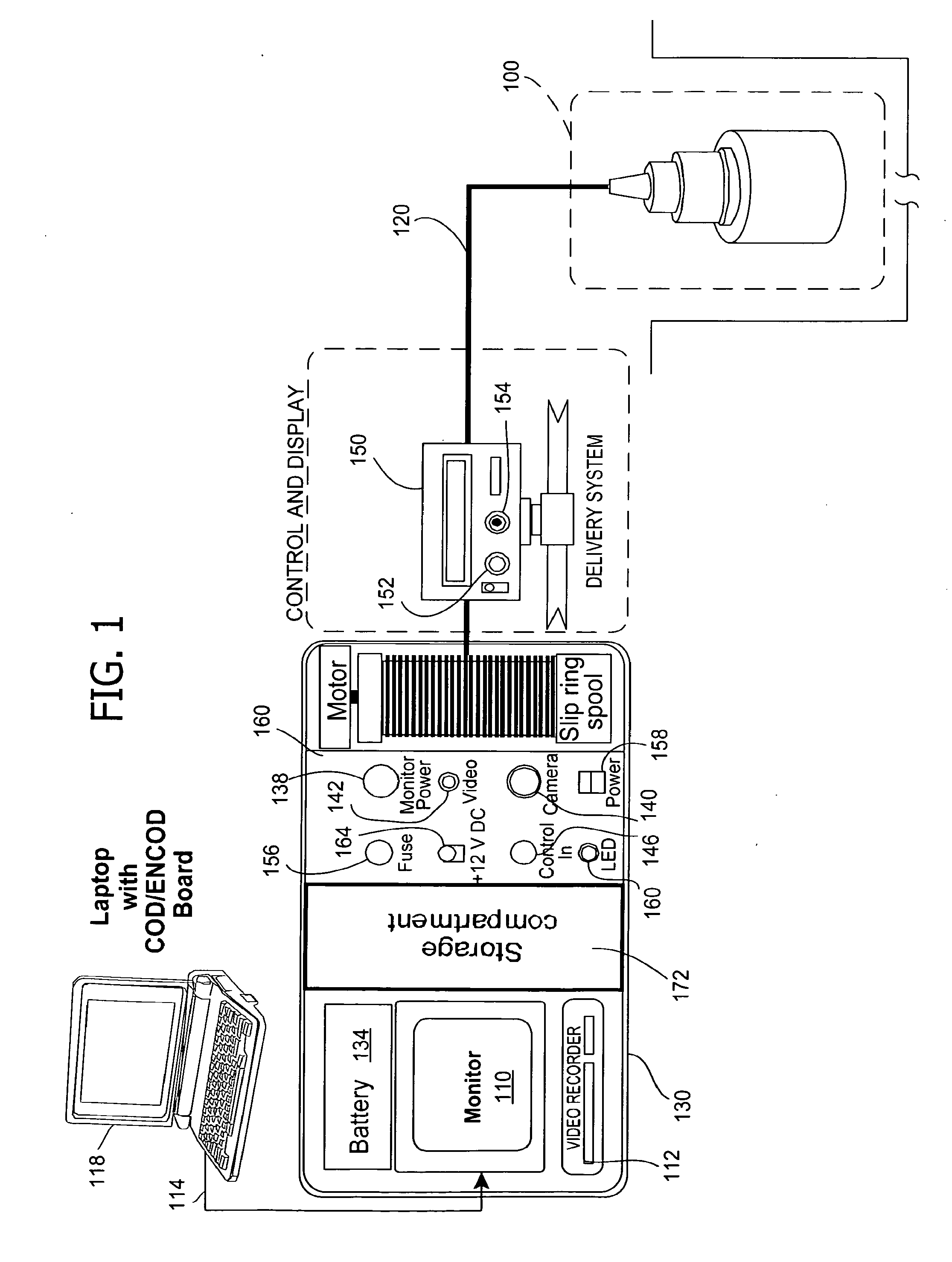

Borescope for drilled shaft inspection

InactiveUS7187784B2Economical and inexpensiveEfficient storageElectric/magnetic detection for well-loggingSurveyComputer graphics (images)Visual inspection

Visual inspection of an interior surface of a borehole. A housing adapted to be lowered in the borehole supports a portable camera for generating images of a portion of the interior surface of the borehole and a light source for illuminating an area adjacent the camera. A monitor receives signals from the camera and, in response thereto, displays the images generated by the camera. A viewing envelope positioned adjacent the camera defines a viewing area adjacent the camera, particularly for use in visually inspecting slurry-filled boreholes.

Owner:AVER TECH INC

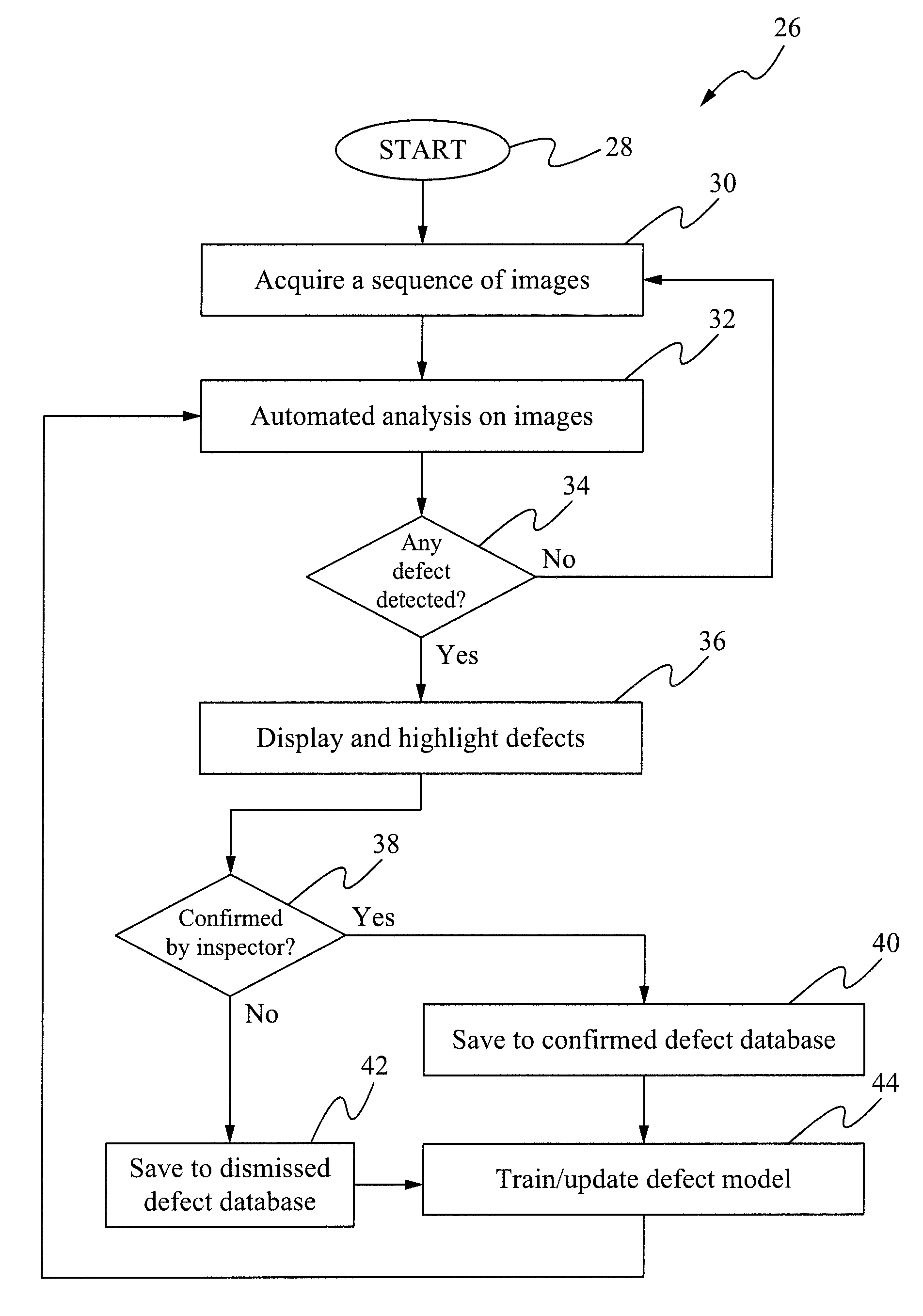

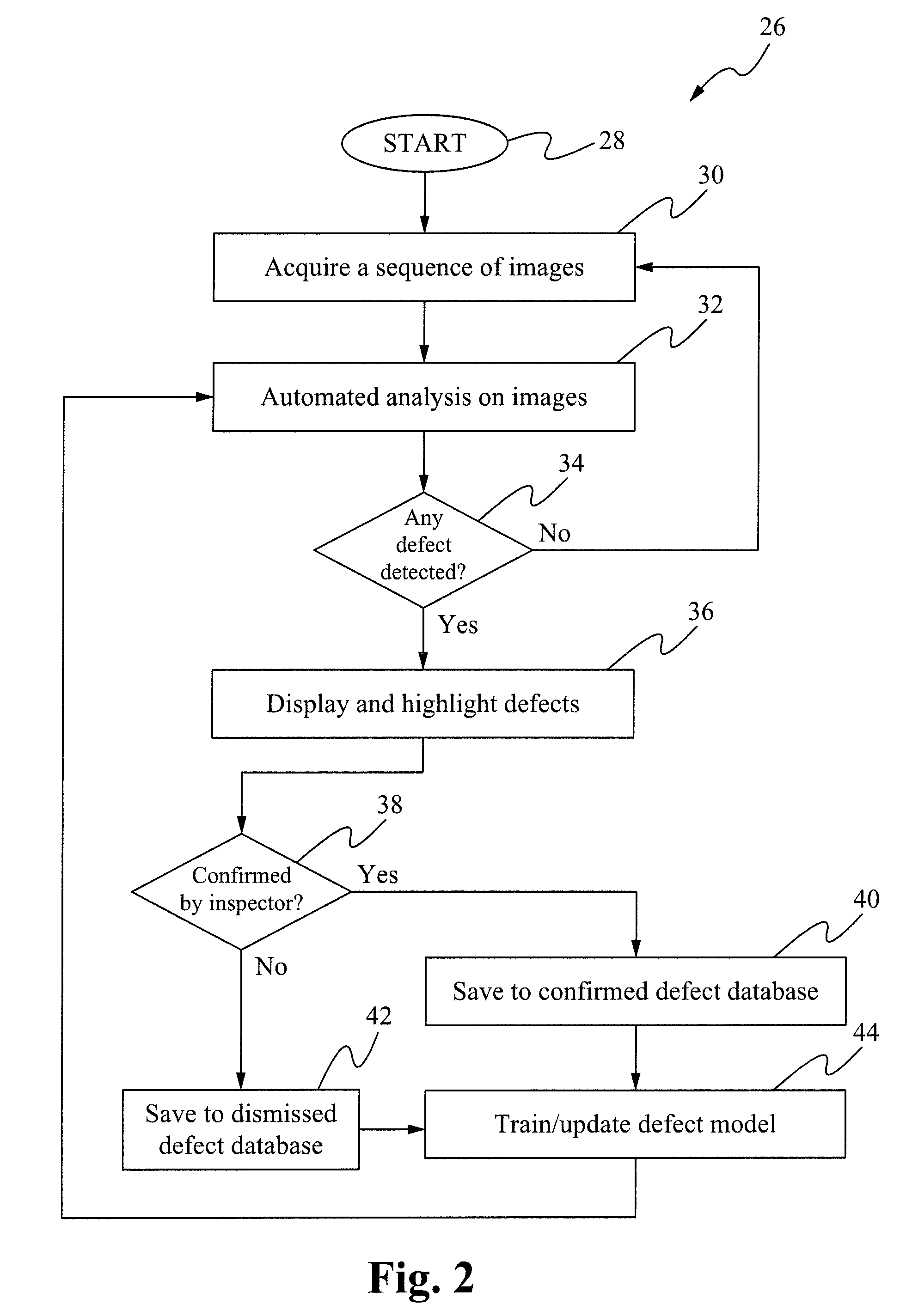

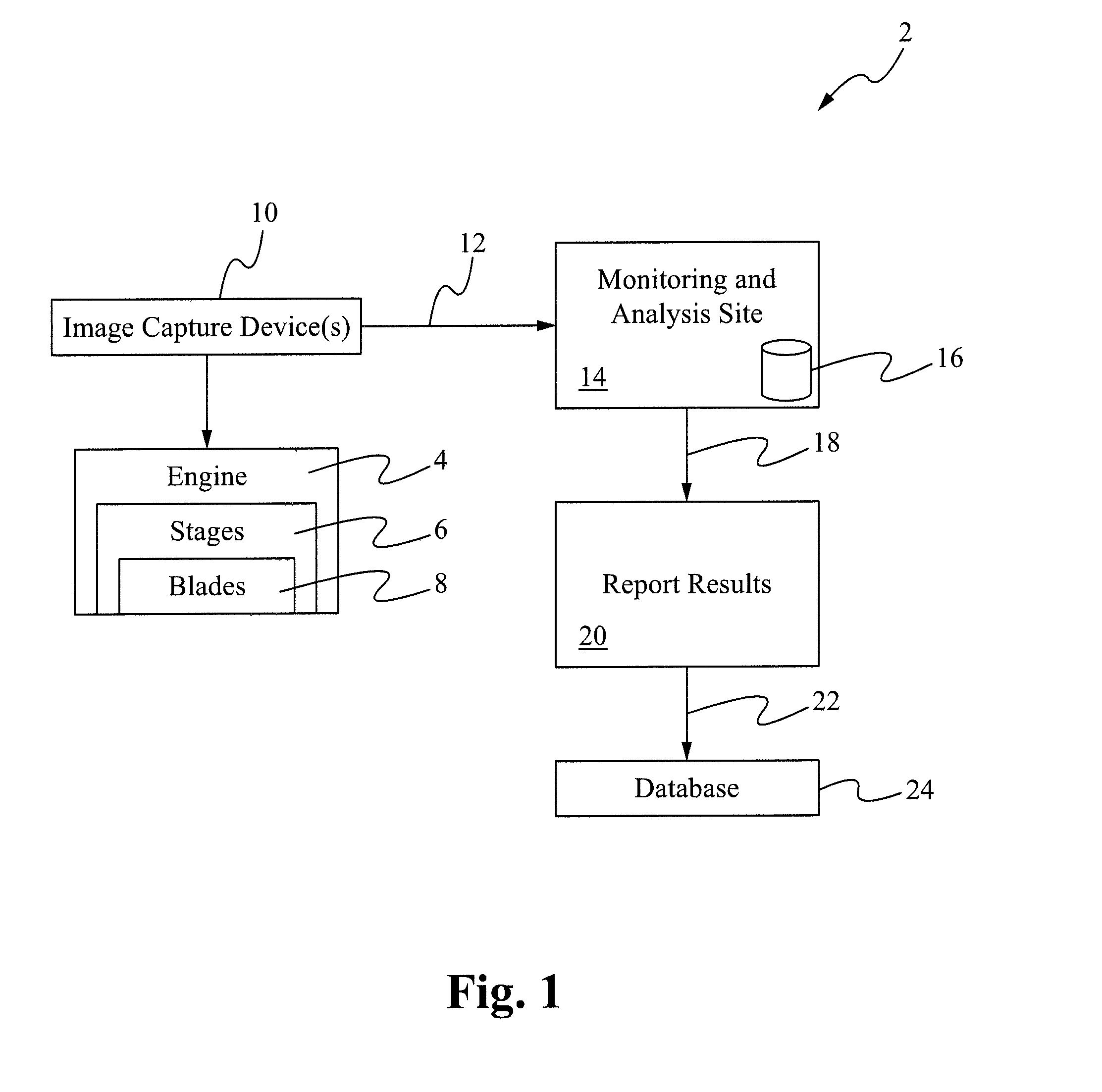

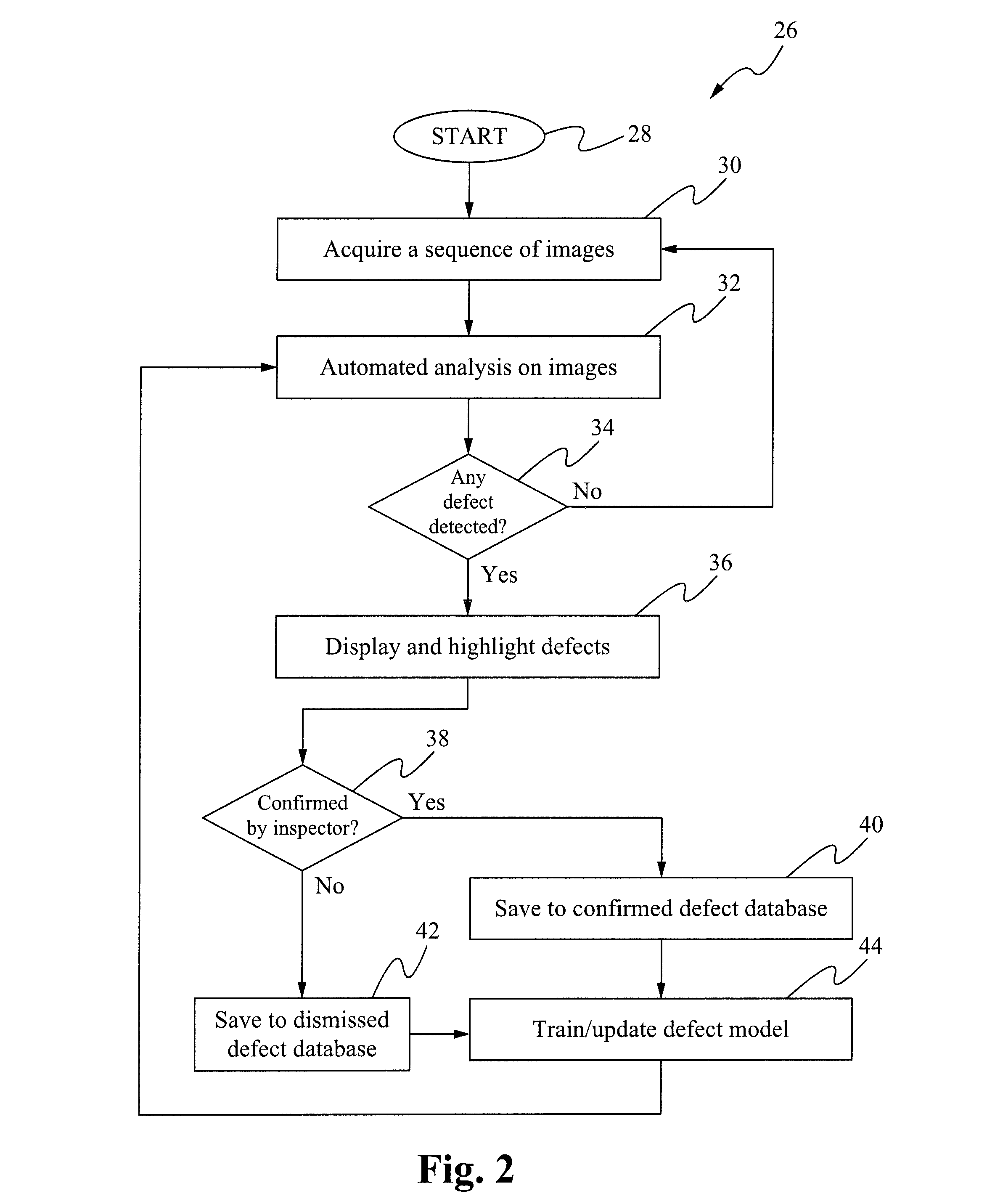

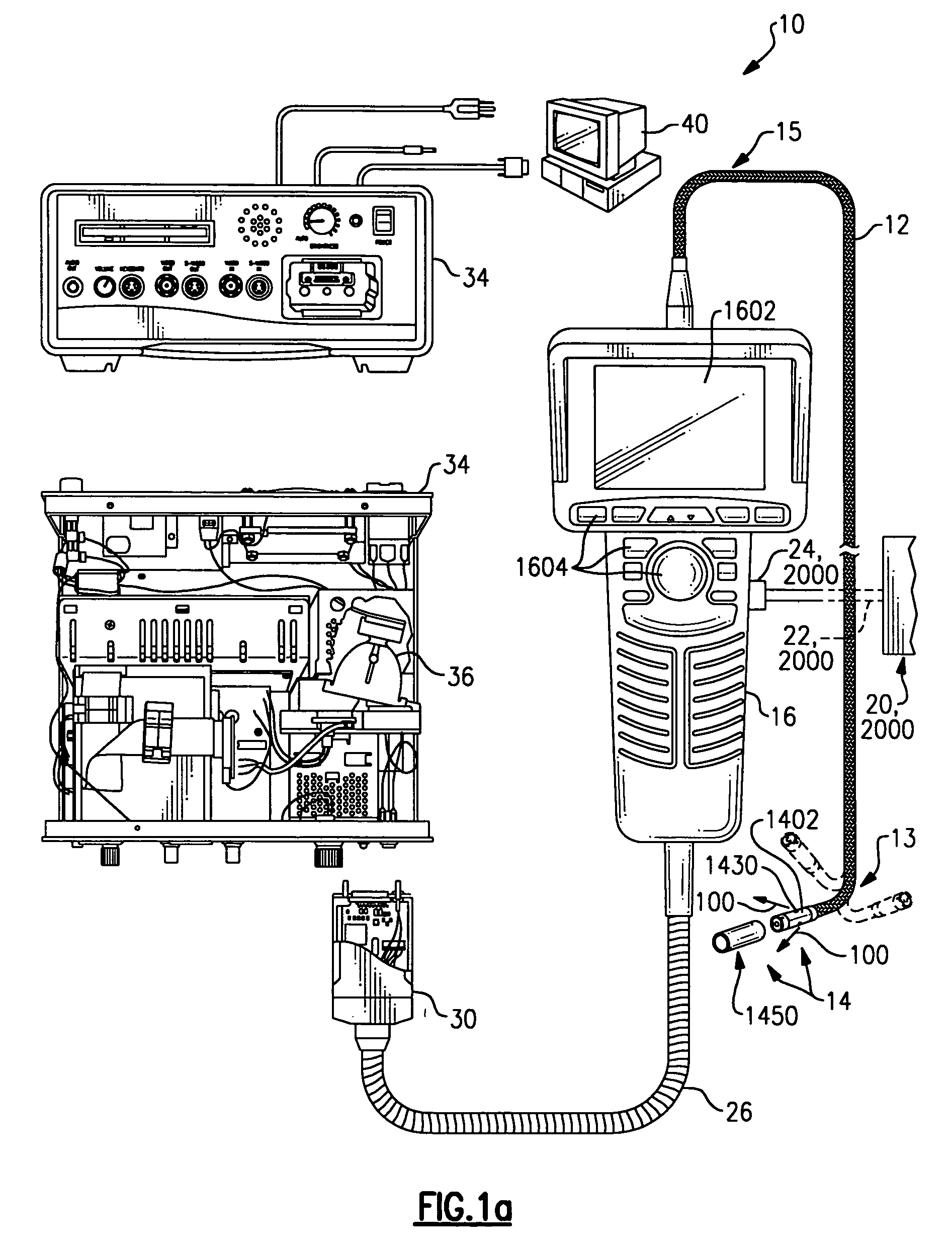

System and method for automated borescope inspection user interface

ActiveUS8761490B2Easy defect detectionMaterial analysis by optical meansCharacter and pattern recognitionHuman–machine interfaceBorescope

A system and method for improving human-machine interface while performing automated defect detection is disclosed. The system and method may include an image capture device for capturing and transmitting data of an object, performing automated analysis of the data and reviewing results of the automated analysis by a human inspector and providing feedback. The system and method may further include refining the automated analysis of the data based upon the feedback of the human inspector.

Owner:PRATT & WHITNEY +1

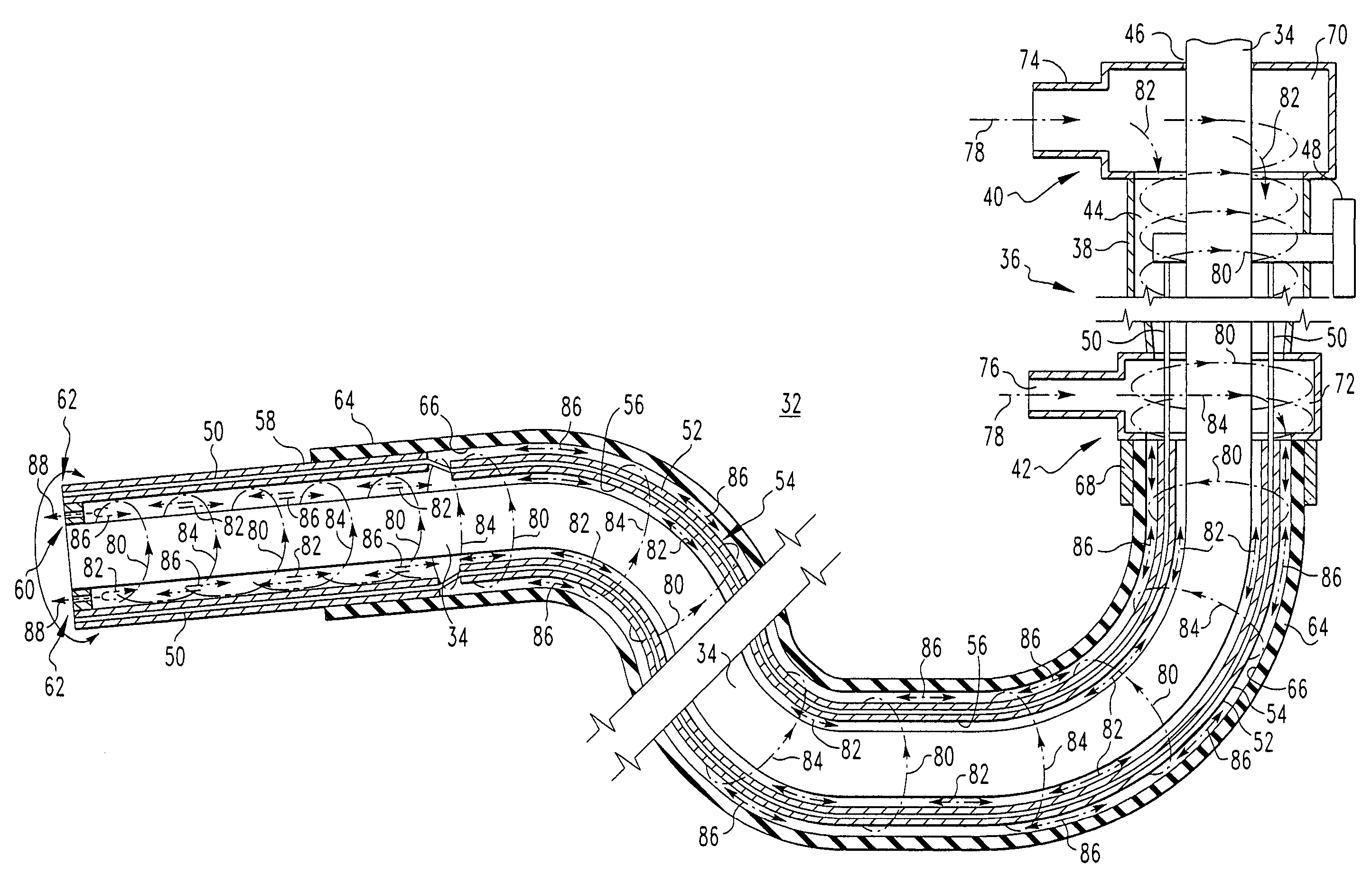

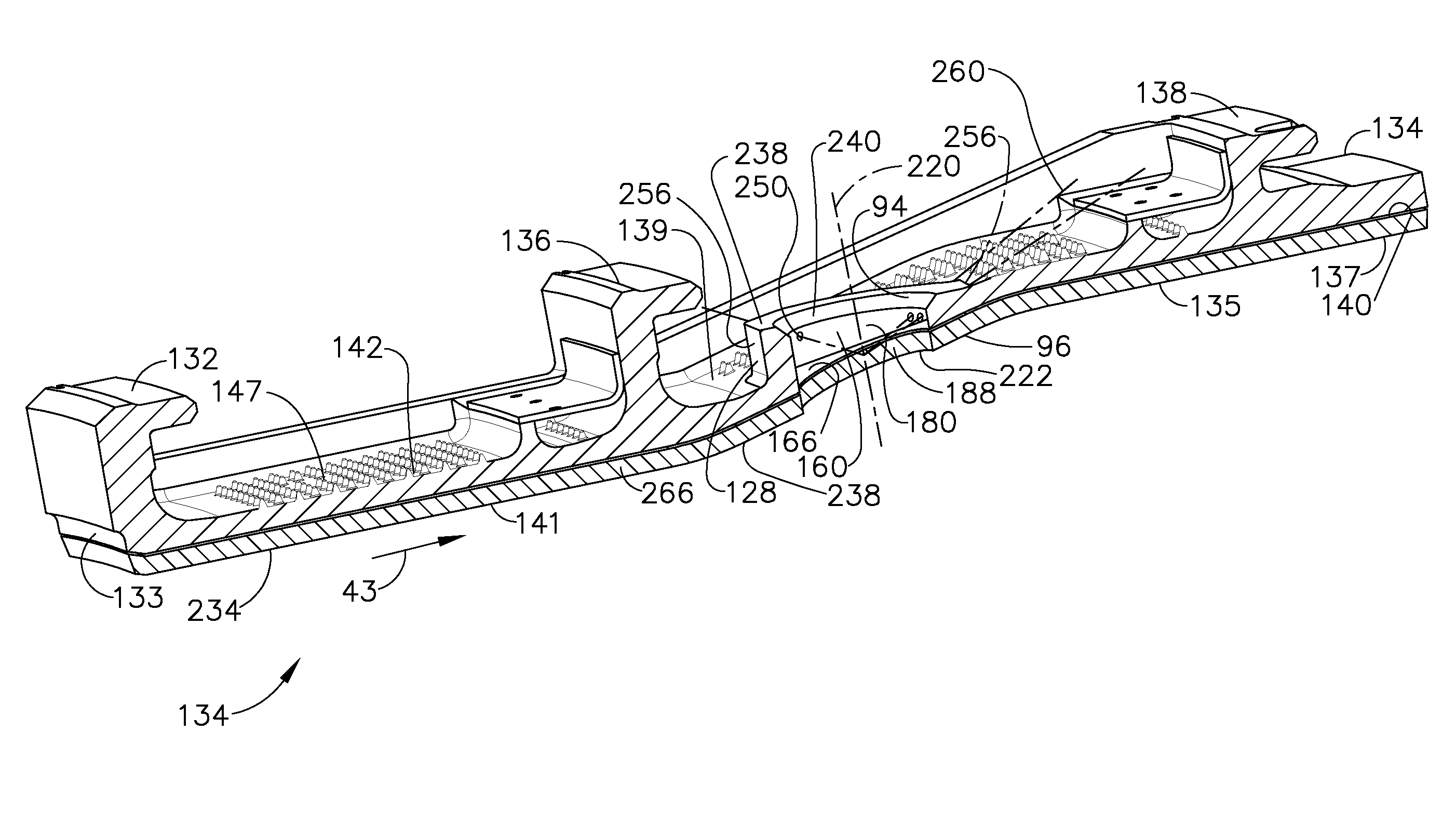

Borescope boss and plug cooling

A coolable borescope boss includes cooling passages extending through the boss and oriented for spraying cooling air into a hole extending through the boss. Centerlines of the cooling passages may intersect the a hole axis of the hole. The cooling passages may be cylindrical or open slots disposed through the boss. The boss may be on an arcuate gas turbine engine shroud segment circumscribed about an axial centerline axis. The segment may be part of an annular segmented turbine shroud having cylindrical shroud first and second sections and a conical shroud midsection therebetween and the segment having cylindrical segment first and second sections and a conical segment midsection therebetween. A hole exit of the hole being flush with the conical segment midsection. A borescope plug tip having a spherical tip chamfer may be used to seal against a conical boss chamfer of the boss.

Owner:GENERAL ELECTRIC CO

System and Method for Automated Borescope Inspection User Interface

ActiveUS20130113914A1Easy defect detectionMaterial analysis by optical meansColor television detailsHuman–machine interfaceEngineering

A system and method for improving human-machine interface while performing automated defect detection is disclosed. The system and method may include an image capture device for capturing and transmitting data of an object, performing automated analysis of the data and reviewing results of the automated analysis by a human inspector and providing feedback. The system and method may further include refining the automated analysis of the data based upon the feedback of the human inspector.

Owner:PRATT & WHITNEY +1

Borescope comprising fluid supply system

InactiveUS7422559B2Minimize temperature lossReduce entrySurgeryMaterial analysis by optical meansBorescopeBiomedical engineering

A borescope device having an insertion tube, a camera head assembly, and a fluid supply system. The camera assembly includes through holes allowing fluid escape. The fluid supply system is controllable to force fluid through the through holes. The fluid supply system may be actuated to cool the camera head assembly.

Owner:GE INSPECTION TECH LP

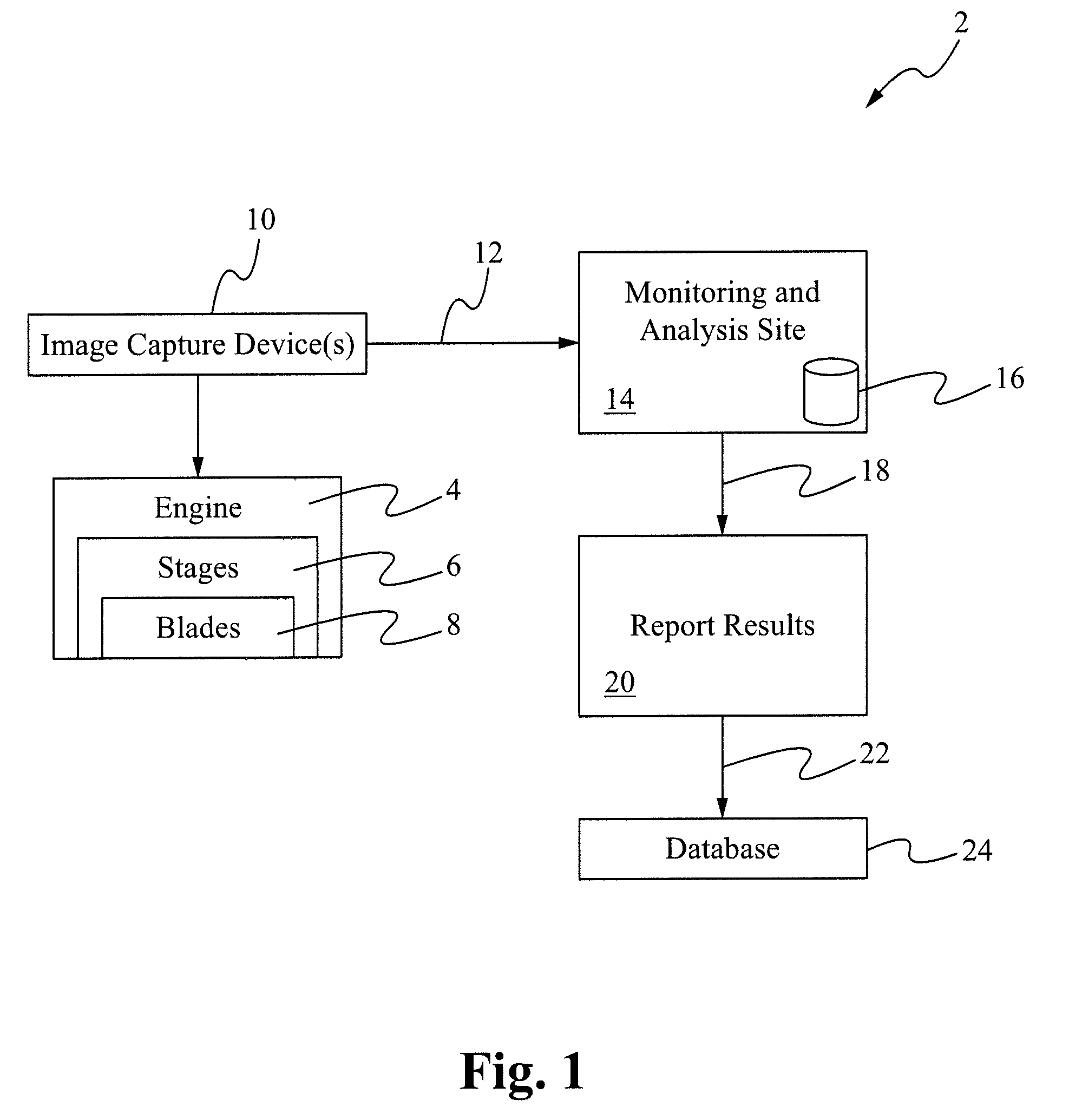

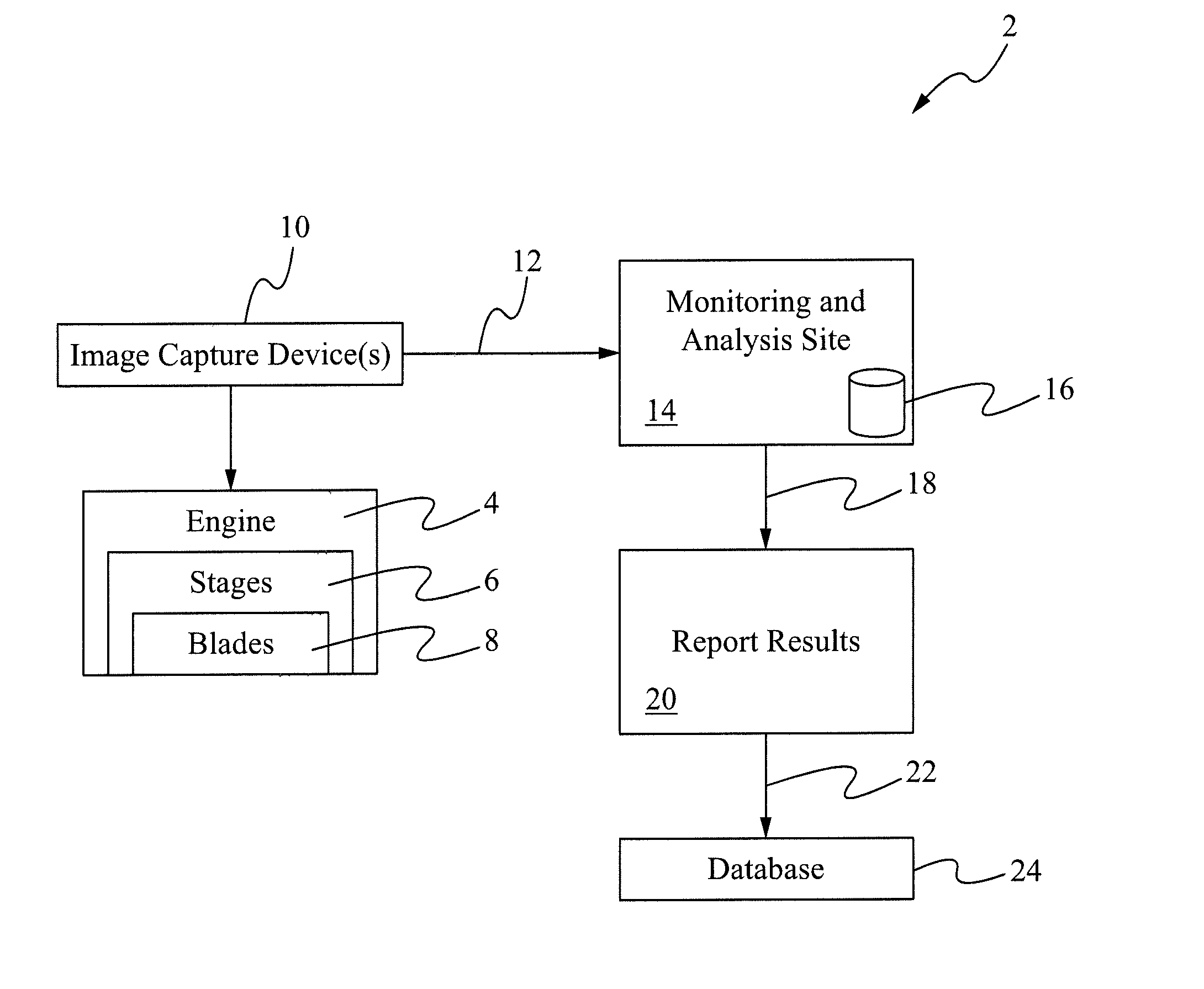

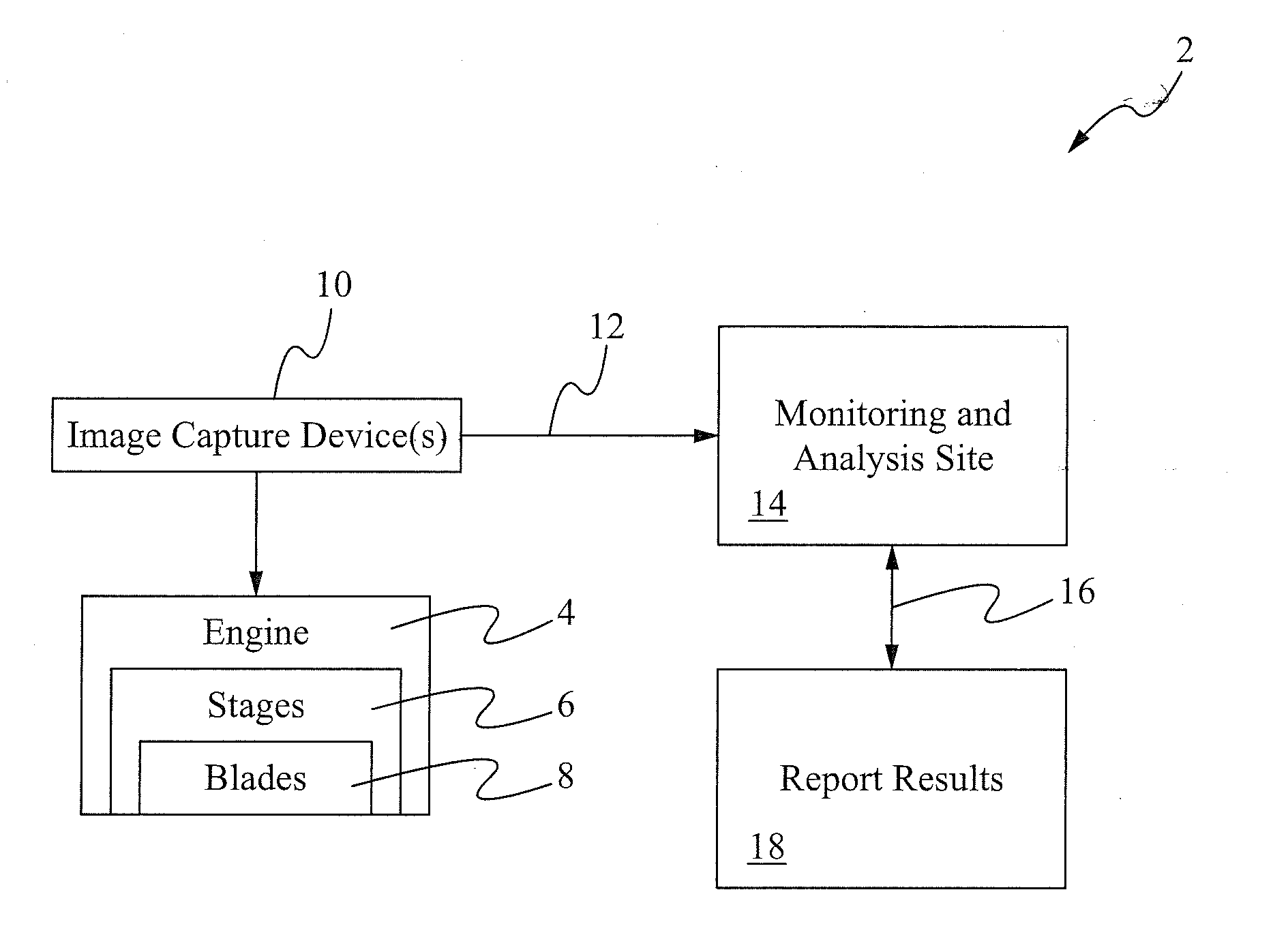

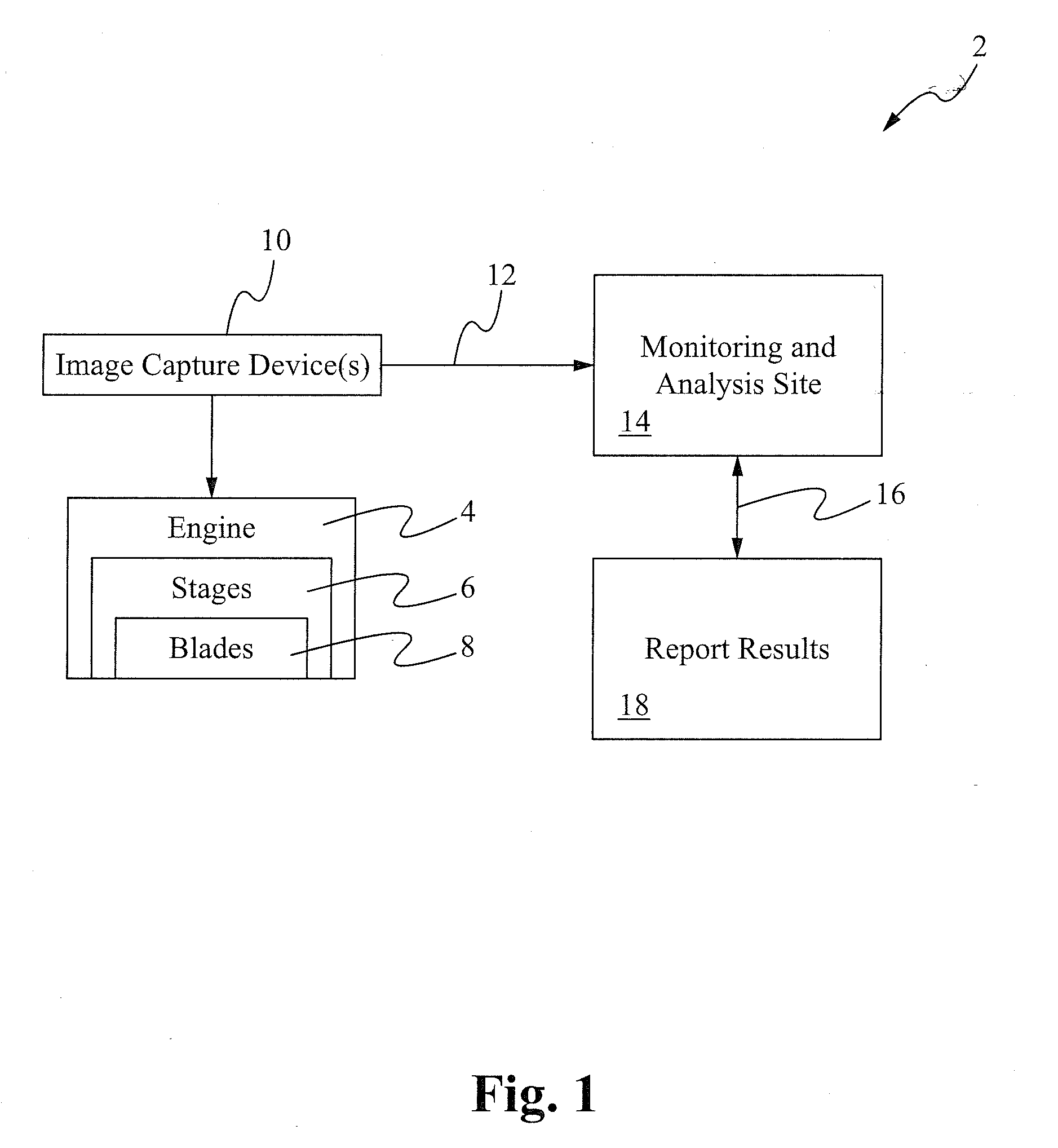

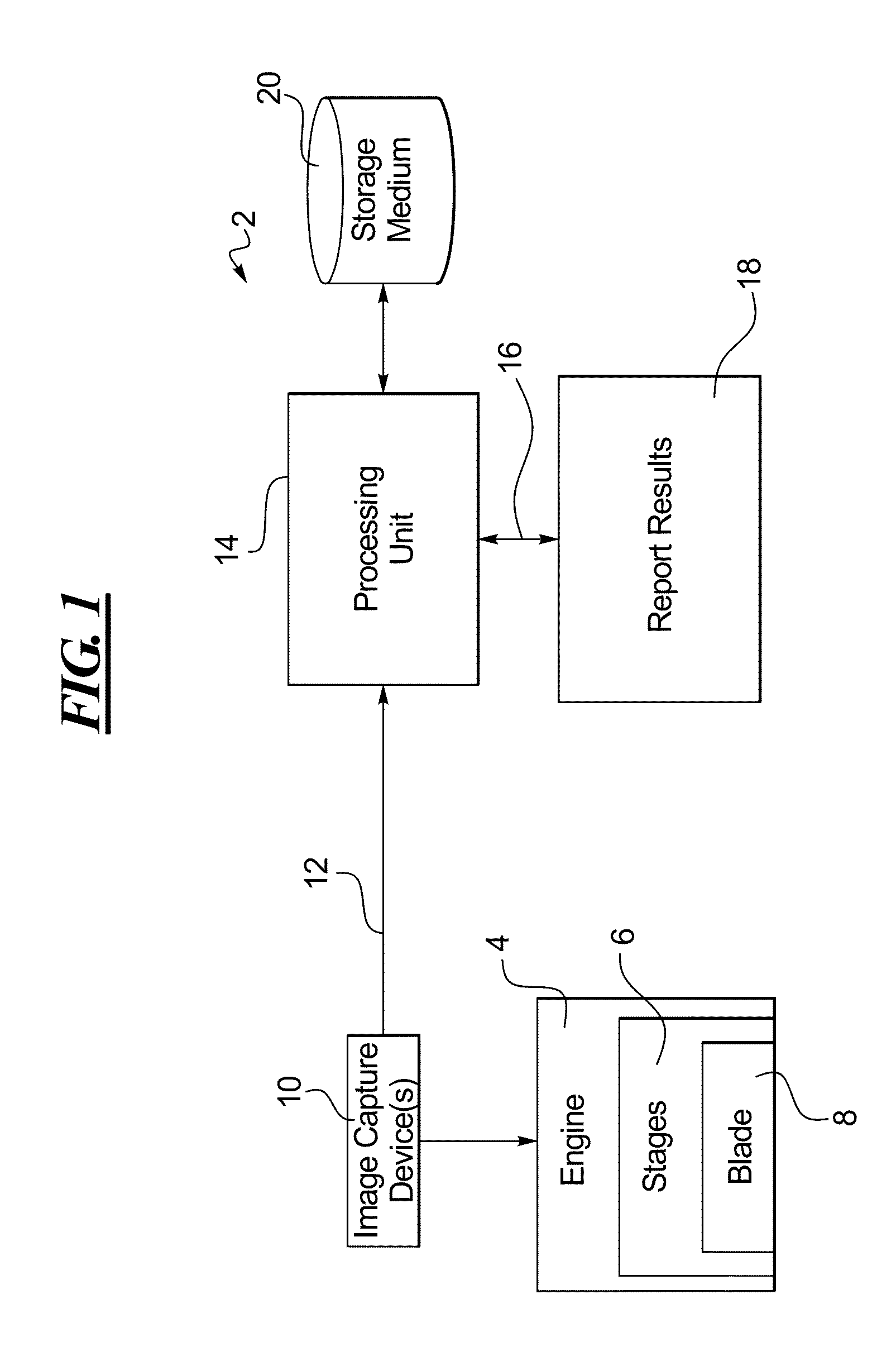

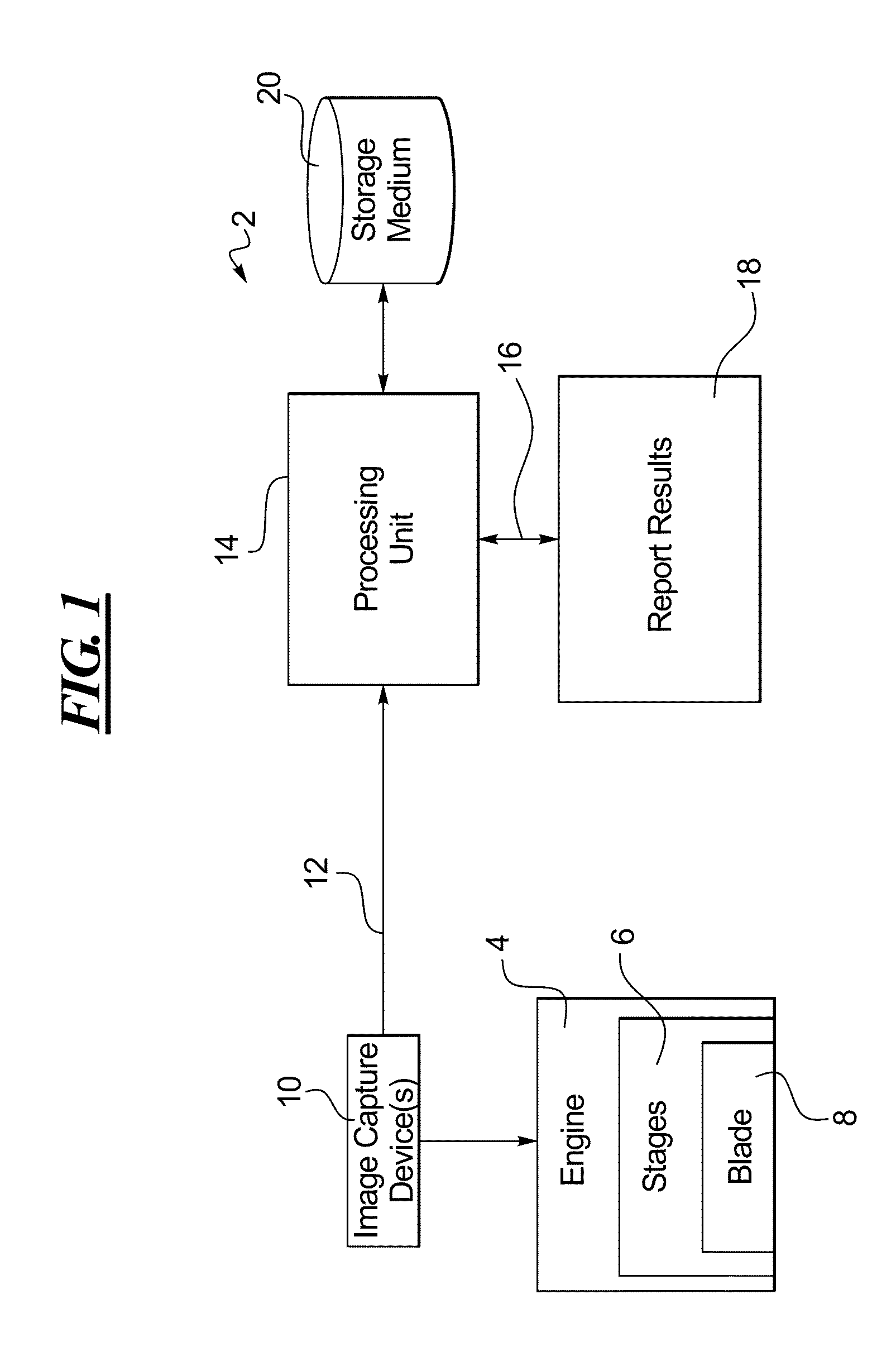

System and Method for Data-Driven Automated Borescope Inspection

A system and method for performing automated defect detection of blades within an engine is disclosed. The system and method may include an image capture device capable of capturing and transmitting images of a plurality of blades of an engine, creating a normal blade model of an undamaged one of the plurality of blades and determining defects within the plurality of blades by utilizing the normal blade model.

Owner:RAYTHEON TECH CORP +1

Flexible borescope assembly for inspecting internal turbine components at elevated temperatures

Owner:GENERAL ELECTRIC CO

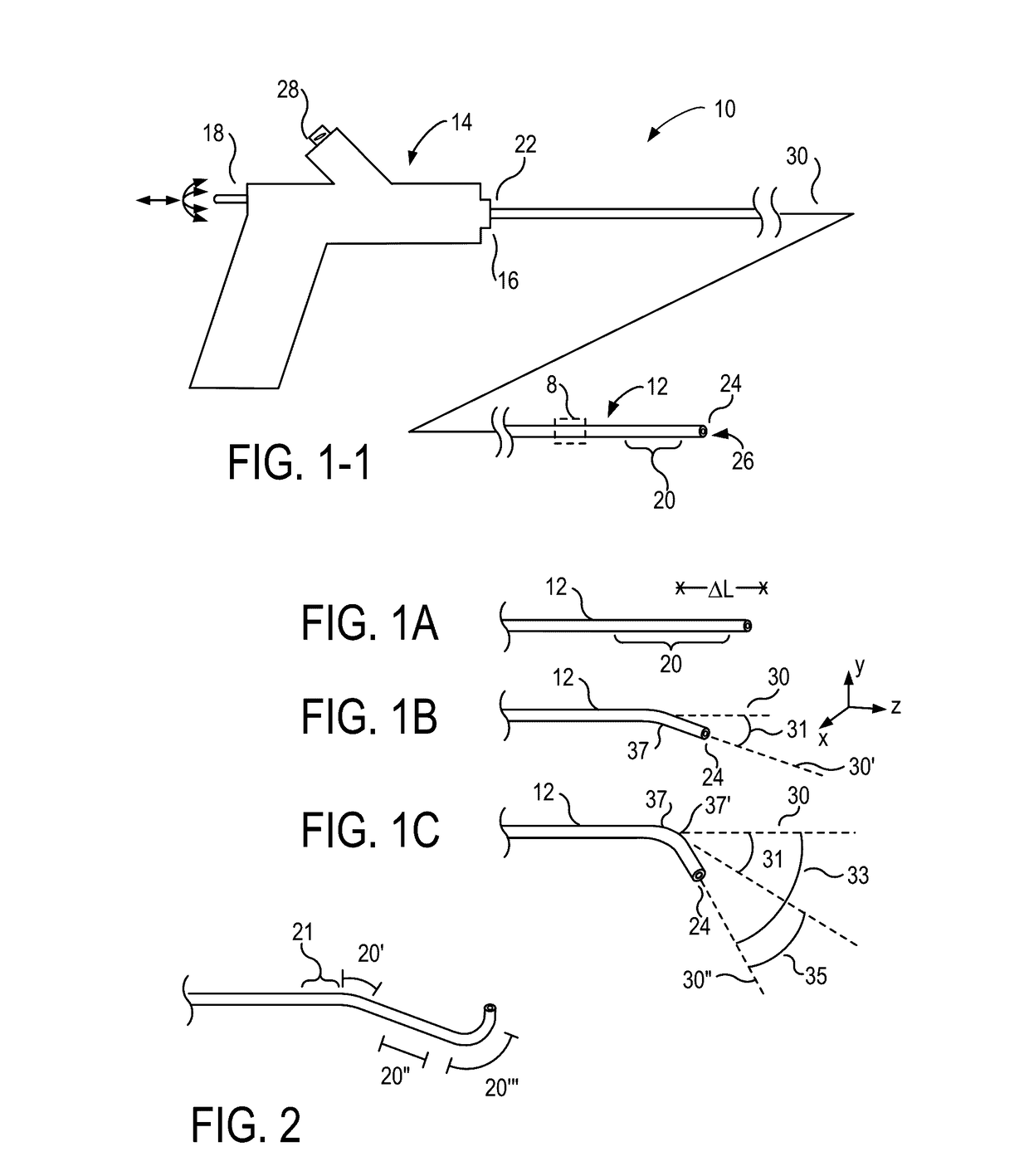

Lateral articulation anchors for catheters and other uses

Medical devices, systems, and methods provide improved control over the flexing of an articulated catheter adjacent a therapeutic or diagnostic tool by laterally bending the catheter so as to anchor an articulated portion of the catheter locally relative to an internal tissue site. Alternative embodiments may be used for a wide variety of non-medical applications, including with borescope systems and for other industrial applications.

Owner:PROJECT MORAY INC

Optical coherence tomography apparatus, optical fiber lateral scanner and a method for studying biological tissues in vivo

InactiveUS20030206321A1Data augmentationImprove performanceSurgeryInterferometersElectrical conductorIn vivo

The present invention relates to the analysis of the internal structures of objects using optical means. According to the invention there were designed an apparatus suited for optical coherence tomography (OCT), an optical fiber lateral scanner (15), which is a part of said apparatus and is incorporated into an optical fiber probe (8), and a method for studying biological tissue in vivo, which allows for making a diagnostics of the biological tissue under study on basis of the state of the basal membrane (46). The moving part of lateral scanner (15) of sampling arm (4) of interferometer (2) is arranged comprising a current conductor (19), which envelopes a magnetic system (17) in the area of one of its poles (25) and an optical fiber (13), which is rigidly fastened to current conductor (19), whereas optical fiber (13) serves as a flexible cantilever, allowing to miniaturize the optical fiber probe (8). Constructing magnetic system (17) as two permanent magnets (22, 28) which are aligned at their analogous poles (25, 29), and placing optical fiber (13) in a throughhole (30), the throughhole (30) being formed by the facing grooves made in said analogous poles (25, 29) of permanent magnets (22, 28), ensure optimization of the design of optical fiber probe (8), the body (11) of said optical fiber probe (8) having limited dimensions. Optical fiber probe (8) is placed at the distal end of an instrumental channel of an endoscope or borescope. Studying of biological tissue in vivo with the aid of the developed apparatus allows for non-invasive diagnostics of biological tissue on basis of the state of basal membrane (46).

Owner:IMALUX CORP

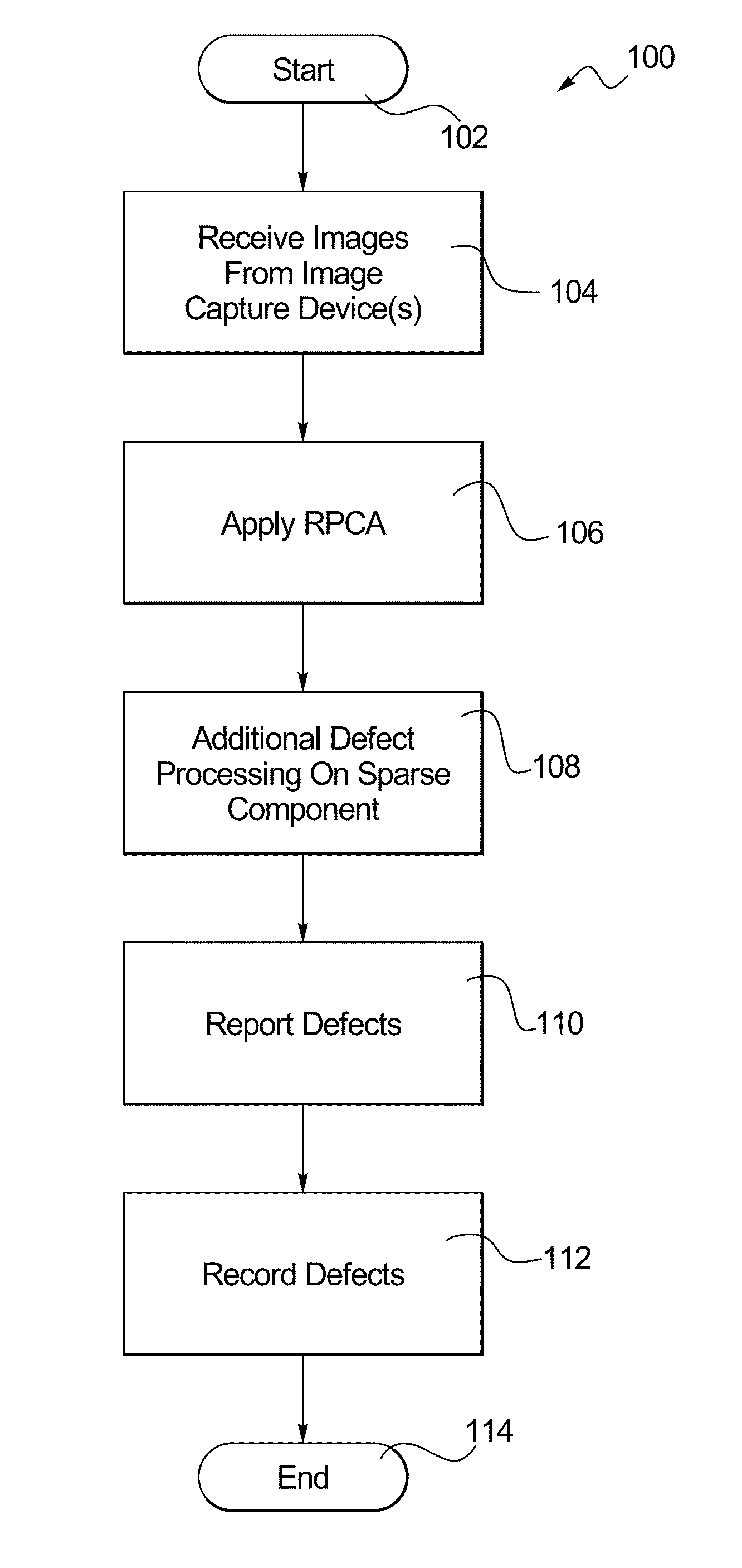

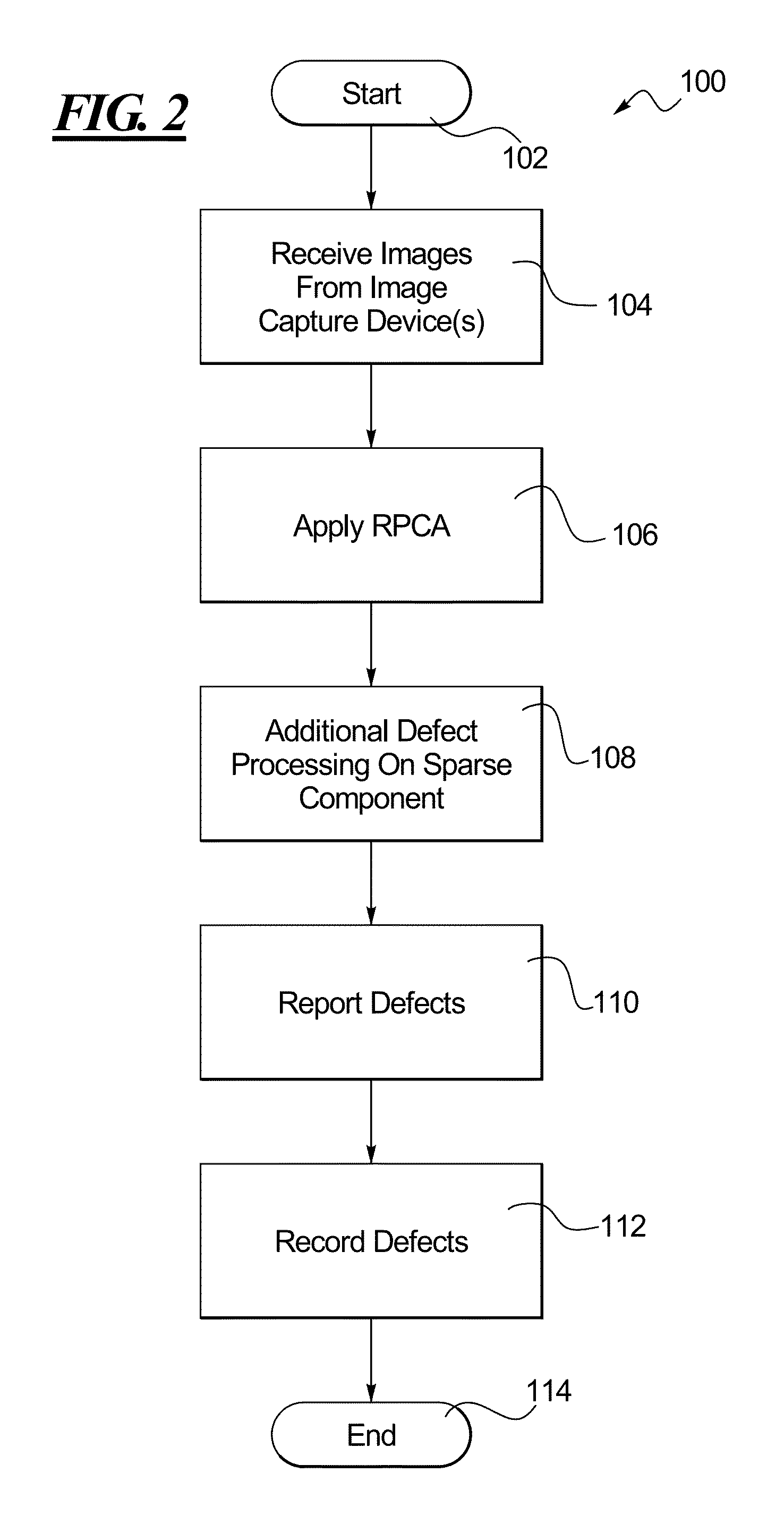

Method and system for automated defect detection

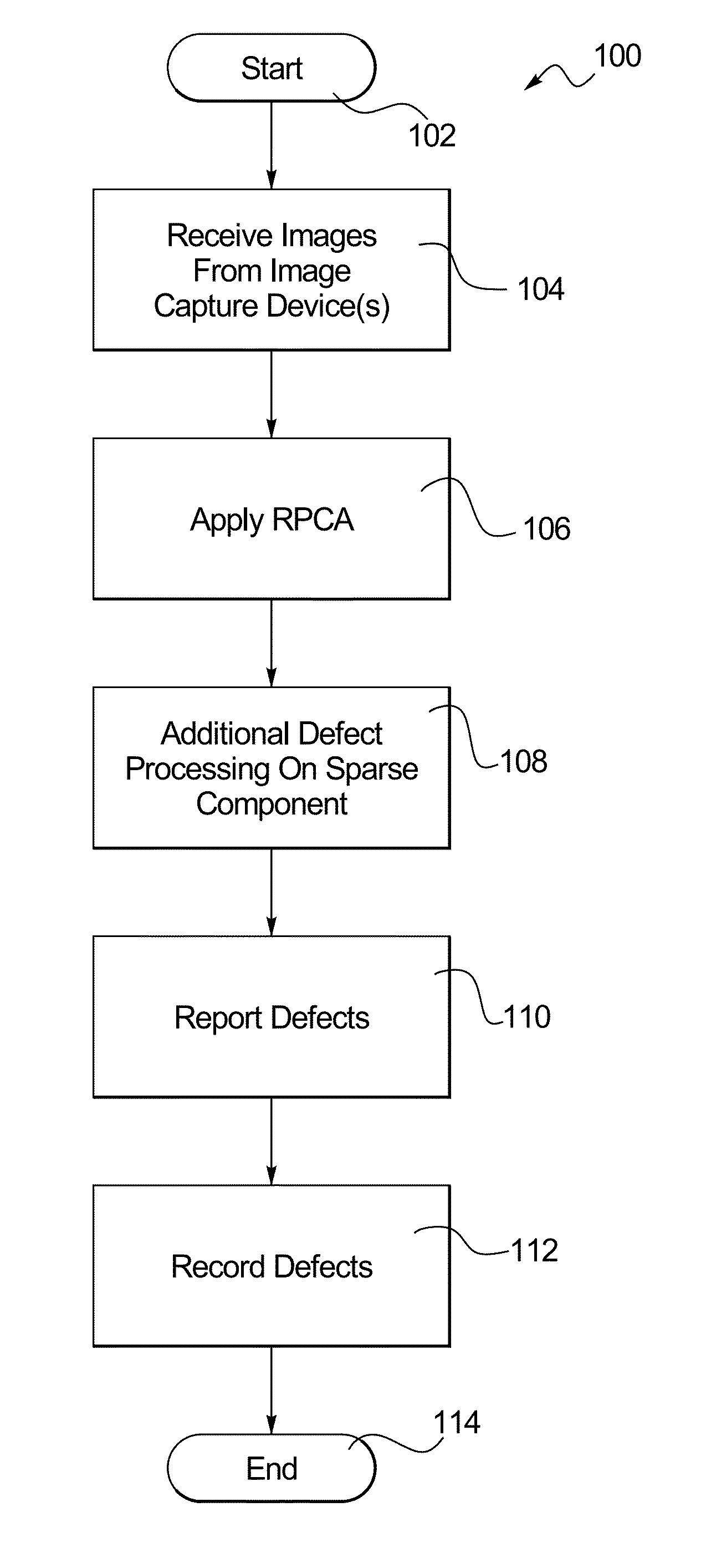

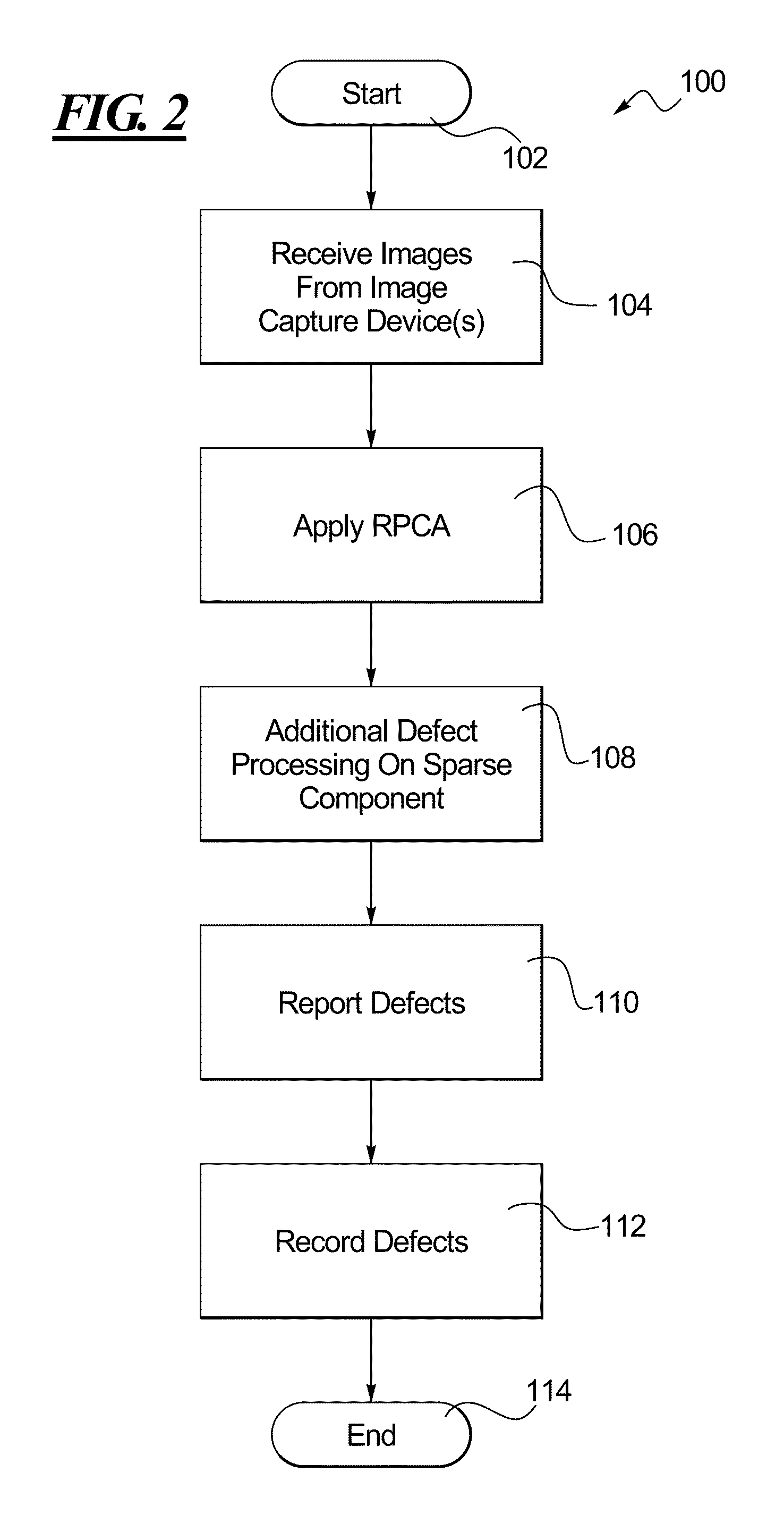

A computer program product and method for performing automated defect detection of blades within an engine is disclosed. The method may include providing a storage medium for storing data and programs used in processing video images, providing a processing unit for processing images, receiving from a borescope an initial set of images of a plurality of members inside of a device, and using the processing unit to apply Robust Principal Component Analysis to decompose the initial set of images into a first series of low rank component images and a second series of sparse component images, wherein there are at least two images in the initial series.

Owner:PRATT & WHITNEY +1

Method and System for Automated Defect Detection

A computer program product and method for performing automated defect detection of blades within an engine is disclosed. The method may include providing a storage medium for storing data and programs used in processing video images, providing a processing unit for processing images, receiving from a borescope an initial set of images of a plurality of members inside of a device, and using the processing unit to apply Robust Principal Component Analysis to decompose the initial set of images into a first series of low rank component images and a second series of sparse component images, wherein there are at least two images in the initial series.

Owner:RAYTHEON TECH CORP +1

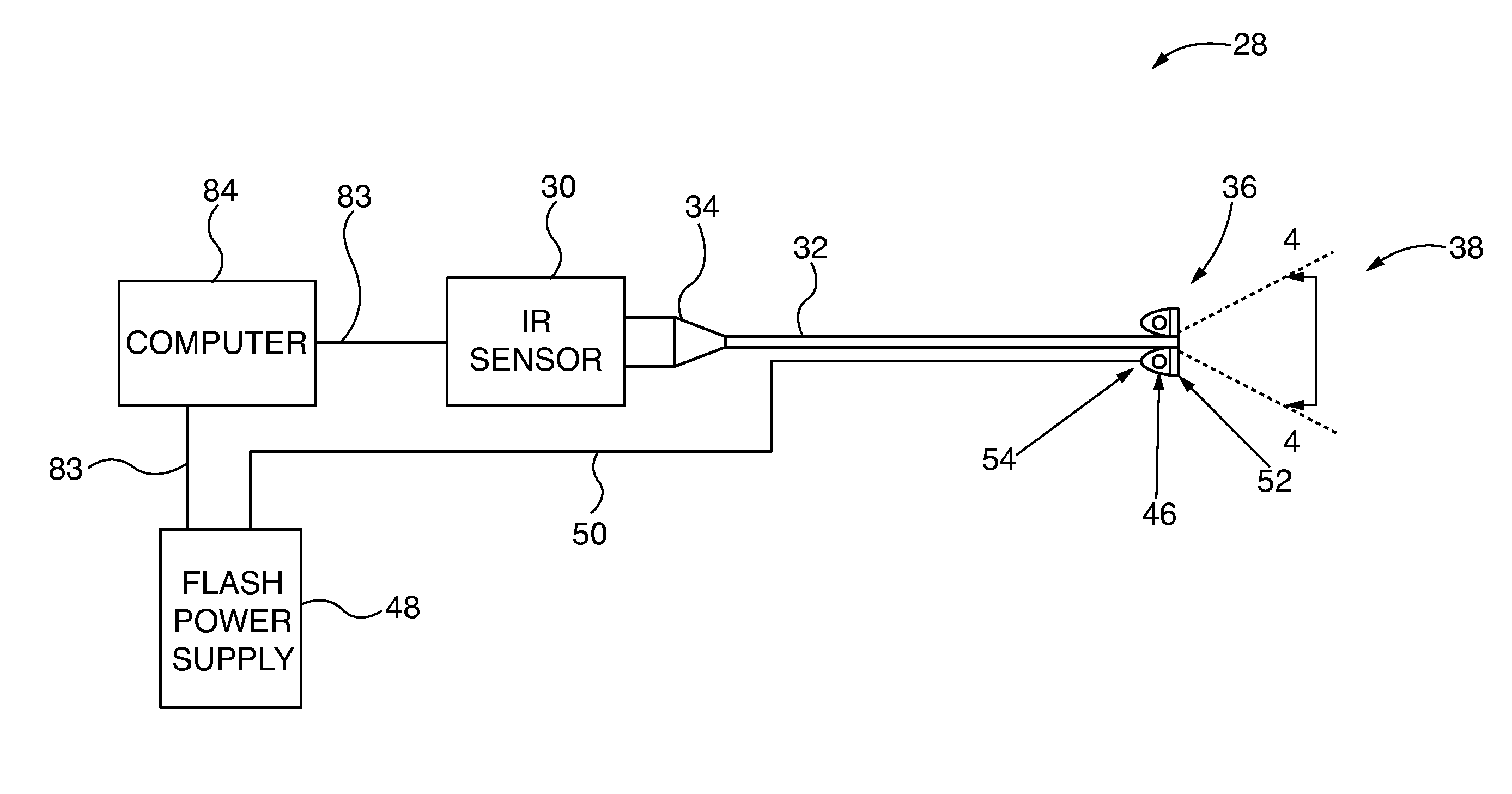

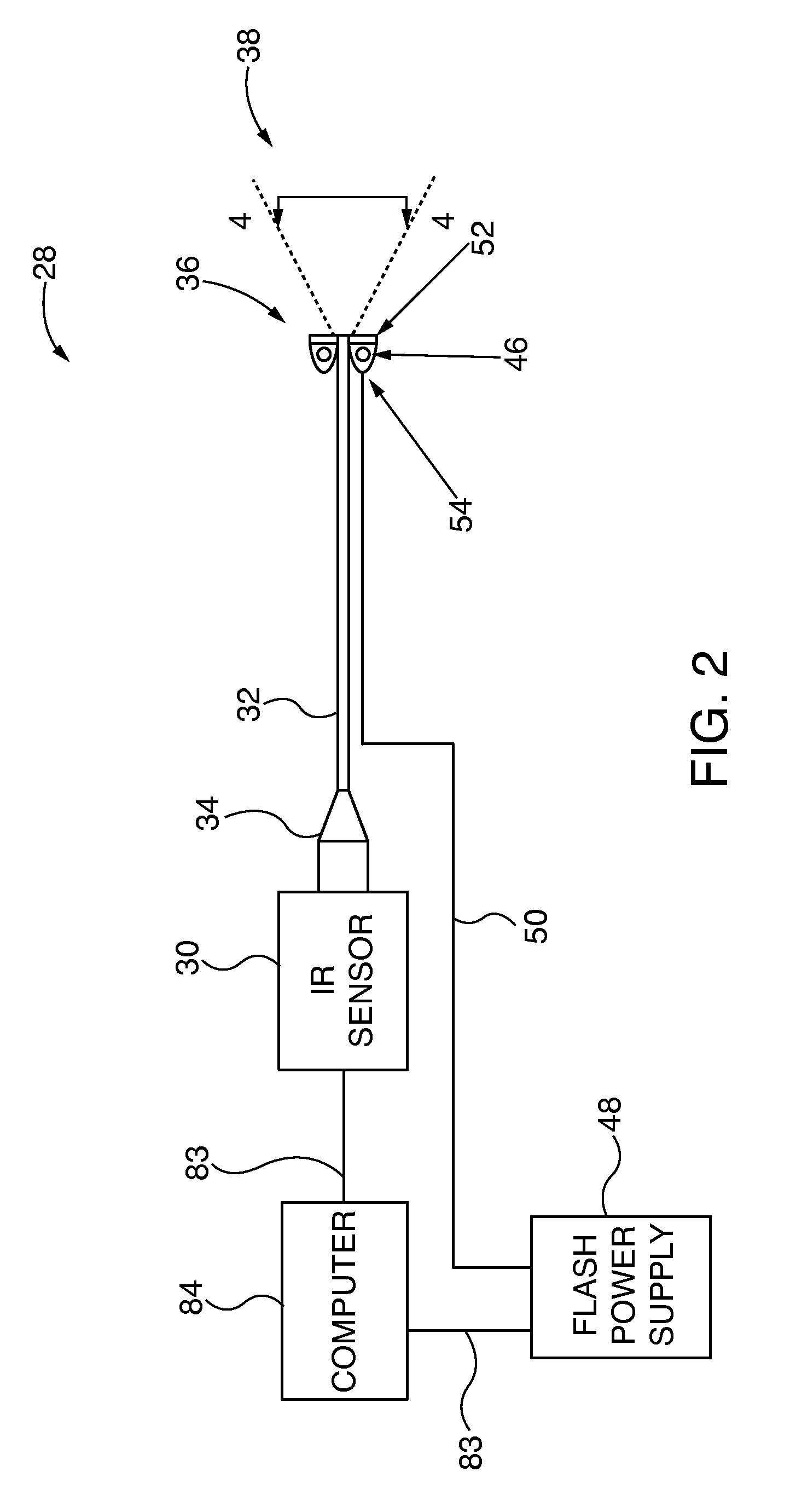

System to prognose gas turbine remaining useful life

A flash thermography device for generating an infrared image of a turbine component located inside a turbine, wherein the turbine includes at least one inspection port. The device includes a flash source that generates a light pulse that heats the turbine component and an infrared sensor for detecting thermal energy radiated by the turbine component. The device also includes a borescope having a sensor end, a viewing end that includes the flash source and an interior hollow that extends between the sensor and viewing ends. The borescope is positioned in the inspection port such that the viewing end is located inside the turbine. Thermal energy radiated from the turbine component is transmitted through the hollow to the infrared sensor to enable generation of the infrared image. The device further includes a reflector located on the viewing end that directs the light pulse toward the turbine component and a flash power supply for energizing the flash source.

Owner:SIEMENS ENERGY INC

Digital video borescope for drilled shaft inspection

InactiveUS20070127780A1Economical and inexpensiveEfficient in storing and retrievingSurveyConstructionsDigital videoComputer graphics (images)

Visual inspection of an interior surface of a borehole. A housing adapted to be lowered in the borehole supports a portable camera for generating images of a portion of the interior surface of the borehole and a light source for illuminating an area adjacent the camera. A monitor receives signals from the camera and, in response thereto, displays the images generated by the camera. A viewing envelope positioned adjacent the camera defines a viewing area adjacent the camera, particularly for use in visually inspecting slurry-filled boreholes.

Owner:AVER TECH INC

Automated borescope measurement tip accuracy test

Measurement accuracy of a remote visual inspection (RVI) system is tested using a test object including a test feature having a known geometric characteristic. Using a controller, attachment of a detachable measurement optical tip to an RVI probe is detected. A user is then prompted to perform testing of the measurement accuracy. When the user indicates the test feature is visible, the system captures one or more images of the test feature, determines coordinates of the test feature from the images, and measures a geometric characteristic of the test feature using the coordinates. An accuracy result is determined using the measured geometric characteristic and the known geometric characteristic, and an indication is provided, e.g., to the user, of the result of the comparison. An RVI system with a user-prompt device is also described.

Owner:BAKER HUGHES INC

Borescope boss and plug cooling

A coolable borescope boss includes cooling passages extending through the boss and oriented for spraying cooling air into a hole extending through the boss. Centerlines of the cooling passages may intersect the a hole axis of the hole. The cooling passages may be cylindrical or open slots disposed through the boss. The boss may be on an arcuate gas turbine engine shroud segment circumscribed about an axial centerline axis. The segment may be part of an annular segmented turbine shroud having cylindrical shroud first and second sections and a conical shroud midsection therebetween and the segment having cylindrical segment first and second sections and a conical segment midsection therebetween. A hole exit of the hole being flush with the conical segment midsection. A borescope plug tip having a spherical tip chamfer may be used to seal against a conical boss chamfer of the boss.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com