Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10257 results about "Turbine blade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

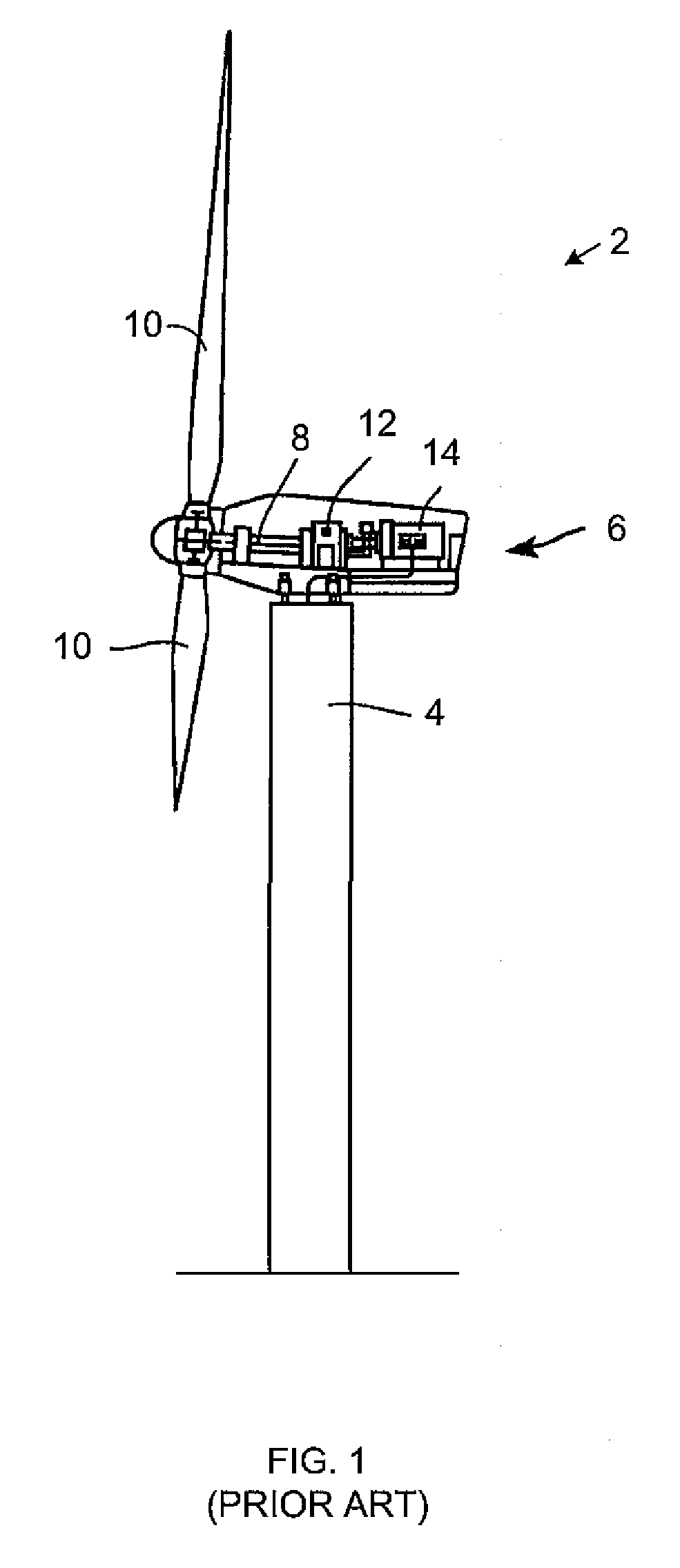

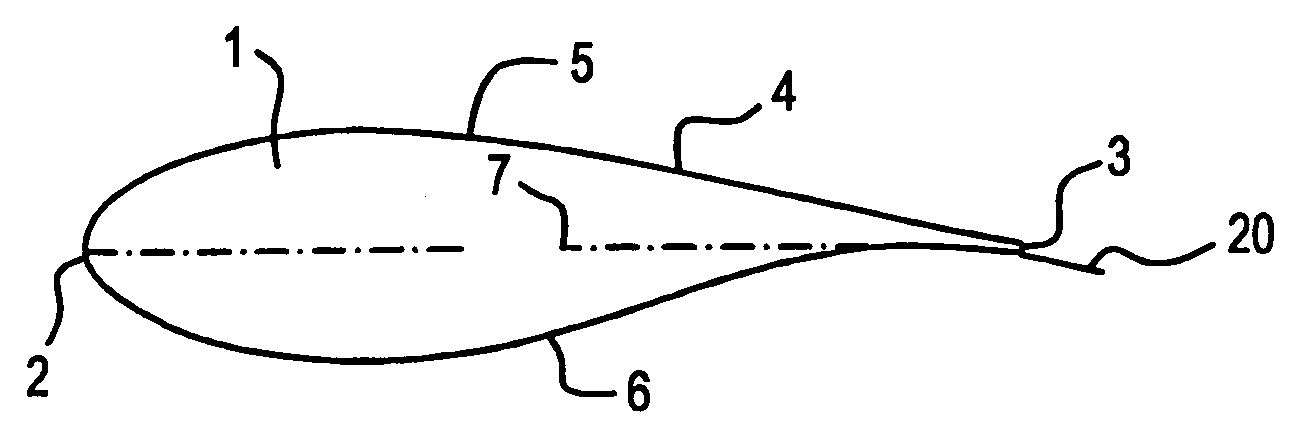

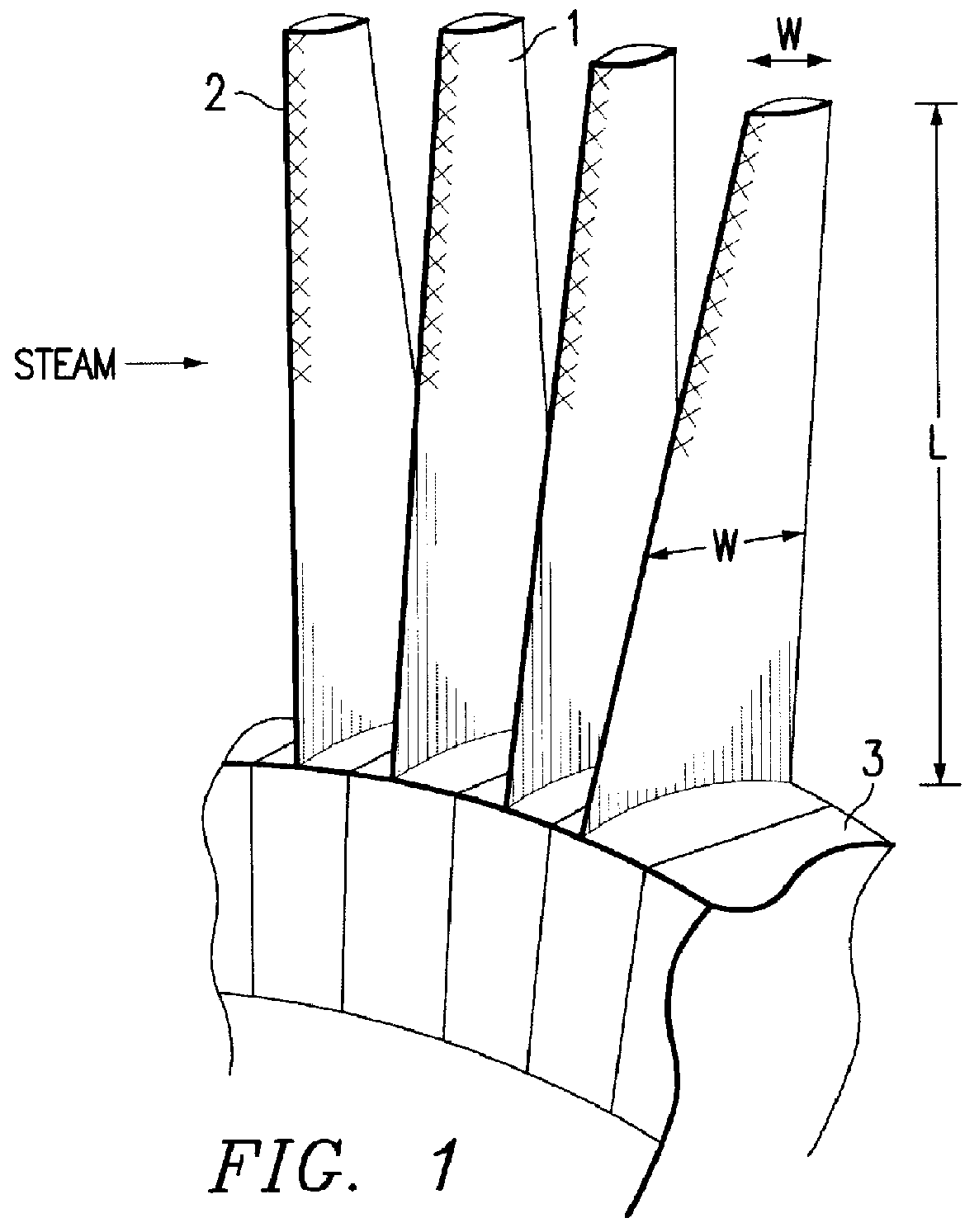

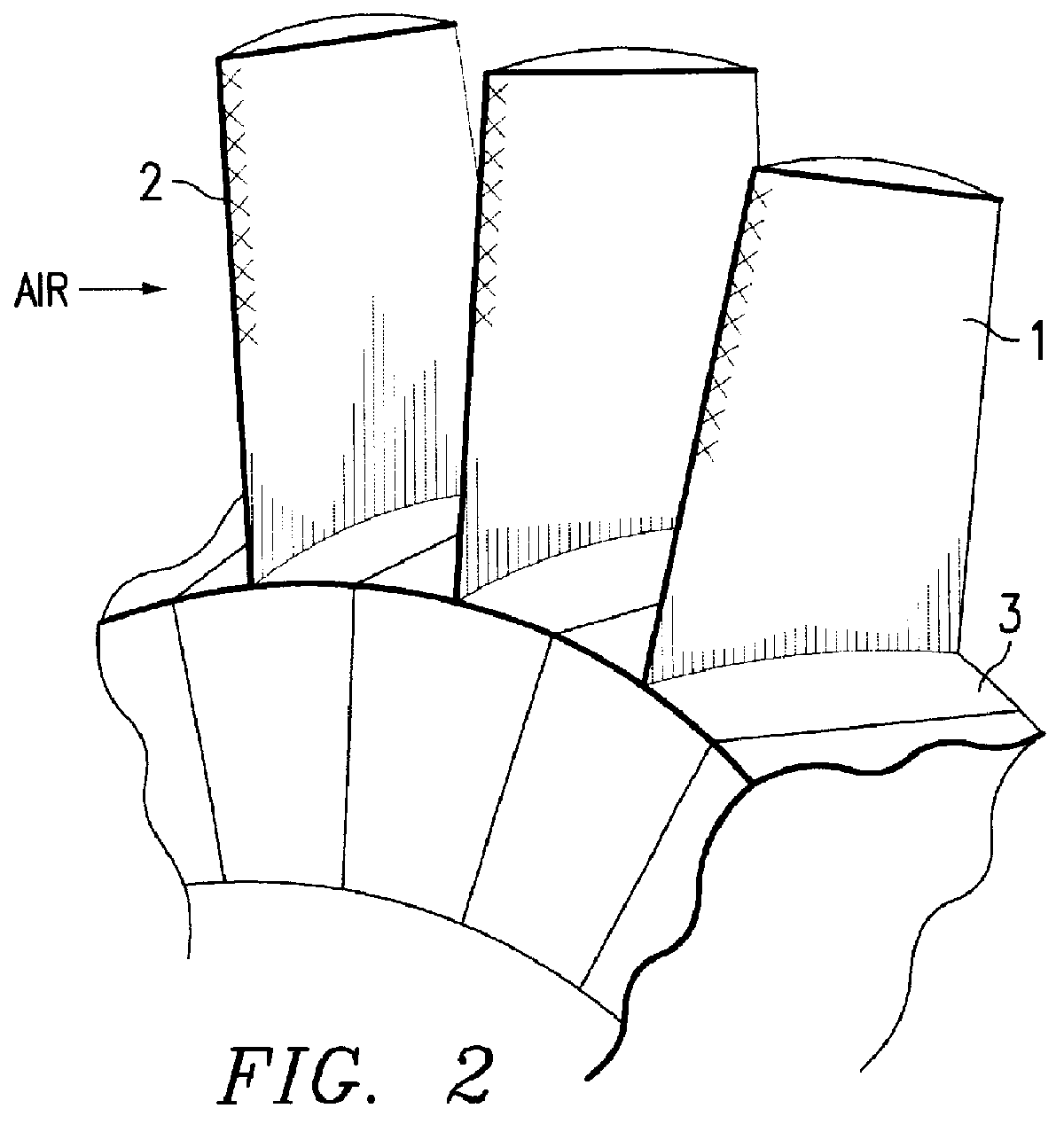

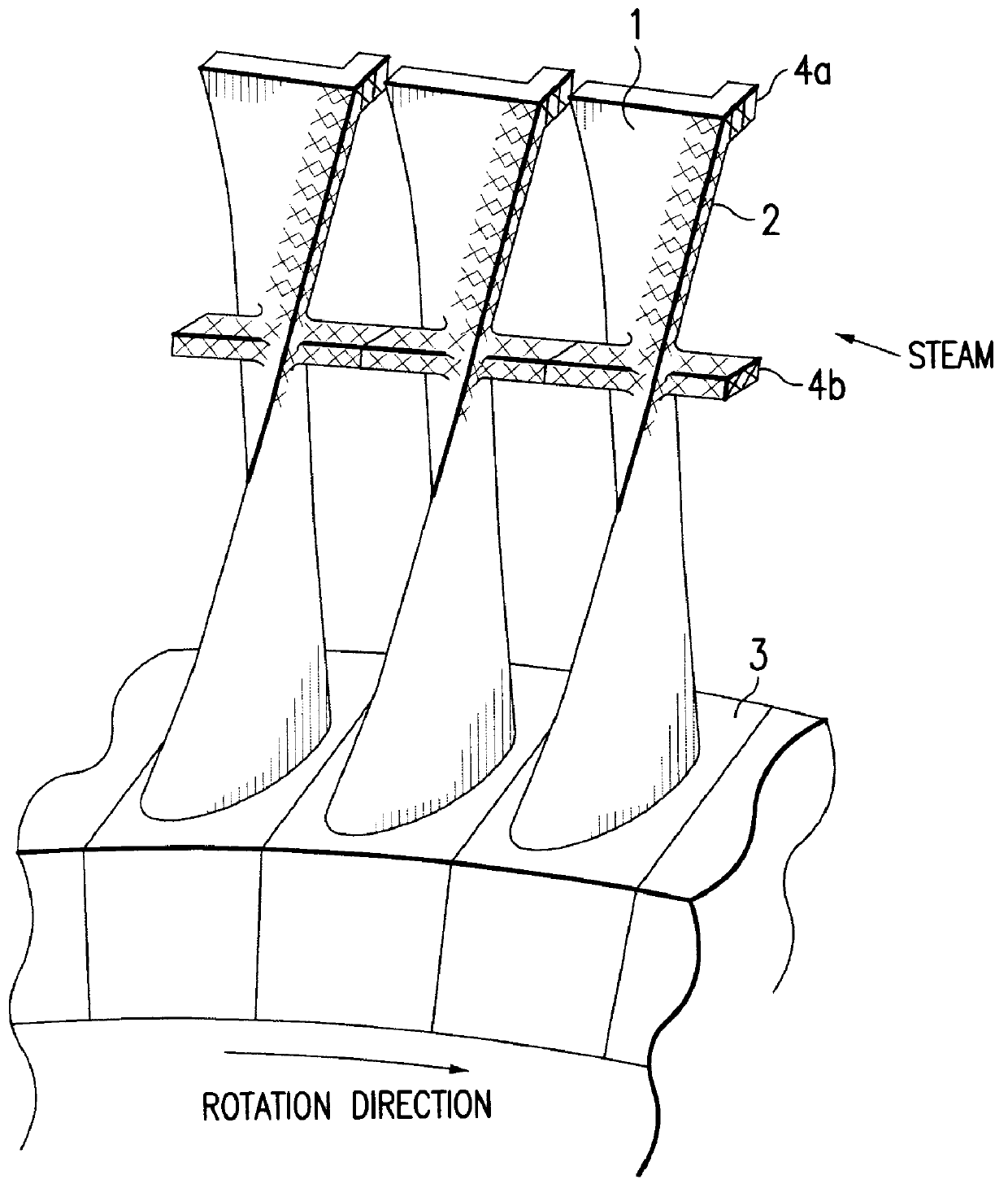

A turbine blade is the individual component which makes up the turbine section of a gas turbine or steam turbine. The blades are responsible for extracting energy from the high temperature, high pressure gas produced by the combustor. The turbine blades are often the limiting component of gas turbines. To survive in this difficult environment, turbine blades often use exotic materials like superalloys and many different methods of cooling that can be categorized as internal and external cooling , and thermal barrier coatings. Blade fatigue is a major source of failure in steam turbines and gas turbines. Fatigue is caused by the stress induced by vibration and resonance within the operating range of machinery. To protect blades from these high dynamic stresses, friction dampers are used.

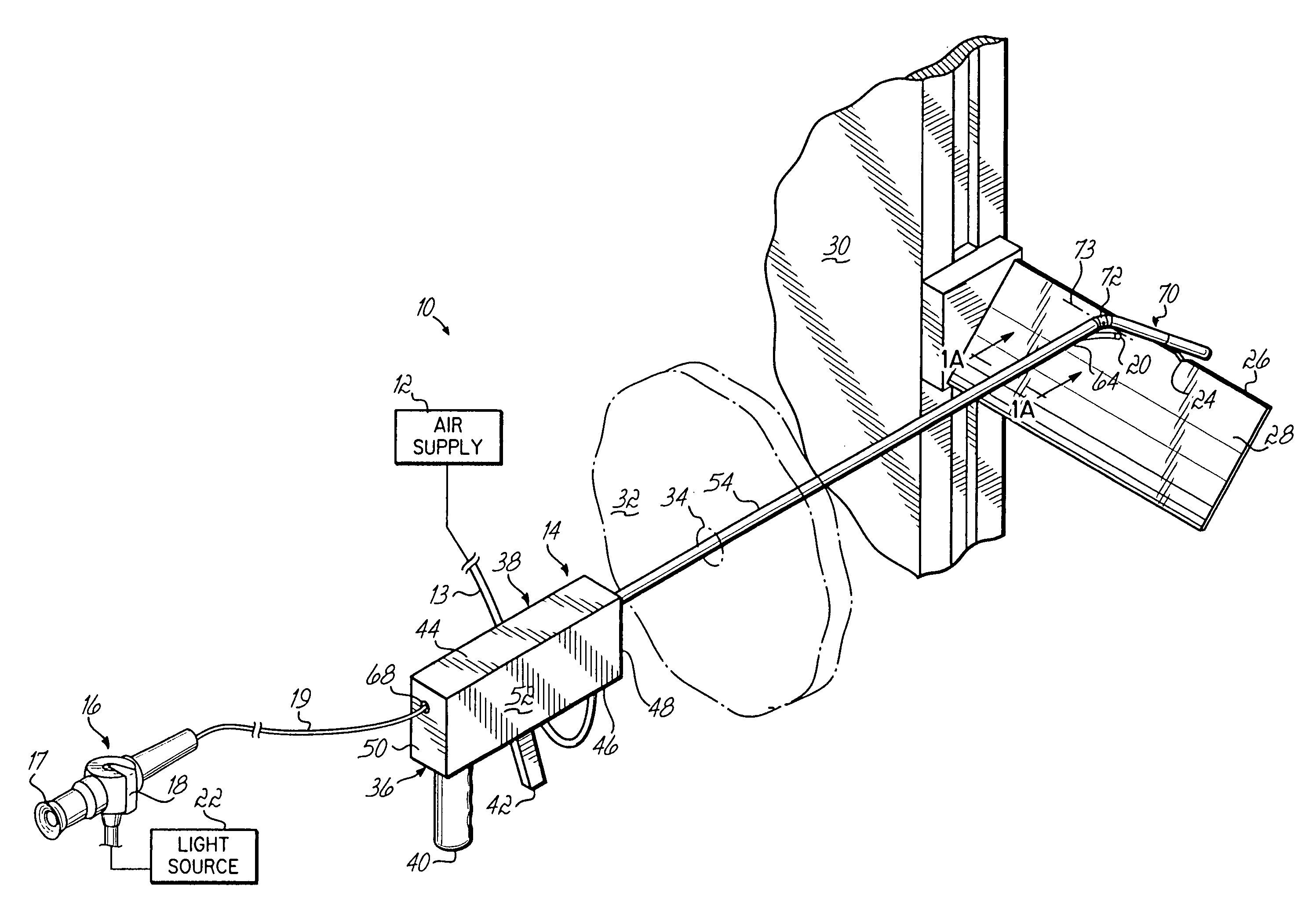

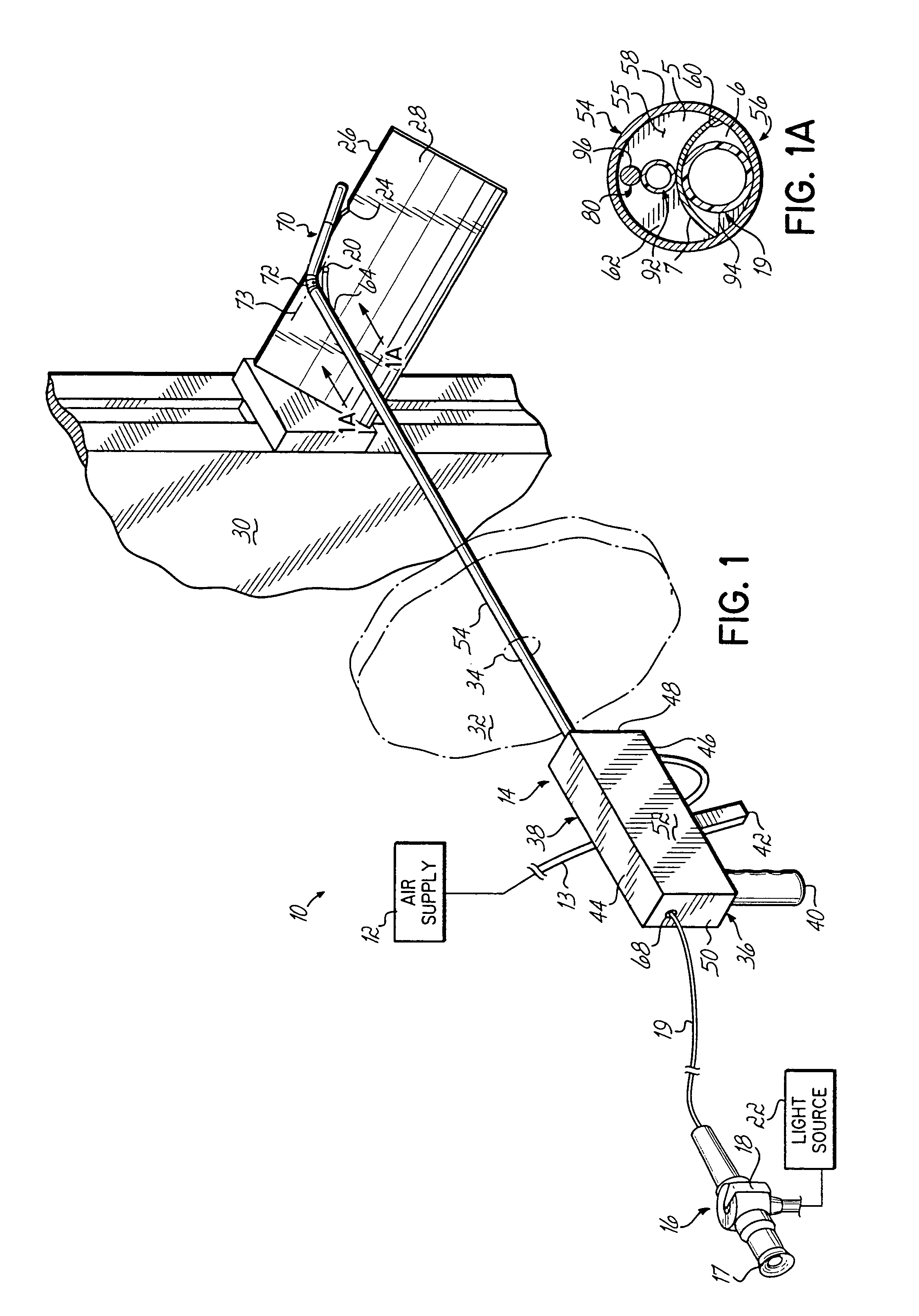

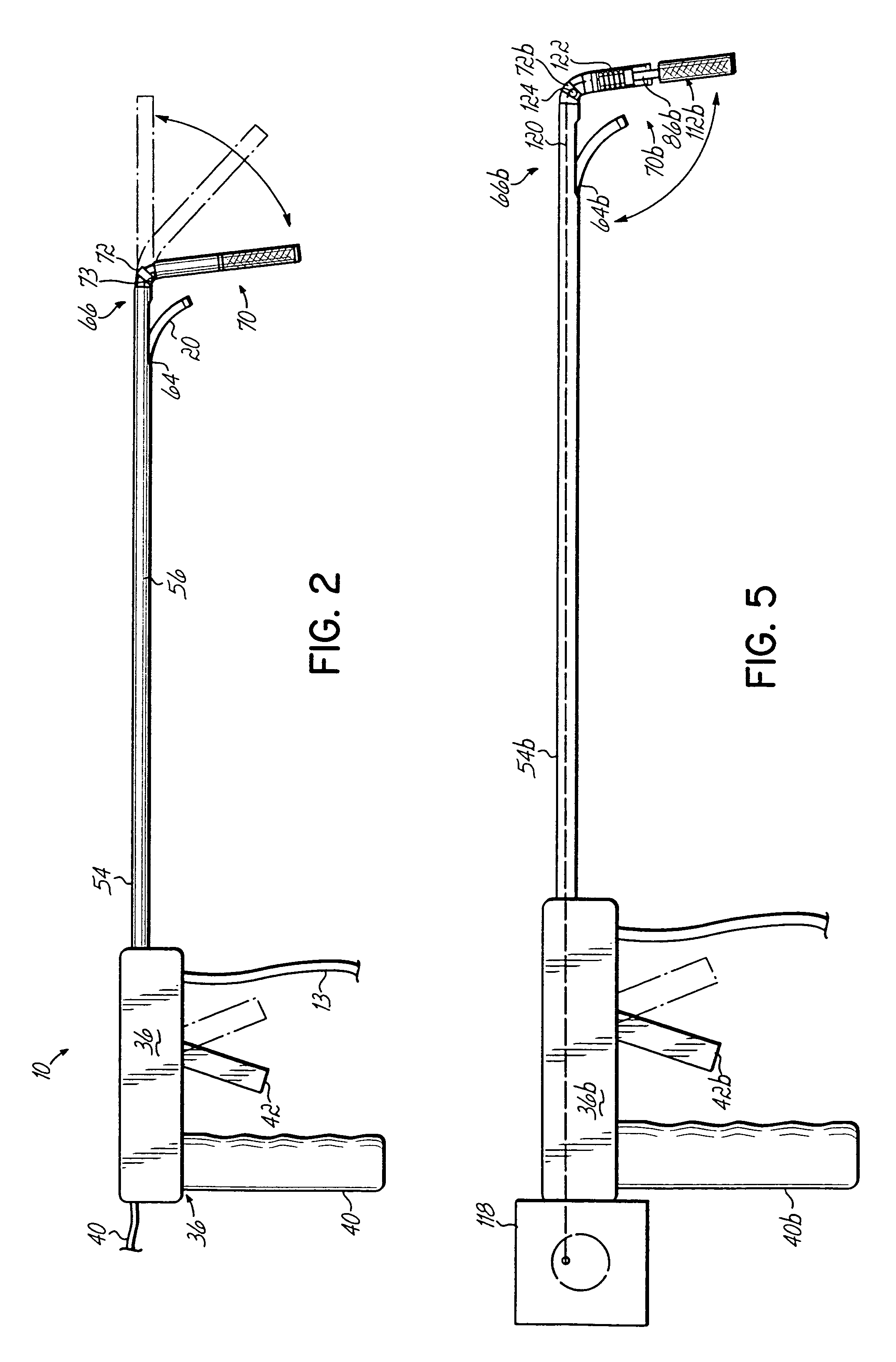

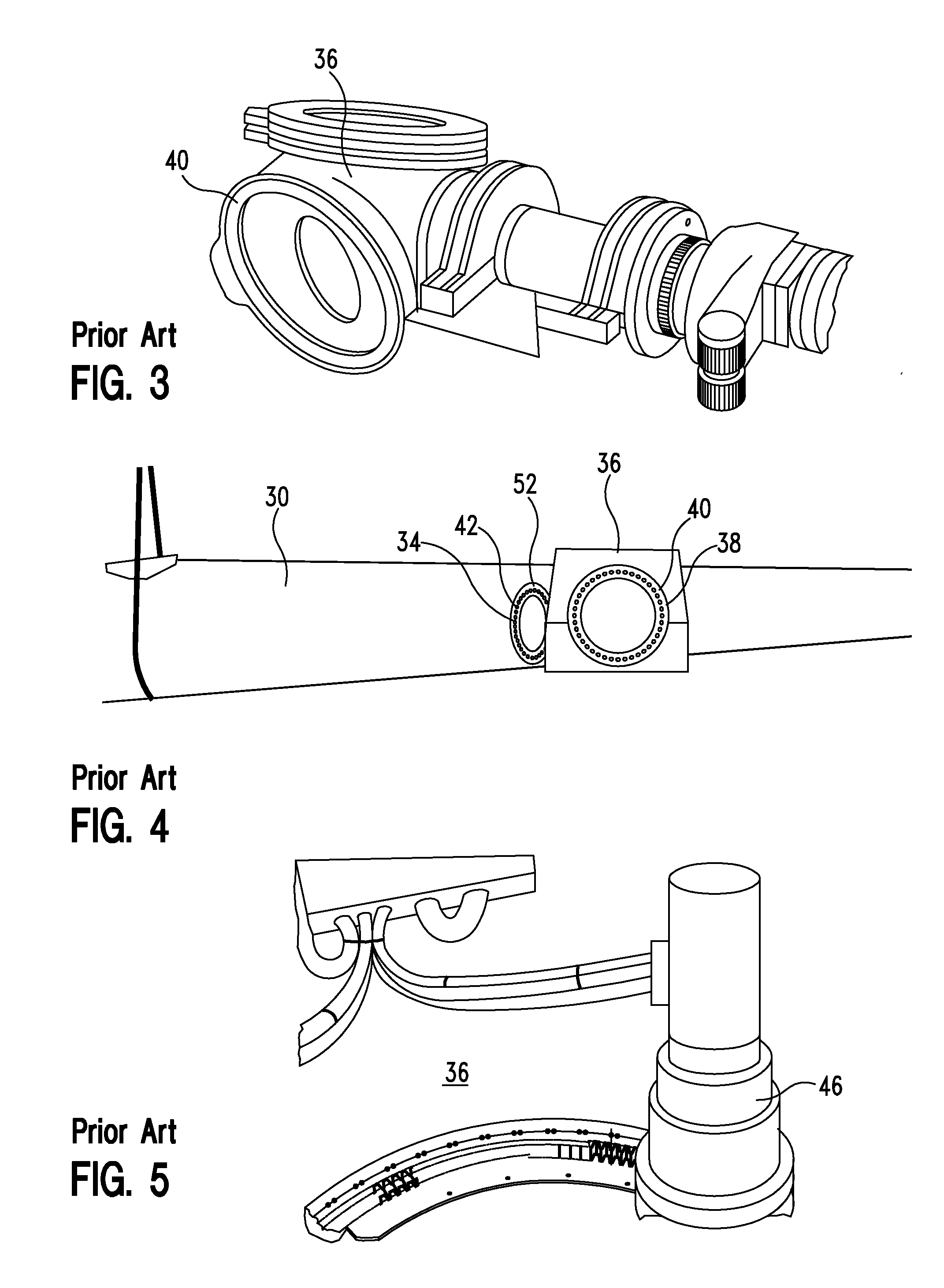

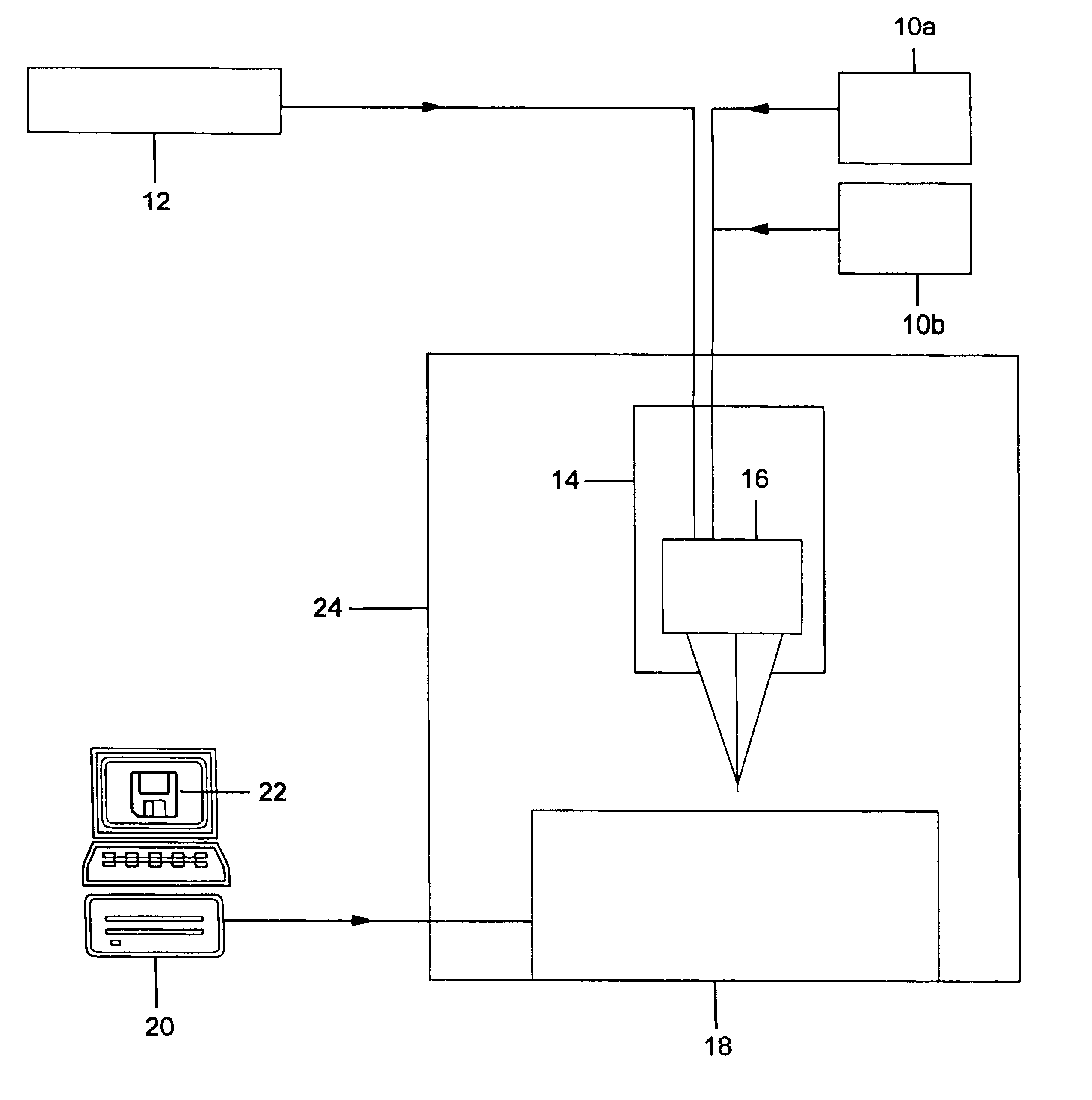

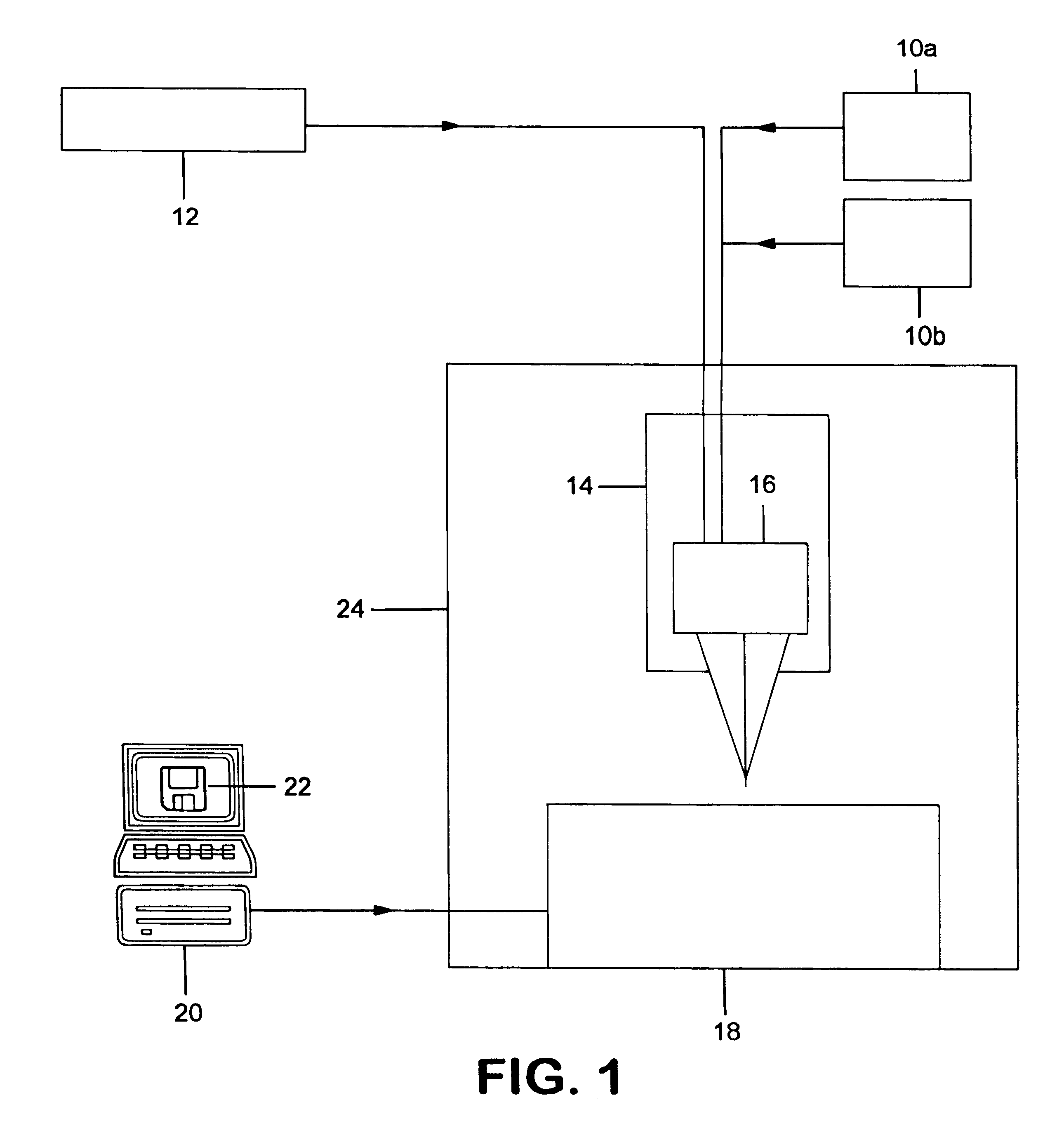

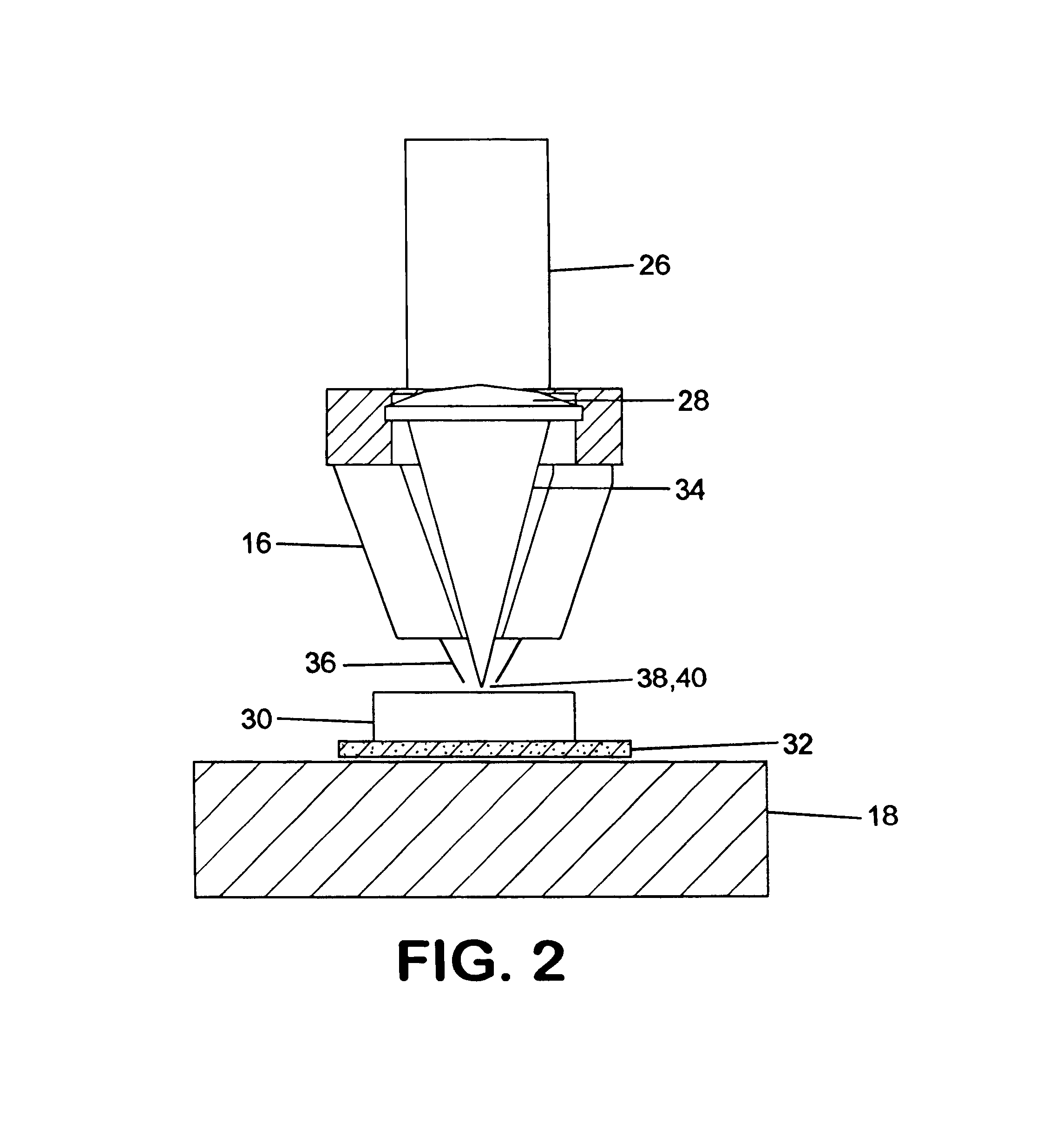

Grinding apparatus for blending defects on turbine blades and associated method of use

InactiveUS6899593B1Revolution surface grinding machinesBlade accessoriesReciprocating motionTurbine blade

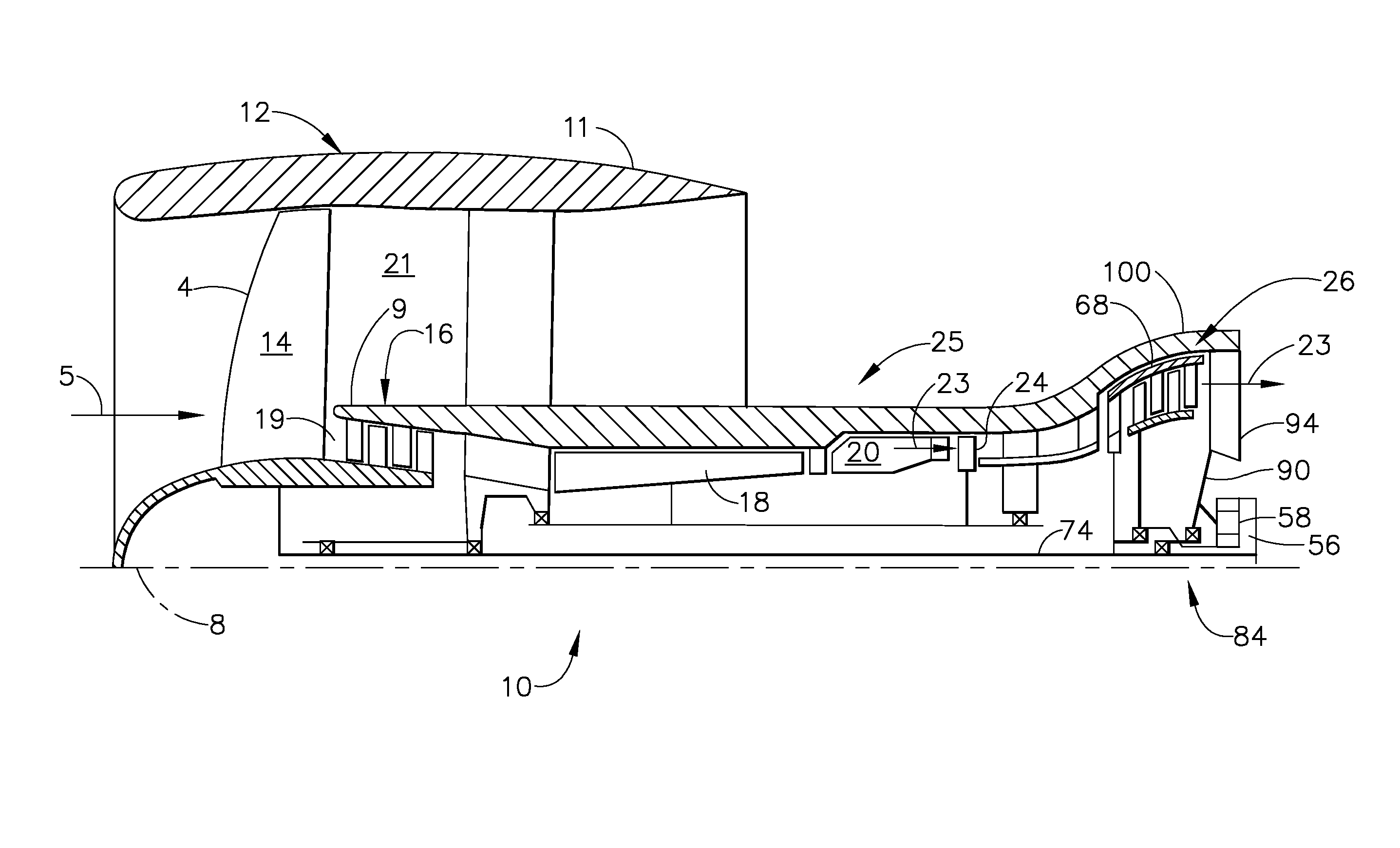

A grinding apparatus for use with an endoscope for viewing and blending defects on a turbine engine blade is provided. In one preferred embodiment air pulses from an air supply cause a grinding head on the end of a grinding tool to reciprocate at a predetermined speed. The position of the grinding head is fixed via the operator via a trigger on the grinding tool which articulates an outer portion of a support tube of the grinding tool. In another preferred embodiment, fluid is used to reciprocate the grinding head.

Owner:MOELLER DIETER +2

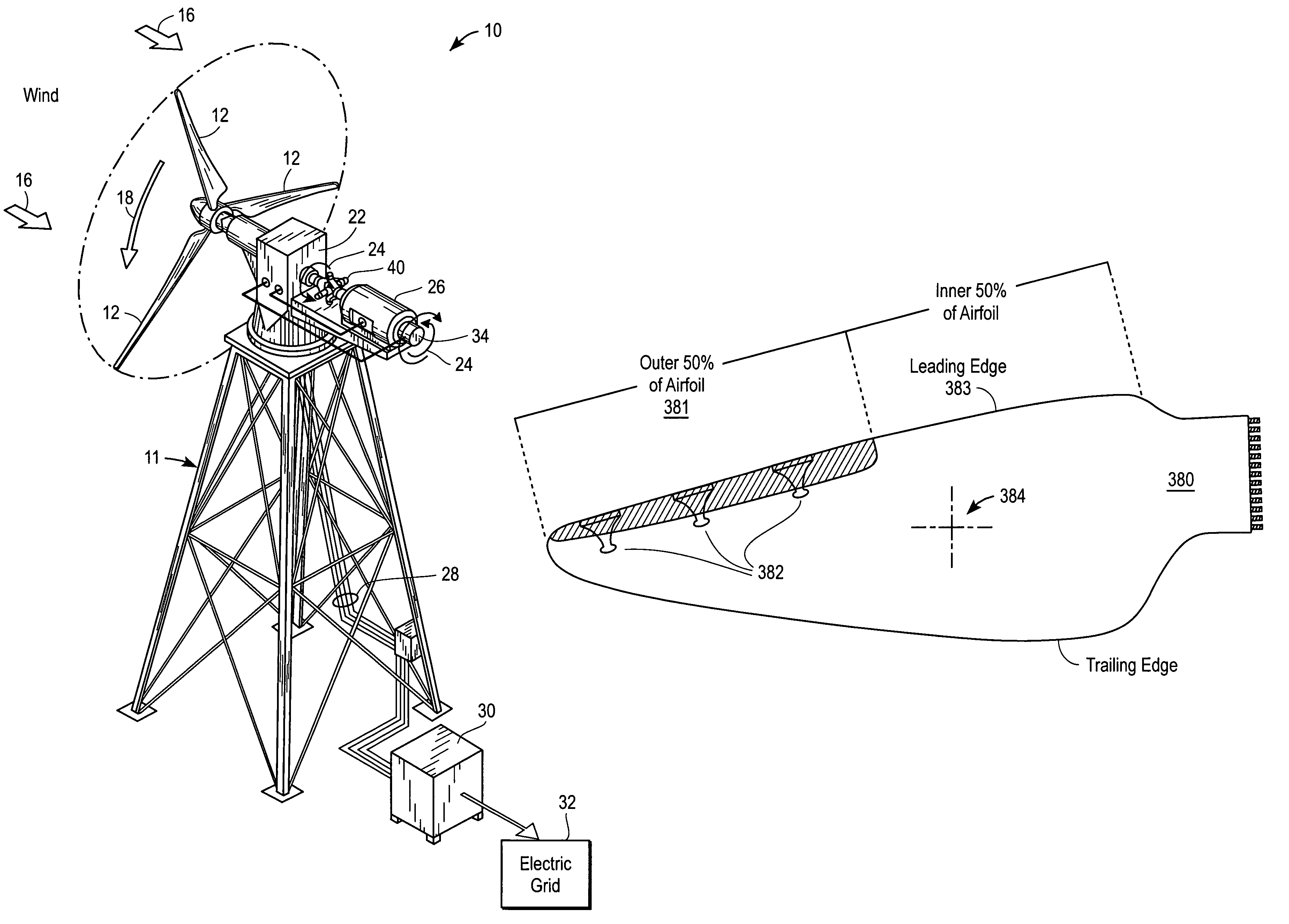

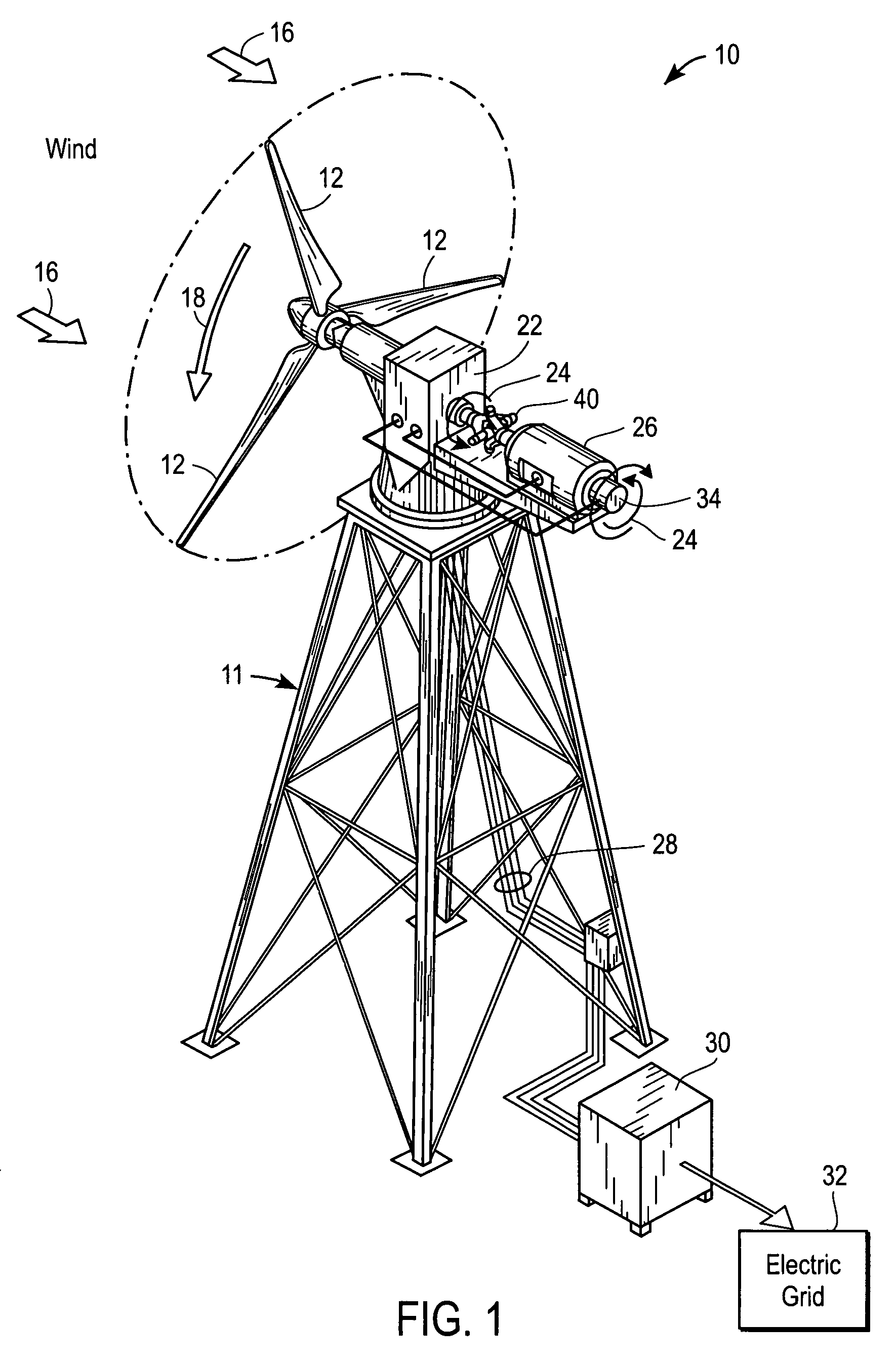

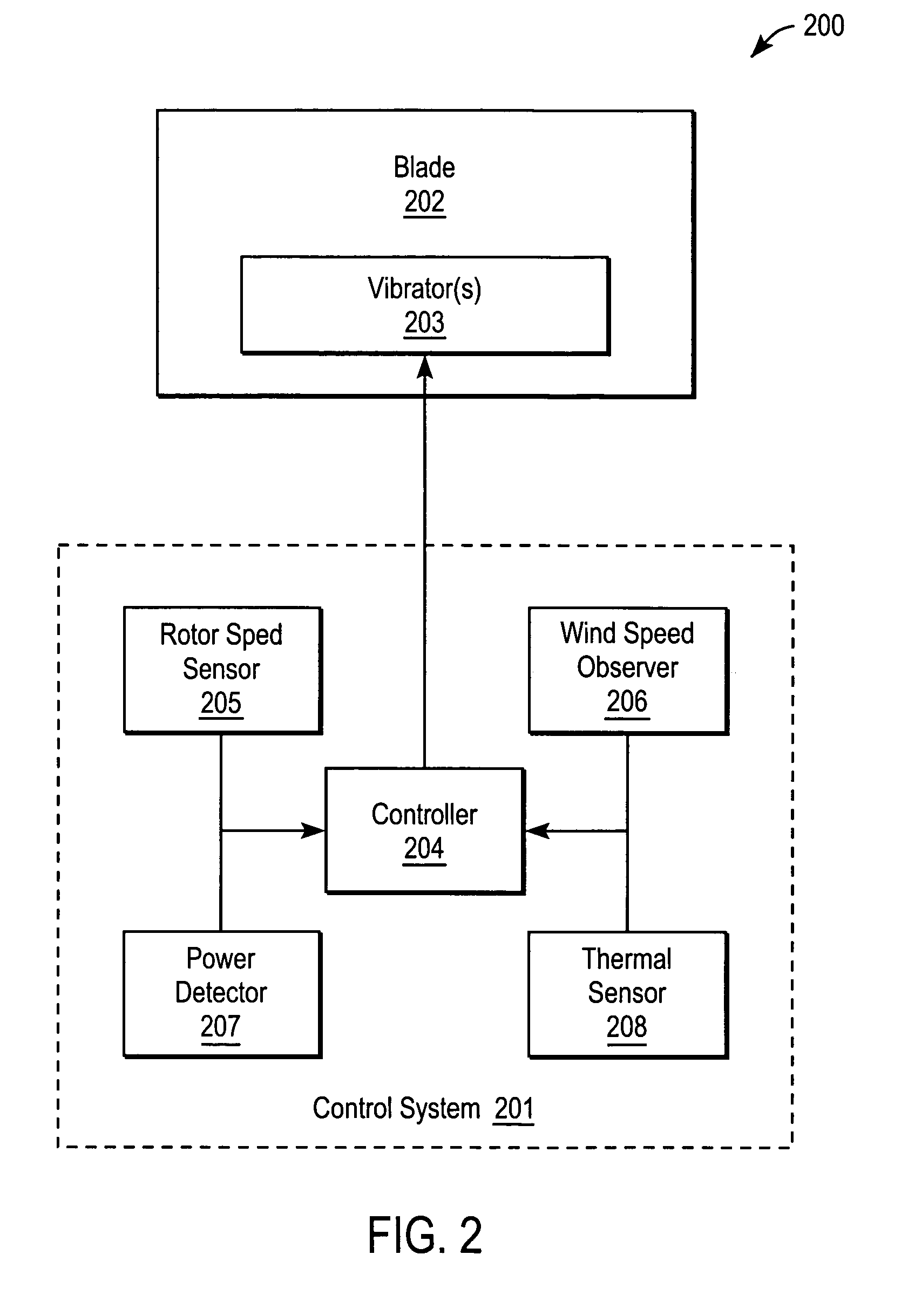

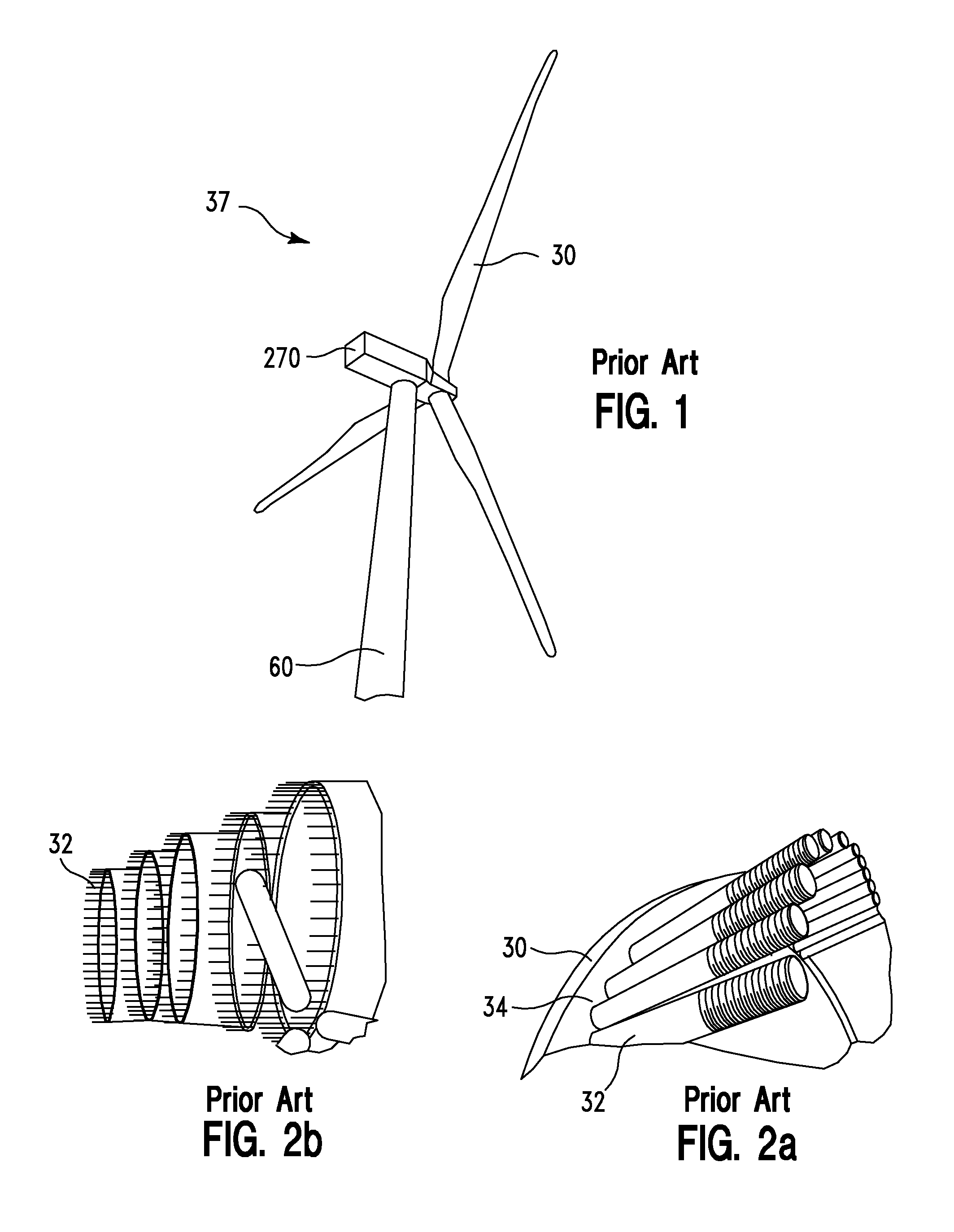

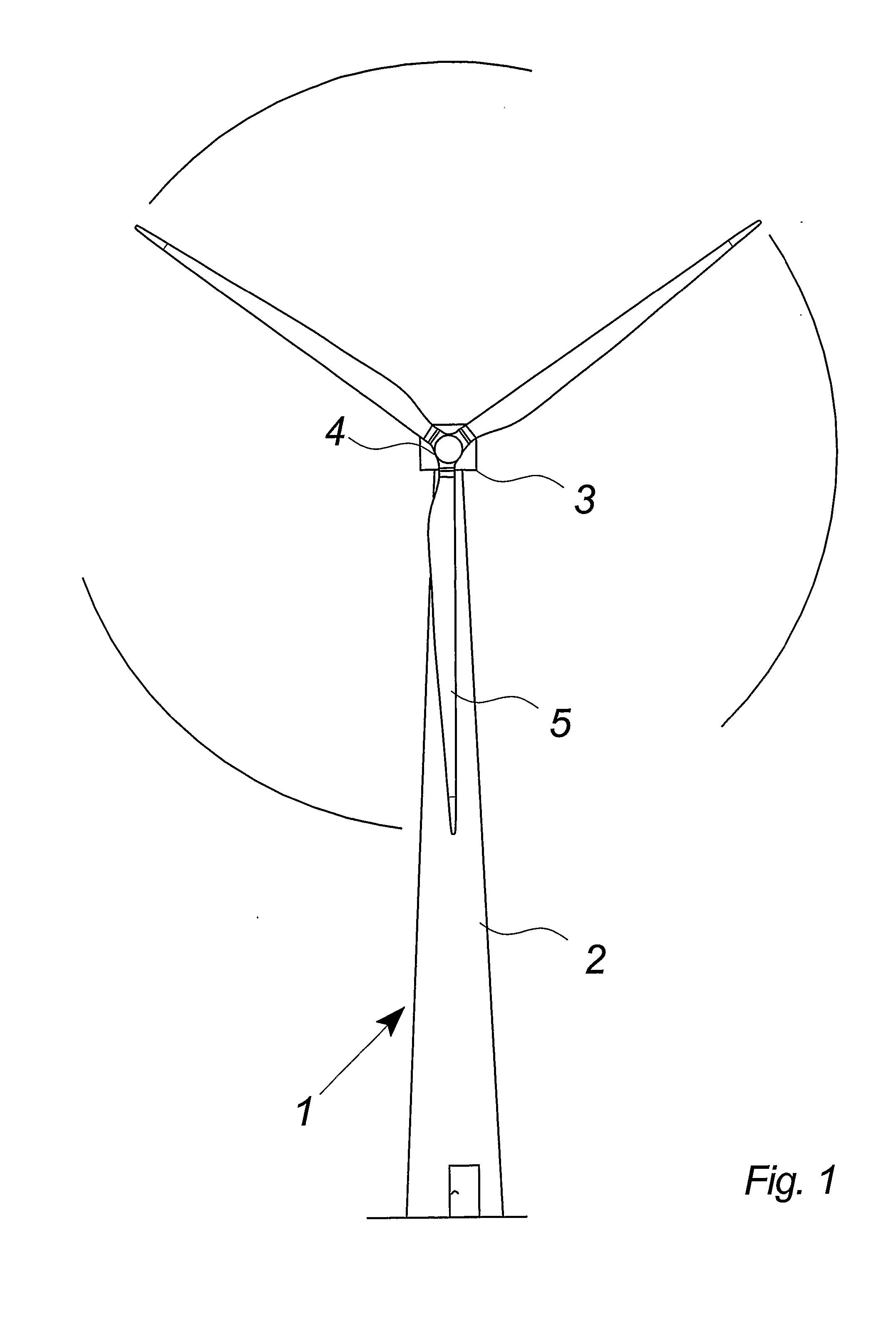

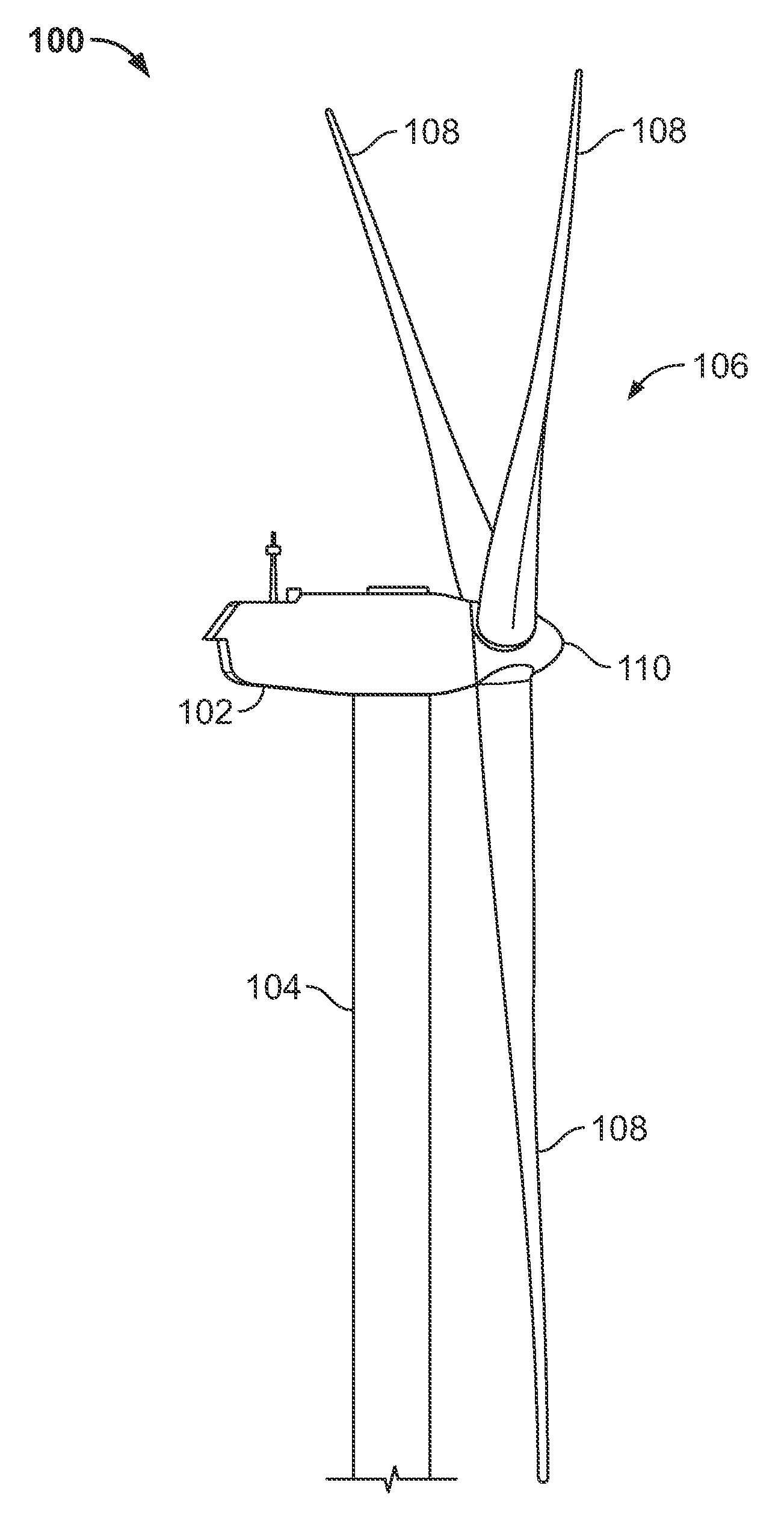

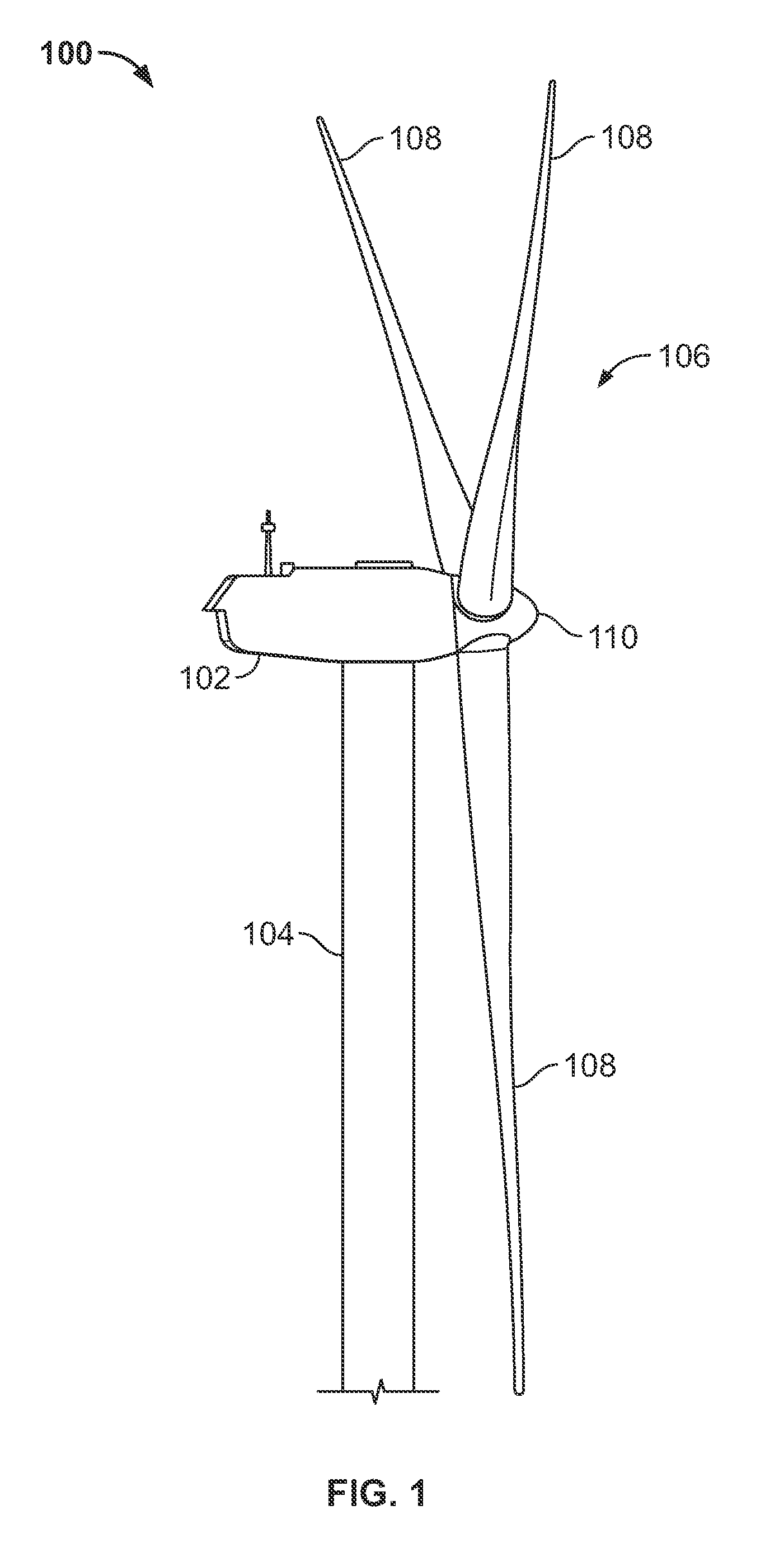

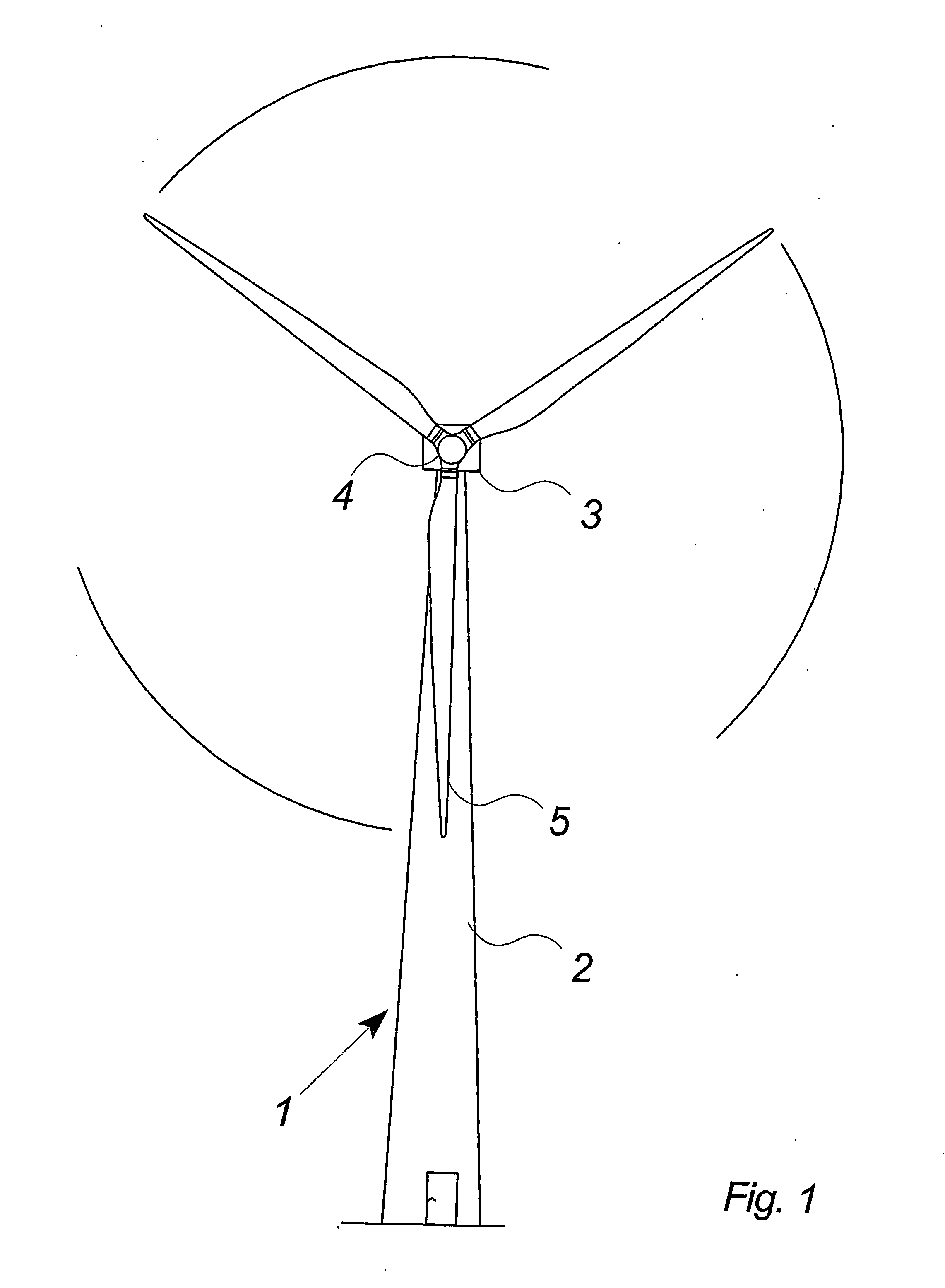

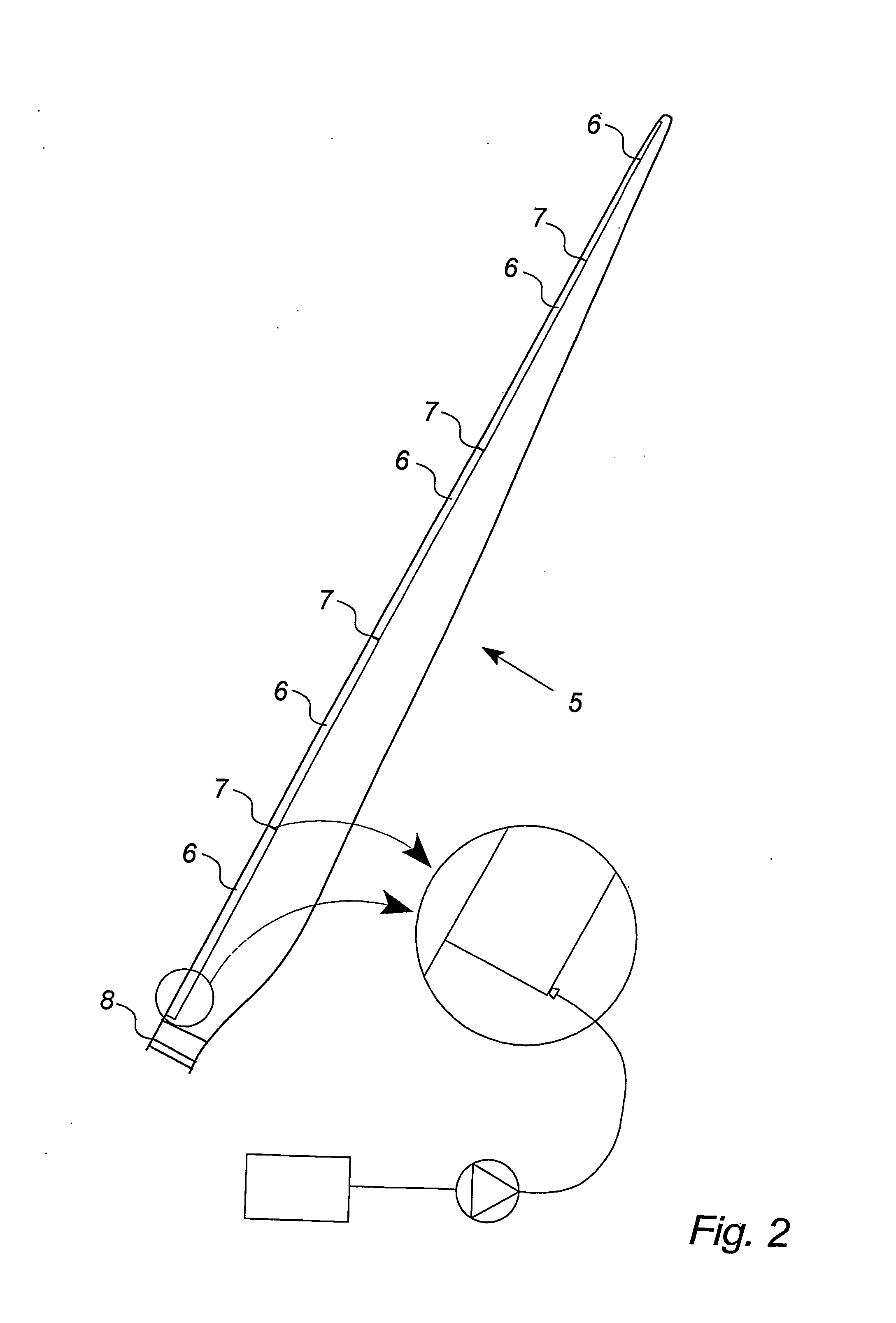

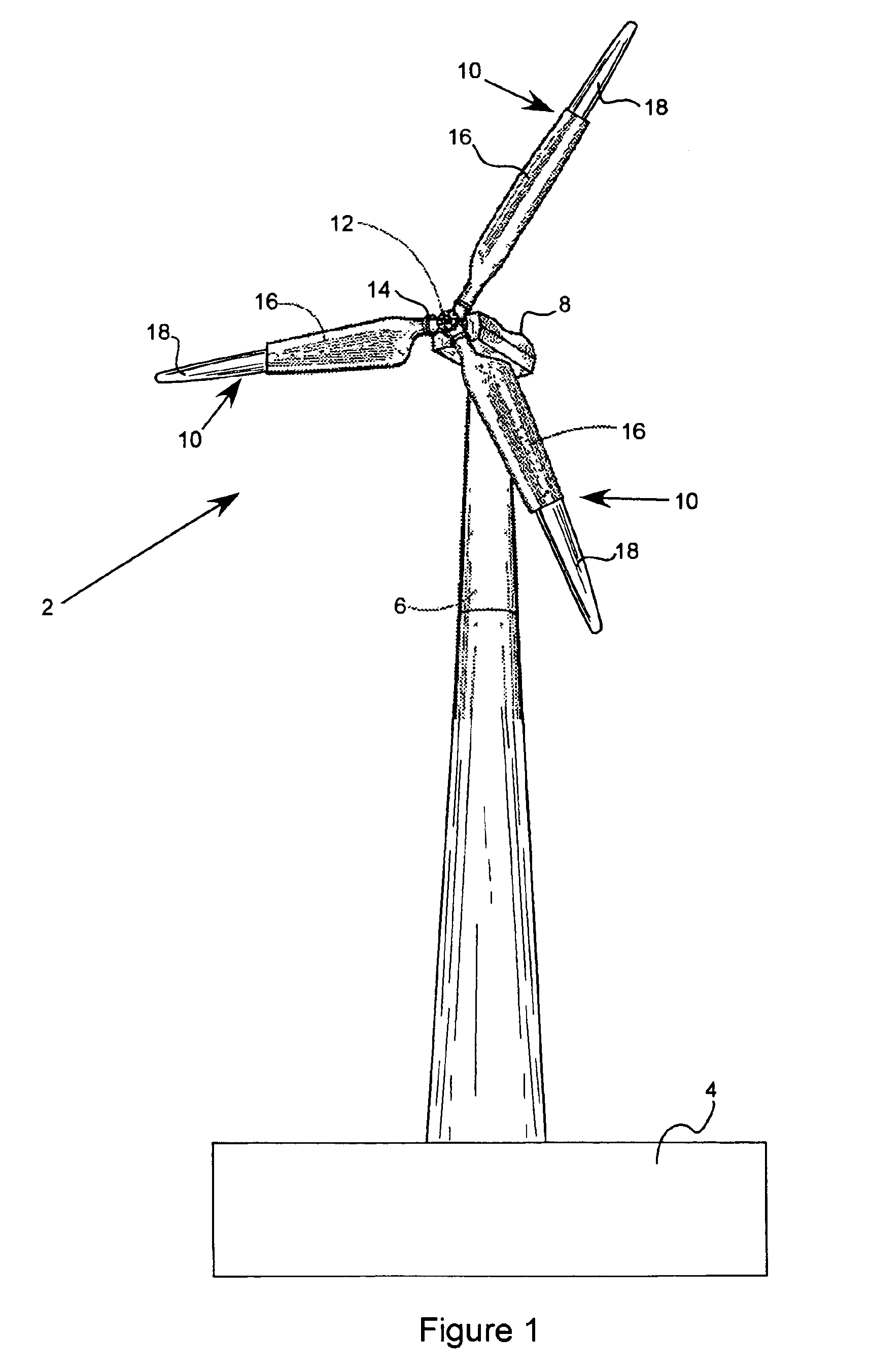

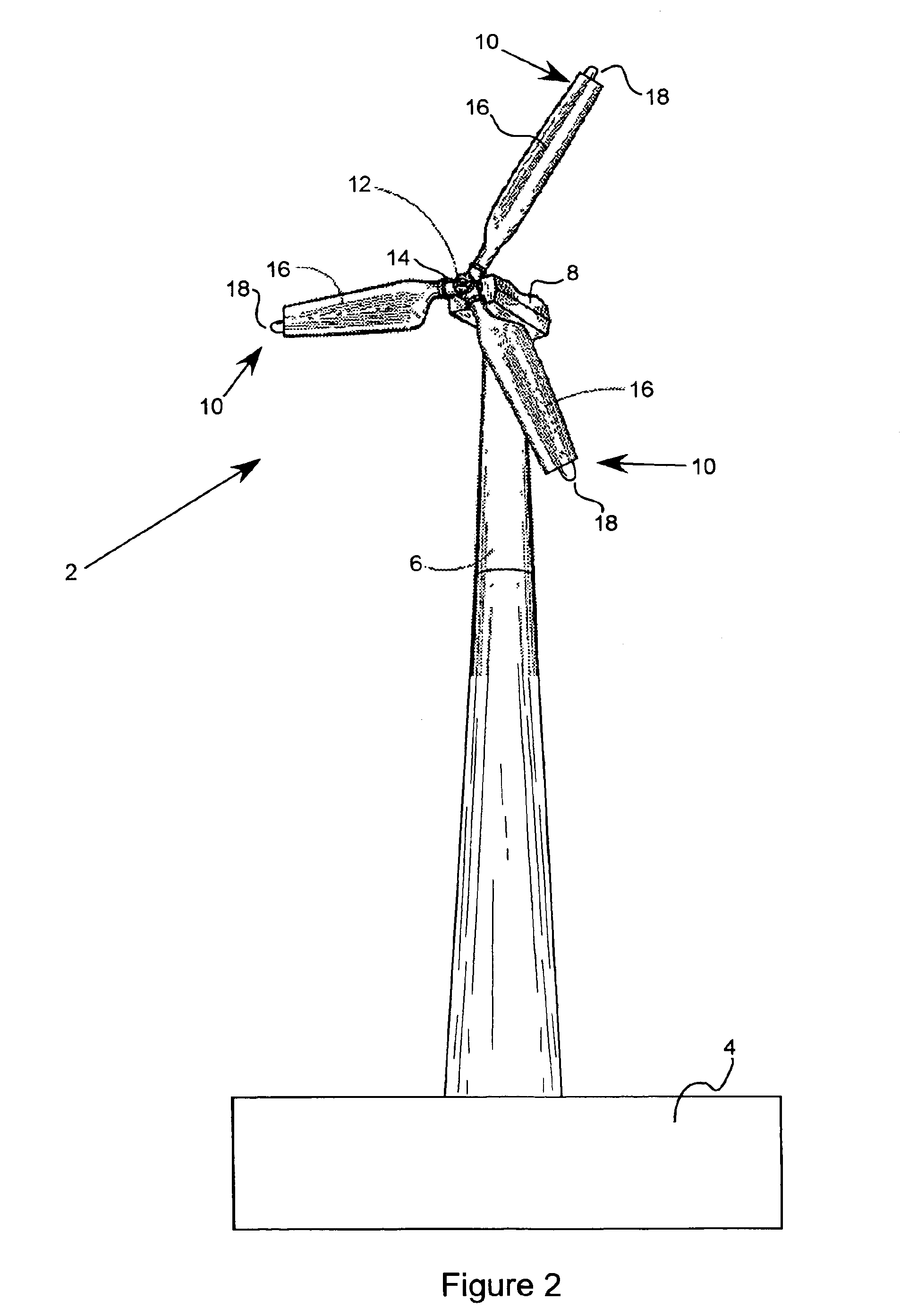

Deicing device for wind turbine blades

Methods and Apparatuses for deicing a wind turbine blade are described herein. In one embodiment, an exemplary process includes detecting an icy condition on a wind turbine blade and causing at least a portion of the wind turbine blade to vibrate, causing the ice built up on the wind turbine blade to break off.

Owner:GENERAL ELECTRIC CO

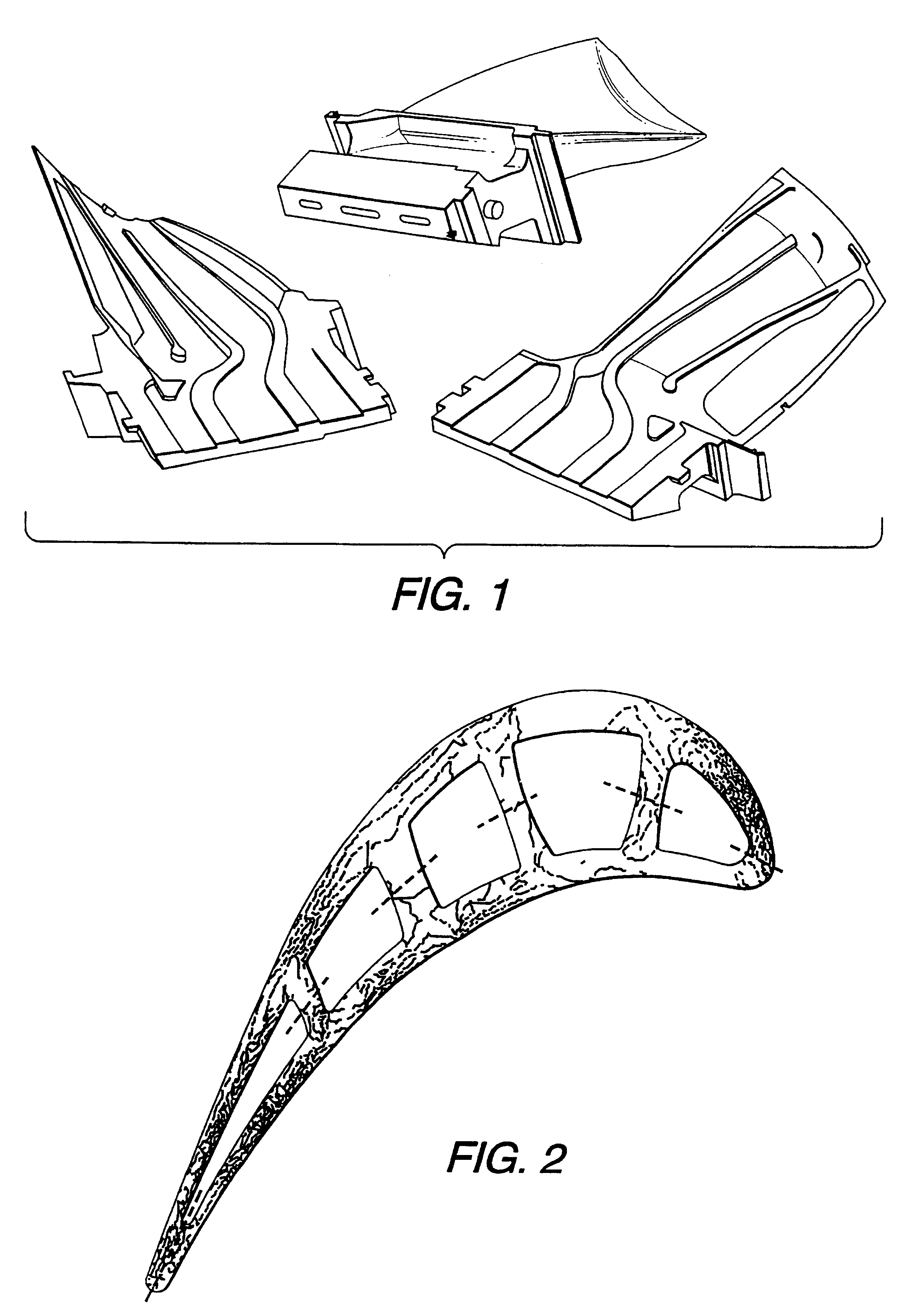

Turbine blades made from multiple single crystal cast superalloy segments

InactiveUS6331217B1Improve bindingQuality improvementPropellersFrom frozen solutionsTurbine bladeSingle crystal

Large gas turbine blades made from separate cast segments of superalloys are disclosed. The turbine blade is designed such that bond lines between adjacent segments are placed in low stress regions of the blade. The cast superalloy segments of the blades are aligned and fitted together with specified tolerances. The turbine blade segments are then joined by transient liquid phase bonding, followed by a controlled heat treatment which produces the desired microstructure in the bond region. The method allows for the production of large, high quality turbine blades by joining small, high quality cast superalloy sections, in comparison with prior attempts to cast large turbine blades as single pieces which have produced very low yields and high individual component costs.

Owner:SIEMENS ENERGY INC

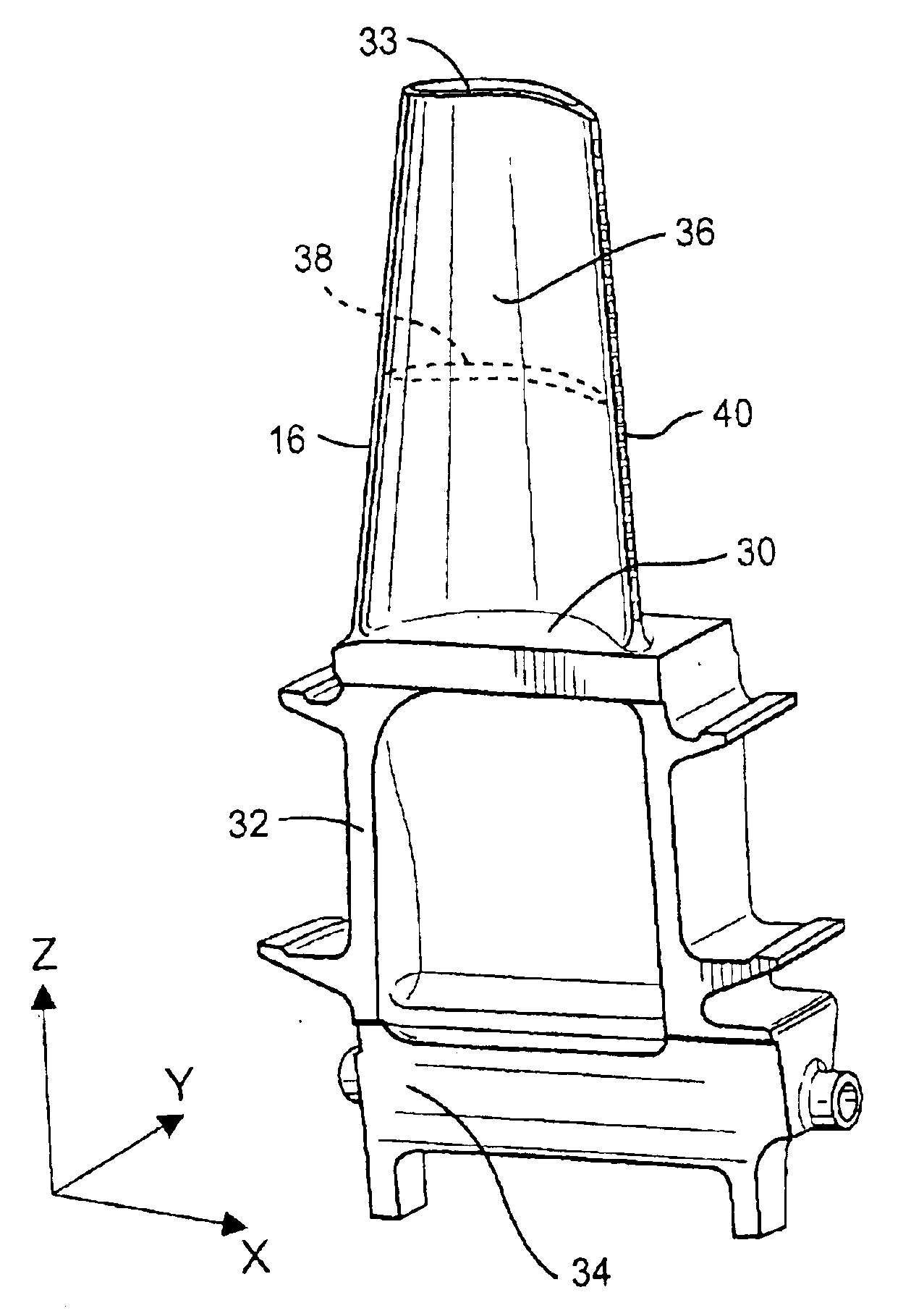

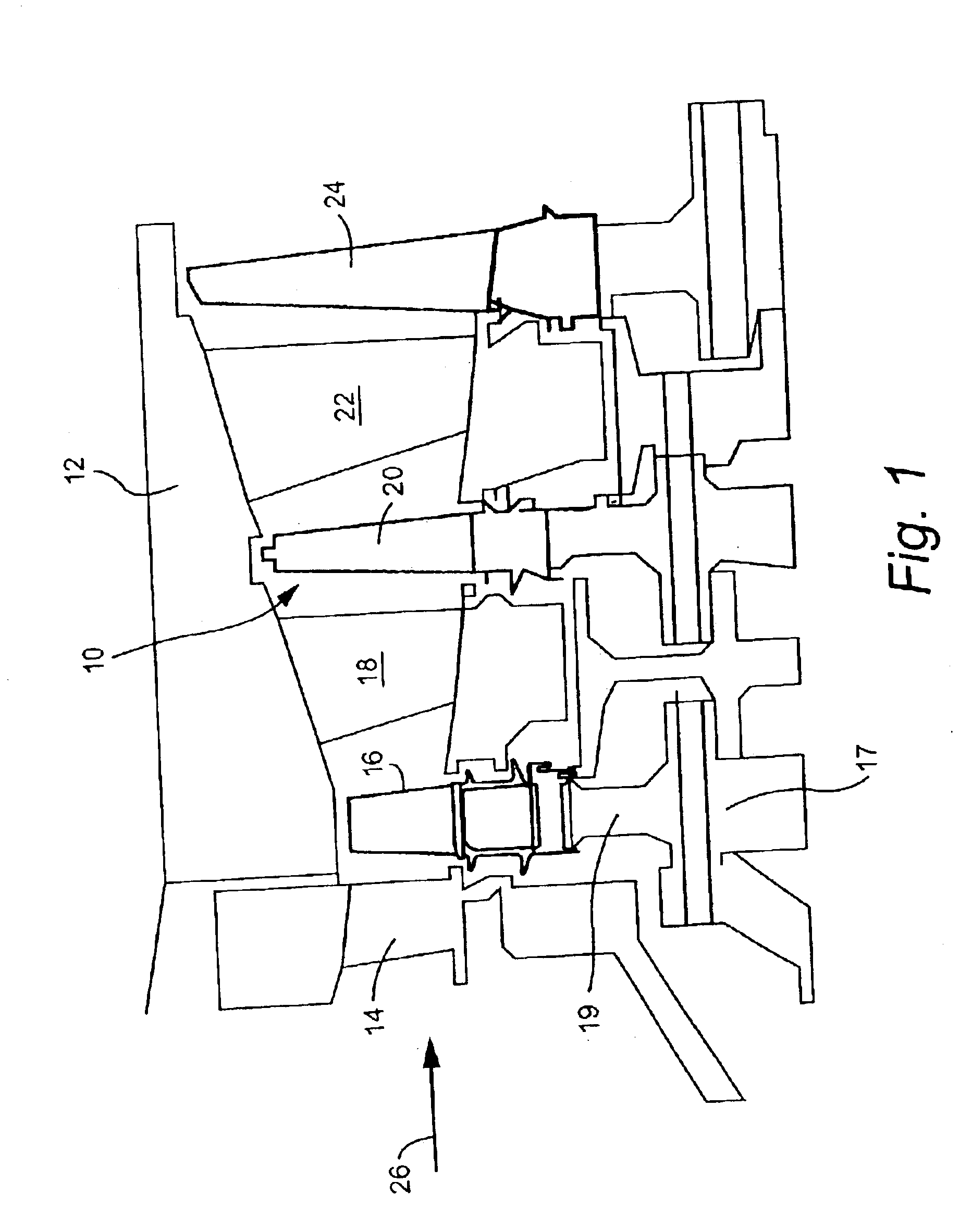

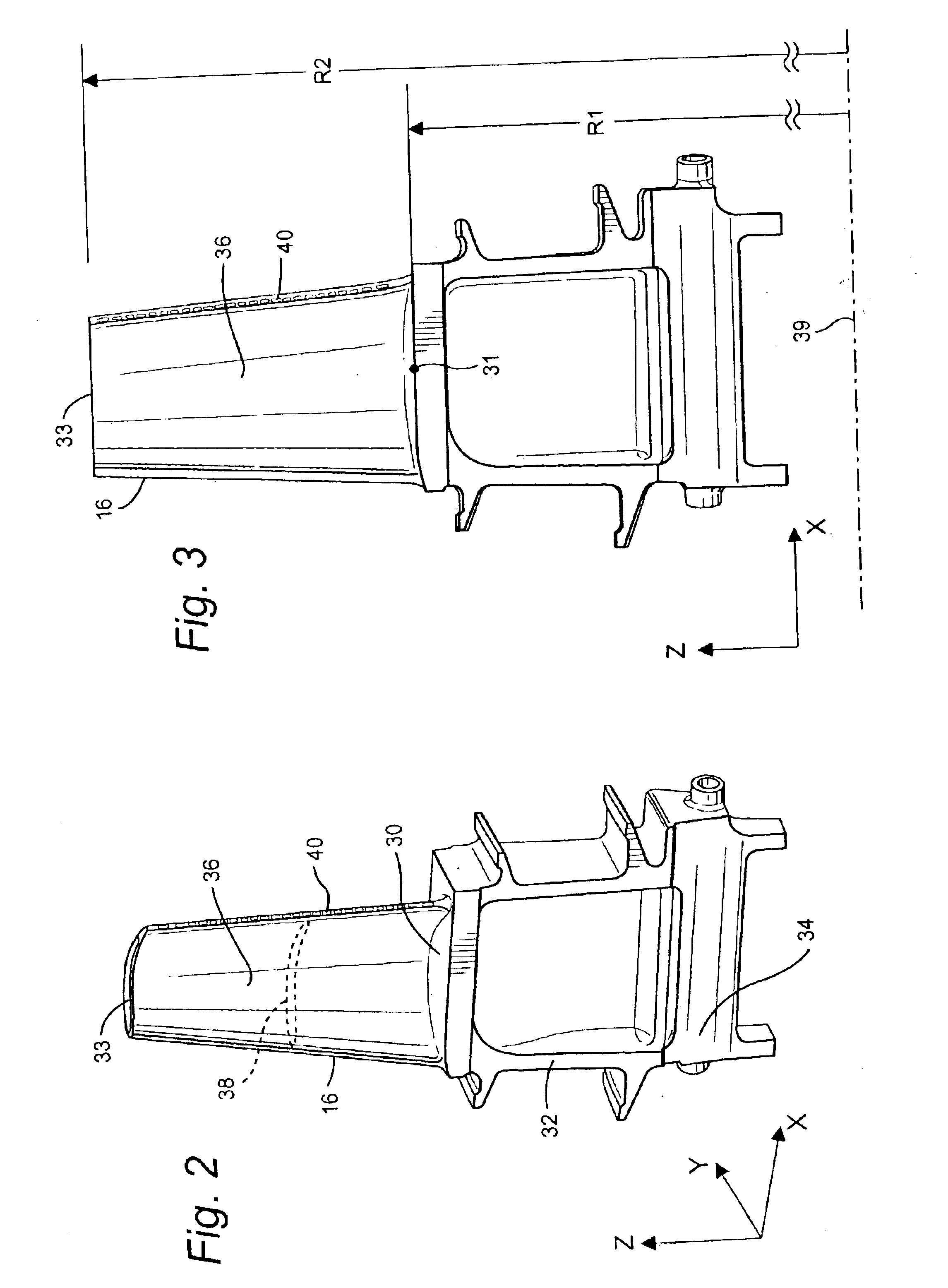

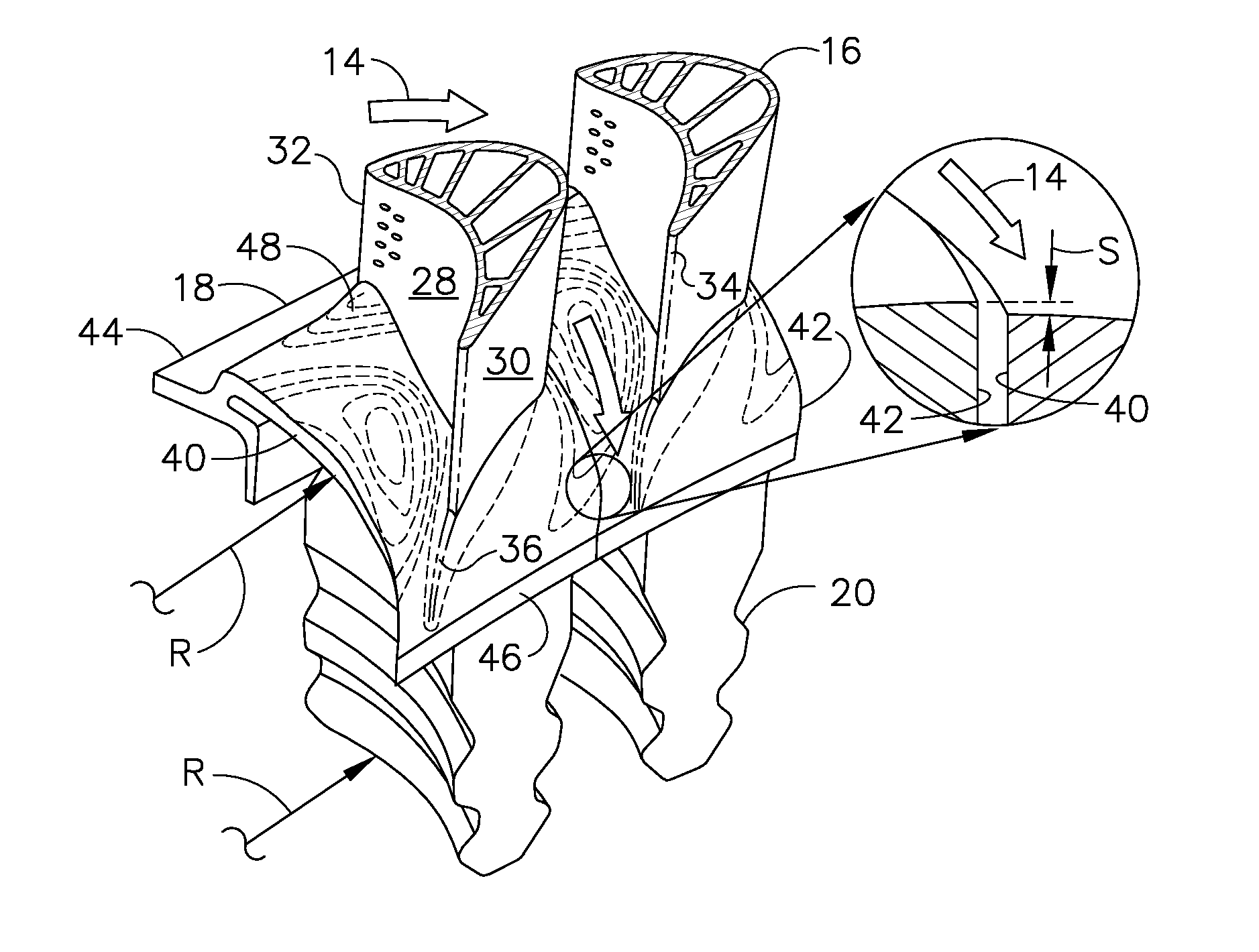

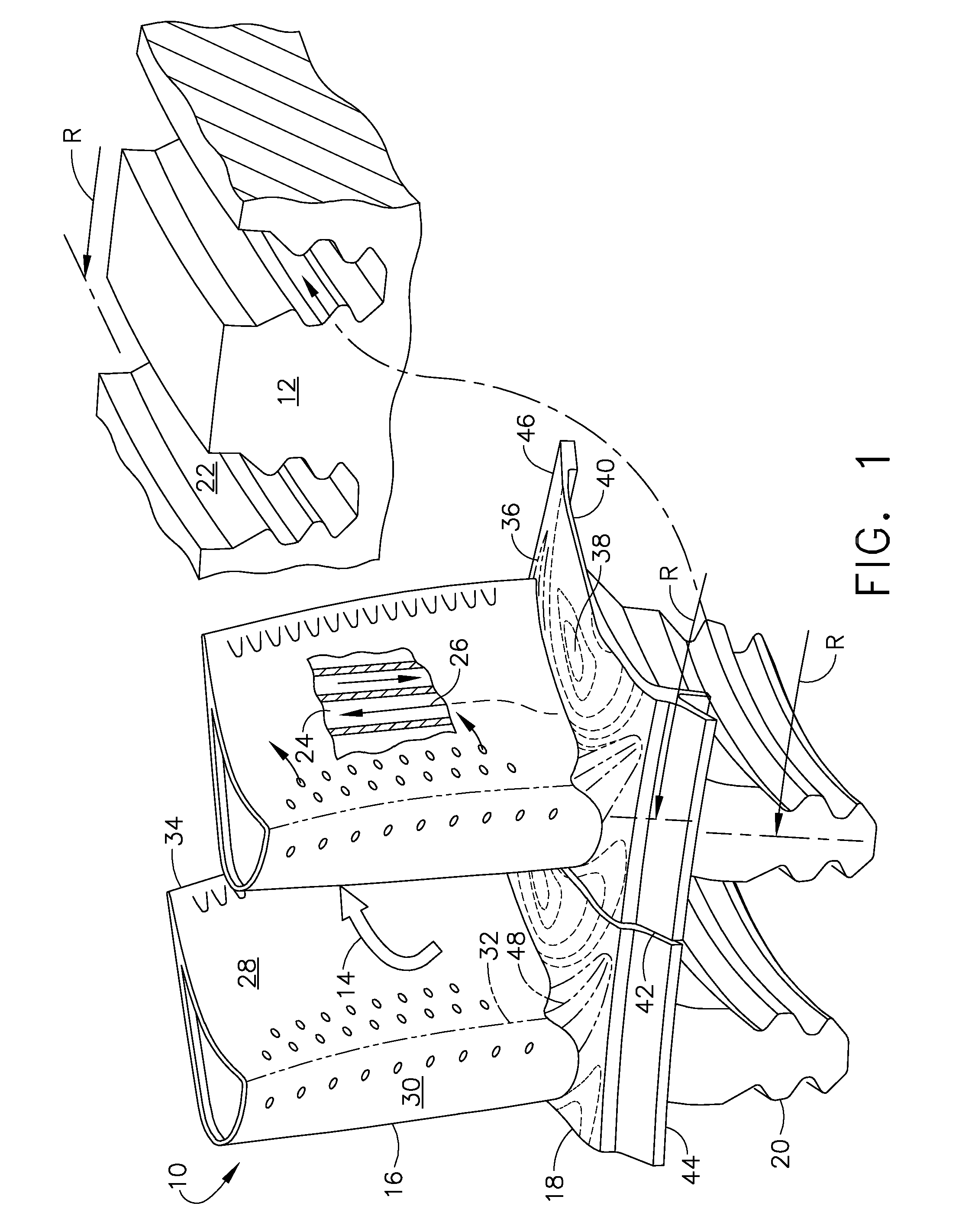

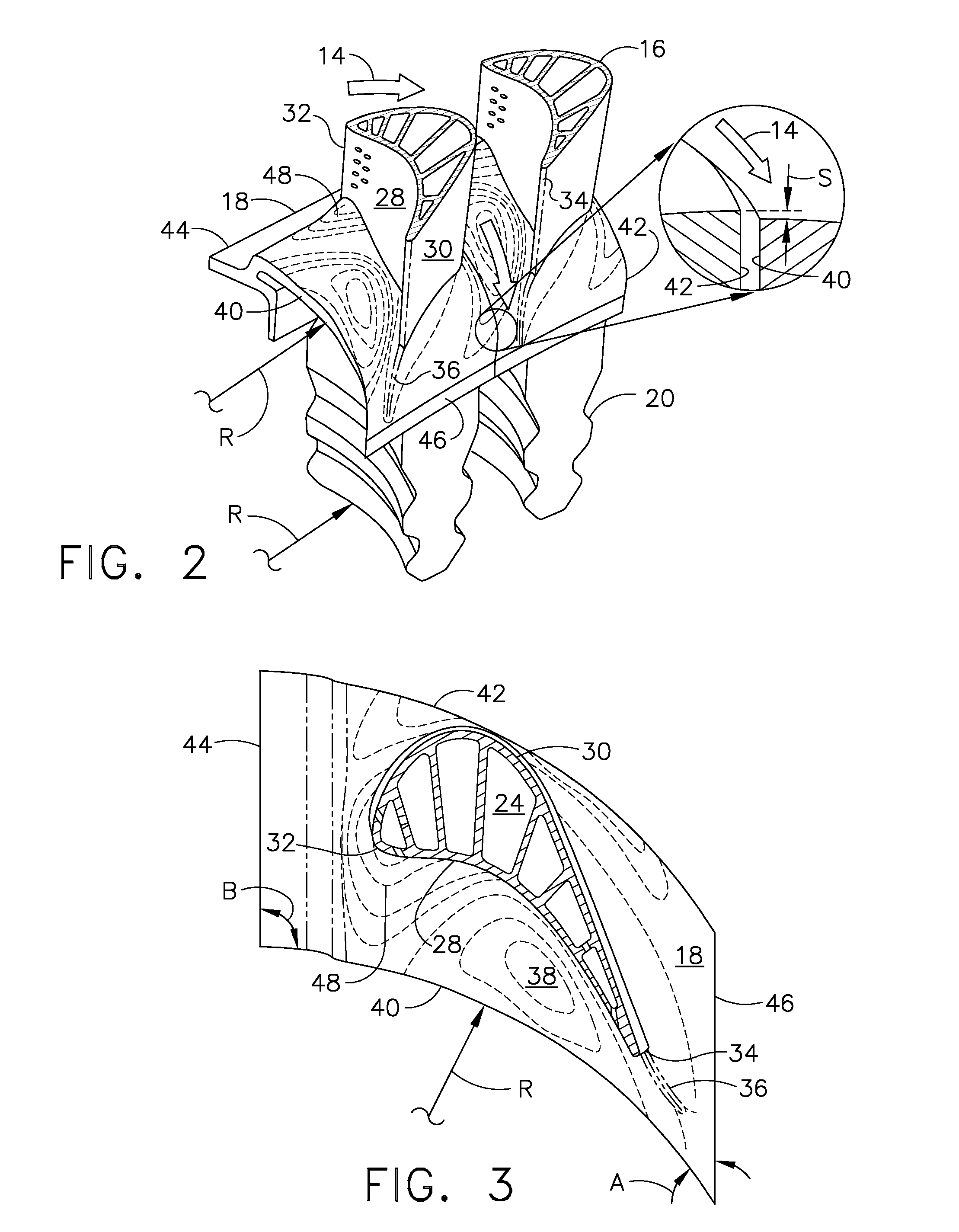

High effectiveness cooled turbine vane or blade

InactiveUS6974308B2Improve cooling efficiencyEasy to manufacturePump componentsEngine fuctionsSuction stressConventional casting

A robust multiple-walled, multi-pass, high cooling effectiveness cooled turbine vane or blade designed for ease of manufacturability, minimizes cooling flows on highly loaded turbine rotors. The vane or blade design allows the turbine inlet temperature to increase over current technology levels while simultaneously reducing turbine cooling to low levels. A multi-wall cooling system is described, which meets the inherent conflict to maximize the flow area of the cooling passages while retaining the required section thickness to meet the structural requirements. Independent cooling circuits for the vane or blade's pressure and suction surfaces allow the cooling of the airfoil surfaces to be tailored to specific heat load distributions (that is, the pressure surface circuit is an independent forward flowing serpentine while the suction surface is an independent rearward flowing serpentine). The cooling air for the independent circuits is supplied through separate passages at the base of the vane or blade. The cooling air follows intricate passages to feed the serpentine thin outer wall passages, which incorporate pin fins, turbulators, etc. These passages, while satisfying the aero / thermal / stress requirements, are of a manufacturing configuration that may be cast with single crystal materials using conventional casting techniques.

Owner:HONEYWELL INT INC

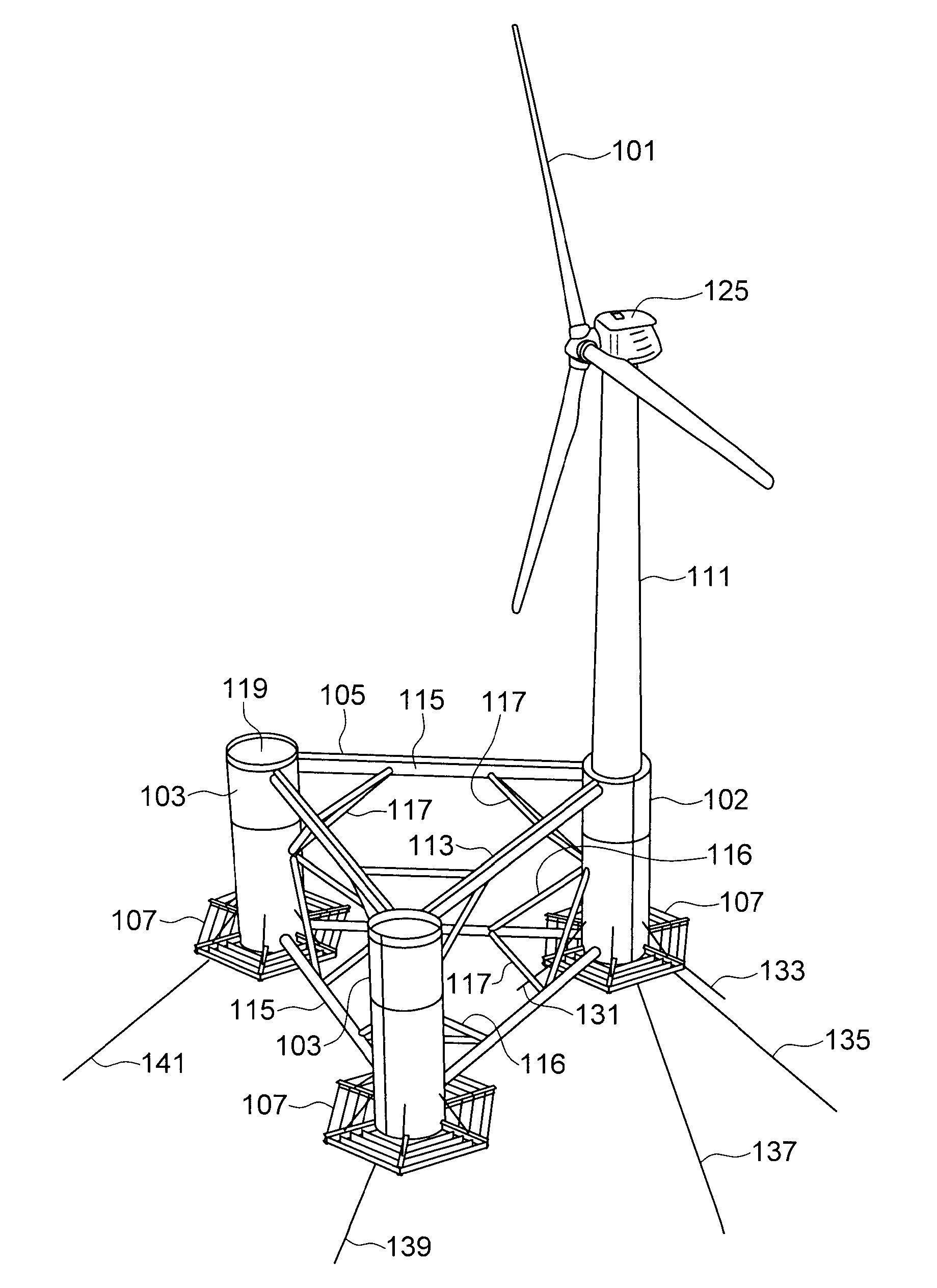

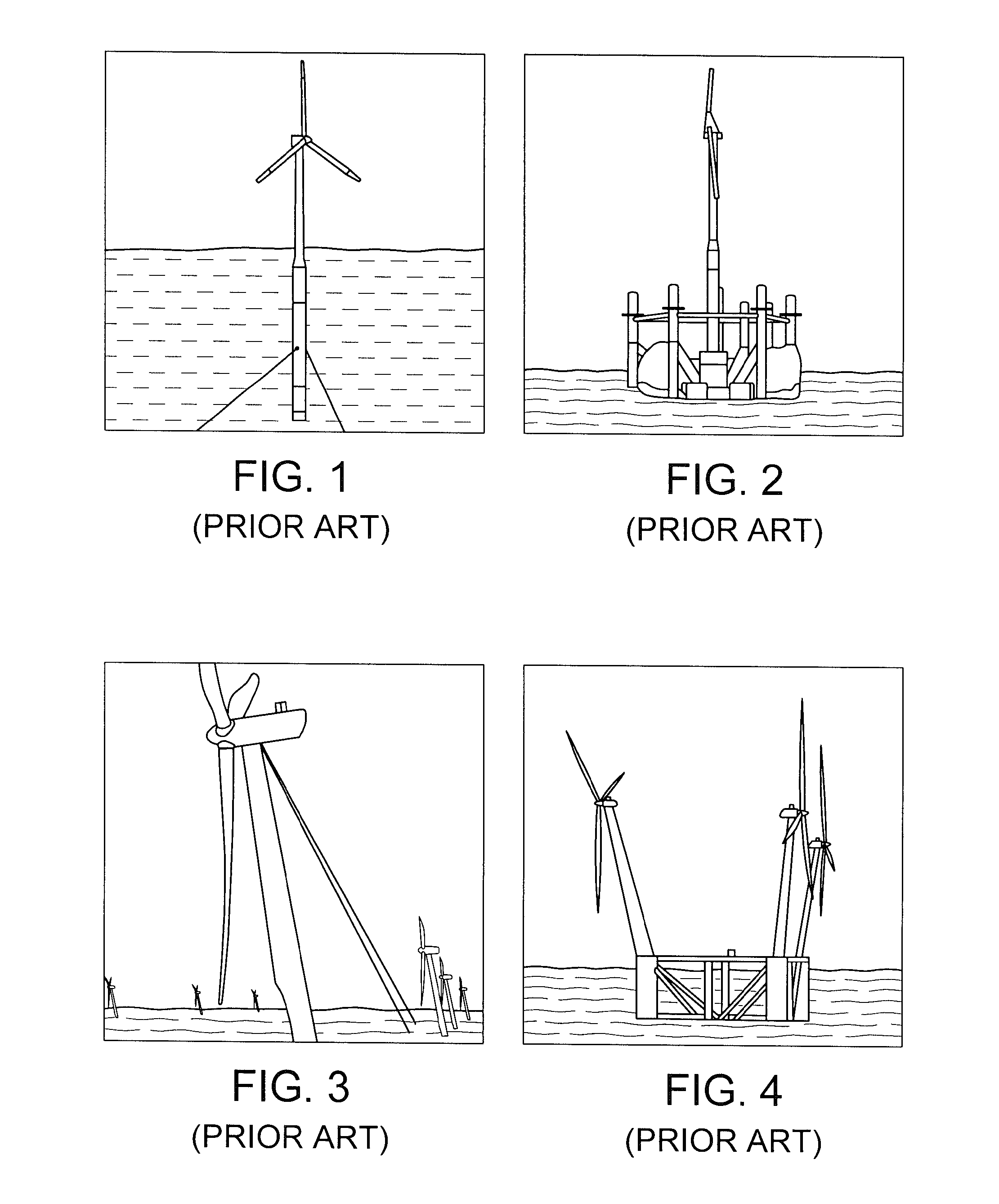

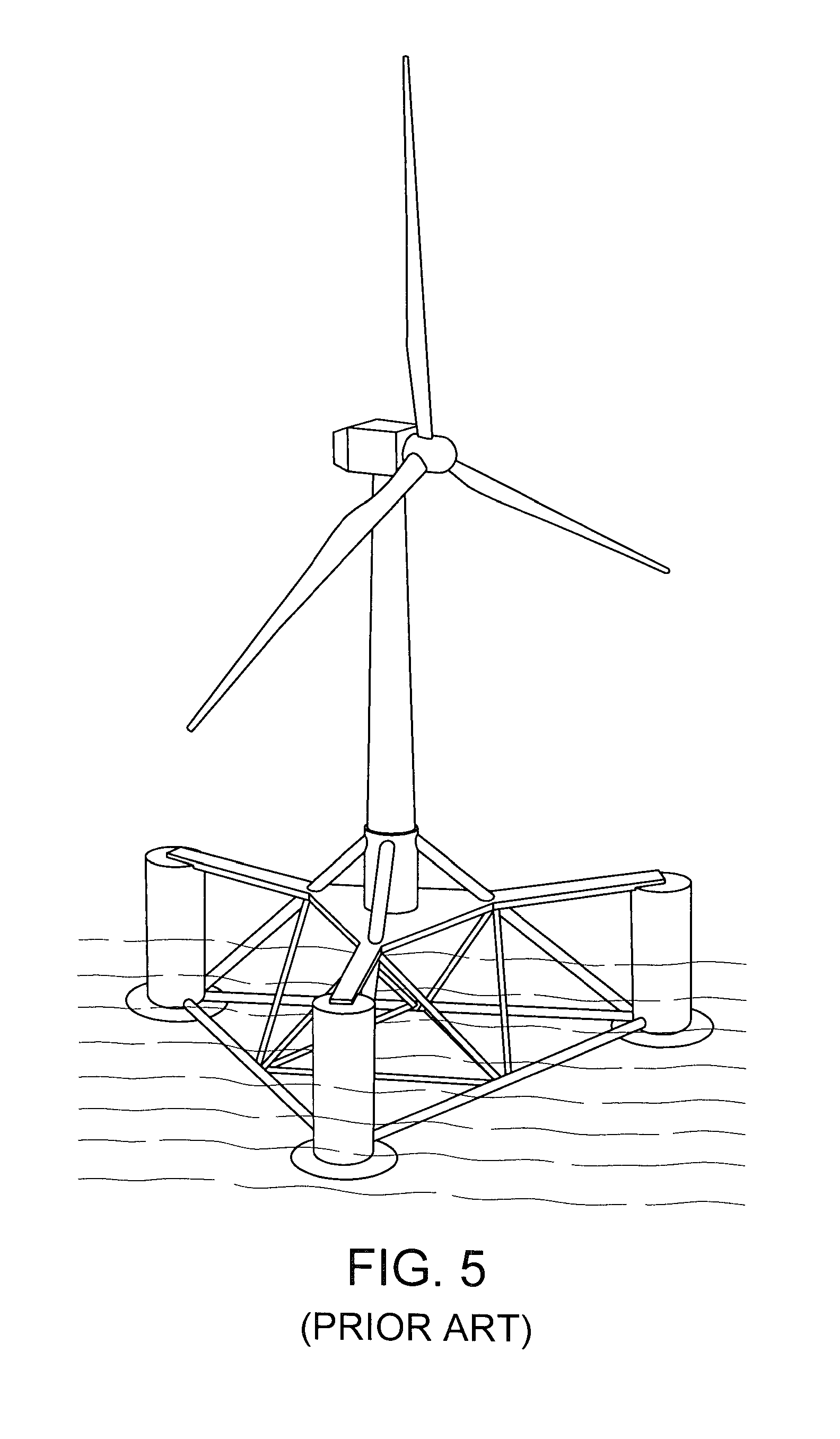

Column-stabilized offshore platform with water-entrapment plates and asymmetric mooring system for support of offshore wind turbines

ActiveUS20110037264A1Improve performanceEasy to produceWind motor controlWind motor assemblyNacelleMooring system

A floating wind turbine platform includes a floatation frame (105) that includes three columns (102, 103) that are coupled to each other with horizontal main beams (115). A wind turbine tower (111) is mounted above a tower support column (102) to simplify the system construction and improve the structural strength. The turbine blades (101) are coupled to a nacelle (125) that rotates on top of the tower (111). The turbine's gearbox generator and other electrical gear can be mounted either traditionally in the nacelle, or lower in the tower (111) or in the top of the tower-supporting column (102). The floatation frame (105) includes a water ballasting system that pumps water between the columns (102, 103) to keep the tower (111) in a 10 vertical alignment regardless of the wind speed. Water-entrapment plates (107) are mounted to the bottoms of the columns (102, 103) to minimize the rotational movement of the floatation frame (105) due to waves.

Owner:PRINCIPLE POWER

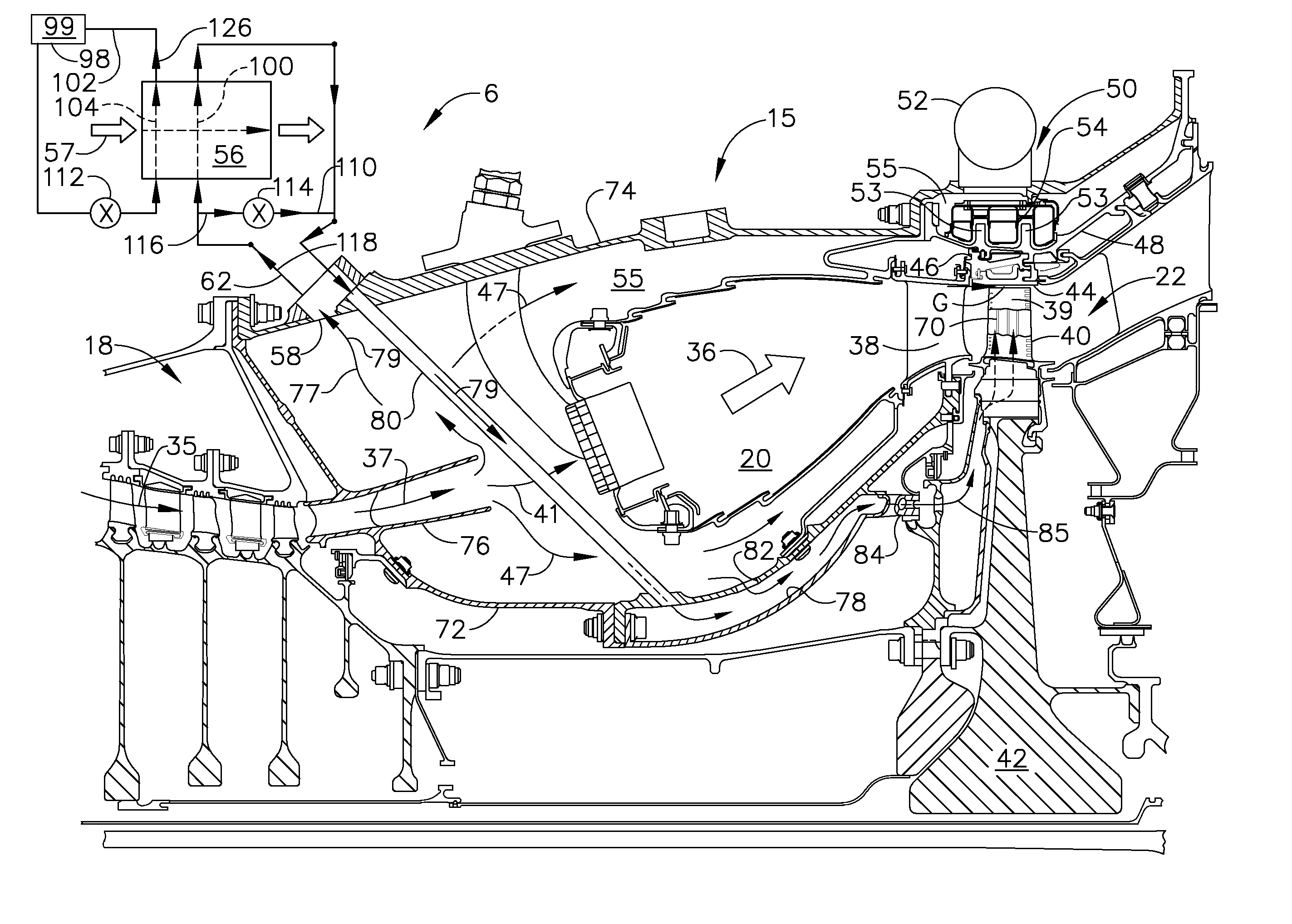

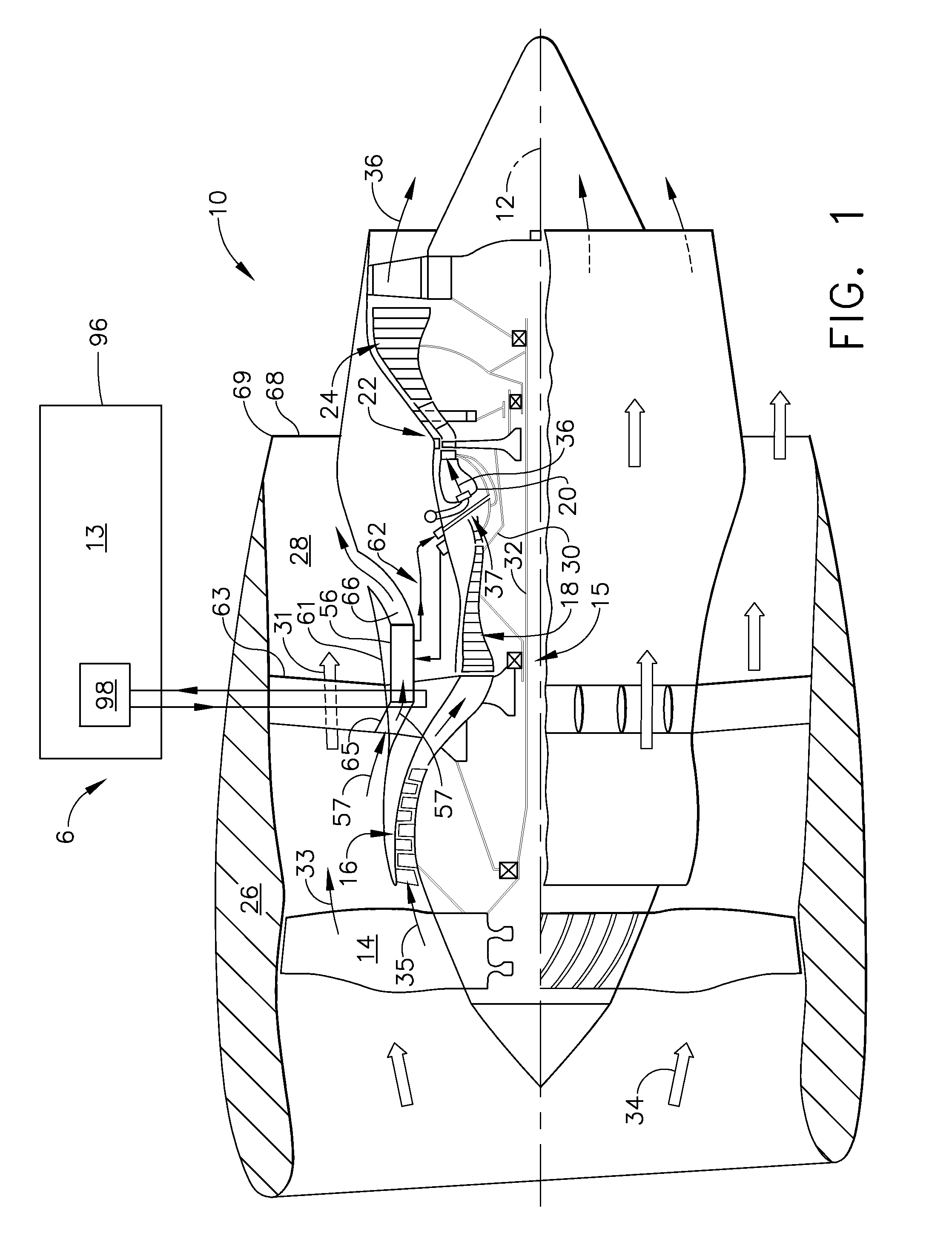

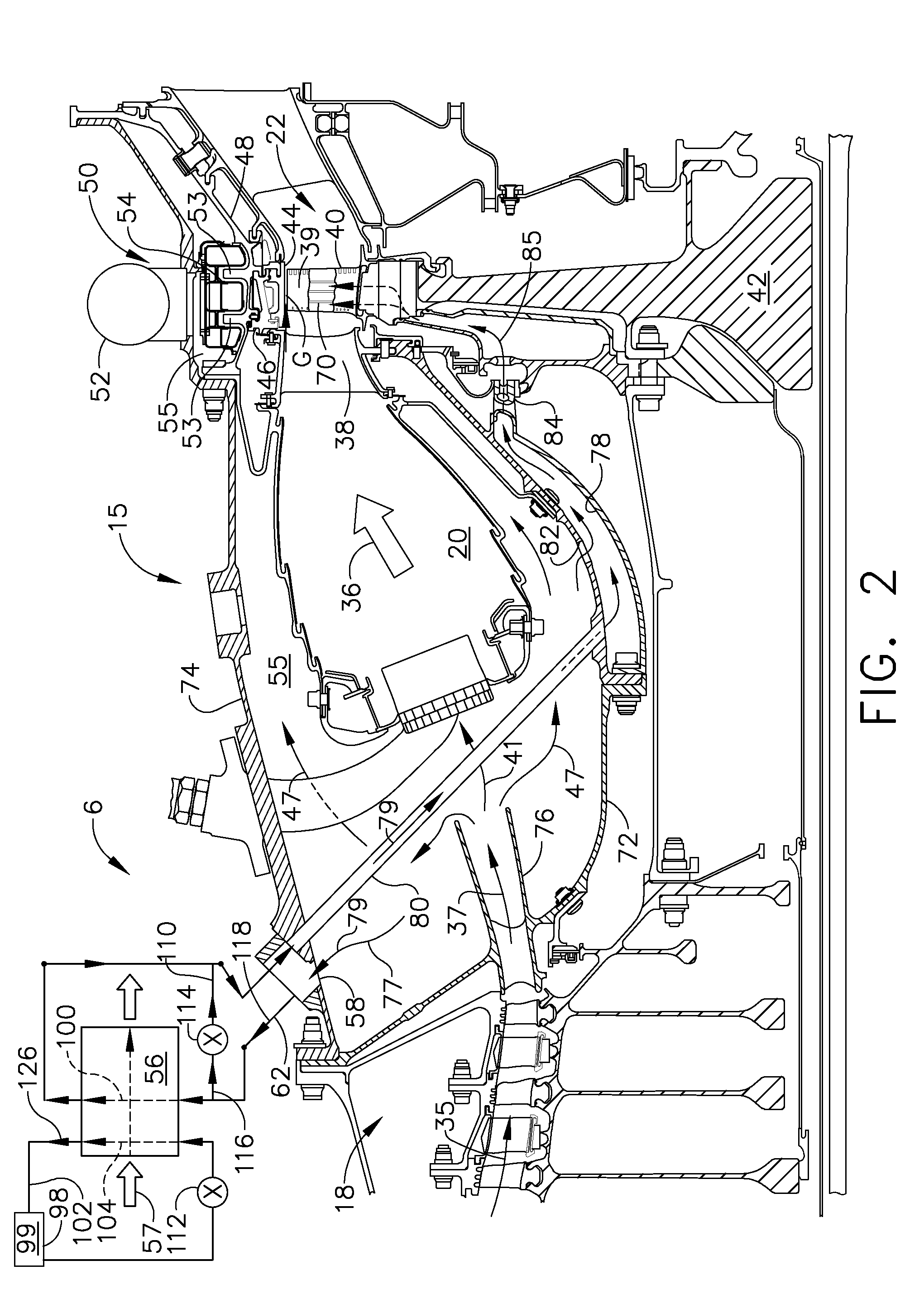

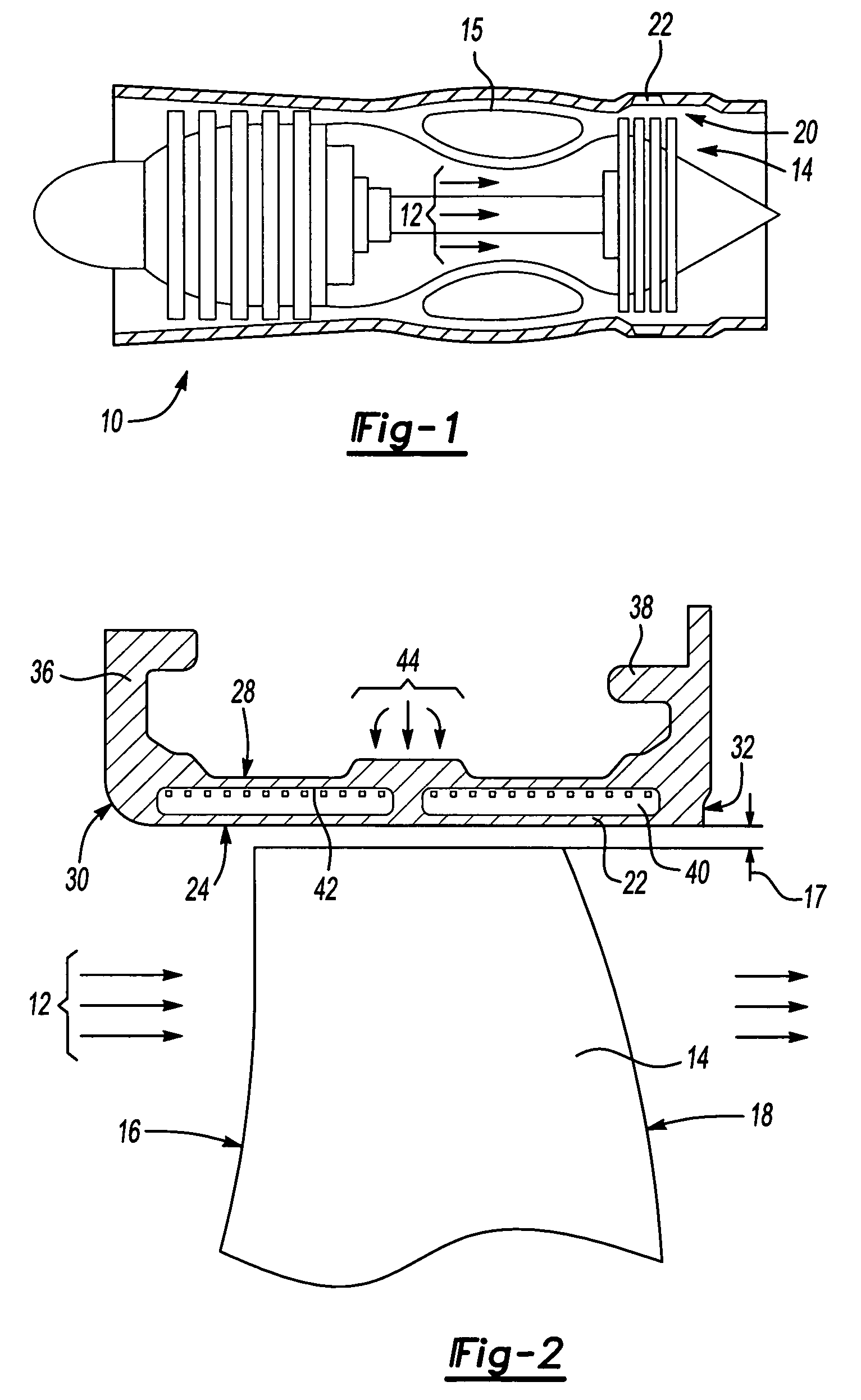

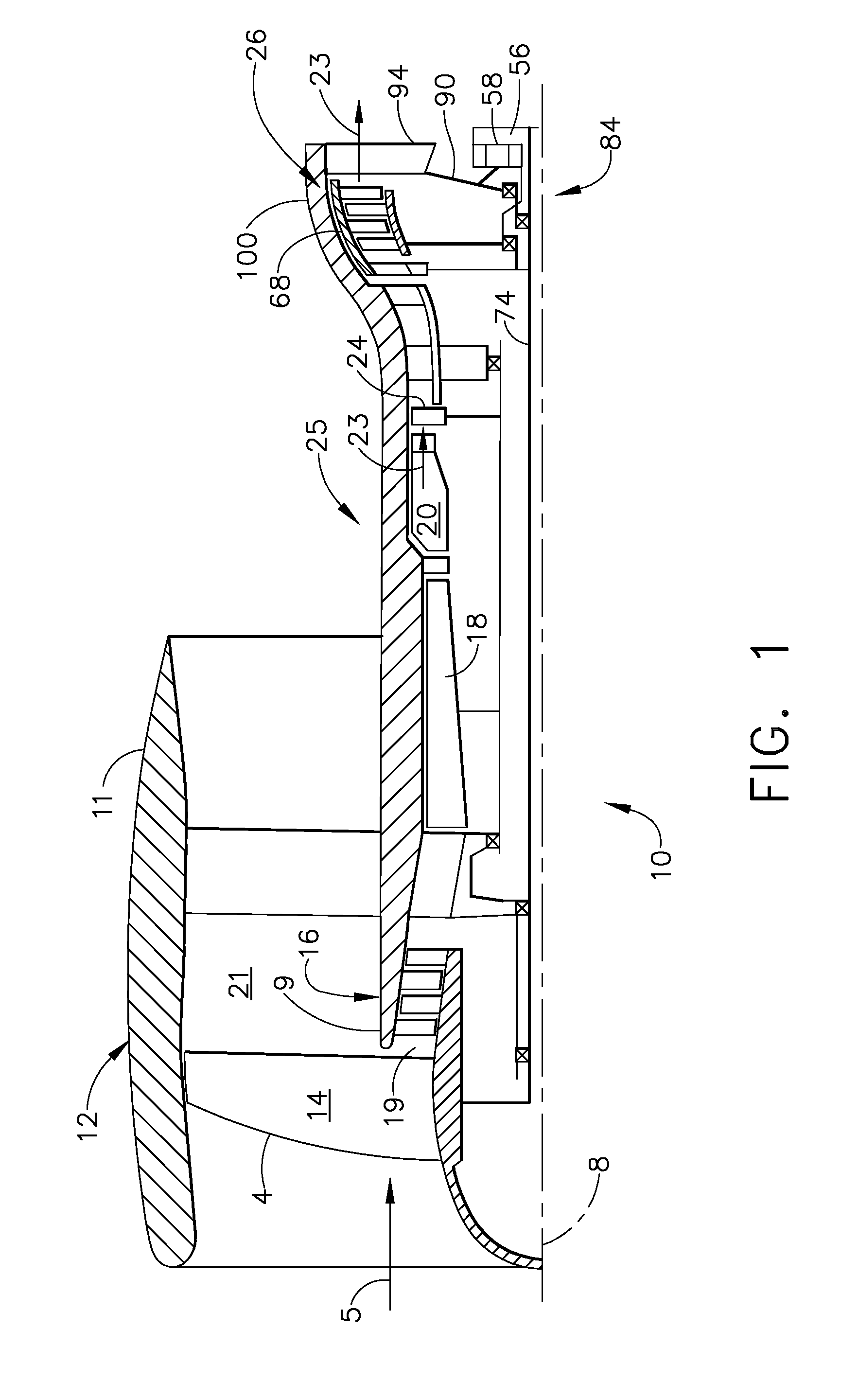

Gas turbine engine temperature modulated cooling flow

ActiveUS20110088405A1Improved blade cooling controlImprove efficiencyPump componentsTurbine/propulsion engine coolingPlate heat exchangerTurbine blade

A gas turbine engine cooling system includes a heat exchanger in fluid communication with a source of cooling air, a first cooling circuit including a first heat exchanger circuit in the heat exchanger and a first bypass circuit with a first bypass valve for selectively bypassing at least a portion of first airflow around the first heat exchanger circuit. A second cooling circuit may be used having a second heat exchanger circuit in the heat exchanger and a shutoff control valve operably disposed in the second cooling circuit upstream of the second heat exchanger circuit and the heat exchanger. A circuit inlet of the first cooling circuit may be used to bleed a portion of compressor discharge bleed air for the first airflow to cool turbine blades mounted on a rotor disk using an annular flow inducer downstream of the first bypass valve and the heat exchanger.

Owner:GENERAL ELECTRIC CO

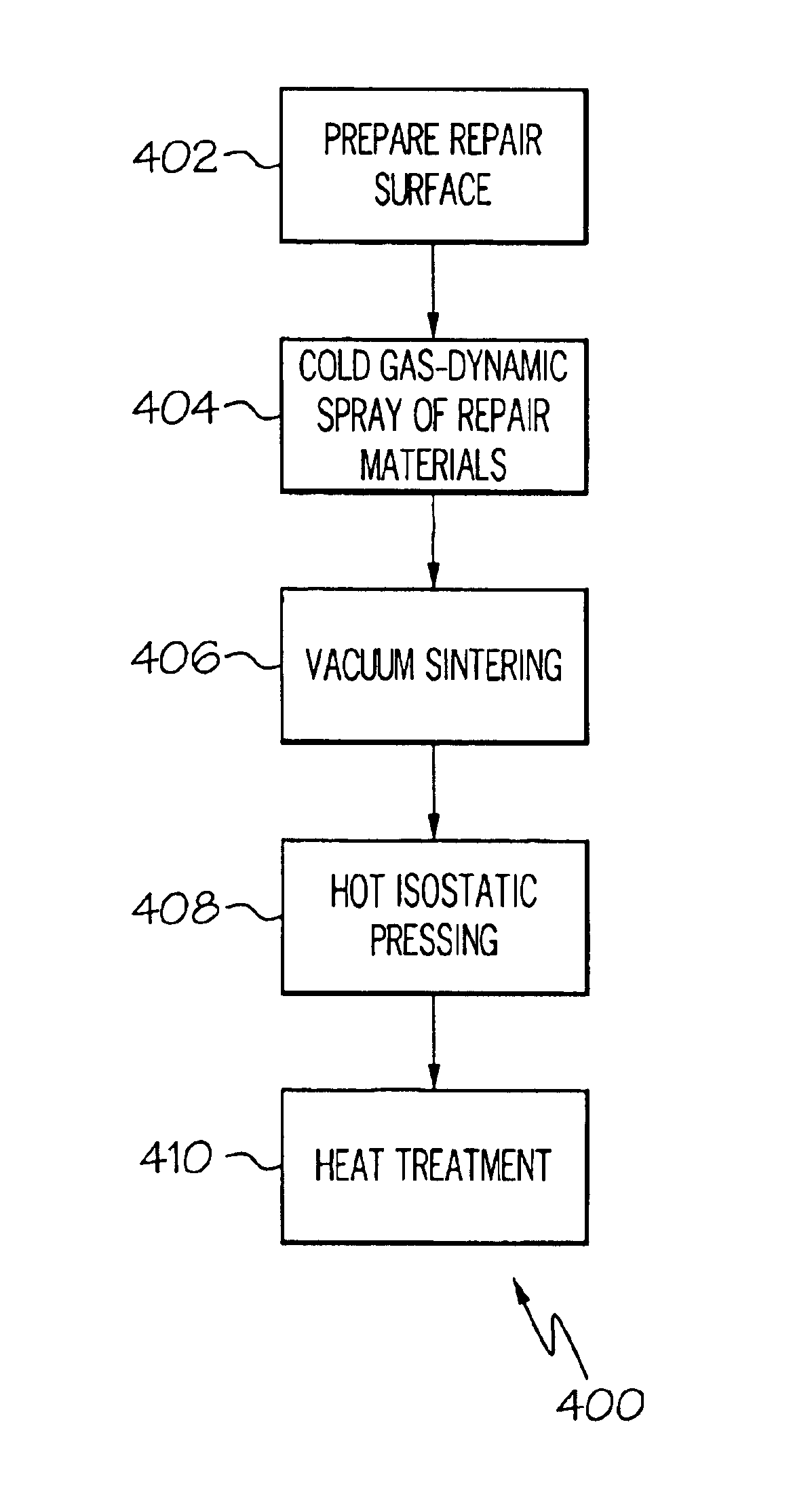

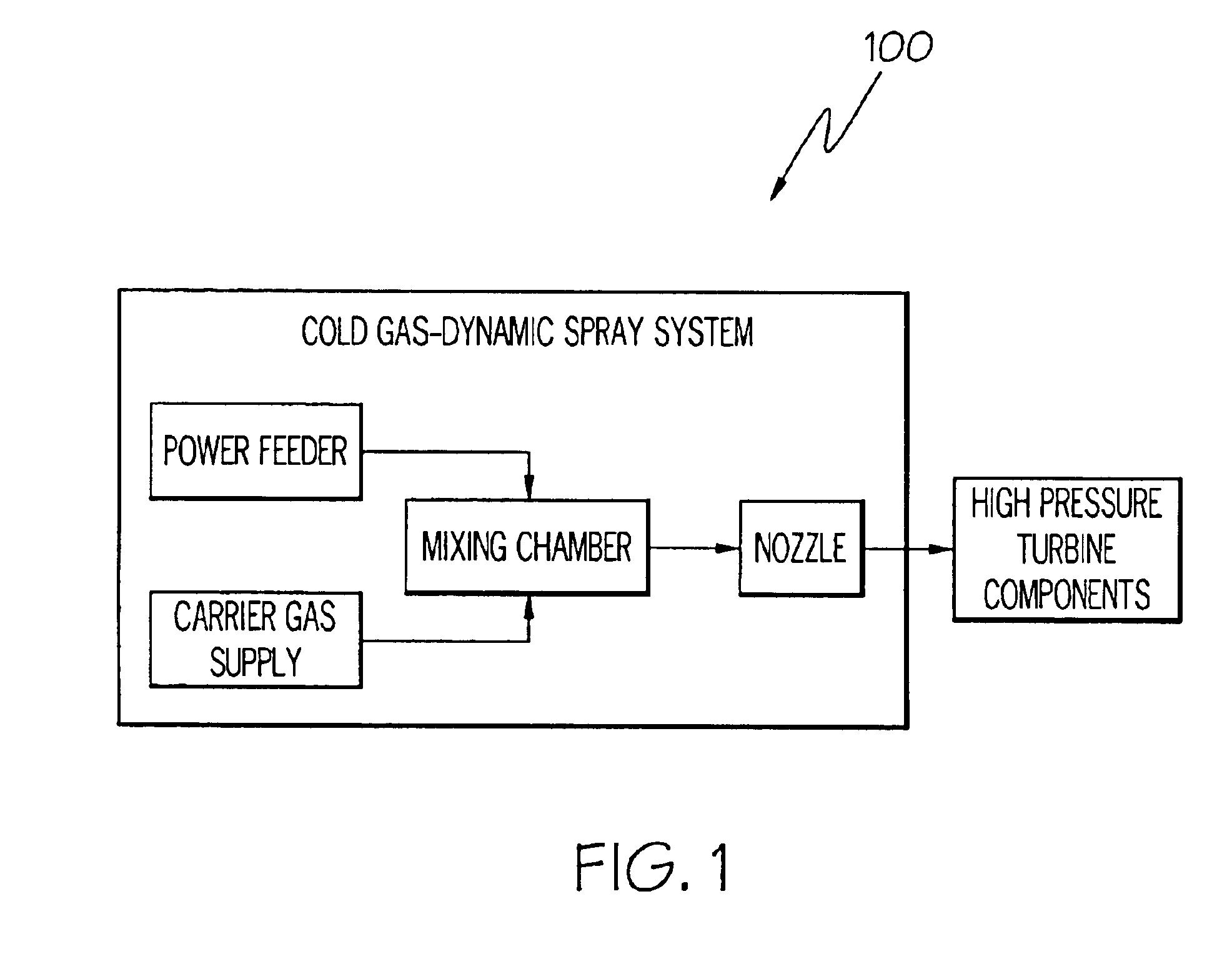

Cold gas-dynamic spray repair on gas turbine engine components

ActiveUS6905728B1Simple methodEasy to weldLayered productsBlade accessoriesTarget surfaceTurbine blade

A new method for repairing turbine engine components is provided. The method utilizes a cold gas-dynamic spray technique to repair degradation on turbine blades, vanes and other components. In the cold gas-dynamic spray process particles at a temperature below their fusing temperature are accelerated and directed to a target surface on the turbine blade. When the particles strike the target surface, the kinetic energy of the particles is converted into plastic deformation of the particle, causing the particle to form a strong bond with the target surface. Post-spray processing is then performed to consolidate and homogenize the applied materials and restore integrity to the material properties in the repaired turbine component. Thus, the cold gas-dynamic spray process and post-spray processing can be employed to effectively repair degraded areas on gas turbine components.

Owner:HONEYWELL INT INC

Airfoil shape for a turbine bucket

InactiveUS6854961B2Improve performanceReduction of thermalEngine manufactureOther chemical processesTurbine bladeEngineering

First stage turbine buckets have airfoil profiles substantially in accordance with Cartesian coordinate values of X, Y and Z set forth Table I wherein X and Y values are in inches and the Z values are non-dimensional values from 0 to 1 convertible to Z distances in inches by multiplying the Z values by the height of the airfoil in inches. The X and Y values are distances which, when connected by smooth continuing arcs, define airfoil profile sections at each distance Z. The profile sections at each distance Z are joined smoothly to one another to form a complete airfoil shape. The X, Y and Z distances may be scalable as a function of the same constant or number to provide a scaled up or scaled down airfoil section for the bucket. The nominal airfoil given by the X, Y and Z distances lies within an envelop of ±0.055 inches in directions normal to the surface of the airfoil.

Owner:GENERAL ELECTRIC CO

Multi-piece turbine vane assembly

Owner:SIEMENS ENERGY INC

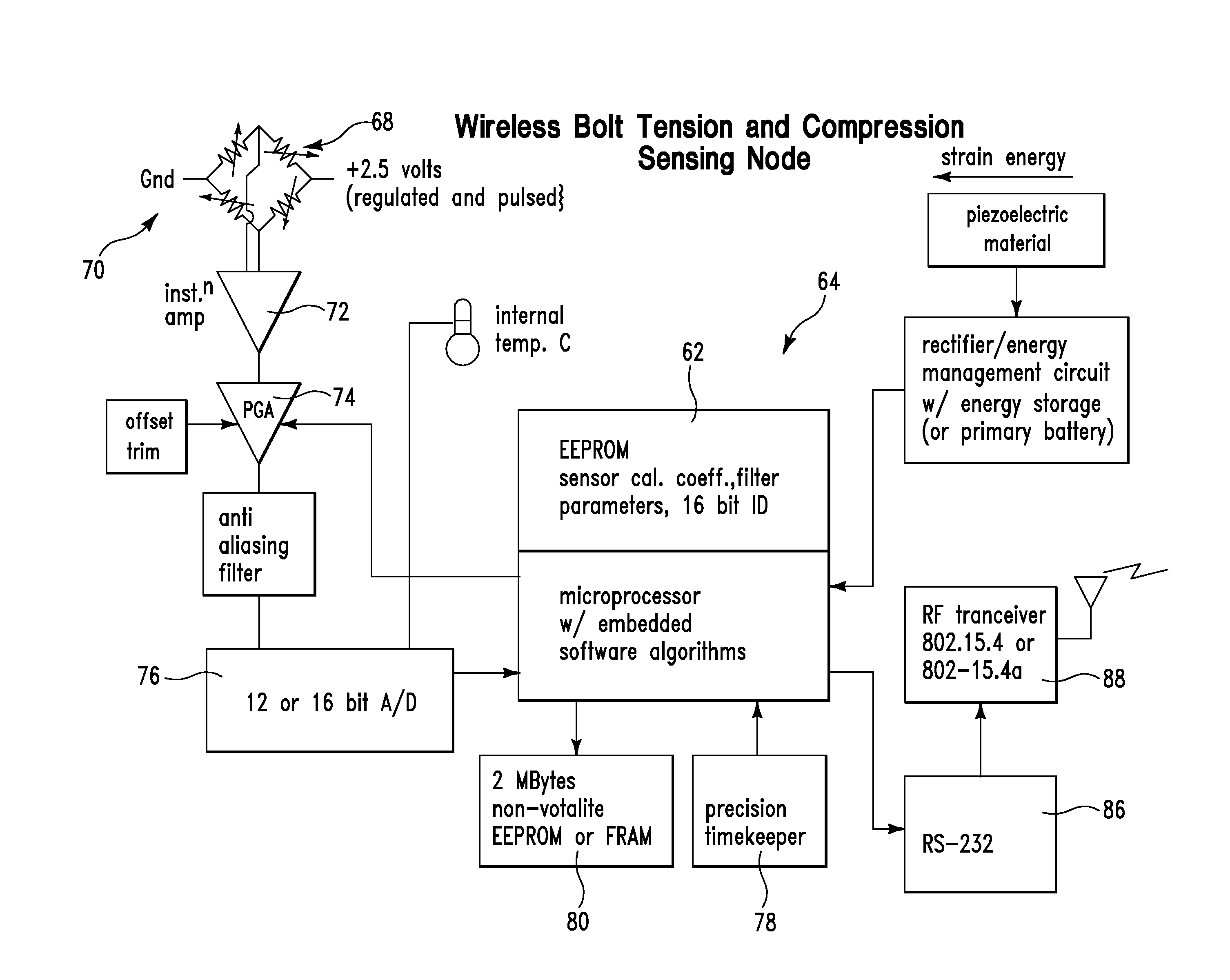

Wind Turbines and Other Rotating Structures with Instrumented Load-Sensor Bolts or Instrumented Load-Sensor Blades

A turbine includes a turbine blade, a plurality of sensors, a wireless sensor module, a data aggregator, and a blade pitch control unit. The plurality of sensors are distributed in a plurality of locations on the turbine blade suitable for determining a moment of the turbine blade. The sensor module is configured to transmit data to the data aggregator to determine the moment. The data aggregator is configured to provide an output to the blade pitch control unit. The blade pitch control unit is configured to adjust pitch of the turbine blade based on the moment.

Owner:LORD CORP

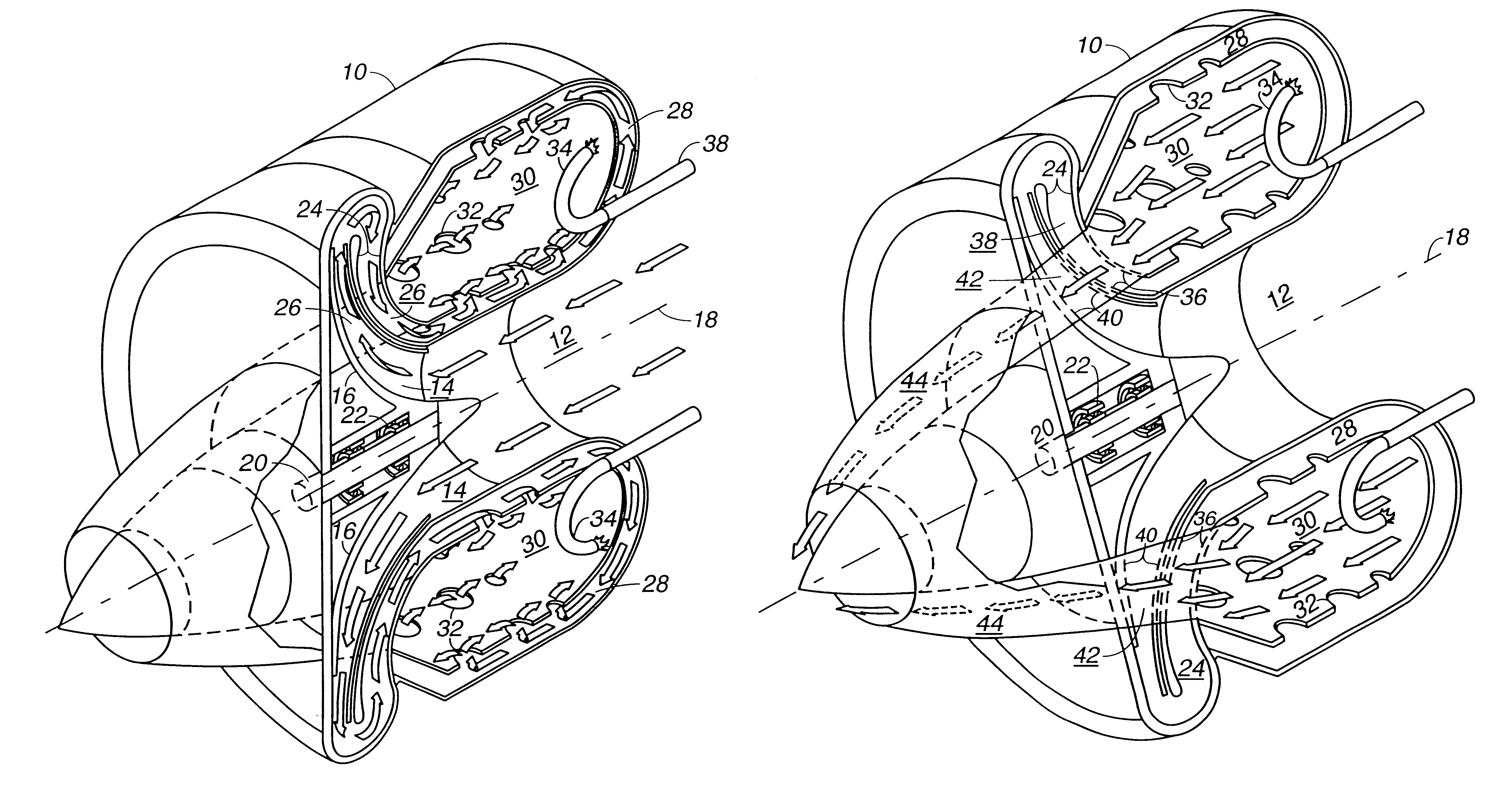

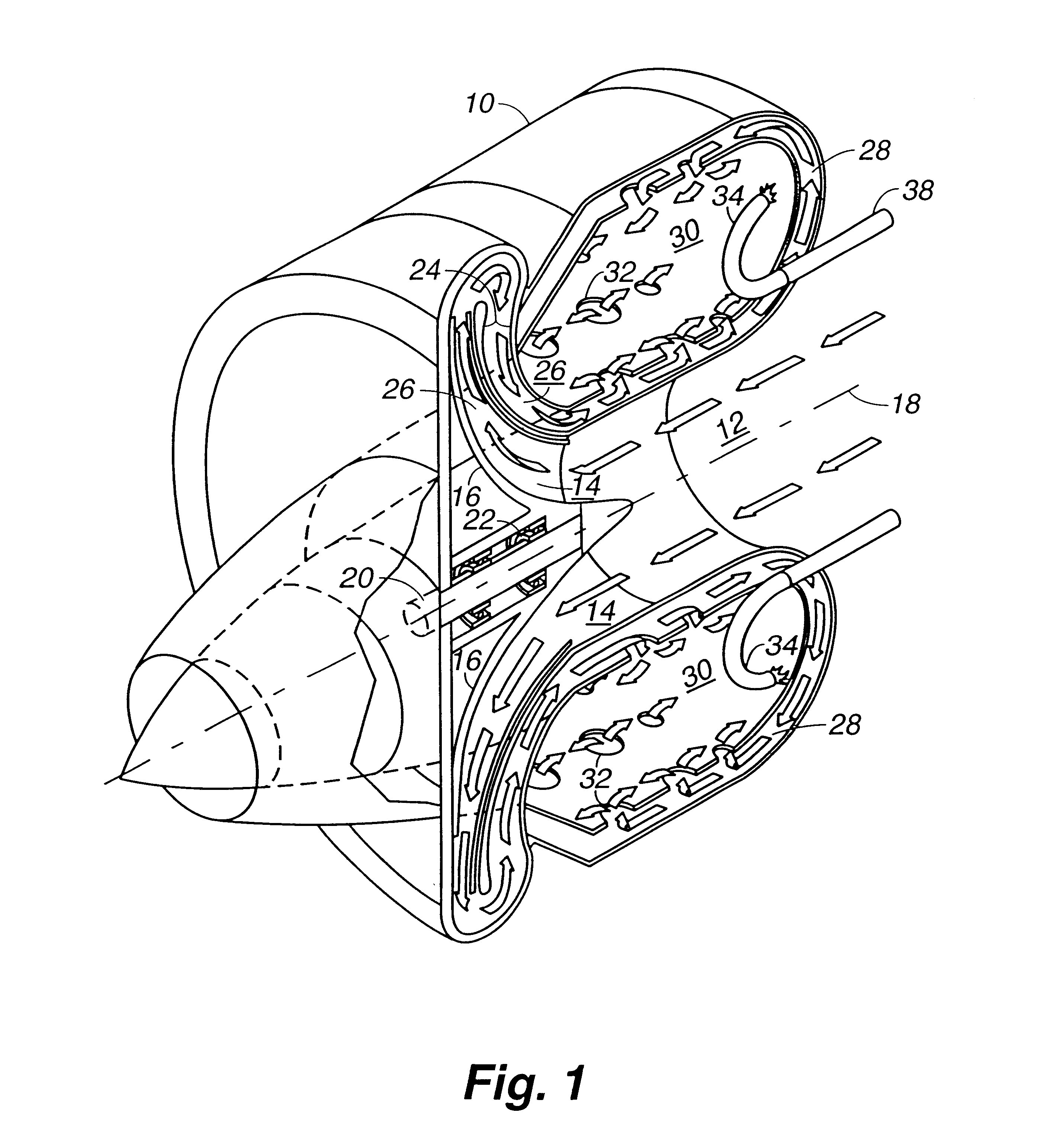

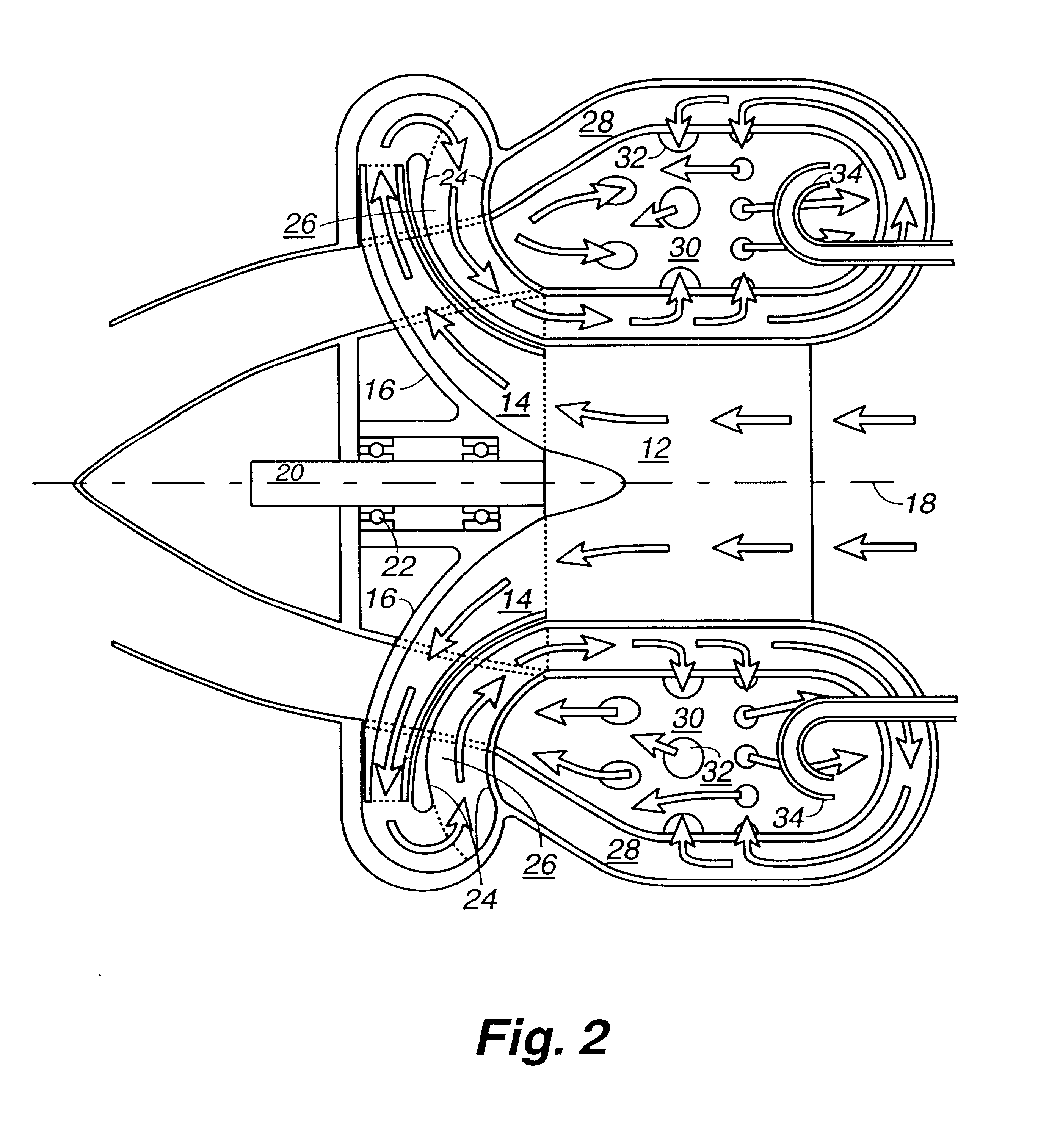

Single rotor turbine engine

There has been invented a turbine engine with a single rotor which cools the engine, functions as a radial compressor, pushes air through the engine to the ignition point, and acts as an axial turbine for powering the compressor. The invention engine is designed to use a simple scheme of conventional passage shapes to provide both a radial and axial flow pattern through the single rotor, thereby allowing the radial intake air flow to cool the turbine blades and turbine exhaust gases in an axial flow to be used for energy transfer. In an alternative embodiment, an electric generator is incorporated in the engine to specifically adapt the invention for power generation. Magnets are embedded in the exhaust face of the single rotor proximate to a ring of stationary magnetic cores with windings to provide for the generation of electricity. In this alternative embodiment, the turbine is a radial inflow turbine rather than an axial turbine as used in the first embodiment. Radial inflow passages of conventional design are interleaved with radial compressor passages to allow the intake air to cool the turbine blades.

Owner:LOS ALAMOS NATIONAL SECURITY

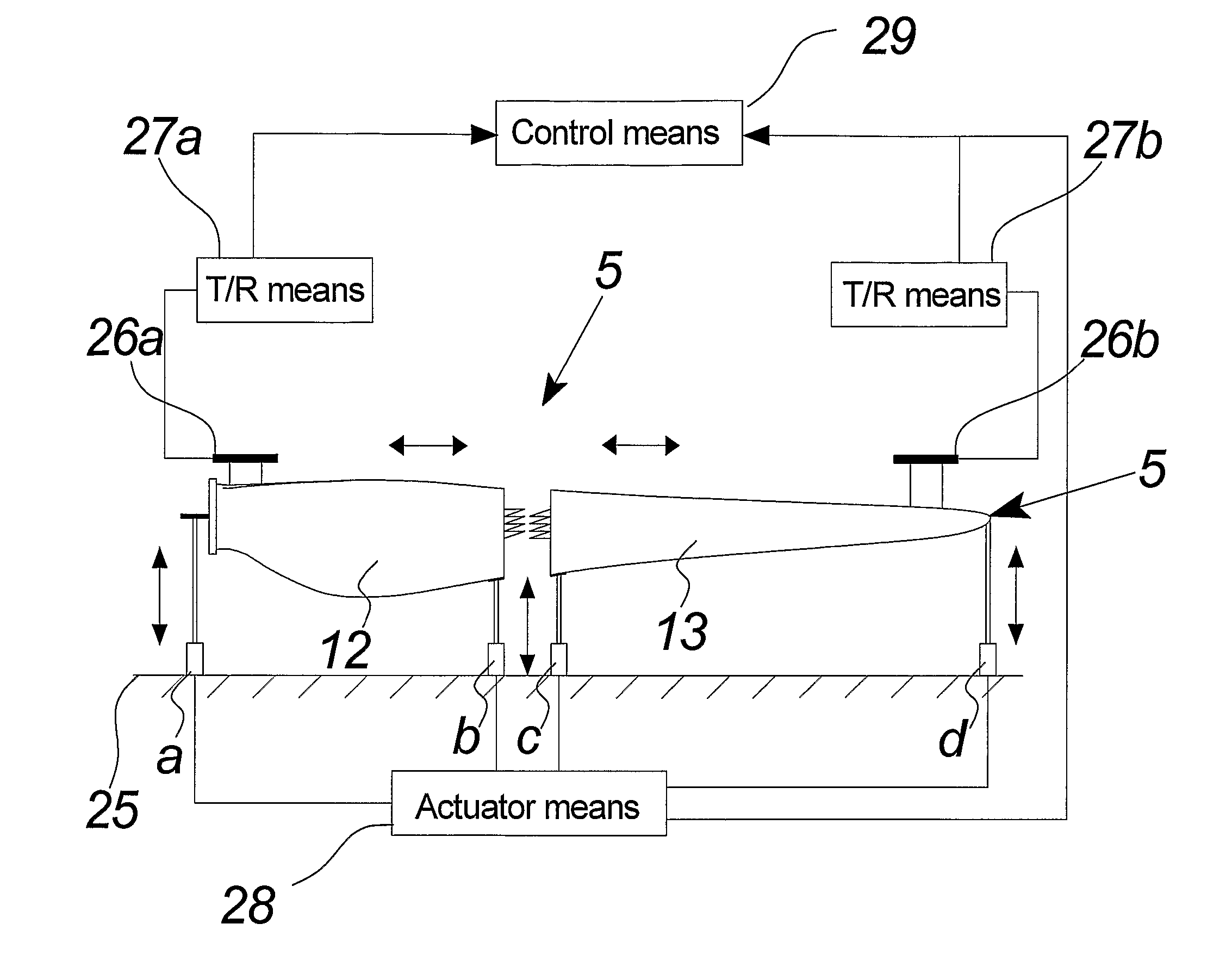

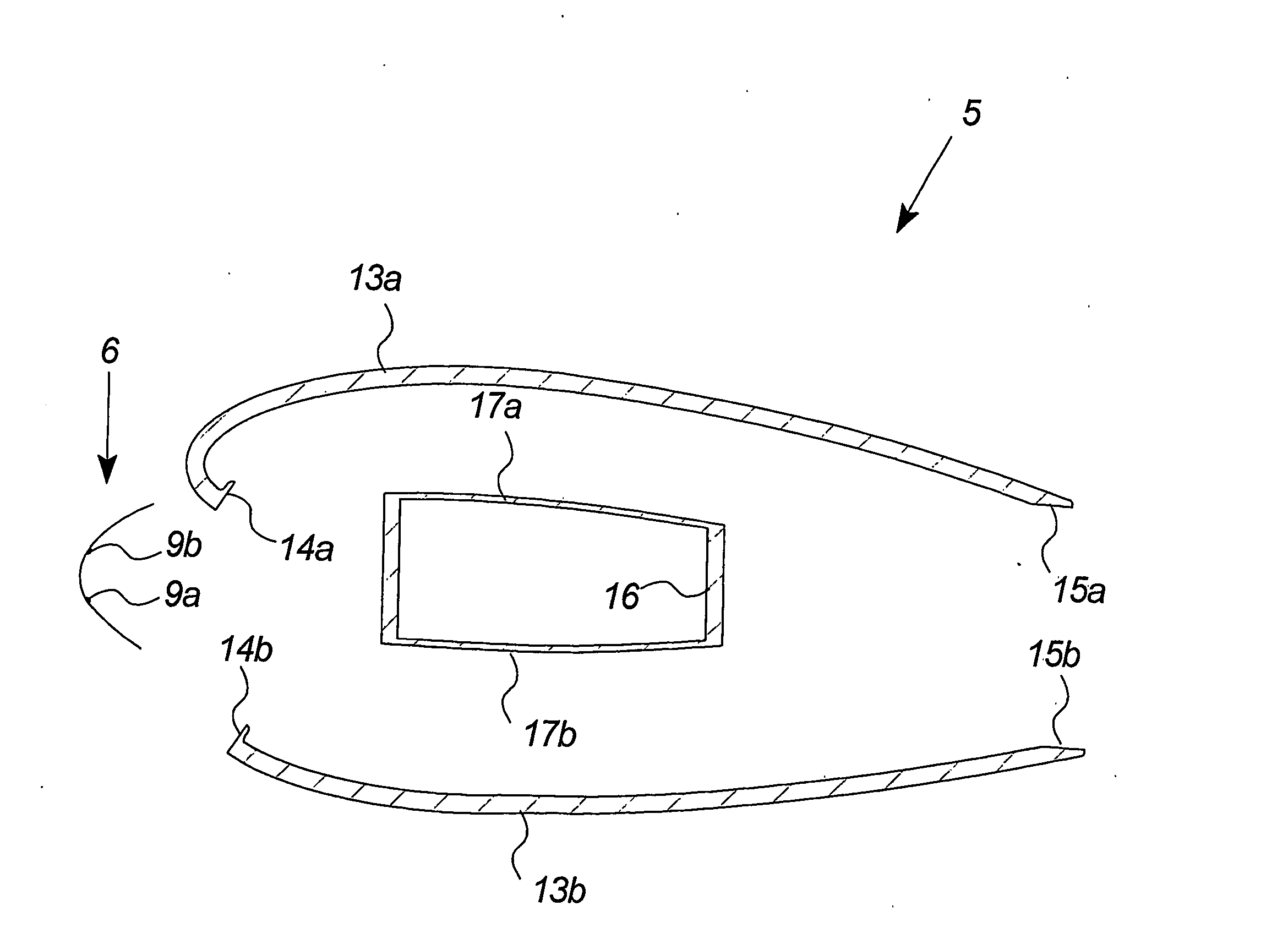

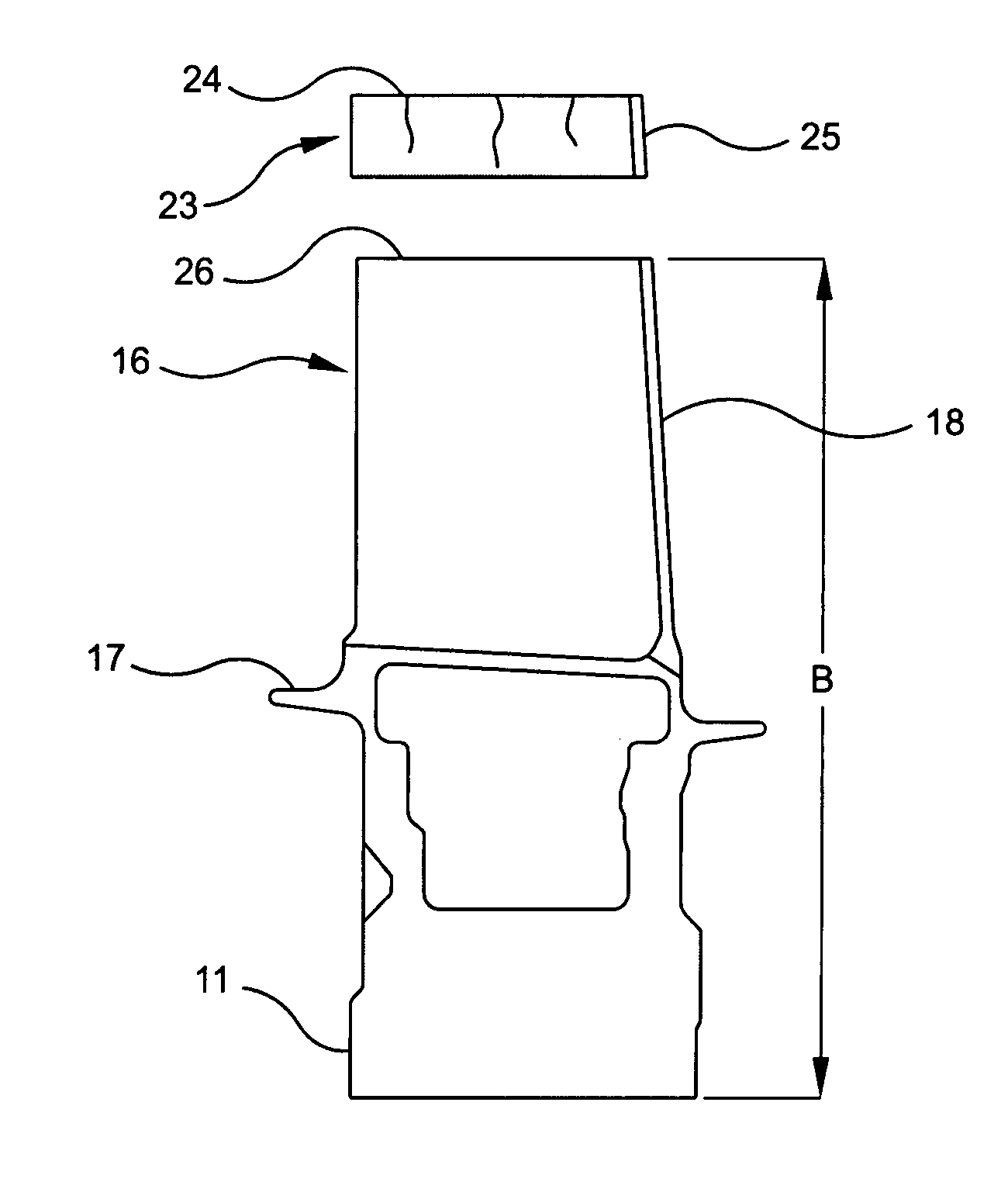

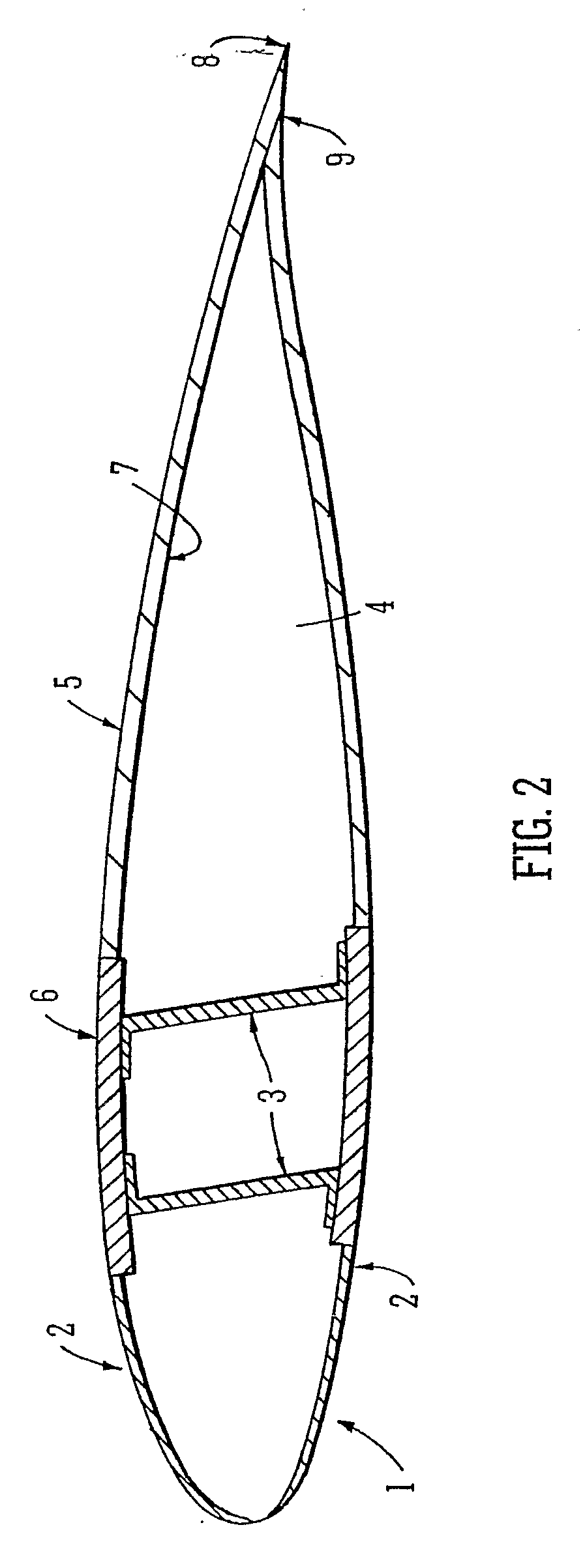

Wind Turbine Blades Made of Two Separate Sections, and Method of Assembly

ActiveUS20080069699A1Enhance and accelerate bonding processStrong adhesive connectionEngine manufactureFinal product manufactureFiberGlass fiber

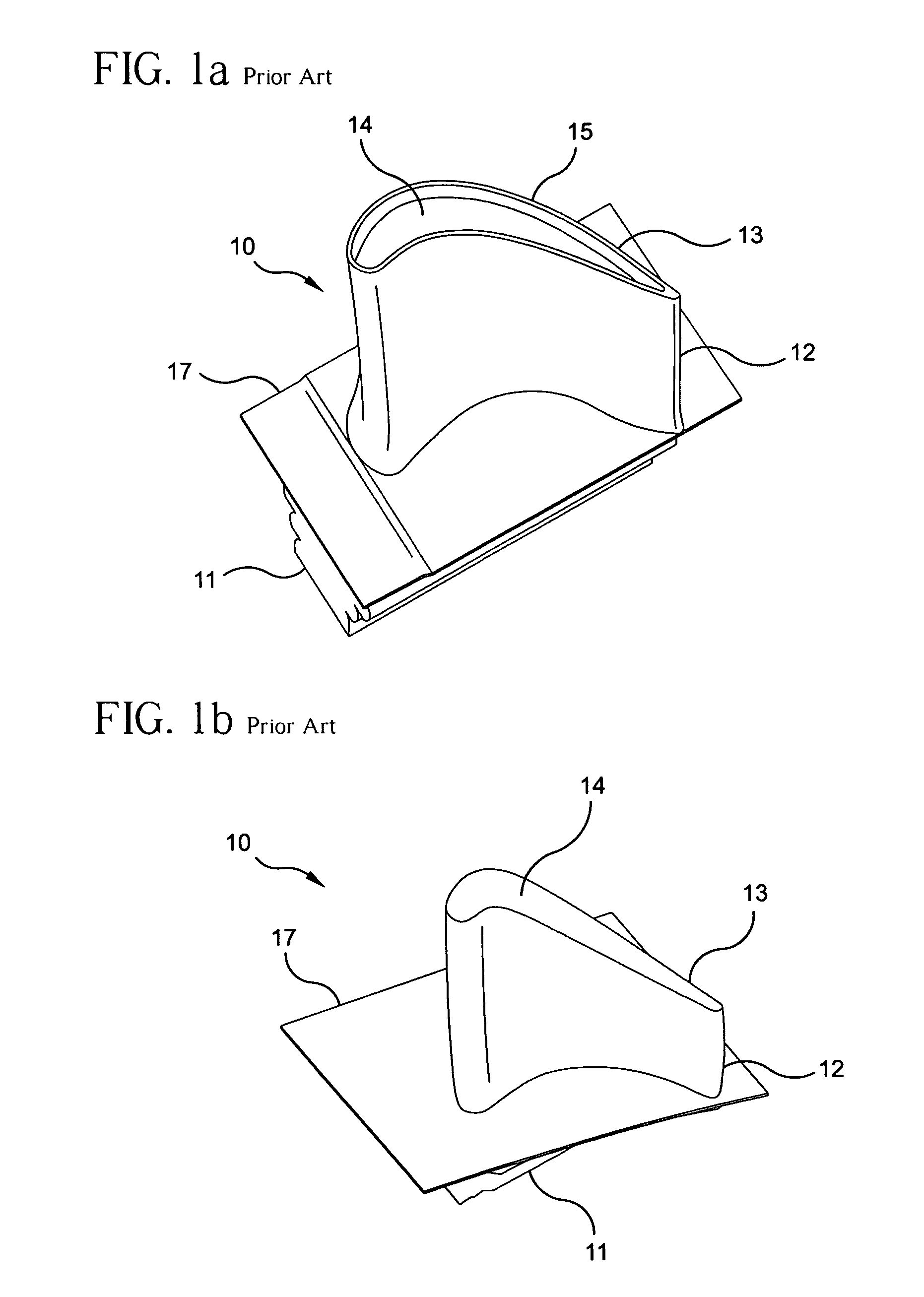

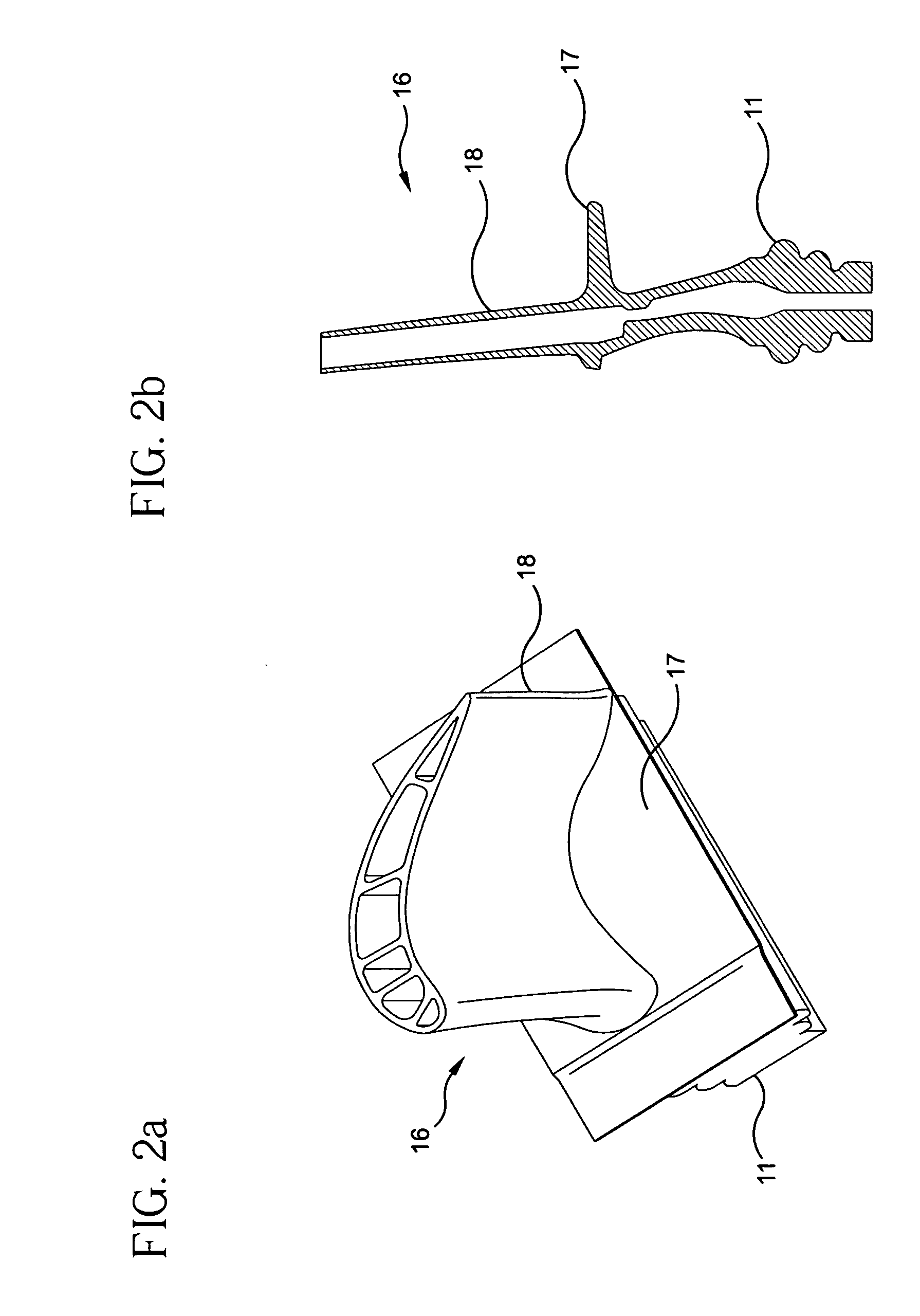

The invention relates to a wind turbine blade (5) comprising at least two wind turbine blade sections (12, 13) that include one or more strengthening structures (6, 6a, 6b), the ends (14, 15) of said strengthening structures being connected in a connection joint. The ends include corresponding connection surfaces, the one or more relevant dimensions of said surfaces being larger than the dimensions of the transverse surfaces of the strengthening structures at said ends. The one or more relevant dimensions of said connection joint are larger than that of the adjacent strengthening structure. The invention also relates to a wind turbine blade in which the at least two wind turbine blade sections include a number of substantially oblong carbon fiber strips and strips of one or further materials such as wood or glass fiber. The invention further relates to a wind turbine blade section, an assembly plant for assembling wind turbine blade sections (12, 13) and to a method and use of such wind turbine blades.

Owner:VESTAS WIND SYST AS

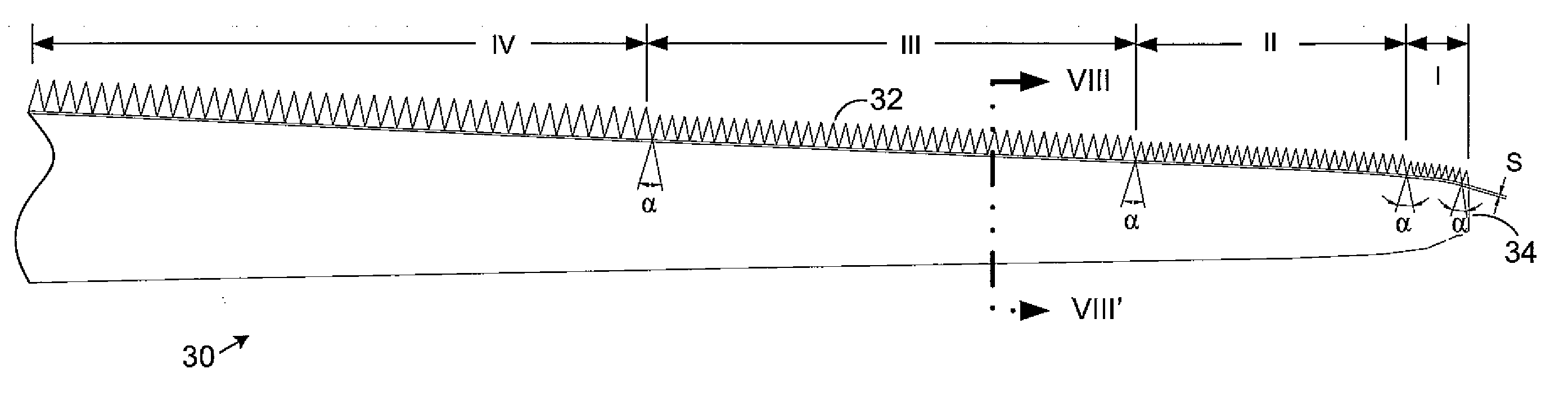

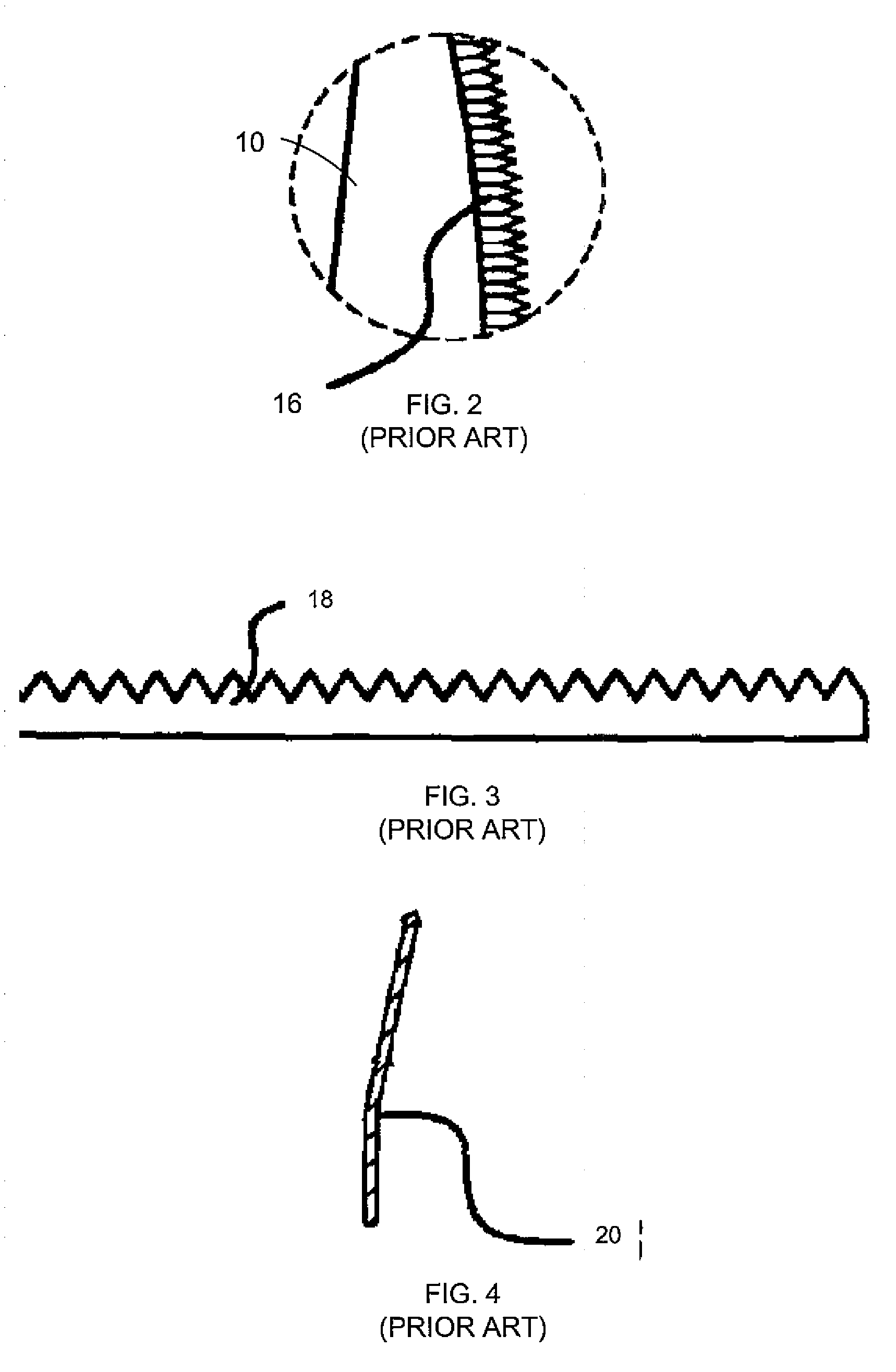

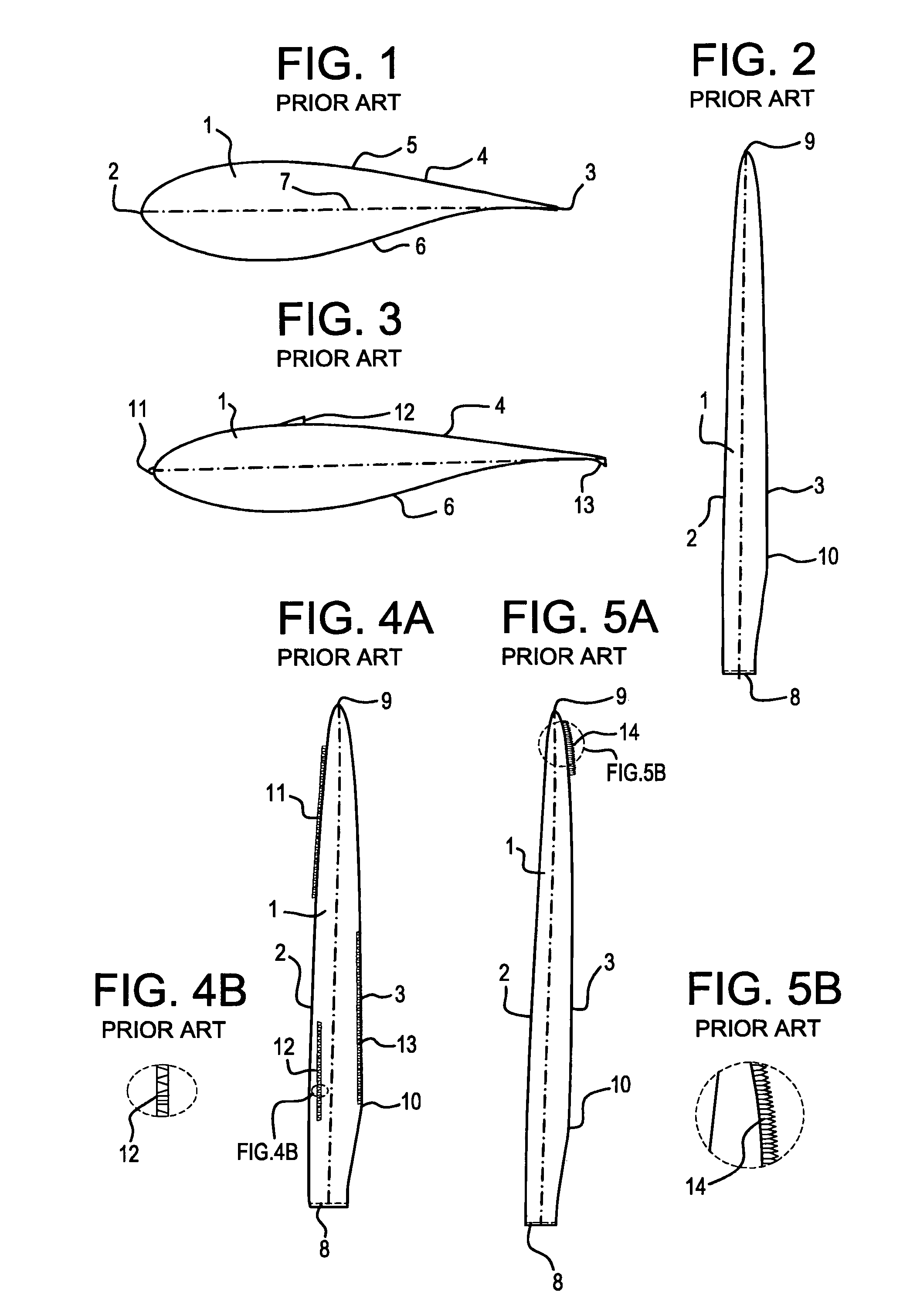

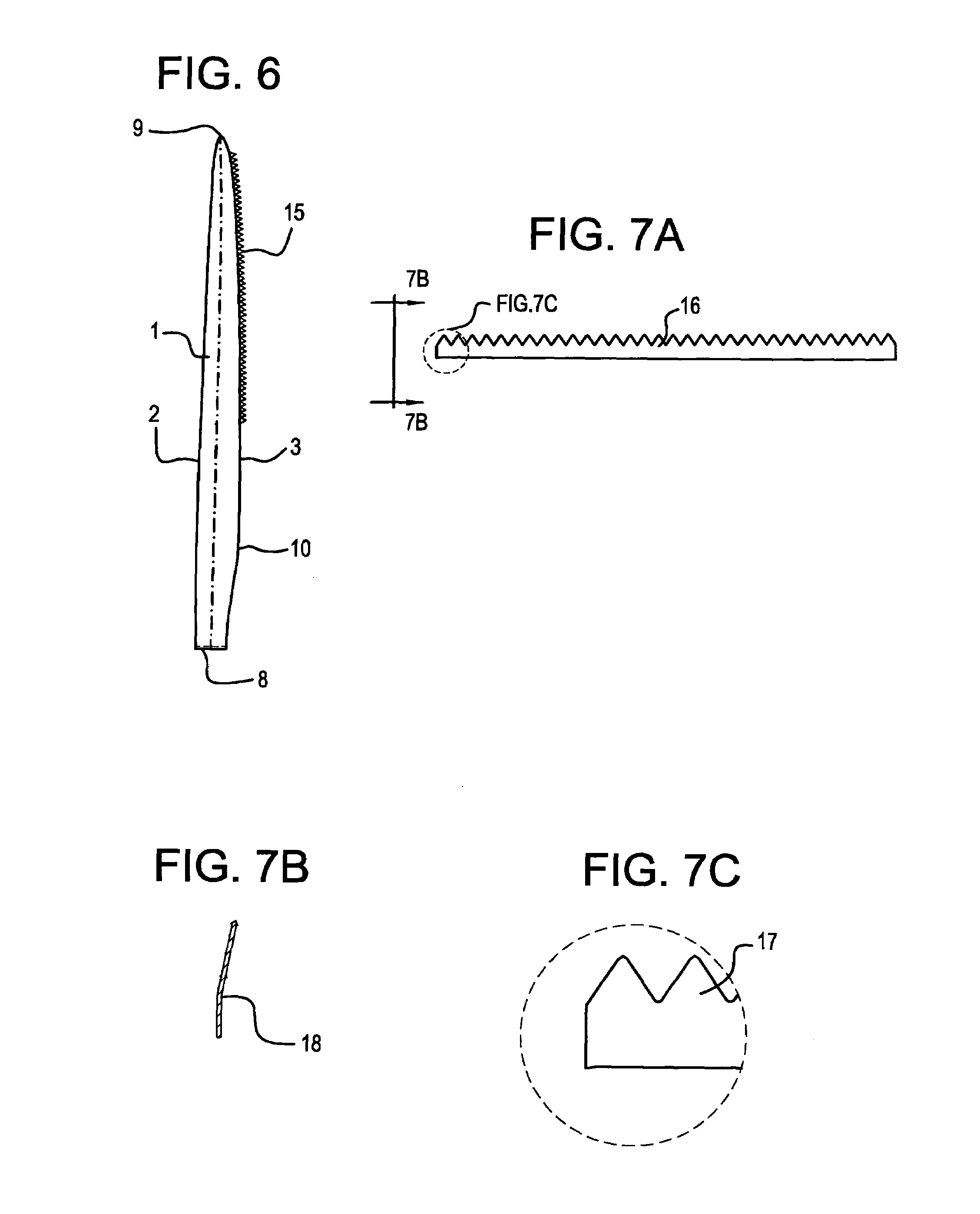

Wind turbine blades with trailing edge serrations

A wind generator and turbine blade includes a trailing edge having several serrations, a length of the serrations in each of a plurality of sections of the trailing edge is between approximately 10% and 40% of a mean chord for the corresponding section; and a length to width ratio of each of the serrations is between approximately 1:1 to 4:1.

Owner:GENERAL ELECTRIC CO

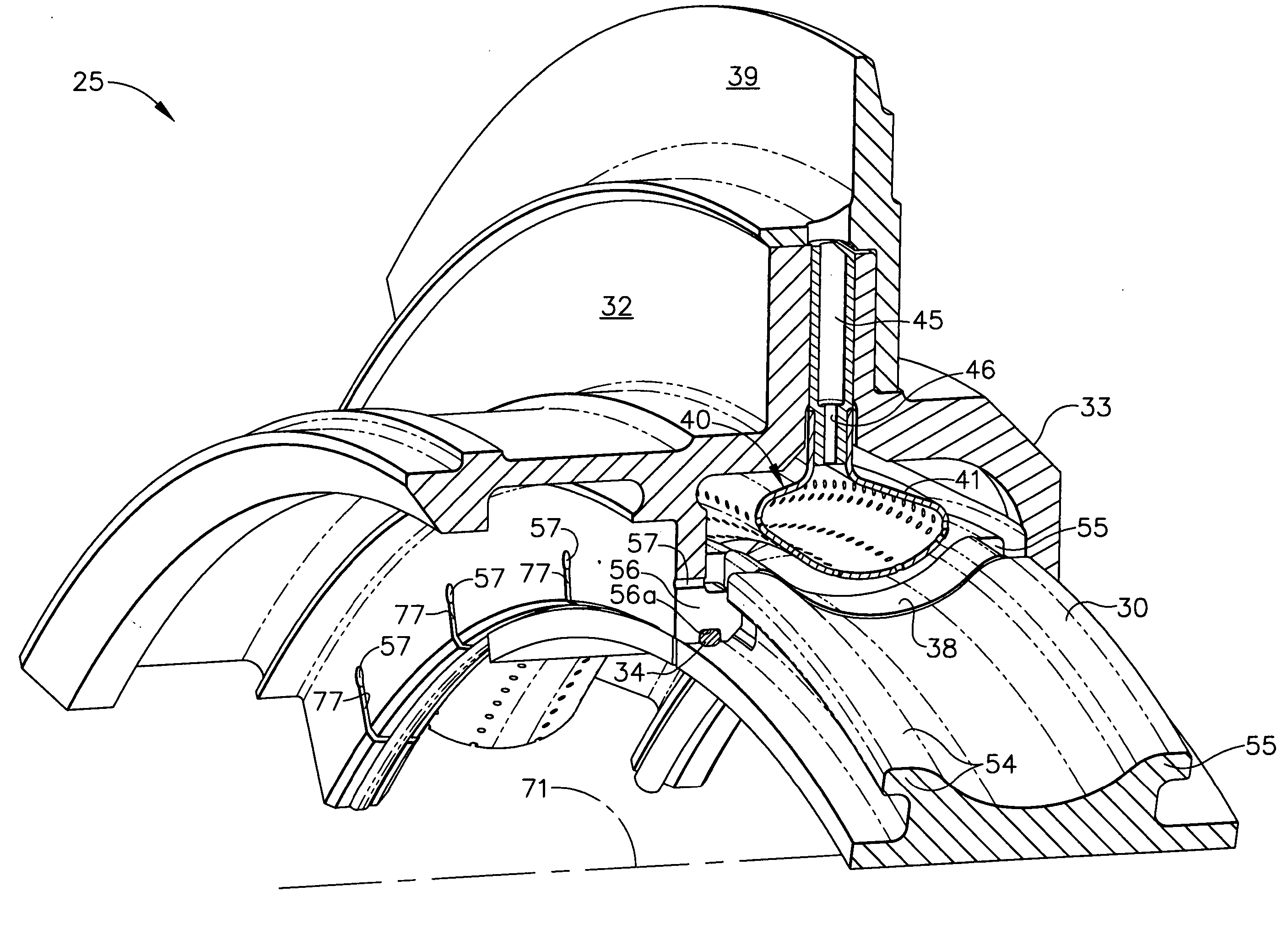

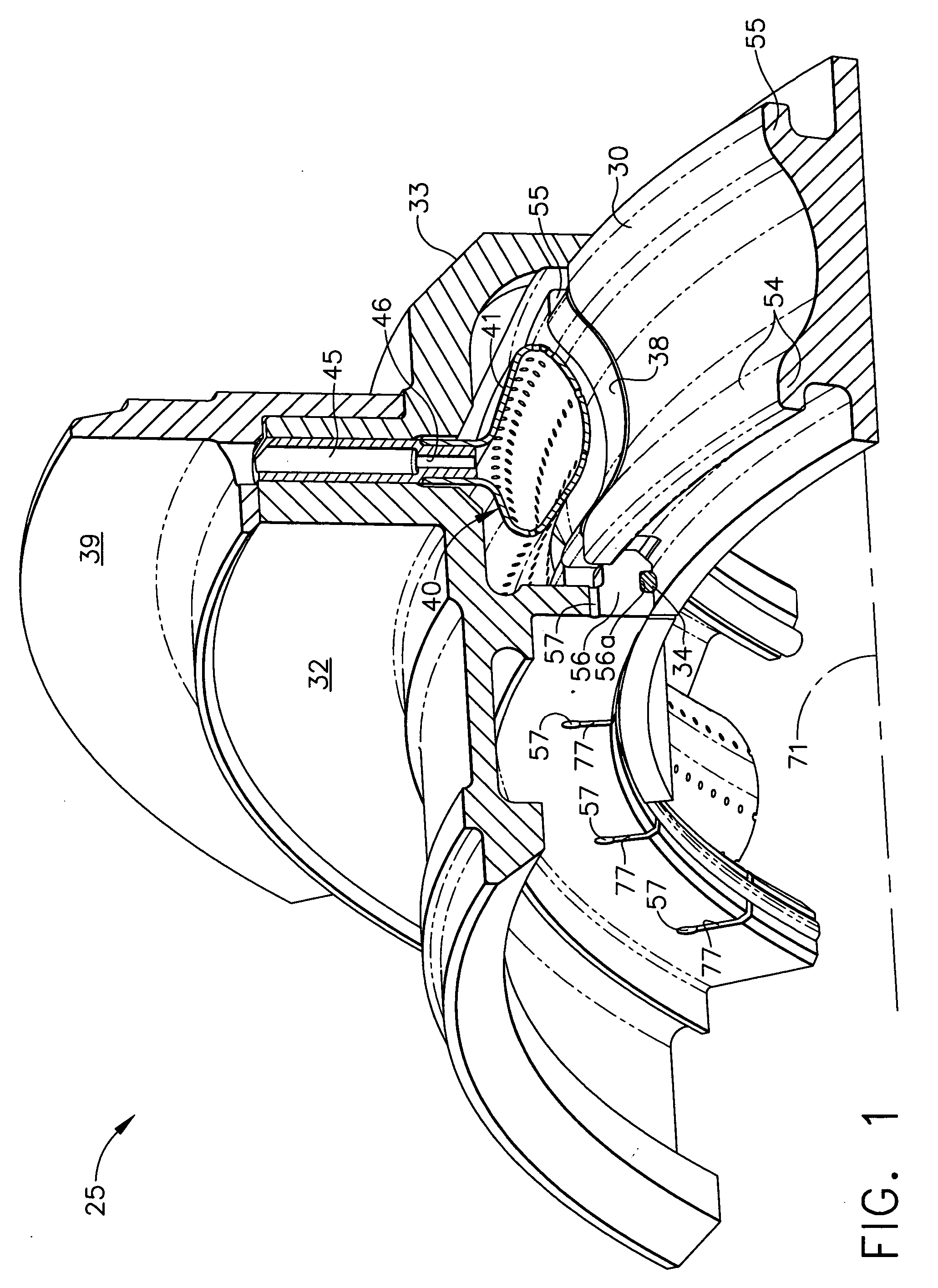

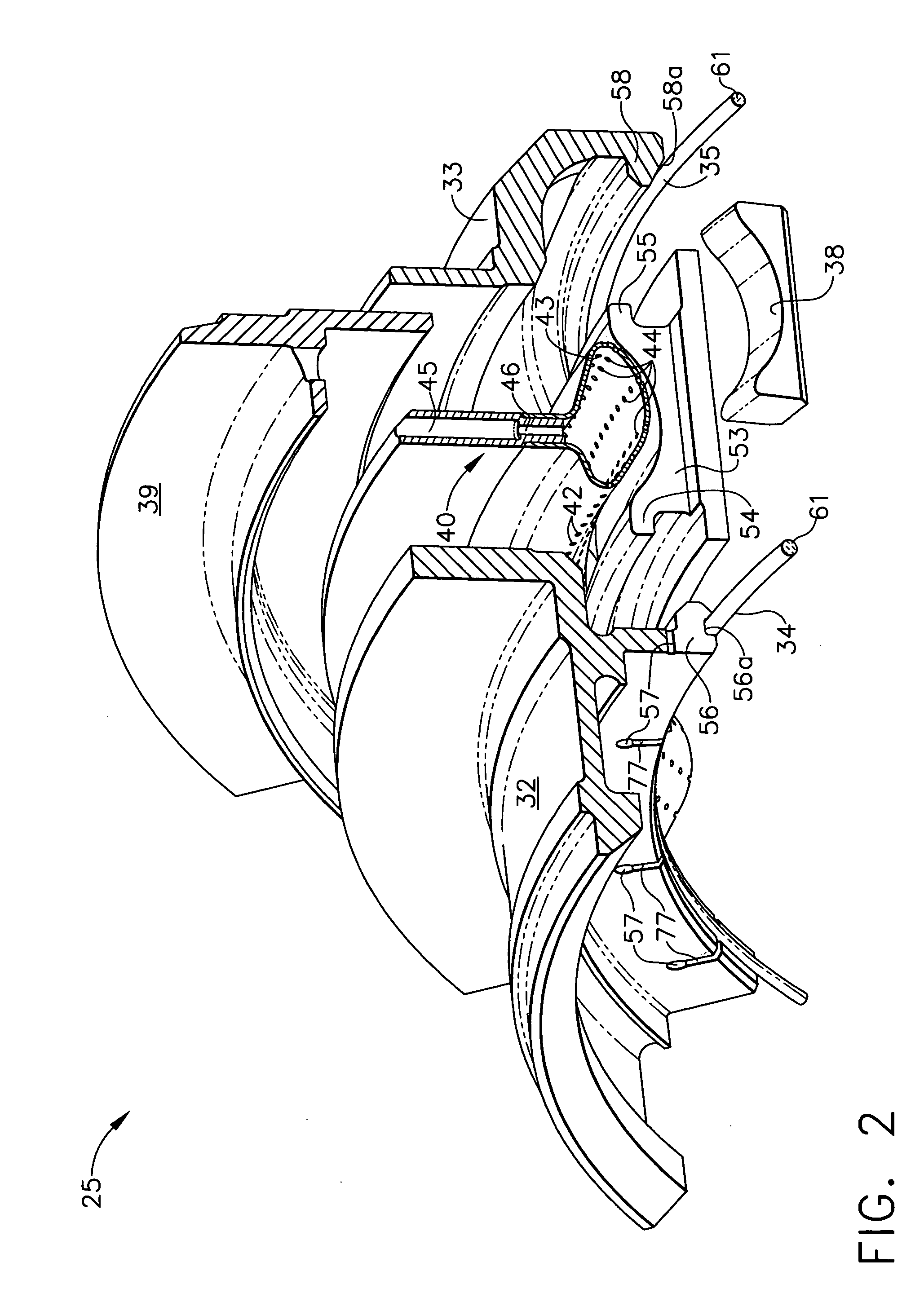

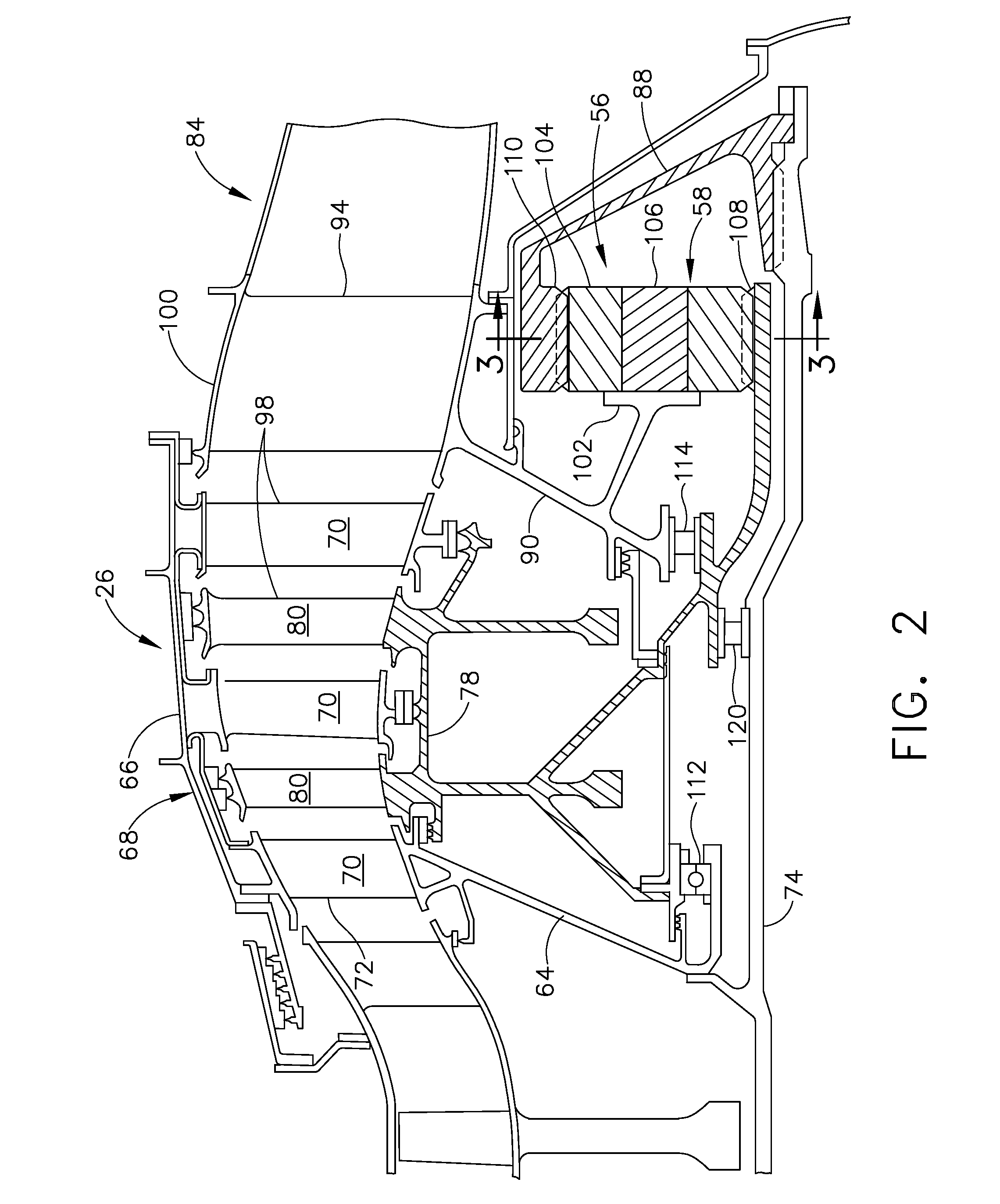

Gas turbine high temperature turbine blade outer air seal assembly

A turbine shroud assembly includes forward and aft hangers, an axisymmetric plenum assembly, ceramic shroud segments, ceramic spacers, and forward and aft rope seals. The plenum assembly supplies impingement cooling to the shroud and the hangers. The impingement cooling to the forward and aft hangers is controlled independently to improve blade tip clearance. The rope seals are radially inward from the hangers and reduce cooling flow leakage. The turbine shroud assembly can operate in a higher temperature environment using less cooling flow than the prior art.

Owner:HONEYWELL INT INC

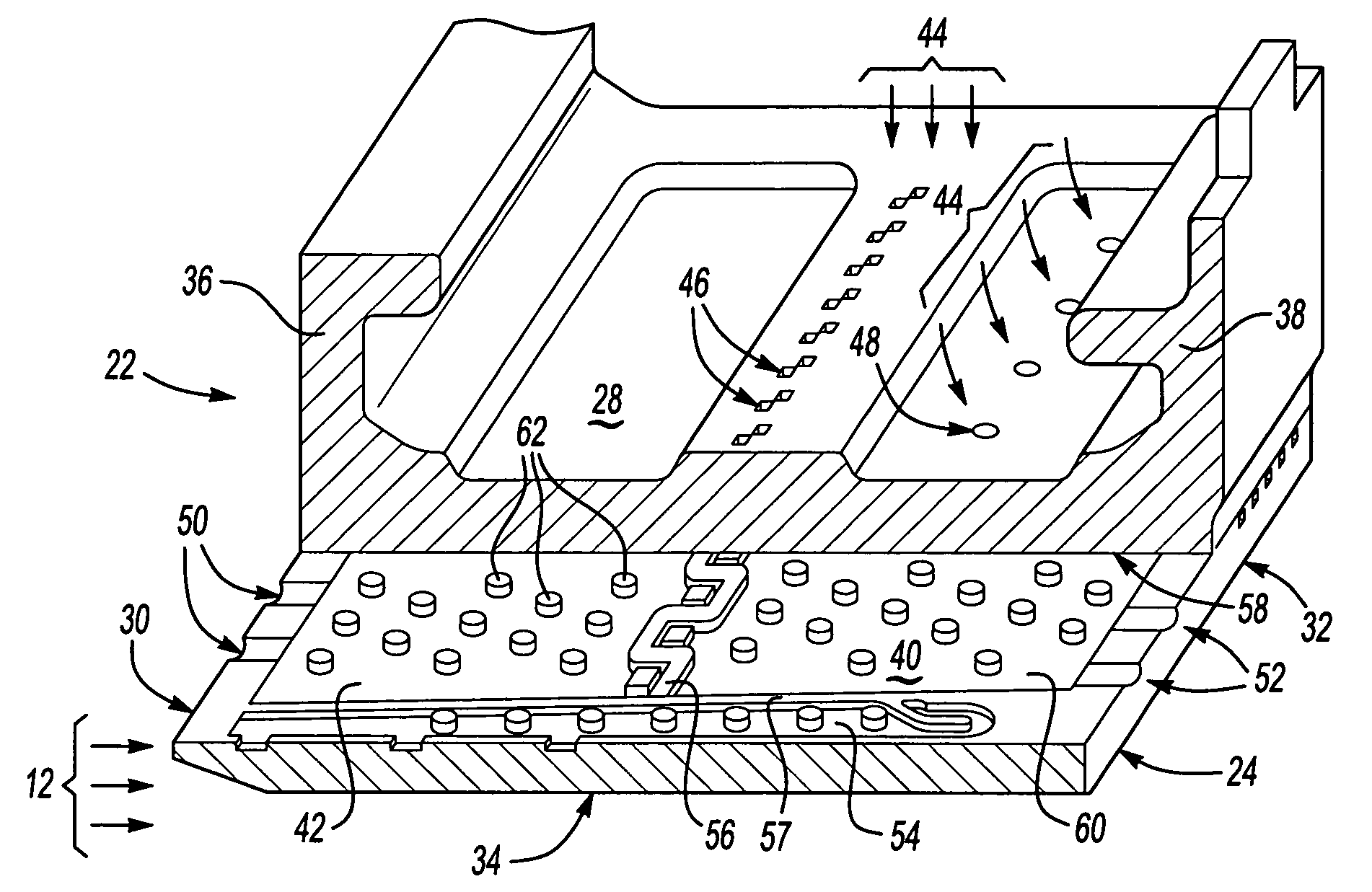

Blade outer seal with micro axial flow cooling system

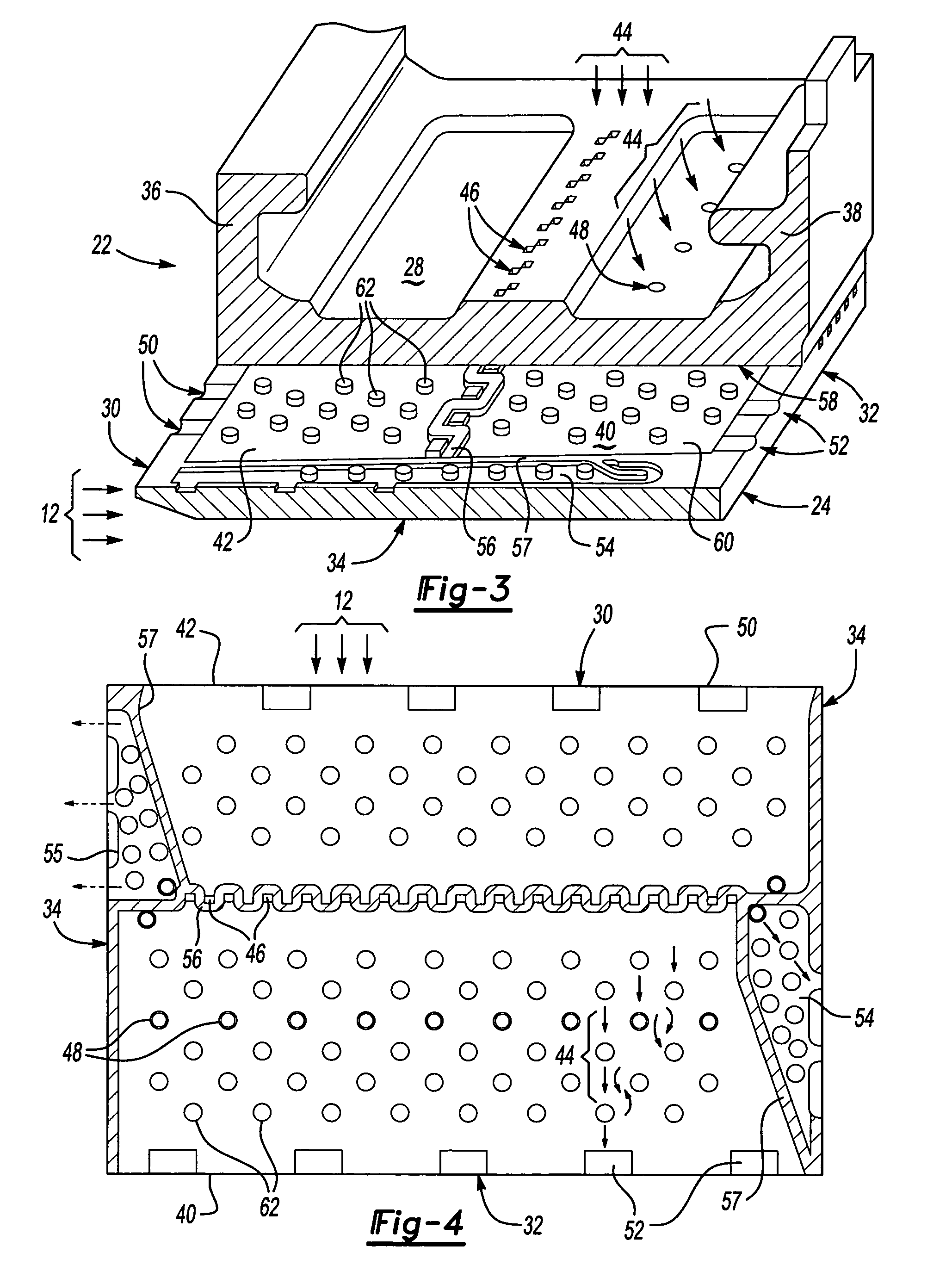

ActiveUS7306424B2Increase surface areaImprove cooling effectPump componentsEngine fuctionsLeading edgeCombustion

A turbine blade outer air seal assembly includes a hot side exposed to a combustion hot gas flow, and a back side that is exposed to a supply of cooling air. The outer air seal segment includes a trailing edge cavity and a leading edge cavity separated by a divider. The cavities are feed cooling air through a plurality of inlet openings disposed transverse to the gas flow. The cooling air enters the cavities and flows toward a plurality of outlets at the leading edge and a plurality of outlets along the trailing edge. A plurality of pedestals within each of the cavities disrupts cooling air flow to increase heat absorption capacity and to increase the surface area capable of transferring heat from the hot side.

Owner:RTX CORP

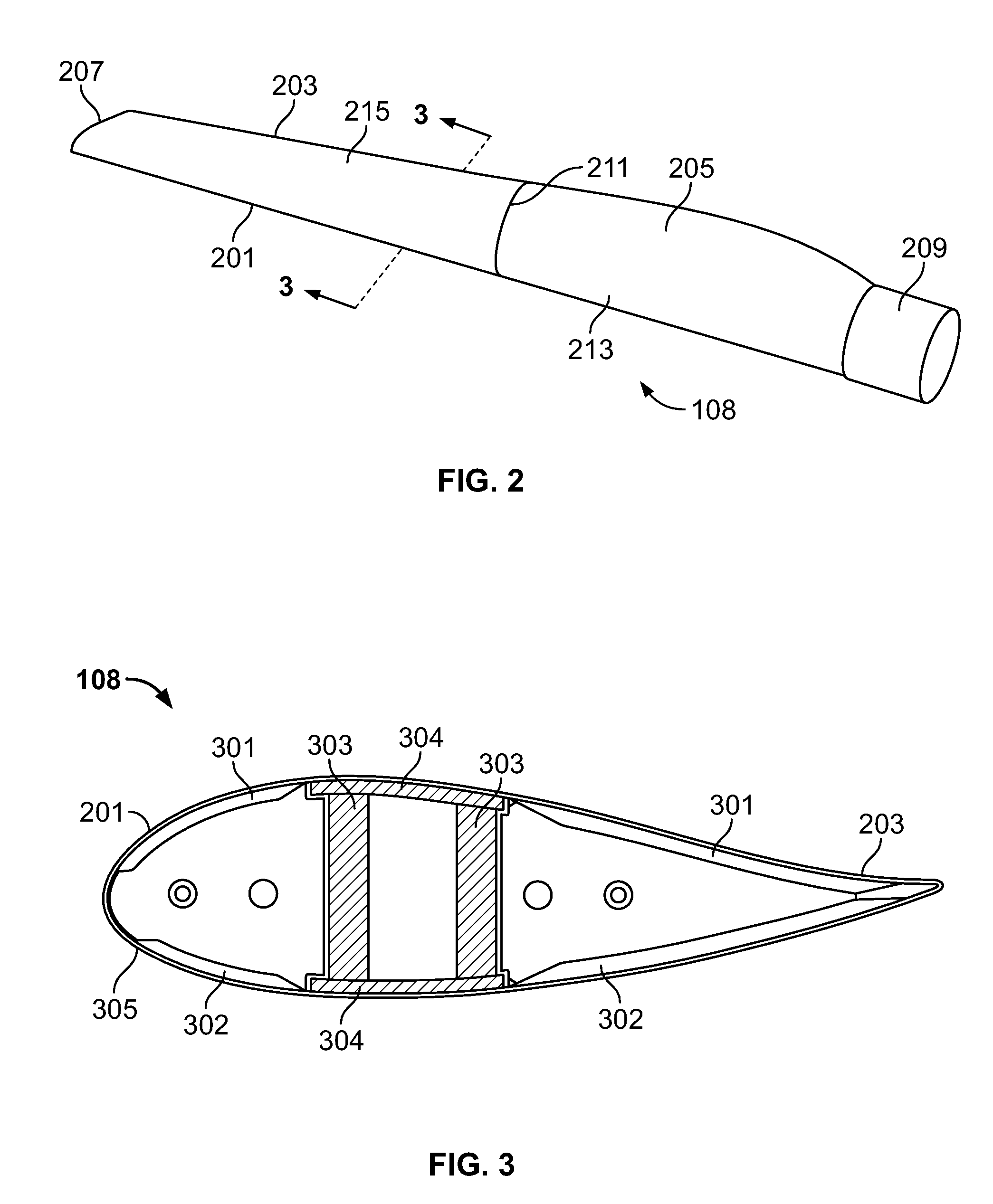

Wind blade joint bonding grid

ActiveUS20090155084A1Strong and uniform junctionEvenly distributedEngine manufactureFinal product manufactureTurbine bladeAdhesive

A method and system for assembling large wind turbine blades that includes providing a plurality of wind turbine blade segments. An adhesive distribution arrangement is disposed on a surface of at least one of the plurality of the wind turbine blade segments. The adhesive distribution arrangement includes a bonding grid having a plurality of adhesive distribution openings. The wind turbine blade segments are directed together and sufficient adhesive is provided to the bonding grid to substantially fill an area between the wind turbine segments. The adhesive is then cured to form a bonded joint, the bonding grid being incorporated into the bonded joint. A bonding grid for use with the method and system and a segmented wind turbine blade are also disclosed.

Owner:GENERAL ELECTRIC CO

Manufacturable geometries for thermal management of complex three-dimensional shapes

Uniform cooling of complex surface shapes in injection mold tooling can be accomplished with cooling channels that conform to the shapes of the mold cavity or mold cone. By conventional methods this can be very difficult to accomplish. By applying methods of material deposition or material sintering, which include but are not limited to, laser metal deposition, where material is deposited on a layer by layer basis, certain cooling or heating passages could be integrated into the manufactured component that follow the contours and profiles of the mold's complex surfaces. These passages would act as internal heat sinks with a much higher surface area for heat transfer than traditional drilled and plugged straight passages. These geometries could also be incorporated into complex geometries such as, but not limited to, turbine blades where the cooling passages can follow the contour of the outer shape, provide a more uniform or controlled heat transfer from the component. Multiple loops of cooling or heating channels could be designed and manufactured into solid objects for small-scale heat exchanger technologies.

Owner:OPTOMEC DESIGN CO

Method of making a part of large dimensions out of composite material

InactiveUS6264877B1Avoid disadvantagesRisk of pollutionFinal product manufactureLaminationGlass fiberFiber

A method of making a composite material part, in particular a wind turbine blade of great length, consists in placing a thickness of a cloth made up of threads comprising a mixture of polypropylene threads or fibers and of glass fibers or threads in two mold portions having the shape of the part that is to be made, placing an inflatable envelope on the cloth inside one of the mold portions, in closing the mold, in placing it in an enclosure fed with hot gas under pressure to melt the polypropylene of the cloth, thereby embedding the glass fibers or threads, then in allowing it to cool, and in unmolding.

Owner:ALTERNATIVES ENERGIES

Method of manufacturing a wind turbine blade, wind turbine blade, front cover and use of a front cover

The invention relates to a method of manufacturing a wind turbine blade, said method comprising the steps of: casting at least two wind turbine shells and preferably one or more load bearing structures, forming a wind turbine blade structure including at least two longitudinal joints by adhering said at least two wind turbine shells and said one or more load bearing structures together, forming one or more front covers to a shape substantially corresponding to said wind turbine blade structure or sections hereof, positioning said one or more front covers in relation to said wind turbine blade structure, and fastening said one or more front covers to said wind turbine blade structure with adhering means. The invention also relates to a wind turbine blade, front cover and the use of a front cover as a unit for supplementary mounting on a wind turbine blade.

Owner:VESTAS WIND SYST AS

Method for improvement of the efficiency of a wind turbine rotor

InactiveUS7059833B2Improvement of wind turbine rotor efficiencyImprove efficiencyPropellersWind motor controlTurbine bladeTrailing edge

A method for the improvement of wind turbine rotor efficiency blades of a wind turbine rotor with serrated trailing edges each having a plurality of span-wise, periodic indentations, in the form of saw teeth having approximately 60 degrees included angles between adjacent vertices. The efficiency of an existing wind turbine rotor is improved by the attachment of an apparatus to at least part of the trailing edge of the wind turbine blades, the apparatus being in the form of a serrated panel that is fixed to the surface of the blade and has the serrations extending into the airflow behind the trailing edge of the existing blade. The efficiency of a new wind turbine blade is improved by manufacturing the blade with serrations of at least part of the trailing edge of the wind turbine blade.

Owner:BONUS ENERGY +1

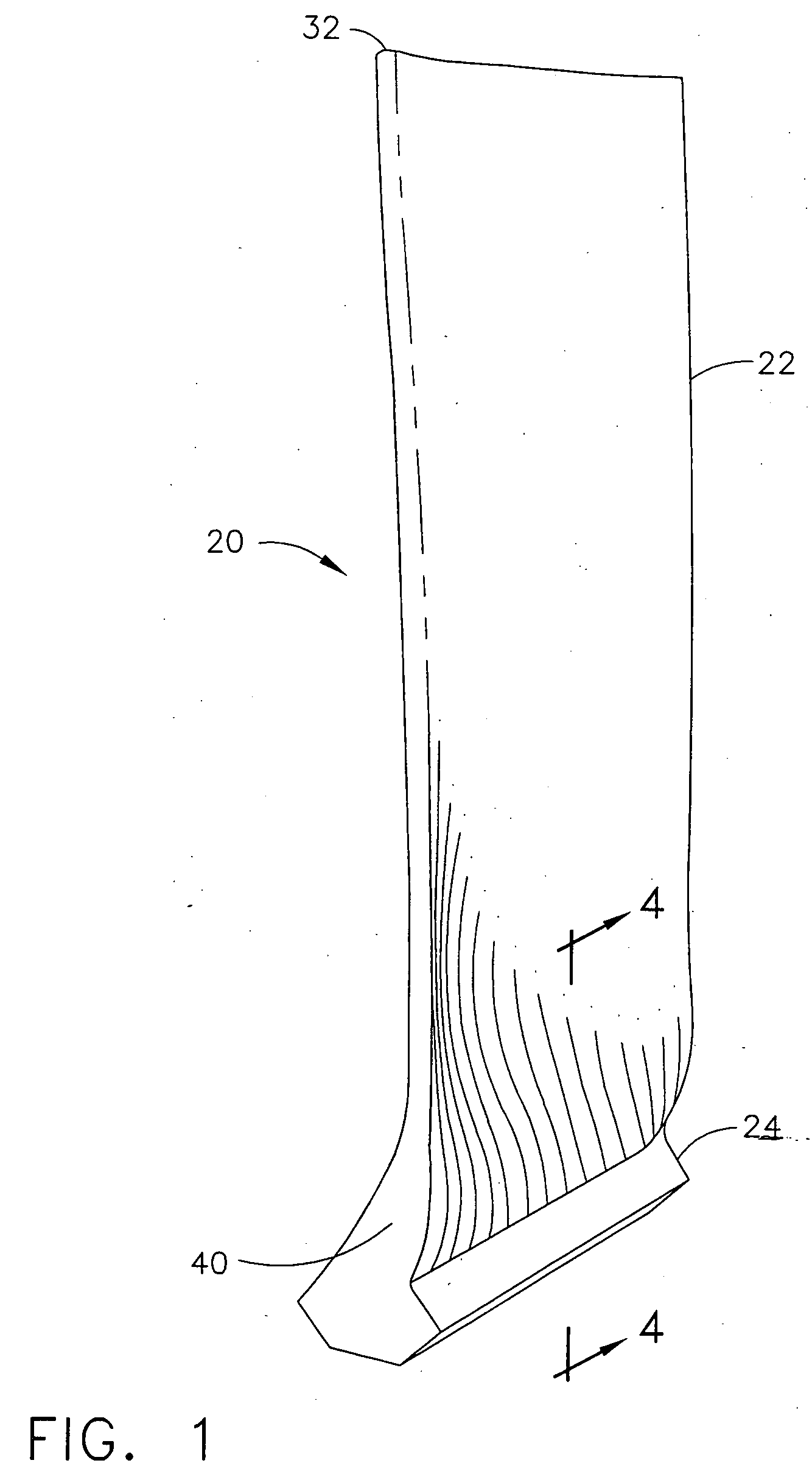

Turbine blade and a method of manufacturing and repairing a turbine blade

A turbine blade and a process for manufacture of turbine blades is provided comprising: casting as one piece a blade body and a first portion of an airfoil; forming a tip section having a tip cap and a second portion of an airfoil which is sized to fit on the first portion of the airfoil; and attaching the first portion of the airfoil to the second portion of the airfoil. A process for repairing turbine blades is provided which comprises: removing the tip cap and a portion of the airfoil from the blade to form a repair surface on the airfoil; forming a replacement tip section comprising a replacement tip cap and a replacement portion of the airfoil sized to fit onto the repair surface; and attaching the replacement tip section to the repair surface.

Owner:CHROMALLOY GAS TURBINE

Geared differential speed counter-rotatable low pressure turbine

A counter-rotatable low pressure turbine includes counter-rotatable outer and inner drum rotors. The outer drum rotor is connected to a sole shaft for transmitting torque and power out of the low pressure turbine. Low pressure outer drum turbine blade rows extend radially inwardly from an outer shell of the outer drum rotor. Low pressure inner drum turbine blade rows extend radially outwardly from the low pressure inner drum rotor. The outer drum turbine blade rows are interdigitated with the inner drum turbine blade rows. The drum rotors are geared together through an epicyclic gearbox for transmitting all the torque and power produced by the drum rotors to the shaft. The gearbox may be located aft of the drum rotors. A differential thrust bearing is disposed between the drum rotors. A single stage fan section of an engine is connected to the turbine by the shaft.

Owner:GENERAL ELECTRIC CO

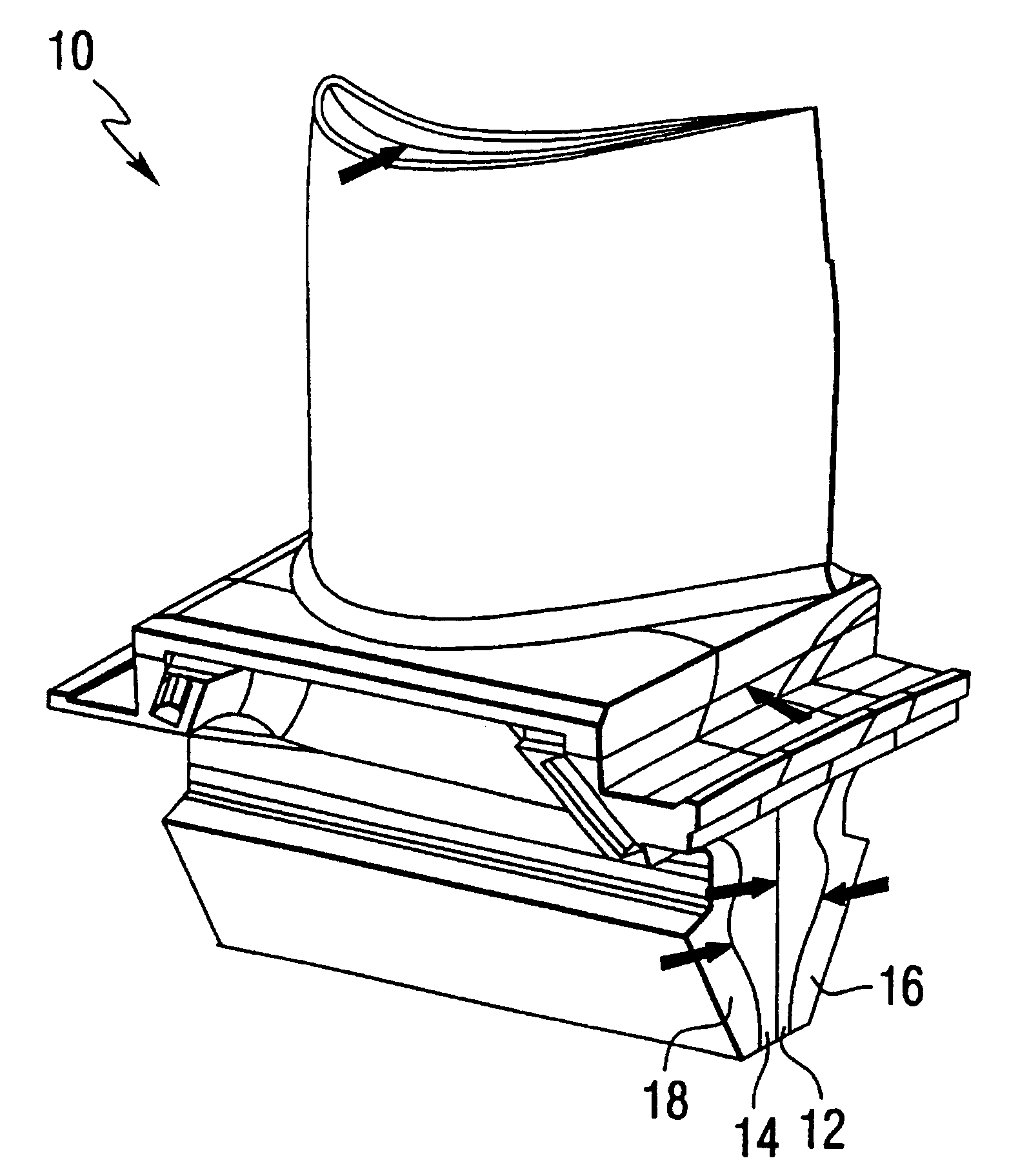

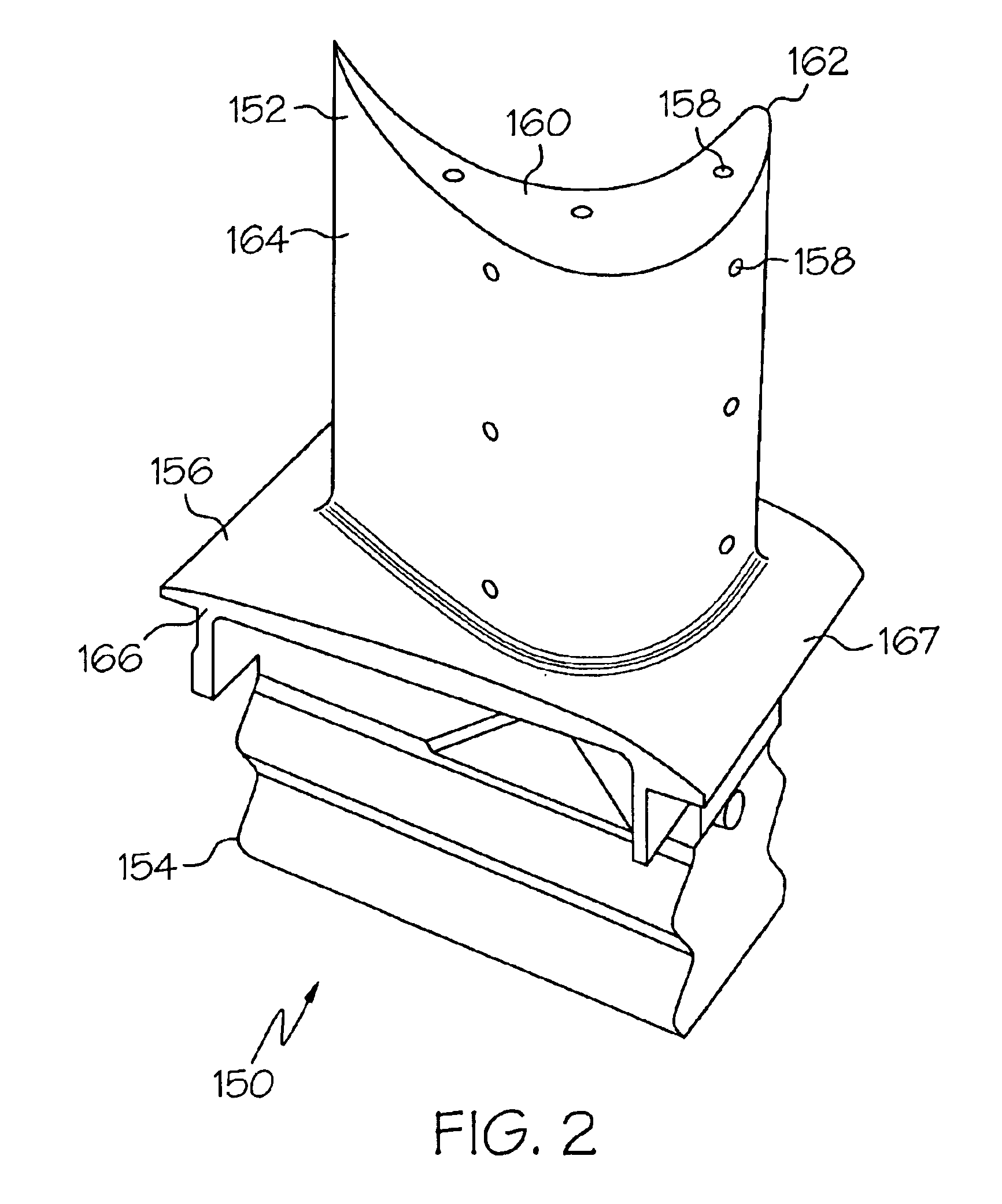

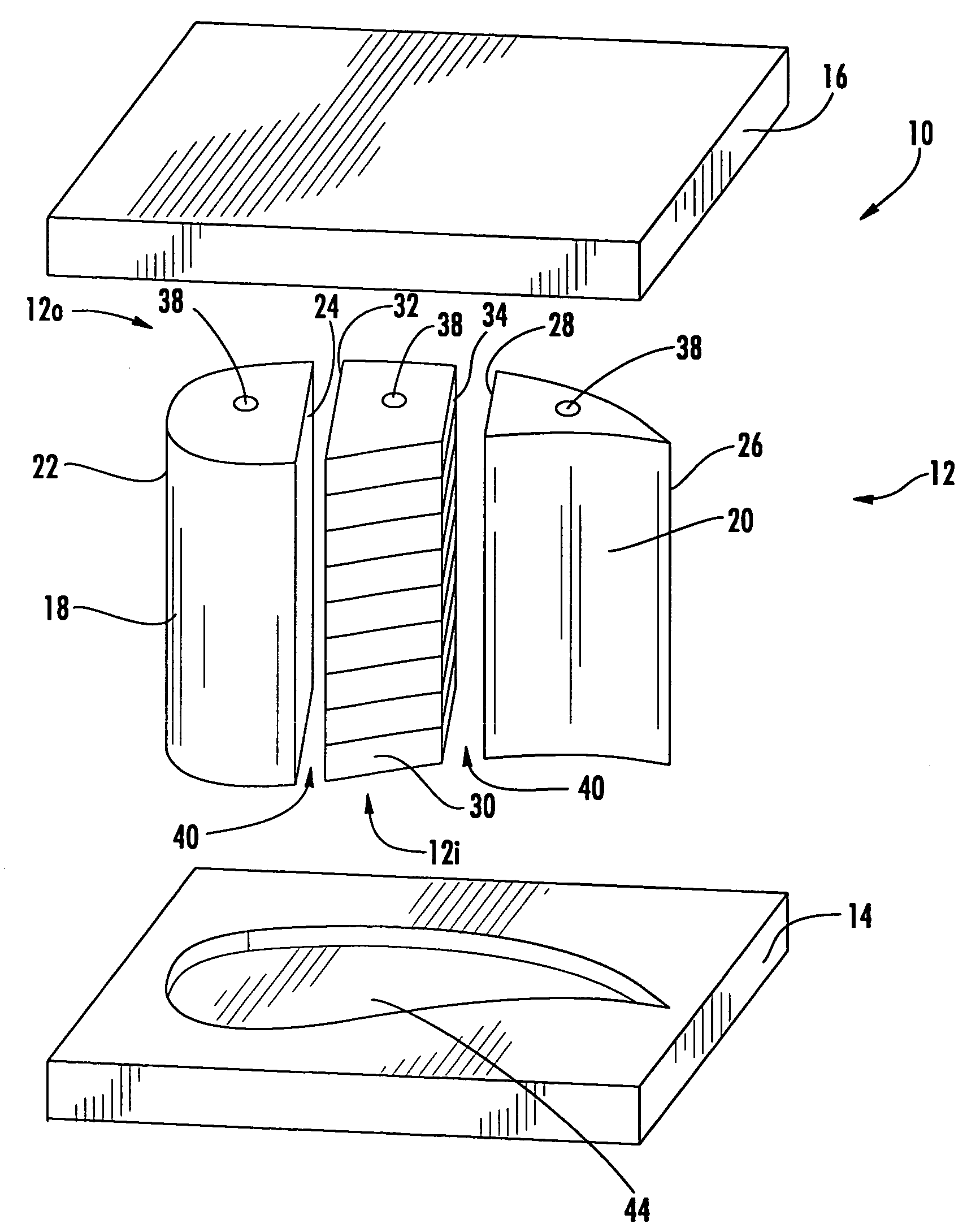

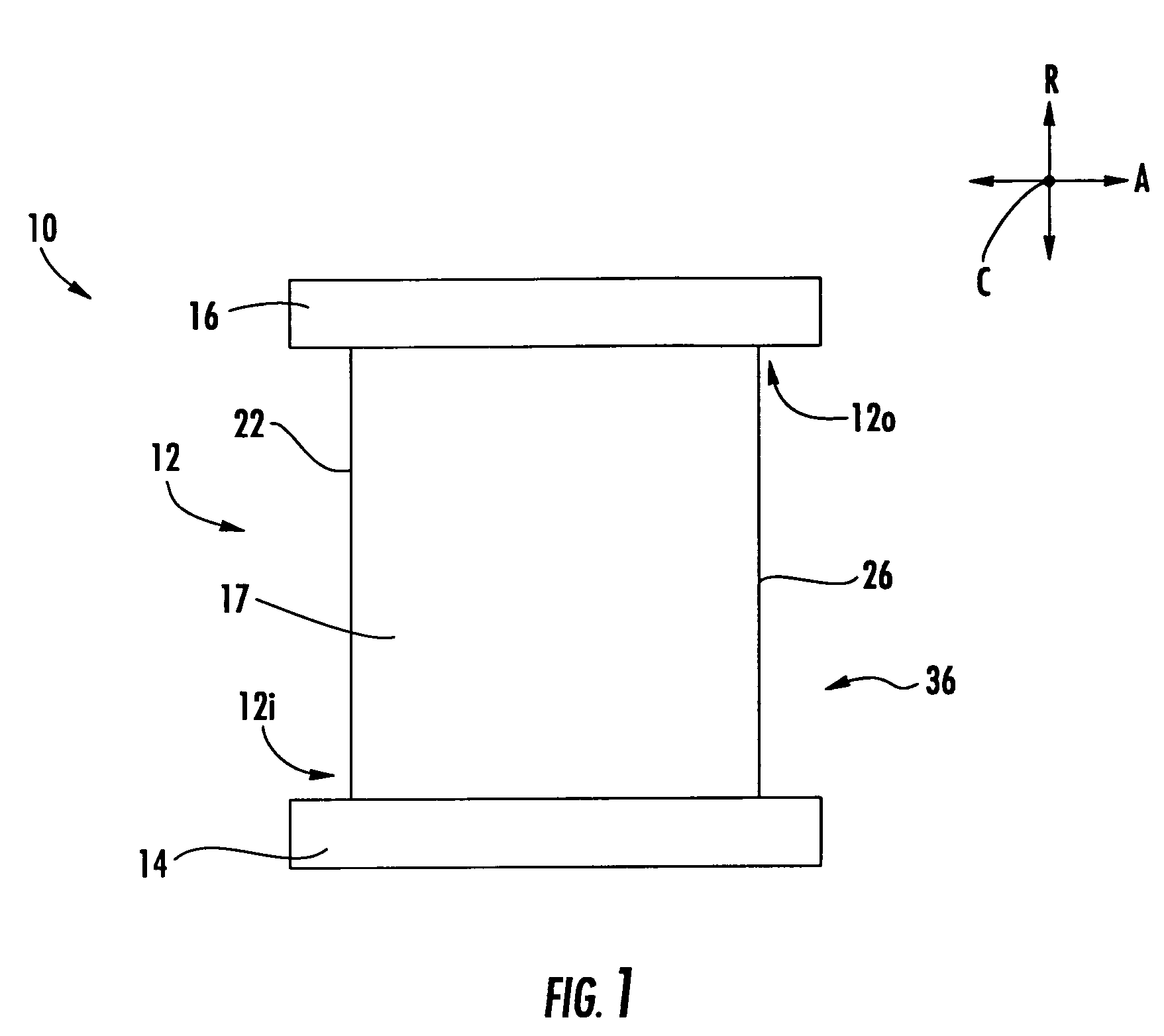

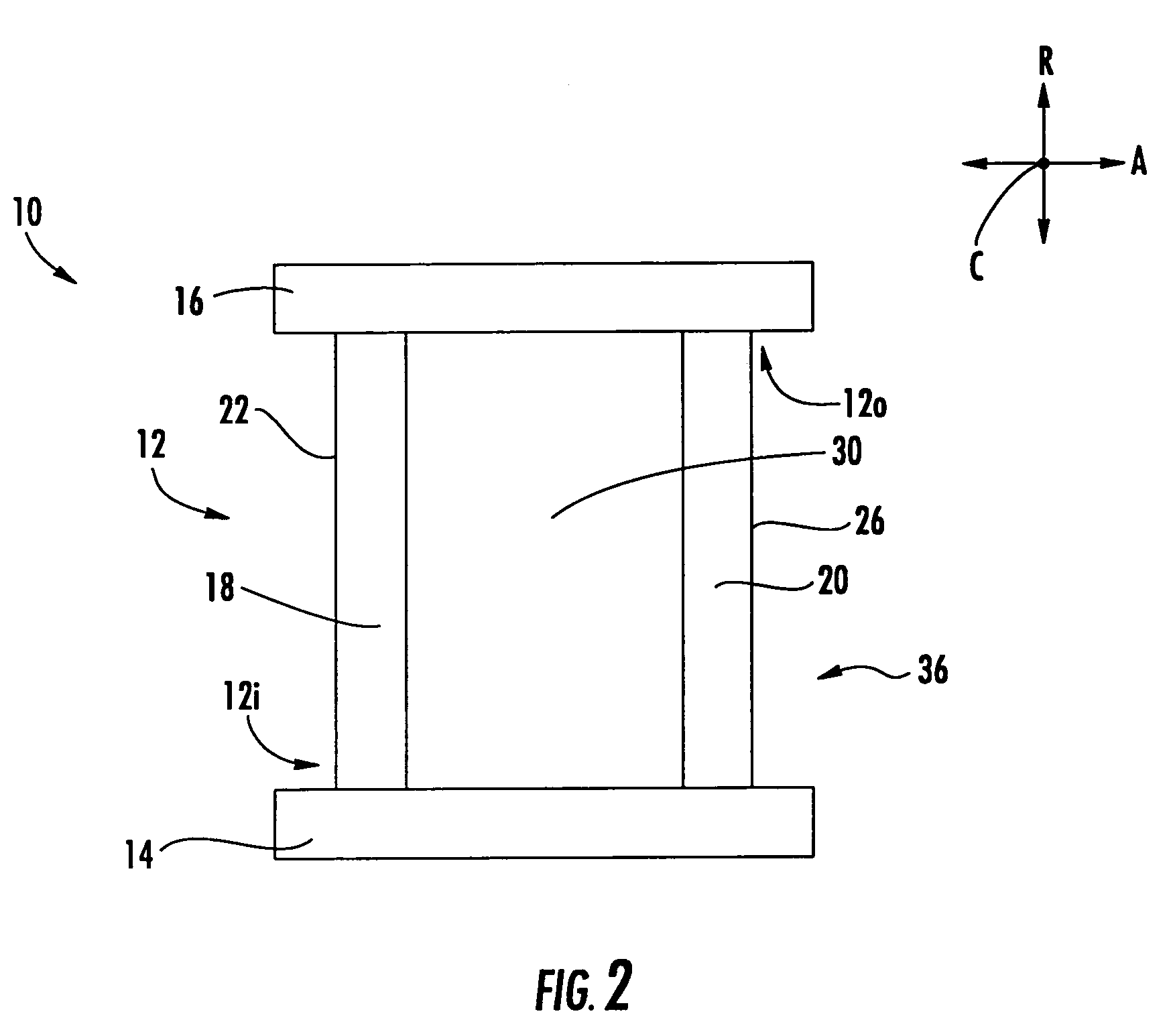

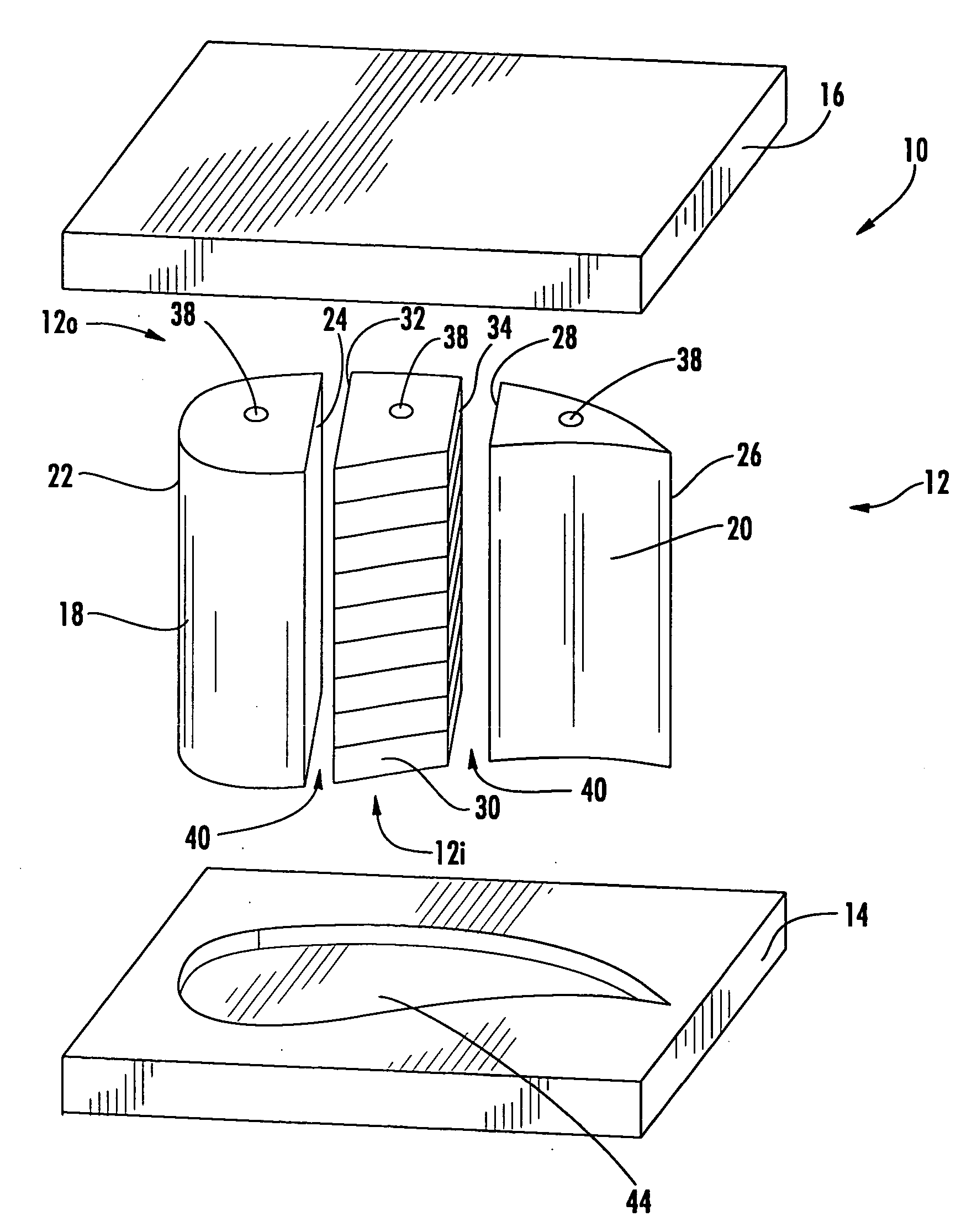

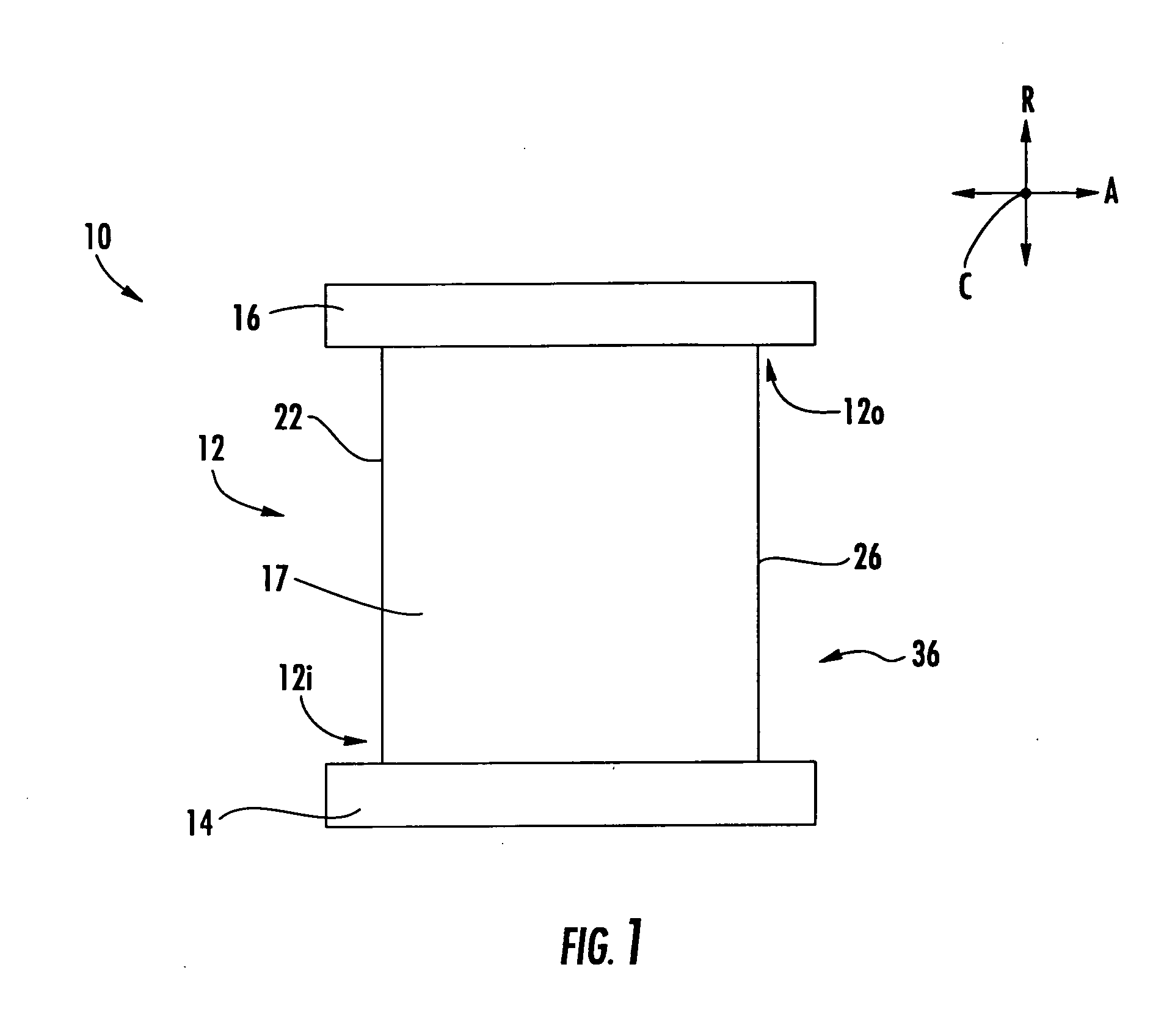

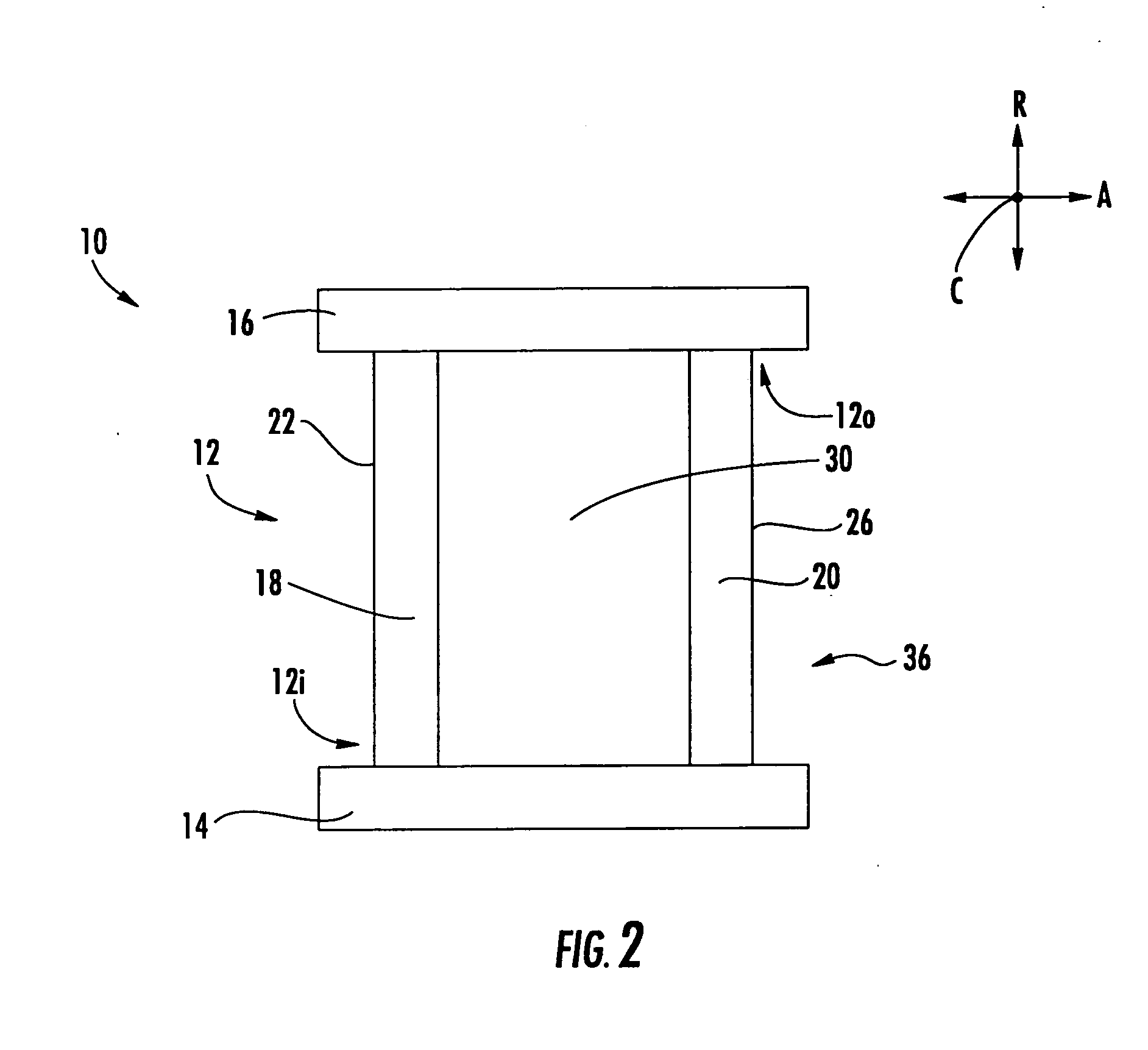

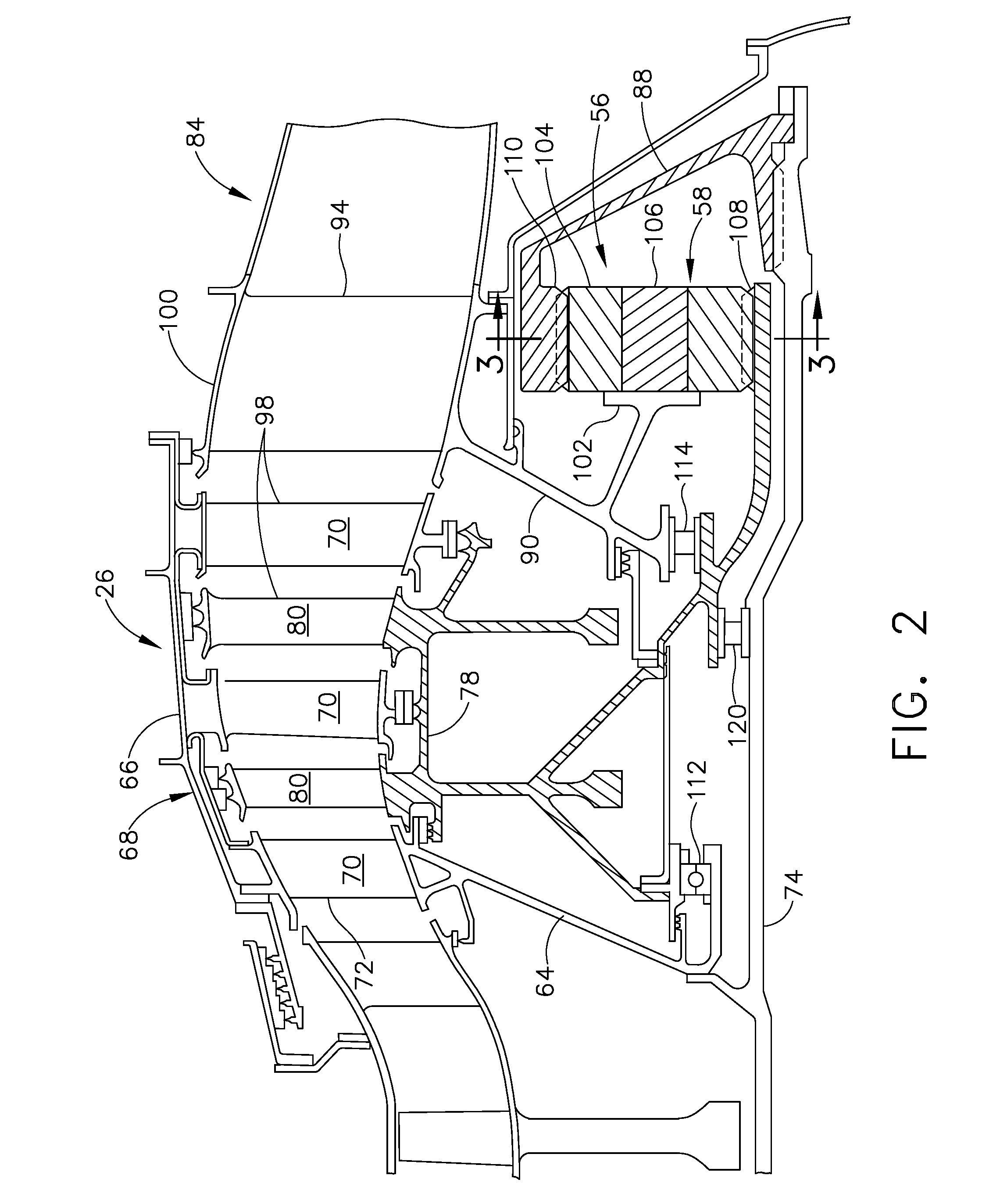

Multi-piece turbine vane assembly

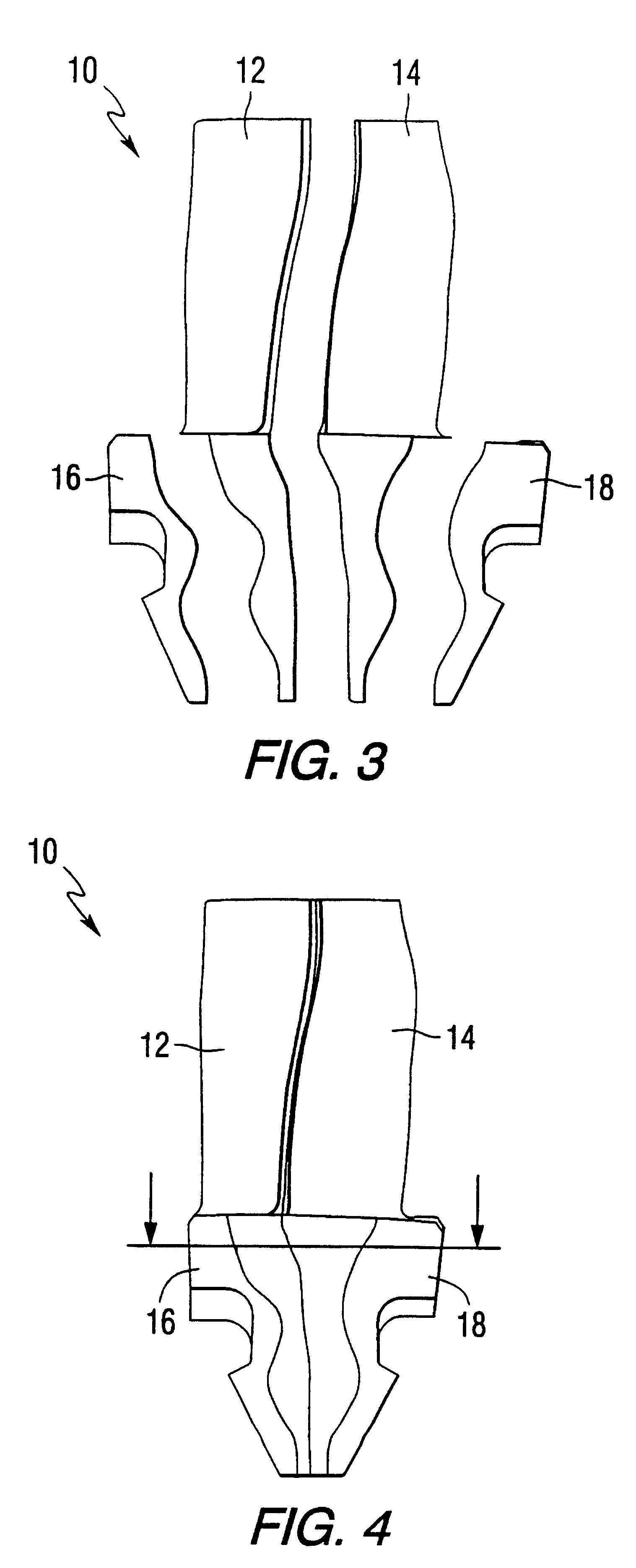

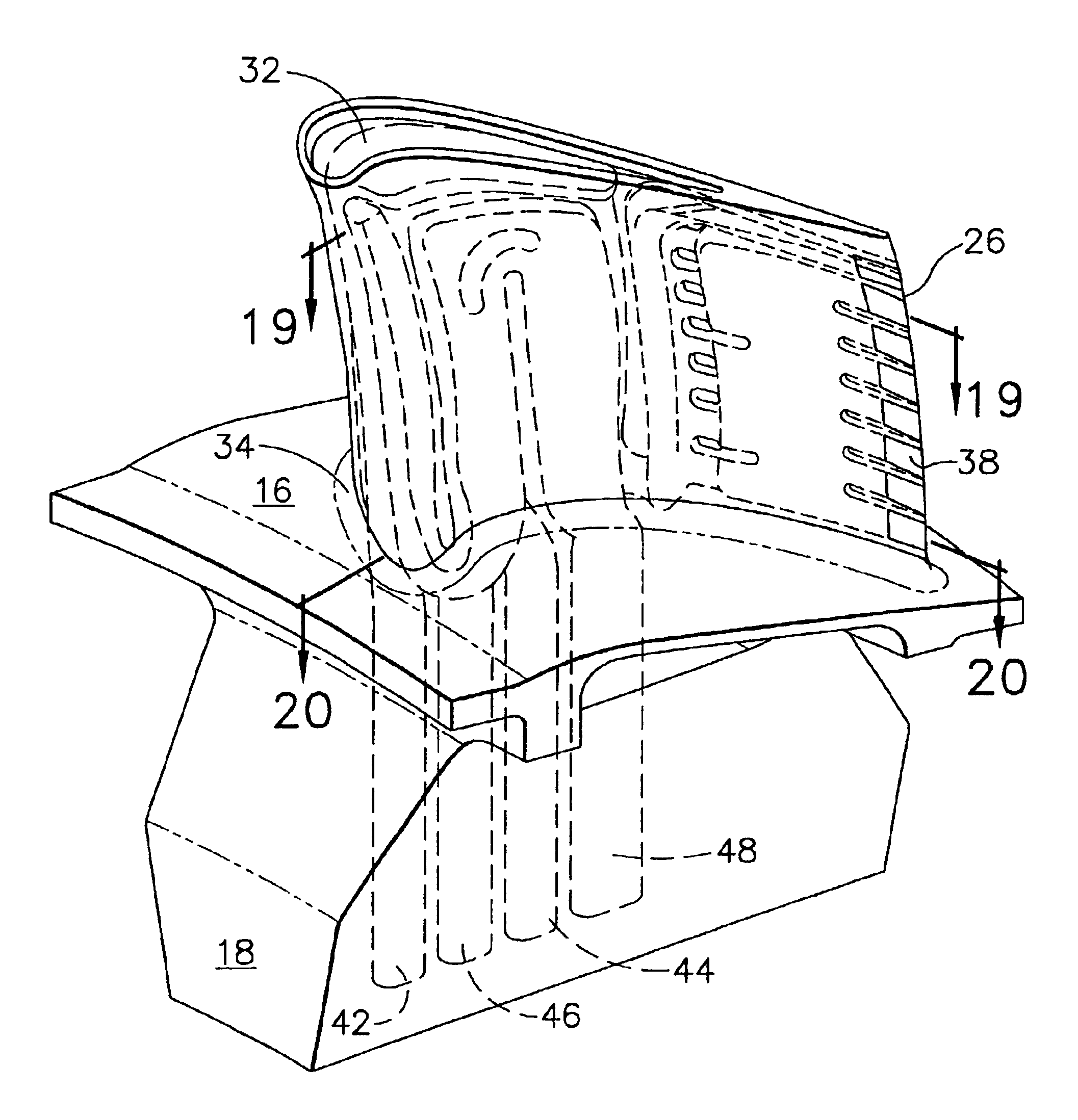

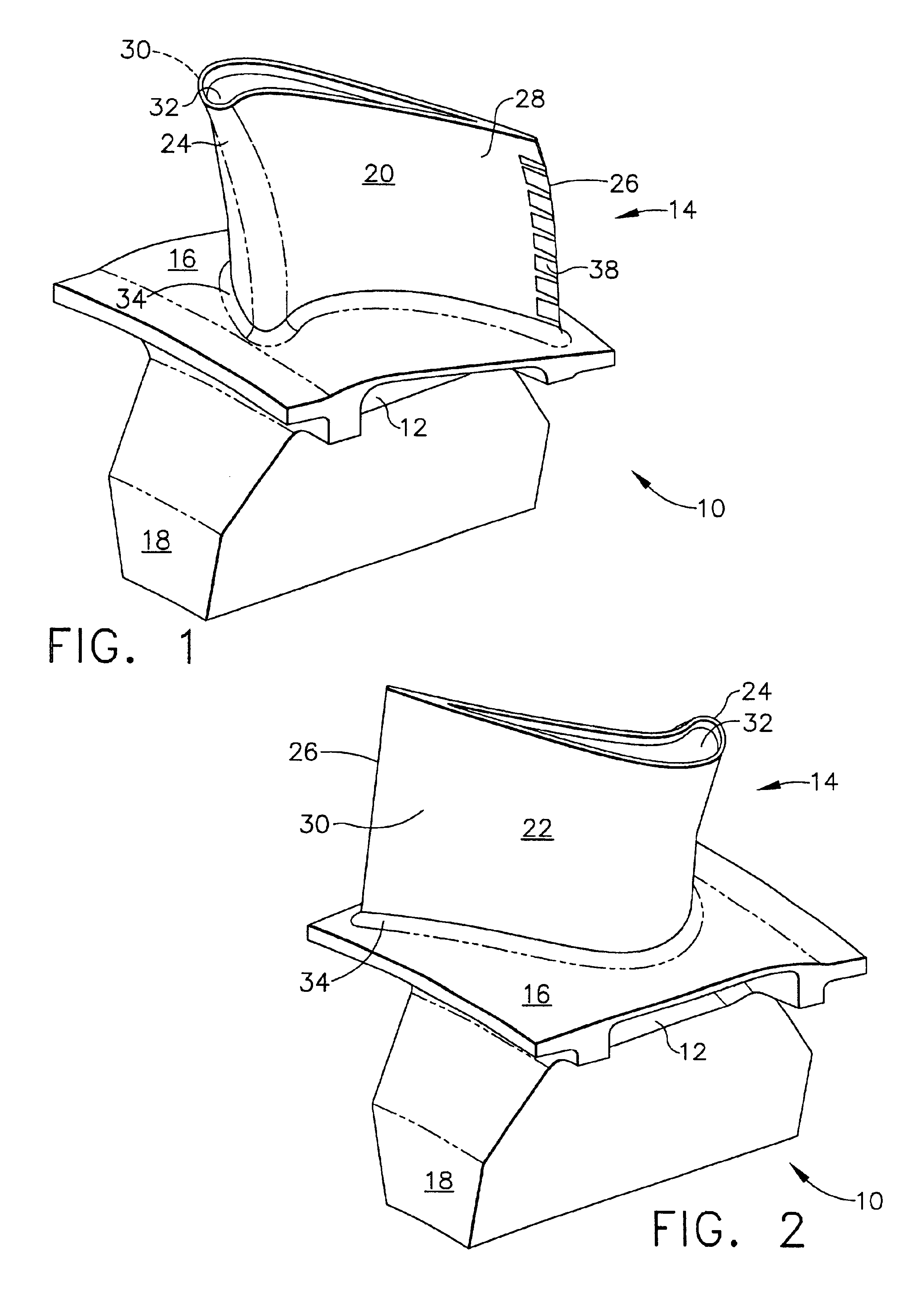

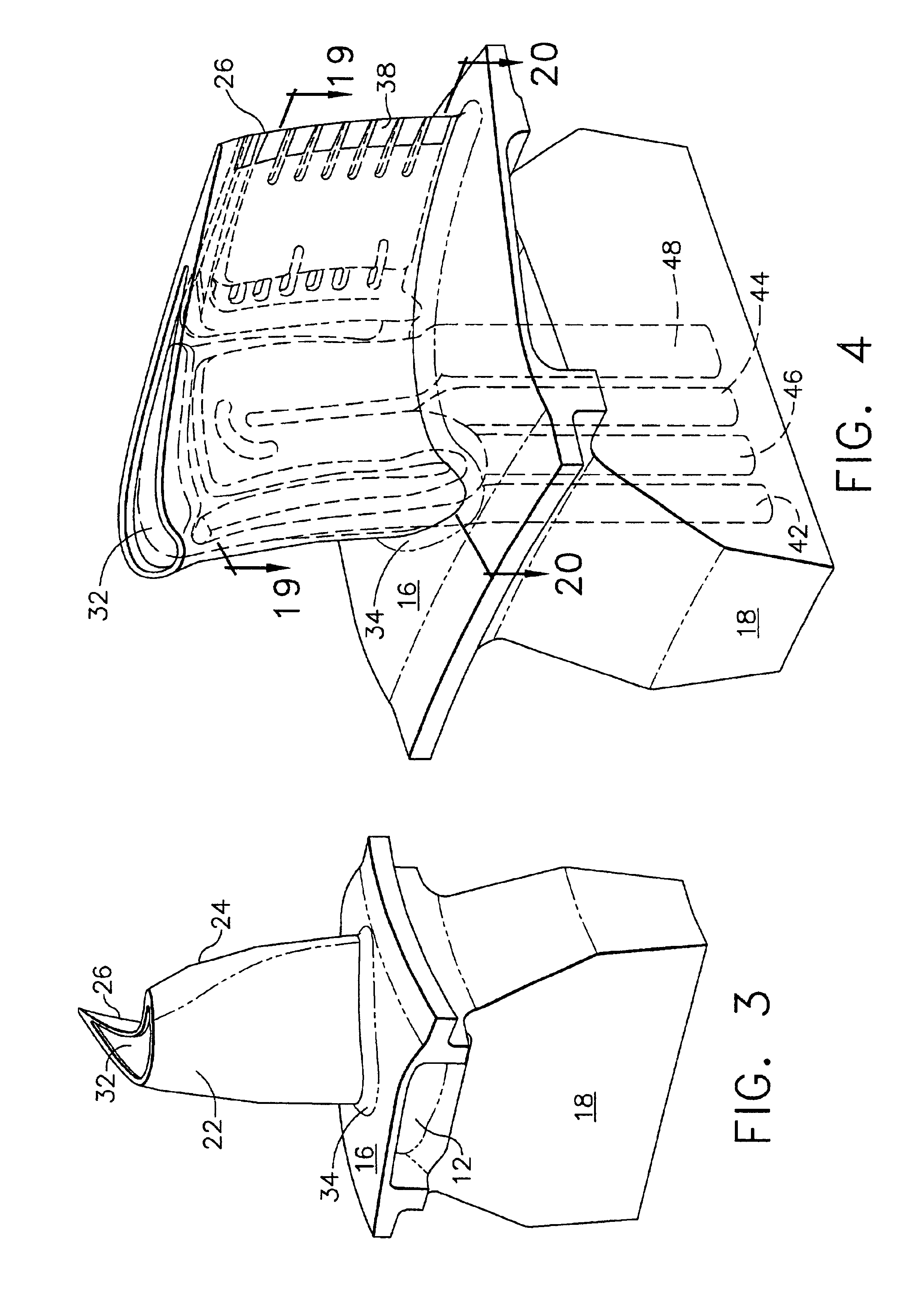

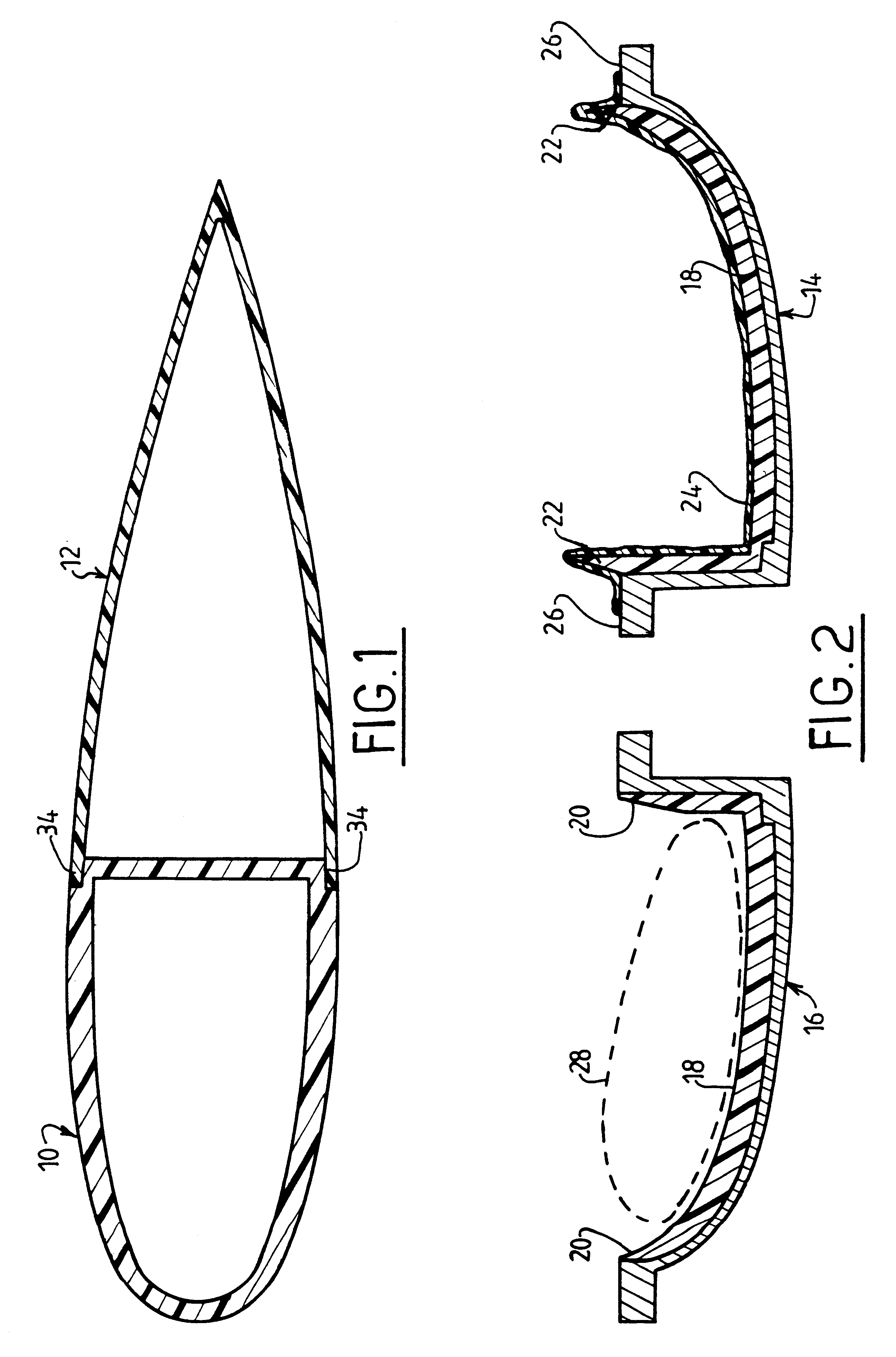

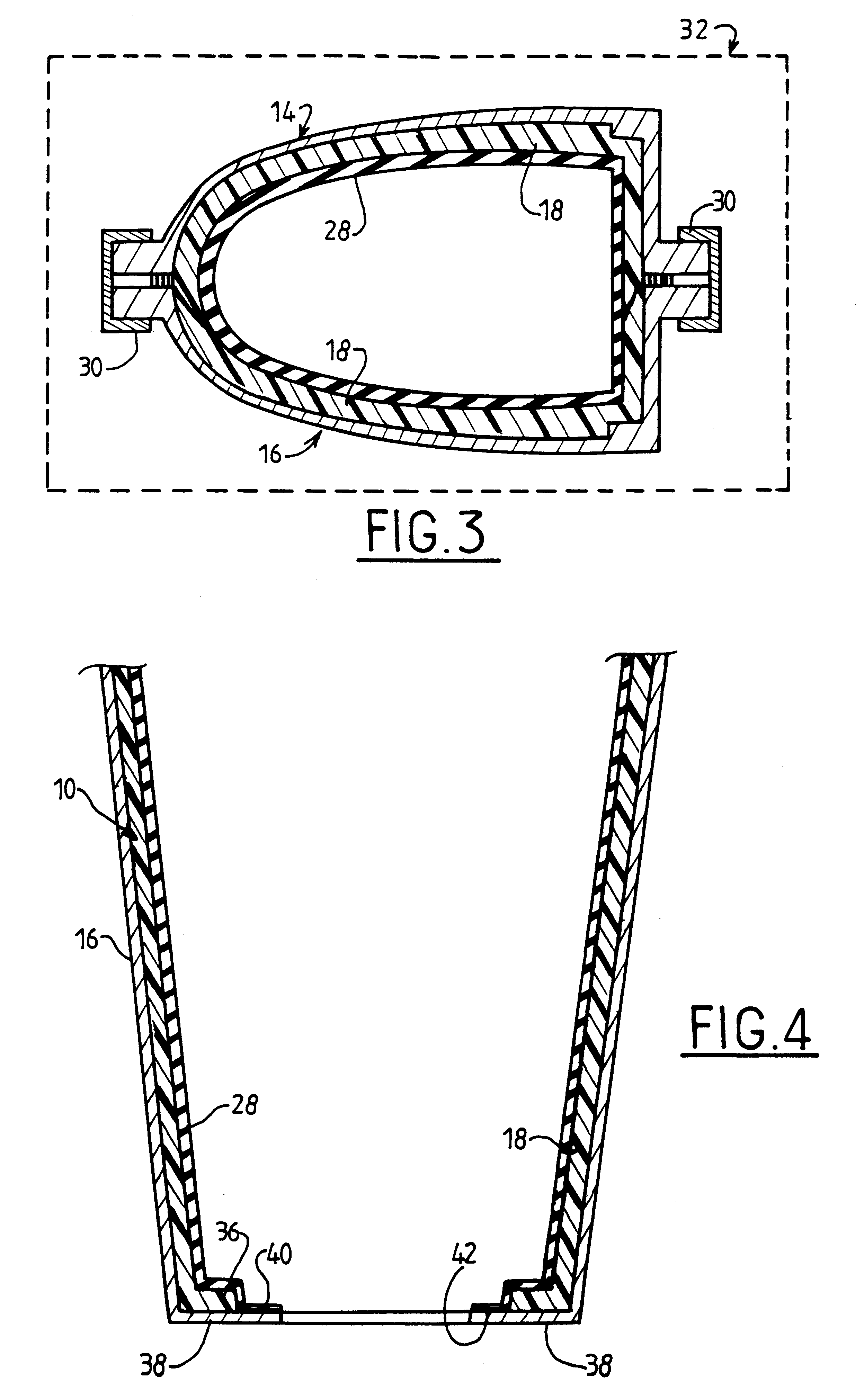

InactiveUS20060228211A1Prevent pre-tensioningPump componentsReaction enginesTurbine bladeModular design

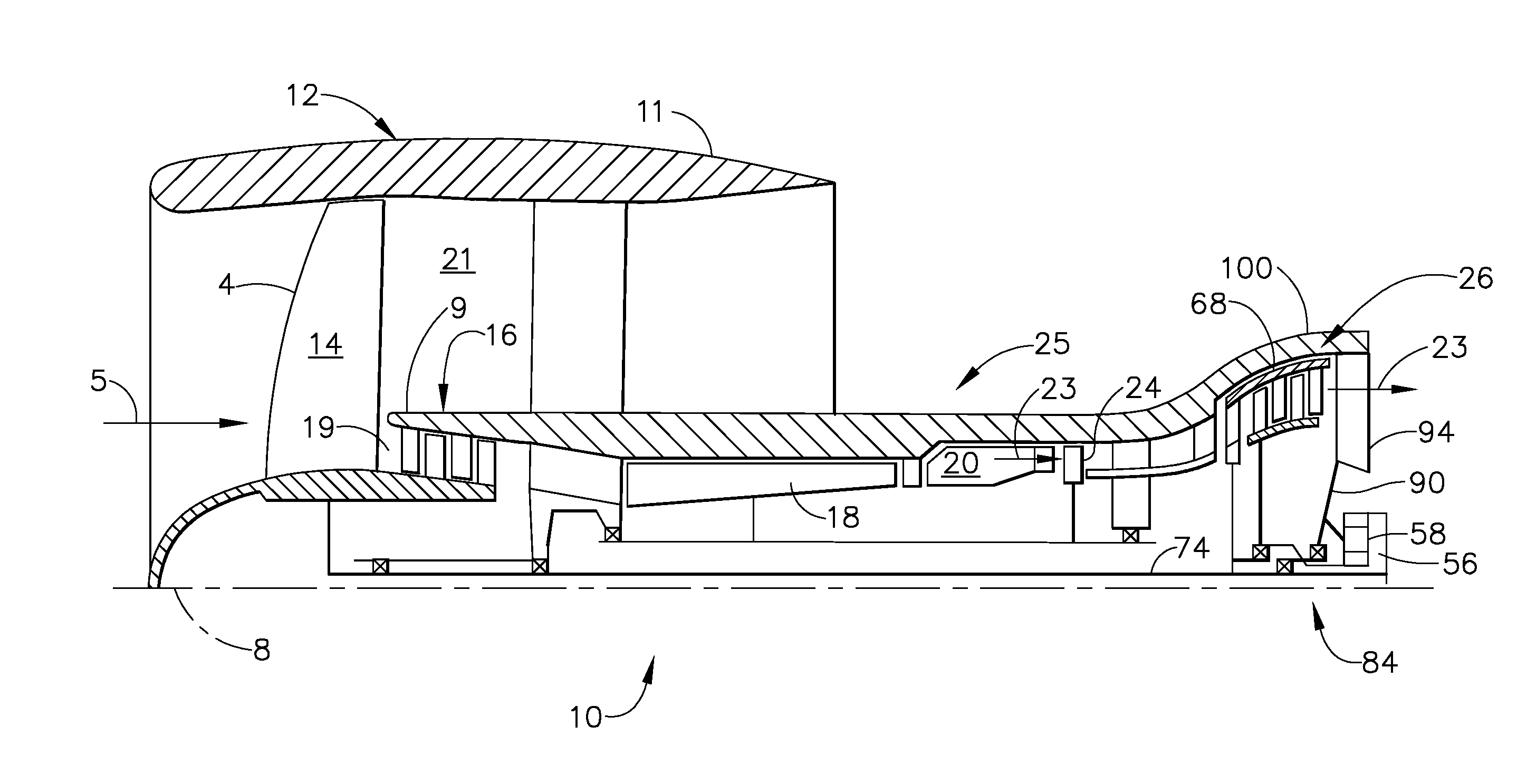

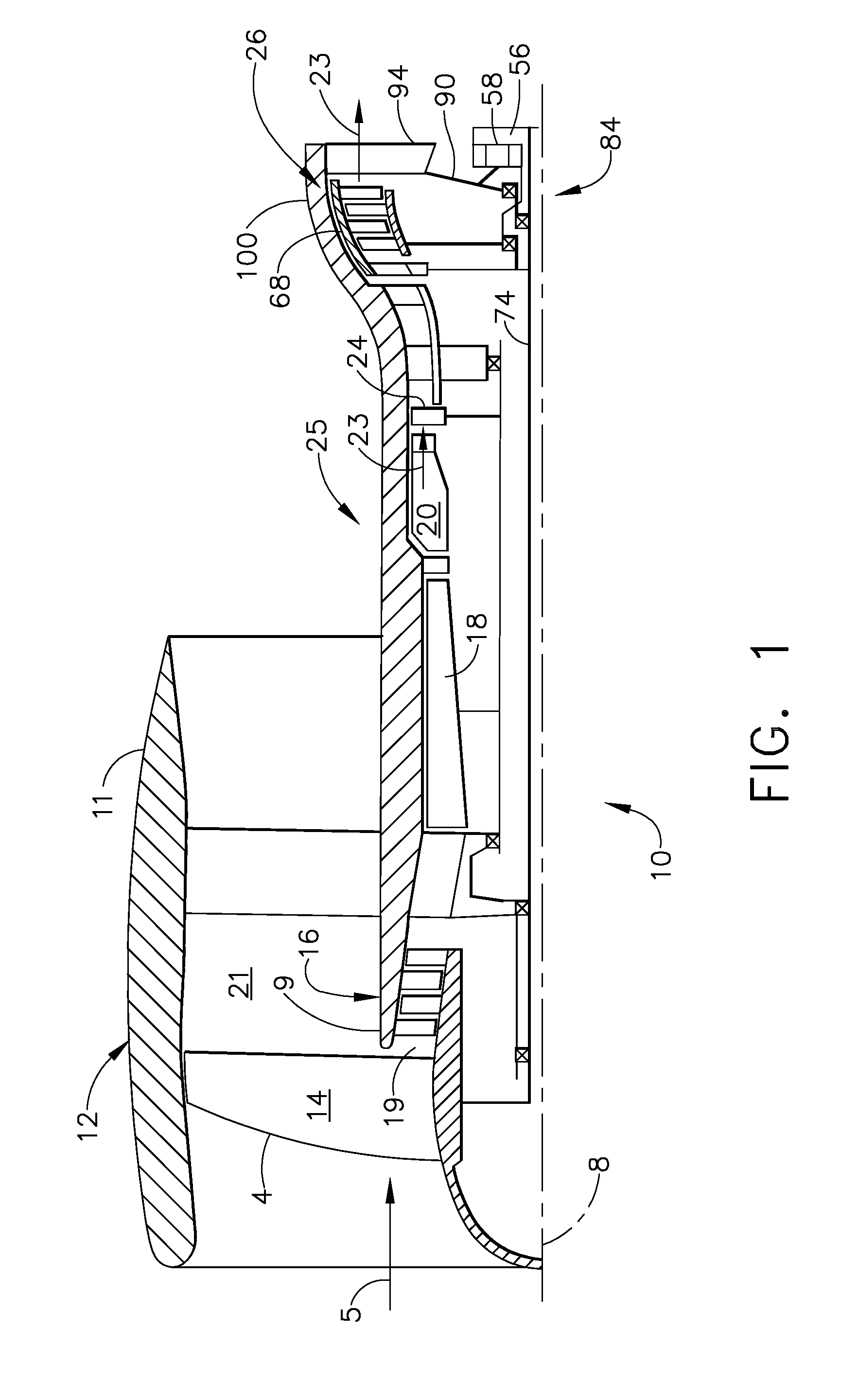

Aspects of the invention relate to a modular turbine vane assembly. The vane assembly includes an airfoil portion, an outer shroud and an inner shroud. The airfoil portion can be made of at least two segments. Preferably, the components are connected together so as to permit assembly and disassembly of the vane. Thus, in the event of damage to the vane, repair involves the replacement of only the damaged subcomponents as opposed to the entire vane. The modular design facilitates the use of various materials in the vane, including materials that are dissimilar. Thus, suitable materials can be selected to optimize component life, cooling air usage, aerodynamic performance, and cost. Because the vane is an assemblage of smaller sub-components as opposed to one unitary structure, the individual components of the vane can be more easily manufactured and more intricate features can be included.

Owner:SIEMENS ENERGY INC

Method for producing titanium alloy turbine blades and titanium alloy turbine blades

InactiveUS6127044ALess abrasionSuperior in water droplet erosion resistancePropellersEngine manufactureLeading edgeTurbine blade

PCT No. PCT / JP95 / 01817 Sec. 371 Date Jun. 2, 1998 Sec. 102(e) Date Jun. 2, 1998 PCT Filed Sep. 13, 1995 PCT Pub. No. WO97 / 10066 PCT Pub. Date Mar. 20, 1997A method for producing titanium alloy turbine blades comprising the steps of (a) forming turbine blades of titanium alloy through hot forging or machining, (b) cooling leading edges on tip portions of the turbine blades including covers thereof formed through hot forging or machining faster than blade main body after final hot forging or solid solution treatment, and (c) heat treating the cooled turbine blades. With this method, it is possible to manufacture titanium turbine blades in an economical fashion and obtain titanium alloy turbine blades superior in reliability by preventing erosion.

Owner:KK TOSHIBA +1

Geared differential speed counter-rotatable low pressure turbine

A counter-rotatable low pressure turbine includes counter-rotatable outer and inner drum rotors. The outer drum rotor is connected to a sole shaft for transmitting torque and power out of the low pressure turbine. Low pressure outer drum turbine blade rows extend radially inwardly from an outer shell of the outer drum rotor. Low pressure inner drum turbine blade rows extend radially outwardly from the low pressure inner drum rotor. The outer drum turbine blade rows are interdigitated with the inner drum turbine blade rows. The drum rotors are geared together through an epicyclic gearbox for transmitting all the torque and power produced by the drum rotors to the shaft. The gearbox may be located aft of the drum rotors. A differential thrust bearing is disposed between the drum rotors. A single stage fan section of an engine is connected to the turbine by the shaft.

Owner:GENERAL ELECTRIC CO

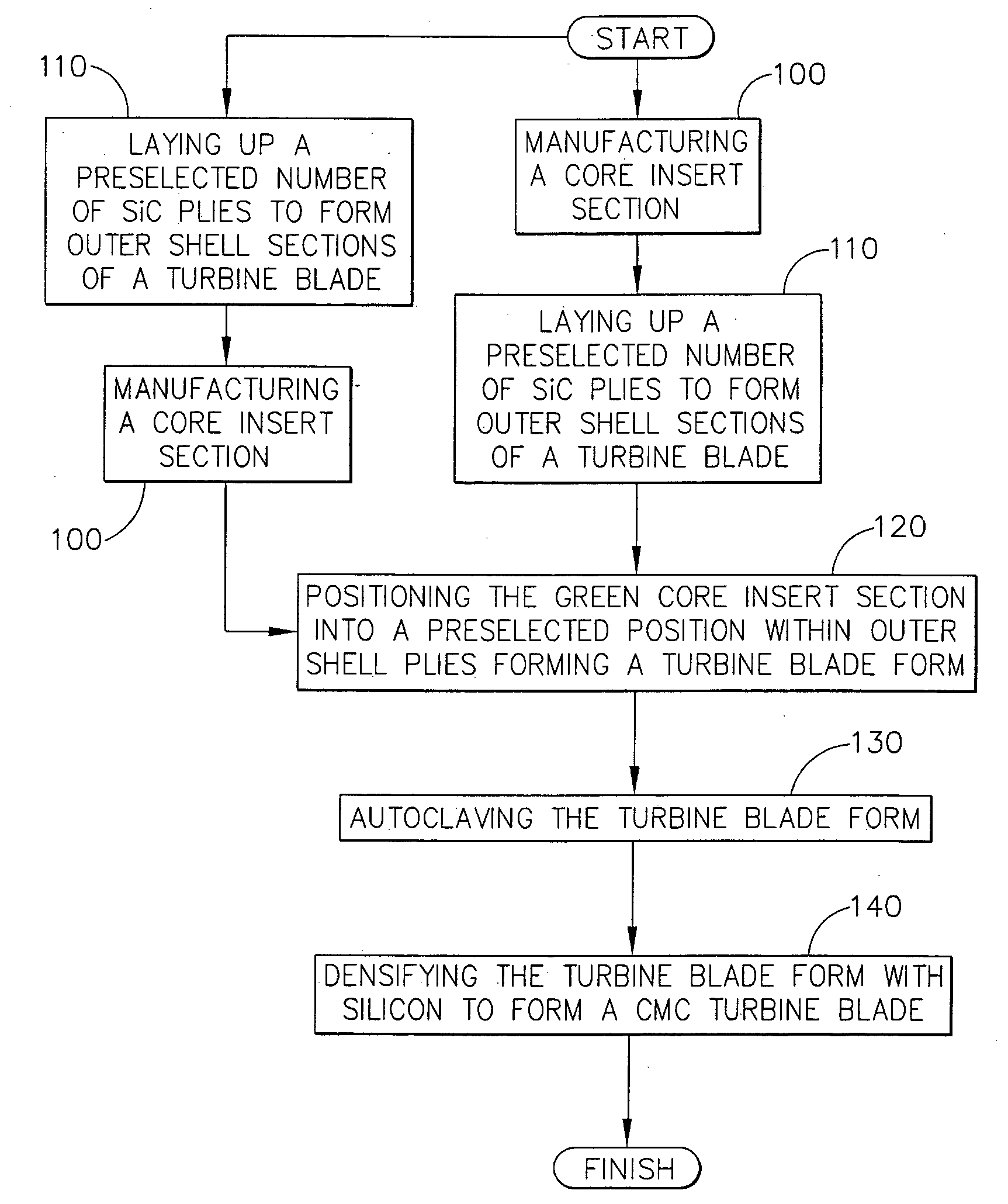

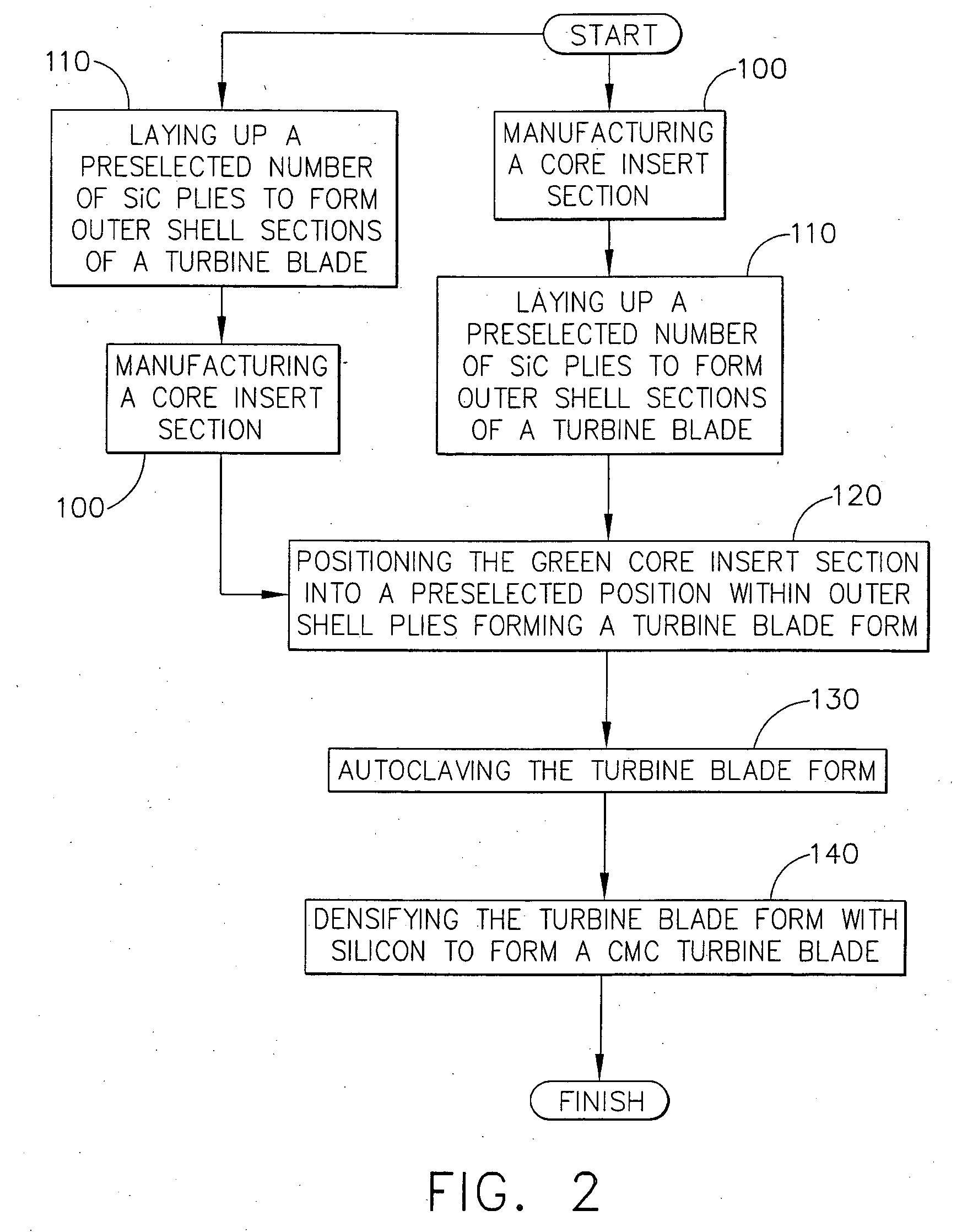

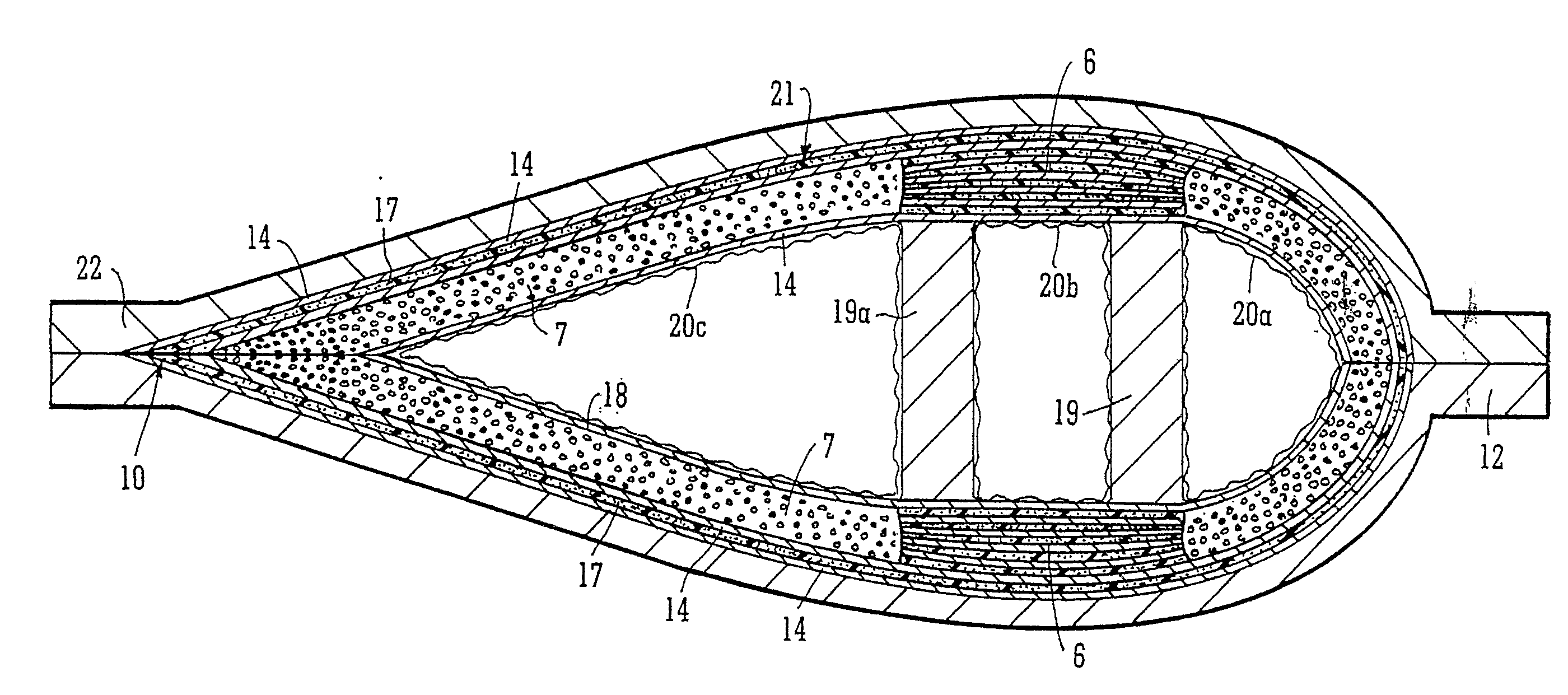

Hybrid ceramic matrix composite turbine blades for improved processibility and performance

InactiveUS20050158171A1Easy to buildImproving back fracture toughnessPump componentsGas turbine plantsMetallurgyTurbine blade

The present invention is a hybrid ceramic matrix composite turbine engine component comprising an outer shell section(s) and an inner core section(s), wherein the outer shell section(s) and the inner core section(s) were bonded together using an MI process. The outer shell section(s) comprises a SiC / SiC material that has been manufactured using a process selected from the group consisting of a slurry cast MI process and a prepreg MI process. The inner core section(s) comprises a material selected from the group consisting an Si / SiC composite material and a monolithic ceramic material. The Si / SiC composite material may be manufactured using the Silcomp process. The present invention may be a high pressure turbine blade, a high pressure turbine vane, a low pressure turbine blade, or a low pressure turbine vane. The present invention is also a method of manufacturing a hybrid ceramic matrix composite turbine engine component.

Owner:GENERAL ELECTRIC CO

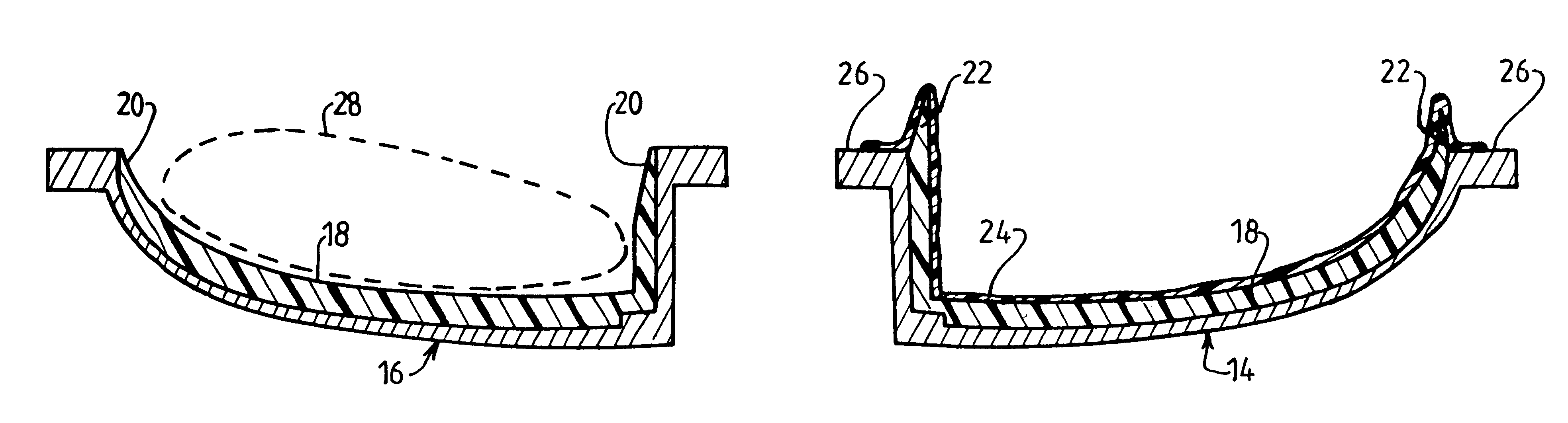

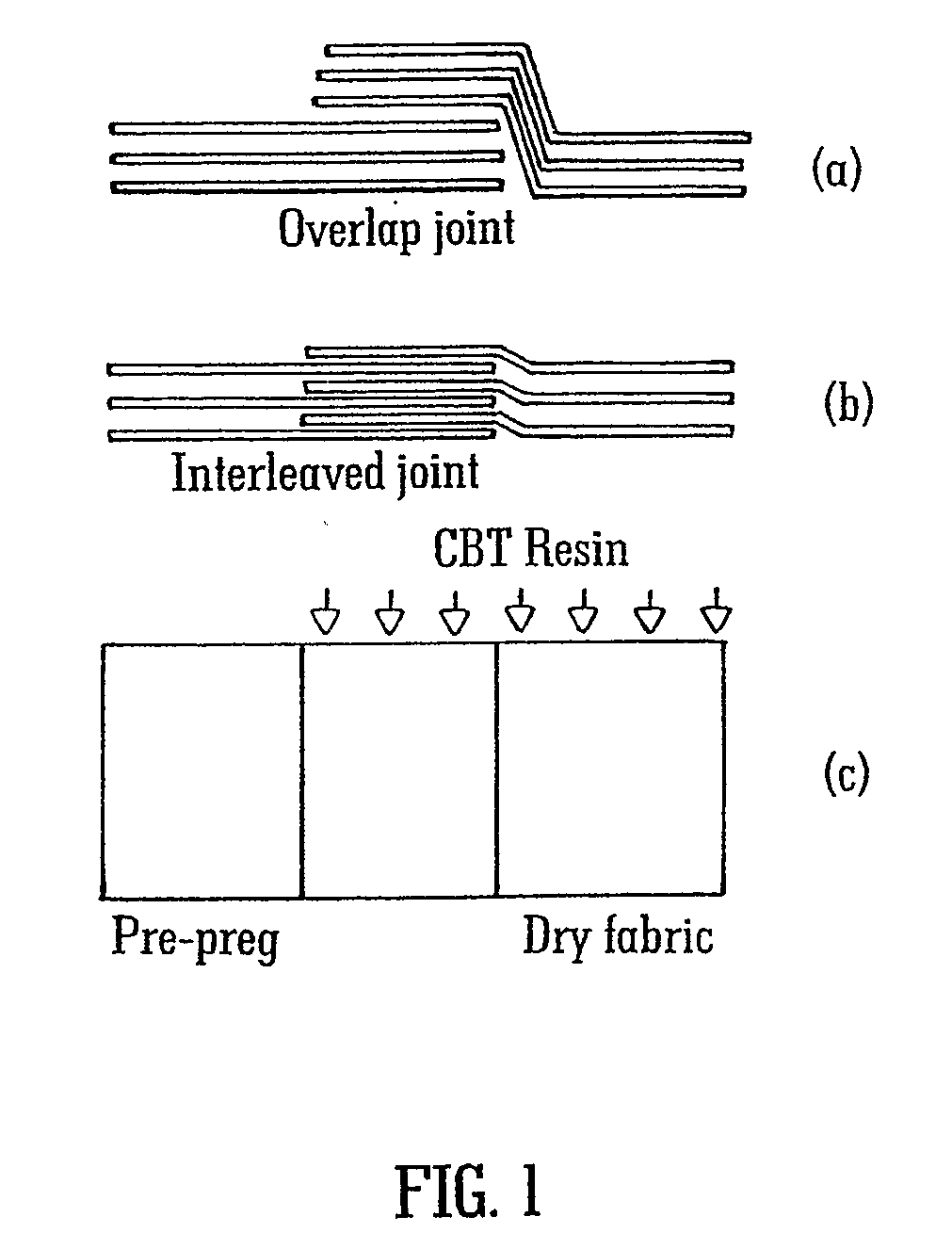

Composite Articles Comprising In-Situ-Polymerisable Thermoplastic Material and Processes for their Construction

InactiveUS20100062238A1Reliable constructionLow costFinal product manufacturePretreated surfacesTurbine bladeIn situ polymerization

A process for the manufacture of a composite article is described wherein the process comprises the steps of (i) providing on a tool (22) a fibrous material (14) having associated therewith in at least one region thereof an in-situ polymerisable non-fibrous form of a thermoplastic material; (ii) applying heat and a vacuum to said material; and additionally (iii) drawing into the fibrous material, from a source external to the tool, additional thermoplastic pre-polymer material. The process described is particularly useful for the manufacture of a large composite structure such as thermoplastic composite wind turbine blade, for example.

Owner:UNIVERSITY OF LIMERICK +2

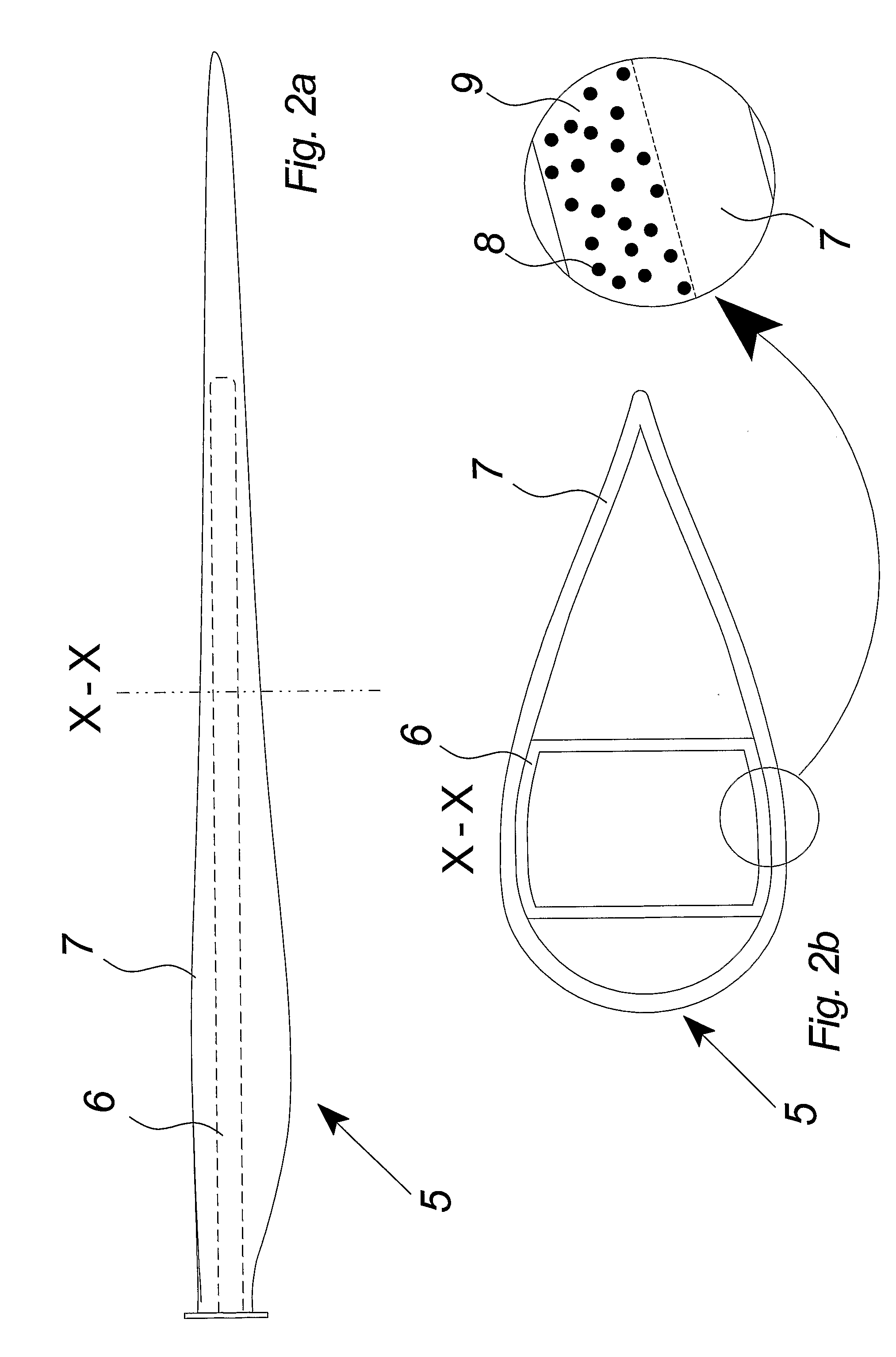

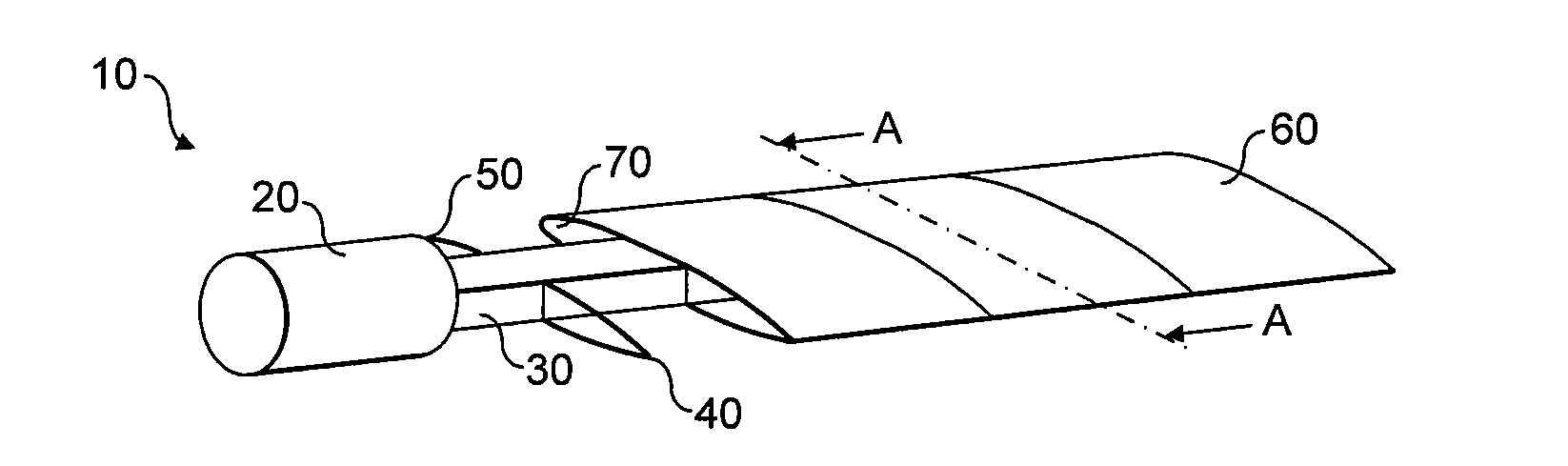

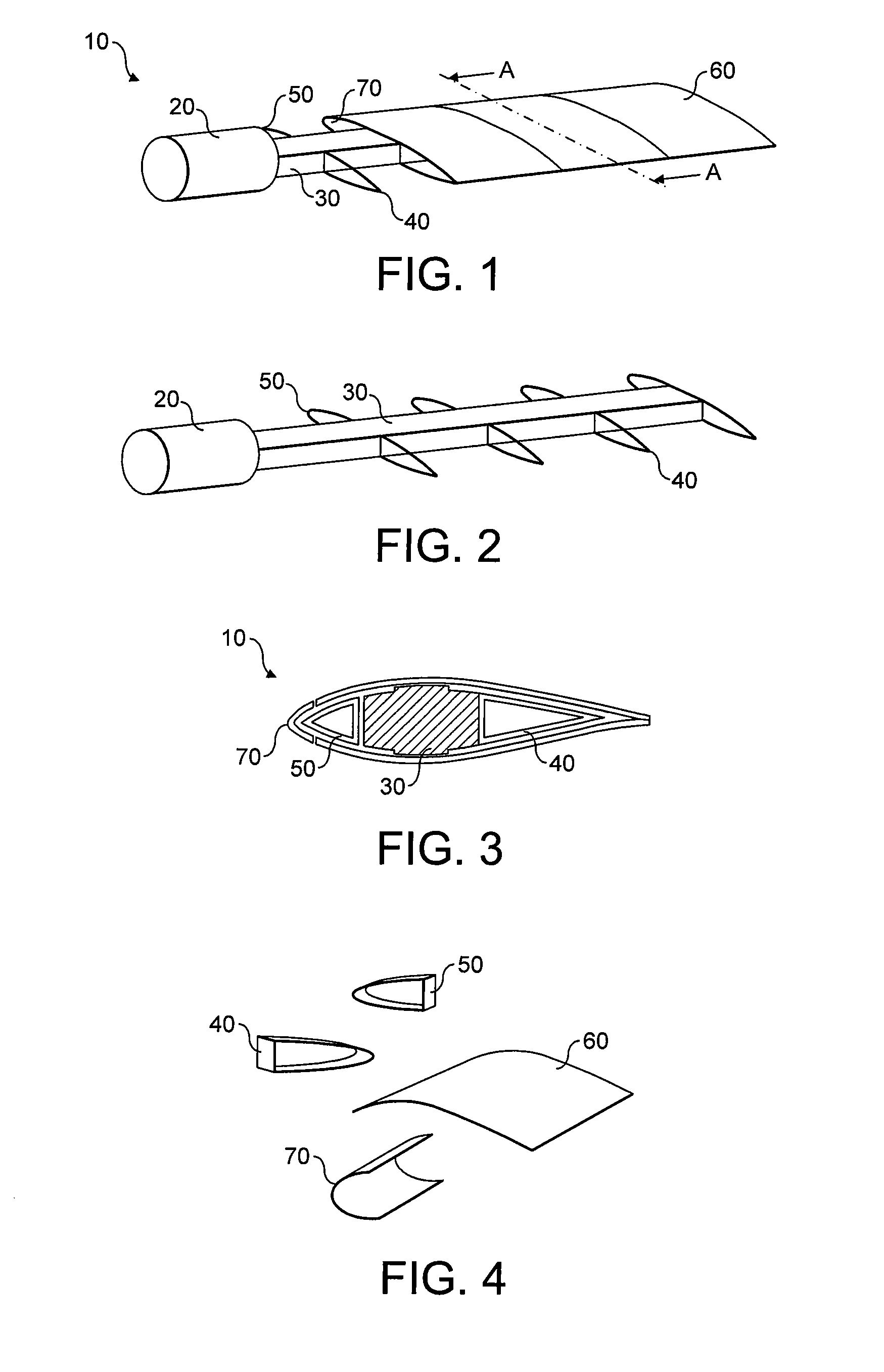

Wind turbine blade

ActiveUS20090068017A1Low production costComplex shapePropellersEngine manufactureTurbine bladeEngineering

Owner:BLADE DYNAMICS LTD

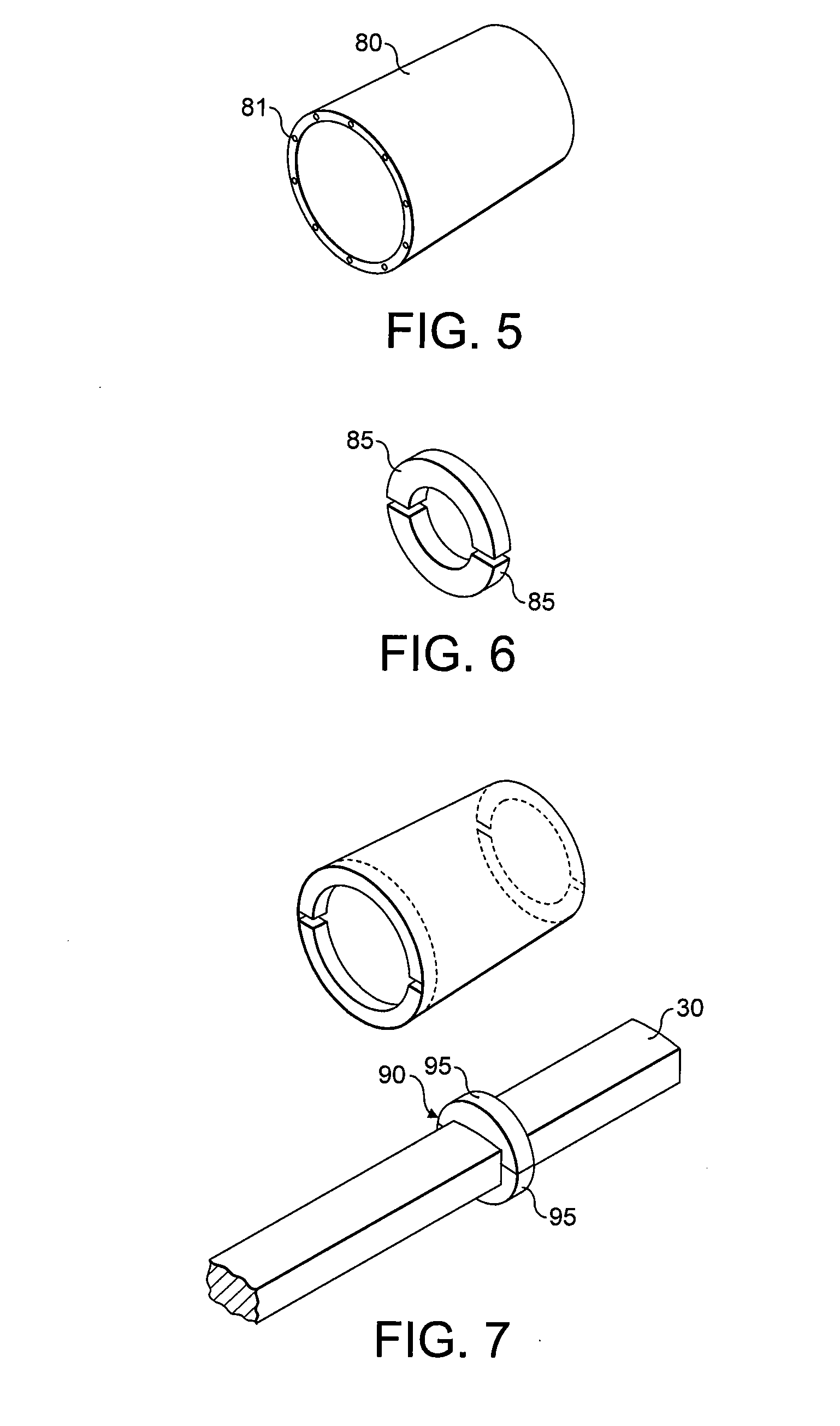

Telescoping wind turbine blade

A wind turbine blade made of a fixed blade section with an integral mounting flange for attachment to a wind turbine hub. A moveable blade section is attached to the fixed blade section and is free to move in a longitudinal direction relative to the fixed blade section. A positioning device controllably positions the moveable blade section to vary the overall length of the blade. This allows the wind turbine's rotor diameter to be adjusted. The rotor diameter can be increased in order to provide high power output in low wind conditions and it can be decreased in order to minimize loads in high wind conditions.

Owner:FRONTIER WIND LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com