Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3371 results about "Inlet temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inlet temperature. The temperature signal taken in the engine inlet to measure air density and sent to the fuel control unit as a fuel-scheduling parameter.

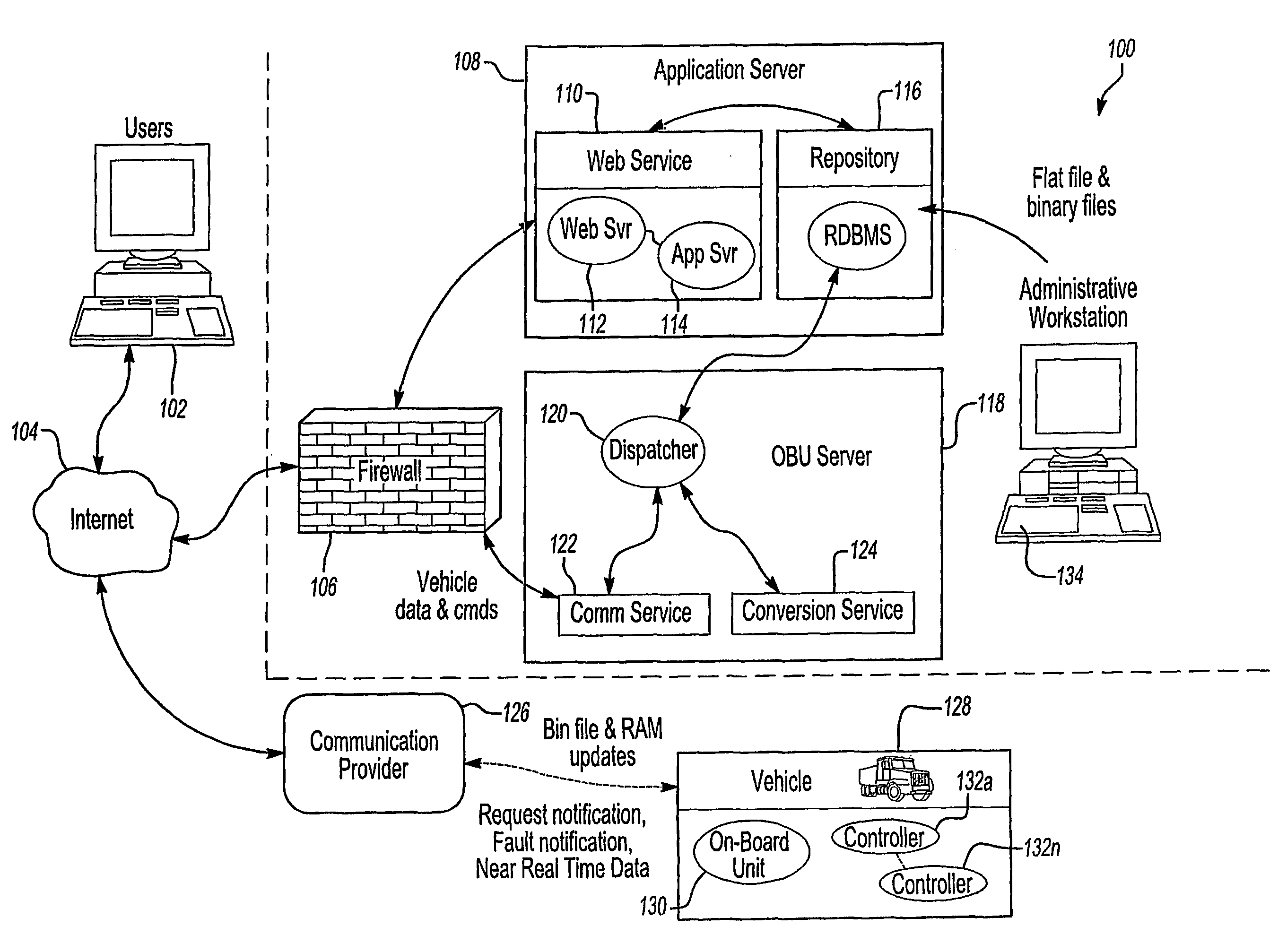

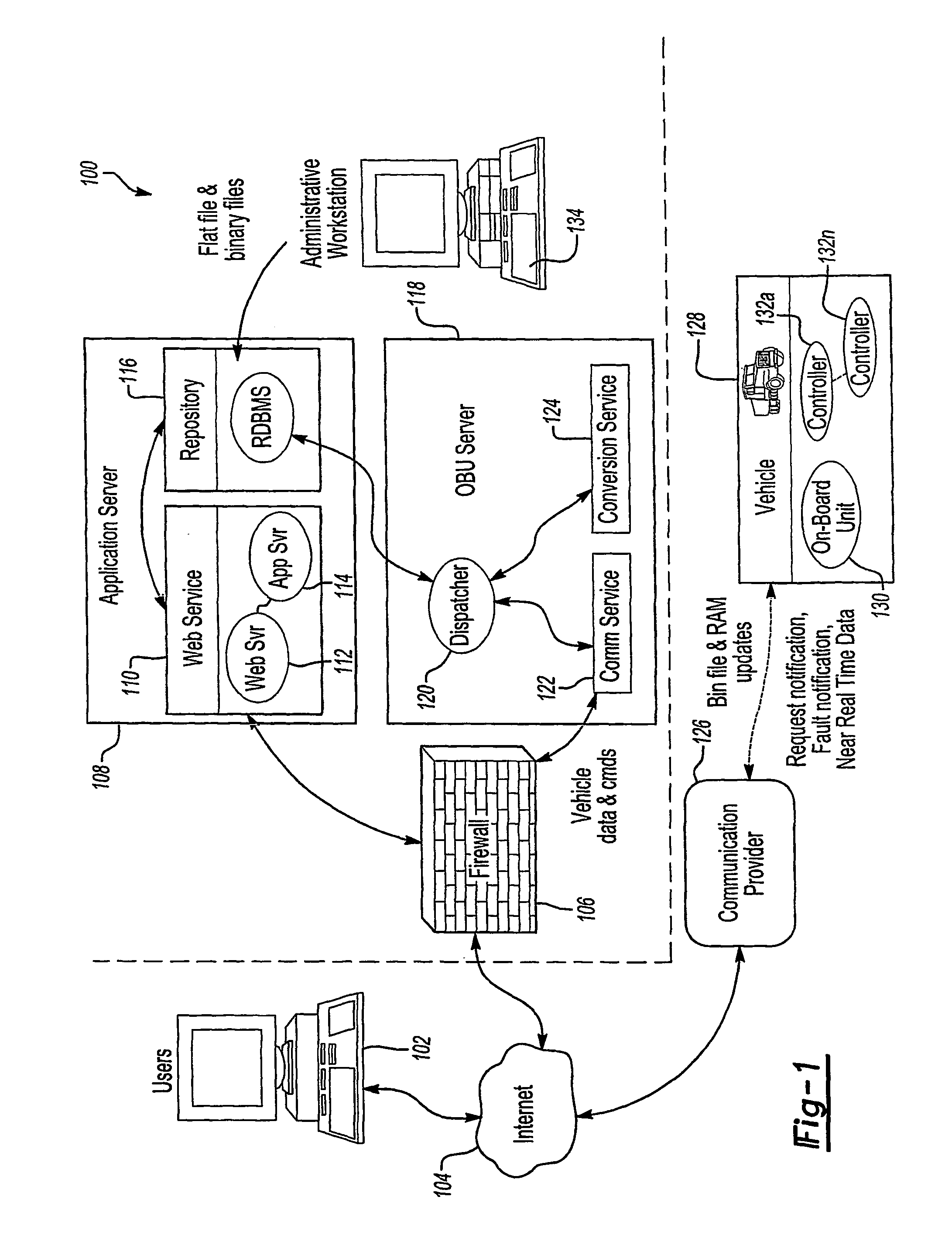

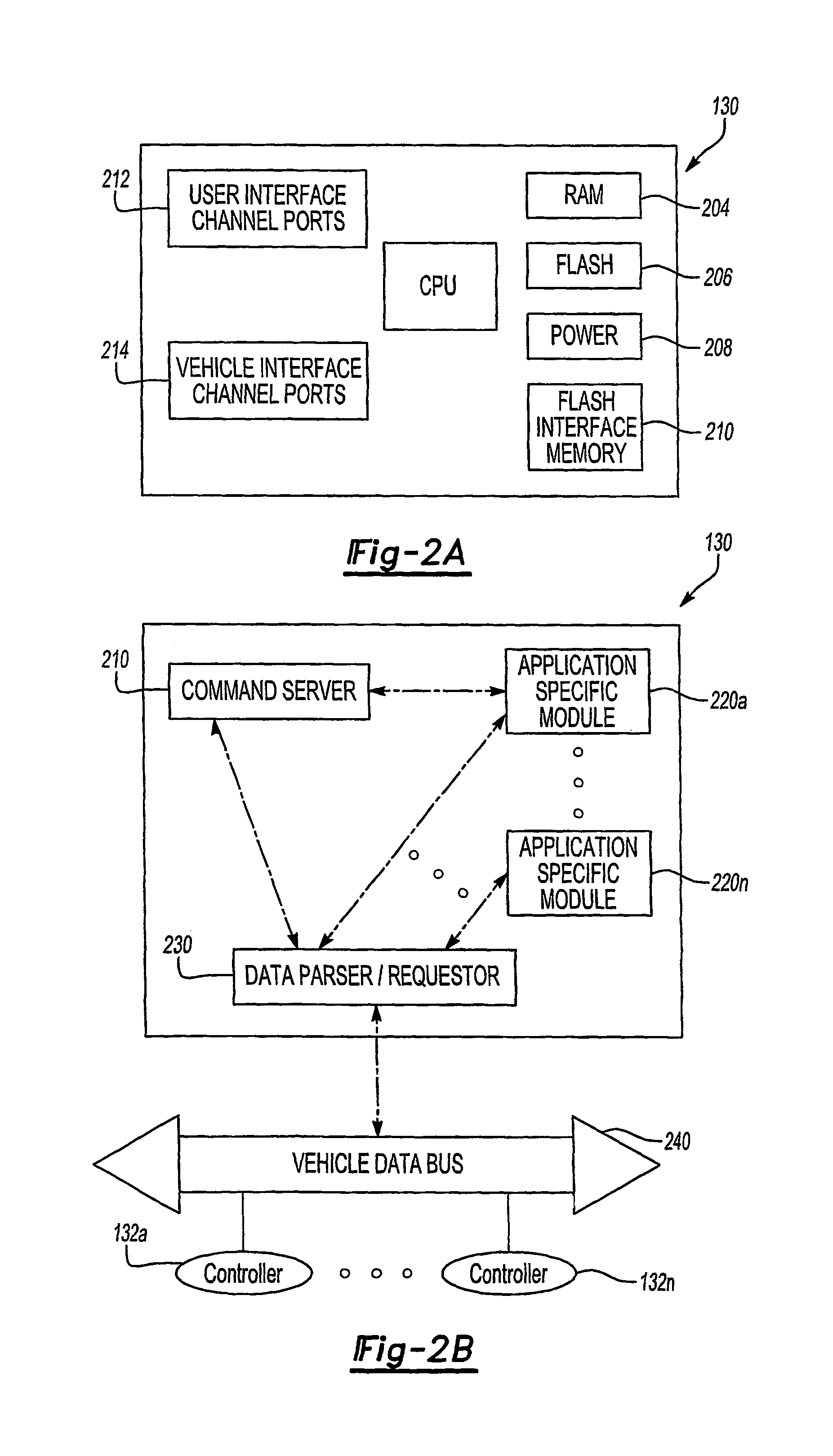

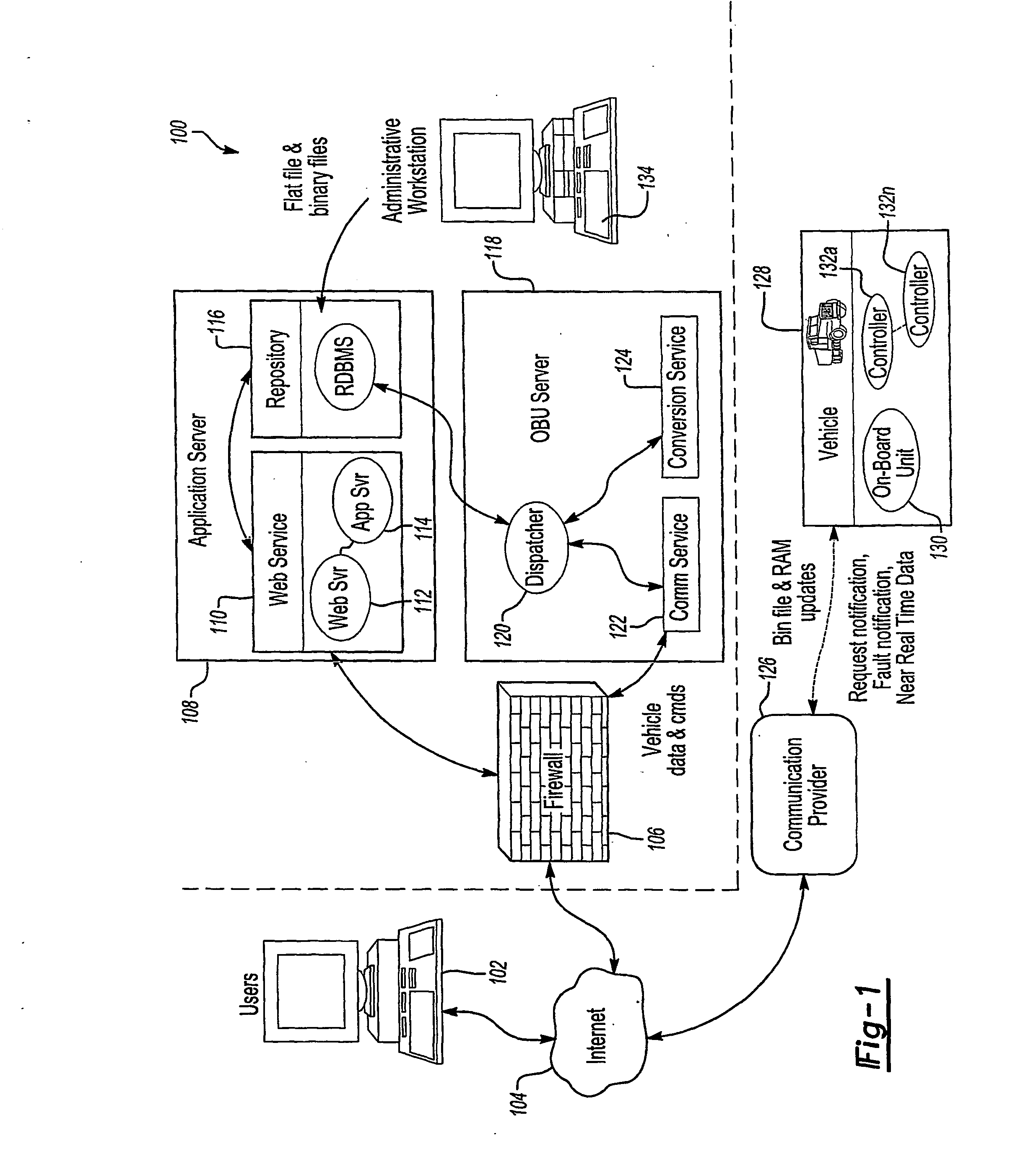

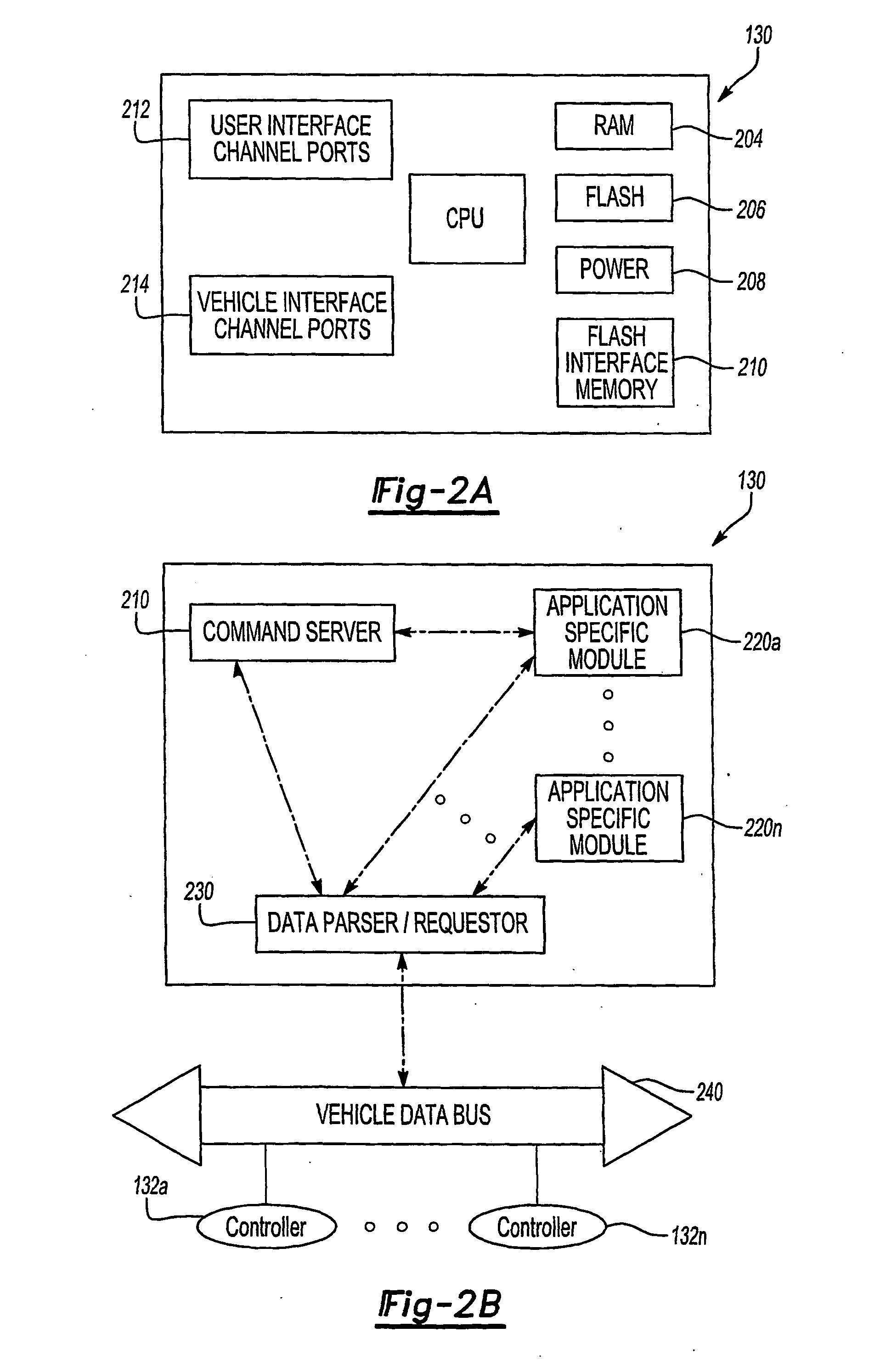

System, method and computer program product for remote vehicle diagnostics, monitoring, configuring and reprogramming

InactiveUS7155321B2Eliminate needVehicle testingRegistering/indicating working of vehiclesFleet managementLogistics management

A remote vehicle diagnostics, monitoring, configuration and reprogramming tool is provided. The system includes a fleet of vehicles equipped with wireless mobile communications means that enable fleet managers to remotely diagnose, monitor and reprogram vehicles in their fleet via an Internet Web-based browser environment. Each vehicle within the fleet is equipped with a smart device that is coupled to the data bus within each vehicle. Date commands relating to the vehicle's parameters (e.g., diagnostic parameters such as max road speed, engine RPM, coolant temperature, air inlet temperature, etc.) are sent and received using satellite and terrestrial wireless communications technology. The invention allows users to remotely perform total fleet logistics and eliminates (or reduces) the need to physically bring fleet vehicles to a repair, maintenance or configuration facility.

Owner:IDSC HLDG

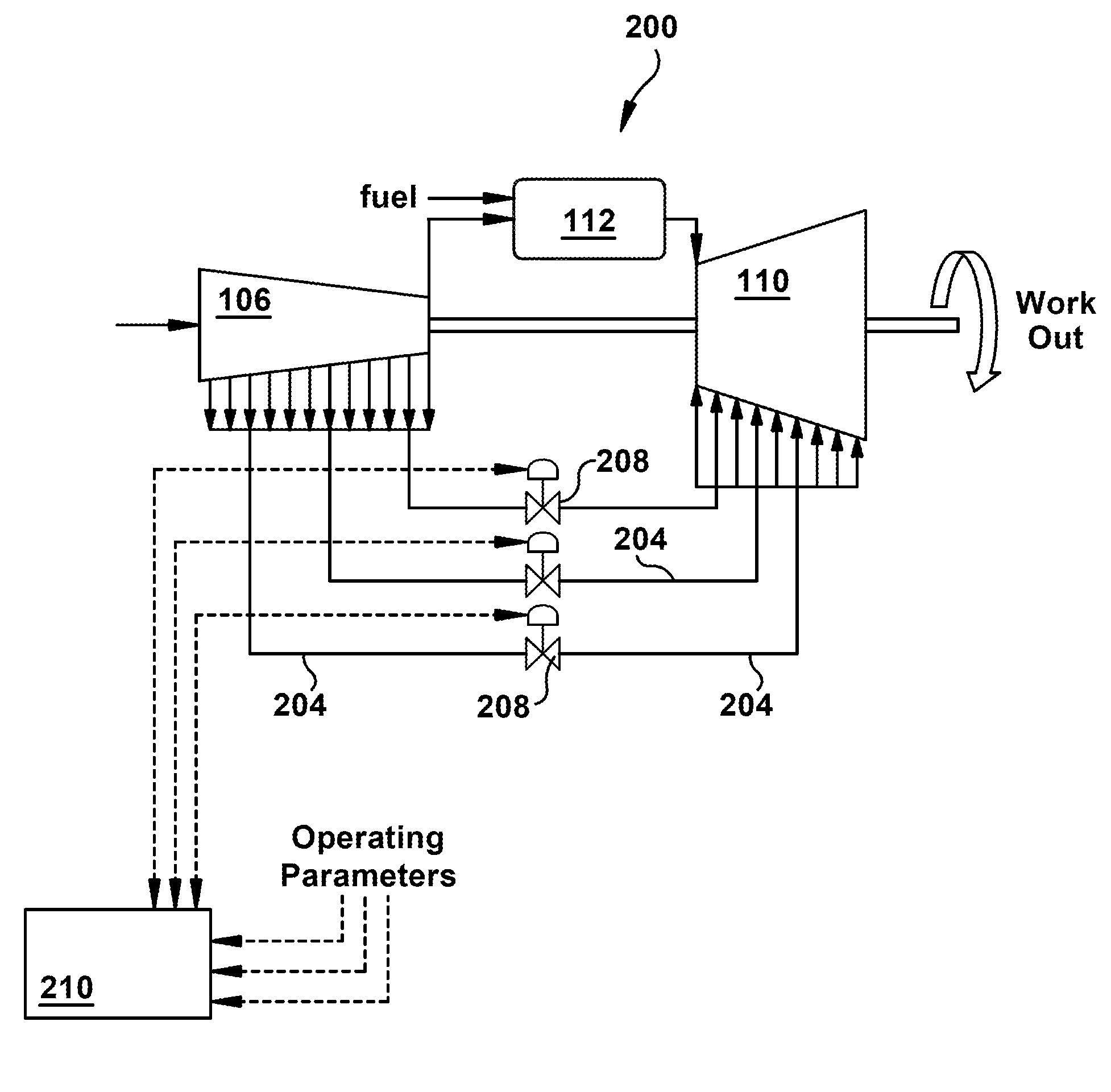

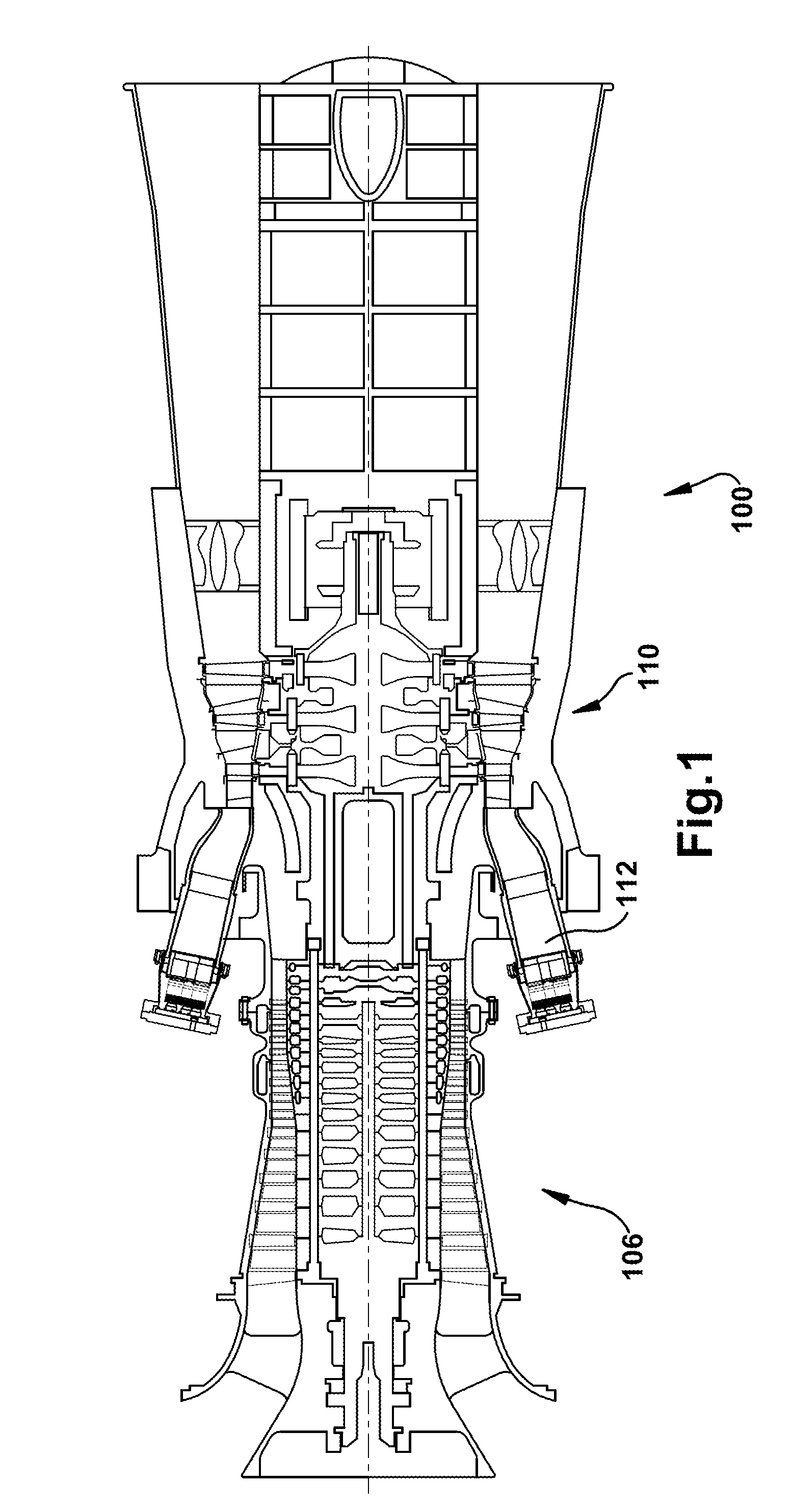

Supercharging system for gas turbines

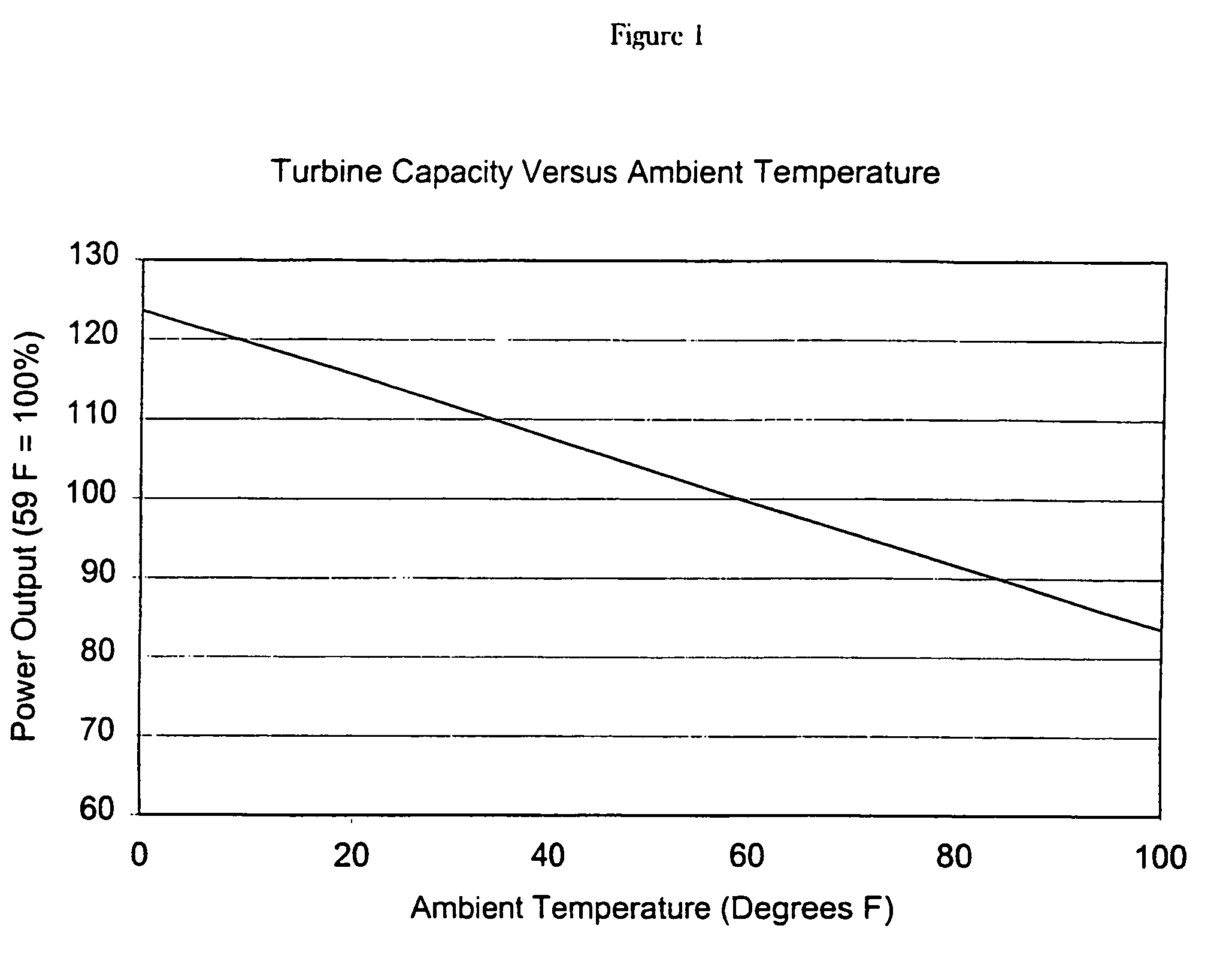

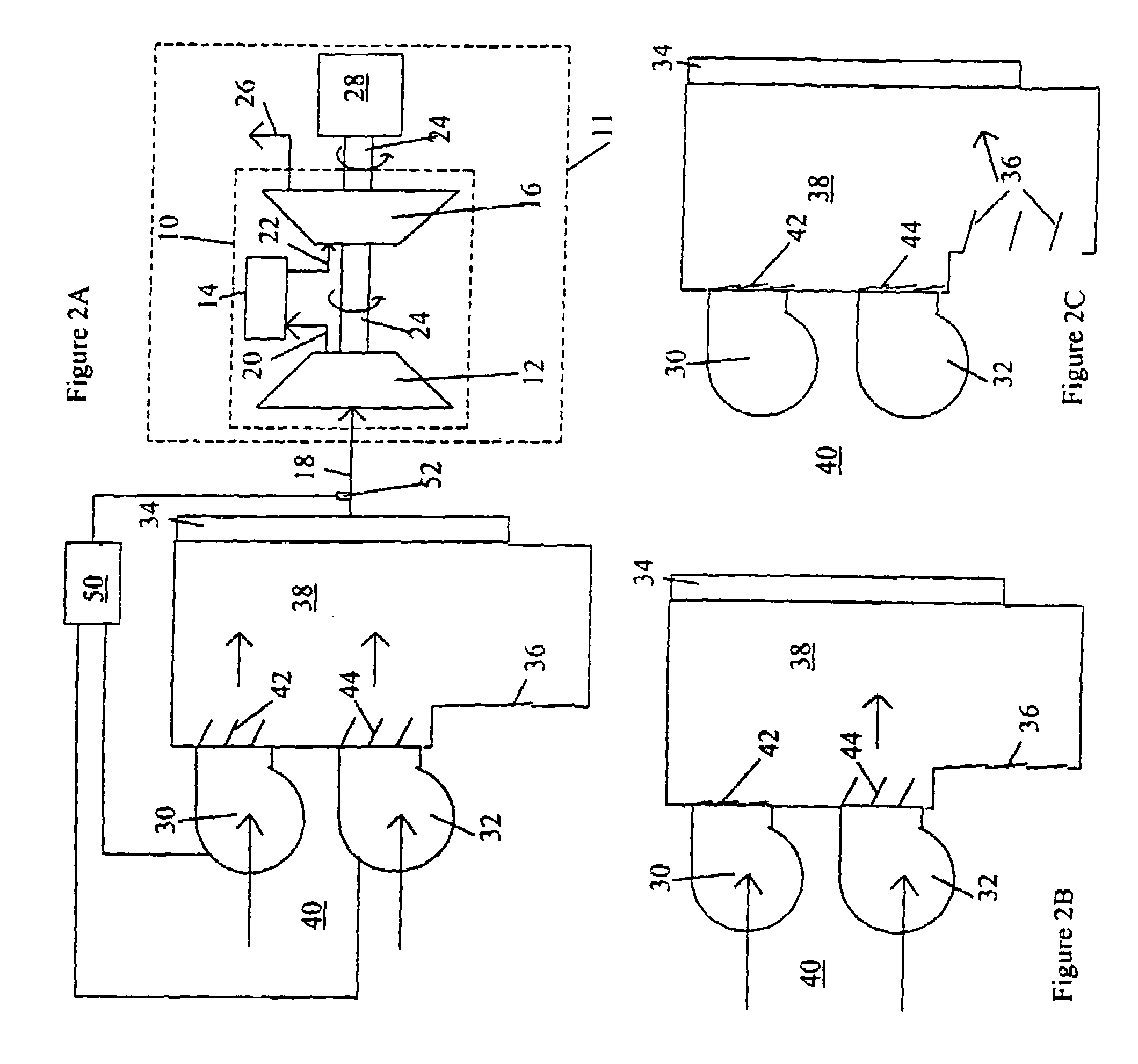

InactiveUS7065953B1Increase turbine capacityReduce installation costsEfficient propulsion technologiesGas turbine plantsCombustorPower station

A supercharging system for gas turbine power plants (11). The system includes a supercharging fan (30, 32) and controller (50) for limiting turbine power output to prevent overload of the generator (28) at lower ambient temperatures. The controller can limit power output by burner control, inlet temperature control, control of supercharging fan pressure and other options. The system can be retrofit on an existing turbine without replacing the generator and associated parts.

Owner:ENHANCED TURBINE OUTPUT HLDG

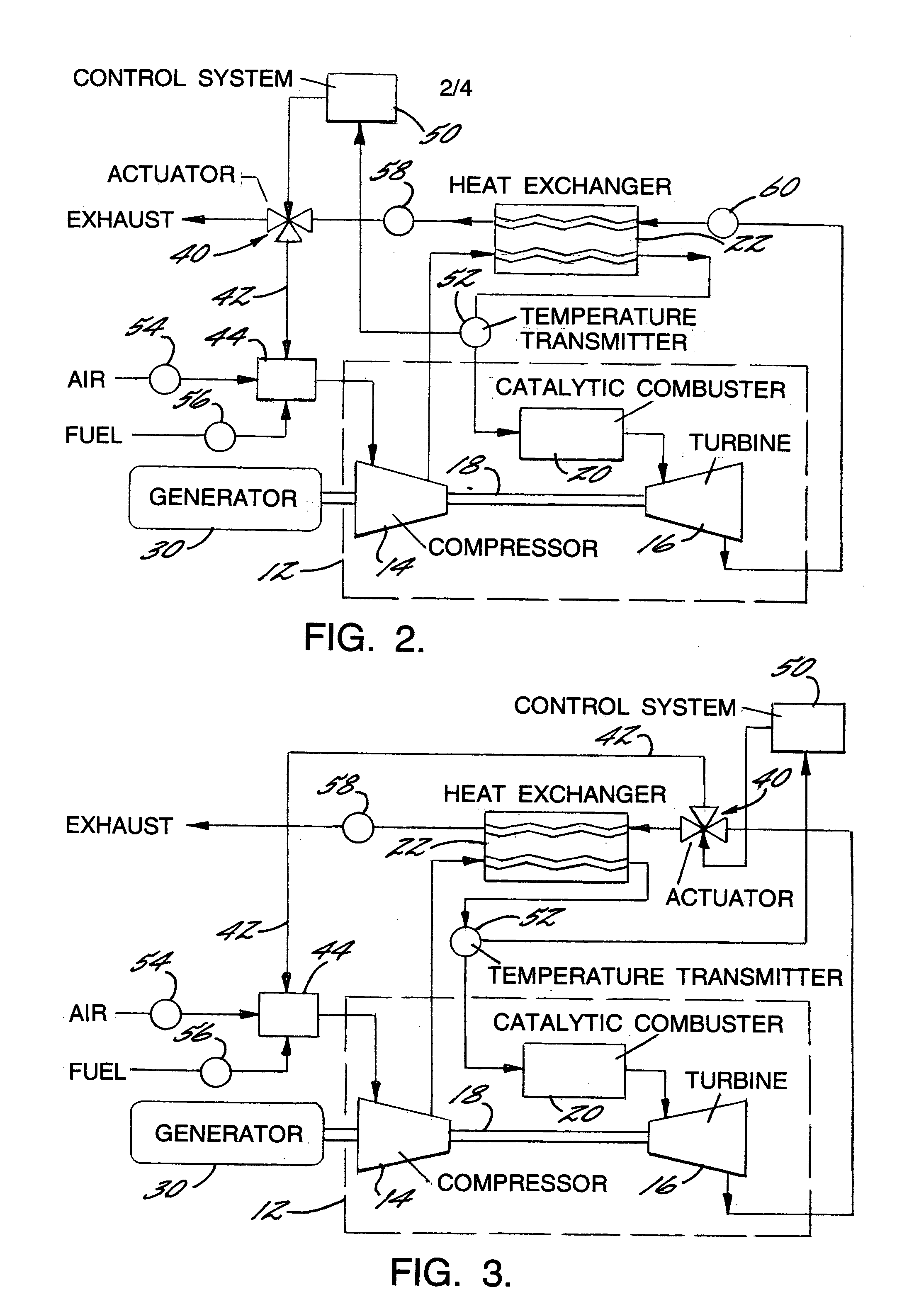

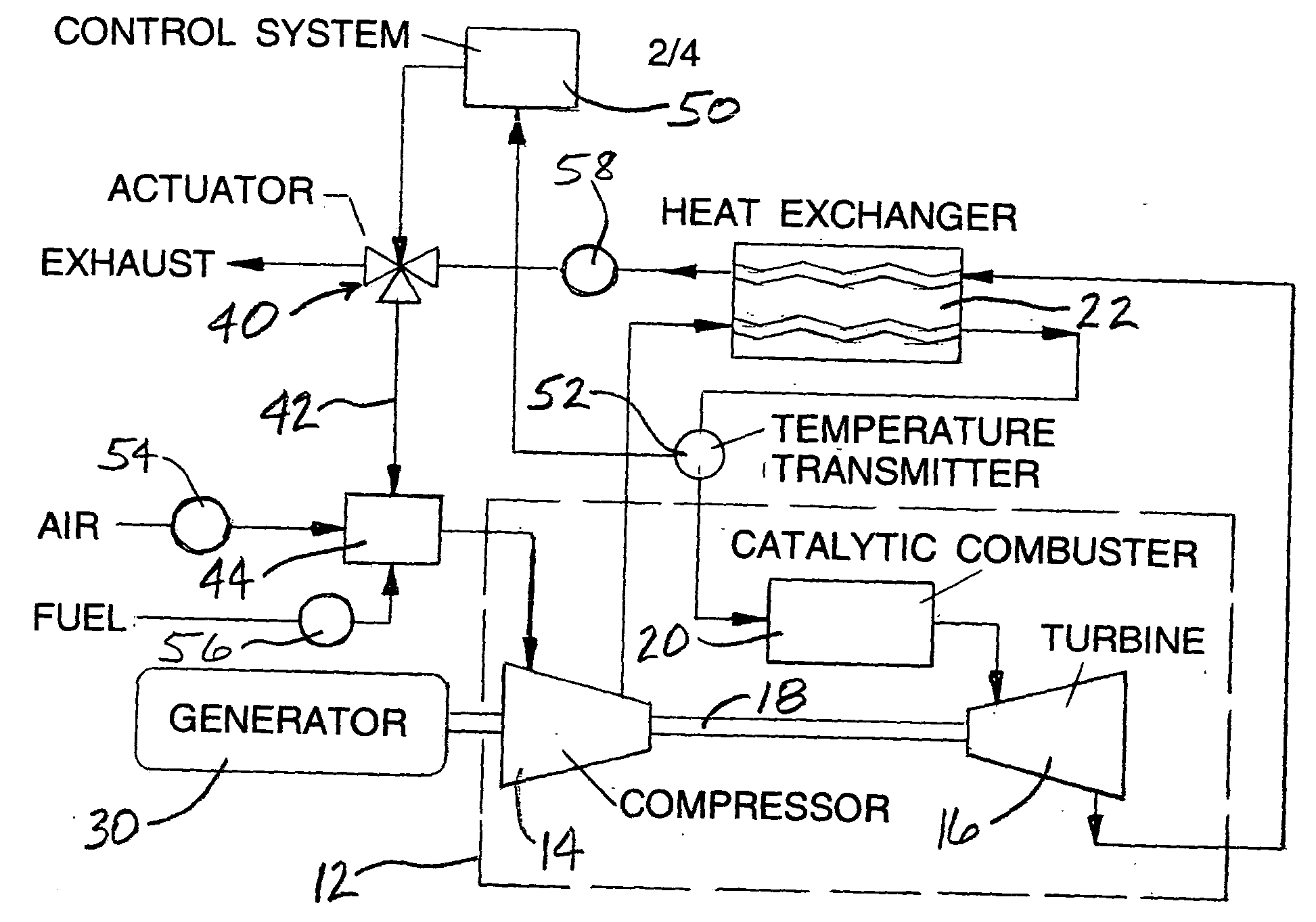

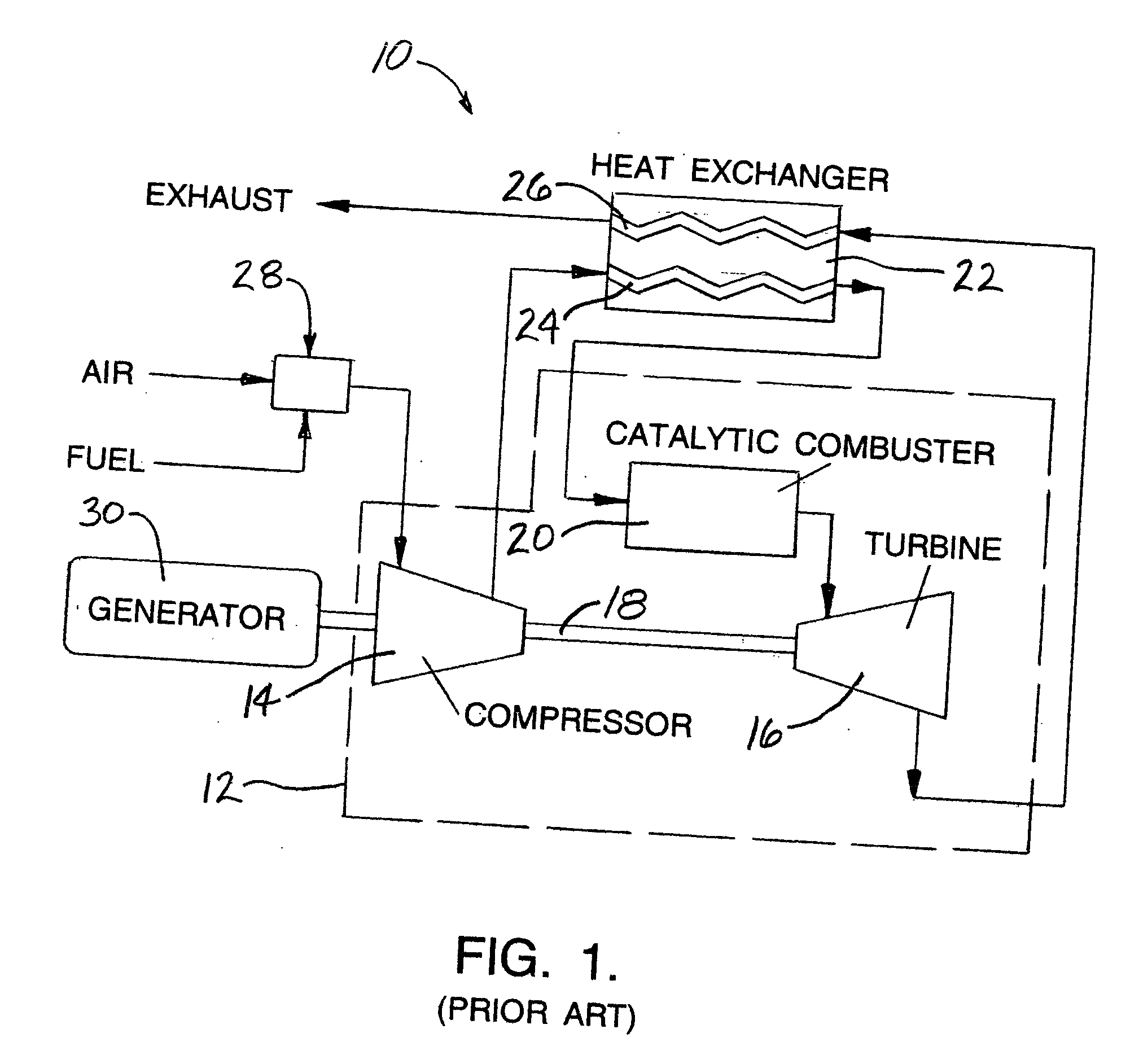

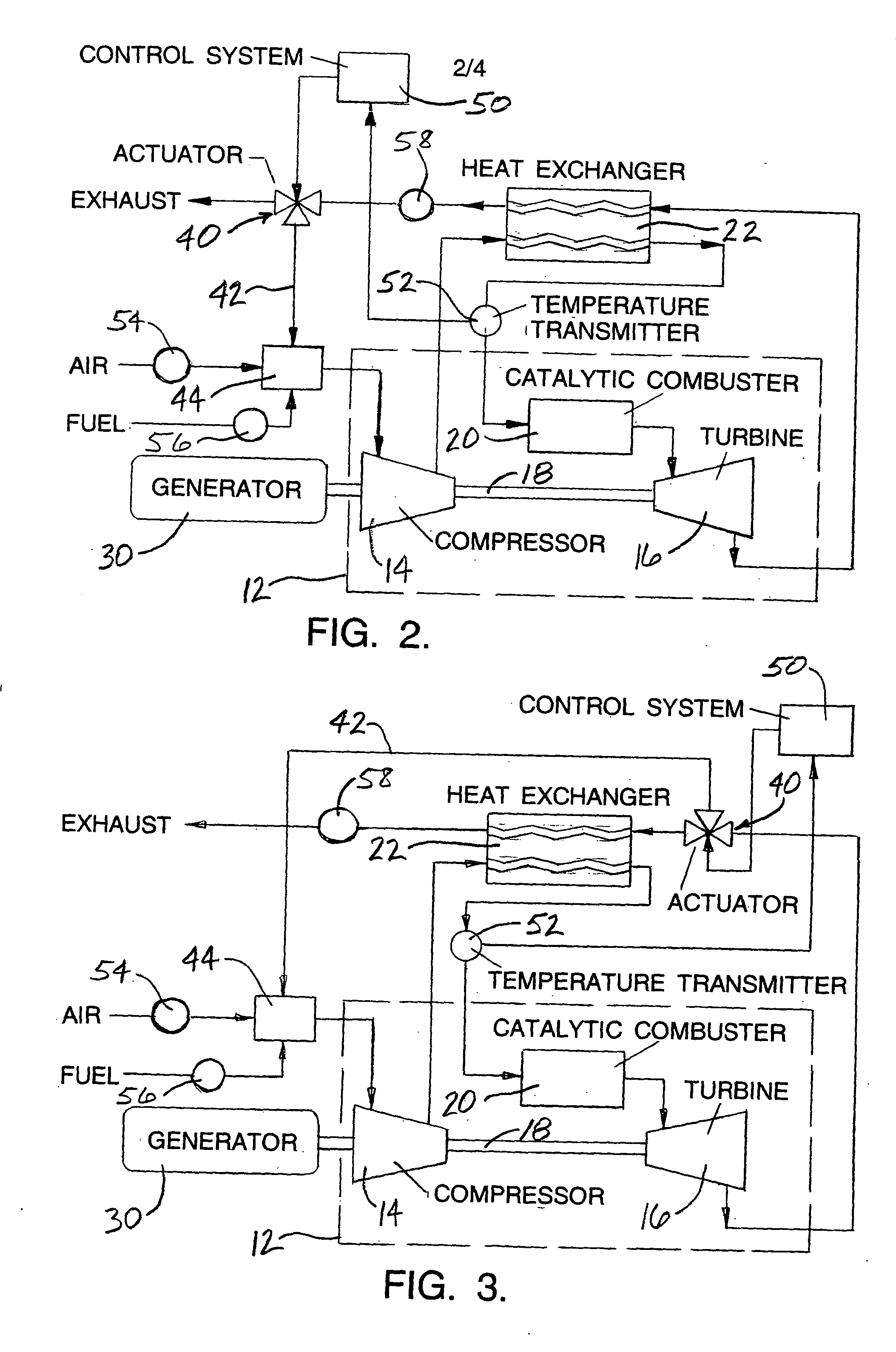

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS7007487B2Maximize efficiencyReduce air pollutionTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorCold weather

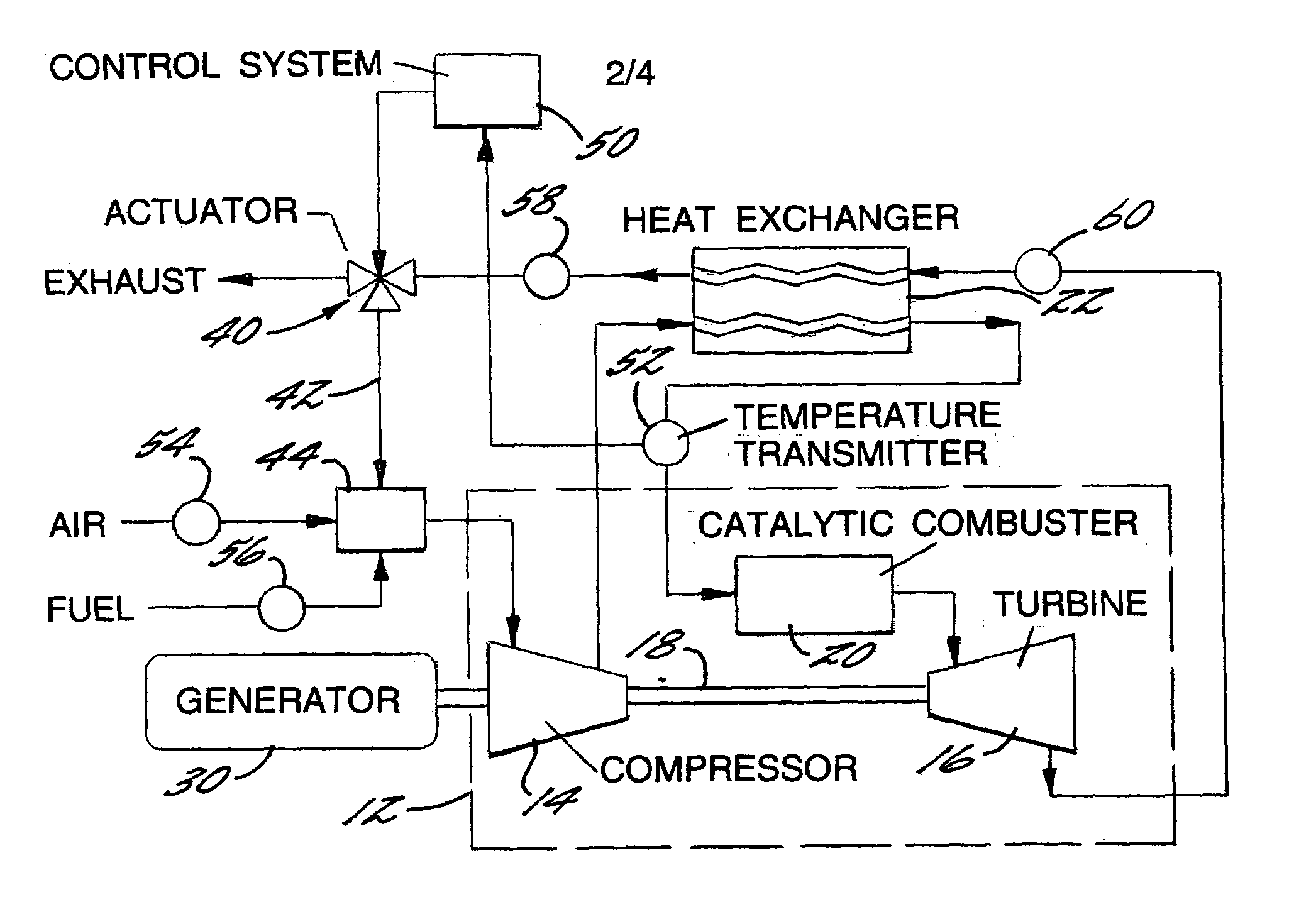

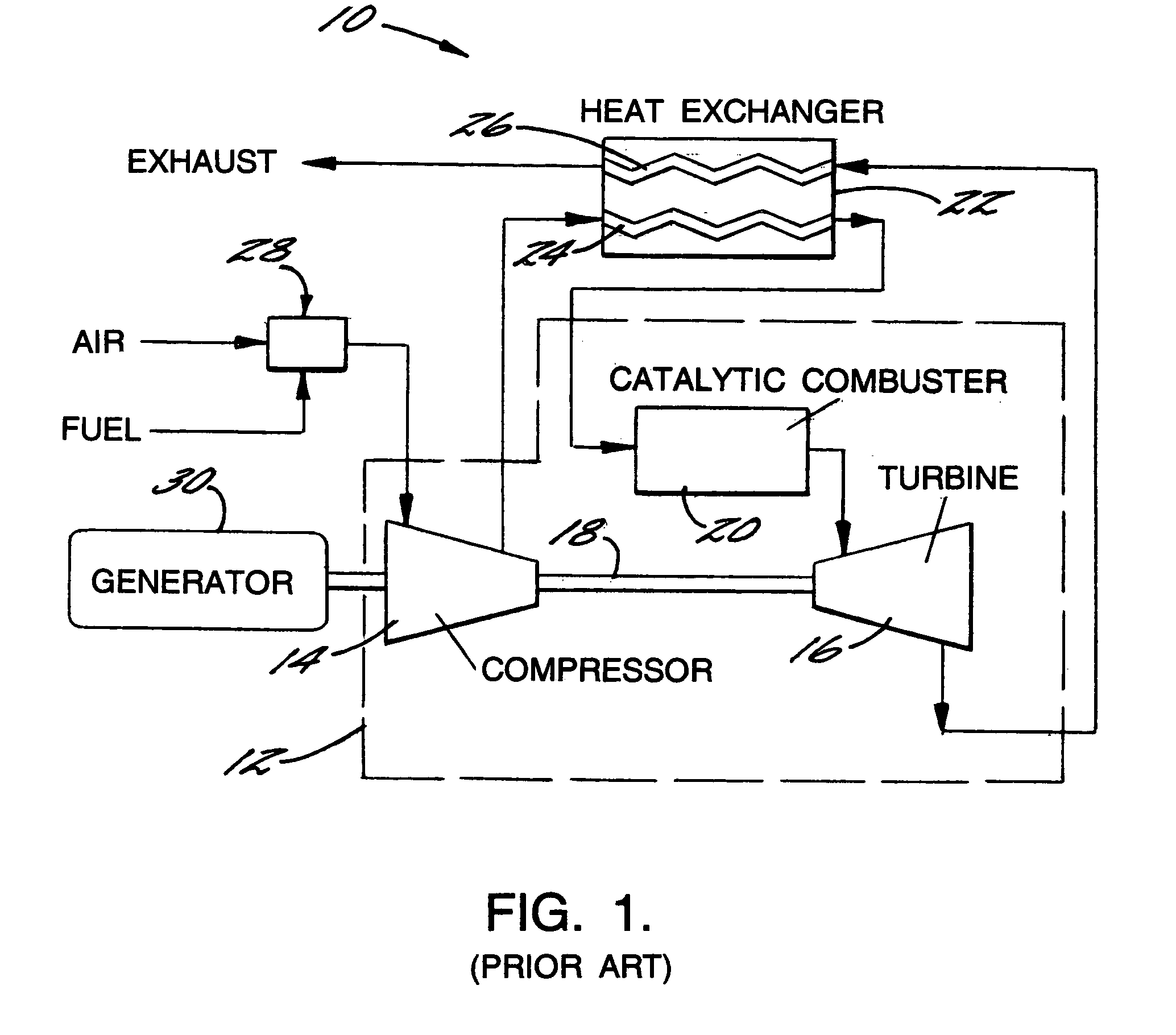

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

System, method and computer program product for remote vehicle diagnostics, monitoring, configuring and reprogramming

InactiveUS20040167689A1Vehicle testingRegistering/indicating working of vehiclesFleet managementLogistics management

A remote vehicle diagnostics, monitoring, configuration and reprogramming tool is provided. The system includes a fleet of vehicles equipped with wireless mobile communications means that enable fleet managers to remotely diagnose, monitor and reprogram vehicles in their fleet via an Internet Web-based browser environment. Each vehicle within the fleet is equipped with a smart device that is coupled to the data bus within each vehicle. Date commands relating to the vehicle's parameters (e.g., diagnostic parameters such as max road speed, engine RPM, coolant temperature, air inlet temperature, etc.) are sent and received using satellite and terrestrial wireless communications technology. The invention allows users to remotely perform total fleet logistics and eliminates (or reduces) the need to physically bring fleet vehicles to a repair, maintenance or configuration facility.

Owner:IDSC HLDG

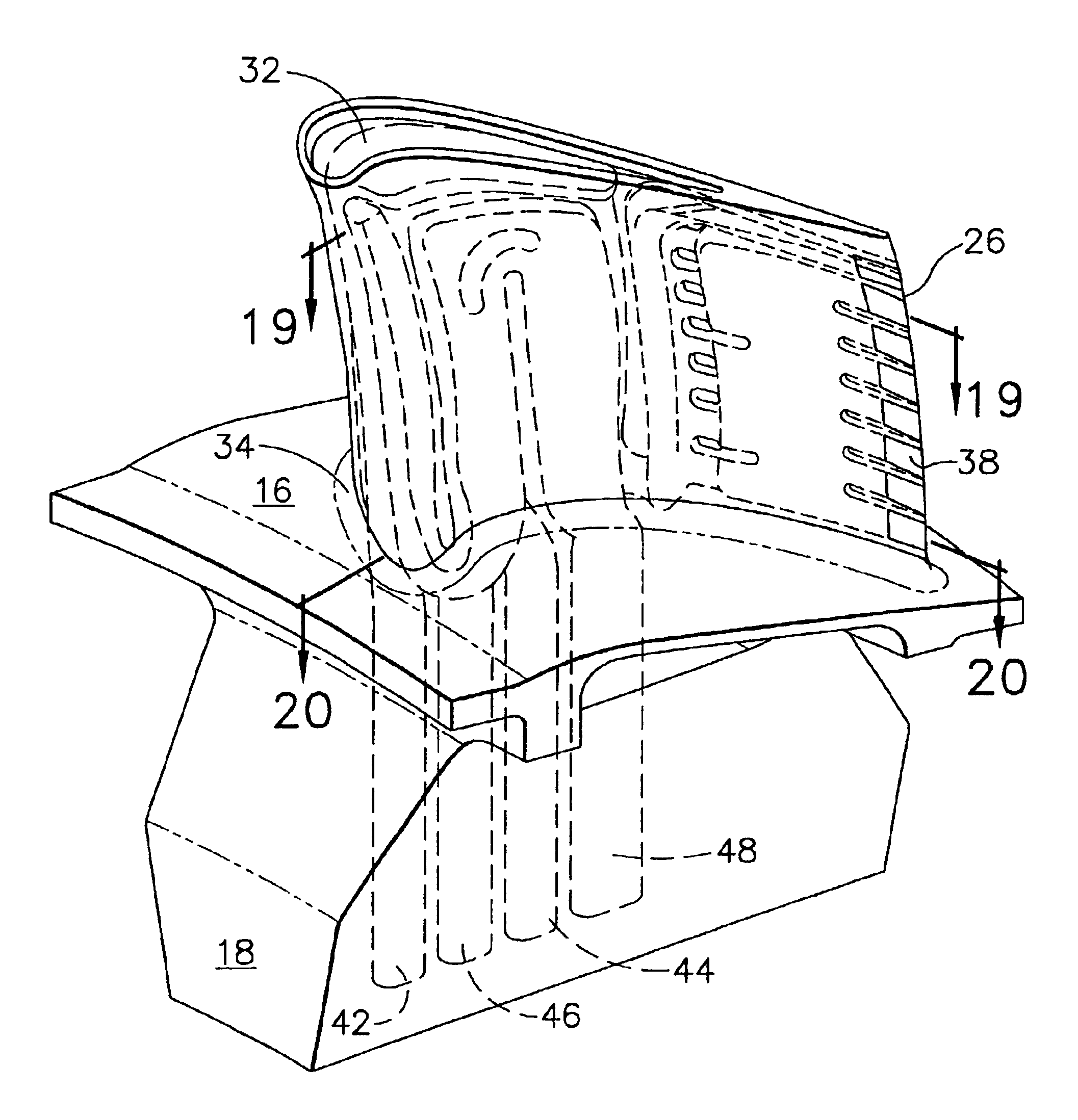

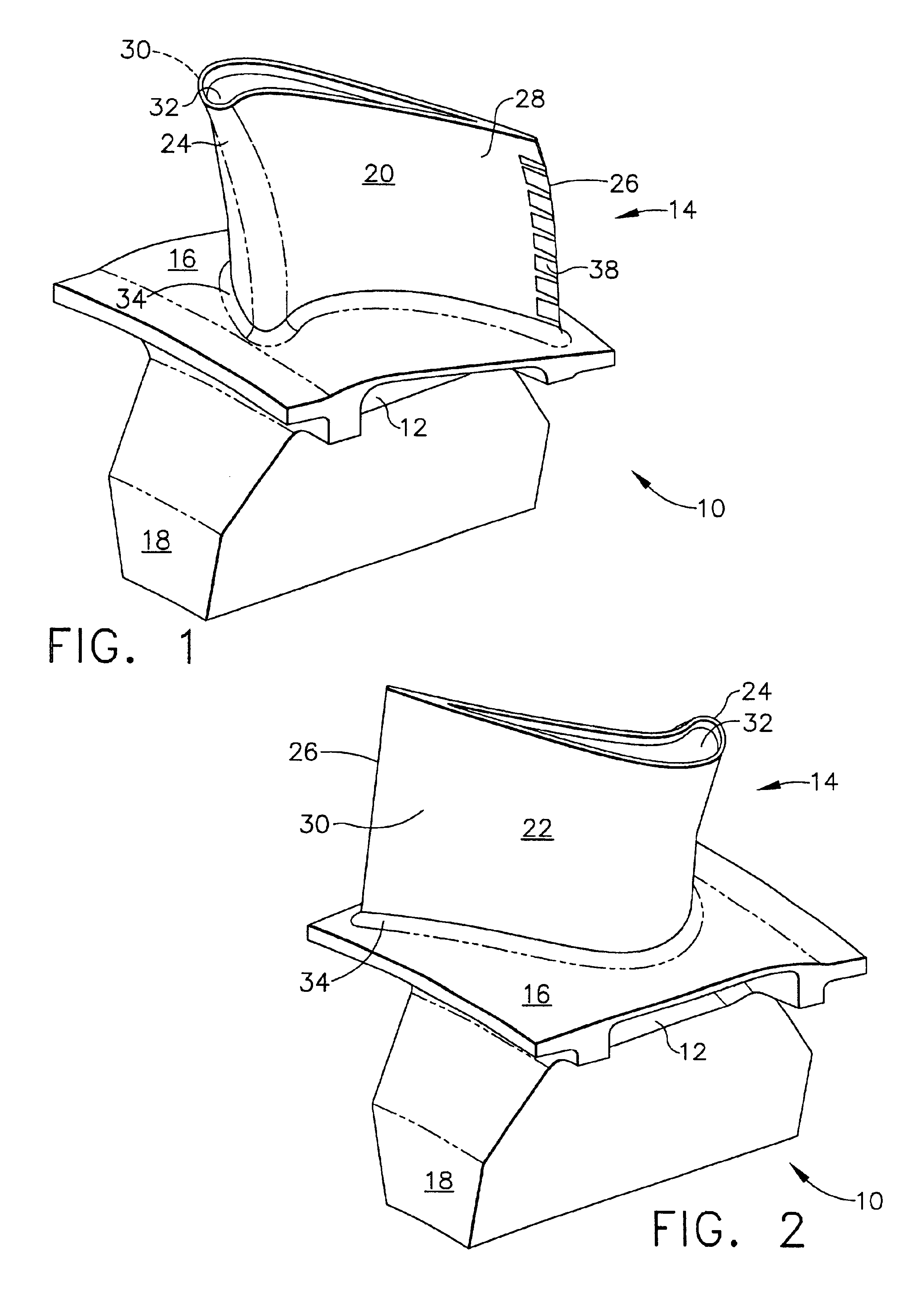

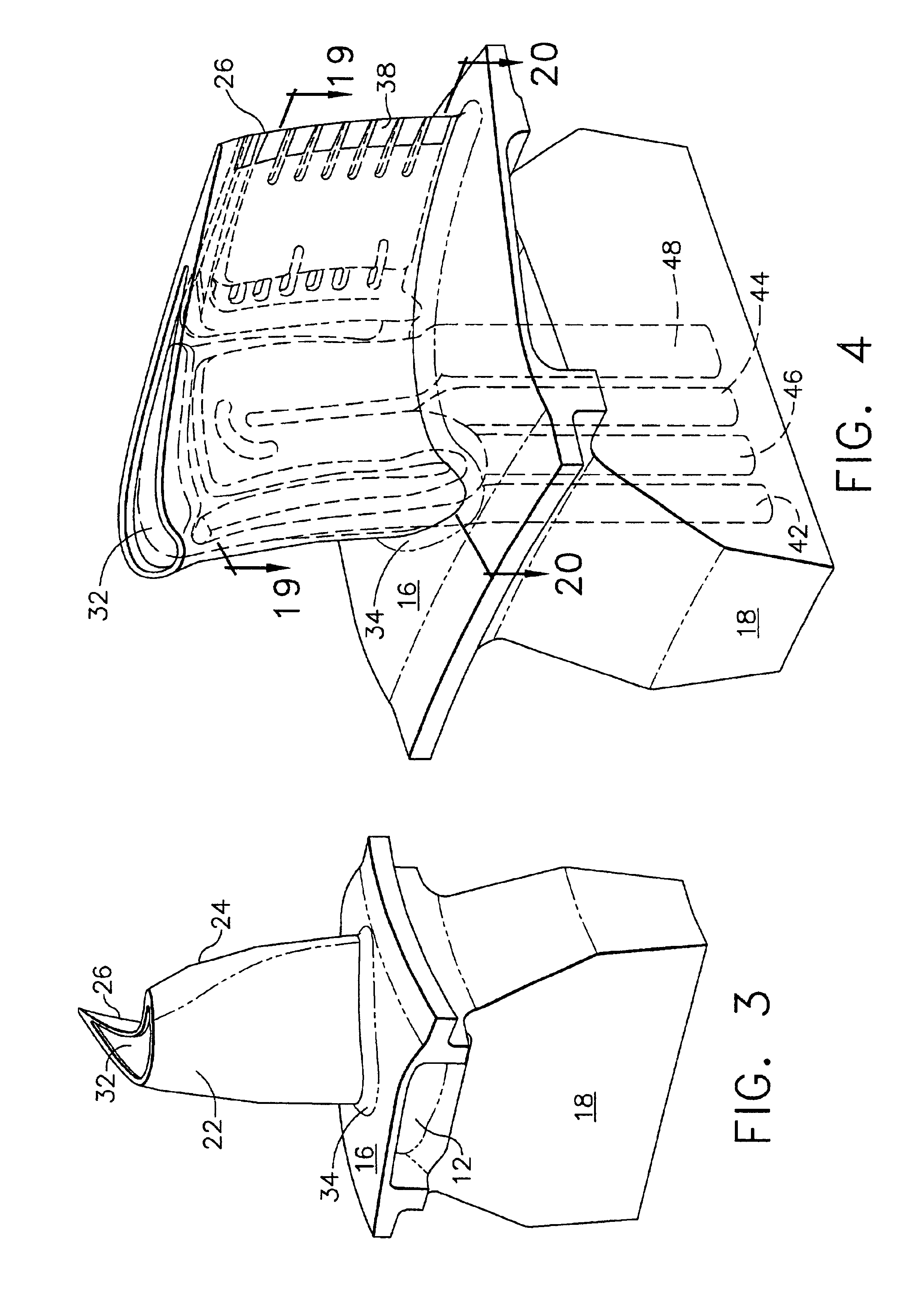

High effectiveness cooled turbine vane or blade

InactiveUS6974308B2Improve cooling efficiencyEasy to manufacturePump componentsEngine fuctionsSuction stressConventional casting

A robust multiple-walled, multi-pass, high cooling effectiveness cooled turbine vane or blade designed for ease of manufacturability, minimizes cooling flows on highly loaded turbine rotors. The vane or blade design allows the turbine inlet temperature to increase over current technology levels while simultaneously reducing turbine cooling to low levels. A multi-wall cooling system is described, which meets the inherent conflict to maximize the flow area of the cooling passages while retaining the required section thickness to meet the structural requirements. Independent cooling circuits for the vane or blade's pressure and suction surfaces allow the cooling of the airfoil surfaces to be tailored to specific heat load distributions (that is, the pressure surface circuit is an independent forward flowing serpentine while the suction surface is an independent rearward flowing serpentine). The cooling air for the independent circuits is supplied through separate passages at the base of the vane or blade. The cooling air follows intricate passages to feed the serpentine thin outer wall passages, which incorporate pin fins, turbulators, etc. These passages, while satisfying the aero / thermal / stress requirements, are of a manufacturing configuration that may be cast with single crystal materials using conventional casting techniques.

Owner:HONEYWELL INT INC

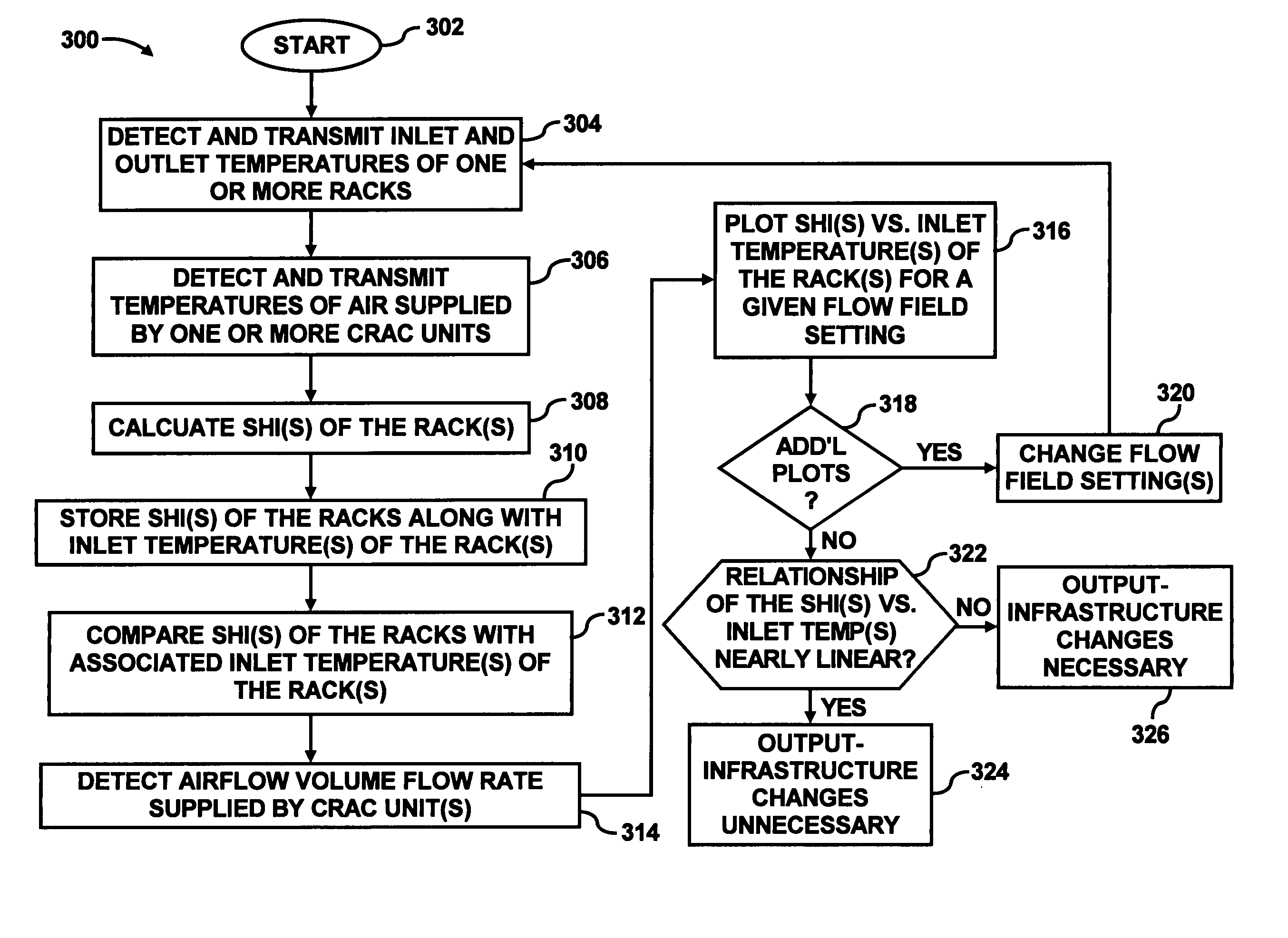

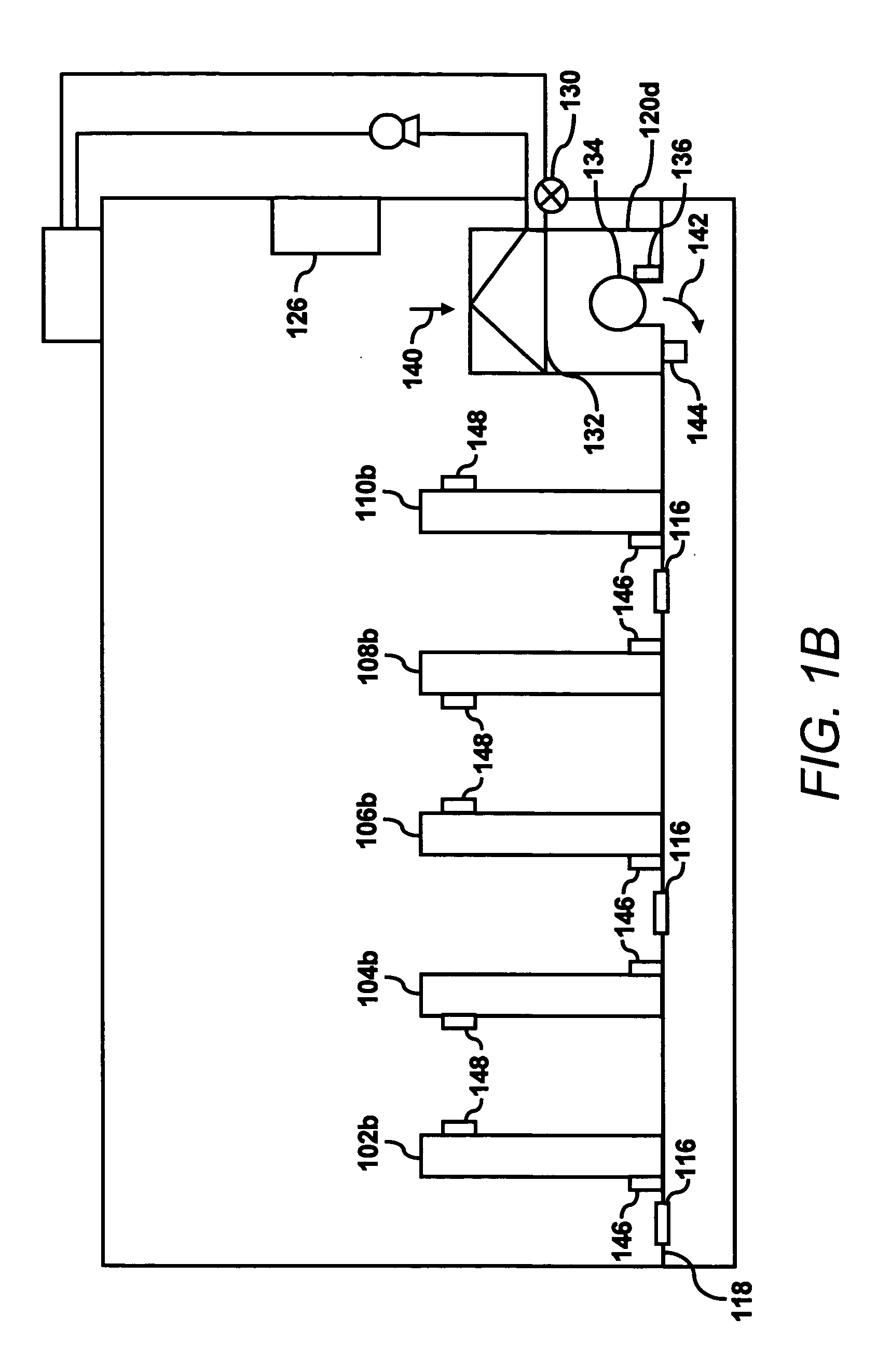

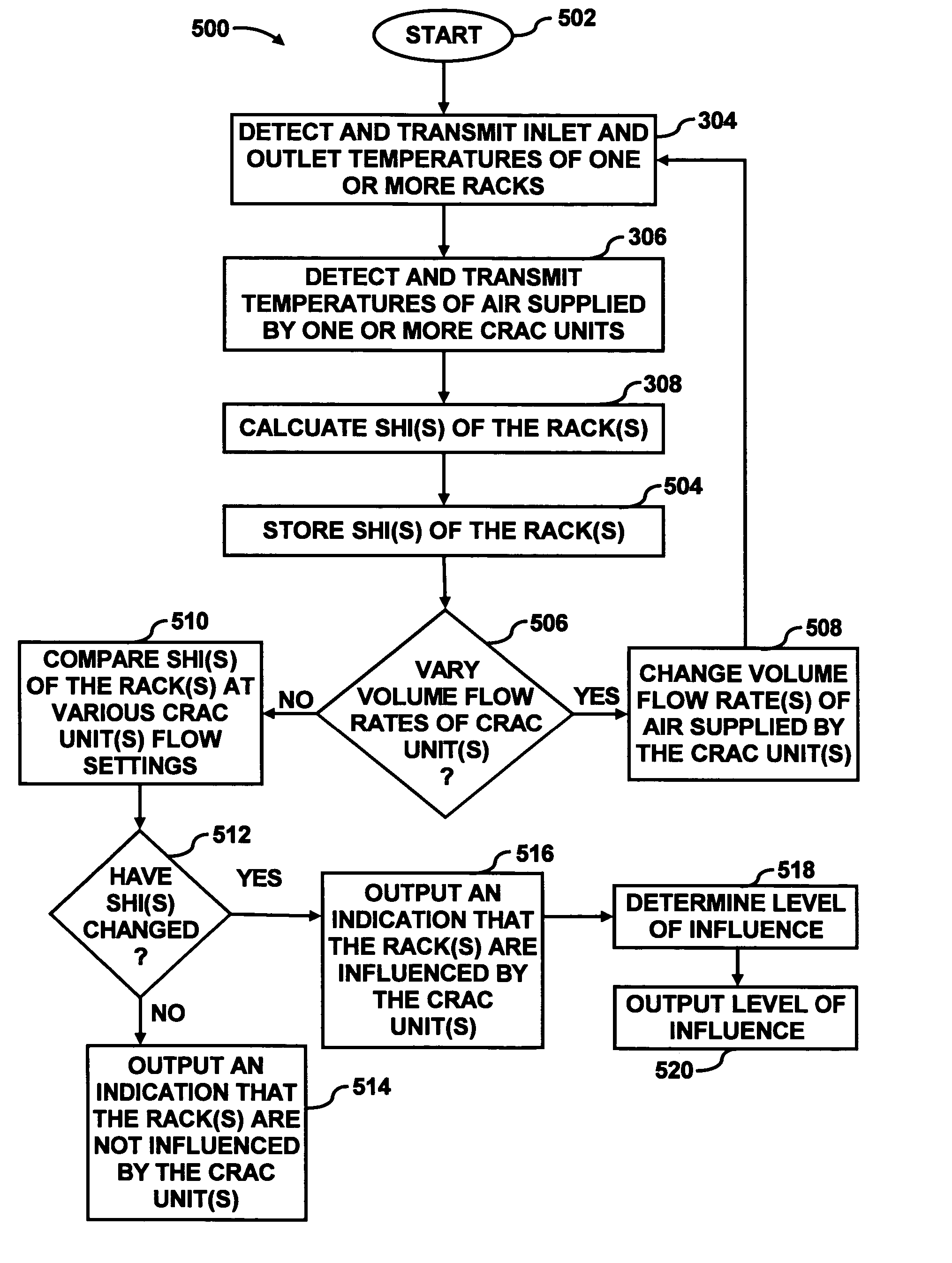

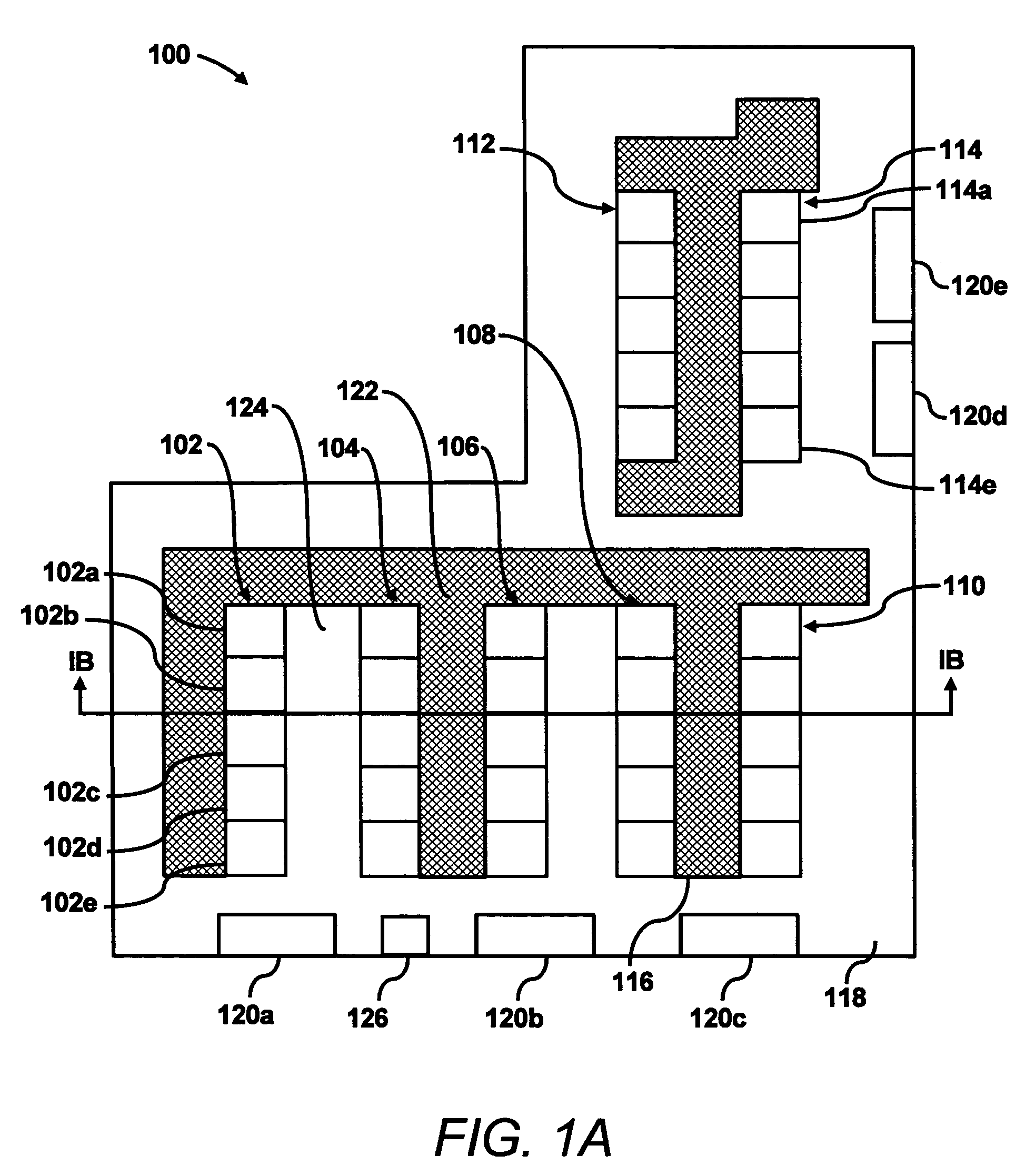

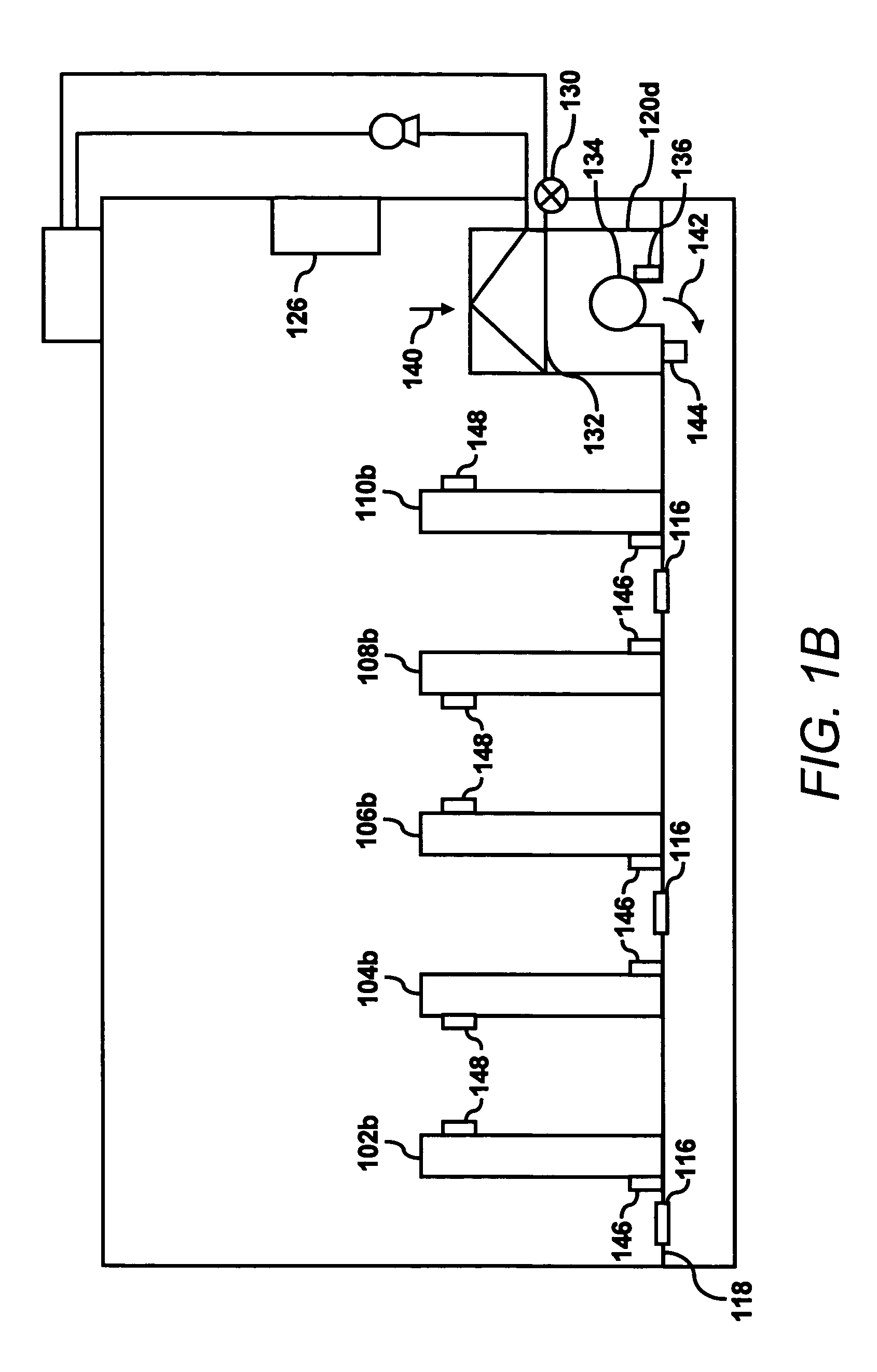

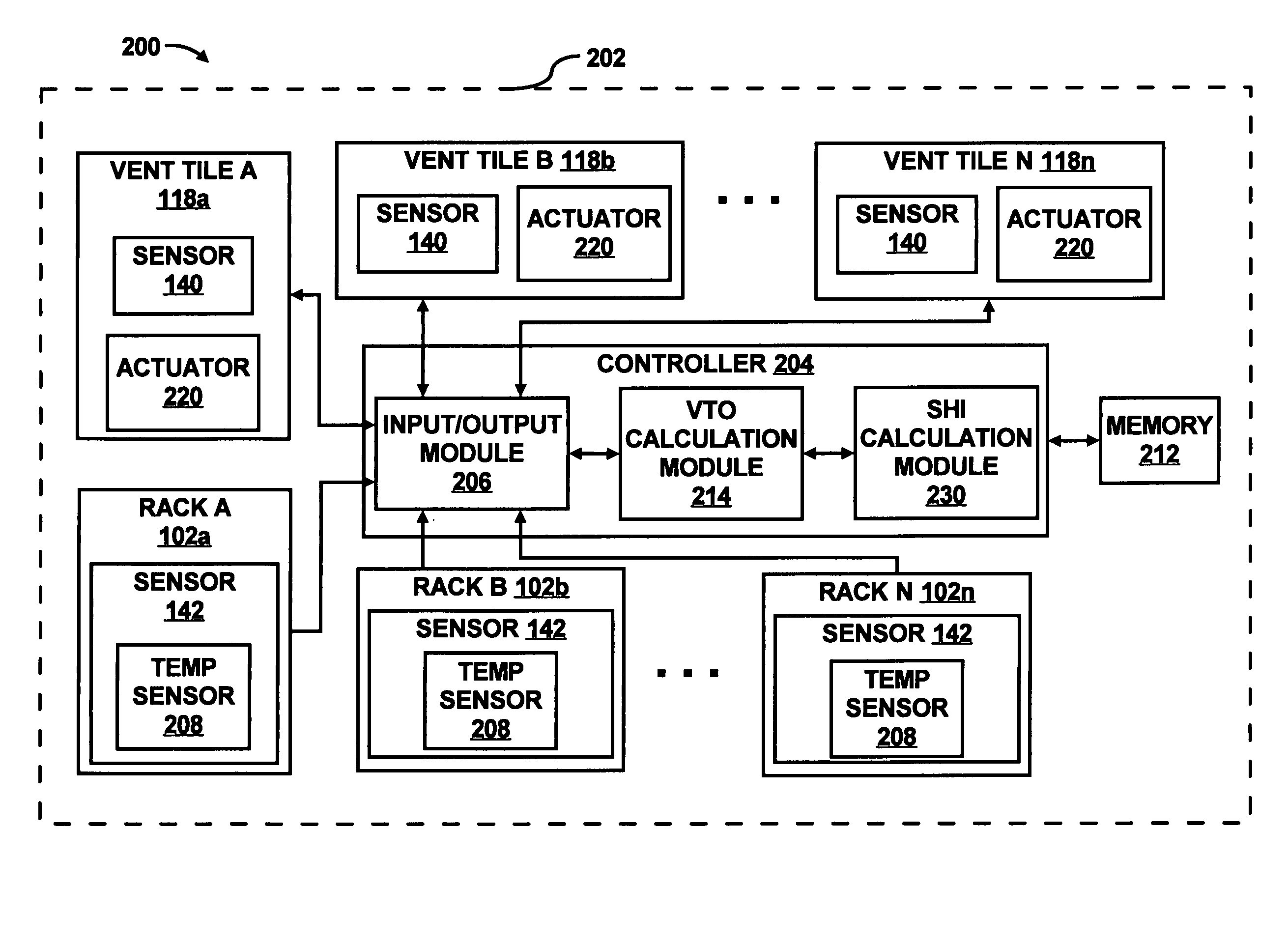

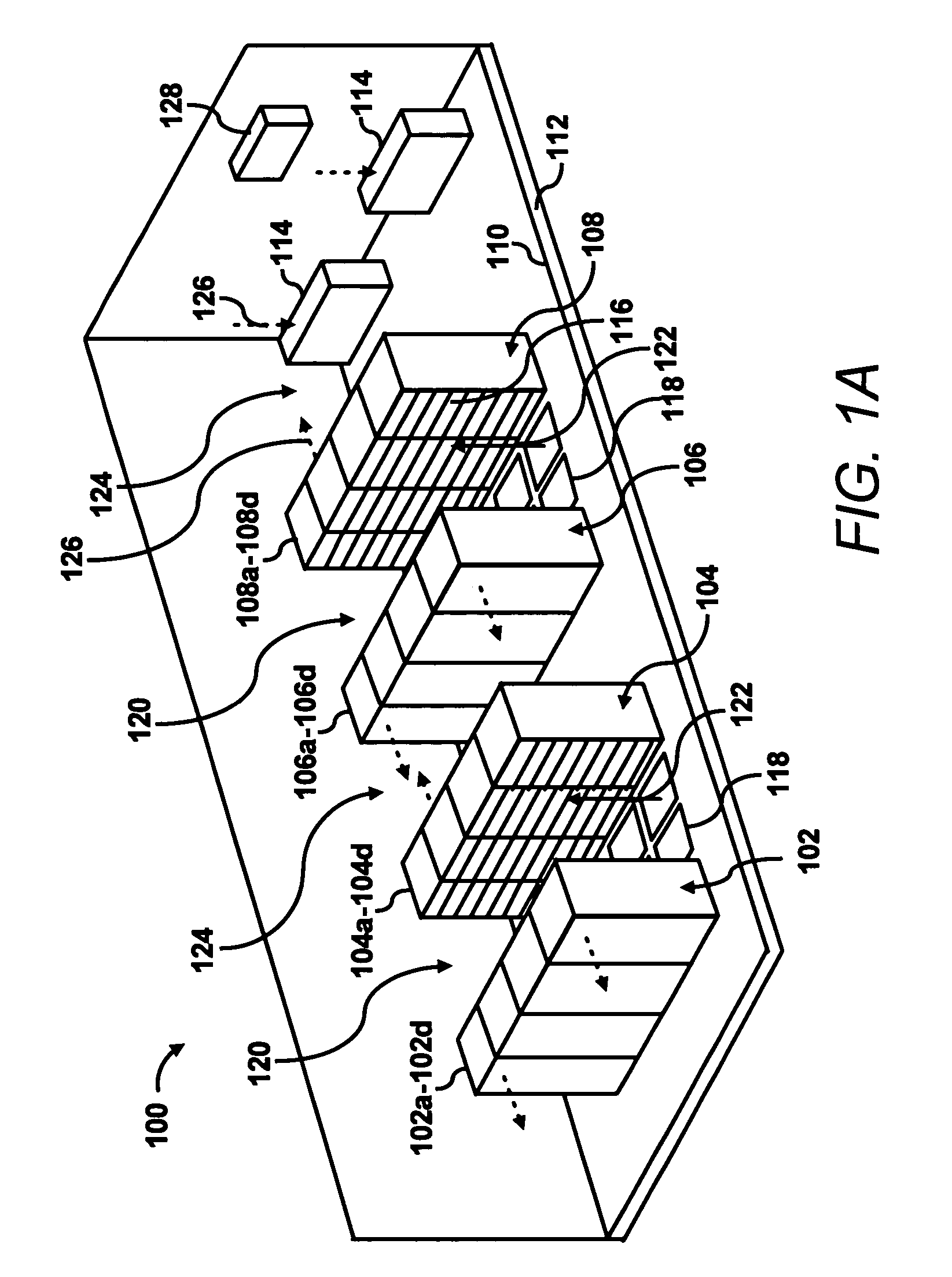

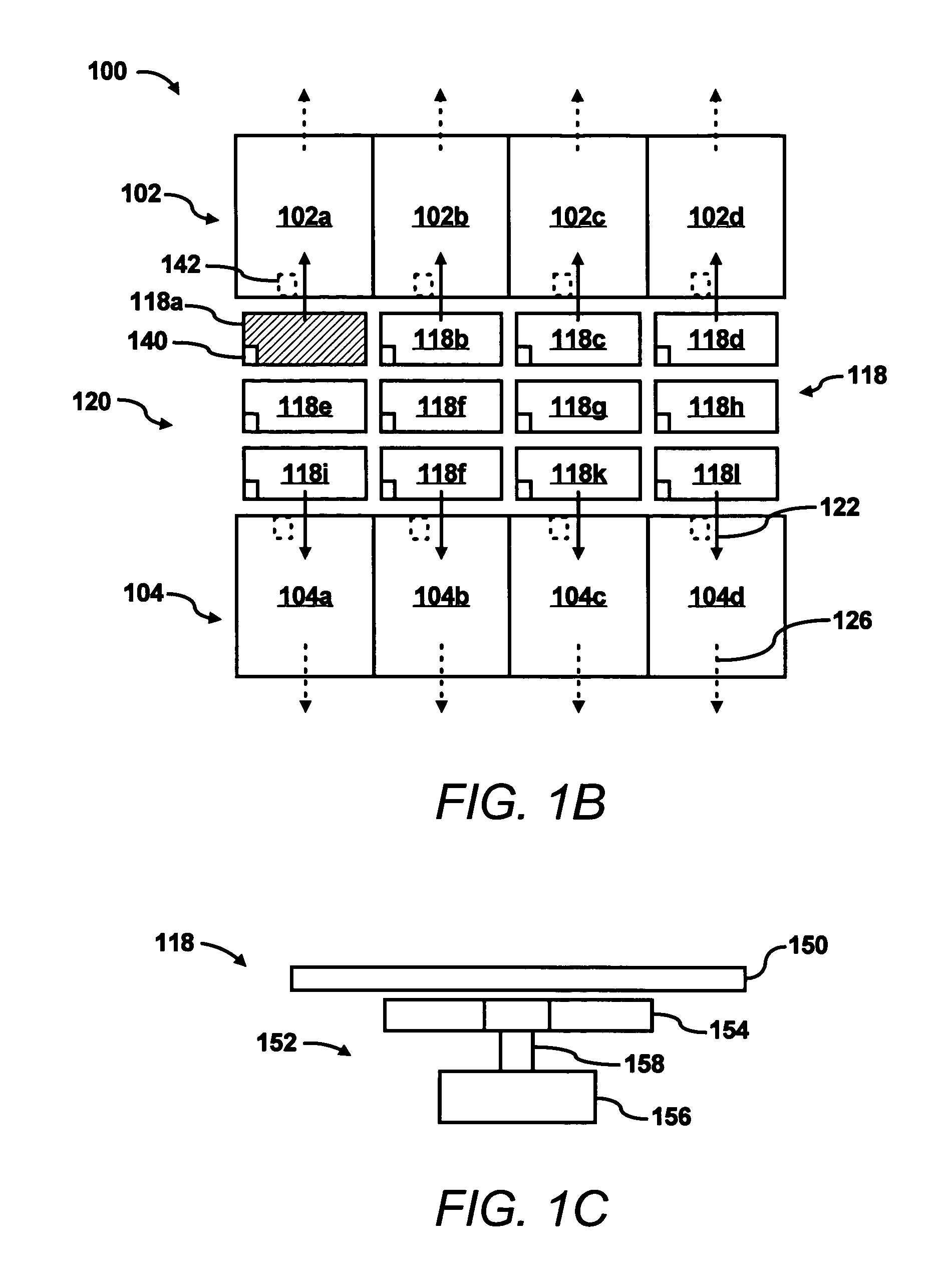

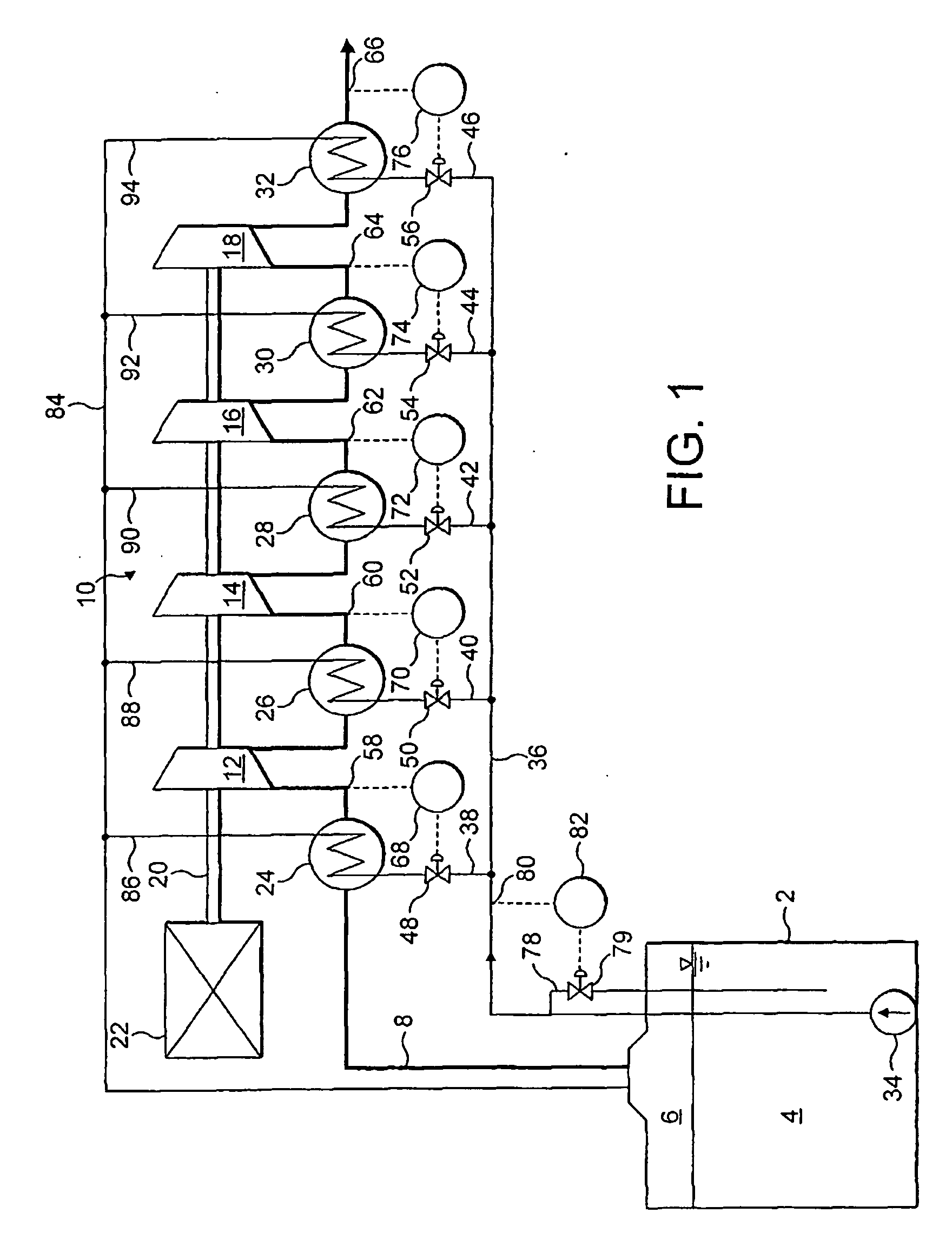

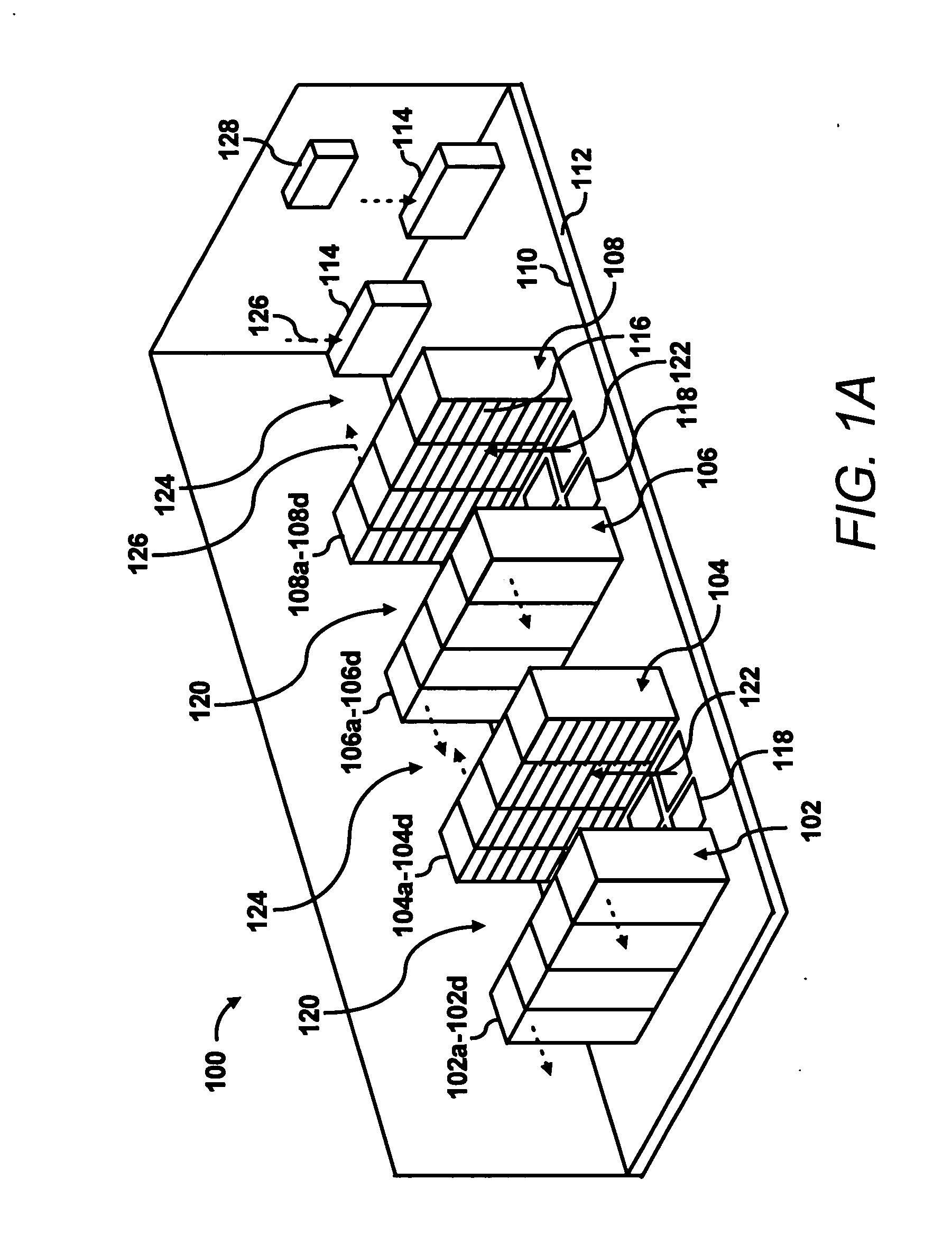

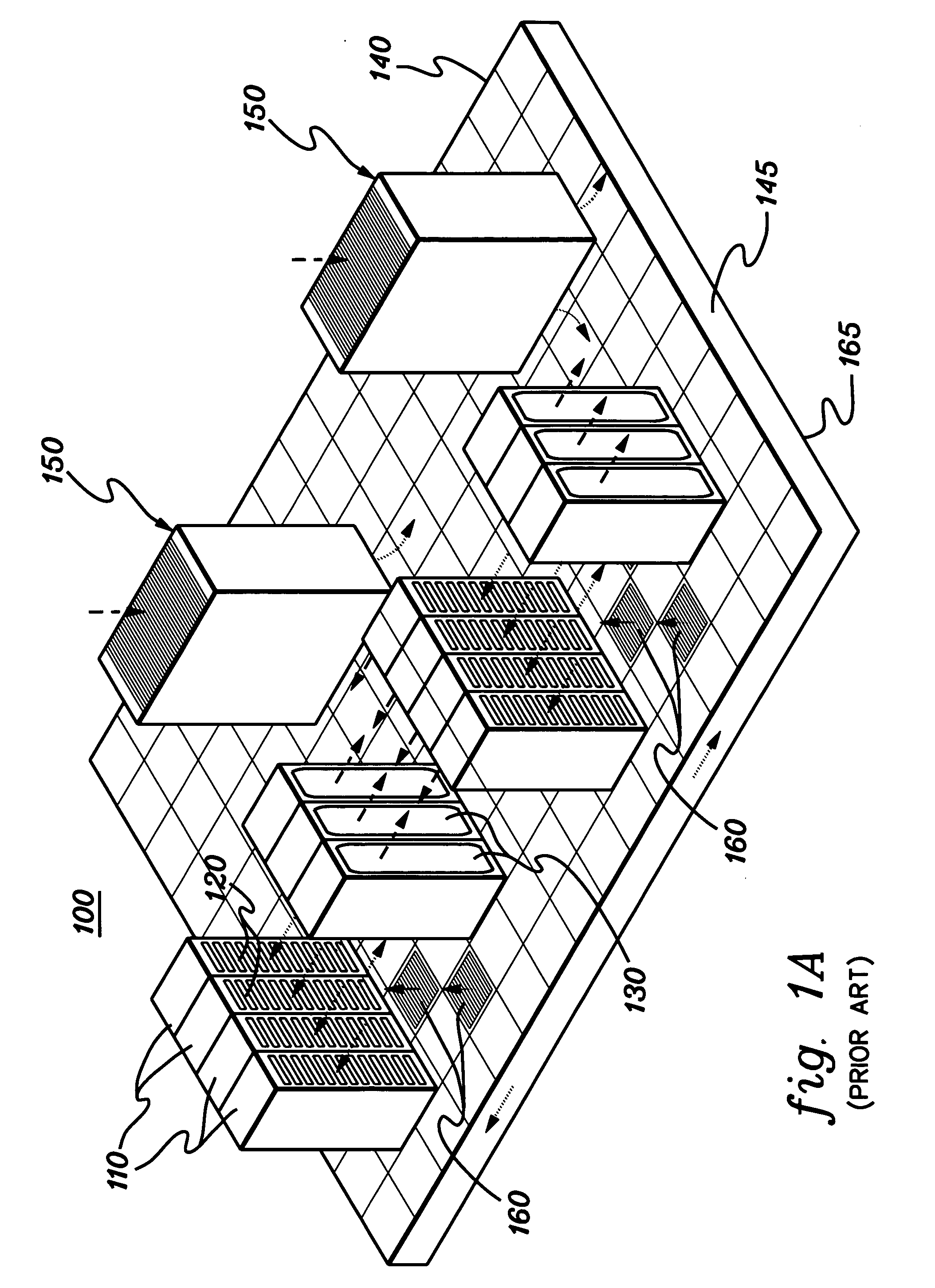

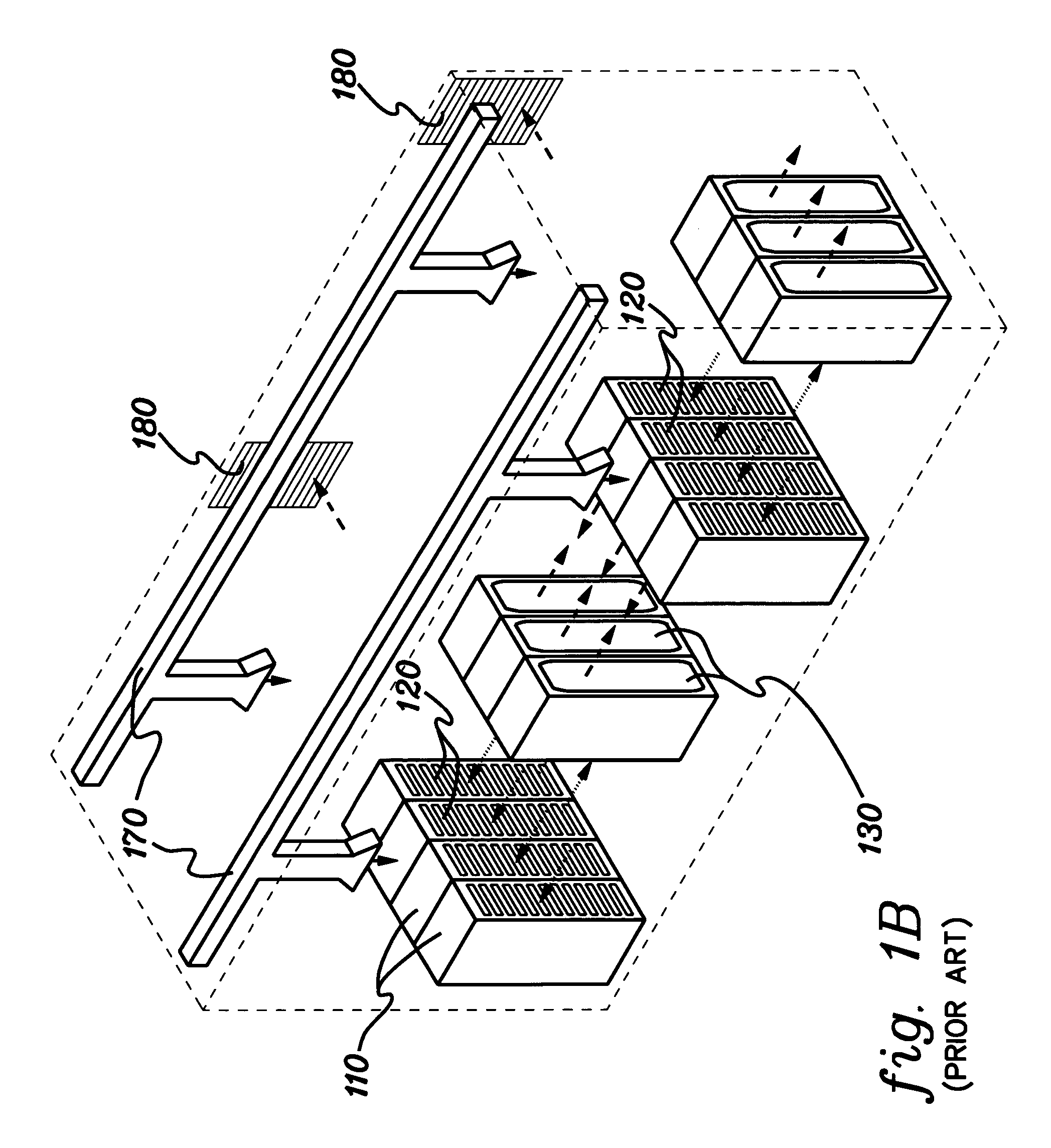

Data center evaluation using an air re-circulation index

In a method for evaluating one or more components in a data center, inlet and outlet temperatures of one or more heat dissipating devices are detected. In addition, the temperatures of air supplied by one or more computer room air conditioning (CRAC) units are also detected. Indices of air re-circulation for the one or more heat dissipating devices are calculated based upon the detected inlet temperatures, outlet temperatures and supplied air temperatures. The indices of air re-circulation are determined at various flow field settings of air delivered to the one or more heat dissipating devices and the one or more components are evaluated based upon changes in the indices of air re-circulation for the one or more heat dissipating devices at the various flow field settings.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

Data center evaluation using an air re-circulation index

ActiveUS7031870B2Sampled-variable control systemsSpace heating and ventilationData centerProcess engineering

In a method for evaluating one or more components in a data center, inlet and outlet temperatures of one or more heat dissipating devices are detected. In addition, the temperatures of air supplied by one or more computer room air conditioning (CRAC) units are also detected. Indices of air re-circulation for the one or more heat dissipating devices are calculated based upon the detected inlet temperatures, outlet temperatures and supplied air temperatures. The indices of air re-circulation are determined at various flow field settings of air delivered to the one or more heat dissipating devices and the one or more components are evaluated based upon changes in the indices of air re-circulation for the one or more heat dissipating devices at the various flow field settings.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP +1

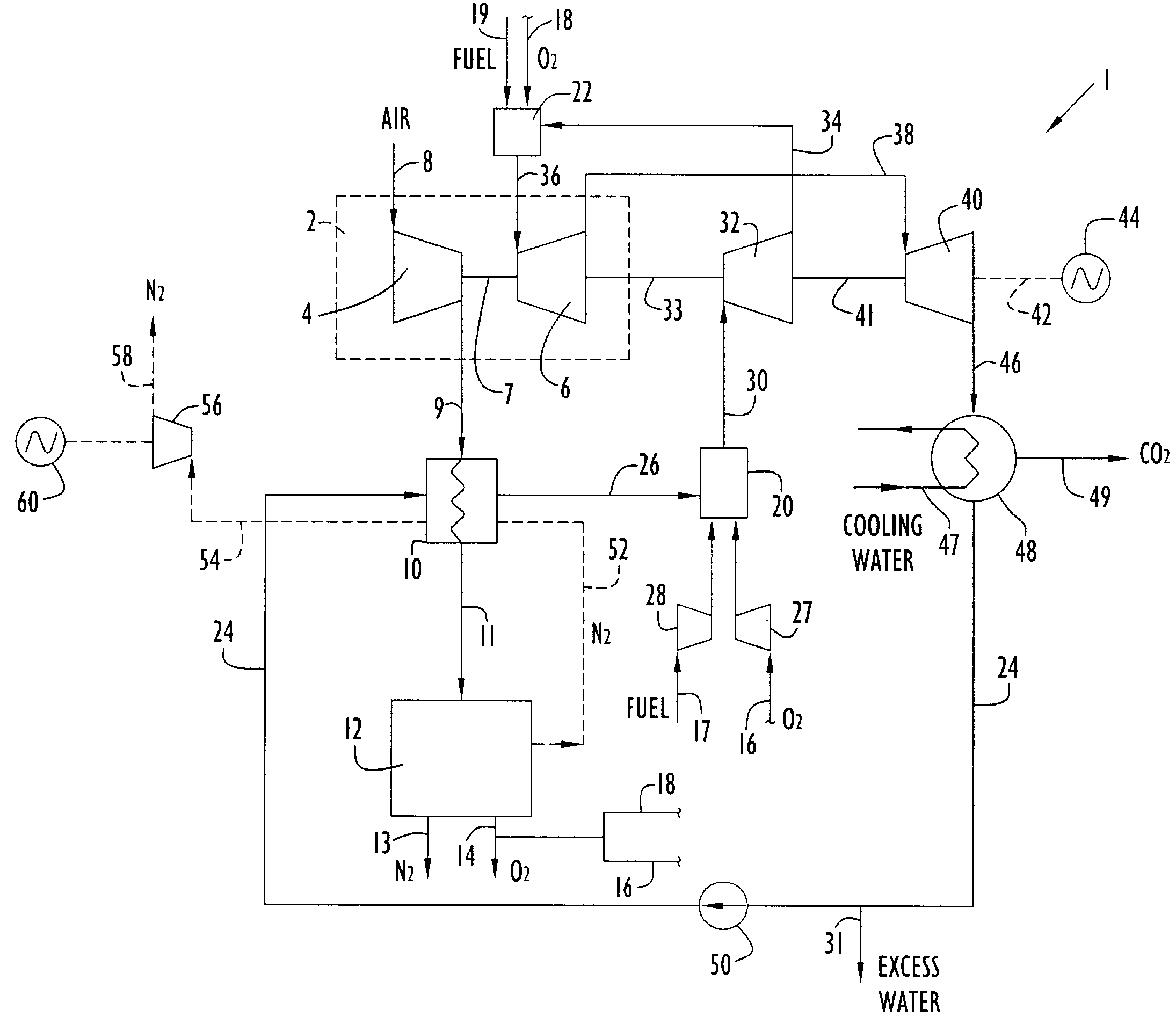

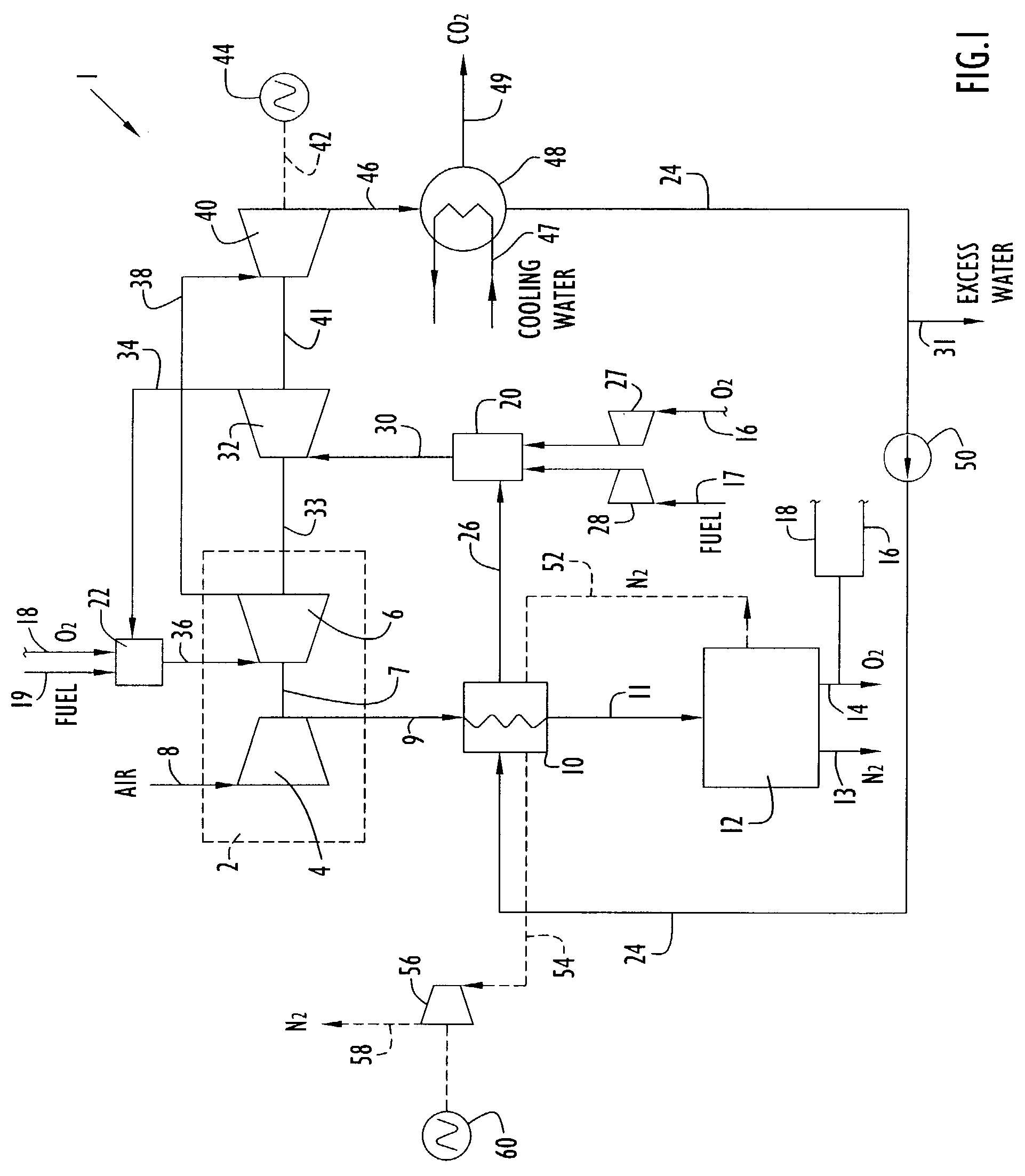

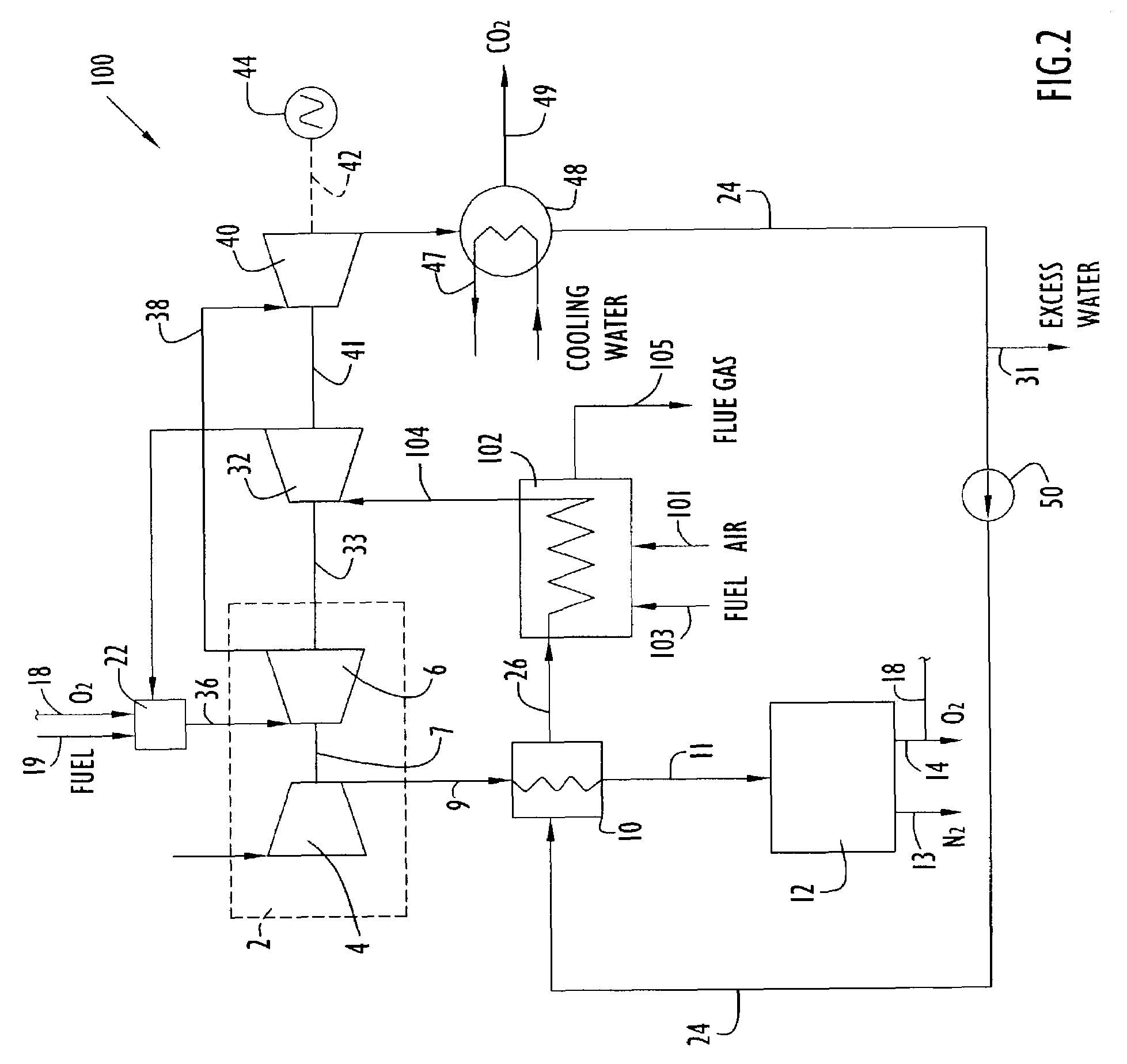

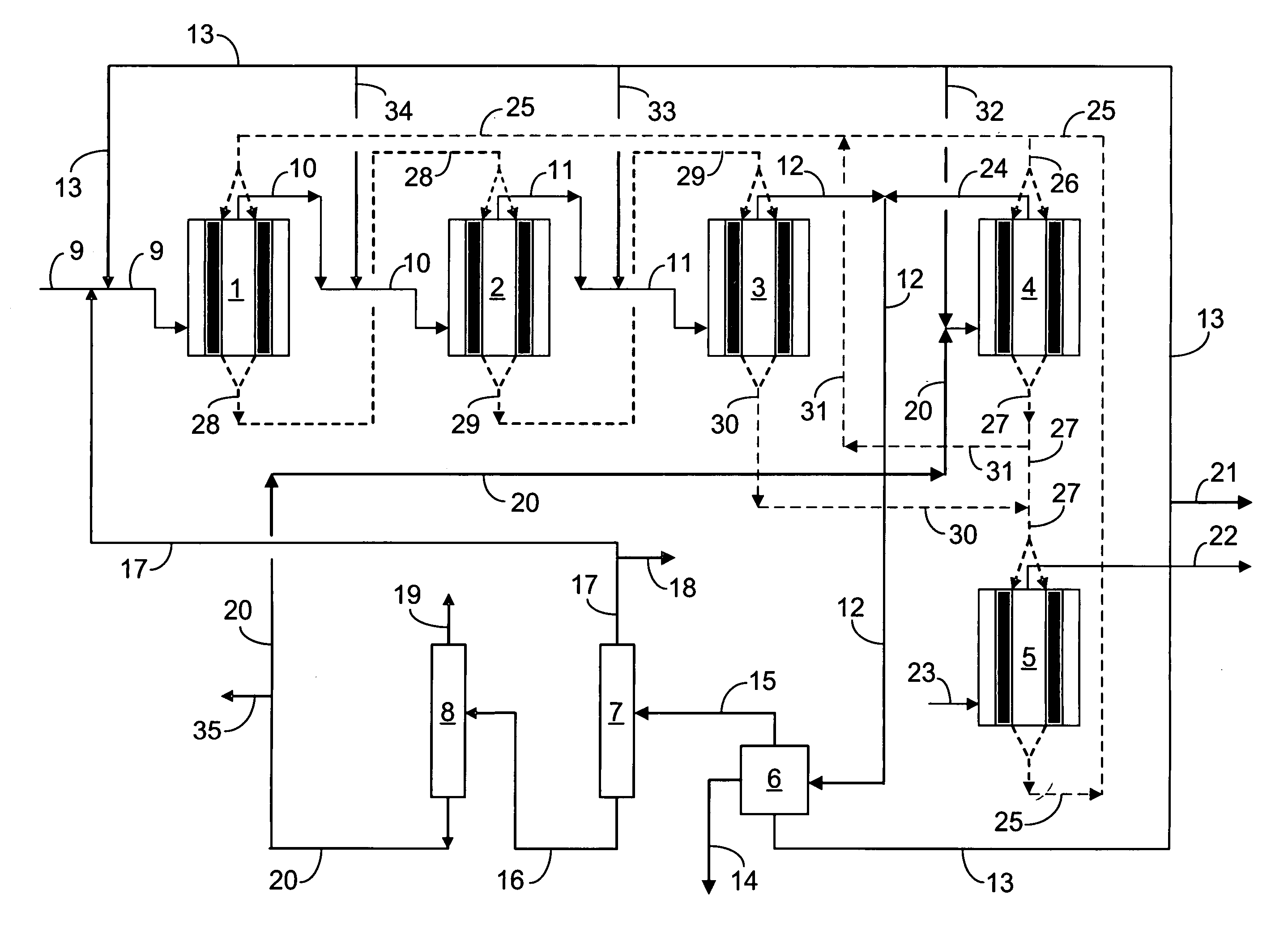

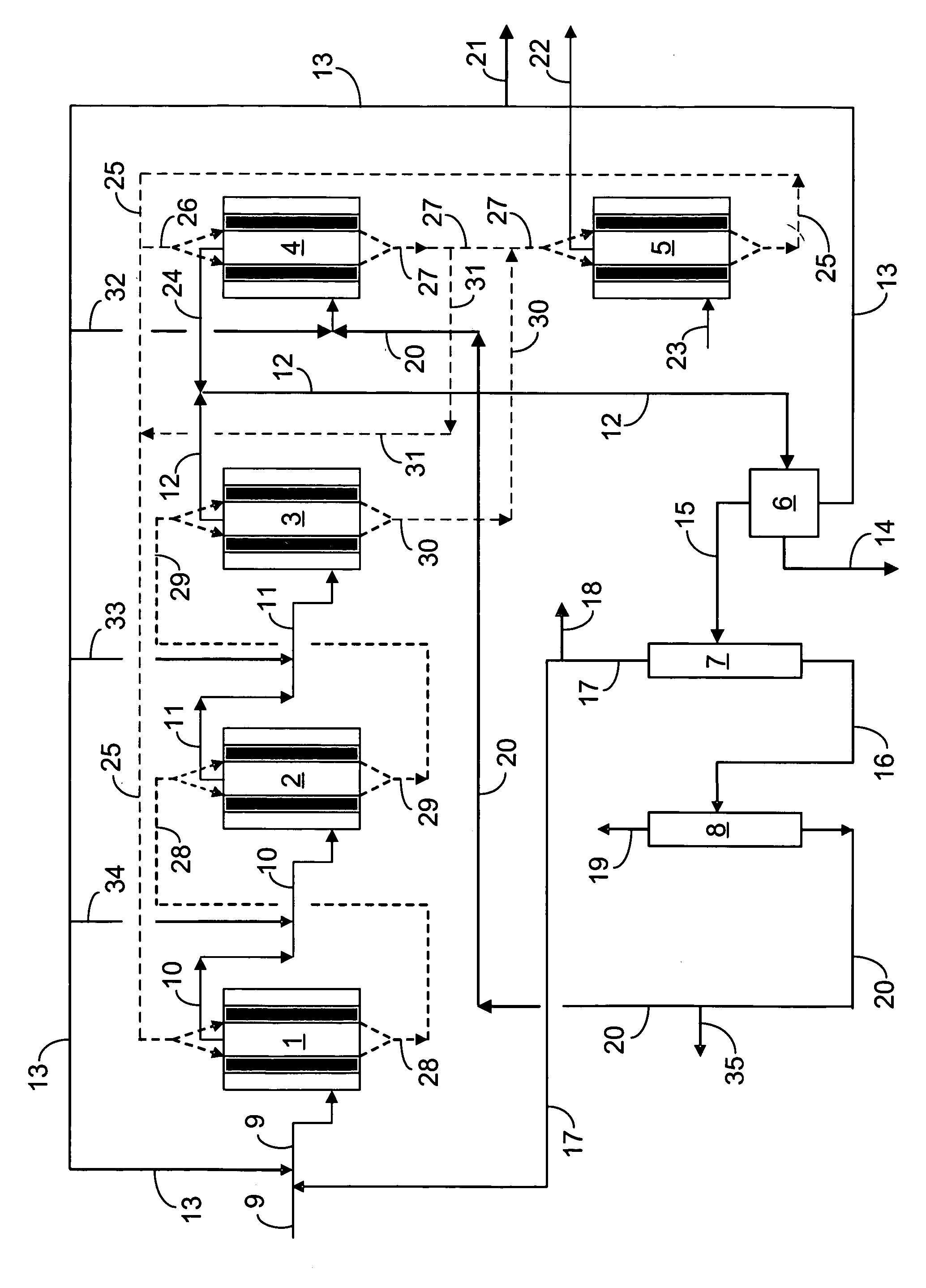

Integrated air separation and oxygen fired power generation system

An integrated air separation and oxygen fired power generation system includes an air separation unit and a gas turbine including an air compressor to provide compressed air for the air separation unit. The system further includes a gas turbine expander and at least one additional turbine to drive the air compressor, as well as at least one combustion unit to provide drive gas for expander and additional turbine(s). A portion of oxygen produced by the air separation unit is delivered to the combustor(s) to facilitate production of drive gas for use by the expander and additional turbine(s). Turbine inlet temperatures are controlled by recycling water or steam to the combustor(s).

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

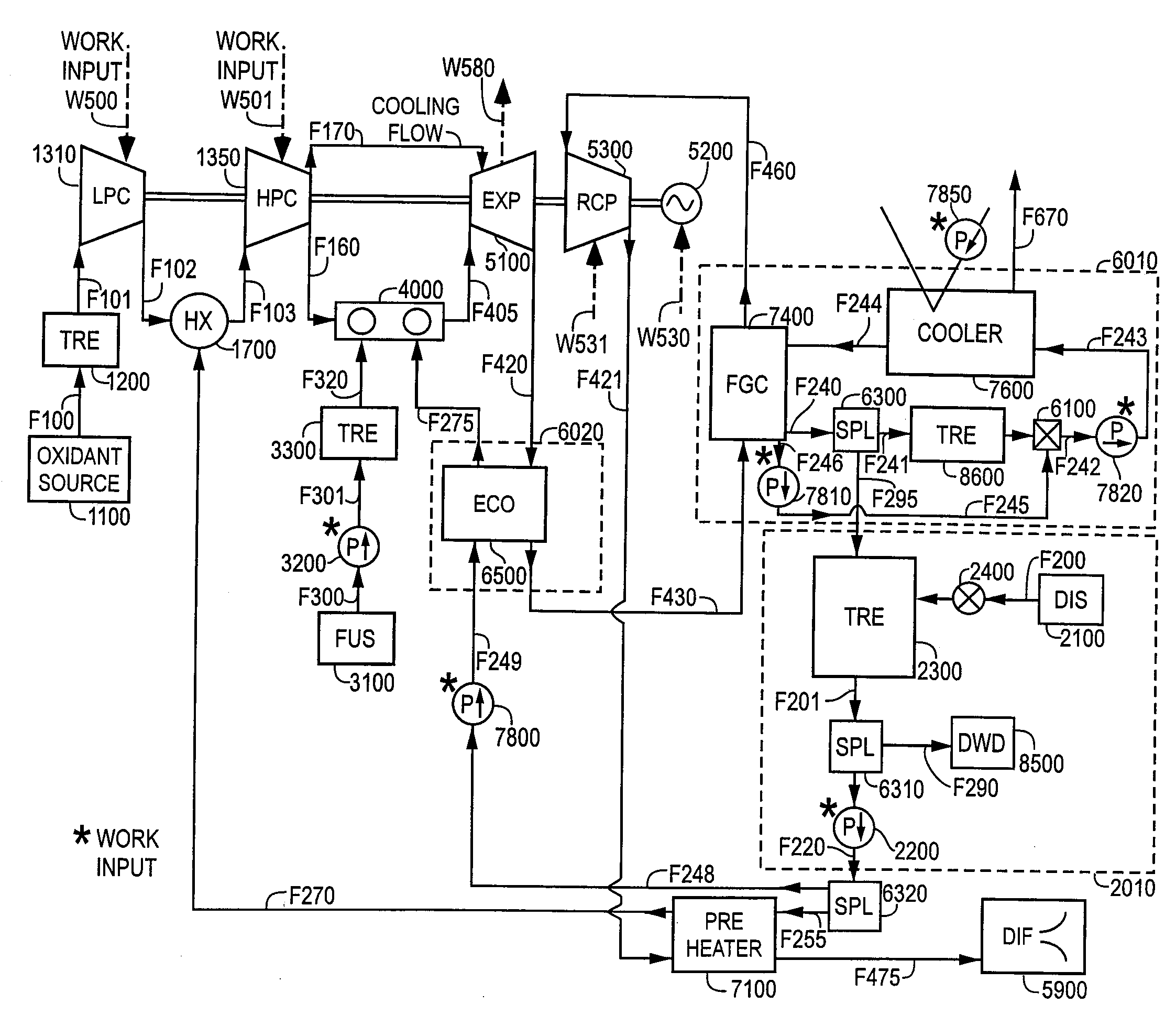

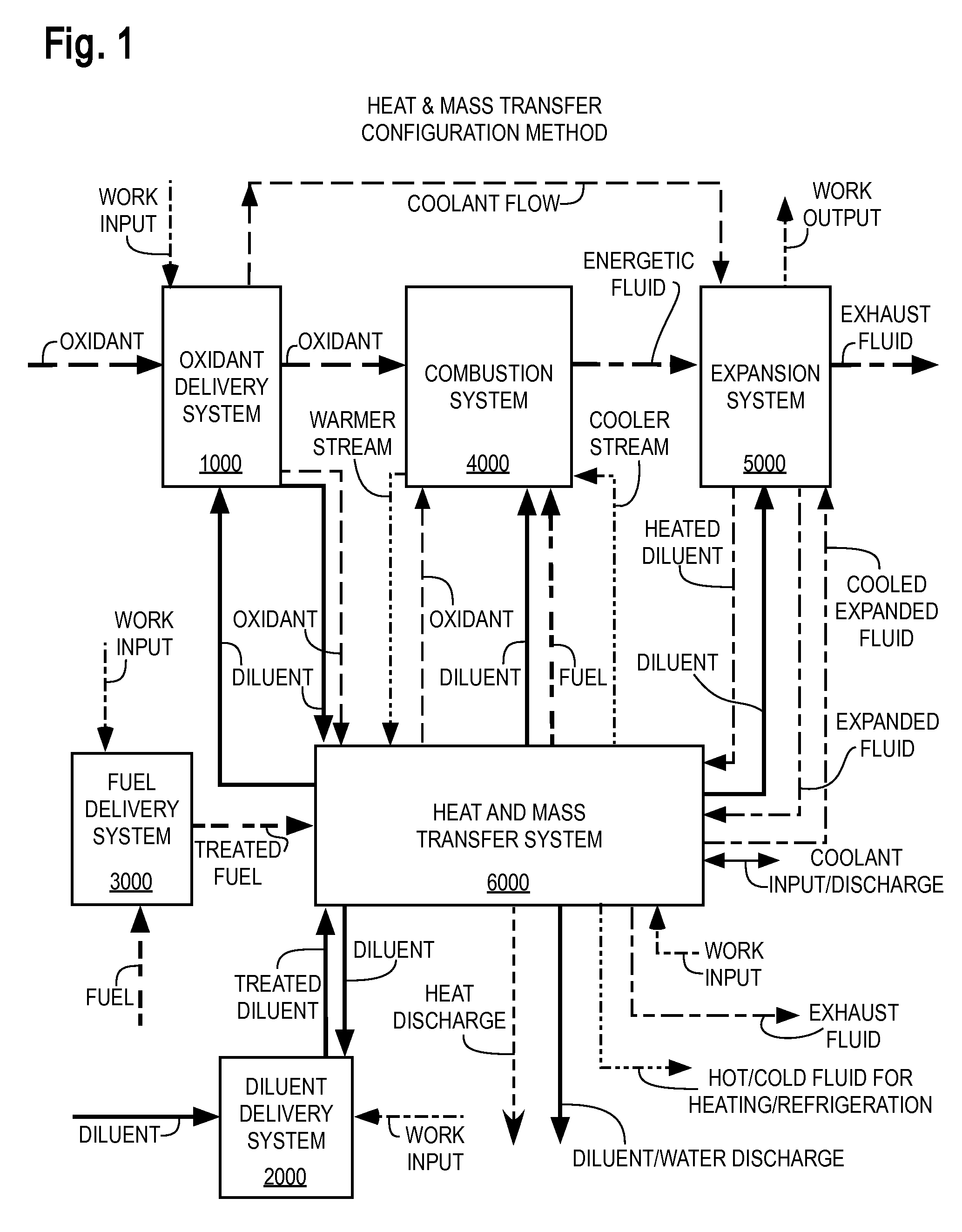

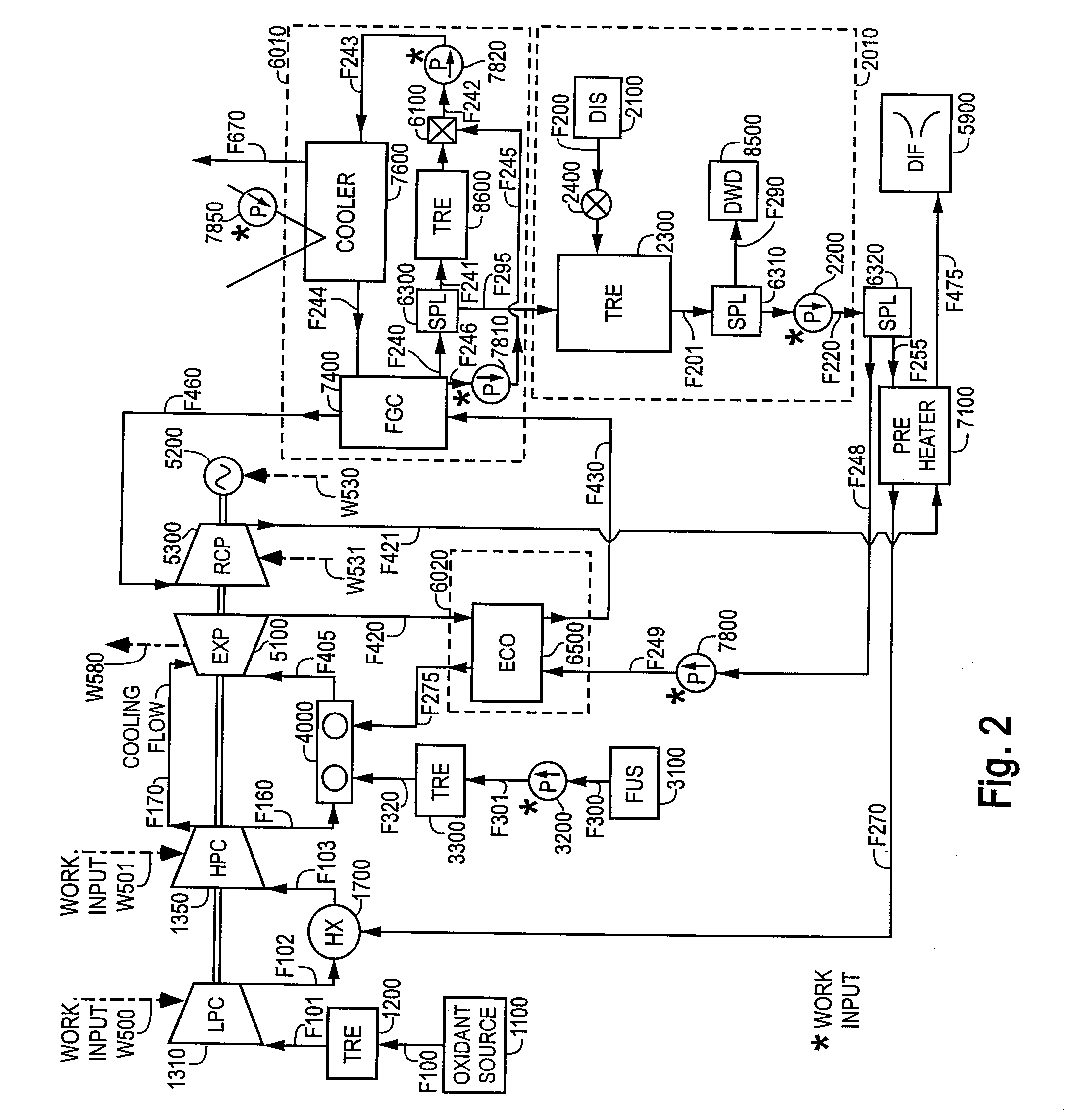

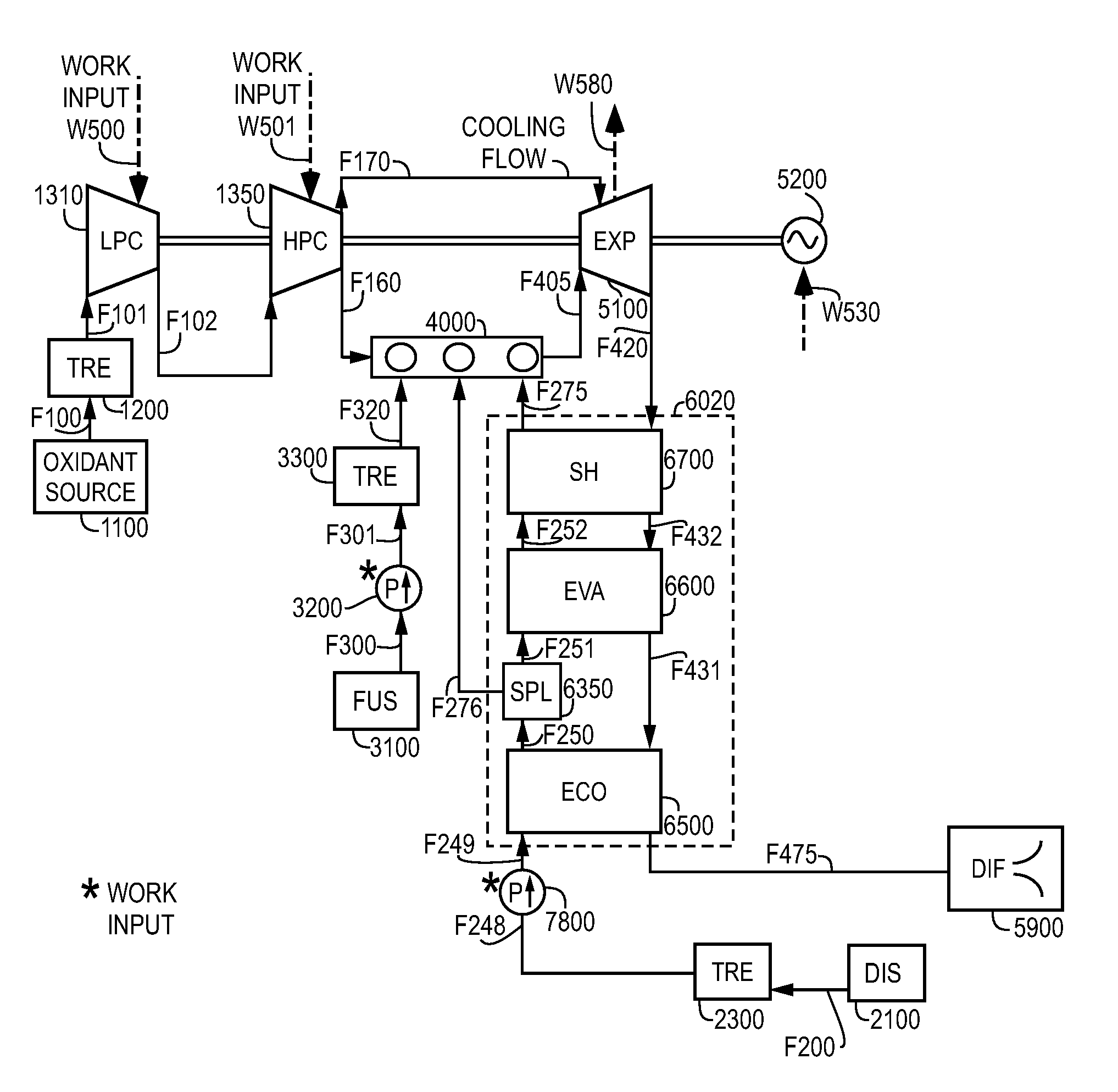

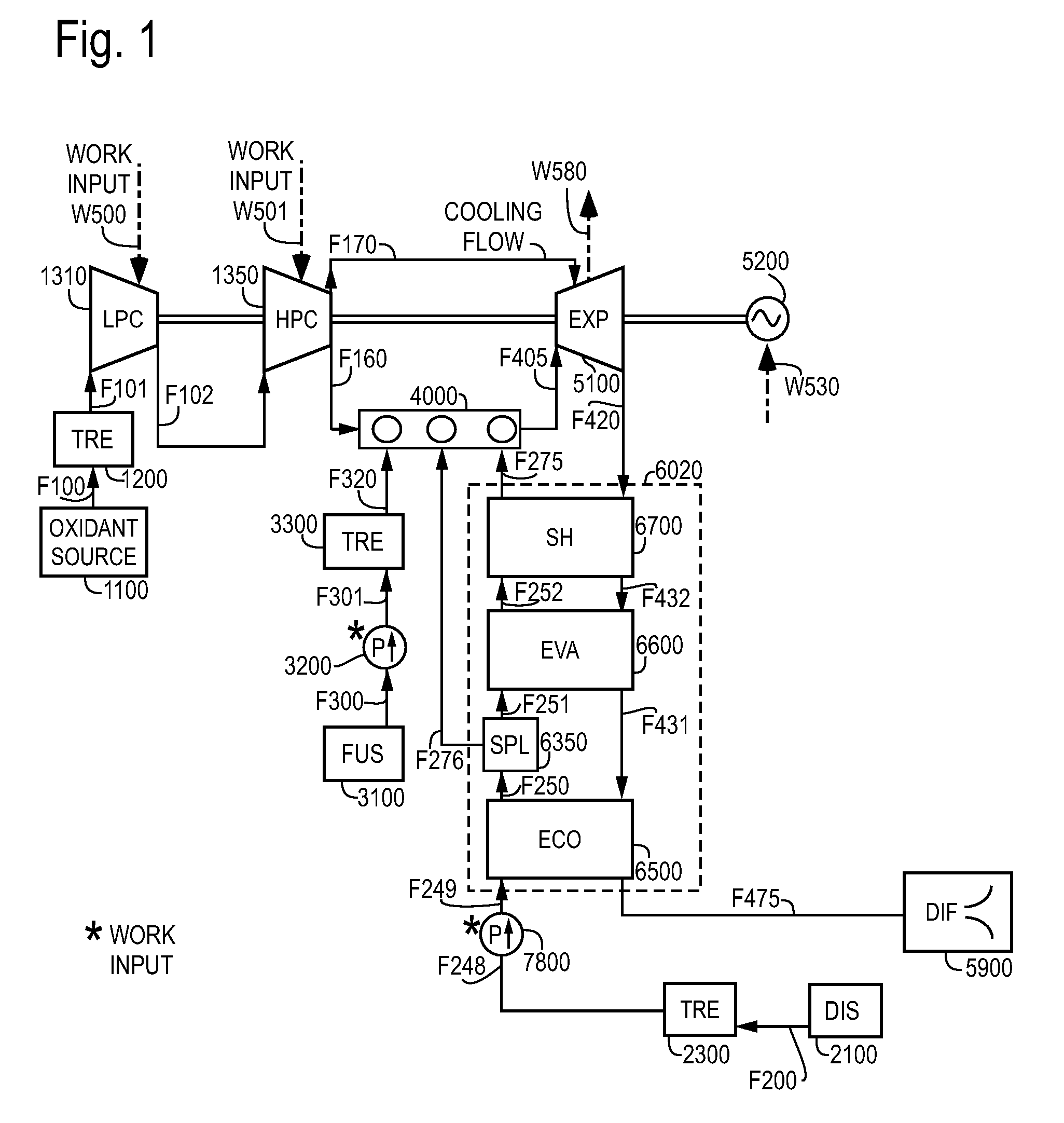

Thermodynamic cycles using thermal diluent

ActiveUS20090071166A1Low costEmission reductionSpace heating and ventilationSulfur compoundsCombustion systemCombustion

A thermodynamic system that produces mechanical, electrical power, and / or fluid streams for heating or cooling. The cycle contains a combustion system that produces an energetic fluid by combustion of a fuel with an oxidant. A thermal diluent may be used in the cycle to improve performance, including but not limited to power, efficiency, economics, emissions, dynamic and off-peak load performance, and / or turbine inlet temperature (TIT) regulation and cooling heated components. The cycle preferably includes a heat recovery system and a condenser or other means to recover and recycle heat and the thermal diluent from the energetic fluid to improve the cycle thermodynamic efficiency and reduce energy conversion costs. The cycle may also include controls for temperatures, pressures, and flow rates throughout the cycle, and controls power output, efficiency, and energetic fluid composition.

Owner:VAST HLDG LLC

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS20060161035A1Improve economyEfficient OTP processMolecular sieve catalystCatalystsFixed bedOxygenate

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

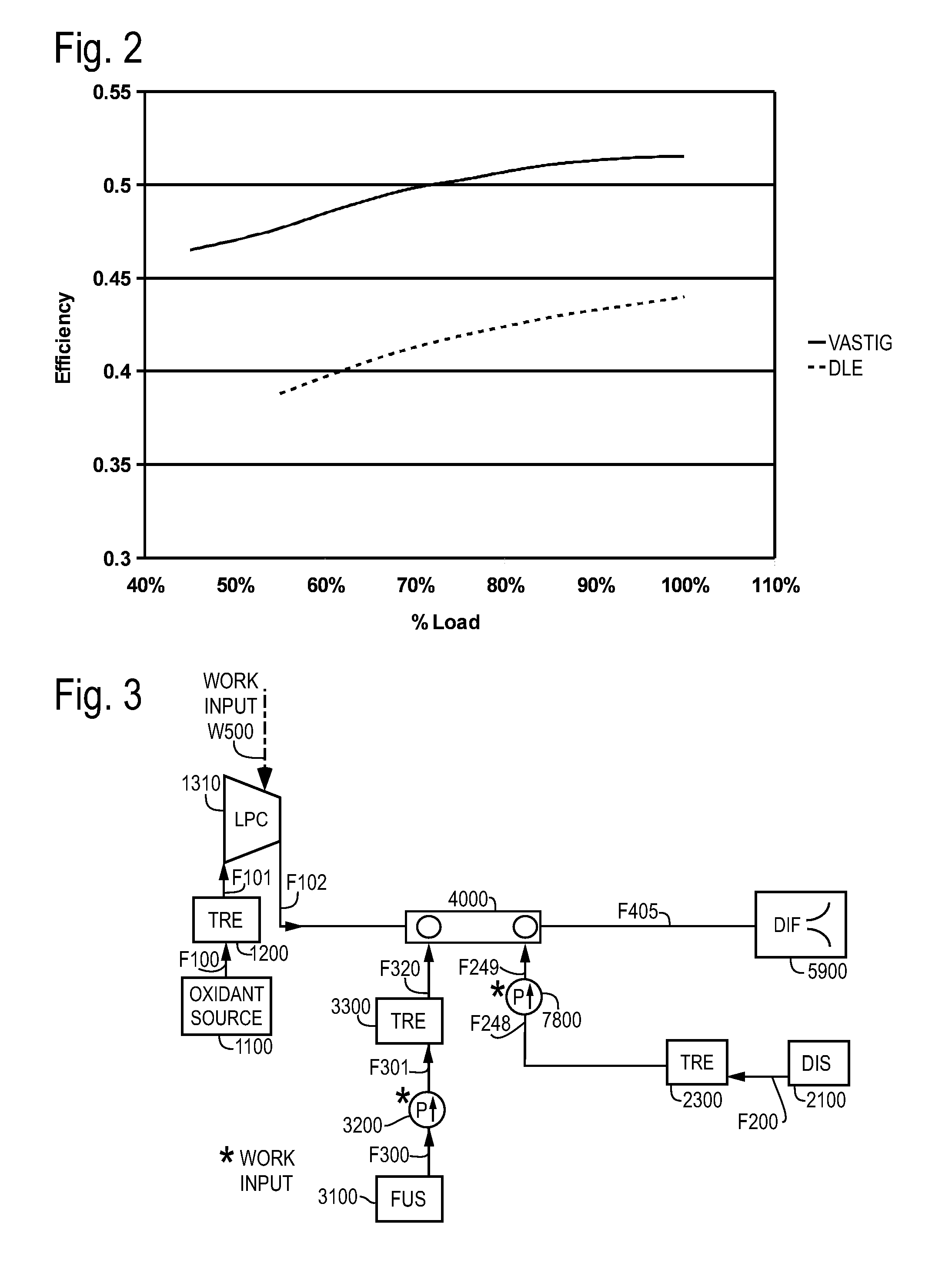

Partial load combustion cycles

ActiveUS20090064653A1Improve efficiencyReduced Power RequirementsGas turbine plantsVehicle heating/cooling devicesBrayton cycleCombustion

The part load method controls delivery of diluent fluid, fuel fluid, and oxidant fluid in thermodynamic cycles using diluent, to increase the Turbine Inlet Temperature (TIT) and thermal efficiency in part load operation above that obtained by relevant art part load operation of Brayton cycles, fogged Brayton cycles, or cycles operating with some steam delivery, or with maximum steam delivery. The part load method may control the TIT at the design level by controlling one or both of liquid and / or gaseous fluid water over a range from full load to less than 45% load. This extends operation to lower operating loads while providing higher efficiencies and lower operating costs using water, steam and / or CO2 as diluents, than in simple cycle operation.

Owner:VAST HLDG LLC

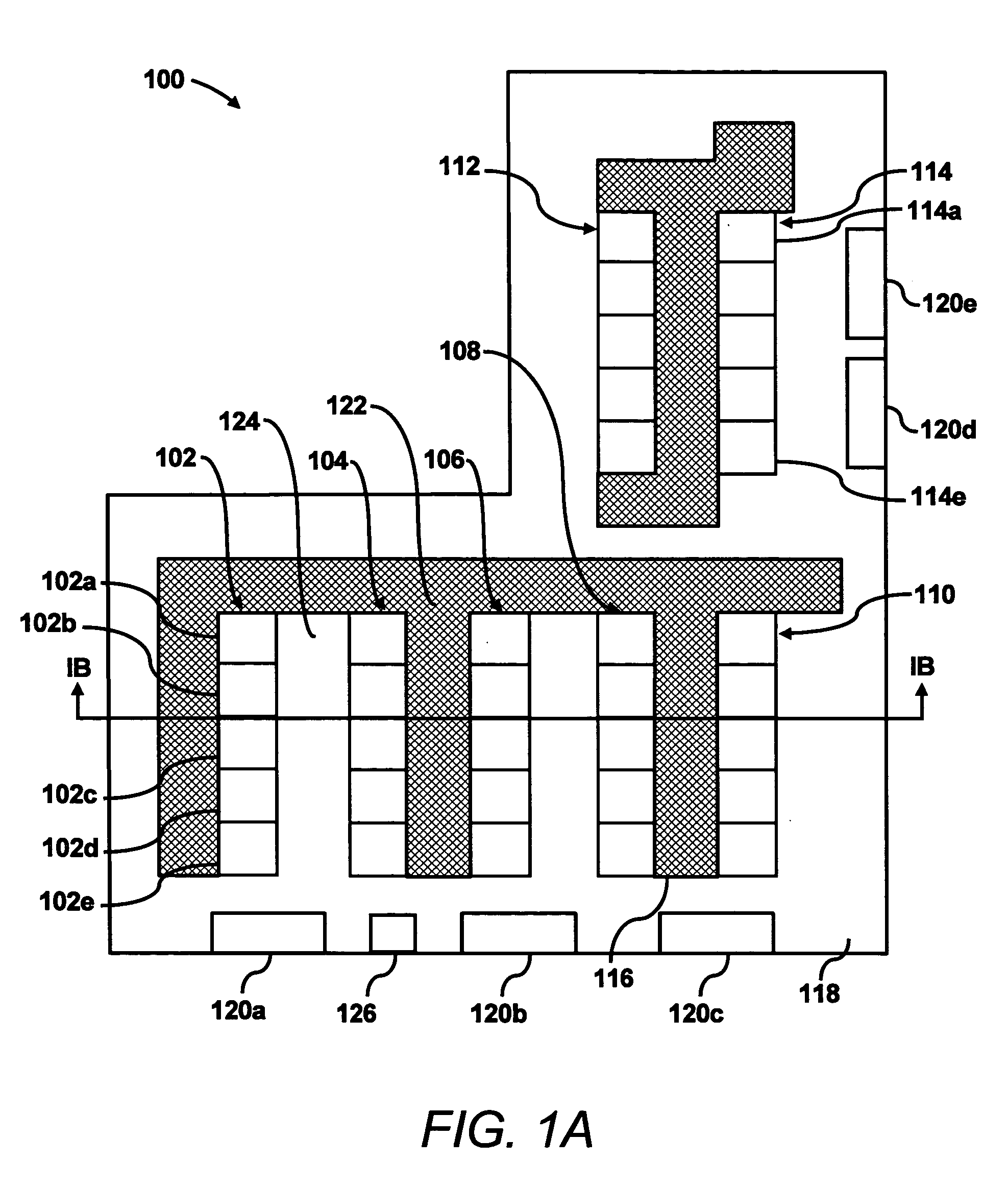

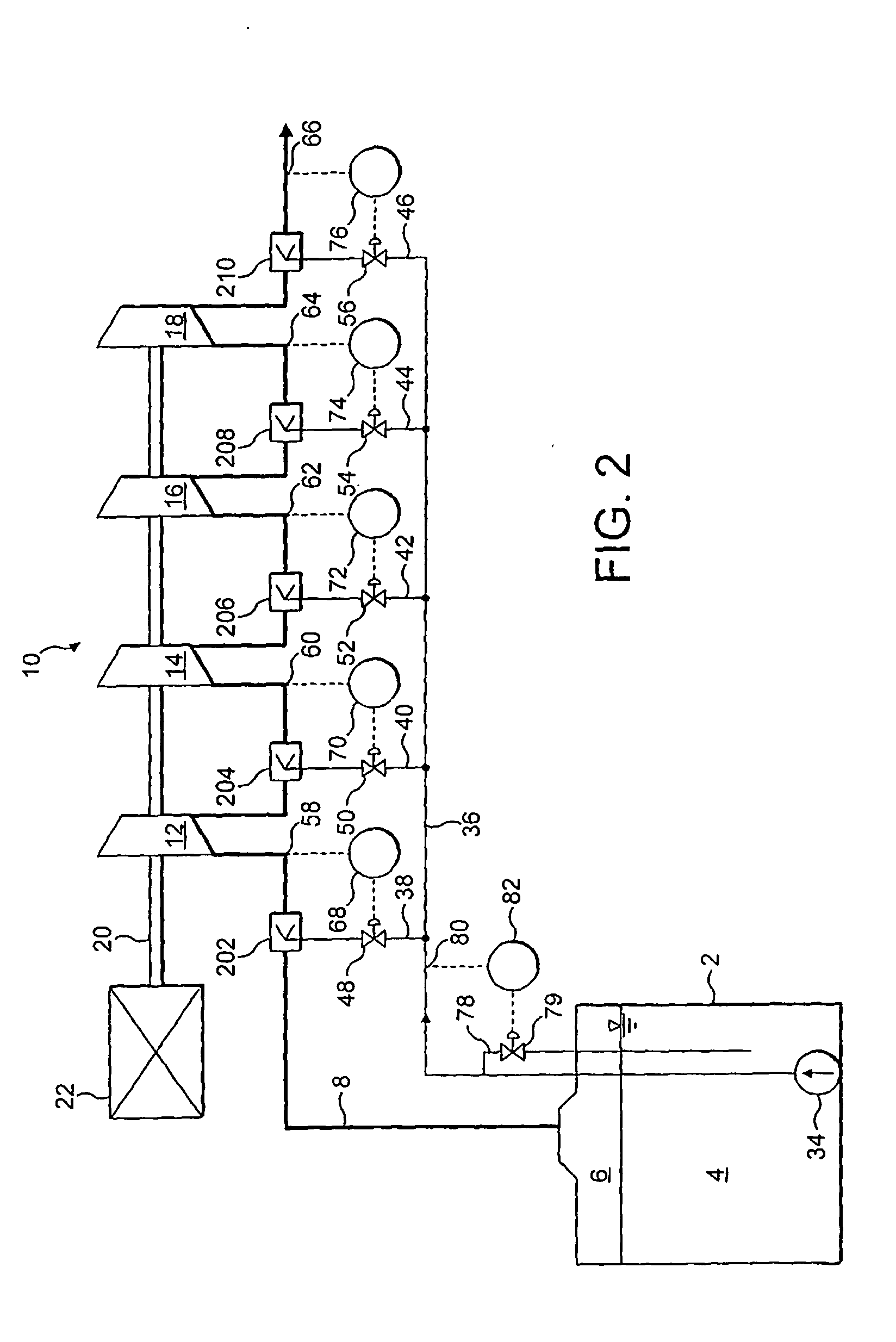

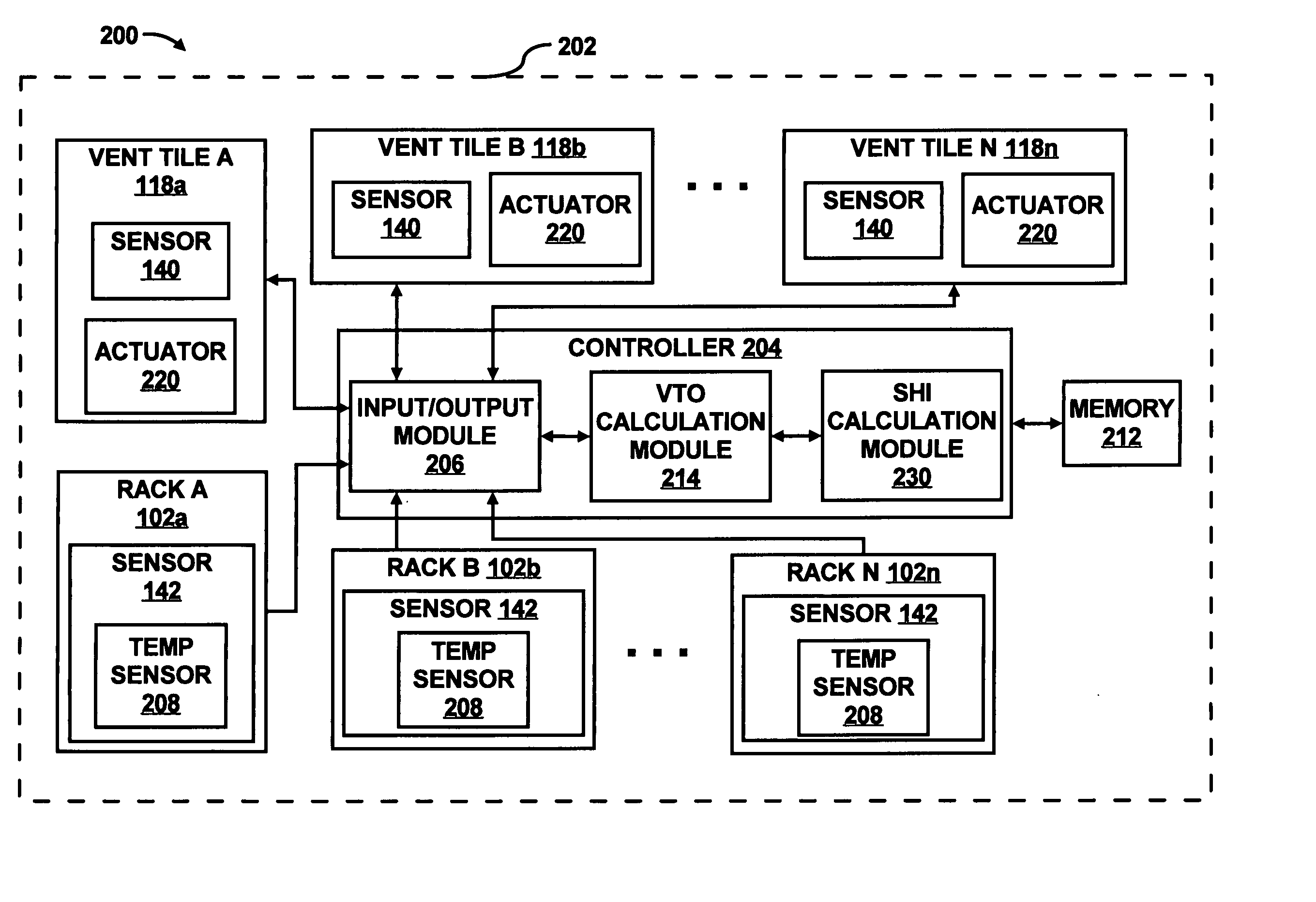

Correlation of vent tile settings and rack temperatures

Owner:VALTRUS INNOVATIONS LTD +1

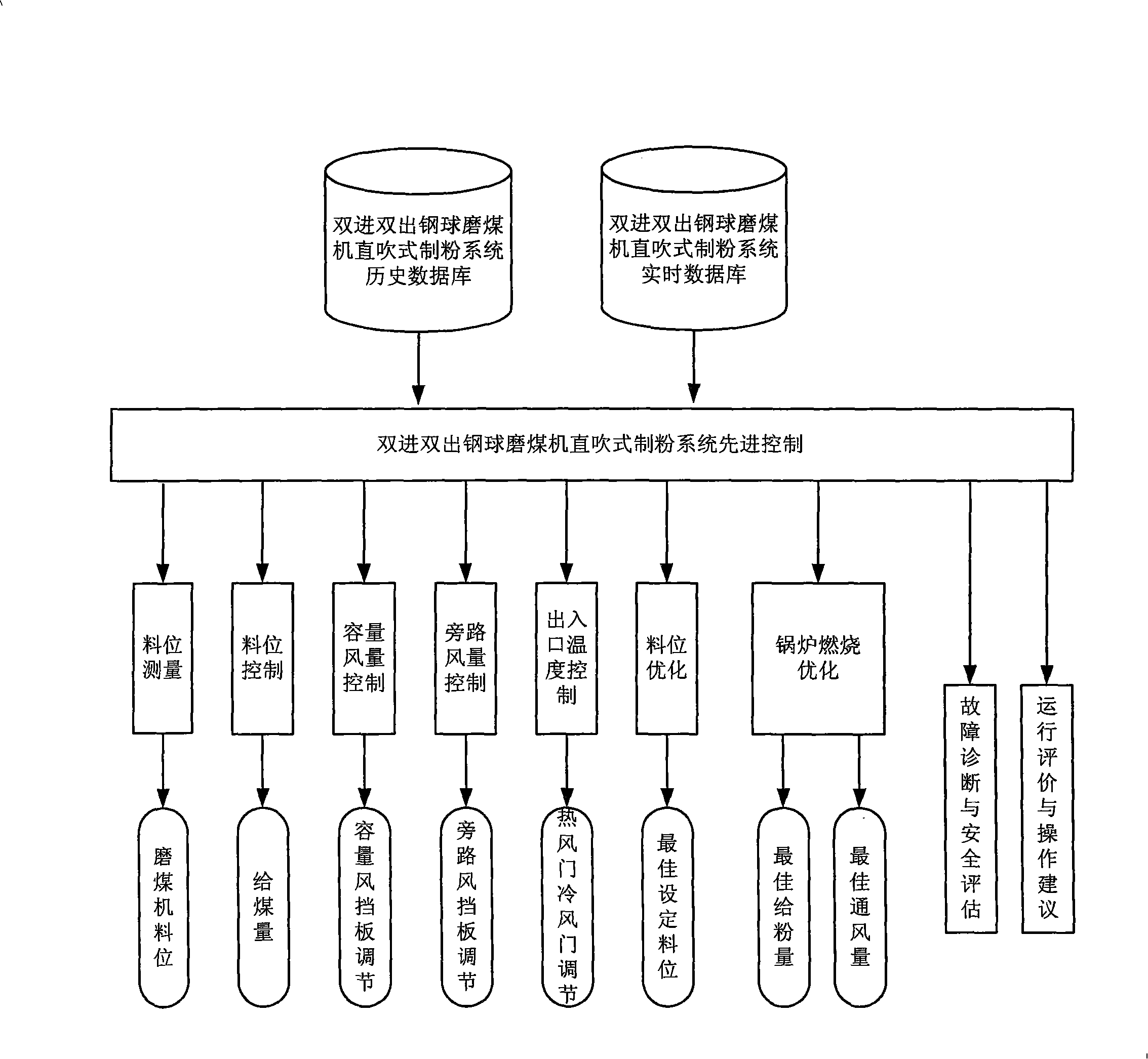

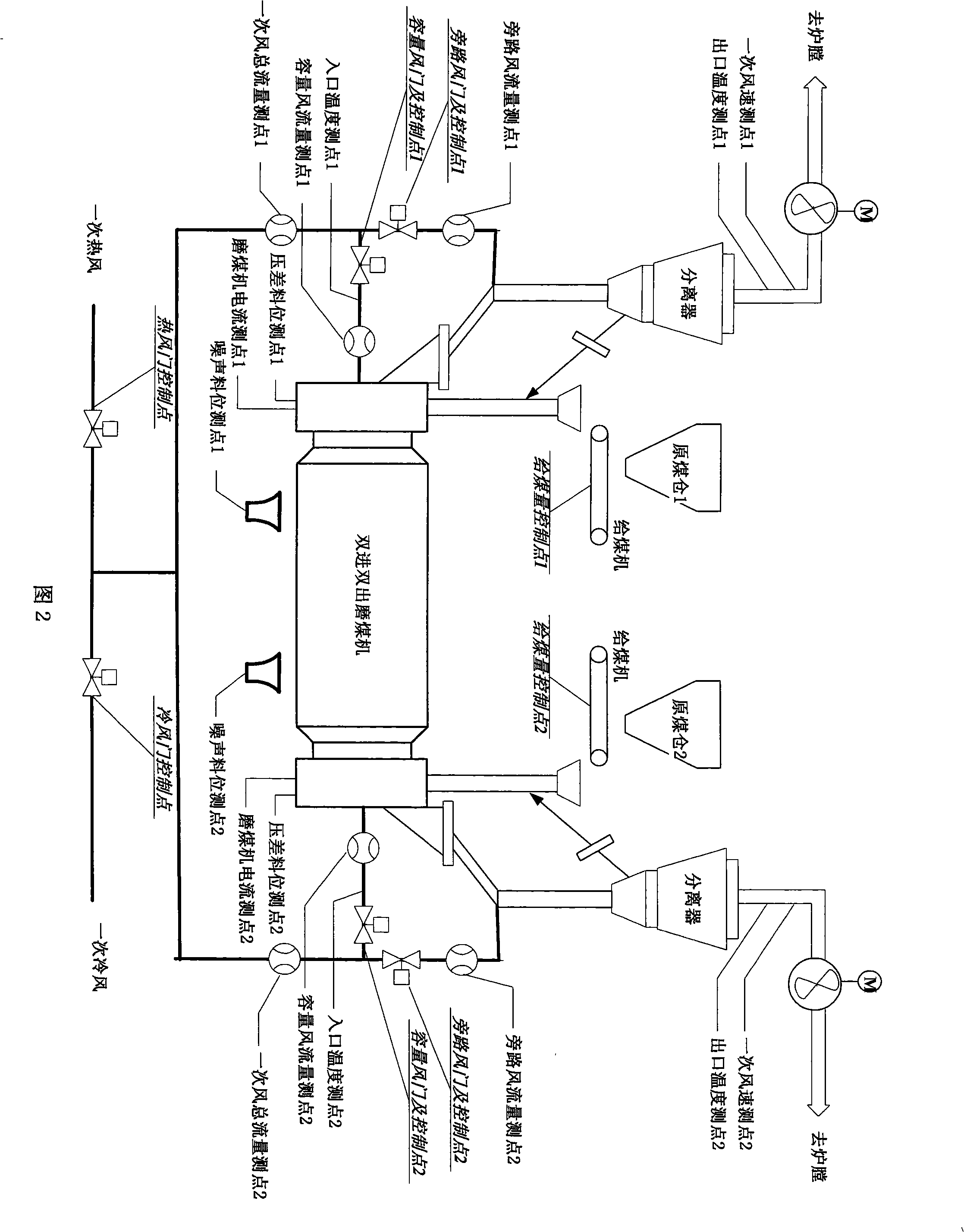

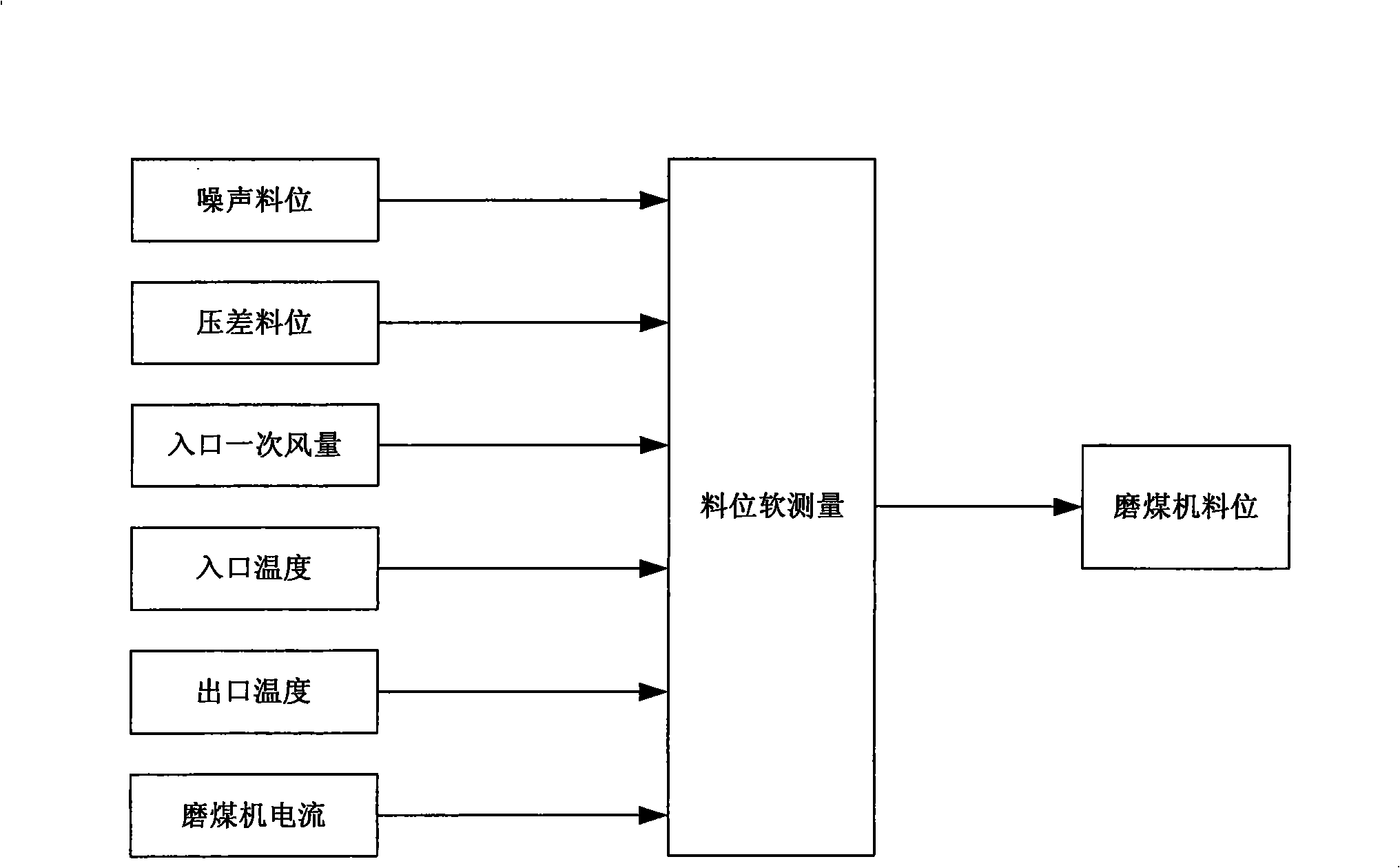

Double-inlet double-outlet steel ball coal mill straight blowing type milling system optimized control method

ActiveCN101334666AImprove combustion efficiencyGuaranteed uniformityGrain treatmentsProgramme total factory controlTemperature controlCombustion

The invention discloses an optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method. The method obtains the material position of the coal grinding machine after carrying out soft-measurement processing by collecting the noise material position of the coal grinding machine, the material position of pressure difference, the current of the coal grinding machine, one-time air quantity, one-time opening of the hot wind door and the cold wind door of an inlet, inlet temperature and outlet temperature; the control comprises material position control, air quantity capacity control, bypass air quantity control and the temperature control of the inlet and the outlet; the material position is optimized and the best material position of the coal grinding machine is searched online so as to ensure the combustion safety of the boiler and coal powder supply quantity when the load of the boiler is adjusted. The boiler combustion is optimized: according to the boiler technology, the load and the running working conditions, the powder supply quantity and the ventilation quantity of each coal grinding machine are optimized and the combustion efficiency of the boiler is improved. Malfunction diagnosis, running evaluation and analysis are carried out to the system and reasonable suggestions are provided so as to ensure the system to run continuously, stably, safely and economically; the optimum dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation control method is widely applied to the dual-inlet and dual-outlet steel ball coal grinding machine direct-blow type powder-preparation system or industrial similar systems in other industries.

Owner:西安蓝海机械仪表成套有限责任公司

Recuperated gas turbine engine system and method employing catalytic combustion

InactiveUS20050022499A1Increase flow rateReduce the temperatureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorCold weather

A recuperated gas turbine engine system and associated method employing catalytic combustion, wherein the combustor inlet temperature can be controlled to remain above the minimum required catalyst operating temperature at a wide range of operating conditions from full-load to part-load and from hot-day to cold-day conditions. The fuel is passed through the compressor along with the air and a portion of the exhaust gases from the turbine. The recirculated exhaust gas flow rate is controlled to control combustor inlet temperature.

Owner:MES INT INC

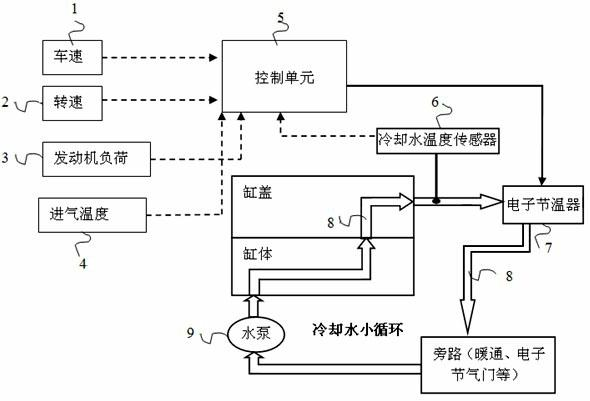

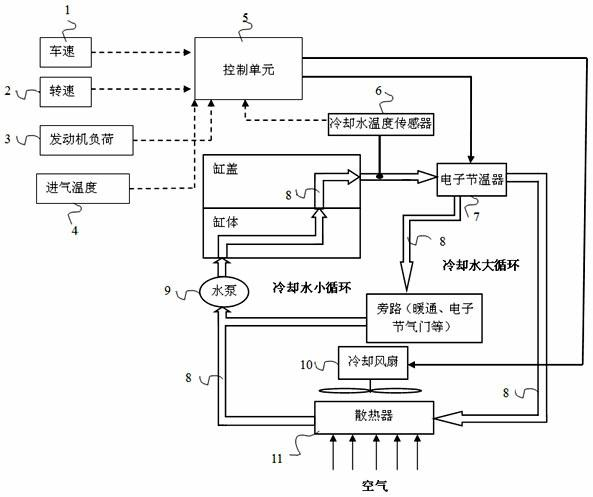

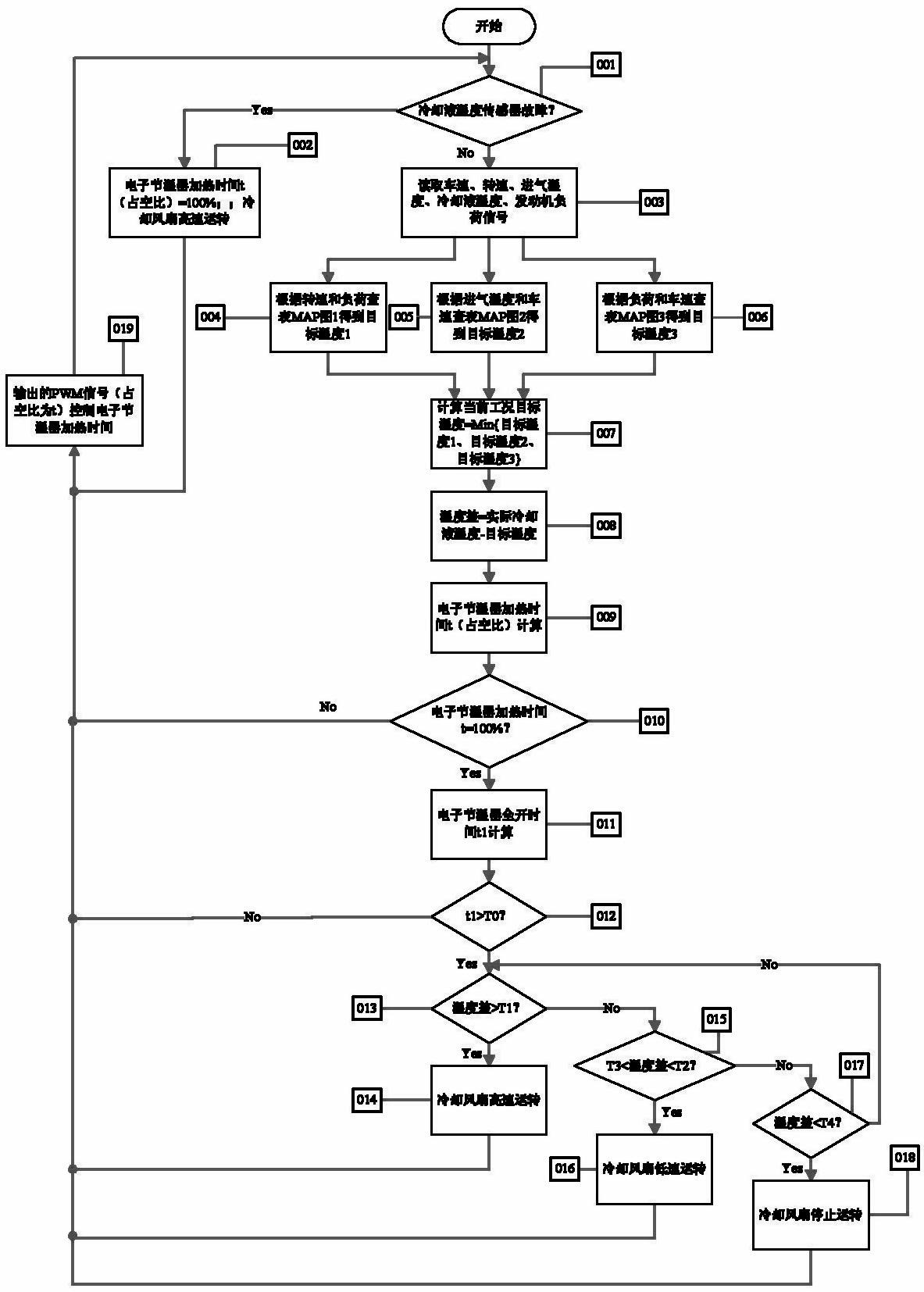

Engine cooling system and temperature control method of cooling liquid thereof

ActiveCN102182540AEmission reductionReduce turn-on timeCoolant flow controlMachines/enginesLow speedLiquid temperature

The invention discloses an engine cooling system and a temperature control method of cooling liquid thereof. The engine cooling system comprises a heat radiator, a water pump, a circulating water jacket, an electronic thermostat, a cooling fan, a cooling liquid temperature sensor and an engine control unit, wherein the control unit determines the cooling liquid target temperature of an engine under the current operation working condition according to acquired signals, such as engine rotating speed, load, speed, air inlet temperature, and the like and ensures that the engine works under the optimal cooling liquid temperature condition by controlling the heating time of the electronic thermostat and the high and low speed running of the cooling fan.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

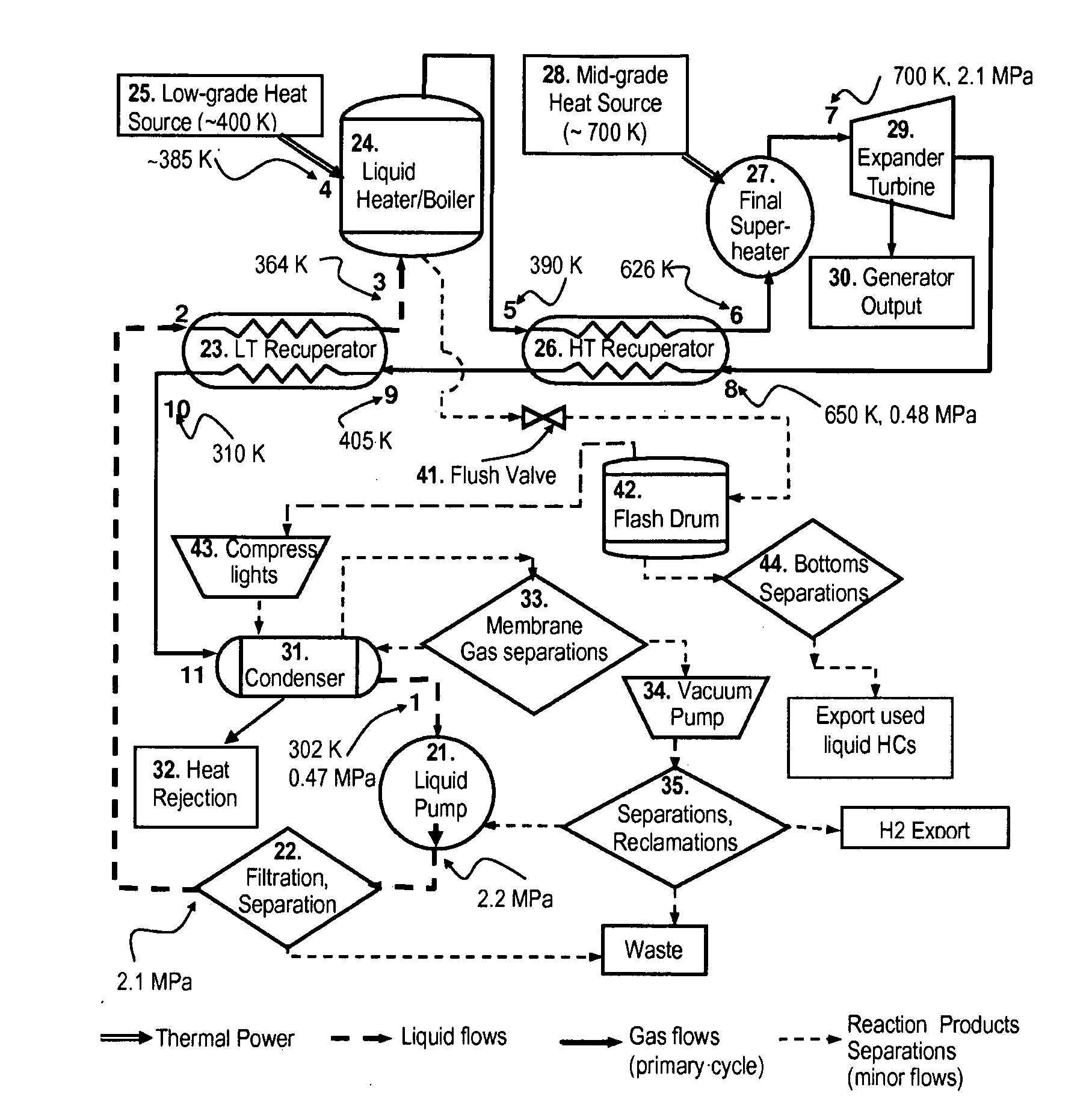

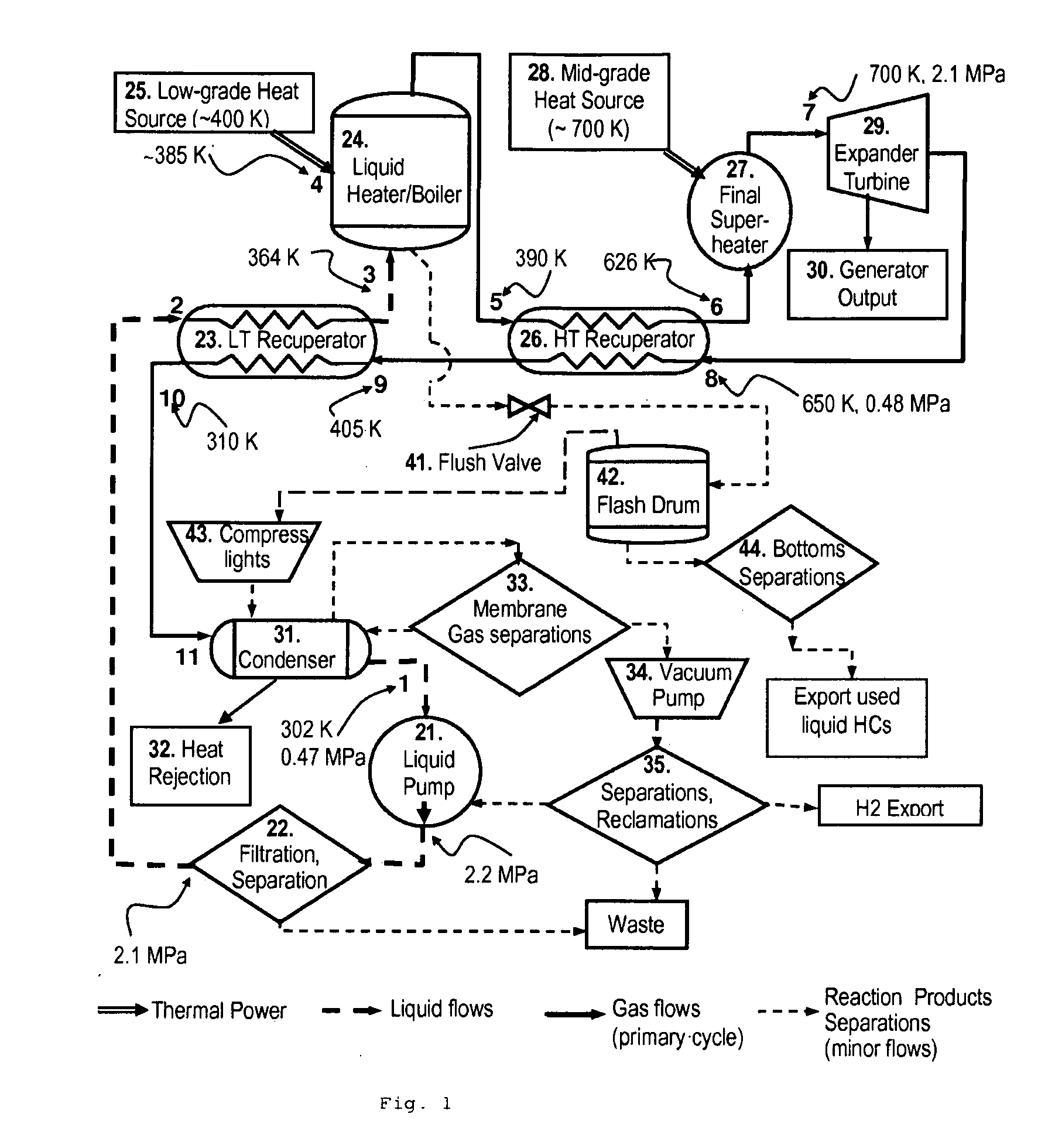

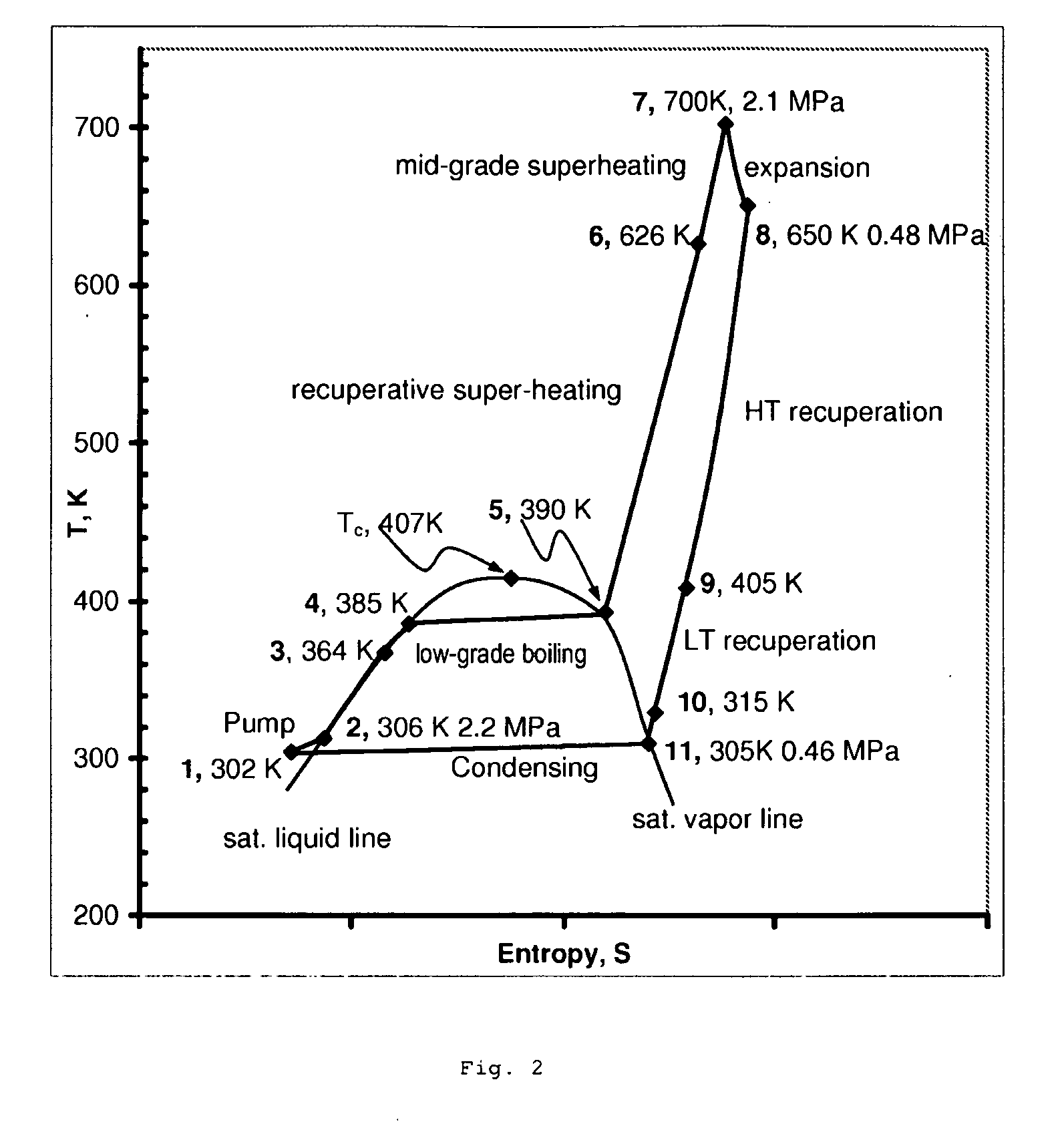

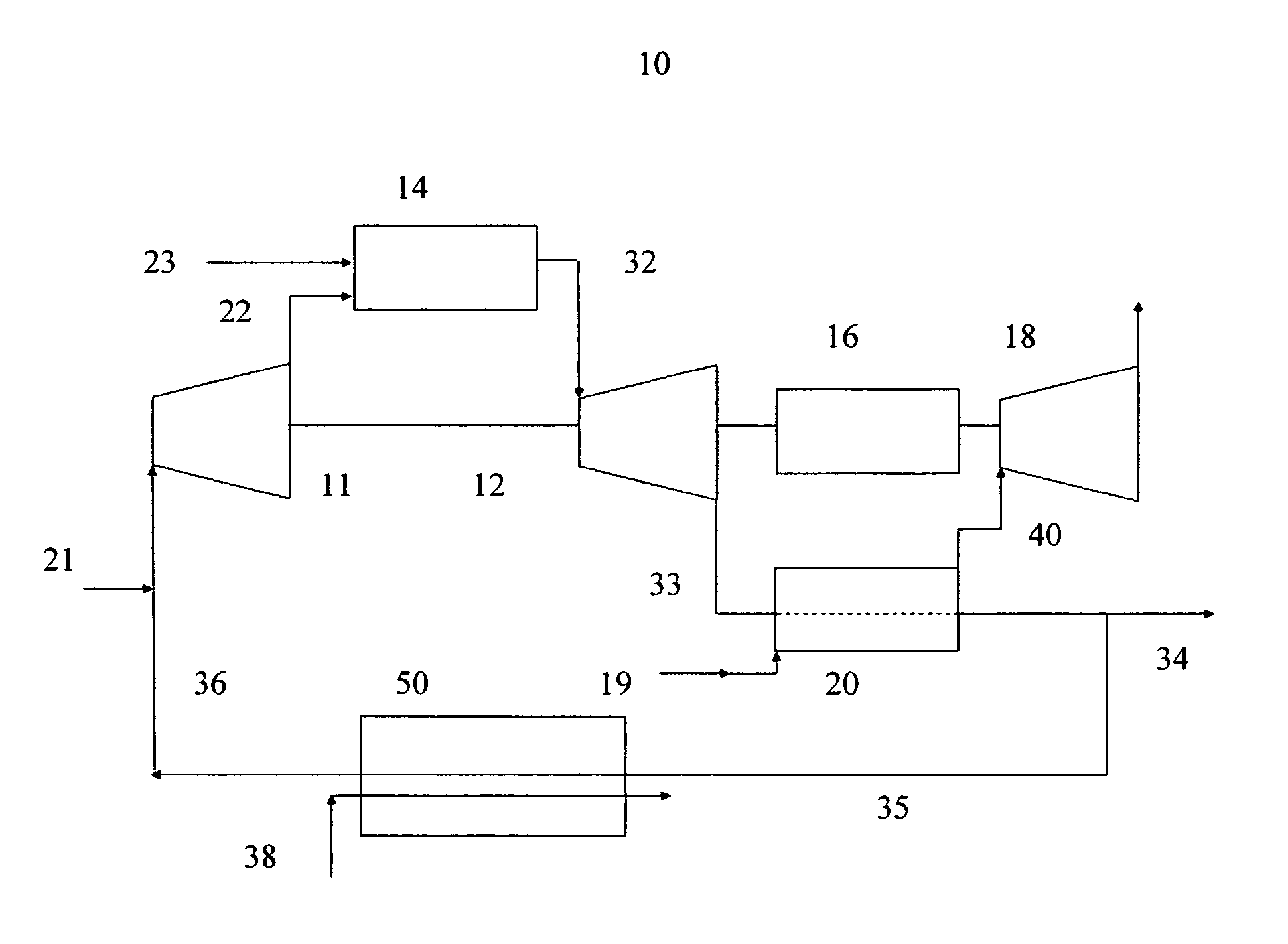

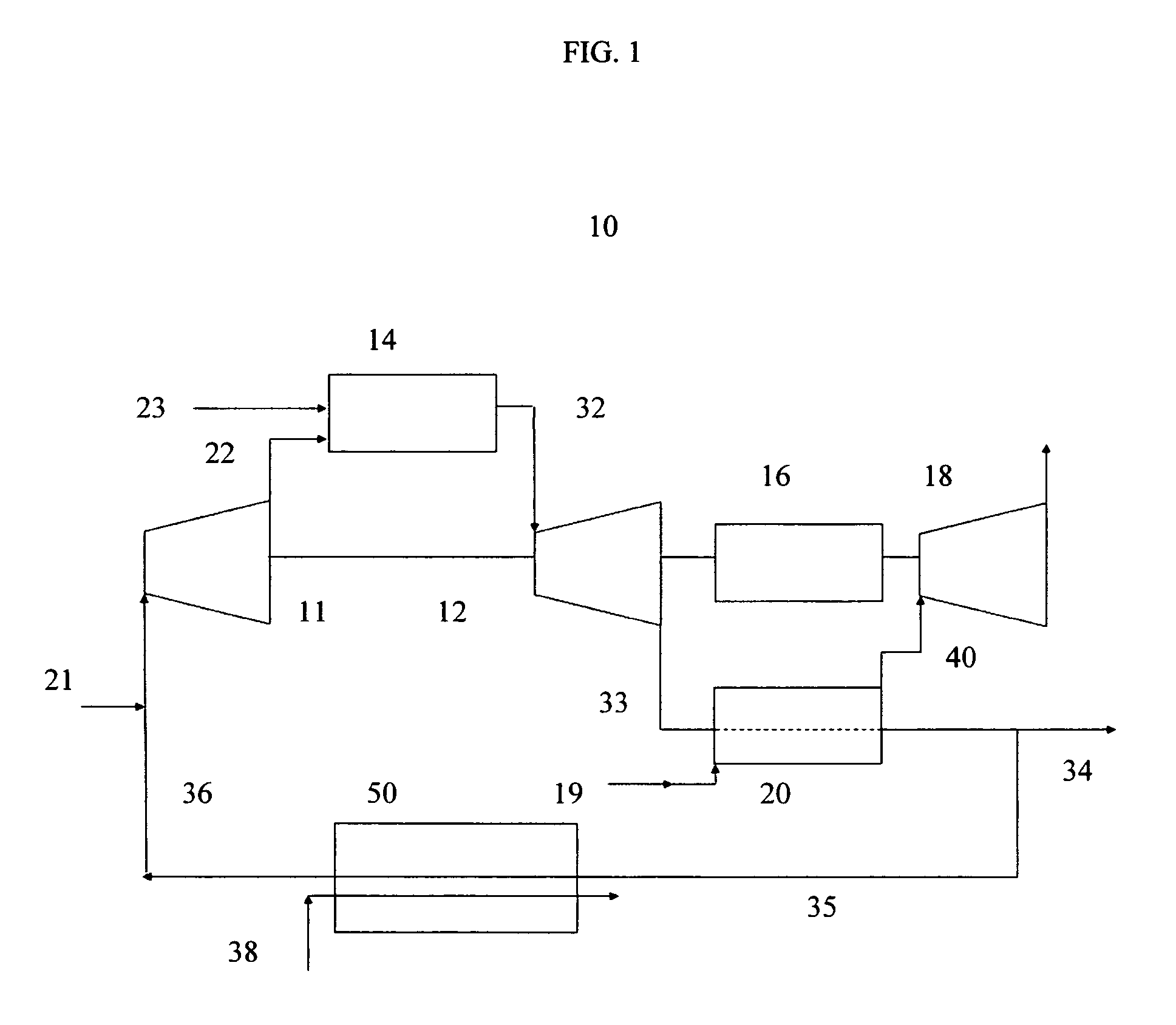

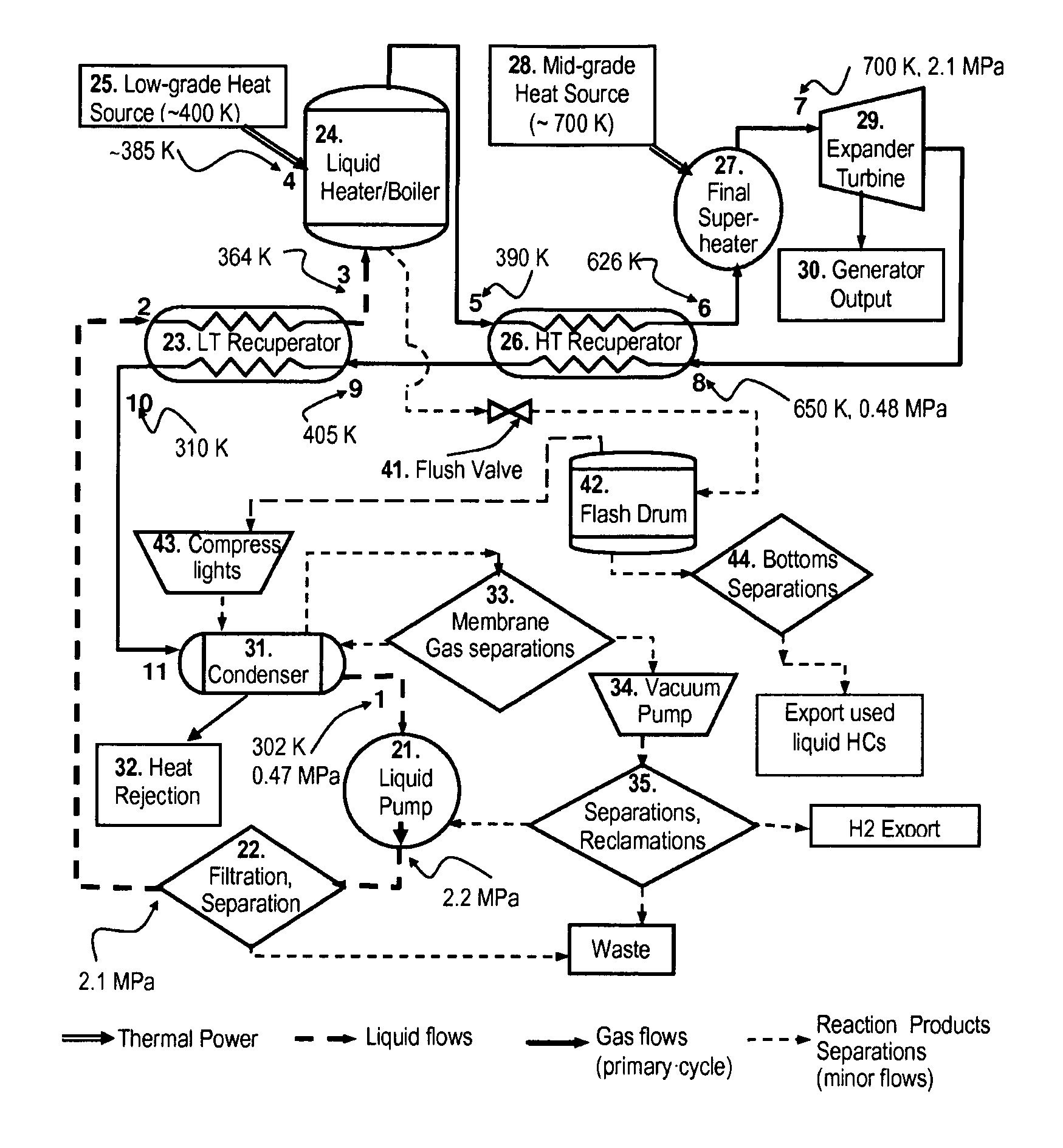

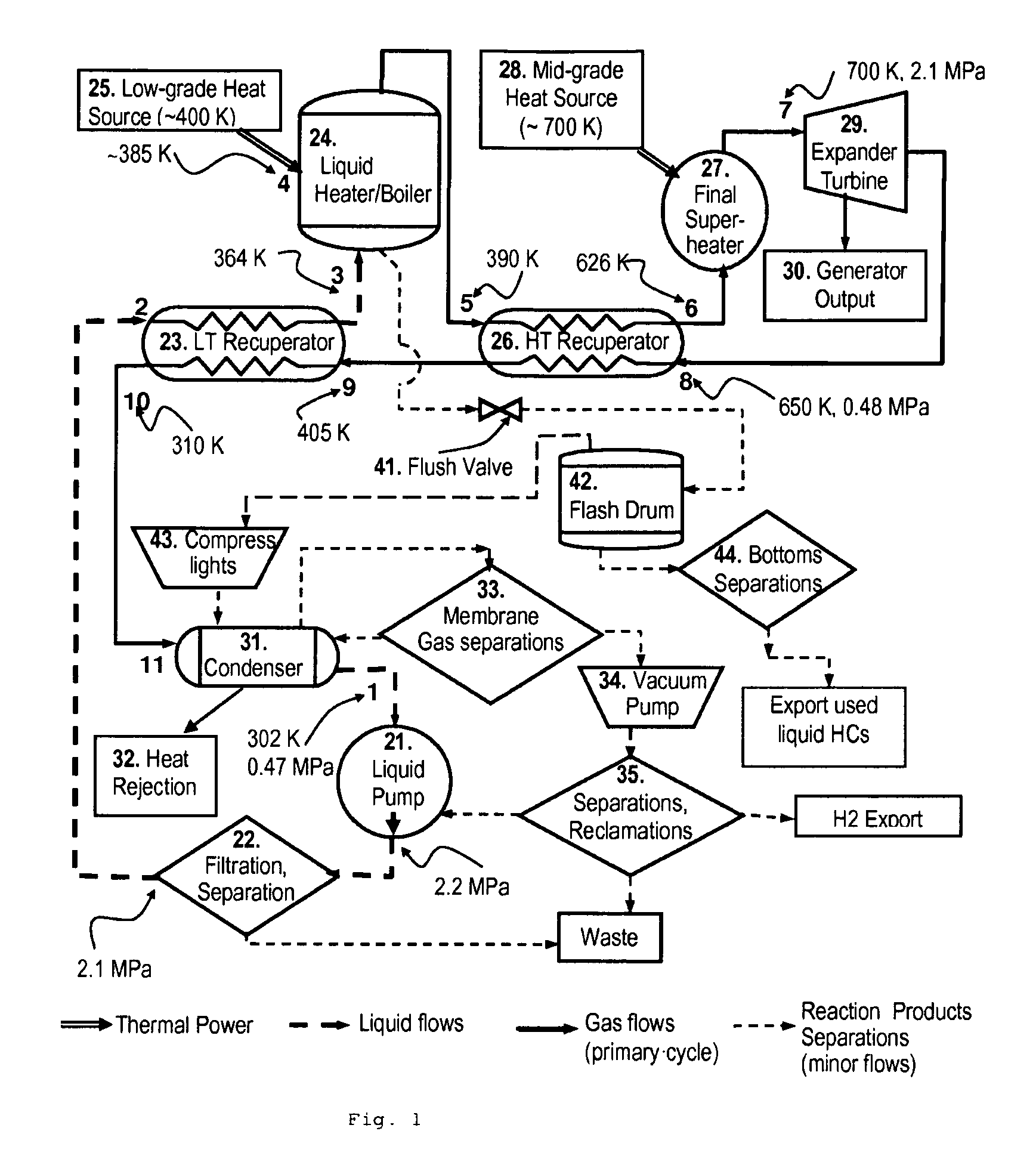

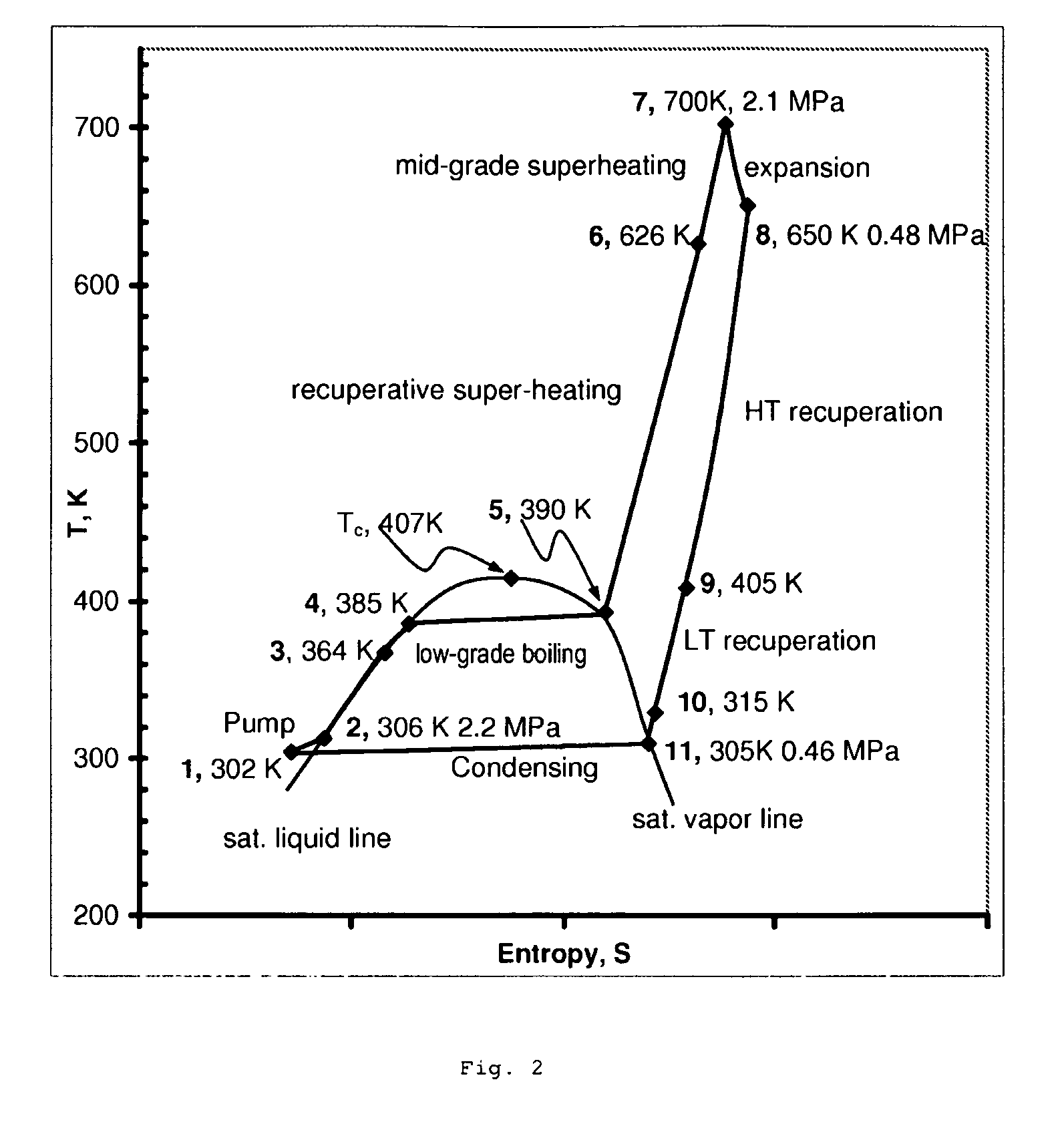

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS20100300093A1Increase temperatureMinimize timeAuxillary drivesInternal combustion piston enginesWorking fluidOrganic Rankine cycle

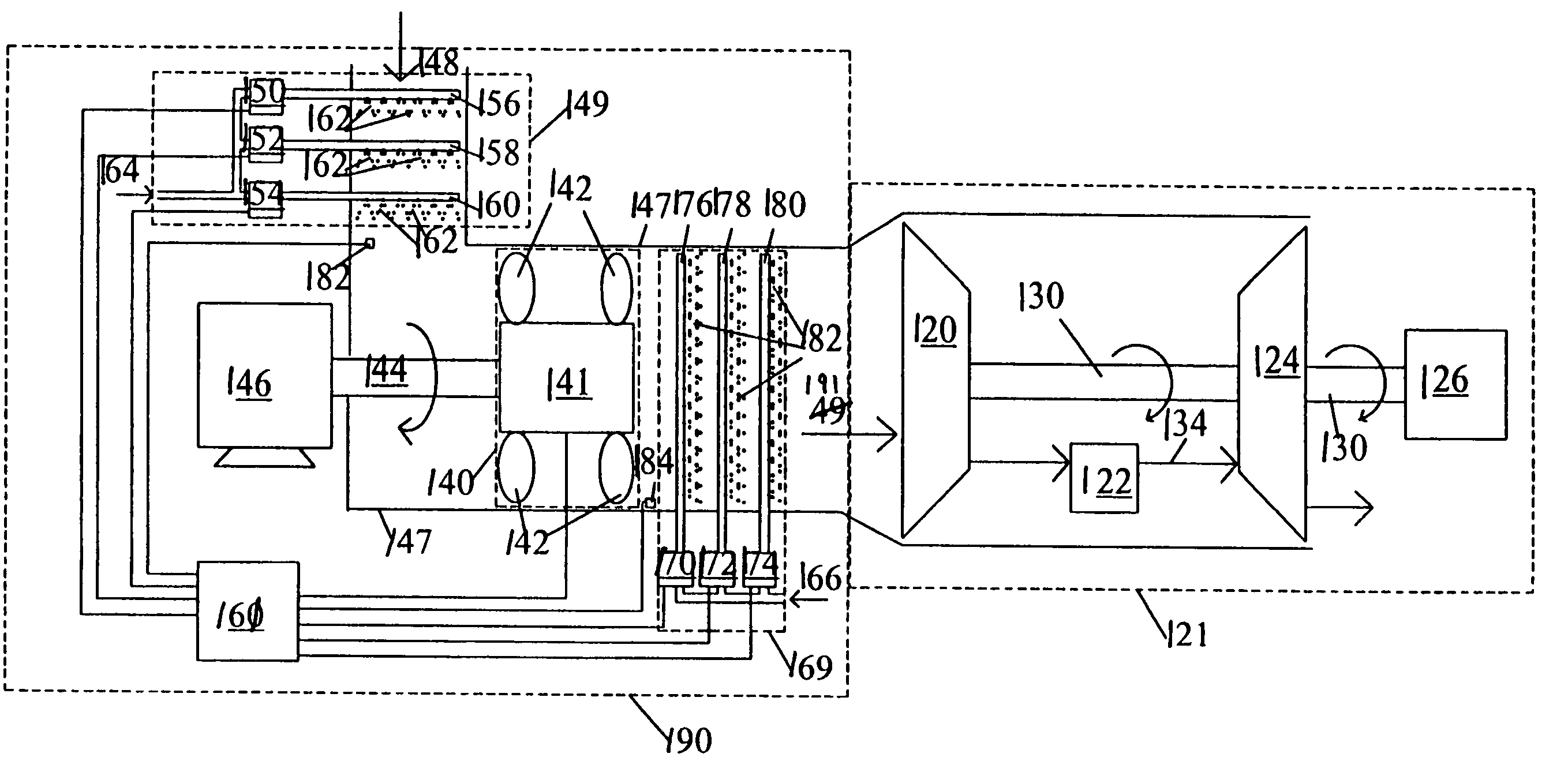

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

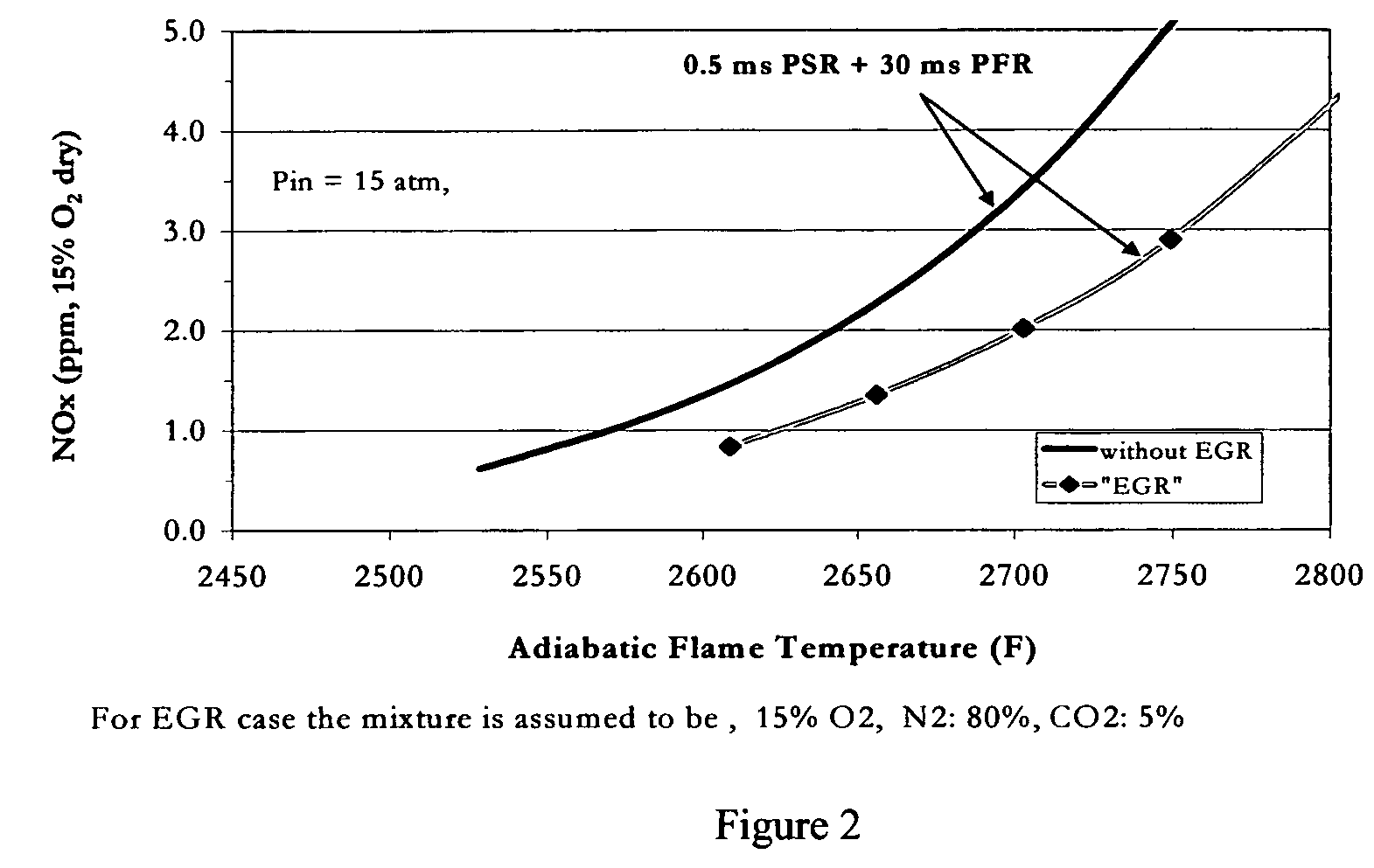

Method for obtaining ultra-low NOx emissions from gas turbines operating at high turbine inlet temperatures

ActiveUS7765810B2Improve combustion stabilityEasy to controlTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionCombustion chamberEquivalence ratio

A method of lowered NOx combustion is taught wherein the kinetic rate of NOx formation is reduced for a given combustion temperature in a gas turbine combustor. A supply of fuel is provided along with a supply of ambient air in sufficient quantity to form a fuel / air mixture having an equivalence ratio greater than about 0.55 when mixed with the fuel. The fuel / air mixture is mixed with a supply of cooled combustion gases in sufficient quantity such that the oxygen content of the resulting air mixture is less than about 18 percent. The resulting air mixture is then passed into the combustor.

Owner:PRECISION COMBUSTION

High-temperature dual-source organic Rankine cycle with gas separations

InactiveUS8046999B2Increase temperatureMinimize timeAuxillary drivesFrom solar energyWorking fluidOrganic Rankine cycle

In a dual-source organic Rankine cycle (DORC), the condensed and slightly sub-cooled working fluid at near ambient temperature (˜300 K) and at low-side pressure (0.1 to 0.7 MPa) is (1) pumped to high-side pressure (0.5-5 MPa), (2) pre-heated in a low-temperature (LT) recuperator, (3) boiled using a low-grade heat source, (4) super-heated in a high-temperature (HT) recuperator to a temperature close to the expander turbine exhaust temperature using this exhaust vapor enthalpy, (5) further super-heated to the turbine inlet temperature (TIT) using a mid-grade heat source, (6) expanded through a turbine expander to the low-side pressure, (7) cooled through the HT recuperator, (8) cooled through the LT recuperator, (9) mostly liquefied and slightly subcooled in a condenser, and (10) the condensed portion is returned to the pump to repeat this cycle.

Owner:DOTY SCI

Compressor

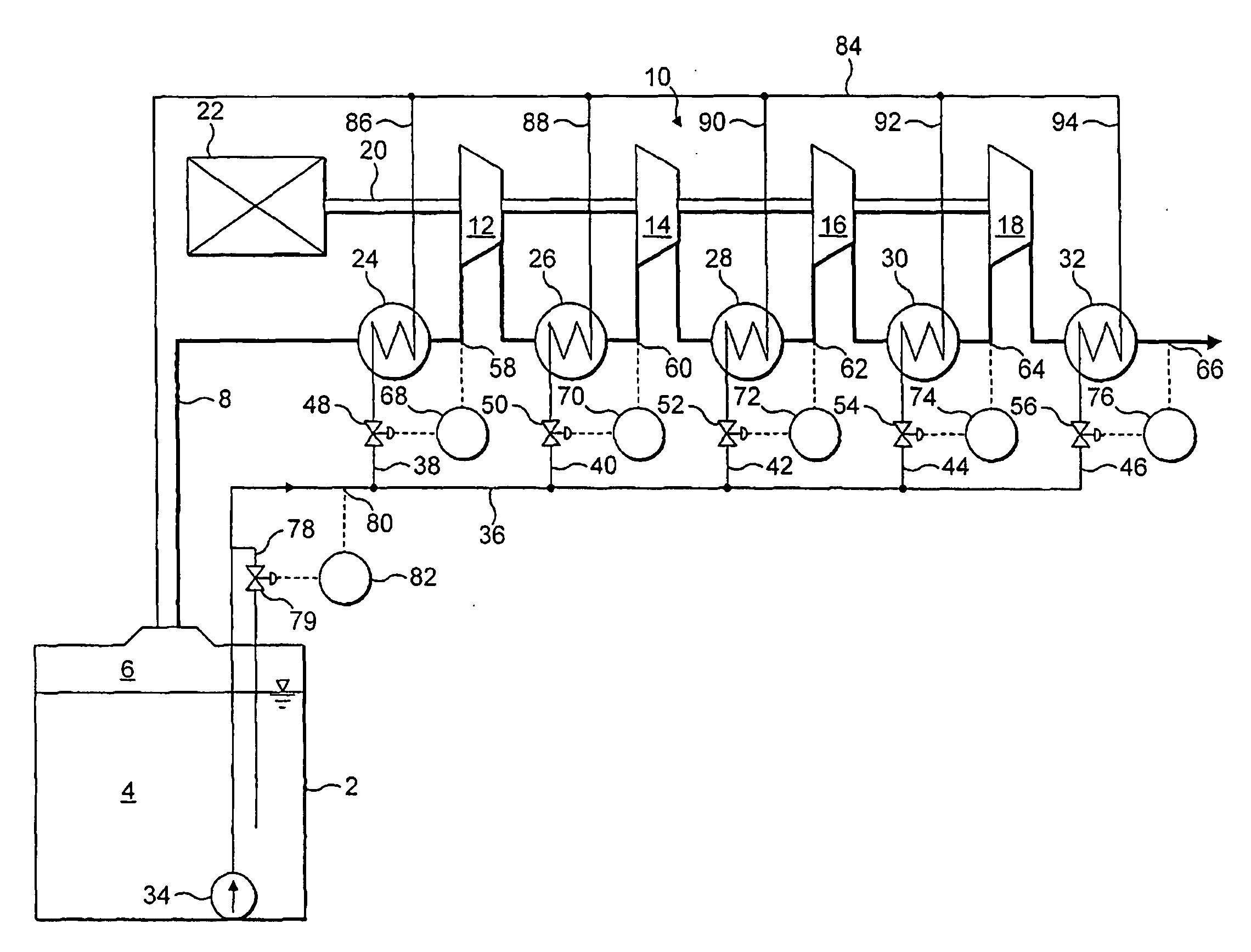

InactiveUS20080008602A1Reduce consumptionSmall sizeAuxillariesContainer filling methodsEngineeringControl valves

A rotary liquefied natural gas boil-off compressor has a series of compression stages. A gas passage passes through the series of compression stages. The gas passage extends through and is in heat exchange relationship with cooling means in the form of indirect heat exchangers. Each of the heat exchangers is cooled by LNG supplied from a pipeline. Flow control valves are provided for controlling the flow of LNG to the heat exchangers respectively. The valves are controlled in response to temperature sensors respectively, so as to maintain the inlet temperature of each of the compression stages at a chosen sub-ambient temperature or between chosen sub-ambient temperature limits.

Owner:THE BOC GRP PLC

Correlation of vent tile settings and rack temperatures

Owner:VALTRUS INNOVATIONS LTD +1

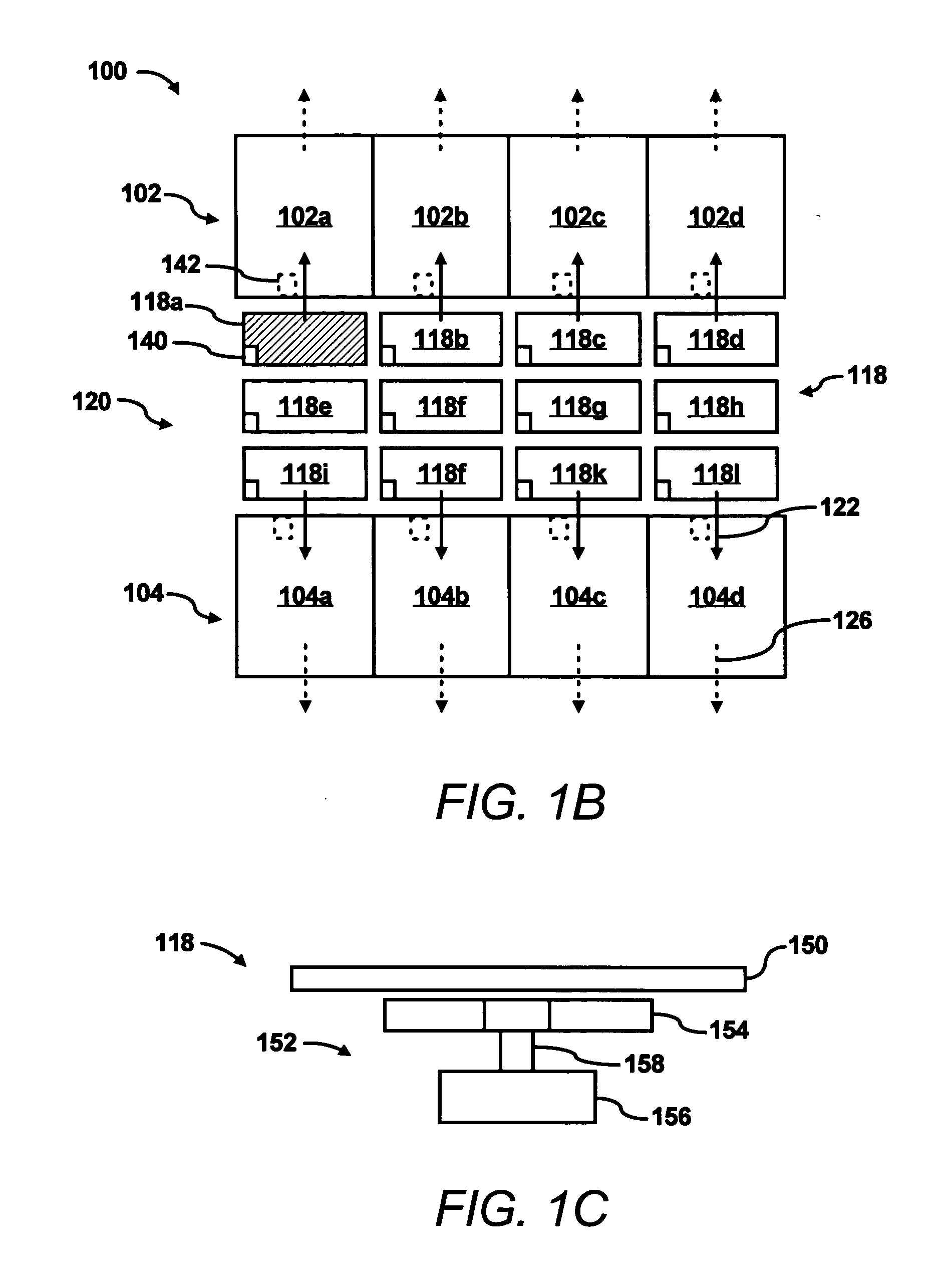

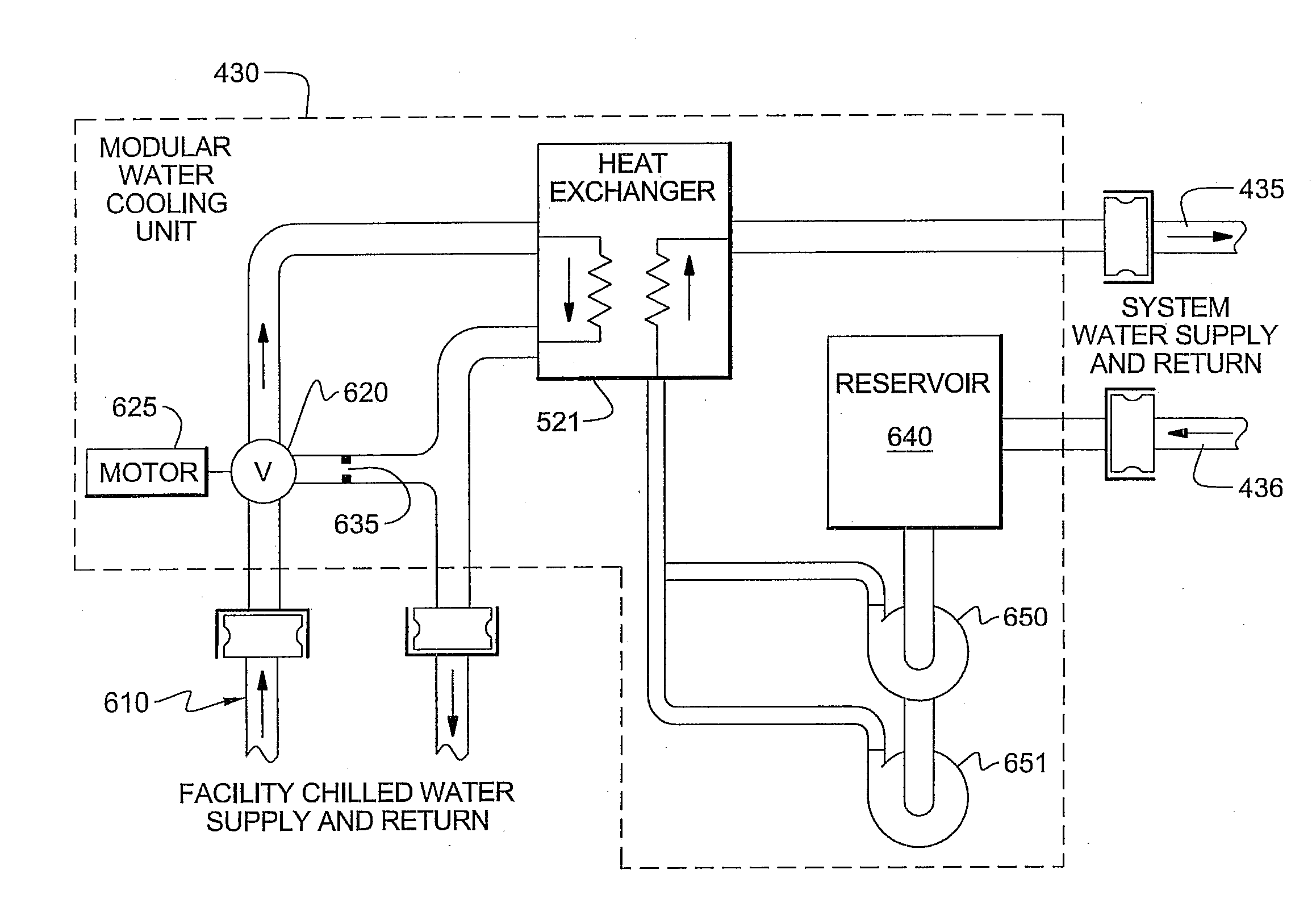

Environmental control of liquid cooled electronics

A method, system, and computer program product are provided for controlling liquid-cooled electronics, which includes measuring a first set point temperature, Ta, wherein the Ta is based on a dew point temperature, Tdp of a computer room. A second set point temperature, Tb, is measured, wherein the Tb is based on a facility chilled liquid inlet temperature, Tci, and a rack power, Prack, of an electronics rack. A Modular Cooling Unit (MCU) set point temperature, Tsp, is selected. The Tsp is the higher value of said Ta and said Tb. Responsive to the selected Tsp, a control valve is regulated. The control valve controls a flow of liquid that passes through a heat exchanger.

Owner:IBM CORP

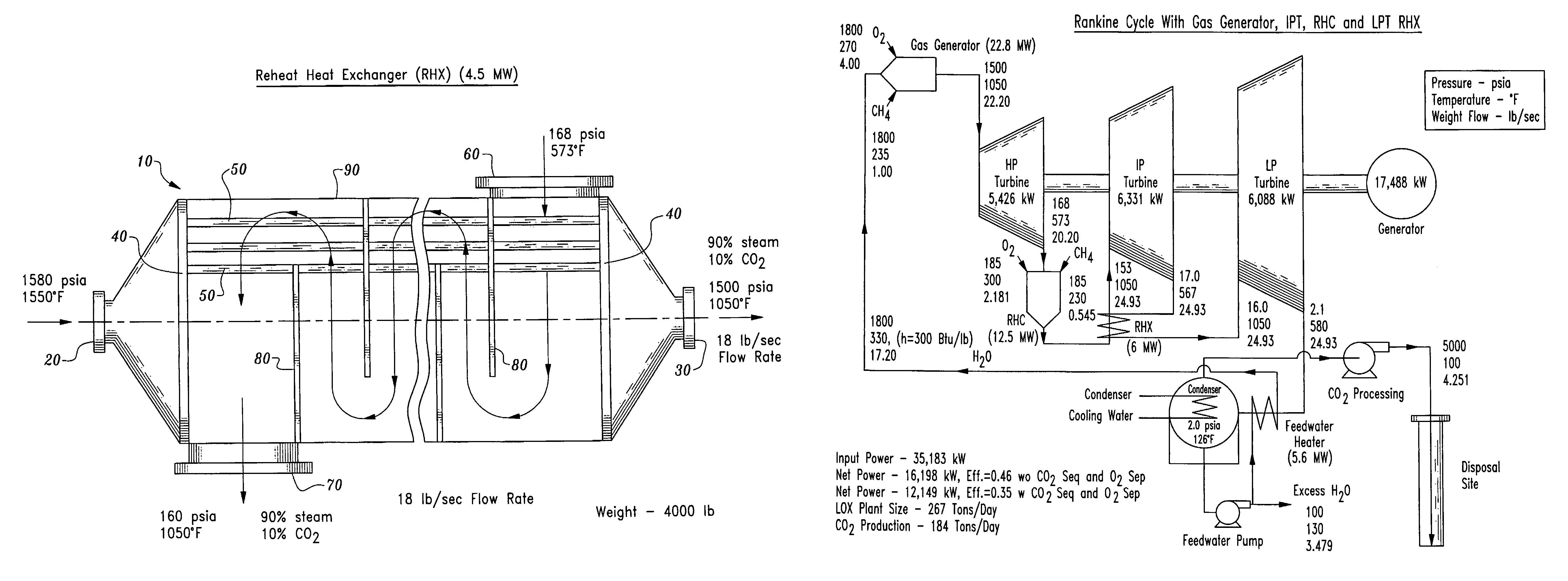

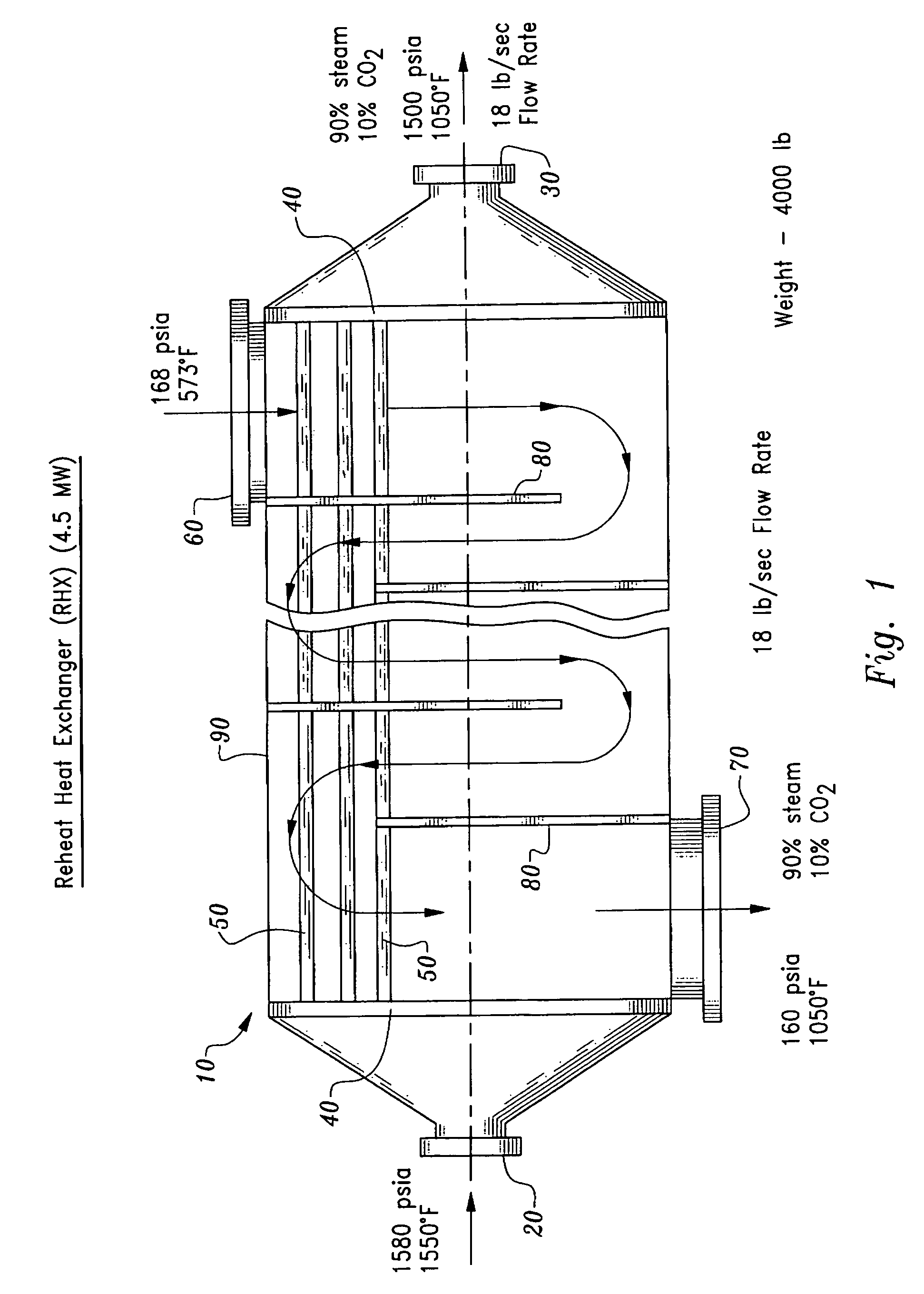

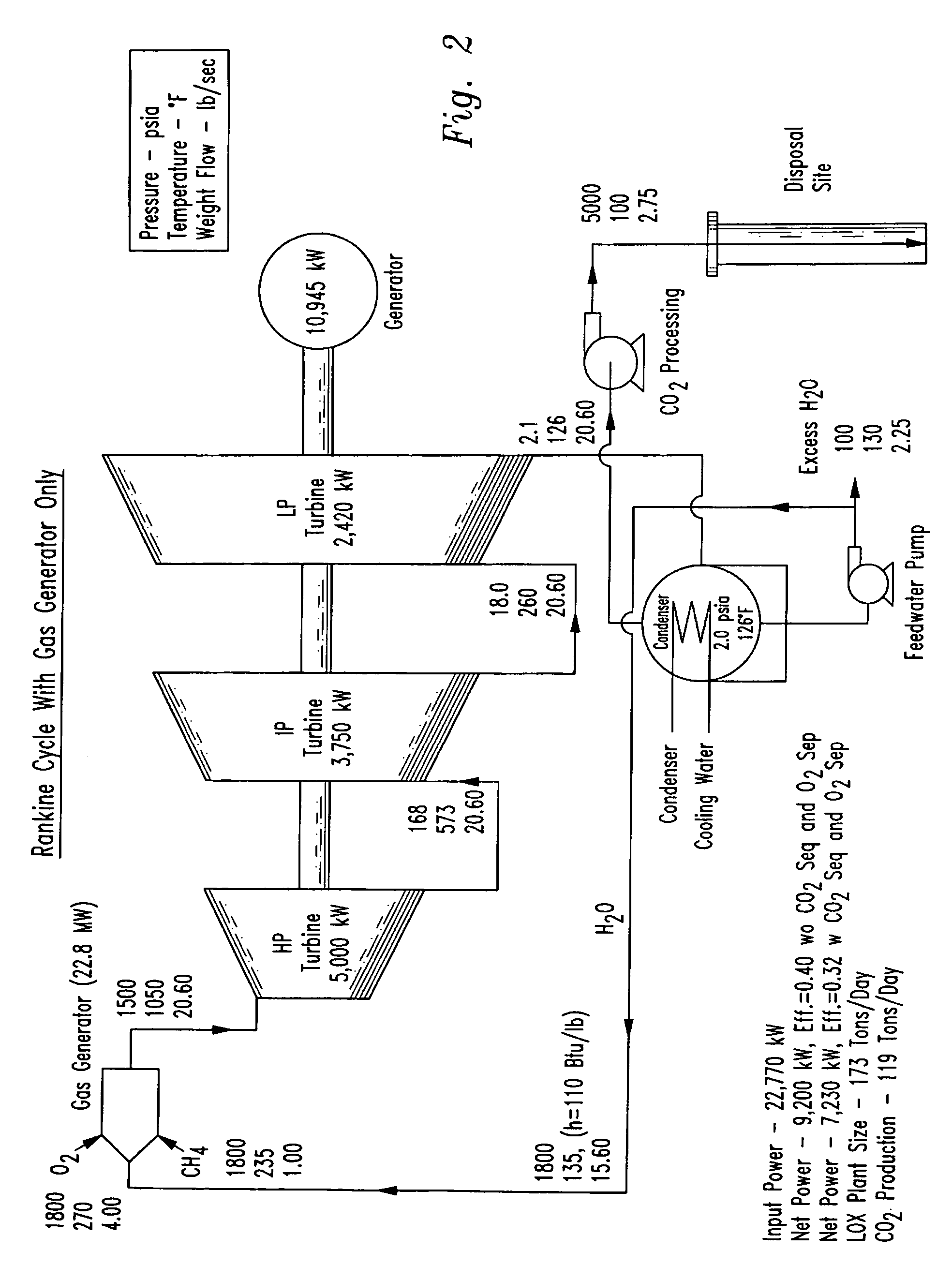

Reheat heat exchanger power generation systems

InactiveUS7021063B2High thermal efficiencyLow costGas turbine plantsDirect carbon-dioxide mitigationWorking fluidPlate heat exchanger

A reheat heat exchanger is provided particularly for use in Rankine cycle power generation systems. The reheat heat exchanger includes a high pressure path between a high pressure inlet and a high pressure outlet. The reheat heat exchanger also includes a low pressure path between a low pressure inlet and a low pressure outlet. The two paths are in heat transfer relationship. In a typical power generation system utilizing the reheat heat exchanger, the high pressure inlet is located downstream from a source of high temperature high pressure working fluid. An expander is located downstream from the high pressure outlet and upstream from the low pressure inlet. A second expander is typically provided downstream from the low pressure outlet. The reheat heat exchanger beneficially enhances the efficiency of power generation systems, particularly those which utilize expanders having inlet temperatures limited to below that produced by the source of working fluid.

Owner:CLEAN ENERGY SYST

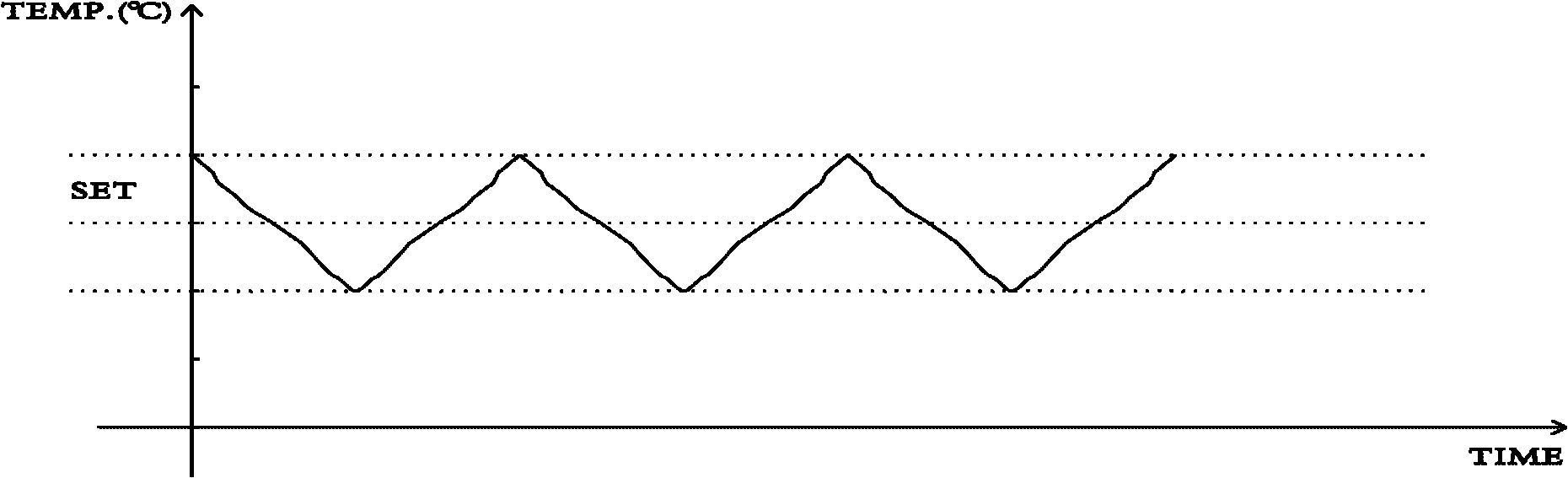

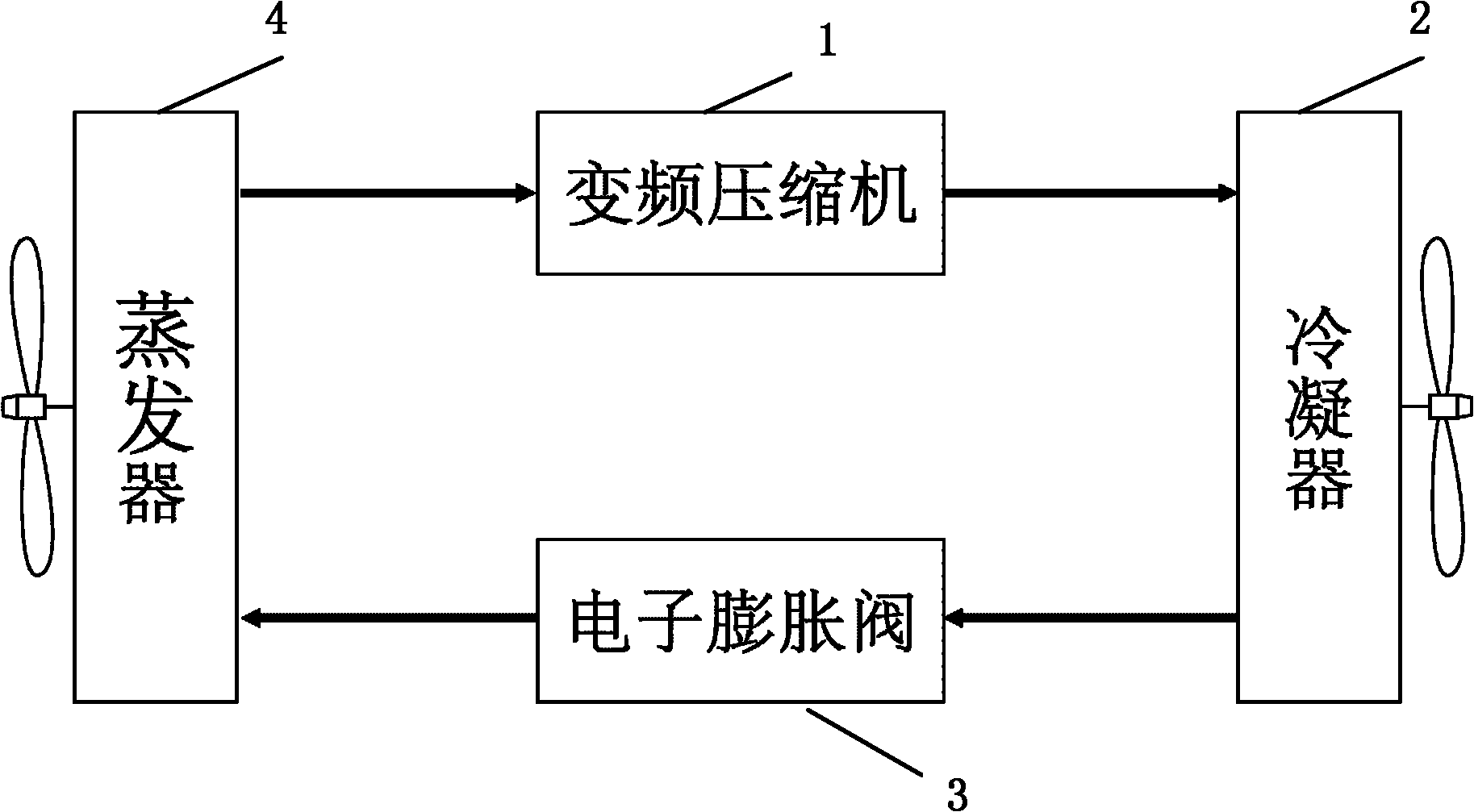

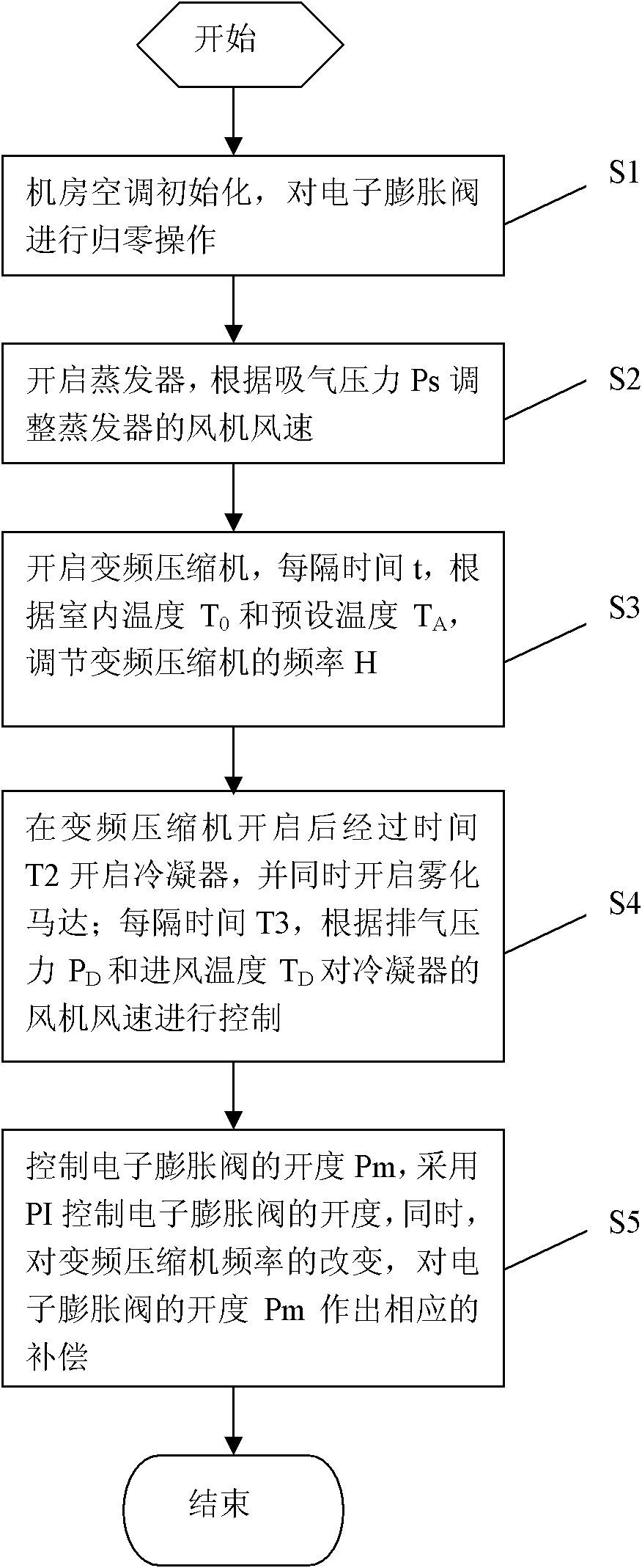

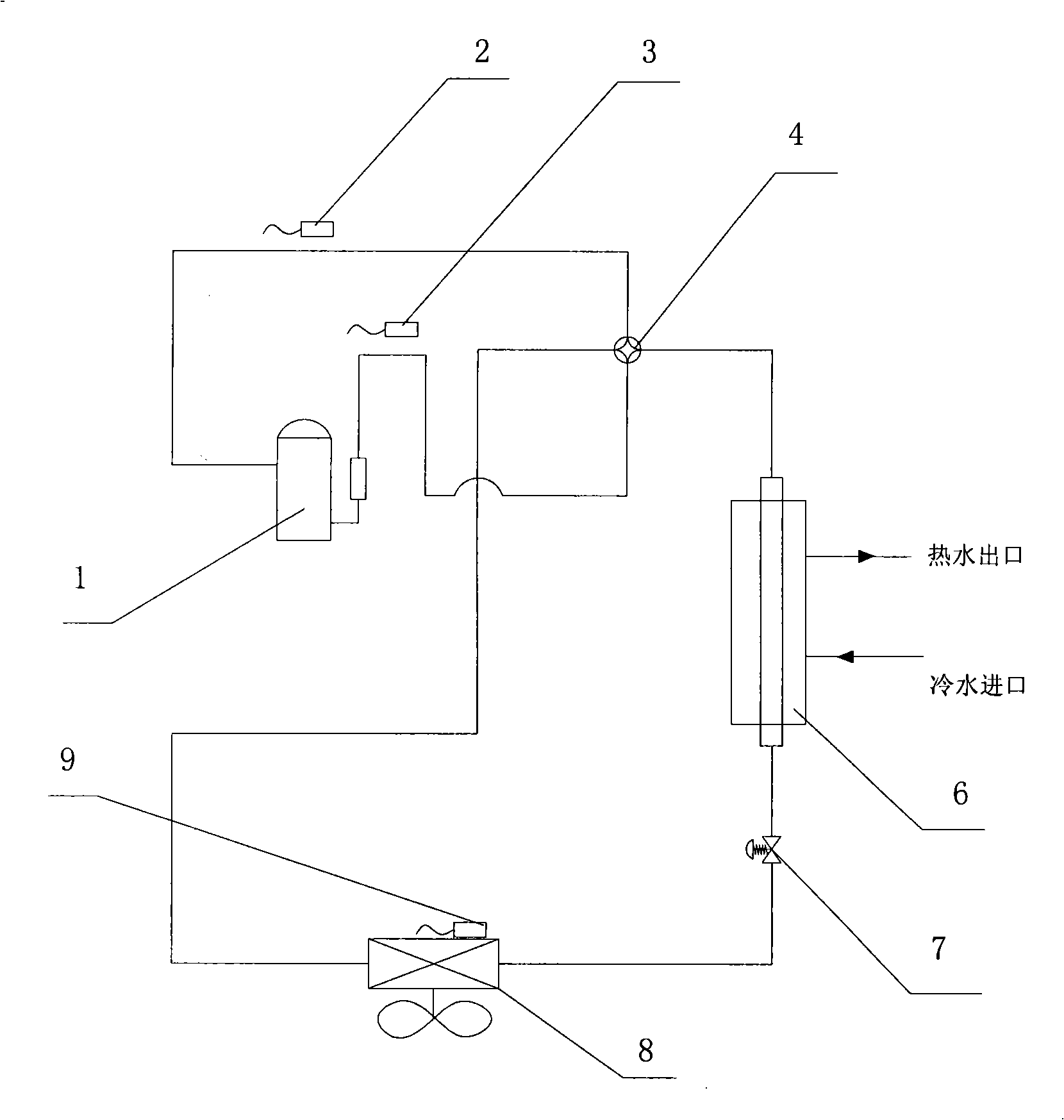

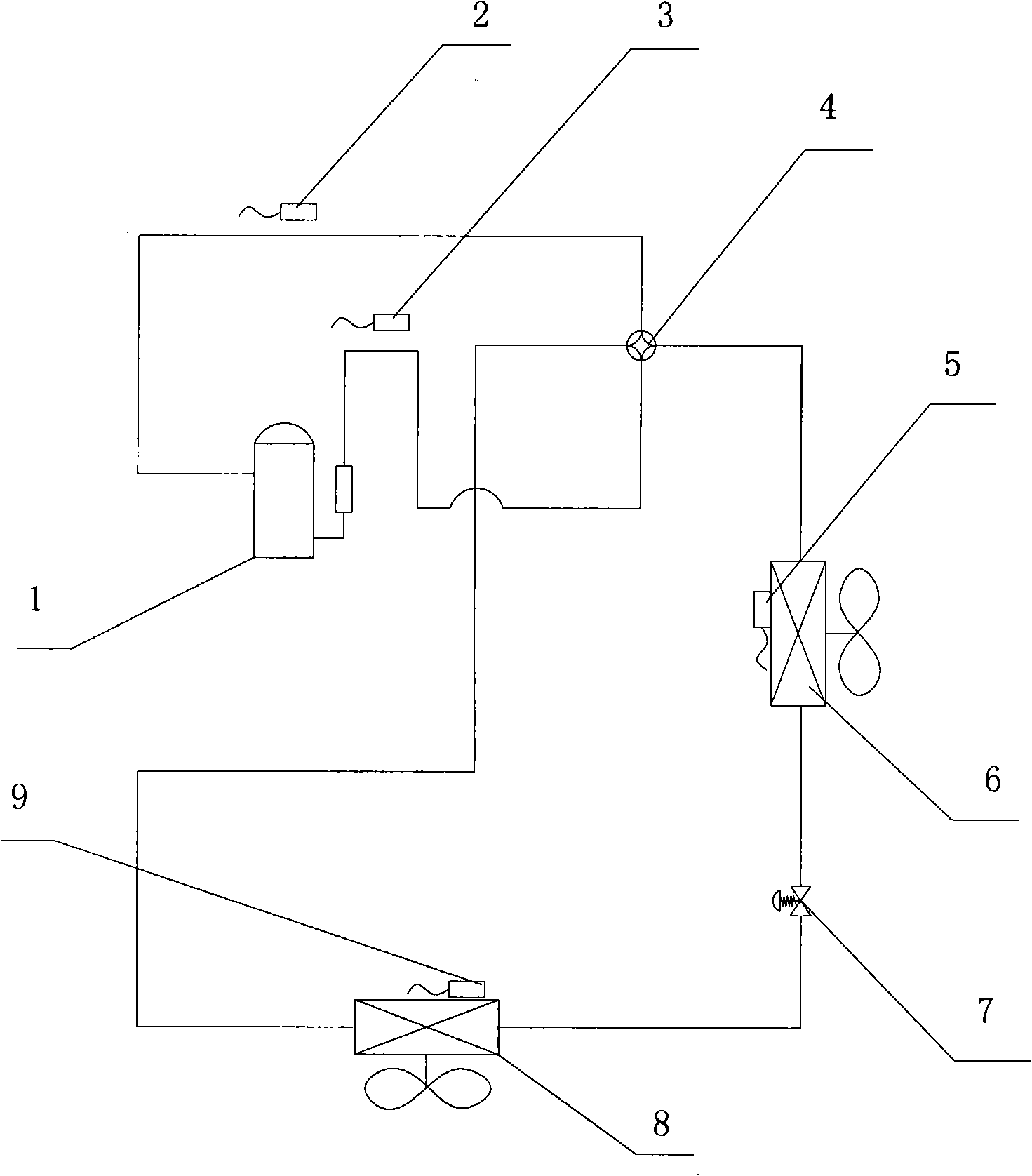

Method for controlling machine room air conditioner based on variable frequency compressor

InactiveCN102425841AImprove cooling efficiencyReduce consumptionSpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlControl theory

The invention relates to a method for controlling a machine room air conditioner based on a variable frequency compressor. The method comprises the following steps of: 1, initializing the machine room air conditioner, and returning an electronic expansion valve to zero; 2, starting an evaporator, and regulating the air velocity of a fan of the evaporator according to air suction pressure Ps; 3, starting the variable frequency compressor, and regulating the frequency H of the variable frequency compressor according to the indoor temperature T0 and the preset temperature TA; 4, starting a condenser in time T2 after the variable frequency compressor is started, and controlling the air velocity of a fan of the condenser according to exhaust pressure PD and the air inlet temperature TD; and 5, controlling the opening Pm of the electronic expansion valve, and performing corresponding compensation on the opening Pm of the electronic expansion valve according to the frequency of the variable frequency compressor. By adopting the method for controlling the machine room air conditioner based on the variable frequency compressor, the temperature is controlled more stably and the fluctuation is low; and the opening of the expansion valve is compensated through the variable frequency compressor, so that the superheat degree is more stable and close to the expected target value.

Owner:深圳市深蓝新能源电气有限公司

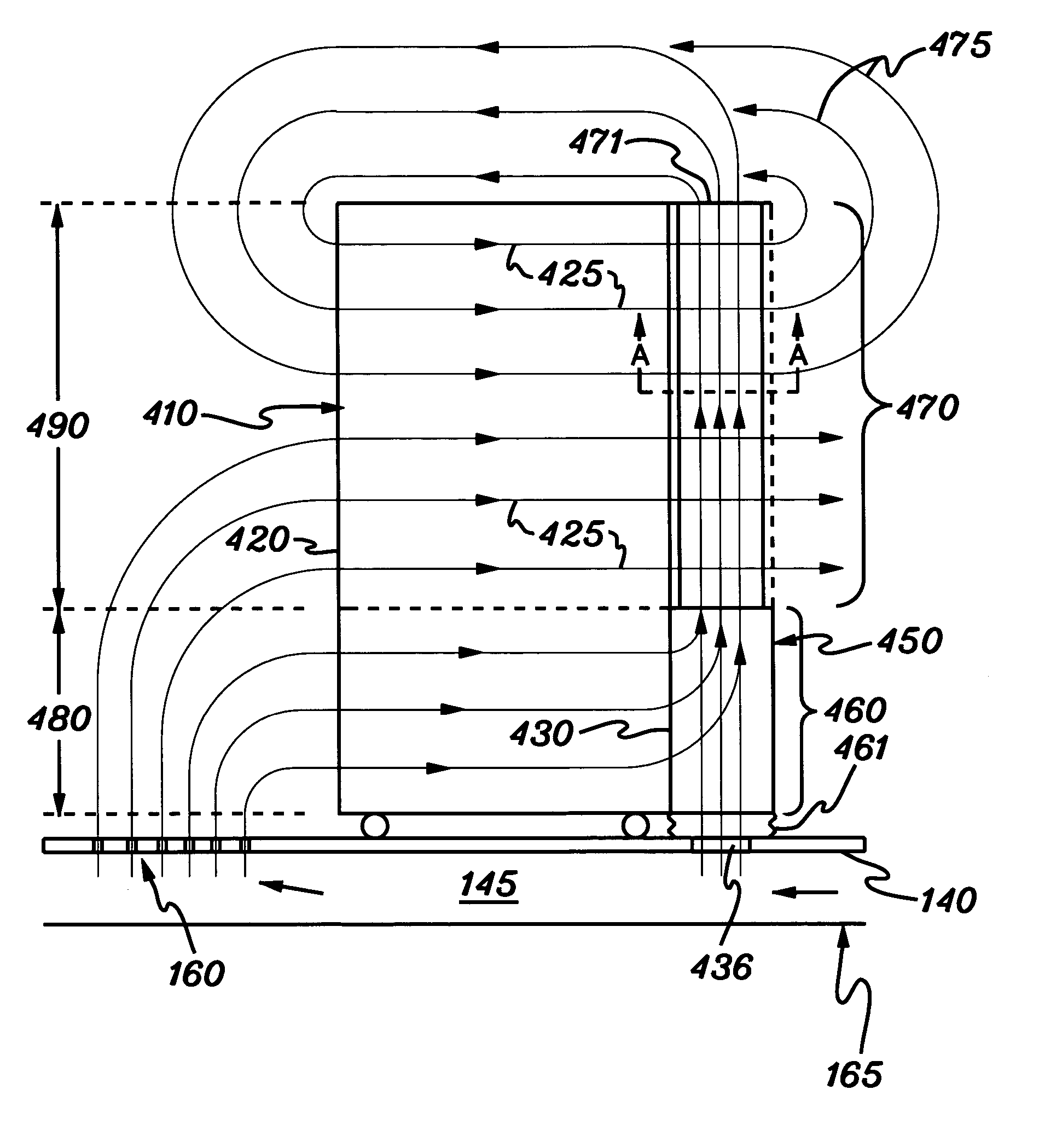

Apparatus and method for facilitating cooling of an electronics rack by mixing cooler air flow with re-circulating air flow in a re-circulation region

ActiveUS7283358B2Improve cooling effectWell mixedDucting arrangementsDigital data processing detailsRe circulationInlet temperature

Apparatus and method are provided for facilitating cooling of an electronics rack employing an air delivery structure coupled to the electronics rack. The air delivery structure delivers air flow at a location external to the electronics rack and in a direction to facilitate mixing thereof with re-circulating exhausted inlet-to-outlet air flow from the air outlet side of the electronics rack to the air inlet side thereof. The delivered air flow is cooler than the re-circulating exhausted inlet-to-outlet air flow and when mixed with the re-circulating air flow facilitates lowering air inlet temperature at a portion of the air inlet side of the electronics rack, thereby enhancing cooling of the electronics rack.

Owner:INT BUSINESS MASCH CORP

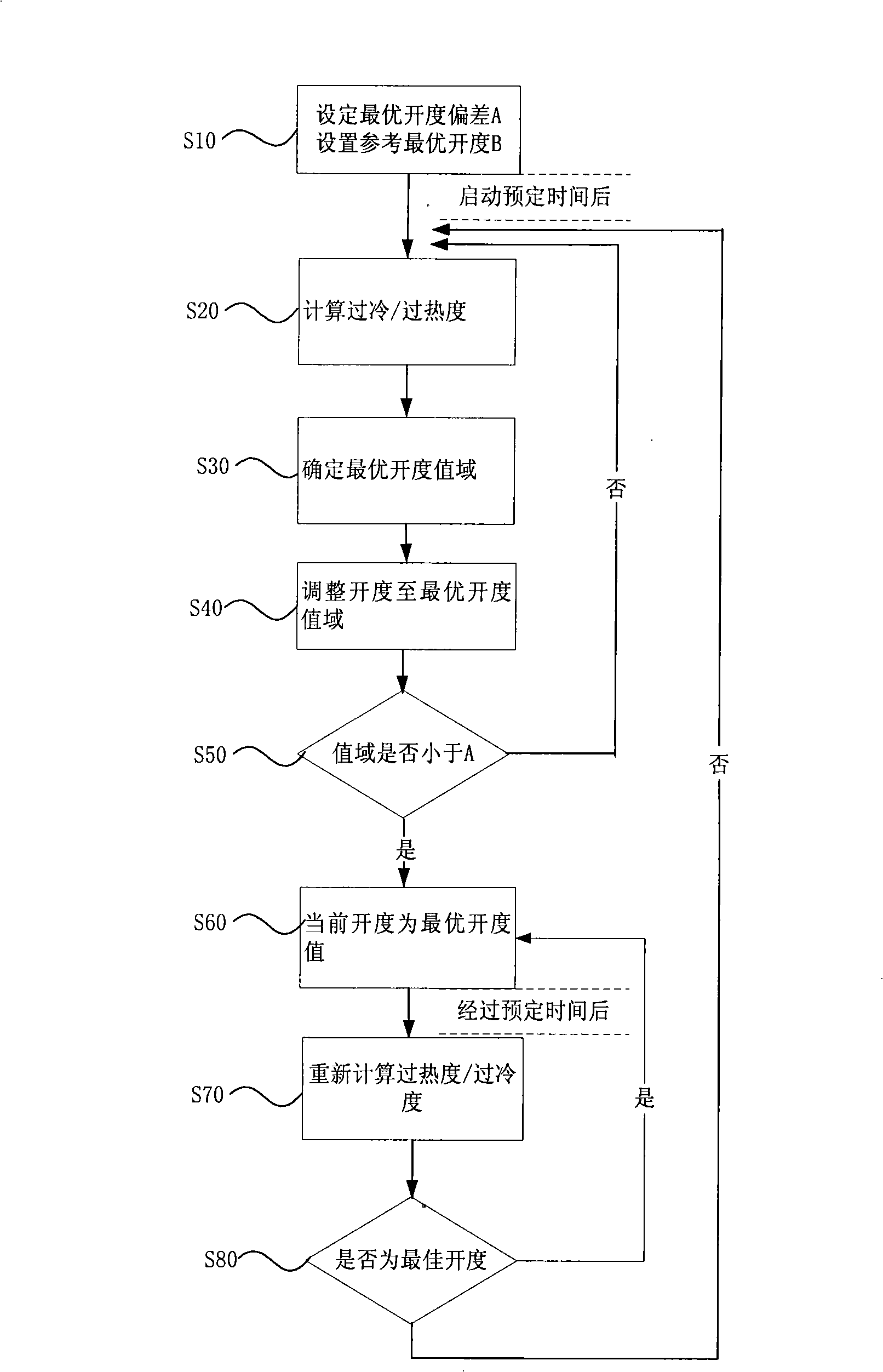

Control method of electronic expansion valve

ActiveCN101276226ARealize automatic controlGuaranteed uptimeEfficient regulation technologiesFluid circulation arrangementAutomatic controlEngineering

The present invention provides a control method of an electronic expansion valve, the electronic expansion valve is provided in a refrigerant circulation loop of equipment, the circulation loop is also provided with an evaporator, characterized in that the control method includes following steps: S10: starting the electronic expansion valve to process initialization, setting the opening of the electronic expansion valve in a predetermined initial value; S20: after starting the predetermined time, determining the real superheat / subcooling of the electronic expansion valve according to the difference between the outlet temperature and the inlet temperature of the evaporator; S30: comparing the object superheat / subcooling with the real superheat / subcooling, determining the optimal opening range of the electronic expansion valve; S40: adjusting the opening of the electronic expansion valve to the optimal opening range. The invention realizes the automatic control of refrigerant volume and throttle degree of equipment, and capable of adapting the working condition to control automatically, so as to protect the optimal state in the system operation ,ensuring credibility and safety operation.

Owner:GREE ELECTRIC APPLIANCES INC

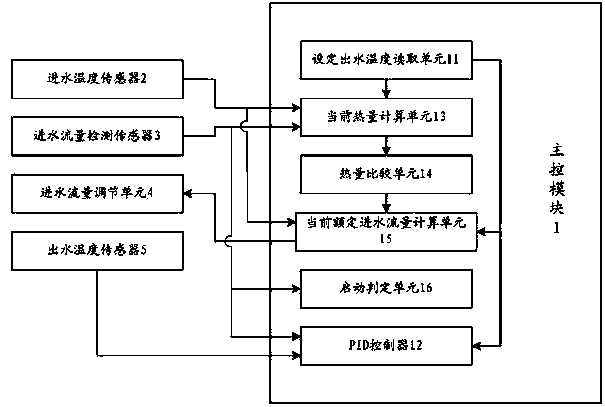

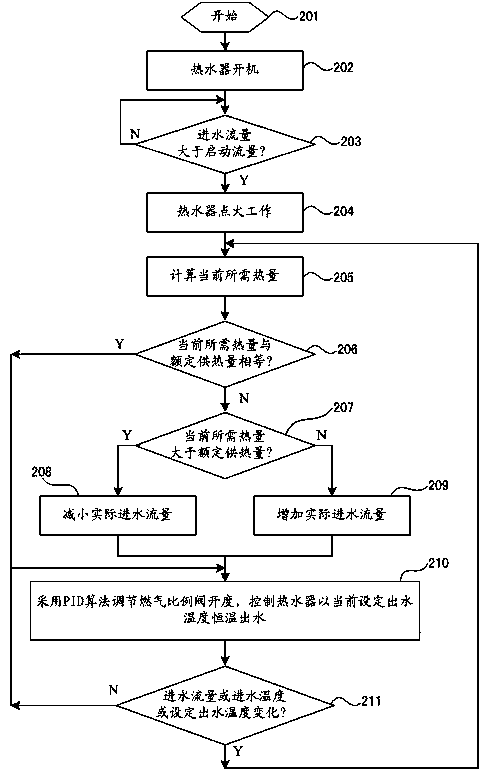

Control method and control device of constant-temperature gas water heater

ActiveCN104236109AImprove use comfort performanceRaise the water temperatureFluid heatersProportion integration differentiationEngineering

The invention discloses a control method and a control device of a constant-temperature gas water heater. The control method includes steps of detecting current water inlet temperature, current water inlet flow and current set water outlet temperature of the water heater and calculating current required heat; comparing the current required heat with rated heat supply of the heater; when the current required heat is higher than the rated heat supply, reducing practical water inlet flow of the heater, and when the current required heat is lower than the rated heat supply, increasing practical water inlet flow of the heater; adjusting opening of a gas proportion valve of the water heater by an PID (proportion integration differentiation) algorithm, and controlling the water heater so as to supply water at constant temperature by the current set water outlet temperature. By the control method and the control device of the constant-temperature gas water heater, the water heater is controlled, water outlet temperature reaches the set temperature, water outlet temperature can be quickly and stably adjusted, and service performance of the water heater is improved.

Owner:HAIER GRP CORP +1

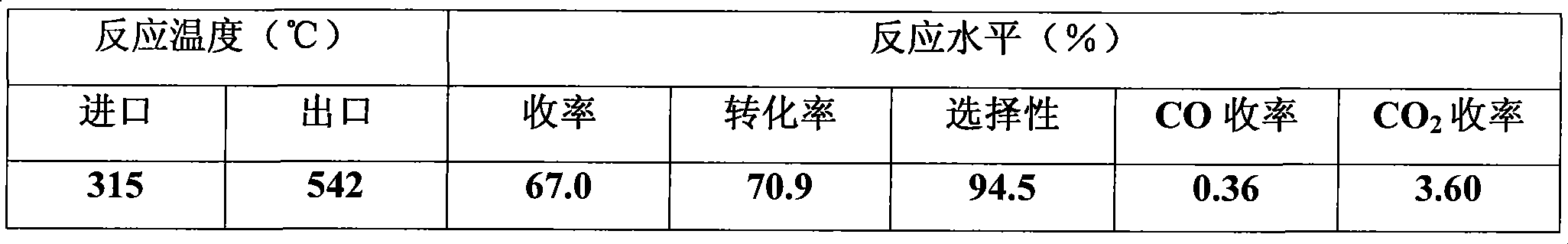

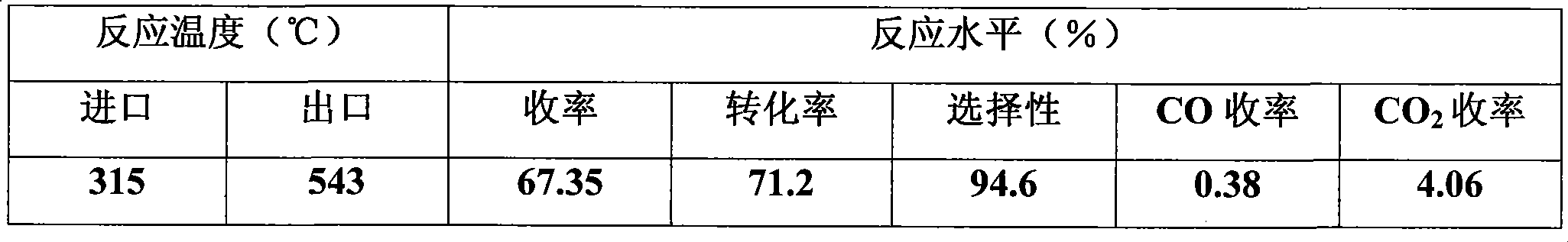

Method for preparing butadiene with butylene oxo-dehydrogenation of axially-located bed

ActiveCN101367702AIncrease productionReduce unit consumptionHydrocarbonsHydrocarbon preparationInlet temperatureFixed bed

The invention relates to a method of preparing butadience with a butylene oxydehydrogenation device in a fixed bed, which belongs to the chemical technical field. The butylene, air and water vapor give an oxydehydrogenation reaction in an axial fixed bed reactor and generate the butadience. The axial fixed bed reactor has two segments. Process equipment consists of a first segment of axial fixed bed reactor, an inter -segment heat exchanger, a second segment of axial fixed bed reactor, a waste heat boiler and a back heat exchanger in turn. The reactor is filled with iron-based catalyst. The ingredient of the water vapor of the first segment of reactor acts with the first segment via the inter-segment heat exchanger to generate gas in addition to exchanging heat and raising temperature and then is mixed with the ingredient butylene and the air of the first segment to achieve the inlet temperature of the first segment of reactor. The ingredient of the first segment enters to the first segment of reactor to react. After heat exchange and temperature reduction through the inter-segment heat exchanger, the gas generated in the first segment is mixed with the feed butylene of the second segment and the air to achieve the inlet temperature of the second segment of reactor and reacts in the second segment of reactor. The invention has the advantages of high yield coefficient, high selectivity and steam of low unit consumption. Heat energy can be used reasonably.

Owner:ZIBO QIXIANG TENGDA CHEM

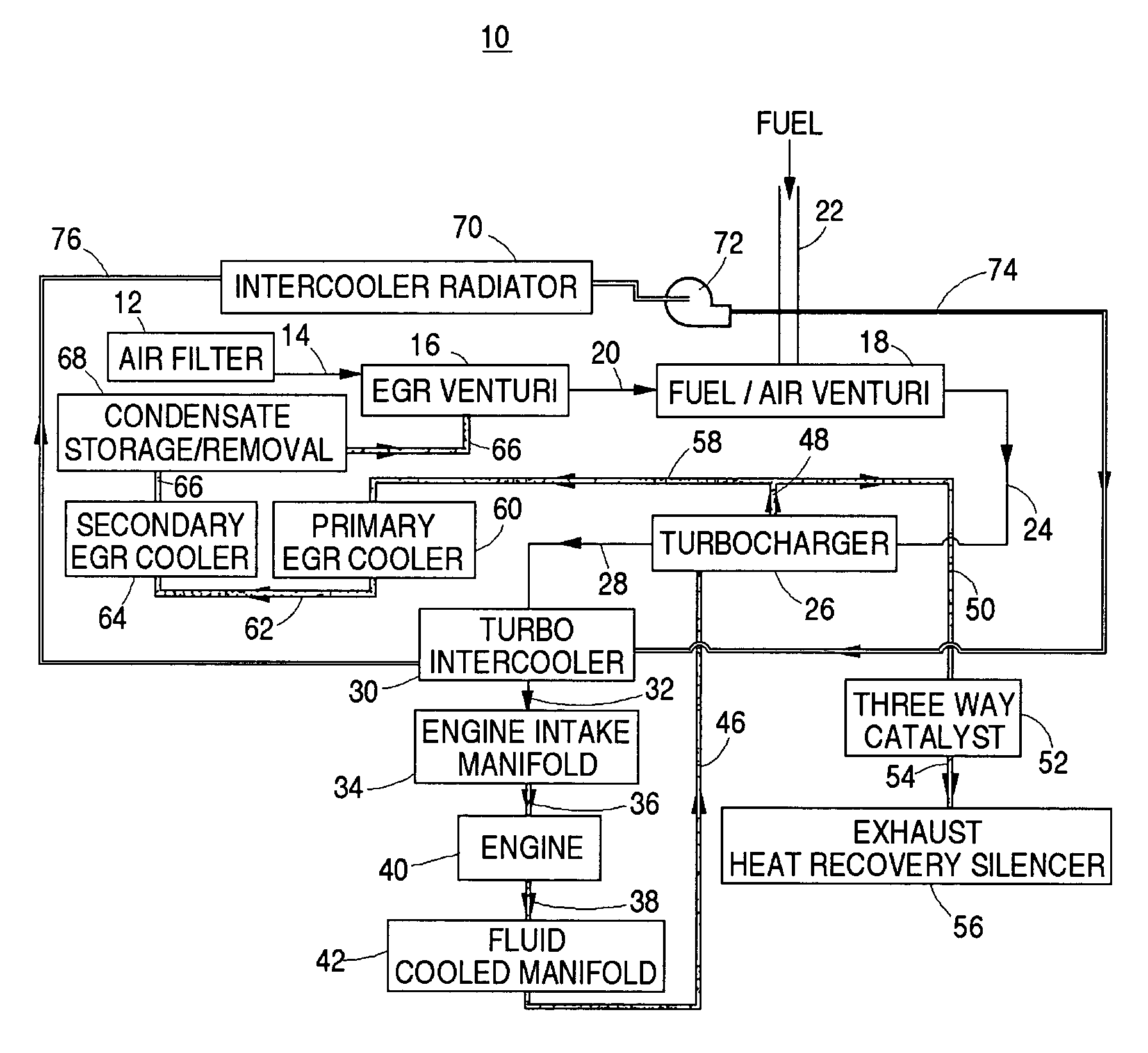

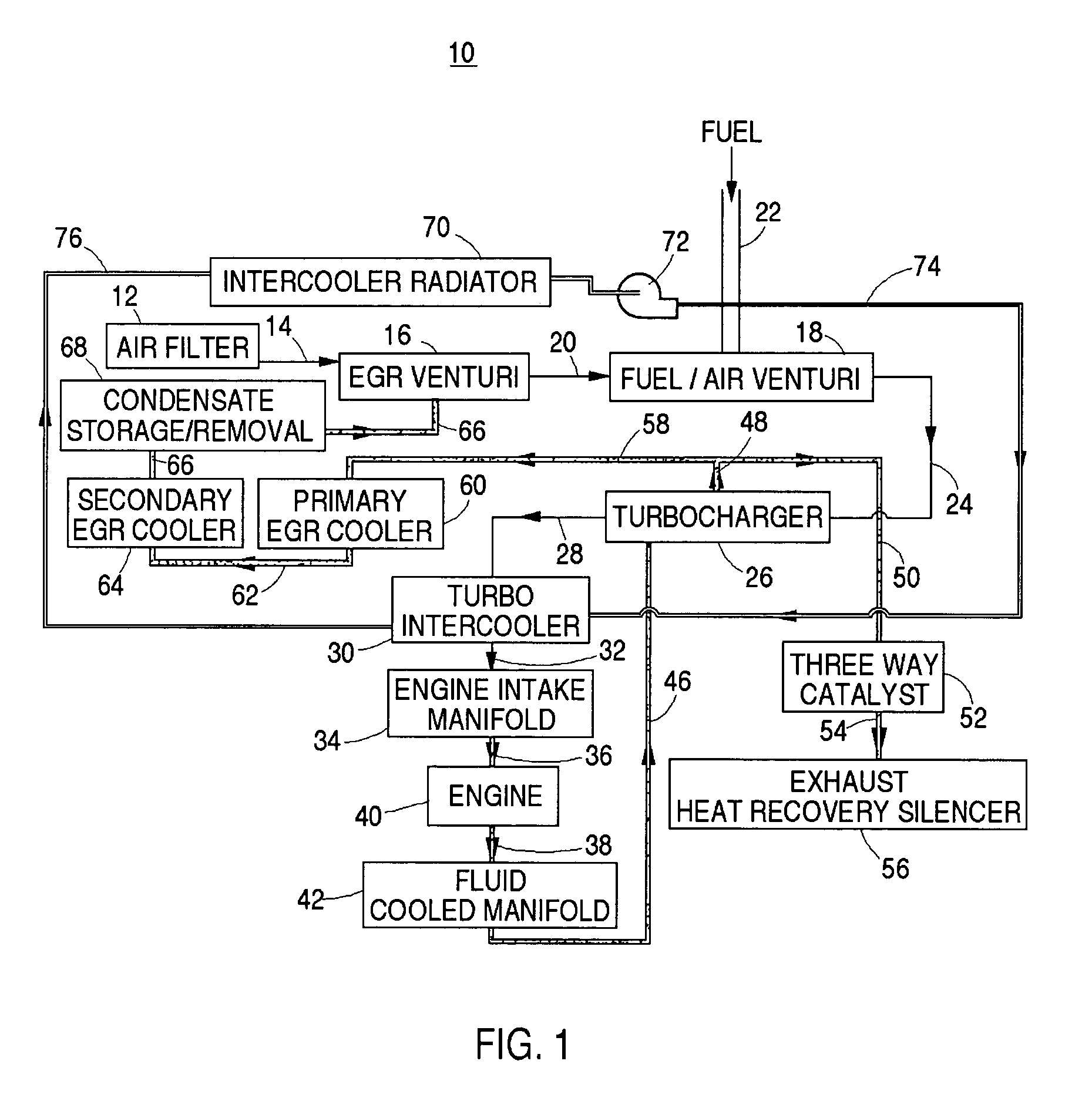

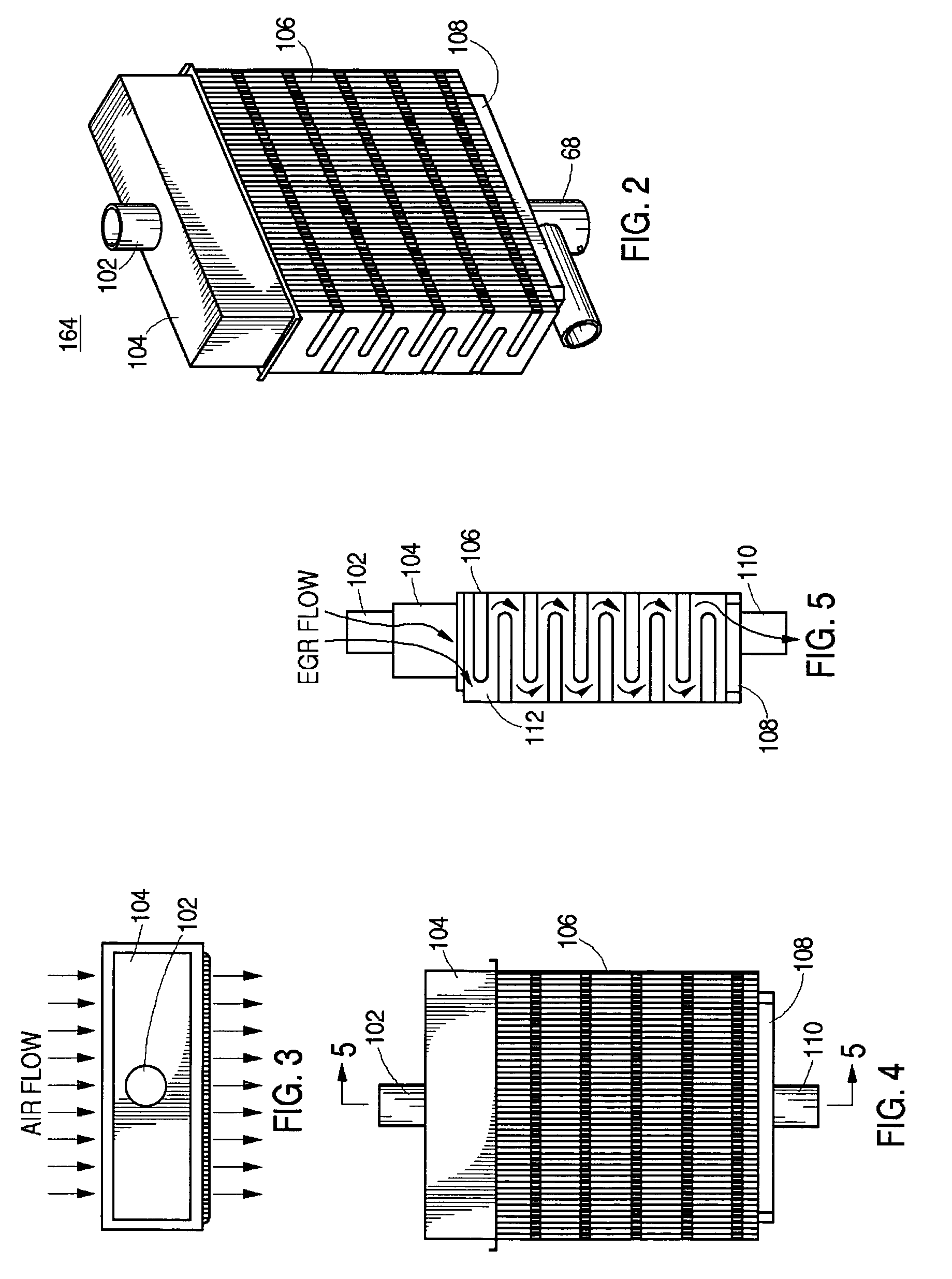

EGR cooling and condensate regulation system for natural gas fired co-generation unit

InactiveUS6978772B1Improve efficiencyReduce condensationNon-fuel substance addition to fuelInternal combustion piston enginesWater vaporCogeneration

A recycled exhaust gas cooling and condensate regulation system for a natural gas fired internal combustion engine driven co-generation plant, which allows efficient exhaust recycled gas combustion while maintaining lower head temperatures to reduce thermal NOx emissions and delivering increased process / utility heat to a proximate co-generation client, is provided. The recycled exhaust gas cooling and condensate regulation system has primary and secondary, air-to-gas, exchanger units, coupled in series, such that the first unit, designed to take exhaust gas exiting the engine, cools the gas to a first exhaust gas temperature effectively super saturating the water vapor in the cooled exhaust gas; and, the second unit, designed to handle lower inlet temperatures, condenses the water vapor and super cools the exhaust gas to <130 F. In one embodiment, the engine intake mixture including the exhaust gas is supercharged. In another embodiment, a separate intercooler circuit is used to cool the compressed intake charge containing the recycled gas prior to entry into the intake engine manifold to further reduce head temperatures and control thermal NOx emissions.

Owner:CHAPEAU

Methods relating to gas turbine control and operation

ActiveUS20100286889A1Increased and maximum levelAnalogue computers for vehiclesGas turbine plantsMaximum levelStream flow

A method of controlling variable extraction flow in a combustion turbine engine, wherein extraction flow comprises a supply of compressed air extracted from the compressor and supplied to the turbine through extraction conduits, and wherein the extraction conduits includes a variable extraction orifice, the method comprising the steps of: measuring a plurality of turbine engine operating parameters; monitoring, by a control unit, the measured operating parameters of the combustion turbine engine; setting the variable extraction orifices to a setting that allows an approximate maximum level of extraction flow; calculating, by the control unit, at least one calculated operating parameter based upon model-based control and the measured operating parameters, including at least a current turbine inlet temperature and a maximum turbine inlet temperature; and manipulating the setting for the supply of fuel to the combustor such that an increased and / or maximum level of engine output is determined by comparing the values for the current turbine inlet temperature and the maximum turbine inlet temperature.

Owner:GENERAL ELECTRIC CO

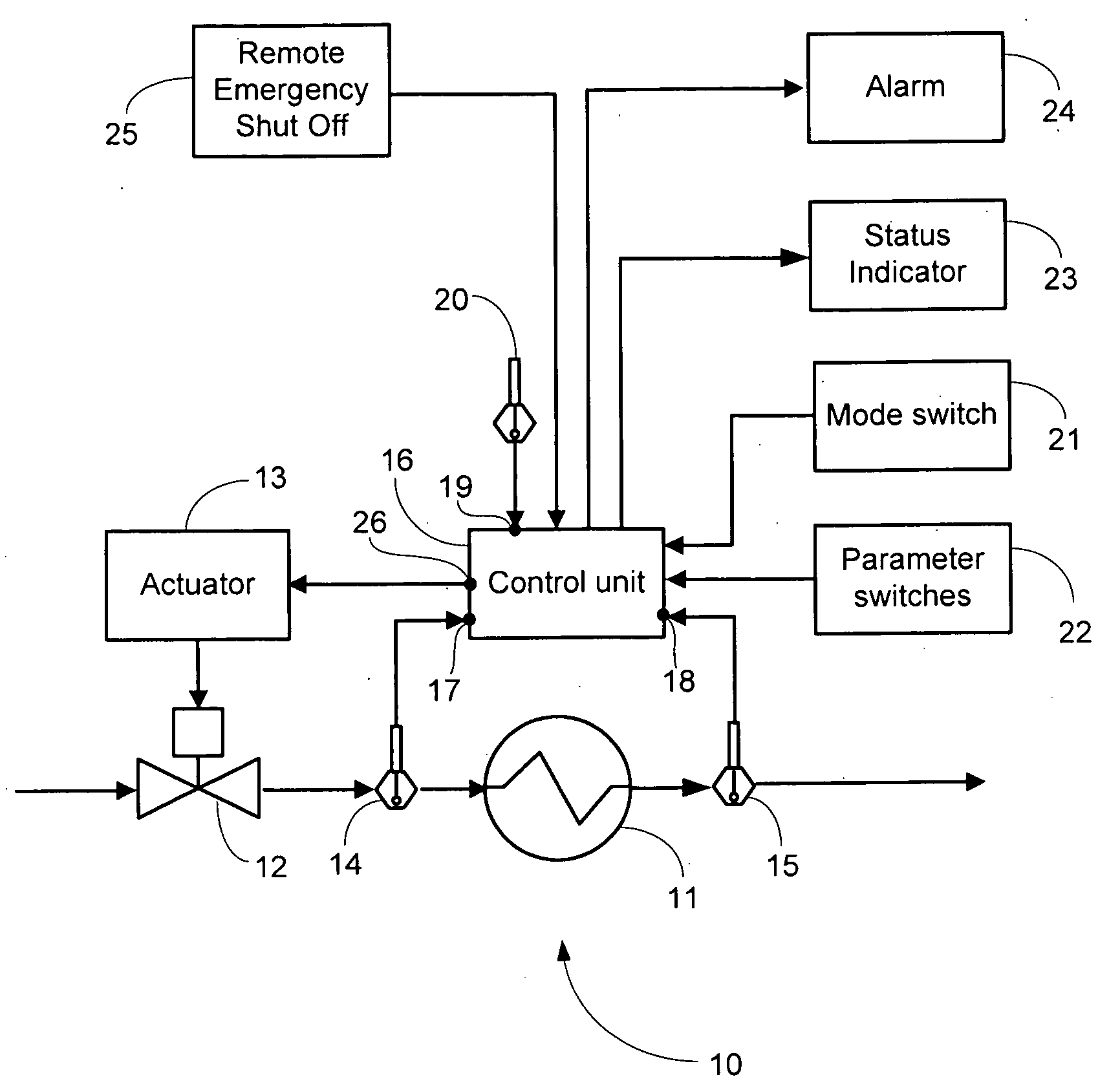

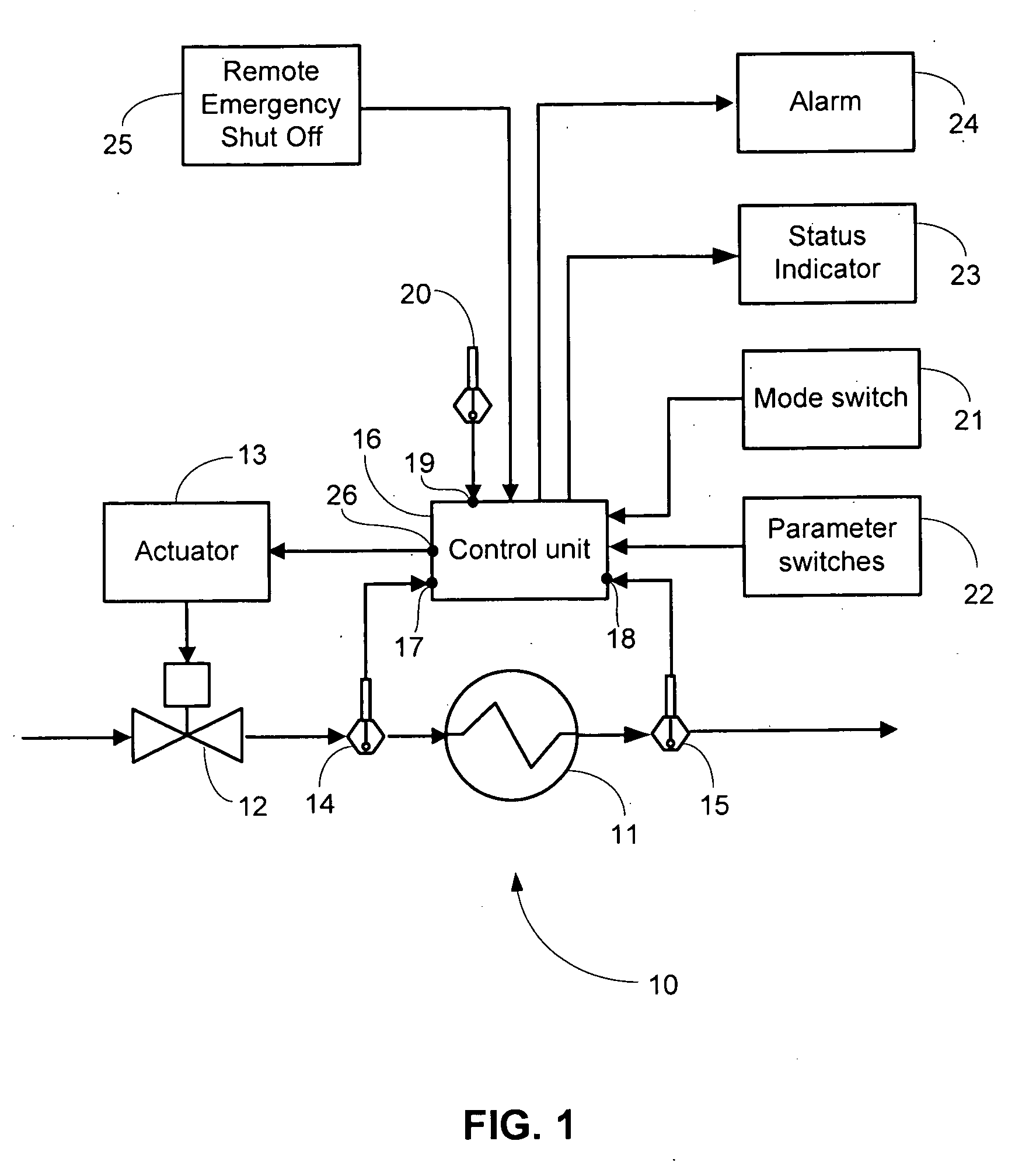

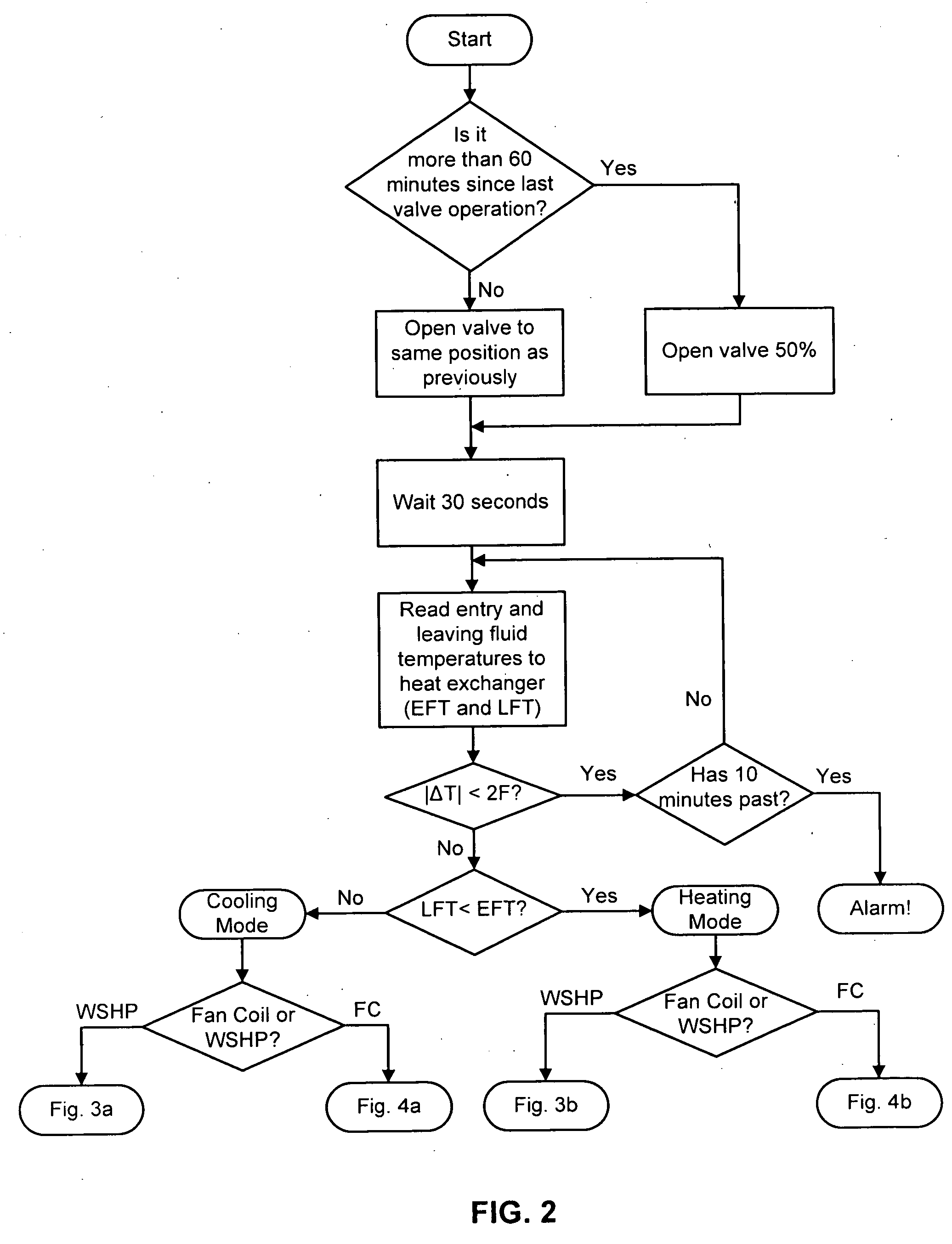

Standalone flow rate controller for controlling flow rate of cooling or heating fluid through a heat exchanger

InactiveUS20090314484A1Improve performanceSave energyTemperatue controlControl flowPlate heat exchanger

A standalone flow rate controller for controlling flow rate of cooling or heating fluid through a heat exchanger by providing a control signal to a flow valve actuator so as to open or close a flow valve in response thereto. A first temperature sensor measures an entry temperature of the cooling or heating fluid flowing into the heat exchanger and a second temperature sensor measures an exit temperature of the cooling or heating fluid flowing out of the heat exchanger. A control unit is responsive to a temperature difference between the entry temperature and the exit temperature for adjusting the control signal so as maintain the temperature difference substantially constant.

Owner:AKZ TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com