Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2406 results about "Moving bed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

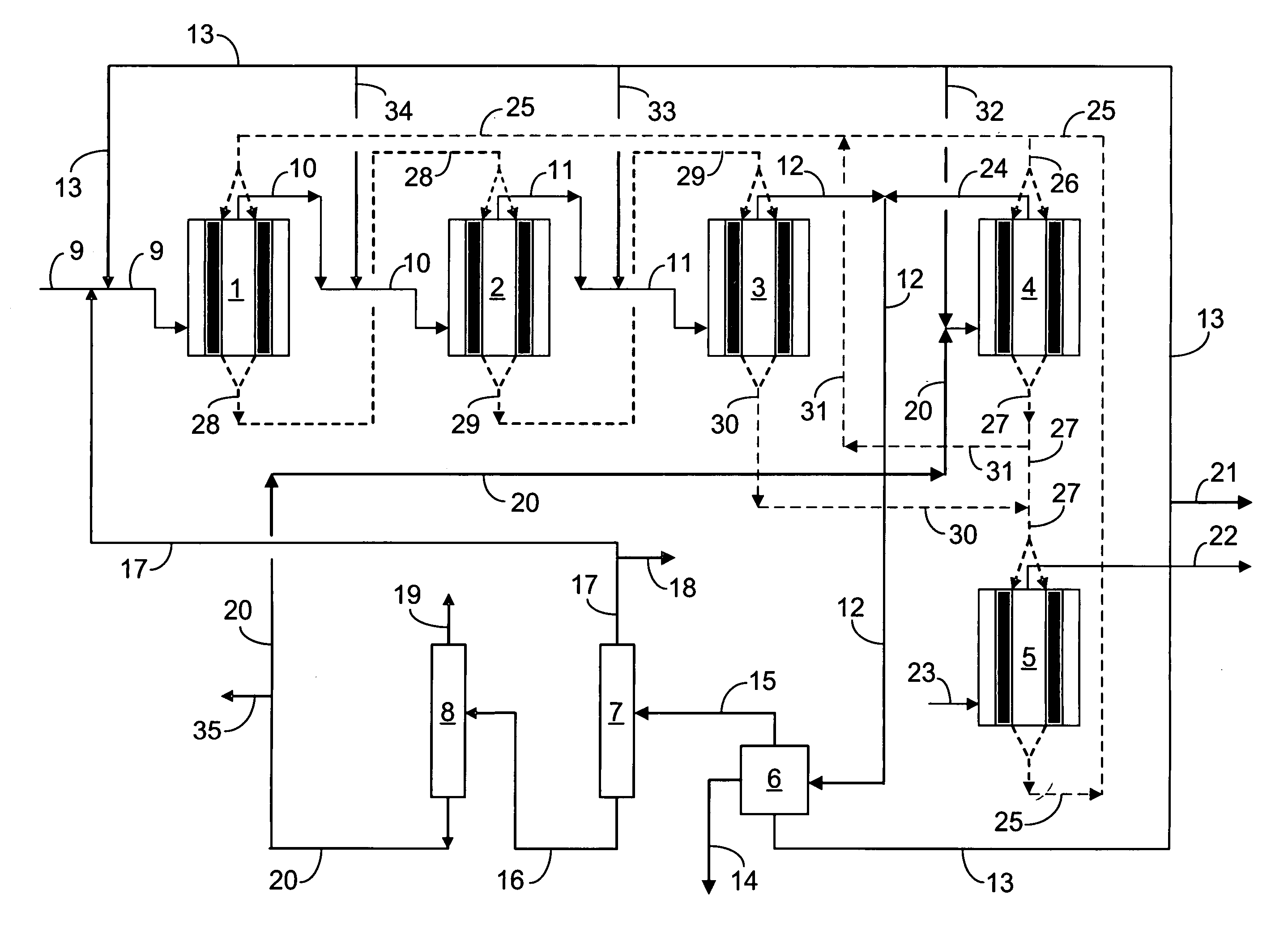

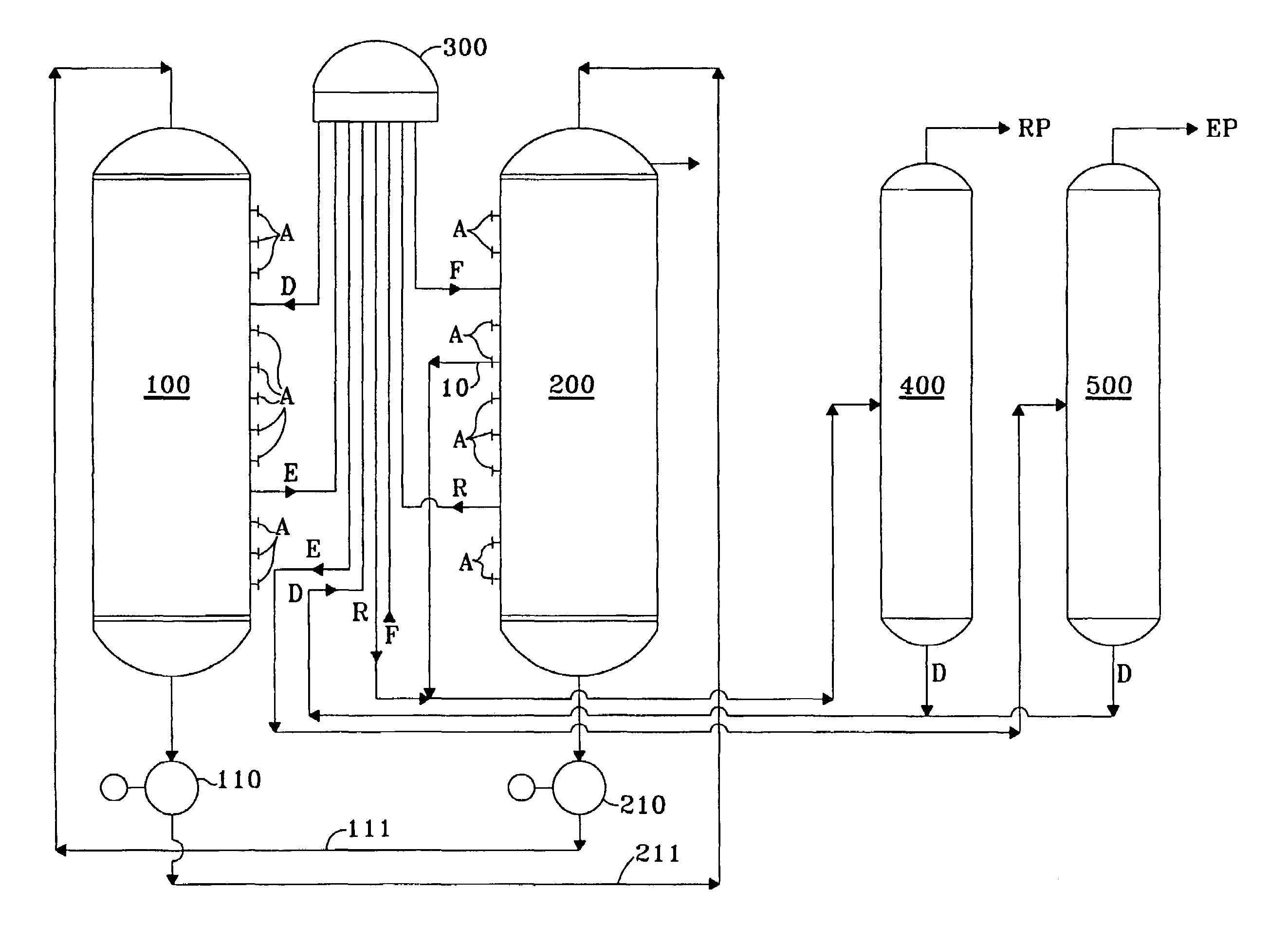

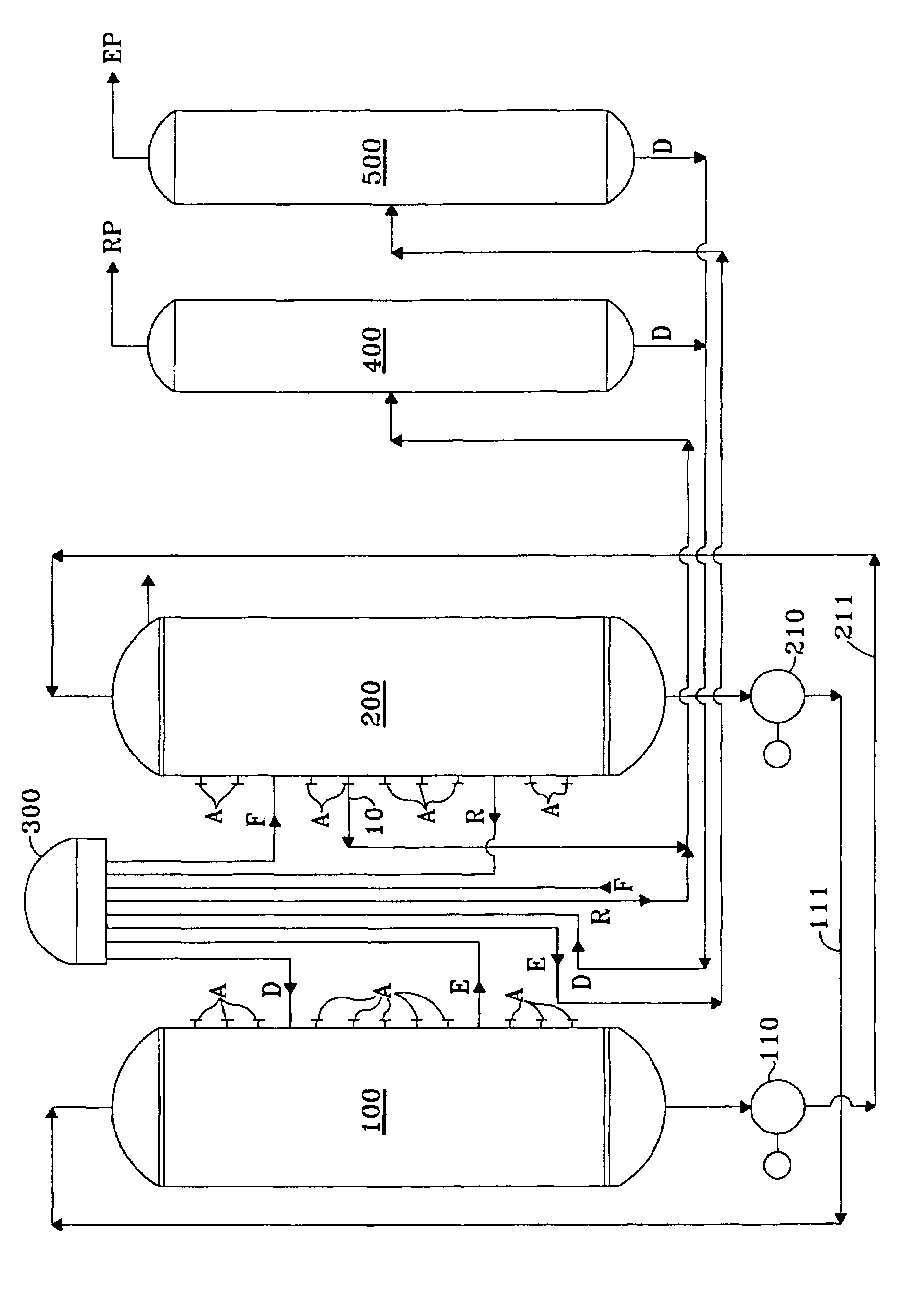

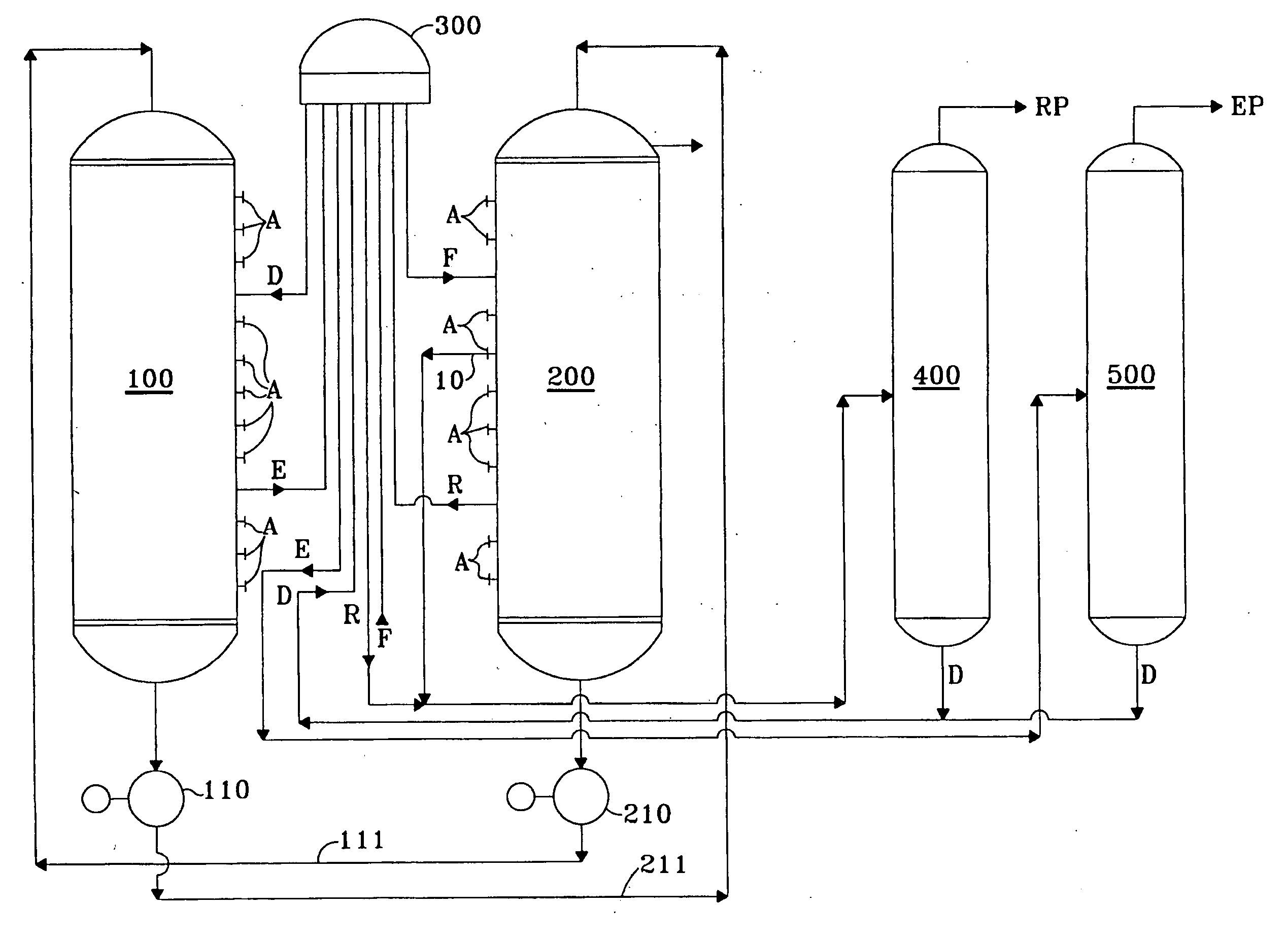

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS20060161035A1Improve economyEfficient OTP processMolecular sieve catalystCatalystsFixed bedOxygenate

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

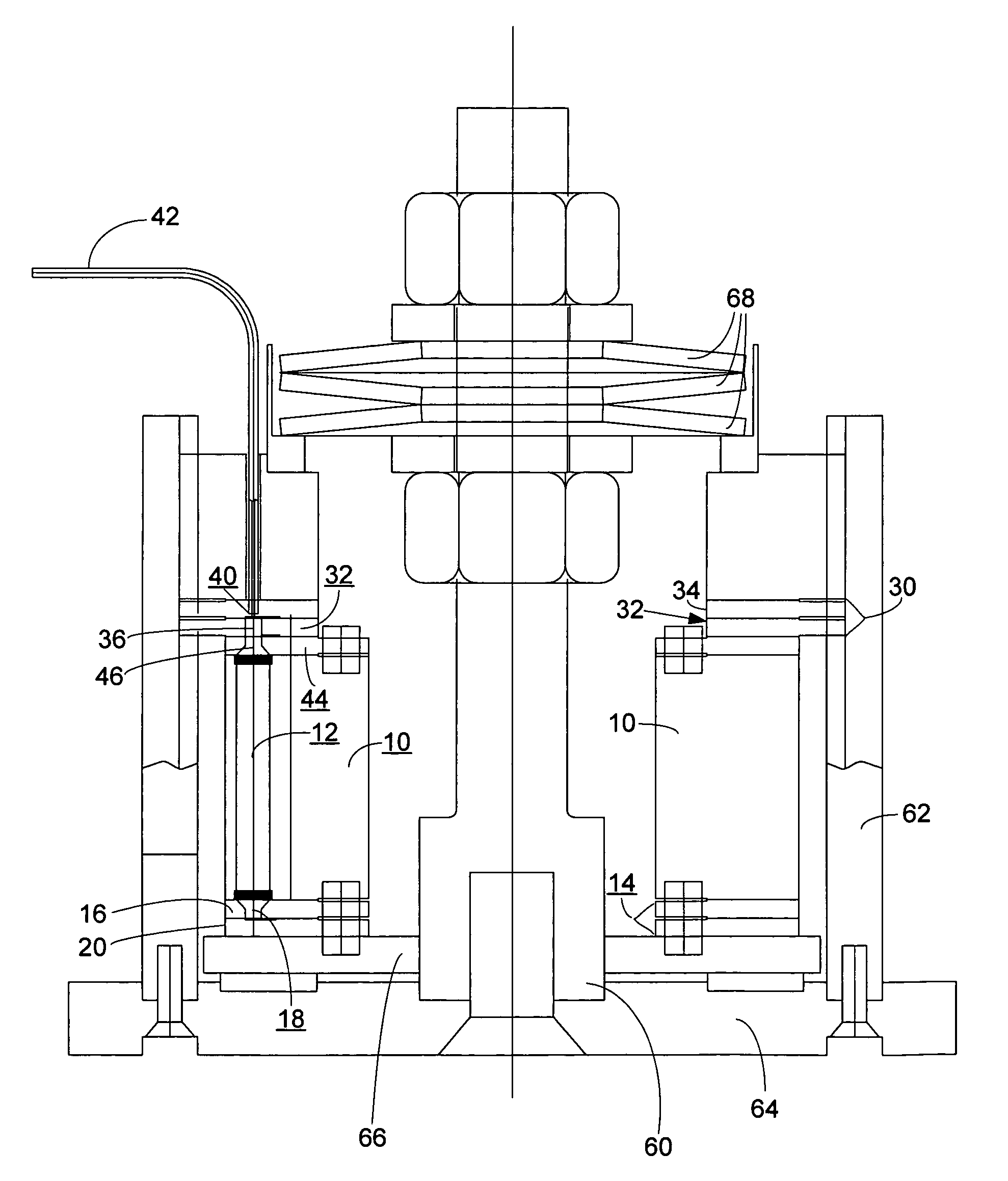

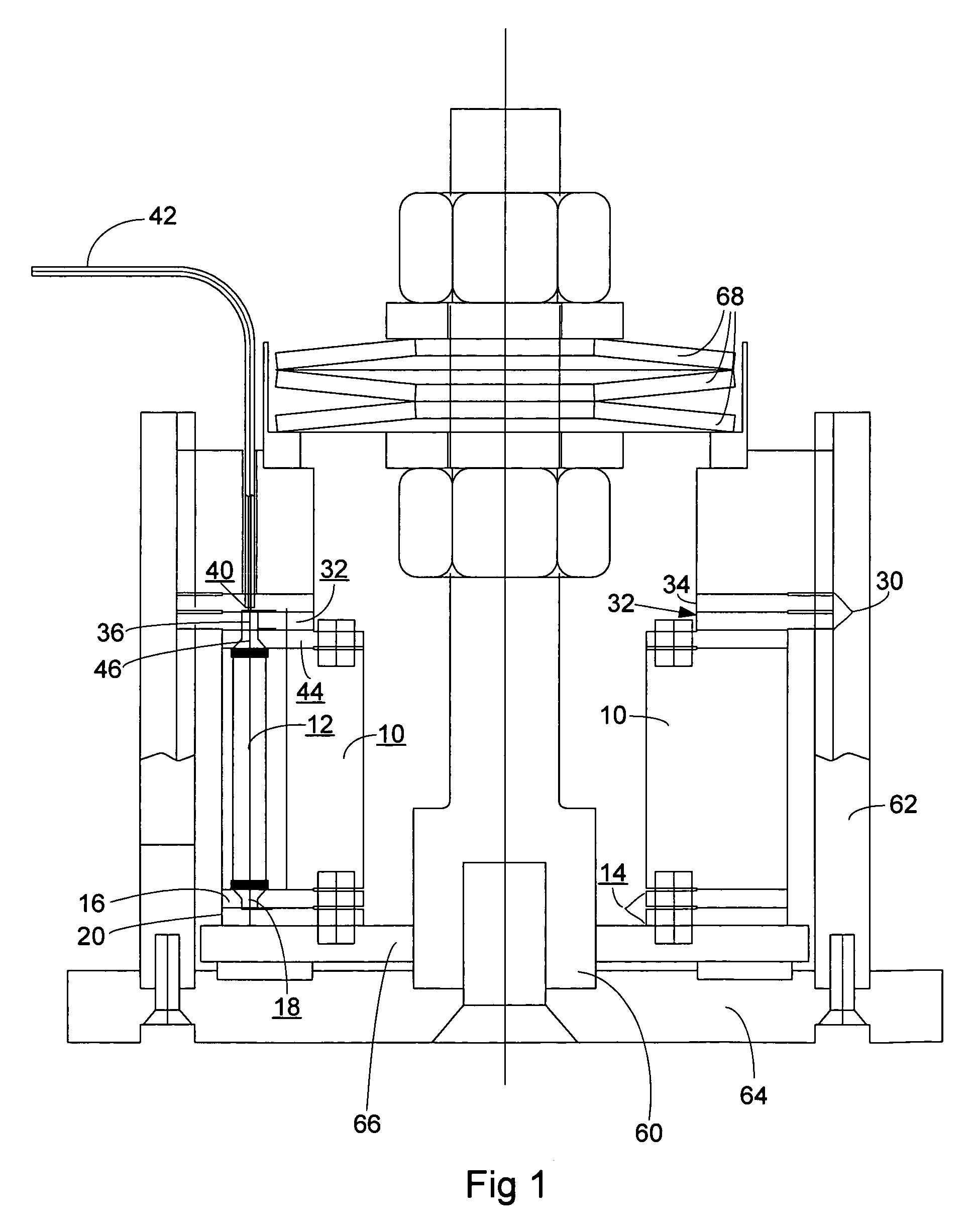

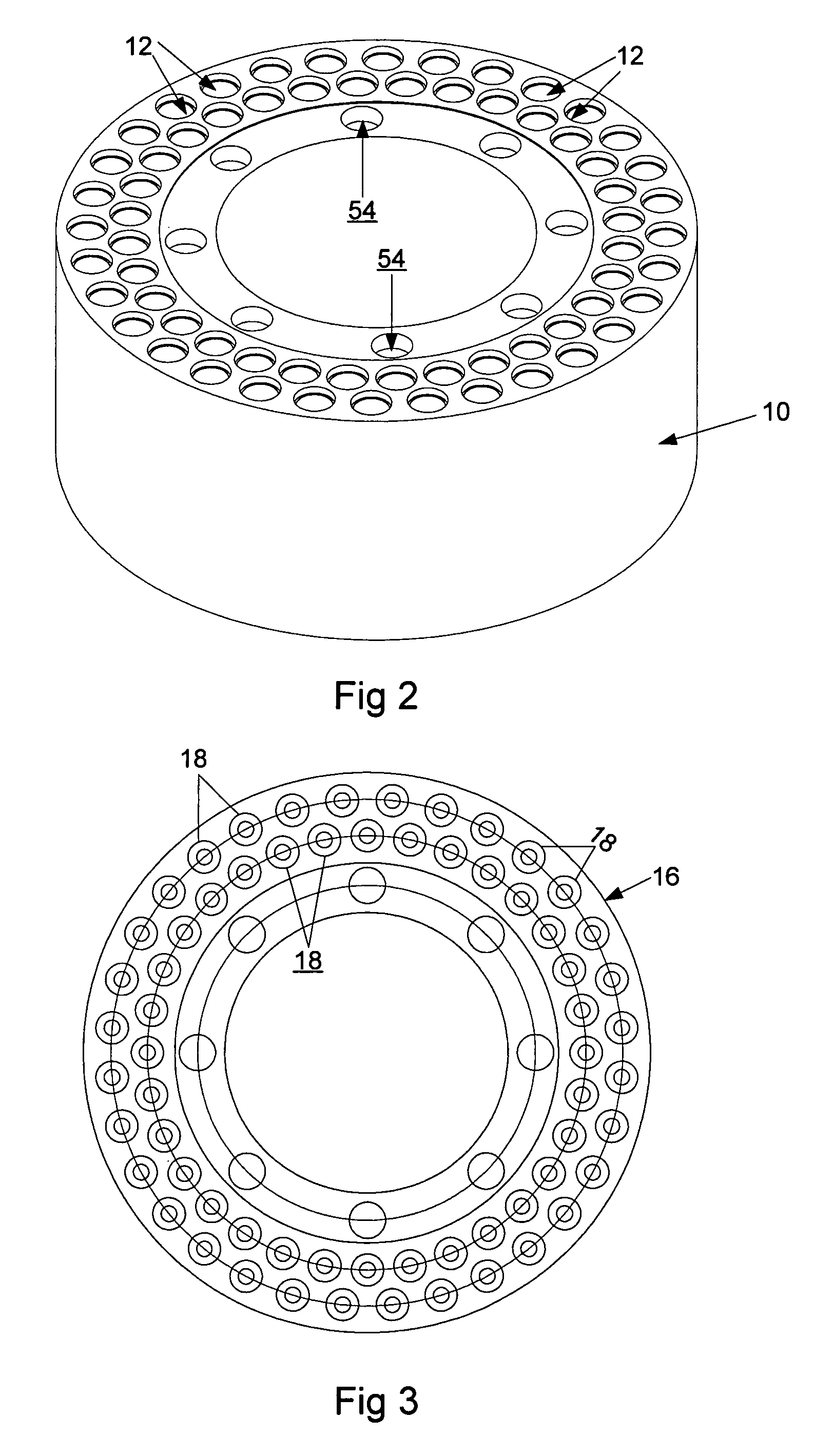

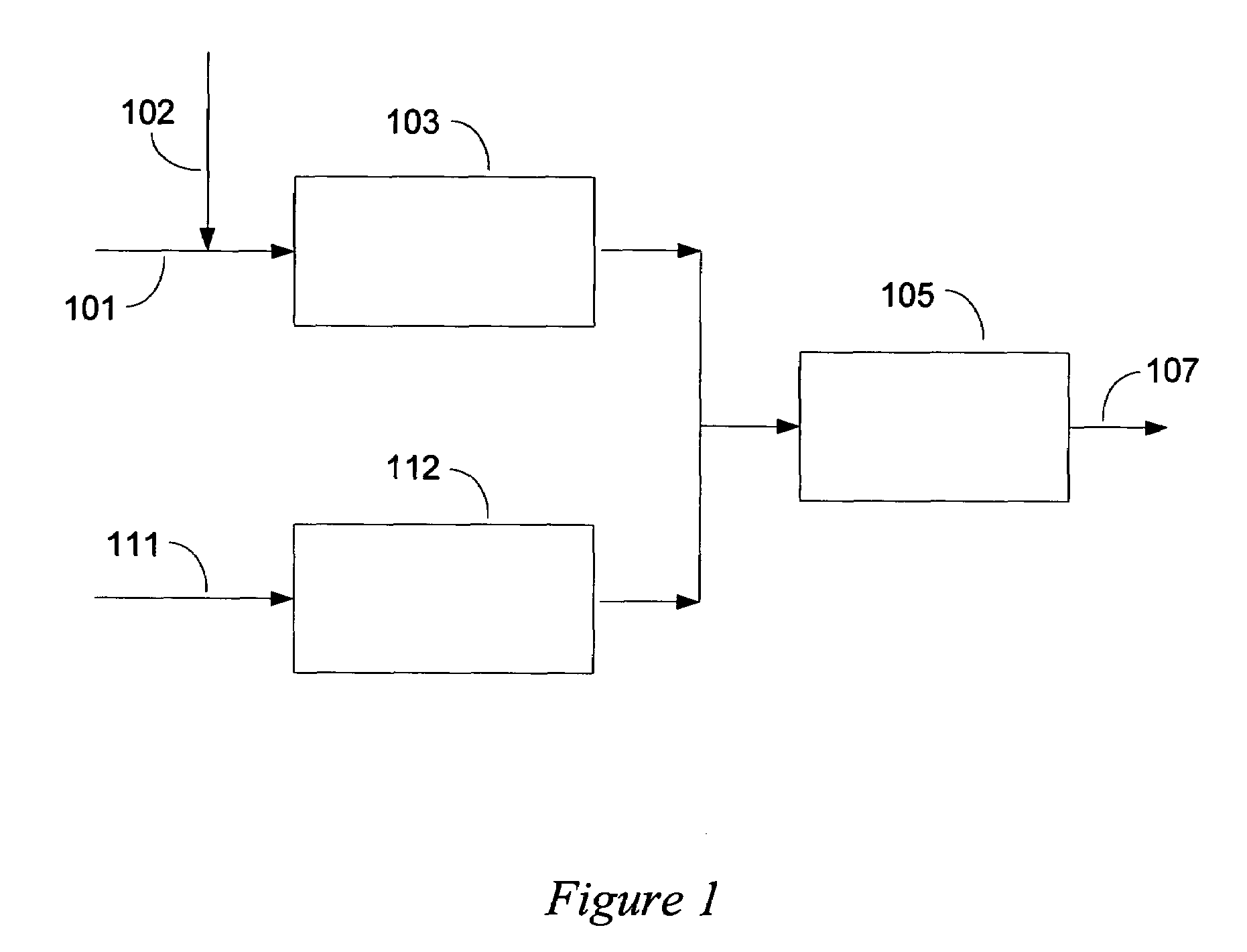

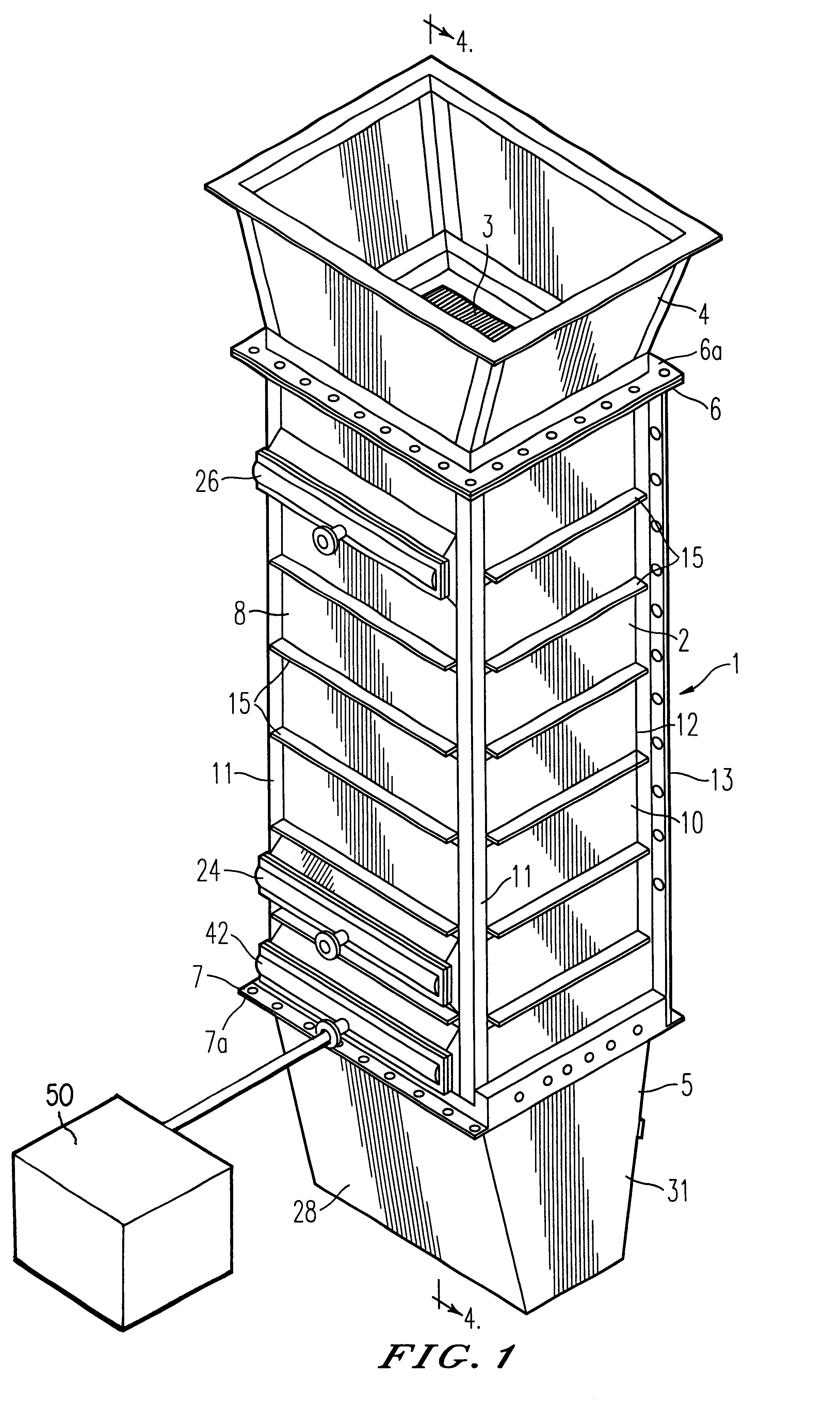

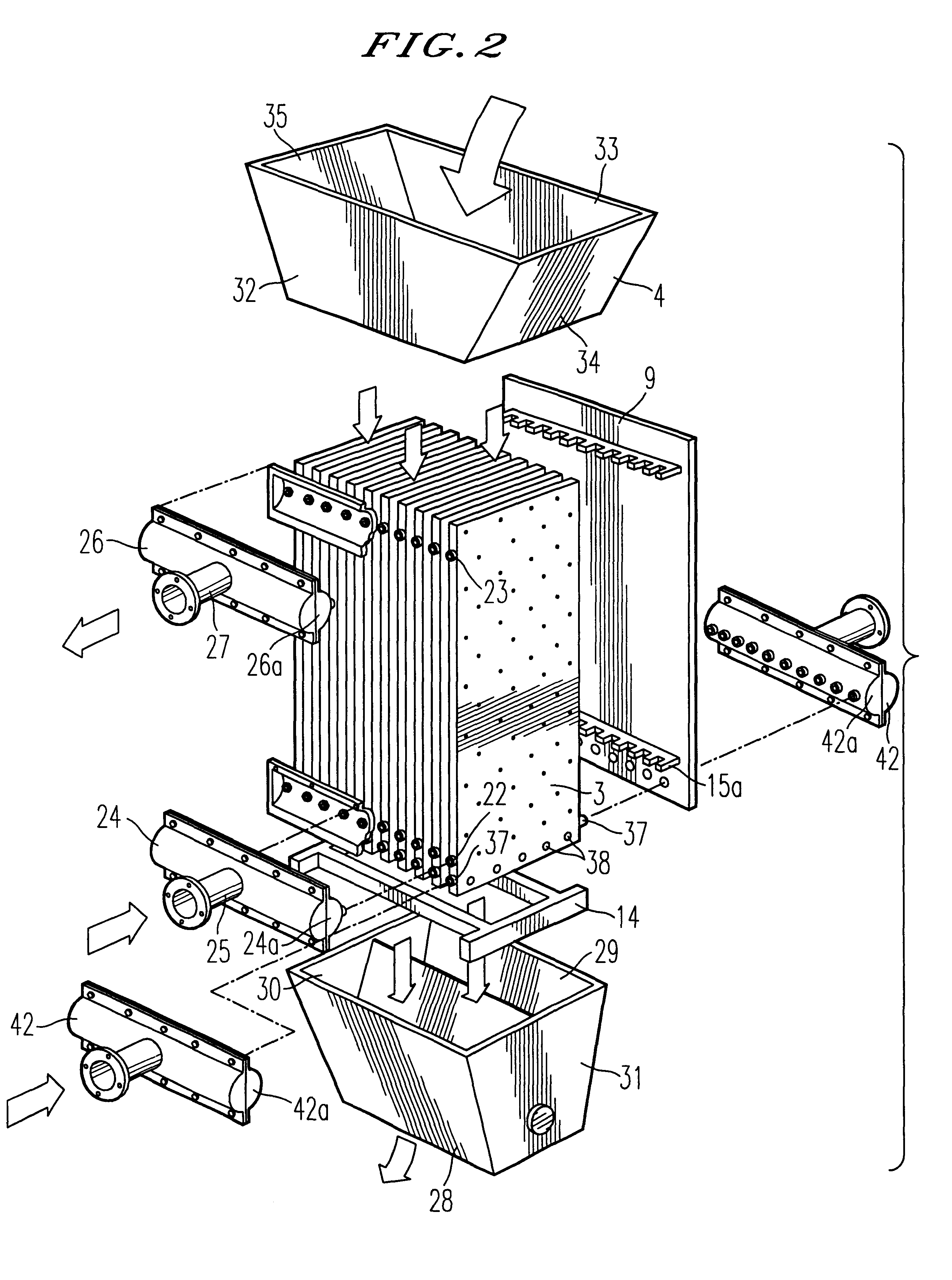

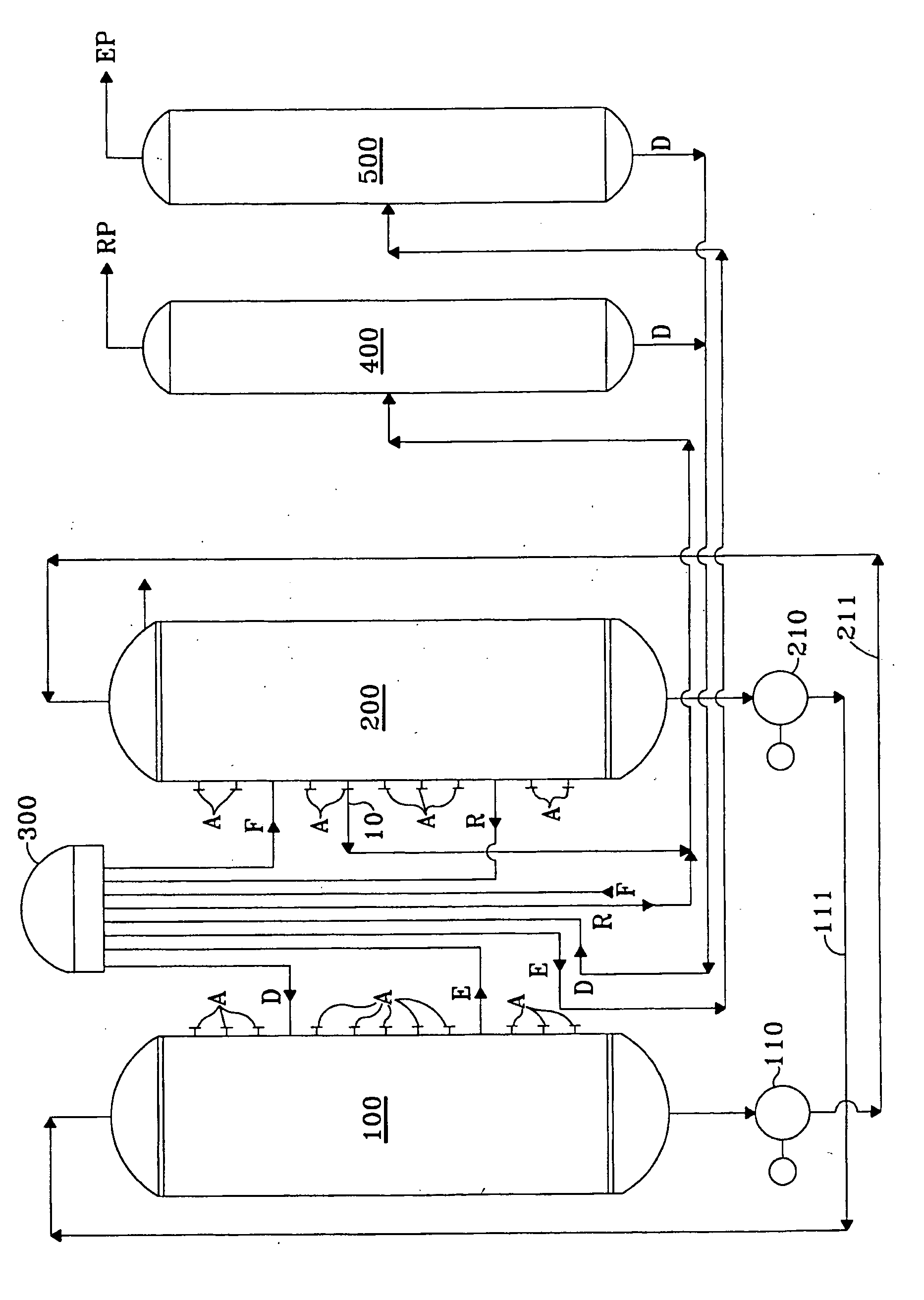

Miniature actual moving bed assembly

An apparatus is presented for separating chemicals using adsorption separation methods. The apparatus uses a plurality of adsorption units holding adsorbent, where the adsorption units positioned in a cylindrical spool, are serially connected and the spool is rotated to shift the relative position of the feeds and drawoffs to the apparatus.

Owner:UOP LLC

Method for making single-wall carbon nanotubes using supported catalysts

InactiveUS7250148B2Suitable for growthAppropriate densityMaterial nanotechnologyFibre chemical featuresCarbon nanotubeMoving bed

A method for growing single-wall carbon nanotubes involves preparing a catalyst comprising catalytic metals, iron and molybdenum, and magnesium oxide support material and contacting the catalyst with a gaseous carbon-containing feedstock at a sufficient temperature and for a sufficient contact time to make single-wall carbon nanotubes. The weight ratio of iron and molybdenum can range from about 2 to 1 to about 10 to 1 and the metals loading up to about 10 wt % of the MgO. The catalyst can be sulfided. Methane is a suitable carbon-containing feedstock. The process can be conducted in batch, continuous or semi-continuous modes, in reactors, such as a transport reactor, fluidized bed reactor, moving bed reactors and combinations thereof. The process also includes making single-wall carbon nanotubes with catalysts comprising at least one Group VIB or Group VIIIB metal on supports such as magnesia, zirconia, silica, and alumina, where the catalyst is sulfided.

Owner:UNIDYM

Moving bed biomass fractionation system and method

InactiveUS20080029233A1Improve production yieldIncrease pressureWashing/displacing pulp-treating liquorsDigestersChemical reactionFiltration

Countercurrent extraction of lignocellulosic biomass such as trees, grasses, shrubs, and agricultural residues or waste involves the separation of cellulose fibers from other constituents, for subsequent use in the manufacture of paper, plastics, ethanol, and other industrial chemicals. Systems and methods involve continuous, multiple processing steps that may include chemical reactions with mixing at elevated temperature and / or pressure, efficient reagent or solvent utilization, filtration at elevated temperature and / or pressure, controlled discharge of liquid and solid products, and energy recuperation.

Owner:PUREVISION TECH

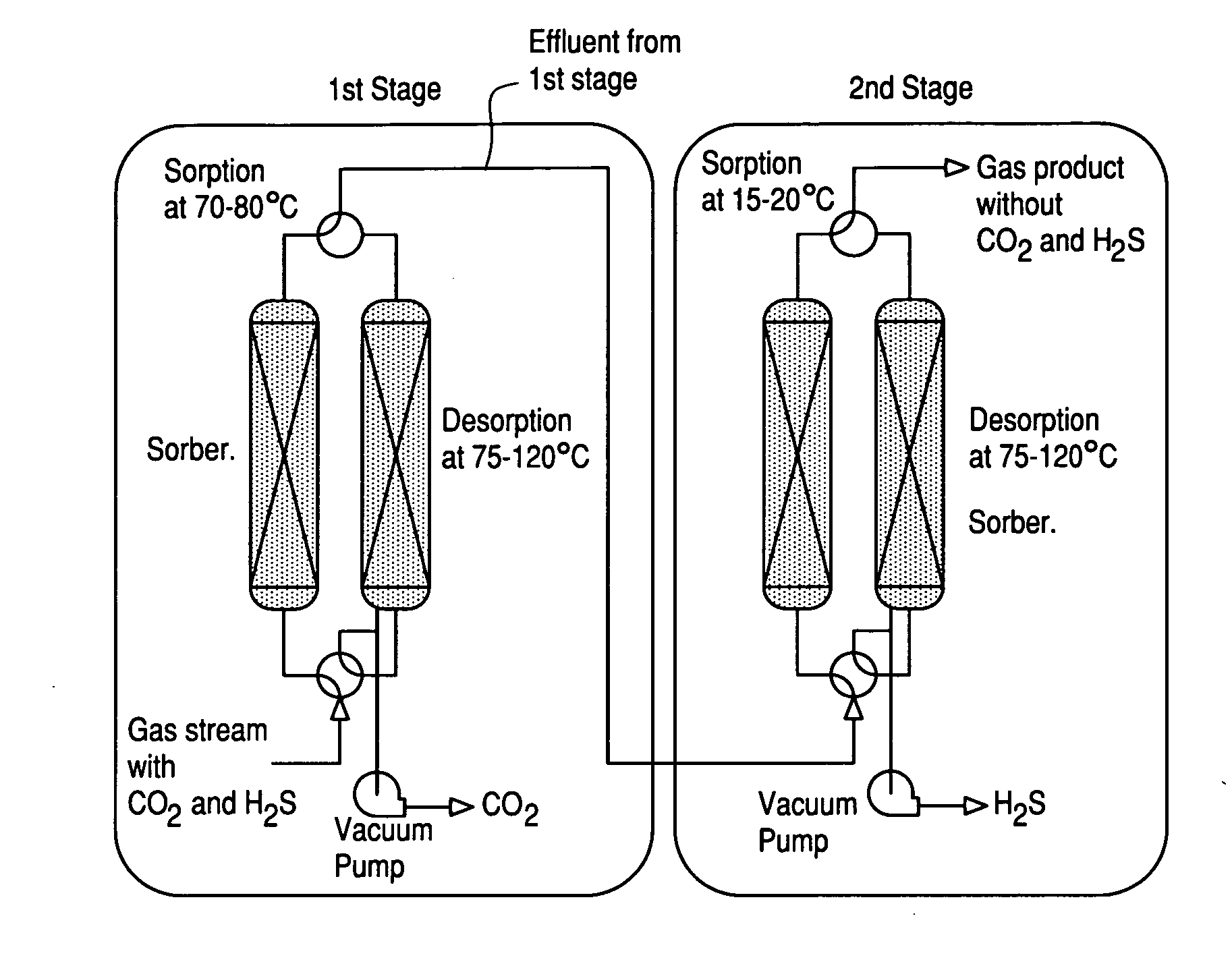

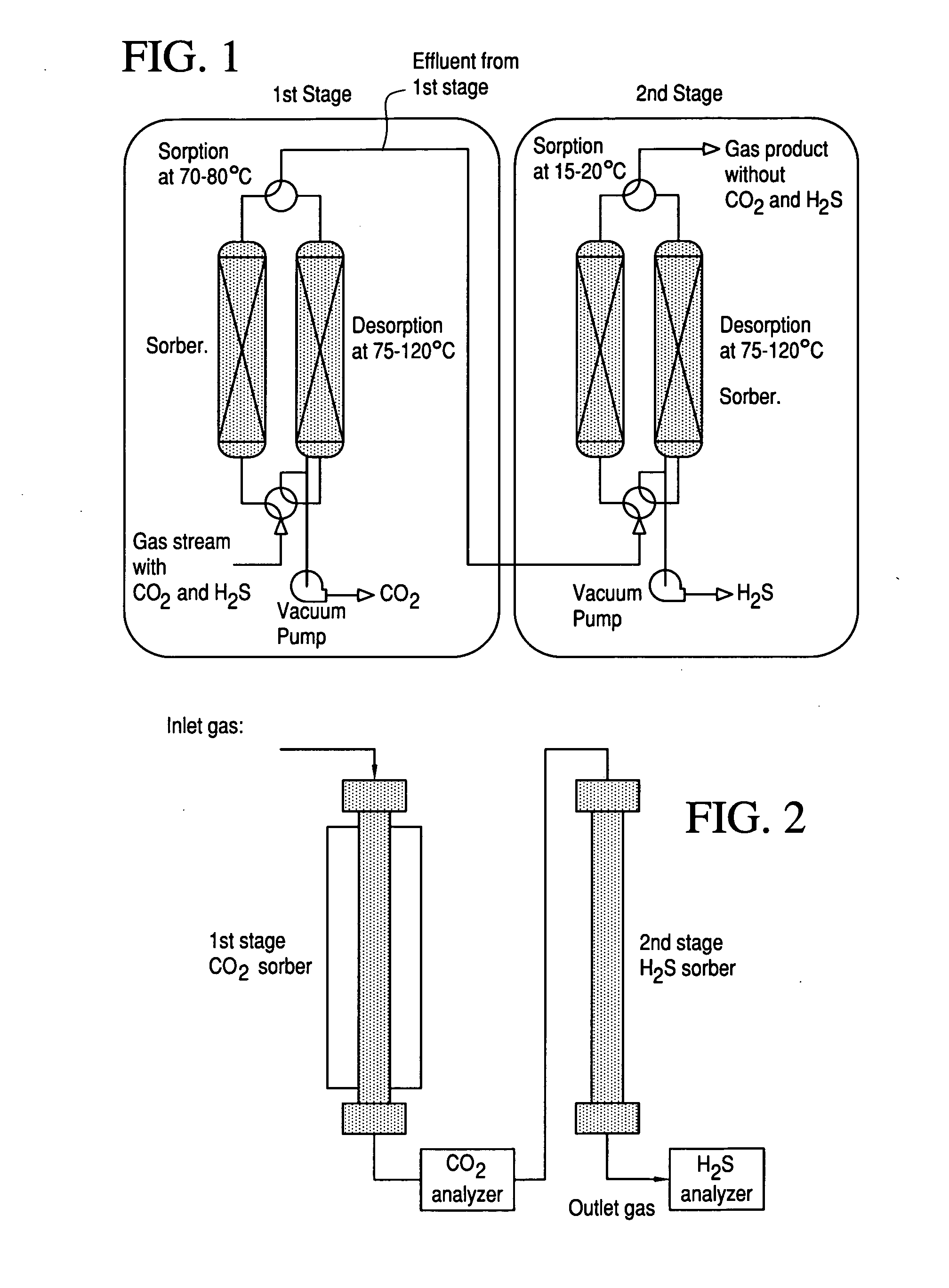

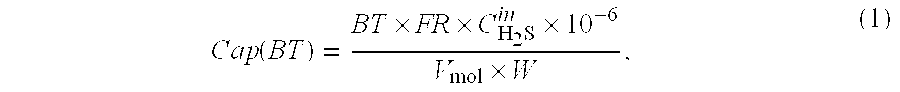

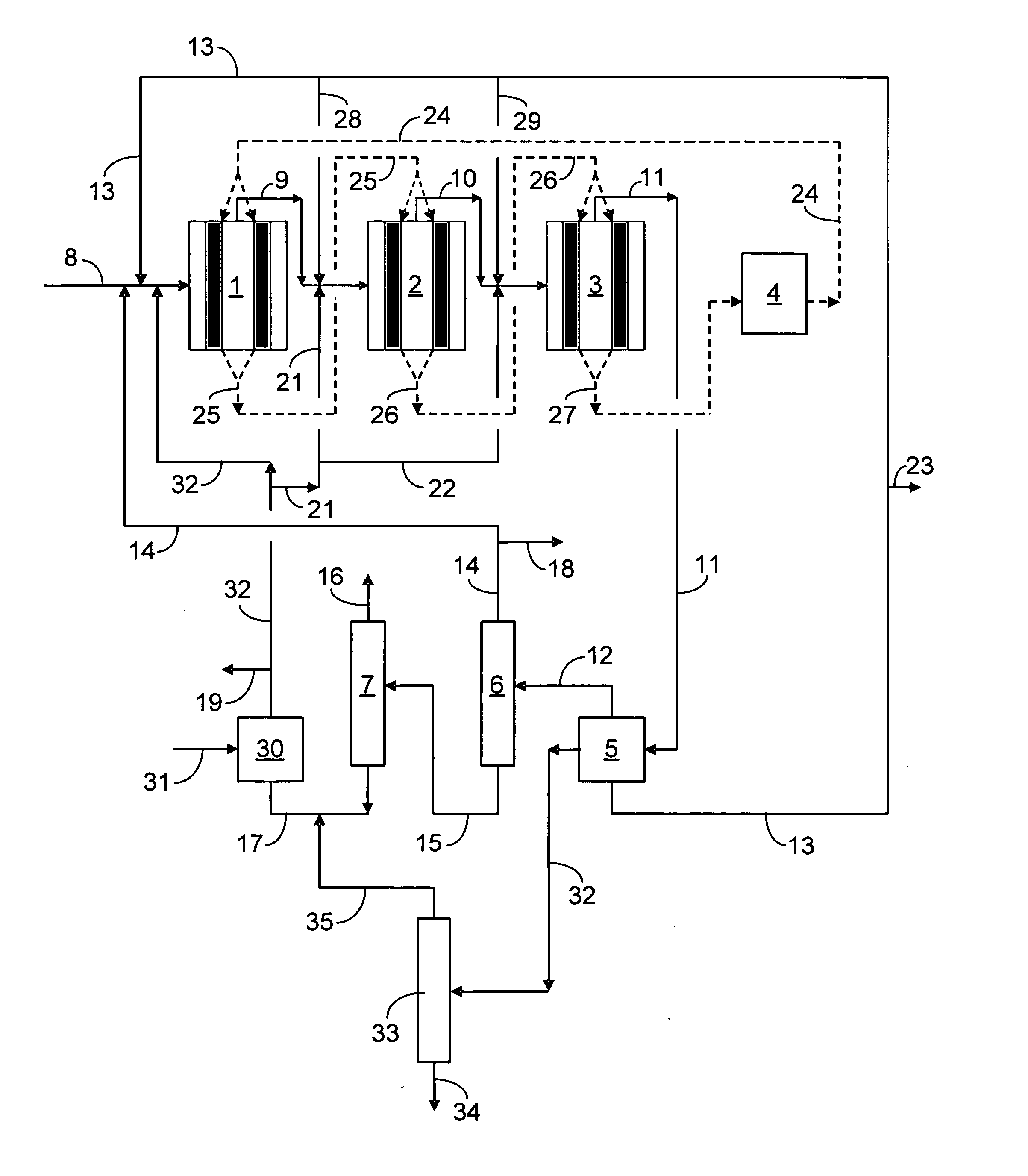

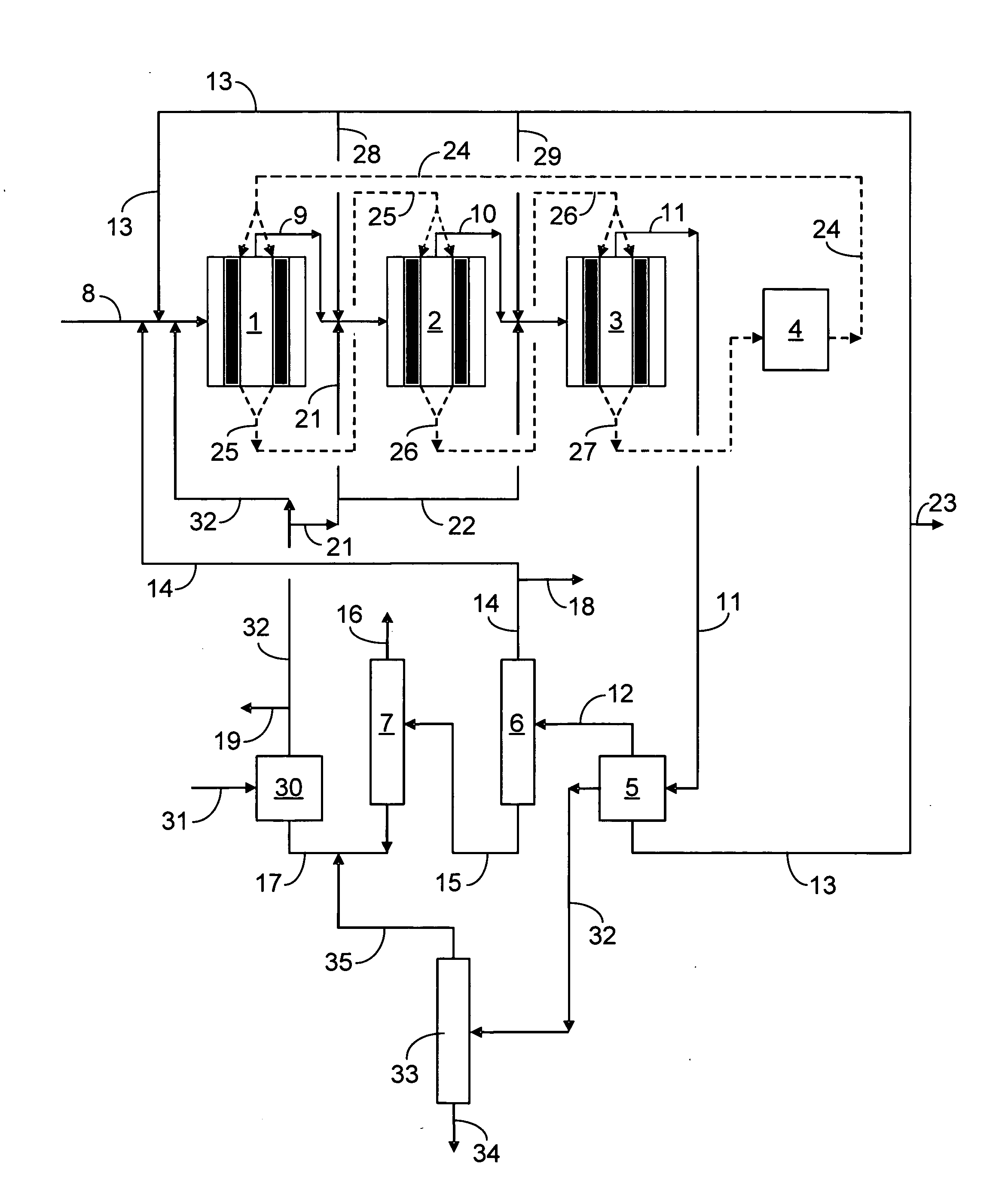

Novel sorbents and purification and bulk separation of gas streams

InactiveUS20080264254A1Large capacityLittle and no corrosive effectNitrous oxide captureGas treatmentSorbentDesorption

Porous-material-supported polymer sorbents and process for removal of undesirable gases such as H2S, COS, CO2, N2O, NO, NO2, SO2, SO3, HCl, HF, HCN, NH3, H2O, C2H5OH, CH3OH, HCHO, CHCl3, CH2Cl2, CH3Cl, CS2, C4H4S, CH3SH, and CH3—S—CH3 from various gas streams such as natural gas, coal / biomass gasification gas, biogas, landfill gas, coal mine gas, ammonia syngas, H2 and oxo-syngas, Fe ore reduction gas, reformate gas, refinery process gases, indoor air, fuel cell anode fuel gas and cathode air are disclosed. The sorbents have numerous advantages such as high breakthrough capacity, high sorption / desorption rates, little or no corrosive effect and are easily regenerated. The sorbents may be prepared by loading H2S—, COS—, CO2—, N2O, NO—, NO2—, SO2—, SO3—, HCl—, HF—, HCN—, NH3—, H2O—, C2H5OH—, CH3OH—, HCHO—, CHCl3—, CH2Cl2—, CH3Cl—, CS2—, C4H4S—, CH3SH—, CH3—S—CH3-philic polymer(s) or mixtures thereof, as well as any one or more of H2S—, COS—, CO2—, N2O, NO—, NO2—, SO2—, SO3—, HCl—, HF—, HCN—, NH3—, H2O—, C2H5OH—, CH3OH—, HCHO—, CHCl3—, CH2Cl2—, CH3Cl—, CS2—, C4H4S—, CH3SH—, CH3—S—CH3-philic compound(s) or mixtures thereof on to porous materials such as mesoporous, microporous or macroporous materials. The sorbents may be employed in processes such as one-stage and multi-stage processes to remove and recover H2S, COS, CO2, N2O, NO, NO2, SO2, SO3, HCl, HF, HCN, NH3, H2O, C2H5OH, CH3OH, HCHO, CHCl3, CH2Cl2, CH3Cl, CS2, C4H4S, CH3SH and CH3—S—CH3 from gas streams by use of, such as, fixed-bed sorbers, fluidized-bed sorbers, moving-bed sorbers, and rotating-bed sorbers.

Owner:PENN STATE RES FOUND +1

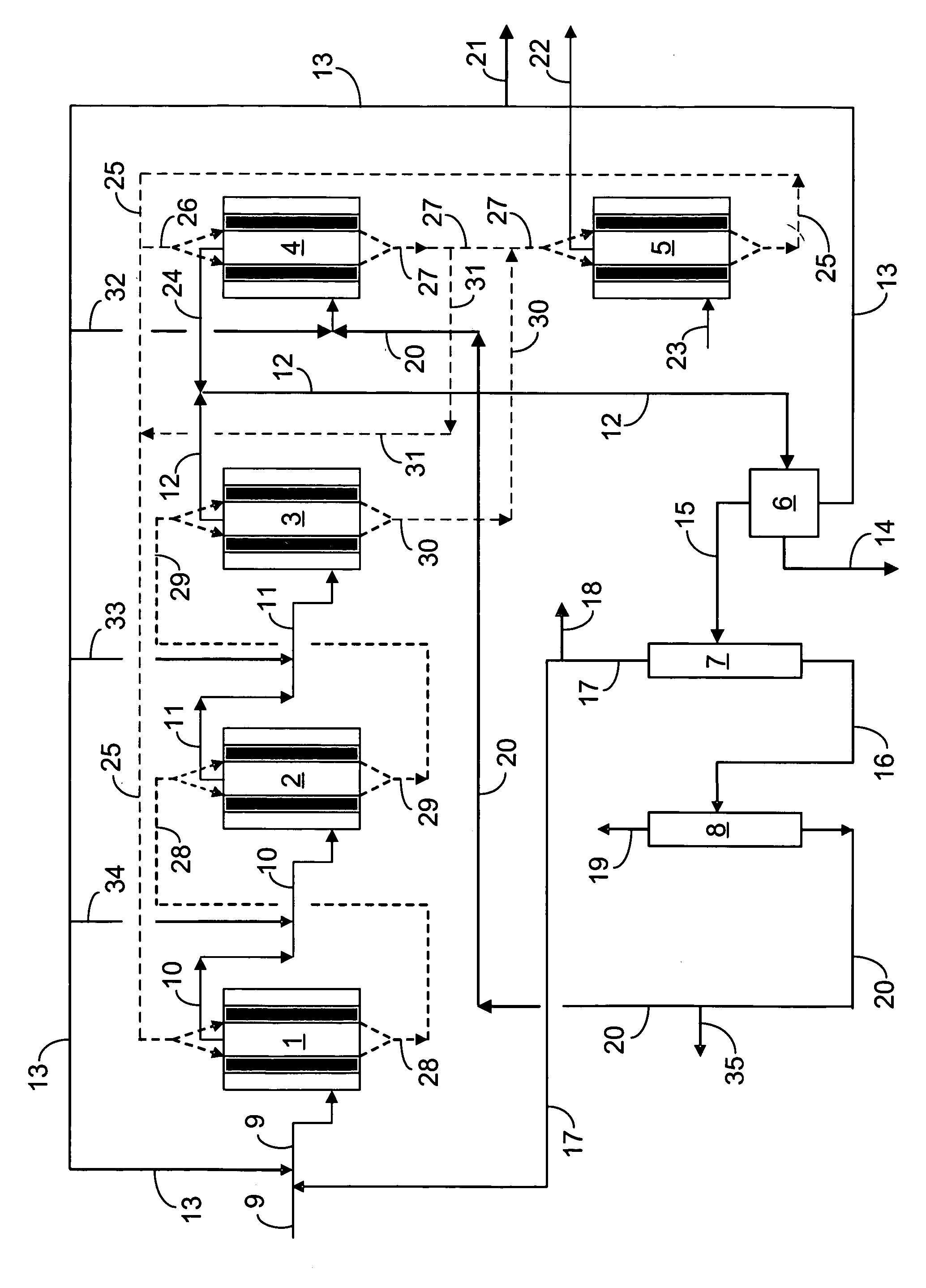

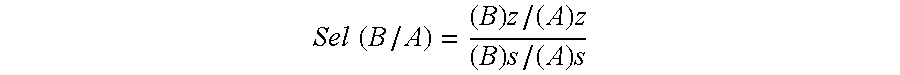

Selective conversion of oxygenate to propylene using moving bed technology and a hydrothermally stabilized dual-function catalyst

ActiveUS20060106270A1Improve economyAvoid severe deactivationMolecular sieve catalystCatalystsMolecular sieveFixed bed

The average propylene cycle selectivity of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the hydrocarbon synthesis portion of the OTP flow scheme in lieu of the fixed bed technology of the prior art; 2) a hydrothermally stabilized and dual-functional catalyst system comprising a molecular sieve having dual-function capability dispersed in a phosphorus-modified alumina matrix containing labile phosphorus and / or aluminum anions; and 3) a catalyst on-stream cycle time of 400 hours or less. These provisions stabilize the catalyst against hydrothermal deactivation and hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield near or at essentially start-of-cycle levels.

Owner:UOP LLC

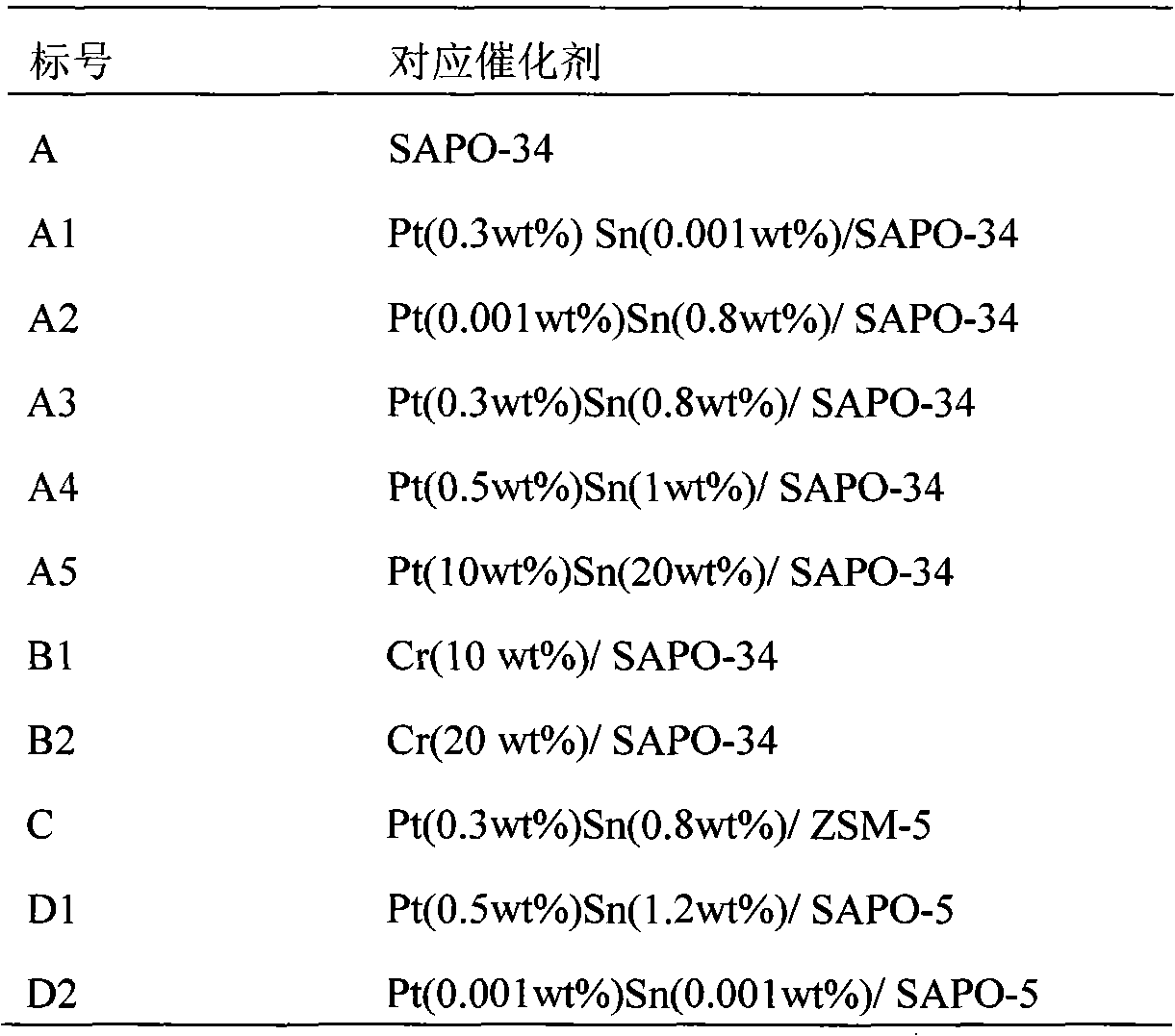

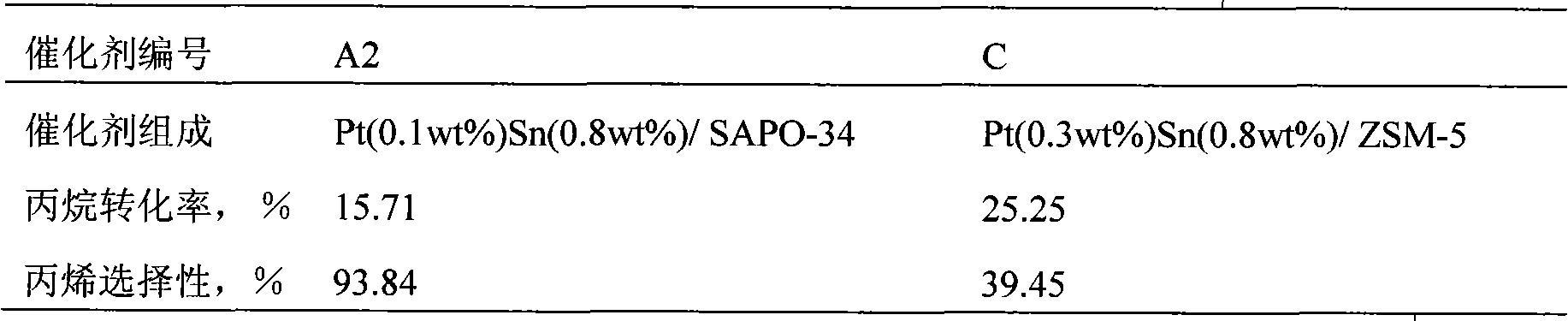

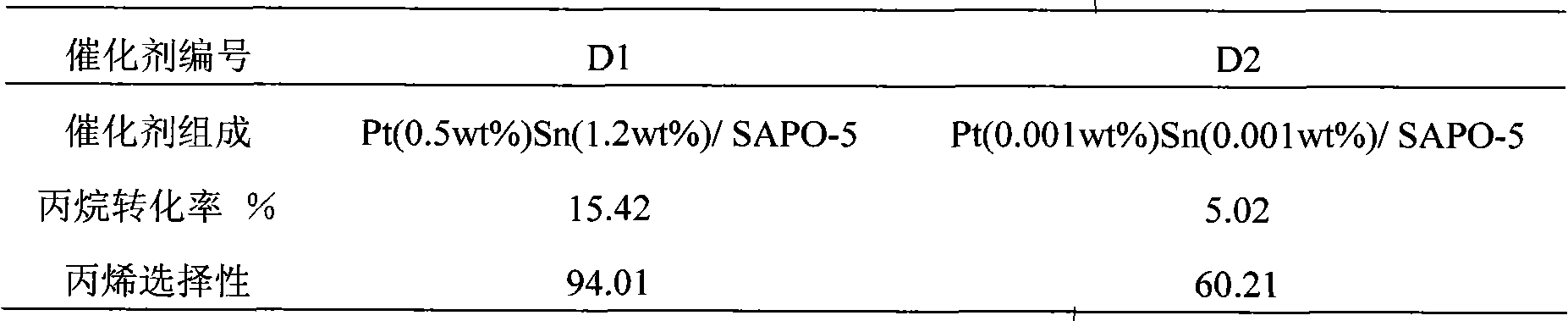

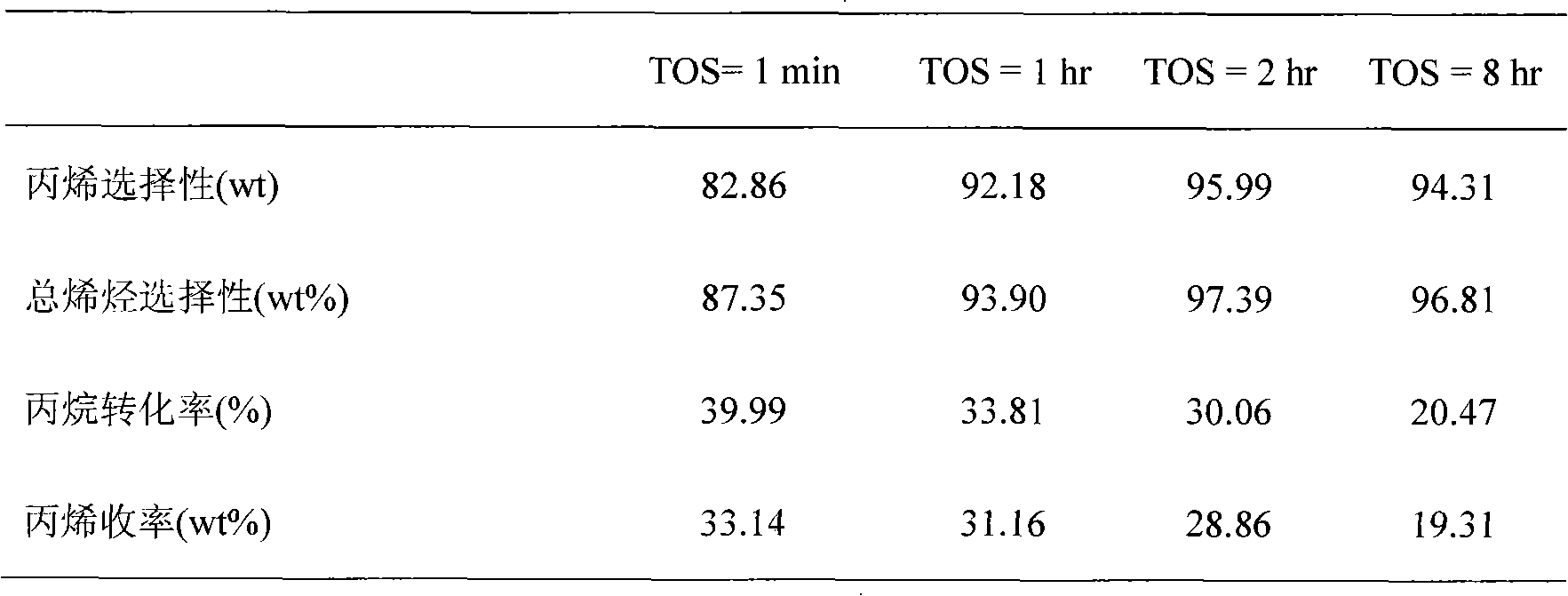

Catalyst for preparing olefin by dehydrogenating low-carbon alkane, and preparation method and application thereof

InactiveCN101623633AHigh selectivitySuitable for acidityCatalyst activation/preparationHydrocarbonsAlkaneMolecular sieve

The invention relates to a catalyst for preparing olefin by dehydrogenating low-carbon alkane, and a preparation method and an application thereof, which belong to the technical field of the preparation of basic organic chemical raw materials. The catalyst is prepared by a dipping method of using an aluminium silicophosphate molecular sieve as a carrier, VIII group or VIB group elements as active constituents and IVA group elements as an auxiliary agent. In the process for preparing olefin by dehydrogenating low-carbon alkane, the catalyst is firstly reduced by hydrogen gas, then participates in a reaction, and is finally regenerated. Compared with the existing catalyst for preparing olefin by dehydrogenating low-carbon alkane, the catalyst has a pore shape selecting function and moderate acidity, thereby the selectivity of the low-carbon alkane can reach more than 90 percent in the process for preparing olefin by dehydrogenating low-carbon alkane. The preparation method of the catalyst is simple; the regeneration process flow of the reaction has a large choice, a fixed bed, a fluidized bed or a moving bed can be used as a reactor, and the catalyst can be regenerated in the reactor or outside the reactor.

Owner:TSINGHUA UNIV

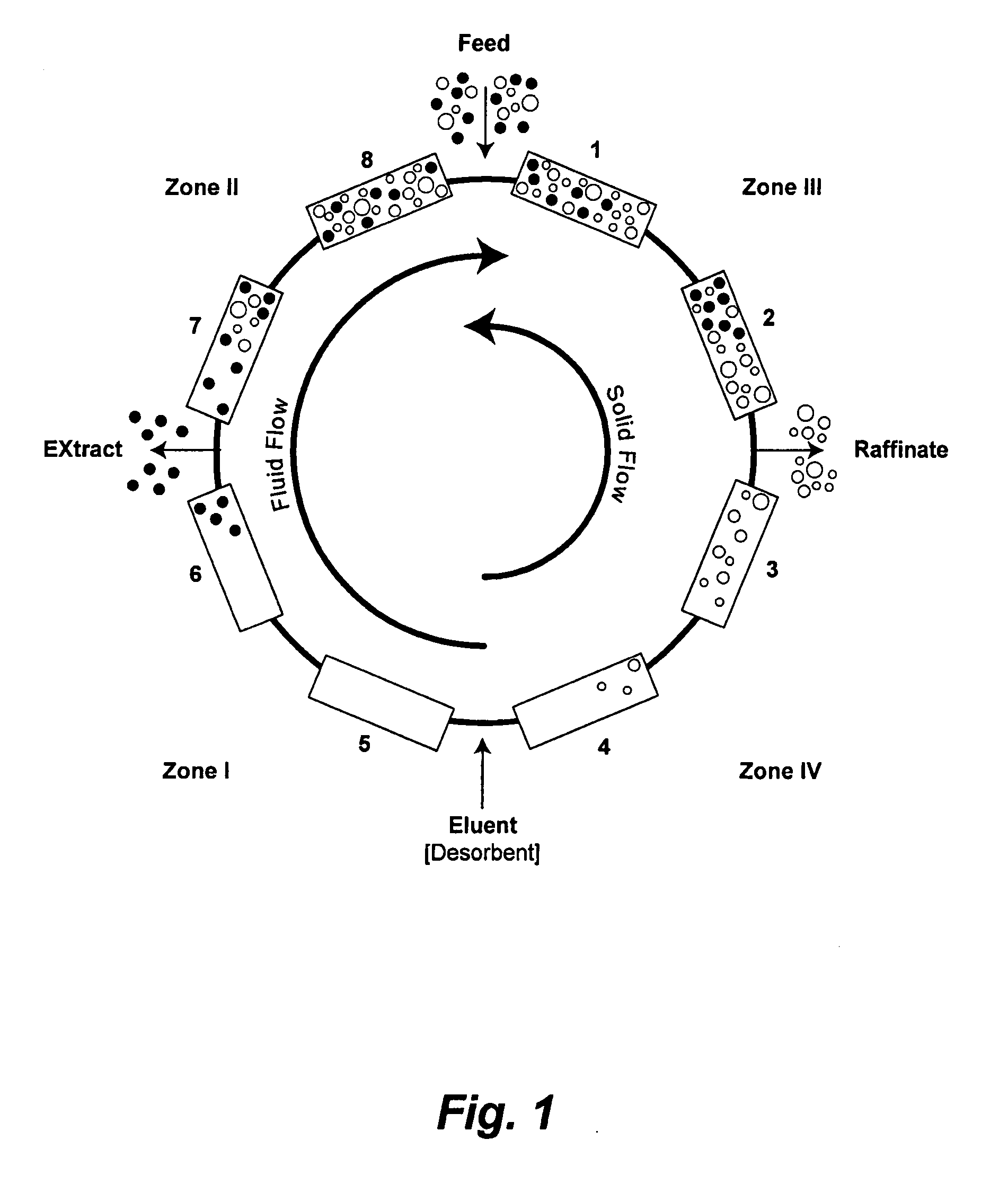

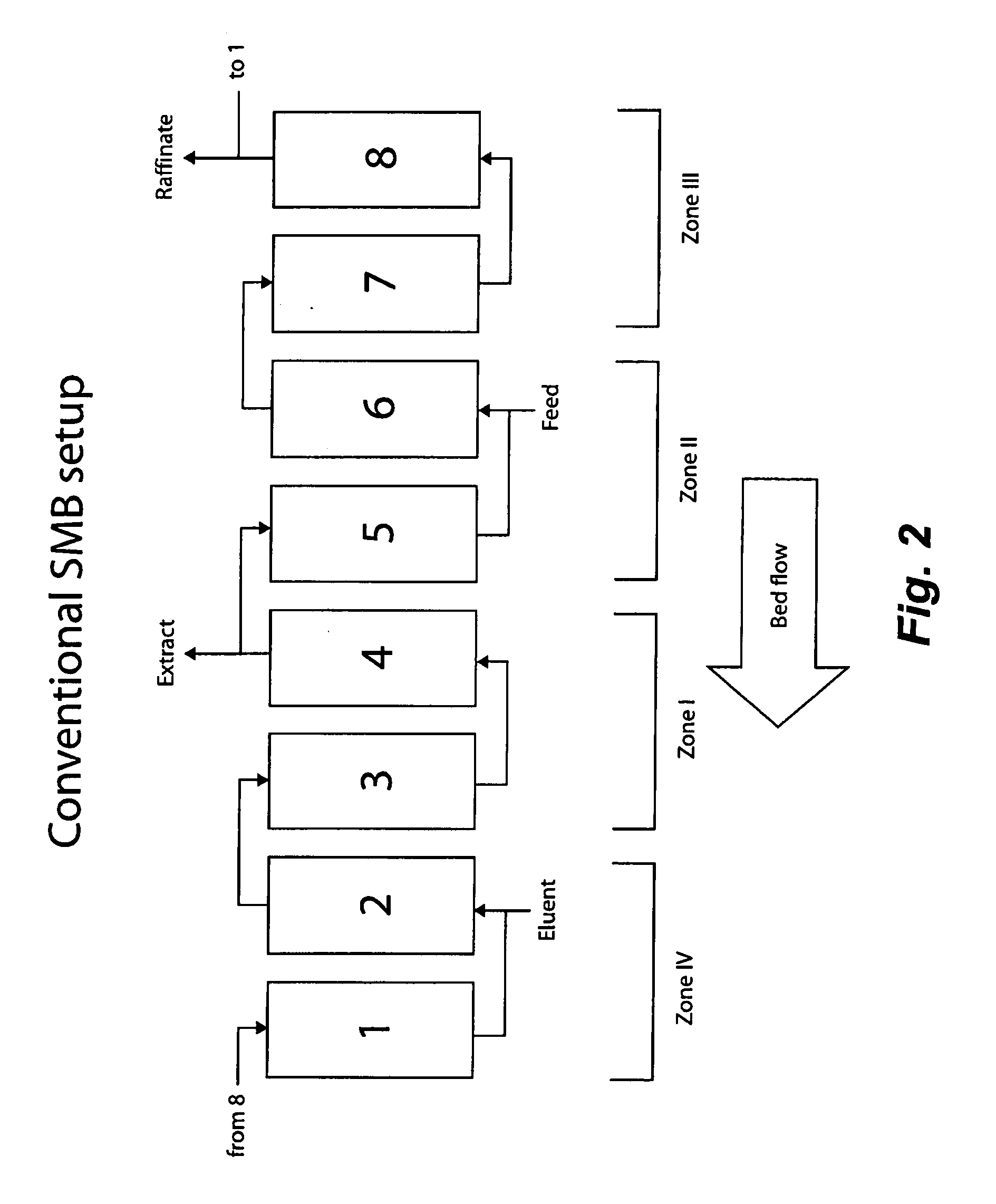

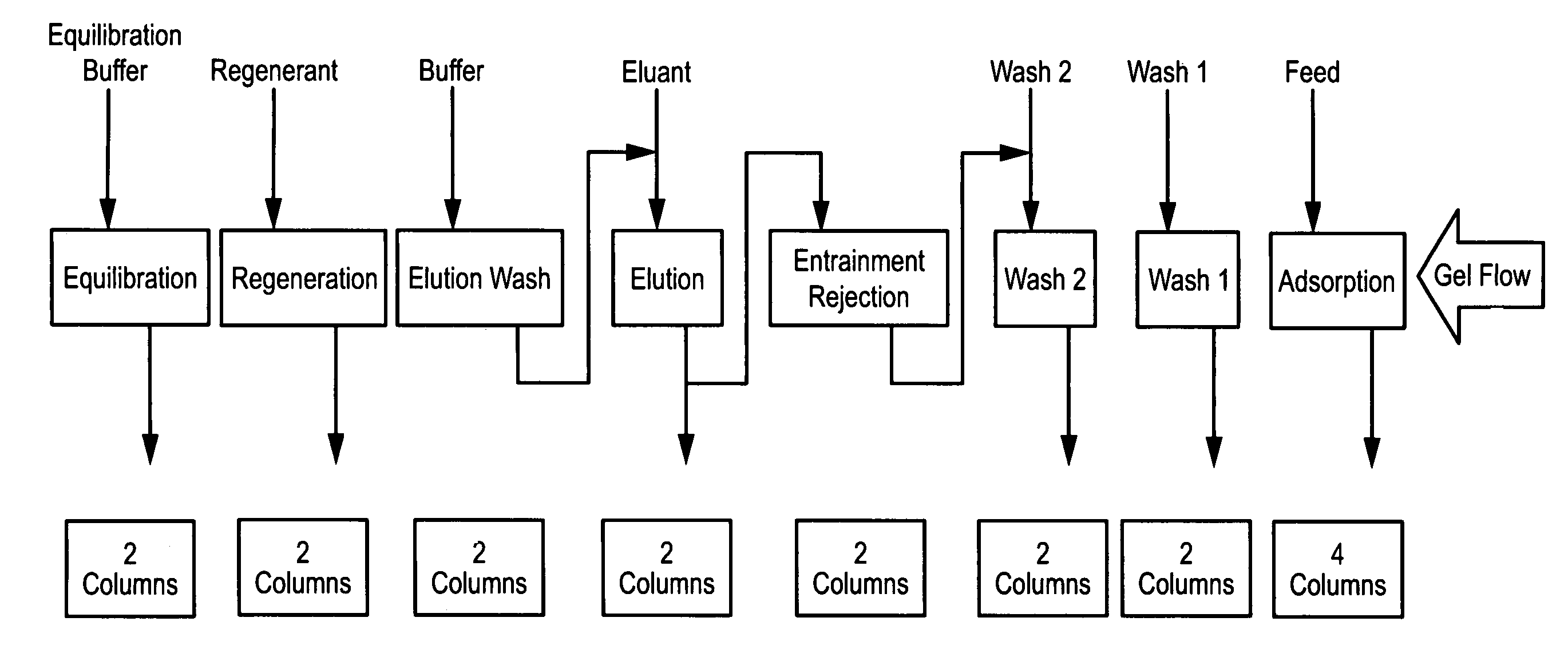

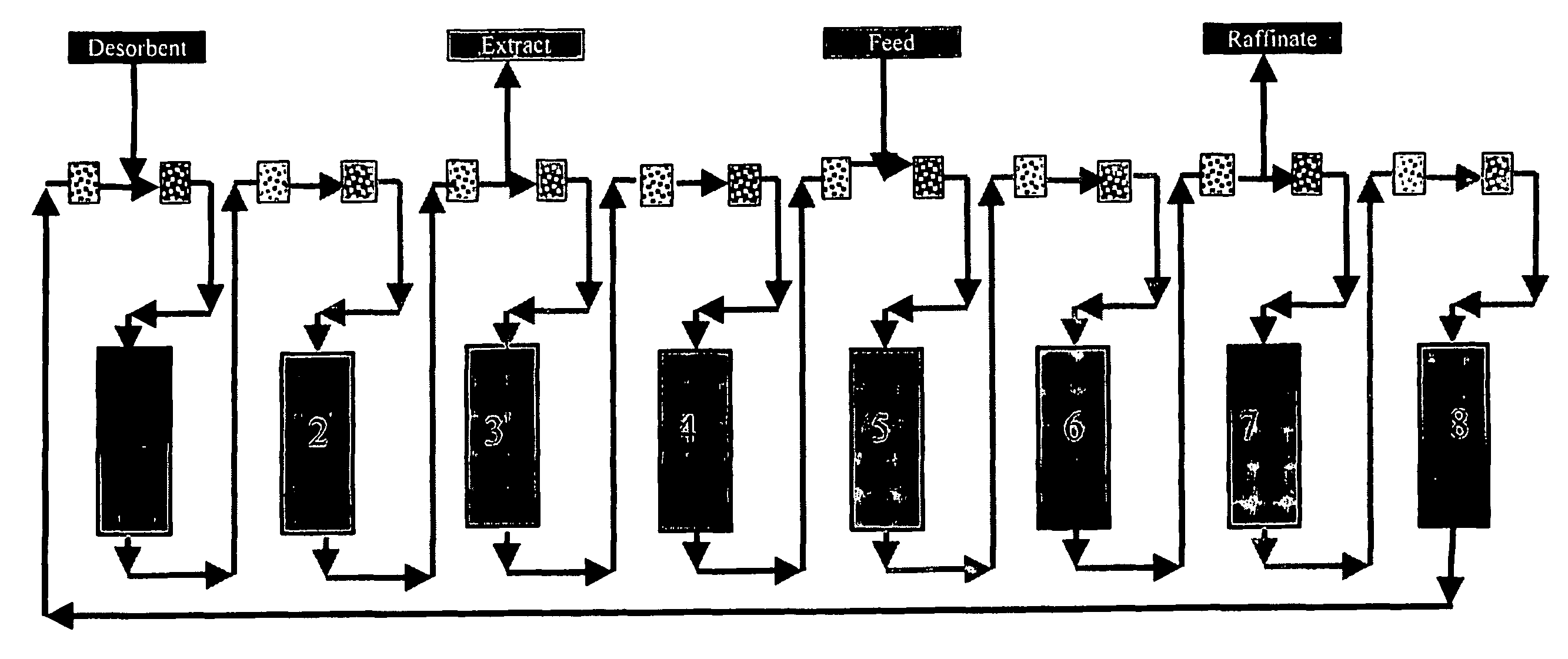

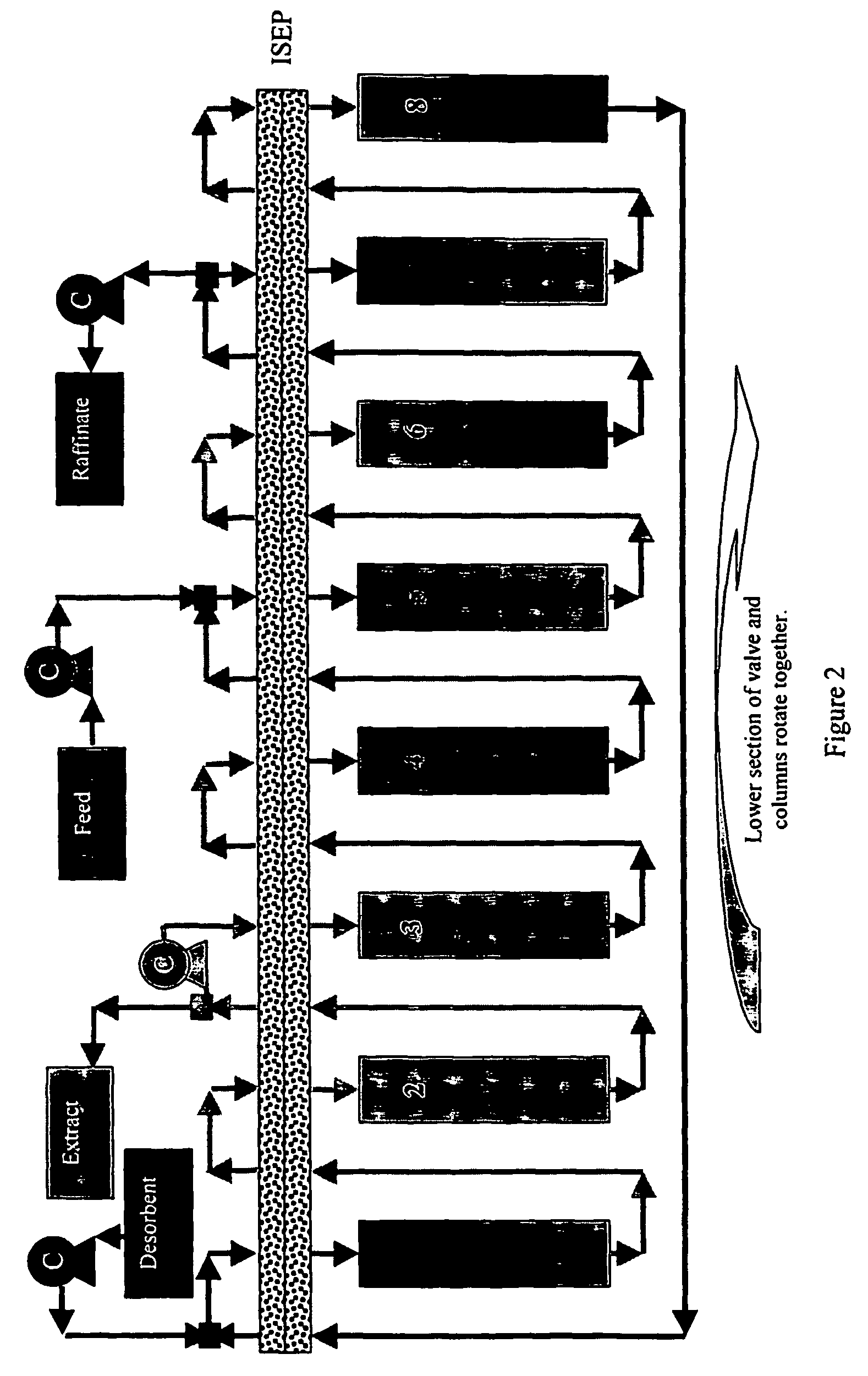

Product recovery from simulated-moving-bed adsorption

Product purity from or capacity of a simulated-moving-bed adsorptive separation process is increased by flushing the contents of the transfer line previously used to remove the raffinate stream away from the adsorbent chamber, preferably into the raffinate column used to separate desorbent from raffinate product. Preferably a stream from the adsorbent chamber at an intermediate point between the feed entry point and raffinate withdrawal is used as the flushing liquid. This flush step eliminates the passage of a quantity of the raffinate material into the adsorbent chamber in the transfer-line flush period or when the process conduit is subsequently used to charge the feed stream to the adsorbent chamber.

Owner:UOP LLC

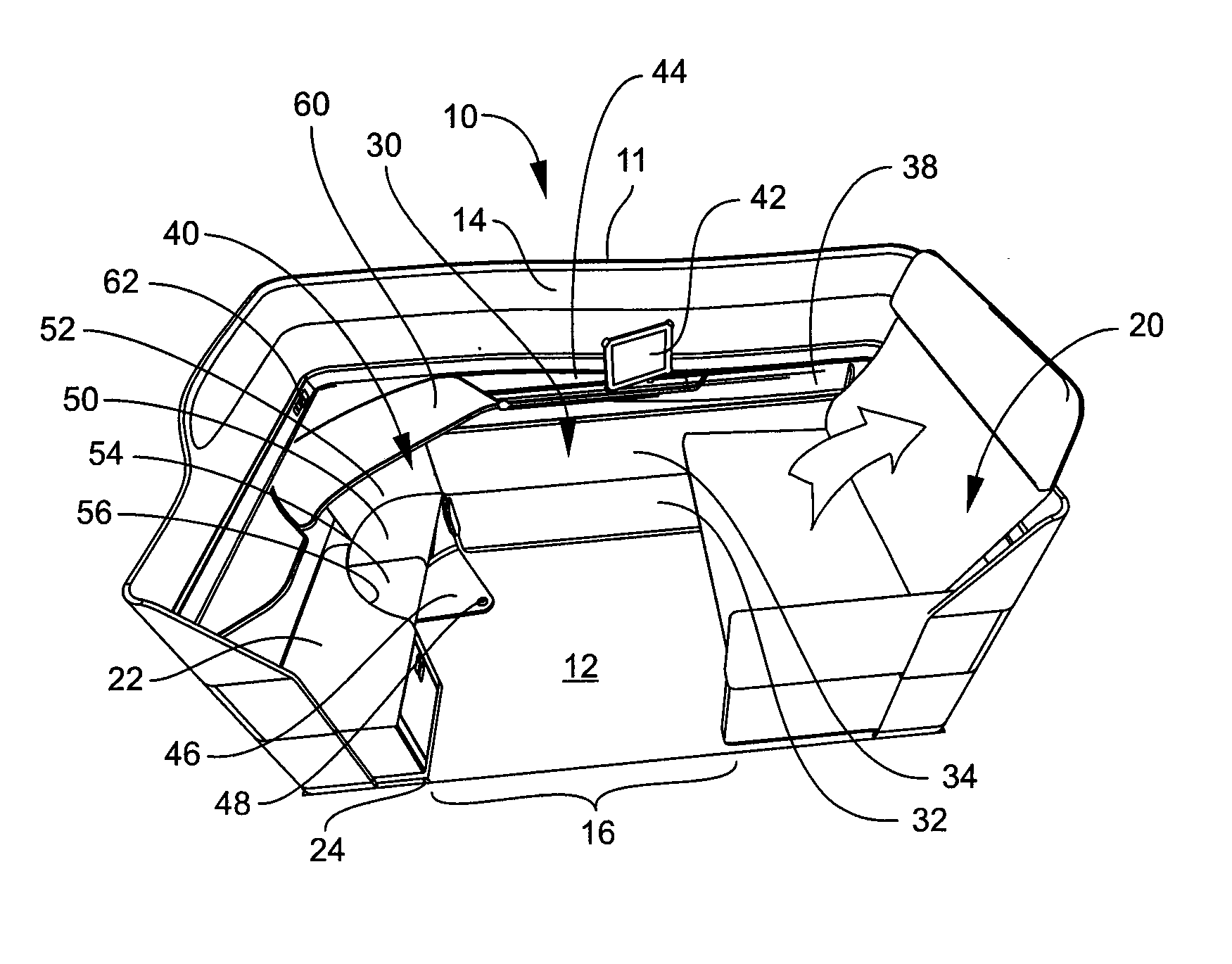

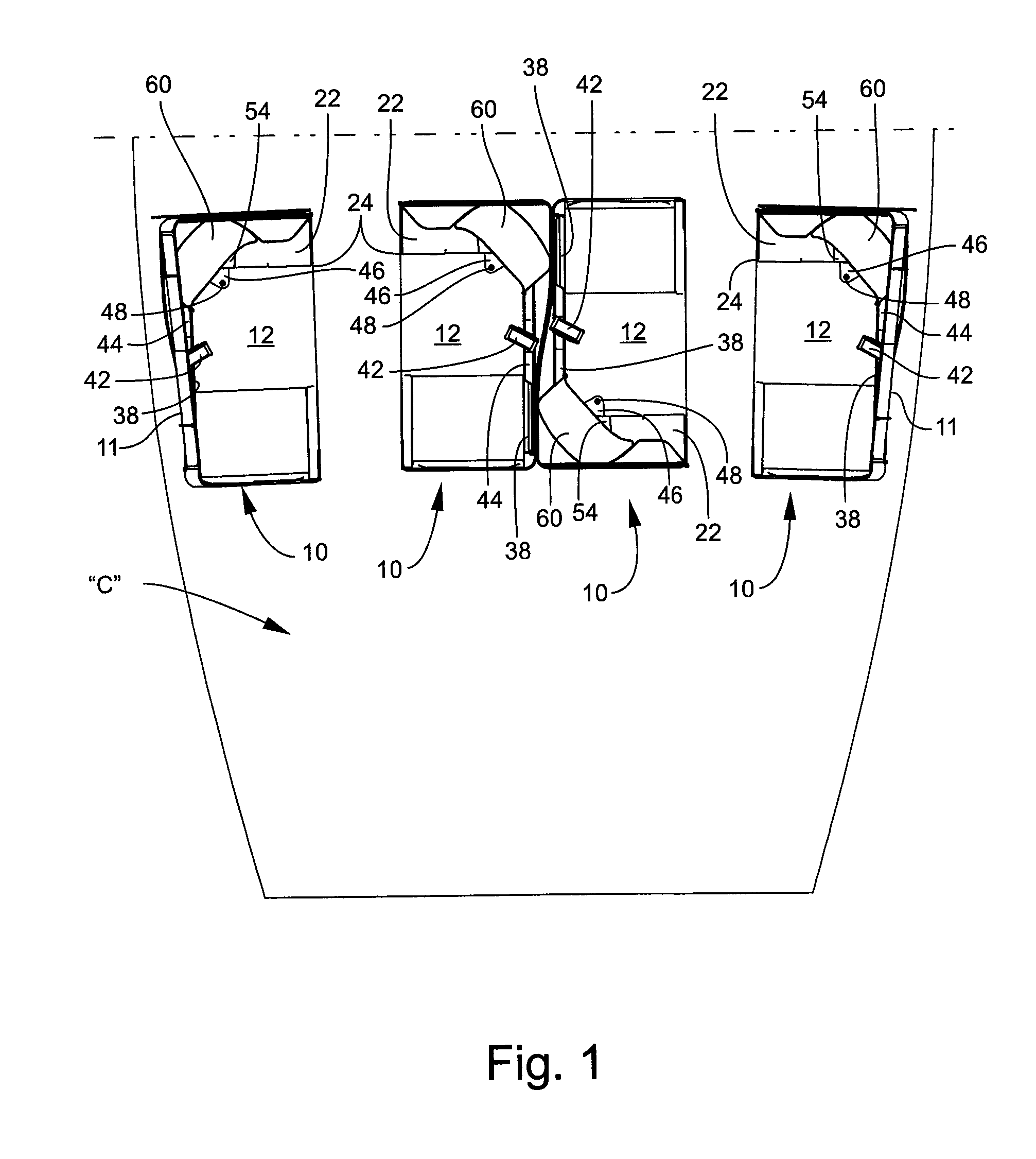

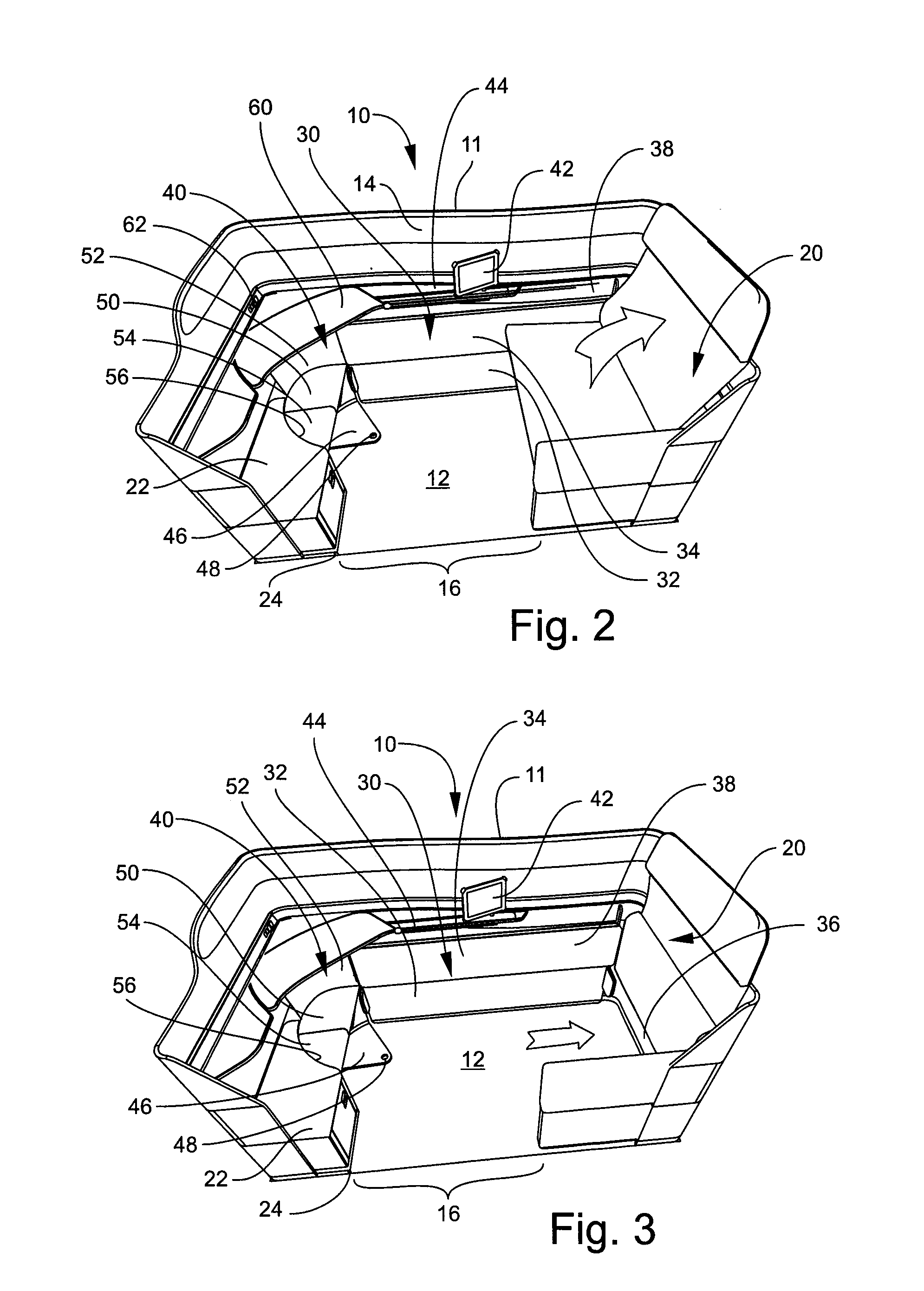

Flexible-usage travel suite

ActiveUS20120318918A1Seating arrangementsAir-treatment apparatus arrangementsAerospace engineeringStructural engineering

A flexible-usage travel suite that includes an enclosure having a floor, surrounding walls defining a predetermined area and an egress / ingress opening. A seat is positioned adjacent a first side of the enclosure and is moveable between a deployed seating configuration and a stowed storage configuration against the first side of the enclosure. A bed is positioned adjacent a second side of the enclosure and is moveable between a deployed lie-flat configuration when the seat is in its stowed storage configuration, and a stowed storage position when the seat is in its deployed seating configuration. A utility chair and utility table are positioned within the enclosure and are moveable among a stowed position and a use position.

Owner:BE AEROSPACE INCORPORATED

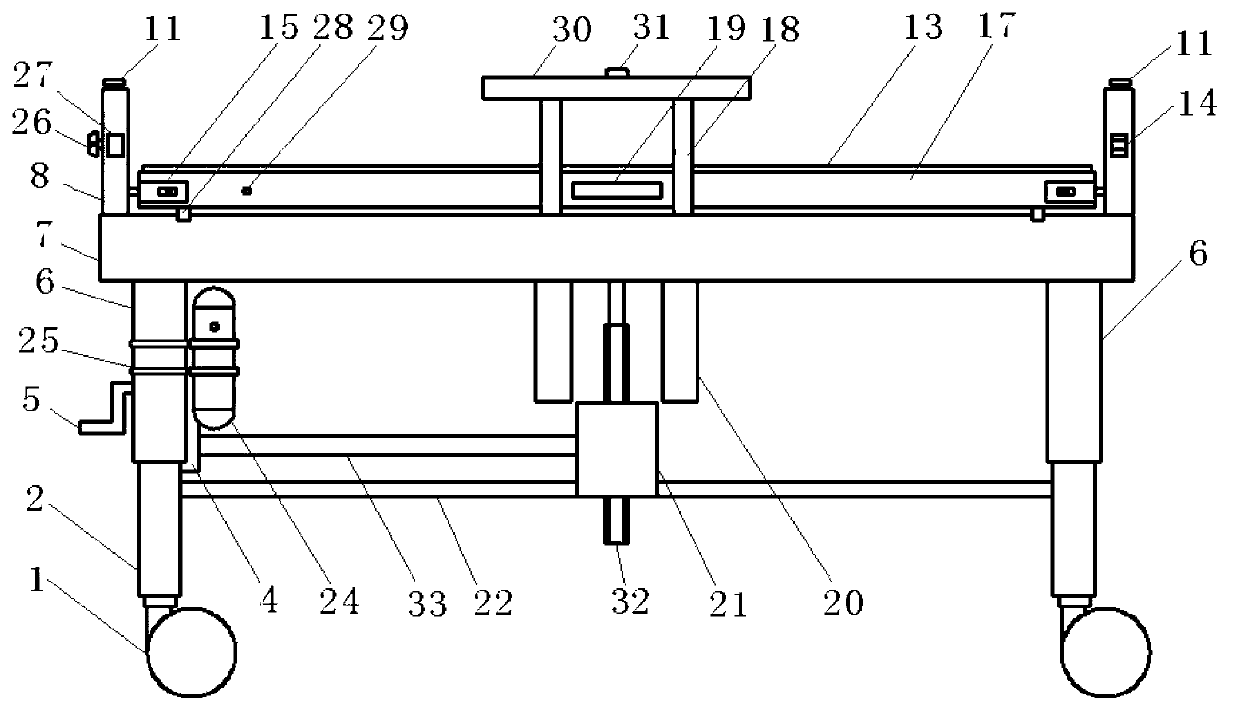

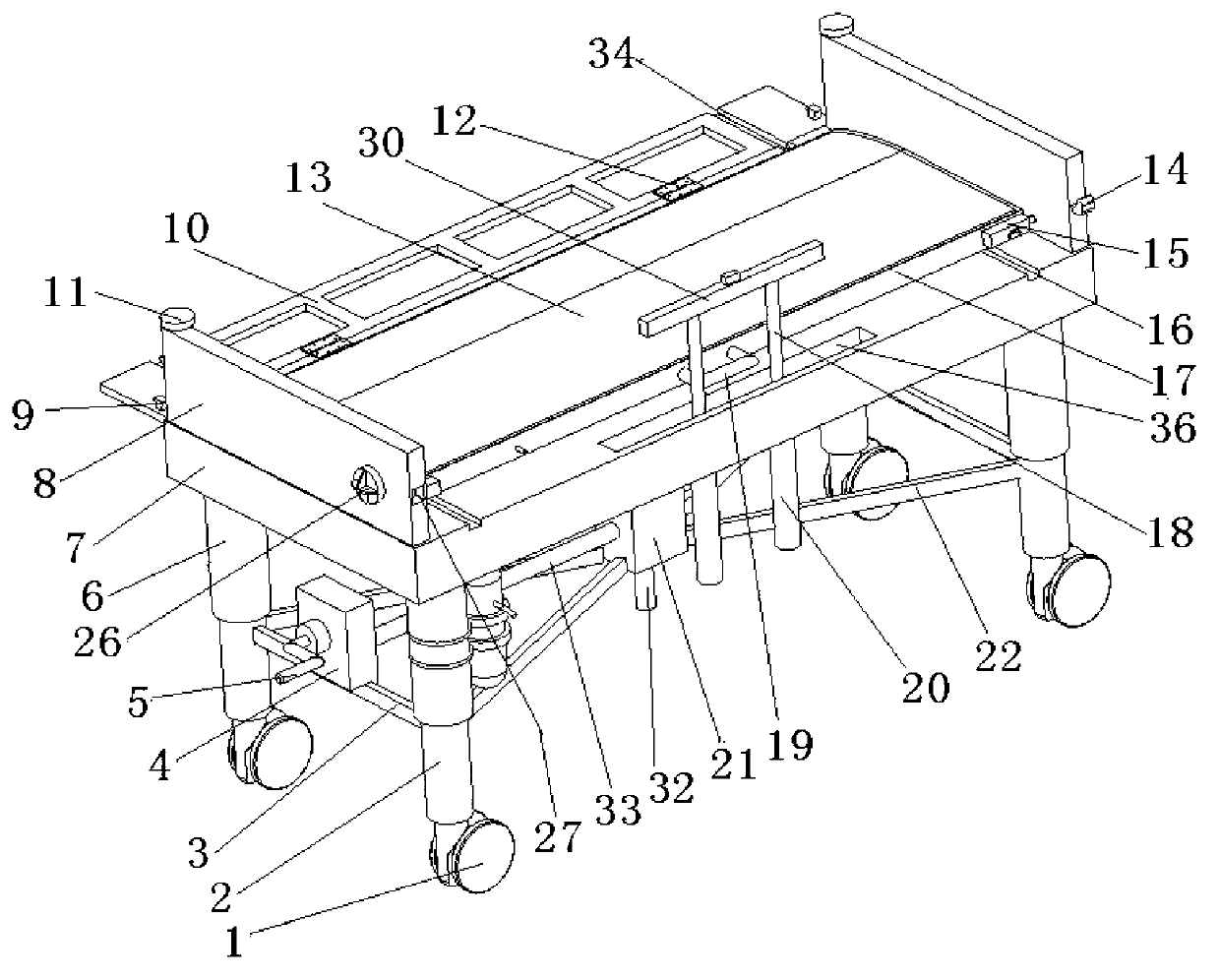

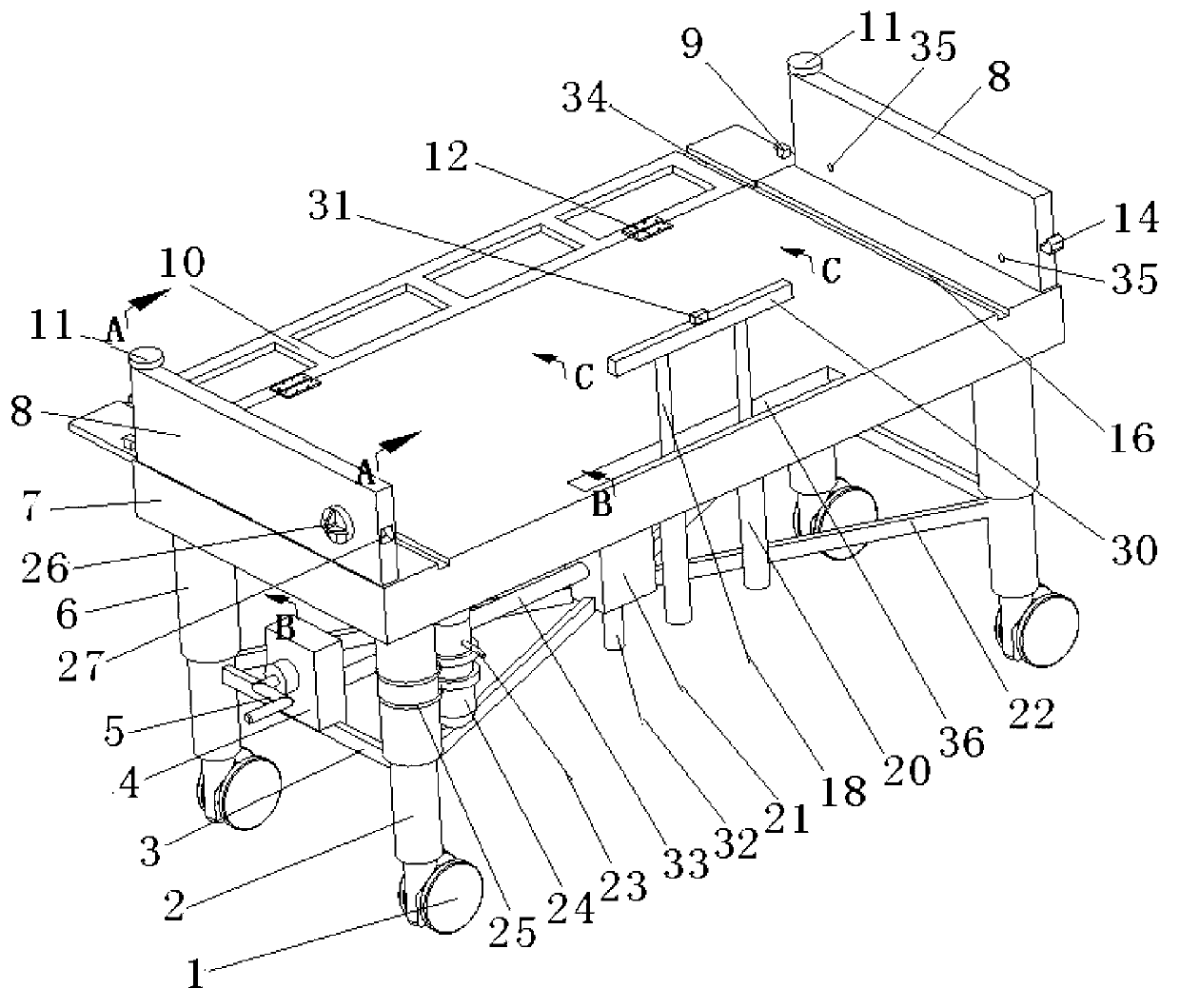

Butt joint type operation patient transfer trolley

The invention discloses a butt joint type operation patient transfer trolley and belongs to the technical field of medical apparatus. The butt joint type operation patient transfer trolley comprises a transverse moving bed and a transfer trolley. The transverse moving bed with a tiltable bed top is disposed on a transfer trolley plate of the transfer trolley and locked by a bed locking device. The transfer trolley comprises a transfer trolley body, a transfer trolley base and a lifting device. The transfer trolley body is supported on the transfer trolley base through the lifting device. The transverse moving bed mainly comprises a transverse moving bed frame, a bed board, an air cushion and rollers. Inflation of the air cushion enables the bed board to tilt. By the butt joint technology, an operation patient along with the moving bed is transferred from the transfer trolley outside an operating room to the transfer trolley in the operating room, cross infection is avoided, operating environments are kept clean, and operating safety is increased. By the moving bed with the tiltable bed top, the patient can be transferred from the operation patient transfer trolley to an operating table conveniently and time- and labor-savingly. The butt joint type operation patient transfer trolley is suitable for transferring seriously-injured patients from ambulances to operating rooms of hospitals.

Owner:HAINAN UNIVERSITY

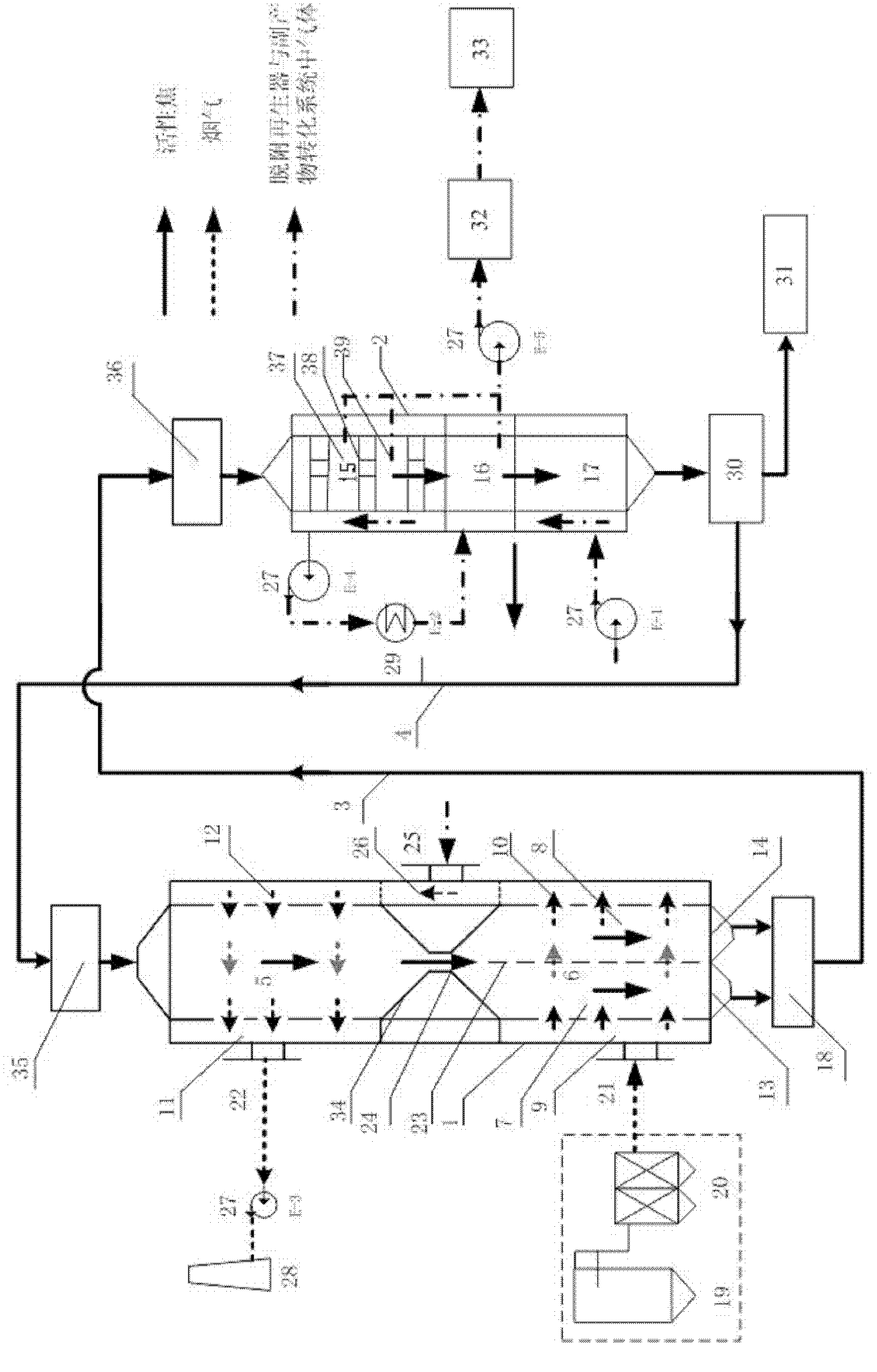

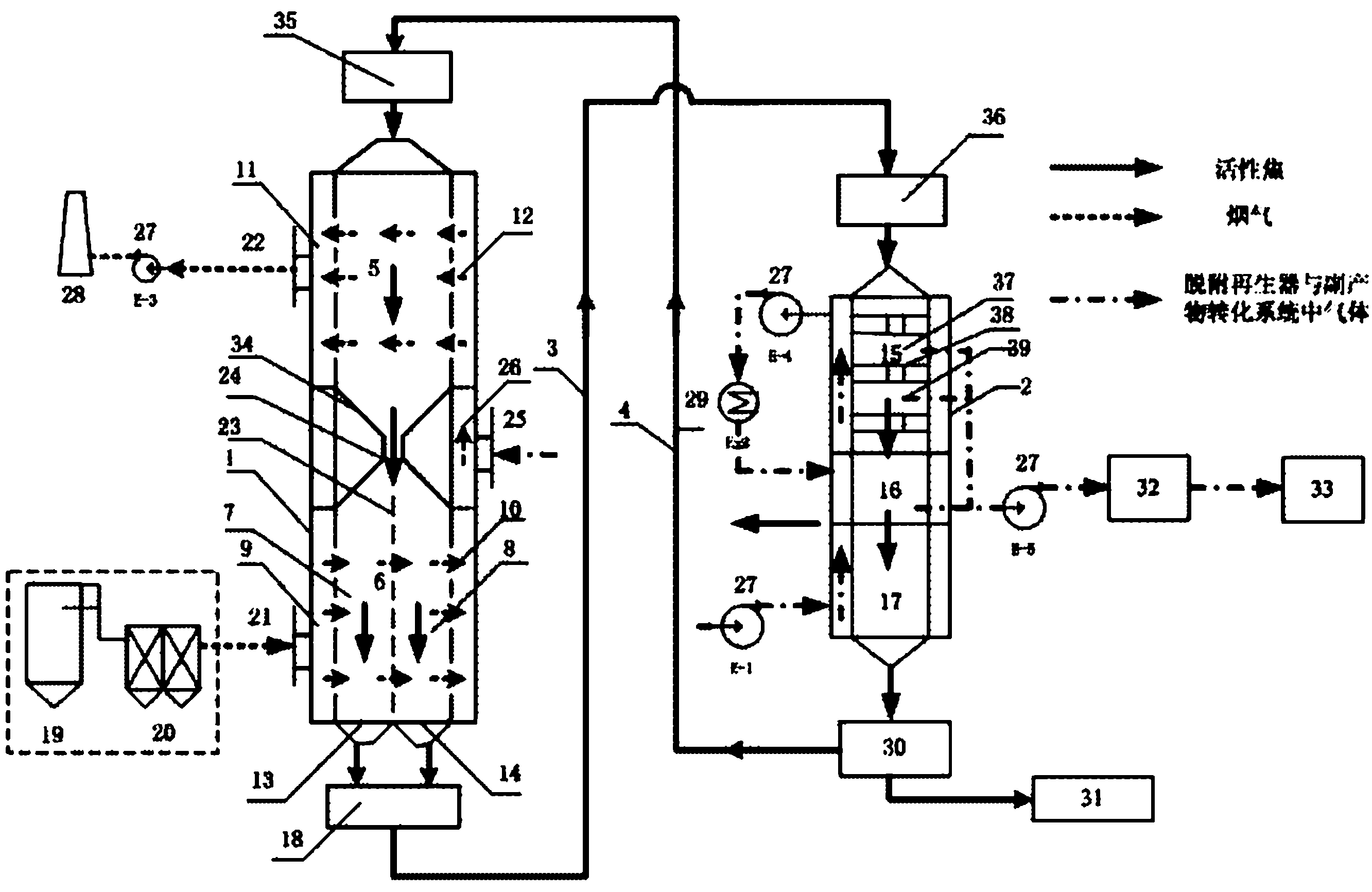

System for desulfurizing and denitrating active coke flue gas, and process method

ActiveCN102430318AIntegrated purification effect is obviousImprove utilization efficiencyDispersed particle separationSulfurDesorption

The invention discloses a system for desulfurizing and denitrating active coke flue gas, and a process method. The system comprises an adsorption reactor, a desorption regenerator, a material conveying device and a byproduct conversion device, wherein the devices are connected by specific pipelines and functions of the devices are realized by using a specific process method; the adsorption reactor is a composite layer double-section cross flow moving bed and consists of a denitration section and a desulfurization section, so that SO2, NOx, dioxin, mercury and smoke dust in flue gas are purified in an integrated mode; the desorption regenerator is divided into a preheating area, a regeneration area and a cooling area, so that active coke on which the mercury, and the dioxin are enriched are extracted, and subsequent harmless treatment of the active coke is realized; the desorption regenerator performs heat exchange by a heater and circulates heat energy for recovering, and the byproduct conversion device is used for performing sulphur recycling on desorption regenerated gas generated in the regeneration process; and by the process method, the integrated purification of the flue gas and the harmless treatment of the active coke can be realized.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

Moving bed smoke desulfur denitrate and dust removal technology

InactiveCN1911491ASimple processImprove efficiencyDispersed particle separationAir quality improvementSulfatePhysical chemistry

The present invention relates to fume desulfurizing, denitrating and dedusting process in moving bed. During the reverse contact between fume and active coke, the fume first has its adsorbed SO2 eliminated in the desulfurizing layer and then has its NOx reacted with injected NH3 to produce N2, H2O and other harmful products. The active coke after finishing desulfurization and denitration is regenerated in a regenerator physically through heating to decompose and desorb sulfuric acid and sulfate and chemically through the reaction between the created SO3 and the inner surface of the active coke to produce surface functional group. Experiment shows that the technological scheme of the present invention has the advantages of simple process, high efficiency, low cost, low power consumption, low water consumption and other advantages.

Owner:长春惠工净化工业有限公司

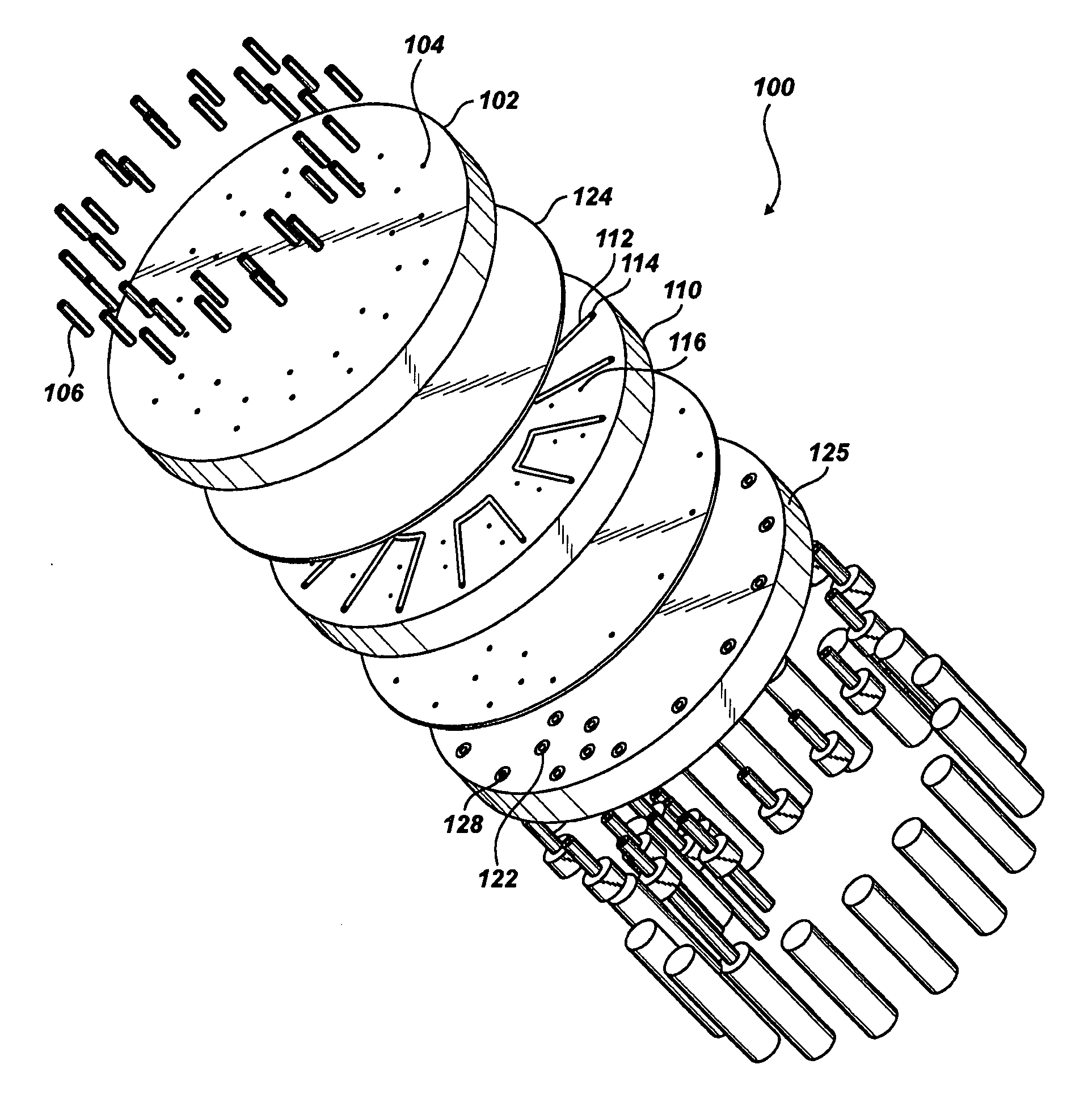

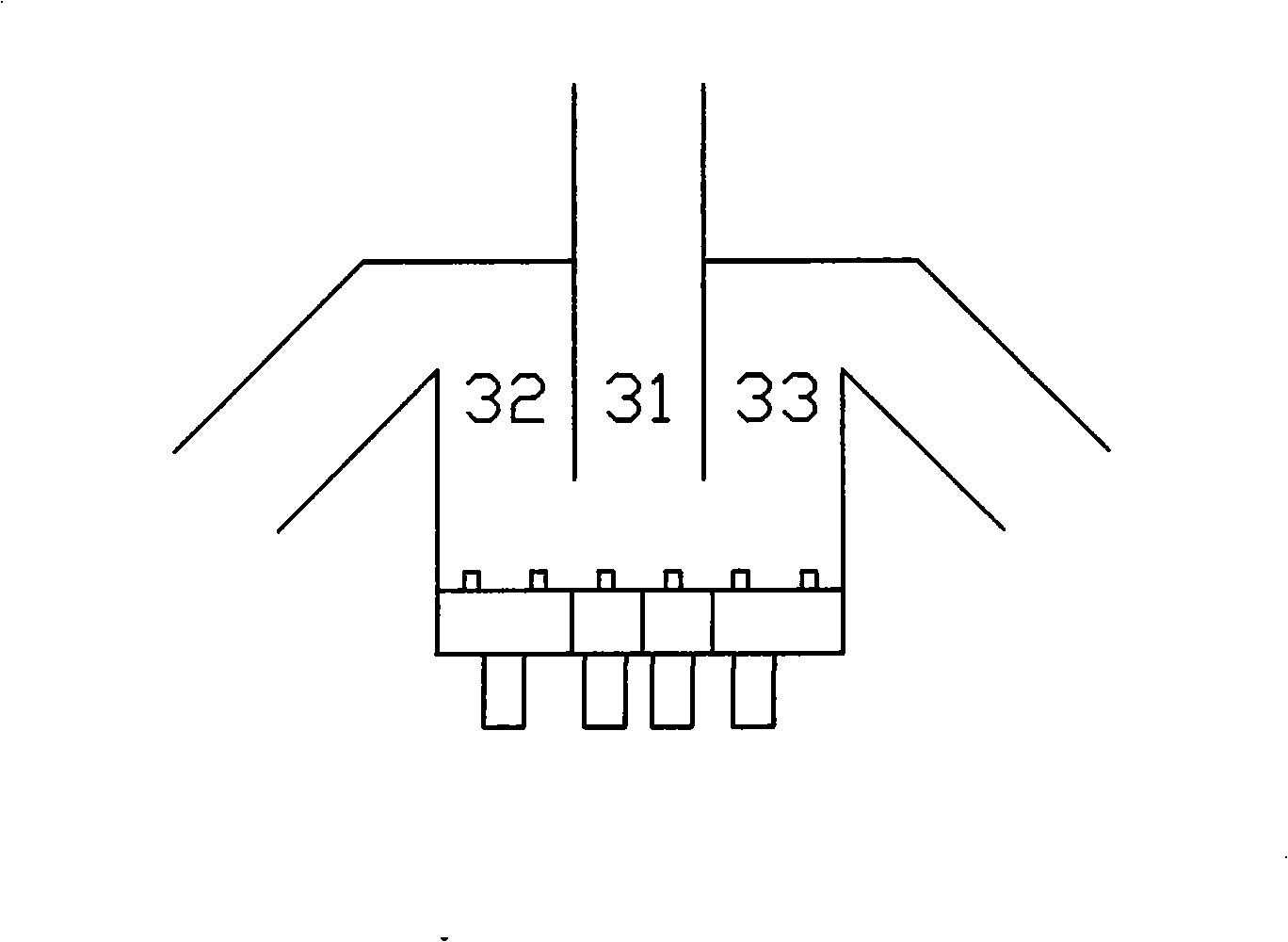

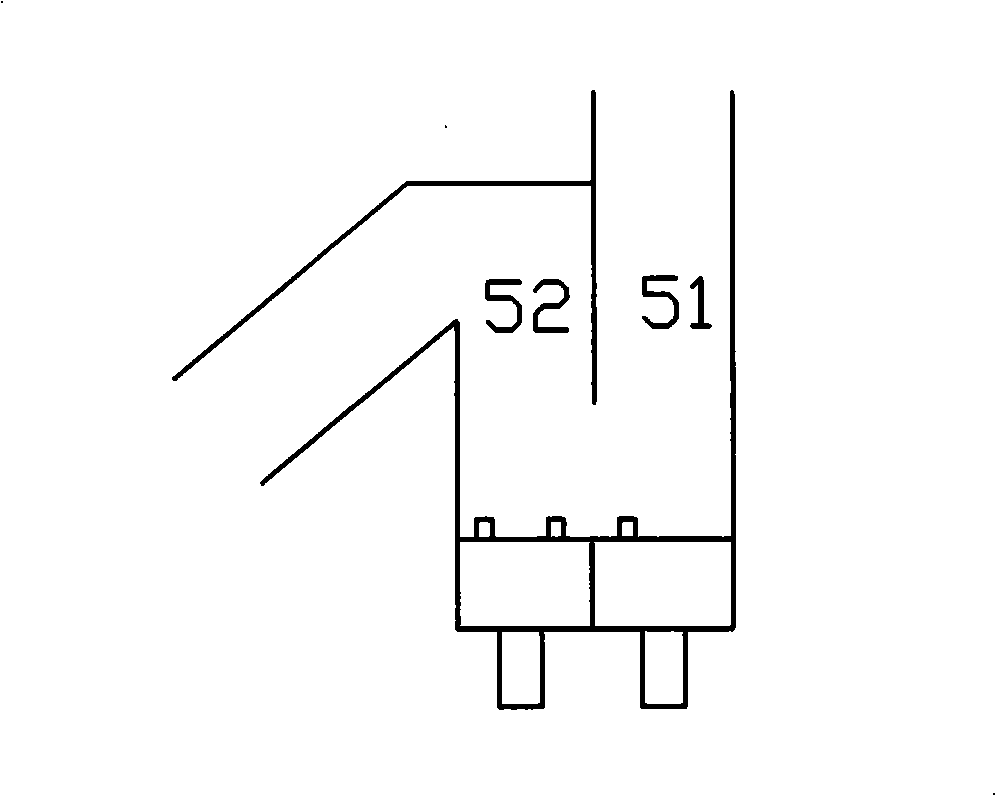

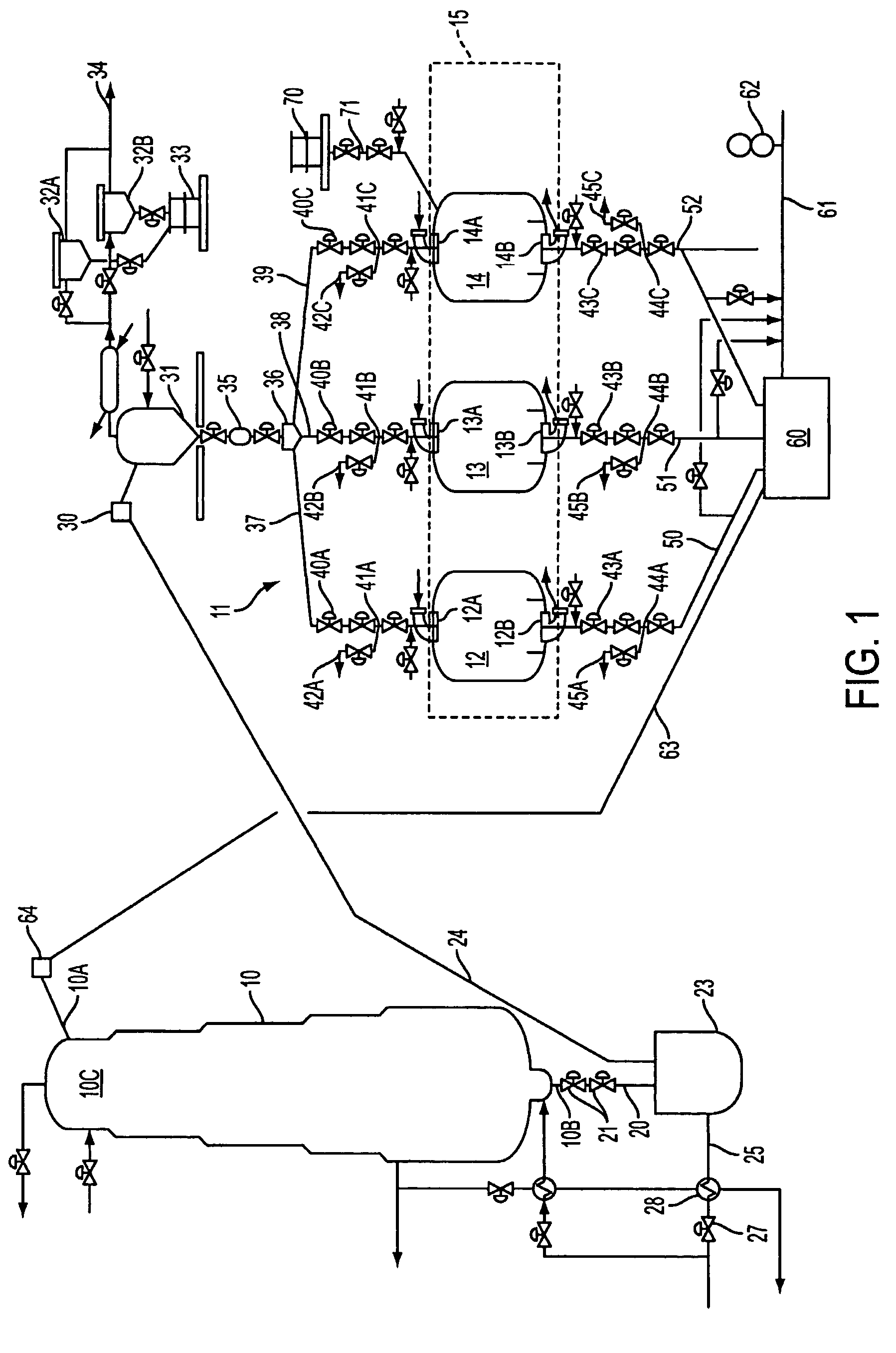

Valve Module And Methods For Simulated Moving Bed Chromatography

ActiveUS20080053543A1Simple and easily programmable controlPromote repairComponent separationSolid sorbent liquid separationSimulated moving bedMoving bed

The present invention provides devices and methods for micro-scale simulated moving bed chromatography (SMB) for continuous preparation of analytic quantities of highly pure fractions of target molecules. The present apparatus and method of the invention is adapted in a preferred embodiment to separations by affinity chromatography involving three discontinuous liquid flow loops. An alternative embodiment of affinity chromatography utilizes standard SMB operating under isocratic conditions.

Owner:TOSOH BIOSCIENCE LLC

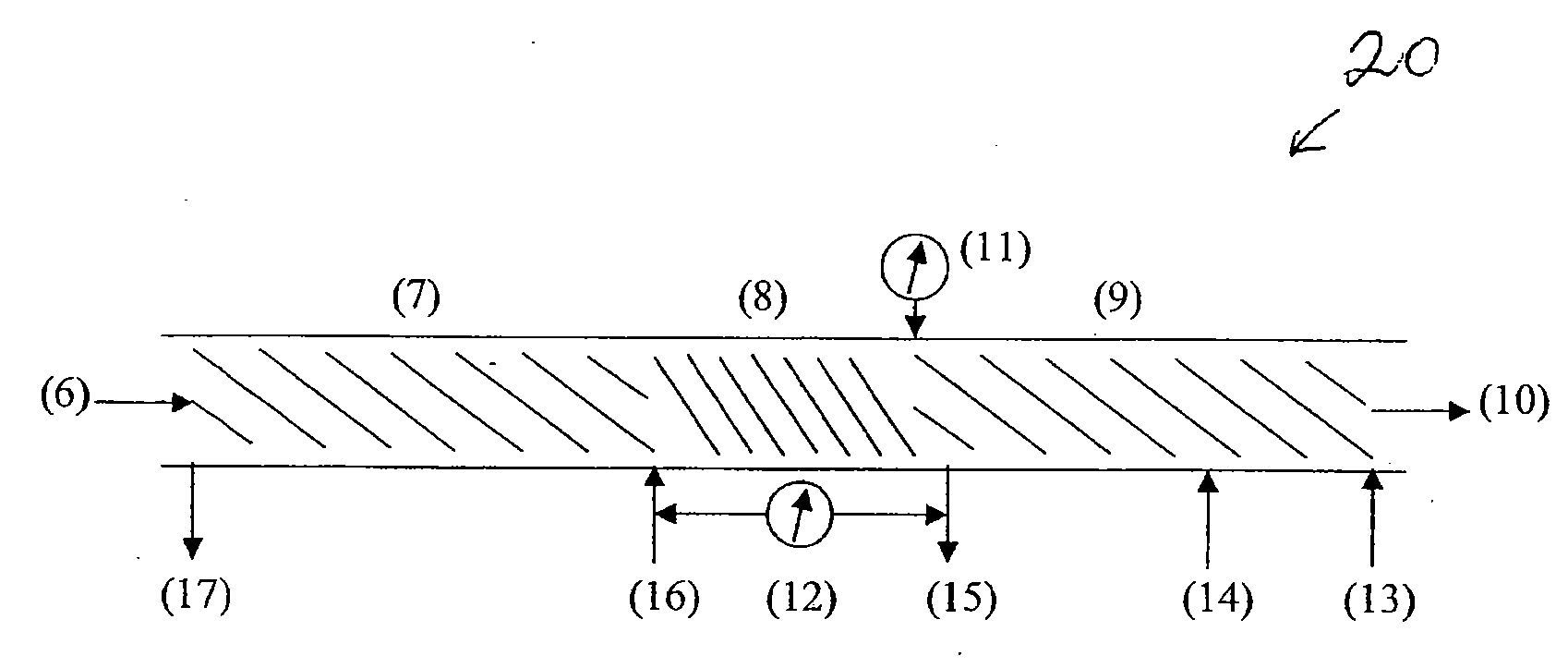

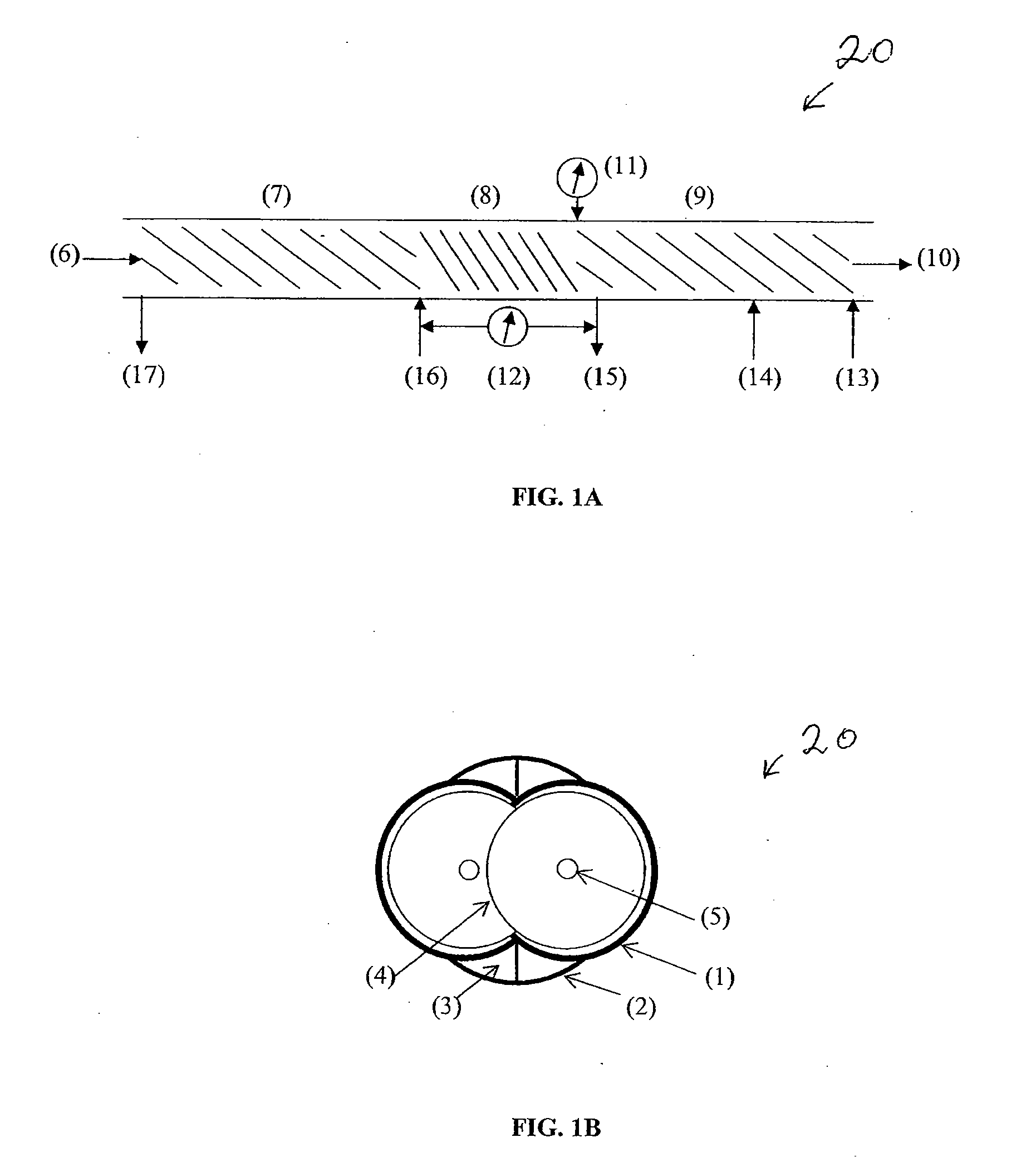

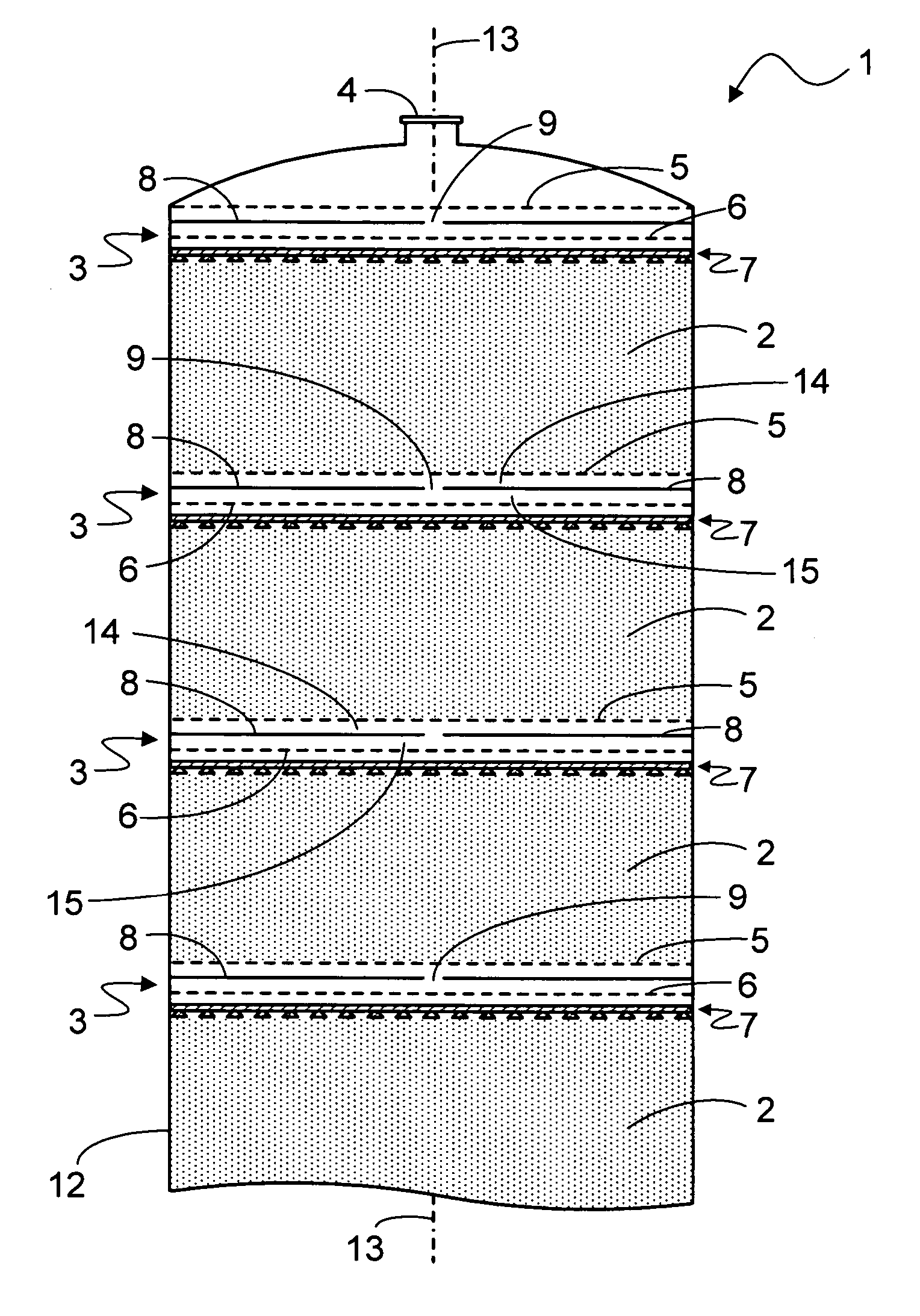

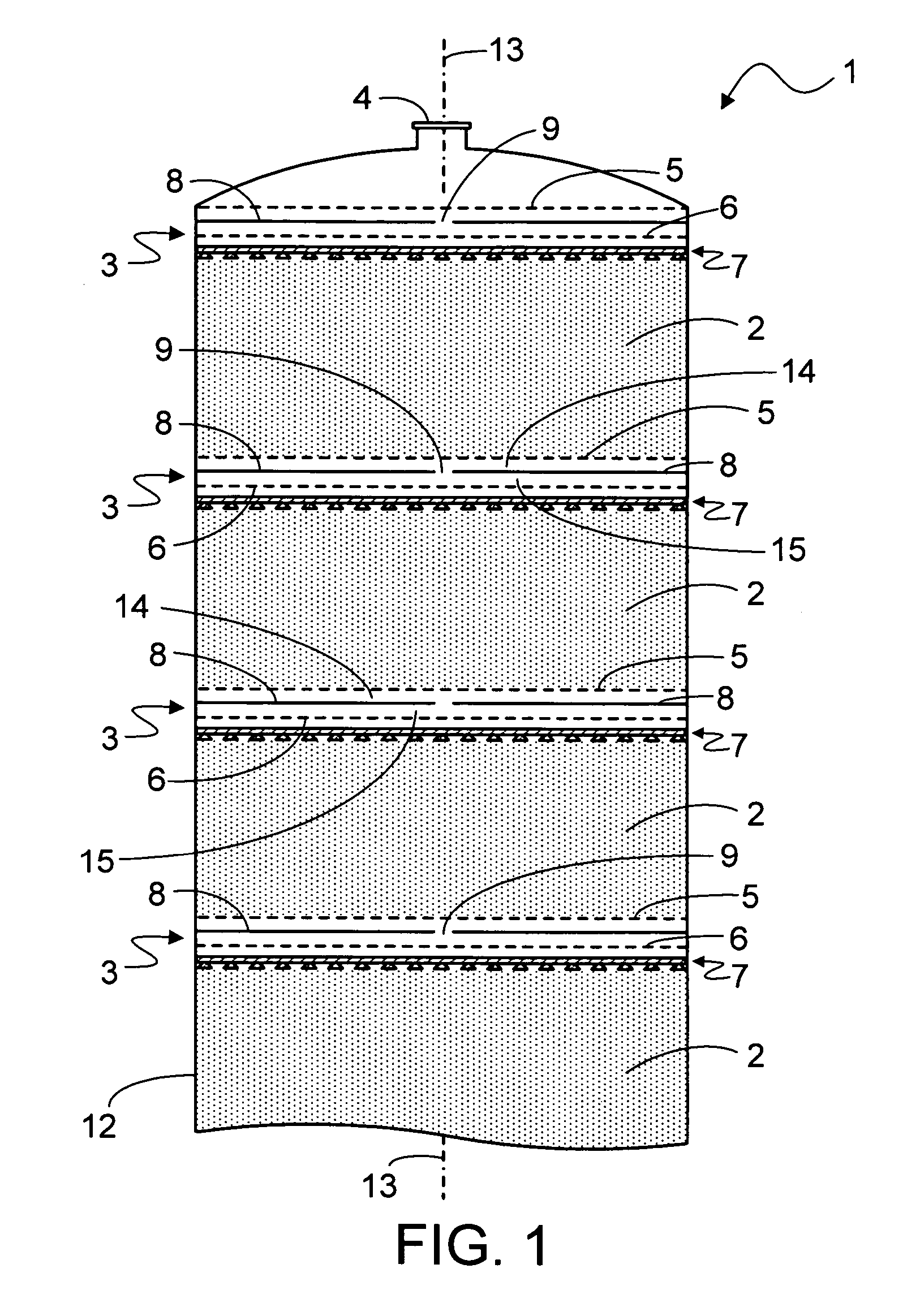

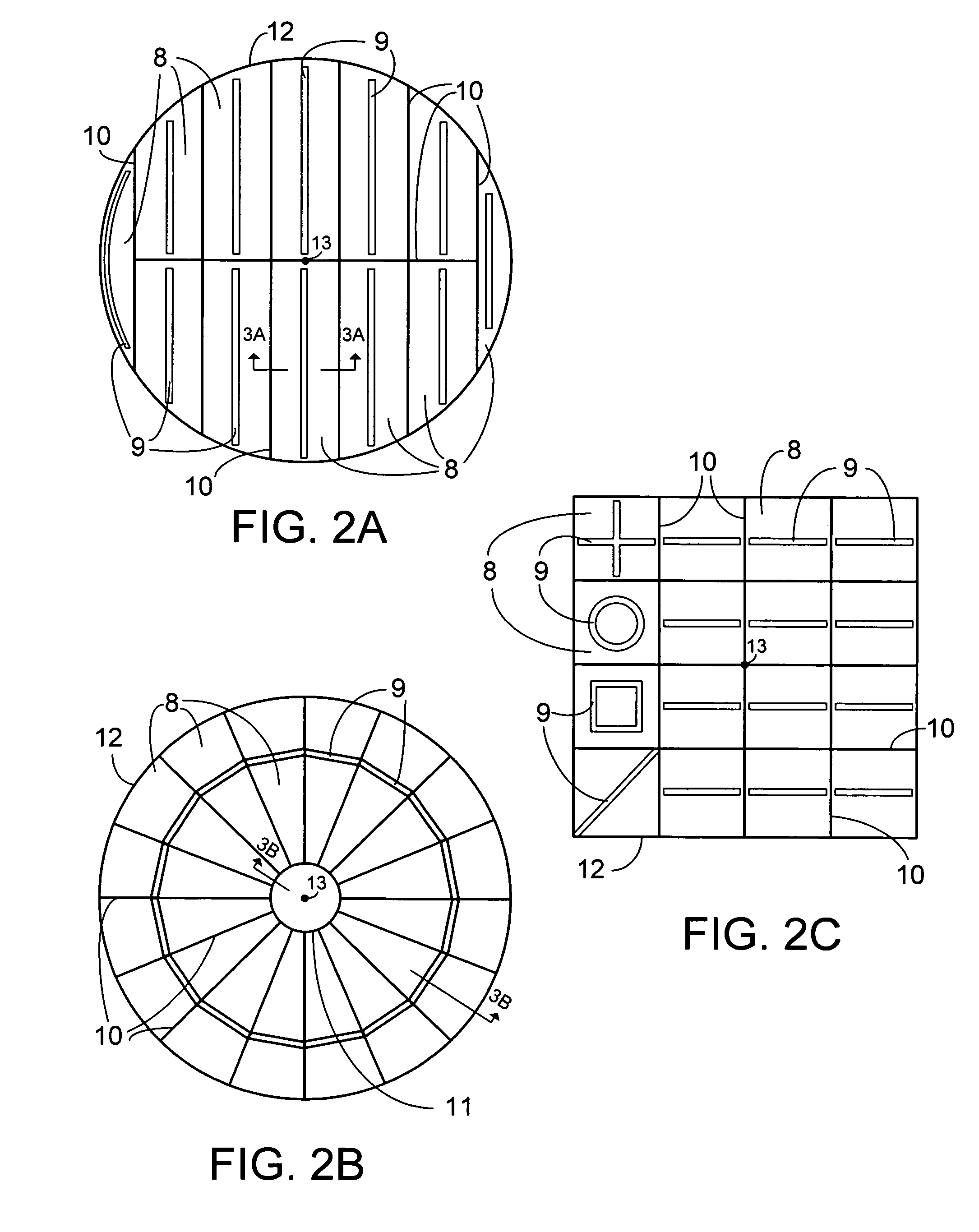

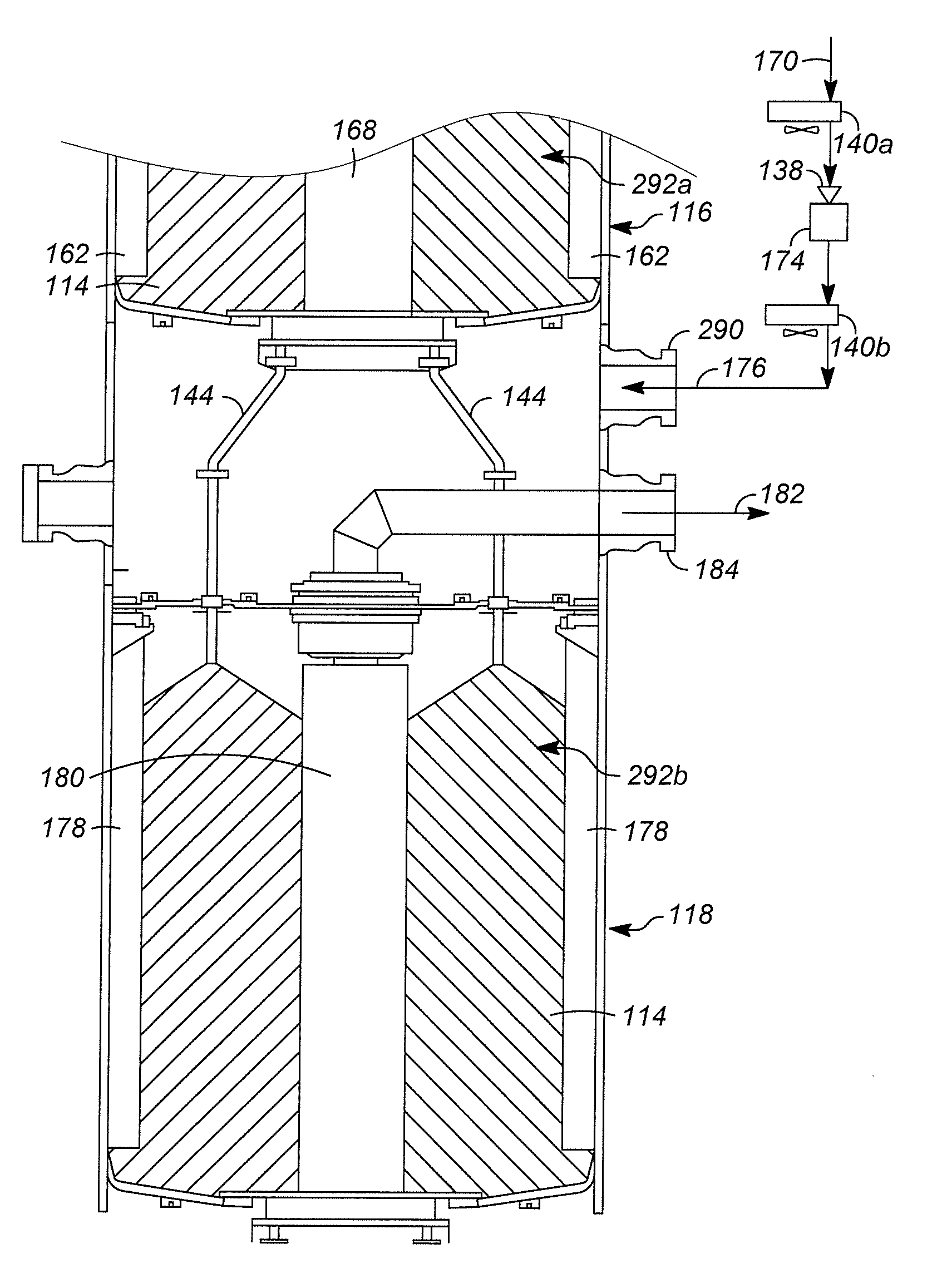

Flow distribution apparatus

ActiveUS20060108274A1Minimizes eliminatesIon-exchange process apparatusIon-exchanger regenerationStream flowHoneycomb

Disclosed is a mixer-distributor-collector apparatus for use between beds of solid particles in a fluid-solid contacting vessel. The apparatus includes a solids retaining screen, fluid deflector, passageway, fluid distributor, and flow manipulator. The flow manipulator is a device such as a honeycomb, porous solid, perforated plate, screen, or grid having an open area greater than the open area of the fluid distributor and is located below and spaced apart from the fluid distributor. The apparatus improves the fluid flow characteristics by minimizing or eliminating fluid velocity jets and / or other turbulence which can disturb the downstream particle bed. In an exemplary application, the invention finds use in simulated moving bed (SMB) adsorptive separation processes.

Owner:UOP LLC

Agglomerated zeolitic adsorbents, method for obtaining same uses thereof

InactiveUS6884918B1Amino compound purification/separationOrganic compound preparationSorbentSimulated moving bed

The present invention relates to agglomerated zeolitic adsorbents based on zeolite X with an Si / Al ratio such that 1.15<Si / Al≦1.5, at least 90% of the exchangeable cationic sites of the zeolite X of which are occupied either by barium ions alone or by barium ions and potassium ions whose Dubinin volume is greater than or equal to 0.240 cm3 / g.They are obtained by agglomerating zeolite powder with a binder, followed by the zeolitization of the binder, the exchange of the ions of the zeolite by barium ions (and potassium ions) and the activation of the adsorbents thus exchanged.These adsorbents are particularly suited to the adsorption of the para-xylene present in C8 aromatic hydrocarbon fractions in the liquid phase in processes of simulated moving bed type but also to the separation of sugars, polyhydric alcohols, cresols or substituted toluene isomers.

Owner:ARKEMA FRANCE SA

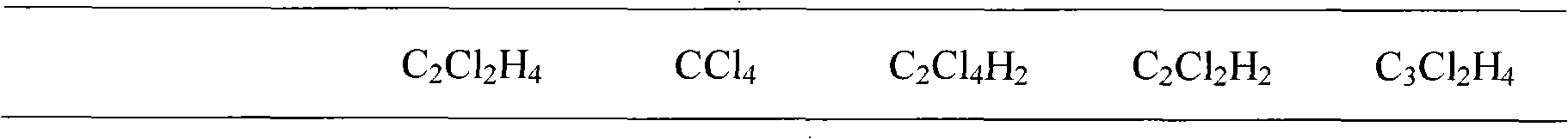

Catalyst for manufacturing olefin by low-carbon alkane dehydrogenation and application thereof

ActiveCN101773850AHigh selectivityHigh activityMolecular sieve catalystsHydrocarbonsAlkaneRare-earth element

The invention discloses a catalyst for manufacturing olefin by low-carbon alkane dehydrogenation and application thereof, belonging to the technical field of preparation of basic organic chemical materials. The catalyst takes silicoaluminophosphate molecular sieve and alumina mixture as carriers, VIII group or IVA group elements as active components and alkaline-earth metal or rare-earth elements as auxiliary agents for the process of olefin preparation by ethane, propane, butane or pentane dehydrogenation. In the process of olefin preparation by low-carbon alkane dehydrogenation, catalyst is firstly reduced by hydrogen and then reacts, and finally the catalyst is in charcoaling regeneration and chlorination update; and reaction regeneration process flow has big choice, the reactor can adopt a fixed bed, a moving bed, a fluidized bed or a double-particle fluidized bed, and catalyst regeneration can be carried out in a device or out of the device. Compared with the existing catalyst for manufacturing olefin by low-carbon alkane dehydrogenation, the catalyst provided by the invention ensures that low-carbon alkane selectivity is above 95% in the olefin preparing process by low-carbon alkane dehydrogenation under high conversion rate.

Owner:TSINGHUA UNIV

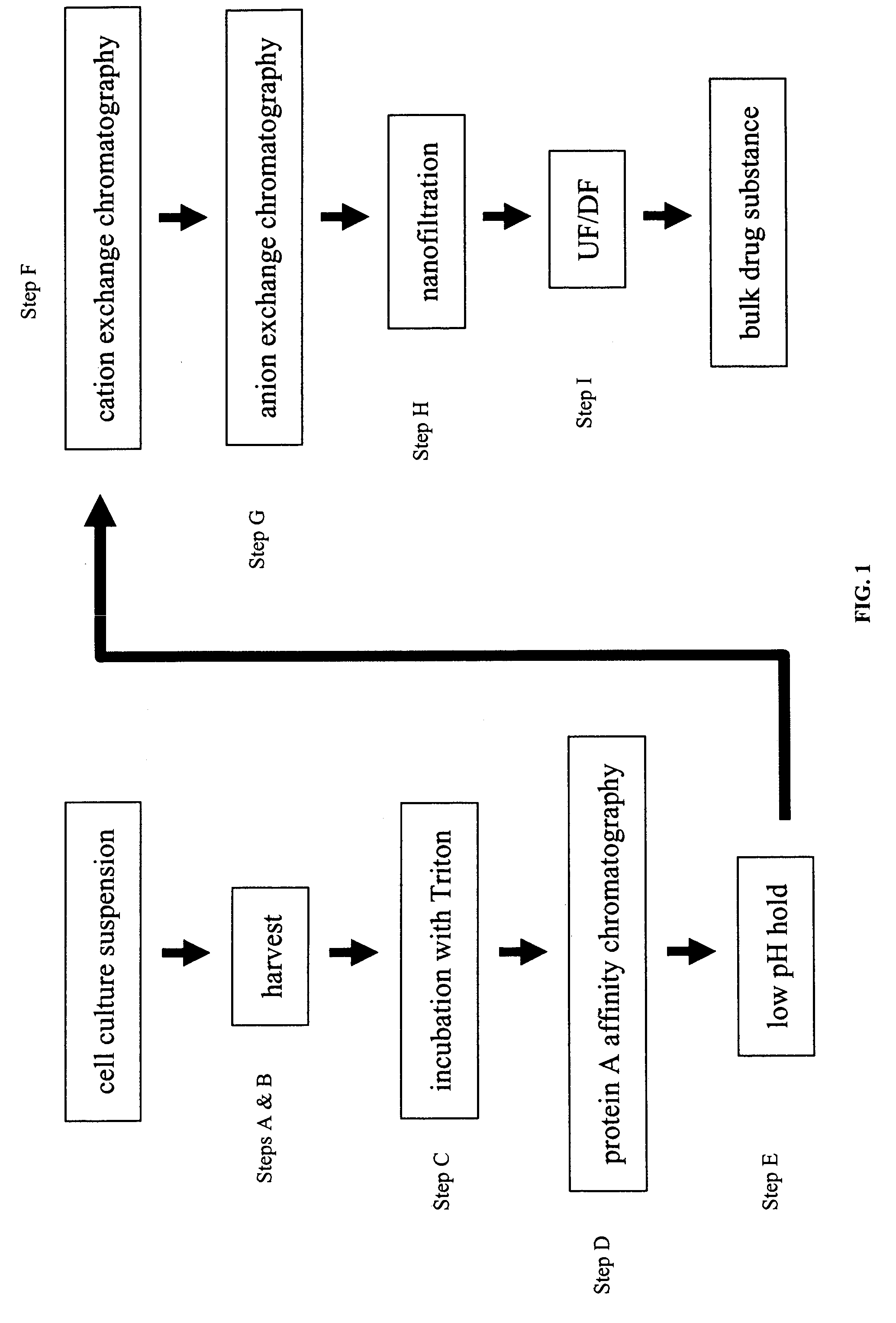

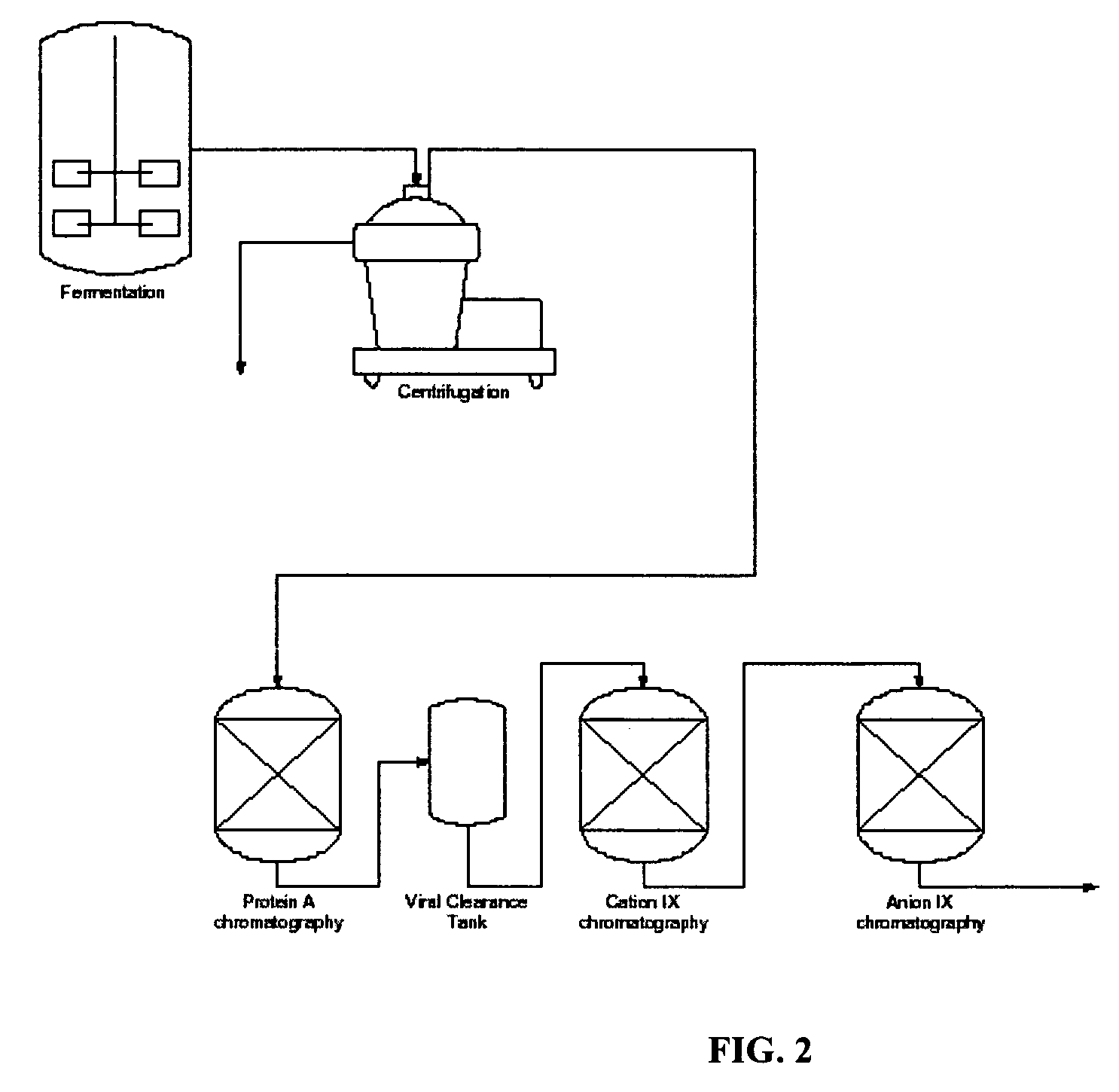

Method of purifying polypeptides by simulated moving bed chromatography

Provided are methods of separating an immunoreactive compound from at least one immaterial component, using a simulated moving bed (“SMB”) system and a SMB apparatus for use in these methods. Also provided are purified immunoreactive compounds prepared using the SMB methods and apparatus and methods of treatment with the purified immunoreactive compounds.

Owner:BIOGEN INC

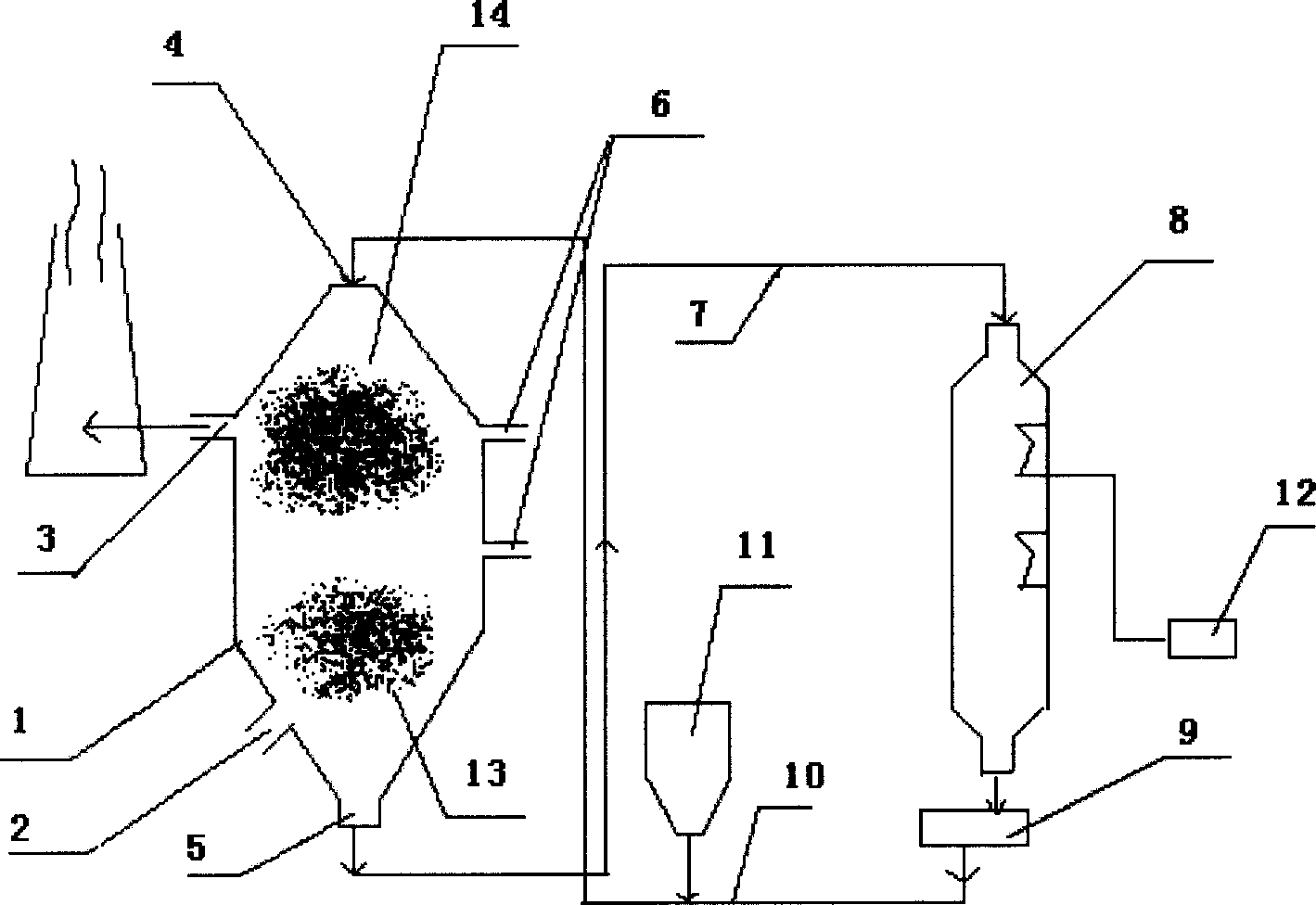

Solid heat carrier rapid pyrolysis method and apparatus

ActiveCN101353582AStable and reliable distributionEasy to control temperatureDirect heating destructive distillationHeat carrierCombustion chamber

The invention relates to a method and a device for the quick pyrolysis of solid heat carriers; the device comprises a circulating fluidized bed combustor, a cyclone separator, an aerodynamic hot ash distributor, a pyrolysis chamber and a differential bed material return device; fuel is burnt in the circulating fluidized bed combustor, the high-temperature circulation ash of flue gas collected by the cyclone separator is divided into two parts by the hot ash distributor aerodynamically controlled, one part enters the pyrolysis chamber of a moving bed as the solid heat carrier to supply heat for flue pyrolysis, the other part does not enter the pyrolysis chamber but returns to the combustor, together with the semicoke and circulation ash discharged from the bottom of the pyrolysis chamber through the differential bed material return device. The method and the device for the quick pyrolysis of solid heat carrier provided by the invention can distribute the high-temperature circulation ash between combustion and pyrolysis loops stably and reliably, with controllable temperature of the pyrolysis chamber, strengthen the balance capacity between combustion and pyrolysis by virtue of a hot ash cooler, have good adaptability of the flue, and can be used for the pyrolysis of coal, biomass and other carbonaceous refuses.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

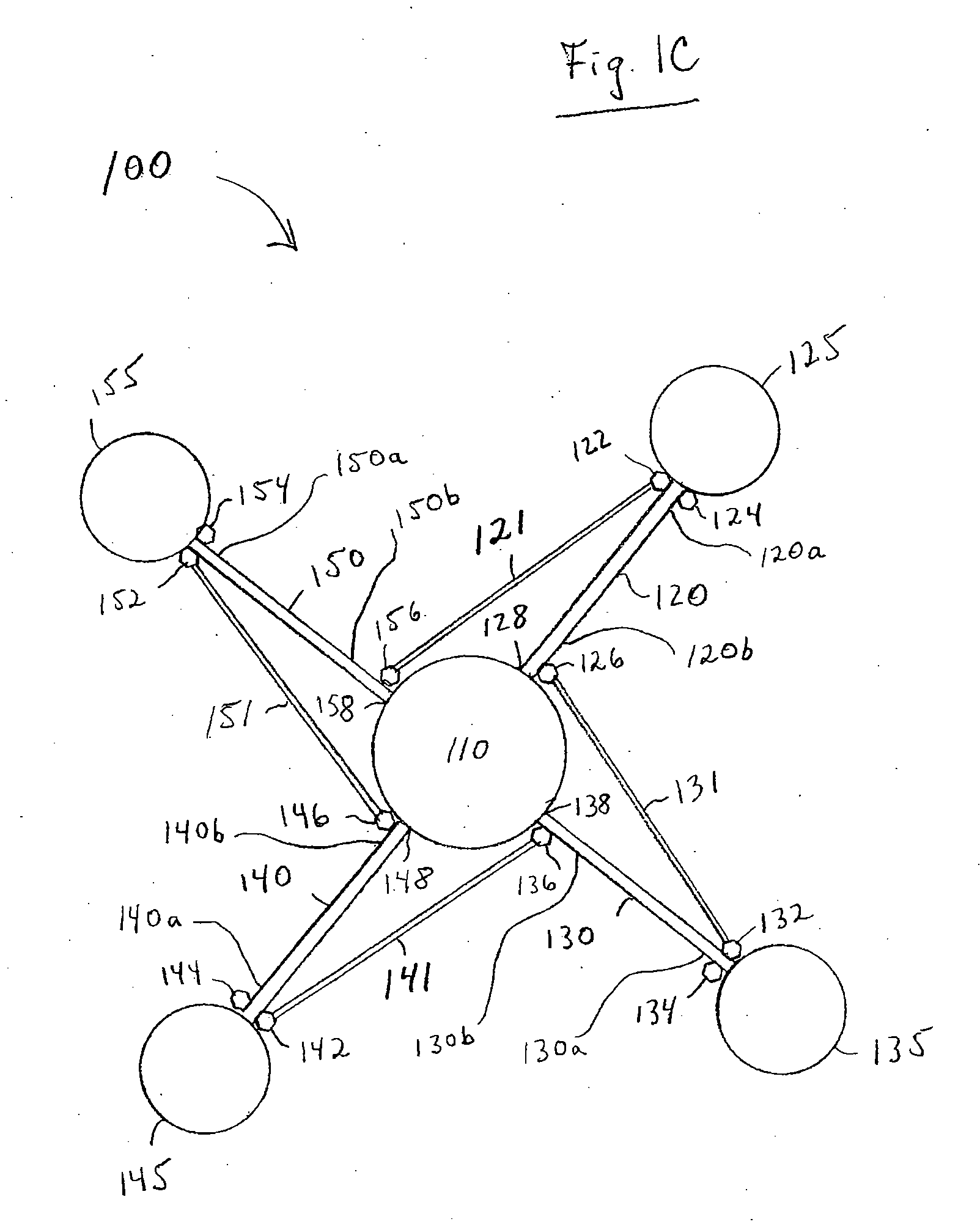

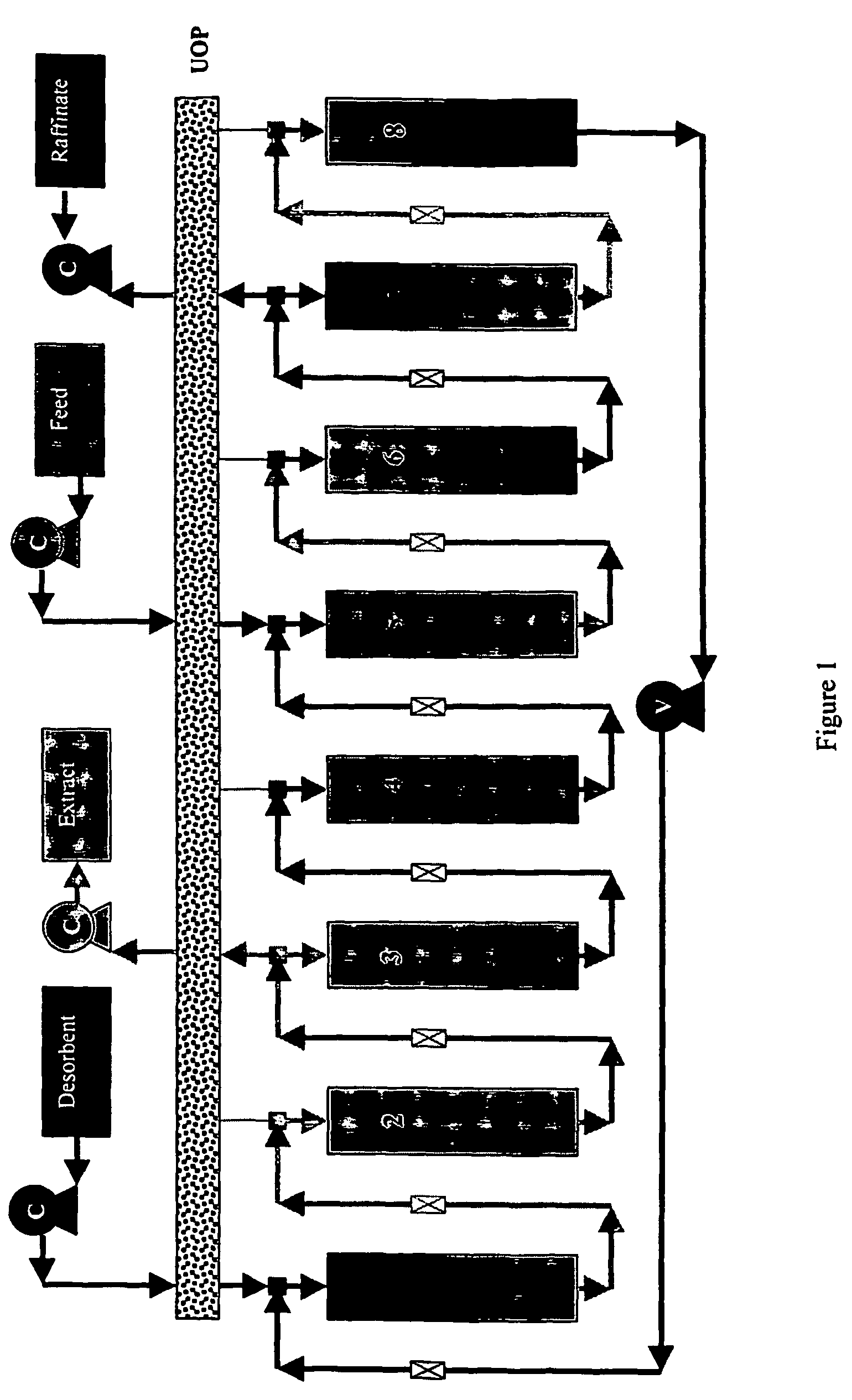

Versatile simulated moving bed systems

InactiveUS7141172B2Increase flexibilityImprove performanceIon-exchange process apparatusGas treatmentSimulated moving bedEngineering

Owner:PURDUE RES FOUND INC

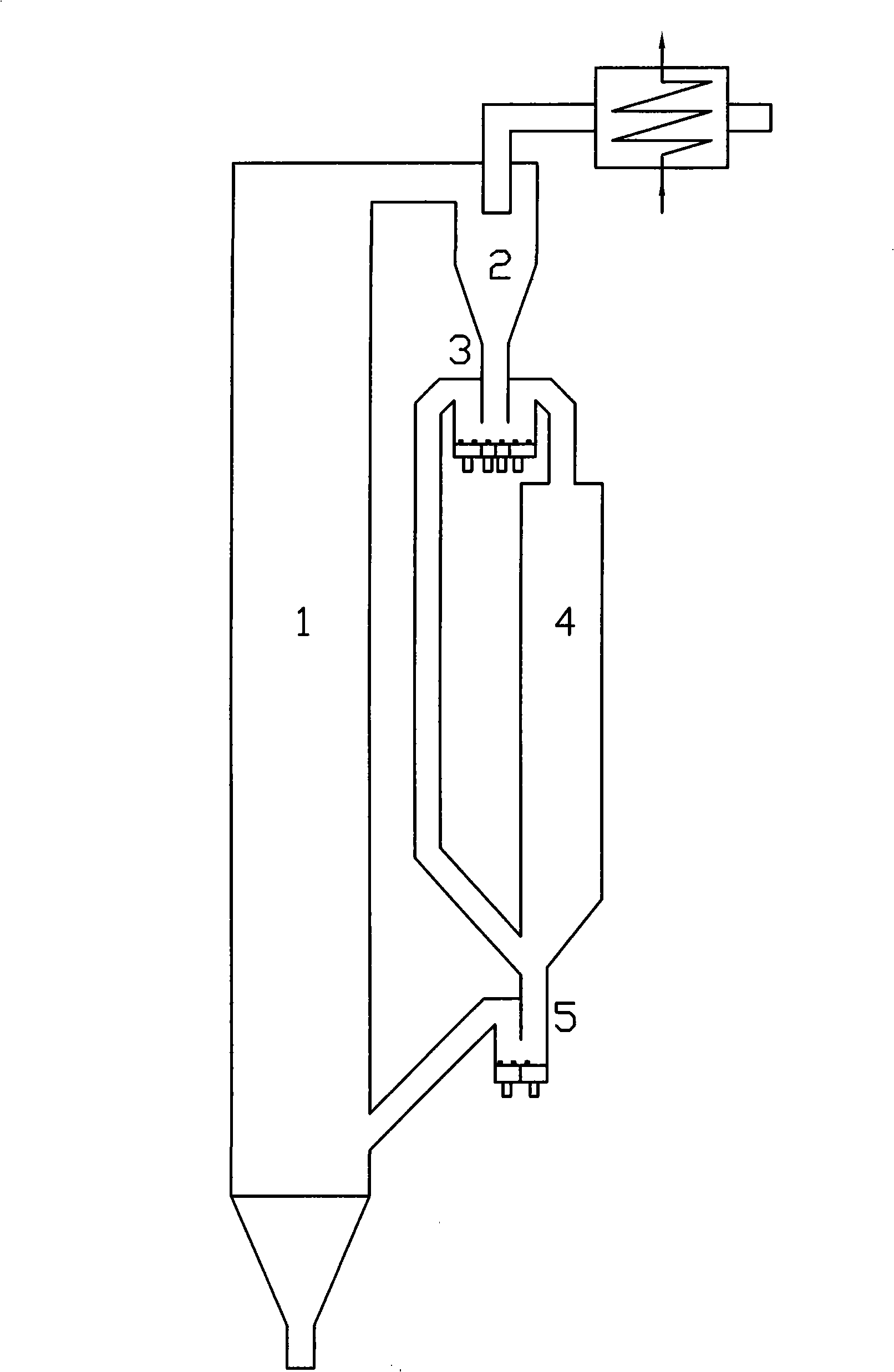

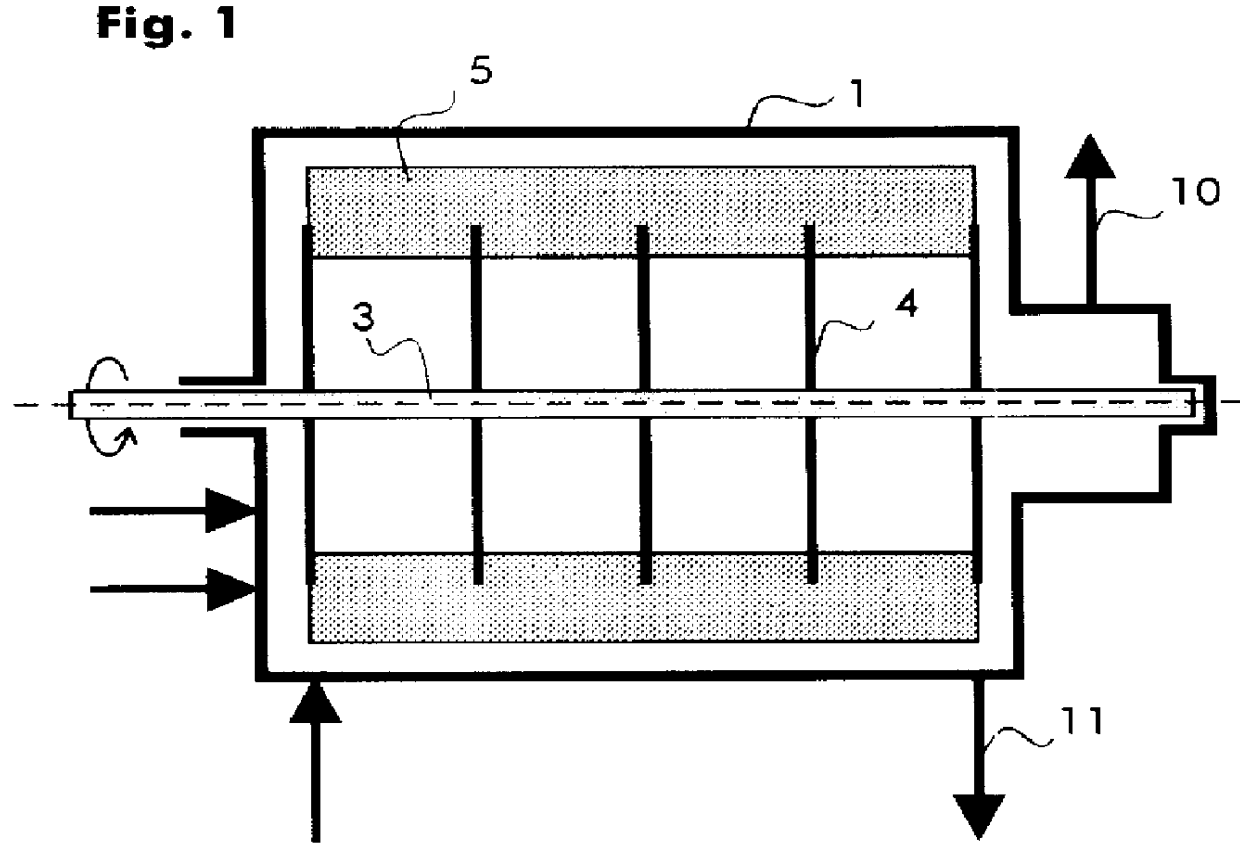

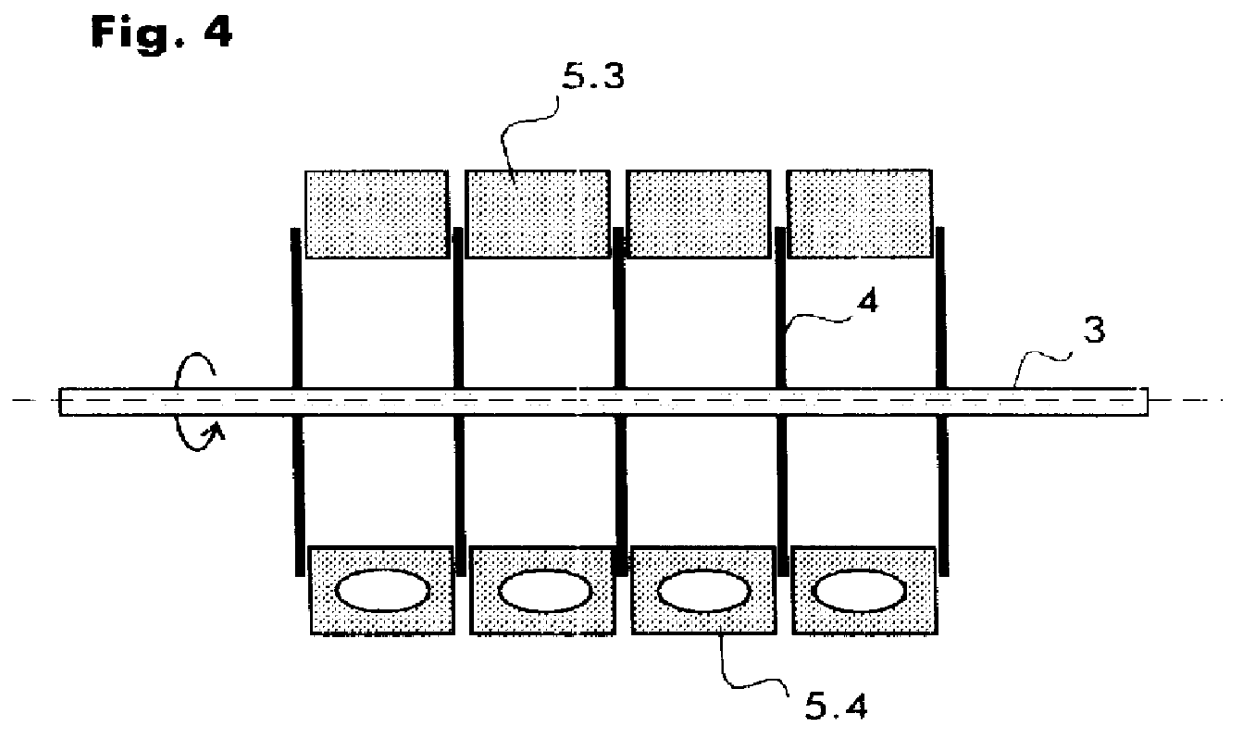

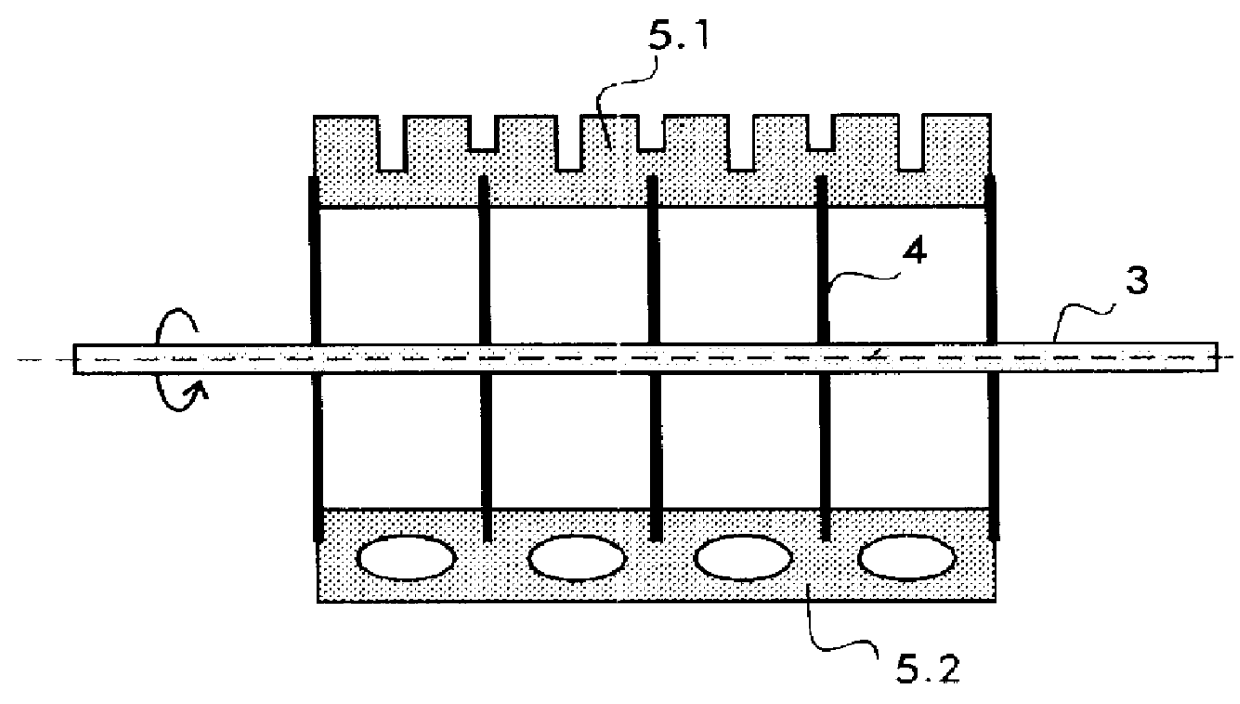

Process for thermal and/or catalytic decomposition and/or depolymerization of low-grade organic substances and device for carrying out the process

InactiveUS6165349AImprove economyEfficient processingCatalytic crackingSolid waste disposalDepolymerizationLower grade

PCT No. PCT / SK97 / 00006 Sec. 371 Date Jun. 1, 1999 Sec. 102(e) Date Jun. 1, 1999 PCT Filed Jul. 4, 1997 PCT Pub. No. WO98 / 39368 PCT Pub. Date Sep. 11, 1998The nature of the process consists in that the low-grade organic substances are subject, at a temperature of 150 DEG C. to 700 DEG C. and at a pressure of 0.1 MPa to 2.5 MPa, to the action of a moving bed of solid particles of a substance which perform whirling motion, whereby the solid particles of a substance constituting the moving bed are set to whirling motion by intensive agitation. The device consists of a reaction chamber (1) with a rotation mechanism (2) which rotation mechanism (2), located rotably in the faces of the reaction chamber (1), consists of a shaft (3) to which vanes (5) are symetrically attached by means of driving discs (4). The vanes (5) may be arranged in 3 to 10 rows, and they may be provided with openings (5.1) or cut-outs (5.2) of various geometrical shapes, and they may be divided into individual segments (5.3). Also the driving discs (4) may be provided with openings (4.1) of various geometrical shapes.

Owner:MADAR IVAN

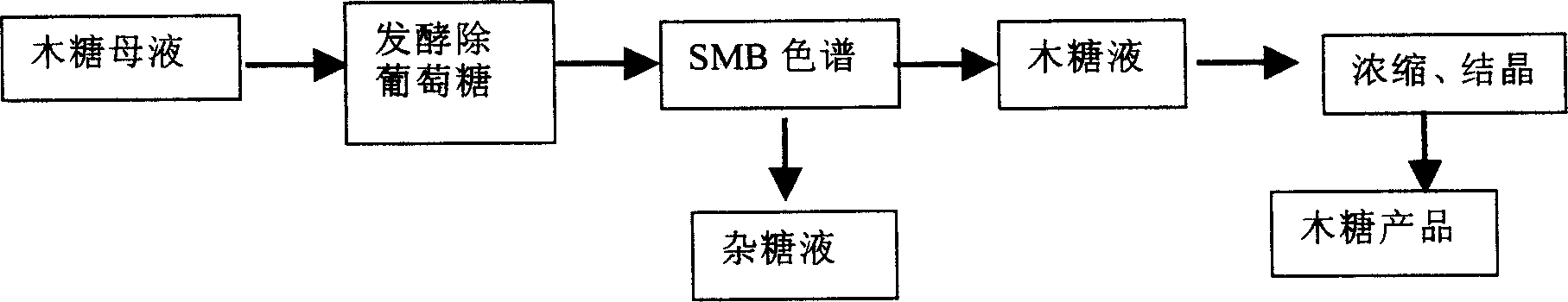

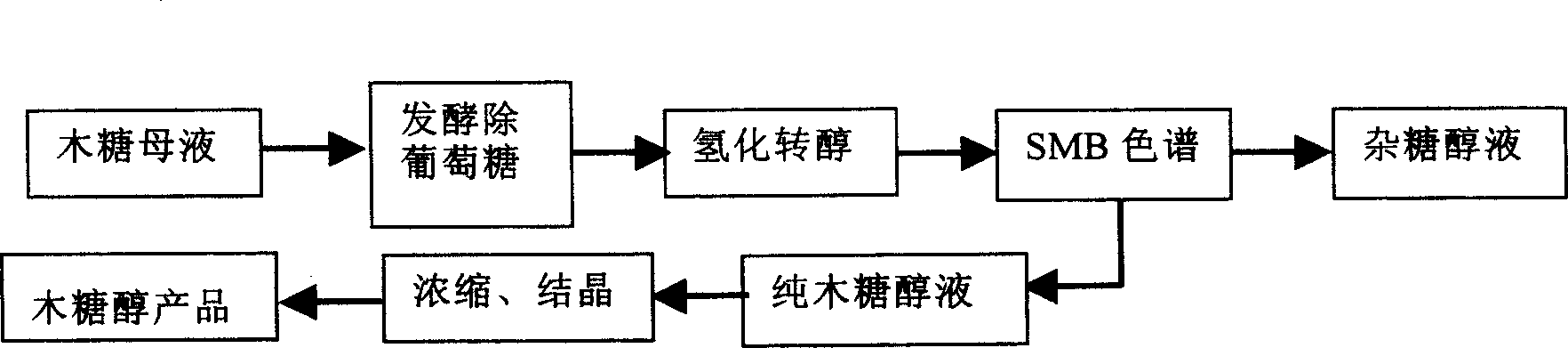

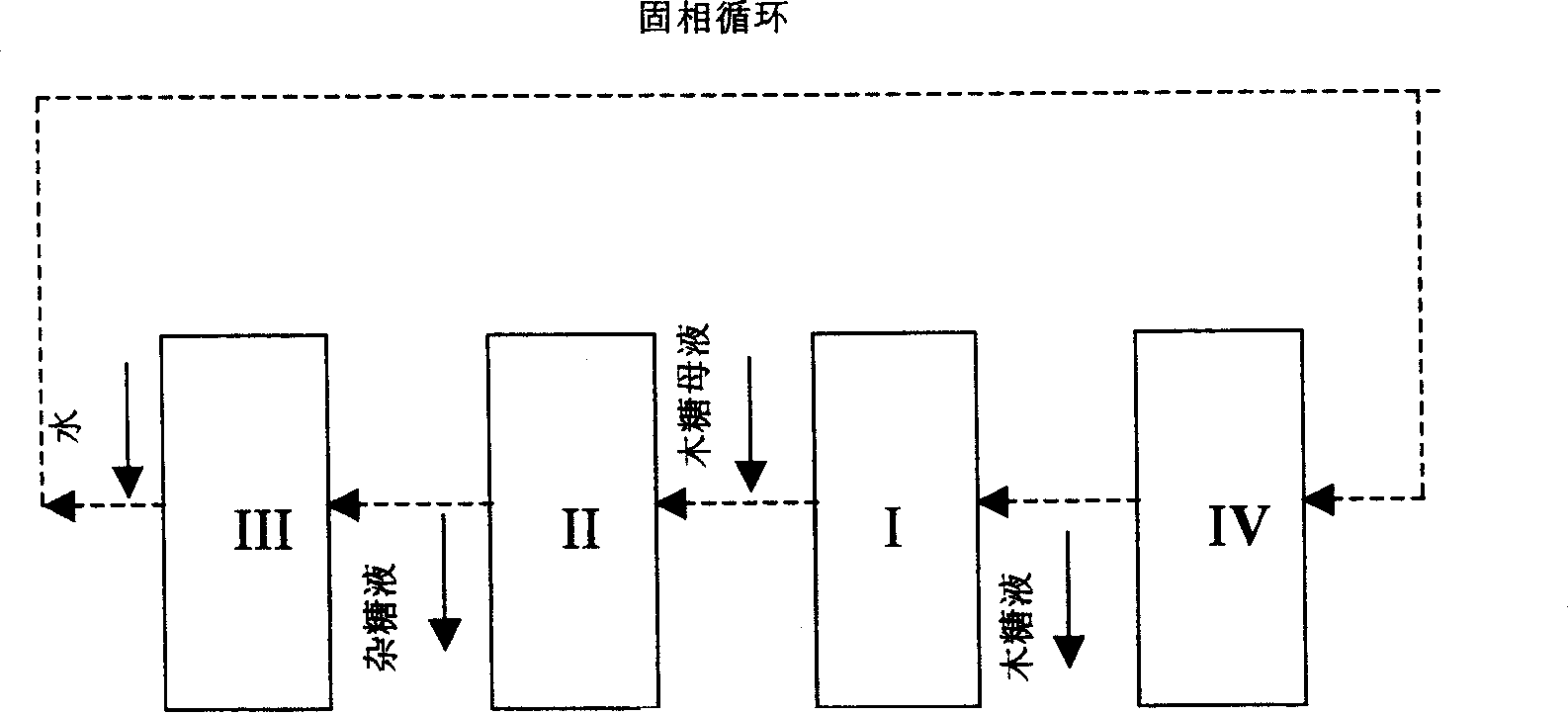

Process for extracting xylose and xylitol from a xylose mother liquor or a xylose digest

InactiveCN1699587AImprove physical stabilityImprove adsorption capacitySugar derivativesFermentationForeign matterHydrolysate

Owner:JIANGNAN UNIV

Moving bed dryer

InactiveUS6328099B1Drying solid materials with heatFluidised bed heat exchangersProduct gasSolid particle

Free-flowing solid particles are dried in a moving bed dryer by passing the particles adjacent to a heat exchanger plate containing a heated fluid while passing a dehumidified gas into the solid particles from a gas flow manifold in the heat exchanger plate.

Owner:MISSISSIPPI CHEM

Parex unit feed

ActiveUS8529757B2More of of capacityMore of efficiencyIon-exchange process apparatusIon-exchanger regenerationArylSimulated moving bed

A process for separating a product from a multicomponent feedstream to an adsorption apparatus or system. The apparatus or system may comprise a moving-bed or a simulated moving-bed adsorption means. The product comprises at least one organic compound, such as an aryl compound with alkyl substitutes. In embodiments the conduits used to supply the feedstream to the apparatus or system are flushed with media of multiple grades. In embodiments the process achieves improvements in one or more of efficiency of adsorption separation, capacity of adsorption apparatus systems, and purity of product attainable by adsorption process.

Owner:EXXONMOBIL CHEM PAT INC

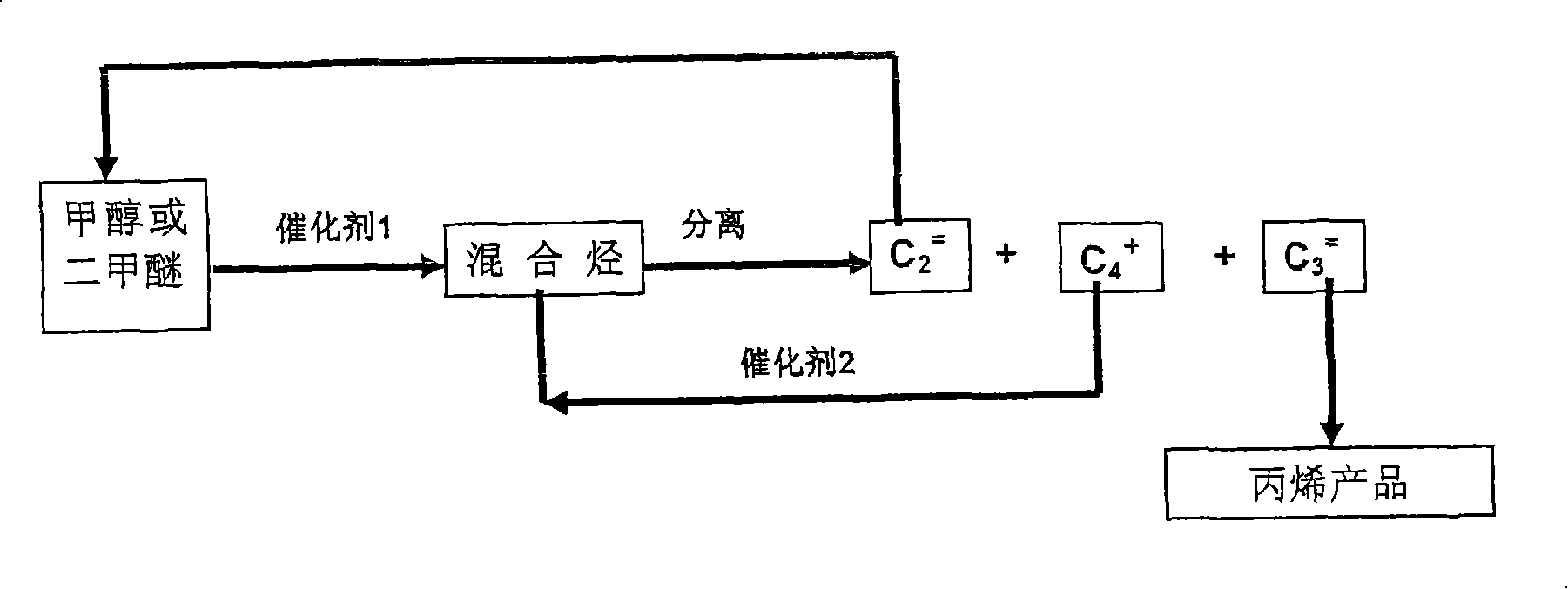

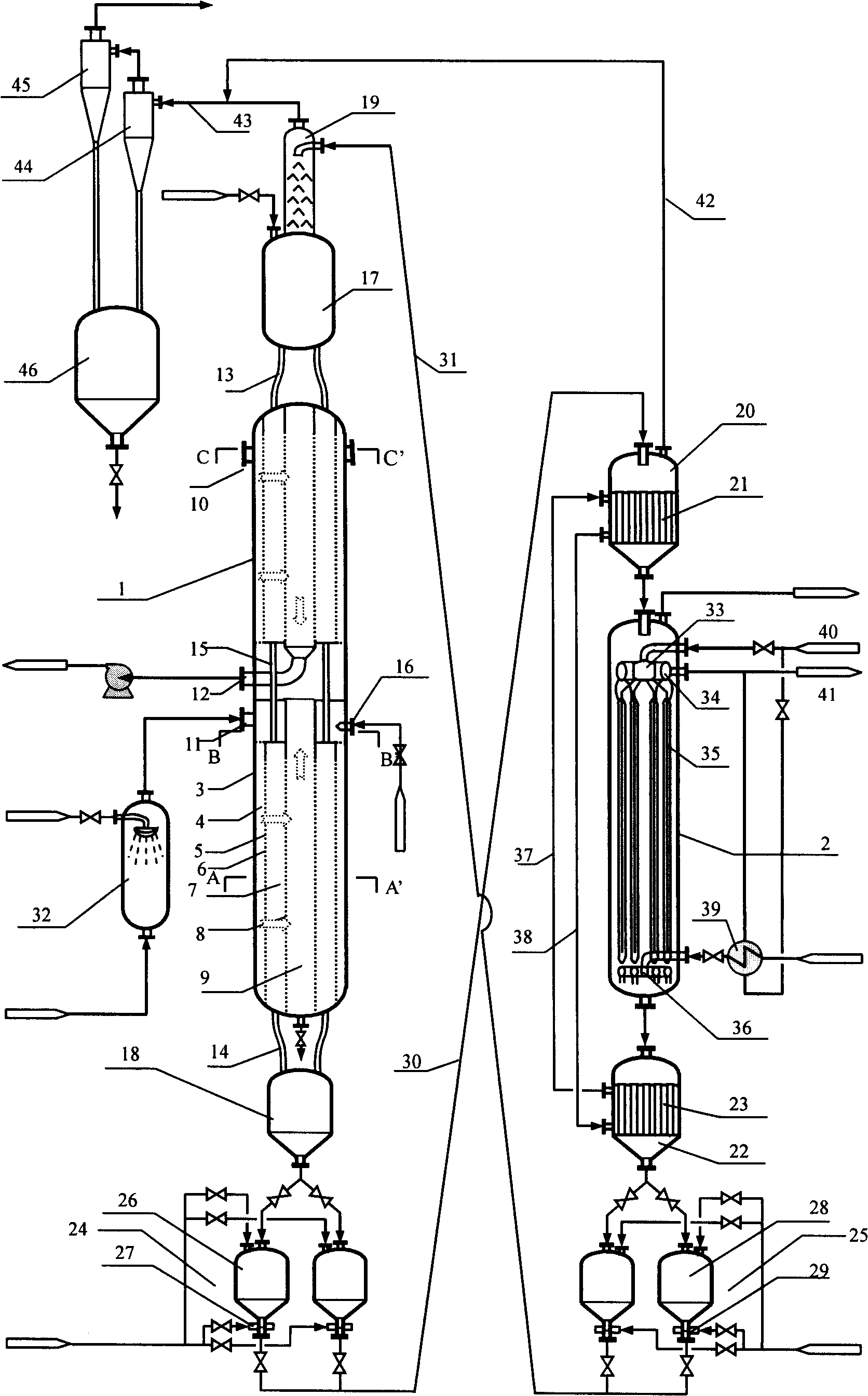

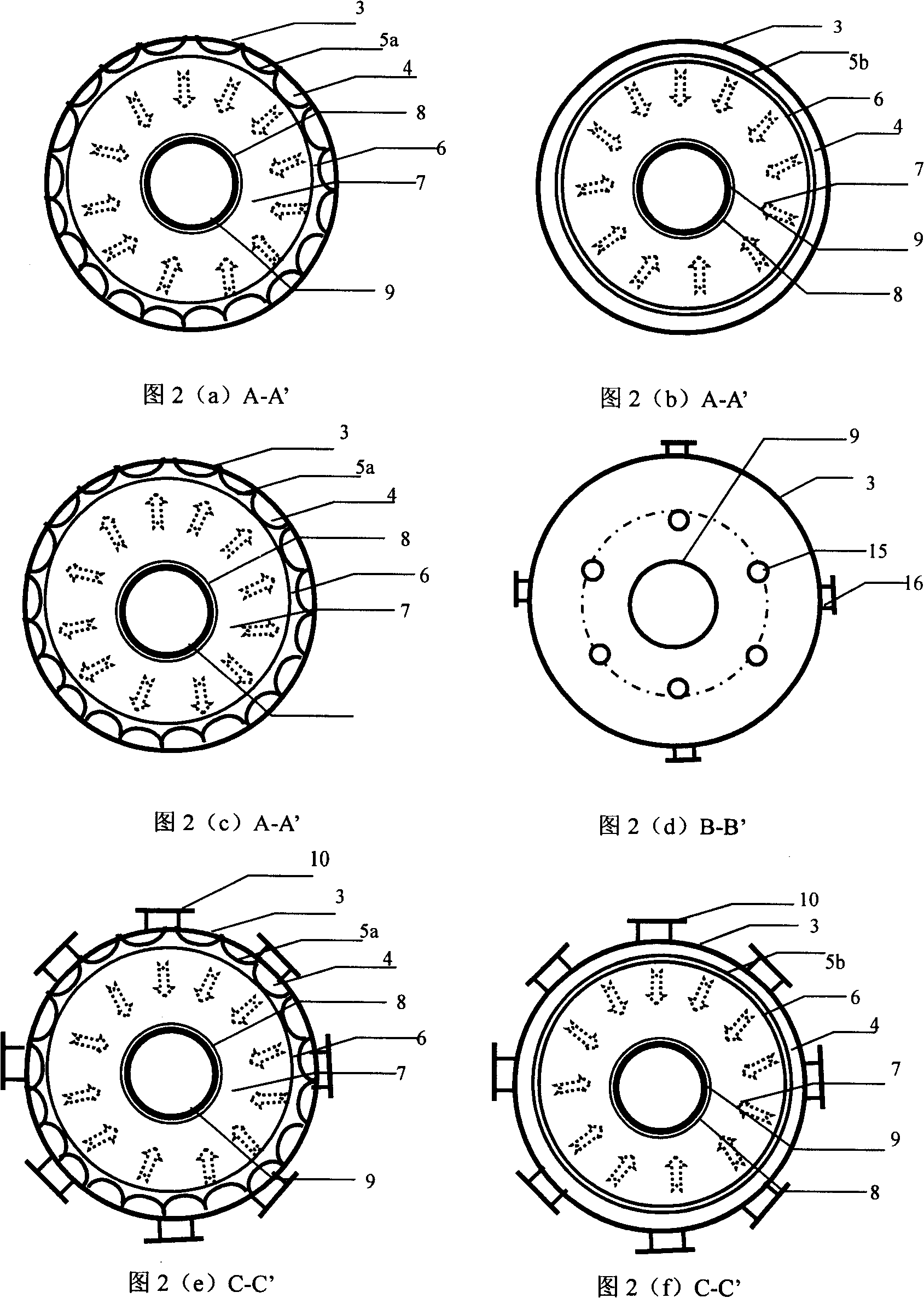

Method for producing propylene by carbinol or dimethyl ether

ActiveCN101177374AHighly selective preparationHydrocarbon from oxygen organic compoundsEthylene productionHydrocarbon mixturesMoving bed

The invention relates to a method for preparing olefin by methanol or dimethyl ether, in particular to a high selectivity preparation method of propylene, which comprises a conversion reaction of methanol or dimethyl ether, alkylation of methanol and ethylene and a catalytic cracking reaction of a plurality of heavy components above C4. A hydrocarbon mixture rich in propylene is generated by preheated material contacting with a first catalyst in a circulating fluidized bed or a moving bed reactor. After the propylene is separated from the hydrocarbon mixture, a plurality of light components of the hydrocarbon mixture comprising hydrogen and methane return to a methanol conversion reactor, the propylene is generated by the alkylation of methanol and ethylene in the light components. The invention is characterized in that the C4 and the heavy components above C4 separated from separation system are contacted with cracking catalyst in the circulating fluidized bed, generating hydrocarbonmixture contained ethylene, propylene and other light components by the catalytic cracking reaction, then the hydrocarbon mixture returns to the separation system for obtaining propylene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

System for purifying flue gas and recovering sulfur and technique

InactiveCN101274193ARealize integrated utilizationAchieve recyclingChemical industryDispersed particle separationThermal energySorbent

The invention provides a flue gas purification and sulphur recovery system and a process, comprising an adsorber, a desorber, an adsorbent delivery system, a heat energy integrated recovery system and a carbon powder separation and recovery system; meanwhile, suitable processing methods are adopted. The adsorber adopts a single-device dual-section radial staggered moving bed shaped like a reversed u and selective wide spectrum purification; the desorber adopts an axial reflux moving bed to realize the integrated recovery and utilization of the heat energy, regeneration of the adsorbent and the recovery of sulphur resource; the adsorbent adopts dense phase pneumatic conveying, thus leading the system to run continuously and stably; the flue gas purification and the sulphur recovery are realized by the carbon-based column-shaped or sphere-shaped desulfurization and denitration adsorbent. The system effectively integrates the energy-saving, exhaust and consumption reduction and resource recovery and utilization together, and has the advantages of high-effect wide spectrum purification and sulphur resource recovery, good gas distribution, grain movement and low pressure reduction, integrated recovery and utilization of heat energy, delivering the absorbent with no mechanical parts, continuous and stable operation of system, saving equipment investment and operation expense, etc.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

Catalyst and sorbent material for the production of hydrogen

A catalyst and sorbent is disclosed which comprises pellets with an absorbent core and a protective shell with a catalyst in the shell. Such material is especially well suited for steam reforming of hydrocarbons to produce hydrogen since a reforming catalyst can be incorporated in the shell and a sorbent for the by-product carbon dioxide can be used for the core. It is also well suited for producing hydrogen from carbon monoxide by means of the water gas shift reaction. The shell can be made sufficiently strong and durable for moving bed applications as well as fixed bed applications.

Owner:IOWA STATE UNIV RES FOUND

Product recovery from simulated-moving-bed adsorption

Product purity from or capacity of a simulated-moving-bed adsorptive separation process is increased by flushing the contents of the transfer line previously used to remove the raffinate stream away from the adsorbent chamber, preferably into the raffinate column used to separate desorbent from raffinate product. Preferably a stream from the adsorbent chamber at an intermediate point between the feed entry point and raffinate withdrawal is used as the flushing liquid. This flush step eliminates the passage of a quantity of the raffinate material into the adsorbent chamber in the transfer-line flush period or when the process conduit is subsequently used to charge the feed stream to the adsorbent chamber.

Owner:UOP LLC

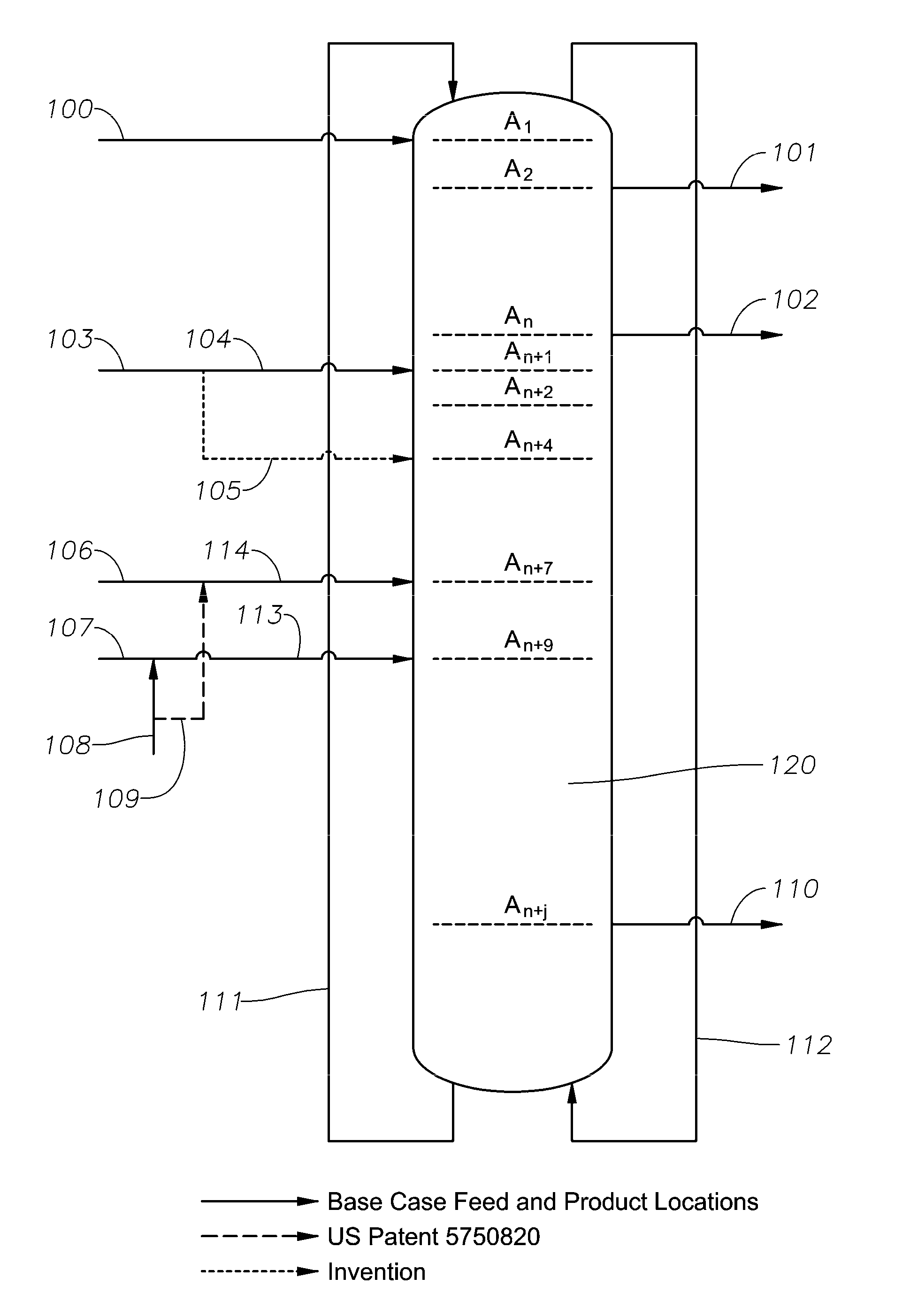

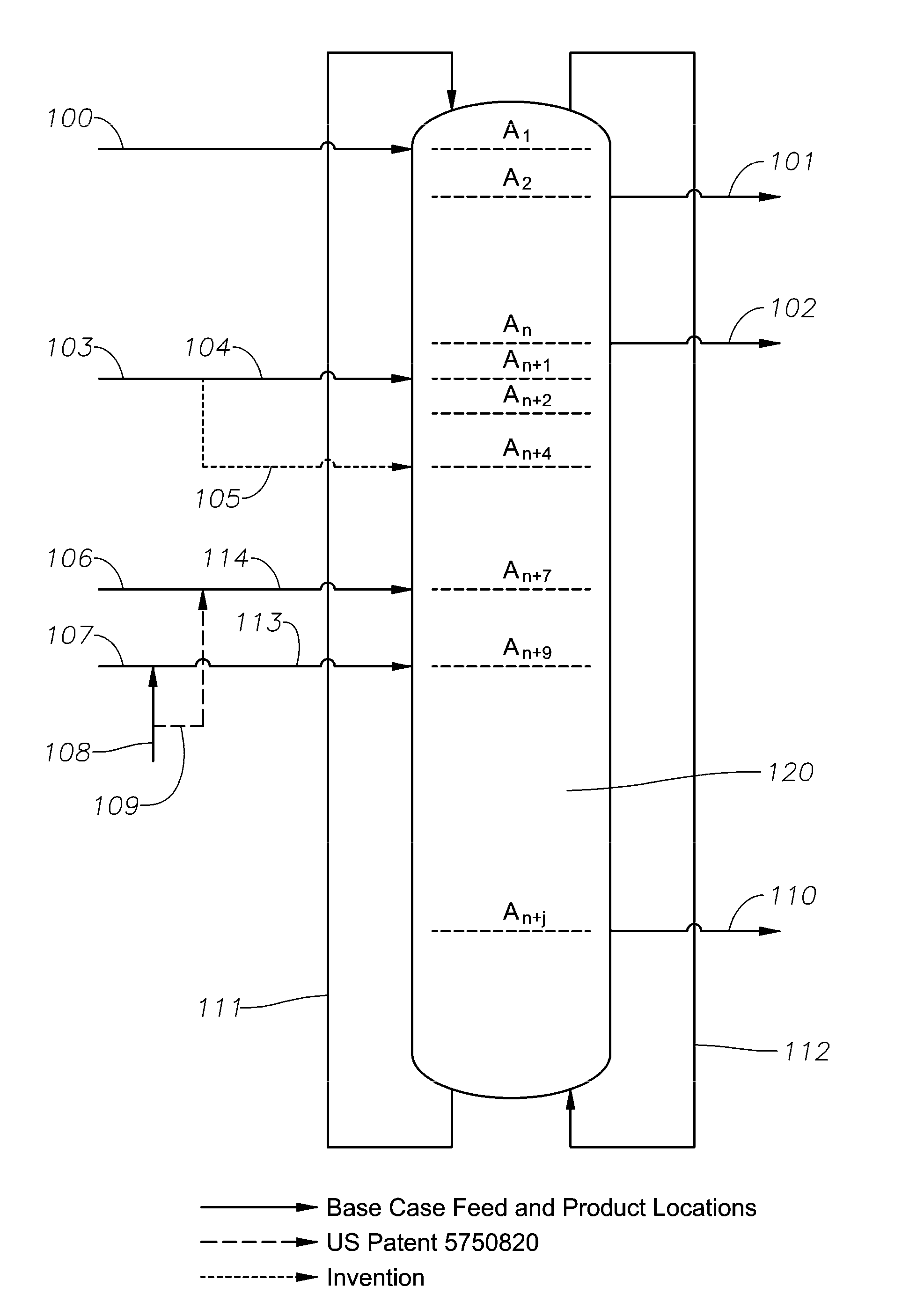

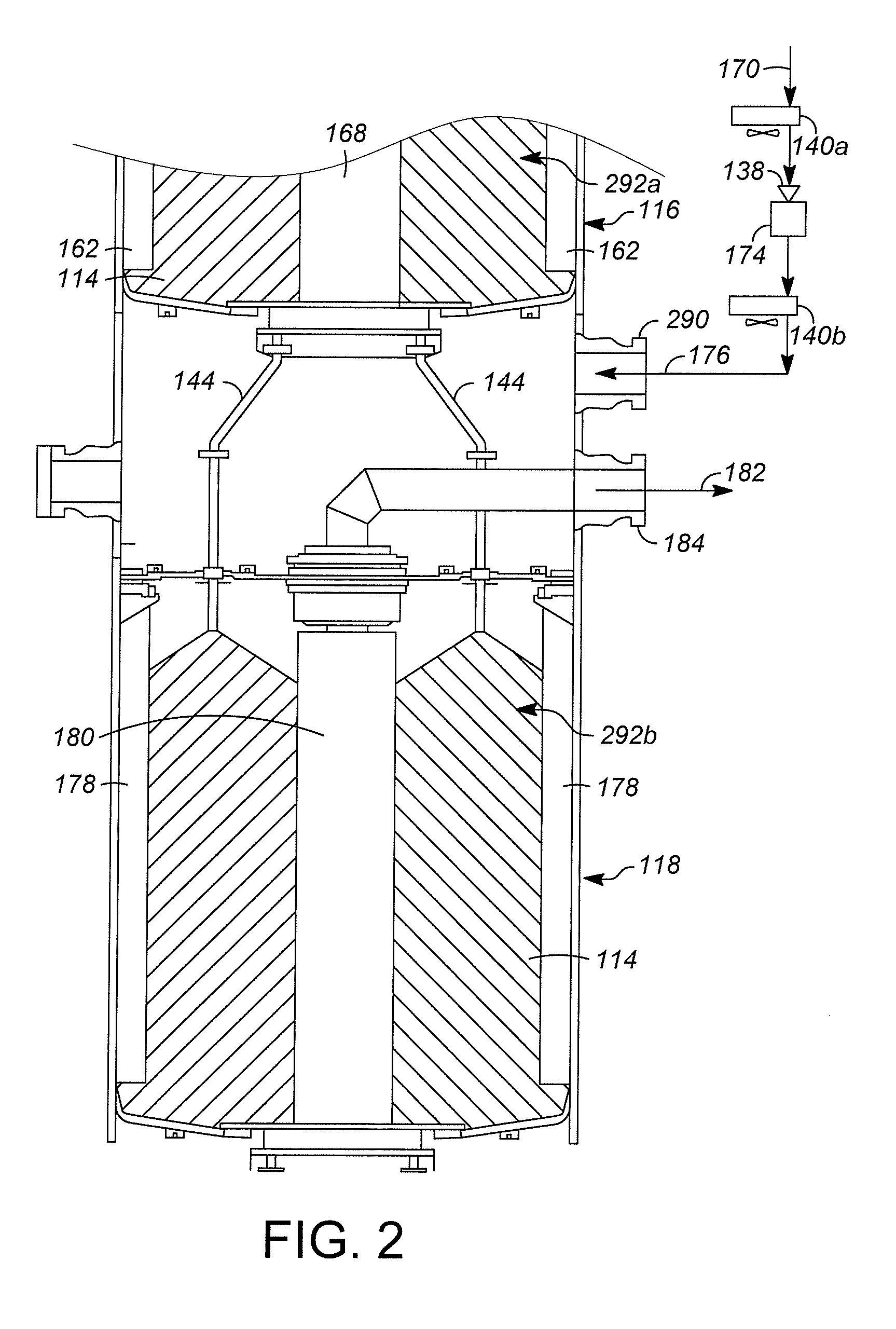

Method for revamping fixed-bed catalytic reformers

InactiveUS20050274648A1Avoids major expenseQuality improvementCatalytic naphtha reformingBed hydrotreatment processes apparatusCatalytic reformingThermodynamics

A fixed-bed catalytic reformer unit is converted to moving bed reactor / cyclic regenerator operation by re-using the fixed bed reactors of the original unit as regenerator vessels operated in cyclic regeneration mode in a new catalyst regeneration section. A flow connection, suitably a liftpipe, is provided to convey spent catalyst from the spent catalyst outlet of a new moving bed reactor section to the converted regenerator section, together with a flow connection for regenerated catalyst from the regenerator section to the regenerated catalyst inlet of the new moving bed reactor section. A flow control distributor directs spent catalyst sequentially to each of the regenerator vessels to carry out the regeneration with regeneration gas. Each regenerator vessel is cycled through a fill, regeneration, discharge sequence to maintain a continuous flow of catalyst to and from the reactor section.

Owner:EXXON RES & ENG CO

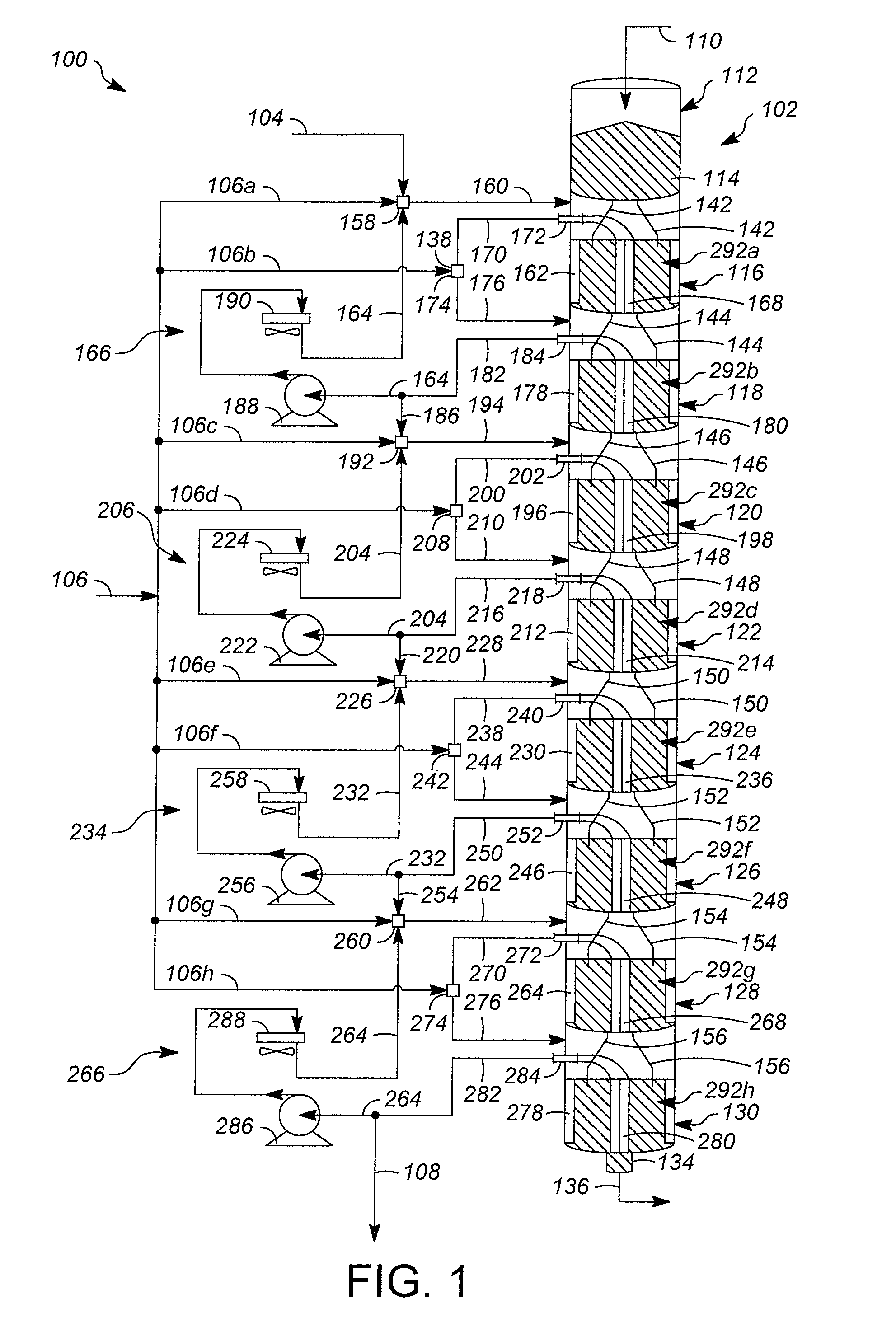

Solid catalyst hydrocarbon alkylation using stacked moving bed radial flow reactors

Systems and processes for the alkylation of a hydrocarbon are provided that utilize a plurality of moving bed radial flow reactors. An olefin injection point can be provided prior to each reactor by providing a mixer that mixes olefin with a hydrocarbon feed, or with the effluent stream from an upstream reactor, to produce a reactor feed stream. Catalyst can be provided from the reaction zone of one reactor to the reaction zone of a downstream reactor through catalyst transfer pipes, and can be regenerated after passing through the reaction zones of the reactors. The moving bed radial flow reactors can be stacked in one or more reactor stacks.

Owner:UOP LLC

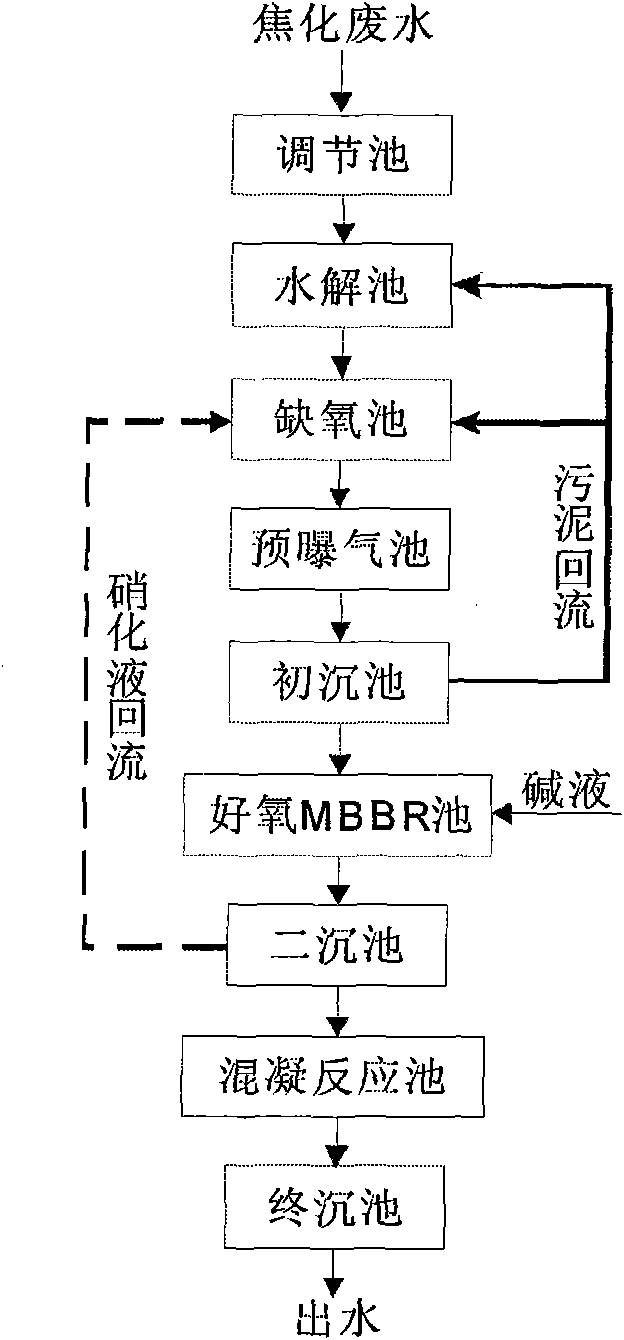

Method for treating coking wastewater

InactiveCN101602564AHigh activityNo reflow requiredTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationSludge

The invention discloses a method for treating coking wastewater, which belongs to the field of wastewater treatment. The method comprises the following steps that: wastewater of a coking plant enters a regulating reservoir for the adjustment of water quality and water amount, and orderly enters a hydrolytic tank, an anaerobic tank, a preaeration tank, a preliminary sedimentation tank, an aerobic tank, a secondary sedimentation tank and a coagulation reaction tank for treatment, wherein the hydrolytic tank and the preaeration tank are filled with a bio-cord filler; the sludge of the preliminary sedimentation tank refluxes into the hydrolytic tank and the anaerobic tank respectively; a clarifying solution of the secondary sedimentation tank refluxes into the anaerobic tank; and the aerobic tank adopts a moving bed bio-film reactor. The bio-cord filler adopted in the invention has short film formation time and high biomass, does not need repeated washing, and has strong shock resistance; and the moving bed bio-film reactor can fix a large amount of nitrobacteria with long generation time, and has no the problem of blocking. The method can remove high-concentration ammonia nitrogen and organic substances in the coking wastewater, and the COD and the ammonia nitrogen of treated effluent can synchronously achieve the primary standard of the national integrated wastewater discharge standard (GB9878-1996).

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com