Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2277results about "Adsorption purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

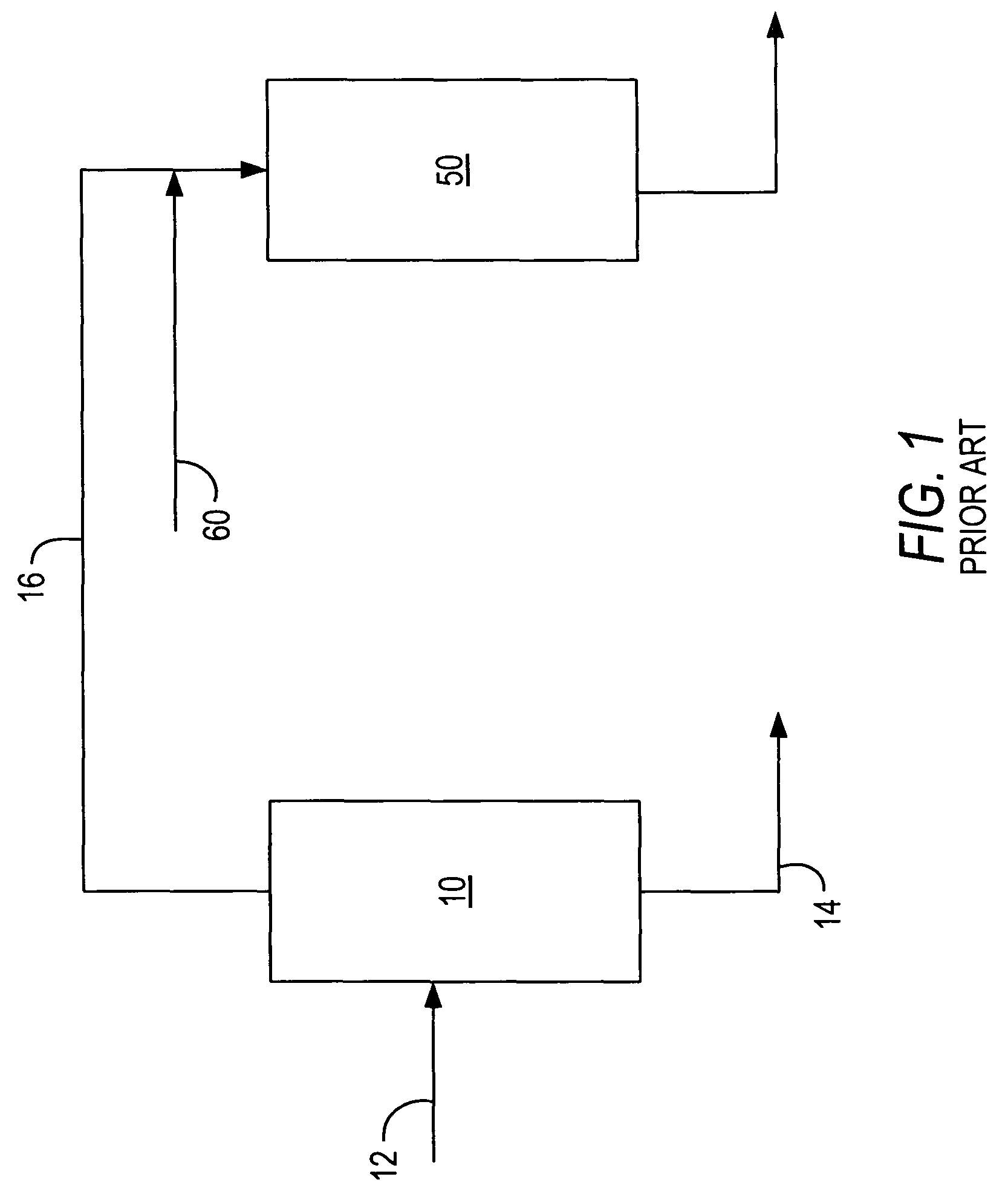

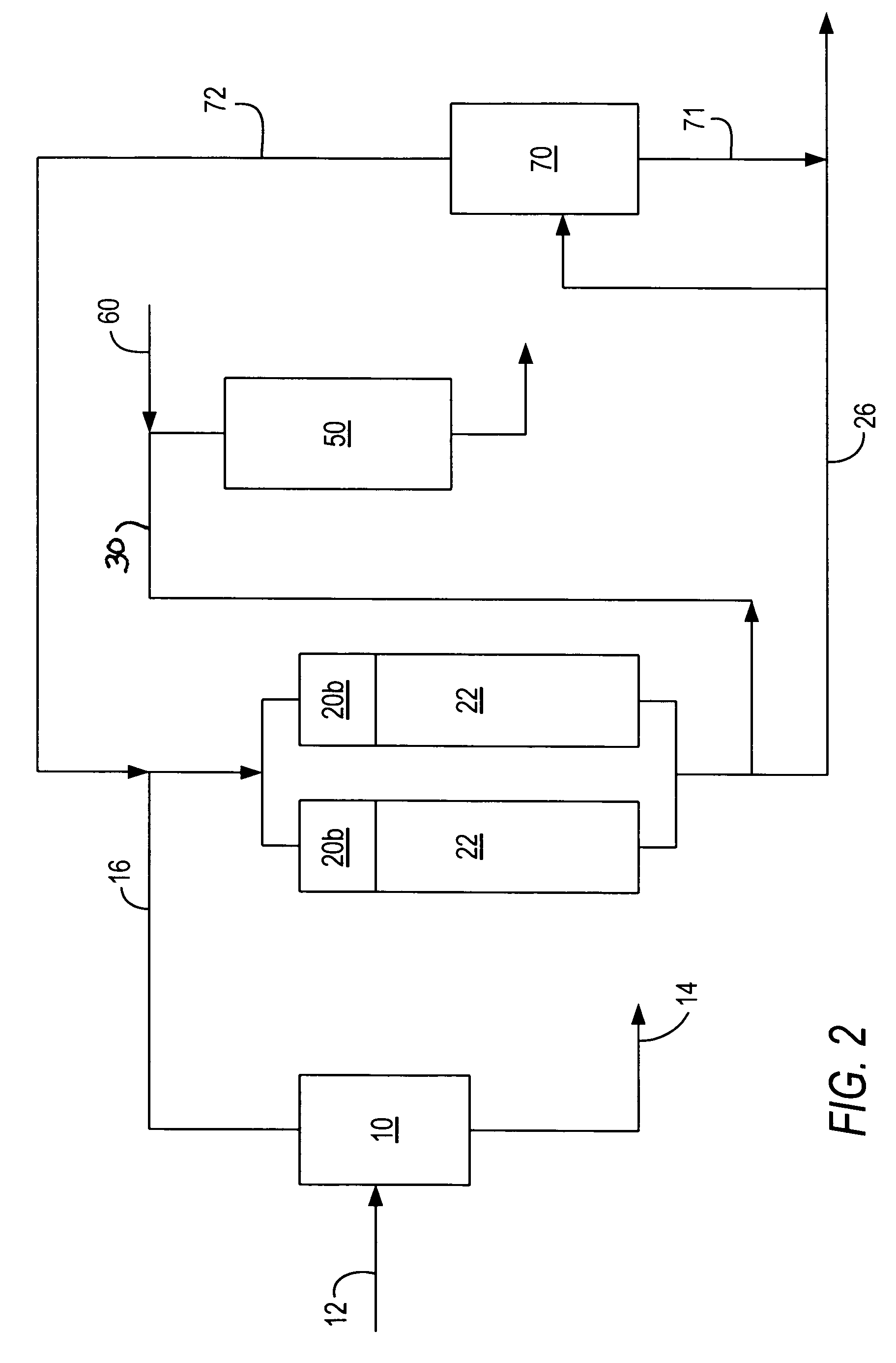

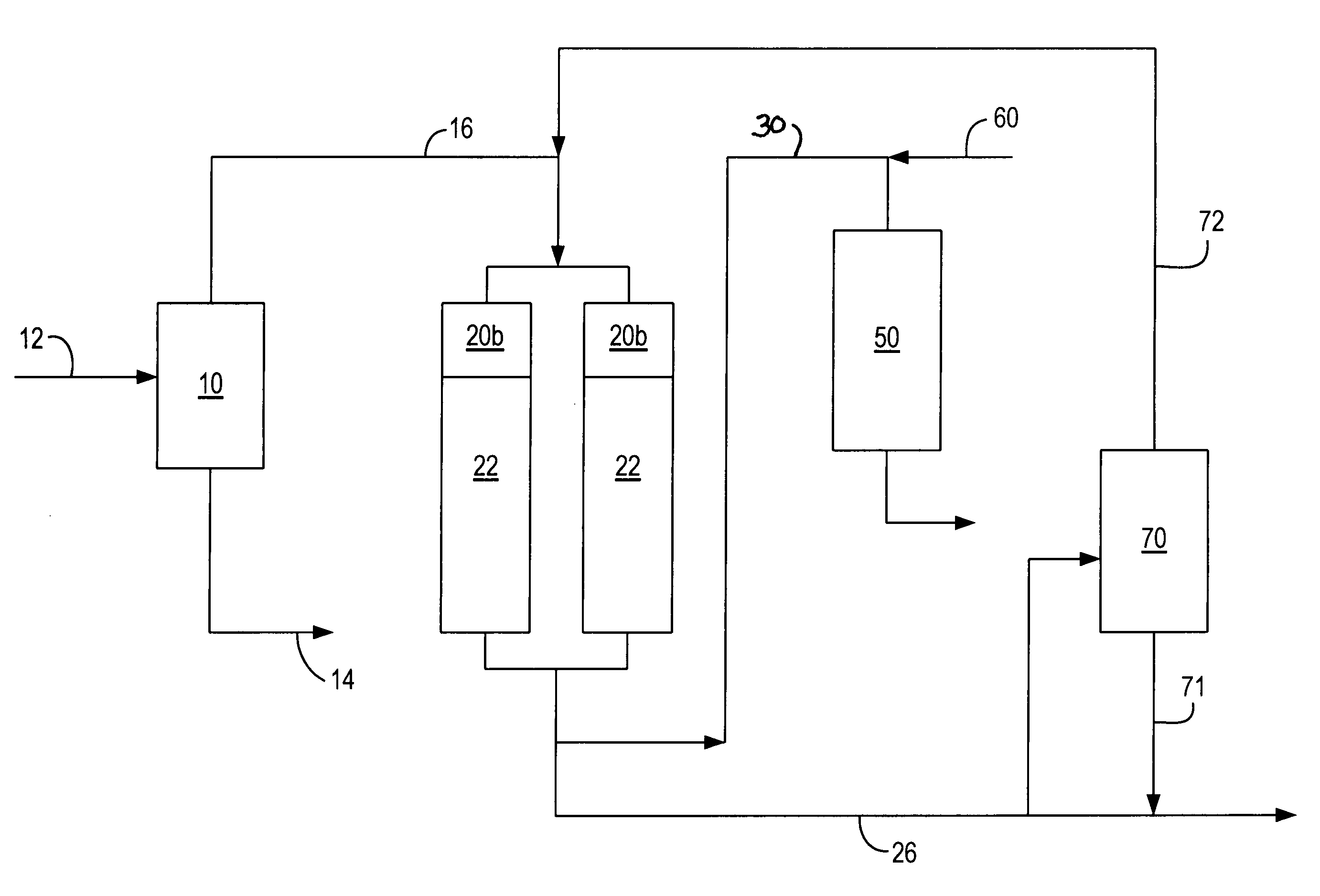

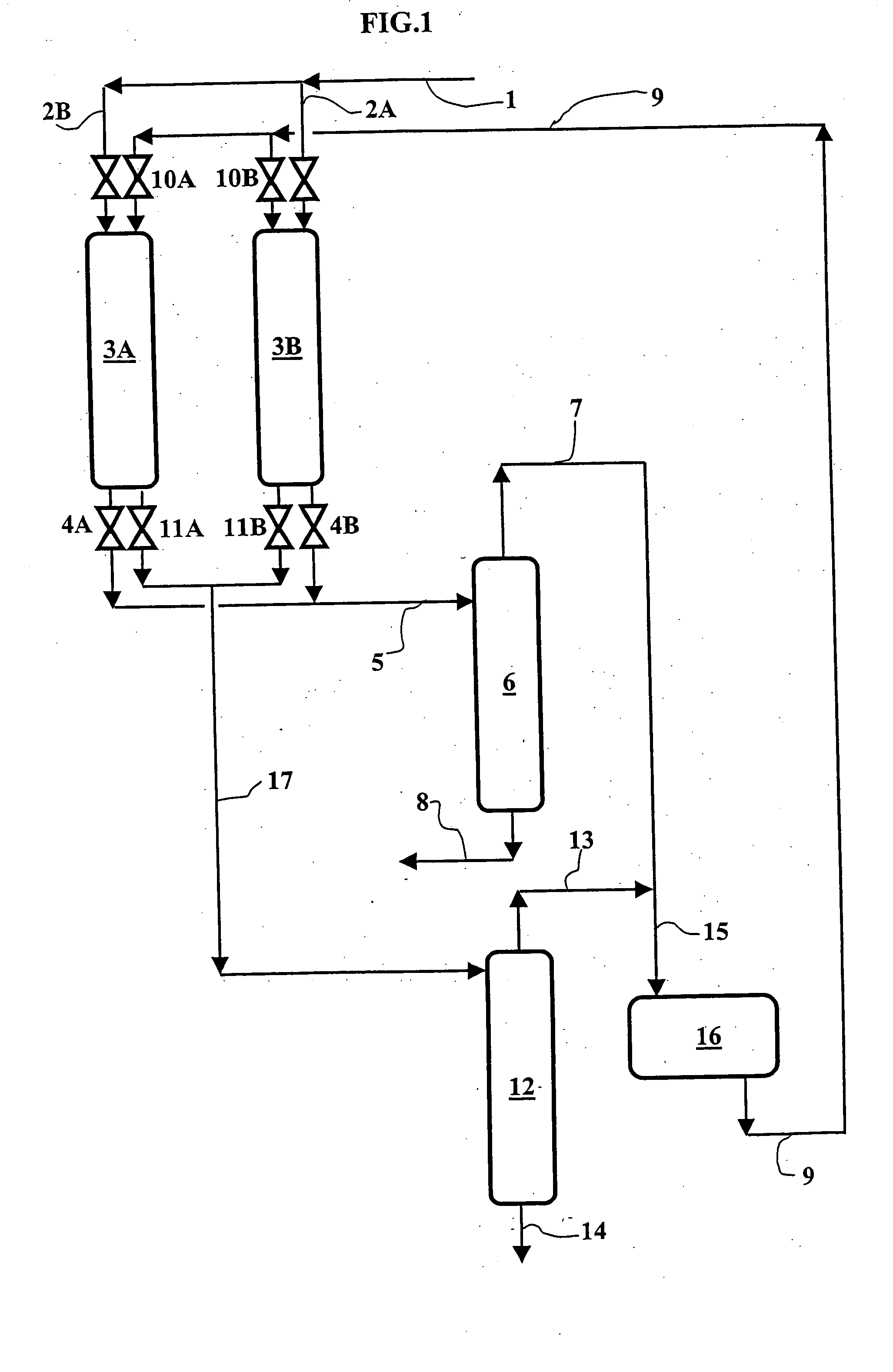

Process for the manufacture of diesel range hydrocarbons

ActiveUS20070010682A1Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationReaction temperature

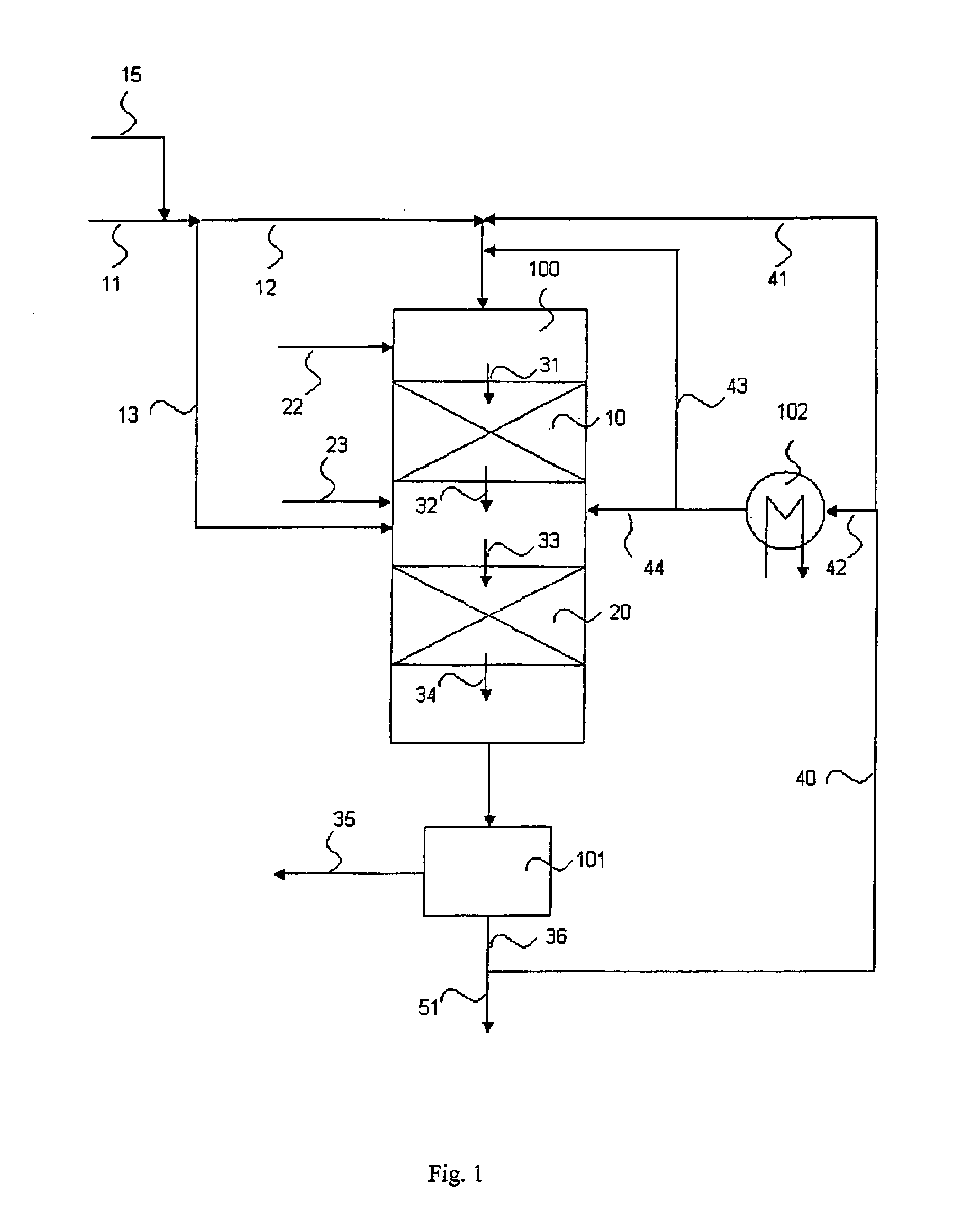

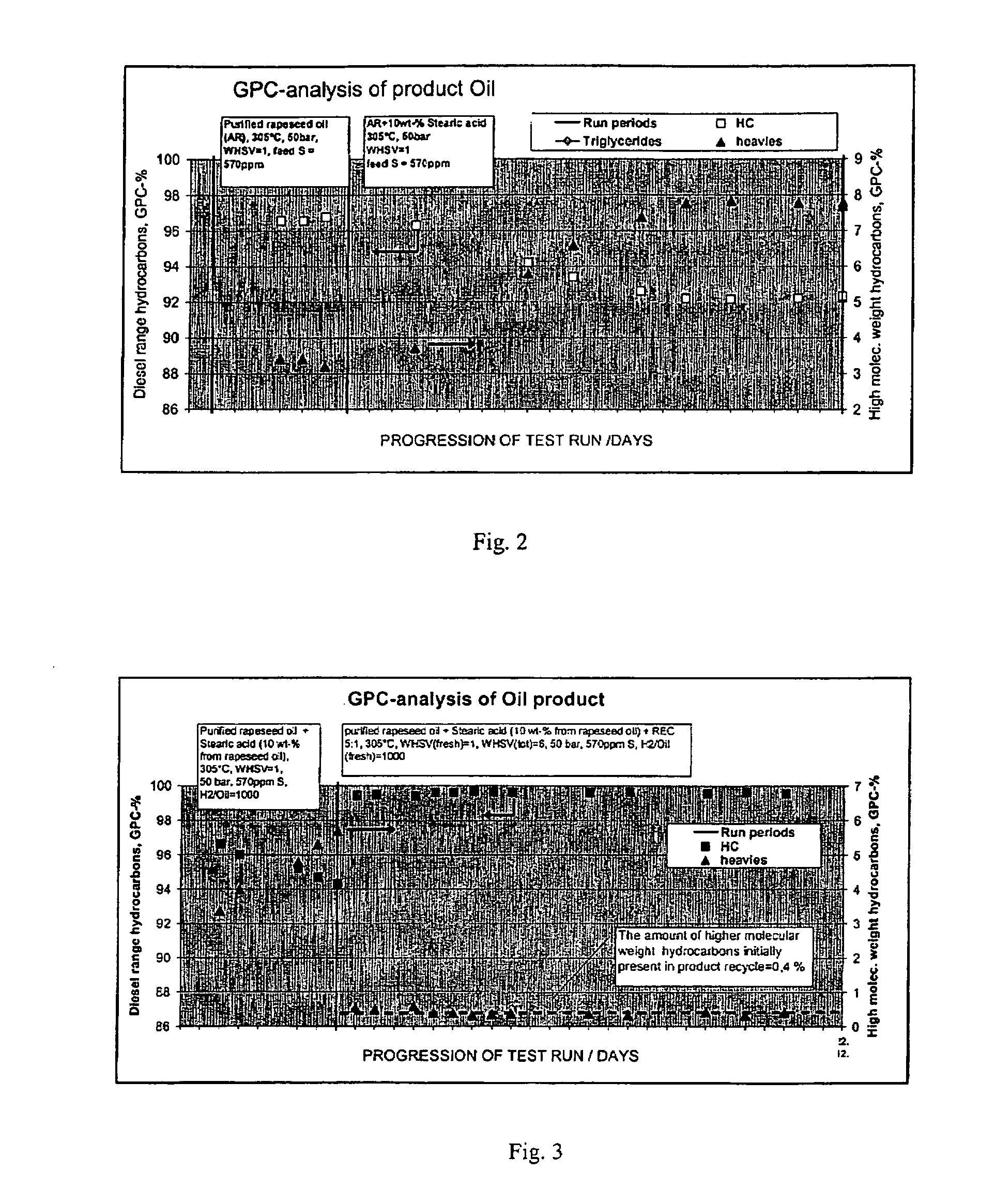

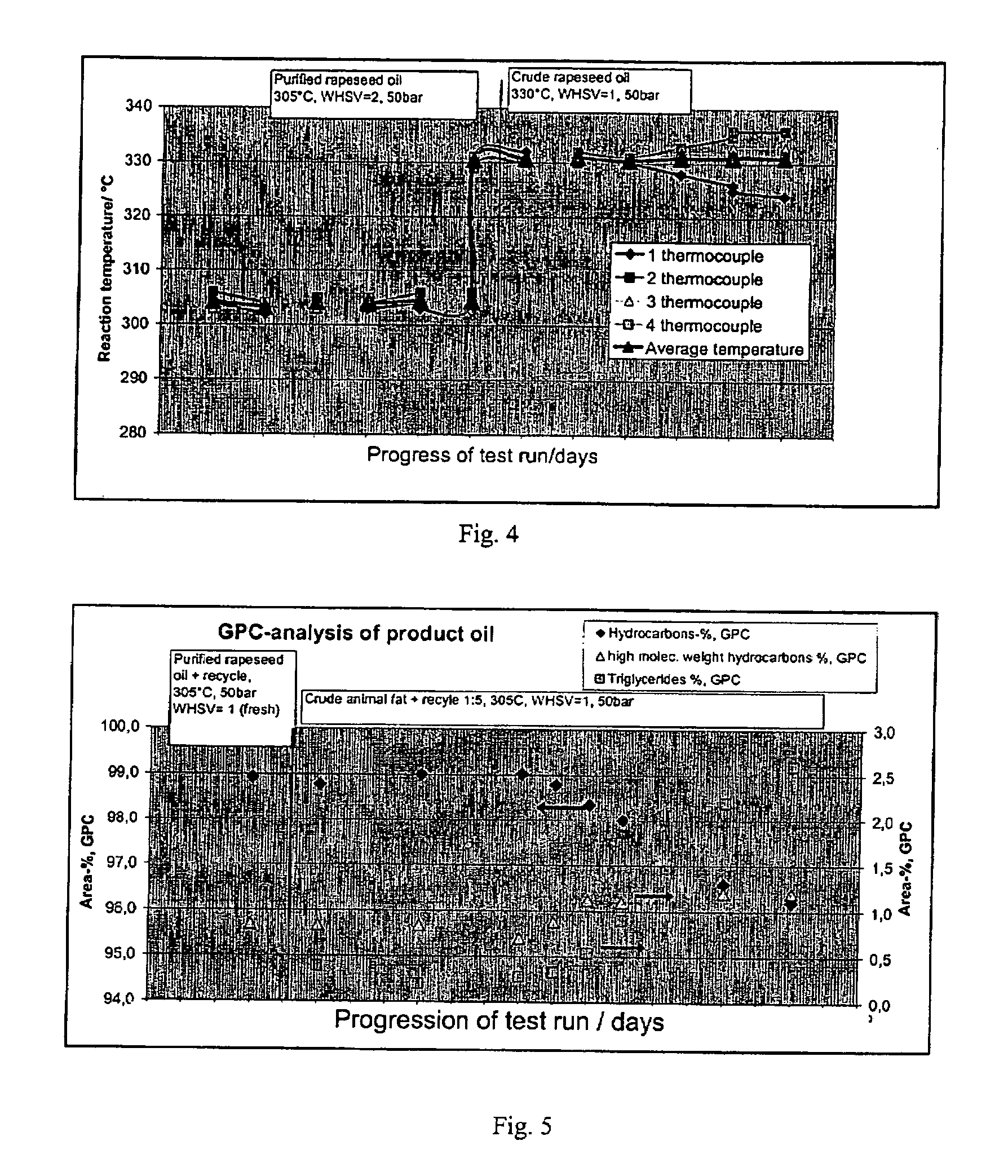

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

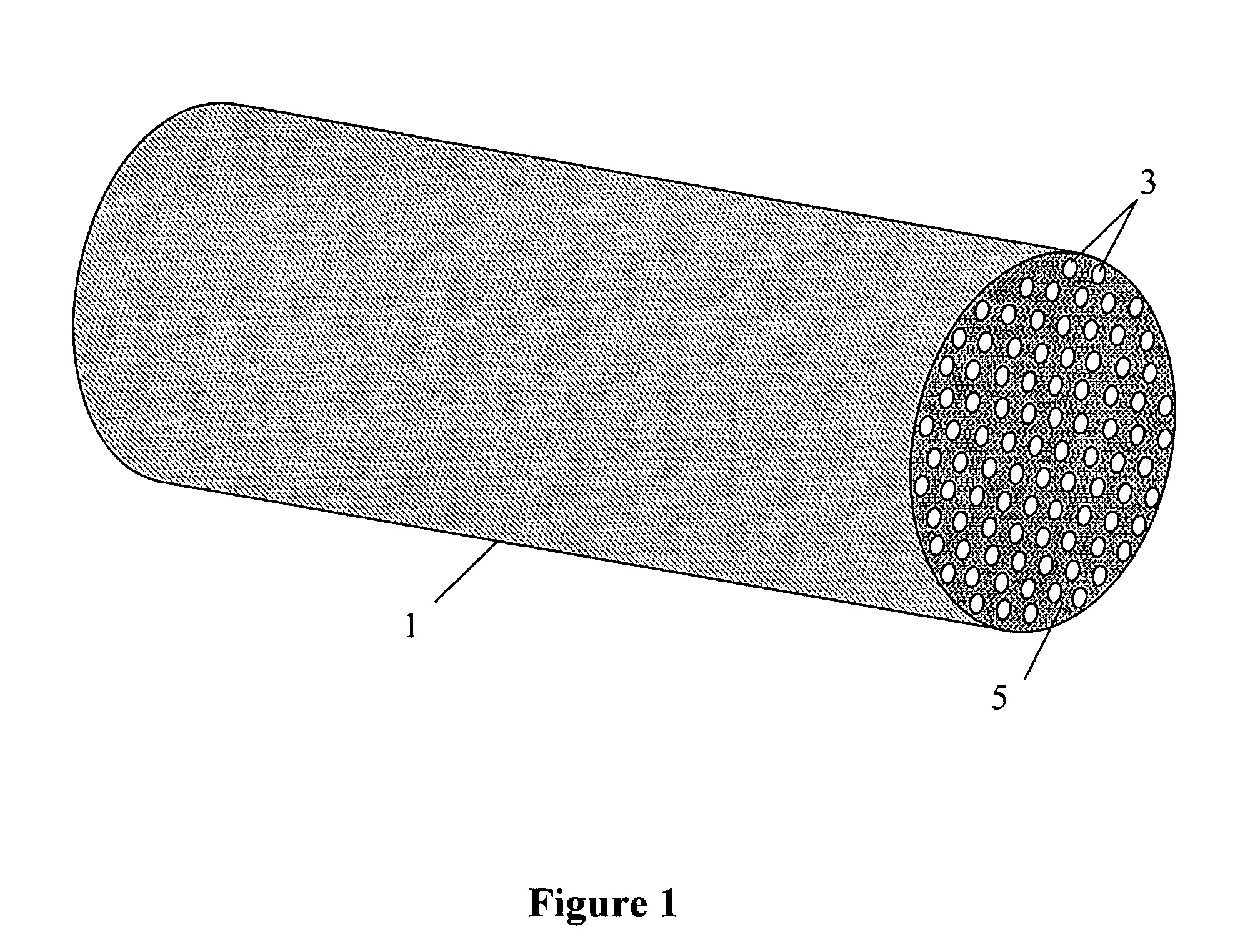

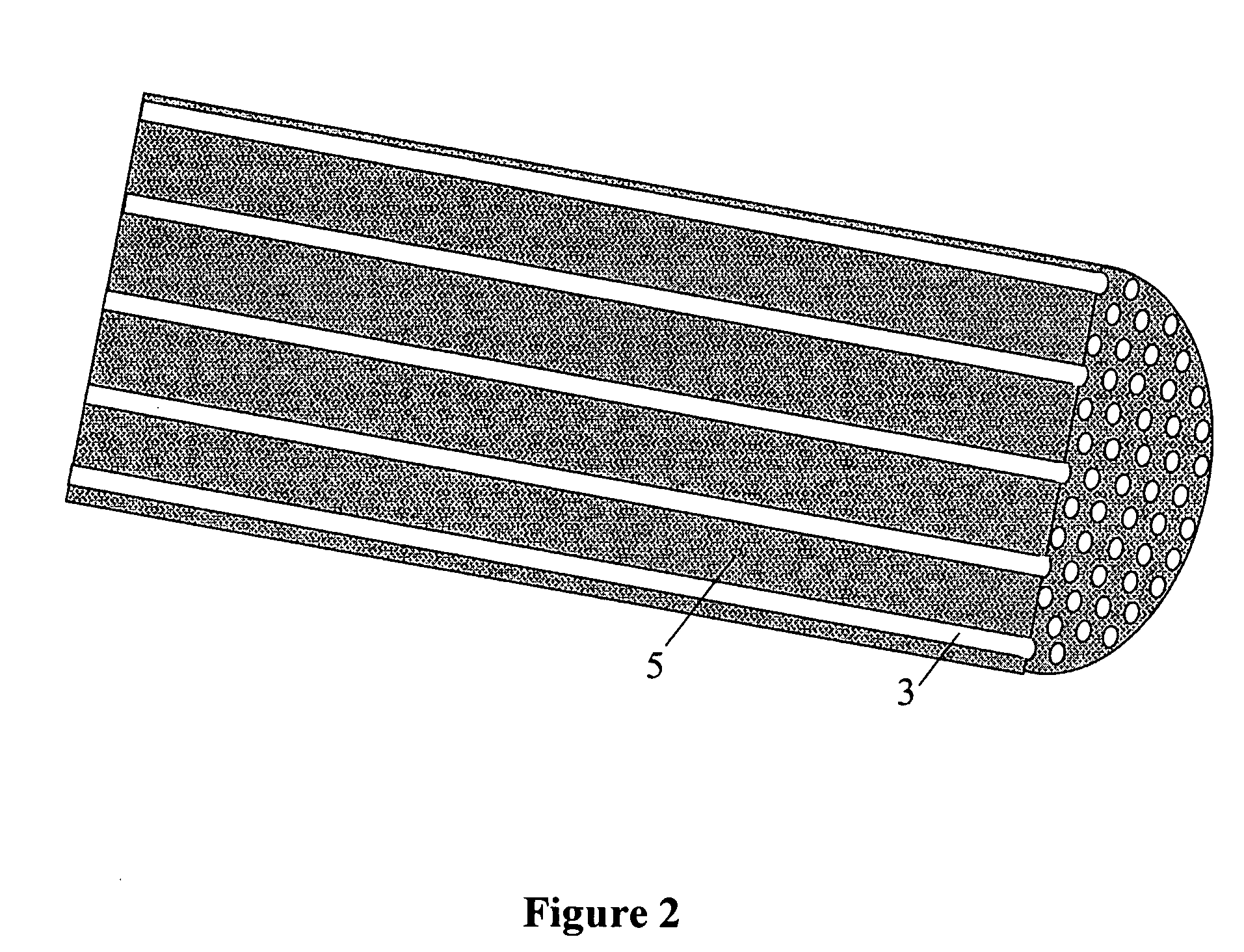

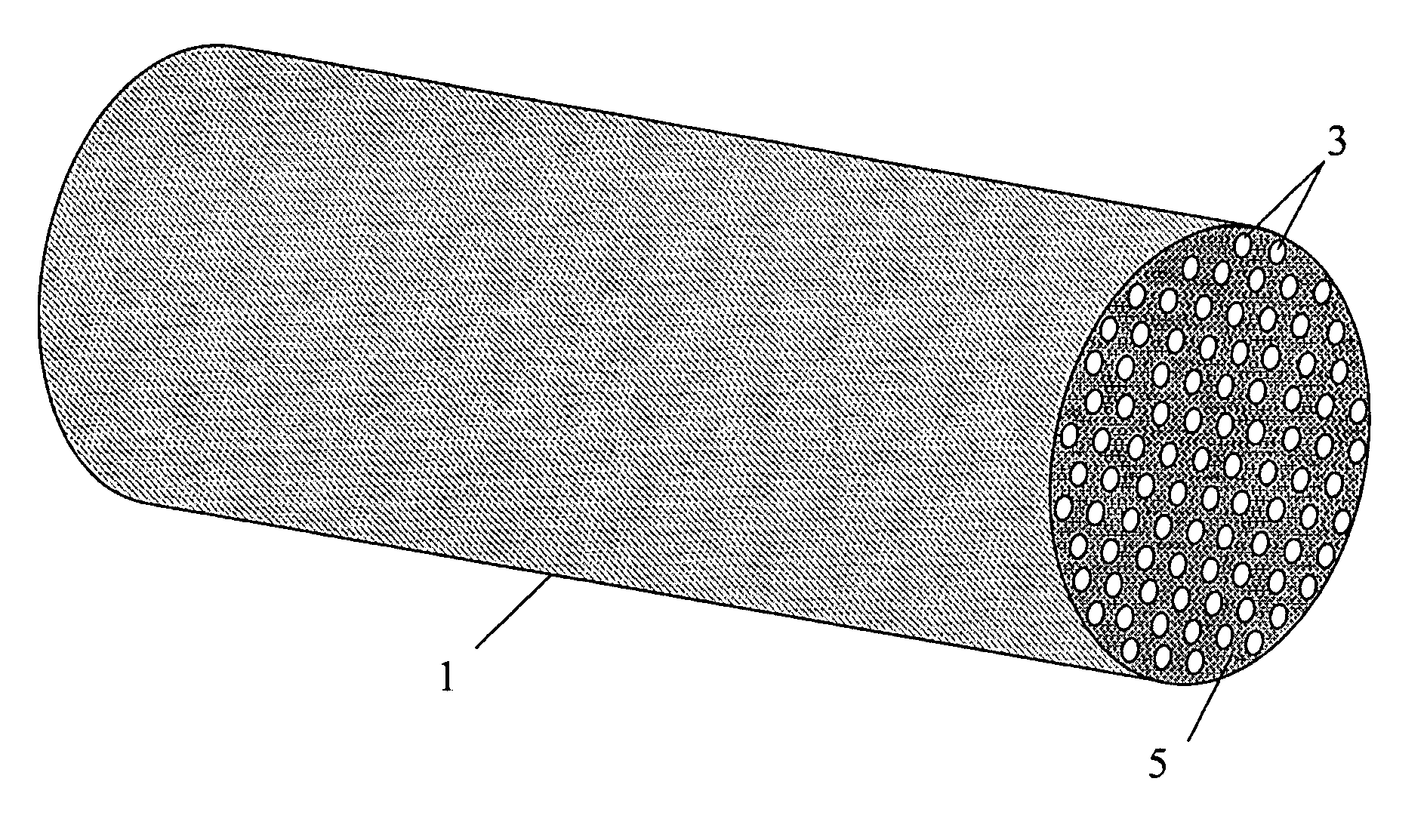

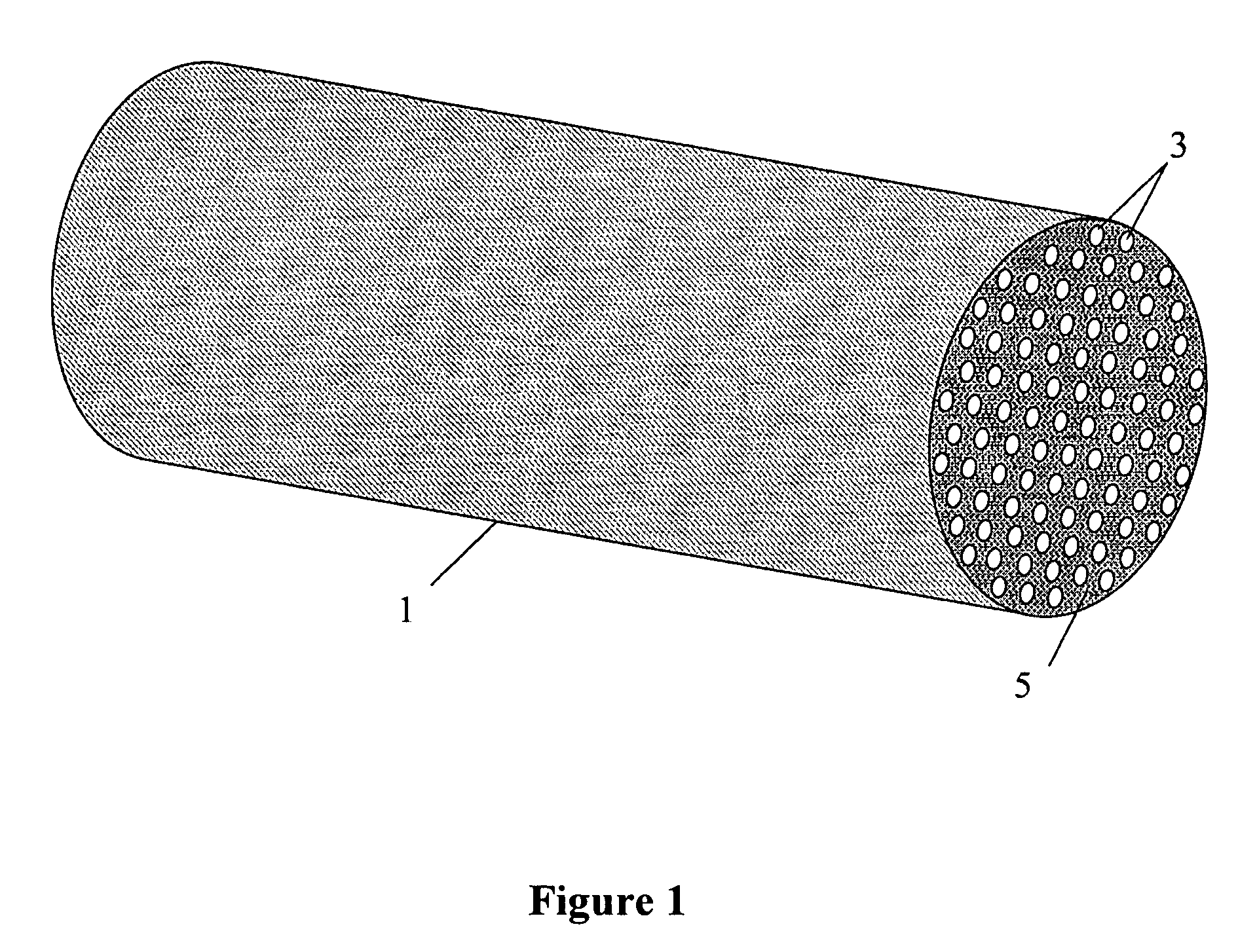

Low mesopore adsorbent contactors for use in swing adsorption processes

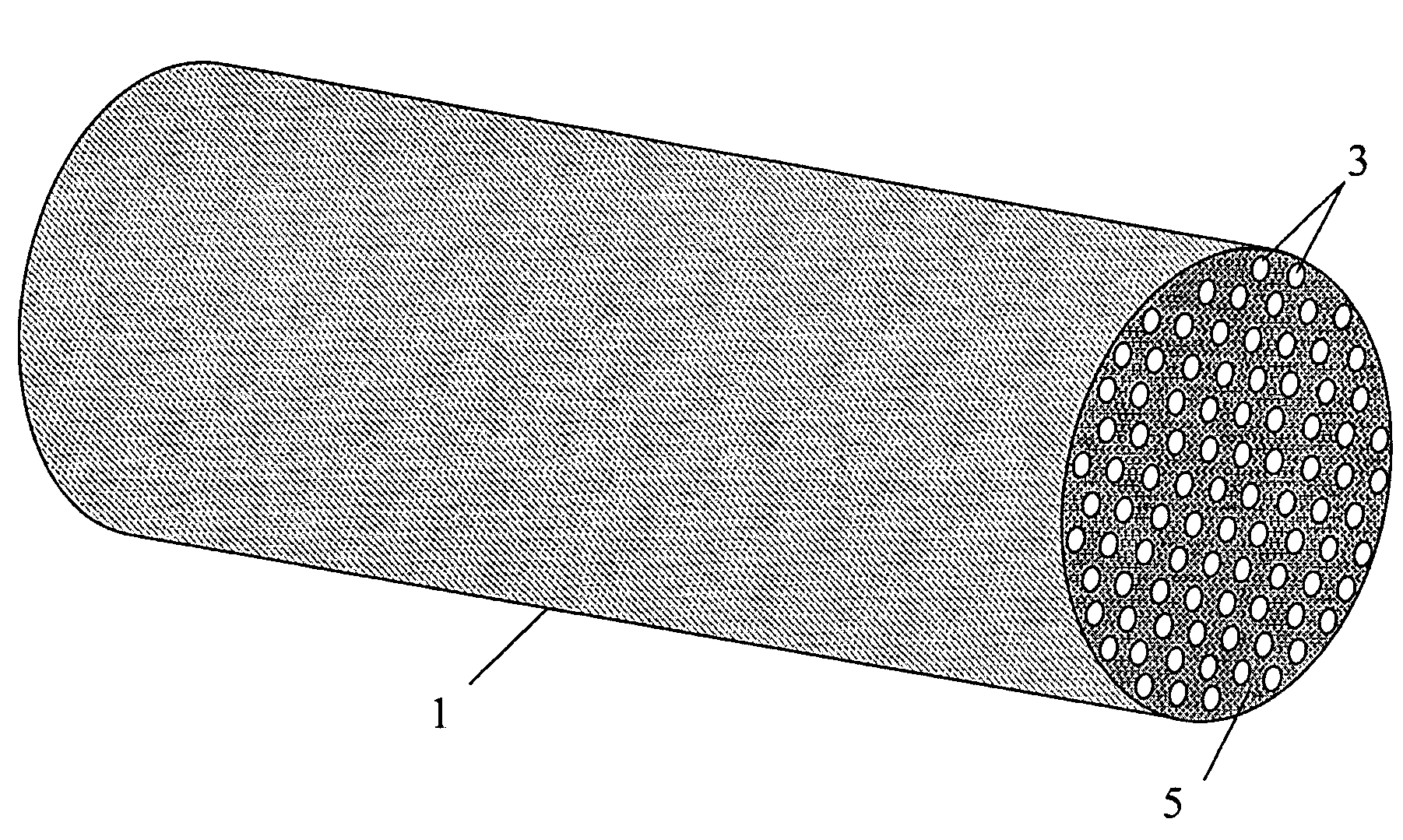

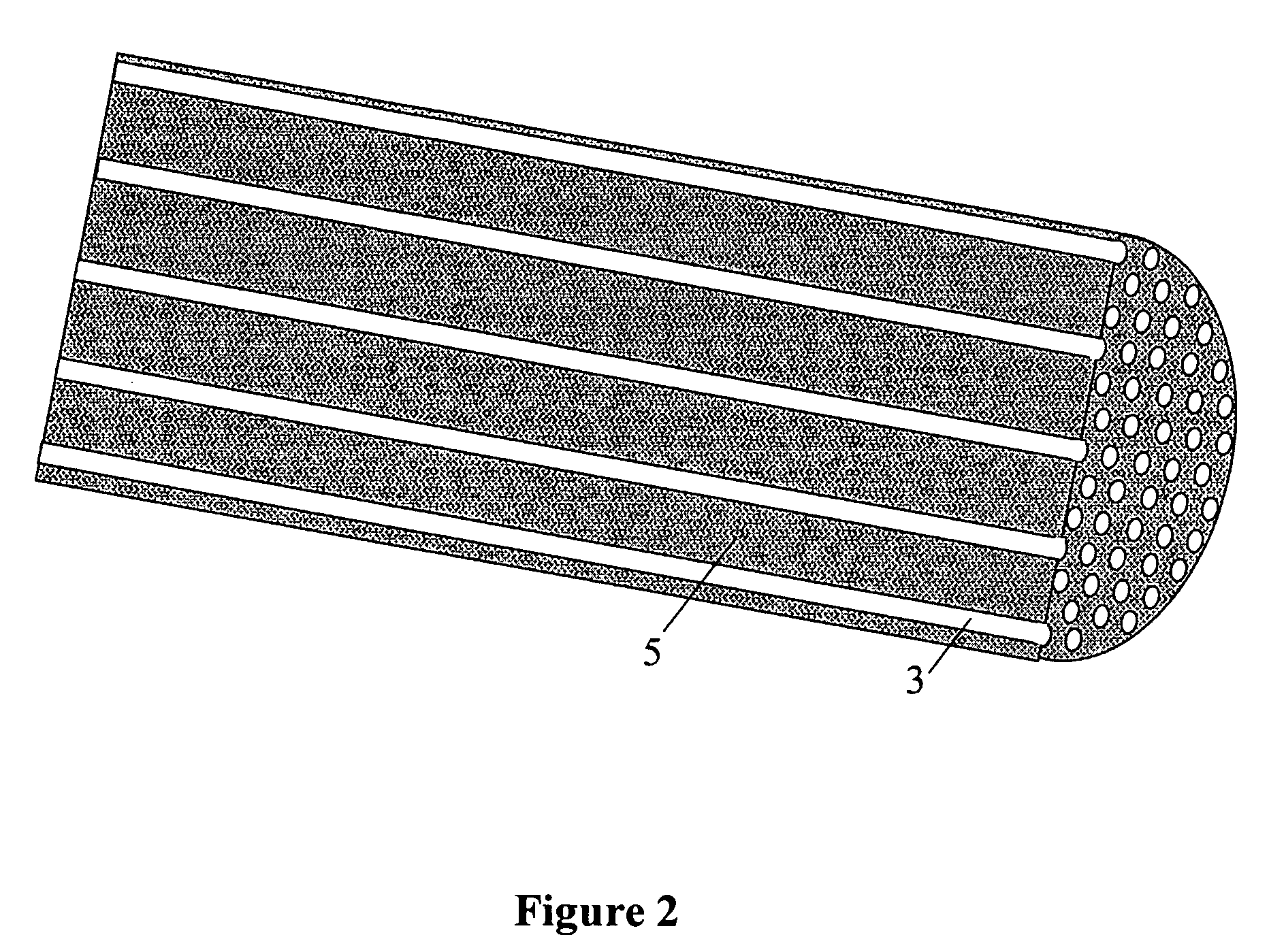

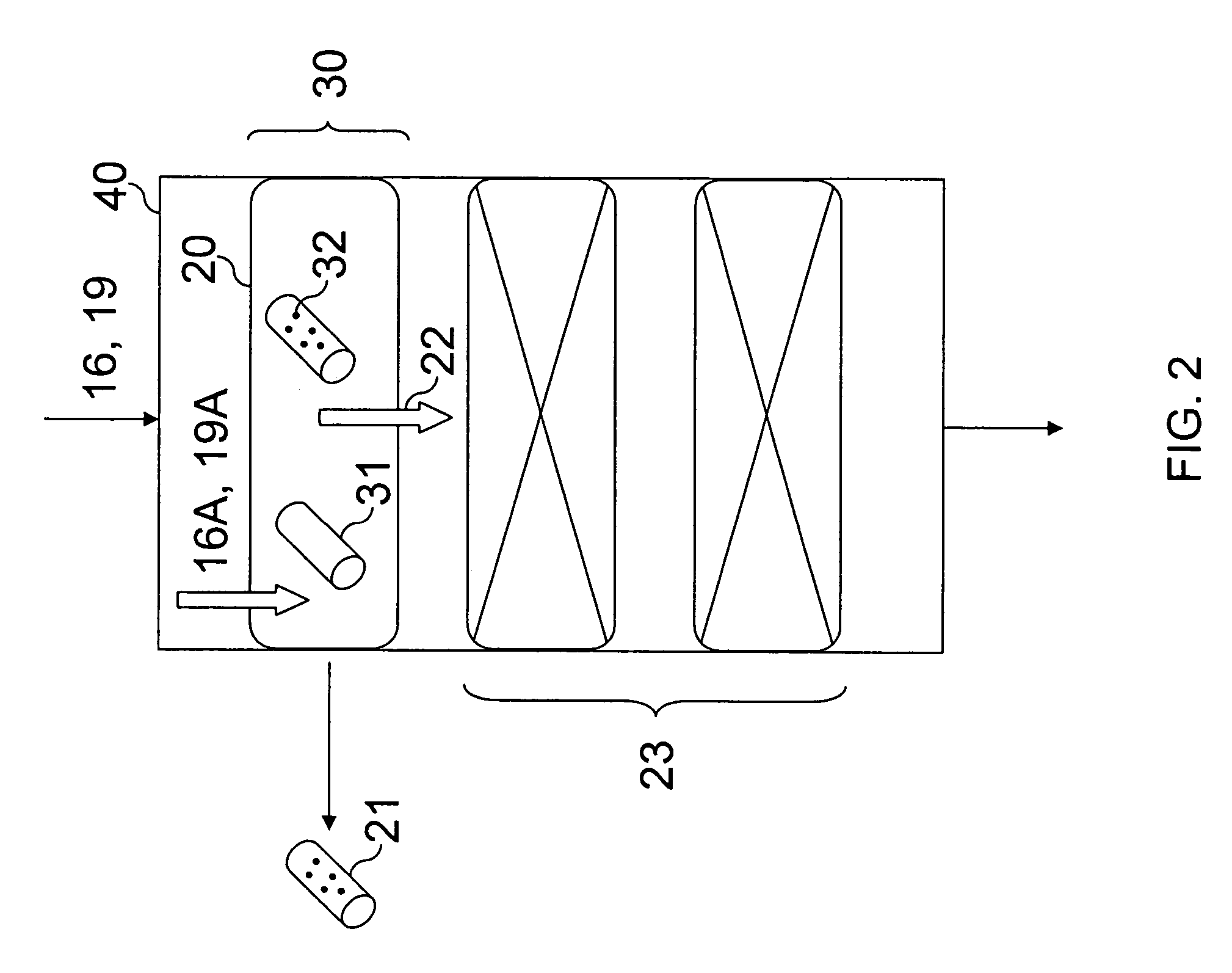

The present invention relates to engineered structured adsorbent contactors for use in pressure swing adsorption and thermal swing adsorption processes. Preferably, the contactors contain engineered and substantially parallel flow channels wherein 20 volume percent or less of the open pore volume of the contactor, excluding the flow channels, is in the mesopore and macropore range.

Owner:EXXON RES & ENG CO

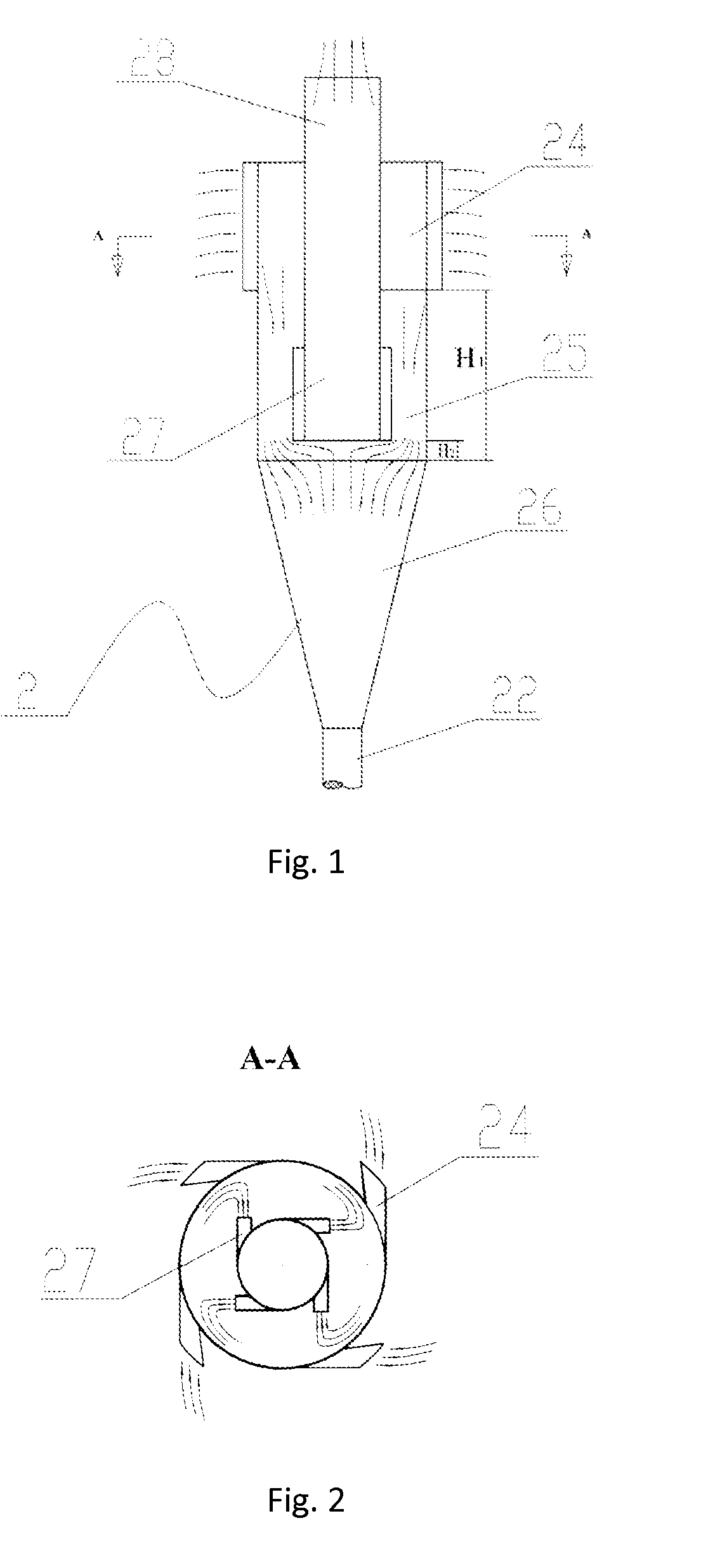

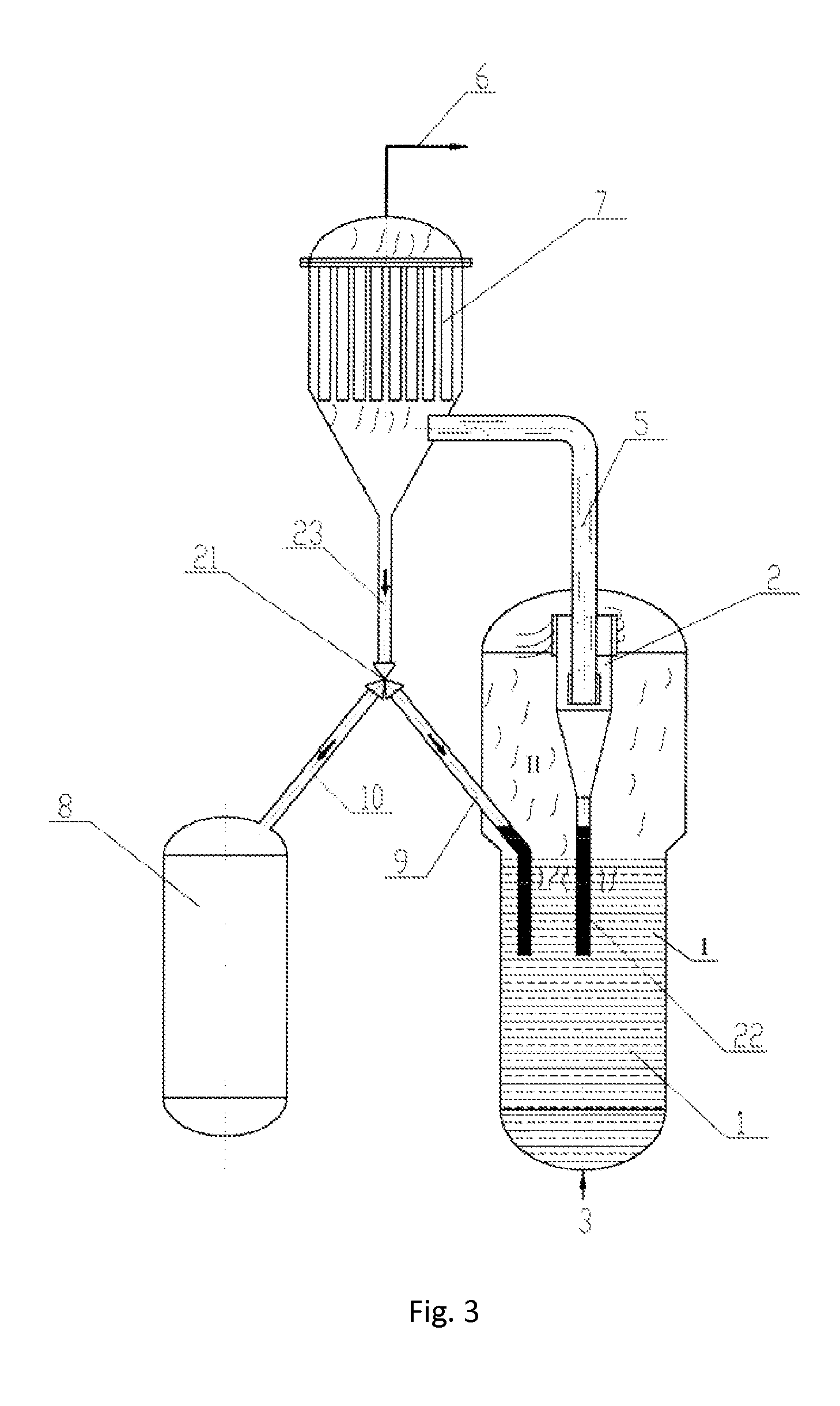

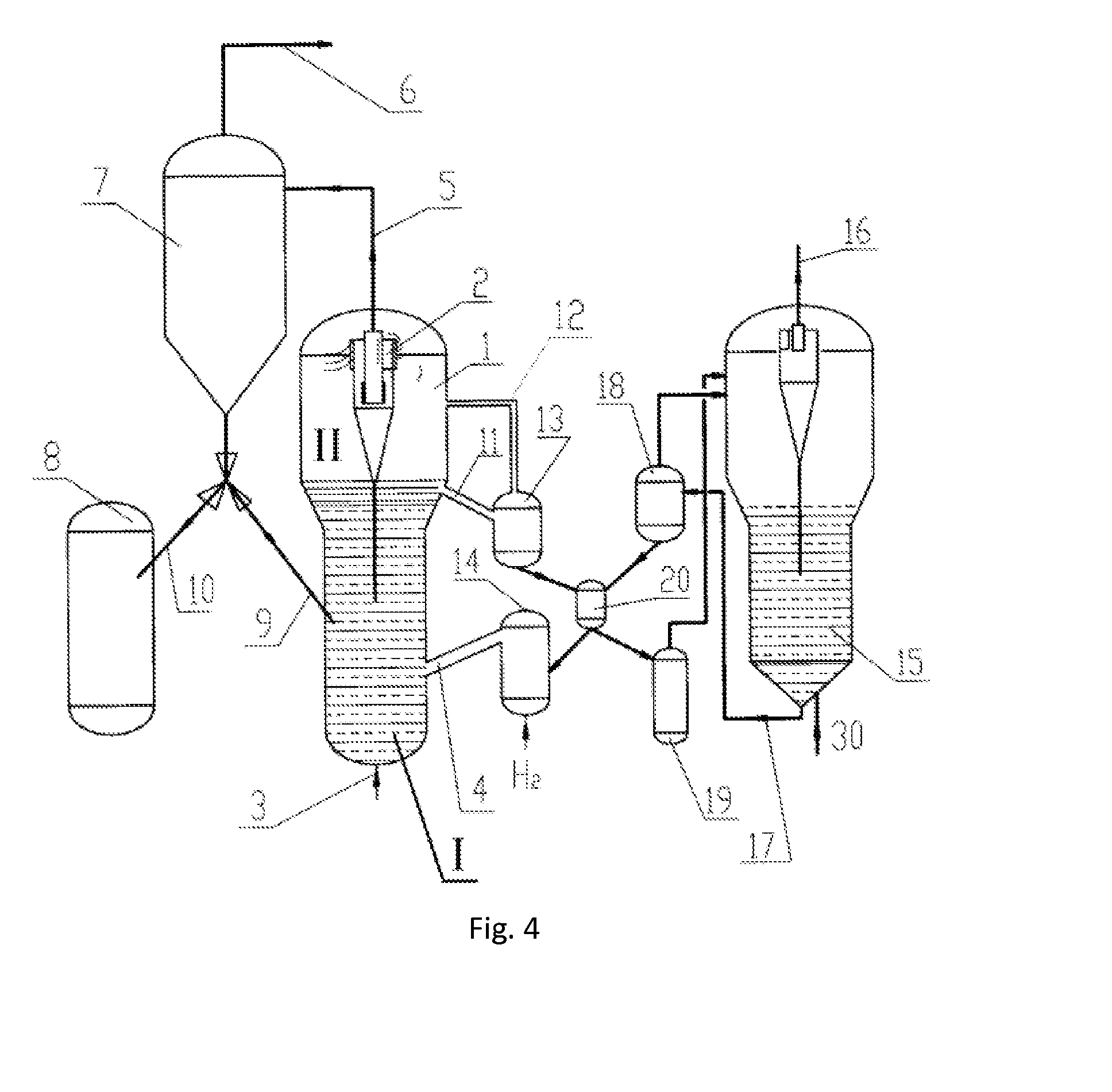

Adsorption Desulfurization Process for Hydrocarbons and a Reaction Apparatus Therefor

ActiveUS20140121438A1Efficient removalReduce flow rateReversed direction vortexHydrocarbonsFluidized bedStraight tube

The present invention relates to an airflow particle sorter, comprising: a top-sealed sorter main body, a discharge port, an outtake tube and at least one directing-intake port; the inner space of the sorter main body, from the above to the bottom, includes, a straight tube zone and a cone zone, the conical bottom of the cone zone is connected to the straight tube zone; the discharge port is located at the bottom of the cone zone; the directing-intake port is installed in the upper part of the straight tube zone in a tangential direction of the straight tube zone, and is communicated with the inner space of the sorter main body; the outtake tube is hermetically inserted into the top of the sorter main body, and extends downwardly to the lower part of the straight tube zone, and the outtake tube has a sealed bottom end; the lower part of the outtake tube is installed with at least one directing-outtake port, which communicates the outtake tube with the inner space of the sorter main body, the directing-outtake port is installed in a tangential direction of the outtake tube. The present invention further relates to a fluidized bed reactor and an adsorption desulfurization reaction apparatus as well as an adsorption desulfurization process.

Owner:CHINA PETROCHEMICAL CORP +1

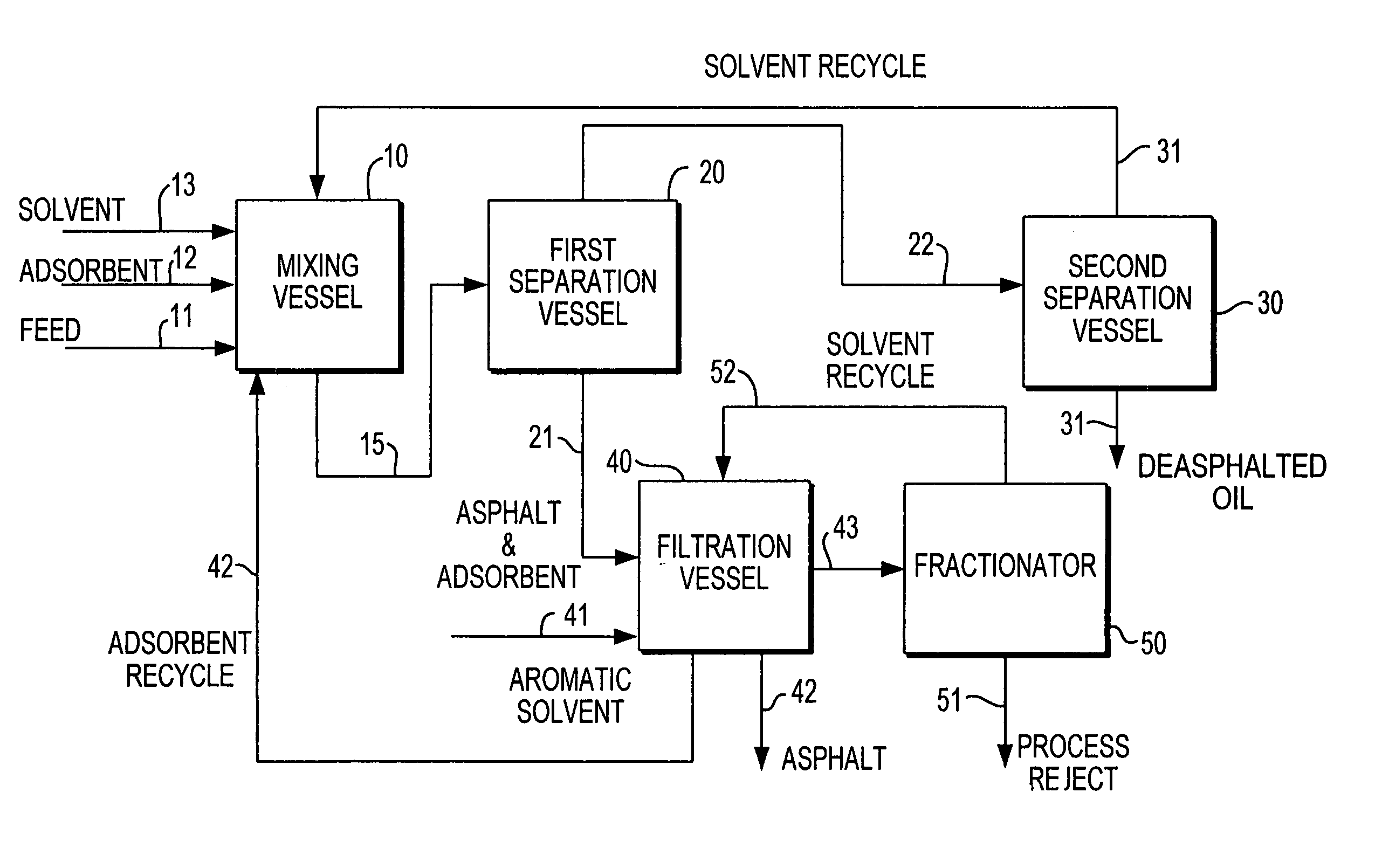

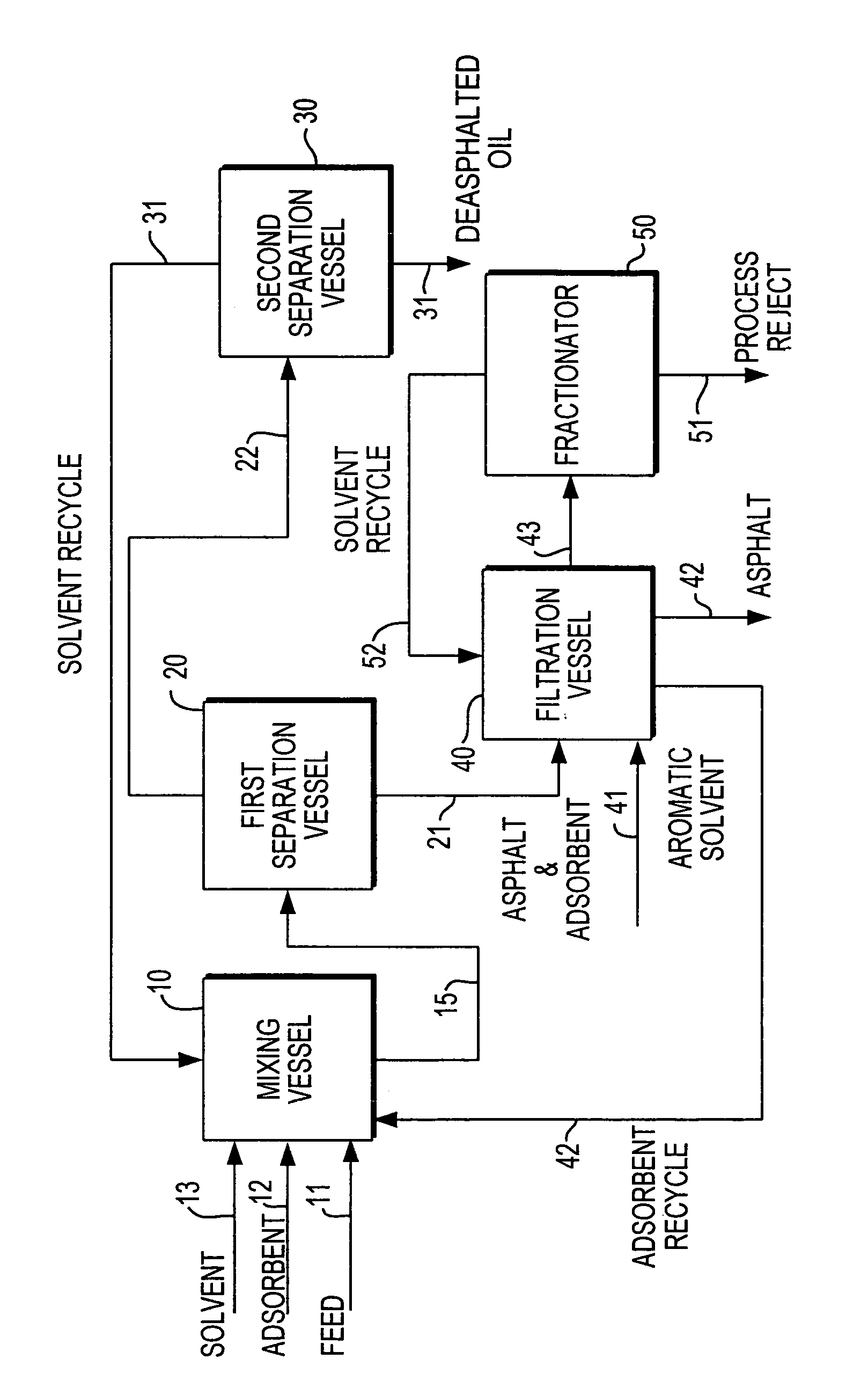

Enhanced solvent deasphalting process for heavy hydrocarbon feedstocks utilizing solid adsorbent

ActiveUS7566394B2Improve performanceImprove current efficiencyWorking-up pitch/asphalt/bitumen by selective extractionHydrocarbon distillationBenzeneActivated carbon

A solvent deasphalting of crude oil or petroleum heavy fractions and residues is carried out in the presence of a solid adsorbent, such as clay, silica, alumina and activated carbon, which adsorbs the contaminants and permits the solvent and oil fraction to be removed as a separate stream from which the solvent is recovered for recycling; the adsorbent with contaminants and the asphalt bottoms is mixed with aromatic and / or polar solvents to desorb the contaminants and washed as necessary, e.g., with benzene, toluene, xylenes and tetrahydrofuran, to clean adsorbant which is recovered and recycled; the solvent-asphalt mixture is sent to a fractionator for recovery and recycling of the aromatic or polar solvent. The bottoms from the fractionator include the concentrated PNA and contaminants and are further processes as appropriate.

Owner:SAUDI ARABIAN OIL CO

Process for the removal of nitrogen compounds from a fluid stream

ActiveUS7205448B2Increase capacityReduce accumulationMolecular sieve catalystsHydrocarbonsMolecular sieveNitrite

At lower temperatures an acidic molecular sieve adsorbent preferentially adsorbs water and basic organic nitrogen compounds over weakly basic organic nitrogen compounds such as nitrites. Elevated temperatures improve the capacity of acidic molecular sieve adsorbents to adsorb nitrites in the presence of water.

Owner:UOP LLC

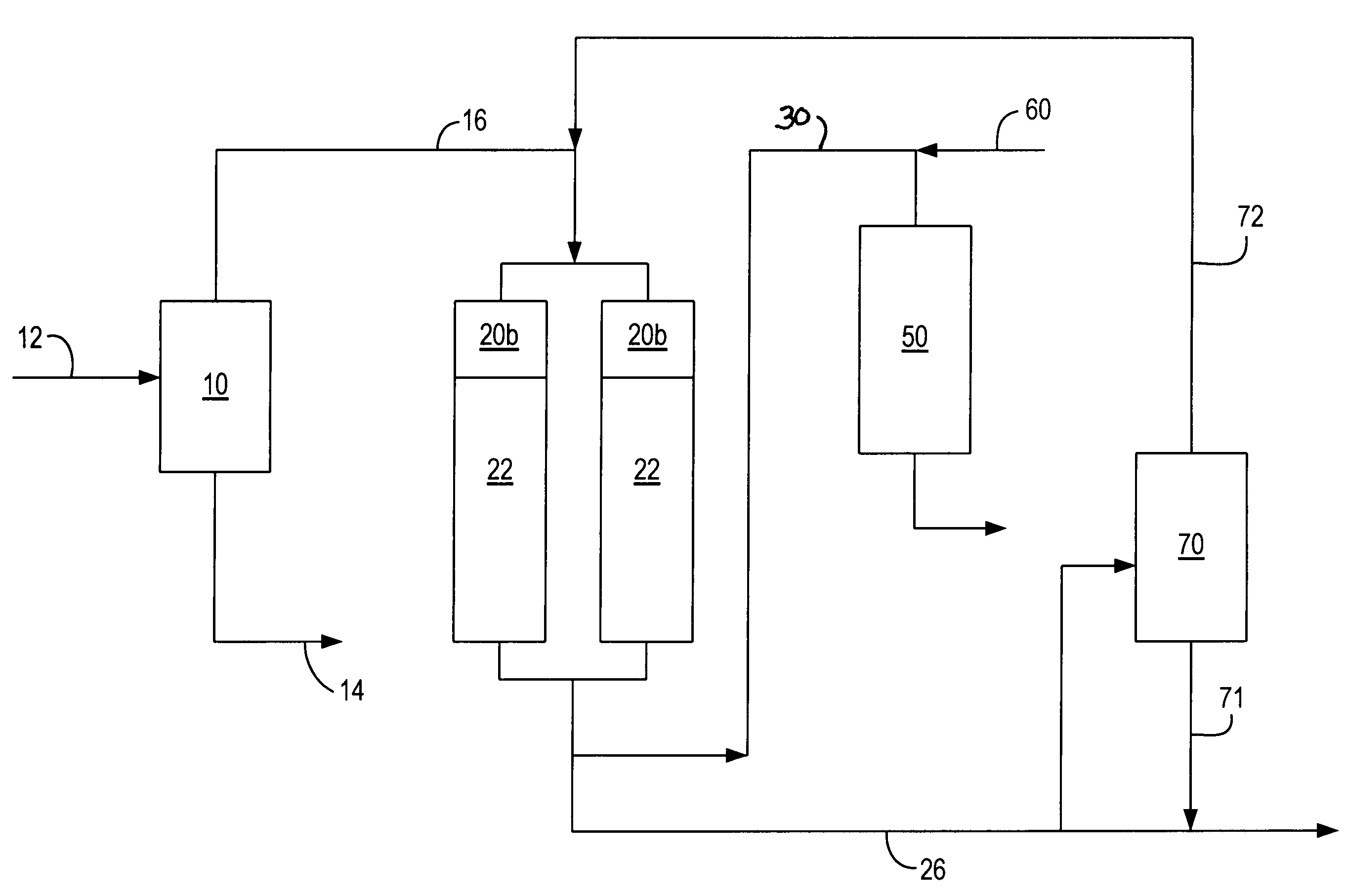

Process for removal of nitrogen and poly-nuclear aromatics from hydrocracker feedstocks

A feedstream to a hydrocracking unit is treated to remove or reduce the content of polynuclear aromatics and nitrogen-containing compounds by contacting the feedstream with an adsorbent compound selected from attapulgus clay, alumina, silica gel and activated carbon in a fixed bed or slurry column and separating the treated feedstream that is lower in the undesired compounds from the adsorbent material. The adsorbent can be mixed with a solvent for the undesired compounds and stripped for re-use.

Owner:SAUDI ARABIAN OIL CO

Low mesopore adsorbent contactors for use in swing adsorption processes

Owner:EXXON RES & ENG CO

Removal of ethane from natural gas at high pressure

ETS-10 type materials preferentially adsorb ethane and, if present, C3+ paraffins from mixtures comprising methane, ethane and optionally C3+ paraffins at pressures above 200 psia. A process in which ETS-10 type materials are used to separate ethane and C3+ paraffins from natural gas streams at over 200 psia is provided.

Owner:THE GOVERNORS OF THE UNIV OF ALBERTA

Feed purification at ambient temperature

ActiveUS6987152B1Hydrocarbons from unsaturated hydrocarbon additionHydrocarbonsOxygenOlefin polymerization

A method for olefin polymerization is provided. A feed stream comprising more than 0.1 ppm by volume of oxygen and 0.3 ppm by volume of water is passed through a first packed bed to selectively remove at least a portion of the oxygen. The feed stream is then passed through a second packed bed to selectively remove at least a portion of the water, providing a purified feed stream comprising less than 0.1 ppm by volume of oxygen and 0.3 ppm by volume of water. Both the first and second packed beds operate at a temperature of from about 0° C. to about 50° C. The purified feed stream is then passed to a polymerization reactor.

Owner:UNIVATION TECH LLC

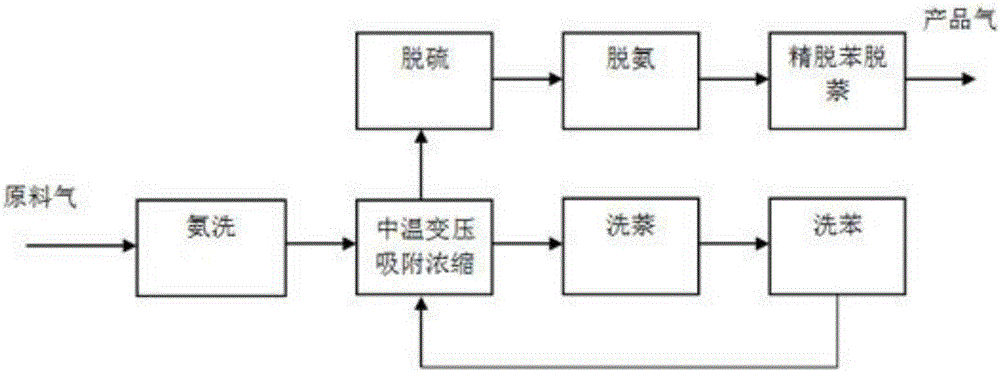

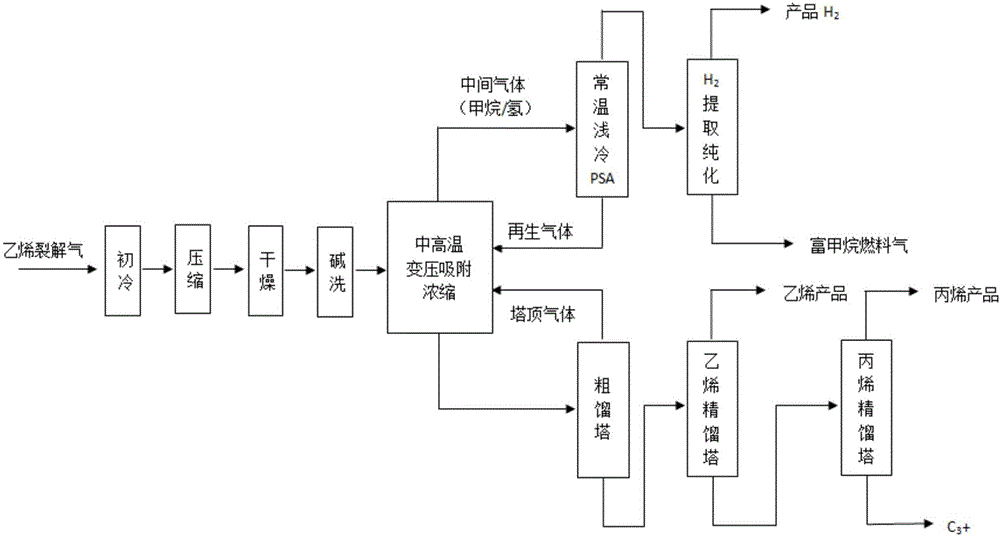

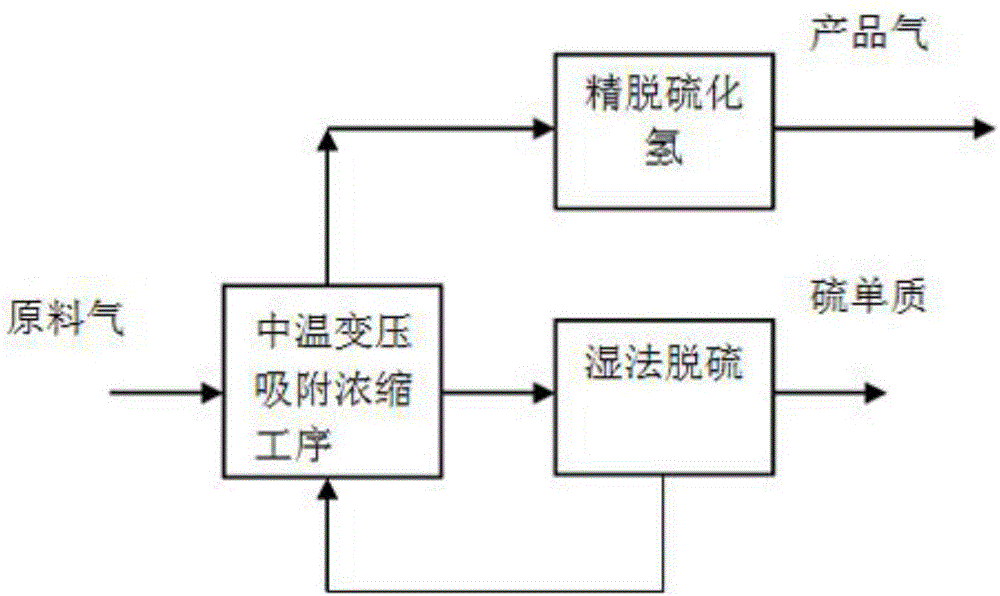

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

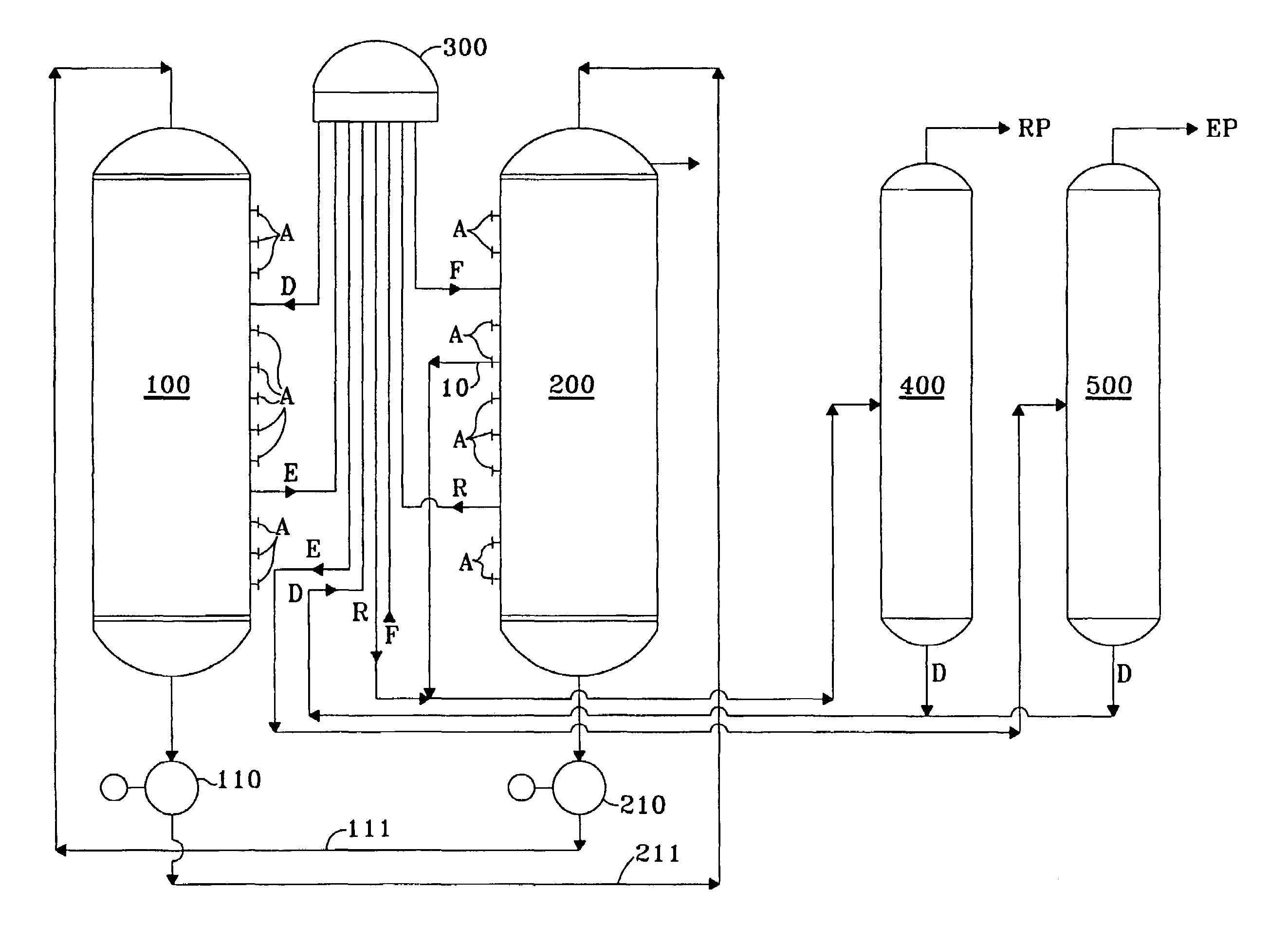

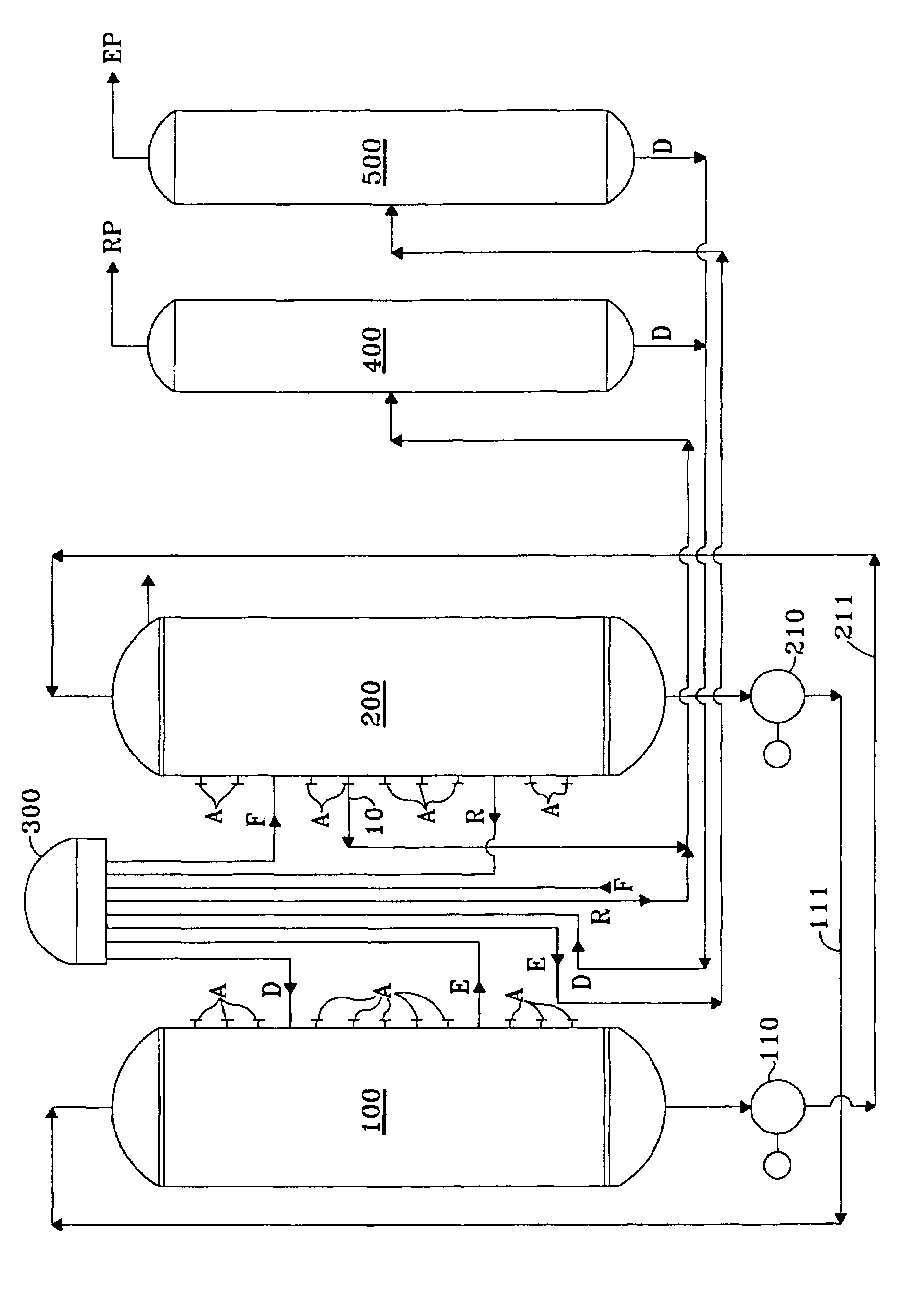

Product recovery from simulated-moving-bed adsorption

Product purity from or capacity of a simulated-moving-bed adsorptive separation process is increased by flushing the contents of the transfer line previously used to remove the raffinate stream away from the adsorbent chamber, preferably into the raffinate column used to separate desorbent from raffinate product. Preferably a stream from the adsorbent chamber at an intermediate point between the feed entry point and raffinate withdrawal is used as the flushing liquid. This flush step eliminates the passage of a quantity of the raffinate material into the adsorbent chamber in the transfer-line flush period or when the process conduit is subsequently used to charge the feed stream to the adsorbent chamber.

Owner:UOP LLC

Process for removal of nitrogen and poly-nuclear aromatics from hydrocracker and FCC feedstocks

ActiveUS20080105595A1Increase heightCatalytic crackingTreatment with plural serial stages onlyActivated carbonSorbent

A feedstream to a hydrocracking unit is treated to remove or reduce the content of polynuclear aromatics and nitrogen-containing compounds by contacting the feedstream with an adsorbent compound selected from attapulgus clay, alumina, silica gel and activated carbon in a fixed bed or slurry column and separating the treated feedstream that is lower in the undesired compounds from the adsorbent material. The adsorbent can be mixed with a solvent for the undesired compounds and stripped for re-use.

Owner:SAUDI ARABIAN OIL CO

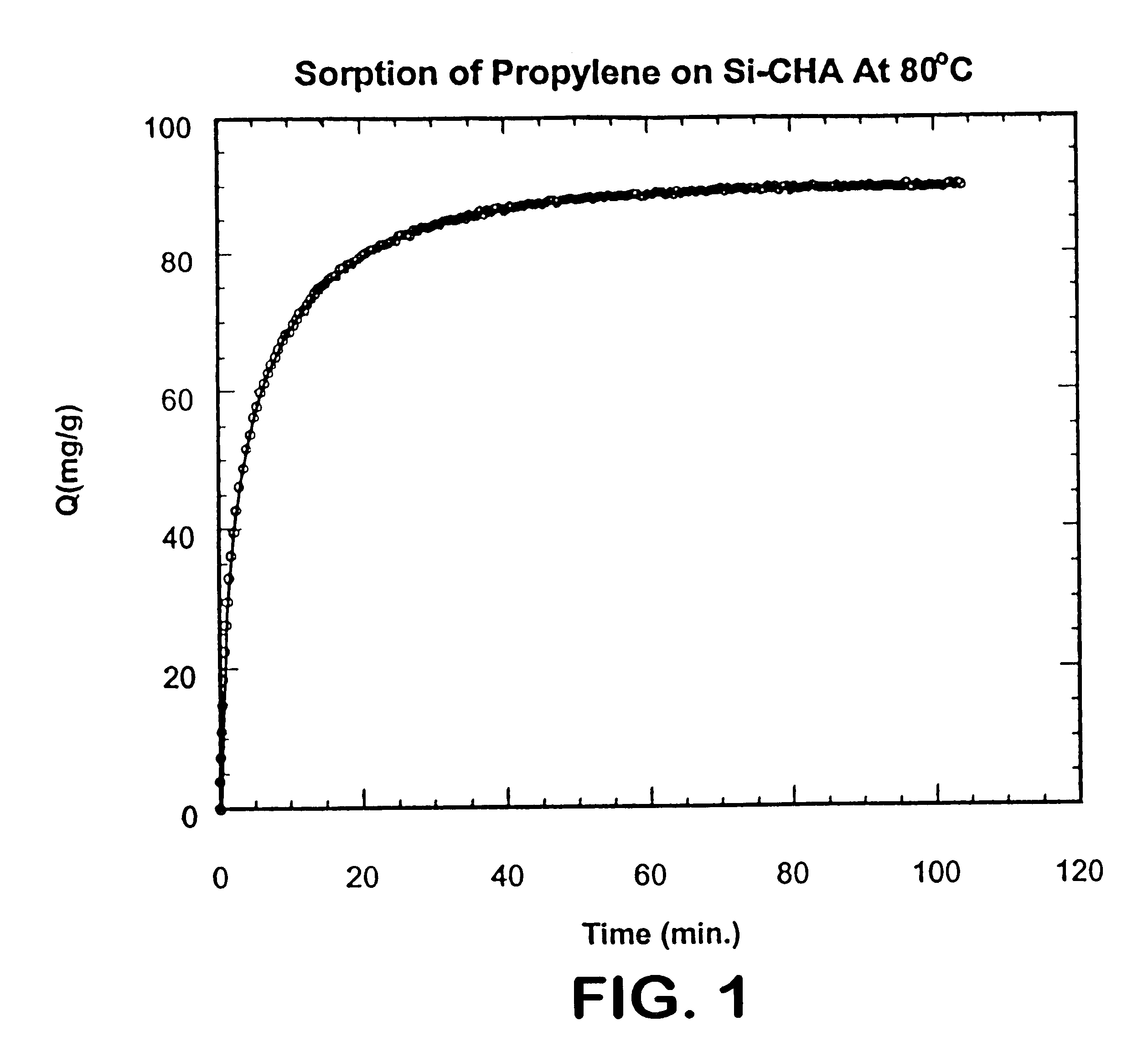

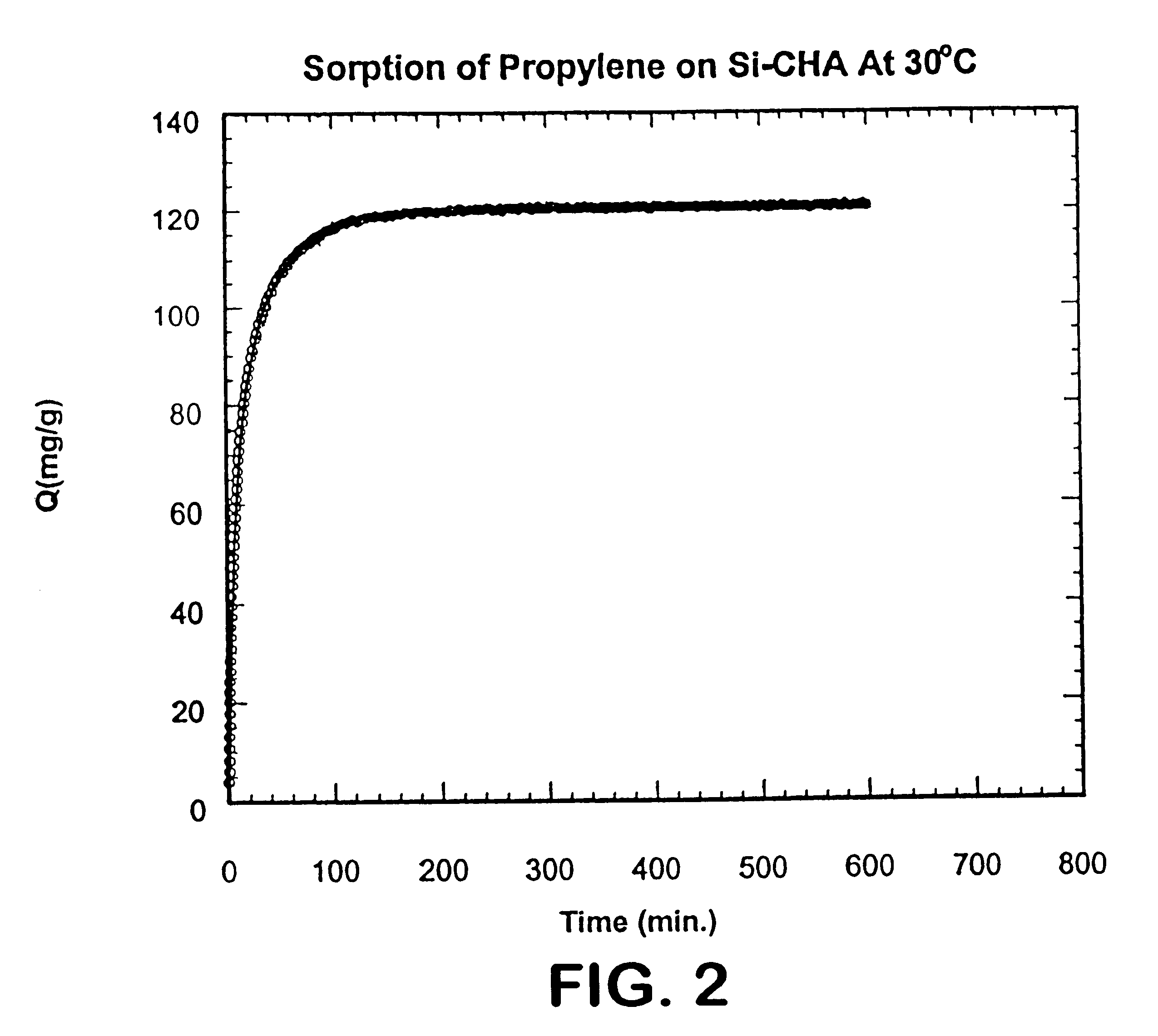

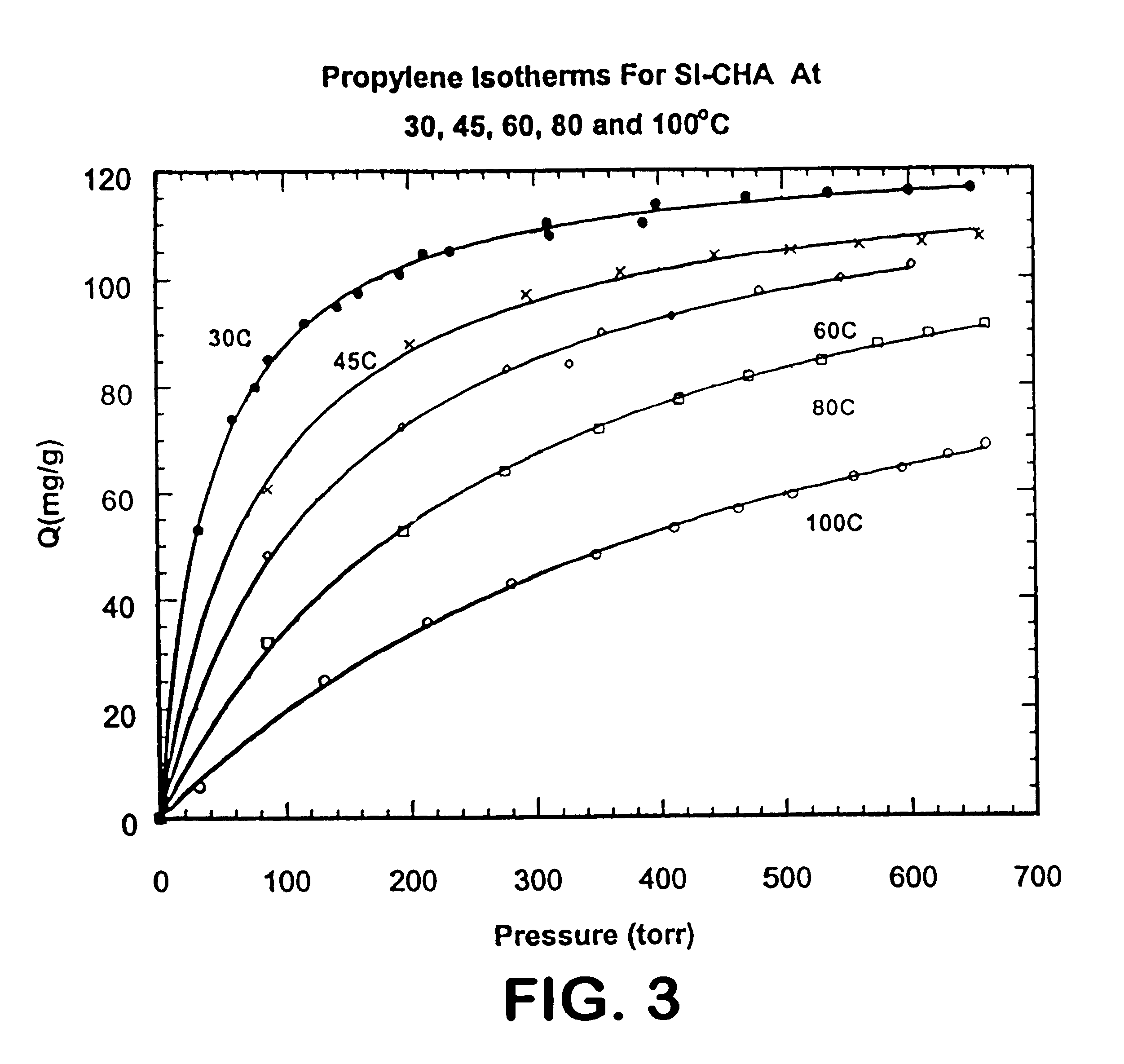

Light hydrocarbon separation using 8-member ring zeolites

InactiveUS6488741B2Improve efficiencyImprove diffusivityGas treatmentIsotope separationSorbentPropane

A method of selectively adsorbing propylene in mixtures of propylene / propane and propylene / olefins through the use of zeolites having structures with a maximum of 8-member rings of tetraheda controlling the diffusion rate. Suitable zeolite adsorbents are those having the CHA and ITE structure types. Other 8-member ring zeolites, including aluminosilicates, with a Si:Al molar ratio of at least about 200 and having substantially no free acid are also suitable adsorbents.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

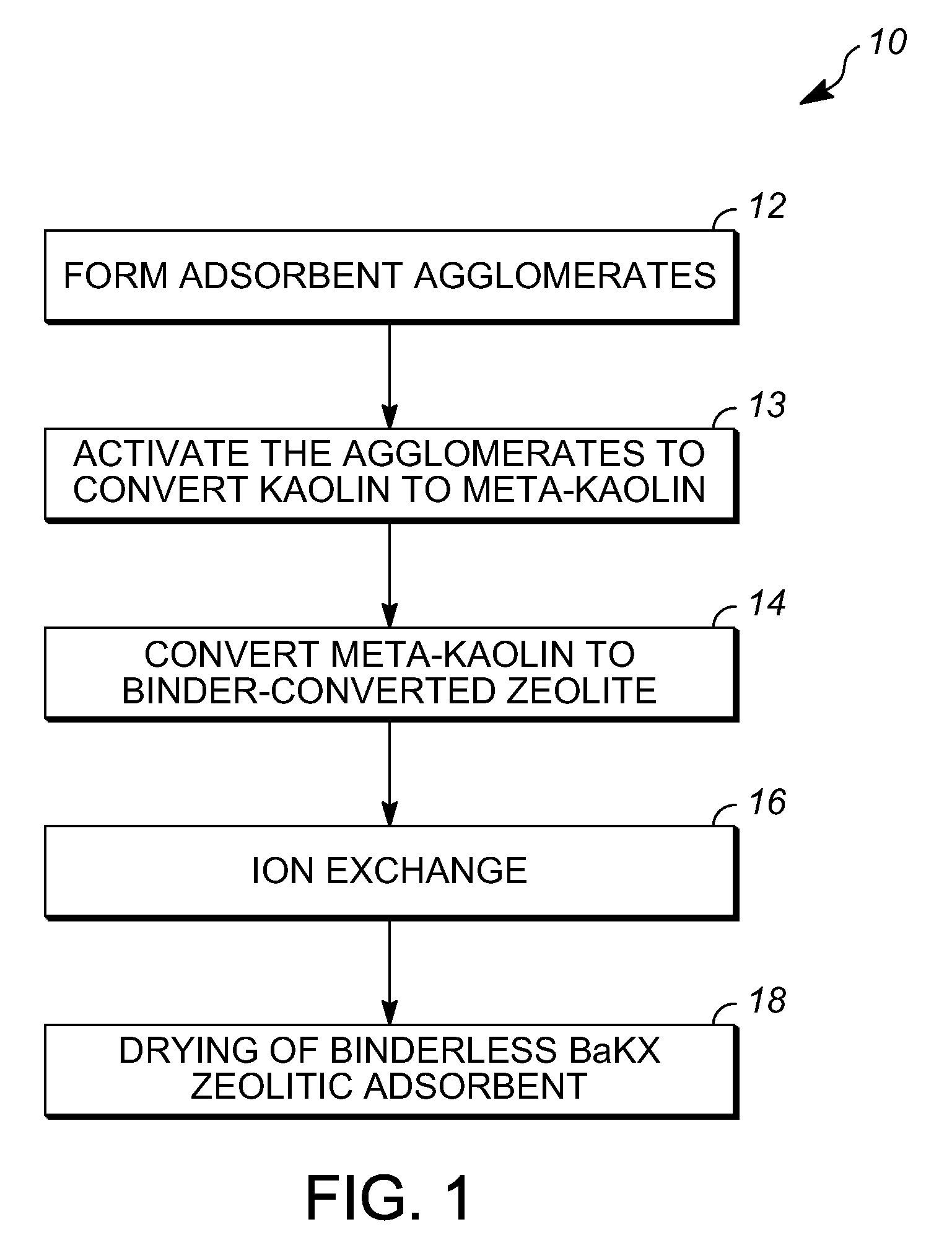

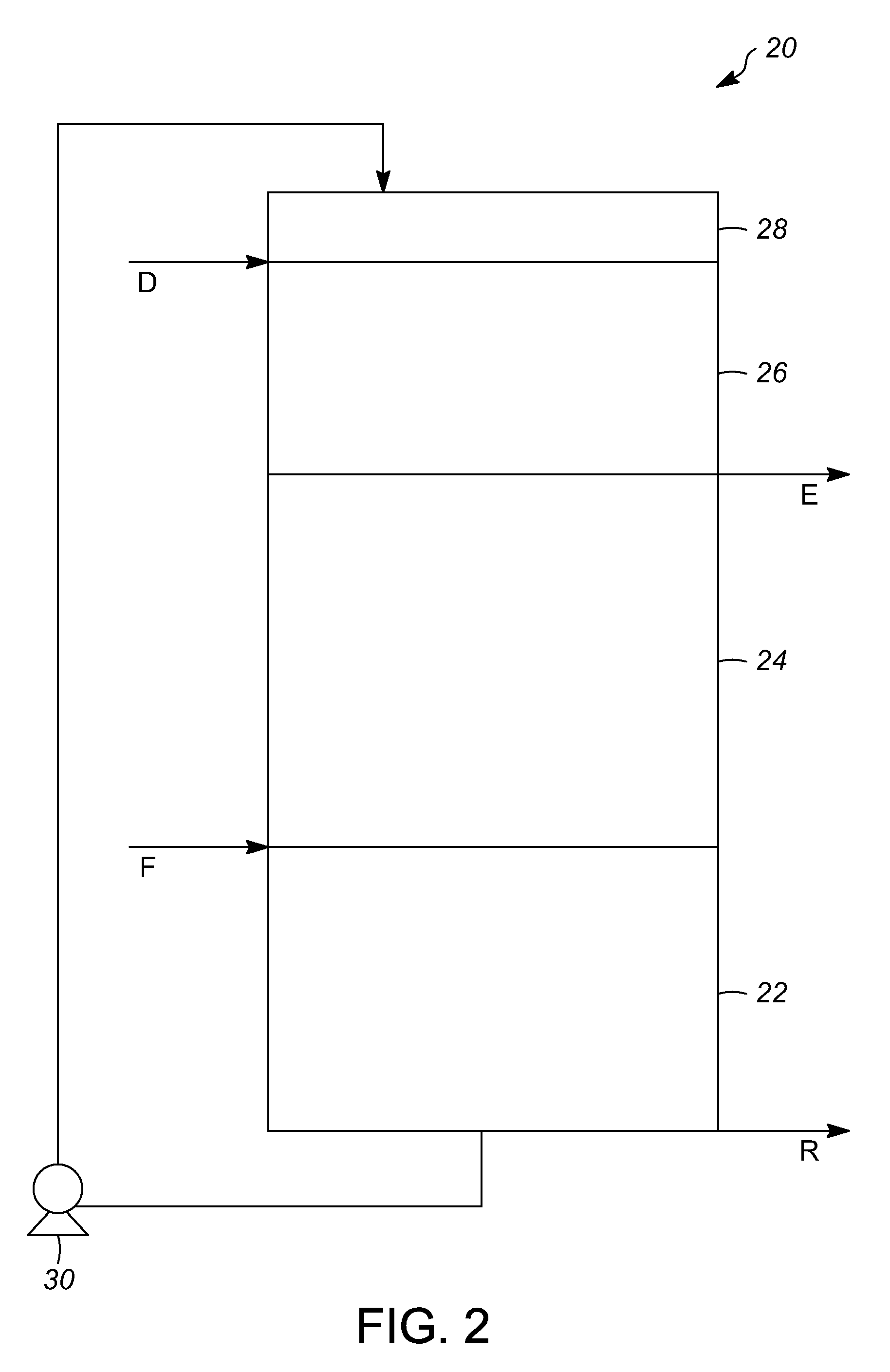

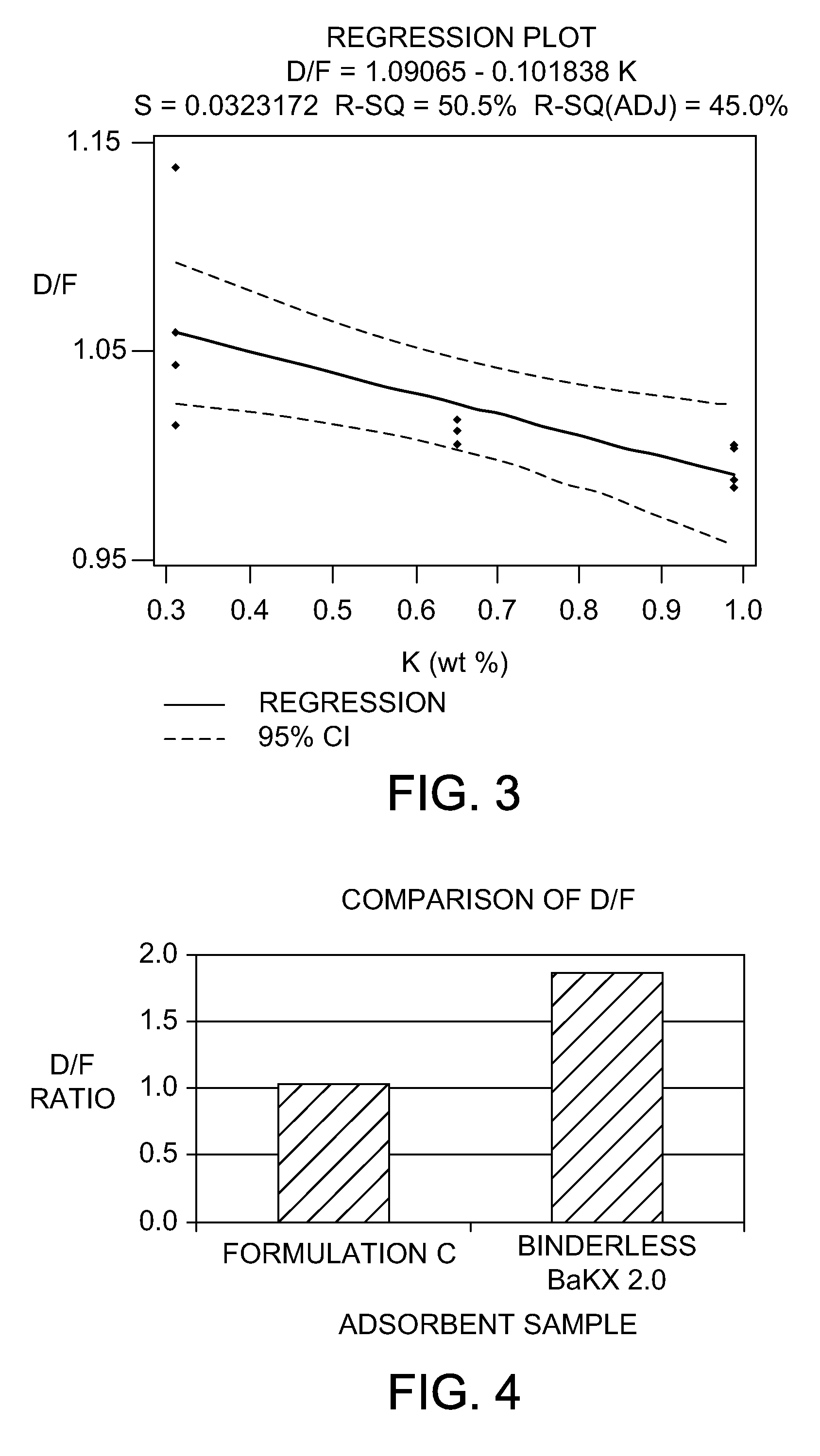

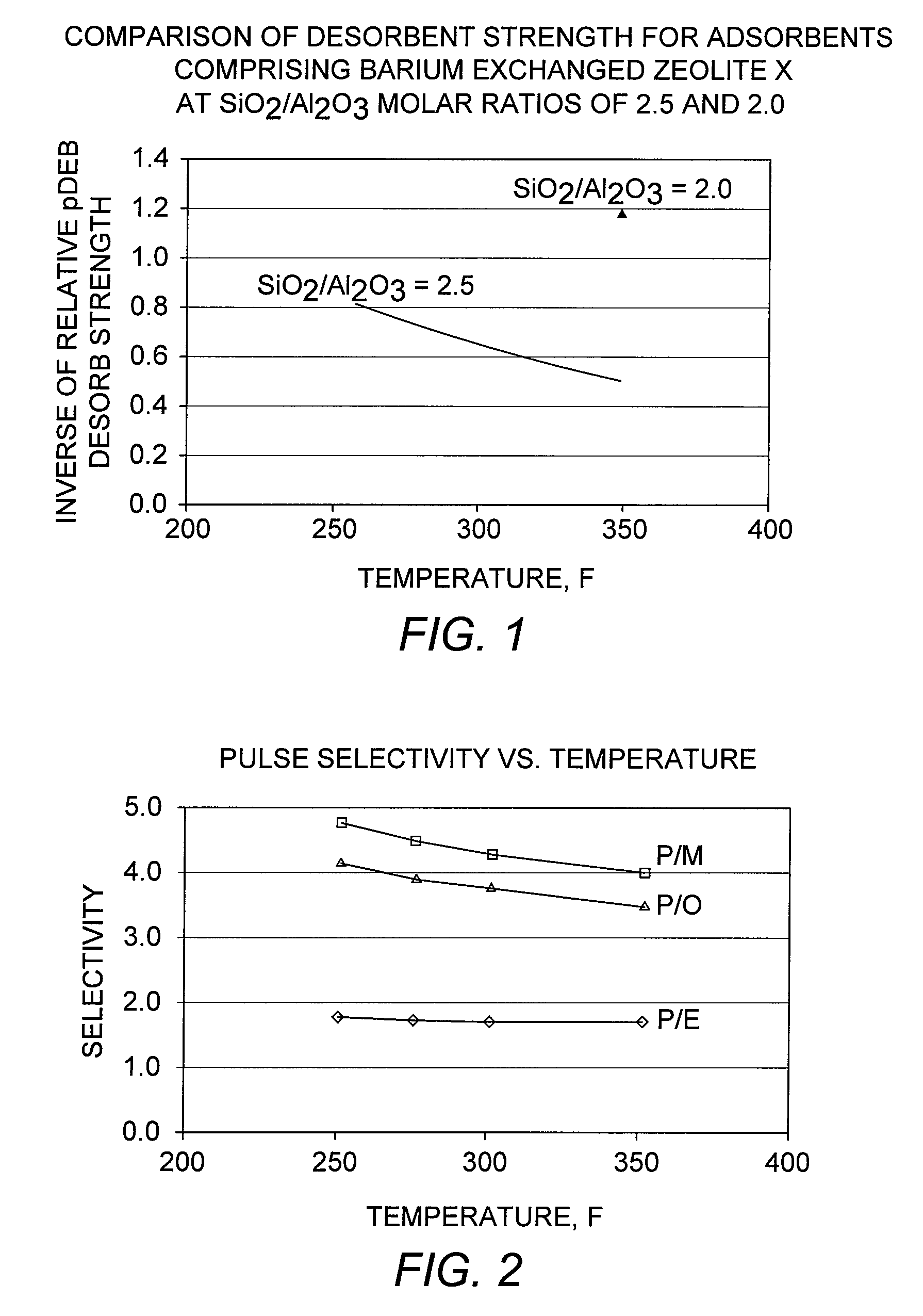

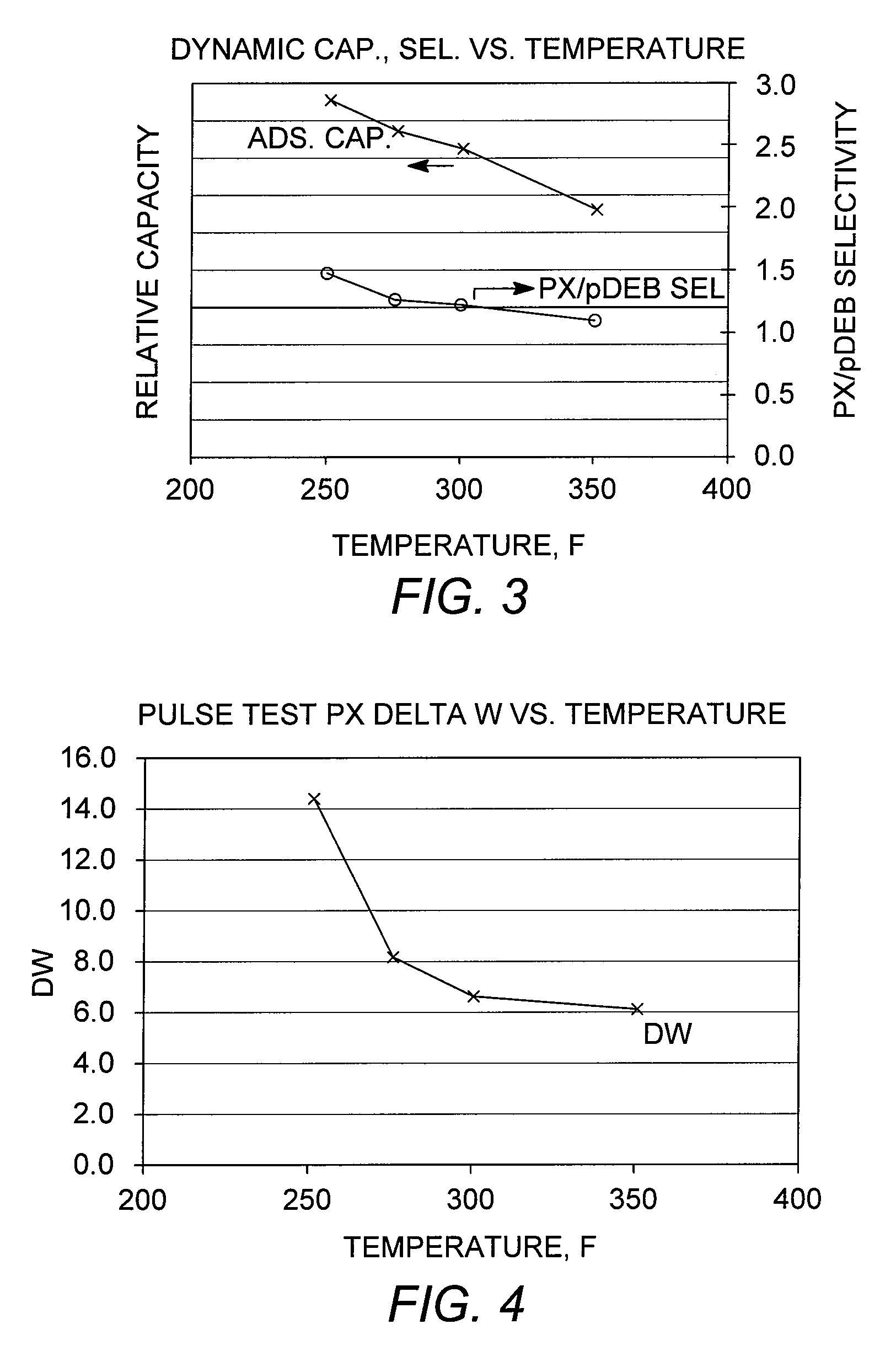

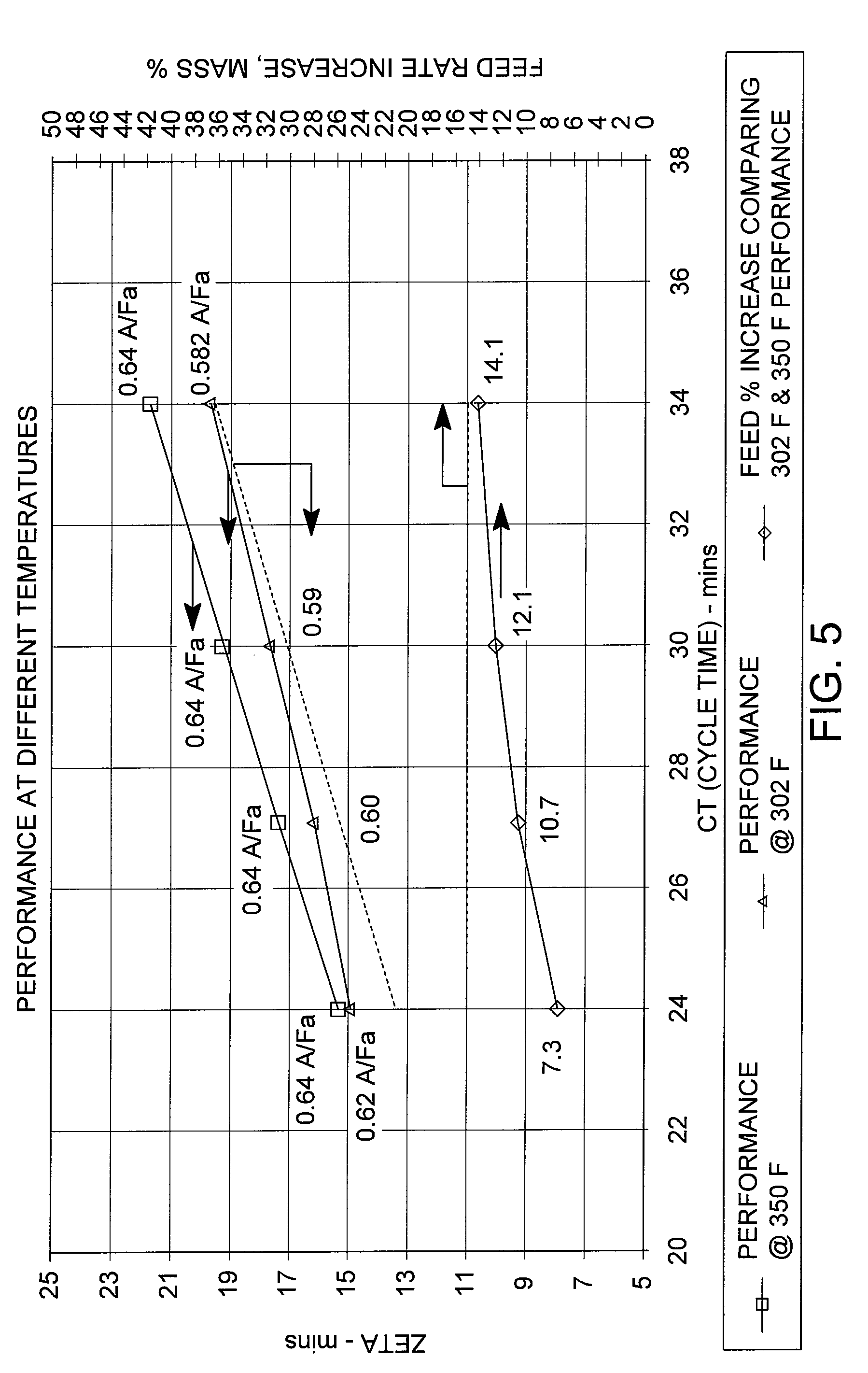

Binderless zeolitic adsorbents, methods for producing binderless zeolitic adsorbents, and processes for adsorptive separation of para-xylene from mixed xylenes using the binderless zeolitic adsorbents

Binderless BaKX zeolitic adsorbents, methods for their production, and processes for their use in a liquid phase adsorptive separation process are provided. An adsorbent includes a binder-converted zeolite portion formed from x wt % kaolin clay binder and (100-x) wt % unconverted Zeolite X with a silica:alumina molar ratio of about 2.5. The kaolin clay binder is in the range of about 10 to about 20 wt %. Ba and K occupy cationic exchangeable sites within the adsorbent. K is in the range of about 0.25 to about 0.9% by weight and Ba is greater than about 31.6% by weight of the binderless BaKX zeolitic adsorbent. Cornstarch may be added to the Zeolite X and kaolin clay binder to increase adsorbent macro-porosity and pore volume. Productivity of the adsorbent is improved decreasing process operating costs. The mechanical strength of the adsorbent is also improved.

Owner:UOP LLC

Agglomerated zeolite adsorbents, process for their preparation, and their use for adsorbing paraxylene from aromatic C8 fractions

InactiveUS6410815B1Improve efficiencyImproved kineticsMolecular sieve catalystsOther chemical processesSorbentPotassium

The present invention relates to agglomerated zeolite adsorbents based on faujasite with an Si / Al ratio such that 1<=Si / Al<=1.15, at least 70% exchanged with barium and optionally with potassium, and on a binder, preferably a zeolitizable binder.They are obtained by agglomerating zeolite powder with a binder, followed by exchange of the zeolite ions for barium ions and activation of the adsorbents thus exchanged.These adsorbents are particularly suitable for the adsorption of the para-xylene contained in aromatic C8 hydrocarbon fractions in the liquid phase, in processes of simulated fluid-bed type.

Owner:INST FR DU PETROLE +1

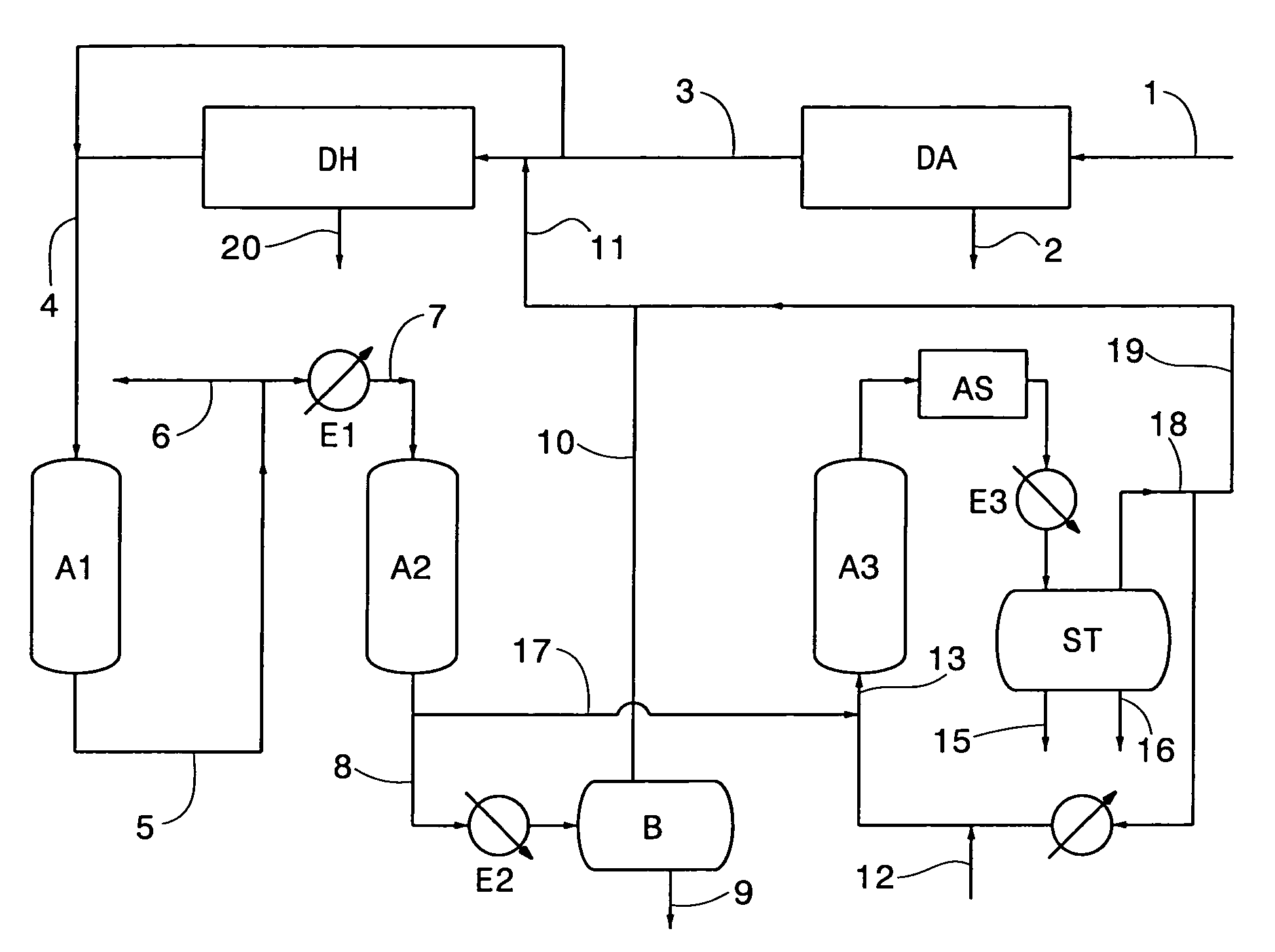

Method of purifying a natural gas by mercaptan adsorption

InactiveUS7449049B2Limit losses of purified natural gasHeavy hydrocarbon losses are minimizedGas treatmentUsing liquid separation agentThiolSorbent

The raw natural gas is deacidized and dehydrated in units DA and DH. The treated gas is then purified by adsorption of the mercaptans in first enclosure A1. Part of the purified gas is heated in E1, then fed into second enclosure A2 so as to discharge the water adsorbed by the adsorbent material contained in this second enclosure. A steam-rich stream is fed into third enclosure A3 containing a mercaptan-laden adsorbent material. In A3, the mercaptans are desorbed and replaced by the steam.

Owner:INST FR DU PETROLE

Binderless adsorbents with improved mass transfer properties and their use in the adsorptive separation of para-xylene

ActiveUS7812208B2Improve performanceImprove mass transfer effectOther chemical processesMolecular-sieve and base-exchange compoundsProduction rateSorbent

Owner:UOP LLC

Process for removal of catalyst residues from poly-alpha-olefins

ActiveUS20050101761A1Reduce raw material usageOperation efficiency can be improvedHydrocarbonsAdsorption purification/separationCalcium silicateHalogen

A method is disclosed for reducing levels of residual halogen and Group IIIb metals in a crude poly(α-olefin) polymerized in the presence of a catalyst comprising the halogen and Group IIIb metals, wherein the method comprises: A) washing the crude poly(α-olefin) with water; B) separating the aqueous and organic phases; C) then adding an adsorbent selected from the group consisting of magnesium silicates, calcium silicates, aluminum silicates, aluminum oxides, and clays to the organic phase to form a slurry; D) heating the slurry under reduced pressure at a temperature of at least about 180° C. for at least about thirty minutes; and then E) separating the adsorbent from the slurry.

Owner:CHEMTURA CORP

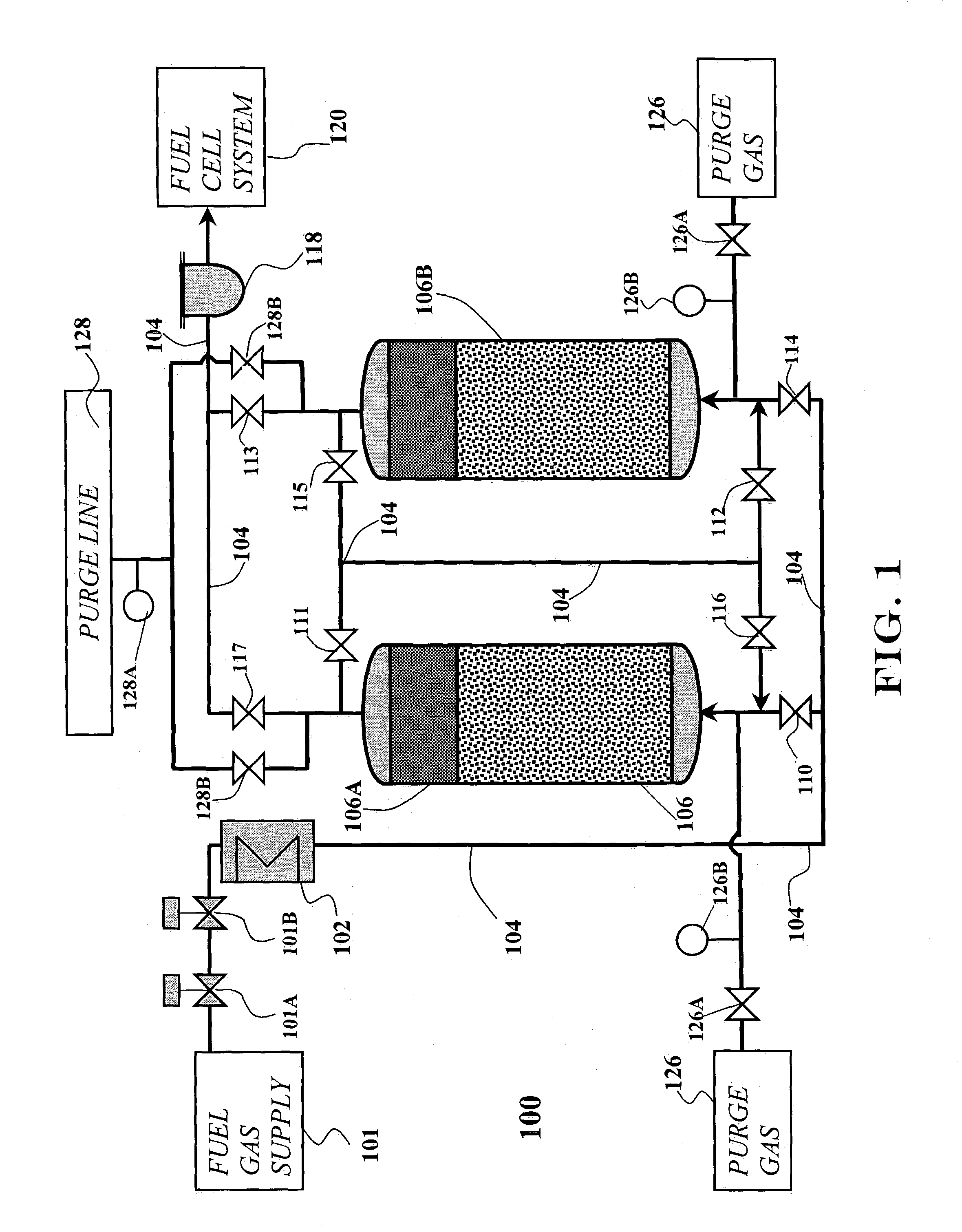

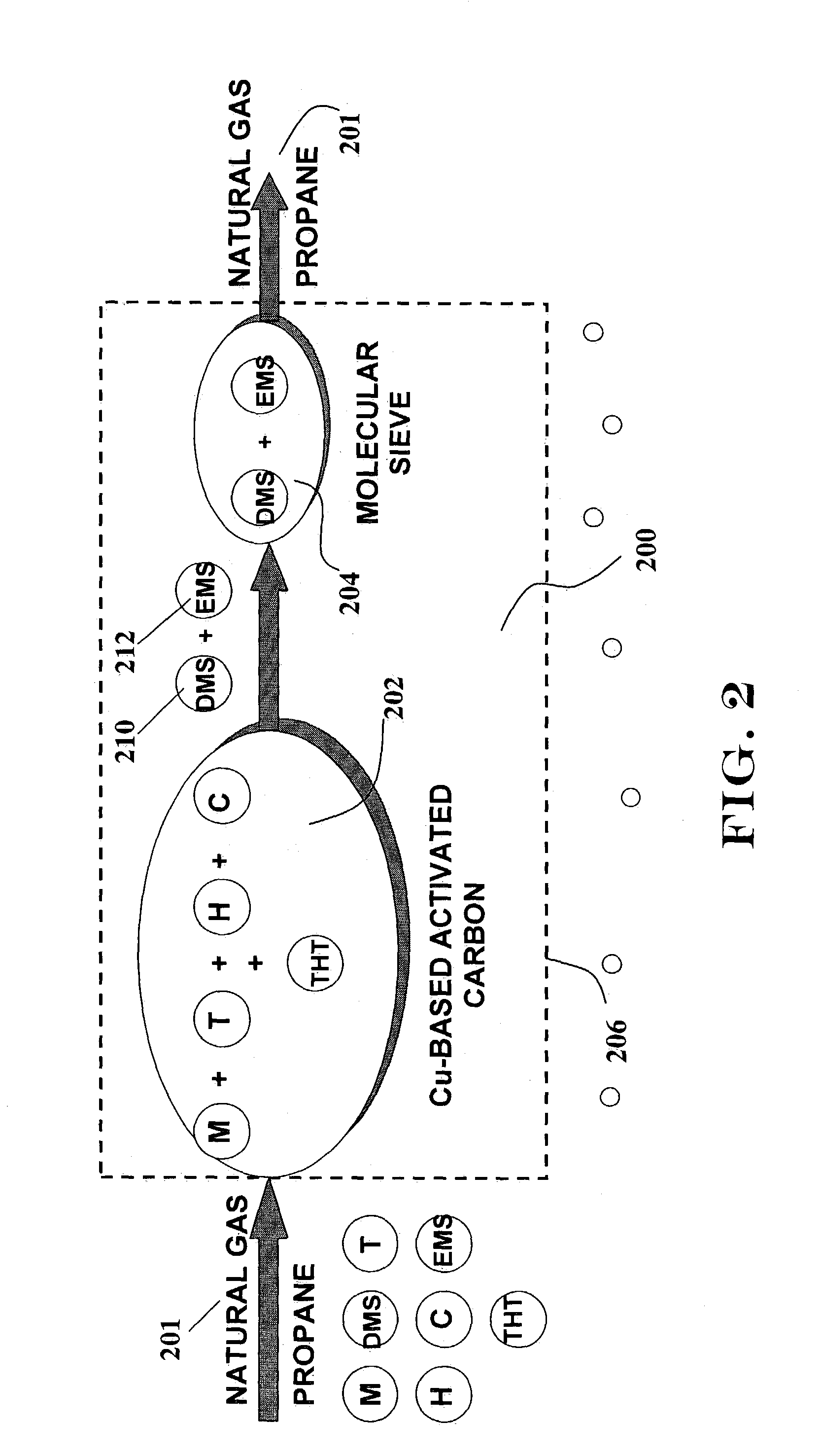

High-capacity sulfur adsorbent bed and gas desulfurization method

Owner:FUELCELL ENERGY INC

Method of Producing Propylene Containing Biomass-Origin Carbon

InactiveUS20080312485A1Quality improvementSwitch-over frequencyMolecular sieve catalystsBiofuelsButeneDecomposition

Ethanol obtained from ordinary biomass resources contains many impurities other than water and these impurities themselves or their decomposition products contaminate ethylene when the ethylene is produced by a dehydration reaction, whereby the activity of metathesis catalyst is adversely affected. A method for producing propylene of the present invention is characterized in that the ethanol obtained from biomass is converted to ethylene by a dehydration reaction, the ethylene is separated from the generated water, the separated ethylene is purified by adsorption in an adsorption tower filled with an adsorbent, and then a metathesis reaction is carried out along with a raw material containing n-butene. With the present invention, propylene having biomass-derived carbon and reduced-environmental burden can be efficiently produced without lowering the catalysis activity.

Owner:MITSUI CHEM INC

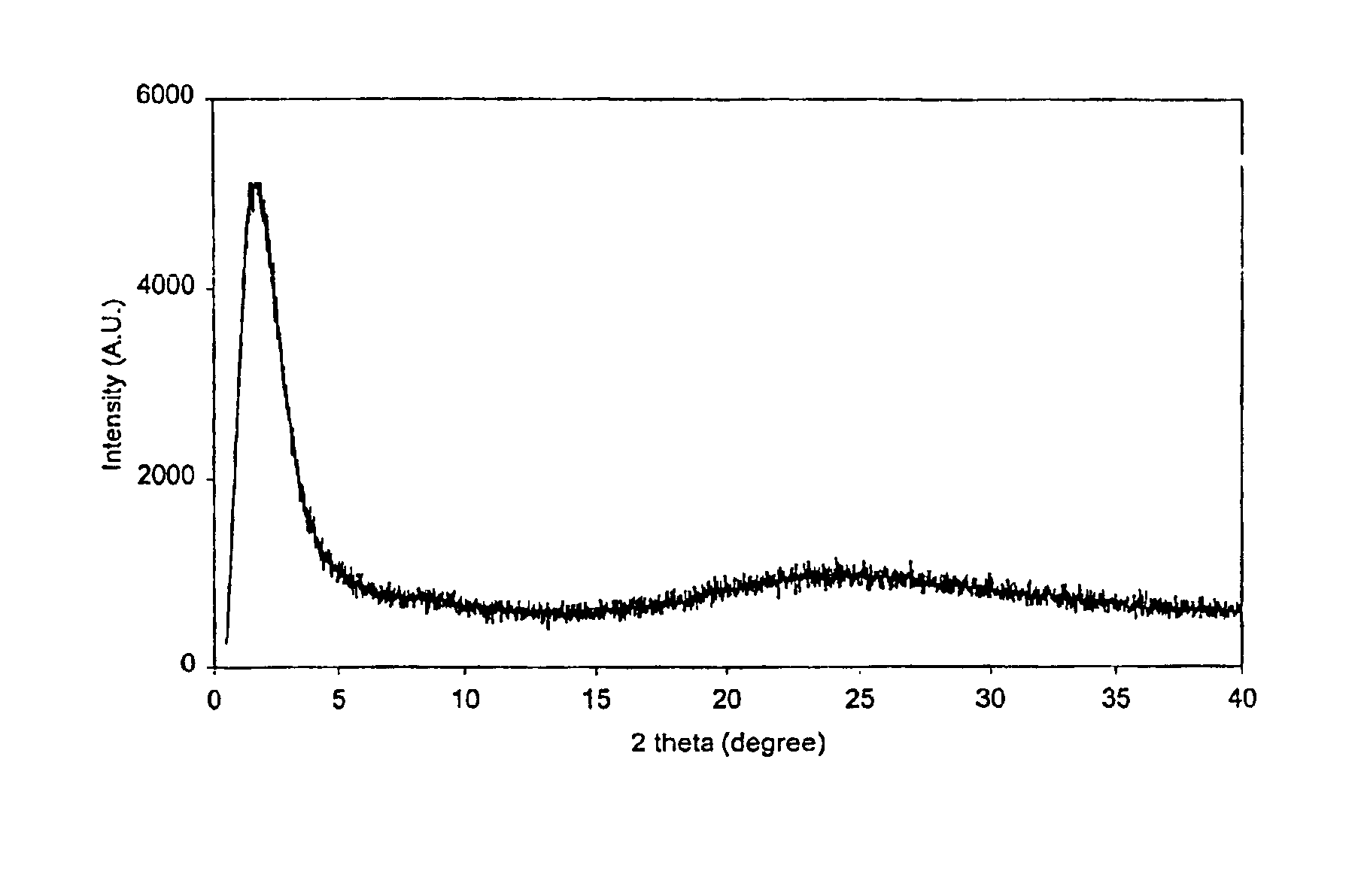

Mesoporous material with active metals

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of silica containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2θ. The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:ABB LUMMUS GLOBAL INC

Agglomerated zeolite adsorbents and process for producing the same

ActiveUS20110105301A1Large hole volumeImprove mass transfer effectMolecular sieve catalystsOther chemical processesSorbentIon exchange

An agglomerated zeolite adsorbent which comprises 95-99.5 mass % of X zeolite and 0.5-5.0 mass % of binder, wherein the exchangeable cationic sites of said X zeolite are occupied by Group IIA metal and / or K, the total pore volume of said adsorbent is no less than 0.26 mL / g as measured by mercury porosimetry, the volume of pores with pore diameters from 100 to 500 nm is at least 60% based on the total pore volume. During shaping, a pore-forming agent is added to this adsorbent, and then the adsorbent is alkali treated for in-situ crystallization, followed by ion exchange. Said adsorbent has high adsorption capacity, fast mass transfer rate and good mechanical strength. Said adsorbent is suitable for liquid phase adsorptive separation of para-xylene from C8 aromatic hydrocarbons and is also suitable for adsorptive separation of other alkyl aromatic hydrocarbons isomers.

Owner:CHINA PETROCHEMICAL CORP +1

Catalytic filtering of a Fischer-Tropsch derived hydrocarbon stream

InactiveUS7150823B2Avoid cloggingRefining with metalsPhysical/chemical process catalystsParticulatesUltra fine

Novel methods of treating a Fischer-Tropsch derived hydrocarbon stream with an active filtering catalyst are disclosed. Such methods are capable of removing soluble (and ultra-fine particulate) contamination, fouling agents, and / or plugging precursors from the Fischer-Tropsch derived hydrocarbon stream such that plugging of the catalyst beds of a subsequent hydroprocessing process is substantially avoided.

Owner:CHEVROU USA INC

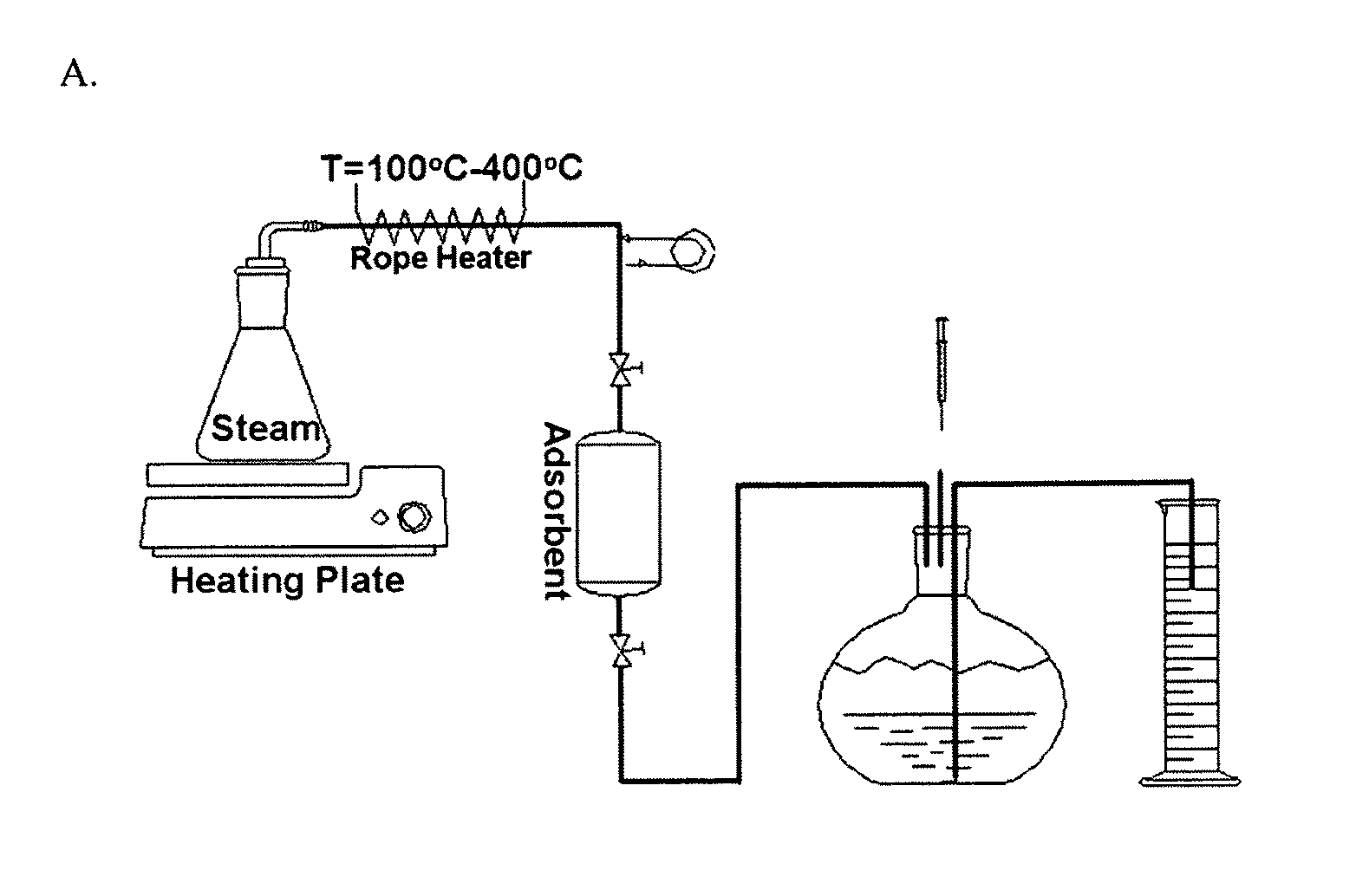

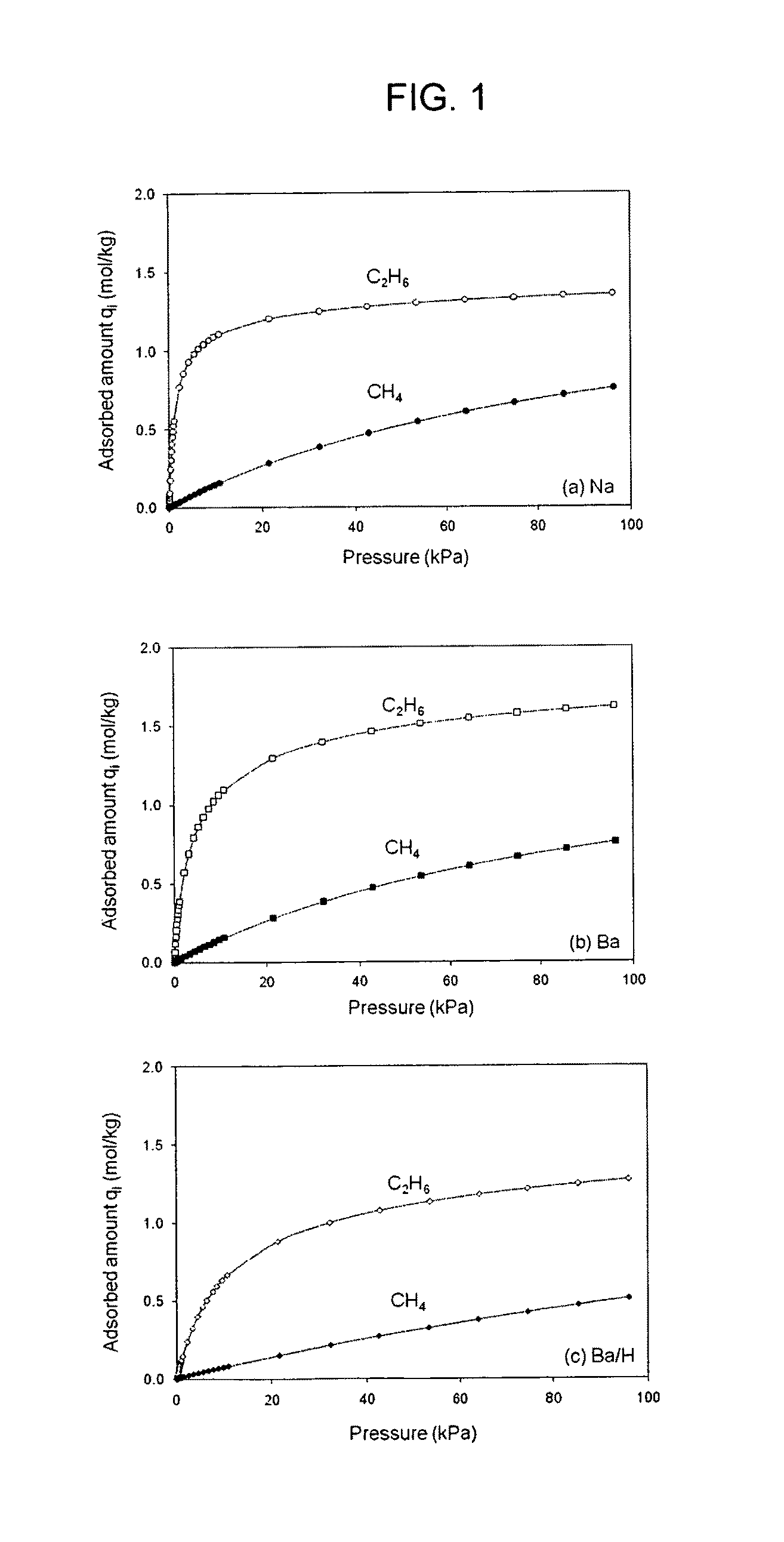

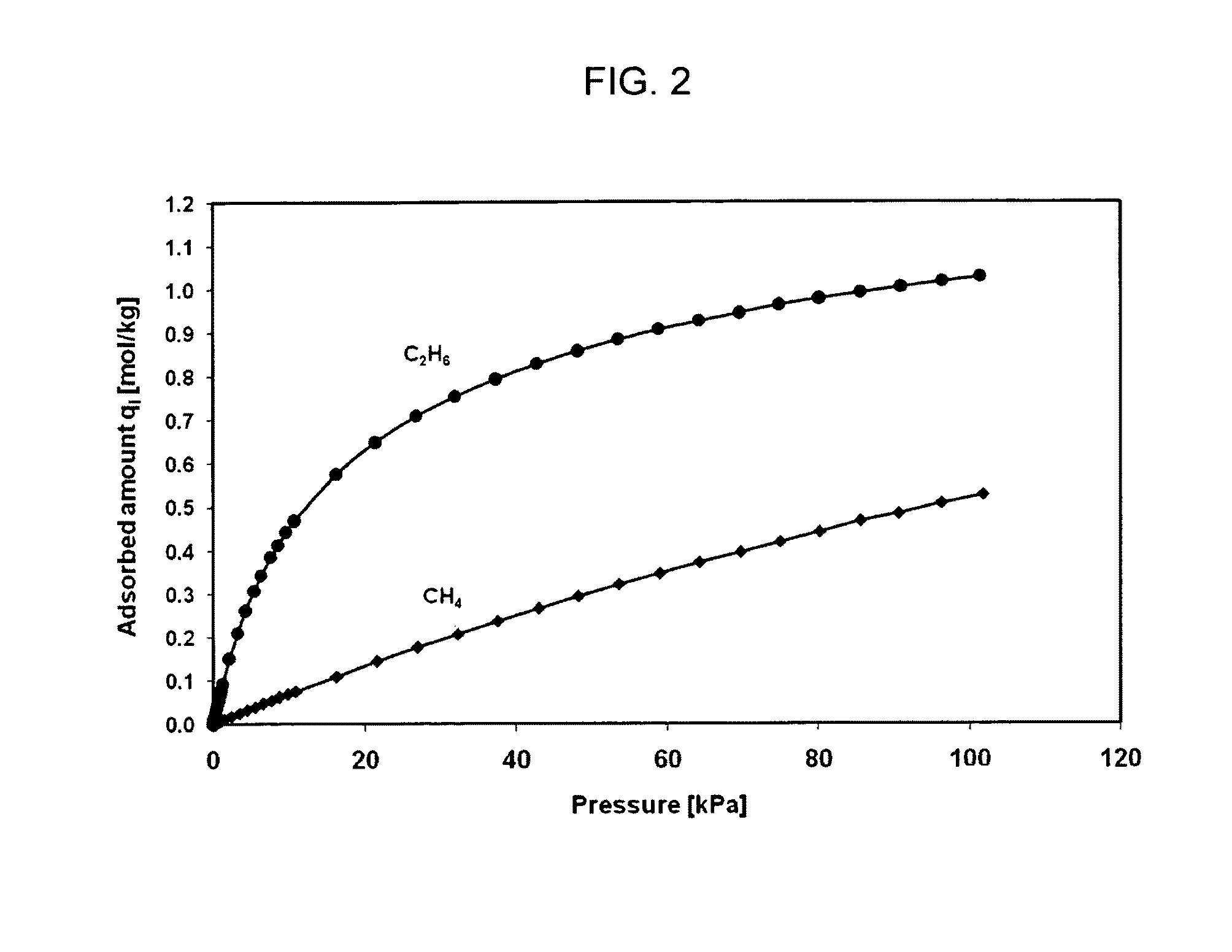

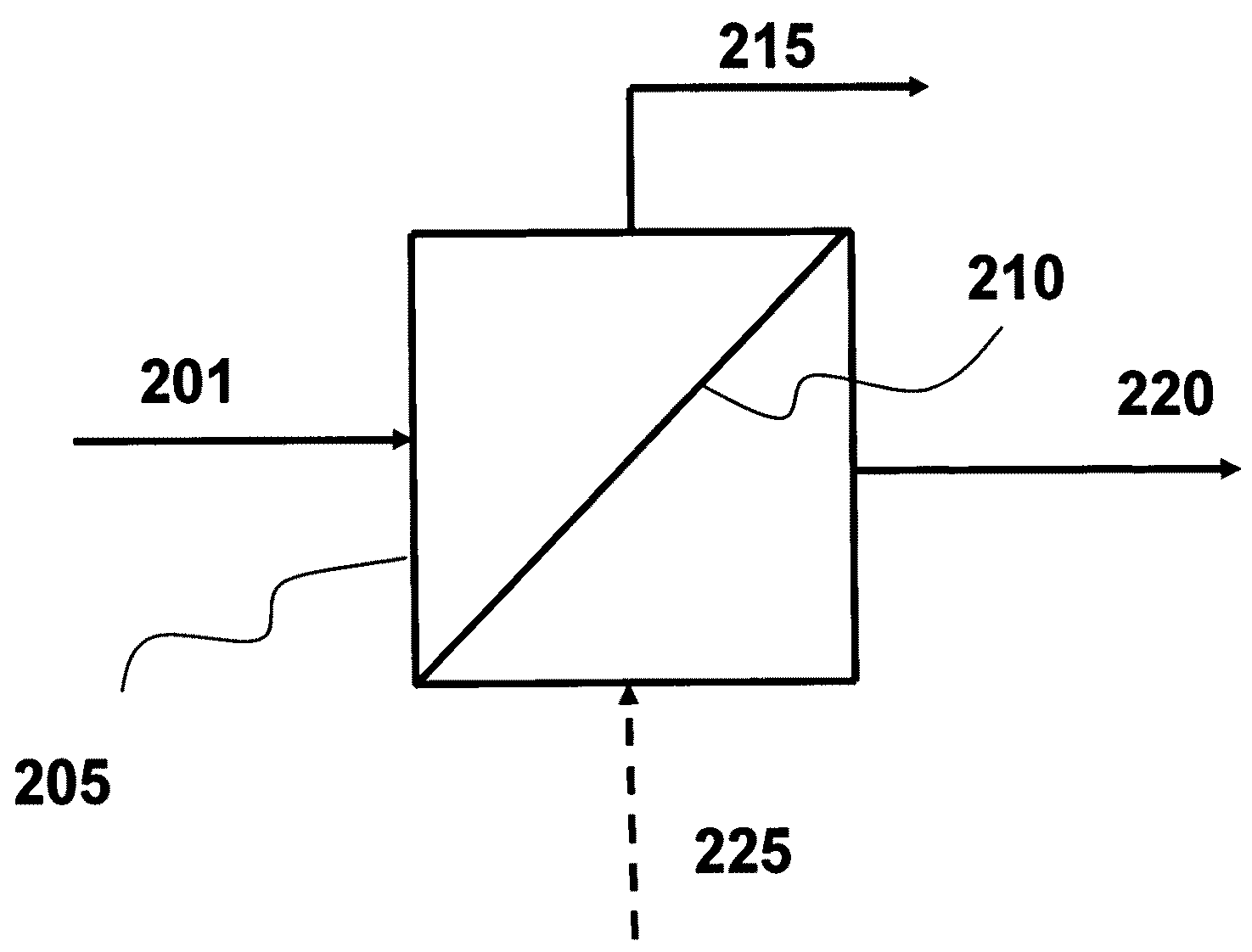

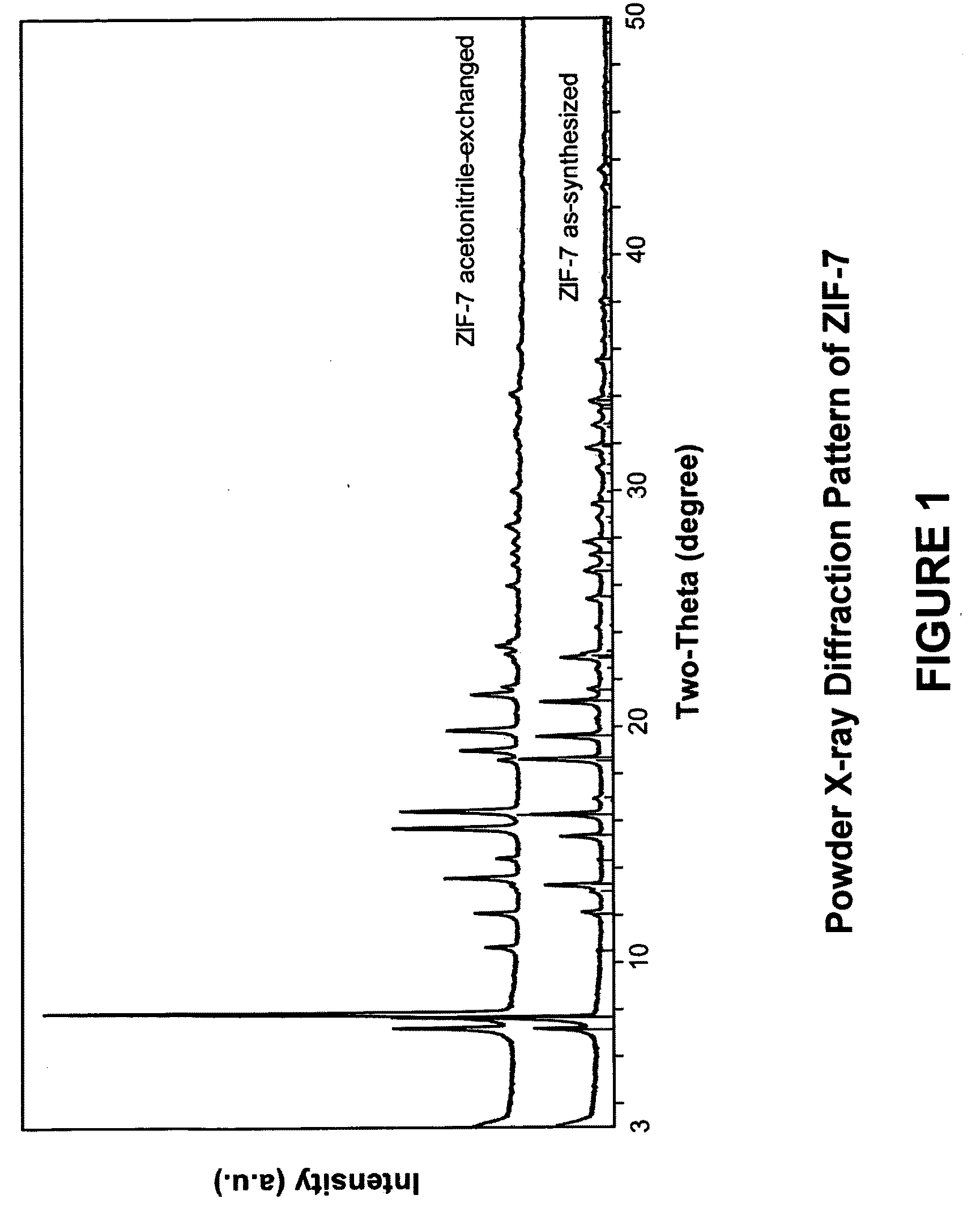

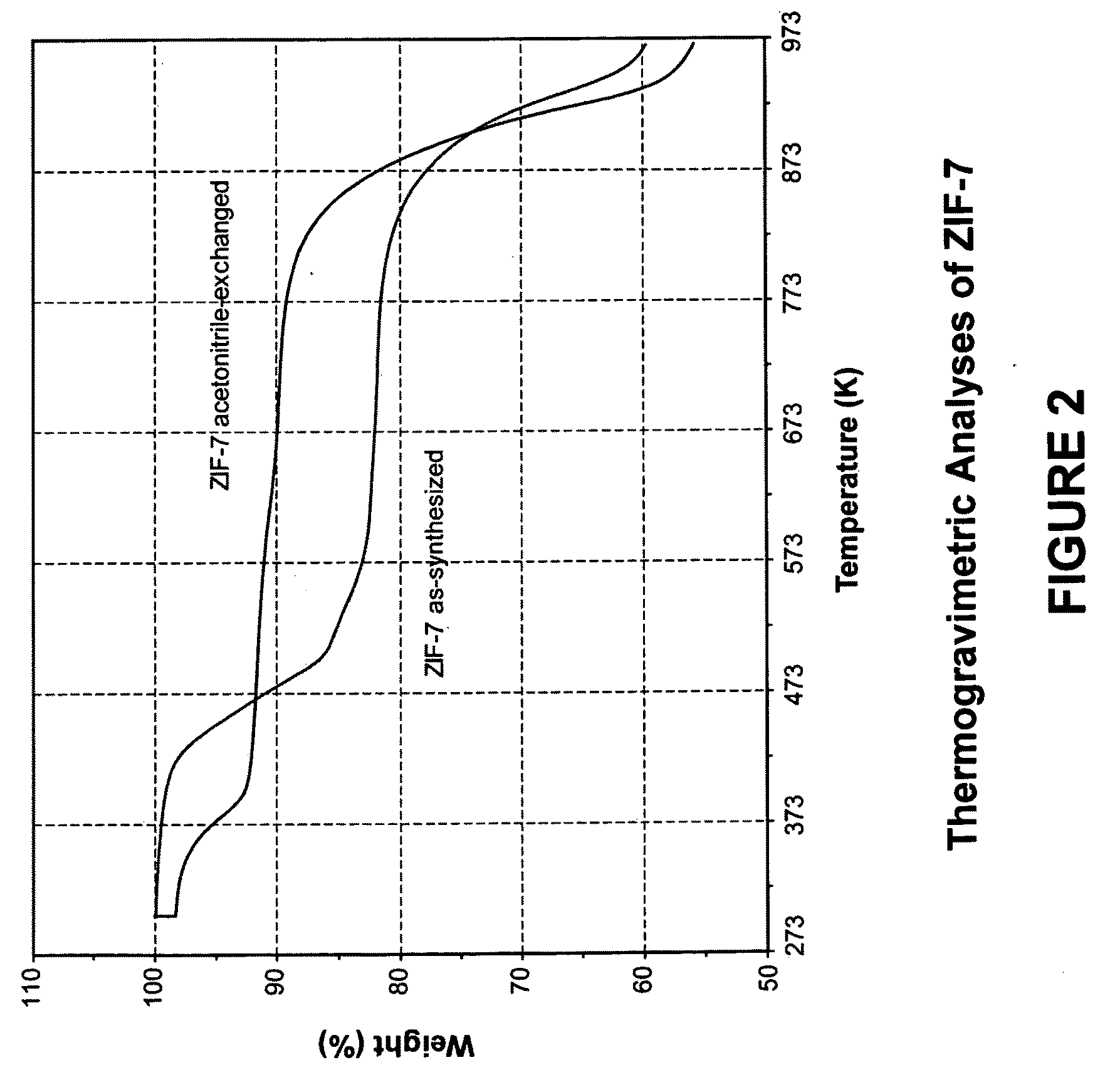

Separation of methane from higher carbon number hydrocarbons utilizing zeolitic imidazolate framework materials

ActiveUS20090216059A1Efficient separationAluminium compoundsDispersed particle filtrationCarbon numberHigh carbon

The present invention relates to the selective separation of methane (“CH4”) from higher carbon number hydrocarbons (“HHC”s) in streams containing both methane and higher carbon number hydrocarbons (e.g. ethylene, ethane, propylene, propane, etc.) utilizing a zeolitic imidazolate framework (“ZIF”) material. Preferably, the stream to be separated is fed to the present process in a substantially gaseous phase. In preferred embodiments, the current invention is utilized in a process to separate methane from higher carbon number hydrocarbons in natural gas streams.

Owner:EXXON RES & ENG CO

Agglomerated zeolitic adsorbents, method for obtaining same uses thereof

InactiveUS6884918B1Amino compound purification/separationOrganic compound preparationSorbentSimulated moving bed

The present invention relates to agglomerated zeolitic adsorbents based on zeolite X with an Si / Al ratio such that 1.15<Si / Al≦1.5, at least 90% of the exchangeable cationic sites of the zeolite X of which are occupied either by barium ions alone or by barium ions and potassium ions whose Dubinin volume is greater than or equal to 0.240 cm3 / g.They are obtained by agglomerating zeolite powder with a binder, followed by the zeolitization of the binder, the exchange of the ions of the zeolite by barium ions (and potassium ions) and the activation of the adsorbents thus exchanged.These adsorbents are particularly suited to the adsorption of the para-xylene present in C8 aromatic hydrocarbon fractions in the liquid phase in processes of simulated moving bed type but also to the separation of sugars, polyhydric alcohols, cresols or substituted toluene isomers.

Owner:ARKEMA FRANCE SA

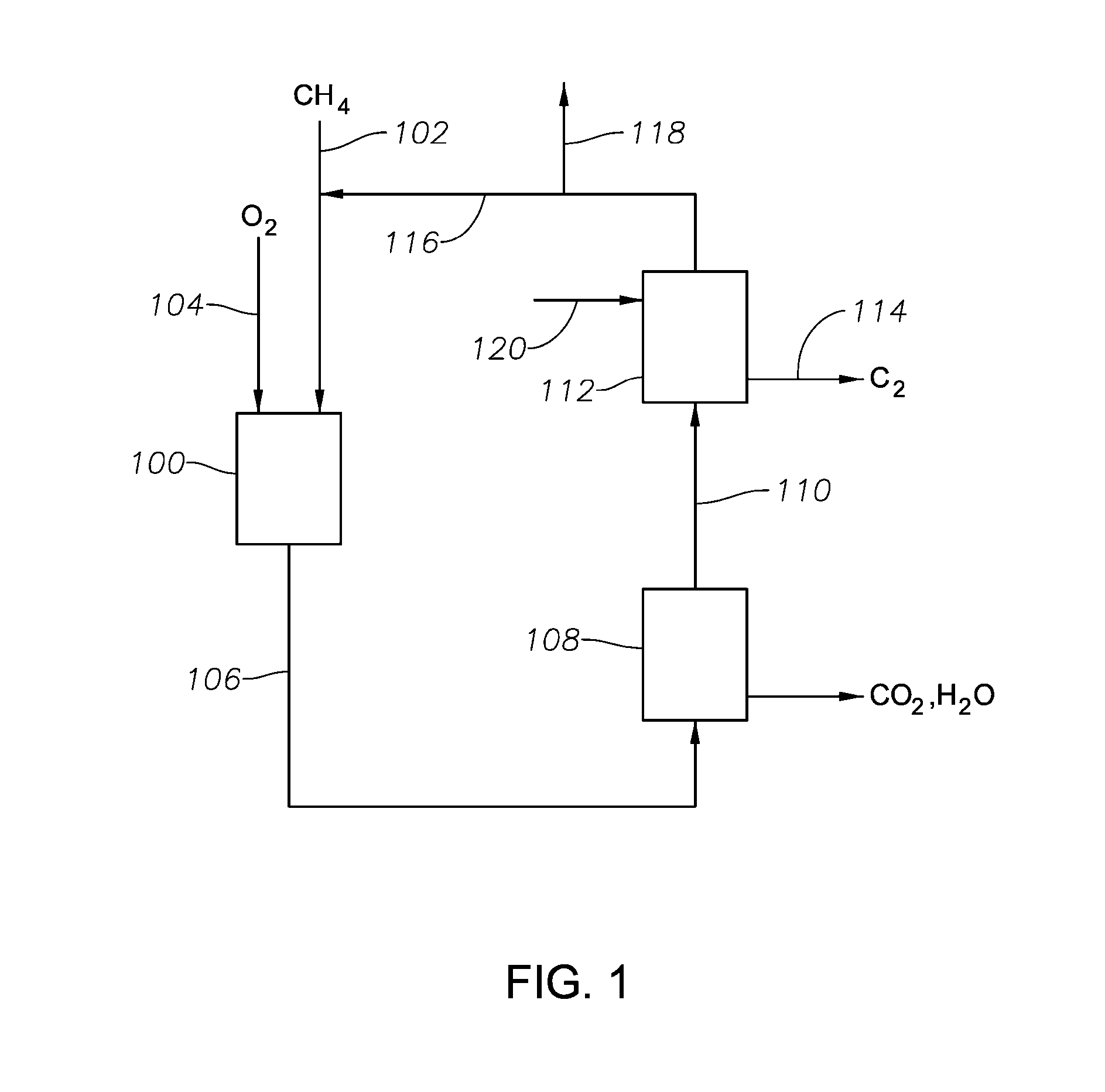

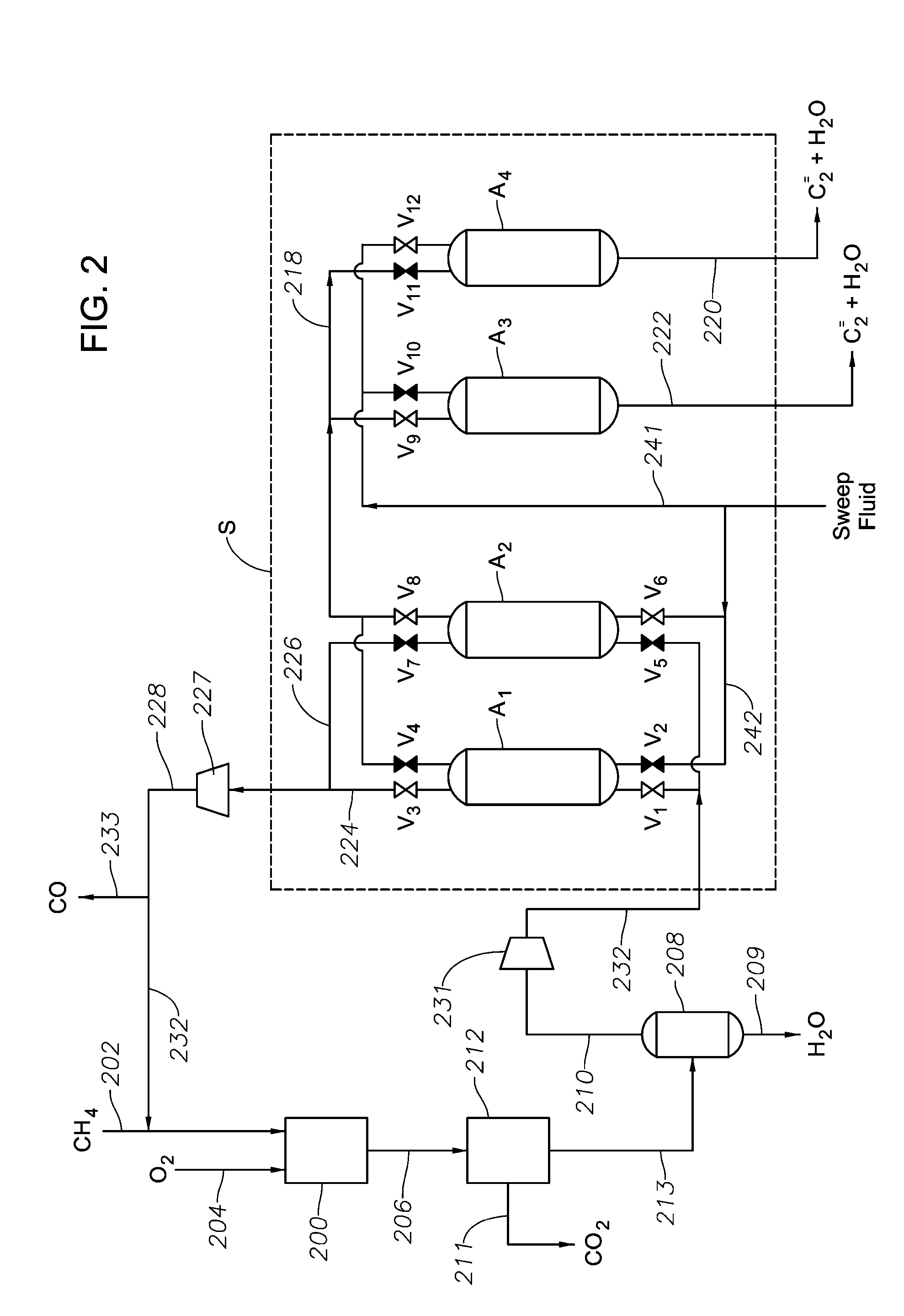

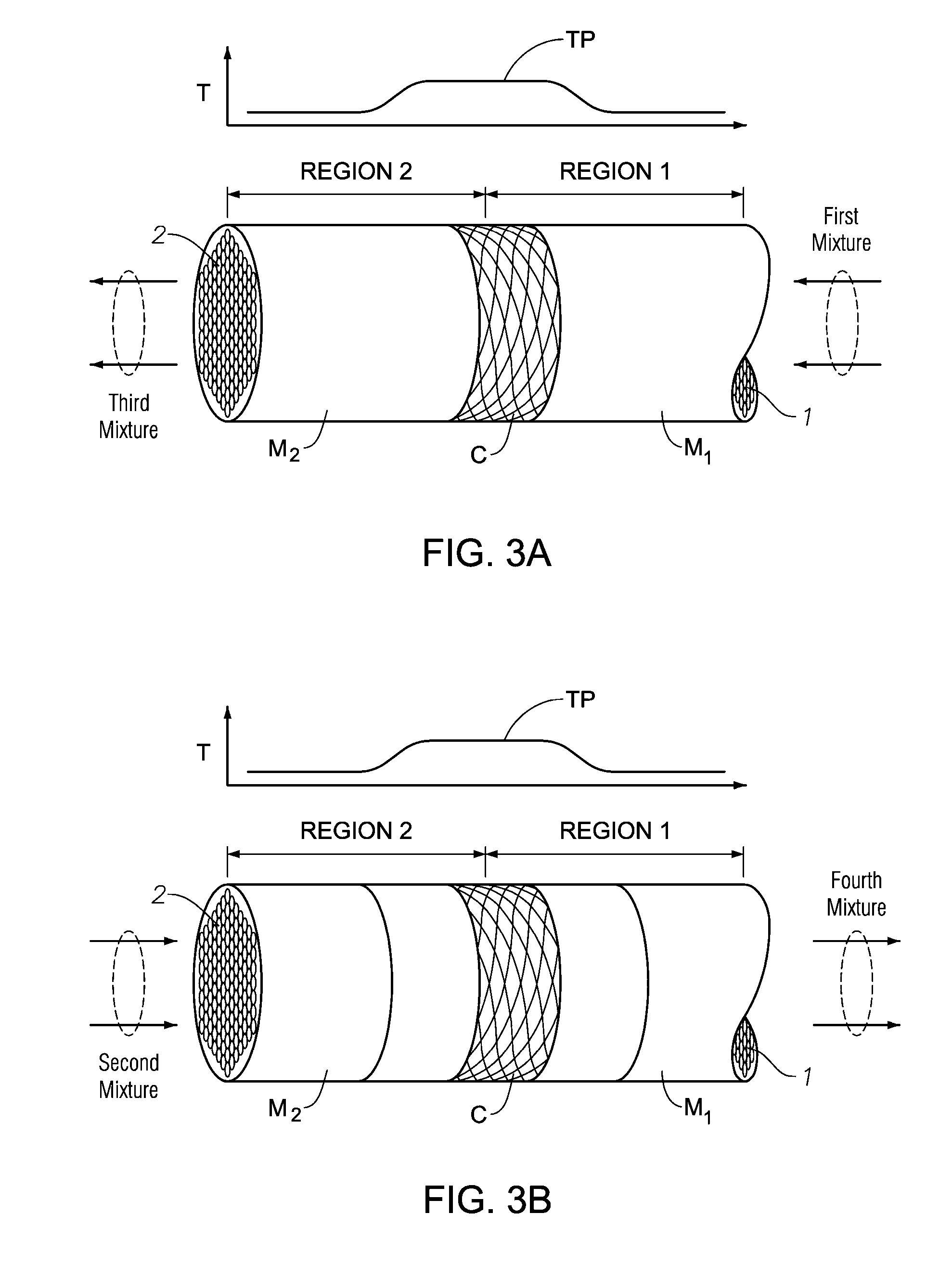

Catalytic Alkane Conversion and Olefin Separation

Disclosed is a hydrocarbon conversion process that is less energy intensive than comparable processes. The hydrocarbon conversion process is particularly desirable for converting alkanes, such as methane into C2+ olefins, such as ethylene and propylene, particularly with increasing selectivity to ethylene production. It is also desirable for effectively removing a C2 composition (i.e., ethane, ethylene and / or acetylene) produced from the catalytic conversion of hydrocarbon comprised of C2+ olefins. In addition, the hydrocarbon process is desirable for providing a substantially non-cryogenic separation of the desired C2 compositions from the hydrocarbons (e.g., methane) present in the reaction mixture.

Owner:EXXONMOBIL CHEM PAT INC

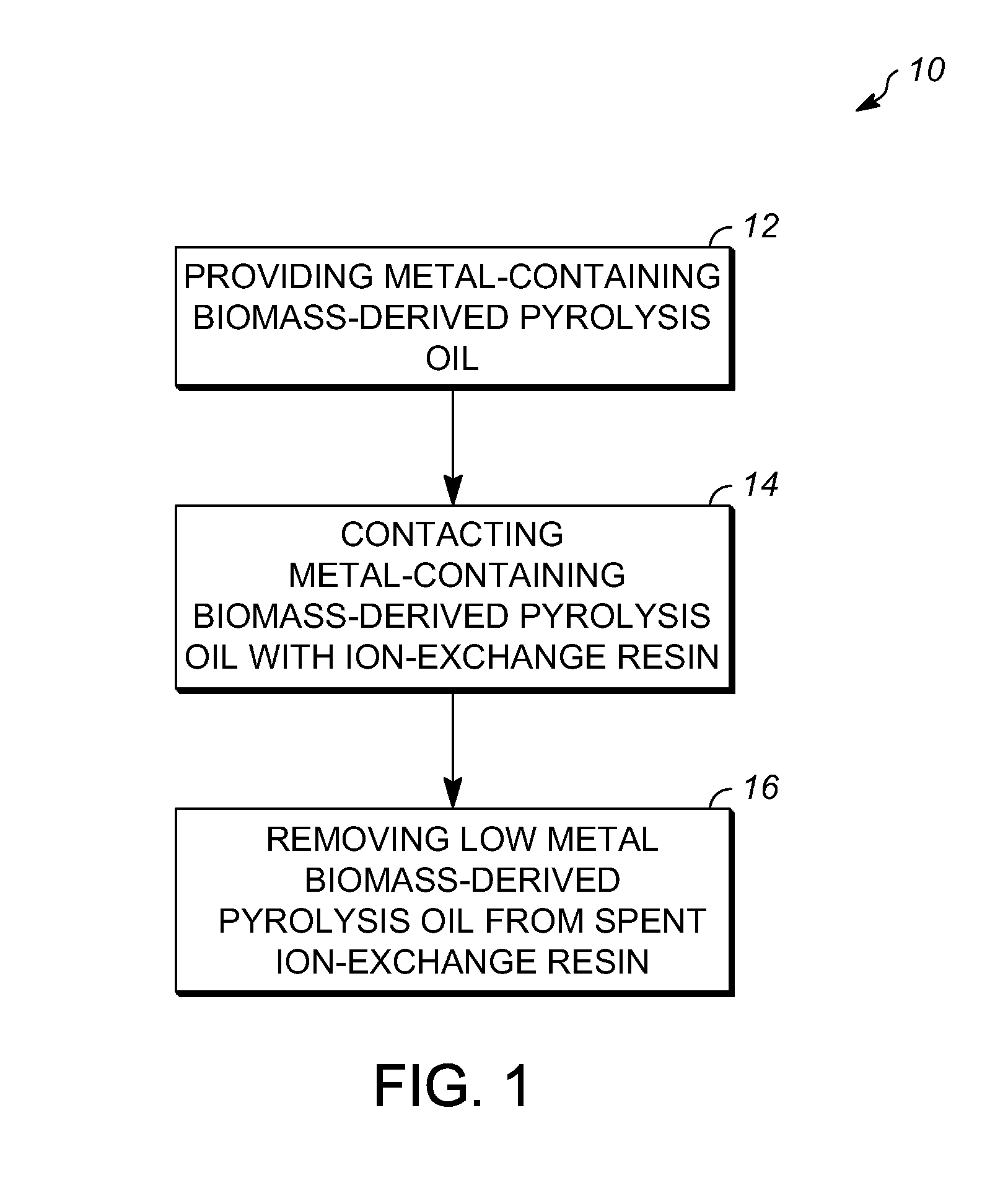

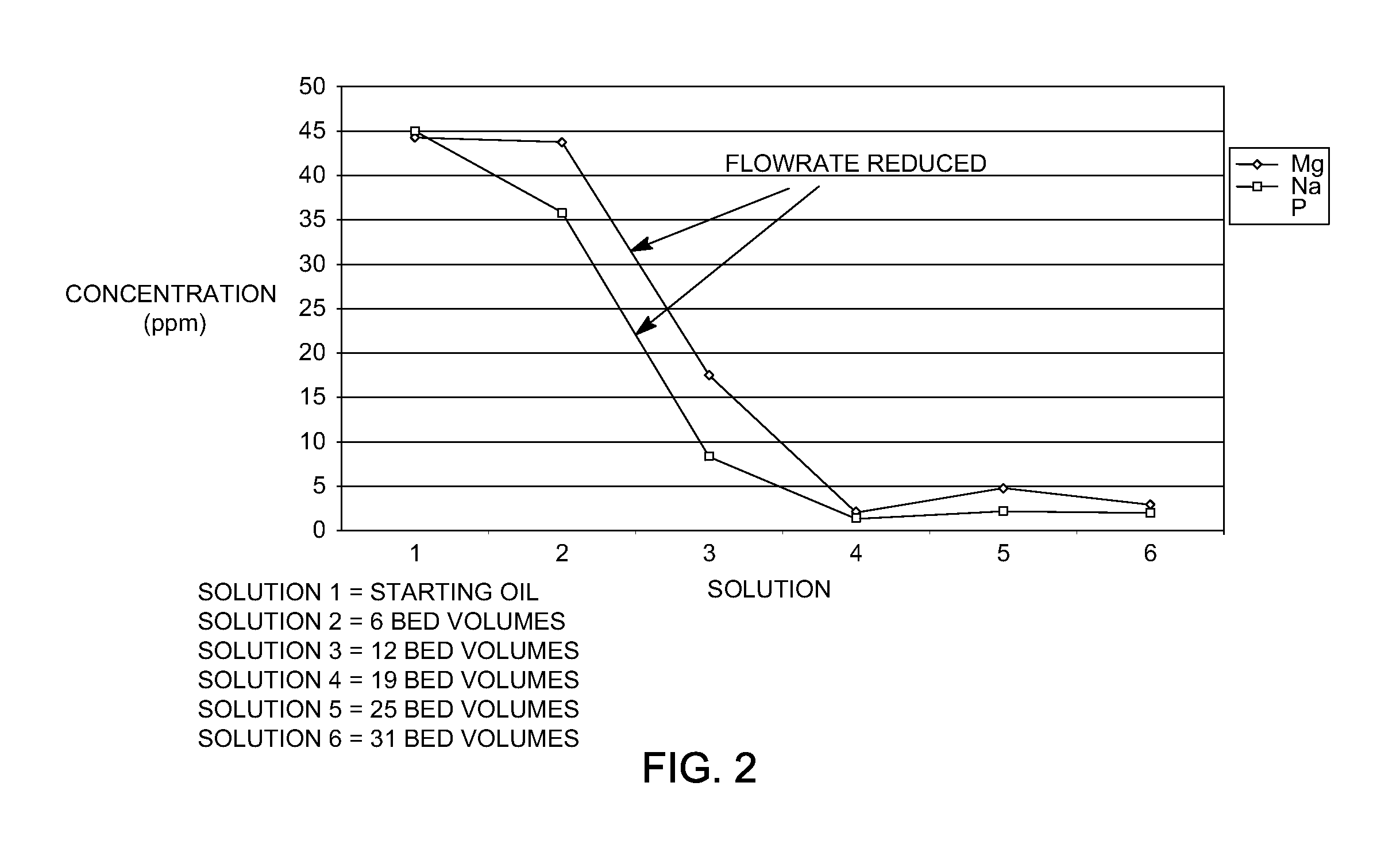

Low metal biomass-derived pyrolysis oils and processes for producing the same

Low metal biomass-derived pyrolysis oils and processes for producing the same are provided. Low metal biomass-derived pyrolysis oil is produced by a process of contacting metal-containing biomass-derived pyrolysis oil with an acidic ion-exchange resin having sulfonic acid groups. Low metal biomass-derived pyrolysis oil is removed from spent acidic ion-exchange resin after ion-exchange.

Owner:UOP LLC

Preparation method and use of carbon molecular sieve

InactiveCN101935032ASolve the problem of difficult and efficient separation of methane-nitrogenNitrogen purification/separationOther chemical processesHigh concentrationLoss rate

The invention relates to a preparation method and use of a carbon molecular sieve. The preparation method comprises the following steps: preparing a conventional carbon molecular sieve; and expanding the pores in the conventional carbon molecular sieve by using a secondary activation technique and modifying the conventional carbon molecular sieve by adjusting the pores. The new carbon molecular sieve is prepared by using coal, coconut shell or phenolic resin, and the like as raw materials, by the conventional production steps of crushing, forming, carbonizing, steam activating, hydrocarbon settling and shrinking and the like and by secondary activation with KOH or CO2 as an activator. The activation temperature is between 550 and 850 DEG C; and the ignition loss rate of the product is kept be between 0.1 and 30 percent. In aspect of use, the carbon molecular sieve can be used for absorbing nitrogen molecules and can also be used for absorbing and separating methane and nitrogen in seam gas under a variable pressure while achieving an adsorption dynamic separation effect and allowing high-concentration methane gas to be collected at the exit of an adsorption tower directly; and thus, the methane in the seam gas can be used efficiently.

Owner:TONGJI UNIV

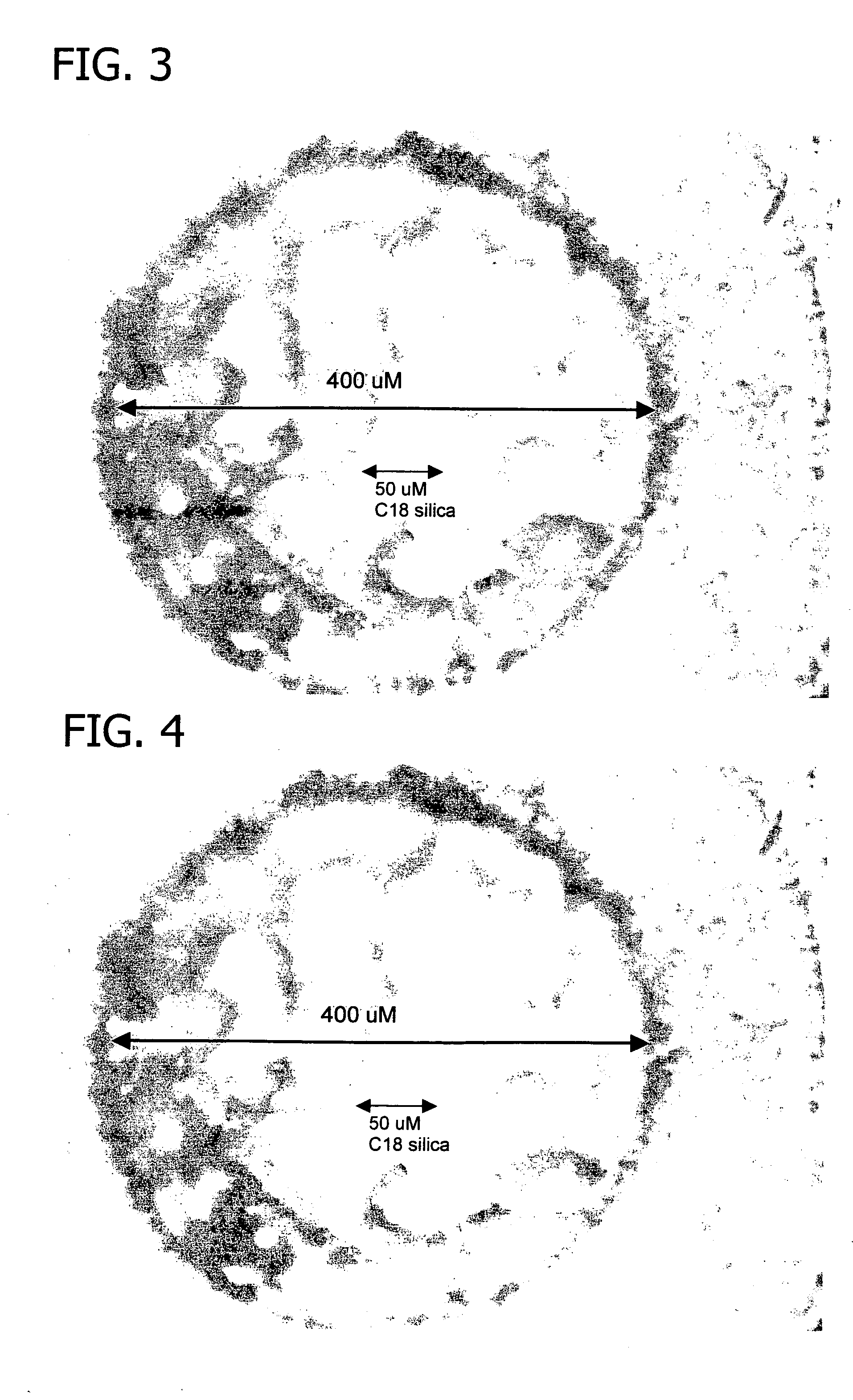

Polysilazane thermosetting polymers for use in chromatographic systems and applications

Owner:SIGMA ALDRICH CO LLC

Proess for desulfurization, denitrating and/or dearomatization of a hydrocarbon feedstock by adsorption on a spent solid adsorbent

InactiveUS20050075528A1Low market valueNegative is costCombustible gas purificationHydrocarbonsSorbentHeat treated

A process for purification by adsorption of a hydrocarbon feedstock that uses a novel adsorption agent is described. This adsorption agent is a spent solid adsorbent that has been used in a first application of catalytic treatment of hydrocarbon feedstocks, or of adsorption, and whose adsorption or catalytic performance levels are degraded such that its use for the first application has become impossible. The use of this spent solid adsorbent for the purification of hydrocarbon feedstocks by adsorption does not require specific treatment in advance, in particular not heat treatment.

Owner:INST FR DU PETROLE

Popular searches

Refining to change hydrocarbon structural skeleton Hydrocarbon by hydrogenation Fatty-oils/fats refining Fatty-oils/fats separation Liquid hydrocarbon mixture production Treatment with hydrotreatment processes Bio-feedstock Hydrocarbon oils treatment products Refining to eliminate hetero atoms Catalysts

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com