Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13351 results about "Crude oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

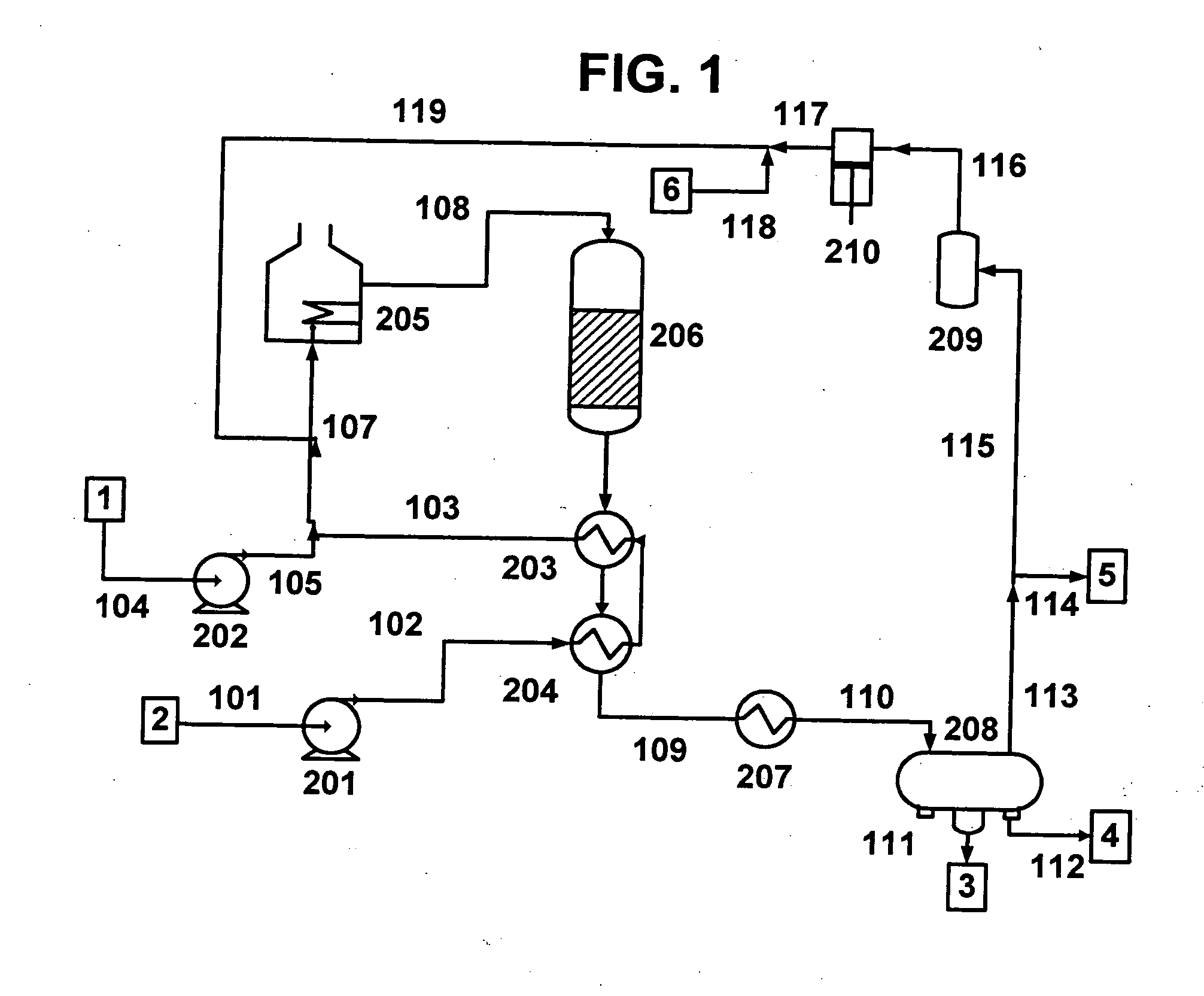

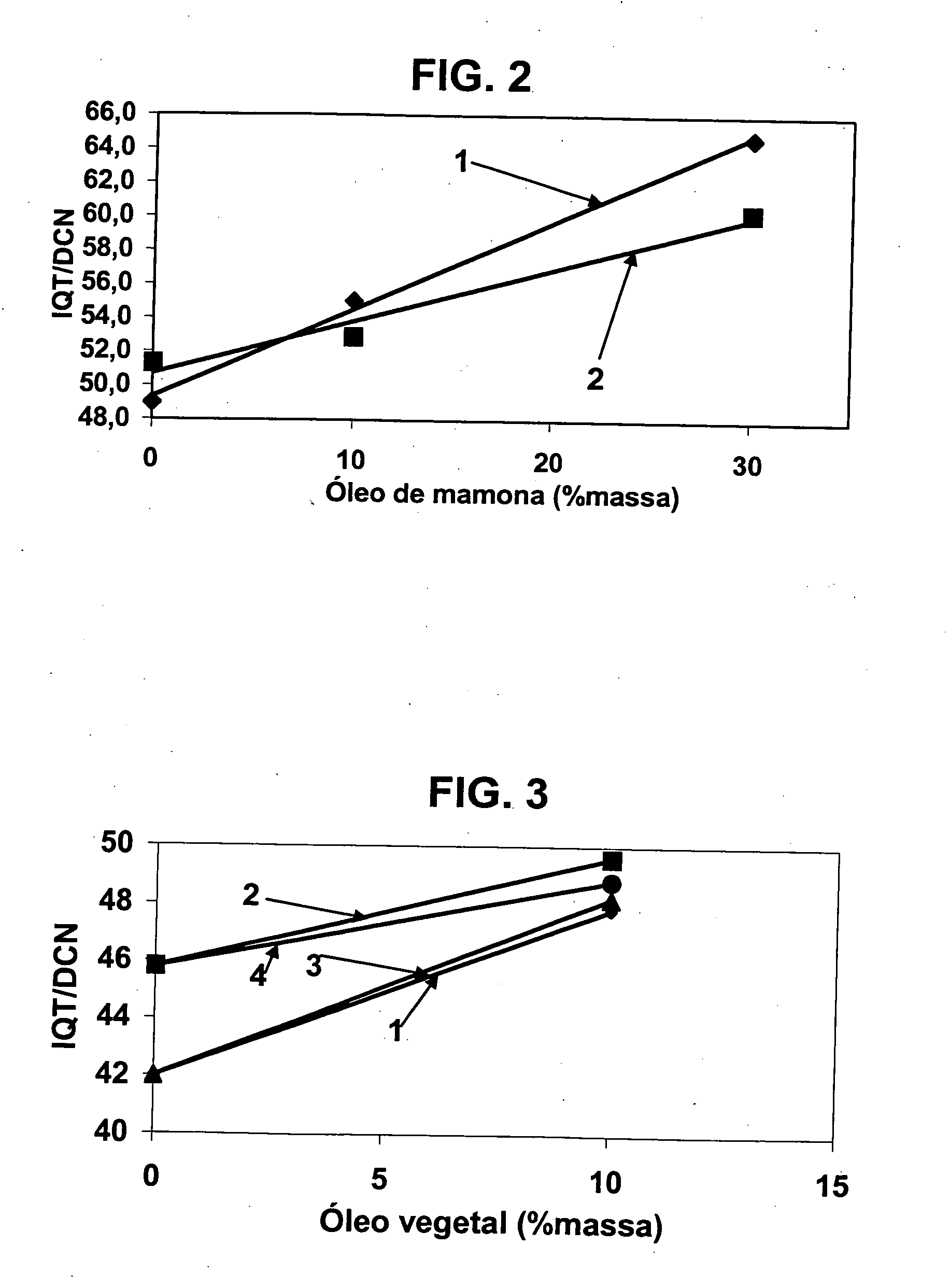

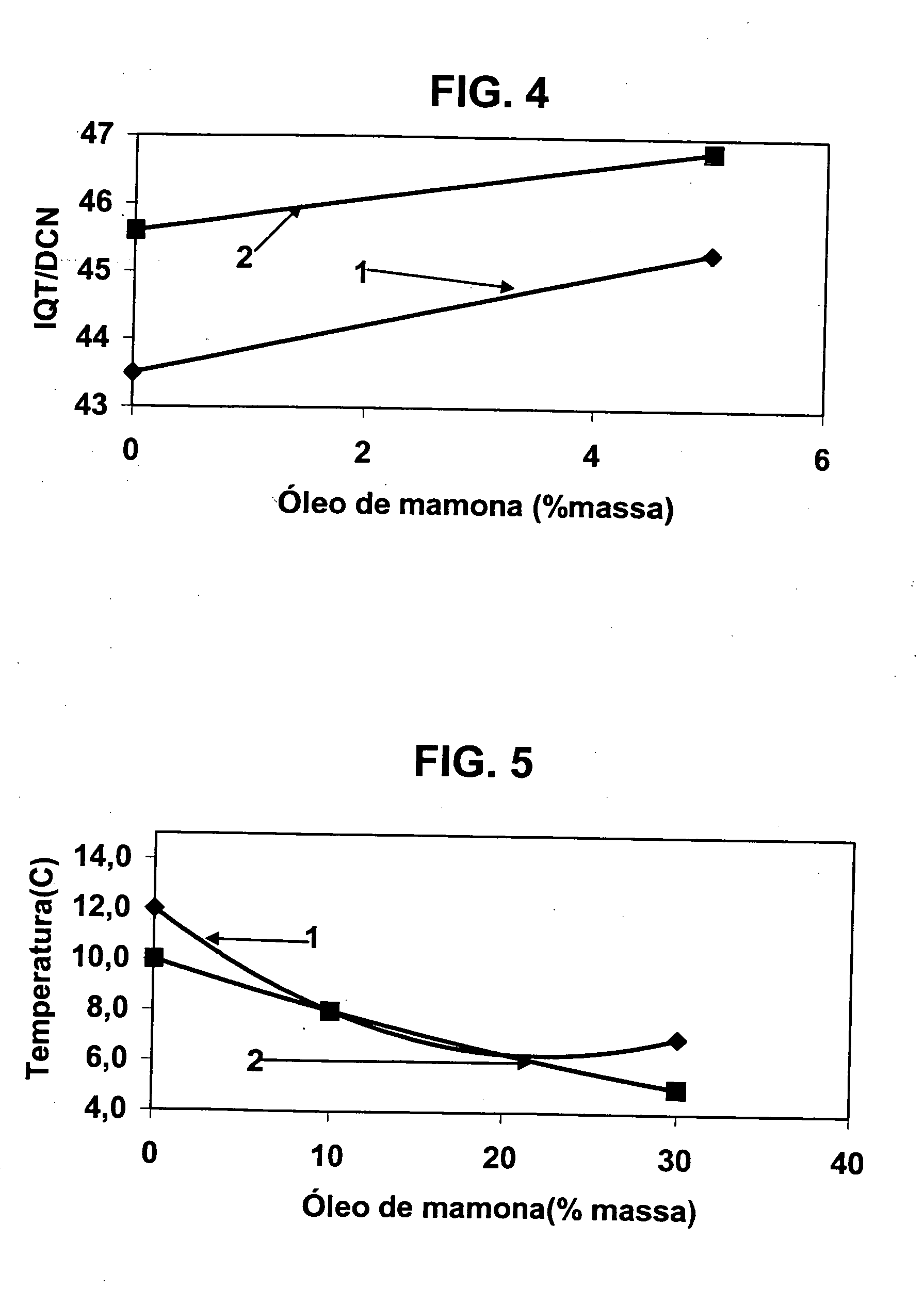

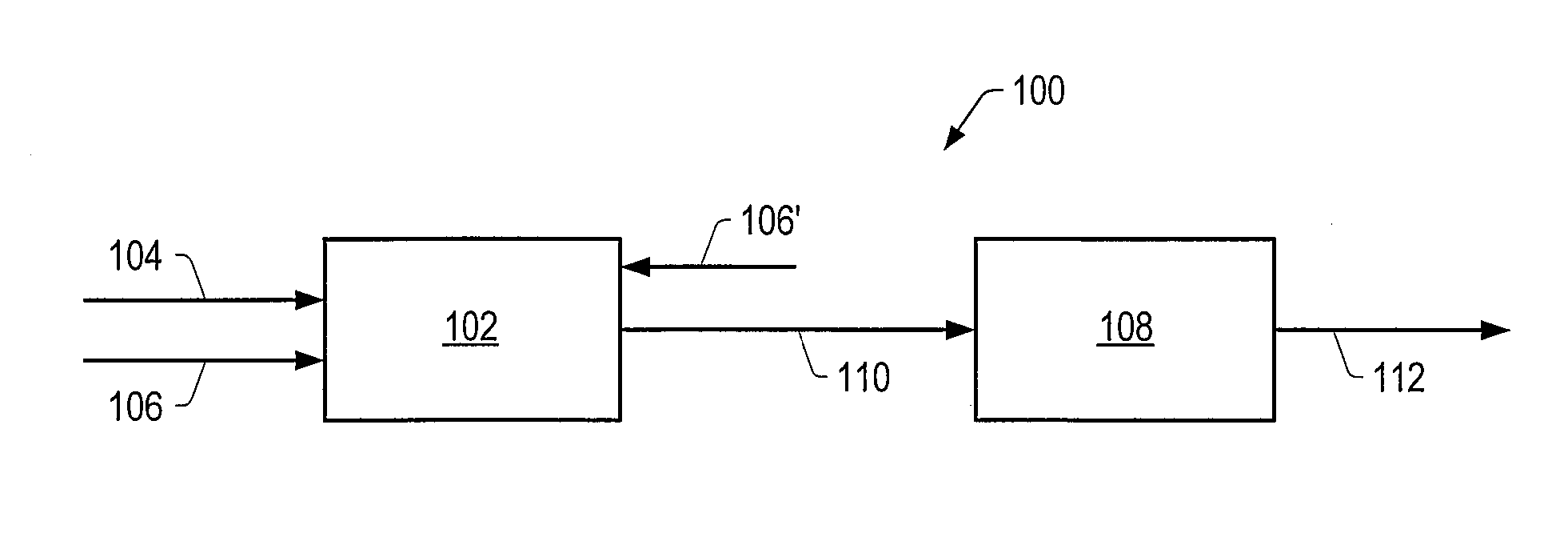

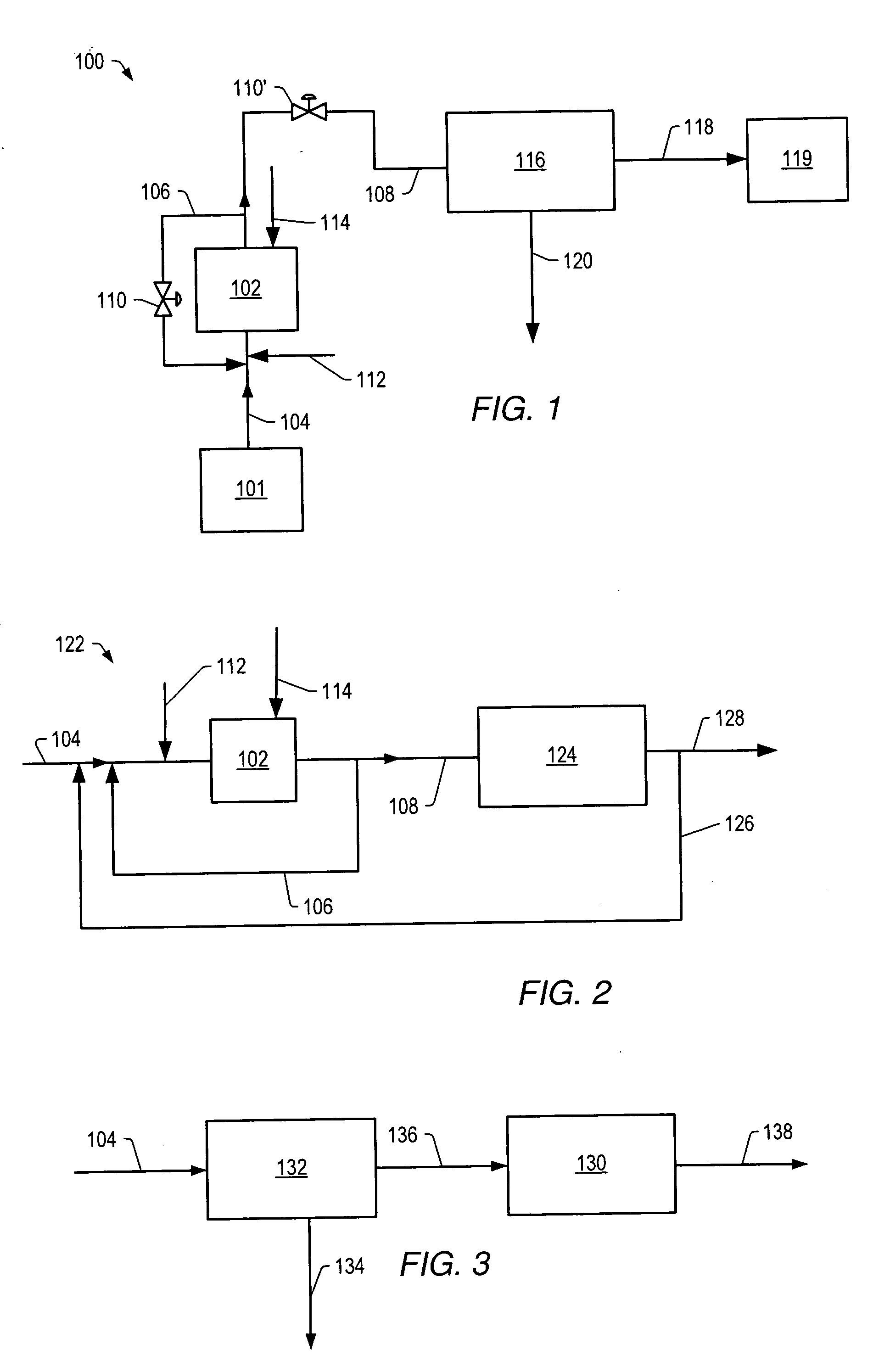

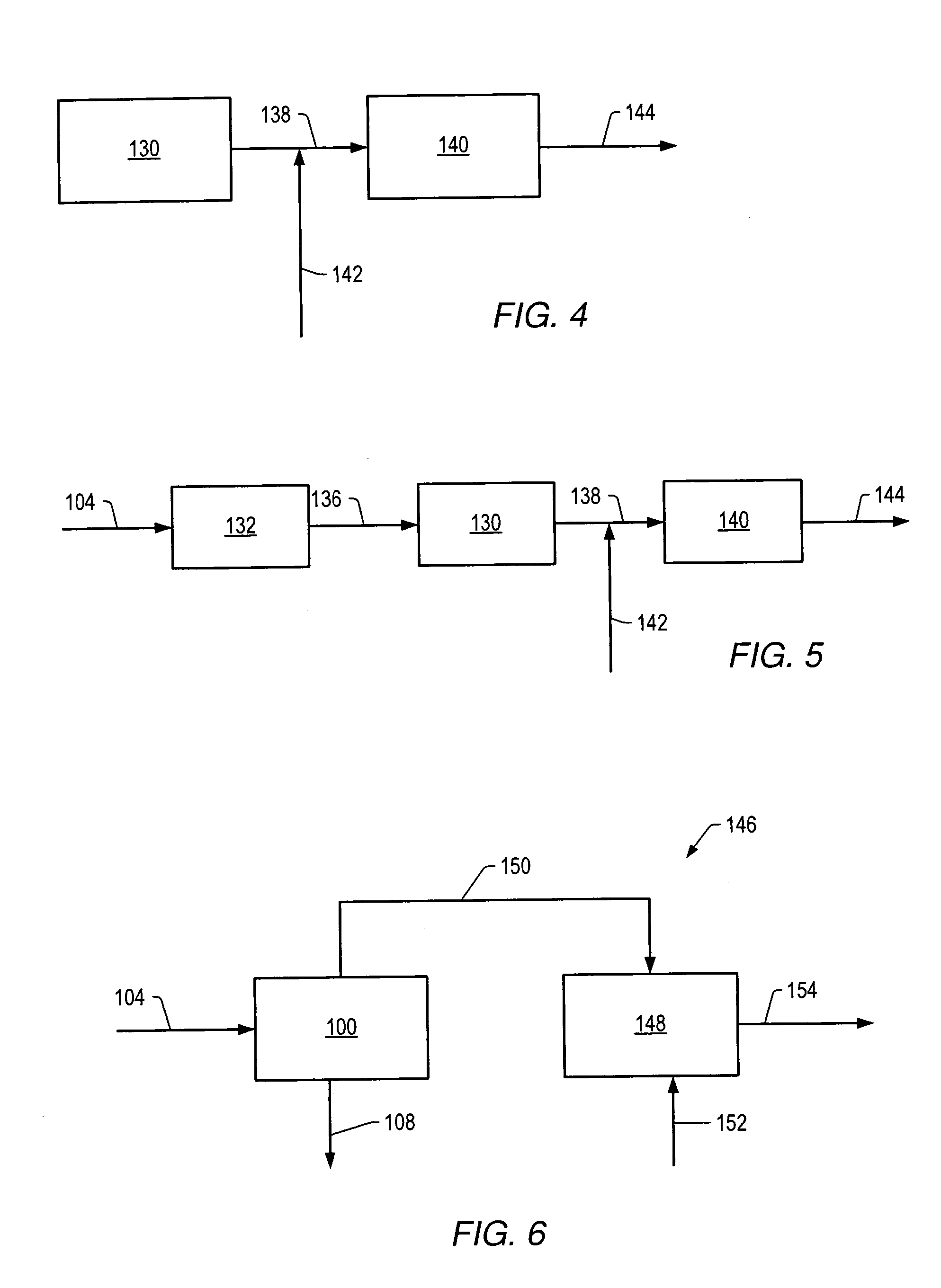

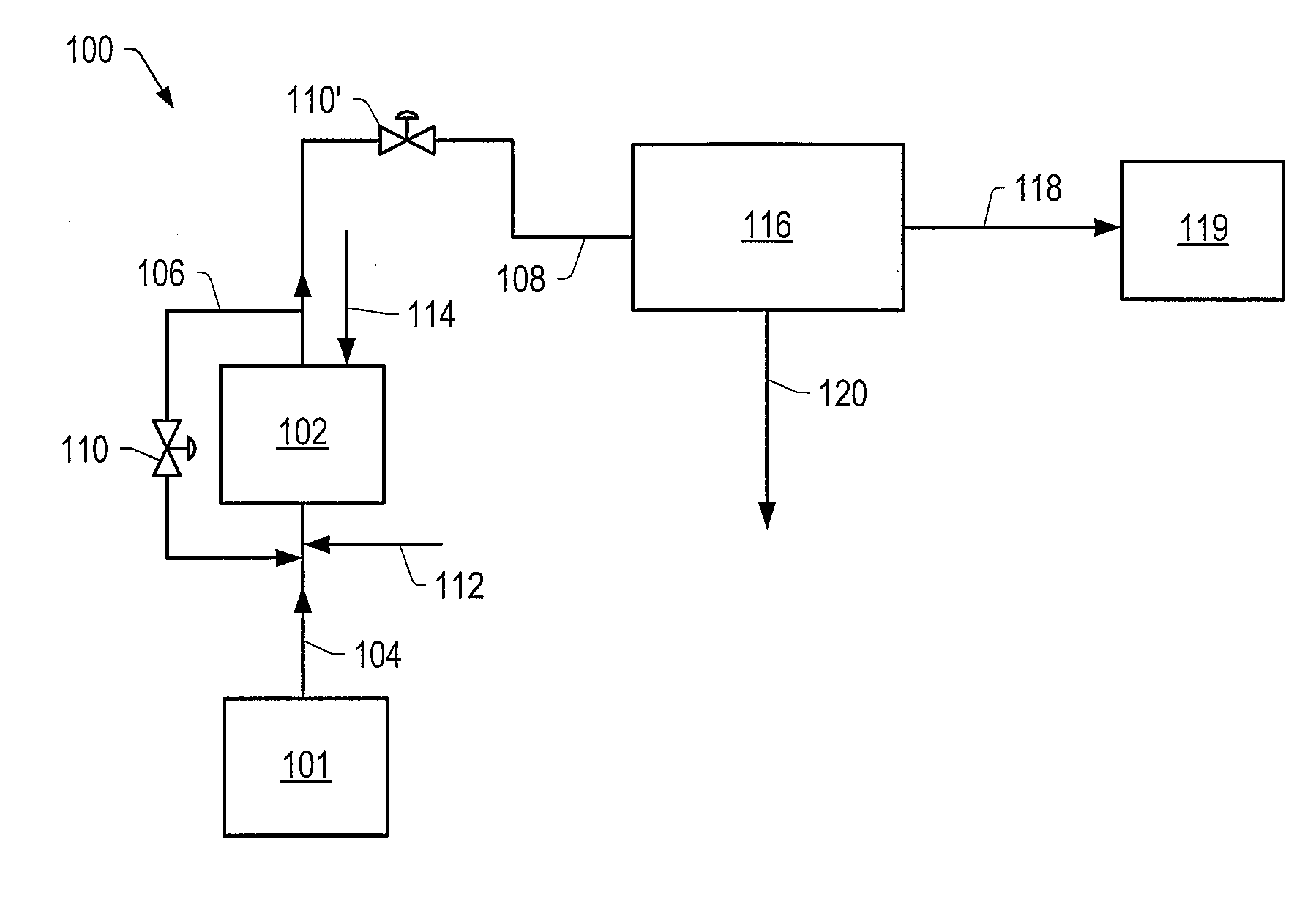

Vegetable oil hydroconversion process

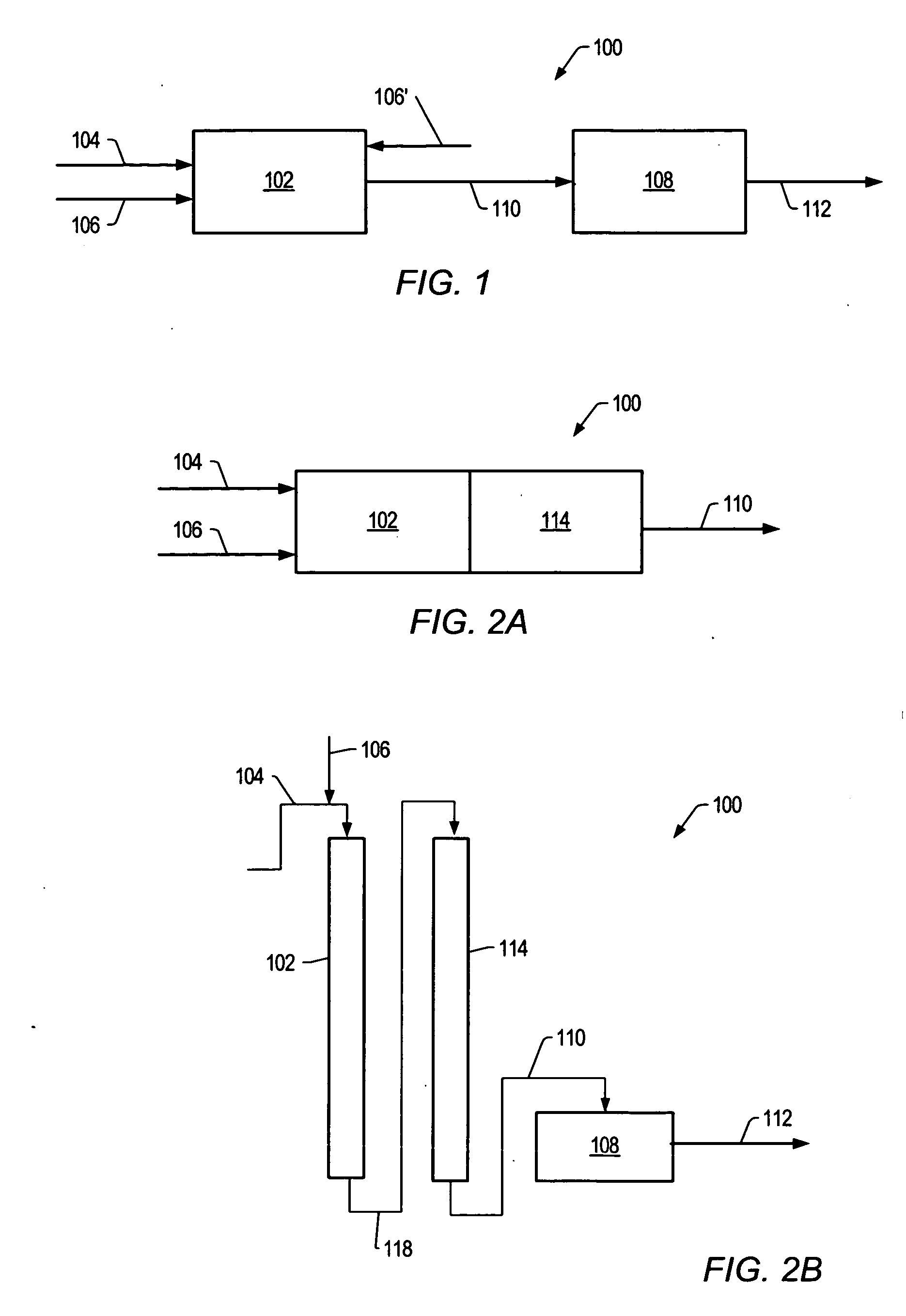

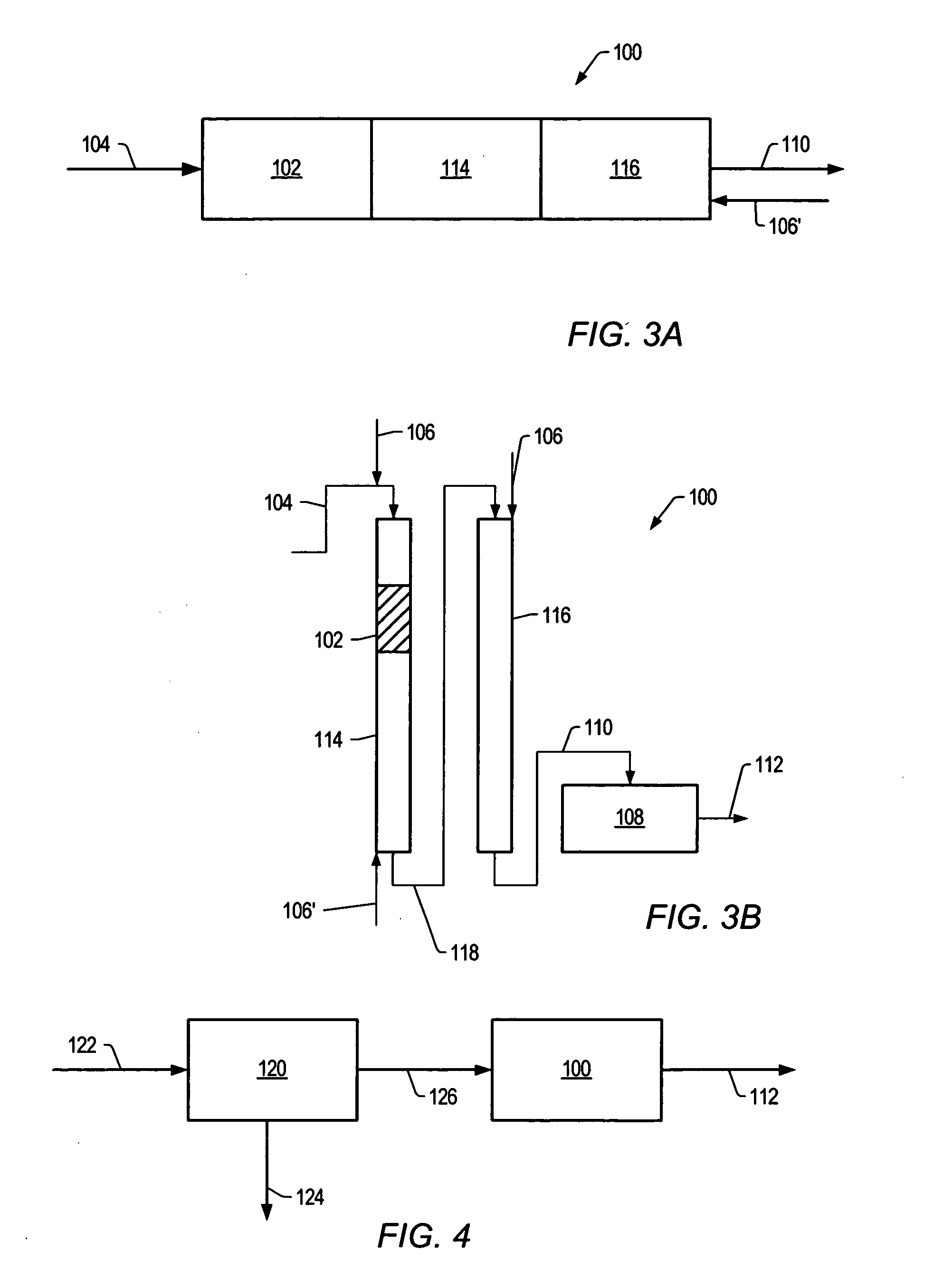

InactiveUS20060186020A1Improved cetane indexAvoid excessive densityMolecular sieve catalystsBiofuelsVegetable oilHydrogen

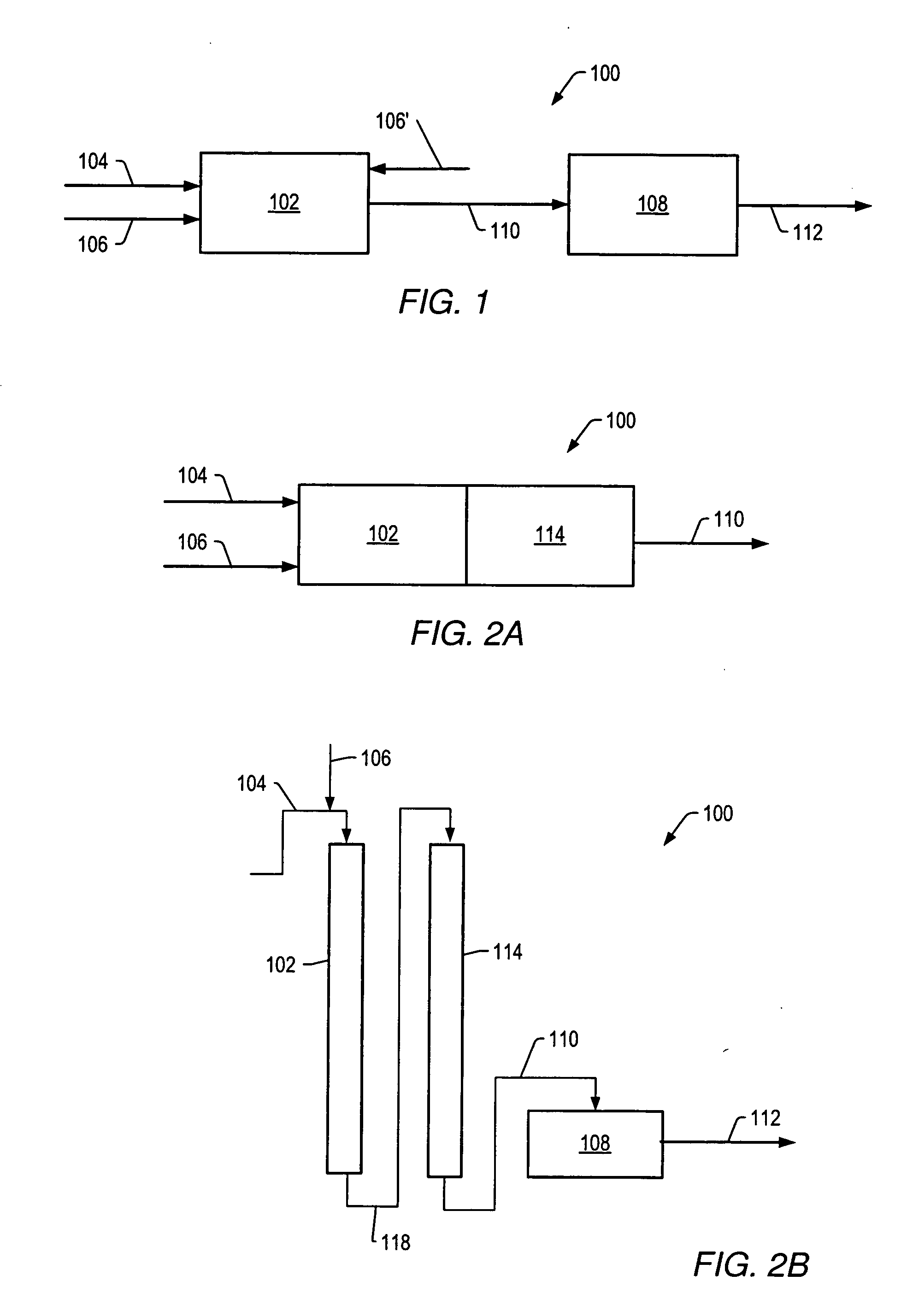

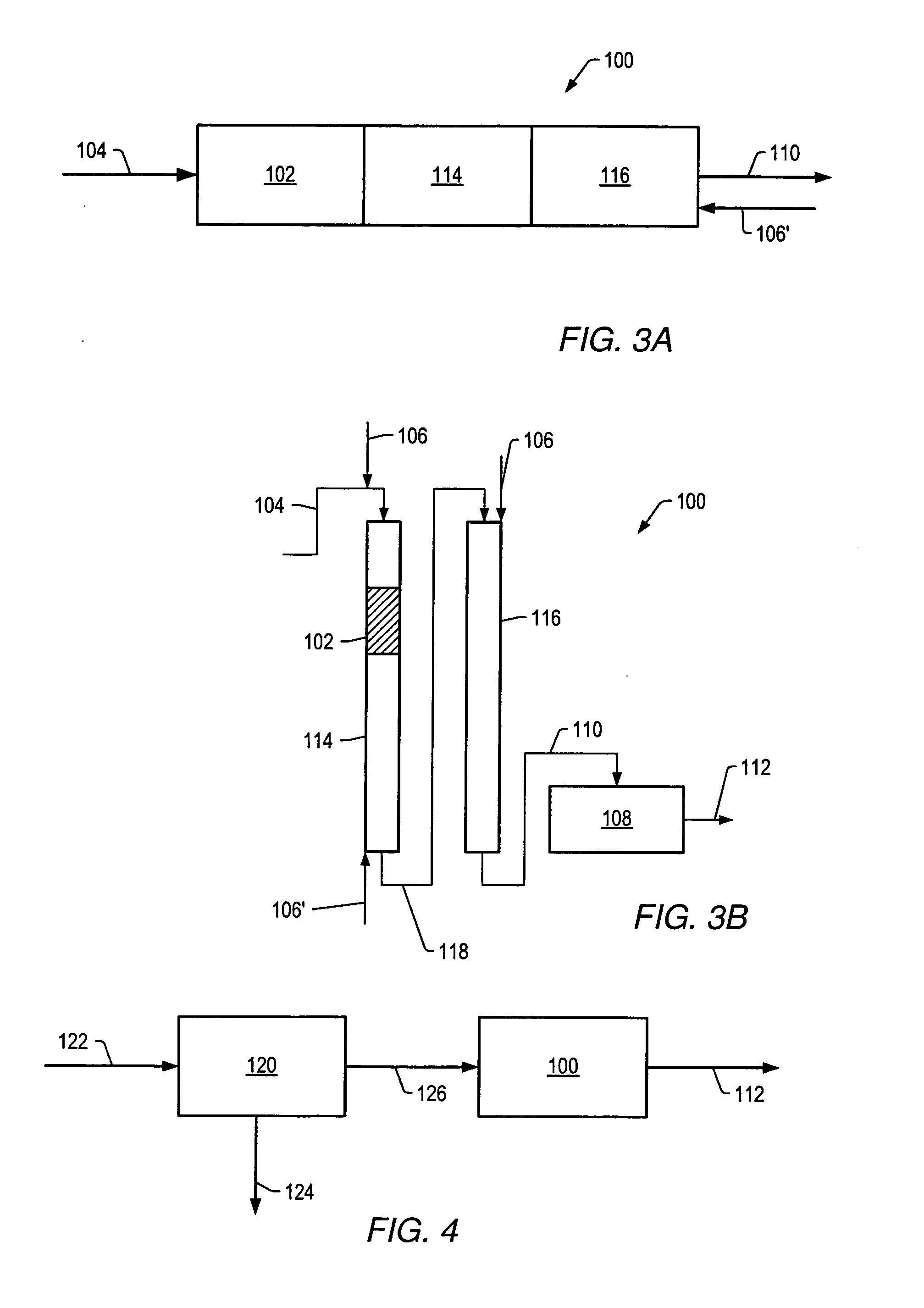

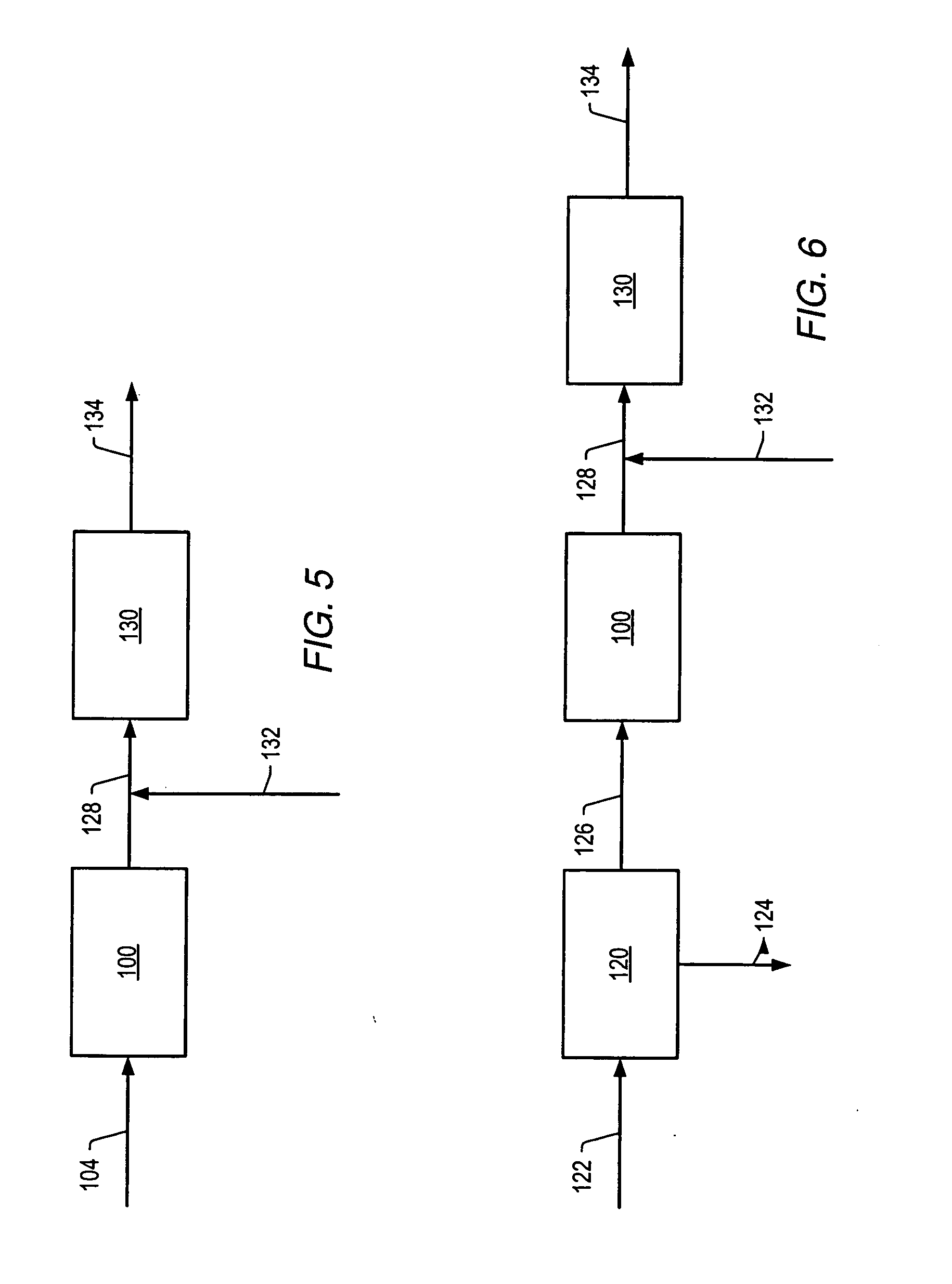

A vegetable oil hydroconversion process is described for hydroconverting a mixture between 1 to 75% in mass of oil or natural fat (1) and the rest mineral oil (2), hydroconverted in a reactor (205) under conditions of pressure, temperature, hydrogen (flow 119) and sulfide catalyst of Groups VIII and VIB, obtaining, after sour water separation (flow 111) and rectification (flow 112), a specified diesel product (4). The product (4) has an ITQ / DCN (cetane number) higher than a product obtained from a pure mineral based oil would have, lower density than from a base oil and a plugging point depending on the mineral oil flow, as well as greater oxidation stability than the base oil.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

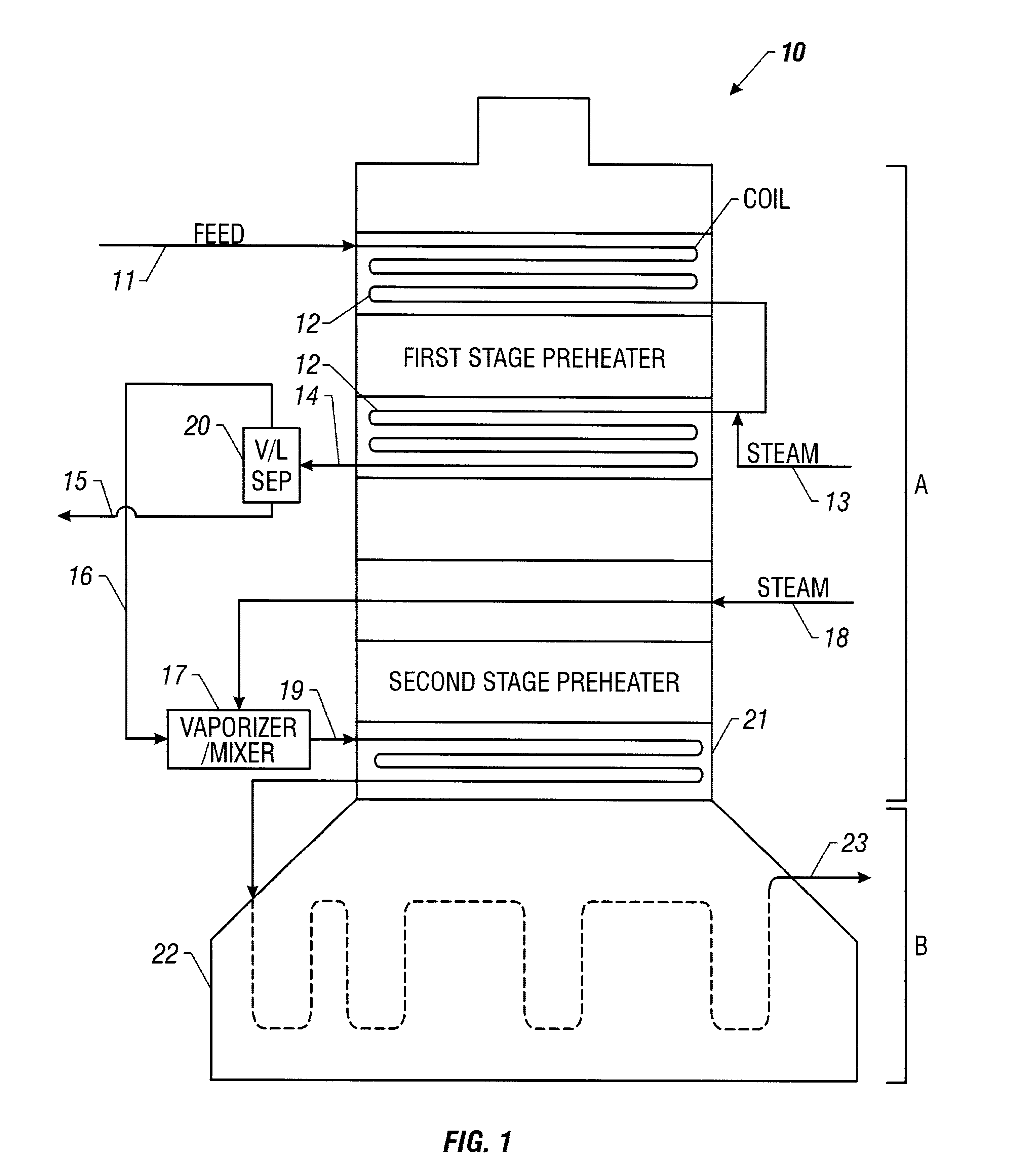

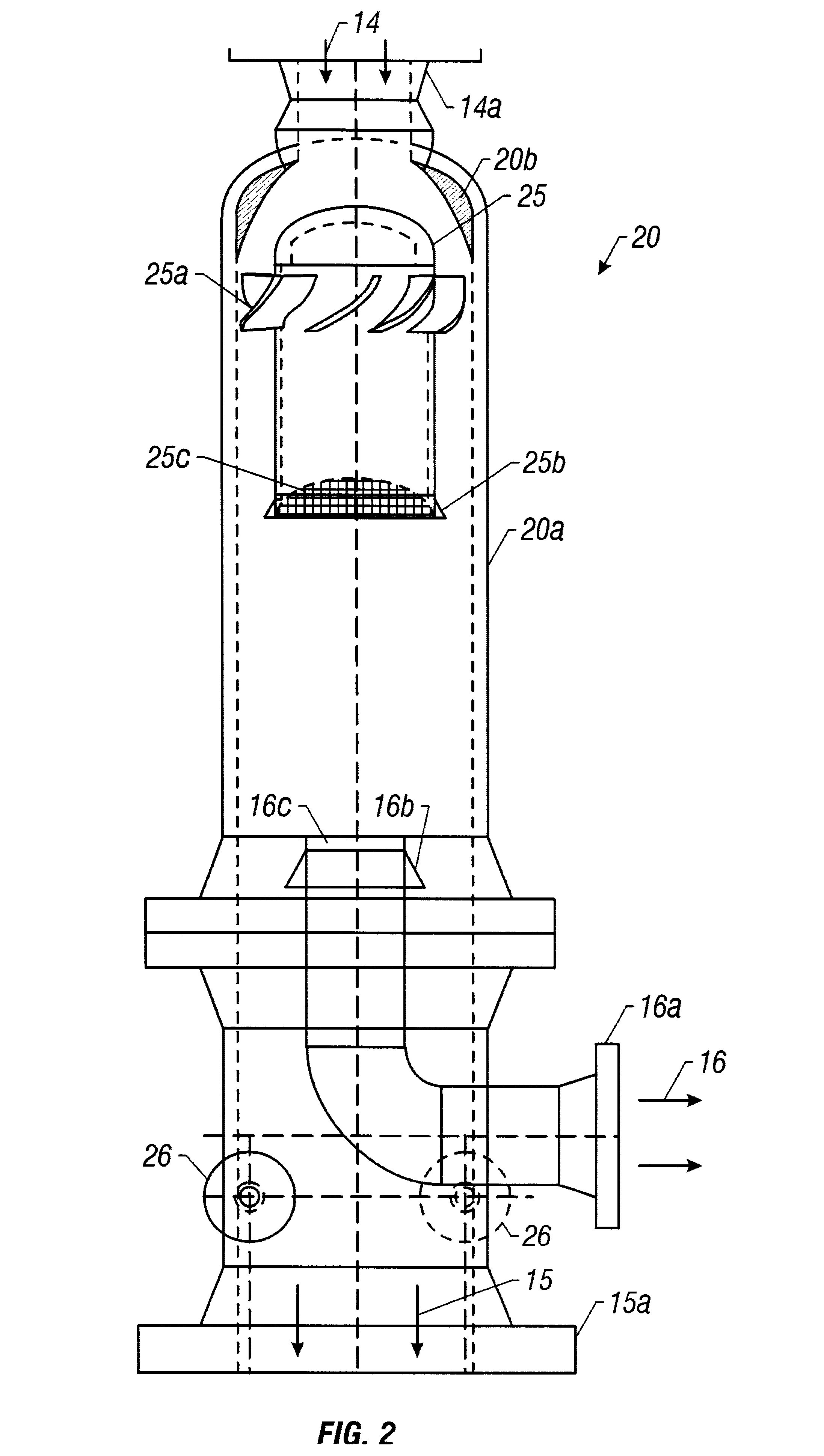

Thermal cracking of crude oil and crude oil fractions containing pitch in an ethylene furnace

InactiveUS6632351B1Cheap sourceMinimizing coke formationThermal non-catalytic crackingHydrocarbonsEthyleneChemistry

Owner:SHELL OIL CO

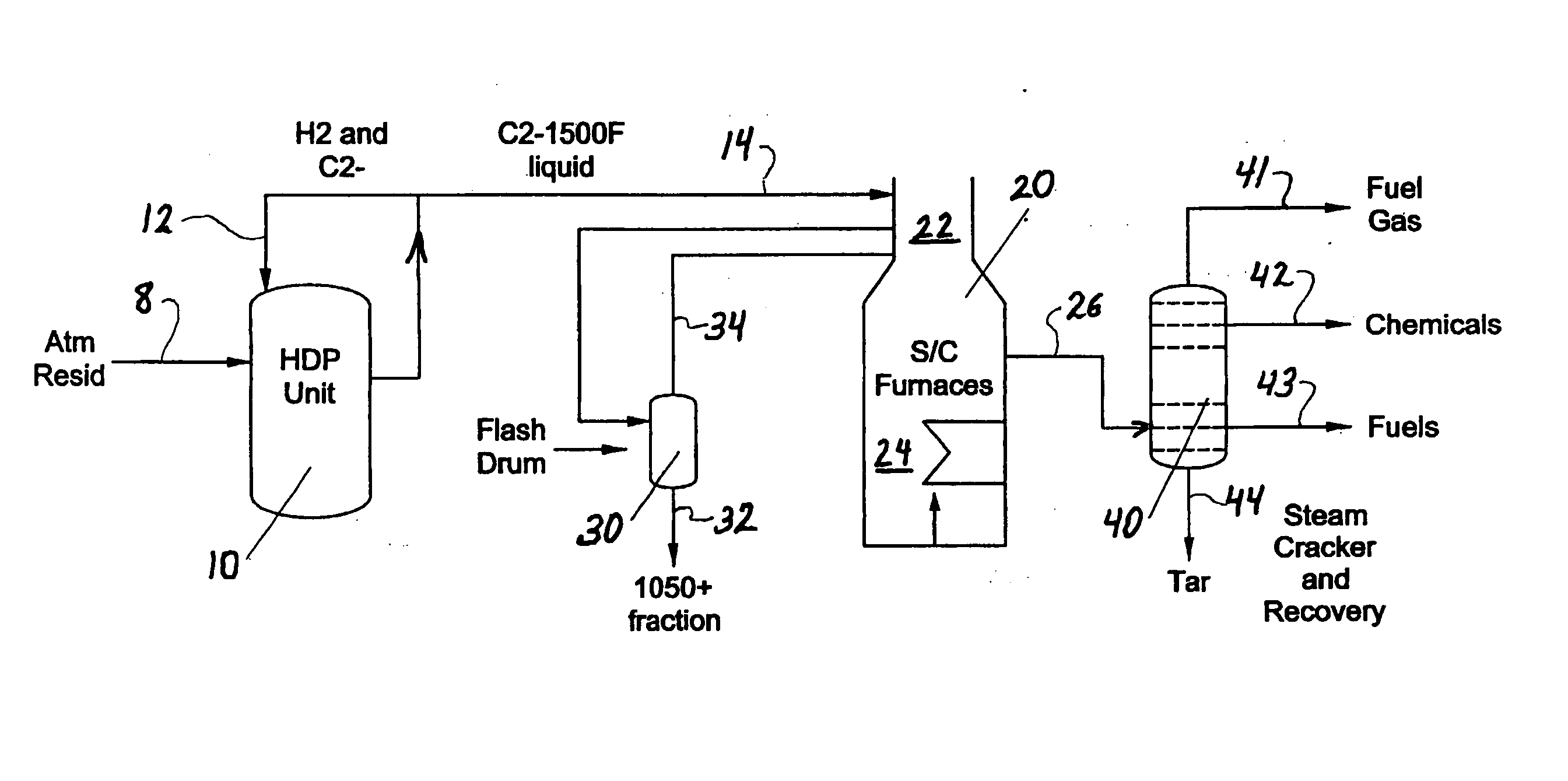

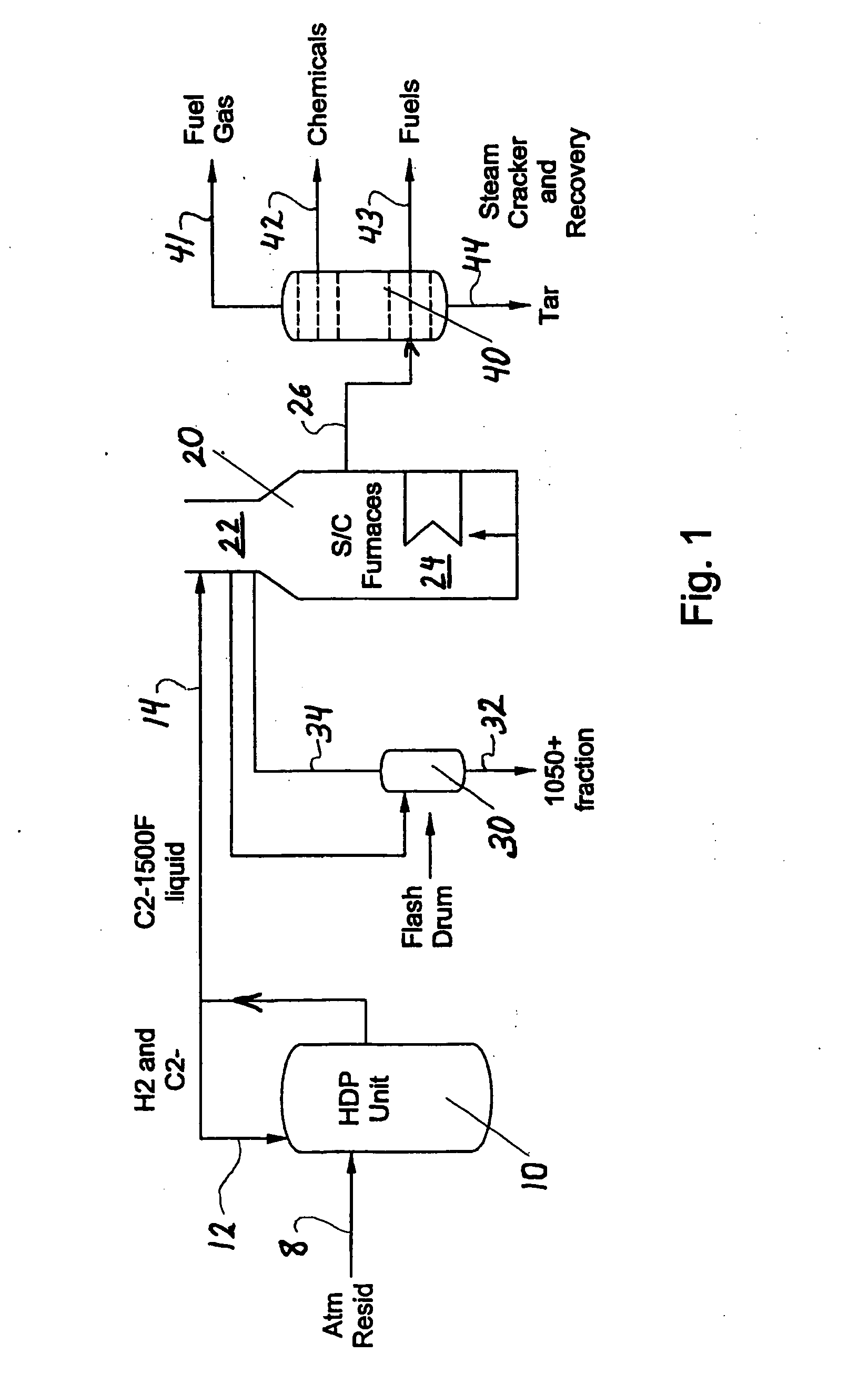

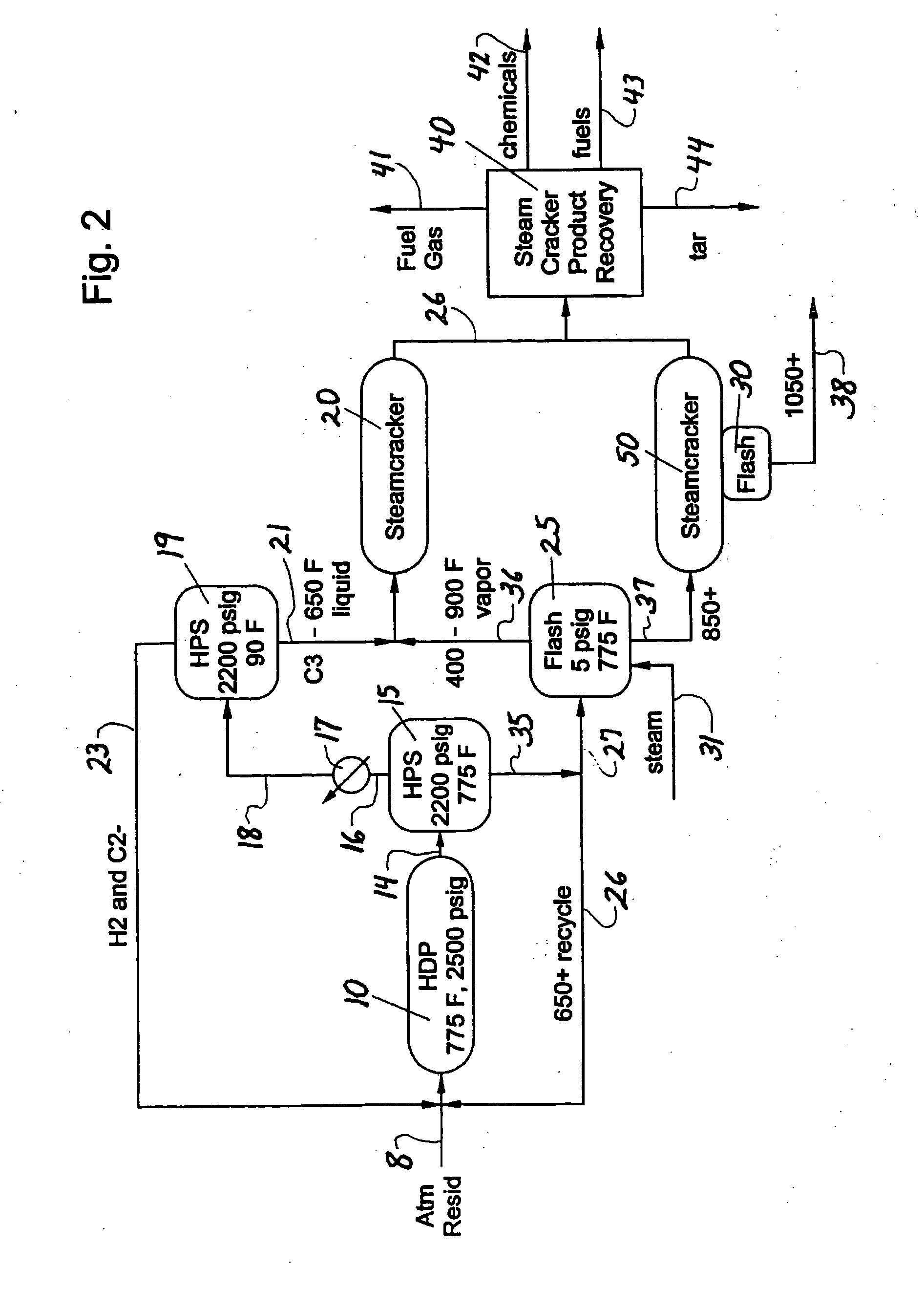

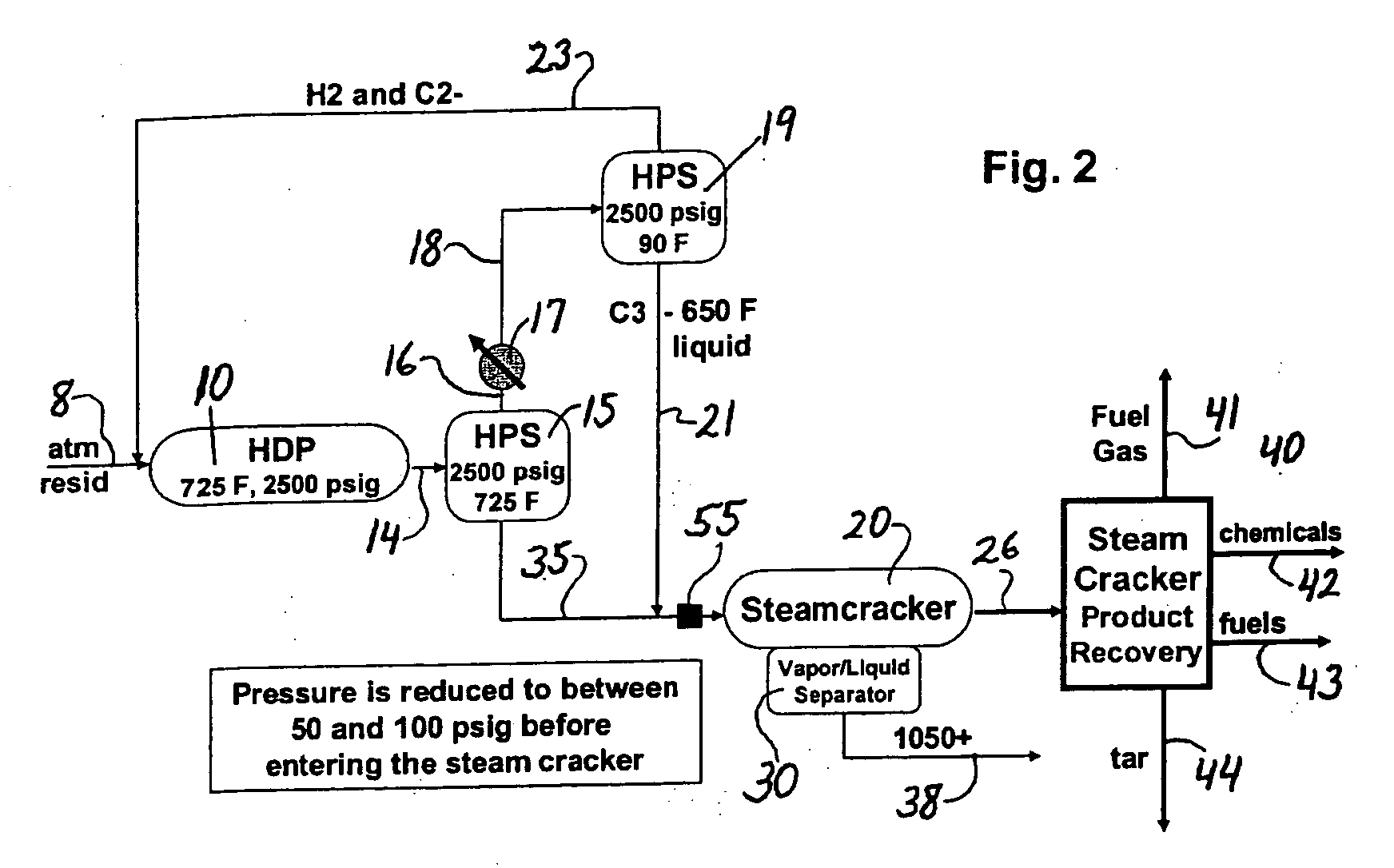

Hydrocarbon resid processing

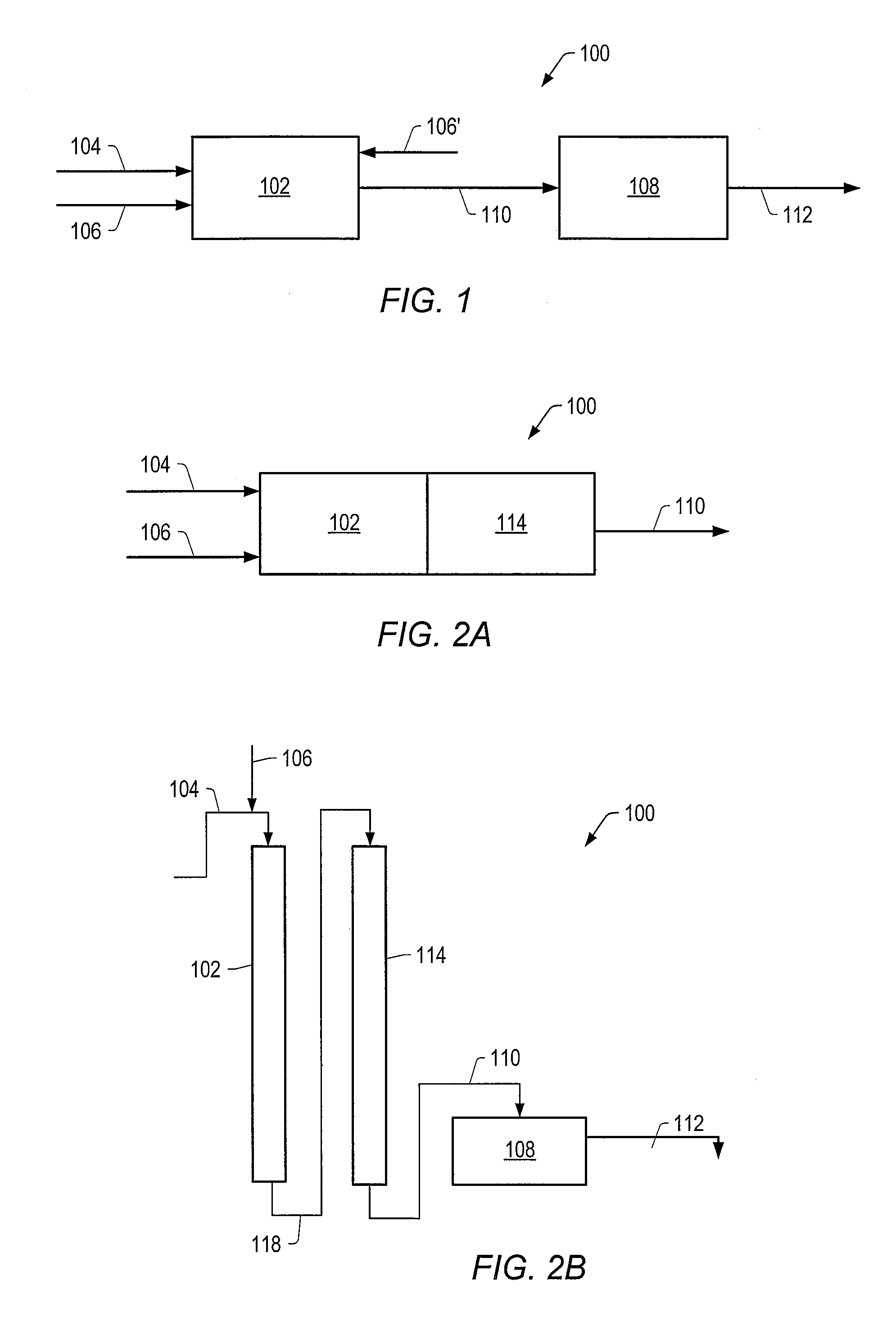

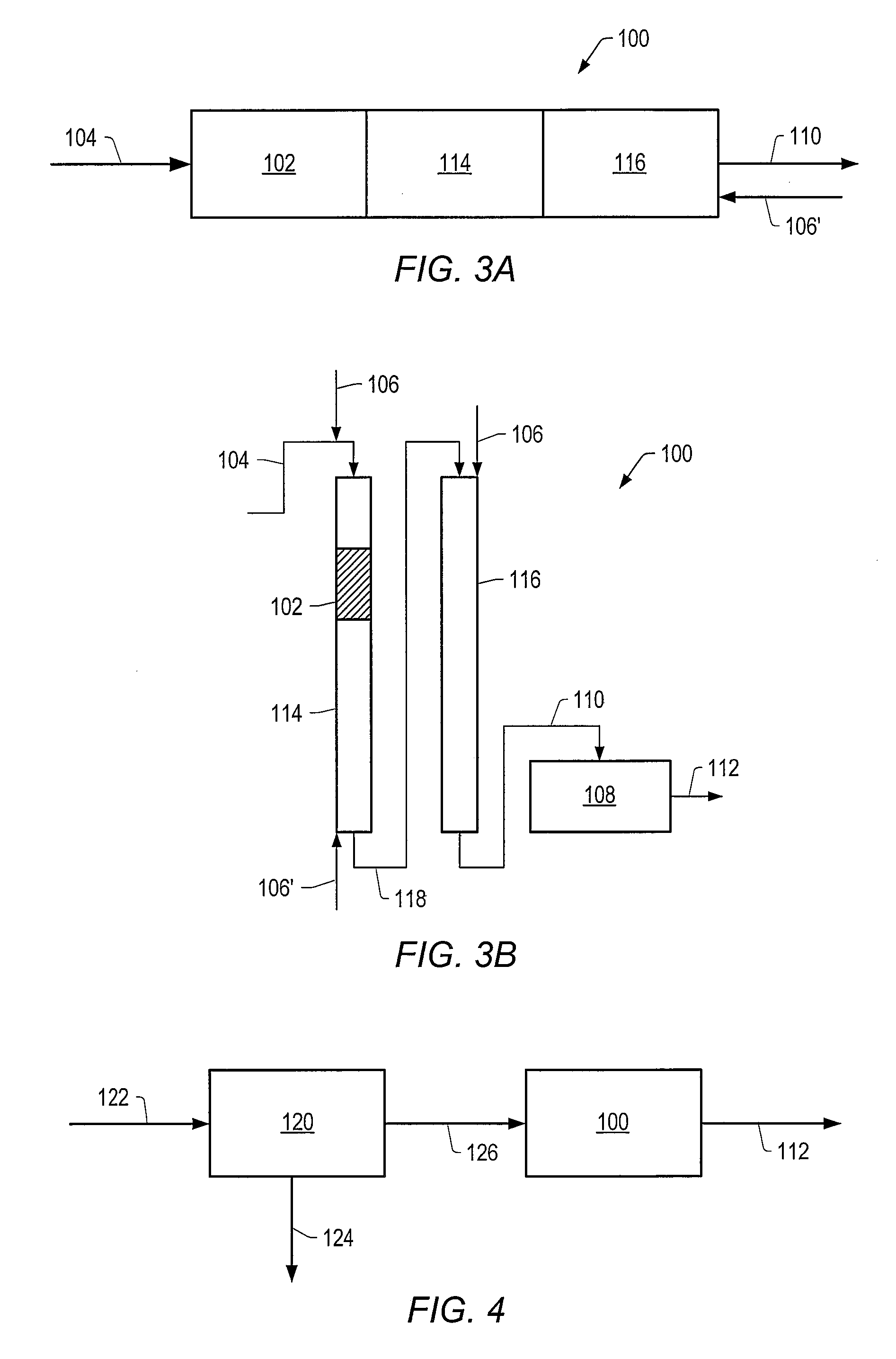

ActiveUS20070090018A1Increase in severityReduce pressureThermal non-catalytic crackingHydrocarbon oil cracking processHydrocarbonChemistry

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is severely hydrotreated and passed to a steam cracker to obtain an olefins product.

Owner:EXXONMOBIL CHEM PAT INC

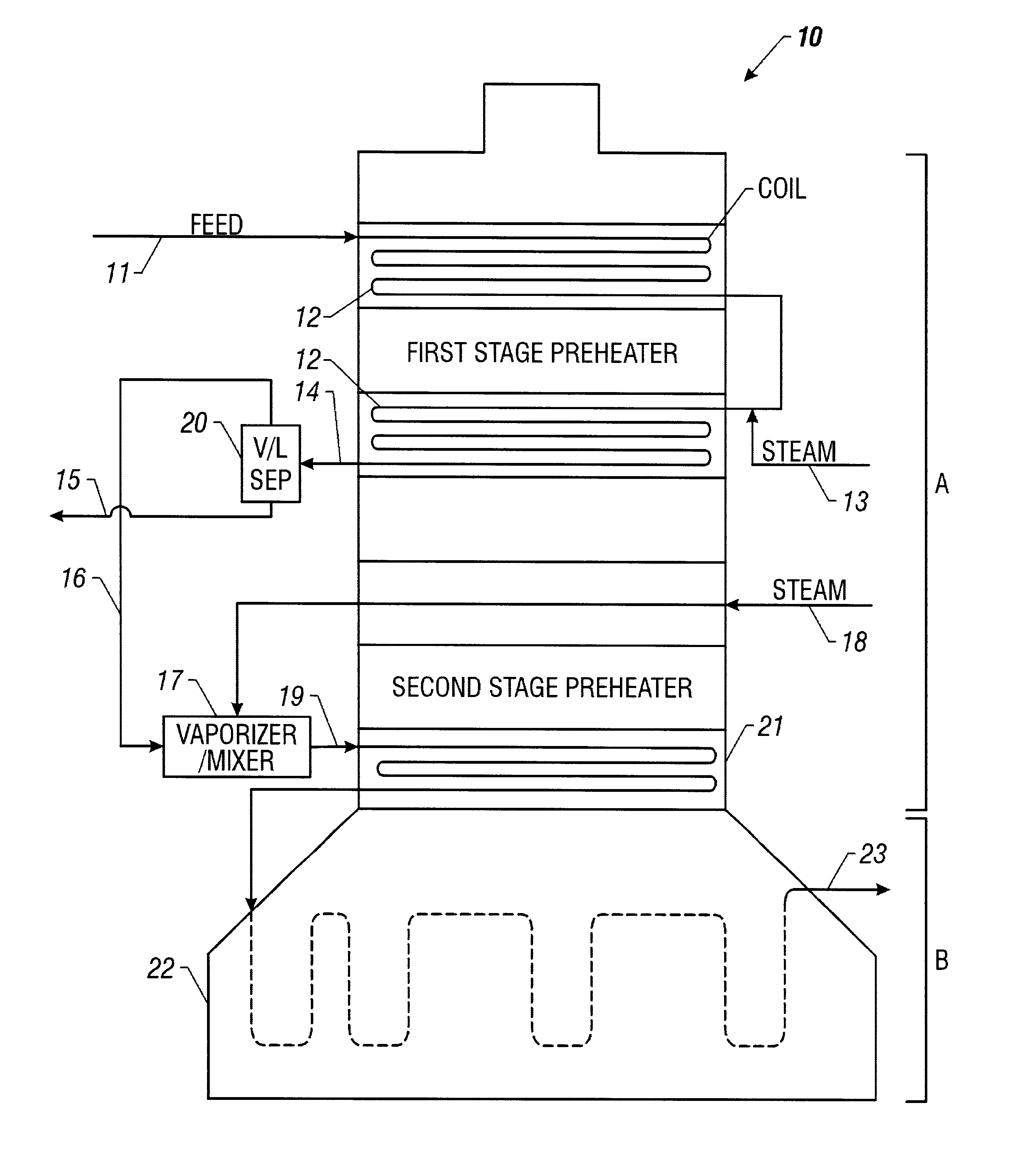

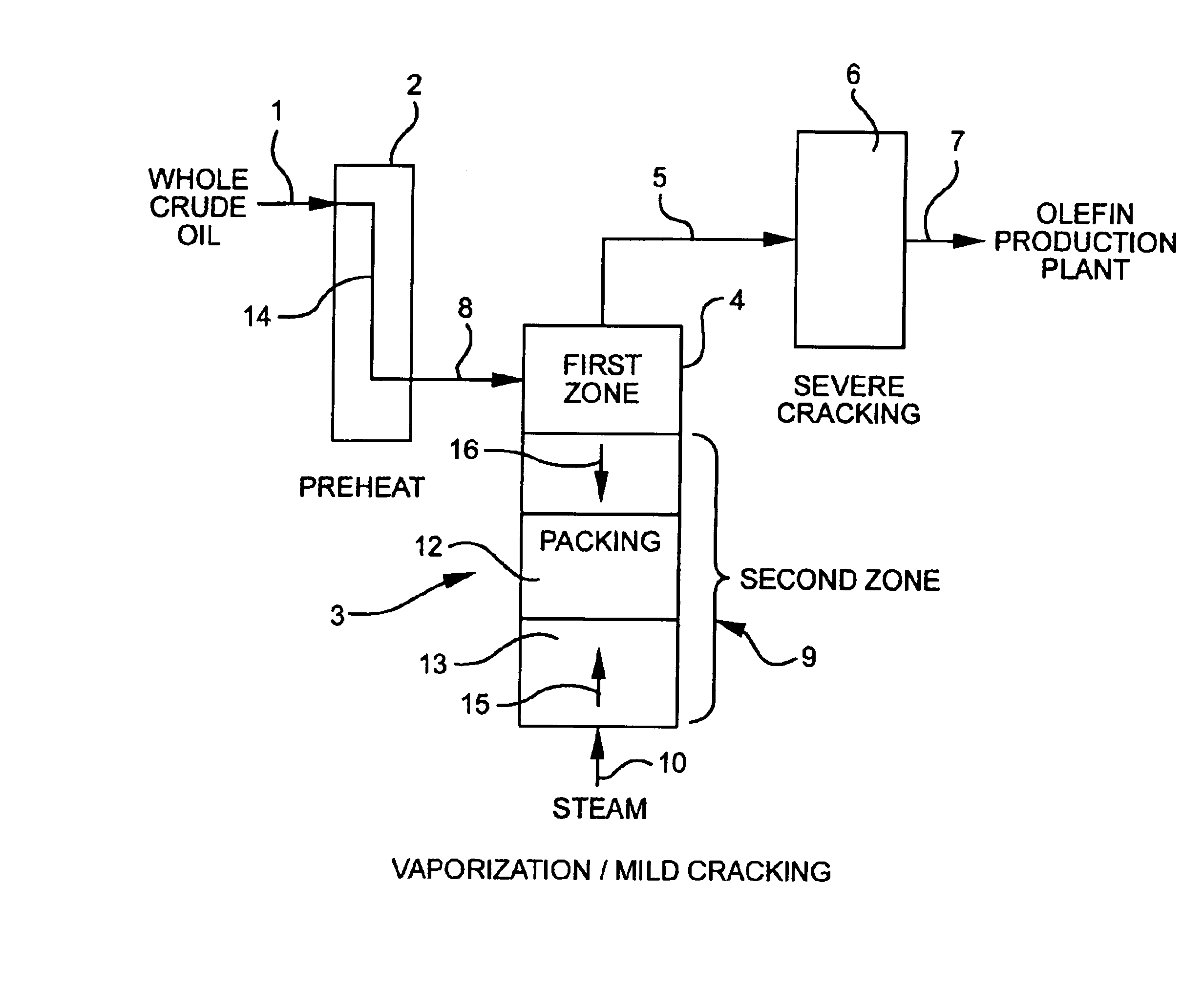

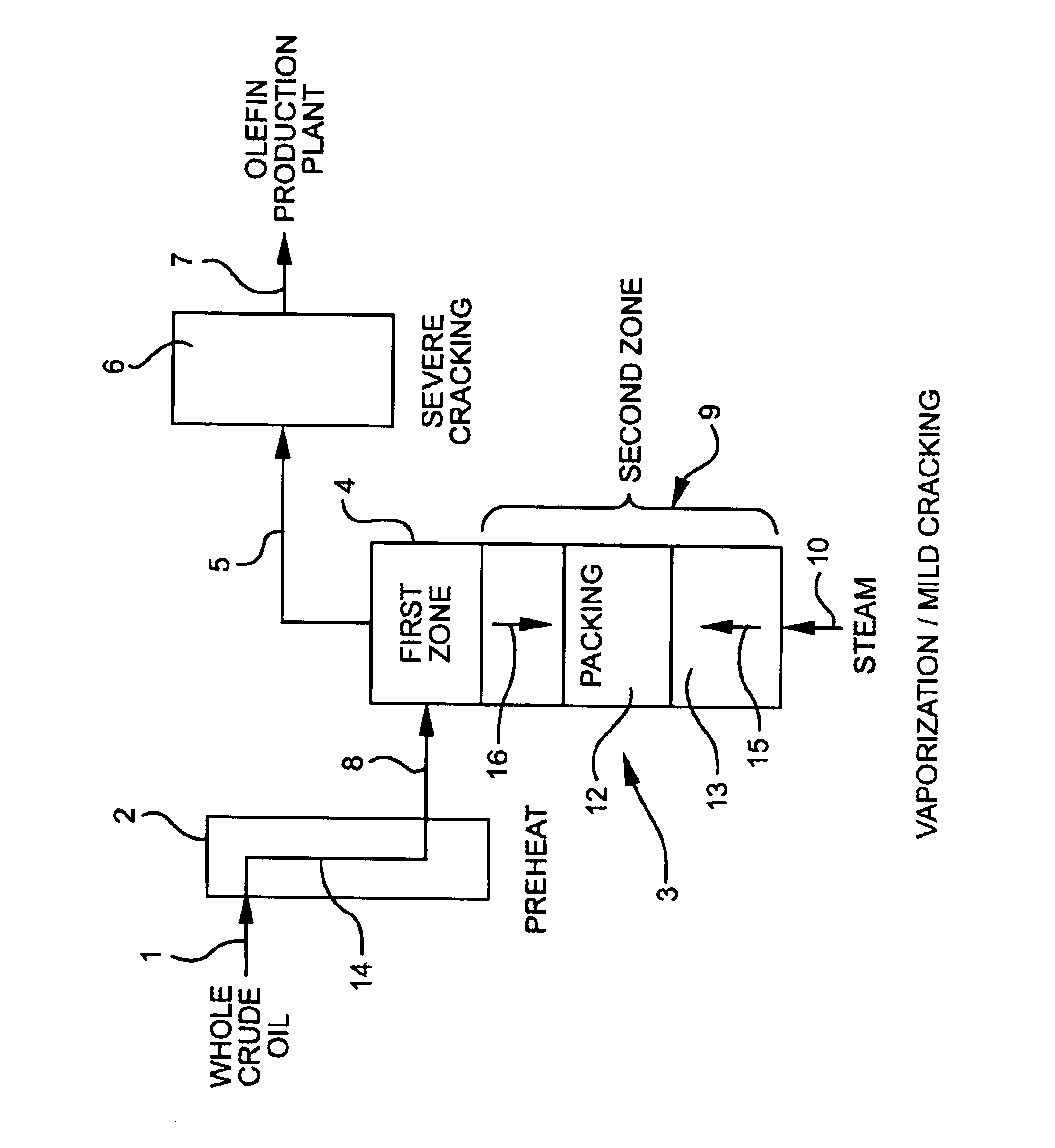

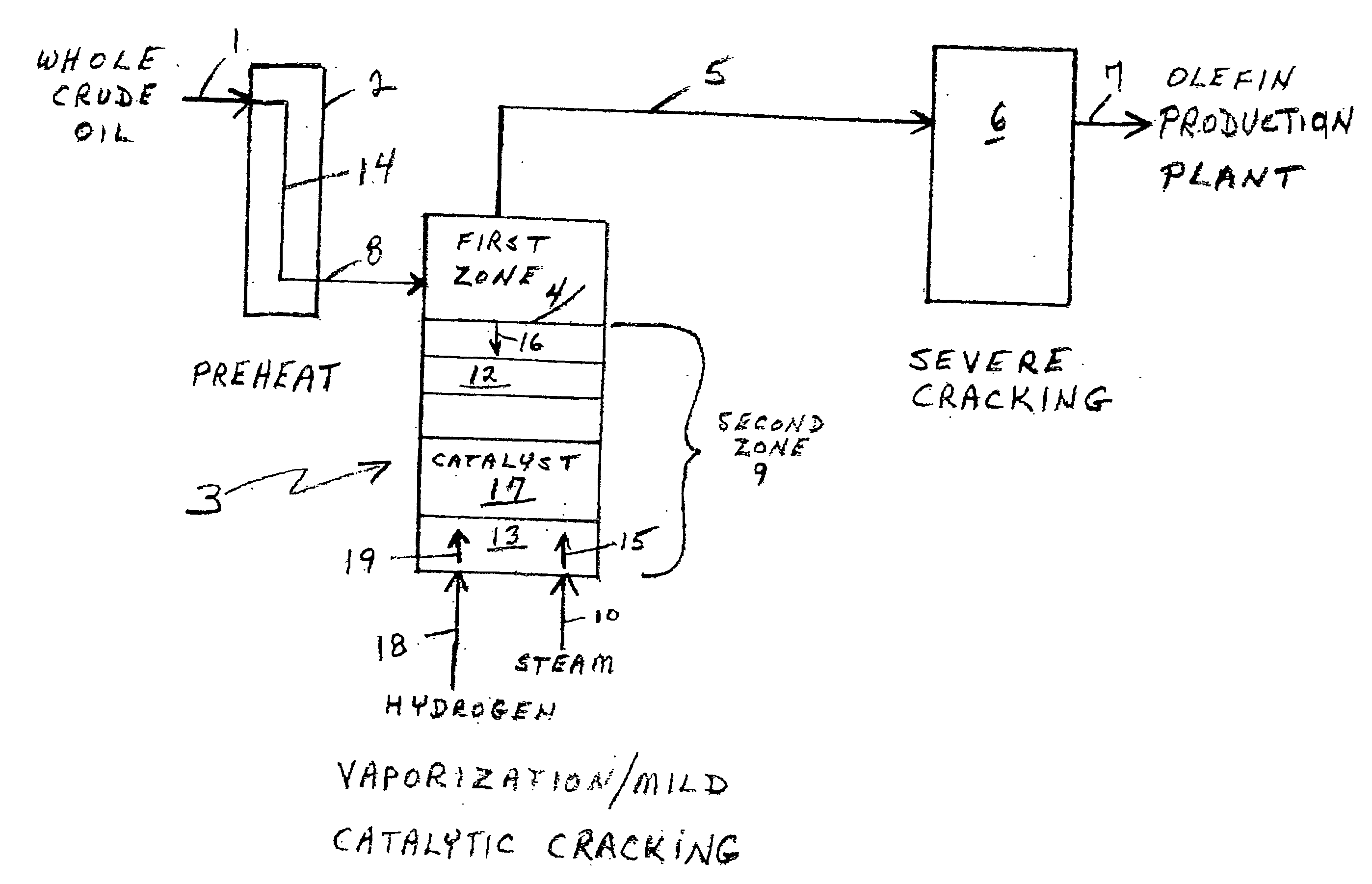

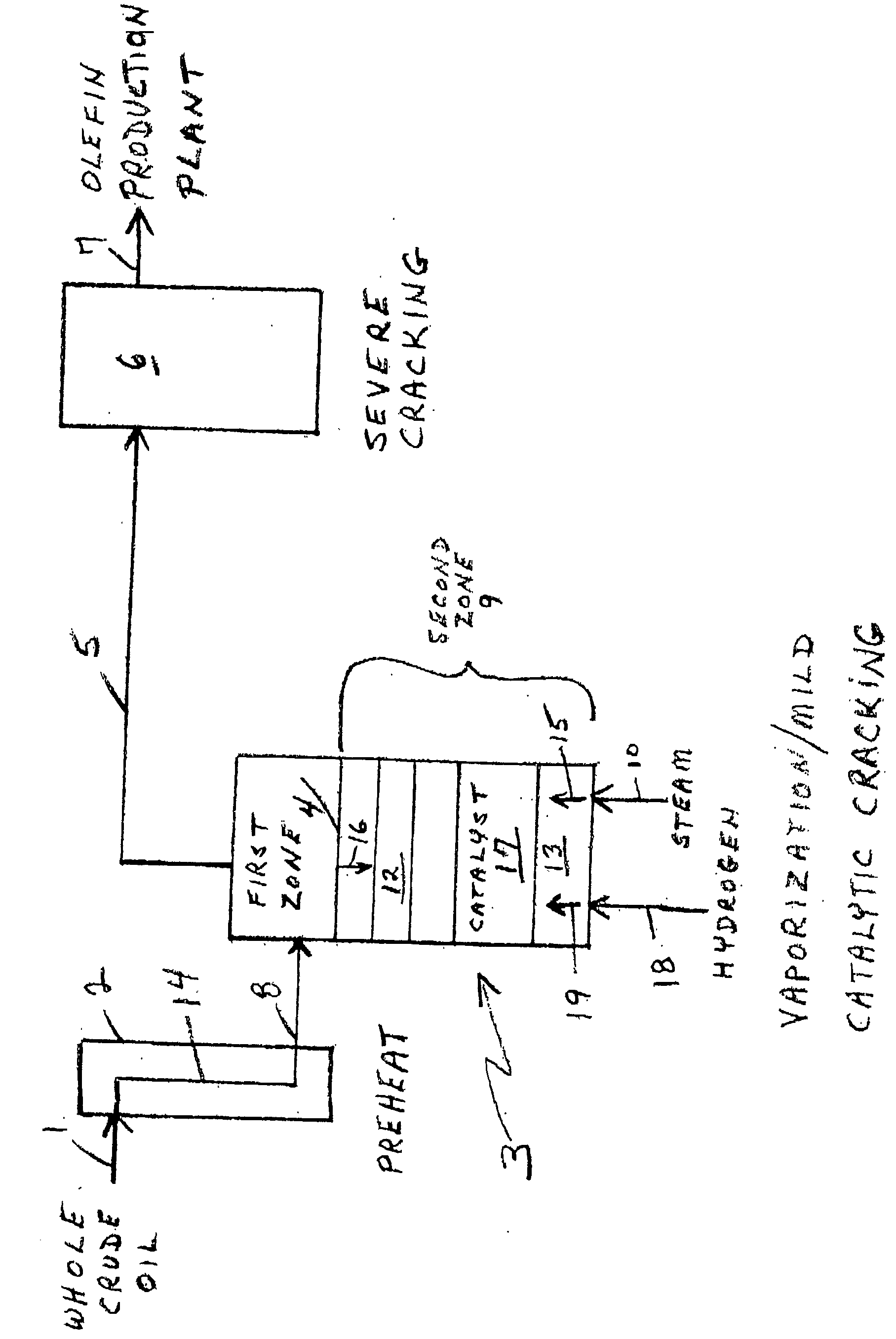

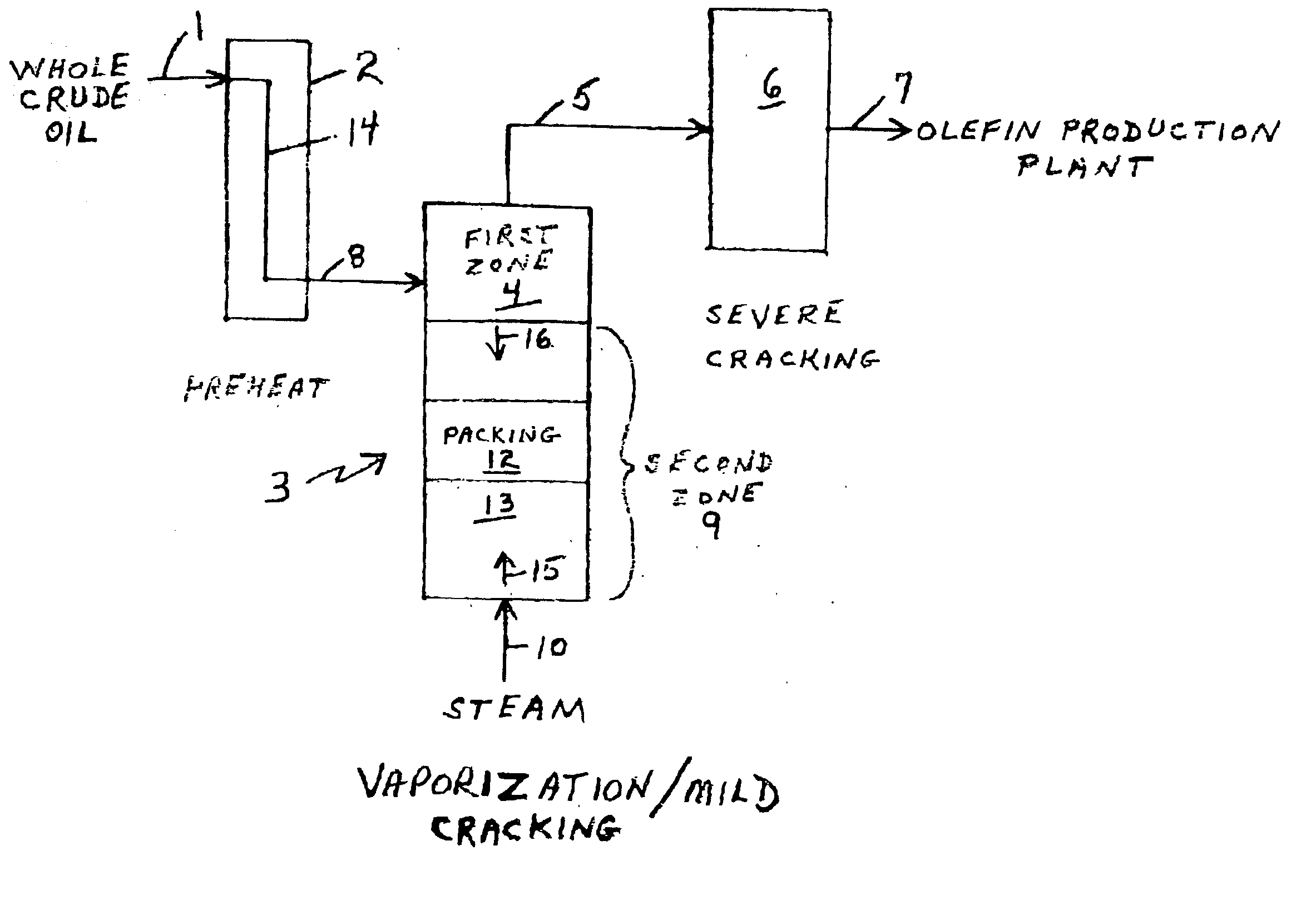

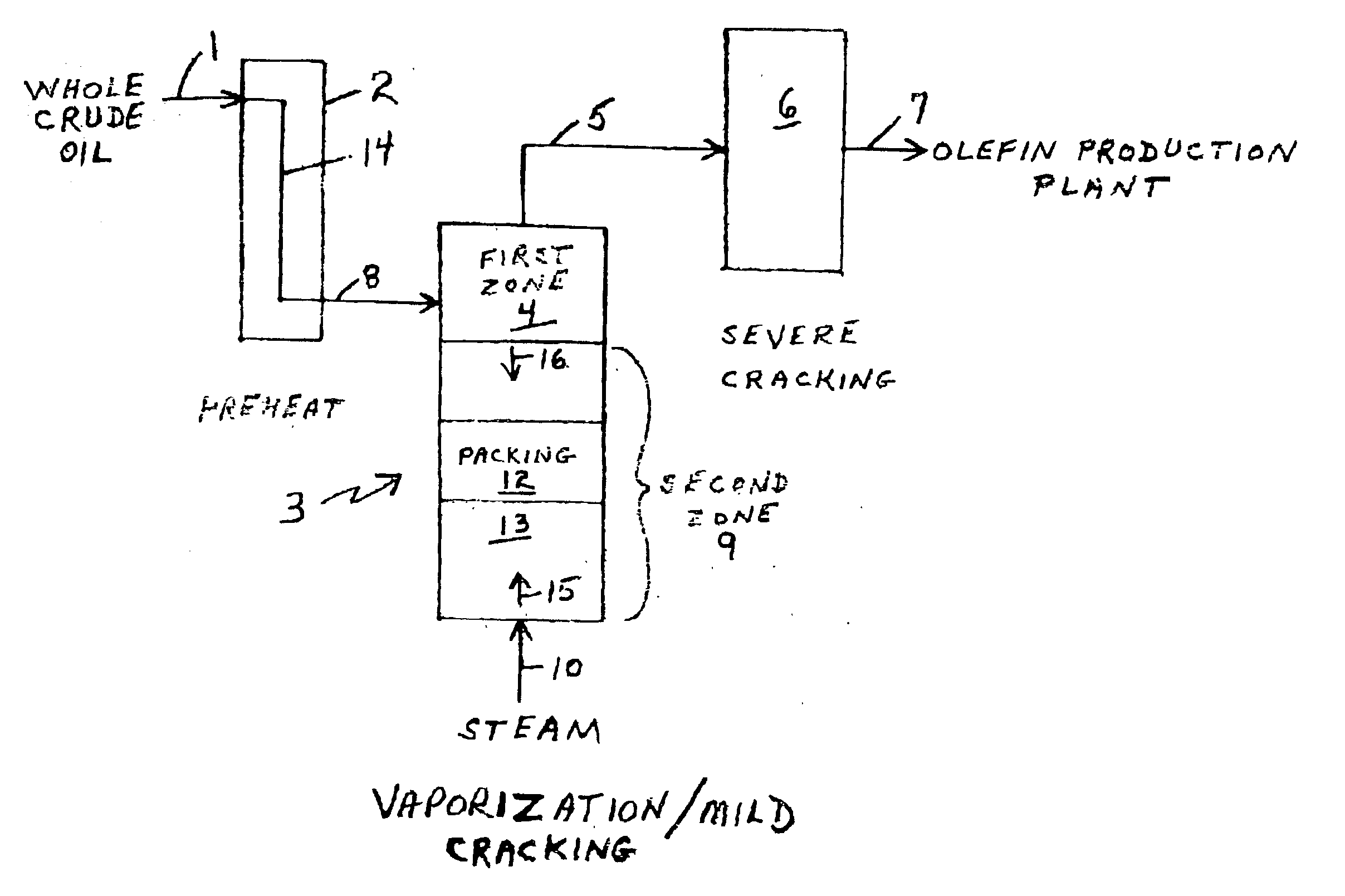

Olefin production utilizing whole crude oil

InactiveUS6743961B2Lower temperature rangeReduce molecular weightThermal non-catalytic crackingHydrocarbonsOil productionAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild cracking conditions until substantially vaporized, the vapors from mild cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

Method for producing a crude product with reduced tan

InactiveUS20070000810A1Catalytic crackingRefining with metal saltsOrganic chemistryContact condition

Contacting a crude feed with one or more catalysts to produce a total product that includes the crude product is described. The crude feed has a TAN of at least 1. At least one of the catalysts includes one or more metals from Columns 6-10 of the Periodic Table and / or one or more compounds of one or more metals from Columns 6-10 of the Periodic Table. Contacting conditions are controlled contacting such that the crude product has a TAN from about 0.001 to about 0.5.

Owner:SHELL OIL CO

Olefin production utilizing whole crude oil and mild catalytic cracking

InactiveUS20040054247A1Lower temperature rangeImproved vaporizationThermal non-catalytic crackingCatalytic crackingChemistryPyrolysis

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild catalytic cracking conditions until substantially vaporized, the vapors from the mild catalytic cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

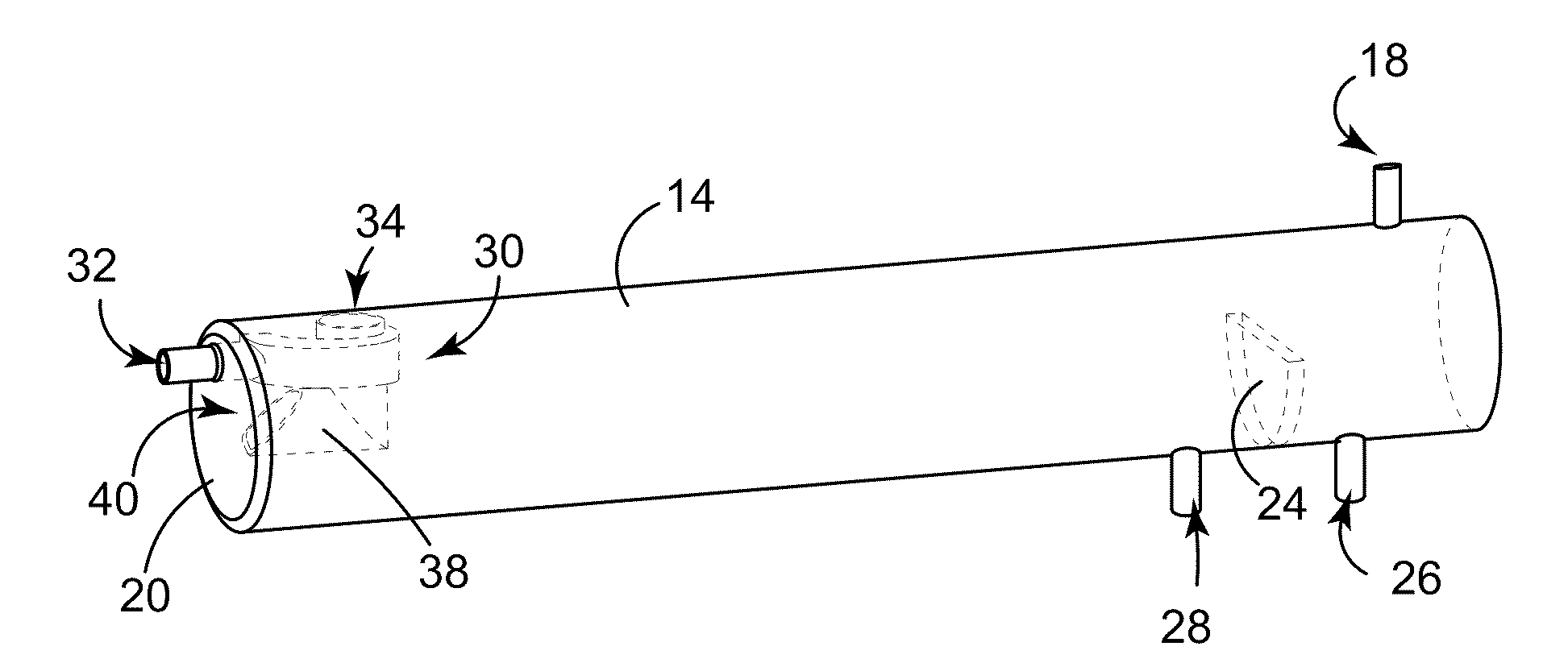

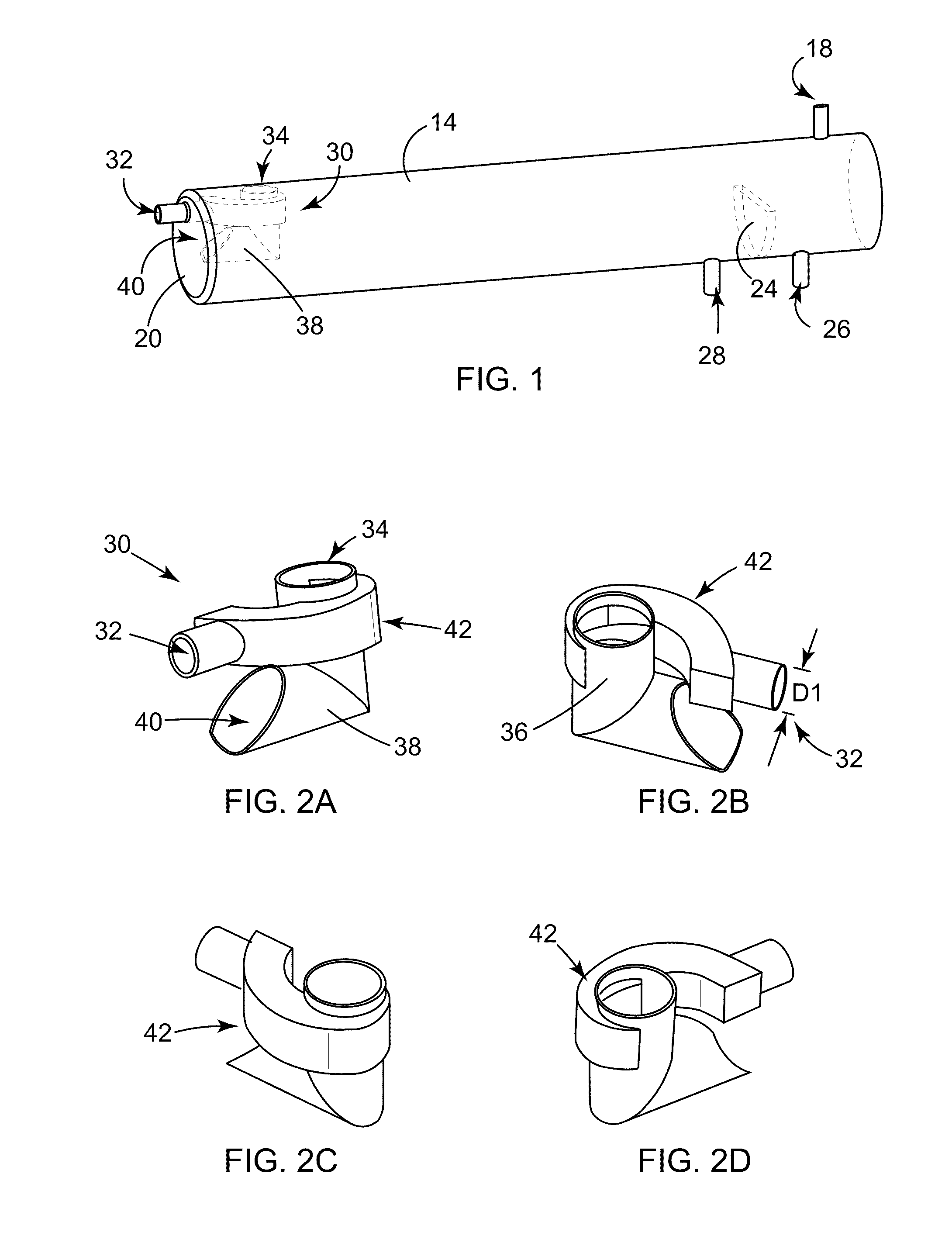

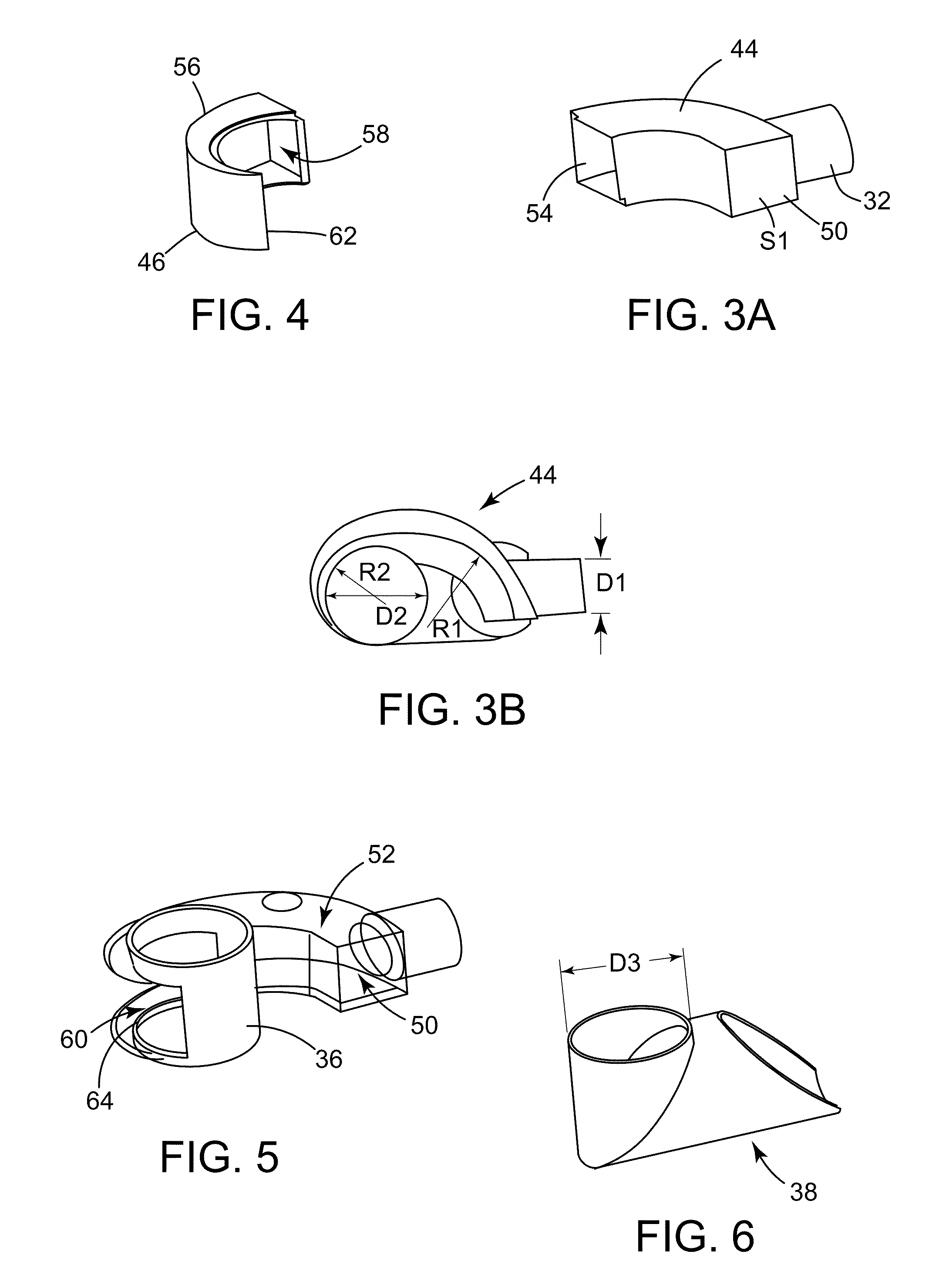

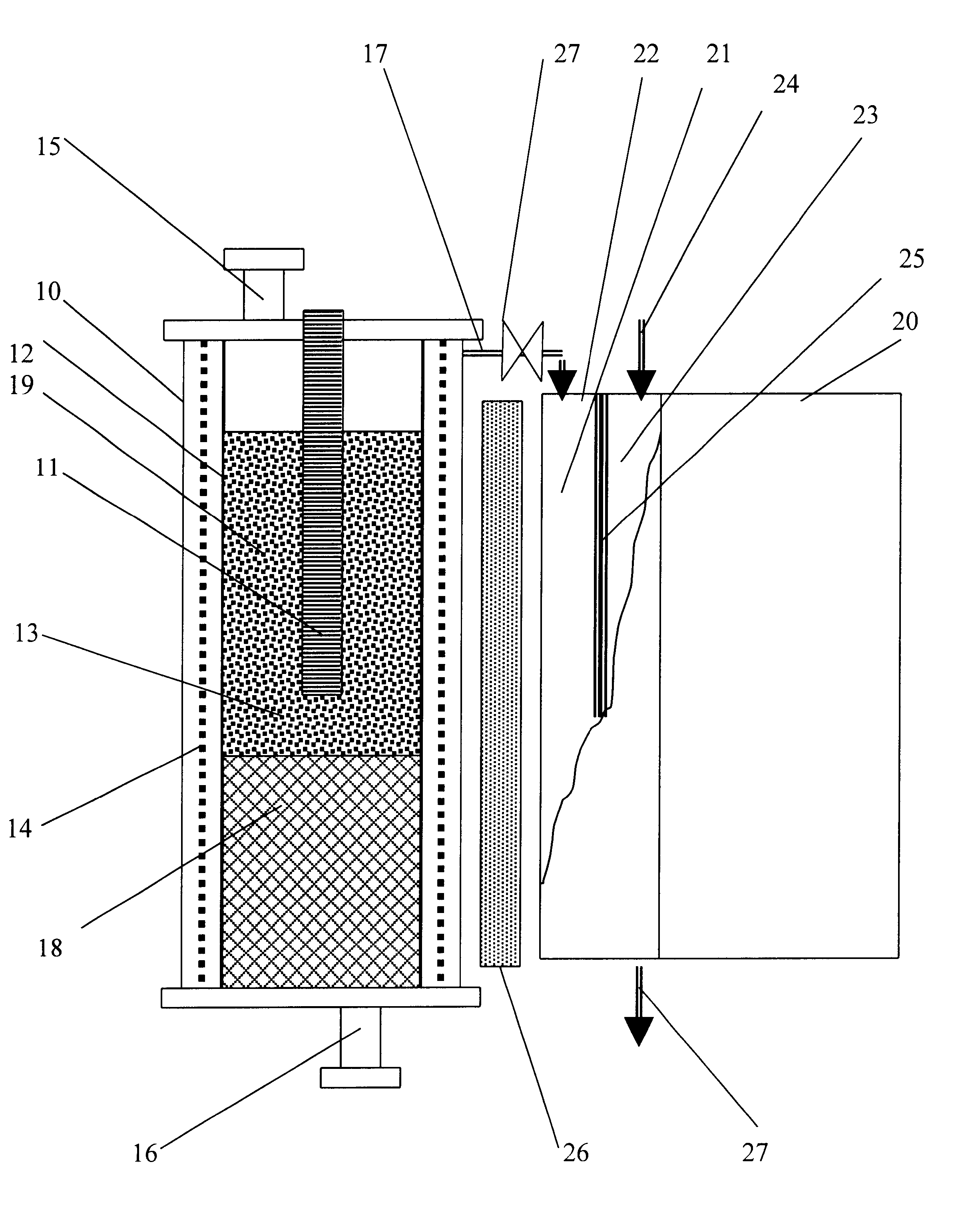

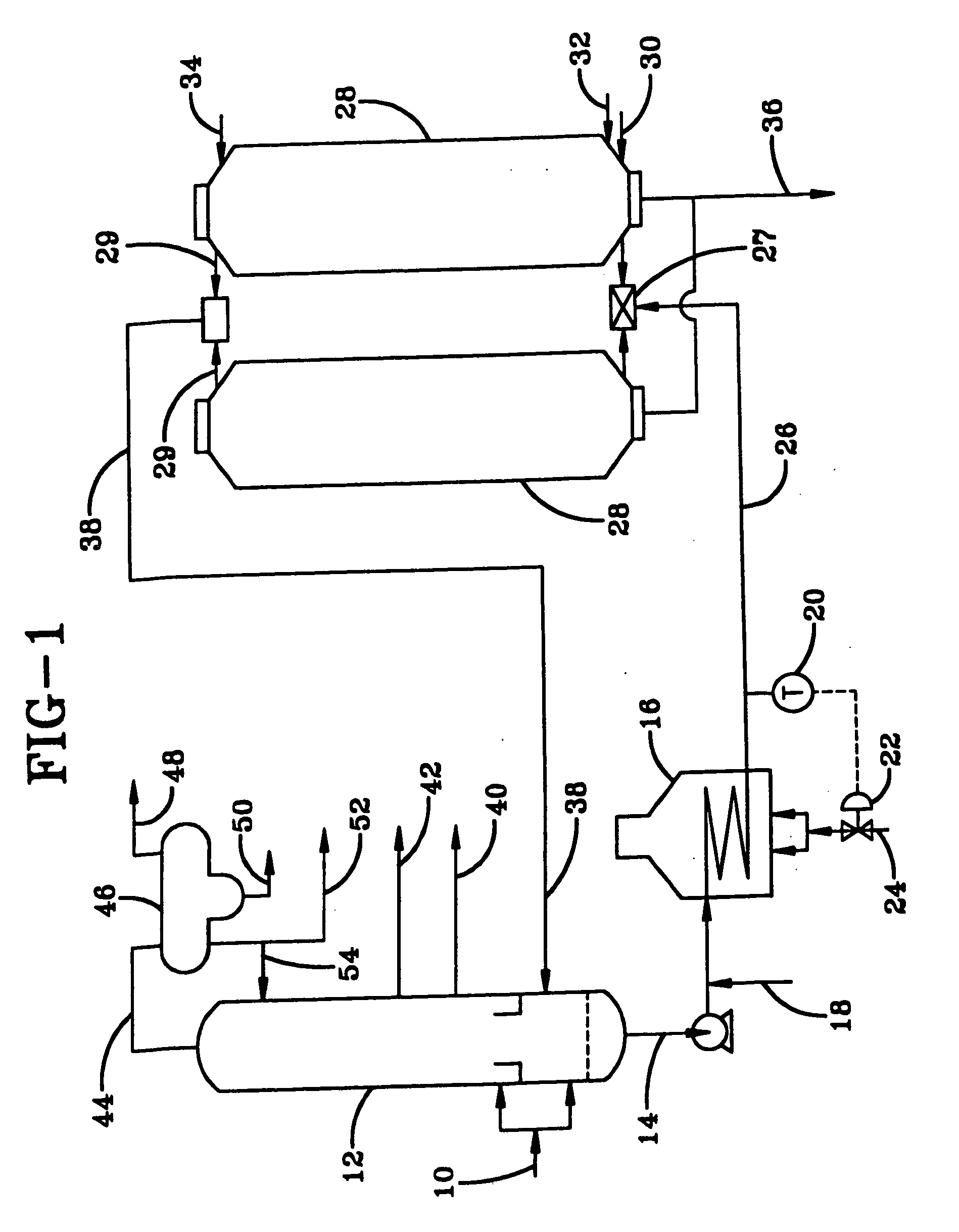

Apparatus for separation of gas-liquid mixtures and promoting coalescence of liquids

ActiveUS20110247500A1Reduce momentumPromote droplet coalescenceLiquid degasificationReversed direction vortexChemical physicsOil separation

Provided herein is a conditioning apparatus that includes a geometrical configuration having an inlet flow deceleration conduit and a cyclonic tube to effectuate both liquid-gas separation and droplet coalescence. The apparatus is typically positioned at the inlet of a separator vessel used for removing water and gas from extracted crude oil containing entrained water and gas. The apparatus promotes droplet coalescence and gas separation for mixed fluids flowing into an existing water and oil separation device.

Owner:SAUDI ARABIAN OIL CO

Systems, methods, and catalysts for producing a crude product

InactiveUS20060231465A1Reduce contentRefining with metalsOrganic-compounds/hydrides/coordination-complexes catalystsChemistryCrude oil

Owner:SHELL OIL CO

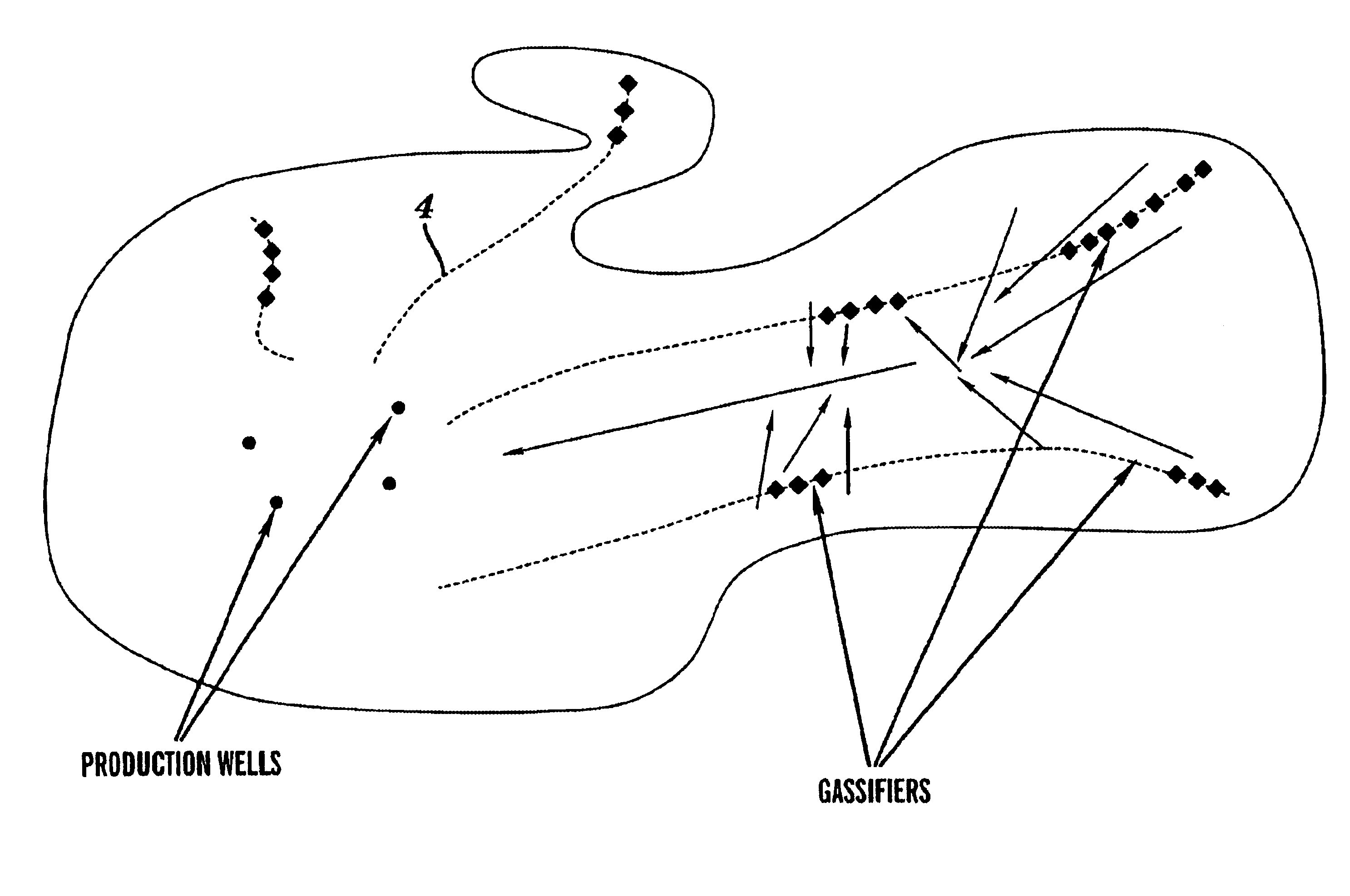

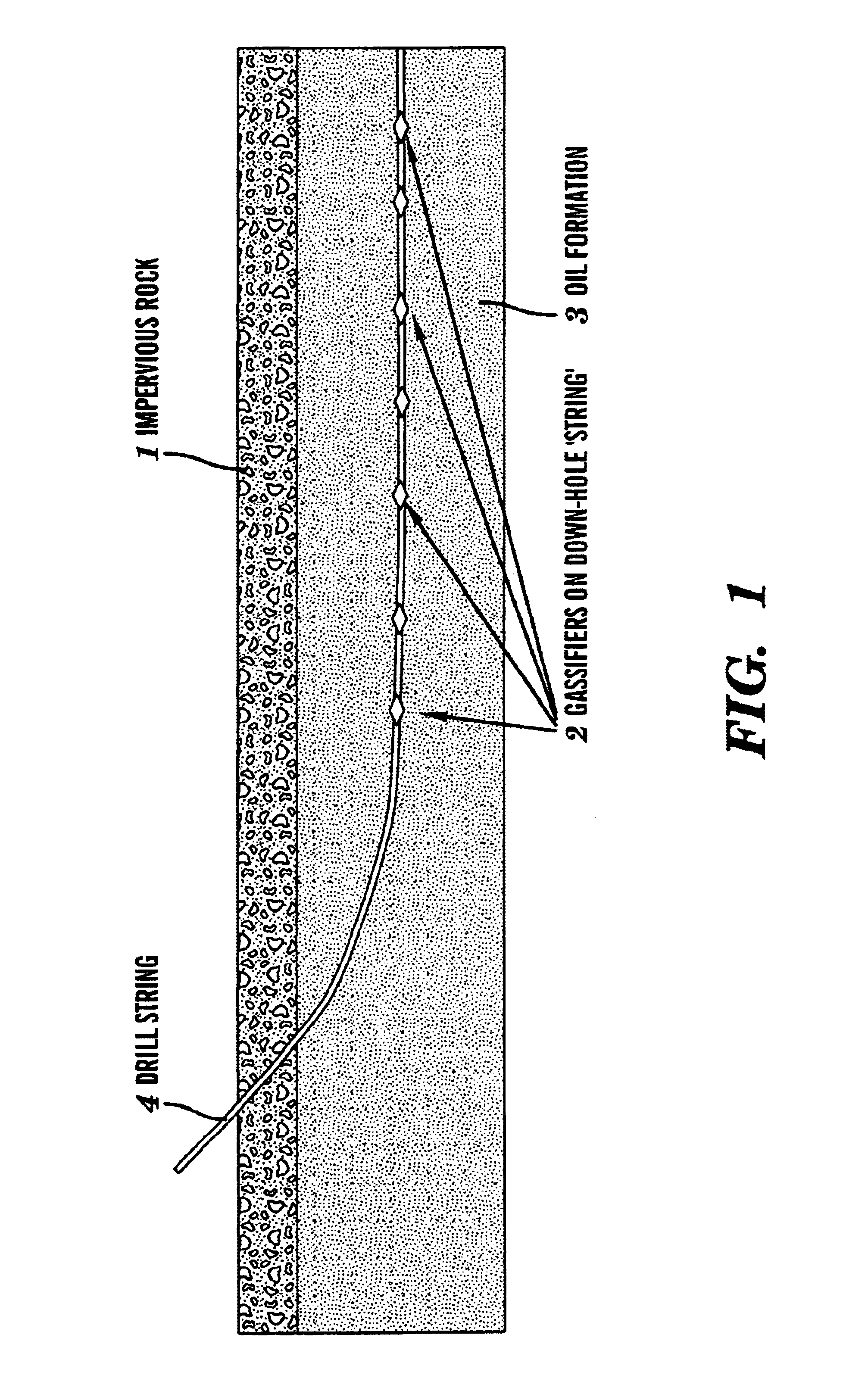

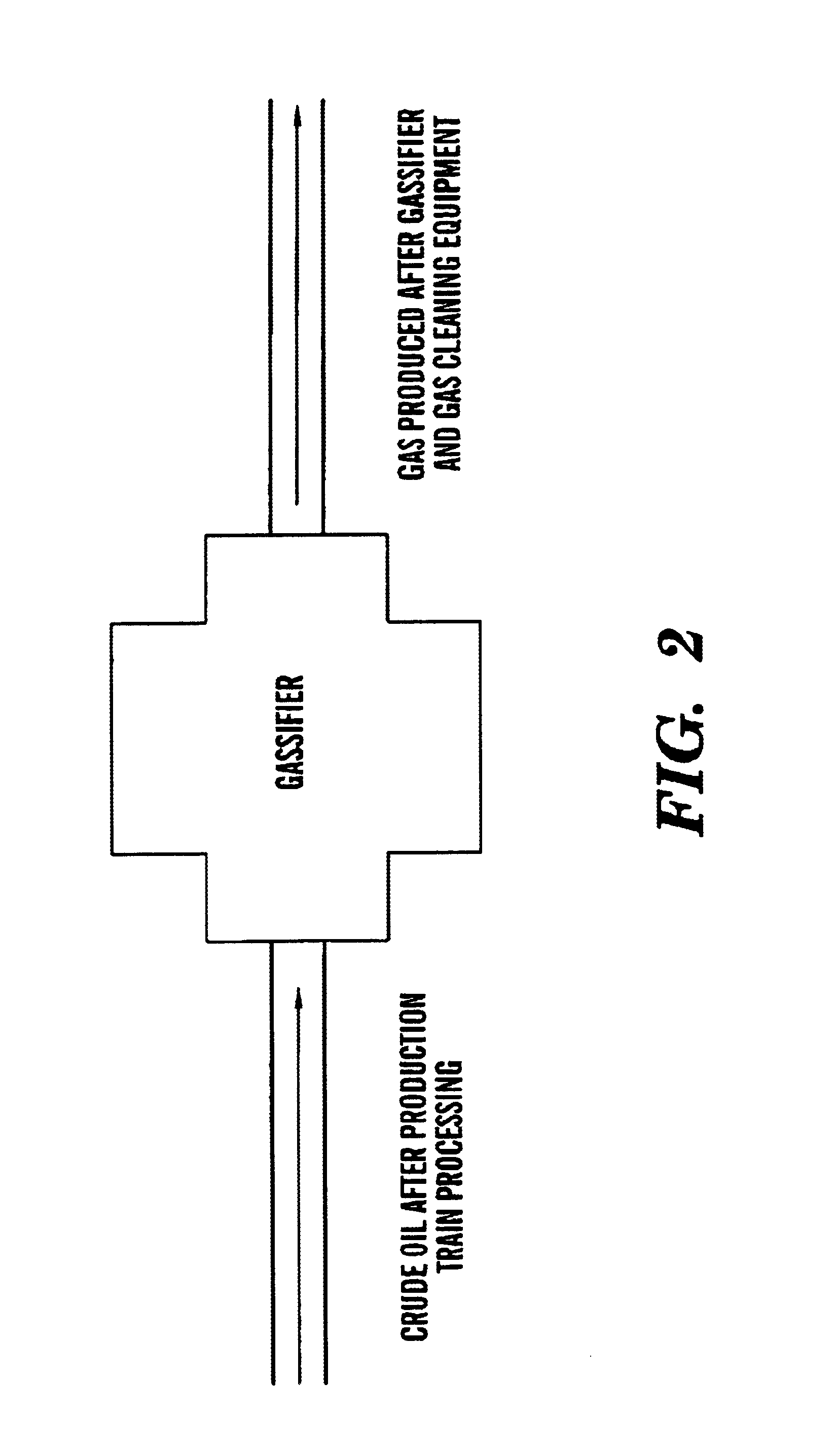

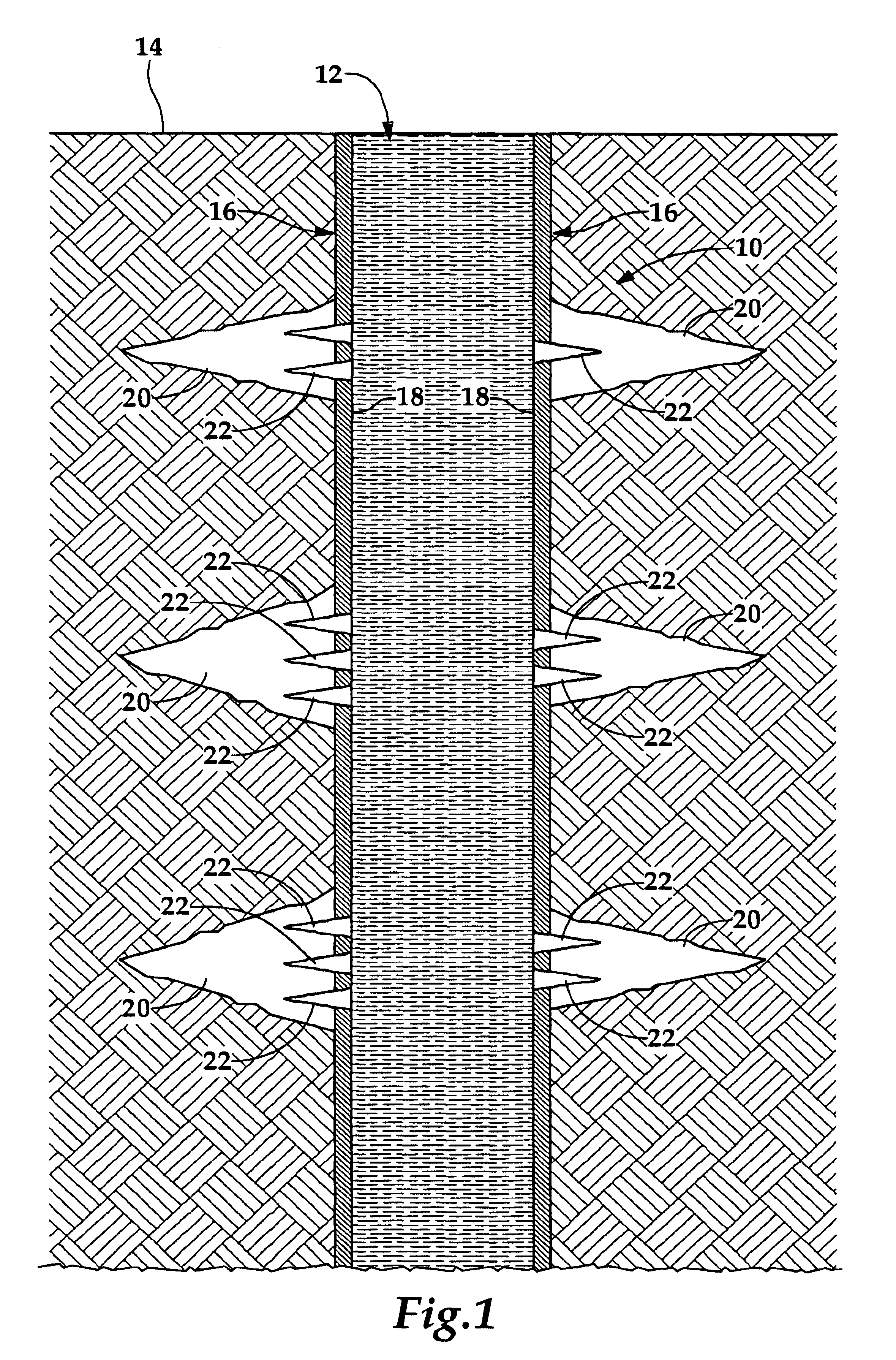

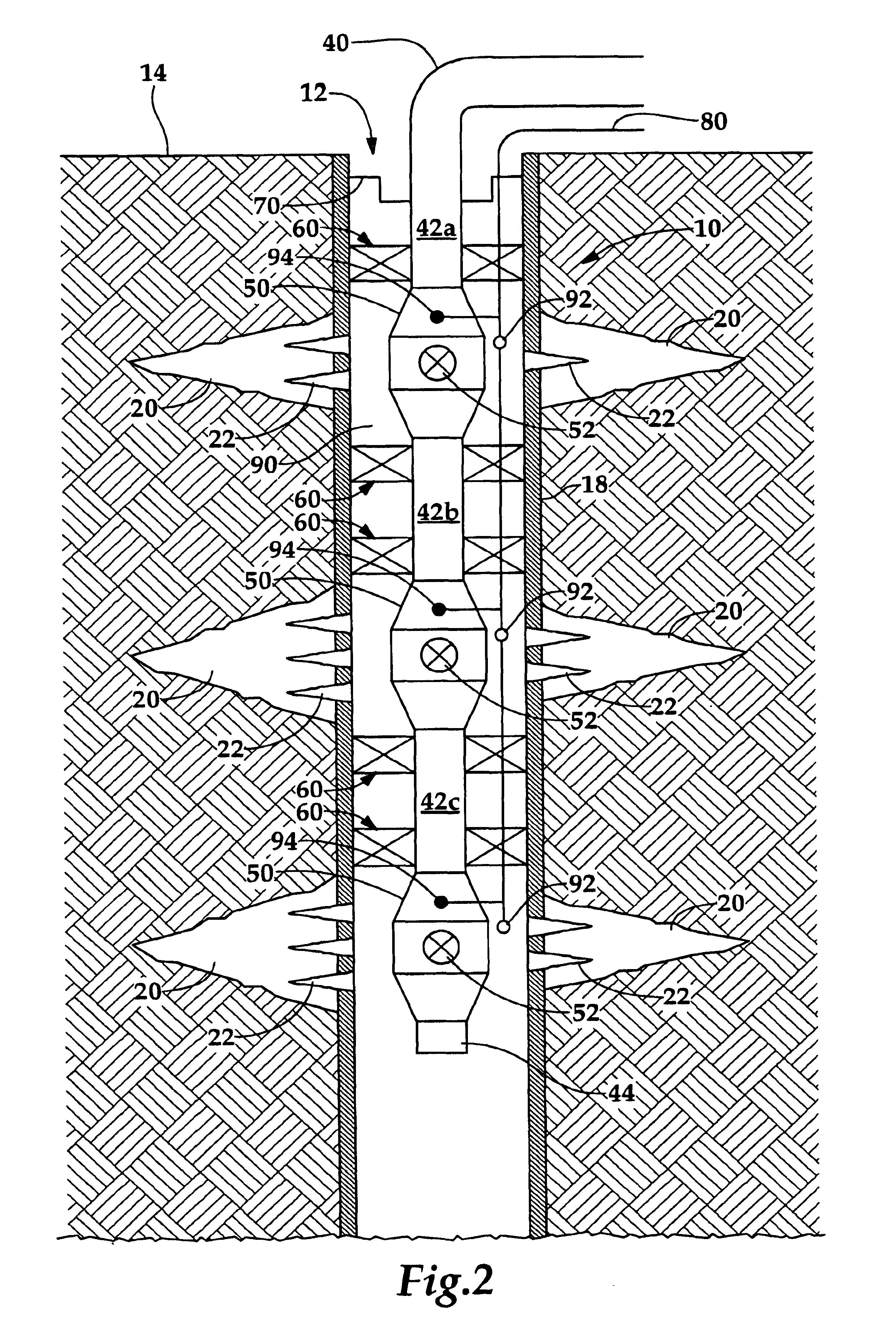

Gas and oil production

A process for in situ gasification of mineral oil in a subterranean formation comprises running a tool having a controllable thermal device therein from a surface production facility down to the subterranean formation, bringing said tool into operational proximity with the mineral oil in said subterranean formation, and activating the tool to operate the thermal device within a predetermined temperature range to generate gases or oily vapours from said mineral oil, which permits either an enhanced oil recovery (EOR) method with reduced water contamination, or a gas production process (GPP) which is useful in reducing environmental risks normally associated with transport of crude oil.

Owner:SCOTOIL SERVICES

Systems, methods, and catalysts for producing a crude product

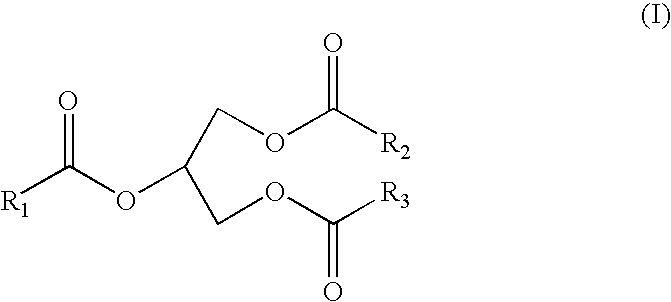

InactiveUS20050133414A1Reduce contentCatalytic crackingRefining with metal saltsOxygen contentChemistry

Contact of a crude feed with one or more catalysts produces a total product that includes a crude product. The crude feed may include Micro-Carbon Residue (MCR), oxygen, sulfur, or mixtures thereof. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The crude product may have a MCR residue and / or oxygen content of at most 90% of the MCR residue content and / or oxygen content of the crude feed. In some instances, the crude product may have a sulfur content of about 30% to about 70% of the sulfur content of the crude feed. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

Systems, methods, and catalysts for producing a crude product

InactiveUS20050133417A1Reduce contentCatalytic crackingRefining with metal saltsAcid valueTotal acid

Contact of a crude feed with one or more catalysts produces a total product that include a crude product. The crude feed may a total acid number of at least 0.3. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The crude product may have a total acid number of at most 90% of the total acid number of the crude feed. At least one of the catalysts may include one or more Column 6 metals of the Periodic Table and one or more Column 10 metals of the Periodic Table. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

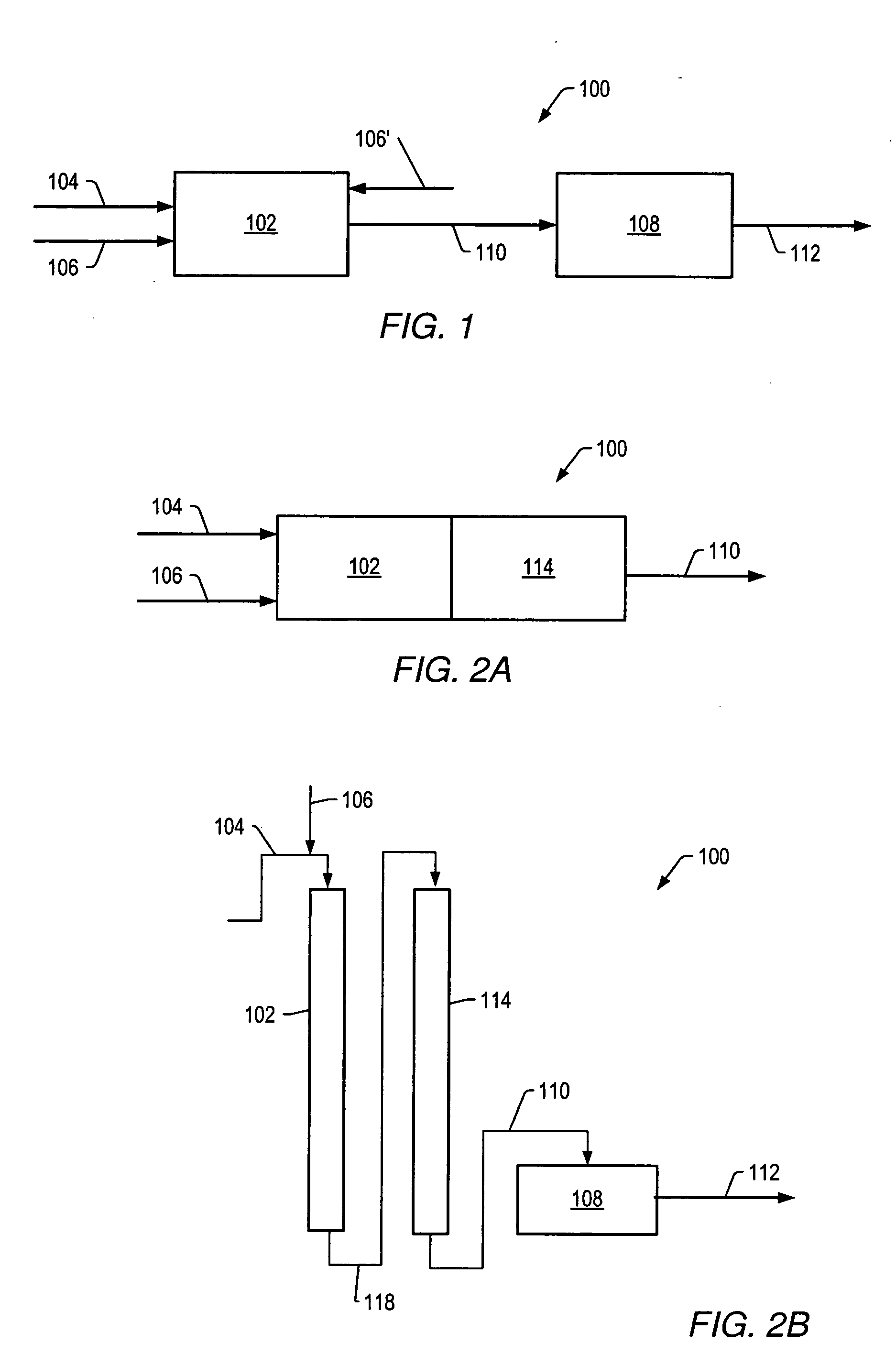

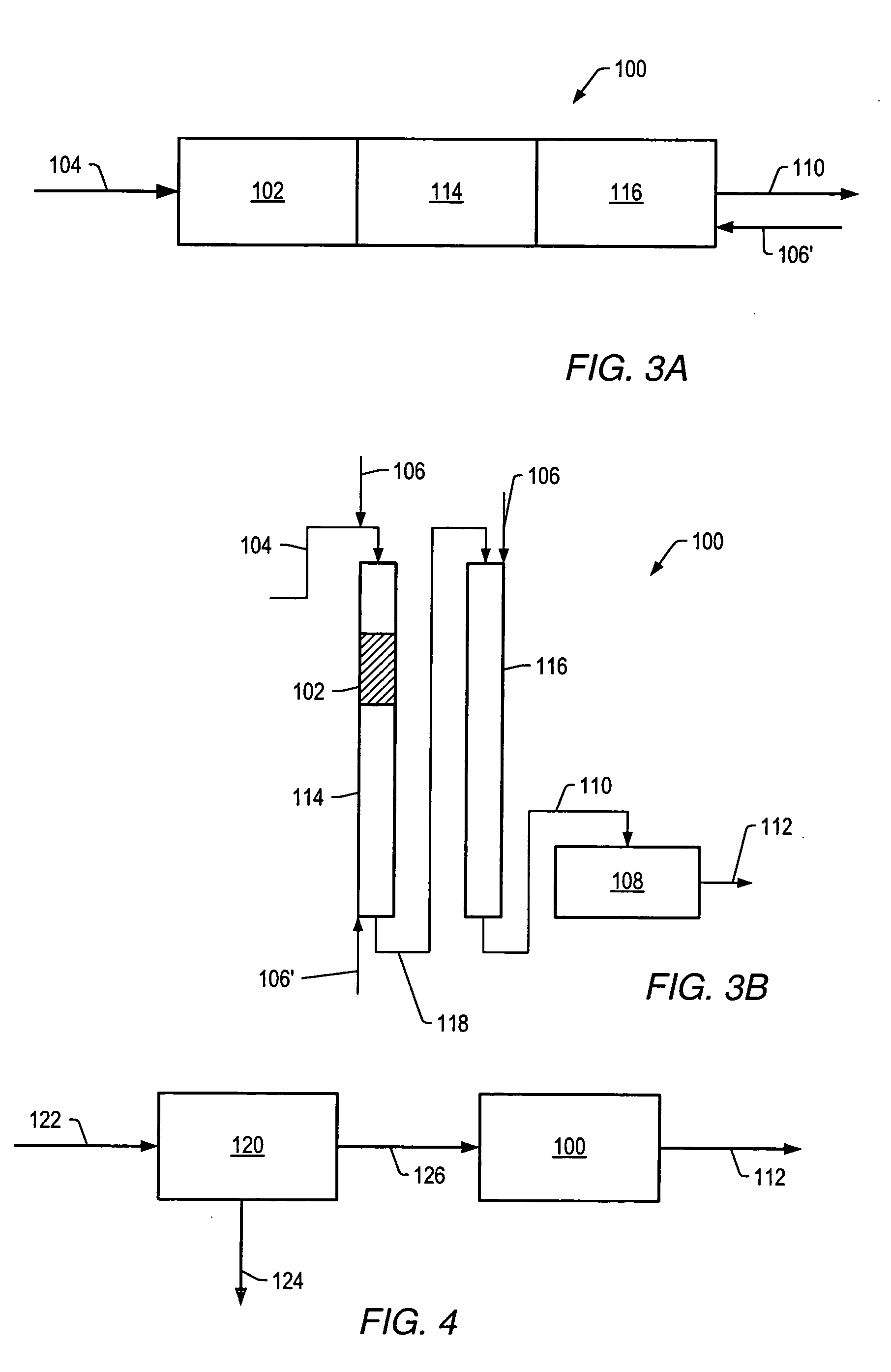

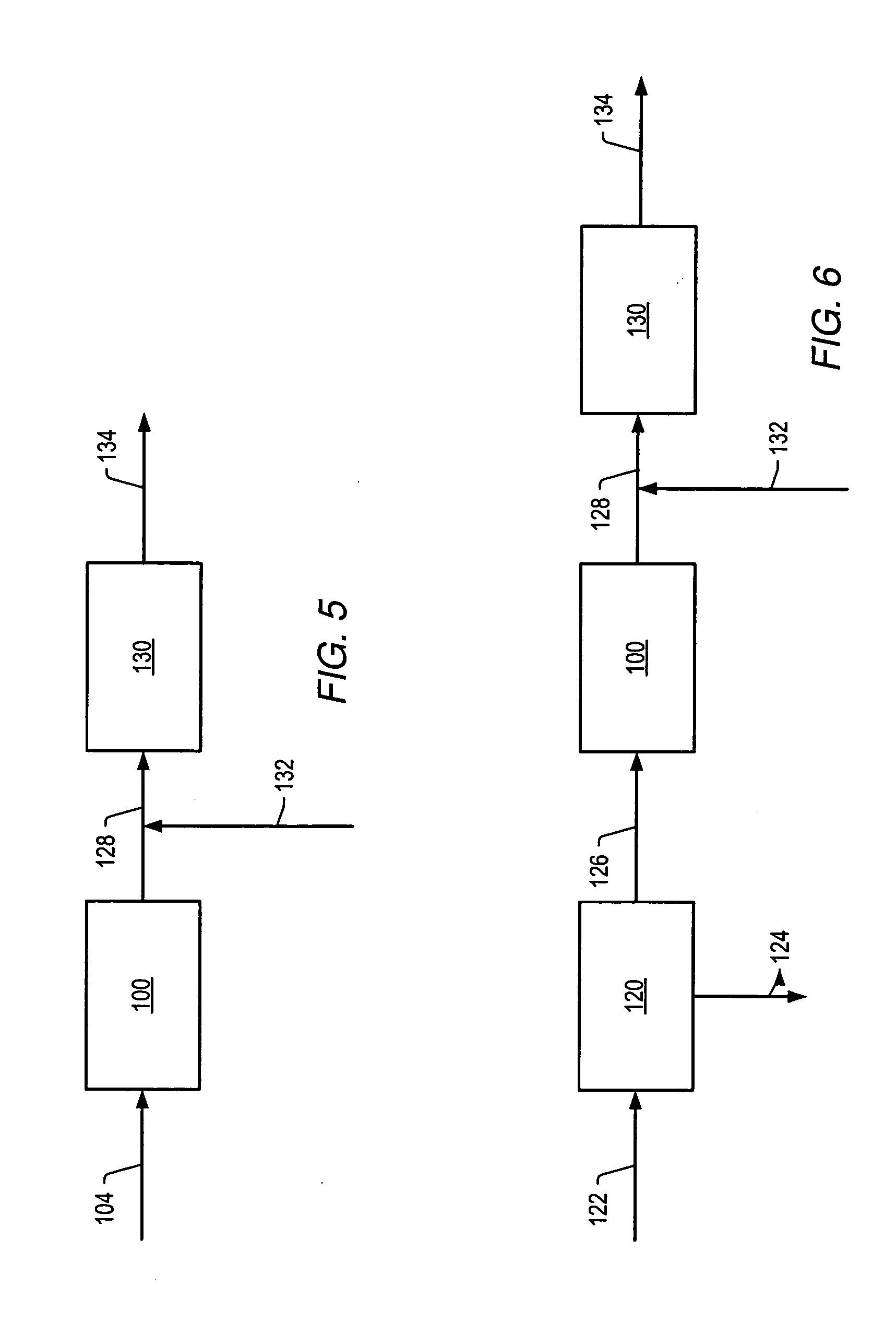

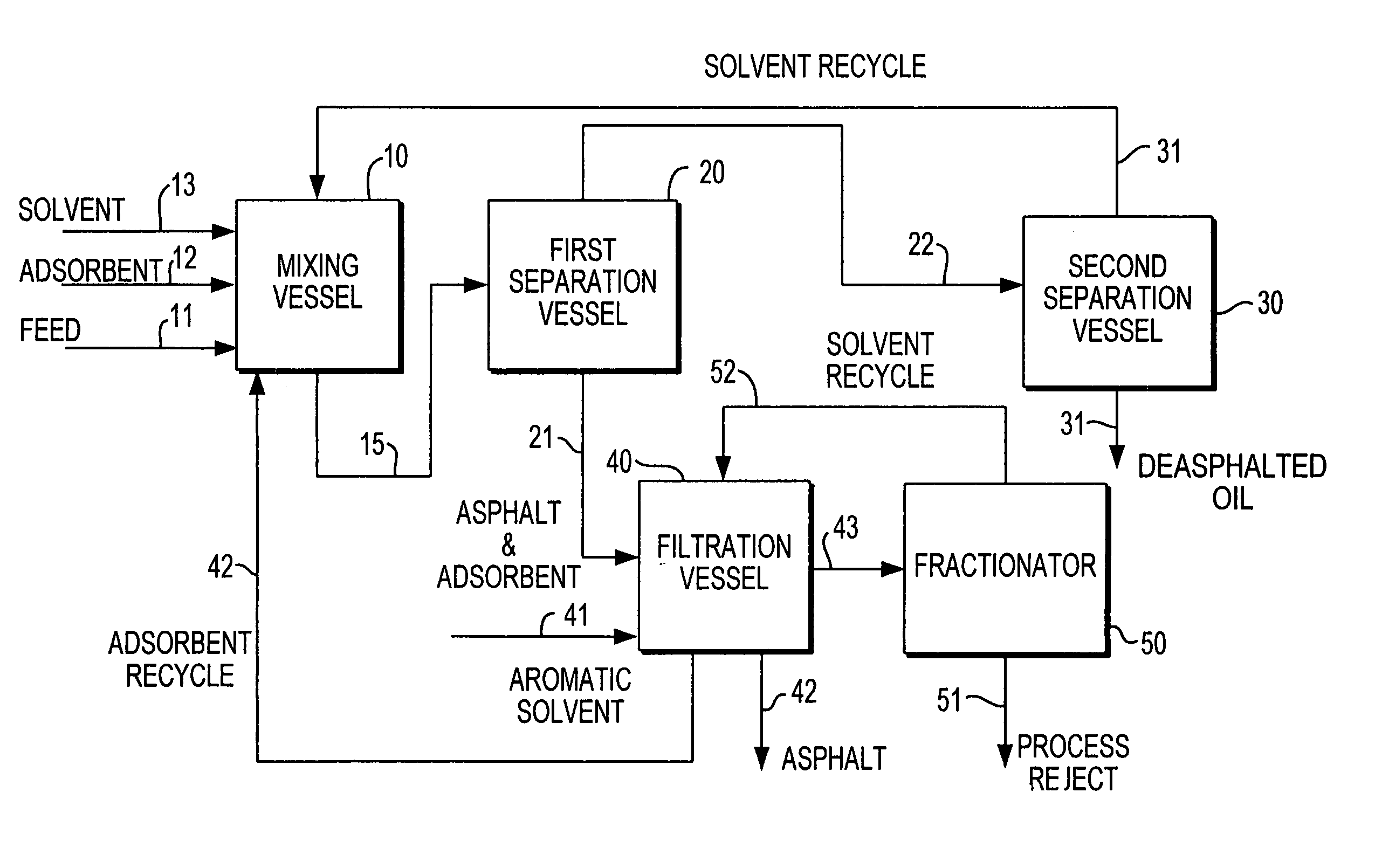

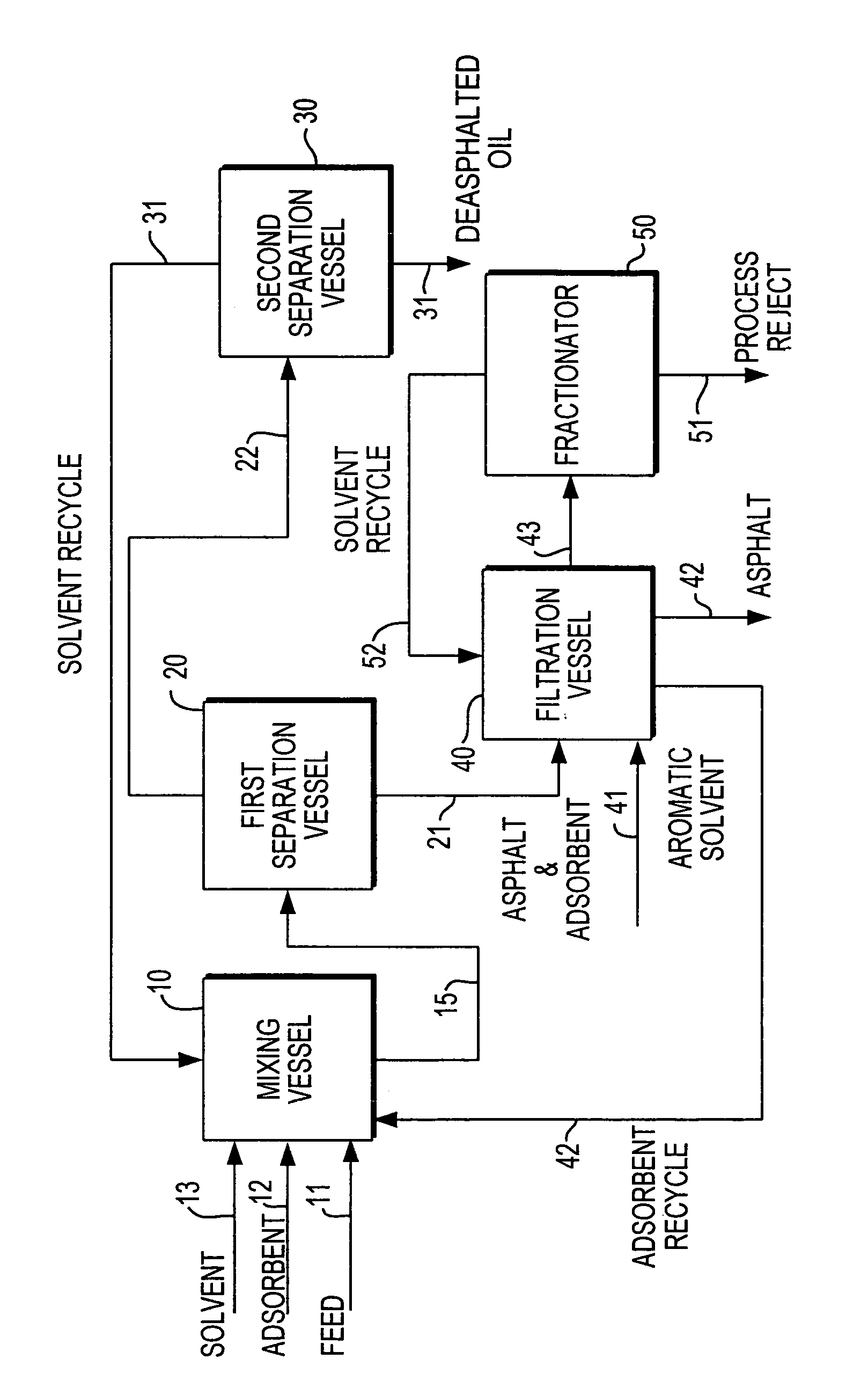

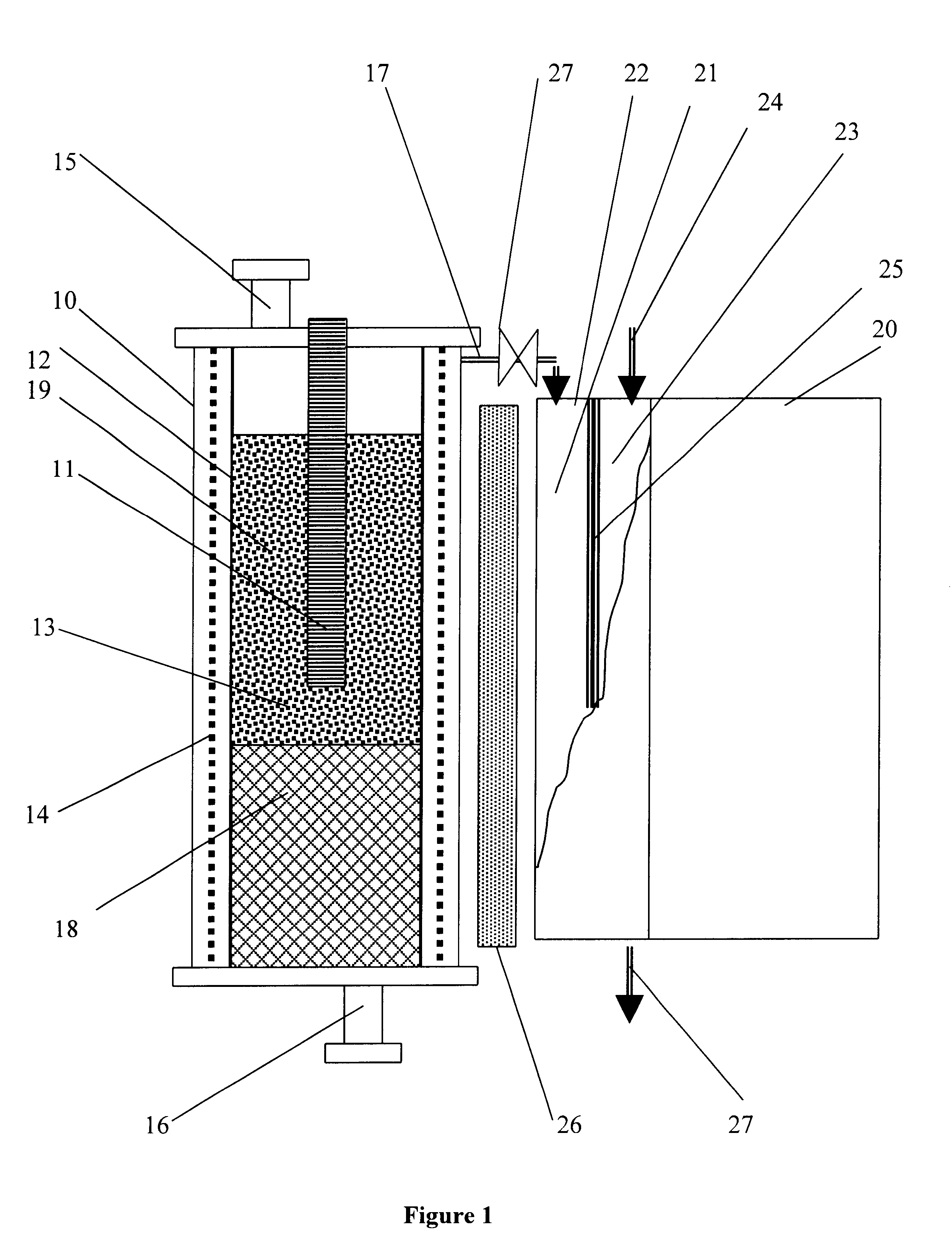

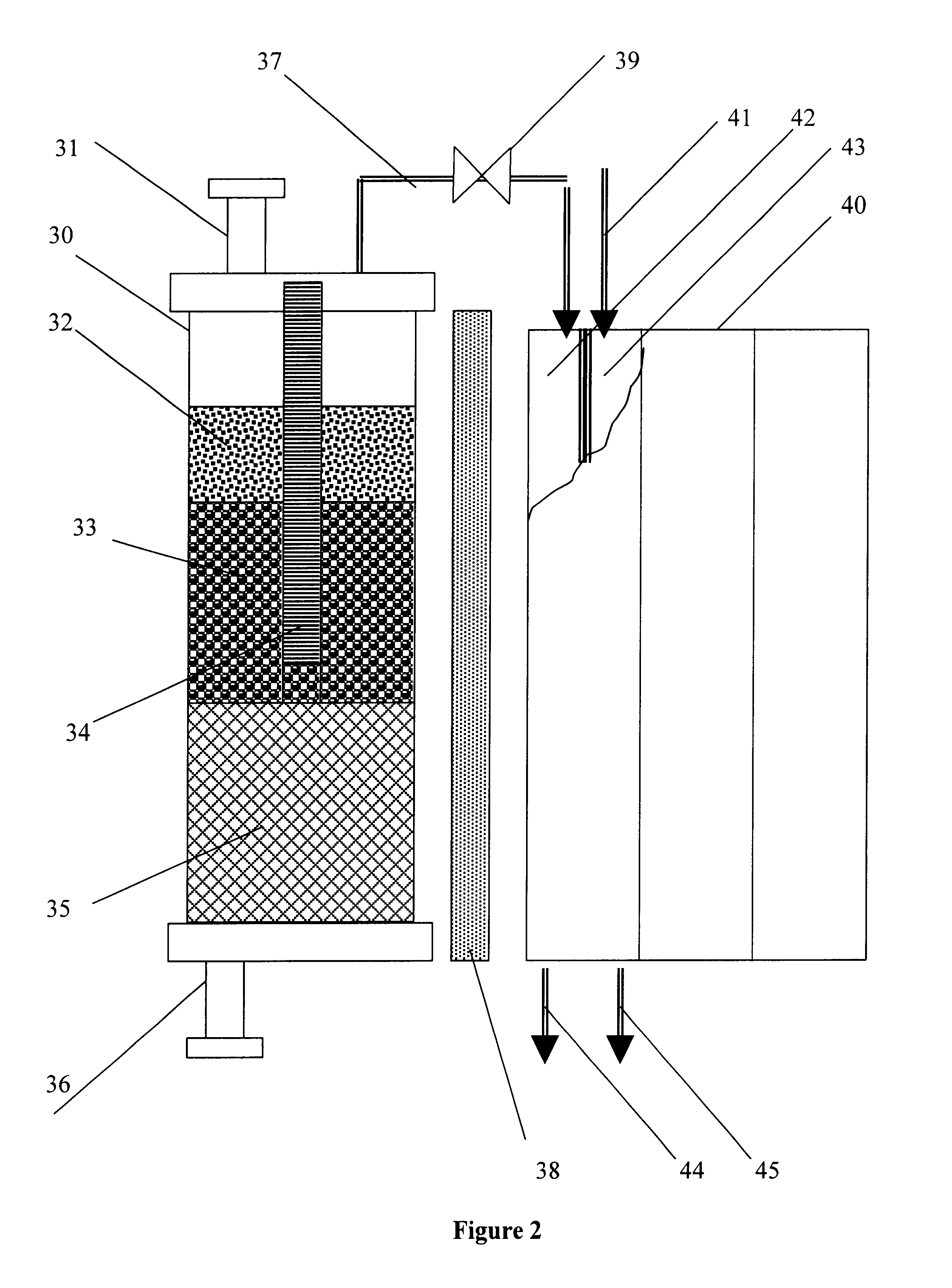

Enhanced solvent deasphalting process for heavy hydrocarbon feedstocks utilizing solid adsorbent

ActiveUS7566394B2Improve performanceImprove current efficiencyWorking-up pitch/asphalt/bitumen by selective extractionHydrocarbon distillationBenzeneActivated carbon

A solvent deasphalting of crude oil or petroleum heavy fractions and residues is carried out in the presence of a solid adsorbent, such as clay, silica, alumina and activated carbon, which adsorbs the contaminants and permits the solvent and oil fraction to be removed as a separate stream from which the solvent is recovered for recycling; the adsorbent with contaminants and the asphalt bottoms is mixed with aromatic and / or polar solvents to desorb the contaminants and washed as necessary, e.g., with benzene, toluene, xylenes and tetrahydrofuran, to clean adsorbant which is recovered and recycled; the solvent-asphalt mixture is sent to a fractionator for recovery and recycling of the aromatic or polar solvent. The bottoms from the fractionator include the concentrated PNA and contaminants and are further processes as appropriate.

Owner:SAUDI ARABIAN OIL CO

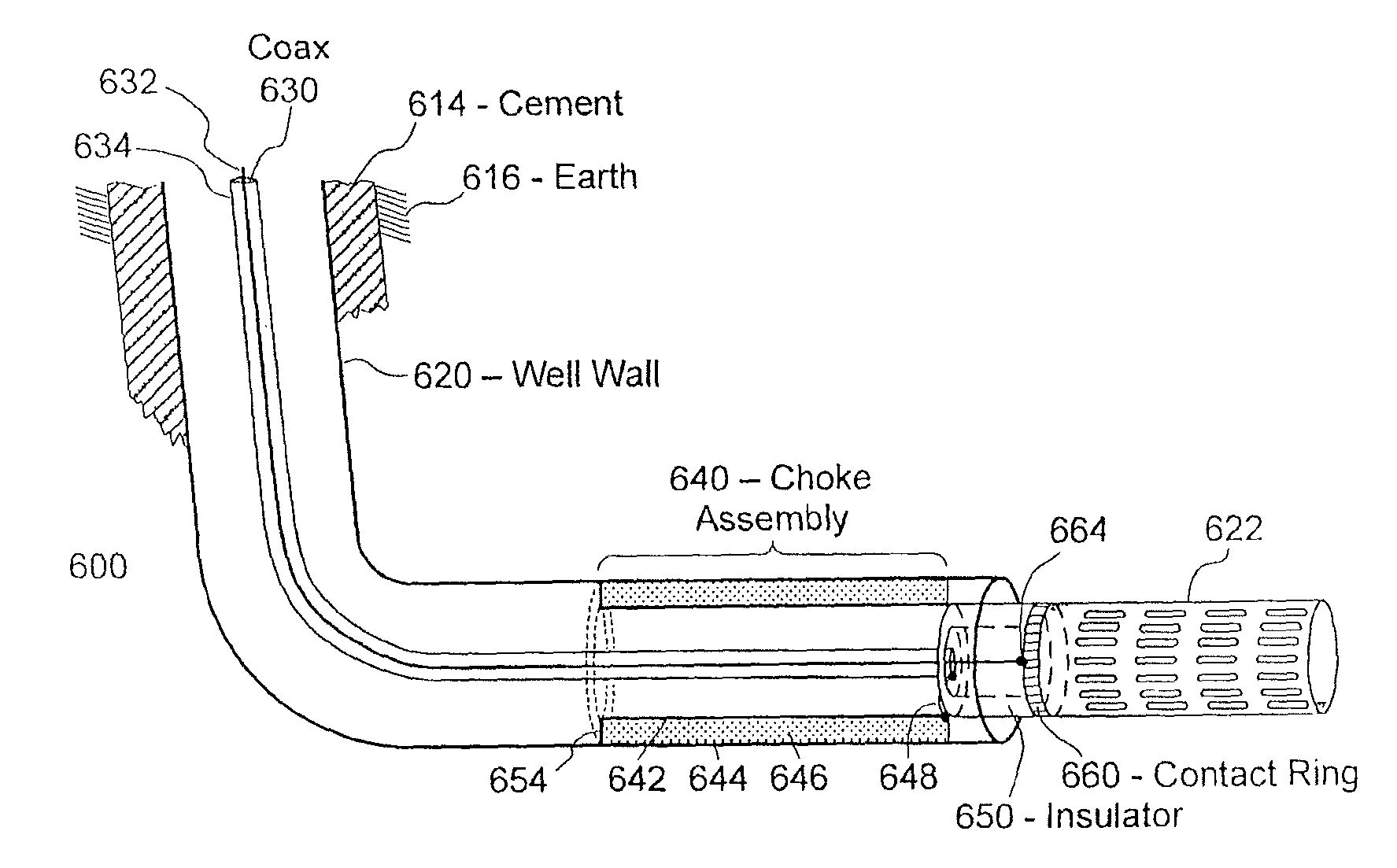

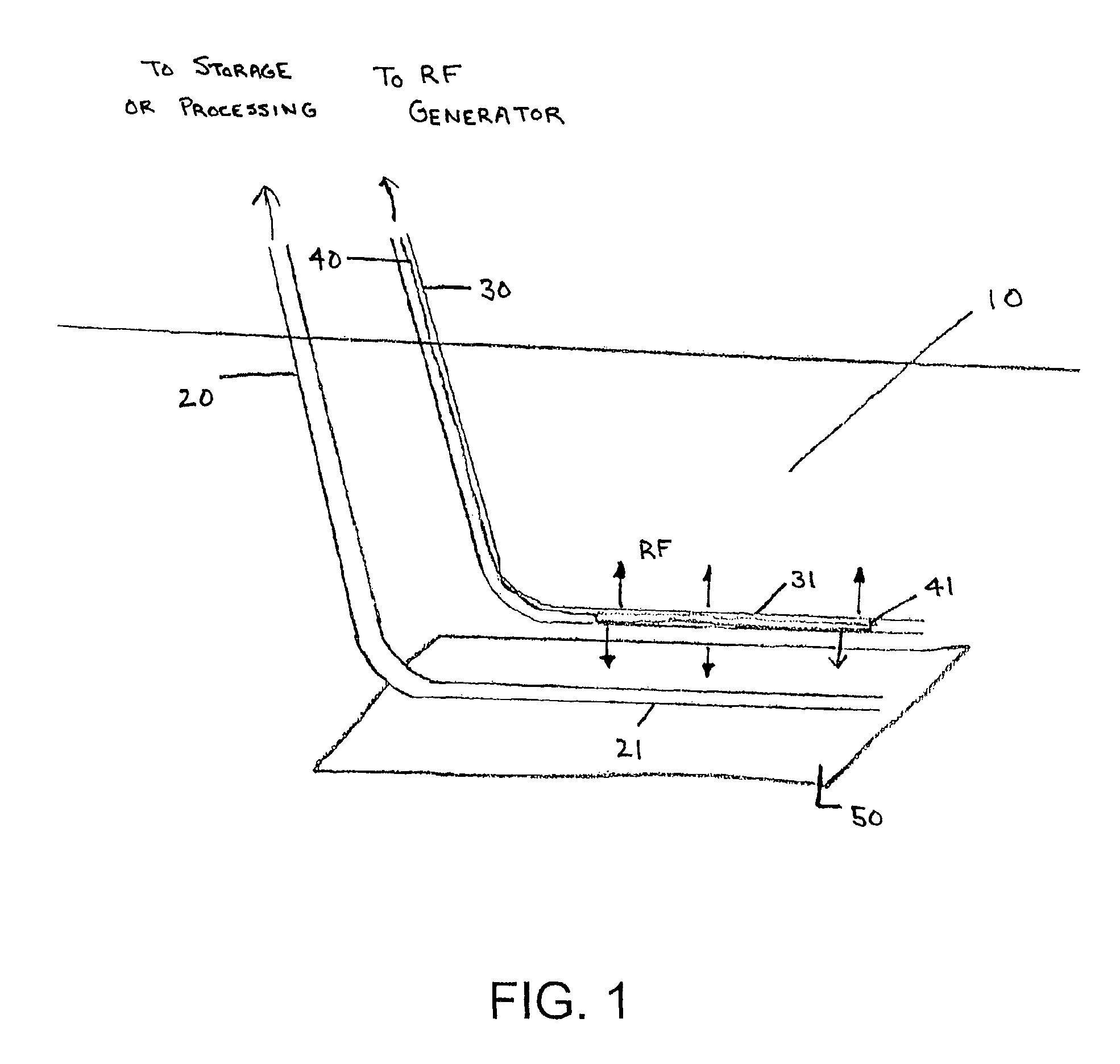

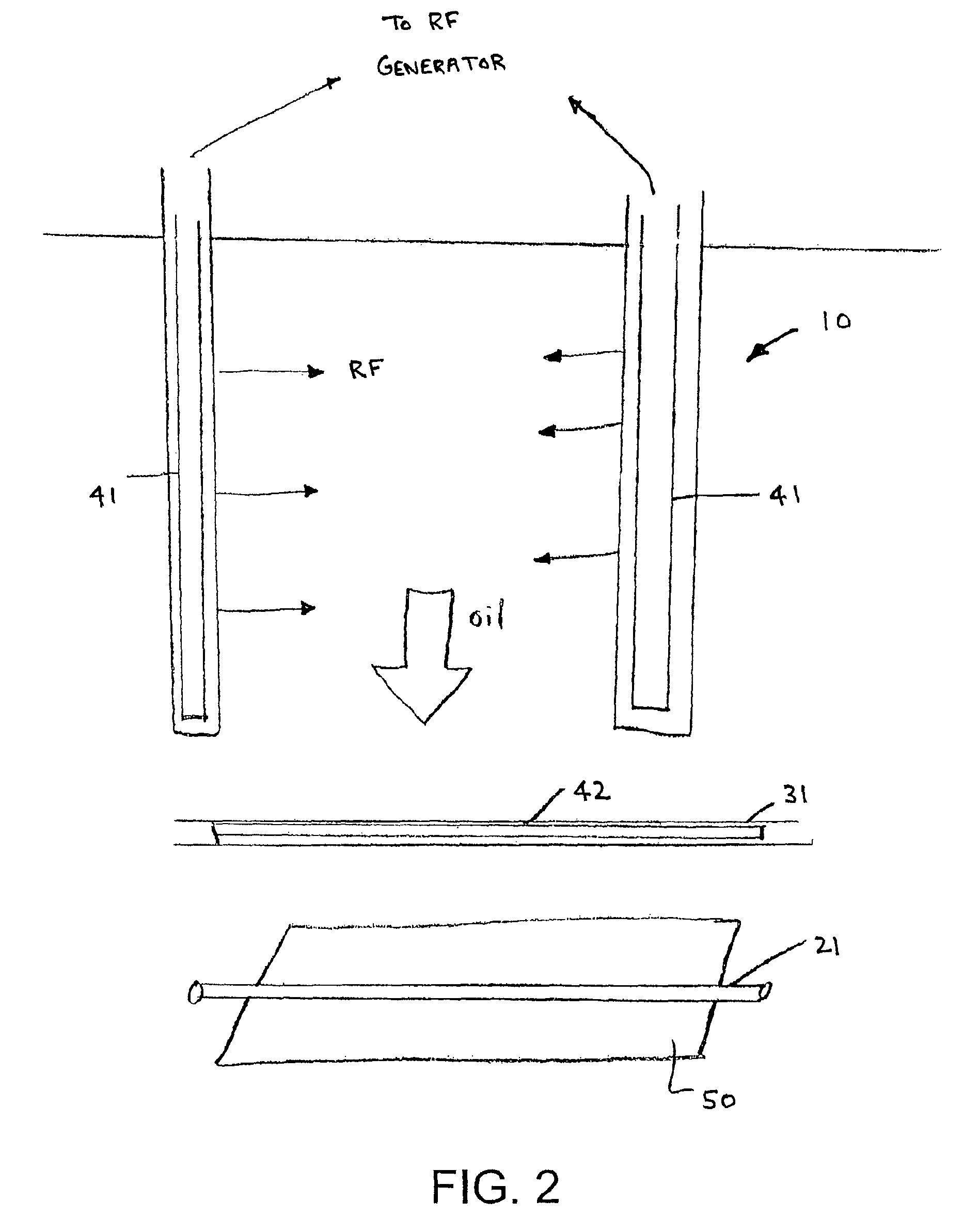

Method and apparatus for in-situ radiofrequency heating

InactiveUS7891421B2Promote recoveryEnhanced overall recoveryInsulationFluid removalElectricityNuclear engineering

Owner:TURBOSHALE INC

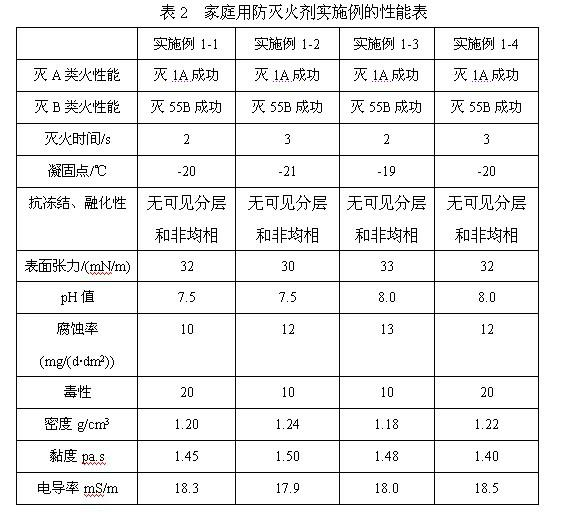

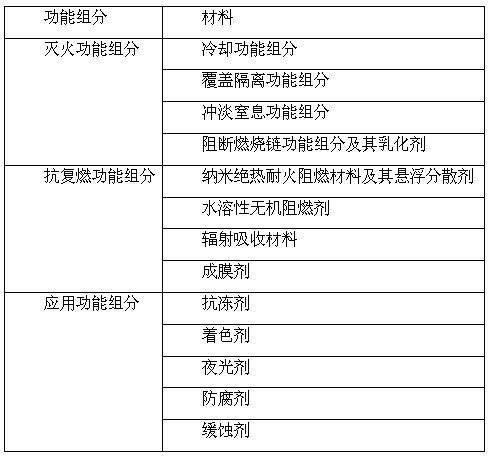

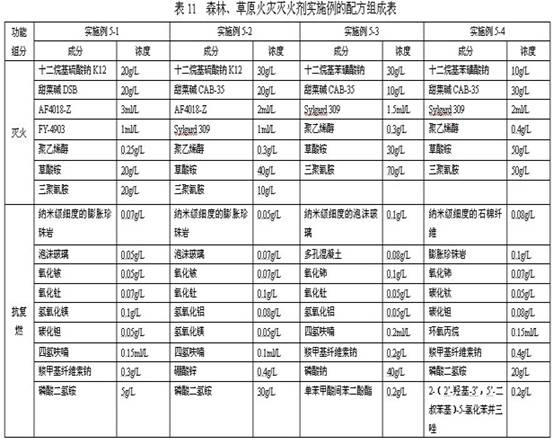

Built-up synergetic class-A/B water extinguishing agent series

The invention discloses a built-up synergetic class-A / B water extinguishing agent series. Class-A fires caused by solid substances (such as woods, cottons, wools, linens, paper) and products thereof and class-B fires caused by liquid or melted solids such as gasoline, kerosene, diesel oil, crude oil, methanol, ethanol, asphalt, paraffin waxes and the like can be put out rapidly through the functions such as heat absorption and cooling, diluting and smothering, insulating and covering, suppressing and blocking combustion chains, and the like which are synergetically performed by various extinguishing functional components, and a high-temperature-resistant thermal-insulation and fire-retarding covering layer is formed on the surface of an inflammable matter by various after-combustion functional components so as to achieve the effect of after-combustion resistance. Because the class A / B fires relate to multiple occasions of daily life and production activities, the extinguishing agent disclosed by the invention can be used in the fields of home fire prevention and extinguishing, urban architecture fire prevention and extinguishing, oil depot and gasoline station fire prevention and extinguishing, vehicle and ship fire prevention and extinguishing, forest and grassland fire prevention and extinguishing, mine fire prevention and extinguishing, confined spaces (such as civil air-defense architectures) fire prevention and extinguishing.

Owner:NANJING UNIV OF SCI & TECH

Portable hydrogen generator-fuel cell apparatus

InactiveUS6653005B1Increase specific energy and overall energy efficiencyHydrogenFuel cell auxillariesKeroseneImpurity

A compact hydrogen generator is coupled to or integrated with a fuel cell for portable power applications. Hydrogen is produced via thermocatalytic decomposition (cracking, pyrolysis) of hydrocarbon fuels in oxidant-free environment. The apparatus can utilize a variety of hydrocarbon fuels, including natural gas, propane, gasoline, kerosene, diesel fuel, crude oil (including sulfurous fuels). The hydrogen-rich gas produced is free of carbon oxides or other reactive impurities, so it could be directly fed to any type of a fuel cell. The catalysts for hydrogen production in the apparatus are carbon-based or metal-based materials and doped, if necessary, with a sulfur-capturing agent. Additionally disclosed are two novel processes for the production of two types of carbon filaments, and a novel filamentous carbon product. The hydrogen generator can be conveniently integrated with high temperature fuel cells to produce an efficient and self-contained source of electrical power.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

Systems and methods of producing a crude product

Contact of a crude feed with one or more catalysts produces a total product that includes a crude product. The crude feed has a residue content of at least 0.2 grams of residue per gram of crude feed. At least a portion of the crude product may be produced as a vapor. The crude product is a liquid mixture at 25° C. and 0.101 MPa. One or more properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

Fuel composition for a diesel engine

InactiveUS20040055209A1Meet quality requirementsImprove low temperature performanceSolid fuelsLiquid carbonaceous fuelsProcess engineeringDiesel engine

The invention is directed to a fuel composition for diesel engines. The fuel composition comprises 0.1-99% by weight of a component or a mixture of components produced from biological raw material originating from plants and / or animals and / or fish. The fuel composition comprises 0-20% of components containing oxygen. Both components are mixed with diesel components based on crude oil and / or fractions from Fischer-Tropsch process.

Owner:NESTE OIL OY

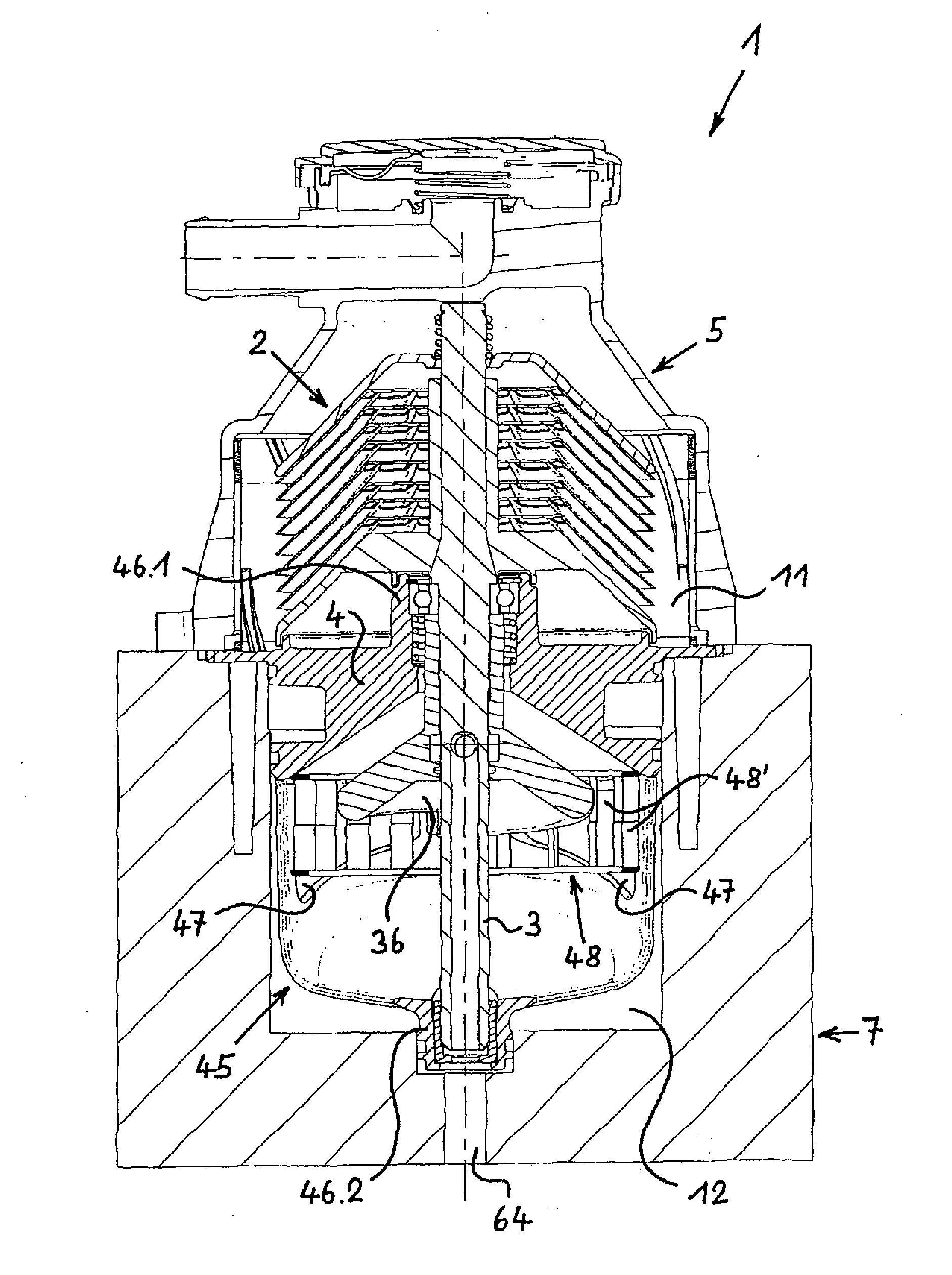

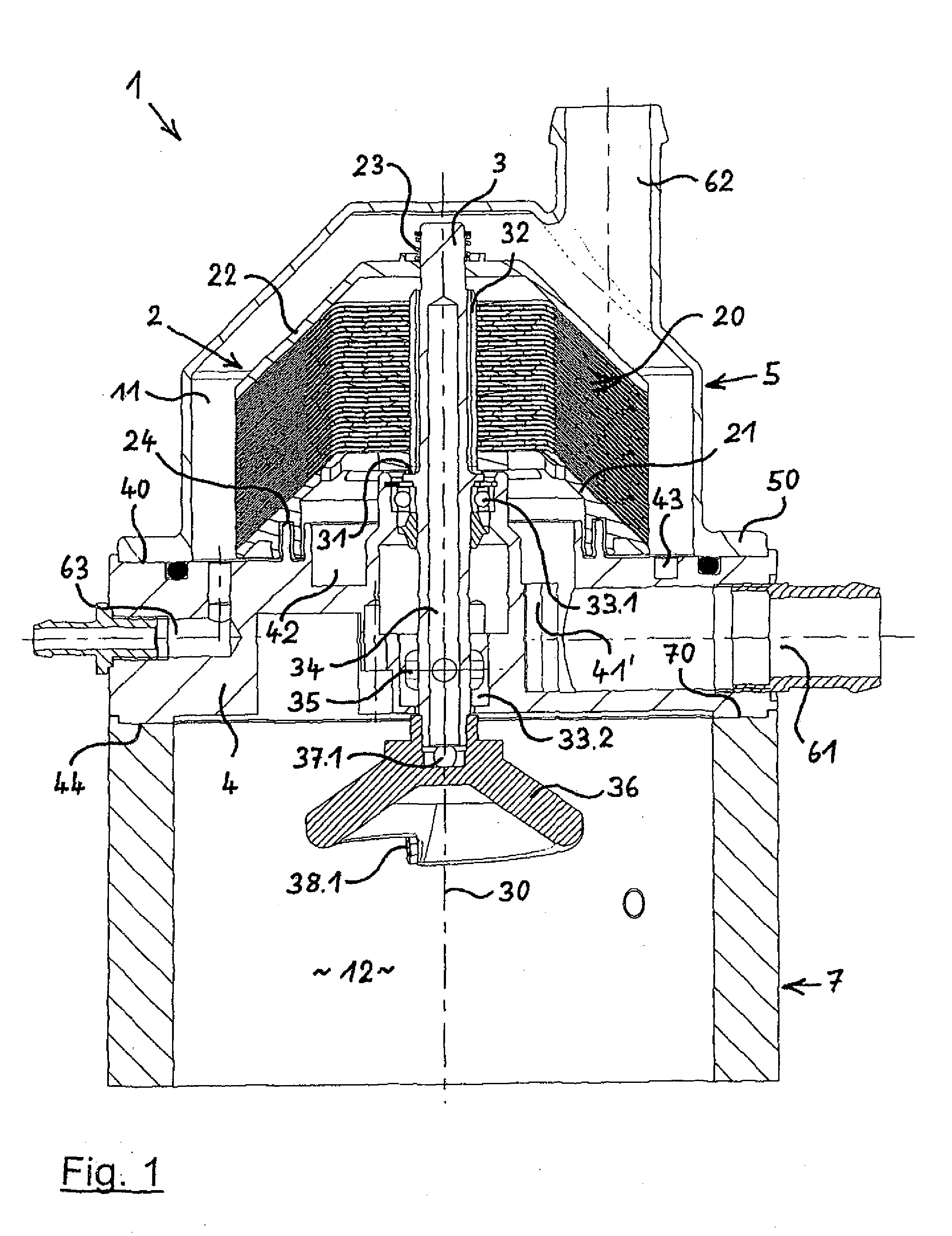

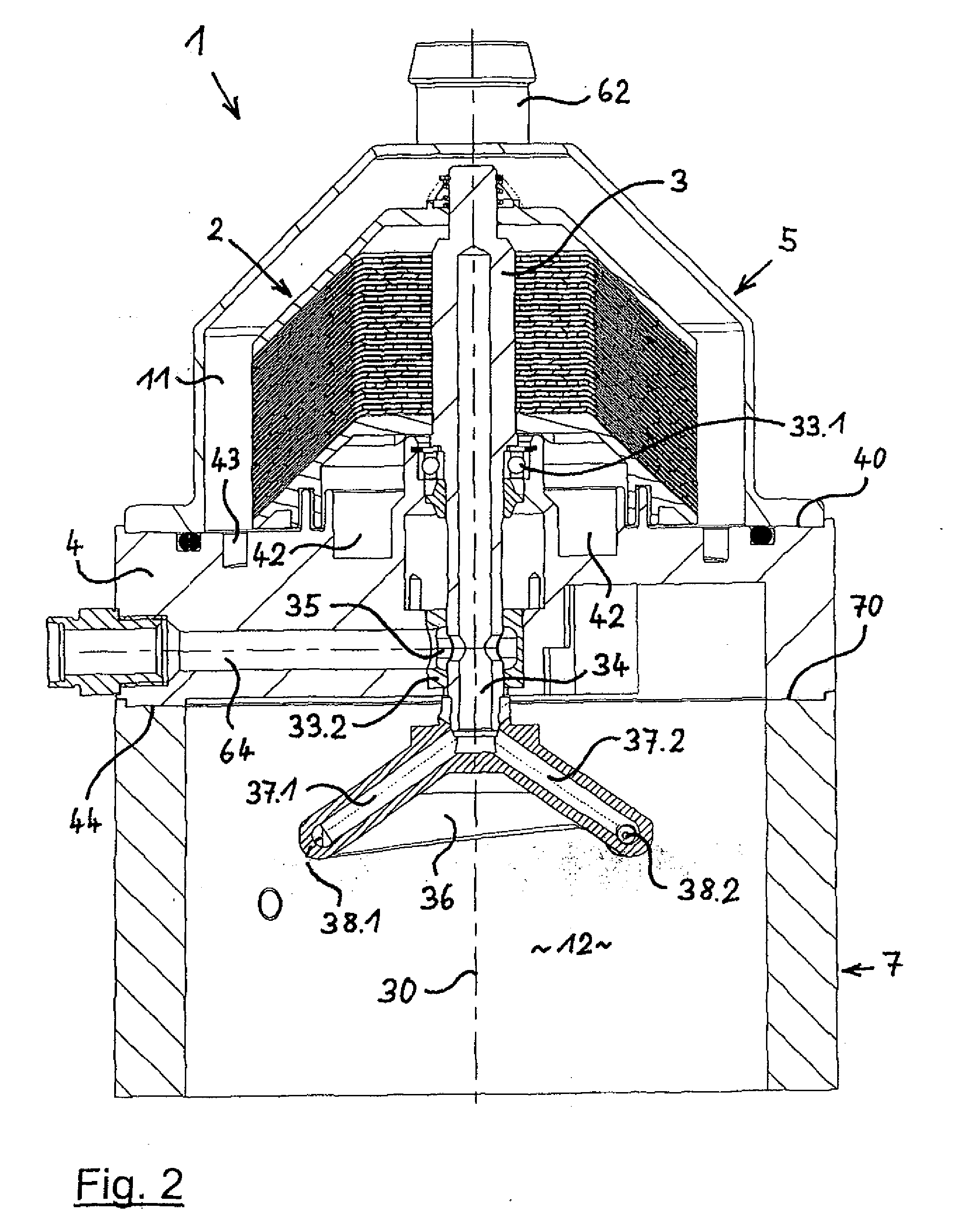

Separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, and functional module and internal combustion engine comprising a separator

ActiveUS20100180854A1Increase speedEasy to separateCombination devicesLubrication of auxillariesExternal combustion engineEngineering

A separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, especially of a motor vehicle. The separator includes a gas purification chamber inside which a rotatably mounted centrifugal rotor is arranged. The gas purification chamber has a crude gas inlet, a pure gas outlet, and an oil outlet. The crankcase ventilation gas can be conducted into a radially internal zone of the centrifugal rotor via the crude gas inlet, while pure gas that is liberated from oil mist can be discharged from the gas purification chamber via the pure gas outlet, and oil separated from the gas can be discharged from the gas purification chamber via the oil outlet. The separator further includes a rotary drive for the centrifugal rotor. The rotary drive is disposed in a drive chamber of the separator, can be operated using pressurized lubrication oil of the internal combustion engine, and is connected to the centrifugal rotor by means of a shaft extending from the drive chamber into the gas purification chamber, from which the drive chamber is separated. The rotary drive is formed by at least one thrust nozzle which is connected to the shaft and to which the pressurized lubrication oil of the internal combustion engine can be fed. The separator includes at least one part of a base that forms the separation between the gas purification chamber and the drive chamber and extends into the drive chamber, the part of the base being fitted with a seat for a bearing of the shaft. The bearing is located at a distance from the centrifugal rotor.

Owner:HENGST WALTER

Fuel composition for a diesel engine

Owner:NESTE OIL OY

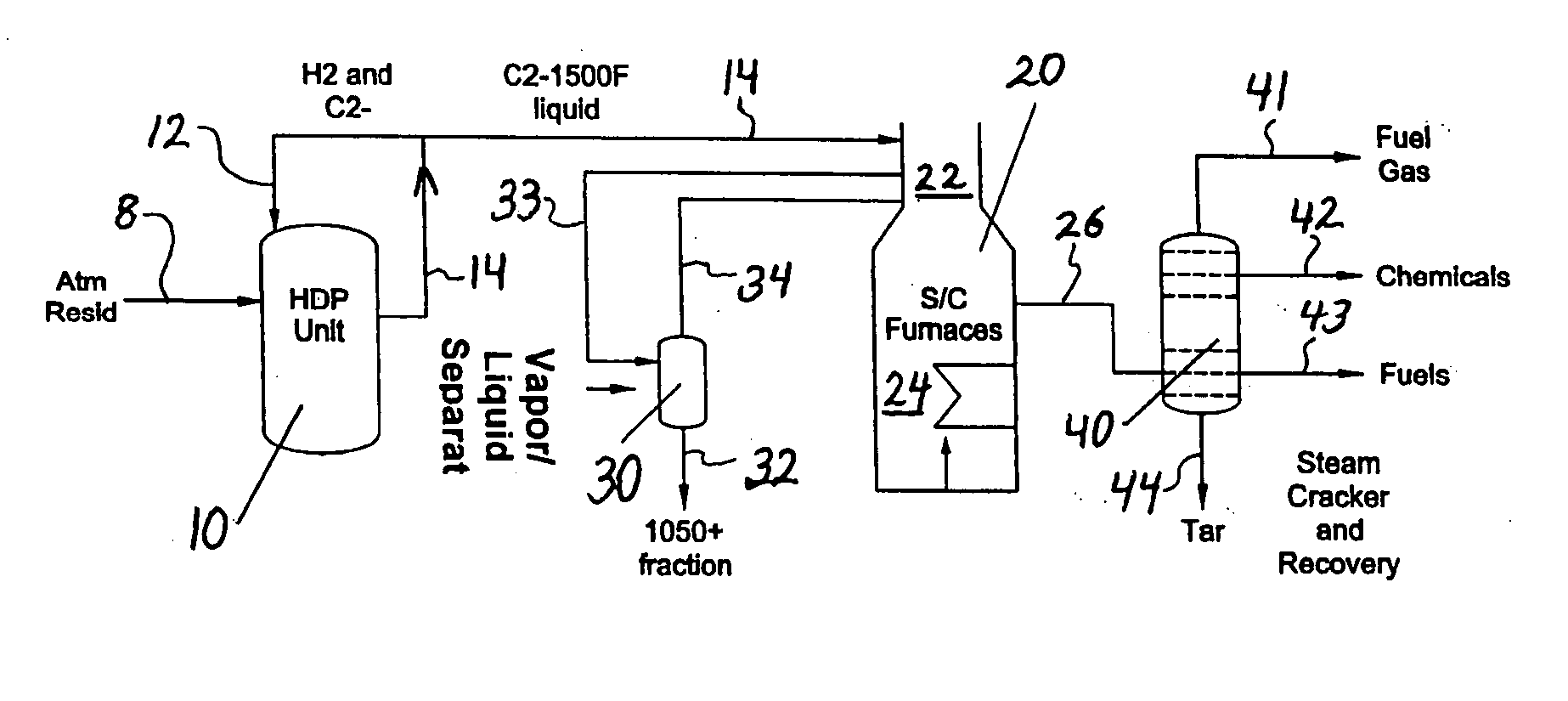

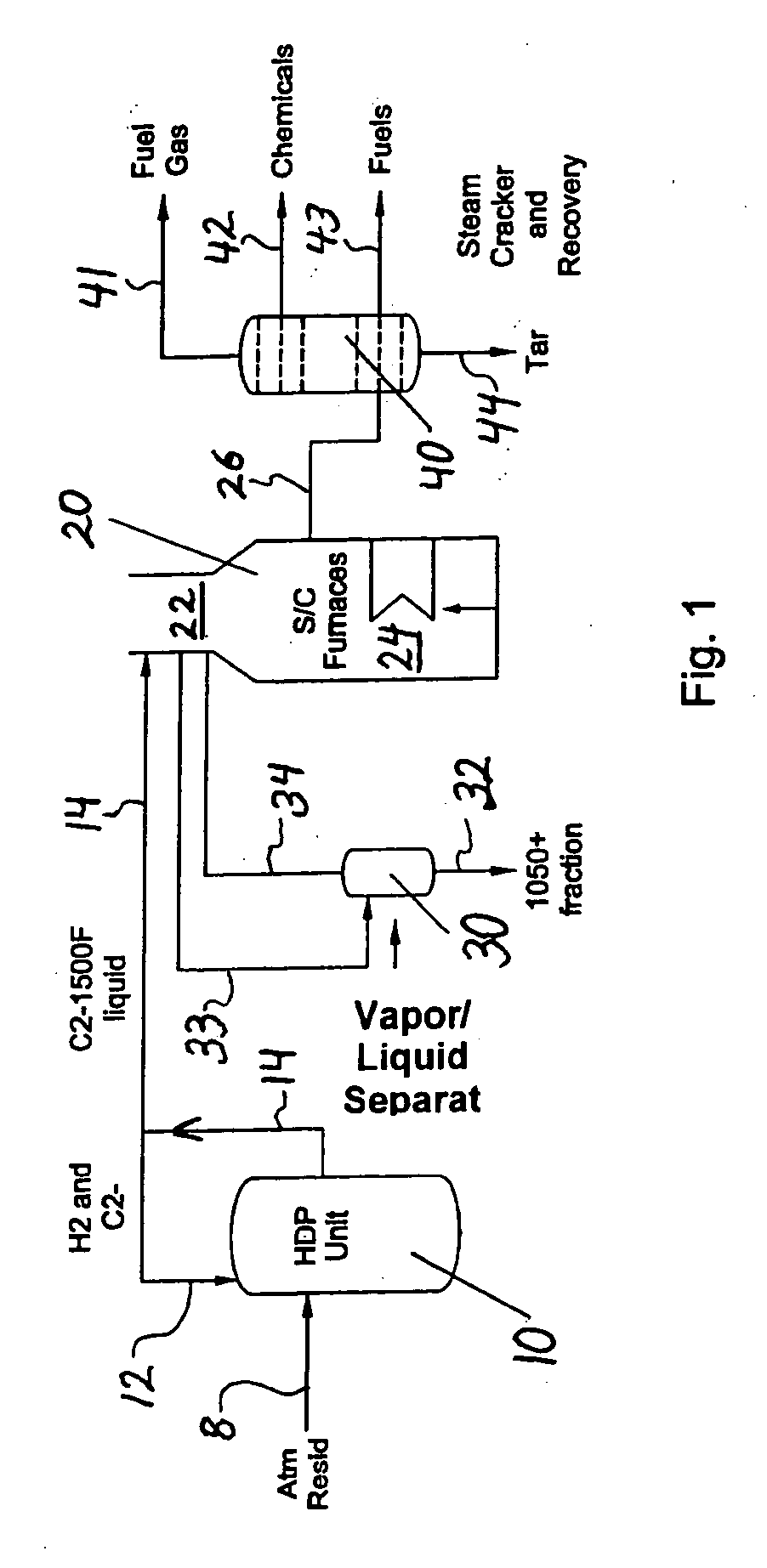

Resid processing for steam cracker feed and catalytic cracking

ActiveUS20070090020A1High hydrogen contentEliminate needThermal non-catalytic crackingHydrocarbon oil cracking processProcess engineeringAlkene

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is treated by hydroprocessing and visbreaking and then passed to a steam cracker to obtain a product comprising olefins.

Owner:EXXONMOBIL CHEM PAT INC

Method for cleaning oil tank

The invention discloses a method for cleaning an oil tank. The method for cleaning the oil tank is characterized by adopting the following sequential steps under the totally closed condition: crude oil transporting, inert gas filling, homogenic oil cleaning, warm water cleaning, tank ventilating, tank slag removing and other pure physical and mechanical cleaning methods. After the method is adopted for cleaning, above 95% of residual oil in the tank can be recycled and reused, so the comprehensive benefit is obvious; the tank is cleanly and thoroughly cleaned, and even the metal can be seen; and the flame operation standard can be realized in the tank.

Owner:JEREH ENERGY SERVICES

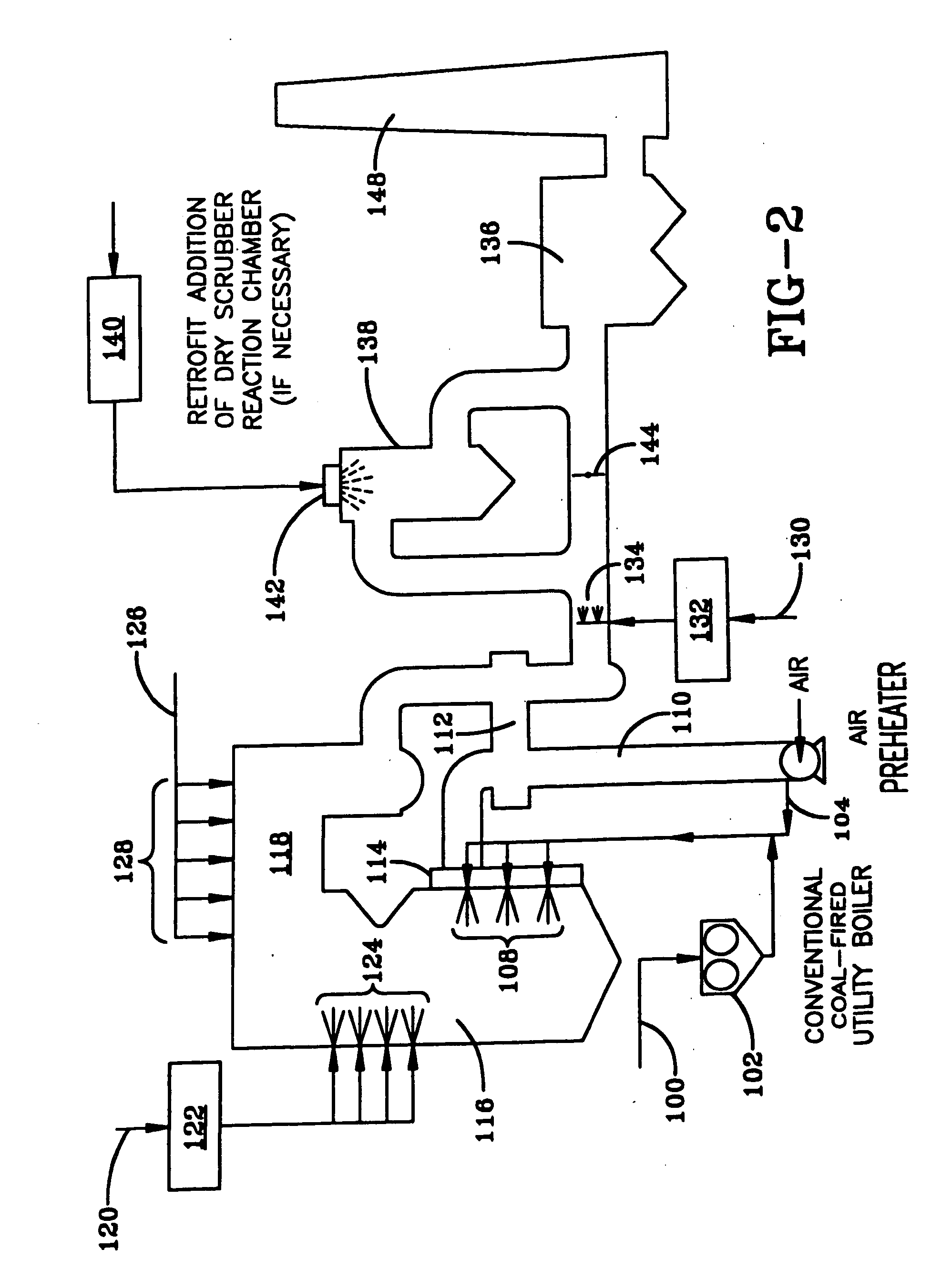

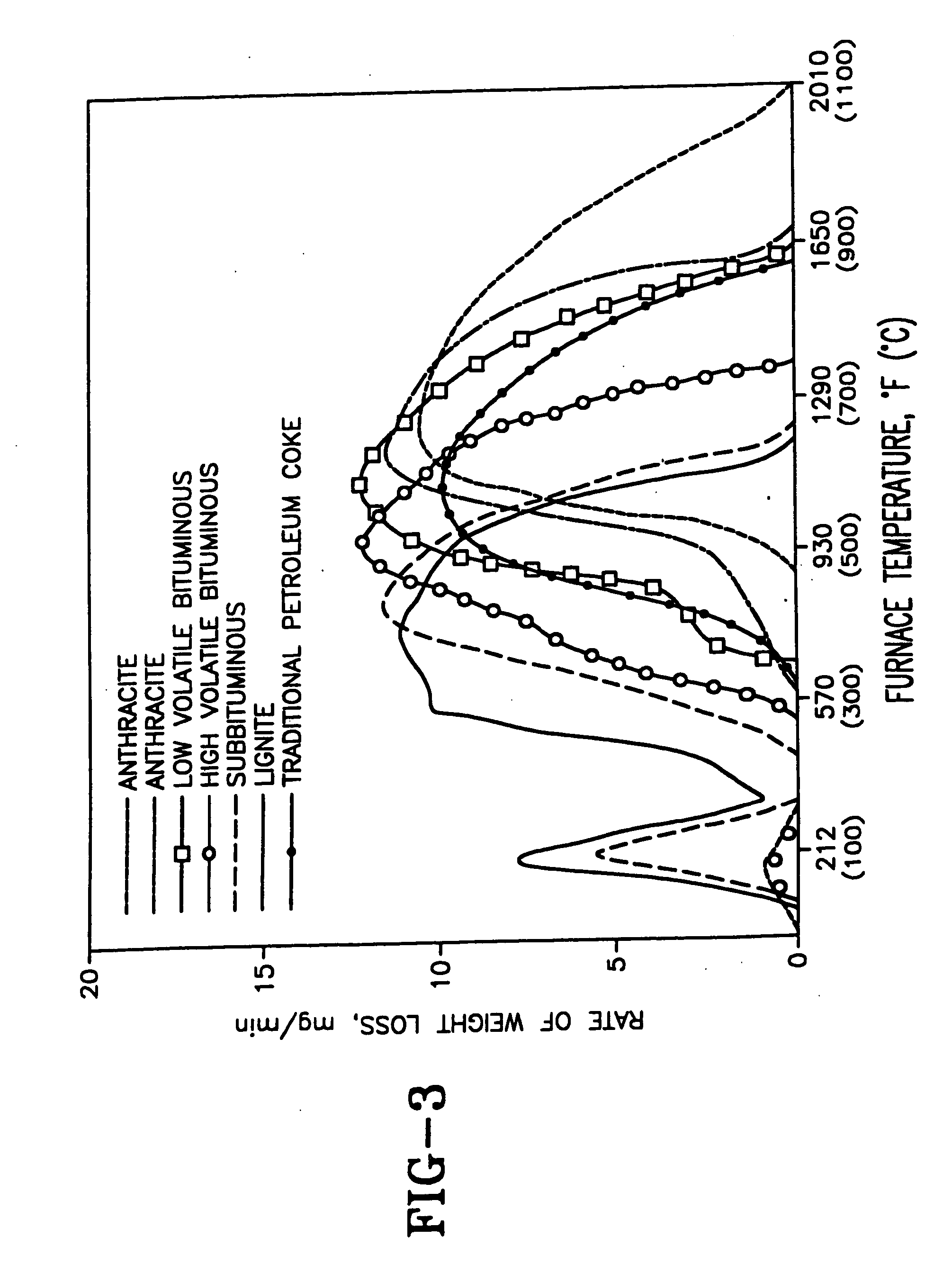

Production and use of a premium fuel grade petroleum coke

InactiveUS20060032788A1Thermal non-catalytic crackingLiquid organic insulatorsCombustionSufficient time

A premium “fuel-grade” petroleum coke is produced by modifying petroleum coking technology. Coking process parameters are controlled to consistently produce petroleum coke within a predetermined range for volatile combustible material (VCM) content. The invention includes a process of producing a coke fuel, the method comprising steps: (a) obtaining a coke precursor material derived from crude oil and having a volatile organic component; and (b) subjecting the coke precursor material to a thermal cracking process for sufficient time and at sufficient temperature and under sufficient pressure so as to produce a coke product having volatile combustible materials (VCMs) present in an amount in the range of from about 13% to about 50% by weight. Most preferably, the volatile combustible materials in the coke product typically may be in the range of from about 15% to about 30% by weight. The present invention also provides methods for (1) altering the coke crystalline structure, (2) improving the quality of the coke VCM, and (3) reducing the concentration of coke contaminants. Fuels made from the inventive coke product and methods of producing energy through the combustion of such fuels are also included. Finally, novel environmental control techniques are developed to take optimal advantage of the unique characteristics of this upgraded petroleum coke.

Owner:ETTER ROGER G

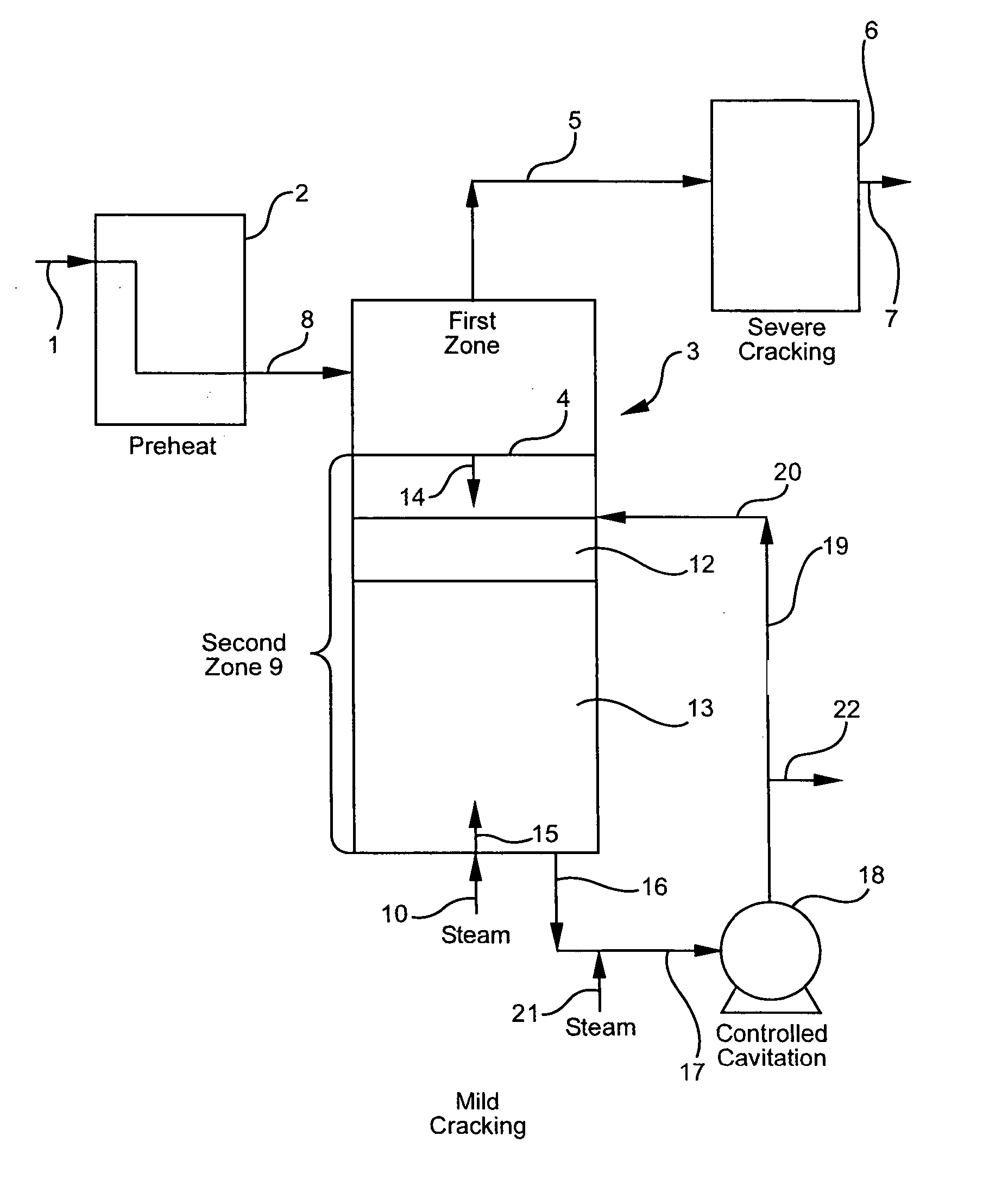

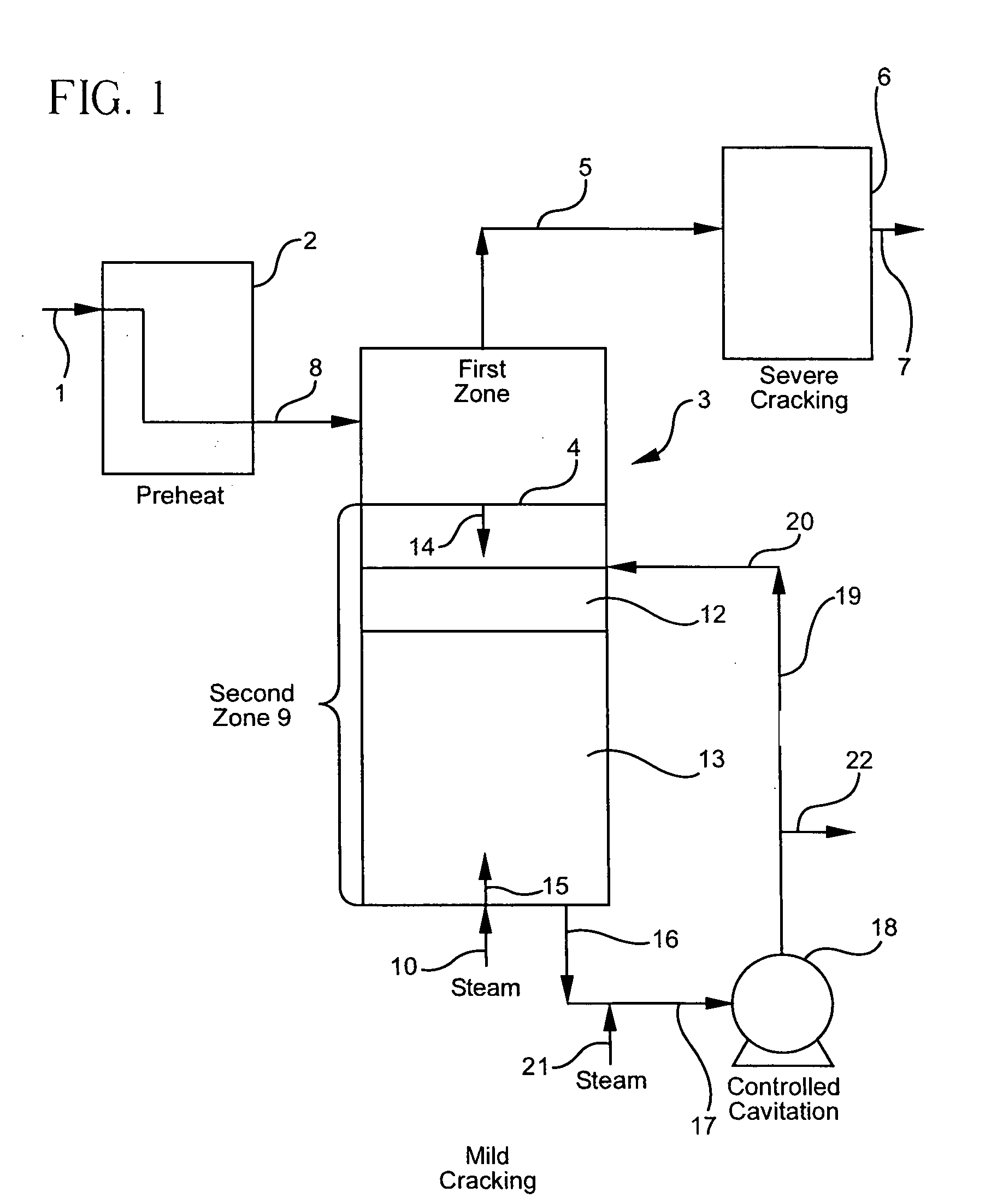

Olefin production utilizing whole crude oil and mild controlled cavitation assisted cracking

InactiveUS20050010075A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyCavitationAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild thermal cracking assisted with controlled cavitation conditions until substantially vaporized, the vapors being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

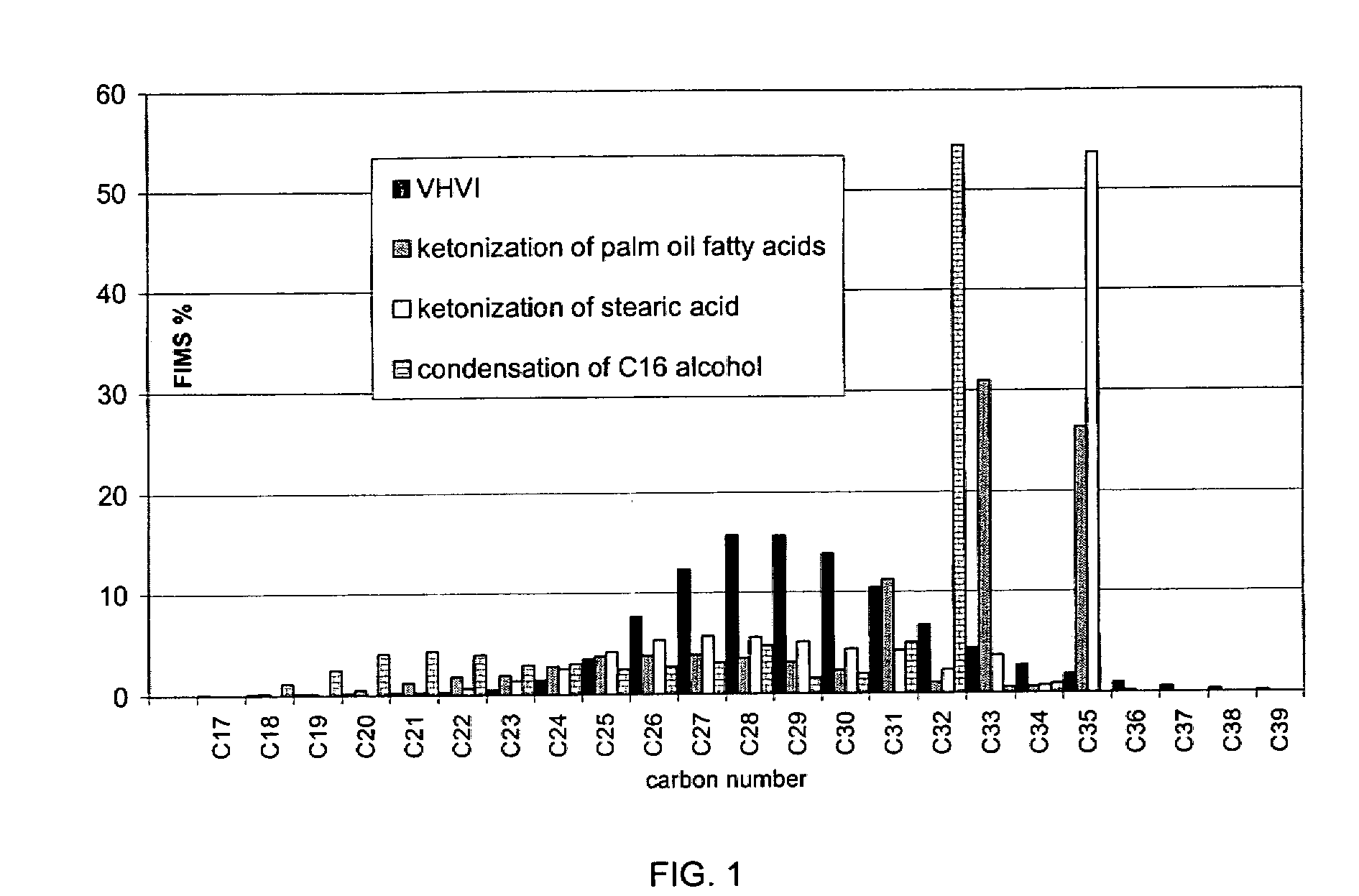

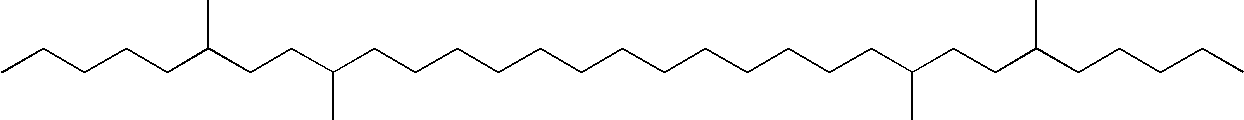

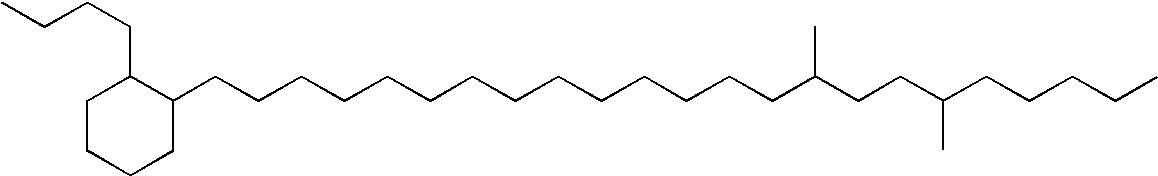

Base oil

ActiveUS20070135663A1Improve technical effectReduce fuel consumptionHydrocarbon purification/separationLiquid carbonaceous fuelsCarbon numberViscosity index

The invention relates to a new base stock material. Specifically the invention relates to a saturated hydrocarbon composition and particularly to a composition based on biological raw materials, to be used as a high-quality base oil or to be used as a component in the production of a base oil having a high viscosity index and good low temperature properties. The composition contains saturated hydrocarbons and has a narrow carbon number range.

Owner:NESTE OIL OY

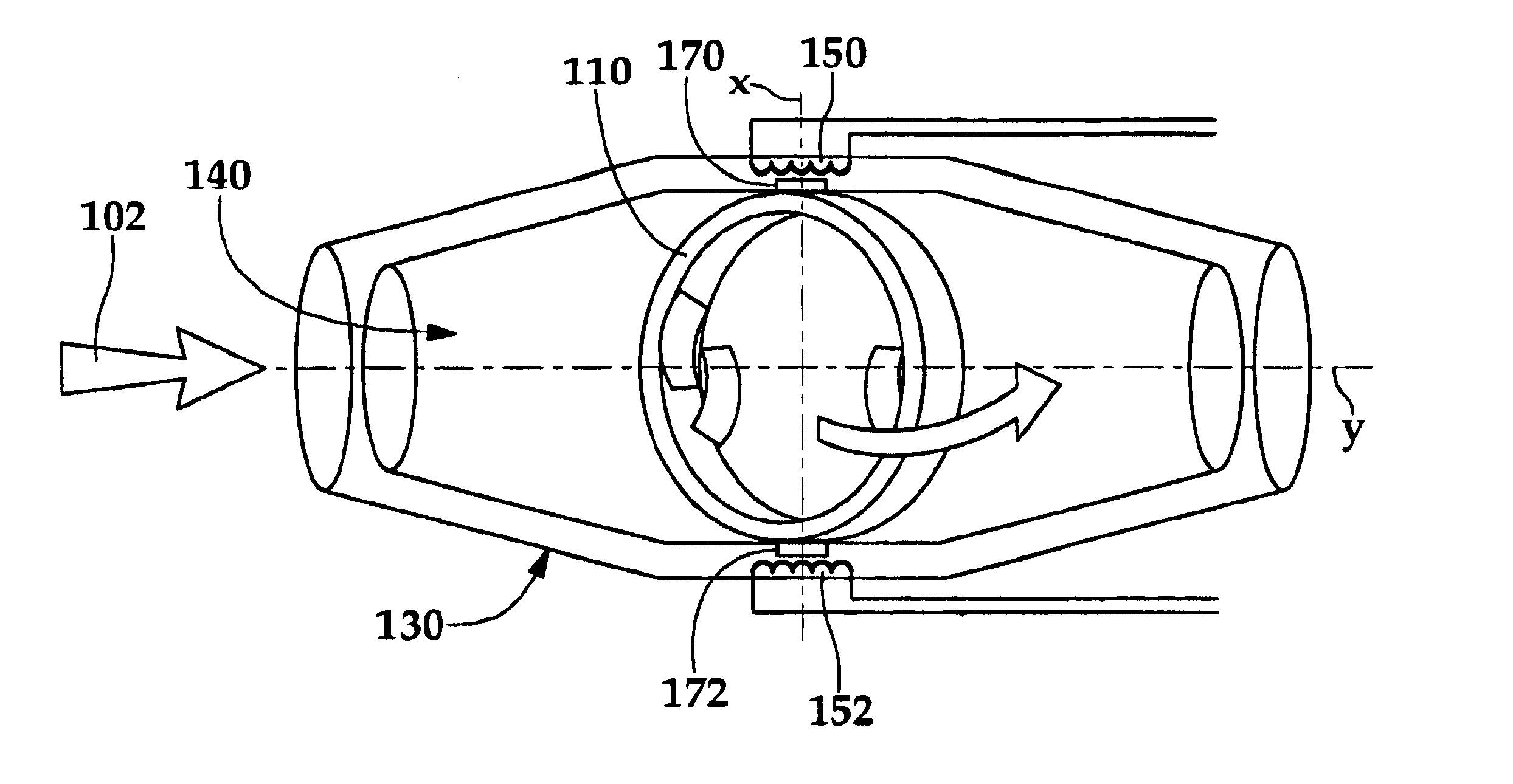

Wellbore power generating system for downhole operation

InactiveUS6848503B2Full accessSolution to short lifeMagnetic circuit rotating partsFluid removalElectricityPower conditioner

A power generating system (100) for a downhole operation (10) having production tubing (40) in a wellbore (12) includes a magnetized rotation member (110) coupled to the wellbore (12) within the production tubing (40), the rotation member (110) having a passageway (112) through which objects, such as tools, may be passed within the production tubing (40). Support braces (170, 172) couple the rotation member (110) to the production tubing (40) and allow the rotation member (110) to rotate within the production tubing (40). Magnetic pickups (150, 152) are predisposed about the rotation member (110) within the wellbore (12) and a power conditioner (200) is provided to receive currents from the magnetic pickups (150, 152) for storage and future use. The rotation member (110) rotates due to the flow of fluid, such as crude oil, through the production tubing (40) which causes the rotation member (110) to rotate and induce a magnetic field on the magnetic pickups (150, 152) such that electrical energy is transmitted to the power conditioner (200), the power conditioner able to store, rectify, and deliver power to any one of several electronic components within the wellbore (12).

Owner:HALLIBURTON ENERGY SERVICES INC

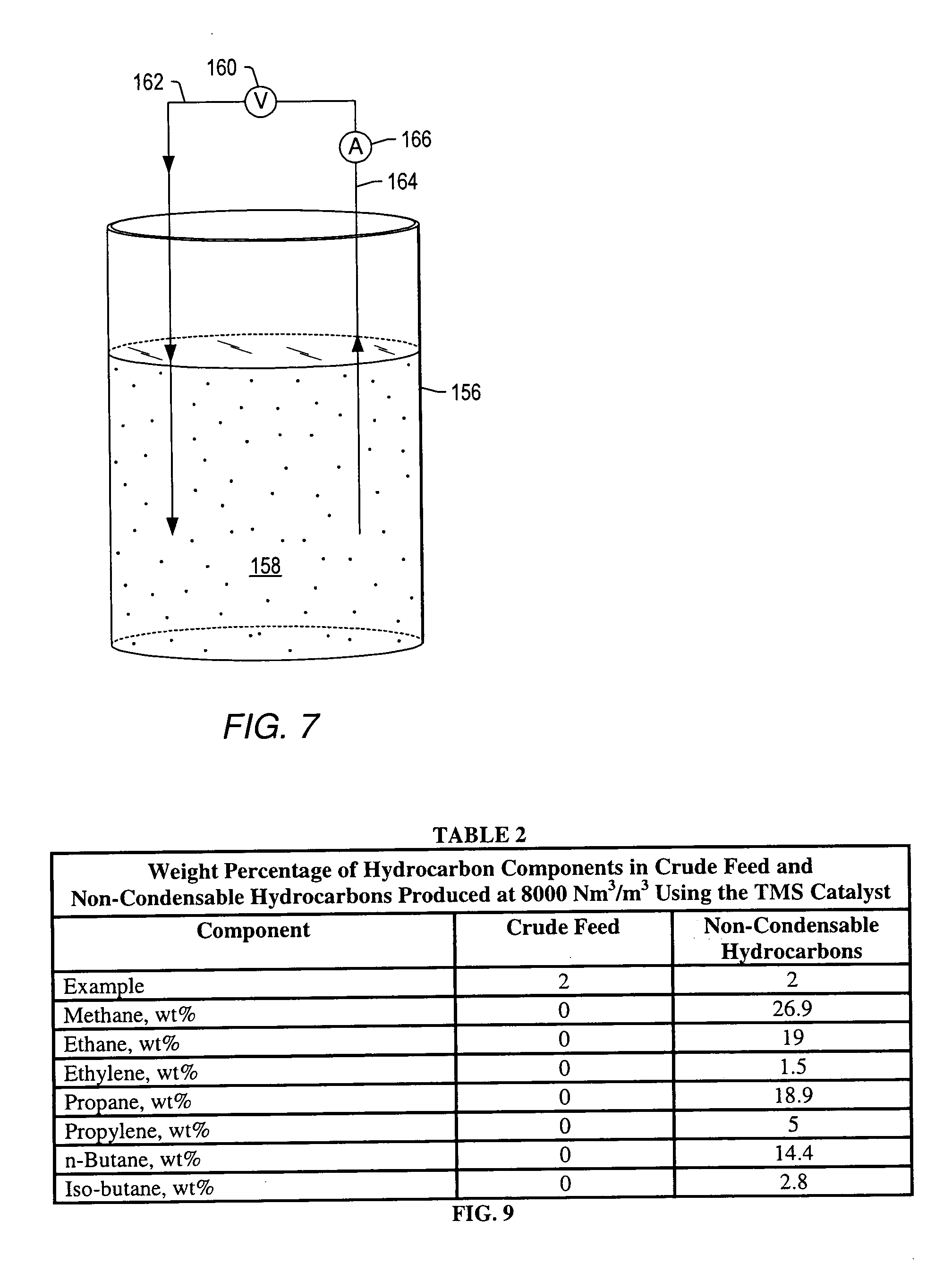

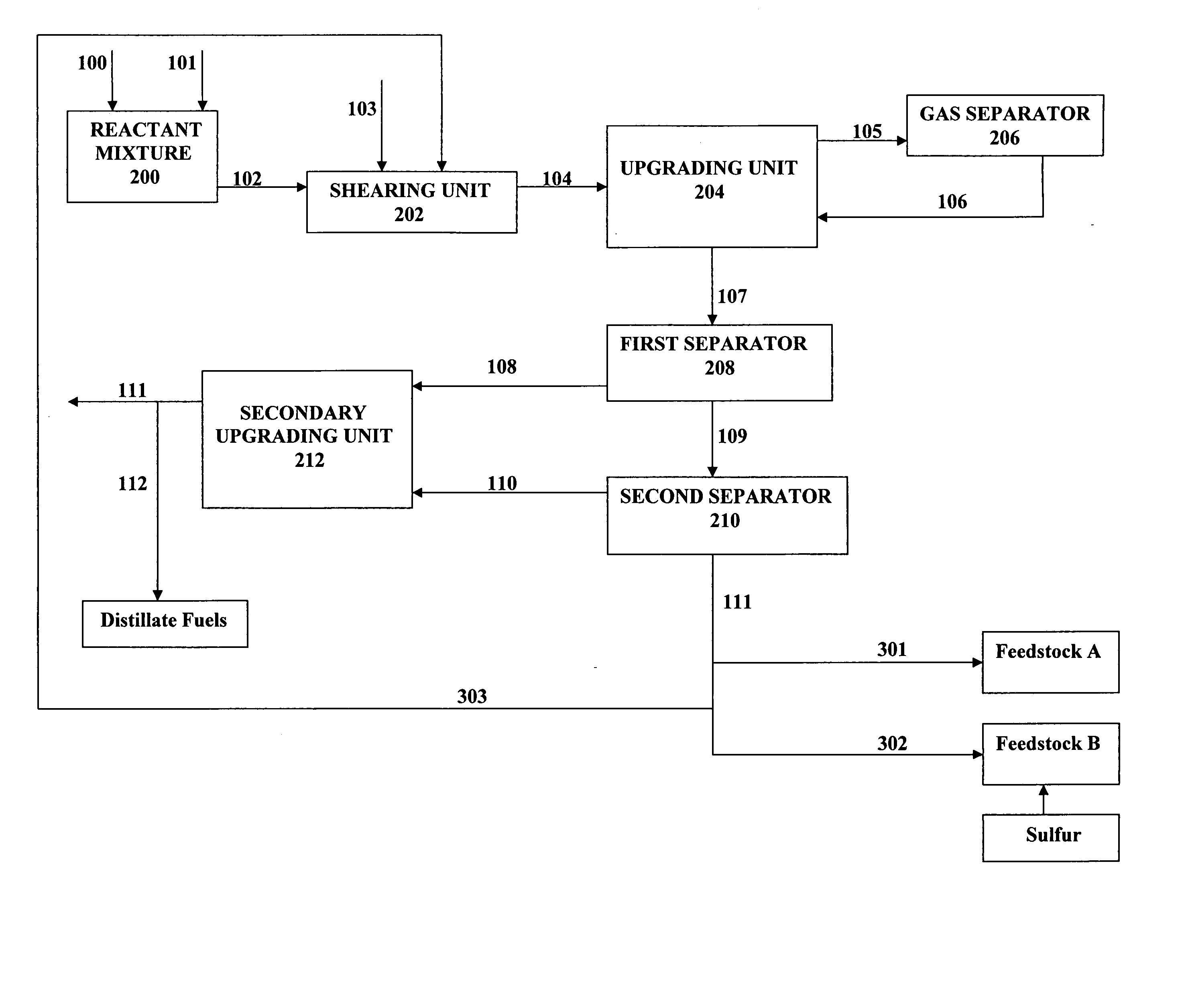

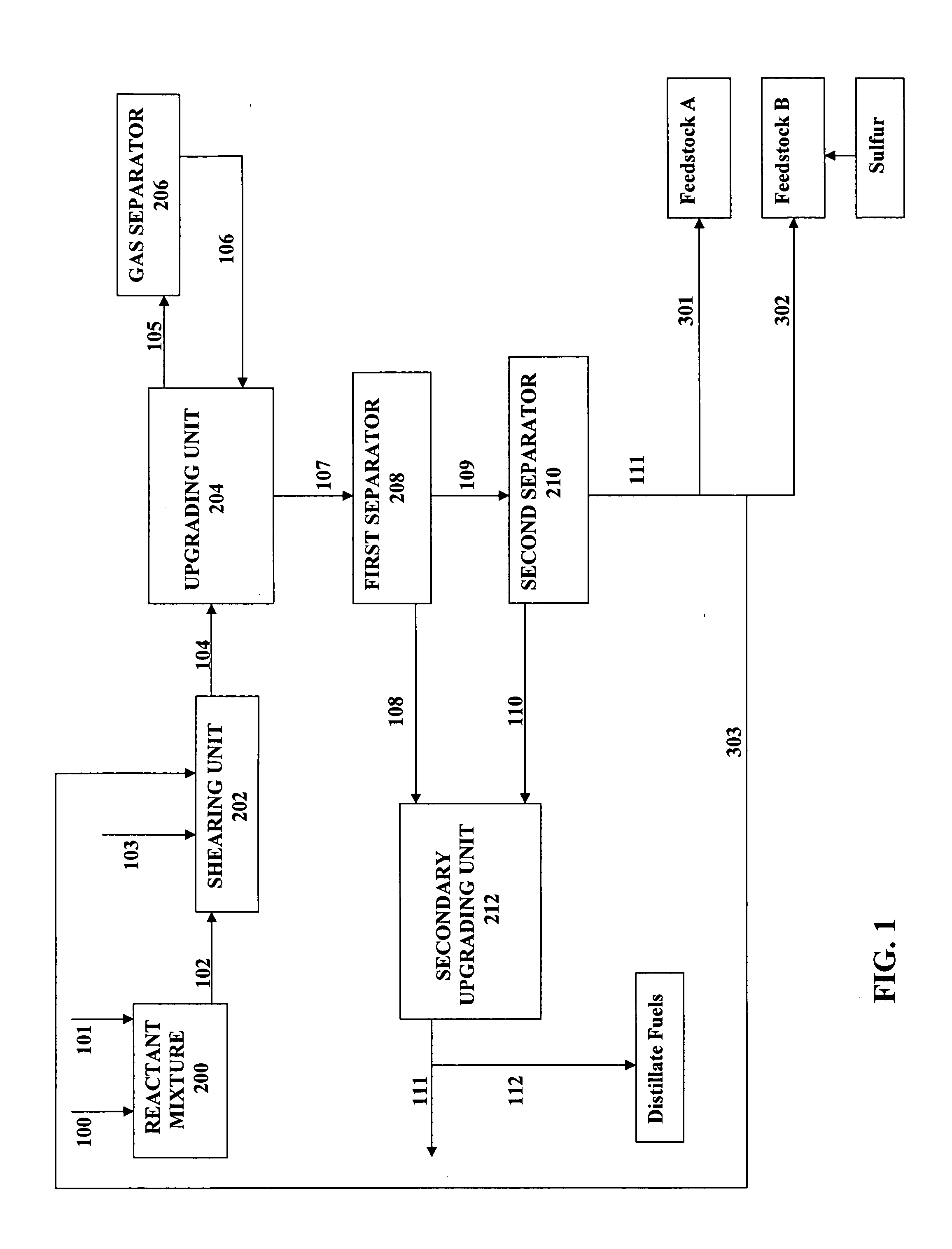

Methods for producing a total product in the presence of sulfur

Methods of producing a total product are described. A method includes continuously contacting a feed with a hydrogen source in the presence of one or more inorganic salt catalysts and steam to produce a total product, wherein the feed has at least 0.02 grams of sulfur, per gram of feed; and producing a total product that includes coke and the crude product. The crude product has a sulfur content of at most 90% of the sulfur content of the feed.

Owner:SHELL OIL CO

Methods for making higher value products from sulfur containing crude oil

ActiveUS20060254956A1High purityLow operating pressureHydrocarbon oil crackingTreatment with hydrotreatment processesFiberHydrogen

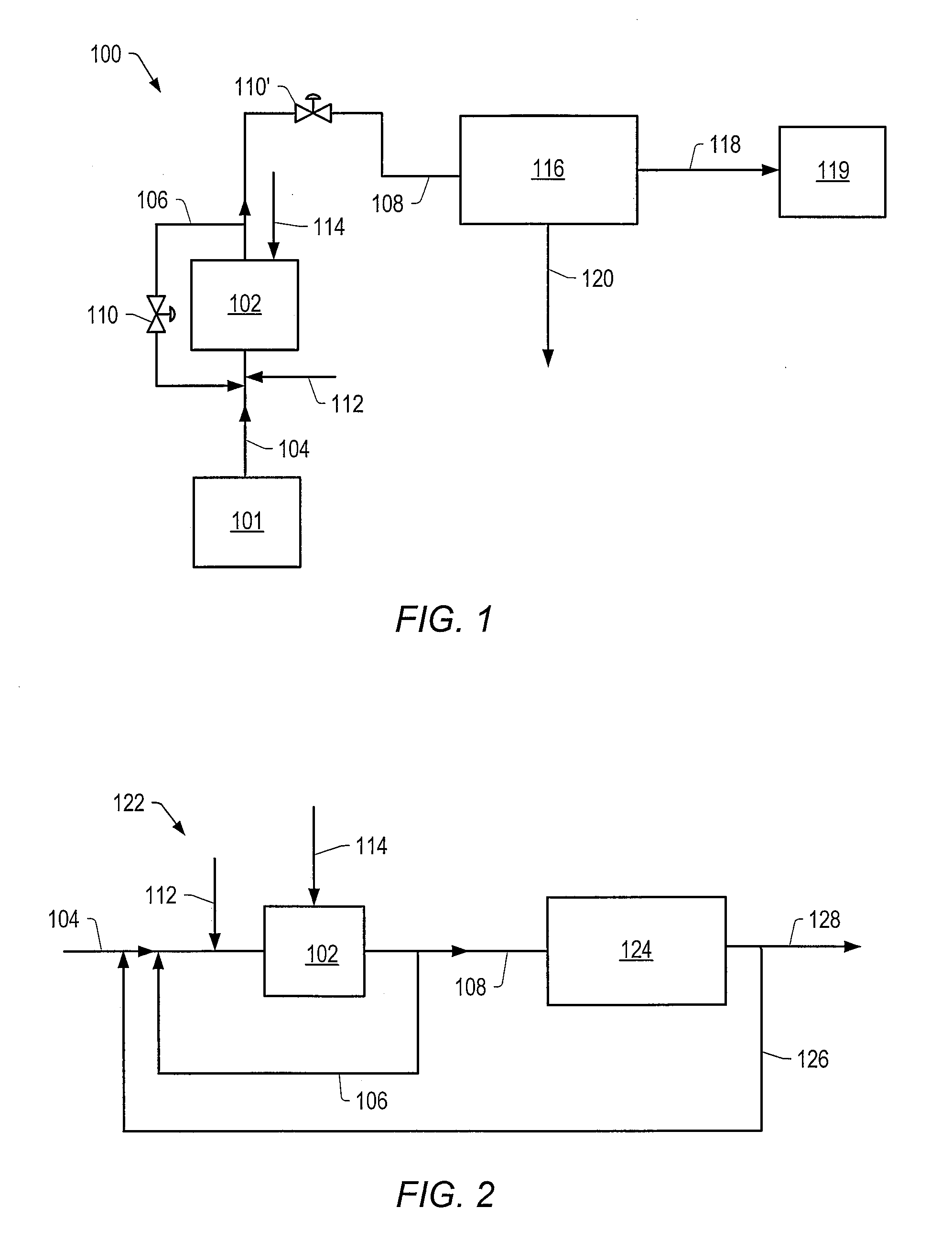

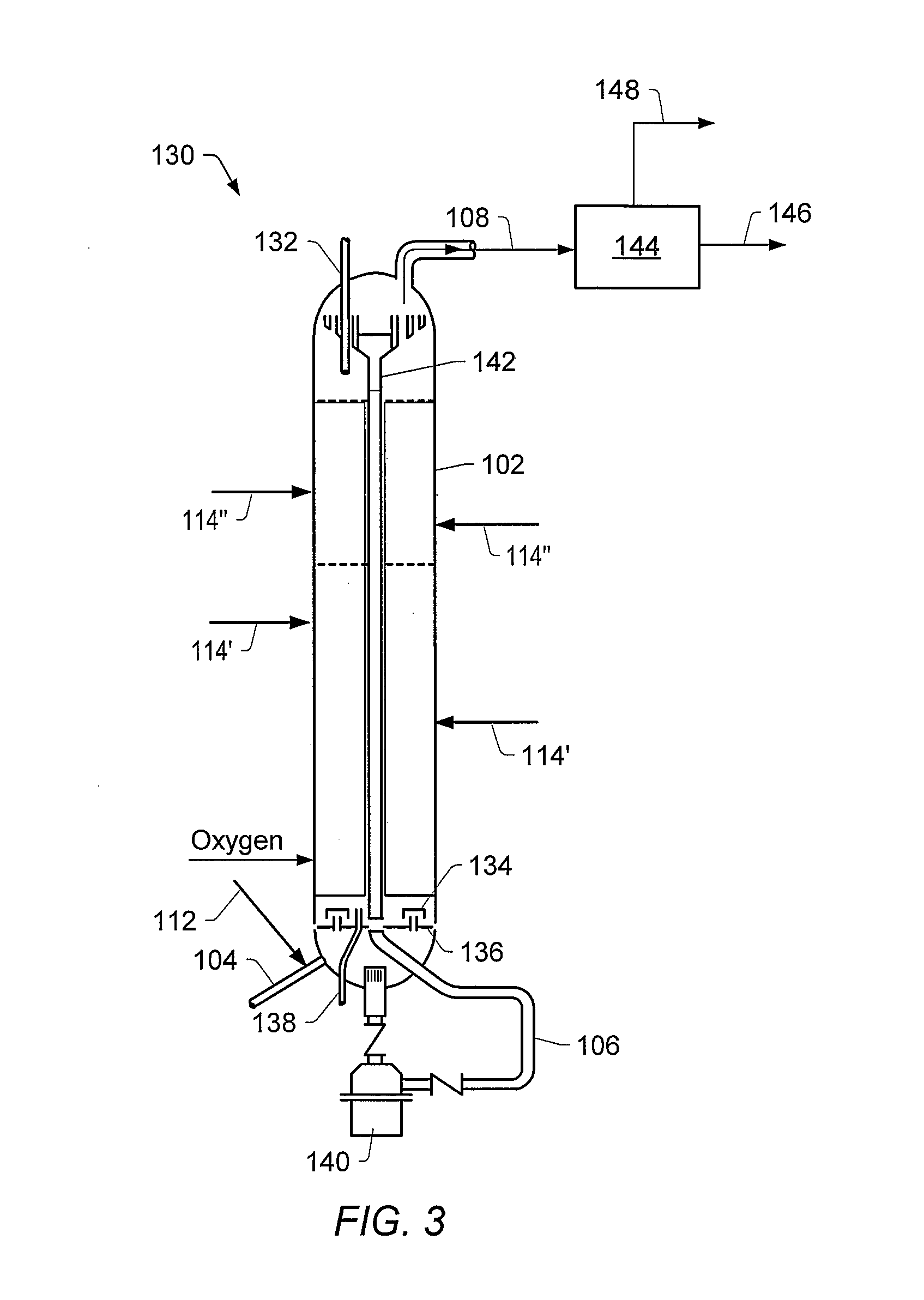

A process for upgrading, or refining, high sulfur containing heavy hydrocarbon crude oil to a lighter oil having a lower sulfur concentration and, hence a higher value product, is disclosed. The process includes reacting the high sulfur heavy hydrocarbon crude oil in the presence of a catalyst and low pressure hydrogen to produce a reaction product stream from which the light oil is recovered. Part of the reaction product is separated and subjected to further upgrading to produce a lower sulfur oil product for application as distillate fuels. The upgrading process also produces residual oil that is suitable for making olefins, carbon fiber or road asphalt. Catalysts utilized in the processes of the invention can include a transition metal containing compound, the metal being selected from Group V, Group VI, and Group VIII of the Periodic Table, and mixtures of these metals.

Owner:SAUDI ARABIAN OIL CO

Profile control oil-displacement agent for core-shell type inorganic/organic polymer composite microballoon

InactiveCN102485830AGood expansion performanceGood temperature and salt resistanceDrilling compositionCross-linkMicrosphere

The invention discloses a profile control oil-displacement agent for a core-shell type inorganic / organic polymer composite microballoon. A preparation method of the core-shell type inorganic / organic polymer composite microballoon comprises the following steps of carrying out surface modification of inorganic cores of inorganic nano-particles such as silica particles and magnetic particles, and carrying out graft polymerisation by a dispersion polymerization method or an inverse emulsion polymerization method to form polymer shells (such as polyacrylamide cross-linked copolymers) on the surfaces of the inorganic cores. The inorganic components and the organic components bind by chemical bonds so that the core-shell type inorganic / organic polymer composite microballoon has very stale structure. The core-shell type inorganic / organic polymer composite microballoon retains the advantages of polymer microballoons and inorganic particles, and has strong heat-resistant and mineralization-resistant capabilities, high plugging strength and good dilatancy. The core-shell type inorganic / organic polymer composite microballoon can move in rock pores and can plug the rock pores. When a plugging pressure difference is improved to a certain degree, elastic deformation of the core-shell type inorganic / organic polymer composite microballoon can be produced and the deformed core-shell type inorganic / organic polymer composite microballoon sequentially moves to a deep rock stratum part so that a liquid flow direction is changed gradually and a crude oil yield is improved. The profile control oil-displacement agent provided by the invention has a large potential.

Owner:BEIJING UNIV OF CHEM TECH

Olefin production utilizing whole crude oil

InactiveUS20040039240A1Lower temperature rangeReduce molecular weightThermal non-catalytic crackingHydrocarbonsOil productionAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild cracking conditions until substantially vaporized, the vapors from mild cracking being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

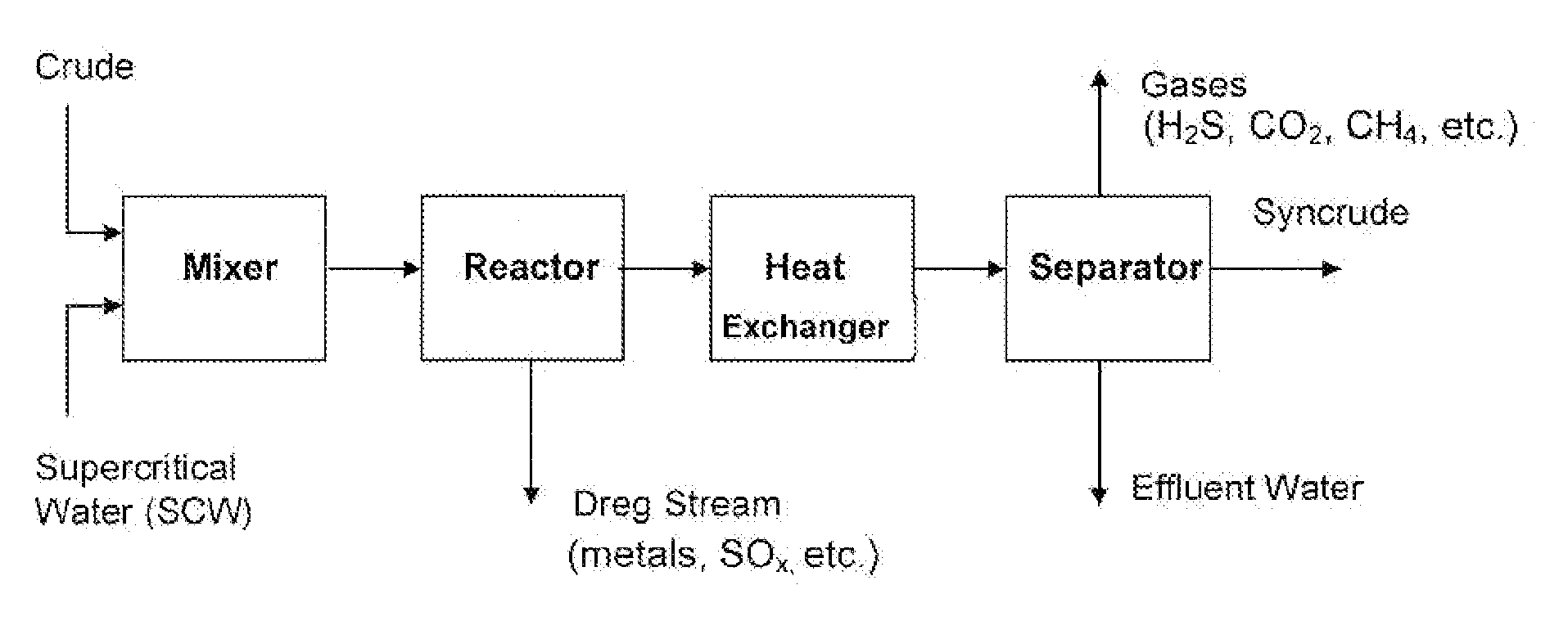

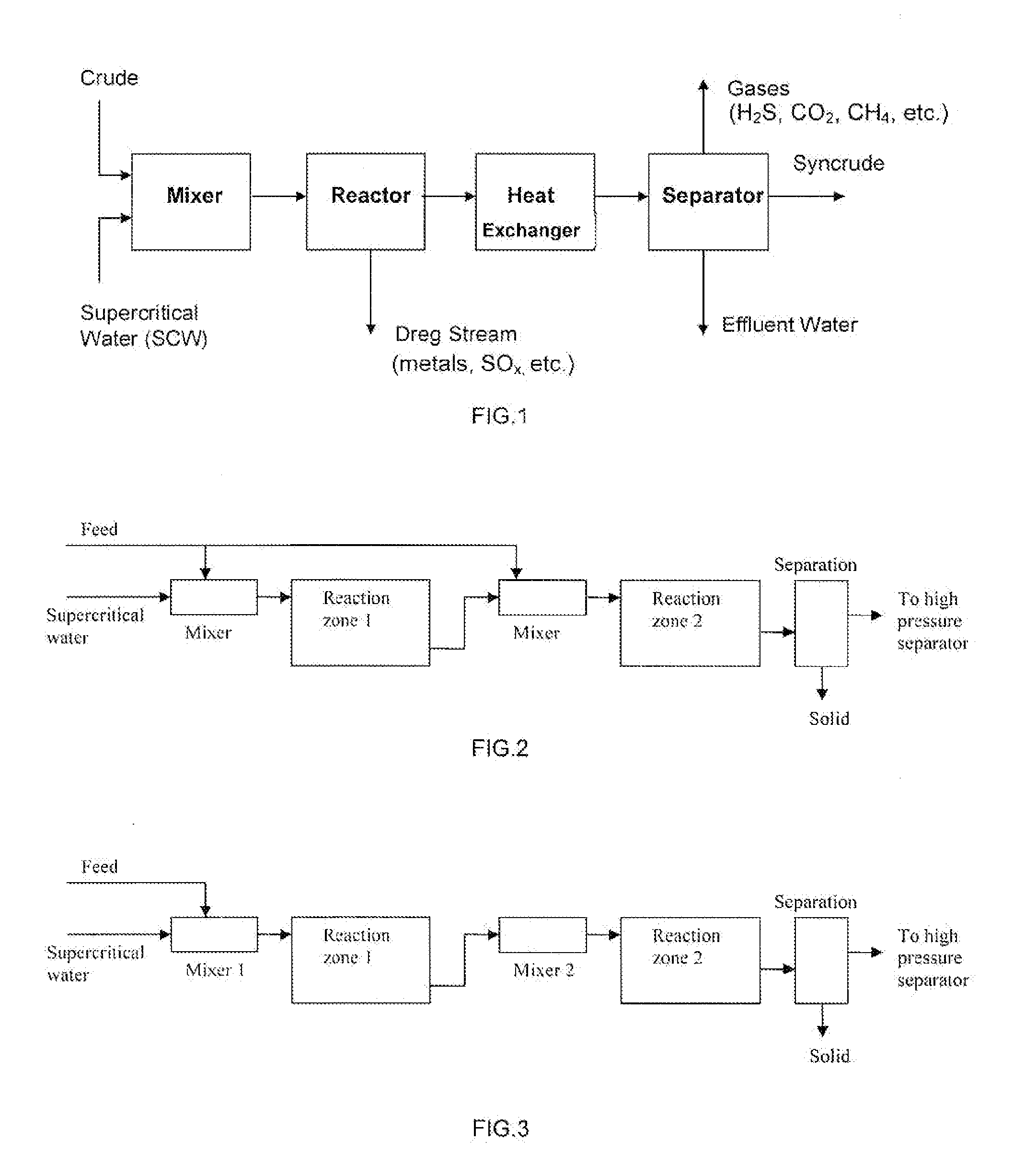

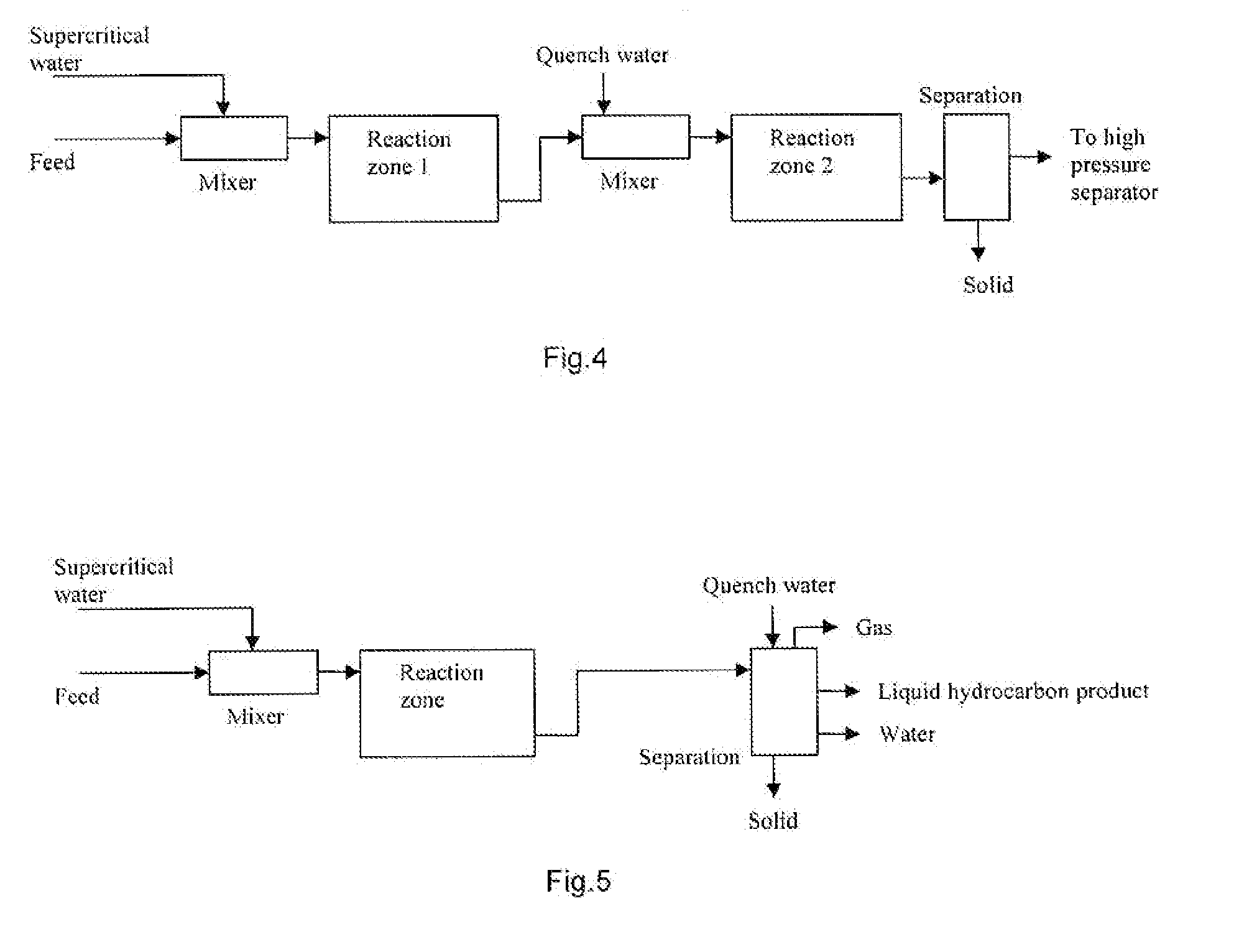

Reactor and process for upgrading heavy hydrocarbon oils

InactiveUS20080099374A1Prevent subsidenceRefining by water treatmentFeed devicesMomentumVolumetric Mass Density

A reactor for conducting a process using supercritical water to upgrade a heavy hydrocarbon feedstock into an upgraded hydrocarbon product or syncrude with highly desirable properties (low sulfur content, low metals content, lower density (higher API), lower viscosity, lower residuum content, etc.) is described. The reactor is operable under continuous) semi-continuous or batch mode and is equipped with means to enable momentum, heat and mass transfer in and out of and within the reactor.

Owner:CHEVROU USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com