Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

383results about How to "High hydrogen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

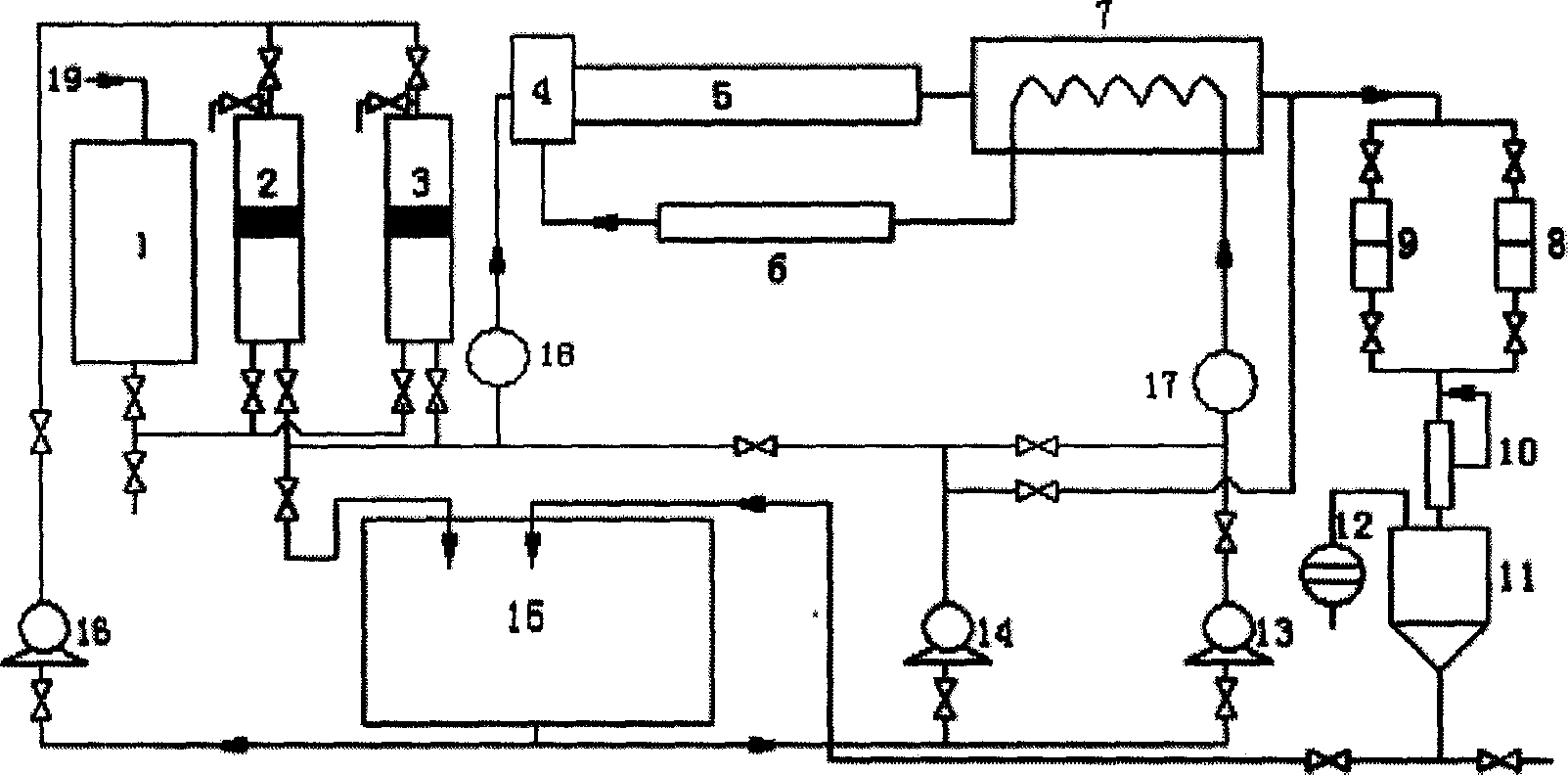

Process and system for converting carbonaceous feedstocks into energy without greenhouse gas emissions

ActiveUS20070099038A1High hydrogen contentFuel cells groupingHydrogen separation using solid contactPetroleum cokePetroleum

The process of the invention converts carbonaceous feedstock such as coal, hydrocarbon oil, natural gas, petroleum coke, oil shale, carbonaceous-containing waste oil, carbonaceous-containing medical waste, carbonaceous-containing military waste, carbonaceous-containing industrial waste, carbonaceous-containing medical waste, carbonaceous-containing sewage sludge and municipal solid waste, carbonaceous-containing agricultural waste, carbonaceous-containing biomass, biological and biochemical waste, and mixtures thereof into electrical energy without the production of unwanted greenhouse emissions. The process uses a steam / CO2 reformer operating in the exit range of at least 700° to about 1600° C. (1300-2900°0 F.) to convert the carbonaceous feedstock and a greenhouse gas stream into a synthesis gas comprising mostly carbon monoxide and hydrogen that contains poisons and the compounds that poison fuel cells. The syngas is sent to an interface zone to remove these poisons and other fouling compounds that are electrochemically oxidized in an electricity-producing fuel cell into an exit gas comprising carbon dioxide and water.

Owner:RAVEN SR INC

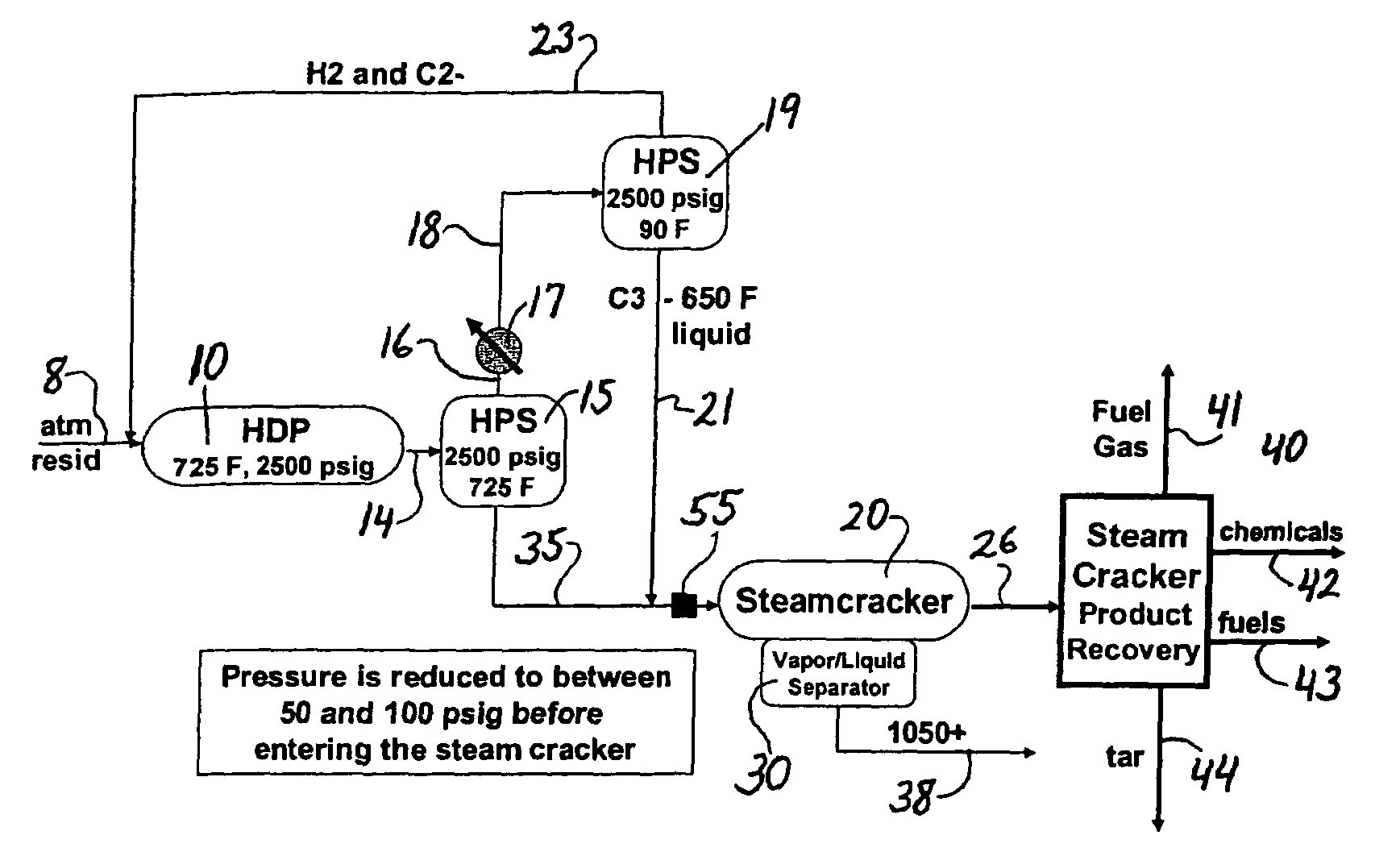

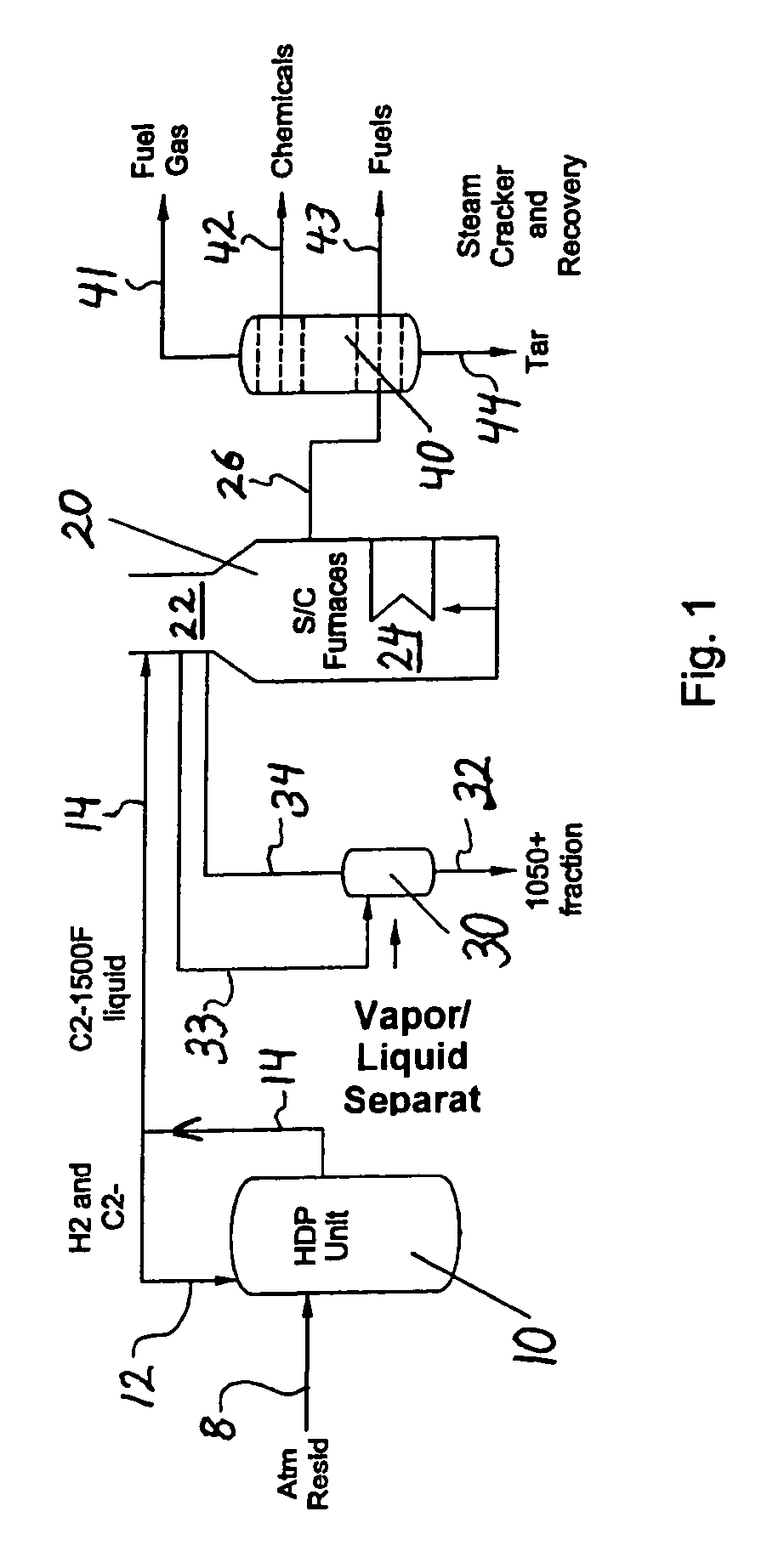

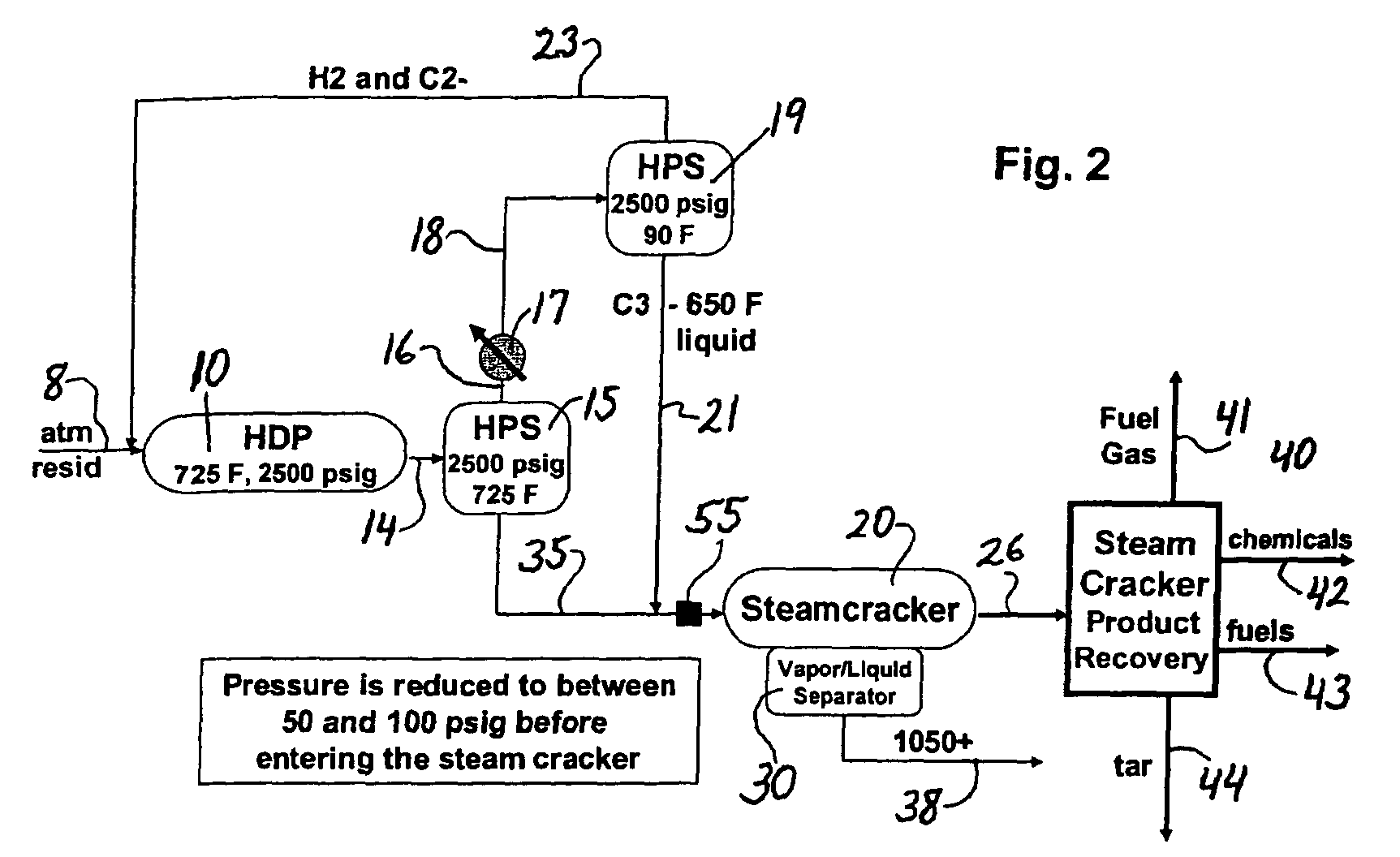

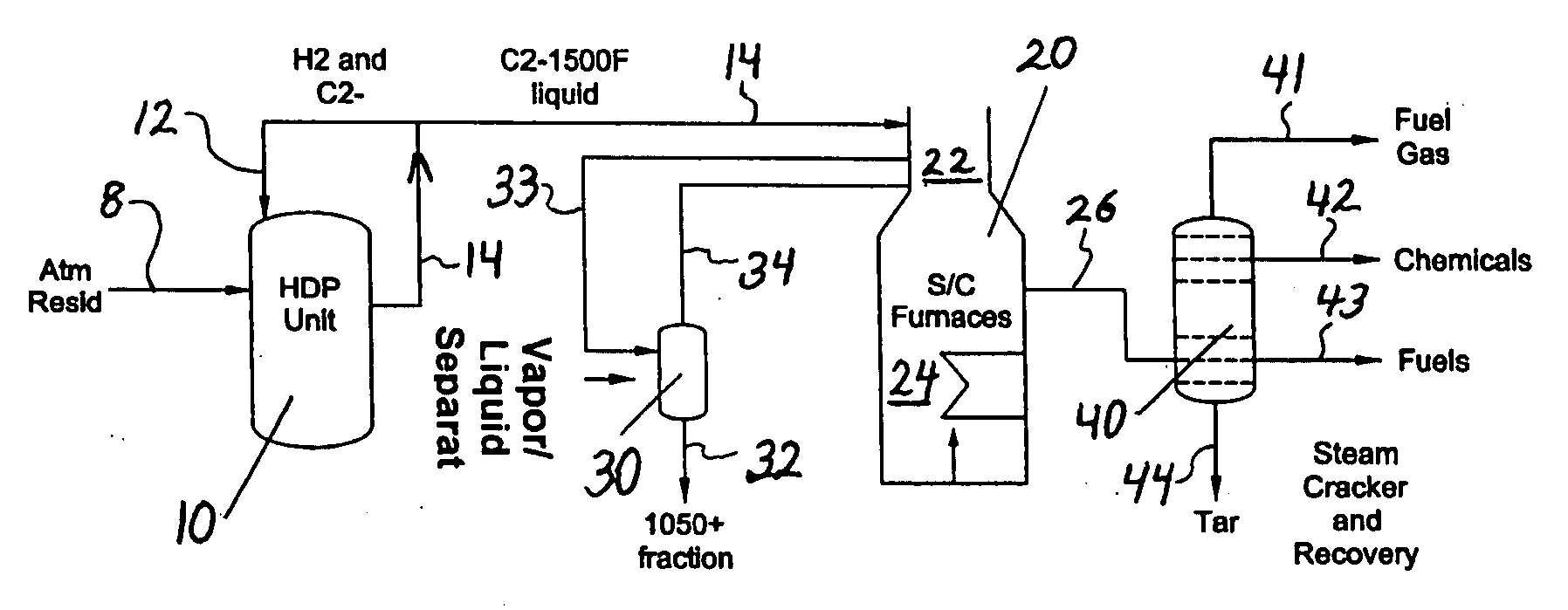

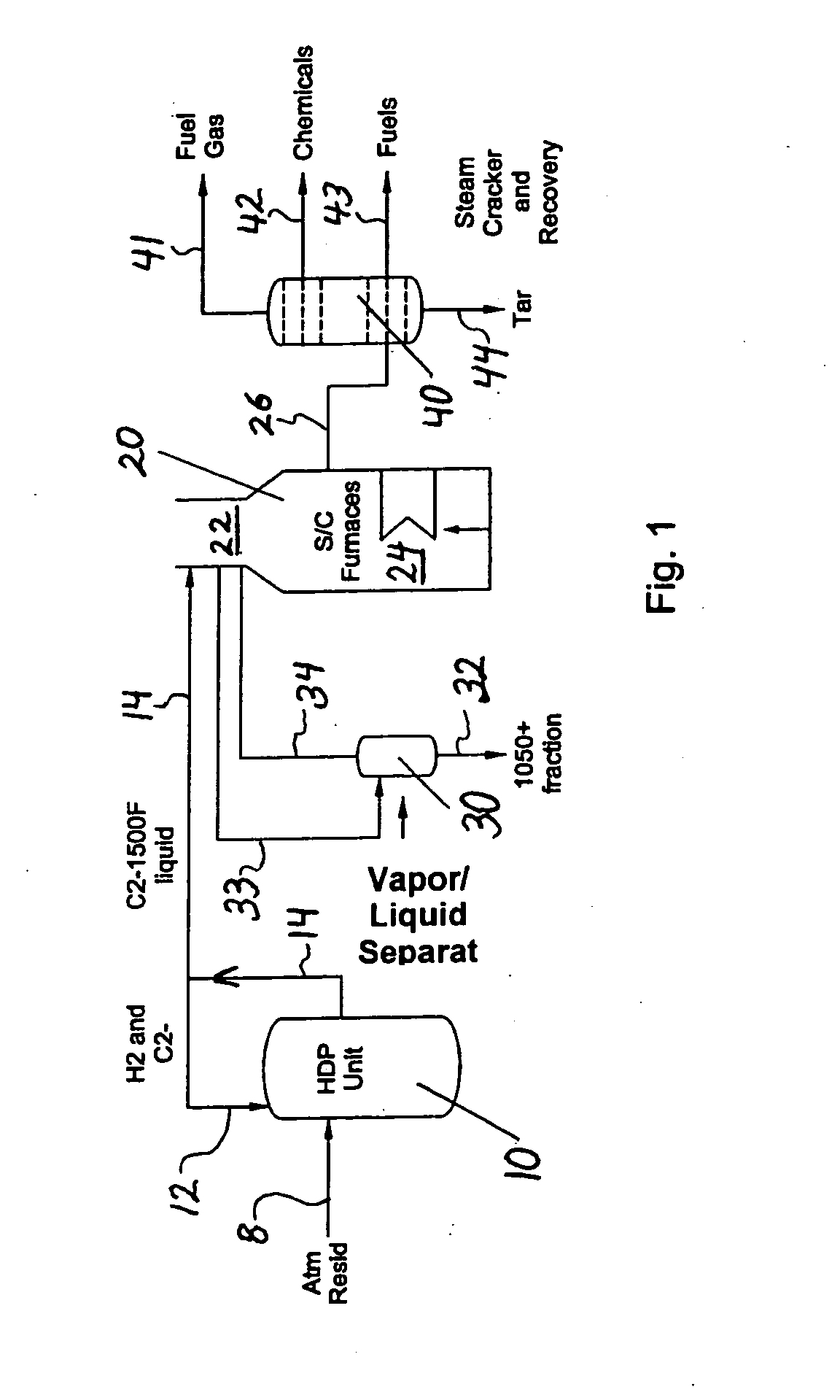

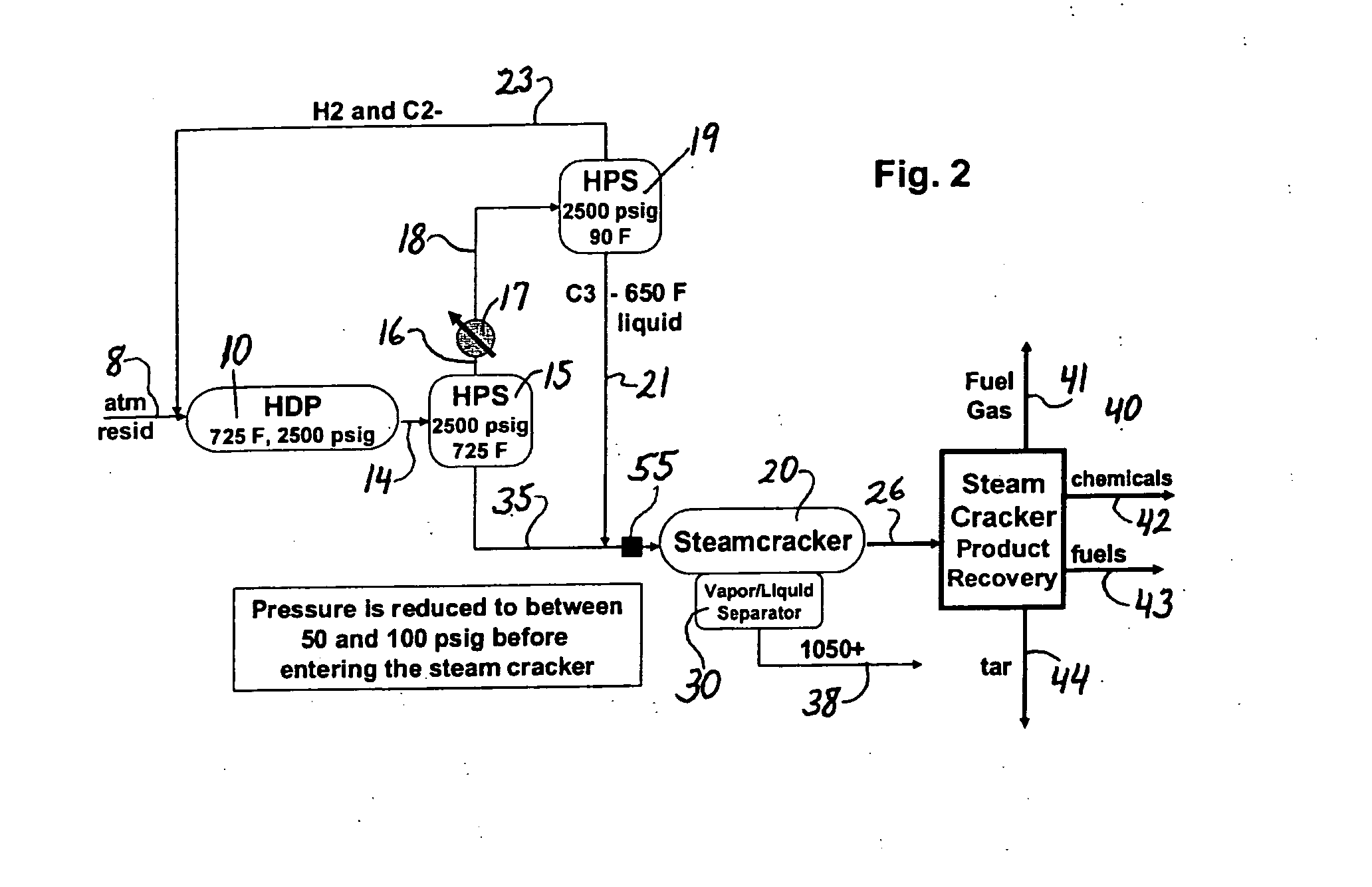

Resid processing for steam cracker feed and catalytic cracking

ActiveUS7972498B2Eliminate needHigh hydrogen contentThermal non-catalytic crackingHydrocarbon oil cracking processProcess engineeringAlkene

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is treated by hydroprocessing and visbreaking and then passed to a steam cracker to obtain a product comprising olefins.

Owner:EXXONMOBIL CHEM PAT INC

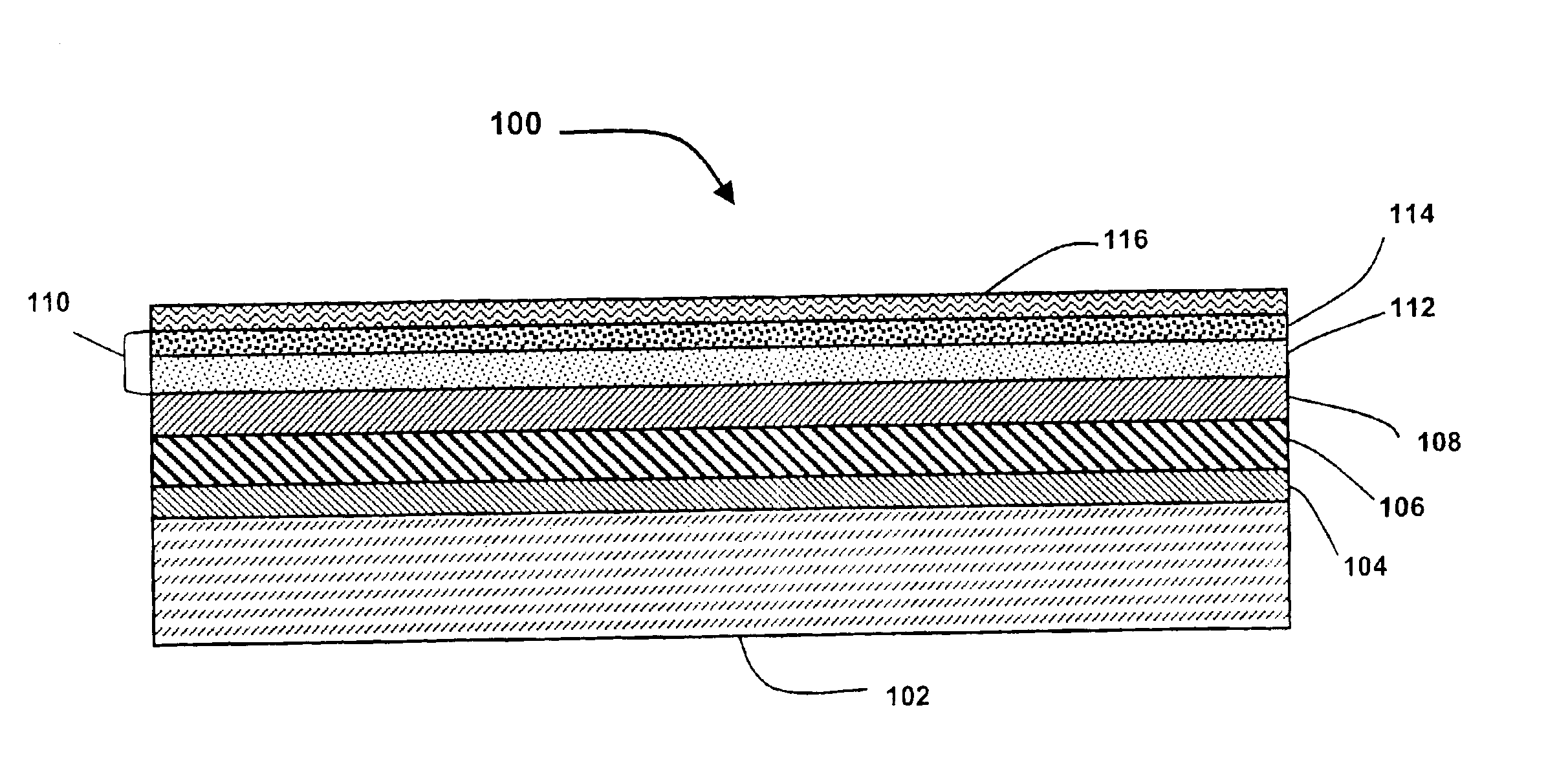

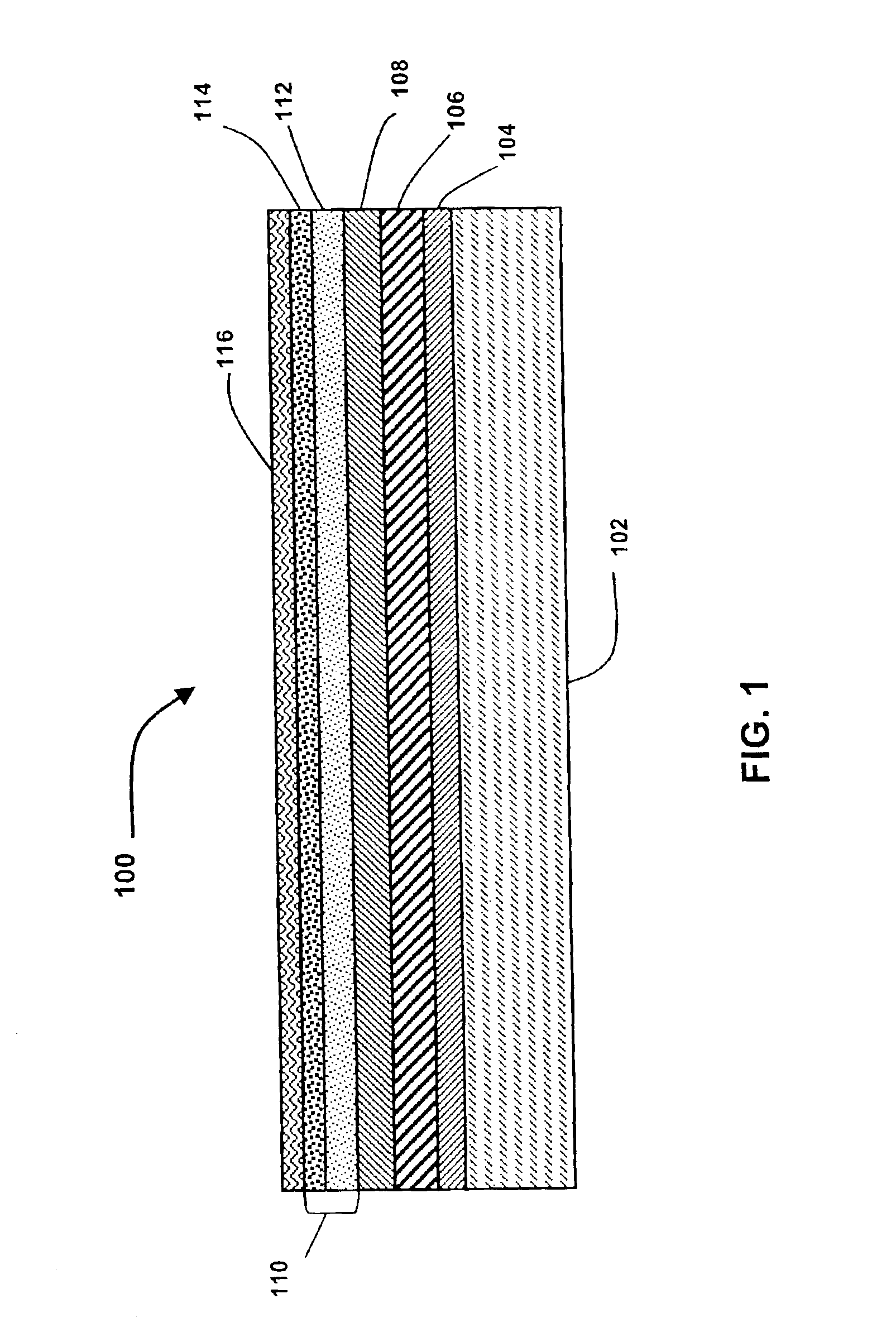

Carbon overcoat for magnetic recording medium

InactiveUS6875492B1Thin carbon overcoatImprove tribological propertiesProtective coatings for layersLayered productsRecording layerMaterials science

Magnetic recording media having a protective carbon overcoat adapted to protect the magnetic recording layer from surface contact events and corrosion. The carbon overcoat includes at least two layers. A first layer is adapted to protect the magnetic recording layer from surface contact events and corrosion. The second layer is disposed on the first layer and is adapted to enhance the bonding of a lubricant to the carbon overcoat and to minimize head degradation. The magnetic recording media of the present invention advantageously enables the use of thin carbon overcoats, enhancing areal density, while maintaining good tribological properties.

Owner:MAXTOR

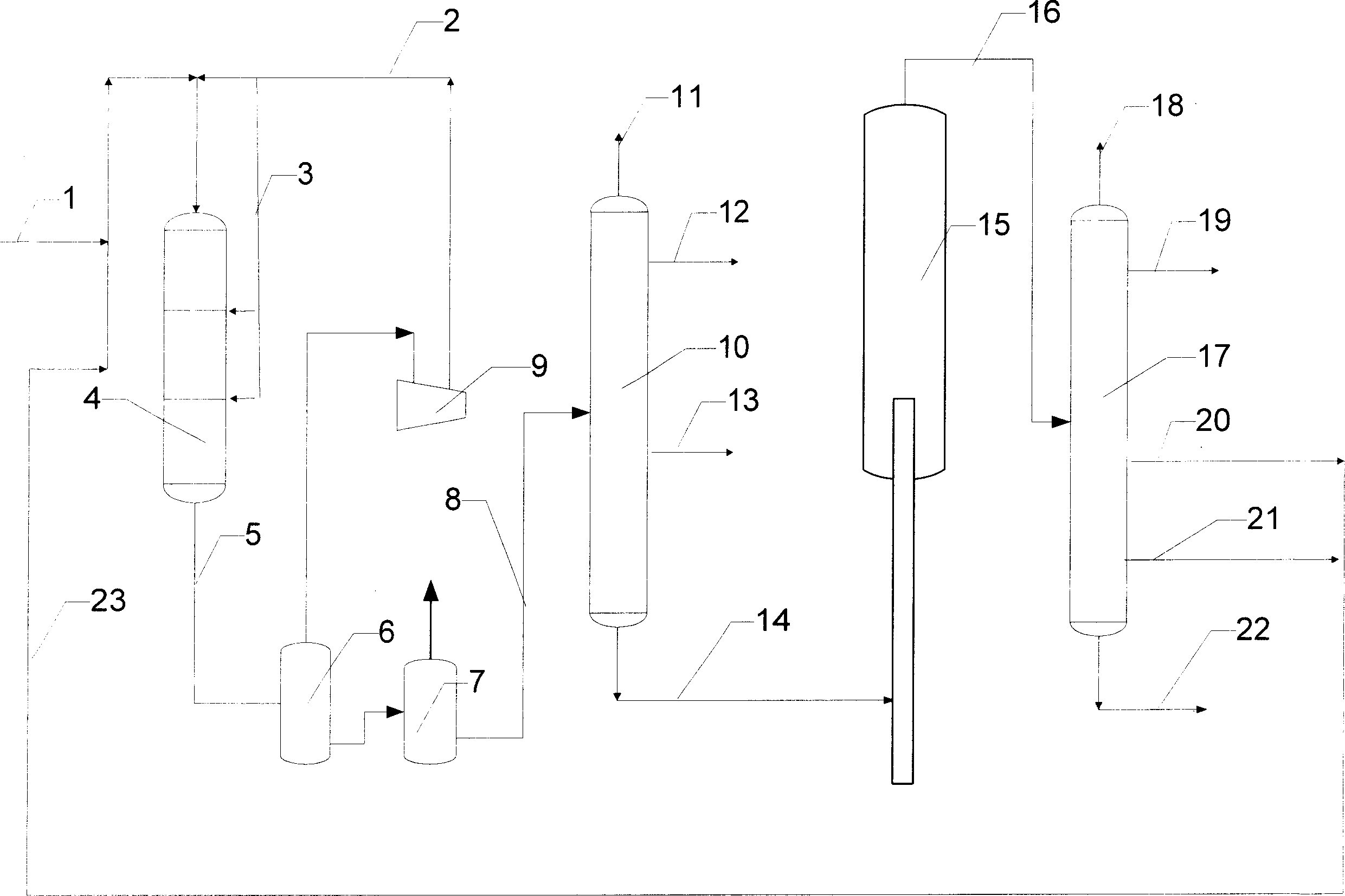

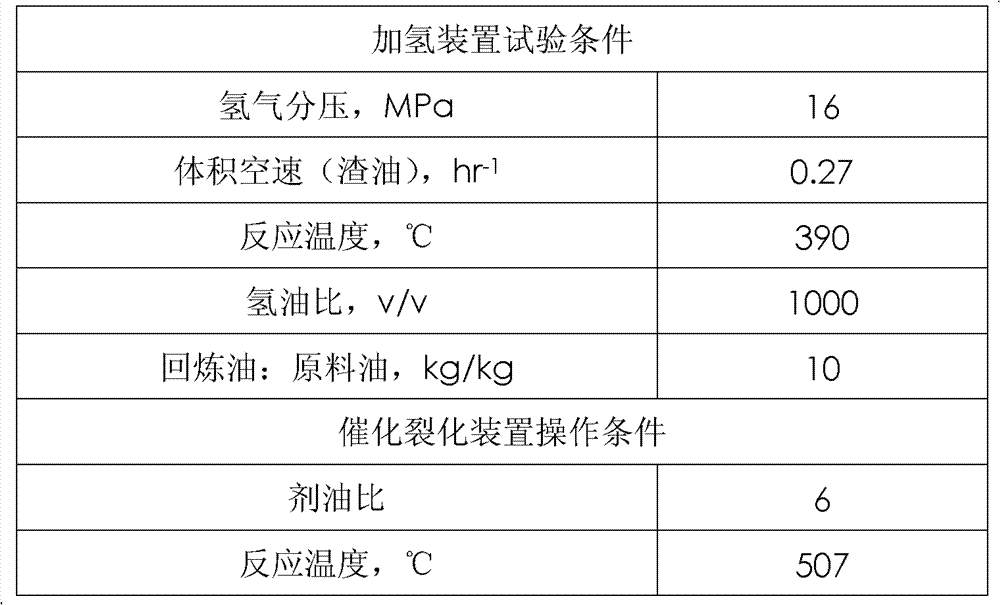

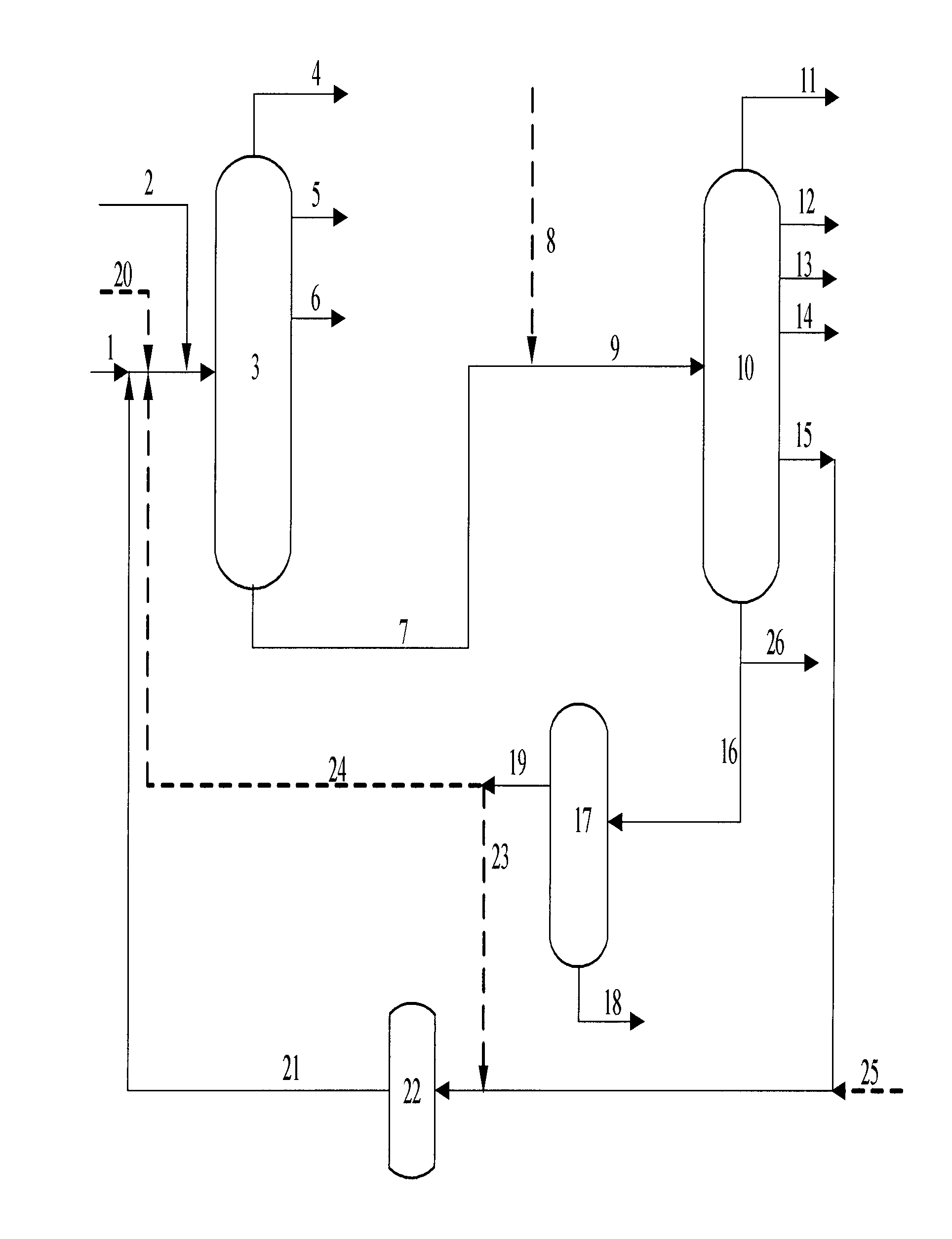

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

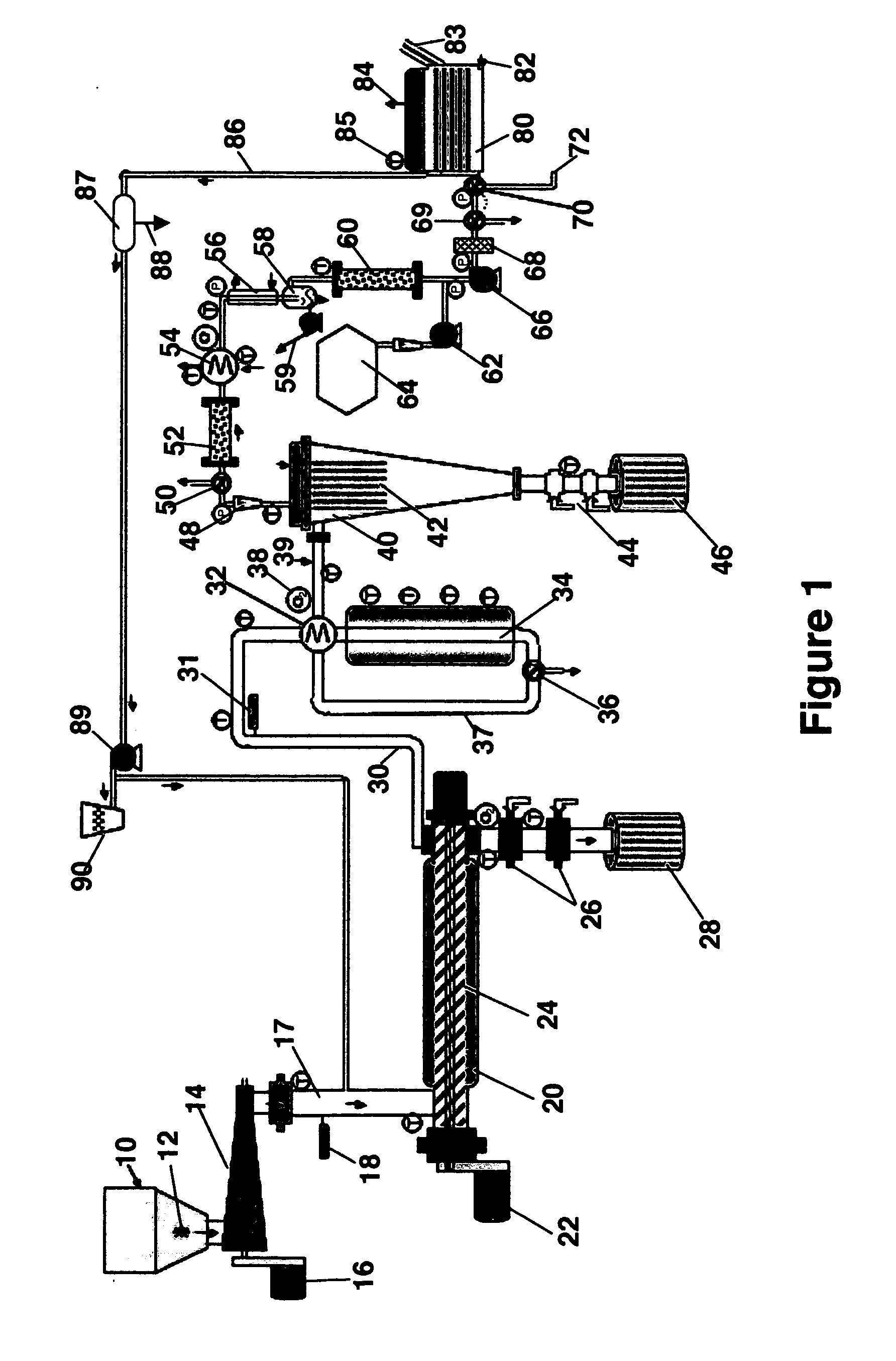

Hydrocarbon resid processing and visbreaking steam cracker feed

ActiveUS20070090019A1High hydrogen contentEliminate needThermal non-catalytic crackingHydrocarbon oil cracking processProcess engineeringHydrogen treatment

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is treated by hydroprocessing and visbreaking and then passed to a steam cracker to obtain a product comprising olefins.

Owner:EXXONMOBIL CHEM PAT INC

Coal-biomass co-overcritical water catalysis-gasification hydrogen production plant and method

ActiveCN1654313AMild reaction conditionsEasy to controlHydrogen productionBulk chemical productionCO2 contentHydrogen content

The present invention discloses one kind of supercritical water catalytic coal and biomass gasifying process and apparatus for producing hydrogen. The apparatus has material feeder with one inlet connected to the outlet of the material pump and the other inlet connected to the outlet of feeding tank, pre-heater with outlet connected to the preheated water inlet and inlet connected to the outlet of inner pipe outlet of the cooler, cooler with inlet connected to the inlet of water pump, water pump with outlet connected to the water tank, cooler jacket with outlet connected to the inlet of the first filter and the inlet of the second filter, and back pressure valve with inlet connected to the outlets of the first filter and the second filter. The present invention has special heating mode for fast heating of the reaction material, raised hydrogen content in the gas product, raised CO2 content in the gas product, and easy separation of CO2 and feeding of CO2 to the processing terminal. The present invention is simple, effective and feasible.

Owner:陕西中核交大超洁能源技术有限公司

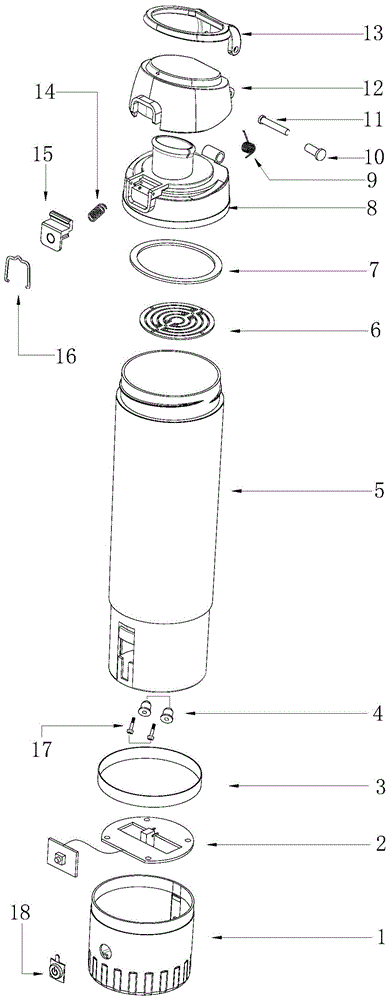

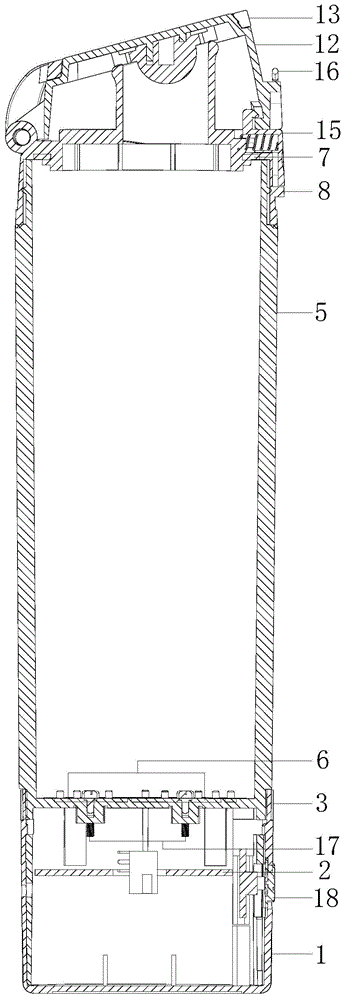

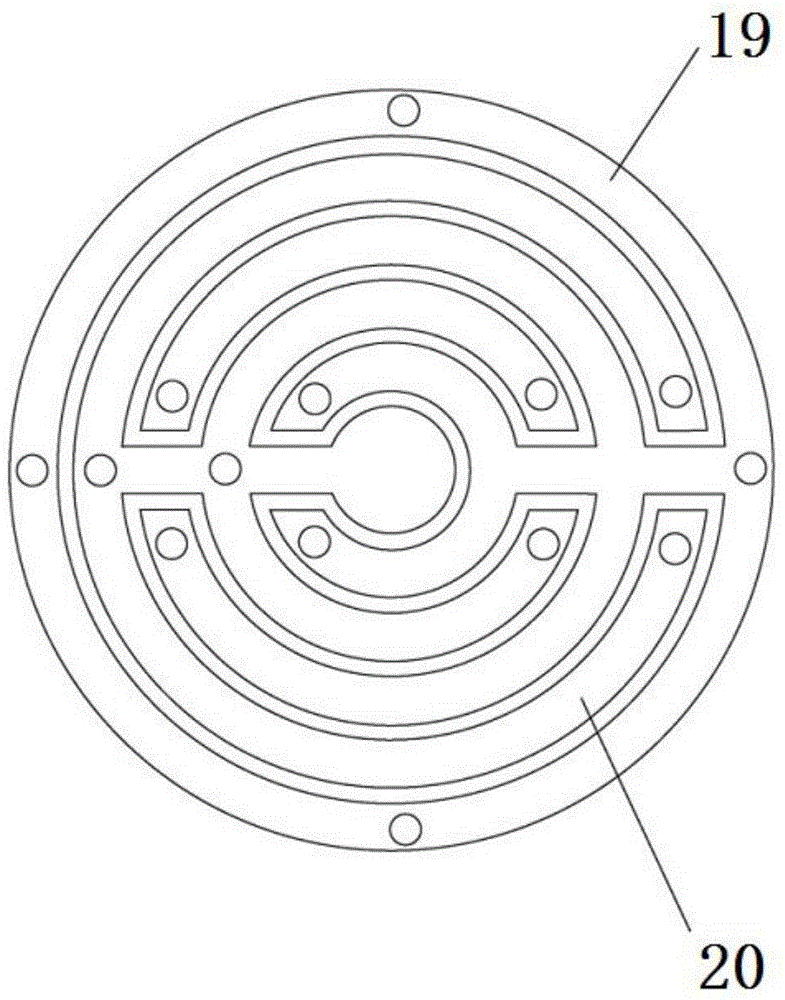

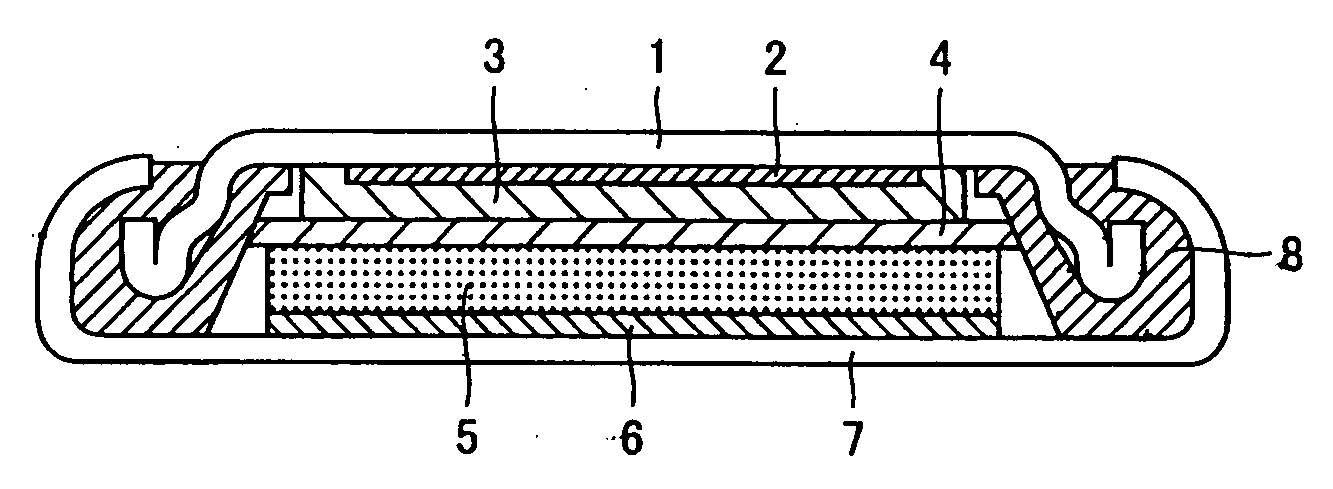

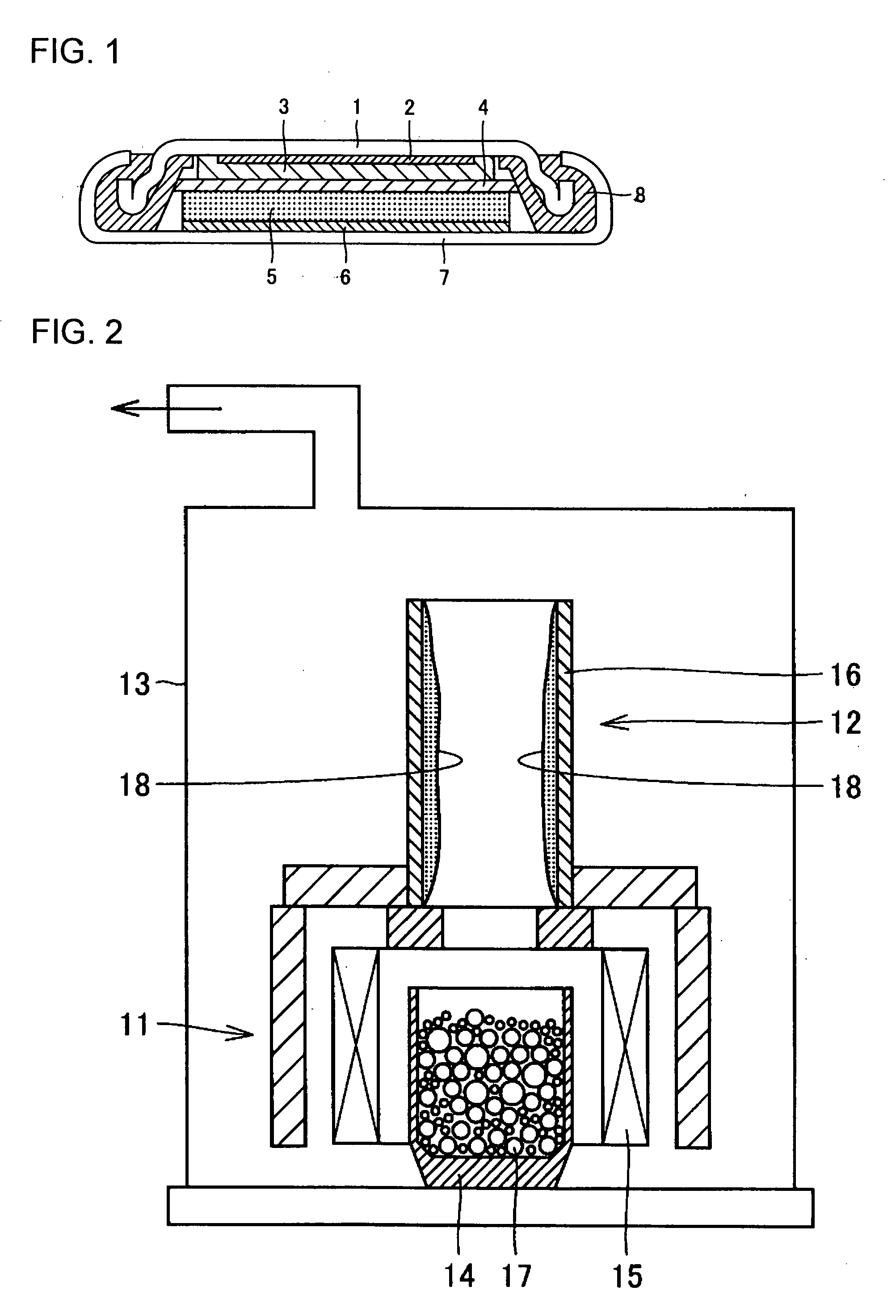

Electrolytic type hydrogen-rich health-care cup

ActiveCN104921549AHigh hydrogen contentNo heavy metalsWater/sewage treatment by substance additionDrinking vesselsHydrogenEngineering

The invention discloses an electrolytic type hydrogen-rich health-care cup comprising a bottom lid, a cup body and a cup lid main body. The bottom lid is connected to the cup body and is internally provided with a PCB, and the PCB is connected to a power switch button. The cup body is internally provided with an electrode plate comprising anodes and cathodes which are annularly arranged in sheet shapes, and the anodes and the cathodes are located on the same plane and are arranged at intervals. The upper portion of the cup body is in threaded connection with the cup lid main body, and is provided with a transparent cup lid. The upper portion of the transparent cup lid is provided with a cup lid handle. The cup lid main body is provided with a cup lid button, a pressure spring is arranged between the cup lid button and the cup lid main body, and a clamping spring used for buckling the transparent cup lid is arranged on the cup lid button. According to the invention, the PCB and the electrode plate is added to a conventional cup to form the health-care cup, and the drinking water is hydrolyzed by the use of the electrode plate so as to obtain the hydrogen-rich water, so that the cup has a health-care function.

Owner:广东氢时代健康产业科技有限公司

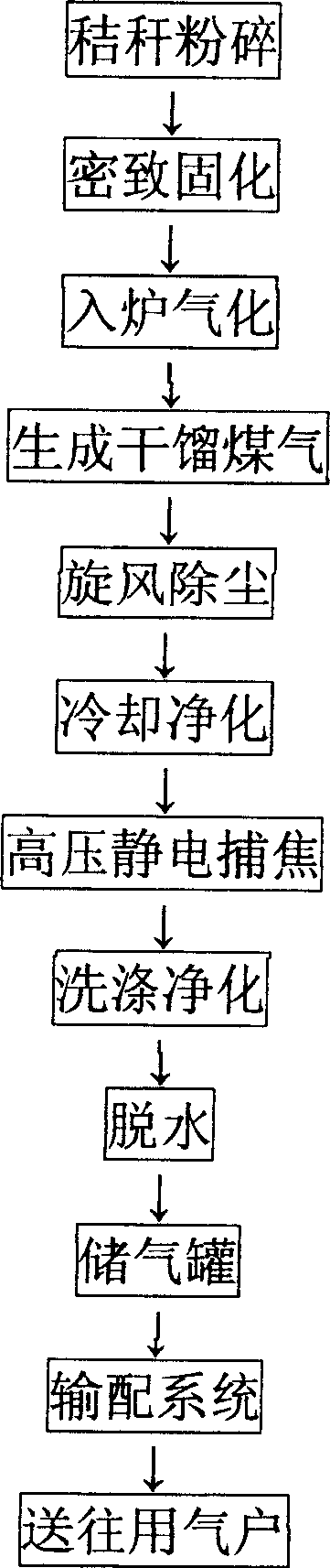

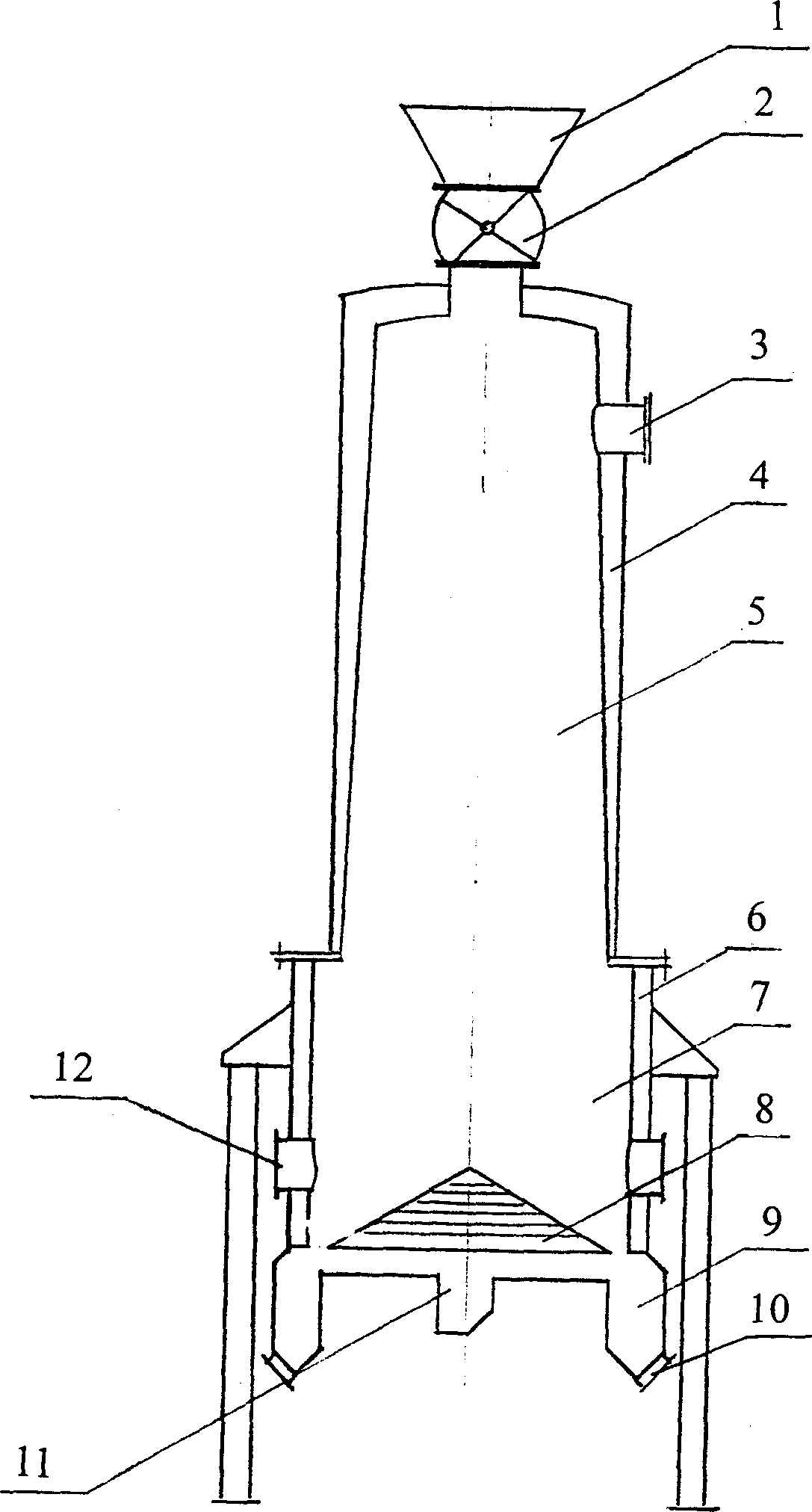

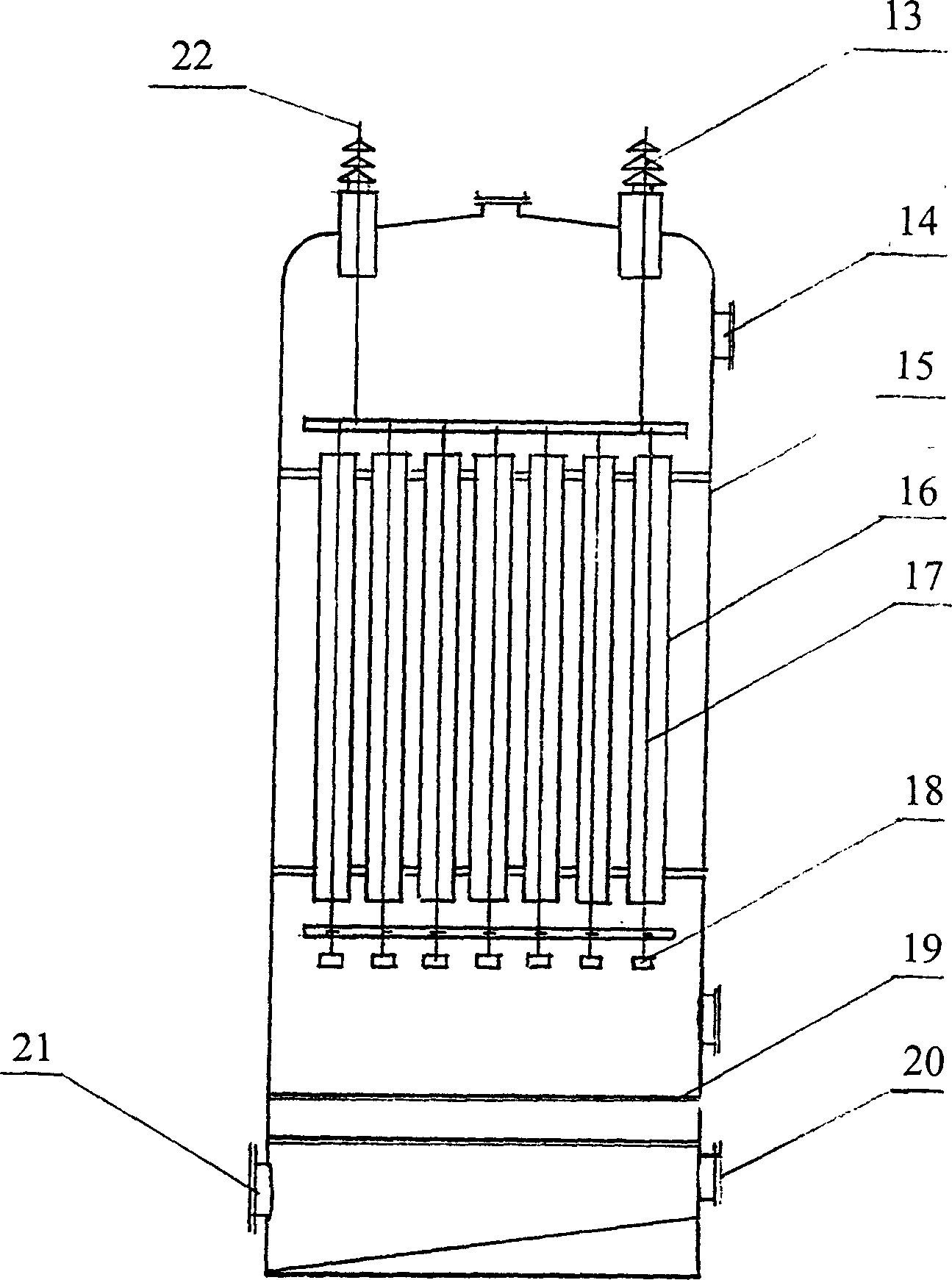

Biomass pyrogenation gasification and purification method

InactiveCN1730609AHigh calorific valueHigh hydrogen contentBiofuelsCombustible gas purificationCyclonePurification methods

The invention provides a biological mass thermal decomposition, gasification and purification method which comprises, disintegrating the biological mass, gasifying in a furnace, obtaining retort gas, cyclone dedusting, cooling down and purifying, high voltage static coke trapping, making the coke tar bubbles and dust in the coal gas deposit onto the coke collection poles, thus purifying the coal gas, finally washing and dewatering.

Owner:MIANYANG TONGMEI ENERGY SCI & TECH CO LTD

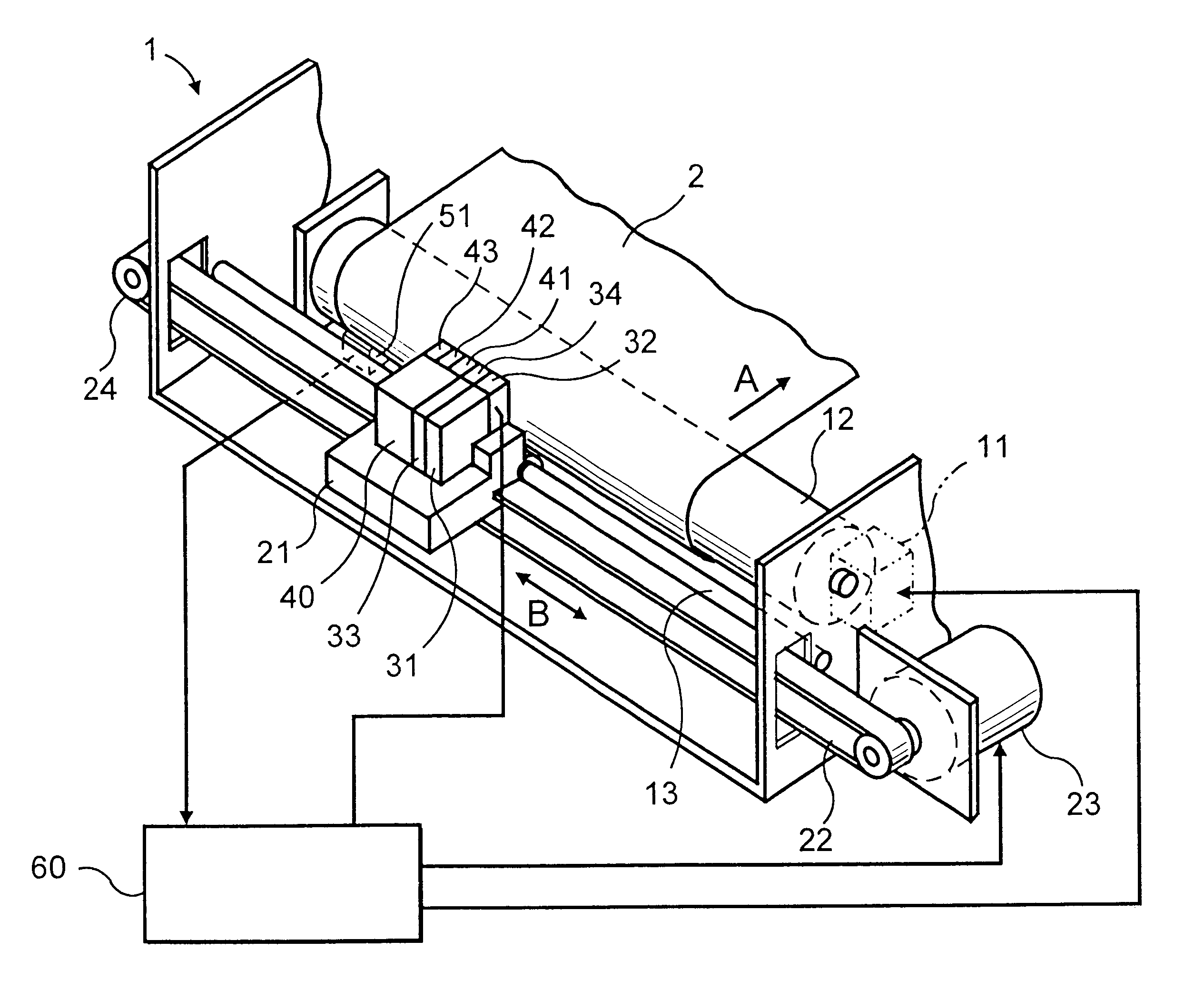

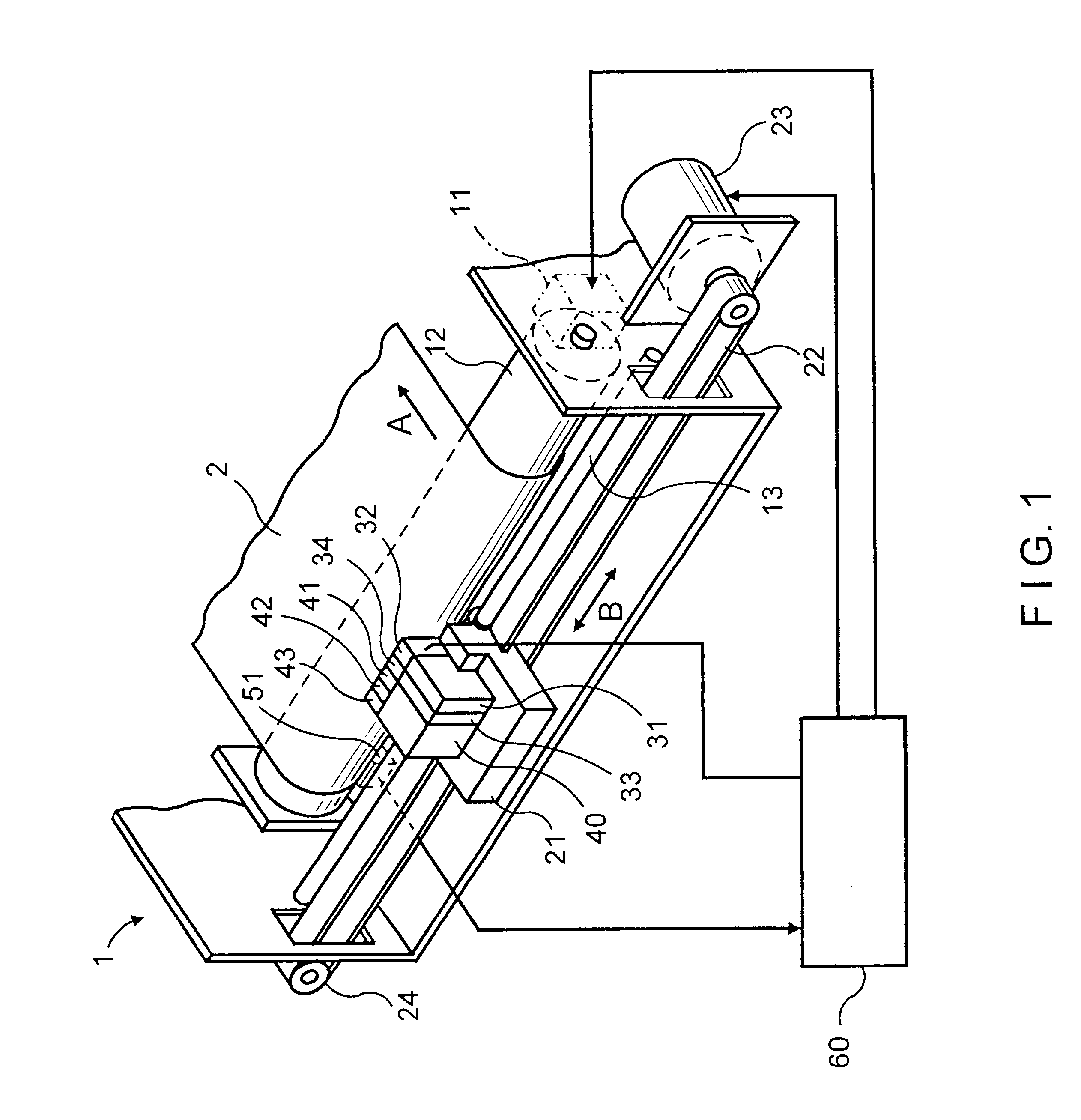

Ink jet recording method and apparatus for forming an image on either plain paper or a specialty recording medium

InactiveUS6234601B1Good dispersionHigh hydrogen contentMeasurement apparatus componentsDuplicating/marking methodsEngineeringPigment

Owner:SEIKO EPSON CORP

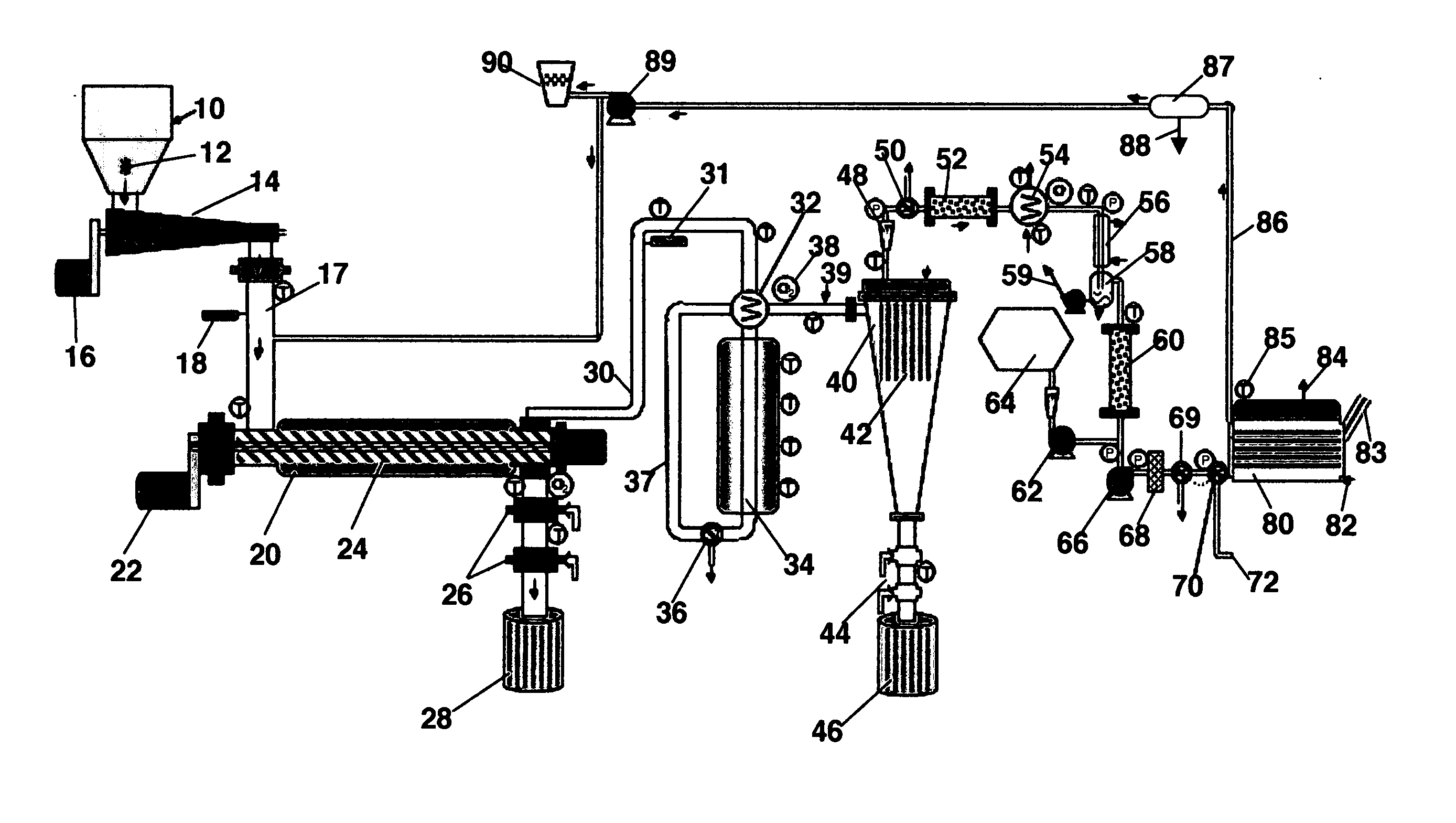

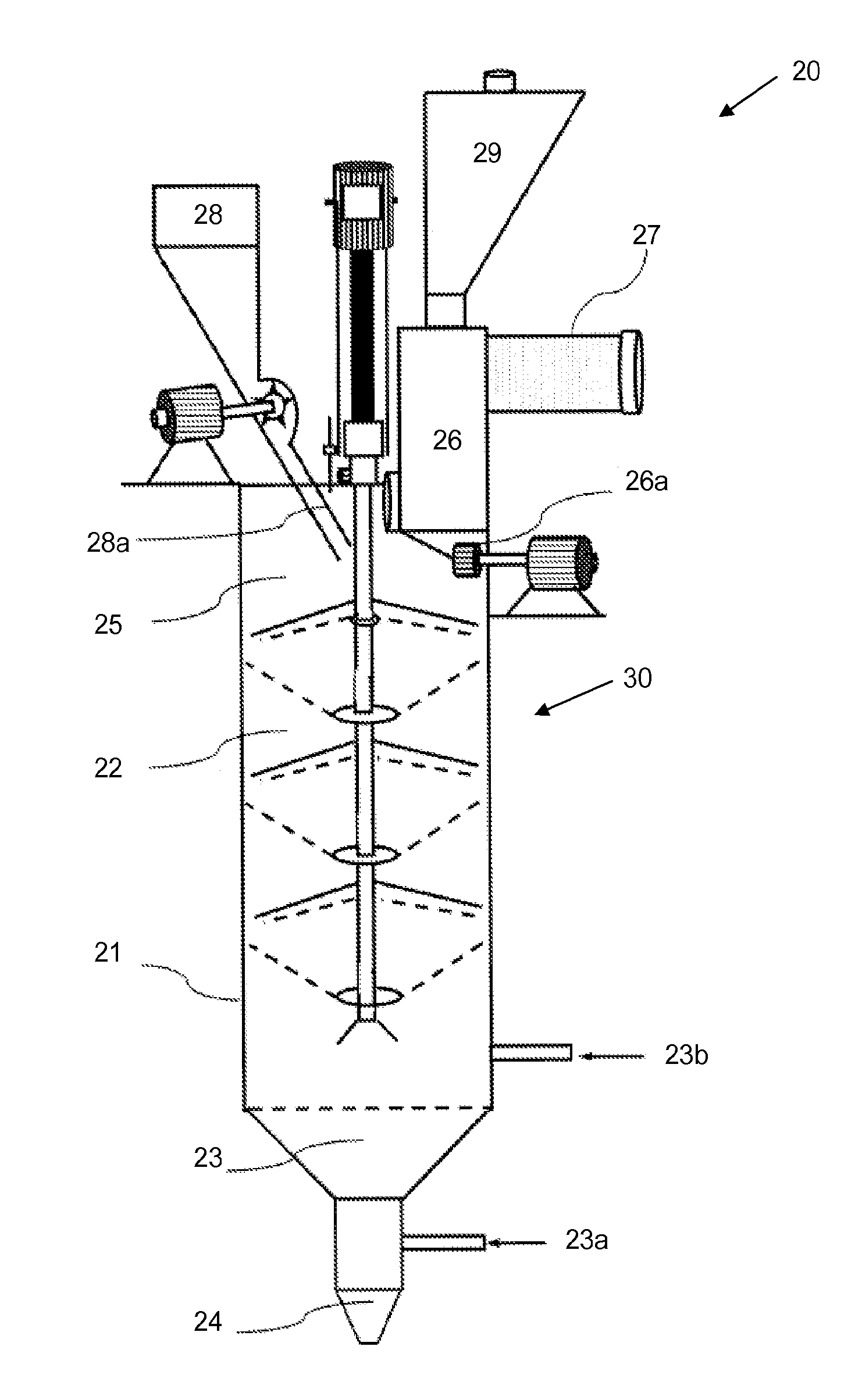

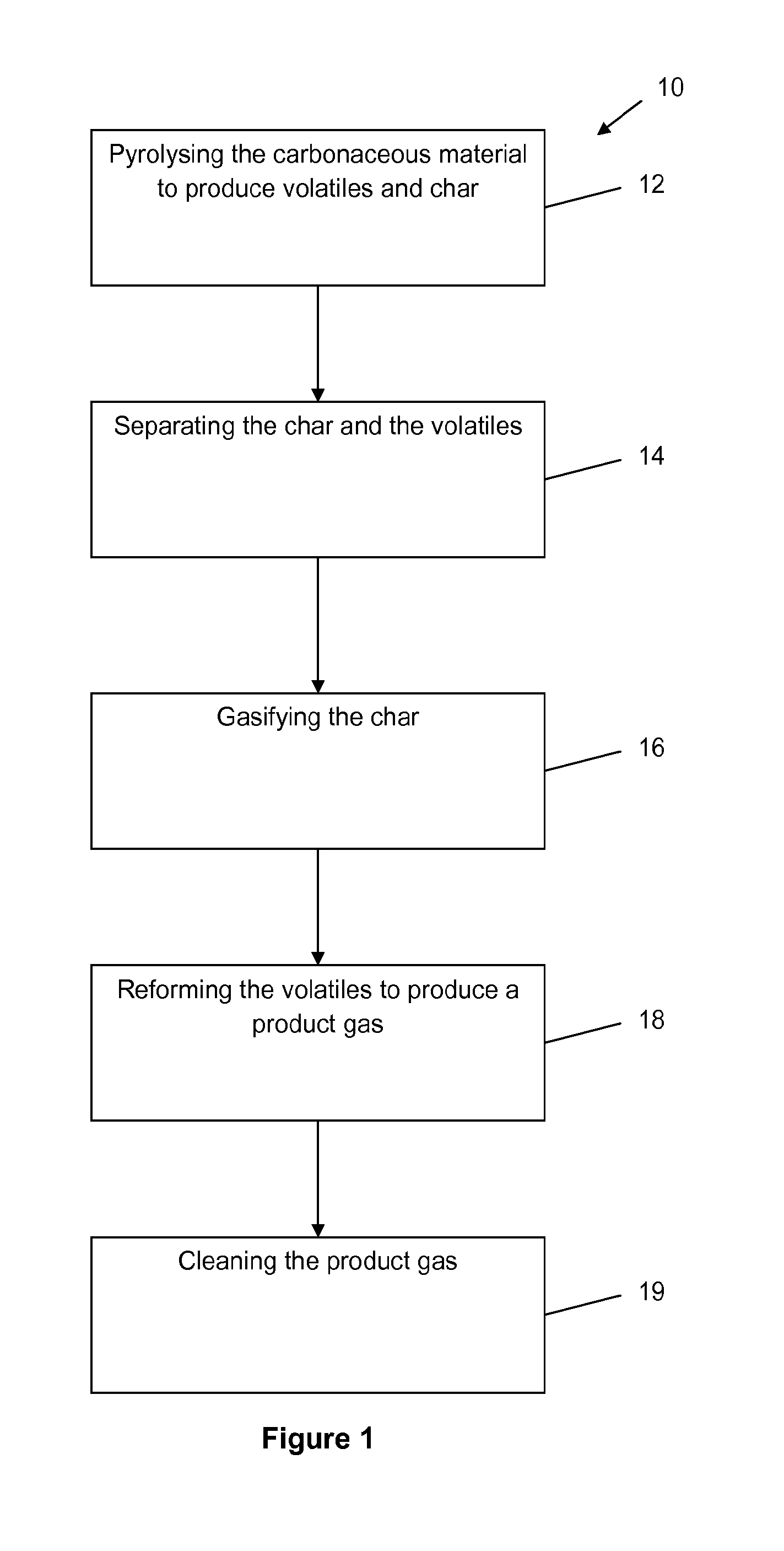

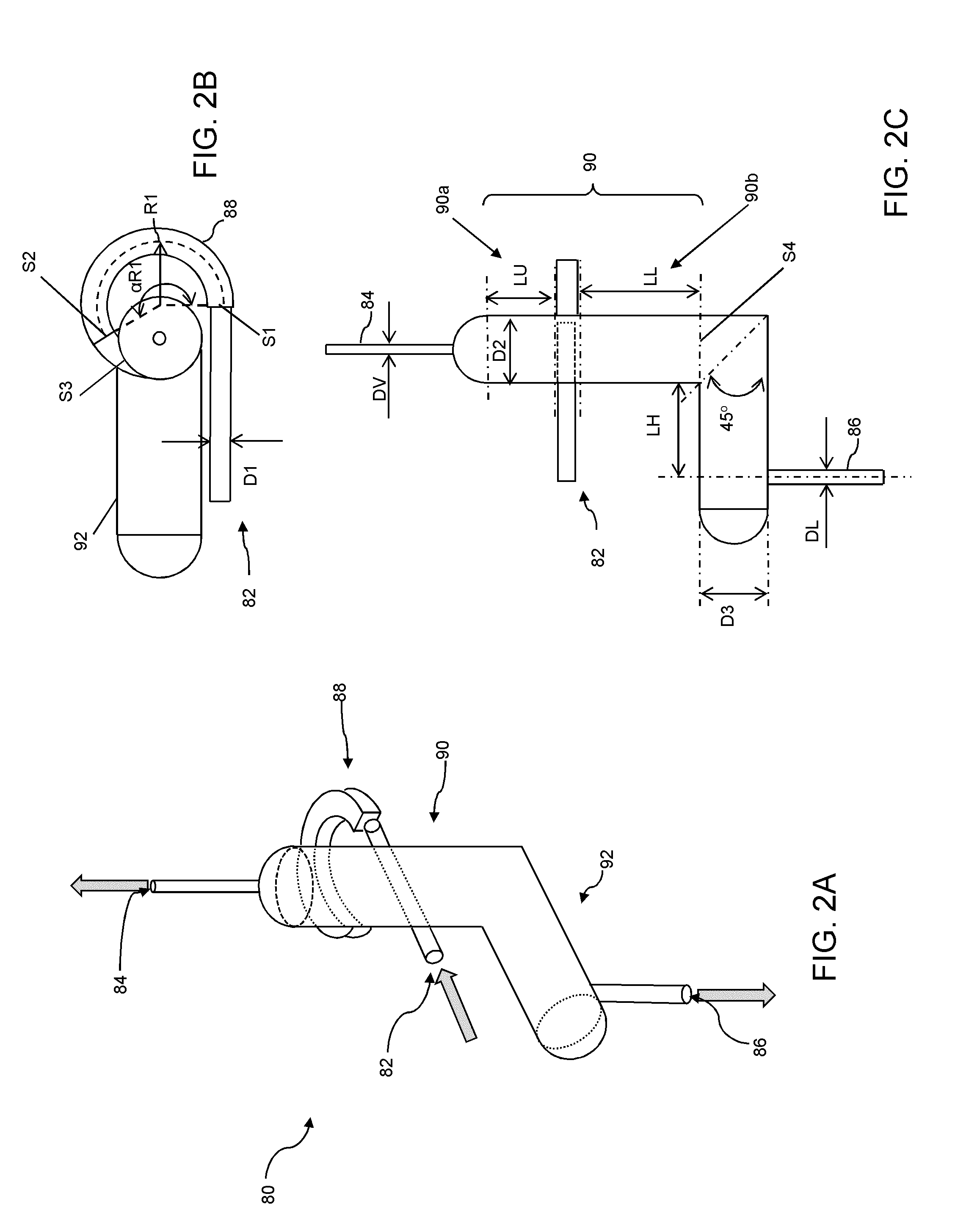

Method of gasifying carbonaceous material and a gasification system

InactiveUS20130306913A1Minimize interactionHigh hydrogen contentCombustible gas coke oven heatingGasifier mechanical detailsProduct gasOrganic chemistry

A method of gasifying carbonaceous material is described. The method comprises a first step of pyrolysing and partially gasifying the carbonaceous material to produce volatiles and char. The volatiles and the char are then separated and, subsequently, the char is gasified and the volatiles are reformed. The raw product gas is then finally cleaned with char or char-supported catalysts or other catalysts.

Owner:CURTAIN UNIV OF TECH

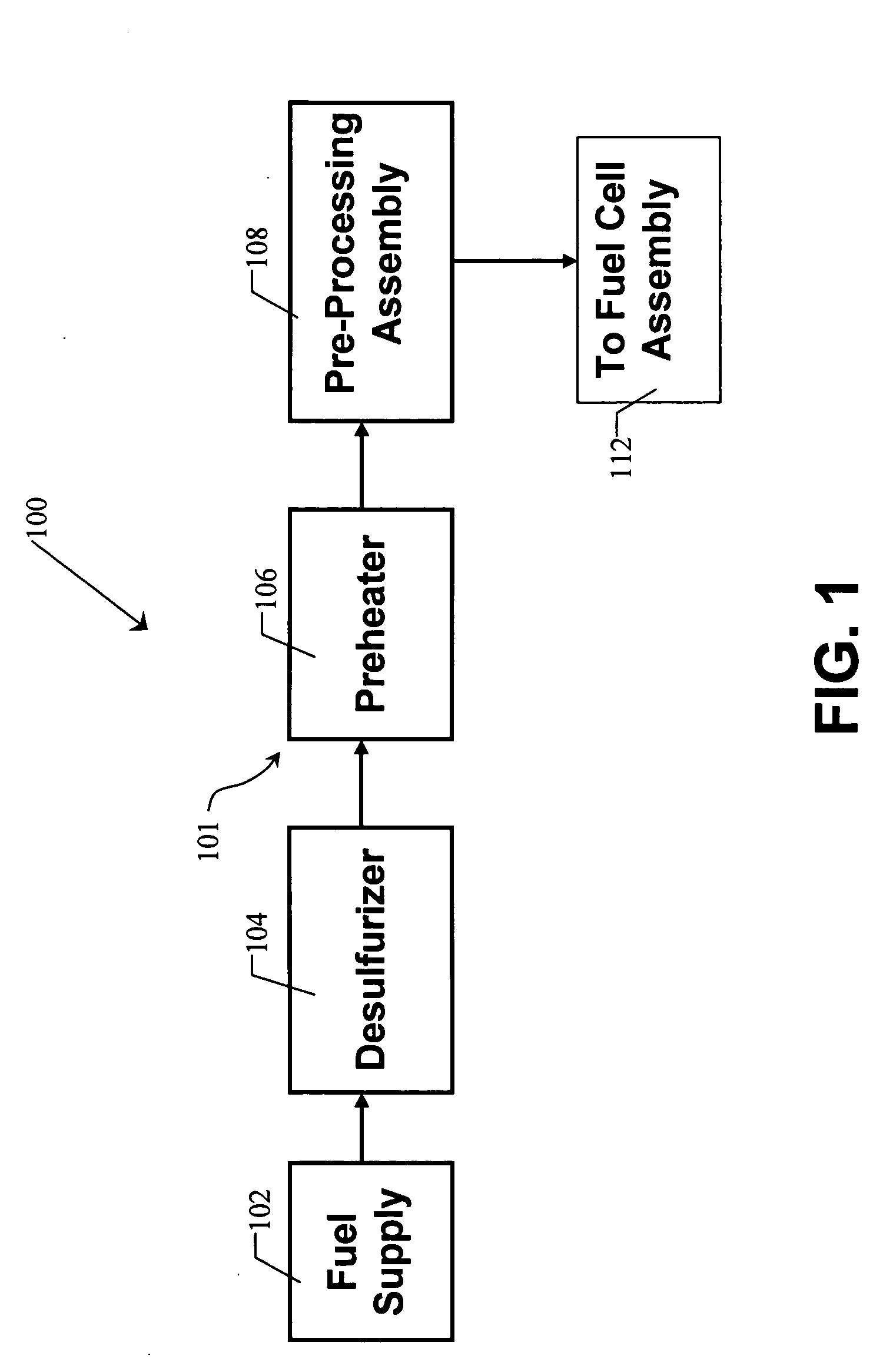

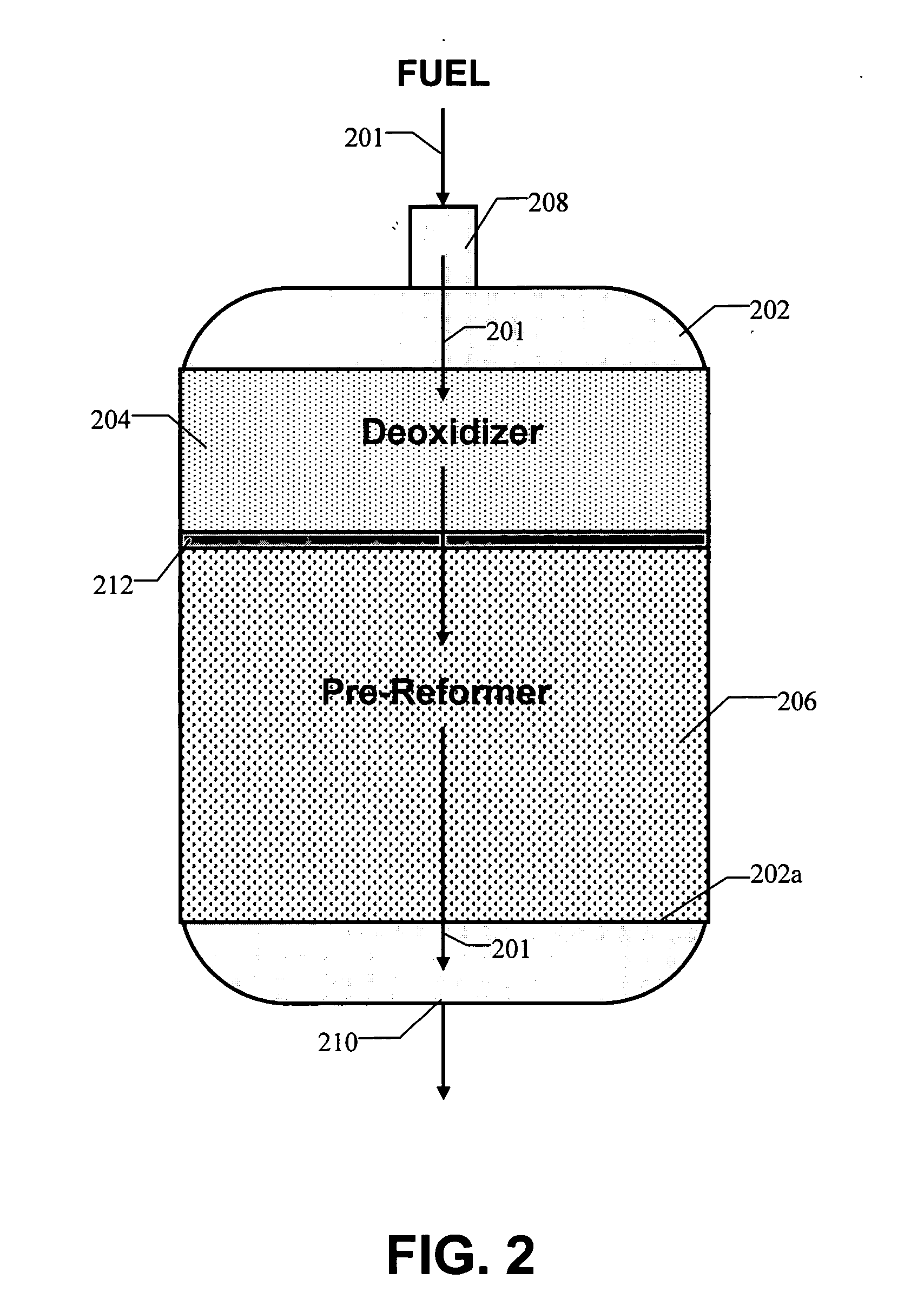

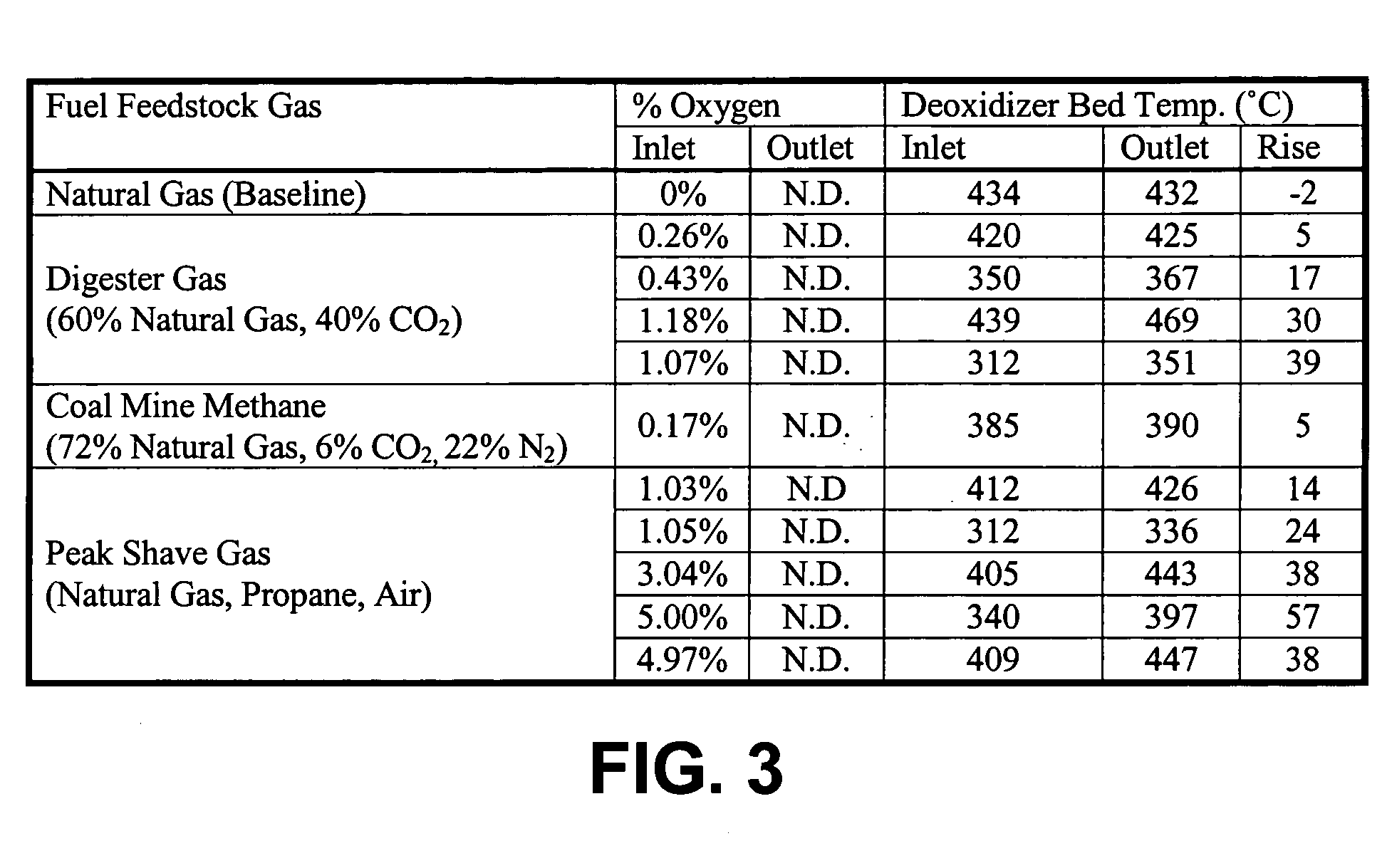

Pre-processing assembly for pre-processing fuel feedstocks for use in a fuel cell system

InactiveUS20060090398A1High hydrogen contentHigh normal hydrocarbon contentHydrogenHydrogen/synthetic gas productionEngineeringMechanical engineering

A pre-processing assembly and method for processing fuel feedstock containing oxygen and hydrocarbons having higher and lower hydrocarbon content for a fuel cell, wherein the pre-processing assembly has a deoxidizing bed for reducing oxygen in the fuel feedstock and a pre-reforming bed for reducing higher hydrocarbon content in the fuel feedstock and wherein the deoxidizing bed and the pre-reforming bed are disposed within a common reaction vessel such that the fuel feedstock first passes through the deoxidizing bed and thereafter through the pre-reforming bed. The pre-reforming assembly may further include a propane processor bed for processing propane and propylene in the fuel feedstock, where the propane processor bed is disposed within the common reaction vessel with the deoxidizing bed and the pre-reforming bed.

Owner:FUELCELL ENERGY INC

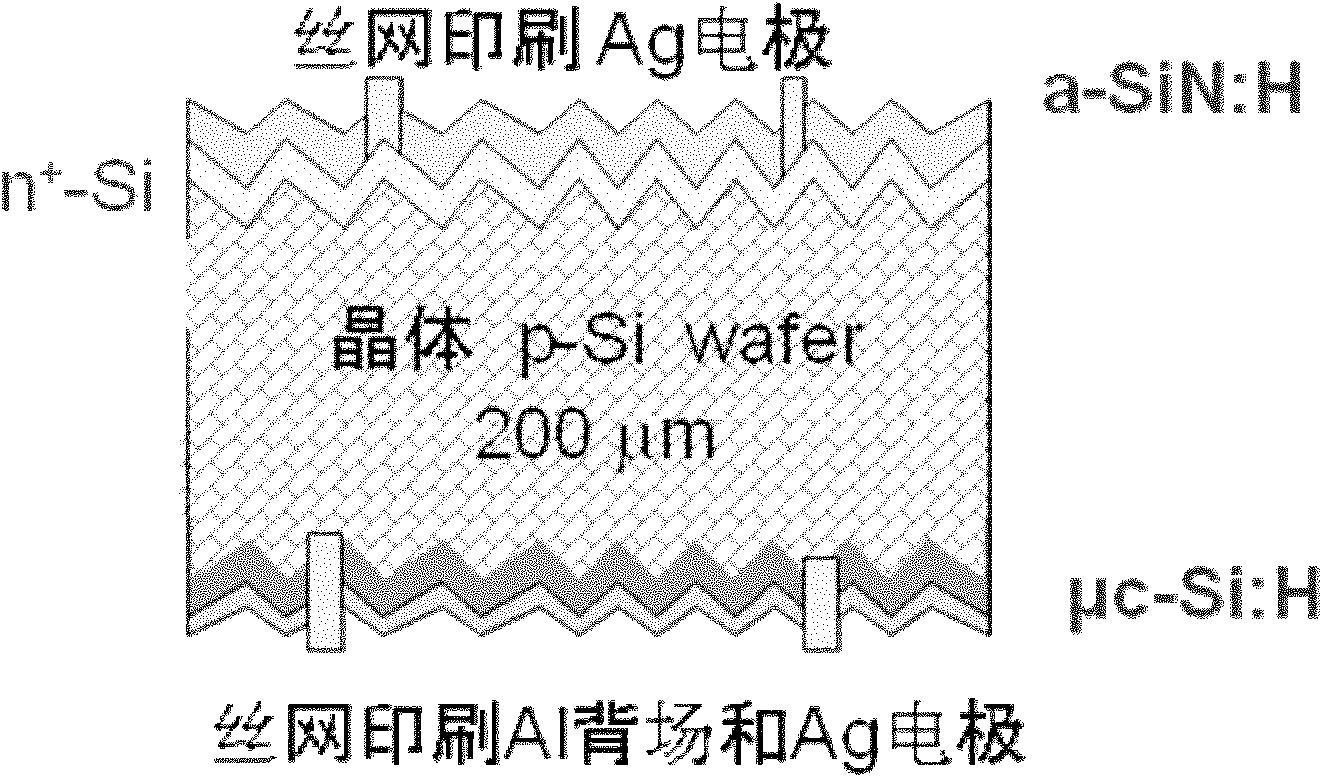

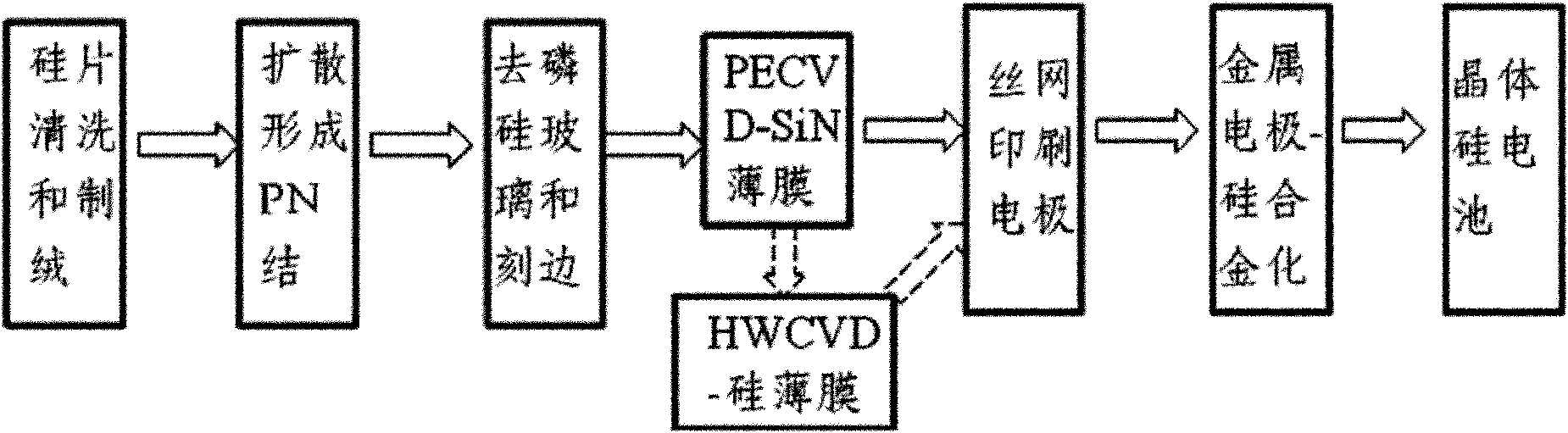

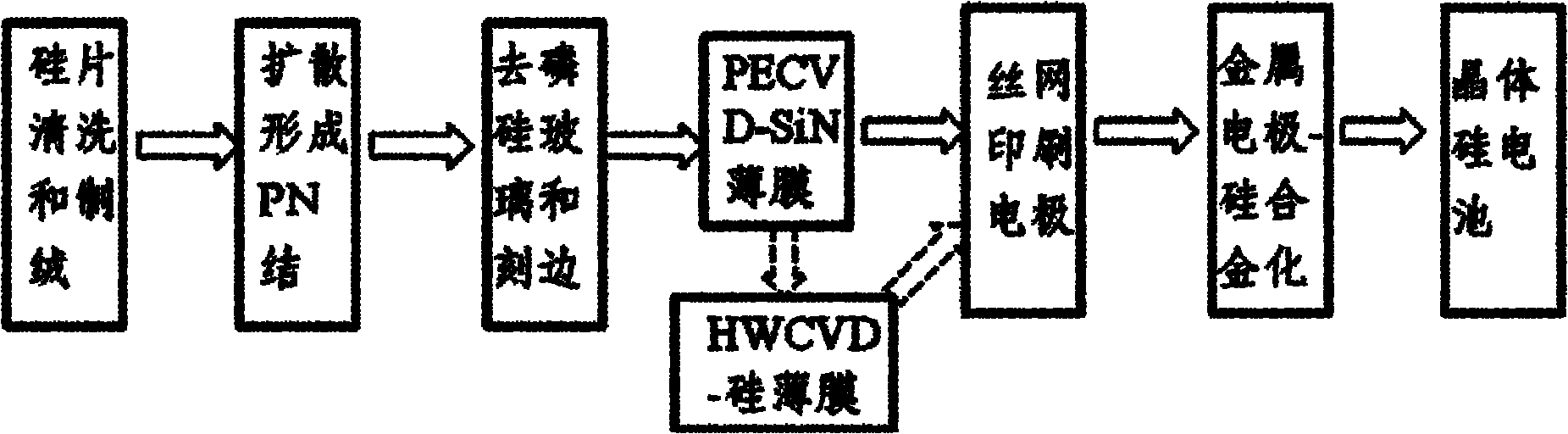

Preparation method of double-sided passivated crystalline silicon solar cell

InactiveCN101937944APrevent escapeAdjustable bandgapSemiconductor devicesP type siliconMicrocrystalline silicon

The invention discloses a preparation method of a double-sided passivated crystalline silicon solar cell, belonging to the technical field of photovoltaic power generation. The preparation method comprises the following steps of: firstly, respectively carrying out surface precleaning and surface texturing on P-shaped single crystal silicon and a polycrystalline silicon wafer by adopting an alkaline solution and an acid solution; secondly, diffusing by using phosphorus oxychloride as a diffusion source to form a PN junction; thirdly, removing a phosphosilicate glass on the surface of the silicon wafer by adopting a chemical wet method, and etching the edge of the silicon wafer by adopting a plasma; fourthly, preparing a silicon nitride film on the surface of an emitting region of a P-type silicon wafer by adopting a plasma enhanced chemical vapor deposition method; fifthly, preparing a mixed phase film material of hydrogenated microcrystalline silicon and amorphous silicon by adopting a hot filament chemical vapor deposition method, depositing a film at one side of the P-type silicon wafer, and passivating the defects and a dangling bond on the surface of the P-type silicon wafer; and sixthly, sintering a screen printing back electrode and a screen printing positive electrode to form the solar cell. The invention lowers the probability of compounding photo-generated minority carriers on the back surface, enhances the long-wave light quantum efficiency and creates the conditions of transportation and collection of the photo-generated carriers.

Owner:SHANGHAI JIAO TONG UNIV

Silicon Monoxide Powder For Secondary Battery and Method For Producing the Same

InactiveUS20080135801A1Miniaturization and cost reductionEfficient productionElectrode thermal treatmentPositive electrodesLithiumHydrogen

A silicon monoxide powder for secondary battery of the present invention is characterized in that the silicon monoxide powder for secondary battery is used in a negative-electrode material of a lithium secondary battery and a hydrogen gas content is not less than 80 ppm. In the silicon monoxide powder for secondary battery, a discharge capacity and a cycle capacity durability rate can dramatically be improved, and miniaturization and cost reduction of the lithium secondary battery can be achieved. In a method for producing the silicon monoxide powder for secondary battery of the present invention, a silicon dioxide powder and a silicon powder with a hydrogen gas content of not less than 30 ppm are mixed together, heated to temperatures of 1250° C. to 1350° C. to vaporize a silicon monoxide, wherein the silicon monoxide thus vaporized is deposited on a deposition substrate to be subsequently crushed. Therefore, the silicon monoxide powder can efficiently be produced to largely reduce production costs such as electric power cost, thus enabling the present invention to be widely applied to the silicon monoxide powder for secondary battery.

Owner:OSAKA TITANIUM TECHNOLOGIES

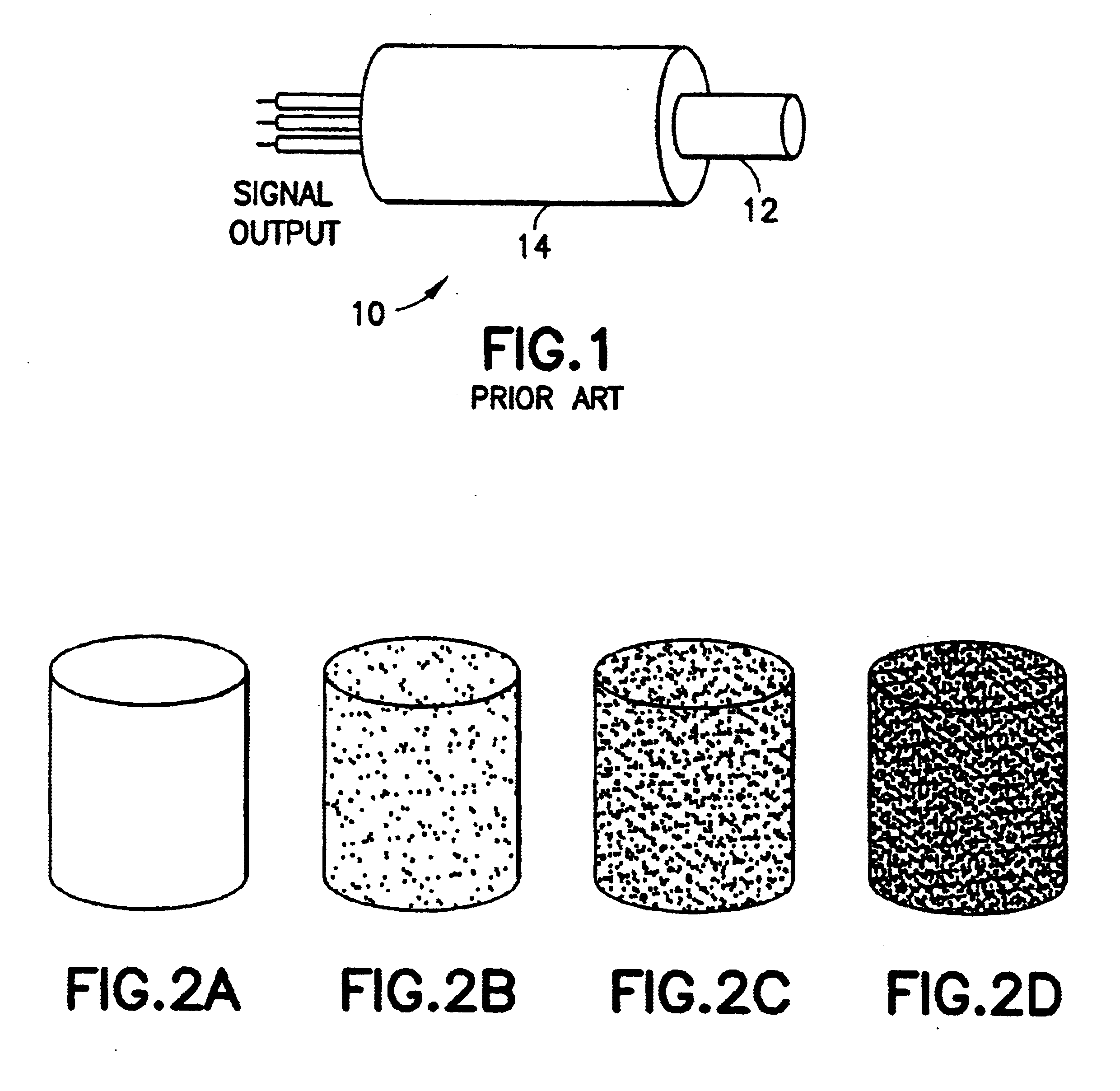

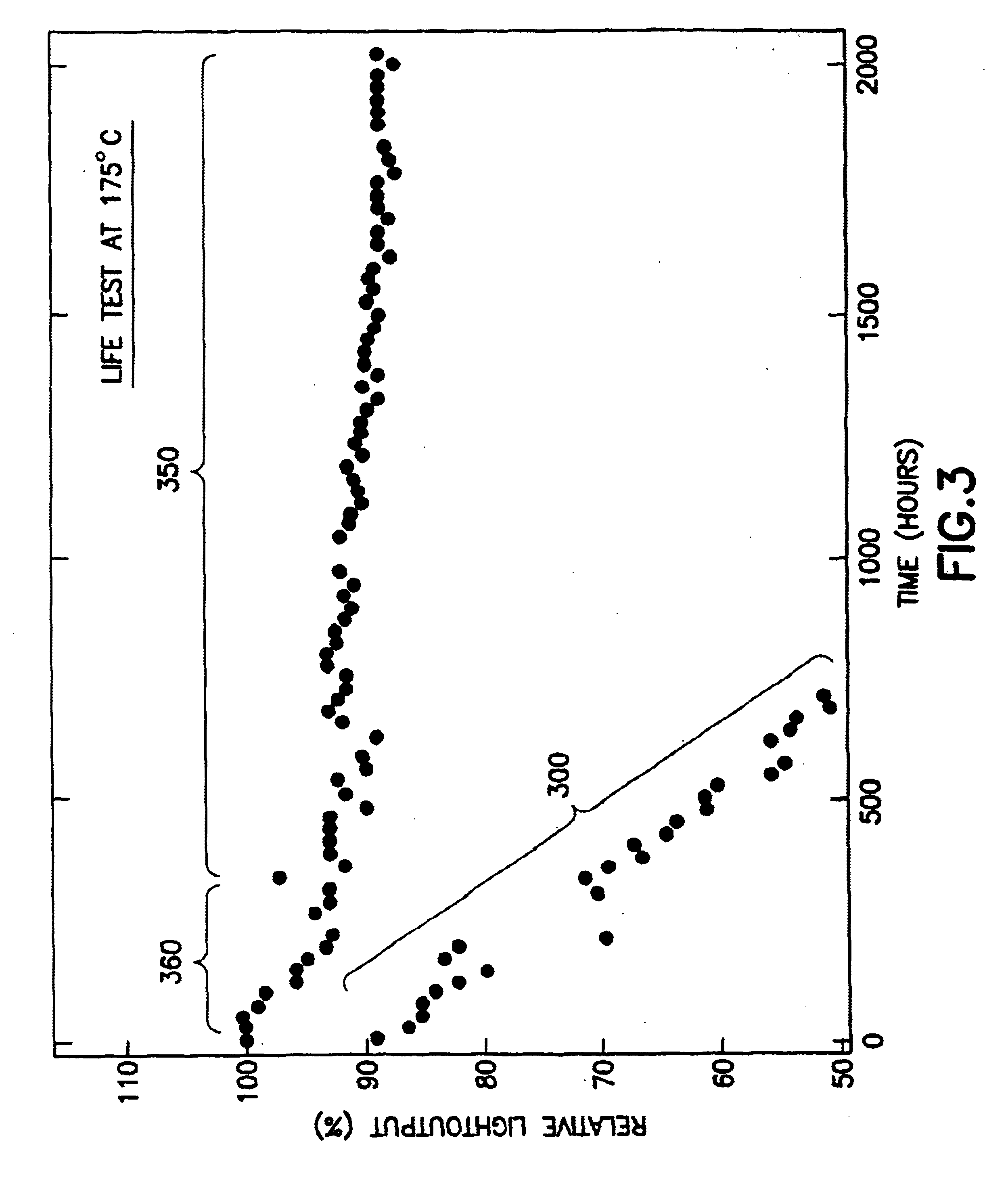

High temperature scintillator

InactiveUS6884994B2Maintain stable propertiesGood optical performanceShieldingX/gamma/cosmic radiation measurmentCross-linkOptical transparency

Owner:SCHLUMBERGER TECH CORP

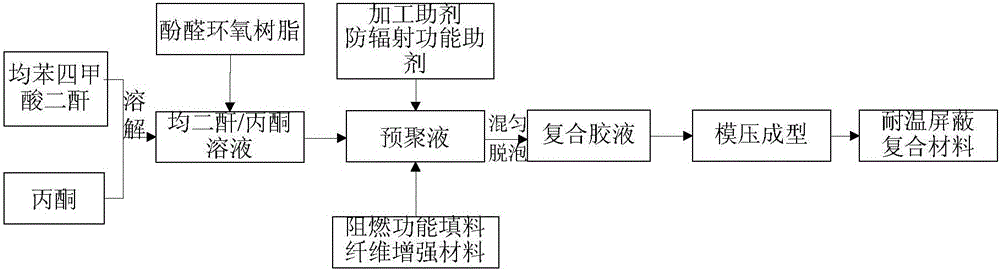

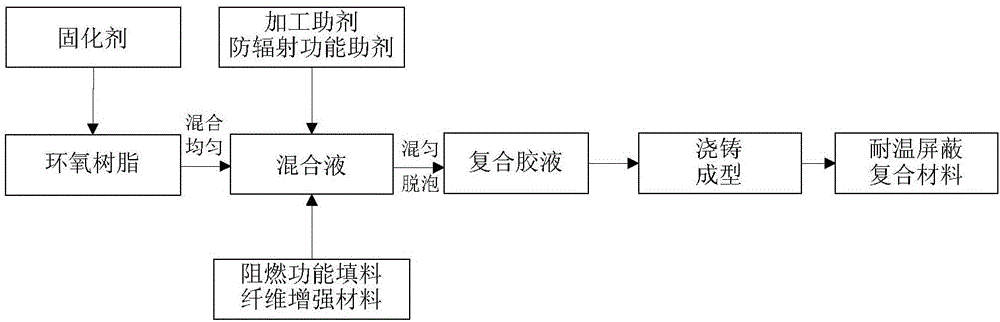

High-temperature-resistant epoxy resin-based neutron and gamma-ray shielding composite material and preparation method thereof

The invention provides a high-temperature-resistant epoxy resin-based neutron and gamma-ray shielding composite material and a preparation method thereof. The high-temperature-resistant epoxy resin-based neutron and gamma-ray shielding composite material is prepared from, by weight, 50-100 parts of epoxy resin, 10-100 parts of curing agent, 100-800 parts of radiation-resistant functional auxiliary, 5-100 parts of fiber reinforced material, 10-150 parts of flame retardant functional filler and 1-50 parts of processing aid. The high-temperature-resistant epoxy resin-based neutron and gamma-ray shielding composite material has excellent neutron and gamma-ray shielding performance, dimensional stability and flame retardation and keeps stable neutron and gamma-ray shielding performance when working within 120-200 DEG C for a long time.

Owner:BEIJING RADIATION APPL RES CENT

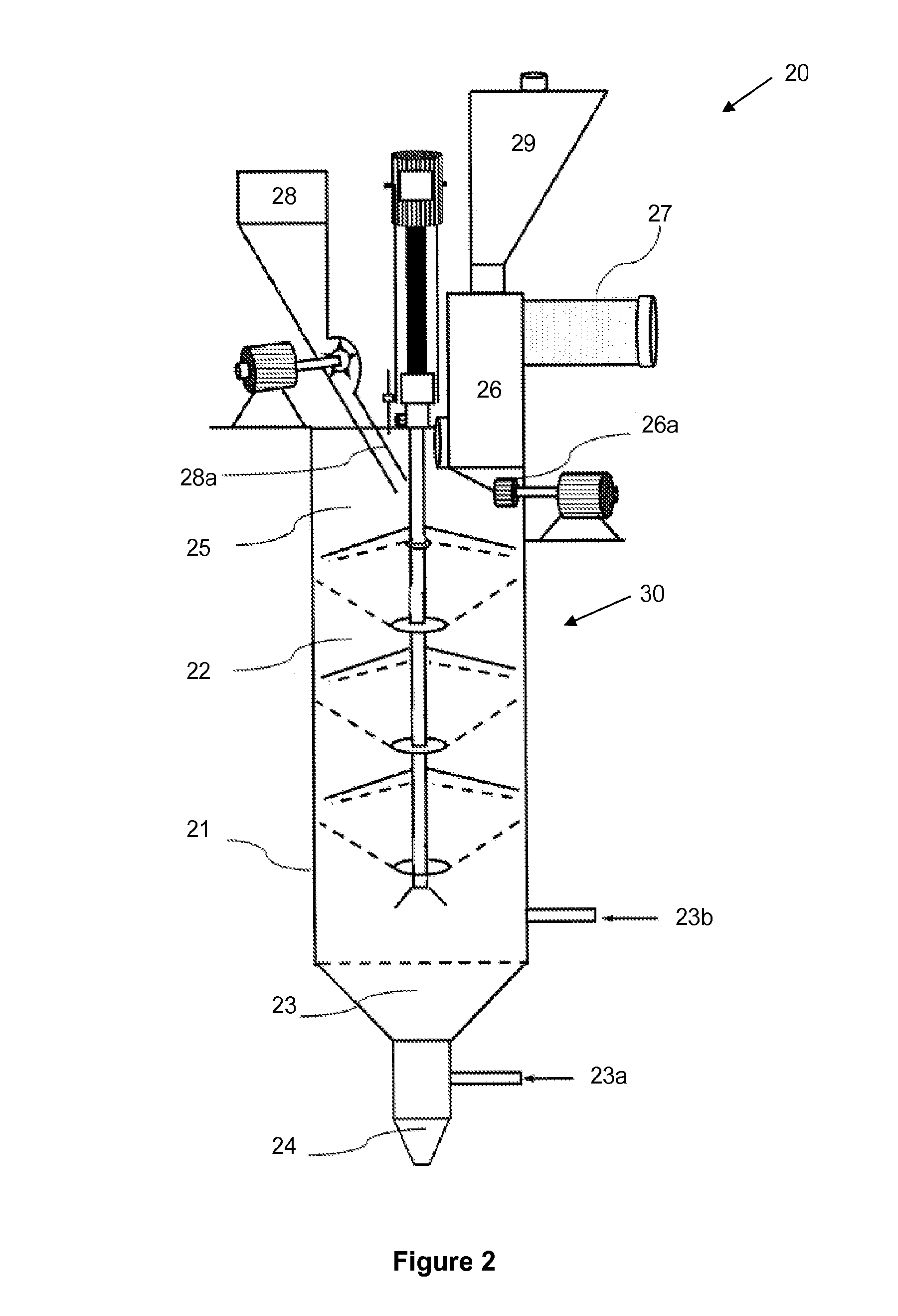

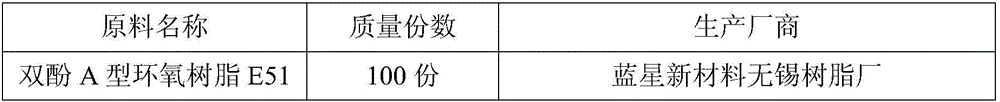

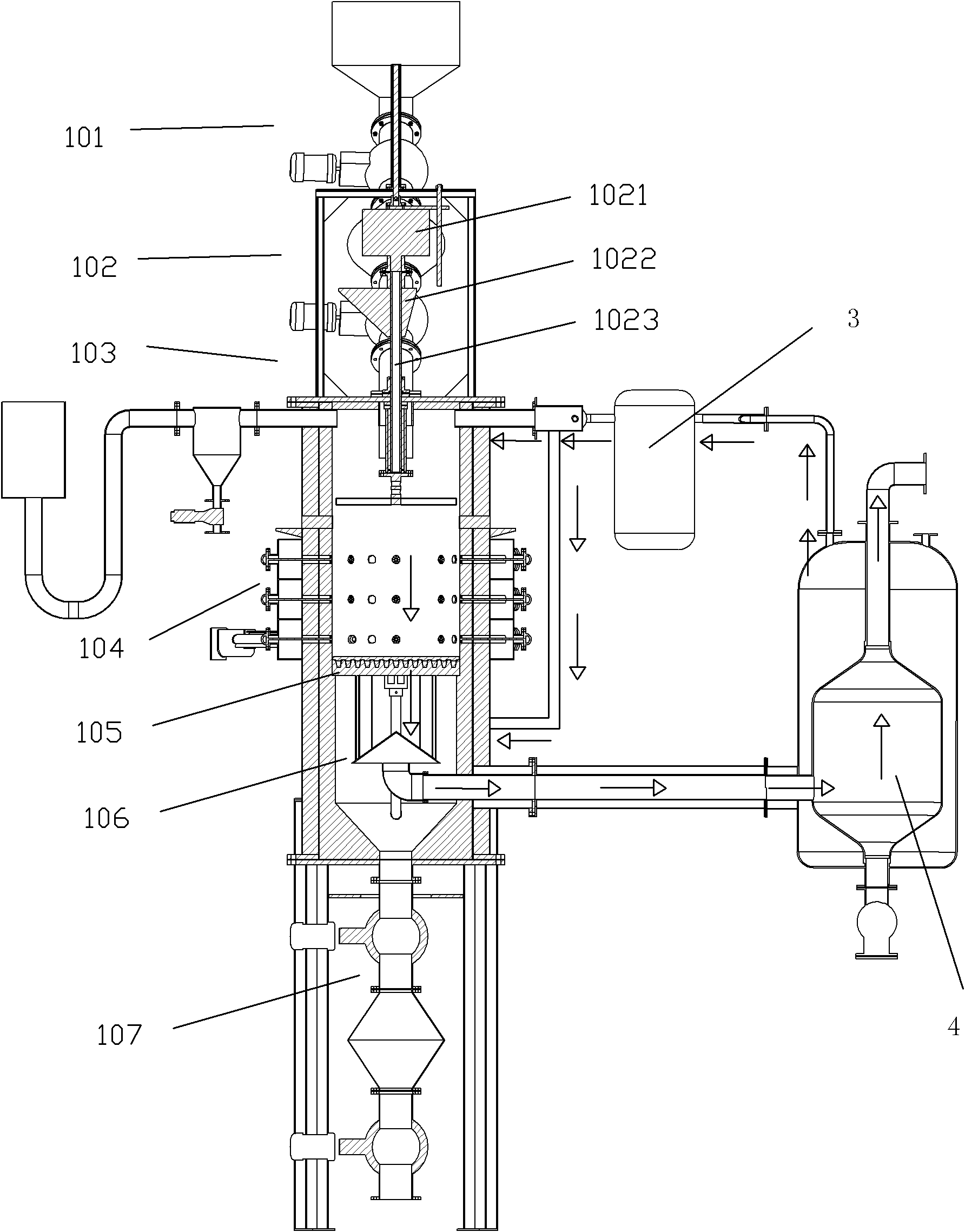

Multilevel-control polyradical biomass-gasification energy regeneration system

ActiveCN101519604AImprove gasification efficiencyHigh reforming efficiencyBiofuelsEnergy inputOxygenMoisture

The invention provides a multilevel-control free-polyradical biomass-gasification energy regeneration system, which can transform extensive biomass and carbon-containing raw materials, including energy crops, agriculture-forestry byproducts, organic waste, industrial and dangerous waste and the like, into high-grade energy. The system is designed for continuous operation. Gasification comprises the following steps of performing pretreatment, performing pyrolysis, transforming carbon, fusing ash, cracking tar, reforming syngas and utilizing waste heat, wherein the steps are precisely controlled one by one and integrated so as to achieve optimum; moisture from the pretreatment of the materials is led into a carbon-transforming unit so as to realize oxygen-free pyrolysis; gasification gas is in contact with a large number of free polyradicals in a free-polyradical reaction-accelerating unit; and the obtained product is purified and then enters downstream application, such as power generation, hydrogen production and biomass methanol / ethanol production. The system has the advantages of needing no auxiliary fuel, maximizing gasification efficiency and thoroughly cracking tar and clearing pollutants, and is an upstream technique for the application of biomass renewable energy. As energy utilization meets all strict environmental protection standards, the system is also an energy-saving environment-friendly technique for non-incineration harmless treatment.

Owner:浙江瑞拓展泰再生能源有限公司

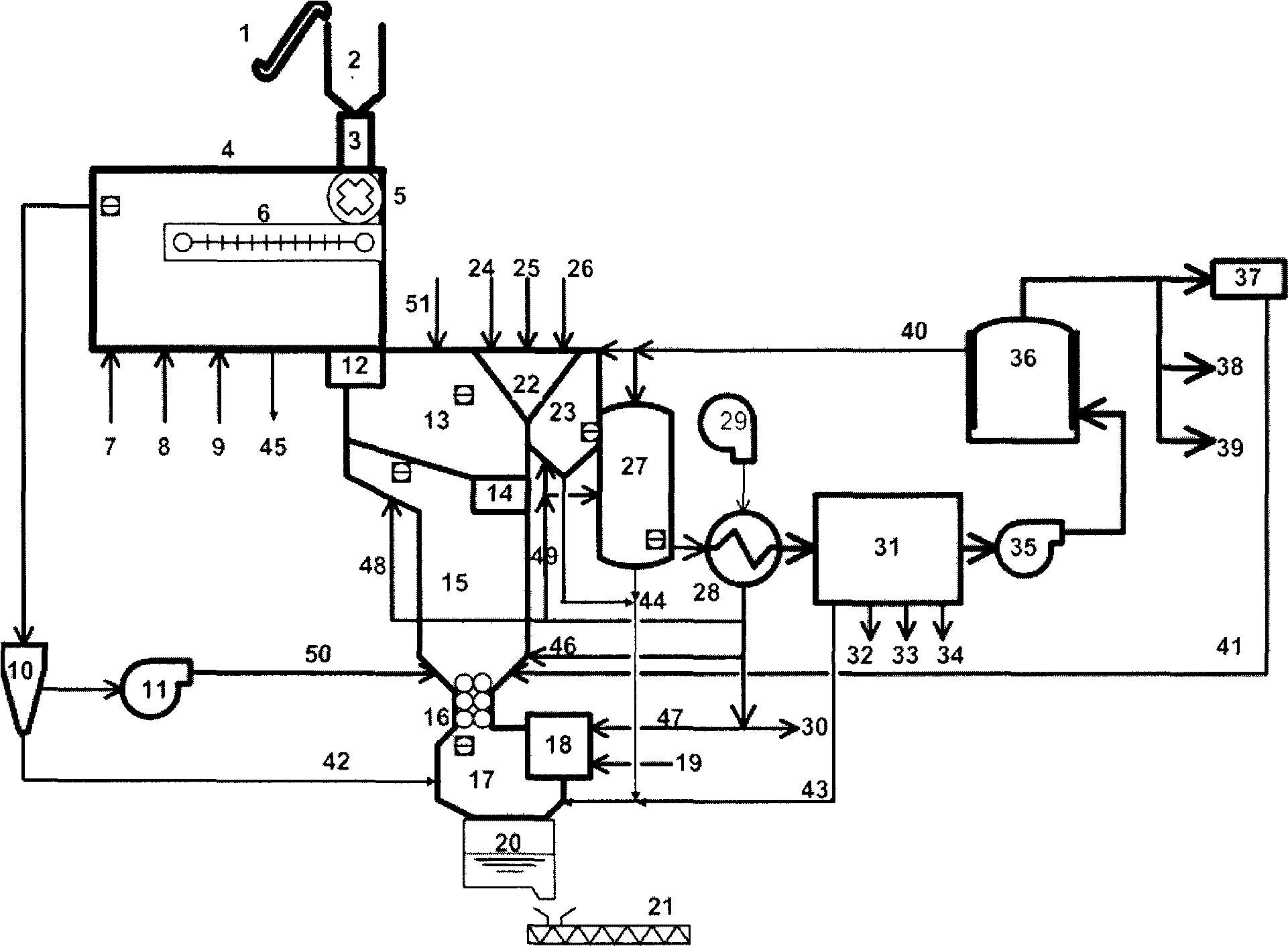

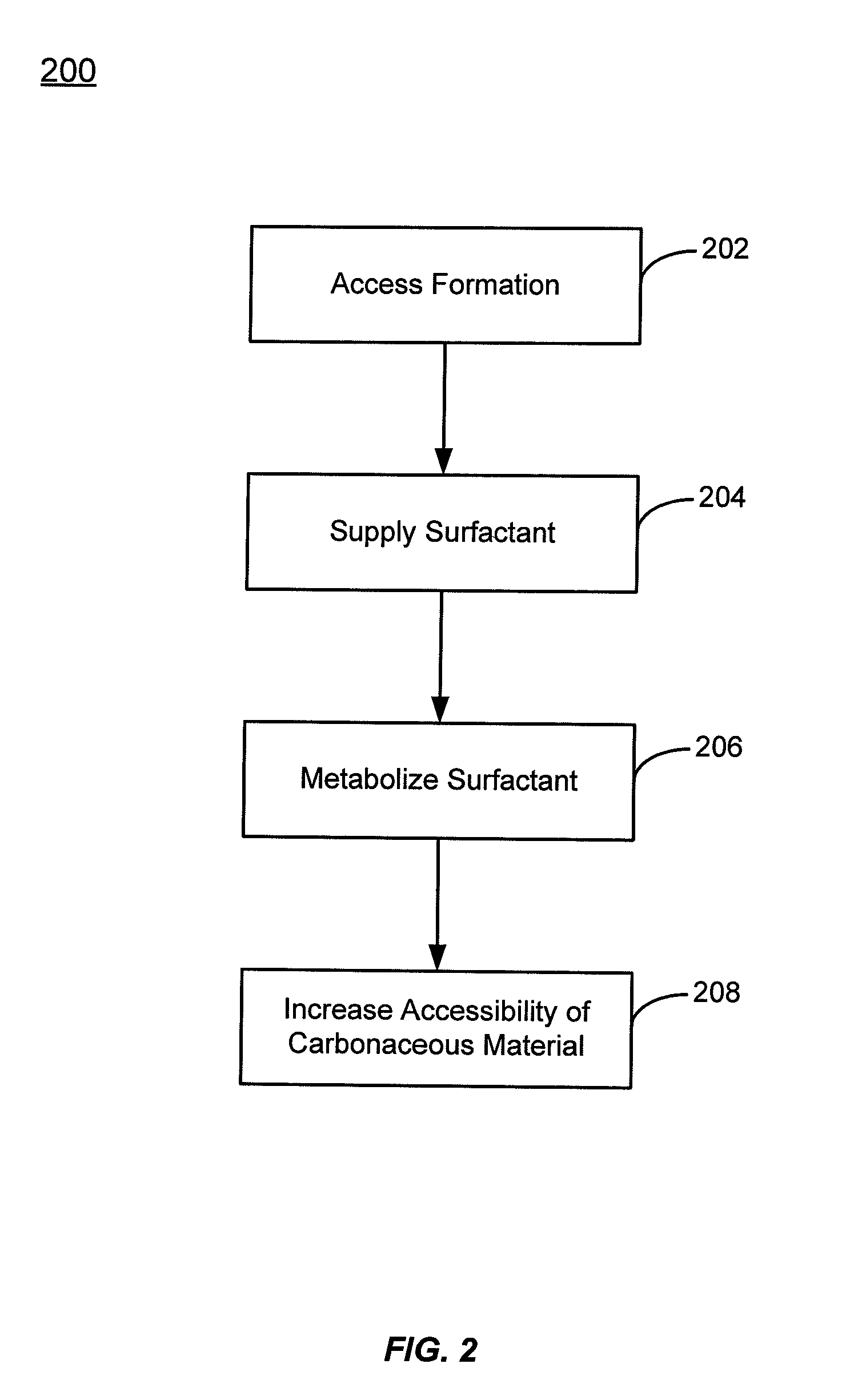

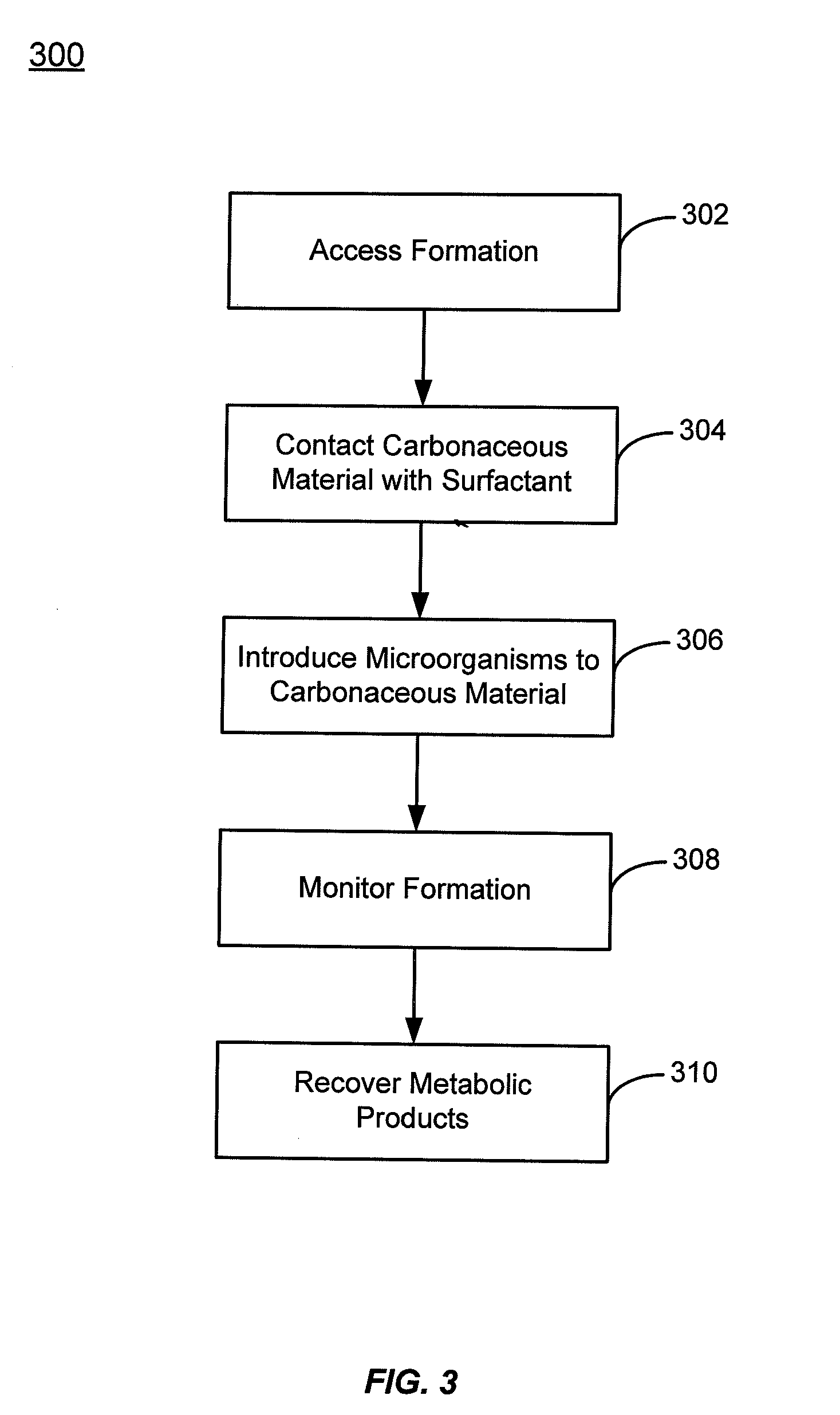

Surfactant amendments for the stimulation of biogenic gas generation in deposits of carbonaceous materials

InactiveUS20100248321A1Increase biogenic productionImprove accessibilityFluid removalDrilling compositionMicroorganismHydrogen content

Methods of conditioning a carbonaceous material in a subterranean geologic formation for metabolism into a compound with enhanced hydrogen content by a microorganism consortium are described. The methods may include the steps of accessing the subterranean geologic formation through an access point, and contacting the carbonaceous material with a surfactant. The microorganism consortium can utilize the surfactant as a first nutrient source. The surfactant also increases accessibility of the carbonaceous material as a second nutrient source for the microorganism consortium. The microorganism consortium metabolizes the carbonaceous material into the compound with the enhanced hydrogen content.

Owner:TRANSWORLD TECH

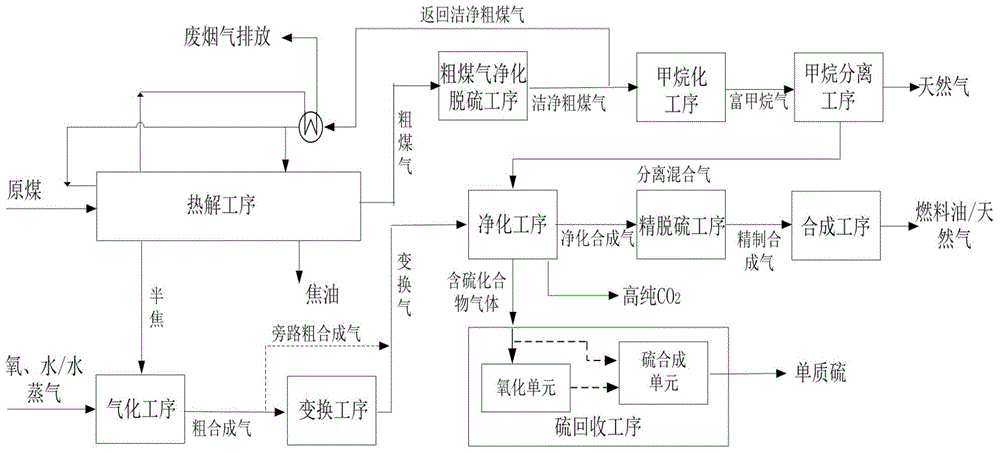

Method for producing tar and hydrocarbon fuel products from coal

InactiveCN104893748AIncrease varietyImprove utilization efficiencyGaseous fuelsLiquid hydrocarbon mixture recoveryWater dischargeMethanation

The invention relates to a method for producing tar and hydrocarbon fuel products from coal. The method comprises steps of pyrolysis, raw gas purification and desulfurization, a methanation process, a methane separation process, a gasification process, a conversion process, a purification process, a sulfur recovery process, a fine desulfurization process, a synthesis process and the like. With the adoption of the method, raw coal is firstly subjected to low-temperature pyrolysis and then subjected to gasification conversion, the types of coal chemical products are increased, and the utilization efficiency of the coal raw material is improved; the problem that low-rank coal cannot be gasified and utilized by a wet-process entrained-flow bed is solved, the raw material consumption during gasification is reduced, the waste water discharge is reduced, the greenhouse gas production amount in the process is reduced, and efficient class-based and quality-based utilization of the coal resource is realized.

Owner:XIAN ORIGIN CHEM TECH +1

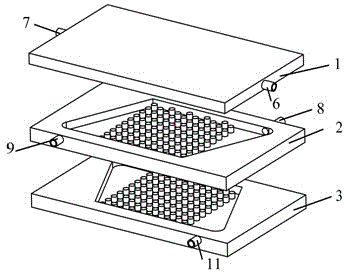

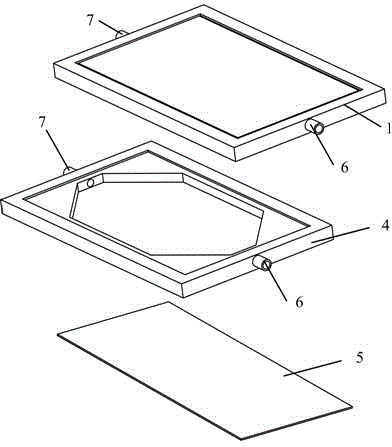

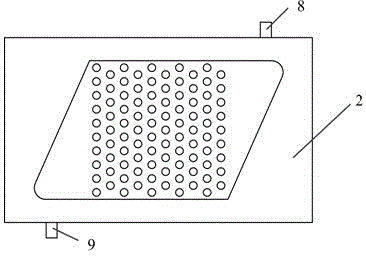

Self-heating staggered-arrangement micro-boss array type alcohol reforming device

InactiveCN103601151AEnhance heat and mass transferHigh heat and mass transfer efficiencyHydrogenHydrogen fuel cellHydrogen fuel

The invention discloses a self-heating staggered-arrangement micro-boss array type alcohol reforming device. The self-heating staggered-arrangement micro-boss array type alcohol reforming device comprises a hydrogen purification component, a reforming hydrogen production plate and a catalytic combustion plate sequentially from top to bottom. A reforming hydrogen production cavity is arranged in the reforming hydrogen production plate and loaded with a hydrogen production catalyst which is used for alcohol reformation so as to produce hydrogen; a catalytic combustion cavity is arranged in the catalytic combustion plate and loaded with a combustion catalyst which is used for alcohol combustion and heat supply. Heat is supplied for the reforming hydrogen production through alcohol combustion, so that the natural operation of the alcohol reforming device can be realized. Staggered-arrangement micro-boss array structures are arranged in the reforming hydrogen production cavity and the catalytic combustion cavity, so that the specific area is large and the heat transfer and mass transfer efficiency is high. In addition, the alcohol reforming device comprises the hydrogen purification component, so that the fuel conversion efficiency of the reforming hydrogen production cavity can be improved, and hydrogen at an outlet can be directly used for a hydrogen fuel battery. The self-heating staggered-arrangement micro-boss array type alcohol reforming device is compact in structure, convenient for catalysts to load, easy for the whole structure to assemble, and capable of being used in intermediate and small flow alcohol reforming hydrogen production situations.

Owner:ZHEJIANG UNIV

Residual oil hydrotreating process

InactiveCN102816597AHigh yieldHigh hydrogen contentTreatment with hydrotreatment processesHydrogenFixed bed

The invention relates to a residual oil hydrotreating process. A feeding port is added in front of a demetalization agent bed layer of a residual oil hydrotreater, residual oil and hydrogen enter the device to react through a raw material feeding port of the residual oil hydrotreater, and catalytic cracking recycle oil enters the device to react through the added feeding port. The residual oil hydrotreater adopts catalyst grading loading, is filled with three or more catalysts including a protective agent, a demetalization agent and a desulfurizing agent sequentially, each catalyst is filled into one bed layer, and the protective agent adopts an up-flow type reactor or a fixed bed reactor. By means of the method, impurity removing rate in residual oil hydrotreating can be improved, an operation period of the residual oil hydrotreater can be prolonged, and the yield of light liquid with high added value can be improved.

Owner:PETROCHINA CO LTD

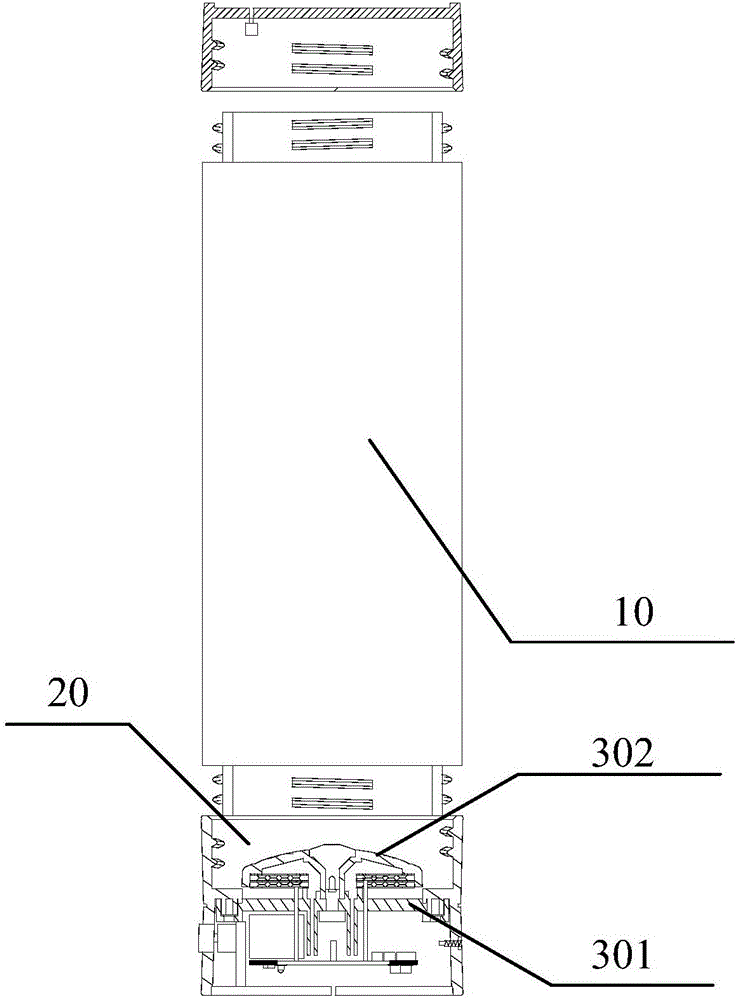

System and method of increasing synthesis gas yield in a fluid catalytic cracking unit

ActiveUS20090158662A1Reduce carbon dioxide emissionsIncrease productionCombination devicesCatalytic crackingHydrogenUnit system

Systems and methods of reducing refinery carbon dioxide emissions by improving the overall synthesis gas yield in a fluid catalytic cracking unit having a reactor and a regenerator are discussed. In one example, a method comprises introducing spent catalyst and a feed gas comprising oxygen to the regenerator at gasification conditions. The method further comprises heating the spent catalyst to burn coke therefrom to produce a synthesis gas. The method further comprises combining the synthesis gas with a dry gas comprising hydrogen, creating the overall synthesis gas and thereby increasing the yield of the overall synthesis gas produced in the FCC unit.

Owner:UOP LLC +1

Control method for biomass gasification equipment

InactiveCN102433160APrecise method of operationHigh degree of automationFixed-bed gasificationCycloneCooling tower

The invention relates to a control method for biomass gasification equipment, which comprises the following components: controlling a biomass filler; regulating a fire grate; controlling dust removal; controlling temperature in a furnace; controlling an internal and external double cyclone heat exchange dust collector; controlling a cooling tower; controlling an inertia separator; controlling an electric tar collector; controlling a hydrogen sulfide removing sprayer; controlling a gas-water separator; controlling a vapor generator; controlling a vapor and air storage tank; and controlling an air zone and a secondary oxidation area. In the invention, the operation method is accurate, safe and controllable, and the automation degree of the method is high; and the method can greatly reduce production cost and is suitable to be widely promoted in the field of biomass gasification.

Owner:张建超

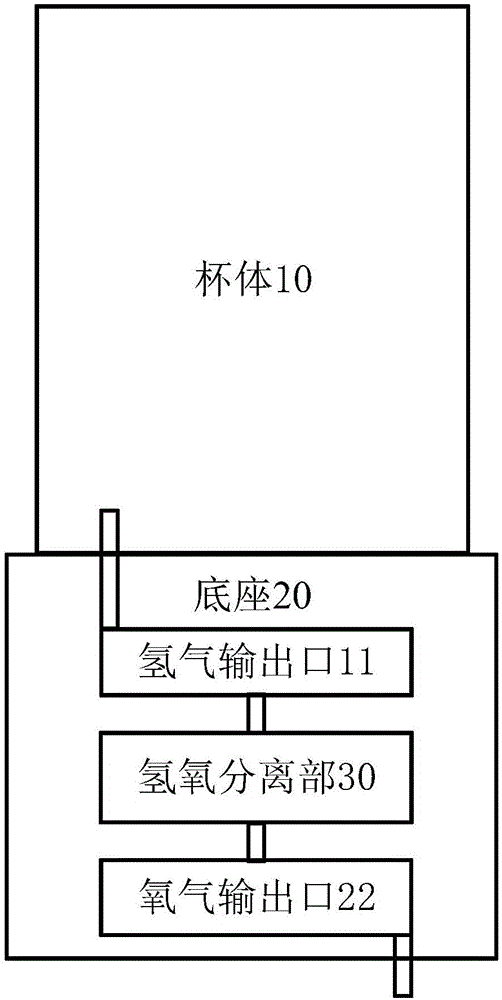

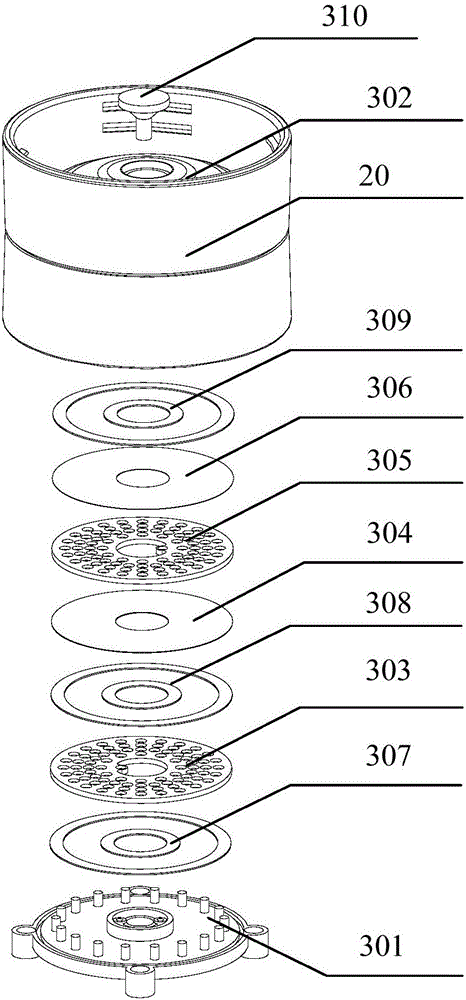

Water cup for separating hydrogen from oxygen

ActiveCN106361099AInhibition of dissolutionIncrease the hydrogen contentCellsDrinking vesselsElectrolysisHydrogen

The invention provides a water cup for separating hydrogen from oxygen. The water cup comprises a hydrogen and oxygen separating part arranged in a water cup base, wherein the hydrogen and oxygen separating part is provided with a hydrogen output port and an oxygen output port; the hydrogen output port is communicated with the inside of a cup body; the oxygen output port is communicated to the outside of the cup body; hydrogen is output into the cup body through the hydrogen output port; oxygen is output to the outside of the cup body through the oxygen output port. The hydrogen and oxygen separating part is arranged outside the cup body to perform a hydrogen and oxygen separating process outside the cup body, then the hydrogen is output to the inside of the cup body, and the oxygen is discharged to the outside of the cup body, so that mixing of oxygen generated by electrolyzed water with drinking water in the cup body is avoided; in particular, an ozone component in the oxygen is prevented from being dissolved into the drinking water, so that higher-purity oxygen is dissolved into the cup body, and the hydrogen component in the drinking water is increased; the hydrogen can effectively eliminate free radicals generated by excess oxygen in a human body, so that the function of preventing various diseases is realized, and meanwhile the drinking experience of a user can be improved.

Owner:广东蜗品科技有限公司

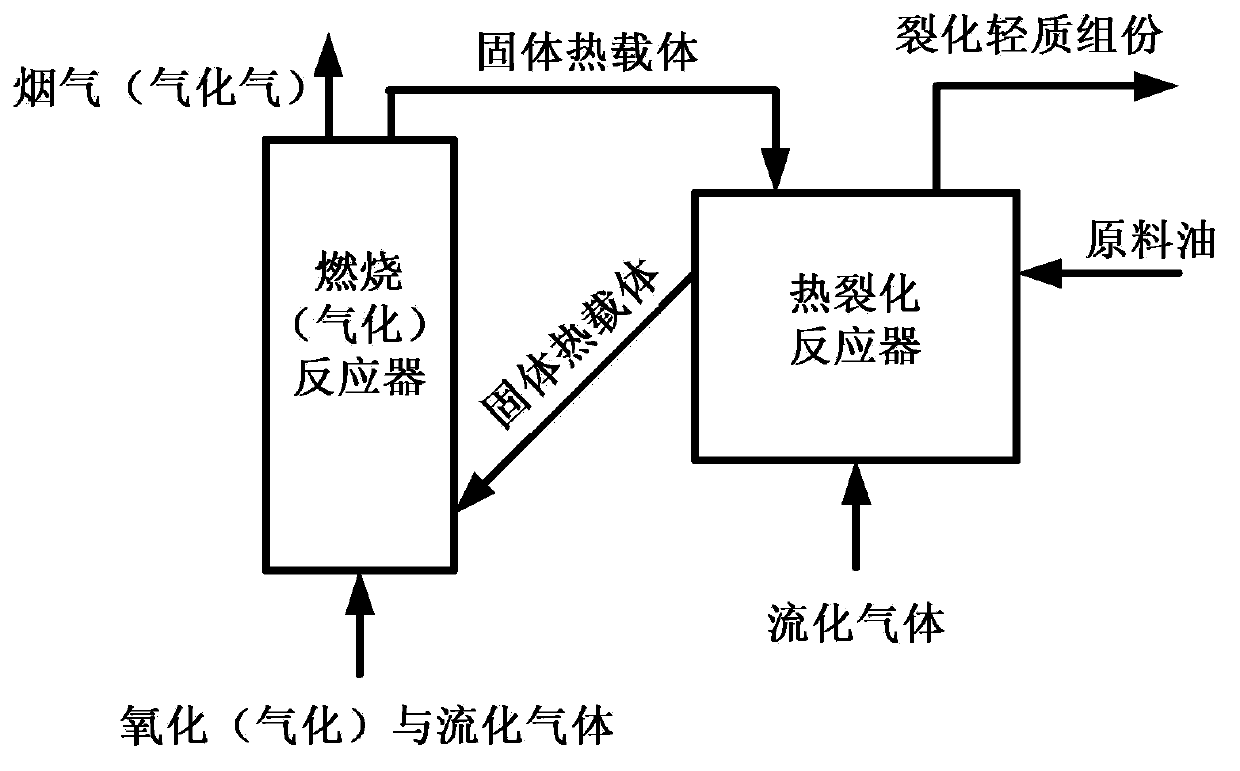

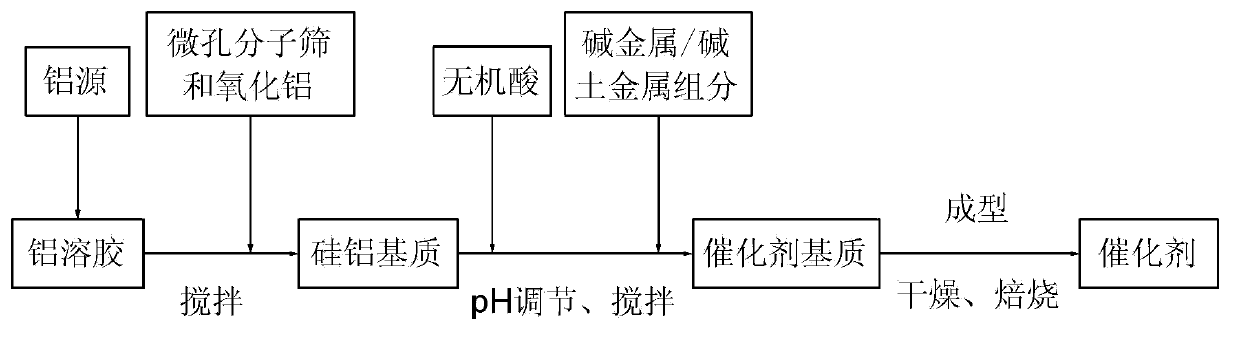

Bifunctional catalyst for heavy oil cracking and coke gasification, and preparation method thereof

InactiveCN103962175AWide adaptabilityIncrease valueCatalytic crackingMolecular sieve catalystsMolecular sieveAlkaline earth metal

The invention relates to a bifunctional catalyst for heavy oil cracking and coke gasification. The bifunctional catalyst contains a microporous molecular sieve and a gasification active component, wherein the microporous molecular sieve is one or a mixture of at least two selected from the group consisting of a Y-type molecular sieve, an ultra-stable Y-type molecular sieve, an X-type molecular sieve and an A-type molecular sieve, and the gasification active component is an alkali metal element and / or an alkali earth metal element. The catalyst can be applied to heavy oil cracking and gasification technology; as a heavy oil cracking catalyst, the bifunctional catalyst has adaptability to a wide range of raw oil and can process heavy oil with high carbon residue, high sulfur-nitrogen content and high heavy metal content so as to obtain high-value lightweight distillate oil; and as a coke gasification agent, the bifunctional catalyst can remove coke on the surface of a carbon deposit catalyst through gasification, produces synthetic gas and has high hydrothermal stability in the process of regeneration.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

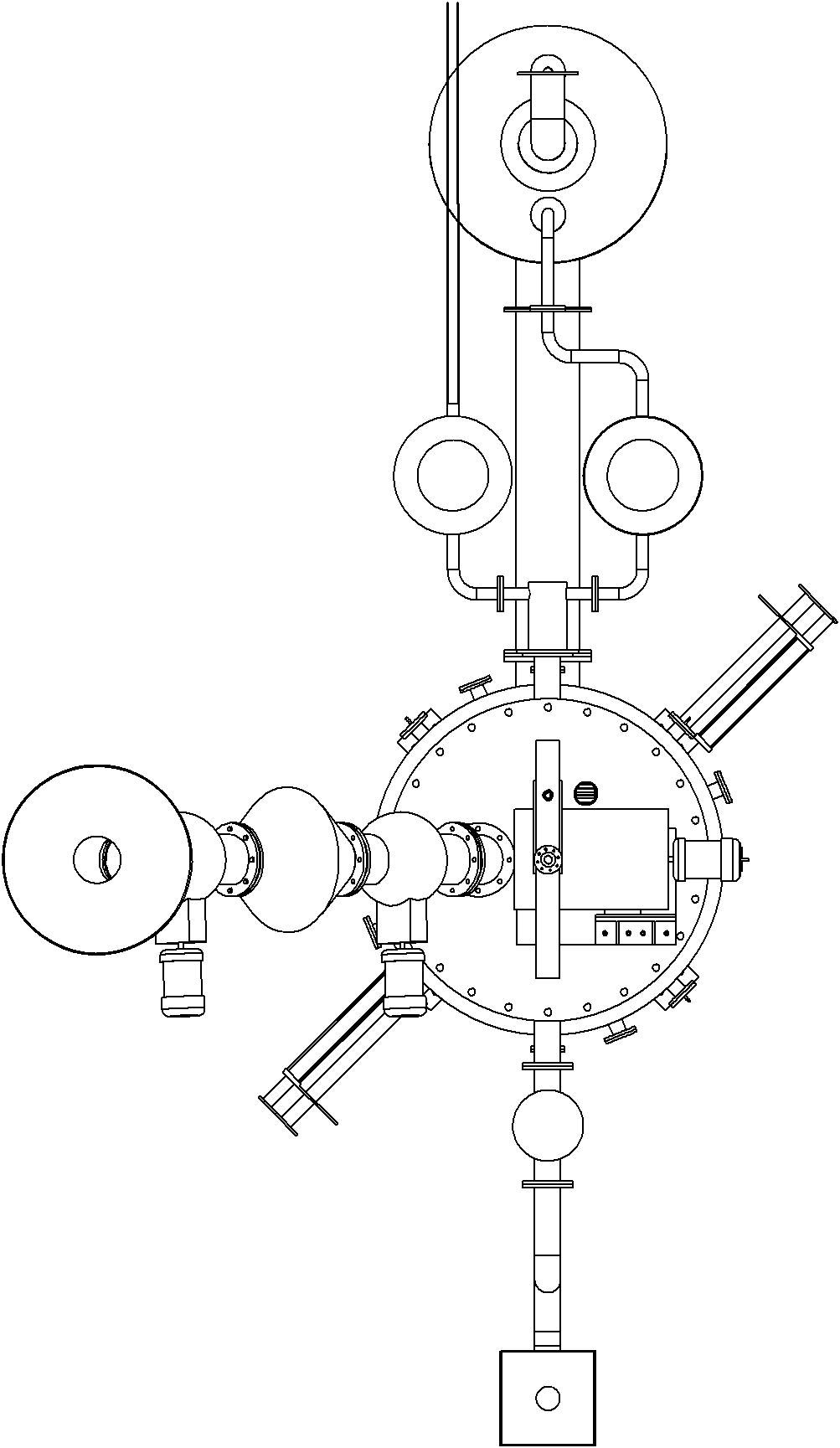

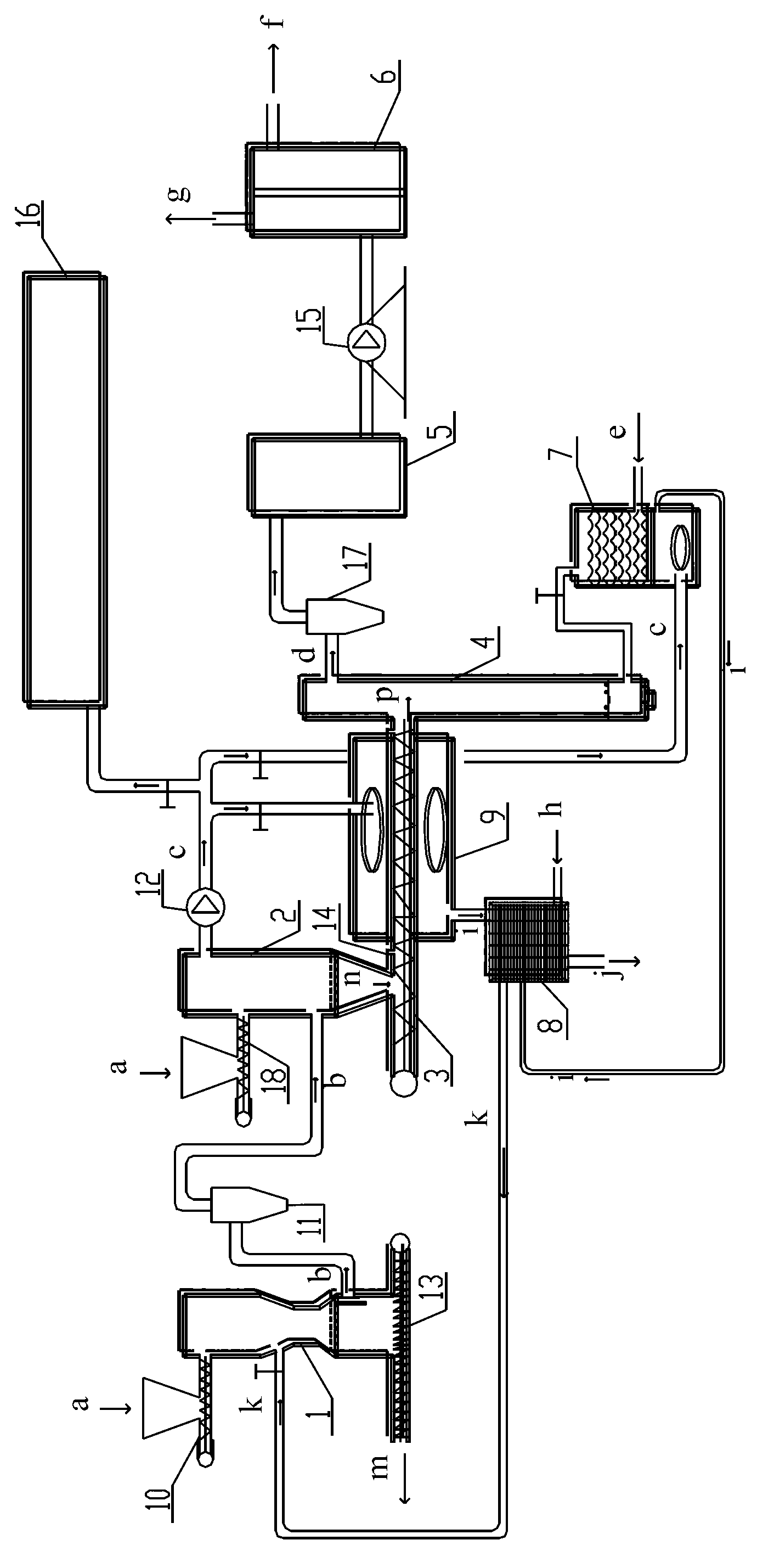

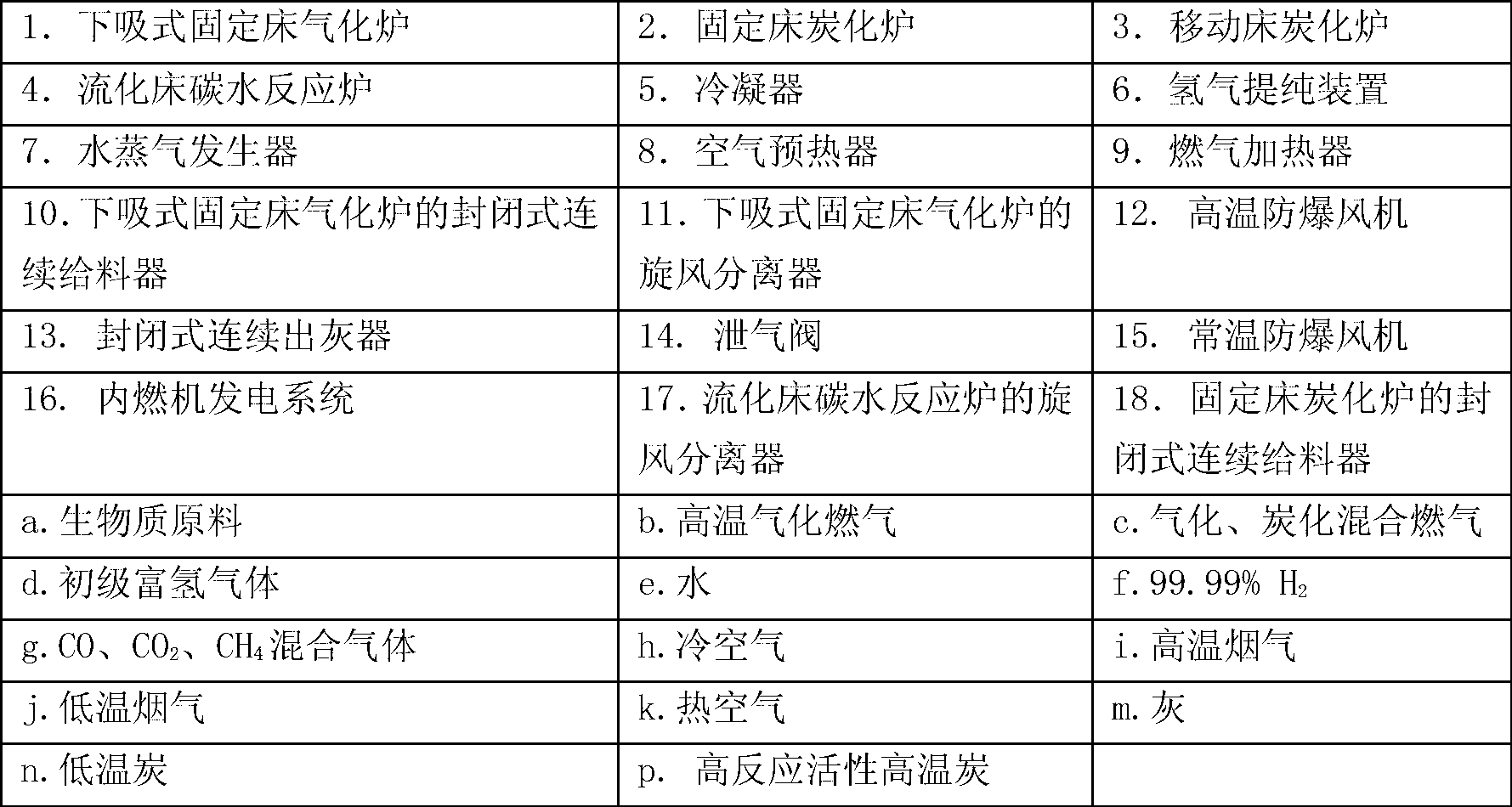

Method and device for preparing high-purity hydrogen from biomass

InactiveCN103011072ARapid responseHigh reactivityHydrogen separationDirect heating destructive distillationThermal energyCarbonization

The invention discloses a method and a device for preparing high-purity hydrogen from biomass. A thermal chemical hydrogen preparation process of biomass is divided into three steps, namely biomass gasification, step-by-step biomass carbonization and water-charcoal reaction. The combustible gas generated by biomass gasification provides heat energy required by the whole production line, and electricity is generated by gas to provide electric energy required by all power equipment, so that biomass is the only energy source of the whole process and ensures zero consumption of external power. The step-by-step biomass carbonization process overcomes the defects of low yield and low biomass charcoal reaction activity of the conventional carbonization process, and greatly improves the reaction activity of the biomass charcoal while ensuring a high yield of biomass charcoal by coupling a slow low-temperature carbonization reaction and a fast high-temperature carbonization reaction; therefore, the water-charcoal reaction is accelerated and the energy consumption in the water-charcoal reaction process is reduced. The content of hydrogen of the generated primary hydrogen-rich gas is over 85%, and can even be more than or equal to 99.99% after purification of a hydrogen purification device.

Owner:TIANJIN UNIV

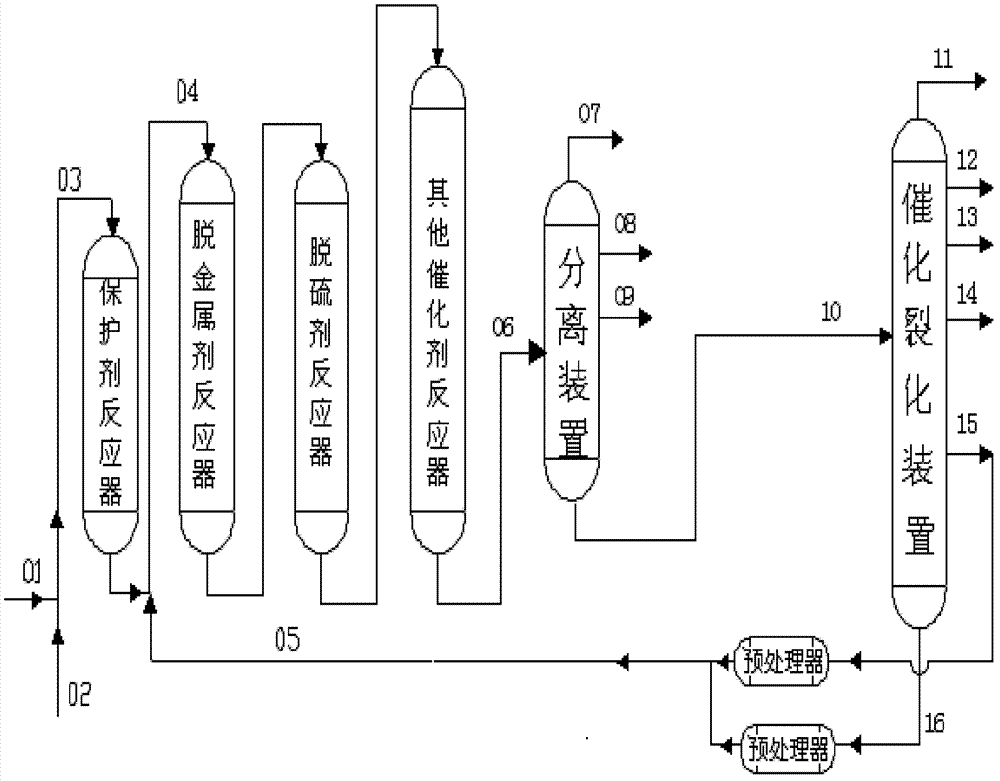

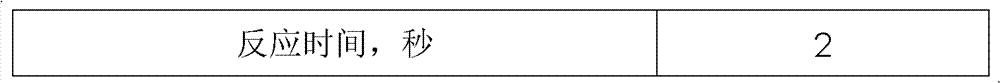

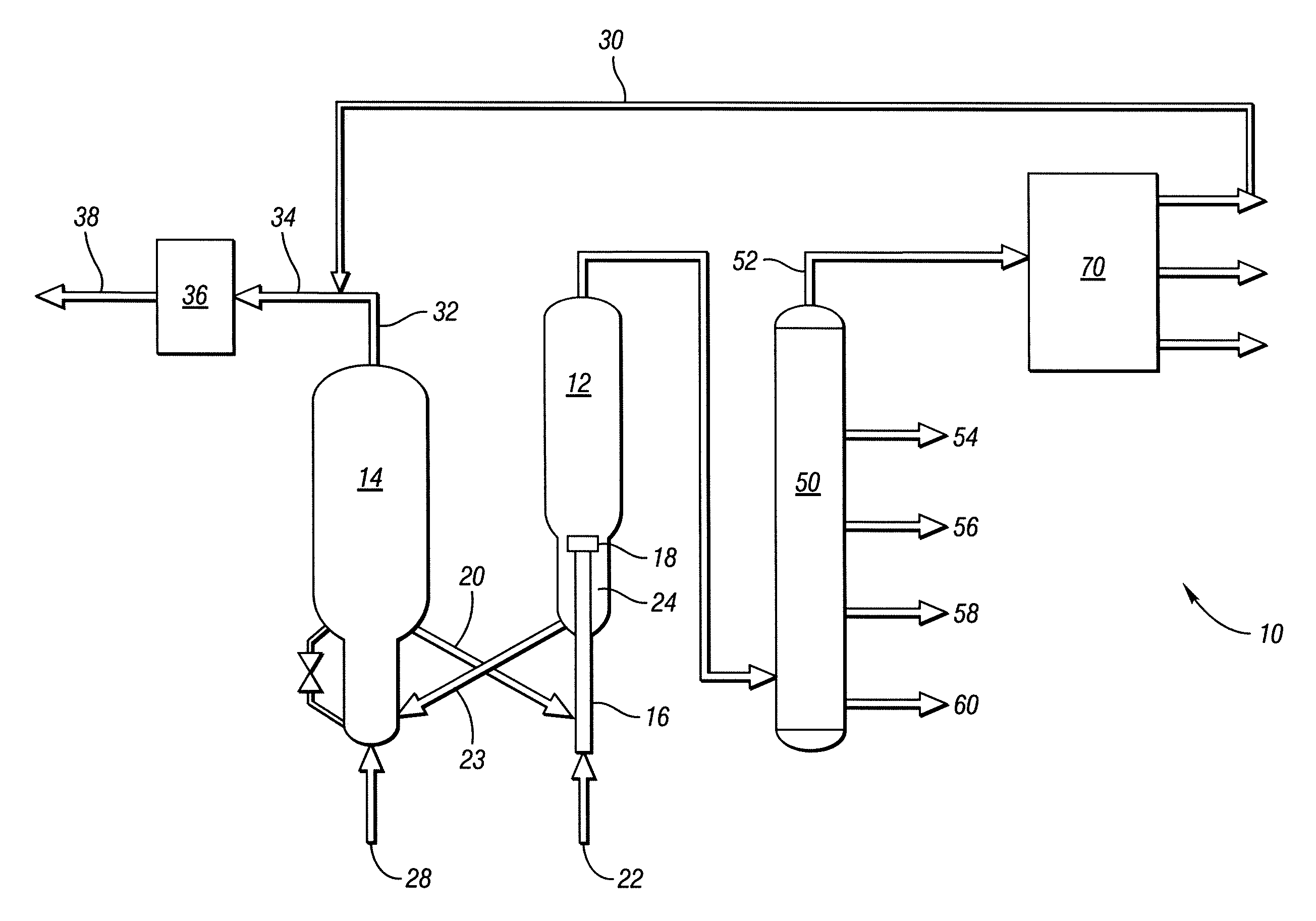

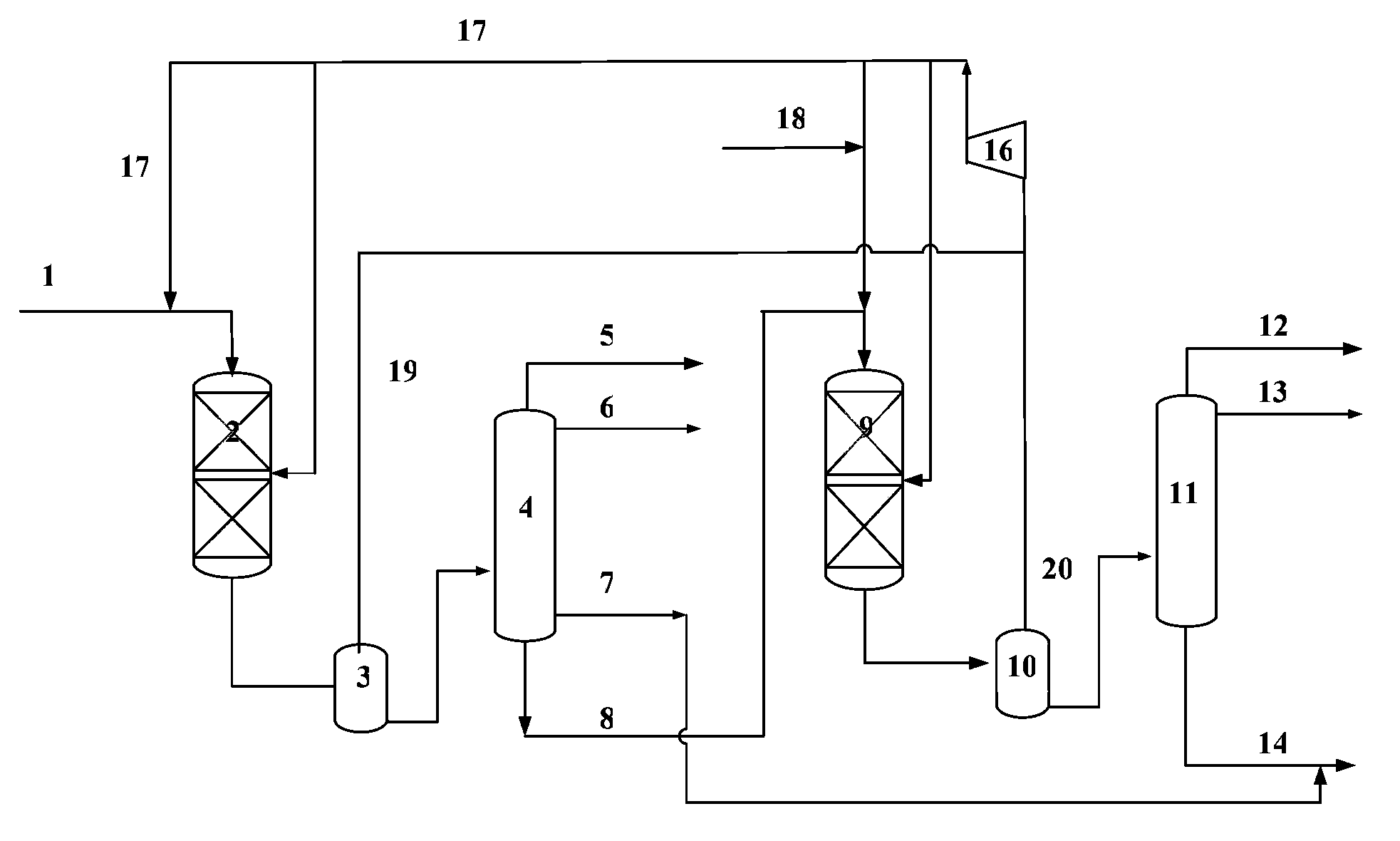

Combined process for hydrotreating and catalytic cracking of residue

ActiveUS20100314287A1Promote resultsEfficient combinationThermal non-catalytic crackingCatalytic crackingSlurryImpurity

Disclosed is a combined process for hydrotreating and catalytic cracking of residue, wherein the residue, catalytic cracking heavy cycle oil with acidic solid impurity being removed, optional distillate oil and adistillate of catalytic cracking slurry oil from which the acidic solid impurity is removed are fed into residue hydrotreating unit, the hydrogenated residue obtained and optional vacuum gas oil are fed into catalytic cracking unit to obtain various products; the catalytic cracking heavy cycle oil from which the acidic solid impurity is removed is circulated to the residue hydrotreating unit; the catalytic cracking slurry oil is separated by distilling, the distillate of the catalytic cracking slurry oil after removing off the acidic solid impurity is circulated to the residue hydrotreating unit. This process makes the residue hydrotreating and catalytic cracking being combined together more effectively such that it is not only able to improve product quality of the residue hydrotreating, elongate operation cycle of the residue hydrotreating unit, but also increases the yield of the hydrogenated diesel oil and catalytic cracking light oil, and decreases coking quantity of the catalytic cracking.

Owner:CHINA PETROCHEMICAL CORP +1

Catalyst for hydrogen production by catalytic reforming with biological oil and preparation method

InactiveCN102974362AHigh hydrogen contentHigh calorific valueHydrogenChemical recyclingCatalytic reformingChain scission

The invention relates to a catalyst for hydrogen production by catalytic reforming with biological oil and a preparation method. The catalyst comprises catalyst active components and a catalyst carrier; the catalyst active components refer to the following components in percentage by weight of 10-15 wt% of Ni, 5-13 wt% of Mo, 5-10 wt% of Fe and the balance being attapulgite and sepiolite mixed clay pit catalyst carrier. The catalyst provided by the invention has the advantages of large surface area, strong absorption function and strong promotion function; the cheap and easiest available attapulgite and sepiolite mixed clay pit are used as the catalyst carrier; and the catalyst active components comprise nickel, molybdenum and iron composite components, so that the molecules of the biological oil are subjected to splitting and chain scission to form high-quality synthesis gas of low-molecule hydrocarbon and high-content hydrogen. The catalyst provided by the invention has the advantages of simple catalyst preparation, large strength, strong catalyst activity, and regeneration. Not only can the catalyst be used for hydrogen production by catalytic reforming with the biological oil, but also the catalyst can be applied to direct hydrogen production by catalytic gasification with biomass.

Owner:ANHUI UNIV OF SCI & TECH

Hydrogenation method for reducing condensation point of diesel

ActiveCN103773488AHigh yieldHigh selectivityTreatment with hydrotreatment processesNaphthaPtru catalyst

A hydrogenation method for reducing the condensation point of diesel comprises the following steps: raw oil is in contact with a hydrofining catalyst in a first reaction area for reaction, effluents in the first reaction area are subjected to separation and fractionation to obtain gases, naphtha fractions, low-condensation-point diesel fractions I and high-condensation-point heavy diesel fractions; the obtained high-condensation-point heavy diesel fractions enter a second reaction area, and are in contact with a hydro-upgrading condensation point reducing catalyst to carry out an isocracking condensation point reducing reaction; effluents in the second reaction area are subjected to separation and fractionation to obtain low-condensation-point diesel fractions II; the low-condensation-point diesel fractions and the low-condensation-point diesel fractions II are mixed to obtain low-condensation-point diesel. According to the invention, the process selectivity is improved, so that the low-condensation-point diesel yield is improved remarkably. Through the adoption of the hydrogenation method, No.-10 to No.-50 low-condensation-point diesel can be produced flexibly, the cetane number is increased as compared with that of the raw material, the content of impurities such as sulfur and nitrogen is reduced greatly, and the Europe IV diesel standard and the Europe V diesel standard can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

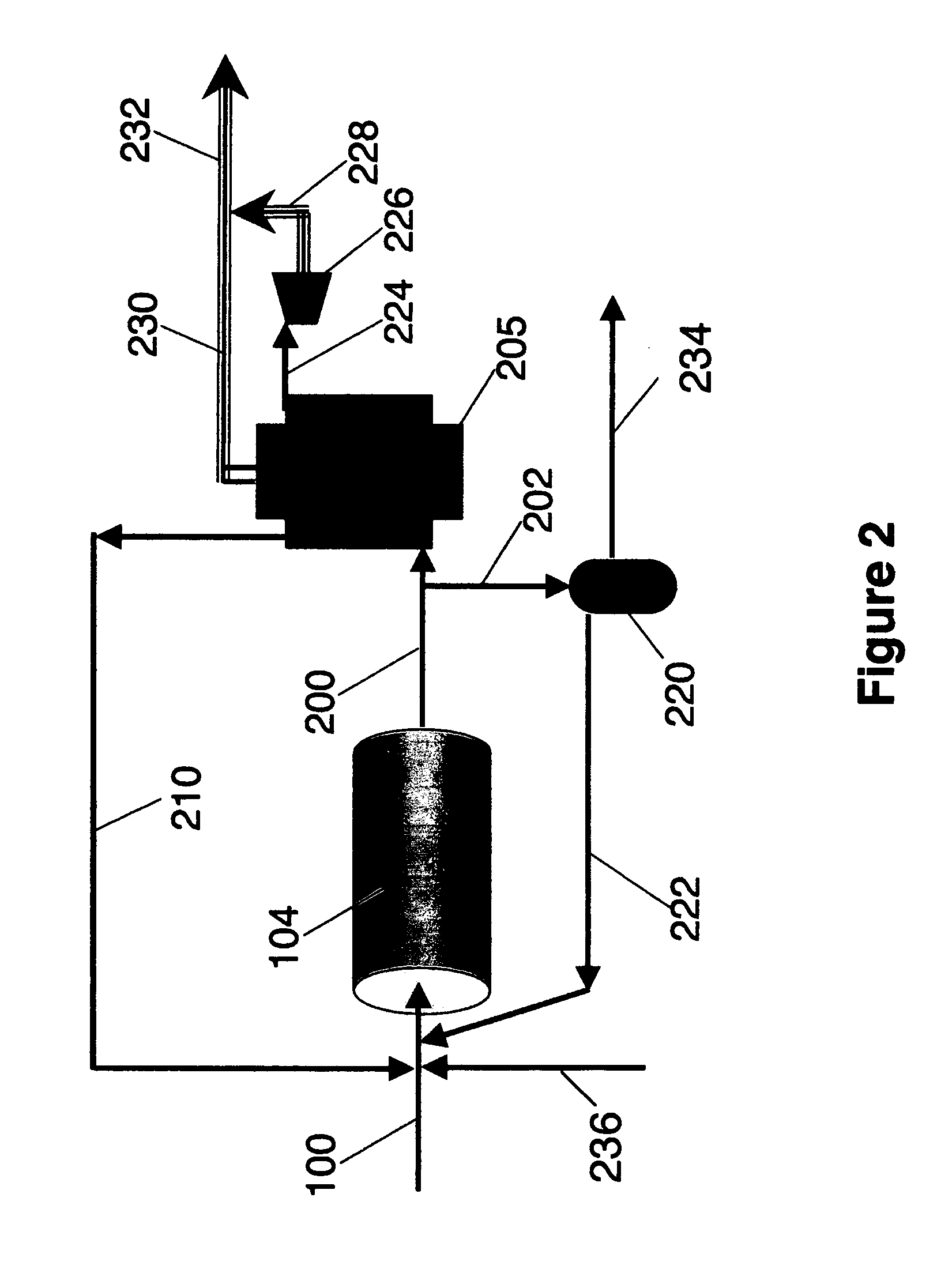

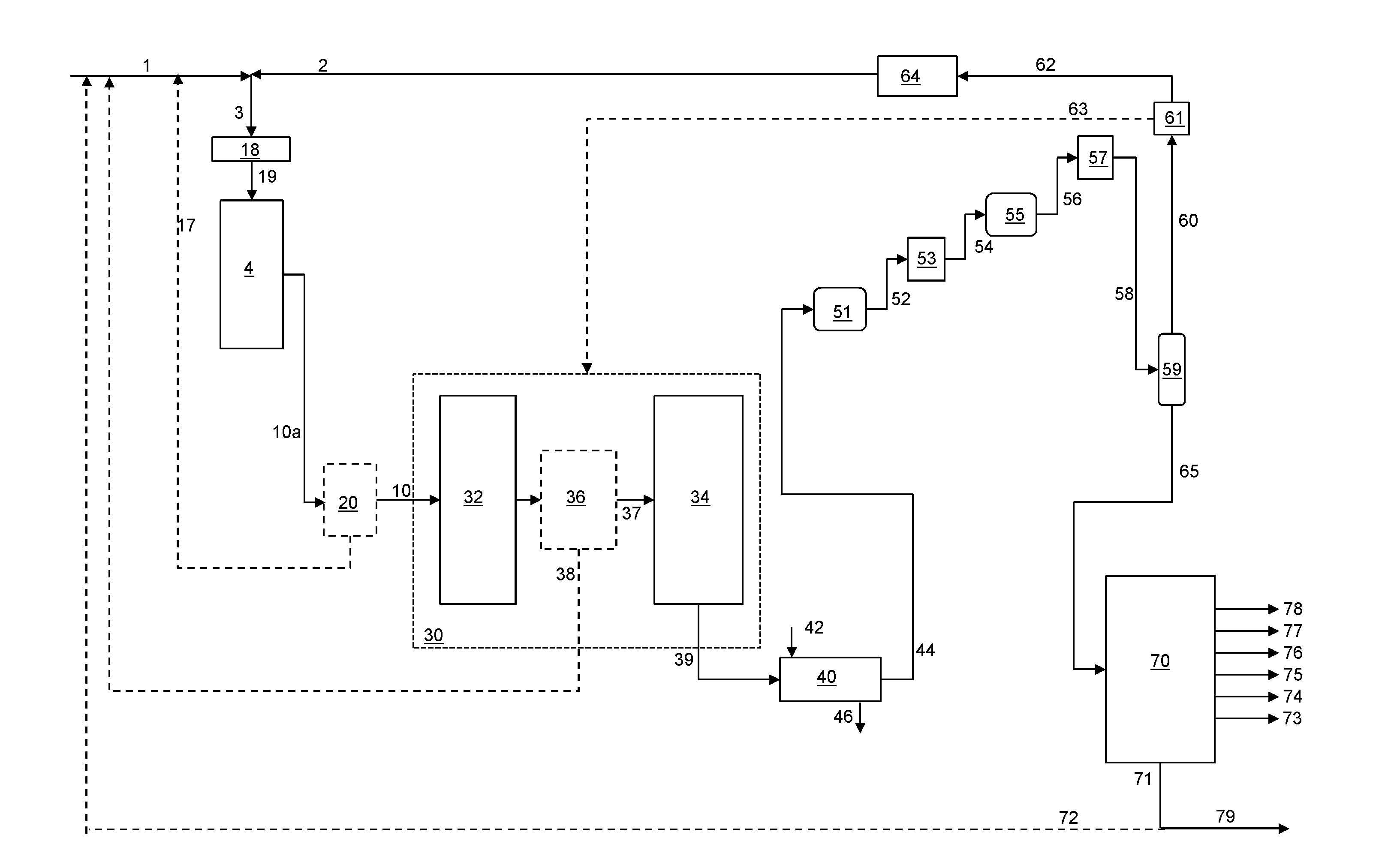

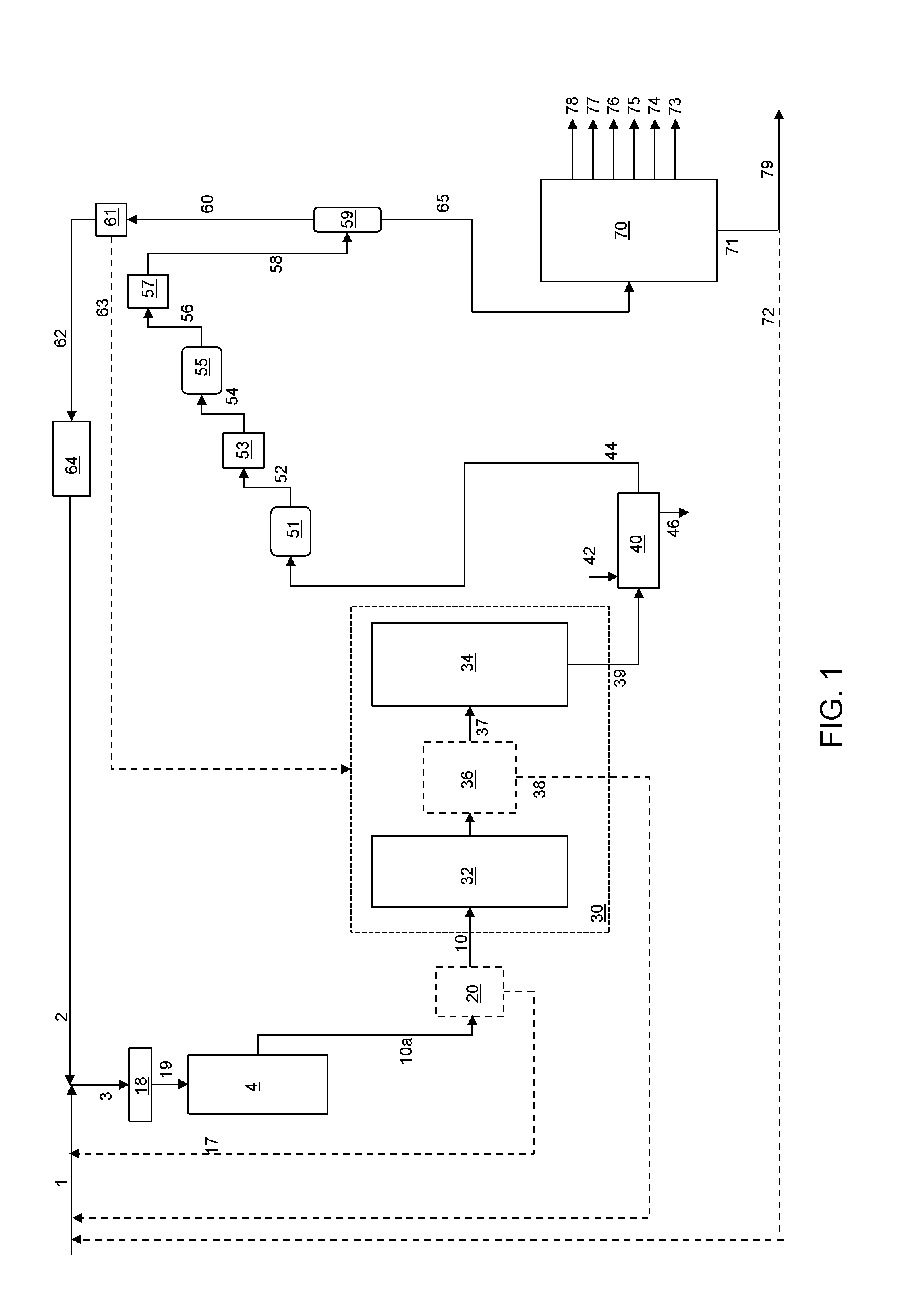

Integrated slurry hydroprocessing and steam pyrolysis of crude oil to produce petrochemicals

ActiveUS20130248418A1High hydrogen contentThermal non-catalytic crackingHydrocarbon oil crackingHydrogen contentSlurry

An integrated slurry hydroprocessing and steam pyrolosyis process for the production of olefins and aromatic petrochemicals from a crude oil feedstock is provided. Crude oil, a steam pyrolysis residual liquid fraction and slurry reside are combined and treated in a hydroprocessing zone in the presence of hydrogen under conditions effective to produce an effluent having an increased hydrogen content. The effluent is thermally cracked with steam under conditions effective to produce a mixed product stream and steam pyrolysis residual liquid fraction. The mixed product stream is separated and olefins and aromatics are recovered and hydrogen is purified and recycled.

Owner:SAUDI ARABIAN OIL CO

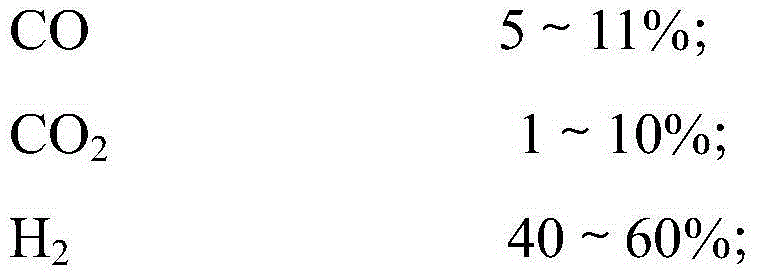

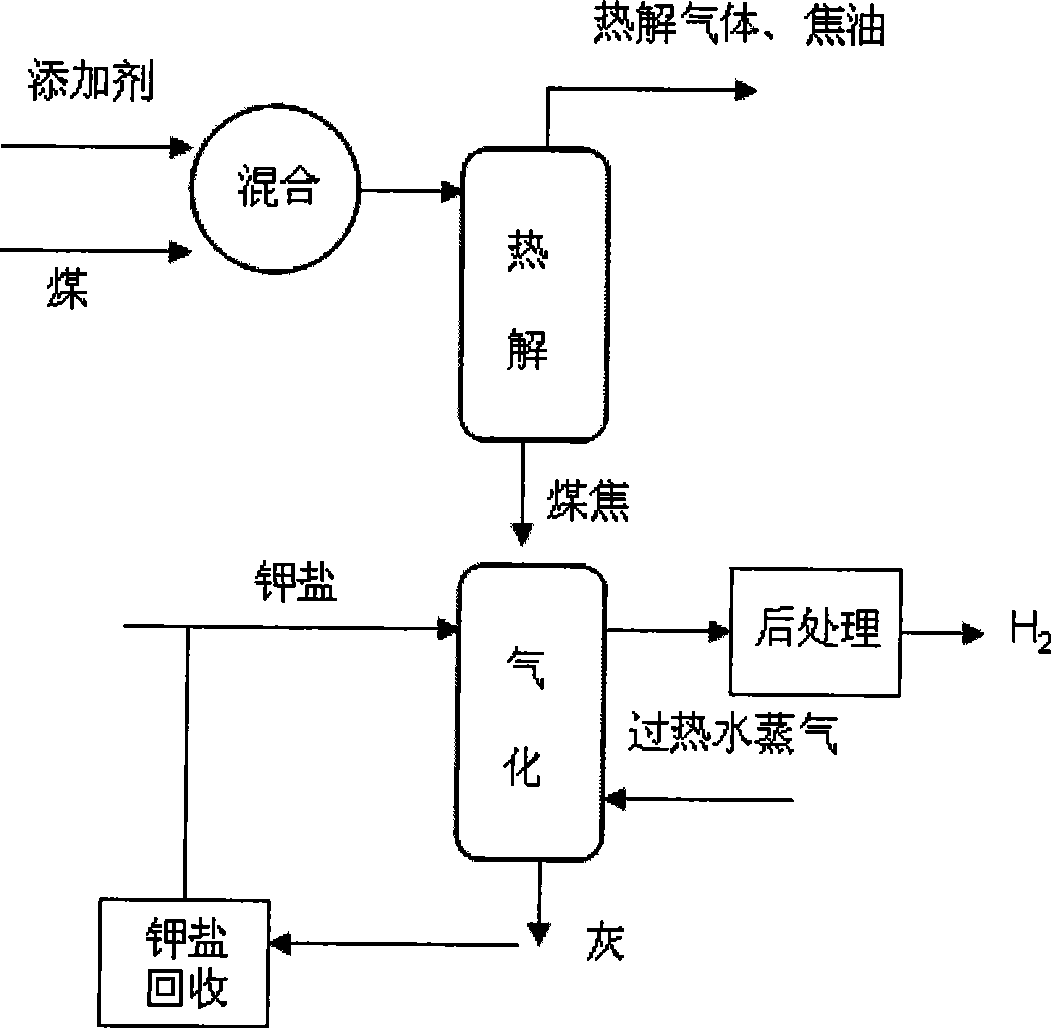

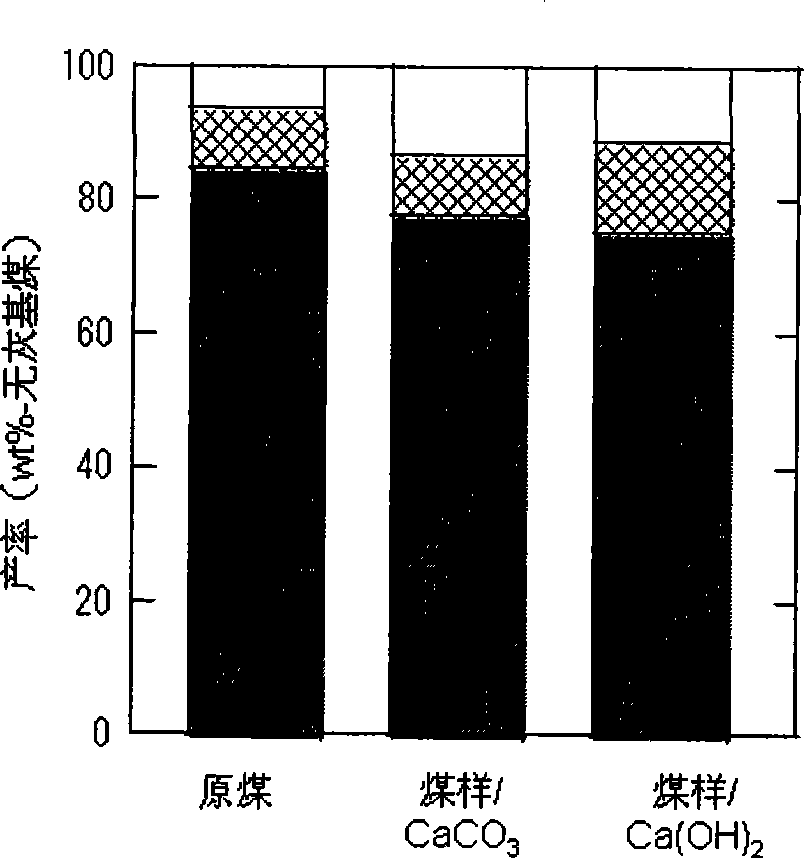

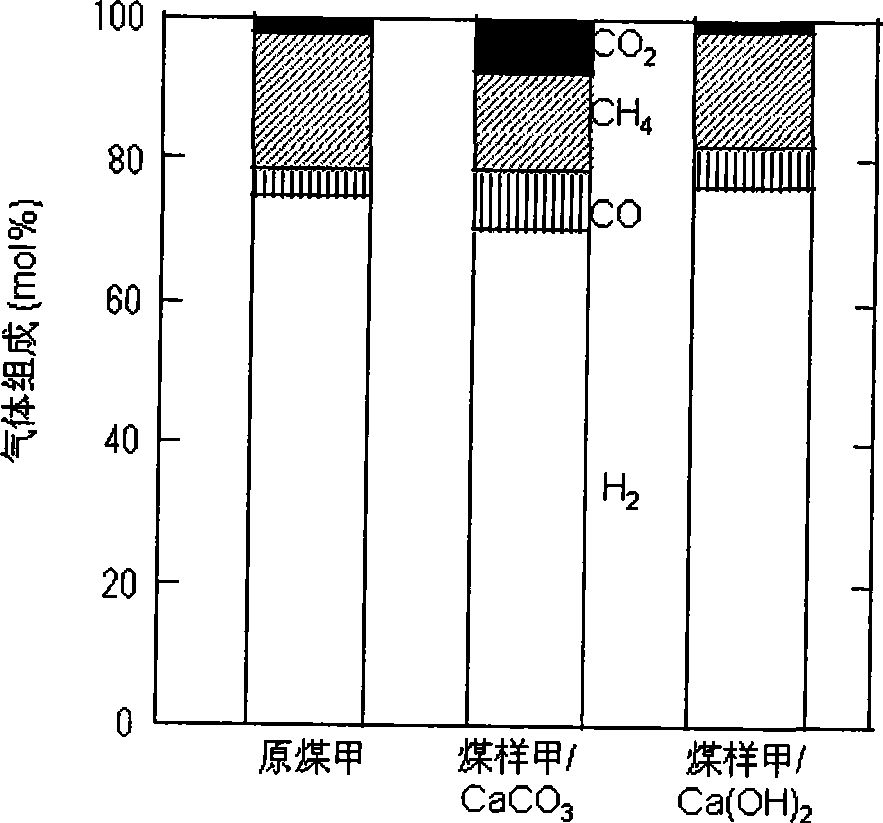

Method for preparing hydrogen by coal gasification

InactiveCN101372312ALow costHigh selectivityHydrogen productionCombustible gas productionCatalytic reformingTar

The invention relates to a method for preparing hydrogen by coal gasification. The method for preparing hydrogen includes the following steps: (1) thermal cracking of coal is carried out under the condition of isolating from air and at the temperature of 900 DEG C to essentially obtain coal thermal cracking gas, tarre and coal coke, and the coal thermal cracking gas and the tarre are removed to obtain the coal coke; (2) at the temperature below 800 DEG C, a gasifying agent is used for gasifying the coal coke obtained from the step (1) to obtain coal coke gas, and the obtained coal coke gas is purified to obtain a target object. In the invention, a 'two-stage type' gasifying method is adopted for gasifying coal, and the obtained coal coke gas (the coal coke gas contains about 70v / v% of hydrogen, less than 3v / v% of carbon monoxide and no methane) is used as the 'raw material gas' for preparing hydrogen. Therefore, a methane catalytic reforming technique and a carbon monoxide conversion process in a post treatment process can be omitted, and a beforehand desulfuration process required in these techniques can also be omitted, that is to say, pure hydrogen can be prepared only after the processes of removing acidic gas and purifying a little residual gas.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com