Biomass pyrogenation gasification and purification method

A technology for pyrolysis gasification and biomass, applied in the field of purification and biomass pyrolysis gasification, it can solve the problems of little improvement in structure, influence on gas quality, low carbon conversion rate, etc., and achieve wide practicability and good purification effect. , the effect of increasing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: refer to each accompanying drawing.

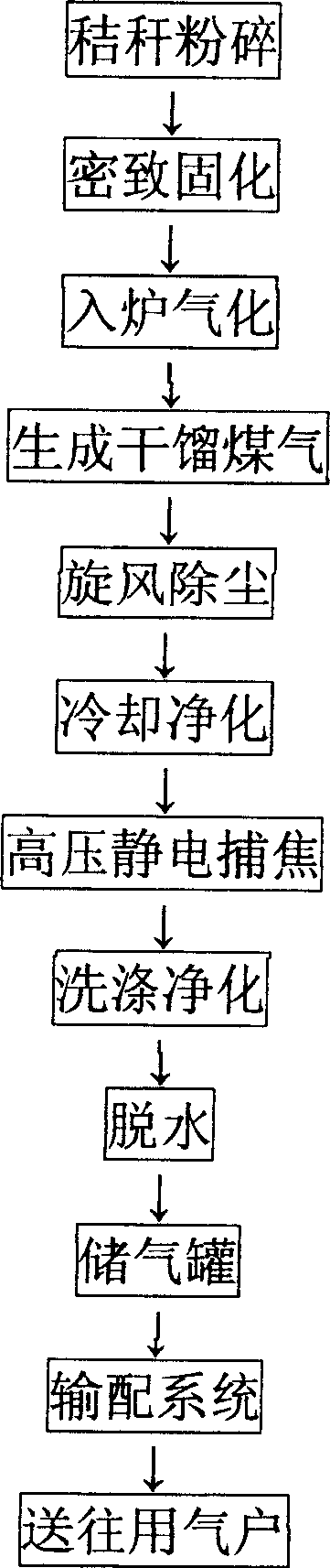

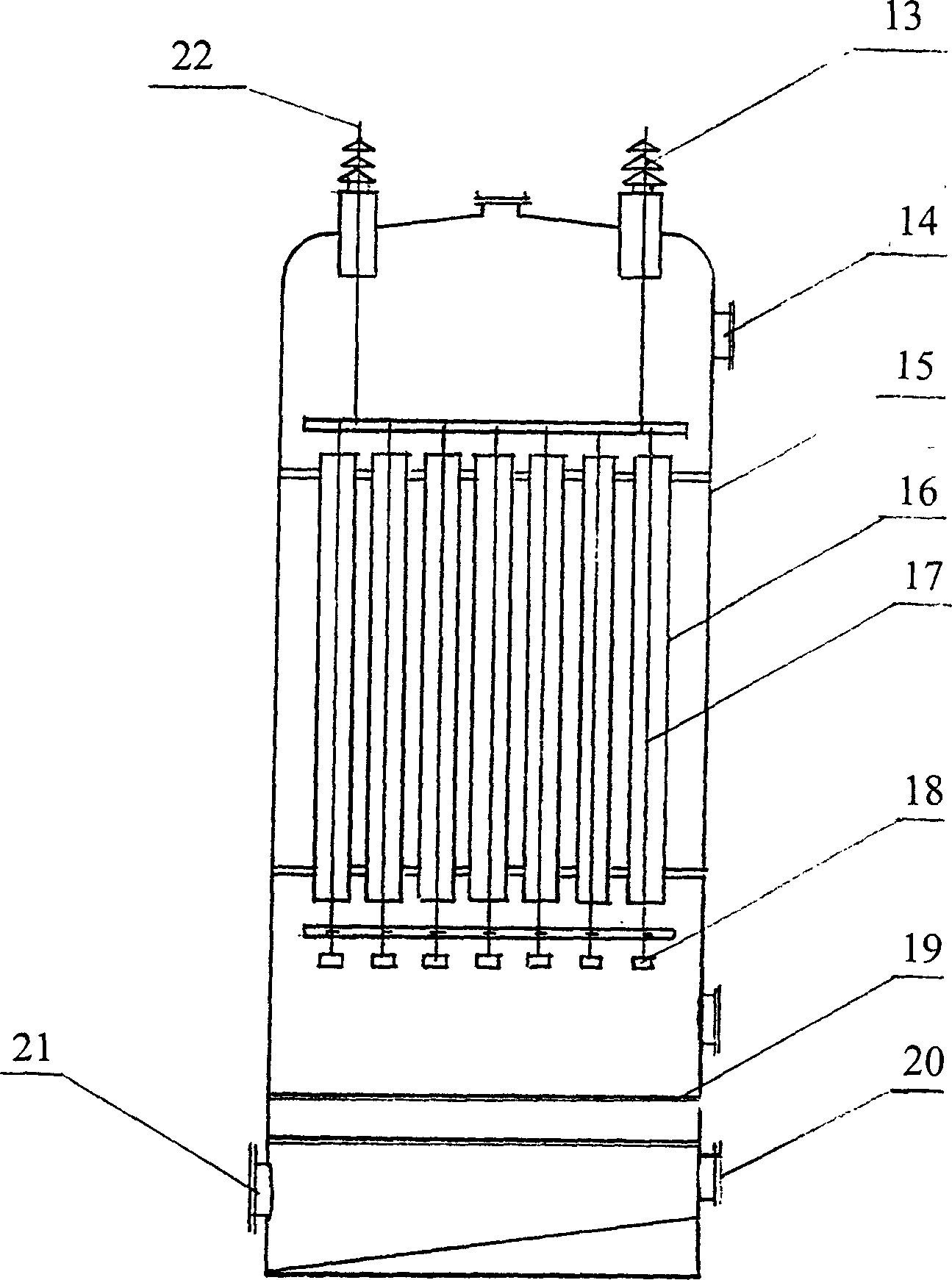

[0046] A biomass pyrolysis gasification and purification method mainly consists of the following steps:

[0047] (1) Crush biomass: remove biomass (which can be one or more mixtures of wheat straw, straw, corn stalk, rape stalk, reed, rattan, bamboo, herbs or other cellulose-containing materials ) in soil impurities, dry the water until the water content is not more than 20%, then pulverize the biomass through a pulverizer, and leak out through a sieve with an aperture of 3-15mm in the pulverizer;

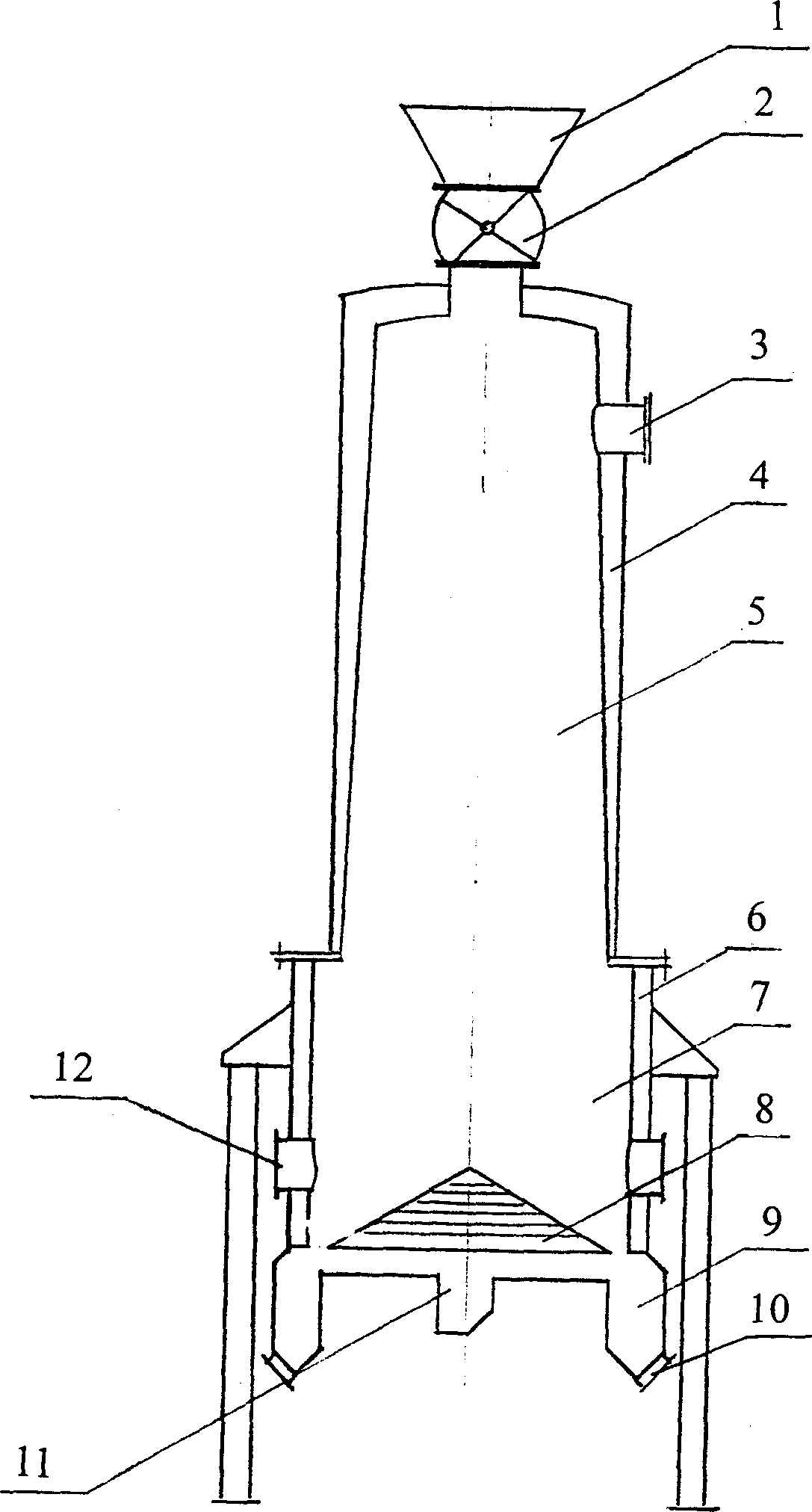

[0048] (2) Furnace gasification: The pulverized biomass is intermittently fed into the two-stage straw gasification generator, and the gasification agent air-water vapor or water vapor-oxygen is sent to the two-stage straw gasification In the middle gasification section of the producer, the producer gas is produced by the pyrolysis reaction between the two at 800-1000°C;

[0049] The specific process is: after the crushed...

Embodiment 2

[0064] Embodiment 2: refer to each accompanying drawing.

[0065] A biomass pyrolysis gasification and purification method mainly consists of the following steps:

[0066](1) Grinding biomass into shape: removing biomass (which can be one or more of wheat straw, rice straw, corn stalk, rape stalk, reed, rattan, bamboo, herbs or other cellulose-containing materials) the soil impurities in the mixture), dry the water until the water content is not more than 20%, then pulverize the biomass through a pulverizer, and leak out through a sieve with an aperture of 3-15mm in the pulverizer;

[0067] Then the crushed biomass is extruded into granules by a pellet press; the extruded granules can be cylinders with a diameter of 3-50mm and a length of 4-80mm or similar shapes, or a side length of 4-80mm cuboid, cube or similar shape.

[0068] (2) Furnace gasification: The formed biomass is intermittently fed into the two-stage straw gasification generator, and the gasification agent air-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com