Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

644 results about "Rattan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rattan (from the Malay rotan) is the name for roughly 600 species of old world climbing palms belonging to subfamily Calamoideae (from the Greek 'kálamos' = reed). Rattan is also known as manila, or malacca, named after the ports of shipment Manila and Malacca City, and as manau (from the Malay rotan manau, the trade name for Calamus manan canes in Southeast Asia). The climbing habit is associated with the characteristics of its flexible woody stem, derived typically from a secondary growth, makes rattan a liana rather than a true wood.

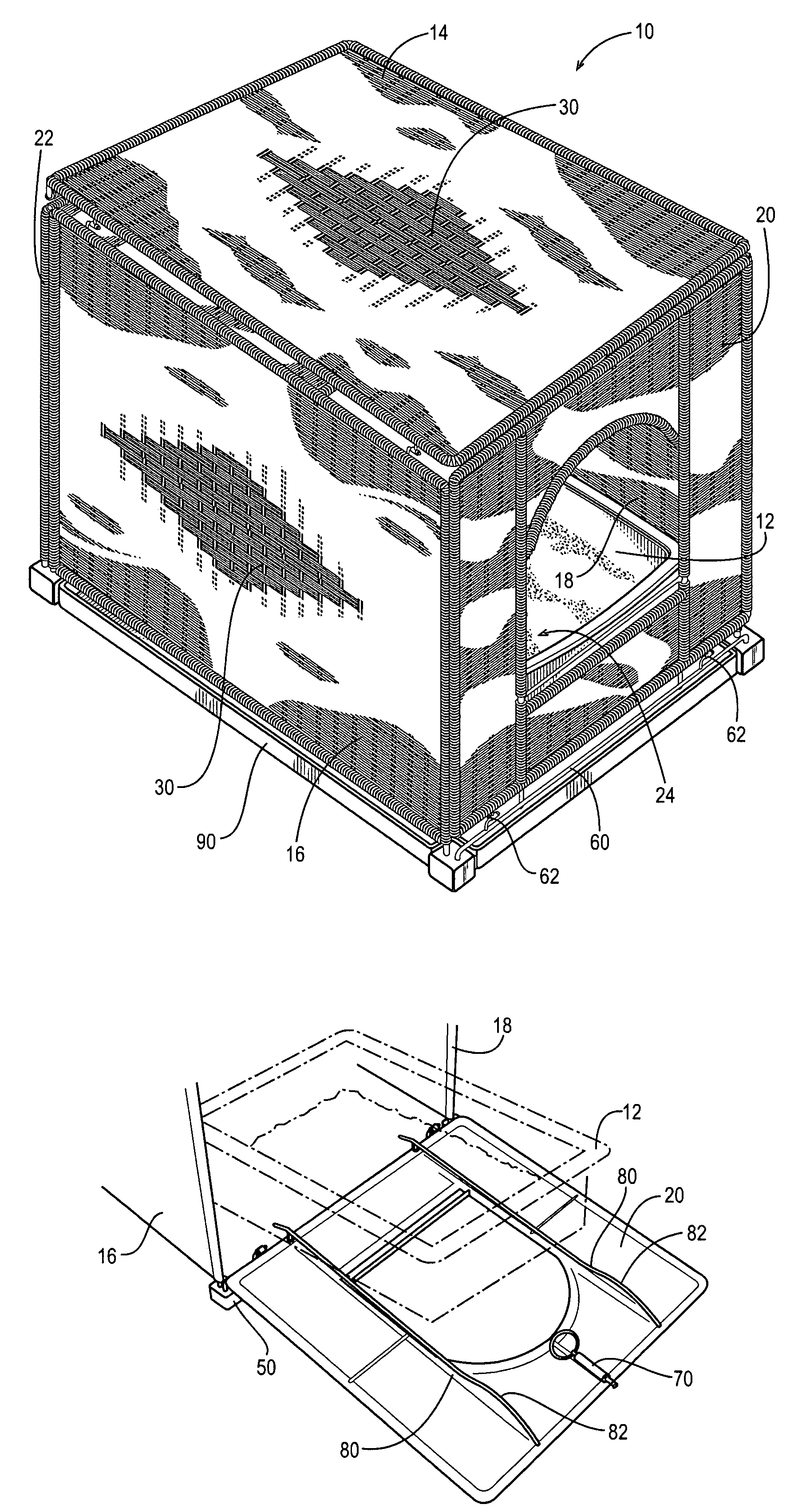

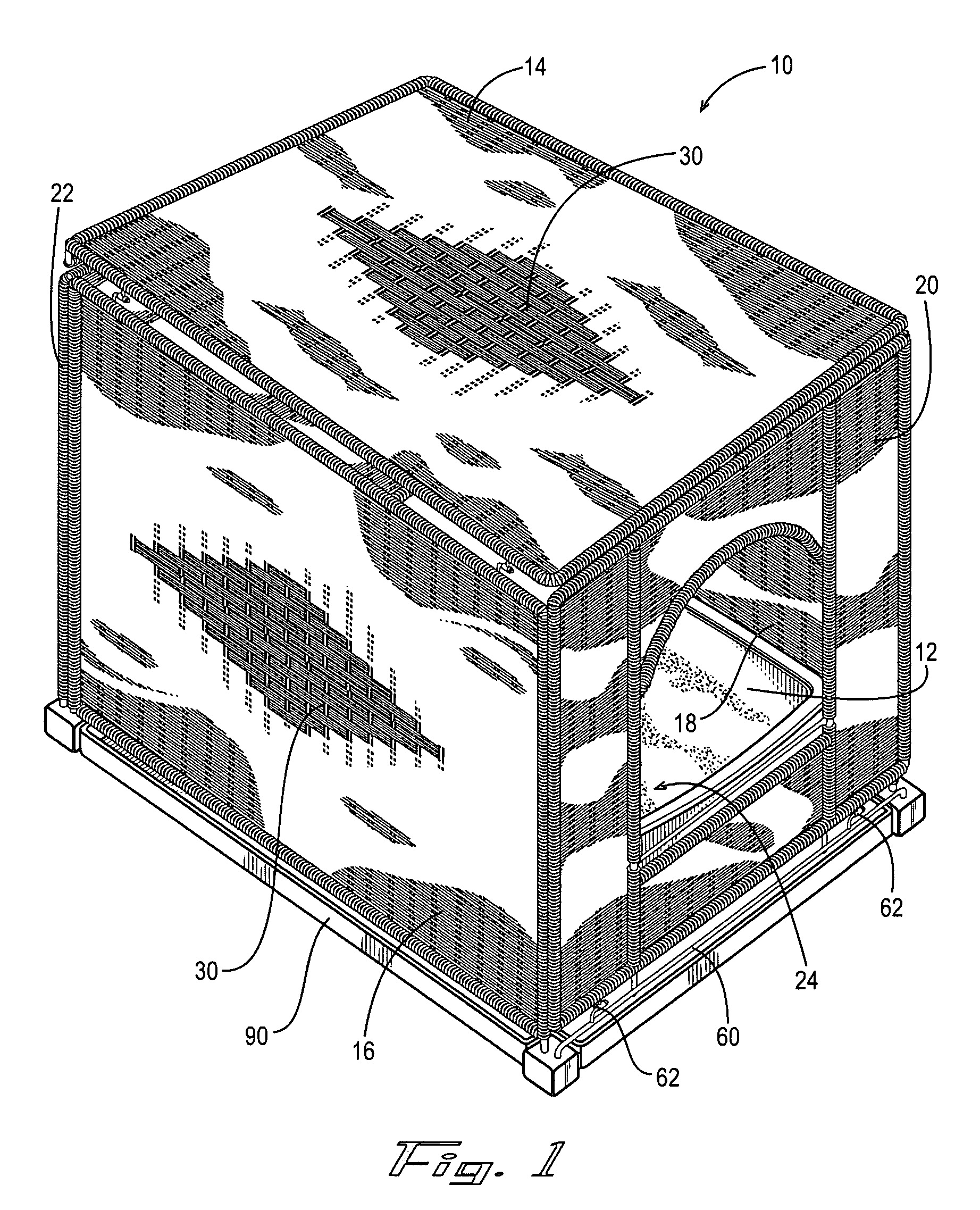

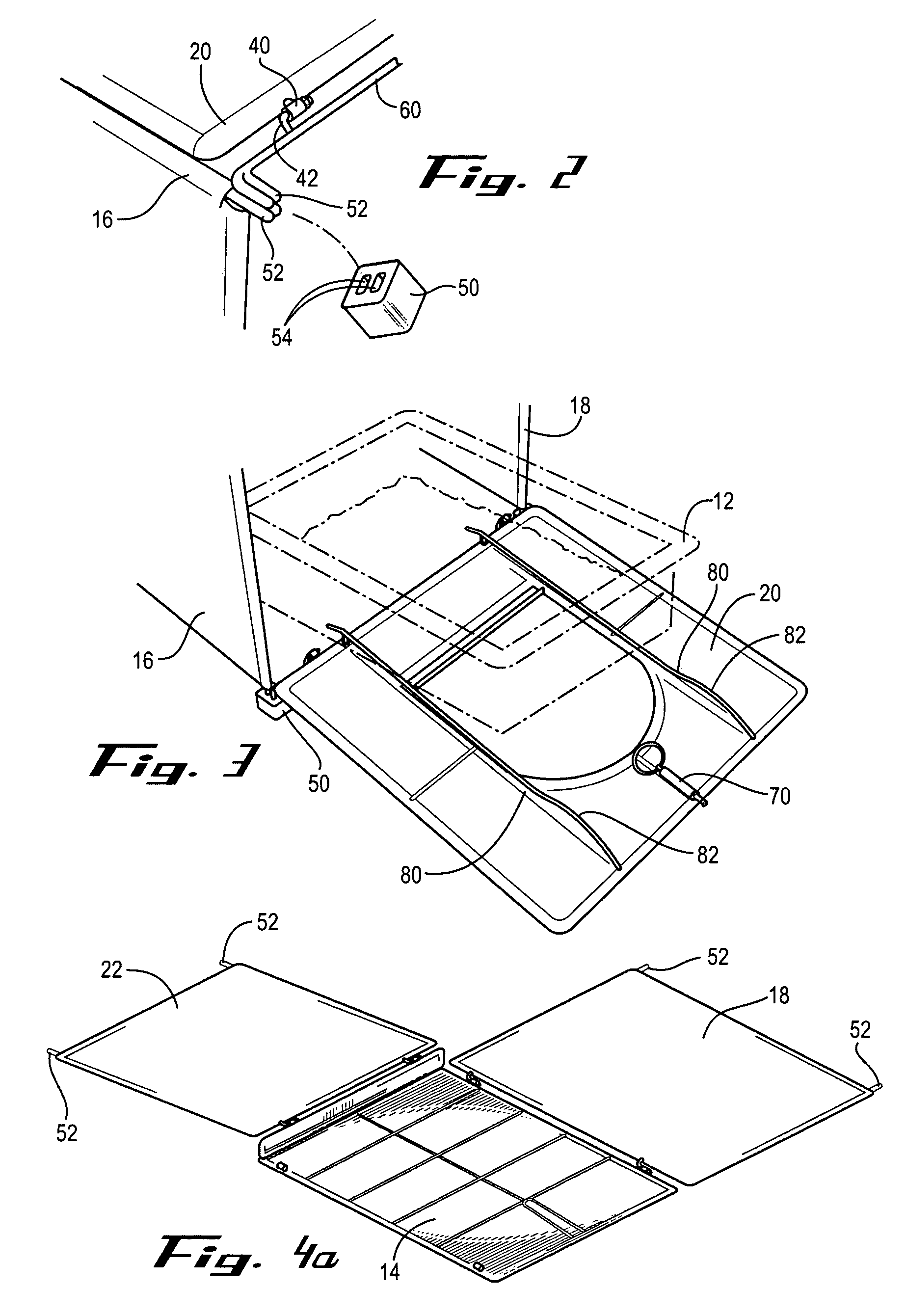

Pet litter pan enclosure

An enclosure for a pet litter pan, having a moisture and odor-resistant plastic rattan-like material woven on a wire frame. The enclosure is quickly and easily assembled from multiple panels using pin connectors and connector feet. An openable panel provides access to remove the litter pan for cleaning, and has low-friction rails along its interior for facilitating easier removal and replacement of the pan.

Owner:RADIO SYST CORP

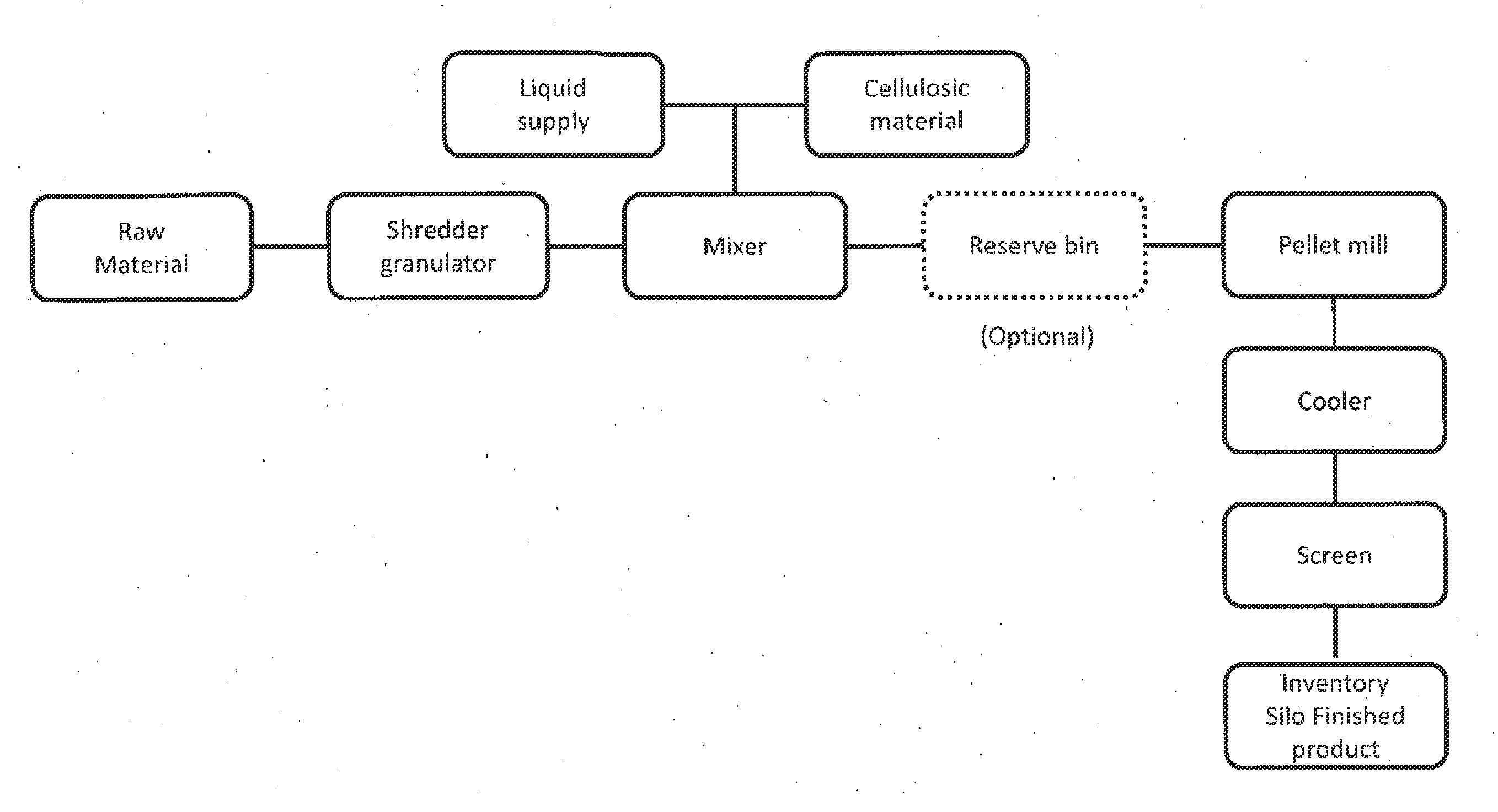

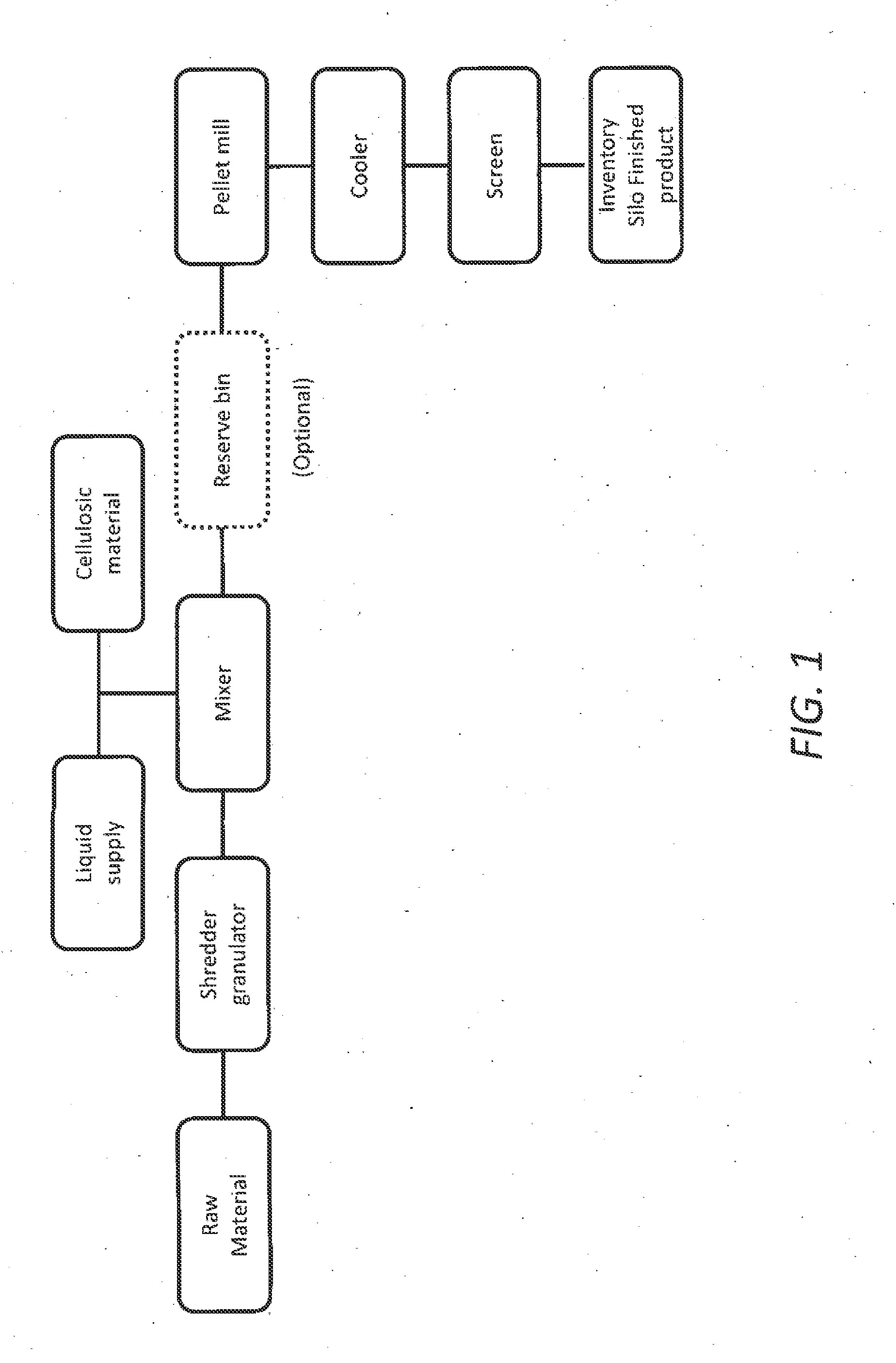

Multipurpose pellets and method of making same

A multipurpose pellet is provided comprising: from about 0.1% to about 100% by weight of a vegetable fiber chosen from cotton, bamboo fiber, rice fiber, esparto, papaya, coir, sisal, kapok, jute, ramie, flax, roselle hemp, hemp, kenaf, abaca, soybean fiber, okra fiber, vine fiber, banana fiber, rattan and nettlesjute; and from about 99.9% to about 0% by weight of cellulosic material.

Owner:LEFEBVRE ROBERT

Anti-blushing transparent woodwork coating and production process thereof

The invention relates to an anti-blushing transparent woodwork coating and a production process thereof. The anti-blushing transparent woodwork coating consists of main paint, a curing agent and a thinner, wherein 2.0-4.0 weight percent of zinc stearate powder is used. Due to the use of the zinc stearate, the method not only can maintain the transparency of the paint membrane, but also can significantly improve the rubbing property of the dry membrane. However, if the zinc stearate is not used properly, serious blushing can occur in the late period. The invention solves the problem that blushing can easily occur to the double-component polyurethane transparent woodwork primer coated thickly at the low temperature and synchronously realizes the purposes of good closure, easy rubbing and long-term clear and transparent effect of the paint membrane through controlling the ratio of the zinc stearate and hydroxyl alkyd resin, the dispersion of the zinc stearate powder and the production indexes. Therefore, the invention can be widely applied in the surface protection and decoration of indoor and outdoor bamboo, wood and rattan products.

Owner:陈姣英

Soaking finishing agent of rattan and corn straw as raw materials for weaving crafts and use method thereof

The invention discloses a soaking finishing agent of rattan and corn straw as raw materials for weaving crafts. The soaking finishing agent is prepared from the following raw materials in percentage by weight: 10-20 parts of kuh-seng, 10-15 parts of frutus cnidii, 10-15 parts of stemona root, 10-15 parts of betelnut, 1-2 parts of entomomycete pesticide, 20-30 parts of lime and 20-30 parts of tea.When the soaking finishing agent is in use, the raw materials are mixed and dissolved in water according to a certain proportion, and weaving materials are soaked in a soaking solution for a certain of time, taken out and dried or aired. The soaking finishing agent provided by the invention is non-toxic, harmless and environment-friendly, and the products woven with straw or rattan soaked by the soaking finishing agent provided by the invention can not be mildewed and damaged by worms for dozens of years and keep vivid color and luster.

Owner:FUNAN TENGXIANG ARTS & CRAFTS

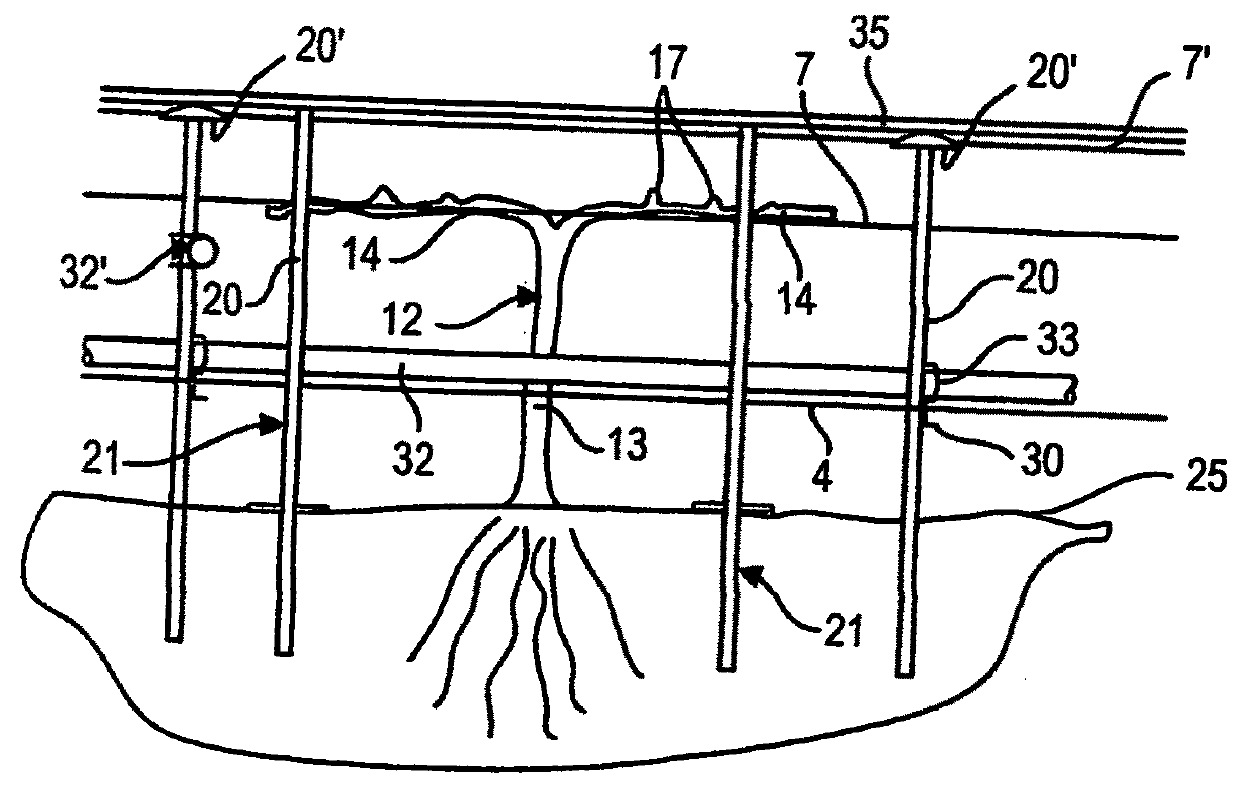

Method for protecting and greening rocky side slope

InactiveCN101831914ASuitable for growthEffective soil fixationWatering devicesExcavationsGrowth plantCombined method

The invention discloses a method for protecting and greening a rocky side slope, which relates to the field of side slope construction in highways, railways, hydroelectricity and municipal projects. The method is a combined method for protecting, reinforcing and greening the superficial layer of a rocky side slope, and comprises the following steps of: (1) smoothing the slope surface; (2) driving an anchor rod; (3) installing a water spray pipeline and a device; (4) excavating a pit groove for a ground beam, and laying a reinforcing cage for the ground beam; (5) pouring the whole ground beam by bundling the reserved reinforcing steel bar for the anchor rod and the reinforcing cage for the ground beam; (6) prefabricating and inserting a soil blocking plate; (7) filling farming soil; and (8) planting and maintaining rattan plants. The invention has the advantages of effectively conserving soil and providing the objective environment suitable for plant growth; pre-burying a water spray device, ensuring the humidity of soil and improving the survival rate of plants; and realizing the purpose of reinforcing and greening the superficial layer of the rocky side slope comprehensively, and the invention is suitable for the project for protecting and greening the rocky side slope in highways, railways, hydroelectricity and municipal projects.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

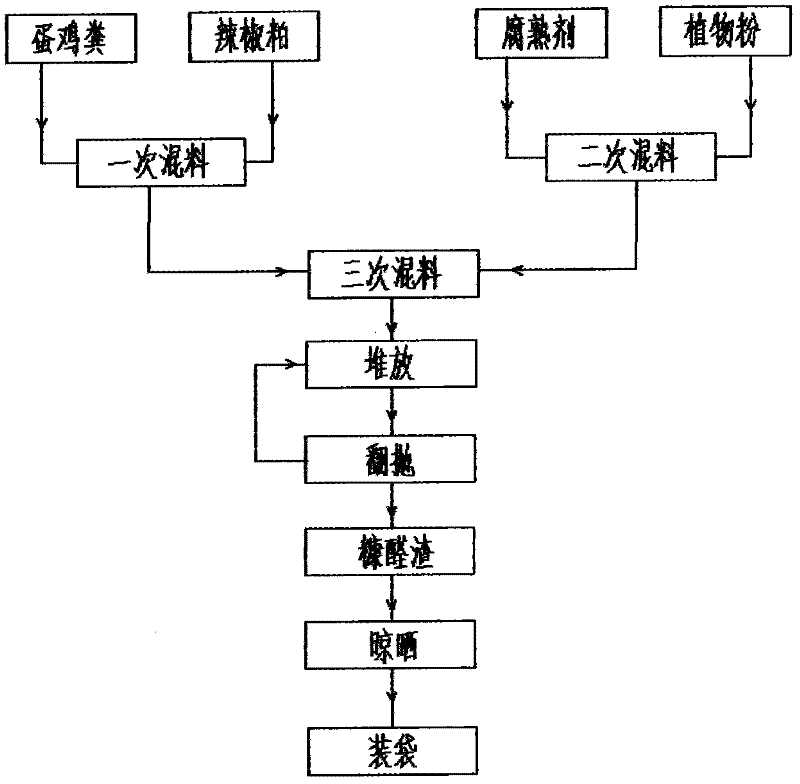

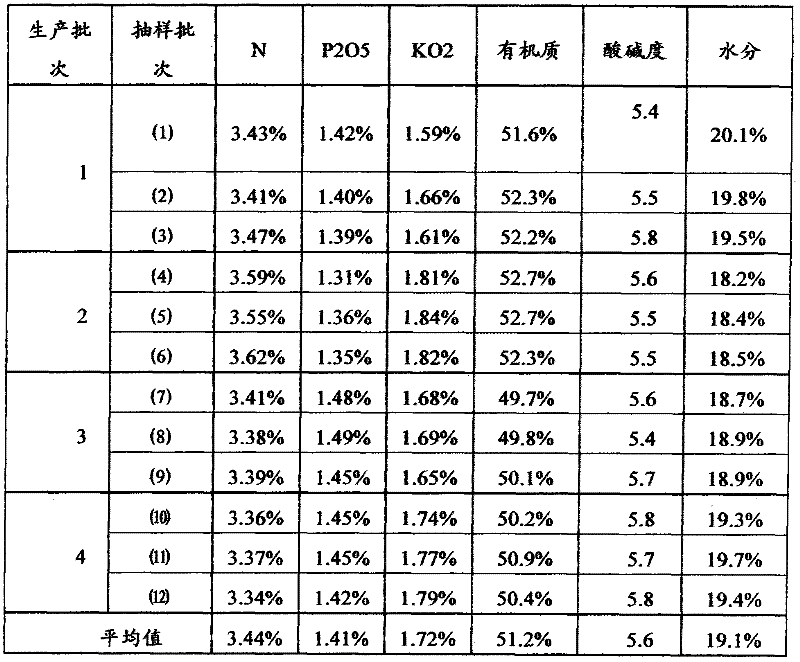

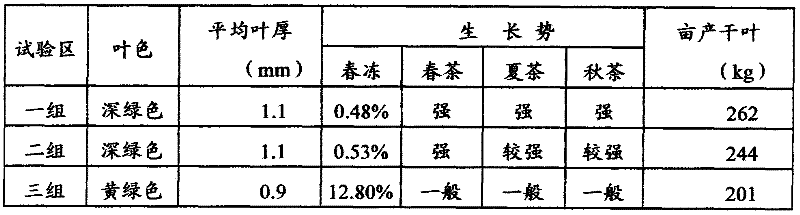

Fertilizer special for tea tree and preparation method

InactiveCN102173911AImprove the environmentRaise the pHBio-organic fraction processingOrganic fertiliser preparationDiseaseInsect pest

The invention provides a fertilizer special for a tea tree. The fertilizer special for the tea tree is prepared from the following raw materials in percentage by weight: 60 to 79 parts of egg chicken manure, 11 to 29 parts of hot pepper dreg, 2 to 5 parts of zeolite powder, 0.05 to 0.1 part of decomposing agent, 50 to 65 parts of furfural dreg and 0.45 to 0.9 part of plant powder, wherein the hotpepper dregs may be any one or more of chrysanthemum dreg, peanut dreg, rapeseed dreg and corn germ dreg; the decomposing agent is Aspergillus oryzae; the granular size of the zeolite powder is 100 to 200 meshes; the plant powder is formed by crushing any one or more of core straw, wheat straw, rice straw, sweet potato rattan, horsebean straw, rape stalk, weed and leaf; and the granular size of the plant powder is 80 to 120 meshes. The fertilizer special for the tea tree has a simple process, is convenient to prepare, inhibits diseases and insect pests, improves soil environment and pH value,increases the nitrogen content of the fertilizer, and contributes to growth of crops.

Owner:QINGDAO TIANRUI ECOLOGICAL TECH

Method for testing fracture toughness of rattan canes based on three-point bending mode

InactiveCN104568605AImprove test accuracyImprove accuracyMaterial strength using steady bending forcesCritical loadStress strength

The invention provides a method for testing the fracture toughness of rattan canes based on a three-point bending mode. The method comprises the following steps: preparing a sample, and regulating a water content rate so as to obtain a sample of which the water content rate is 10-12%; recording a load-crack opening displacement (PV) curve, measuring actual crack depths, and calculating critical loads PQ and critical stress intensity factors KQ. According to the method provided by the invention, the crack opening displacement is measured by a C.O.D Gauge, and the test precision is improved. Aiming at the characteristics of the rattan materials, the sampling method for testing the fracture toughness of rattan canes is ensured, and the measured results having high accuracy and good reproducibility are obtained. The calculation method for testing the fracture toughness of rattan cane, provided by the invention, provides qualitative and quantitative bases for the utilization of the rattan canes.

Owner:INT CENT FOR BAMBOO & RATTAN

Rattan softening method

InactiveCN104589445ASoftening method is simpleImprove corrosion resistanceReed/straw treatmentWood impregnation detailsUltimate tensile strengthSoftening

A related rattan softening method comprises the following steps: (1) processing rattan at 75 DEG C at relative humidity of 85% for 1.5 h, and then cooling to 15 DEG C; (2) immersing rattan processed in the step (1) by using a mixed solution of glycerin, sodium hexametaphosphate and water according to the weight ratio of 5:1:40 for 2 h; (3) processing rattan processed in the step (2) at 80 DEG C at relatively humidity of 70% for 3 h; and (4) putting rattan processed in the step (3) into a urea solution with the temperature of 25 DEG C and the concentration of 8% for immersing for 20 min, and then using clean water for flushing, so as to obtain the finally processed rattan. The provided rattan softening method is simple, and the processed rattan is improved in anti-corrosion performance, greatly improved in flexibility, and convenient for braiding. After a product is braided, the product is dried, and thus the product strength is substantially improved, and the usage performance of rattan products is guaranteed.

Owner:安徽省阜南志峰工艺品有限公司

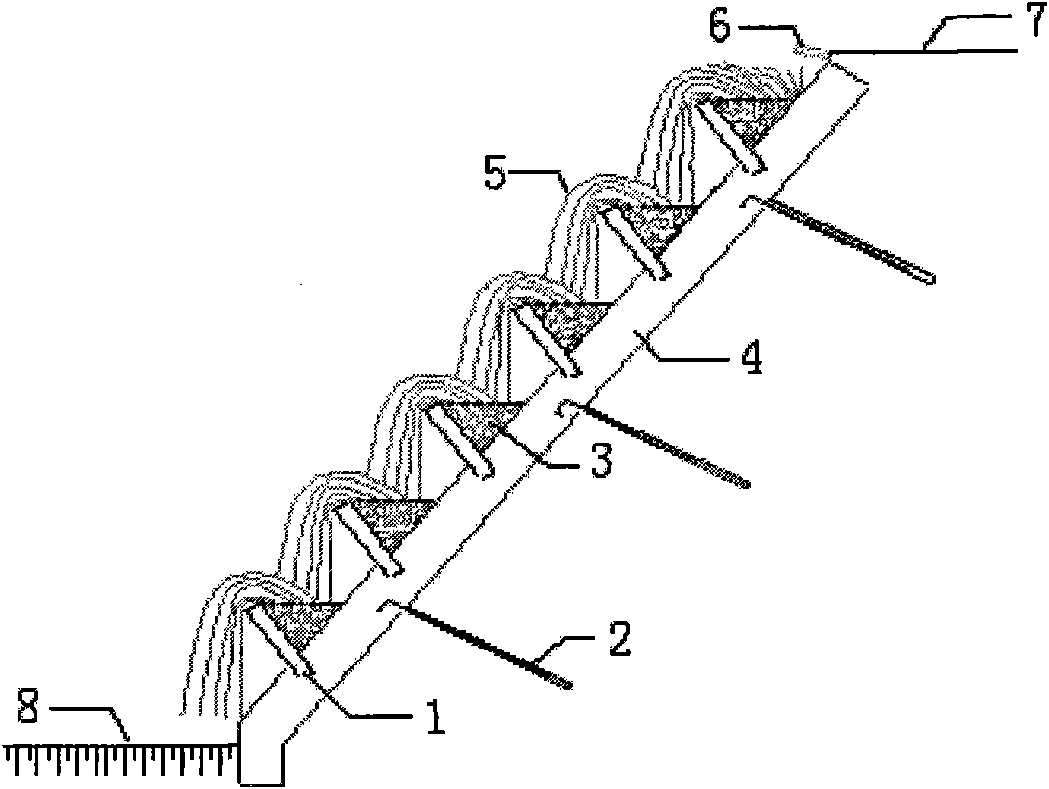

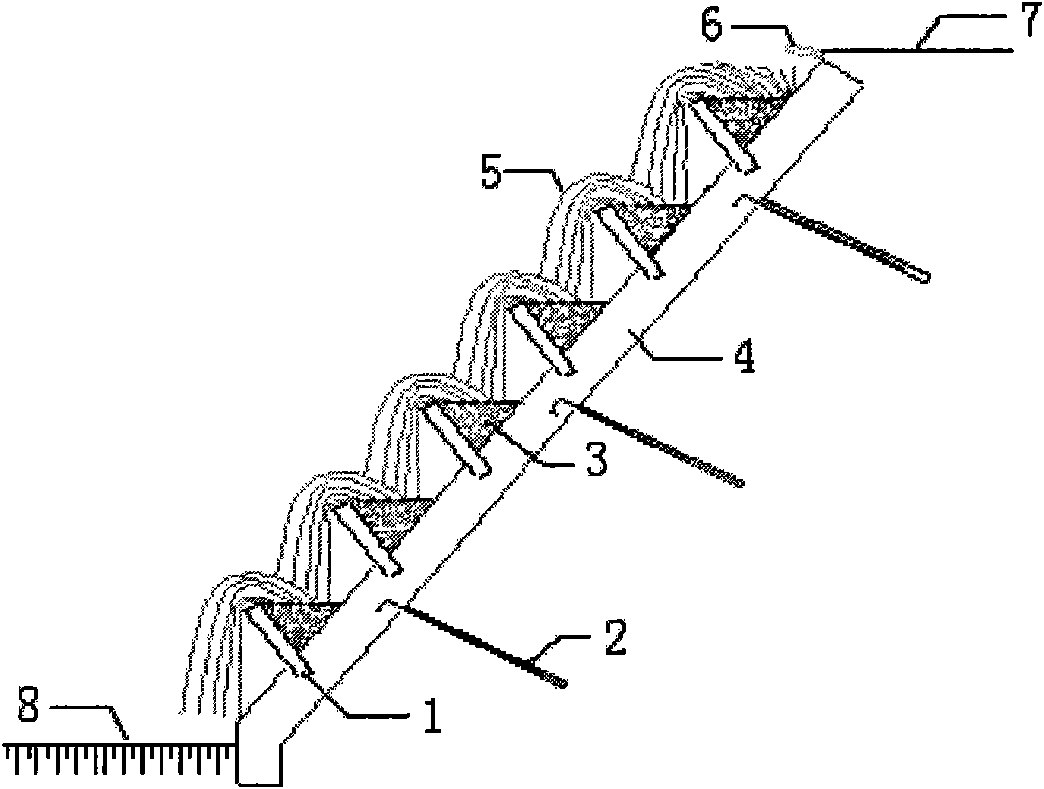

Rattan bamboo plus material and preparation method thereof

InactiveCN101264679AWide range of usesImprove breathabilityLamination ancillary operationsCane mechanical workingUltravioletBiomedical engineering

The invention provides a cany bamboo fabric and preparation method, which comprises a cany skin layer or a bamboo skin layer (1) and a lapping cloth layer (2); wherein, the cany skin layer or the bamboo skin layer (1) are produced through the scraping and silking or drawing out and planishing treatments; the cany skin layer or the bamboo skin layer (1) are compounded with the lapping cloth layer (2) together. The cany bamboo fabric is characterized in that (a) the processes of degreasing, purifying, stewing, acid treatment and bleaching treatment are added between the process of silking or drawing out and the process of planishing, (b) the cany skin or the bamboo skin are weaved into the cany skin layer or the bamboo skin layer (1), and (c) the processes of softening finishing and hot compression and fixation are processed as the cany skin layer or the bamboo skin layer (1) are compounded with the lapping cloth layer (2) together. The cany bamboo fabric has the advantages of beautiful appearance, good performance of ultraviolet resistance, soft texture, uneasy to fold, free of yellowing, easy to clean, being applicable to the production of clothing, bedding articles, high grade car pad set, slipcover, window curtain, carpet, and shoes and hats, and versatility.

Owner:周觉民

Method for propagating radix tetrastigme underground officinal tubers

ActiveCN102726203AAvoid rotImprove survival rateSeed and root treatmentHorticultureGreenhousePlant propagation

The invention relates to a plant propagation method, and particularly relates to a method for propagating radix tetrastigme underground officinal tubers. The method comprises the following steps of: 1) low-temperature moisture preservation, sand storage and dormancy release; 2) germination acceleration and transplanting; and 3) large field transplanting. According to the invention, the radix tetrastigme underground officinal parts are utilized; through the technologies of low-temperature sand storage, dormancy release, greenhouse germination acceleration and large field transplanting, the radix tetrastigme underground officinal parts root after about 45 days. The method provided by the invention has the advantages of rapid propagation, low cost, high seedling rate, low corrosion rate and the like, thereby breaking through the technical defect that the original radix tetrastigme propagation technology is restricted to overground rattan cottage, which is easy for degradation, instable in variety characteristic, high in tissue culture investment, in need of professionals and the like.

Owner:浙江仲兴生物医药科技有限公司

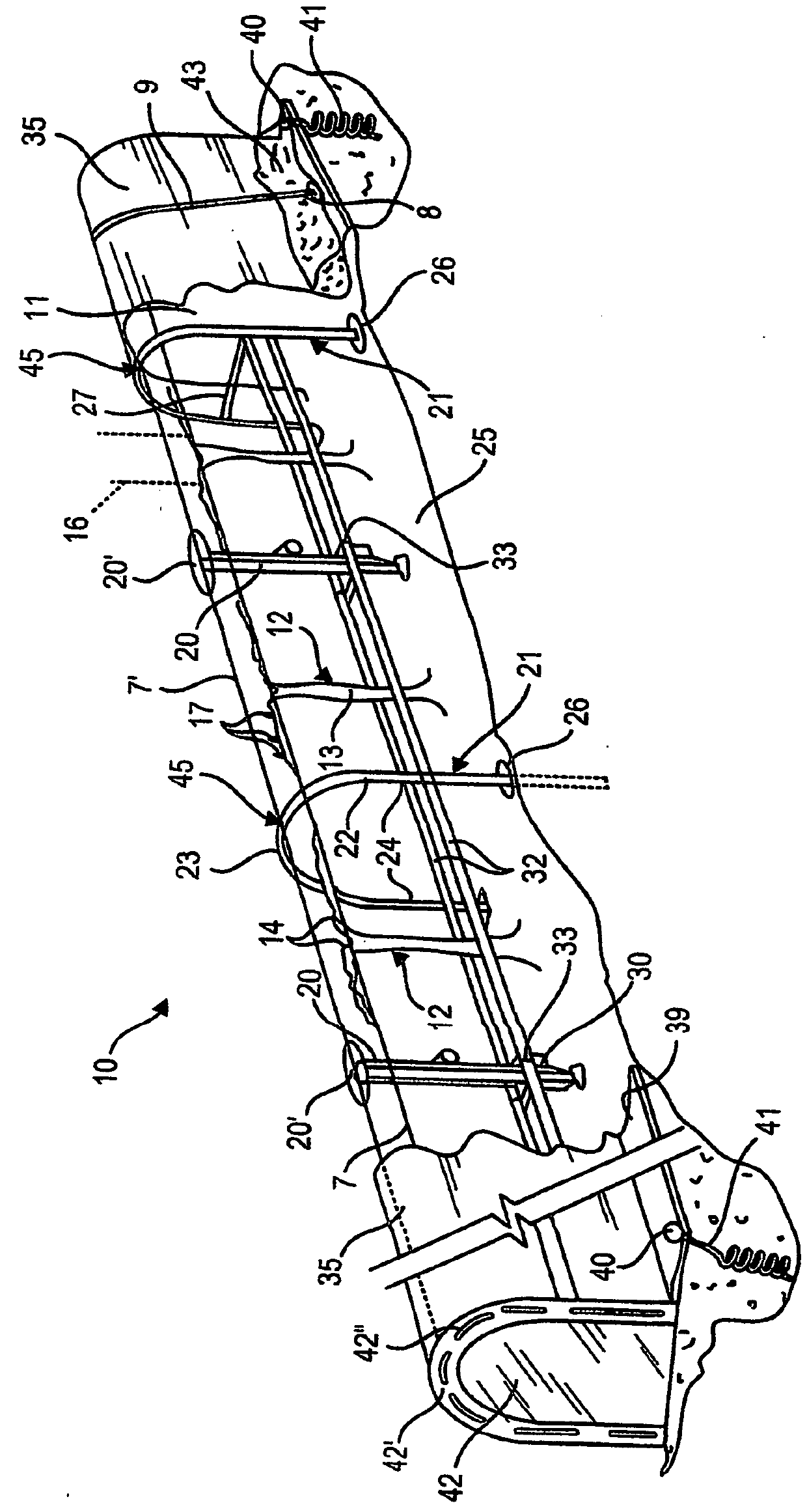

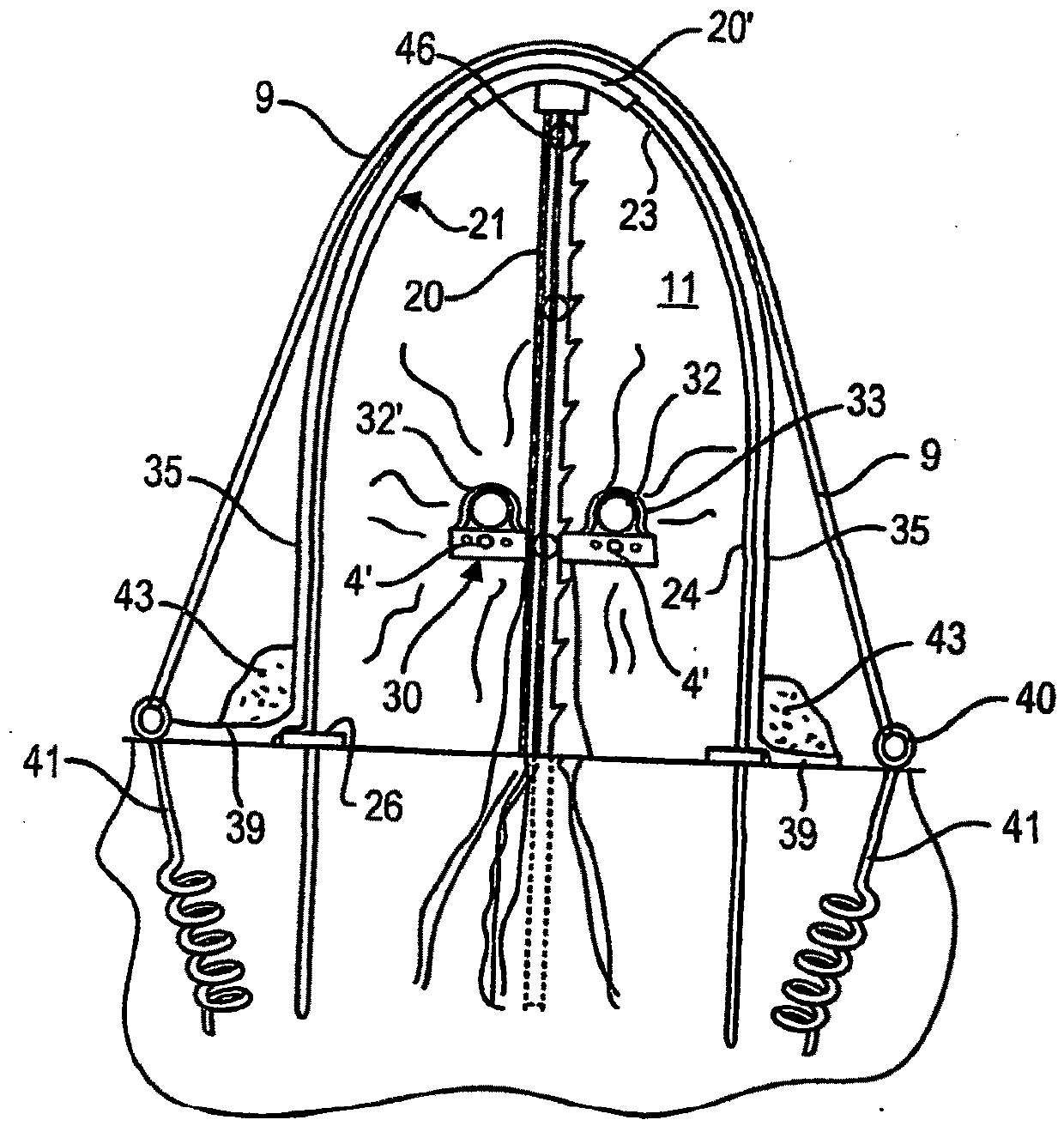

Method and system for increasing days for the cultivation of particular fruit bearing vines in unfavourable climatic regions

ActiveUS20180177141A1Increasing degree dayPrevent temperature drops damagingFluid heatersClimate change adaptationDegree dayVitis riparia

A method and a system for increasing the degree days in the immediate environment of fruit bearing vines for the cultivation of particular fruit bearing vines, such as non-rustic vinifera variety vines, in unfavourable climatic regions where the degree days is insufficient for the full maturity of the fruit, is described. Rows of the vines are protected in removable shelters which have a removable tarp cover disposed over a support frame structure to shield the rows of vines from the harsh, vine damaging, winter month temperatures while keeping the vines in a controlled temperature environment. Heated liquid circulation conduits are supported in the shelters at predetermined locations and provide controlled heat during the winter months to prevent the vines and the cordon bearing spuds of the vines from damaging cold temperatures. In the early spring the roots are activated early and the tarp is removed and a transparent film sheet covering is substituted to admit sunlight to help activate the vine early to gain degree days. The method and system is also applicable to semi-rustic or rustic wine producing grape vines grown in these climatic regions having degree days down to about 1200.

Owner:LAMOUREUX NORMAND

Method for producing diverse extracts of berry tea

ActiveCN102106931AReduce usageReduce pollutionFood preparationPlant ingredientsDesorptionEthanol precipitation

The invention provides a method for producing diverse extracts of berry tea, comprising the following steps: drying Ampelopsis grossedentata tender stems rattans and leaves, crushing, carrying out microwave extraction, macroporous resin separation, concentrating column-over effluent liquid at reduced pressure, carrying out ethanol precipitation on concentrated liquid, and drying ethanol precipitation substance, so as to obtain a berry tea polysaccharide extract; eluting desorption liquid, collecting desorption eluent, concentrating, and carrying out spray drying on the concentrated liquid, soas to obtain a berry total flavone extract; and ultrafiltrating the desorption eluent, passing though a reverse osmosis membrane, concentrating retentate, adding 3-5% of active carbon, filter pressing, cooling and crystallizing filtrate, centrifugally dewatering and vacuum drying so as to obtain crude dihydromyricetin. The method provided by the invention is in favor of comprehensively using Ampelopsis grossedentata plant resources; and the microwave extraction, macroporous resin elution and membrane separation methods based on water as a medium are used, thereby being beneficial to reductions of use amount of organic solvents, energy consumption, production cost and environment pollutions.

Owner:ZHANGJIAJIE MAOYANMEI

Preparation method of water hyacinth rattan

InactiveCN103264423ADoes not affect flexibilityIncrease productivityReed/straw treatmentDrying timeWater Hyacinths

The invention relates to a preparation method of water hyacinth rattan. The preparation method comprises the following steps of: collecting stalk of water hyacinth, drying the stalk of the water hyacinth for 48-72 hours in air by using a natural air drying method, and subsequently drying the stalk by using a heating and drying method till the water content of the stalk is 10-15%, wherein the temperature of the heating and drying environment is 75-85 DEG C and the humidity is 30-50% in the heating and drying method. With the combination of the natural air drying method and the heating and drying method, the drying time is shortened on the premise that the flexibility of the water hyacinth rattan is not affected, so that the production efficiency of the water hyacinth rattan is greatly improved.

Owner:GUANGDONG DOER SCI & TECH

Environmentally friendly mildew preventives for willow rattans

InactiveCN105058529AStrong environmental protectionNo mildewBiocideReed/straw treatmentBelamcanda chinensisPhellodendron

The invention discloses environmentally friendly mildew preventives for willow rattans, and relates to the technical field of mildew prevention for willow rattans. The environmentally friendly mildew preventives for willow rattans are made of the following raw materials: by mass, 50-60 parts of cinnamon, 40-50 parts of eucommia, 20-30 parts of sophora flavescens, 18-25 parts of cortex dictamni, 15-20 parts of cortex phellodendri, 15-22 parts of belamcanda chinensis, 13-18 parts of fennel, 12-15 parts of garlicin, 10-15 parts of water banyan barks, 8-12 parts of litsea cubeba oil, 9-12 parts of bamboo juice, 15-20 parts of jasmine flowers, 5-10 parts of radix glycyrrhizae, 6-10 parts of platycodon grandiflorum and 5-10 parts of essence. The environmentally friendly mildew preventives for willow rattans are safe, free of toxicity and highly environmental-friendly. The jasmine flowers and the essence are added to neutralize the pungent smell of medicines, so that soaked willow rattans emit fresh scent. Willow rattans soaked in the environmentally friendly mildew preventives have no mildew and worm damage phenomena.

Owner:孙晨

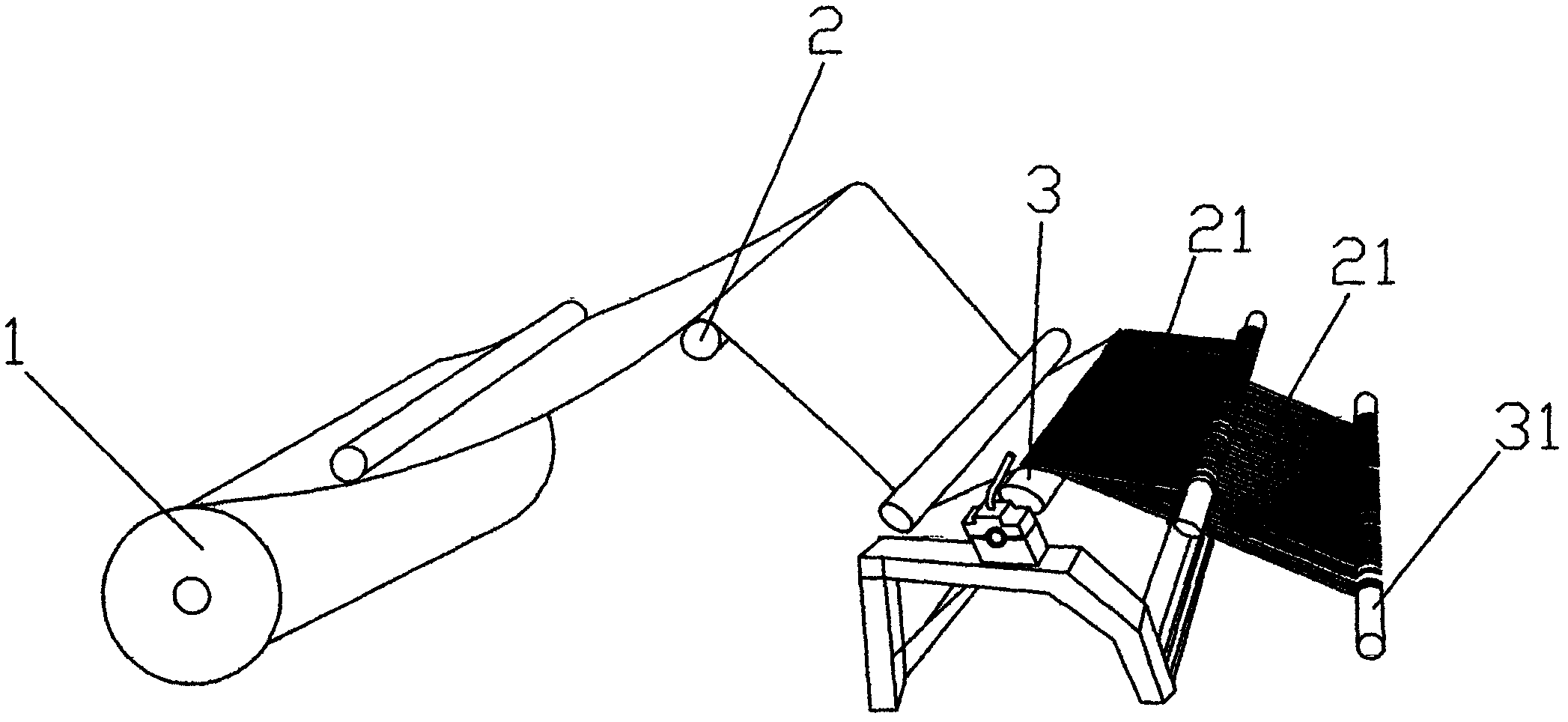

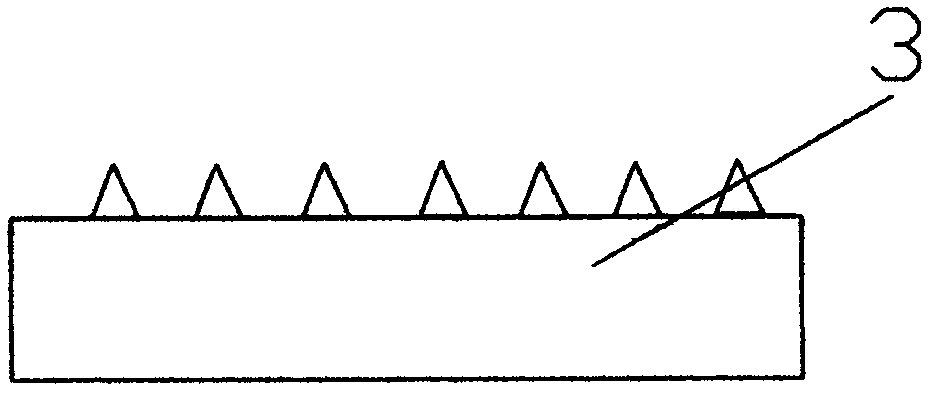

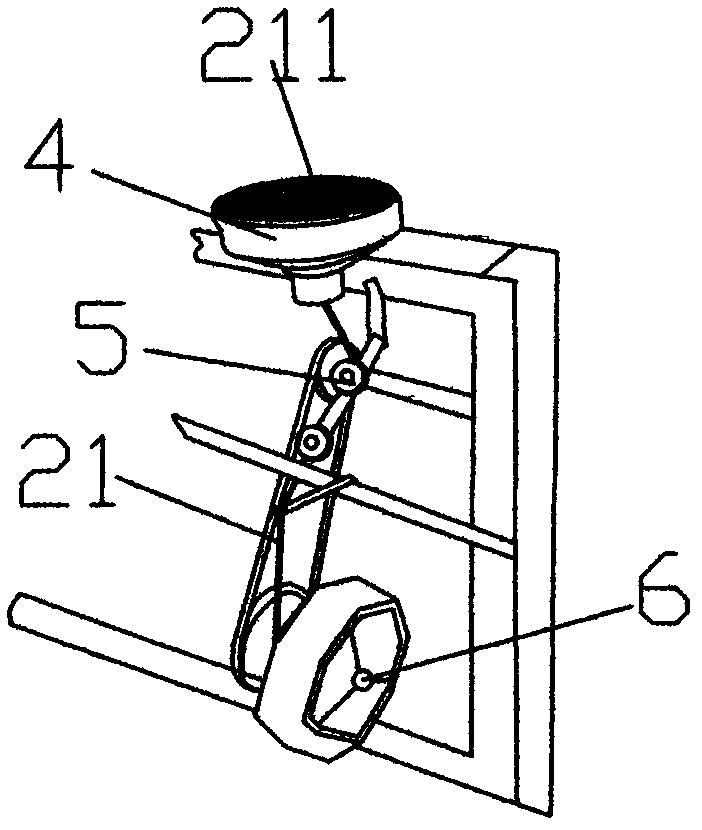

Processing technology, product and equipment of rattan-simulated paper mat

InactiveCN102529176AEasy to recycleDon't destroyPaper/cardboard articlesBed-coversYarnPulp and paper industry

The invention discloses a processing technology, a product and equipment of a rattan-simulated paper mat. The method comprises the following steps of: (1) processing into paper pulp by using native paper or regenerative paper according to a papermaking technology; (2) processing a piece of paper with different colors by using the paper pulp processed in the step (1) according to a paper processing technology; (3) partitioning the whole paper into strips through a paper strip partitioning device; (4) twining the strip-type paper to form a rope shape through a twiner, and coiling the rope-shaped paper on wire coiling ring; and (5) spinning the rope-shaped paper yarn to form the mat through a spinning machine. The beneficial effects of the invention are as follows: paper can be recycled and is environment-friendly; and the waste mat is convenient to be recycled; the environment is not damaged; a large number of bamboos, rattans or reeds are not required to be felled; by adopting the assembly line work, the mat is convenient to be processed; mats with various colors and styles can be manufactured according to the requirements of different customers.

Owner:浙江朵云藤艺有限公司

Sterilization processing method of rattan plaited article materials

InactiveCN104476639ASimple processing methodInsect-resistantBiocideWood treatment detailsMildewSoftening

The invention provides a sterilization processing method of rattan plaited article materials, and belongs to the technical field of rattan plaited article production. The sterilization processing method comprises following steps: rattan is harvested, and each 10 to 20 strips are bonded with a consistent direction so as to obtain one bouquet of rattan; the bonded rattan bouquets are immersed in a processing solution with the end tip of rattan upward, and are exposed to sunlight for 3 to 6 h; leaves of the rattan bouquets are removed, the rattan bouquets are dried with hot air, wherein at a first stage, the rattan bouquets are dried to medium dry, and are subjected to moisture retention for 30 to 50 min for a first time with softening steam, at a second stage, the rattan bouquets are dried to be sixty percent dry, and are subjected to moisture retention for 1 to 3 h for a second time with softening steam, and at a third stage, the rattan bouquets are dried to be eighty percent dry; and the processed rattan bouquets are stored at shade places for natural air drying. According to the sterilization processing method, the fresh rattan is processed firstly; the sterilization processing method is simple, is capable of realizing sterilization, insect prevention, moth prevention, and mildew and rot prevention, and prolonging service life of rattan plaited articles; the obtained steam used for softening is capable of realizing rattan softening, and volatile substances contained by the steam is capable of realizing sterilization and fragrance improvement of rattan.

Owner:ANHUI HONGFU CRAFTS

Method for improving and modifying palm rattan

InactiveCN103817757AHigh strengthImprove stabilityWood treatment detailsWood impregnation detailsAdditional valuesMelamine

The invention belongs to a method for improving and modifying a palm rattan. The method comprises the steps that a modified melamine urea resin solution for impregnation is prepared; the modified melamine urea resin solution, water and an assistant are mixed; a rattan impregnated modified treatment solution is prepared; the rattan is placed in the impregnated modified treatment solution for impregnation treatment, so that the rattan sufficiently absorbs the impregnated modified treatment solution; the impregnated rattan is dried via a gradual temperature rise gradient drying method; and the modified rattan is obtained. With the adoption of the method, the strength and the stability of the rattan are improved, and the rattan has good toughness. The method has the advantages that the poor rattan can be optimized; the service life of the rattan can be prolonged; a use range of the rattan can be widened; an additional value of a rattan product can be increased; production is easy to control; equipment is simple; the production cycle is short; the cost is lower; the treated rattan can be widely applied to the industries of furniture, indoor decoration and the like; and an application prospect is wide.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Weaving method of willow rattan product

InactiveCN104400854AExtended use timeHas a softening effectWood treatment detailsCane mechanical workingToxic materialEngineering

The invention provides a weaving method of a willow rattan product, and relates to the technical field of production of the willow rattan product. The method comprises the following steps: trimming willow rattans, immersing the trimmed willow rattans in a mildew and moth resistant treatment liquid for 18-48h, taking out the willow rattans, and draining to remove water; placing the mildew and moth resistant treated willow rattans in a drying oven, and drying; and weaving the dried willow rattans. The weaving method is simple and feasible, and prolongs the service life of the willow rattan product and avoids infestation or mildew through the mildew and moth resistant treatment of the willow rattans. The mildew and moth resistant treatment liquid does not release toxic substances in the use process, has good mildew and moth resistance, greatly prolongs the service life of the willow rattan product, makes the mildew and moth resistance time reach above 5 years, makes the willow rattan product have a delicate taste, has no side effects to human bodies, also has a softening effect on the willow rattans, and is in favor of weaving.

Owner:GP TOPARTS MFR ANHUI

Planting method for passion fruit

InactiveCN106588503ASimple structureGood characterMagnesium fertilisersAlkali orthophosphate fertiliserNutritionBud

The invention provides a planting method for passion fruit and belongs to the technical field of agricultural planting. The planting method comprises the following steps that fields and seeds which are suitable for passion fruit panting are selected firstly; the seeds are put into a germination bed to be subject to germination accelerating after treated through seed-dressing agents, a certain light and humidity are maintained in the period, and the obtained buds are transplanted into a seedling bed for seedling growing; water and nutrient solutions are poured at regular intervals, and when the buds grow to 30-35 mm in height, the buds are transplanted into a planting pit for field planting; base fertilizers which are made of homemade organic fertilizers, phosphate fertilizers and potash fertilizers are applied in the planting pit, wherein the homemade fertilizers are prepared by mixed fermentation of passion fruit rattan, sunflower straw, rice straw, mango leaves, areca nut leaves, peanut bran, waste fungi bag powder, peat, sheep manure, night soil, radix stemonae, fructus kochiae, diaminoethane aminobenzyl-edta disodium, ferrous sulfate, boric acid, copper sulfate and decomposition agents; and management is conducted termly until harvesting is conducted. According to the planting method for the passion fruit, the fertilizers can be saved, the yield is increased, the disease is prevented, nutrition value of products is improved, and yield and revenue increasing for farmer households is achieved.

Owner:罗城仫佬族自治县金陆地种养农民专业合作社

Momordica grosvenori cultivation method

InactiveCN105103845AMaintain nutrientsIncrease productionCultivating equipmentsPlant cultivationPollinationBud

The invention discloses a momordica grosvenori cultivation method and relates to the technical field of agricultural planting. The momordica grosvenori cultivation method comprises the steps of: selecting a land and digging planting pits; carrying out soil disinfection by quick lime; sufficiently applying a basic fertilizer required by growth of seedlings; planting the seedlings; building a traction shed frame; binding main stems to stick rods to lead the main stems to the shed frame; carrying out topping, bud picking and vine finishing; carrying out topdressing in good time; carrying out artificial pollination; timely carrying out disease control so as to improve the rate of seat fruit. Compared with the prior art, the momordica grosvenori cultivation method disclosed by the invention has the advantages that vines and rattans are avoided being excessively crossed and overlapped, so that an irradiation area of plant functional leaves is increased; yield of momordica grosvenori is improved, fruits are uniform in size and the fruits are high in quality.

Owner:广西鹿寨方田贸易有限公司

Herbal health-care tea and making method thereof

ActiveCN101919465AReserve the tasteCan relieve alcohol and nourish the liverPre-extraction tea treatmentAlcoholMedicine

The invention discloses herbal health-care tea comprising the following materials in parts by weight: 13-17 parts of fructus momordicae flowers, 20-30 parts of acacia rattan leaves, 1-2 parts of polyporus lucidus, 15-20 parts of jasmine flowers, 12-15 parts of chrysanthemum, 2-5 parts of oolong tea and 8-12 parts of pu-erh tea. The herbal health-care tea not only retains the taste of tea, but also has the effects of neutralizing alcohol and nourishing liver, and cooling and reducing fire. The invention also discloses a making method of the herbal health-care tea, mainly comprising four steps of: baking; matching; sterilizing; and sub-packaging. The herbal health-care tea made through the method not only has good colour and lustre, but also is suitable for brewing.

Owner:QUANZHOU DIFENG ECOLOGY TEA DEV

A mildew-resistant willow rattan softener and a preparing method thereof

InactiveCN104085007AReduce corrosionSoften evenlyWood treatment detailsWood impregnation detailsSodium bicarbonateHouttuynia

A mildew-resistant willow rattan softener is disclosed. The softener is prepared from following raw materials by weight in part: 12-15 of glycerol, 4-7 of sodium hexametaphosphate, 5-7 of sodium bicarbonate, 6-7 of sodium citrate, 3-4 of wild chrysanthemum flower, 5-7 of the tuber of stemona, 2-4 of cordate houttuynia, 4-5 of povidone-iodine, 3-4 of auxiliary agents and 100 of water. The softener adopts a weak acid and a weak base, and is low in surface corrosion, uniform in softening and good in toughness. By using the glycerol and the sodium hexametaphosphate, surfaces of rattans are smooth and the weaving efficiency is increased. By using the tuber of stemona and other Chinese herbal medicines, mildew and damage by worms can be prevented.

Owner:ANHUI HUAYU CRAFTS GRP

Production technology for rattan-woven wood bottom vase

InactiveCN105904552AImprove corrosion resistanceImprove antioxidant capacityWood treatment detailsCane mechanical workingUltravioletOxidation resistant

The invention provides a production technology for a rattan-woven wood bottom vase. The production technology comprises the following steps that fresh willows are selected and processed into a circular or rectangular wood board, and then the wood board is immersed for 1-2 h through preservative liquid; freshly-cut rattan is naturally aired and dried, the interior of a pressure tank is pressurized through mixed gas of nitrogen and carbon dioxide, and the interior of the pressure tank continues to be pressurized to 0.15 MPa-0.2 MPa through hot steam; the processed wood board and the processed rattan are input into a drier to be dried, and the rattan is utilized for being woven on the wood board to form the vase; distilled water is sprayed to the vase for wetting, and drying is conducted again through the drier. According to the production technology, the corrosion resistance and oxidation resistance of the vase are greatly improved, planting soil can be placed in the vase and used for planting flowers, and the vase cannot be decomposed by humus bacteria. The vase manufactured through the production technology is particularly suitable for being used near the equator, and the vase can bear long-time and continuous high-temperature scorching in the open and resist the high-intensity ultraviolet irradiation.

Owner:FUNAN FANGLIU ARTS & CRAFTS CO LTD

Rattan processing method

InactiveCN104441160ASimple processing methodAvoid corrosionWood treatment detailsReed/straw treatmentComputational scienceRattan

The invention relates to a rattan processing method. The rattan processing method comprises the steps of (1) removing leaves of rattan and carrying out air drying; (2) processing rattan by utilizing a processing agent; and (3) processing rattan by using a processing agent B. The rattan processing method provided by the invention can be used for greatly improving the mould-proof and insect resistant effects, and prolonging the use time of rattan products.

Owner:阜南县永盛工艺品有限公司

Softening agent for thin willow rattans and preparation method of softening agent

The invention discloses a softening agent for thin willow rattans. The softening agent is prepared from the following raw materials in parts by weight: 10-12 parts of bicarbonate, 2-3 parts of diphenyl ethyl compound phenol polyoxyethylene ether, 1-2 parts of oleic acid polyoxyethylene ester, 3-4 parts of radix aconiti sinensis, 2-3 parts of flos daturae, 4-5 parts of lavender, 6-8 parts of cassia twig, 5-7 parts of povidone iodine, 3-4 parts of auxiliaries and 100 parts of water. By the use of weak alkaline and a non-ionic surfactant, the softening agent for the thin willow rattans is uniform in softening, low in speed and suitable for softening of the thin willow rattans and cannot excessively corrosion the thin willow rattans; by the virtue of the traditional Chinese herbs such as the flos daturae and the lavender and the povidone-iodine, the softening agent can be prevented from being mildewed and damaged by worms and can disperse fragrance for a long time.

Owner:FUNAN YONGXING ARTS & CRAFTS

Foaming polymer material special for vine art furniture and method of producing the same

ActiveCN101270209APrecise temperature controlPrecision Vacuum Exhaust EquipmentFoaming agentLubricant

The invention discloses foaming polymer material specially used for rattan furniture is novel plastic blend consisting of polyethylene resin, a polymer foaming agent, a compatibilizer, an antiaging agent, nano-filler, a coupling agent, a lubricant, etc. which are blended by a twin-screw extruder and achieves the effect of material shrinkage after foaming which cannot be achieved by the traditional foaming agents. The unique antiaging agent makes the material have outstanding weathering resistance; the polyethylene resin accounts for 25 percent to 90 percent in the blend, the polymer foaming agent accounts for 5 percent to 55 percent, the compatibilizer accounts for 1 percent to 15 percent, the antiaging agent accounts for 0.1 percent to 2 percent and the nano inorganic filler accounts for 5 percent to 20 percent; the consumption of the coupling agent is 0.1 percent to 1 percent of that of the nano inorganic filler; and the lubricant accounts for 0.1 percent to 1 percent of the blend. The plastic imitating rattan furniture produced by the blend mentioned in the invention has the multi-pore structure, the natural texture and the natural color of natural rattan, and is used to weave rattan furniture, such as rattan chairs, flower baskets, tea tables, etc.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

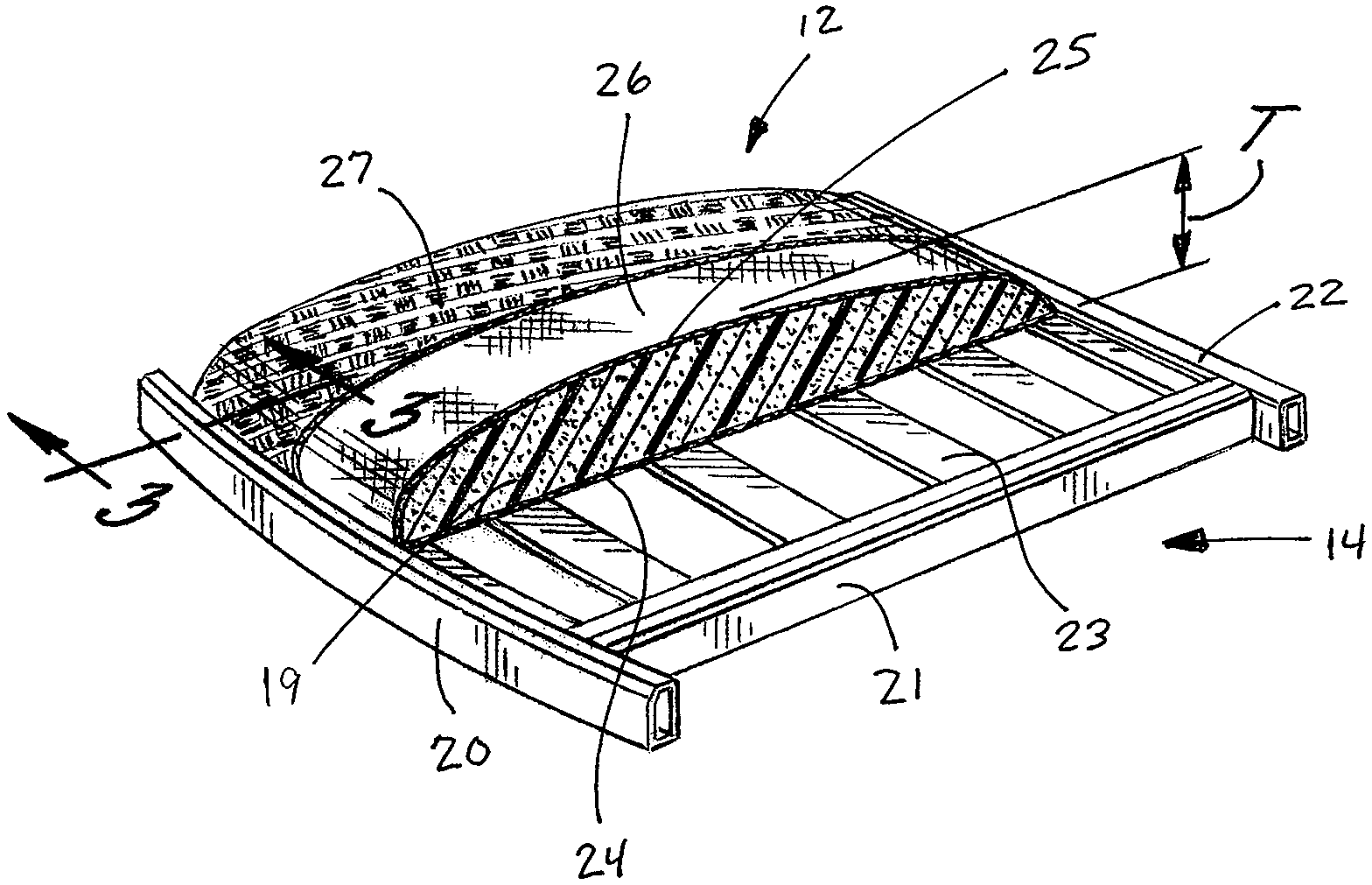

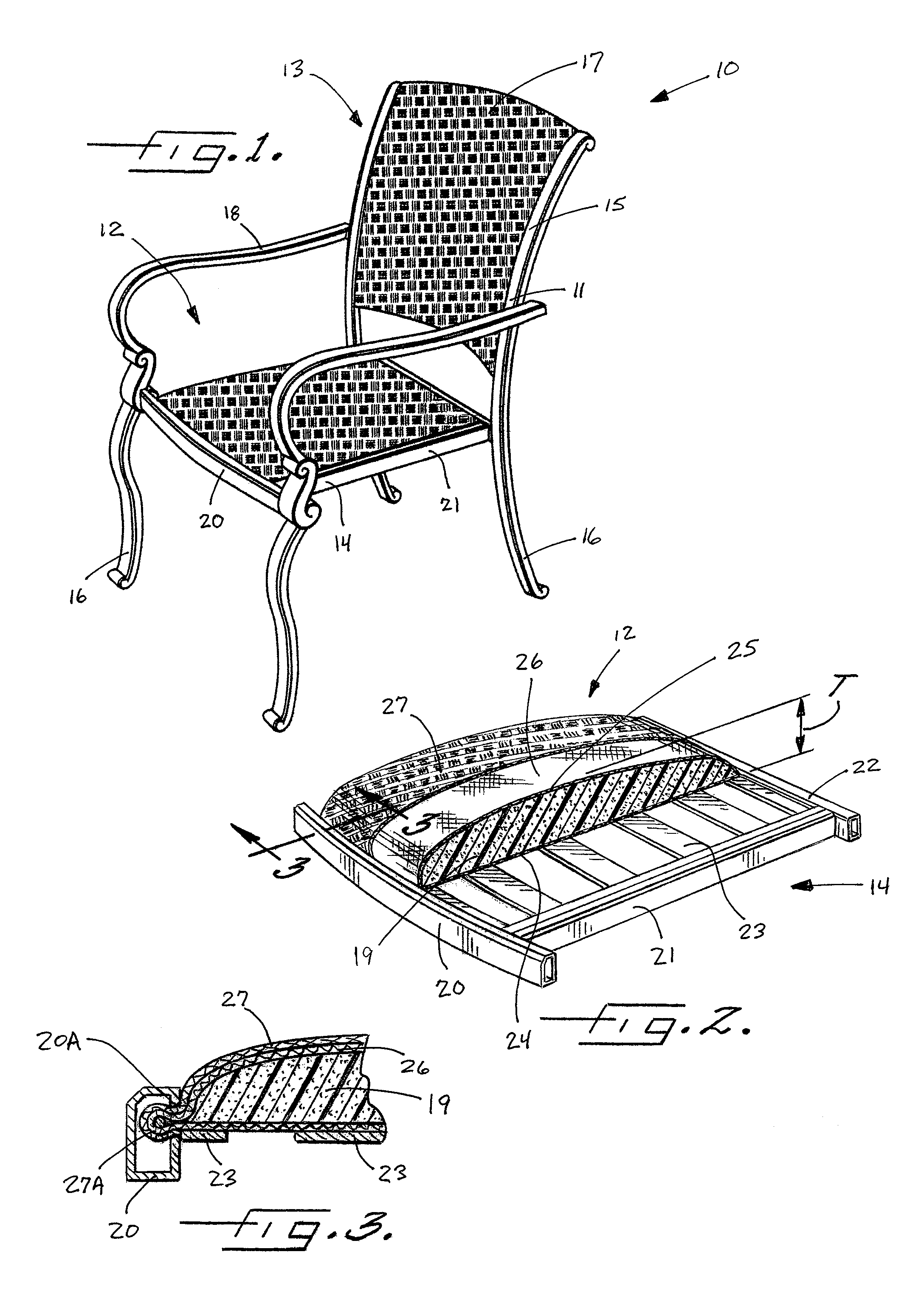

Article of rattan furniture having a seat support cushion

InactiveUS7267408B2Improve comfortMaintaining aesthetic appealStoolsPlant material mechanical workingEngineeringBack support

An improved support area for use with rattan furniture. The present invention provides a frame, a seat contact portion, and a back contact portion. In various embodiments, the chair includes a seat cushion that is supported by a seat support portion of the frame. The seat cushion is covered on its outside by a rattan outer layer that is attached to the seat support structure such that the rattan outer layer conforms to the shape of the seat cushion and the presence of the seat cushion is obscured by the rattan outer layer. In other embodiments, the back support portion may include a similarly configured back cushion. As a result, the present invention has the appearance and aesthetic appeal of a typical article of rattan furniture, having rattan seat and back surfaces, however the present invention provides a level of comfort that is not typically provided by rattan seat and / or back surfaces.

Owner:ZHEJIANG YOTRIO GRP CO LTD

Antioxidant willow-rattan softening agent and preparation method thereof

ActiveCN103692517AFast softening speedSoften evenlyWood treatment detailsWood impregnation detailsAntioxidantRaw material

The invention discloses an antioxidant willow-rattan softening agent which is prepared from the following raw materials in parts by weight: 6-8 parts of citric acid, 3-4 parts of sodium metabisulfite, 3-5 parts of alkanolamide, 4-6 parts of ethylenediamine tetraacetic acid, 7-10 parts of eupatorium, 3-4 parts of wild chrysanthemum flower, 2-3 parts of scutellaria baicalensis, 4-5 parts of clove, 2-3 parts of safflower carthamus, 5-6 parts of radix sophorae flavescentis, 3-4 parts of povidone-iodine, 3-4 parts of an assistant and 100 parts of water. According to the antioxidant willow-rattan softening agent, the citric acid and the sodium metabisulfite are used, thus the antioxidant willow-rattan softening agent is high in softening speed, and capable of resisting oxidization; through using the ethylenediamine tetraacetic acid, the antioxidant willow-rattan softening agent is more uniform in softening and good in flexibility; through using the alkanolamide, rattans are smooth in surface, soft in hand feel, and the weaving efficiency can be increased; by using the Chinese herbal medicines such as the scutellaria baicalensis and the povidone-iodine, the antioxidant willow-rattan softening agent is capable of preventing from being mildewed and damaged by worms, emits fragrance, and is capable of refreshing.

Owner:FUNAN YONGXING ARTS & CRAFTS

Sterilizing processing liquid for processing rattans

InactiveCN104397071ASimple processing methodInsect-resistantBiocidePest repellentsBiotechnologyOyster

The invention provides a sterilizing processing liquid for processing rattans, and relates to the technical field of rattan-weaved product production. The processing liquid is composed of the following raw materials in parts by weight: 3 to 7 parts of andrographis paniculata, 2 to 4 parts of cordate houttuynia, 1 to 3 parts of basil, 2 to 4 parts of wild chrysanthemum, 3 to 7 parts of tribulus terrestris, 2 to 4 parts of prunella vulgaris, 3 to 6 parts of santal, 4 to 8 parts of honeysuckle flower, 3 to 7 parts of purslane, 2 to 4 parts of perilla leaf, 2 to 5 parts of Chinese magnoliavine, 2 to 5 parts of hairyvein agrimony, 1 to 3 parts of tabasheer, 2 to 4 parts of fructus forsythiae, 2 to 4 parts of yellow gentian, 2 to 4 parts of rhizoma atractylodis, 2 to 4 parts of eupatorium, 1 to 3 parts of cyrtomium rhizome, 1 to 3 parts of common cnidium fruit, 1 to 3 parts of rheum officinale, 1 to 3 parts of stemona, 2 to 4 parts of smoke stalk, 1 to 3 parts of oyster, and 3 to 7 parts of tree peony bark. In the processing method, live rattans are processed by the provided liquid. The processing method is simple. The processed rattans are sterilized and have the functions of insect resistance, mothproof property, and mold resistance. The service life of rattan-weaved products can be prolonged. The prepared softening steam can soften the rattans, and the volatile substances in the steam can sterilize the rattans and increase the aroma of the rattans.

Owner:ANHUI HONGFU CRAFTS

Neuter breed cultivation method for fibraurea recisa pierre

InactiveCN101156527AReduce sizeImprove flatnessFertilising methodsCultivating equipmentsTwigPlant breeding

The invention provides an asexual propagation cultivating method for rhubarb vine, and relates to a plant breeding method, in particular to a medicinal plant breeding and cultivating method. The invention uses a twig of the rhubarb vine for cuttage and seedling, and the breeding method is as follows: A. the selection of a cuttage bed; B. the tidying up of the cuttage bed; C. the collection of the cuttage tress; D. the disinfection process of the tress; E. the cottage and management; F. the selection and the tidying up of the planting filed and the growth environment; G. the transplant and the management of the water and the fertilizer; I. to the arranging the rattan for climbing the frame; J. the prevention and cure of the pest. The actualization of the invention can improve the artificial breeding rate of the rhubarb vine, shorten the breeding period, avoid the excess pick of the wild rhubarb vine, protect the resource of the rhubarb vine, realize the industrialization planting of the rhubarb vine, facilitate the development and utilization of the rhubarb vine, provide process material to the pharmacy corporation for bright-marketing product, protect the wild resource, and preserve the water and oil.

Owner:屏边苗族自治县生物资源开发创新办公室

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com