Processing technology, product and equipment of rattan-simulated paper mat

A processing technology and processing equipment technology, applied in the field of paper mat processing technology, can solve the problems of bamboo consumption, environmental damage, high cost, etc., and achieve the effects of easy recycling, multiple styles, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

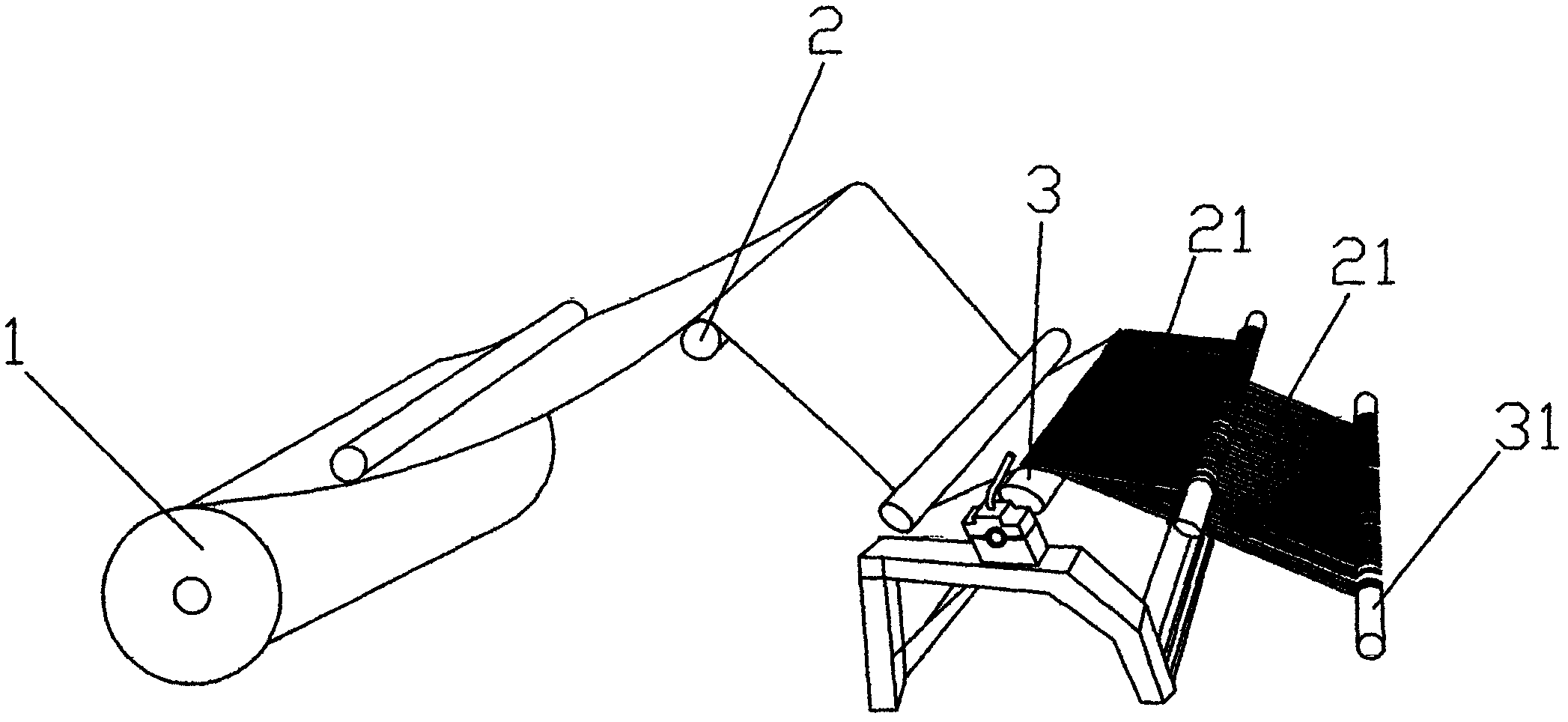

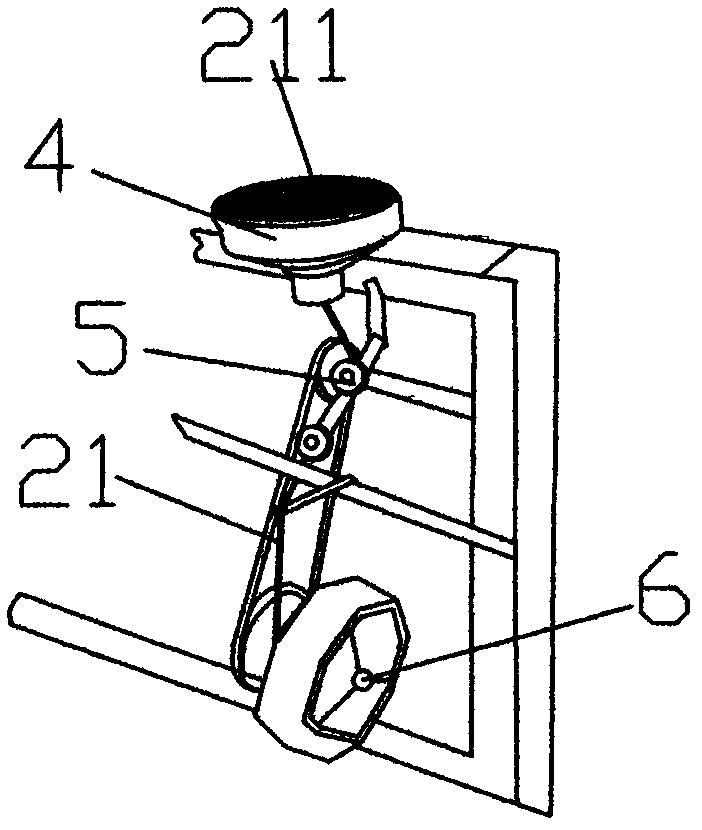

[0018] The processing technology of imitation rattan paper mat, its steps are as follows:

[0019] (1) Use raw paper or recycled paper to process it into pulp according to the papermaking process; the pulp process is a common process, so I will not repeat it here.

[0020] (2) The pulp processed in the above steps is processed into a whole sheet of paper. This step is also an existing paper production process, such as white paper, kraft paper, etc., are all processed in this way.

[0021] It also includes the dyeing process. The dyeing process is realized in the process of making the whole paper. Through the paper dyeing process, the paper can be dyed into different colors, and dyed into different colors according to different needs.

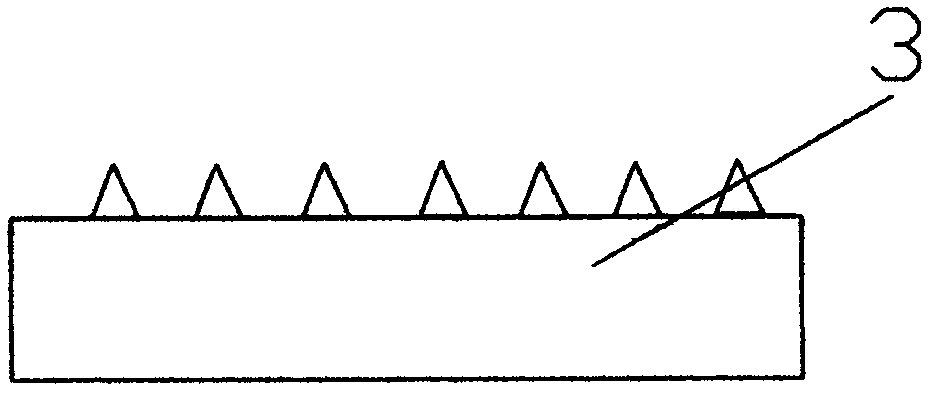

[0022] (3) Then the whole sheet of paper is divided into strips by a paper strip dividing device, which is divided into strips of a certain width by a paper dividing machine. The general width is about 5 mm, and different widths can be set acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com