Method for extracting heavy liquefaction oil and intermediate-phase bitumen matter from coal liquefaction residuals and application thereof

A technology of heavy liquefied oil and mesophase pitch, which is applied in the field of deep coal processing, can solve the problems of easy catalyst deactivation, heavy distillates, and high aromatic content, and achieve strong controllability of properties, low quinoline insolubles, and aromatic high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

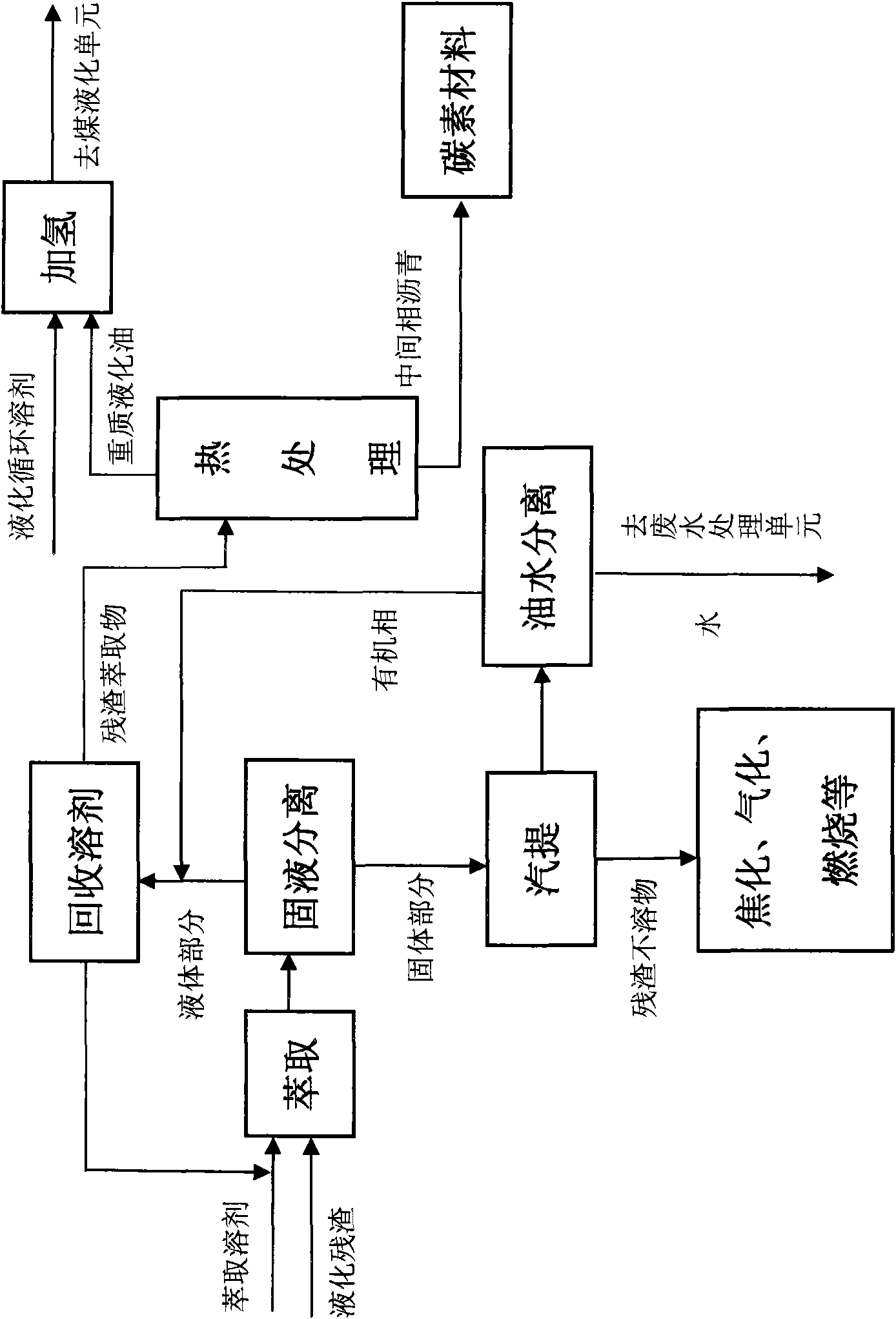

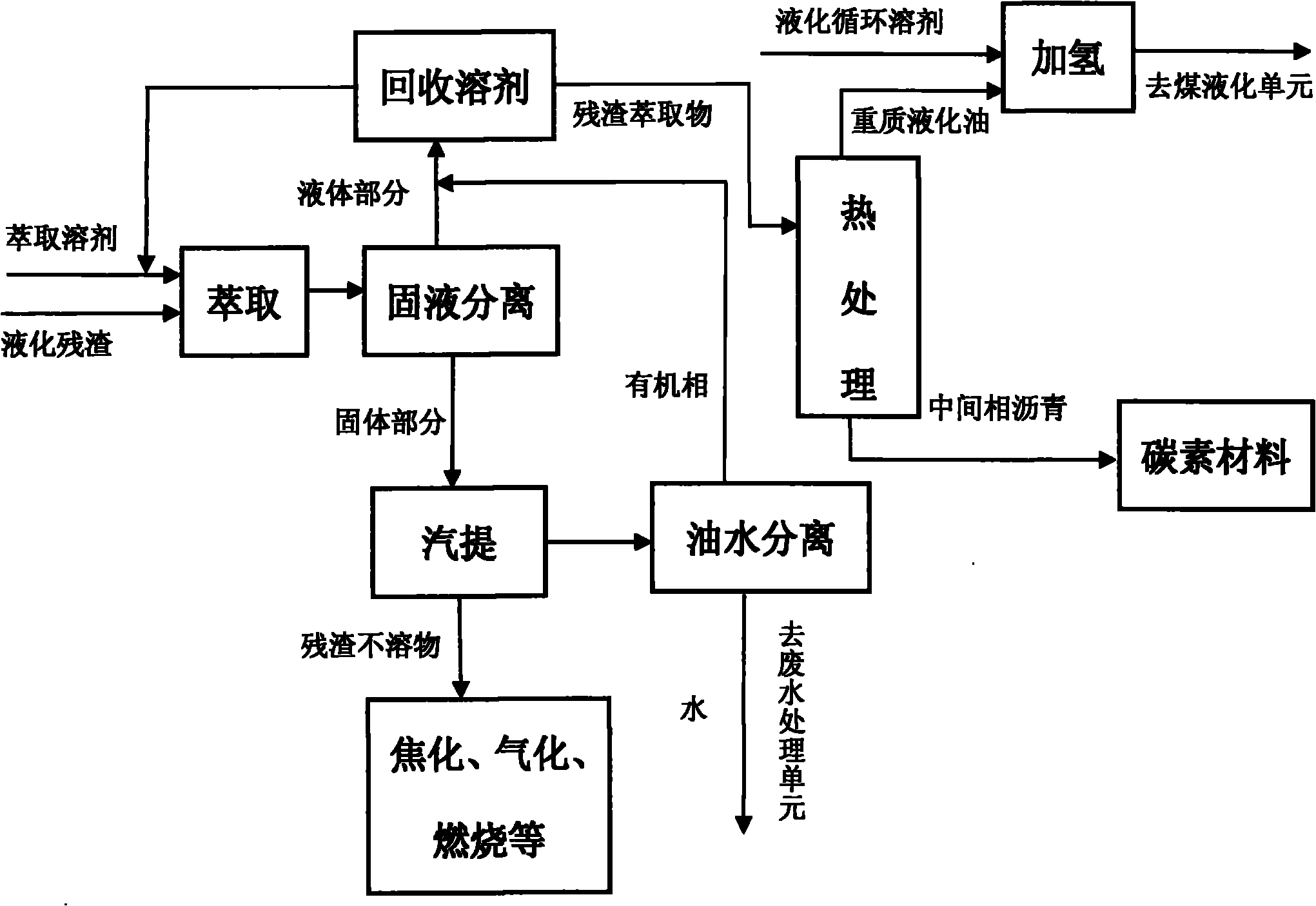

Method used

Image

Examples

Embodiment 1

[0071] Crush 100kg of coal direct liquefaction residue into coal liquefaction residue powder with a particle diameter of less than 3mm, fully mix with 800Kg of coal direct liquefaction light oil (distillation range 30-220°C), add to the stirring tank, and fill with N 2 Gas to 2.0MPa, heat up to 250°C at a heating rate of 5°C / min, stir at a stirring rate of 200r / min for 60 minutes to obtain a mixture, and then carry out pressurized hot filtration, the filtration temperature is 180°C, and the filtration pressure is 0.5MPa , to obtain the extract mixture S1, the detected extraction rate is 51.46% daf (the daf specifically refers to the dry ash-free base).

[0072] After the filtered filter residue is steam stripped and oil-water separated, continue to recover the extraction solvent and a small amount of liquefied residue extract, mix the organic phase with the extract mixture, send it to an atmospheric distillation tower, and cut off the distillate at <220°C. part, recover the ex...

Embodiment 2

[0076] Fully mix 50Kg coal direct liquefaction residue powder with 150Kg coal direct liquefaction medium oil (distillation range 220-260°C), add to the stirring tank, fill with N 2 Gas to 1.0MPa, heat up to 250°C at a heating rate of 5K / min, stir at a stirring rate of 300r / min for 45 minutes to obtain a mixture, and then carry out hot filtration with suction filtration, the filtration temperature is 150°C, and the filtration pressure is 5×10 -2 KPa, to obtain the extract mixture S1, the extraction rate of the soluble matter was 56.57% (daf).

[0077] After the filtered filter residue is stripped by water vapor and separated from oil and water, continue to recover the extract mixture, mix it with the extract mixture S1, and then send it to the evaporation kettle. The extraction solvent is recycled, and the residue is the extract of the liquefaction residue, which is sent to the heat treatment unit for dry distillation at 450°C. The yield of heavy oil is 29.6%, and the yield of ...

Embodiment 3

[0081] Fully mix 100Kg coal direct liquefaction residue powder with 500Kg coal direct liquefaction hydrogenation stable light oil (distillation range 130-260°C), add to the stirring tank, fill with H 2 Gas to 0.5MPa, raise the temperature to 200°C at a heating rate of 7K / min, stir at a stirring rate of 400r / min for 30 minutes to obtain a mixture, and then carry out sedimentation and separation, the sedimentation temperature is 180°C, the pressure is 0.3MPa, and the time is 20min , the supernatant obtained the extract mixture S1, and the extraction rate of the soluble matter was 57.37% (daf).

[0082] The bottom flow of the sedimentation is stripped by steam, and after the oil and water are separated, the extraction solvent and a small amount of liquefaction residue extract are recovered, the organic phase is mixed with the extract mixture S1, and then sent to the atmospheric distillation tower, and the distillate at 130-260°C is cut. The extraction solvent is recovered for rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com