Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1652 results about "Dry distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dry distillation is the heating of solid materials to produce gaseous products (which may condense into liquids or solids). The method may involve pyrolysis or thermolysis, or it may not (for instance, a simple mixture of ice and glass could be separated without breaking any chemical bonds, but organic matter contains a greater diversity of molecules, some of which are likely to break). If there are no chemical changes, just phase changes, it resembles classical distillation, although it will generally need higher temperatures. Dry distillation in which chemical changes occur is a type of destructive distillation or cracking.

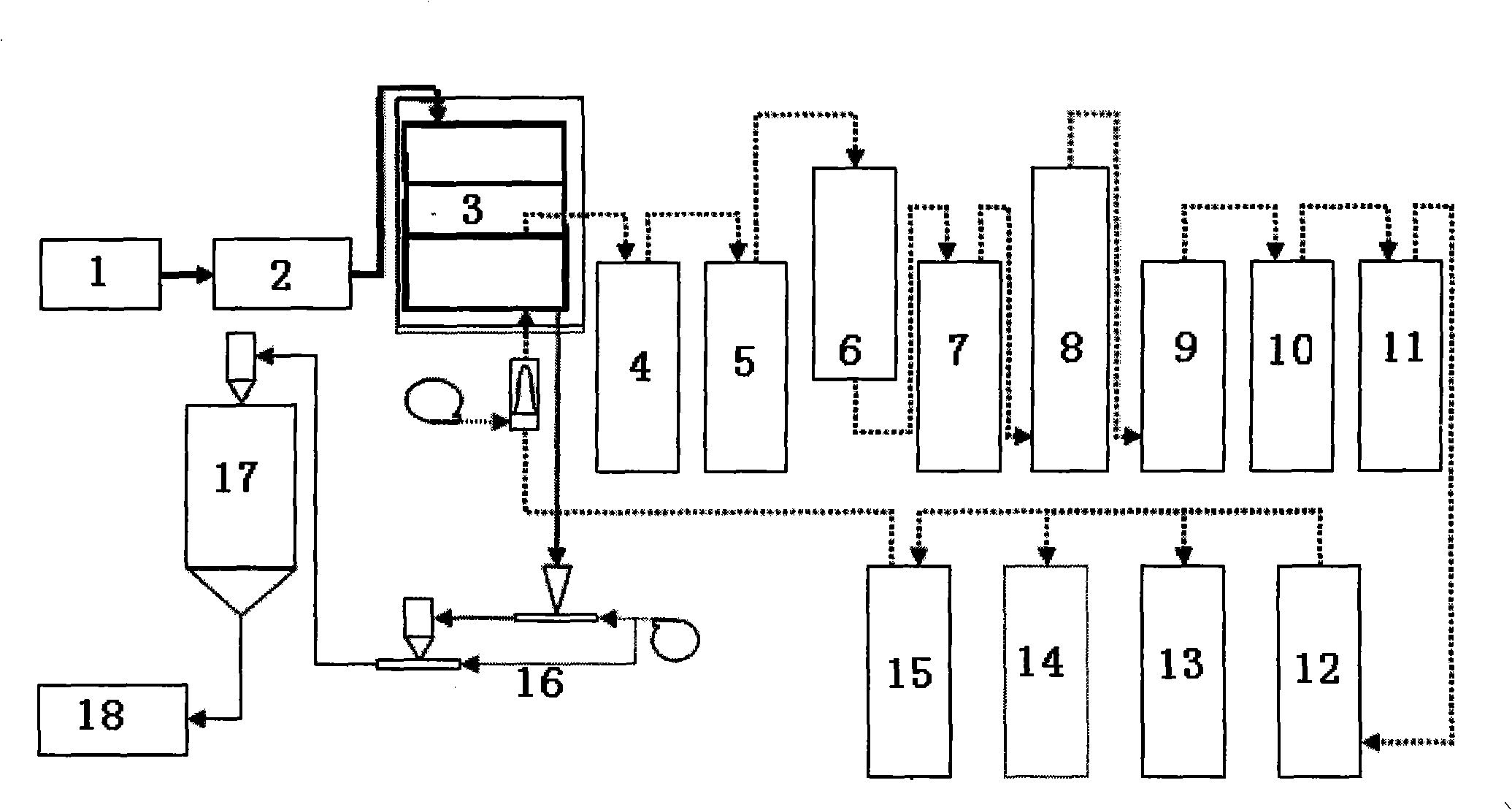

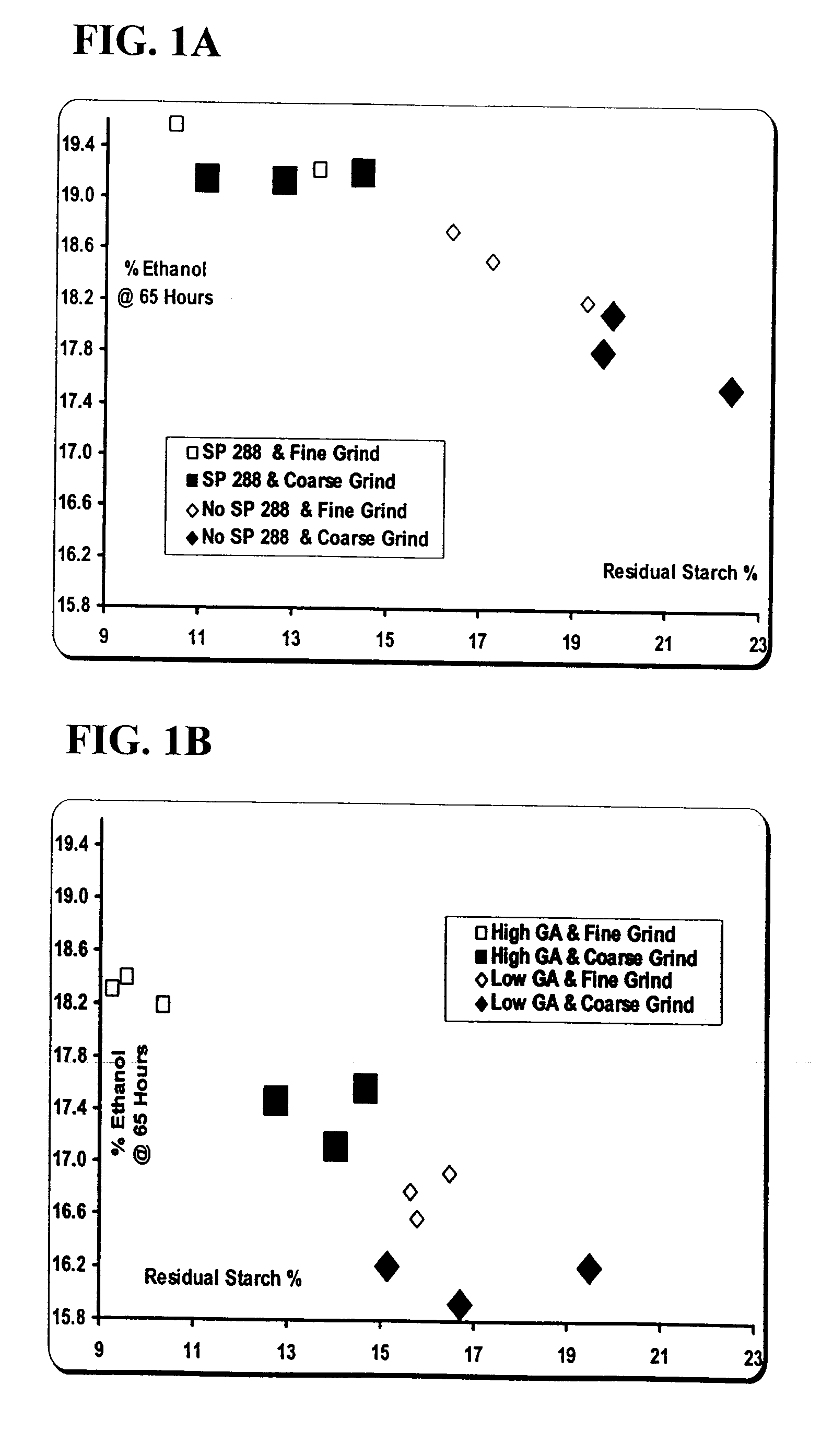

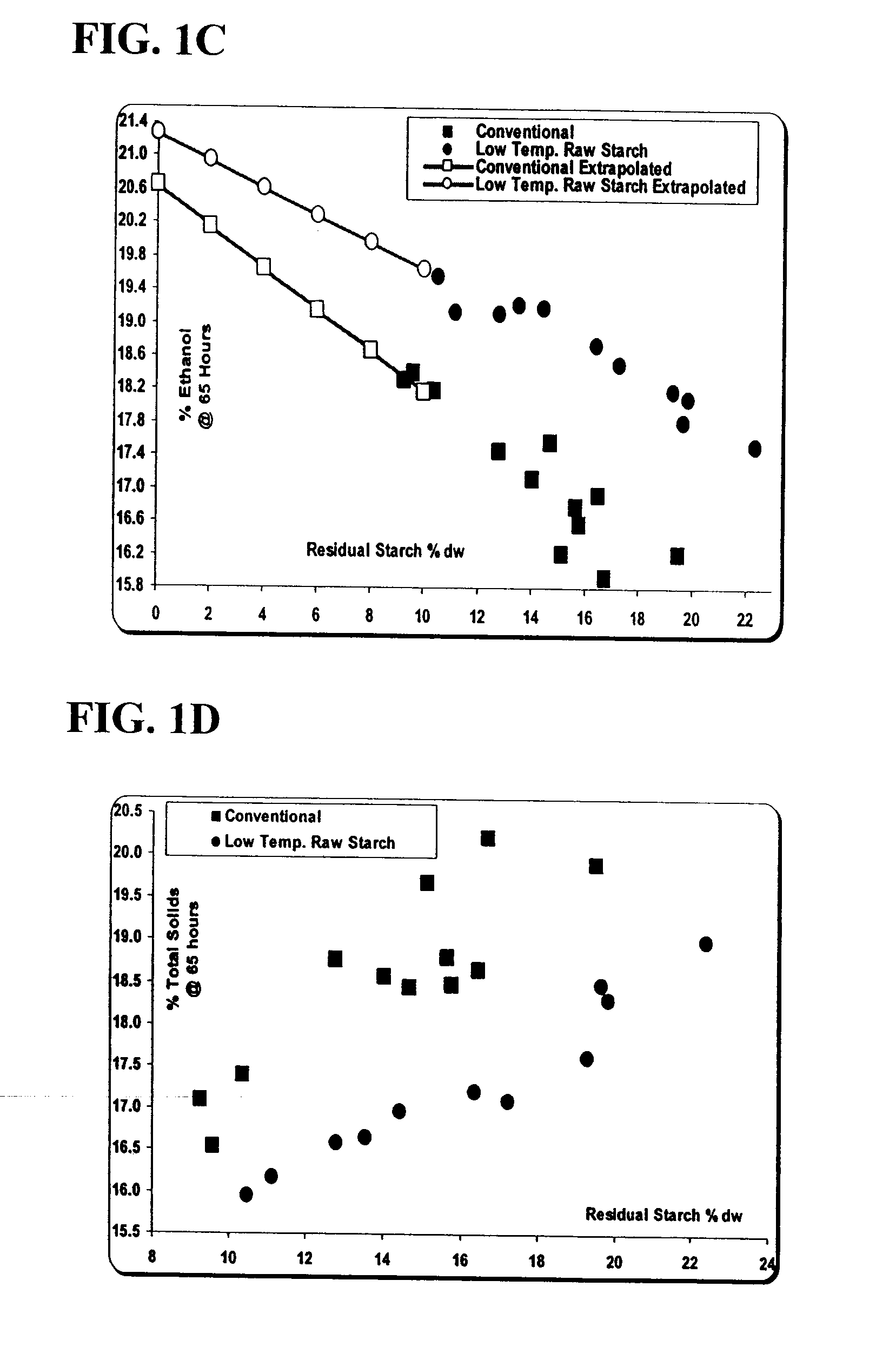

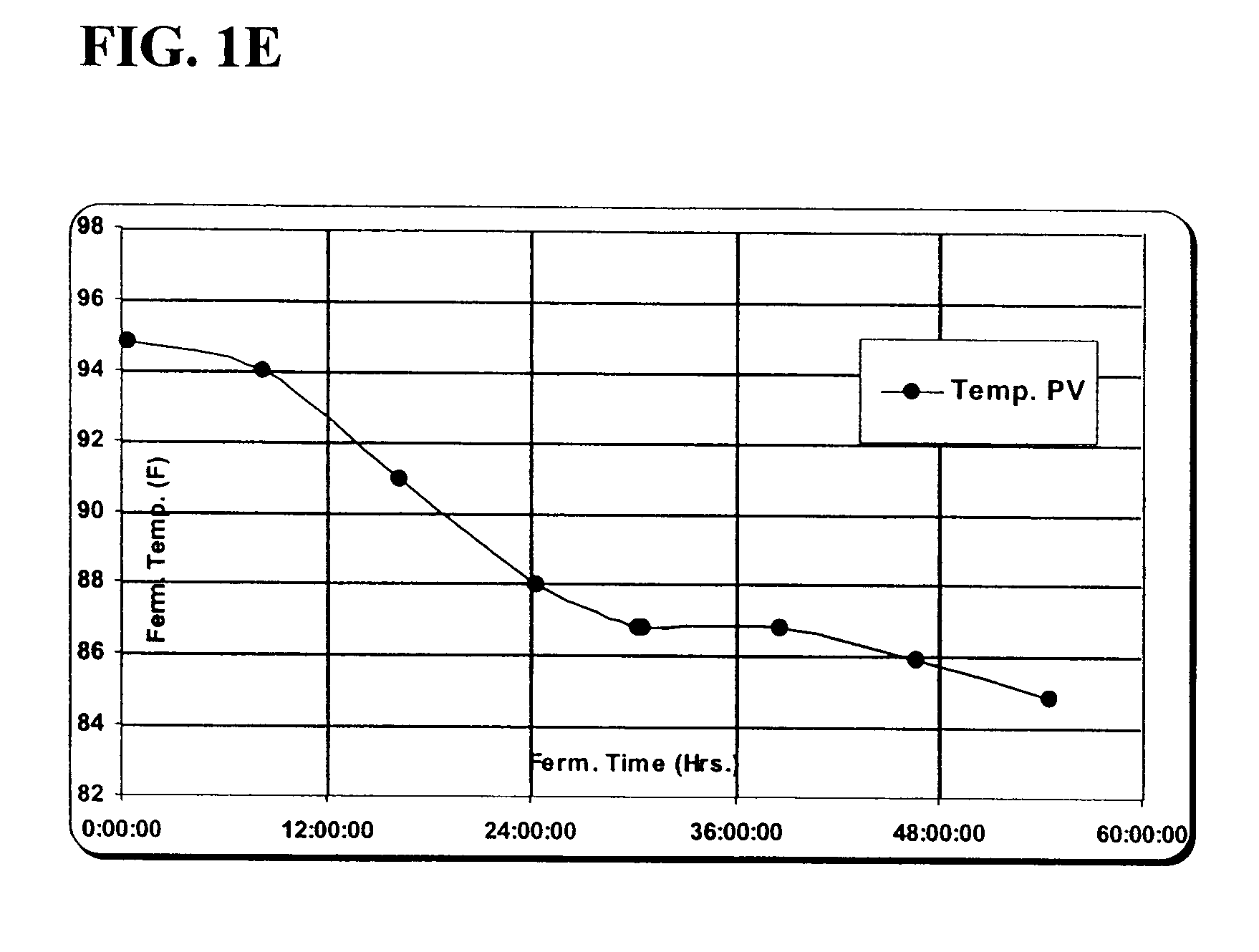

Methods and systems for producing ethanol using raw starch and fractionation

InactiveUS20070037267A1Improve the level ofImprove the immunityBiofuelsFermentationFluidized bed dryingHigh alcohol beer

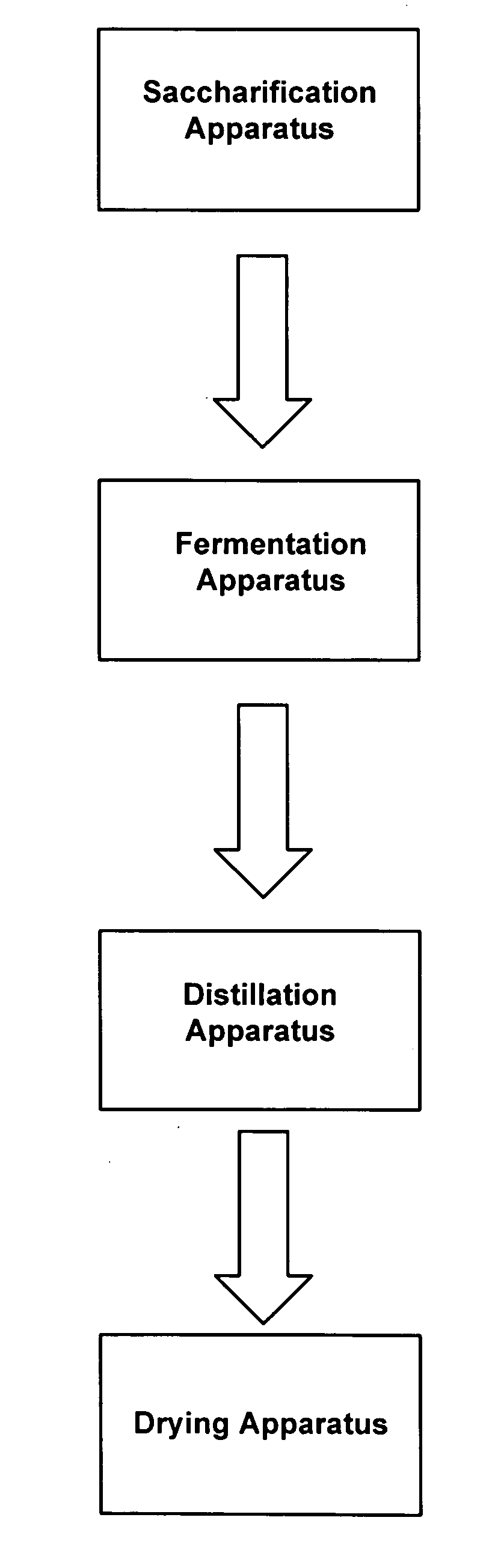

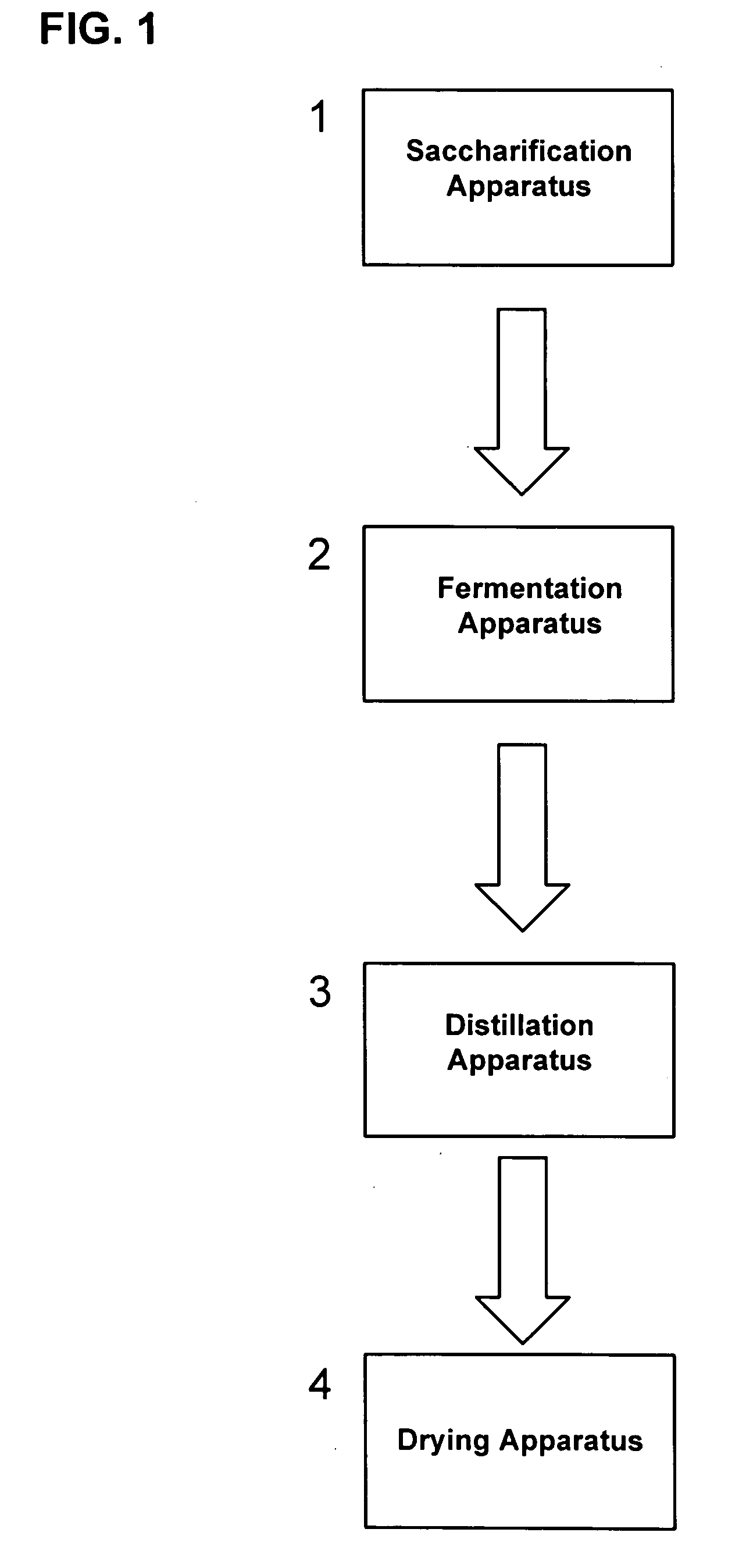

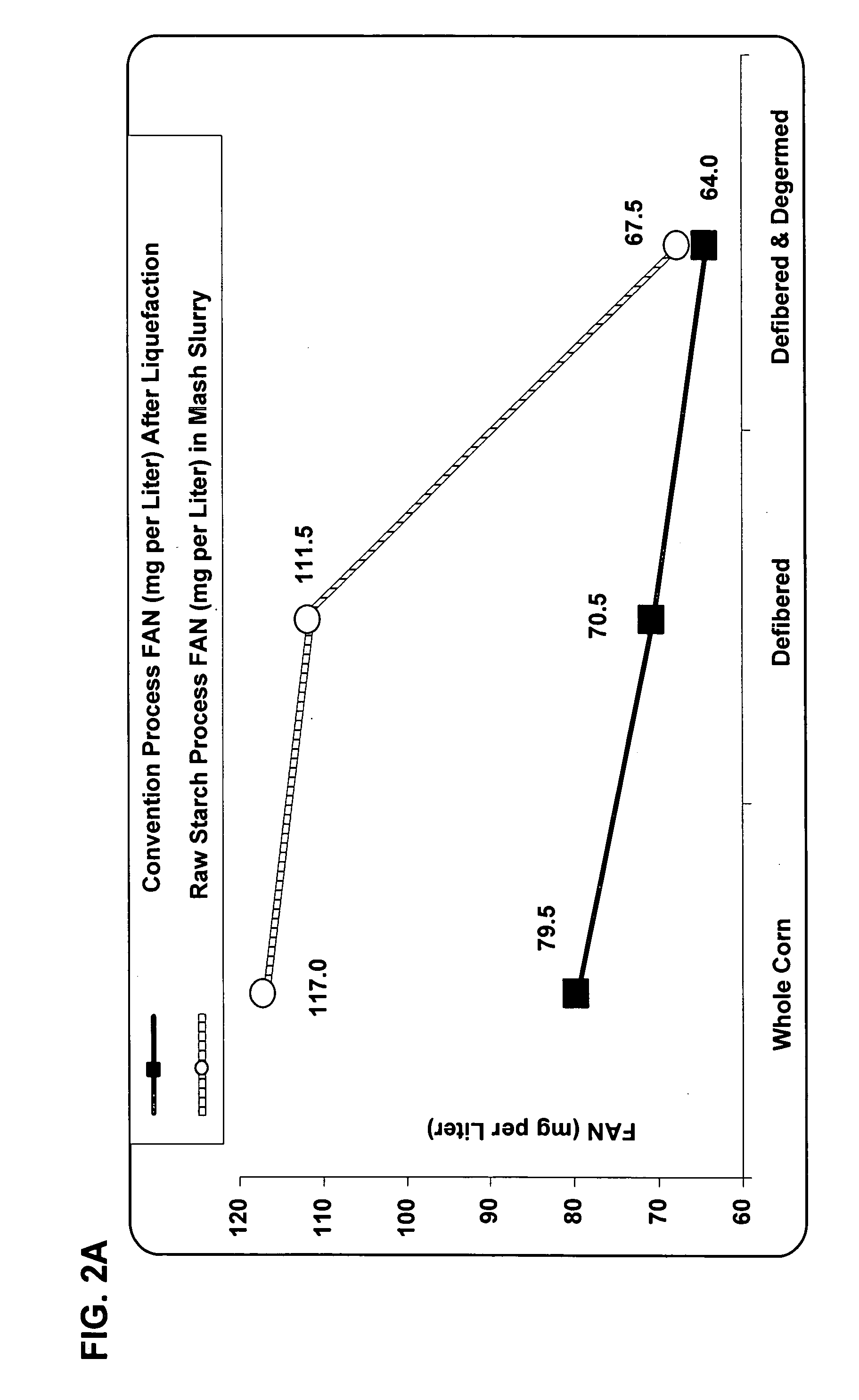

The present invention relates to methods for producing high levels of alcohol during fermentation of plant material, and to the high alcohol beer produced. The method can include fractionating the plant material. The present invention also relates to methods for producing high protein distiller's dried grain from fermentation of plant material, and to the high protein distiller's dried grain produced. The method can include drying a co-product by ring drying, flash drying, or fluid bed drying. The present invention further relates to reduced stack emissions from drying distillation products from the production of ethanol.

Owner:BROIN & ASSOC

Method for extracting heavy liquefaction oil and intermediate-phase bitumen matter from coal liquefaction residuals and application thereof

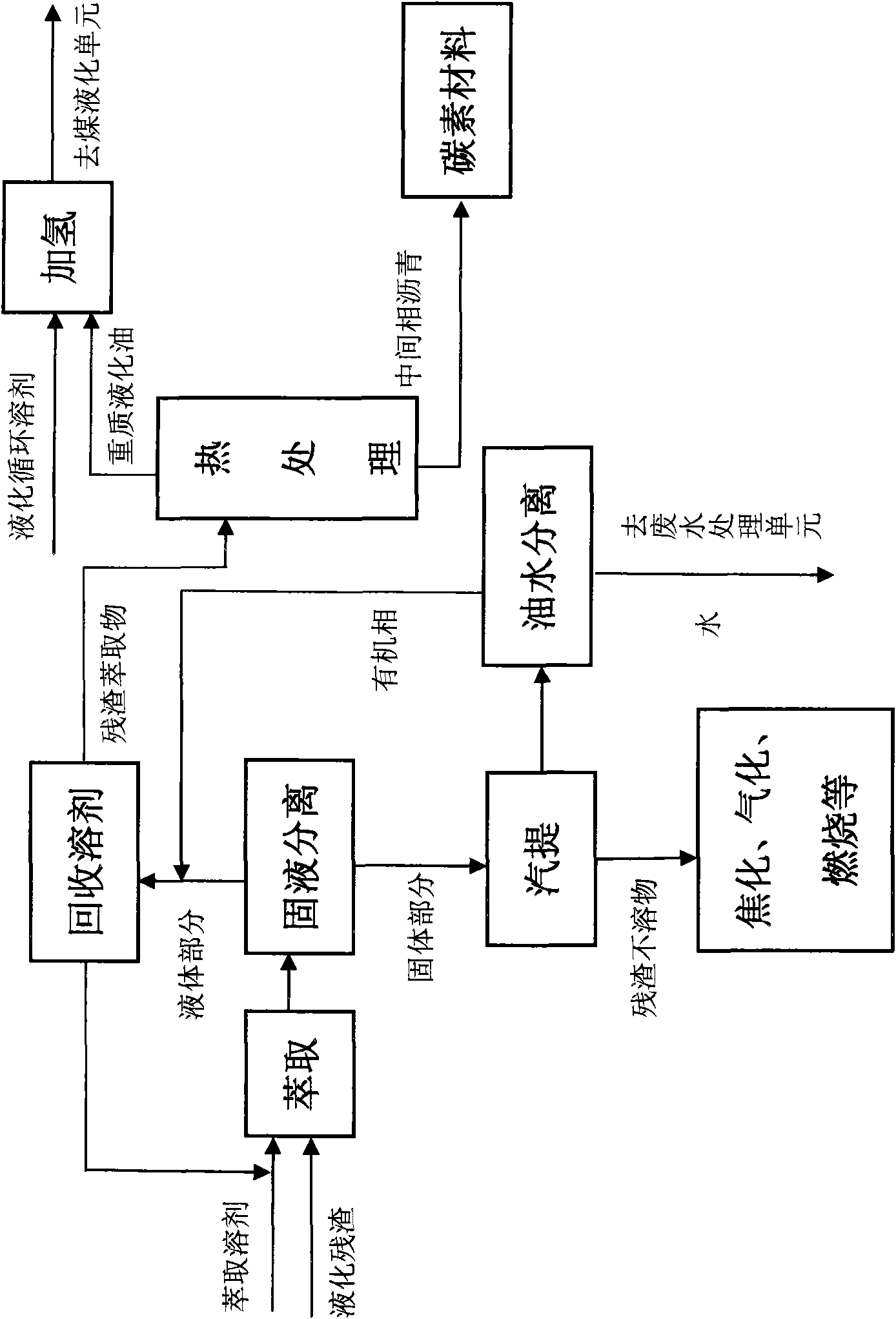

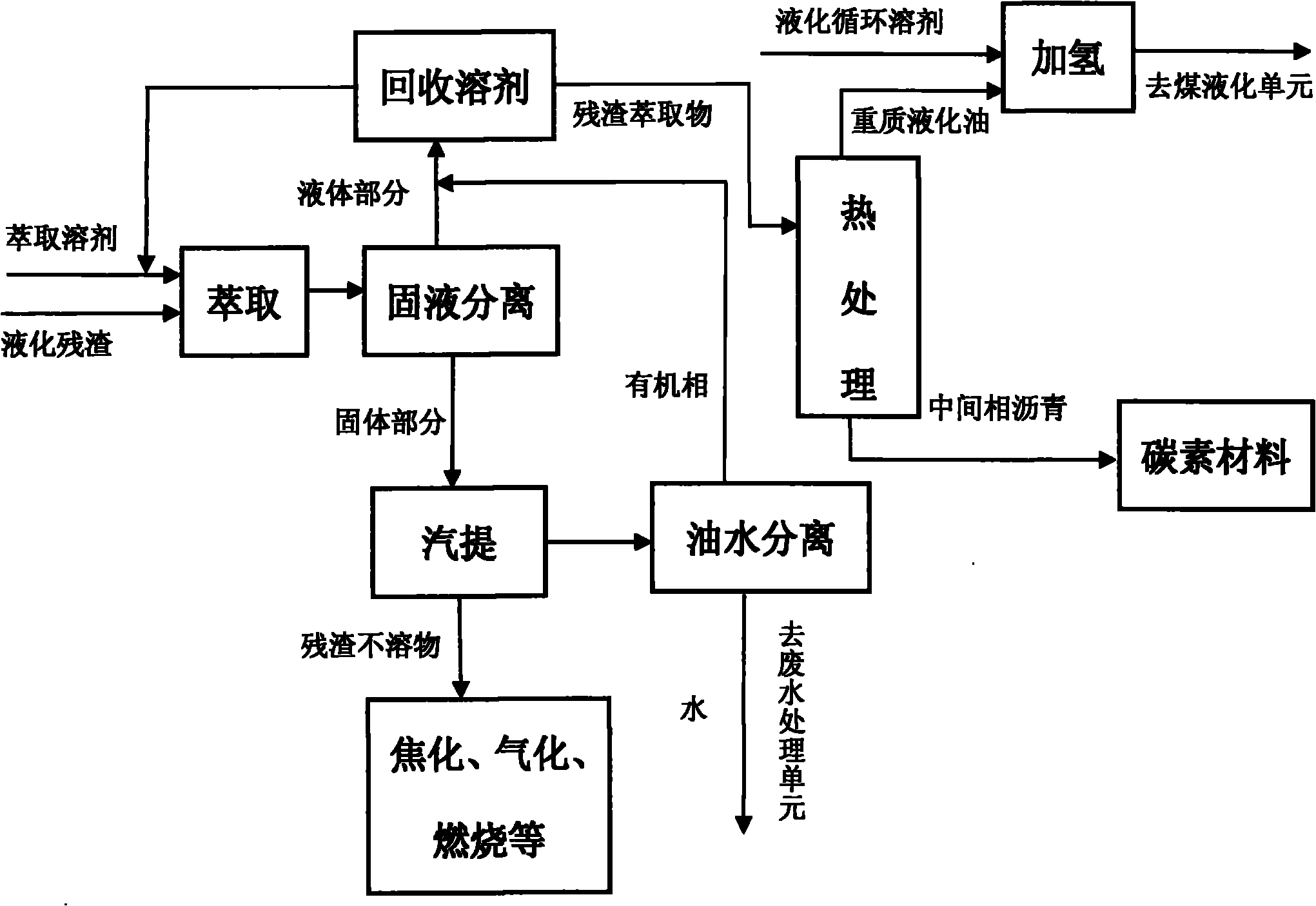

ActiveCN101885976ARealize rationalityRealization of high value-added utilizationThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionEvaporationOil water

The invention provides a method for extracting heavy liquefaction oil and an intermediate-phase bitumen matter from coal liquefaction residuals and application thereof. The method comprises the following steps of: adding coal liquefaction residual powder and an extraction solvent to a stirring kettle together for extraction to obtain extraction liquid and extraction residues; carrying out solid-liquid separation on the obtained extraction liquid and extraction residues; carrying out steam stripping on the obtained extraction residues, and recovering an organic phase after oil-water separation; mixing the extraction liquid with the organic phase, and then delivering into a solvent recovery unit; recovering the extraction solvent for recycling use or being returned to a liquefaction productprocessing unit by using a distillation method and / or an evaporation method, wherein residuals obtained after the extraction solvent is recovered are liquefaction residual extractives; delivering theobtained liquefaction residual extractives into a heat treatment unit, and separating the heavy liquefaction oil from the intermediate-phase bitumen matter by using a heating dry distillation method;and adding the obtained heavy liquefaction oil and other recycling solvents in a direct liquefaction process to a coal liquefaction solvent hydrogenation unit together.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

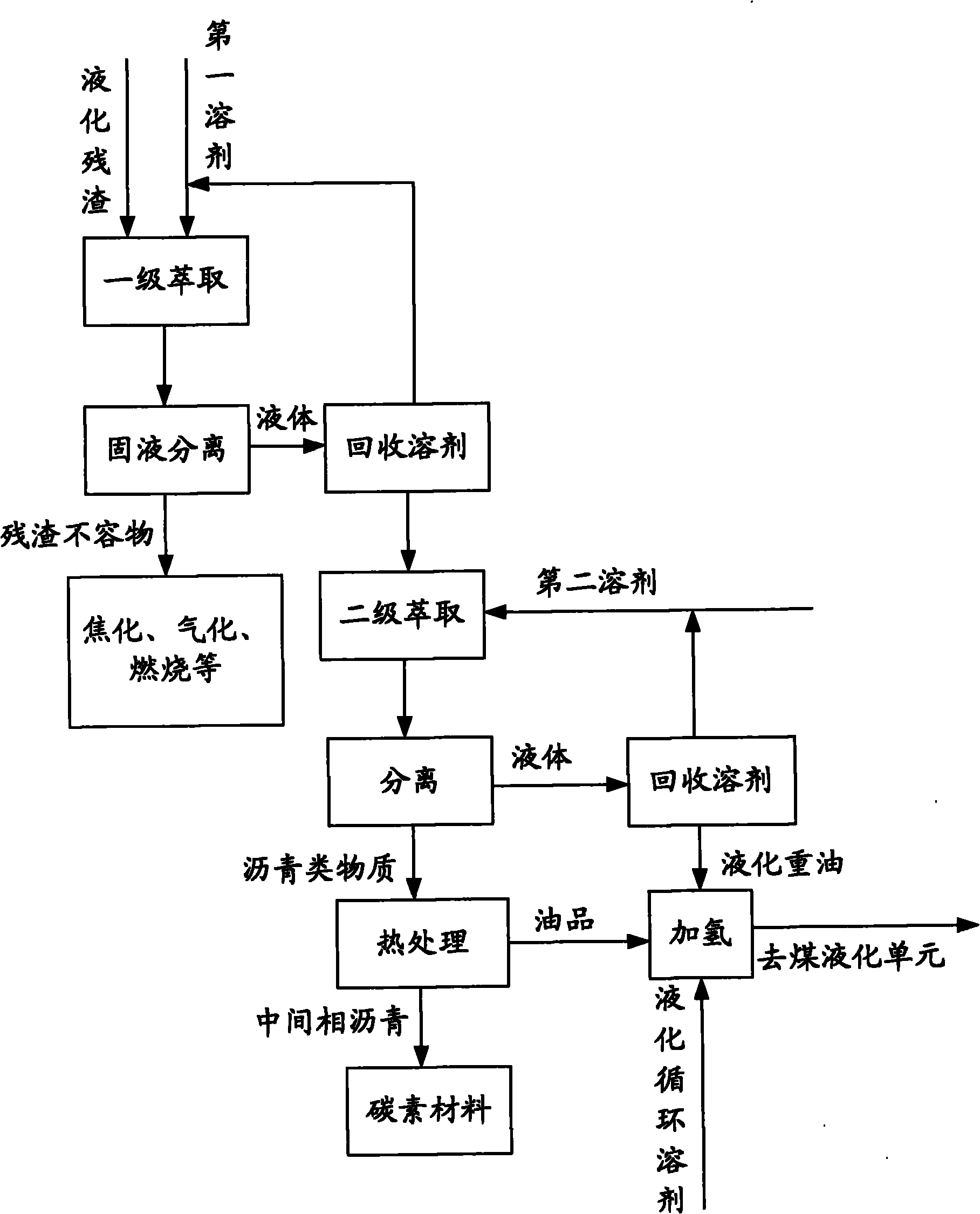

Extraction method of direct coal liquefaction residues and application of extracts

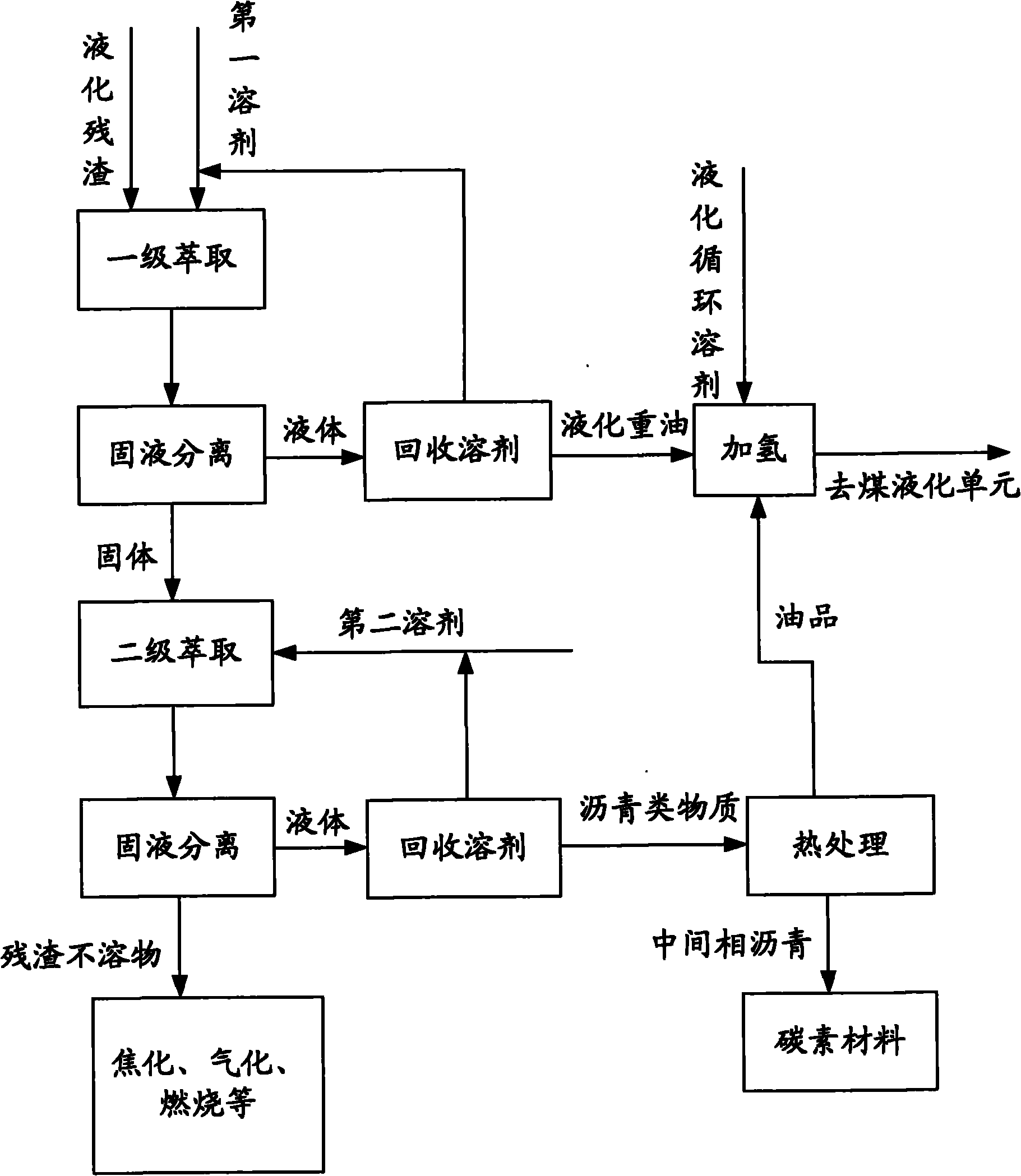

ActiveCN101962560ASimple processOperational securityWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionSolventAsphalt

The invention relates to an extraction method of direct coal liquefaction residues and application of extracts. The extraction method comprises the following steps: a) adding coal liquefaction residue powder and a first extraction solvent to a stirred tank to undergo primary extraction; b) carrying out solid-liquid separation on the extracted mixture obtained in the step a), recovering the first extraction solvent from the obtained liquid in a solvent recovery unit and recycling the first extraction solvent, obtaining heavy liquefied oil after recovering the first solvent, carrying out moderate hydrogenation on the heavy liquefied oil and other recycled solvents in a coal liquefaction solvent hydrogenation unit and using the product as the recycled solvent in the coal liquefaction process; c) mixing solid obtained through solid-liquid separation of extracts obtained after primary extraction with a second extraction solvent to undergo secondary extraction; d) carrying out solid-liquid separation on the extracted mixture obtained after secondary extraction, obtaining asphaltic substances after recovering the second solvent from the obtained liquid in the solvent recovery unit and carrying out heat treatment on the asphaltic substances by heating and carbonizing to obtain mesophase asphalt and oils.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

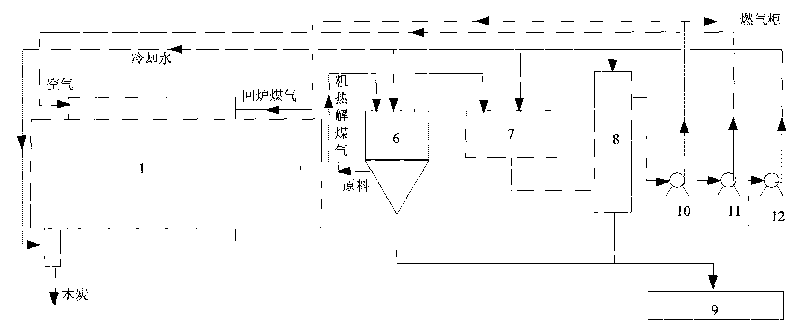

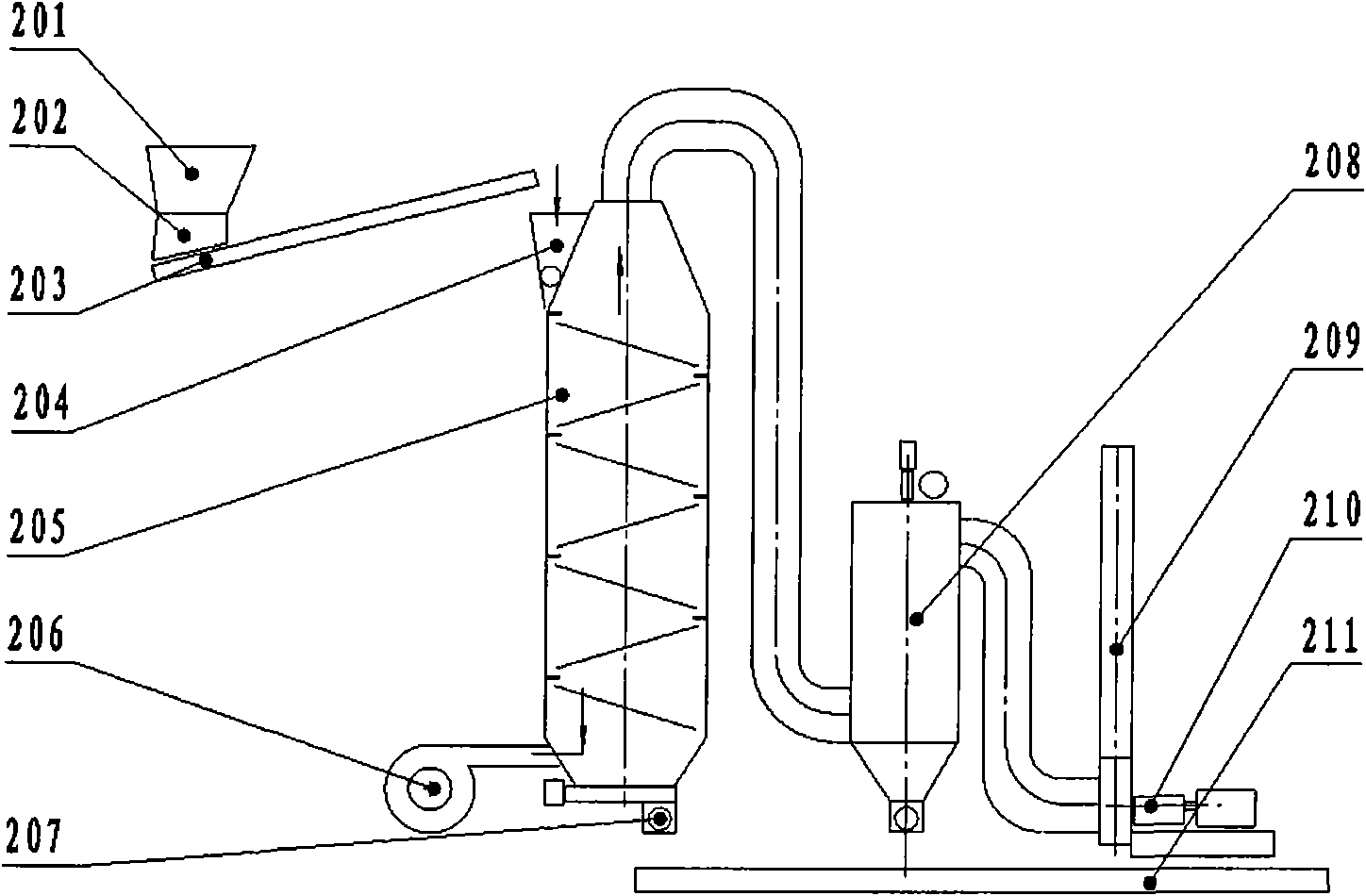

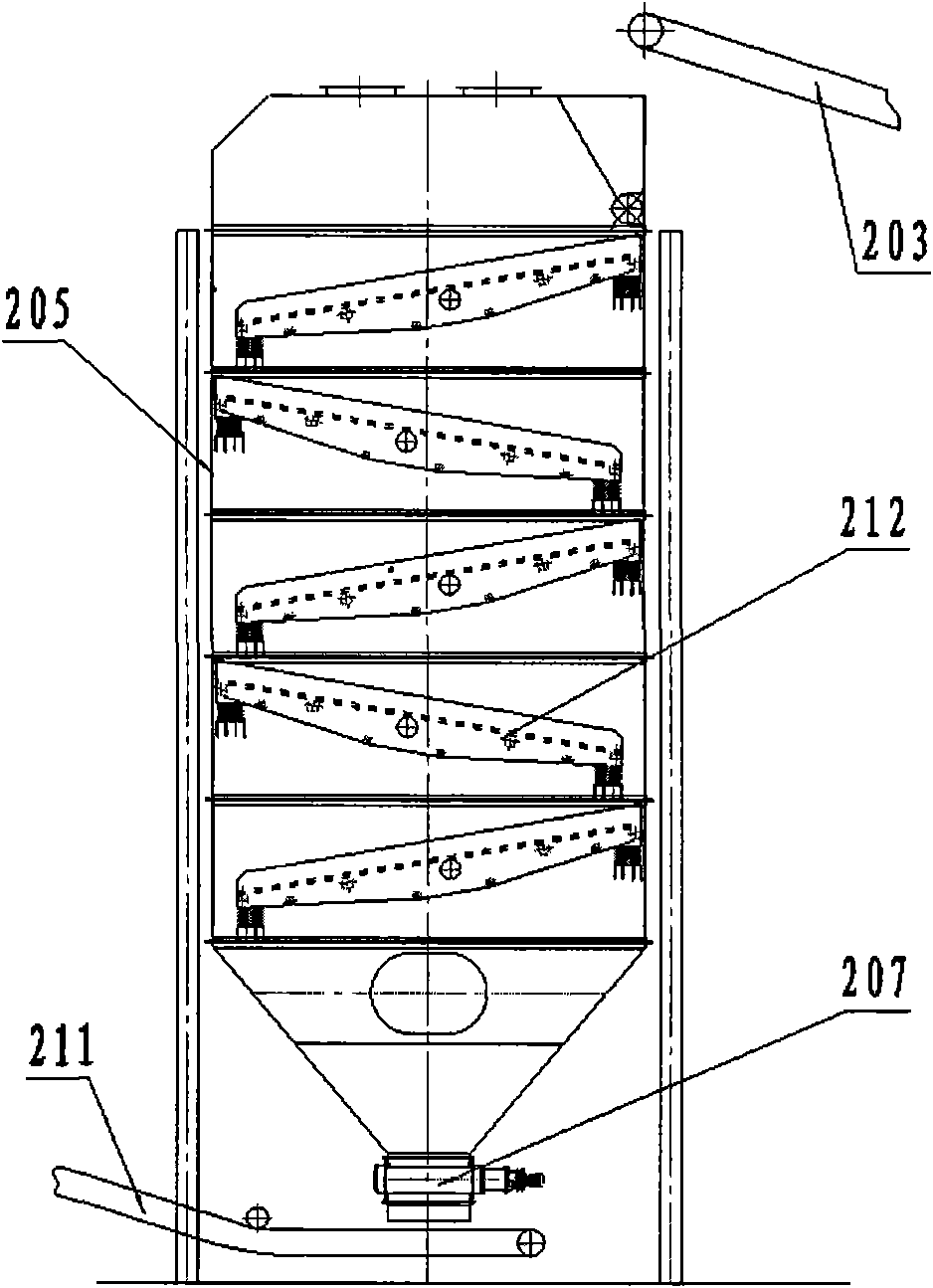

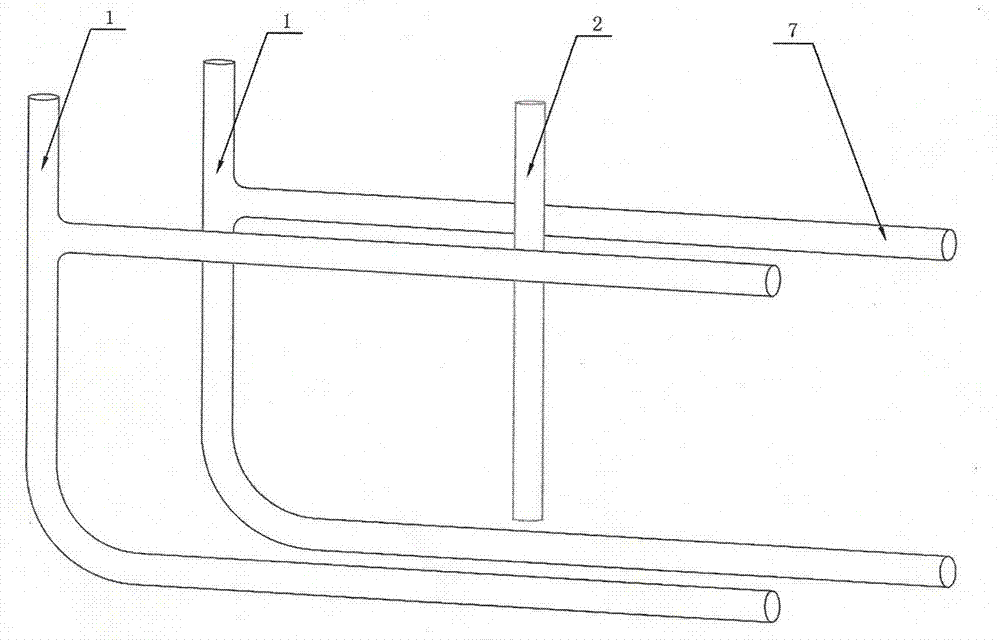

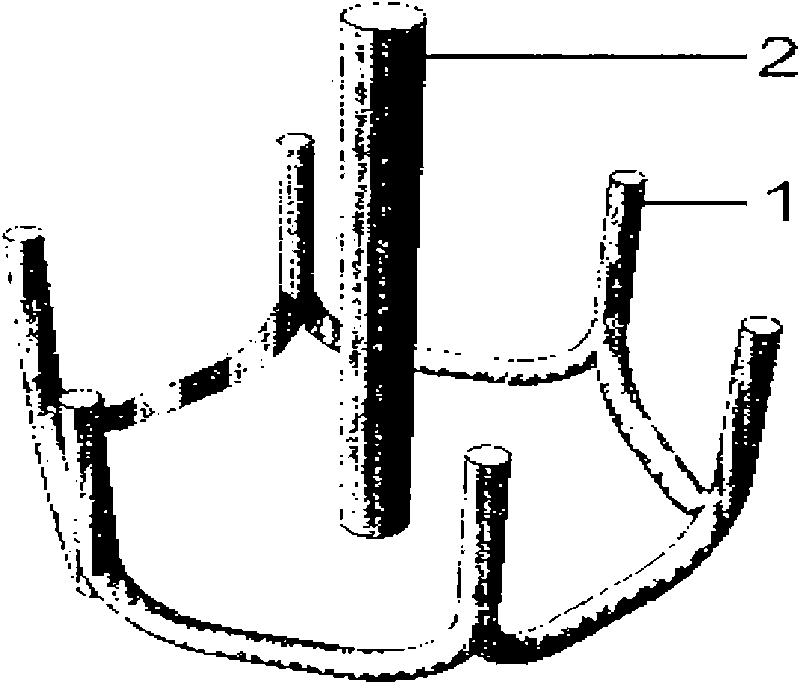

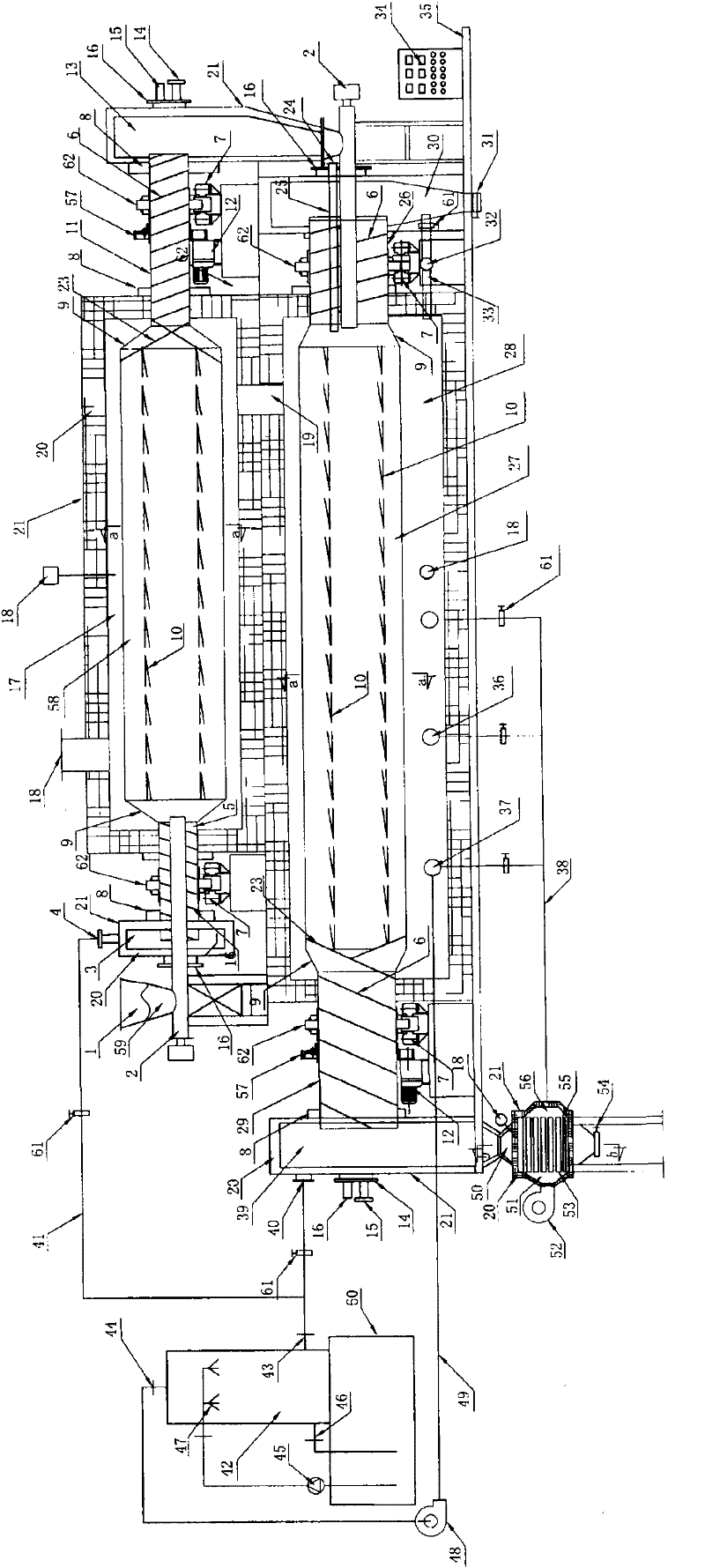

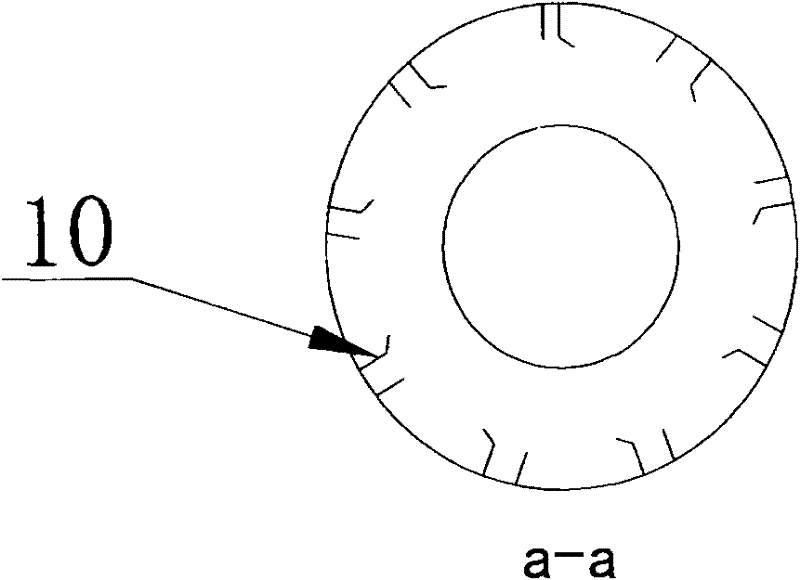

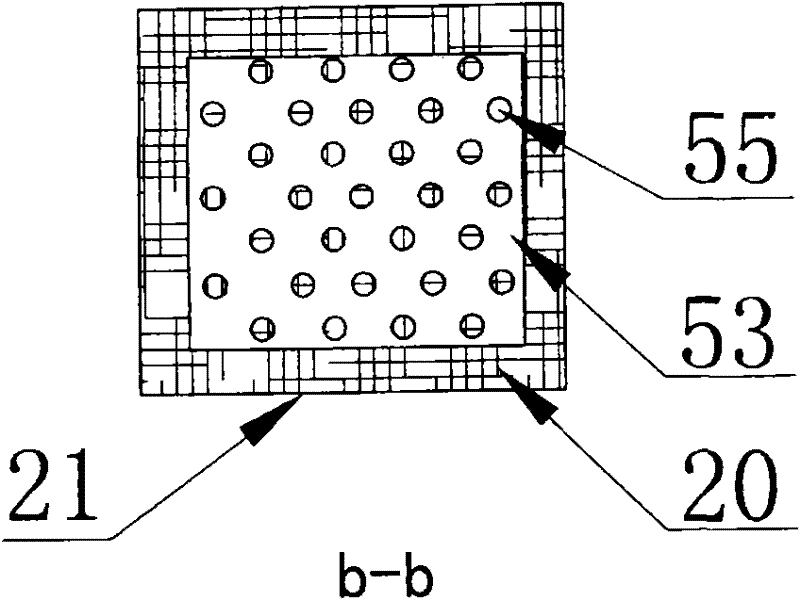

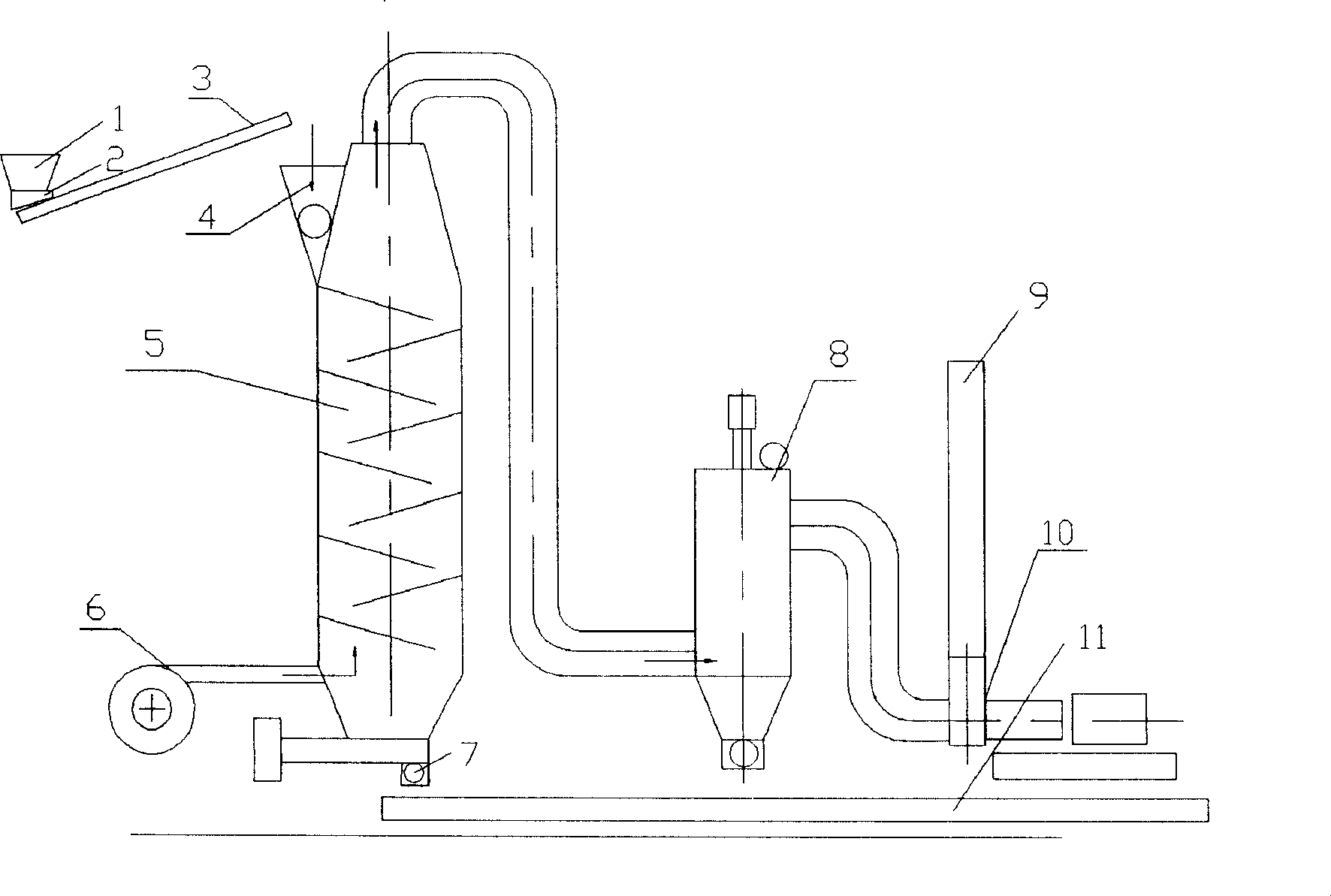

Process for internally heated continuous preparing biomass pyrolysis gasification gas and rotary furnace utilized by same

ActiveCN101693848ASmall footprintProvide continuous and stableBiofuelsSpecial form destructive distillationThermal energyDecomposition

The invention discloses a process for integrally heated continuous preparing biomass pyrolysis gasification gas and a rotary furnace utilized by the same. At a furnace tail cooling section, red charcoal at a temperature of 600-800 DEG C after pyrolyzing and destructive distilling reacts with steam generated by cooling spray water on the lower portion in the furnace so as to absorb large quantities of heat and simultaneously generate water gas and semi-water gas. Heat generated by burning recycled gas and air is used for maintaining pyrolysis temperature of biomass material layers and providesenough heat for further, pyrolysis, destructive distillation and steam decomposition reaction. By aid of the heat, biomass inside the furnace is pyrolyzed and destructively distilled to generate large quantities of volatile matters, and the biomass is gradually heated to decompose destructive gas with high heat value. The rotary furnace utilizes a three-section design: a first section is a furnace head preheating section, which is mainly used for preheating and drying raw materials, a second section is a rotary furnace body pyrolysis section, which is mainly used for pyrolysis and destructivedistillation and is a core operation portion of the furnace, and a third section is a furnace tail cooling section, which is mainly used for cooling charcoal. Prepared gas is high in heat value, and devices occupy small space.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

Method for making coal fine into form coke by microwave energy

InactiveCN101497835AReduce manufacturing costIncrease productivitySolid fuelsMicrowave heatingMicrowaveWork in process

The invention relates to a method for producing formed coke, in particular to a method for preparing coal powder into the formed coke by microwave. The method adopts coal powder as raw material and comprises the following steps: sieving the coal powder for preparing fine coal powder, sending the fine coal powder into a first microwave heating device for dehydration until the water content of the heated fine coal powder is below 1 percent, and sending the heated fine coal powder into a second microwave heating device by a conveying device for dry distillation; performing the dry distillation to the fine coal powder by the second microwave heating device to analyze other materials in the coal powder, preparing carbocoal after the dry distillation, sending the carbocoal into a mixer by the conveying device to prepare the mixture after adding bonding material; sending the mixture to a forming machine by a conveyer for forming so as to prepare a formed coke semi-finished product; sending the reformed coke semi-finished product into a third microwave heating device for being heated and carbonized to prepare red coke, and sending the carbonized red coke into a coke car to prepare a formed coke product. The invention has low production cost, high production efficiency, cleanness and environment protection because coke powder and waste are not produced during the production.

Owner:唐山金强恒业压力型焦有限公司

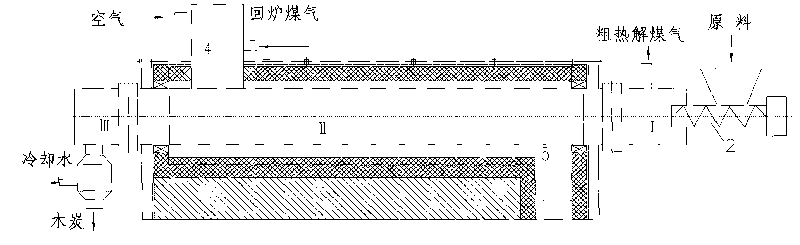

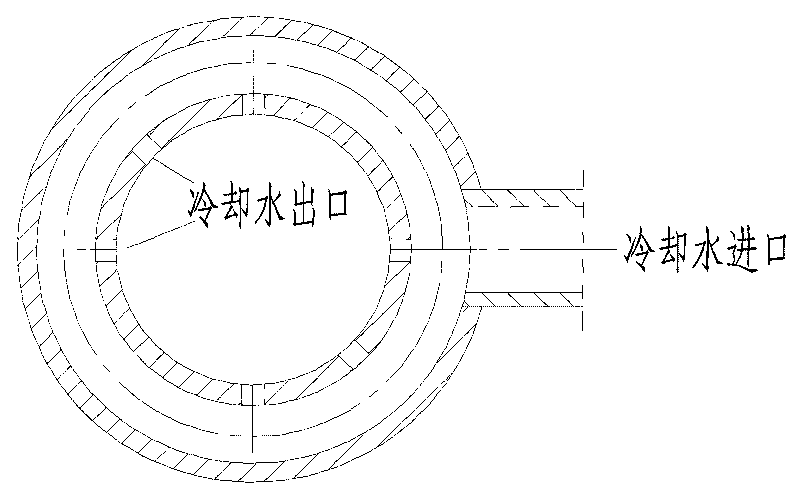

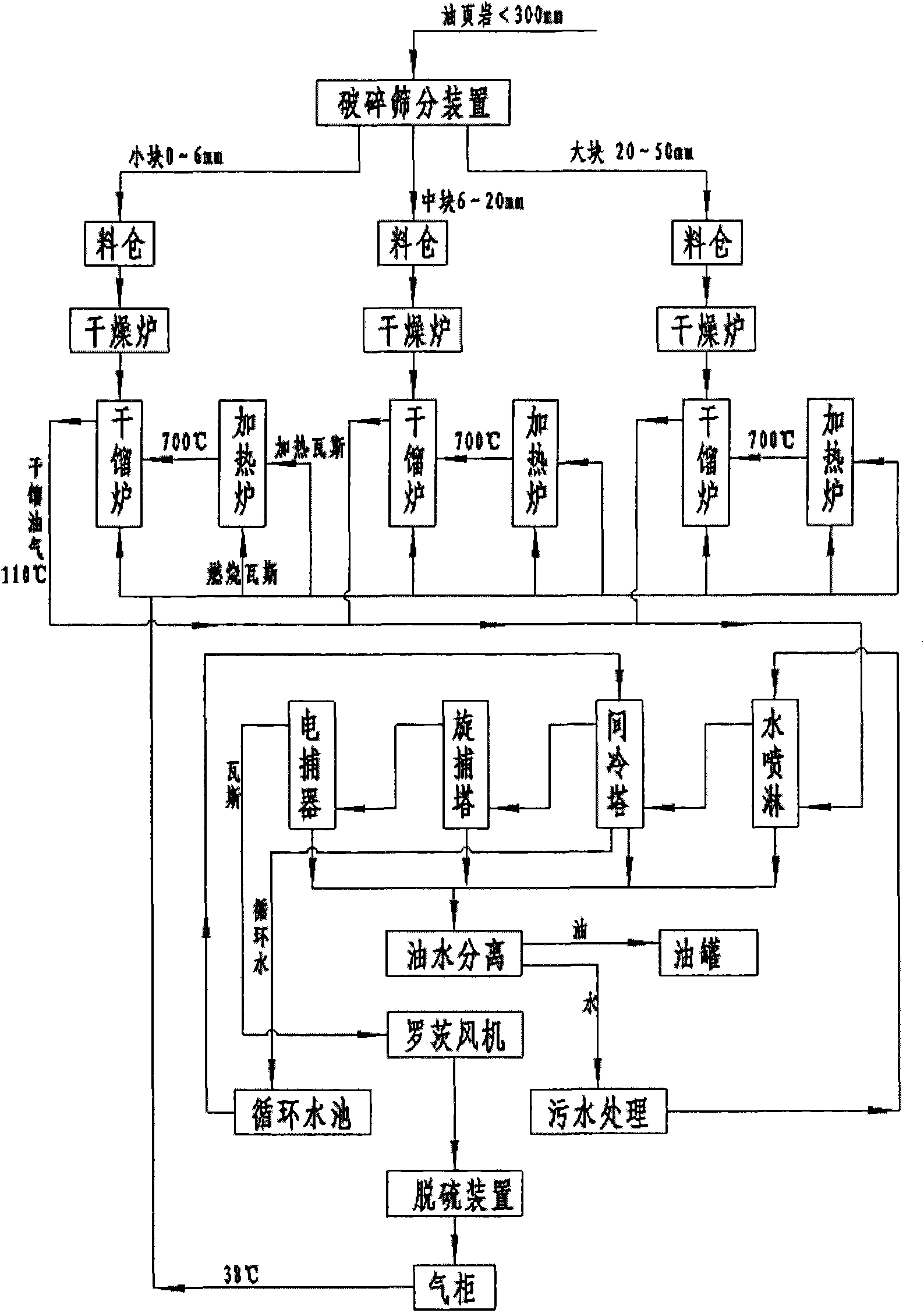

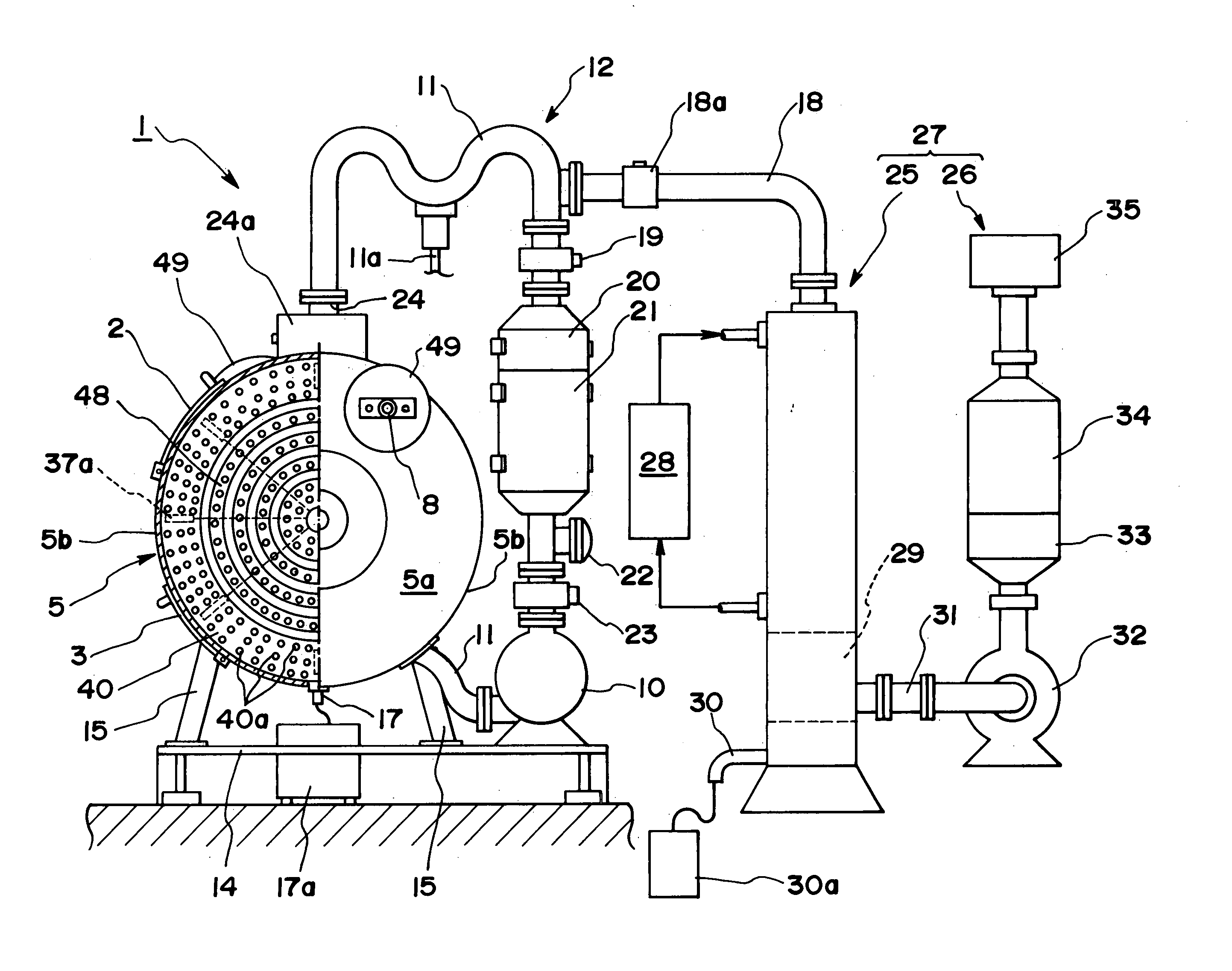

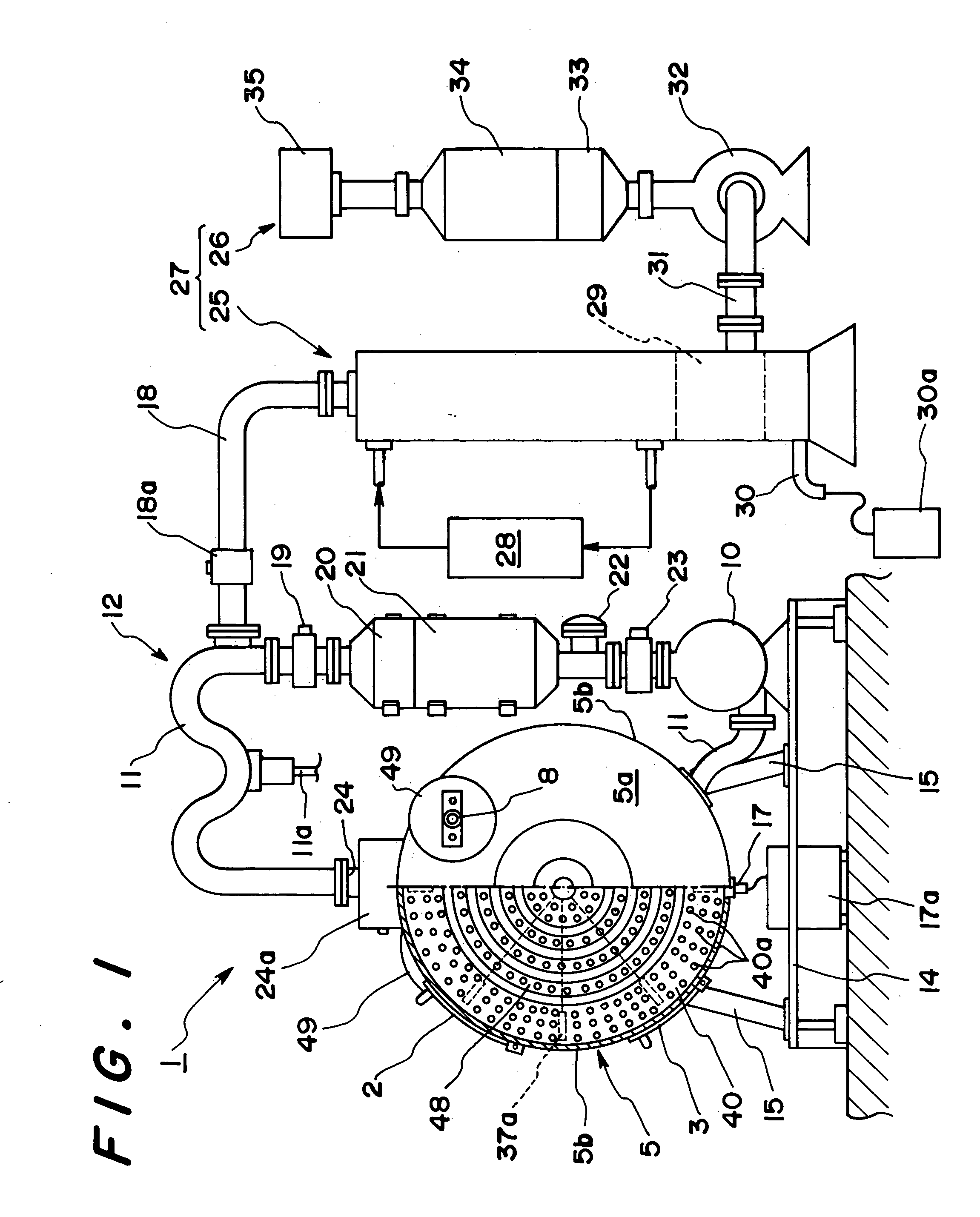

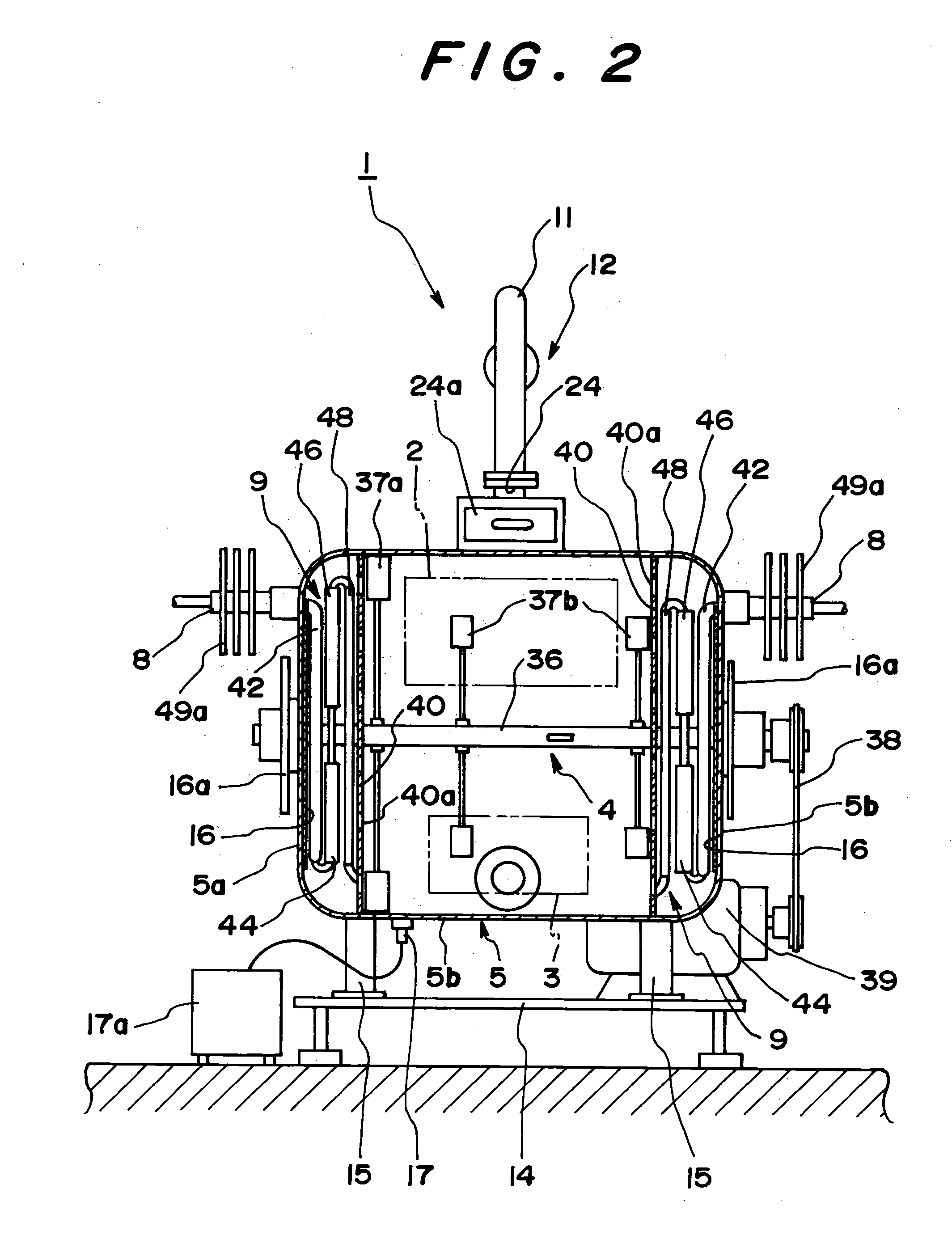

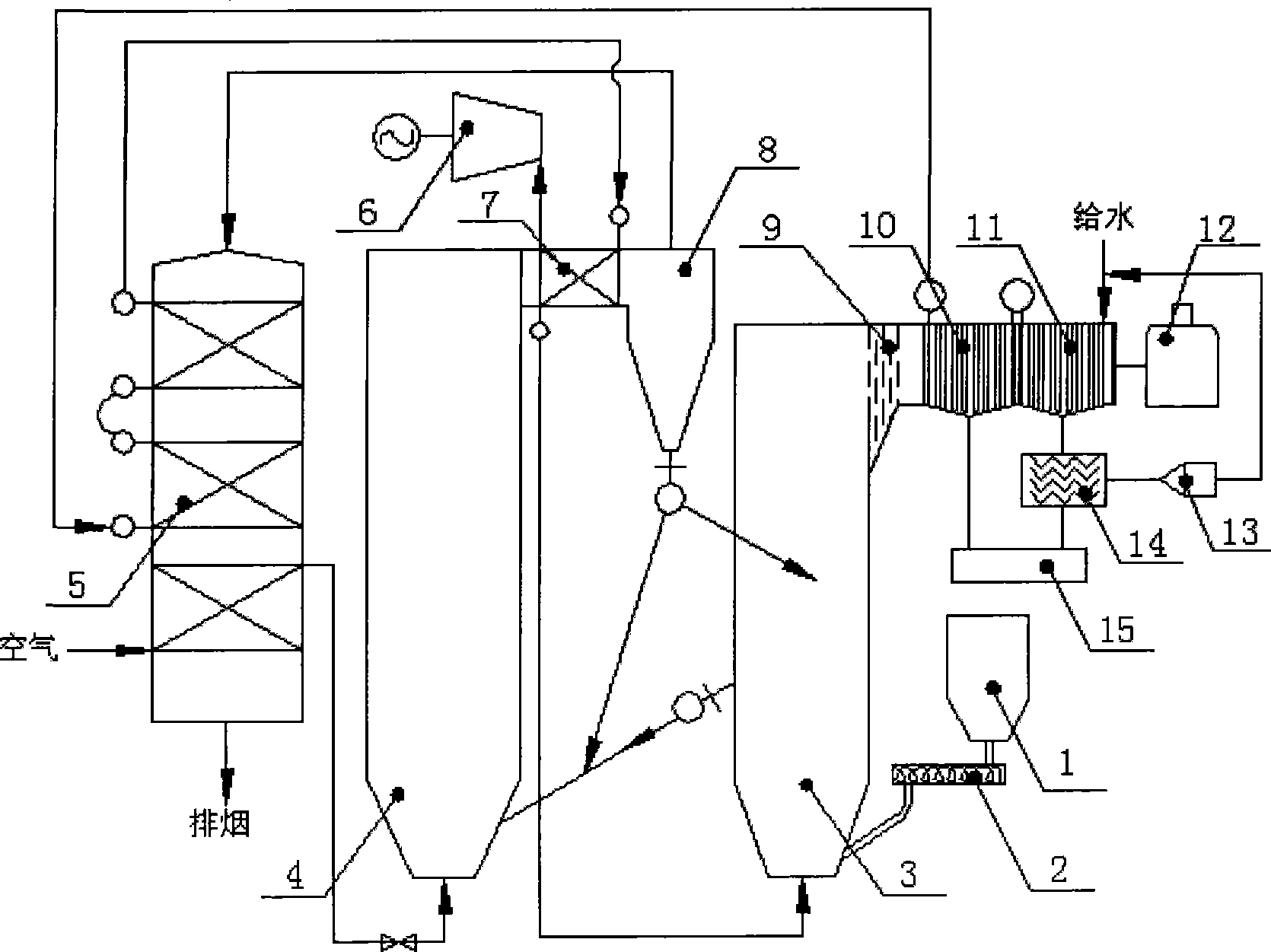

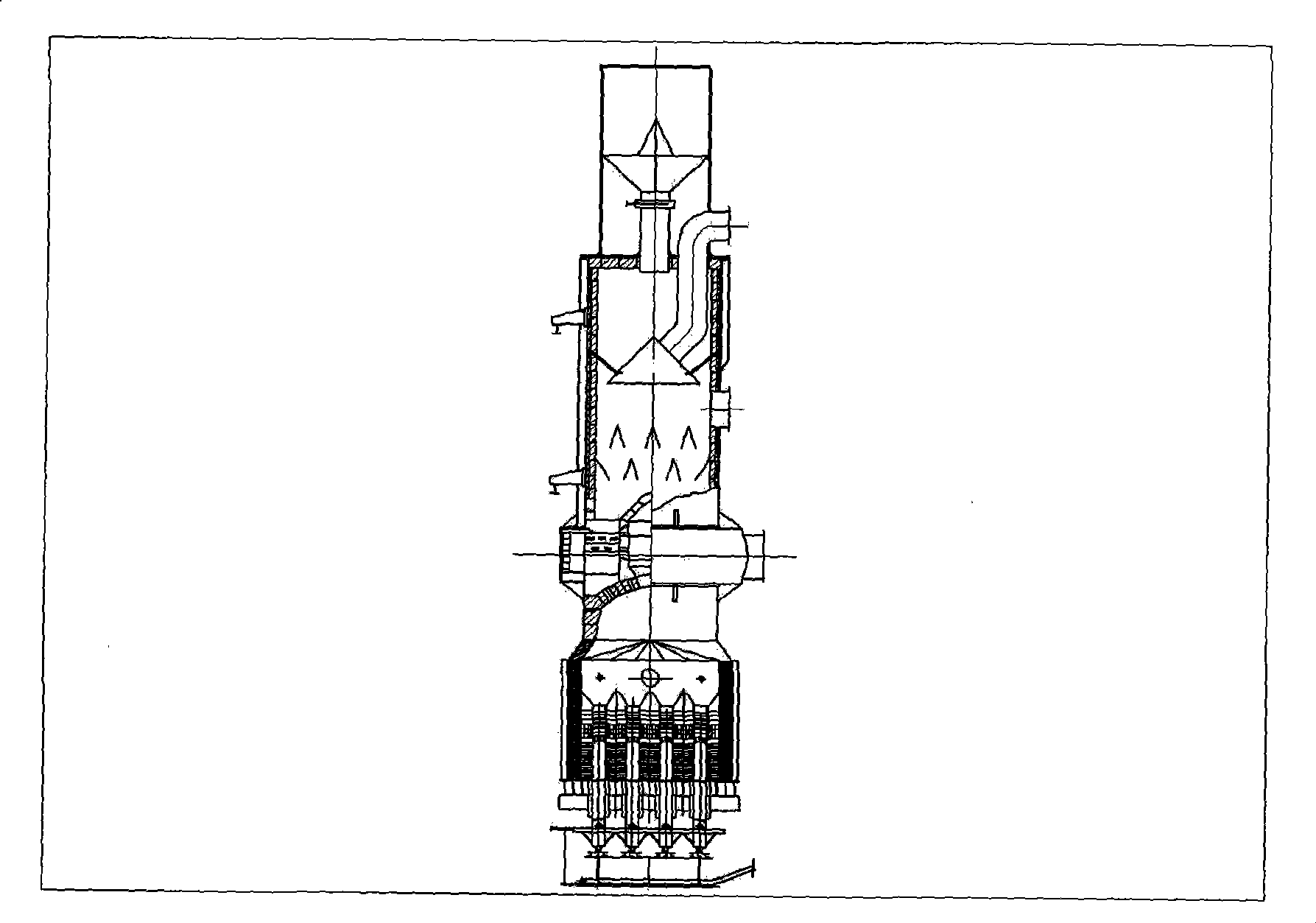

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

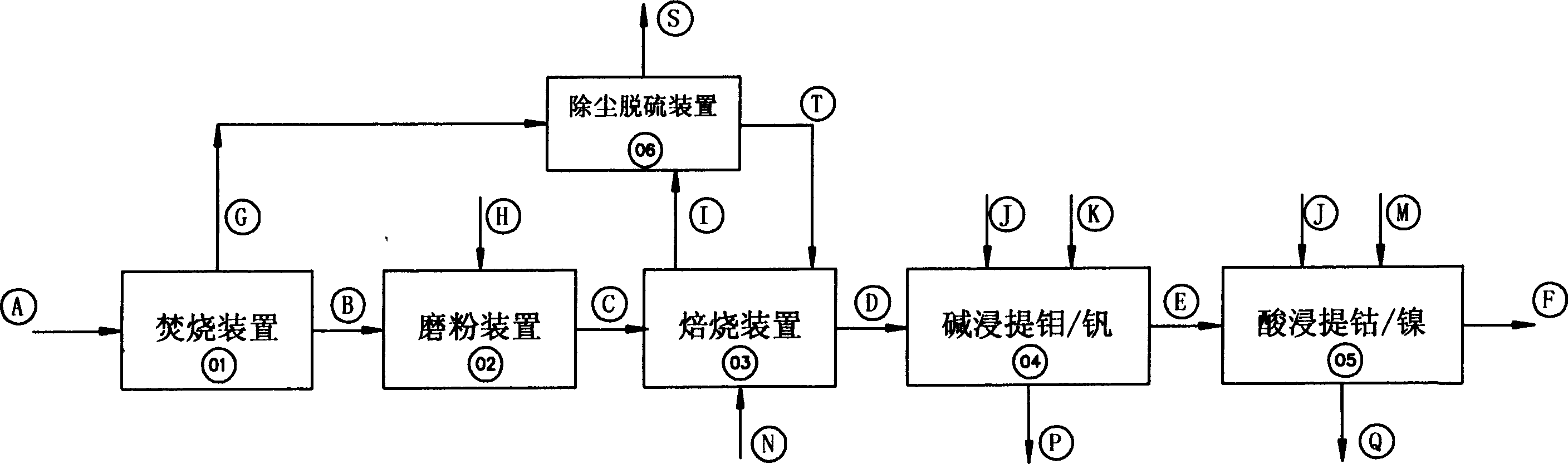

Method of handling spent catalyst

The present invention belongs to the field of environment protection and resource utilization ,and is especially waste catalyst processing method. The waste catalyst processing process includes pre-treatment; dry distillation at temperature 400-800 deg.c for 1-2.5 hr to obtain dewatered, deoiled and desulfurized water catalyst white recovering dried gas; mixing waste catalyst with flux, trapping agent and reductant to obtain mixed material; high temperature smelting at 1500-1900 deg.c to convert into melt and smelted tail gas and treated for reuse. The present invention is one environment protecting process producing no secondary pollutant while recovering the components in waste catalyst, has metal recovering rate as high as 93 % and full utilization of waste catalyst resource.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

Method for extracting shale oil and gas from oil shale in situ

The invention discloses a method for extracting shale oil and gas from oil shale in situ. The method comprises the steps that hot nitrogen is injected into an oil shale layer to crack kerogen in situ; after being extracted and separated, combustible gas which is generated initially is injected into a well together with the nitrogen by a certain proportion to have chemical reaction with the oil shale, so as to further crack organic substances in the oil shale, and extract shale oil and combustible gas; the hot nitrogen is an inert gas which is not only a carrier for transferring heat but also a carrier which carries shale oil and gas to above the ground; meanwhile, due to the pressure action of fluid, an oil and gas channel is favorably formed in the oil shale layer. The circulating combustible gas can have chemical reaction with the kerogen in the oil shale, so as to accelerate the reaction. According to the method for extracting shale oil and gas from the oil shale in situ, mining cost and risks are greatly reduced, the operability is greatly improved, problems caused by a surface dry distillation technology and an existing in-situ technology are fundamentally solved, the construction difficulty and cost are effectively reduced, and the method does not pollute underground water, is environment-friendly and is non-toxic.

Owner:JILIN UNIV +1

Method for preparing carbon molecular sieve adsorbent

InactiveCN101596445ALow costReduce pollutionOther chemical processesAdsorption purification/separationPolymer scienceSorbent

The invention discloses a method for preparing a carbon molecular sieve adsorbent. The steps are as follows: (1) solidification: polymer is used as a raw material and is arranged in a thermostatic drying oven to be solidified; (2) dry distillation: the solidified macromoleclar polymer is pulverized by a pulverizer and then is processed by dry distillation; (3) fine pulverization: the macromoleclar polymer which is pulverized and processed by dry distillation is further processed by fine pulverization in the premise that the particle diameter of the macromoleclar polymer does not meet the requirement, and ball milling or gas milling is used for preparing micro-particles; (4) molding: the macromoleclar polymer which is processed by fine pulverization is mixed and uniformly stirred with agglomerant by mass ratio, and the mixture obtained is pressed and molded by an oil hydraulic press and then is dried; (5) carbonization and activation: under the state of N2 protection, temperature is raised for carbonization so as to increase the CMS surface area; and (6) carbon precipitation and hole adjustment: the hole adjustment agent is decomposed in the carbon molecular sieve for carbon deposition, the particle diameter is shortened and is enabled to be uniform, and the carbon molecular sieve product can be obtained after cooling. The carbon molecular sieve has the advantages of high CH4 adsorbing capacity, high selectivity factor of adsorption, favorable strength, low cost and no pollution, and the performance achieves or surpasses the standard of a sample of Japan carbon molecular sieve.

Owner:ANHUI UNIV OF SCI & TECH

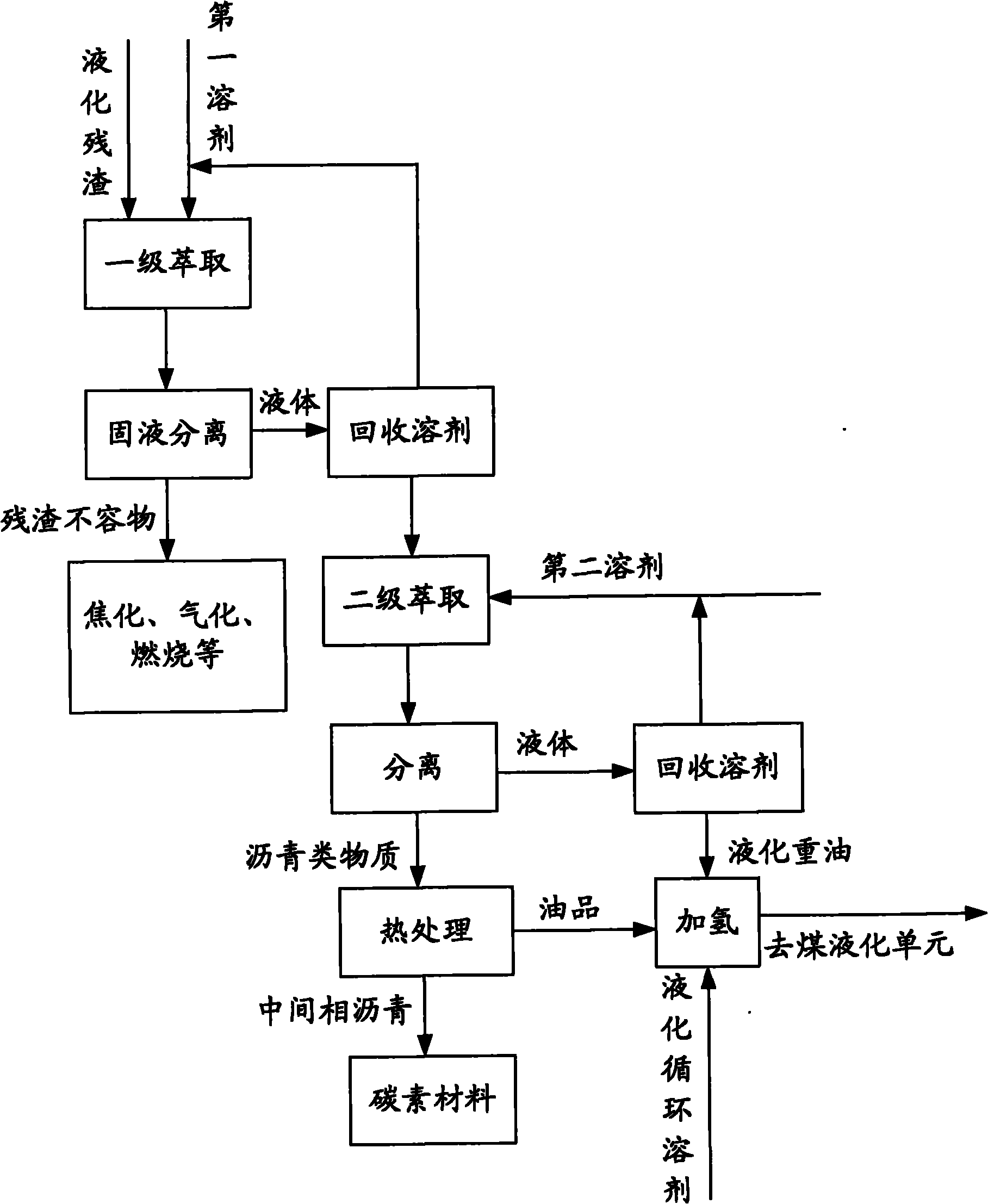

Extraction method of direct coal liquefaction residues and application of extracts

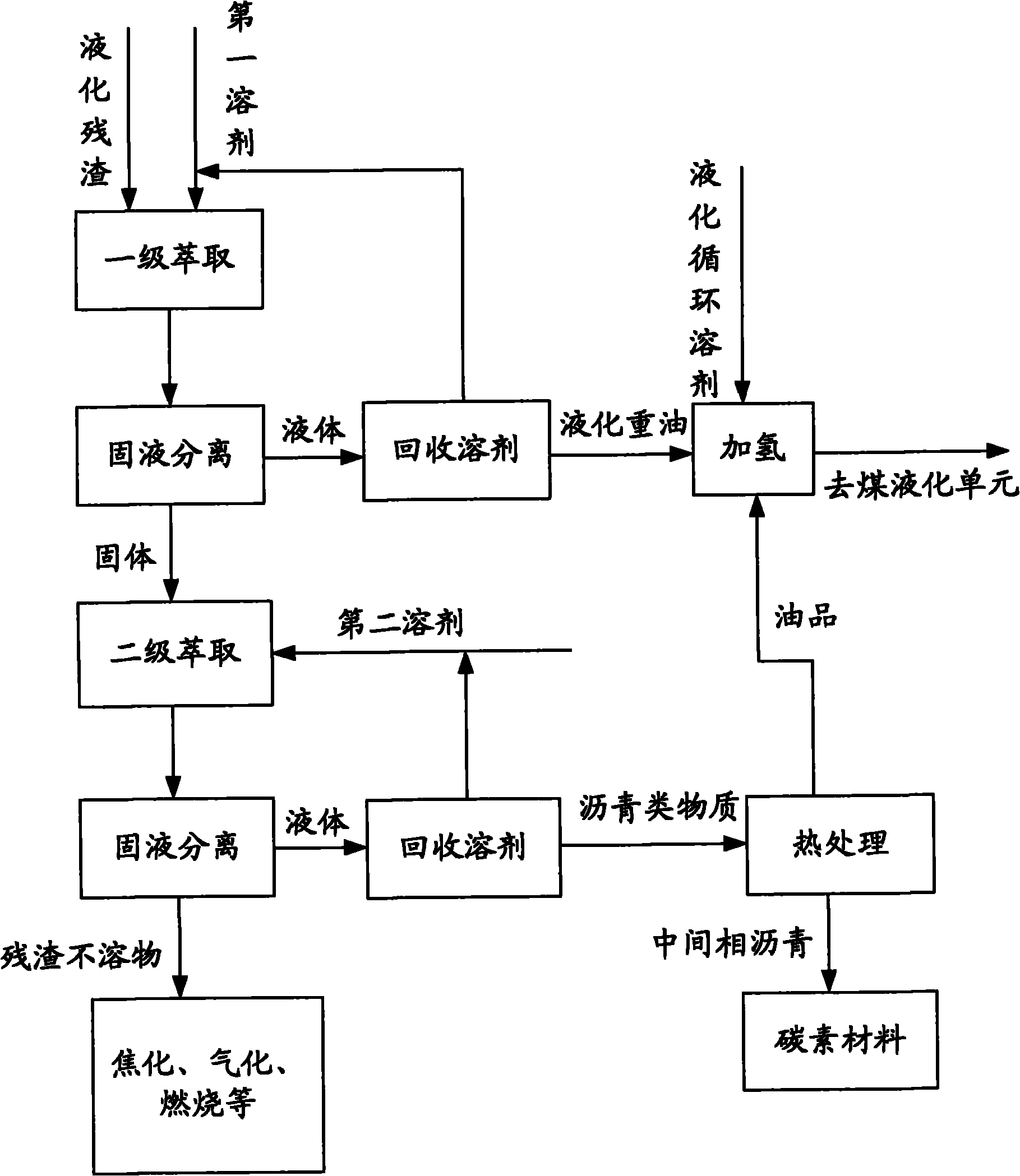

ActiveCN101962561AMake full use ofSimple processWorking-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionSolventThermal treatment

The invention relates to an extraction method of direct coal liquefaction residues and application of extracts. The extraction method comprises the following steps: a) adding coal liquefaction residue powder and a first extraction solvent to a stirred tank to undergo primary extraction; b) carrying out solid-liquid separation on the extracted mixture obtained in the step a) and recovering the first extraction solvent from the obtained liquid in a solvent recovery unit and recycling the first extraction solvent; c) obtaining extracts after recovering the first solvent and mixing the extracts with a second extraction solvent to undergo secondary extraction; d) carrying out solid-liquid separation on the extracted mixture obtained in the step c), obtaining heavy liquefied oil after recovering the second extraction solvent from the obtained liquid in the solvent recovery unit and then carrying out moderate hydrogenation on the heavy liquefied oil and other recycled solvents in a coal liquefaction solvent hydrogenation unit and using the product as the recycled solvent in the coal liquefaction process; and e) carrying out heat treatment on the asphaltic substances obtained in the step d) by heating and carbonizing to obtain mesophase asphalt and oils.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

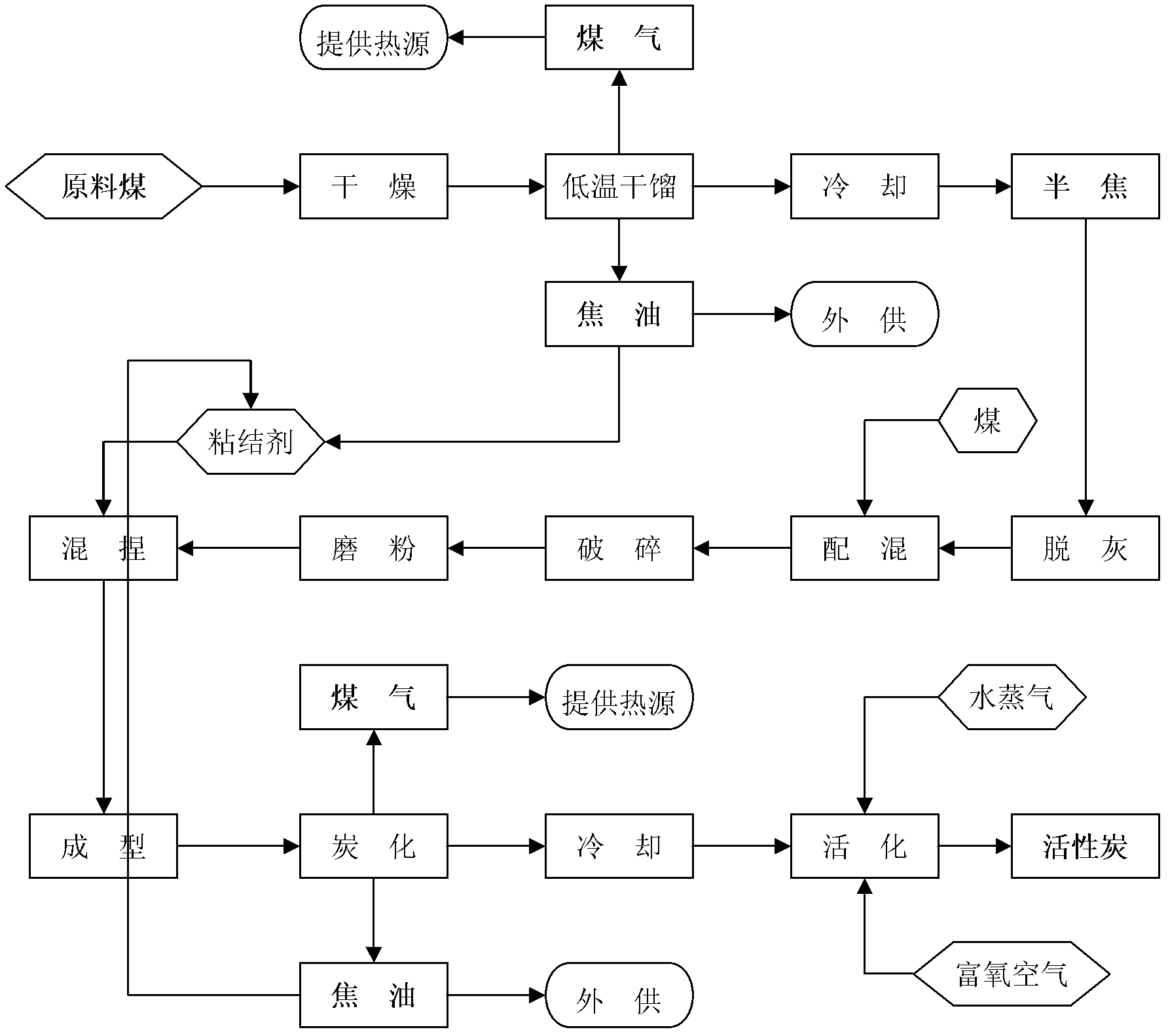

Method for preparing active carbon by using coal

The invention provides a method for preparing active carbon by using coal. The method comprises the following steps: after feed coal is dried, dry-distilled at low temperature and cooled, semicoke is obtained; deashing is carried out on the semicoke in which the ash content can not meet the production requirement of the active carbon; coal is mixed with certain viscosity into the semicoke which can not meet the strength of the active carbon according to the characteristics; after mixed with the coal, the raw materials are mixed fully by crushing and grinding; after a certain amount of binding agent is added, the powder is mixed and kneaded, and is pressed into a forming material with a special shape in forming equipment; the forming material enters a carbonization furnace by a conveying device, carrying out heat treatment, dry-distillation, heat cracking and condensation reaction at different temperature sections to prepare carbonized materials; the carbonized materials are conveyed to a cooling furnace for cooling by the conveying device; and the cooled carbonized materials are conveyed to an activating furnace, and is activated by utilizing an activating agent. The method has the advantages that the industrial chain for comprehensive utilization of subcannel coal is extended, the utilization bottleneck of the semicoke is broken, products with increasing market demand are produced, the strategic resources short in China can be effectively recovered, and large economic and social benefits can be created.

Owner:西安三瑞实业有限公司

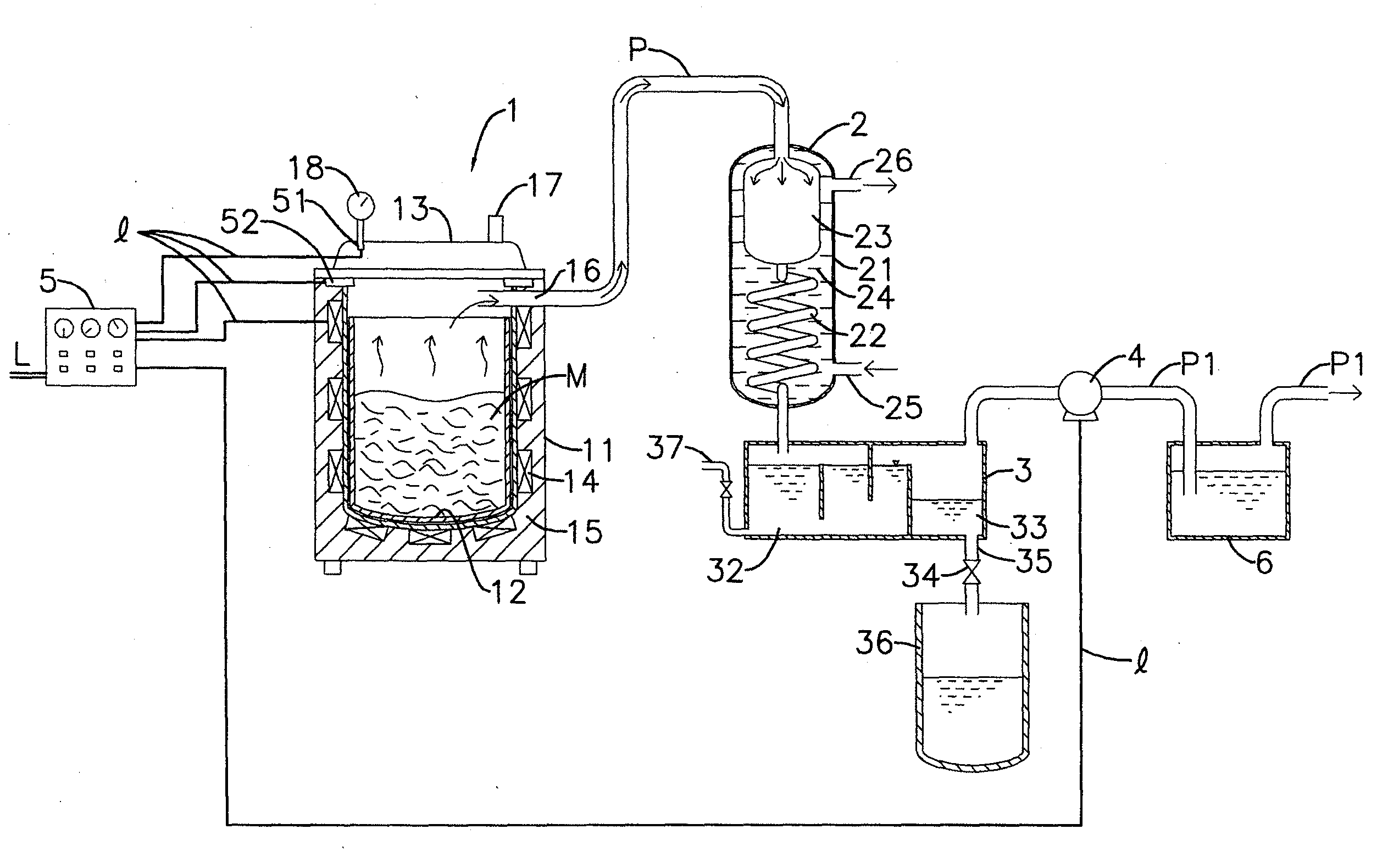

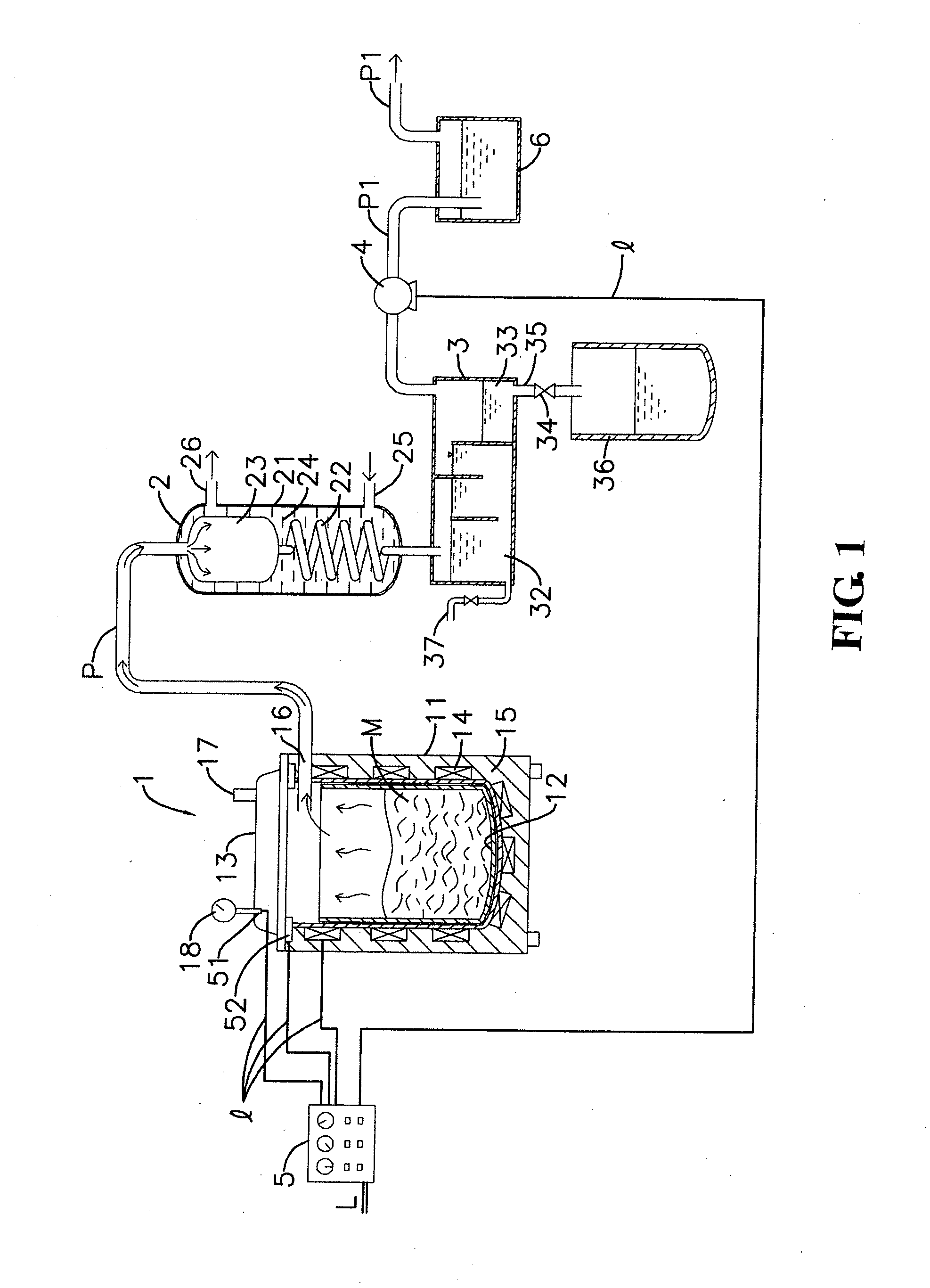

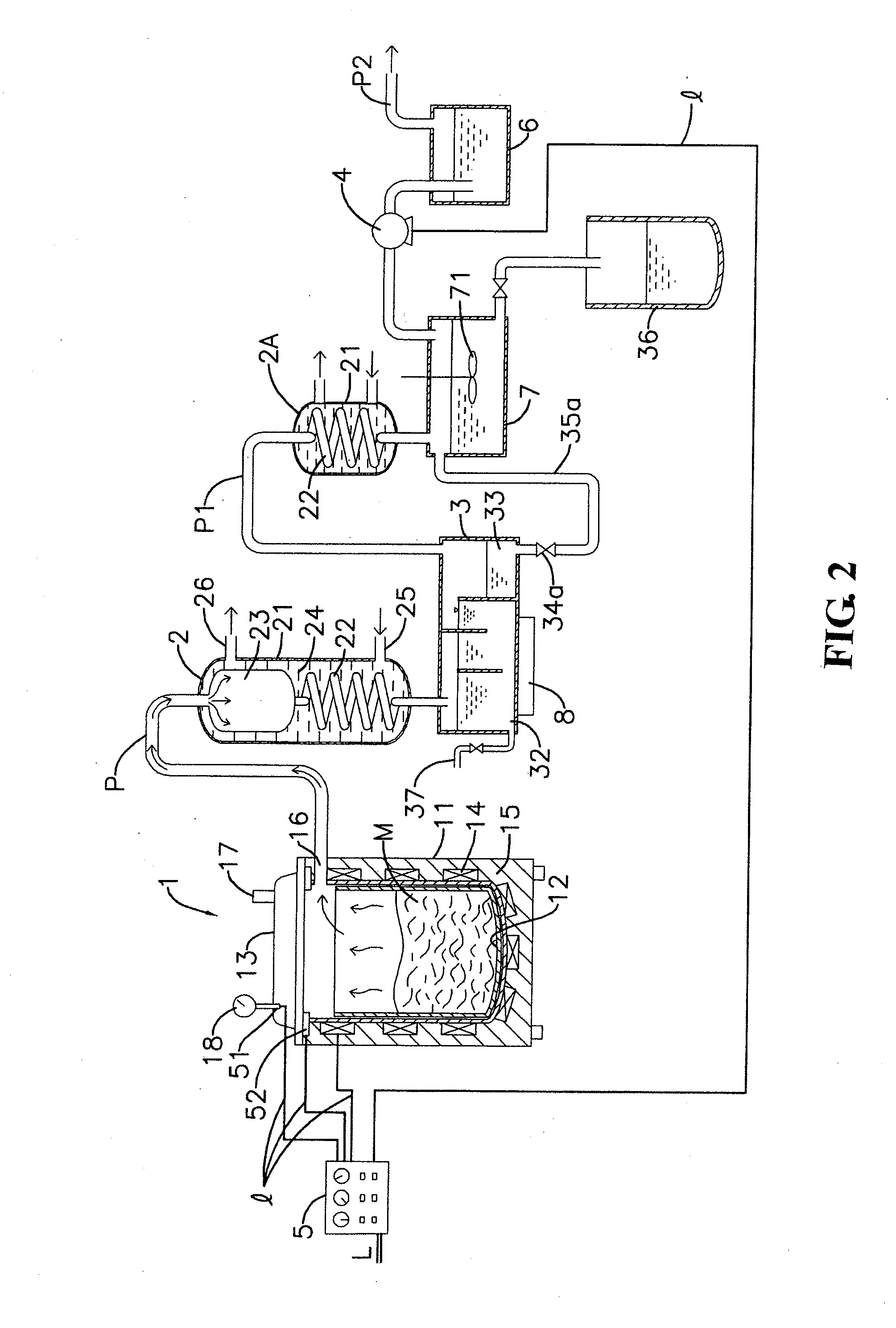

Method of extracting essential oil from biomass wastes and a device thereof

InactiveUS20110034712A1Reduce processing timeQuality improvementRetortsLiquid hydrocarbon mixture productionEngineeringOxygen

A method of extracting essential oil from biomass wastes puts biomass wastes, such as wood residuals, wood chips or other plants, in an air-tight oxygen-free reaction vessel to be heated up indirectly, for conducting a thermal pyrolysis cracking reaction (i.e. dry distillation); and guides volatile gas which is distilled when the processed wastes disintegrate, into a condenser to be condensed as liquid which is then separated into water and oil through an oil-water separation tank. Whereas, non-liquefied gas is discharged outside after deodorizing, and residuals in the reaction vessel are processed with high-temperature dry distillation once to become activated carbons. In processing, temperature and pressure in the reaction vessel are controlled in multiple phases, along with using a suction pump of a changeable speed and a changeable flow rate to suck out air in high speed in phases, to keep internal pressure of the reaction vessel at a low pressure condition, thereby shortening a processing time and acquiring high quality essential oil and activated carbons as by-products.The present invention also includes a system device to implement this method. In the oil-water separation tank of this device, an ultrasonic generator is provided to re-disintegrate tars, which improves quality of the oil products.

Owner:LIN WEI CHIH

Gasification method and device for biomass and coal mixed fluidized-bed

ActiveCN1557919AEasy to makeRich sourcesGranular/pulverulent flues gasificationWater vaporProduced water

The present invention relates to energy source apparatus, and is one kind of simple biomass-coal mixture gasifying method and apparatus capable of producing high heat value gas and no tar. Inside fluidized bed gasifying furnace, biomass and coal as gasified material is burnt and gasified intermittently. In the burning stage, coal and blast are supplied to the furnace, so that coal is burnt in fluidizing state to produce heat; in the gasifying stage, vapor and biomass are supplied to the furnace, so that the high temperature carbon material layer produces water gas reaction in fluidizing state and biomass is dry distilled and pyrolyzed at high temperature to produce high heat value gas, which is cooled and made to enter the gas purifying system. By combining of biomass and coal with different advantages, the present invention produces high heat value fuel gas without tar.

Owner:JIANGSU UNIV

High-efficiency lignite low-temperature dry distillation quality-enhancing process by using dry distillation coal gas as heat-carrying medium

InactiveCN101812310AReduce in quantityEfficient use ofCoke quenchingChemical industryEconomic benefitsTar

The invention relates to a low-temperature dry distillation process for coal, in particular to a high-efficiency lignite low-temperature dry distillation quality-enhancing process by using dry distillation coal gas as a heat-carrying medium. The process comprises a coal-preparing flow, a drying flow, a dry distillation flow, a heat source flow, a coal gas and tar processing flow and a semicoke cooling transfer flow; in the process, vapor self-generated by a drying tower is used as a drying medium, the coal gas of a generator is taken as a heat source to heat the self-generated dry distillation coal gas, and serves as a dry distillation medium, and the coal gas of the generator is used as fuel of a hot air furnace; the dry distillation semicoke is cooled in a cooling mode of drying fume exhaust plus semi water spraying; and condensation water is used for coke-quenching water, a gasifier of the coal gas of the generator and a tar cooling agent. The process has the advantages of producing high-index dry coal and dry semicoke, high-heating value coal gas and high-quality tar, having a flawless and high-efficiency energy recycling system, not using outside nature water, hardly discharging water to the outside, saving huge cost for sewage treatment, creating the maximum economic benefits for customers and having quite strong competitive power on economy, technology and market.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

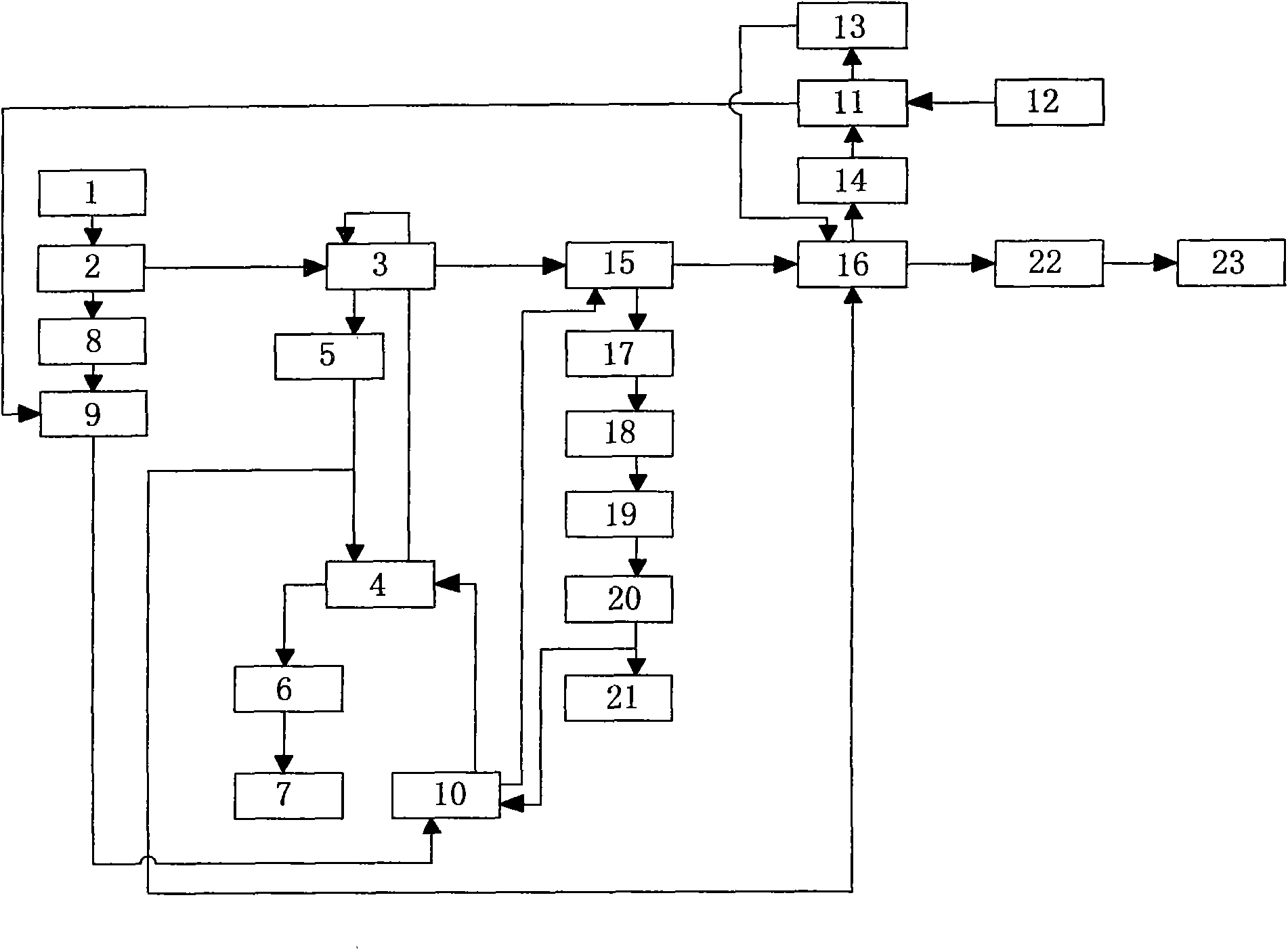

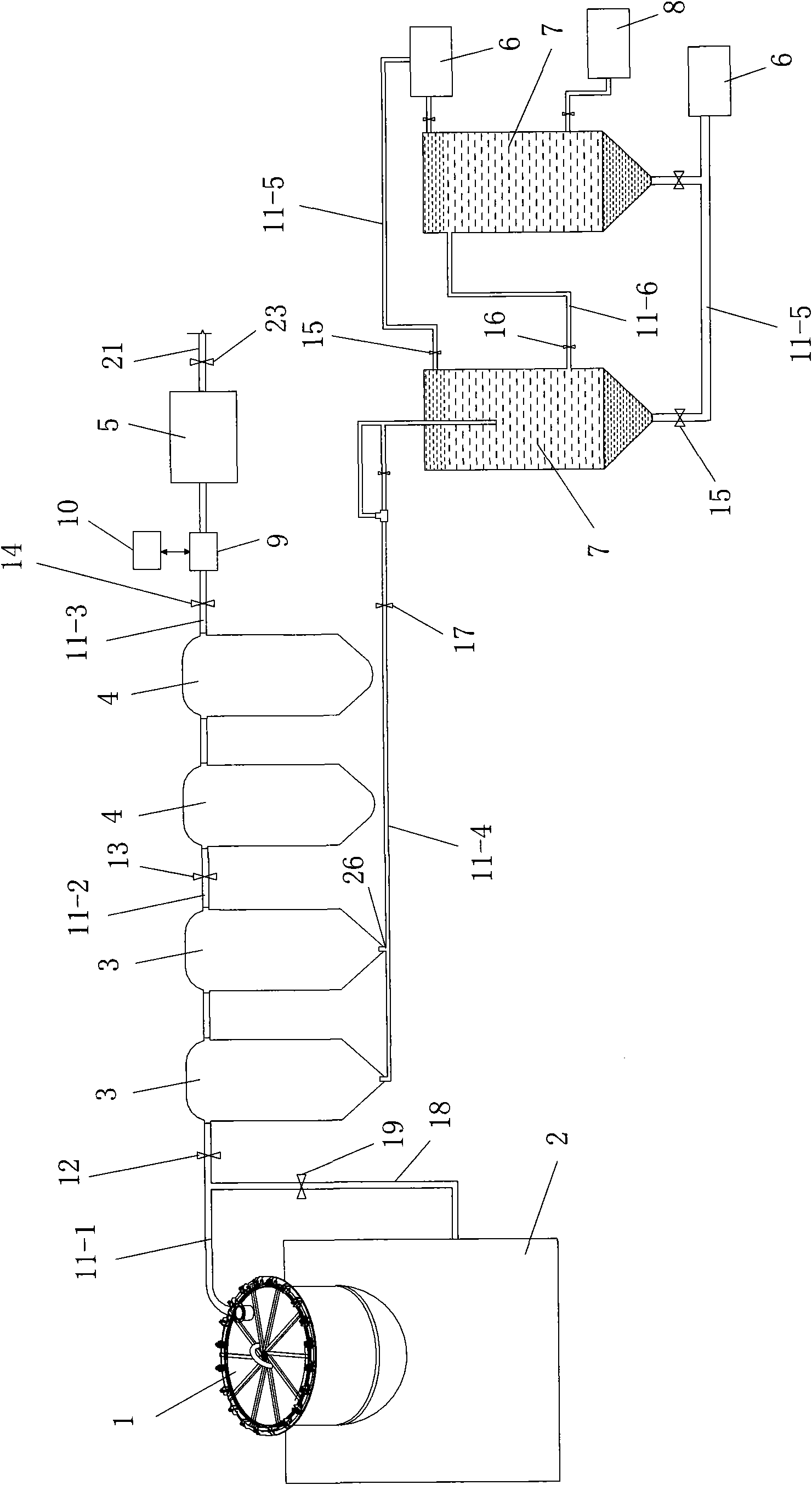

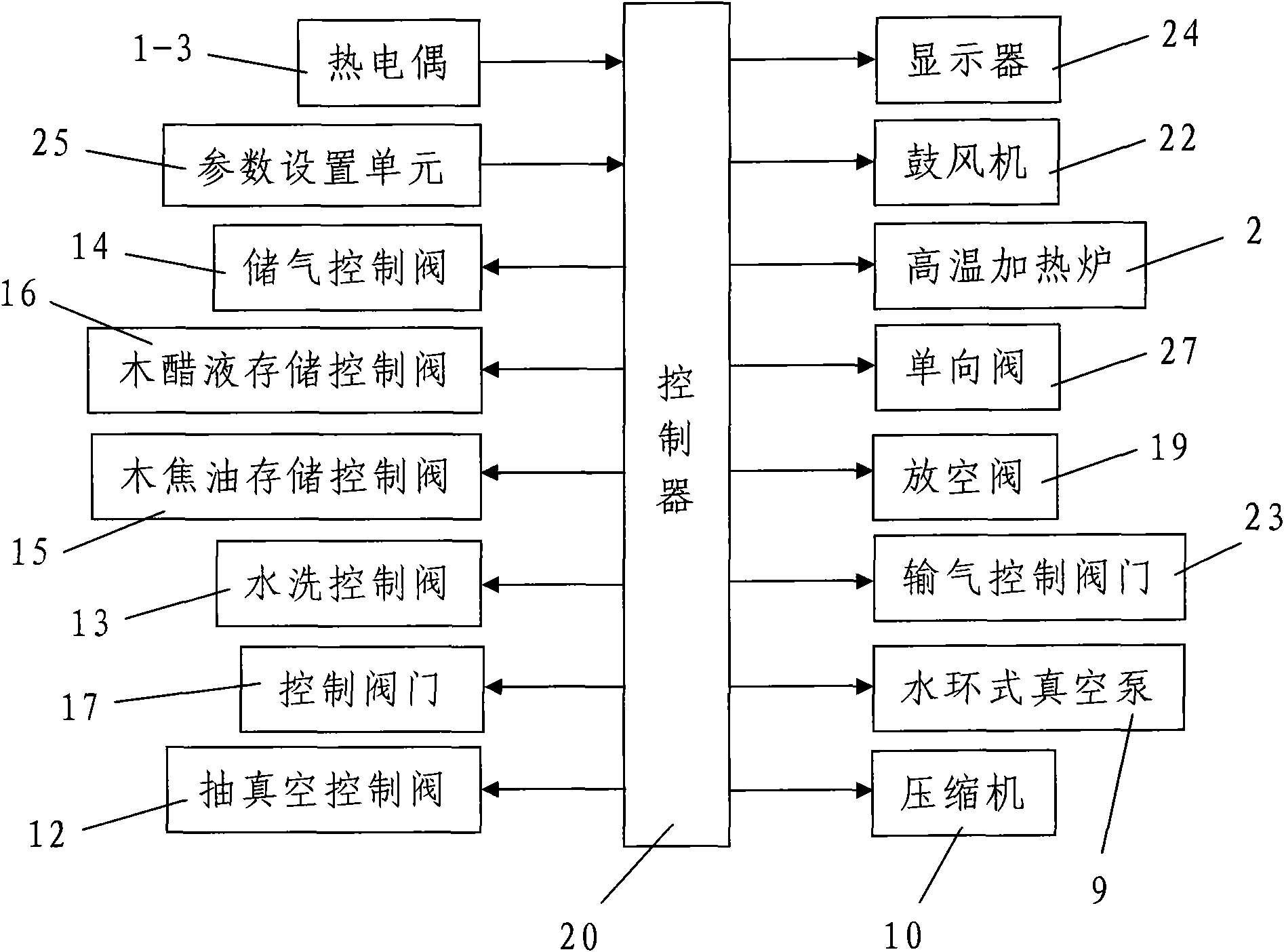

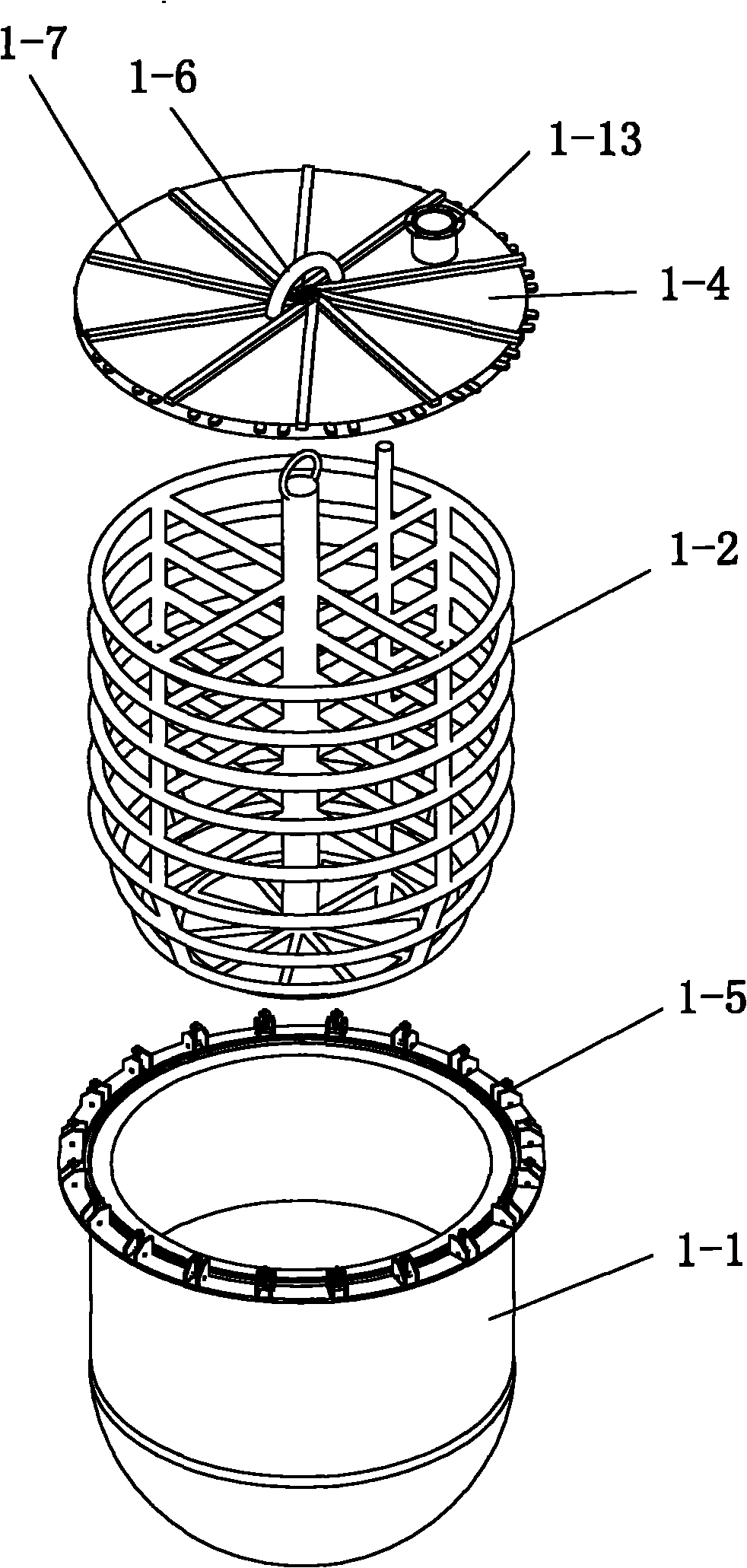

Co-production system and co-production method for biomass carbon, gas, wood tar and wood vinegar

InactiveCN101955780AFirmly connectedReasonable designBiofuelsPyroligneous acid productionSocial benefitsBiomass carbon

The invention discloses a co-production system and a co-production method for biomass carbon, gas, wood tar and wood vinegar. The co-production system comprises a biomass dry distillation kettle, a high-temperature heating furnace, a water cooling device, a washing device, a liquid separation device, a gas storage tank, a water-ring vacuum pump, a compressor, wood tar storage tank and a wood vinegar storage tank, wherein the liquid separation device separates wood vinegar and wood tar in the mixed liquid obtained by gas-liquid separation of the water cooling device; the co-production method comprises the following steps: 1, charging; 2, high-temperature carbonization: water cooling and gas-liquid separation, washing, gas storage and separation and storage of liquid matters; and 3, obtaining of the biomass carbon after the high-temperature carbonization. The co-production system for the biomass carbon, gas, wood tar and wood vinegar has the advantages of reasonable design, convenient processing, simple mounting arrangement, easy operation and good effect; and the co-production method has the advantages of convenient realization, high yield, low cost, fast co-production and relatively high production purity and has obvious economic and social benefits and wide popularization and application prospect.

Owner:陕西亿鑫生物能源科技开发有限公司

Heat treatment system using superheated steam

The present invention provides a heat treatment system, which includes a treatment chamber having an input port and a discharge port for charging and discharging materials to be treated. A heating system including a plurality of pipe-like heaters positioned one after another in serial arrangement is provided so that the heating temperature is gradually increased for heating the steam or the atomized water introduced from the water feeding system into the heaters by applying voltage on the heaters to turn the steam and the atomized water to superheated steam, and for performing heat treatment on the materials to be treated by injecting the superheated steam into the treatment chamber. A circulating system is provided for sucking the superheated steam and the dry distillation gas in the treatment chamber and for supplying the steam and the gas again into the treatment chamber after deodorizing and filtering, and a control unit is provided for controlling operating conditions such as supply quantity of the steam, duration of treatment, etc.

Owner:AOKI IND +1

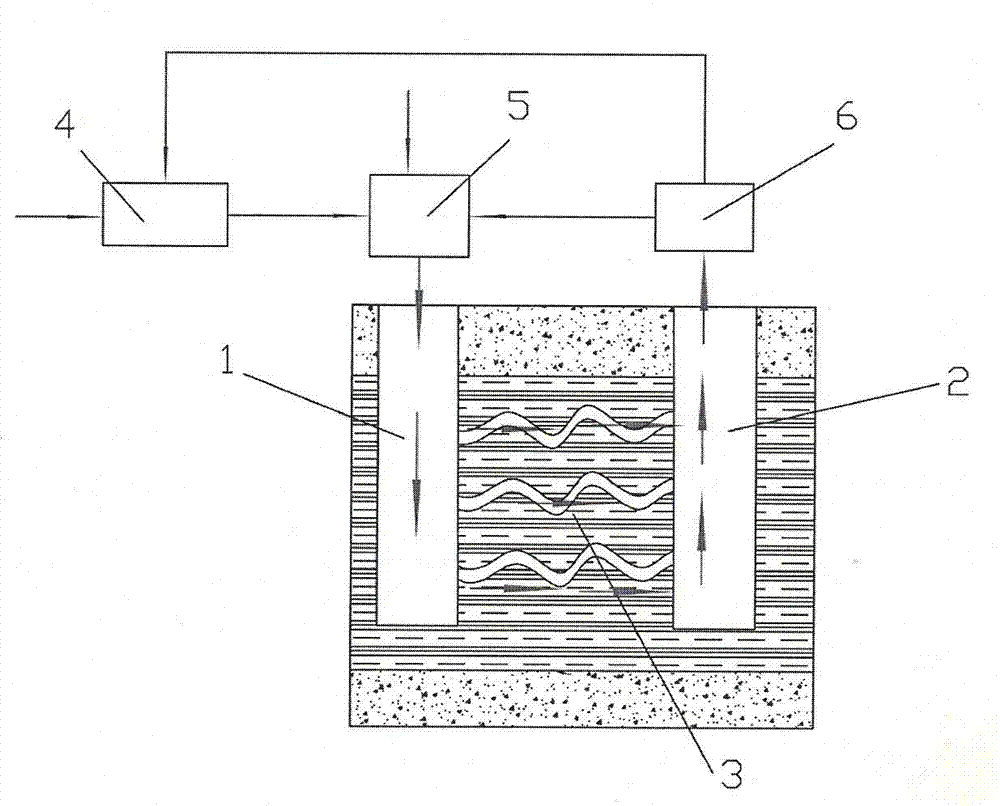

Method for underground in-situ extraction of hydrocarbon compound in oil shale

The invention relates to a method for the underground in-situ extraction of a hydrocarbon compound in an oil shale, which comprises the following steps: arranging at least one working well and one production well in an enclosed working region where the hydrocarbon compound in the oil shale is extracted, communicating the bottoms among the working wells by directional drilling after a drilling well enters an oil shale ore layer, injecting water and inert gas water vapor into the working well to form a near-critical water microenvironment, cracking the oil shale into organic compounds with different chain lengths to form an oil-water mixture, lifting the oil-water mixture to the ground through the production well, and obtaining the hydrocarbon compound through an oil-water separating system. The heat utilization ratio is improved through a multi-well integrated heat circulating system, the extraction ratio of hydrocarbon substances is greatly improved through repeated oil-water separating and circulating processes, and the technical process is shortened. A water micro-pool is formed after an oil shale layer is overflowed by water, the cracking of the oil shale can be realized within3 to 5 hours after a near-critical state is reached, and more energy sources and time are saved than an underground dry distillation method.

Owner:JILIN UNIV

Piston type fluidized bed low temperature dry distillation technological process

InactiveCN101328415AReduce lossesIncrease profitSpecial form destructive distillationHeat carrierOxygen

The invention relates to a process method for low temperature carbonization on a fluidized bed. The process method uses the principle of a lift pipe fluid catalytic cracker, uses a lift pipe reactor of the lift pipe fluid catalytic cracker as a carbonization reactor, uses a catalyst regenerator of the lift pipe fluid catalytic cracker as a high-temperature water gas generator, and uses high-temperature water gas as a fluidizing medium and a heat carrier of a carbonization raw material. The carbonization method comprises the following steps that: a carbonizing raw material is conveyed to the lift pipe fluidized bed reactor for a carbonization reaction of the raw material; the reacted oil and gas are separated to produce a carbonized product; carbonized carbocoal enters the water gas regenerator; carbon in the carbonized carbocoal, oxygen and water vapour in air are subjected to oxidation reaction and water gas reaction; the water gas obtained in the reaction is used as the fluidizing medium and the heat carrier during the carbonization process; and solid clinkers produced after the carbonized carbocoal is subjected to the water gas reaction are discharged. Compared with the prior art, the method has the advantages of simple process, high production capacity, less equipment and so on, and can be used in oil shale, oil sand, coal and other substances to produce liquid petroleum products.

Owner:ZHUHAI TOP ENERGY TECH

Carbonization process of high-volatilize content coal

InactiveCN101113340AGuaranteed not to oxidizeGuaranteed to burnDirect heating destructive distillationHeat carrierVolatiles

The invention relates to a carbonization process of high volatile coal, a direct heating process that heats and distills high volatile coal by using high temperature cycle gas in a shaft furnace as a carrier. Lump coal that moves up and down in the shaft furnace is heated by rising hot gas and the discharged volatiles form char; the char is cooled by cold gas that is introduced by the furnace bottom from the lower part of a furnace and then discharged outside the furnace; the rising gas is introduced outside finally by the furnace top, washed, purified and cooled; one part is taken as a cycle cooling medium, one part is taken as a cycle heat carrier after being per-heated and the rest is taken as a gas external supply and the calorific value is equal to that of a coke oven gas.

Owner:万天骥

Device for manufacturing biological carbon

InactiveCN102443404ALow costNo pollution in the processCoke quenchingBiofuelsCombustion chamberCooling tower

The invention relates to a device for manufacturing biological carbon. A pre-heating chamber is positioned in a smoke gas chamber, both ends of the pre-heating chamber are respectively connected with a material outlet rolling tube and a material inlet roller, the other end of the material outlet rolling tube is connected with a middle material cabin, the lower part of the middle material cabin is connected with a material inlet chamber, the other end of the material inlet rolling tube is connected with a gas collection chamber, a mixed gas outlet of the gas collection chamber is connected with a gas inlet of a spraying washing cooling tower, a dry distillation chamber is positioned in a combustion chamber, both ends of the dry distillation chamber are respectively connected with a front rolling tube and a back rolling tube, the other end of the front rolling tube is connected with the material inlet chamber, the other end of the back rolling tube is connected with the material outlet chamber, a cooling chamber is connected under the material outlet chamber, a mixed gas outlet of the material outlet chamber is connected with a gas inlet of the spraying washing cooling tower, an external fuel combustion device and a non-condensed combustible gas combustion device are arranged in a position in the combustion chamber positioned at the lower part of the dry distillation chamber, and a hot smoke gas pipeline is arranged between the top of the combustion chamber and the bottom of the hot smoke gas chamber. The device for manufacturing the biological carbon provided by the invention can be used for industrially manufacturing the biological carbon in a pollution-free way at low cost.

Owner:张大伟 +1

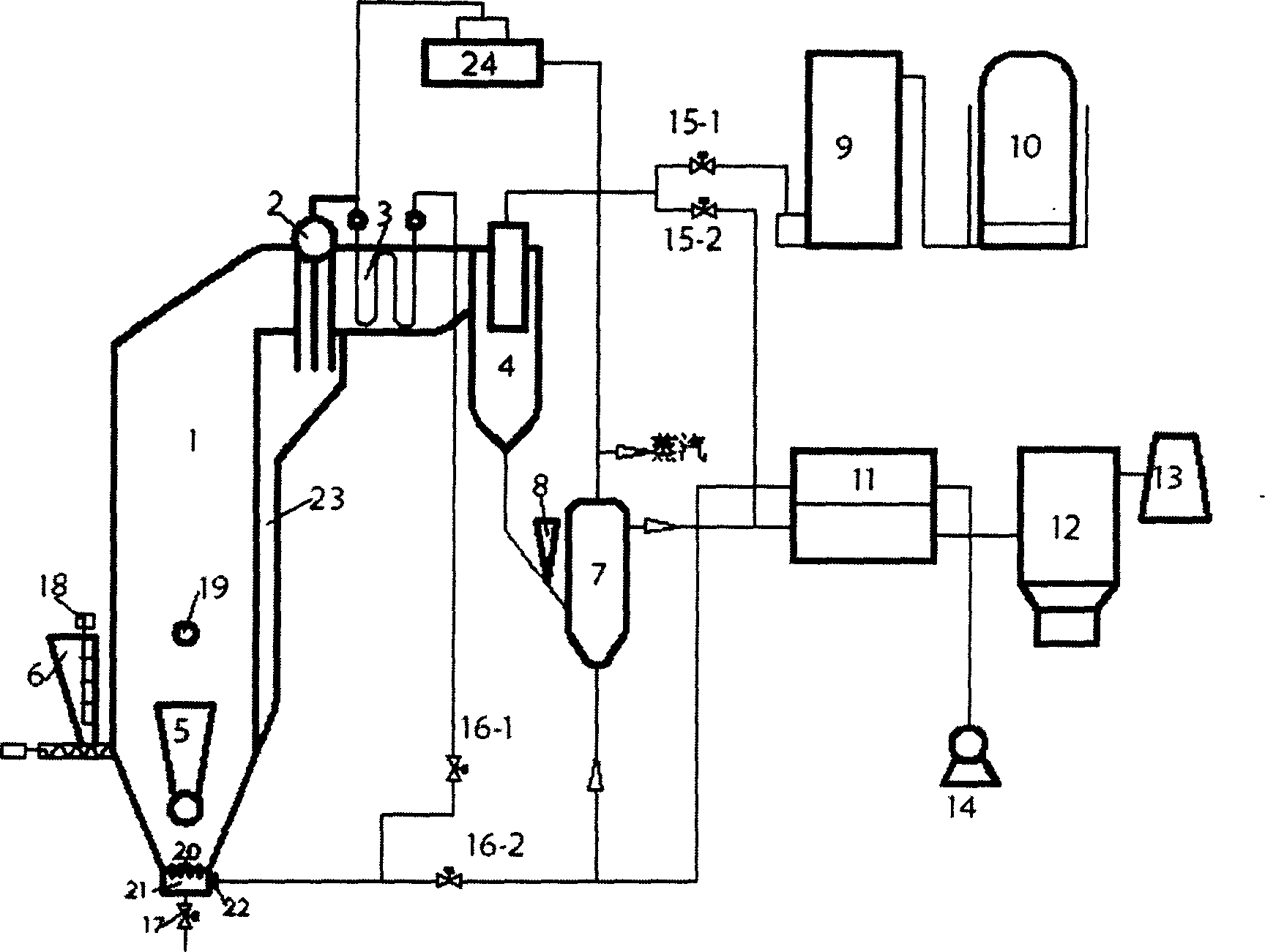

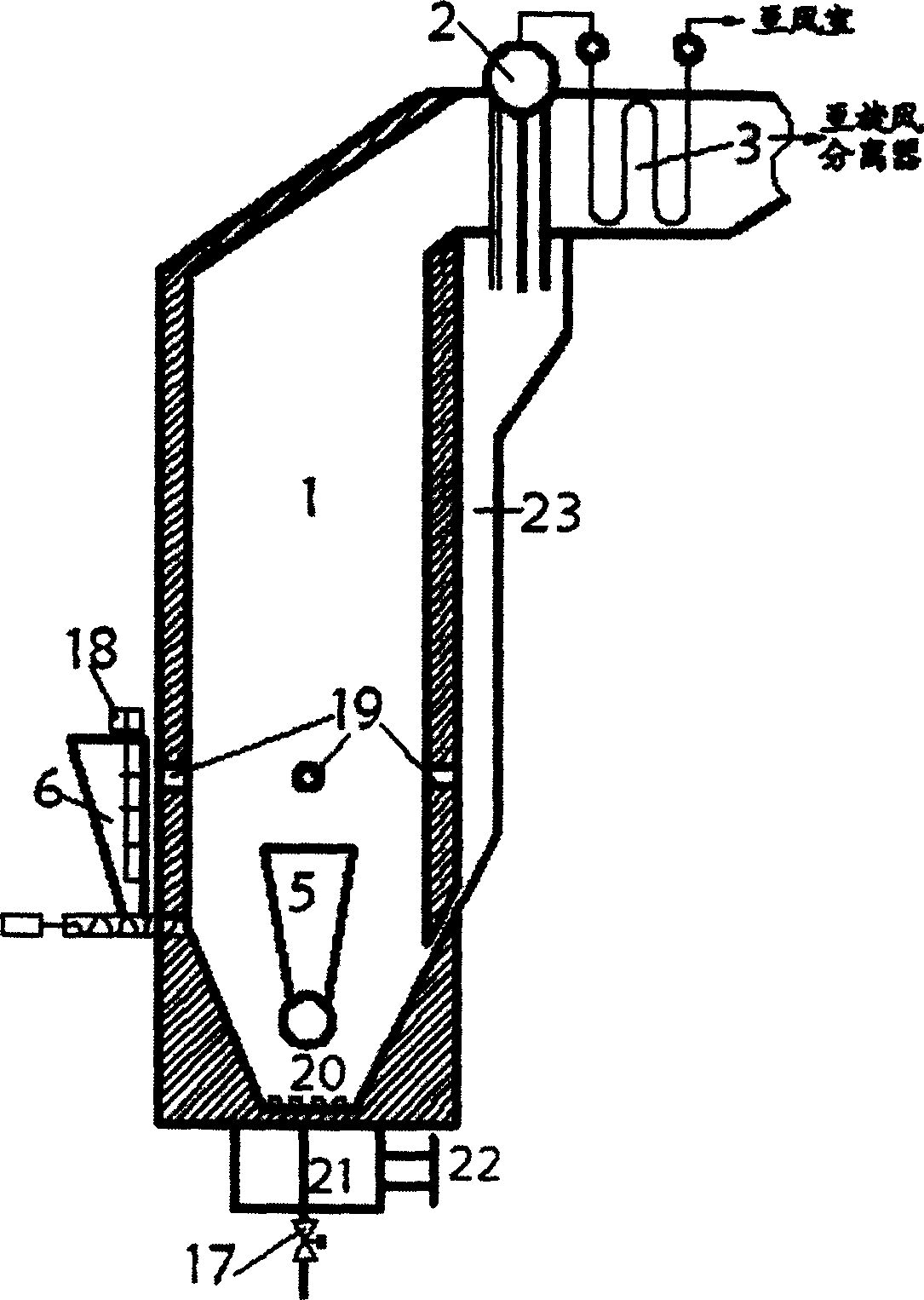

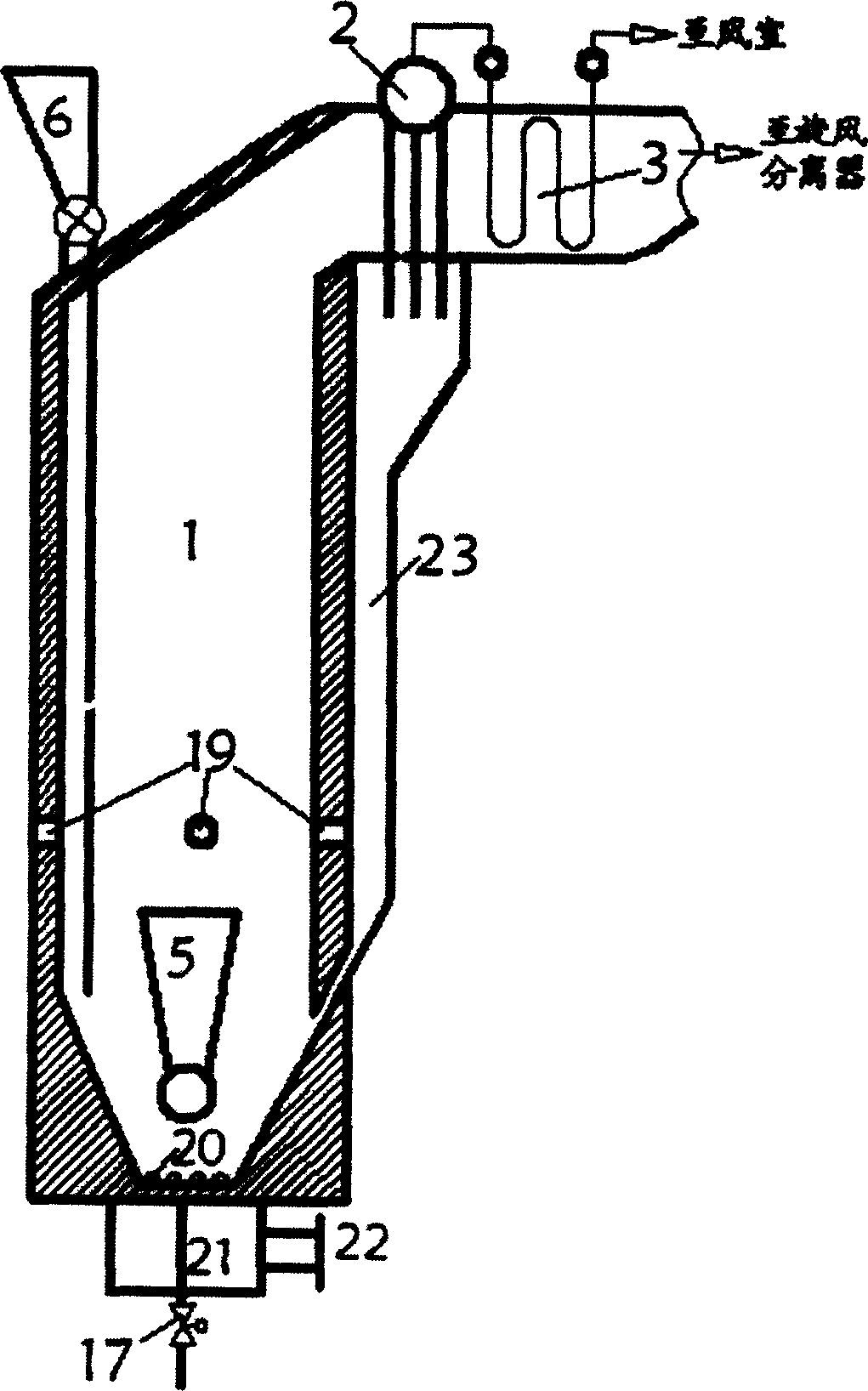

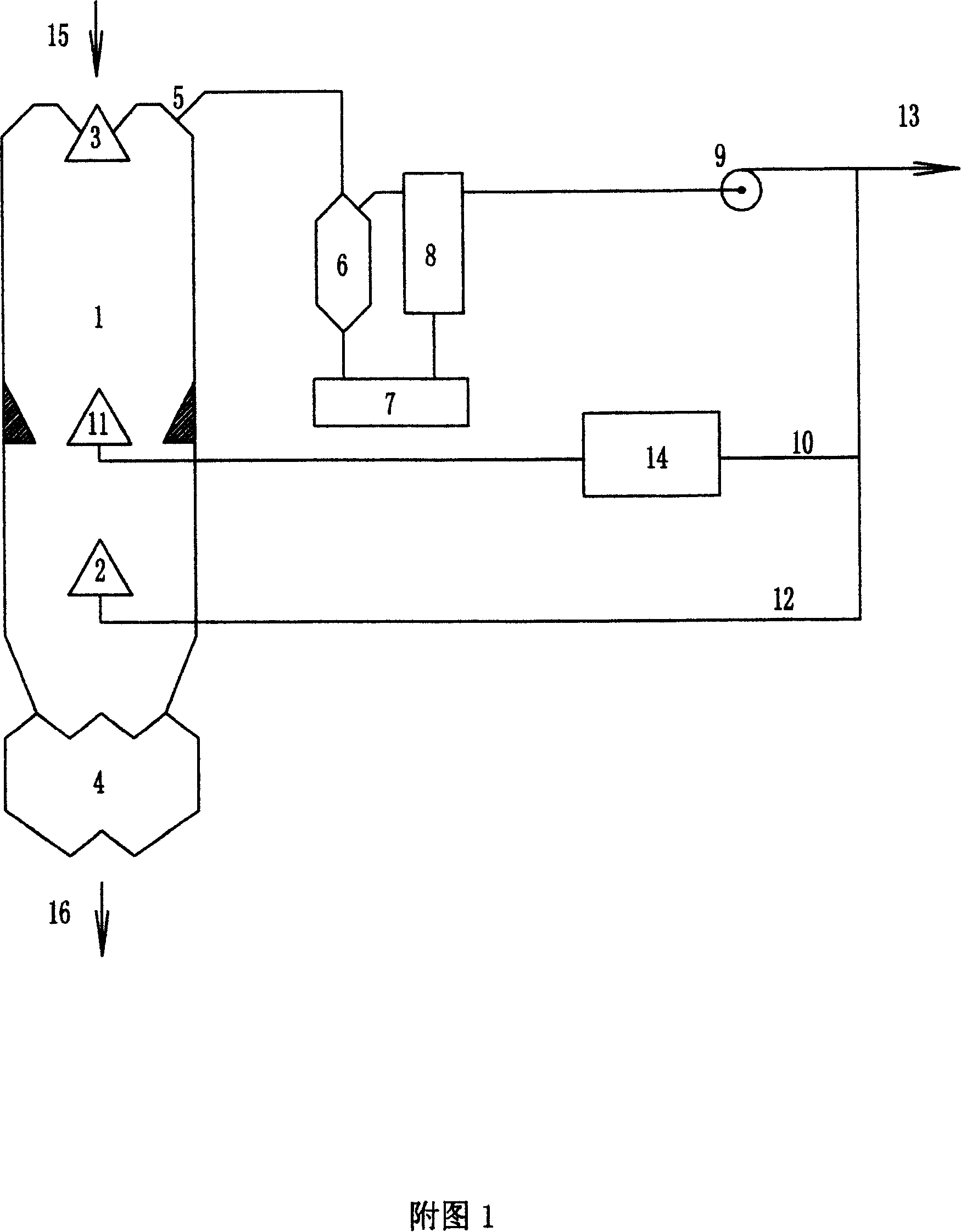

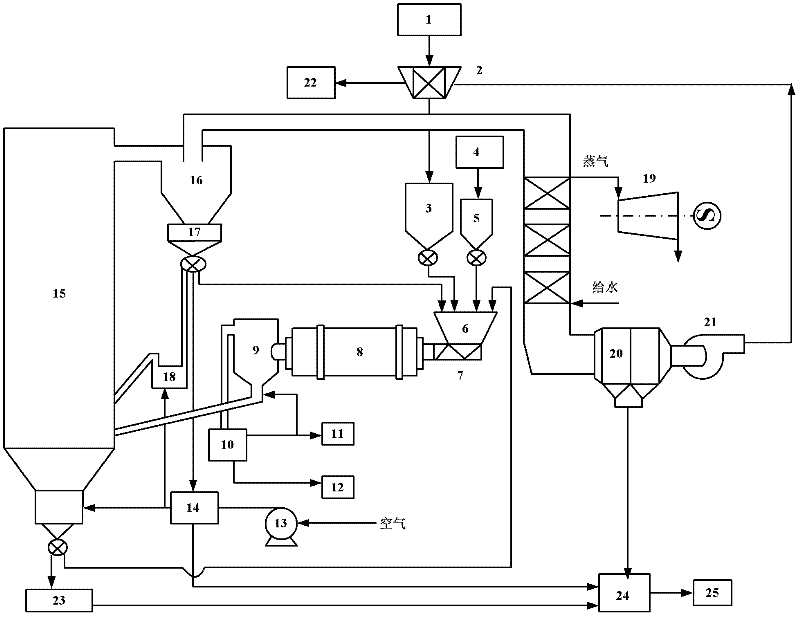

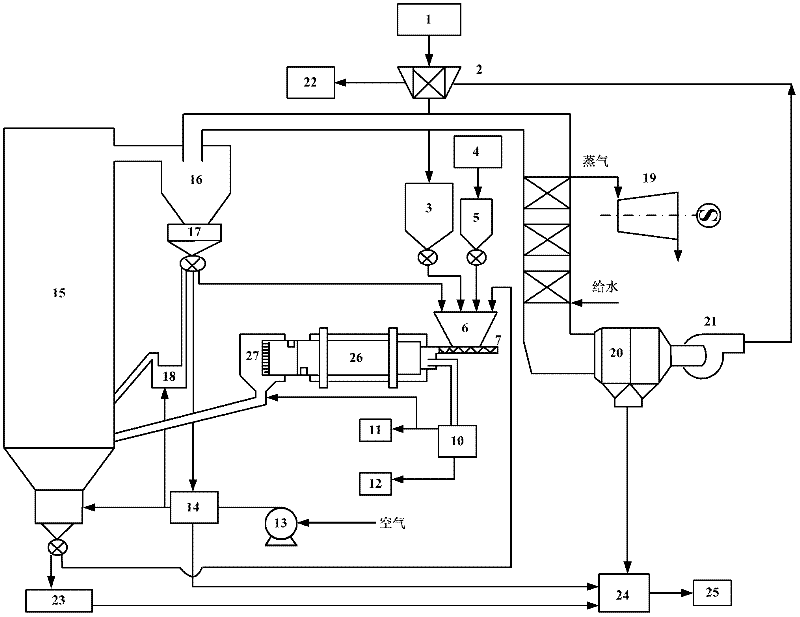

Oil shale fluidized bed dry distillation system

InactiveCN101440293ARealize scientific utilizationImprove heat transfer efficiencySpecial form destructive distillationWater vaporOil shale gas

The invention relates to a carbonization system of an oil shale fluidized bed. Oil shale with high oil content and low pyrolysis temperature is used as a carbonization material; high-temperature steam-gas and circulating hot ash are utilized to fluidize and heat the oil shale in a carbonization chamber of the fluidized bed; after ash removal, mixed airflow of generated shale oil and noncondensable gas and vapour in the carbonization chamber of the fluidized bed enters a cooler; the condensed oil-water mixture is divided into shale oil and water through the oil-water separator; the shale oil is transported to a shale oil storage tank; the water is purified and is conducted to the cooler; and noncondensable gas which is not condensed through the cooler is transported to a fuel gas storage tank. Oil shale carbocoal produced through the carbonization chamber of the fluidized bed is directly transported to a boiler of an oil shale carbocoal circulating fluidized bed, is burned and discharges heat; one part of the produced steam-gas is used as fluidized wind of the carbonization chamber of the fluidized bed; the residual steam-gas is conducted to a steam turbine-dynamo system, applies work and generates electricity; and part of circulating ash in the boiler is used as a heat source of the carbonization chamber of the fluidized bed. The carbonization system can realize high-efficient, clean and economic comprehensive utilization of the oil shale.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing electronic cigarette nicotine liquid by means of tobacco subjected to dry distillation pyrolysis

The invention relates to electronic cigarettes, in particular to a method for applying tobacco subjected to dry distillation pyrolysis to a novel tobacco product to obtain an extract with sensual pleasures and psychological intensity similar to those of traditional cigarettes. The method for preparing electronic cigarette nicotine liquid by means of tobacco subjected to dry distillation pyrolysis comprises the steps of weighing tobacco, placing tobacco in a heating furnace, increasing temperature to 150-1000 DEG C, introducing carrier gas, introducing smoke generated from pyrolysis into an absorption bottle, placing the absorption bottle in a cold trap, conducting smoke collection with an electronic cigarette solvent, washing smoke condensation products in a pipeline out by means of collection liquid, and obtaining smoke extraction solution. The electronic cigarette nicotine liquid has the advantage that sensual pleasures and psychological intensity similar to those of traditional cigarettes are obtained.

Owner:CHINA TOBACCO ZHEJIANG IND

Dry distillation production process for lignite or high volatile coal

InactiveCN101885973AReduce the temperatureQuality improvementDirect heating destructive distillationHeat carrierTar

The invention discloses a dry distillation production process for lignite or high volatile coal. A high-temperature dry distillation gas serving as a heat carrier enter a dry distillation furnace to transmit heat with coal inside the furnace by contact to change the coal into semicoke through pyrolysis and dry distillation; the gas overflowing through the dry distillation flows into a heat carrier gas and then out of the furnace together; after the gas from the furnace is cooled and purified, which is equivalent to that a part of the original heat carrier gas is heated through a partition to a high temperature to serve as a heat carrier to return to the dry distillation furnace for recycling; and the balance of gas serves as an external supply. The dry distillation production process has the advantages of both internal and external heat dry distillation and obtains the approximately same gas purity as that of the external heat dry distillation process, so that the gas for the externalsupply has a high quality, heat value and application value and is an ideal chemical raw material or high-quality fuel; moreover, all the dry distillation gas can be used for the external supply; thecoal is slightly affected by a temperature and uniformly heated; tar has a high yield; the system has a wide heat source and can use low-quality fuel smoke, such as powdered coal, the gas and the like; and the system has a simple flow, is easy to operate and control in production and operation and has less industrialization construction investment.

Owner:NANTONG JINGHUAN ENERGY TECH CO LTD

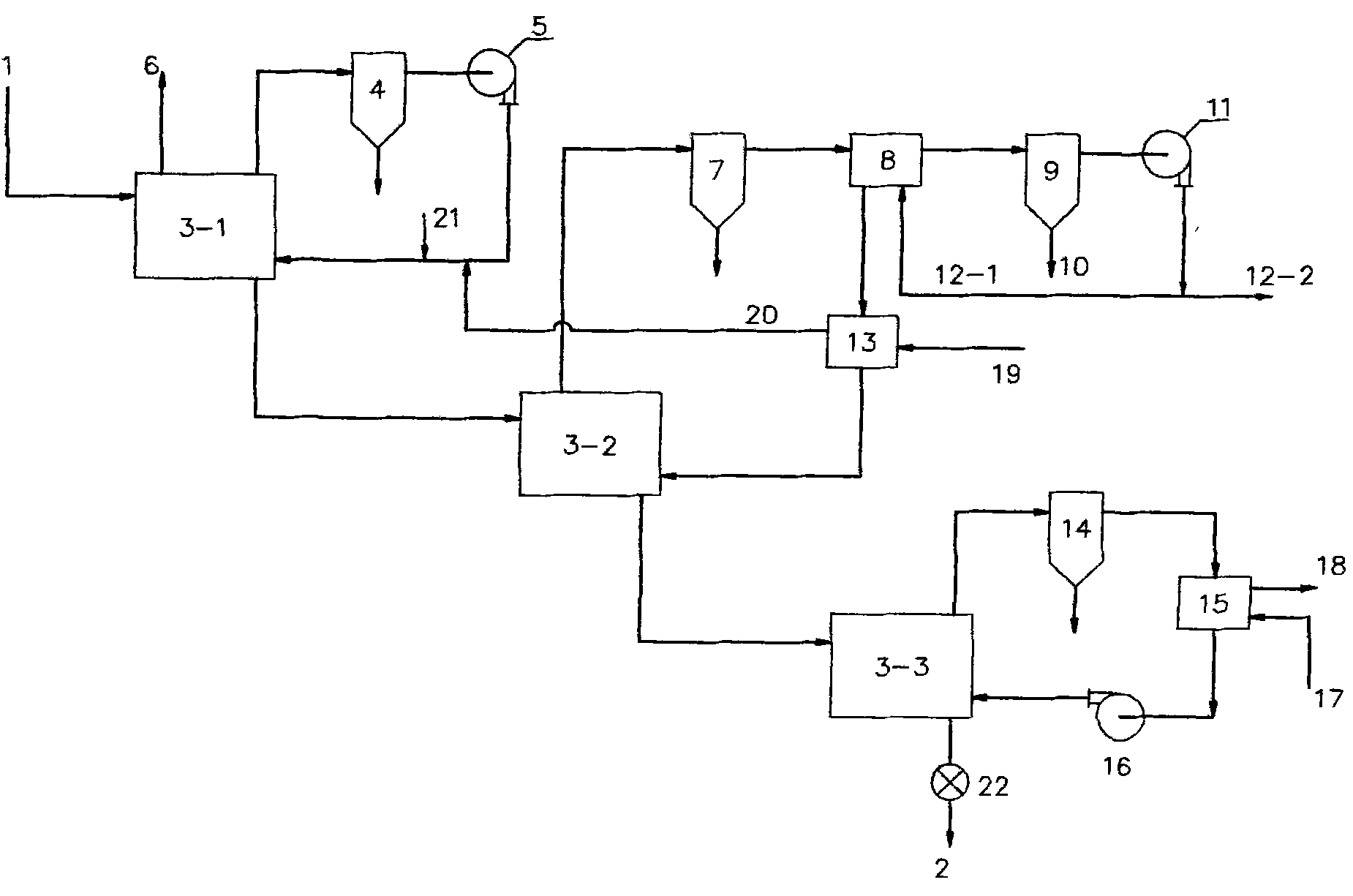

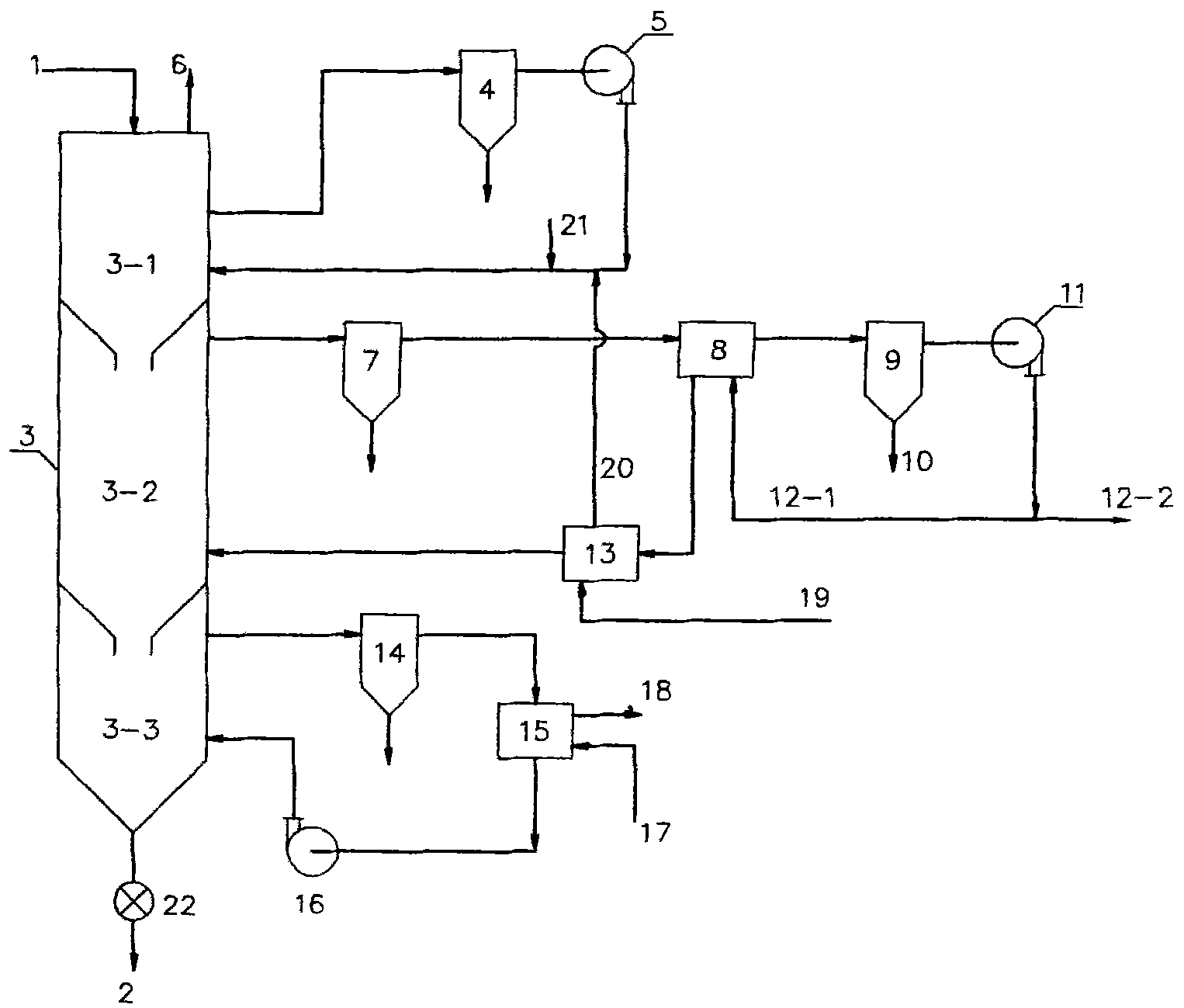

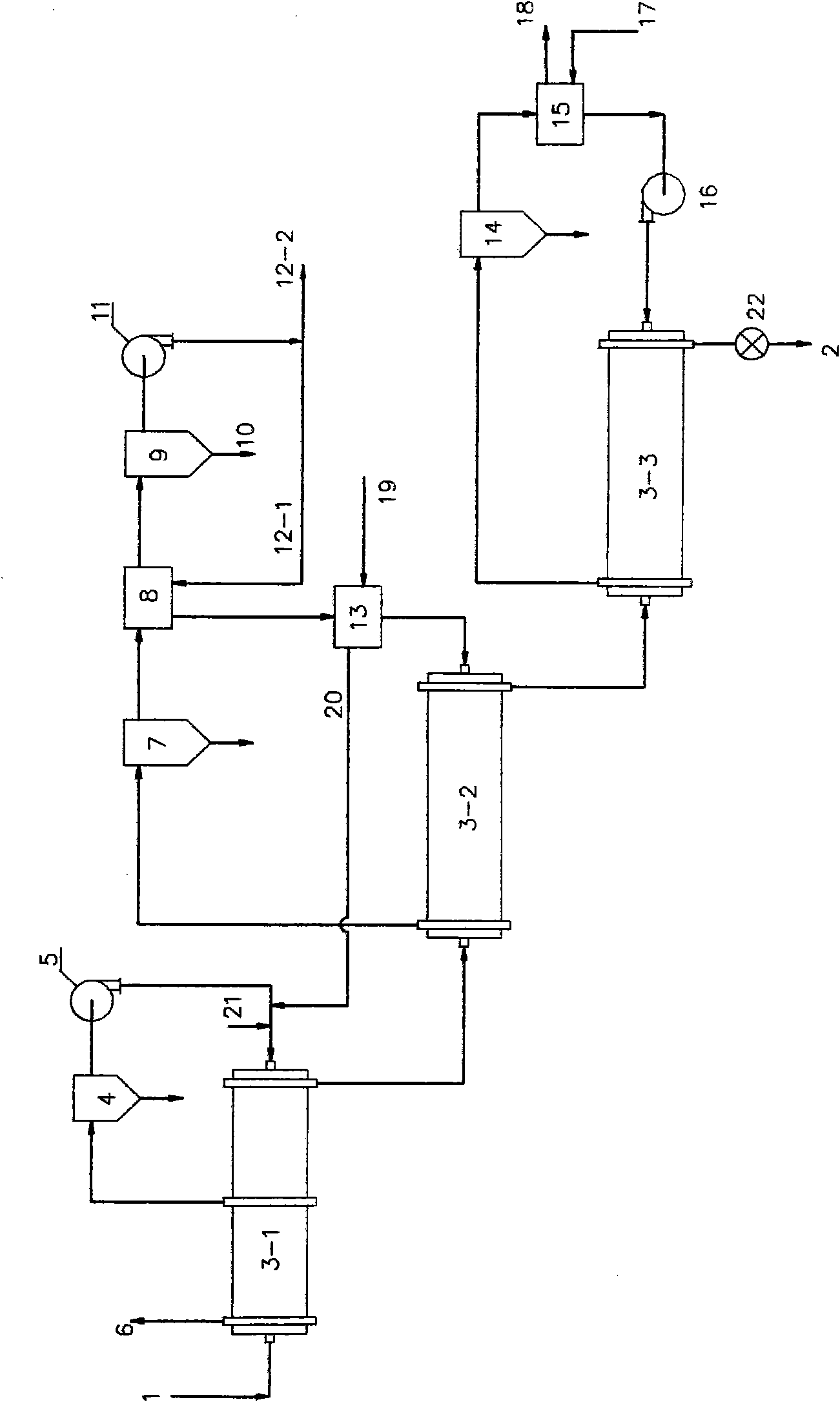

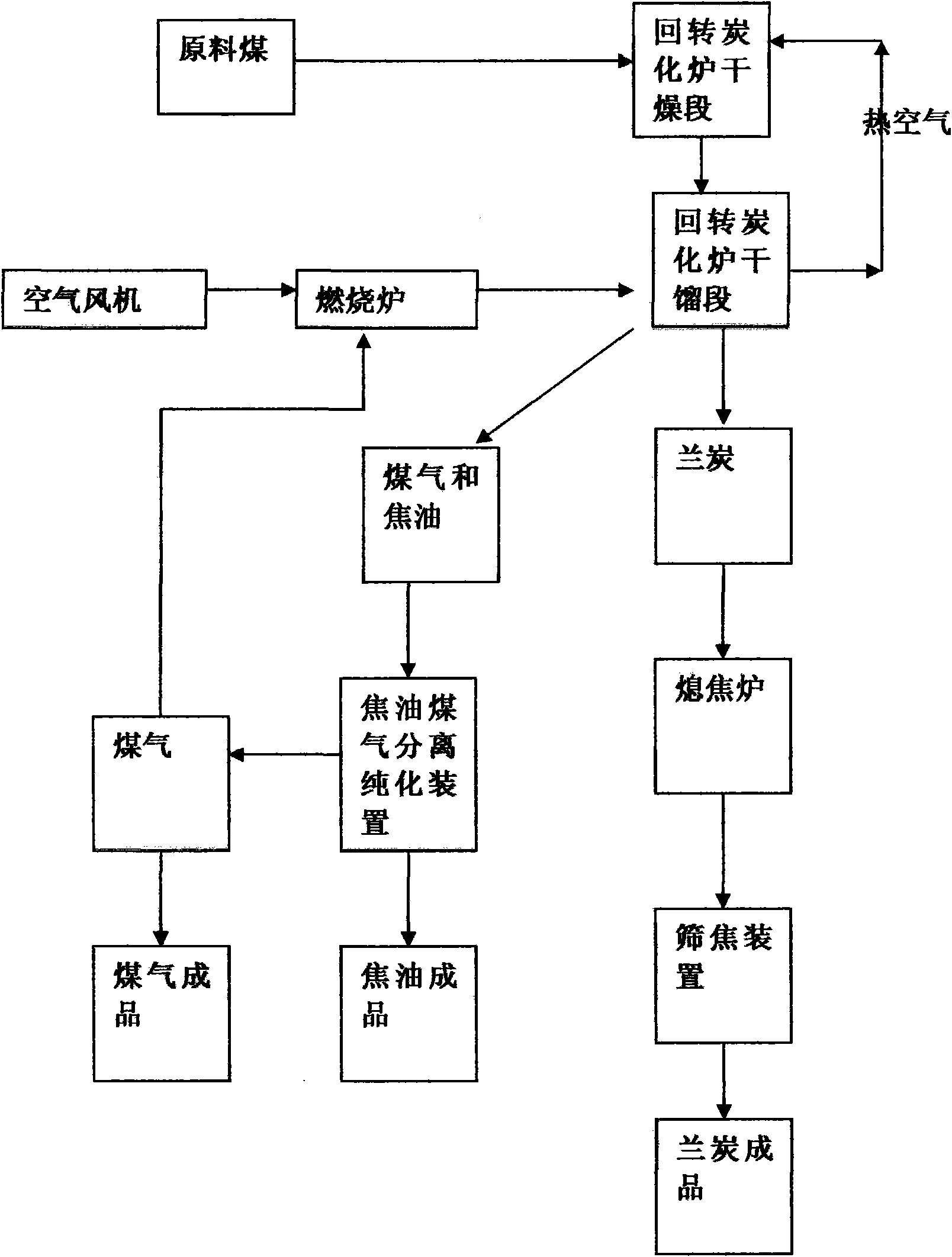

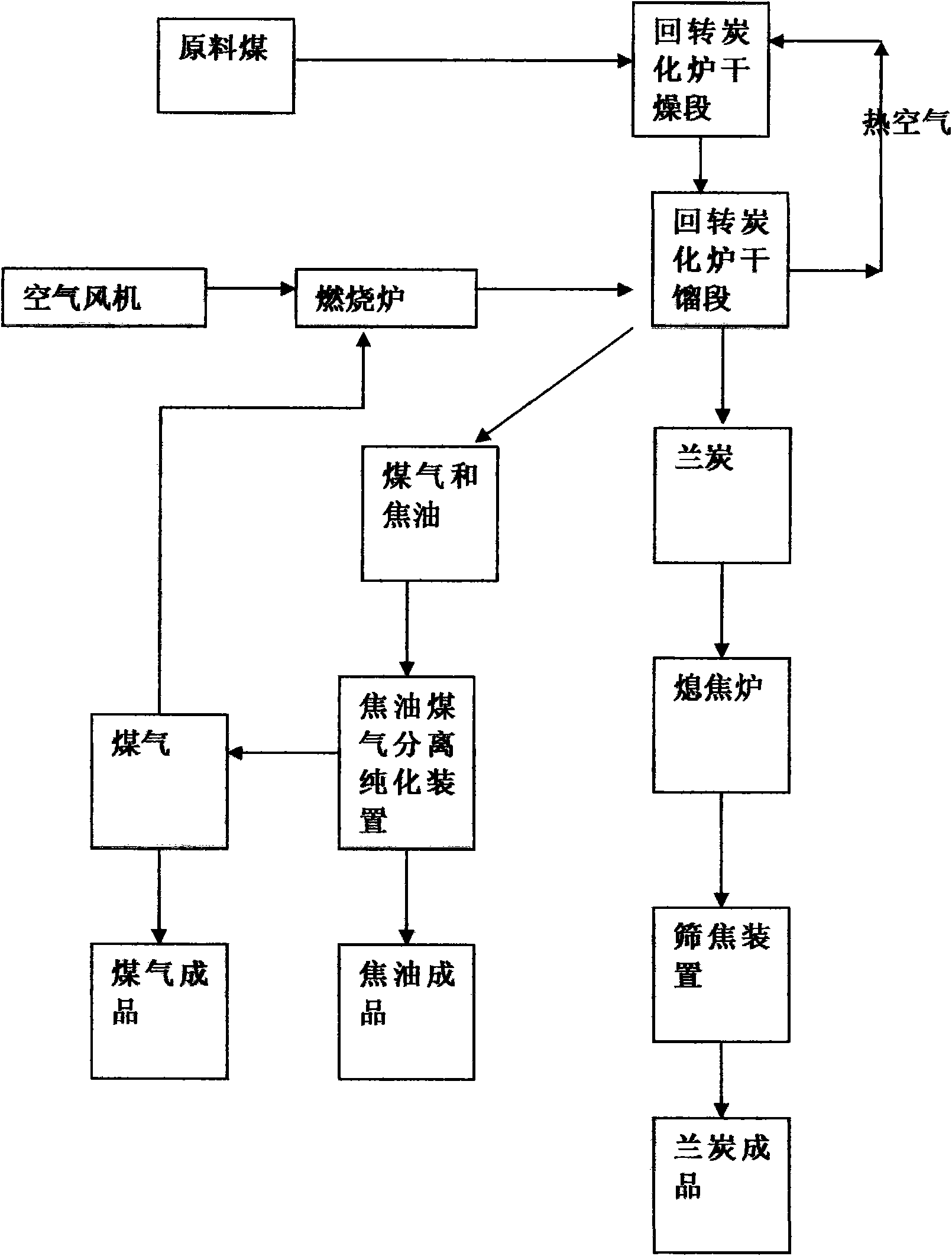

Method for preparing carbocoal by thermally cracking raw coal with external-heat horizontal rotary charring furnace

ActiveCN101805625ASmall granularityIncrease profitCoke quenchingIndirect heating destructive distillationGranularityTar

The invention provides a method for preparing carbocoal by thermally cracking raw coal with an external-heat horizontal rotary charring furnace. The method comprises the following steps of: drying and desorbing the raw coal in a drying section of the rotary charring furnace at the temperature of between 100 and 300 DEG C; delivering the dried raw coal into a dry distillation section of the rotarycharring furnace; thermally cracking the raw coal for 1 to 5 hours at the temperature of between 500 and 700 DEG C of materials; obtaining the carbocoal, tar and coal gas after the thermal cracking; allowing the generated carbocoal to pass through a coke quenching furnace and a coke sieving device to obtain a carbocoal finished product; and allowing the generated tar and coal gas to pass through a coal gas separating and purifying device to obtain a high-quality tar finished product and a high-calorific-value coal gas finished product. The method can reduce the granularity of the raw coal, improve the utilization rate of the raw coal, additionally improve the calorific value of the coal gas and greatly improve the utilization value of the coal gas. The method improves the quality of the carbocoal, saves energy resources and reduces harmful gas by adopting a dry coke quenching and continuous decoking method. The method has the advantages of single reactant in the technical process and no discharge of waste gas, waste water or waste residue, and belongs to a project of environmental protection.

Owner:西安三瑞非常规能源开发有限公司

Porous tobacco material for heating non-combustion type cigarettes and preparation method of porous tobacco material

The present invention discloses a porous tobacco material for heating non-combustion type cigarettes and a preparation method of the porous tobacco material. The preparation method comprises the following steps of: firstly adding tobacco powder, guar gum and fire retardant into a mixer, atomizing and spraying dry distillated flavor to the stirred and lifted materials, continuing to stir the materials to obtain a primarily-mixed material of the tobacco material after spraying is completed, then sending the primarily-mixed material into a single screw extruder for continuous mixing, simultaneously injecting CO2 for foaming extrusion molding, cutting the extrudate into shreds after the extrudate is dried, and obtaining the tobacco material for the heating non-combustion type cigarettes. The tobacco material is uniformly heated under the heating non-combustion state due to porosity of the tobacco material, smoke release is easier, and smoke amount is more sufficient; sensory quality of the smoke is largely improved through adding the dry distillated flavor; and the tobacco material has better flame-retardant performance due to the fact that the fire retardant is cooperatively used.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Oil shale rotary kiln dry distillation and circulating fluidized bed combustion process

InactiveCN102533296AImprove combustion efficiencyControl generationDirect heating destructive distillationBiofuelsBottom ashInternal combustion engine

An oil shale rotary kiln dry distillation and circulating fluidized bed combustion process makes organic combination of a rotary kiln dry distillation with a circulating fluidized bed; oil shale particles are mixed with thermal-cycle ash from a circulating fluidized bed boiler and part of circulating fluidized bed boiler bottom ash, and then are sent into a rotary kiln for dry distillation to prepare shale oil and dry distillation coal gas; the dry distillation coal gas has a high calorific value; a part of the coal gas is used as recycle wind of a semicoke material recycle device, and enters the circulating fluidized bed boiler with oil shale semicoke particles for combustion, and the residual part is delivered into an internal combustion engine for combustion generation. The invention can increase shale oil and coal gas quality, reduce energy loss and environment pollution, and improve the comprehensive utilization degree.

Owner:SHANGHAI JIAO TONG UNIV

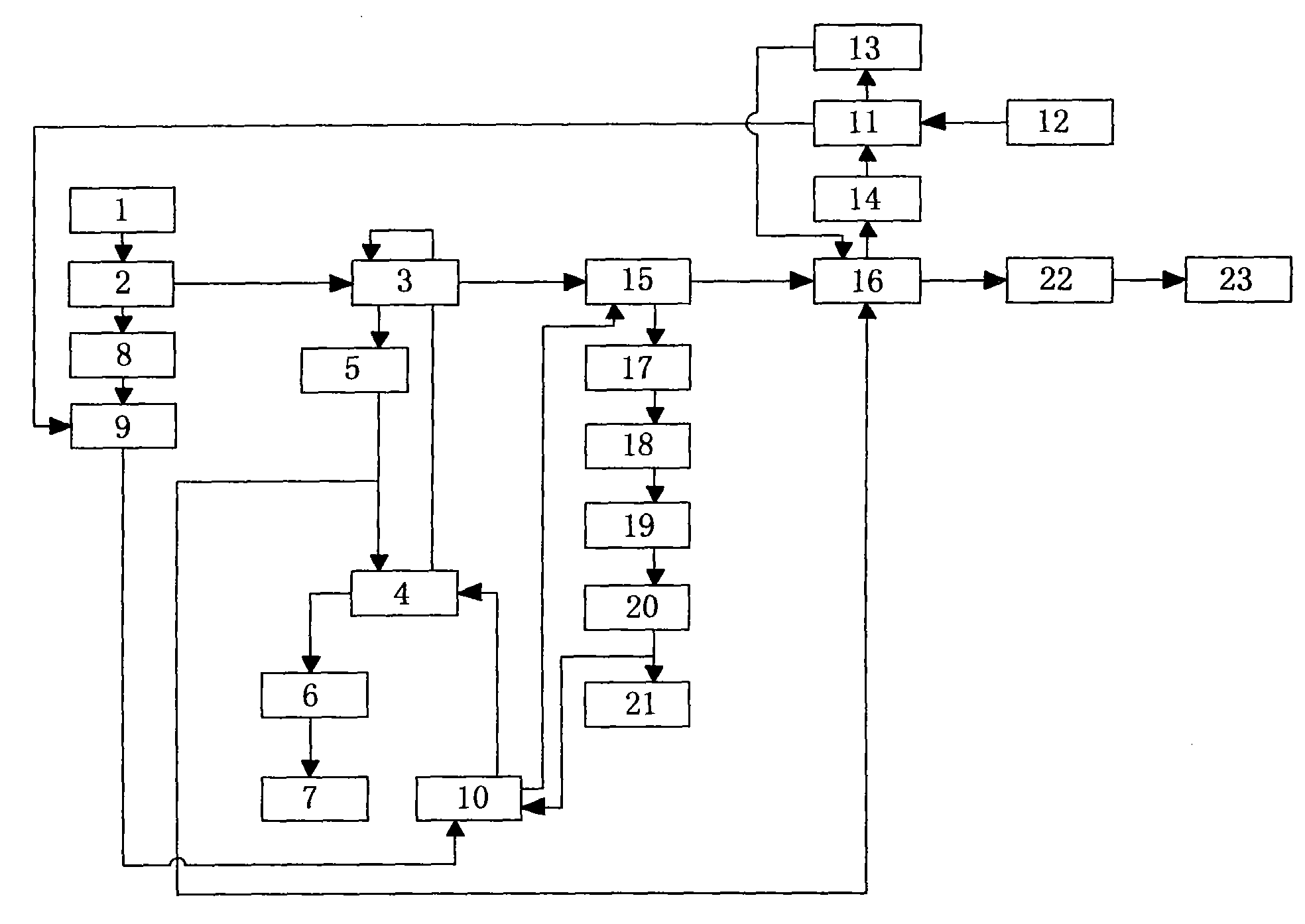

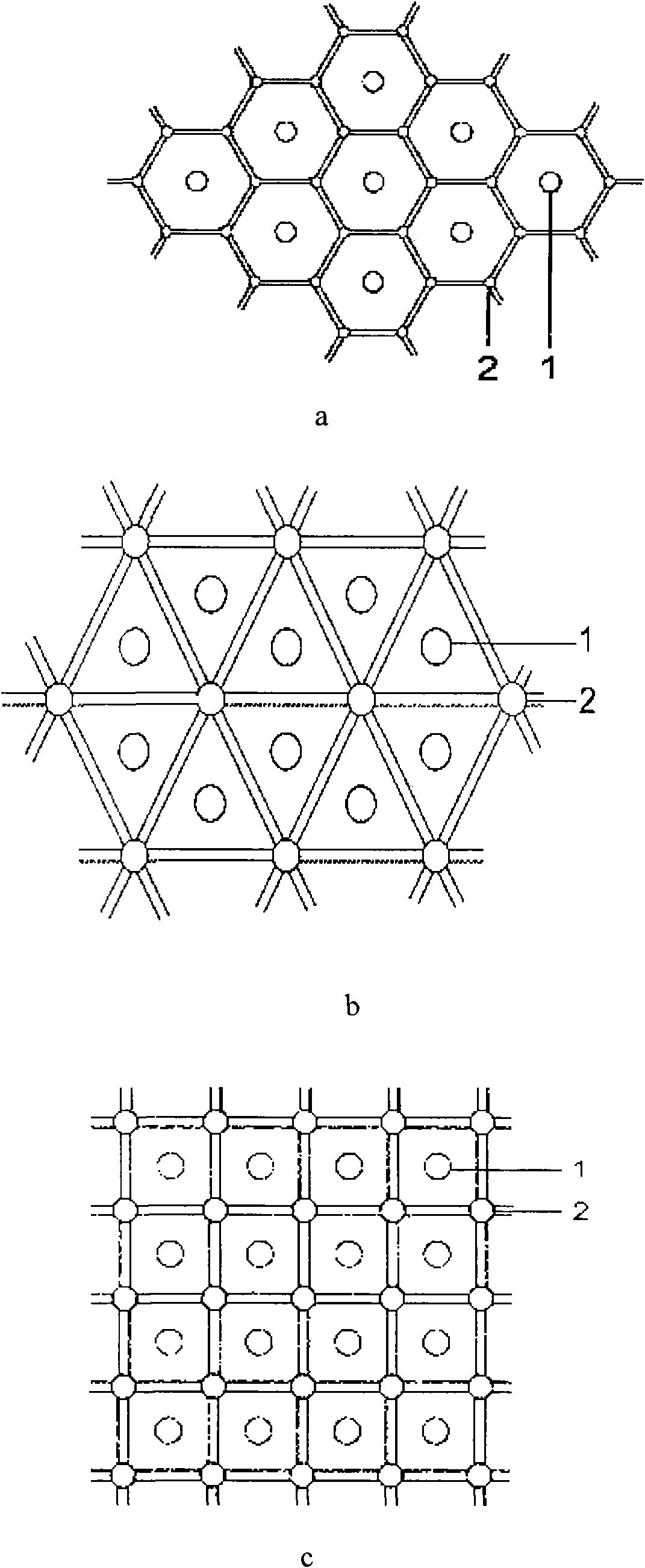

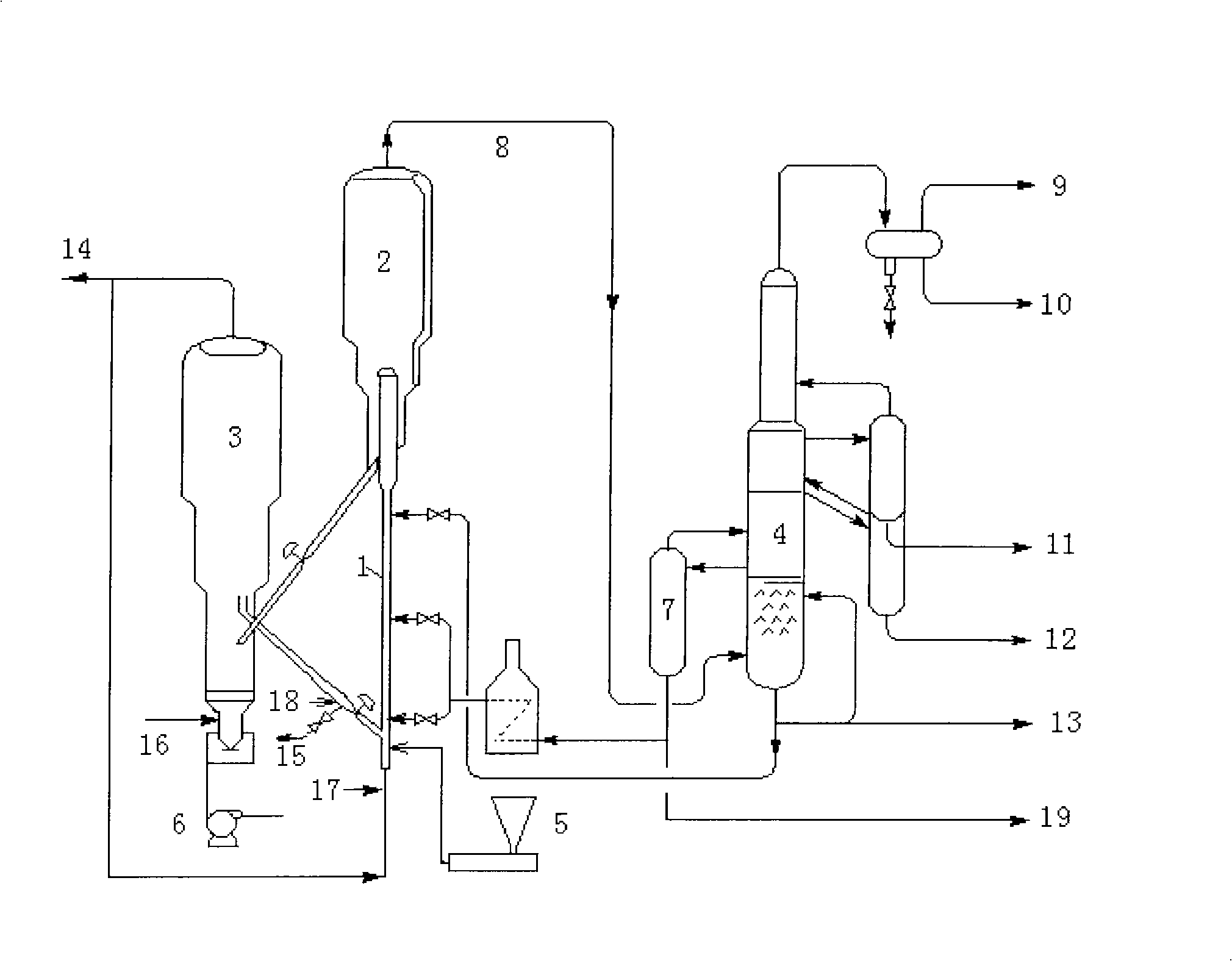

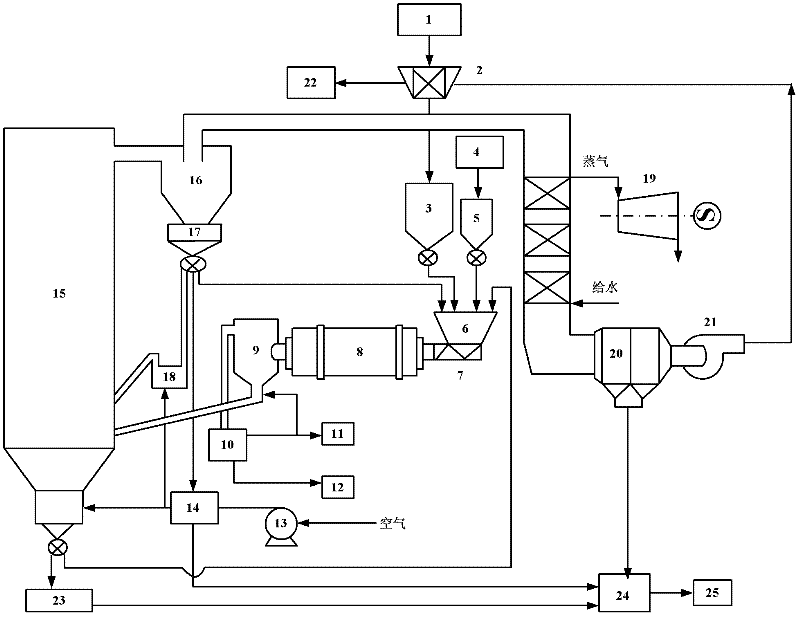

Gas full-circulation oil-shale grading dry distillation technique and apparatus

InactiveCN101381609AHigh recovery rateNo emissionsSpecial form destructive distillationElectricityCooling tower

The invention relates to a process for carrying out fractionation to oil shale by utilizing gas as a thermal carrier under the condition of whole circulation. The oil shale is divided into three classes with different specifications: 0 to 6 millimeters, 6 to 20 millimeters and 20 to 50 millimeters; and the oil shale enters different carbonization furnaces for carbonization. The daily handling capacity of each set of the carbonization furnace is 1,000 tons. The oil shale is crushed and sifted, is dried and heated to the temperature of over 50 DEG C by smoke gas and enters the carbonization furnaces with different specifications for carbonization. The inside of the carbonization furnace is provided with feed distribution perforated wall which is matched with the particle size of the oil shale and a gas distribution structure. Thermal circulating gas is heated to the temperature of 700 DEG C in a heating furnace and is evenly and continuously transported to the middle part of the carbonization furnaces. Cold circulating gas enters from the lower part of the carbonization furnaces; carbonized carbocoal is cooled to the temperature of 250 DEG C, is discharged to a water-sealed carbocoal pool, is cooled to the temperature of 80 DEG C and is discharged to the outside of the furnace. One part of the carbocoal is transported to the heating furnace, is mixed with the gas for combustion; and one part of the carbocoal is transported to a power plant as a fuel. Carbonized oil gas passes through a cooling tower and is subjected to oil collection by an electric catcher and performs oil-gas-water separation; oil enters a storage tank; and water enters a circulating water pool. One part of the gas is used as the thermal carrier and is circularly used. One part of the gas is used as the fuel for the heating furnace; and one part of the gas is used as fuel gas for power generation. The theoretical oil yield of the process can reach over 90 percent.

Owner:辽宁成大能源科技有限公司 +1

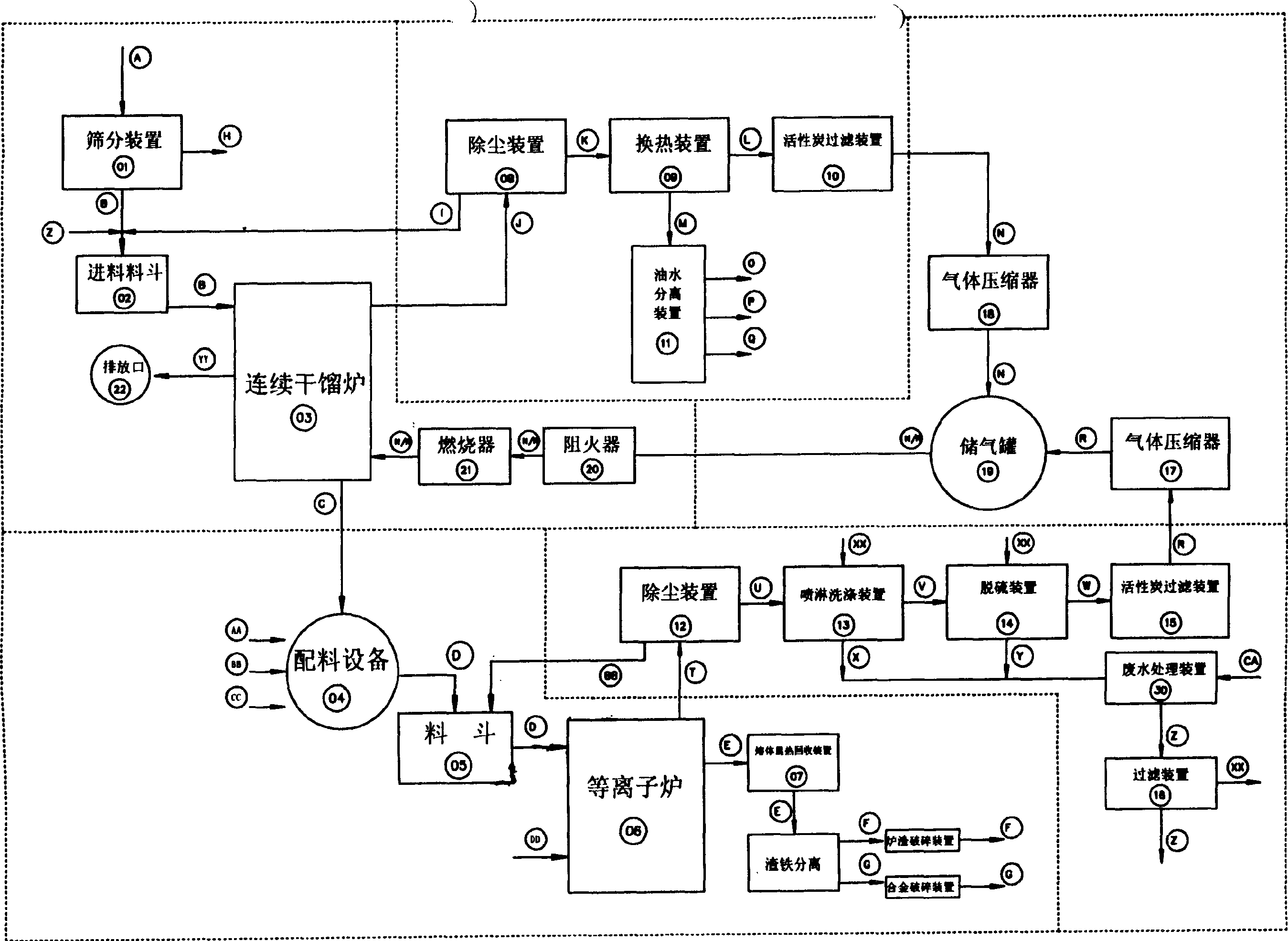

Resource regeneration processing method and equipment for urban sewage sludge

InactiveCN101318759AReduce lossesAdaptableSludge treatment by oxidationByproduct vaporizationSludgeEnvironmental engineering

The invention discloses a resource treatment method for municipal sludge and equipment thereof. The method comprises the following steps that: the dried sludge is subject to carbonization treatment with a carbonization temperature range of between 450 and 650 DEG C and molded to produce a solid product; carbonization fractions in the carbonization treatment are reclaimed and a condensate is separated off; purified wood coal gas is comprehensively utilized; through a carbonization process adopting a biomass dynamic carbonization and pyrogenation comprehensive treatment technology, feeding, drying, carbonization, carbon generation, the dust removal of wood coal gas, condensation, washing and the separation of various byproducts can be continuously completed; carbonization equipment can realize automatic operation and can carry out resource treatment to biomass; the adopted process has strong adaptability to the variety and humidity of the biomass and has small loss of biomass and high treatment efficiency in the treatment process; as the process adopts a full-closed carbonization furnace, product yield is all products, wherein, the produced wood coal gas is used as fuel for drying, carbonization or power generation, thereby reducing production cost; and the whole system has perfect design and reasonable economical technology.

Owner:谢忠诚 +1

Method For Producing Ethanol Using Raw Starch

The present invention is directed to the methods for producing high levels of alcohol during fermentation of plant material, and to the high alcohol beer produced. The present invention is also directed to methods for producing high protein distiller's dried grain from fermentation of plant material, and to the high protein distiller's dried grain produced. The present invention also relates to reduced stack emissions from drying distillation products from the production of ethanol.

Owner:POET RES INC

High-efficiency and quick lignite pyrolysis method

ActiveCN101787291AIncrease profitReduce pollutionDirect heating destructive distillationSpecial form destructive distillationHeat carrierCombustion

The invention discloses a high-efficiency and quick lignite pyrolysis method which comprises raw material pretreatment, drying, primary dry distillation and secondary dry distillation. The method comprises the following steps of: crushing and sorting the lignite, sending the crushed and sorted lignite to a combustion bed and a drying bed respectively; raising the temperature of the lignite entering the drying bed to about 130 DEG C through heat exchange, separating the lignite to obtain lignite particles, removing dust from fume and using the dust-removed fume as combustion-supporting air or for adjusting the fume temperature of the drying bed; enabling the lignite particles to enter a primary dry distiller to exchange heat with heat carriers till the temperature is up to 500 DEG C, and then performing pyrolysis on the lignite particles, separating out solid semi cokes, entering a secondary dry distiller, separating a gaseous part to obtain coal gas and tar oil; and enabling the materials to enter the secondary dry distiller and exchange heat with the heat carrier till the temperature is up to 750 DEG C, and then further performing pyrolysis. The obtained large-particle semi cokesare semi coke products, small particles are used as fuels, and the generated gas portion enters a primary dry distillation step for treatment. The method has high efficiency, quickness and simple andconvenient process, and is suitable for the quick pyrolysis of the lignite of all types, and the pyrolysis efficiency is increased by more than 10 times. Not only the utilization rate of resources isimproved, but also the environmental pollution is reduced.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com