Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9702 results about "Pulverizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

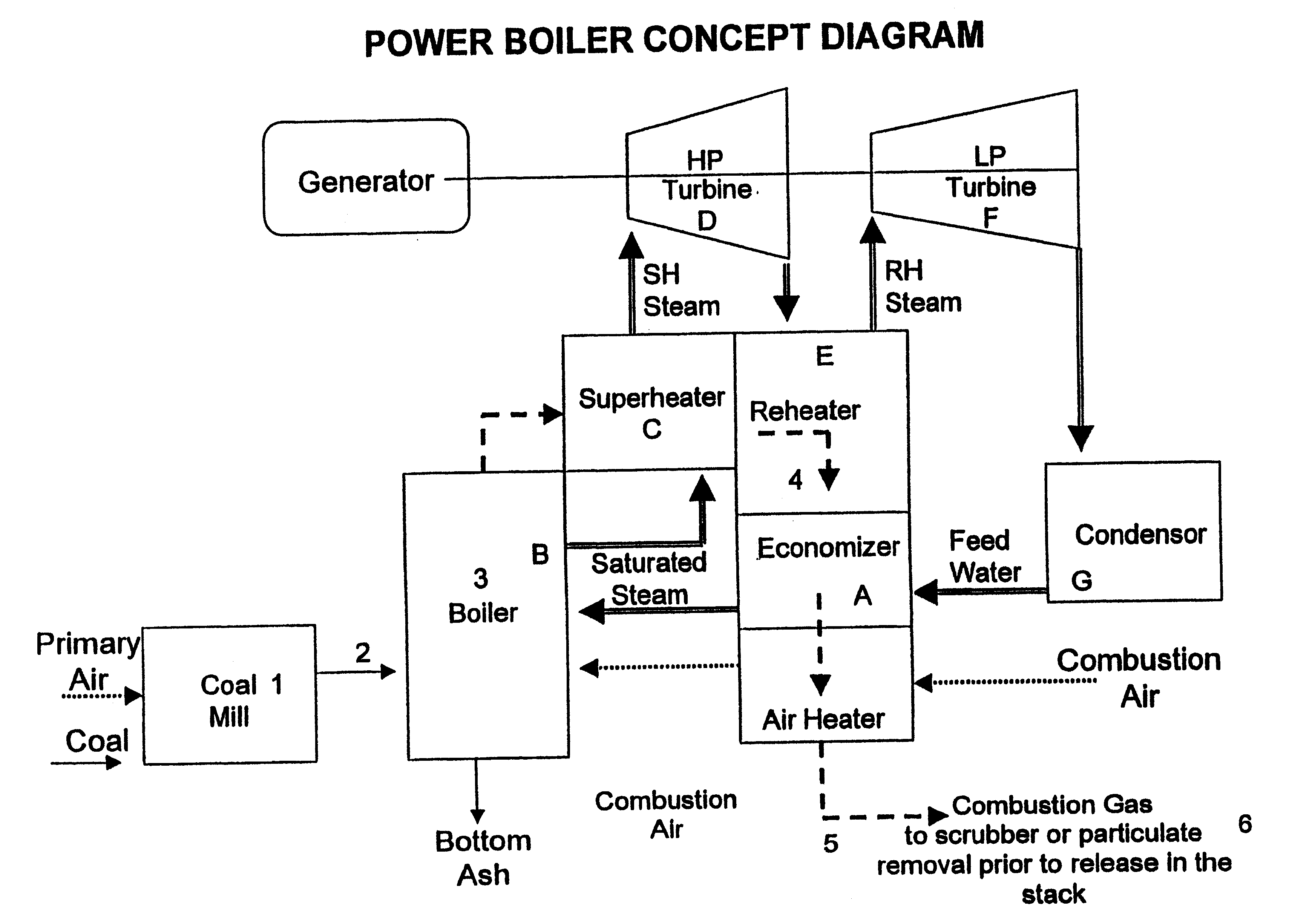

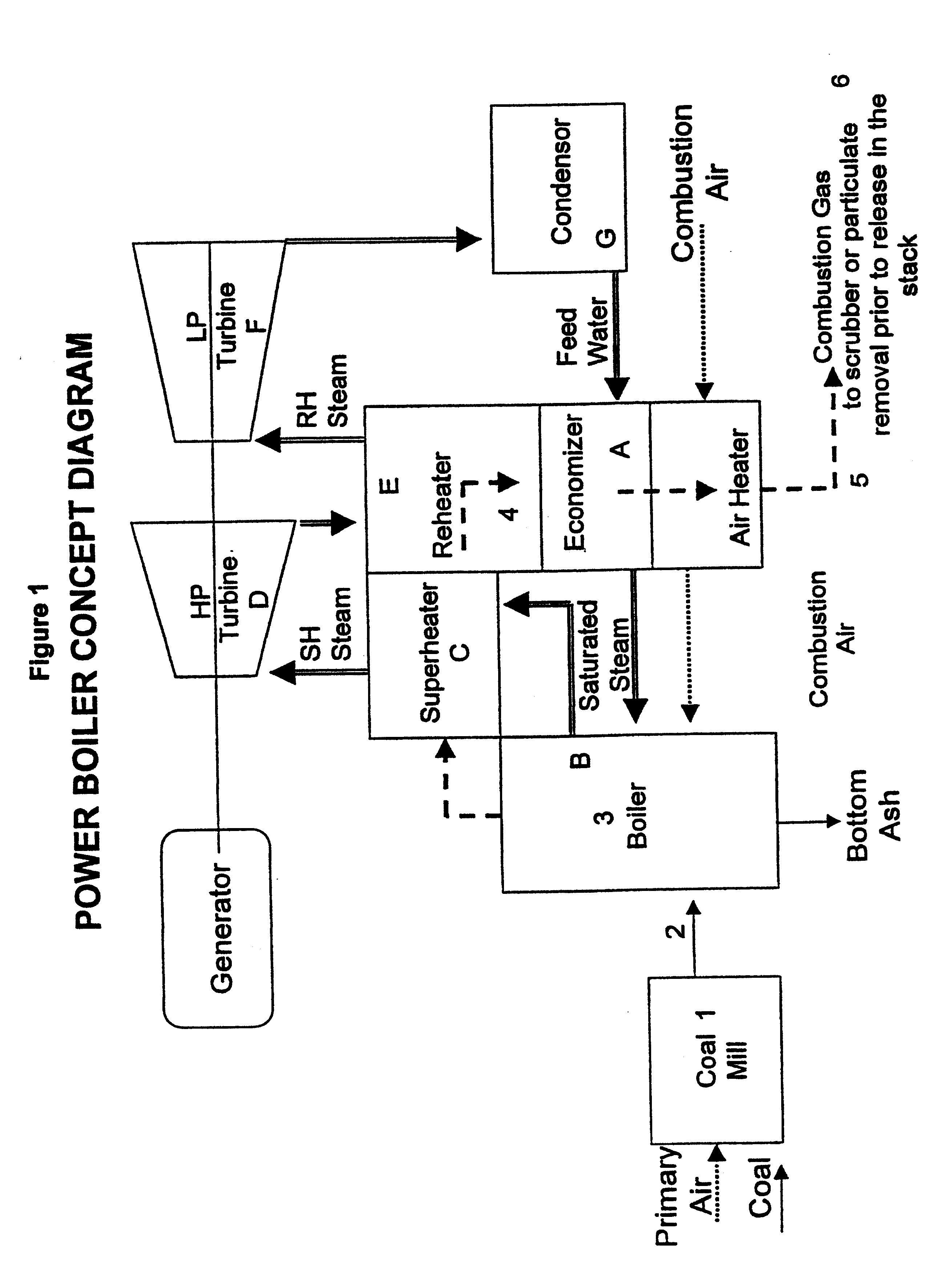

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer puritch is used to pulverize coal for combustion in the steam-generating furnaces of fossil fuel power plants.

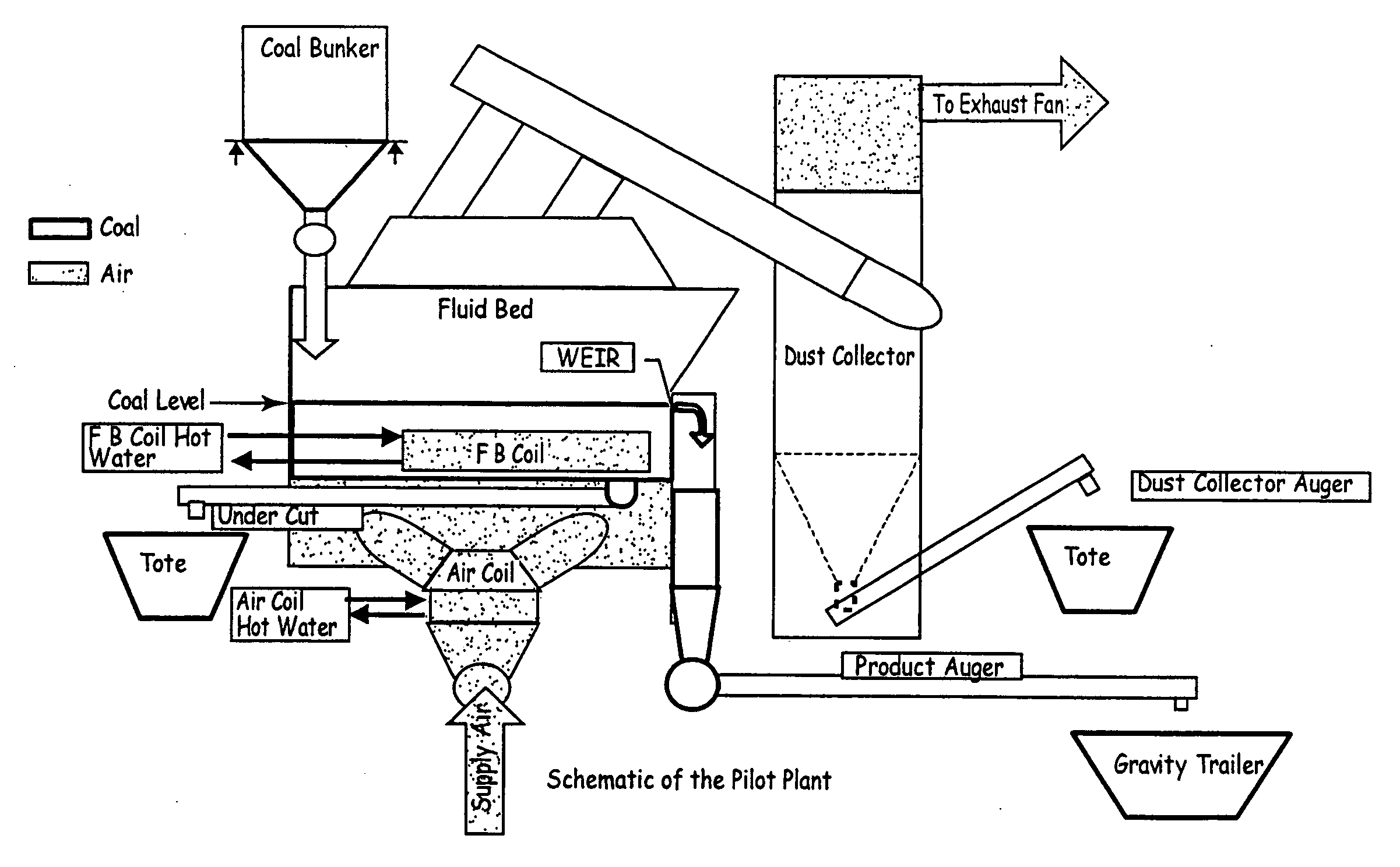

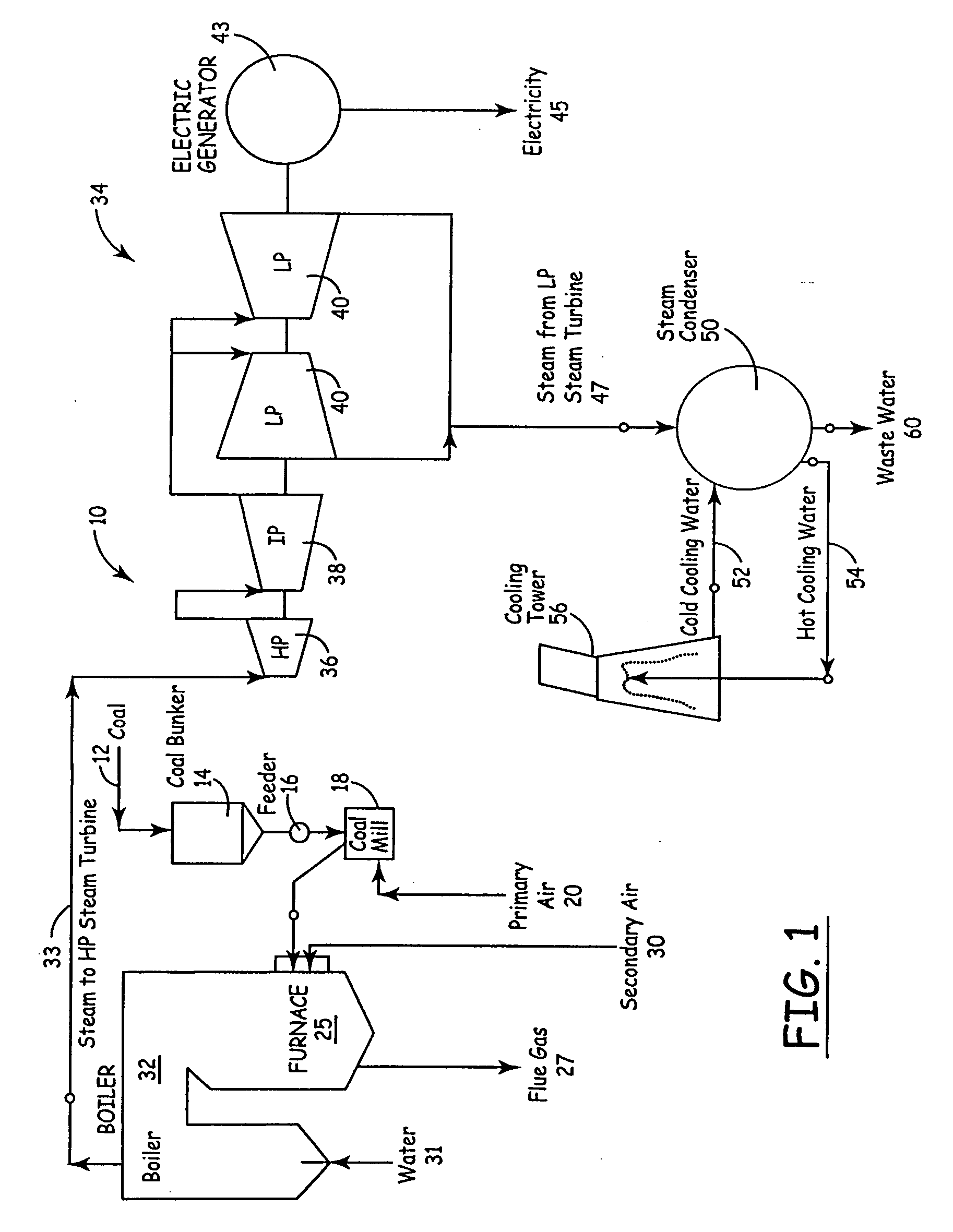

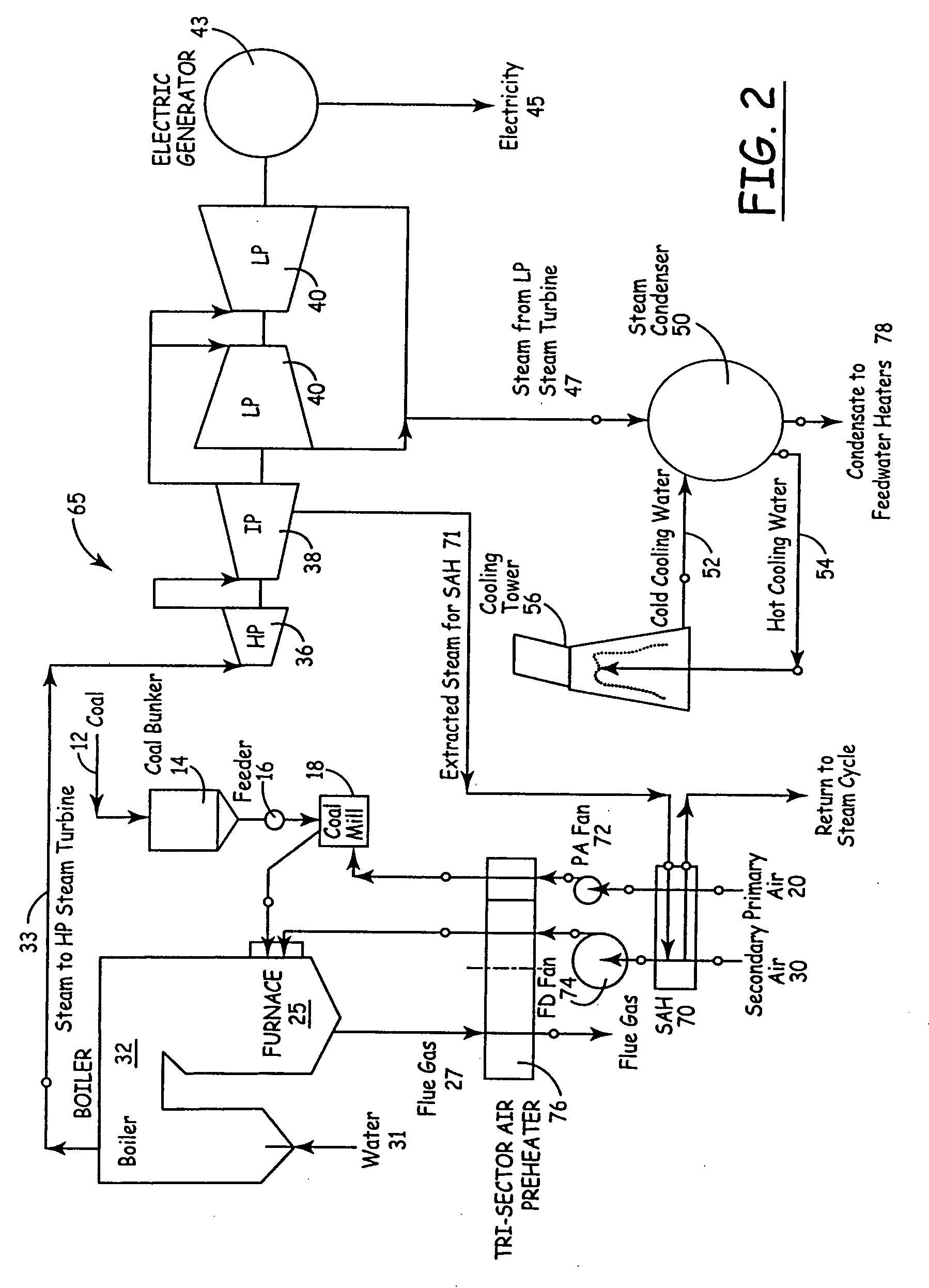

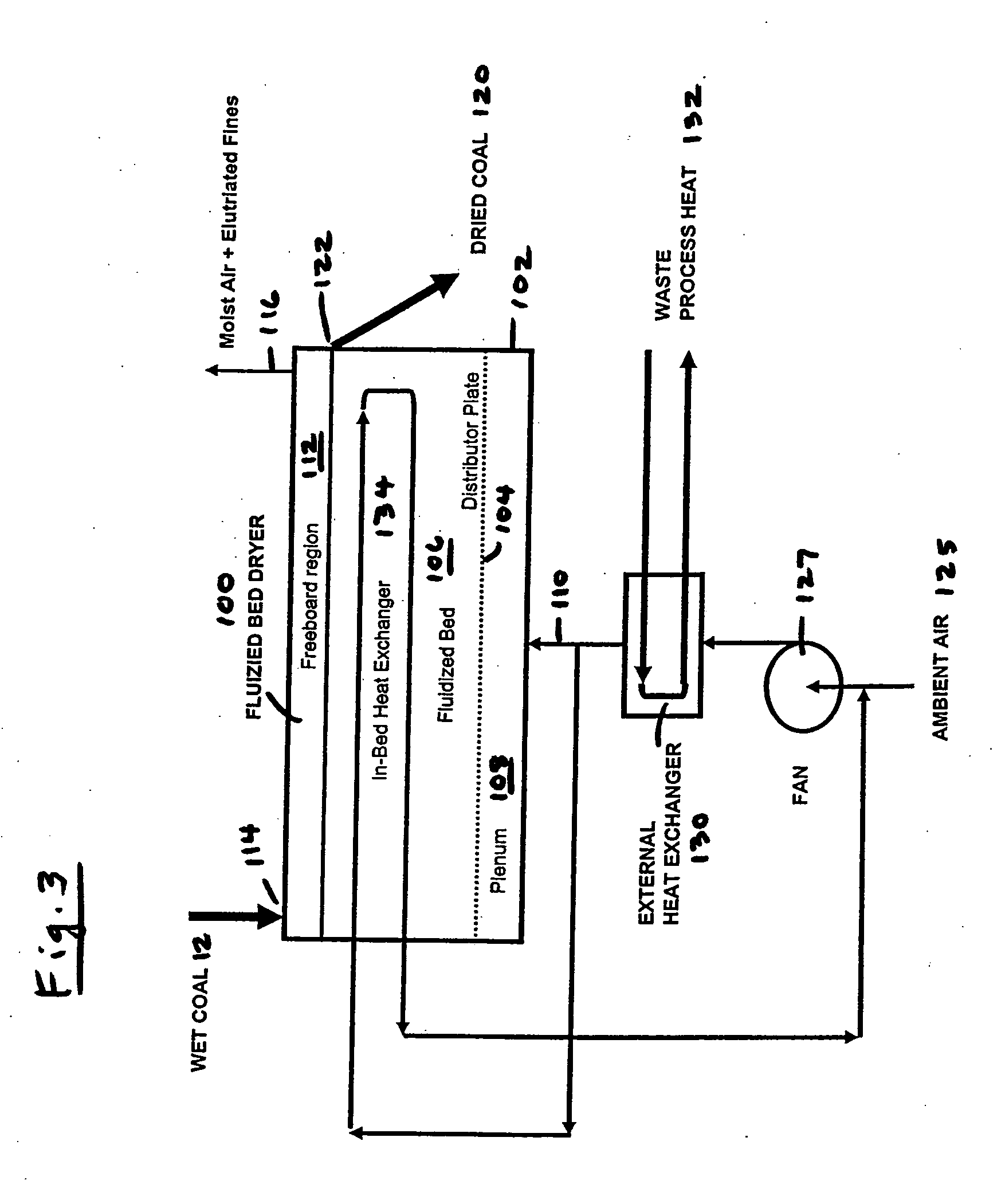

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS20080201980A1Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatSolid fuel pretreatmentParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

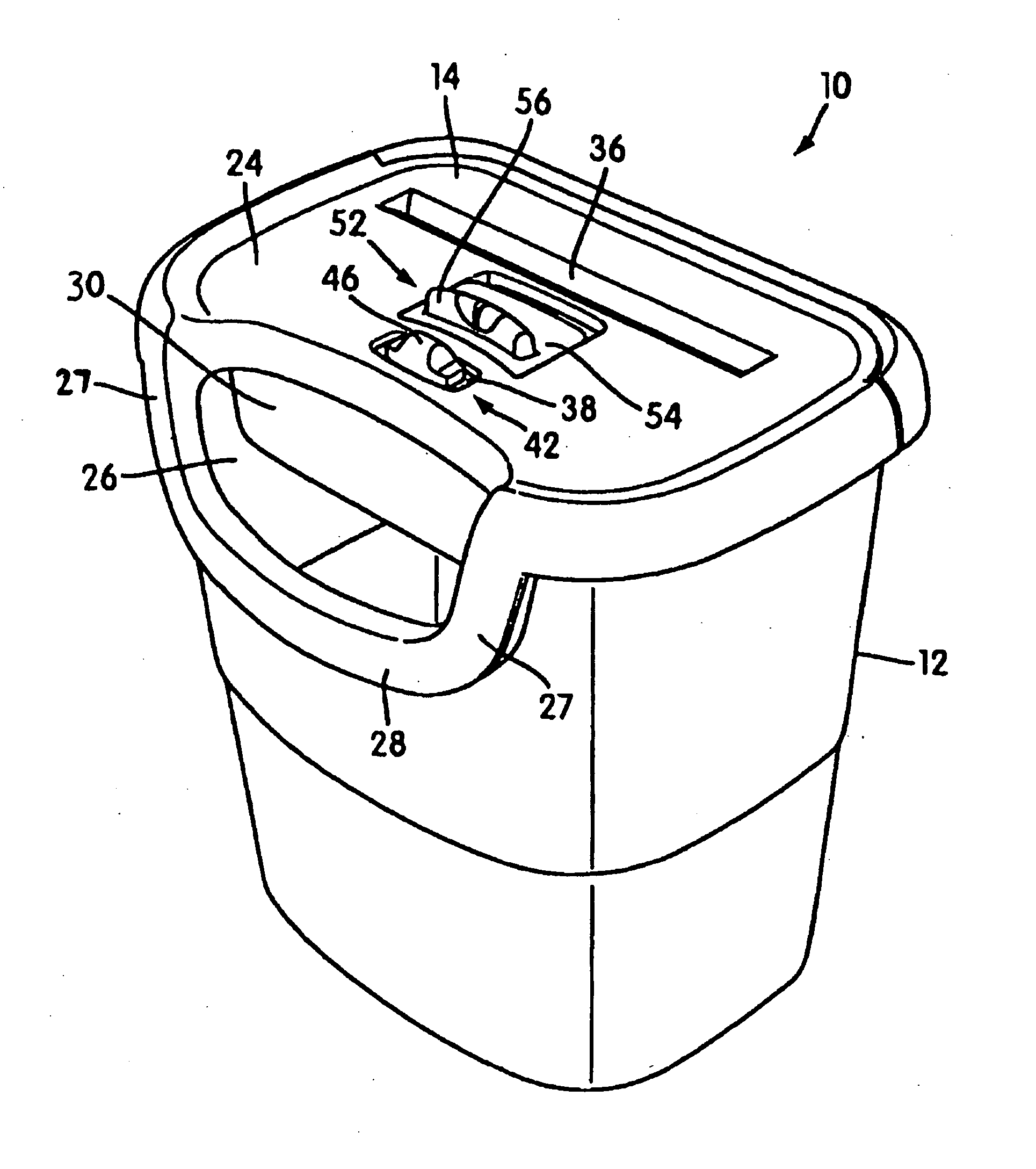

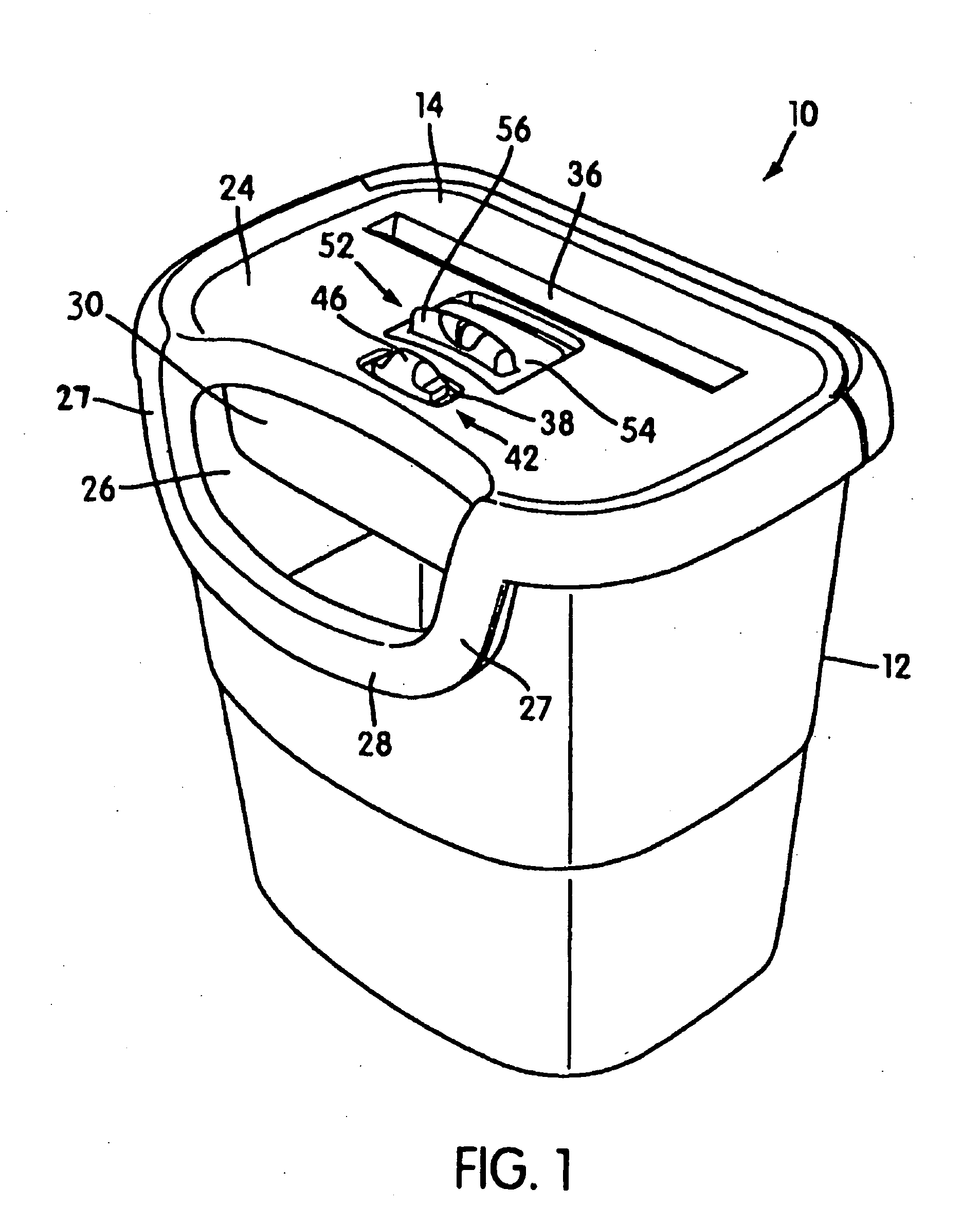

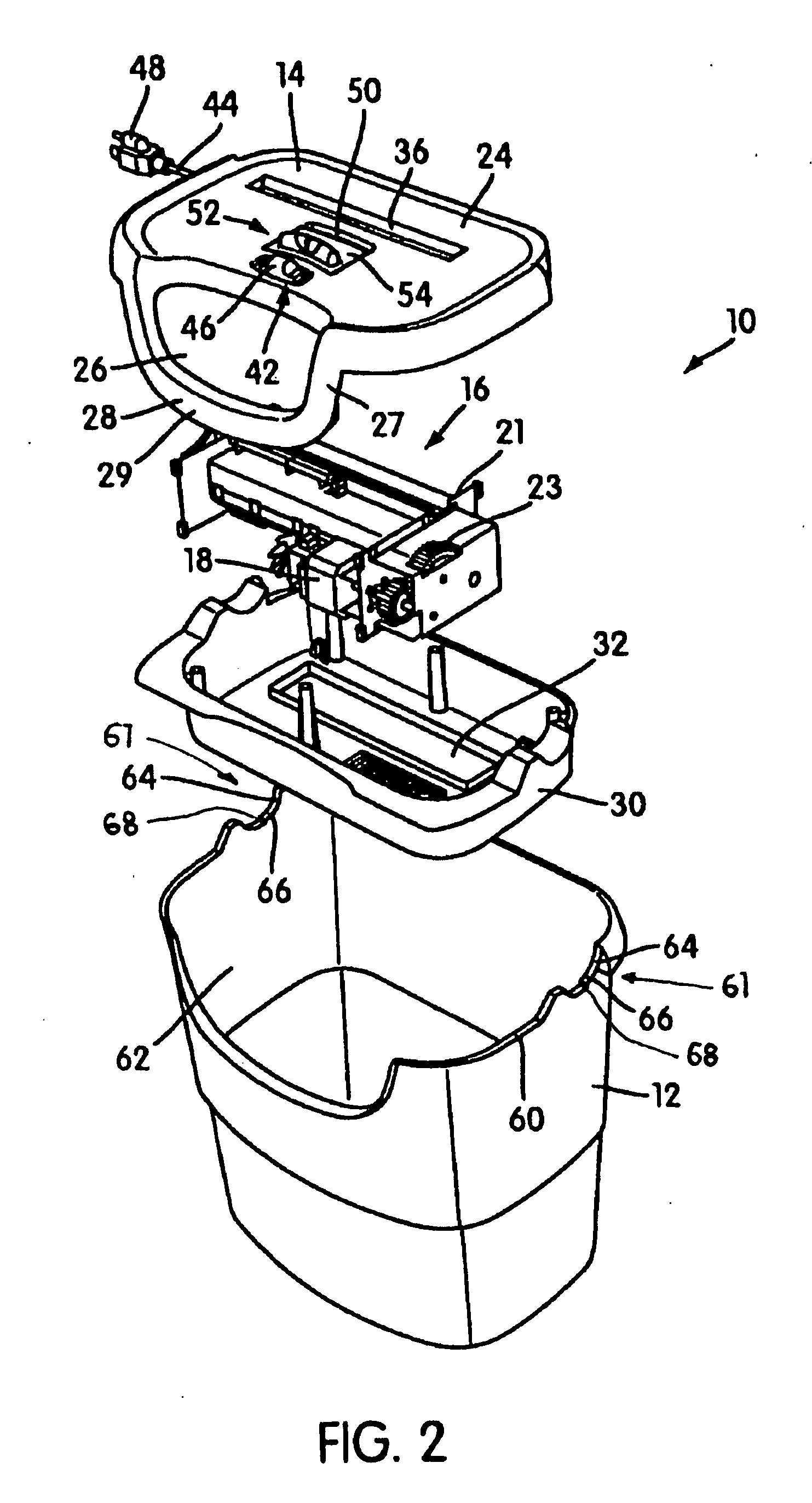

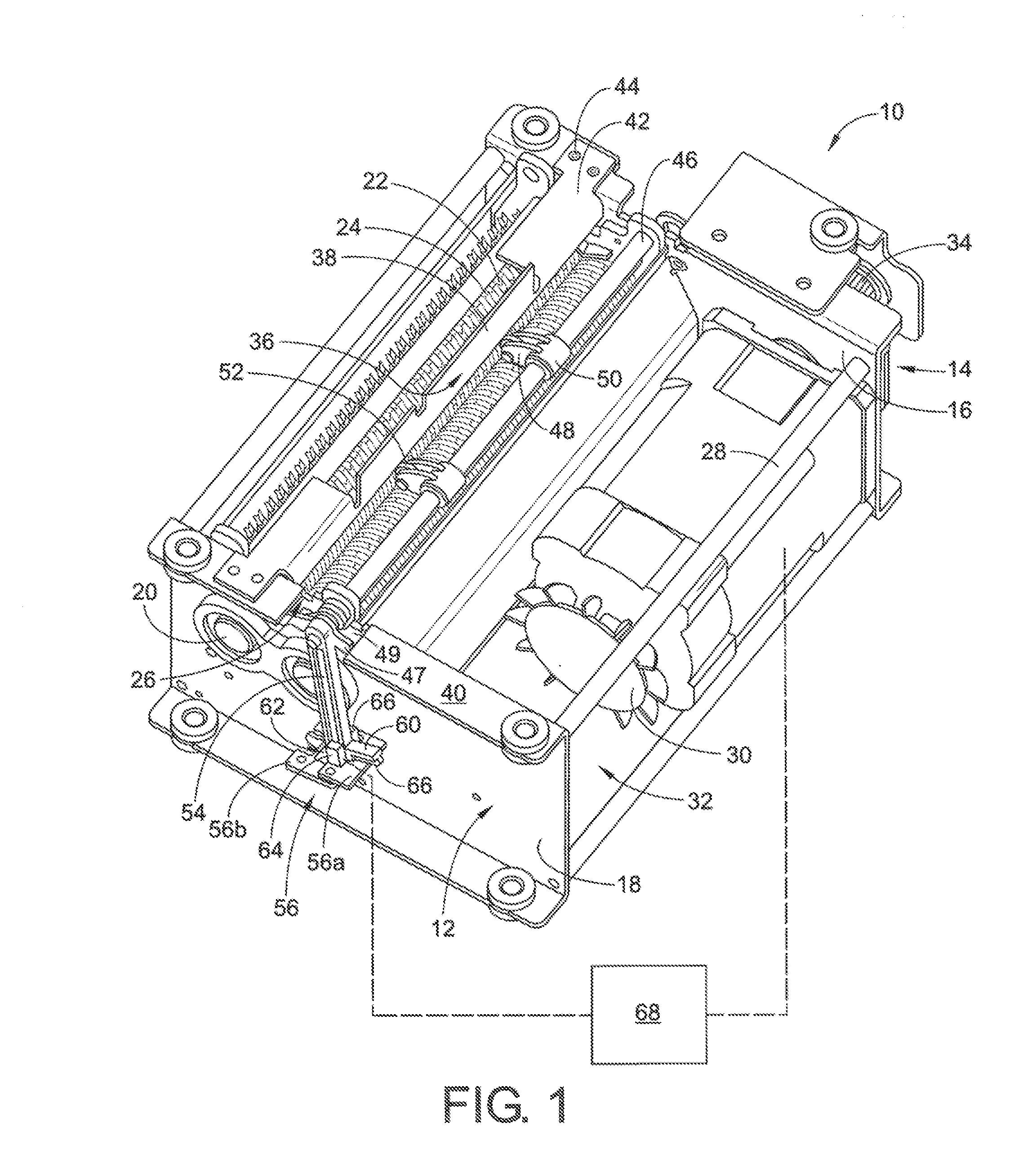

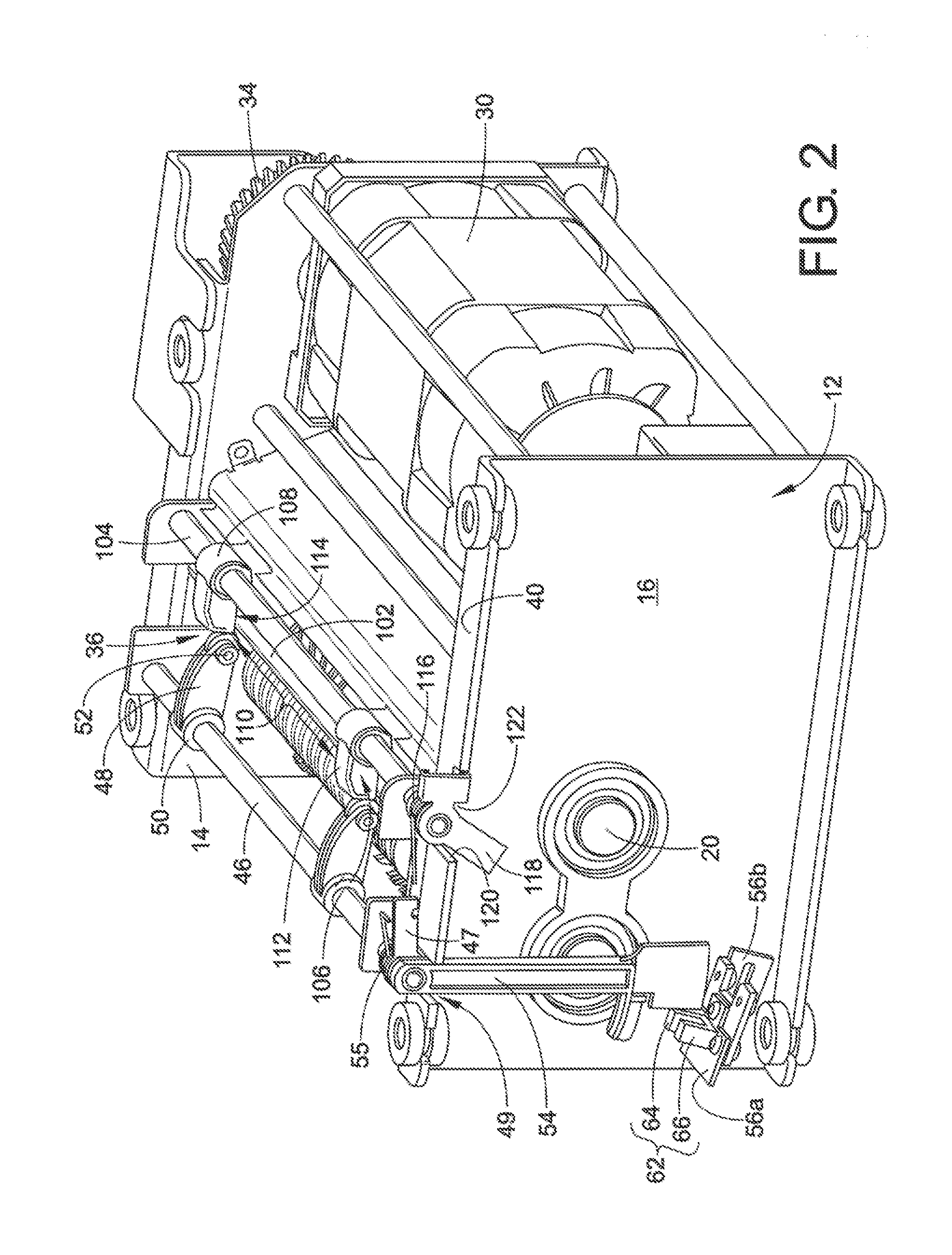

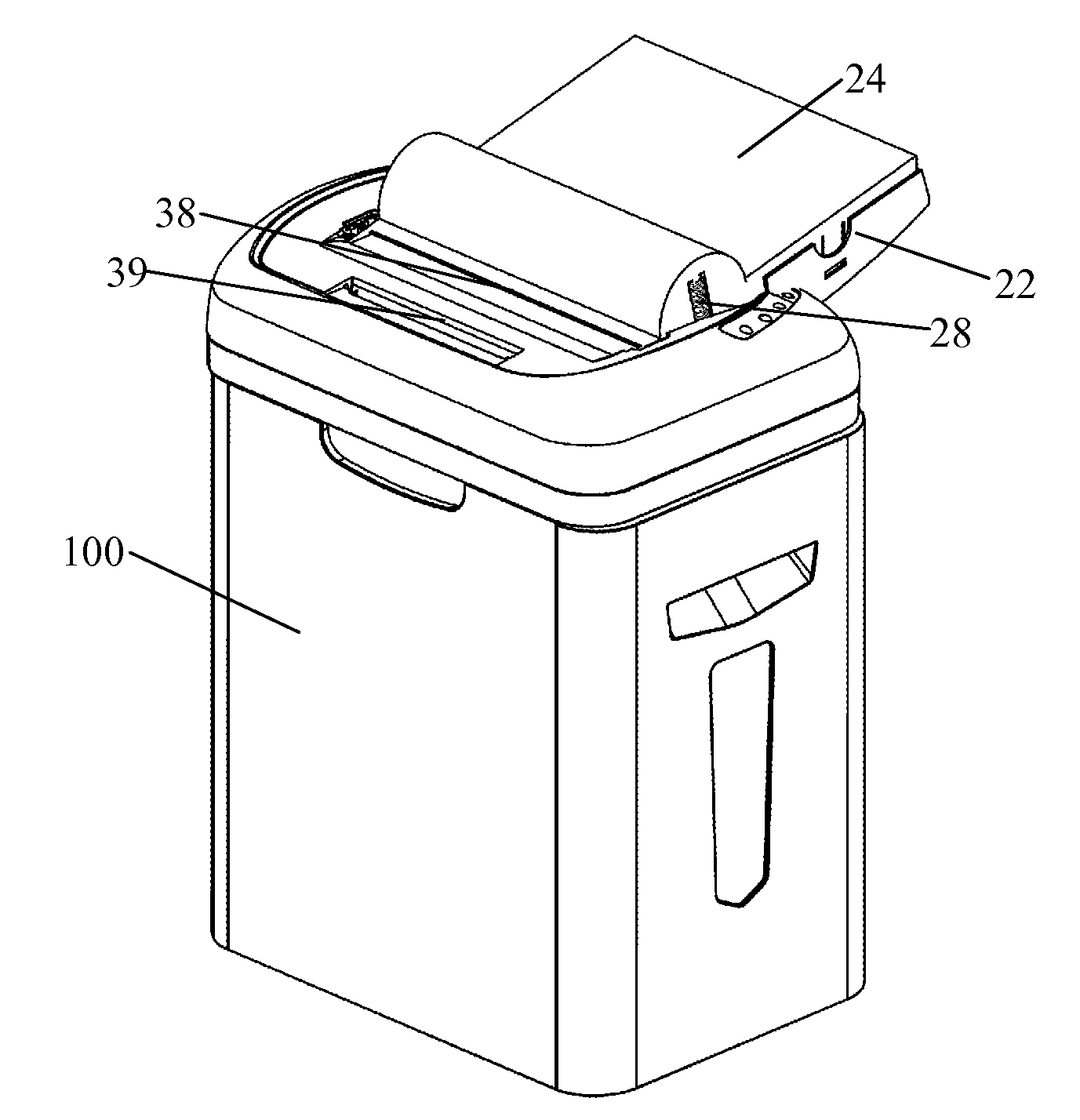

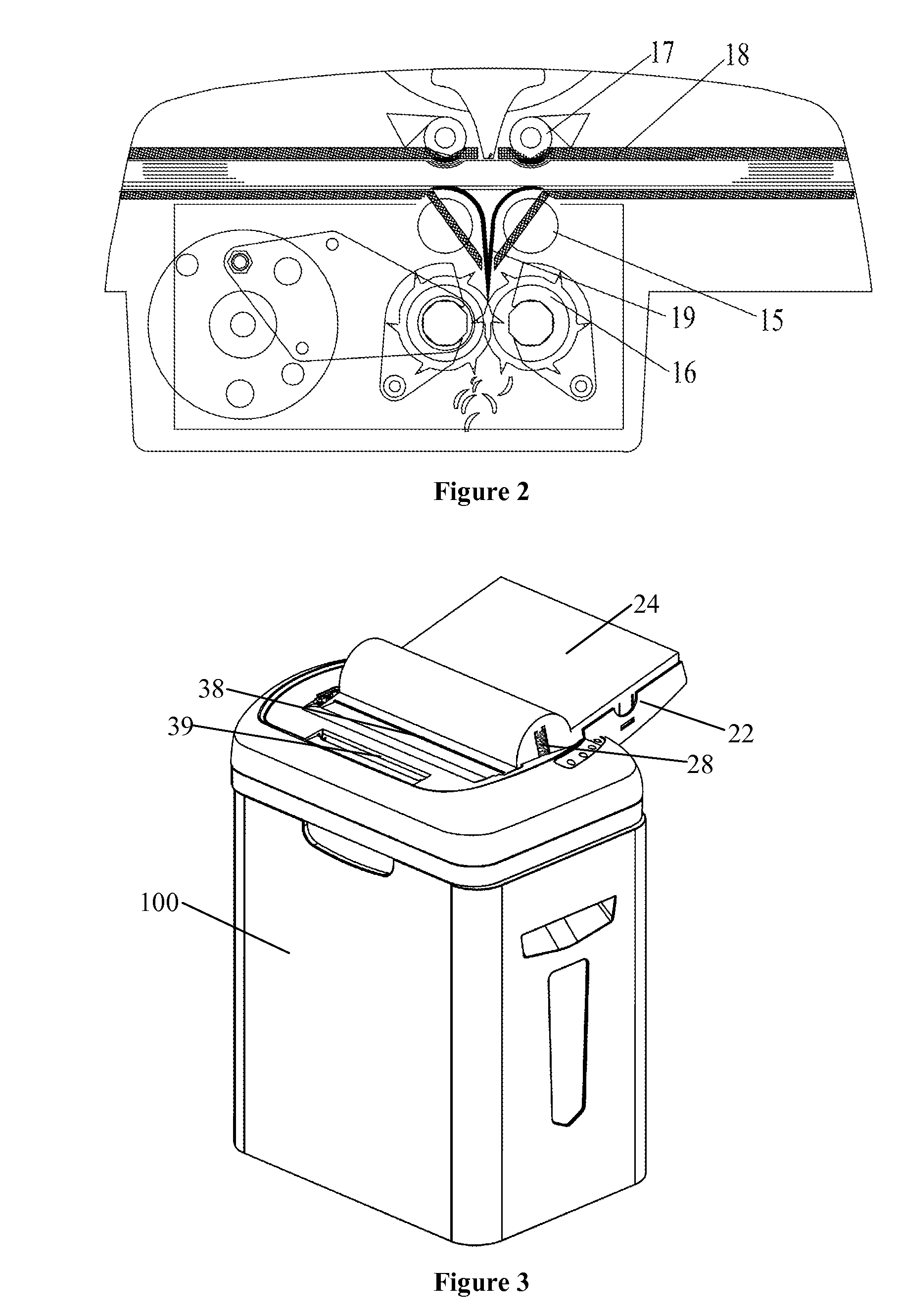

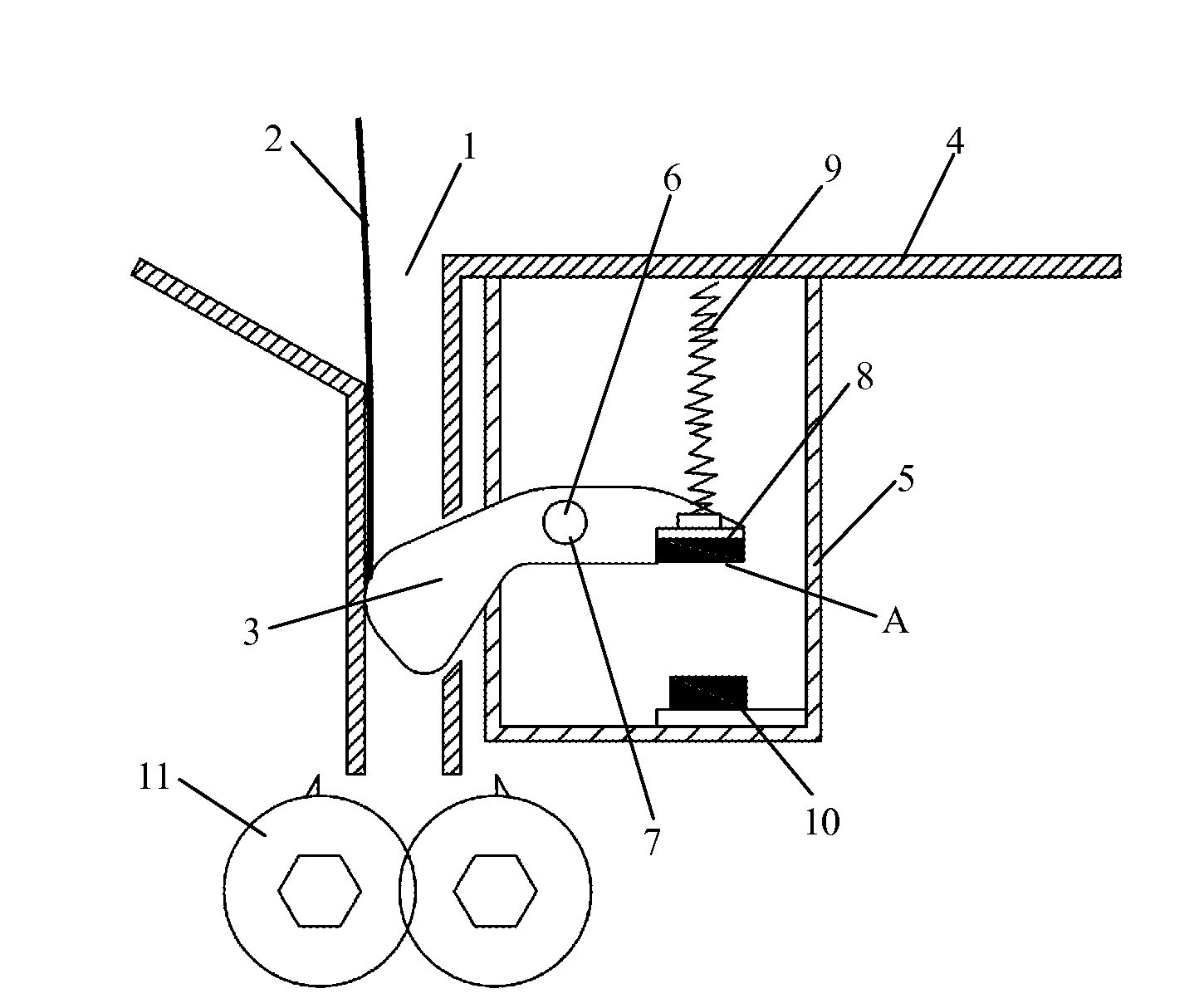

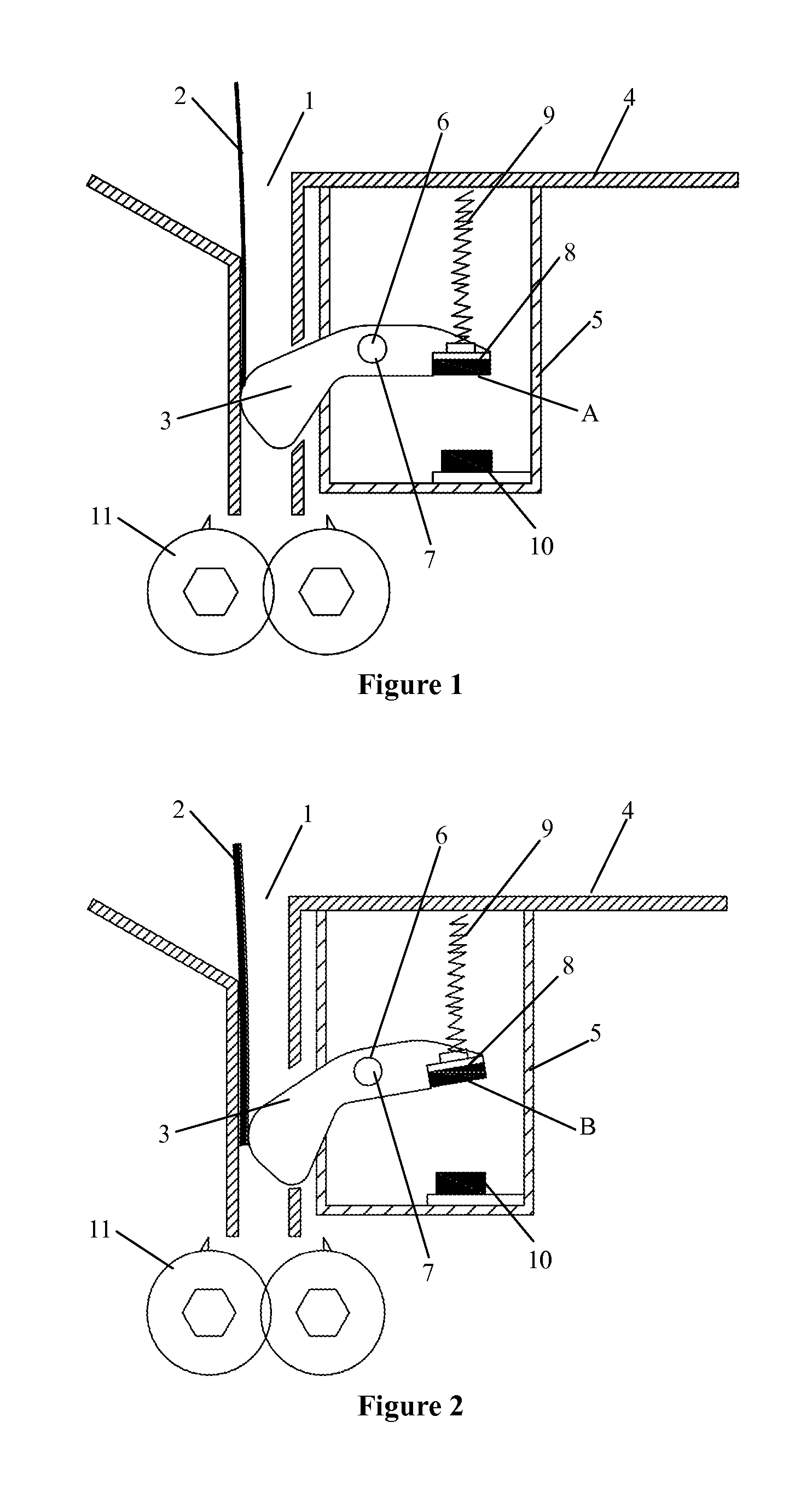

Shredder with thickness detector

A shredder is disclosed. The shredder includes a housing having a throat for receiving at least one article to be shredded, and a shredder mechanism received in the housing and including an electrically powered motor and cutter elements. The shredder mechanism enables the at least one article to be shredded to be fed into the cutter elements. The motor is operable to drive the cutter elements so that the cutter elements shred the articles fed therein. The shredder also includes a detector that is configured to detect a thickness of the at least one article being received by the throat, and a controller that is operable to perform a predetermined operation responsive to the detector detecting that the thickness of the at least one article is at least equal to a predetermined maximum thickness.

Owner:FELLOWES INC

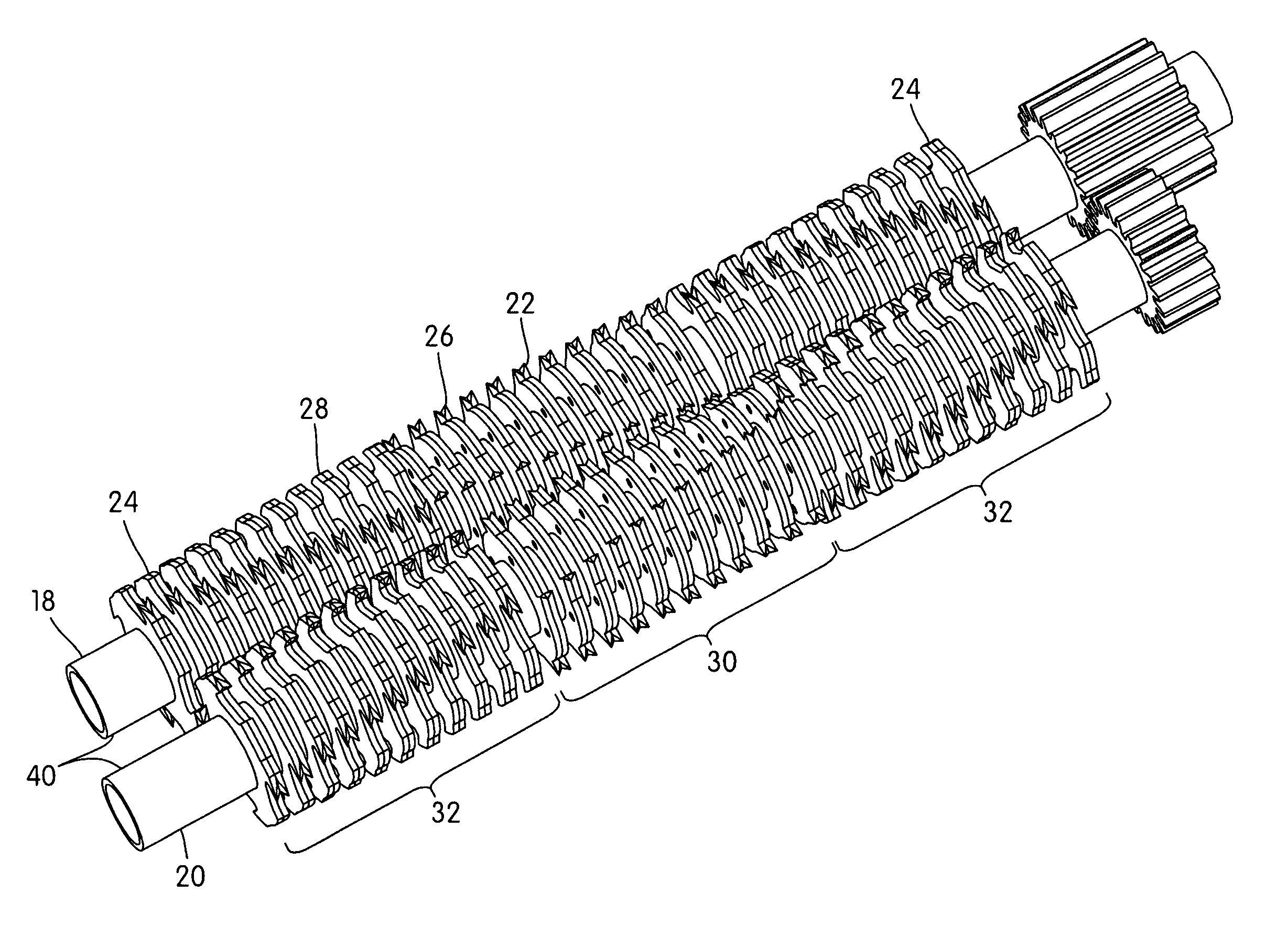

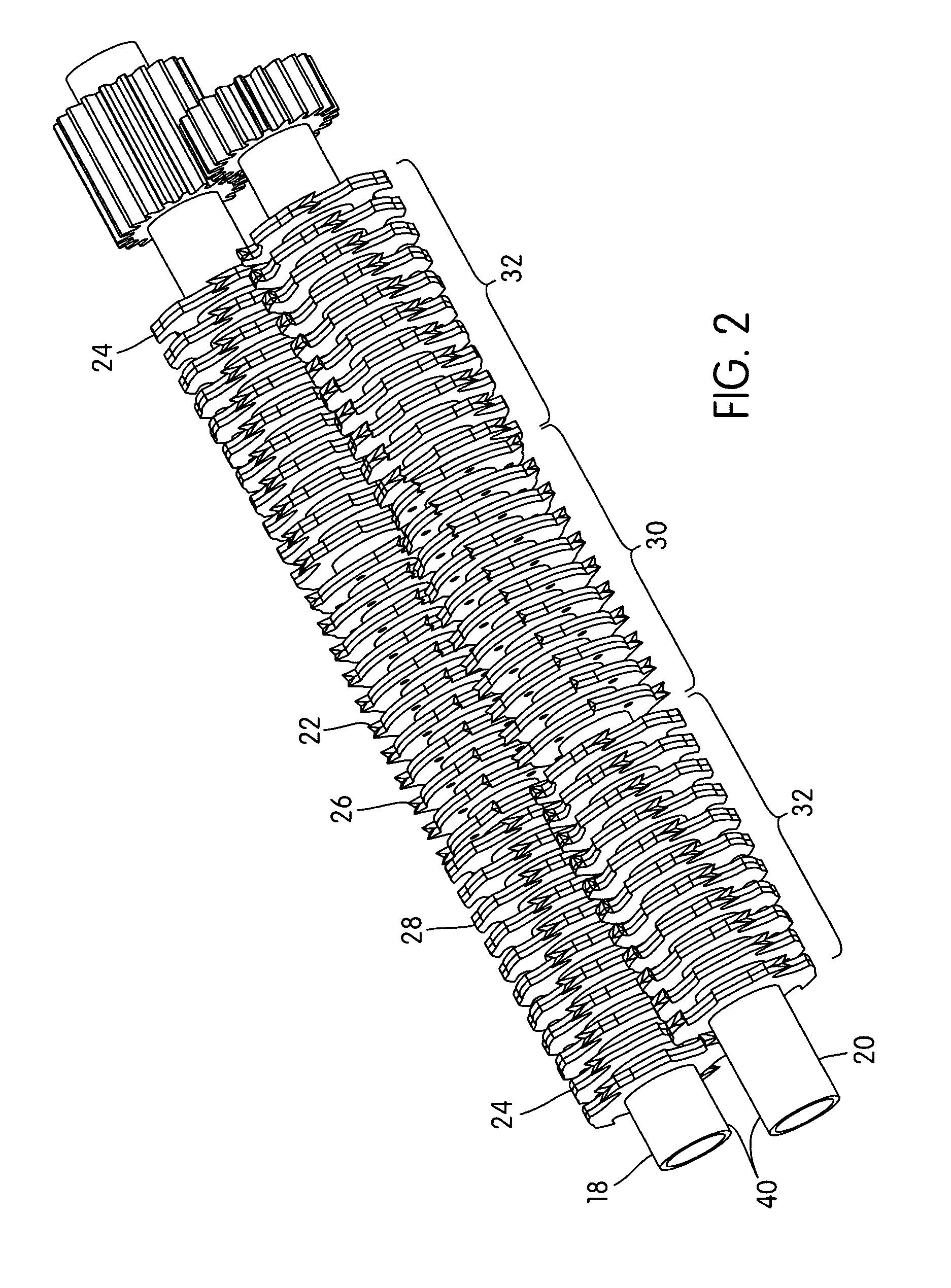

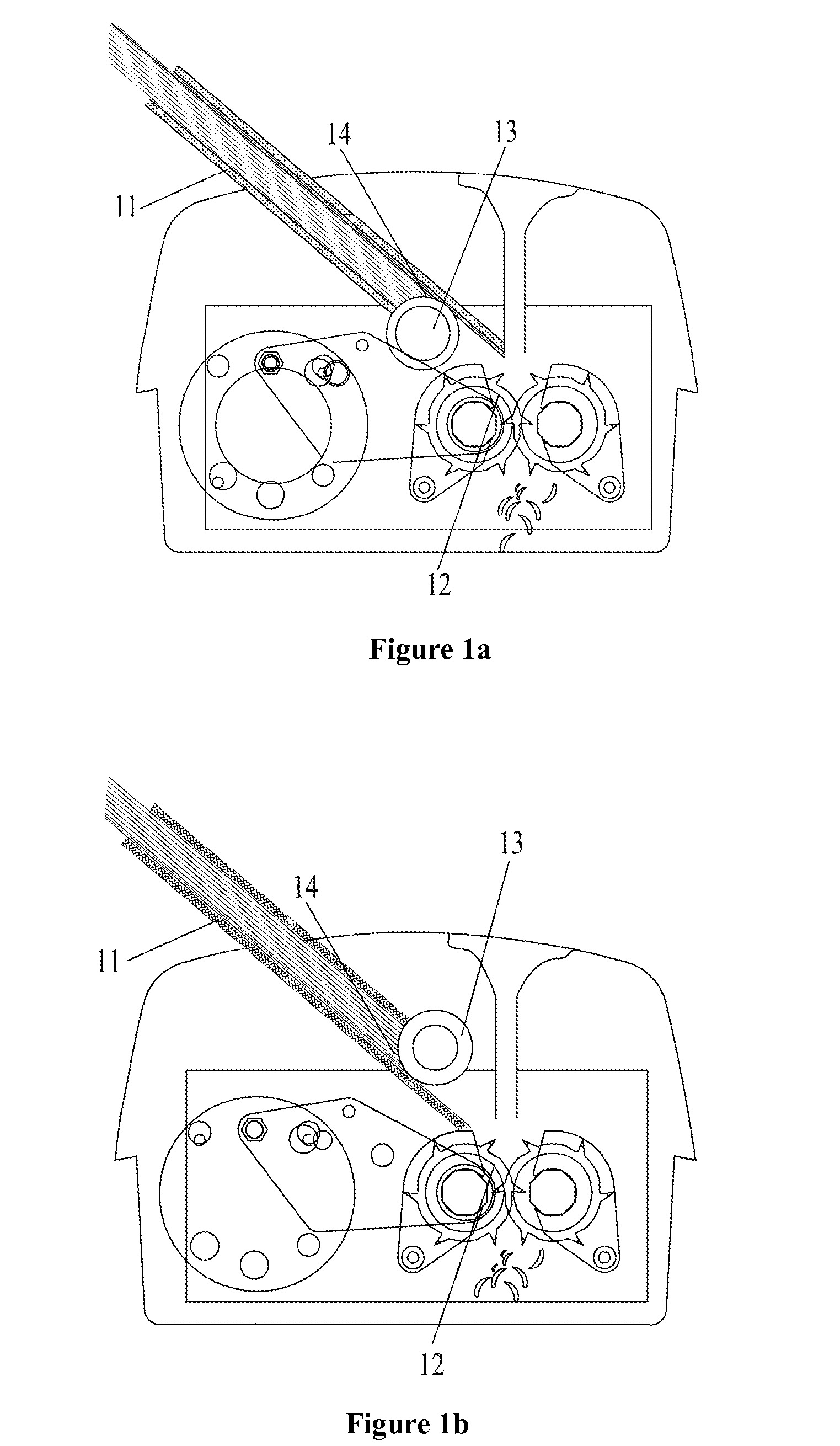

Multi-functional shredder

The present application discloses a multi-functional shredder that is capable of effectively destroying both paper documents and rigid / semi-rigid objects, such as CDs or DVDs. This multifunctional shredder comprises a housing; a drive system including at least one motor; and at least two shafts rotatably mounted within the housing and coupled to the drive system to enable the drive system to counter-drive the shafts in respective opposing rotational cutting directions. Each of the shafts includes positive cutter elements and negative cutter elements, configured to cooperate to shred articles as the shafts are rotationally counter-driven by the drive system in the respective rotational cutting directions thereof. The positive cutting elements on each shaft have positive cutting parts angled in the respective rotational cutting directions of the shafts, and the negative cutting elements on each shaft have negative cutting parts angled opposite the respective rotational cutting directions of the shafts.

Owner:FELLOWES INC

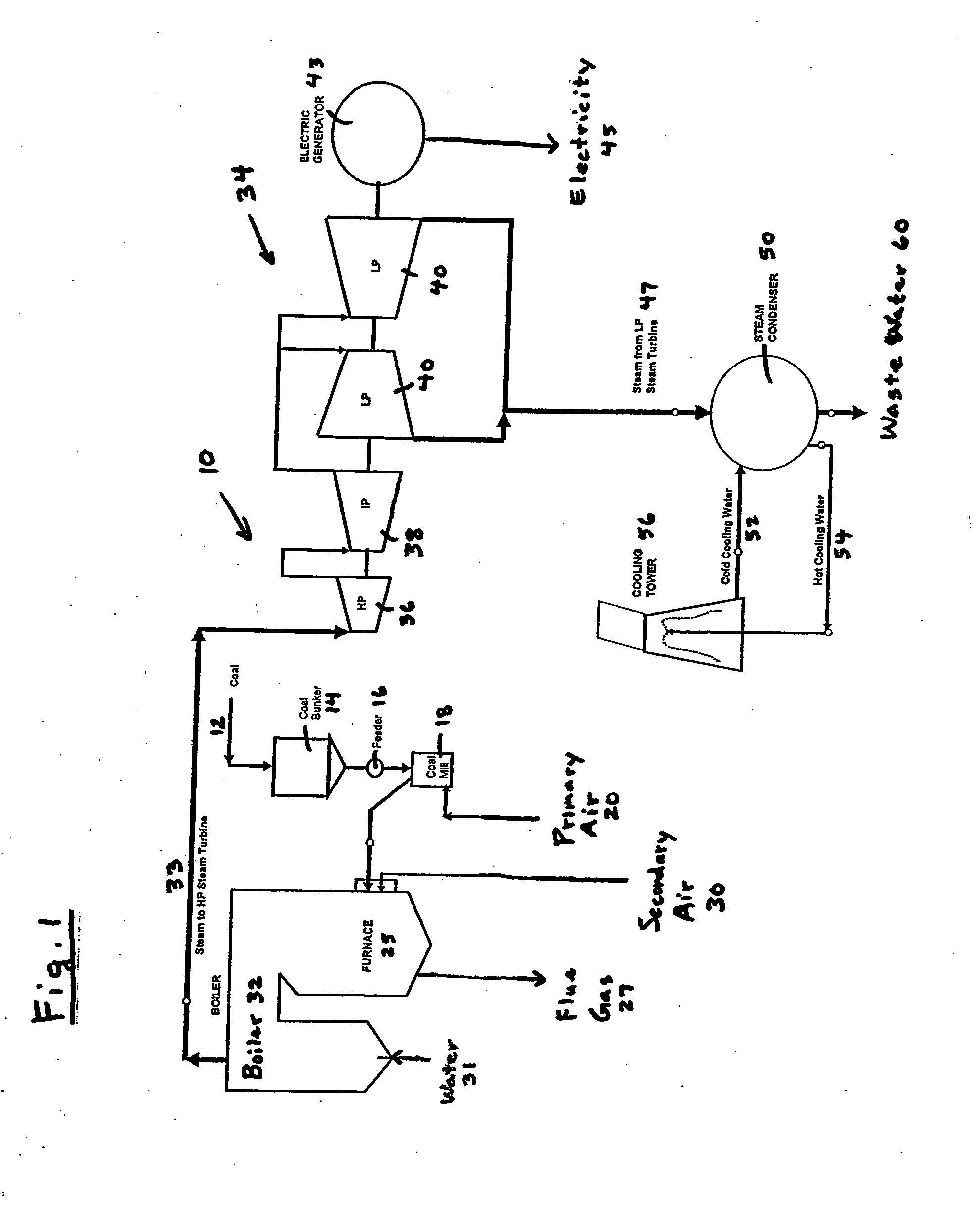

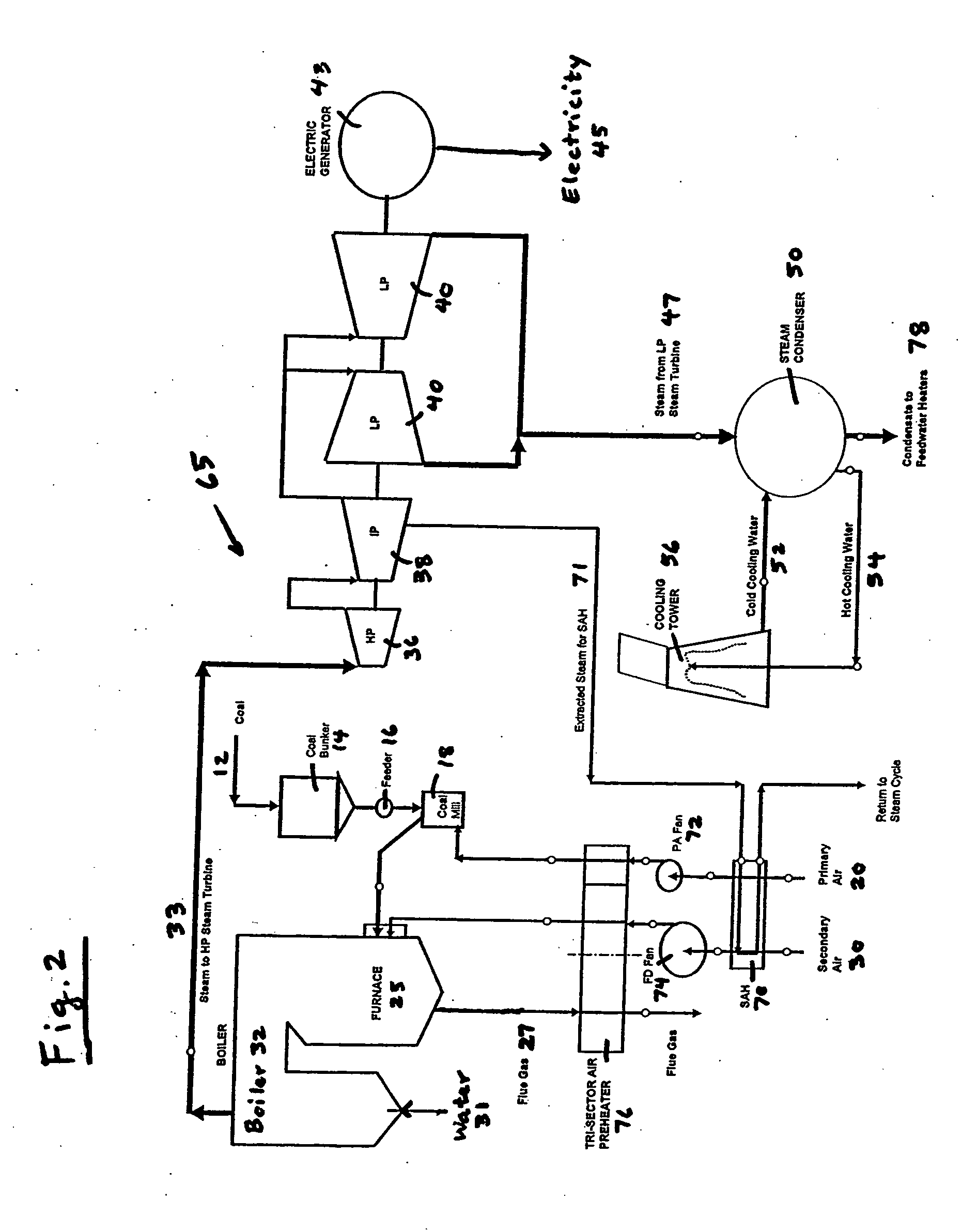

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS20060075682A1Eliminates potential harmEmission reductionDrying solid materials with heatSolid fuelsFluidized bed dryingHeat flow

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

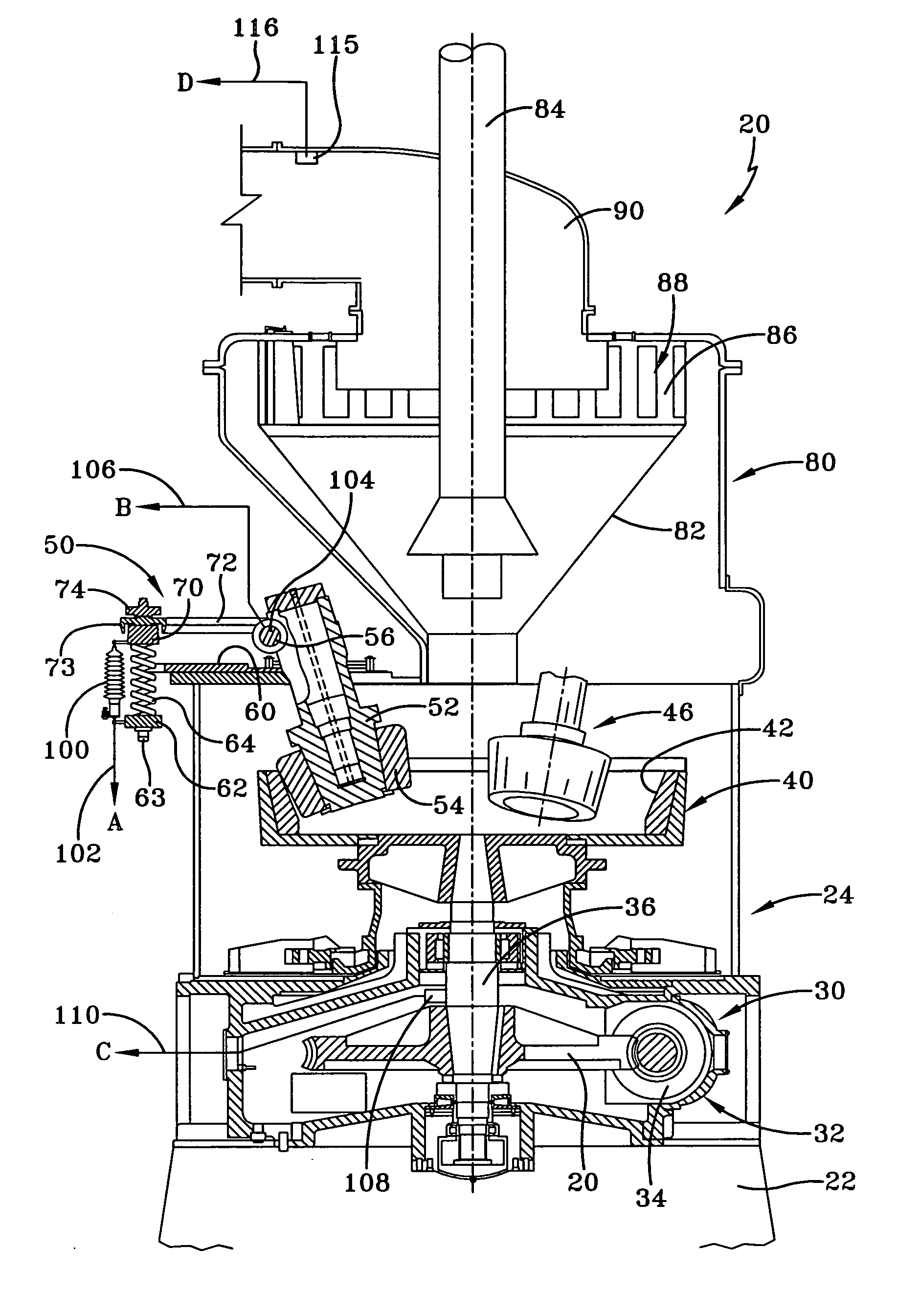

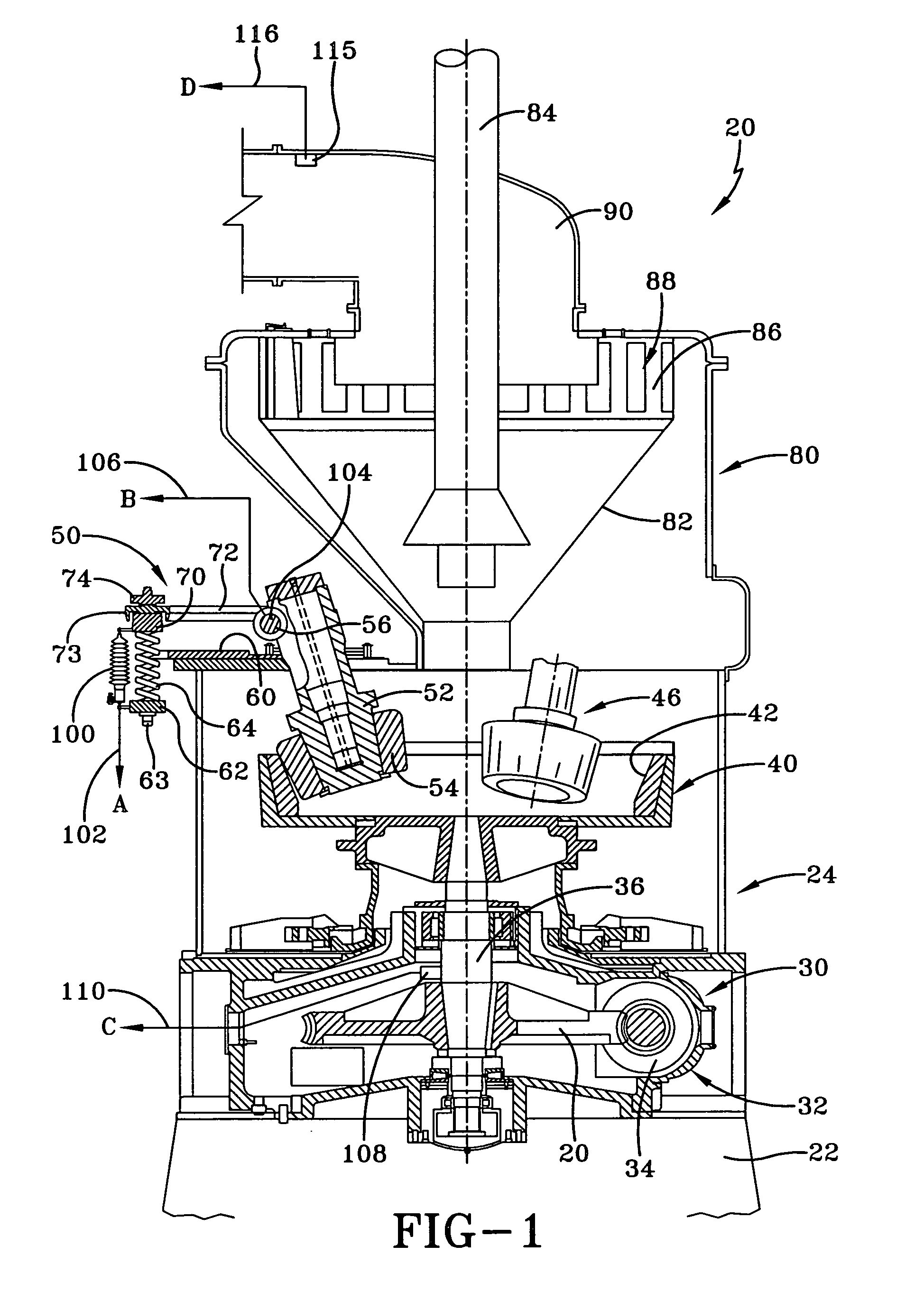

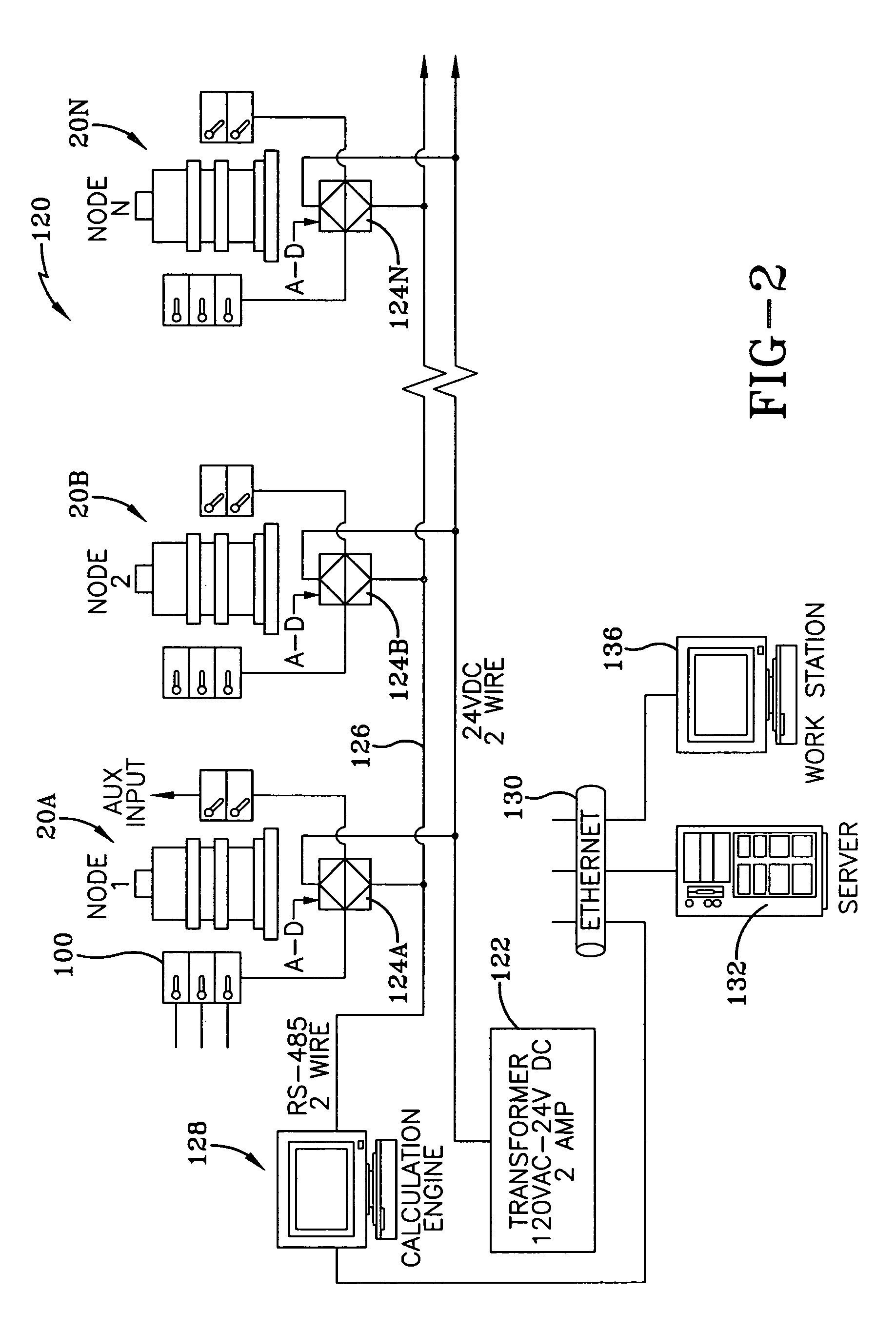

Pulverizer real-time monitoring system

A pulverizer monitoring system is applicable to at least one pulverizer having a rotatable bowl assembly, and at least one journal assembly having a grinding roll positioned proximal the rotatable bowl assembly, wherein the grinding roll is deflected by the feedstock raw material forced under the roll during rotation of the rotatable bowl assembly. A position sensor is mounted to the journal assembly to detect an amount of deflection of the grinding roll and generates a position signal, wherein a data module is associated with each pulverizer so as to receive the position signal. A calculation engine is linked to each data module for the purpose of analyzing the position signal and other operational signals associated with the pulverizer and generating at least one characteristic pulverizer condition report. A web-based server is linked to the calculation engine to provide network access to the characteristic report(s), either real-time or historical trends. A user interface is provided with either the calculation engine and the web-based server to allow the custom setting of alarms and / or formats for the output associated with the characteristic report(s).

Owner:ENG CONSULTANTS GROUP

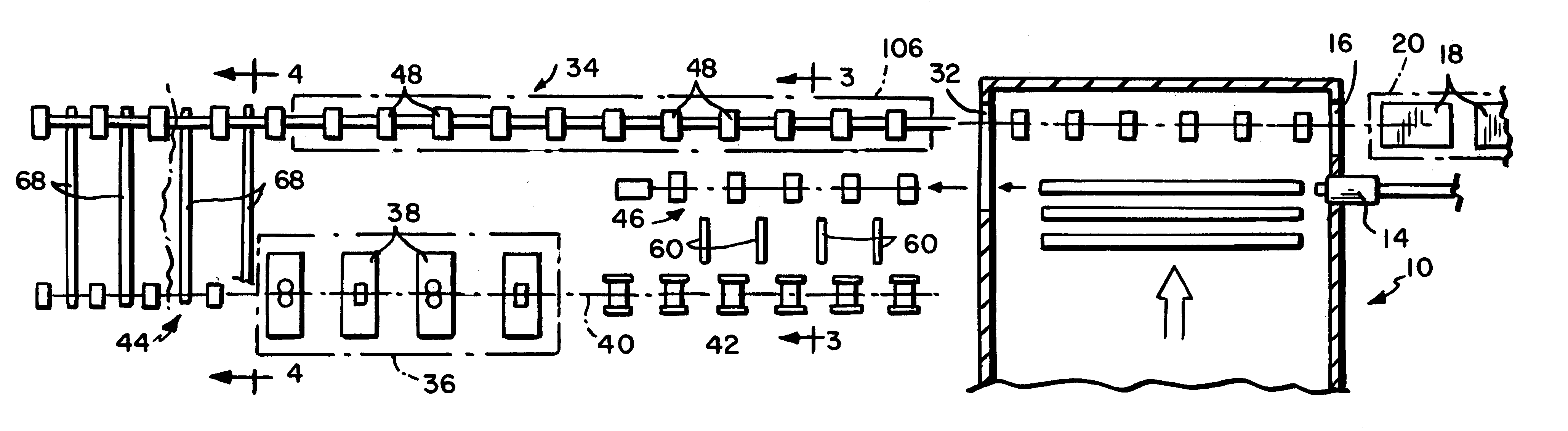

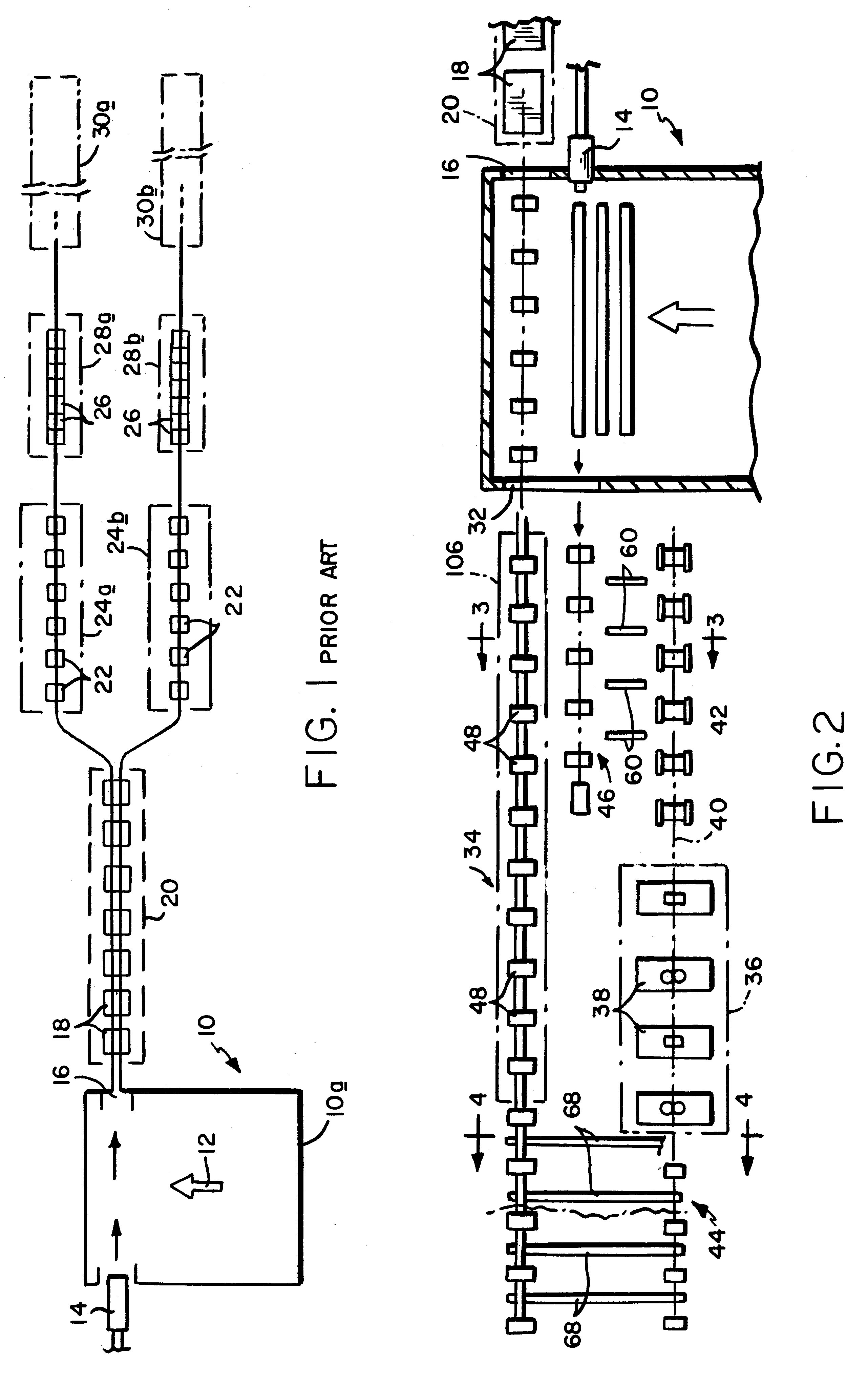

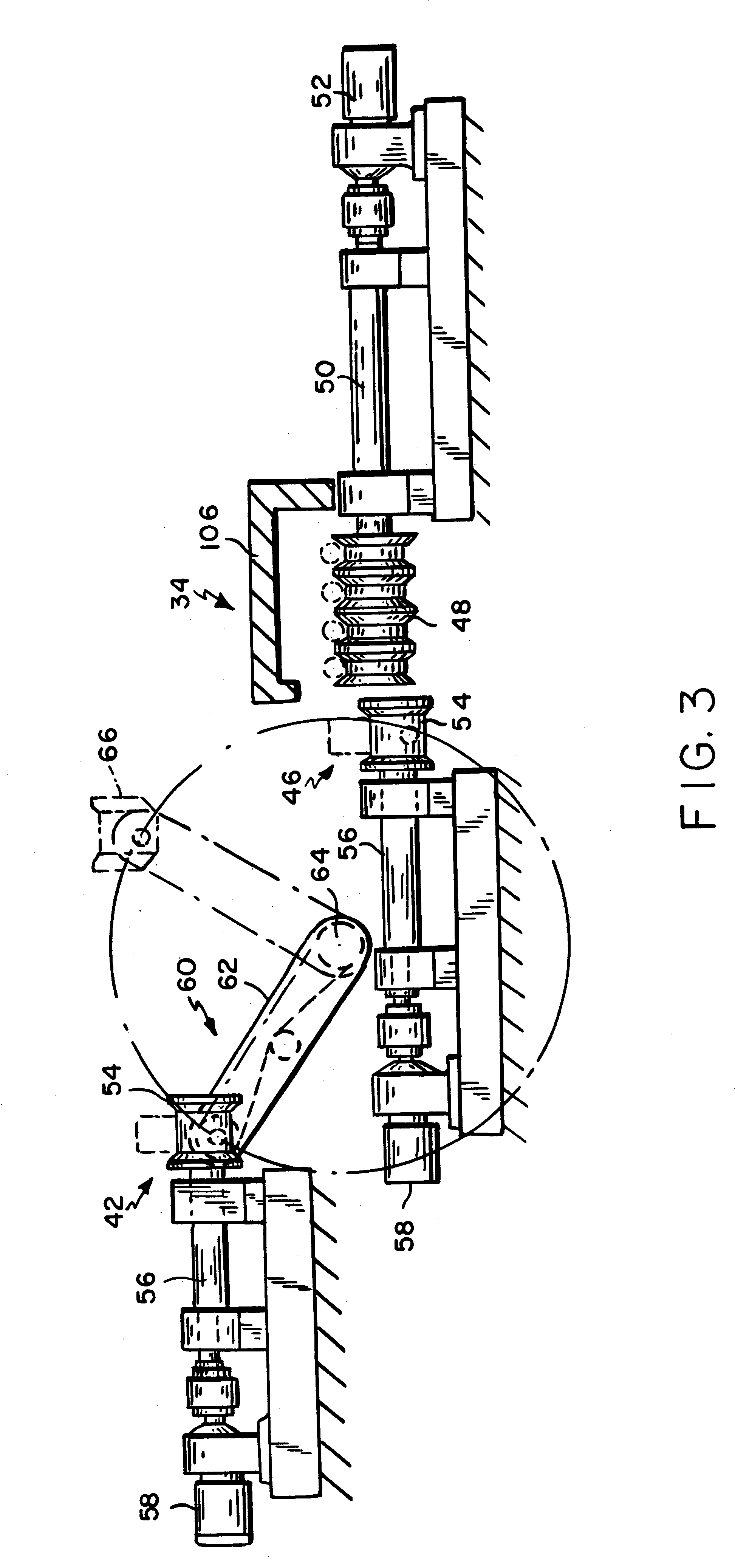

Apparatus for and method of processing billets in a rolling mill

A rolling mill has roughing, intermediate and finishing roll stands on a first side of a billet reheating furnace, and a breakdown mill on an opposite second side of the furnace. Billets are heated to an elevated rolling temperature in the furnace and are then ejected to the second side of the furnace for rolling in the breakdown mill before being directed back through the furnace for continued rolling into finished products at the first side of the furnace in the roughing, intermediate and finishing roll stands.

Owner:MORGAN CONSTR CO

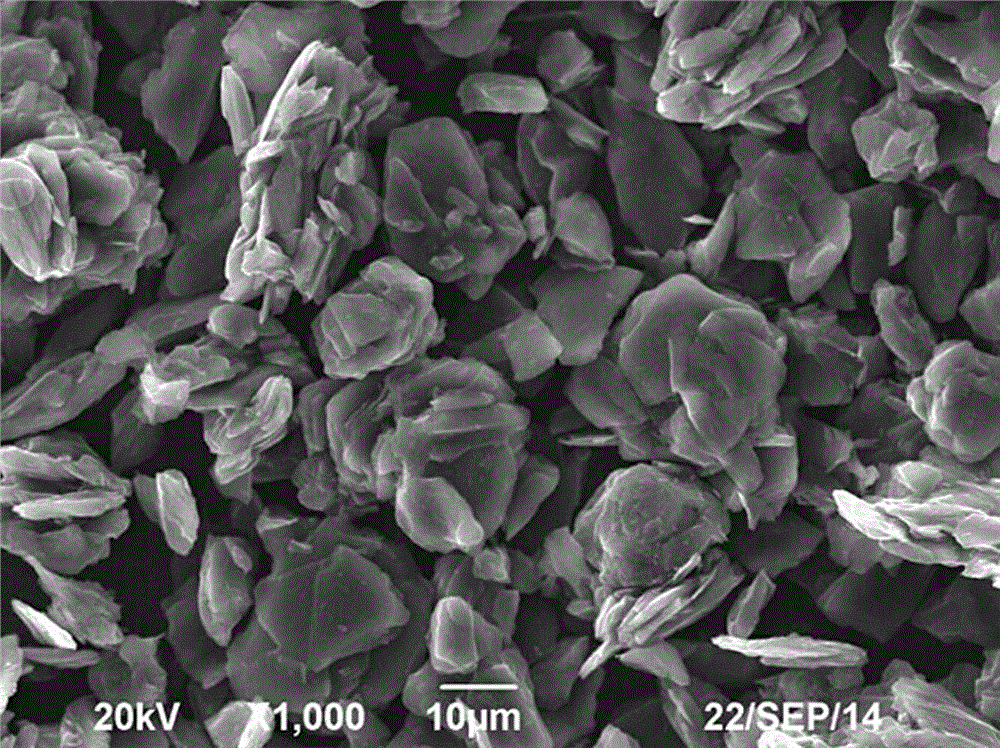

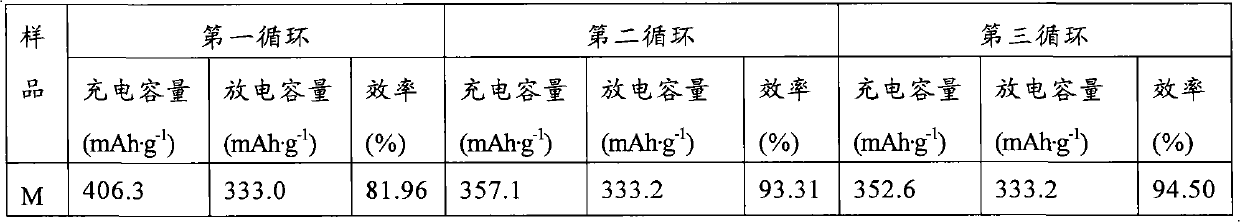

Preparation method of anode material for power lithium ion battery

InactiveCN104659366AImprove electrochemical performanceIncrease capacityCell electrodesSecondary cellsCarbonizationDischarge rate

The invention discloses a preparation method of an anode material for a power lithium ion battery. The preparation method comprises the following steps: by adopting petroleum coke ground until the grain size is 1-6mu m, calcined petroleum coke or needle coke as a raw material, adding additives, adding a mixture to a reaction kettle to carry out first high-temperature carbonization coating under the protection of the inert atmosphere, then grinding the mixture with a grinder until the grain size is 5-13mu m, then carrying out superhigh-temperature graphitization at a temperature above 3200 DEG C, adding one or a mixture of petroleum asphalt, coal asphalt and resin to a material obtained after graphitization, and then enabling the mixture to enter a carburization furnace to undergo second coating under the protection of the inert atmosphere to obtain the anode material for the power lithium ion battery, namely a spheroidal artificial graphite material which is formed through bonding after being coated with granules and undergoes two-time coating and three-time high-temperature treatment. The preparation method has the advantages that the discharge rate property of the anode material is improved, the low temperature properties of the anode material are improved, and the latest requirements of the market for the product are further met.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Anti-jamming assembly for shredders of sheet like material

An anti-jam assembly for incorporation in an article destroying appliance includes a fixed core mount assembly including a first support member spaced apart from a second support member. At least one moveable cutter shaft is disposed between and rotatably mounted to the first and second support members. A third elongate member extends in parallel relationship to the at least one cutter shaft. This third support member is moveable from a first position to at least a second position. The first and the at least second position correspond to a variable width of a feed path directing an article toward the at least one cutter. An arm is affixed to the elongate member and pivotal at a mounting surface when the elongate member moves toward the second position. A sensor activates when it detects movement of the arm. The arm and the sensor are removed from a proximity of the at least one cutter or the feed path.

Owner:STAPLES BRANDS INC

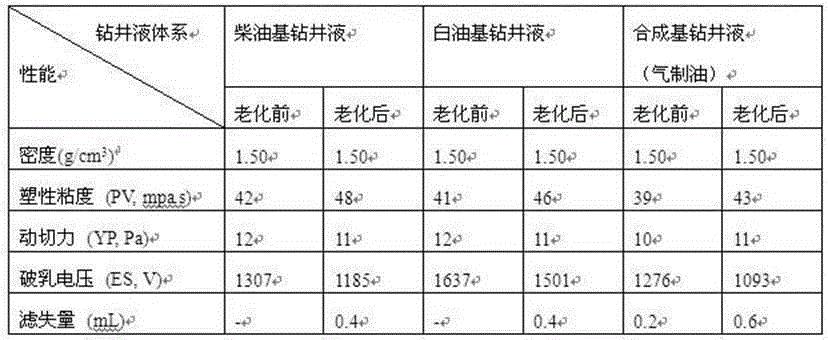

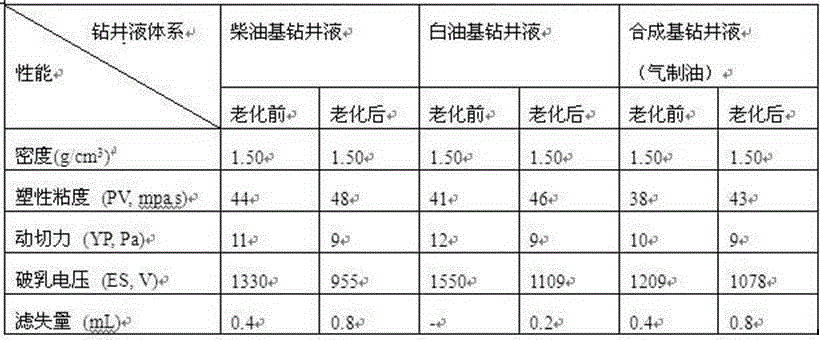

Solid emulsifier used for oil base drilling fluid, preparation method thereof and application of oil base drilling fluid

ActiveCN103980869AStrong emulsifying abilityEasy to storeOrganic compound preparationCarboxylic acid amides preparationRoom temperatureReaction temperature

The invention relates to a solid emulsifier used for oil base drilling fluid, a preparation method and an application of the oil base drilling fluid. The preparation method comprises the following steps: adding diethylenetriamine in organic acidity, adding a catalyst, heating to the temperature of 175-185 DEG C, and reacting for 1-3 hours to obtain an intermediate product which has a code name AMI-1. cooling the reaction temperature to 90-120 DEG C, adding acid anhydrides, continuously reacting for 2-4 hours, cooling to the room temperature, wherein the products is the dark brown solid, using a pulverizer for crushing to obtain the brown-red solid powder which is the emulsifier with code name EmuL-S. The emulsifier has good emulsification effect on the diesel oil, the white oil and a synthesis group, and has strong anti-temperature capability, and is cooperated with organic soil, a filtrate reducer, a wetting agent and a weighting material for constructing a high performance oil base drilling fluid system; because that the emulsifier is the powdery solid, so that the influence due to environment is little, and the storage and transport are convenient.

Owner:中石化石油工程技术服务有限公司 +2

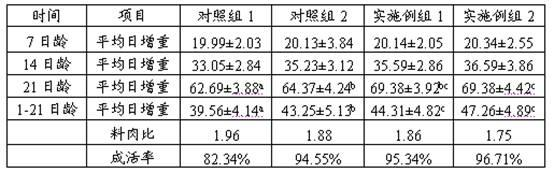

Compound feed for 0-21-days-old broiler chicken and preparation method of compound feed

ActiveCN102657292AEnhance immune functionImprove digestibilityAnimal feeding stuffDiseaseAntimicrobial peptides

The invention discloses a compound feed for 0-21-days-old broiler chicken and a preparation method of the compound feed. The compound feed is prepared from various raw materials of corn, flour, soybean meal, 60% of corn protein powder, soybean oil, limestone, calcium hydrophosphate, salt, antimicrobial peptide for the poultry, choline chloride, methionine, threonine, lysine, compound enzyme of corn and soybean meal, premixed vitamin compound, premix compound of trace elements and traditional Chinese medicine addictives. The preparation method for the compound feed comprises the following steps of: weighing all raw materials; putting the raw materials into a pulverizer to be pulverized; putting the pulverized raw materials into a mixer to be uniformly mixed; and granulating the mixed raw materials in a granulator after mixing. The compound feed has the beneficial effects that the compound feed disclosed by the invention is added with the traditional Chinese medicine addictives, so thatthe compound feed can meet the all nature requirements of the green food, diseases can be prevented, the immunity of the organism is enhanced, and the production performance of the broiler chicken can be improved so as to create favorable social value and economic benefits.

Owner:SHANDONG NEW HOPE LIUHE GROUP

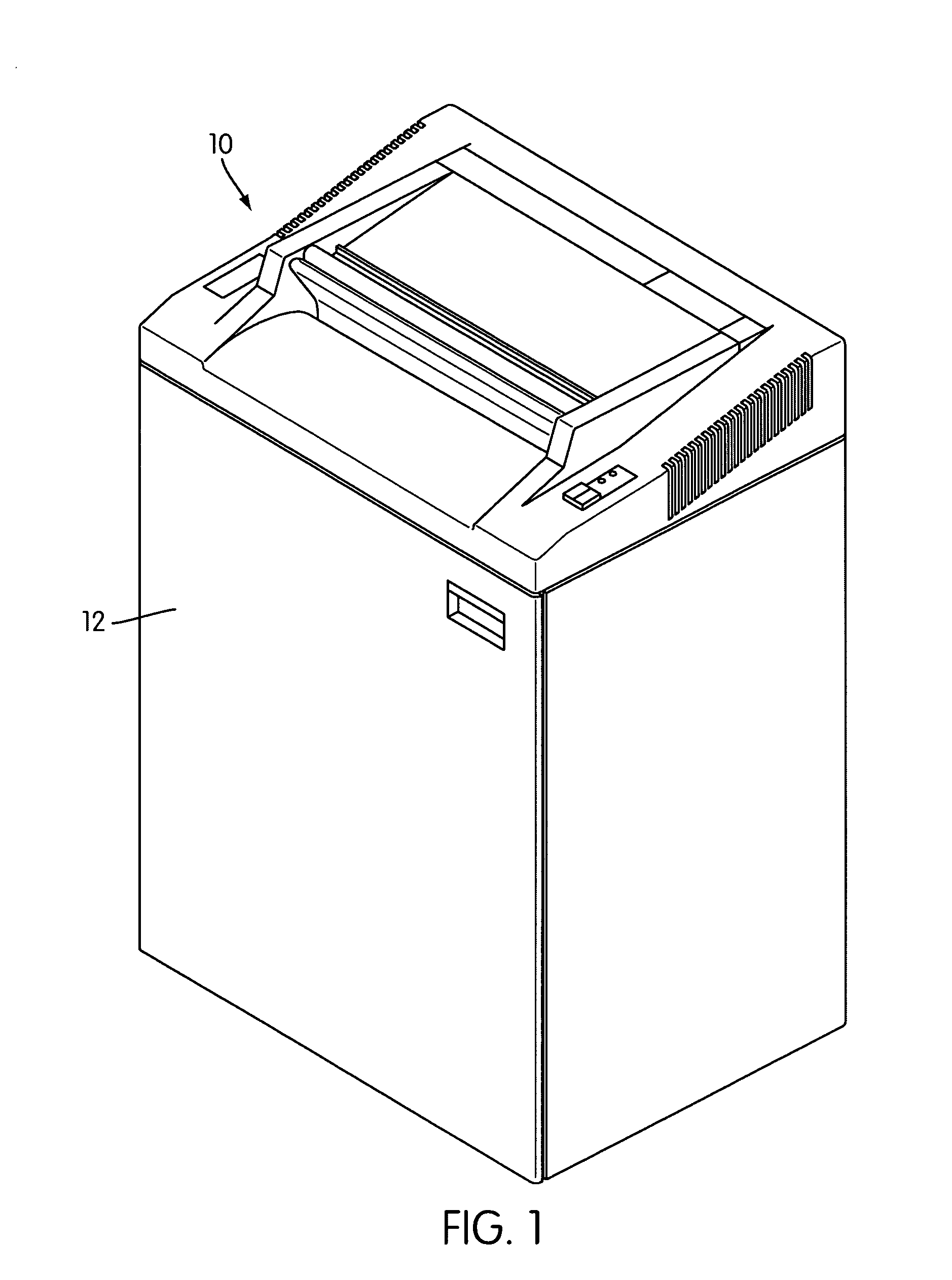

Automatic shredder without choosing the number of paper to be shredded

Owner:AURORA OFFICE EQUIP

Method for preparing carbon molecular sieve adsorbent

InactiveCN101596445ALow costReduce pollutionOther chemical processesAdsorption purification/separationPolymer scienceSorbent

The invention discloses a method for preparing a carbon molecular sieve adsorbent. The steps are as follows: (1) solidification: polymer is used as a raw material and is arranged in a thermostatic drying oven to be solidified; (2) dry distillation: the solidified macromoleclar polymer is pulverized by a pulverizer and then is processed by dry distillation; (3) fine pulverization: the macromoleclar polymer which is pulverized and processed by dry distillation is further processed by fine pulverization in the premise that the particle diameter of the macromoleclar polymer does not meet the requirement, and ball milling or gas milling is used for preparing micro-particles; (4) molding: the macromoleclar polymer which is processed by fine pulverization is mixed and uniformly stirred with agglomerant by mass ratio, and the mixture obtained is pressed and molded by an oil hydraulic press and then is dried; (5) carbonization and activation: under the state of N2 protection, temperature is raised for carbonization so as to increase the CMS surface area; and (6) carbon precipitation and hole adjustment: the hole adjustment agent is decomposed in the carbon molecular sieve for carbon deposition, the particle diameter is shortened and is enabled to be uniform, and the carbon molecular sieve product can be obtained after cooling. The carbon molecular sieve has the advantages of high CH4 adsorbing capacity, high selectivity factor of adsorption, favorable strength, low cost and no pollution, and the performance achieves or surpasses the standard of a sample of Japan carbon molecular sieve.

Owner:ANHUI UNIV OF SCI & TECH

Process for freezing and drying medlar powder in vacuum

ActiveCN102132879ARetain nutrientsPreserve appearanceFood preservationFood shapingEconomic benefitsNutrient

The invention relates to a process for dying medlar powder, in particular to a process for freezing and drying medlar powder in vacuum. The process comprises the steps of soaking, leaching water after washing with clear water, prefreezing, freezing, vacuumizing for drying, pulverizing, and the like. The invention has the characteristics that a medlar fresh fruit is frozen and dried by adopting a vacuum freezing and drying technology disclosed by the invention, nutrient components in the medlar fresh fruit, appearance shape and color are retained to the greatest extent, and the problems that the nutrient components, appearance shape and color of the medlar fruit can not be ensured in the traditional vacuum freezing and drying process, and the like are solved; the pulverizing process adopts a low-humidity, low-rotating speed and screening process and overcomes the process defects of loss, machine bonding, saccharification, and the like of effective components in medlar, caused by overhigh rotating speed of a pulverizer; and because the pulverizing process is divided into a rough pulverizing process step and a supermicropulverizing process step, the invention has considerable comprehensive economic benefits, improves the pulverizing efficiency and ensures the effective components and color in medlar powder as much as possible.

Owner:安永(中国)保健品有限公司

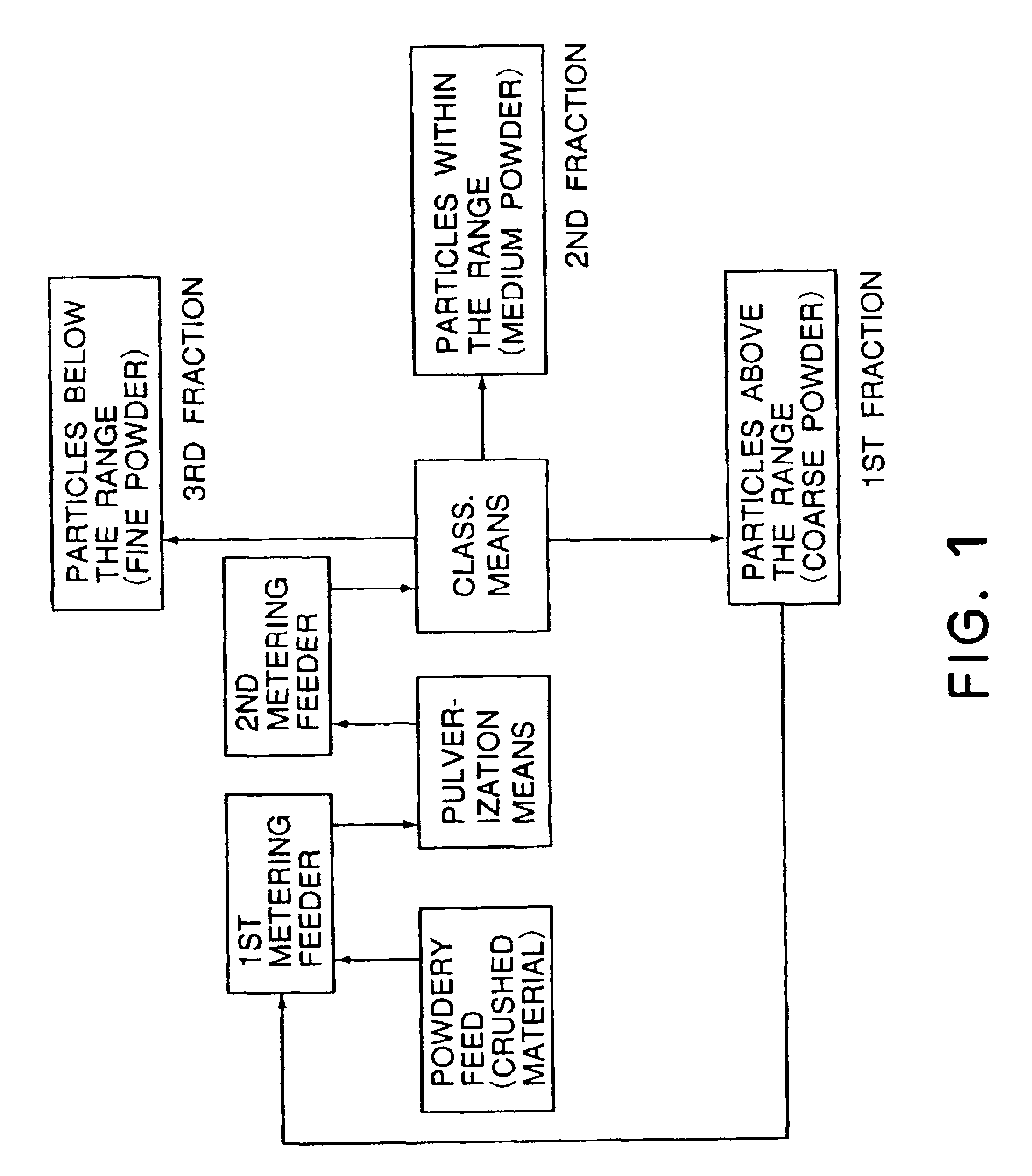

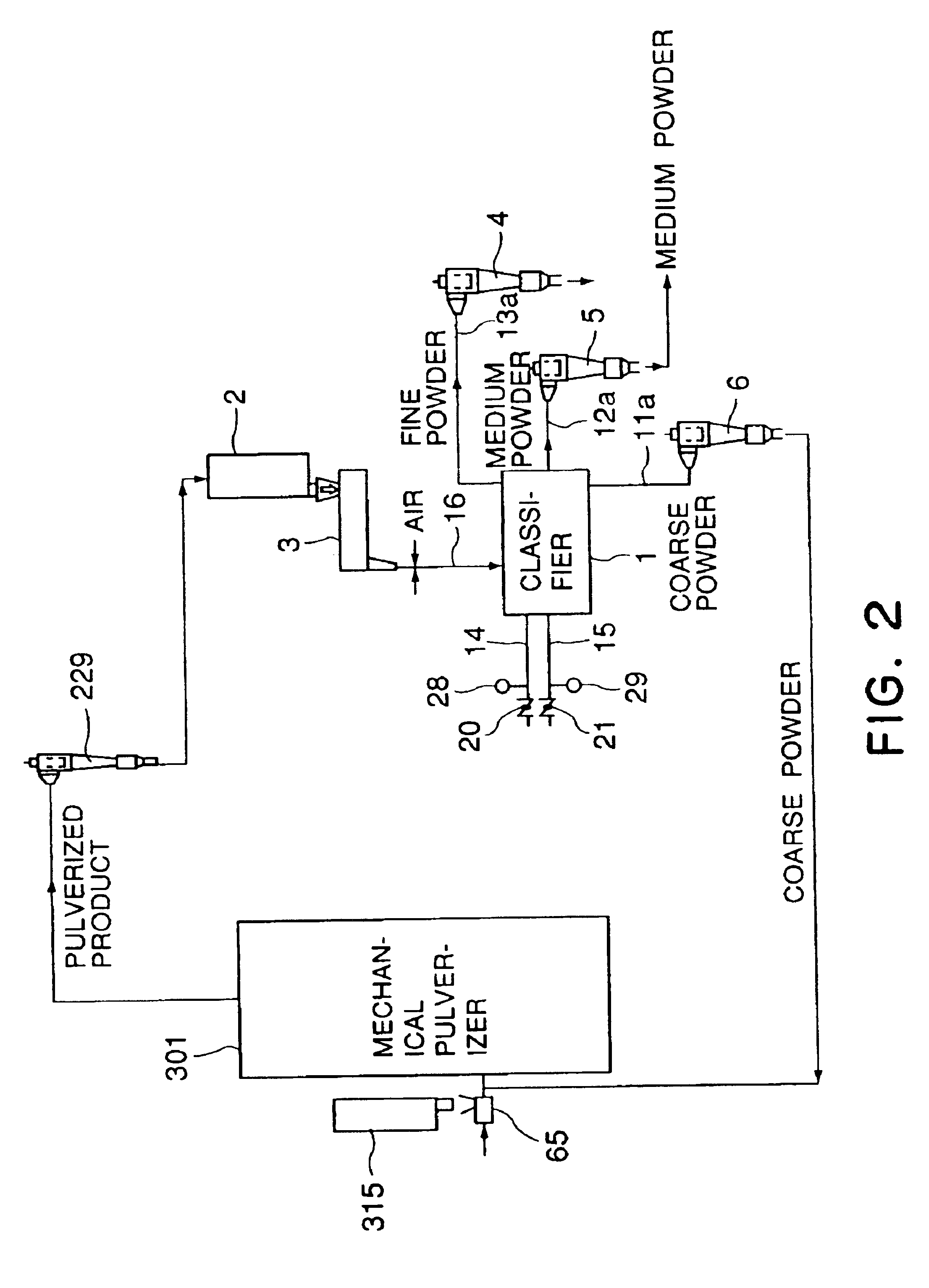

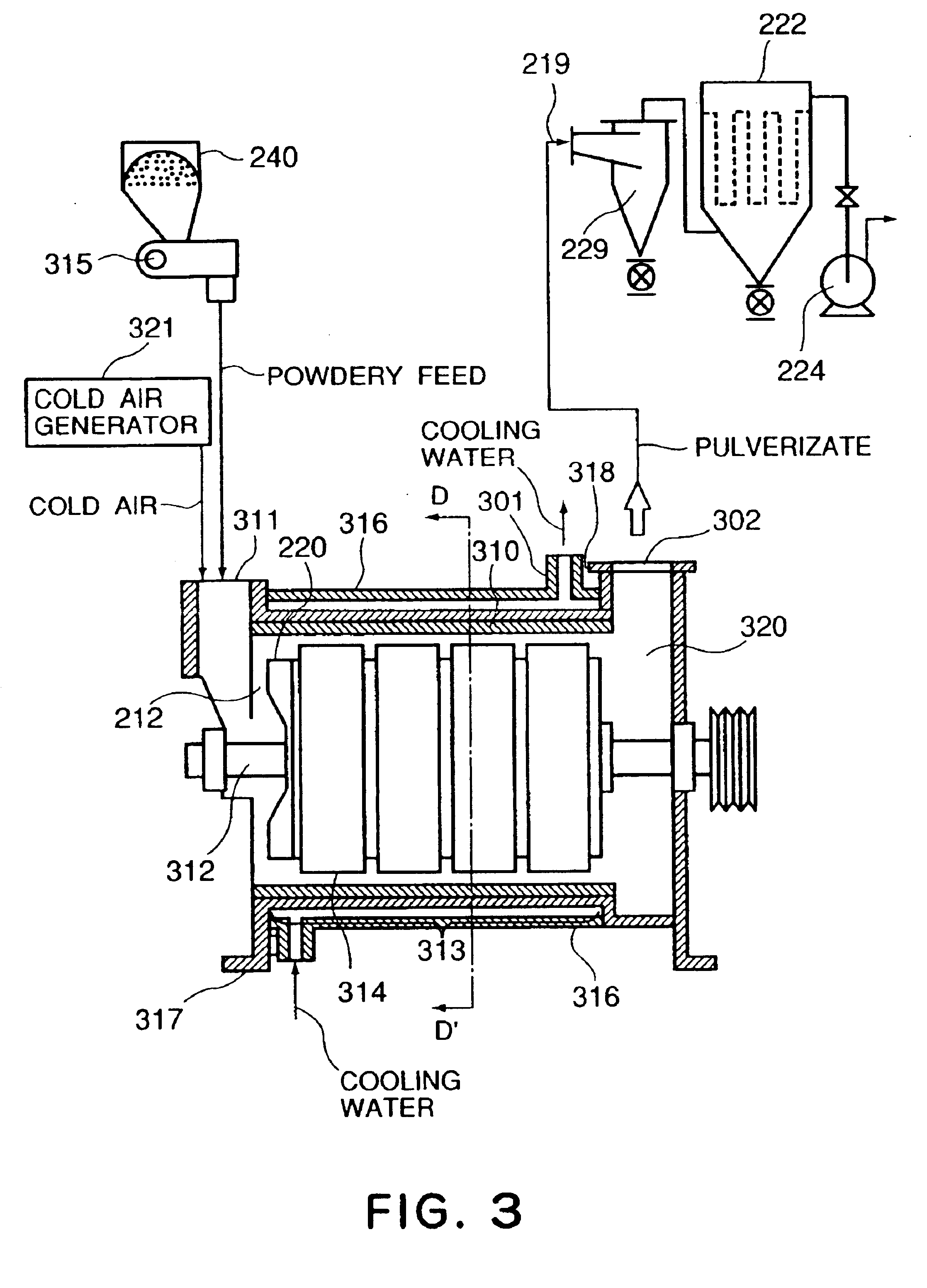

Dry toner, toner production process, image forming method and process cartridge

InactiveUS6875549B2High transfer efficiencyReduce wasteDevelopersElectrographic processes using charge patternOne passImage formation

A toner showing a high transferability and suitable for use in cleanerless image forming system is formed of toner particles comprising at least a binder resin and magnetic iron oxide. The toner is characterized by a specific circularity distribution relative to its weight-average particle size and a controlled degree of surface-exposed magnetic iron oxide providing an extract solution with hydrochloric acid showing an absorbance of 1.0-2.5 at a wavelength of 340 nm. The toner is suitably produced by a production system including a rotary mechanical pulverizer and a one-pass surface treatment apparatus for continuously applying a mechanical impact force to pulverized toner particles therein.

Owner:CANON KK

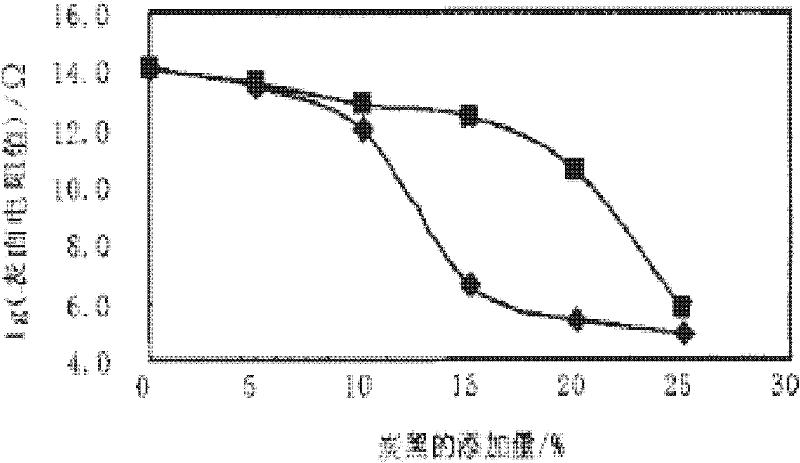

High-electric-conductivity heavy-anticorrosion wave-absorbing powder paint

ActiveCN102408813AImprove corrosion resistanceImprove bending resistanceAnti-corrosive paintsPowdery paintsEpoxyElectrical conductor

The invention relates to a high-electric-conductivity heavy-anticorrosion wave-absorbing powder paint which is prepared from the following raw materials in parts by weight: 450-500 parts of epoxy resin, 50-100 parts of curing agent, 50-100 parts of conductive pigment, 200-250 parts of conductive filler and 30-50 parts of assistant. The preparation method of the high-electric-conductivity heavy-anticorrosion wave-absorbing powder paint comprises the following steps: adding the materials into a high-speed mixer; after carrying out dry mixing, adding the mixture into an extruder, and melting, mixing, cooling and pelleting at the extrusion temperature of 80-90 DEG C; and pulverizing with a pulverizer, grading, screening and packaging to obtain the finished powder paint product. The invention has the characteristic of high electric conductivity, has an absorption action on certain electromagnetic waves, can be used as a preferred coating for electromagnetic shielding, and is applied to thefields of frequency converter shells, micro-current and light-current component shells and the like. In addition, the invention has excellent anticorrosion property and favorable electric conductivity (105 ohm), and the conducting power is almost approximate to that of a metallic conductor; and thus, the high-electric-conductivity heavy-anticorrosion wave-absorbing powder paint is an ideal antistatic coating, and can ensure safety in the aspects of fire resistance and explosion resistance.

Owner:国润恒科(天津)防腐工程技术有限公司

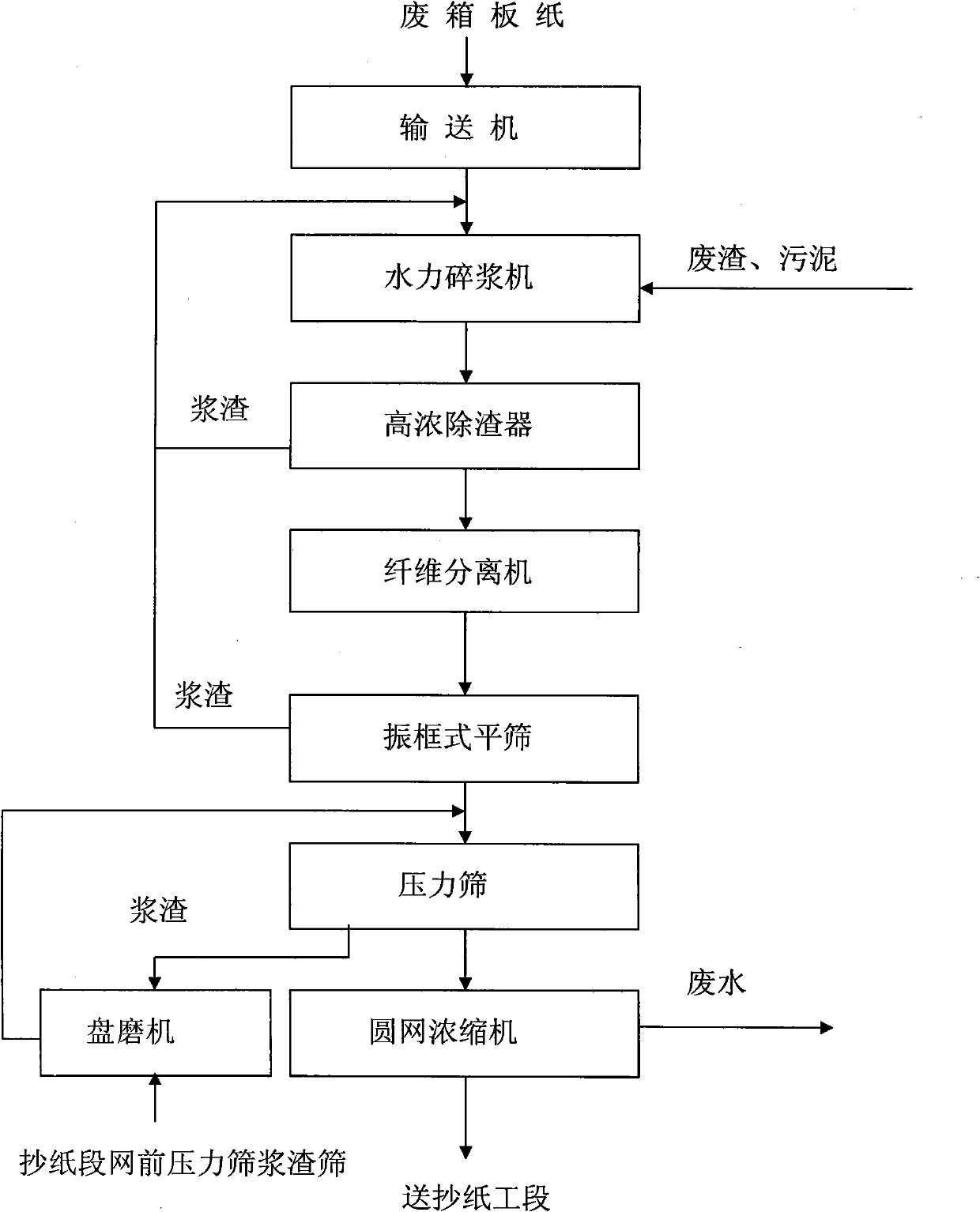

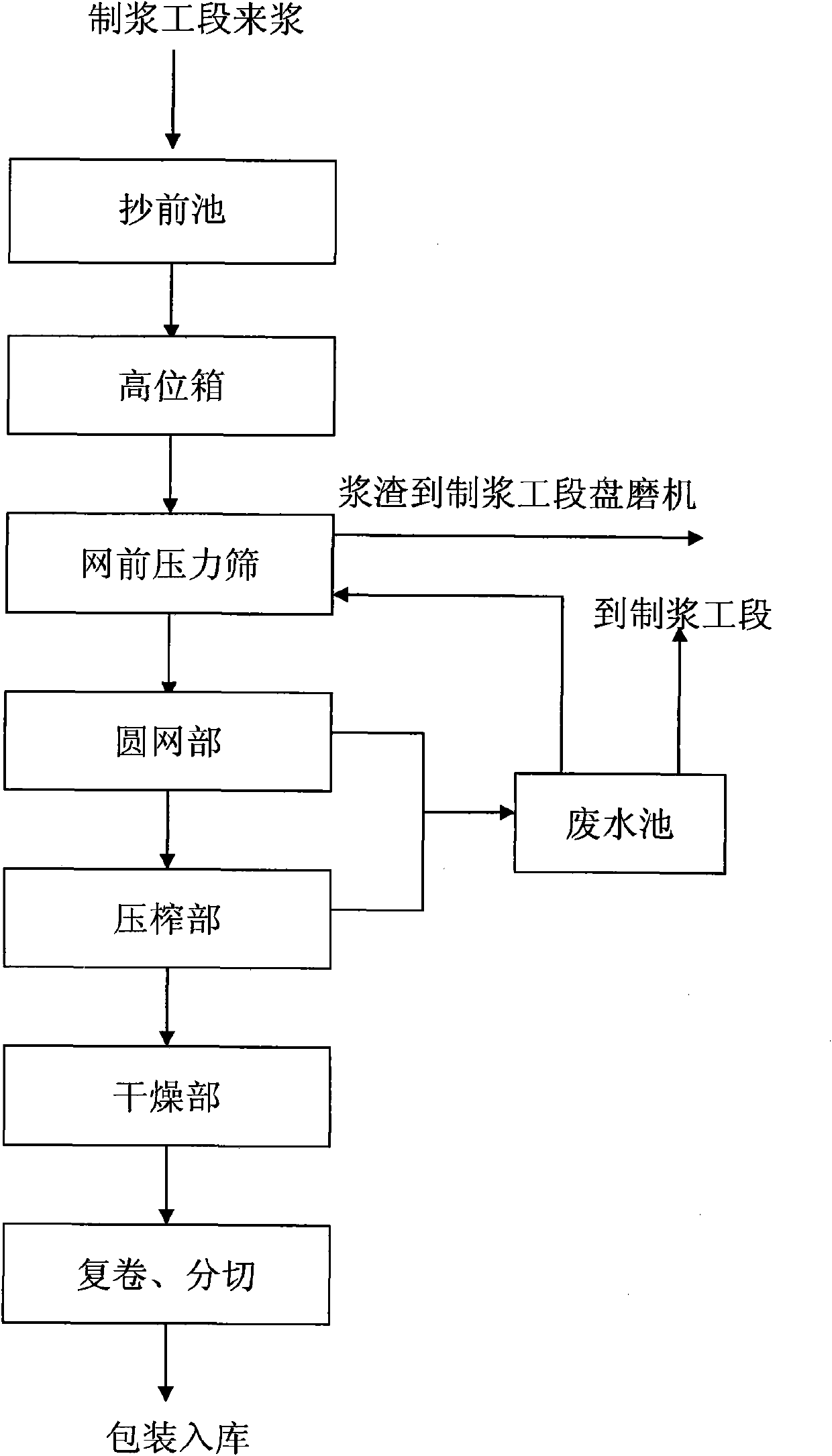

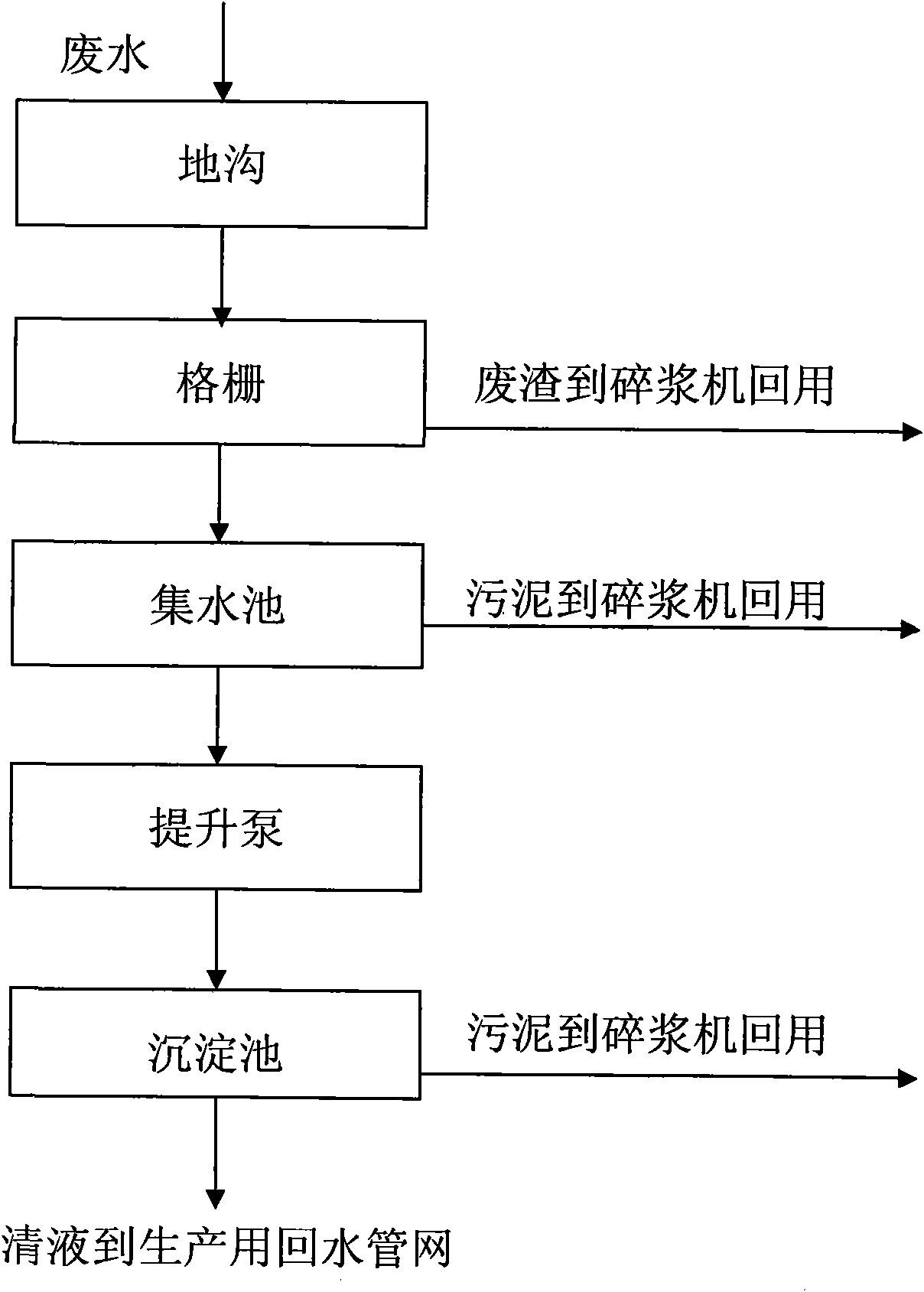

Method for producing corrugated paper by utilizing papermaking waste residues and sludge

InactiveCN102002882AReduce processing costsAvoid emissionsWaste product additionPaper recyclingFiberHigh concentration

The invention discloses a method for producing corrugated paper by utilizing papermaking waste residues and sludge. The production method comprises the following steps of: (1) pulping: breaking waste cardboard paper; meanwhile, introducing the waste residues and sludge into a hydraulic pulverizer and simultaneously pulverizing and mixing; then feeding into a high-concentration residue removing machine and removing heavy impurities; after the heavy impurities are removed from rough slurry, defibering and grading by a defibering machine; vibrating and screening the pulp by a vibration-frame type flat screen; after good pulp is further screened by a pressure screen, feeding qualified fibers into a circular screen concentrator and concentrating and delivering the qualified fibers into a papermaking section; and (2) papermaking: delivering the pulp into a preparing pool; after delivering to a high-level box by a pump, delivering the pulp to a front pressure screen and carrying out fine screening; then delivering to a circular screen part and a squeezing part; and drying in a drying part, then rewinding, cutting and packaging for storage. The method of the invention recycles the waste residues and the sludge generated in the production, saves great papermaking raw materials, prevents the emission of various waste materials and really achieves zero emission.

Owner:SHANDONG TIANDIYUAN IND

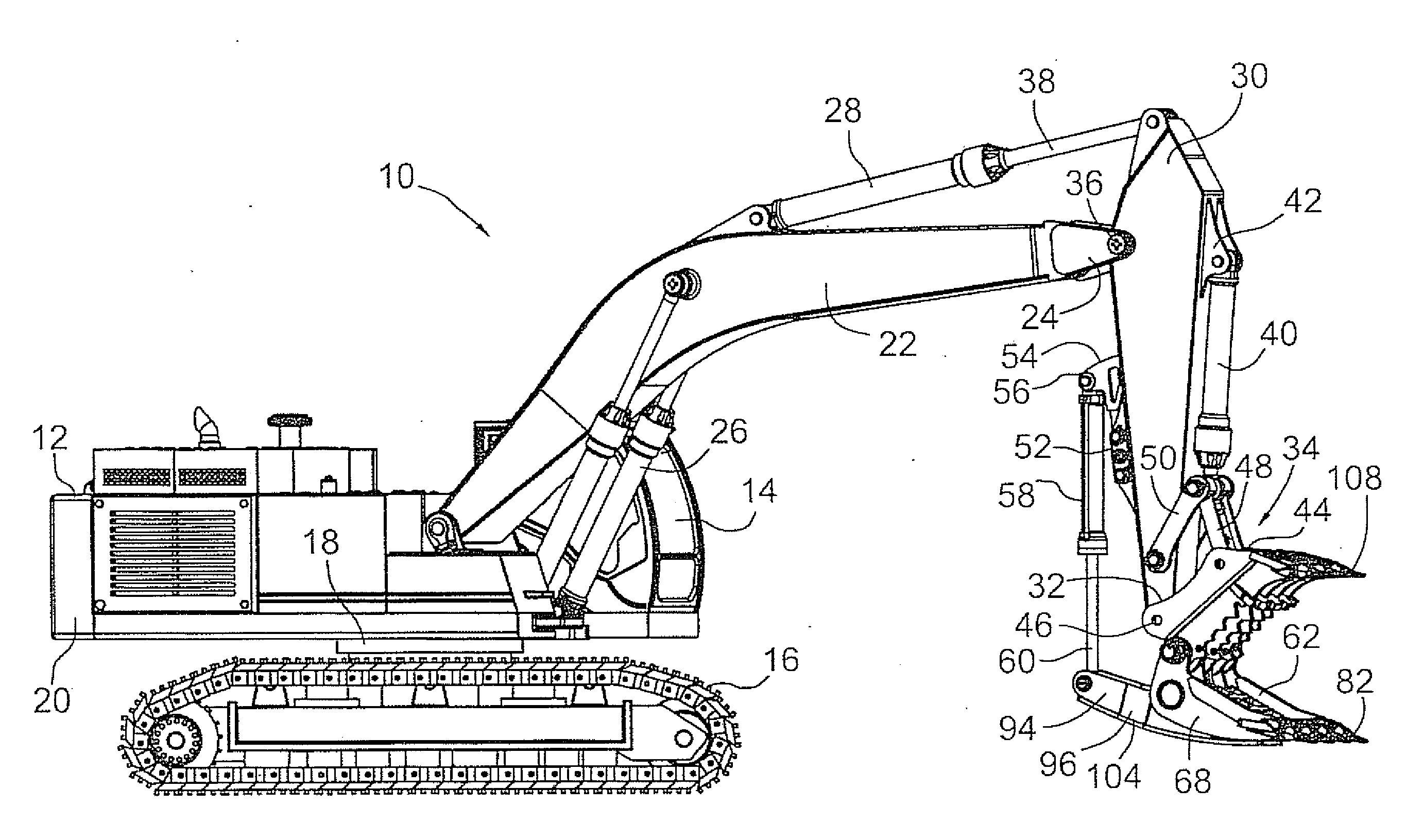

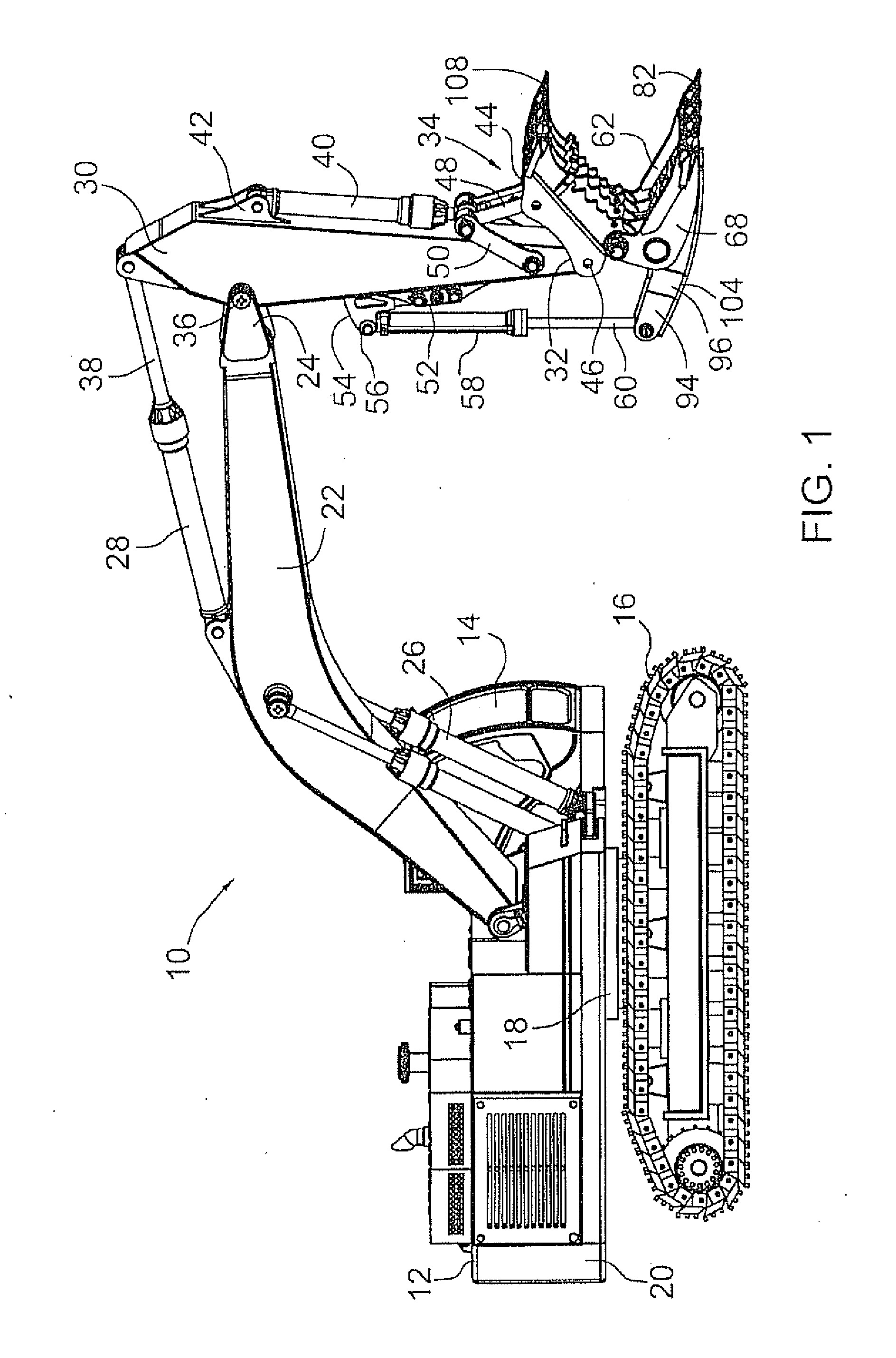

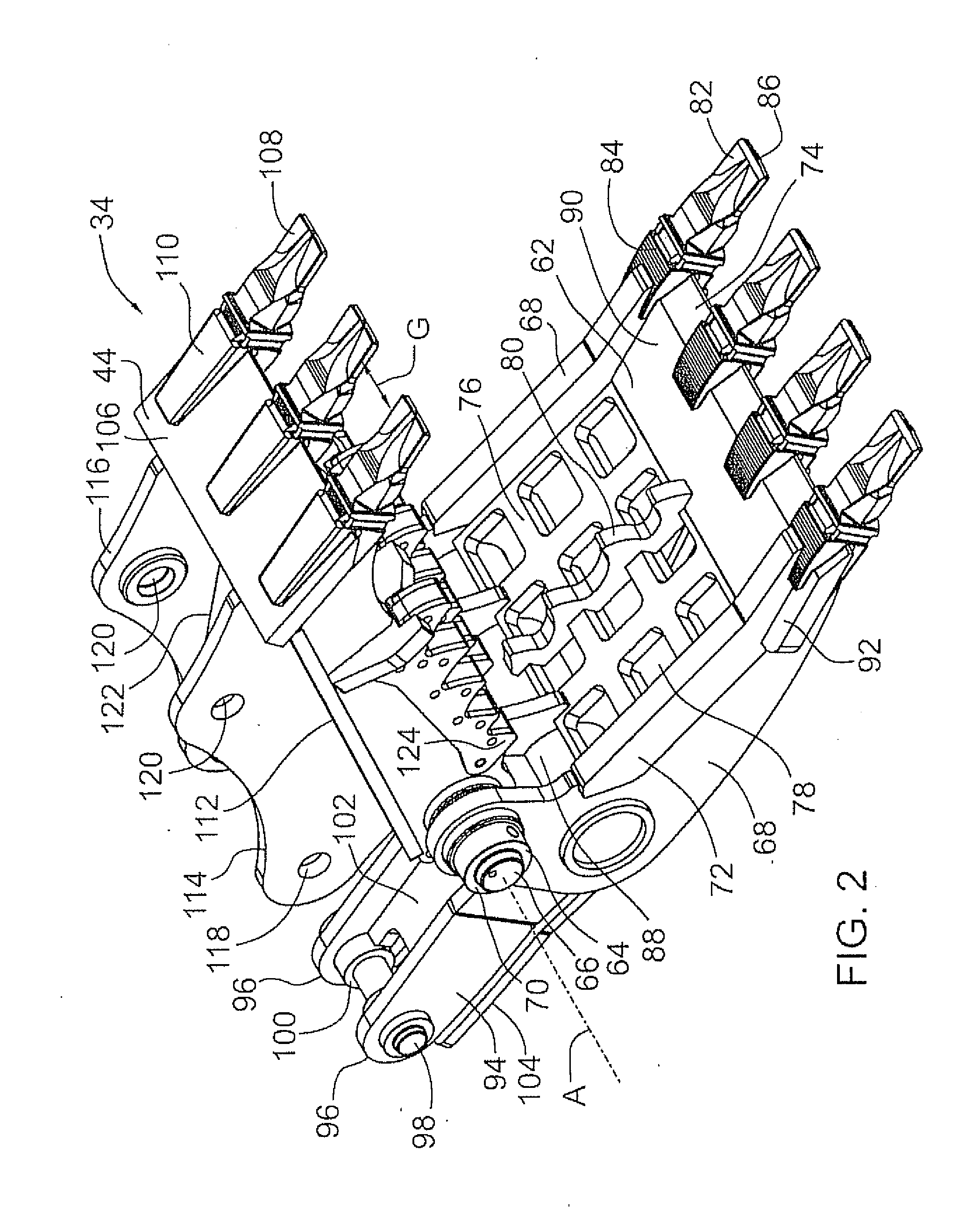

Concrete pulverizer

A concrete pulverizer adapted for mounting on an arm of an excavator including a lower jaw having a first pivot pin mechanism and a crushing surface. The crushing surface on this jaw is formed with concrete waste apertures. An upper jaw has a rear end section connectible to an end of the arm and has crushing teeth mounted on a lower side. This jaw is pivotably connected to the lower jaw by the pivot pin mechanism. The upper jaw is pivotably connected to a hydraulic cylinder actuator on the arm and can be pivoted between an upper position and a crushing closed position. There is a power mechanism for pivoting the lower jaw between a horizontal scooping position and a dumping position and this mechanism can hold the lower jaw in a crushing position while the upper jaw is being pivoted by the hydraulic cylinder actuator.

Owner:NYE MFG

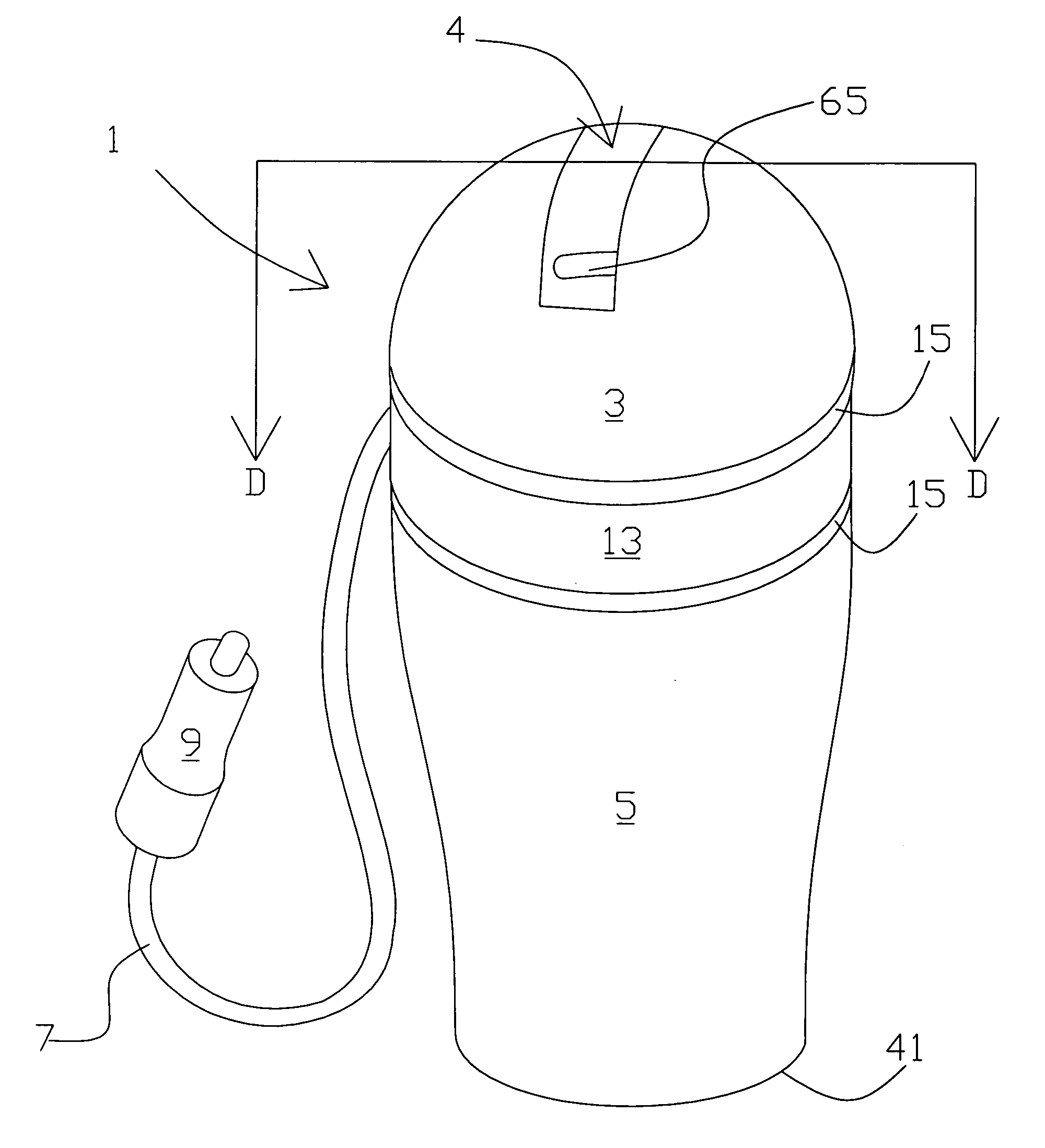

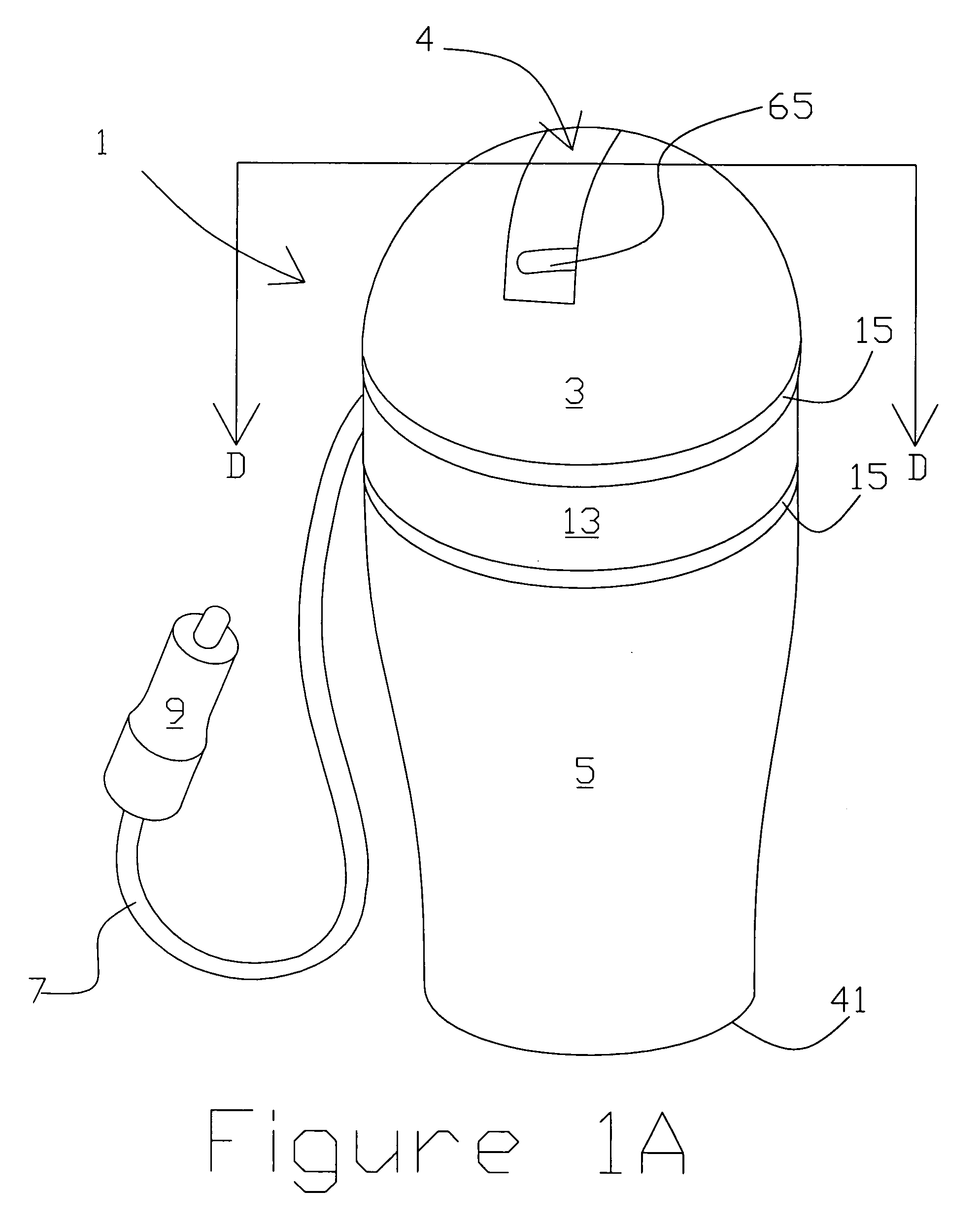

Portable shredder

The invention includes a plurality of parts or elements including at least a cap removably coupled with a container formed in the shape of a cup to provide a portable shredder that may be employed mounted in an automobile for destroying receipts and the like to prevent identity theft. The portable shredder comprises at least one rotating shaft having a first plurality of circular blades that engage a second set of blades to shred a receipt as it passes between the first and second sets of blades. The exterior shredder may be formed in the shape of a cup to be easily accommodated by a cup holder in an automobile. Otherwise, the shredder may be incorporated into an automobile part such as a door, console, dash or the like and installed during manufacture of the automobile.

Owner:BARKLAGE KEVIN

Method for preparing aquatic product cleaning agent based on shell powder

InactiveCN104877808AIncrease alkalinityImprove adsorption capacityDetergent compounding agentsOrganic non-surface-active detergent compositionsMicro nanoAquatic product

The invention provides a method for preparing an aquatic product cleaning agent based on shell powder. The method for preparing the aquatic product cleaning agent based on the shell powder comprises the steps that shells are dried or dried in sun after being degreased and desalted, high-temperature calcination and puffing are conducted after the shells are pulverized by means of a pulverizer, micro-nano crushing is conducted on the calcinated shell powder after cooling, and the natural aquatic product cleaning agent is obtained by adding a natural cleaning assistant. According to the method for preparing the aquatic product cleaning agent based on the shell powder, greasy dirt and fishy matter on the surface of aquatic products can be effectively absorbed and removed, the intrinsic character of food is not changed, the sterilization function and the freshness retaining function are achieved, the cleaning agent is safe, non-toxic and degradable, the aquatic product can be directly eaten or cooked after being cleaned, and the cleaning agent is suitable for cleaning various aquatic products.

Owner:ZHEJIANG OCEAN UNIV

Ceramsite prepared by using smelting wastes, and preparation method thereof

ActiveCN103922698AHarmlessAchieve reductionCeramic materials productionClaywaresSocial benefitsSludge

The invention relates to the technical field of harmlessness treatment of smelting wastes, and especially relates to a ceramsite prepared by using smelting wastes, and a preparation method thereof. The ceramsite comprises 10-90% of smelting waste powder, 5-40% of municipal sludge, 4-20% of fly ash, 0-20% of gangue and 0.1-10% of a curing agent. The preparation method of the ceramsite comprises the following steps: 1, crushing the smelting wastes by using a crusher to prepare the smelting waste powder; 2, weighing the smelting waste powder, the municipal sludge, the fly ash, gangue and the curing agent, mixing, and uniformly stirring to prepare ceramsite powder; 3, conveying the ceramsite powder to a ball forming granulation machine, and carrying out granulation molding to prepare ceramsite balls; 4, drying the ceramsite balls; and 5, calcining he dried ceramsite balls to prepare the finished ceramsite. The ceramsite prepared in the invention has the advantages of light weight, environmental protection and wide uses; and the preparation method recycles the smelting wastes, and has good economic and social benefits.

Owner:DONGGUAN YICHENG ENVIRONMENTAL TECH

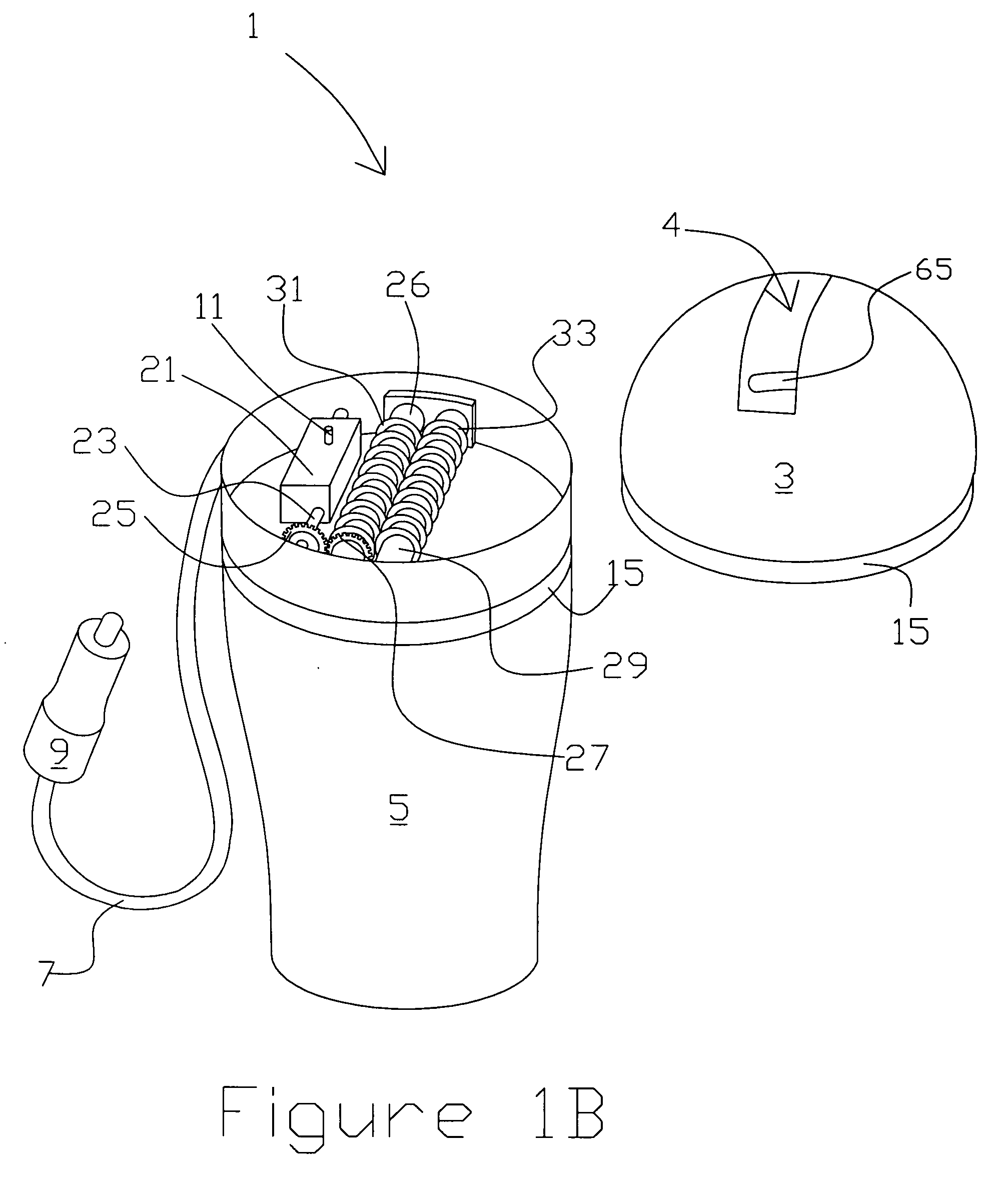

Intermetallic Aluminide Polycrystalline Diamond Compact (PDC) Cutting Elements

InactiveUS20100038148A1Improve heat transfer performanceDissipate quicklyPigmenting treatmentDrill bitsPolycrystalline diamondAdamite

Machining and cutting tools including, but not limited to, rotary drill bits, mining tools, milling tools, wood shredders, reamers and wire dies formed with at least one substrate having a layer of polycrystalline diamond disposed thereon. The polycrystalline diamond layer may be generally described as a polycrystalline diamond compact (PDC) or PDC layer. The PDC may be formed by using an intermetallic aluminide catalyst. One example of such catalyst may include nickel aluminide used to form diamond to diamond bonds between adjacent diamond particles.

Owner:HALLIBURTON ENERGY SERVICES INC

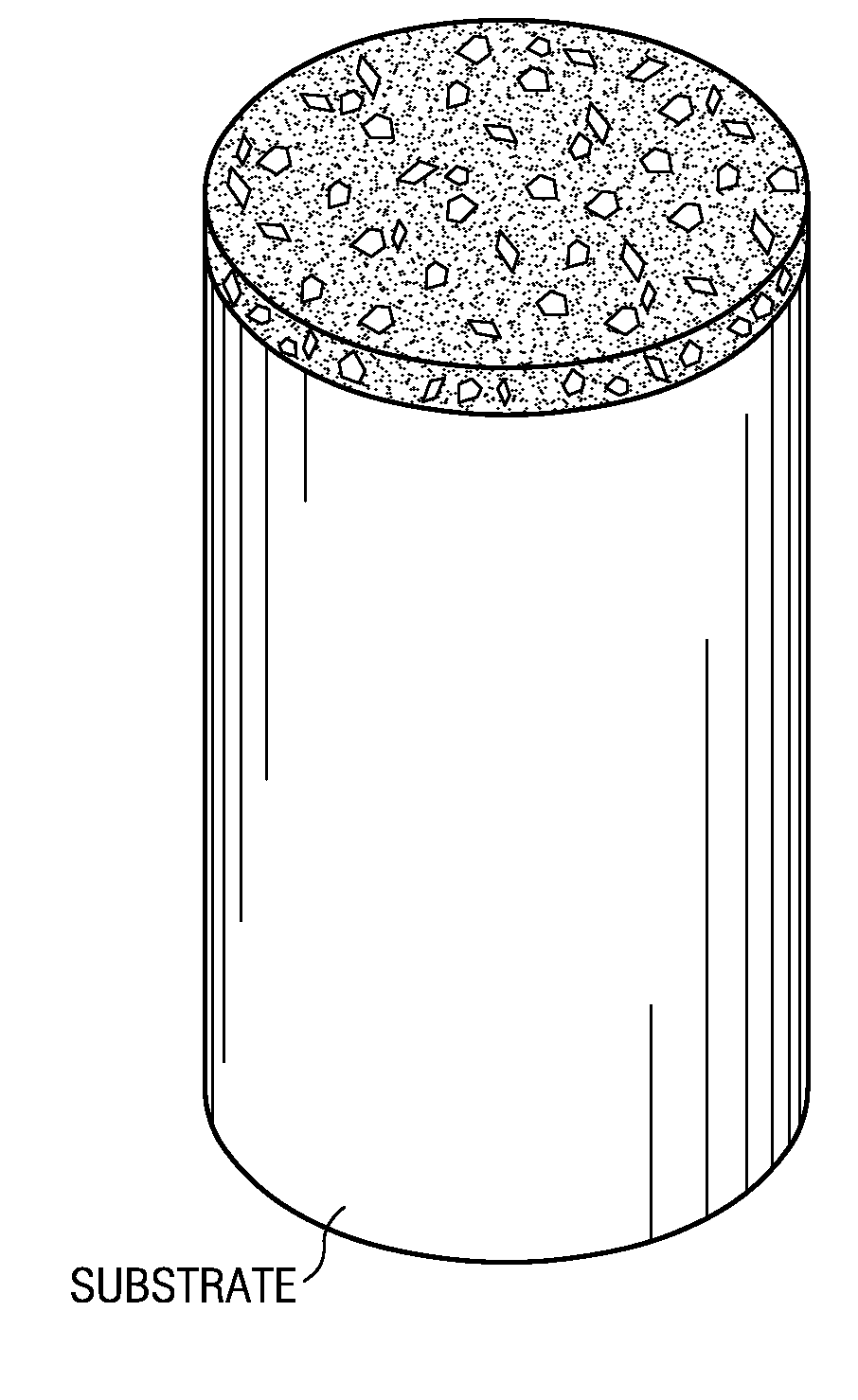

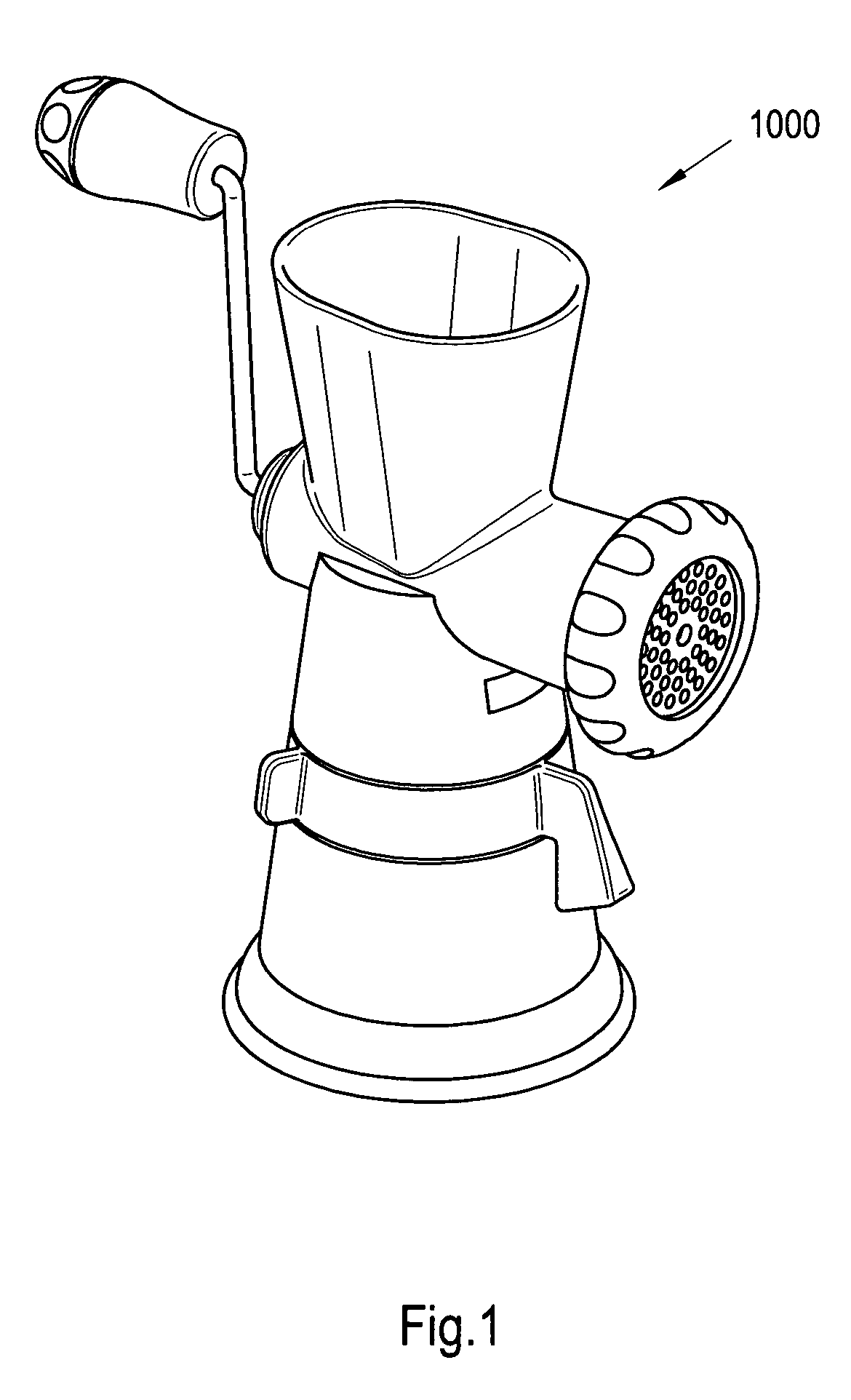

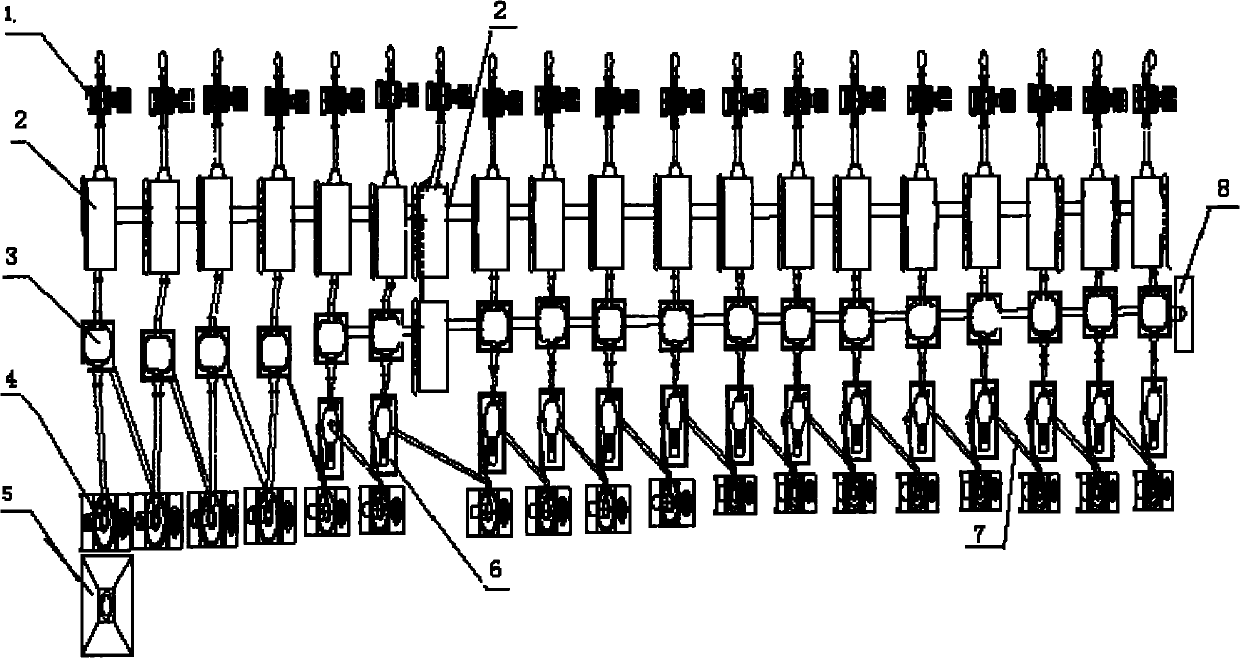

Meat grinder with suction base

ActiveUS20060243837A1Cleansing timeEasy to cleanPicture framesAnimal feeding stuffEngineeringKnife blades

This invention contains a suction base meat grinder consisting of a meat grinder with a suction base and manually operated grinding unit. Turning a rotating disk first, the user will firmly fix this meat grinder to the kitchen table surface, as well as lock the base to the upper grinding part. Then the user can rotate the handle to spin the screw bolt and the pedal blade, pushing meat to go through the pedal blade, and be grinded into ground meat, thus finishing the grinding process. Meanwhile, this grinder is made up by the grinding unit and the sucking base. The grinding unit and the sucking base can be separated at cleansing time, making it easier to clean.

Owner:WONG

Kitchen waste and food waste treatment process and kitchen waste and food waste treatment system

The invention discloses a kitchen waste and food waste treatment process and a kitchen waste and food waste treatment system. The process comprises steps as follows: mixtures of kitchen waste and food waste are sorted by an automatic sorting table and put into a pre-treatment pulverizer for pulverizing; a liquid-phase mixture obtained through the automatic sorting table and an oil-water mixture separated from the pulverizer enter oil-water separating equipment for oil-water separation; a water phase separated from the oil-water separating equipment is filtered and is discharged as life irrigating water finally; an oil phase enters biological separating equipment for biological separation, and biological oil is prepared finally. The kitchen waste and the food waste pulverized by the pre-treatment pulverizer are taken as nutrition sources and are put into a polypide cultivation production line for saprophagous polypide cultivation, adult polypides enter a dryer for drying treatment and are processed and produced into feedstuff for poultry, fish and the like, polypide waste and residues are degraded, a part of a degraded material is used for generating electricity in a biomass fuel mode, and the other part is packed and transported outwards in an organic fertilizer mode for use.

Owner:深圳市德力骏塑胶机械有限公司

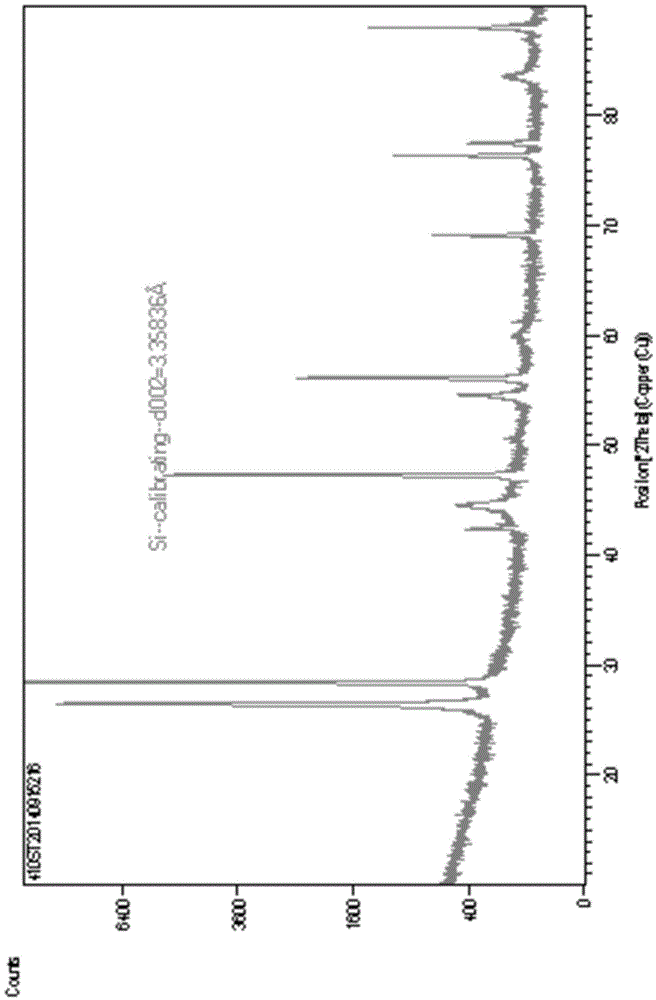

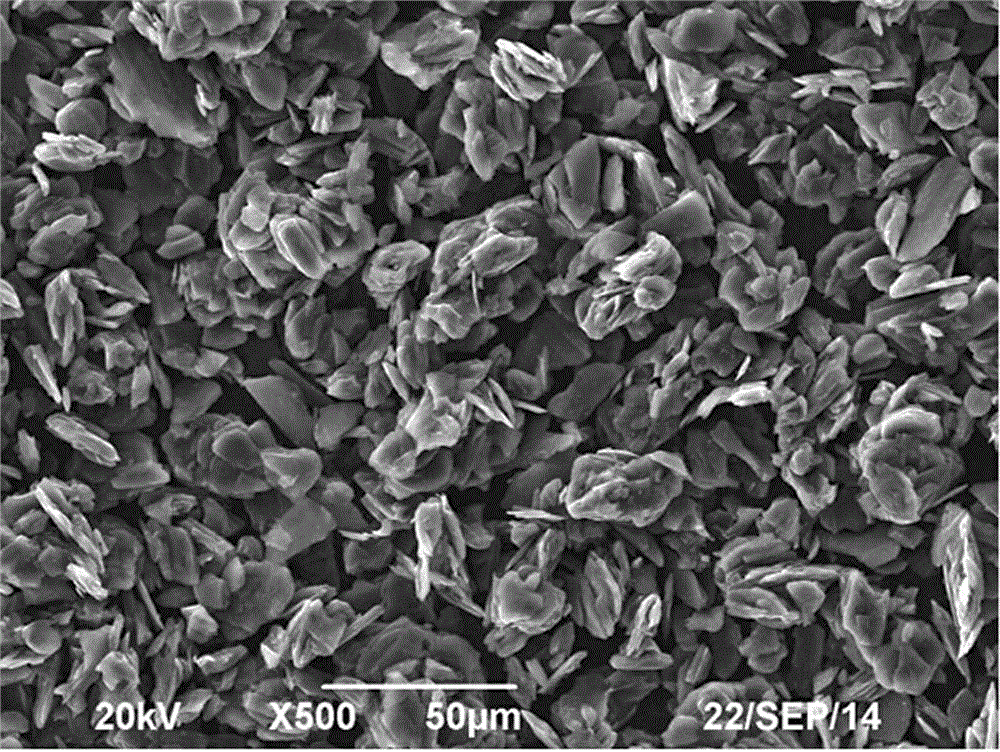

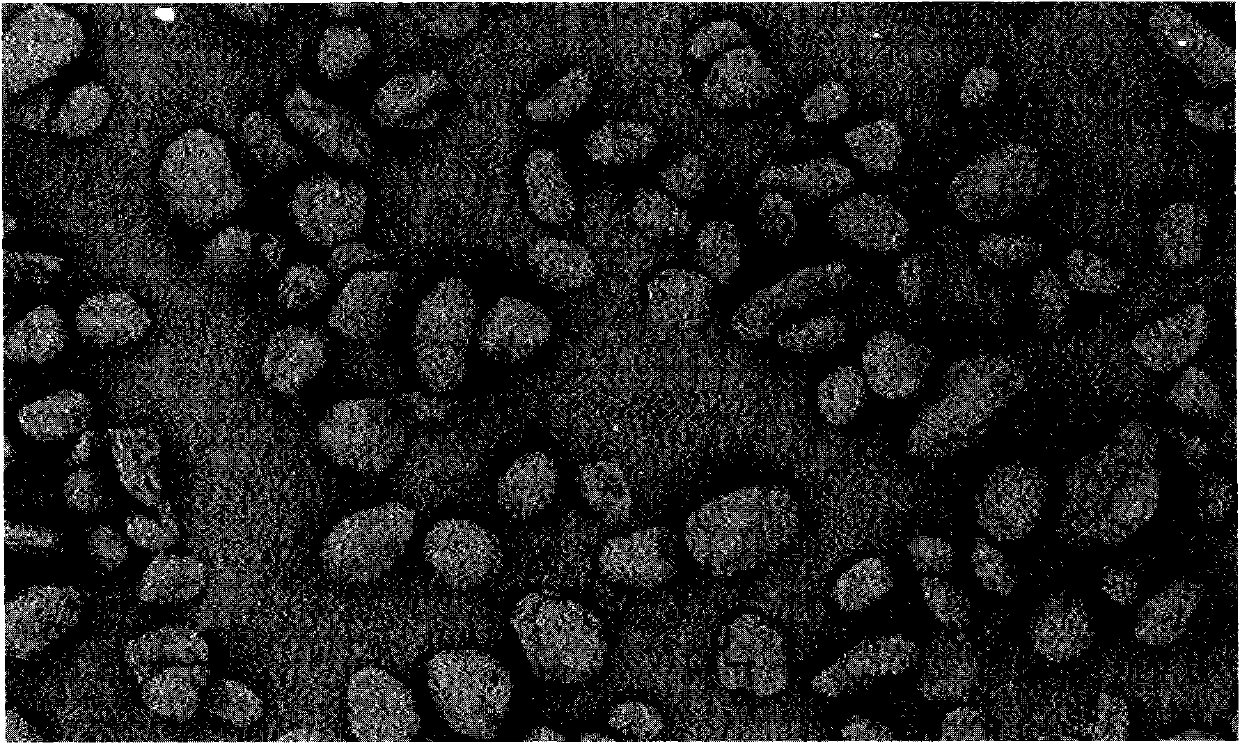

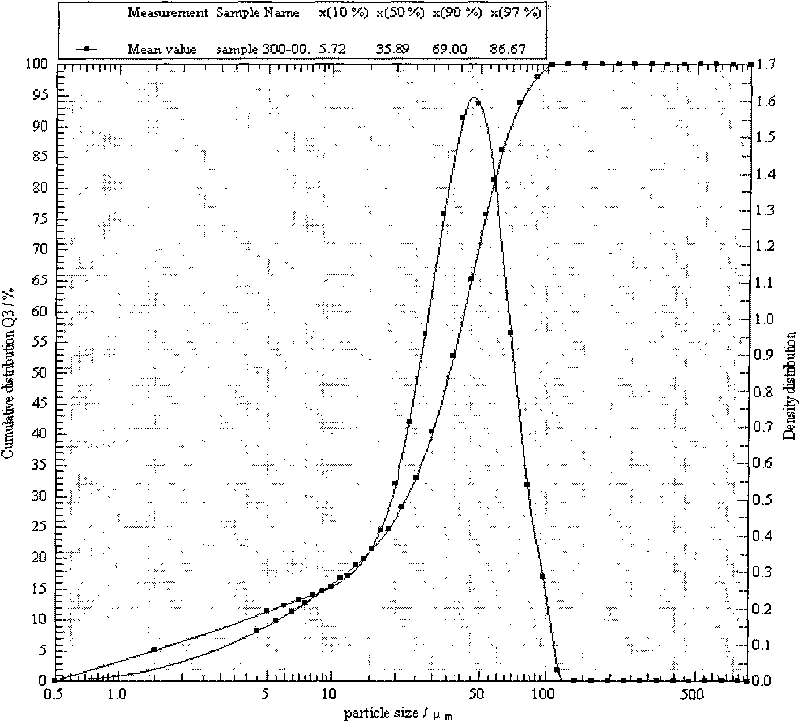

Production method of spherical graphite

The invention relates to a production method of spherical graphite, which is characterized in that spheroidizing equipment is used for processing the graphite into sphericity or potato shape with grain size of 10-45mu m; the spheroidizing equipment comprises n groups of devices; each group is formed by connecting a Roots blower, a dust collector, a cyclone separator and a pulverizer in turn; and a discharge outlet of the cyclone separator in the (n-1)th device is connected with a feed inlet of the pulverizer in the nth device. The method dispenses with personnel operation, is higher in yield and efficiency and lower in cost in unit time and realizes automatic closed production of the whole production line. Compared with the prior art, the method is characterized in that the spherical graphite produced by the method has better sphericity, higher tap density, large specific capacity being more than 350mAh / g, small specific area, excellent lithium intercalation and de-intercalation capabilities and cycle stability and 500-cycle capacity-keeping rate being more than 80%.

Owner:黑龙江省牡丹江农垦湠奥石墨烯深加工有限公司

Magnetorheologicai polishing liquid and preparation method thereof

InactiveCN101139504AEasy to polishImprove uniformityMagnetic liquidsPolishing compositionsSurface finishMagnetization

The invention relates to a magnetic rheological polishing fluid and a preparing method for the fluid. The magnetic rheological polishing fluid comprises by volume magnetic particles 30-40%, pure water 45-55%, additive 5-10%, surface active agent 3-5% and polishing powder 5-8%. The preparing method comprises: the magnetic particles are surface cleaned and activated, the surfaces of the magnetic particles are treated by a hi-speed ball pulverizer. The magnetic rheological polishing fluid prepared by the invention is of hydrolyzation function. The preparing method is simple. The fluid is of a good resistance to settlement and conglobation, low zero-field viscosity, high polishing efficiency, good effect, long service life, and is applicable for optic polishing. The invention solves such problems of prior magnetic rheological polishing fluid as high viscosity, weak magnetizing strength, liable to caking, not stable in settling and conglobation, liable to rust, short service life and low efficiency. The magnetic rheological polishing fluid prepared by the invention is of high efficiency, and can facilitate the surface finish of a k9 glass to increase from 400nm to 0.6 nm in 30 minutes. The invention can be widely used in the super surface polishing of optic glass.

Owner:XIAN TECHNOLOGICAL UNIV

Slow controlled release diatomite fertilizer

InactiveCN101531553AChemically stableCreate pollutionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersParaffin waxPolyvinyl alcohol

The invention relates to a slow controlled release diatomite fertilizer which is characterized in that 16 to 20 portions of urea, 12 to 17 portions of diammonium phosphate, 10 to 15 portions of potassium chloride and 8 to 12 portions of diatomite are put in a pulverizer to be crushed and sieved by a 80-mesh sieve and then are put in a granulator to be granulated by a rotary drum; 50 to 100ml water is added slowly and uniformly to be used as coupling agent during the granulating process; after the granulation, 100 to 120ml coating material of polyvinyl alcohol is sprayed to rotating fertilizer particles by a high-pressure spray gun uniformly in small amount; after coating, rosin and olefin are poured into the rotary drum based on the proportion of 1 to 2 to be melted and made into sealant; the temperature is kept between 70 DEG C to 80 DEG C; and finally, the coated fertilizer is poured into the rotary drum to be sealed. The invention can separate the soil from the fertilizer, avoids the direct contact of the soil and the fertilizer and controls the release of nutrient; the slow controlled release diatomite fertilizer has the functions of preserving moisture and fertility, prolonging the fertilizer effect by slow release and improving the soil; and the slow controlled release diatomite fertilizer causes no pollution to the soil.

Owner:吉林省巨森肥业有限公司

Anti-paper jam protection device for shredders

InactiveUS20100282879A1Shorten maintenance timeEasy to getBalingCocoaPulp and paper industryContact element

The present invention relates to an anti-paper jam protection device for shredders comprising a paper thickness detecting device, an indicating device and a controlling device, wherein the paper thickness detecting device is an electromagnetic induction paper thickness detecting device comprising a contact element, an electromagnetic element and an electromagnetic induction element, the contact element is connected rotatably to the body of the shredder, one end of which is positioned in the paper inserting passage, on the other end of which is mounted the electromagnetic element, the electromagnetic induction element is mounted on the body of the shredder and spaced with the electromagnetic element face to face, and the controlling device is in line connection with the electromagnetic induction element, the present invention controls the thickness of the paper to be shredded during the paper inserting stage, and shreds paper automatically only in a predetermined value range, to avoid abnormalities that result in failure of the machine such as jam and tooth breaking when the shredder is shredding many pieces of paper, so as to reduce maintenance times and cost, extend service life, and make application of shredders safer and more reliable, more convenient and simpler, then to achieve better protection of shredders.

Owner:AURORA OFFICE EQUIP

Method for extracting black fungus polysaccharide

The invention provides a method for extracting black fungus polysaccharide, which comprises the following steps of: (1) taking dry black fungi, mechanically pulverizing the dry black fungi coarsely, screening the pulverized black fungi with a 40-mesh sieve, then pulverizing the black fungi again by an ultrafine pulverizer, and adjusting and controlling the rotating speed of a fan of the ultrafine pulverizer to between 10,000 and 22,000 r / min to obtain ultrafine powder of the black fungi; mixing the ultrafine powder of the black fungi and water in a mass ratio of 1:20-100; extracting the mixture for 20 to 90 minutes by using 10 to 40 kHz ultrasonic waves at the temperature of between 40 and 80 DEG C; centrifugating extracting solution to obtain a supernatant fluid and a deposit; adding the supernatant fluid into a mixture of diatomite and activated carbon in a mass ratio of the diatomite to the activated carbon of 1 to 3, wherein the added amount of the mixture is 2 to 8 percent of the weight of the supernatant fluid; fully stirring the mixture, than then filtering the mixture; performing membrane filtration on the filtrate by using a 50kD polysulphone membrane; and collecting macromolecular concentrated solution which is not filtered through the membrane, and drying the macromolecular concentrated solution to obtain the black fungus polysaccharide. The prepared black fungus polysaccharide has high purity and high bioactivity.

Owner:CHINA JILIANG UNIV

Process for producing methane by dry-type fermentation of stalks

InactiveCN101338325ALess investmentReduce operating costsBio-organic fraction processingClimate change adaptationSlagSlurry

The invention provides a technique for producing biogas by utilizing stalk dry fermentation which includes the steps: I, cracking the stalks into 2 to 8mm by a cracking machine; II, transmitting the cracked stalks into a pre-treatment pool, adding hot water of 40 to 53 DEG C and a stalk fermentation agent in the pre-treatment pool to carry out pre-treatment; the cracked stalks and the biogas slurry refluxed by the anaerobic digester of the pre-treatment pool are mixed according to a proportion of 2 to 1; after stirring, the solid content rate of the stalk liquid is 20 to 35 percent; III, using a mud pump to equally transmit the stalk liquid to the top part of the anaerobic digester with a fermentation temperature of 40 to 53 DEG C; IV, the biogas generated by fermentation is purified to be clean fuel by gas-liquid separation. The technique can lead the stalks of 1.5kg to generate the biogas of 1m<3> (the content of methane is larger or equal to 55 percent); the degrading rate is more than 90 percent. The technique of the invention can continuously feed and discharge; the biogas slurry can be repeatedly used; only biogas slag is discharged; the biogas slag is manufactured into organic fertilizer by processing and can not cause any pollution to the environment.

Owner:HENAN FUCHENG ECOLOGICAL ENERGY TECH

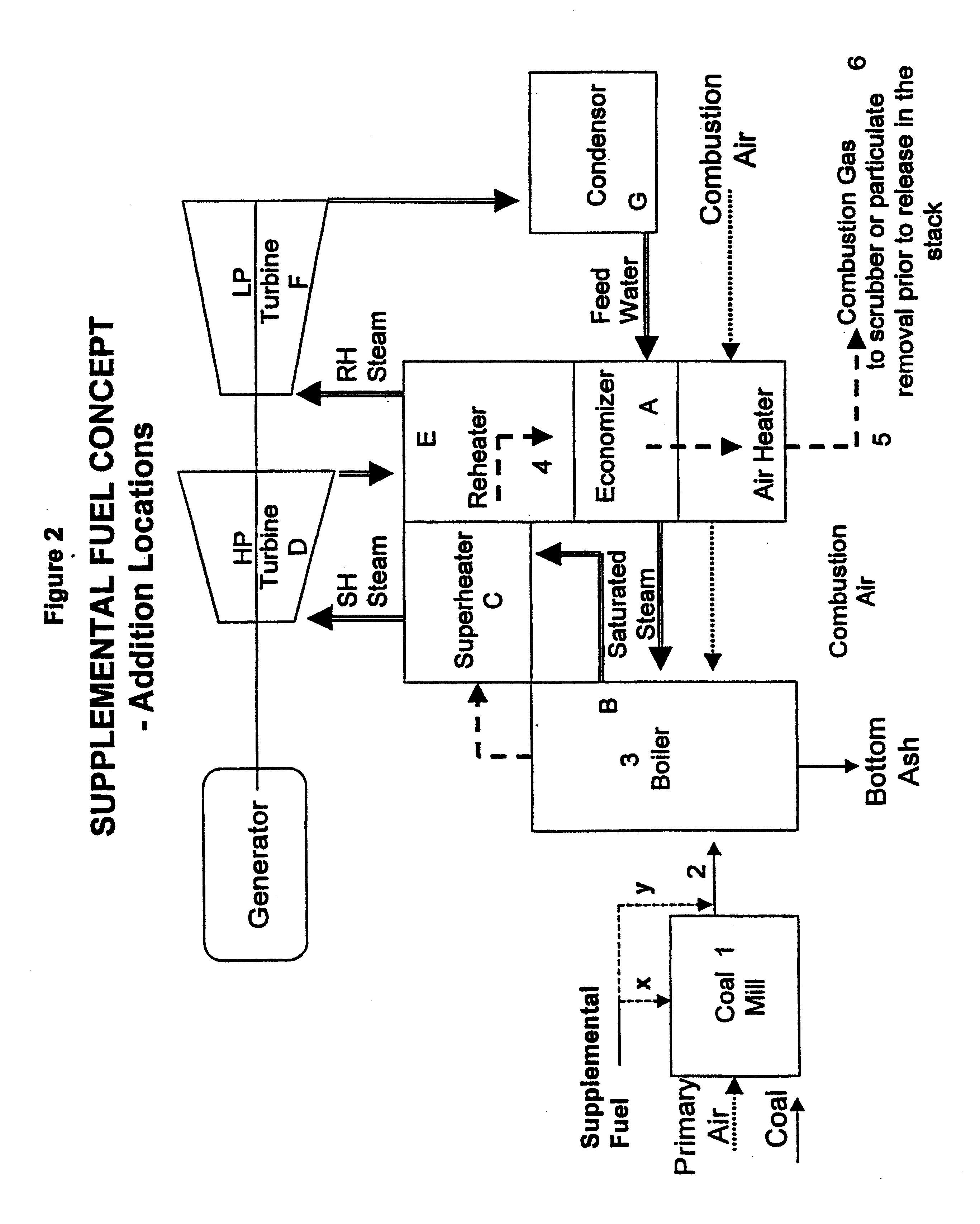

Process to improve boiler operation by supplemental firing with thermally beneficiated low rank coal

InactiveUS6325001B1Improve combustion characteristicsImprove combustion performanceSolid fuel pretreatmentSolid fuelsDevice typeBrown coal

The invention described is a process for improving the performance of a commercial coal or lignite fired boiler system by supplementing its normal coal supply with a controlled quantity of thermally beneficiated low rank coal, (TBLRC). This supplemental TBLRC can be delivered either to the solid fuel mill (pulverizer) or directly to the coal burner feed pipe. Specific benefits are supplied based on knowledge of equipment types that may be employed on a commercial scale to complete the process. The thermally beneficiated low rank coal can be delivered along with regular coal or intermittently with regular coal as the needs require.

Owner:SYNCOAL SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com