Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9312results about "Developers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

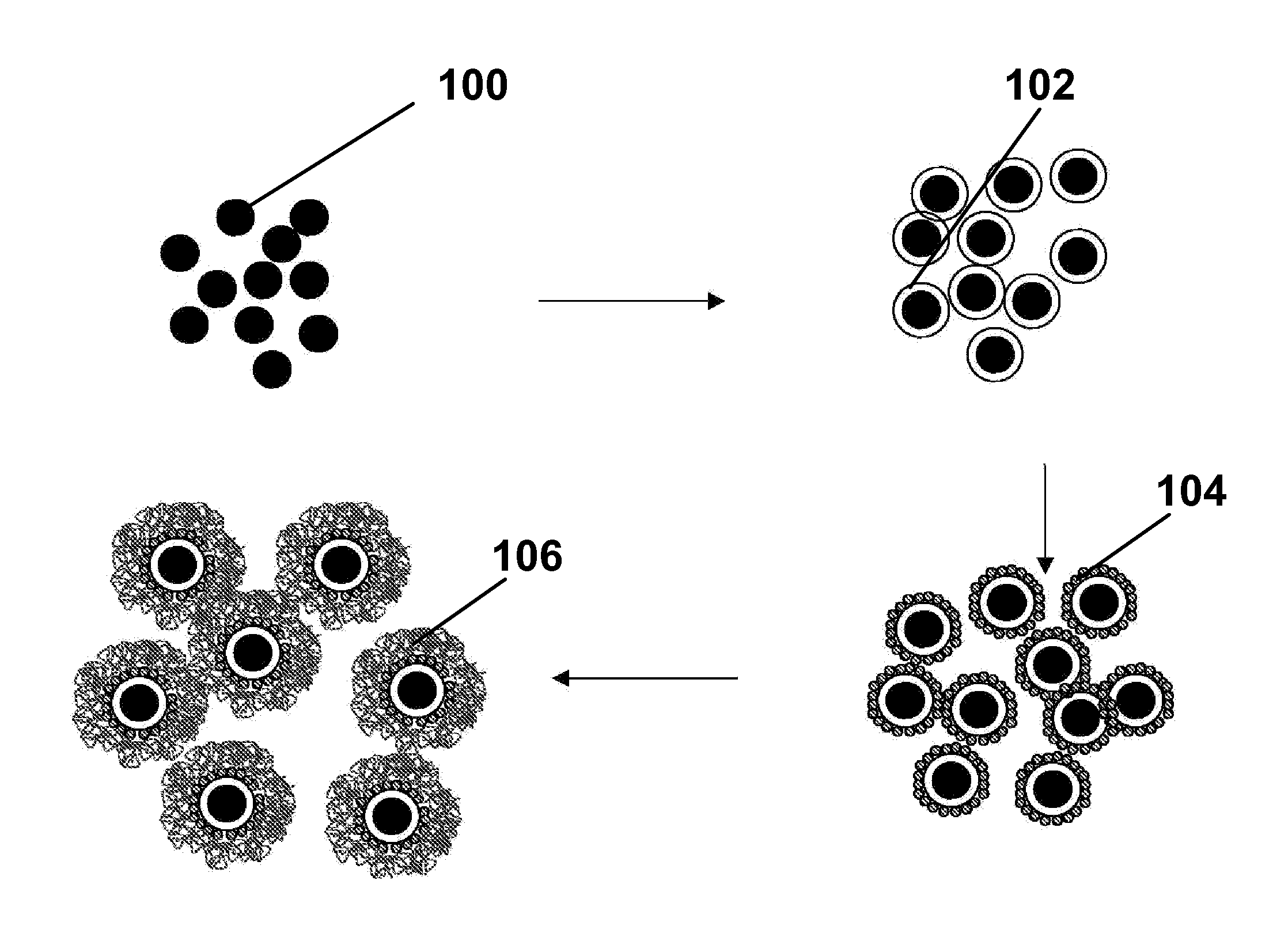

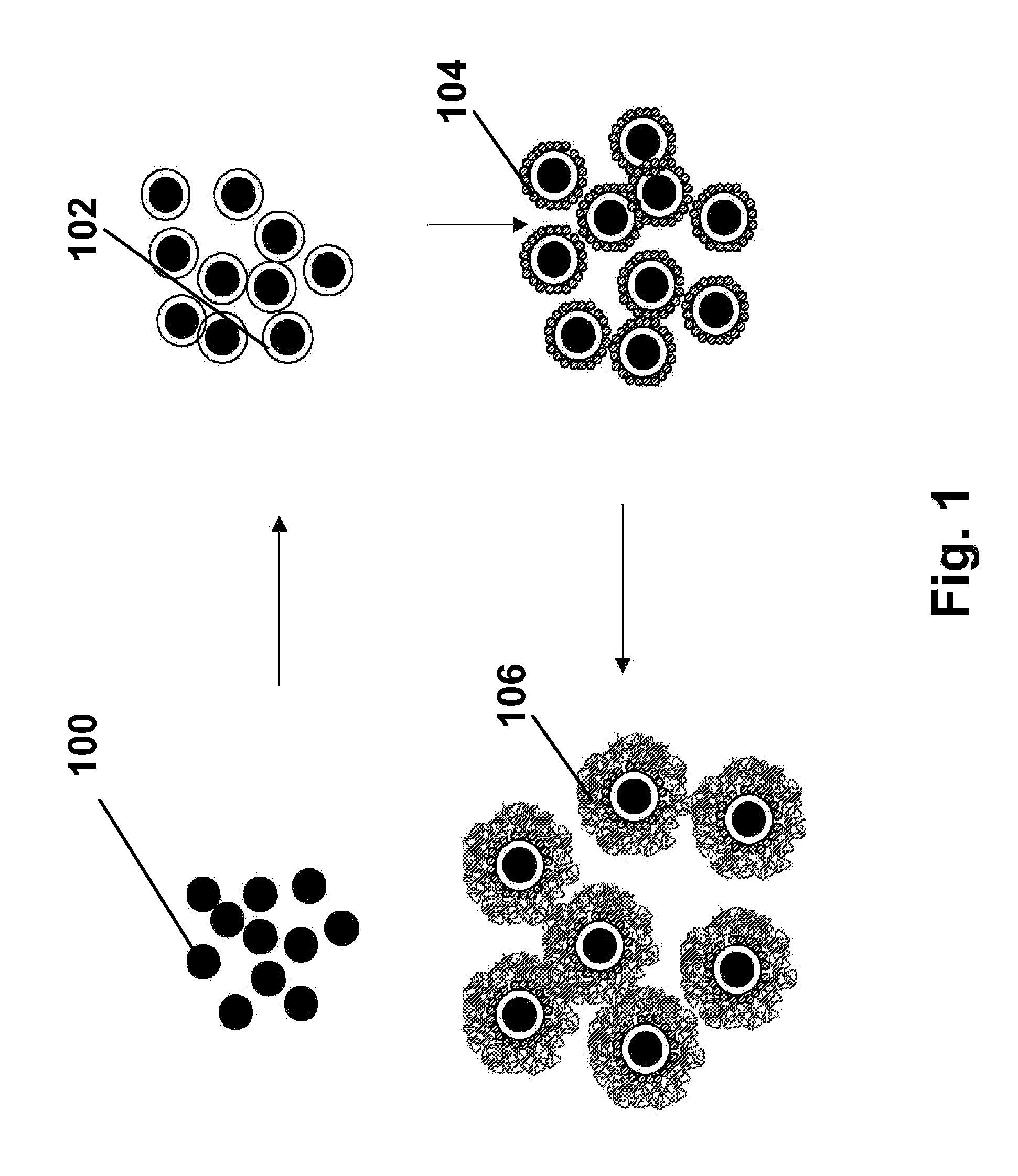

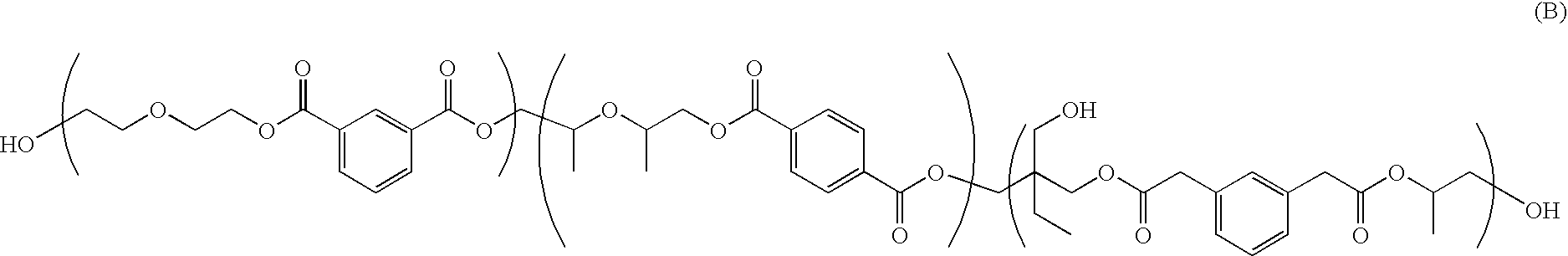

Electrophoretic particles and processes for the production thereof

InactiveUS6822782B2Improve stabilityEasy to adaptMaterial nanotechnologyStatic indicating devicesCross-linkOligomer

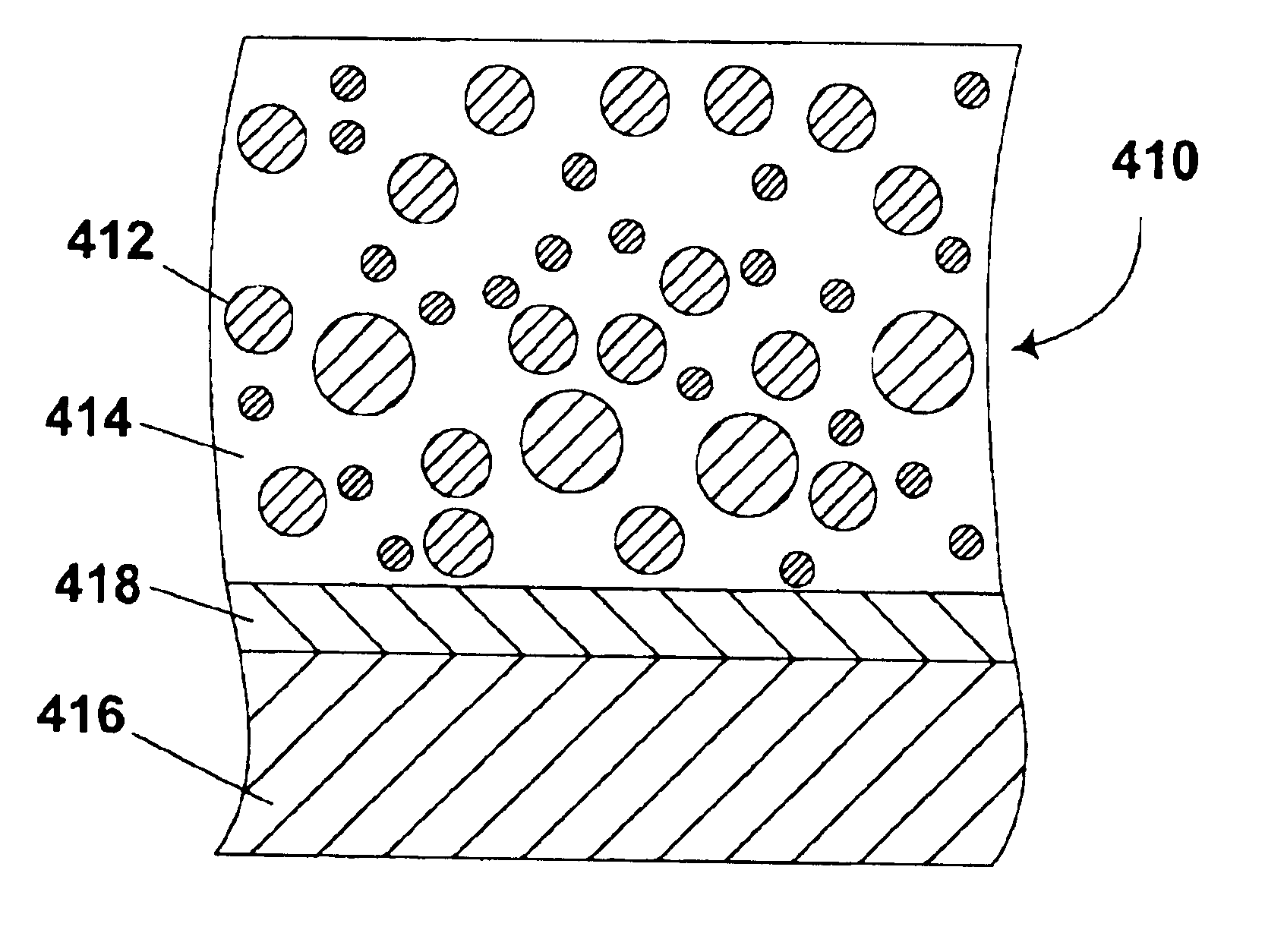

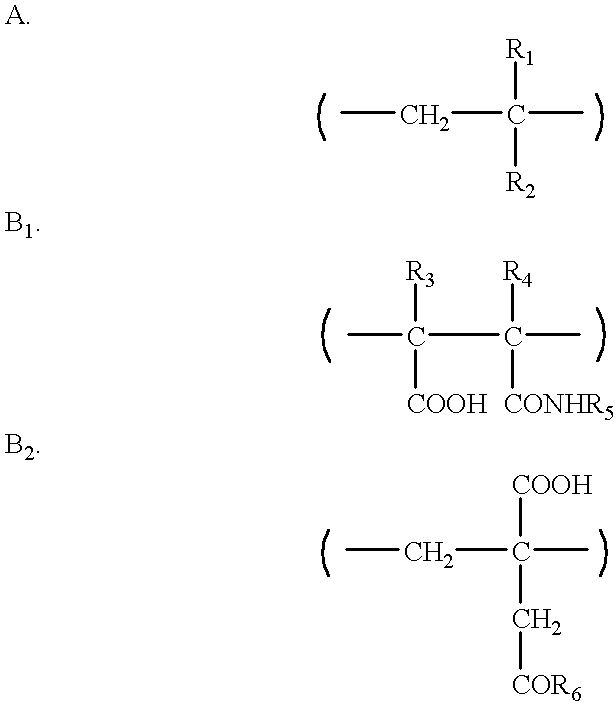

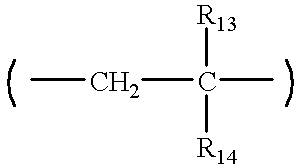

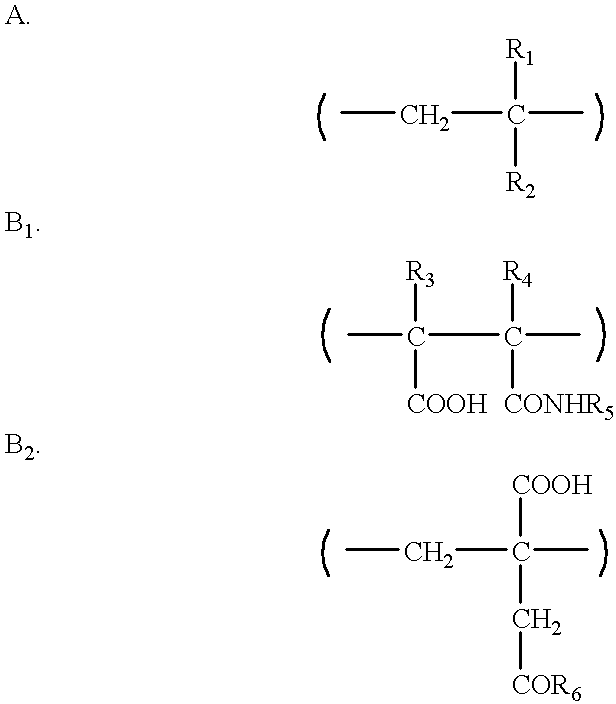

In electrophoretic media, it is advantageous to use pigment particles having about 1 to 15 percent by weight of a polymer chemically bonded to, or cross-linked around, the pigment particles. The polymer desirably has a branched chain structure with side chains extending from a main chain. Charged or chargeable groups can be incorporated into the polymer or can be bonded to the particles separately from the polymer. The polymer-coated particles can be prepared by first attaching a polymerizable or polymerization-initiating group to the particle and then reacting the particle with one or more polymerizable monomers or oligomers.

Owner:E INK CORPORATION

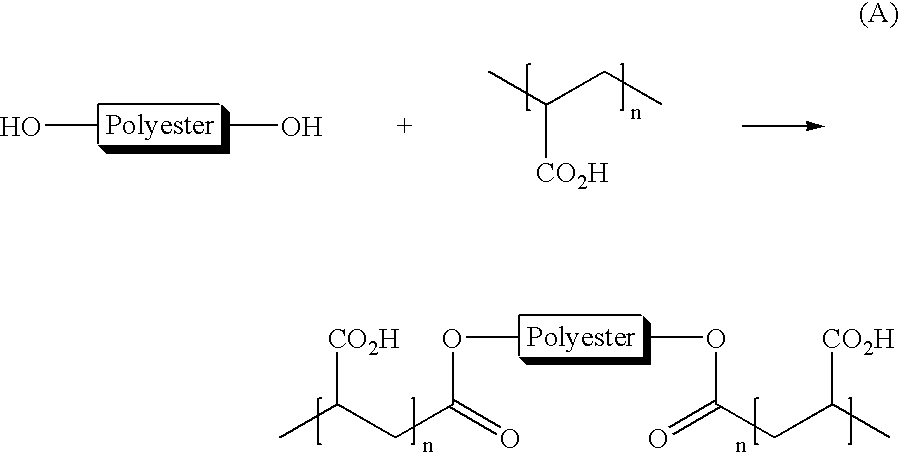

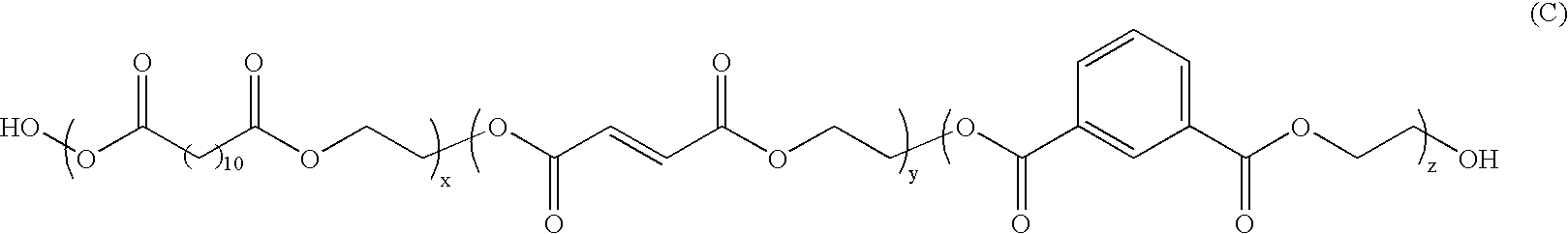

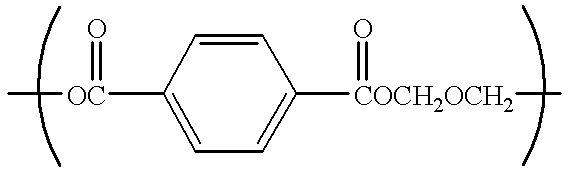

Polyester process

A process for the preparation of an unsaturated polyester which comprises (i) reacting an organic diol with a cyclic akylene carbonate in the presence of a first catalyst to thereby form a polyalkoxy diol, and (ii) optionally adding thereto a further amount of cyclic alkylene carbonate in the presence of a second catalyst, and (iii) subsequently polycondensing the resulting mixture with a dicarboxylic acid.

Owner:XEROX CORP

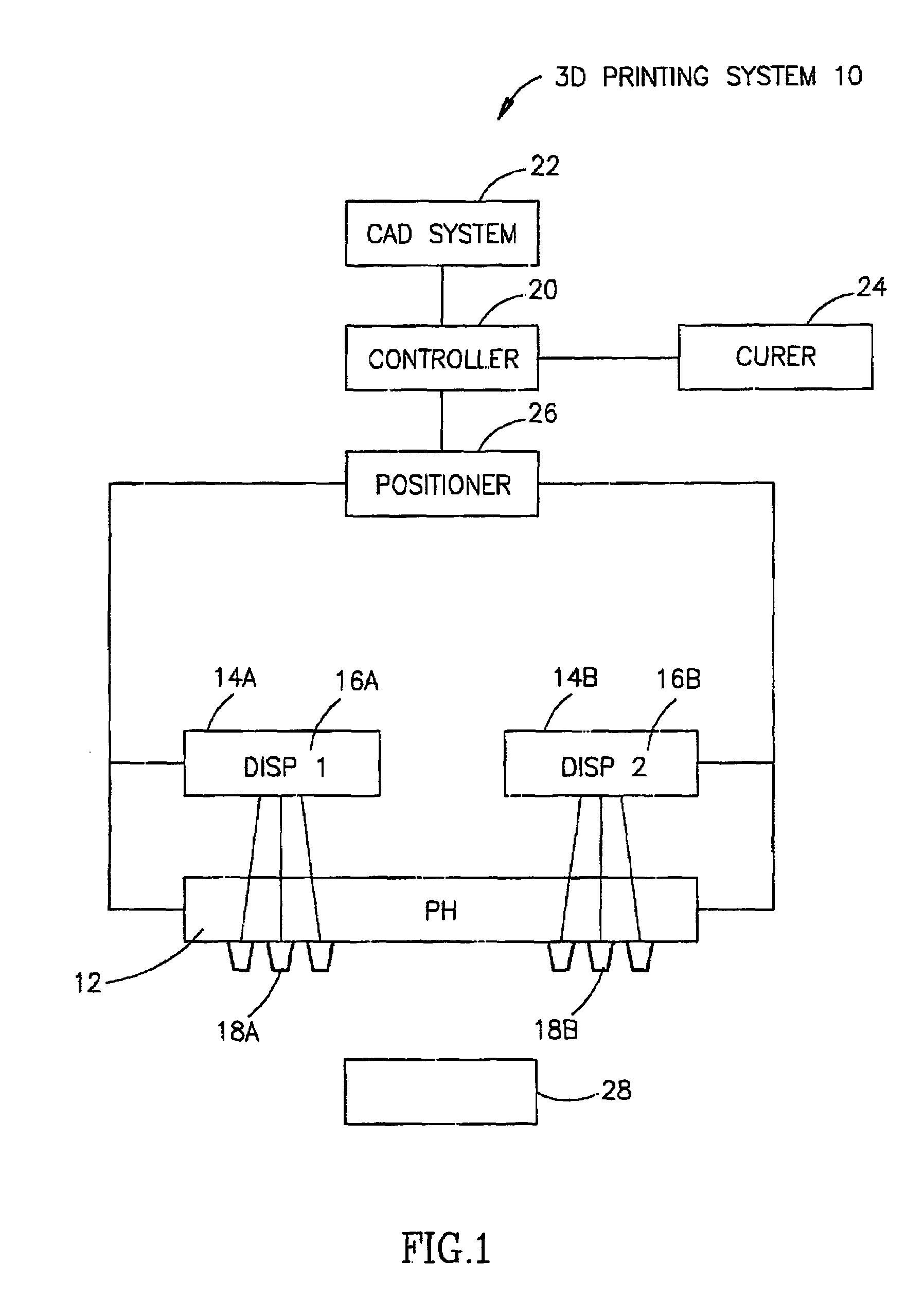

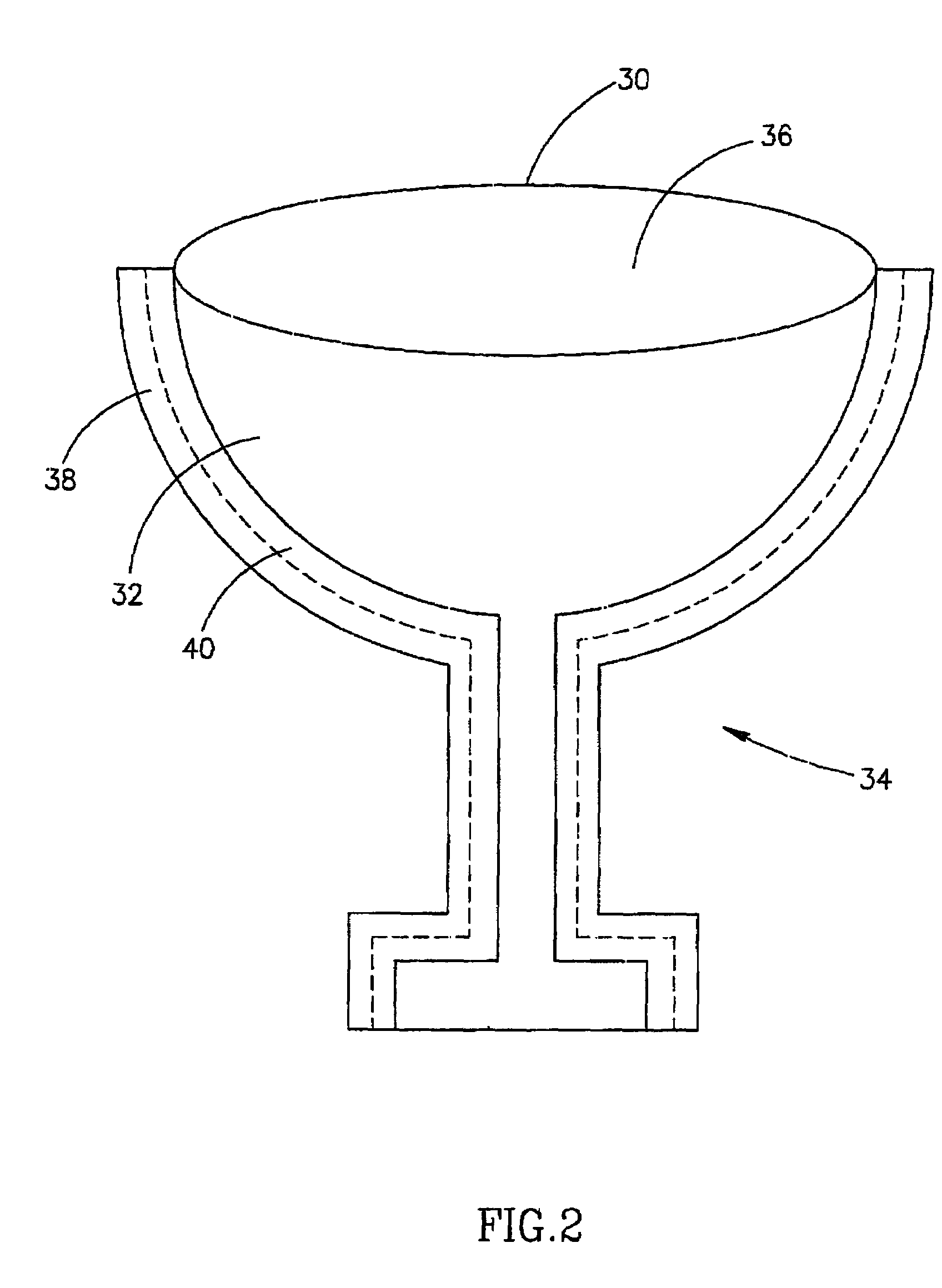

Compositions and methods for use in three dimensional model printing

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

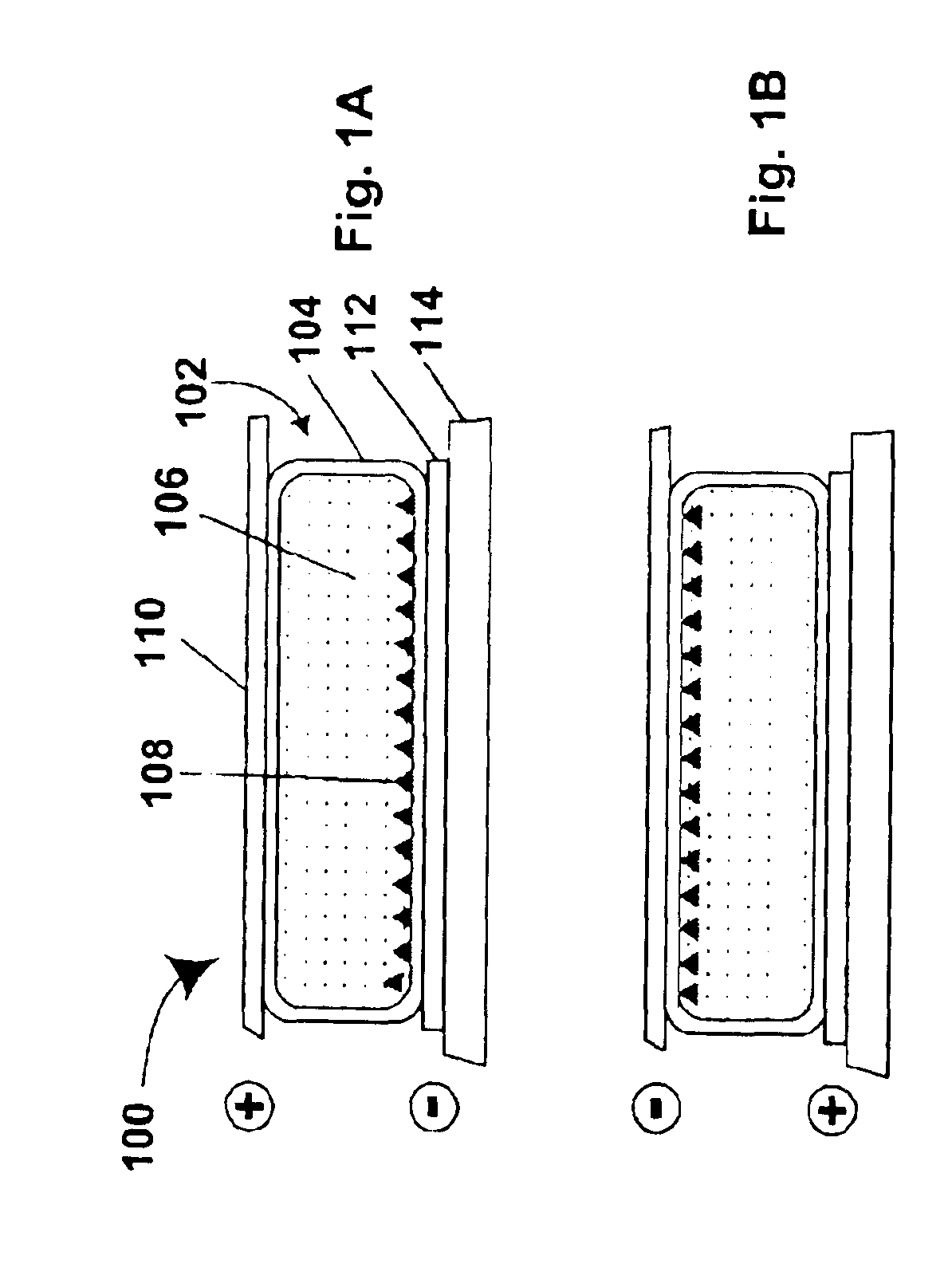

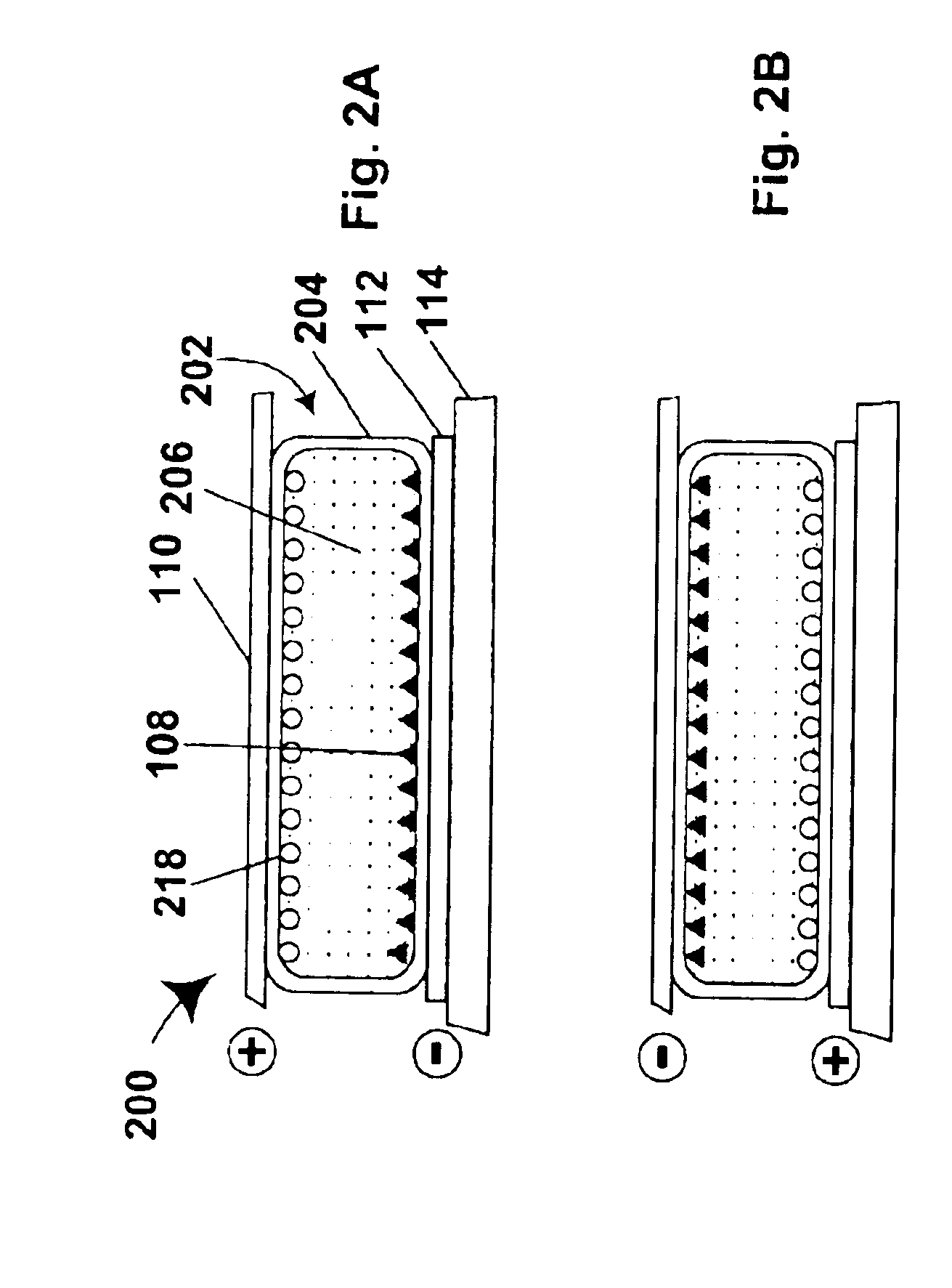

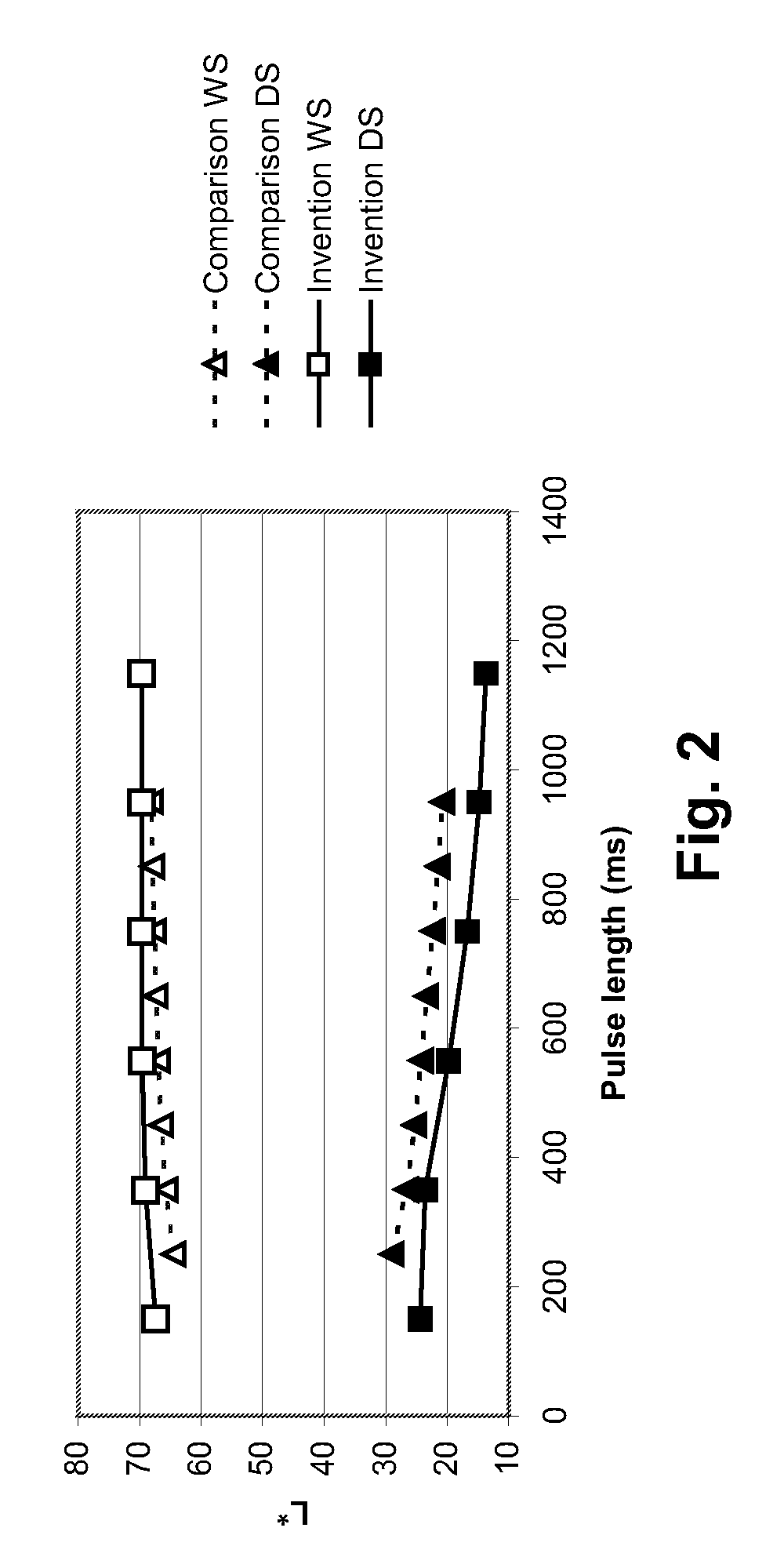

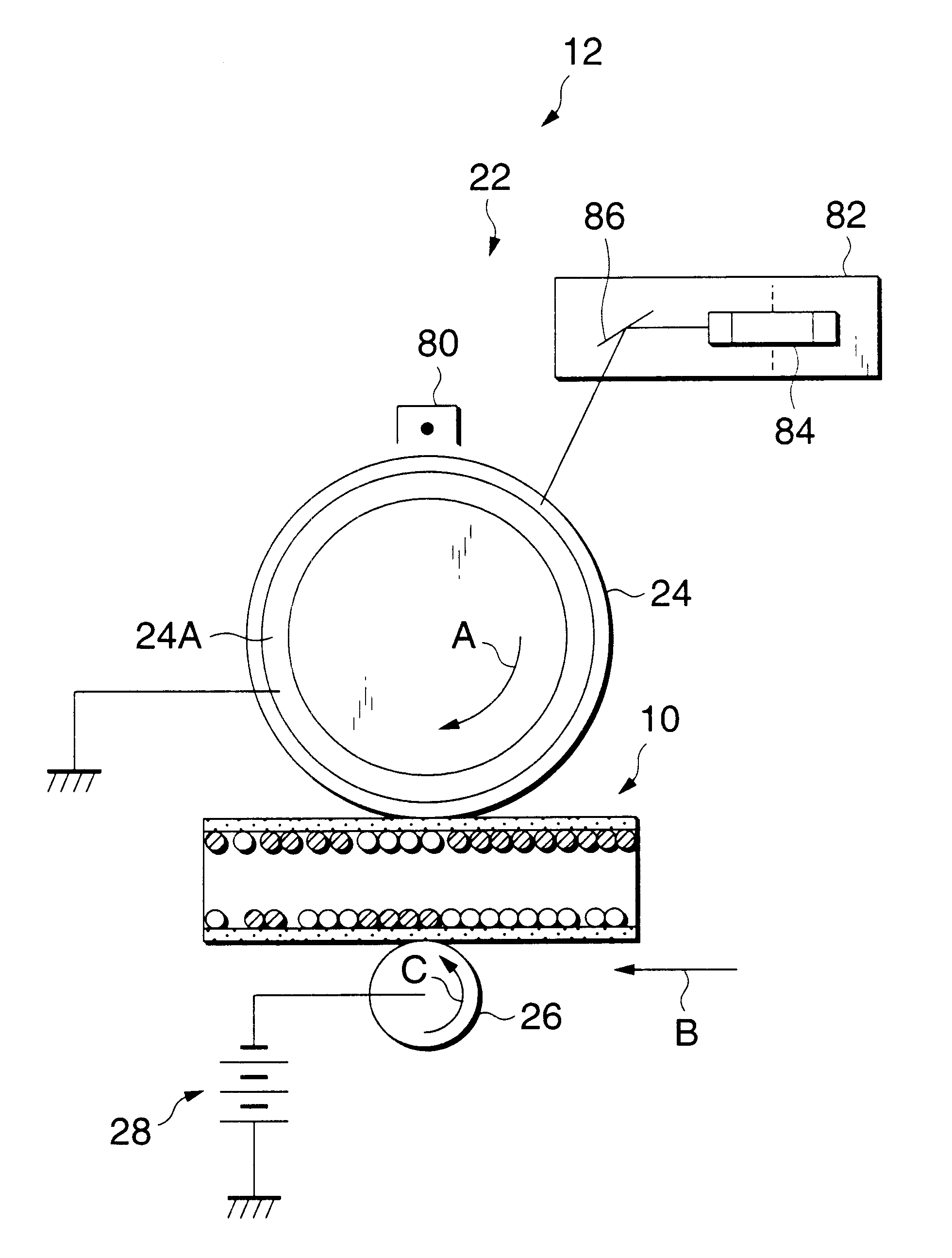

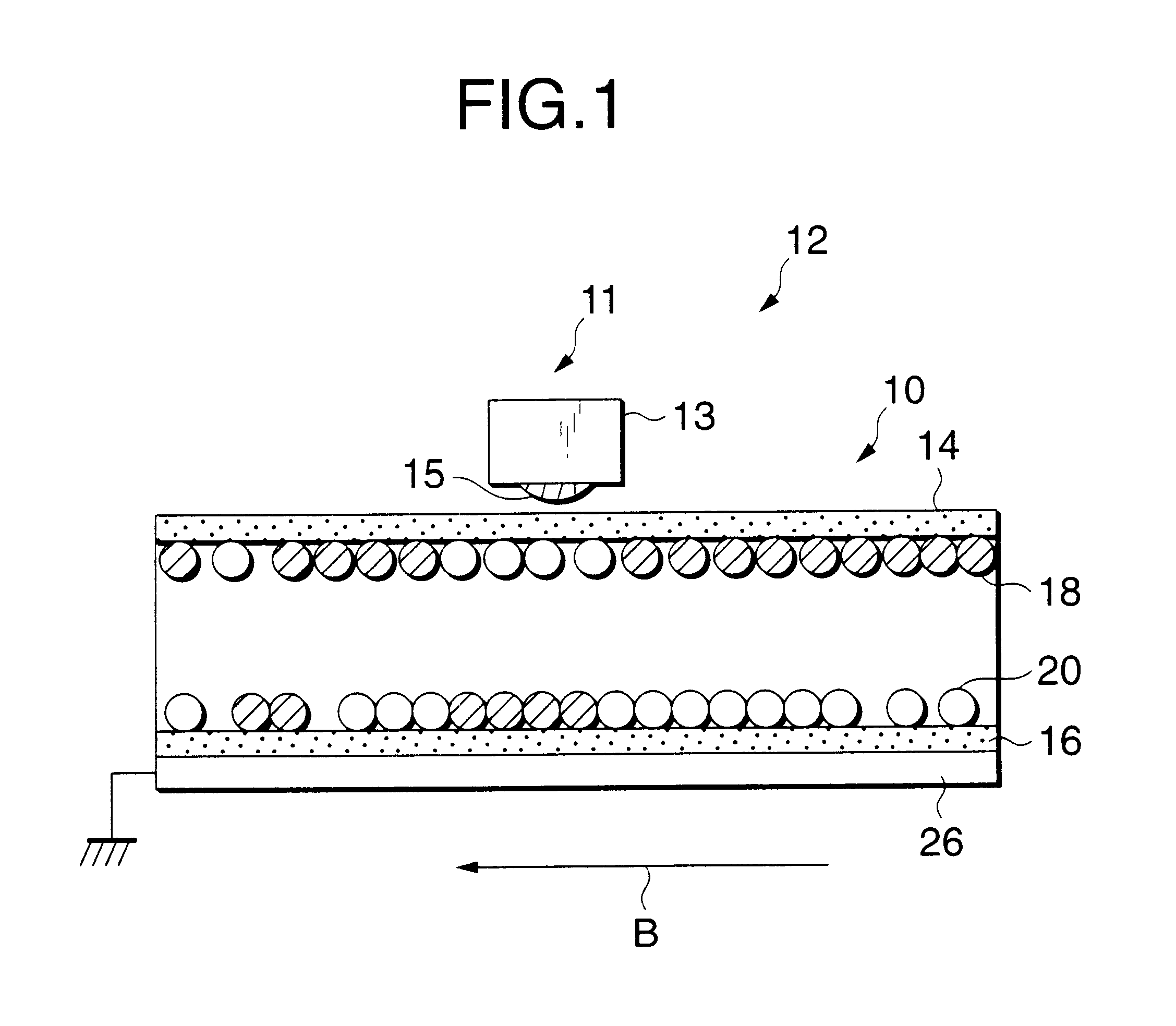

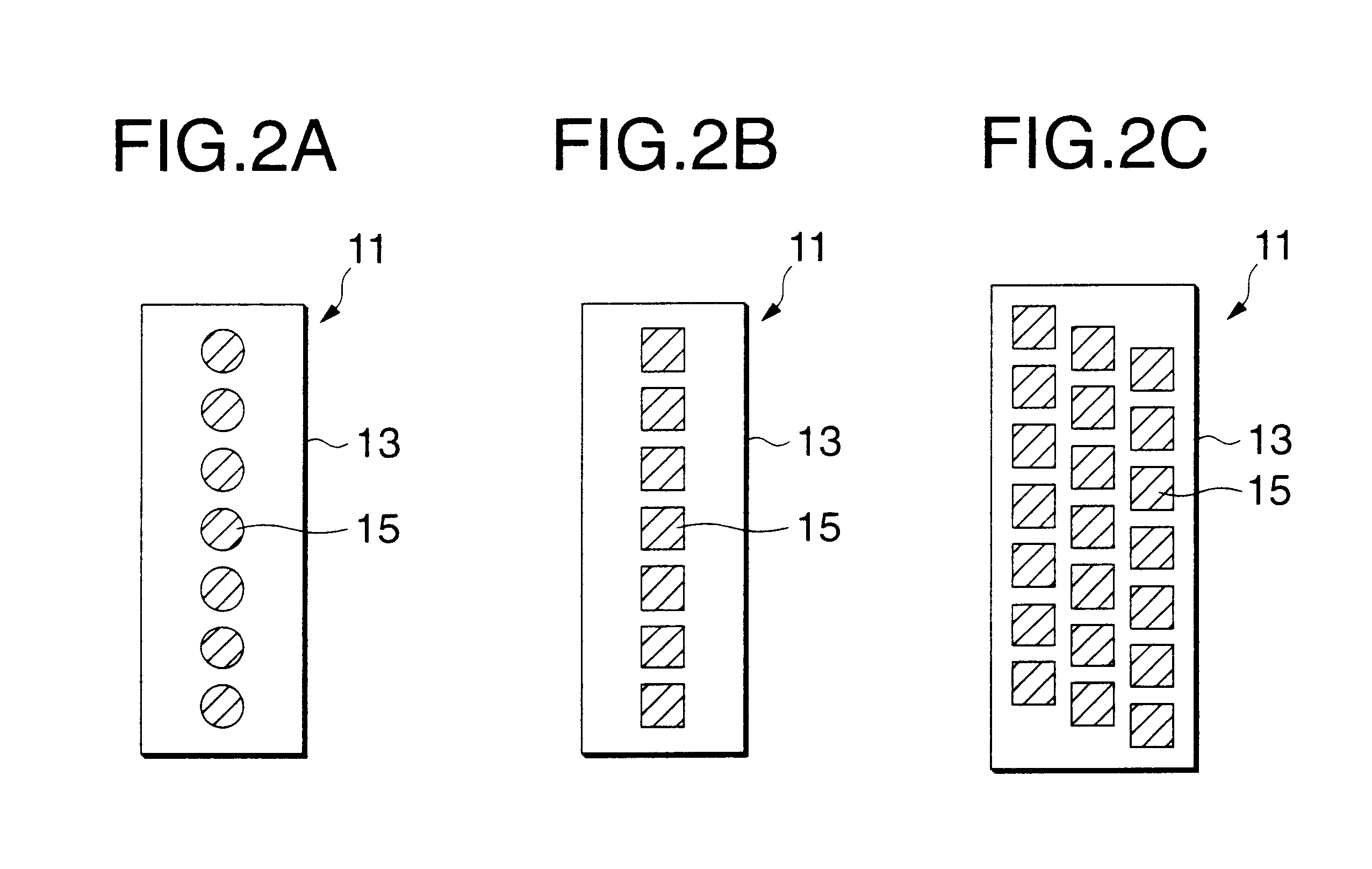

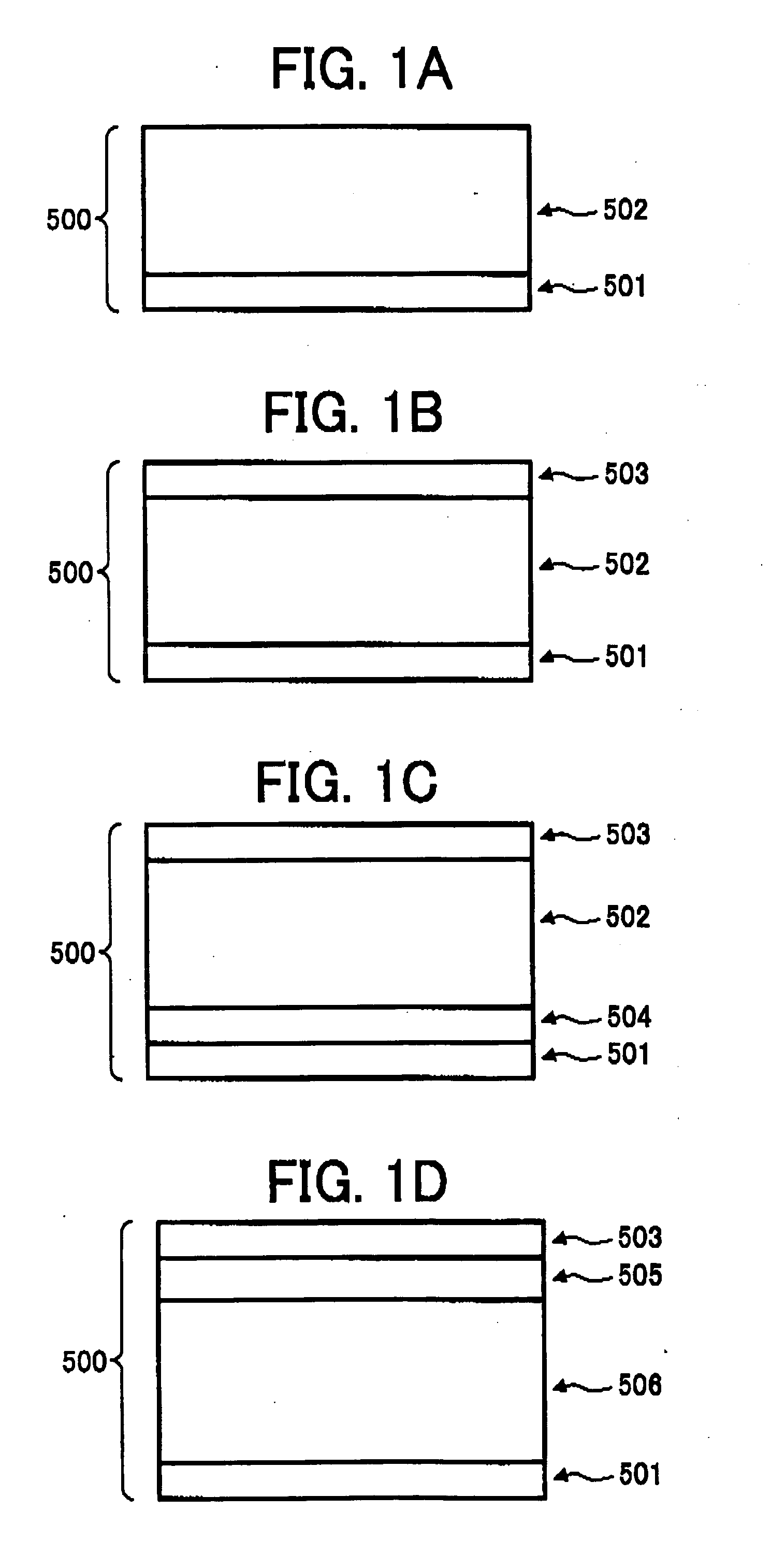

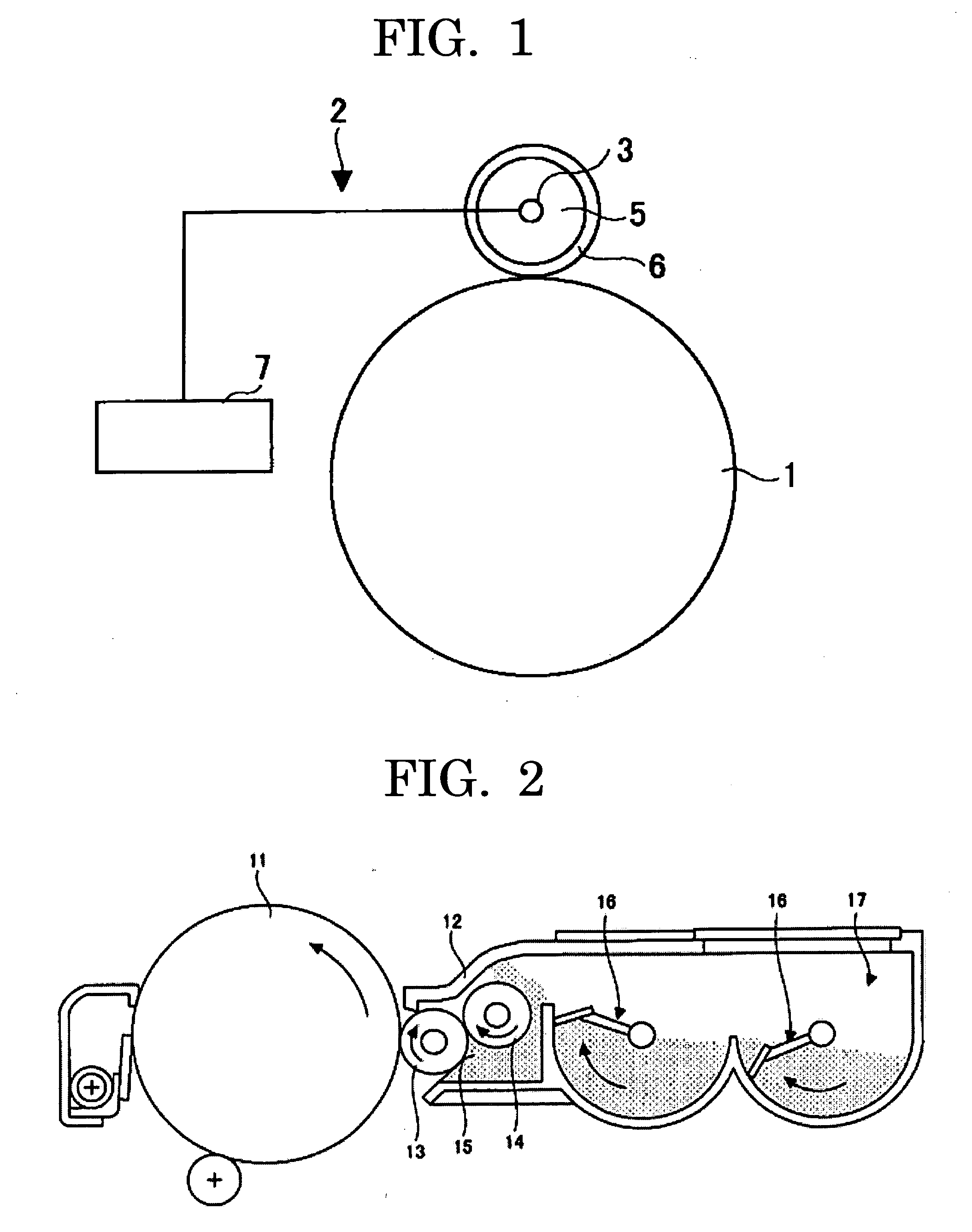

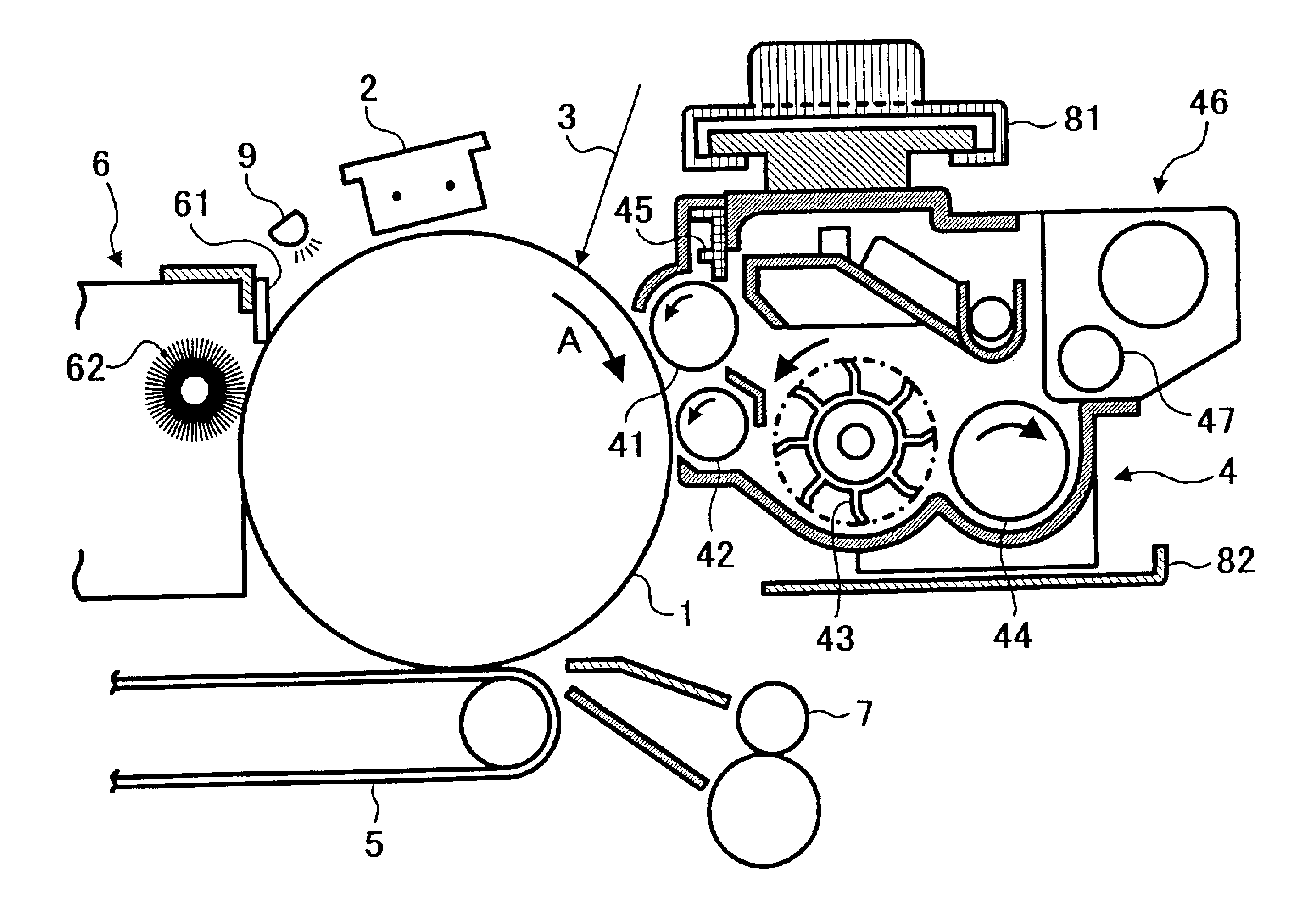

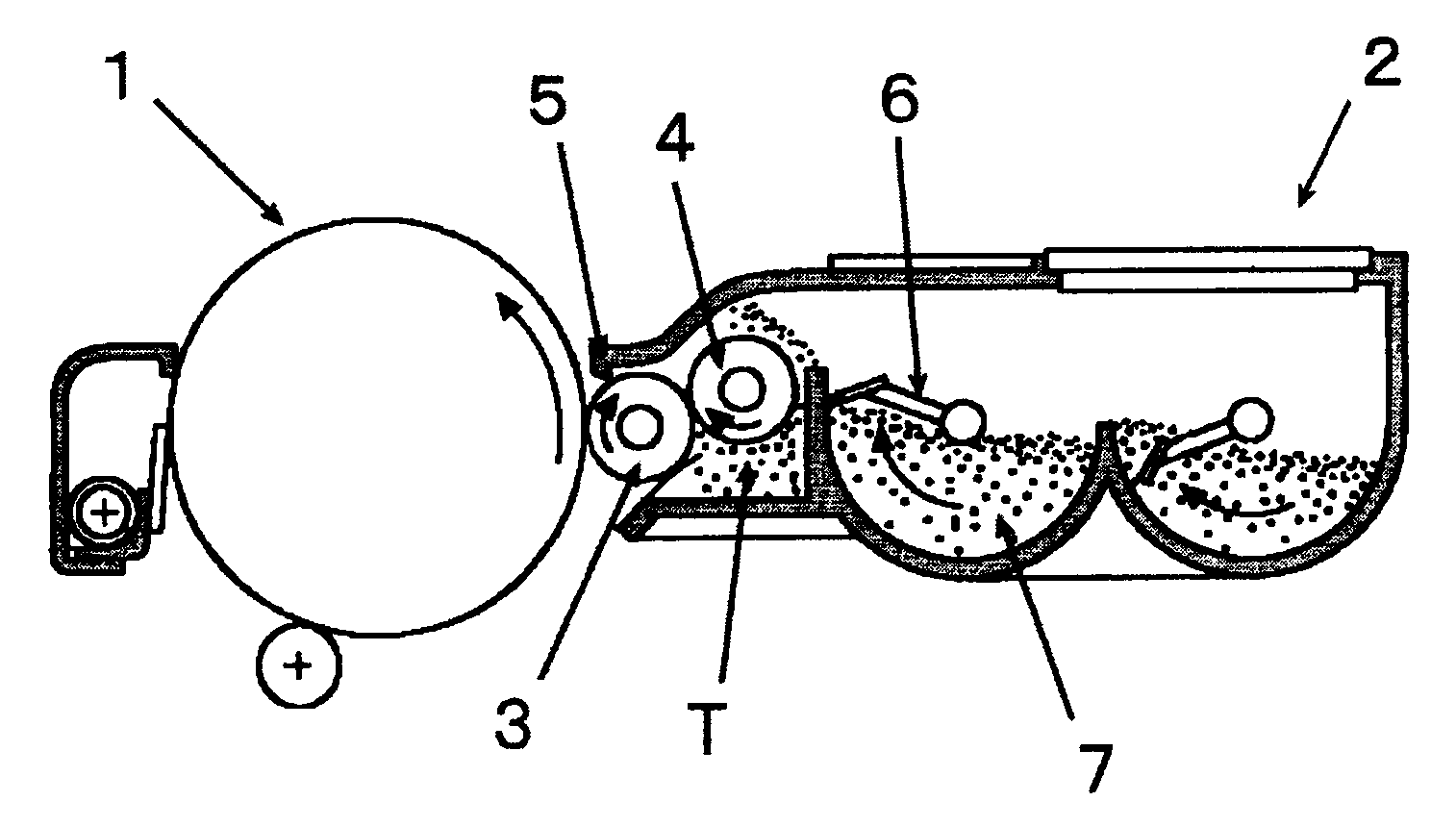

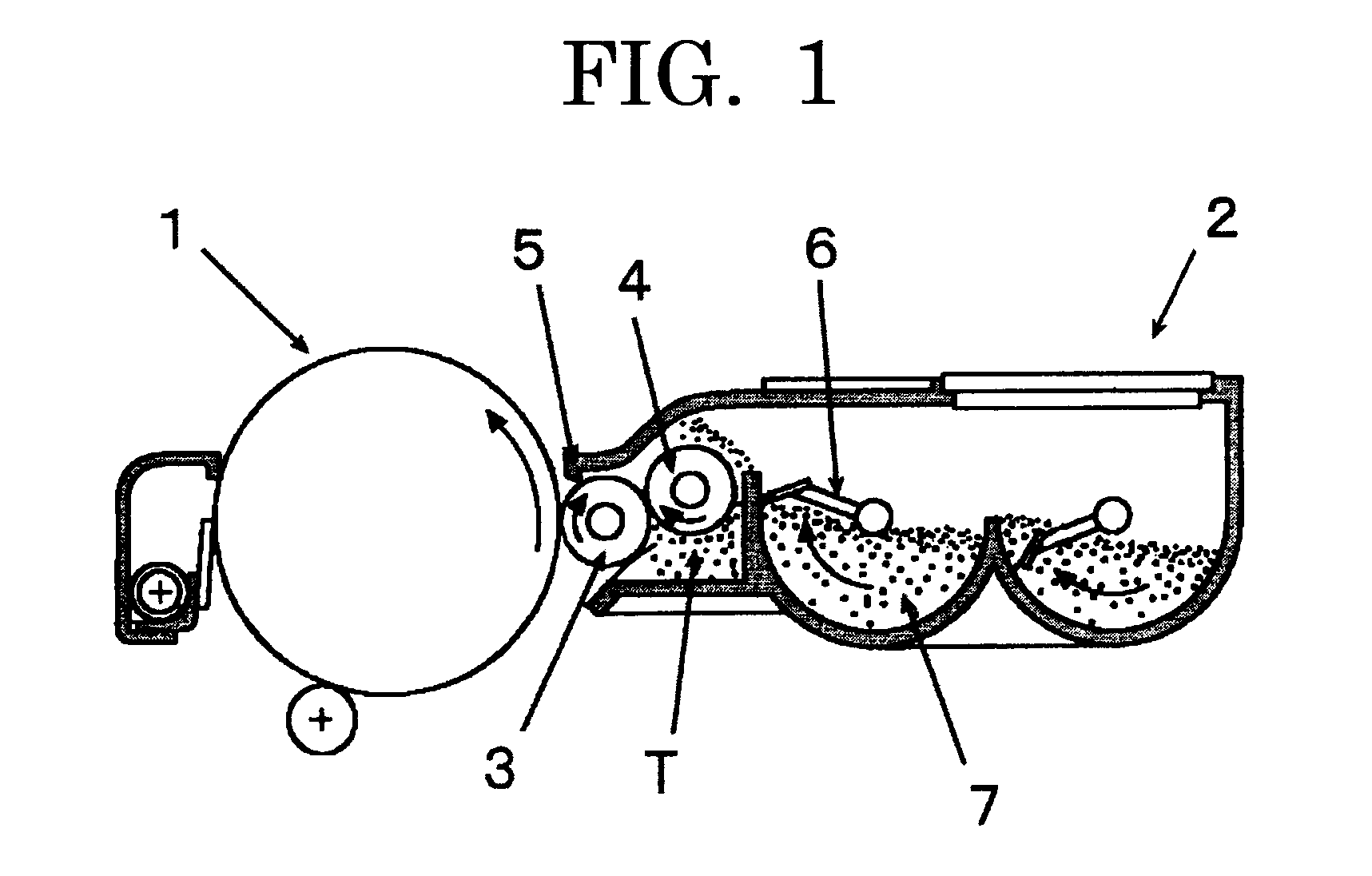

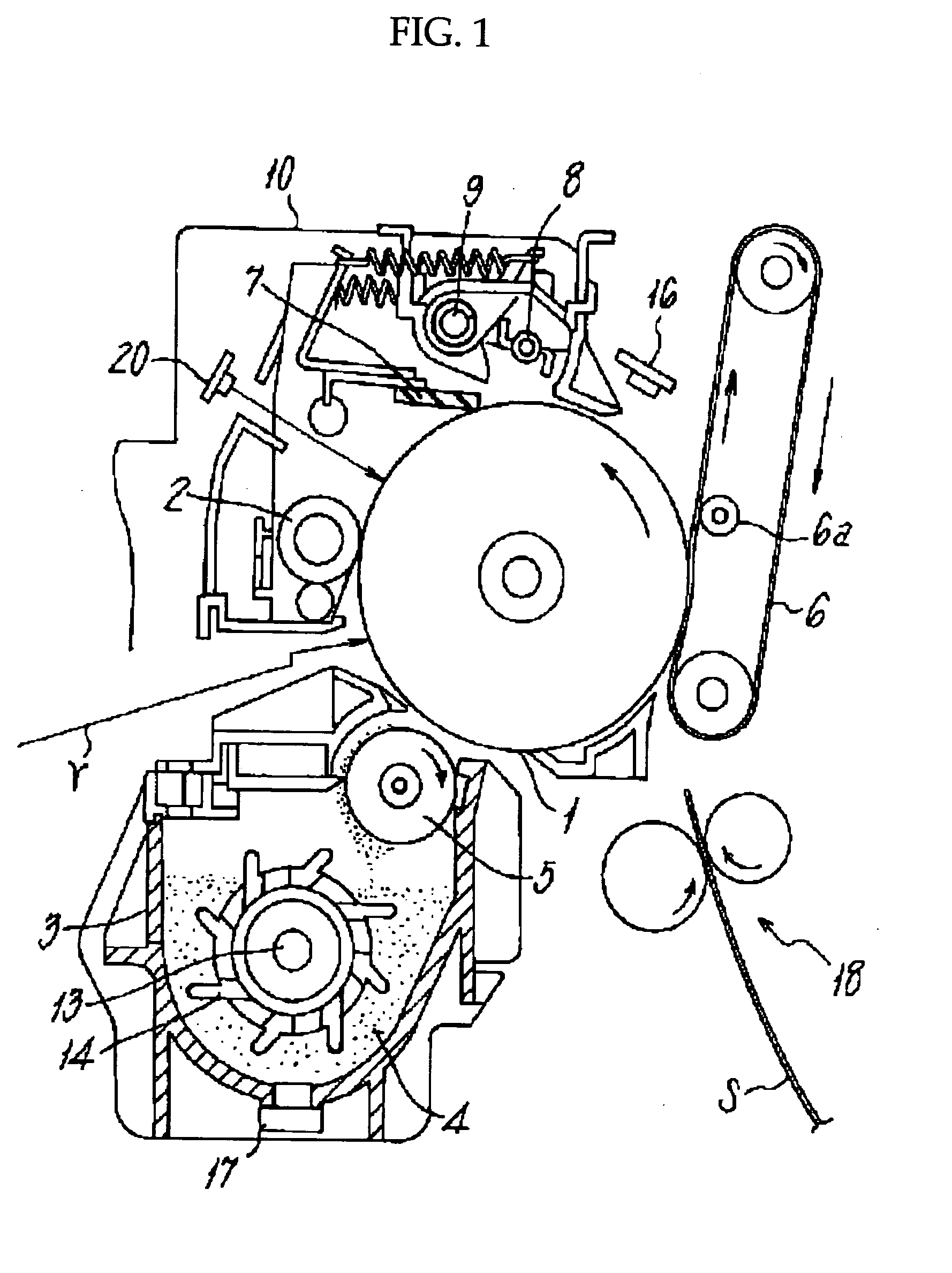

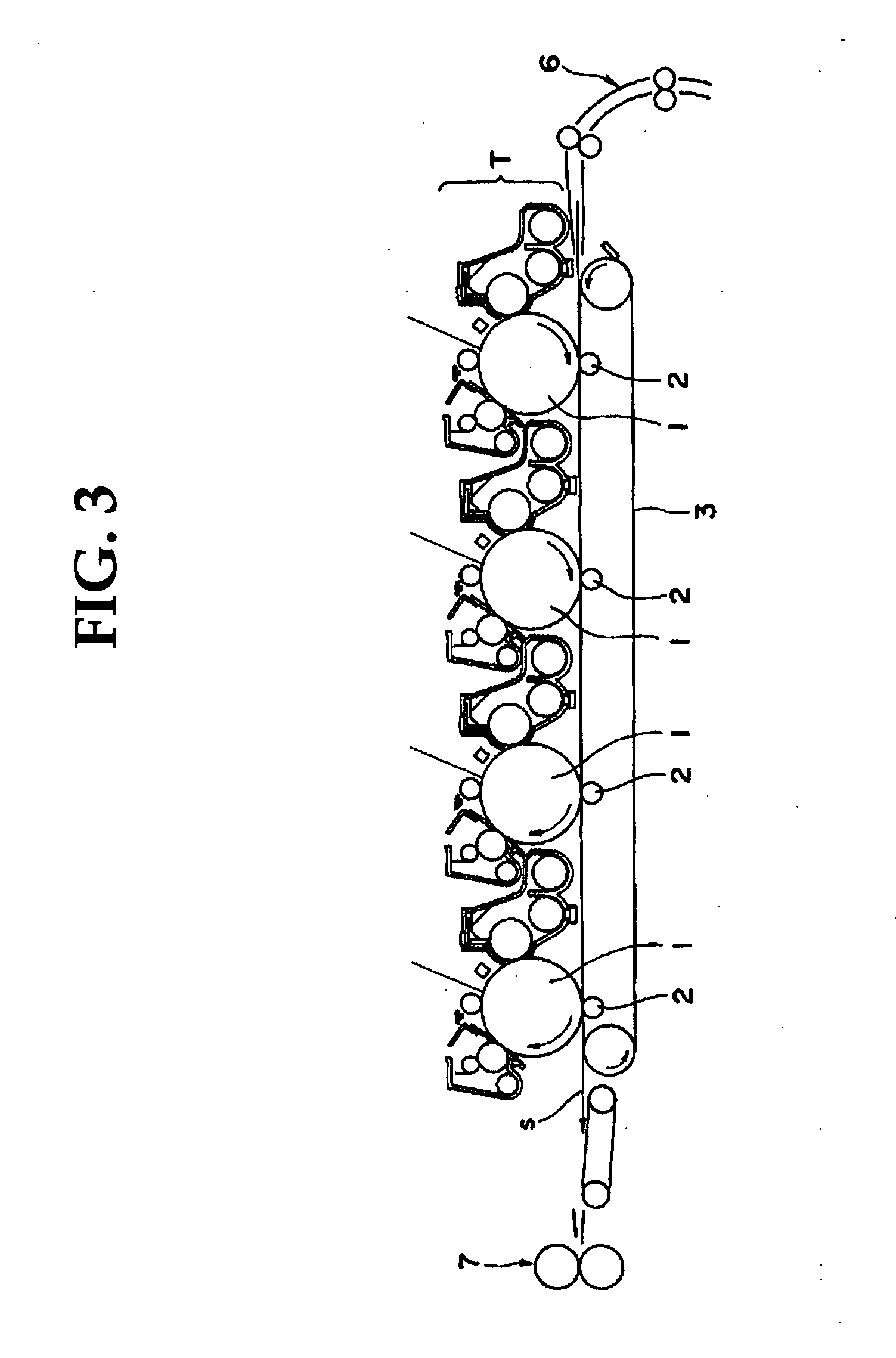

Image display medium, image-forming method and image-forming apparatus capable of repetitive writing on the image display medium

Provided are an image display medium which satisfies, a safety and a high-speed response and which is capable of repetitive rewriting, an image-forming method in which an image can be formed on the image display medium, and an image-forming apparatus. An image display medium is formed by interposing black particles and white particles between a display substrate and a non-display substrate made of a dielectric. A printing electrode first applies an AC voltage to frictionally charge the black and white particles, and then applies a DC voltage adapted to an image between the substrates. The black particles adhered to a portion (non-image portion) to which the voltage of the display substrate is applied are moved to the non-display substrate.

Owner:E INK CORPORATION

Toner processes

ActiveUS20080236446A1Improve blocking propertiesExcellent heat cohesionInksDevelopersPolyesterPolymer chemistry

A toner process comprising the aggregation and coalescence of an amorphous polyester, a crystalline polyester and a colorant, and wherein the coalescence is conducted at a temperature that is about lower than the melting point temperature of the crystalline polyester.

Owner:XEROX CORP

Toner coagulant processes

InactiveUS6132924ASimple and economical processGood dispersionIndividual molecule manipulationDevelopersPolymer scienceOrganic chemistry

Owner:XEROX CORP

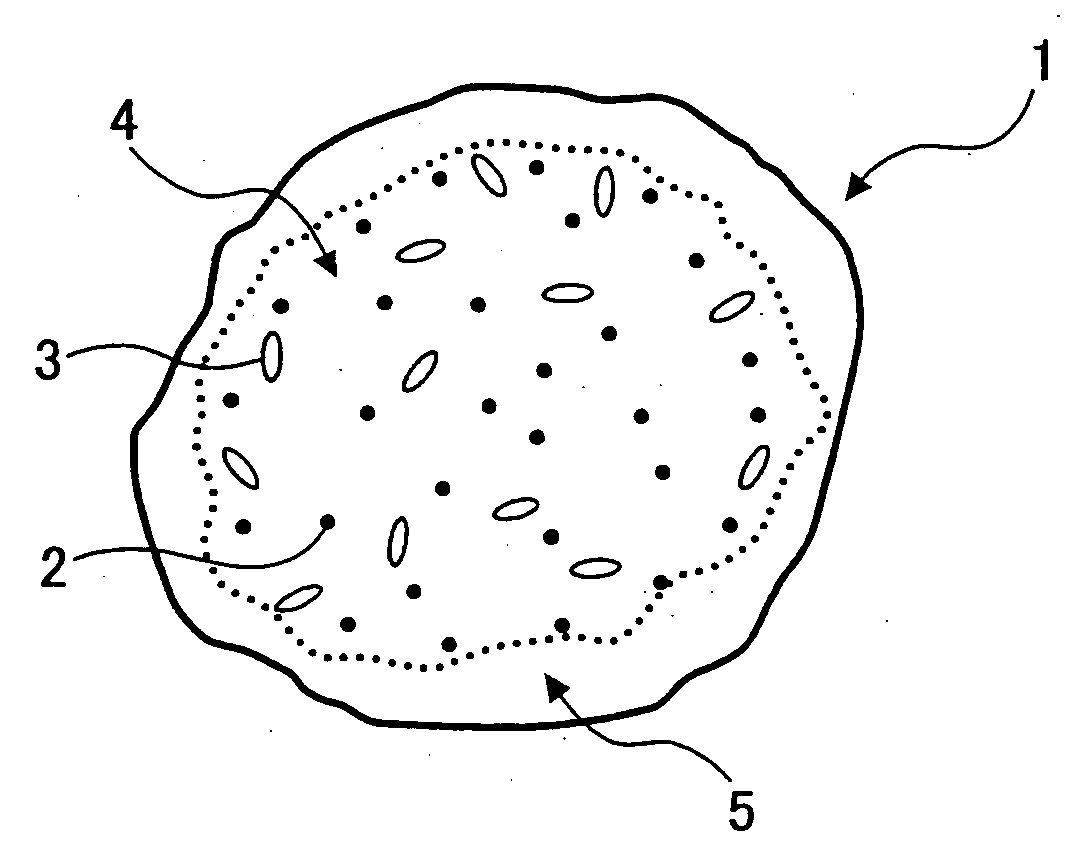

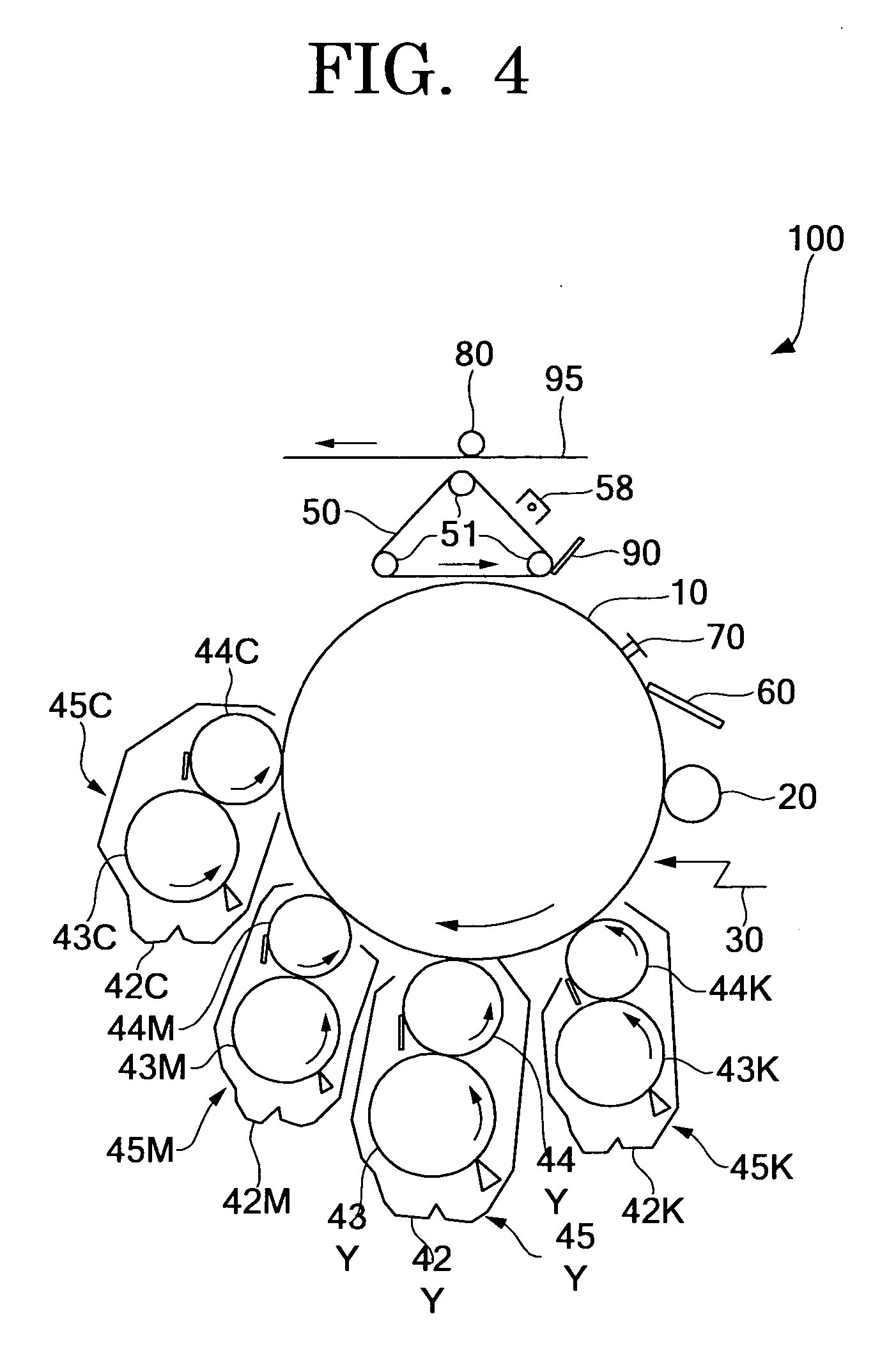

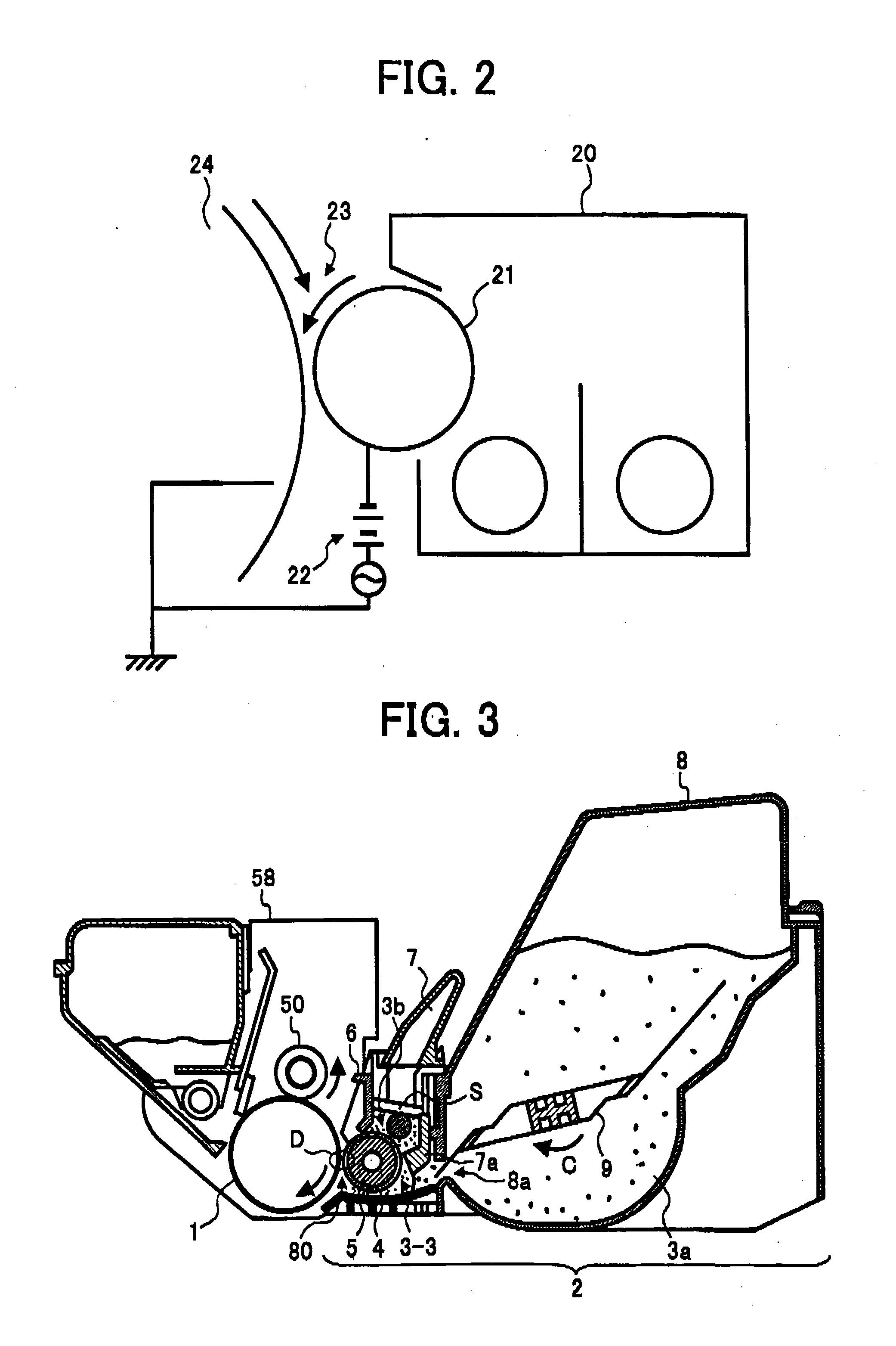

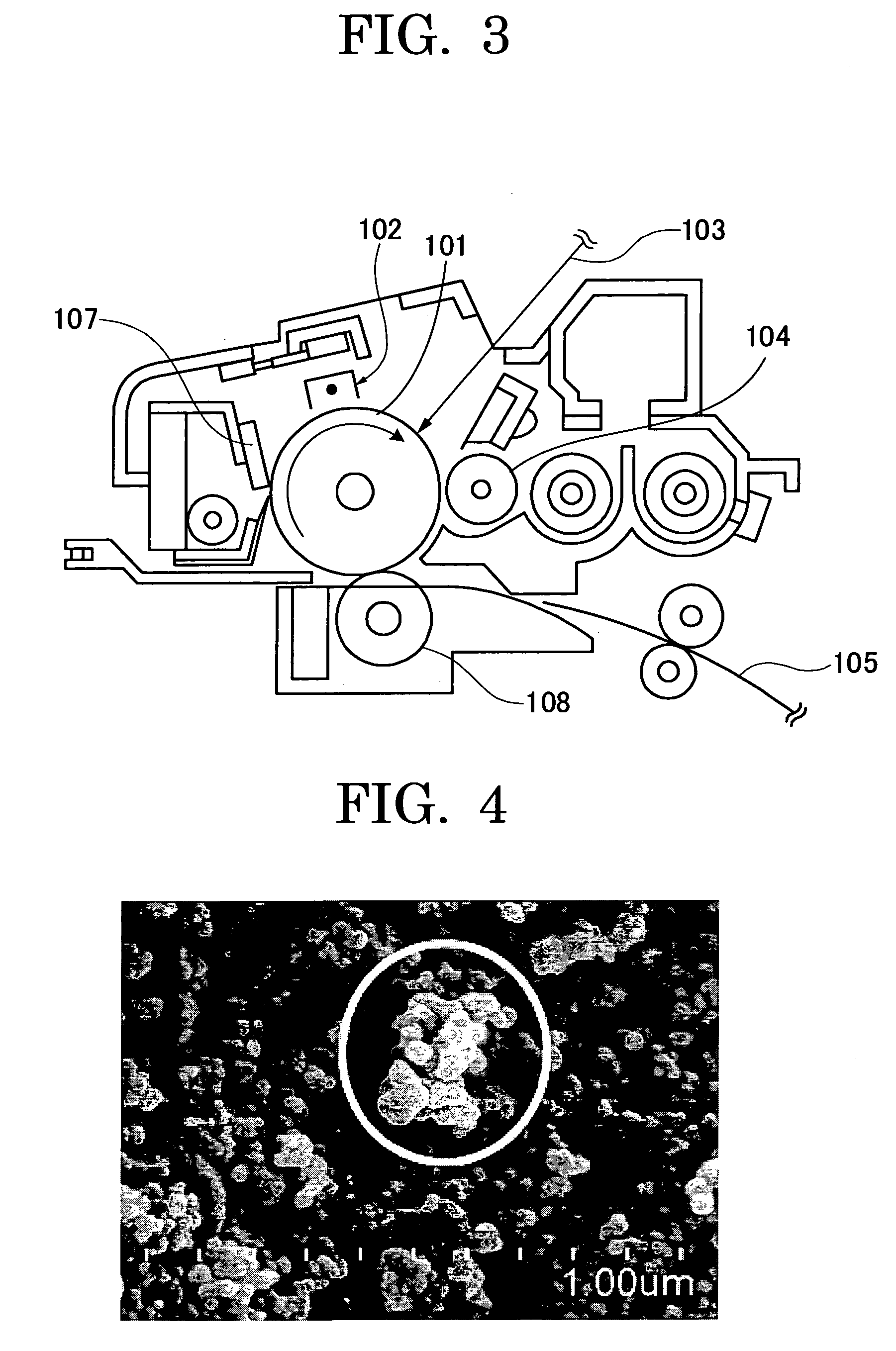

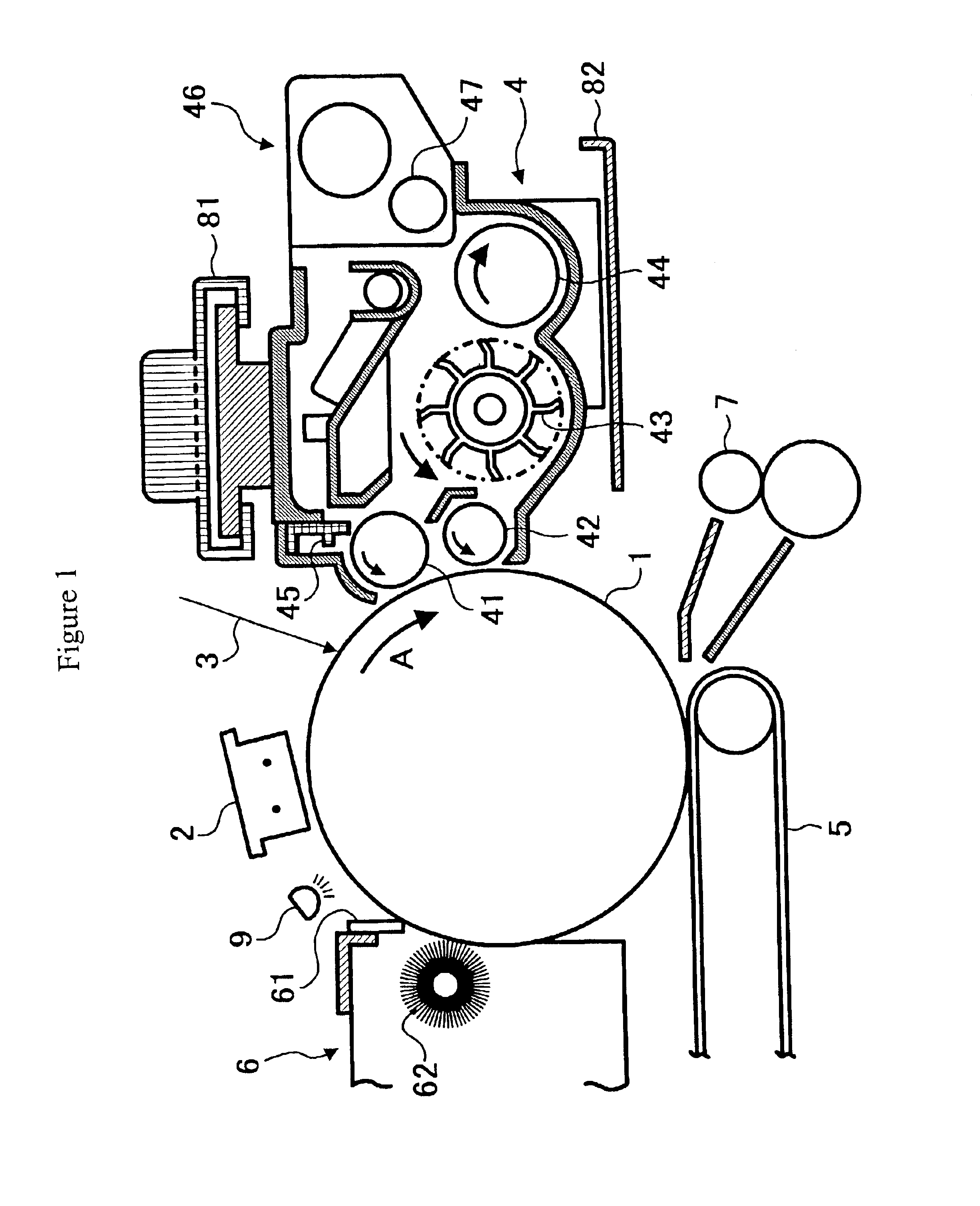

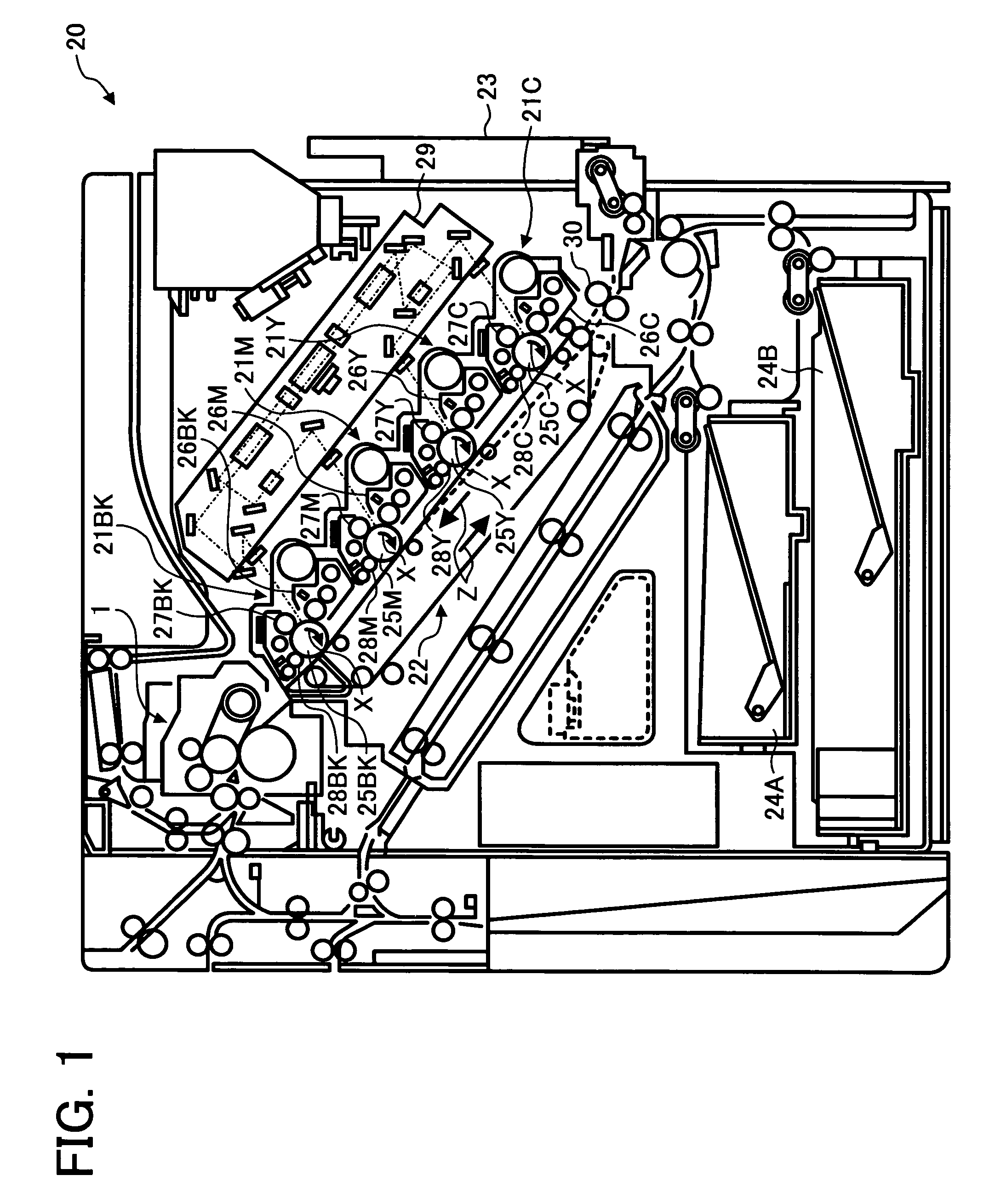

Toner, toner manufacturing method, developer, image forming apparatus, and process cartridge for the image forming apparatus

ActiveUS20060204882A1High quality imagingStable productionElectrographic process apparatusDevelopersPolyesterImage formation

A toner having a core containing a colorant, a release agent and a binder resin (A), and a shell containing a binder resin (B), the shell overlying the core, wherein the binder resin (A) contains a resin having a polyester skeleton, the binder resin (B) contains a vinyl copolymer resin, and a weight ratio of the shell to the core is from 0.05 to 0.5, and wherein the toner has a volume average particle diameter of from 3 to 8 μm; a toner manufacturing method of such the toner can be used in an image forming apparatus and in a process cartridge.

Owner:RICOH KK

Toner for electrostatic development, developer, image forming method, image-forming apparatus and process for cartridge using the same

InactiveUS20060275686A1Improve stabilityEffectively and uniformlyDevelopersElectrographic processes using charge patternImage formationEngineering

It is an object of the present invention to provide a toner containing toner particles and inorganic fine particles wherein the inorganic fine particles are externally added to the toner particles which contain a binder resin and a colorant and at least one type of the inorganic fine particles is a compound oxide having a relative permittivity measured at 1 MHz of 2 to 10 and a volume resistivity of 1011 Ω*cm or more and an image forming method using the toner.

Owner:RICOH KK

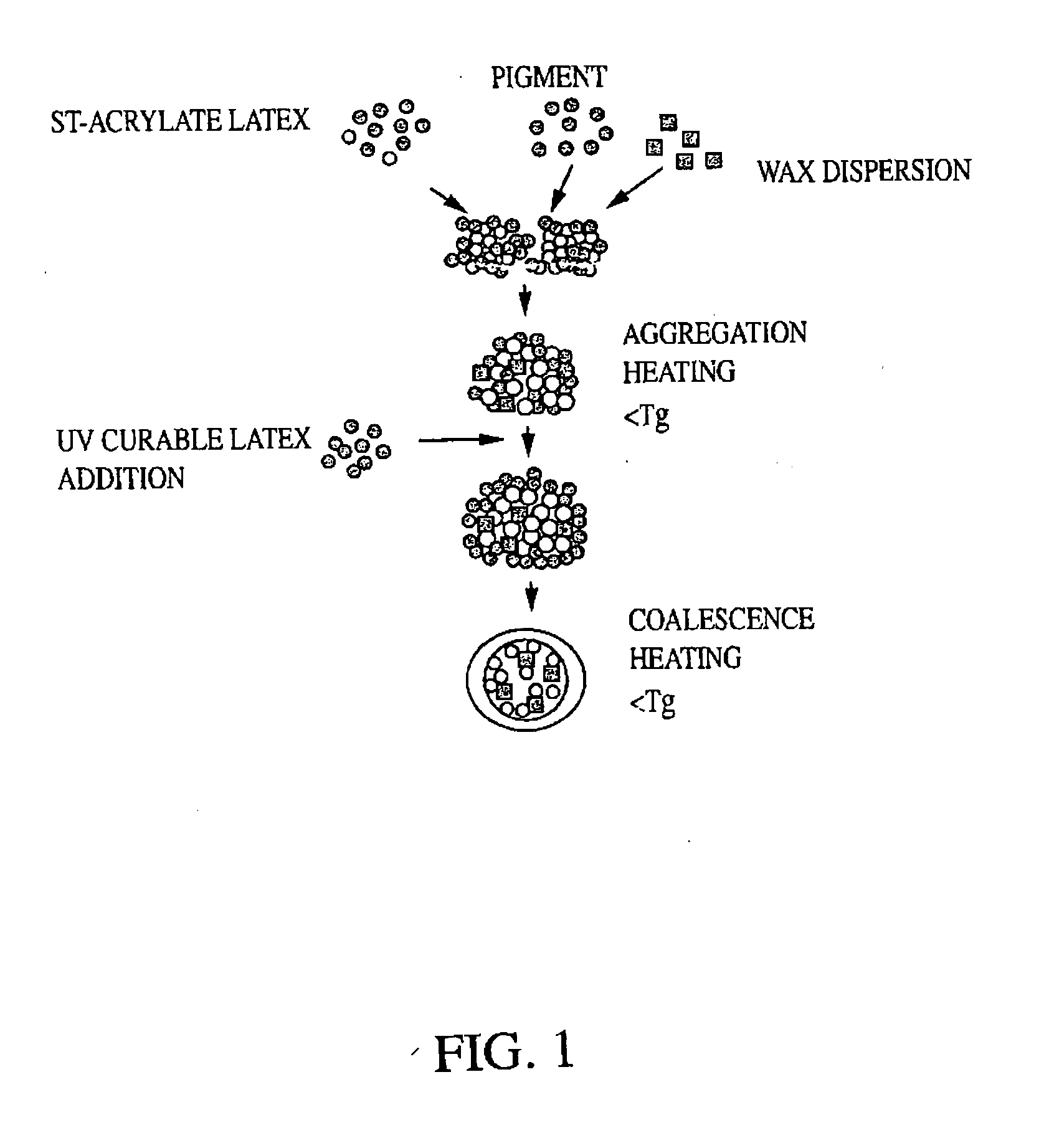

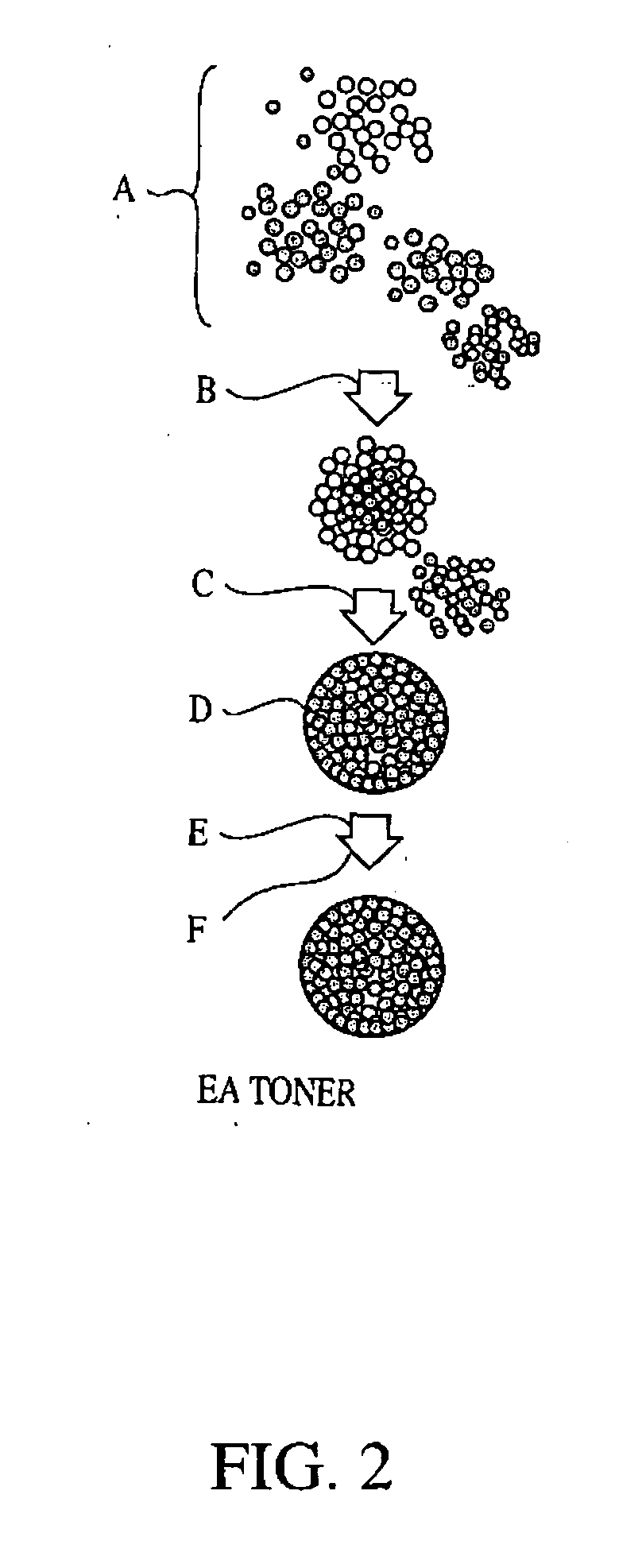

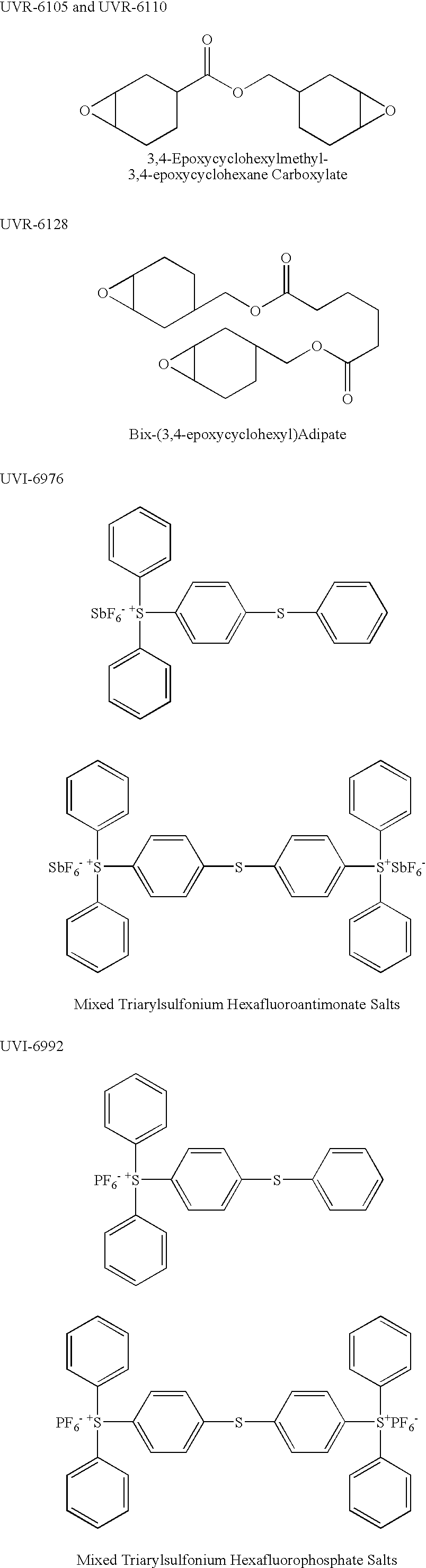

Toners and processes thereof

Disclosed are toner compositions comprised of a polymer, an optional colorant, and an UV light curable oligomer. Also disclosed are methods for producing a UV curable toner compositions, the toner compositions produced thereby, and methods of utilizing the UV curable toner compositions in various painting applications.

Owner:XEROX CORP

Toner and developer, toner container, process cartridge, image forming method and image forming apparatus

InactiveUS20060210902A1DevelopersElectrographic processes using charge patternImage formationEngineering

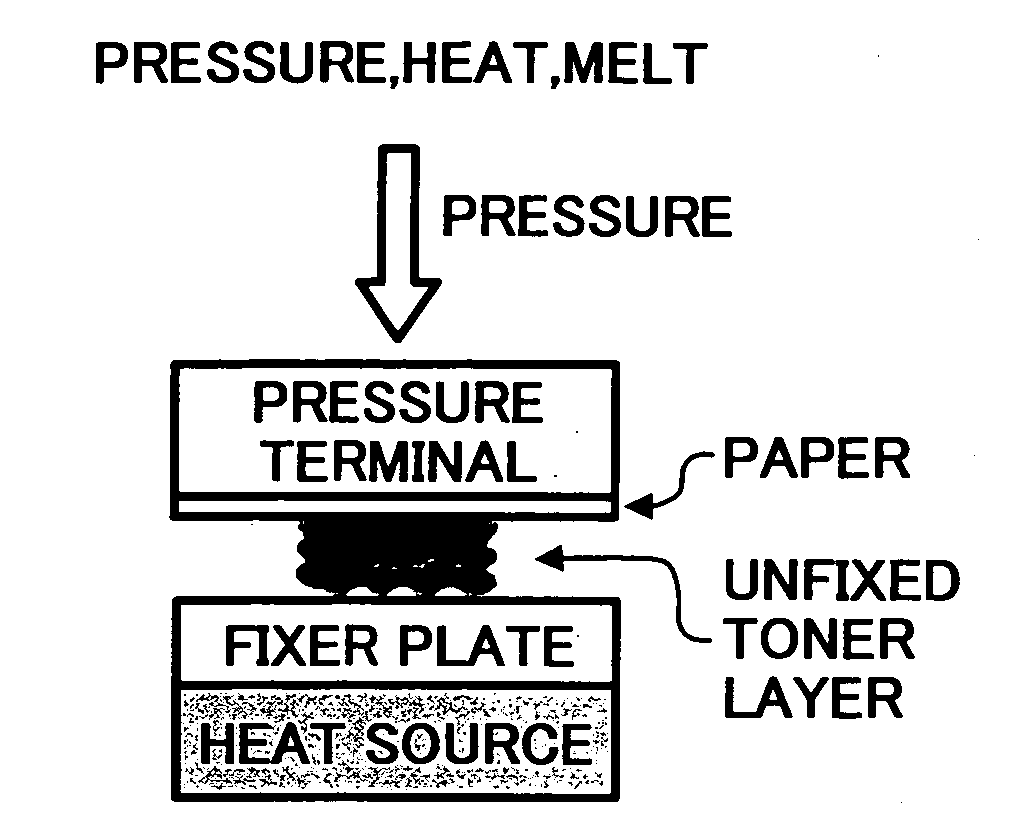

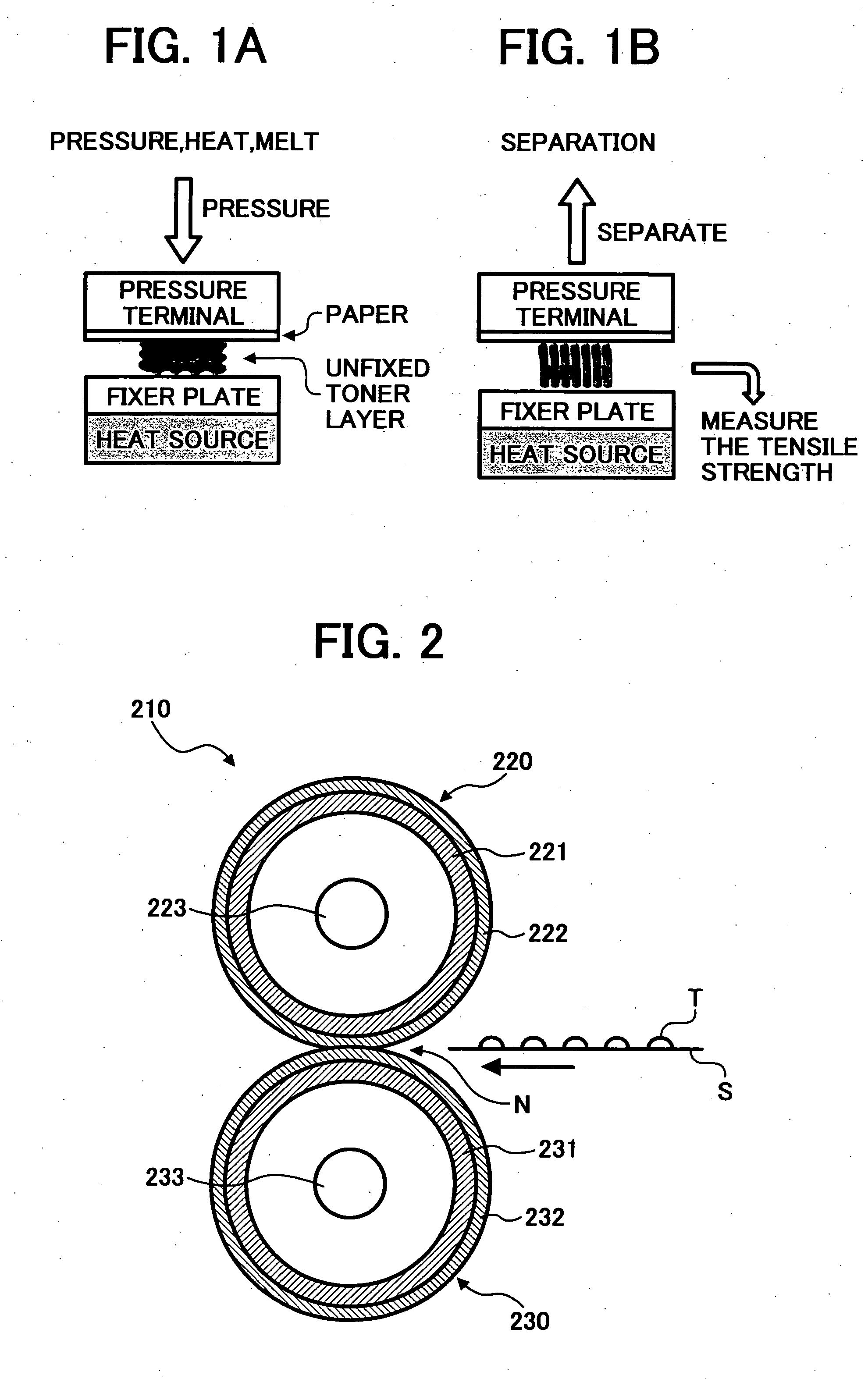

A toner including a binder resin, a colorant and a release agent, and satisfying the following relationships (1) and (2): 1.0≦FT120 / FT160≦1.5 (1) wherein FT120 is a maximum tensile strength (N) when a recording medium having the toner unfixed on is vertically separated from the surface of a substrate having a temperature of 120° C. at a constant speed after pressed thereto at a pressure of 100 kPa, and FT160 is same except that the substrate has a temperature of 160° C.; 1.0≦FP100 / FP200≦1.5 (2) wherein FP100 is a maximum tensile strength (N) when a recording medium having the toner unfixed on is vertically separated from the surface of a substrate having a temperature of 160° C. at a constant speed after pressed thereto at a pressure of 100 kPa, and FP200 is same except that the pressure is 200 kPa.

Owner:RICOH KK

Toner compositions

Toner compositions comprising low-melt toner particles and methods of preparing such toner compositions are provided. The toner particles include a polyester-containing binder, a colorant and an optional wax. The binder includes at least one crystalline polyester resin and at one amorphous acidic polyester resin.

Owner:XEROX CORP

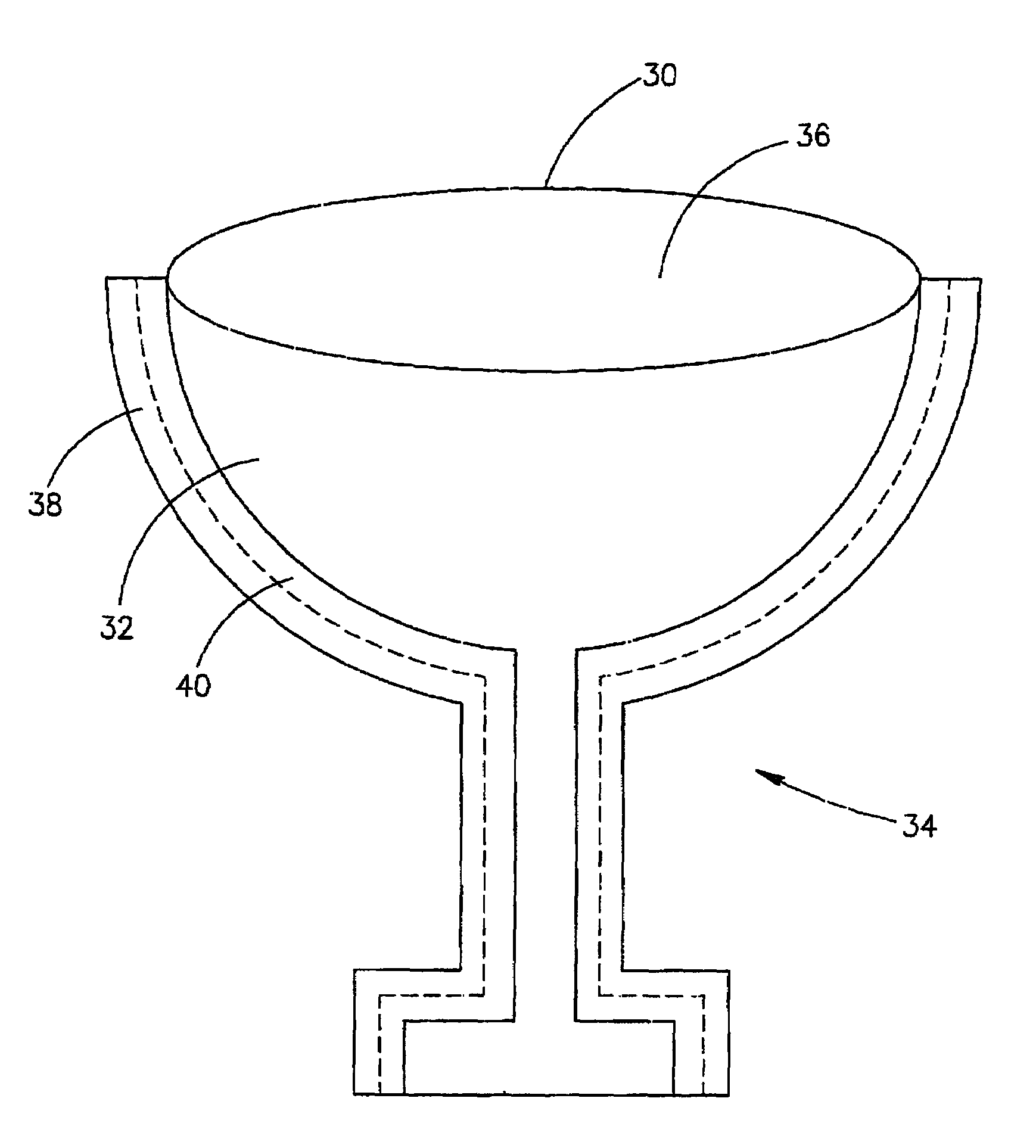

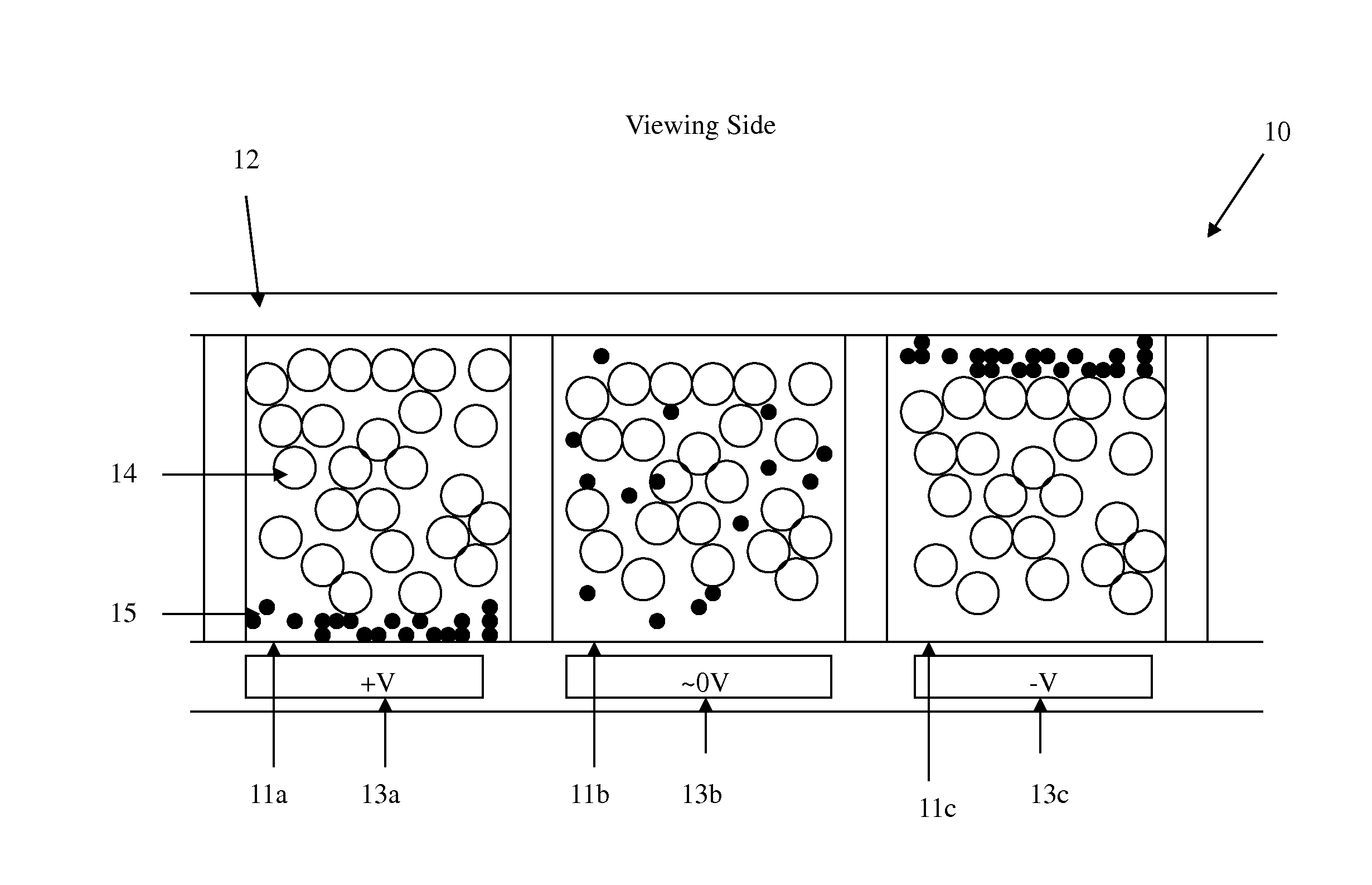

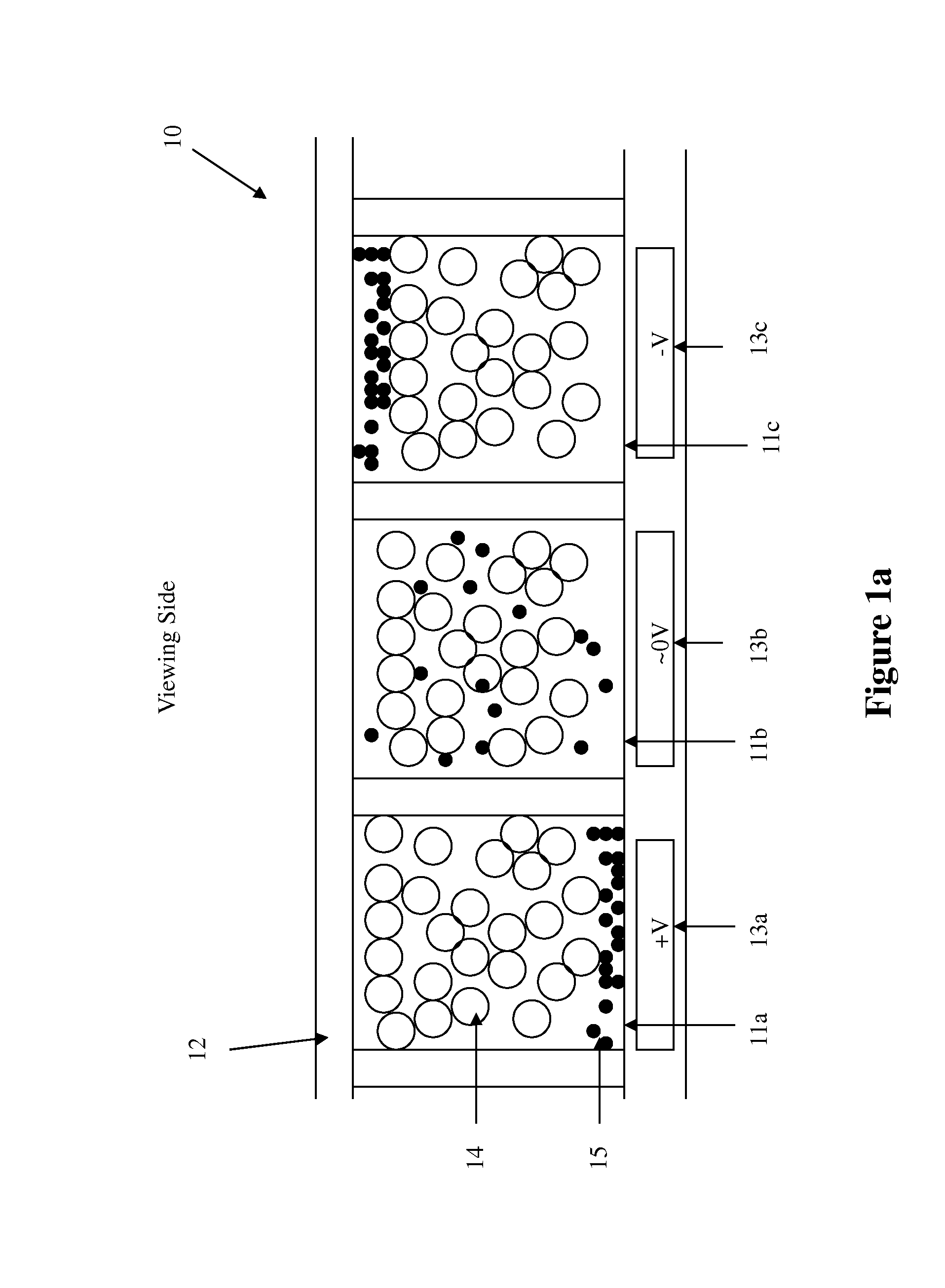

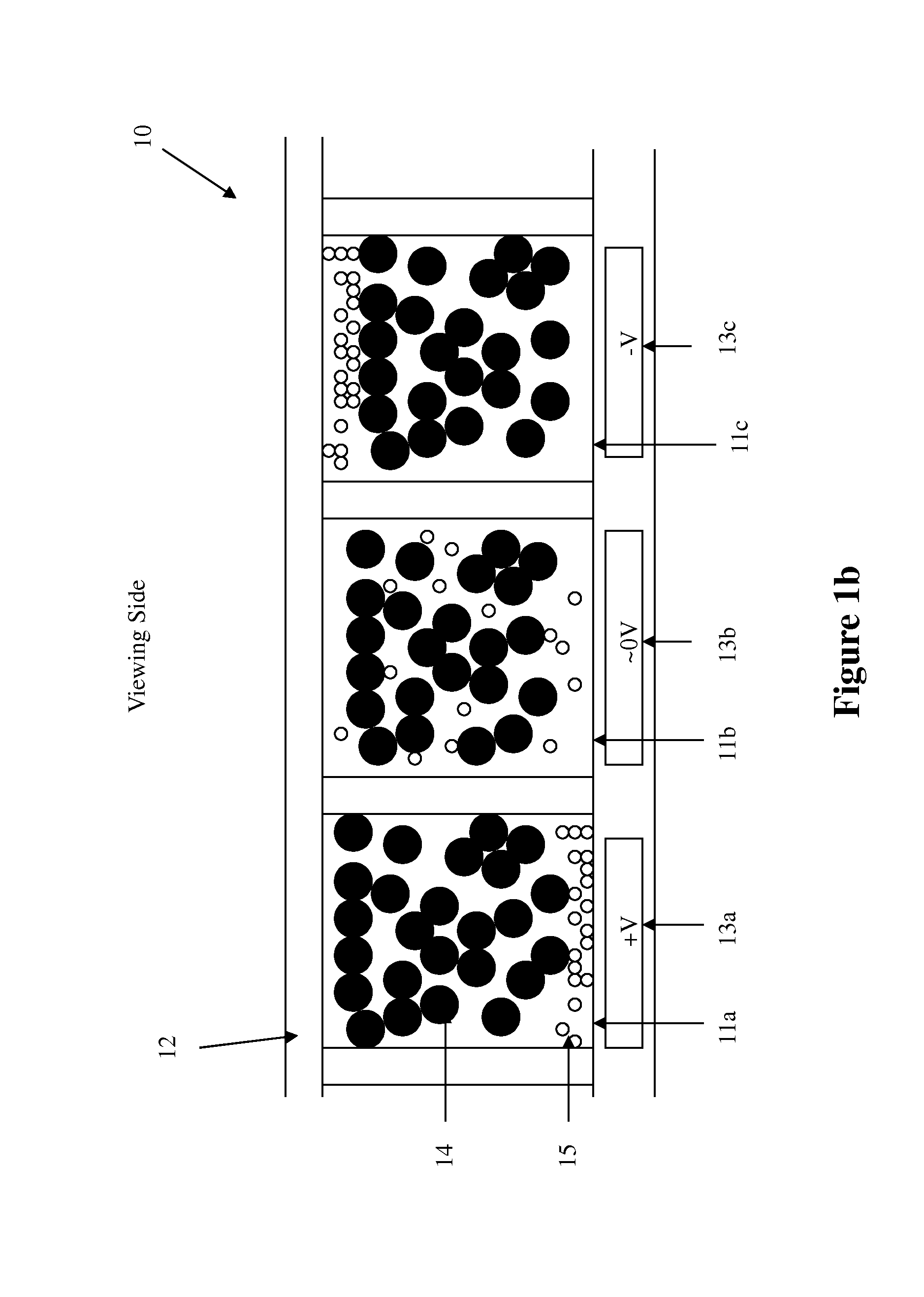

Electrophoretic display device

The present invention is directed to an electrophoretic display device comprising a plurality of display cells, wherein said display cells are filled with an electrophoretic fluid comprising: a) charged pigment particles of a first color; and b) a solid porous matrix of a second color, in which the charged pigment particles dispersed in a solvent. The electrophoretic fluid has many advantages, such as increased contrast without affecting the switching speed.

Owner:E INK CALIFORNIA

Toner and developer, and image forming method and apparatus using the developer

A toner is provided that contains a particulate toner material (mother toner) having an average circularity of from 0.93 to 0.99, and including a modified polyester resin and a colorant; and an external additive in an amount of from 0.3 to 5.0 parts by weight per 100 parts by weight of the mother toner, wherein the toner has a melting viscosity of from 70 to 140 Pa·s at 160° C., a weight-average particle diameter of from 3 to 7 μm, a ratio thereof to a number-average particle diameter of from 1.91 to 1.25, wherein particles satisfy at least one of (I) and (II): (I) particles having a diameter of 4 μm or less in an amount less than 10% by number; or (II) particles having a diameter of 8 μm or more in an amount less than 2% by volume, along with a one or two component developer containing the toner, a cartridge containing the toner, an image forming method using the toner and an image forming apparatus using the toner.

Owner:RICOH KK

Toner for developing a latent electrostatic image, image-forming method, image-forming apparatus and process cartridge using the same

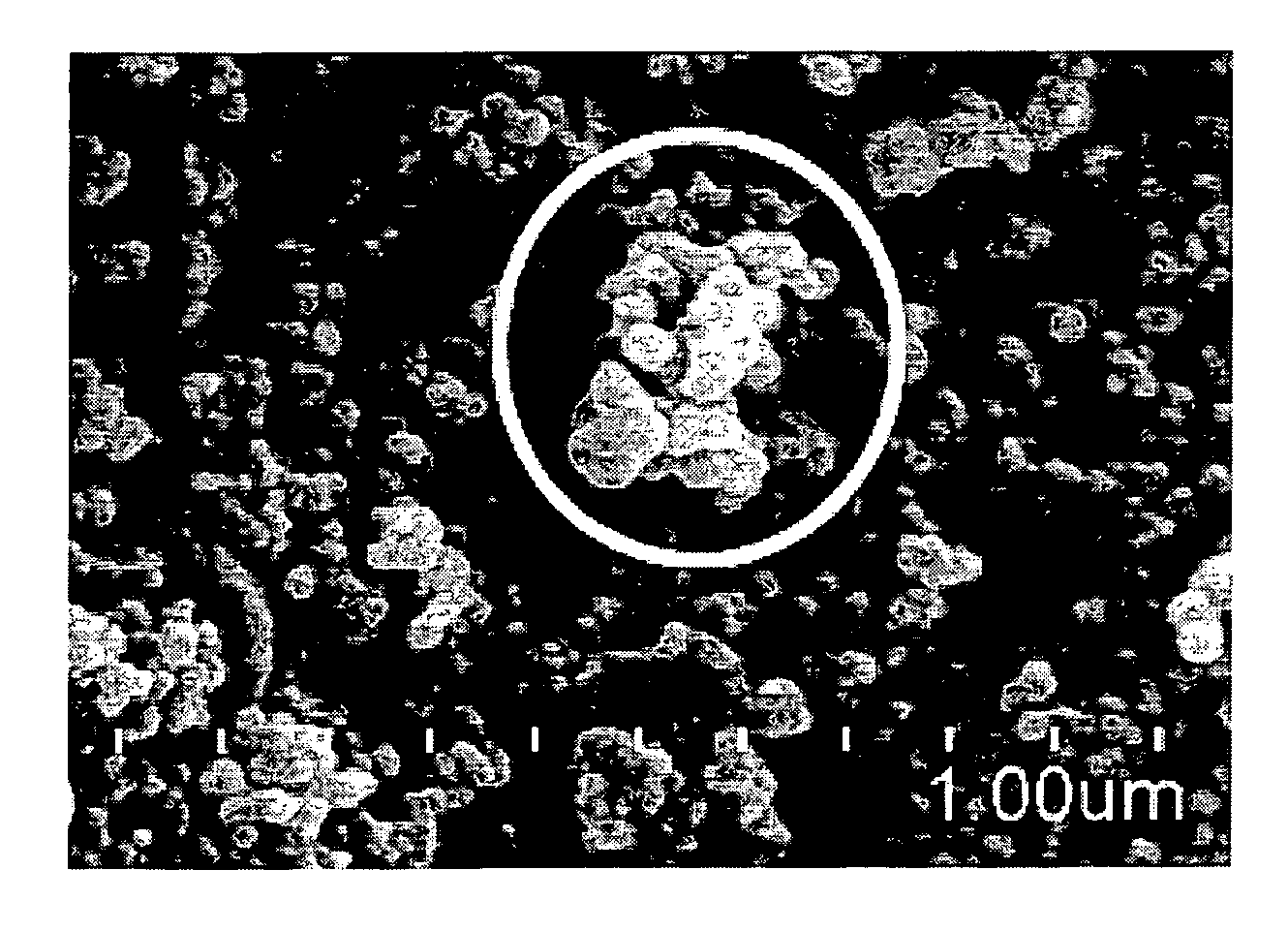

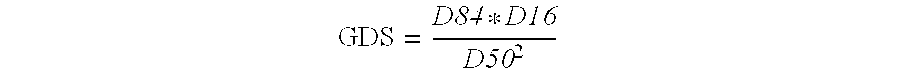

To provide a toner containing at least a toner base containing a binder resin and a colorant, and an inorganic fine particle, wherein the inorganic fine particle contains a compound oxide expressed by the following Composition Formula (1): [M1]aSibOc Composition Formula (1) where “M1” represents a metal element selected from Sr, Mg, Zn, Co, Mn and Ce, “a” and “b” each represents an integer of 1 to 9 and “c” represents an integer of 3 to 9, wherein an average primary particle diameter of the compound oxide is 0.02 μm to 1.5 μm, and an average secondary particle diameter of the compound oxide is 0.08 μm to 3.5 μm, where the secondary particle is an aggregate of the primary particles.

Owner:RICOH KK

Polymerization processes

A process for the preparation of a latex polymer by(i) preparing or providing a water aqueous phase containing an anionic surfactant in an optional amount of less than or equal to about 20 percent by weight of the total amount of anionic surfactant used in forming the latex polymer;(ii) preparing or providing a monomer emulsion in water which emulsion contains an anionic surfactant;(iii) adding about 50 percent or less of said monomer emulsion to said aqueous phase to thereby initiate seed polymerization and to form a seed polymer, said aqueous phase containing a free radical initiator; and(iv) adding the remaining percent of said monomer emulsion to the composition of (iii) and heating to complete an emulsion polymerization thus forming a latex polymer.

Owner:XEROX CORP

Flexible, flame-retardant, aqueous-processable photoimageable composition for coating flexible printed circuits

A flexible, flame-retardant, aqueous processable, photoimageable resin composition for forming a permanent, protective coating film for printed circuitry and a multilayer photoimageable element containing a layer of the photoimageable resin composition in combination with a low tack photoimageable resin sublayer and a temporary support film are disclosed. The photoimageable resin composition has excellent aqueous developability and provides a cured coating film having good flexibility, adhesion, solvent resistance, surface hardness, thermal resistance, electrical insulating properties and flame retardancy.

Owner:EI DU PONT DE NEMOURS & CO

Toner, method of forming the toner, and image forming method and apparatus using the toner

InactiveUS6852462B2Good reproducibilityQuality improvementDevelopersElectrographic processes using charge patternEngineeringVolume average

A toner comprising:a binder resin which is at least a resin selected from the group consisting of modified polyester resins and unmodified polyester resins; anda colorant; the product toner having a volume-average particle diameter (Dv) to a number-average particle diameter (Dn) ratio (Dv / Dn) ranging from 1.00 to 1.30, and the toner having a shape factor SF-1 ranging from 140 to 200.

Owner:RICOH KK

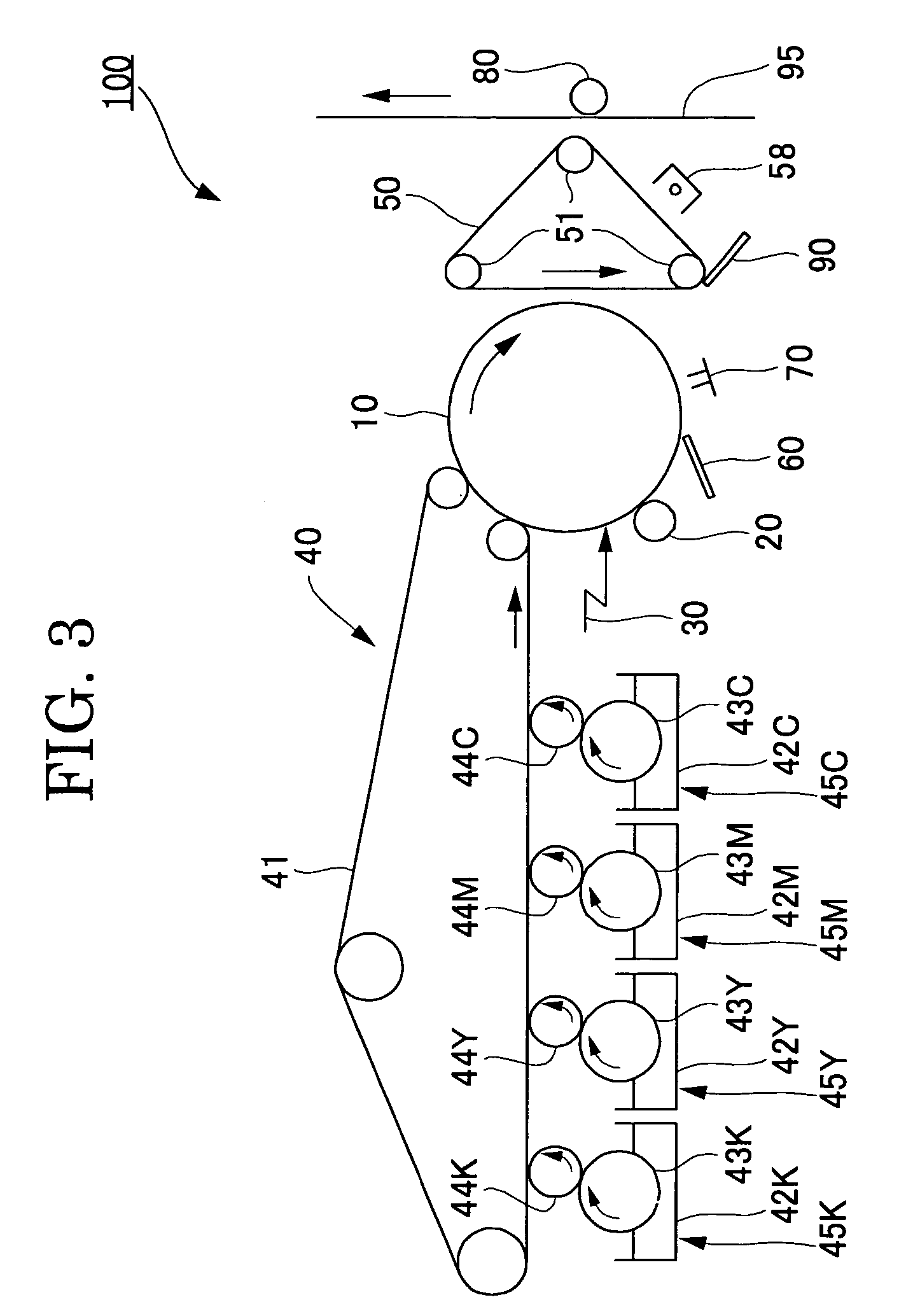

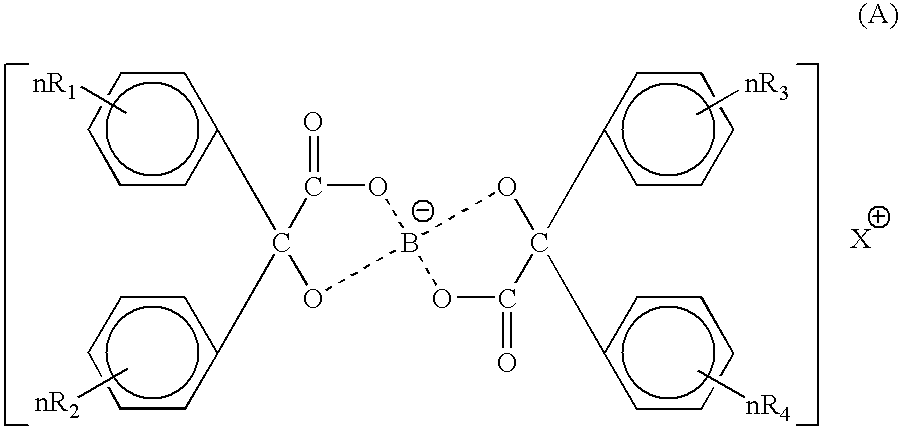

Toner and image forming method

InactiveUS20070207399A1Improve stabilityUniformly and efficiently chargingElectrographic process apparatusDevelopersImage transferLatent image

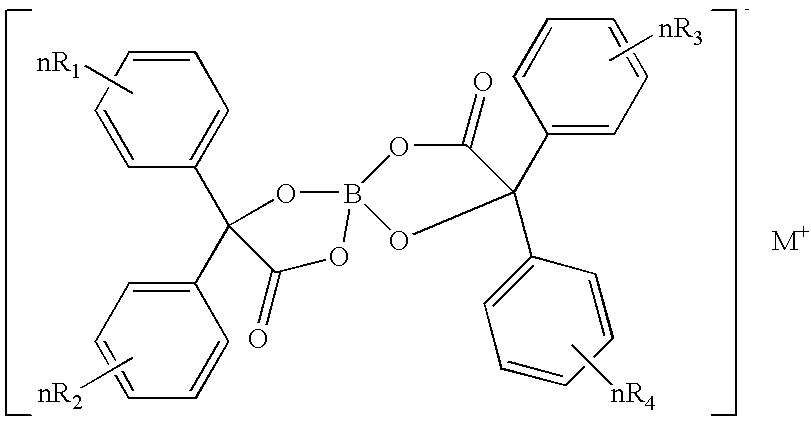

Toner for electrostatic charge development wherein no scumming occurs, and toner leakage caused by charge defect of the toner on a developing roller can be inhibited, and an excellent image stability is obtained is provided.The toner used for an image forming method having a latent electrostatic image forming step of forming a latent electrostatic image on a latent electrostatic image bearing member primarily charged, a developing step of developing the latent electrostatic image by each toner which multiple developing devices have to form a toner image on the latent electrostatic image bearing member, a transferring step of transferring the toner image with respective colors formed on the latent electrostatic image bearing member onto a recording material and a fixing step of fixing the toner image transferred onto the recording material, wherein the toner comprises a colorant and a resin and contains an organic boron compound represented by a following chemical formula (A) as a charge controlling agent, further the toner is treated with an inorganic fine particle and at least one of the inorganic particles is a magnesium silicate compound represented by a following general formula [2] is provided.wherein X is an alkali metal, R1, R2, R3 or R4 each represents a hydrogen atom, an alkyl group having 1 to 4 carbon atoms, an alkoxy group having 1 to 4 carbon atoms, or a halogen atom.MgxSiyO(x+2y) [2]wherein x and y are integers.

Owner:RICOH KK

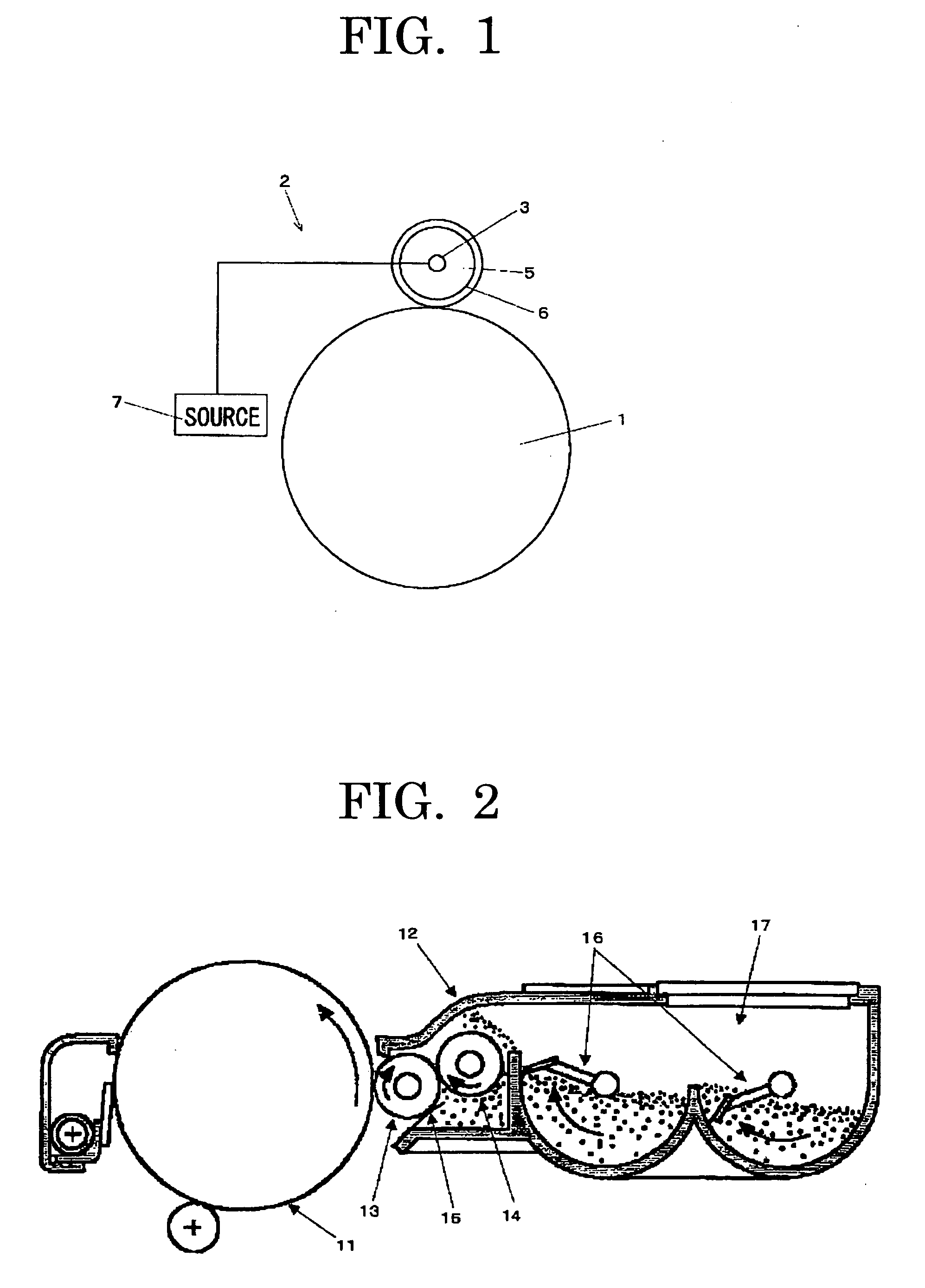

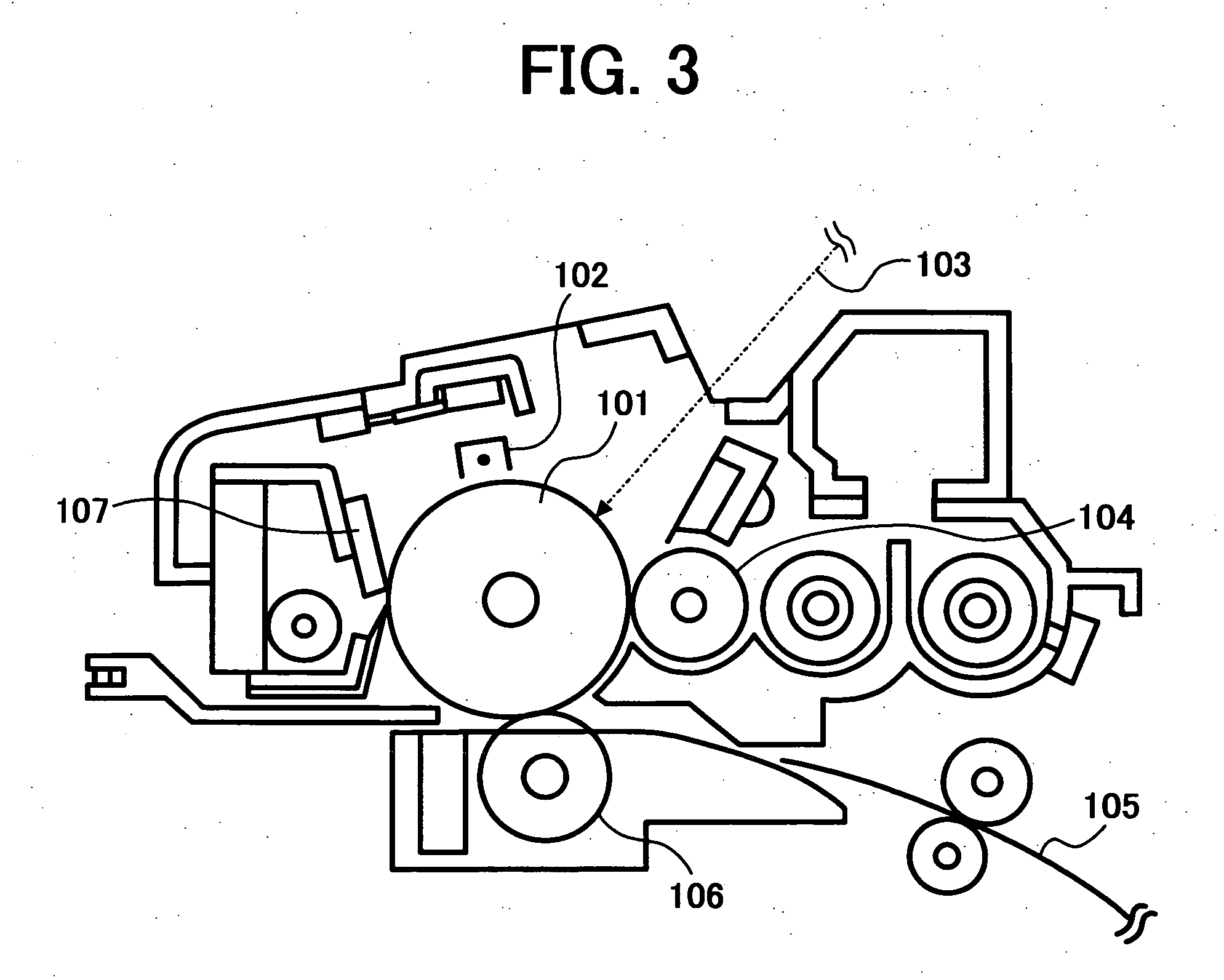

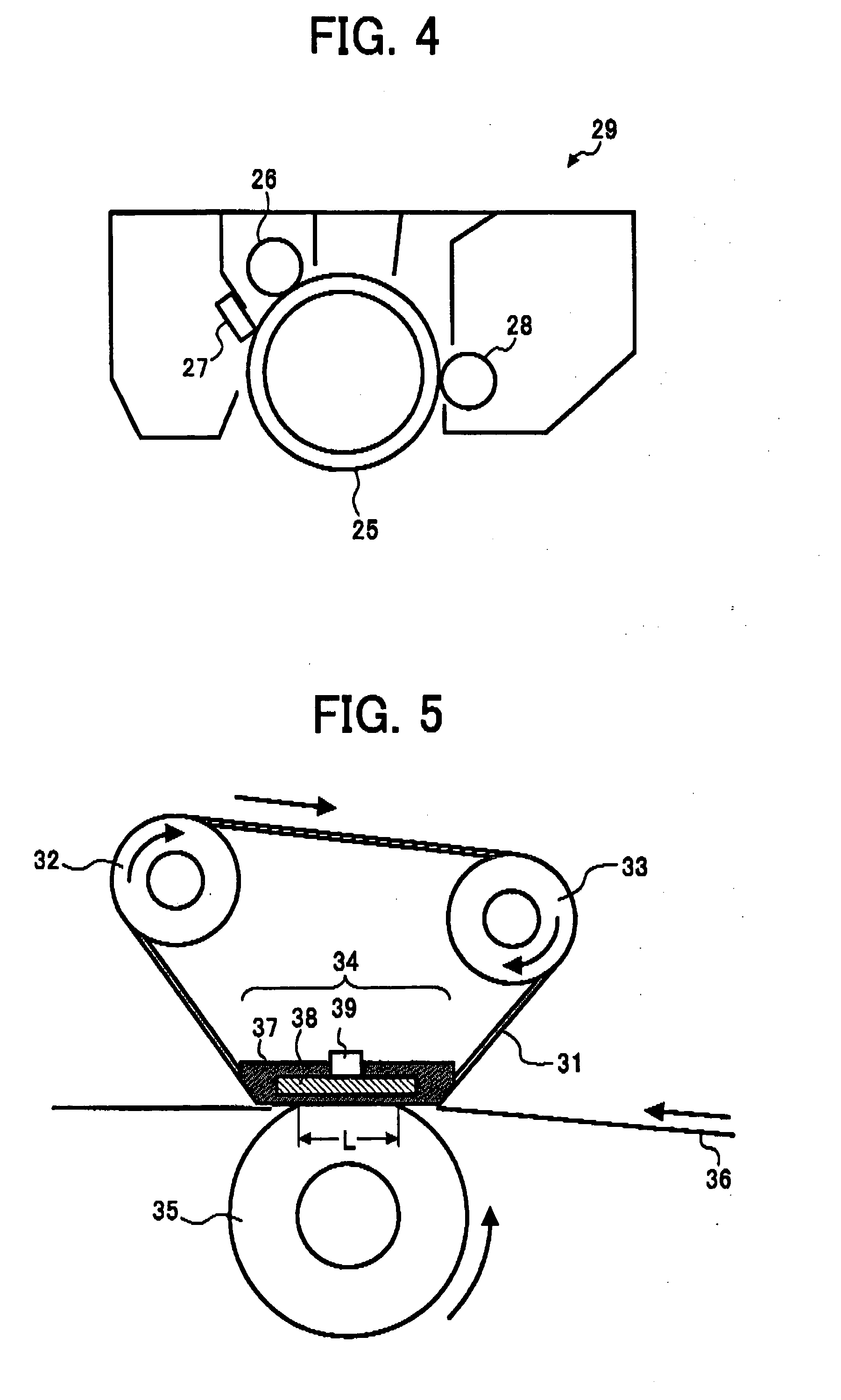

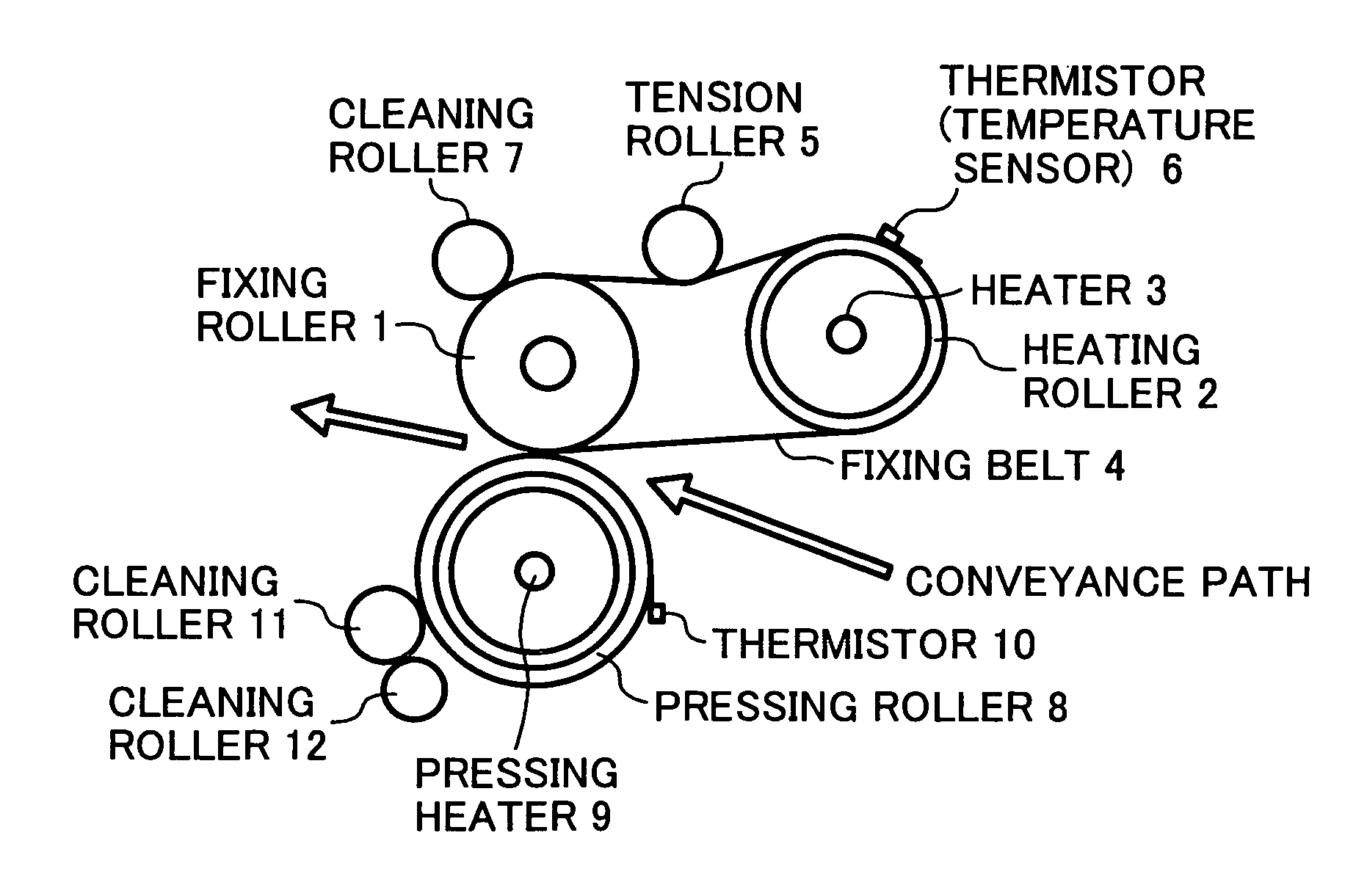

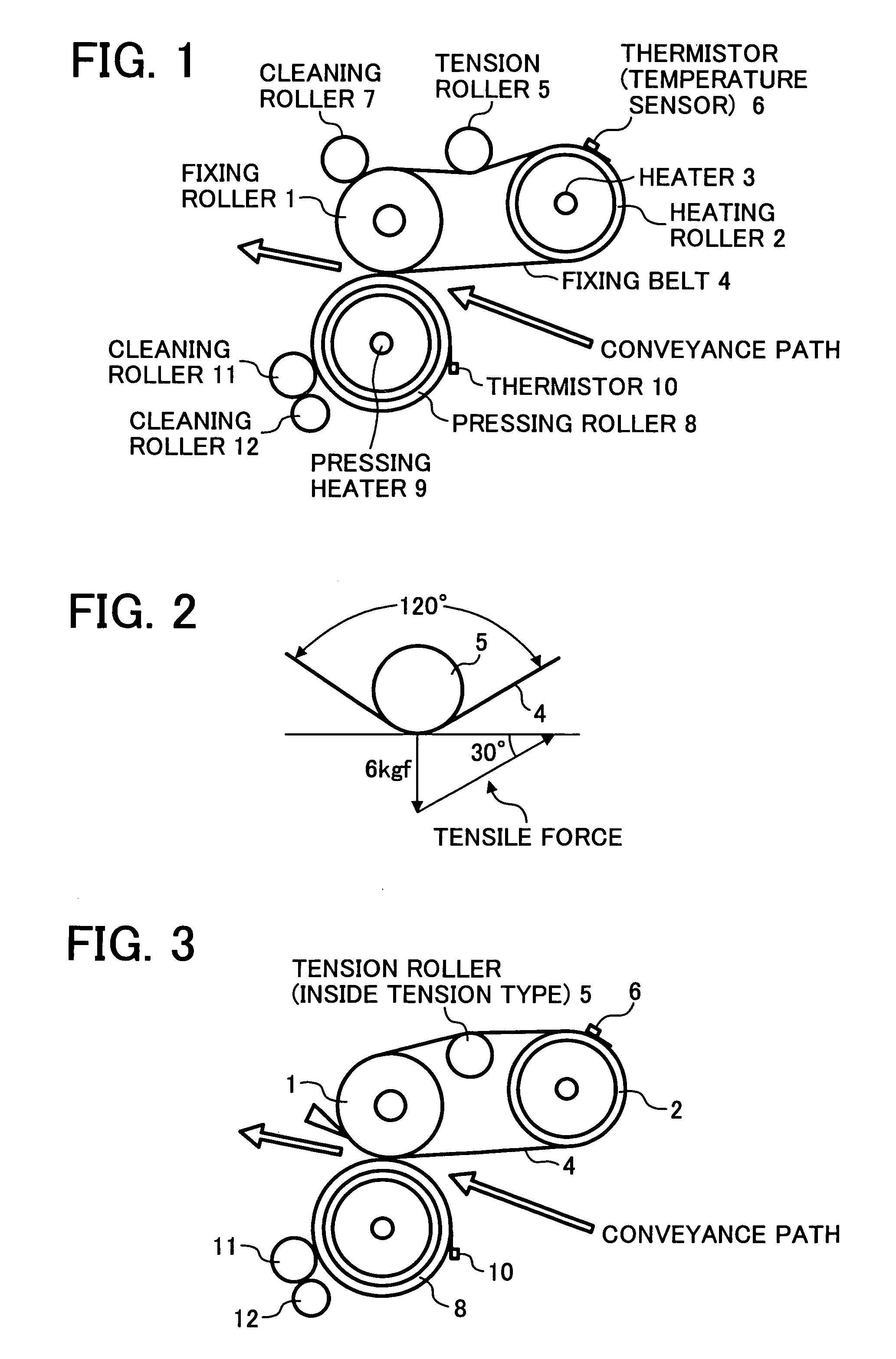

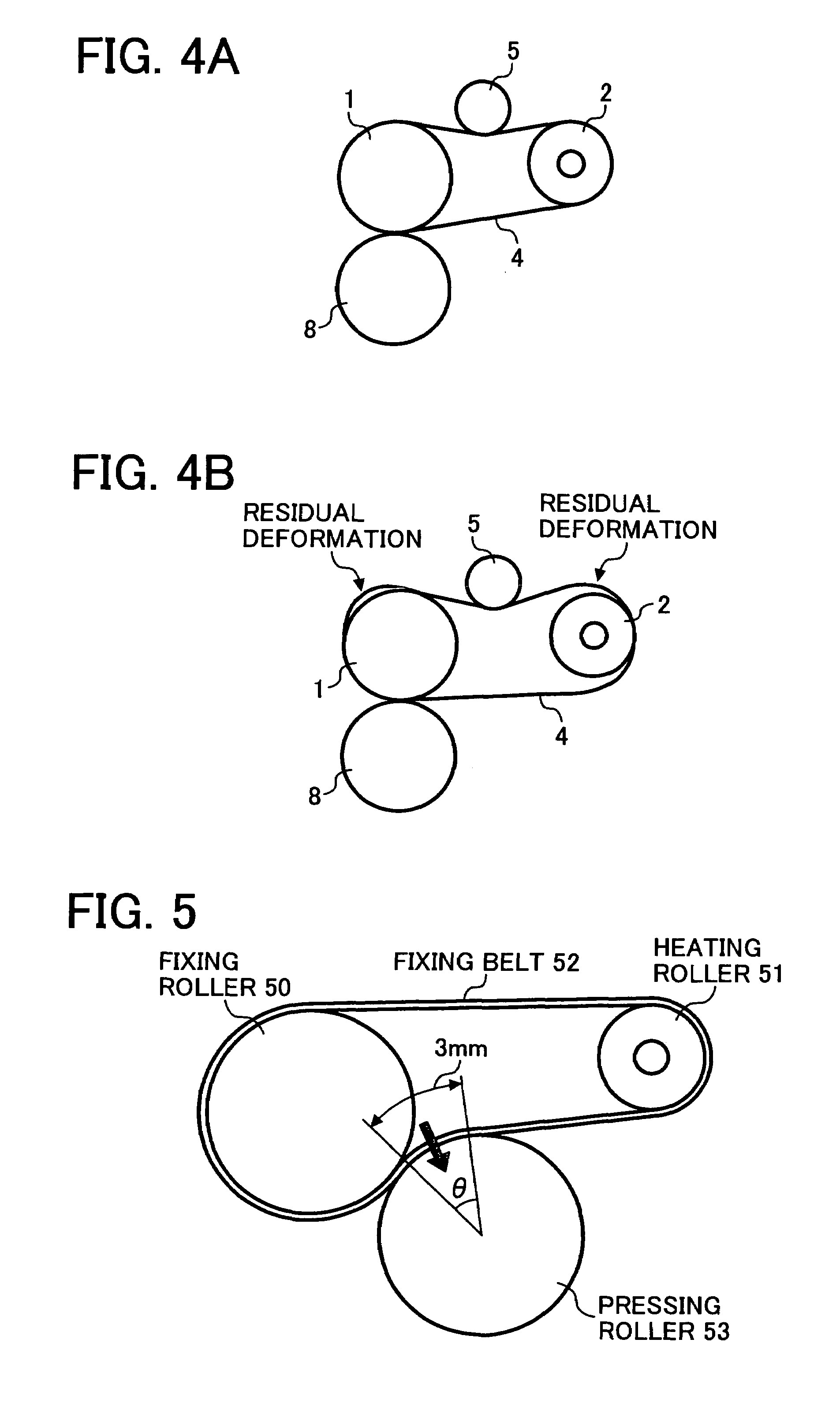

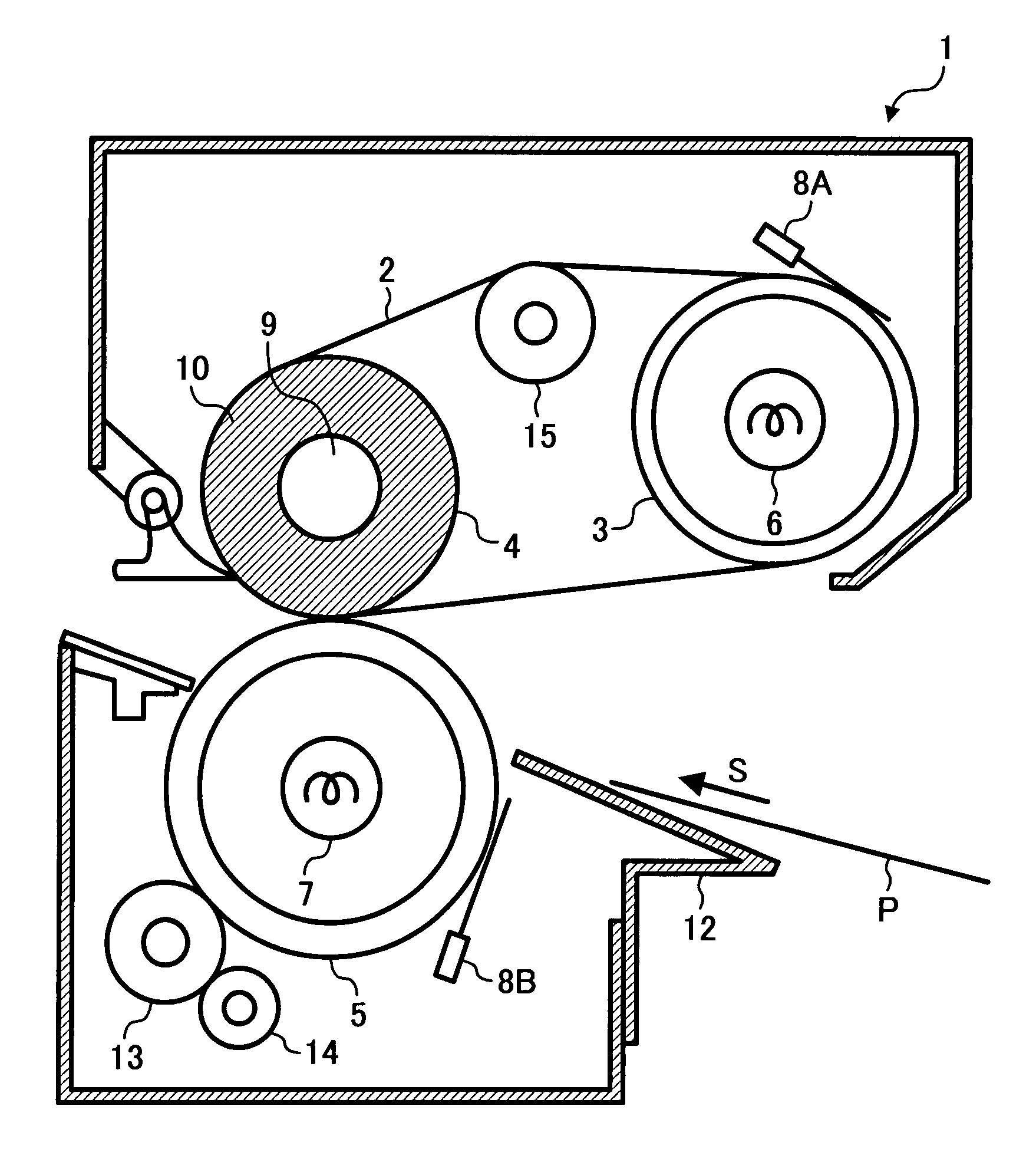

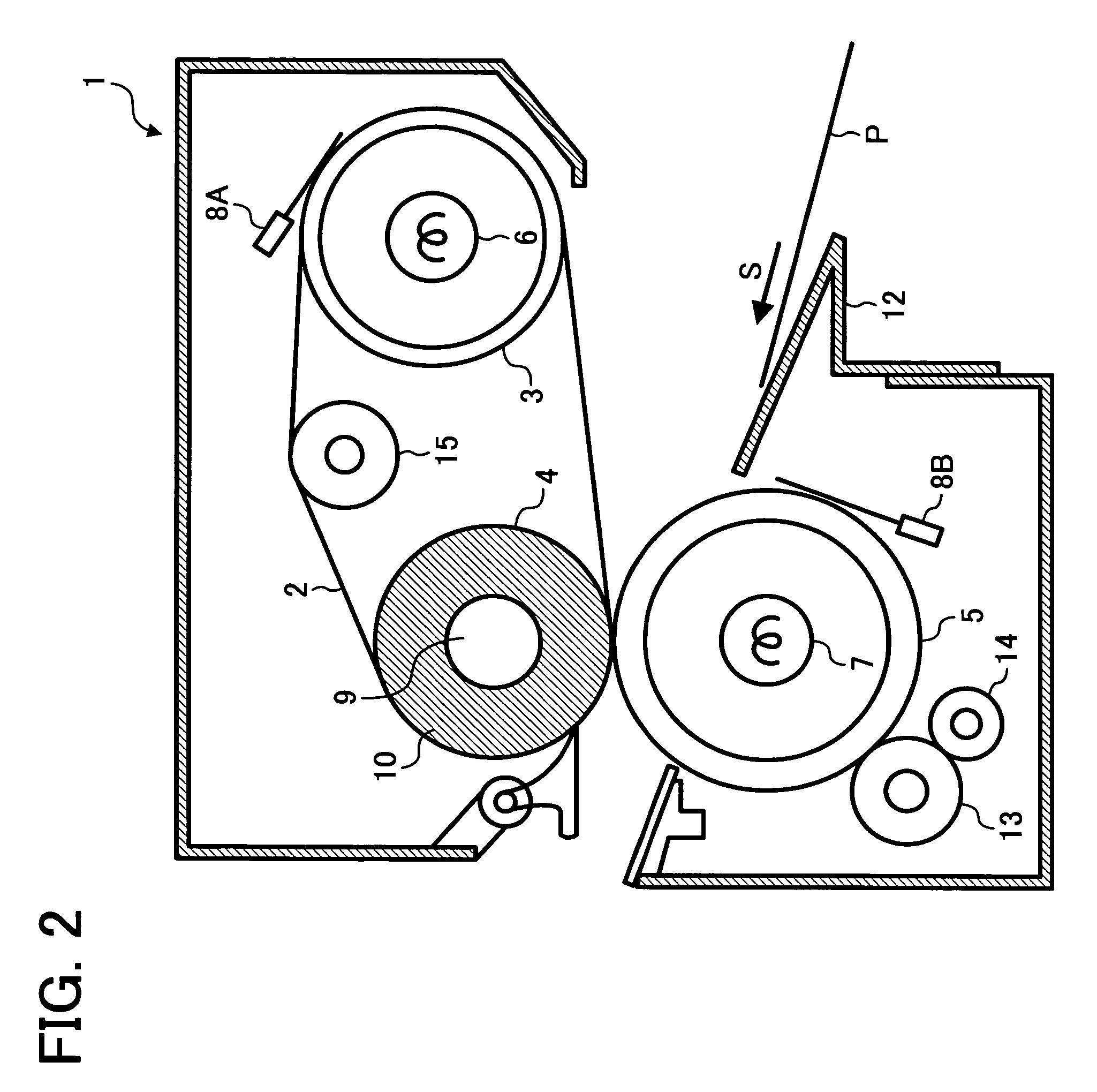

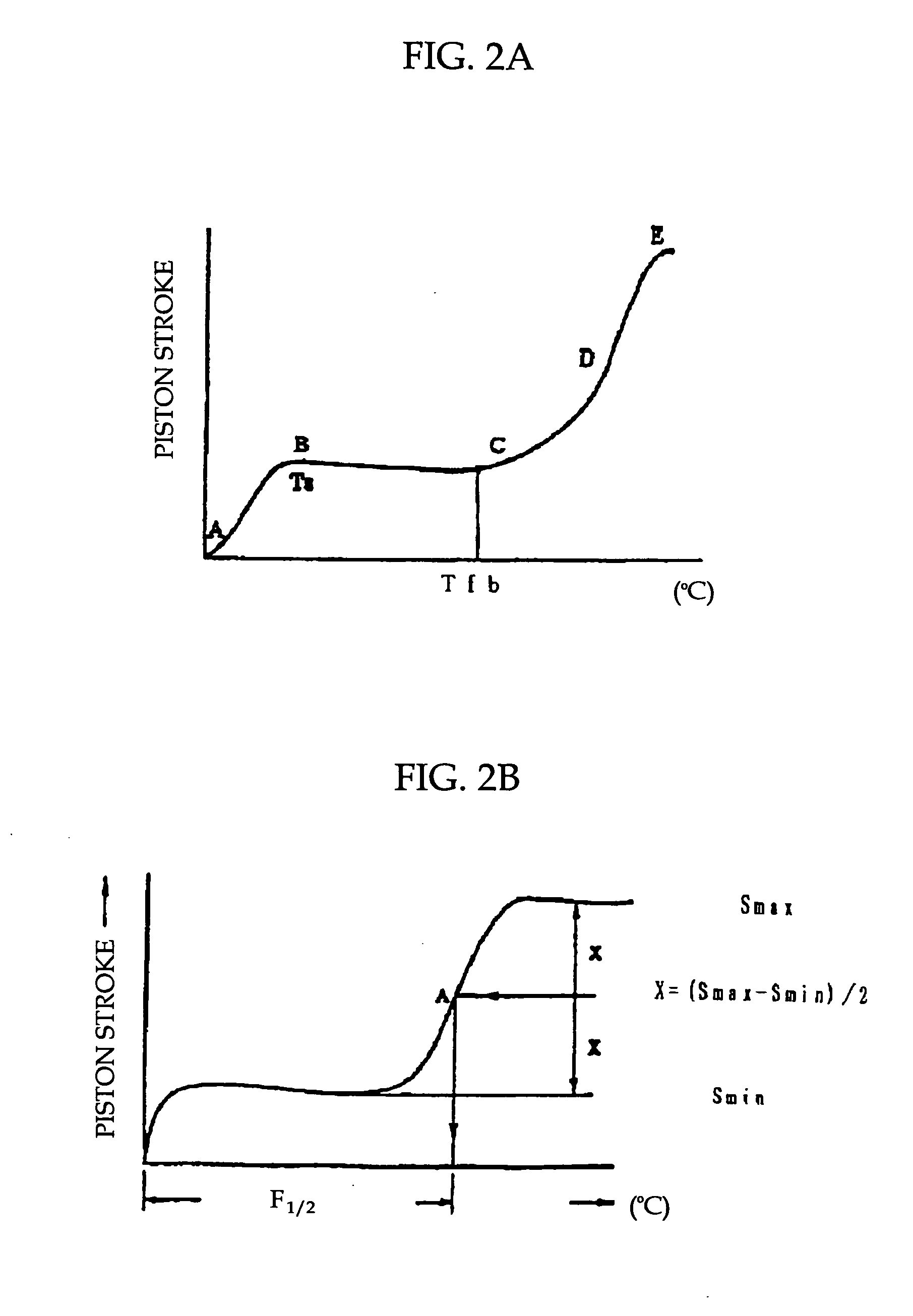

Belt fixing unit with heat-resisting resin base member and image forming toner for use in the fixing unit

A belt fixing unit, an image forming apparatus, and a toner material are disclosed capable of obviating undesirable fixing belt deformation and low image quality. The belt fixing unit includes a fixing roller, a heating roller, a fixing belt, and a pressing roller in contact with the fixing roller to form a fixing nip having the fixing belt intervening there between, the fixing belt including at least a base member formed of a heat-resisting resin having a thickness of 90 μm or smaller and acted upon by a tensile force of 0.49 N / mm or less. The toner is a low-melting point toner formed by subjecting a toner preparatory solution containing at least a prepolymer having a functional group containing a nitrogen atom, a polyester, a colorant and a releasing agent dispersed in an organic solvent to extension and / or crosslinking reactions in an aqueous medium.

Owner:RICOH KK

Toner and image forming method using the toner

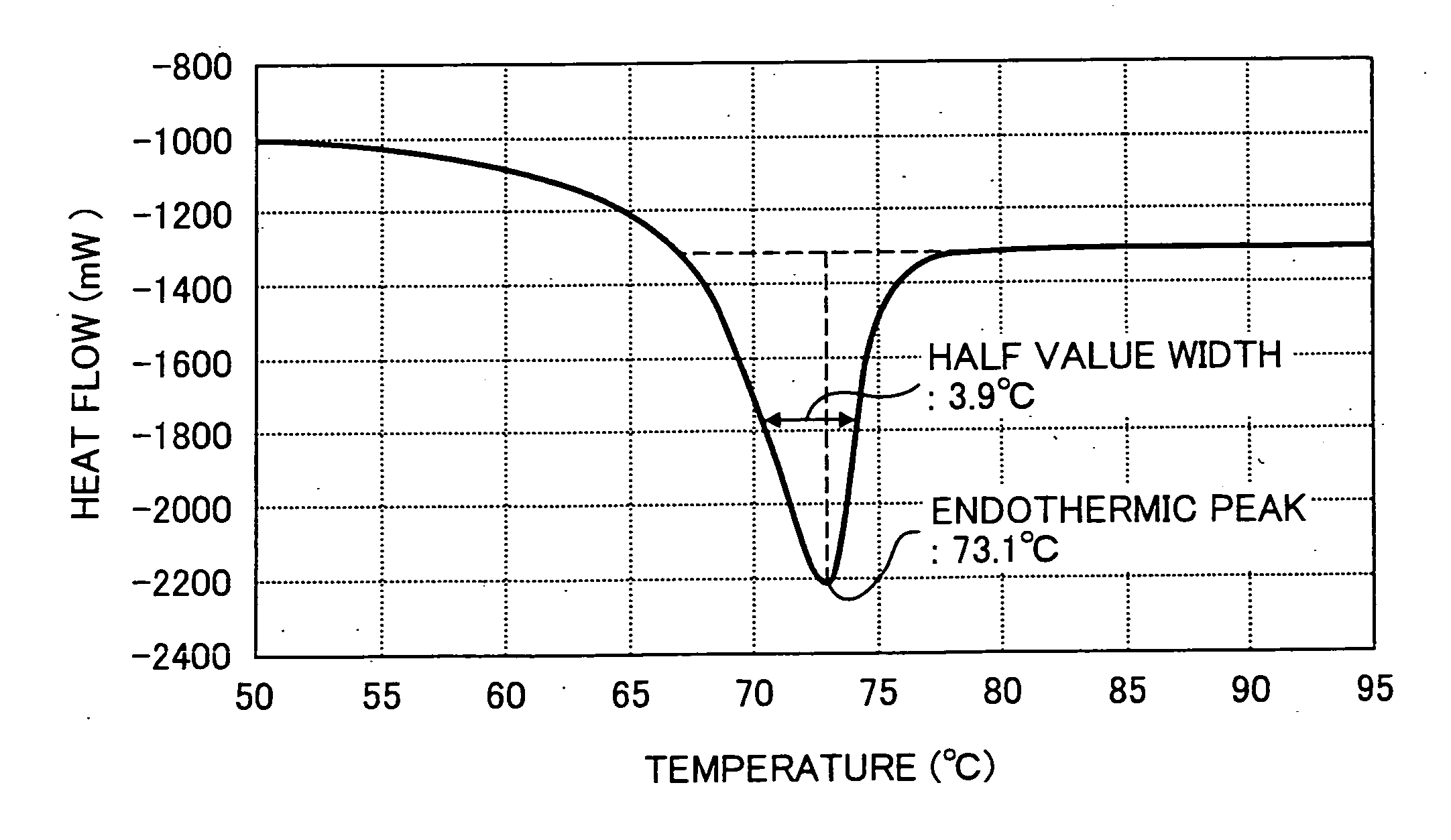

ActiveUS20060057488A1Excellent hot offset resistanceHigh quality imagingDevelopersImage formationGlass transition

A toner satisfying at least one of the following relationships: 10° C.<(T1−T2)<60° C. and 0<Q2 / Q1<2 / 3 wherein T1 represents a glass transition temperature of the toner and Q1 represents an endothermic quantity at a melting point thereof before melting when heated from −20° C. to 150° C. at a heating speed of 10° C. / min, and T2 represents a glass transition temperature thereof and Q2 represents a an endothermic quantity at a melting point thereof after melting after heated from −20° C. to 150° C. at a heating speed of 10° C. / min, cooled to −20° C. at a cooling speed of 10° C. / min and heated again at a heating speed of 10° C. / min.

Owner:RICOH KK

Polymerized toner

A monomer for a shell or a mixture of at least two monomers for a shell was suspension polymerized in the presence of core particles and a polymerization initiator to obtain polymer particles, wherein said core particles are formed of a polymer obtained by polymerization of a monomer for a core or a mixture of at least two monomers for a core and containing a colorant, wherein said monomer for a shell or mixture of monomers for a shell is one which gives upon polymerization a polymer having a glass transition temperature higher than that of the polymer forming the core particle, and wherein said polymerization initiator is represented by the following formula 1: wherein X1, X2, X3 and X4 independently represent oxygen atom, sulfur atom, >NR (wherein R is hydrogen atom, alkyl group, or group); R1, R2, R3, R4, R5 and R6 independently represent alkyl group, aryl group, or alkyl or aryl group having at least one substituent which is -OR, -OH, -NHR, or -NR2(wherein R is alkyl group or aryl group), and n and m independently represent an integer of 1 to 10. An outer additive was applied on the polymer particle to obtain a polymerized toner. This polymerized toner has low fixing temperature, excellent overhead projector transparency, good shelf stability, and exhibiting a less pronounced reduction in electric charge under conditions of high humidity and high temperature.

Owner:ZEON CORP

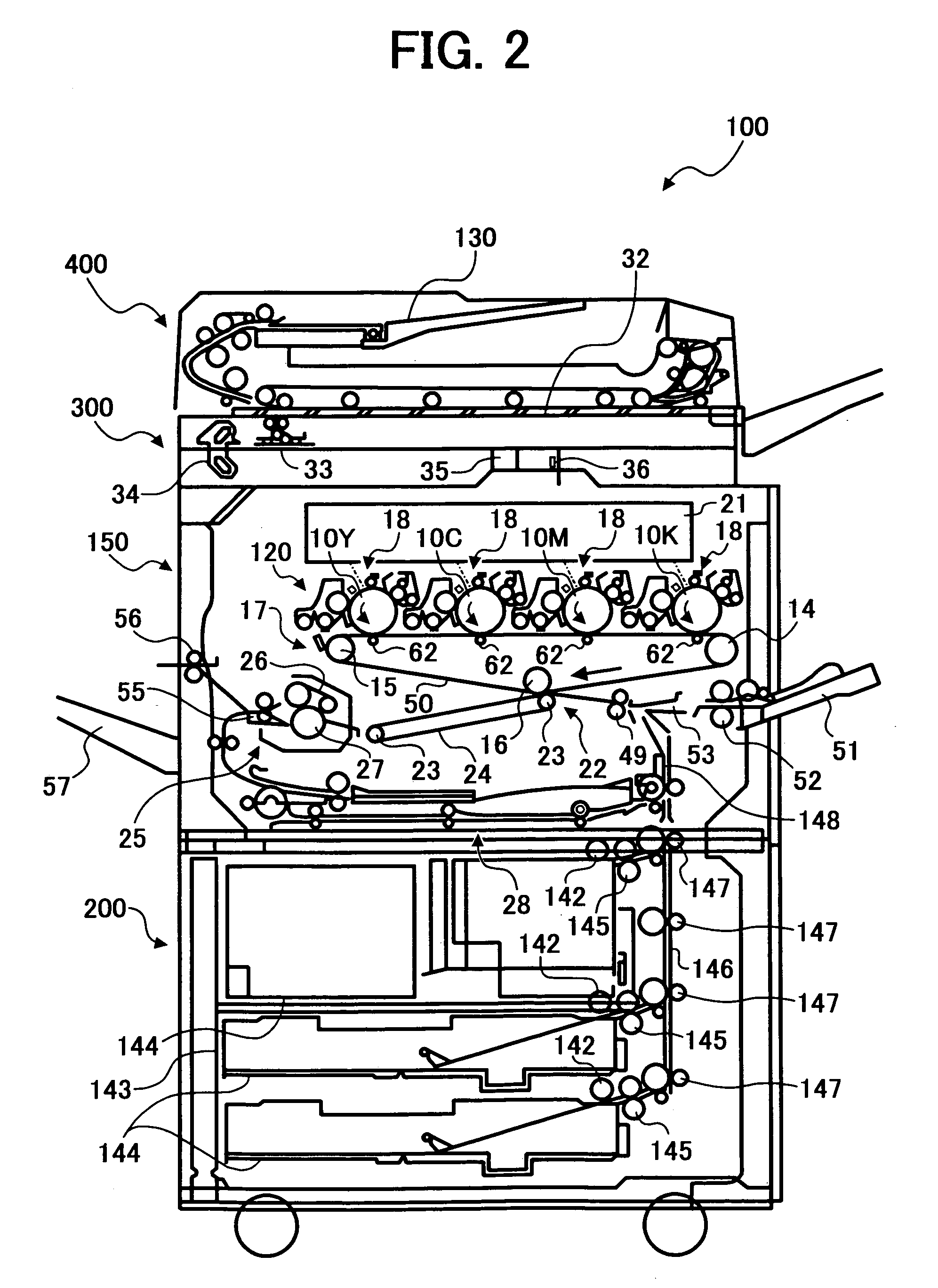

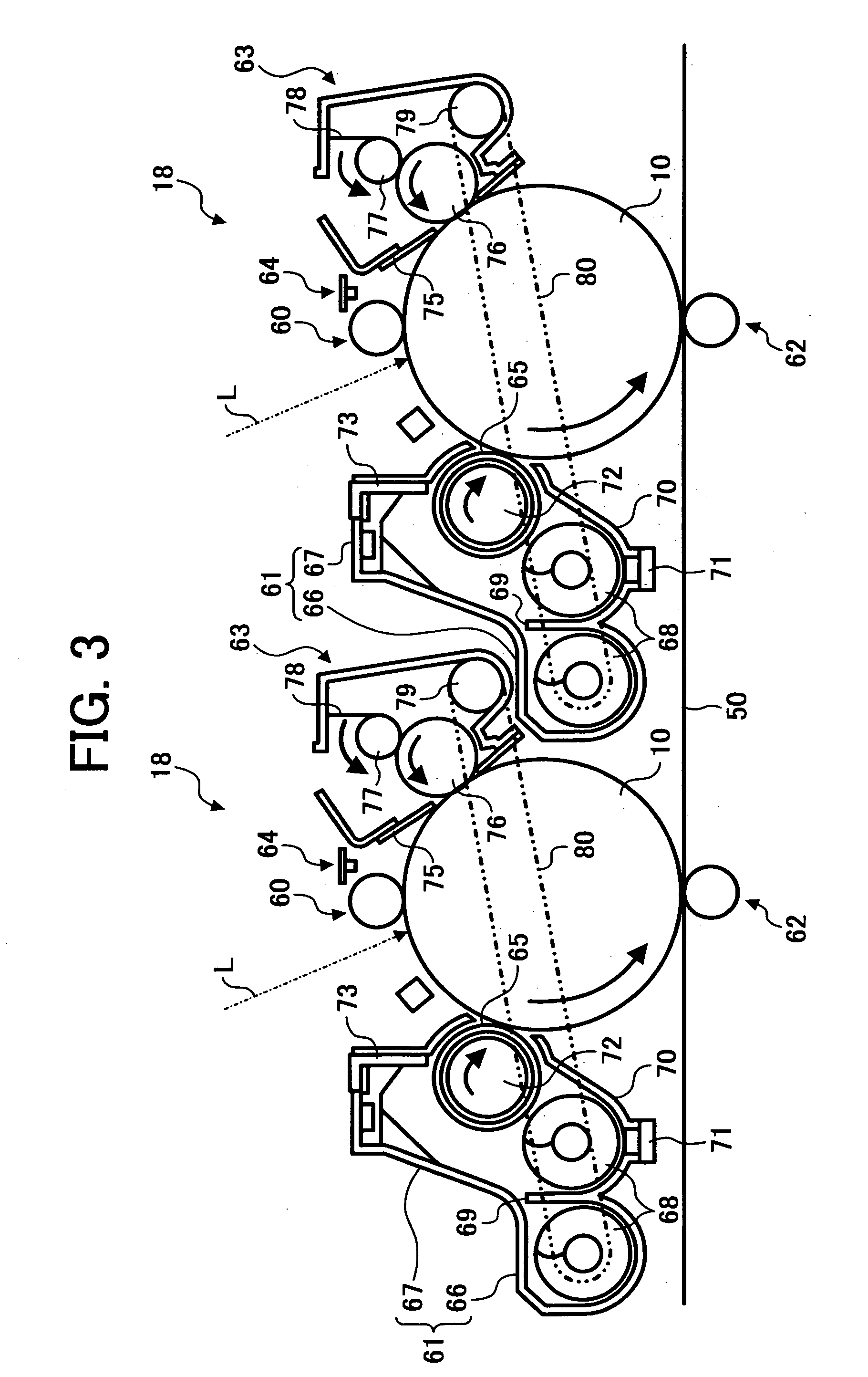

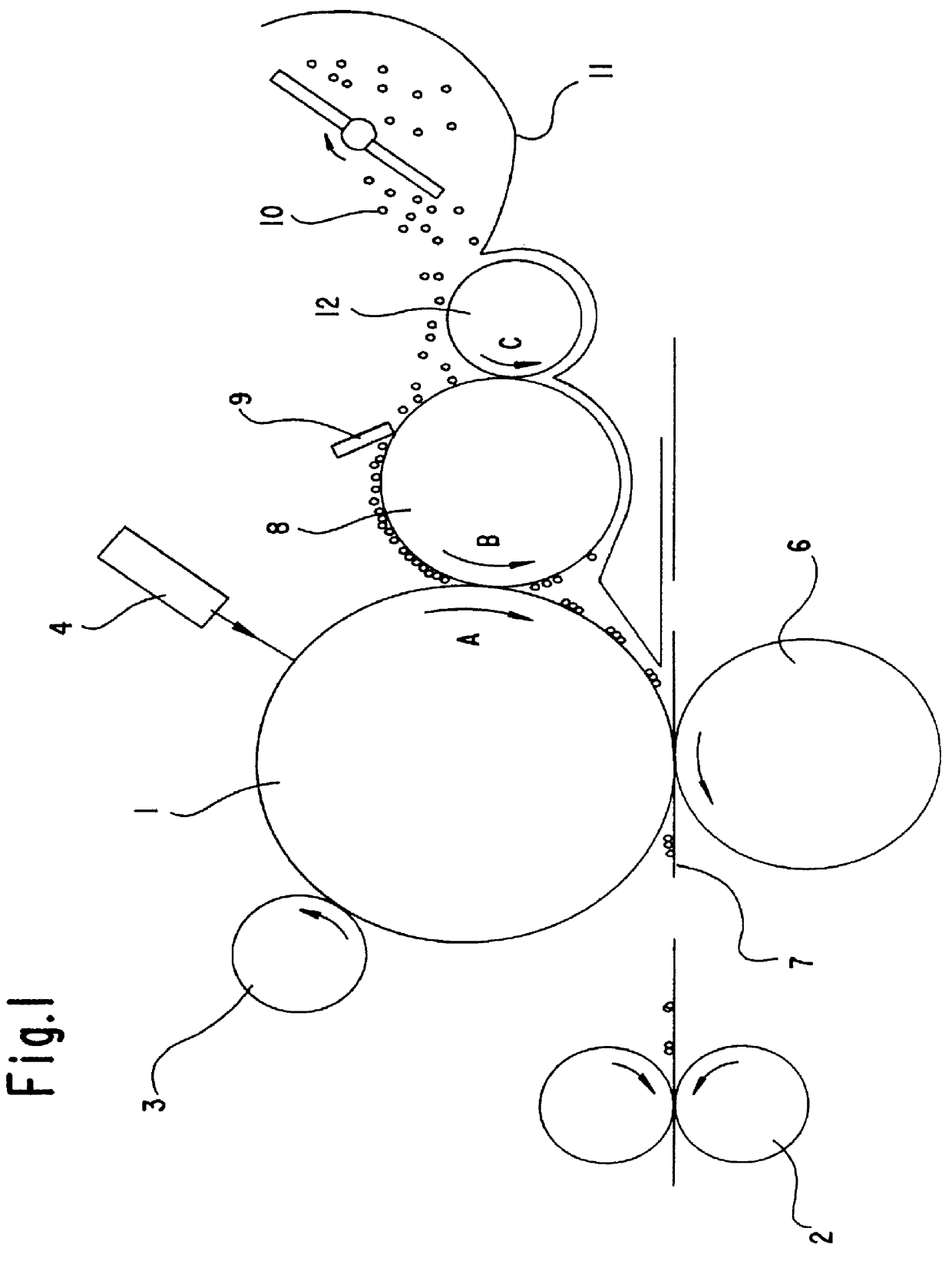

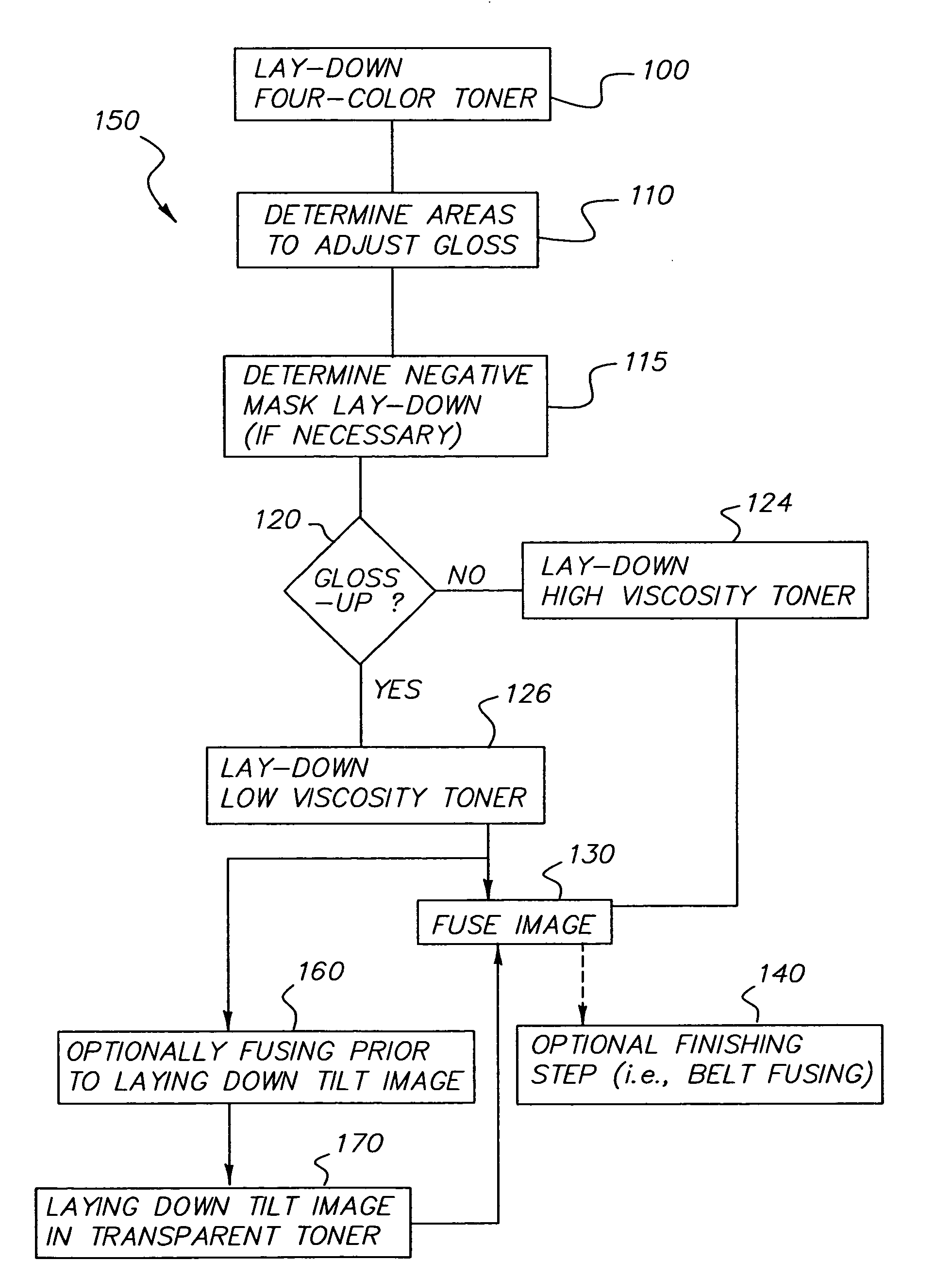

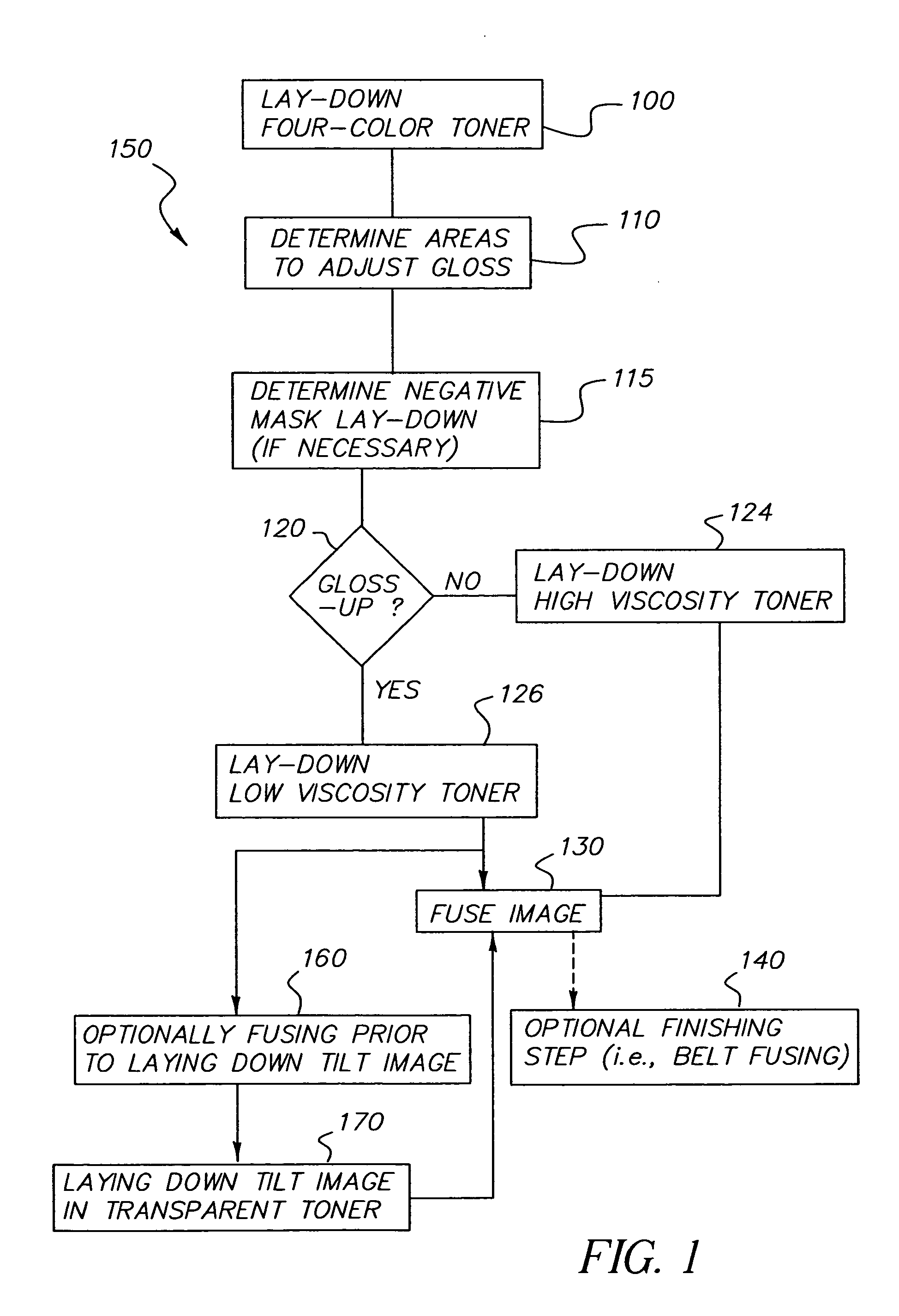

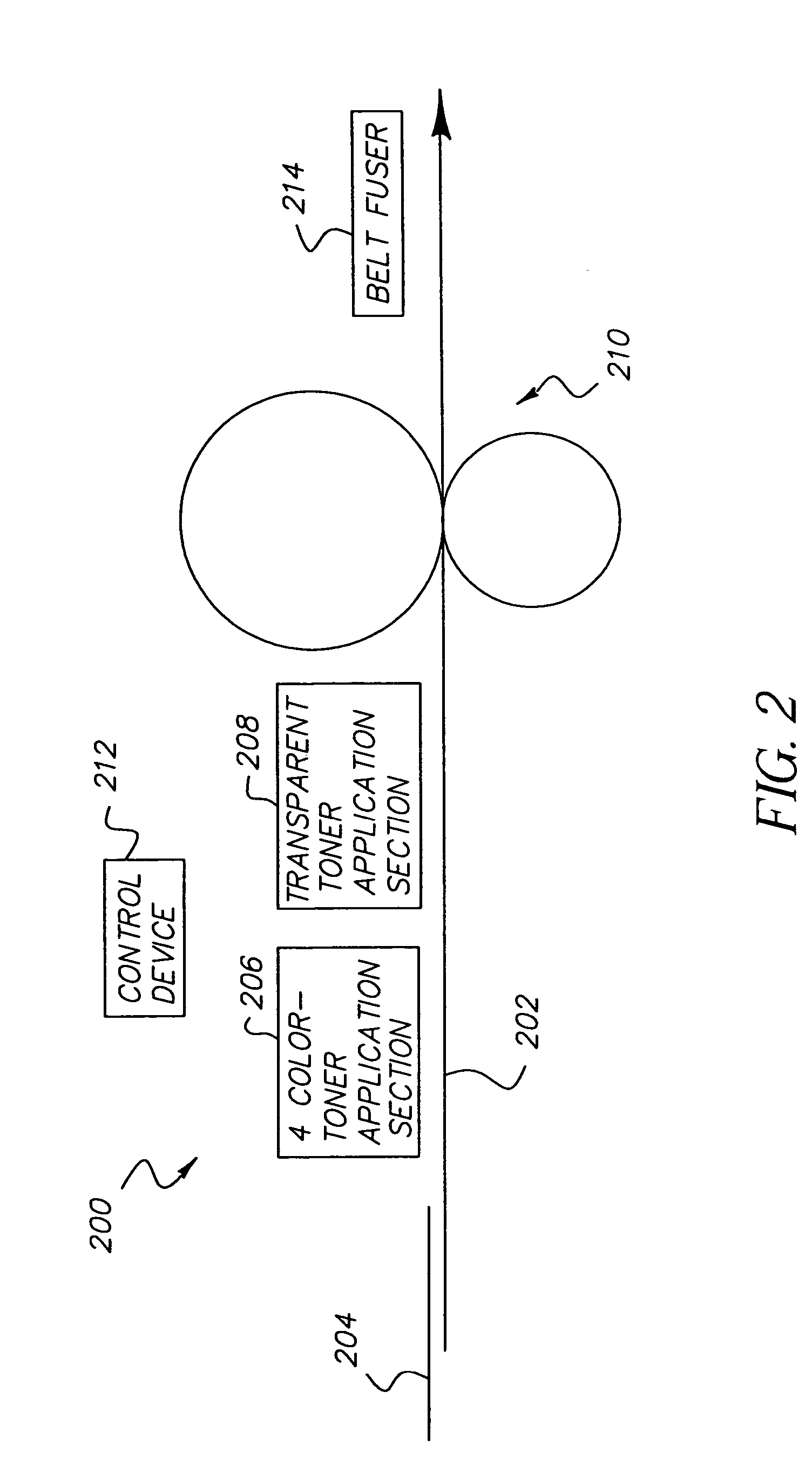

Adjustable gloss control method with different substrates and 3-D image effect with adjustable gloss

ActiveUS20050135851A1Reduce differential glossLow viscosityDevelopersElectrographic process apparatus3d imageEngineering

By using a high or low viscosity transparent toner, with respect to the other color toners, and different amounts of transparent toner lay-down, the gloss of an image printed by an electrophotographic device may be adjusted. By also applying the transparent toner as a negative mask, the differential gloss of the image may be reduced while still adjusting the gloss of certain portions of the image. Further, because different gloss levels may appear different at different viewing angles, transparent toner may be laid down to encode a transparent image within the image being printed. Such a transparent image may be useful as, for example, an authentication means for a document. Additionally, by varying the gloss levels on particular aspects of a printed image, multiple images of different gloss levels, which are prominent at different viewing angles can be made, thereby, a three-dimensional image effect can be achieved on the printed page.

Owner:COMML COPY INNOVATIONS INC

Toner coagulant processes

A process for the preparation of toner comprising mixing a colorant, a latex, optionally a wax and a polyaluminum sulfosilicate.

Owner:XEROX CORP

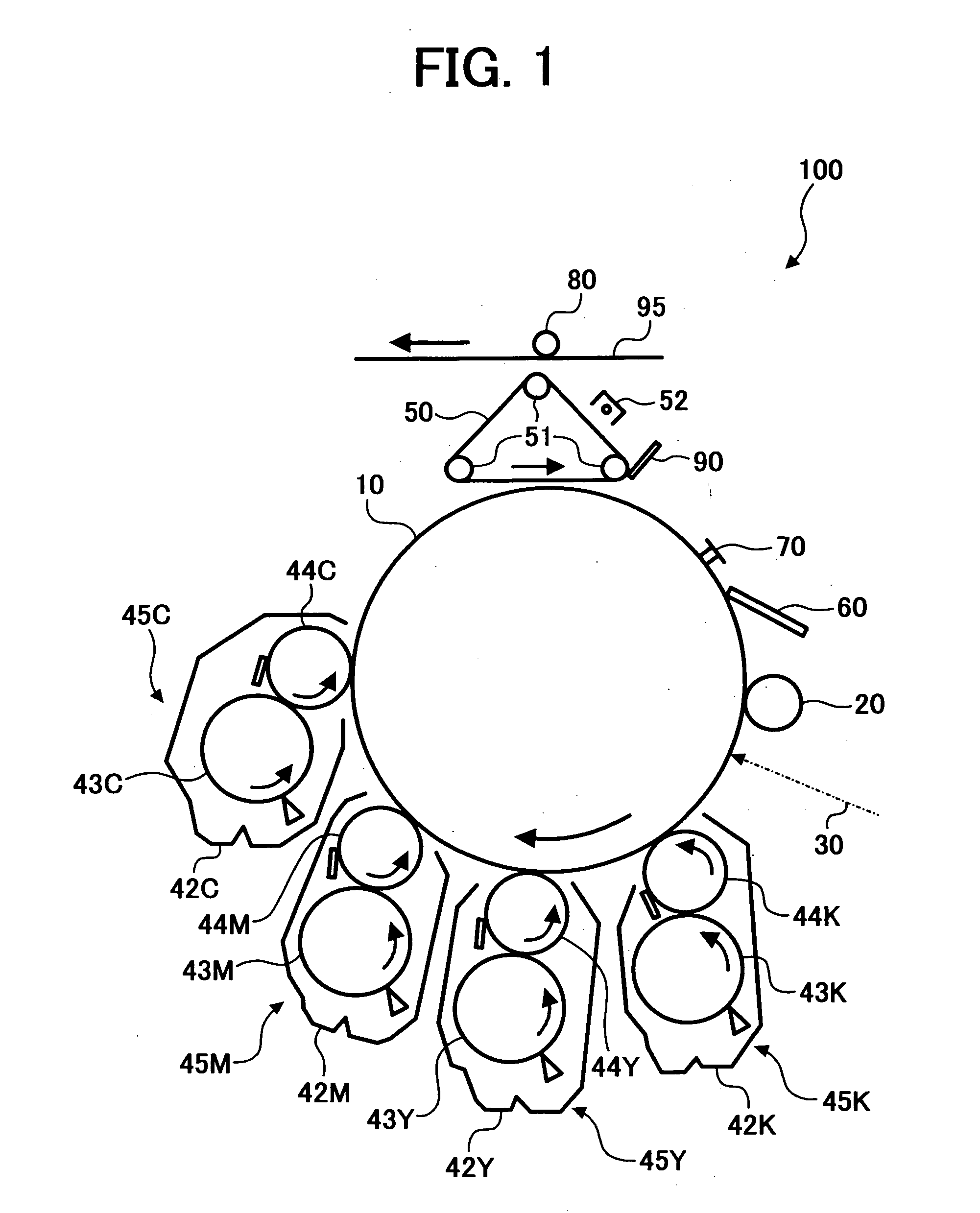

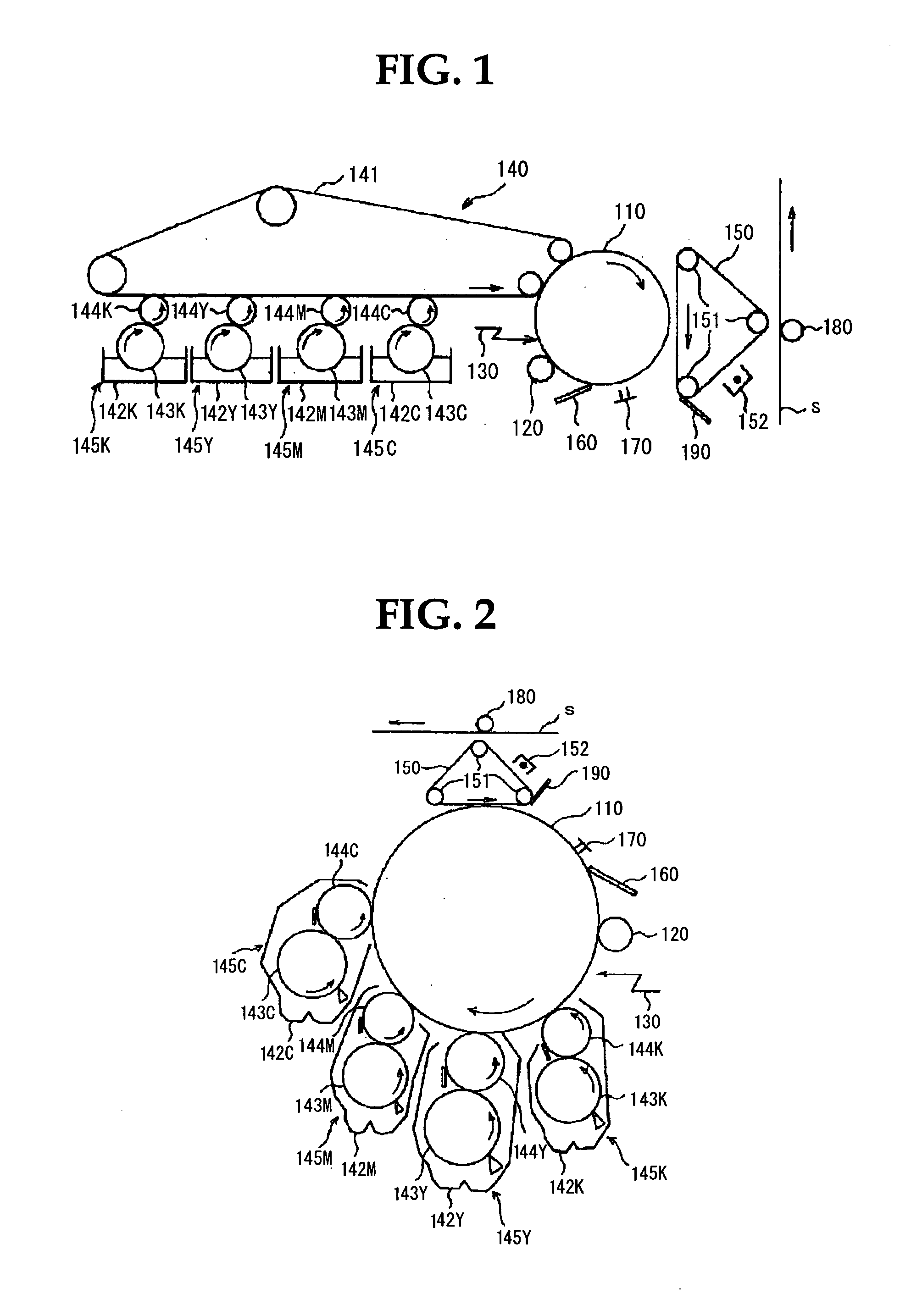

Image forming apparatus, fixing apparatus and toner

Owner:RICOH KK

Toner, image forming method and process cartridge

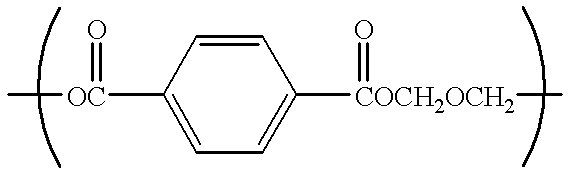

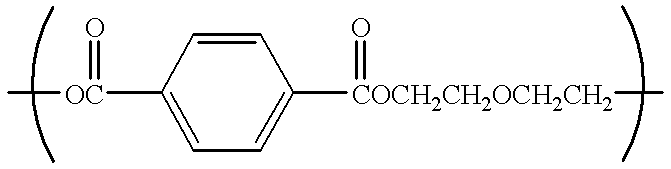

InactiveUS20070026335A1DevelopersElectrographic processes using charge patternChemical structurePolyester

A toner containing a binder resin containing a resin having a polyester skeleton, a wax containing a hydrocarbon based wax, a colorant, and a charge controlling agent represented by the following chemical structure, wherein the toner has at least one endothermic peak in a range of from 60 to 80 ° C. when measured by a differential scanning calorimetry (DSC). In the chemical structure, M represents one of Li, Na and K, R1, R2, R3 and R4 each, independently, represent one of a hydrogen atom, an alkyl group having 1 to 4 carbon atoms, an alkoxy group having 1 to 4 carbon atoms, and a halogen atom, and n represents an integer of from 1 to 5, and when n is from 2 to 5, each of R1, R2, R3 and R4 can be different from the other.

Owner:RICOH KK

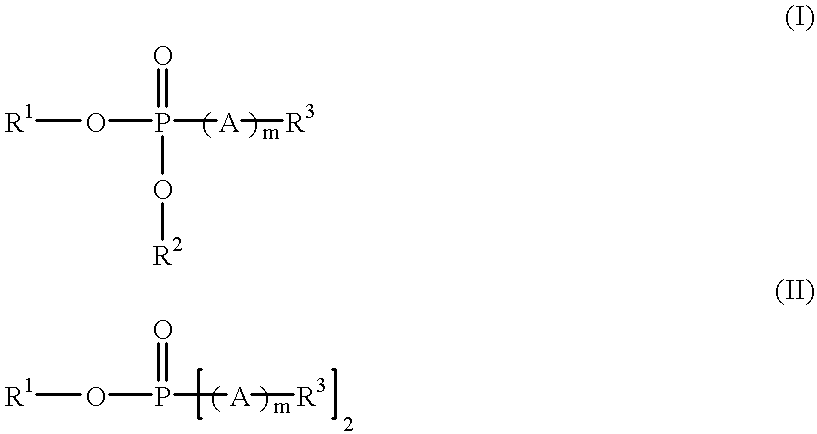

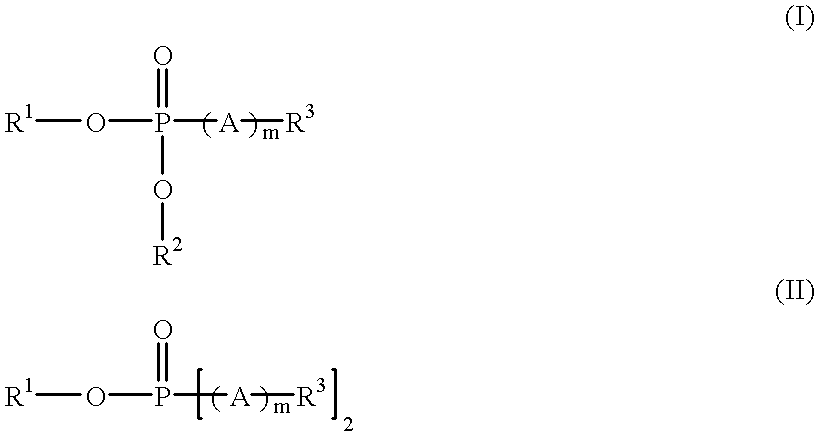

Catalyst for polyester production, process for producing polyester using the catalyst, polyester obtained by the process, and uses of the polyester

InactiveUS6346070B1High catalytic activityLow in acetaldehydeLactams stabilisationDevelopersFiberPolyester

The present invention provides a catalyst for polyester production capable of producing a polyester with high catalytic activity and a process for producing a polyester using the catalyst. The catalyst for polyester production comprises a solid titanium compound which is obtained by dehydro-drying a hydrolyzate obtained by hydrolysis of a titanium halide and which has a molar ratio (OH / Ti) of a hydroxyl group (OH) to titanium (Ti) exceeding 0.09 and less than 4. The present invention also provides a method to obtain a polyester having a small increase of the acetaldehyde content during the molding. This method comprises bringing a polyester, which is obtained by the use of a titanium compound catalyst and in which the reaction has been completed, into contact with a phosphoric ester aqueous solution or the like having a concentration of not less than 10 ppm in terms of phosphorus atom. The present invention further provides a polyester having excellent transparency and tint and molded products of the polyester such as a blow molded article, a film, a sheet and a fiber. The polyester is obtained by polycondensing an aromatic dicarboxylic acid or an ester-forming derivative thereof and an aliphatic diol or an ester-forming derivative thereof in the presence of a catalyst for polyester production which comprises a polycondensation catalyst component comprising a solid titanium compound and a co-catalyst component comprising a magnesium compound. This polyester has a titanium content of 1 to 100 ppm, a magnesium content of 1 to 200 ppm and a weight ratio (Mg / Ti) of magnesium to titanium of not less than 0.01.

Owner:MITSUI CHEM INC

Toner and developer for electrostatic development, production thereof, image forming process and apparatus using the same

ActiveUS20050042534A1Excellent low temperature fixabilitySatisfactory low-temperature image-fixing propertyDevelopersPolymer scienceOrganic solvent

A toner is prepared by dissolving and / or dispersing a modified polyester resin in an organic solvent to yield a solution or dispersion, the modified polyester resin being reactive with a compound having an active hydrogen group, mixing the solution or dispersion with an aqueous medium containing resin particles, and subjecting the modified polyester resin to crosslinking and / or elongation in the aqueous medium. The binder resin further includes a crystalline polyester resin in addition to the modified polyester resin.

Owner:RICOH KK

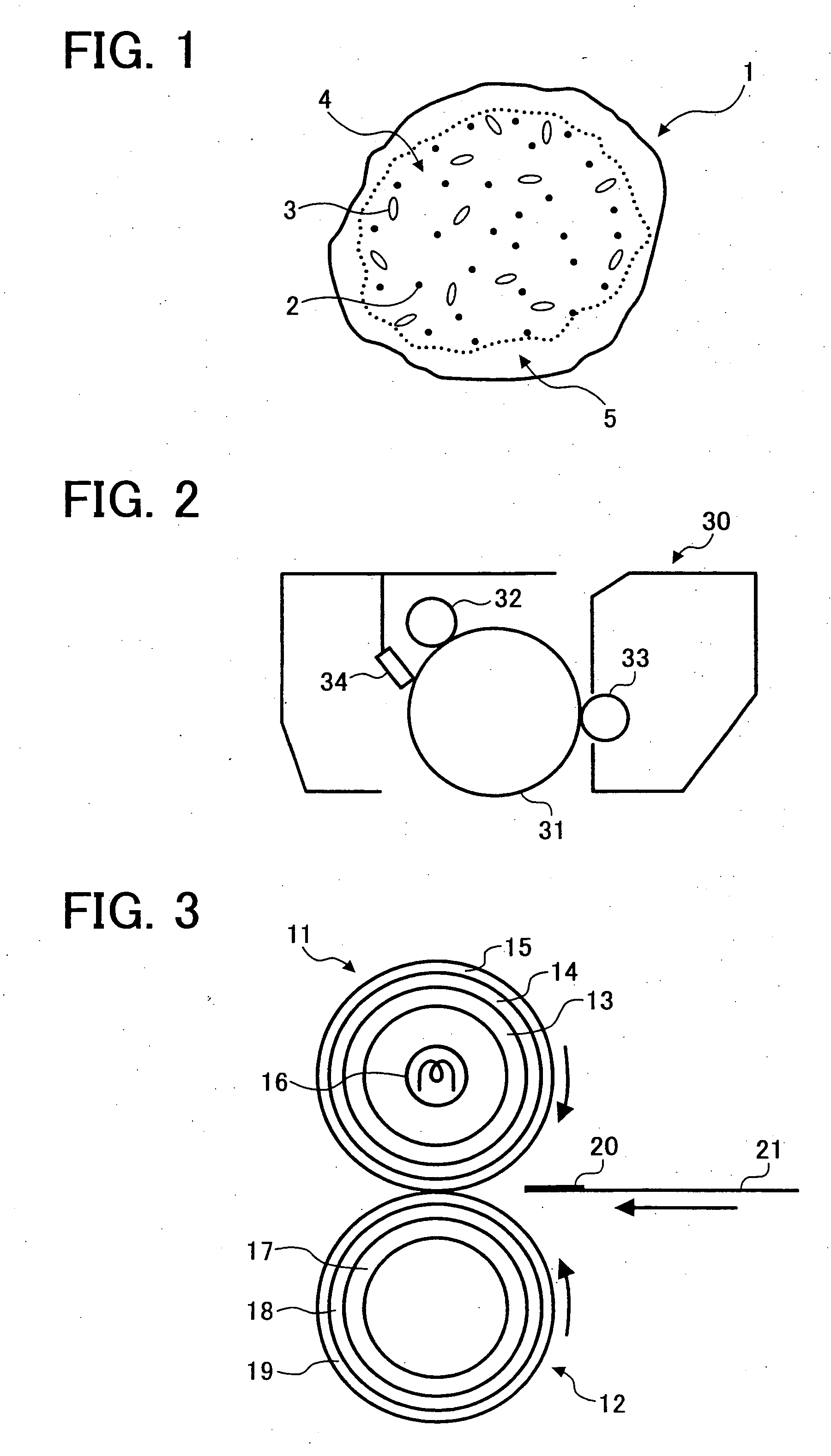

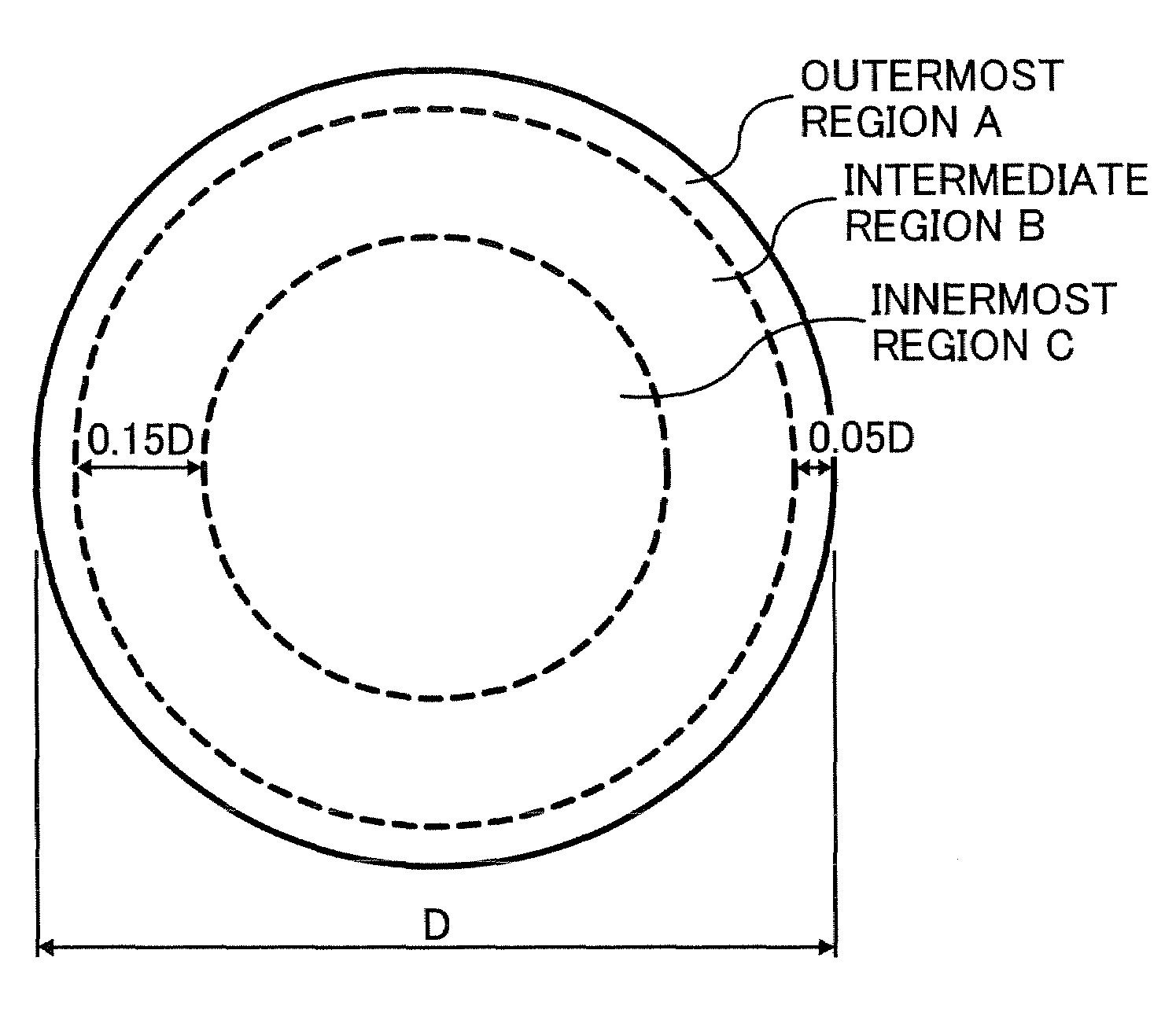

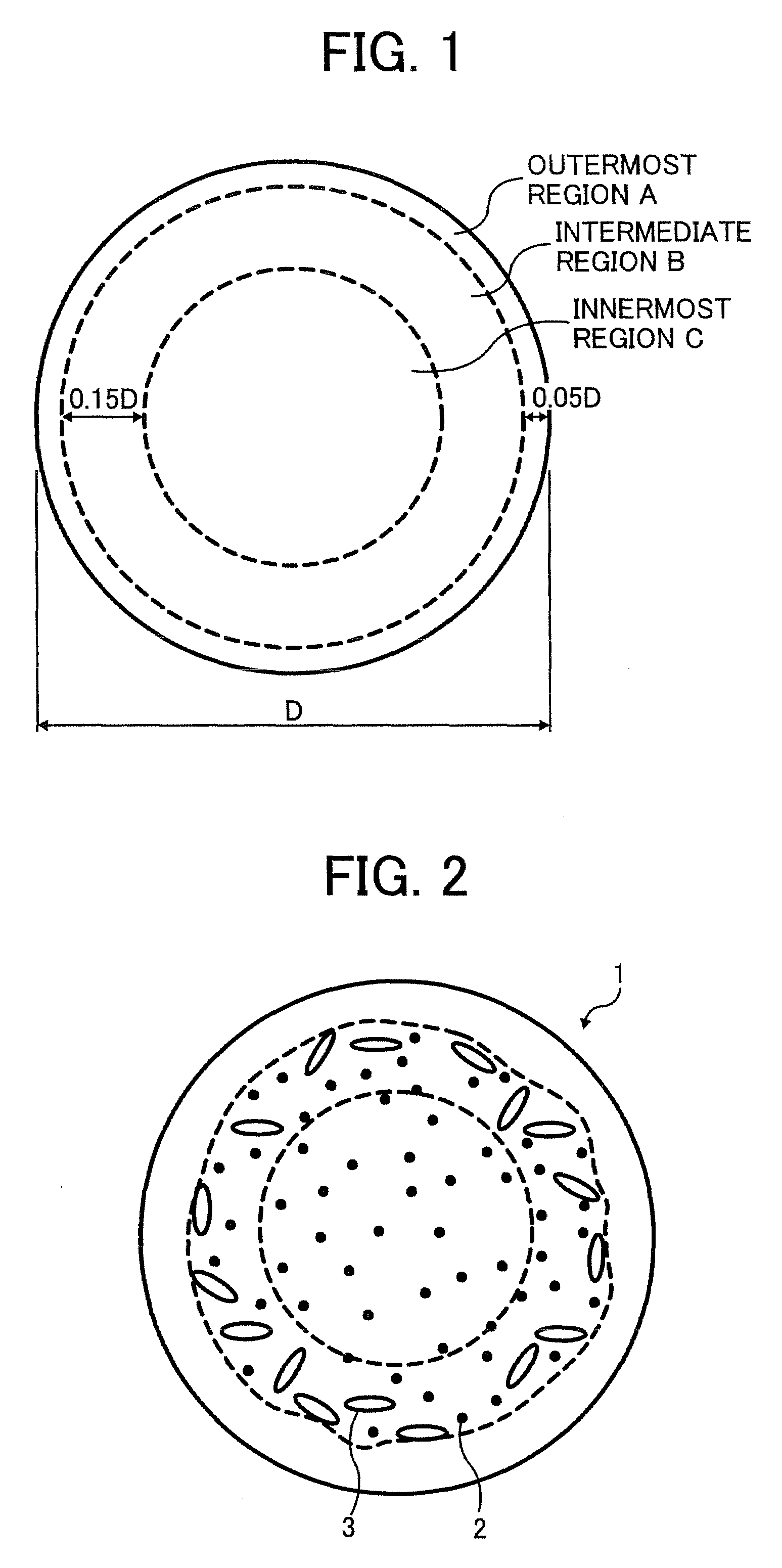

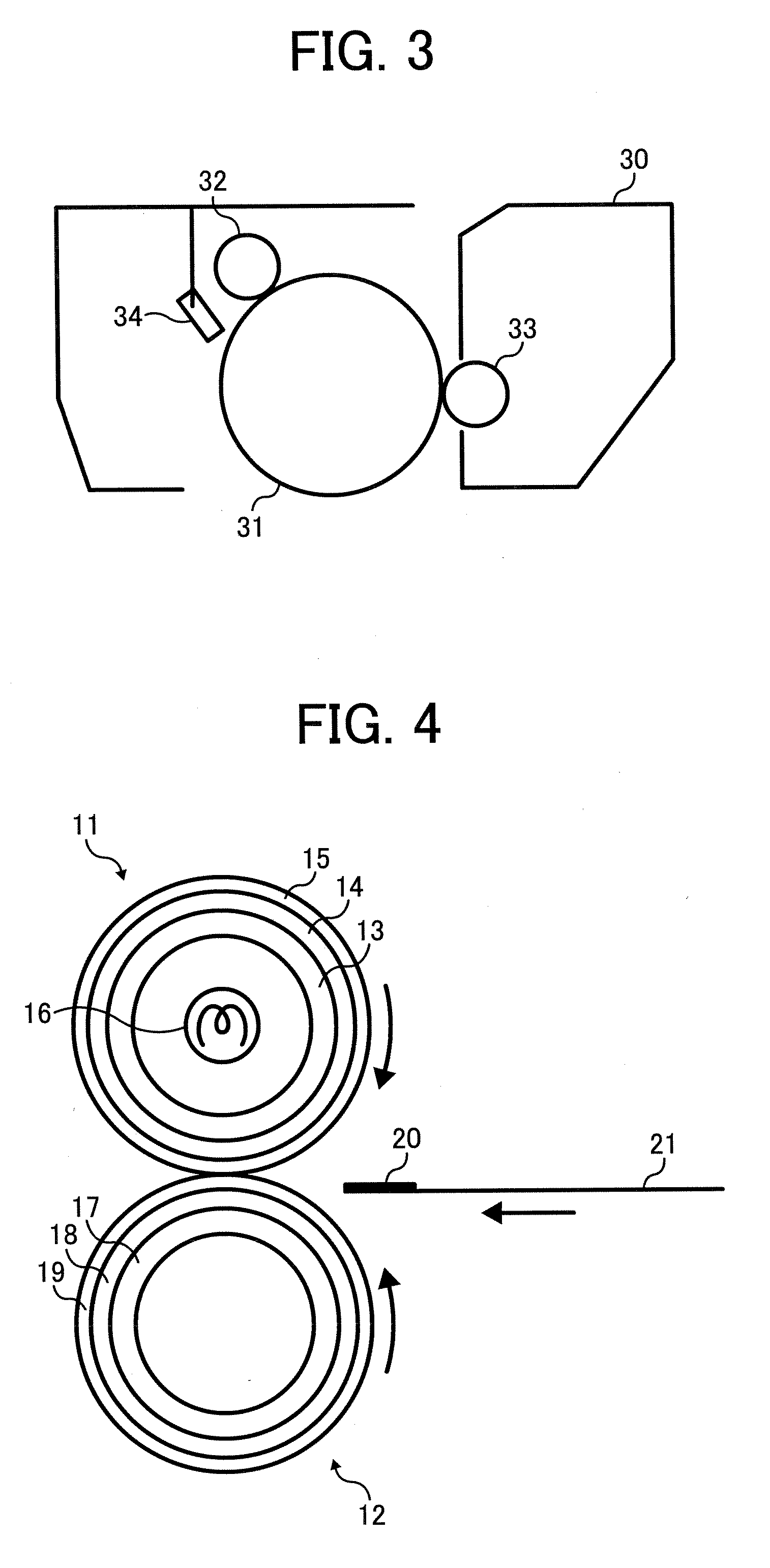

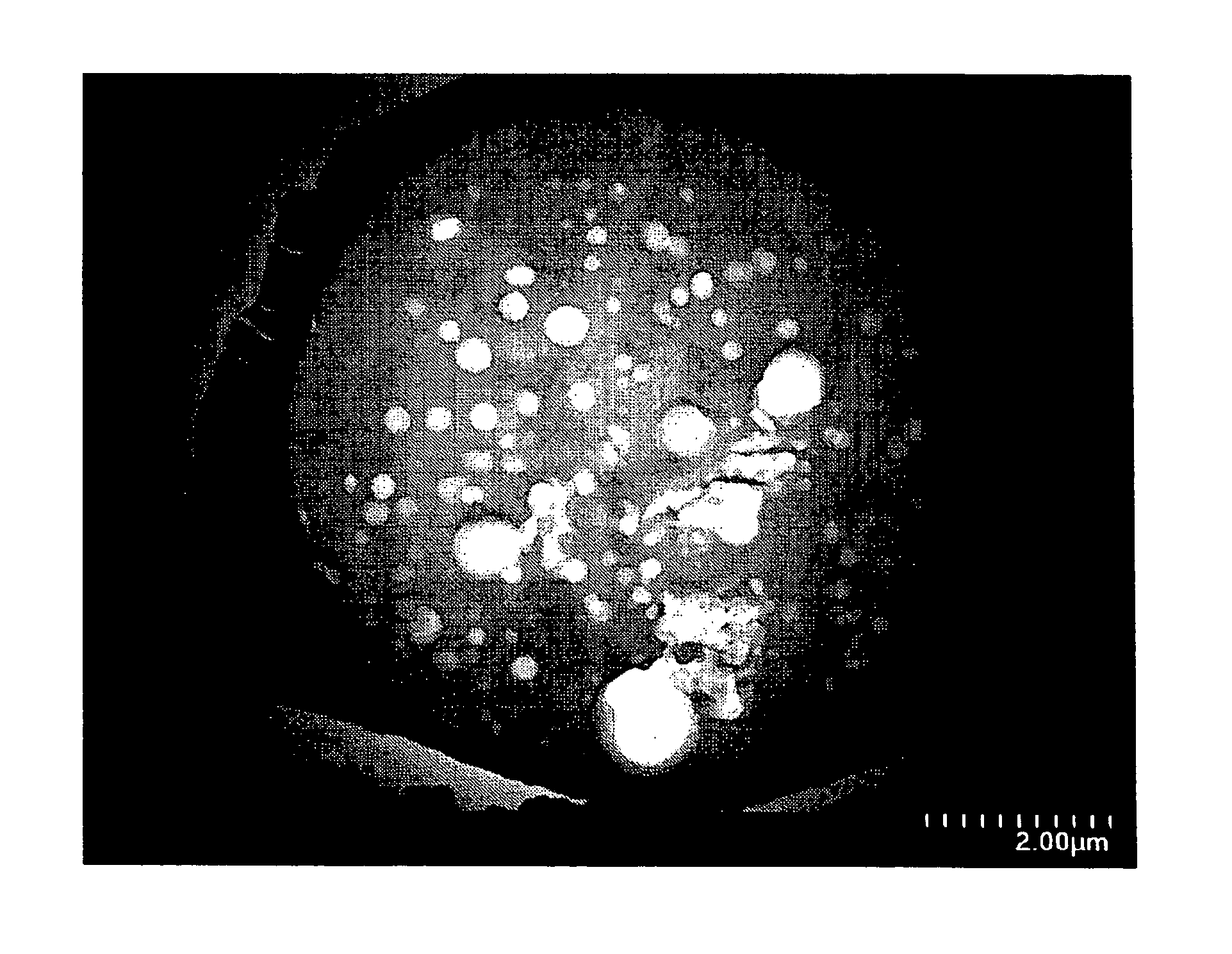

Toner and method of preparing the toner

A toner is provided including a binder resin, a colorant, and a release agent, which has a volume average particle diameter (Dv) of from 3 to 9 μm, and wherein the binder resin and the release agent form a sea-island structure in which the island formed of the release agent is dispersed in the sea formed of the binder resin in a cross-sectional image of the toner obtained by a transmission electron microscope (TEM), and the following relationships are satisfied: IB>IA and IB>IC, wherein each of IA, IB, and IC represents an area ratio (%) of the island in an outermost region (A) of the cross-sectional image of the toner, an intermediate region (B) thereof located under the outermost region (A), and an innermost region (C) thereof located under the intermediate region (B); and a method of preparing the toner.

Owner:RICOH KK

Toner for developing electrostatic image, developer, image forming apparatus, process for forming image, process cartridge, and process for measuring porosity of toner

ActiveUS20050026064A1Control hollow stateReinforce reduced toner hardnessDevelopersPorosityImage formation

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com