Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

647results about "Buttons" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

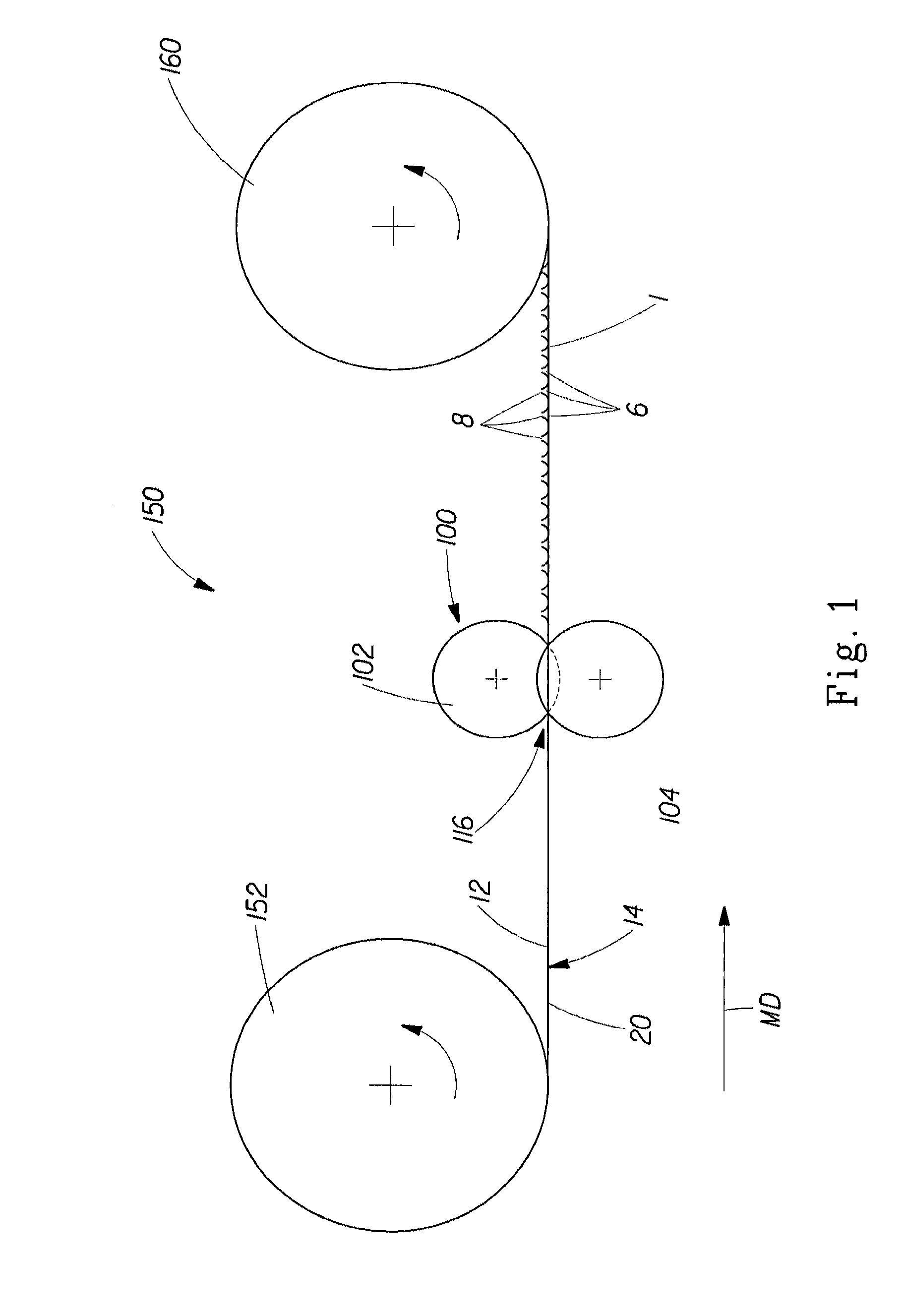

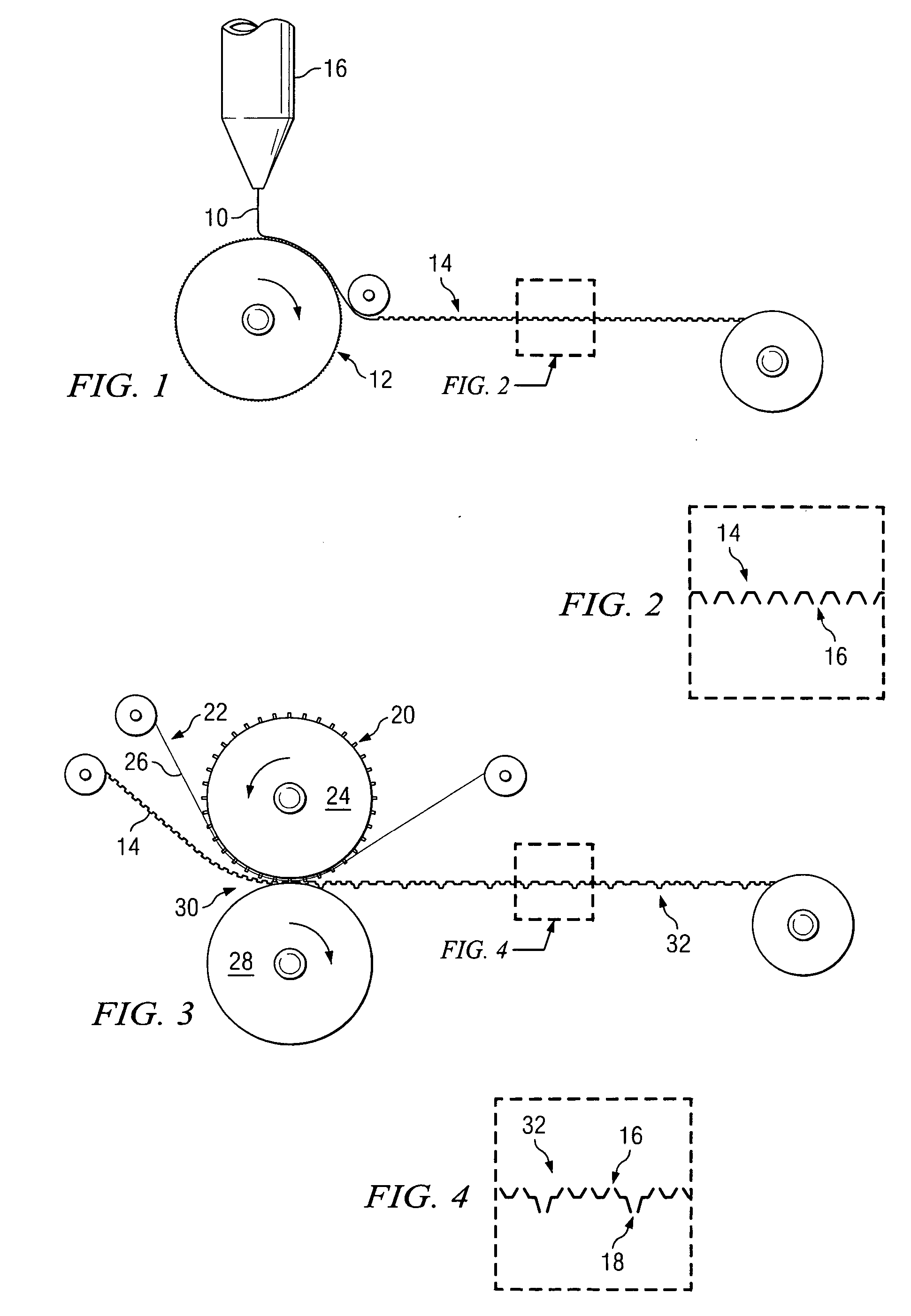

Method and apparatus for making an apertured web

Owner:THE PROCTER & GAMBLE COMPANY

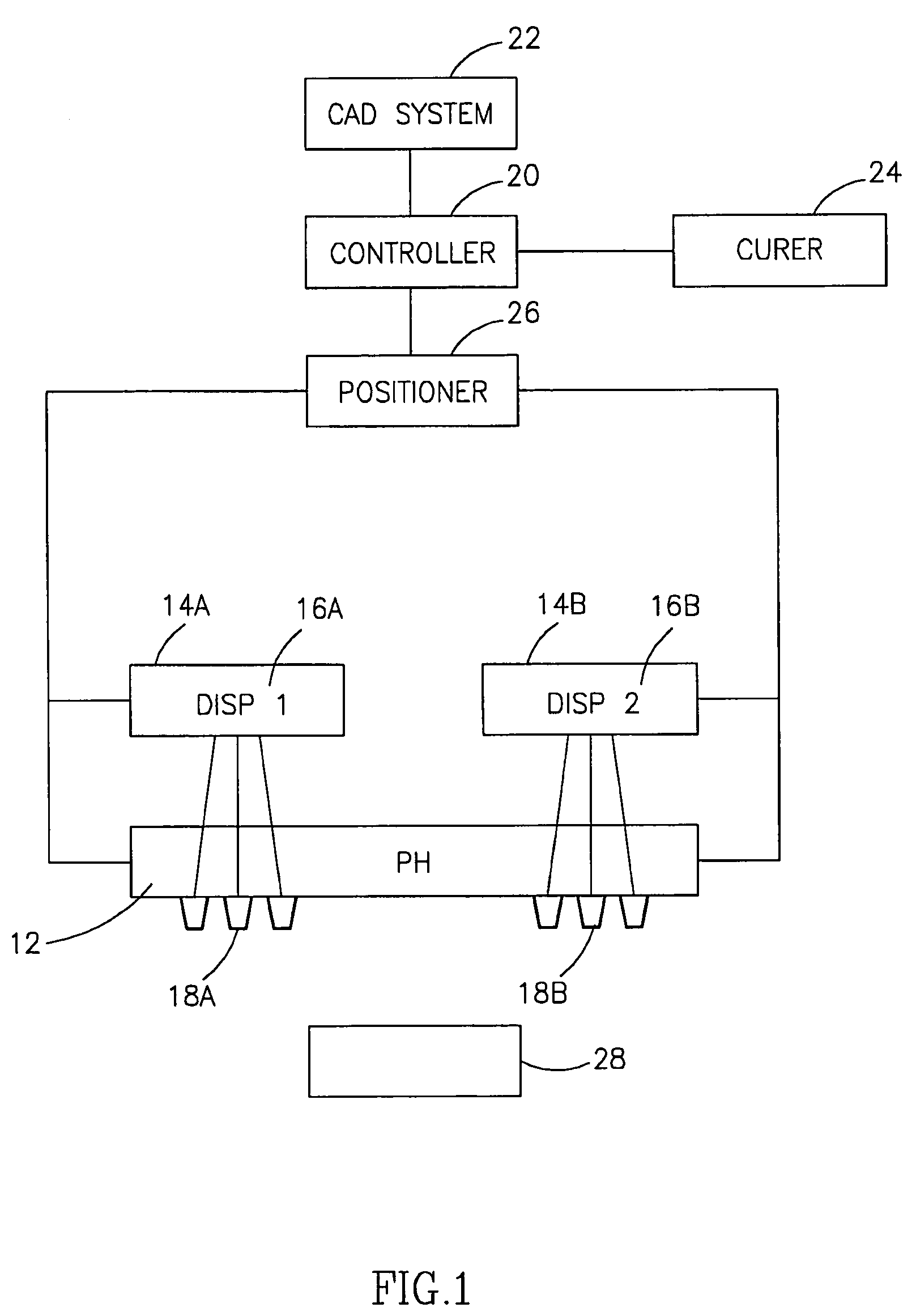

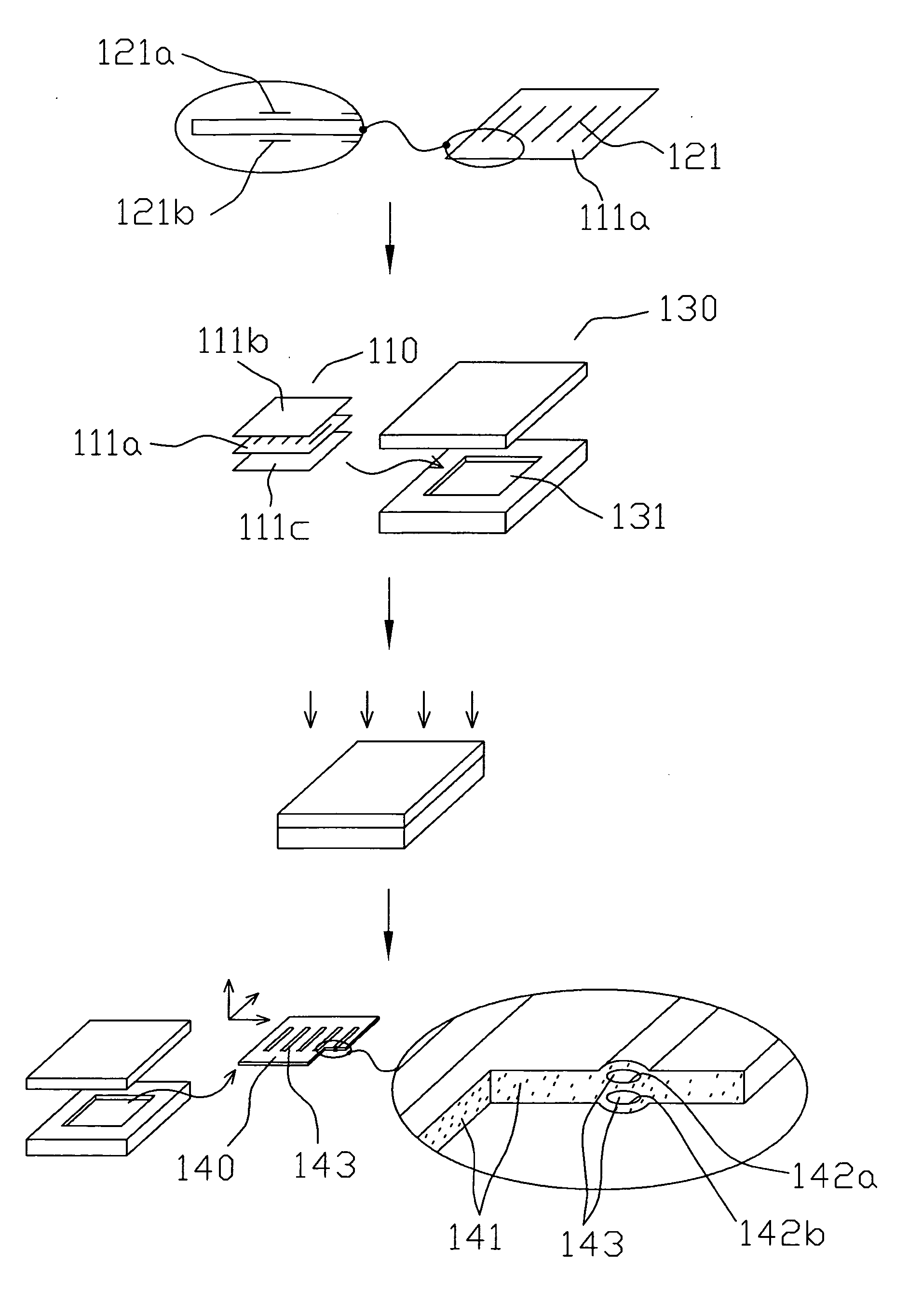

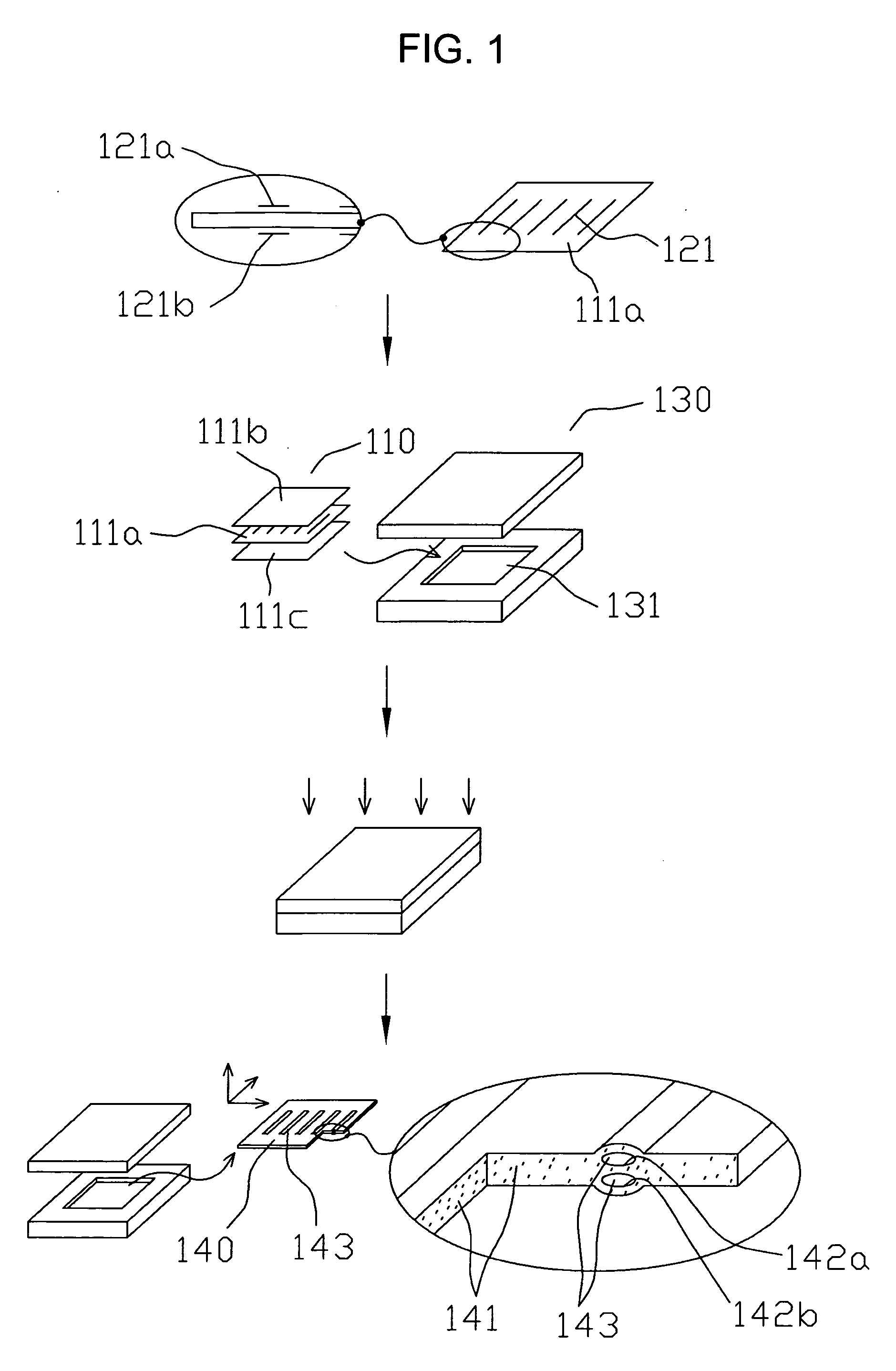

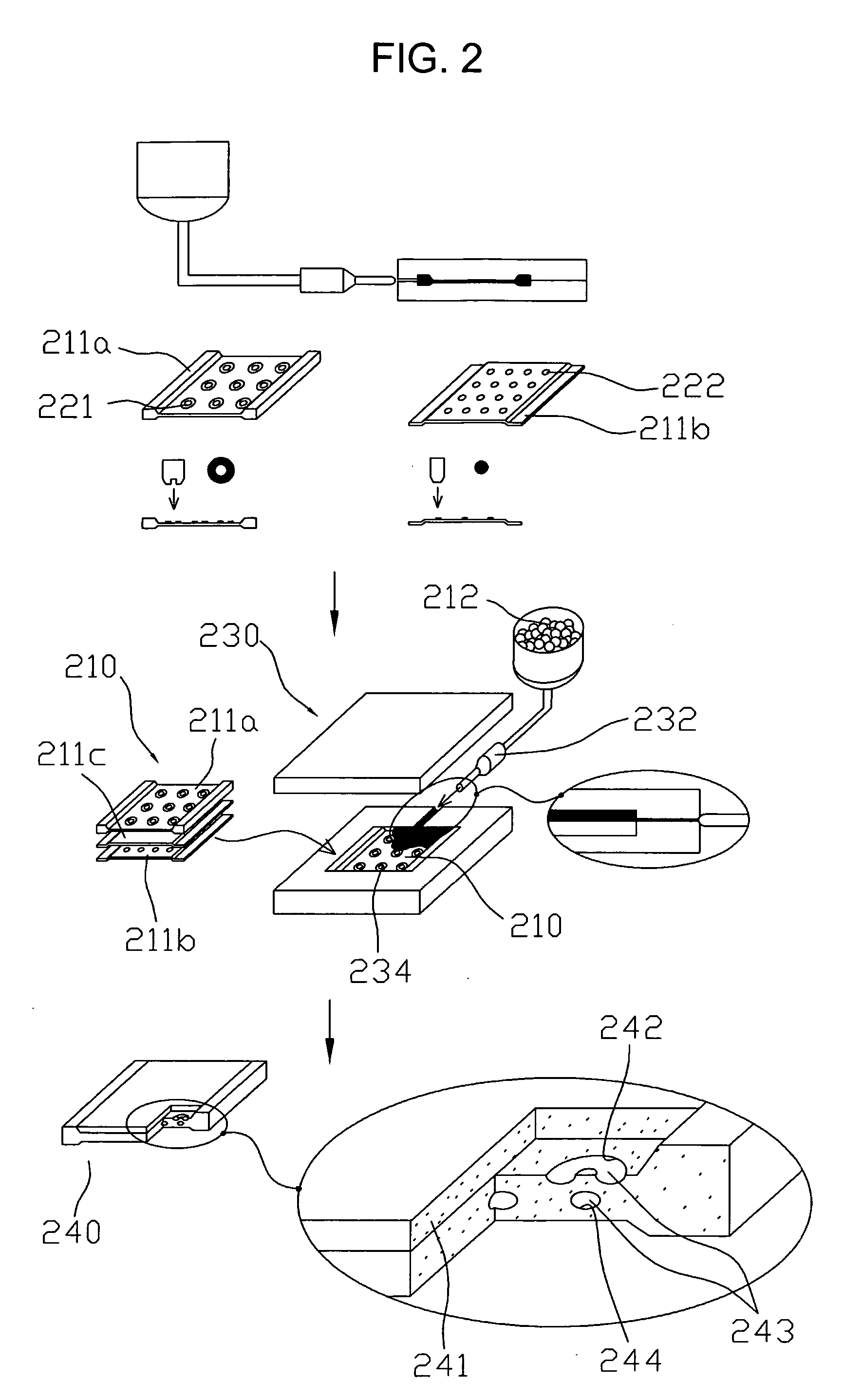

Compositions and methods for use in three dimensional model printing

InactiveUS7300619B2Similar elasticitySimilar strengthButtonsLiquid surface applicatorsOrganic compoundPolymer chemistry

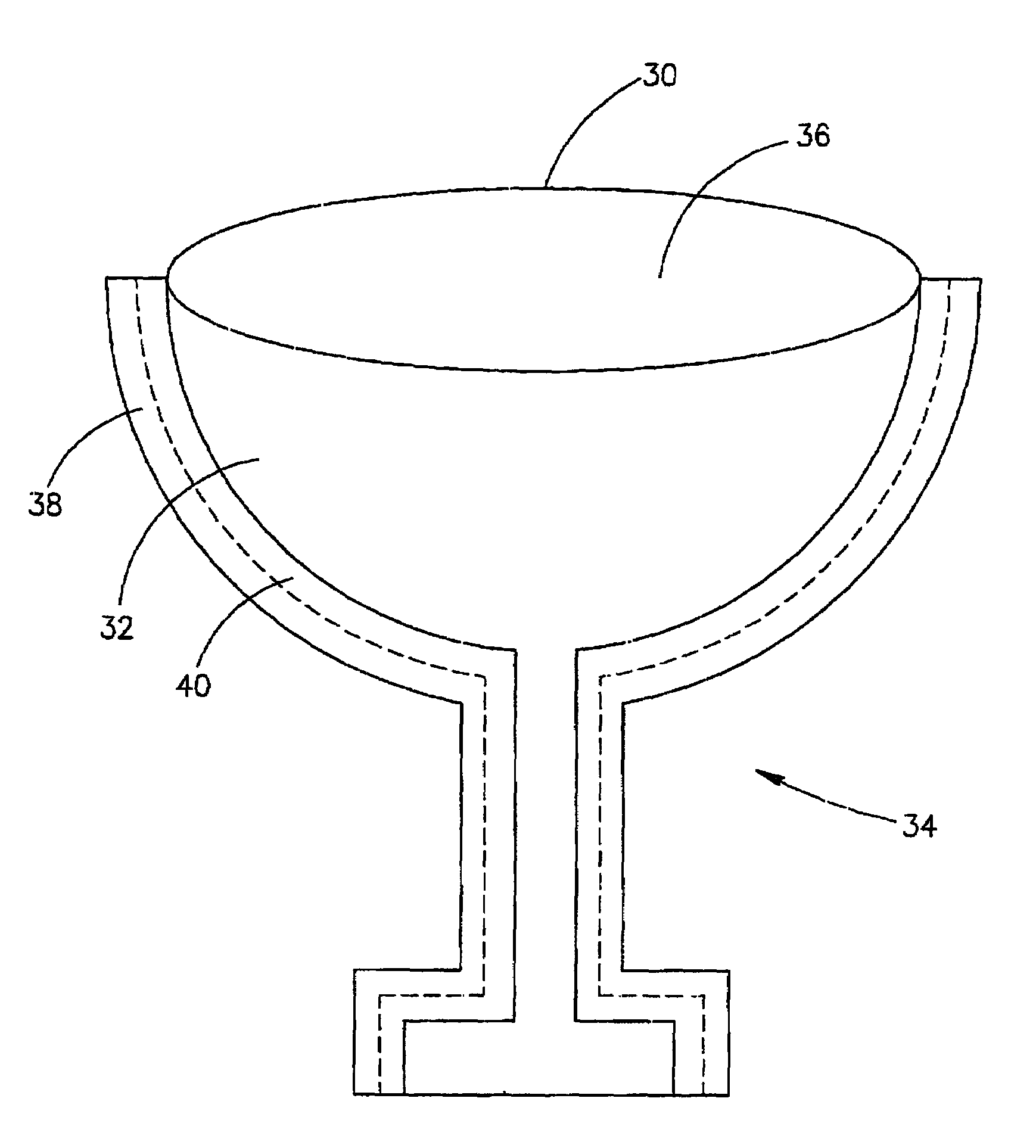

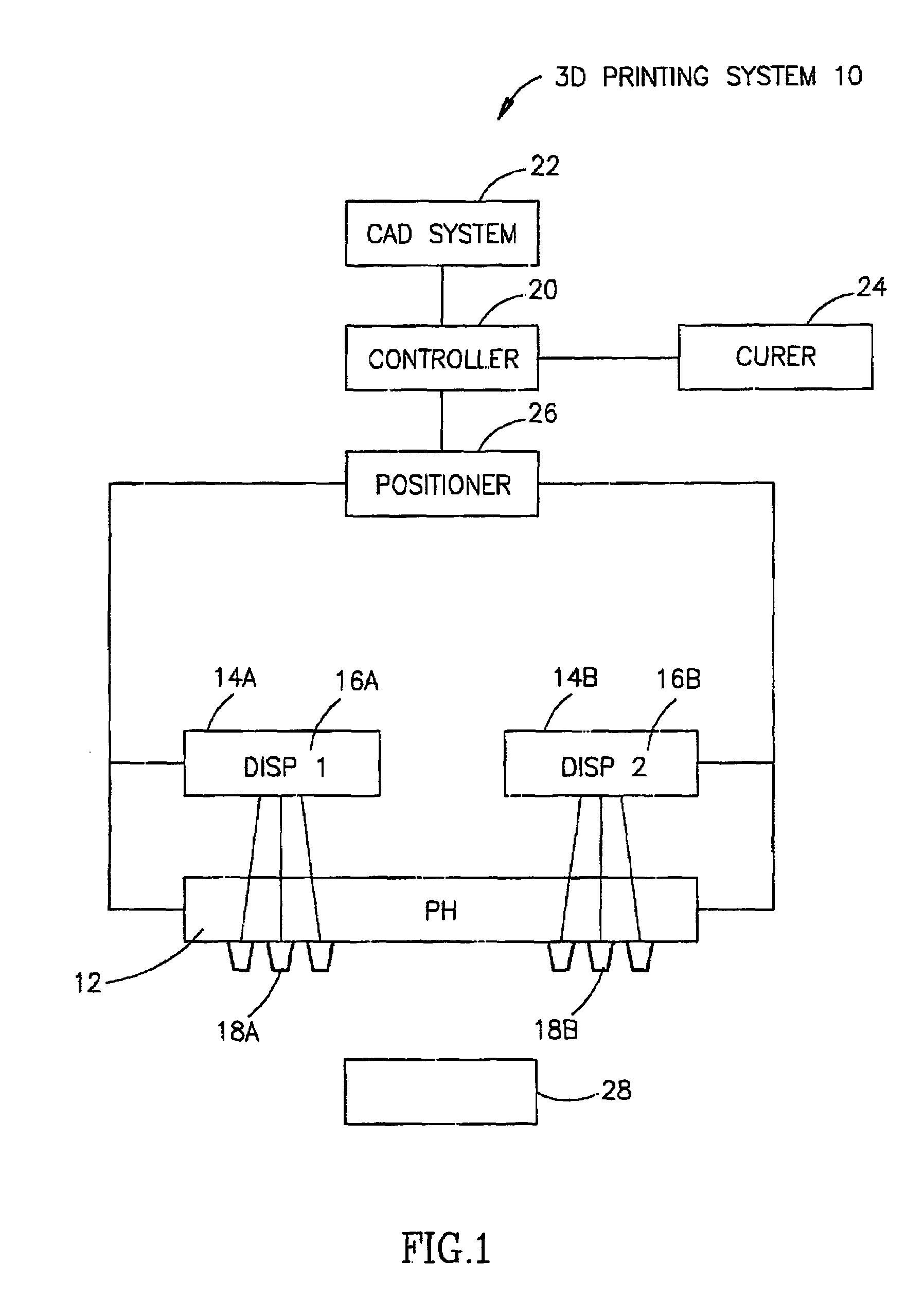

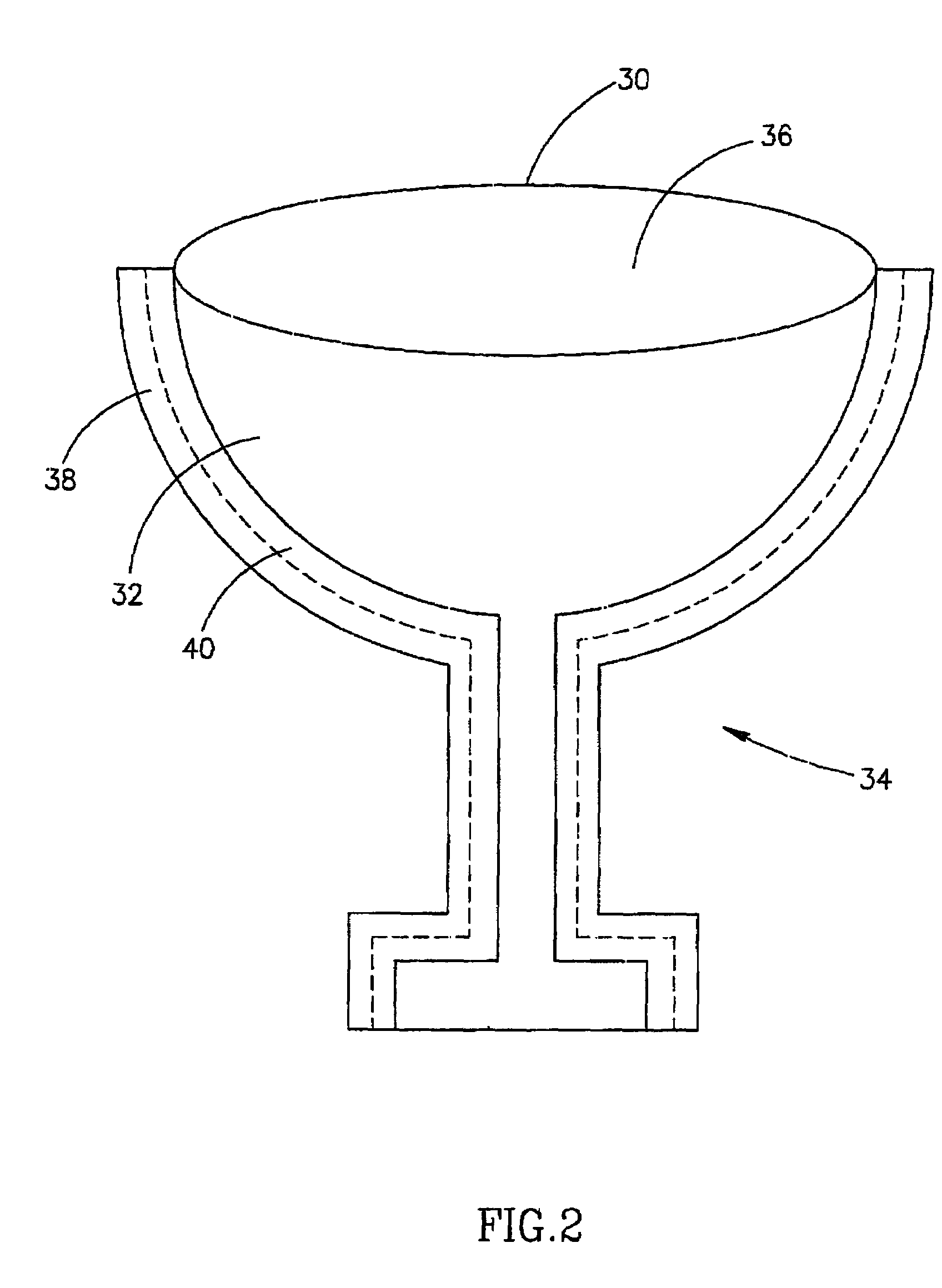

A pseudo composite material, may include, inter alia, a first phase and a second phase, wherein each phase may include, inter alia, an organic compound, wherein each phase comprising a multiplicity of construction layers, wherein the layers were deposited by ink-jet printing, wherein the pseudo composite material exhibits non-homogeneous three-dimensional structure. A method is disclosed for the preparation of a pseudo composite material. An apparatus is disclosed for printing a pseudo composite material. Furthermore, there is disclosed a method for printing a three-dimensional object using various suitable materials.

Owner:STRATASYS LTD

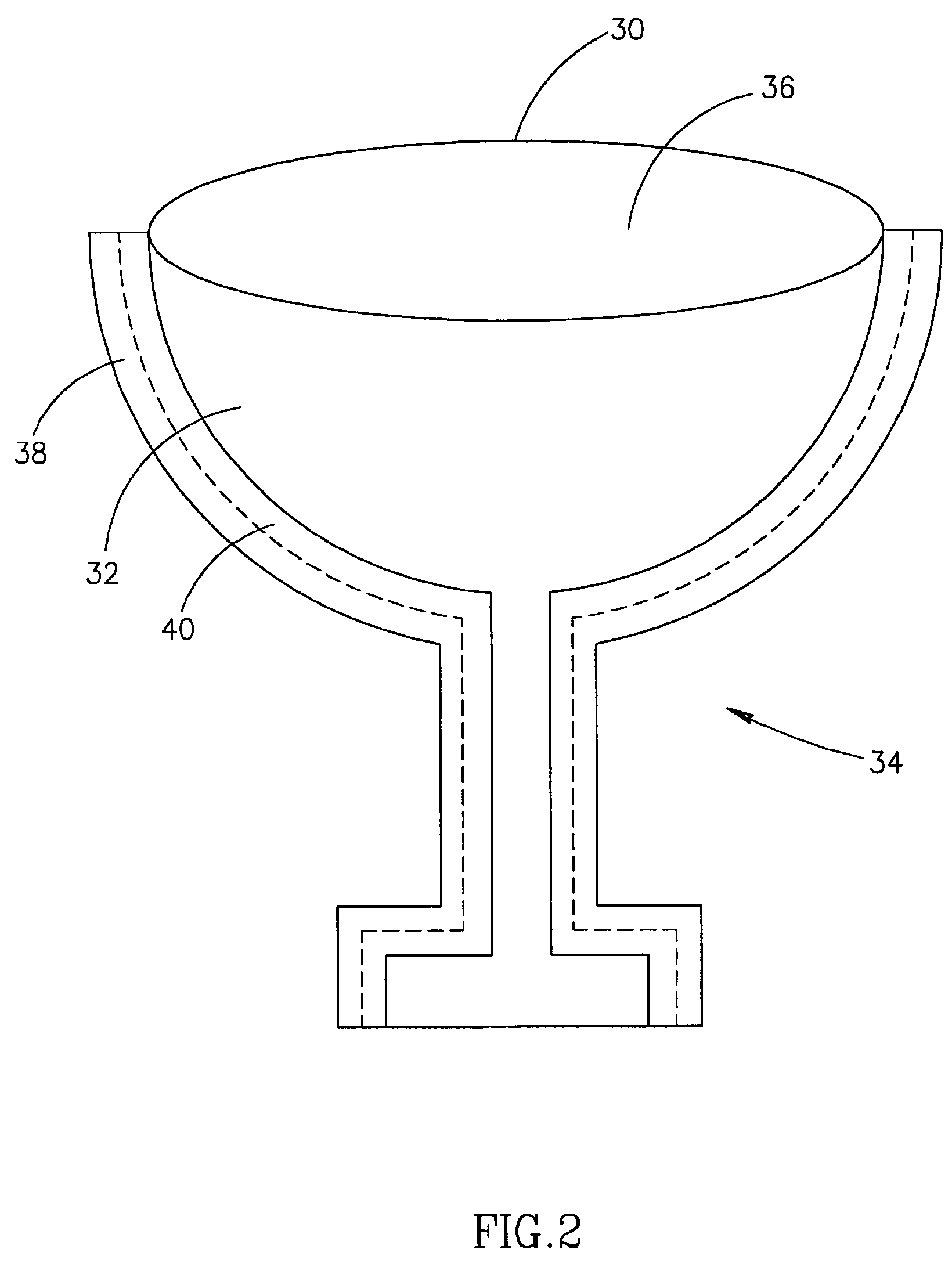

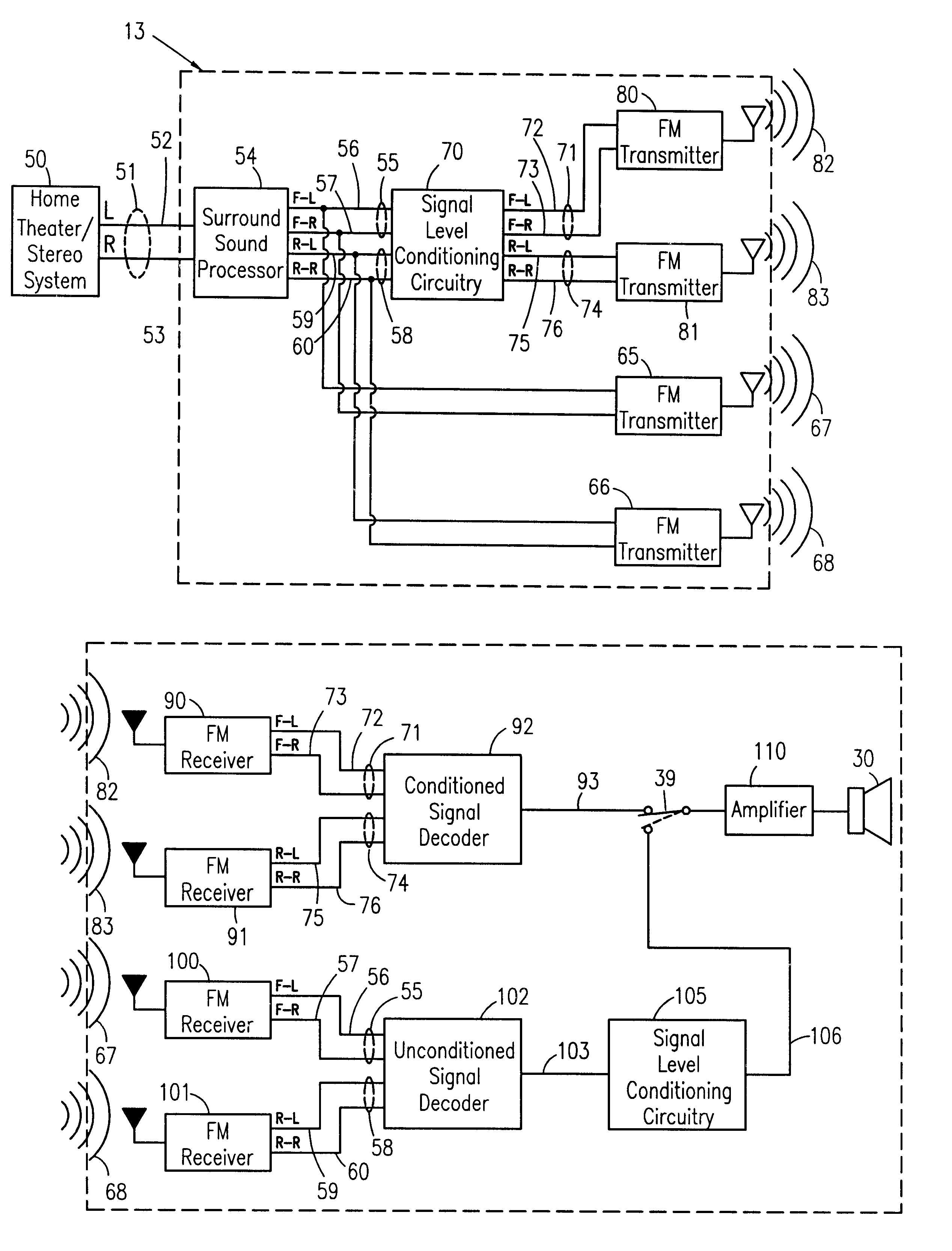

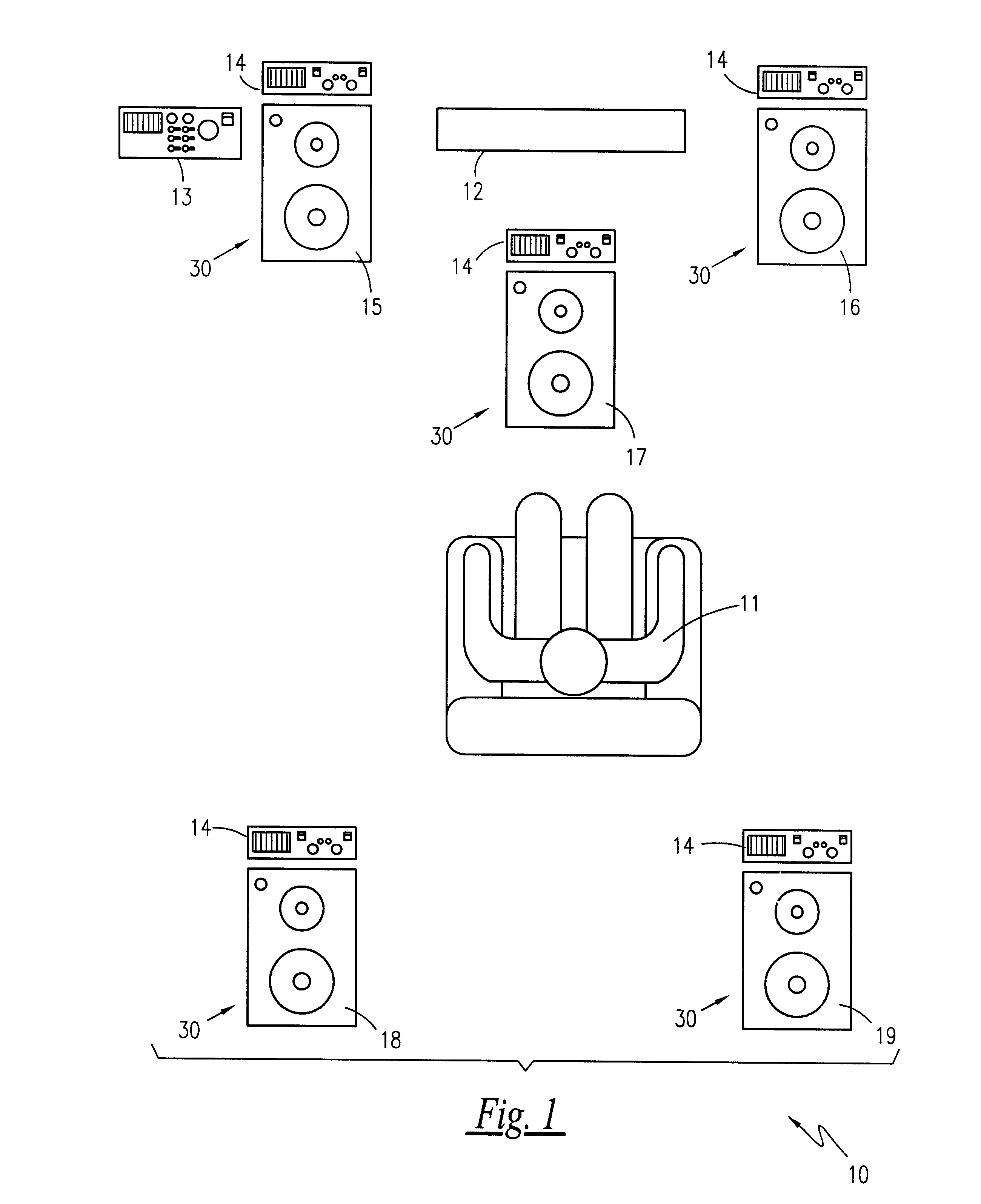

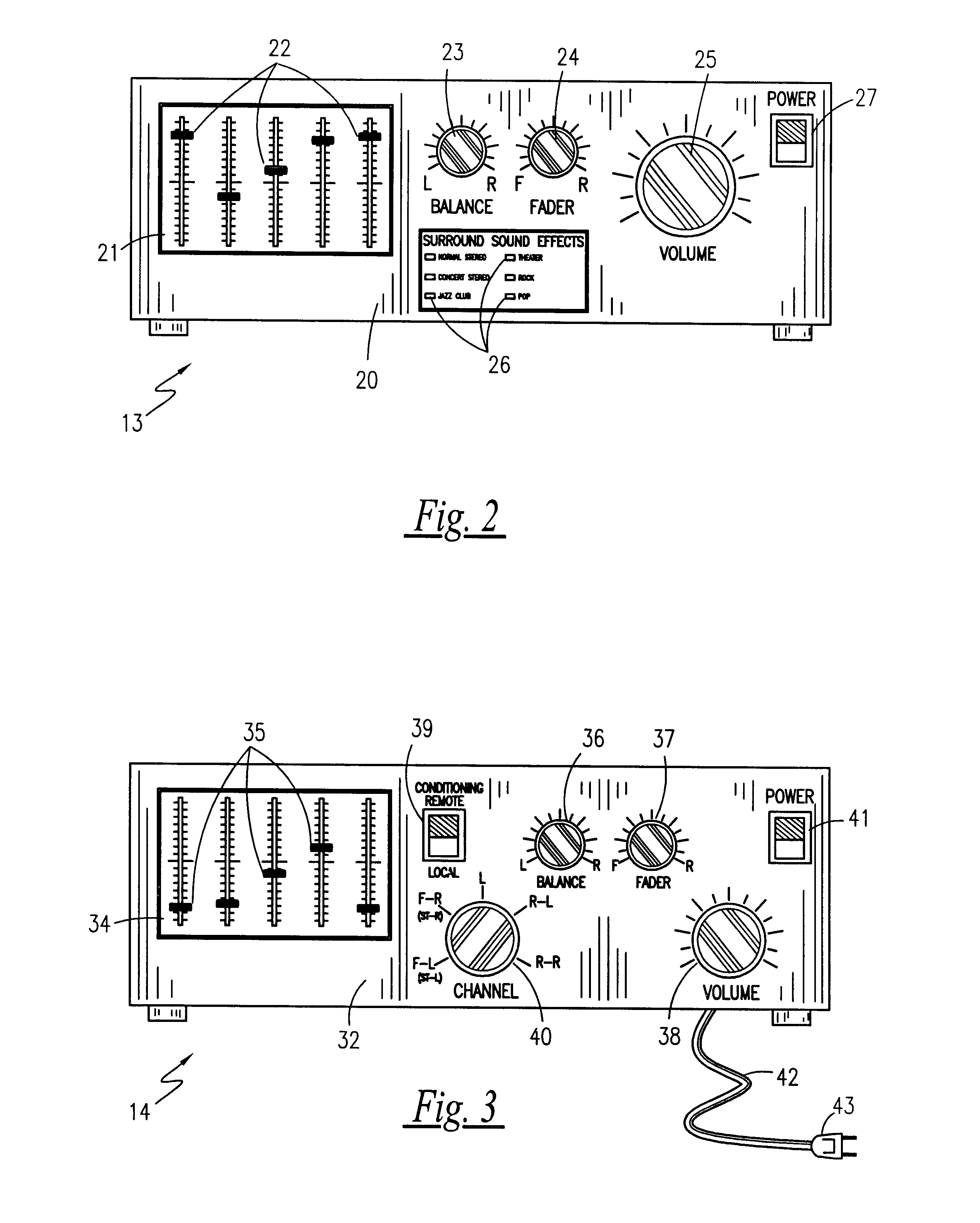

Wireless surround sound speaker system

Disclosed is a wireless surround sound speaker system wherein a transmitter broadcasts a variety of FM signals that correspond to the individual speaker channels commonly found in a surround sound system. Receivers, individually equipped with signal receiving, conditioning and amplification components, are configured to receive any one of the broadcast signals in a remote location and are used to drive a conventional loudspeaker in that location. Powered by wall socket or via DC battery packs, the receivers, used in conjunction with the transmitter, provide surround sound capabilities without the need for complex and difficult wiring.

Owner:ALLEN STEVEN W +1

Compositions and methods for use in three dimensional model printing

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

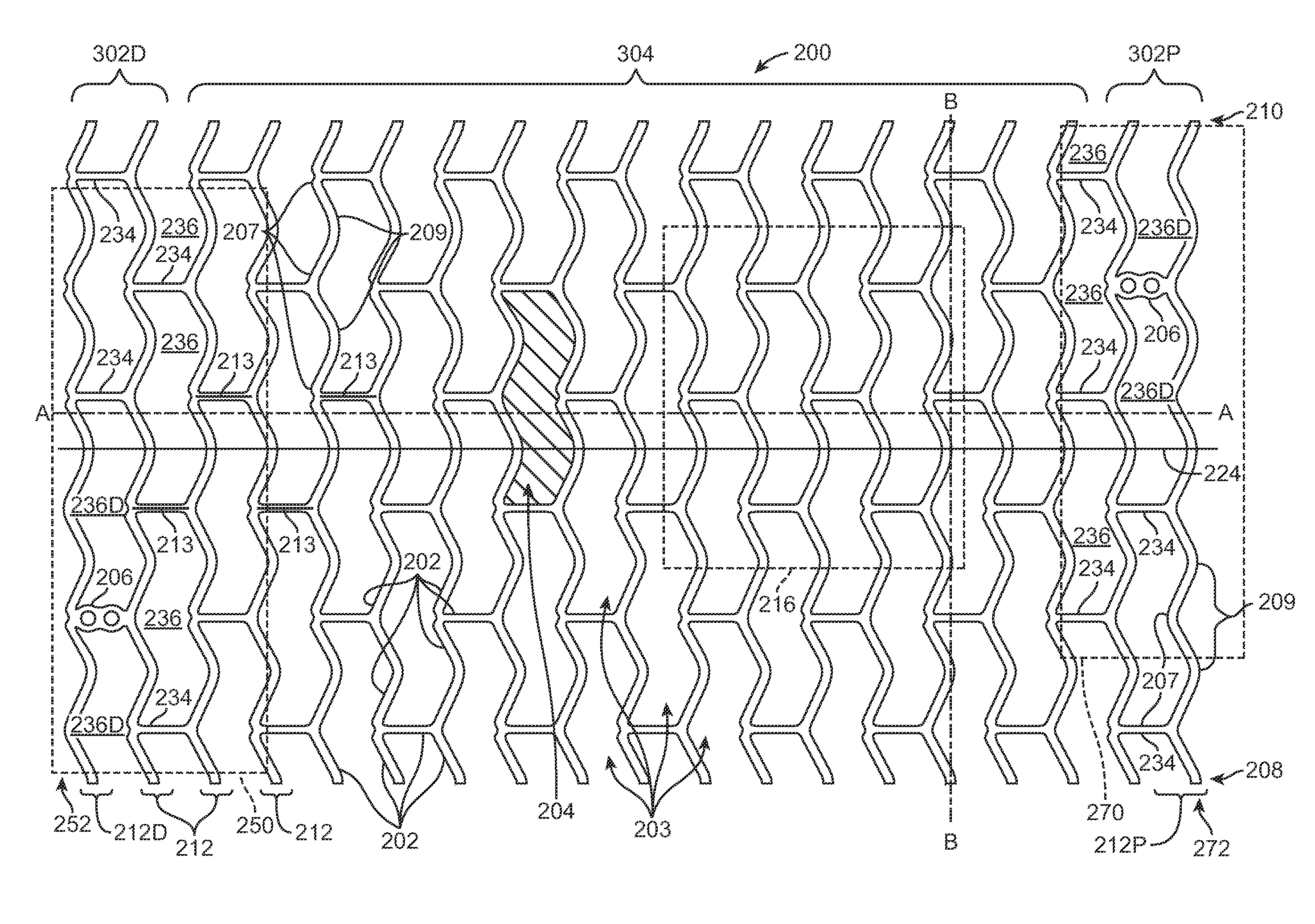

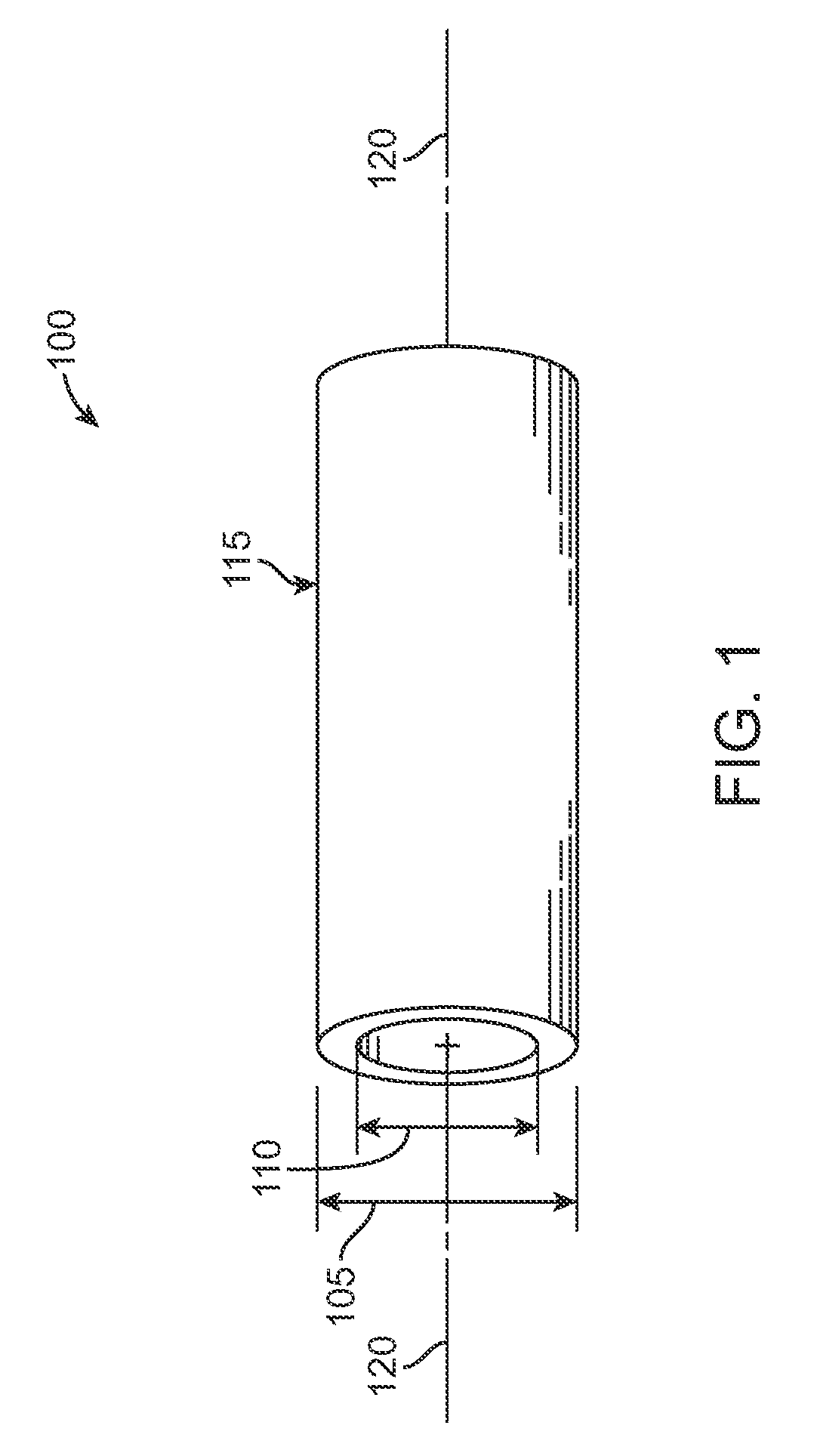

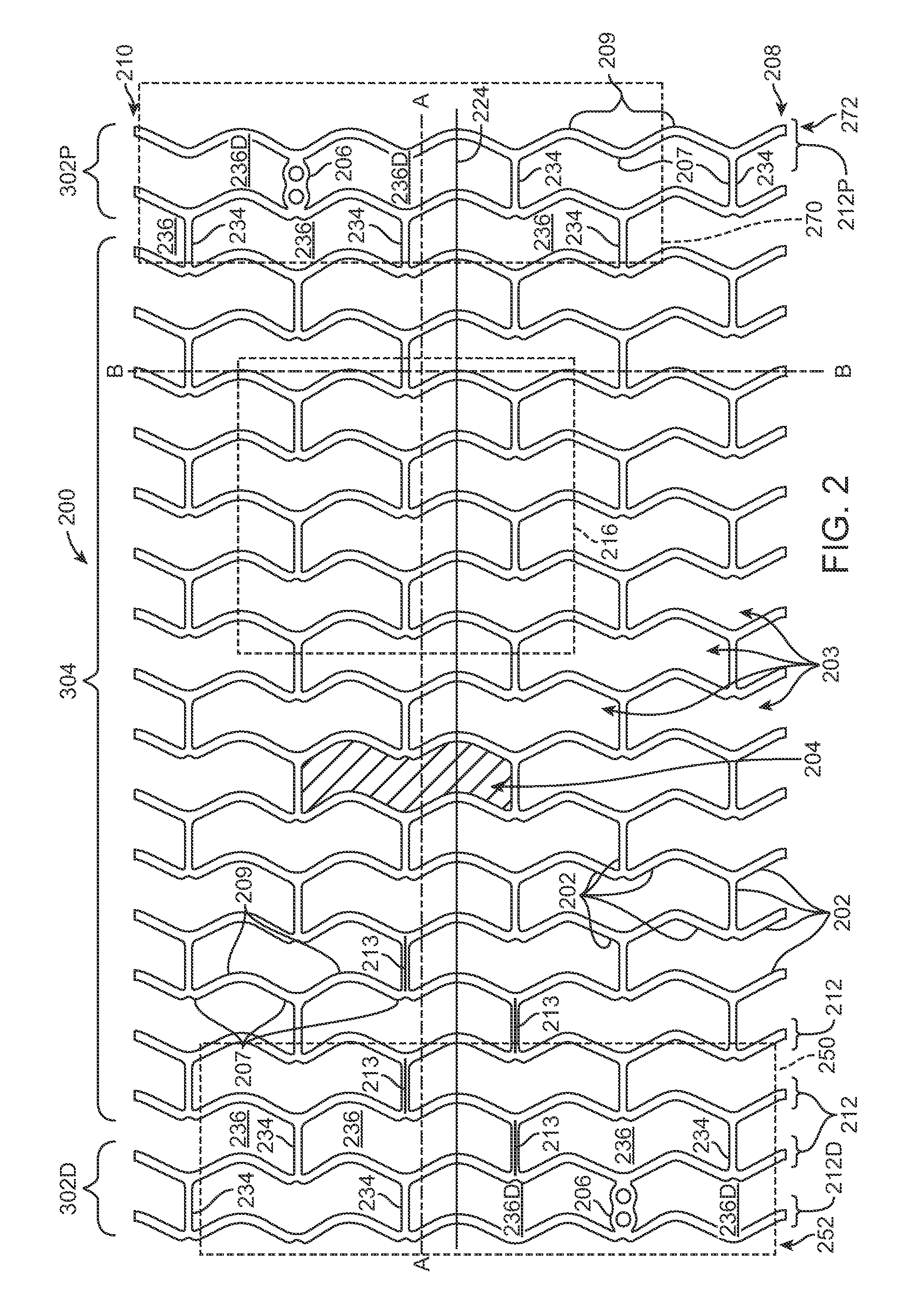

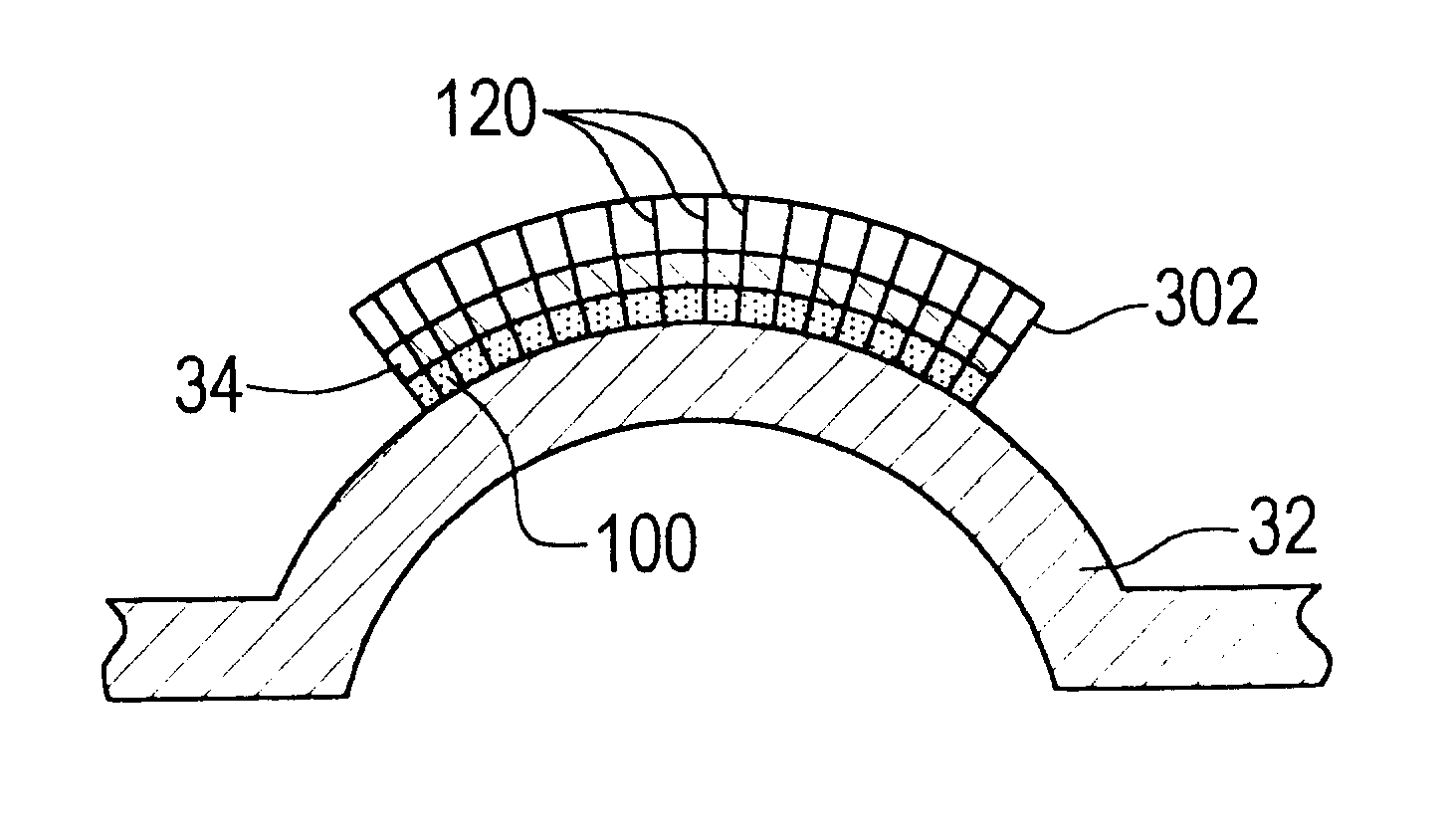

Polymeric Stent

A strut pattern of an endoprosthesis includes a plurality of W-shape cells that define a tubular body, the W-shaped cells at the opposite ends of the tubular body have a modified configuration that is different than the W-shaped cells at the middle portion of the tubular body. At the distal end of the tubular body, the W-shaped cells have crests with axial positions that are axially spaced apart, and have troughs with circumferential positions that are spaced apart. At the intermediate and distal end of the tubular body, the W-shaped cells crests with axial positions that coincide and have troughs with circumferential positions that coincide. The strut pattern is cut from a tubular precursor construct made of PLLA that has been radially expanded and axially extended by blow molding.

Owner:ABBOTT CARDIOVASCULAR

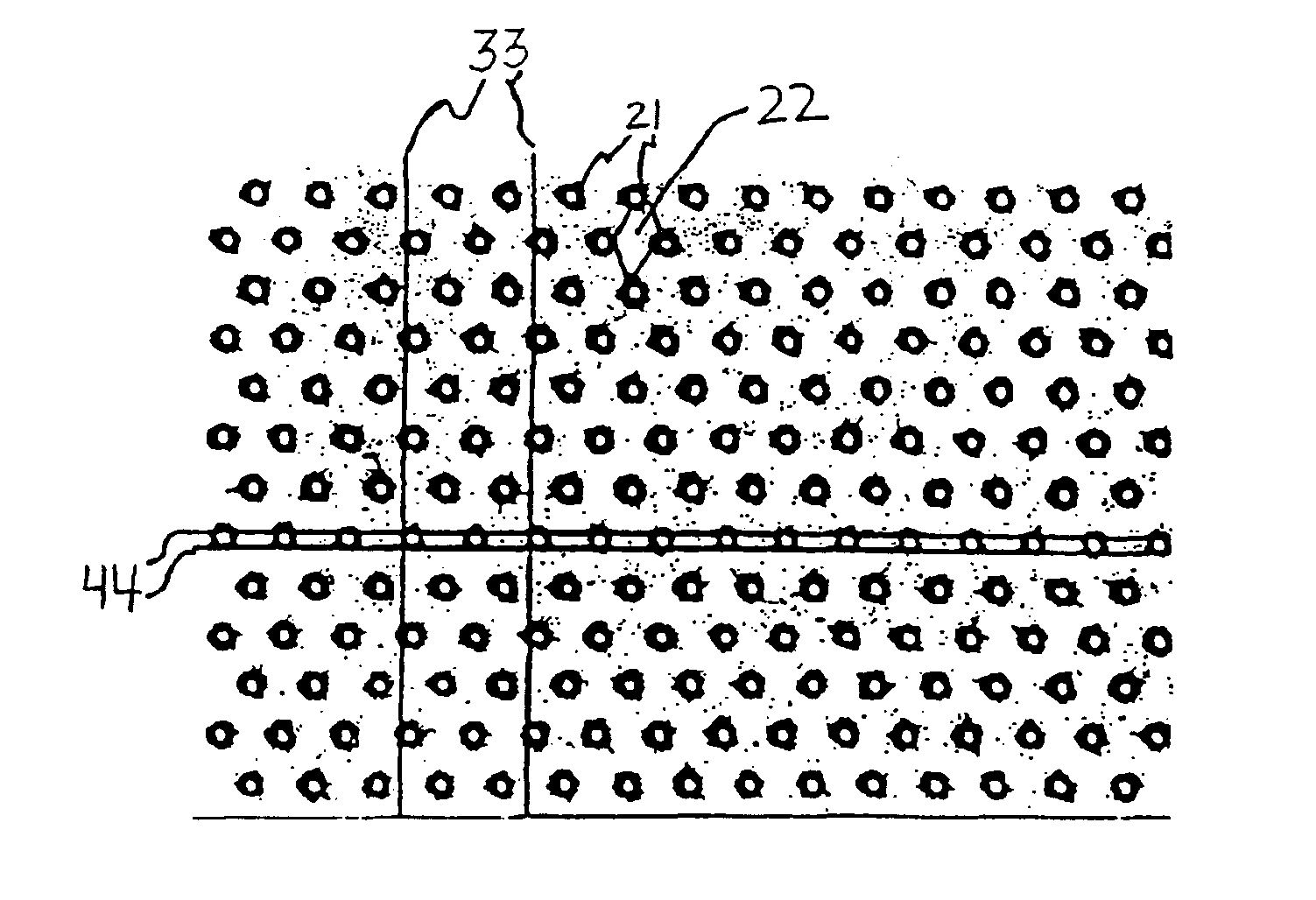

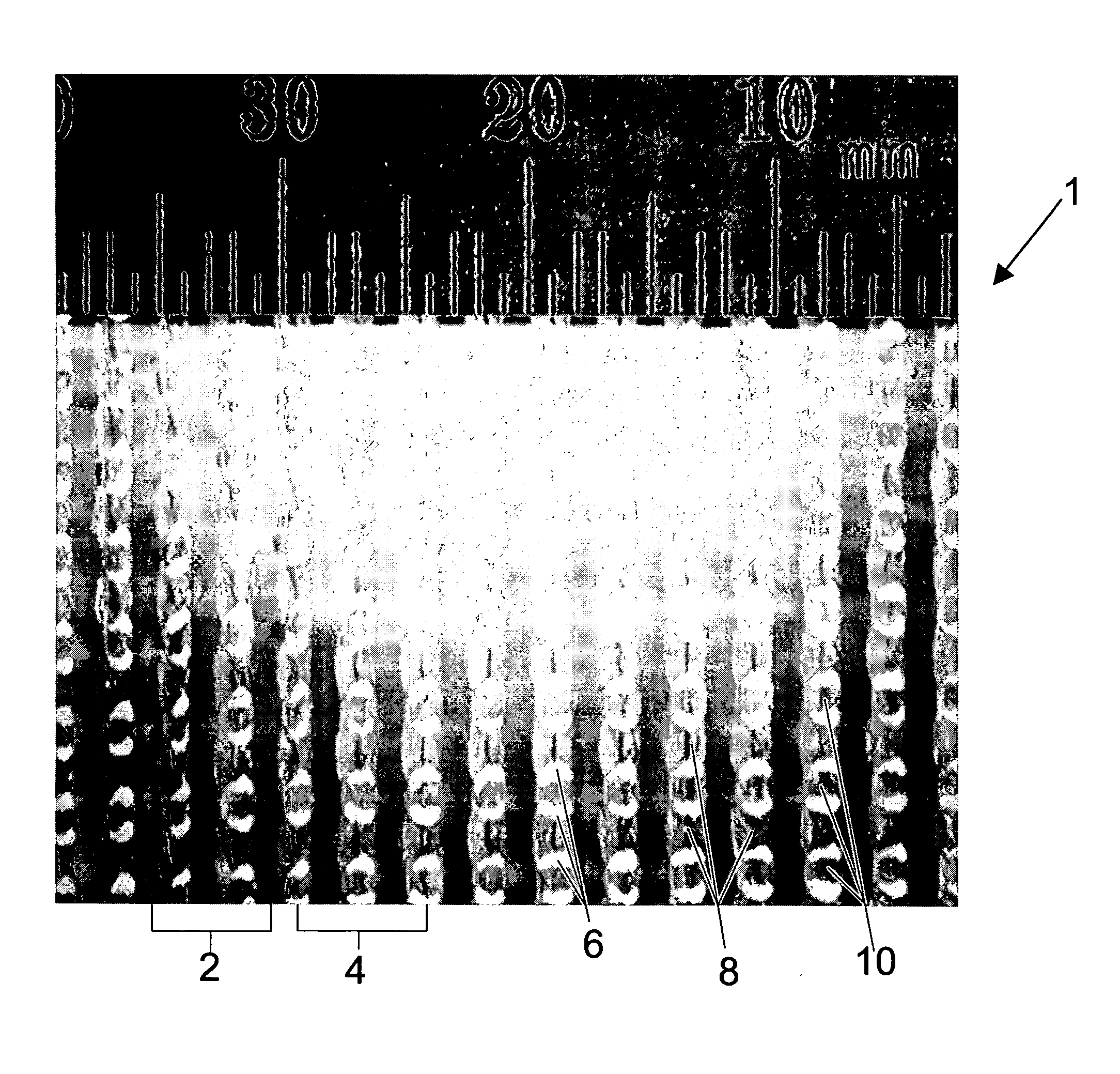

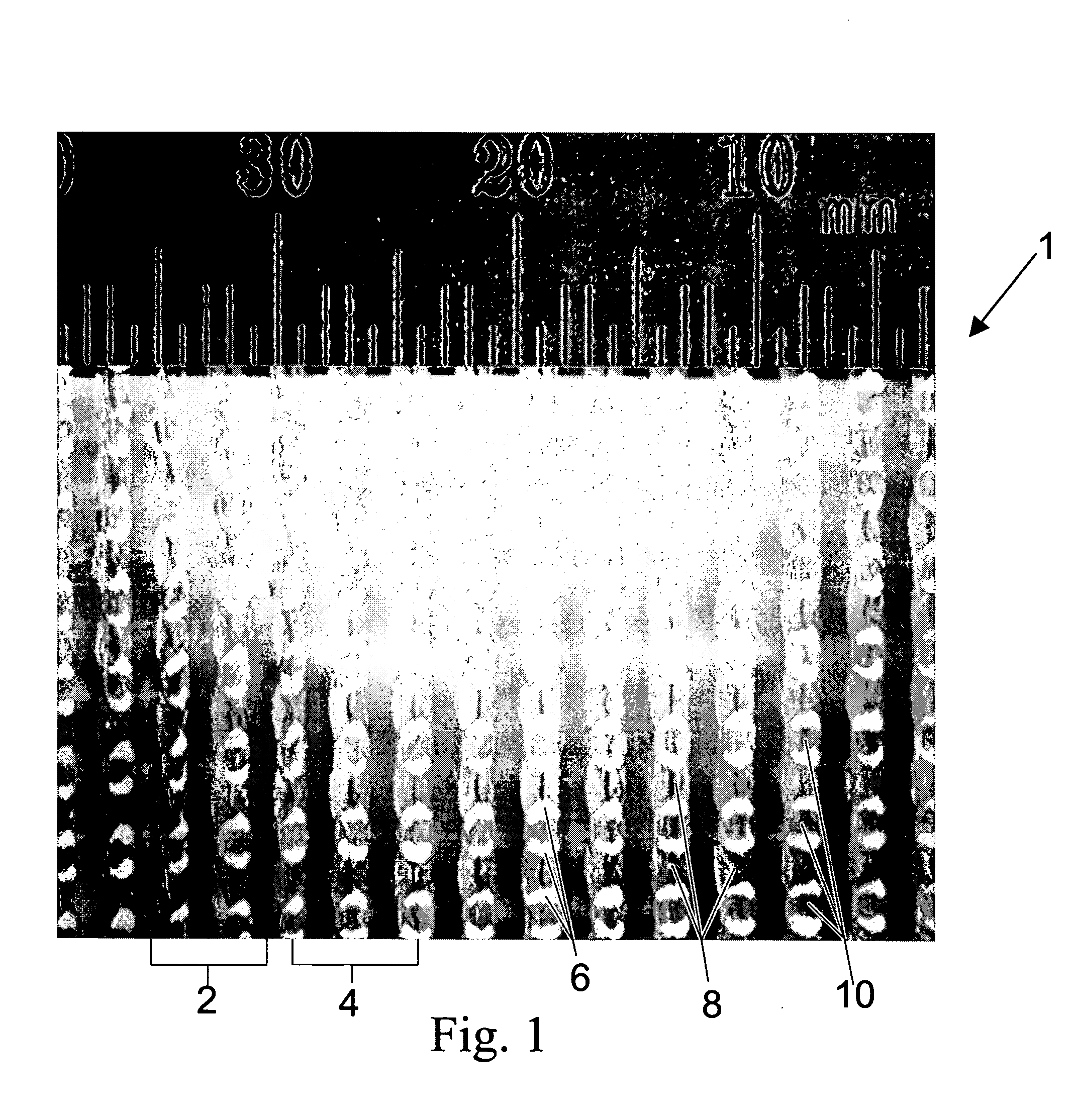

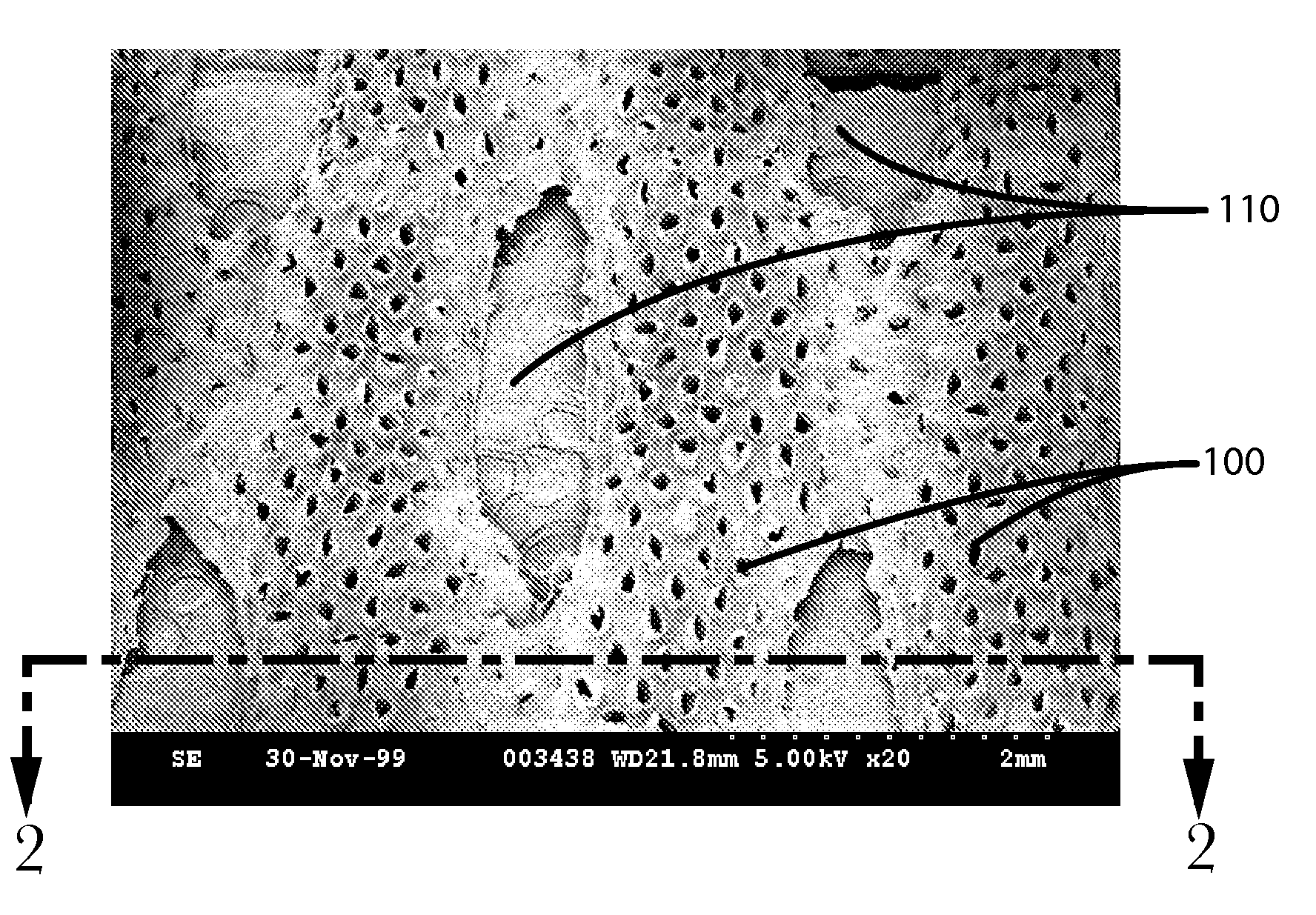

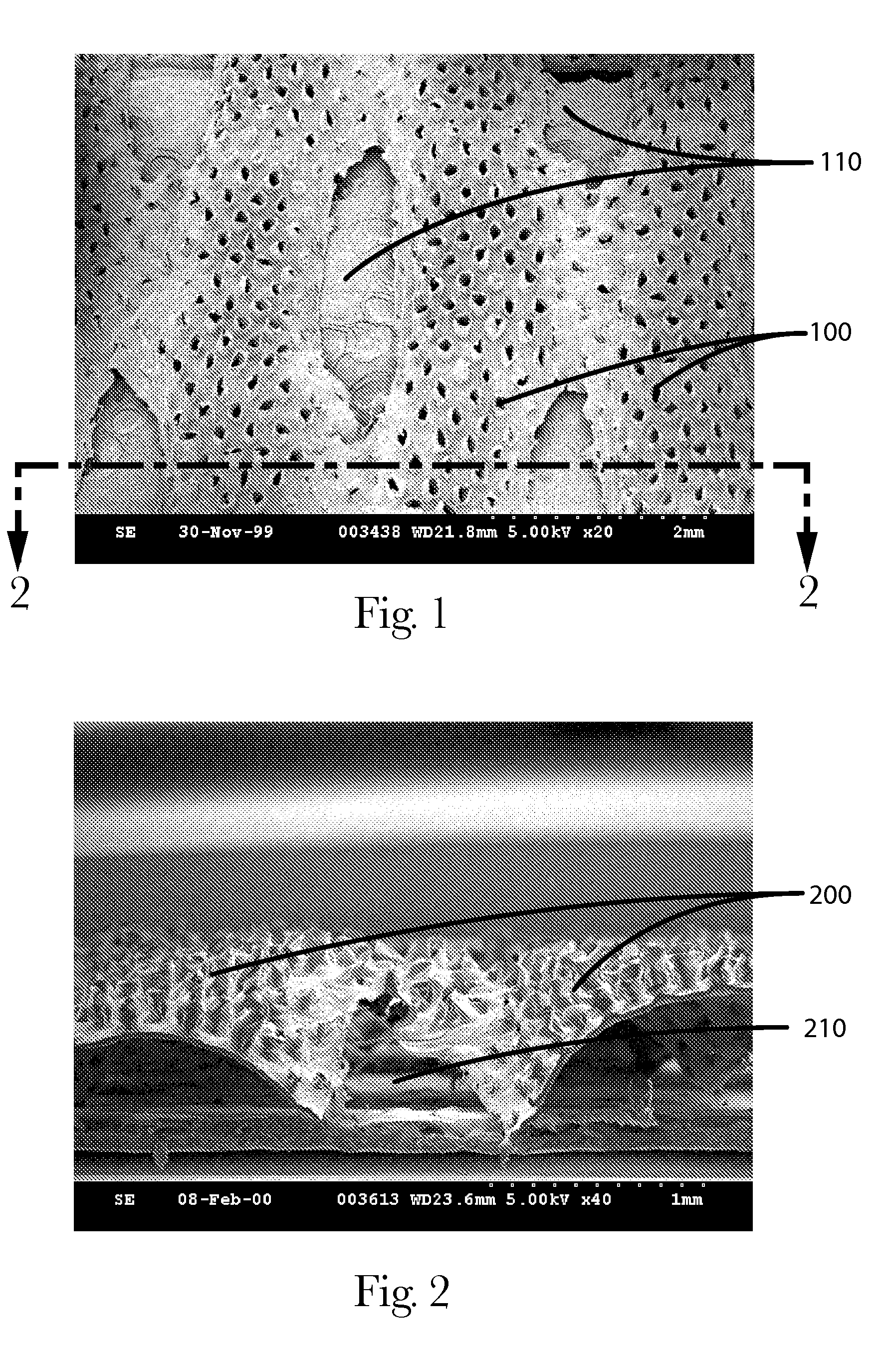

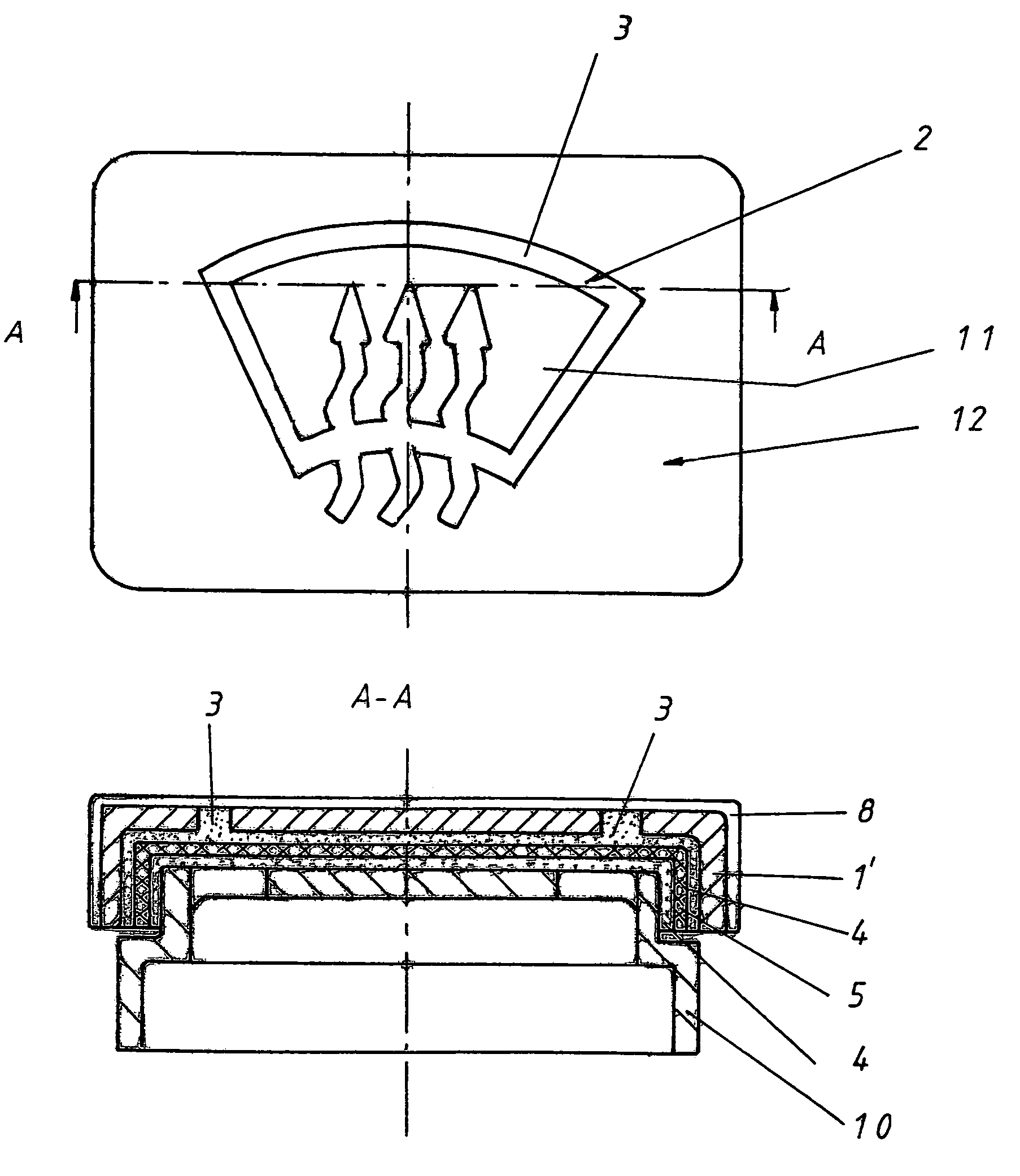

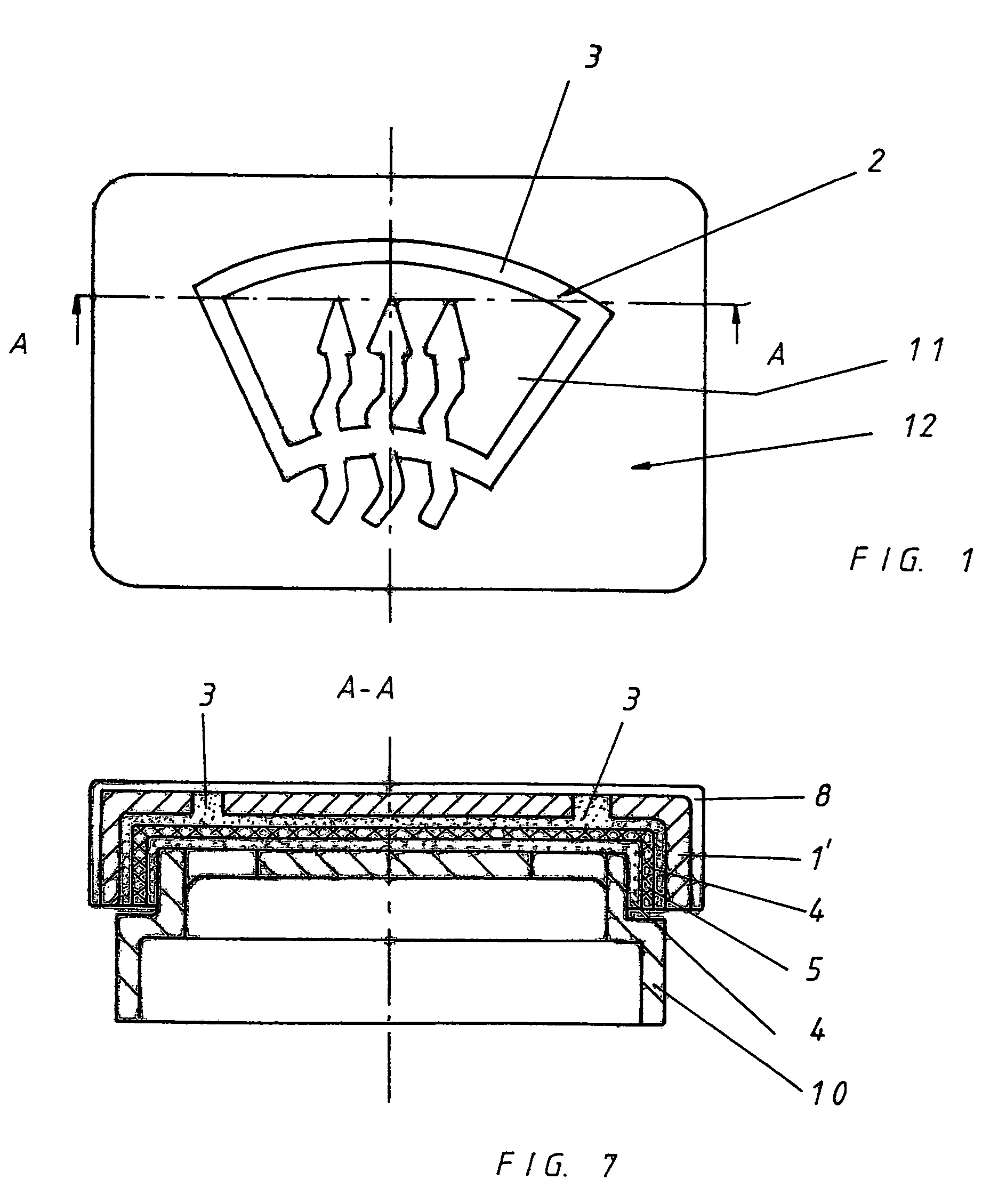

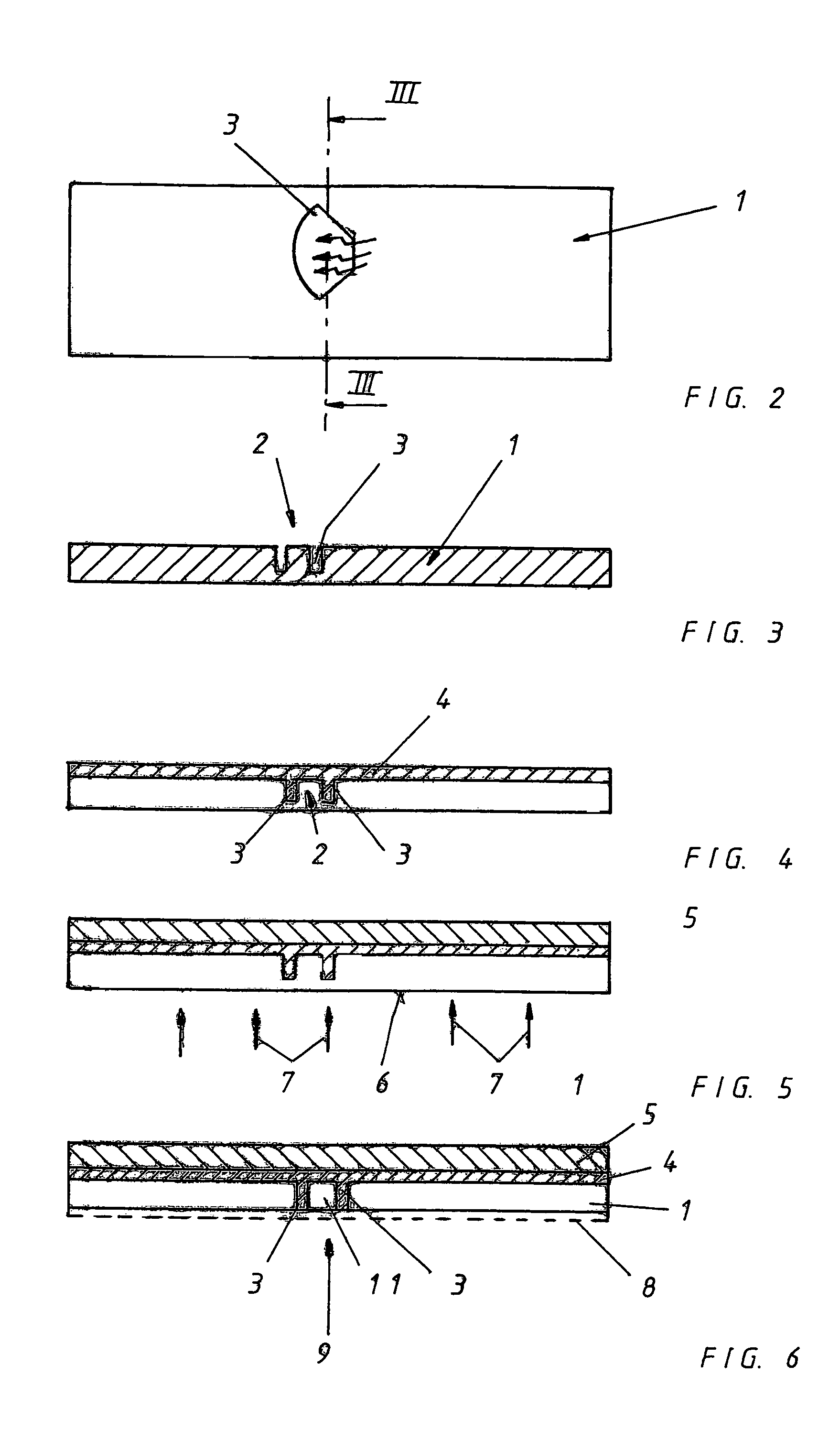

Neovascularization promoting membrane for bioimplants

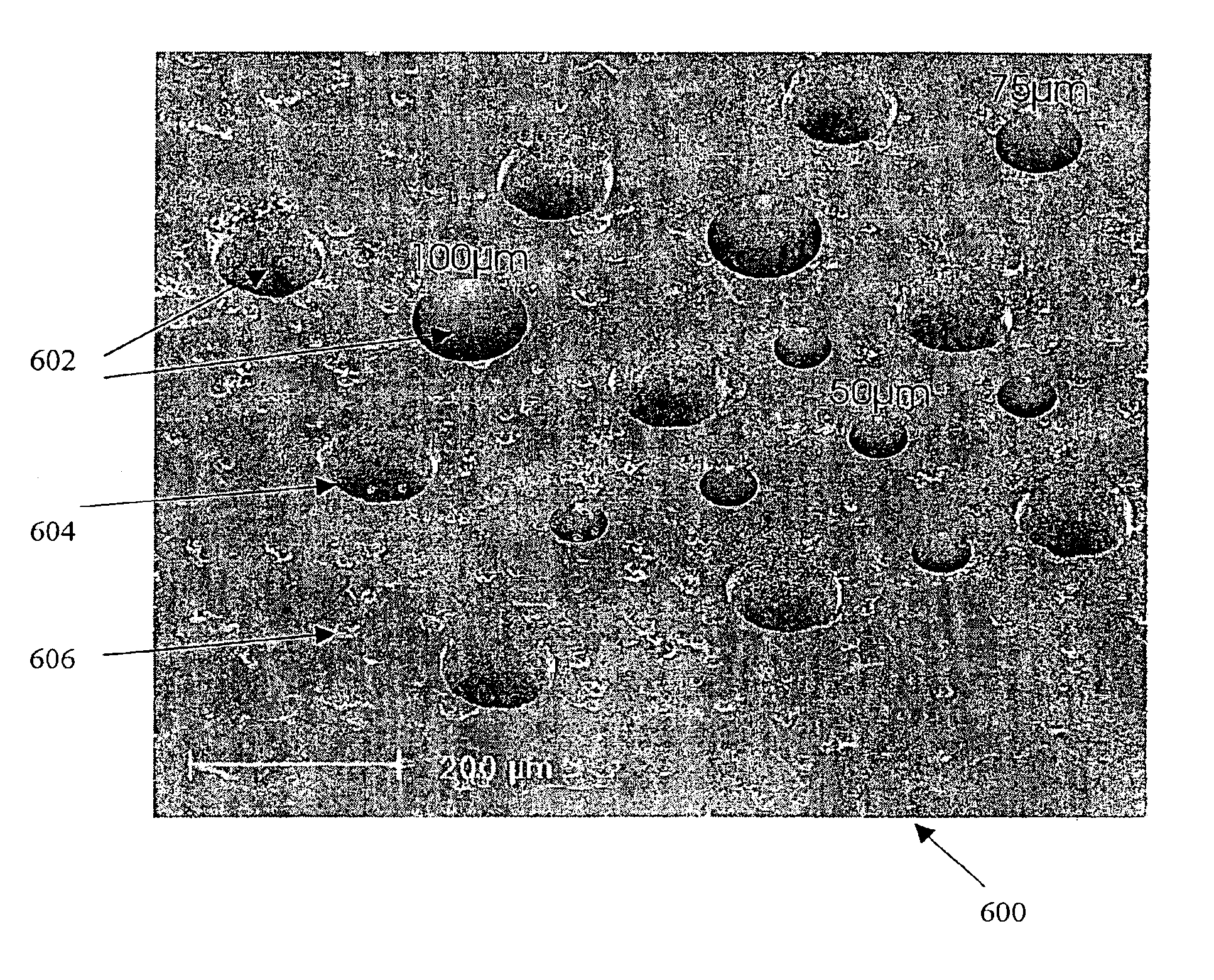

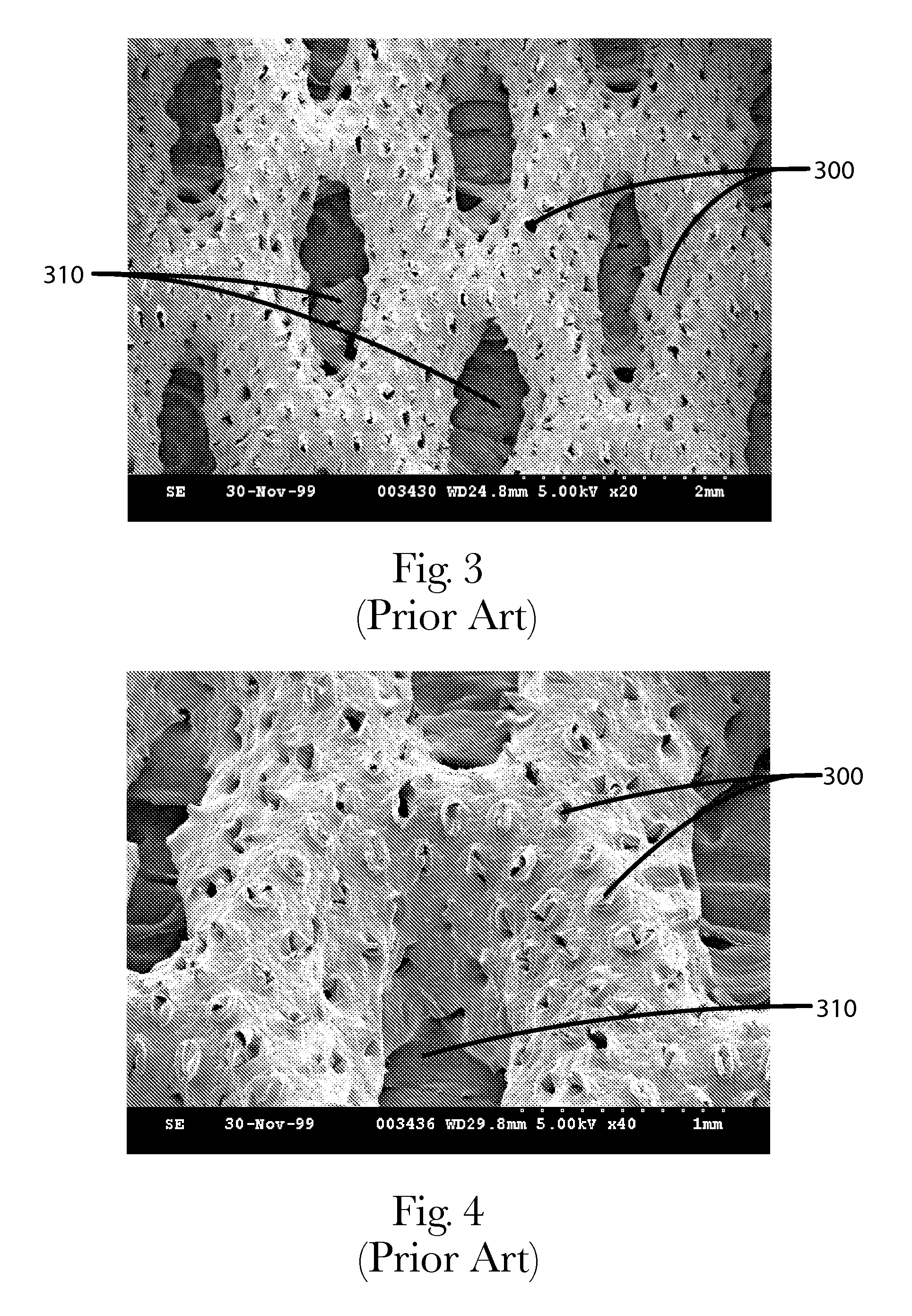

A method of producing a biocompatible microporous membrane comprising the steps of providing a biocompatible membrane and using an energy beam to form a set of pores having a minor axis of less than 15 μm through the biocompatible membrane. One embodiment includes the steps of producing a first layer of material, defining a first set of pores; producing a second layer of material, defining a second set of pores and wherein the second set of pores is defined so as to cooperatively engage the first set of pores; and aligning and joining the first layer of material to the second layer of material to form a laminated membrane, having through-passageways formed by the first set of pores at least partially aligned with the second set of pores.

Owner:WAVEFORM TECH INC

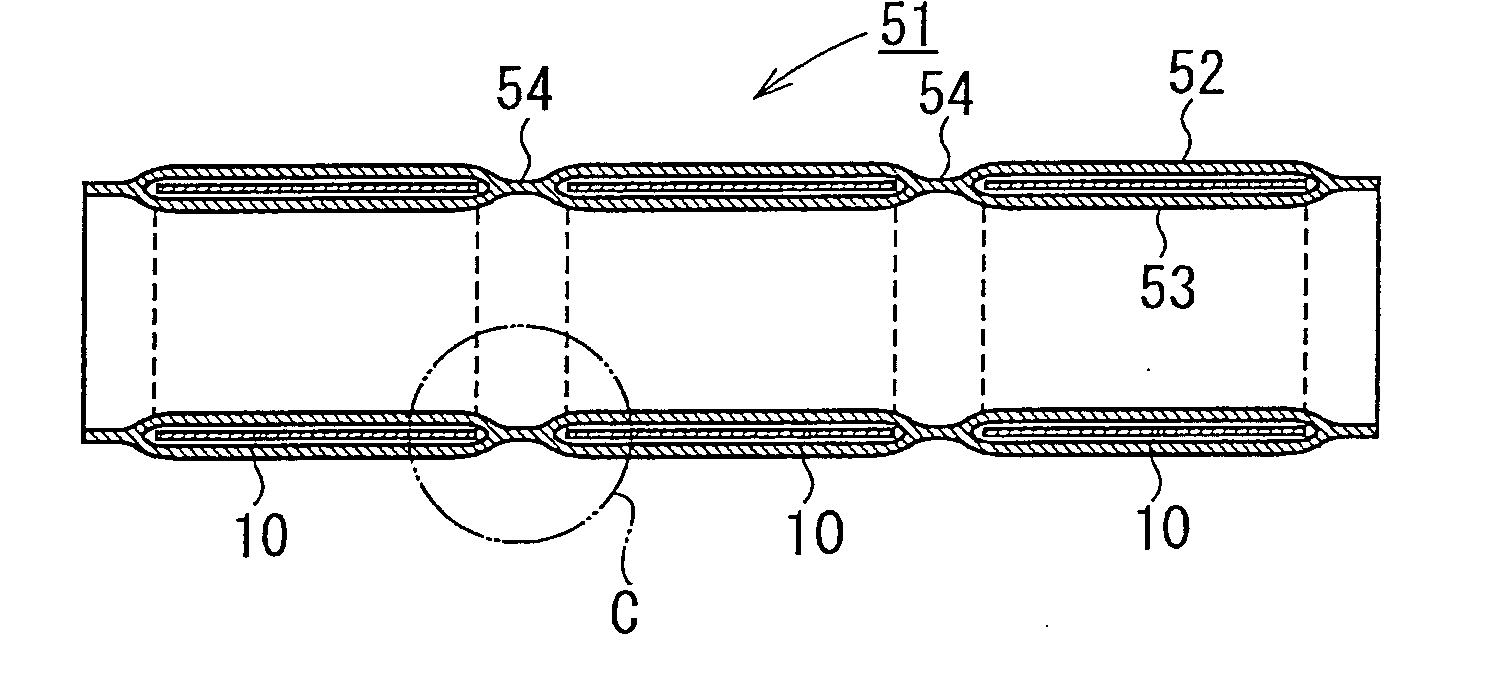

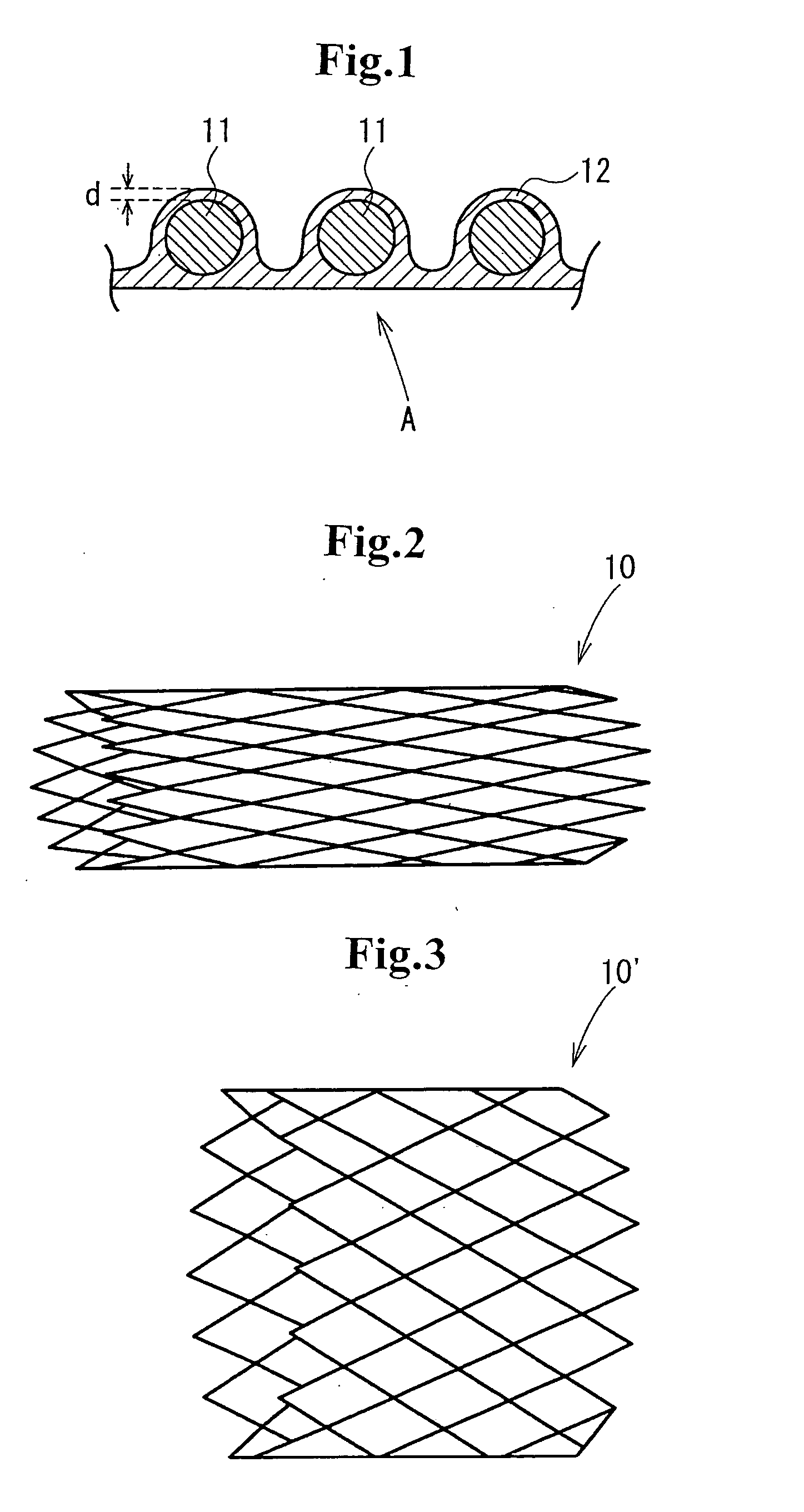

Stent and process for producing the same

A stent comprising a tubular stent matrix of which diameter is extendable and a flexible polymer layer covering the stent matrix. The polymer layer is closely attached to and covers the entire surface of the stent matrix. Since the flexible polymer layer closely covers the entire surface of the stent matrix not only the outer periphery of the stent matrix, the stent has no problem of causing allergic to metal, stimulus of tissues due to metal, and rust development. Since the inner periphery of the stent is a flat and smooth surface covered by the polymer layer without convexes and concaves, the formation of thrombus can be inhibited well. There is no problem of drift between the polymer layer and the stent matrix, thereby maintaining the positional relationship between the stent matrix and the polymer layer before and after the expansion of the stent.

Owner:JAPAN STENT TECH CO LTD +1

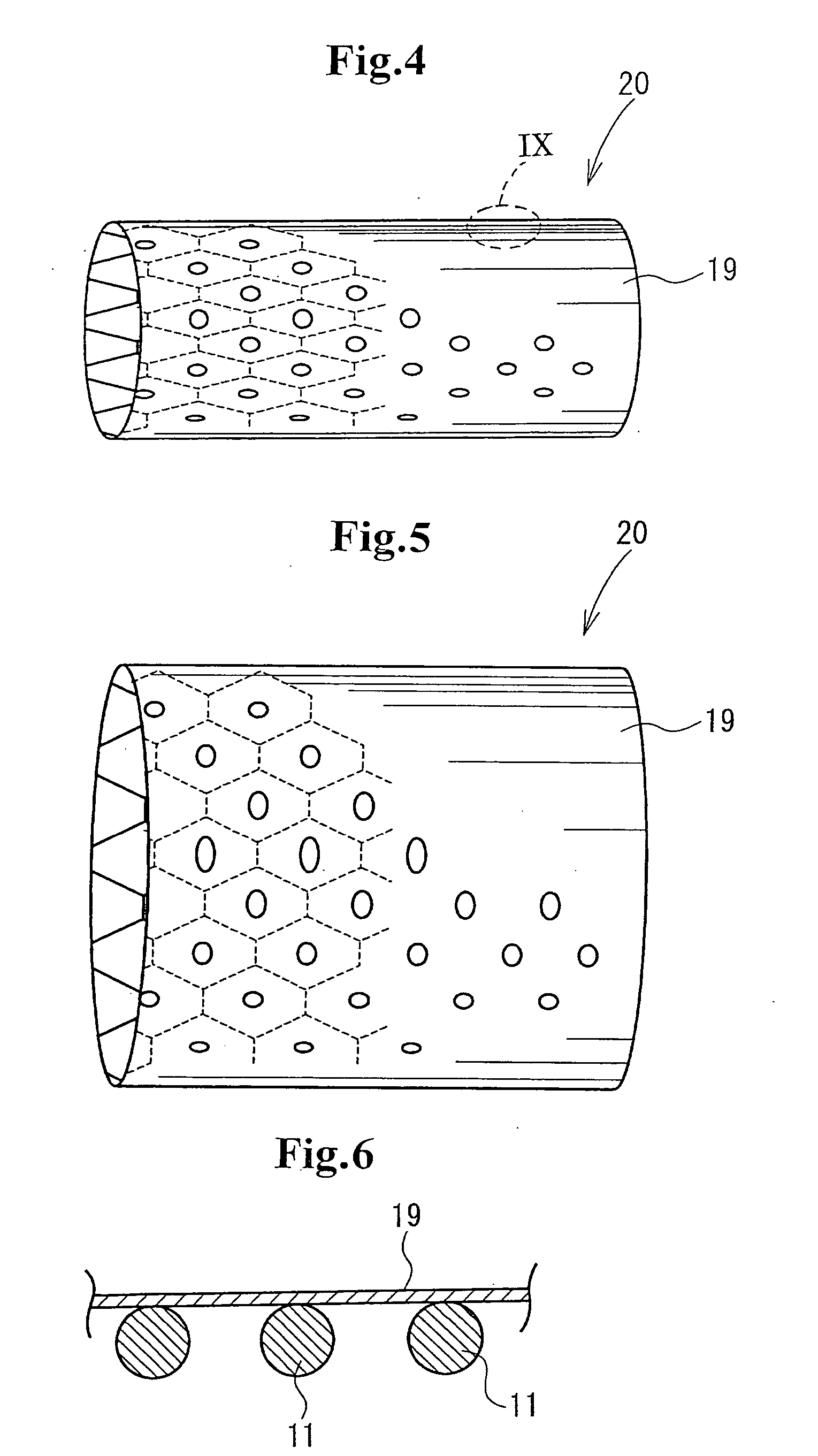

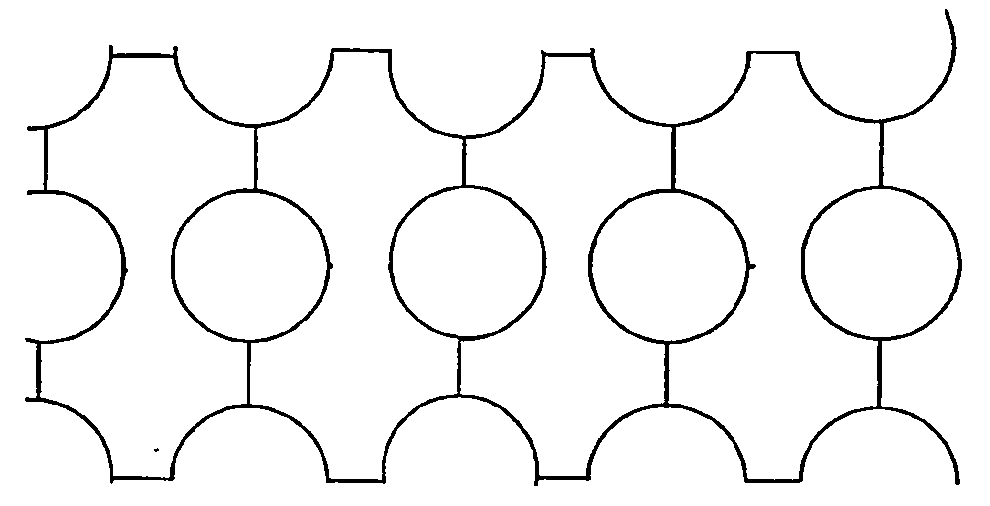

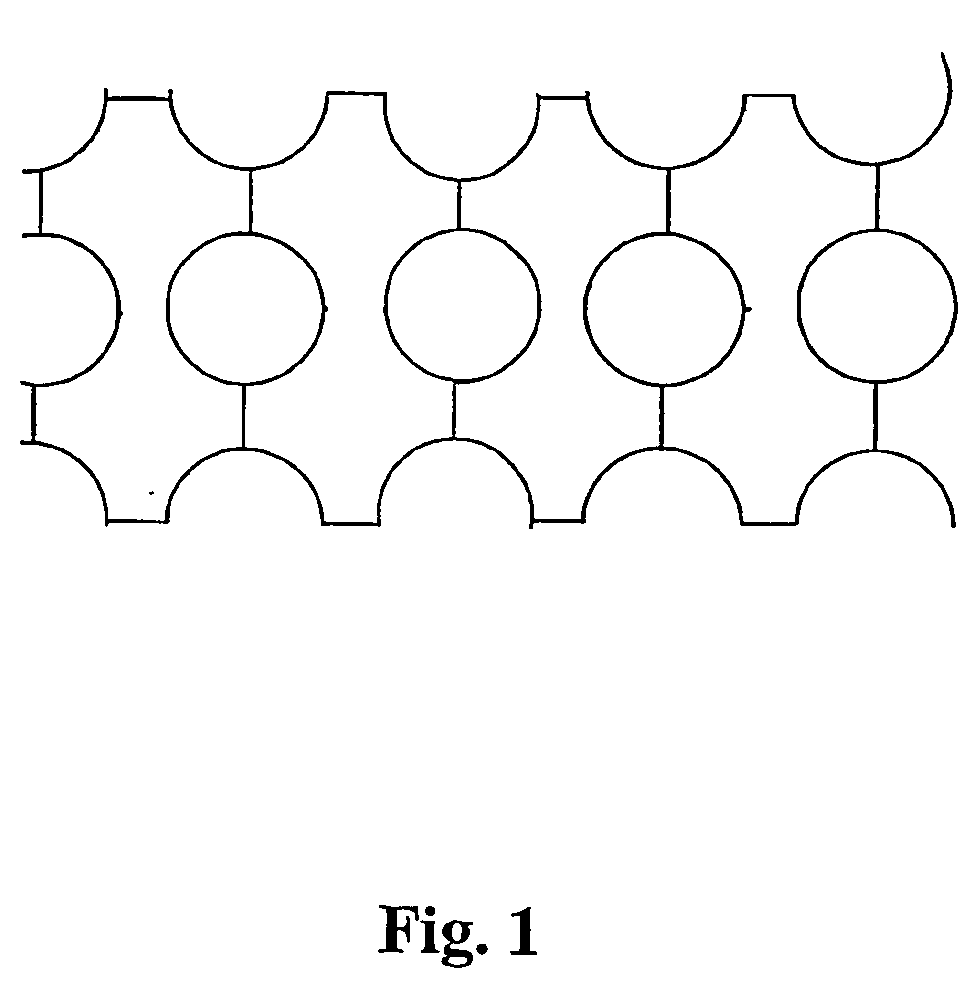

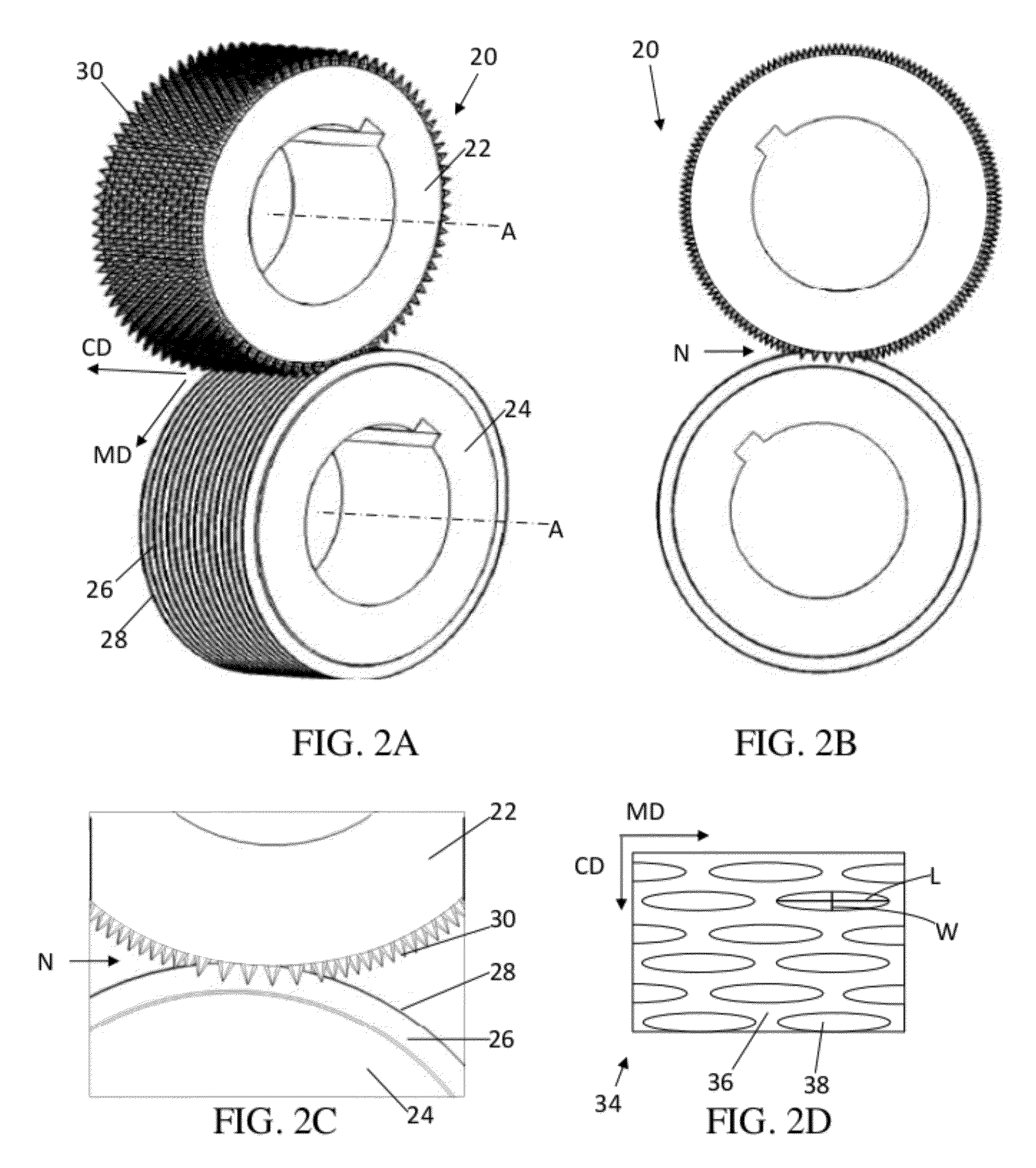

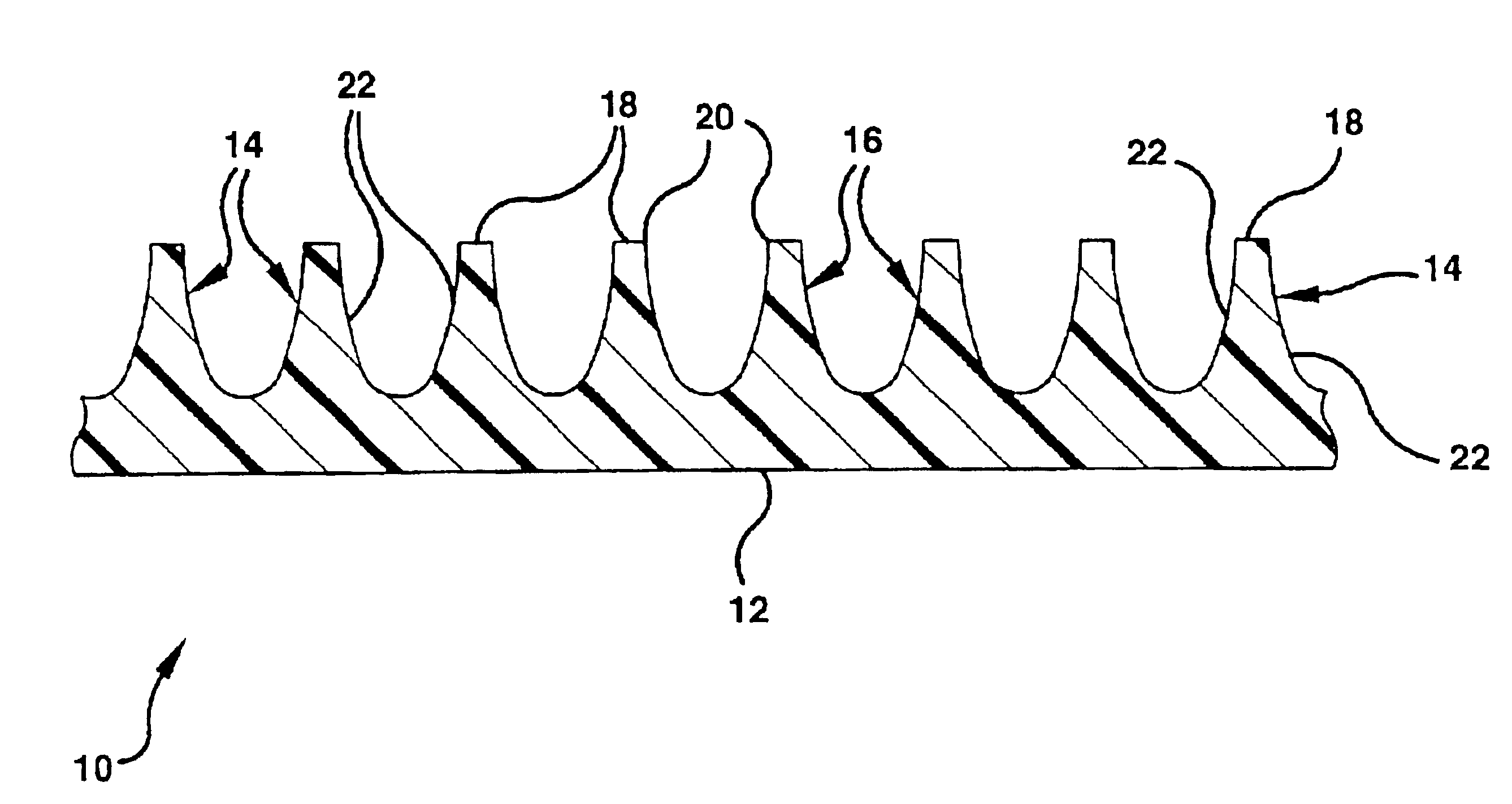

Apertured film

InactiveUS20050064136A1Increase in sizeFlatten filmButtonsLayered productsSheet filmLinear relationship

An apertured film web is disclosed. The web comprises a plurality of first regions having a first molecular orientation and a plurality of second regions having a second molecular orientation, the first and second regions being in an alternating and contiguous generally linear relationship in a first direction, the second molecular orientation being generally orthogonal to the first direction, and wherein the second region comprises openings defining apertures therein.

Owner:THE PROCTER & GAMBLE COMPANY

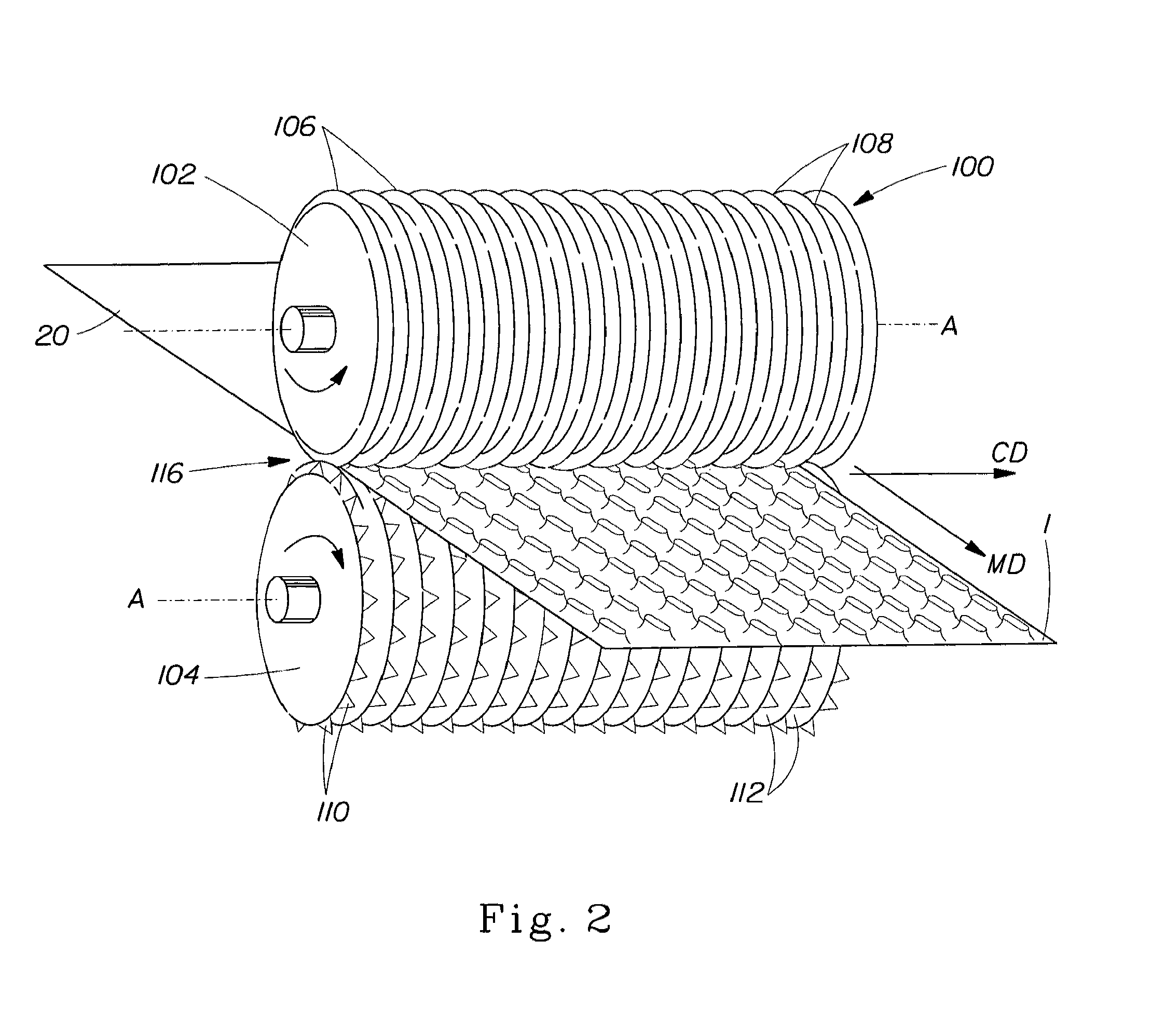

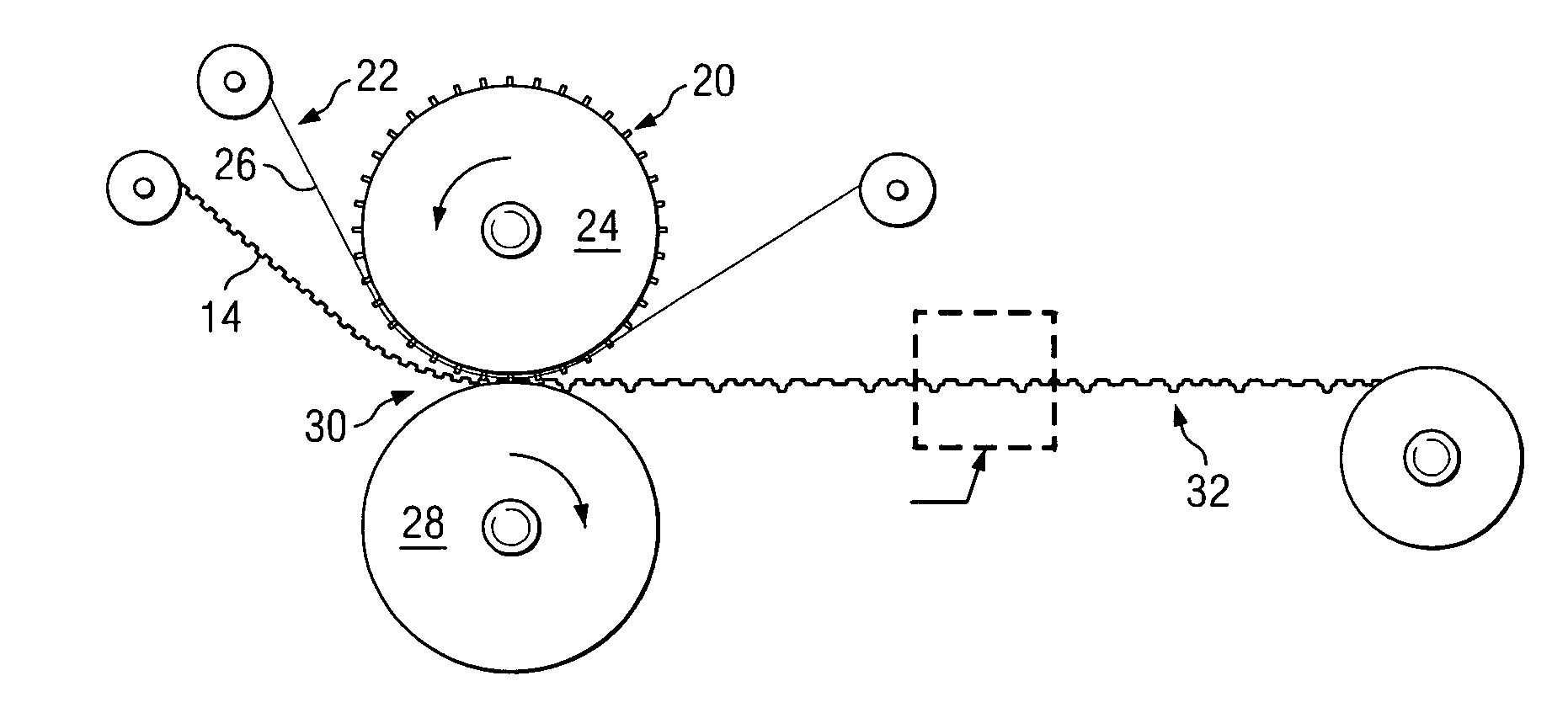

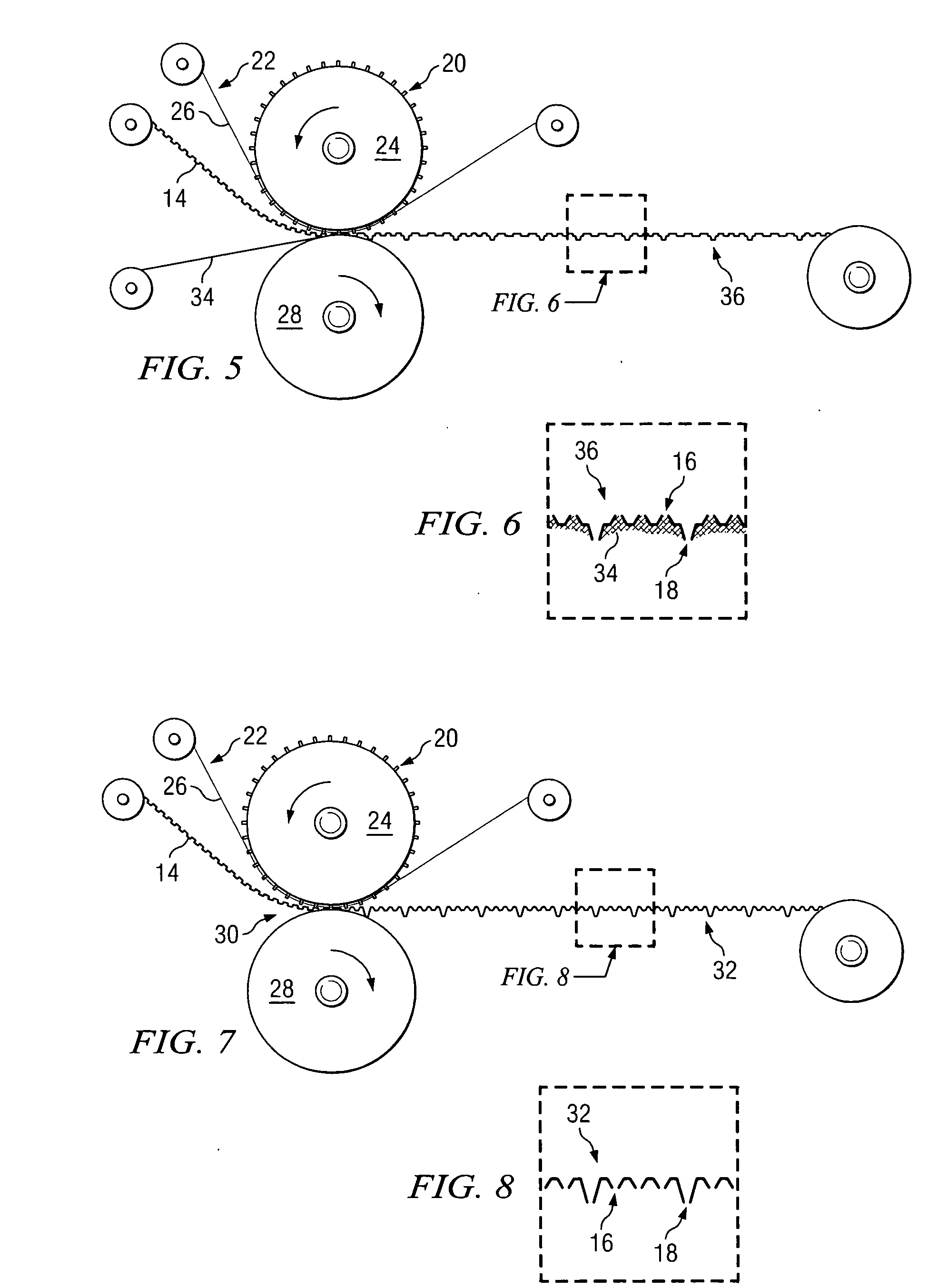

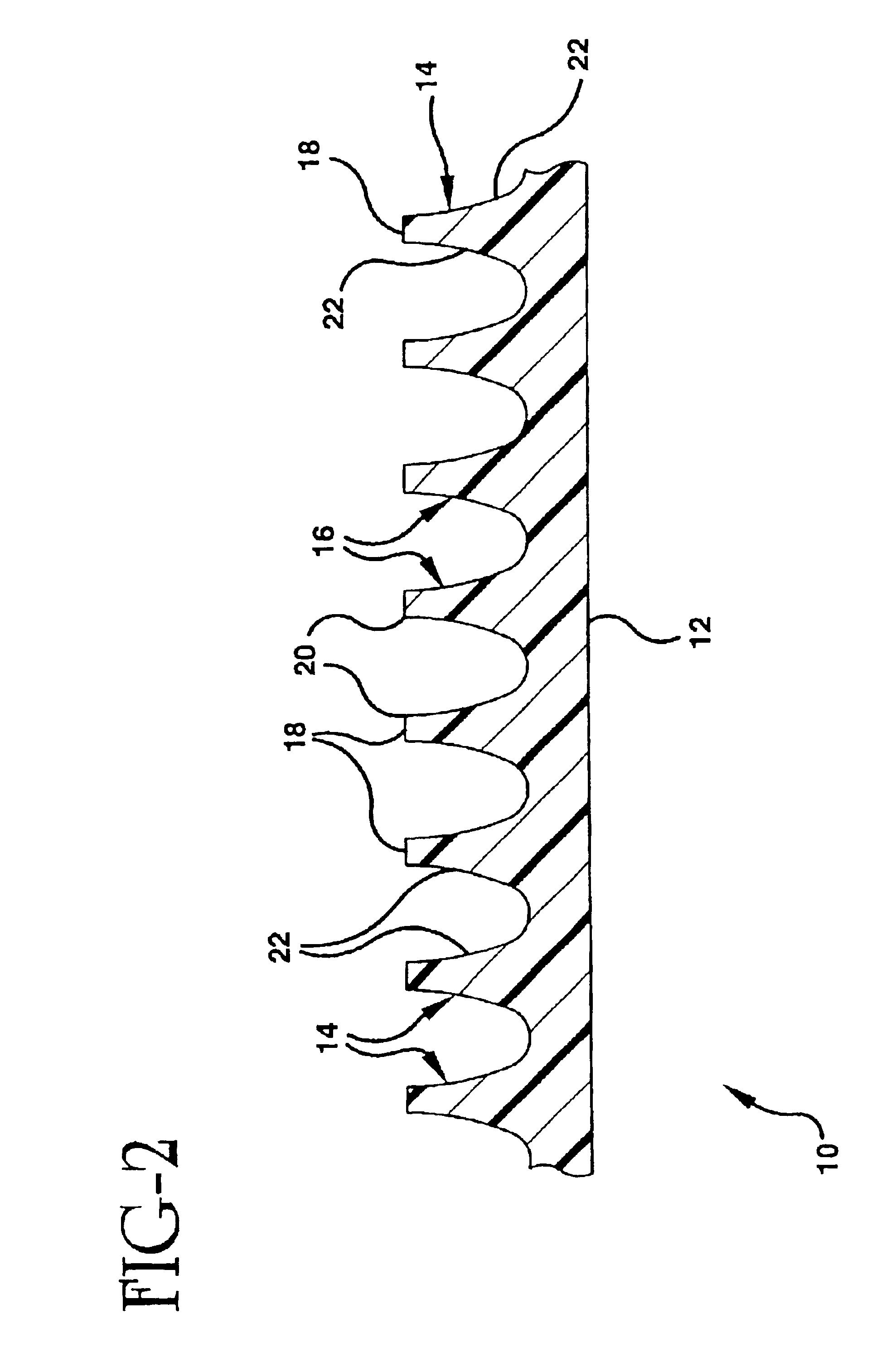

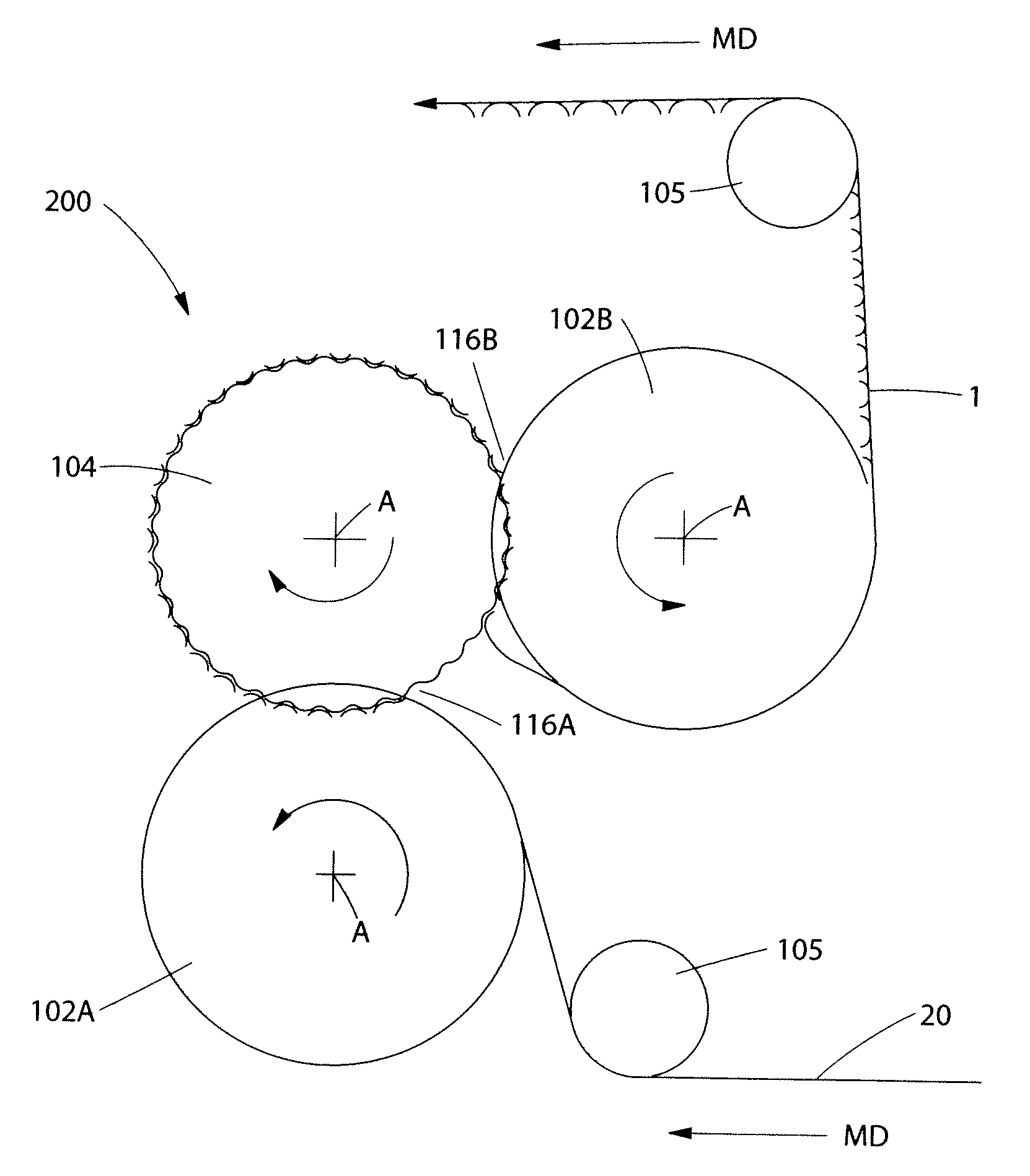

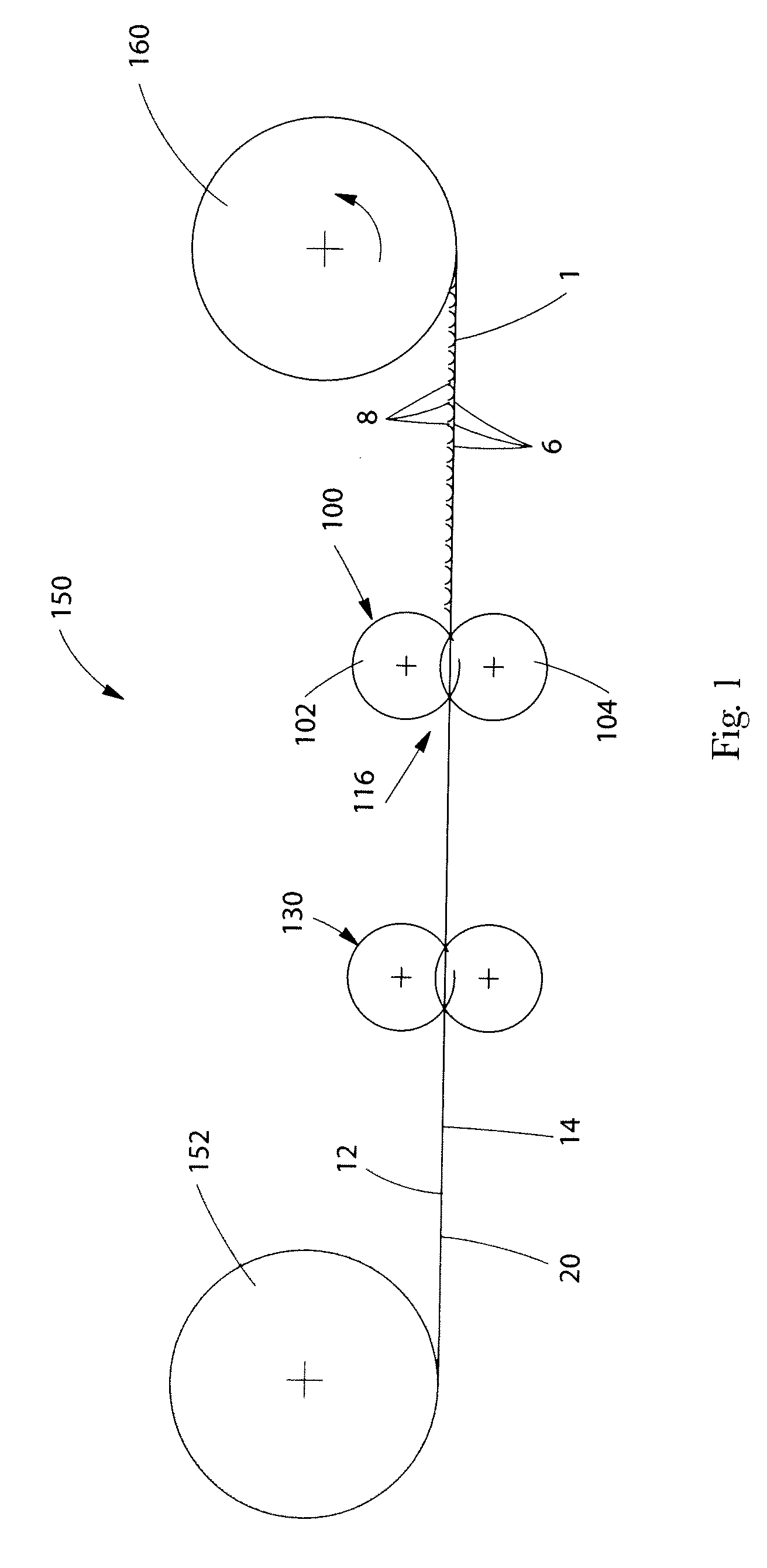

Method for Making an Apertured Web

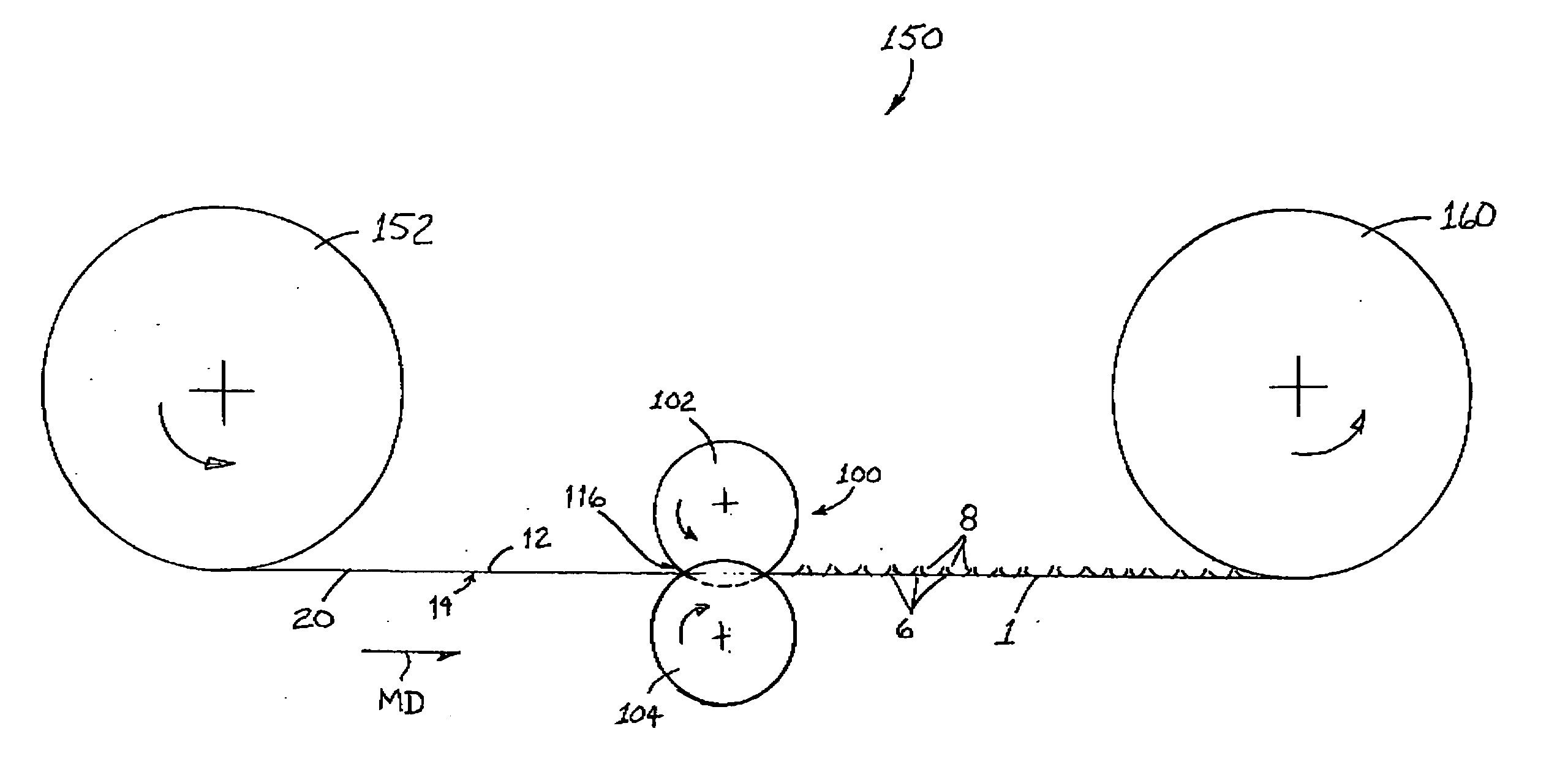

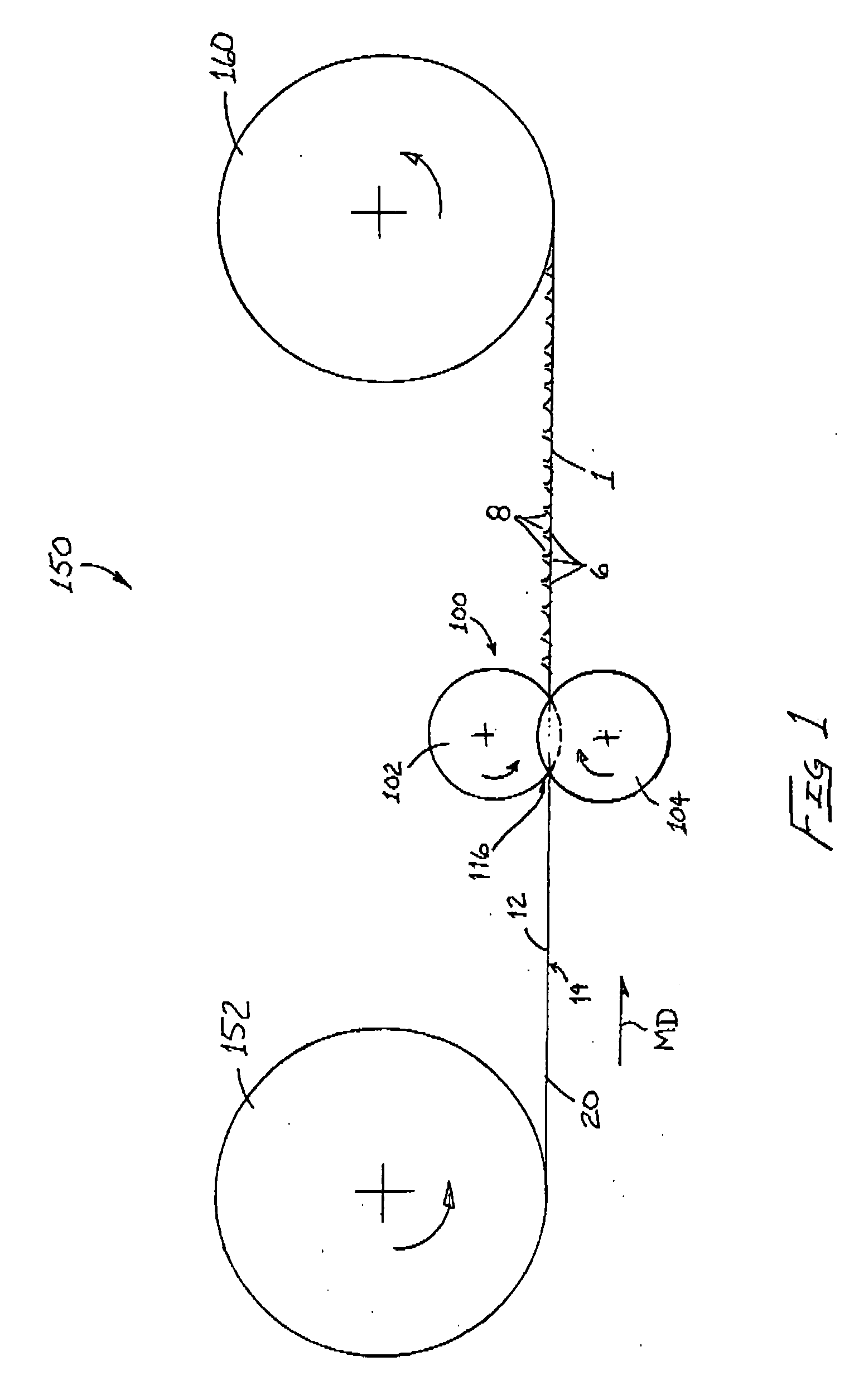

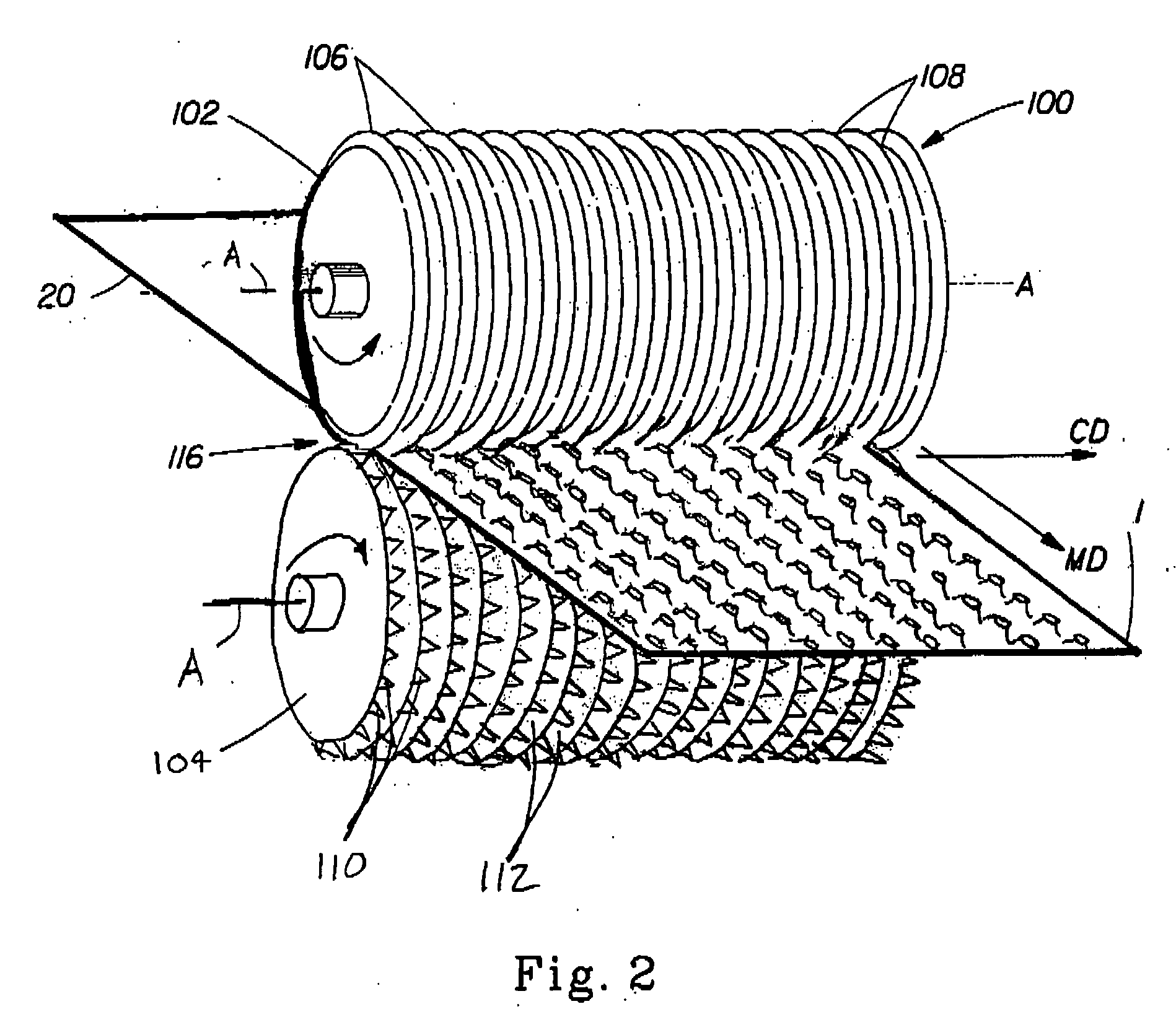

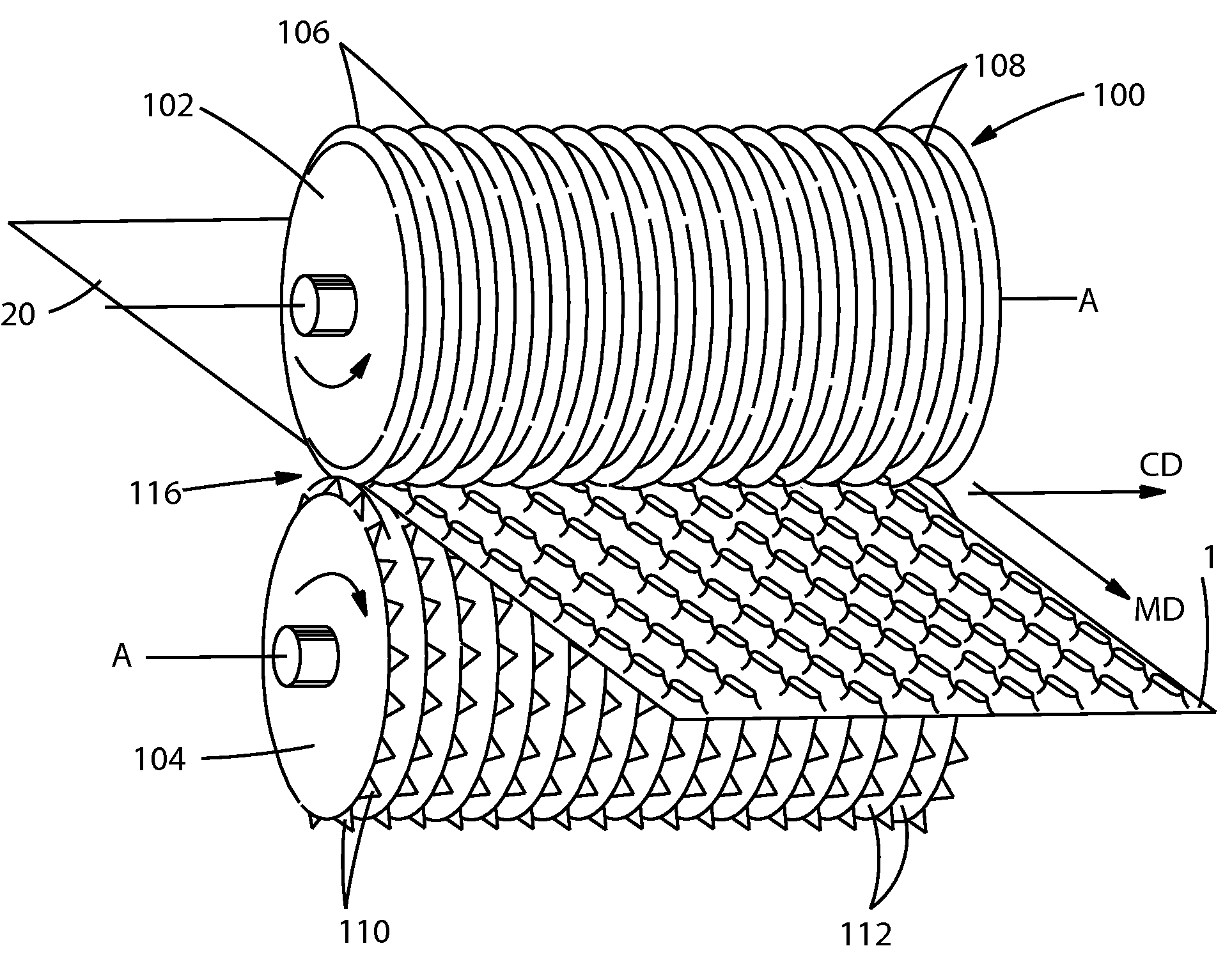

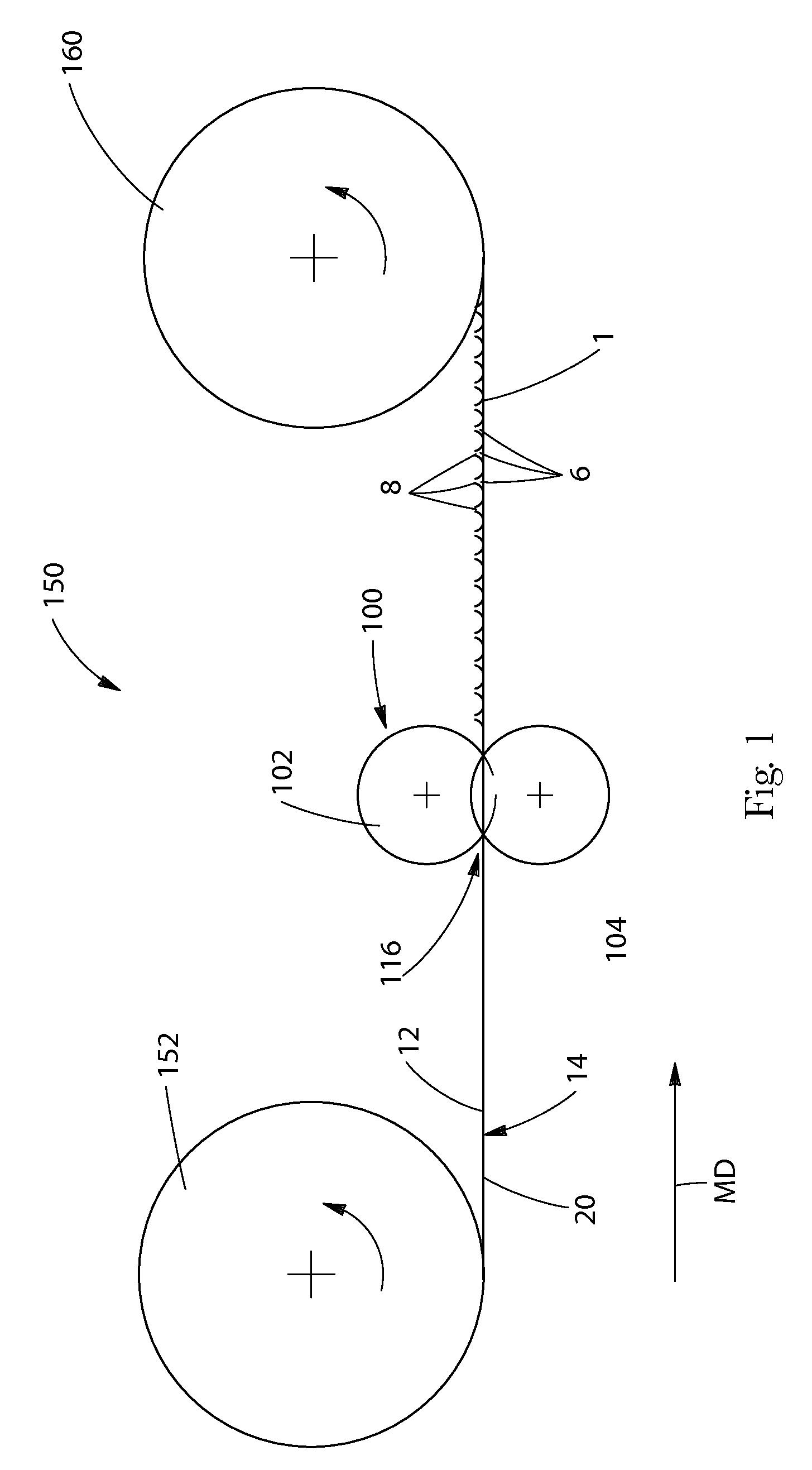

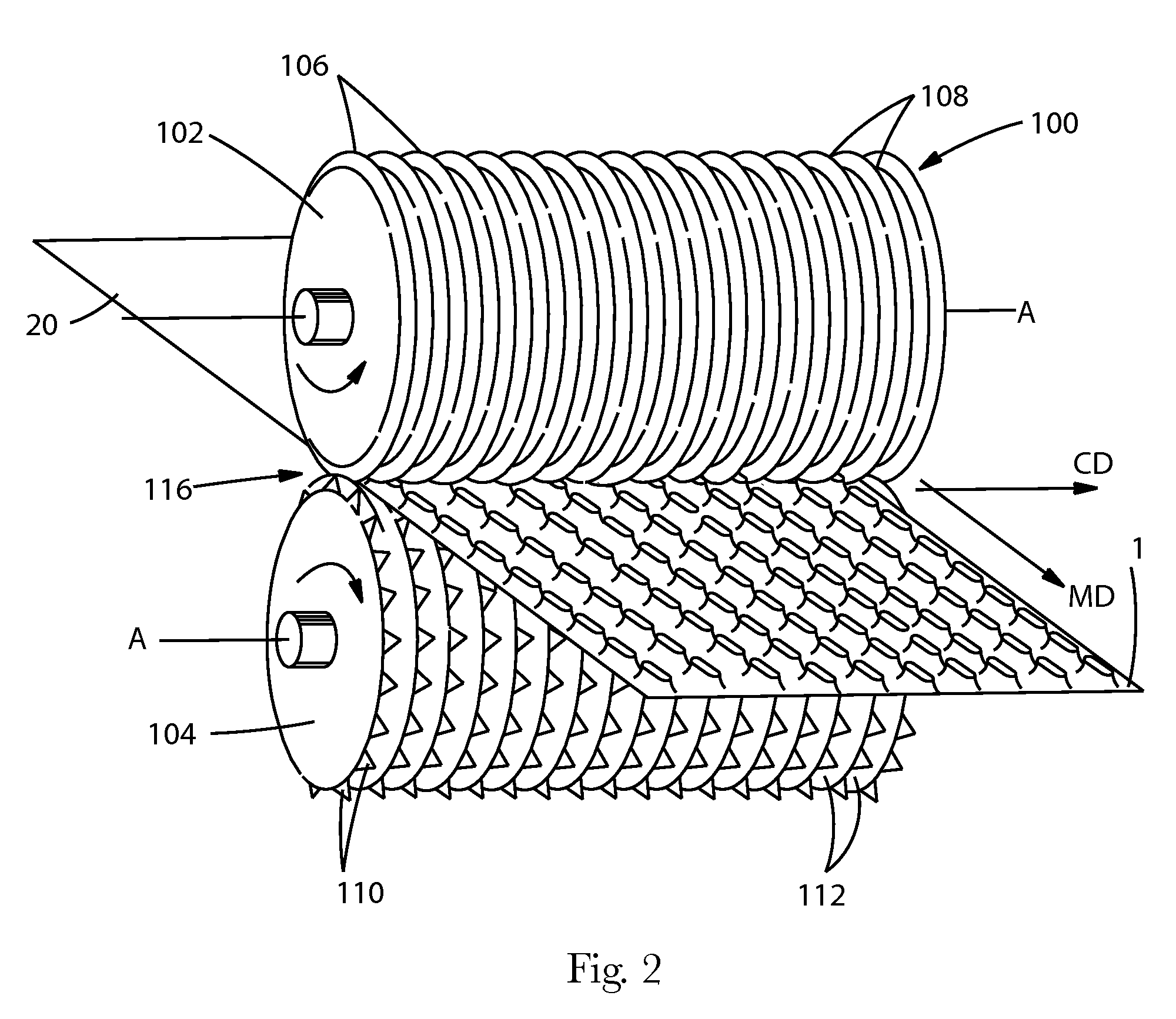

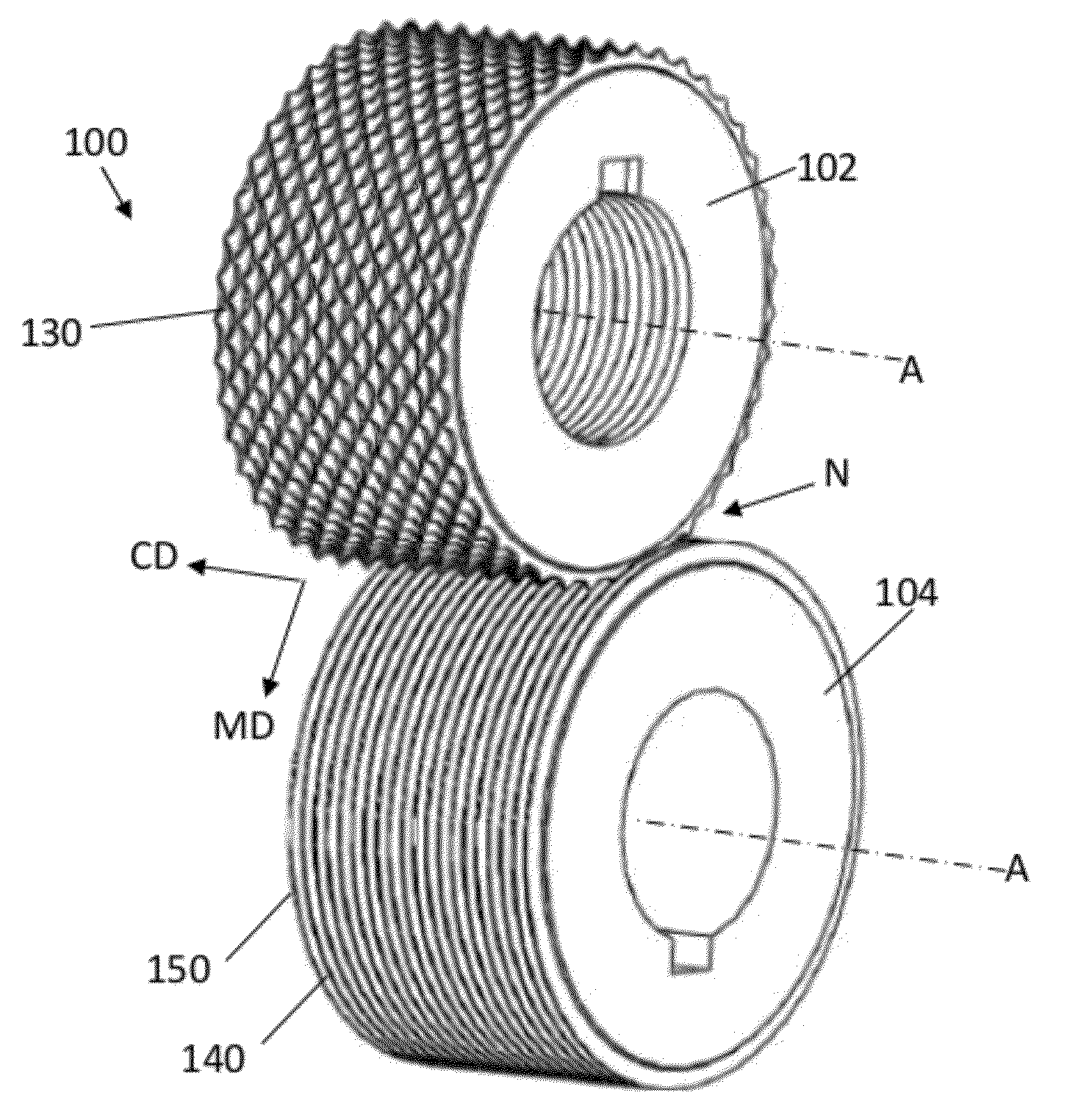

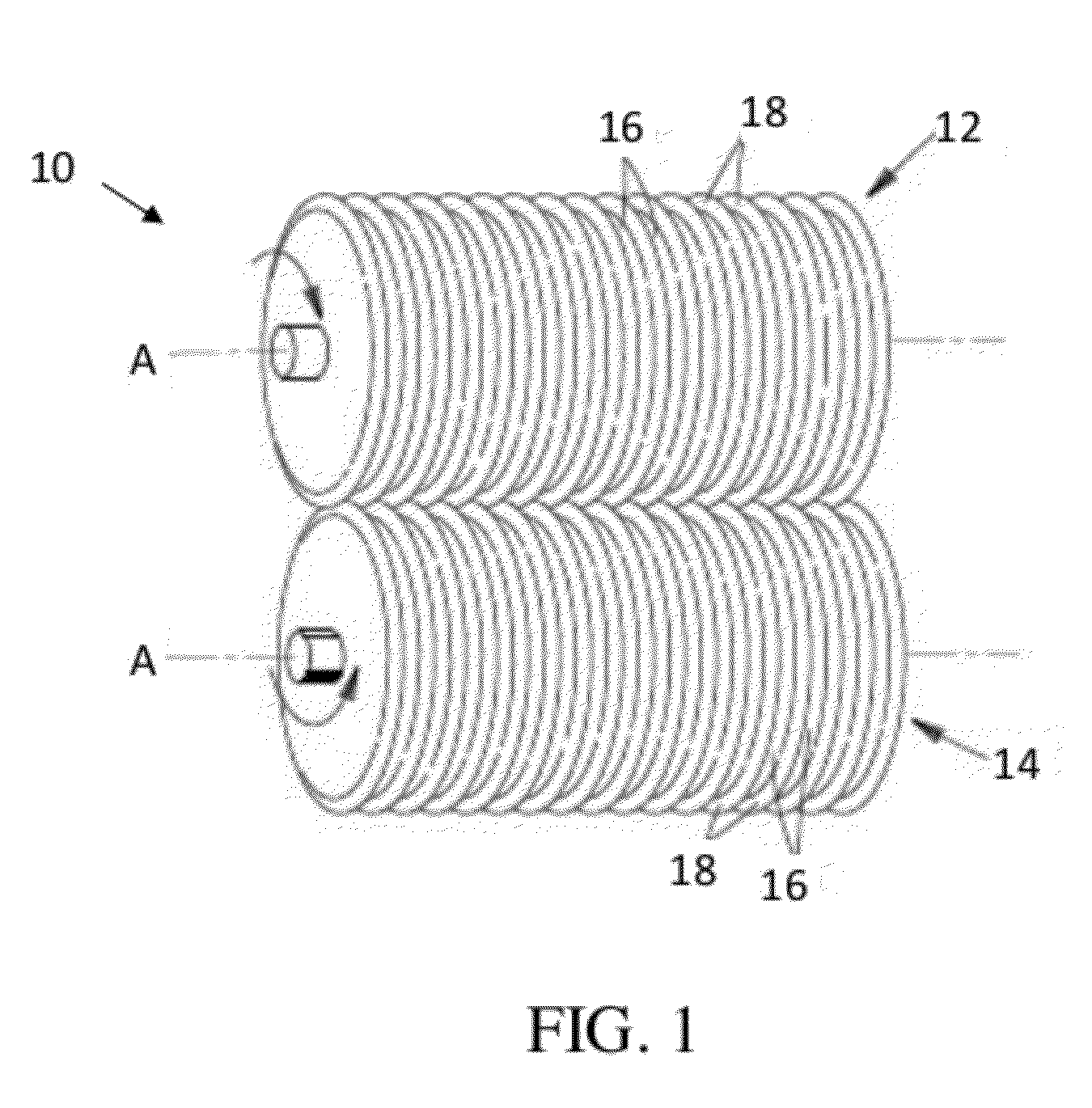

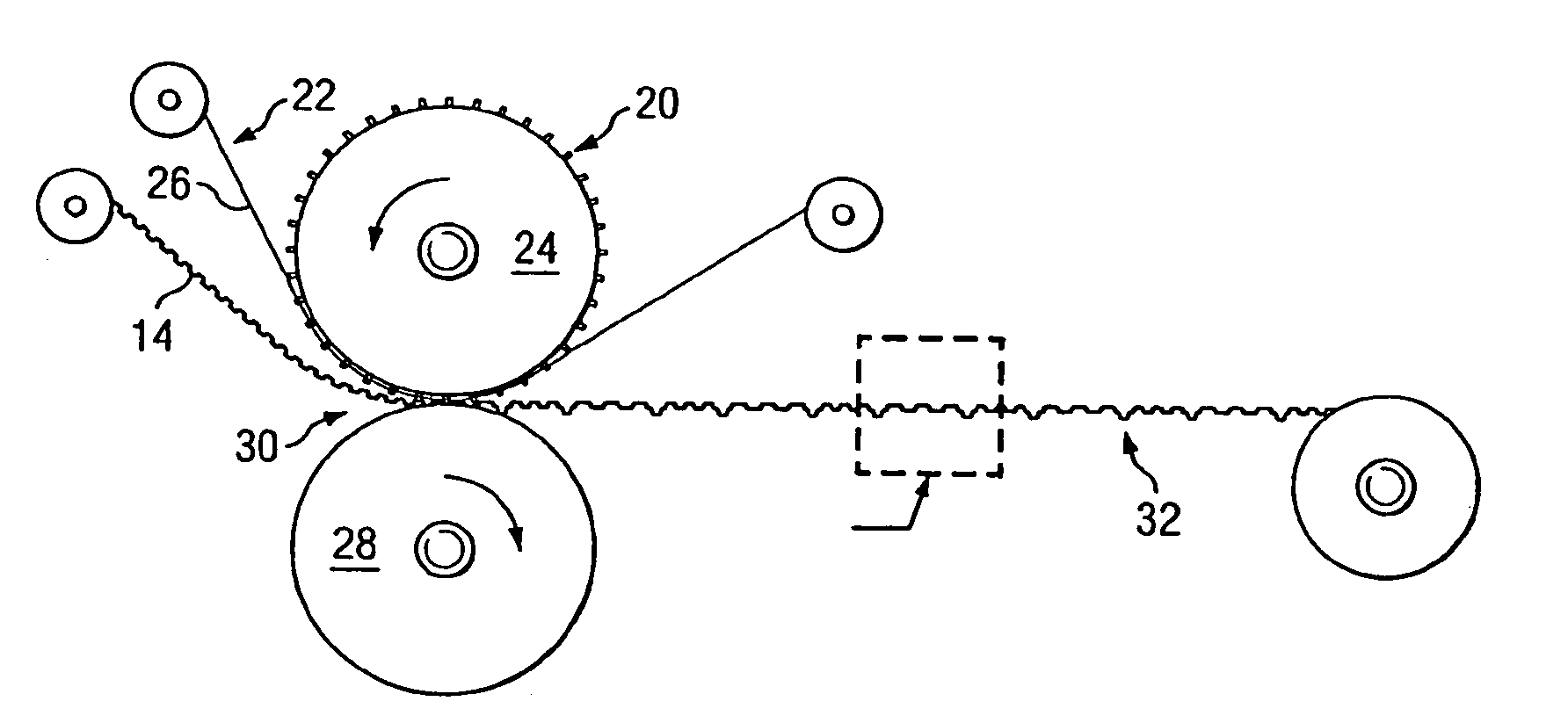

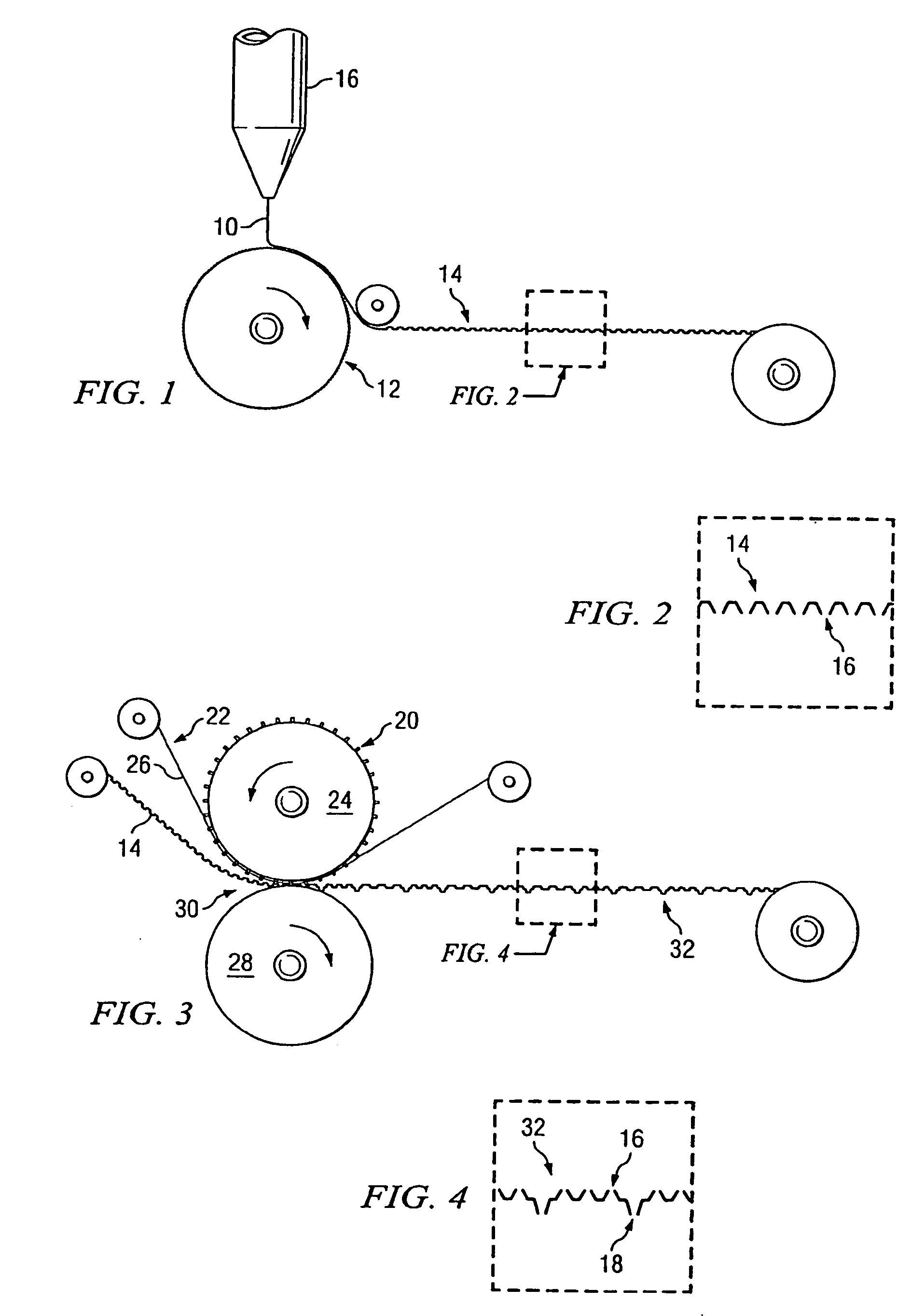

ActiveUS20100201024A1Increase the opening areaImprove rendering capabilitiesButtonsCeramic shaping apparatusFiberEngineering

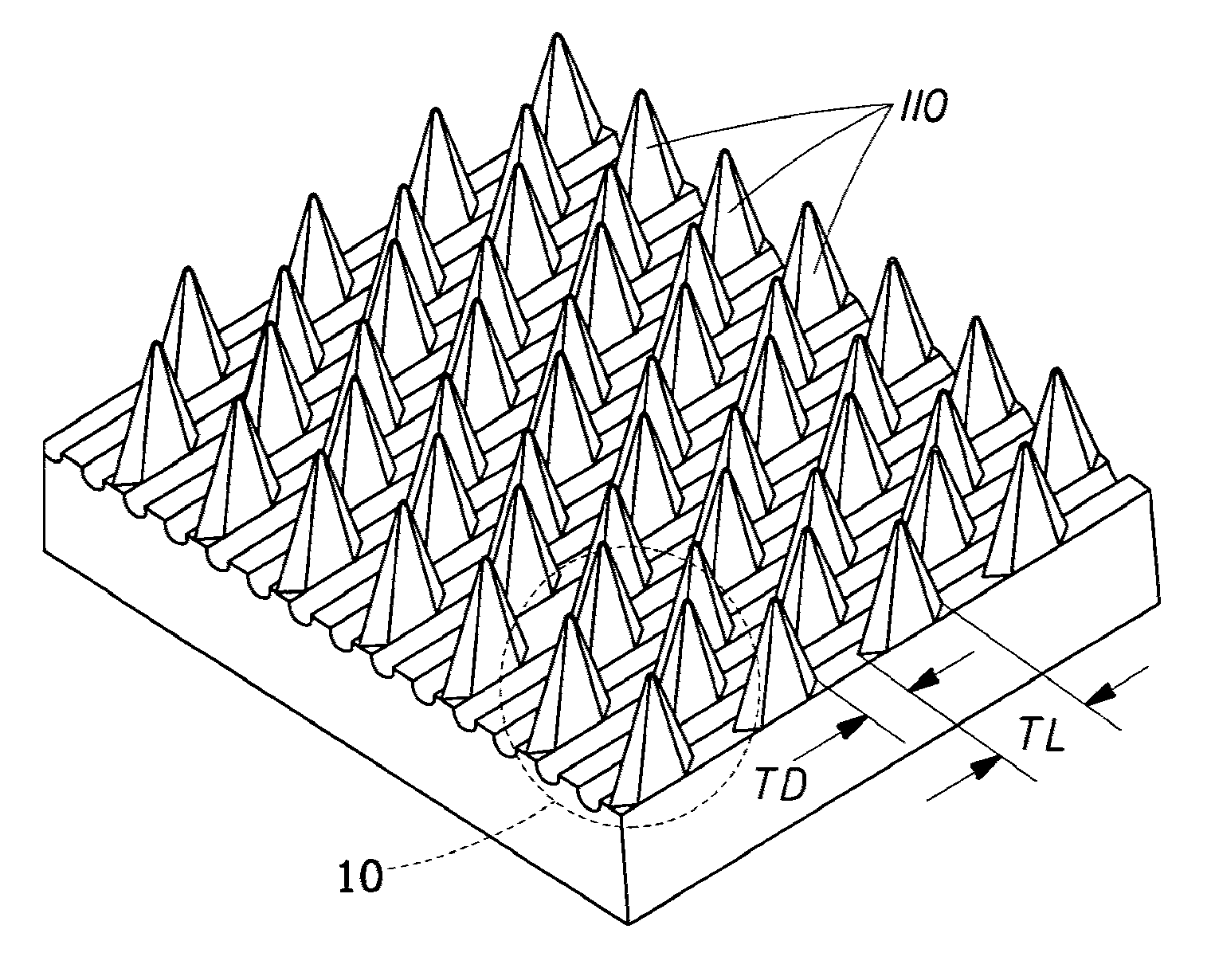

A method for making apertures in a precursor web using a forming apparatus is provided where the web comprises a film having molecular orientation and the forming apparatus comprises an arrangement of teeth. The orientation of the arrangement of teeth and the molecular orientation of the film are predetermined and modified to provide a relative angle between the orientation of the teeth and the molecular orientation of the film. Apertures formed in the precursor web material have a length and width exhibiting a minimal aspect ratio.

Owner:THE PROCTER & GAMBLE COMPANY

Method and apparatus for making an apertured web

Owner:PROCTER & GAMBLE CO

Casting preforms for optical fibres

InactiveUS20050089670A1Difficult and expensive to produceButtonsCladded optical fibreOptoelectronicsPolymer

This invention relates to a method of preparing a preform for an optical fibre, and more particularly to a method of preparing a preform for a polymer holey optical fibre. The invention provides a method of preparing a preform for manufacture of a polymer holey optical fibre comprising casting a preform body in a mould from a suitable material, said mould including at least one protrusion adapted to form a corresponding hole within the preform, and subsequently separating the preform body and mould. The invention also provides a method of preparing a preform for manufacture of a polymeric holey optical fibre comprising separately casting one or more elements of a preform in respective mould(s) from a suitable material, and separating said elements from said respective mould(s) and combining said elements to construct a preform having a plurality of holes therein, each hole being formed in an element or formed by the combination of two or more elements.

Owner:THE UNIV OF SYDNEY +2

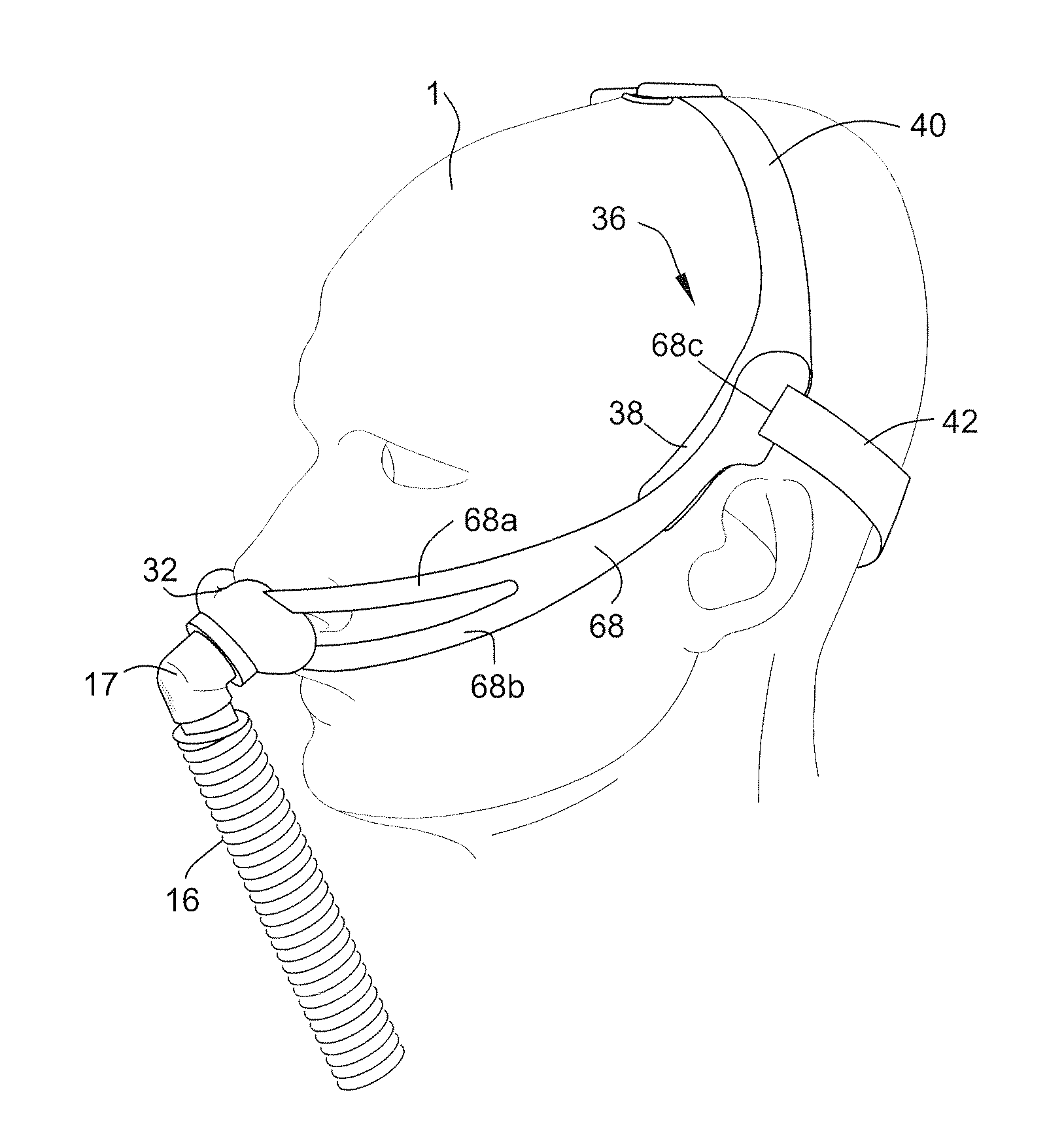

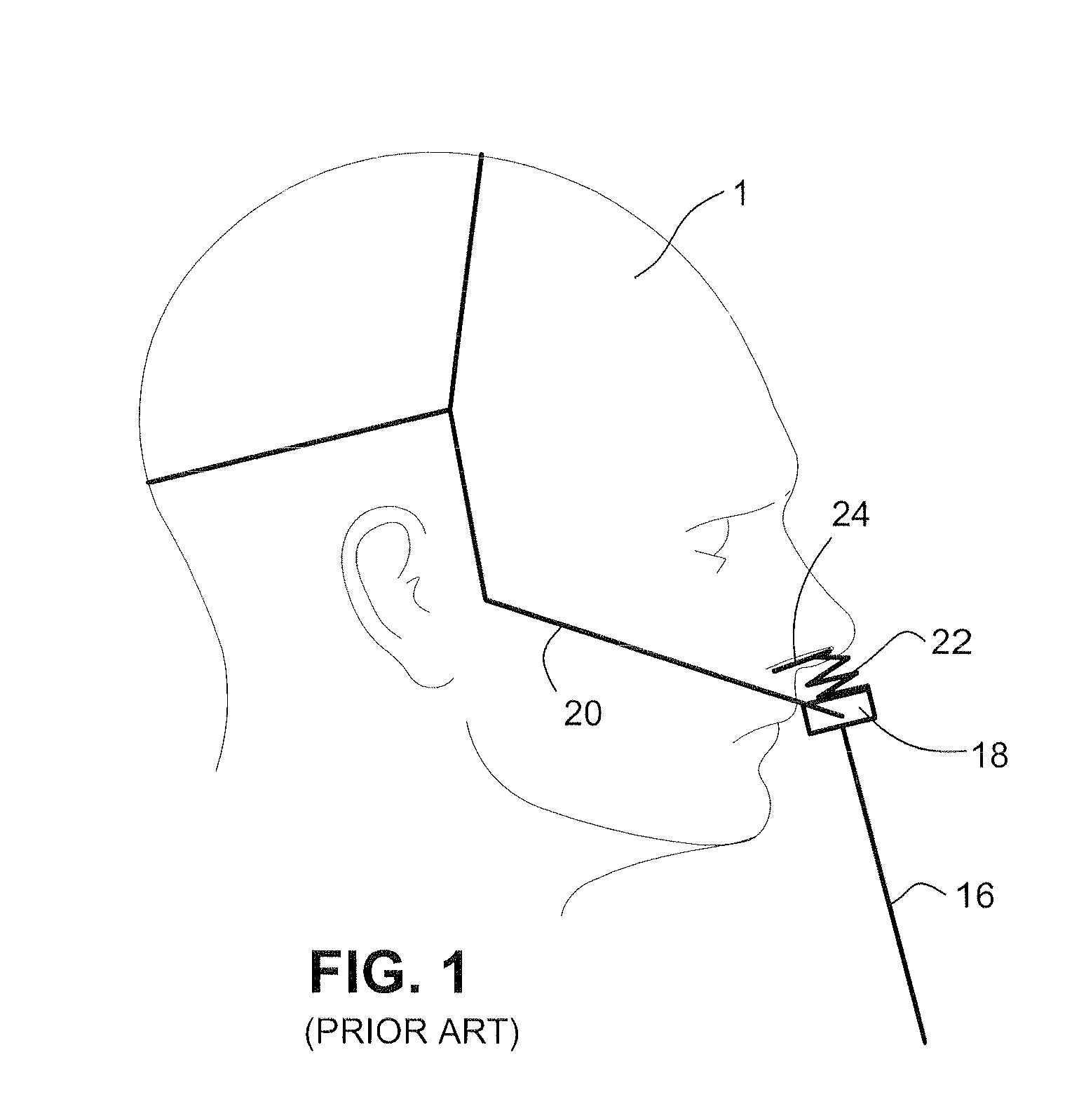

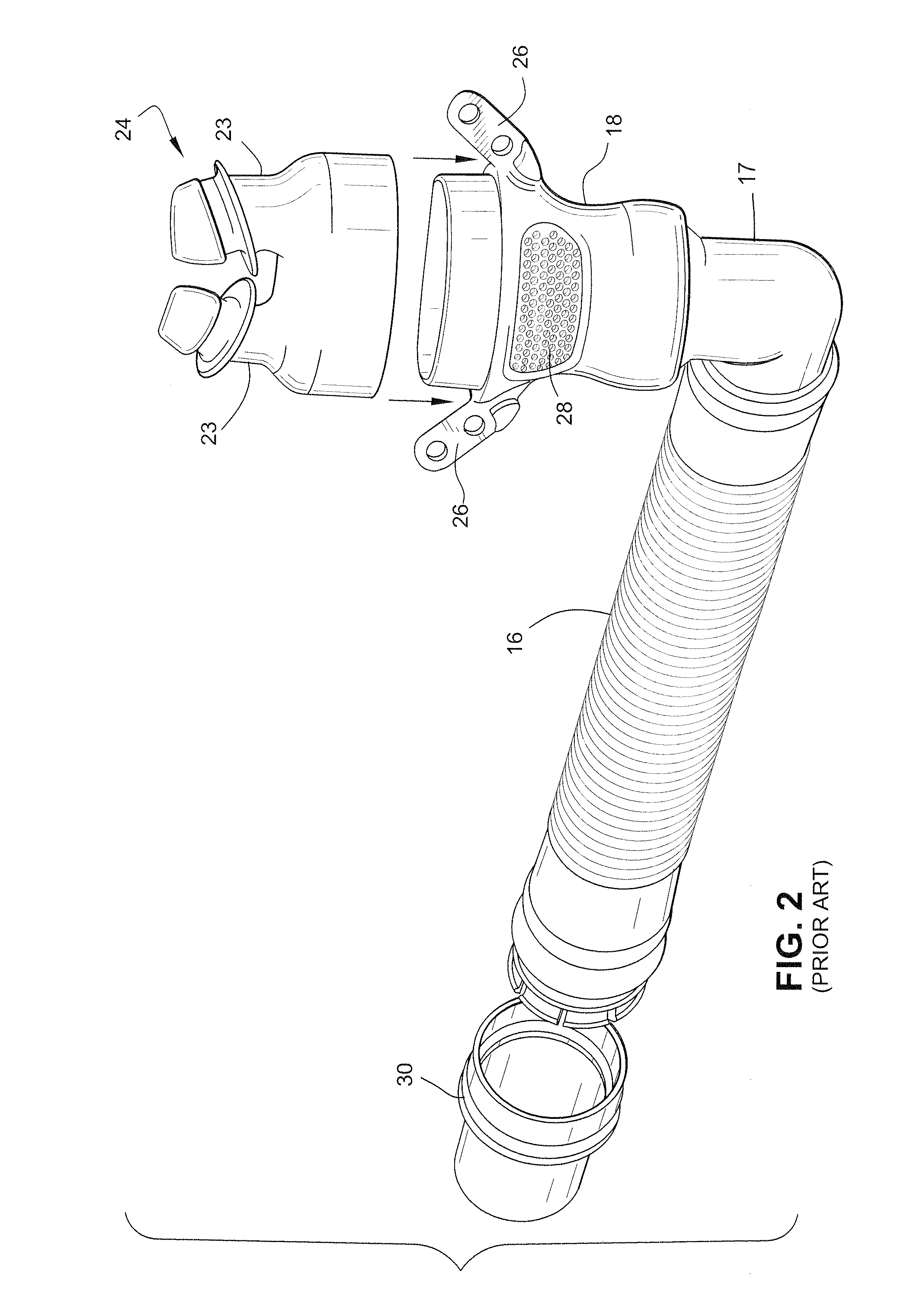

Patient interface systems

InactiveUS20100229868A1Improve manufacturabilityImprove usabilityButtonsBreathing masksEngineeringElbow joints

A headgear for positioning a patient interface structure for delivering a pressurized flow of breathable gas to the airways of a patient includes at least one flexible strap loop which is attachable to the patient interface structure by a forked region of the at least one strap loop that is mountable on the patient interface structure. The at least one strap loop positions the patient interface structure on the face of the patient. The forked region includes two forks adapted to be attached to an upper and lower portion on the patient interface structure. The two forks are connected by a bridge so that the forked region is divided into a first region and a second region, and the first region is mountable on the patient interface structure. An elbow for a patient interface system for delivering a flow of breathable gas to a patient includes a first portion having a first end configured to be connected to the patient interface system; and a second portion having a second end configured to be connected to a tube that delivers the flow of breathable gas. An outer circumferential wall includes a plurality of perpendicular steps formed therein and a plurality of vent holes are provided perpendicular to the plurality of perpendicular steps.

Owner:RESMED LTD

Apertured material for use in absorbent articles and method of making the same

Owner:TREDEGAR FILM PROD CORP

Method of manufacturing a perforated laminate

InactiveUS6190602B1Low costEasy to implementButtonsCylinder headsMaterial PerforationBiomedical engineering

Owner:AZTEX

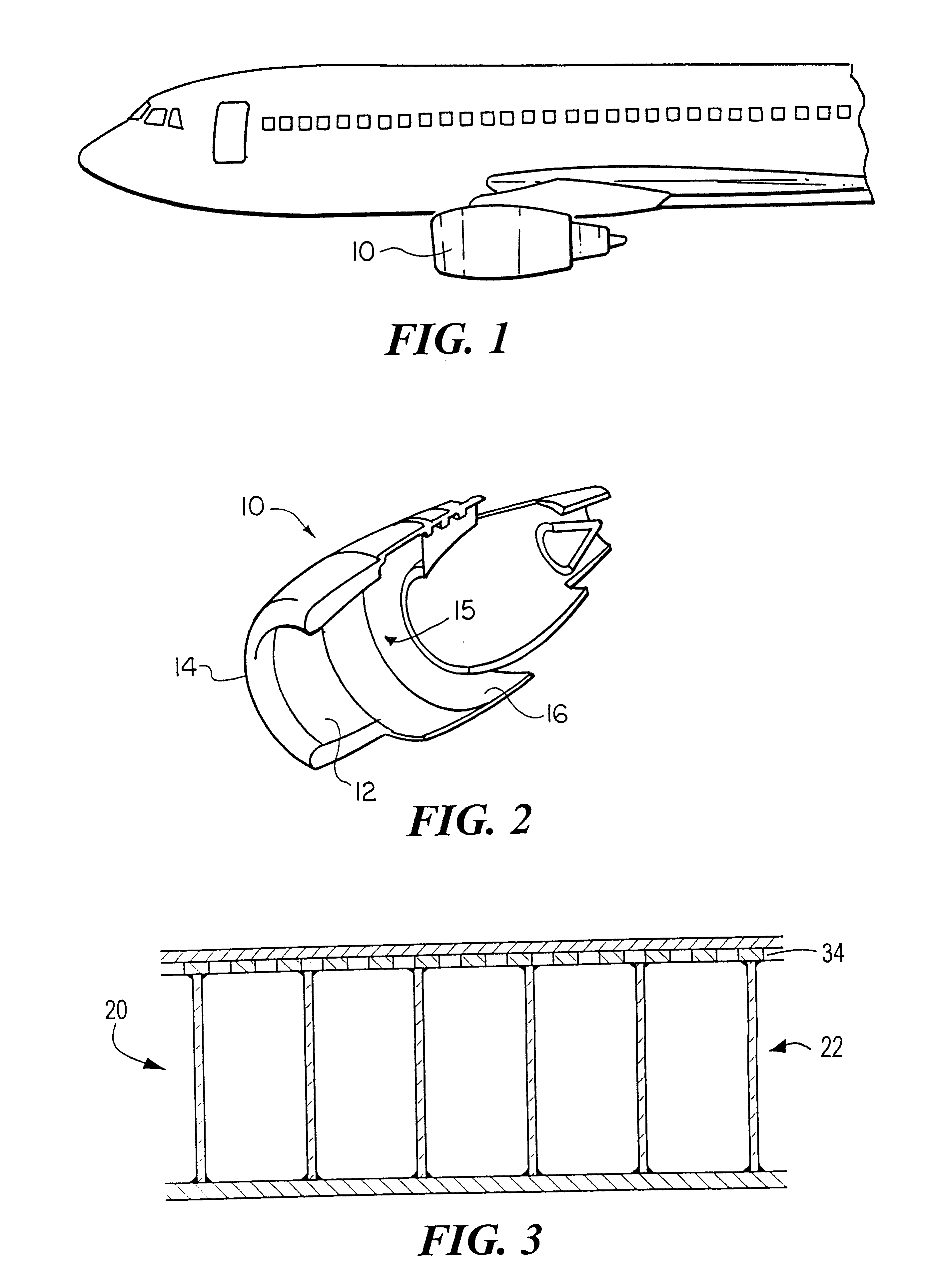

Ceramic exhaust filter

InactiveUS6946013B2Low thermal expansionLarge specific surface areaMaterial nanotechnologyCombination devicesFiberParticulates

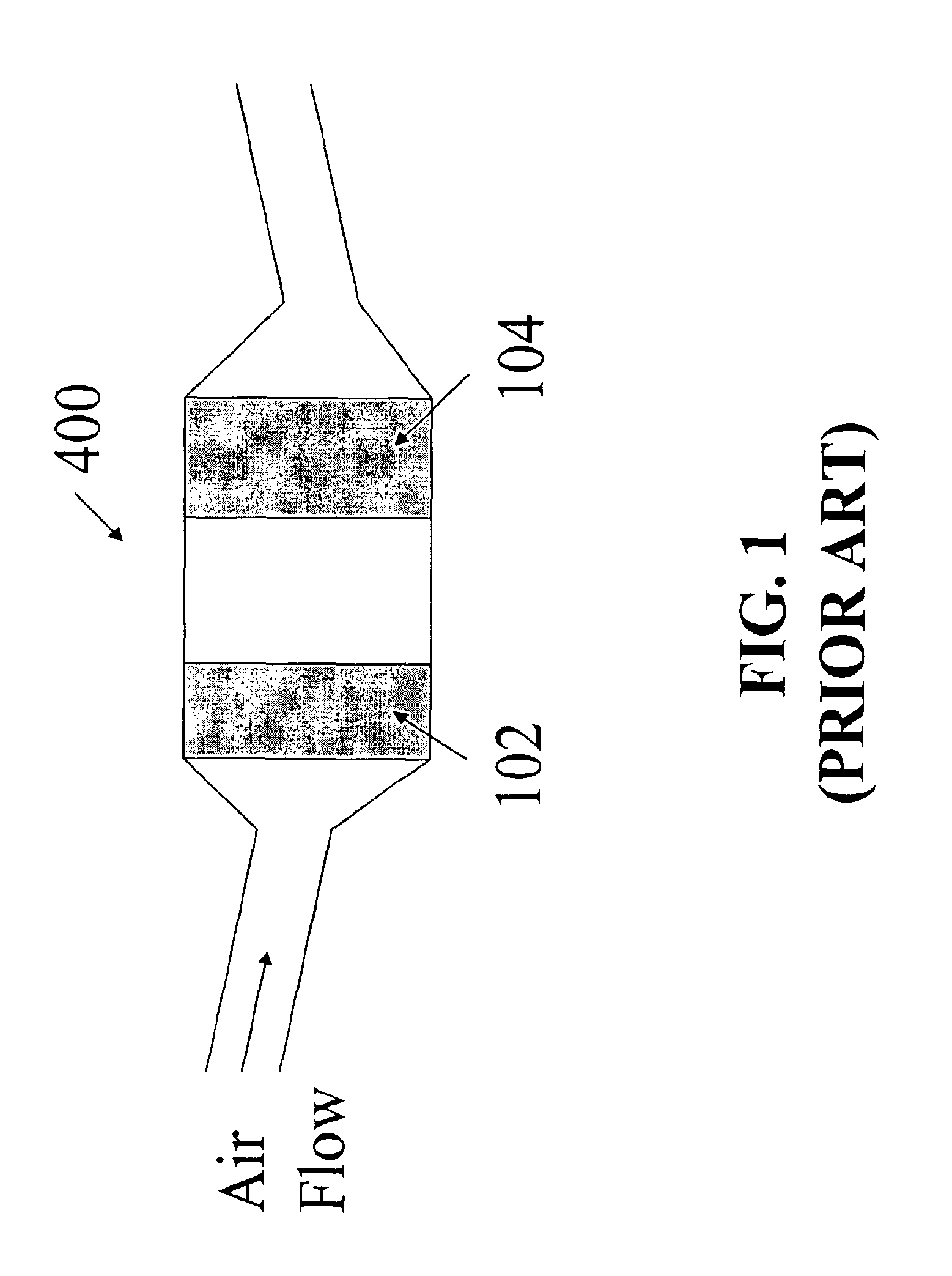

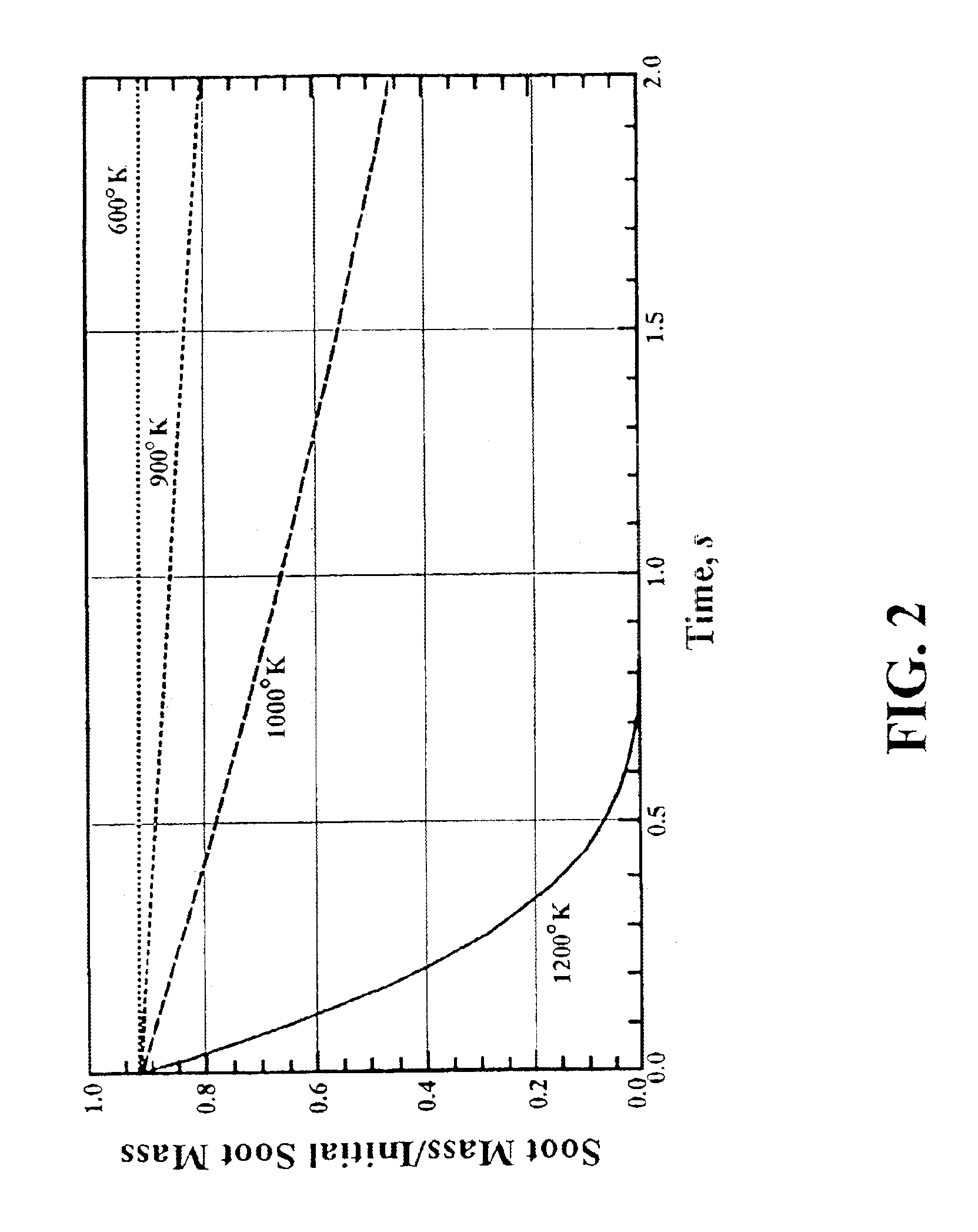

An improved, efficient, and regenerable exhaust emission filter and filter system are provided which incorporate the use of an inorganic, non-woven fiber filter element. The filter is able to capture exhaust pollutants and particulates through the interwoven nature of the filter element and due to area enhancements applied to the filter element including microscopic enhancements. The filter has an improved life and is able to combust a greater percentage of trapped particulates due to the high temperatures the filter element can withstand. The filter element if formed from a non-woven fiber block which is machined or shaped into a filter foundation. The filter element can have a multitude of coatings and catalysts applied and can be wrapped in insulation and a casing. The improved exhaust emission filter is particularly useful for diesel engine exhausts.

Owner:GE02 TECH INC

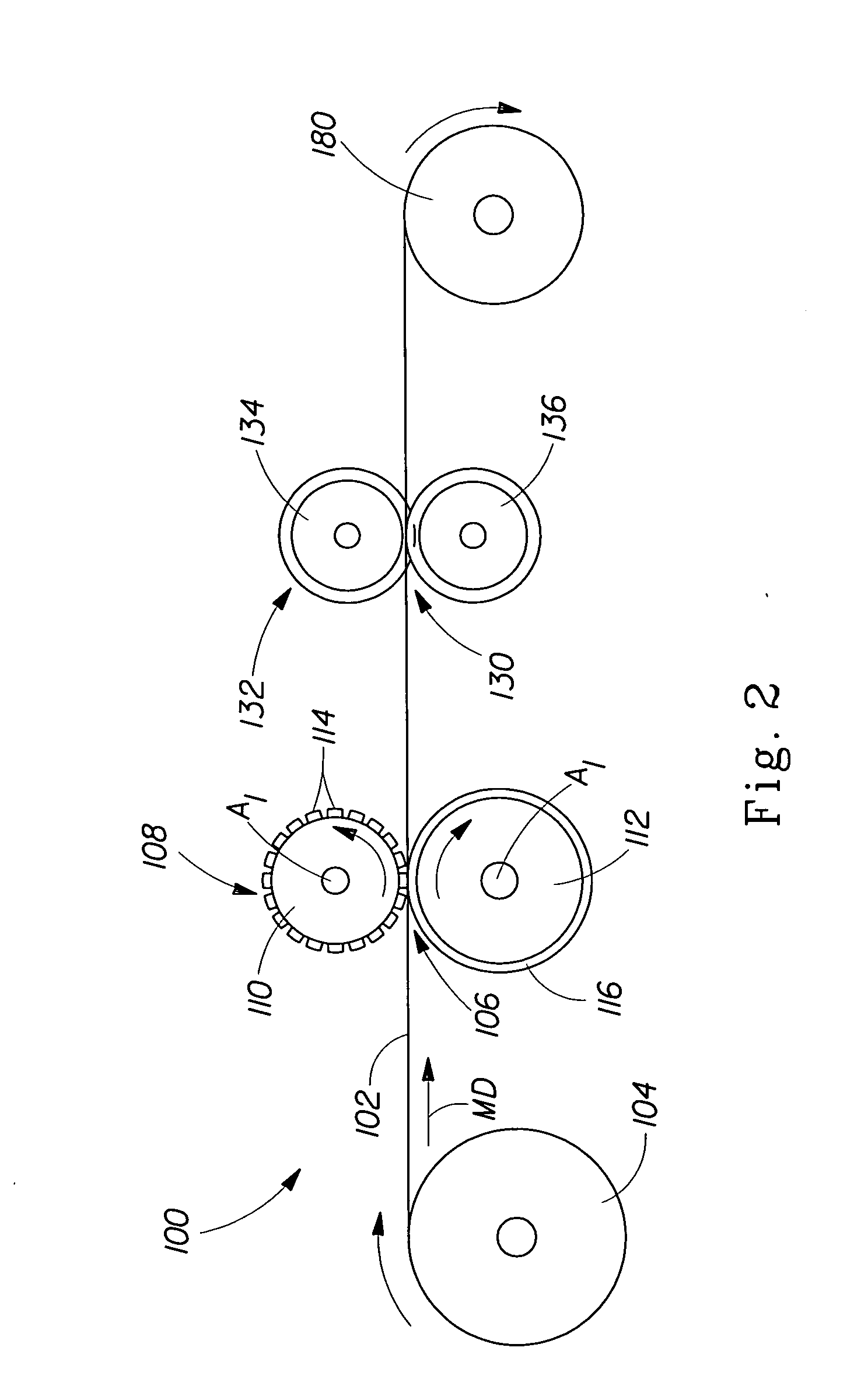

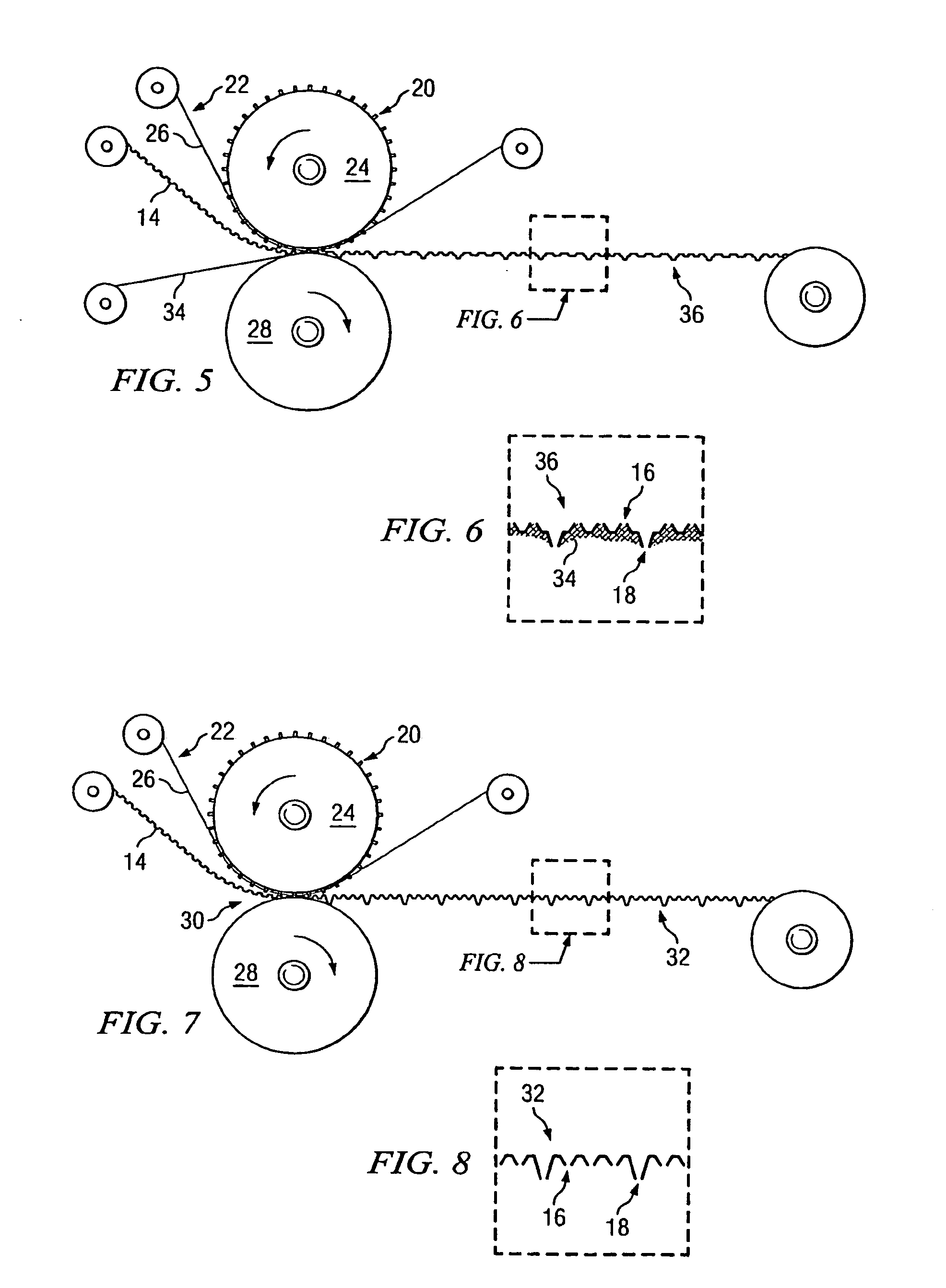

Apparatus and process for aperturing and stretching a web

Apparatuses and processes for aperturing and stretching a web are disclosed. In one embodiment, the method involves feeding a web into a nip that is formed between at least one pair of intermeshing rolls. The first roll is a raised ridge rotary knife aperturing roll and the second roll is a ring roll; both rolls comprise ridges and grooves. The first roll comprises a plurality of spaced-apart teeth extending outwardly from the top surface of the ridges, said teeth having tips, wherein the top surface of said ridges are disposed between the tips of said teeth and the bottom surface of said grooves. These apparatuses and processes enable a web to be formed which comprises apertures having greater open area than previously achievable with traditional processes and apparatuses.

Owner:THE PROCTER & GAMBLE COMPANY

Method of forming a mold and molding a micro-device

A method of forming a device including a plurality of micron or sub-micron sized features is provided. A master having a surface contour defining a plurality of features is provided. The surface contour of the master is coated with at least one layer of material to form a shell. The master is removed from the shell to form a negative image of the surface contour in the shell. The negative image in the shell is filled with material, for example, polycarbonate, polyacrylic, or polystyrene, to form a device having features substantially the same as the master. The negative image may be filled using injection molding, compression molding, embossing or any other compatible technique.

Owner:BECTON DICKINSON & CO

Apertured polymeric film webs and absorbent articles using such webs

A method for making an apertured polymeric film web, the method comprising the steps of:a. providing a polymeric film web;b. providing a first process selected from the group consisting of, hydroforming, vacuum forming, needle punching, mechanical embossing, flocking, ultrasonics, printed hair, brushing, and combinations thereof;c. providing a second process, different from the first process, the second process selected from the group consisting of, hydroforming, vacuum forming, needle punching, mechanical embossing, ultrasonics, stretch rupturing, hydrocutting, hydrosonics, slitting, ring-rolling, and combinations thereof;d. forming three dimensional surface structures in the polymeric film web by the first process; ande. forming fluid transport apertures in the polymeric film web by the second process.

Owner:THE PROCTER & GAMBLE COMPANY

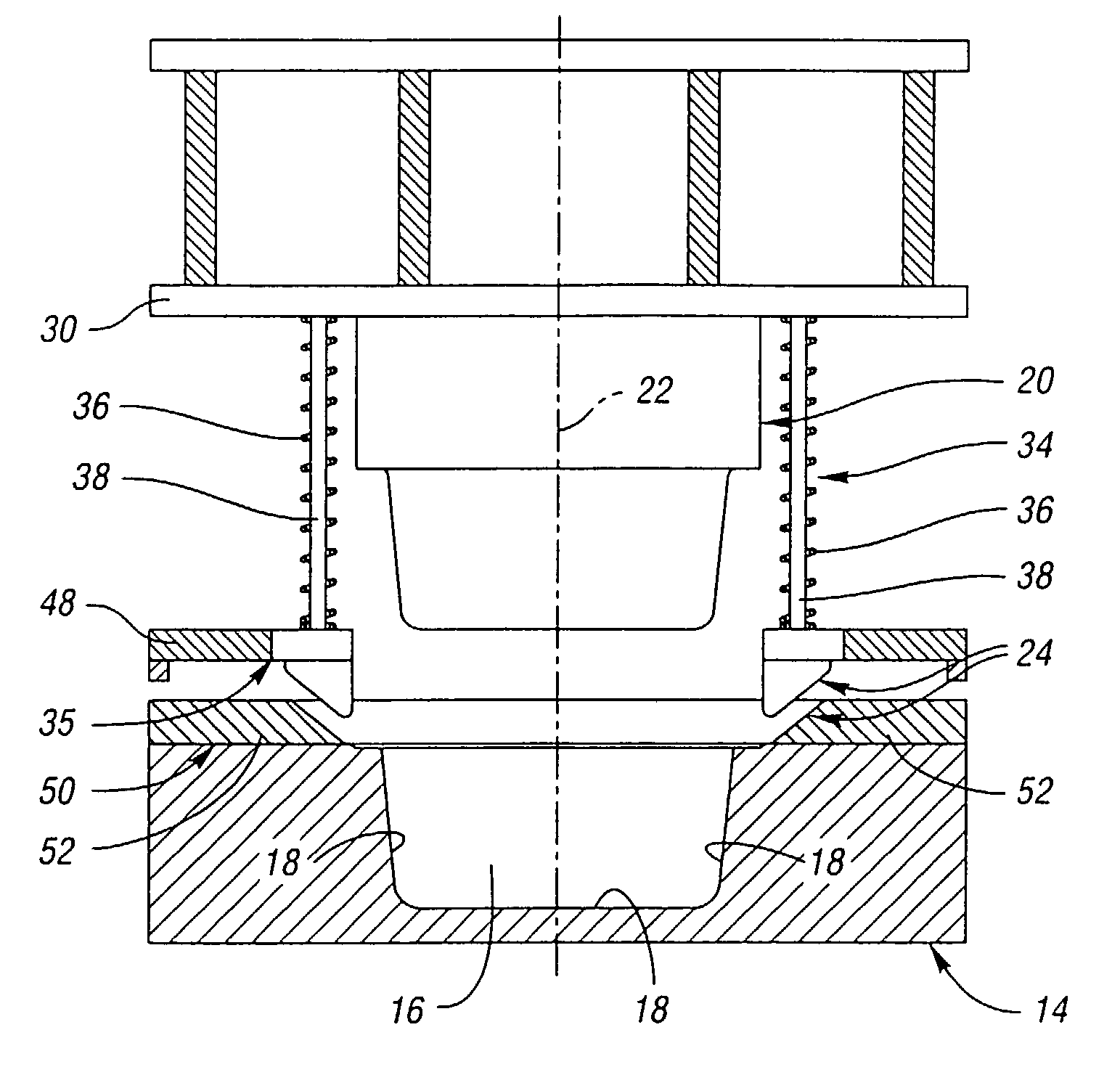

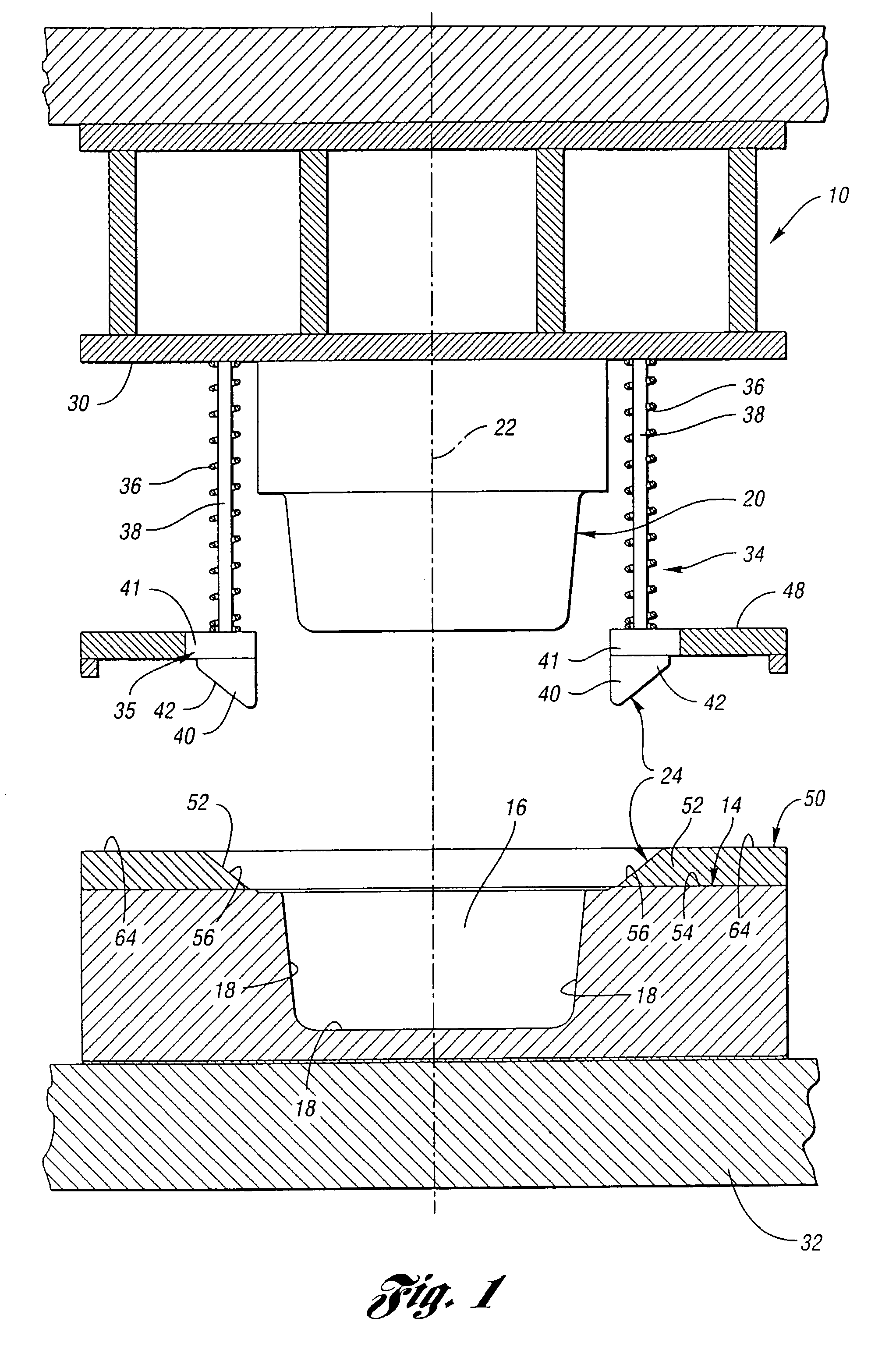

System for molding thermoplastic sandwich material and deep-drawn article produced thereby

A method and system for molding thermoplastic sandwich material to form a deep-drawn article utilizing a unique clamping technique and mechanism are described. The method includes the steps of positioning a blank of thermoplastic sandwich material having a cellular core over a female die having an article-defining cavity defined by inner surfaces of the female die. Then, an inner portion of the blank is forced into the female die along a substantially vertical axis and against the inner surfaces of the female die to obtain deep-drawn material. During the step of forcing at least one outer portion of the blank immediately adjacent the female die is clamped to guide the at least one outer portion of the blank to travel into the article-defining cavity at an acute angle with respect to the vertical axis. Thickness of at least one side wall of the deep-drawn material is substantially the same as thickness of the blank of thermoplastic sandwich material. The deep-drawn material does not significantly stretch or tear during the step of forcing due to the clamping technique and mechanism.

Owner:GLOBAL IP HLDG

Apertured material for use in absorbent articles

A method of thermo-mechanically forming macrotextures in a microtextured film wherein a heat shield is utilized to thermally insulate the microtexture during the forming process.

Owner:JOSEPH TESSARI

Polishing pad

ActiveUS20090253353A1High precision optical detectionPrevent leakageButtonsSpecial ornamental structuresIn planeSlurry

It is an object of the invention to provide a polishing pad capable of high precision optical detection of an endpoint during polishing in progress and prevention of slurry leakage from between a polishing region and a light-transmitting region during the use thereof even after the polishing pad has been used for a long period. It is a second object of the invention to provide a polishing pad capable of suppression of deterioration of polishing characteristics (such as in-plane uniformity) and generation of scratches due to a difference in behavior of a polishing region and a light-transmitting region during polishing. It is a third object of the invention to provide a polishing pad having a polishing region and a light-transmitting region with a concentration of a specific metal equal to or lower than a specific value (threshold value).

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

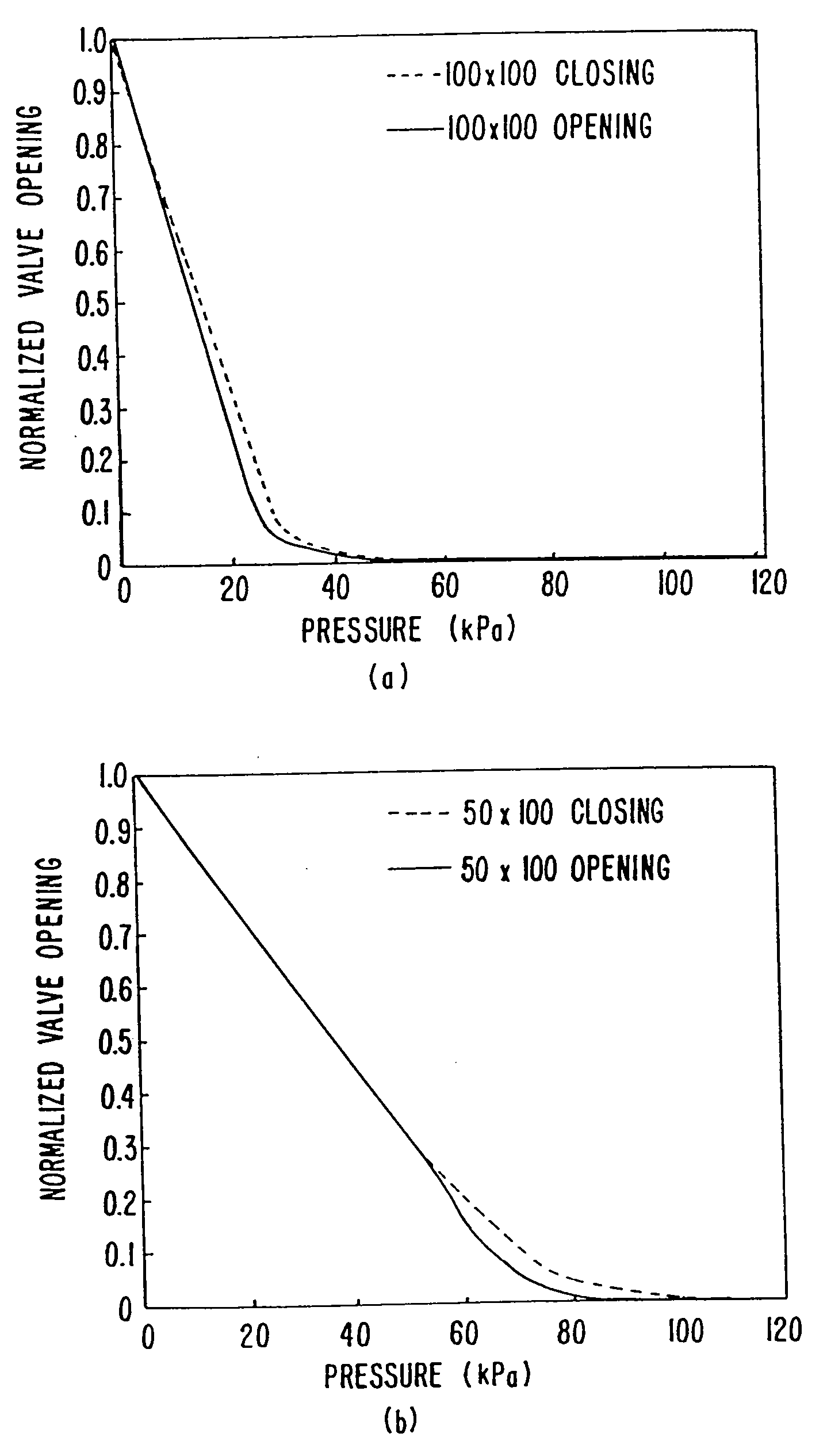

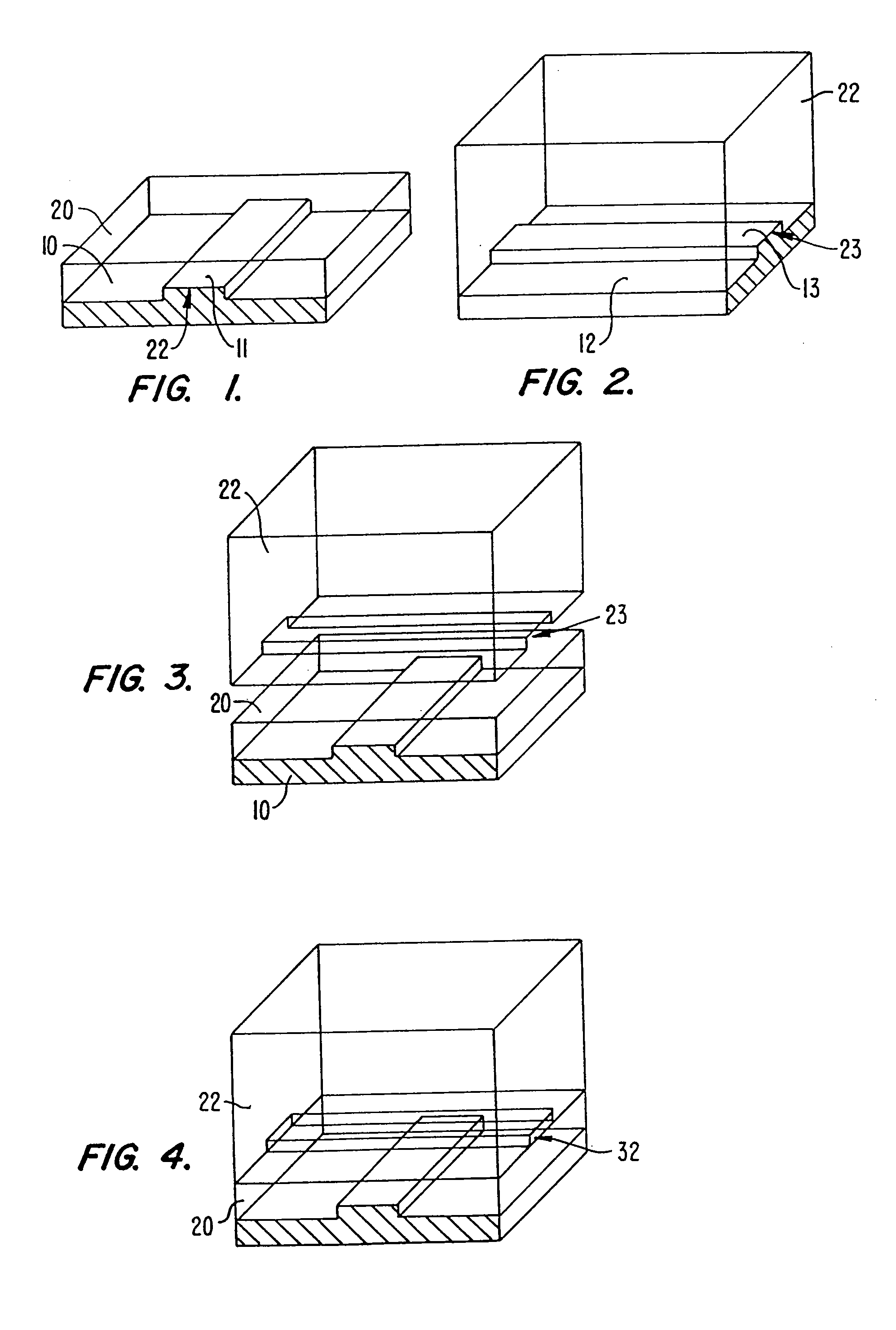

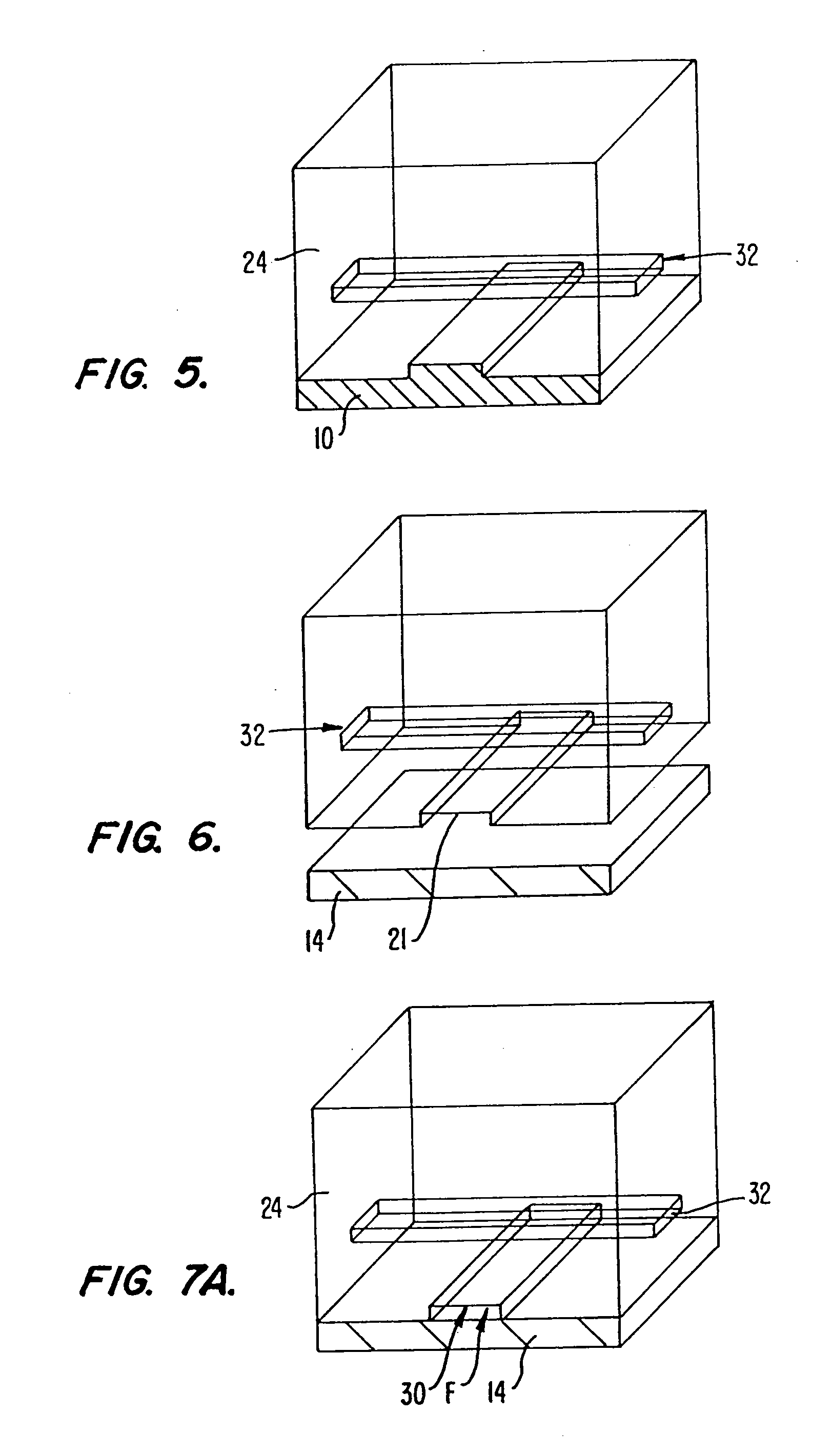

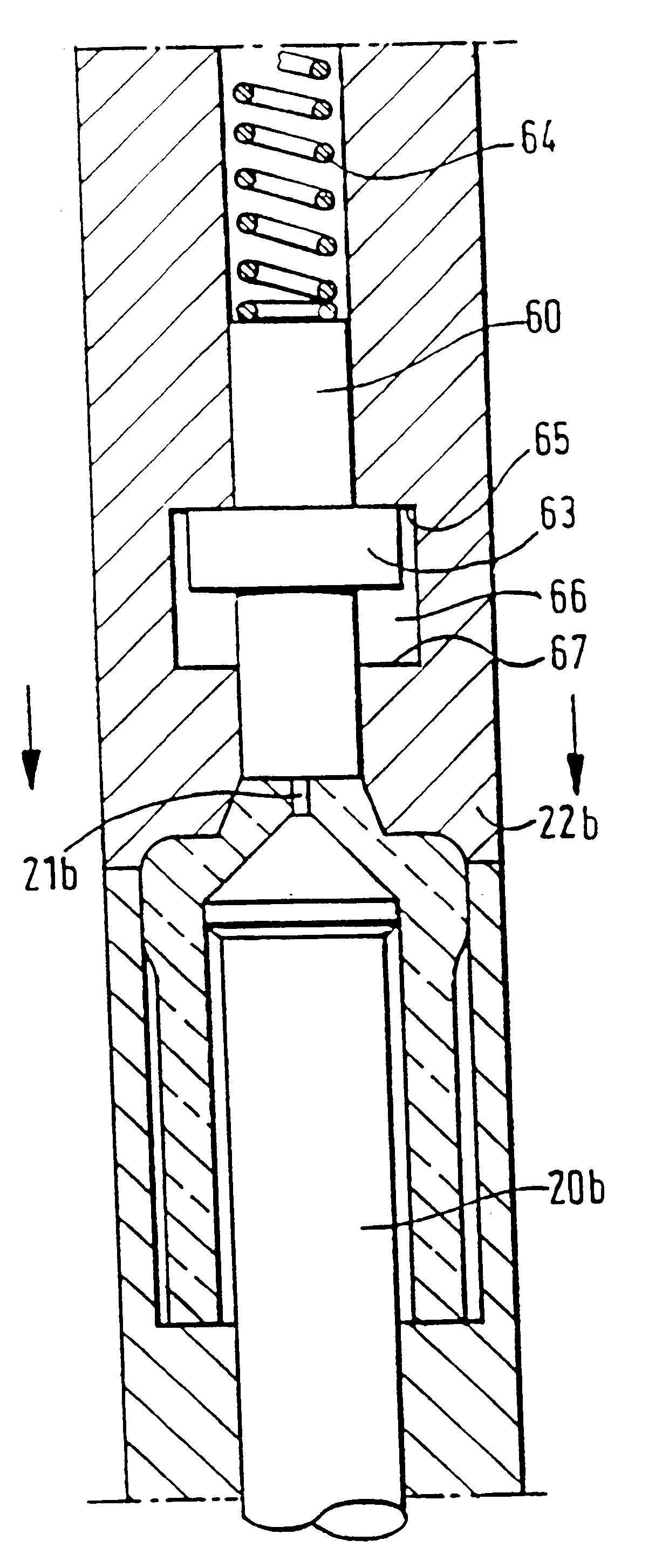

Microfabricated elastomeric valve and pump systems

InactiveUS20080289710A1Increase speedSmall sizeButtonsServomotor componentsElastomerPlanar substrate

A method of fabricating an elastomeric structure, comprising: forming a first elastomeric layer on top of a first micromachined mold, the first micromachined mold having a first raised protrusion which forms a first recess extending along a bottom surface of the first elastomeric layer; forming a second elastomeric layer on top of a second micromachined mold, the second micromachined mold having a second raised protrusion which forms a second recess extending along a bottom surface of the second elastomeric layer; bonding the bottom surface of the second elastomeric layer onto a top surface of the first elastomeric layer such that a control channel forms in the second recess between the first and second elastomeric layers; and positioning the first elastomeric layer on top of a planar substrate such that a flow channel forms in the first recess between the first elastomeric layer and the planar substrate.

Owner:CALIFORNIA INST OF TECH

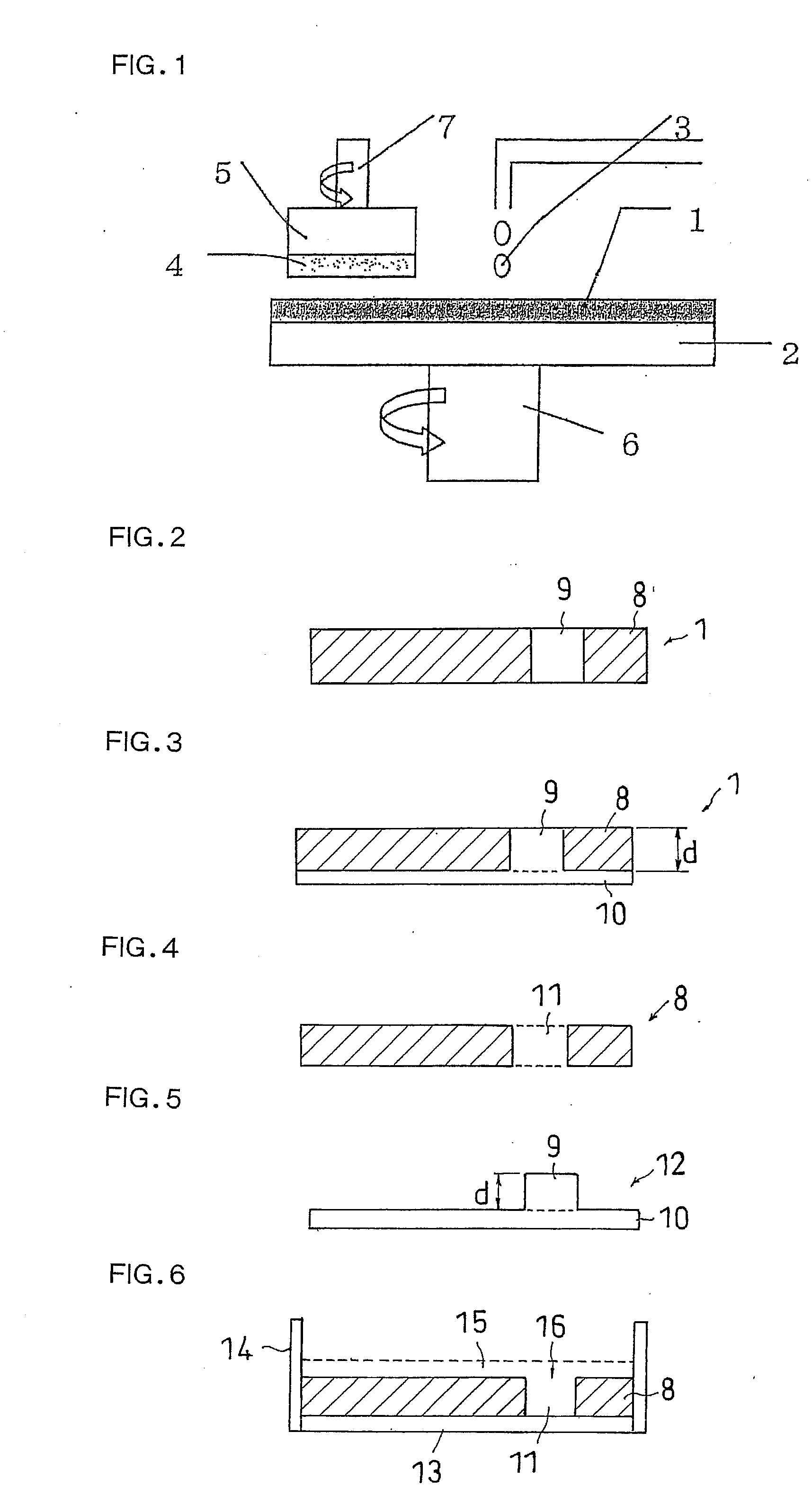

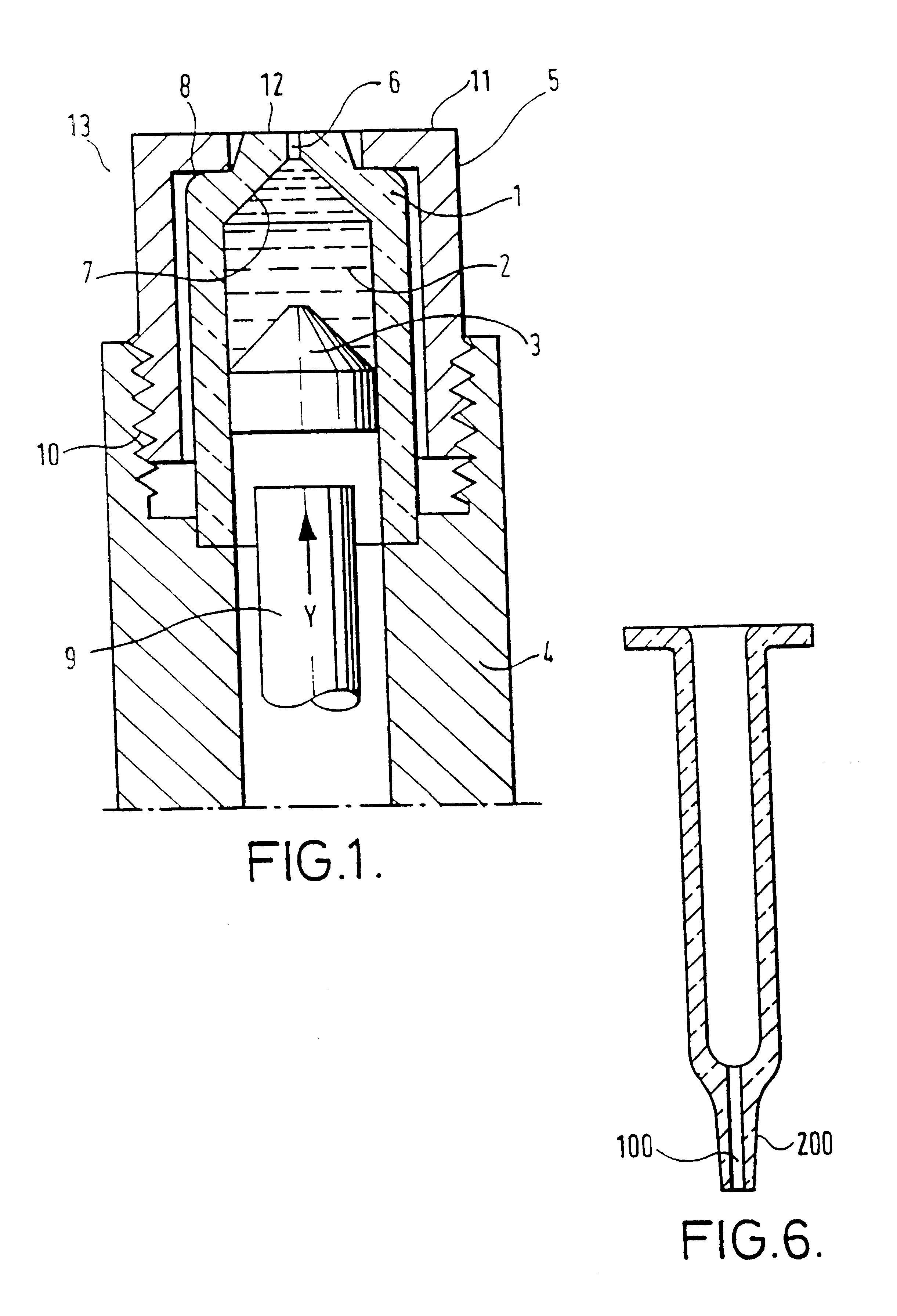

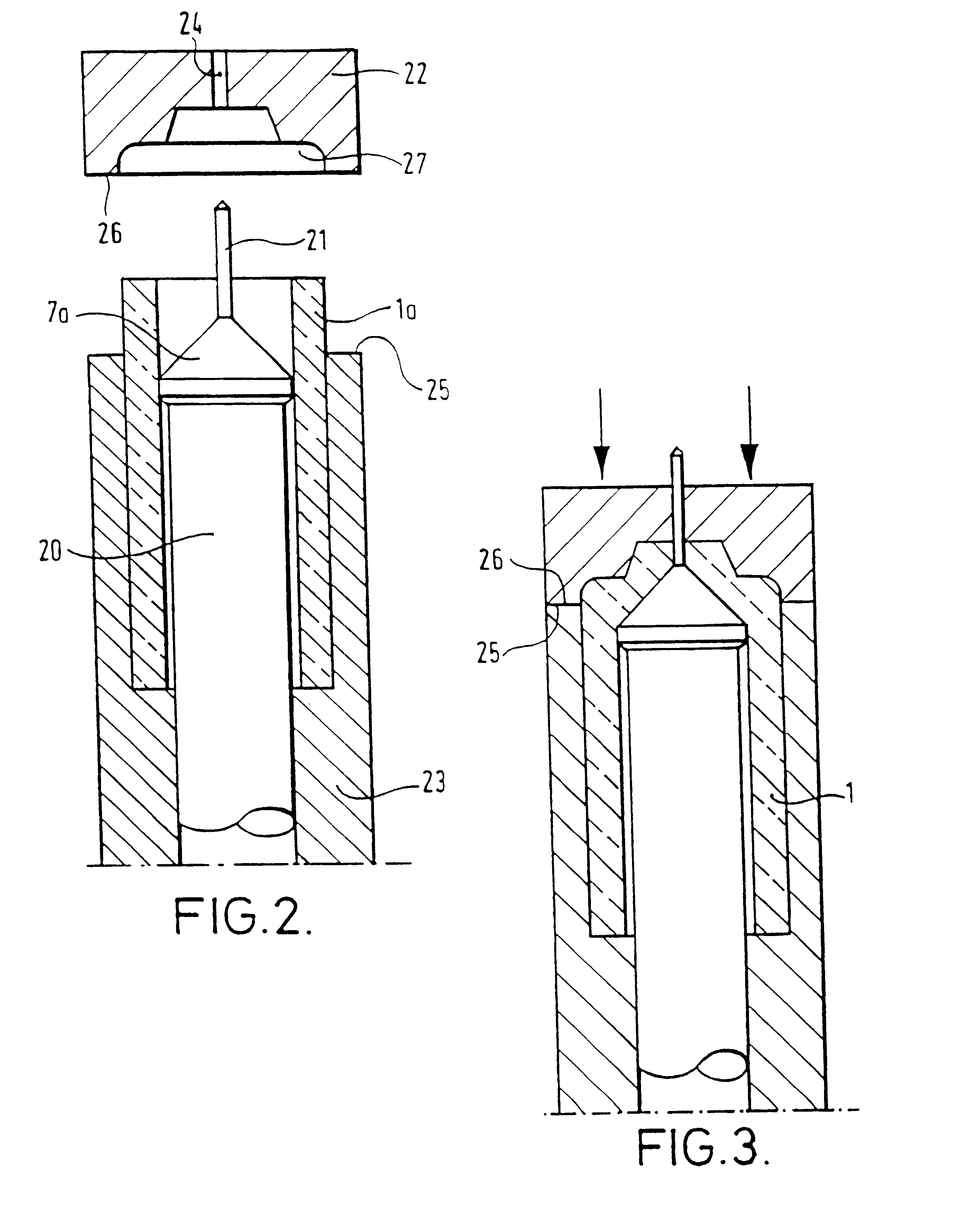

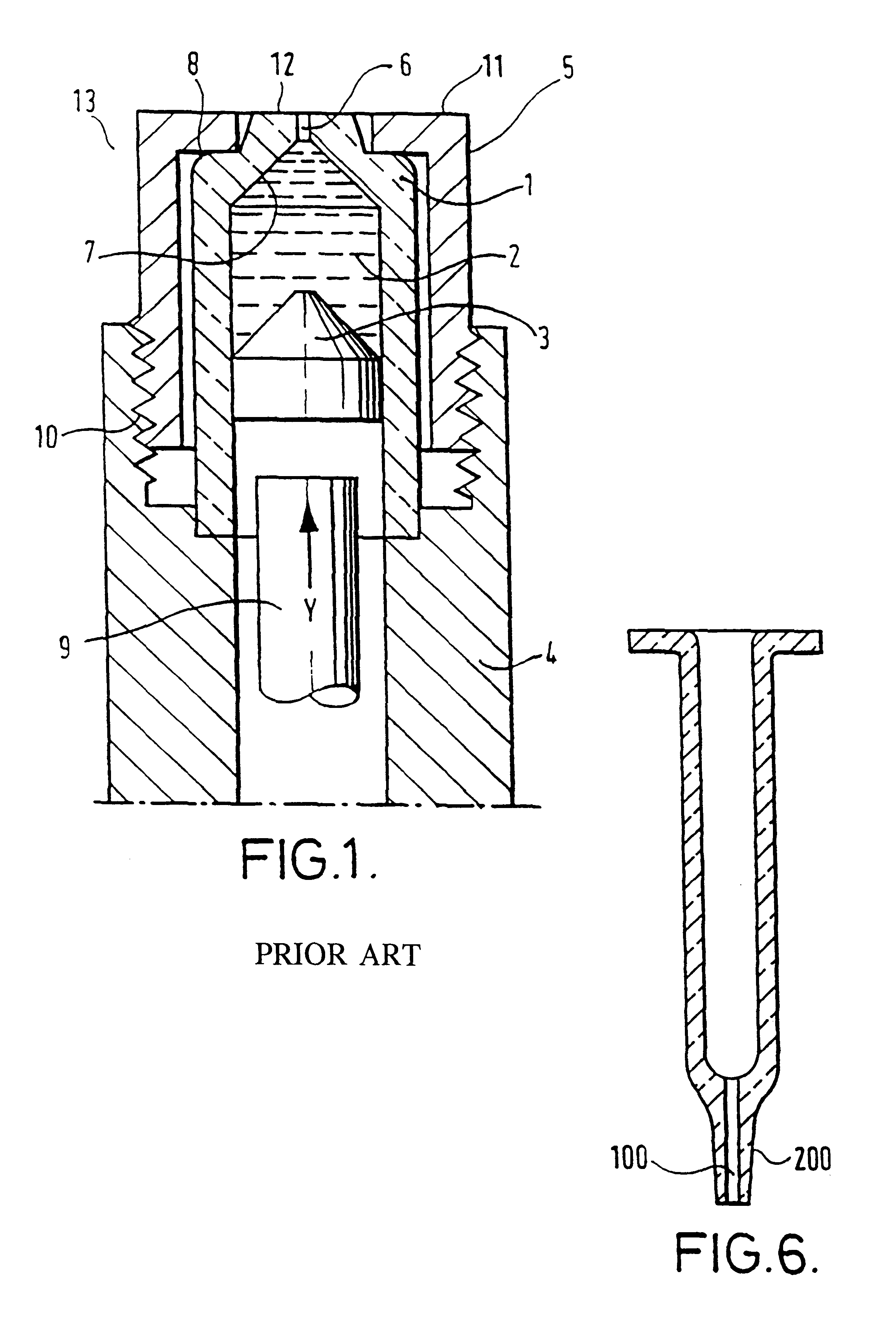

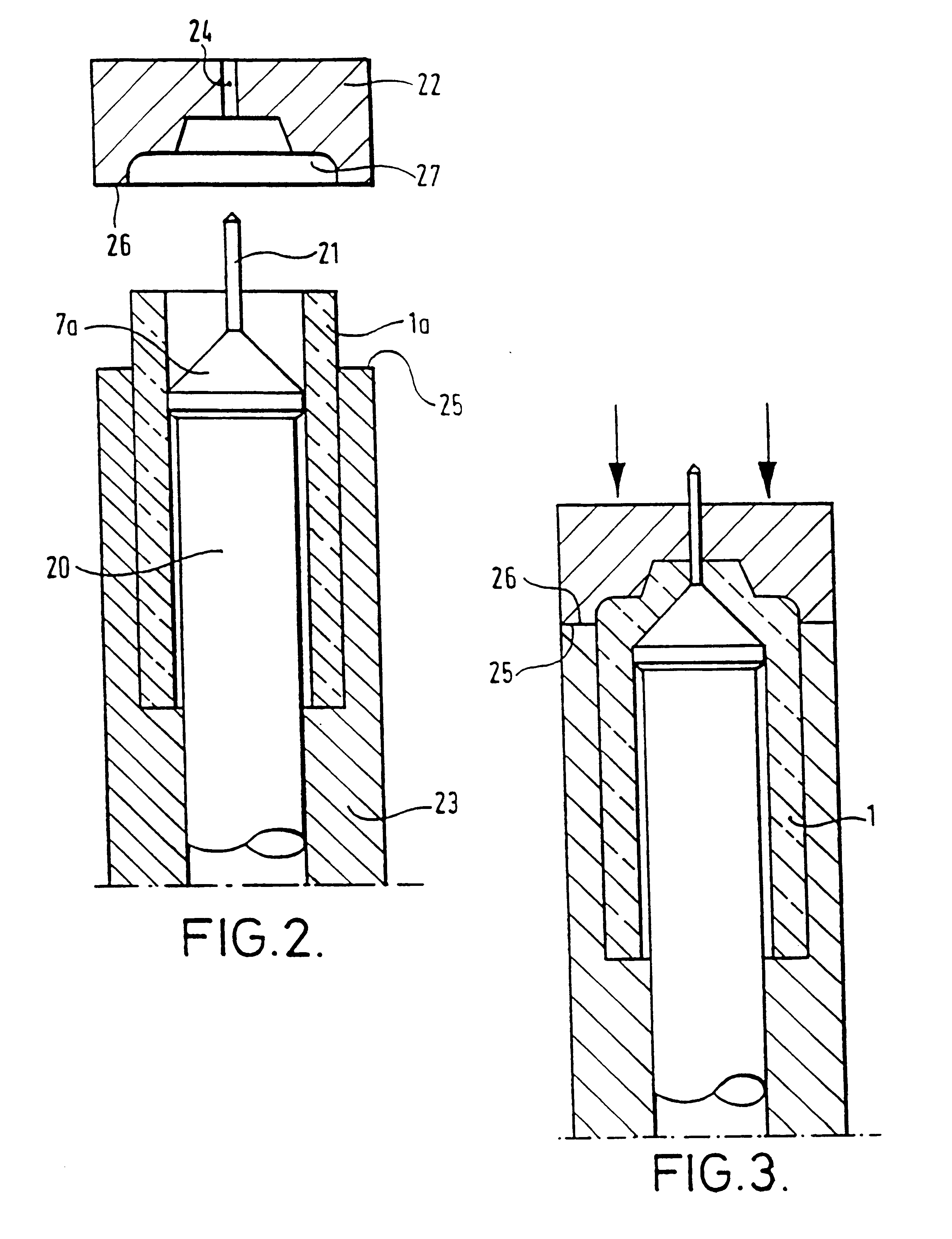

Method and apparatus for making an article from a formable material

InactiveUS6415631B1Good repeatabilityHigh speed productionButtonsAmpoule syringesEngineeringInjector

A method and apparatus are described for making an article such as the body of a needleless injector capsule, from a formable material, such as glass, the article having a cavity communicating with the exterior via an orifice. A blank having an open end is mounted on a first forming tool, and the open end is engaged by a second forming tool while an end region of the blank adjacent the open end is in a condition to permit it to be formed. One of the tools has a pin extending therefrom, and when the tools are brought together to form the end region into the desired shape the pin defines the orifice.

Owner:ZOGENIX INC

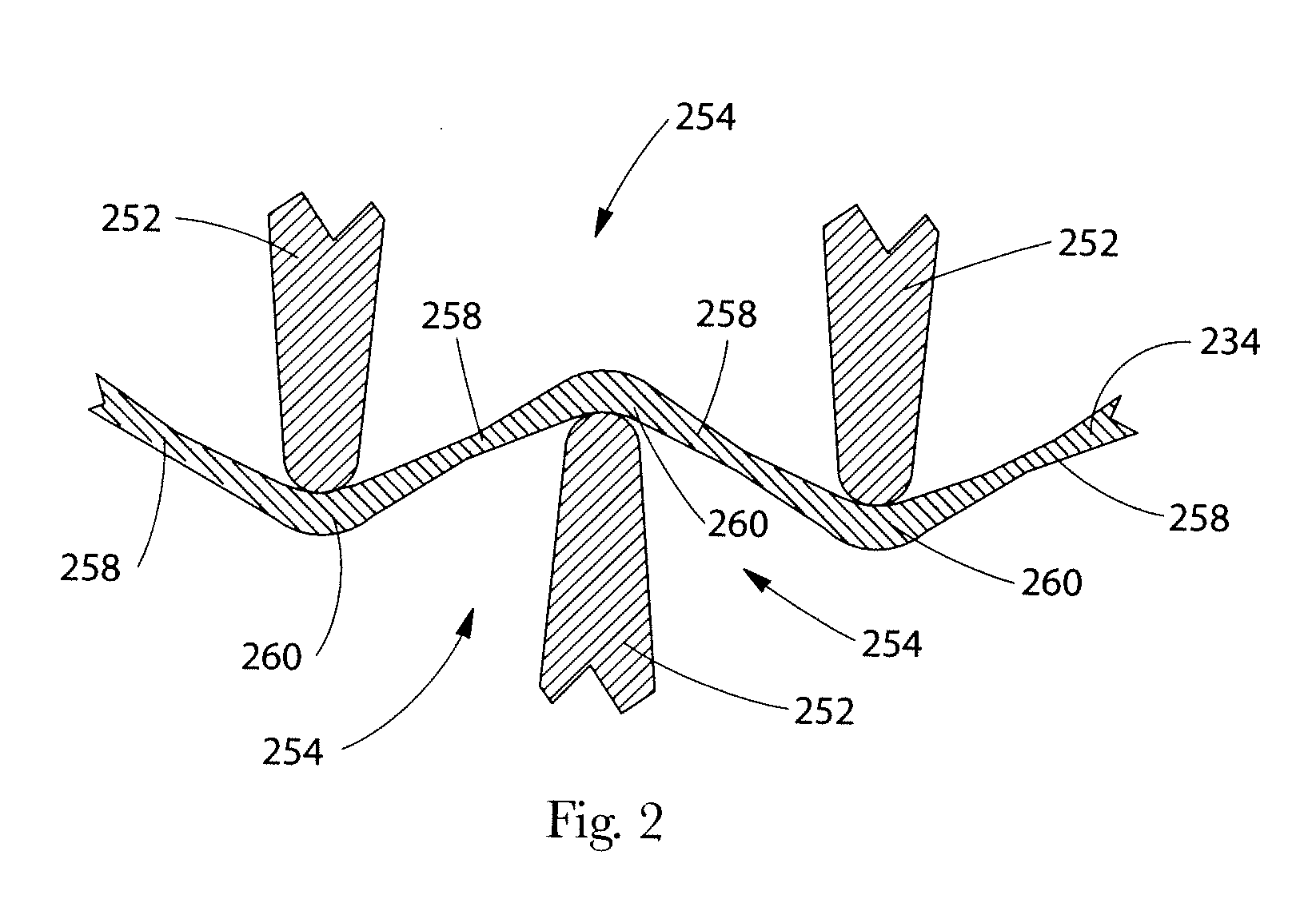

Method For Making An Elastomeric Apertured Web

A method for making an elastomeric apertured web comprises providing a precursor web comprising a laminate which is subjected to incremental stretching to form an elastomeric precursor web. A forming apparatus is provided comprising a first member and a second member, wherein the first member comprises a mating member, and the second member comprises teeth which are joined to the second member. The elastomeric precursor web is moved through the forming apparatus, wherein apertures are formed in the elastomeric precursor web material as the teeth on the second member penetrate the mating member forming an elastomeric apertured web. The elastomeric apertured web exhibits a WVTR of at least about 1000 g / m2 / day.

Owner:THE PROCTER & GAMBLE COMPANY

Method for producing buttons, ornamental and instrument panels with fine symbols, and a button produced with the method

ActiveUS7134205B2Exemption stepsEasy to viewButtonsLamination ancillary operationsFine lineEngraving

A button, knob or control key with an etchable support plate which is engraved on the backside with a fine symbol by laser, erosion or mechanical engraving, which only cuts into the material of the support plate, but not through the support plate. The backside of the support plate is optionally coated. A foil is applied on the laminated layer and affixed thereto. The front side of the support plate is treated with a material-removing substance. The material removal with the material-removing substance is performed until the engraving extending into the support plate is at least partially or completely exposed on the front side. Application of a protective layer to the front side of the support plate from which the material was removed. A function symbol is provided on the button such that it can be backlit. It is engraved in a fine line width providing a sharp optical definition erosion, mechanical engraving.

Owner:FAURECIA ANGELL DEMMEL

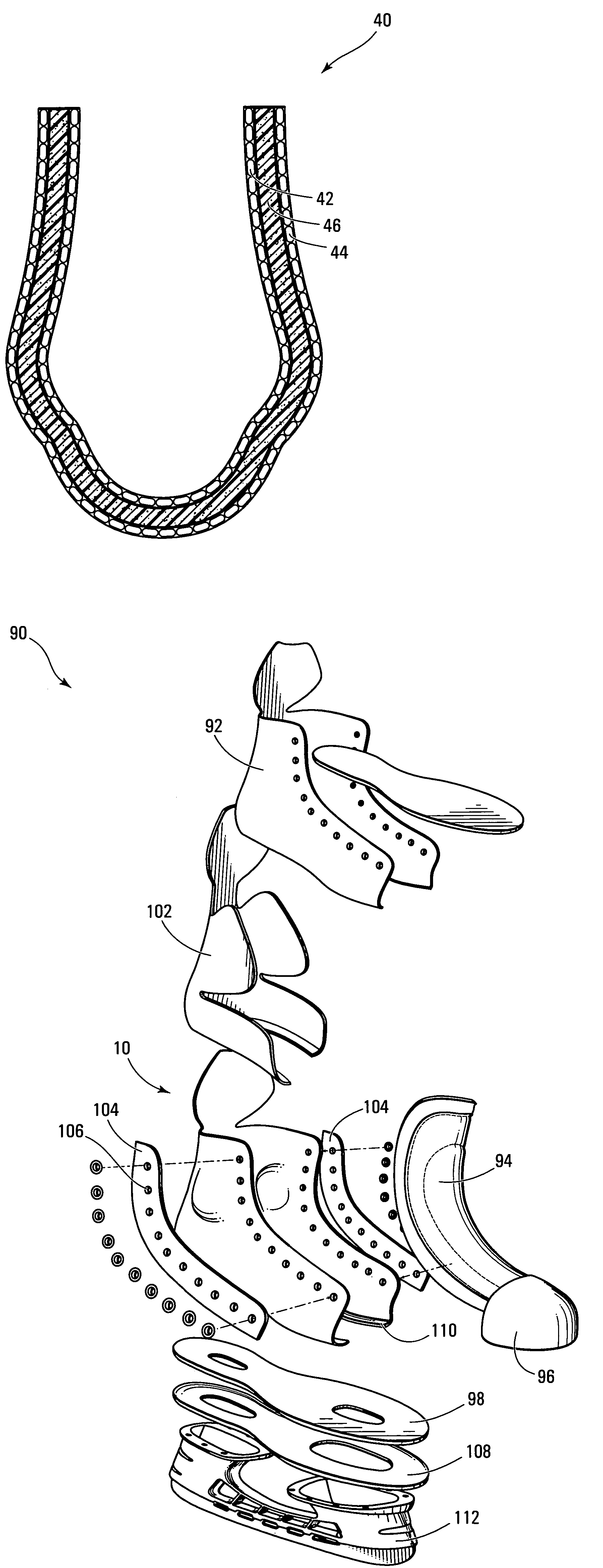

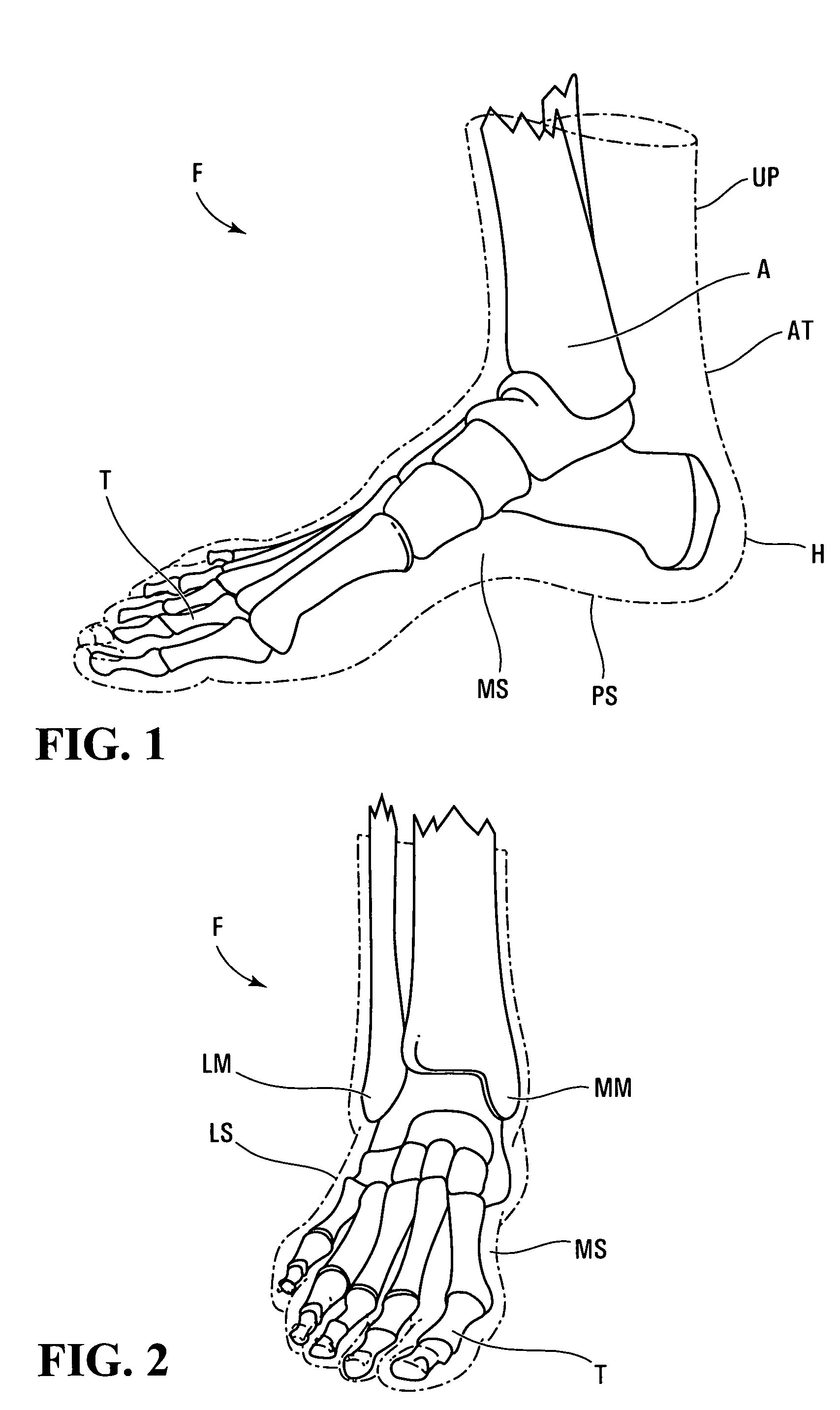

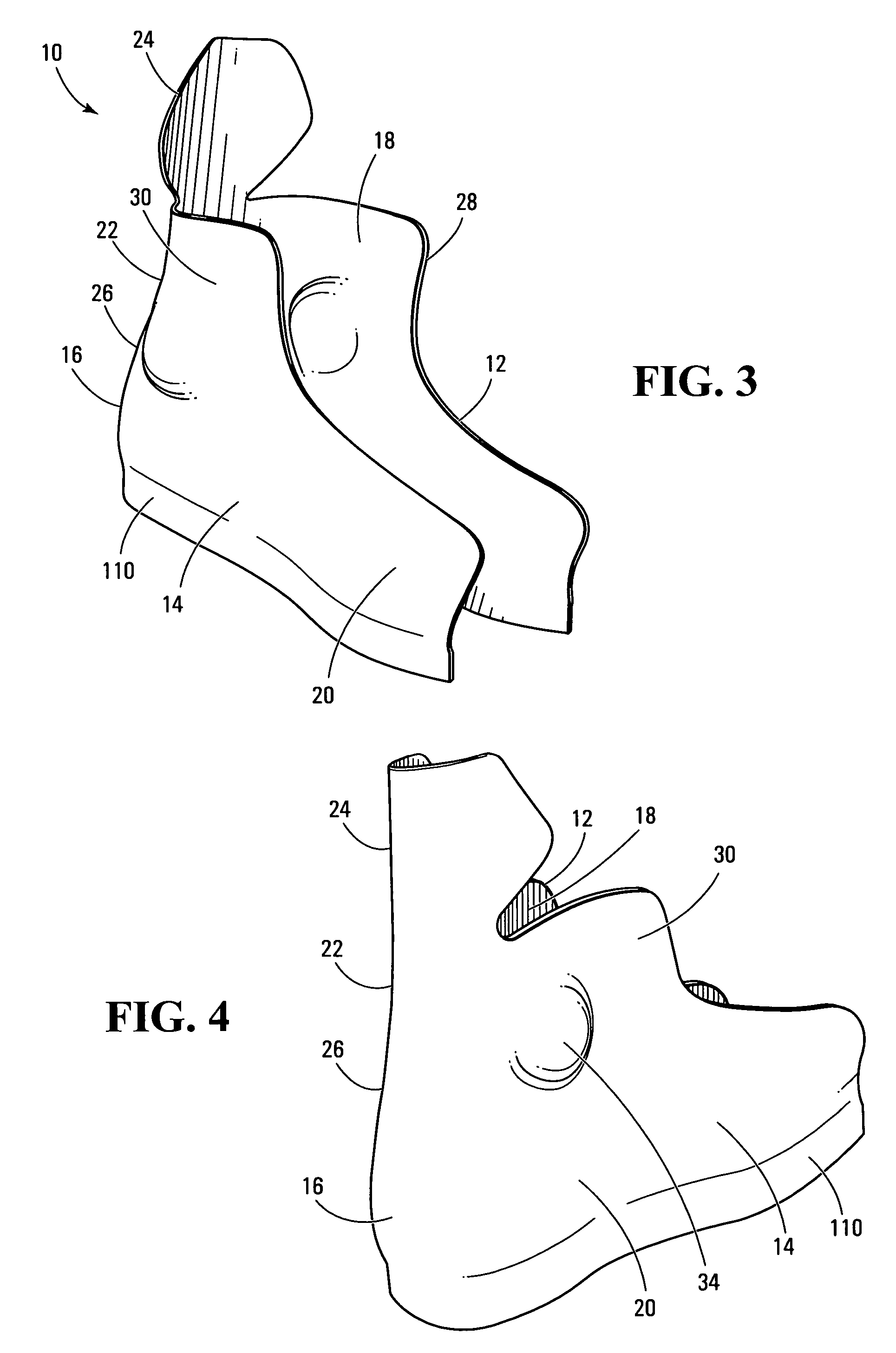

Footwear having an outer shell of foam

The invention relates to a lasted footwear for enclosing a human foot having a heel, an ankle and medial and lateral sides. The footwear comprises an outer shell for receiving the foot and an inner lining mounted in the outer shell. The inner lining is less rigid than the outer shell and has an inner surface adapted to contact the foot in use and an outer surface being affixed to the outer shell. The outer shell is made of a multi-layer composite sheet that is thermoformed for defining a foot-receiving cavity having a three-dimensional geometry that conforms to the foot. The multi-layer composite sheet has a first layer of thermoformable foam having a core and first and second opposite surfaces and a second layer of fibers. One of the first and second opposite surfaces of the layer of thermoformable foam has a skin formed by exposing the surface to temperatures between 200° F. and 300° F. The invention also relates to a method of making a lasted skate boot comprising such an outer shell.

Owner:BAUER HOCKEY LLC

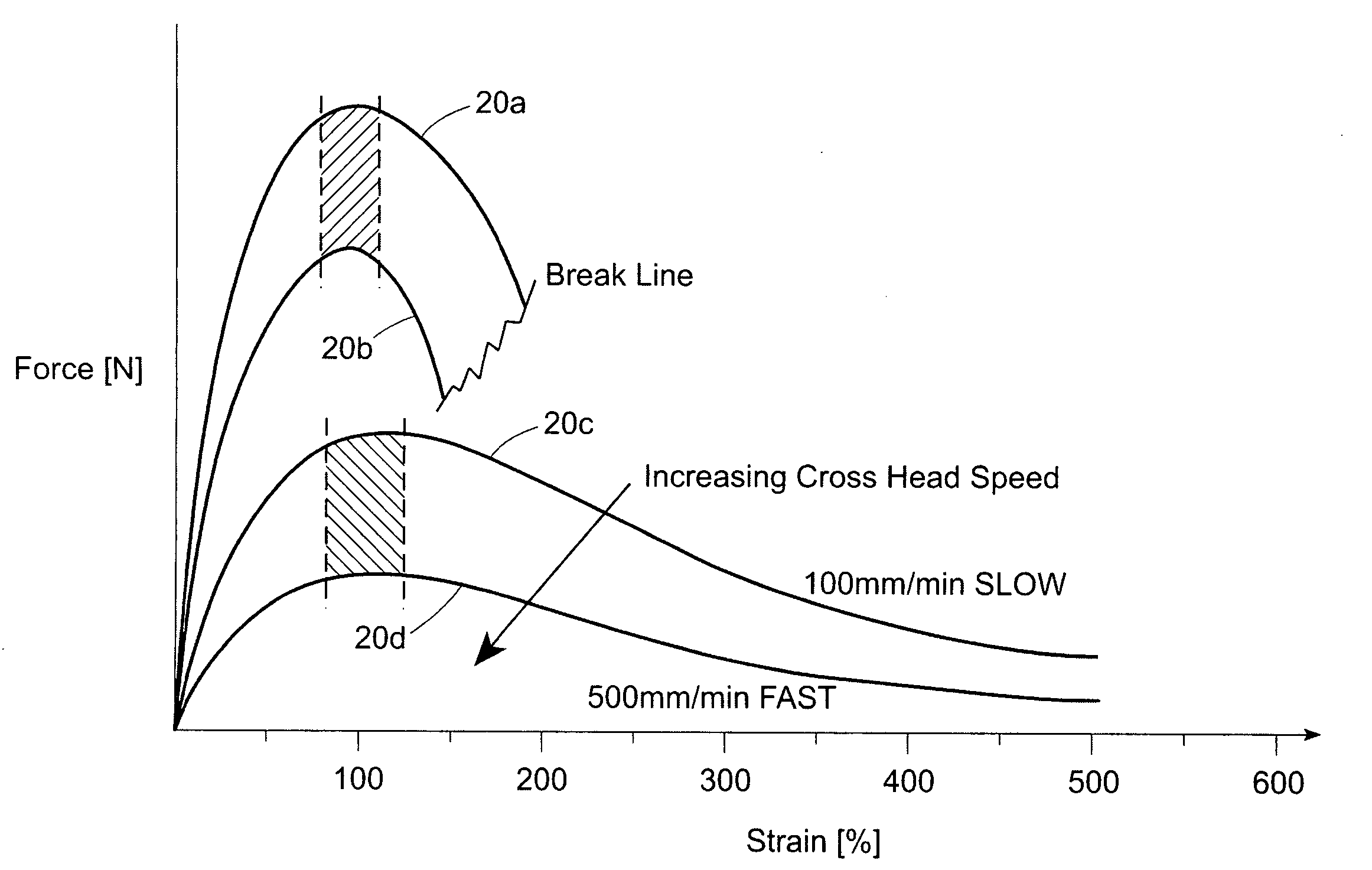

Plastically deformable nonwoven web

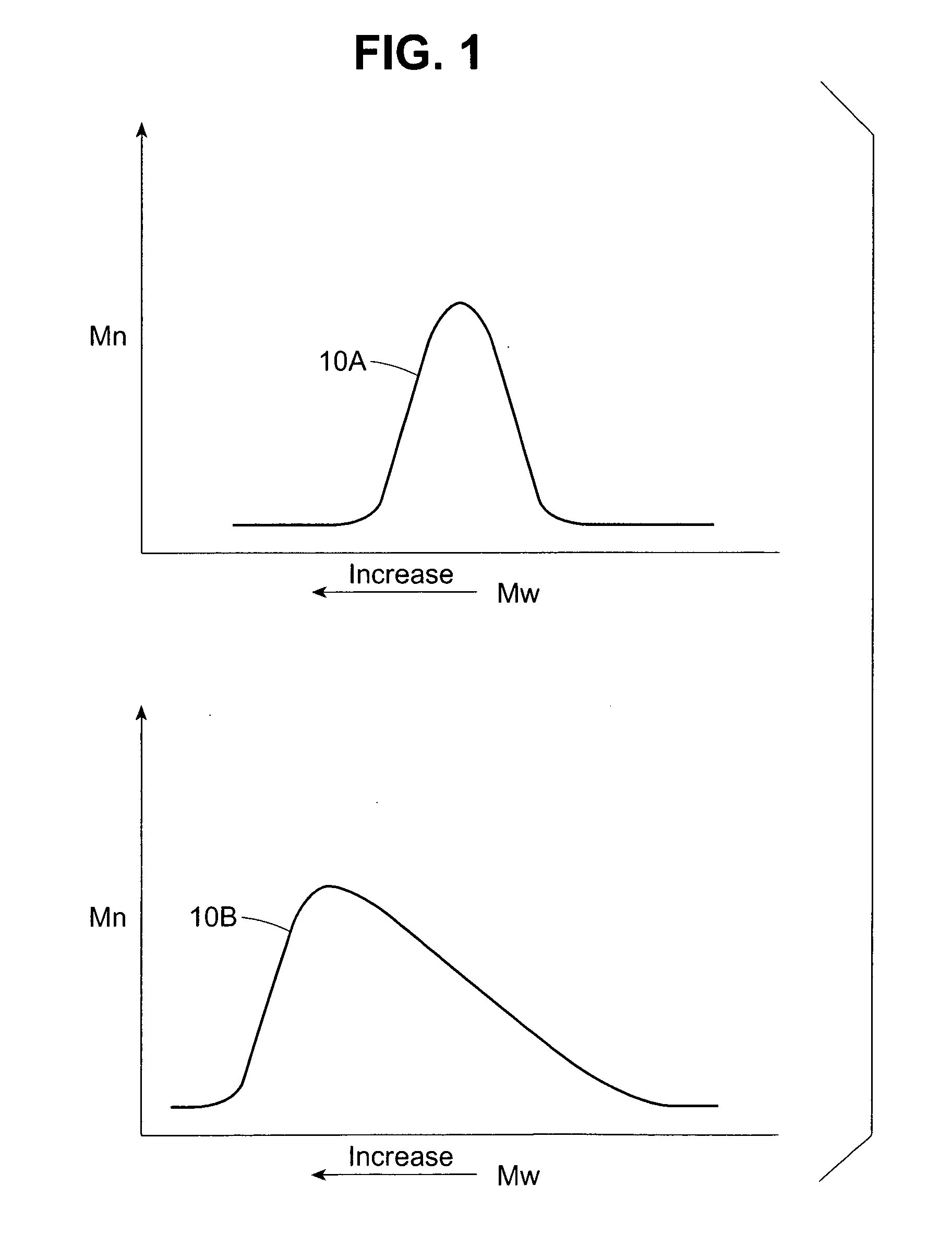

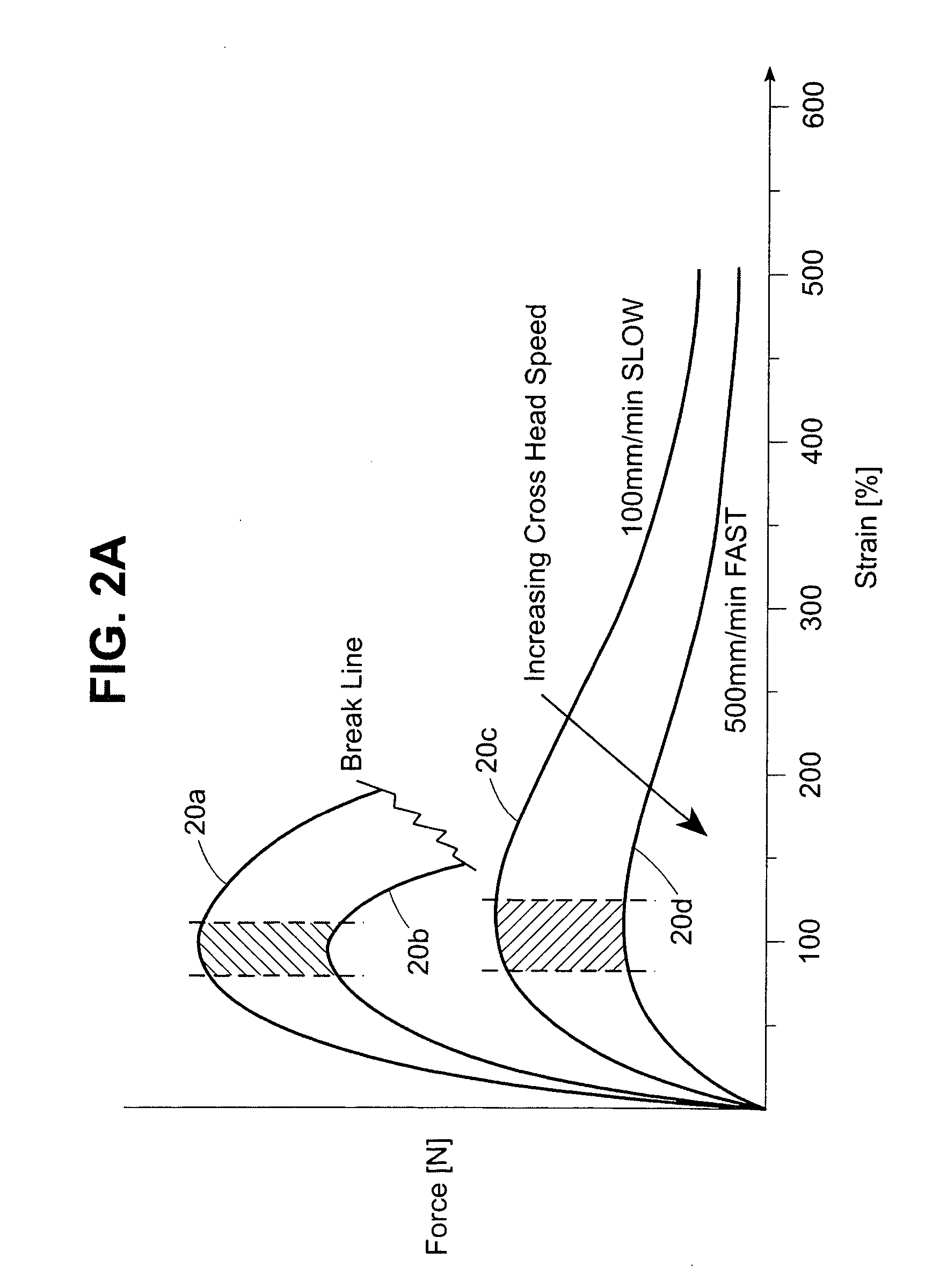

InactiveUS20050244619A1Structural extensibility of the web substantiallyButtonsDecorative surface effectsFiberEthylene Homopolymers

A nonwoven web formed of substantially continuous spunmelt fibers is formed from a homopolymer of polypropylene having a skewed molecular weight distribution and a polydispersity of less than 3.5. The web, when subjected to high speed incremental deformation, is plastically deformed and characterized by, e.g., a tensile strength at 400% elongation which is at least 10% of the peak tensile strength, a tensile strength at 250% elongation which is at least 40% of the peak tensile strength, and a ratio of the viscoelastic deformation energy after the peak tensile strength to the viscoelastic deformation energy before the peak tensile strength which is greater than one.

Owner:FIRST QUALITY NONWOVENS

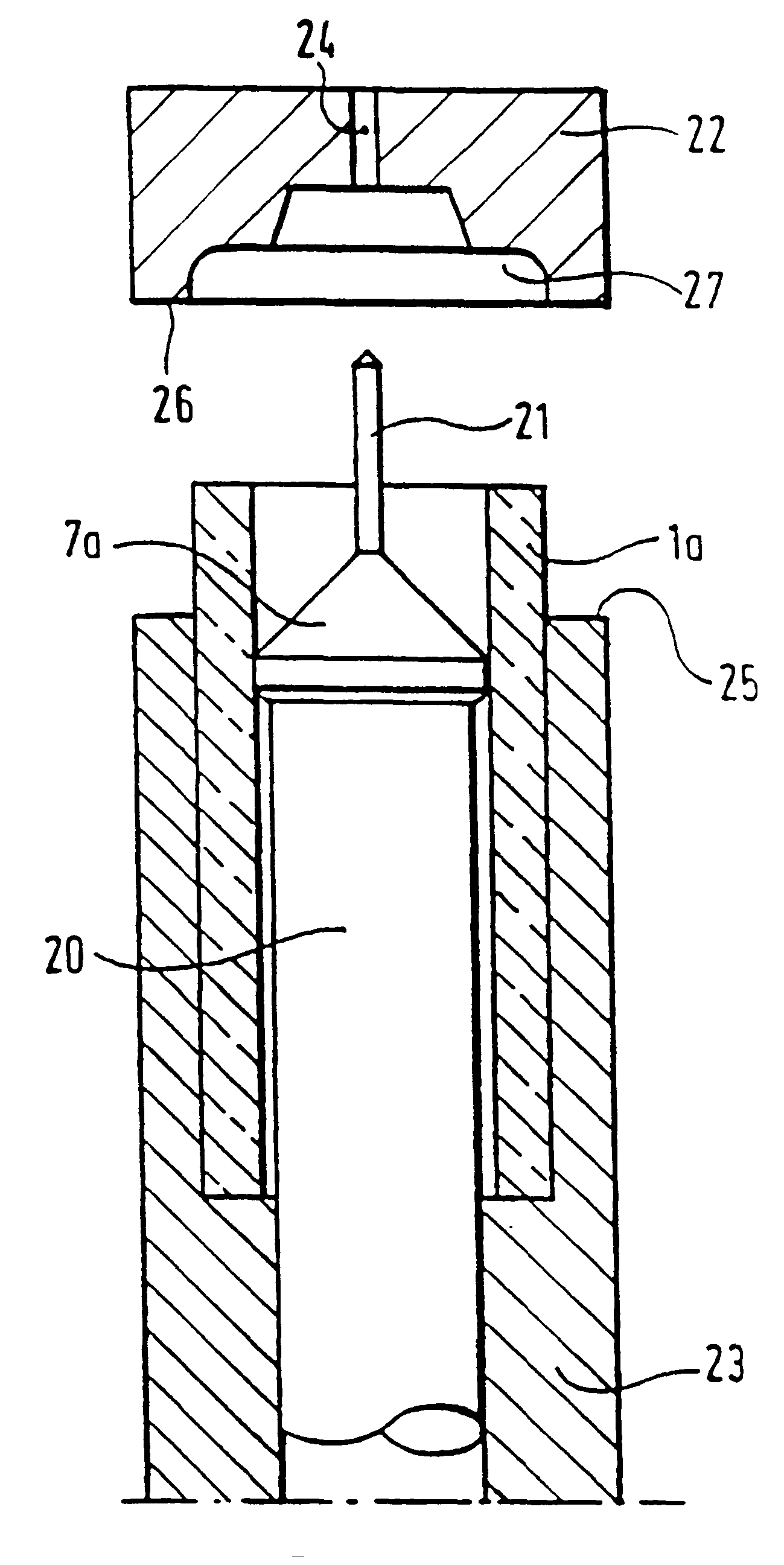

Method and apparatus for making an article from a formable material

InactiveUS6216493B1Good repeatabilityHigh speed productionButtonsAmpoule syringesEngineeringInjector

A method and apparatus are described for making an article such as the body of a needleless injector capsule, from a formable material, such as glass, the article having a cavity communicating with the exterior via an orifice. A blank (1a) having an open end is mounted on a first forming tool, and the open end is engaged by a second forming tool (22) while an end region of the blank (1a) adjacent the open end is in a condition to permit it to be formed. One of the tools (7a) has a pin (21) extending therefrom, and when the tools are brought together to form the end region into the desired shape of the pin (21) defines the orifice.

Owner:ZOGENIX INC

Crosslinked foam which has inner-cavity structure, and process of forming thereof

A method and device for forming a cross-linked foam and a cross-linked foam are provided. The method includes the steps of preparing at least one foaming material for cross-linked foaming, the foaming material processed to have a plane or three-dimensional shape; forming at least one interfacing pattern on a surface of at least one of the foaming material using at least one interfacing material that prevents chemical and physical interaction between the foaming materials; and forming a cross-linked foam by foaming the foaming material having the interfacing pattern thereon, the cross-linked foam having a foam body and an internally-formed surface.

Owner:PARK LTD

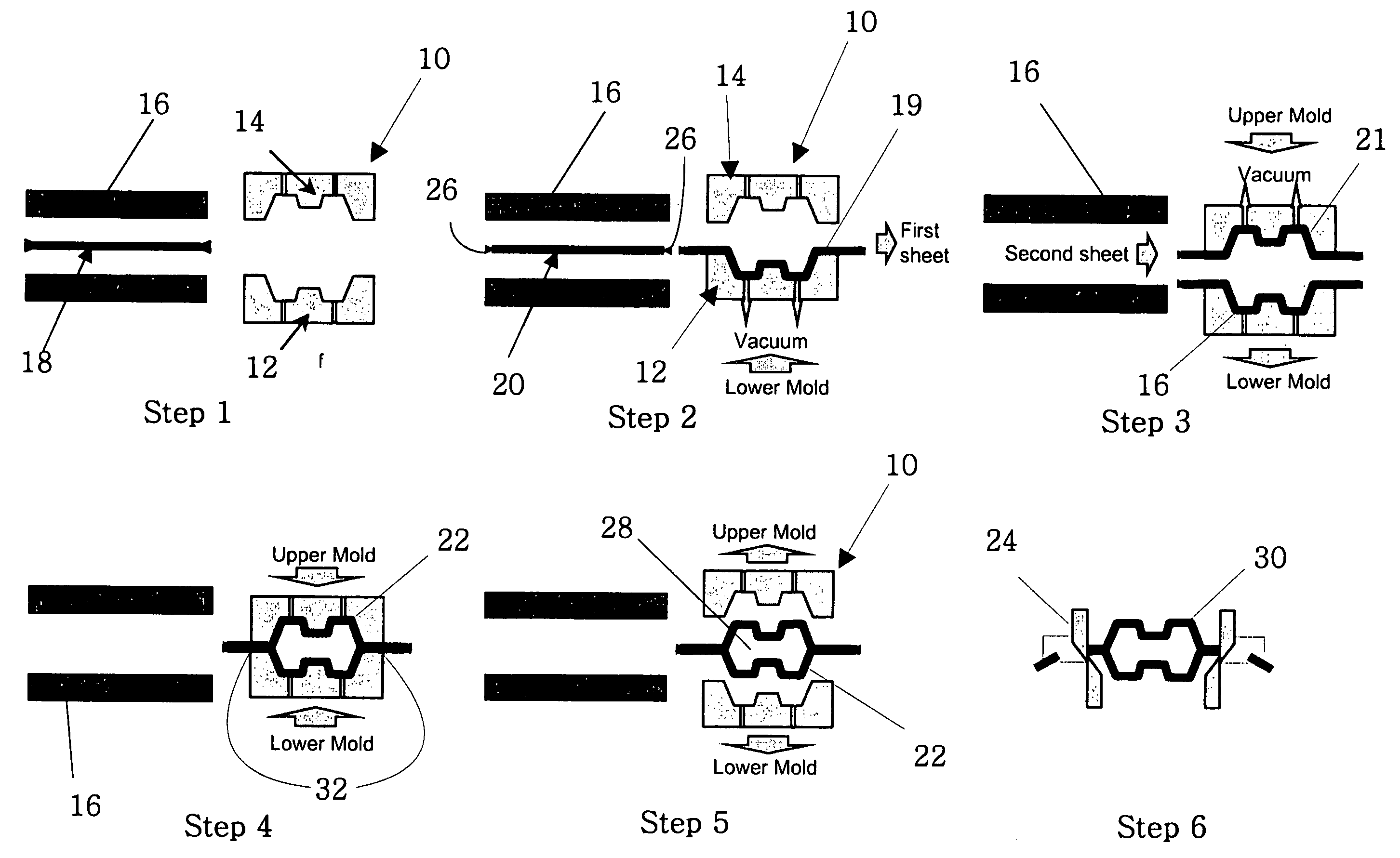

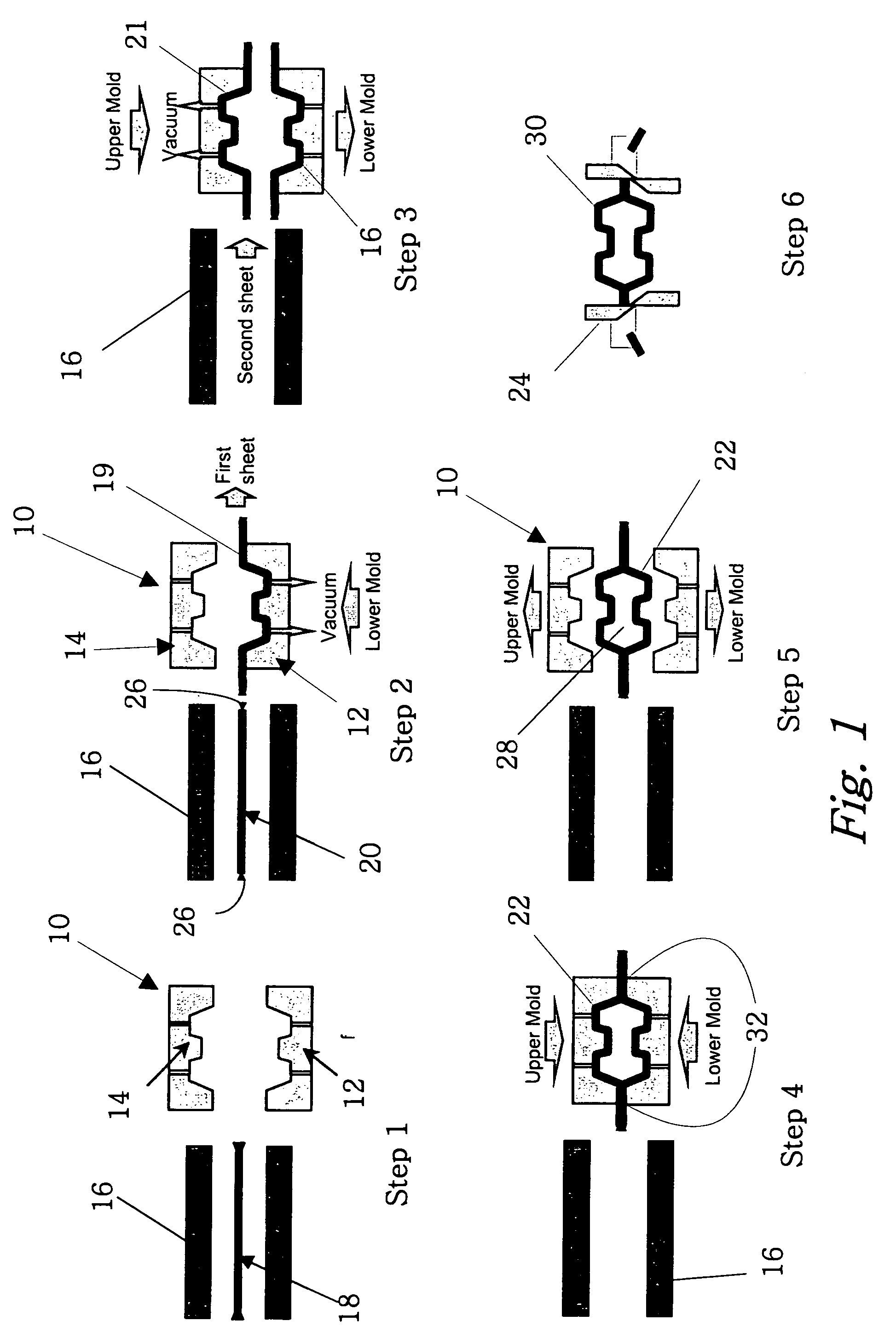

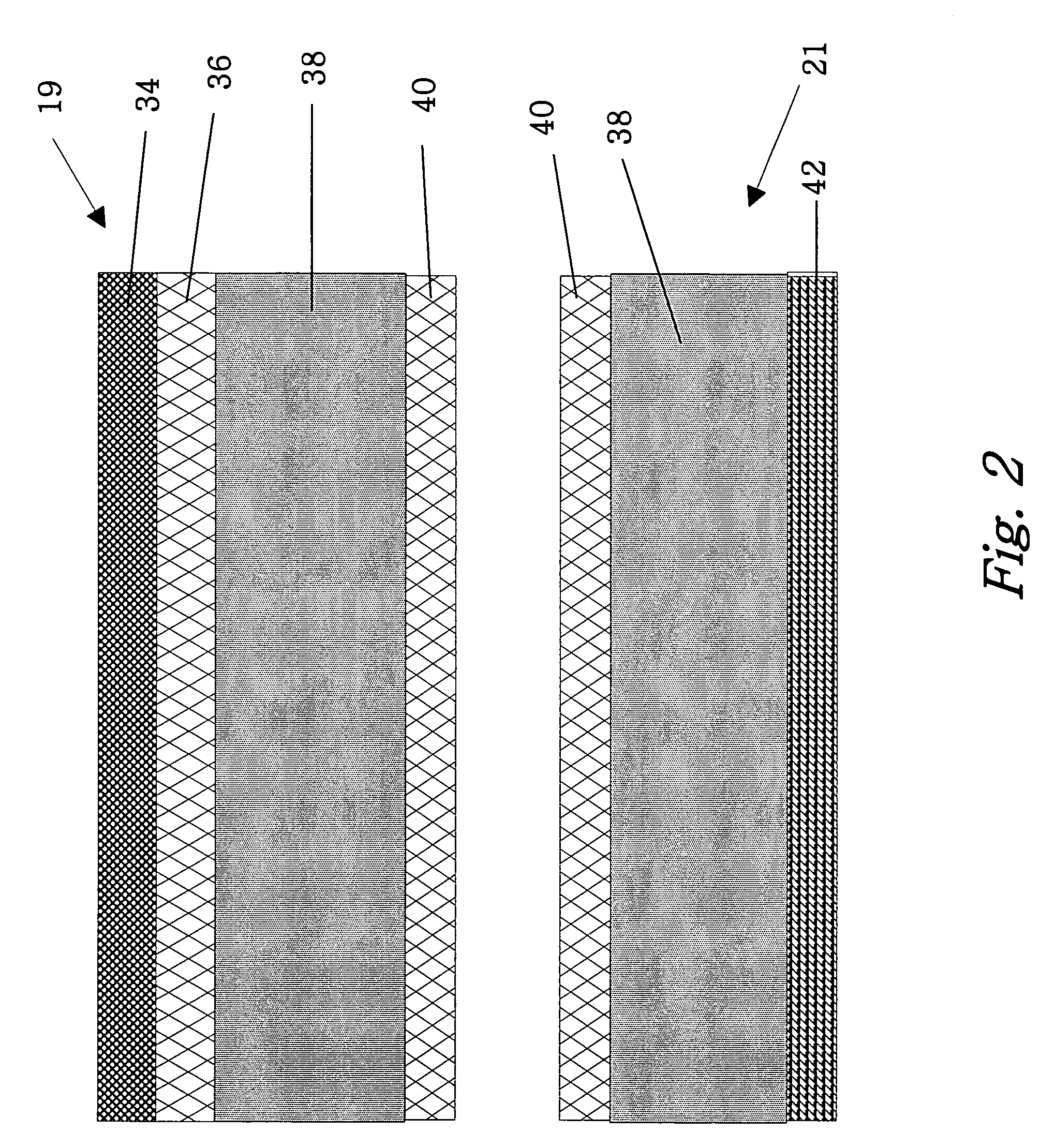

Twin-sheet thermoforming process

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com