Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1382 results about "Engraving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engraving is the practice of incising a design onto a hard, usually flat surface by cutting grooves into it with a burin. The result may be a decorated object in itself, as when silver, gold, steel, or glass are engraved, or may provide an intaglio printing plate, of copper or another metal, for printing images on paper as prints or illustrations; these images are also called "engravings". Engraving is one of the oldest and most important techniques in printmaking. Wood engraving is a form of relief printing and is not covered in this article.

Method for producing buttons, ornamental and instrument panels with fine symbols, and a button produced with the method

ActiveUS7134205B2Exemption stepsEasy to viewButtonsLamination ancillary operationsFine lineEngraving

A button, knob or control key with an etchable support plate which is engraved on the backside with a fine symbol by laser, erosion or mechanical engraving, which only cuts into the material of the support plate, but not through the support plate. The backside of the support plate is optionally coated. A foil is applied on the laminated layer and affixed thereto. The front side of the support plate is treated with a material-removing substance. The material removal with the material-removing substance is performed until the engraving extending into the support plate is at least partially or completely exposed on the front side. Application of a protective layer to the front side of the support plate from which the material was removed. A function symbol is provided on the button such that it can be backlit. It is engraved in a fine line width providing a sharp optical definition erosion, mechanical engraving.

Owner:FAURECIA ANGELL DEMMEL

Artificial sapphire watch and manufacturing method thereof

InactiveCN104880937ASimple structureEasy to makeClockwork casesWatch crystals/clock glassesEngravingEngineering

The invention discloses an artificial sapphire watch and a manufacturing method thereof. The watch comprises a watch casing, a watch bottom, a watch cover and a watch core. The watch cover and the watch bottom are respectively arranged on the upper part and the lower part of the watch casing. The watch core is arranged between the watch cover and the watch bottom of the watch casing. Stainless steel watch pointers are arranged on the watch core. One side of the watch casing is provided with a watch crown connected with the watch casing. The watch casing, the watch bottom, the watch cover and the watch core are made of sapphire materials. The watch casing, the watch bottom, the watch cover and the watch core are made through the following steps of artificial sapphire material preparing, cutting, grinding, CNC engraving, polishing and moulding. After being moulded, each part is sequentially integrally assembled to form an artificial sapphire watch. The watch has an overall simple structure. Most of the parts are made of artificial sapphire materials. The watch which highlights the status of a user has the cost reduced. The watch which is suitable for general consumers is simple to manufacture.

Owner:楼小军

Hybrid optical head for direct engraving of flexographic printing plates

An optical imaging head for direct engraving of flexographic printing plates, comprising: at least two groups of radiation sources, each group comprising at least one radiation source, wherein the radiation sources within each group emit radiation having the same intensity and spot size, different from the intensity and spot size of radiation sources in the other groups, said groups of radiation sources operating simultaneously.

Owner:MIRACLON CORP

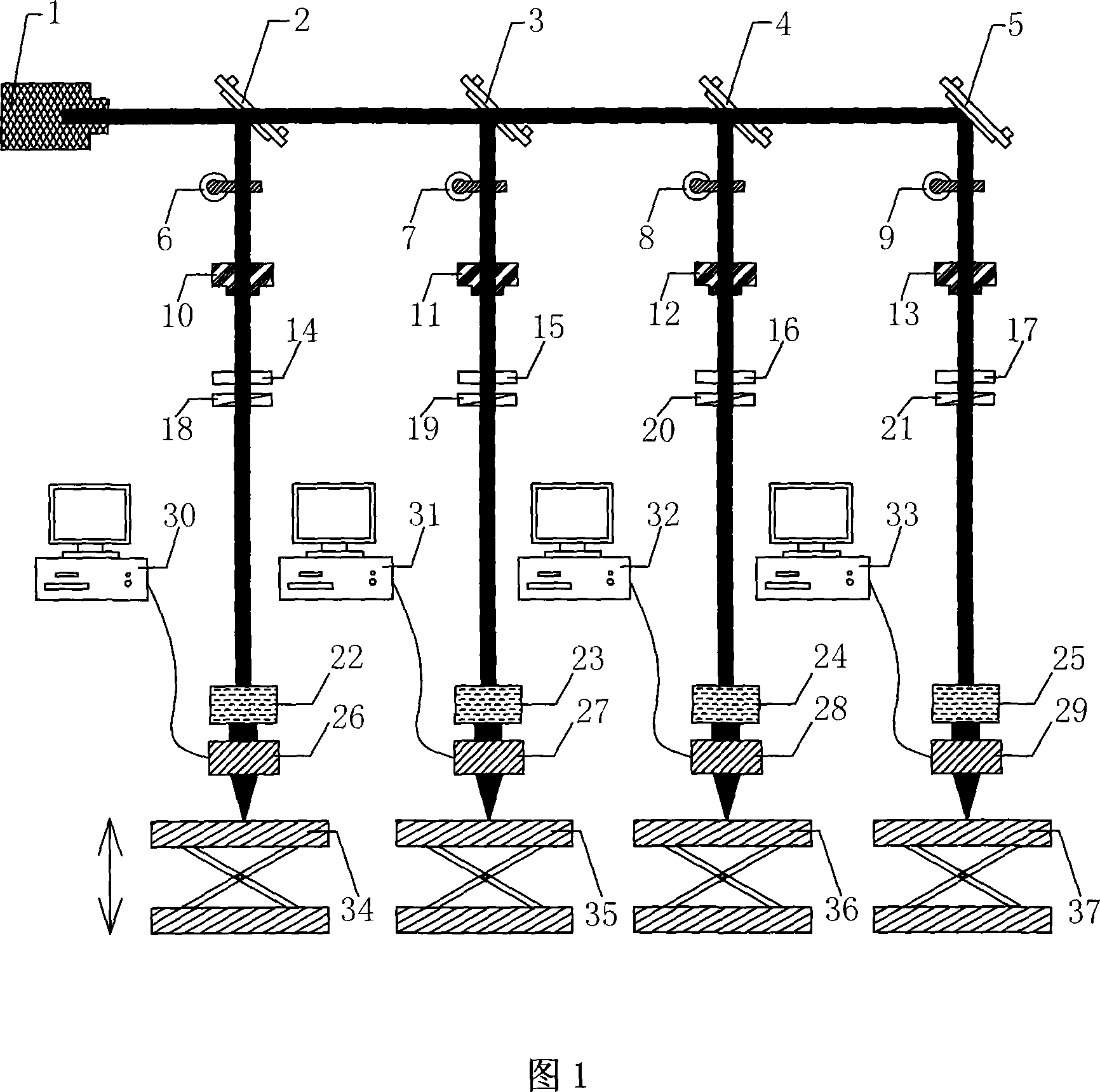

Distributed laser processing system

InactiveCN101020277ALow costNovel structurePolarising elementsLaser beam welding apparatusEngravingLaser processing

The distributed laser processing system includes a laser; a beam splitter in the output of the laser; the first branch comprising a light shutter, a frequency modulator, a rotating half-wave plate, a polaroid, a laser beam shaping and focusing system and a vibrating mirror and connected to the output of the beam splitter; the second beam splitter or a total reflector; the second similar branch; and a computer connected to all the vibrating mirrors. The laser beam from the laser is treated through beam splitting, power regulation and shaping for several laser processing jobs, such as welding, cutting, engraving, etc in obviously lowered production cost.

Owner:SUZHOU DELPHI LASER

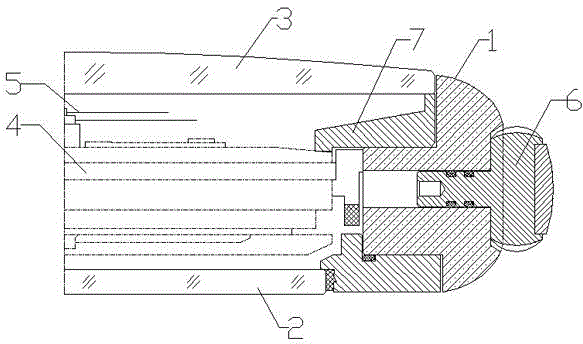

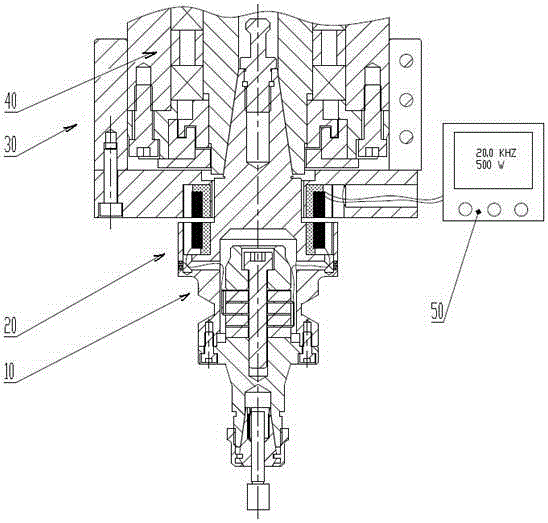

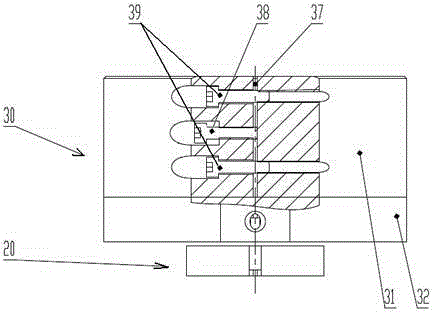

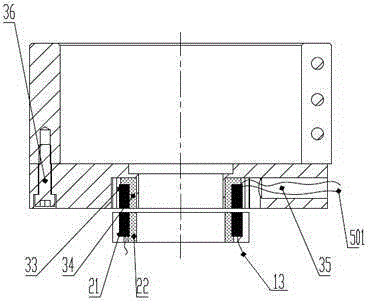

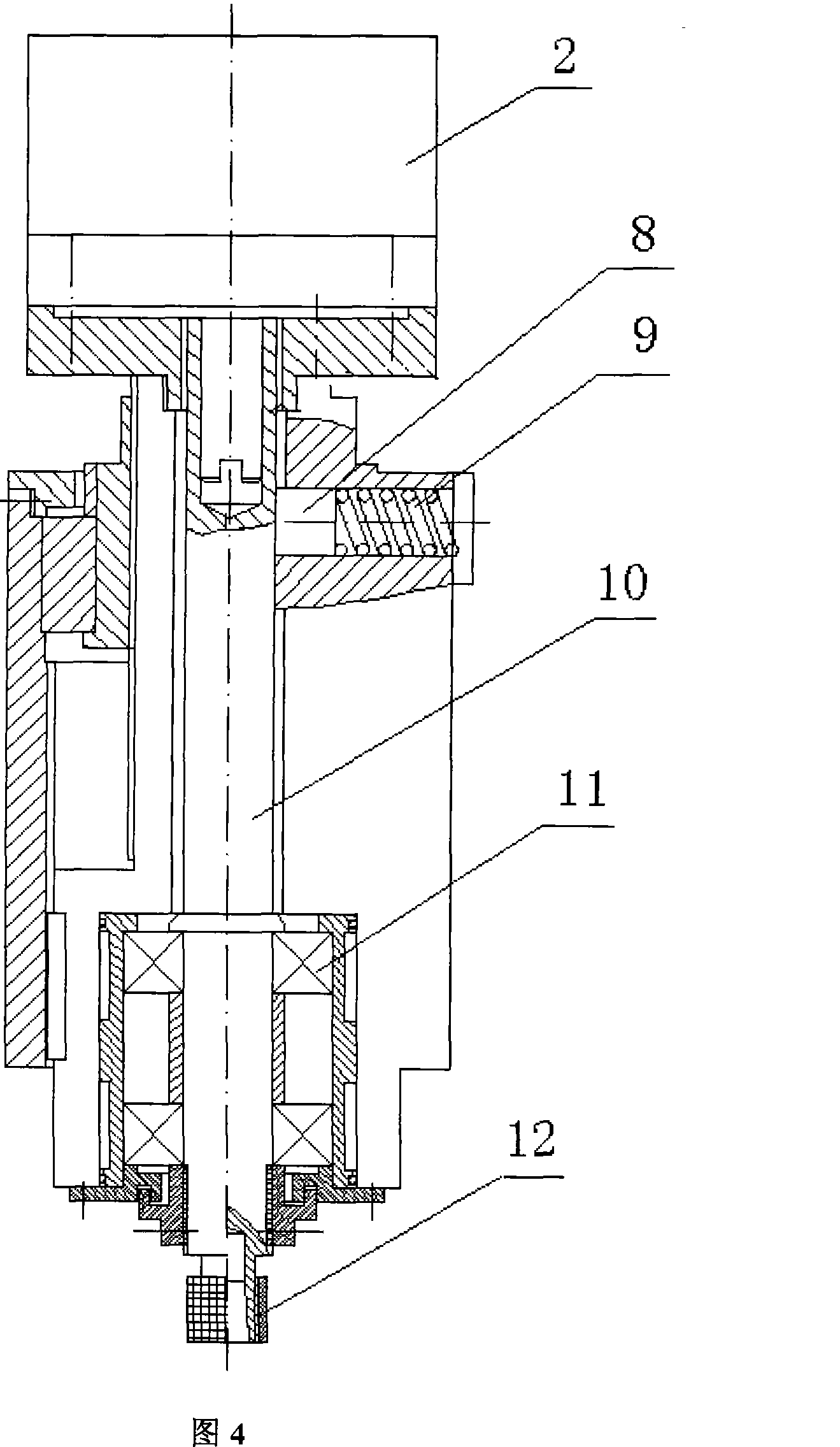

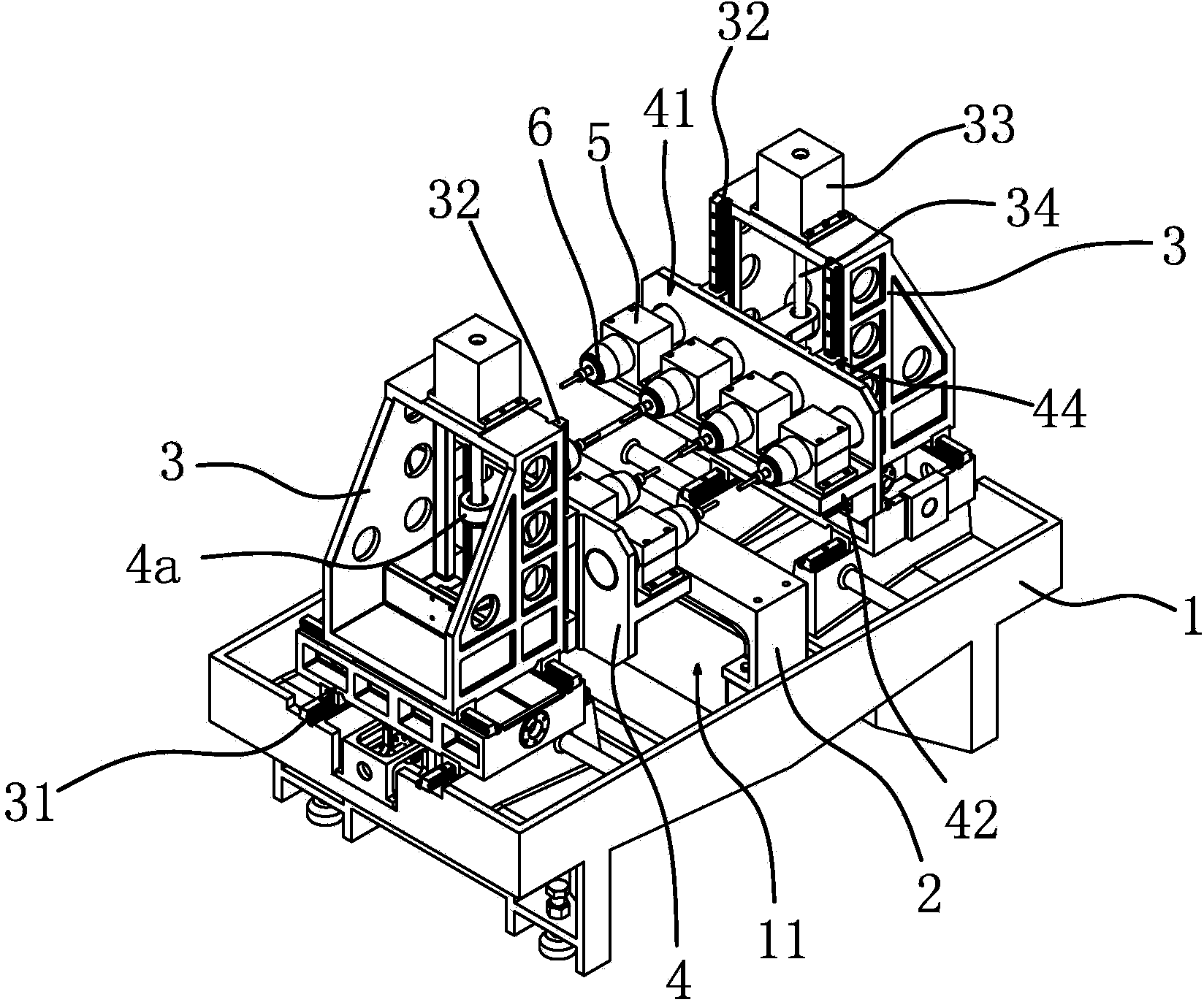

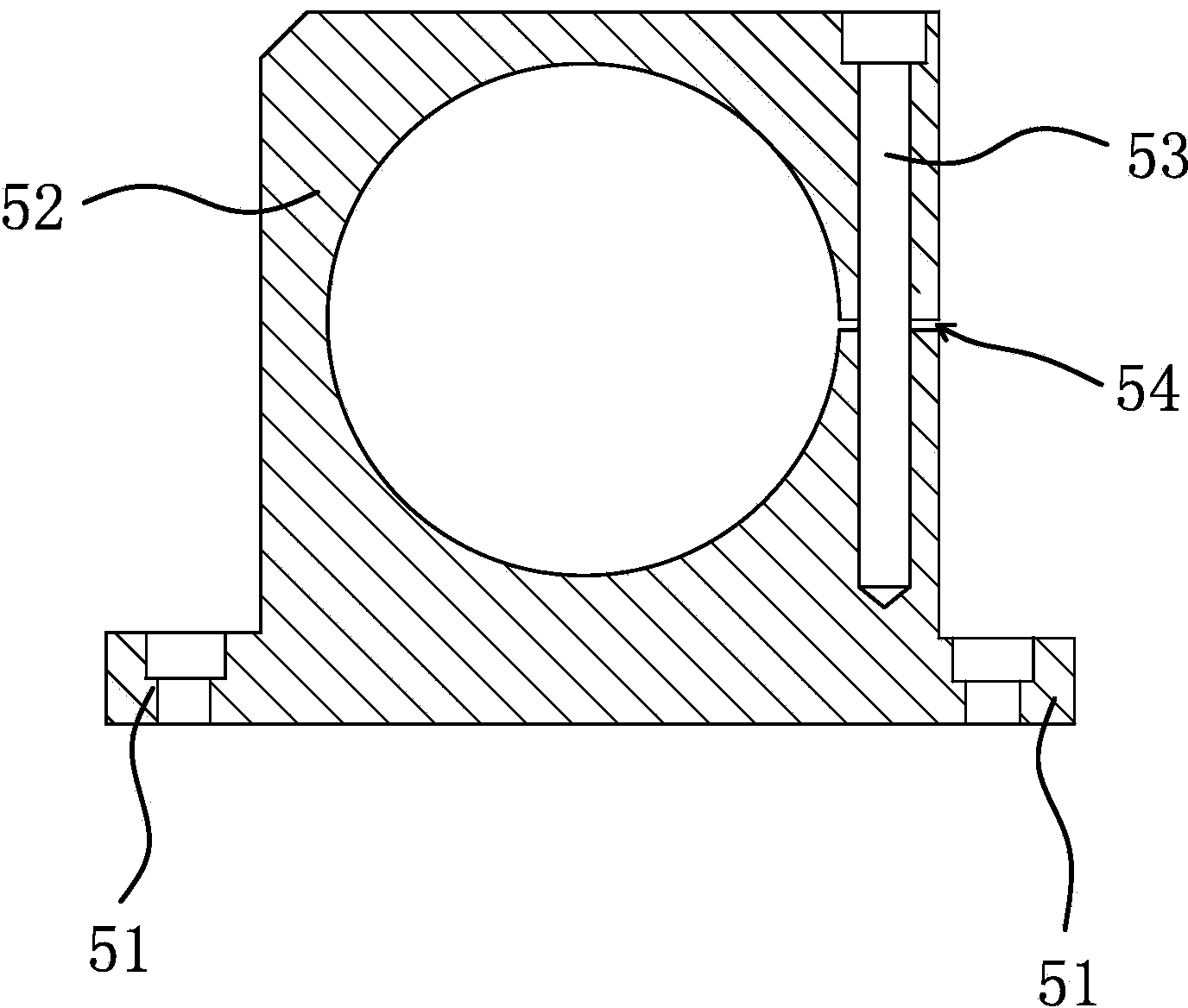

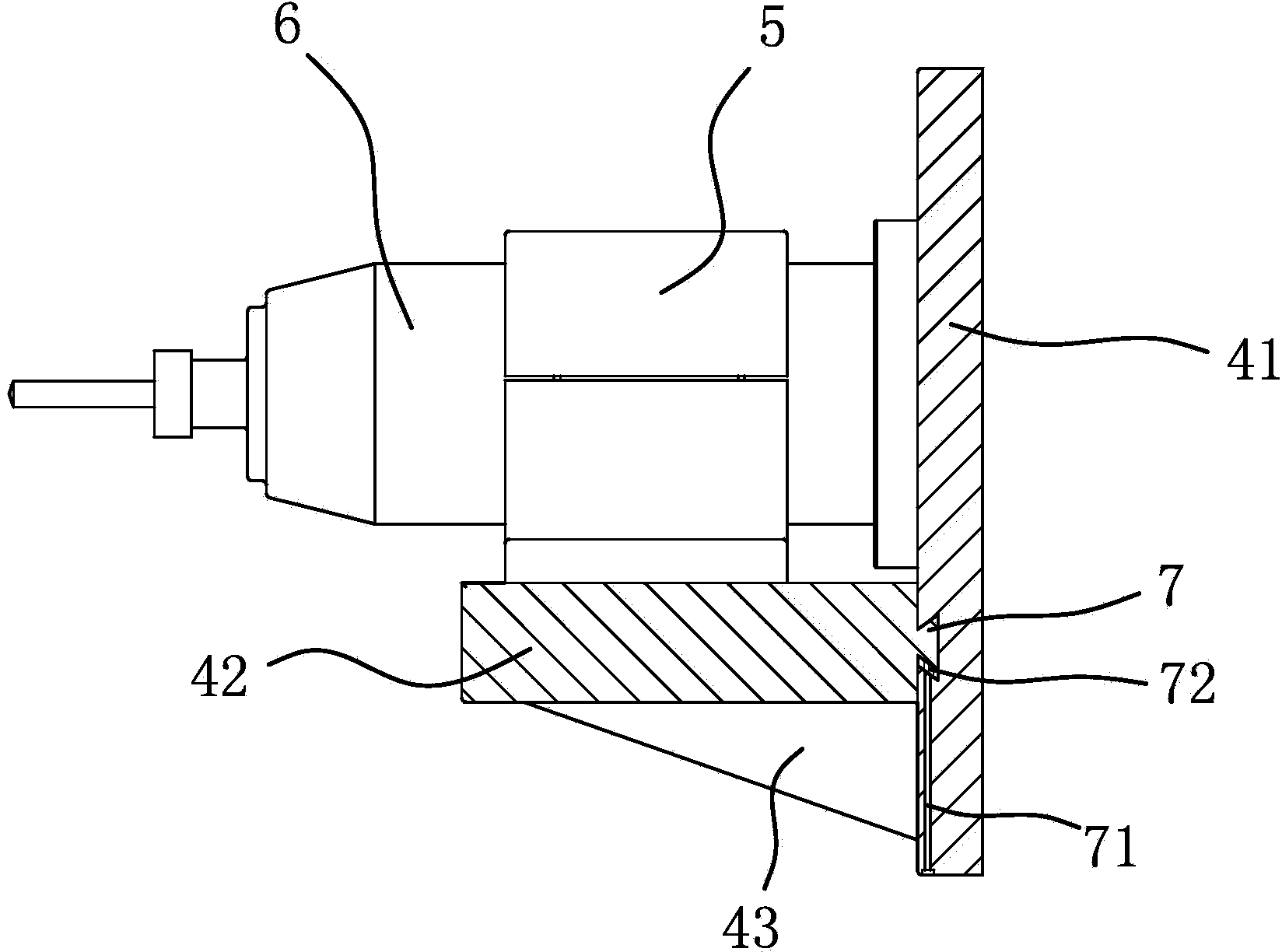

Rotary ultrasonic machining device based on non-contact energy transfer

InactiveCN105171131AImprove processing efficiencyImprove machined surface qualityPositioning apparatusMetal-working holdersNumerical controlEnergy transfer

The invention discloses a rotary ultrasonic machining device based on non-contact energy transfer. The rotary ultrasonic machining device based on non-contact energy transfer comprises a high-speed electric spindle, a primary side assembly fixed to the lower end of the high-speed electric spindle, an ultrasonic knife handle assembly composed of an ultrasonic knife handle and a secondary side assembly arranged on the periphery of the ultrasonic knife handle, and an ultrasonic power supply generator. The ultrasonic knife handle assembly is arranged at the lower end of the high-speed electric spindle, so that the secondary side assembly corresponds to the primary side assembly up and down. The ultrasonic power supply generator is connected with the primary side assembly. According to the rotary ultrasonic machining device based on non-contact energy transfer, the ultrasonic machining technology can be directly combined with existing computer numerical control (CNC) machining centers such as CNC engraving and milling machines, engraving and milling machines, high-gloss CNC machines and drilling and tapping centers, and original spindles do not need to be modified; non-contact energy transfer of ultrasonic waves is achieved through the primary side assembly and the secondary side assembly, and the rotation speed reaches 10,000 turns / min; in addition, the automatic knife switching function can be achieved by using an exiting magazine.

Owner:YUHUAN CNC MACHINE TOOL

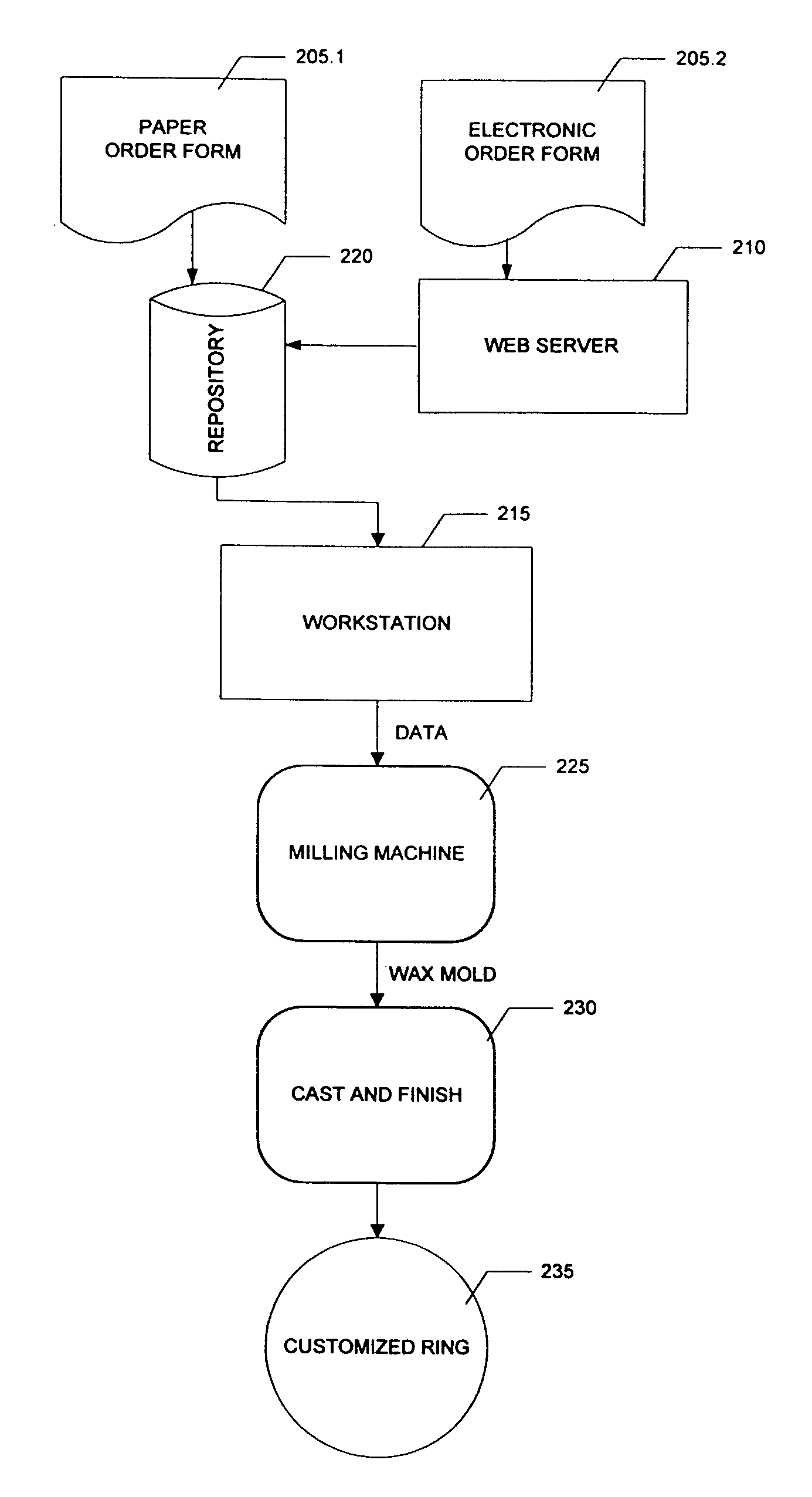

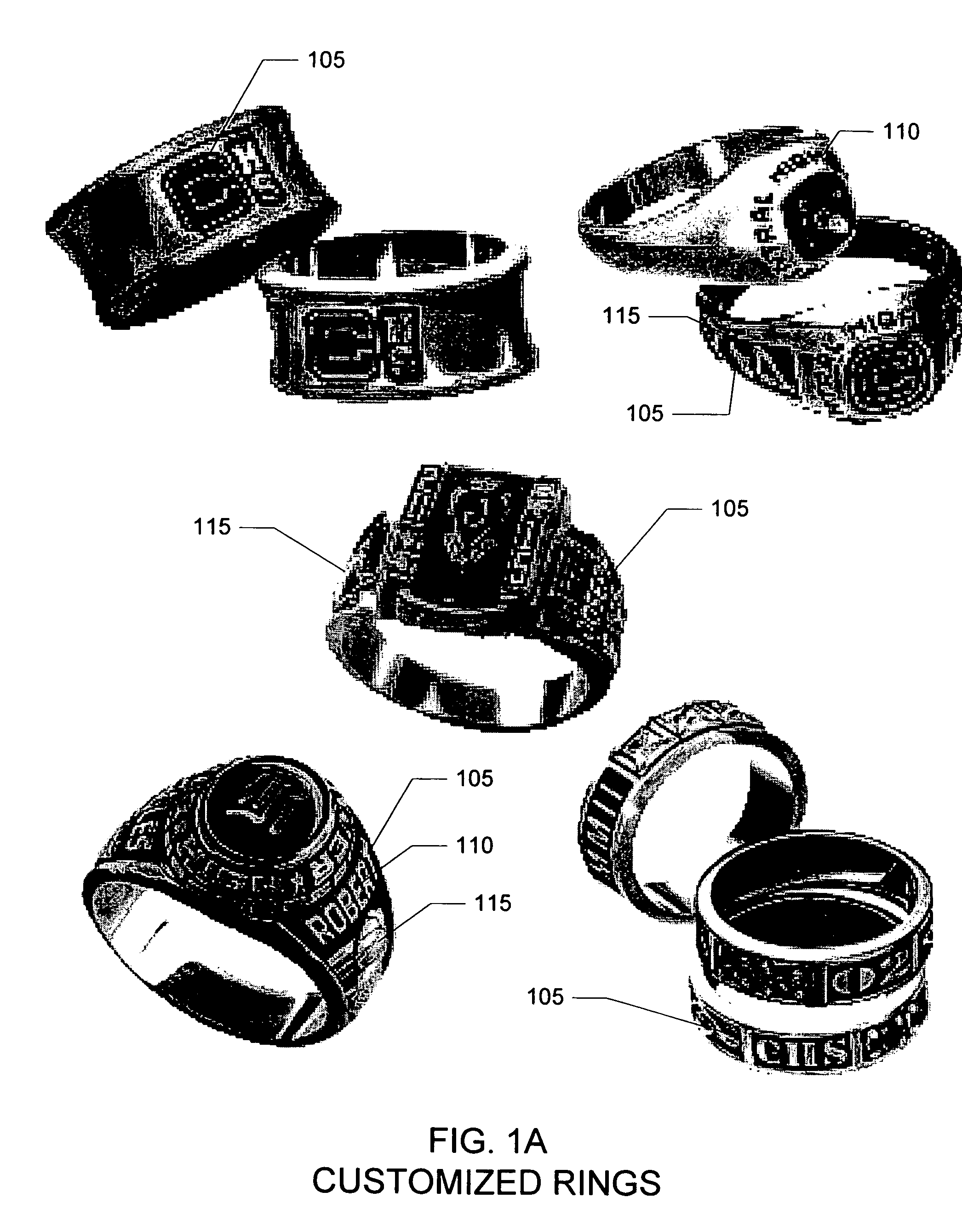

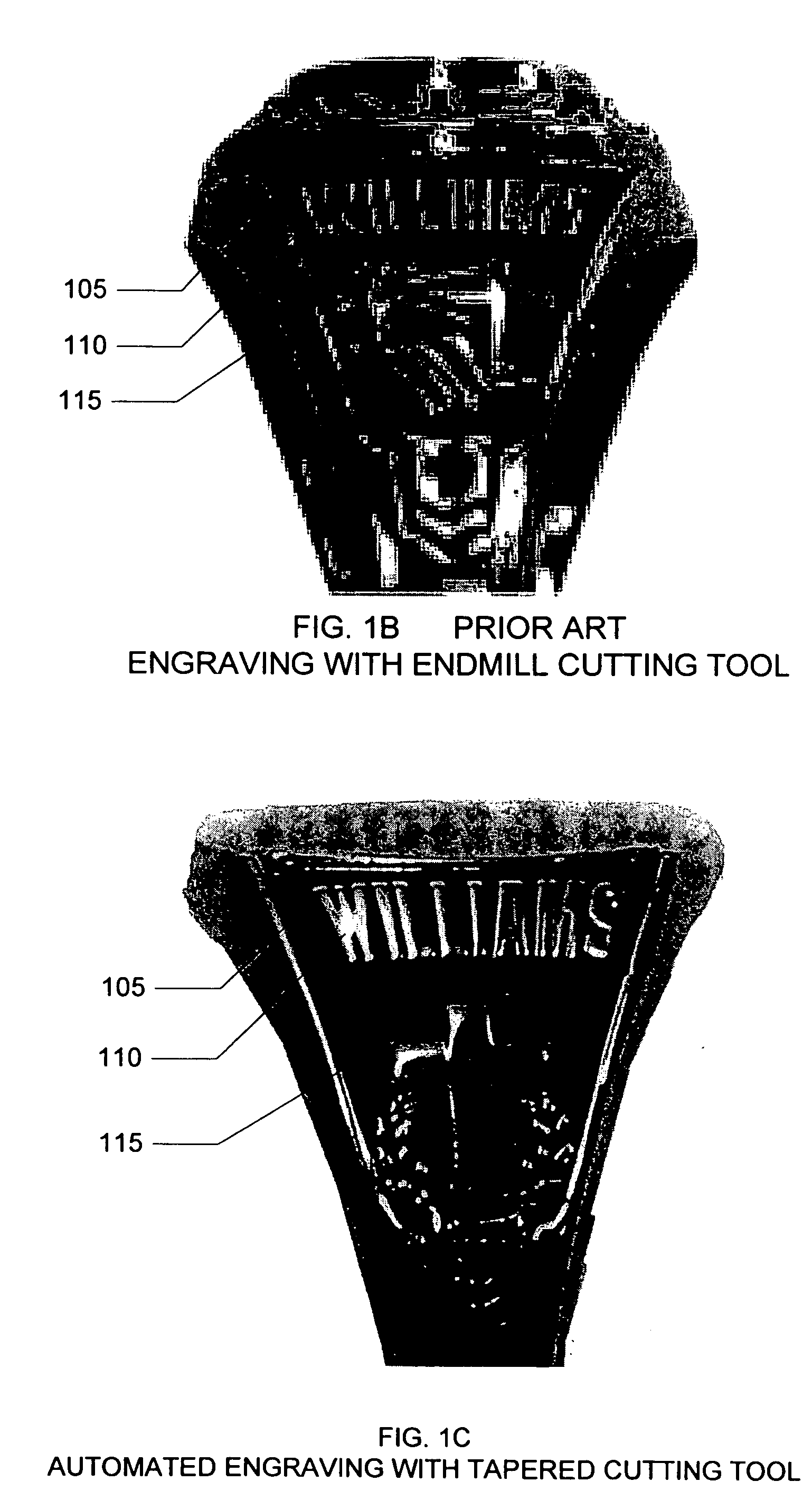

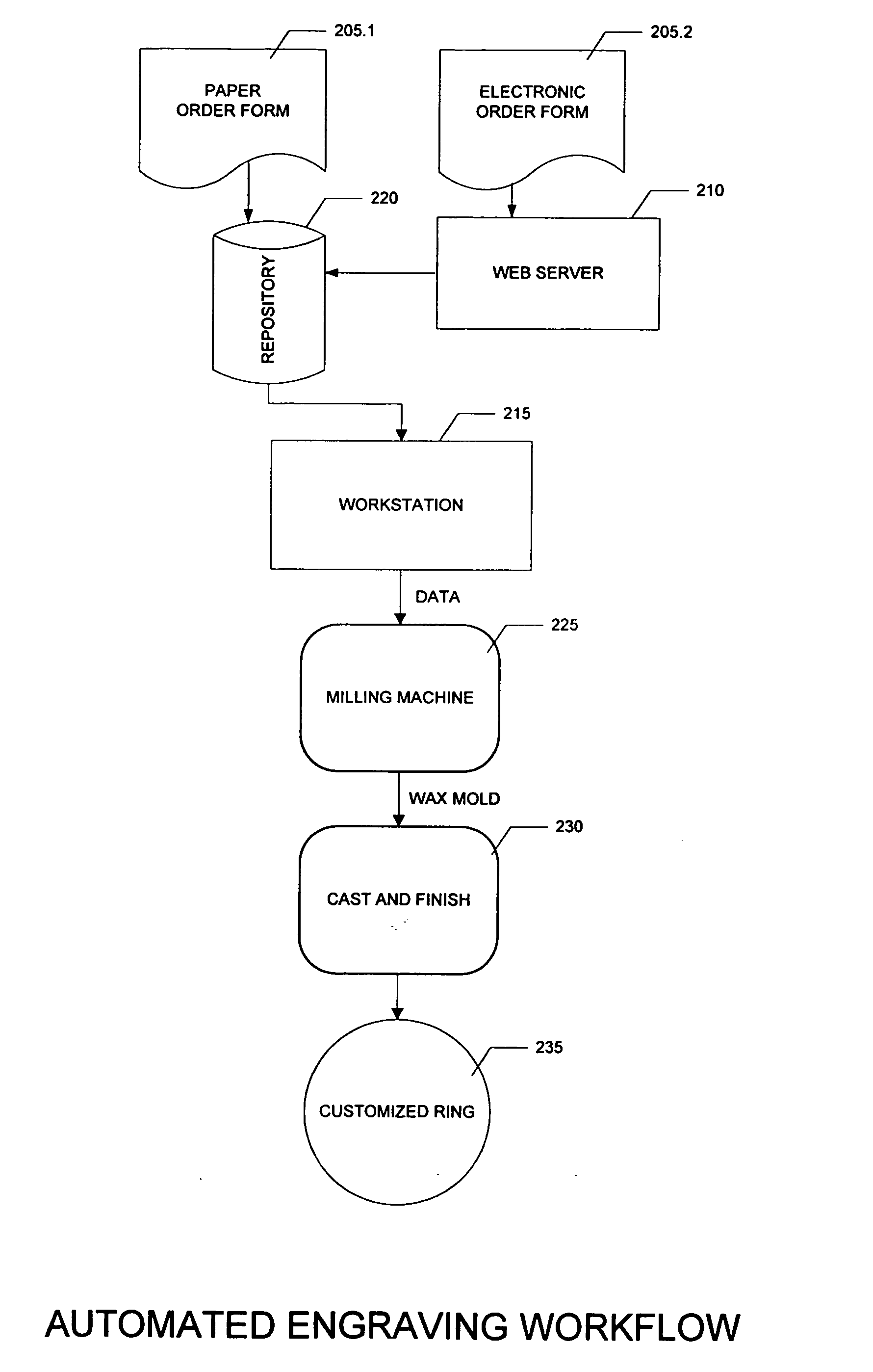

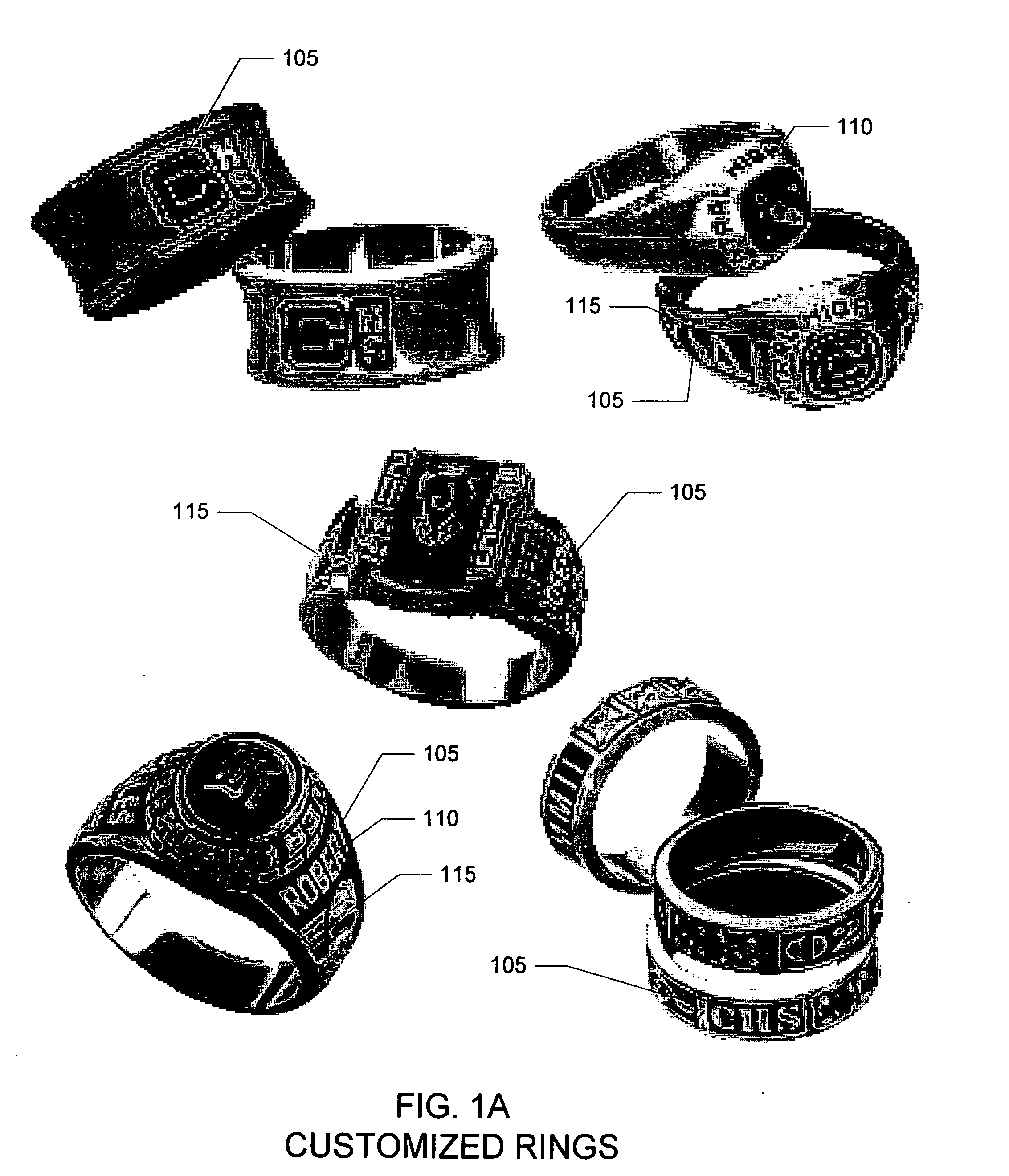

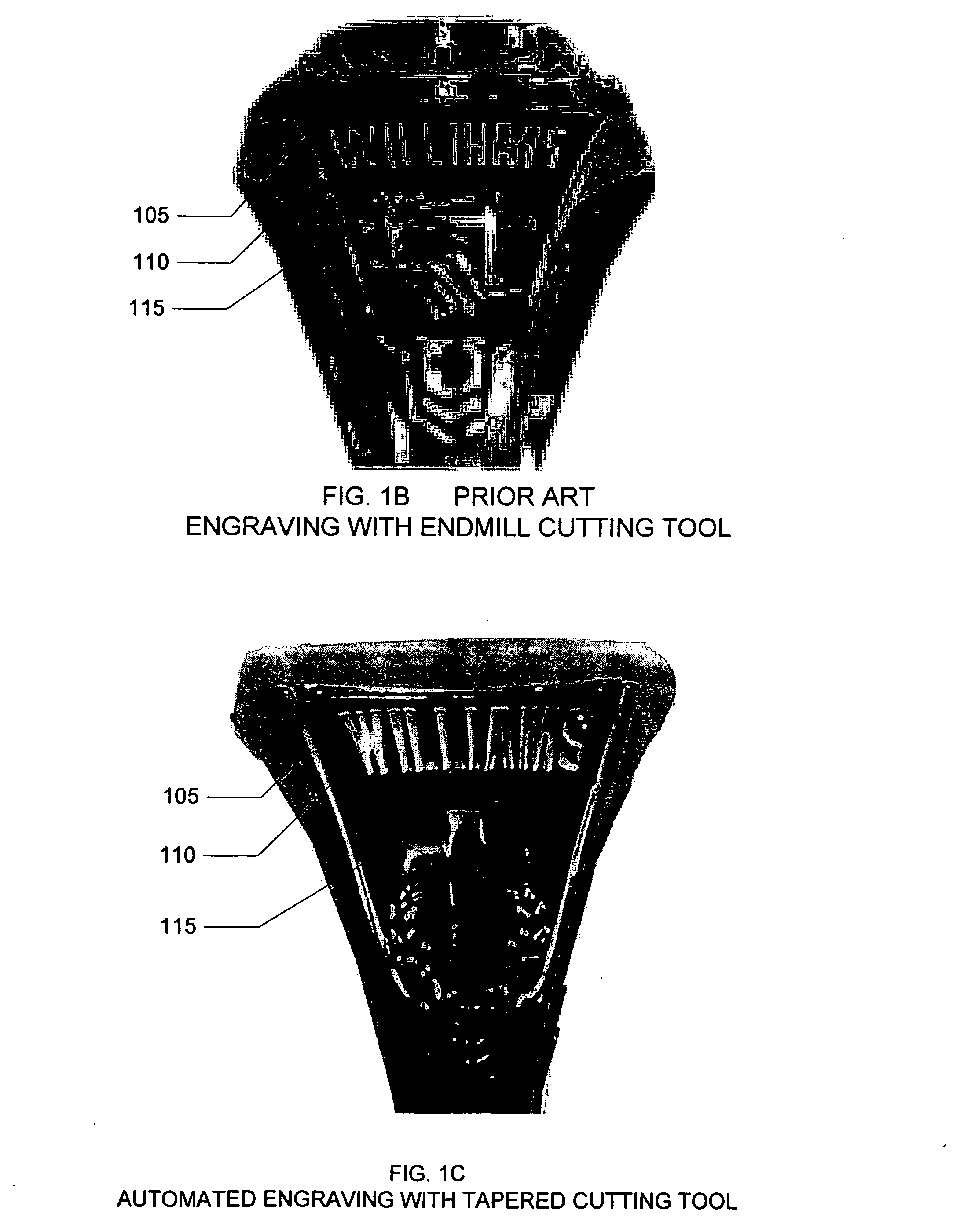

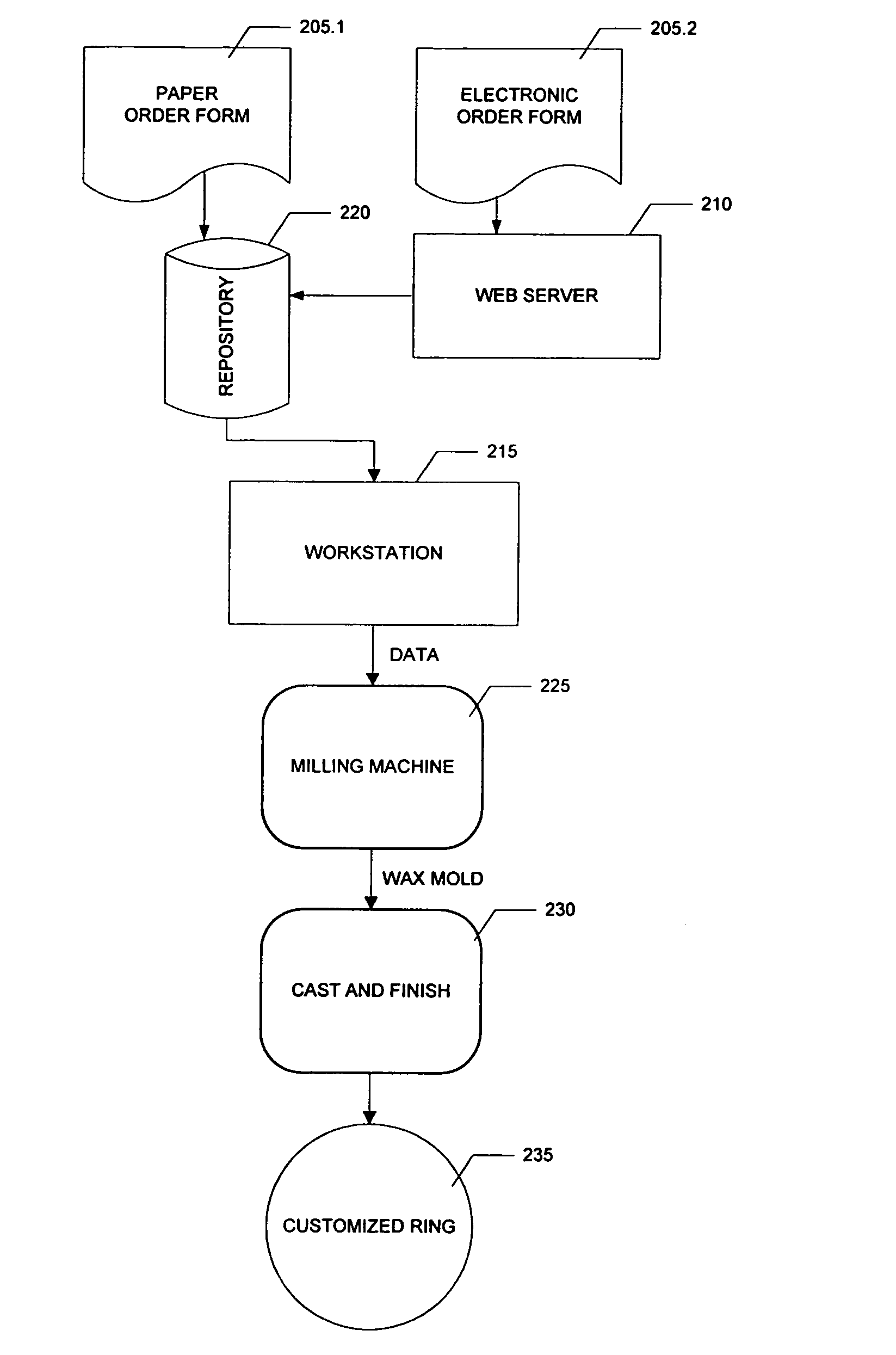

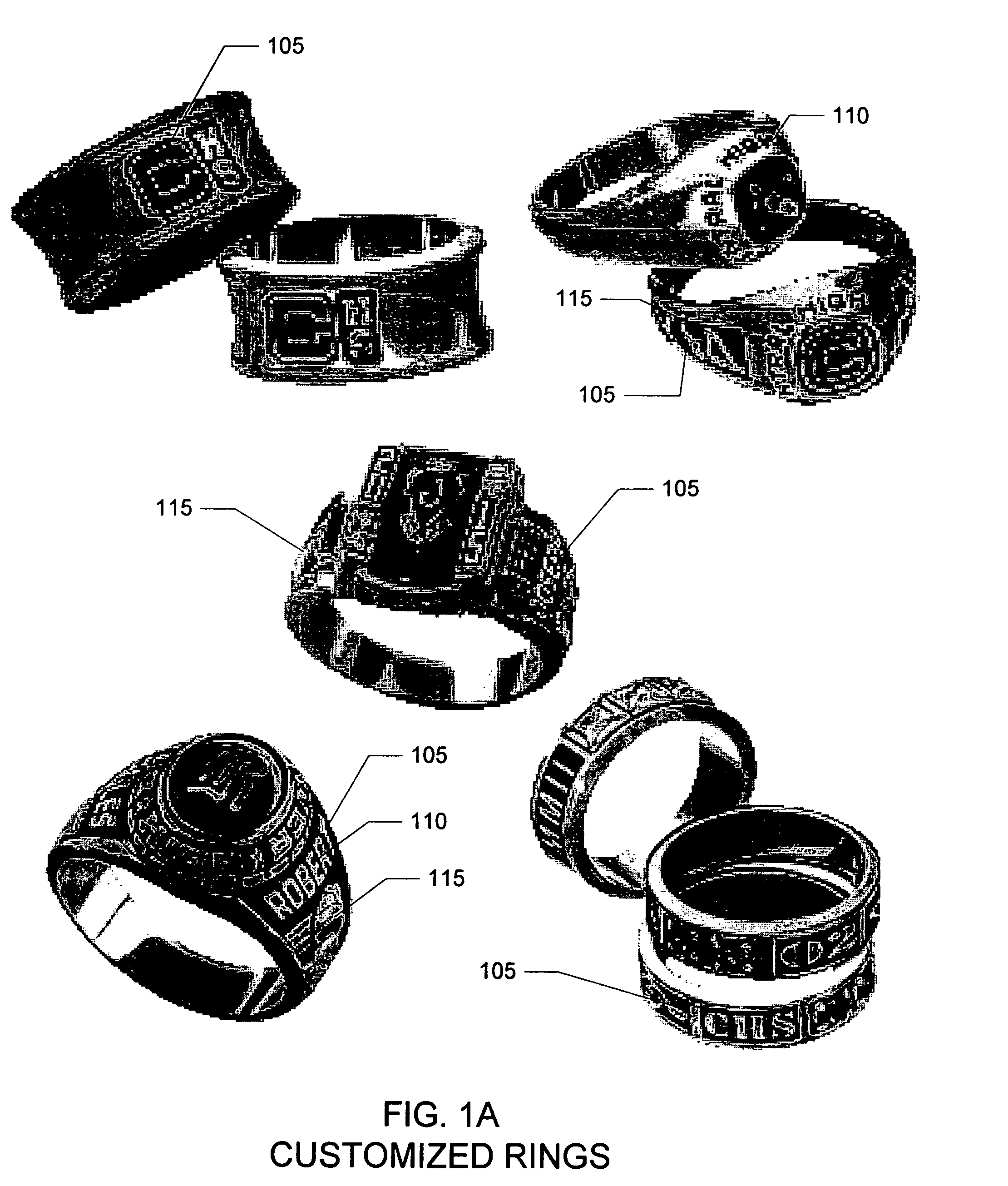

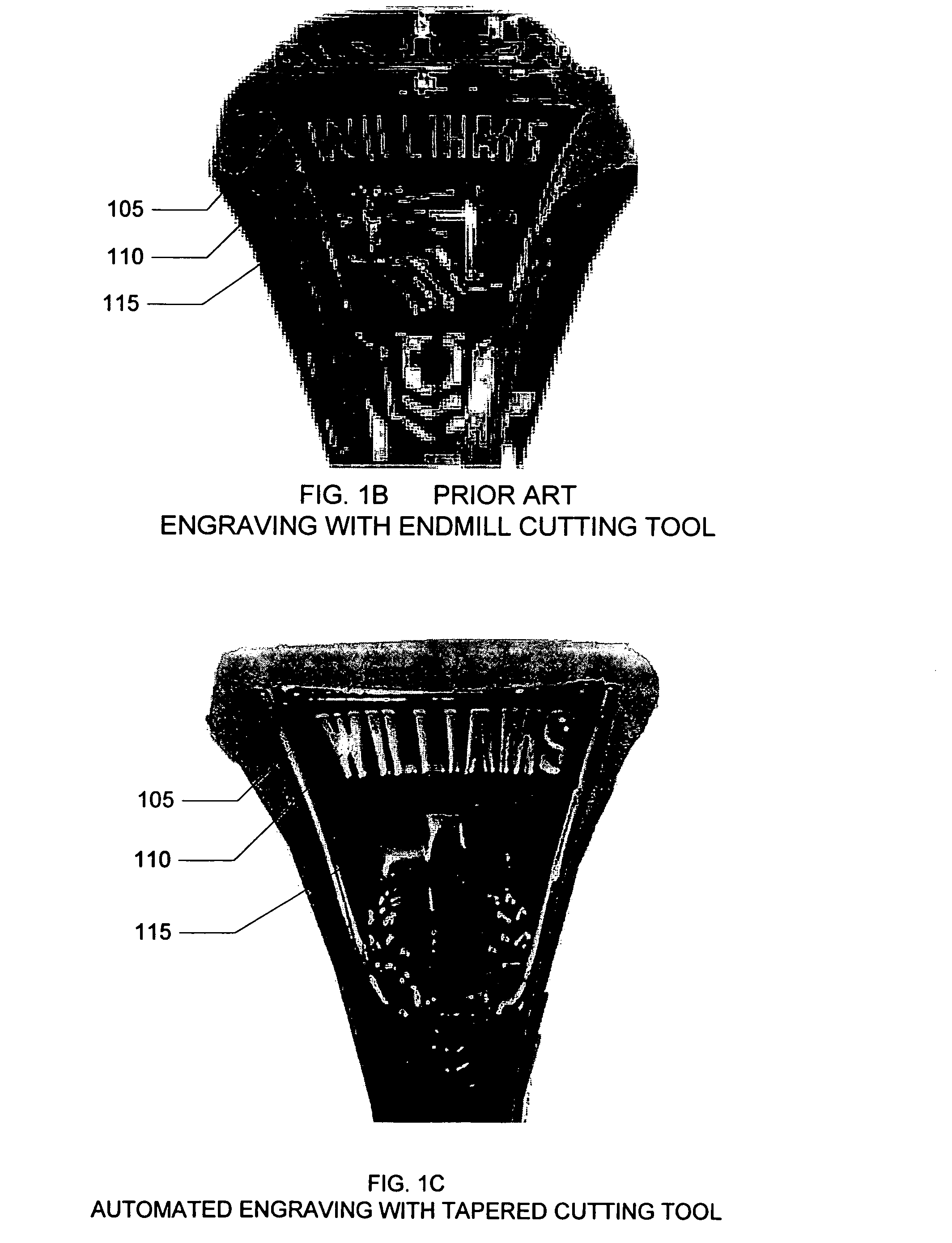

Automated engraving of a customized jewelry item

ActiveUS7069108B2Reduce the amount requiredCost effectiveSpecial data processing applicationsEngravingIcon designPersonalization

A method for manufacturing a ring (i.e. class, championship, or affiliation) begins by receiving order data specifying a series of personalization elements, such as the addition of text and icon designs. A geometric model for each personalization item is constructed. To assemble text panels, the operating system provides font geometry for a desired TrueType font. Then a set of splines are created from the font geometry and are then tessellated to generate polyline sets of data, which are then spaced and mapped between two boundary curves. The personalization elements are then projected onto one of the model's 3D surfaces. A set of machining instructions for a milling machine is generated by obtaining a set of machining pattern strategies, generating a set of curves, projecting the toolpath onto the surface of the ring to calculate the 3D toolpath, and rotating it to a desired angle.

Owner:JOSTENS INC

Method for manufacturing gravure printing roller with electronic carving method

InactiveCN101402275AImprove color saturationIncrease volumePrinting pre-treatmentForme preparationEngravingCopper plating

The invention discloses a method for manufacturing a gravure roller by an electronic engraving method. The method comprises the following steps: firstly, manufacturing a printing plate substrate and plating copper on a printing plate roller, and forming a plate making copper layer on the surface of the printing plate roller; secondly, plating a chrome layer on the plate making copper layer, and engraving; thirdly, eroding an engraved V-shaped ink cell, so as to deepen and widen the plate making copper layer corresponding to the V-shaped ink cell and enlarge the volume of the ink cell; and fourthly, removing chrome from the eroded printing plate roller; and lastly plating the chrome layer functioning as protection. Compared with the prior art, the gravure roller manufactured by the method has the ink cell with larger volume and larger ink capacity, has good color saturation of printed matters when transfer printing, and has higher printing quality.

Owner:泉州运城制版有限公司

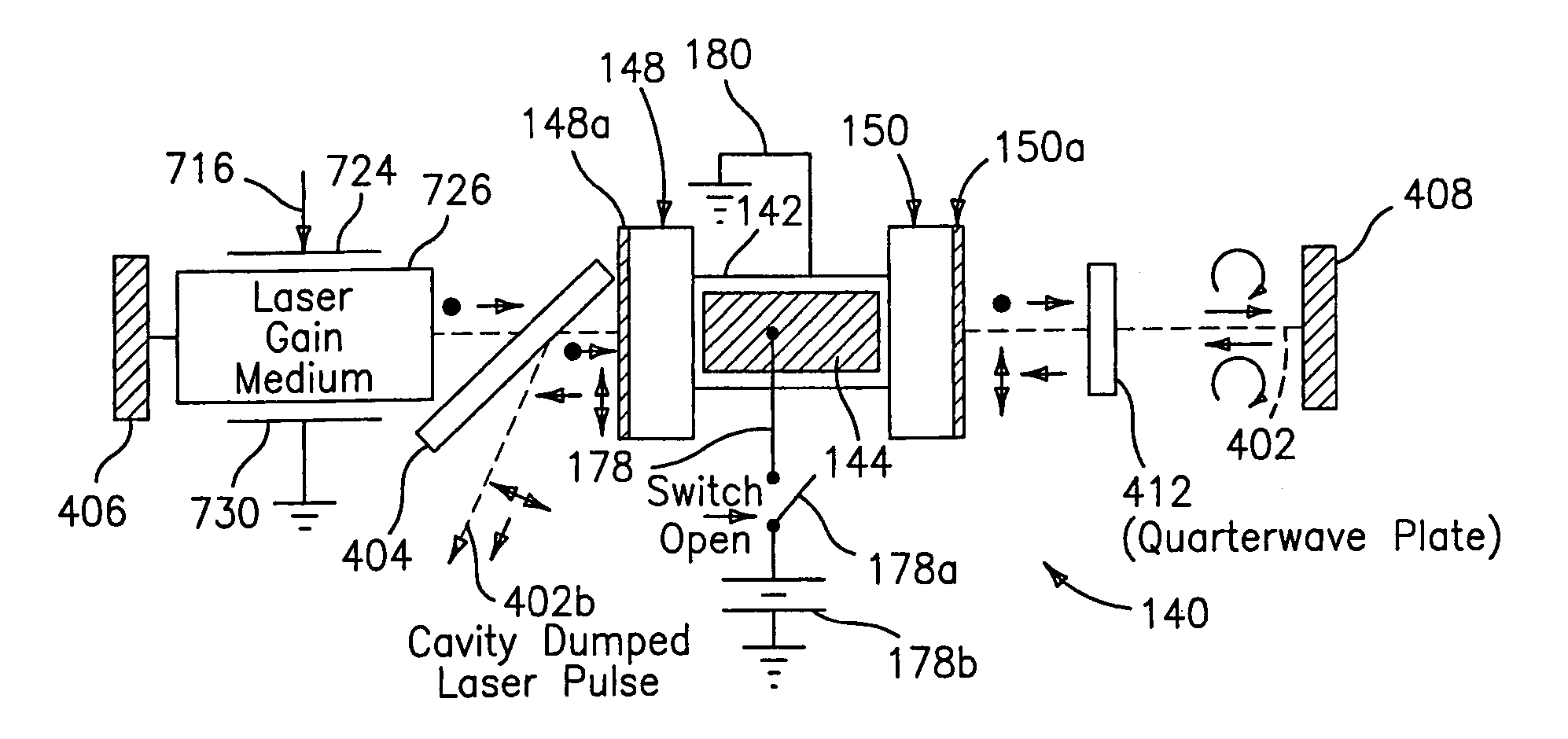

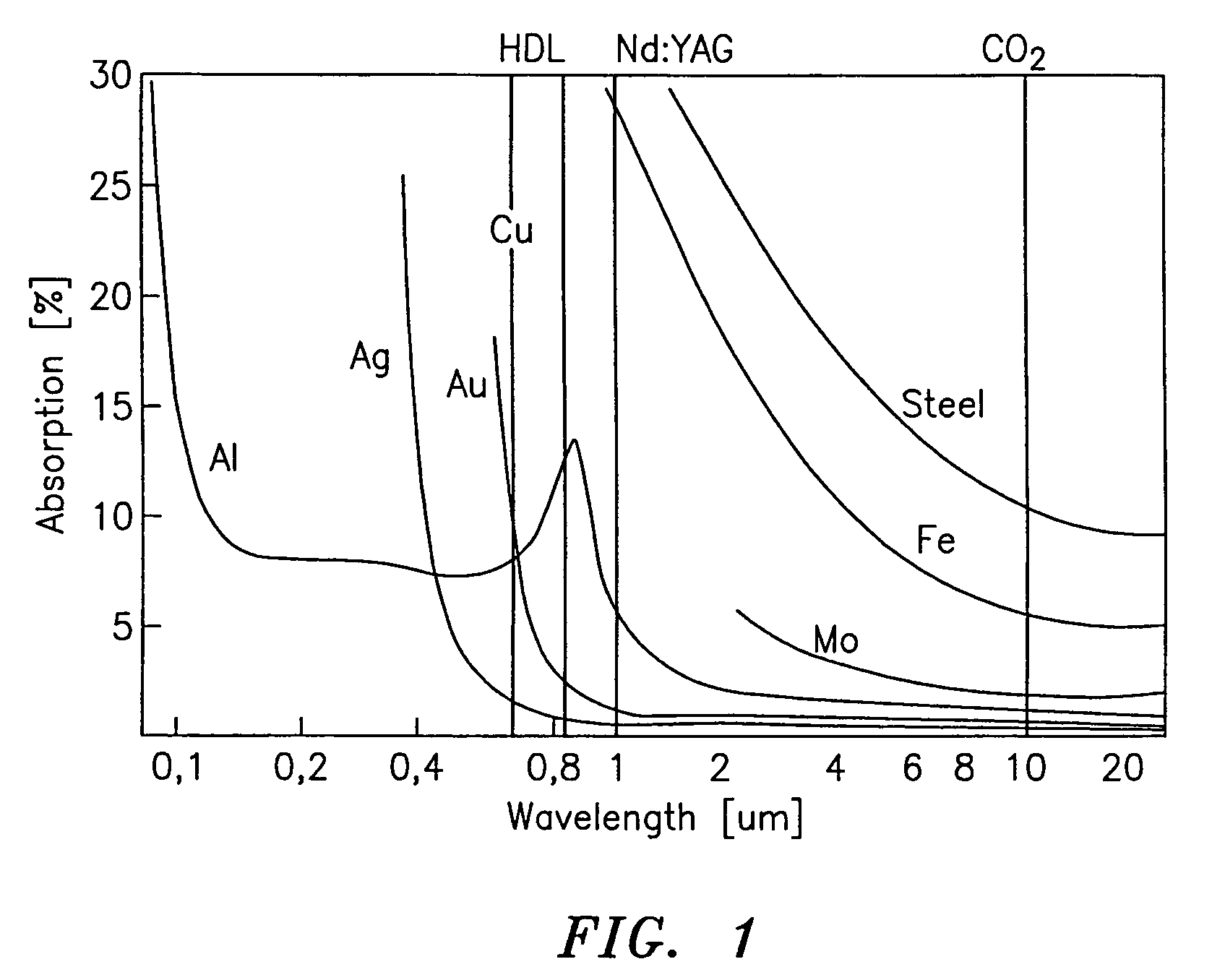

Q-switched, cavity dumped laser systems for material processing

InactiveUS7058093B2High strengthLow powerActive medium materialGas laser constructional detailsEngravingPeak value

This disclosure discusses techniques for obtaining wavelength selected simultaneously super pulsed Q-switched and cavity dumped laser pulses utilizing high optical damage threshold electro-optic modulators, maintaining a zero DC voltage bias on the CdTe electro-optic modulator (EOM) so as to minimize polarization variations depending on the location of the laser beam propagating through the CdSe EOM crystal, as well as the addition of one or more laser amplifiers in a compact package and the use of simultaneous gain switched, Q-switched and cavity dumped operation of CO2 lasers for generating shorter pulses and higher peak power for the hole drilling, engraving and perforation applications.

Owner:COHERENT INC

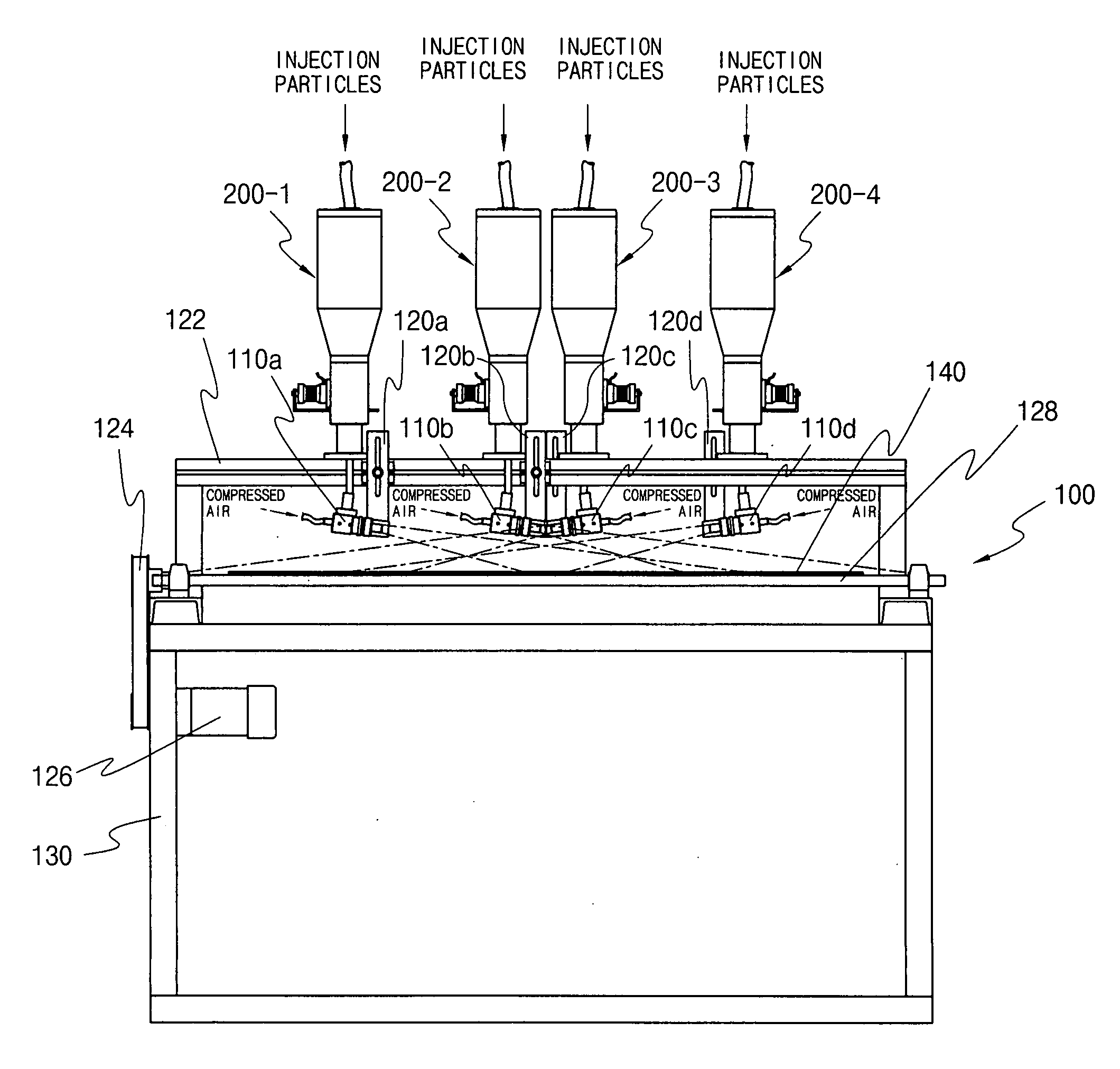

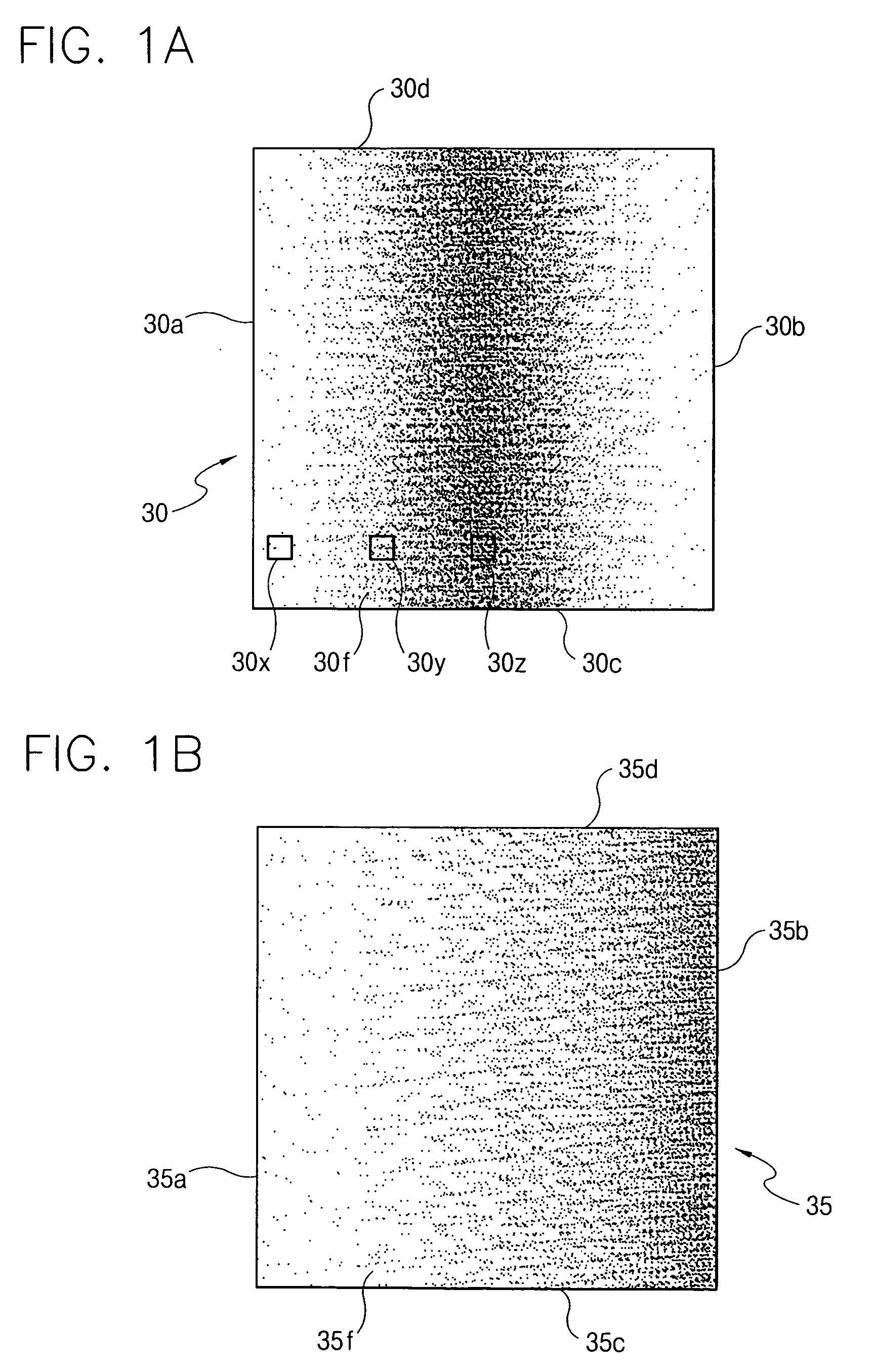

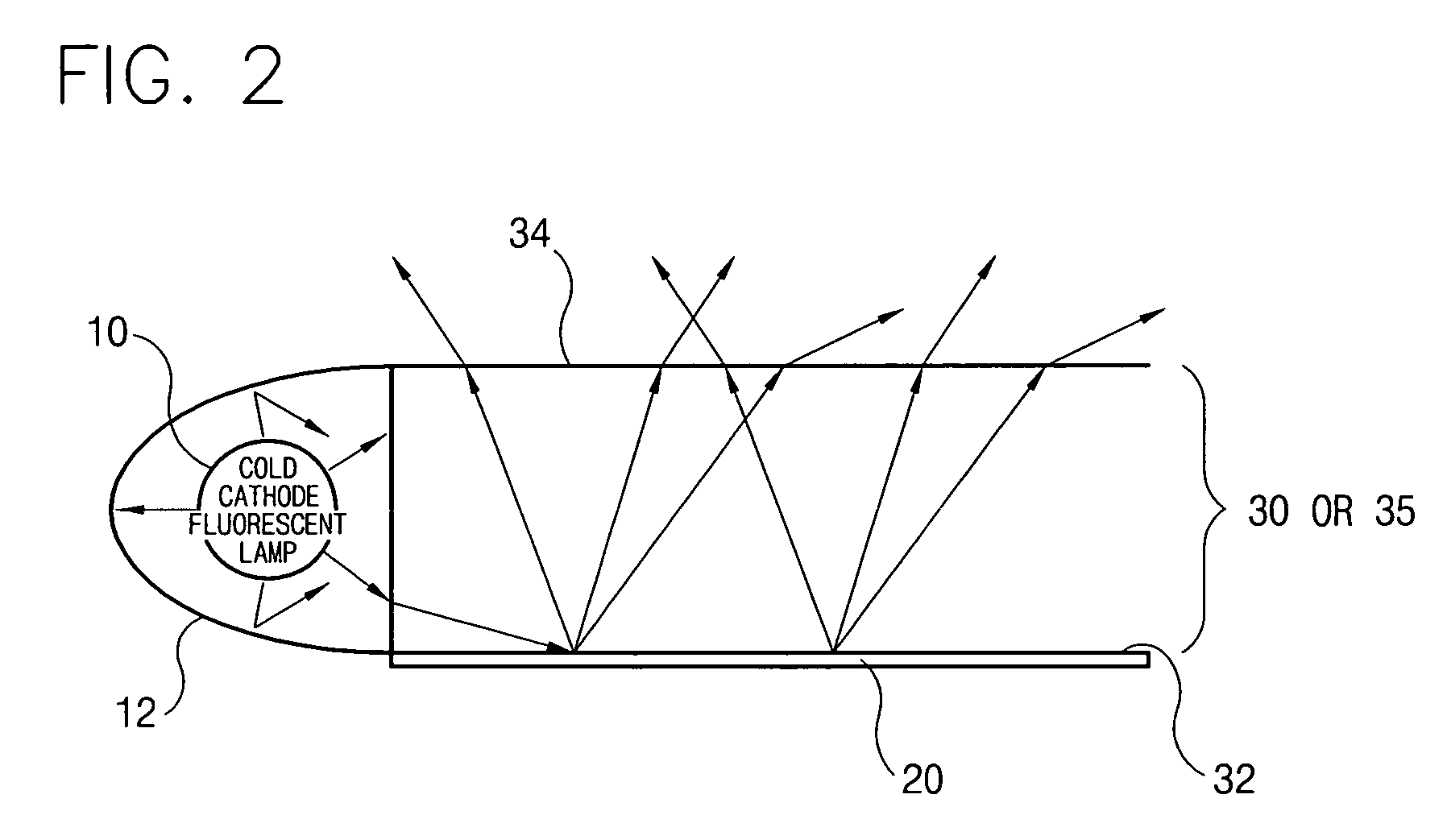

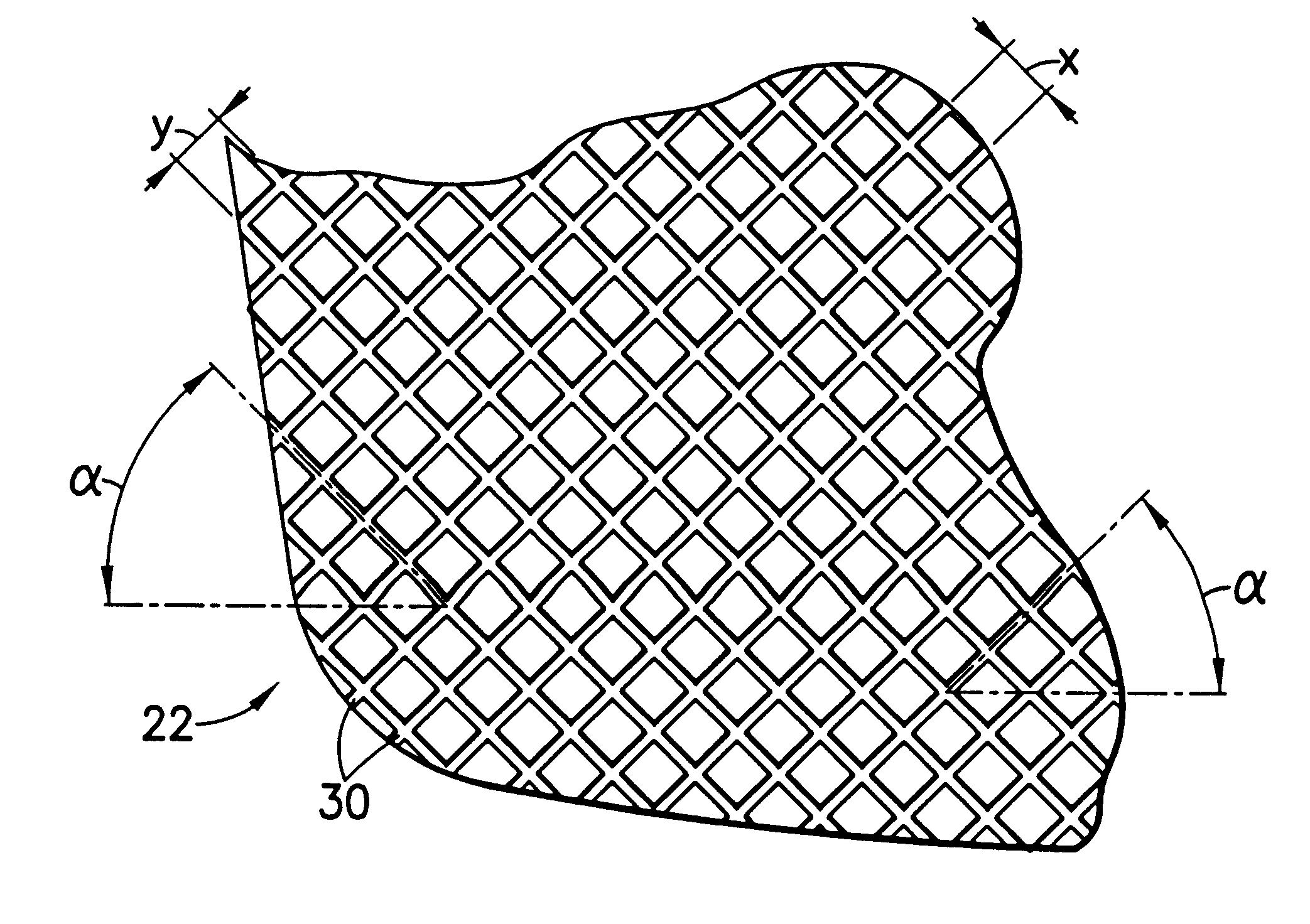

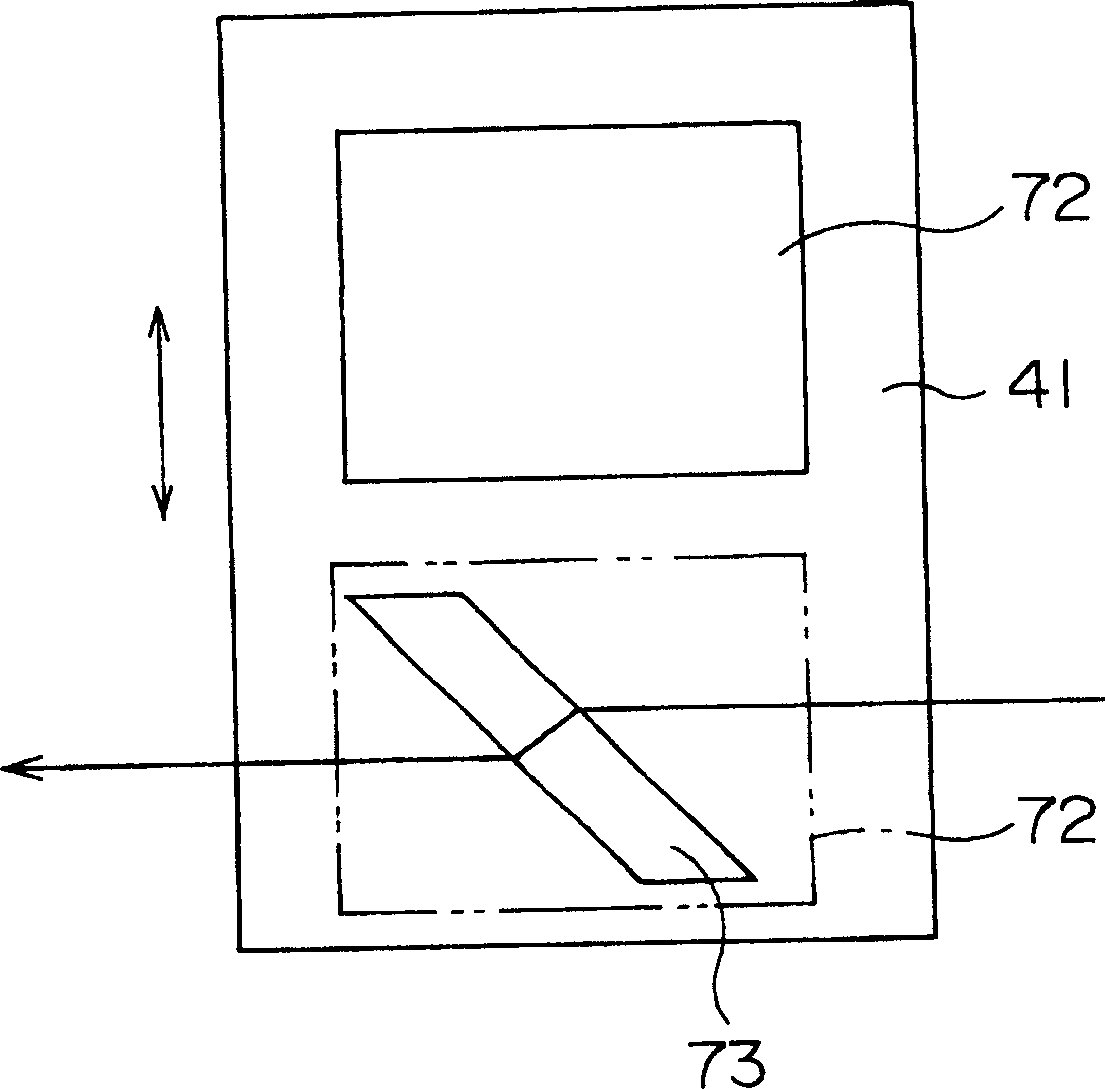

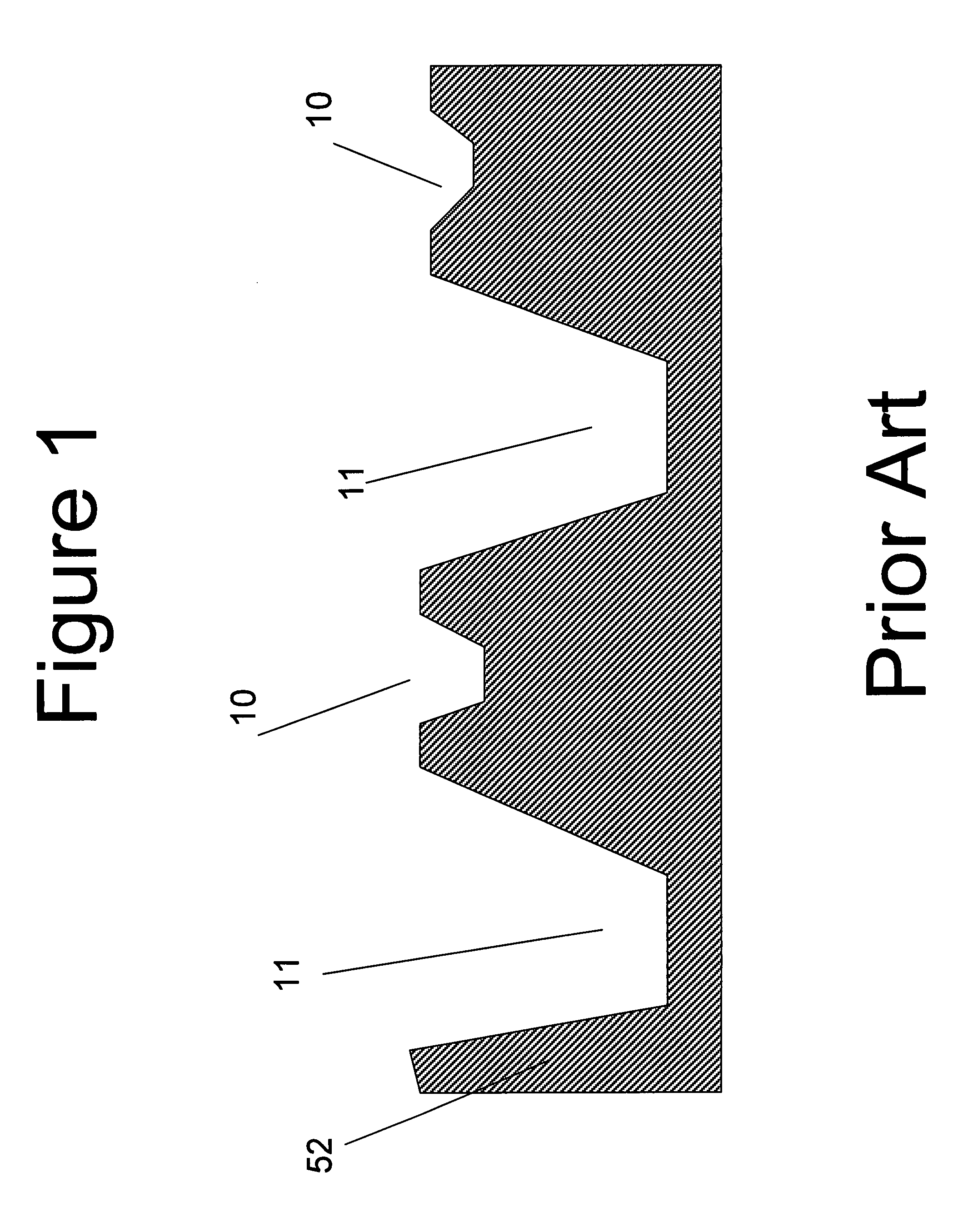

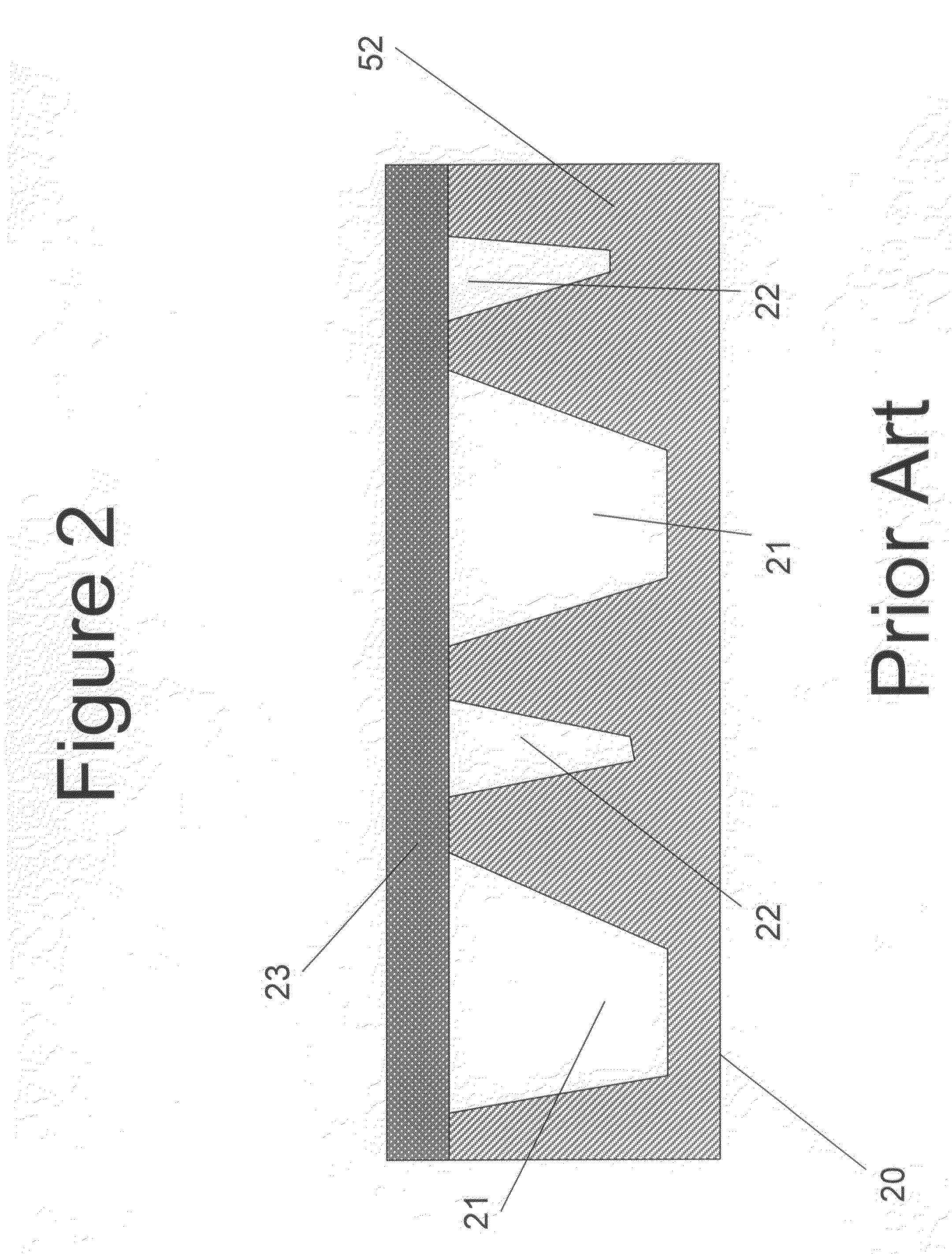

Method of manufacturing a light guiding panel and an apparatus for the same, and a particle blasting apparatus for manufacturing the light guiding panel

InactiveUS20050213021A1Improve brightness uniformityImprove optical efficiencyMechanical apparatusOptical articlesFree fallingEngraving

Disclosed are a method of manufacturing a light guiding panel by means of carving fine engravings on a surface of a transparent substrate by plasting fine particles and an apparatus for the same. A distributed degree of the engravings gradually increases as they become far away from a light source position. In a first method, fine particles are mixed with a high-speed air and then the air-mixed fine particles are diffusively blasted through one or more blasting nozzles so that the fine particles can collide with a surface of a transparent substrate slantly. In a second method, the air-mixed fine particles are diffusively blasted through a plurality of aligned blasting nozzles so that the fine particles can perpendicularly collide with the entire width of a transparent substrate, while appropriately adjusting intervals of the blasting nozzles and / or the amount of blasting as well as swing the blasting nozzles. In a third method, fine particles are mixed with an air generated by a high-speed rotating blower and then the air-mixed fine particles are blasted through a flat funnel-shaped blasting pipe having an outlet of which the width is not narrower than that of the transparent substrate to perpendicularly collide with a transparent substrate. The cross-sectional shape of the outlet of the blasting pipe can be varied by a user's control. The blasting amount of the fine particles is constantly maintained with respect to time by means of a free fall feeding manner of the fine particles. The light guiding panel which has been so manufactured does not need a diffusion sheet and has a good brightness uniformity and a good light effectiveness.

Owner:HUNATECH

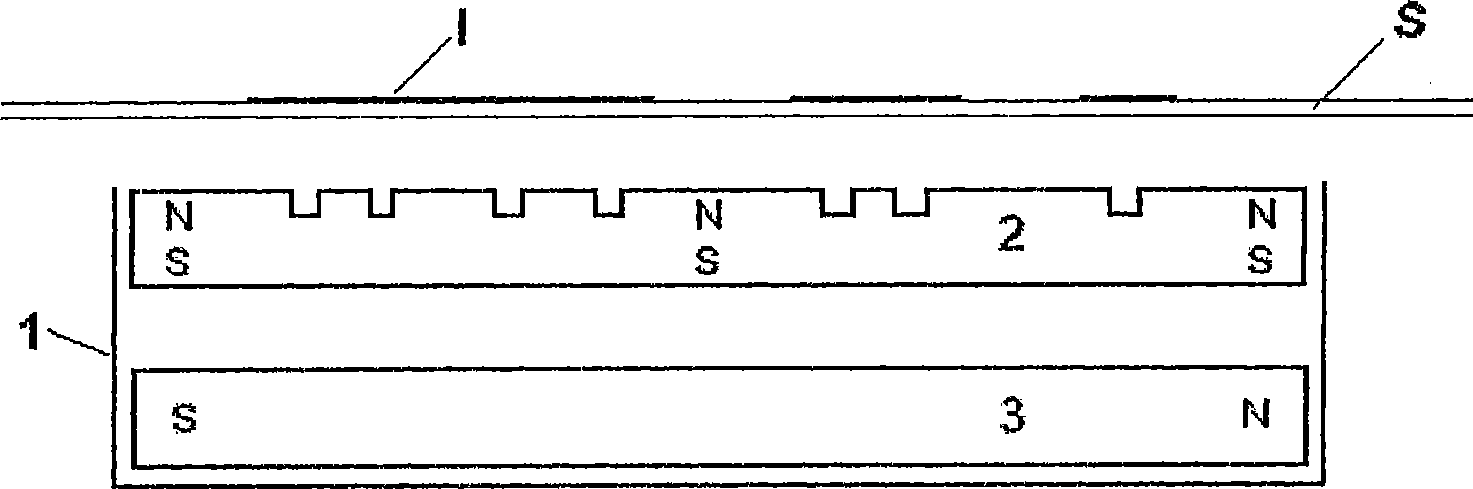

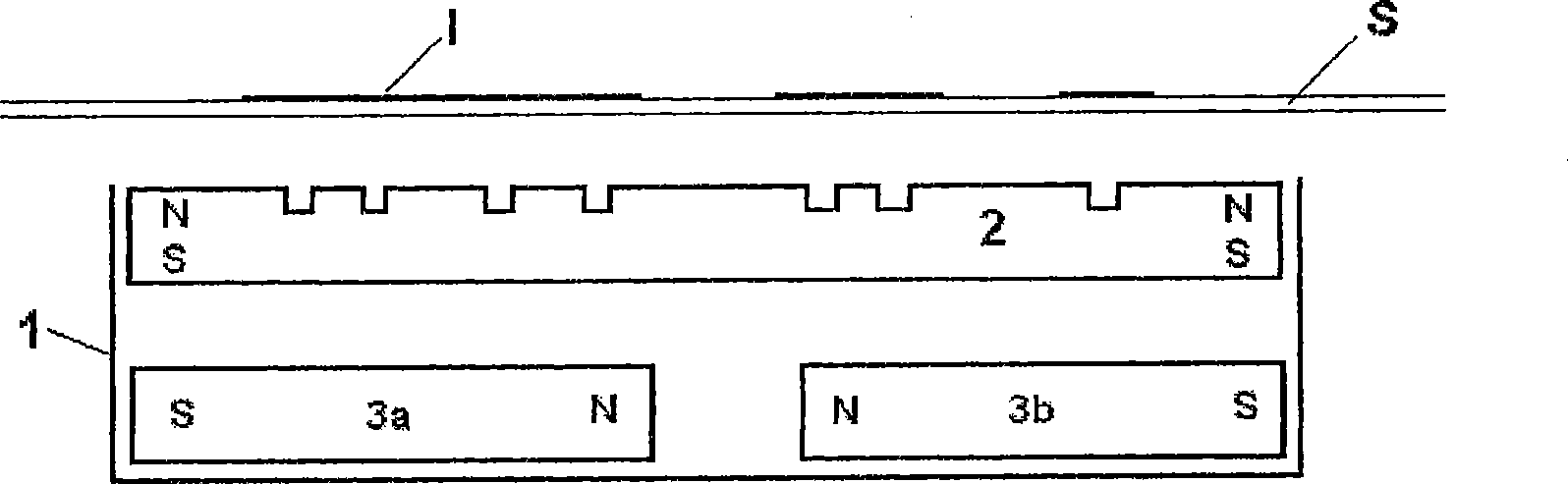

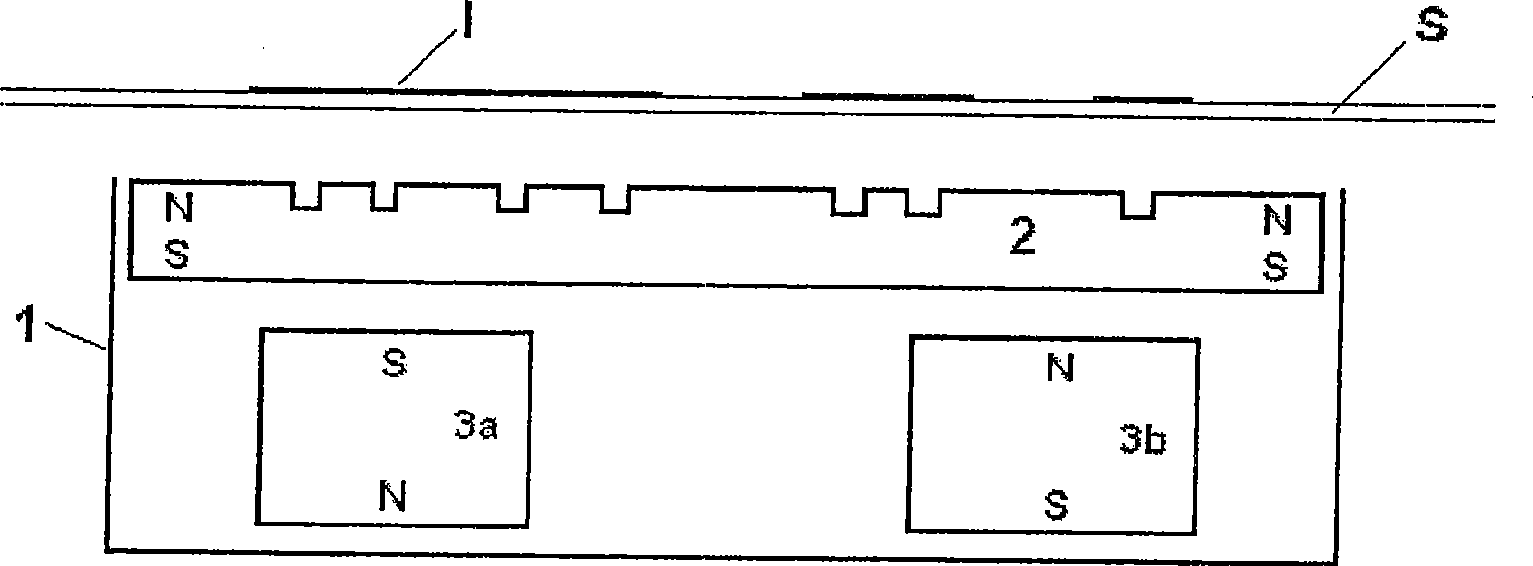

Method and means for producing a magnetically induced indicia in a coating containing magnetic particles

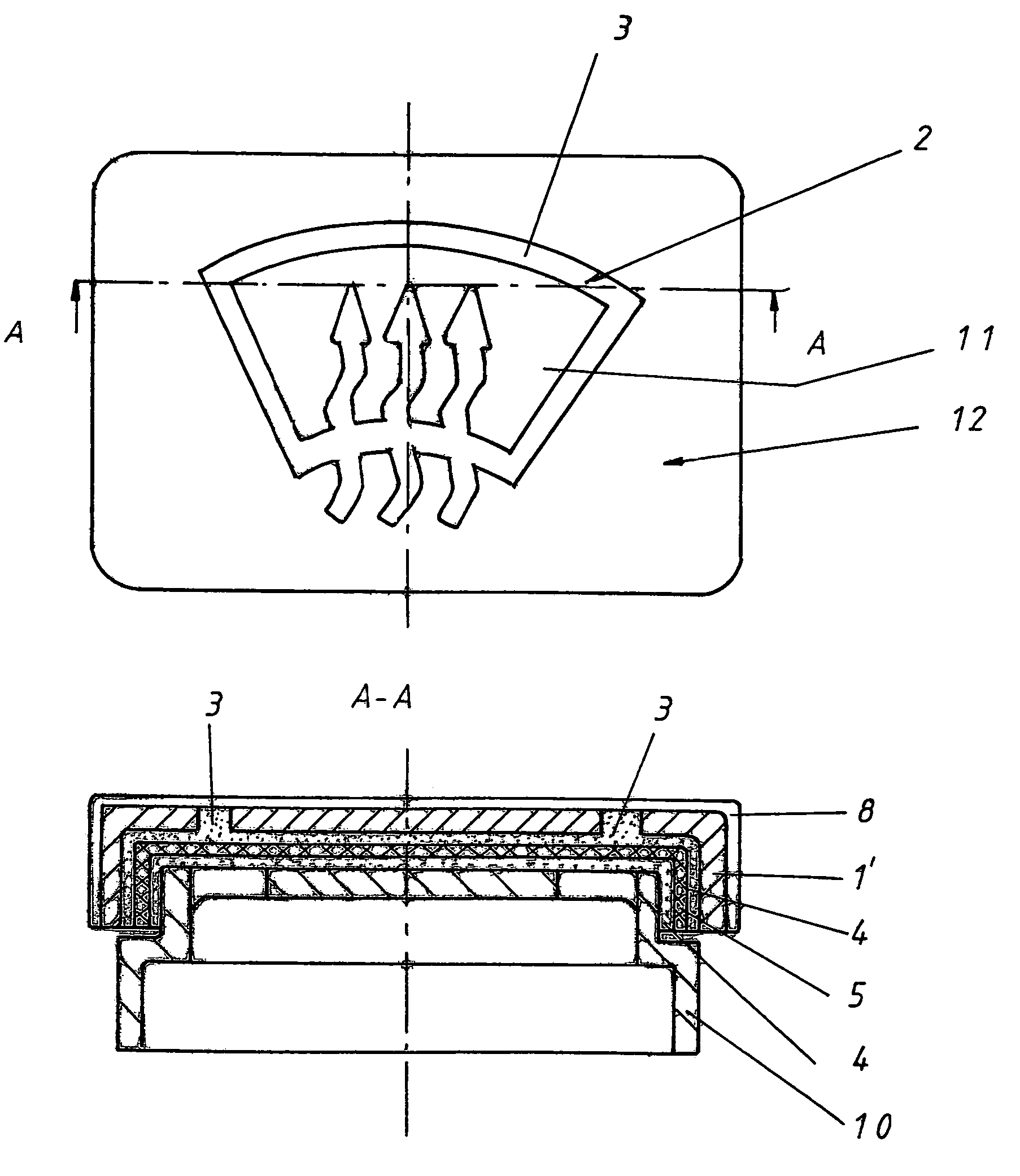

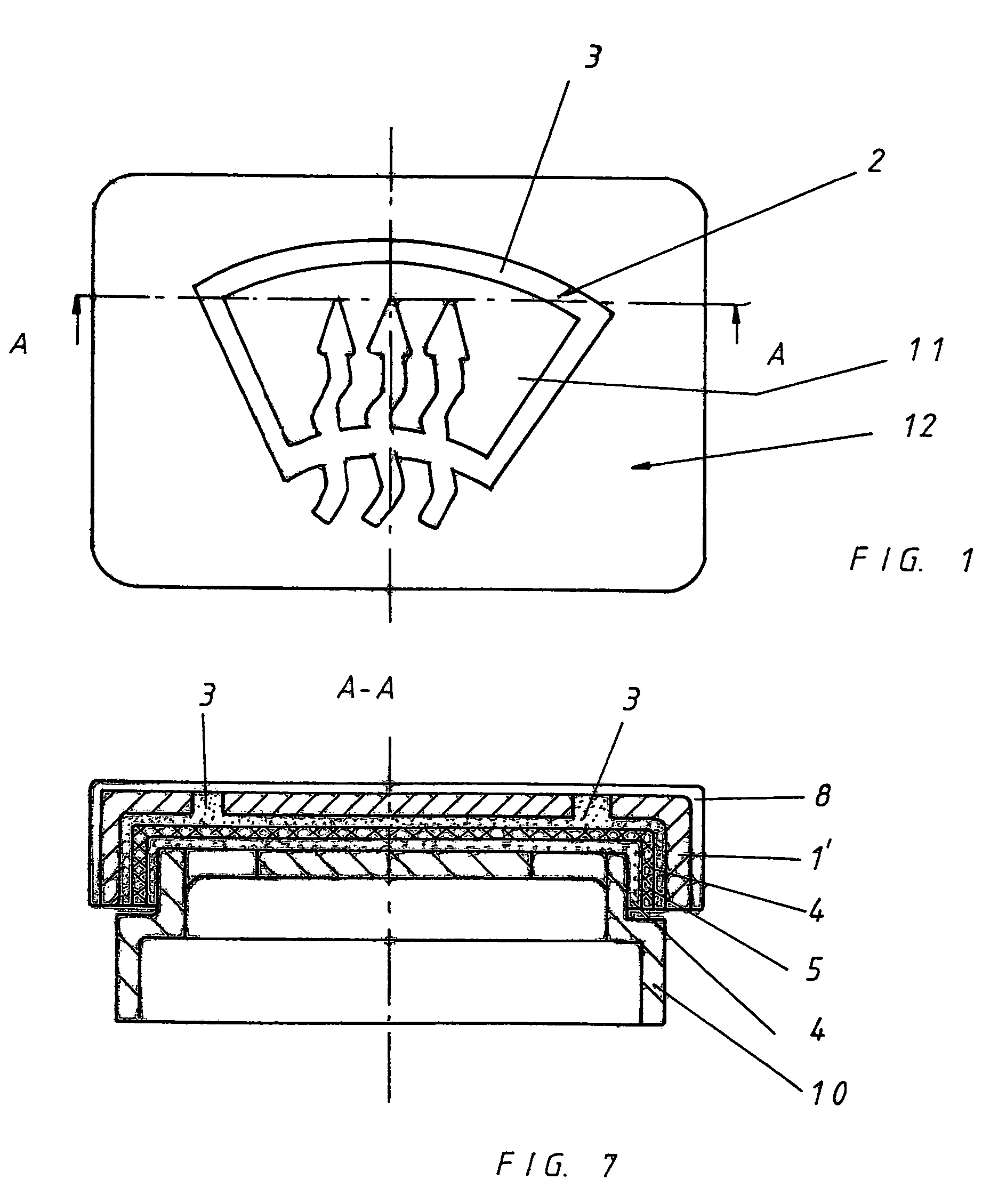

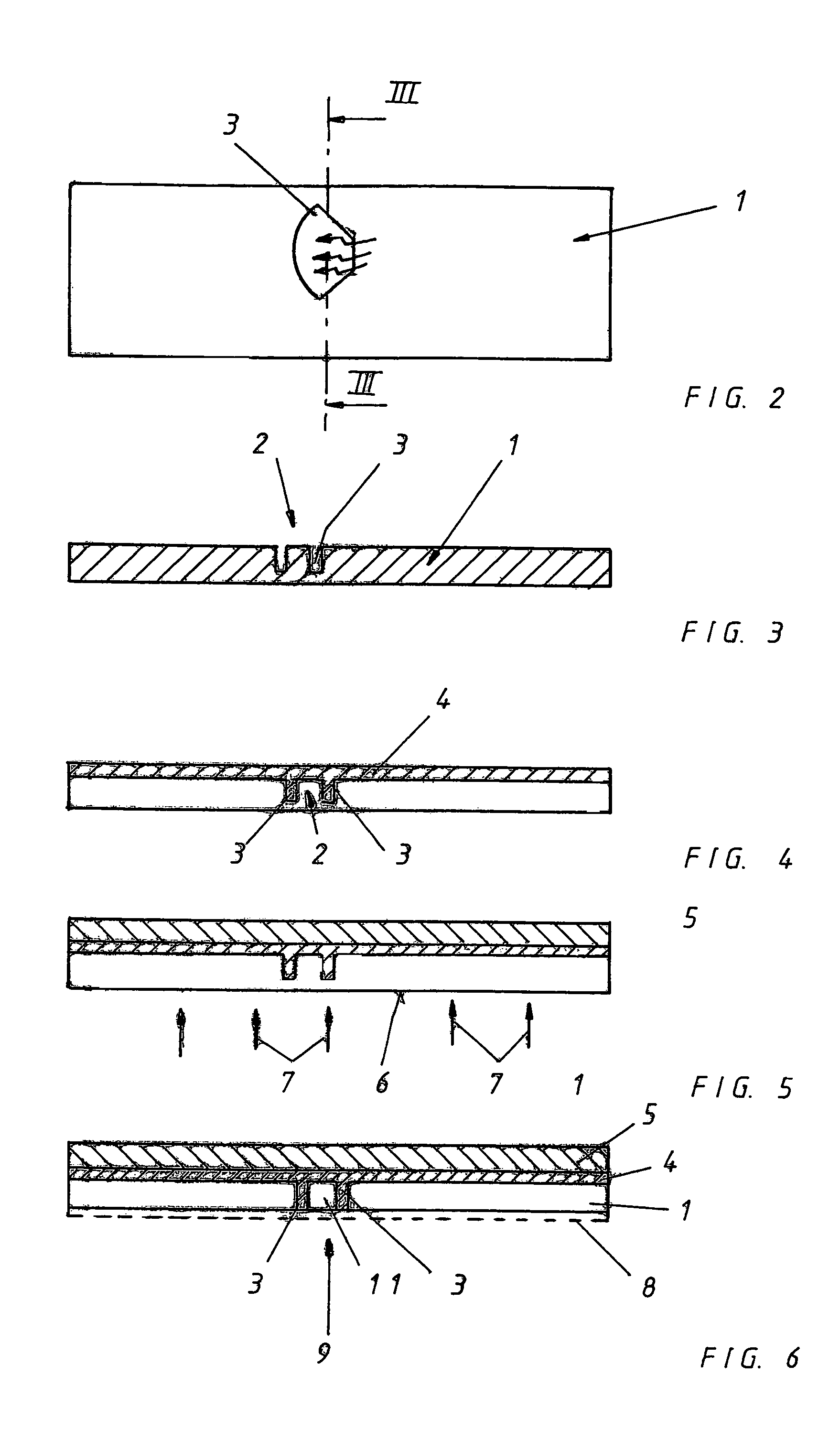

The invention relates to a device for magnetically transferring indicia, such as a design or an image, to a wet coating layer applied on a substrate, such as a sheet or a web, wherein the said coating layer comprises at least one type of magnetic or magnetizable particles; said device comprising a) at least one magnetized permanent-magnetic plate (2) carrying relief, engravings or cut-outs, mounted such that its relief surface remains accessible, b) at least one additional magnet (3), disposed below said at least one permanent-magnetic plate, facing the surface of the magnetic plate which is opposite to the relief, engraving or cut-out, and c) a holder (1), which has the mechanical function to hold the pieces together in fixed positions. A method for producing the device, the use of the device, and magnetically induced designs obtained with the device, which are useful for protecting currency, value- and identity documents, are disclosed as well.

Owner:SICPA HLDG SA

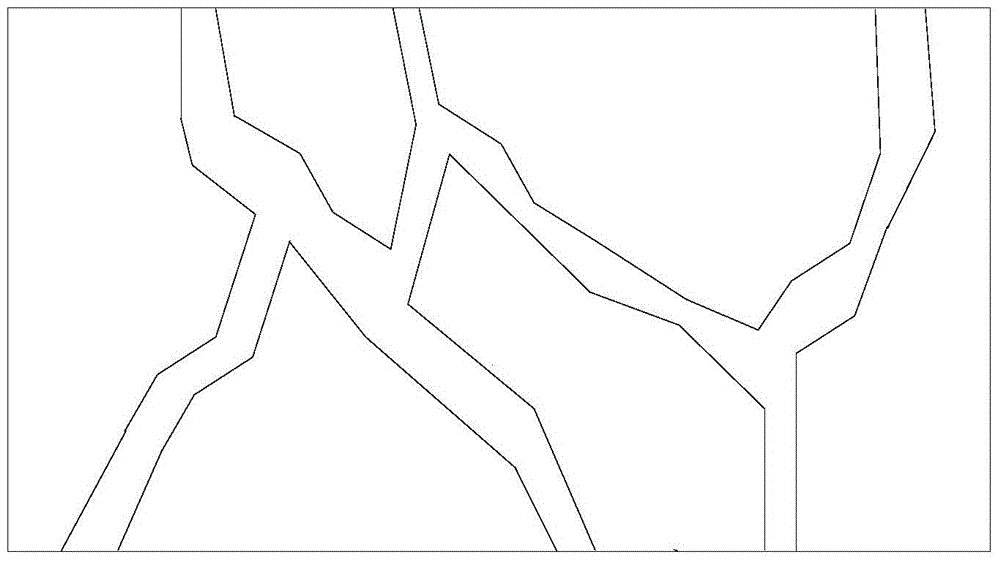

Shearing-seepage coupling experiment method of fracture network rock

InactiveCN103954511AImage and detailed researchLow costMaterial strength using steady shearing forcesNumerical controlDigital video

A coupling experiment device and method for engraving of a fracture network rock test piece and its fracture seepage belong to the fields of hydromechanics and rock mechanics. The method of the invention comprises the following steps: 1. preparing a rock test piece with a certain size required by the experiment; 2. engraving a fracture network by using a full-automatic engraving machine according to real fractures; 3. performing the experiment by using a numerical control direct shearing testing machine with an electro-hydraulic servo microcomputer control system; 4. measuring the pressure of the fracture network, and deriving a flow velocity based on a formula; 5. measuring the change and development state of water or oil in the rock fractures; 6. recording the flowing process and state of colored water in the fractures by a digital video camera; 7. establishing a model with combination of the experiment. The experiment method changes the state in the past that a shearing seepage experiment of a test piece is carried out in a manner that a single fracture is obtained by manual cleavage, and reflects the real state of fractures inside the rock. Experiment materials are low in cost and convenient for manual engraving by onself. The engraving speed is high, the determination device is small in land occupation, and the operation is simple.

Owner:BEIJING UNIV OF TECH

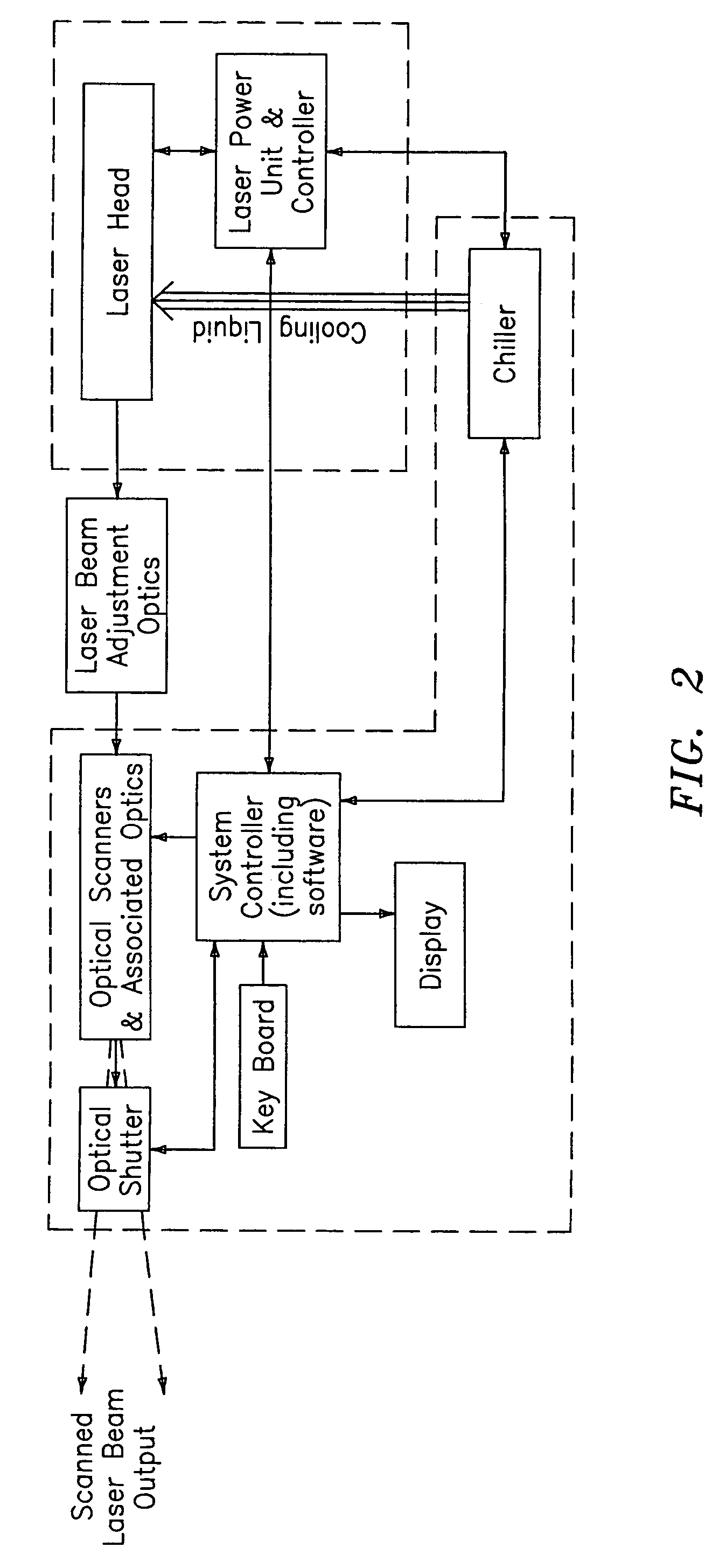

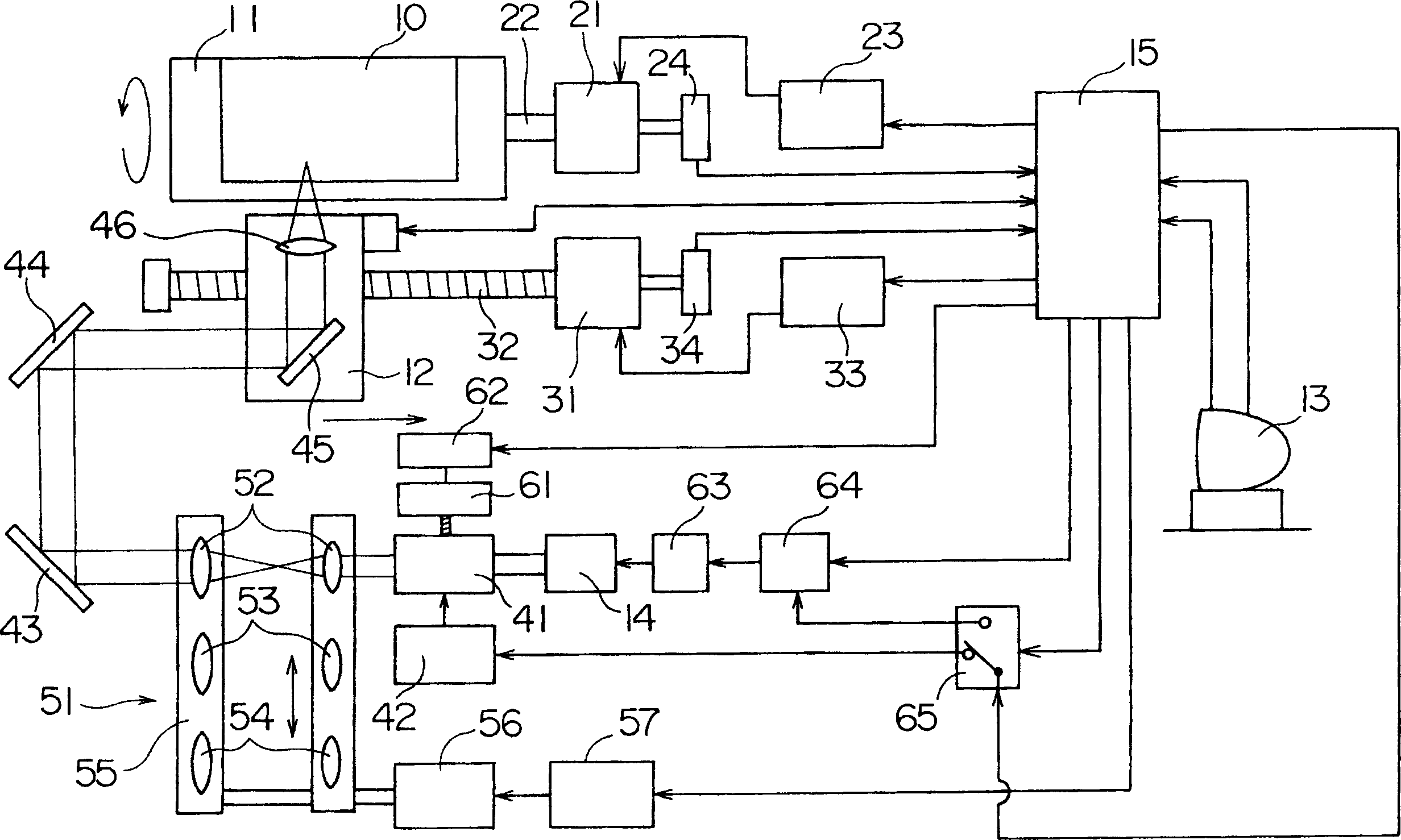

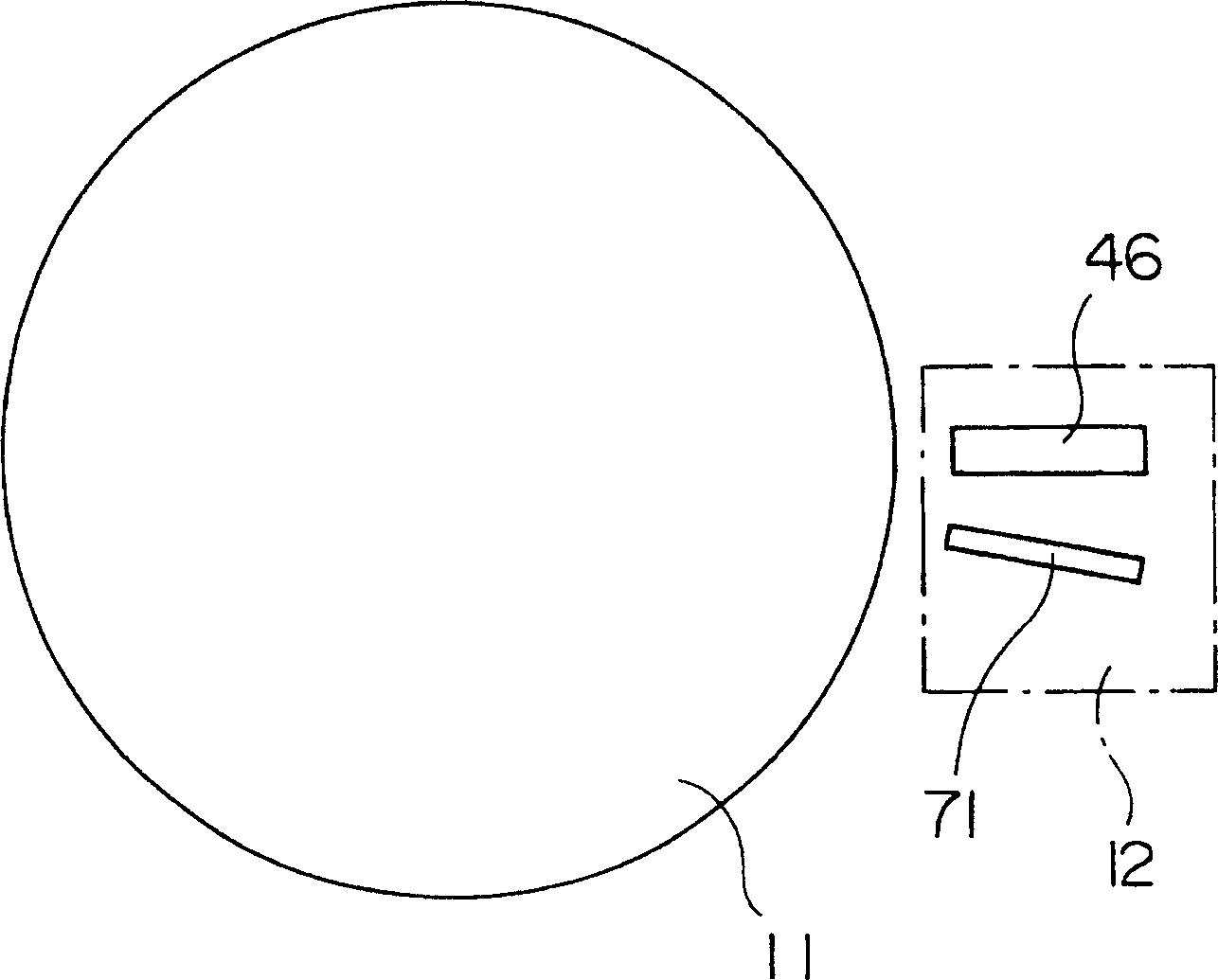

Novel apparatus used for film engraving and dotting of thin-film solar cell

InactiveCN101431126AReach deflectionImprove consistencyFinal product manufactureLaser beam welding apparatusEngravingHigh volume manufacturing

The invention relates to a new device used for scribing and pointing of a thin film solar cell. The device comprises a laser, a support pedestal, an automatic focusing control subsystem, an automatic photographing positioning subsystem, an optical platform, an industrial control computer, a power supply and a dynamic galvanometric scanning subsystem. The device is characterized in that a feeding mechanism is arranged on the optical platform, wherein, the support pedestal, the automatic focusing control subsystem and the automatic photographing positioning subsystem are arranged on one side surface of the optical platform. An X-Y-axis galvanometric scanning unit, a Z-axis front focusing unit and the laser are arranged in a beam of the support pedestal. The industrial control computer is respectively connected with the laser, the X-Y-axis galvanometric scanning unit, the Z-axis front focusing unit and the power supply by cables. The invention has the advantages of simple structure, standard process, low production cost, easy mass production, wide scanning range, small focusing spot, good consistency, automatic and accurate positioning, high working efficiency, and the like, thereby being capable of being widely applied in scribing, pointing and other production fields of amorphous silicon solar cells.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

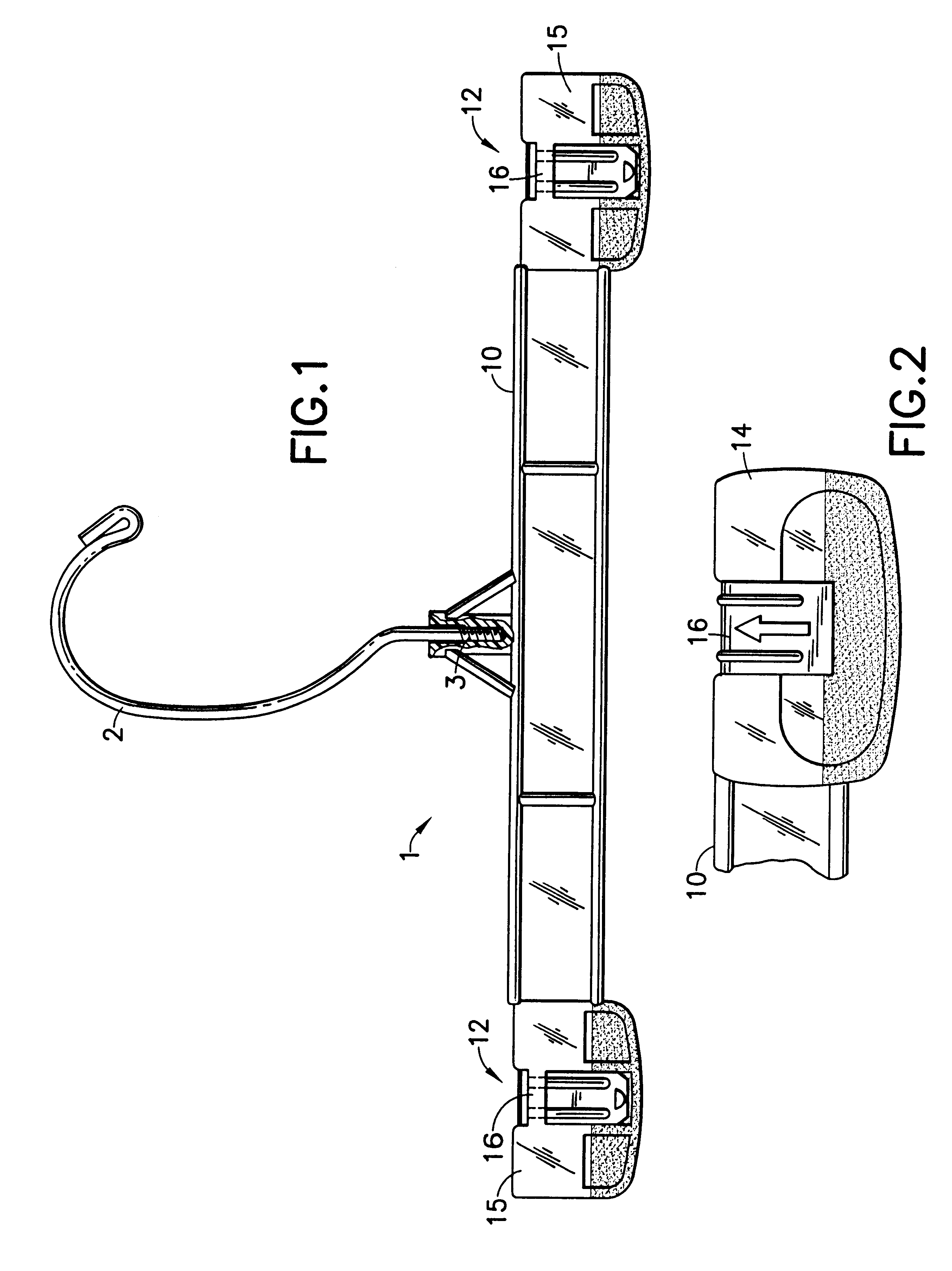

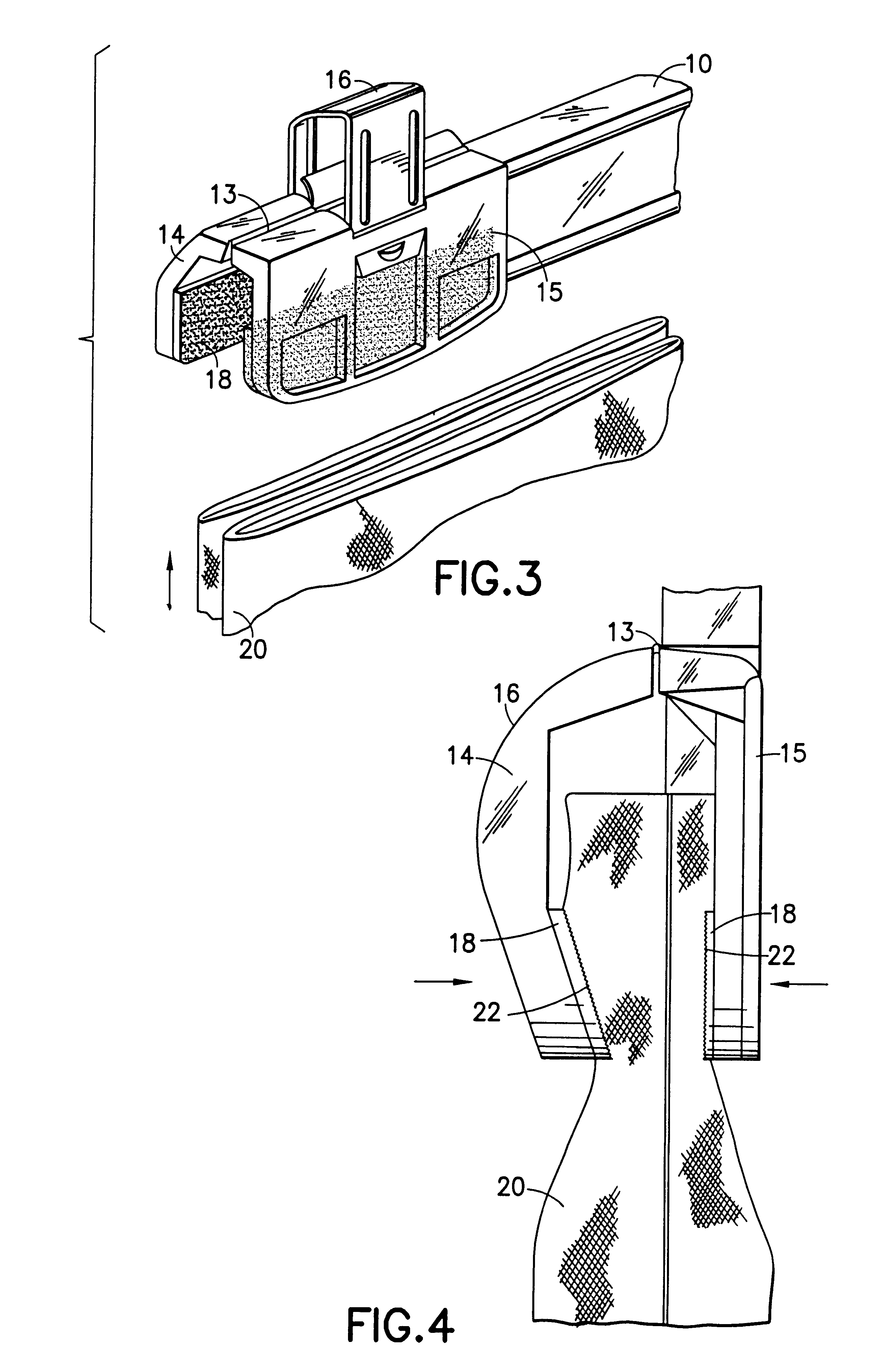

Garment hanger with integral crease-free clamps

A clamp-type garment hanger defined by a pair of opposed jaw members between which a garment is hung. The opposed jaw members have gripping members and opposed non-ribbed gripping surfaces having an enhanced coefficient of friction. The gripping members, opposed gripping surfaces with enhanced coefficient of friction and jaw members are all formed by injection molding in one piece from the same material, which may include either polystyrene, polypropylene, polyethylene, styrene-butadiene copolymers and blends, or polycarbonates. The coefficient of friction is provided to the gripping surface by forming a texture or pattern on the surface with relief structure which does not exceed a maximum elevation, or maximum depth, from the surface. The texture or pattern may be provided by molding, engraving, acid etching, electrical discharge machining, vapor honing, or sandblasting.

Owner:ACCESSORY CORP THE

Platemaking method and platemaking apparatus

InactiveCN1754694AReduce plate making timeOther printing apparatusForme preparationEngravingMaximum depth

The invention provides a plate making method of a printing plate and the plate making device of a print plate. Engraving is conducted by a precise engraving process and a rough engraving process. The precise engraving process uses precise engraving beam of light with small beam diameter to irradiate the flexible photosensitive material at precise engraving pixel intervals. The engraving is conducted until the precise engraving beam of light reaches the maximum depth. The rough engraving process uses rough engraving beam with large beam diameter to irradiate the flexible photosensitive material at rough engraving pixel intervals which are larger than that of the precise engraving pixel intervals, and the engraving is conducted until the beam of light reaches the relief depth.

Owner:DAINIPPON SCREEN MTG CO LTD

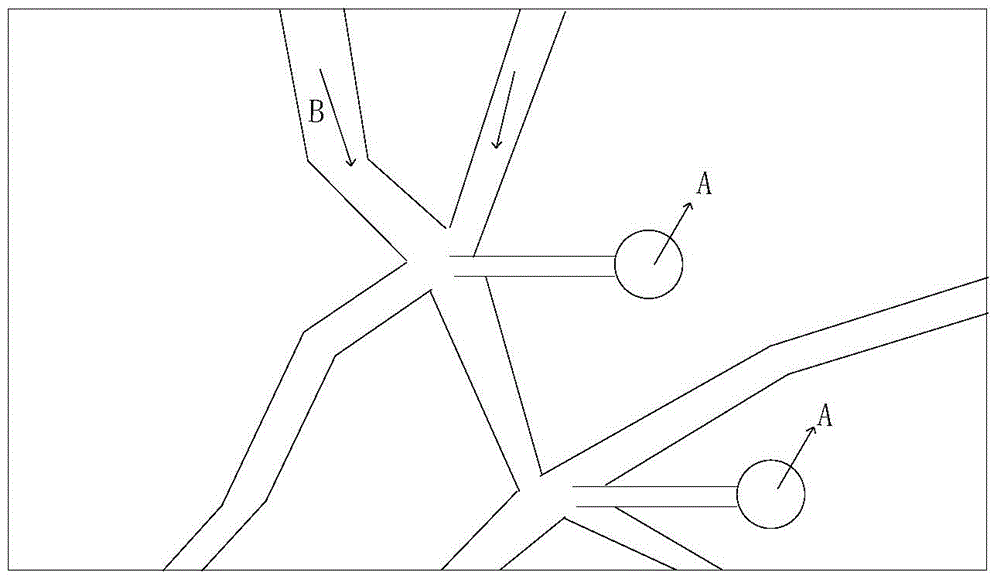

Engraving of printing plates

InactiveUS20090057268A1Decorative surface effectsOptical resonator shape and constructionEngravingLight beam

An optical imaging apparatus (80) for direct engraving of flexographic plates (52) includes at least two laser sources (43), each emitting laser beams (44). A mirror or prism (45) is placed in front of each of the laser sources to alter an optical path of each of the laser beams. The laser beams cut the flexographic plate at different depths and cut out chunks (65) of the flexographic plate.

Owner:MIRACLON CORP

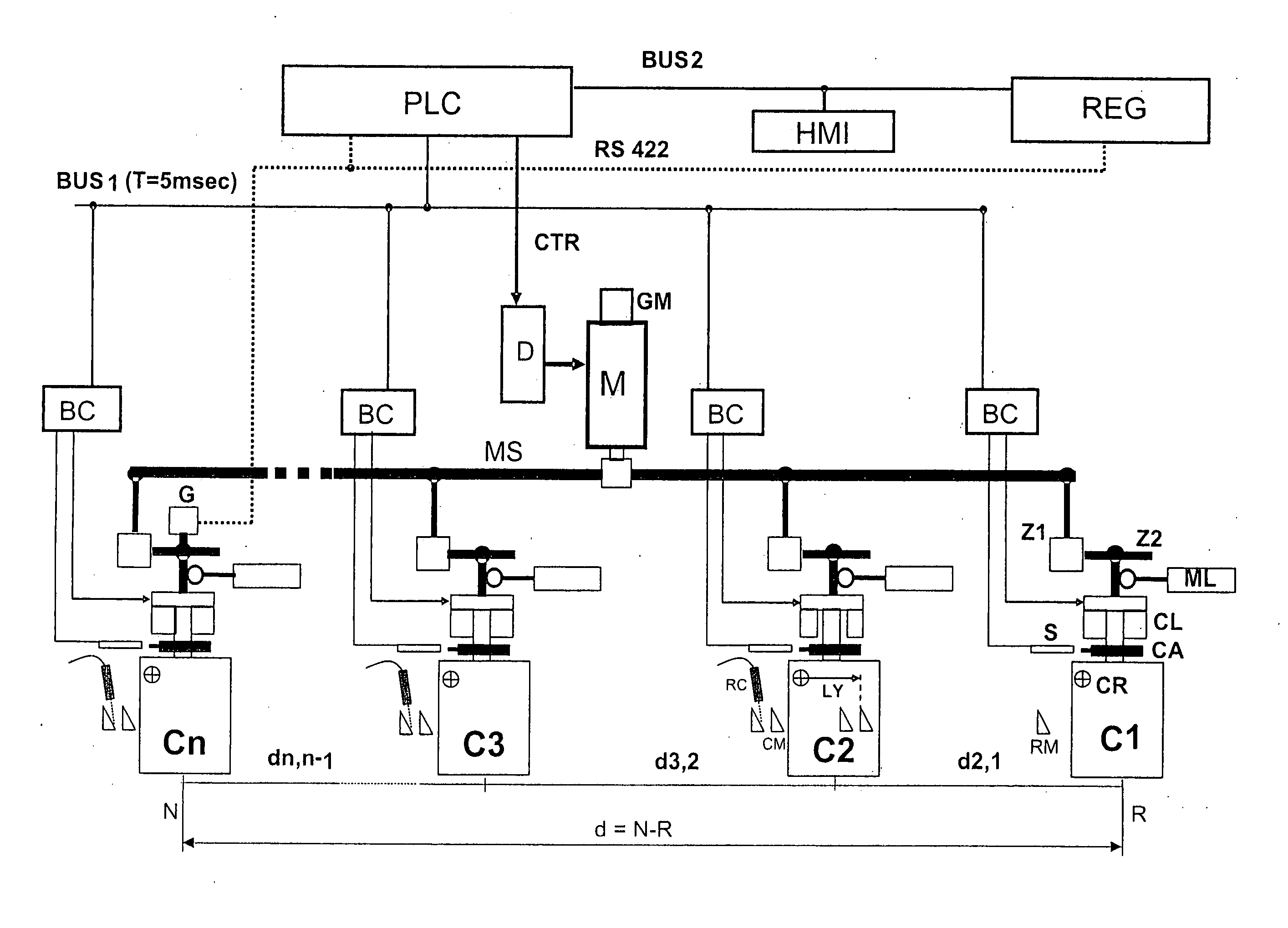

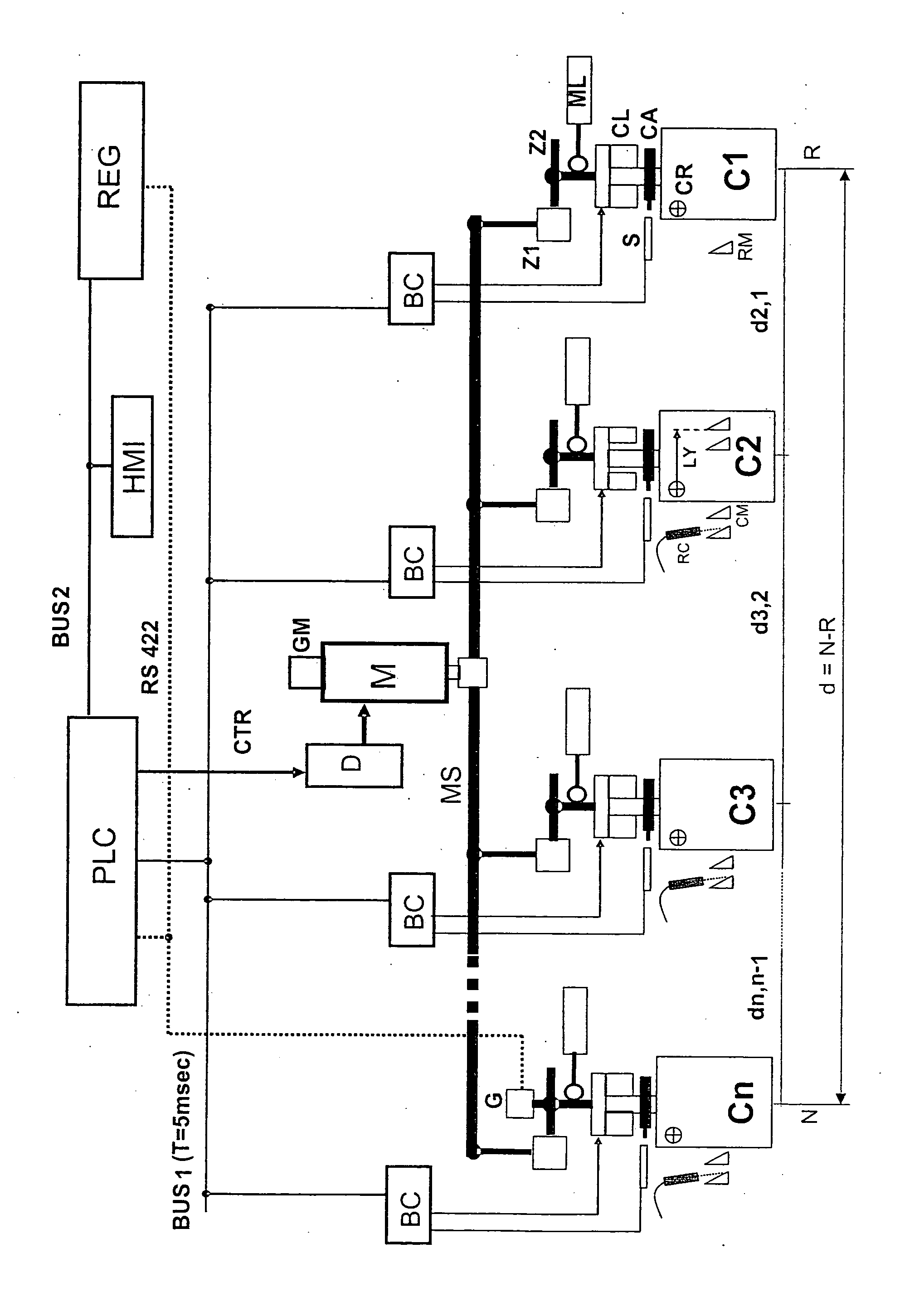

Method and device for initial adjustment of the register of the engraved cylinders of a rotary multicolour press

ActiveUS20050247219A1Exceptional versatility of applicationPlaten pressesRotary intaglio printing pressEngravingPrinting press

To adjust peripheral register of engraved cylinders, the positions of a respective angular register mark arranged on each cylinder is measured with respect to a zero reference, and an angular printing mark characteristic of the position of the engraving is associated with each cylinder. The data of the job to be run are stored. The respective angular displacements of the engraved cylinders are indexed with respect to a reference cylinder in accordance with the job. By determining the web length separating two printing points of two successive engraved cylinders, this length is divided by the peripheral length of the cylinder and the remaining amount of the division is used for determining the angular indexing. Each cylinder is then brought into its angular indexed position, is first disconnected from a common transmission, and then all the cylinders are simultaneously reconnected to the transmission.

Owner:DELPHI TECH INC +1

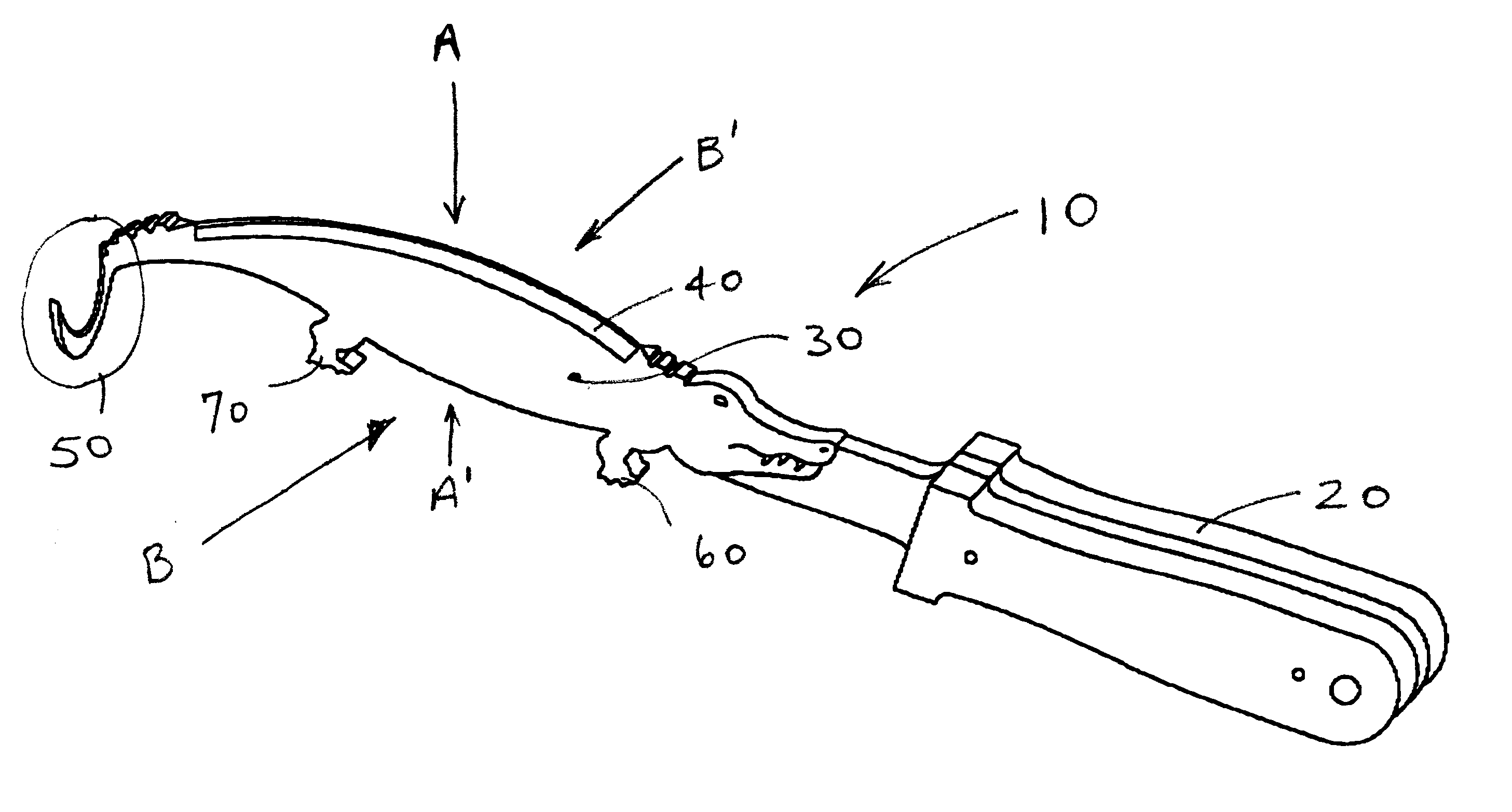

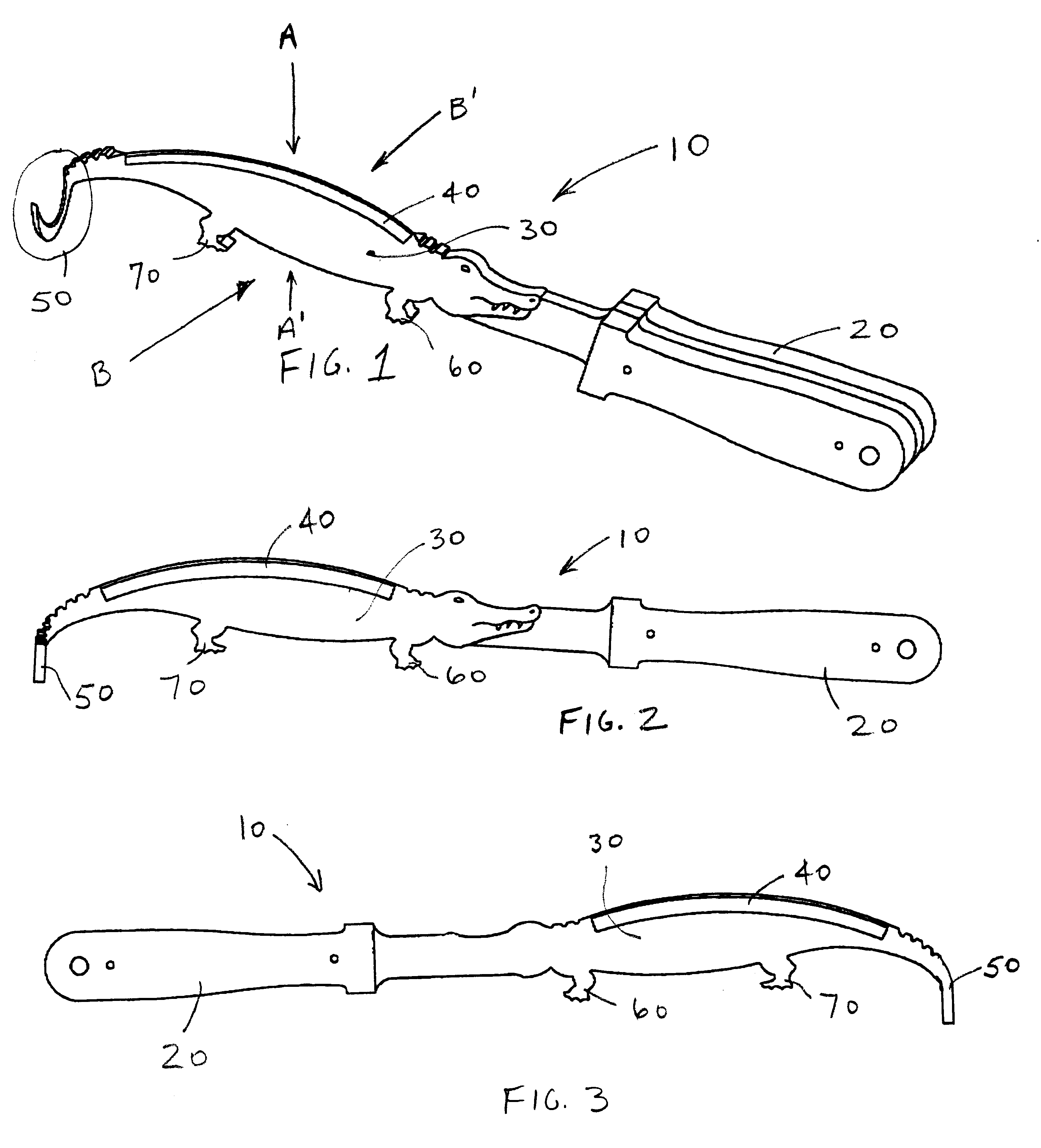

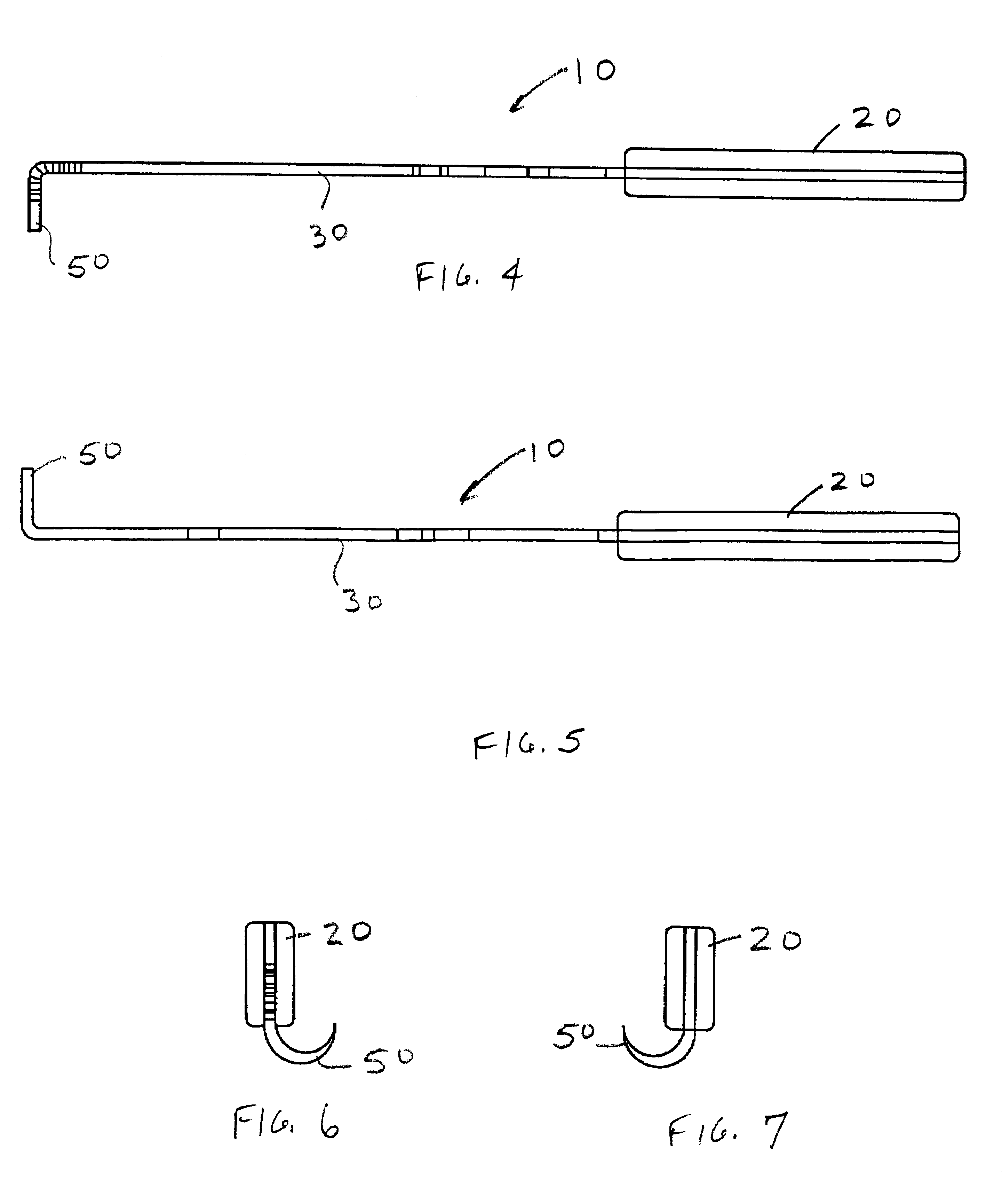

Combination knife, turning hook and bottle de-capper, with animal shape

A combination food preparation and handling tool comprises a handled main blade body, a turning hook, and a pair of legs protruding from the main blade body. In the preferred embodiment, the turning hook is integrally formed from an extended and pointed tip of the main blade body formed into the desired shape and bent at an angle to the main blade body. One edge of the main blade body is preferably arcuate in shape and sharpened to form a primary cutting edge. The legs can form a bottle de-capper and a secondary cutting edge. The preferred arrangement of the main blade body, the turning hook and the legs forms a likeness of a legged animal, such as an alligator. Further enhancement of the animal appearance may be had through etchings or engravings on the main blade body to represent other features of the animal.

Owner:MATT SHANE MICHAEL

Automated engraving of a customized jewelry item

InactiveUS20060200269A1Reduce the amount requiredCost effectiveSpecial data processing applicationsEngravingPersonalizationIcon design

A method for manufacturing a ring (i.e. class, championship, or affiliation) begins by receiving order data specifying a series of personalization elements, such as the addition of text and icon designs. A geometric model for each personalization item is constructed. To assemble text panels, the operating system provides font geometry for a desired TrueType font. Then a set of splines are created from the font geometry and are then tessellated to generate polyline sets of data, which are then spaced and mapped between two boundary curves. The personalization elements are then projected onto one of the model's 3D surfaces. A set of machining instructions for a milling machine is generated by obtaining a set of machining pattern strategies, generating a set of curves, projecting the toolpath onto the surface of the ring to calculate the 3D toolpath, and rotating it to a desired angle.

Owner:JOSTENS INC

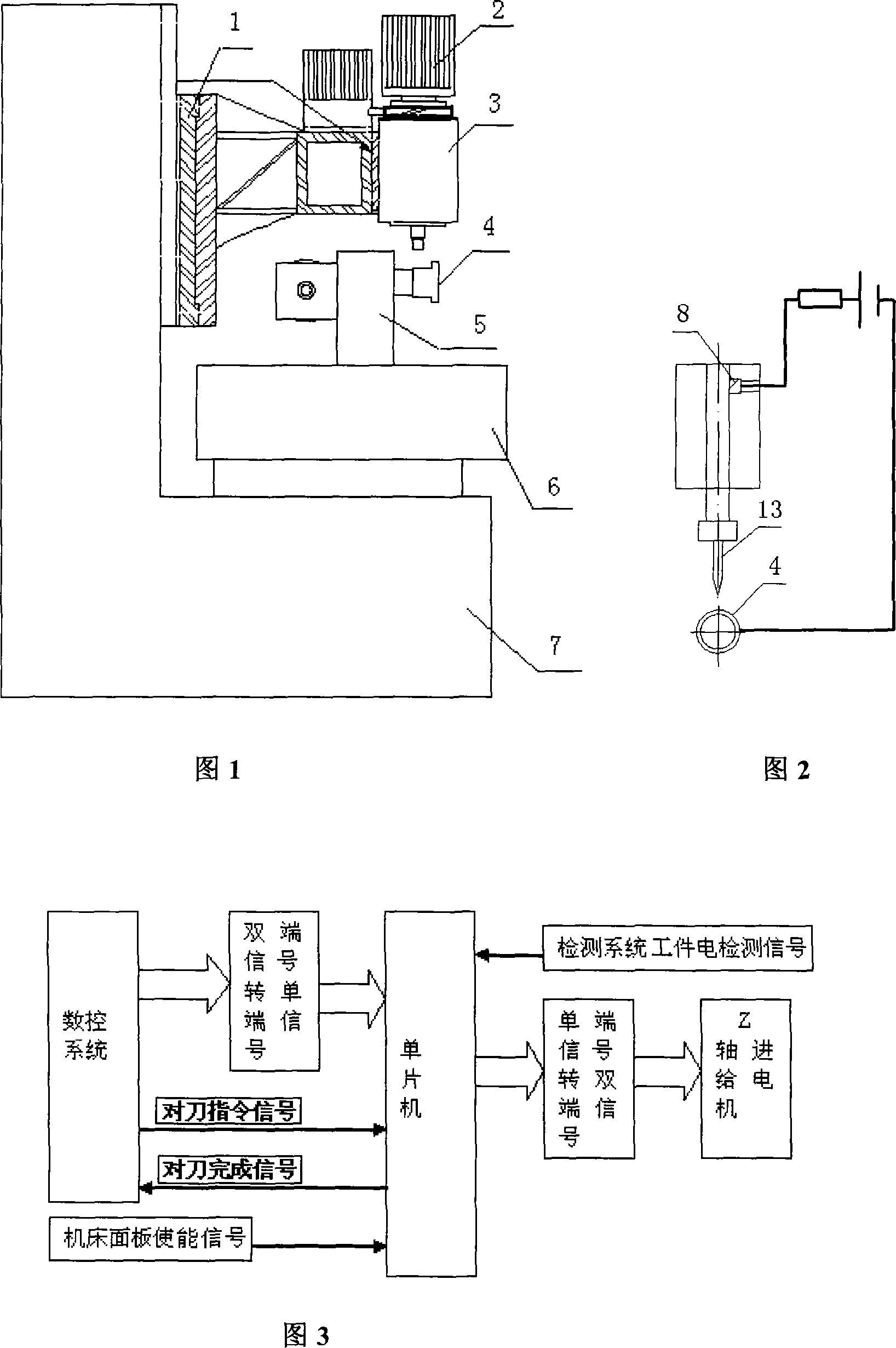

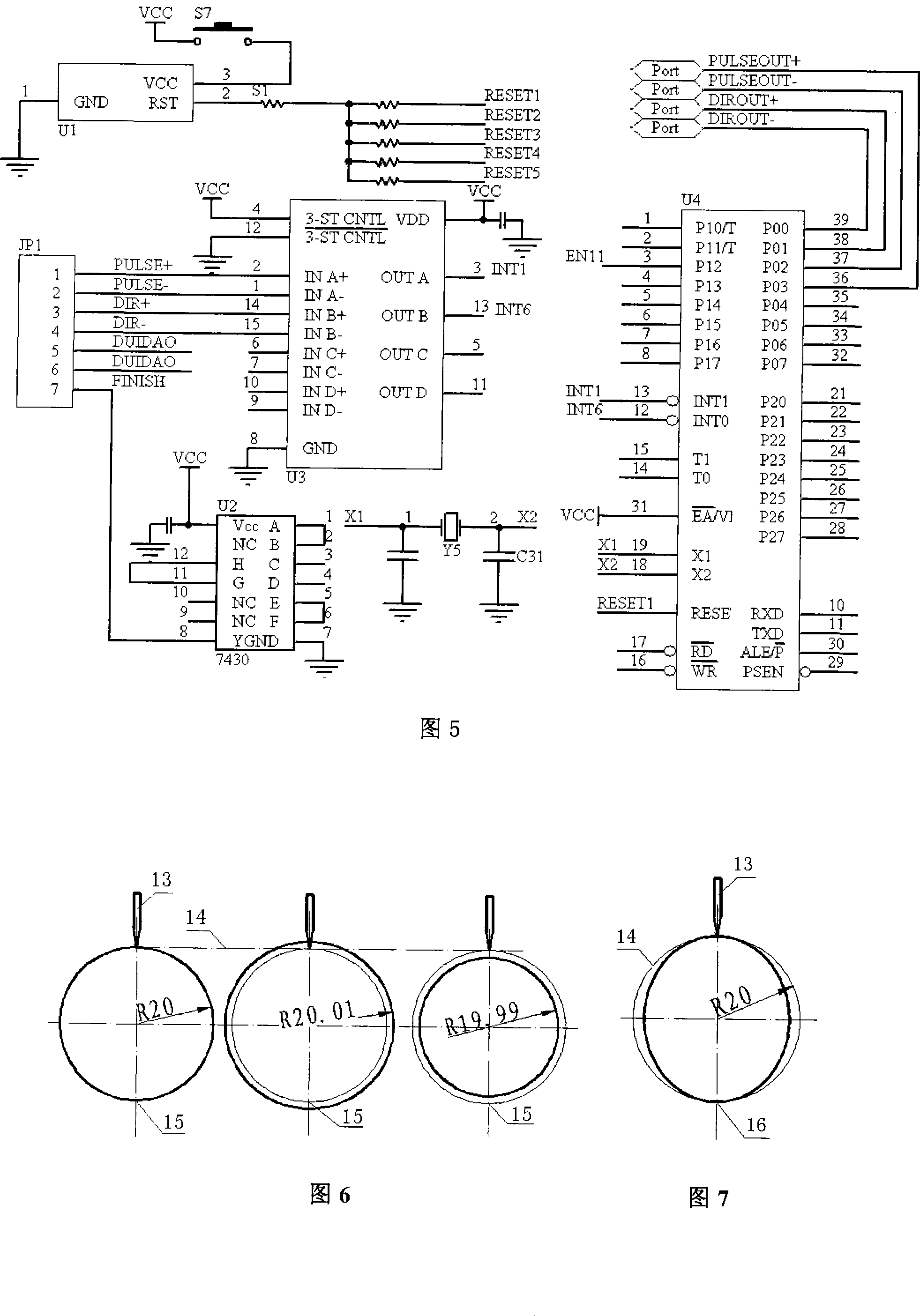

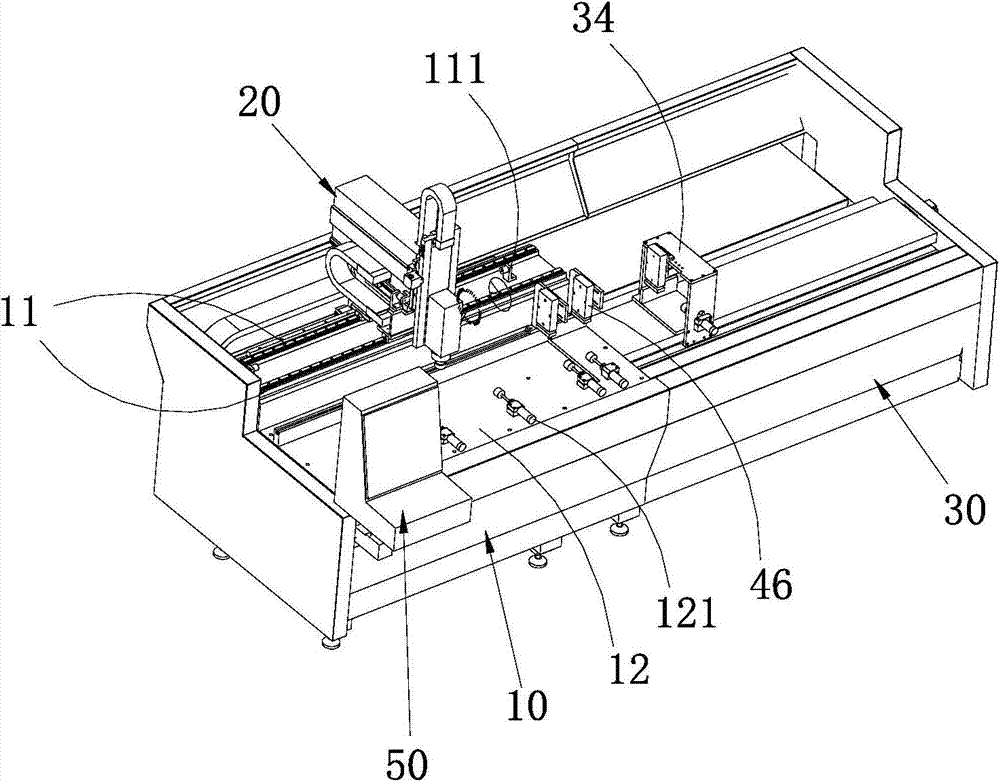

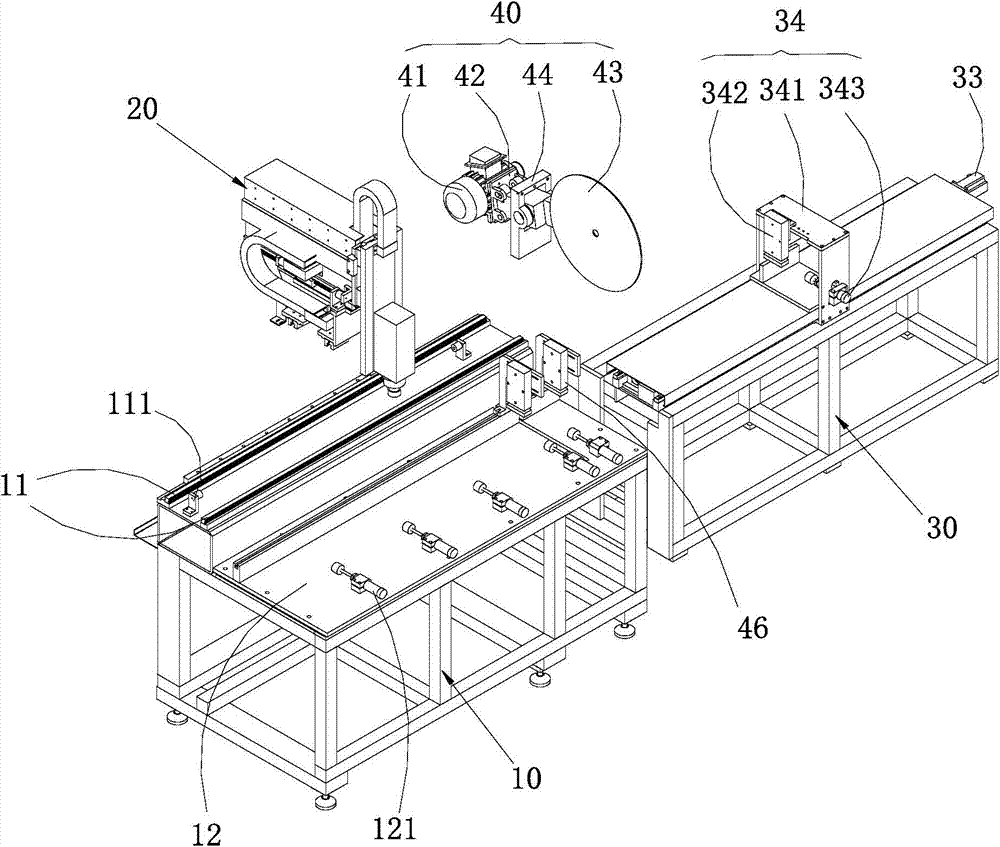

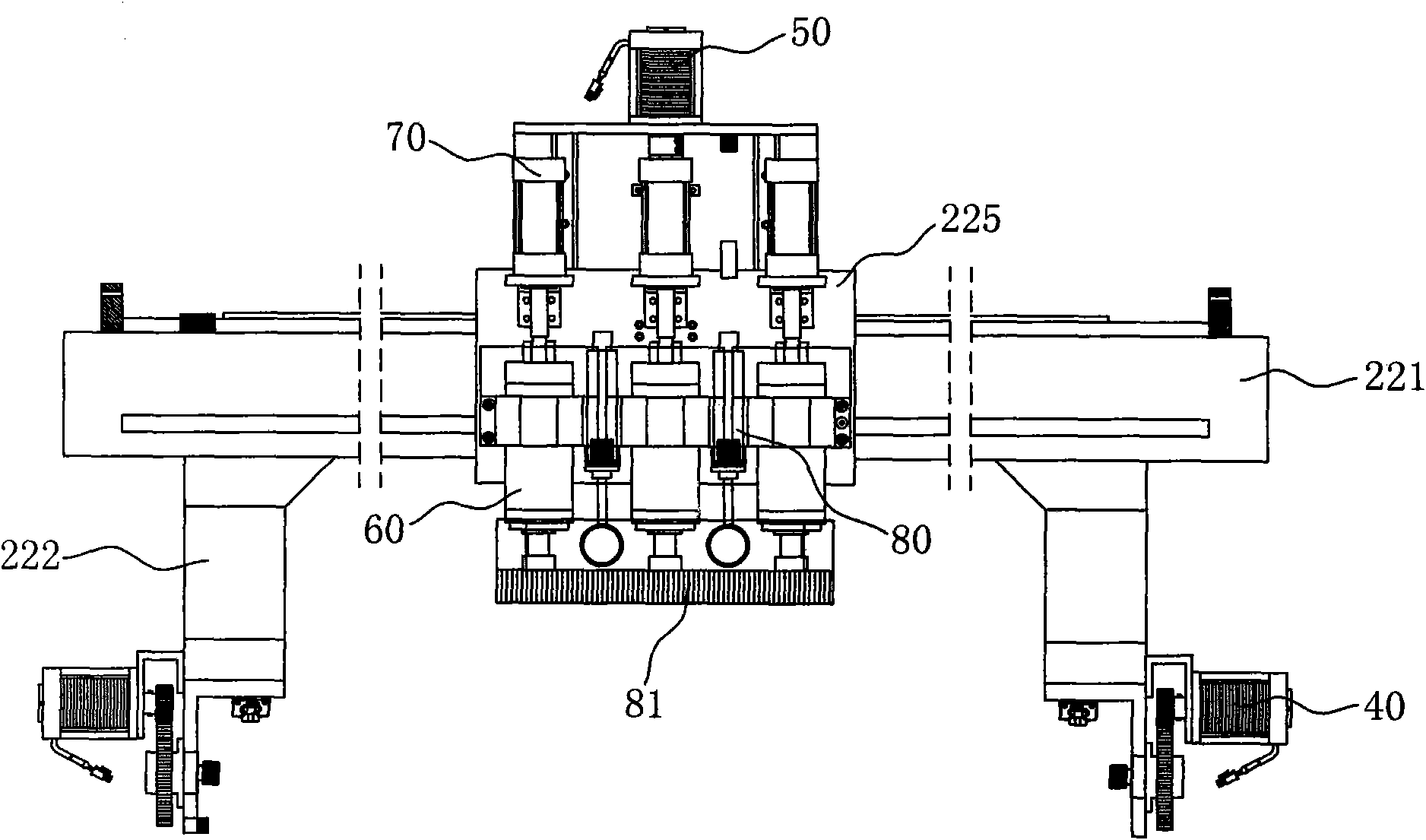

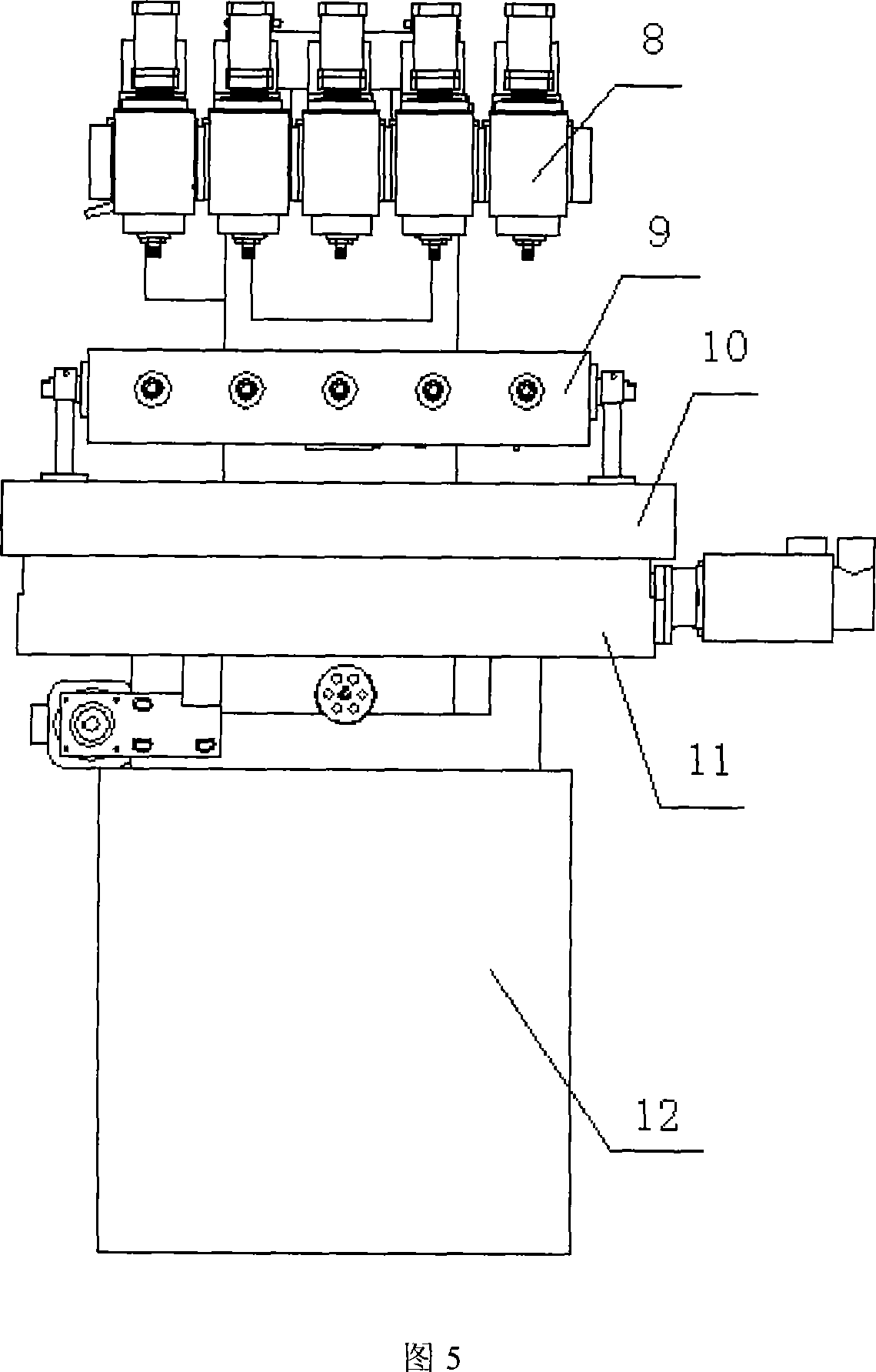

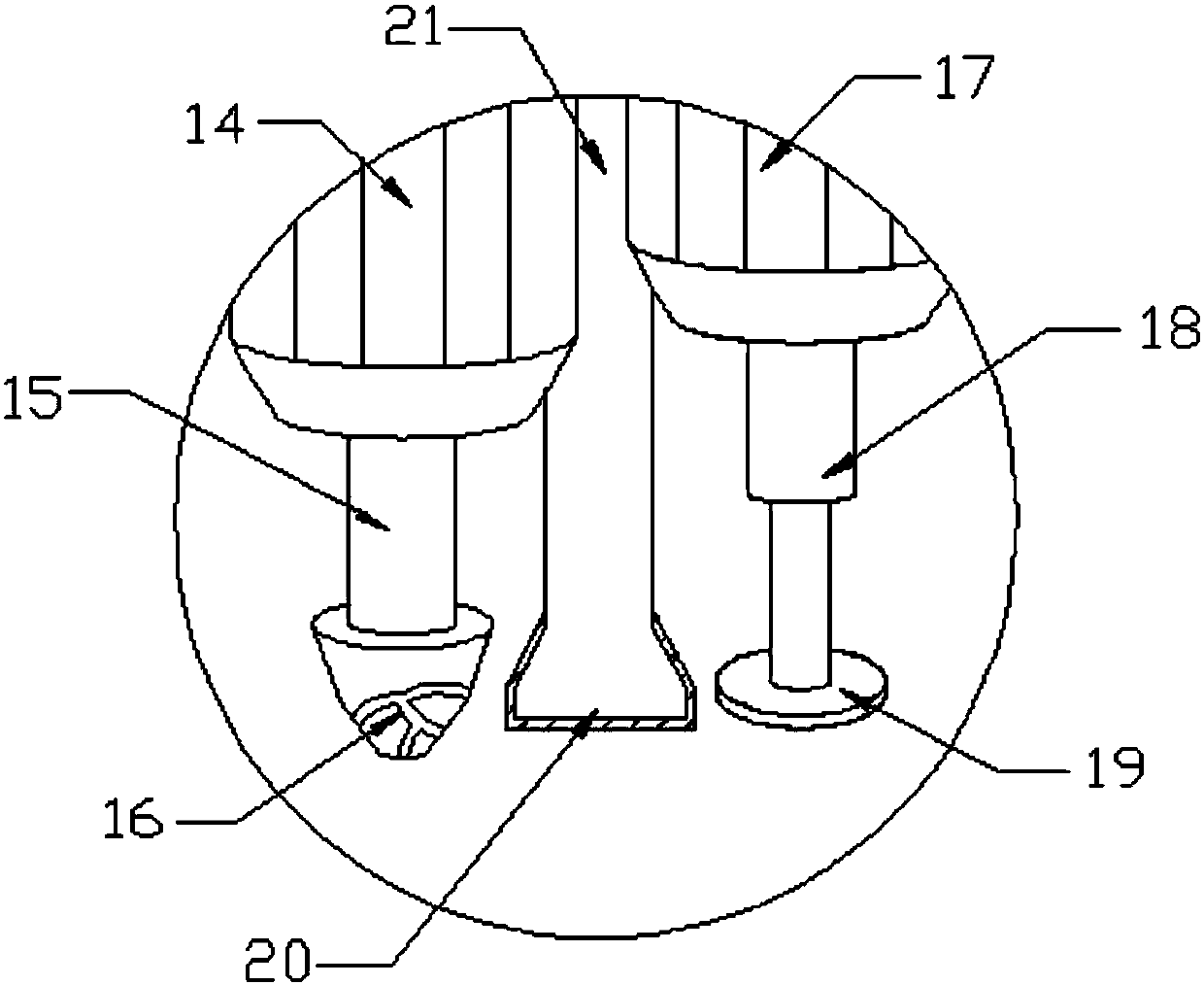

Multi-station numerical controlled carving tool setting device

InactiveCN101195319AGuaranteed engraving depth consistencyHigh precisionAutomatic control devicesFeeding apparatusElectricityNumerical control

The invention provides a tool setting device for multi-station numerical control engraving, which is composed of a control system and an electrical contact signal detecting system, wherein the control system comprises four circuits of a single chip computer control group circuit, a signal input and transformation circuit and a signal output and transformation circuit, the single chip computer control group circuit is composed of a plurality of independent single chip computers U4 and peripheral circuits thereof, the electrical contact signal detecting system is a good conductor composed of a body (7), a worktable, a clamp and a workpiece (4), and connected with the power supply via 'earth' connection, the positive electrode of the power supply is connected with an engraving head (3) which is connected with a main shaft motor (2). The invention can realize automatic tool setting, and enable all the tools to be positioned on the surface of the workpiece before engraving feed, particularly consistency of engraving depth is guaranteed in high precision engraving, further the performance is reliable and the breaking edge rate is smaller than 0.0001%. The device of the invention can be widely applied to precise engraving of numerical control engraving machines and multi-station processing systems of numerical control milling machines, machining centers and the like.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Numerically-controlled drilling and milling machine

InactiveCN103567764ASave cutting processIncrease productivityOther manufacturing equipments/toolsMetal working apparatusEngravingEngineering

The invention discloses a numerically-controlled drilling and milling machine. The numerically-controlled drilling and milling machine comprises a machine frame. A drilling and milling mechanism is arranged on the machine frame. A feeding mechanism is arranged on one side of the machine frame. A sawing mechanism is arranged on the side, close to the feeding mechanism, of the machine frame and comprises a motor, an arm seat and a cutting tool, wherein the motor is arranged at one end of the arm seat, the cutting tool is arranged at the other end, close to the feeding mechanism, of the arm seat, the motor is connected with the cutting tool through a transmission belt, the arm seat is further provided with a swinging arm seat connected with a swinging arm air cylinder, and the arm seat is controlled to ascend and descend by the swinging arm air cylinder through the swinging arm seat. Because the sawing mechanism is arranged on the side, close to the feeding mechanism, of the machine frame, the arm seat is controlled to ascend and descend by the swinging arm air cylinder of the sawing mechanism through the swinging arm seat and the cutting tool is driven to ascend and descend to cut a profile, metal profiles of any length can be subject to orderly engraving, milling and cutting, and the process that the profiles are cut through cutting tools is omitted. The numerically-controlled drilling and milling machine is high in production efficiency, machining precision and automation degree.

Owner:佛山金皇宇企业孵化器有限公司

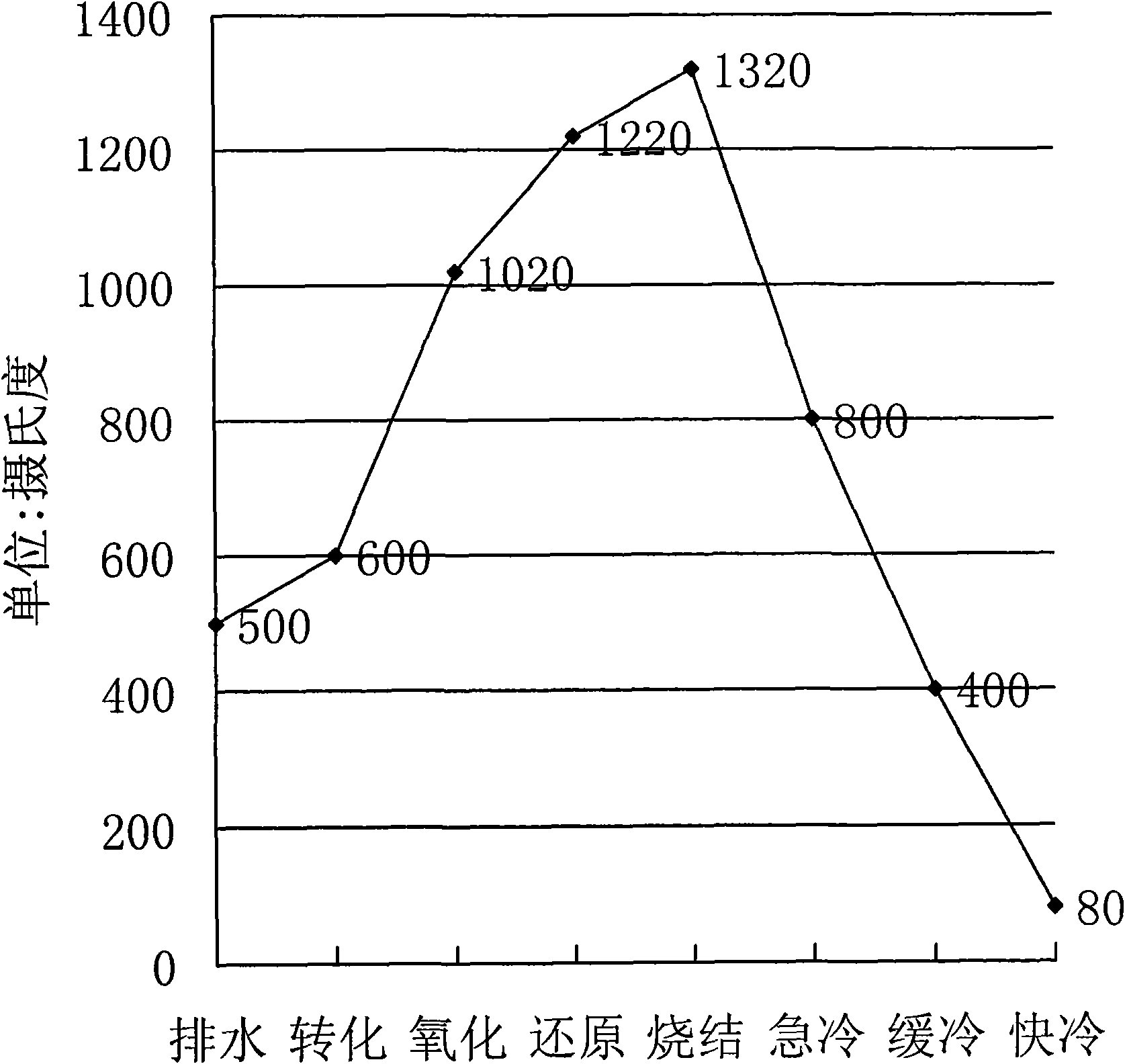

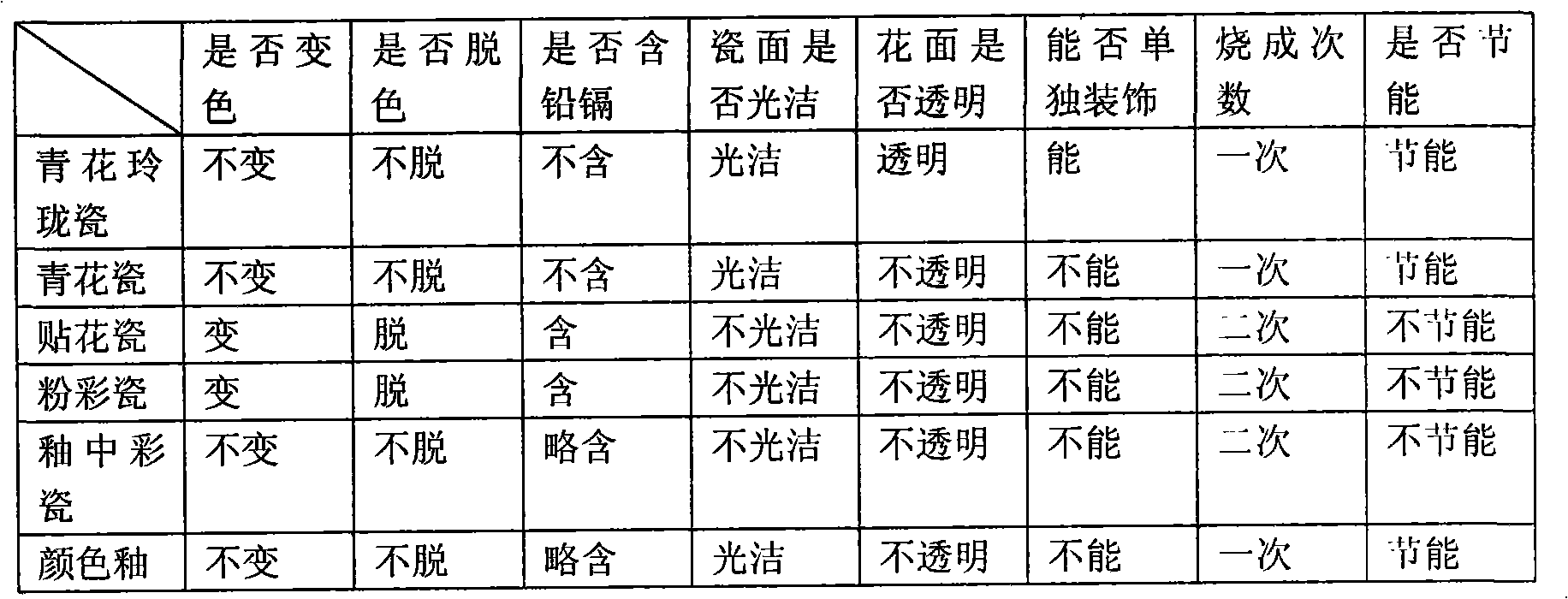

Process technique for producing blue and white delicate porcelain

The invention relates to a process technique for producing blue and white delicate porcelain, which is a process technique for the comprehensive decoration of under-glaze blue and white delicate engravings. The process technique comprises the following steps: making exquisitely carved rice grain shaped holes, namely 'delicate eyes', on a ceramic green body first; and then filling the delicate eyes with a 'delicate glaze', combining fresh and green blue-and-white patterns, glazing the ceramic green body, and burning the ceramic green body in a kiln at a high temperature through one step. The decoration style is extraordinary, the delicate glaze color is transparent with green, small holes have strong transparency and seem as small windows, and the sunlight and lamplight penetrate special patterns of the formed porcelain so that the artistic effect has a unique style; besides, with the combination of blue-and-white decorations and the background of the glaze color with green in white, the porcelain is particularly exquisite and subtle, simple and generous, fresh and bright, and healthy and environment-friendly, and has low manufacturing cost. The blue and white delicate porcelain can be directly used as daily porcelain, display porcelain, architectural porcelain and the like.

Owner:景德镇陶瓷协会

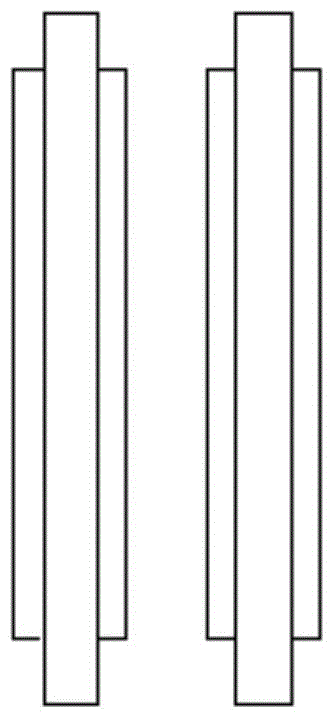

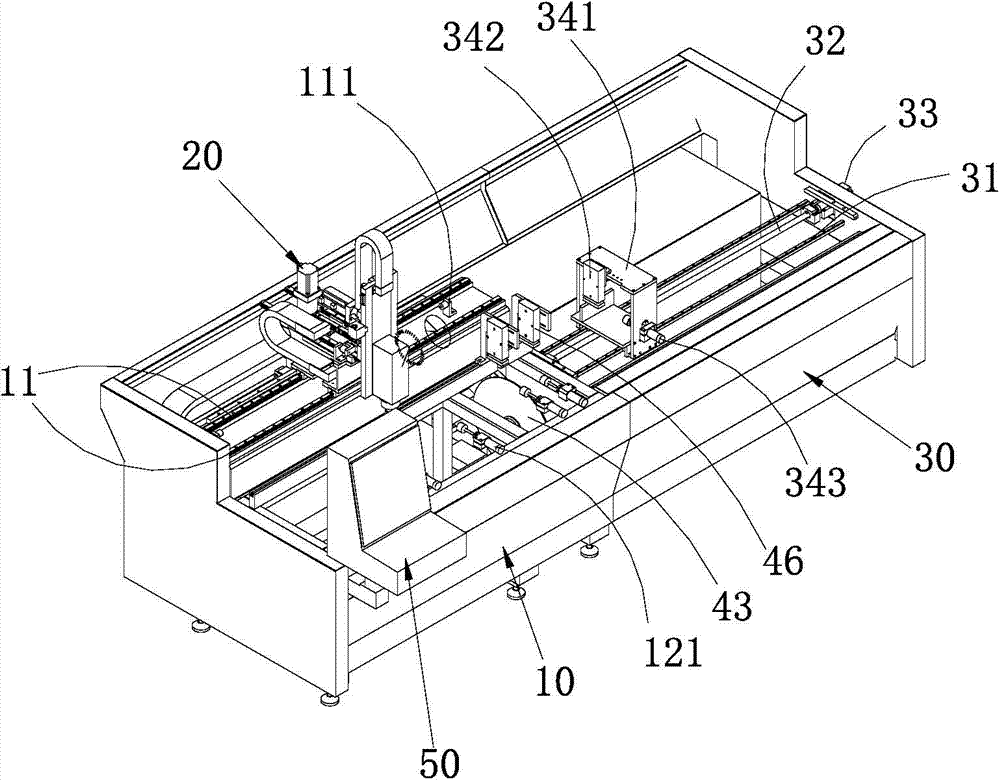

Multi-mainshaft numerical-control processing center

ActiveCN101653842AFlexible processing modeFast processingMilling machinesLarge fixed membersNumerical controlEngraving

The invention relates to a multi-mainshaft numerical-control processing center which belongs to the technical field of machine tools processing. The multi-mainshaft numerical-control processing centercomprises a control cabinet and an engraving and milling machine, wherein the control cabinet is electrically connected with the engraving and milling machine by a control system arranged in the control cabinet; the engraving and milling machine comprises a machine tool frame and a processing mechanism arranged on the machine tool frame; the machine tool frame comprises a tool body and a gantry spanned on the tool body, wherein the gantry comprises a beam transversely arranged above the tool body and upright posts arranged at two sides of the tool body, and the beam is fixedly arranged at theupper parts of the upright posts; the processing mechanism comprises a driving device and mainshaft devices used for engraving and milling, wherein the driving device comprises an X-shaft driving device, a Y-shaft driving device and a Z-shaft driving device; and at least two mainshaft devices are arranged on the gantry. The invention can simultaneously process different surfaces of a workpiece ordifferent areas of the same surface of the workpiece with more processing modes and more flexible processing, greatly accelerate the processing and satisfy production requirements better.

Owner:安徽同兴科技发展有限责任公司

Automated engraving of a customized jewelry item

InactiveUS7593786B2Reduce the amount requiredCost effectiveSpecial data processing applicationsEngravingIcon designPersonalization

A method for manufacturing a ring (i.e. class, championship, or affiliation) begins by receiving order data specifying a series of personalization elements, such as the addition of text and icon designs. A geometric model for each personalization item is constructed. To assemble text panels, the operating system provides font geometry for a desired TrueType font. Then a set of splines are created from the font geometry and are then tessellated to generate polyline sets of data, which are then spaced and mapped between two boundary curves. The personalization elements are then projected onto one of the model's 3D surfaces. A set of machining instructions for a milling machine is generated by obtaining a set of machining pattern strategies, generating a set of curves, projecting the toolpath onto the surface of the ring to calculate the 3D toolpath, and rotating it to a desired angle.

Owner:JOSTENS INC

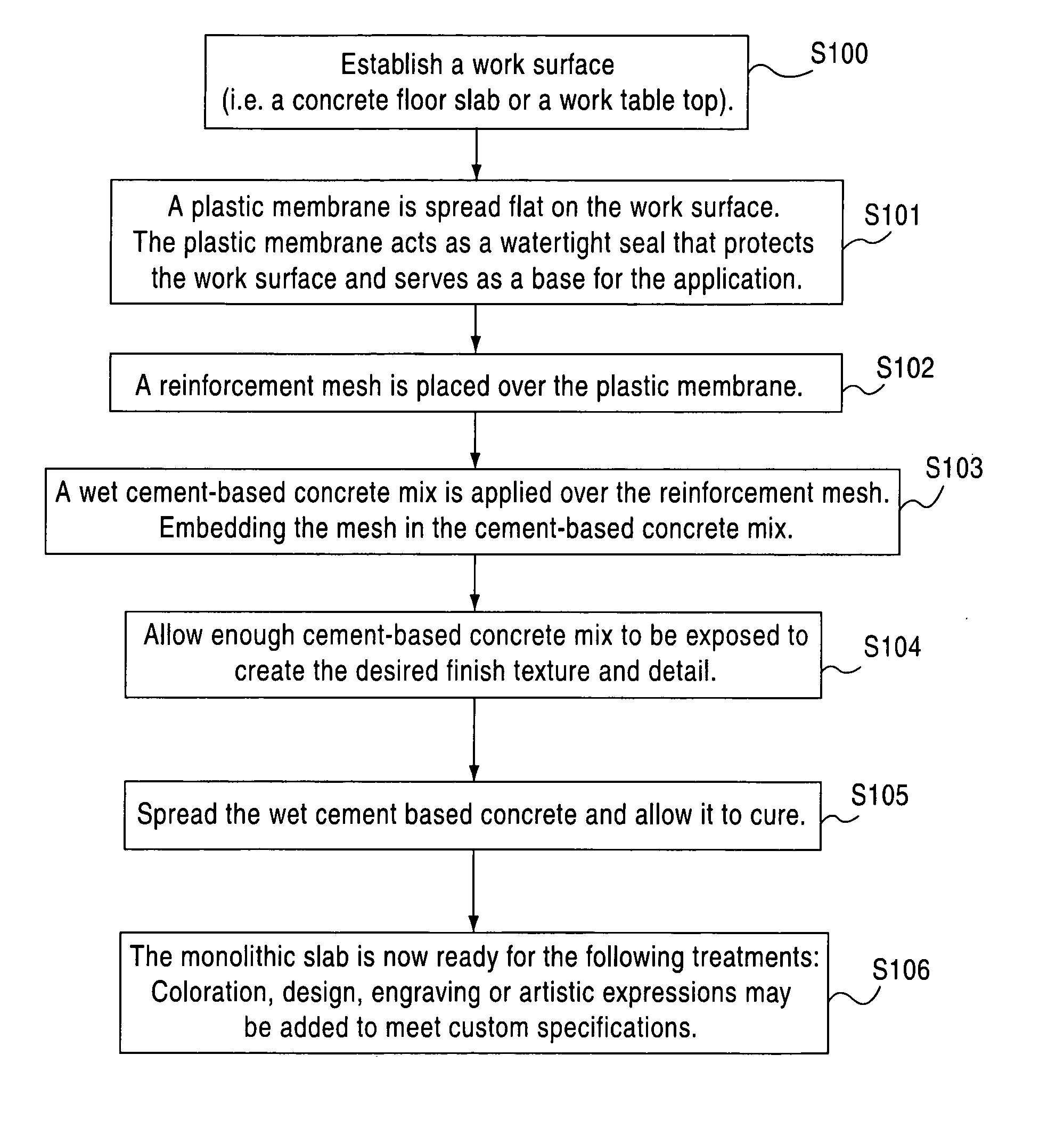

Cement-based, mesh reinforced concrete tiles with integral color and design

A method of manufacturing and installing cement-based concrete tiles, composed of portland cement, polymer-modified cement admixtures, sand, additional ingredients and color pigments integrated with reinforcement mesh for support and strength. The cement-based concrete mix may be dispersed and formed into a single layer cement-based concrete slab configuration with the reinforcement mesh completely embedded within. The cement-based concrete mix is distributed to achieve the desired texture, thickness and finish to form the cement-based concrete slab. After curing, any desired custom designs, engravings, additional colorations and wearing surface sealers are added to render the designs an embodiment of the cement-based concrete slab and thus an embodiment of the cement-based concrete tiles. The concrete slab is then cut into concrete tiles of custom dimensions. The cement-based concrete tiles are identified in sequential order to establish correct placement during the installation process. The custom cement-based concrete tiles may be from ⅛ inch thick to 2 inches thick, and may be installed on floors, walls, counter tops, interior, exterior and at any grade level using excepted professional installation procedure. The cement-based concrete tiles may be custom designed subject to the specifications of the end user.

Owner:BAILEY WAYNE EDWARD

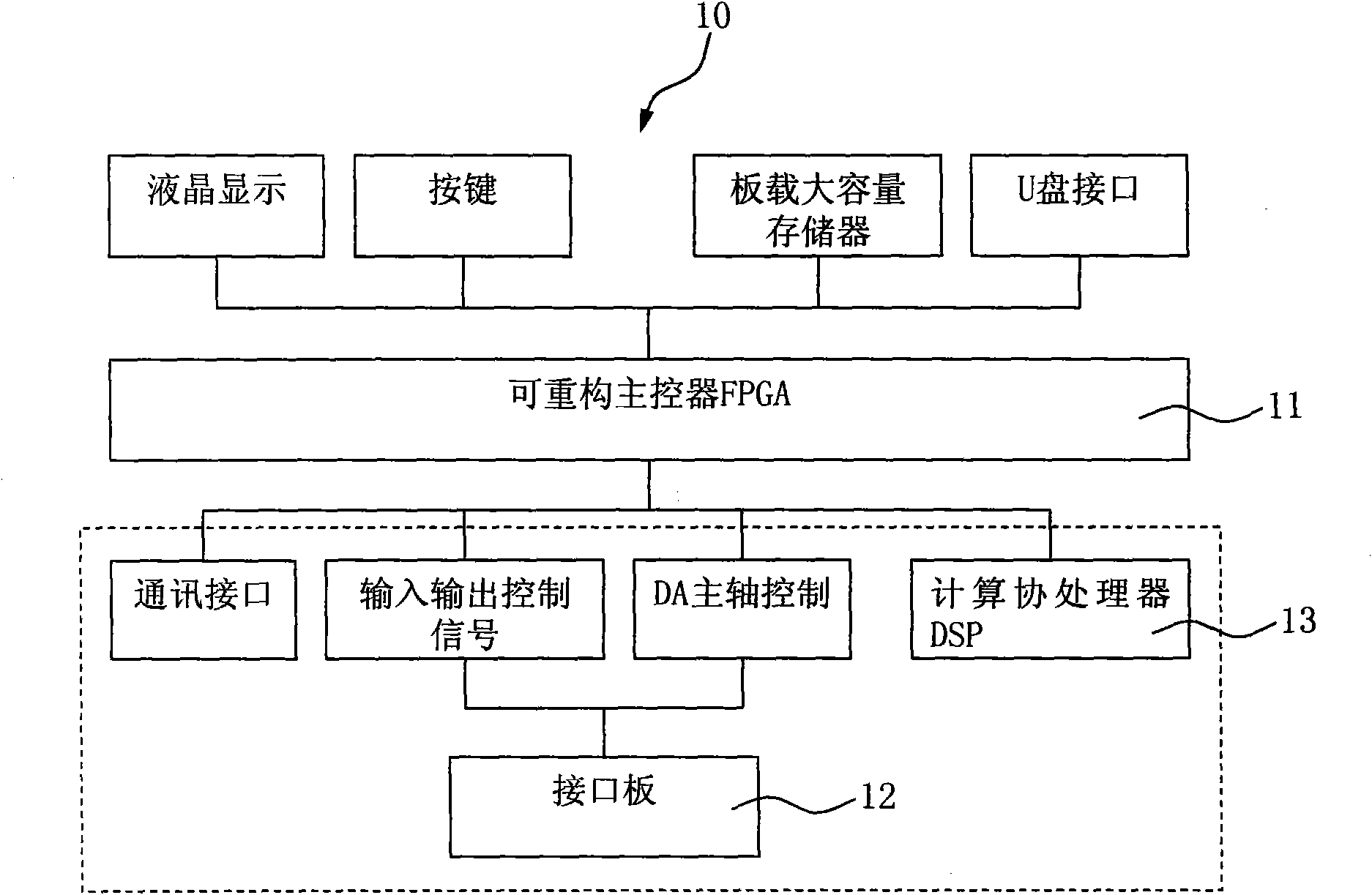

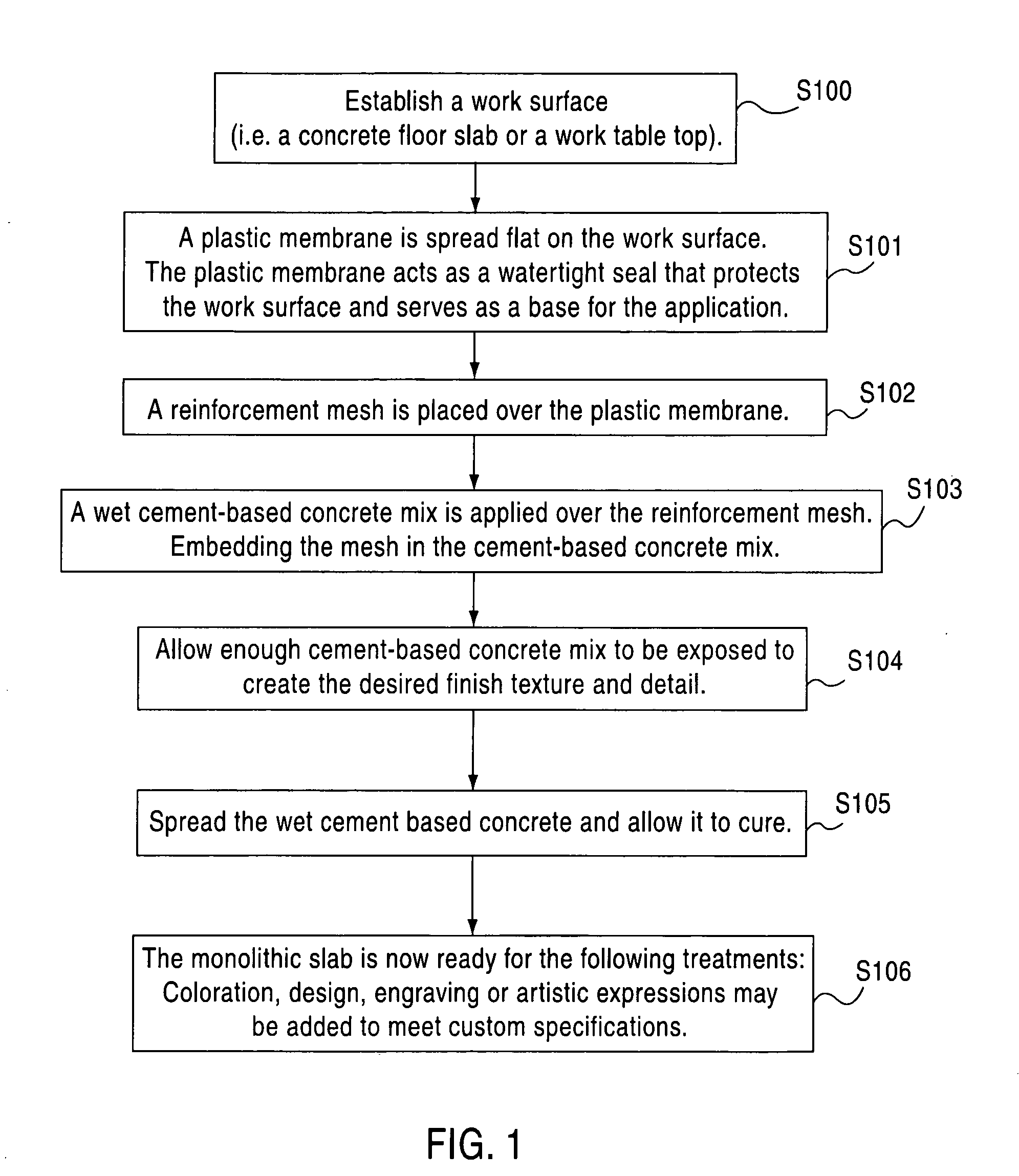

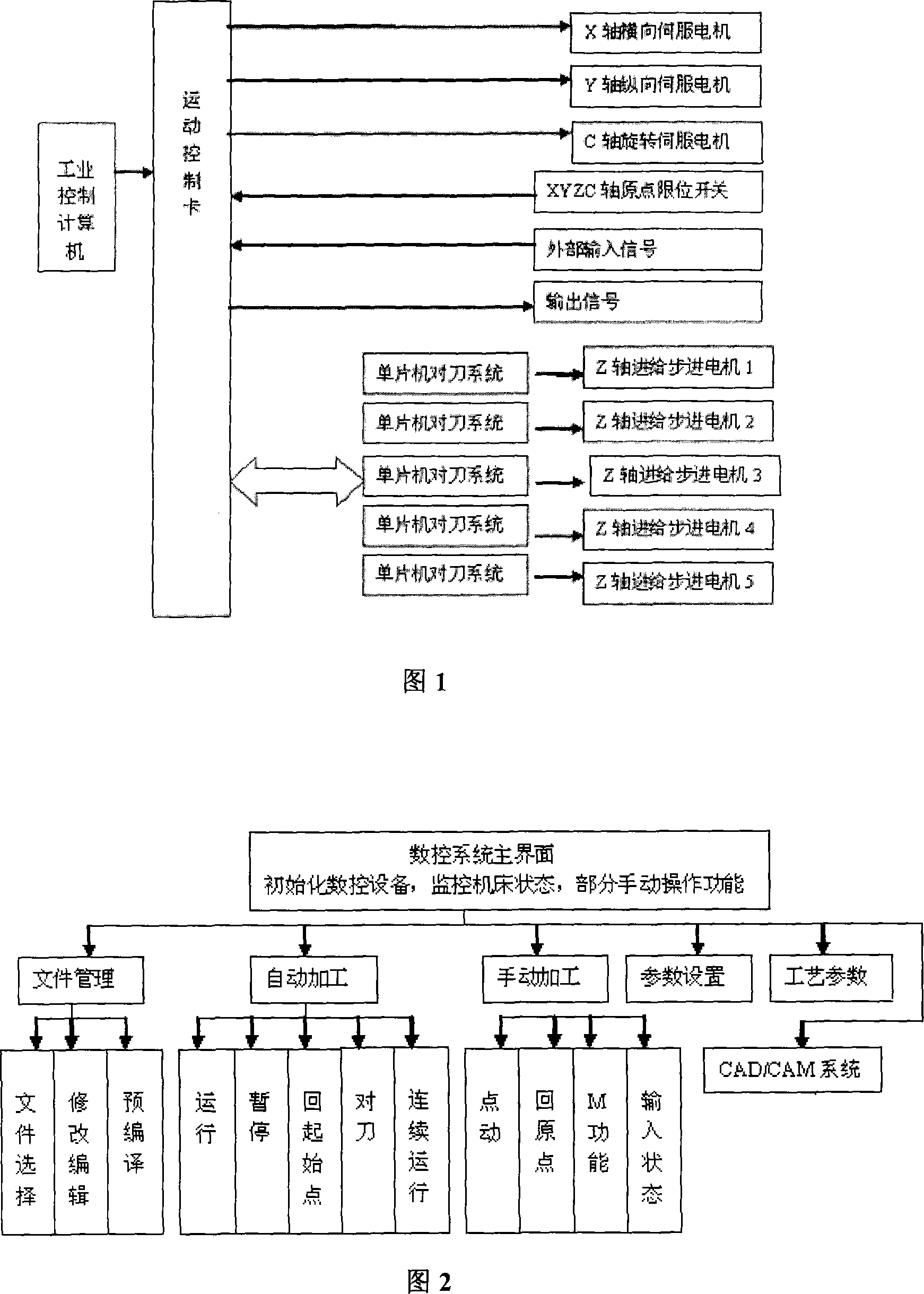

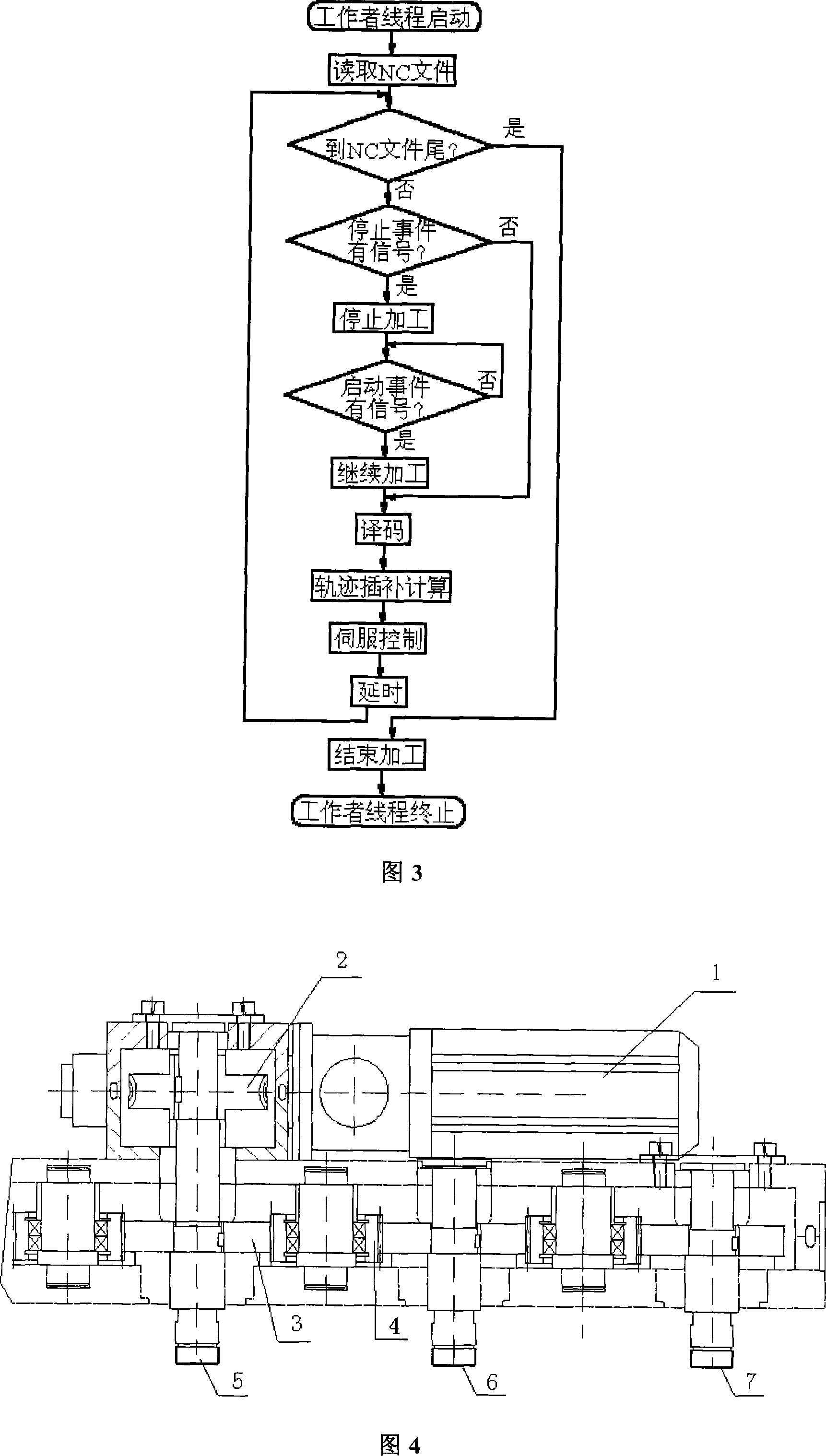

Multi-station numerical control system dedicated for sculpture

InactiveCN101216704APowerful Auxiliary DesignPowerfulNumerical controlEngravingHuman–machine interface

The invention discloses a special control system for multi-station numerical control engraving, which consists of hardware and software; wherein the hardware adopts an open numerical control system composed of an industrial control computer, a motion control card and a digital actuating motor, which are connected in turn via data wires, the industrial control computer and the motion control card constitute the core of the open numerical control system, the industrial control computer takes charge of management on a supervisory computer, and the motion control card controls the motion of a stepping motor with three axes at least or the digital actuating motor; and the software utilizes Visual C++ to compile a multi-threading application program operated under Windows2000 / XP operating systems. The invention can fulfill tool-setting processing of multi-station parts in cooperation with a multi-station numerical control engraving tool-setting device, and is provided with a vivid and friendly human-computer interface, powerful numerical control processing functions and stable and reliable systems; thereby the invention can select any engraving head to work or not to work, and can resolve the problem of inconsistent forward and reverse gap among a plurality of rotary shafts of cylindrical conical surface multi-station engraving.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Machining technology for high-precision outer conical surface thin wall sleeve

InactiveCN103495844AMeet the technical requirements of high-precision outer tapered thin-walled sleevesReduce distortionNumerical controlEngraving

The invention relates to the technical field of high-precision part machining process, in particular to a machining technology for a high-precision outer conical surface thin wall sleeve. The machining technology includes the following technology processes of workblank preparing, spheroidizing annealing, rough turning, thermal refining, semi-finish turning, finish turning, hole drilling, distressing, plane grinding, rough grinding, secondary distressing, plane grinding, spiral groove turning, plane lapping, accurate grinding, wire-electrode cutting, end face turning, serial number engraving, detecting, qualified product obtaining, press fitting, conical surface fit detecting, part matching and serial number printing, cleaning, lubricating oil coating and warehousing. A double-end vertical type numerical control grinder is adopted as a finishing machine, and through the machining methods of rough grinding and accurate grinding or rough grinding, semi-accurate grinding and accurate grinding, the technical requirements of the high-precision outer conical surface thin wall sleeve can be met; through the corresponding distressing heating processing technology, residual stress in the machining process is removed, deformation in the machining process can be reduced, the yield of products is improved, and finally the good manufacturing method of the high-precision outer conical surface thin wall sleeve is provided.

Owner:CRRC QISHUYAN CO LTD

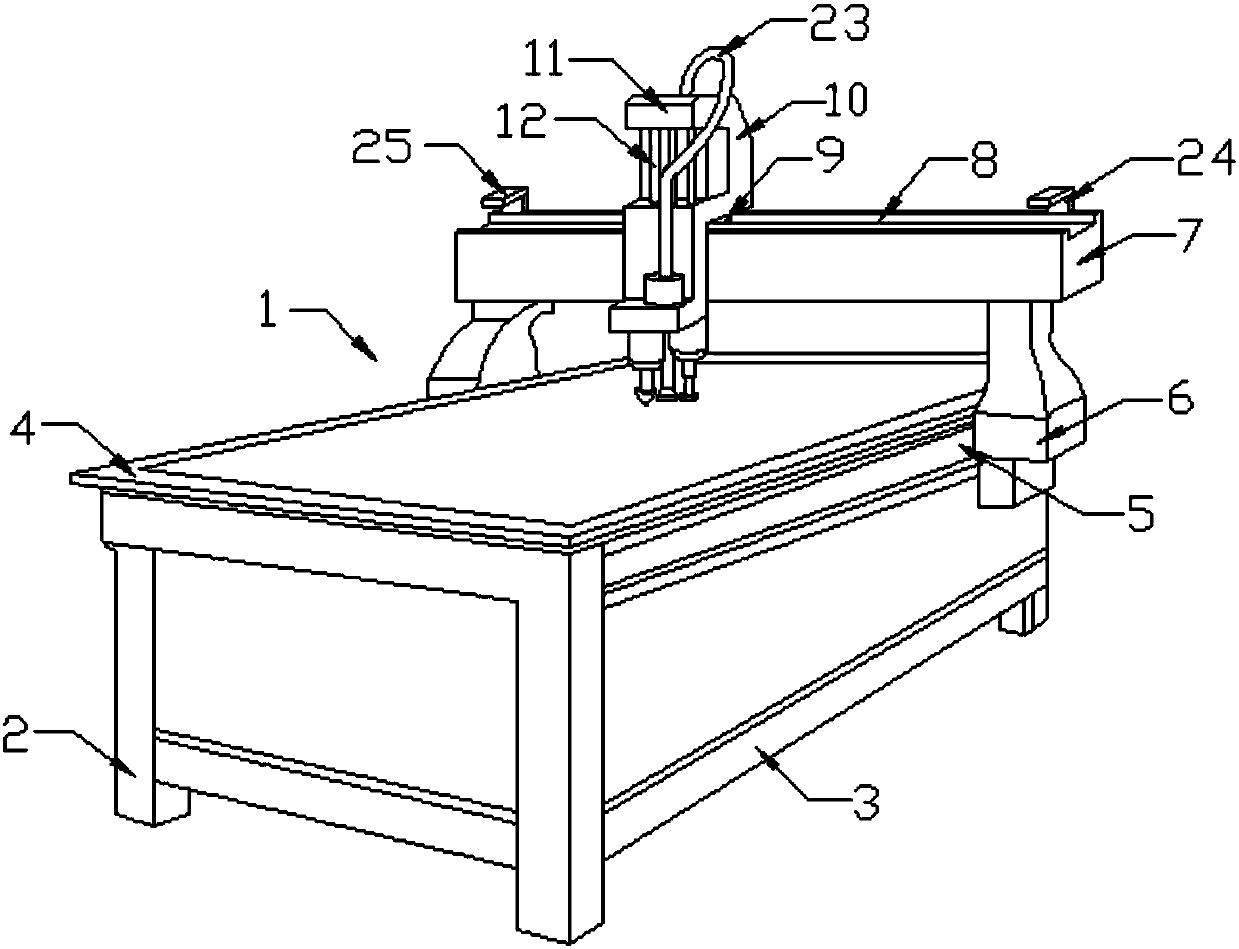

Efficient engraving and milling machine

The invention provides an efficient engraving and milling machine and belongs to the field of mechanical technology. The efficient engraving and milling machine solves the problem that scraps generated during the engraving process of existing engraving and milling machines can stay on workpieces to result in influence on the engraving efficiency and the like. The efficient engraving and milling machine comprises a working table, a support and a plurality of engraving and milling motors, wherein the working table is provided with a fixing table for fixing workpiece clamps, the support is arranged on the working table and on one side of the fixing table and provided with a mounting plate, and the engraving and milling motors are mounted on the mounting plate; the output shafts of the engraving and milling motors are parallel to the surface of the working table and face towards the fixing table; the engraving and milling motor can move in the horizontal direction and the vertical direction relative to the working table. The efficient engraving and milling machine has the advantages of guaranteeing the engraving precision and the operating smoothness.

Owner:陈美青

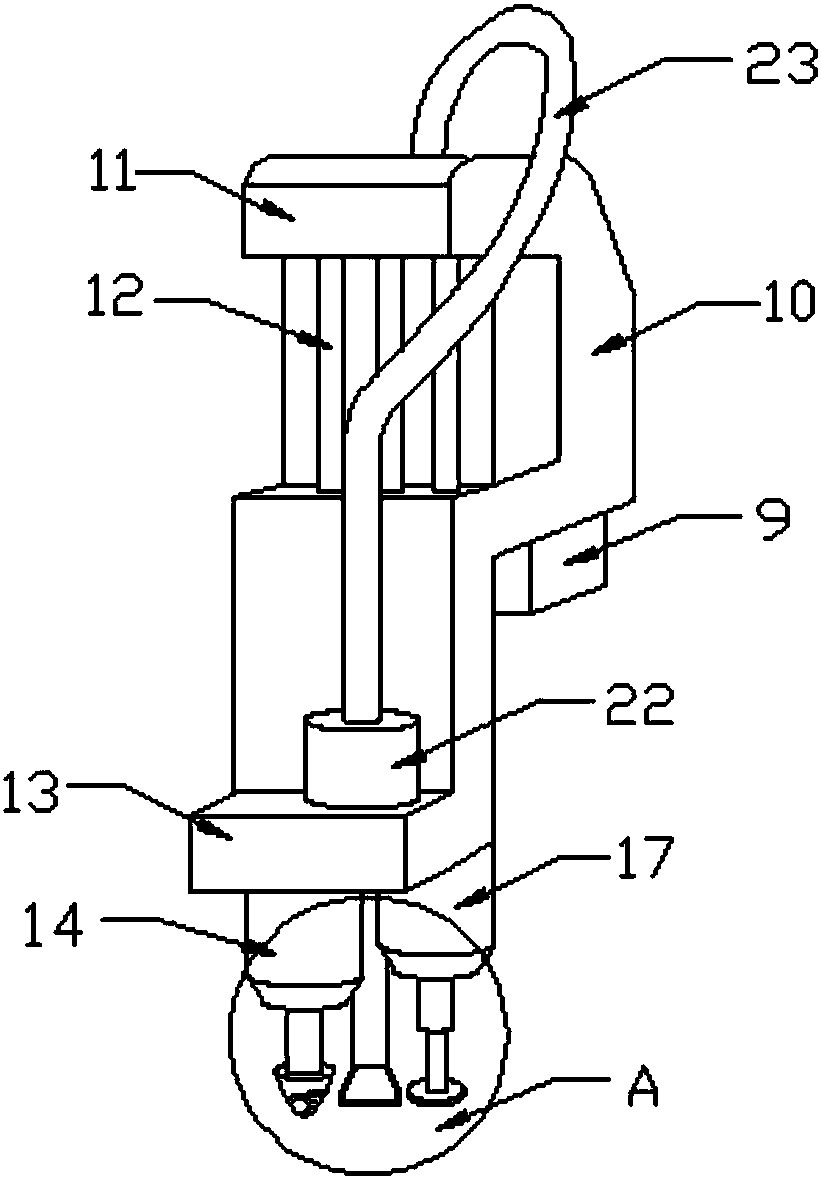

Engraving device for wood board processing

The invention discloses an engraving device for wood board processing. The engraving device for wood board processing comprises an engraver main body and a support, wherein the support is fixedly mounted at the bottom of the engraver main body; the engraving device for wood board processing further comprises a machine base, an engraving workbench, side guide rails, first moving sliding bases, a moving cross beam, a transverse guide rail, a second moving sliding base and a vertical column. The engraving device for wood board processing can polish wood board burrs, formed by engraving, on the surface of an engraved wood board, so that the surface smoothness of the engraved wood board is ensured; a large amount of wood dust and dust, generated in the processes of engraving the wood board by an engraving cutter bit and removing the burrs by a polishing cutter wheel, are sucked from the surface of the wood board through a dust suction fan and a dust suction hood, so that the wood dust generated in the engraving process is prevented from scattering on the surface of the wood board to influence the wood board engraving accuracy of the engraving cutter bit, and the wood dust and the dust are prevented from diffusing into air to cause the environment pollution and endanger the health of people who work in the environment for a long time; an adopted dust suction way helps to clean up thewood dust and the dust in an engraving groove.

Owner:WENZHOU CHUYING TECH CO LTD

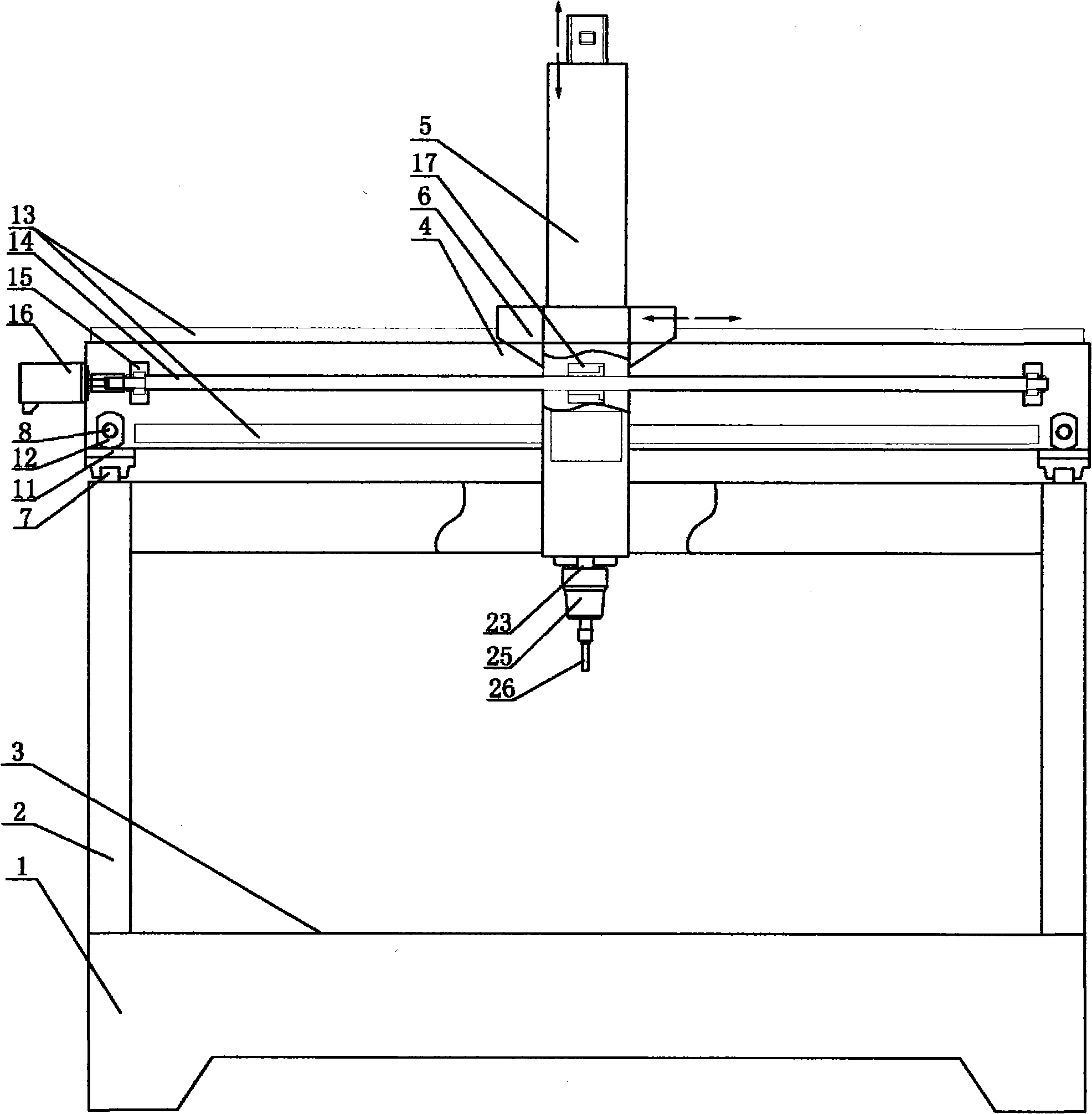

Three-dimensional multi-shaft interlocked numerical controlled engraving and milling device

InactiveCN101491843AImprove processing levelLarge processing spaceMilling machinesLarge fixed membersNumerical controlEngraving

The invention relates to a three-dimensional multishaft ganged digital control engraving and milling machine, which is particularly suitable for performing cutting and engraving and milling processing on large nonmetallic products. The three-dimensional multishaft ganged digital control engraving and milling machine comprises a stand, a body, a work table, a working beam, a Z axial body, a Z axial body support and a digital control unit which is used for controlling the operation of a machine tool, wherein the working beam is connected with the body through a Y axial guide rail and driven by a drive unit to move along a Y axis; the Z axial body support is connected with the working beam through a Z axial guide rail and driven by a drive unit to drive the Z axial body to move along an X axis; the Z axial body is connected with the Z axial support through the Z axial guide rail and driven by a drive unit to move along a Z axis; the body is set to have a frame structure; a Y axial guide rail is arranged on two longitudinal beams of the body respectively; the working beam and a longitudinal beam of the stand form guide rail connection through a beam support; an A axis is arranged on the Z axial body and can perform horizontal and circumferential rotation when being driven by a drive unit; and a C axis is arranged on the A axis and can perform perpendicular and circumferential rotation when being driven by a drive unit. The three-dimensional multishaft ganged digital control engraving and milling machine can implement engraving and milling processing on three-dimensional five axes of the large products when the digital control unit controls various drive units, and the processing level of the machine tool is higher.

Owner:袁焕春 +1

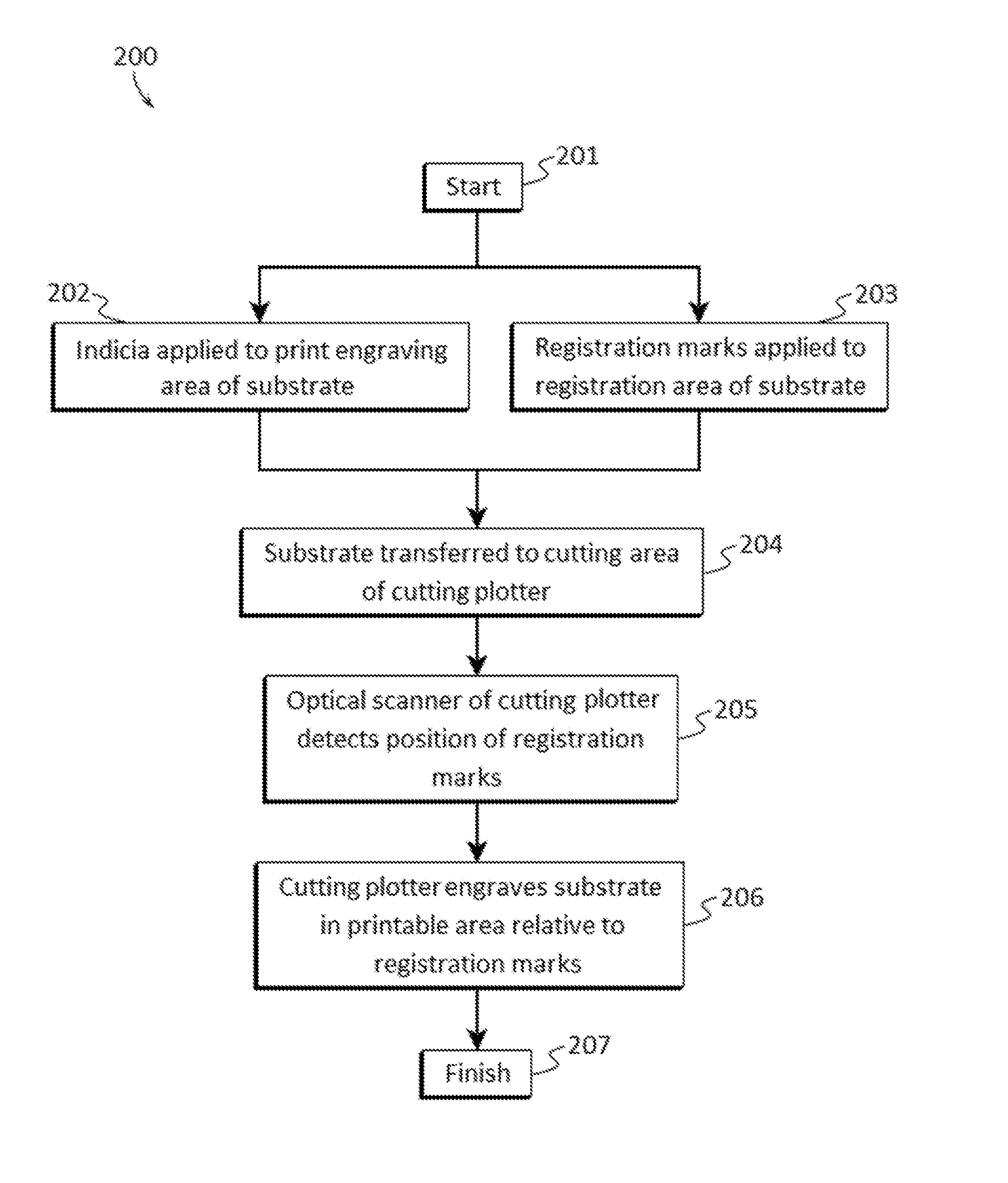

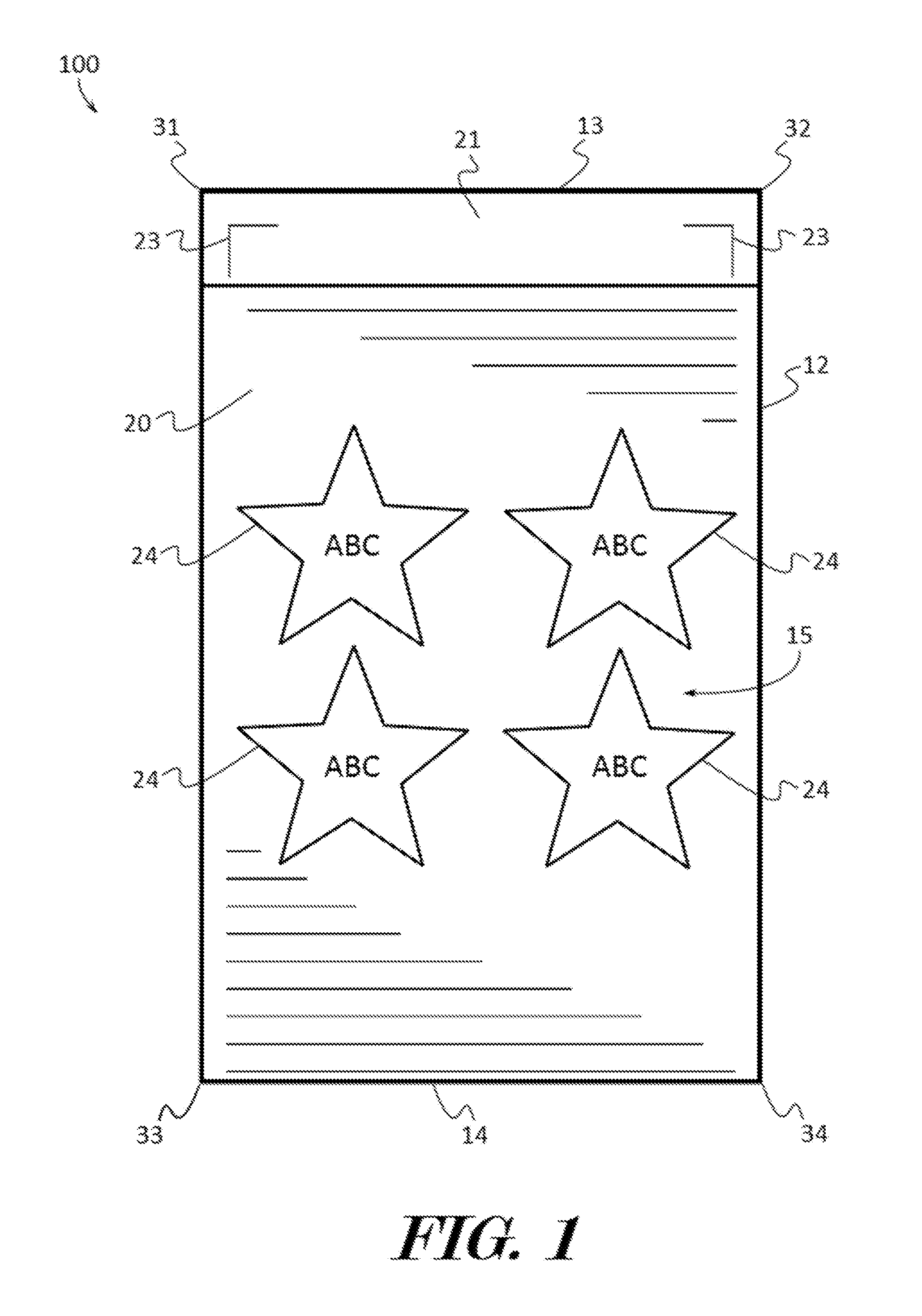

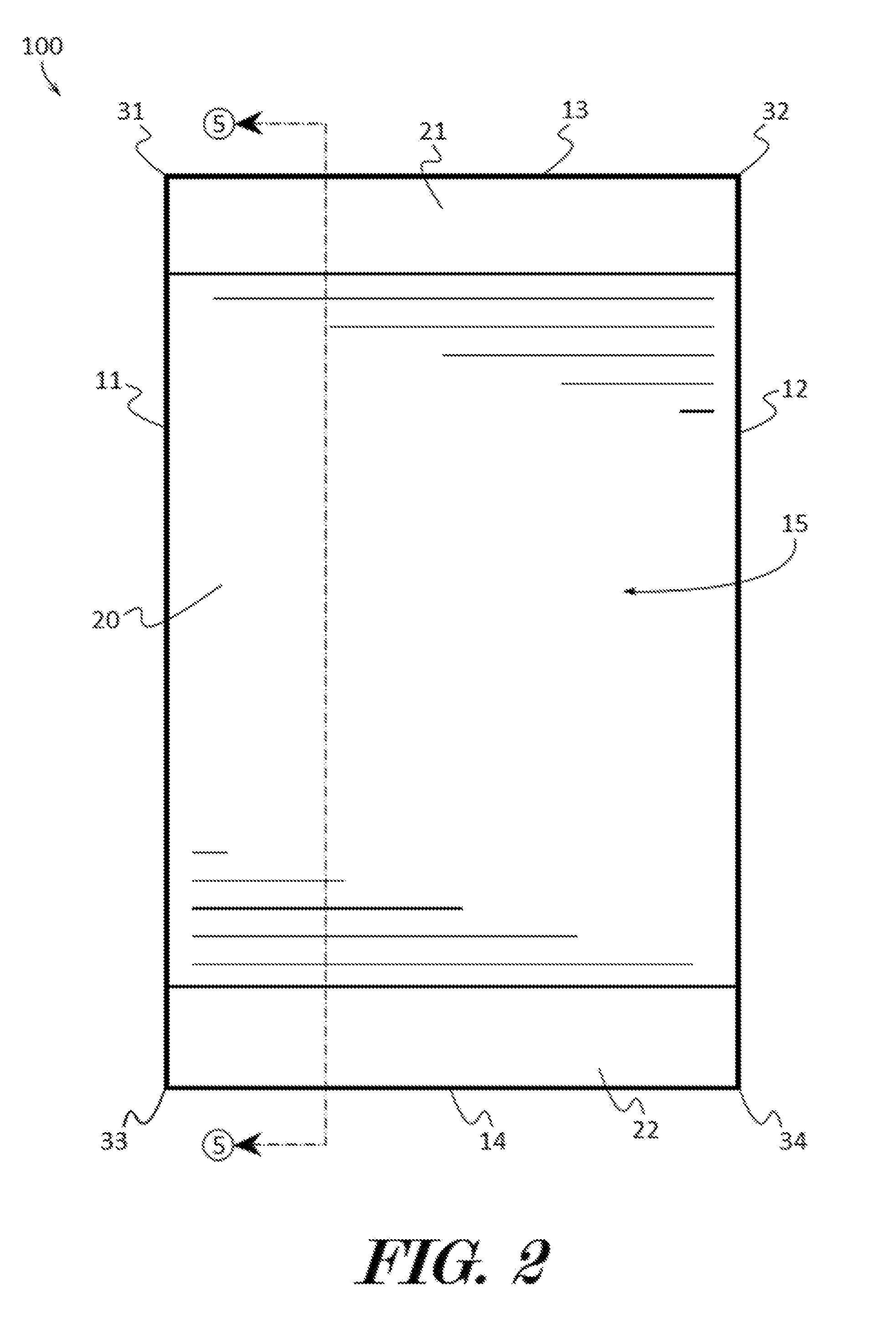

Substrates and method for print engravings

ActiveUS20160303845A1Function increaseIncreasing and perfecting alignmentTypewritersRotary pressesEngravingOptical scanners

A novel print engraving substrate is provided that when used with a cutting plotter, is able to improve the functioning of the cutting plotter. In some embodiments, a print engraving substrate may comprise a print engraving material forming a top surface; an adhesive material coupled to the print engraving material opposite to the top surface; a print engraving area disposed on the top surface; and a registration area disposed on the top surface which may receive one or more registration marks. The print engraving area may be configured to receive indicia such as cutting indicia which may be applied by a printer. The registration area may lack one or more colors or textures applied to the print engraving area thereby facilitating or allowing an optical scanner of a cutting plotter to detect registration marks on a substrate comprising a colored and / or textured print engraving area.

Owner:ARCE VICTOR MANUEL SUD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com