Multi-station numerical control system dedicated for sculpture

A control system and multi-station technology, applied in the field of engraving, can solve problems such as unguaranteed accuracy, low efficiency, and inability to compensate, and achieve the effects of rich error alarm prompts, stable and reliable system, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

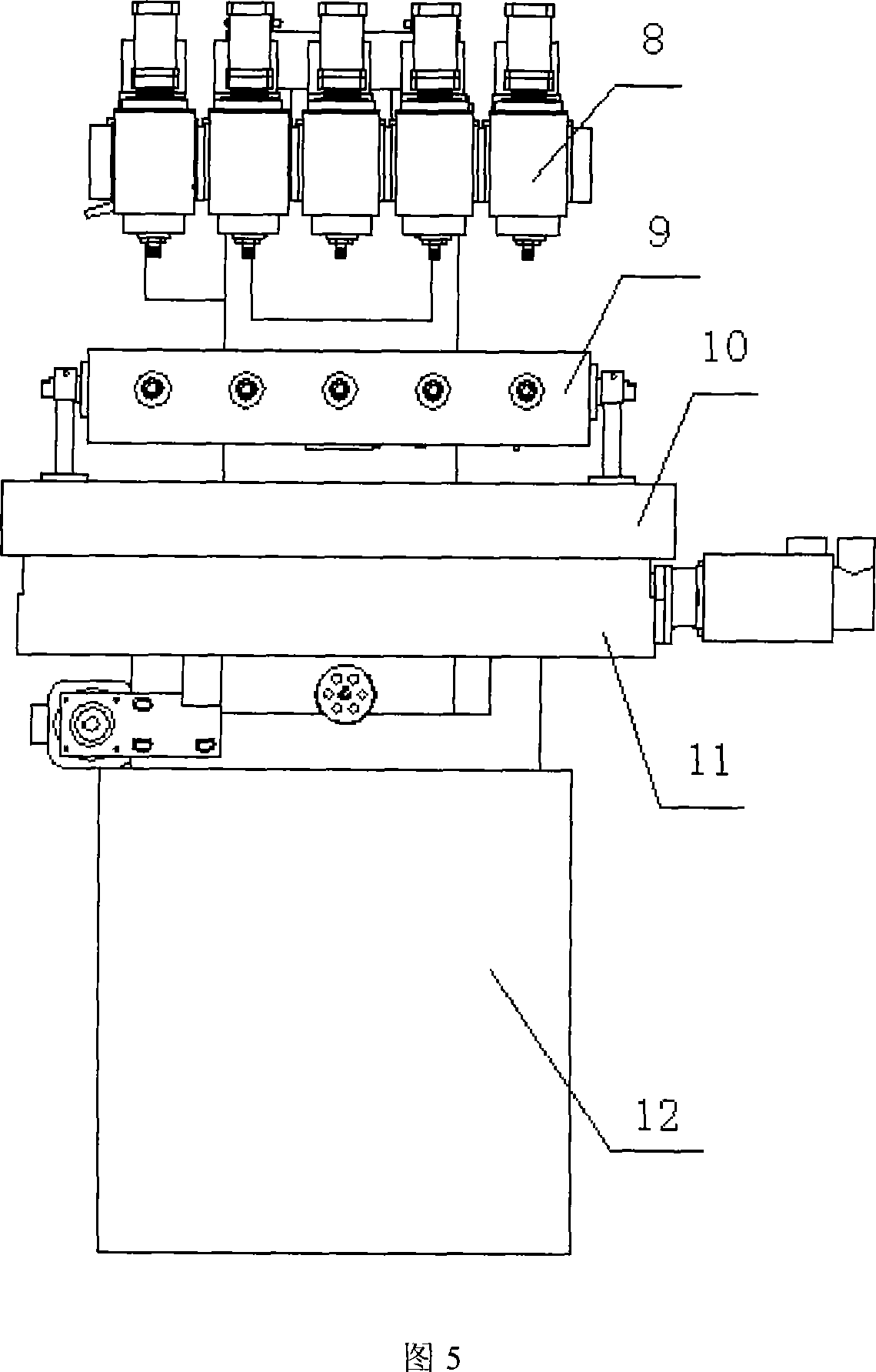

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited.

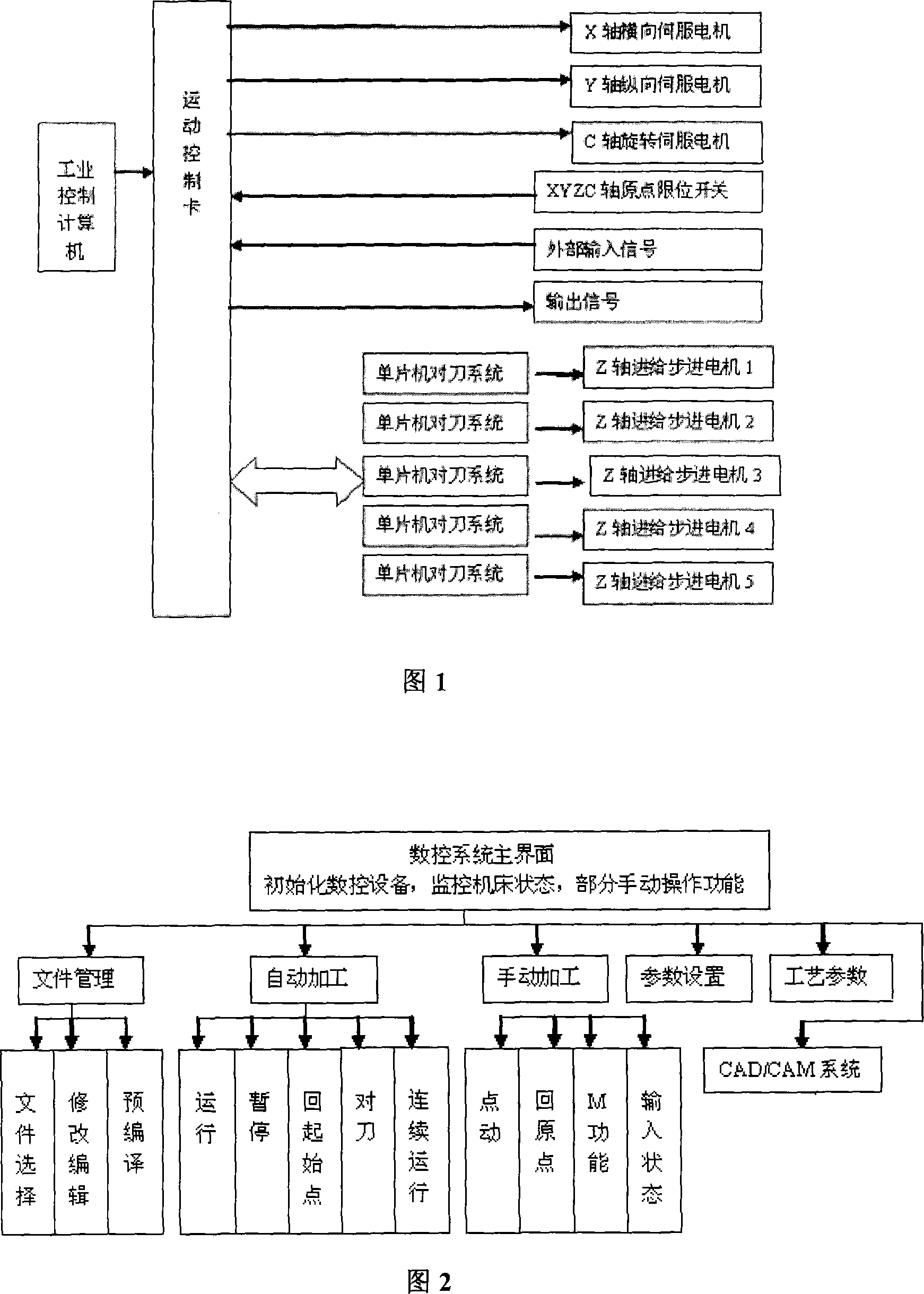

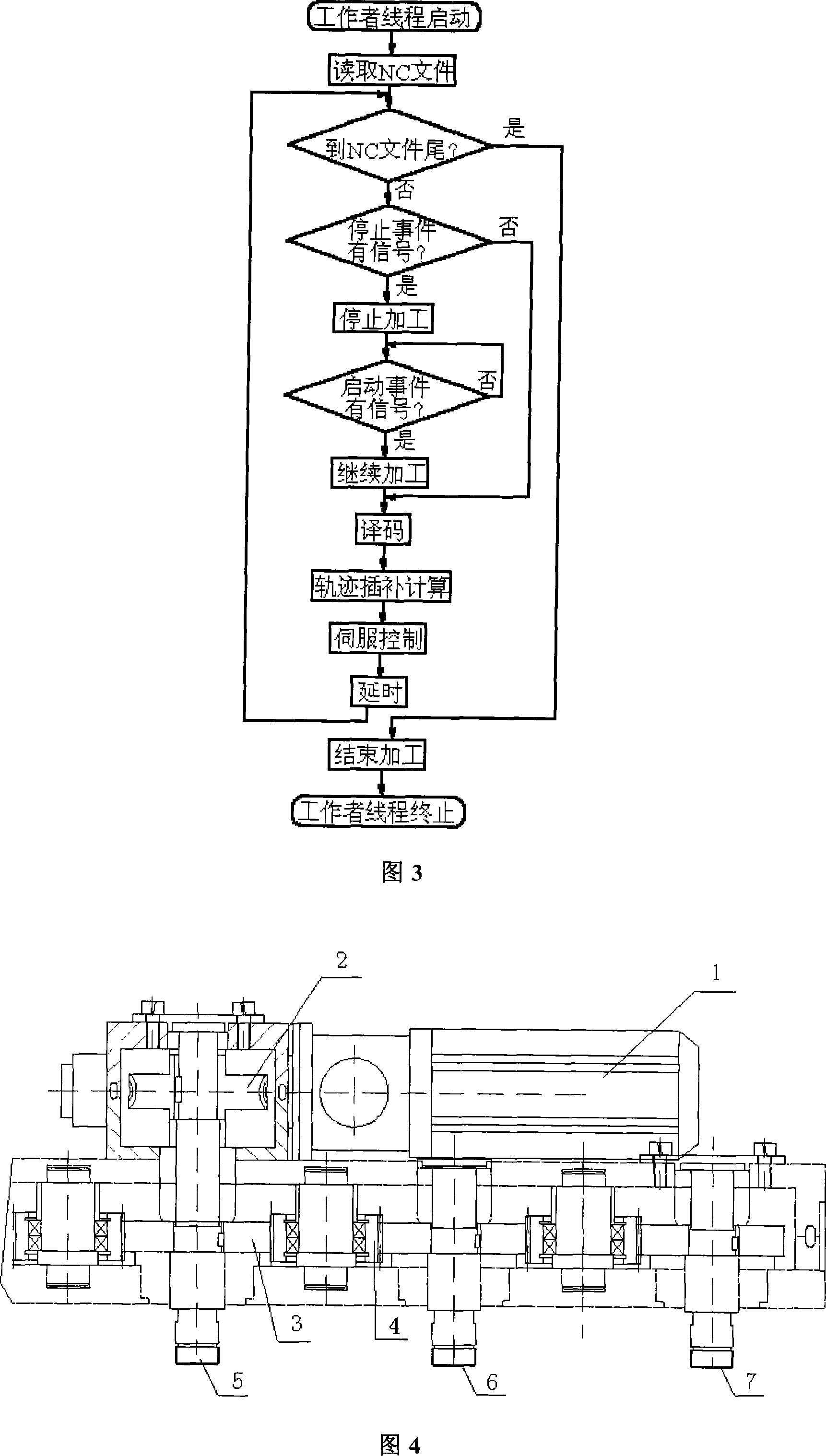

[0026] The CNC engraving control system is composed of hardware and software. The hardware uses high-performance industrial computer PC + motion control card + electromechanical device to form an open CNC system. The software uses Visual C++ to compile the application program under Windows2000 / XP.

[0027] 1. Hardware composition of multi-station engraving CNC system

[0028] The industrial PC adopts Advantech IPC-610P, and the motion control card adopts the PCI four-axis motion control card of Chengdu Lechuang MPC08. The MPC08 control card is the upper control unit of the stepper motor or digital servo motor based on the PCI bus of the PC. The PC machine forms a master-slave control structure: the PC machine is responsible for the management of the human-computer interaction interface and the real-ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com