Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9504 results about "Conical surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geometry, a (general) conical surface is the unbounded surface formed by the union of all the straight lines that pass through a fixed point — the apex or vertex — and any point of some fixed space curve — the directrix — that does not contain the apex. Each of those lines is called a generatrix of the surface. Every conic surface is ruled and developable. In general, a conical surface consists of two congruent unbounded halves joined by the apex.

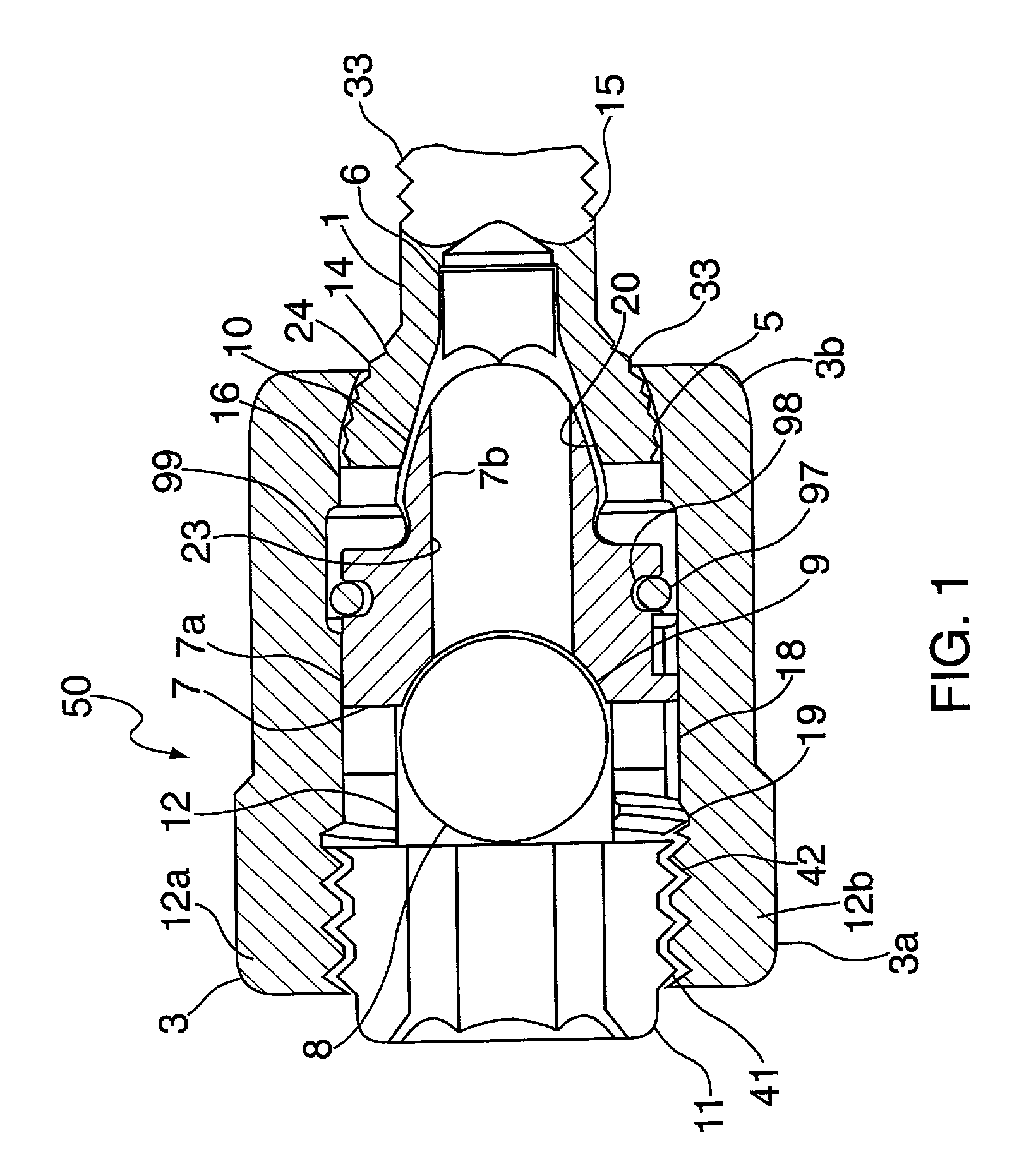

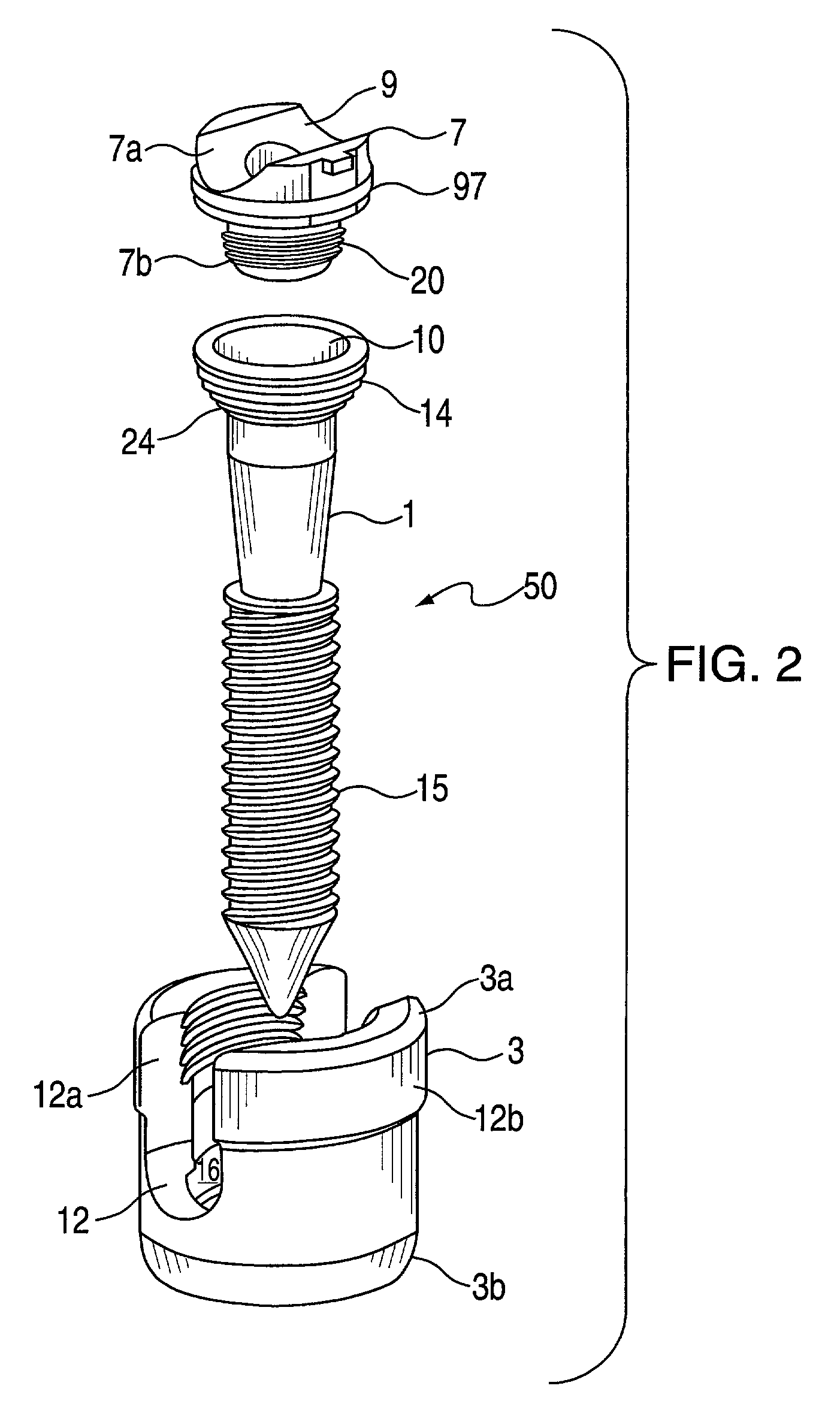

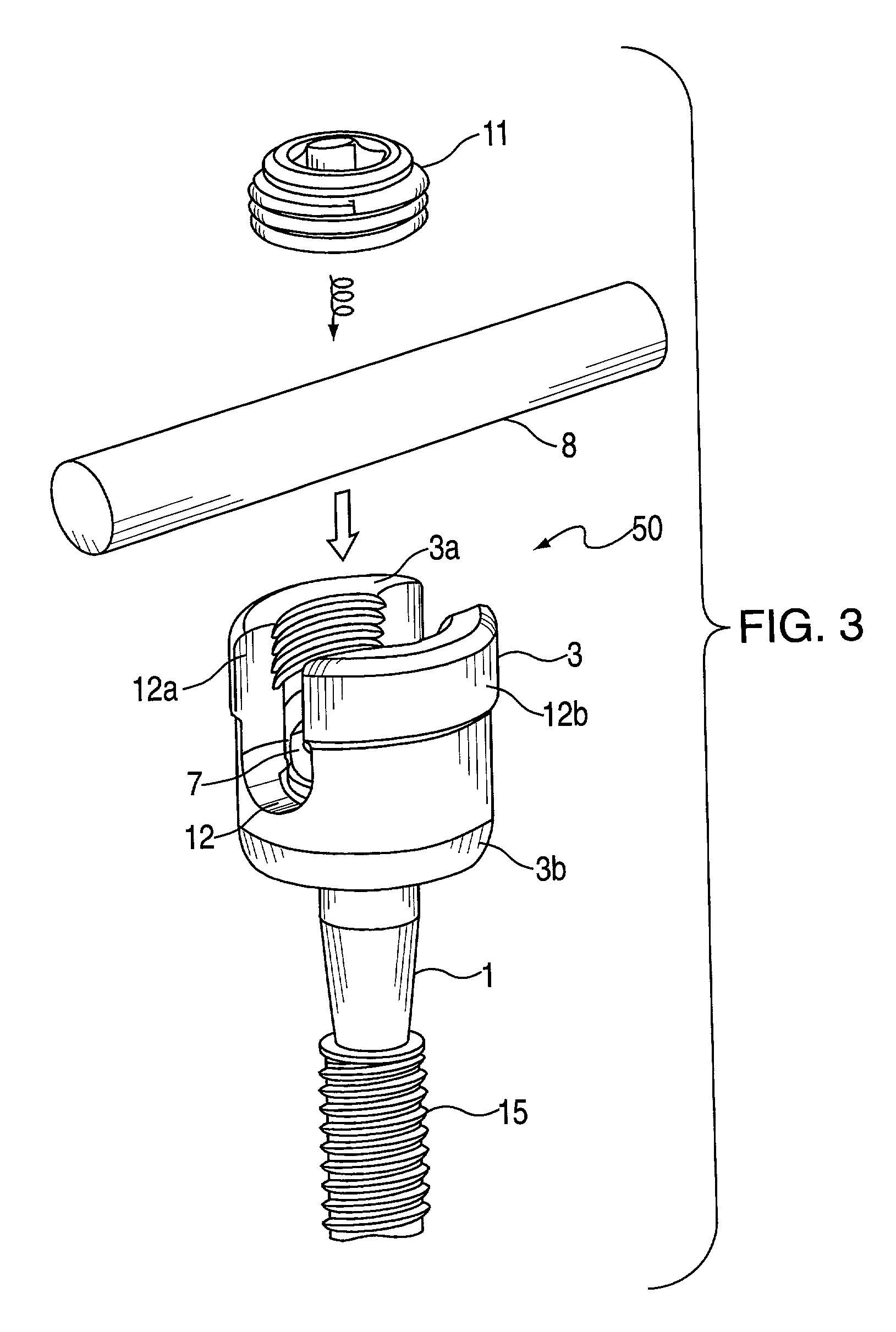

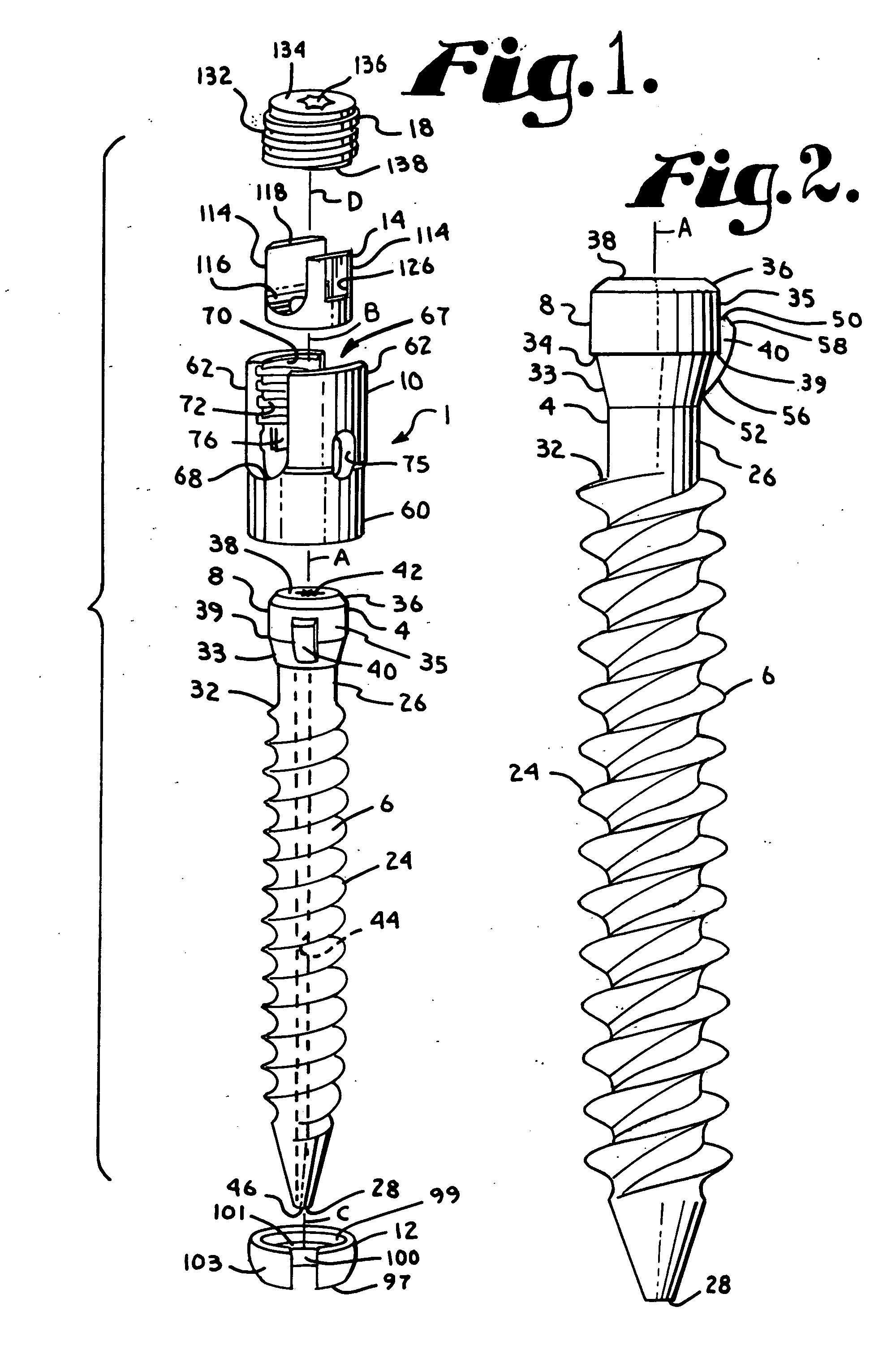

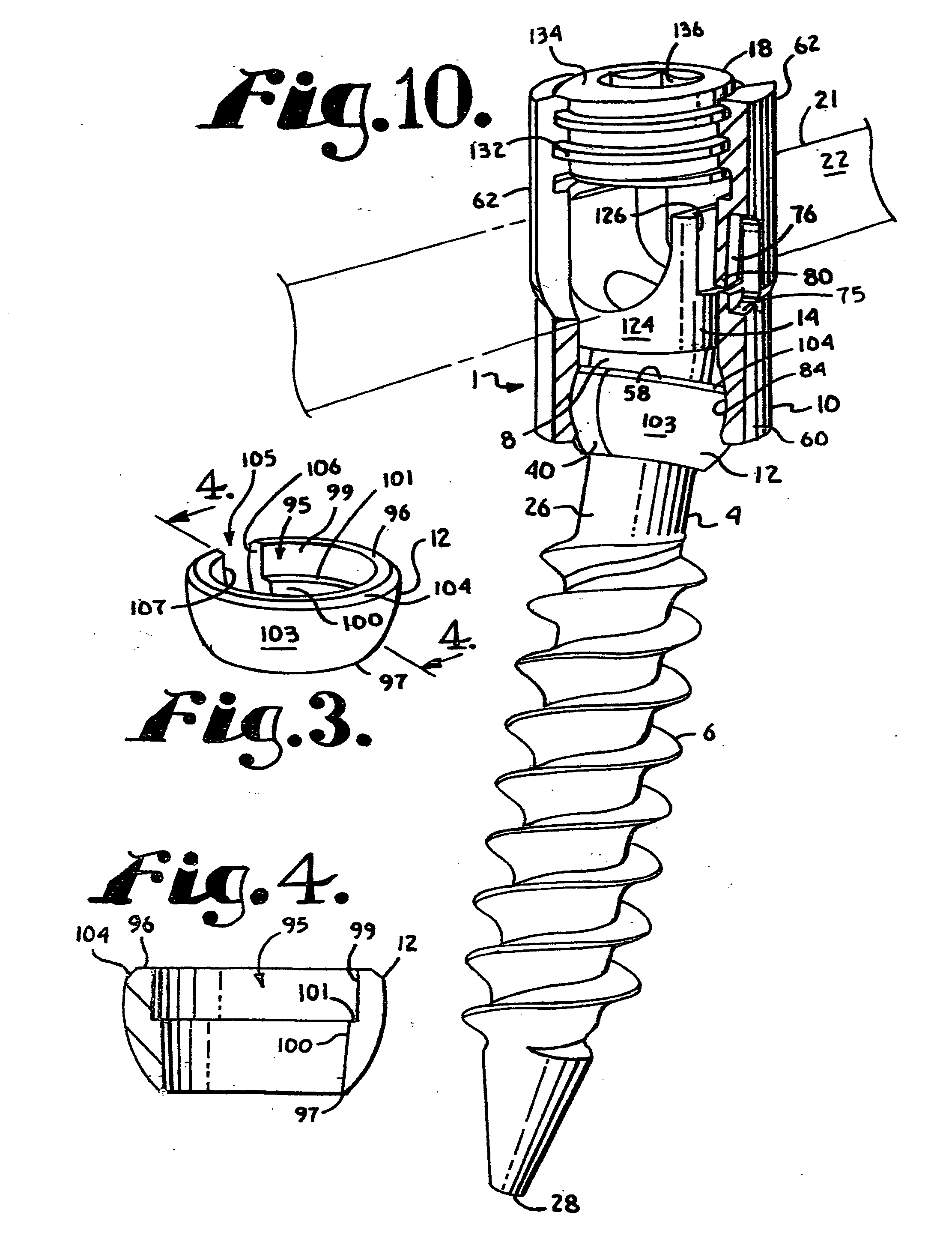

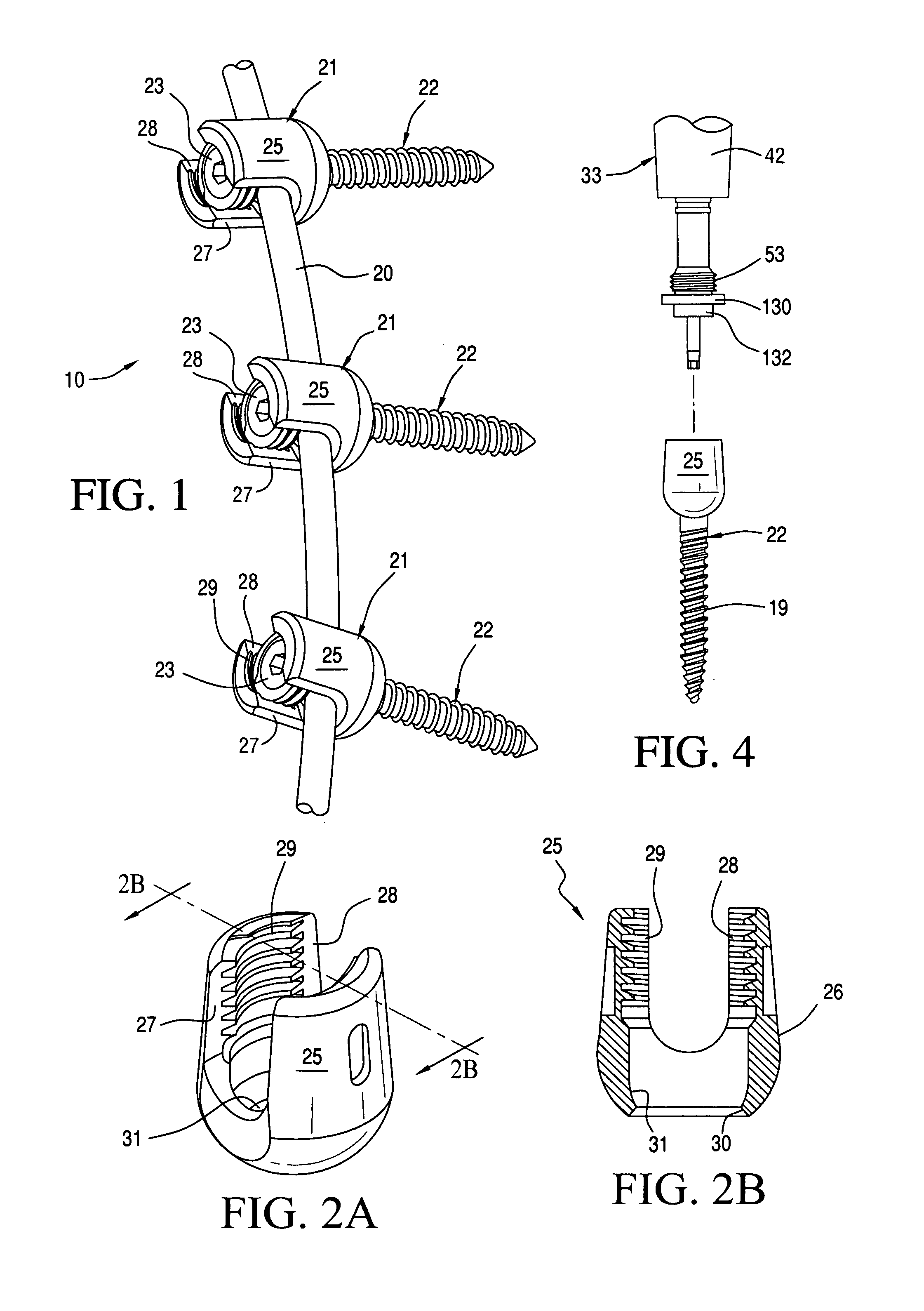

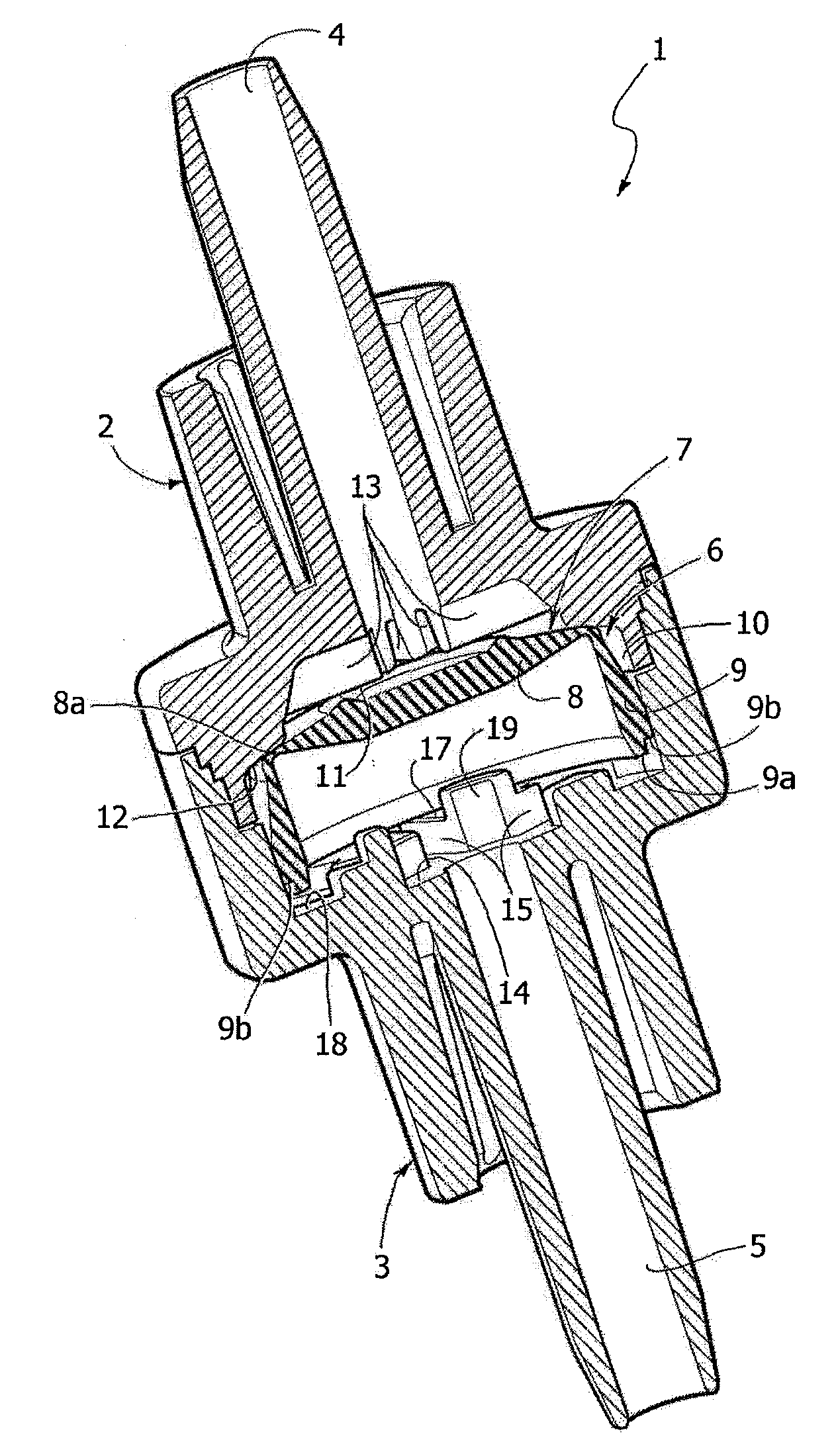

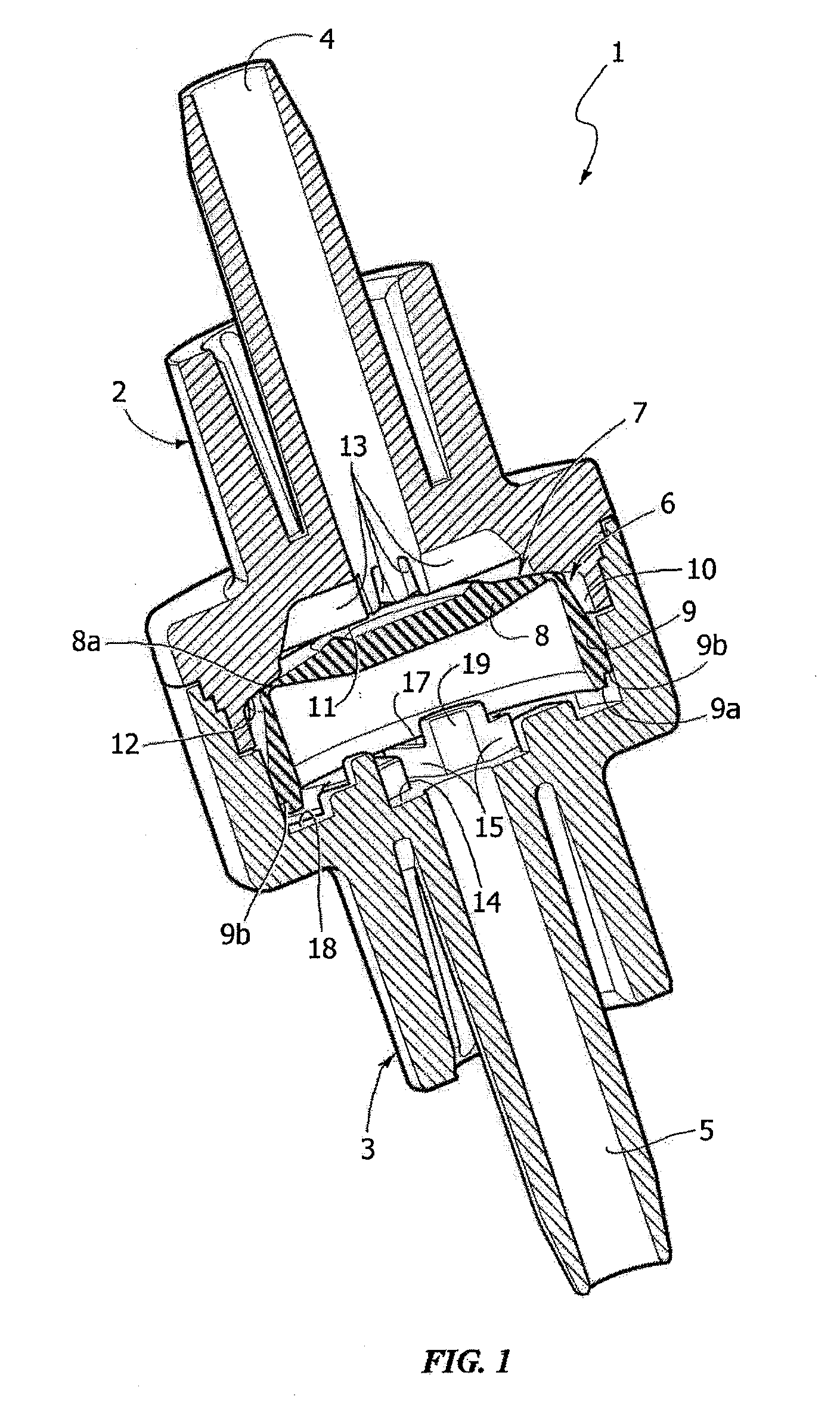

Surgical screw system and related methods

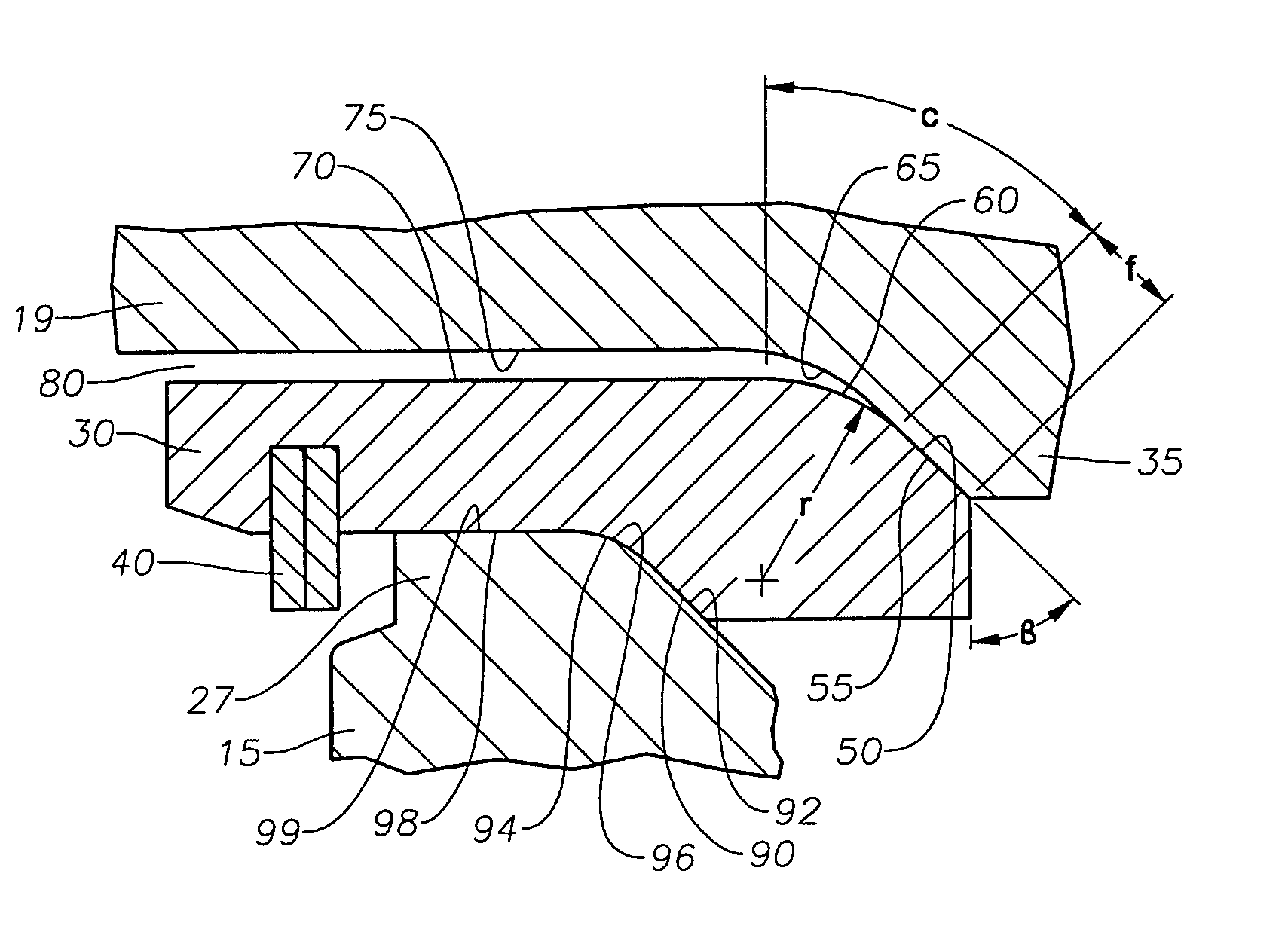

A surgical screw system for use with implantation rods includes a screw member, a receiver member, a pressure cap and a locking device. The screw member has a shaft and a head with a spherical undersurface and a conical tapered recess. The receiver member has an upper and lower portion, a u-shaped rod receiving channel and an axial bore. The u-shaped channel has two lateral legs at the upper portion and forms an opening leading to the axial bore. The axial bore near the lower portion includes an inwardly conical tapered surface which has a diameter larger than the shaft of the screw member but smaller than the head of the screw member. The conical surface forms a support upon which the spherical undersurface of the head of the screw member rests when the screw member is guided through the bore of the lower portion of the receiver member. The pressure cap is positioned within the axial bore and situated upon the head of the screw member. The locking device is designed for securing the rod within the u-shaped channel of the receiver member by applying a tightening torque upon the rod when positioned within the opening and the bore near the upper portion of the receiver member.

Owner:BLACKSTONE MEDICAL

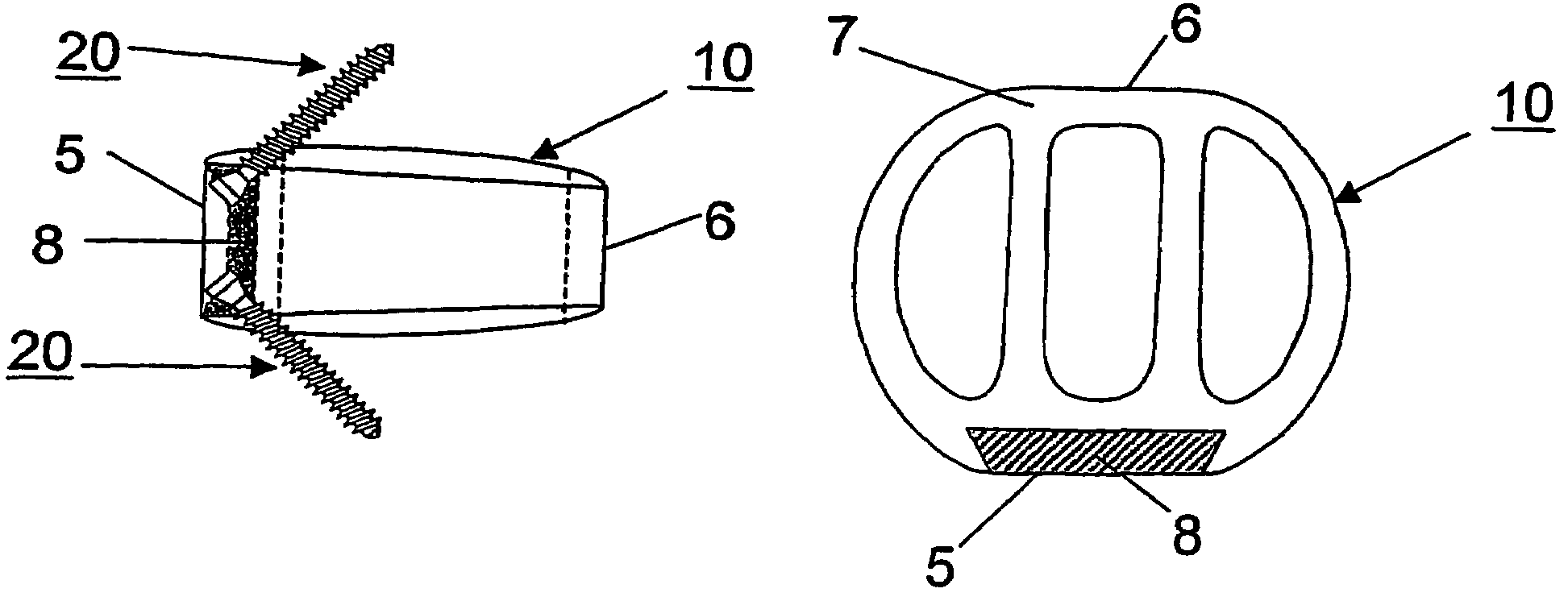

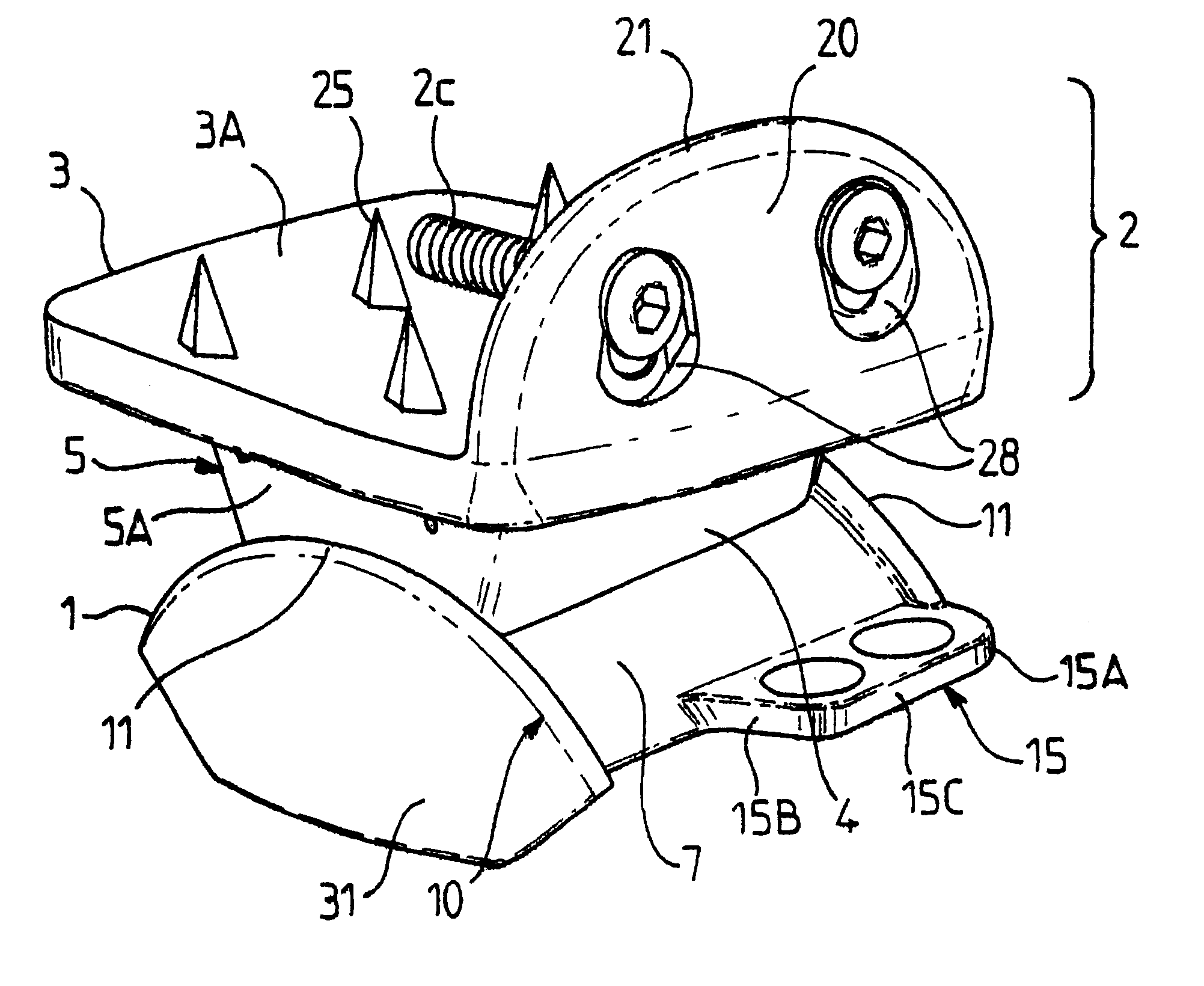

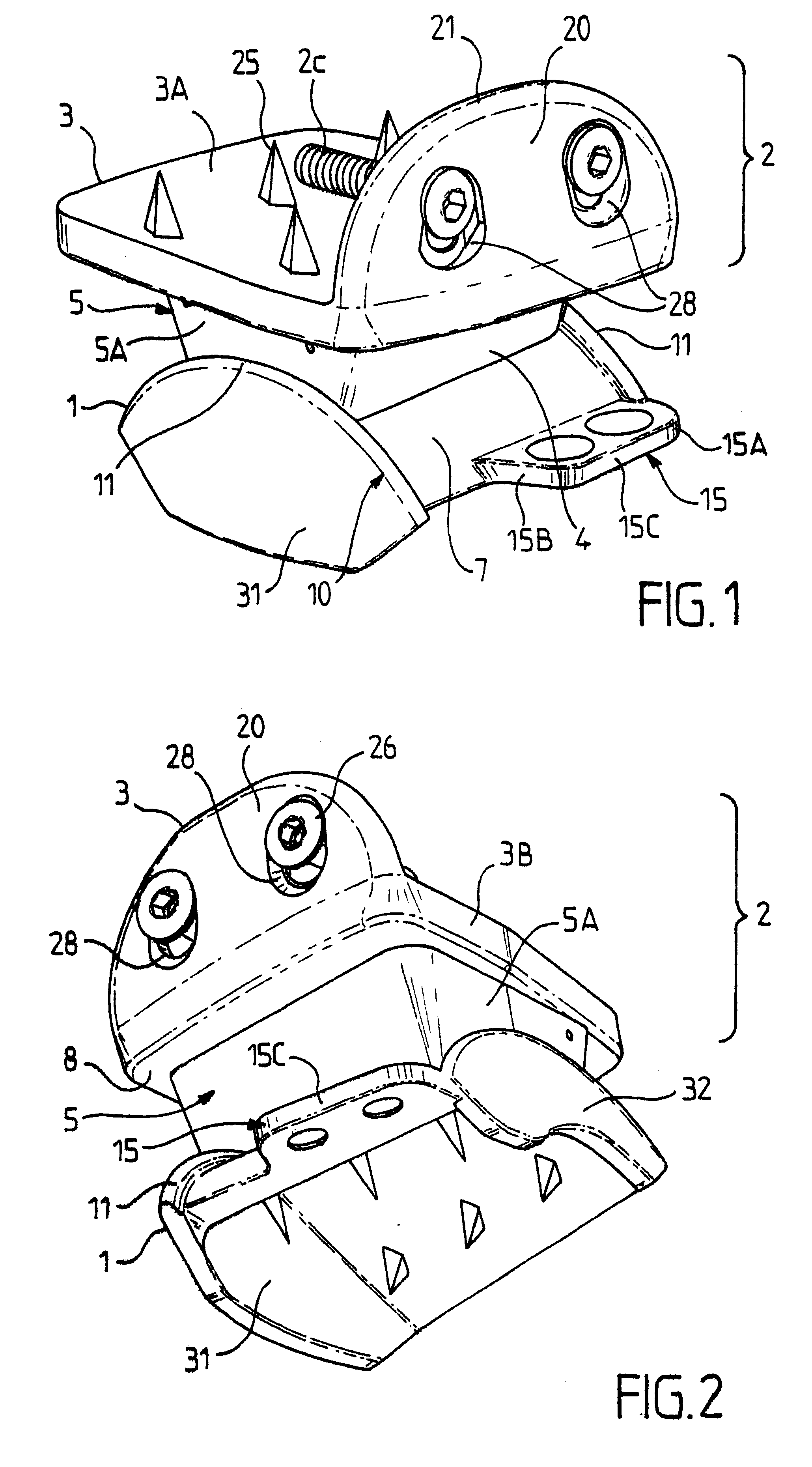

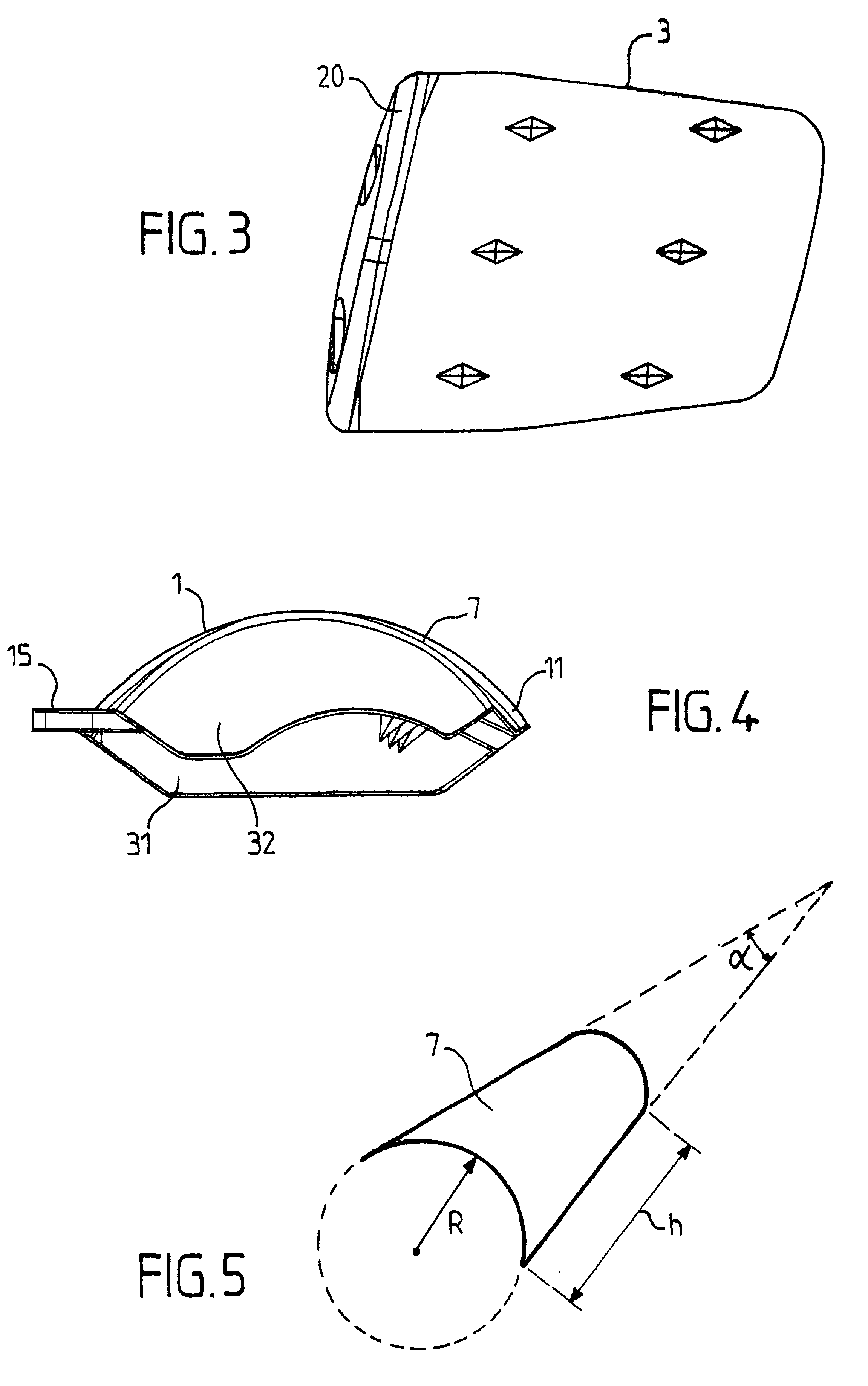

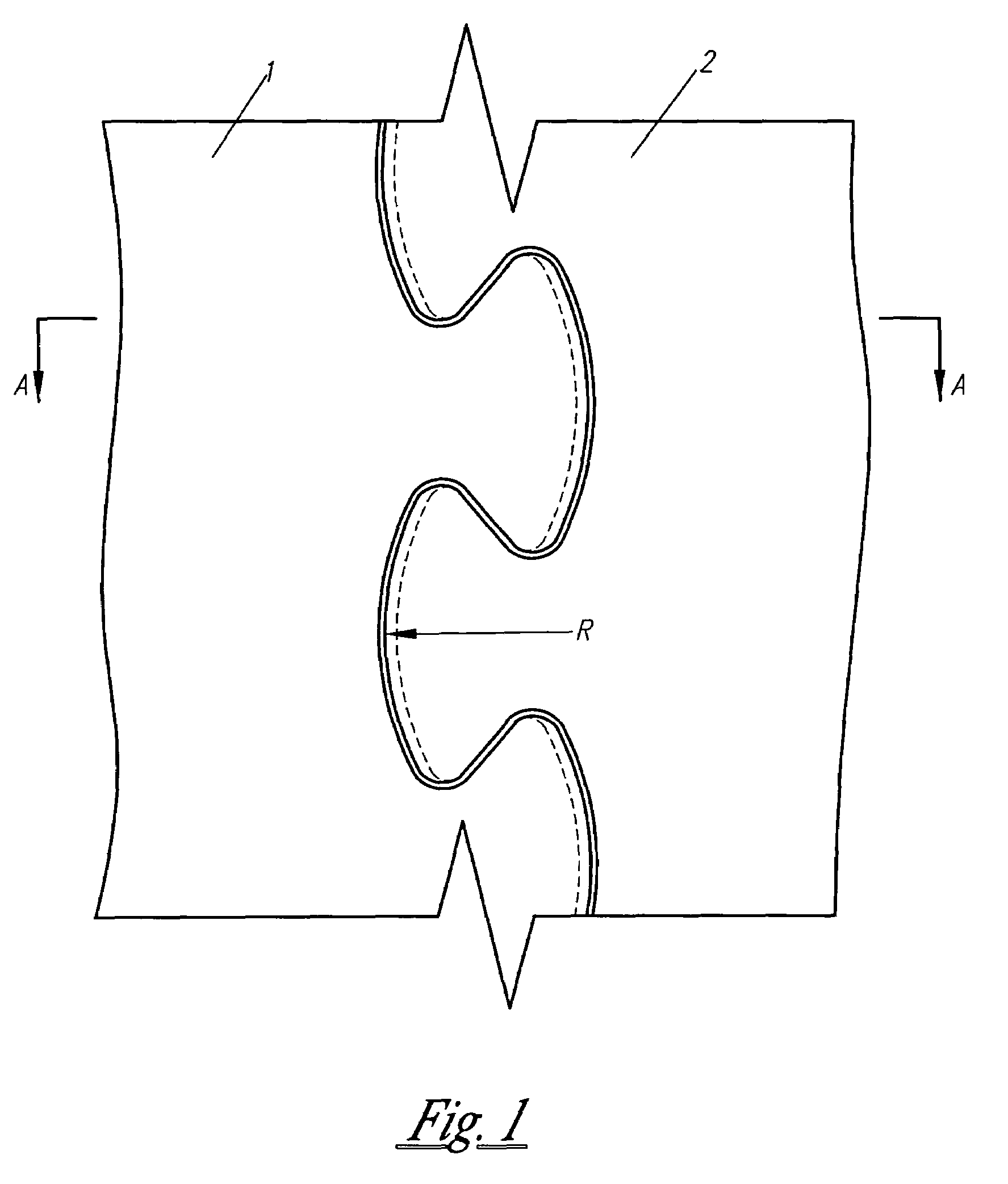

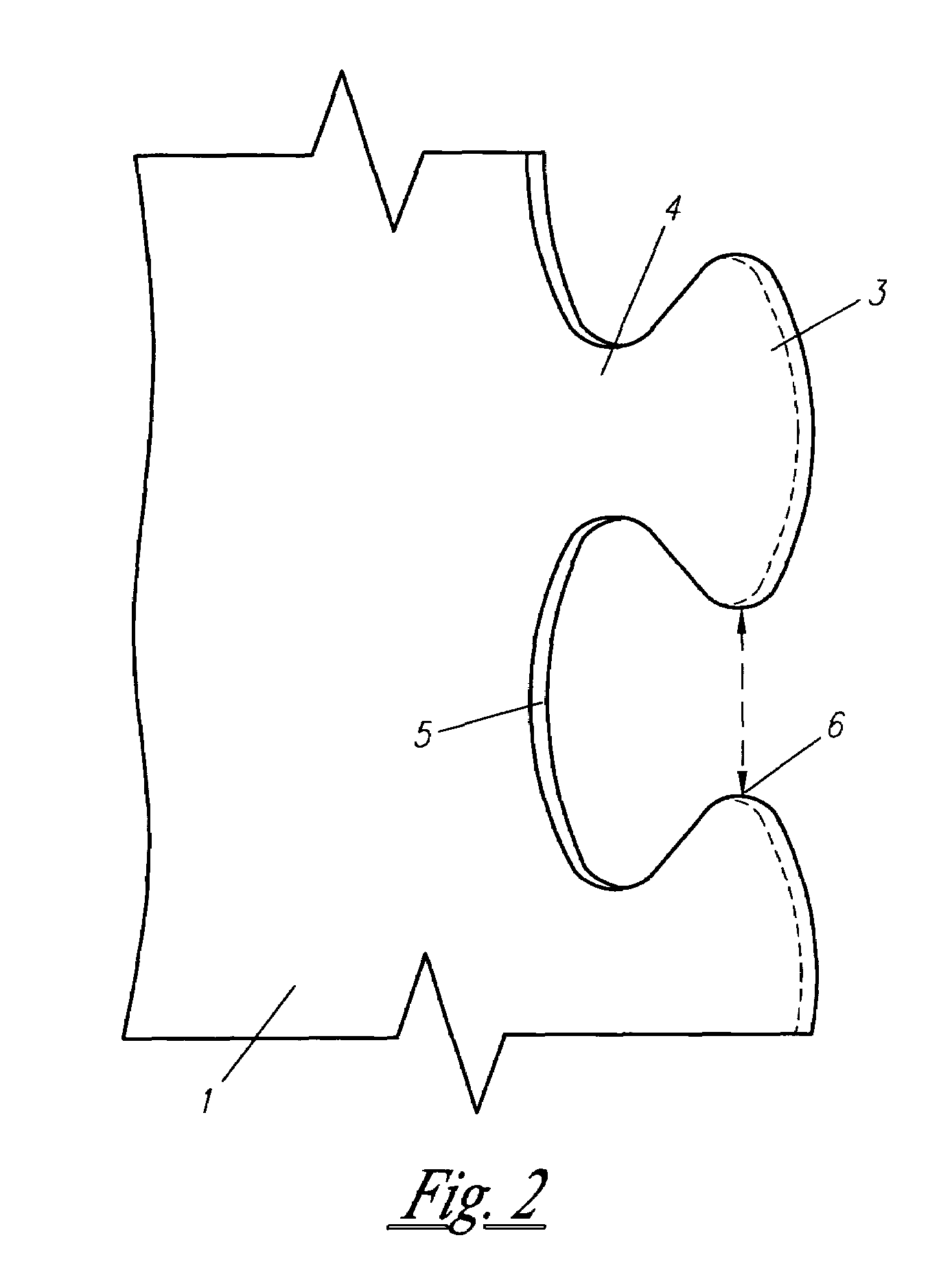

Intervertebral implant

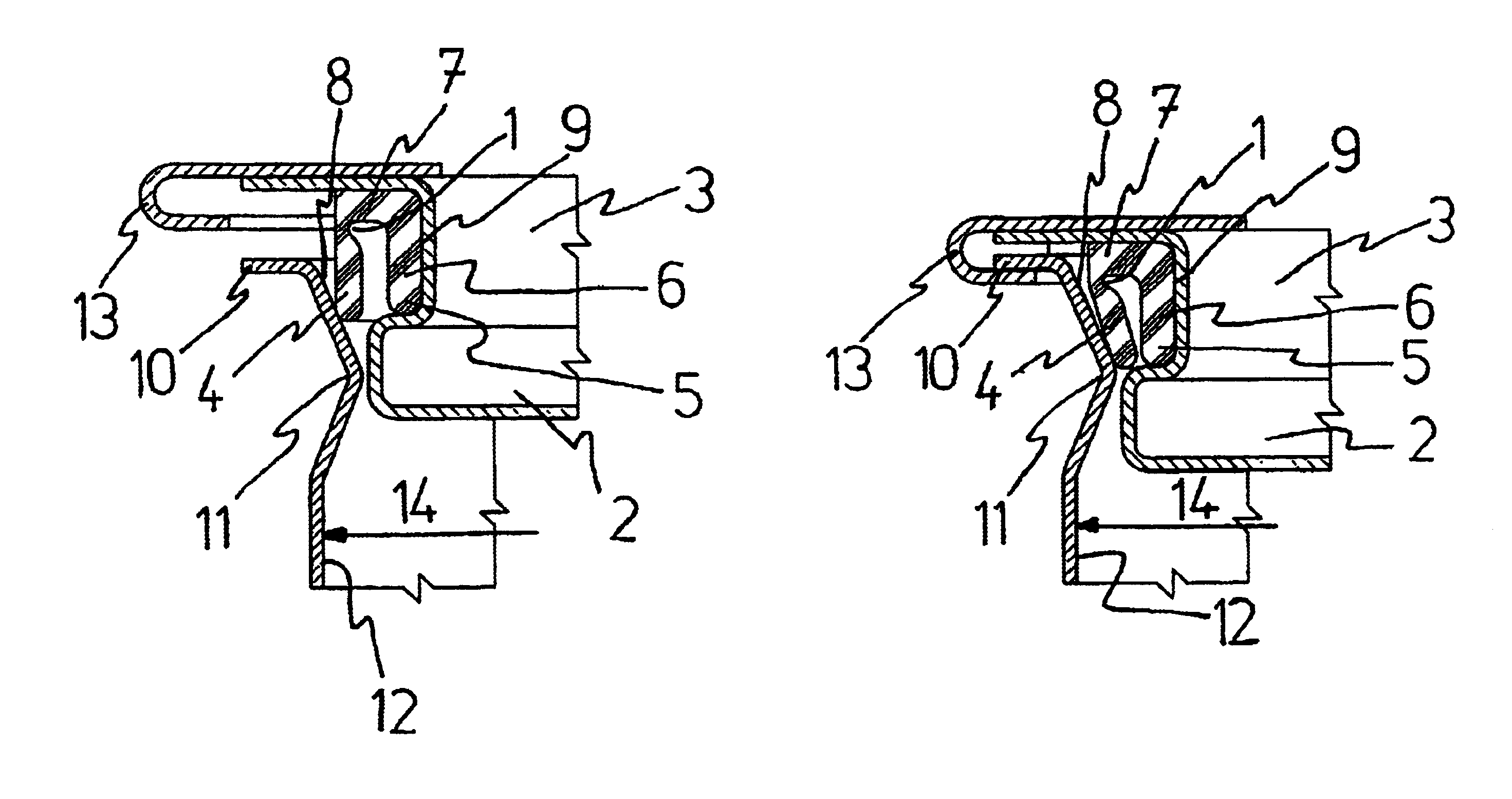

InactiveUS7232464B2The way is simple and fastGreater danger to the surrounding structuresJoint implantsSpinal implantsBiomedical engineeringVertebra

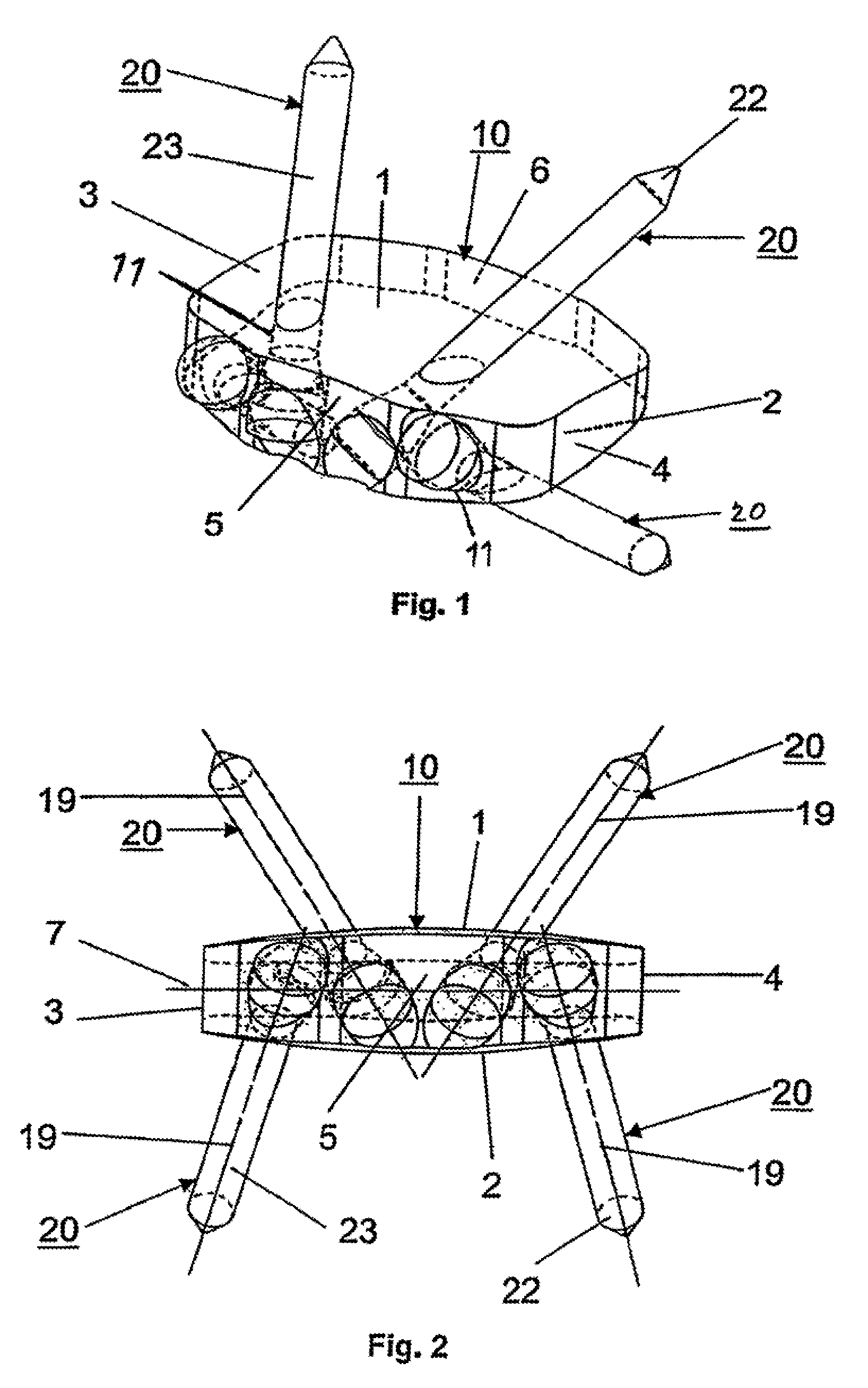

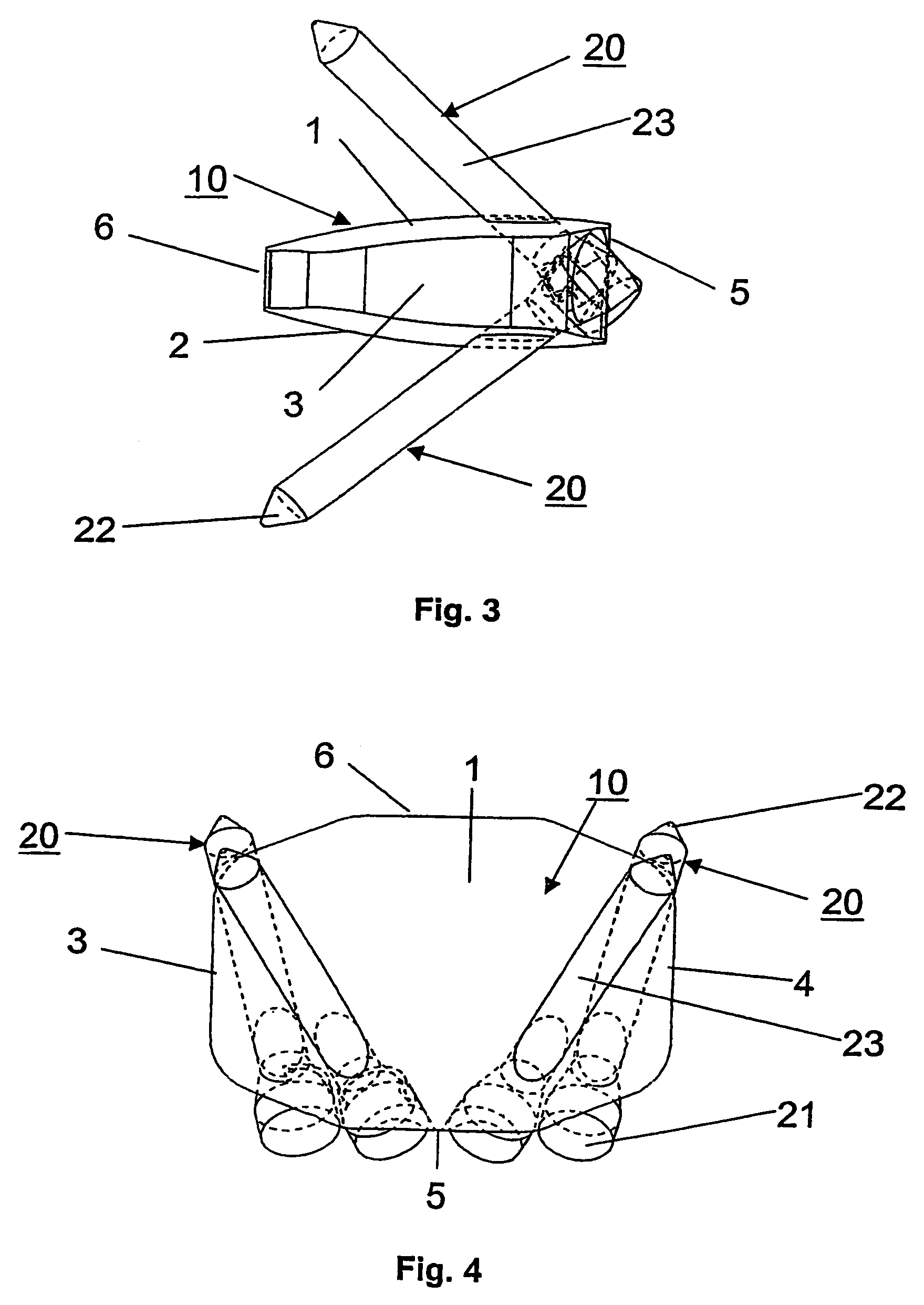

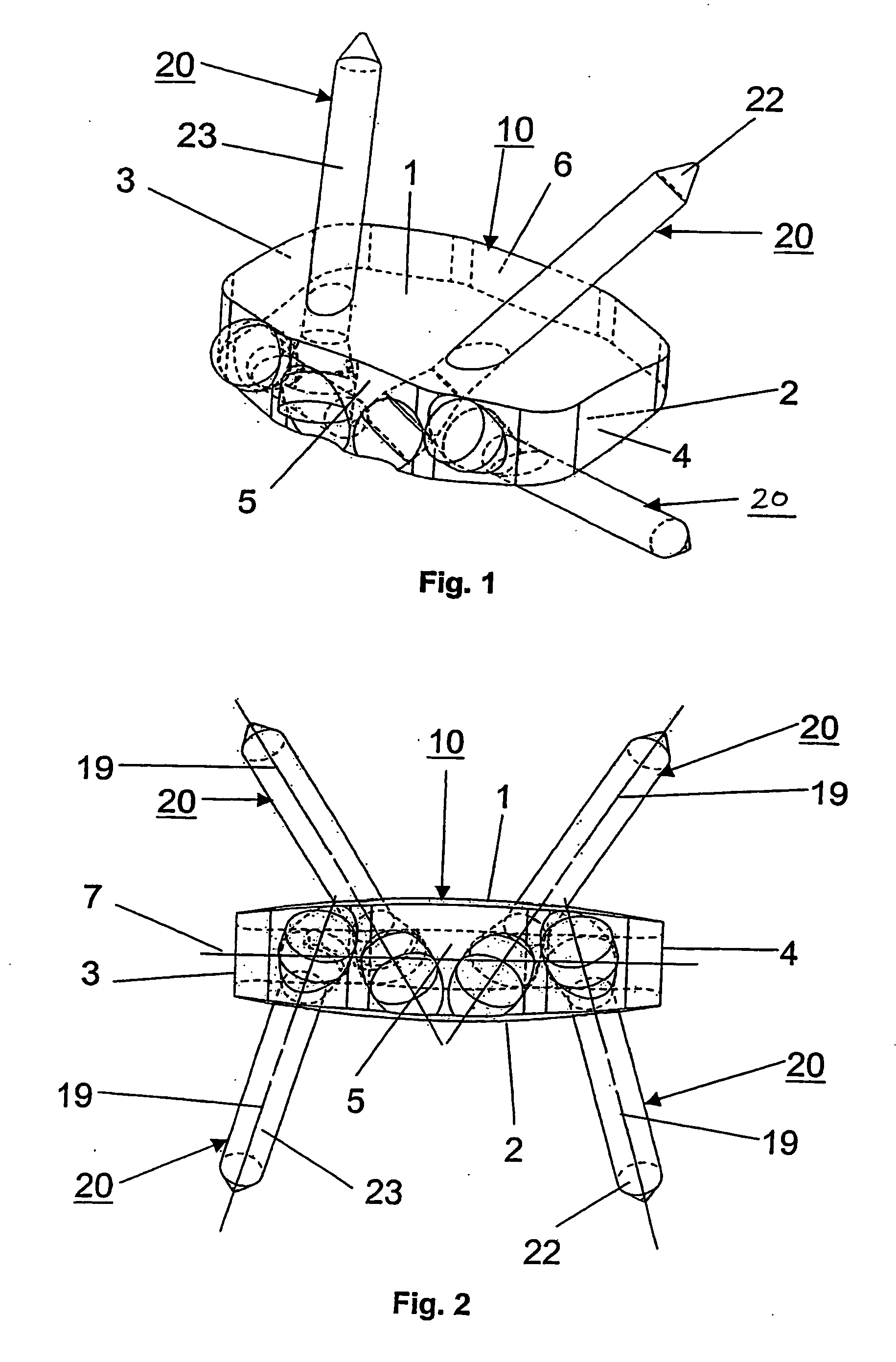

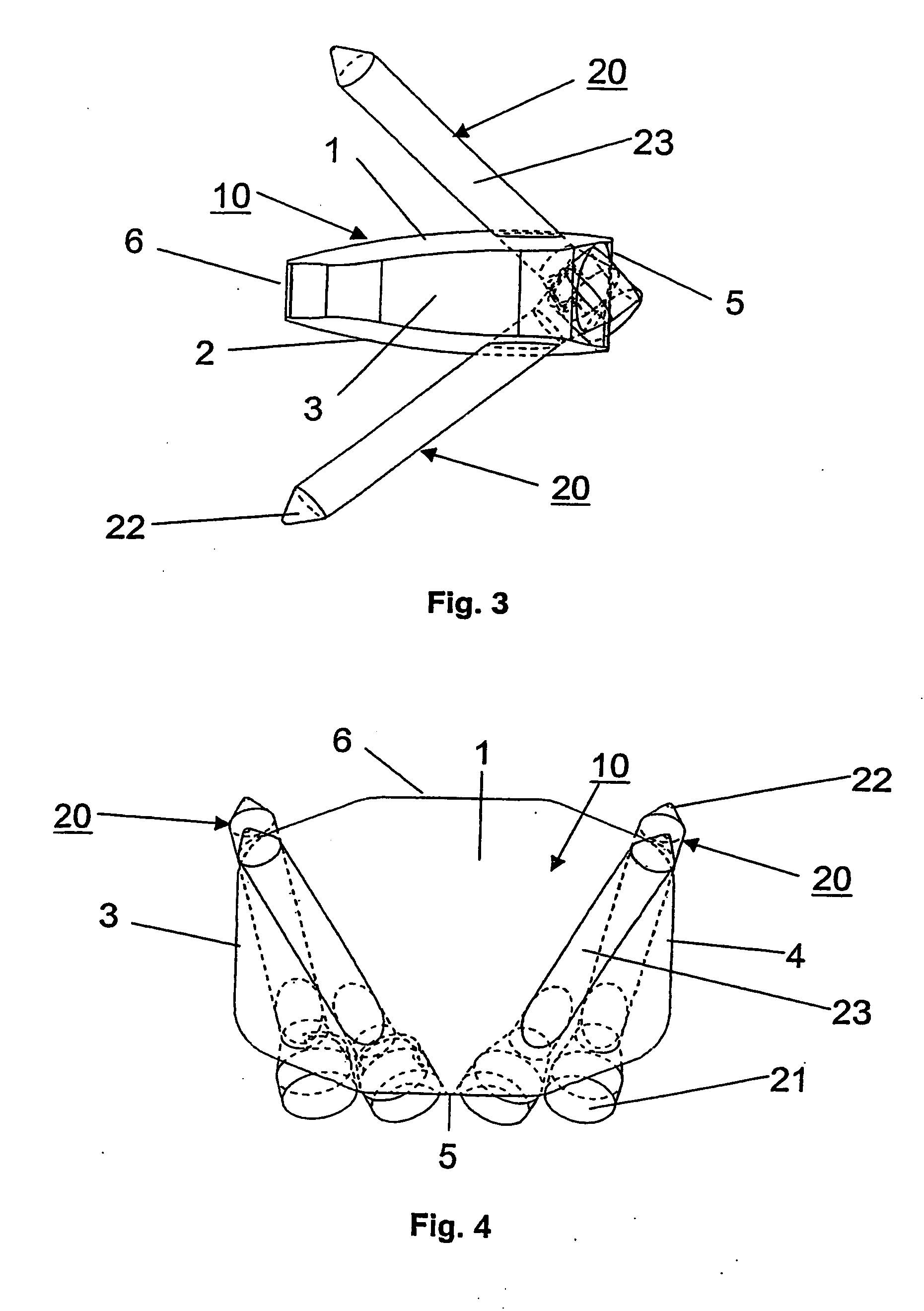

The intervertebral implant is in the form of a three-dimensional structure (10) comprising (a) a top side (1) and an underside (2) which are designed to rest against the end plates of two adjacent vertebras, (b) a left side face (3) and a right side face (4), (c) a front face (5) and a rear face (6), (d) a horizontal center plane situated between the top side (1) and the underside (2), (e) a vertical center plane (8) situated between the left side face (3) and the right side face (8) and (f) a plurality of boreholes (9) passing through the implant structure (10) that are designed to receive longitudinal affixation elements (20), the axes (19) of said elements intersecting the horizontal center plane (7). At least one of the boreholes (9) is designed in a manner that the affixation element (10) received in it can be rigidly connected to the intervertebral implant. Said connection is implemented using a thread or by matching conical surfaces.

Owner:DEPUY SYNTHES PROD INC

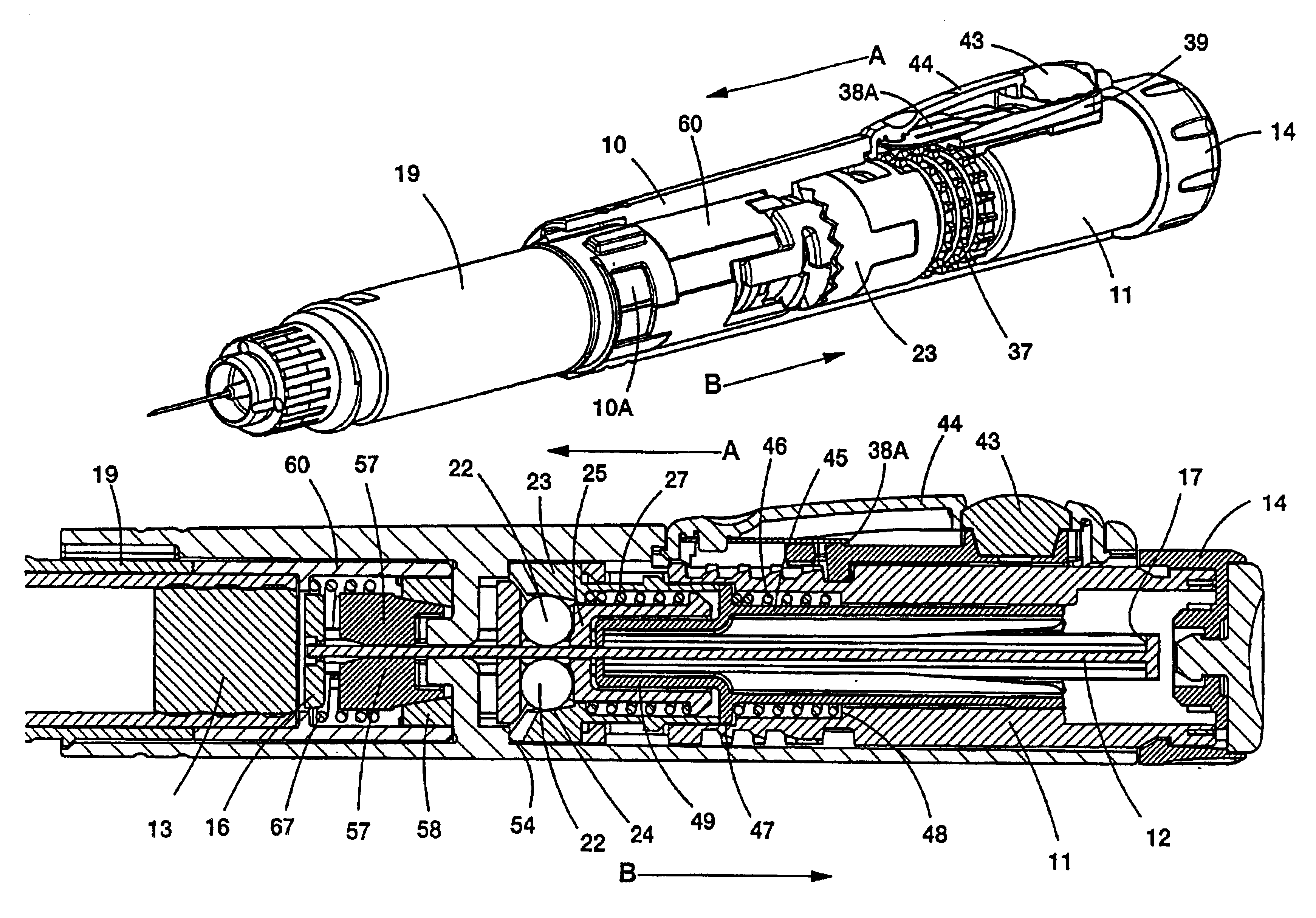

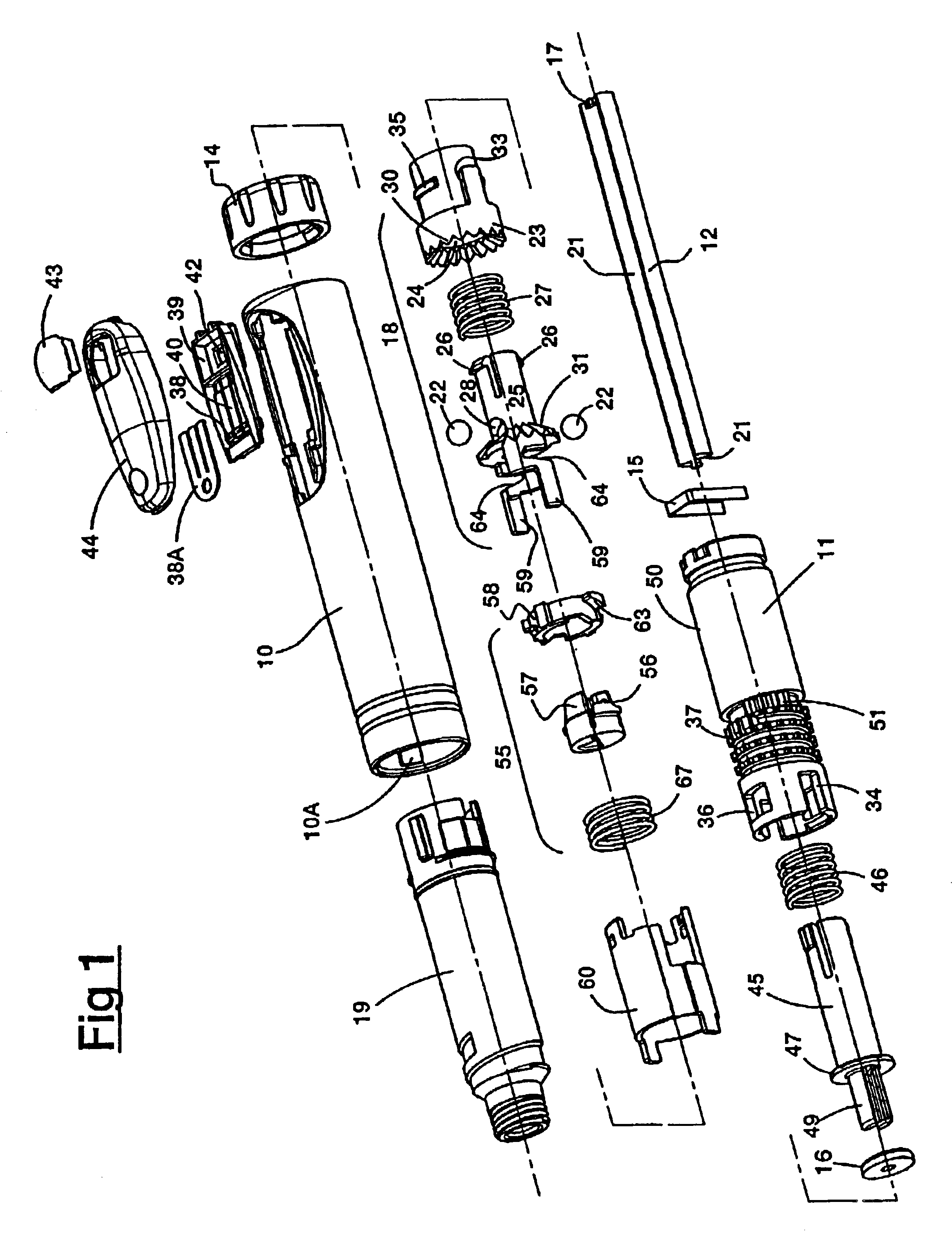

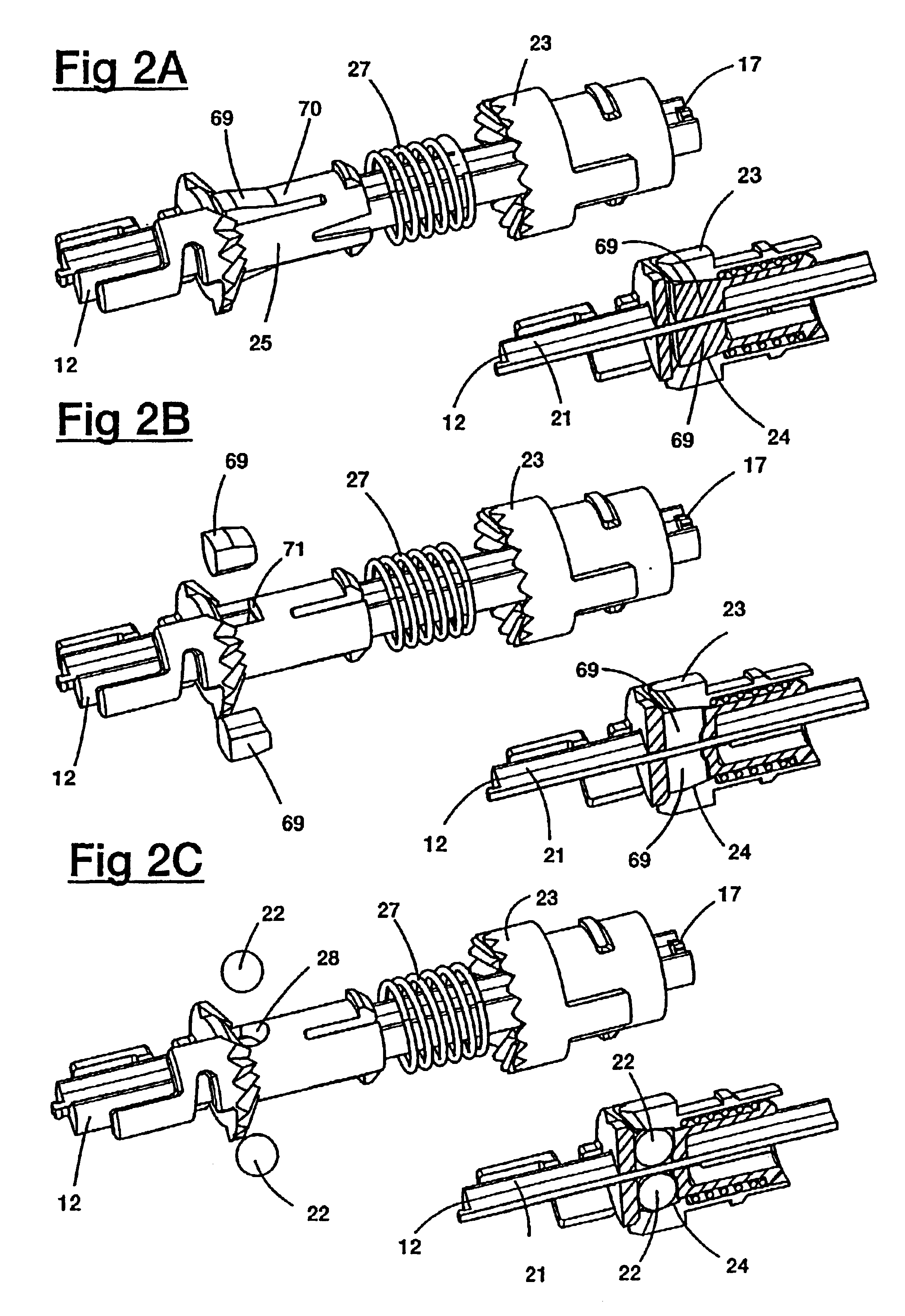

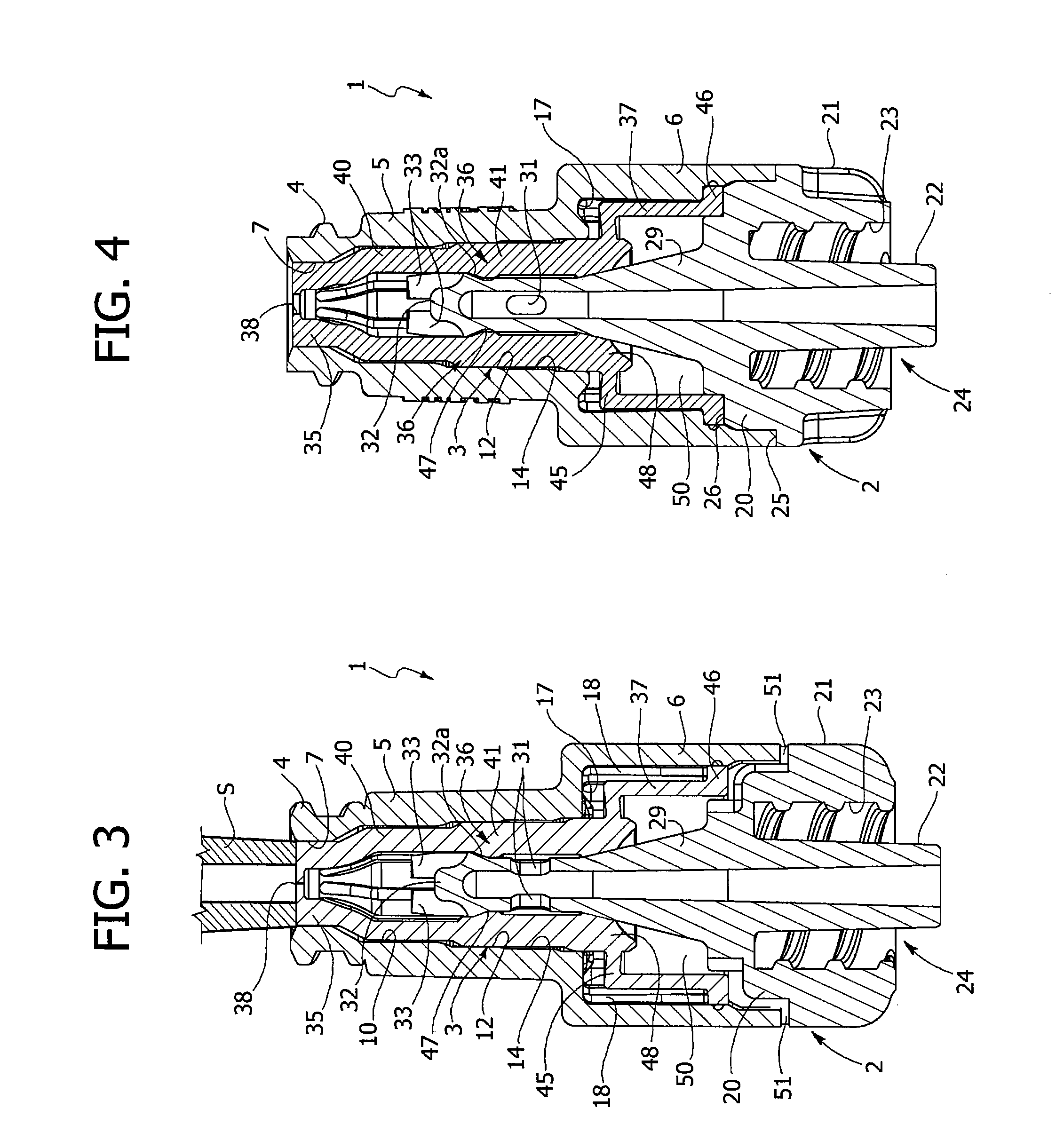

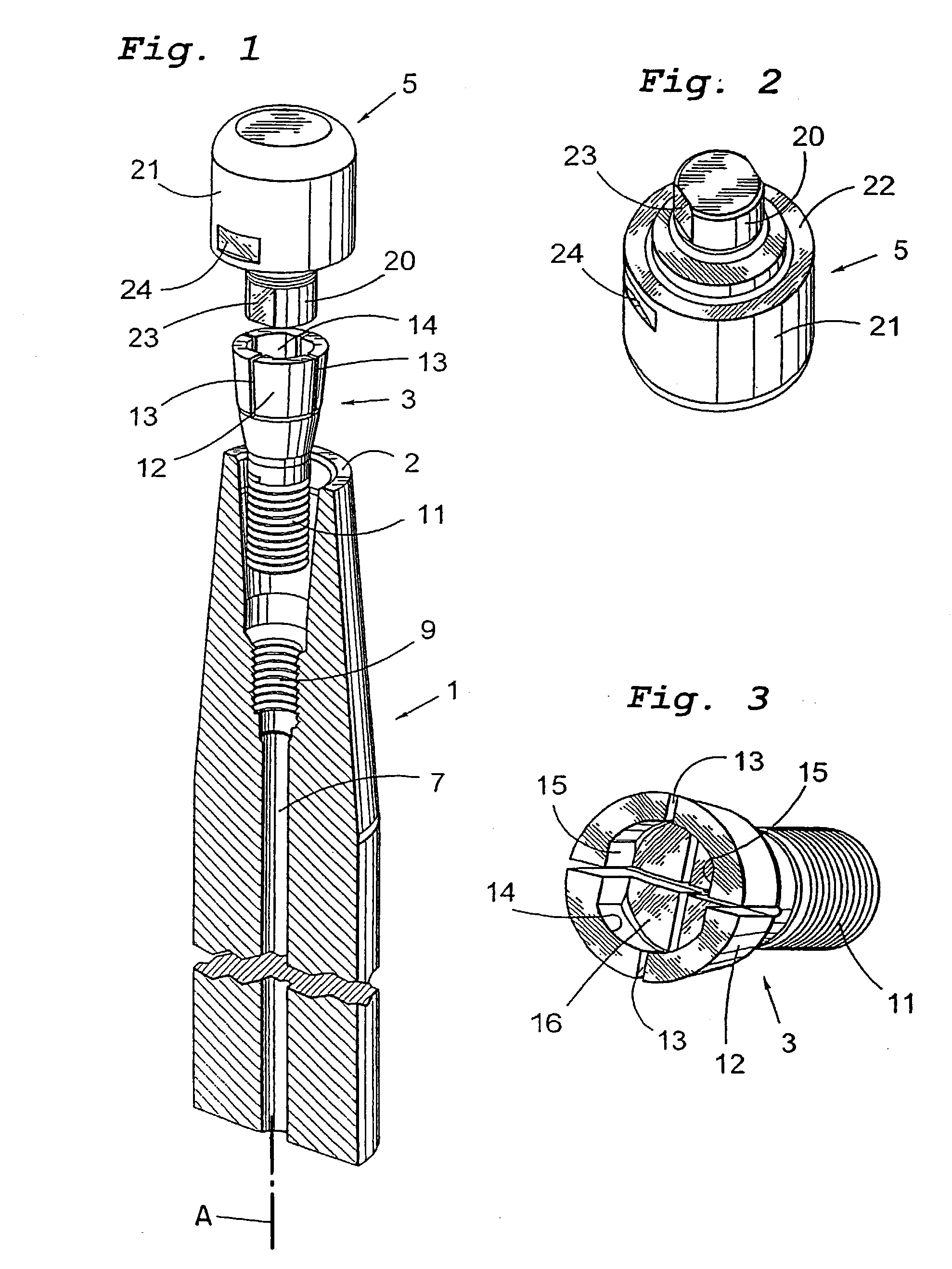

One-way clutch mechanisms and injector devices

An incrementing mechanism suitable for use in a medical injector device has a driving member rotatably and slidably mounted within a tubular body and arranged to advance an elongate element in one direction with respect to the tubular body. A one-way clutch includes a generally conical surface and a blocking clutch member engageable with the conical surface. Means are provided to disengage the clutch, including a pressure component arranged and biased to engage the clutch member. Rotation of the driving member with respect to the pressure component causes two sets of inter-engageable teeth to ride over each other, which successively lifts the pressure component to disengage the clutch member from the conical surface and then allows the pressure component to be biased to a position where the clutch member engages the conical surface.

Owner:SAMS

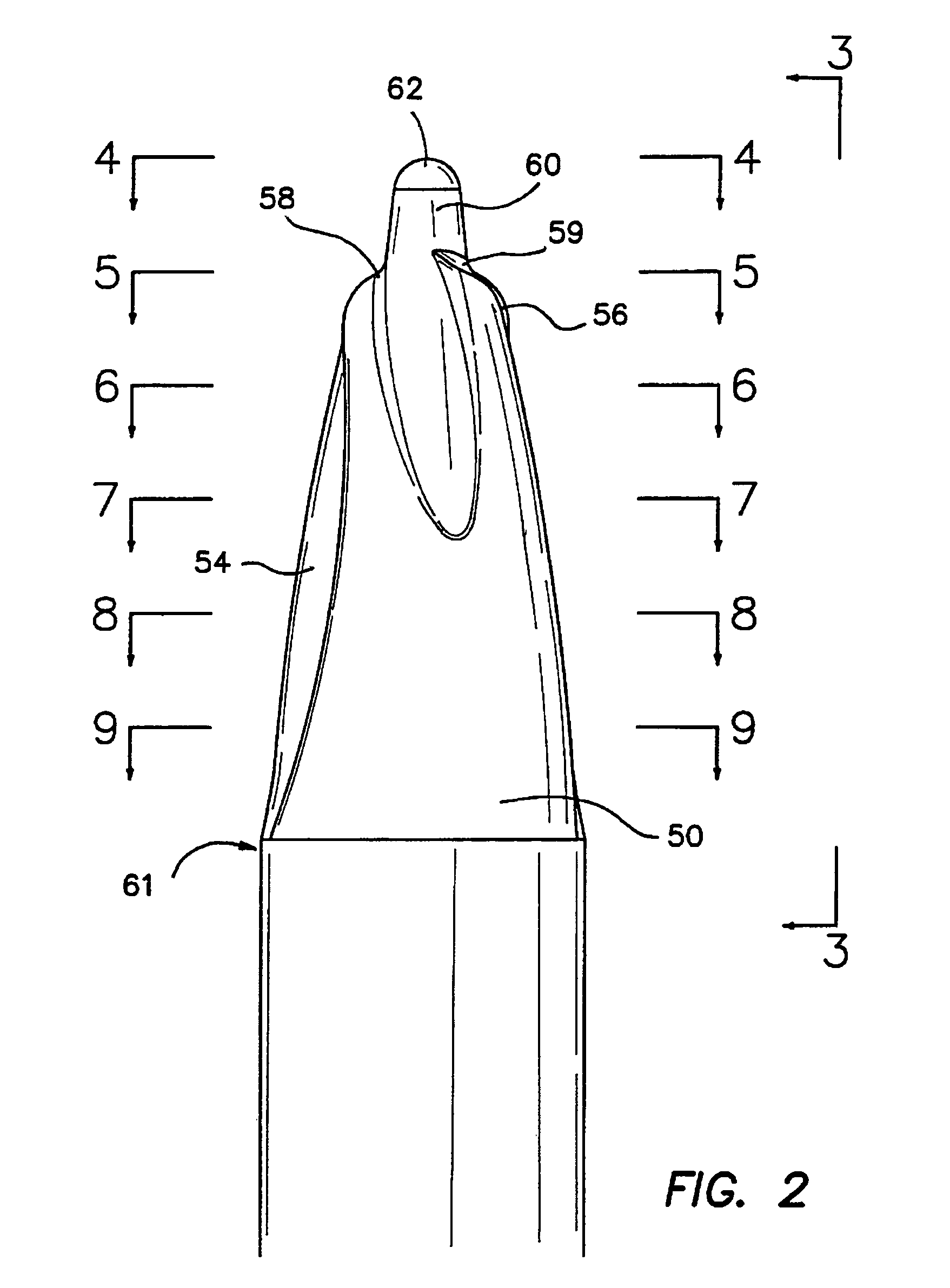

Apparatus and method for anchoring sutures

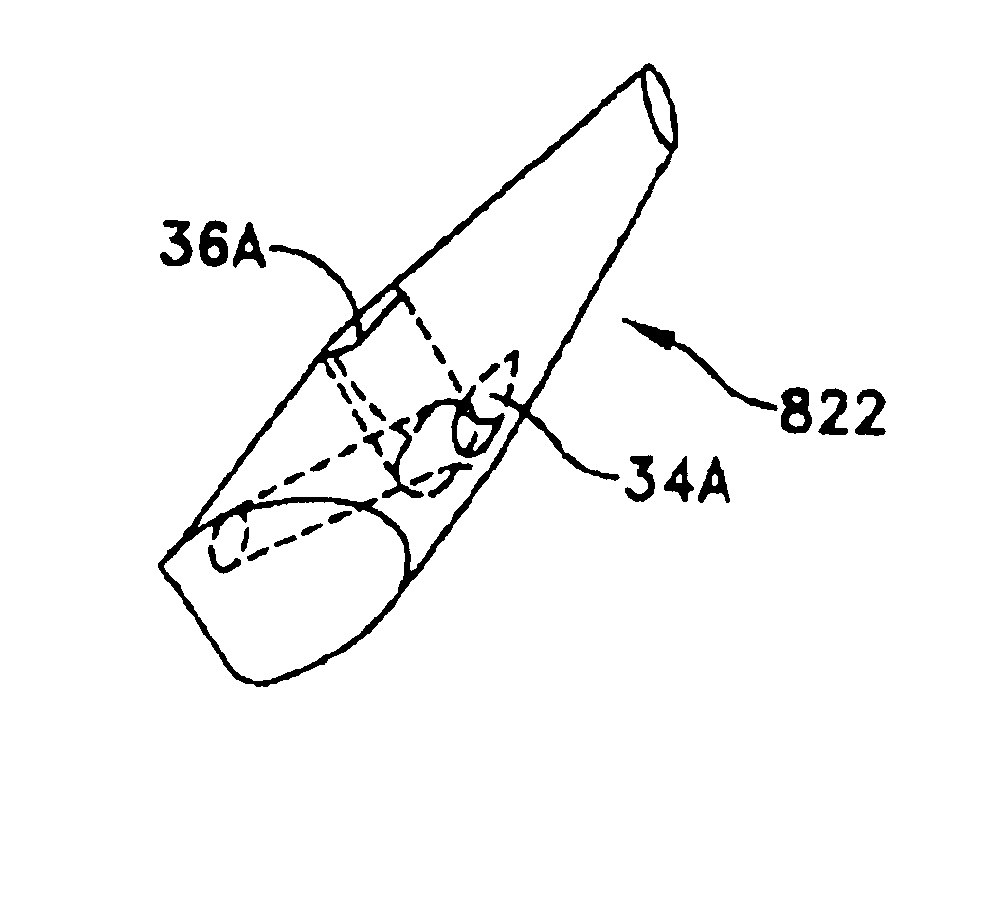

InactiveUS6923823B1Simple and inexpensive to manufactureEasy to insertSuture equipmentsBone implantSuture anchorsCancellous bone

A suture anchor having a conical surface and a bore in which an end of an insertion tool is inserted. The insertion end of the insertion tool is made of material having elastic properties. The bore and base of the suture anchor are angled with respect to the central axis of the suture anchor and preferably are parallel to each other. During insertion, the suture anchor is reoriented to fit into the hole, thereby bending the elastic end of the insertion tool. When the suture anchor is within cancellous bone tissue, the elastic properties of the insertion tool deploys the suture anchor to an orientation in which the suture anchor cannot fit through the bone hole, thereby firmly anchoring the suture anchor in the human bone.

Owner:DEPUY SYNTHES PROD INC

Ankle prosthesis

InactiveUS6409767B1Preventing uncontrolled deformationImprove the situationInternal osteosythesisAnkle jointsTibiaBase of the sacrum

The invention provides an ankle prosthesis for use in the field of orthopedic prostheses comprising a talus implant for implanting in or on the talus and a top element including a tibia implant for implanting in or on the base of the tibia. The top element and the talus implant being mounted to move relative to each other by friction on a contact interface so as to allow the ankle to move. The contact interface presents a friction surface that can be considered as being a fraction of a substantially frustoconical surface. When implanted, the substantially frustoconical surface is oriented so that its larger radius portion is directed substantially towards the outside of the ankle.

Owner:EURON FOOT PLATFORM

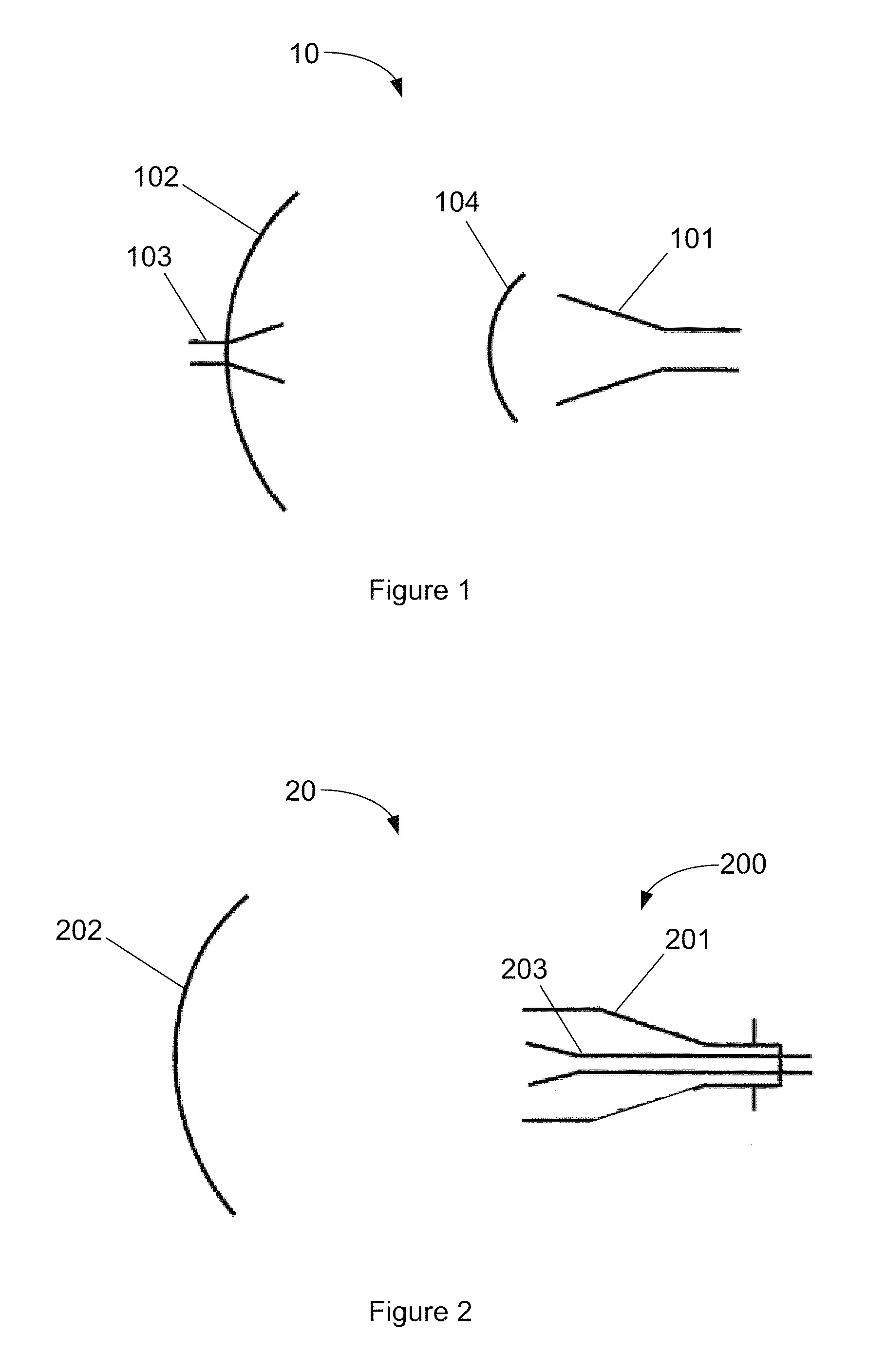

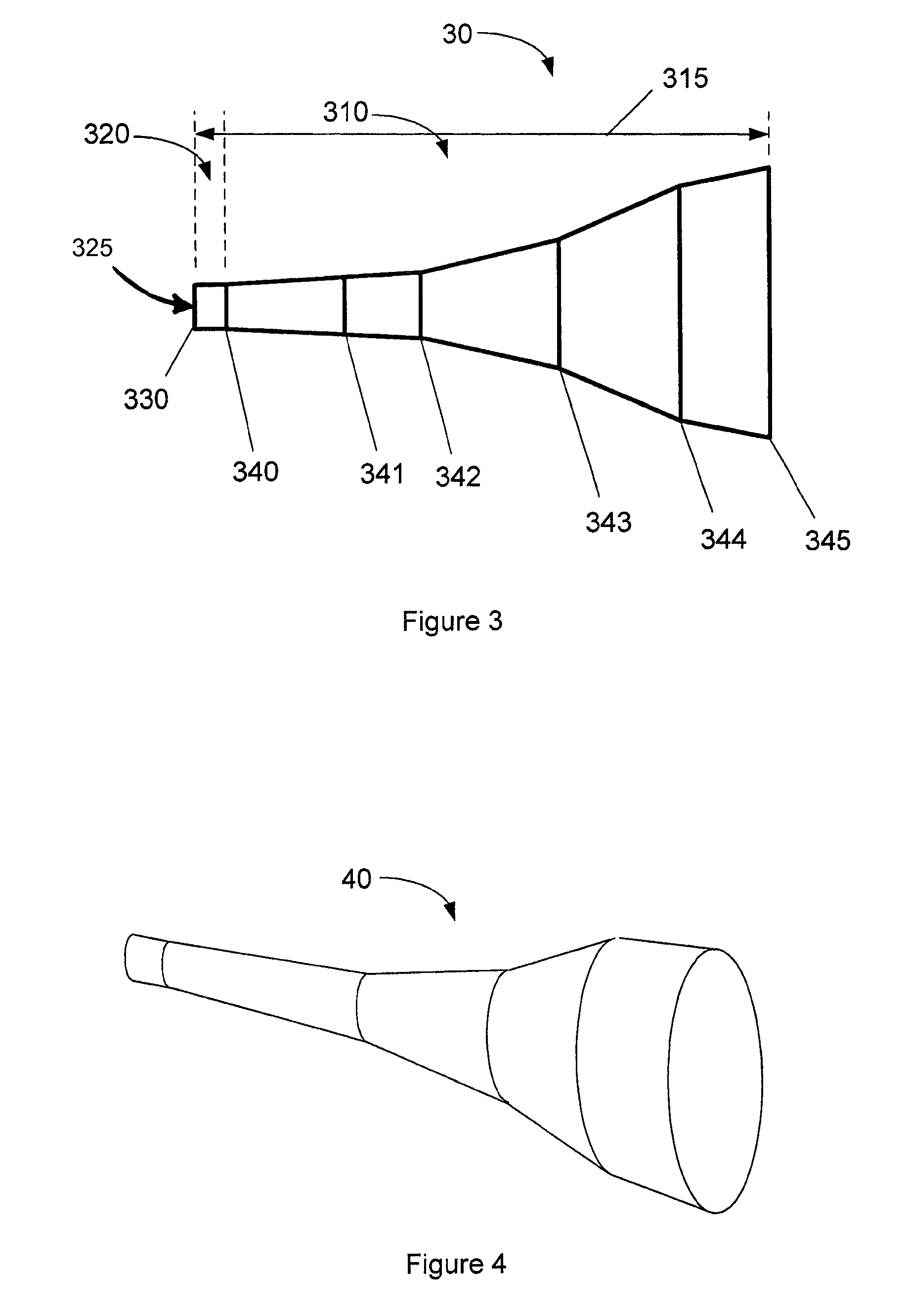

Dual-band feed horn with common beam widths

ActiveUS8957821B1Reduces pointing requirementLow efficiencySimultaneous aerial operationsDual frequencyLow frequency band

Owner:LOCKHEED MARTIN CORP

Intervertebral implant

InactiveUS20050177236A1Increase clamping forceSmall slopeJoint implantsSpinal implantsBiomedical engineeringEuhedral and anhedral

The intervertebral implant is in the form of a three-dimensional structure (10) comprising (a) a top side (1) and an underside (2) which are designed to rest against the end plates of two adjacent vertebras, (b) a left side face (3) and a right side face (4), (c) a front face (5) and a rear face (6), (d) a horizontal center plane situated between the top side (1) and the underside (2), (e) a vertical center plane (8) situated between the left side face (3) and the right side face (8) and (f) a plurality of boreholes (9) passing through the implant structure (10) that are designed to receive longitudinal affixation elements (20), the axes (19) of said elements intersecting the horizontal center plane (7). At least one of the boreholes (9) is designed in a manner that the affixation element (10) received in it can be rigidly connected to the intervertebral implant. Said connection is implemented using a thread or by matching conical surfaces.

Owner:DEPUY SYNTHES PROD INC

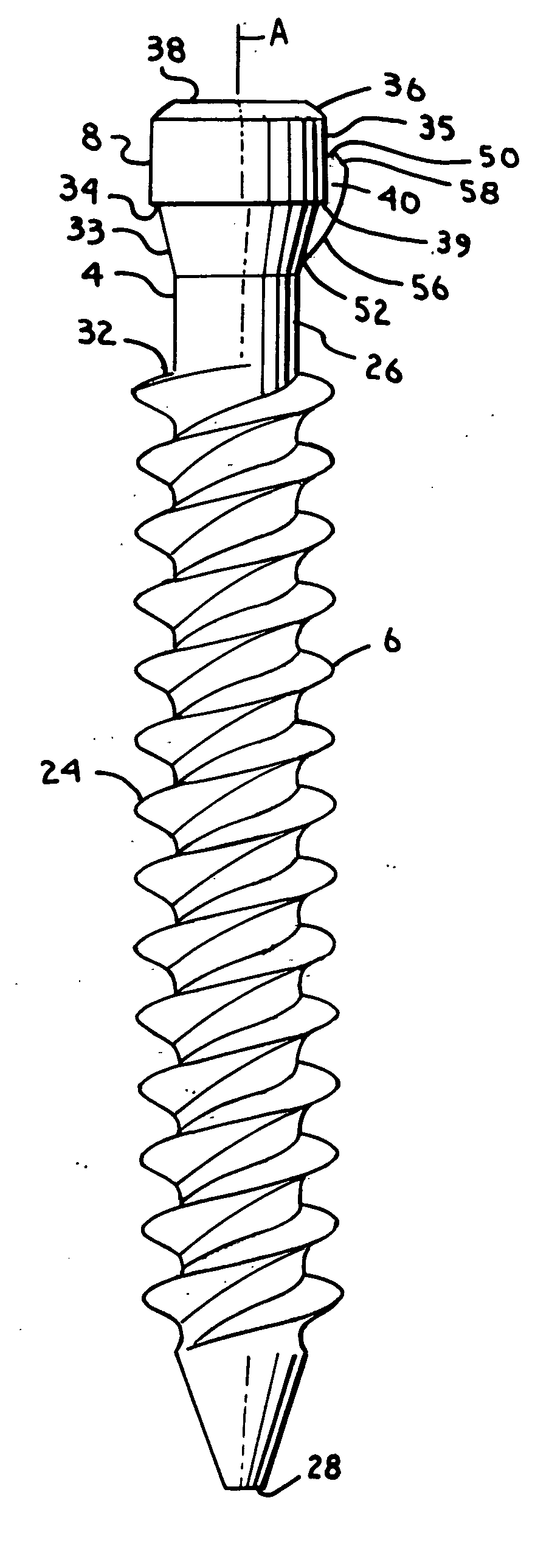

Polyaxial bone screw with shank-retainer insert capture

A polyaxial bone screw assembly includes a threaded shank body member having an upper portion with an internal drive and, alternatively, a laterally extending alignment rib or fin. The bone screw assembly also includes a lockable receiver coupling member, an open retainer ring member having a slit or gap and a compression insert member. An inset conical or cylindrical surface on the shank upper portion frictionally engages a similarly shaped inner surface of the retainer ring. The receiver includes a restrictive lower opening that allows for uploading the shank upper portion and compressed retainer ring into the receiver cavity, but prevents passage of the retainer ring out of the receiver once the ring inner surface engages the conical surface of the shank upper portion.

Owner:JACKSON

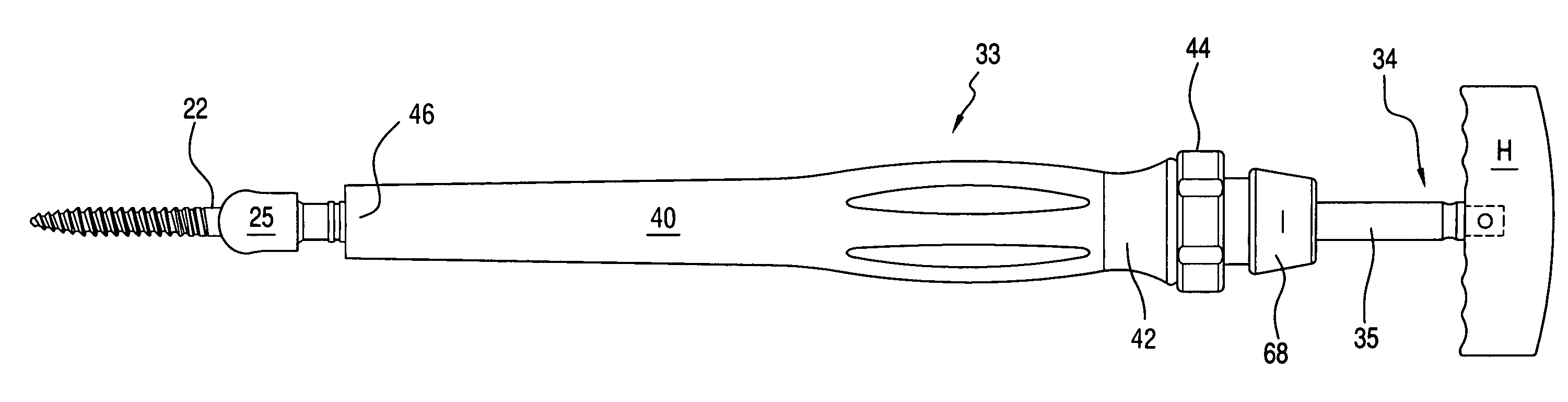

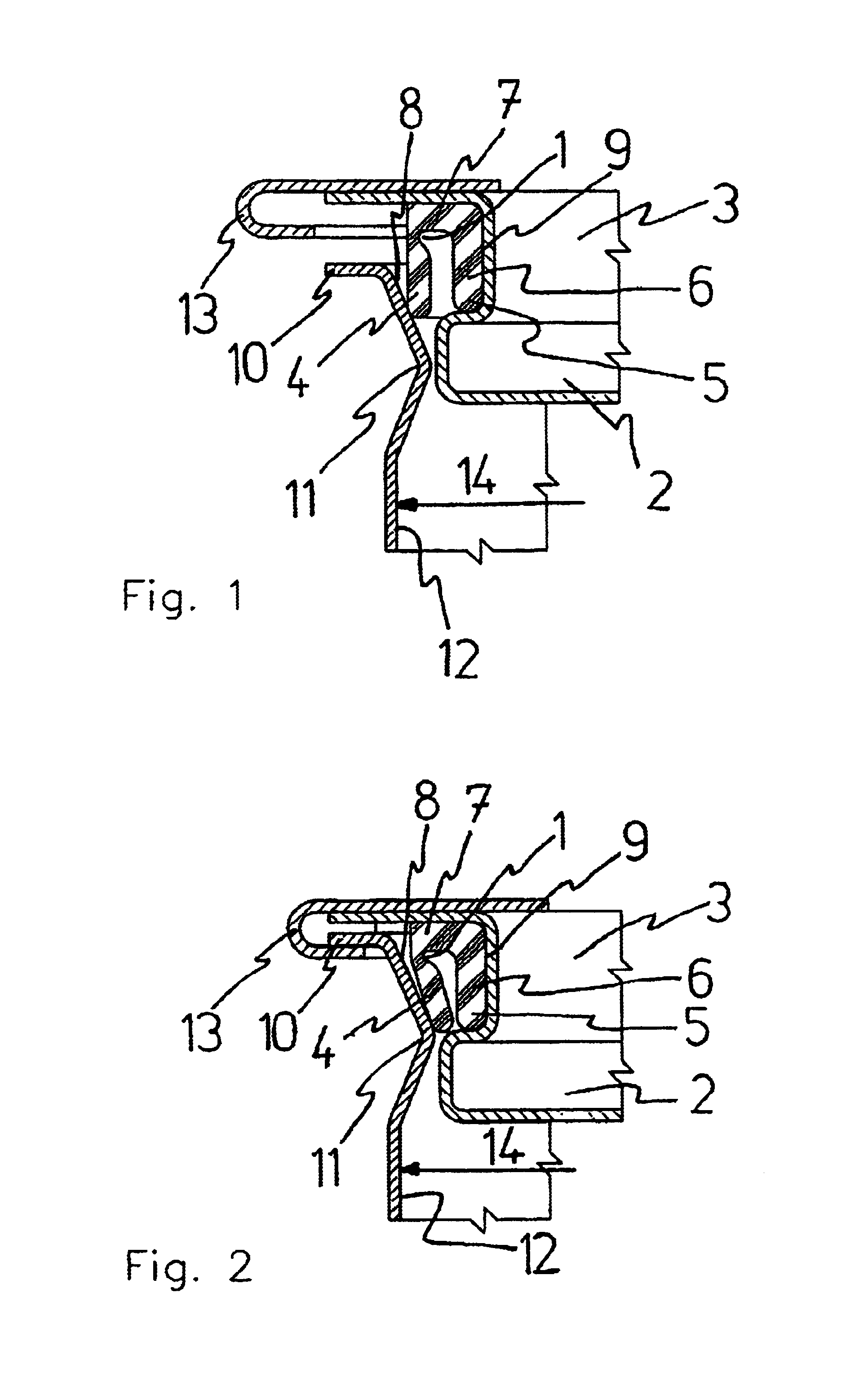

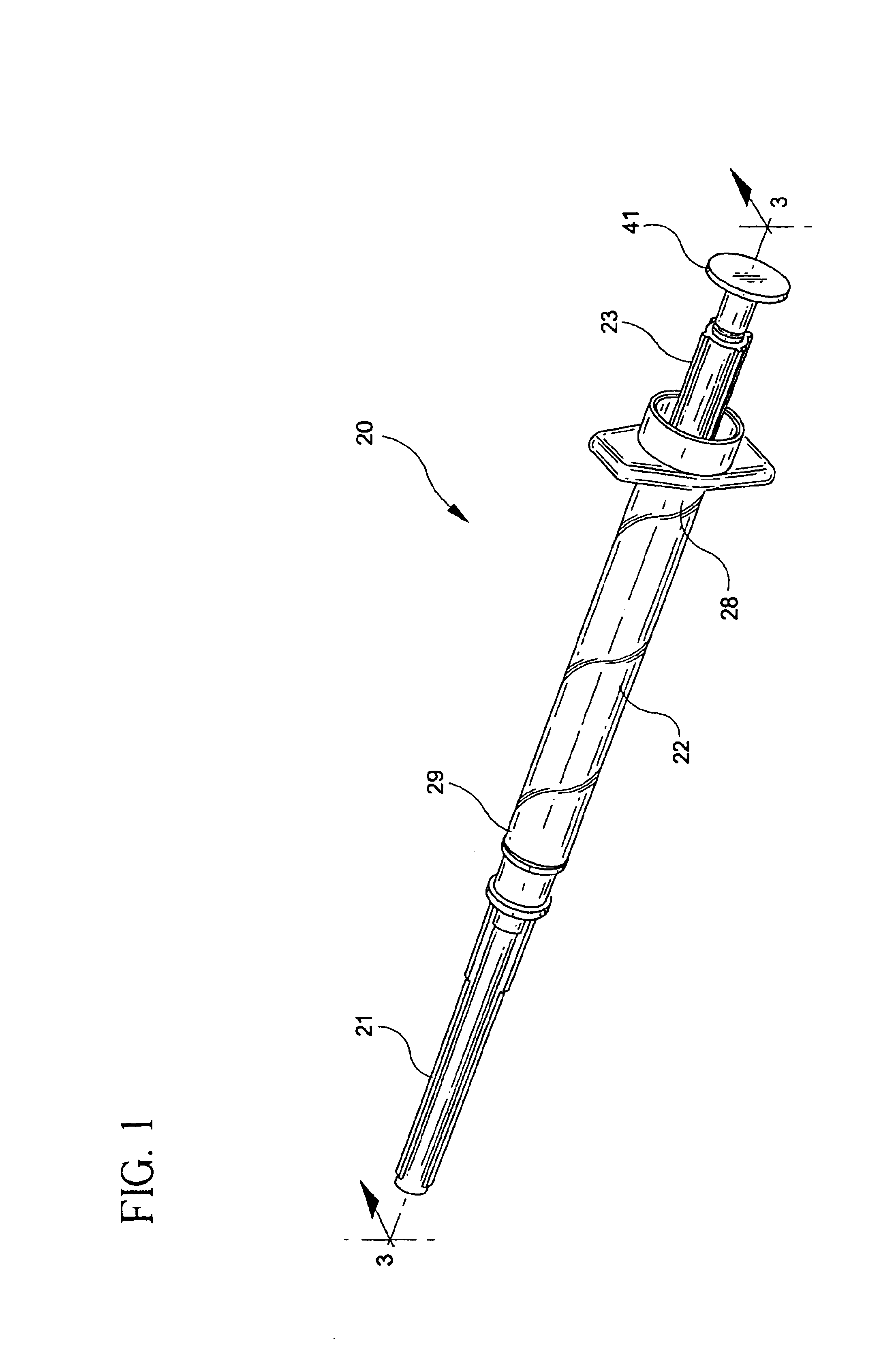

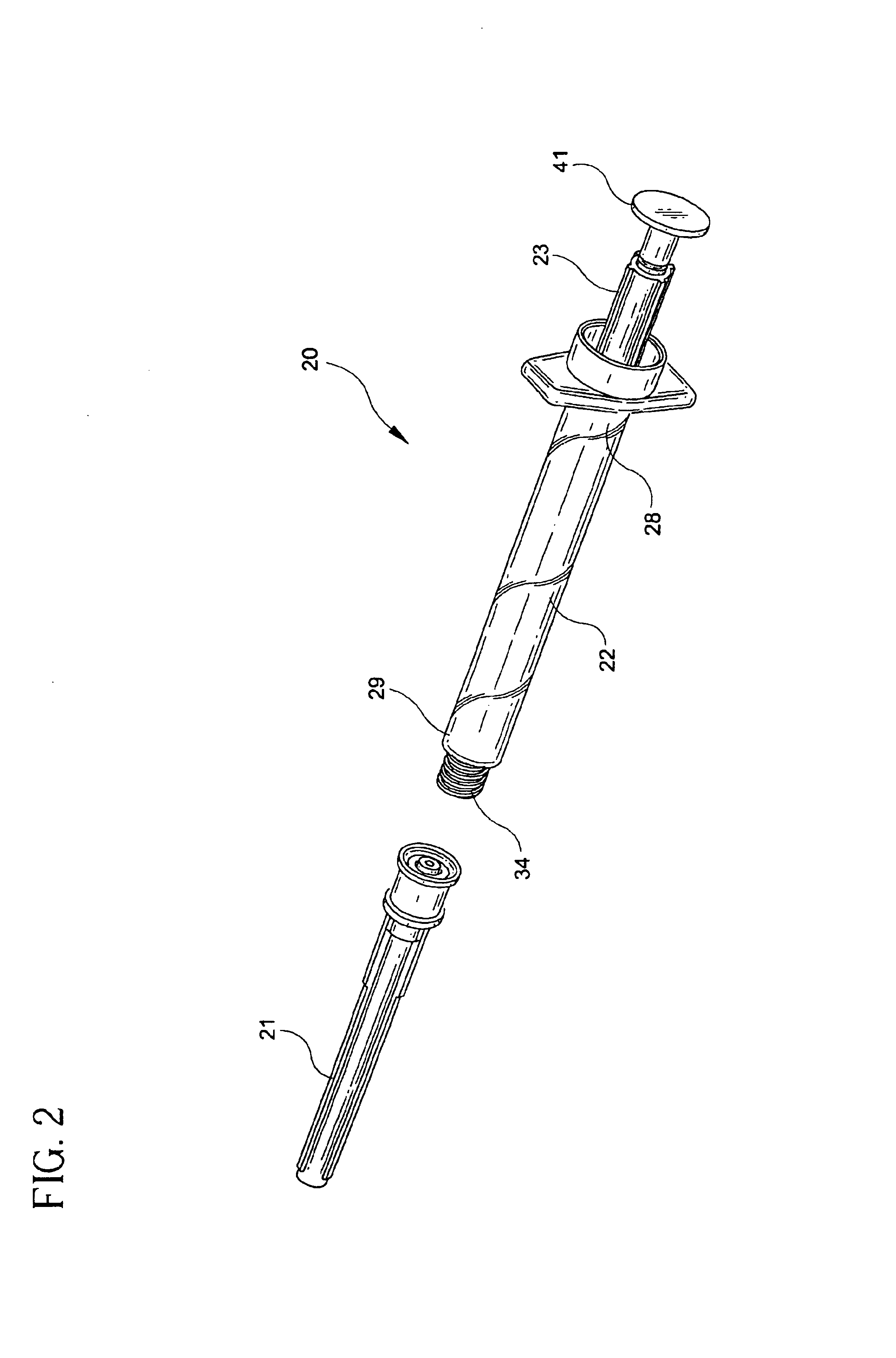

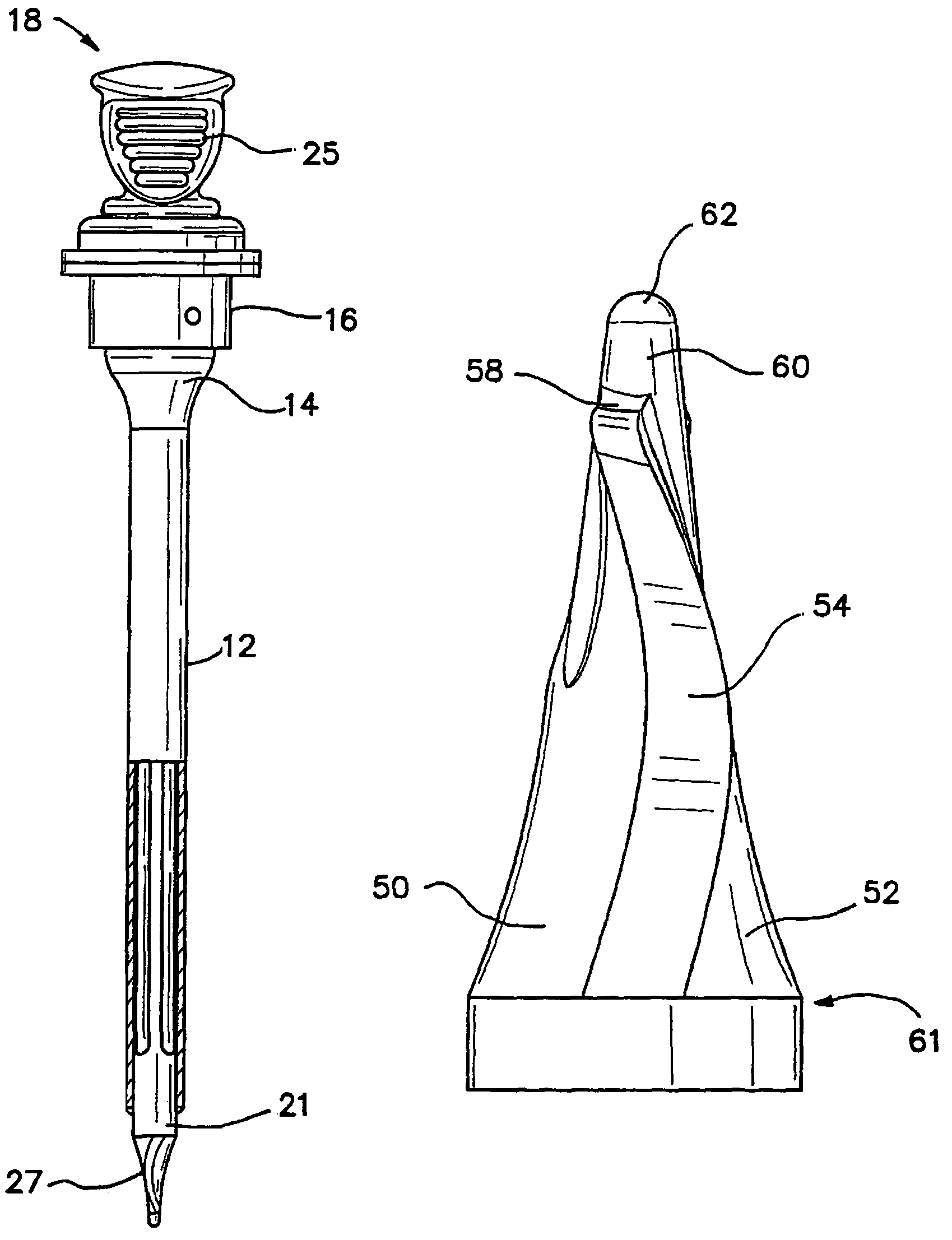

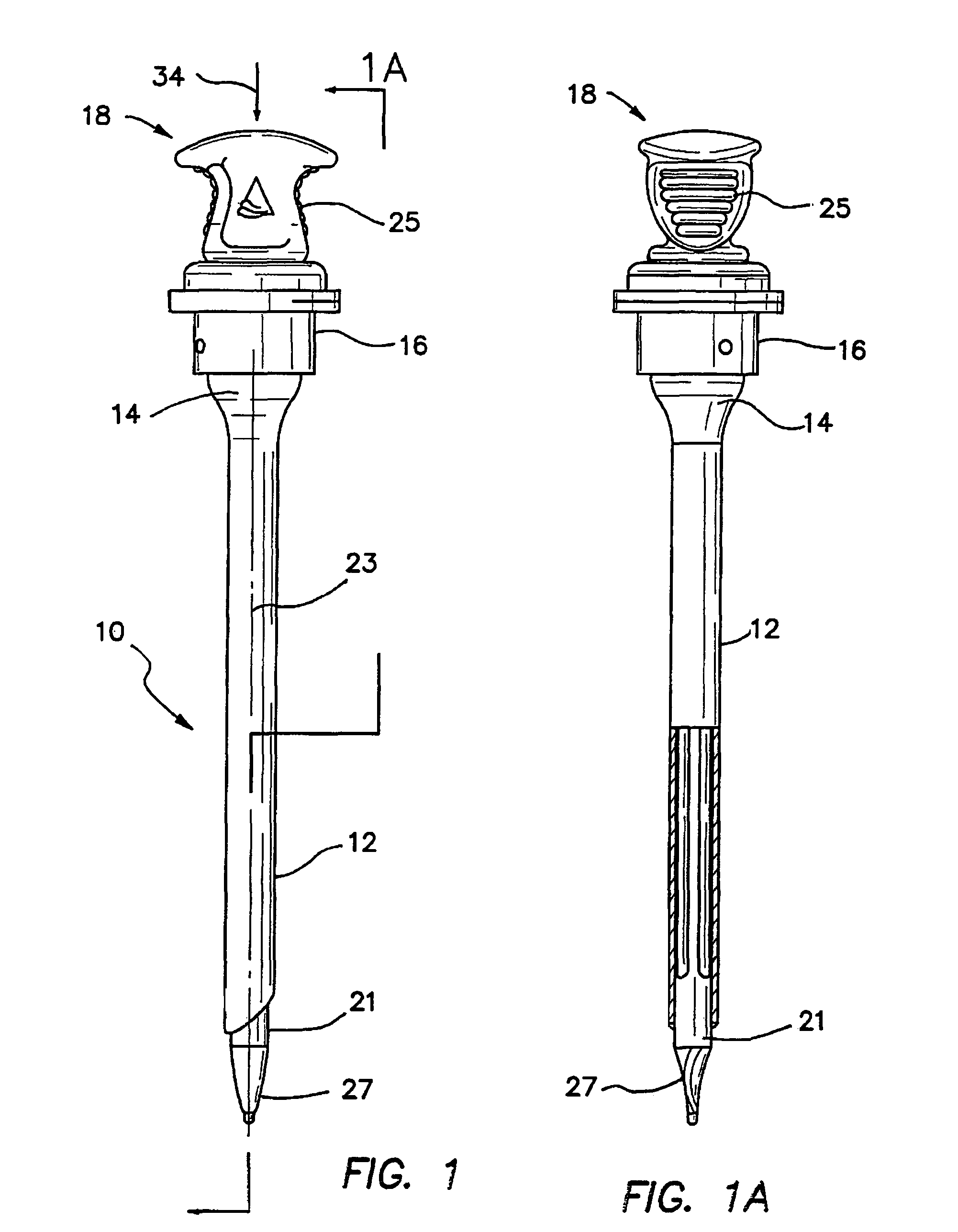

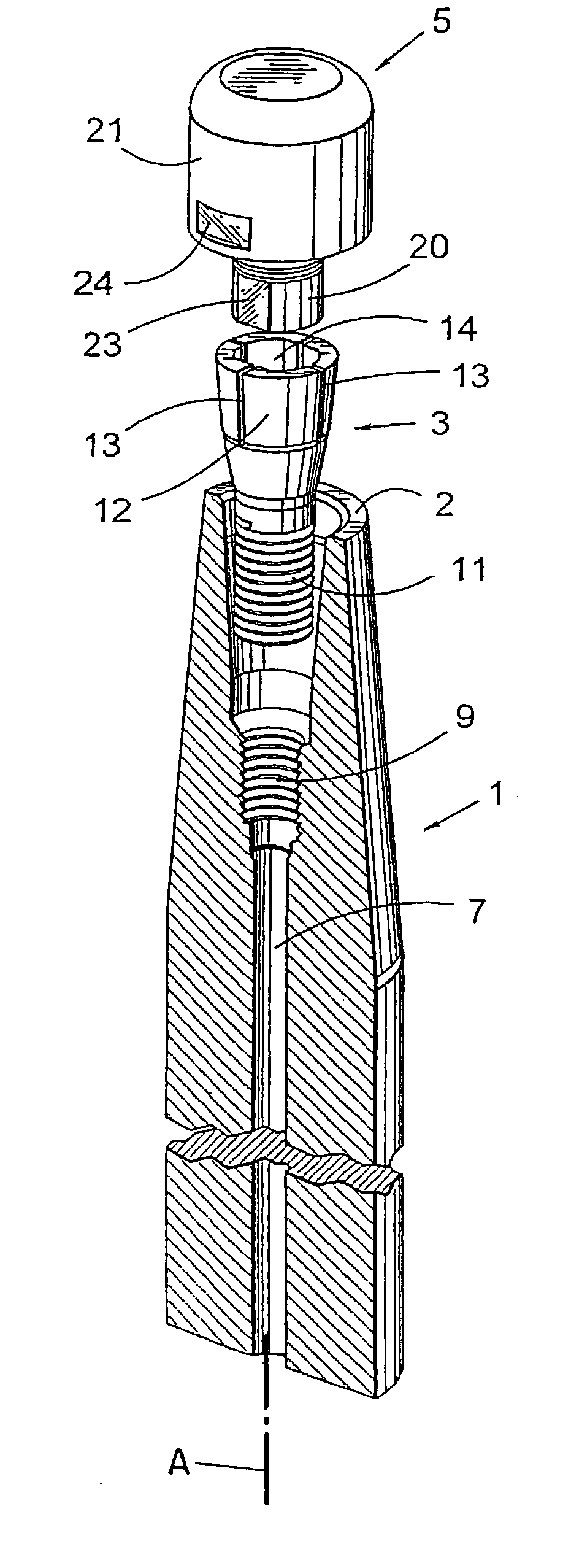

Spinal fixation system and screwdriver tool for use with the same

InactiveUS20120203288A1Improves management of pressureHigh trafficSuture equipmentsInternal osteosythesisDrive shaftScrew thread

A spinal fixation system that utilizes a composite rod to which polyaxial pedicle screw / tulip assemblies are secured, a screwdriver that permits independent threading of a guide member to the tulip and independent threading of the pedicle screw, together with interengaging conical surfaces that true the screwdriver with the pedicle screw. In preferred embodiments, the screwdriver includes an elongated drive shaft having a handle end for imparting rotation and a pedicle screw engaging end, a cylindrical guide member rotatably mounted about said drive shaft, a knob at one end of said guide member for rotating same and a threaded tulip engaging end at the other end thereof. A grip is preferably sleeved around the cylindrical drive member and is longitudinally movable between proximal and distal positions wherein its distal end uncovers and covers, respectively, the screw engaging unit.

Owner:LANGE ROBERT +1

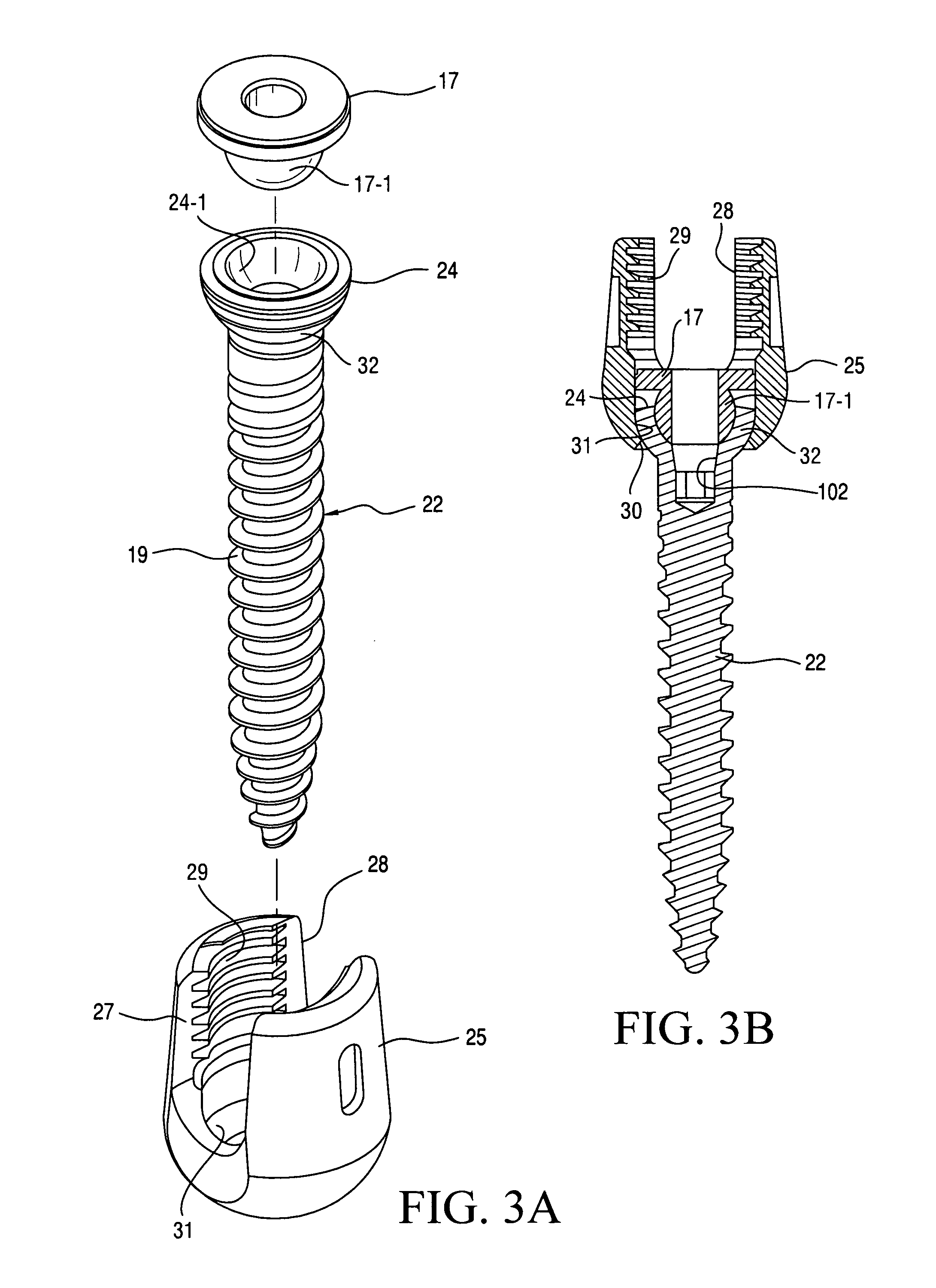

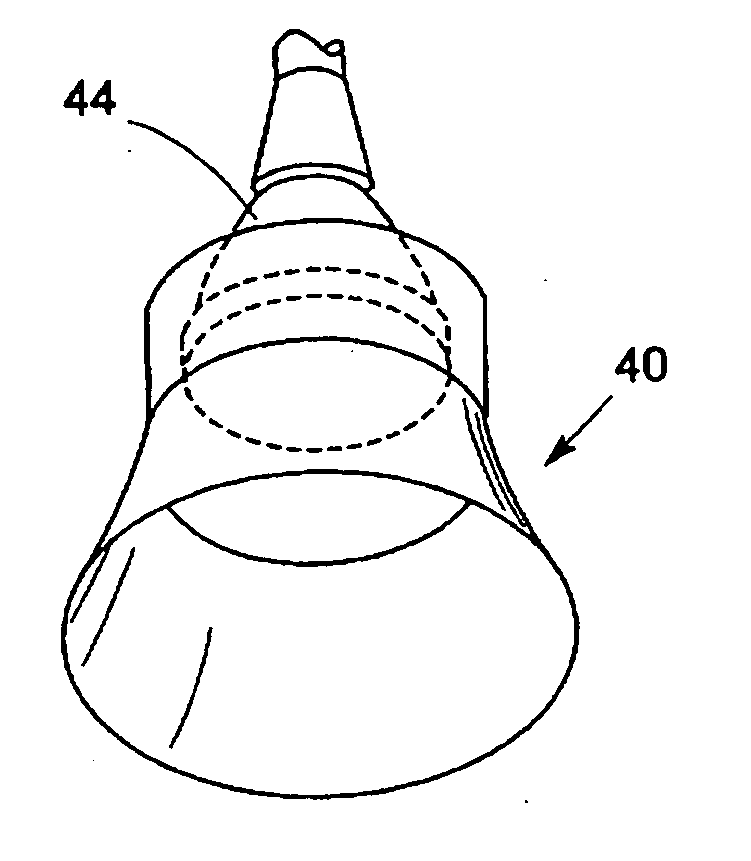

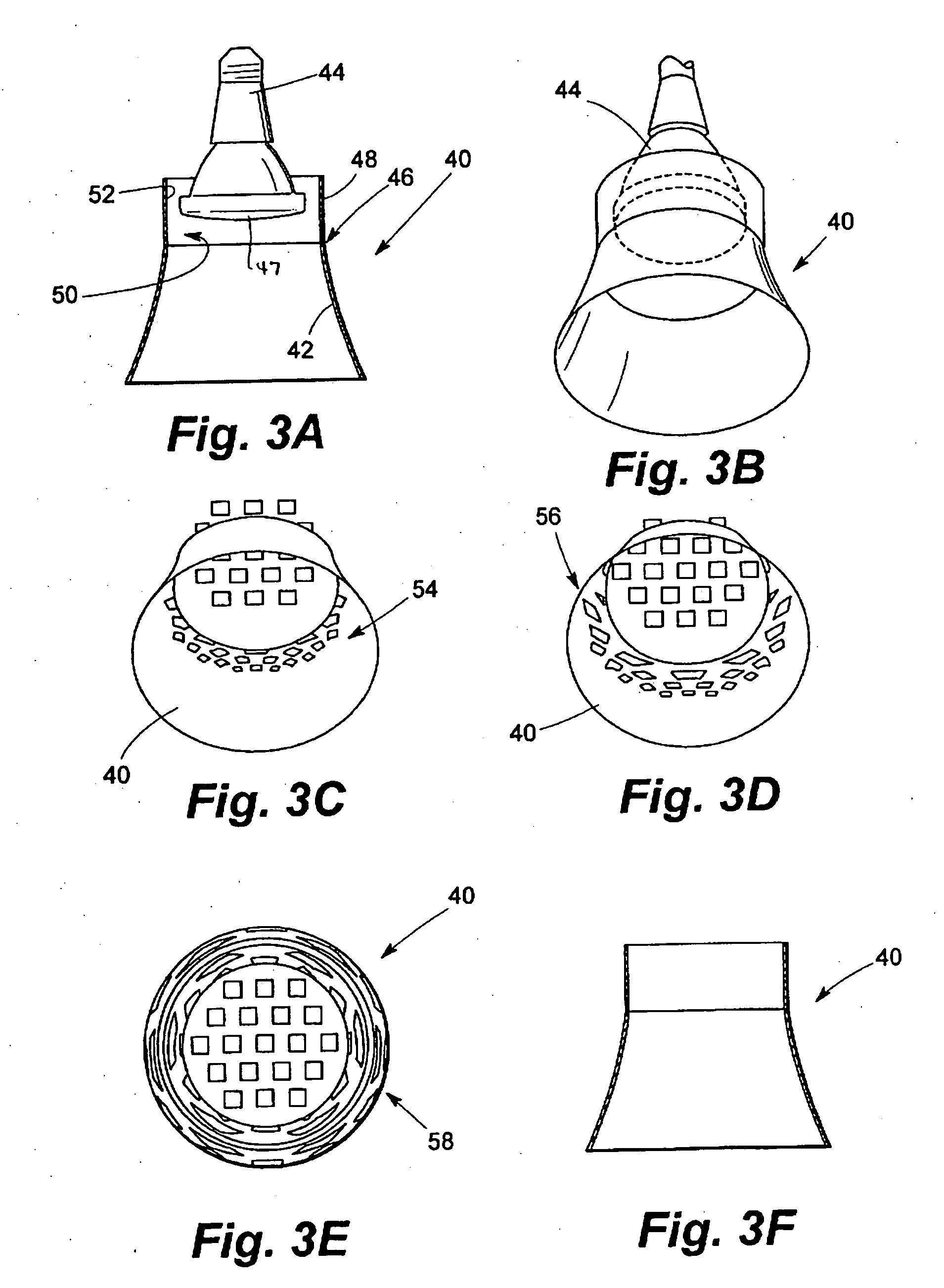

Reflector assemblies for luminaires

InactiveUS20050168986A1Quality improvementReduce eliminatePlanar light sourcesNon-electric lightingLight beamLight-emitting diode

Downlighting luminaires equipped with particular light sources such as PAR lamps, light emitting diode (LED) arrays and the like, are equipped with reflectors that do not converge light rays incident thereon from the light source. Downlighting luminaires configured according to the invention reduce or eliminate undesirable beam striations on horizontal surfaces and “busy” scallops on vertical surfaces with improvement of reflector flash performance. Particular reflectors have divergent reflective surfaces or conical surfaces, the reflectors preferably being optically separated from a face of the lamp such as by means of a matte black annulus or “snoot” disposed between the lamp face and opposing edges of the reflector.

Owner:ACUITY BRANDS

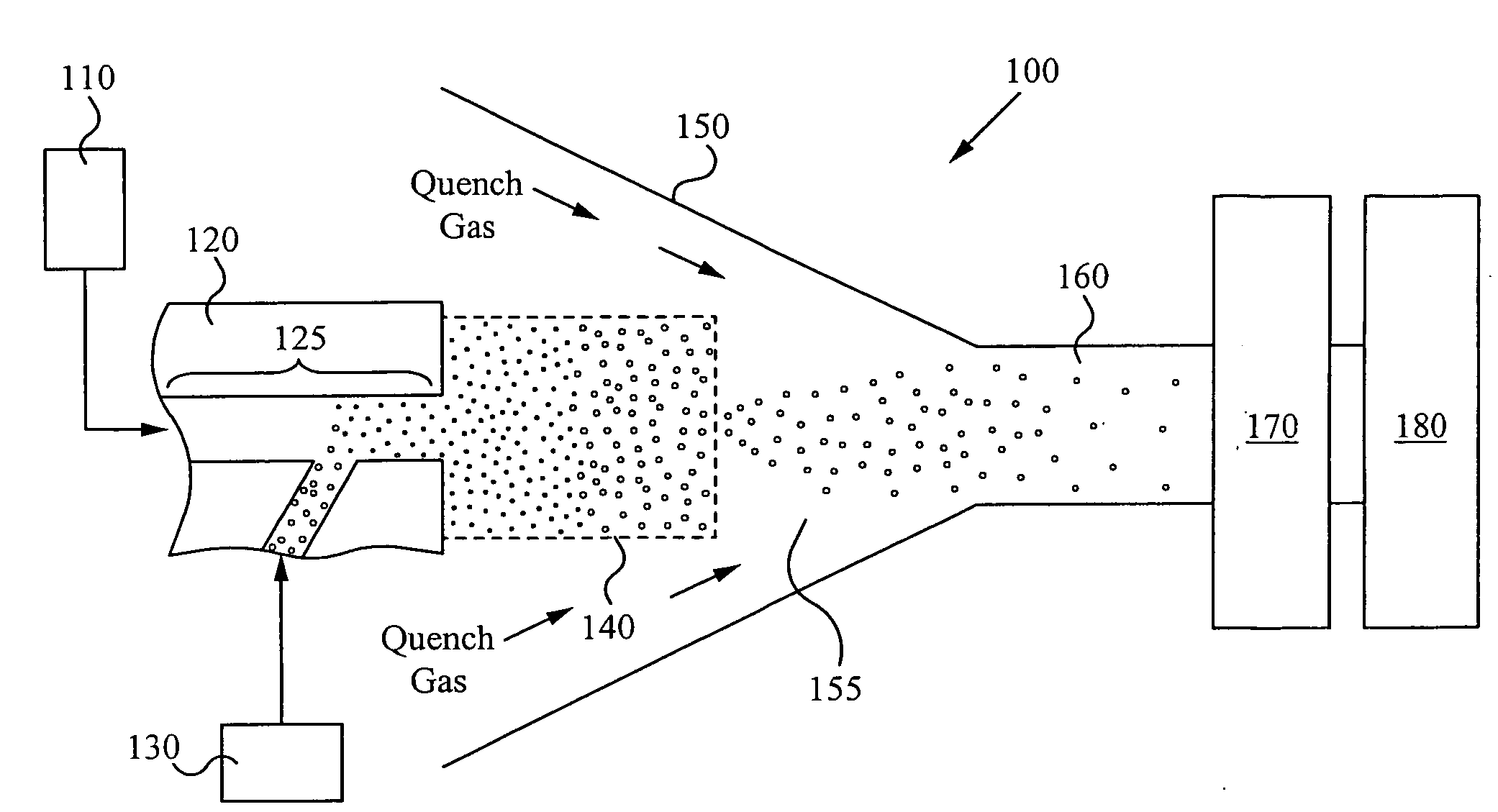

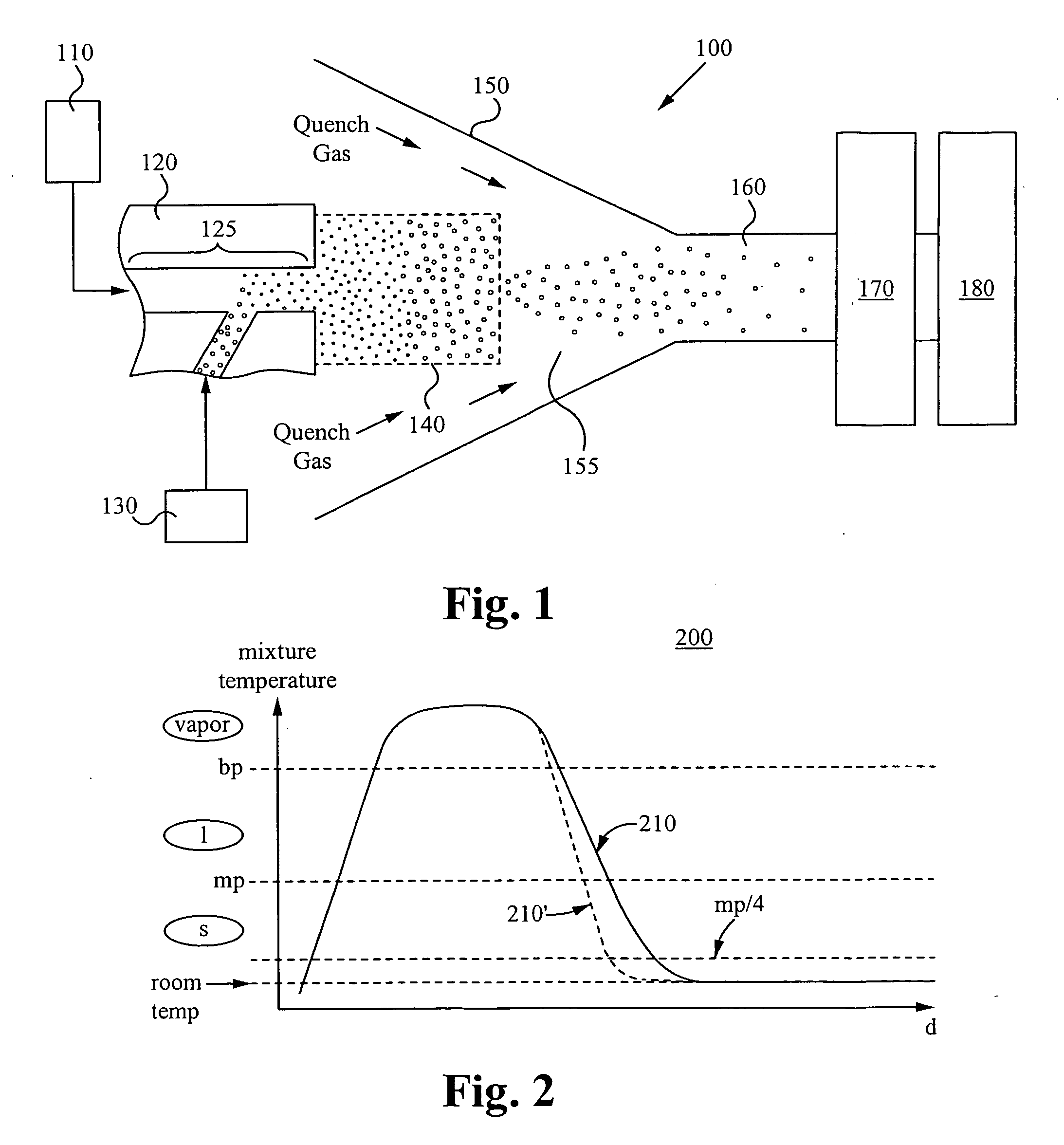

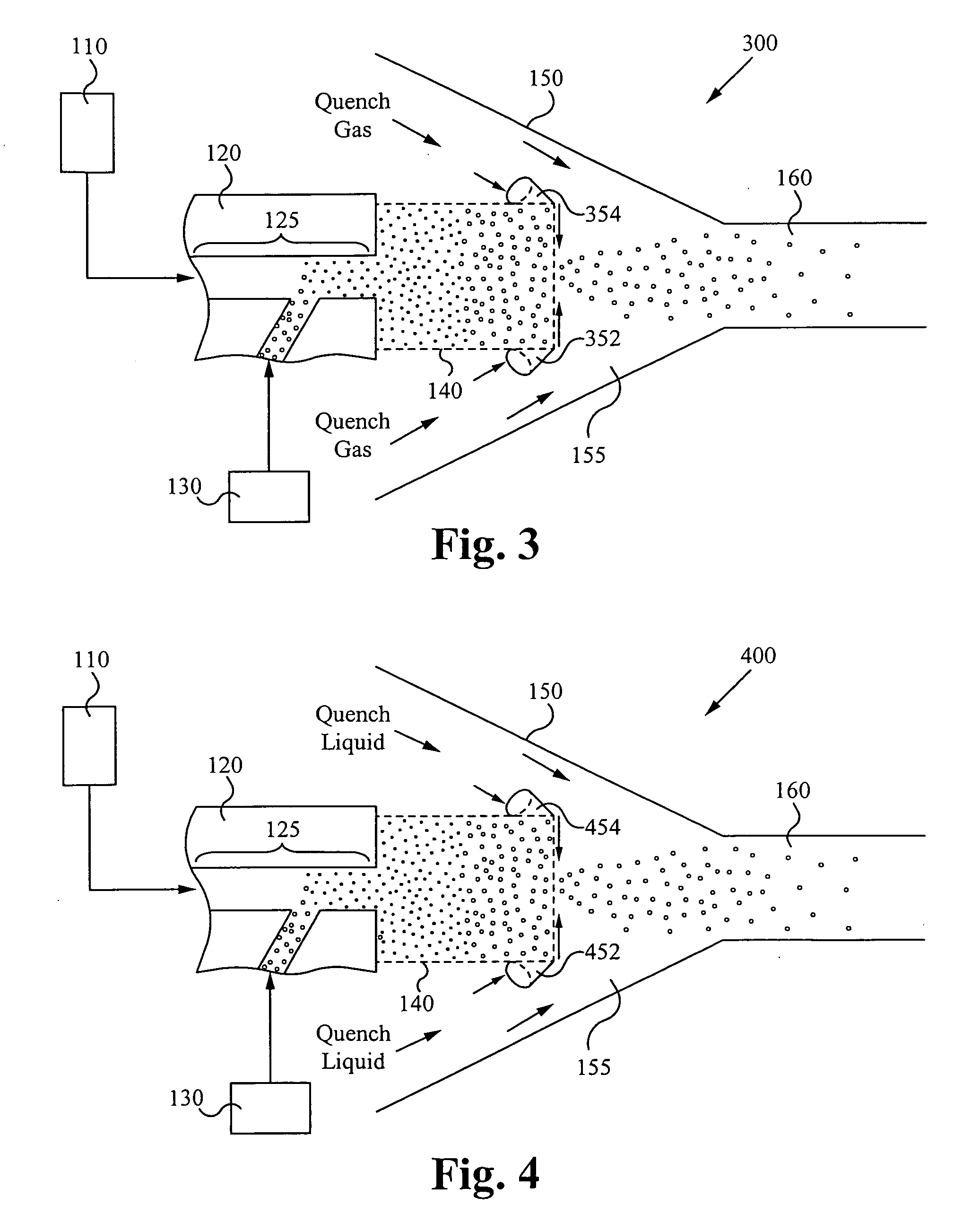

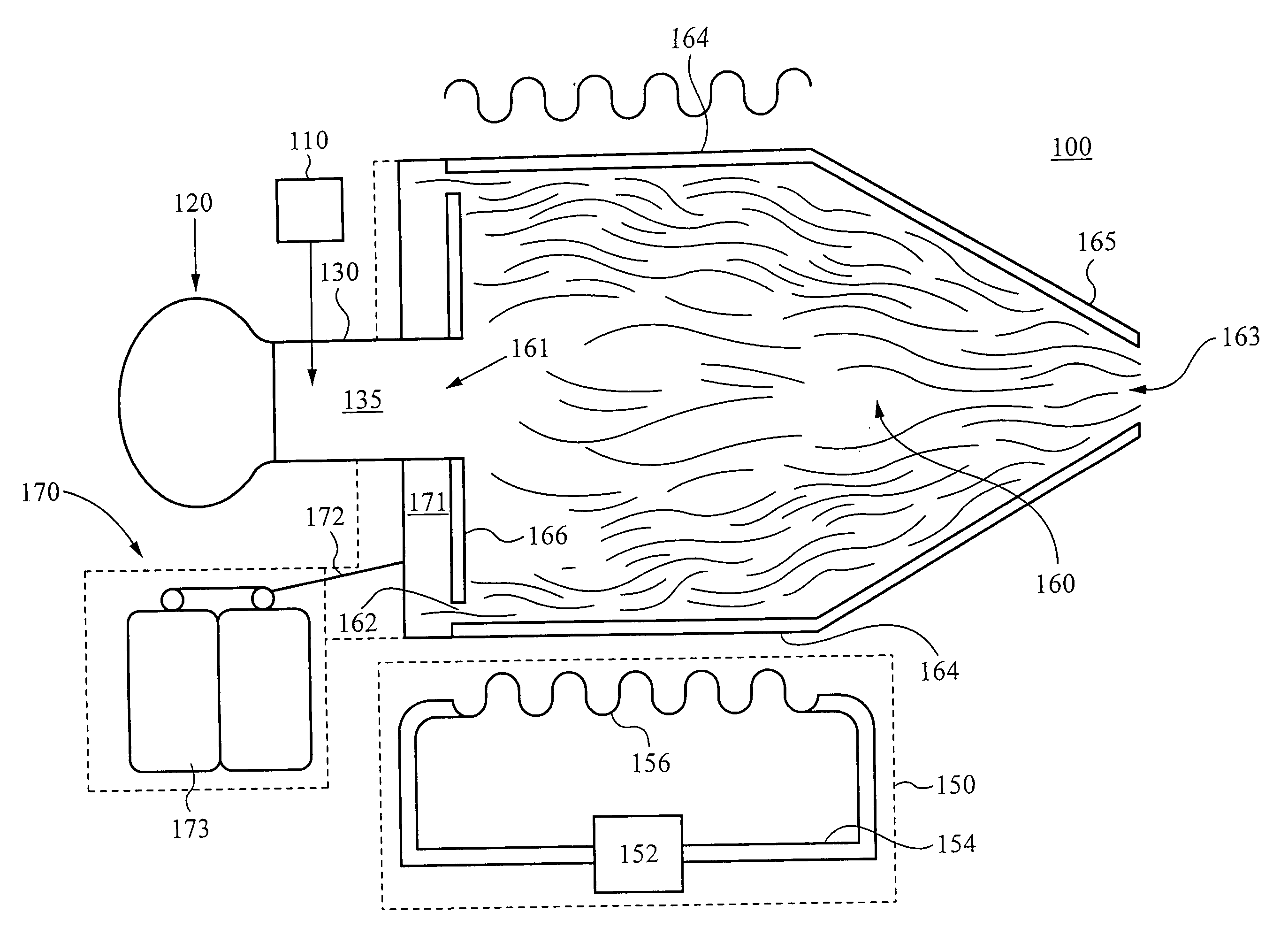

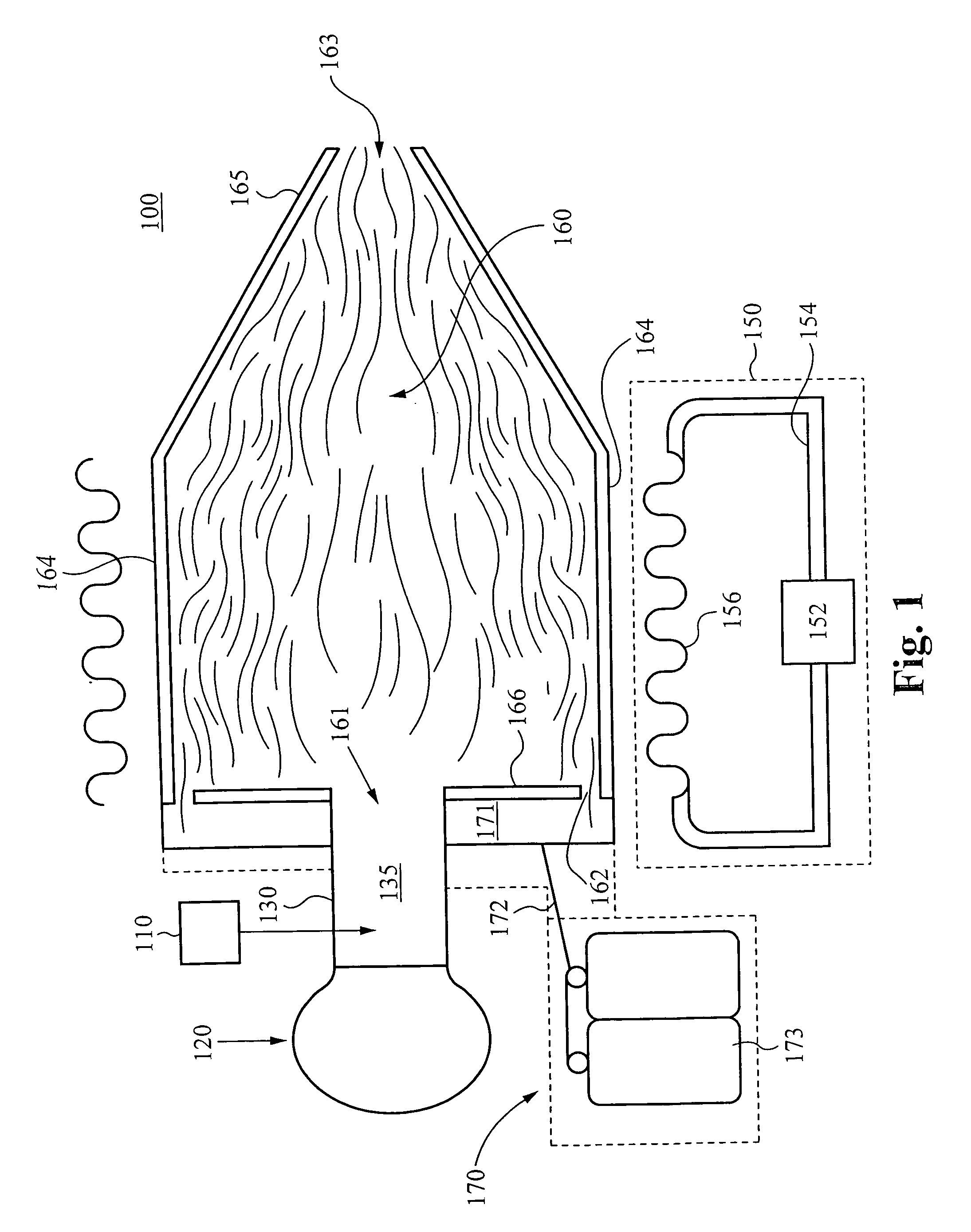

Method and apparatus for making uniform and ultrasmall nanoparticles

ActiveUS20080277270A1Catalyst activation/preparationDirect contact heat exchangersNanoparticleEngineering

A system comprising: a plasma production chamber configured to produce a plasma; a reaction chamber vaporize a precursor material with the plasma to form a reactive mixture; a quench chamber having a frusto-conical surface and a quench region formed within the quench chamber between an ejection port of the reaction chamber and a cooled mixture outlet, wherein the quench region configured to receive the reactive mixture from the ejection port, to cool the reactive mixture to form a cooled mixture, and to supply the cooled mixture to the cooled mixture outlet; and a conditioning fluid injection ring disposed at the ejection port and configured to flow a conditioning fluid directly into the reactive mixture as the reactive mixture flows through the ejection port, thereby disturbing the flow of the reactive mixture, creating turbulence within the quench region and cooling the reactive mixture to form a cooled mixture comprising condensed nanoparticles.

Owner:SDC MATERIALS +1

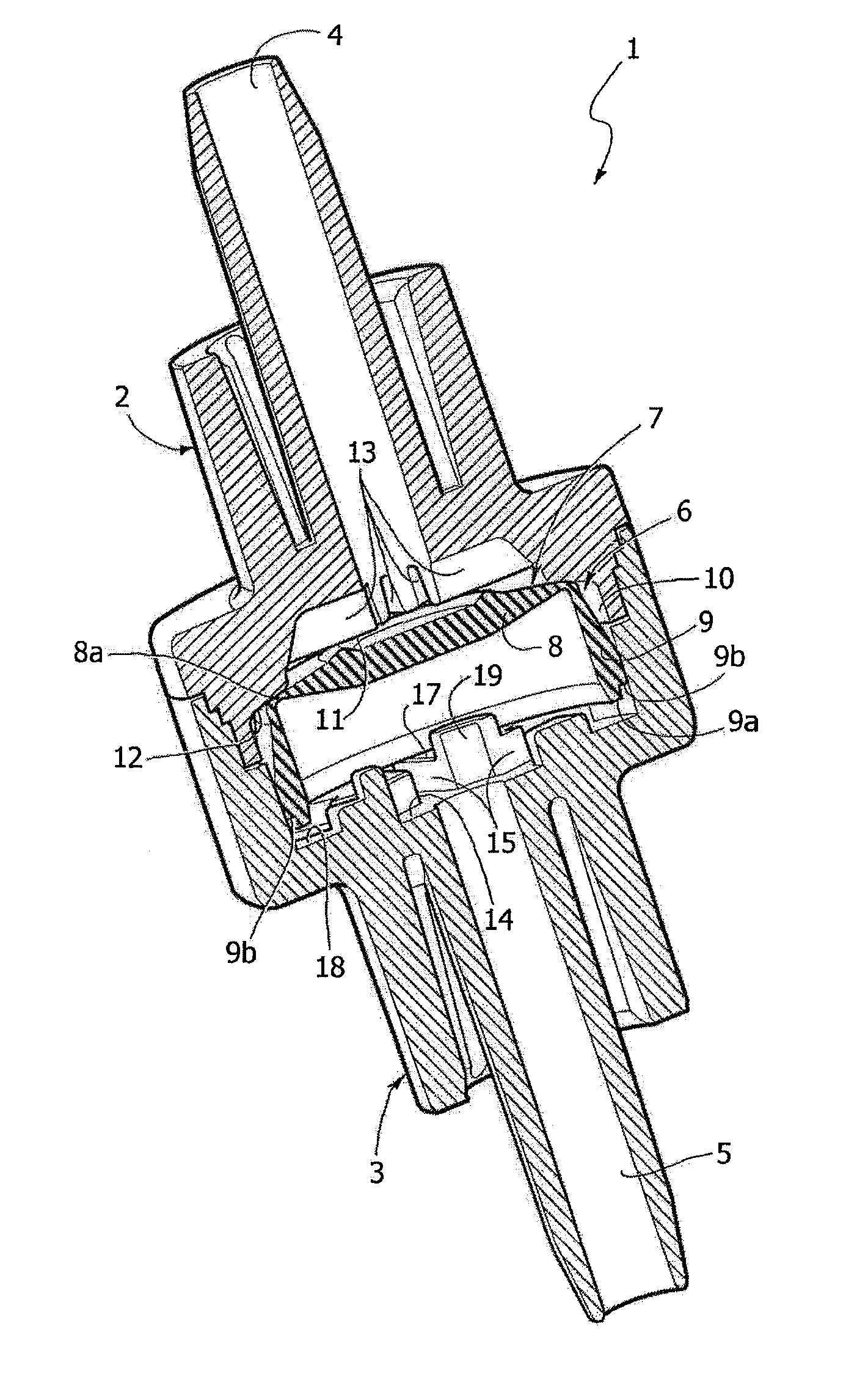

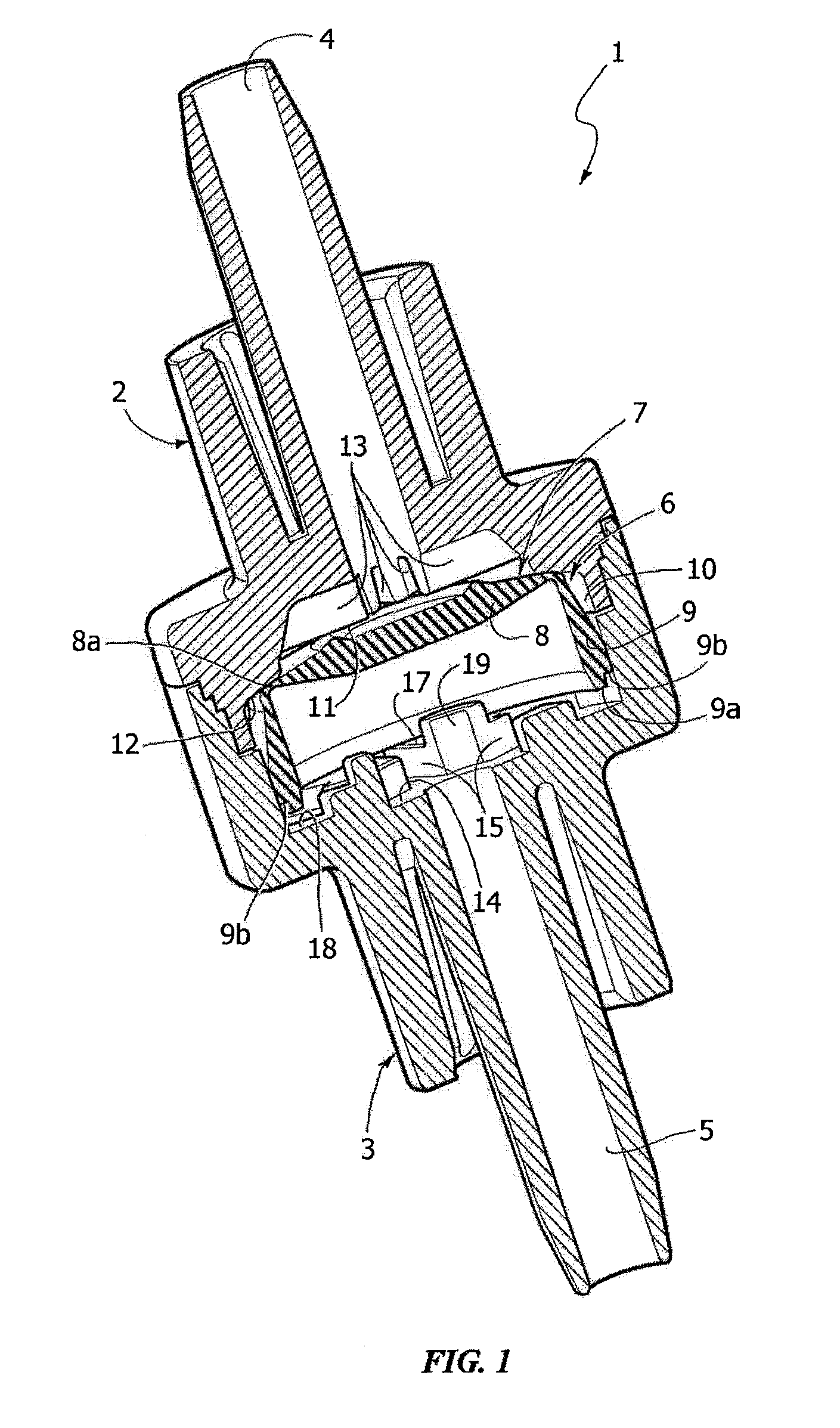

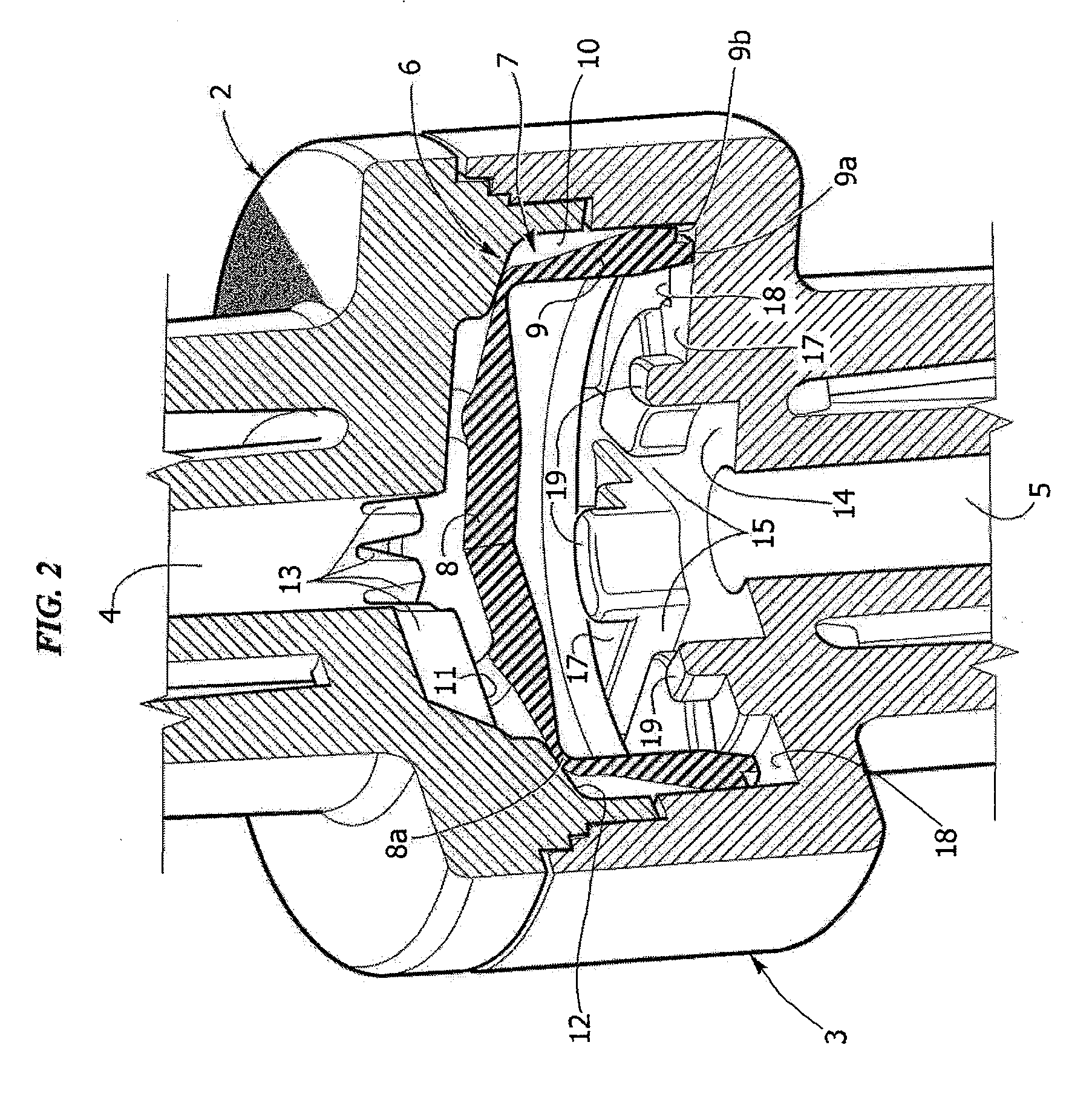

One-way valve for medical infusion lines and the like

A check valve for medical infusion lines and the like, includes a diaphragm made of elastic material set between a first tubular connector and a second tubular connector. The diaphragm includes an end wall of a cup-shaped element, having an outer peripheral edge of which is normally pressed in seal contact against an annular valve seat with a conical surface of the first tubular connector under an axial thrust exerted by a side wall of the cup-shaped element. A free edge of the side wall of the cup-shaped element is set resting against a transverse surface of the second tubular connector only in regions corresponding to angular portions of the latter separated by non-resting angular portions.

Owner:IND BORLA

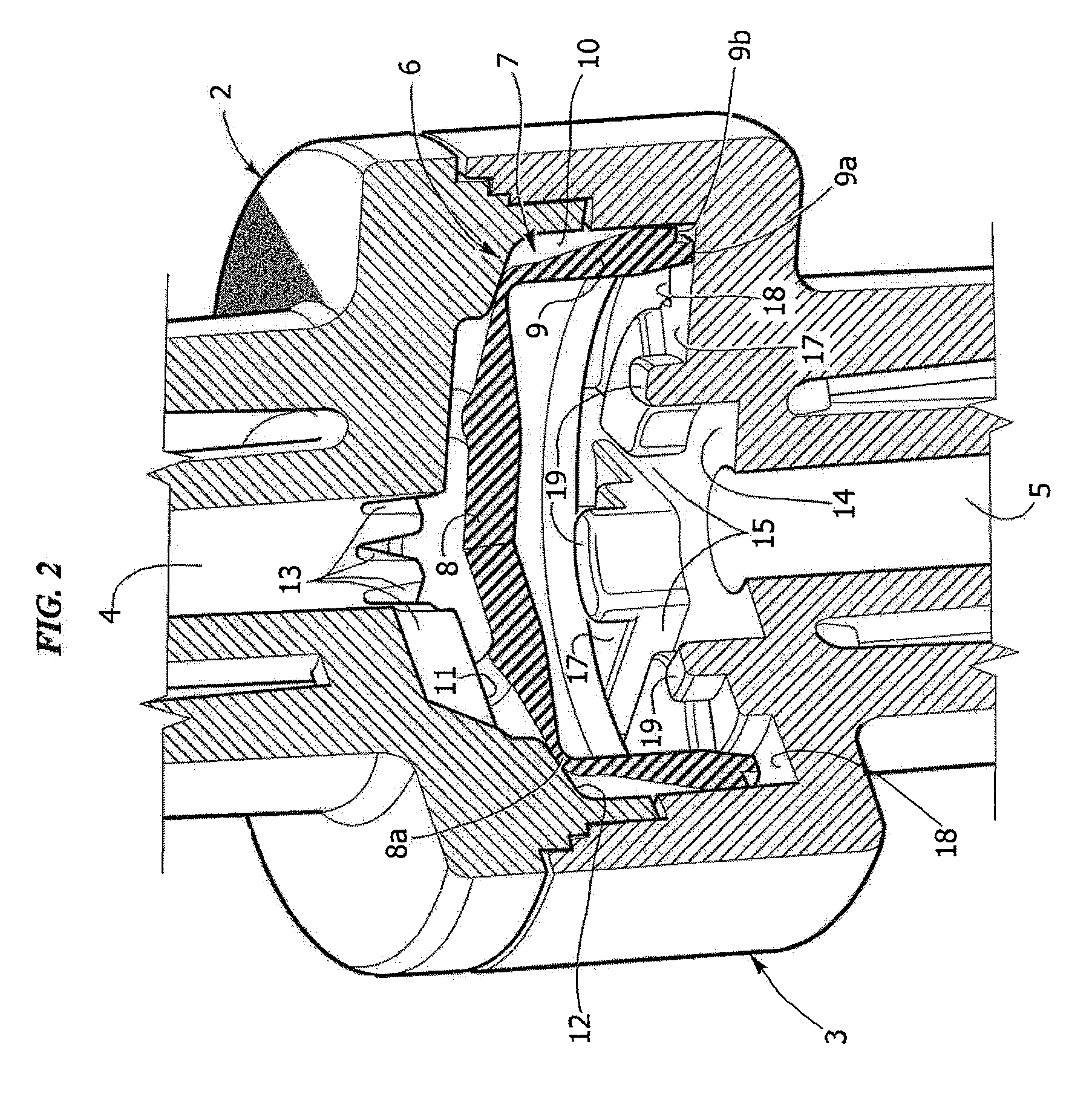

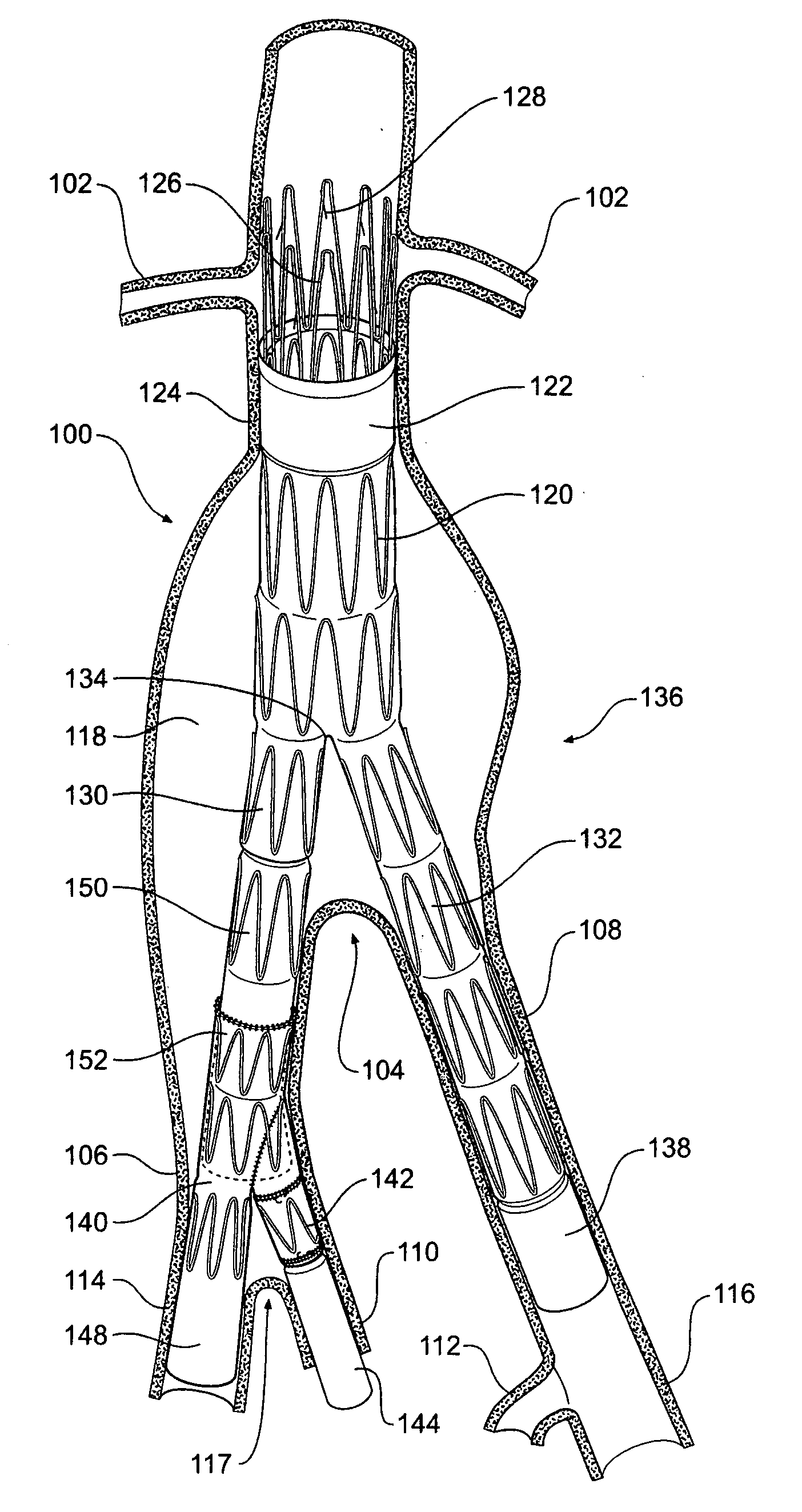

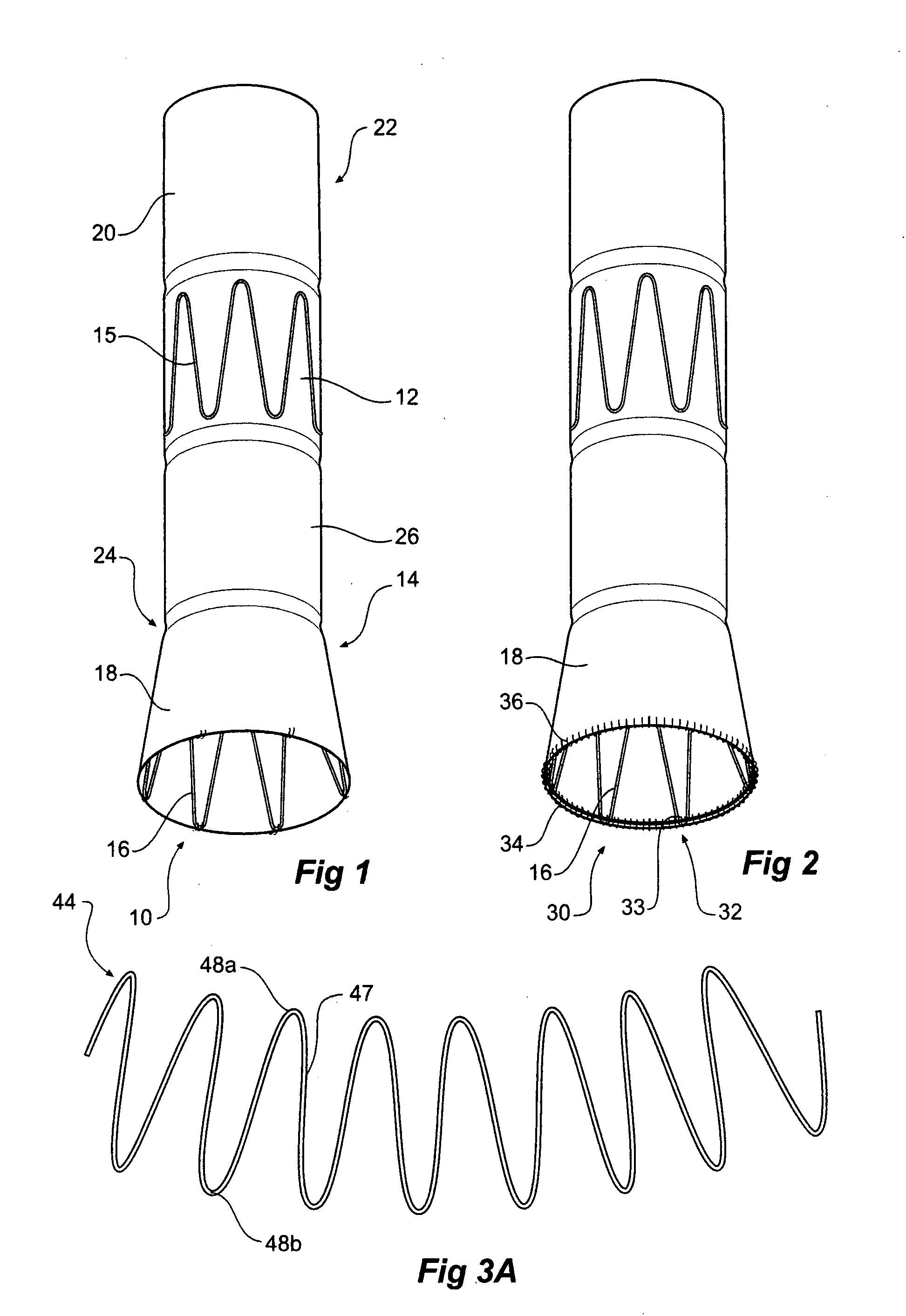

Iliac extension with flared cuff

A leg extension (10) for a stent grafting system to connect between an aortic graft and an iliac graft. The leg extension is a tubular body (12) of a biocompatible graft material with self-expanding stents connected along the length of the tubular body and the tubular body having a distal end with a connection region. The connection region has a flared stent defining an external frusto-conical surface to provide a connection arrangement to engage within an internally flared portion of an iliac graft.

Owner:COOK MEDICAL TECH LLC

One-way valve for medical infusion lines and the like

ActiveUS20080169444A1Good exploitationFor further operationCheck valvesEqualizing valvesLine tubingEngineering

A check valve for medical infusion lines and the like, includes a diaphragm made of elastic material set between a first tubular connector and a second tubular connector. The diaphram includes an end wall of a cup-shaped element, having an outer peripheral edge of which is normally pressed in seal contact against an annular valve seat with a conical surface of the first tubular connector under an axial thrust exerted by a side wall of the cup-shaped element. A free edge of the side wall of the cup-shaped element is set resting against a transverse surface of the second tubular connector only in regions corresponding to angular portions of the latter separated by non-resting angular portions.

Owner:IND BORLA

Steam pressure cooker

InactiveUS6877633B2Thinner nominal wall thicknessSame strength propertyRefuse receptaclesSealingSteam pressureLocking mechanism

A steam pressure cooker includes a pot having an outwardly directed horizontal pouring rim and formed with a V-shaped circumferential depression which points inwardly to define a conical surface in an upper rim area. A lid can be placed upon the pot for closing and includes a circumferential groove. Positioned between pot and lid is a rubberized elastic sealing element which is held in the circumferential groove. The sealing element has a sealing body of substantially U-shaped configuration to define two sealing lips in coaxial parallel relationship to the vertical pot axis. One sealing lip bears against an inner wall of the pot and interacts with the conical surface of the pot, when the lid is placed upon the pot. A locking mechanism embraces and thereby clamps the lid and the pouring rim, when the steam pressure cooker is closed, and clears the pouring rim, when the steam pressure cooker is opened.

Owner:NIESE URSULA

Attachment for a medical device

A fluid transfer adapter for use with a syringe barrel having a collar with adapter engaging structure and a distally-facing frusto-conically shaped surface is disclosed. The adapter includes a hub having a proximally-facing frusto-conically shaped surface for mating with the frusto-conically shaped surface on the barrel, structure for threadably engaging the hub to the collar of the barrel so that the frusto-conically shaped surface of the hub contacts the frusto-conically shaped surface of the barrel to prevent liquid flow between the surfaces and a fluid transfer having a passageway therethrough, connected to the distal end of the hub so that the lumen is in fluid communication with a conduit in the hub. The passageway includes a frusto-conically shaped edge that aligns with the frusto-conically shaped edge of the barrel, when the adapter is connected to the barrel, thereby reducing waste space.

Owner:BECTON DICKINSON & CO

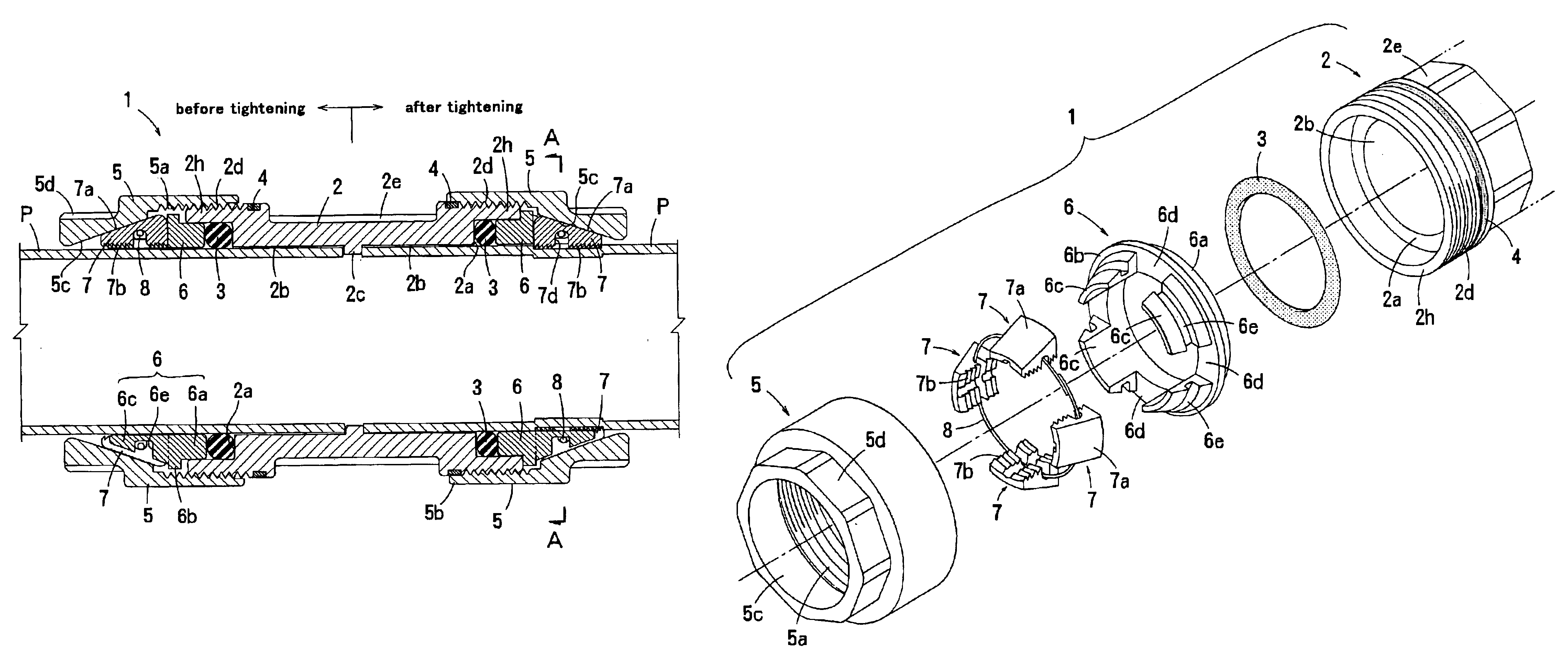

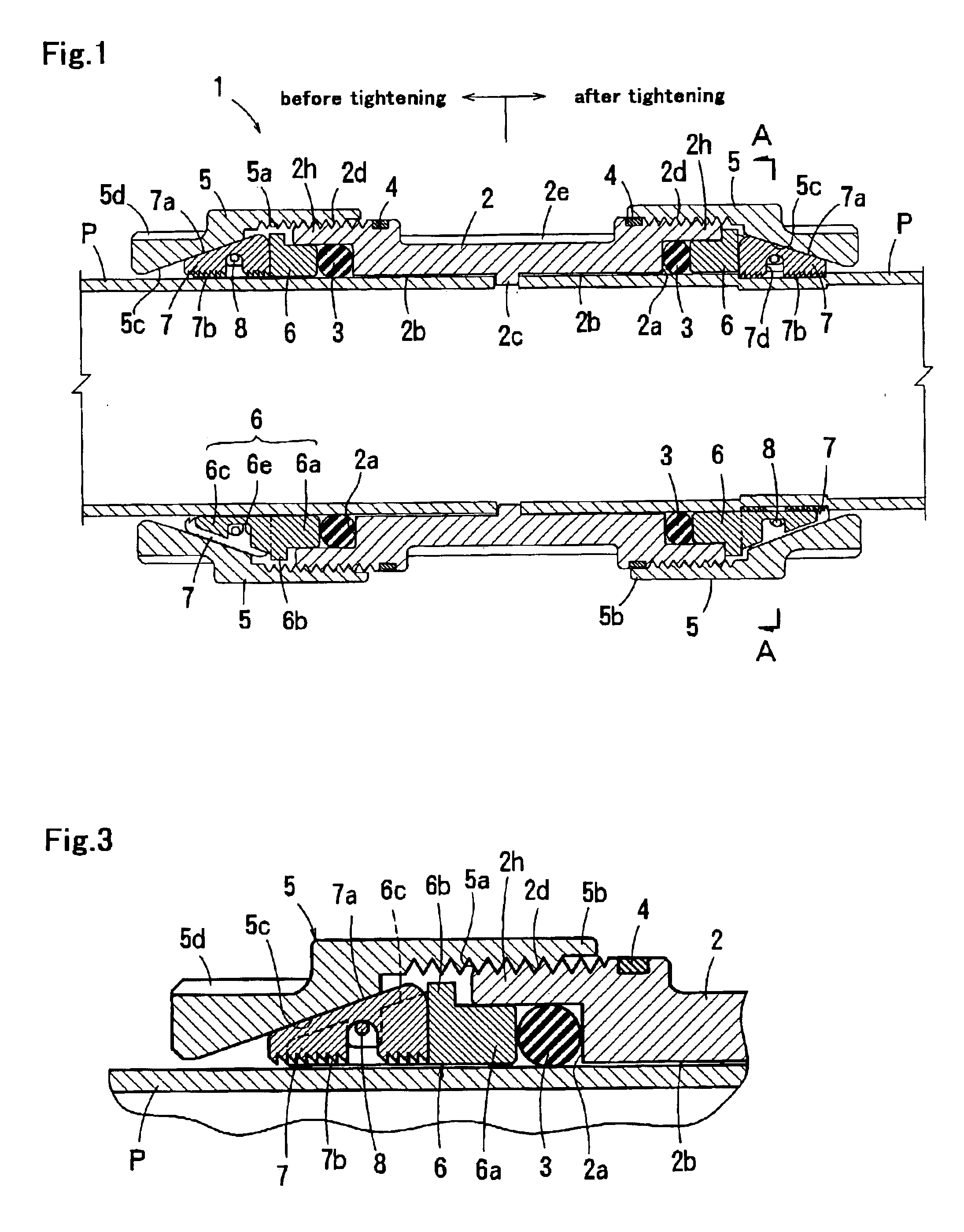

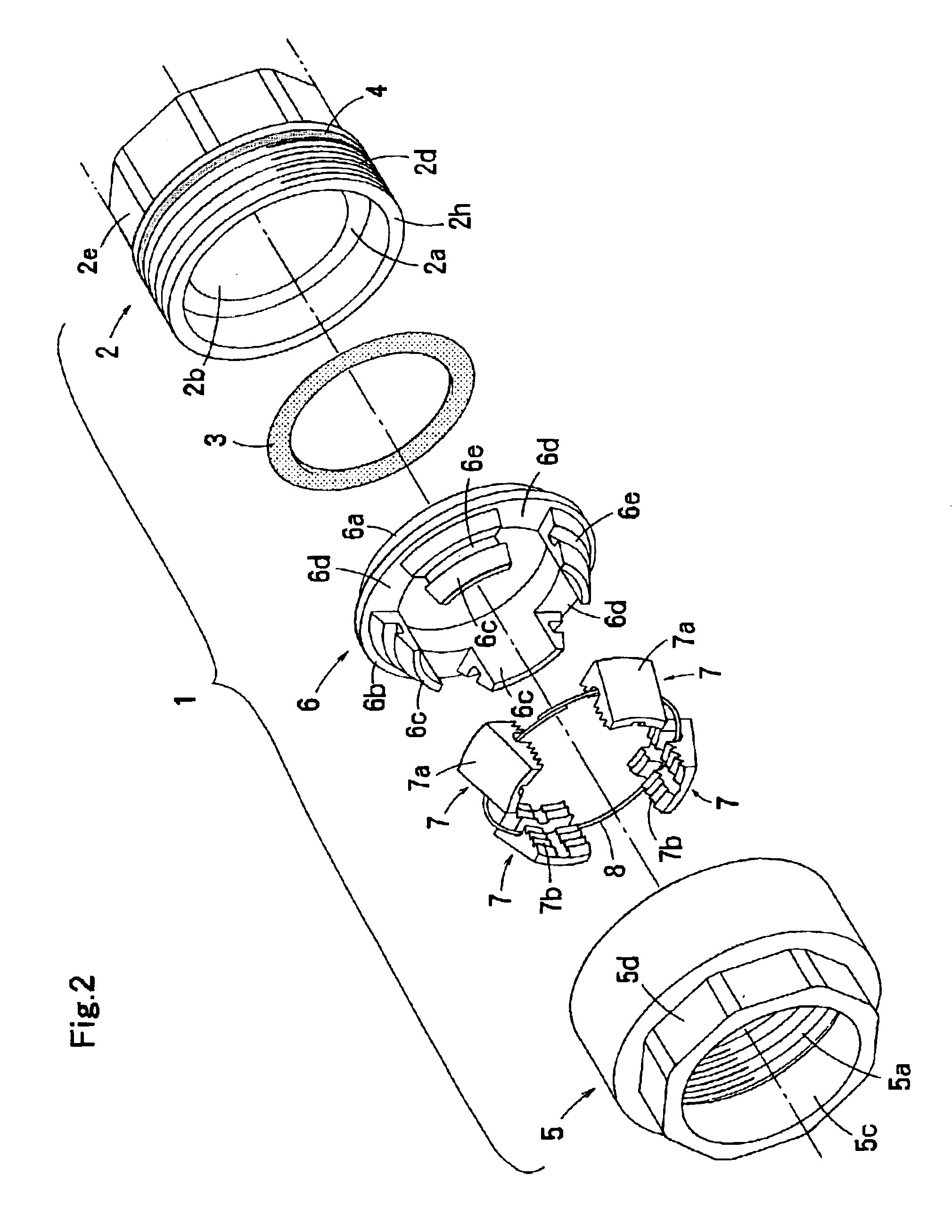

Pipe-coupling device

InactiveUS6851728B2Easy to moveLow costSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

A pipe-coupling device comprises a joint body having an opening with external threads to receive a pipe, a locknut having internal threads engaged with the external threads of the joint body, an annular core member disposed within the locknut, and a plurality of locking members retained in apertures of the core member to be spaced circumferentially apart from each other. Upon tightening rotation of the locknut around the joint body, the internal conical surface of the locknut slidably contacts with the conical surfaces of the locking members so as to press the locking members radially inwardly, to cause the gripping portions of the locking members come into gripping engagement with the outer periphery of the inserted pipe, thereby strongly preventing withdrawal of the pipe from the joint body even when the pipe is made of hard material.

Owner:HAKKO CO LTD

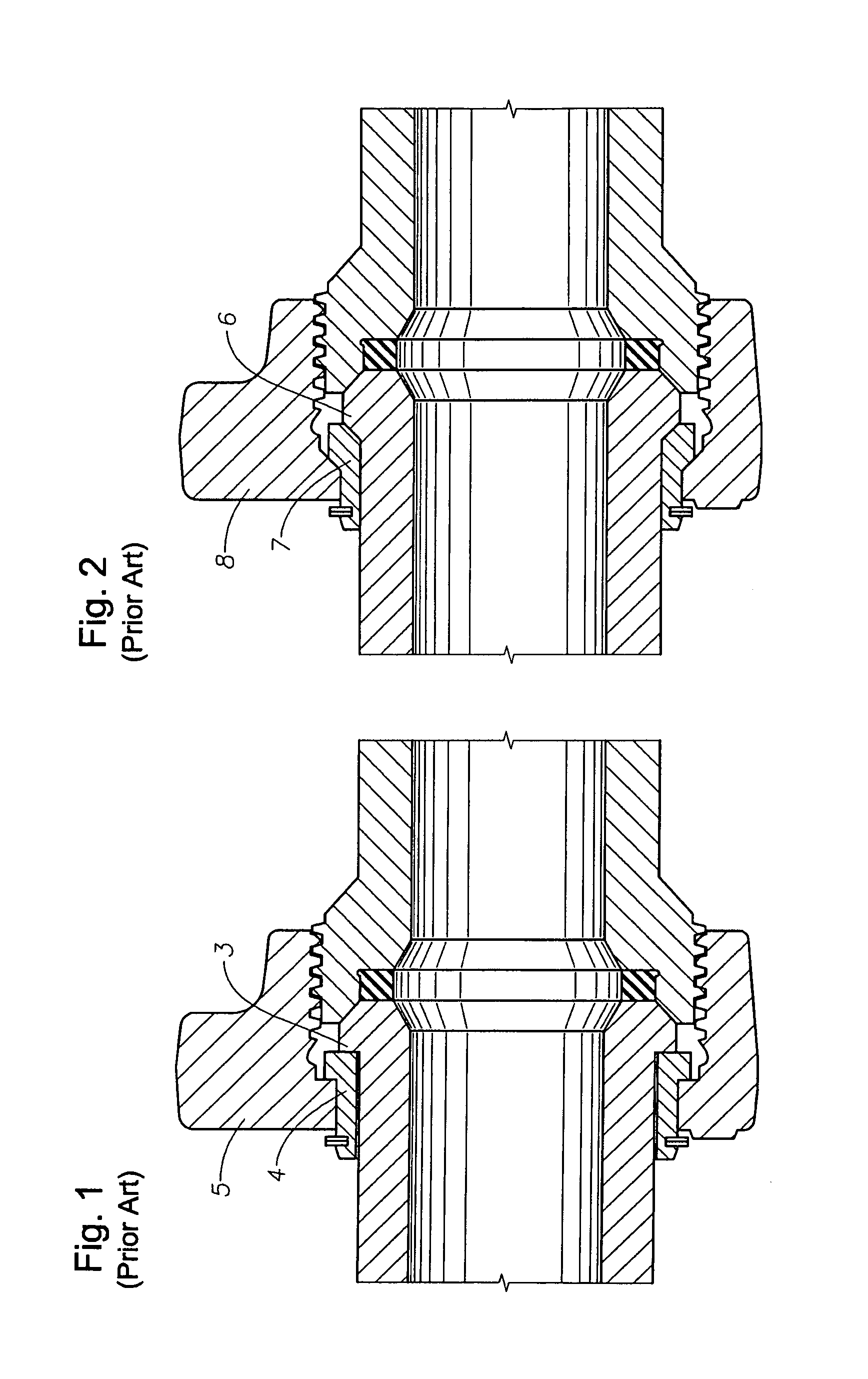

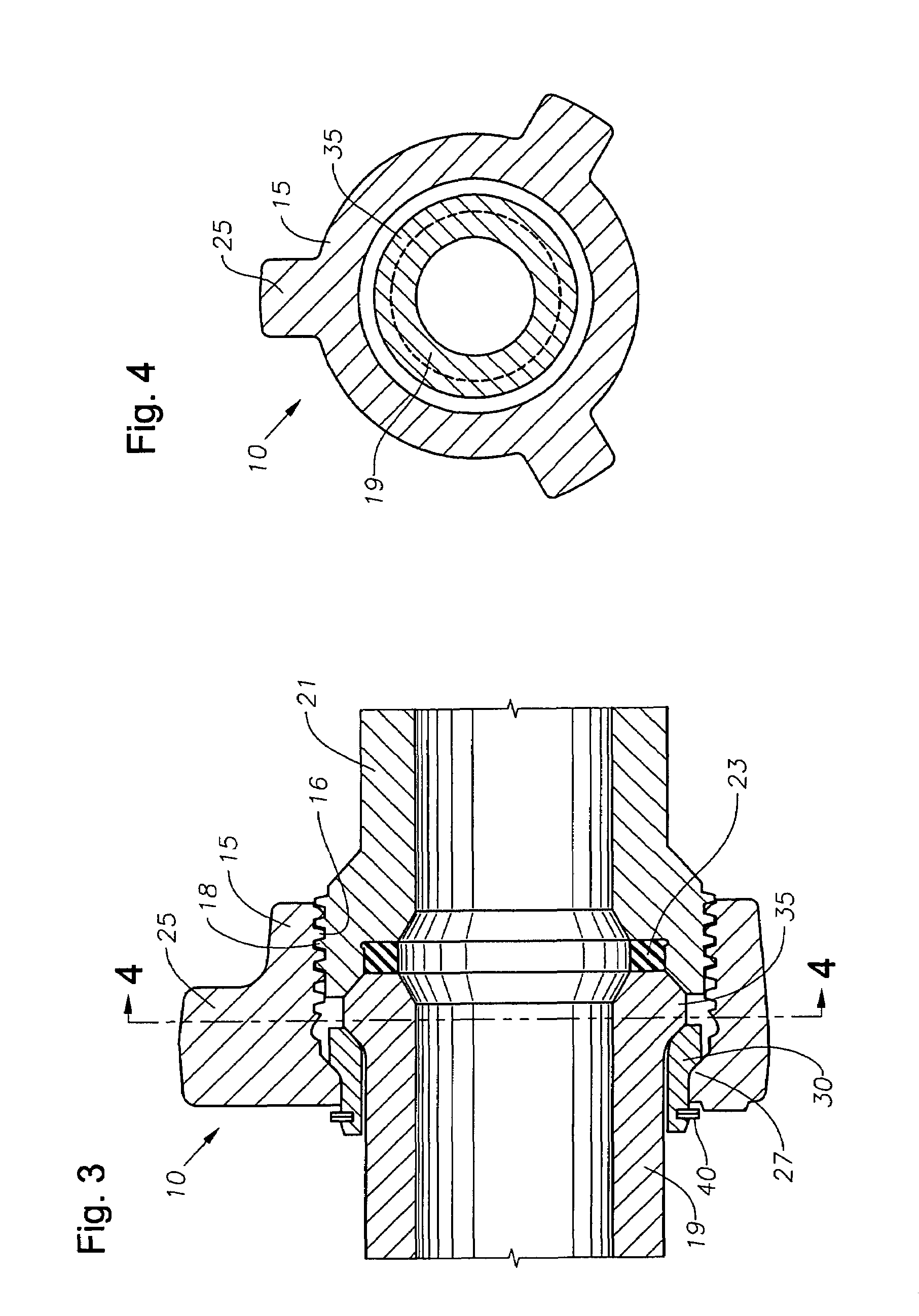

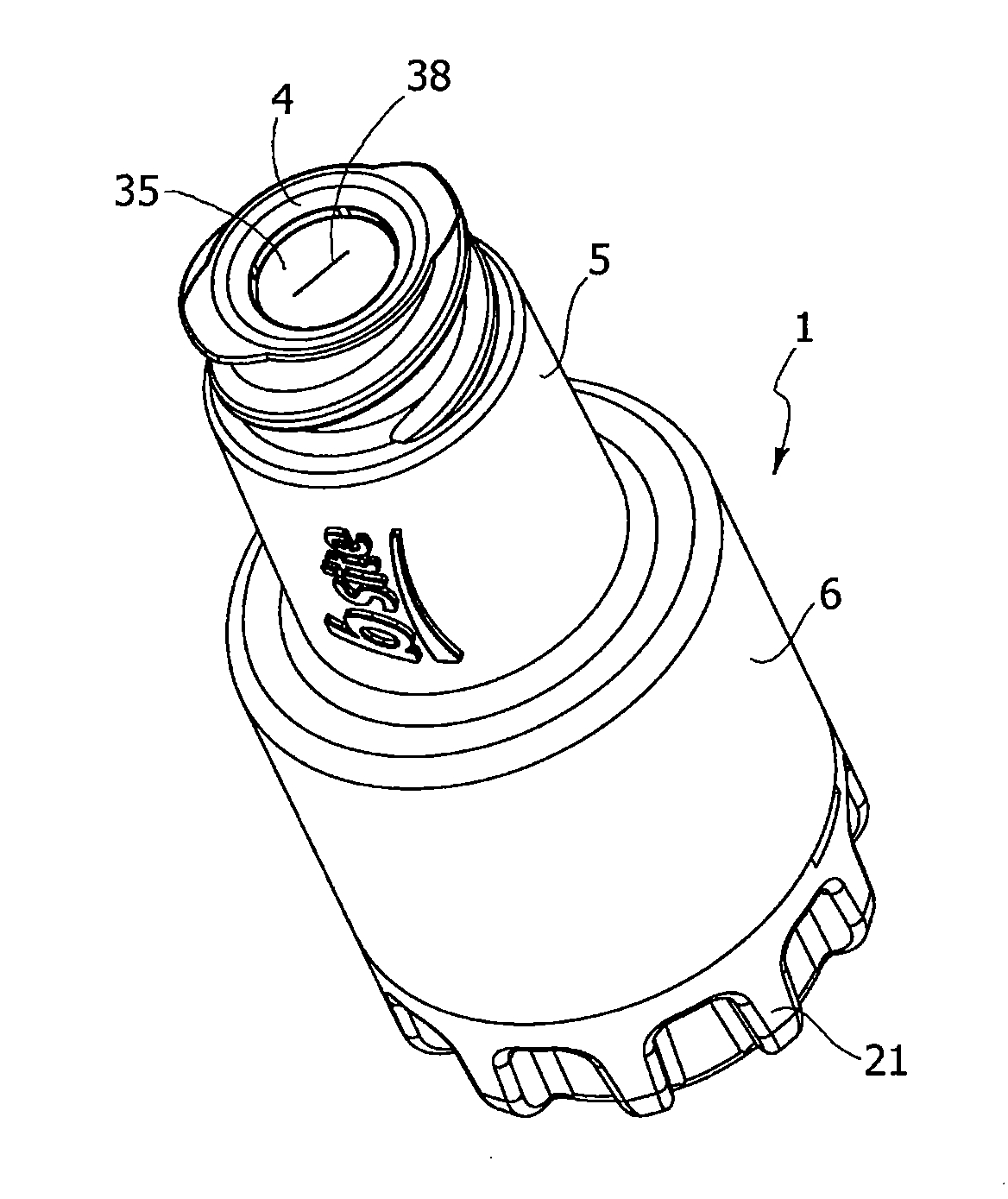

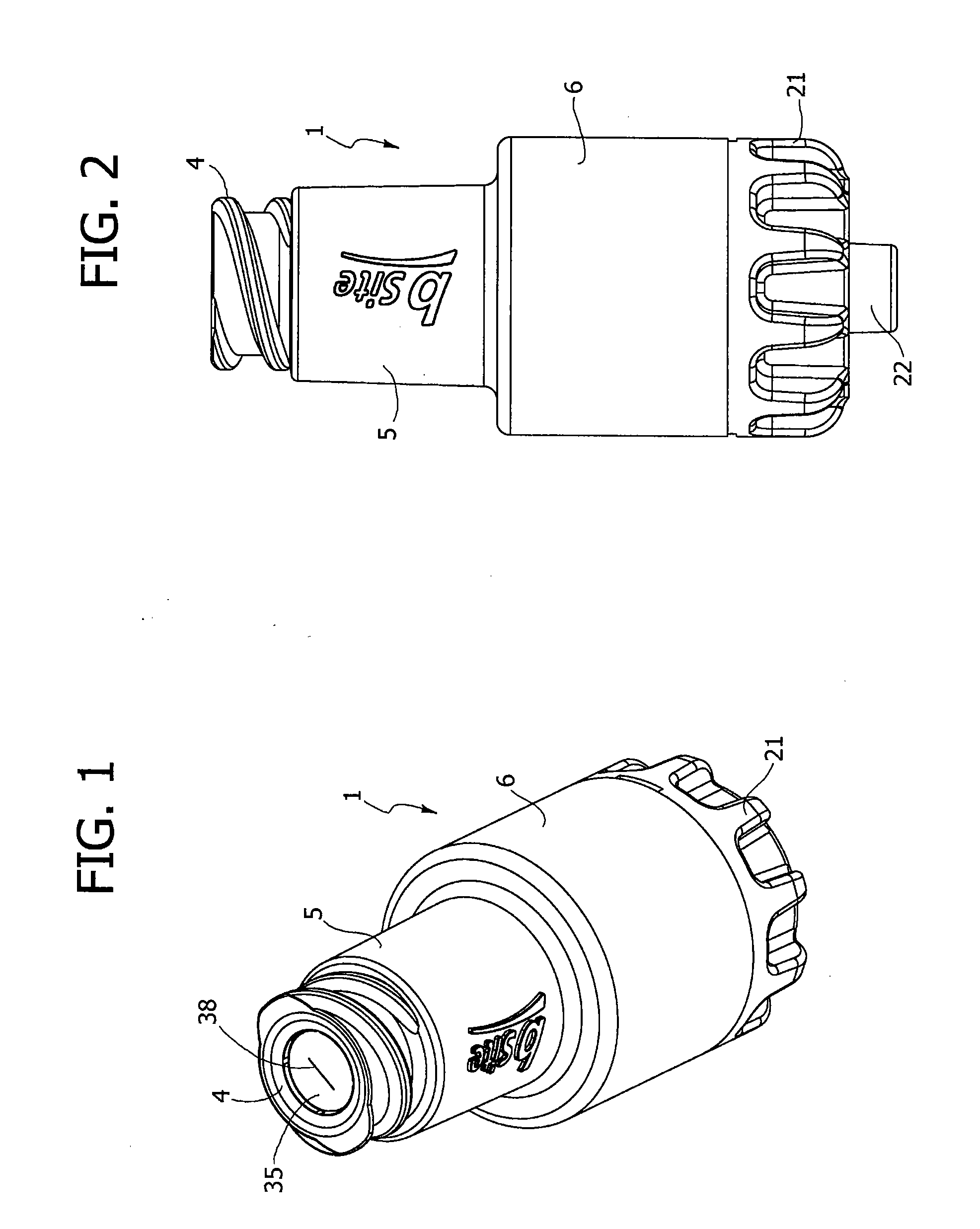

Enhanced durability hammer union

A union for connecting two tubular members. The first tubular member has an external flange, and the second tubular member has a set of external threads. An annular nut surrounds the first tubular member. The nut has an internal flange that surrounds the first tubular member, and a set of threads to engage the threads of the second tubular member. Arcuate segments are circumferentially mated between the internal flange of the nut and the external flange of the first tubular member. A flat conical surface on the inner side of the segment comes into contact with a flat conical surface on the outer side of the external flange. Curved conical surfaces tangentially align with and extend from the flat conical surfaces on the segment and the external flange. Cylindrical surfaces tangentially align and join the curved conical surfaces on the segment and the tubular member.

Owner:S P M FLOW CONTROL

Pump fluid cylinder including load transfer shoulder and valve seat for same

According to one aspect, a pump assembly includes a fluid cylinder, and the fluid cylinder includes a fluid passage that defines a tapered internal shoulder of the fluid cylinder. The tapered internal shoulder defines a first frusto-conical surface. A valve controls flow of fluid through the fluid passage. The valve includes a valve seat, which includes a seat body disposed in the fluid passage, and a bore formed through the seat body and through which fluid flows. The seat body includes inlet and outlet end portions, wherein the fluid flows into the bore at the inlet end portion and flows out of the bore at the outlet end portion. The inlet end portion of the seat body defines a second frusto-conical surface. In one embodiment, the second frusto-conical surface engages the first frusto-conical surface to distribute and transfer loading.

Owner:S P M FLOW CONTROL

Valve connector for medical lines

ActiveUS20070218757A1Reduce axial sizeSimple and inexpensiveValve arrangementsInfusion devicesAxial displacementEngineering

A valve connector for medical infusion lines including an external tubular body with an inlet end and an outlet end, an internal hollow spike and an intermediate sealing member including a head with pre-slit and an elastic hollow element formed with fluid-tight members in contact with the hollow spike and with an elastic thrust means, which tends to maintain the elastic head in a closed condition. The elastic thrust means comprises a base part joined to the elastic hollow element of the sealing member through a generally transverse annular wall, which, during axial displacement of the elastic head from the closed condition to the open condition, bends within an annular chamber defined between the base part and a portion with conical surface of the hollow spike.

Owner:IND BORLA

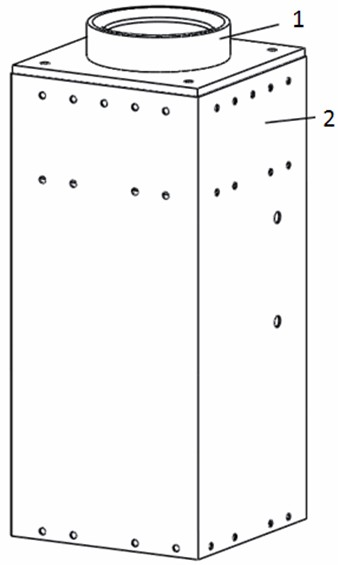

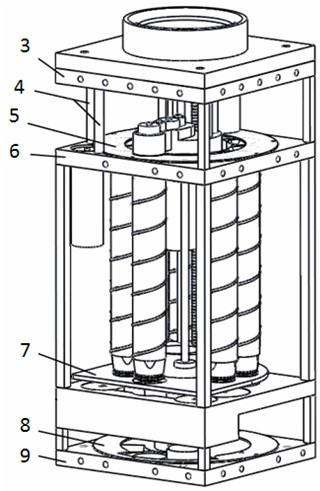

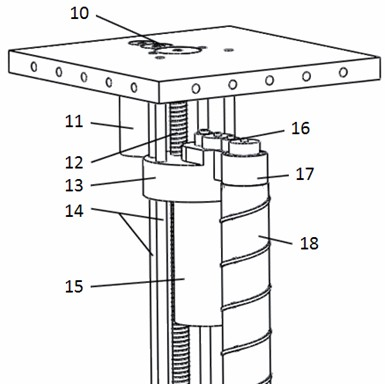

Gatherer of deep soil of moon

ActiveCN102359891APrevent leakageRecycling is simple and reliableWithdrawing sample devicesMotor driveLunar soil

The invention discloses a gatherer of deep soil of the moon. An upper end surface of a housing of the gatherer is provided with a drilling machine and mechanical arm connecting device. A first separator plate, a second separator plate and a third separator plate are installed in the housing from top to bottom. A screw driving motor is installed on the first separator plate and drives a screw by a gear. A slide block in cooperation with the screw is fixed on a slider. Four guide rods pass through four through holes located at an end of the slider. A drill pipe driving motor is installed in the middle of the four guide rods. The drill pipe driving motor drives a drill pipe connector by a gear. Electromagnet driven wedges are arranged in the drill pipe connector. The electromagnet driven wedges stretch out from pin grooves of inner conical surfaces of corresponding drill pipes. A drill pipe rotating disk is installed in the center of the second separator plate. The drill pipe rotating disk is in cooperation with a drill pipe rotating disk driving motor by a gear. The third separator plate is arranged under a clamping device. Multiple drills are installed on a drill rotating disk along a circumferencial direction. On the third separator plate, a drill rotating disk driving motor is in cooperation with the drill rotating disk by a gear. A lunar soil bag is enclosed in the drill pipes having hollow structures. The gatherer of deep soil of the moon has the characteristics of compact structure, small floor space, high reliability of a transmission mode, large drilling and production depth, large sampling amount and simple and reliable sample recovery.

Owner:ZHEJIANG UNIV

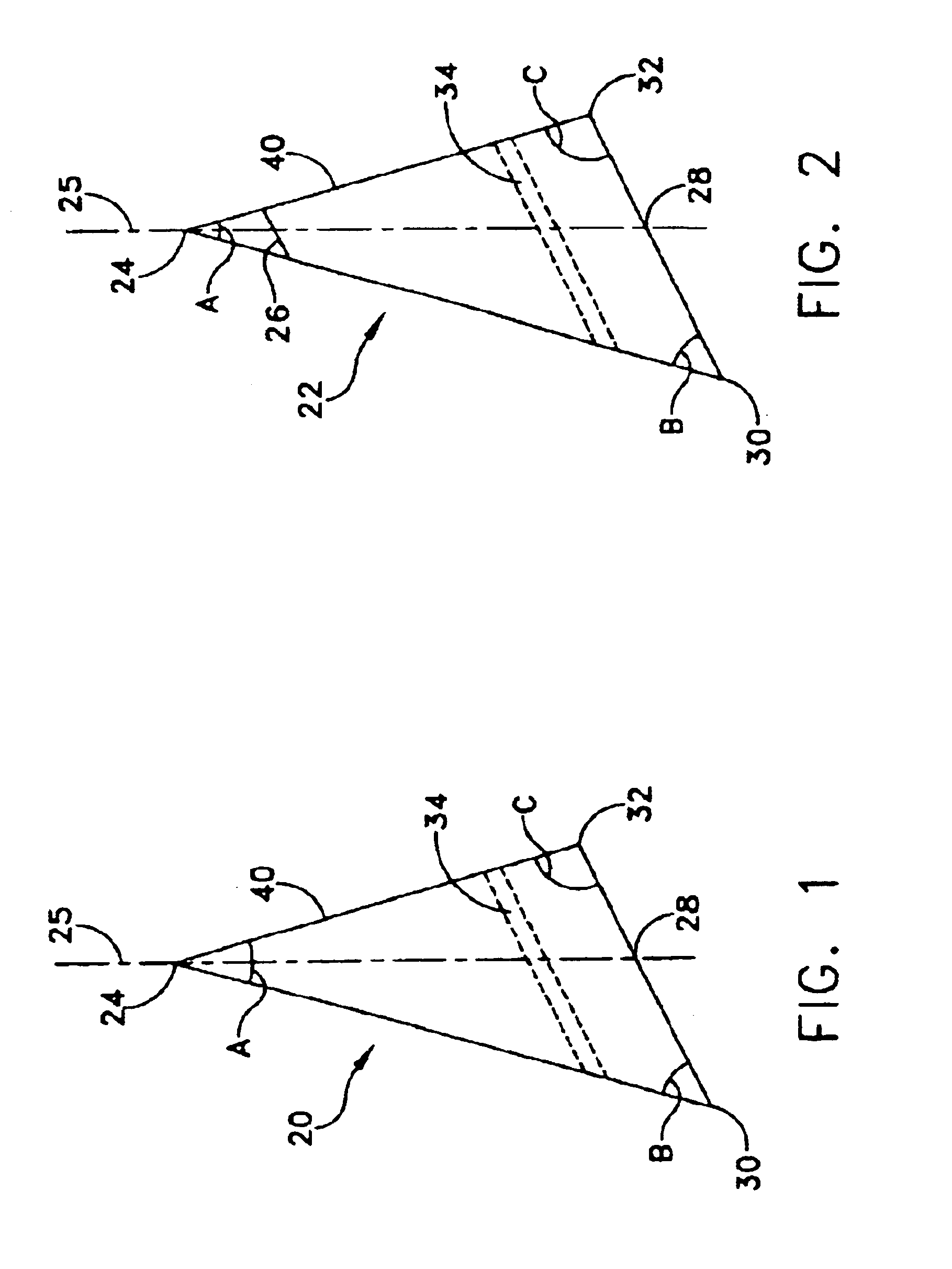

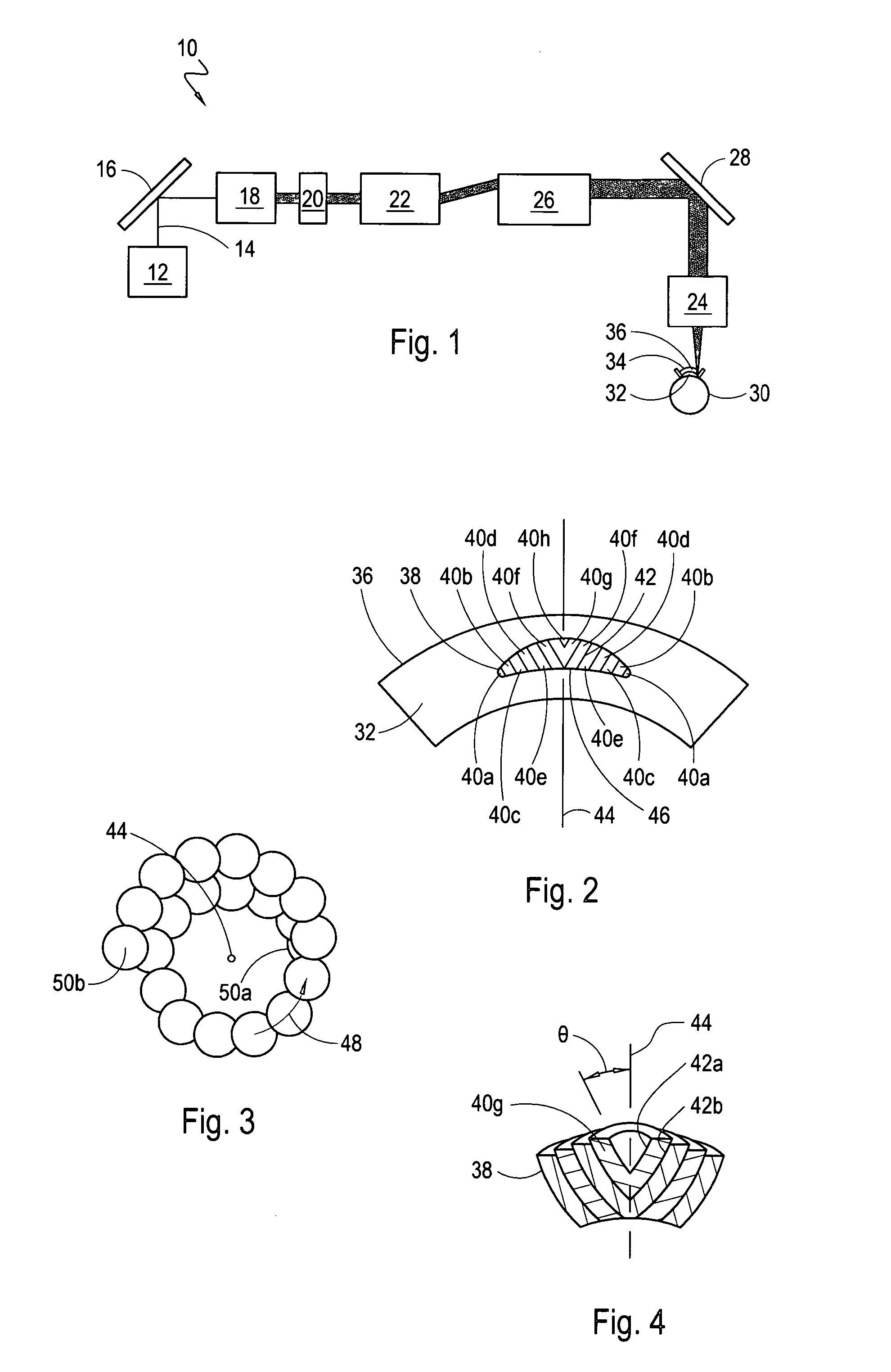

Systems and methods for intrastromal scanning patterns

A method for photodisrupting a preselected subsurface volume of corneal tissue to alter a cornea's refractive properties is disclosed. Specifically, at least one stromal volume having a substantially conical shaped surface is photodisrupted. For this purpose, a laser device having a laser source, laser scanner and one or more optical elements is typically used. In one embodiment, a plurality of stromal volumes, with each stromal volume having a substantially conical shaped surface, is sequentially photodisrupted to form a contiguous stromal cavity. In a particular implementation, each conical shaped surface defines a cone axis that is aligned to be co-linear with a reference axis that passes through the anterior surface of the eye and may be aligned orthogonally to the anterior surface of the eye.

Owner:TECHNOLAS PERFECT VISION

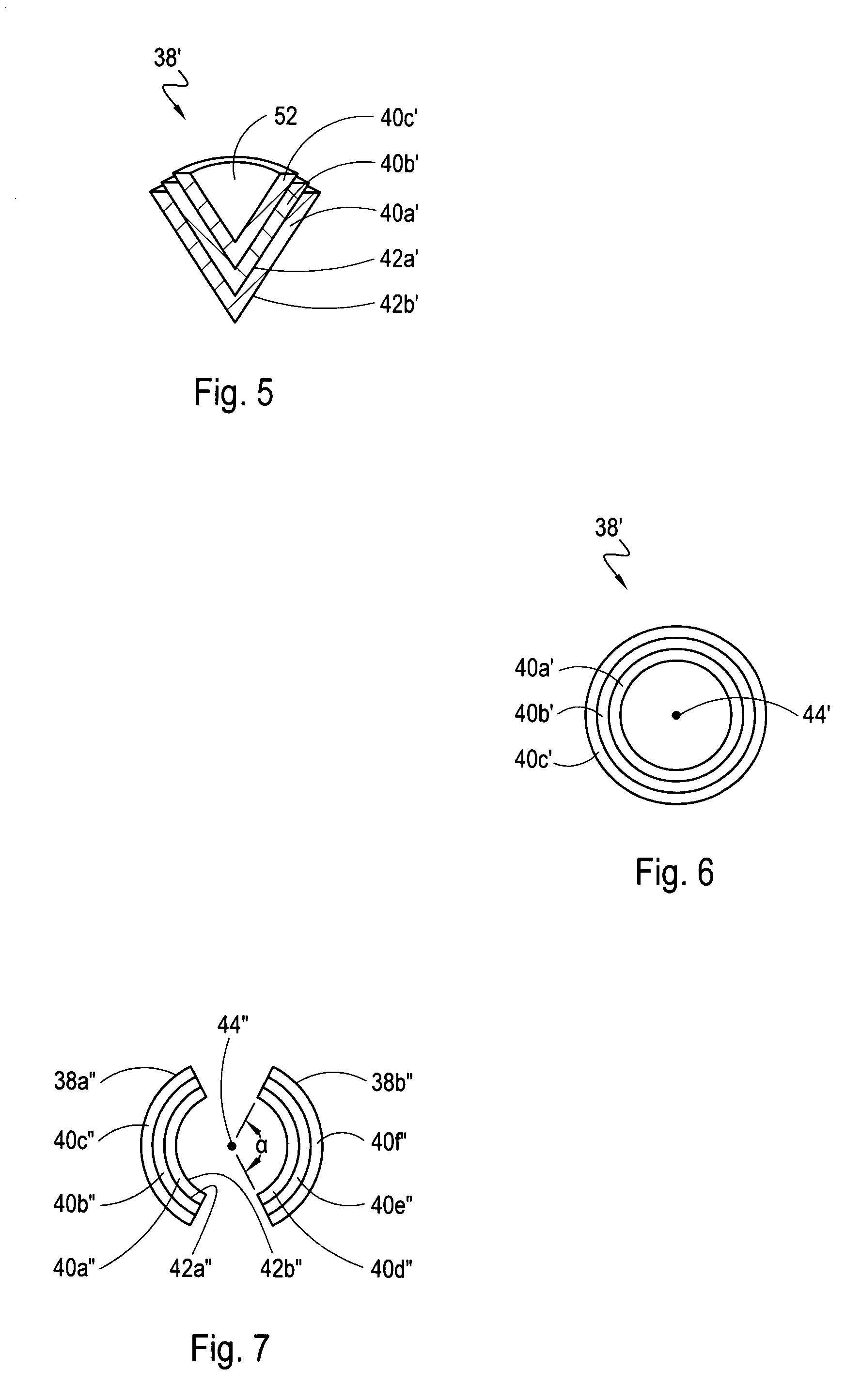

Blunt tip obturator

ActiveUS7758603B2Little strengthTrend downEar treatmentInfusion syringesPenetration forceEngineering

A surgical obturator comprising an elongate shaft extending along an axis between a proximal end and a distal end, and a bladeless tip disposed at the distal end of the shaft having a conical surface forming proximally into an outer surface, the outer surface extending distally to a blunt point and having a pair of side sections. The side sections extend from the blunt point radially outwardly with progressive positions proximally along the axis. The conical surface facilitates insertion of the obturator with a reduced penetration force and minimizes tenting of the body wall. The conical surface further facilitates separation of different layers of the body wall and provides proper alignment of the tip between the layers. The surgical obturator may be constructed from a disposable or reusable material such as a metal or an autoclavable polymer.

Owner:APPL MEDICAL RESOURCES CORP

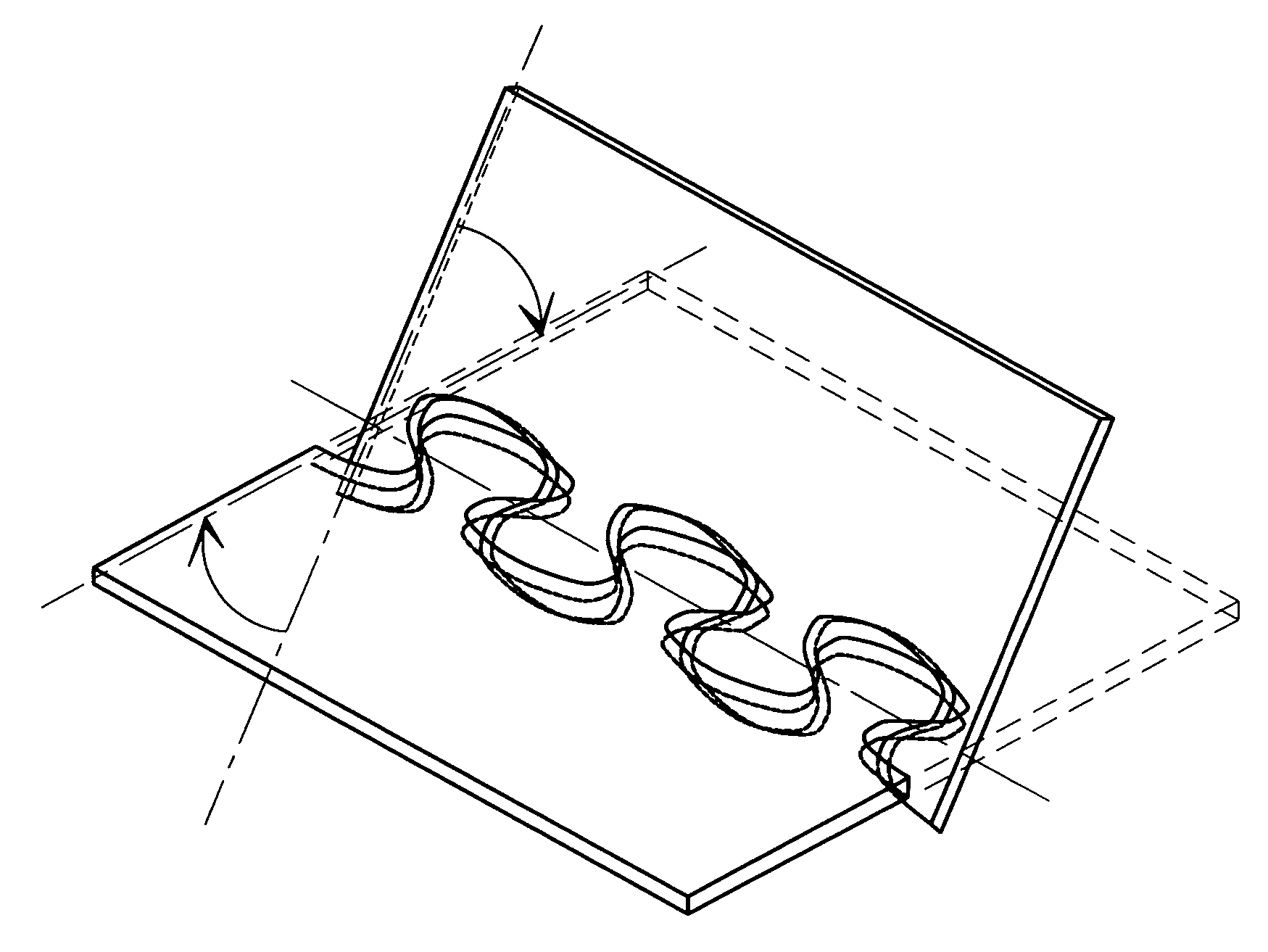

Cooling electronics via two-phase tangential jet impingement in a semi-toroidal channel

InactiveUS20060162365A1Domestic cooling apparatusSemiconductor/solid-state device detailsEvaporationEngineering

A two-fluid-phase cooling device for absorbing high thermal flux from electronics devices and other thermally dissipating devices. It consists of a thermally conductive plate with thermally dissipating elements on one face and a semi-toroidal cavity in the opposite face with the cavity's axis perpendicular to the face of the plate, a liquid refrigerant supply tube ending in a thermodynamic cycle's refrigeration expansion valve that directs jets of liquid to impact the conical surface in the center region of the semi-toroidal cavity in a direction along the cavity's axis and tangent to the conical surface, a second plate with a semi-toroidal protrusion extending into the semi-toroidal cavity to form a thin, semi-toroidal channel between the two plates, and a seal between the liquid supply tube and the second semi-toroidal plate. In operation liquid refrigerant jets strike the conical surface generally tangential to the surface and flow at high velocity in a thin film on the surface of the semi-toroidal cavity from its center radially to the outer edge of the toroidal channel, absorbing heat and boiling as it does so. The high radial acceleration forces caused by the liquid film moving at high velocity on the cavity's concave surface force the liquid film against the surface and create a pressure gradient that biases evaporation toward the liquid / vapor interface. The vapor moves parallel to the liquid flow radially outwards between the liquid film and the surface of the semi-toroidal protrusion at very high velocity, causing extreme turbulence in the liquid film and highly augmented heat transfer between the heated plate and the liquid film, while the liquid film nevertheless remains intact and forced against the heated surface by radial acceleration and carried to a distance significantly greater than in conventional jet impingement systems. The device may also be composed of wedge-shaped sections of the semi-toroidal plates. It may further have two expansion valves in series in the liquid supply line, the first generating a small amount of vapor (increase in quality) so the resulting increase in flow volume greatly increases the velocity through the second expansion valve toward the heated surface to further enhance heat transfer.

Owner:HOANG TRIEM T +1

Rotary tool and cutting part comprised in the tool

InactiveUS20030210963A1Acceptable toleranceTransportation and packagingMilling cuttersInterference fitMilling cutter

A rotary tool for chip removing machining, for example a milling cutter or a drill, includes a shaft, a holder, and a cutting part. The shaft has a conical seating arranged in its front end. The holder has a slightly conical recess, whose cross-sectional dimension decreases toward the open end of the recess. The cutting part has a slightly conical pin designed to be received in the recess and has a cross-sectional dimension which increases in the direction of the free end of the pin. The recess is formed by a wall which is elastically flexible in a radial direction. When the holder is drawn axially into the seating, the wall is flexed radially inwardly, causing the conical surface of the recess to tightly grip the conical surface of the pin and create an interference fit of the pin in the recess.

Owner:SANDVIK AB

Fuel atomization dual orifice fuel nozzle

A pilot fuel injector tip includes concentric primary and secondary pilot fuel nozzles having a circular primary exit axially aft and downstream of an annular secondary exit respectively. A fuel nozzle assembly includes a pilot swirler flowpath section having an annular inwardly tapering conical flowpath section surrounding primary and secondary exits. An inwardly tapering conical wall section radially inwardly bounding flowpath section defines a conical surface. Exits are located at or axially forward or upstream of the conical surface. An annular secondary fuel supply passage in secondary pilot fuel nozzle includes a secondary fuel swirler with an array of helical spin slots that may have rectangular cross sections. A chamfered leading edge of an annular wall section disposed between an outer pilot swirler and an inlet to an injector cooling flowpath surrounding the second pilot swirler includes a radially inwardly facing conical chamfered surface for deflecting dirt from cooling flowpath.

Owner:GENERAL ELECTRIC CO

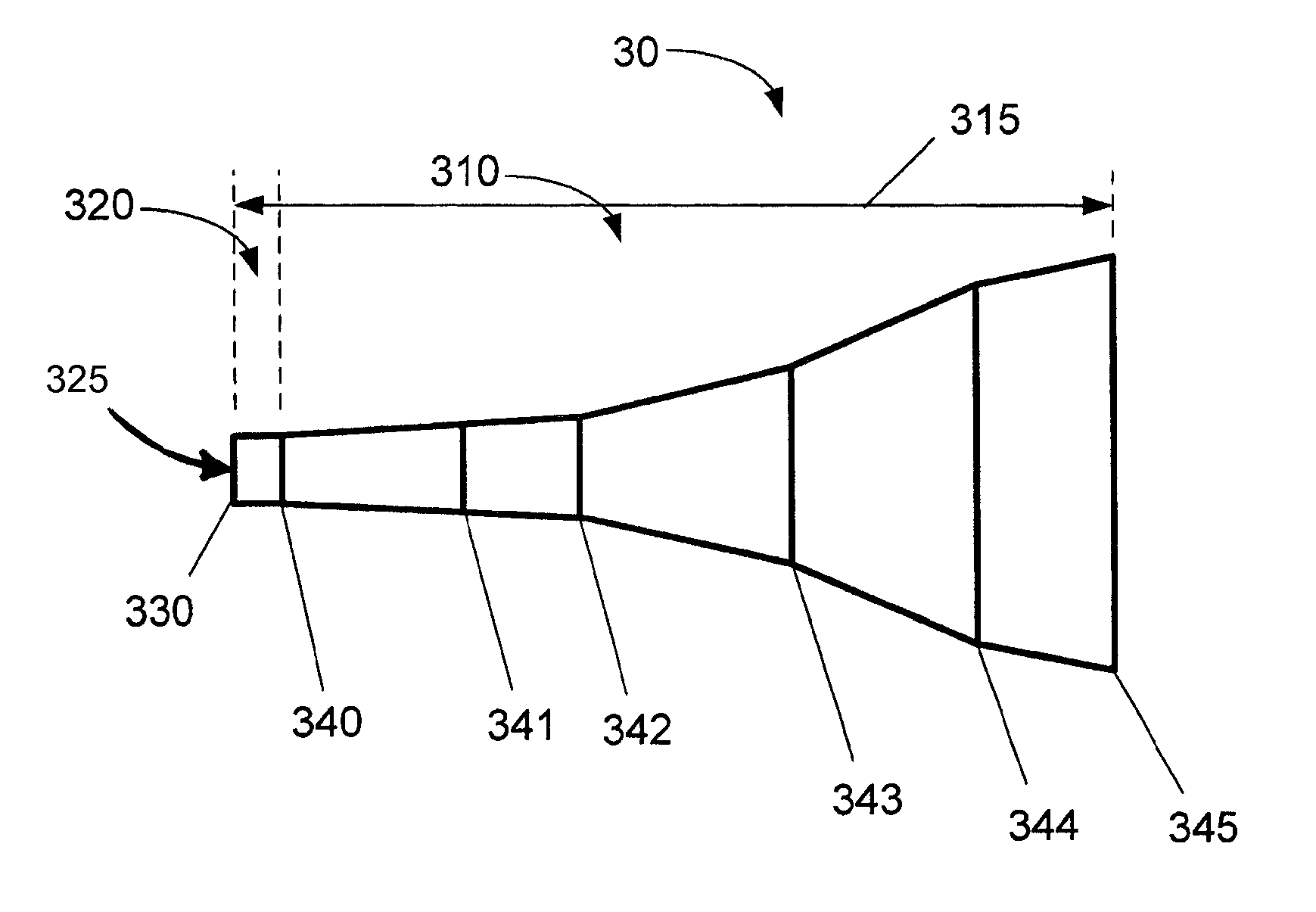

Shape of cone and air input annulus

InactiveUS20080277266A1Minimize occurrenceHigh molecular weightDirect contact heat exchangersStationary tubular conduit assembliesInterior spaceInjection port

A constricting chamber having first and second ends, the chamber comprising: an interior surface formed between the first and second ends, disposed circumferentially around and defining an interior space and a longitudinal axis of the chamber; a frusto-conical surface disposed between the first and second ends and narrowing as it extends away from the first end and into the second end; an ejection port disposed at the second end and substantially aligned with the longitudinal axis; a cover disposed at the first end, substantially perpendicular to the longitudinal axis, and comprising a center substantially aligned with the longitudinal axis; an injection port disposed on the cover proximate the center, and configured to receive a reactive mixture into the chamber; and an annular supply portion disposed circumferentially around the longitudinal axis and comprising supply port(s) configured to supply conditioning fluid into the chamber in an annular formation along the interior surface.

Owner:SDC MATERIALS +1

Corrugated tube fitting

InactiveUS20050023832A1Improve mechanical strength performanceImproved sealing performanceSleeve/socket jointsFluid pressure sealed jointsEngineeringMetal metal

A fitting for an end of a length of corrugated tubing has a split retainer that grips the tubing corrugations, and is engaged between a fitting body and a nut. Upon tightening the nut on the fitting body, the endmost corrugation is compressed between the retainer and a sealing seat on the fitting body arranged to provide a narrow metal-metal sealing junction and also a gasket seal. The fitting body has an inwardly tapered conical surface with a circular outer radius surrounded by an annular groove, thus forming a sealing edge, and the annular groove carries a gasket. The conical surface is dimensioned so that the sealing edge falls between the maximum and minimum diameters of the endmost corrugation. As the fitting is tightened, the endmost corrugation is collapsed between the sealing edge and the retainer, providing a metal / metal clamped sealing junction. The outer diameter part of the endmost corrugation is wrapped into a bead or torus that compresses the gasket, forming a metal / gasket additional seal.

Owner:HIGHLANDS CORP

Corrugated tube fitting

InactiveUS6877781B2Improve performanceHigh strengthSleeve/socket jointsFluid pressure sealed jointsEngineeringMetal metal

A fitting for an end of a length of corrugated tubing has a split retainer that grips the tubing corrugations, and is engaged between a fitting body and a nut. Upon tightening the nut on the fitting body, the endmost corrugation is compressed between the retainer and a sealing seat on the fitting body arranged to provide a narrow metal-metal sealing junction and also a gasket seal. The fitting body has an inwardly tapered conical surface with a circular outer radius surrounded by an annular groove, thus forming a sealing edge, and the annular groove carries a gasket. The conical surface is dimensioned so that the sealing edge falls between the maximum and minimum diameters of the endmost corrugation. As the fitting is tightened, the endmost corrugation is collapsed between the sealing edge and the retainer, providing a metal / metal clamped sealing junction. The outer diameter part of the endmost corrugation is wrapped into a bead or torus that compresses the gasket, forming a metal / gasket additional seal.

Owner:HIGHLANDS CORP

Joint for flat parts

A joint for flat rigid parts comprises projections, which are embodied on the mating sides of the parts in the form of bulbous breadths at the edge thereof and necks at the basis thereof, and complementary joggles, which are embodied in the form of bulbous slots corresponding to the bulbous breadths of the projections and gradually changing into grooves corresponding to the projections necks. The surfaces of the projections edges and the surfaces of the slots bottoms mating therewith are embodied in the form of cones, wherein the peaks of the conical surfaces of the projections edges and of the slats bottoms are arranged an the opposite sides with respect to the connecting parts. The radius of curvature of the guiding lines of the conical surfaces of the projections edges and of the slots bottoms can be embodied in such a way that they tend to infinity; at least one connecting part can be embodied in the form of a through-thickness composite part.

Owner:KOZHUEV VITAL IVANOVICH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com