Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1070 results about "Axial thrust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

What is axial thrust : Axial thrust refers to the unbalanced force acting on the rotor of a pump that tends to displace it in an axial direction or along the axis of its rotation. Axial thrust is one of the hydralic force.

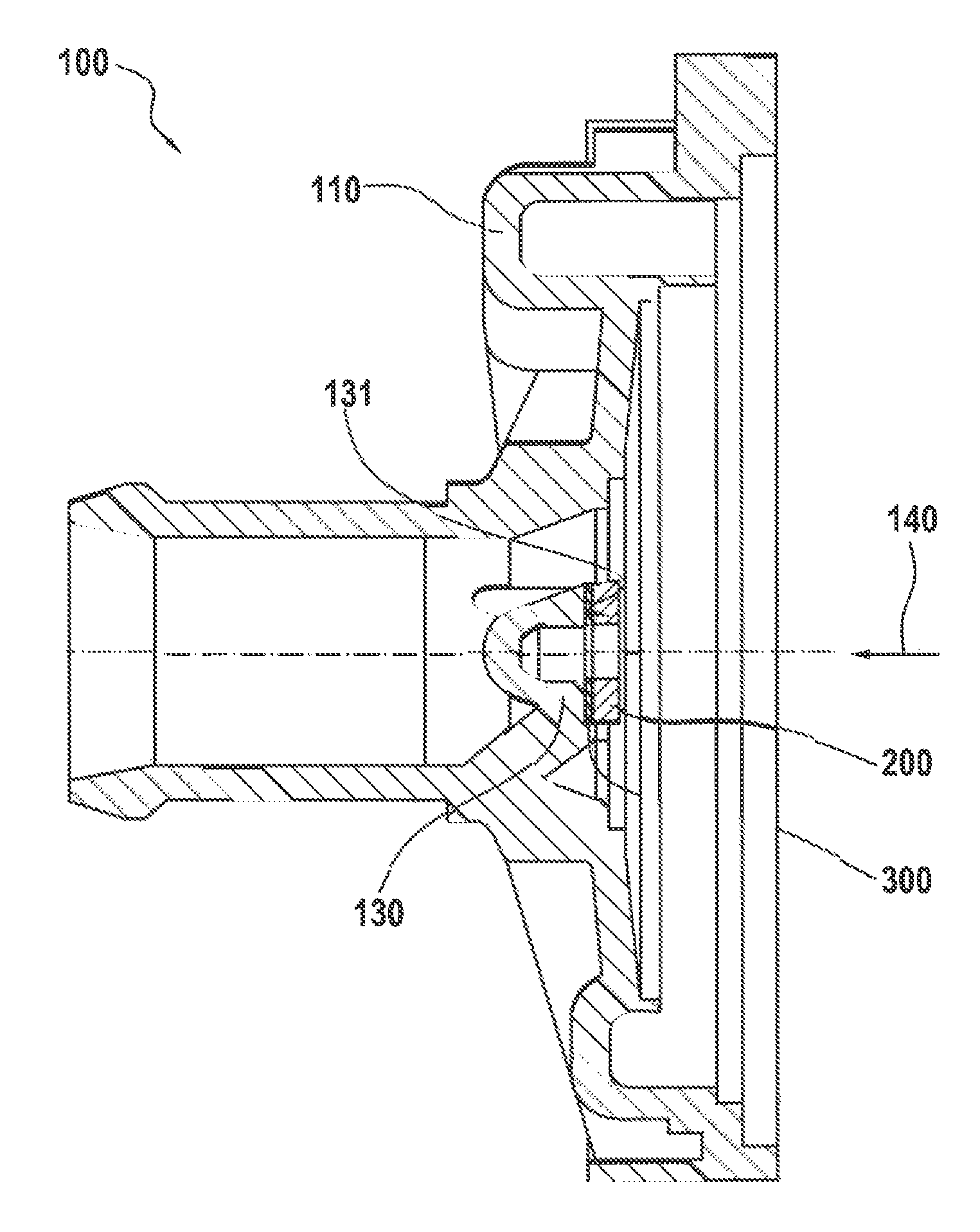

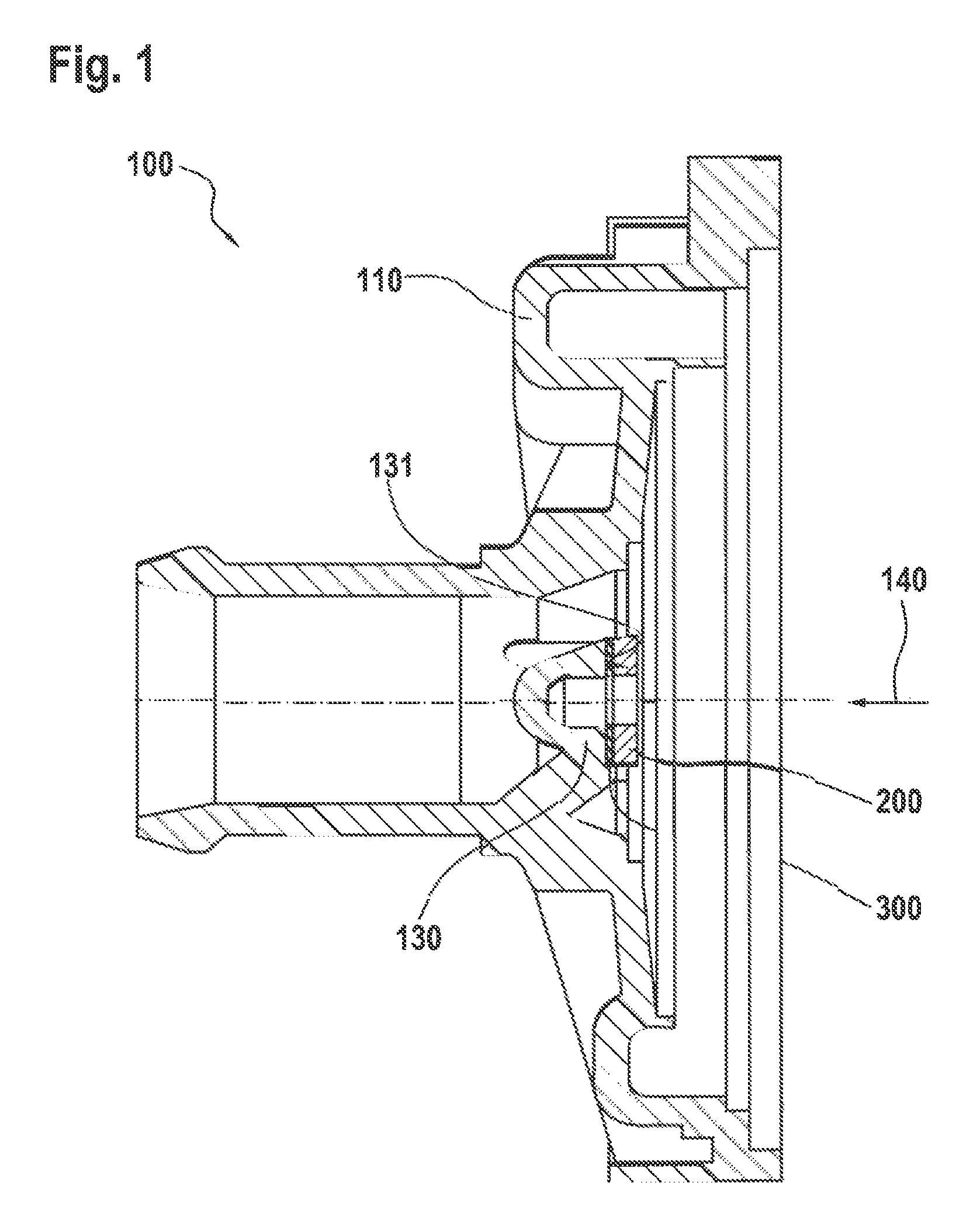

Liquid pump with axial thrust washer

A liquid pump, in particular a water pump, comprises a pump housing, which has a thrust bearing seat, a bearing bolt and a bearing mounted on the bearing bolt. In this case, a thrust washer is arranged between the thrust bearing seat of the pump housing and the bearing. Furthermore, a flexible washer is arranged between the thrust bearing seat and the thrust washer.

Owner:ROBERT BOSCH GMBH

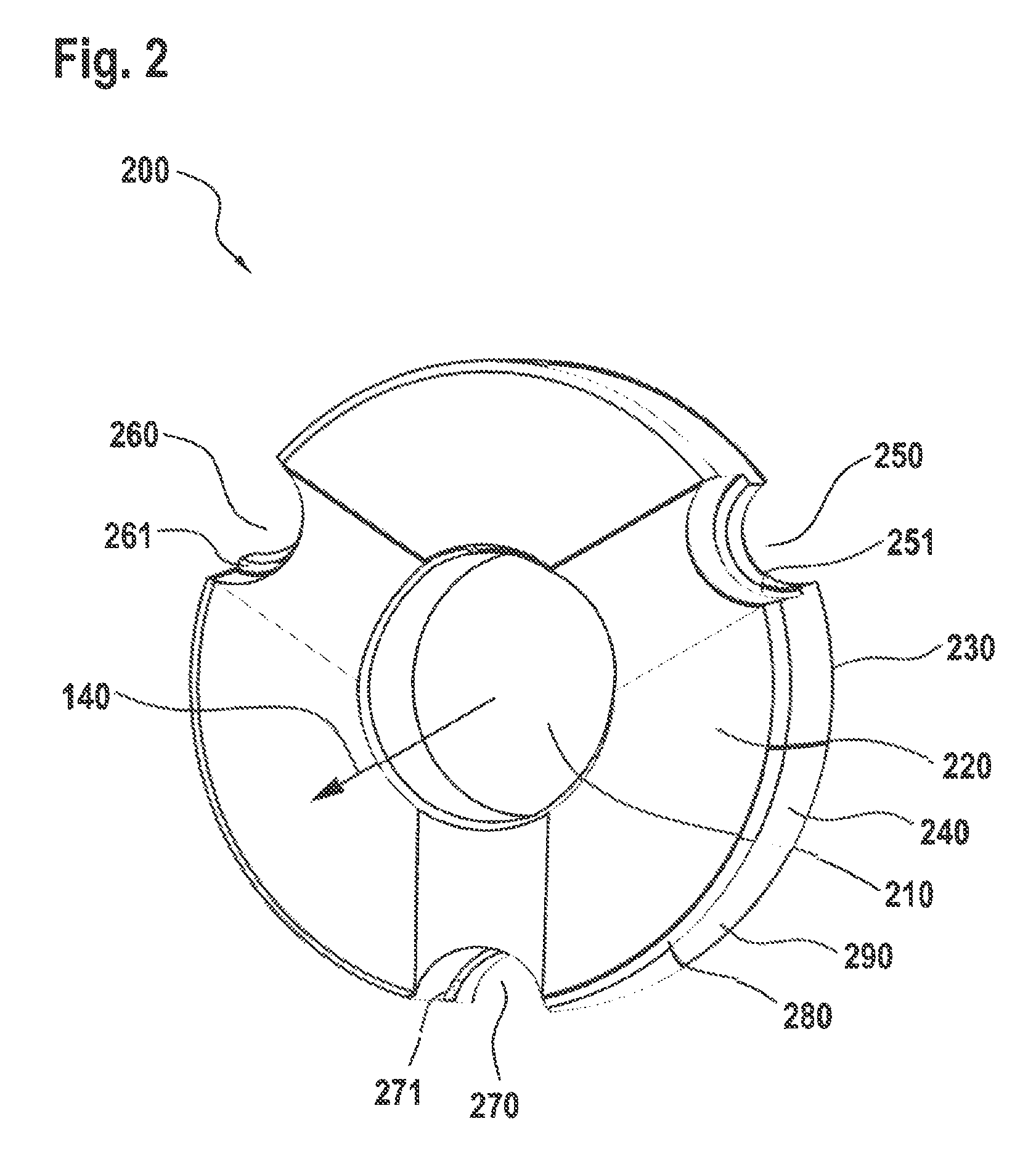

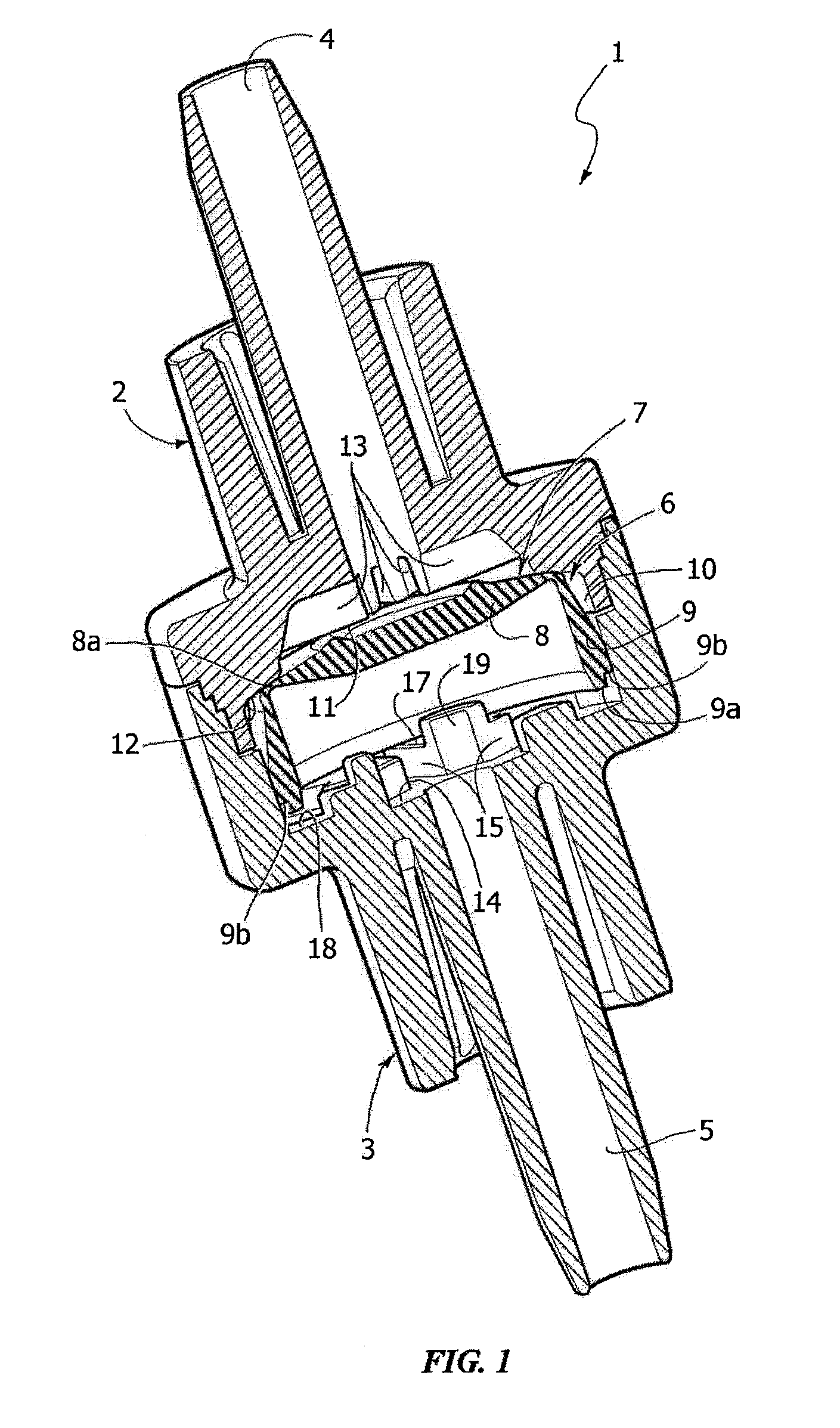

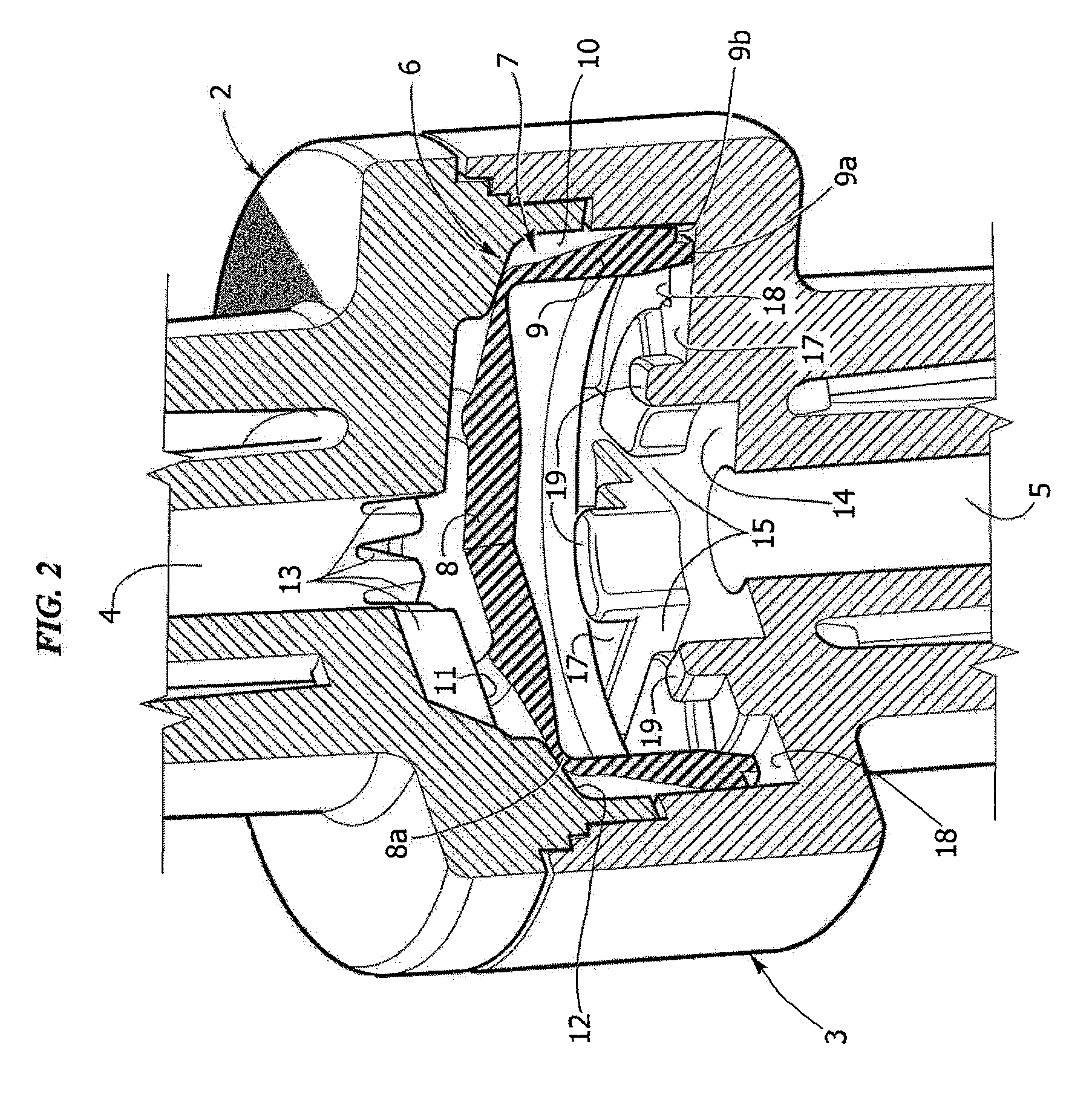

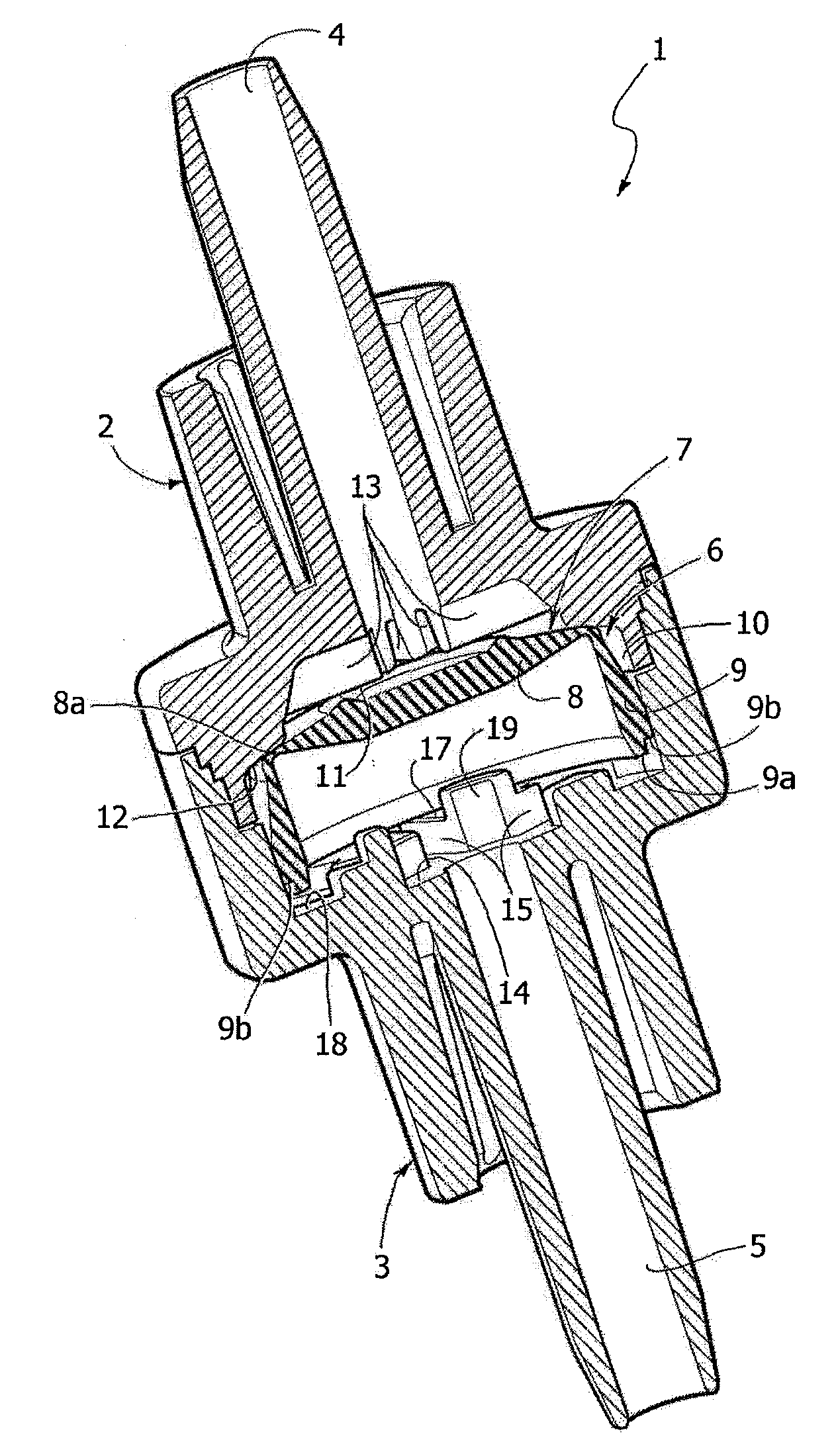

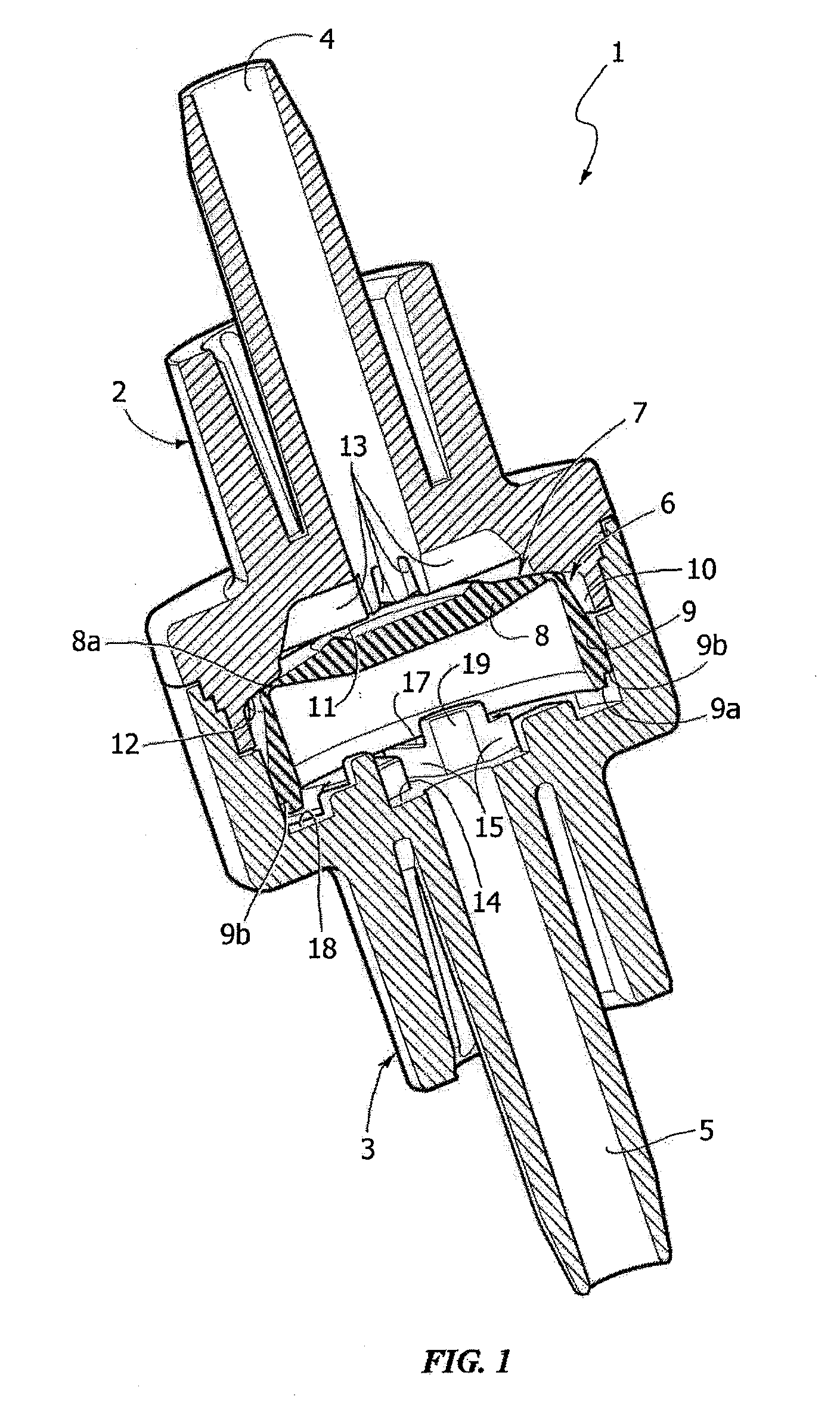

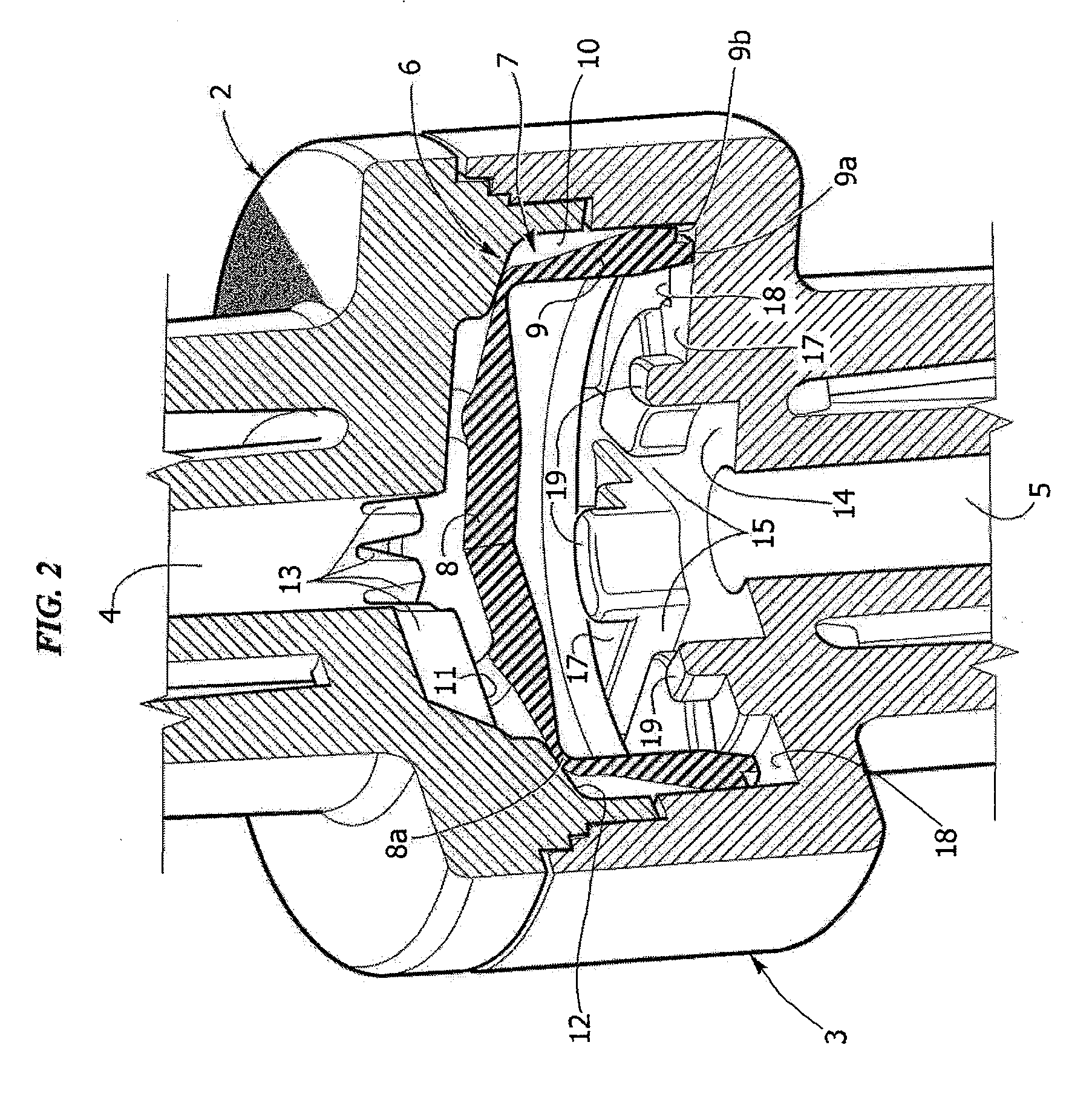

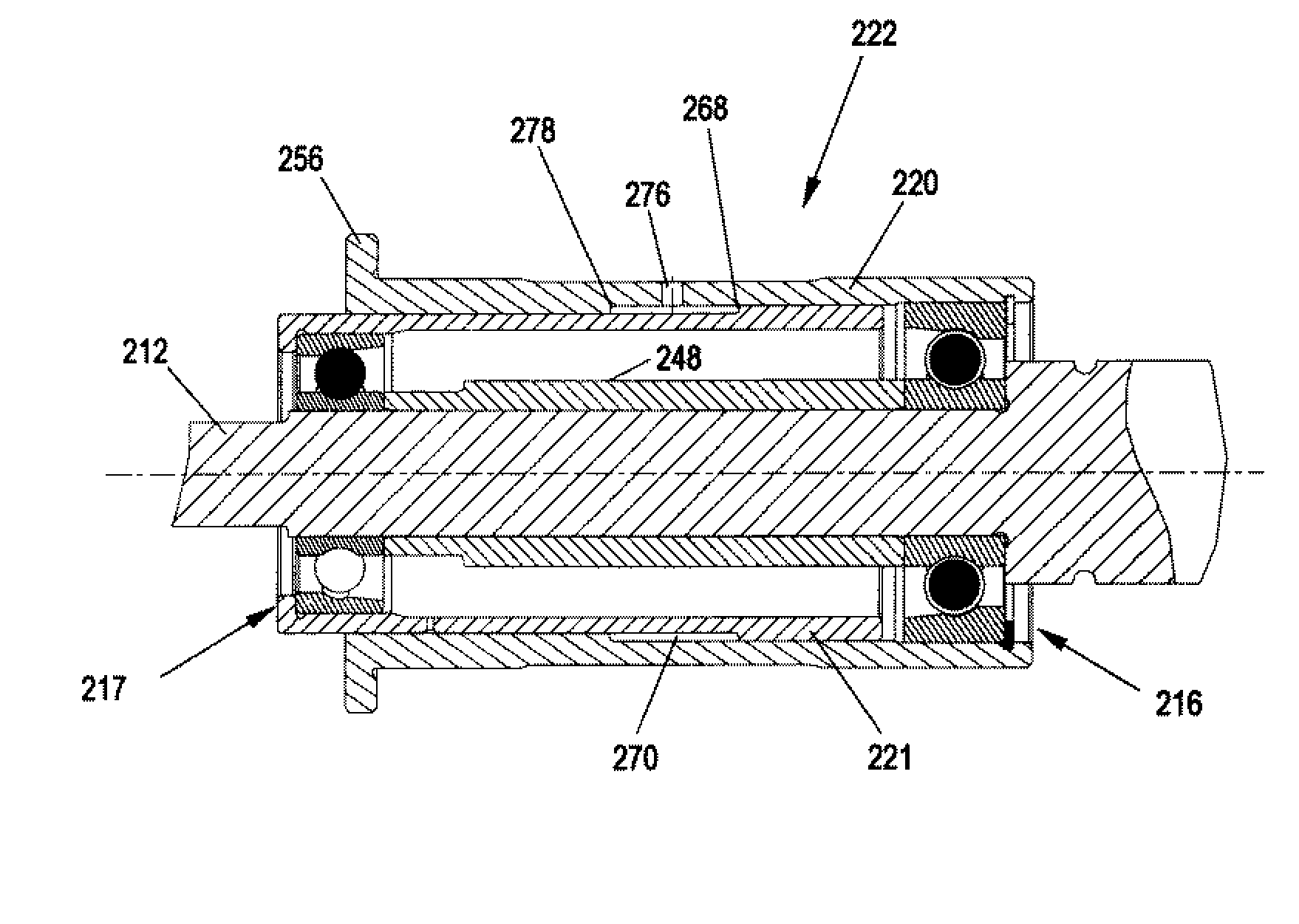

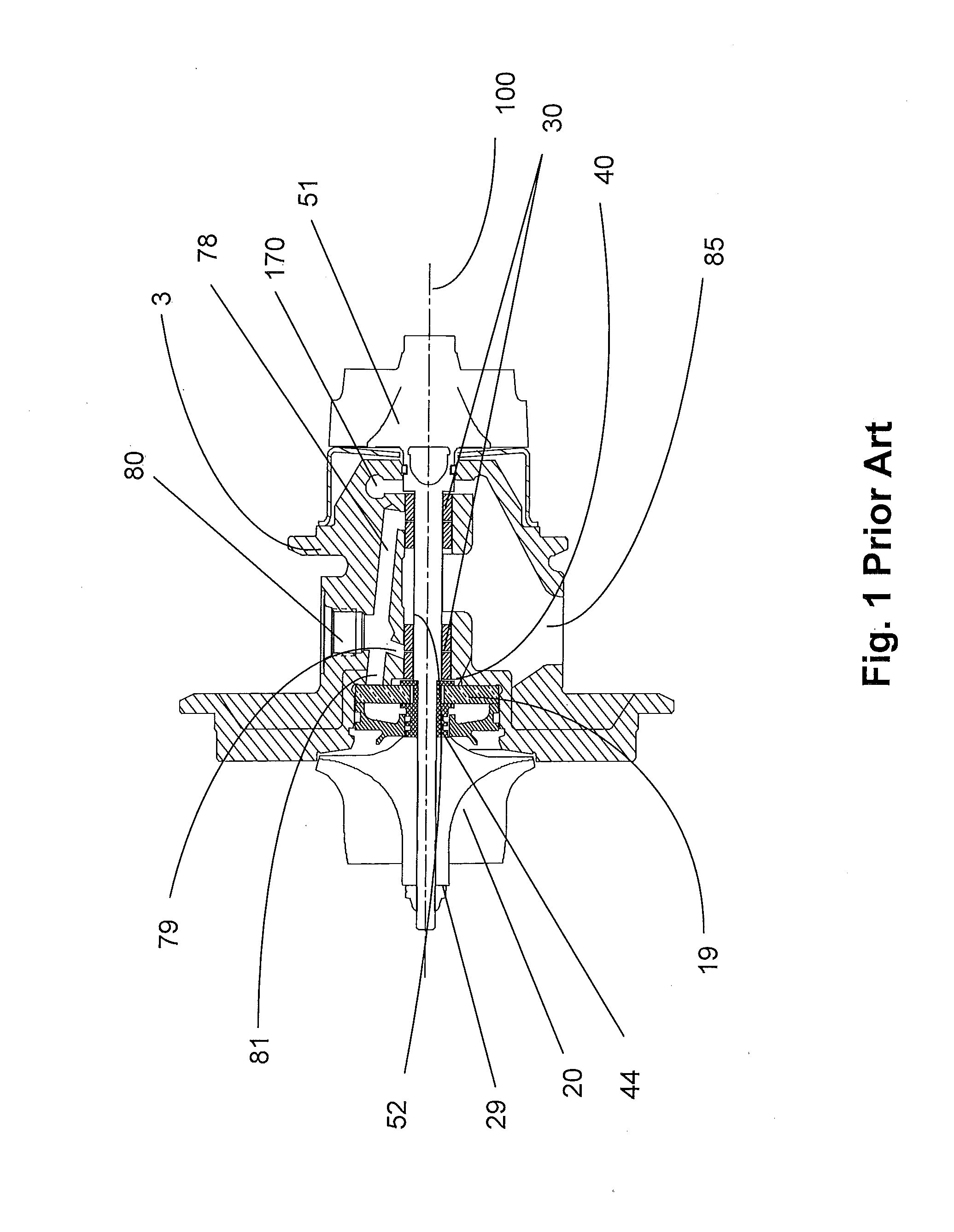

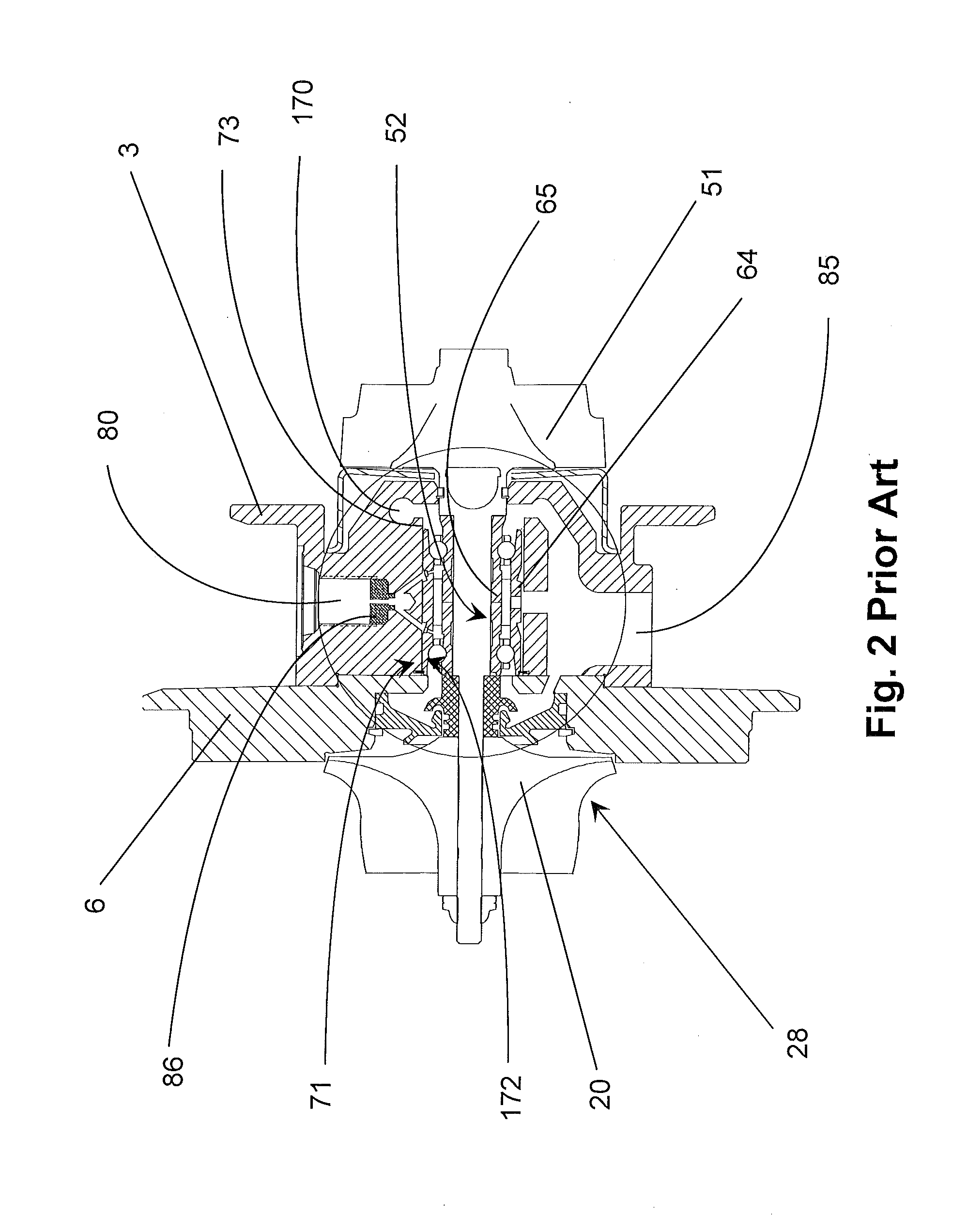

One-way valve for medical infusion lines and the like

A check valve for medical infusion lines and the like, includes a diaphragm made of elastic material set between a first tubular connector and a second tubular connector. The diaphragm includes an end wall of a cup-shaped element, having an outer peripheral edge of which is normally pressed in seal contact against an annular valve seat with a conical surface of the first tubular connector under an axial thrust exerted by a side wall of the cup-shaped element. A free edge of the side wall of the cup-shaped element is set resting against a transverse surface of the second tubular connector only in regions corresponding to angular portions of the latter separated by non-resting angular portions.

Owner:IND BORLA

One-way valve for medical infusion lines and the like

ActiveUS20080169444A1Good exploitationFor further operationCheck valvesEqualizing valvesLine tubingEngineering

A check valve for medical infusion lines and the like, includes a diaphragm made of elastic material set between a first tubular connector and a second tubular connector. The diaphram includes an end wall of a cup-shaped element, having an outer peripheral edge of which is normally pressed in seal contact against an annular valve seat with a conical surface of the first tubular connector under an axial thrust exerted by a side wall of the cup-shaped element. A free edge of the side wall of the cup-shaped element is set resting against a transverse surface of the second tubular connector only in regions corresponding to angular portions of the latter separated by non-resting angular portions.

Owner:IND BORLA

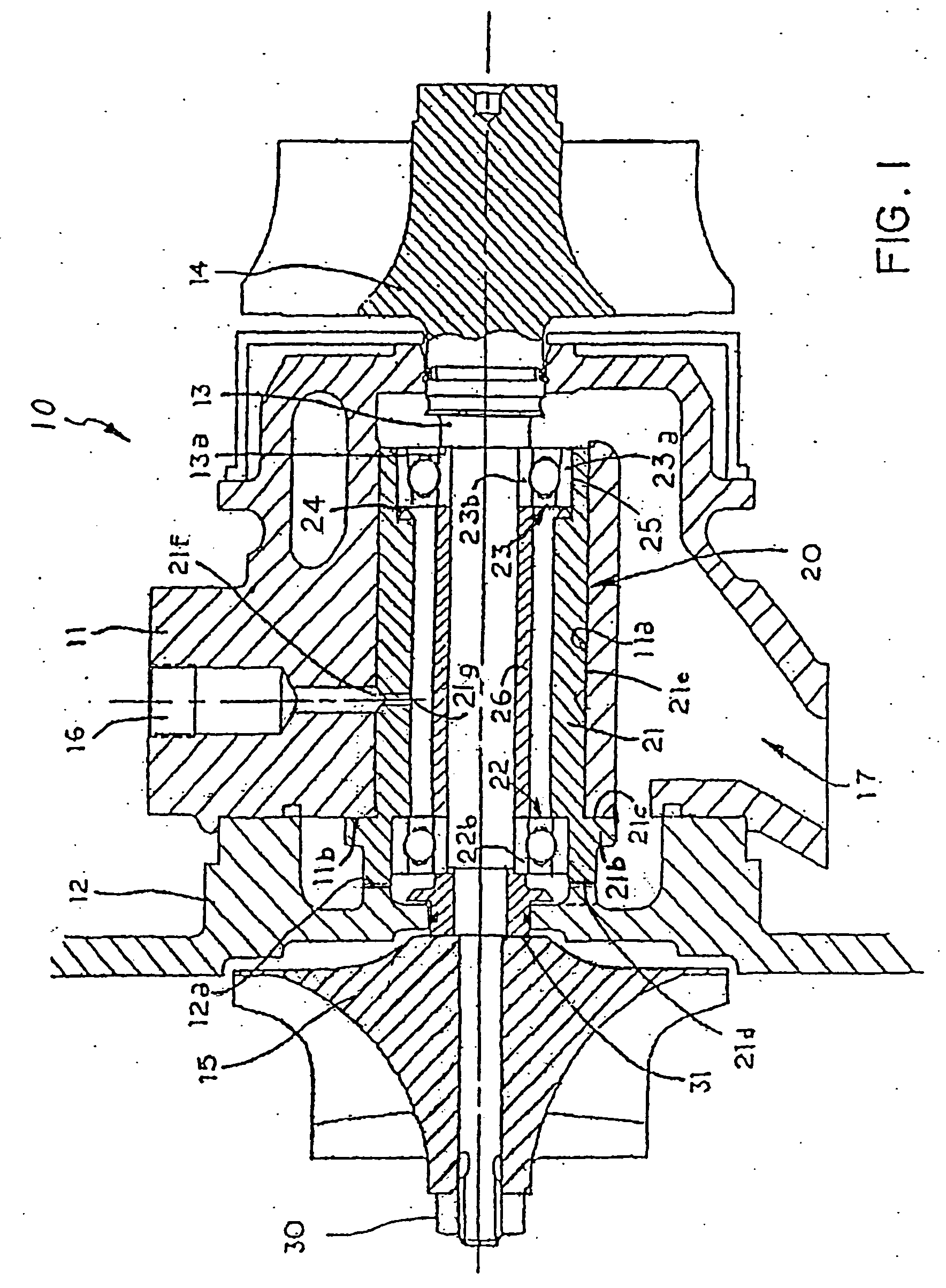

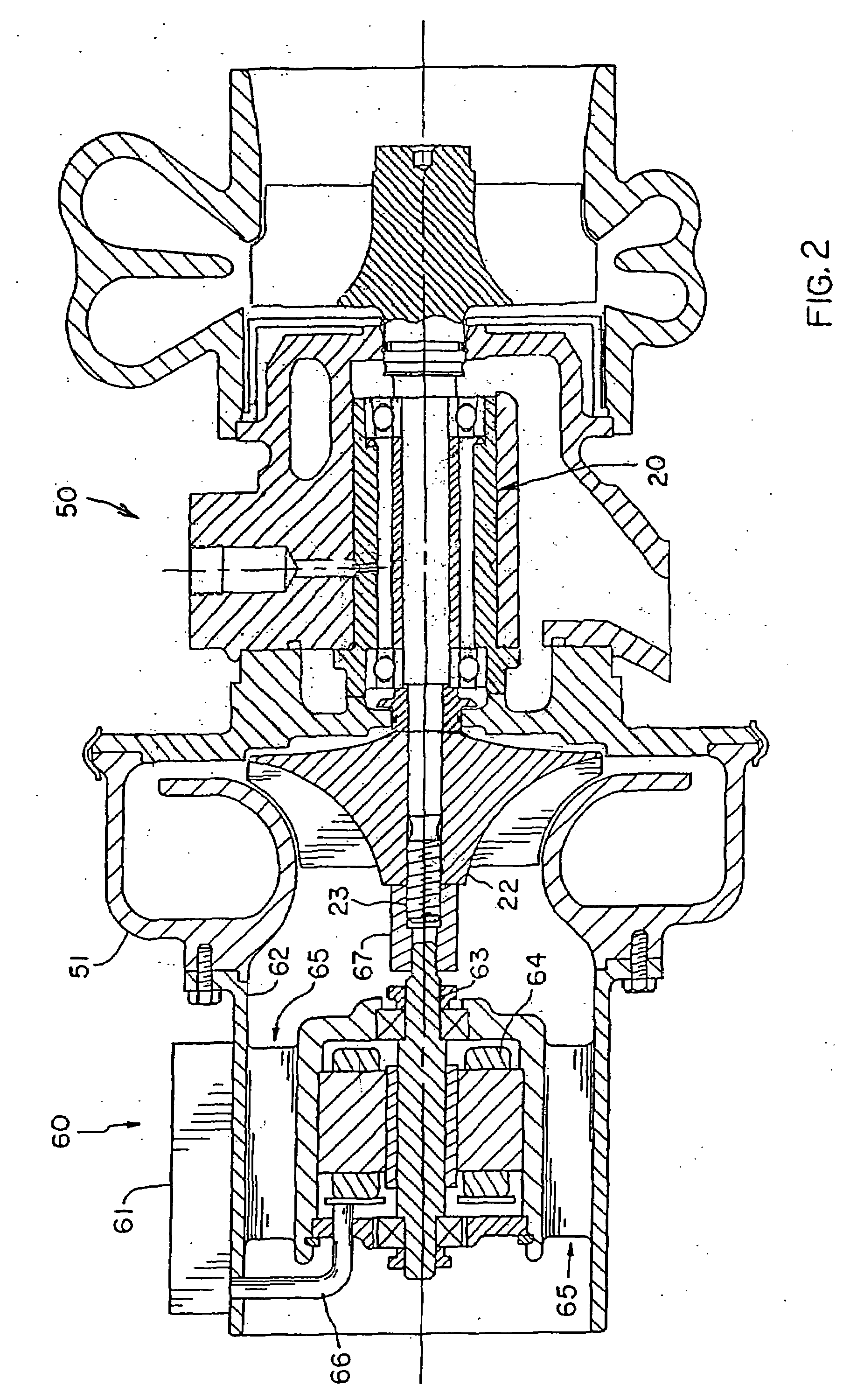

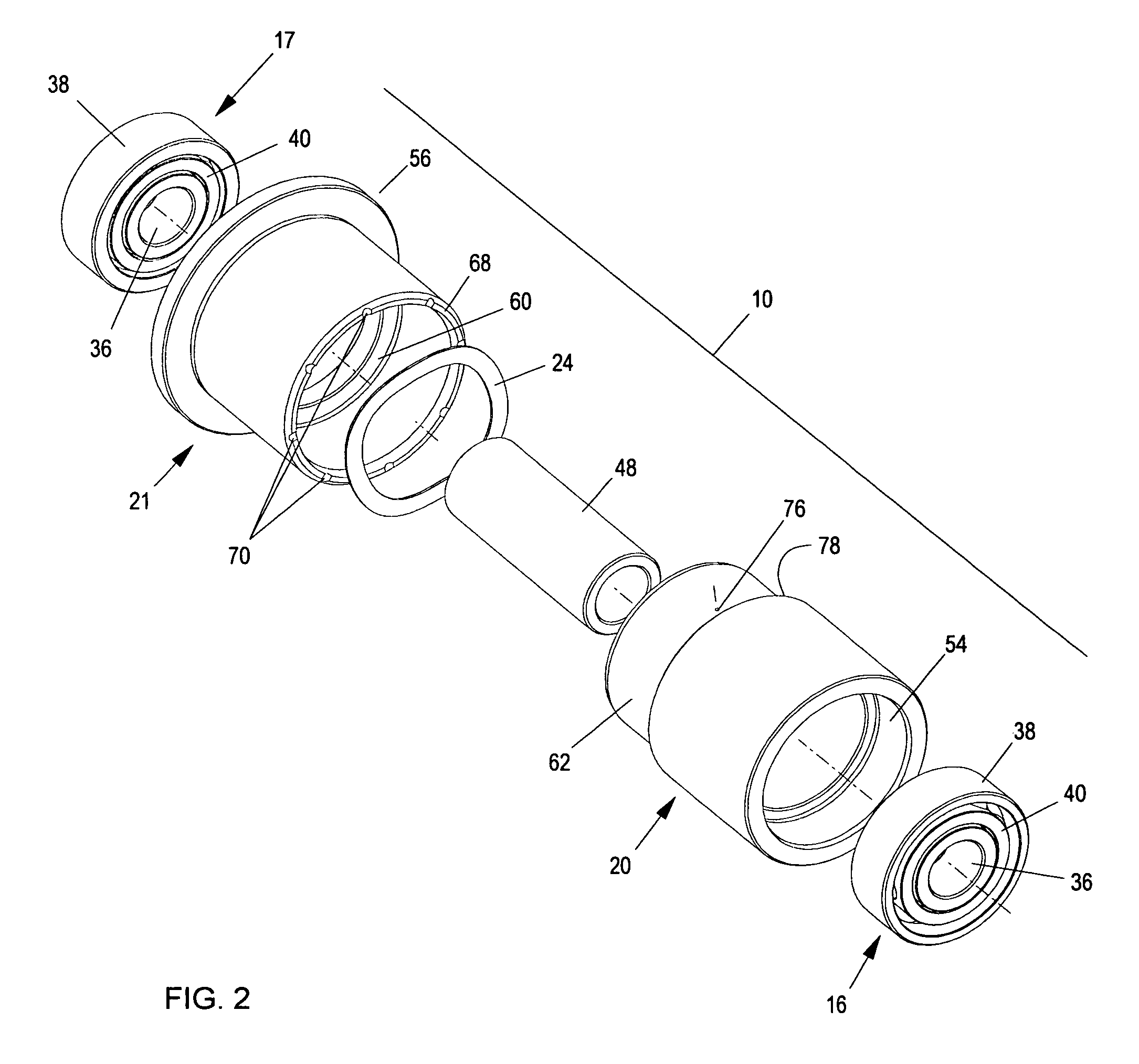

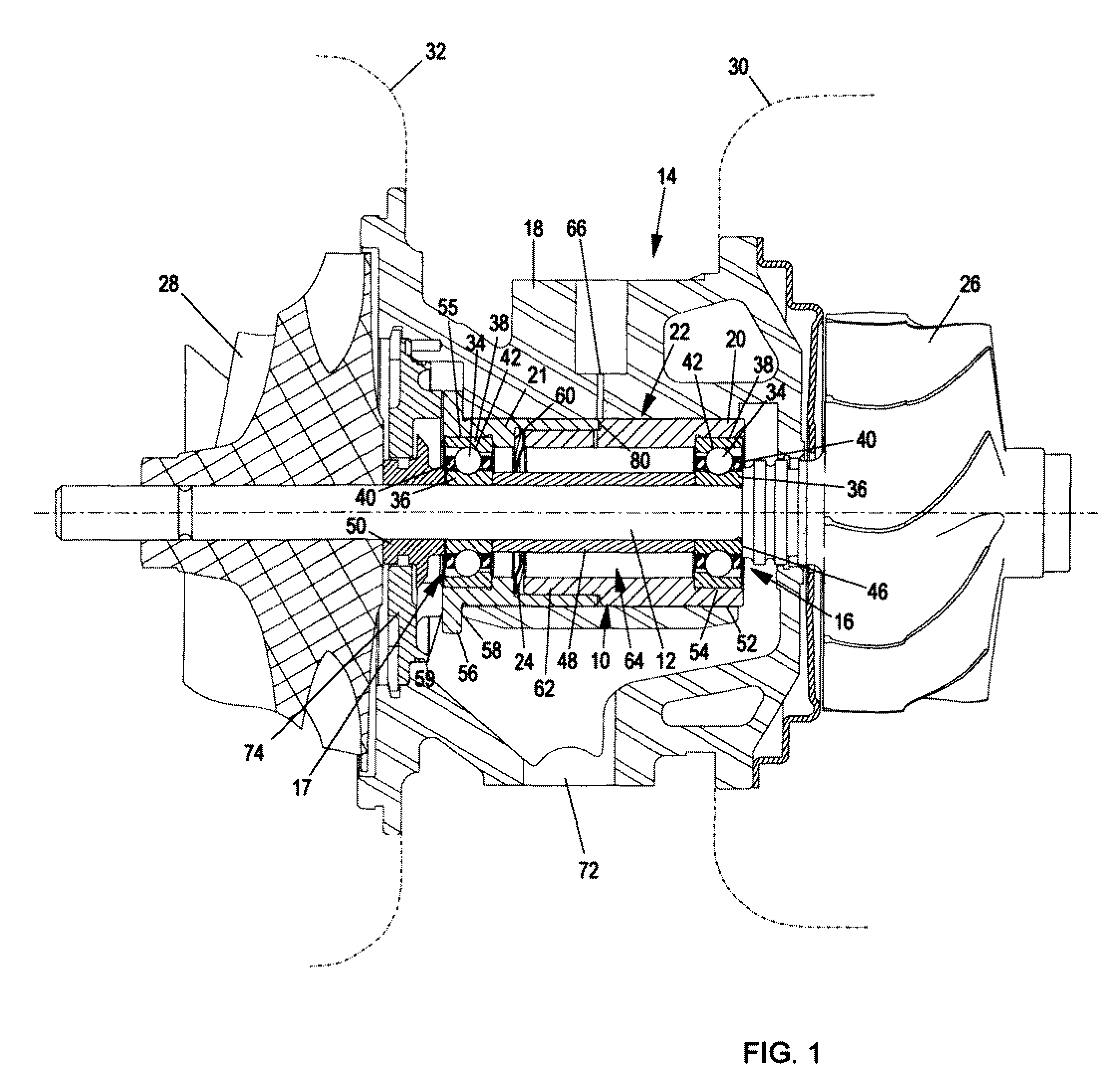

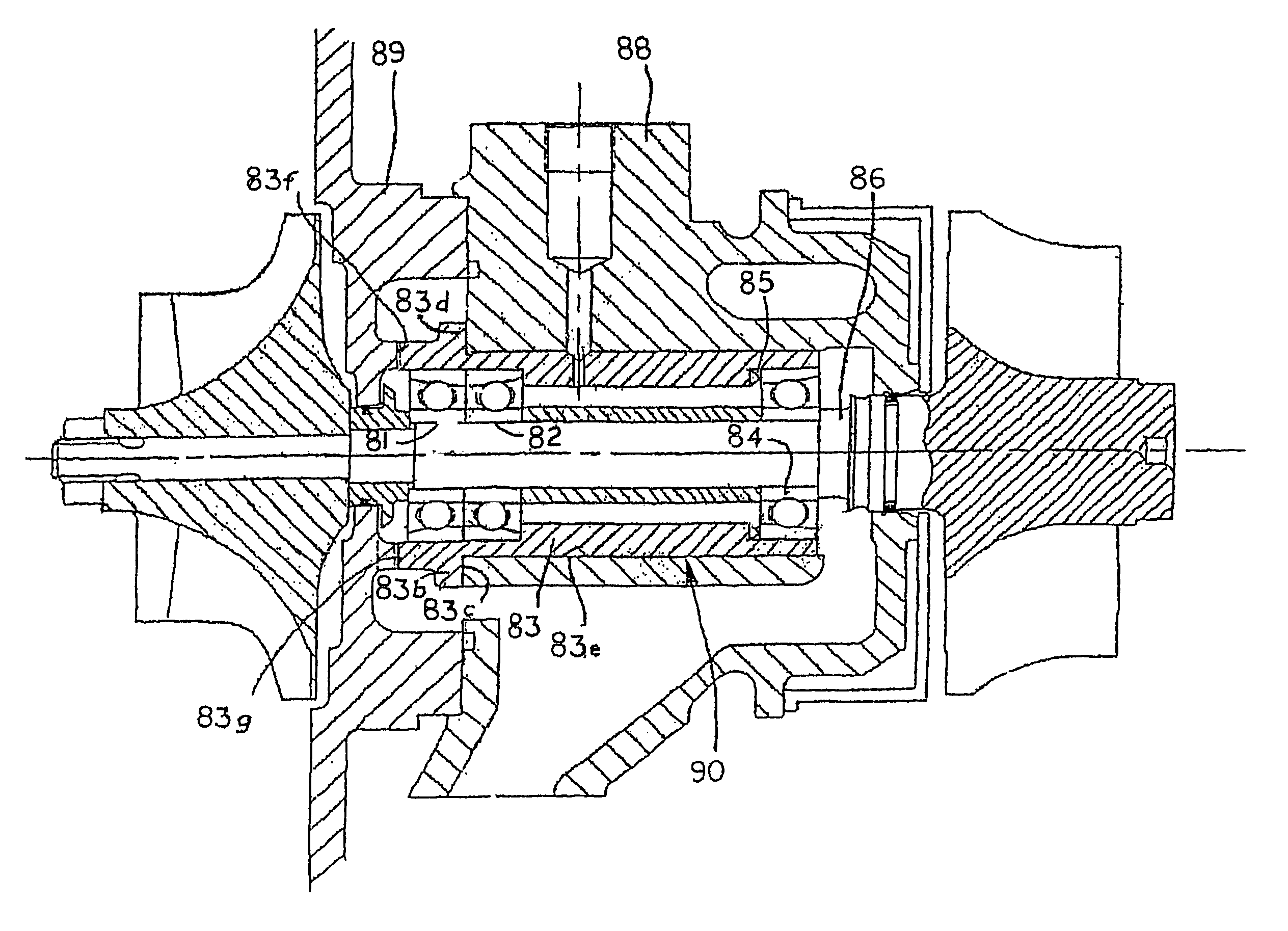

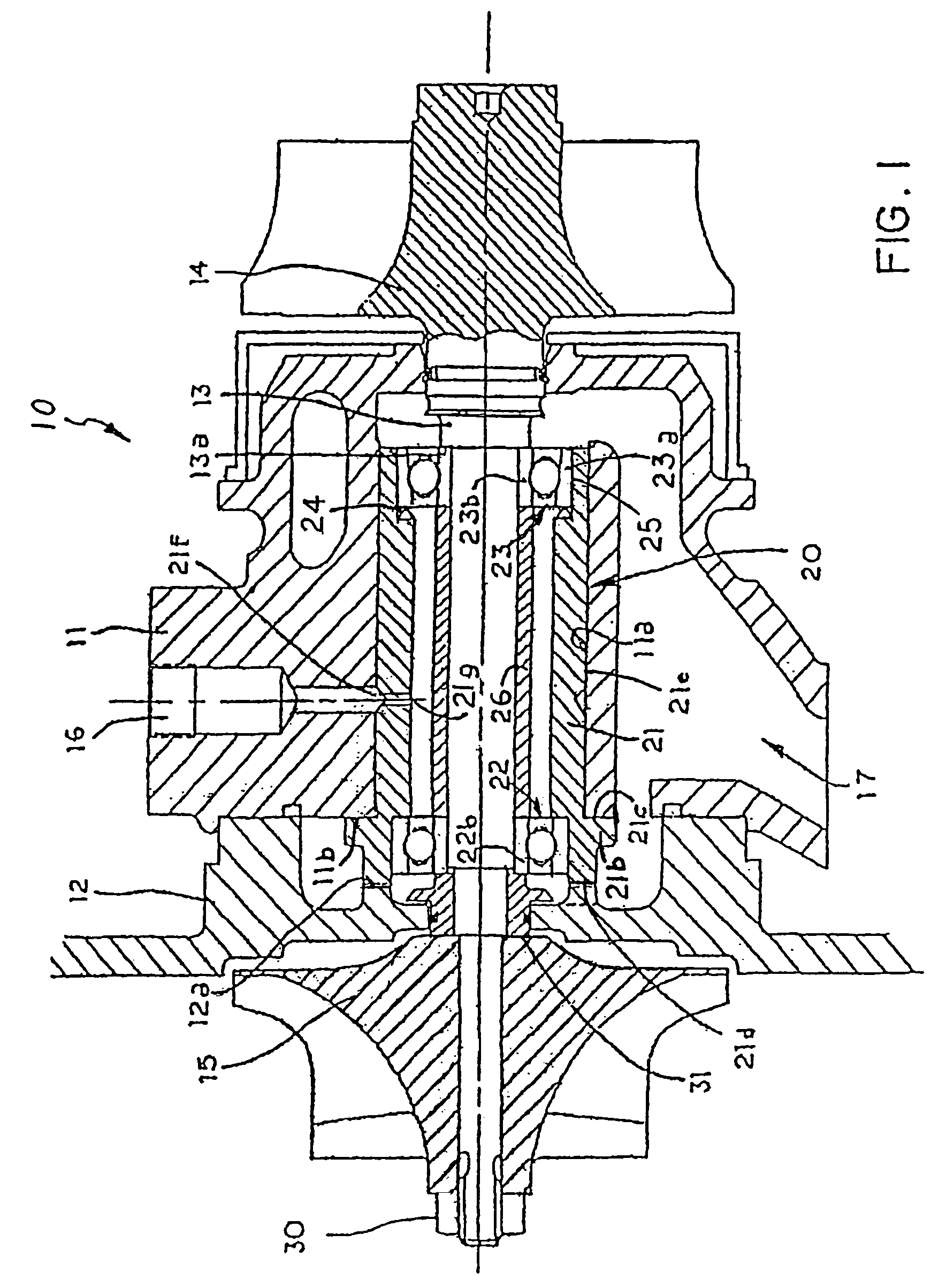

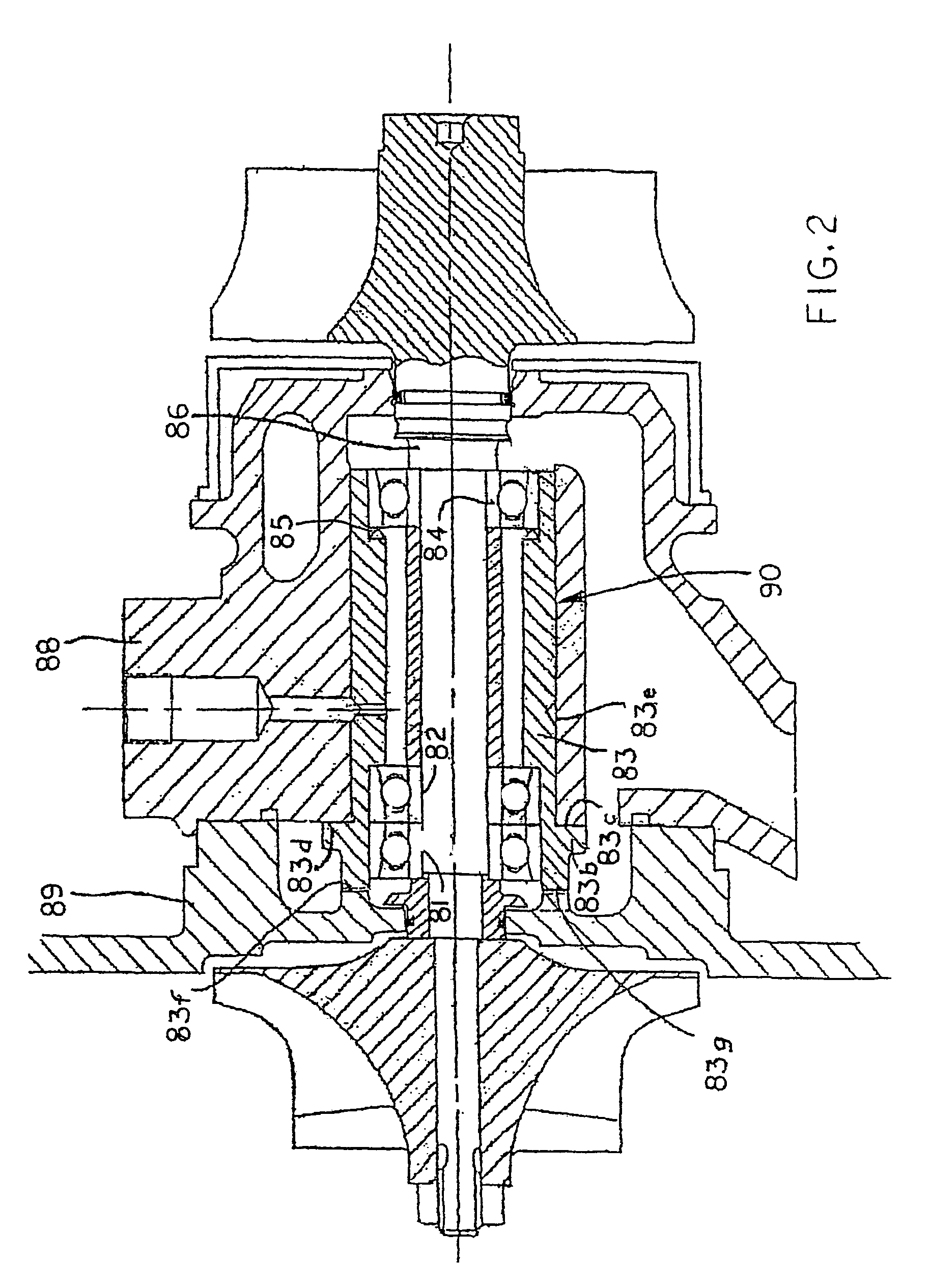

Bearing systems for high-speed rotating machinery

InactiveUS20080087018A1Improve performanceMaintain integrityRolling contact bearingsShaftsBall bearingTurbocharger

Bearing systems for high speed rotating shafts, such as turbocharger shafts, include a first ball bearing in one end of an elongated cylinder capable of carrying axial thrust in both directions and a second ball bearing in the opposite end of the elongated cylinder with its outer race slideably mounted in the cylinder against the biasing force of a preload spring. The second ball bearing is free to move axial with the shaft upon axially expansion of the shaft when exposed to high temperature. The inner races of the ball bearings are clamped to and rotate with the shaft as part of the rotating assembly.

Owner:DELGADO LAUREN N

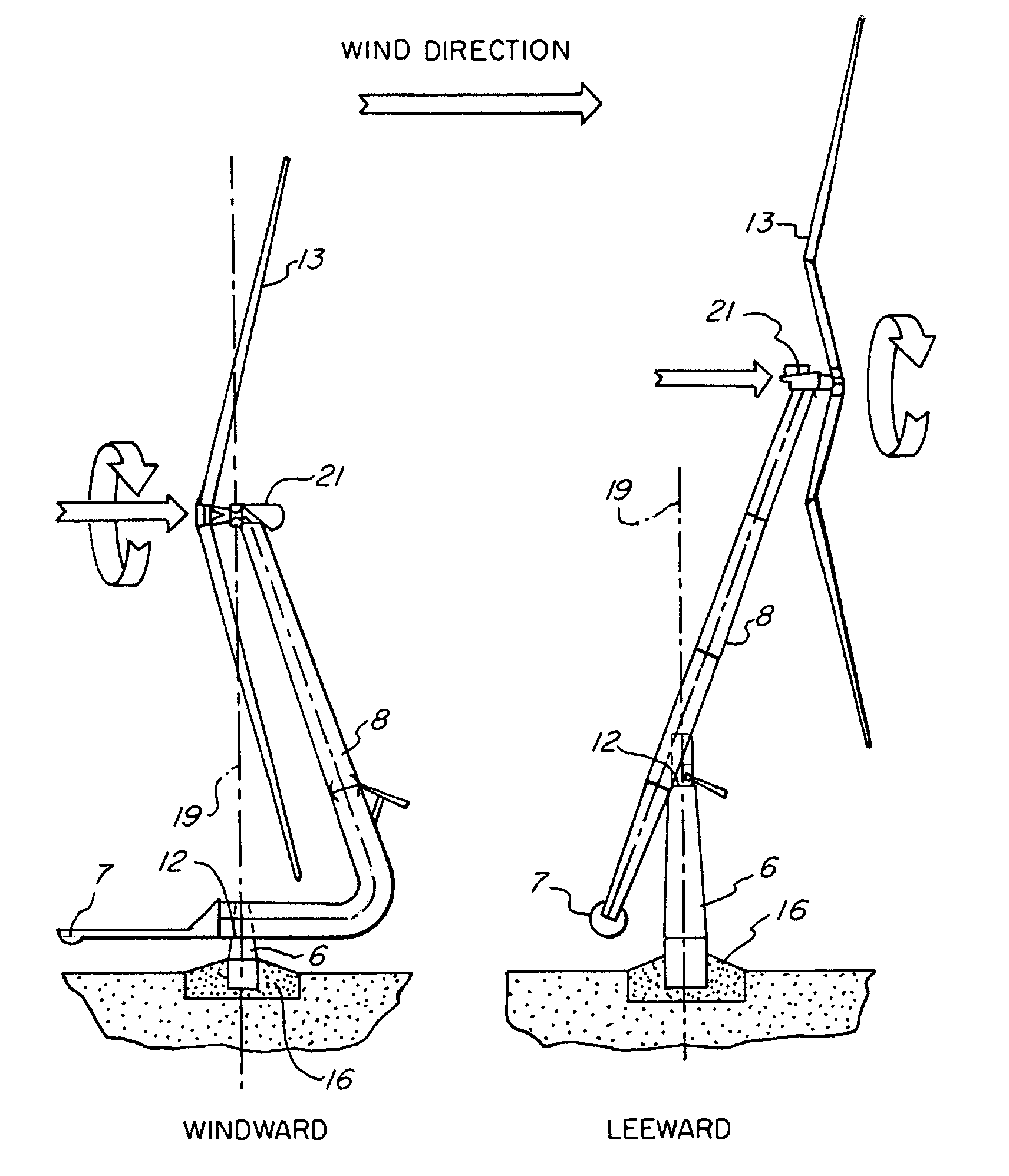

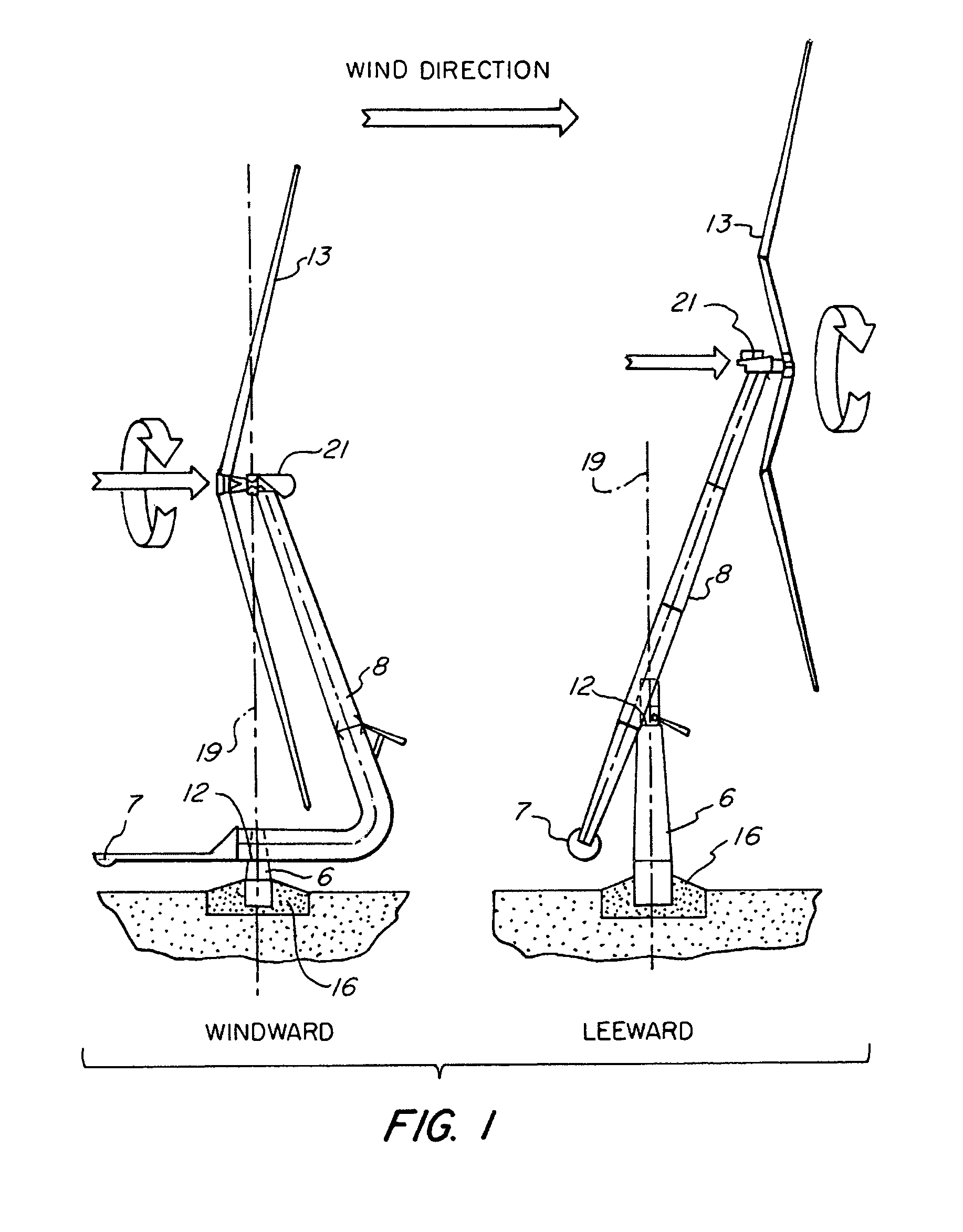

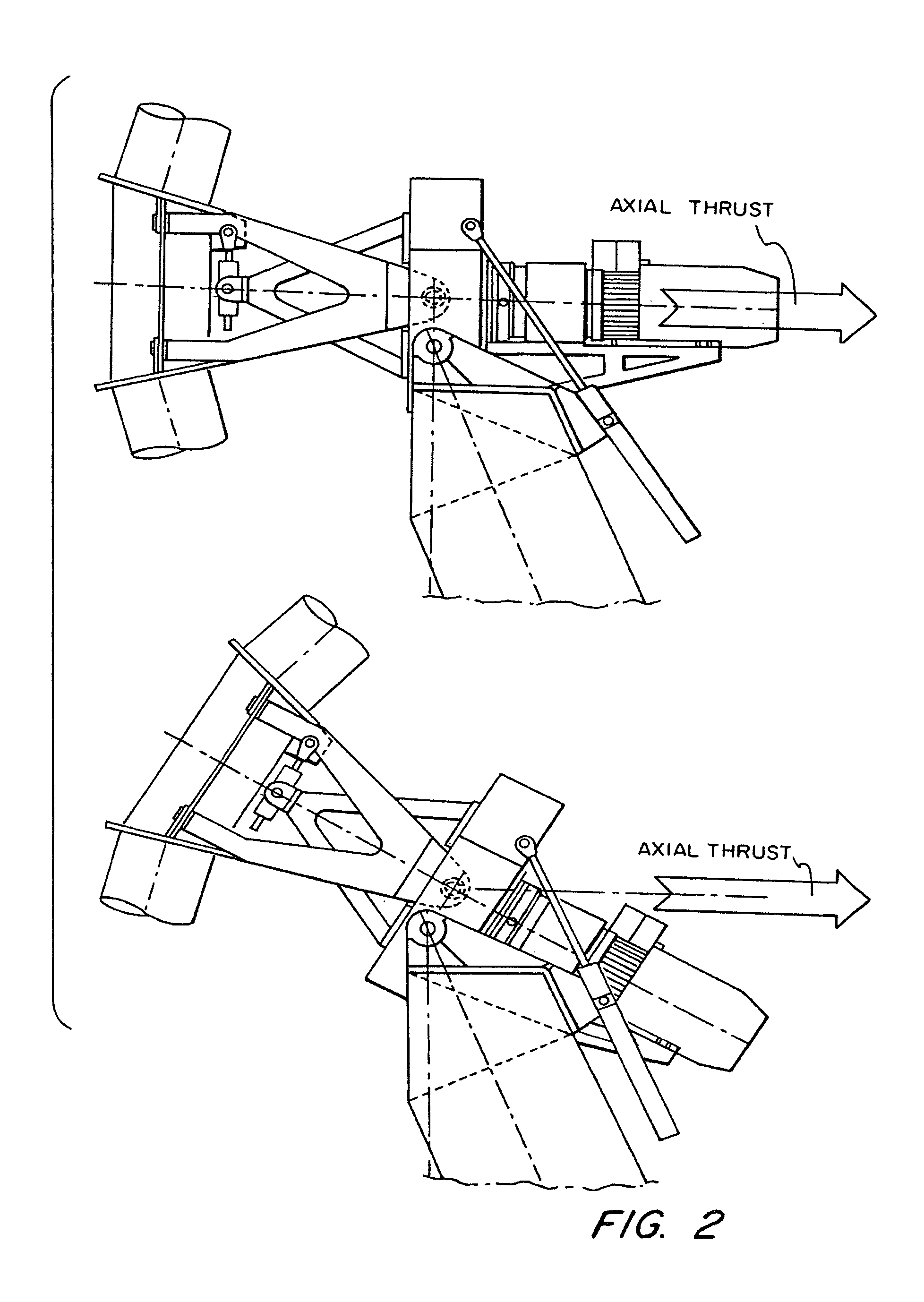

Self-guiding wind turbine

A self-guiding wind turbine made of two reinforced parallel girders whose side center of thrust is displaced from the column axis where it is supported and turns. Its dihedral-shaped two-bladed rotor is self-stabilizing since its center of thrust is behind its center of gravity and the guiding axis of the turbine, thus improving self-guiding whilst in motion. The axial thrust is controlled, whilst the head and rotor are tilting, hydraulically by counter-pressure, ensuring they do not surpass the power collected and the moments on the structure, shoe and ground. The self-guiding structure can tilt hydraulically lowering its head and rotor and facilitating its assembly and maintenance, and can remain “asleep” when not in use, thus reducing the visual impact on the environment. This turbine makes use of the force of the wind to control itself, simplifying the manufacture of large turbines connected to the network or in isolated applications.

Owner:ANTOUNE IVAN LAHUERTA

Method and device for reducing axial thrust in rotary machines and a centrifugal pump using same

InactiveUS6129507AReducing axial thrustReduce and even eliminate effectPump componentsReaction enginesRotation velocityAxial thrust

A method and device for reducing or eliminating axial thrust in a rotary machine such as a centrifugal pump or compressor by altering the fluid pressure in a cavity formed between a rotor and a housing. The device contains a disk placed along the rotor for subdividing the fluid in the cavity in such a way that all annular gap leakage flow is channeled and pumped through the space between that disk and the rotor from the center of the pump towards the periphery. As a result, the pressure in the cavity is altered to reduce and control the axial thrust on the rotor which becomes independent of the wear state of the shaft seals. In another embodiment, the step of flow subdividing is achieved by providing a set of braking vanes along the periphery of the cavity for reducing the rotational speed of the fluid coming from the cavity as well as from the annular gap and a stationary disk placed along the interior wall of the housing for directing the radial flow of that fluid towards the center of the pump.

Owner:TECH COMMLIZATION

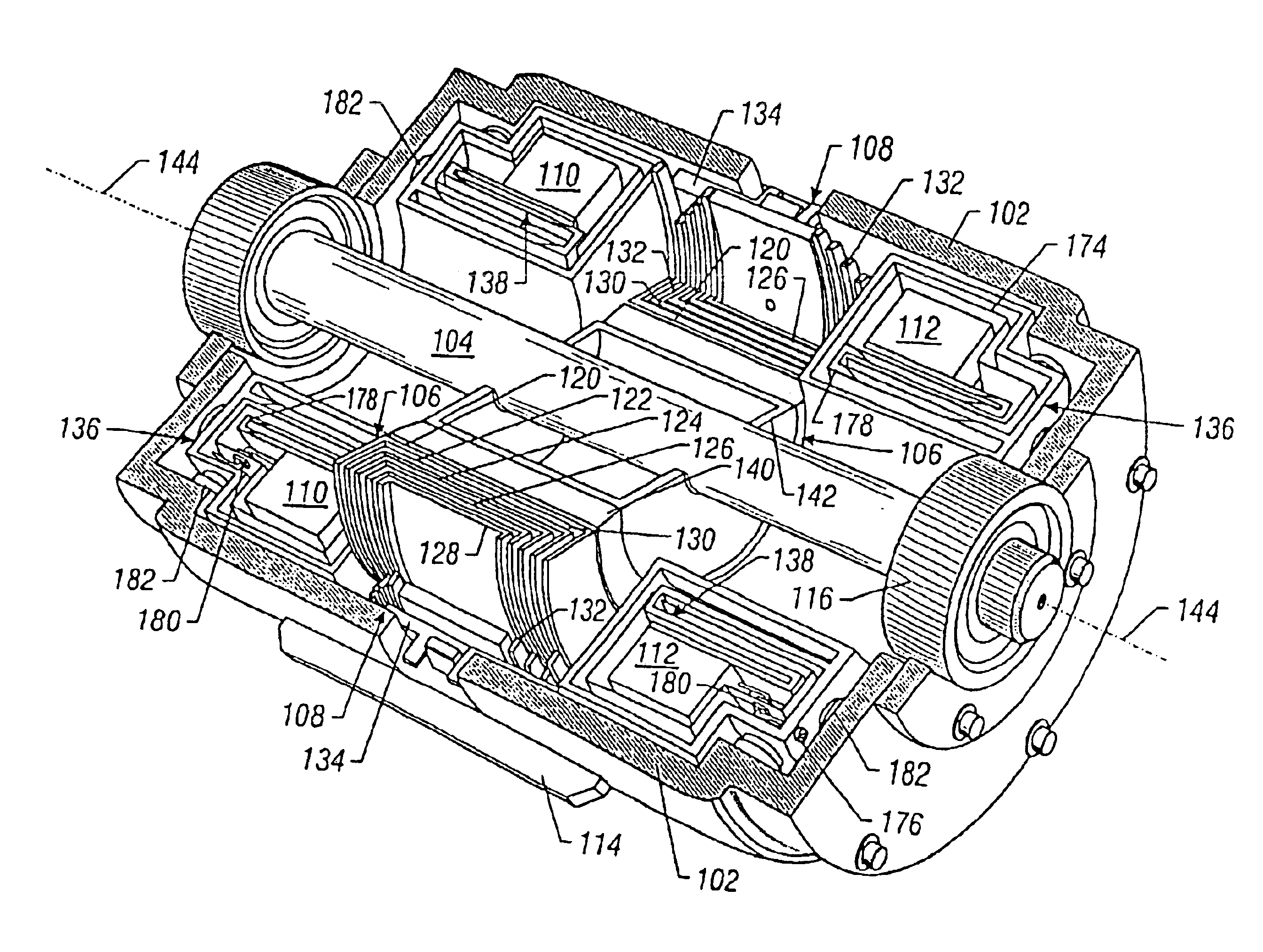

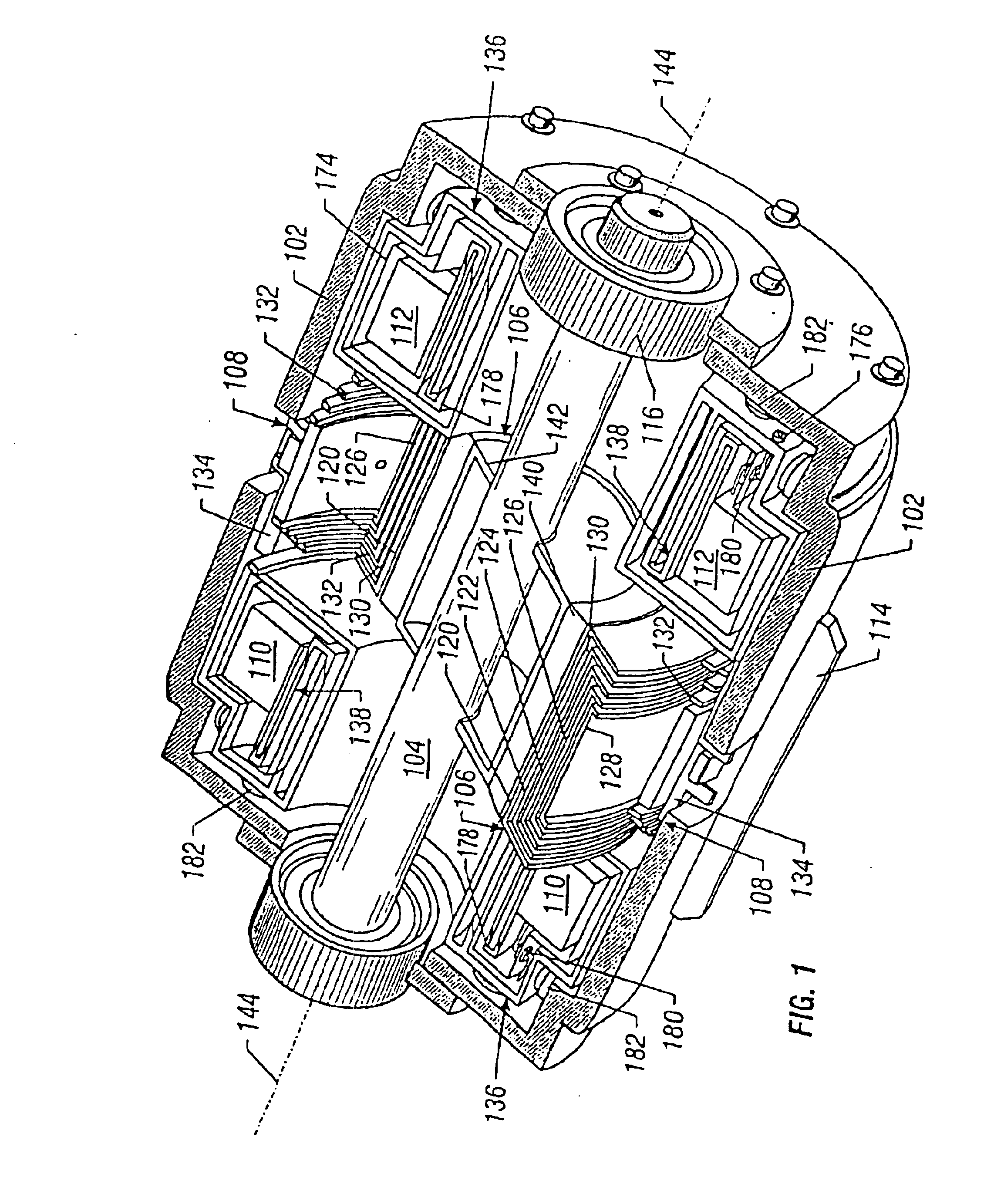

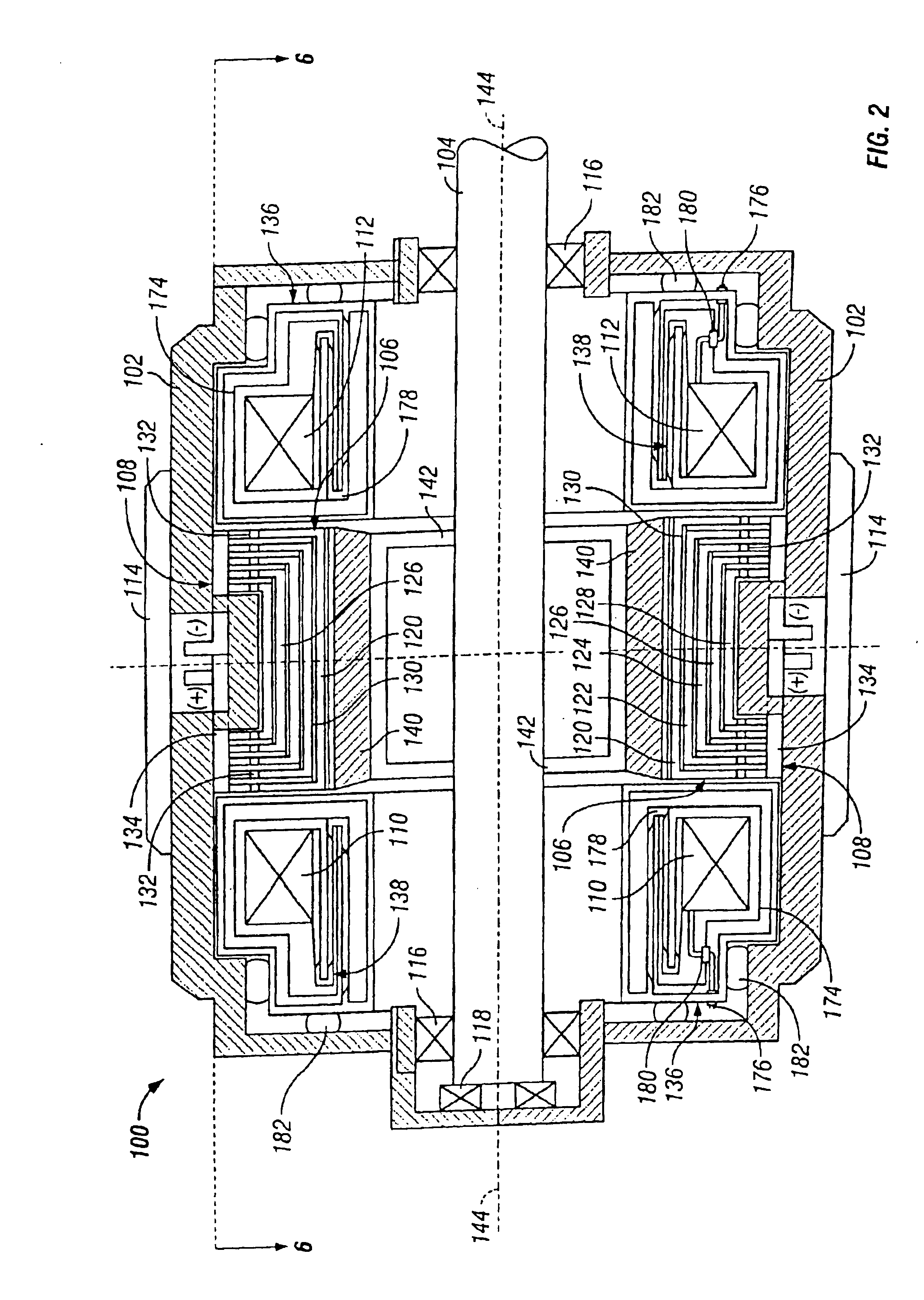

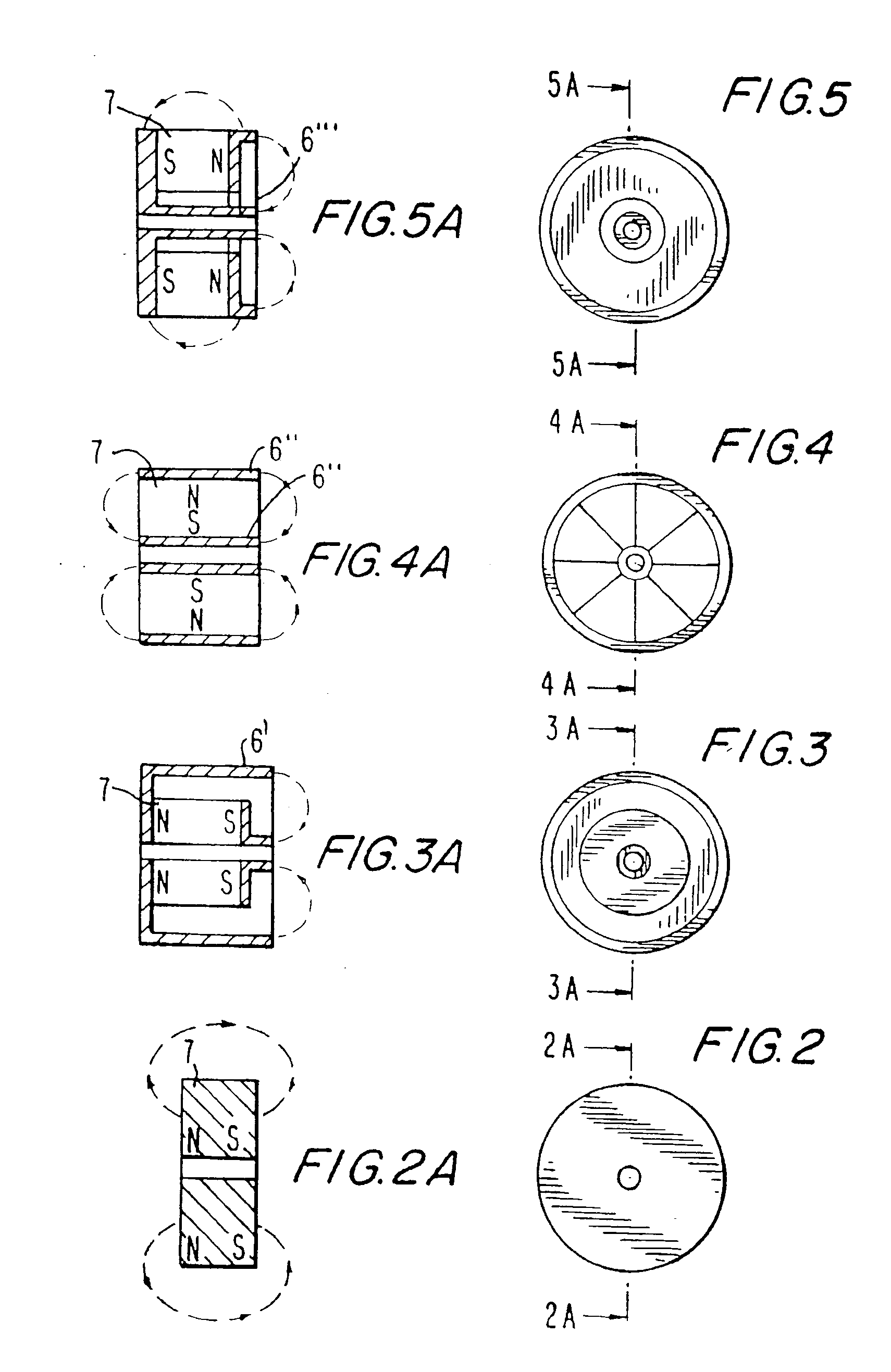

Homopolar machine with shaft axial thrust compensation for reduced thrust bearing wear and noise

InactiveUS6856062B2Reduce induced magnetic forceConstant contact pressureRotary current collectorMagnetic bodiesFiberContact pressure

A homopolar machine produces an axial counter force on the rotating shaft to compensate for the load on the shaft's thrust bearing to reduce wear and noise and prolong bearing life. The counter force is produced through magnetic interaction between the shaft and the machine's field coils and is created by changing the current excitation of the field coils, which results in a magnetic flux asymmetry in an inner flux return coupled to the shaft. The homopolar machine may also have a configuration that uses current collectors that maintain substantially constant contact pressure in the presence of high magnetic fields to improve current collector performance. The current collectors are flexible and may be made from either electrically conductive fibers or stacked strips such that they bear up against the armature so that the pressure is maintained by the spring constant of the current collector material. The homopolar machine may also have a configuration where the brushes are oriented so that the current is aligned as much as is practical with the local magnetic field lines so as to reduce the lateral electromagnetic forces on the brushes.

Owner:GENERAL ATOMICS

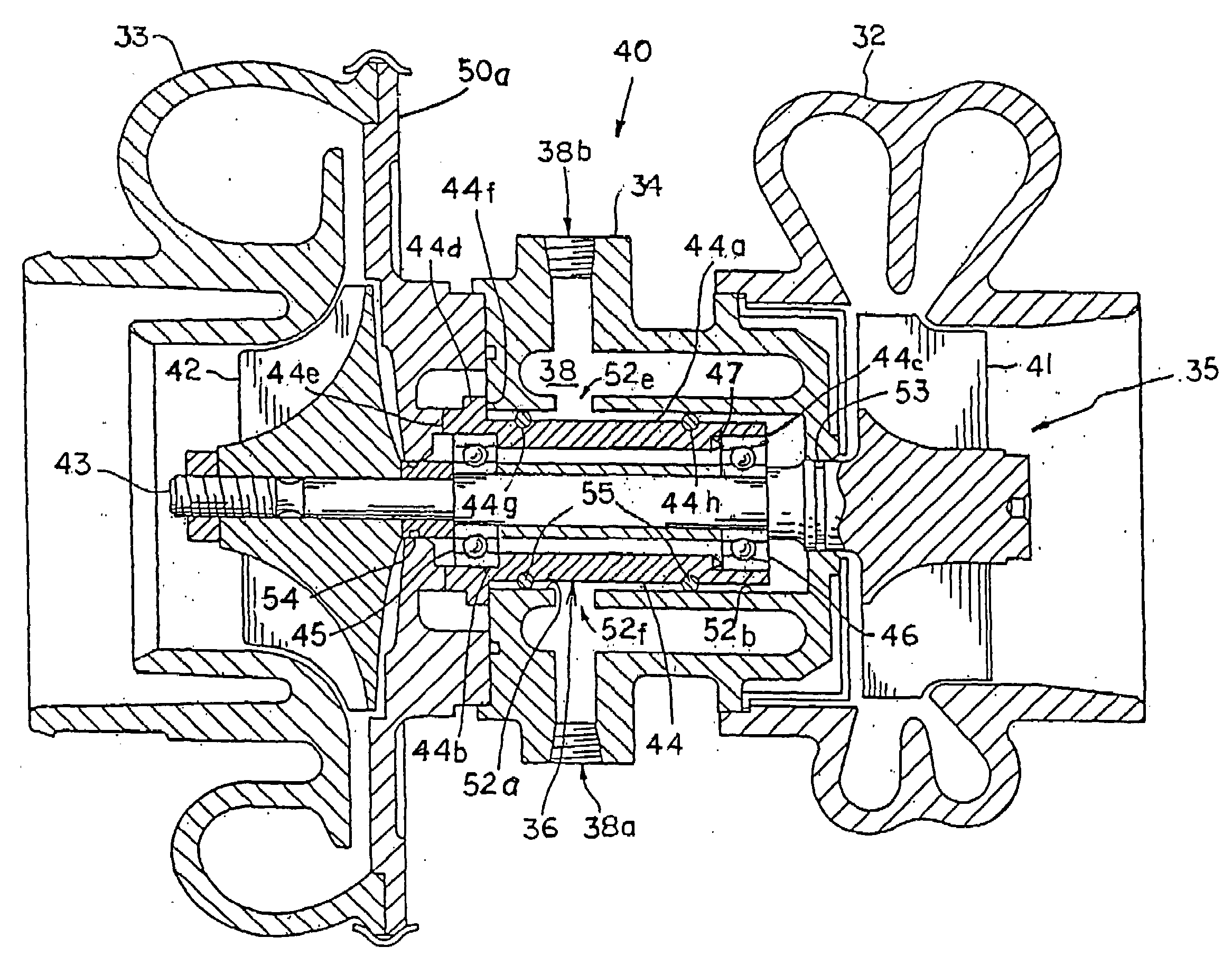

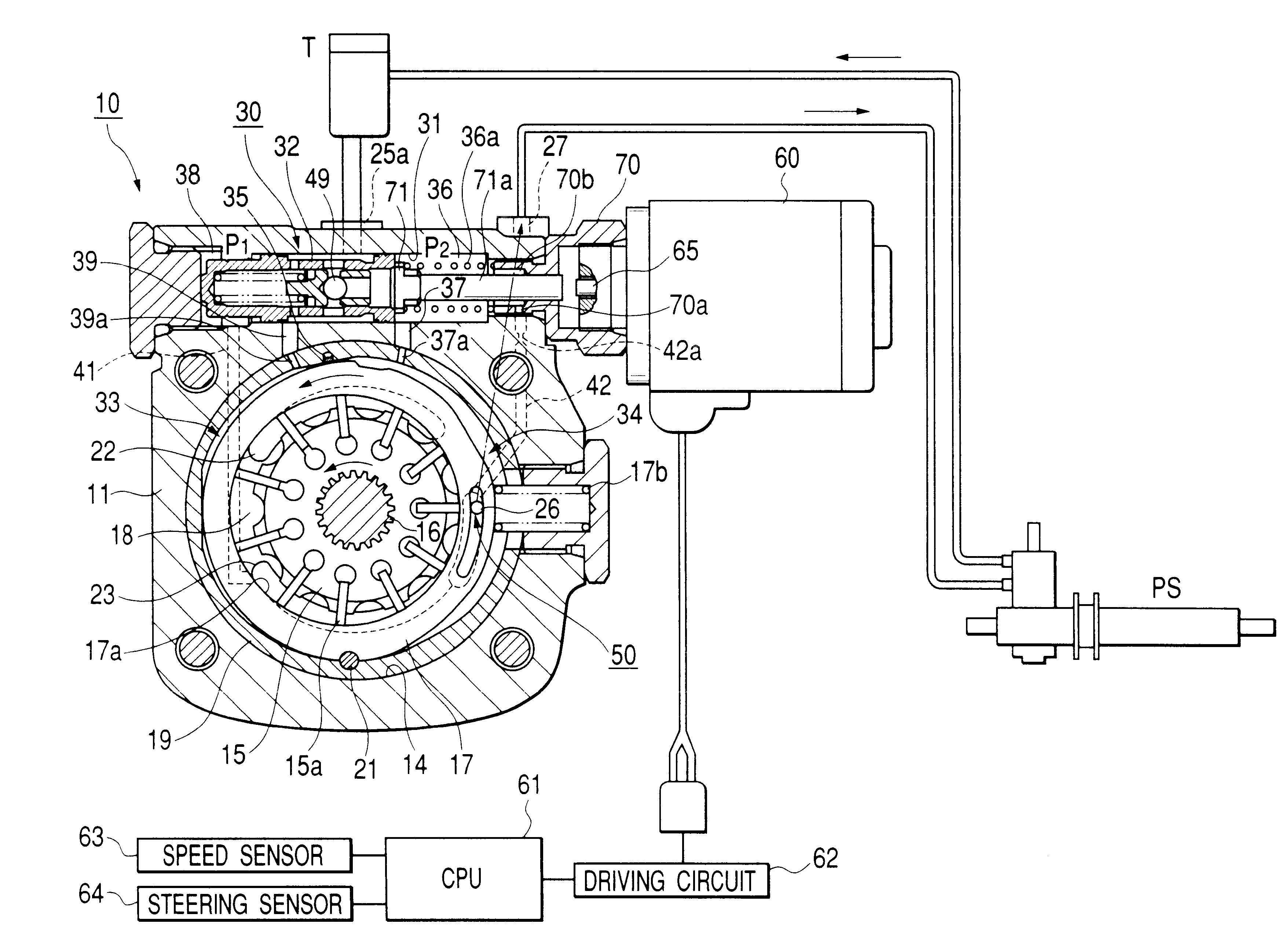

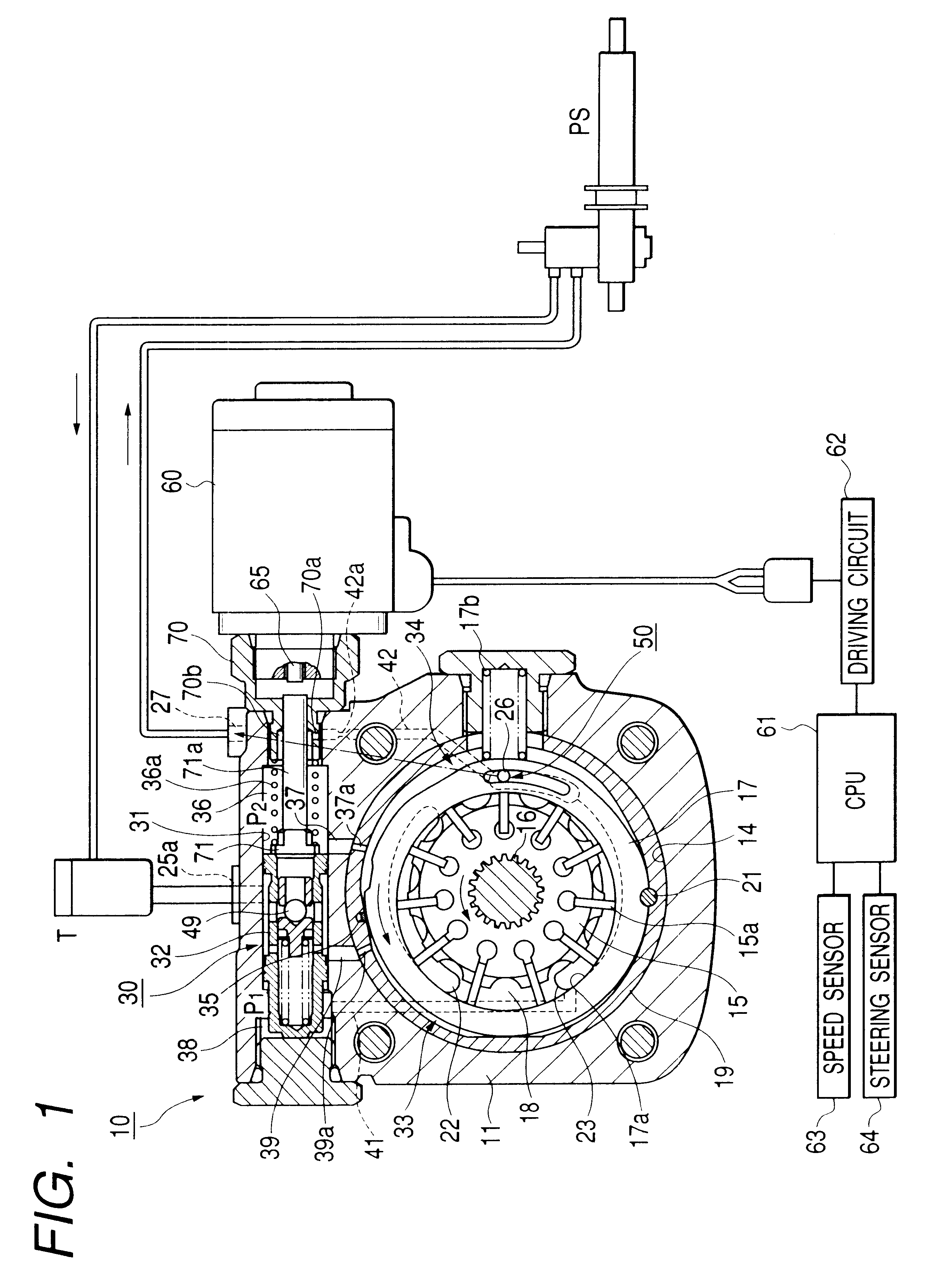

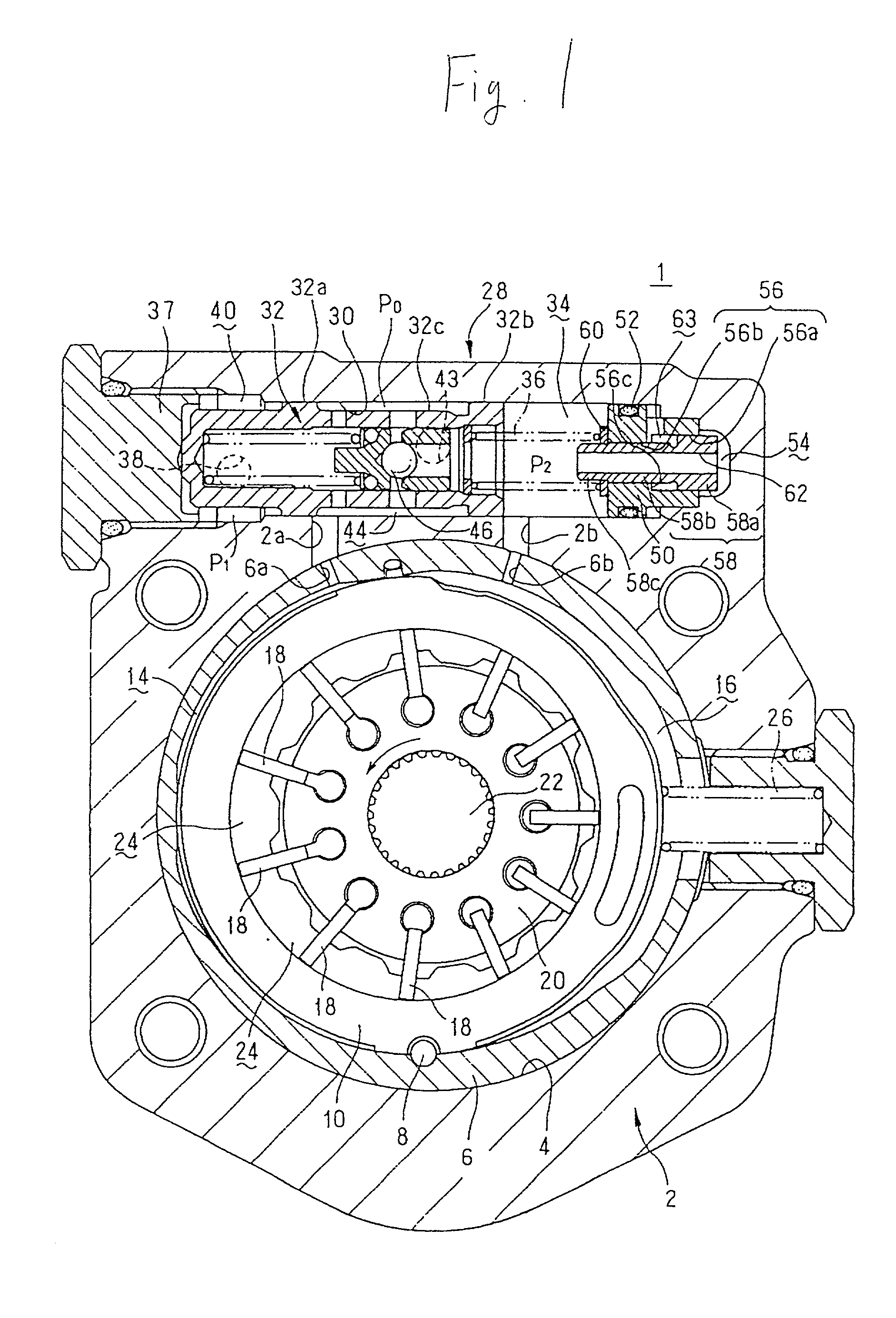

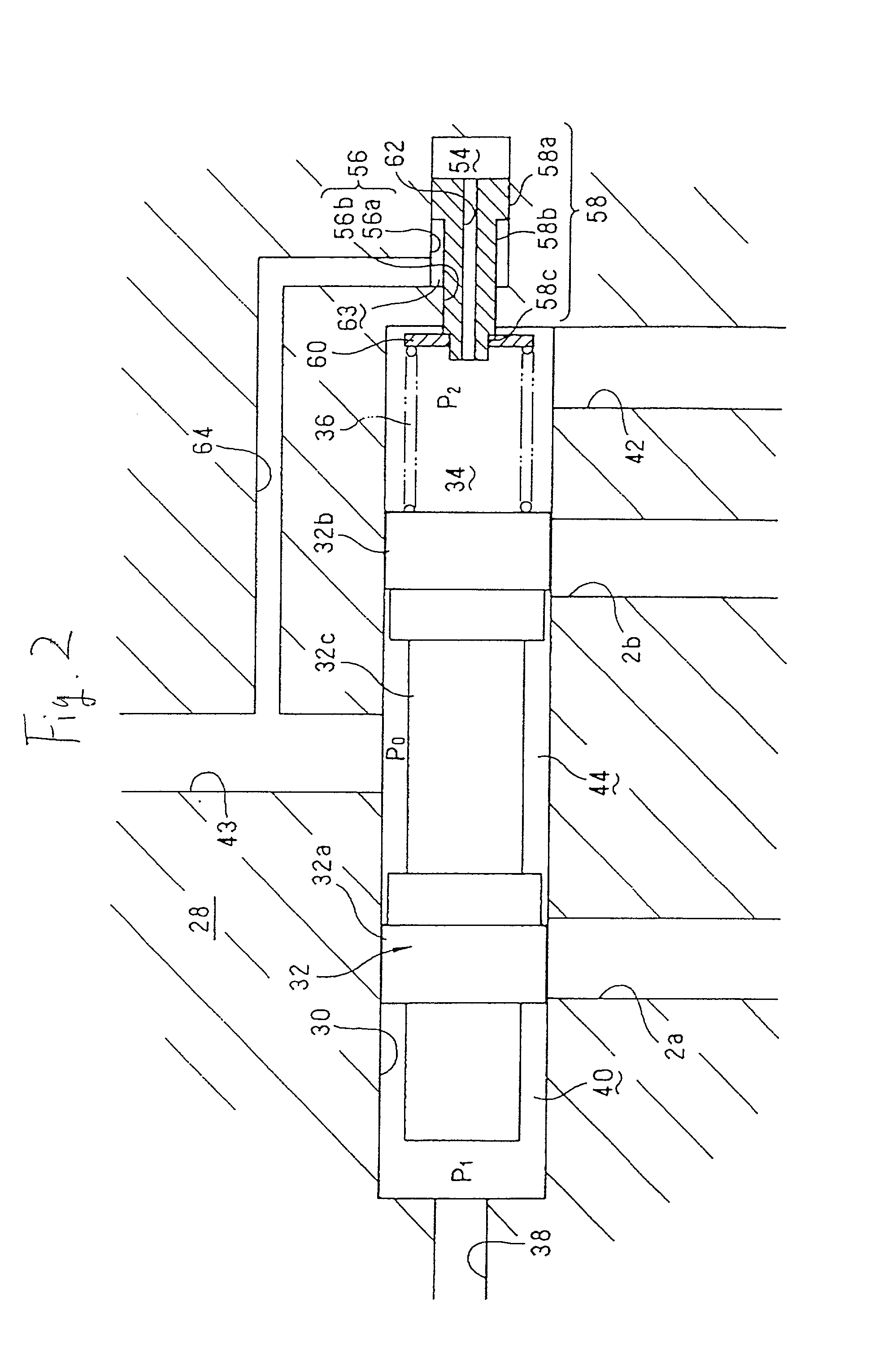

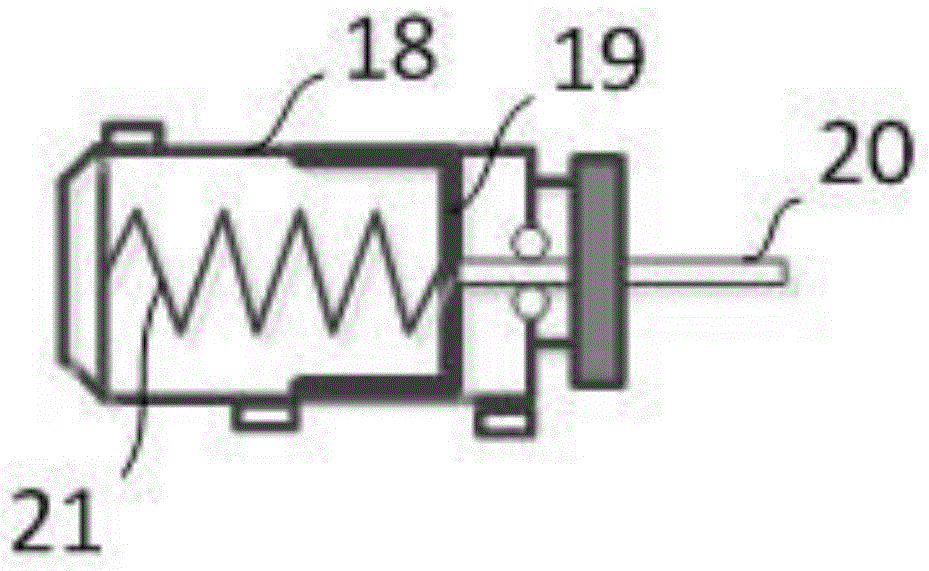

Variable displacement pump including a control valve

InactiveUS6524076B2Feel comfortableSaving effectSteering linkagesRotary piston pumpsPump chamberAxial thrust

A pump including a pump chamber 18, formed in a pump body 11, between a cam ring 17 and a rotor 15. The cam ring is formed so as to move in a direction whereby the pump capacity of the pump chamber increases and decreases. First and second fluid pressure chambers 33 and 34 are formed at opposite sides of the cam ring 17. The pump has a spool that is axially moved by a difference in fluid pressure between upper and lower stream sides of a metering throttle 50 connected to a discharge side passage 27 of the pump chamber. The spool is part of a control valve 30 that controls fluid pressure in at least the first fluid pressure chamber. An electronic driving unit, for example, a solenoid 60, applies axial thrust to the spool of the control valve.

Owner:HITACHI AUTOMOTIVE SYST STEERING

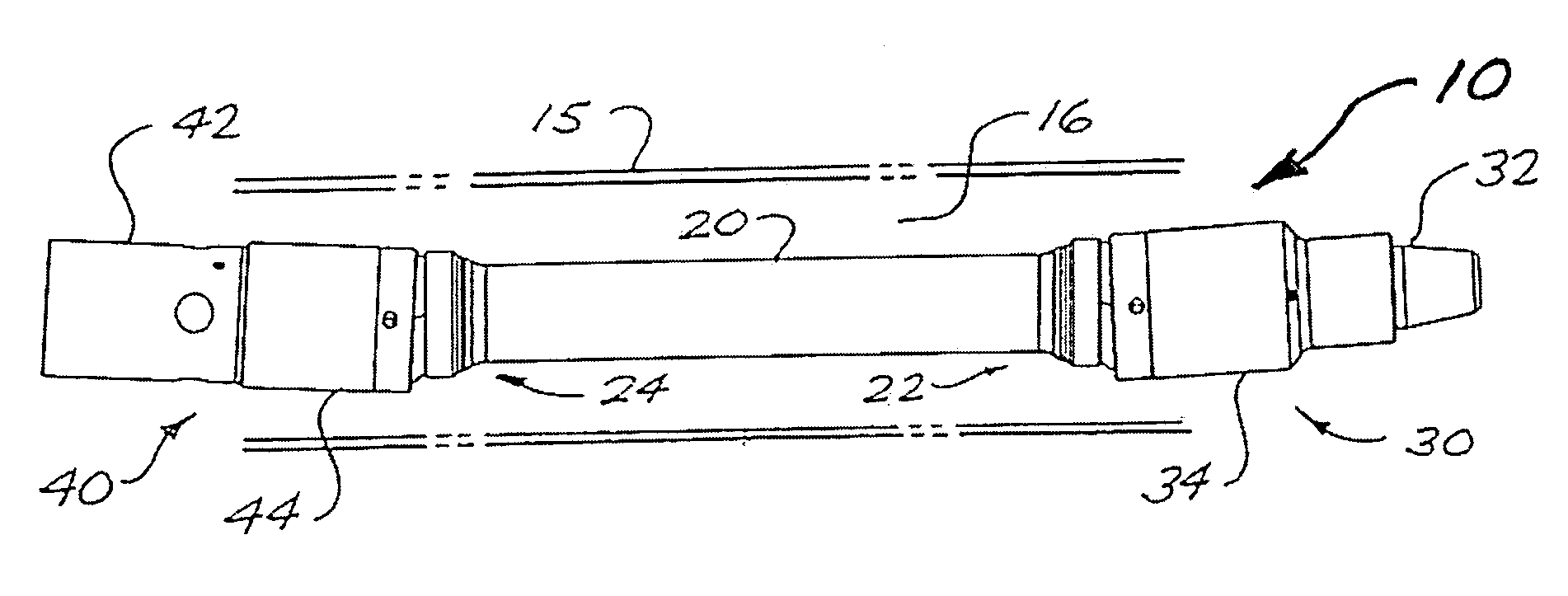

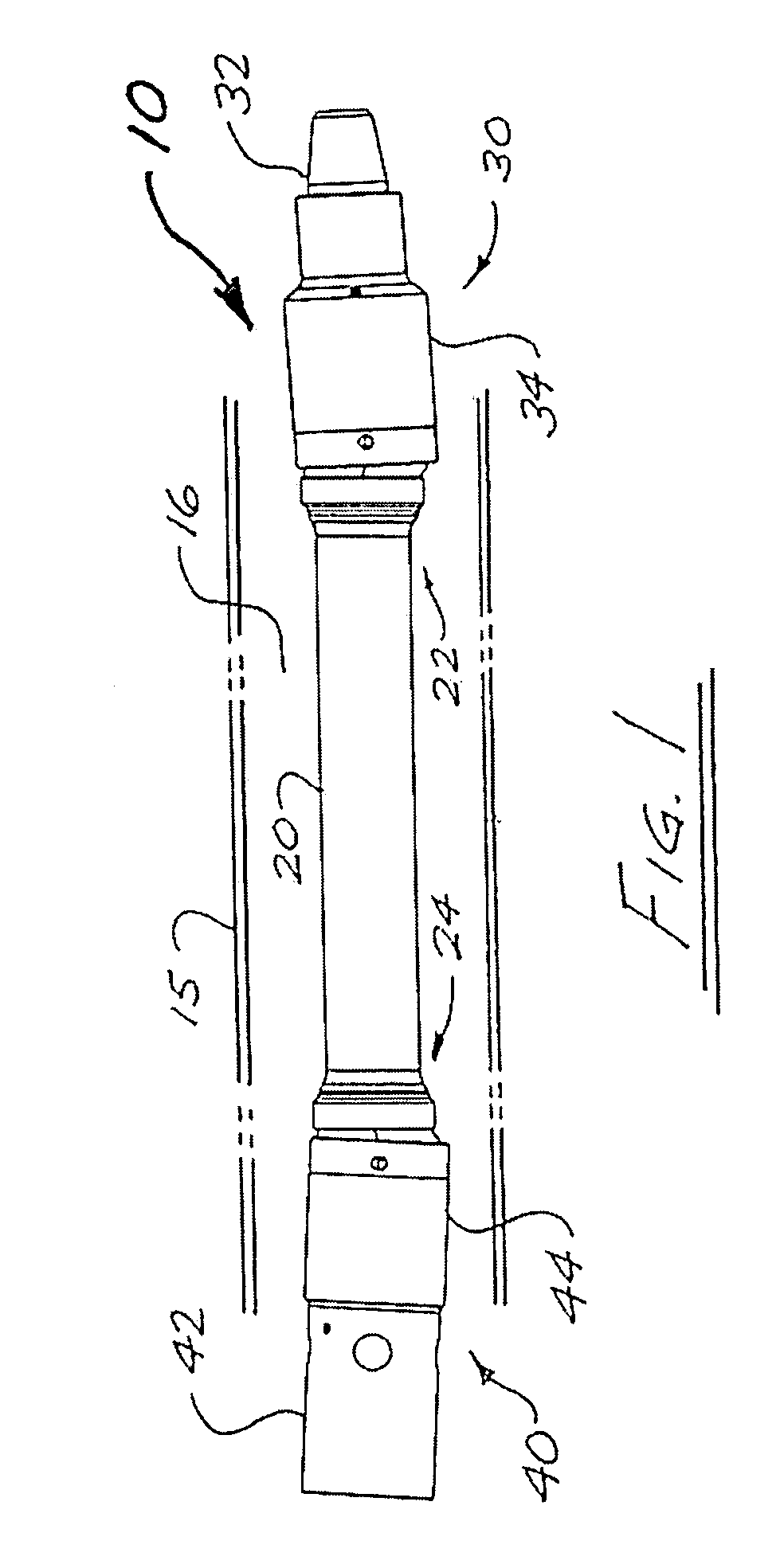

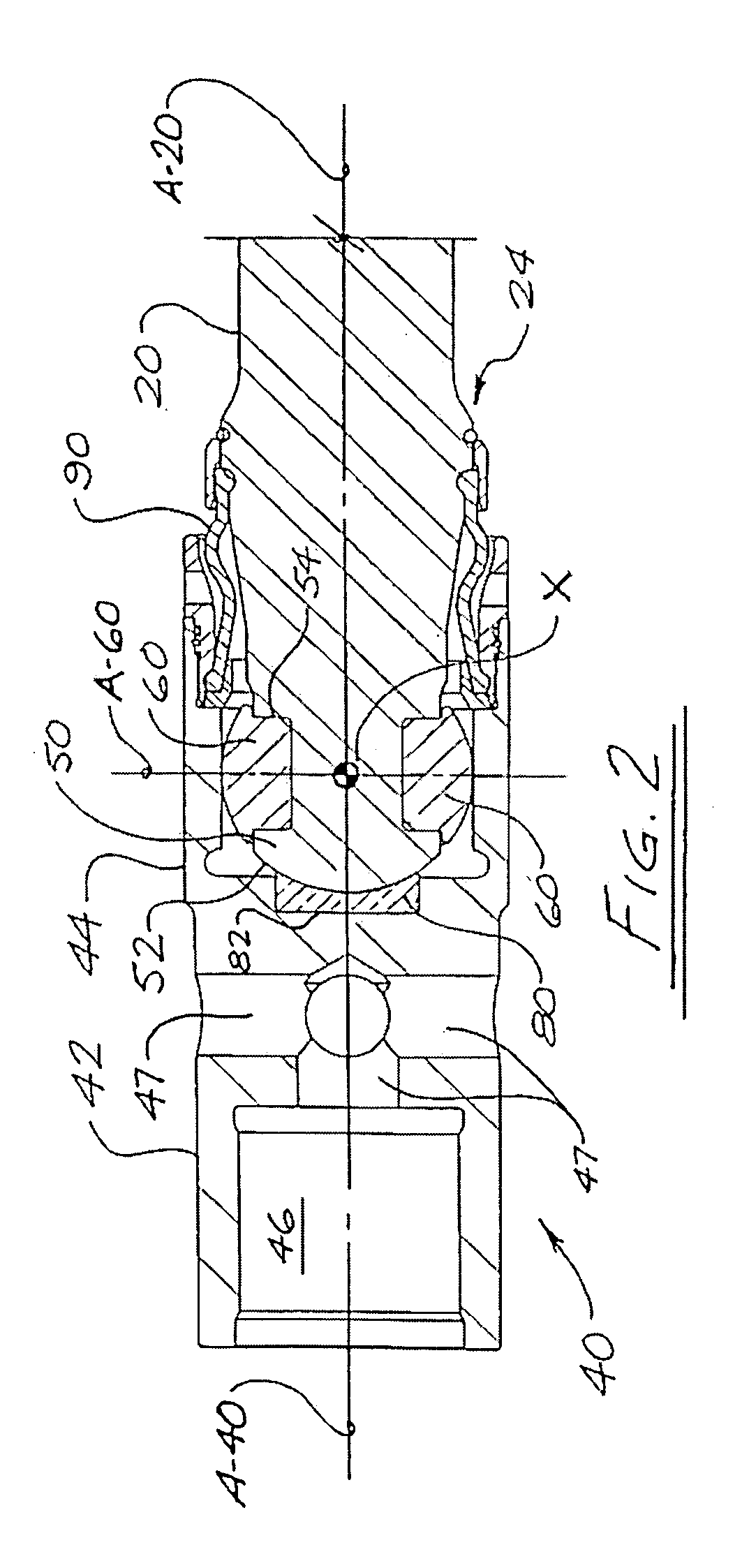

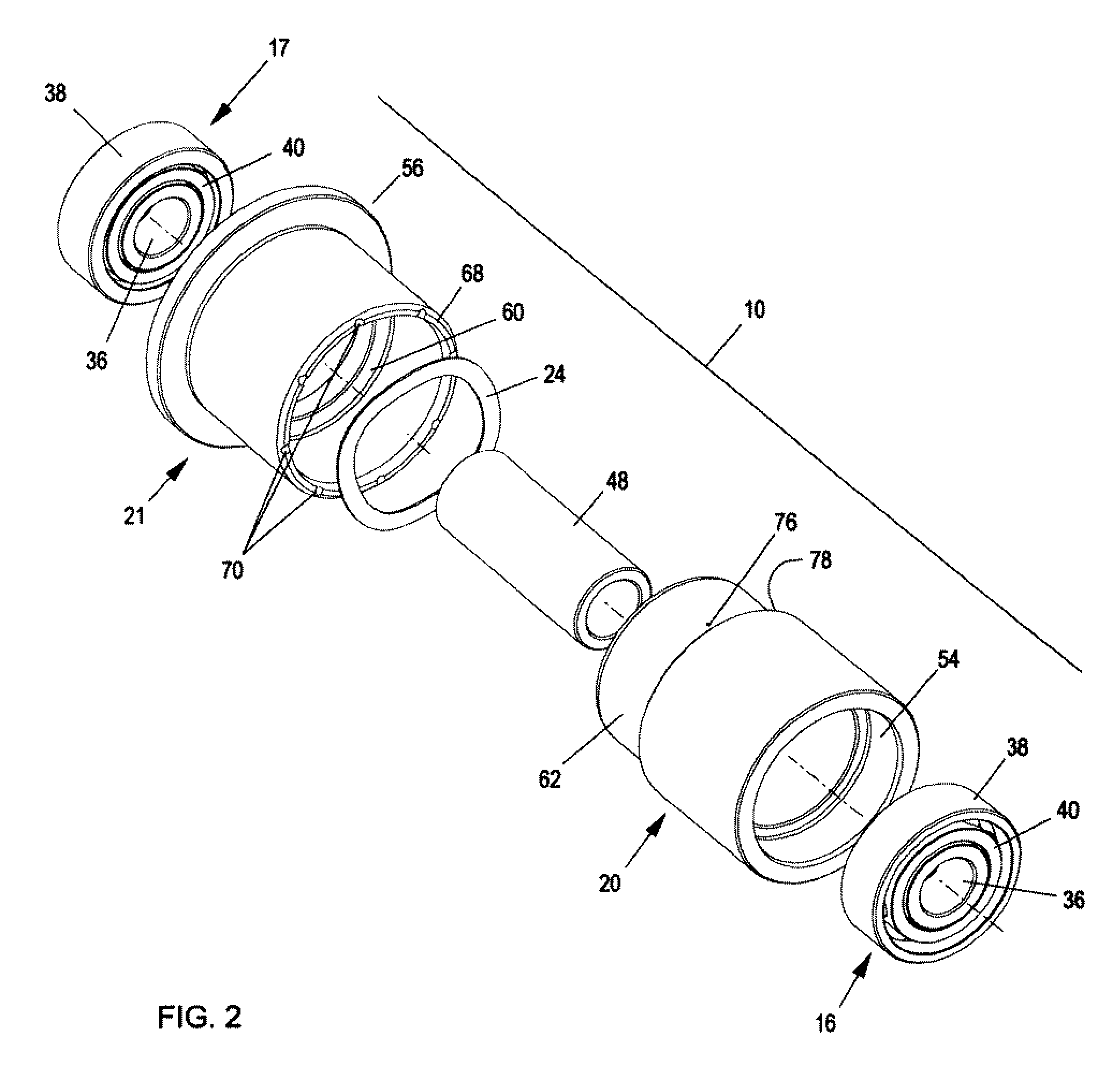

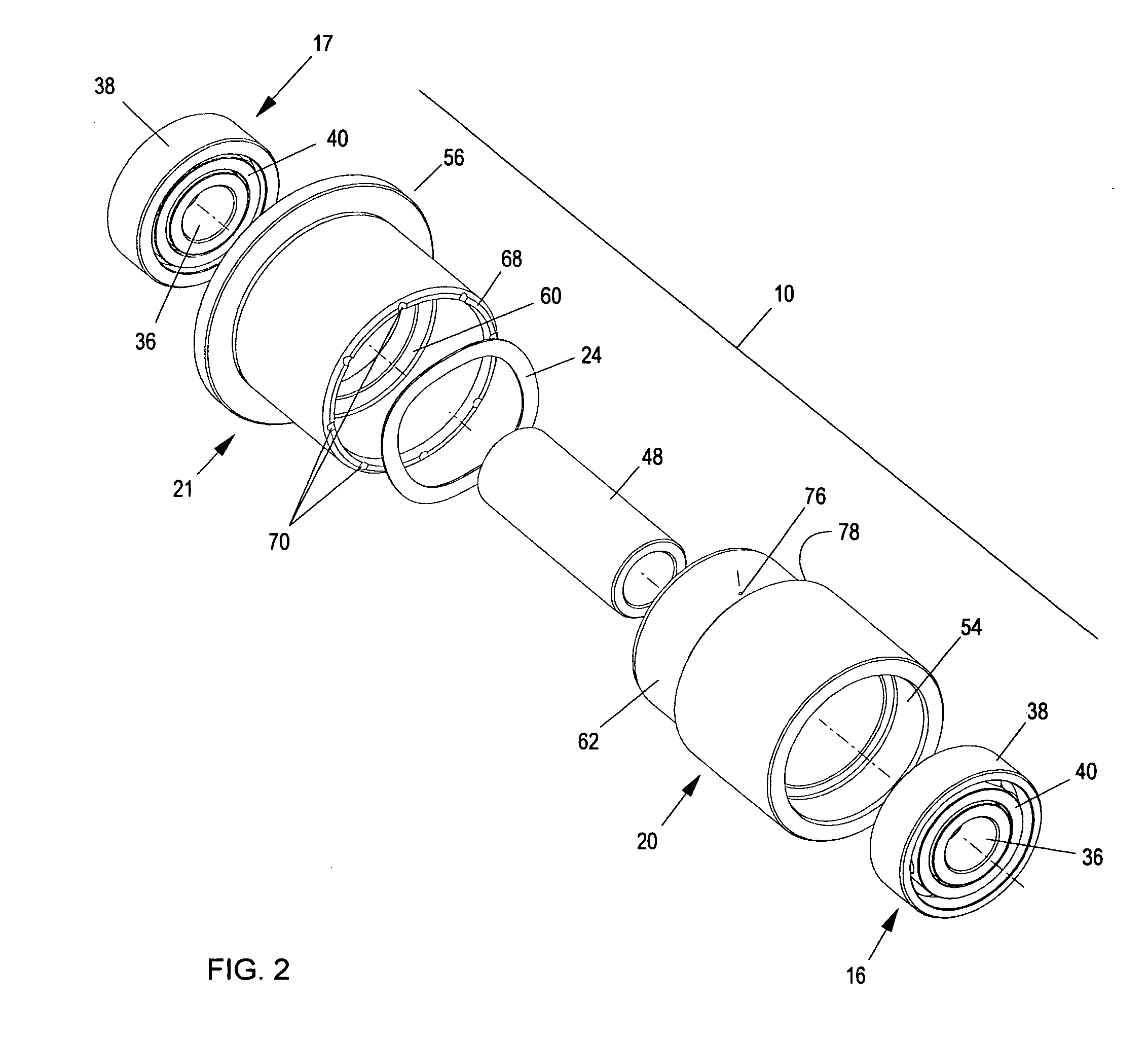

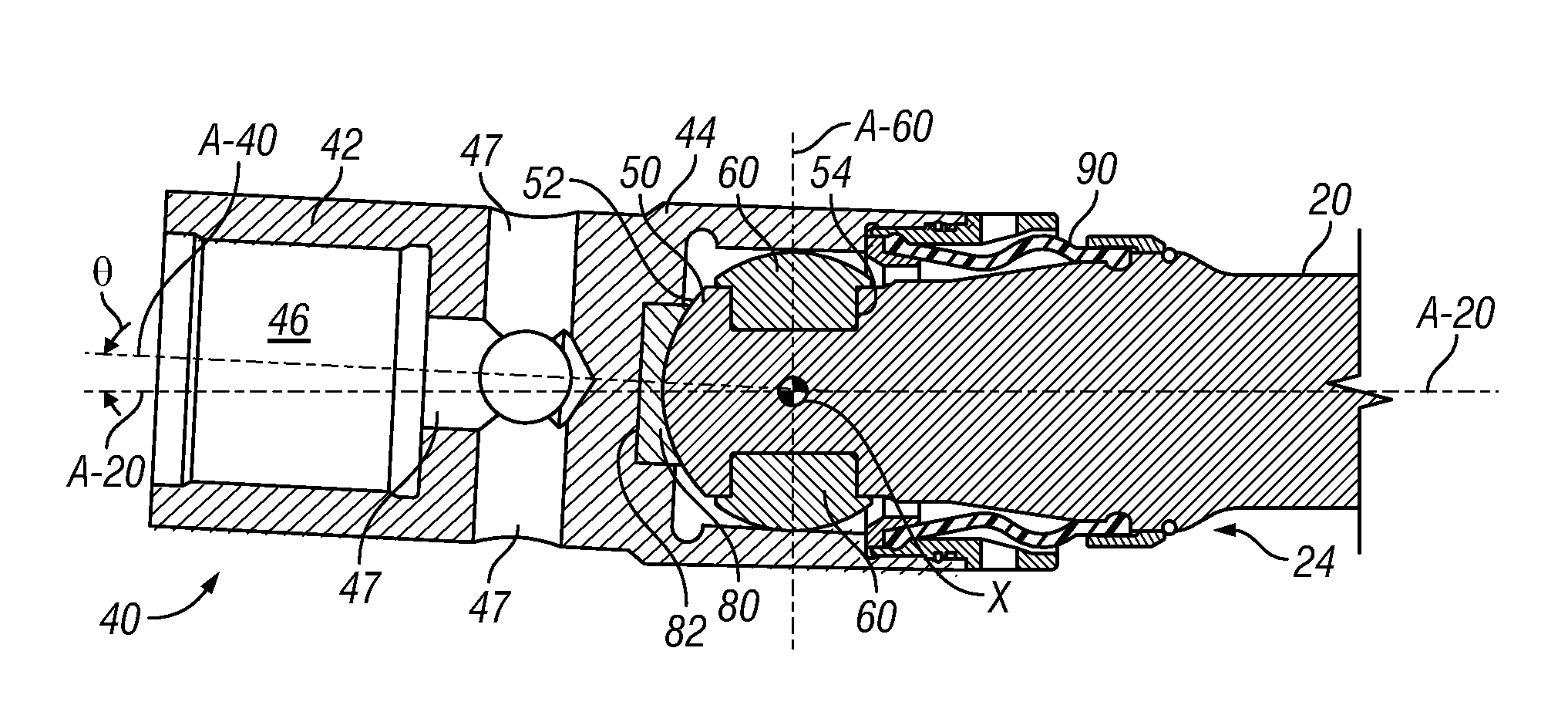

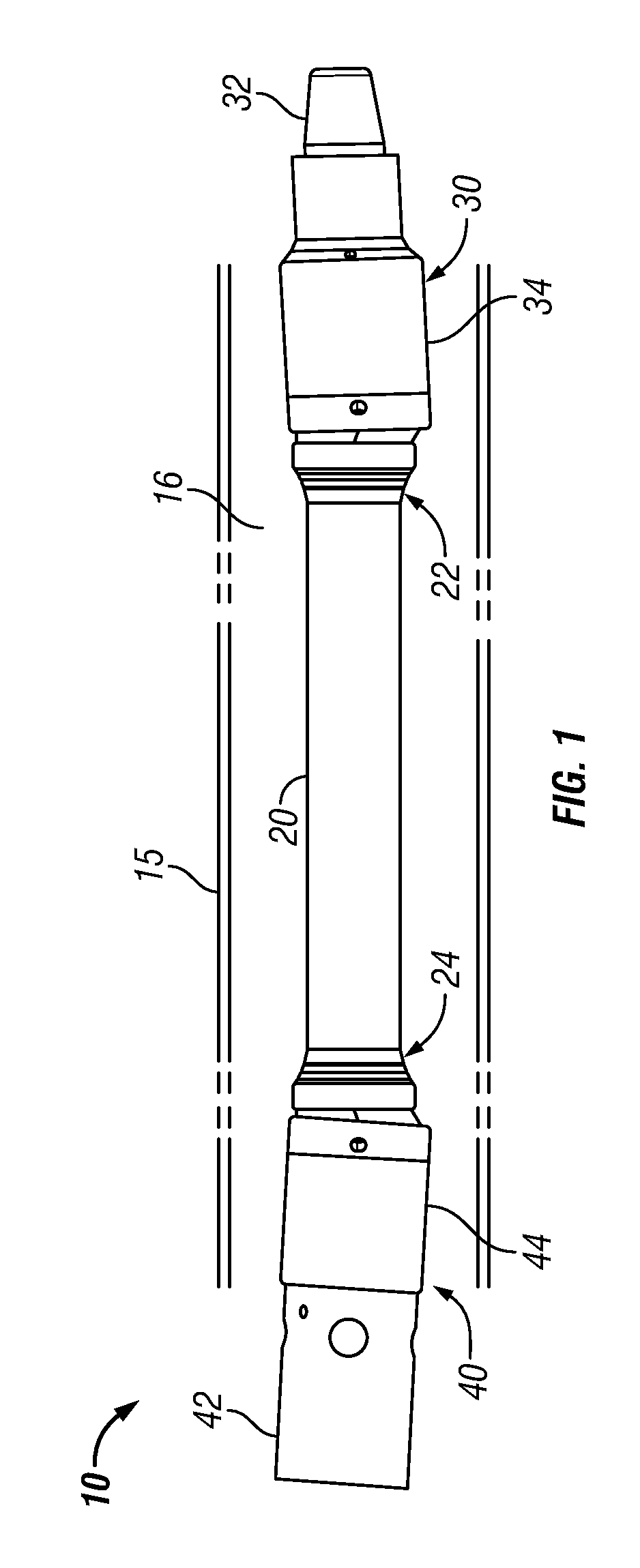

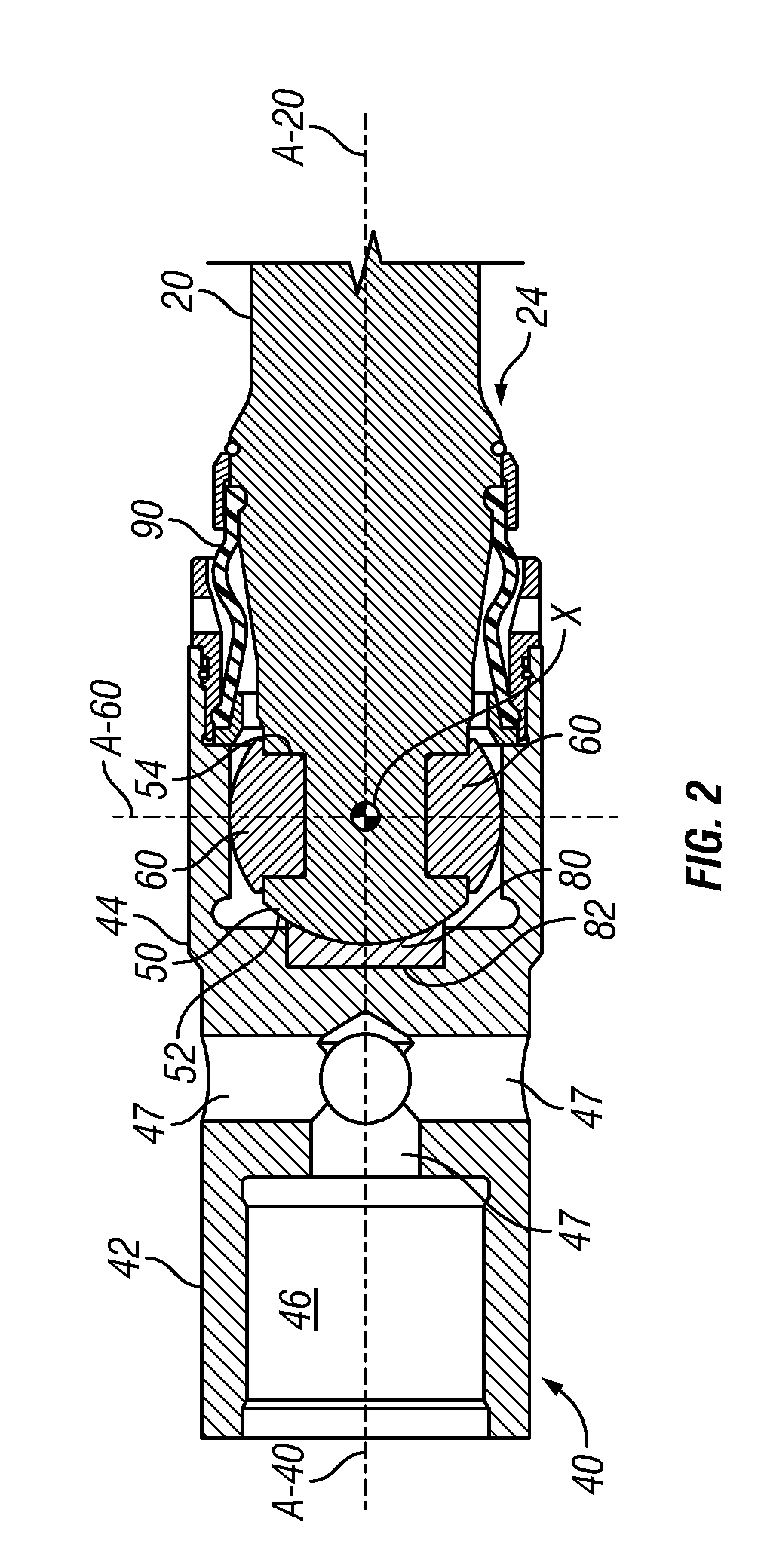

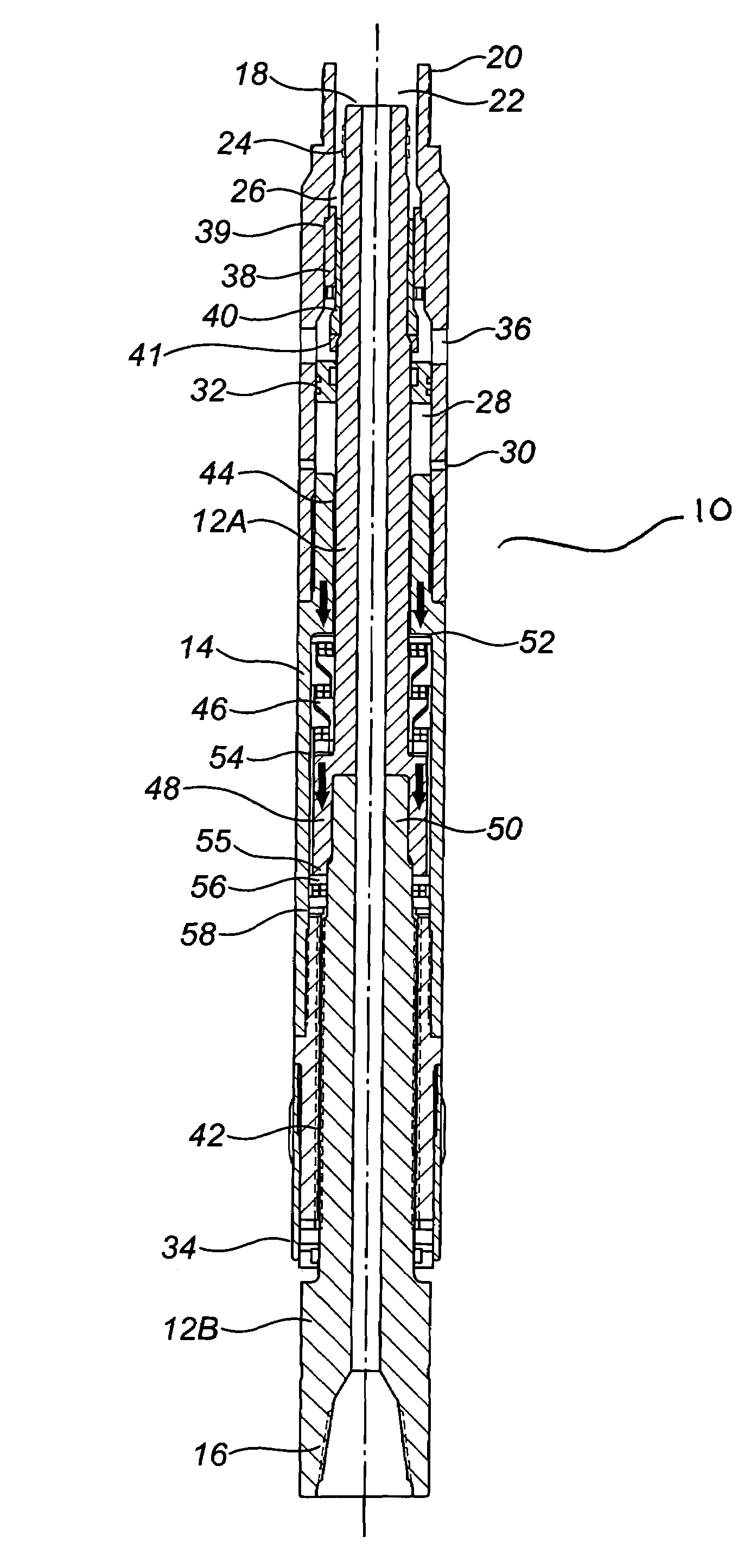

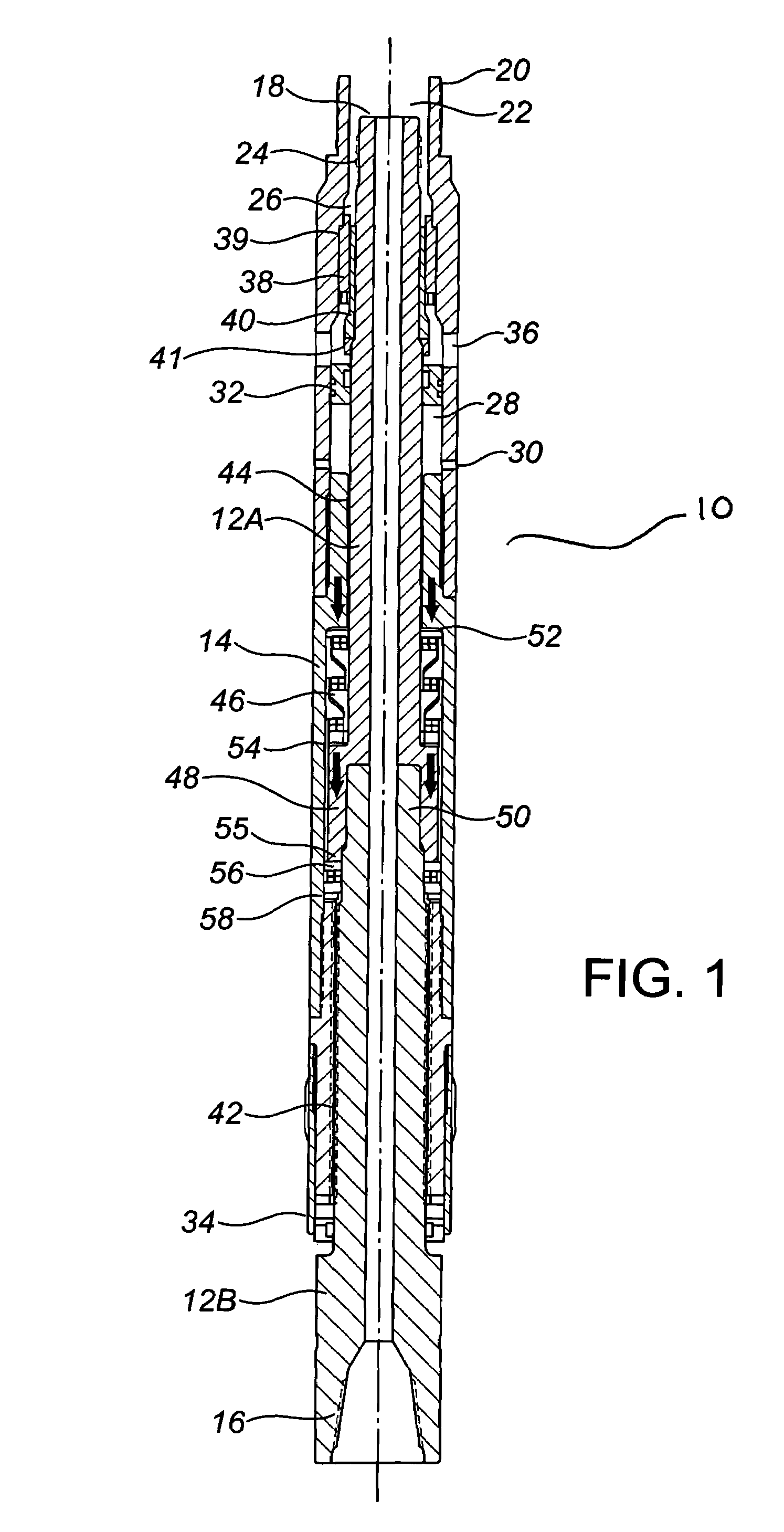

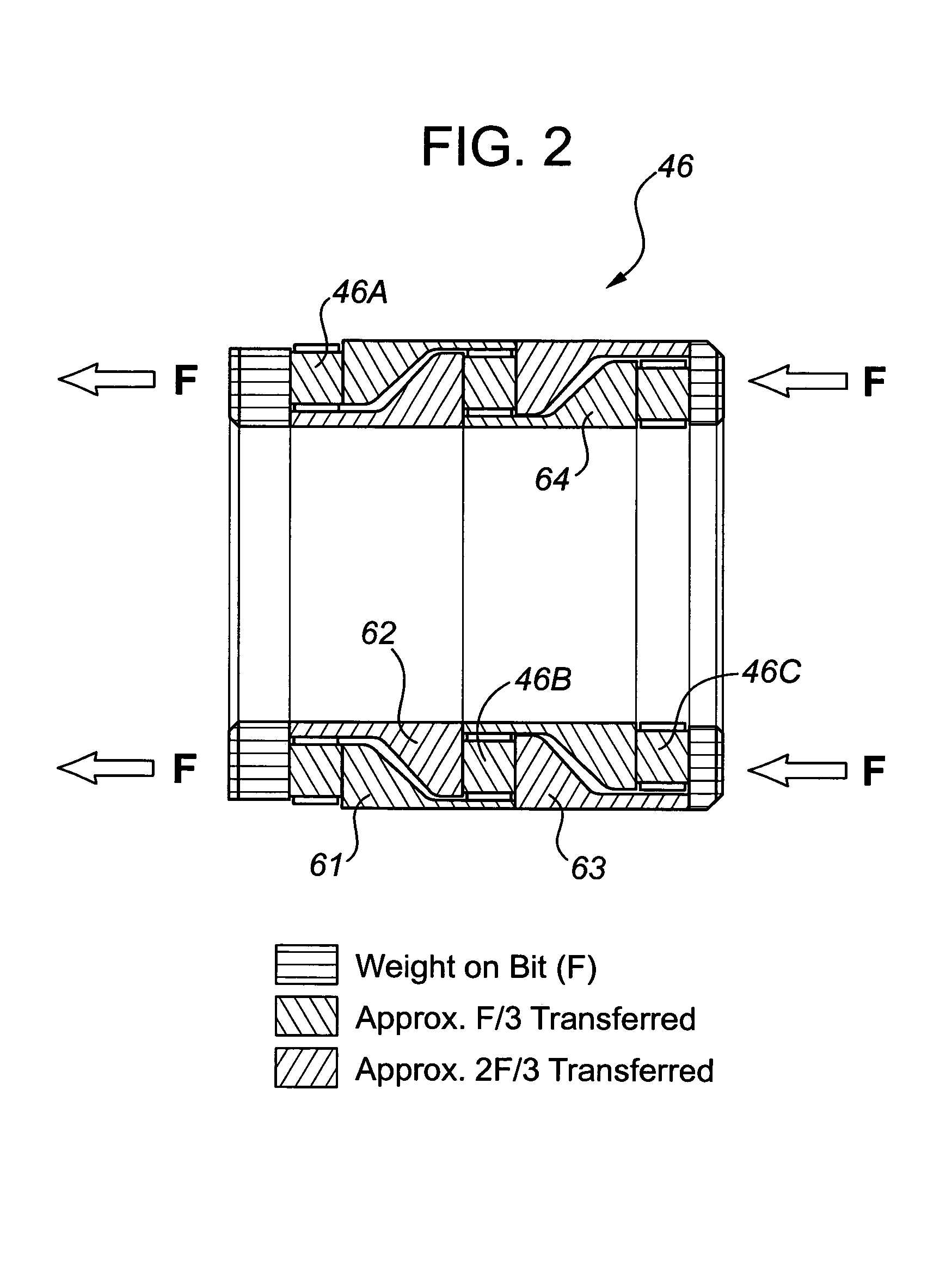

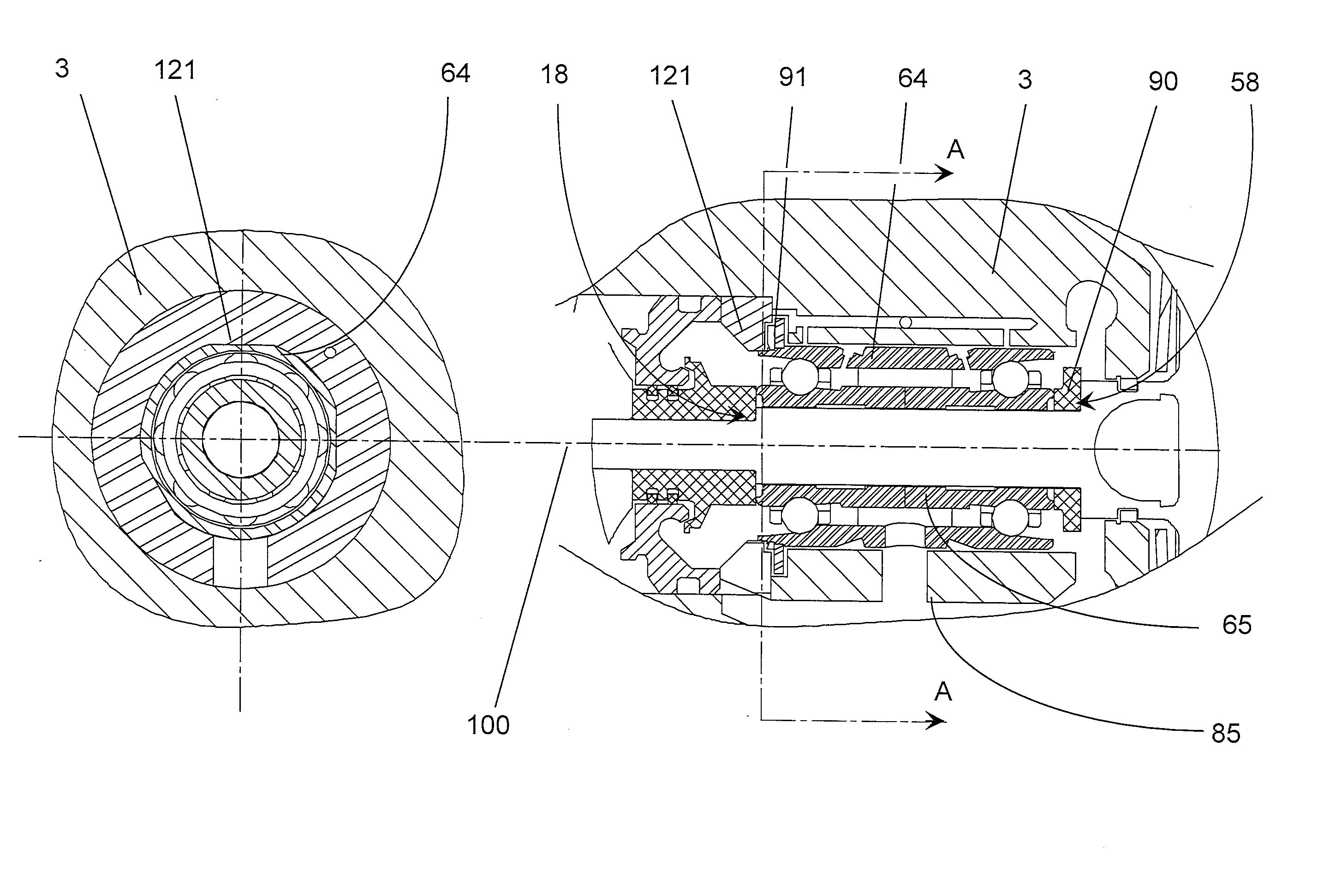

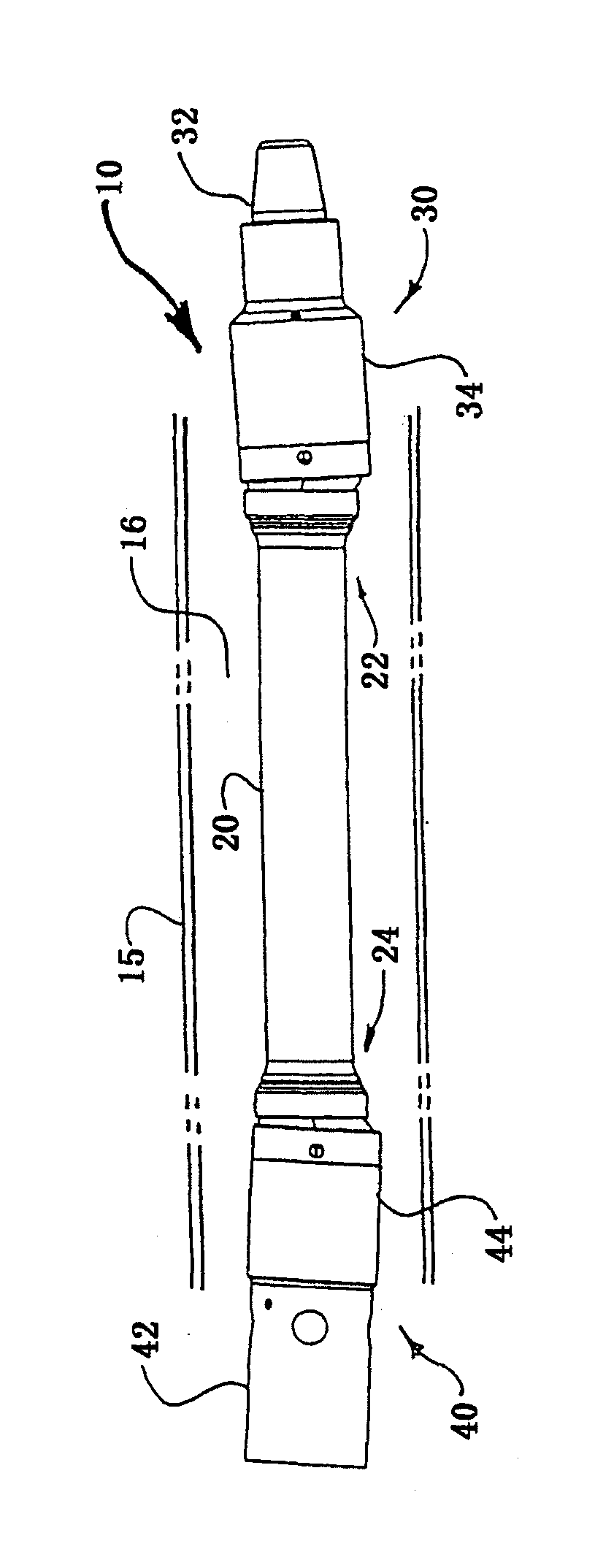

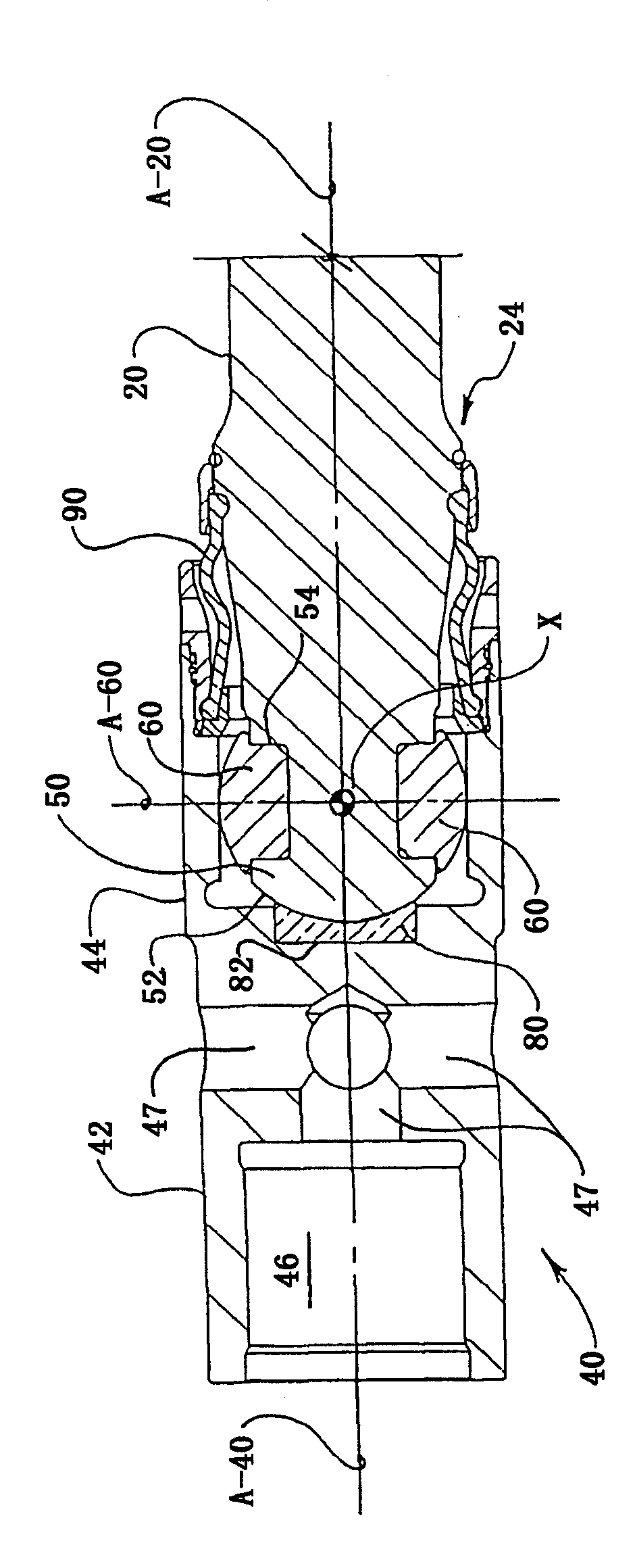

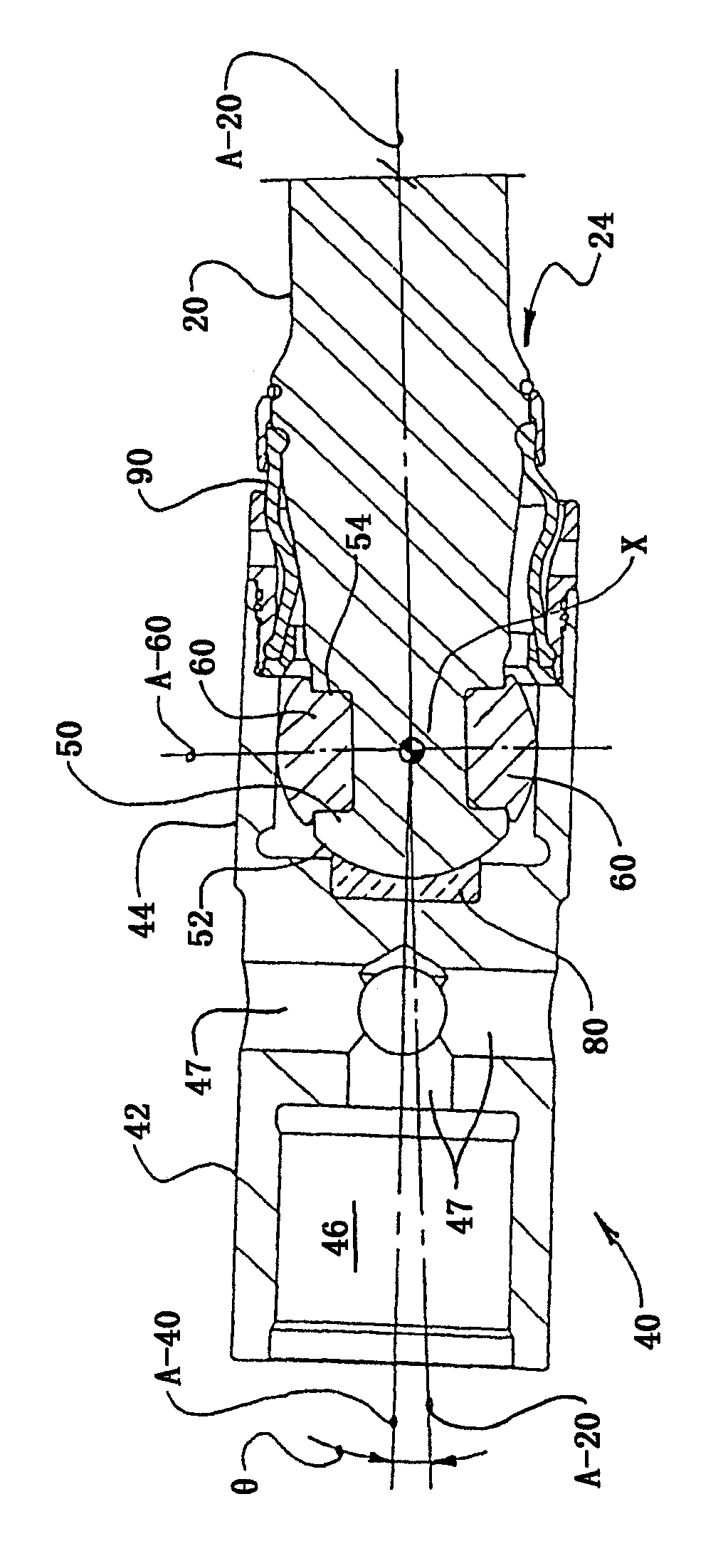

Drive shaft assembly for a downhole motor

ActiveUS20090275415A1Improve pronunciationIncrease capacityYielding couplingDrilling rodsRotational axisSpherical bearing

A drive shaft assembly for a downhole motor includes a drive shaft formed with convexly spherical bearing surfaces on each end, and end housings with concavely spherical bearing surfaces for mating contact with the spherical bearing surfaces of the drive shaft, thereby facilitating omni-directional articulation between the drive shaft and the end housings while transferring axial thrust loads between the drive shaft and end housings across the interface of the mating spherical bearing surfaces. Torque is transferred between the drive shaft and end housings through two or alternatively four swivelling drive keys mounted to each end of the drive shaft and engageable with complementary drive key slots in the end housings. Full and constant torque-transferring contact is thus provided between the swivelling drive keys and the end housings irrespective of any angular offset between the drive shaft and the end housings, resulting from omni-directional articulation of the drive shaft relative to the end housing. The omni-directional center of rotation at each end of the drive shaft coincides with the geometric centerpoint of the corresponding convexly spherical bearing surface, which corresponds to the intersection of the drive shaft's rotational axis, the end housing's rotational axis, and the drive key swivel axis.

Owner:DRECO ENERGY SERVICES ULC

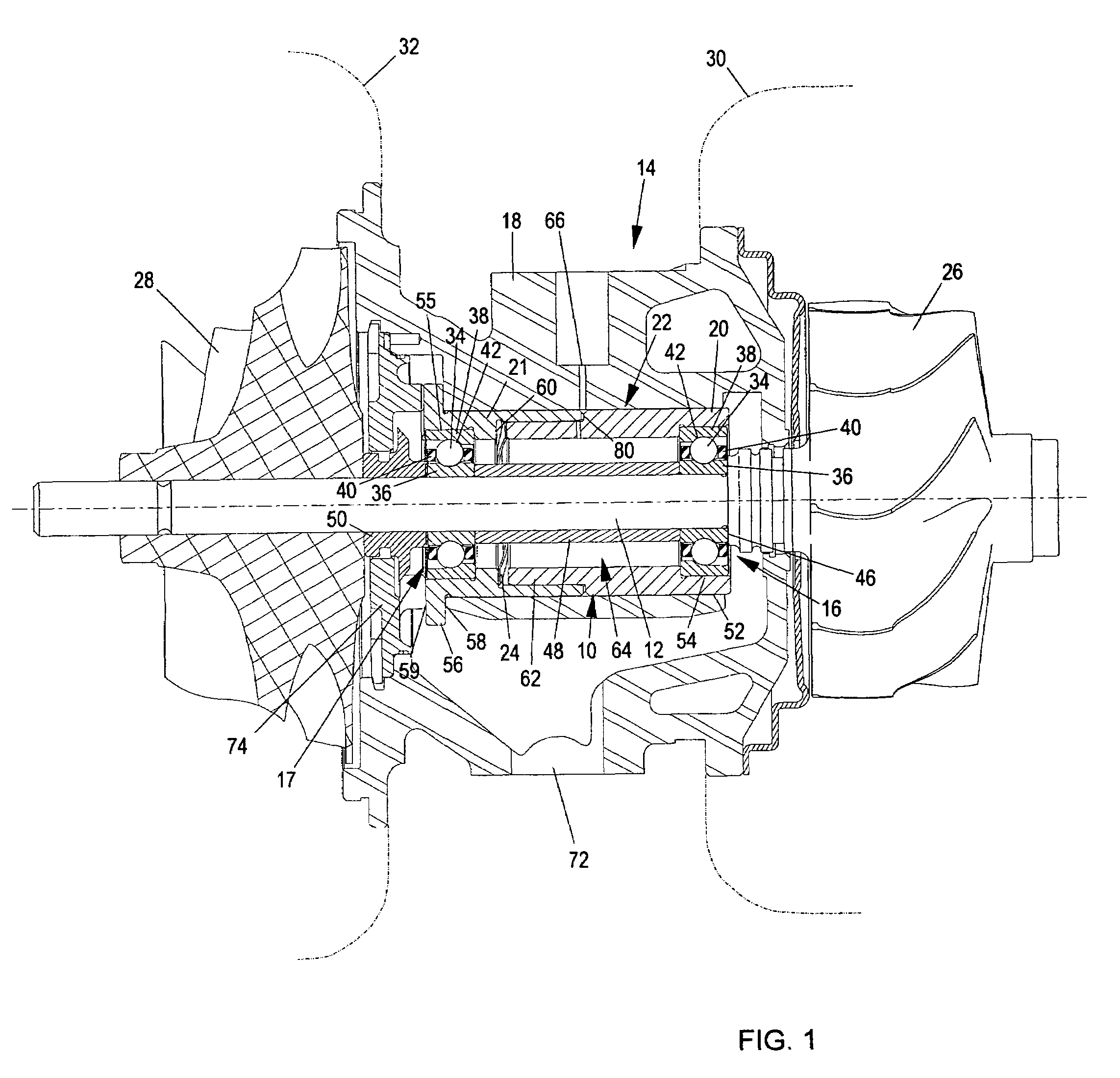

Turbocharger shaft bearing system

Owner:CPI HLDG

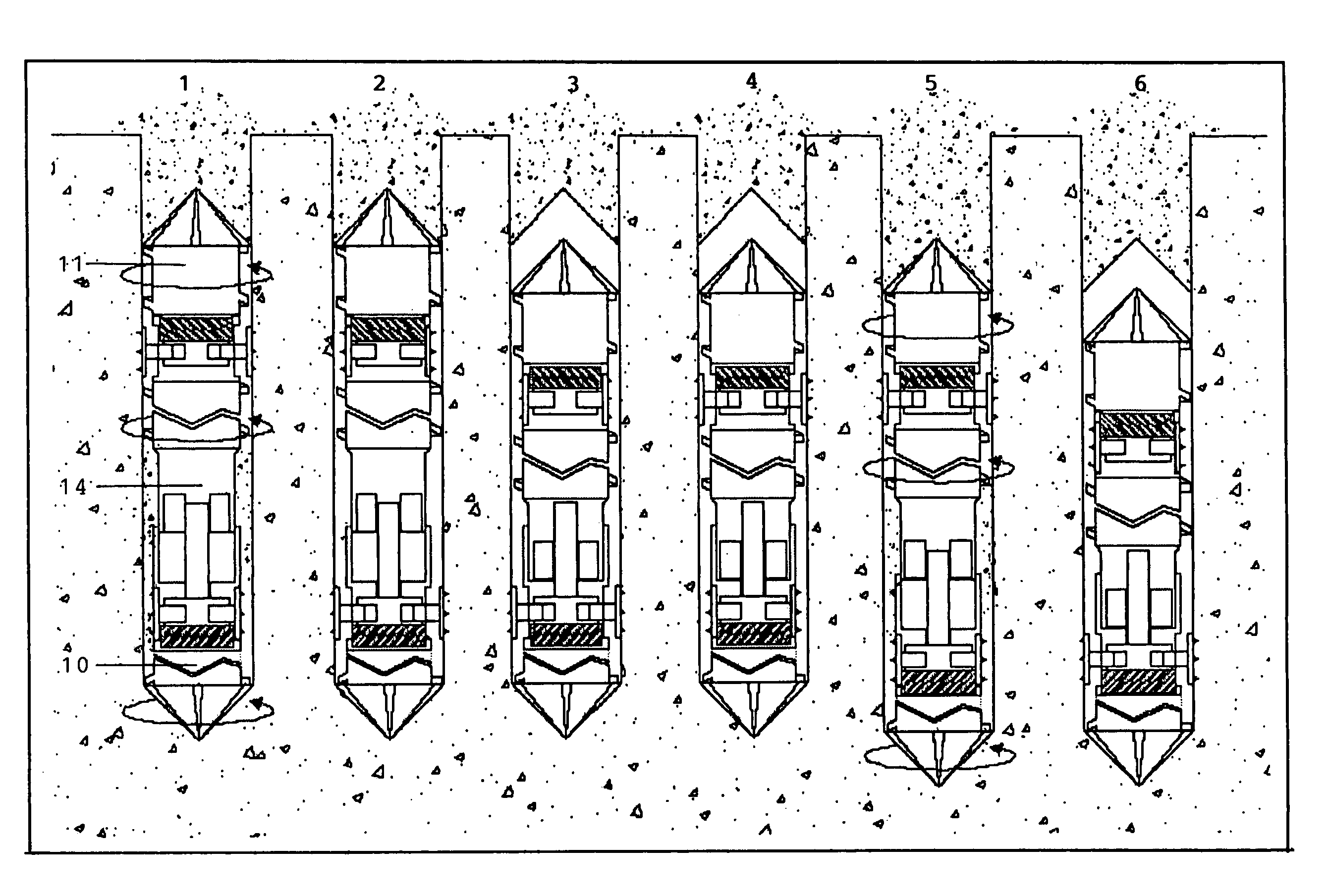

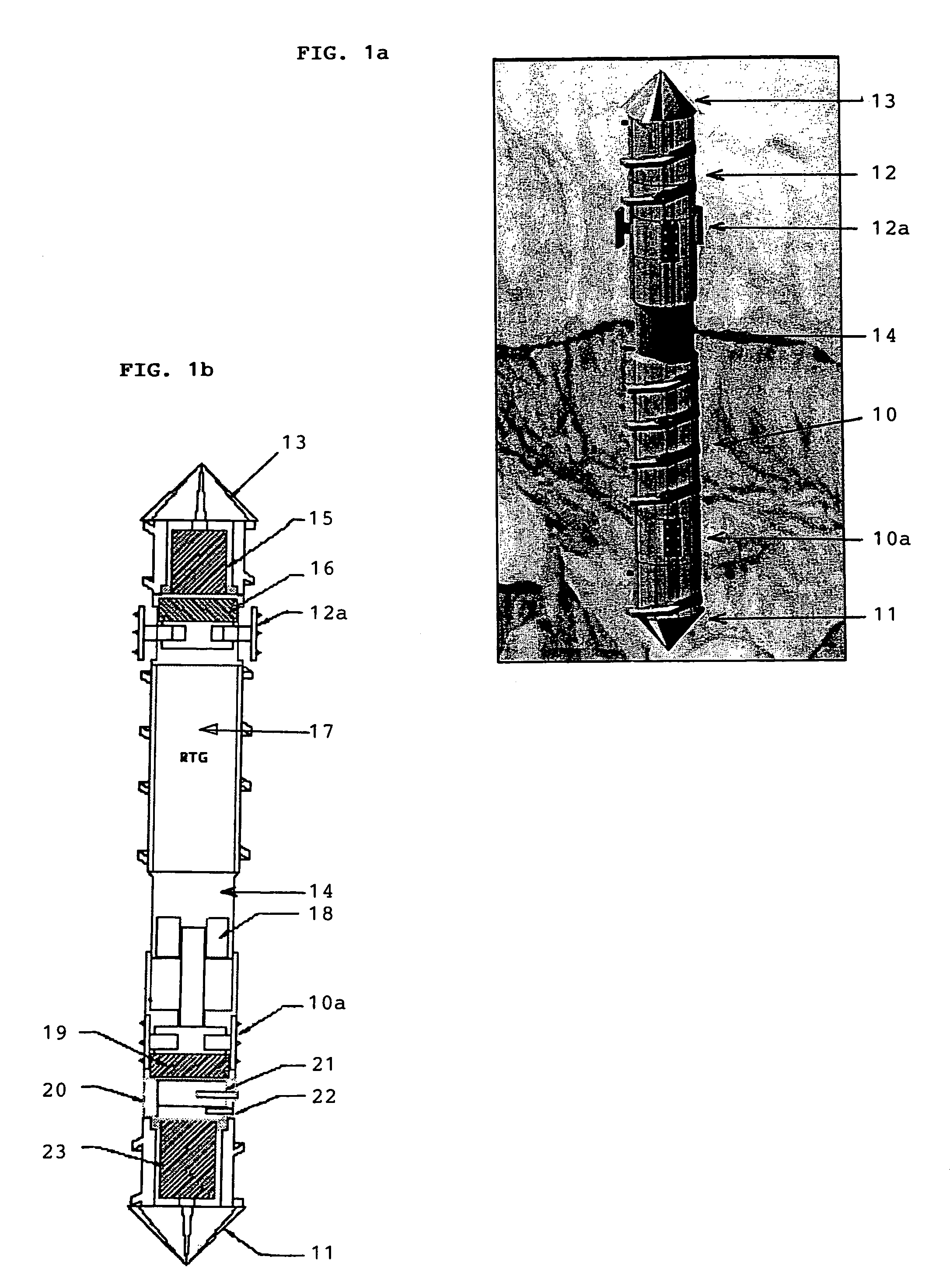

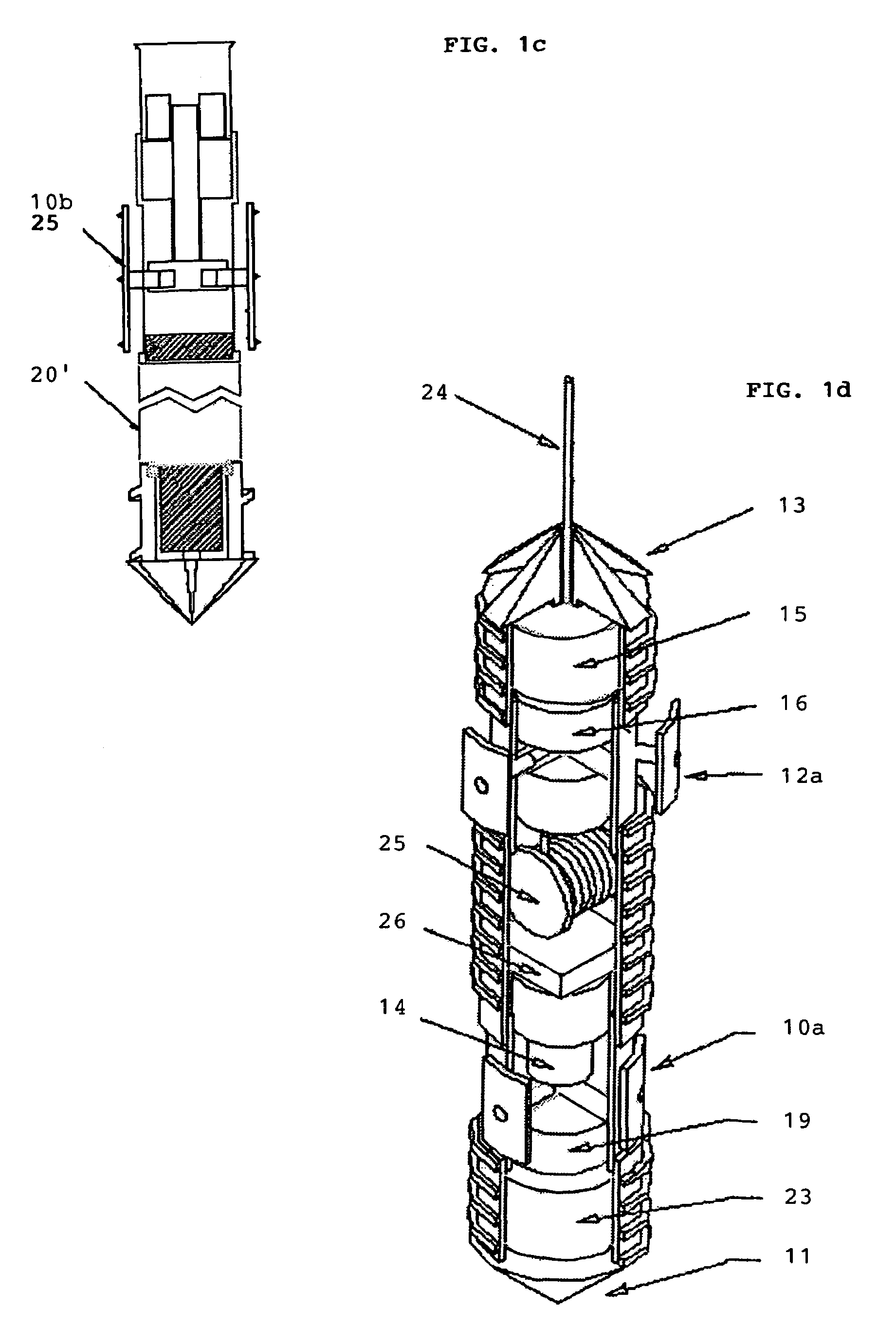

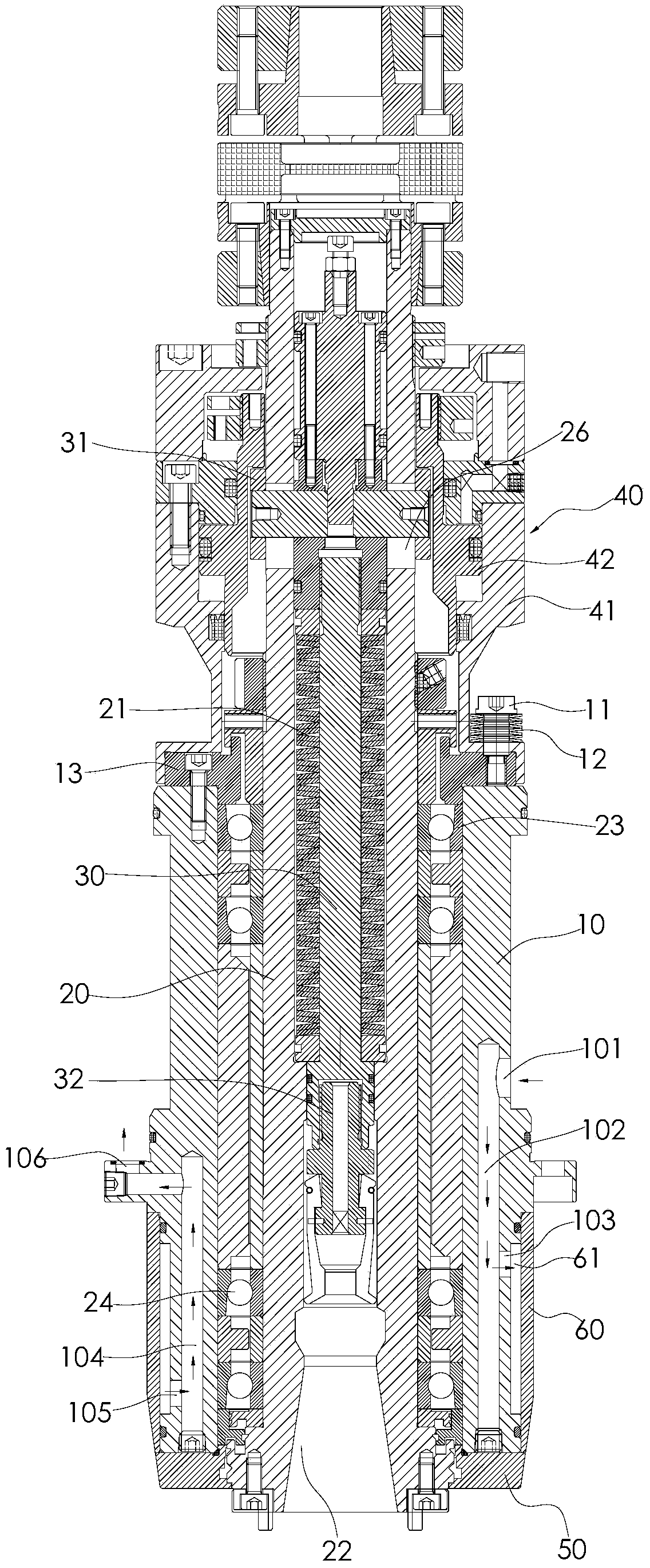

Self-propelled instrumented deep drilling system

InactiveUS7055625B1Improve mobilityEnergy self-sufficientDrilling rodsBorehole drivesOn boardAxial thrust

An autonomous subsurface drilling device has spaced-apart forward and rearward “feet” sections coupled to an axial thruster mechanism between them to operate using an inchworm method of mobility. In one embodiment, forward and rearward drill sections are carried on forward and rearward “feet” sections for drilling into material in the borehole in both forward and rearward directions, to allow the device to maneuver in any direction underground. In another embodiment, a front drill section has a drill head for cutting into the borehole and conveying cuttings through a center spine tube to an on-board depository for the cuttings. The feet sections of the device employ a foot scroll drive unit to provide radial thrust and synchronous motion to the feet for gripping the borehole wall. The axial thrust mechanism has a tandem set of thrusters in which the second thruster is used to provide the thrust needed for drilling, but not walking. A steering mechanism composed of concentric inner and outer eccentric rings provided with the rearward feet section allow small corrections in both direction and magnitude to the drilling direction as drilling commences.

Owner:HONEYBEE ROBOTICS

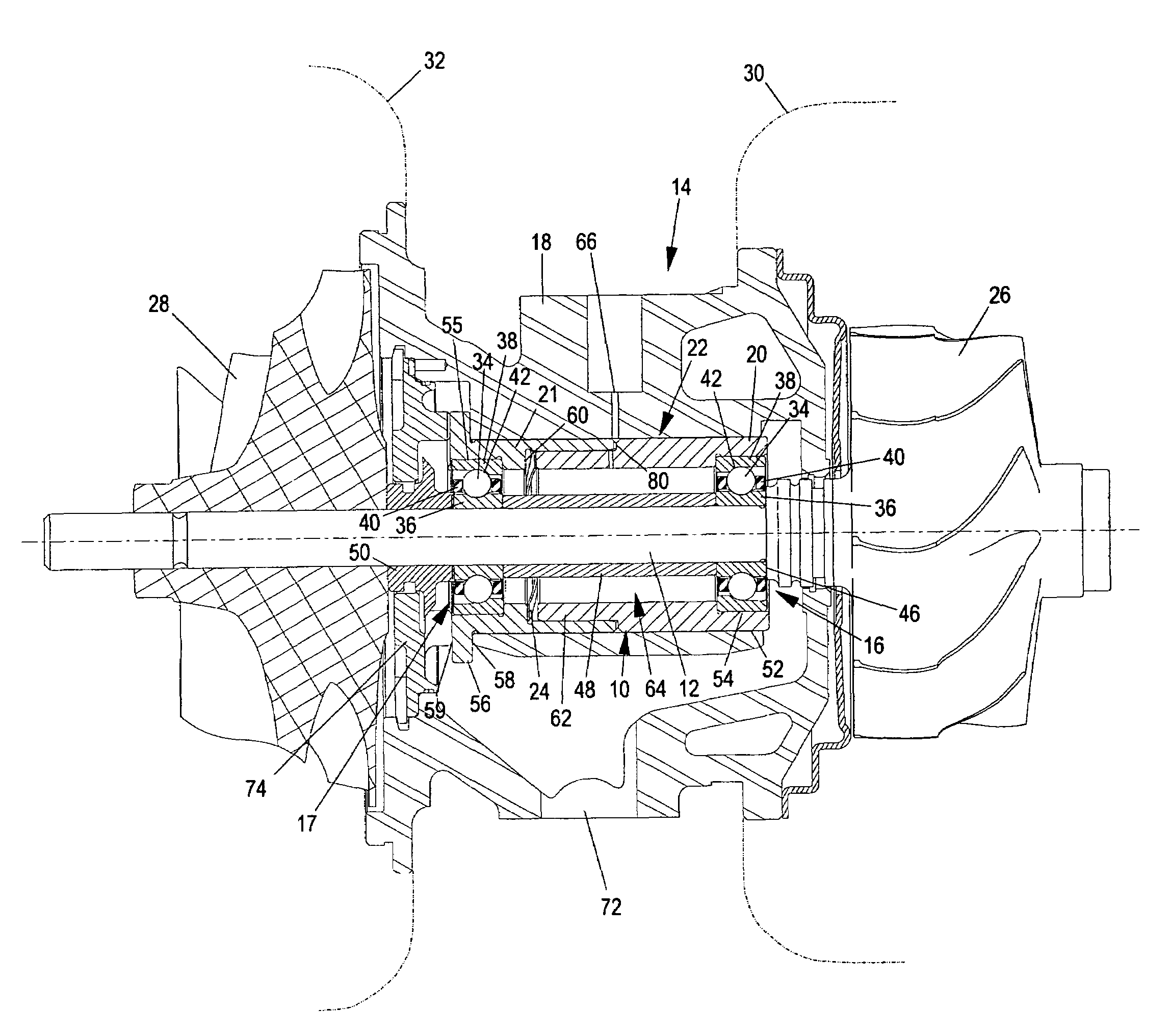

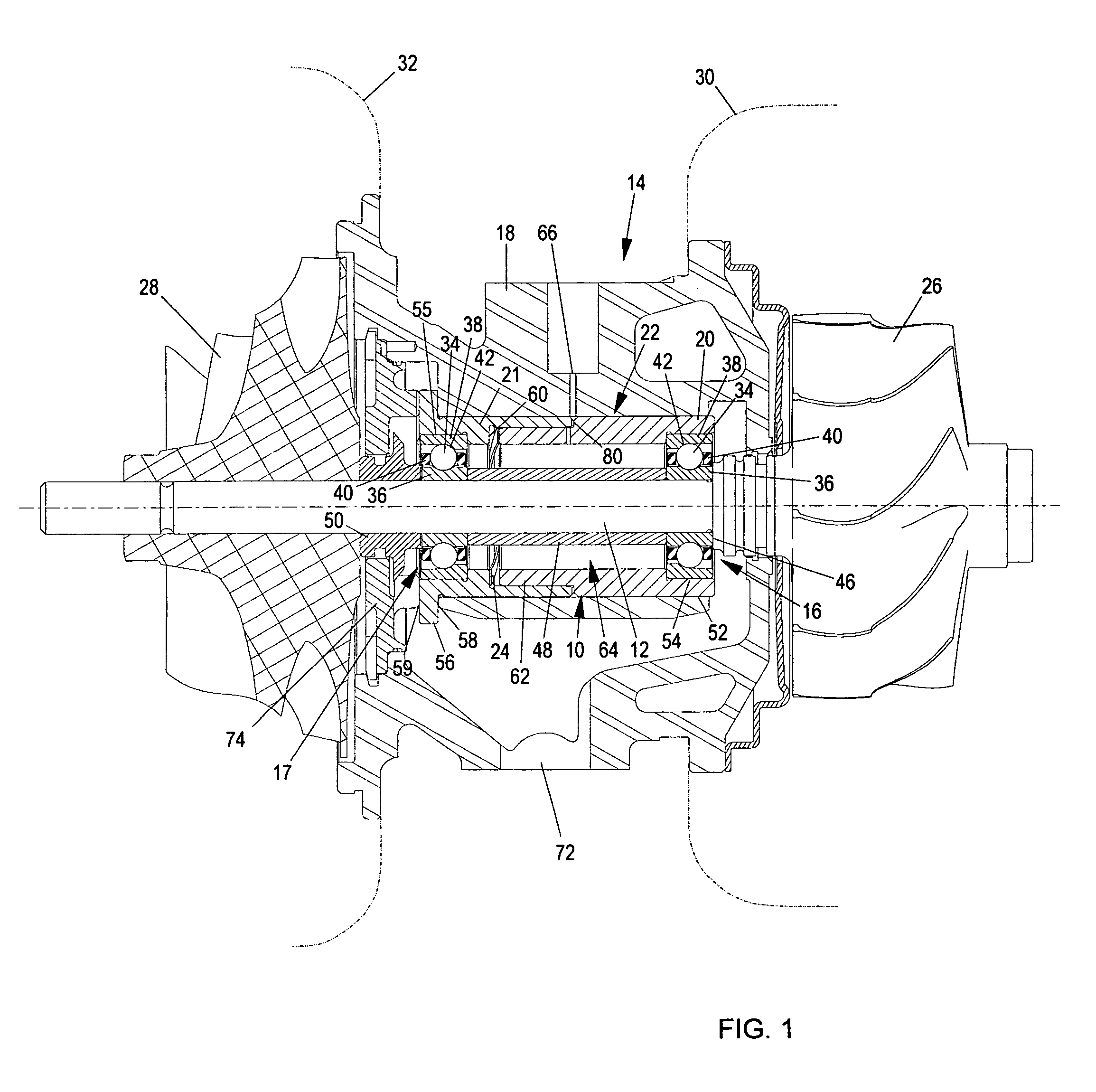

Turbocharger shaft bearing system

An improved bearing system is provided for use in high speed rotating machinery such as a turbocharger, wherein a turbocharger shaft is rotatably supported at opposite ends by a pair of angular contact bearings subjected to a predetermined and substantially constant thrust pre-load. The angular contact bearings are carried respectively within a pair of generally cylindrical bearing sleeves which cooperatively define an axially split bearing carrier mounted within a turbocharger housing. A spring reacts between these bearing sleeves for applying a substantially constant axial thrust pre-load transmitted by the bearing sleeves to the angular contact bearings. The mechanical spring thrust pre-load may be supplemented or substituted by an hydraulic axial thrust load attributable to oil circulated through the split bearing carrier.

Owner:CPI HLDG

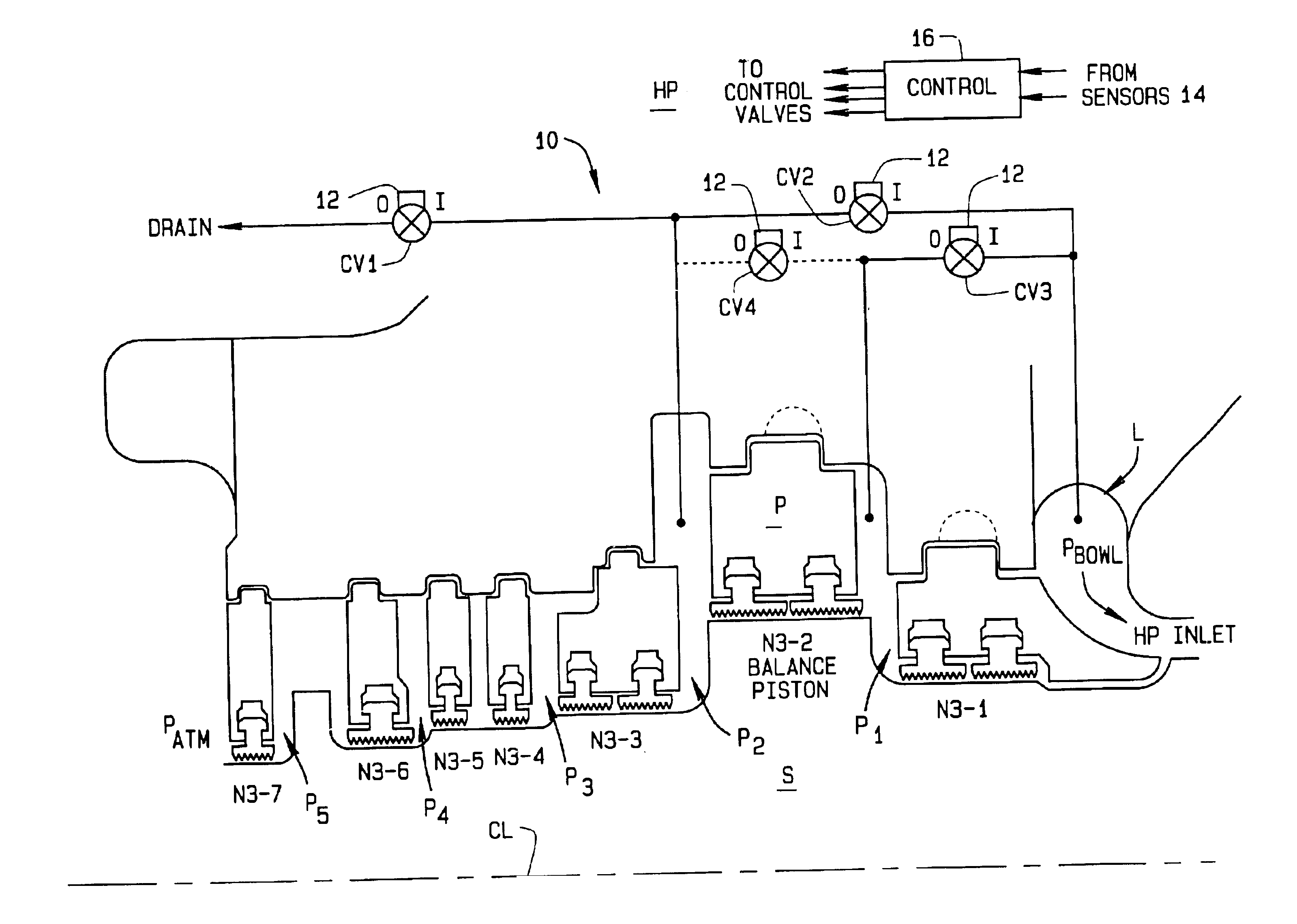

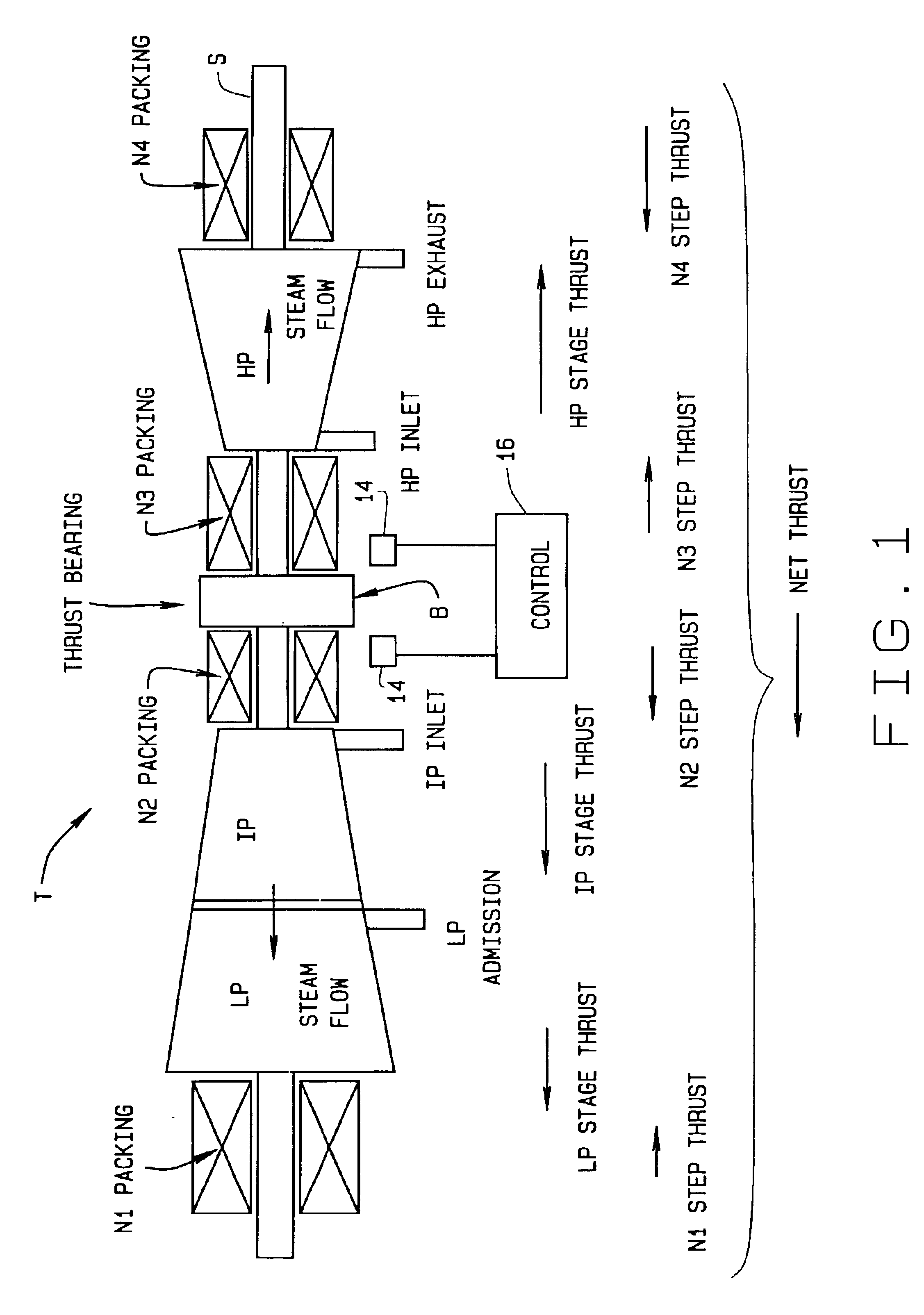

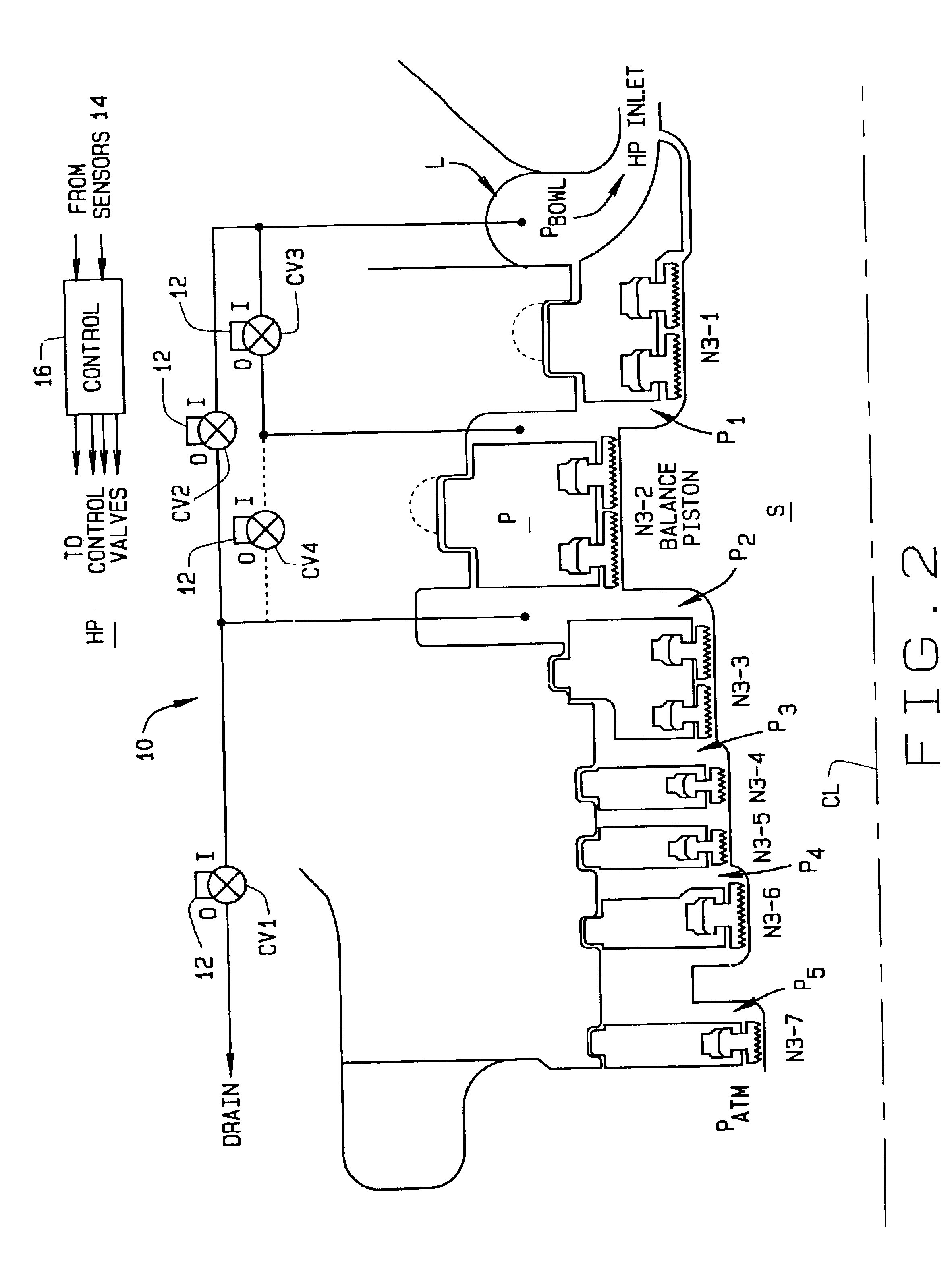

System to control axial thrust loads for steam turbines

Apparatus (10) controls net thrust in a steam turbine (T) in response to changes in the operating condition of the turbine. The turbine includes a thrust bearing (B) positioned between low and intermediate pressure sections (LP, IP) of the turbine and a high pressure section (HP) thereof. Sensors (14) for sense thrust loads on the thrust bearing. A number of control valve (CV1-CV4) are used to balance pressures occurring at locations within the high pressure section of the turbine. A controller (16) is responsive to the sensors sensing a change within the turbine indicative of a significant change in net thrust to energize one or more of the control valves and to adjust the pressure within the high pressure section of the turbine so to maintain net thrust within an acceptable range of thrust values.

Owner:GENERAL ELECTRIC CO

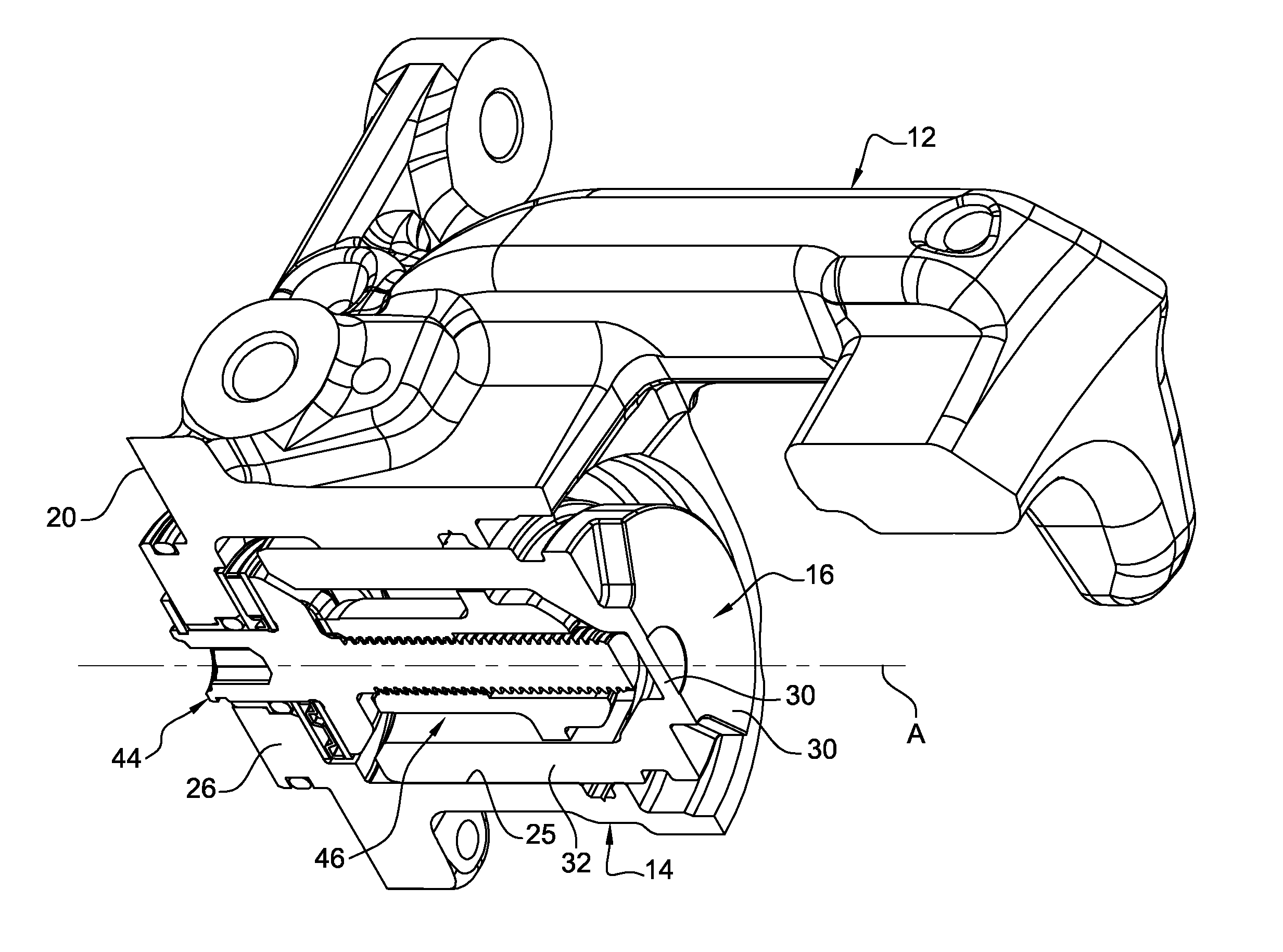

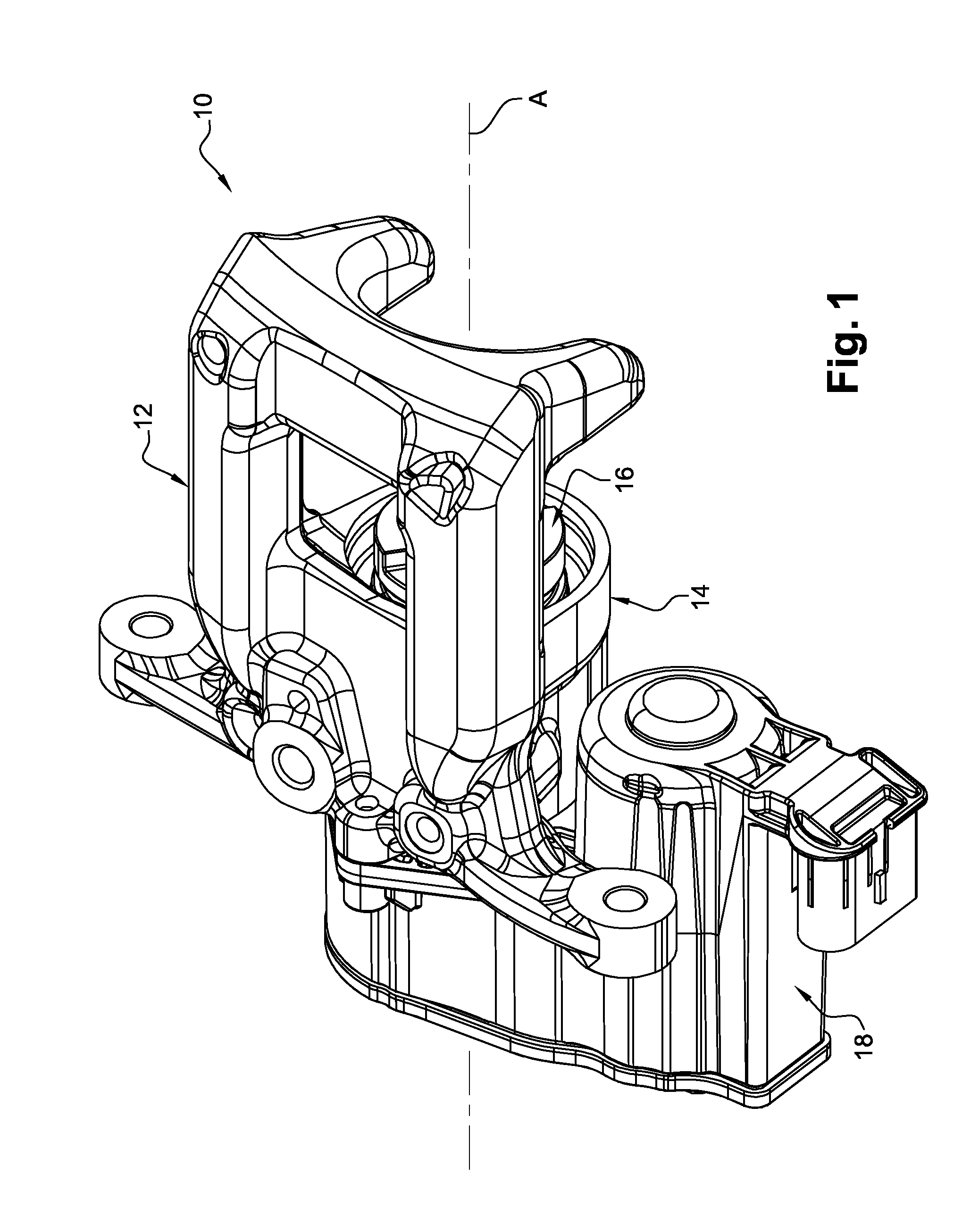

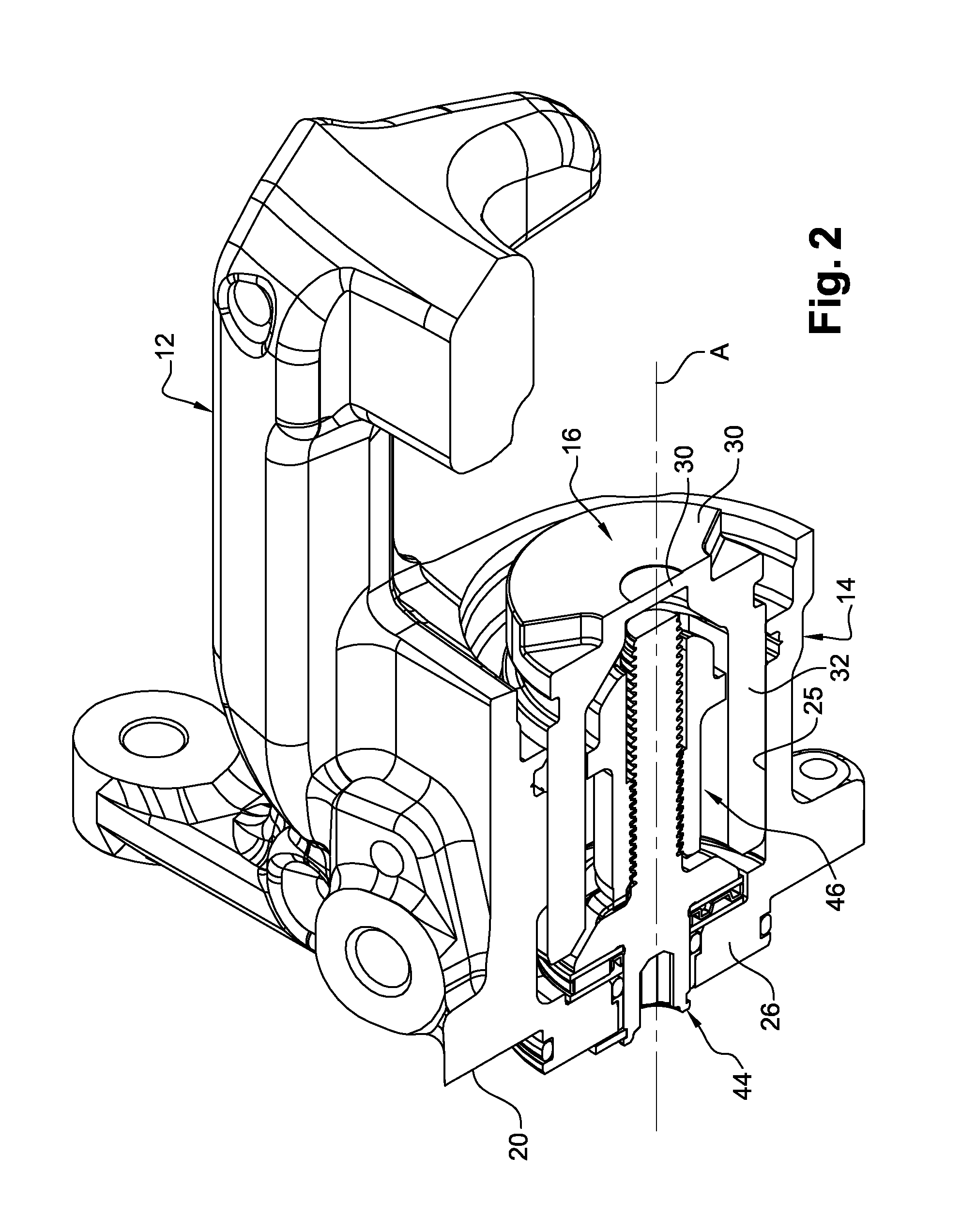

Door system for transit vehicle

InactiveUS6125768AAvoid excessive wearReduce wearVehicle arrangementsWing fastenersThrust bearingAxial thrust

A biparting transit vehicle door system operator. The operator includes a base for attachment to the mass transit vehicle and a motive power source connected to a transmission having an output power shaft. Such operator further includes a teeter plate having a shaft engaging portion for engaging the shaft. The shaft has a teeter plate engaging portion for engaging the operator teeter plate. A thrust bearing is in mechanical contact with a hub portion of the teeter plate and a spring is in mechanical contact with the thrust bearing to exert a first axial thrust thereon. The thrust bearing communicating the first axial thrust to the teeter plate so that the shaft engaging portion of the teeter plate engages the teeter plate engaging portion of the shaft. The operator includes a release member having mechanical contact with the hub portion of the teeter plate for exerting a second axial thrust on the teeter plate. The second axial thrust being opposed to the first axial thrust so that the teeter plate may be disengaged from the shaft by the release member. A pair of drive rod pivots are attached to the teeter plate. Such pair of drive rod pivots are connected to a pair of drive rods for opening and closing the pair of biparting doors.

Owner:WESTINGHOUSE AIR BRAKE CO

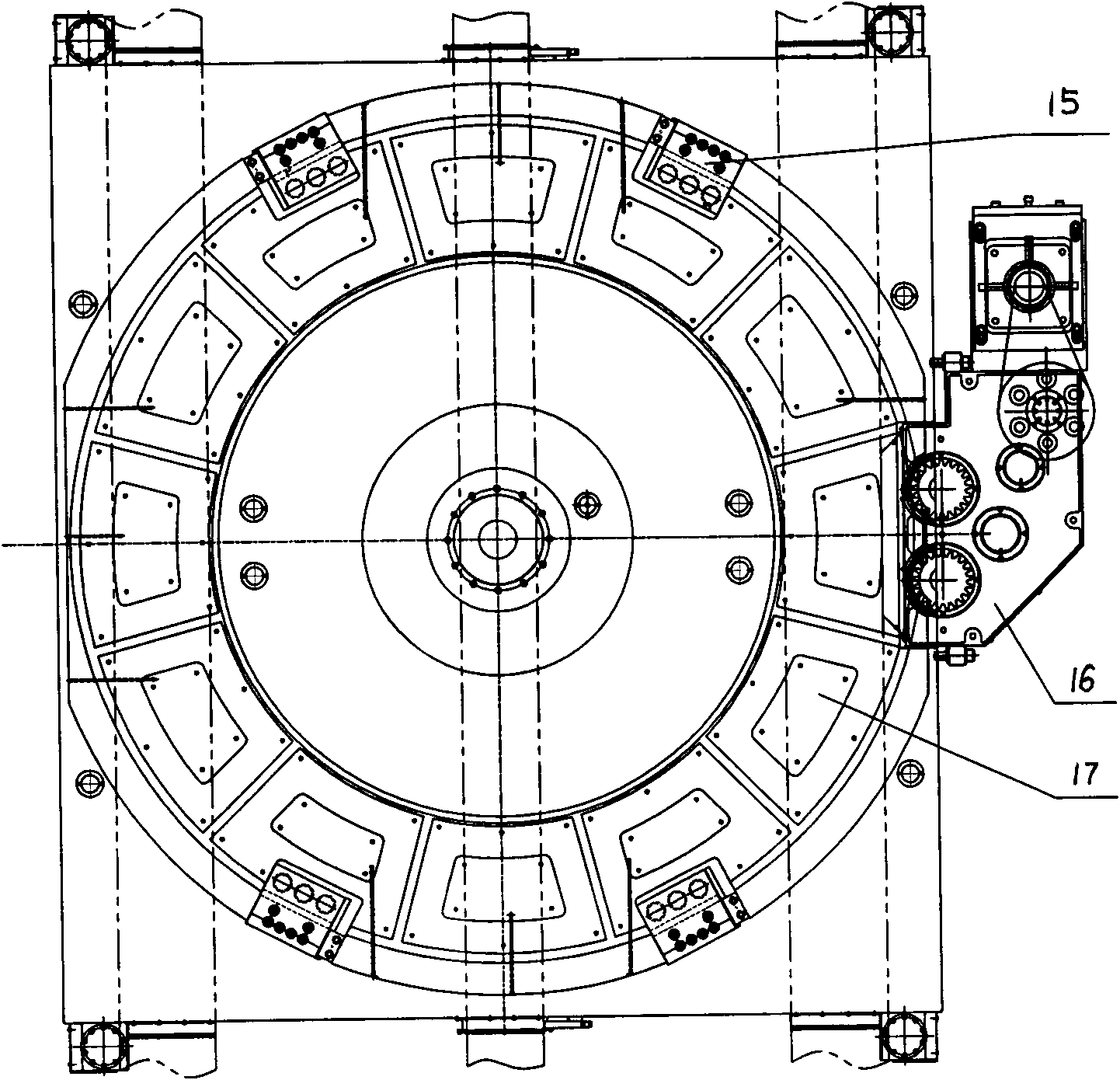

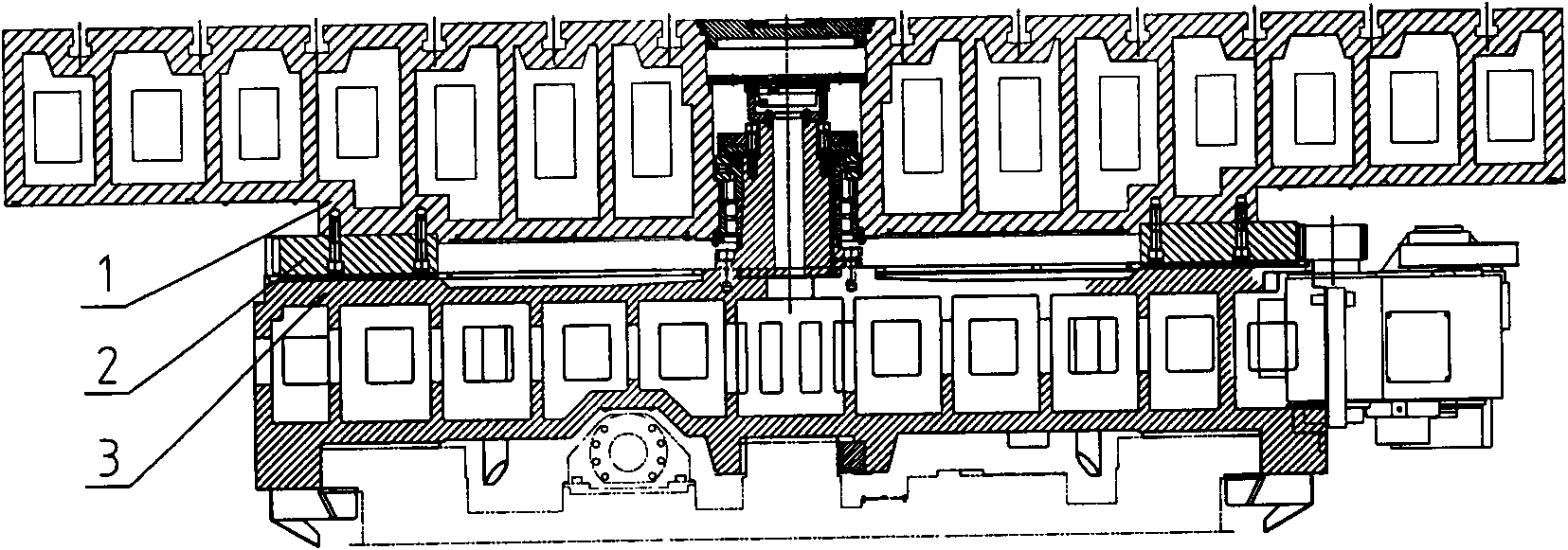

Open-type static pressure rotating table for controlling floating degree and manufacturing method thereof

ActiveCN102039527AImprove motion smoothnessHigh movement precisionLarge fixed membersBearingsThrust bearingHydrostatic pressure

The invention relates to an open-type static pressure rotating table for controlling floating degree and a manufacturing method thereof. The open-type static pressure rotating table is characterized in that: a column on the lower part of a rotary table body and the inner hole of a large gear ring forms clearance fit by a coaxial basic hole system; the large gear ring and the table are arranged ona slide carriage, and the bottom surface of the large gear ring with high planeness and roughness and a static pressure oil chamber on the upper surface of the slide carriage form a hydrostatic pressure guide rail pair; an additional axial thrust bearing structure arranged on a centering structure provides preloads for hydrostatic pressure guide rails of the table; and the bottom surface of the large gear ring is assembled and ground correctly according to design requirements till plane precision, and the upper surface of the static pressure oil chamber on the slide carriage is scraped by facing-up simultaneously to ensure the fit accuracy of the upper and lower hydrostatic pressure guide rails. In the open-type static pressure rotating table, the thrust bearing structure is adopted on the basis of a common centering shaft structure, so the initial preloads of the hydrostatic pressure guide rail pair are controlled effectively and the floating degree of the open-type static pressure rotary table is controlled effectively, the rigidity of an oil film is increased, and the motion stability, motion accuracy and unbalance load-resistant capacity of the open-type static pressure rotarytable are improved.

Owner:沈阳机床中捷友谊厂有限公司

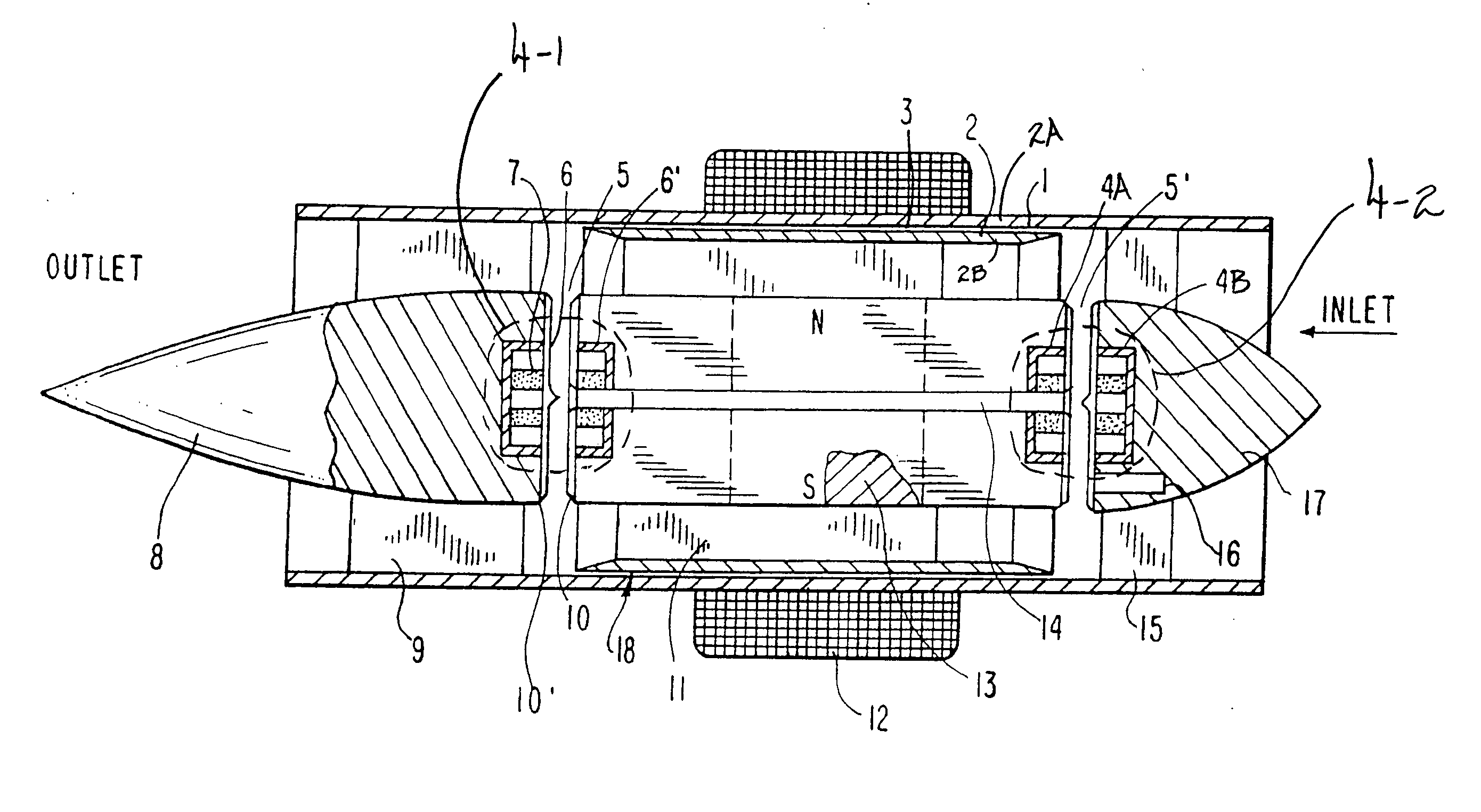

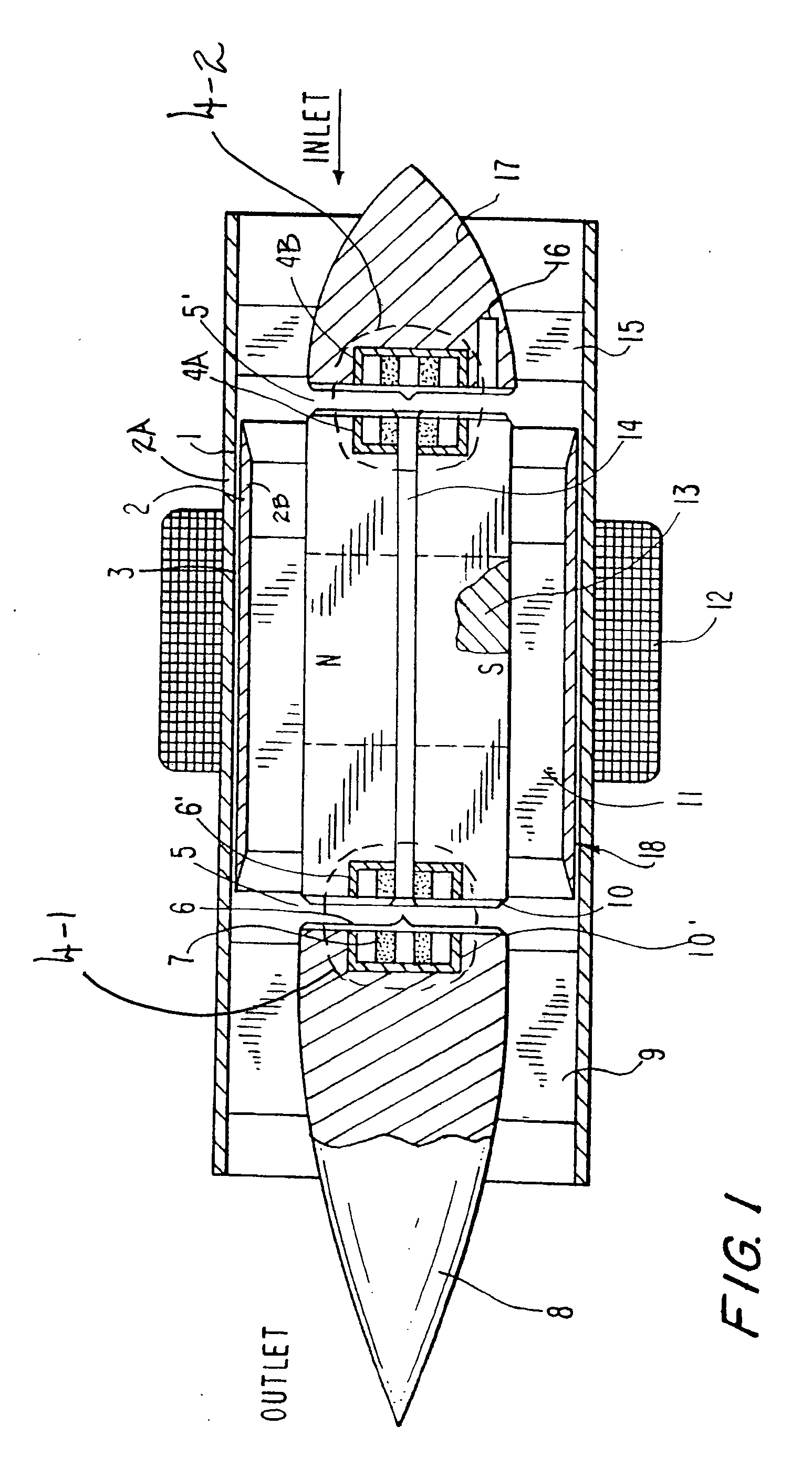

Blood Pump Having A Passive Non-Contacting Bearing Suspension

InactiveUS20080262289A1Sufficient deflectionEasy to measurePump componentsHeart stimulatorsRotational axisDifferential pressure

There is provided a non-contact, passively suspended blood pump that includes (a) a housing; (b) a pump rotor within the housing, wherein the pump rotor has a first end and a second end, and an axis of rotation; (c) a first axial thrust bearing across a first axial gap, between the first end and the housing, that axially suspends the first end; (d) a second axial thrust bearing across a second axial gap, between the second end and the housing, that axially suspends the second end; (e) a first radial hydrodynamic bearing that radially suspends the first end; and (f) a second radial hydrodynamic bearing that radially suspends the second end. Determining pump differential pressure by monitoring rotor axial position allows automatic physiologic control.

Owner:GOLDOWSKY MICHAEL P

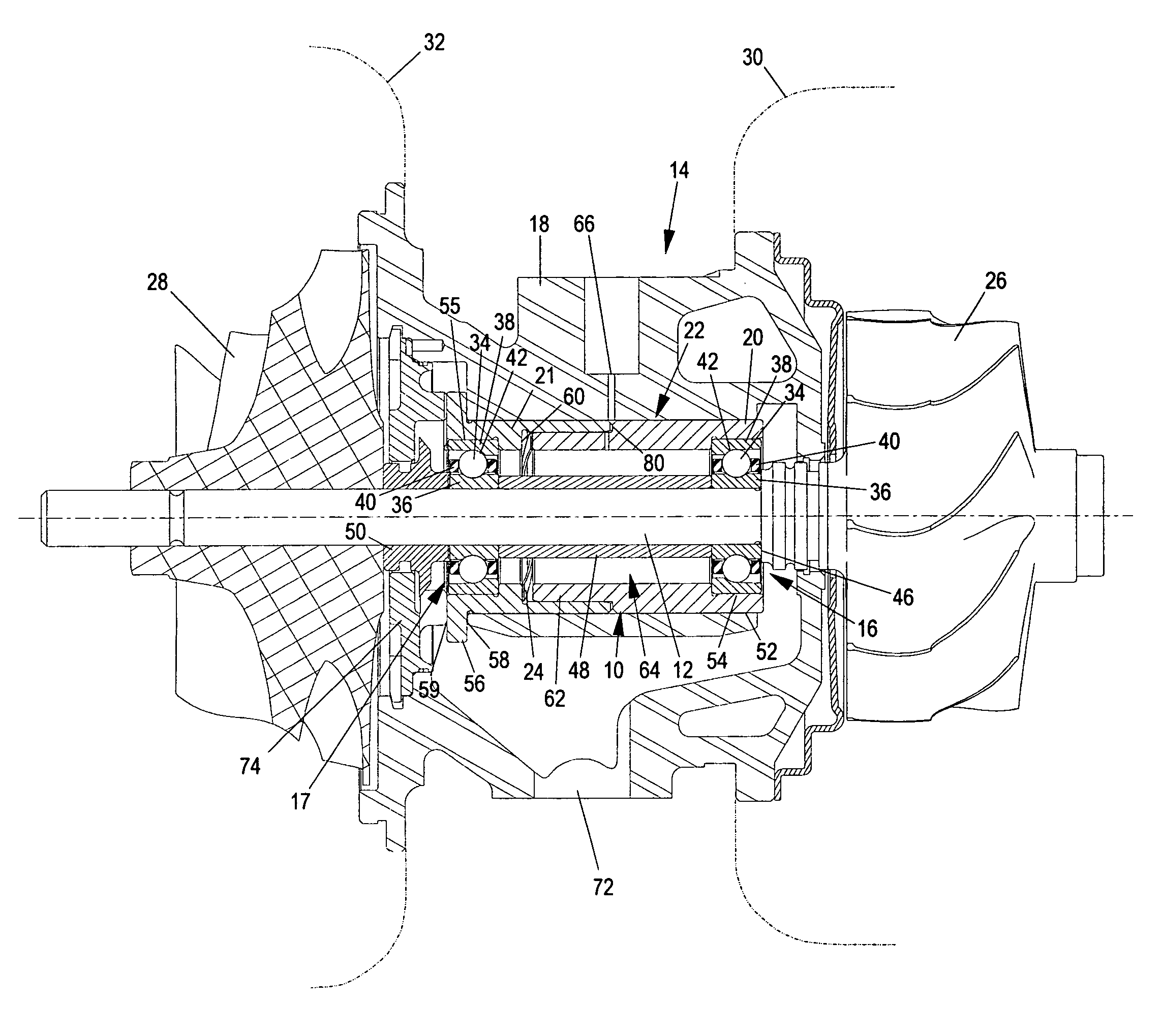

Turbocharger shaft bearing system

InactiveUS20070036477A1Effective applicationRolling contact bearingsEngine manufactureTurbochargerEngineering

An improved bearing system is provided for use in high speed rotating machinery such as a turbocharger, wherein a turbocharger shaft is rotatably supported at opposite ends by a pair of angular contact bearings subjected to a predetermined and substantially constant thrust pre-load. The angular contact bearings are carried respectively within a pair of generally cylindrical bearing sleeves which cooperatively define an axially split bearing carrier mounted within a turbocharger housing. A spring reacts between these bearing sleeves for applying a substantially constant axial thrust pre-load transmitted by the bearing sleeves to the angular contact bearings. The mechanical spring thrust pre-load may be supplemented by an hydraulic axial thrust load attributable to oil circulated through the split bearing carrier.

Owner:CPI HLDG

Drive shaft assembly for a downhole motor

ActiveUS8033917B2Improve pronunciationIncrease capacityYielding couplingDrilling rodsRotational axisSpherical bearing

Owner:NOV CANADA ULC

Bearing systems for high-speed rotating machinery

InactiveUS7677041B2Improve performanceMaintain integrityRolling contact bearingsShaftsBall bearingTurbocharger

Bearing systems for high speed rotating shafts, such as turbocharger shafts, include a first ball bearing in one end of an elongated cylinder capable of carrying axial thrust in both directions and a second ball bearing in the opposite end of the elongated cylinder with its outer race slideably mounted in the cylinder against the biasing force of a preload spring. The second ball bearing is free to move axially with the shaft upon axial expansion of the shaft when exposed to high temperature. The inner races of the ball bearings are clamped to and rotate with the shaft as part of the rotating assembly.

Owner:DELGADO LAUREN N

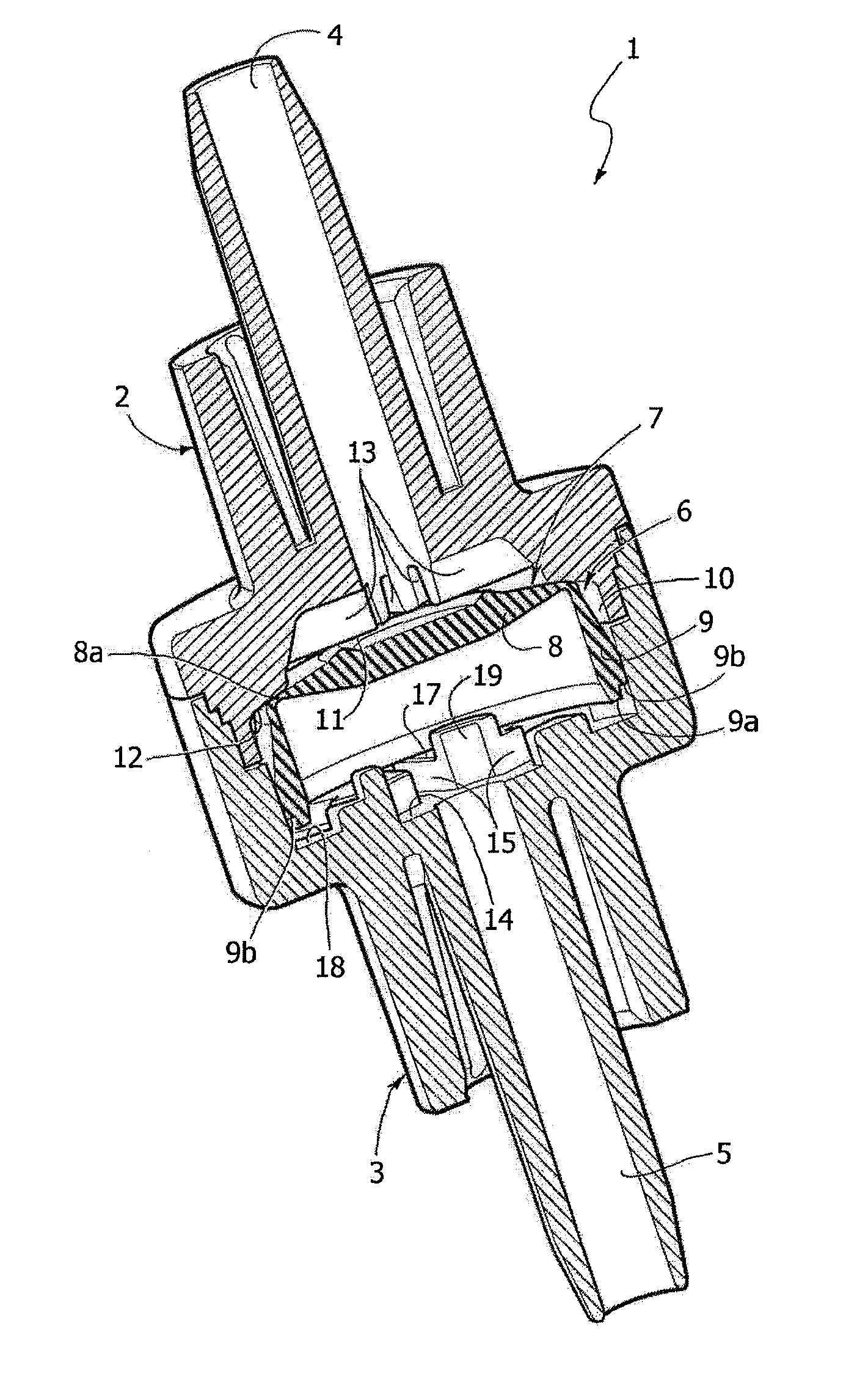

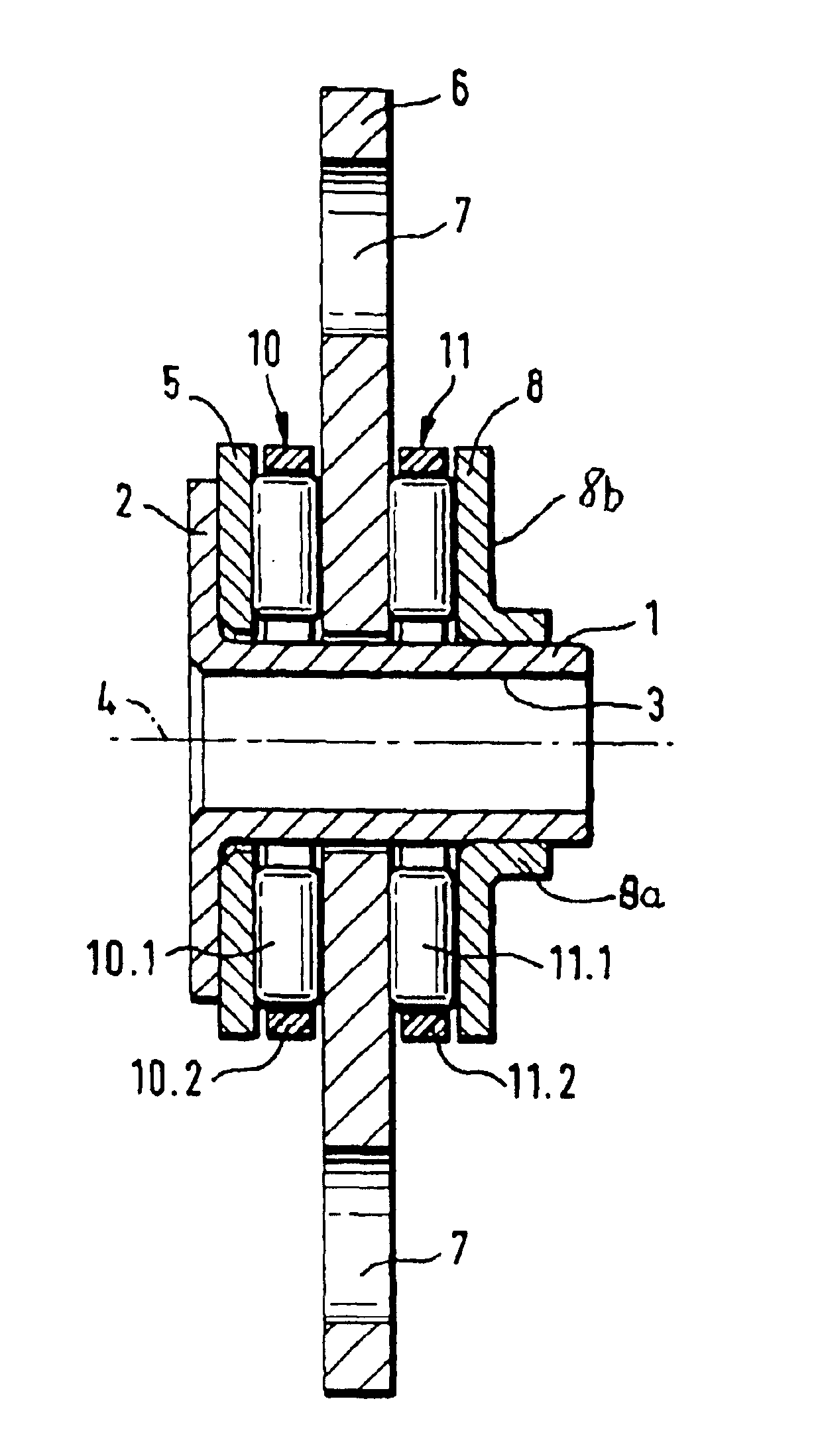

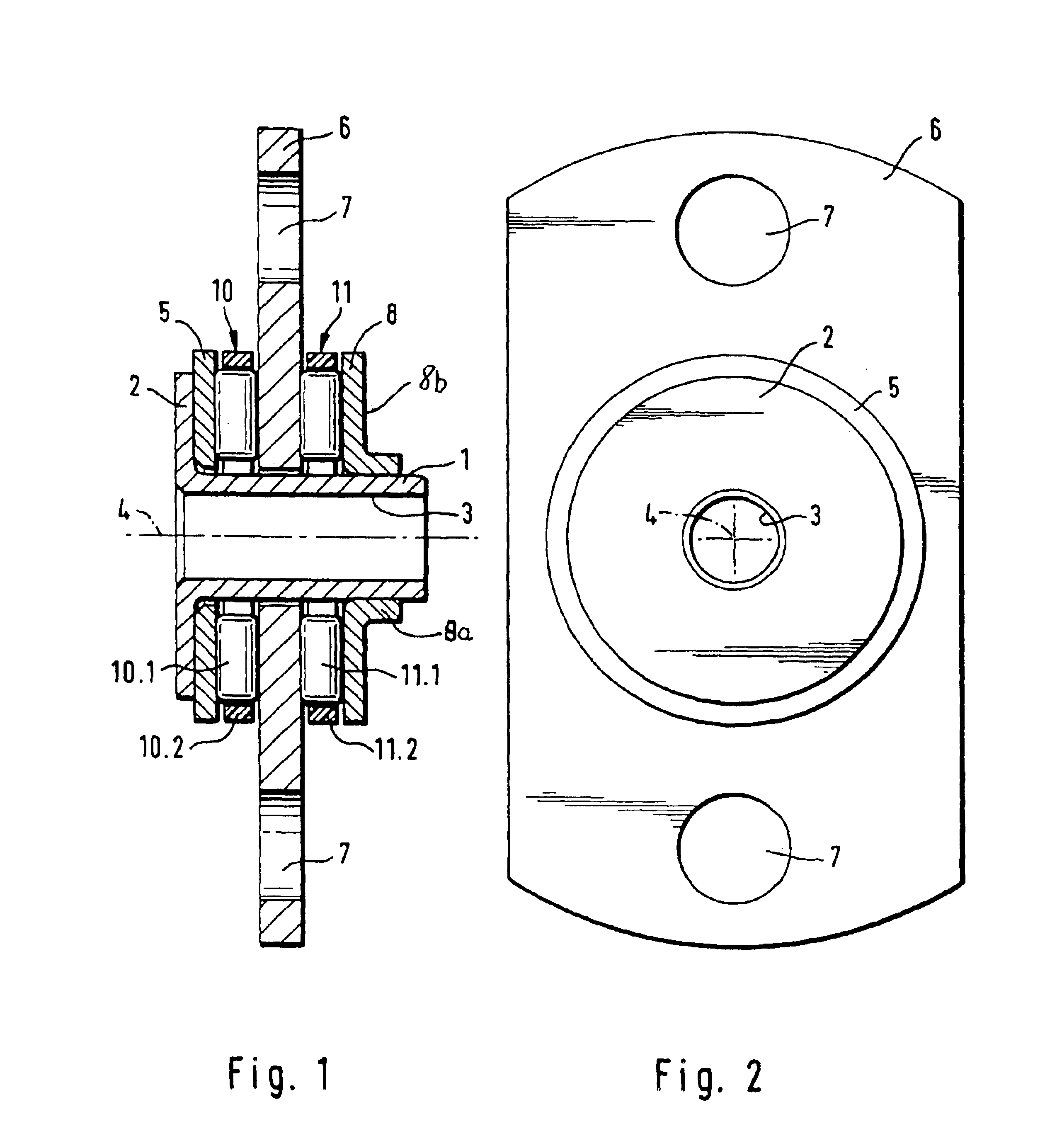

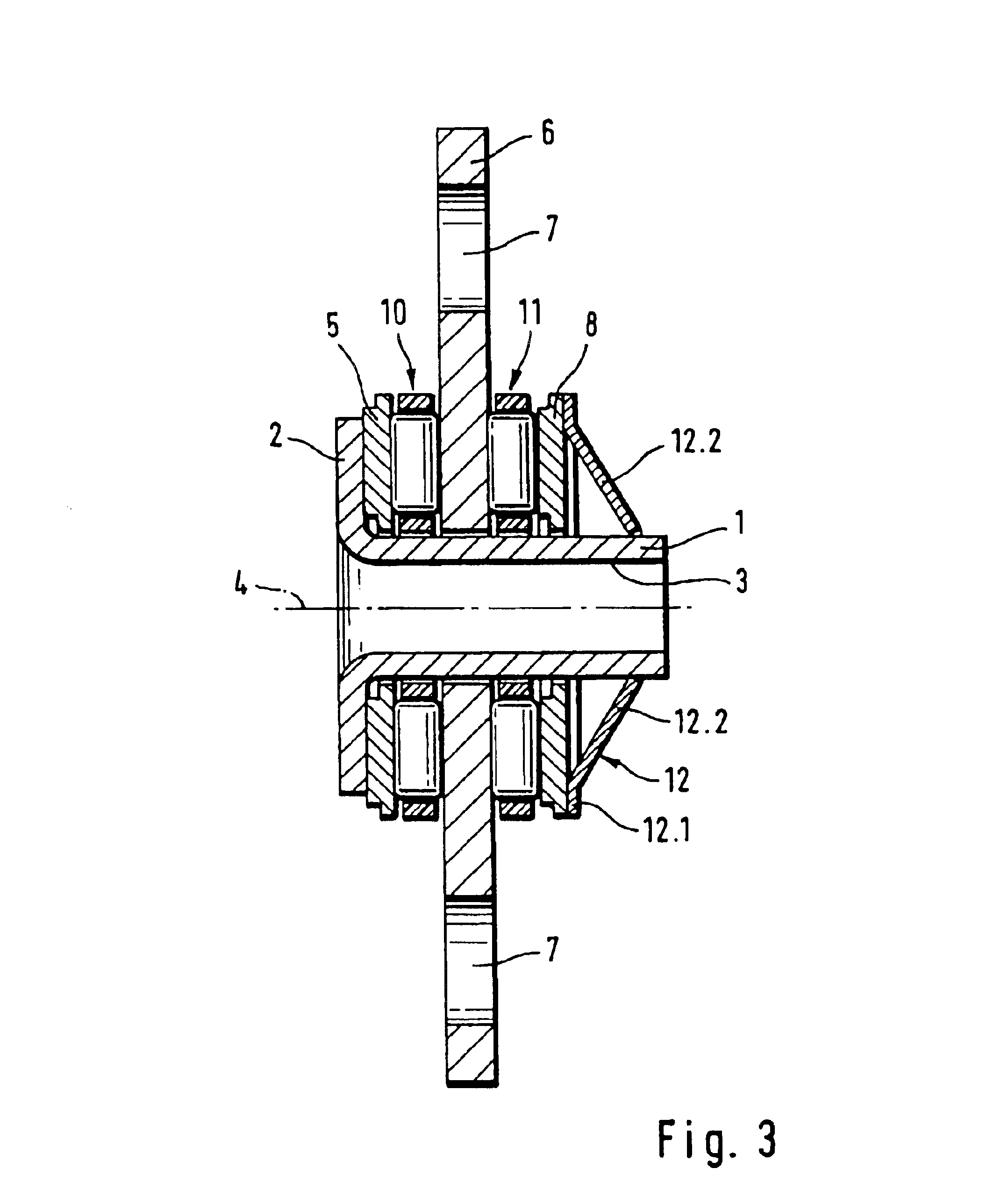

Axial thrust bearing

InactiveUS6857787B1Easy to installWithout risk of disintegrationRoller bearingsBall bearingsThrust bearingAxial thrust

An axial bearing includes three running disks disposed in neighboring disposition, thereby defining two outer running disks and a middle running disk between the outer running disks. A first rim of rolling bodies is arranged between one outer running disk and the middle running disk, and a second rim of rolling bodies is arranged between the other outer running disk and the middle running disk. Received in a bore of the first and second rims and supporting the first and second rims of rolling bodies is a sleeve which is securely fixed to a shaft extends in axial direction beyond the outer running disks. The sleeve has one end formed with a radially outwardly directed flange which embraces the adjacent one of the outer running disks, wherein the other outer running disk is securely connected to the sleeve to thereby form a unitary bearing structure.

Owner:INA SCHAEFFLER KG

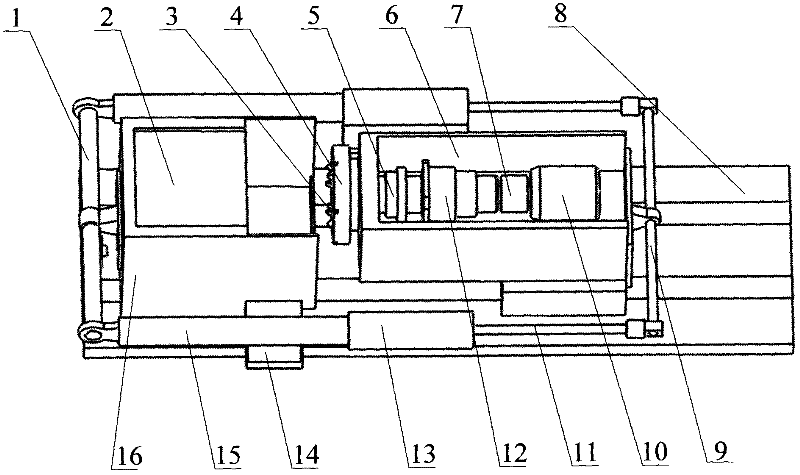

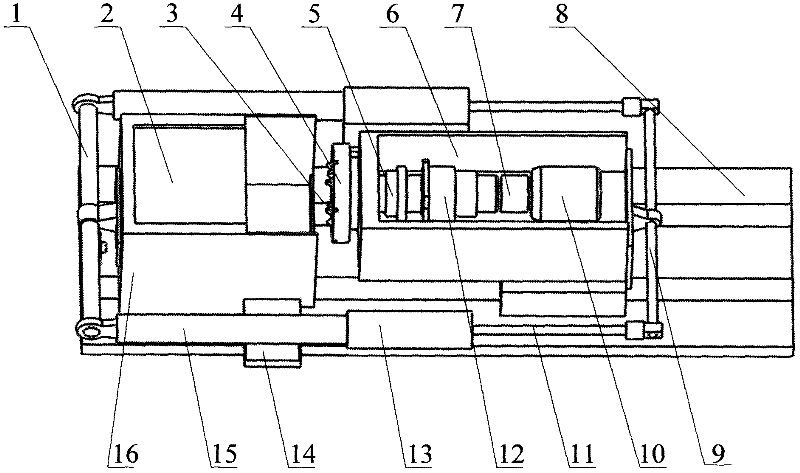

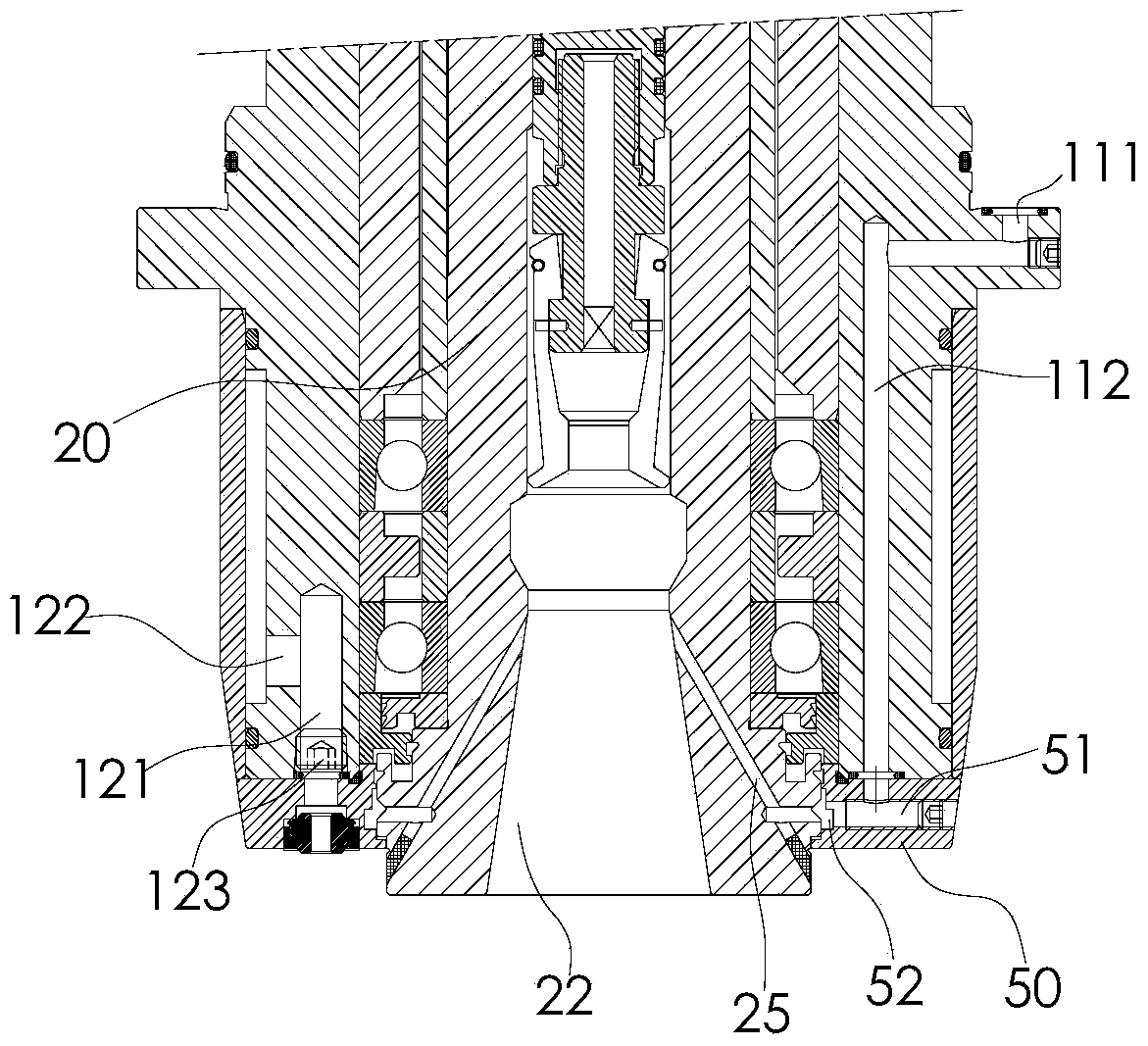

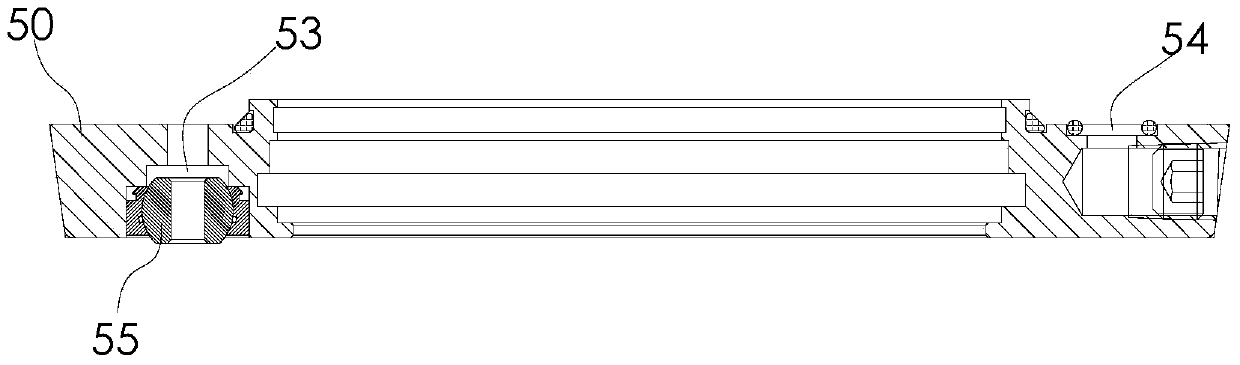

TBM rock breaking test apparatus

ActiveCN102359919AThere is no fixed problemImprove reliabilityMachine part testingInvestigating abrasion/wear resistanceCouplingEngineering

The TBM rock breaking test apparatus provided by the invention comprises a wheel box (6), a rock box (16), a cutterhead (4) and a worktable (8). The wheel box is provided with a motor (10), a torque speed sensor (7) and a decelerator (12); two ends of the torque speed sensor are connected with the motor and the decelerator respectively; the decelerator is connected with the cutterhead arranged onthe wheel box; a cutter (3) is arranged on the cutterhead; and the wheel box and the rock box are slidingly connected with the worktable. A rear distance rod (1) is connected to an external side of the rock box; a front distance rod (9) is connected to an external side of the wheel box; thrust mechanisms are symmetrically arranged on the worktable on two sides of the rock box and the wheel box; rear ends of the thrust mechanisms are connected with the rear distance rod, and front ends of the thrust mechanisms are connected with the front distance rod; the wheel box and the rock box are pushedto simultaneously carry out compressing or loosening movement on the worktable to realize tool feed and retracting. The apparatus can simulate real working process of the cutter to measure a plurality of key parameters of the cutter, such as cutting force, axial thrust, penetration and cutter space.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

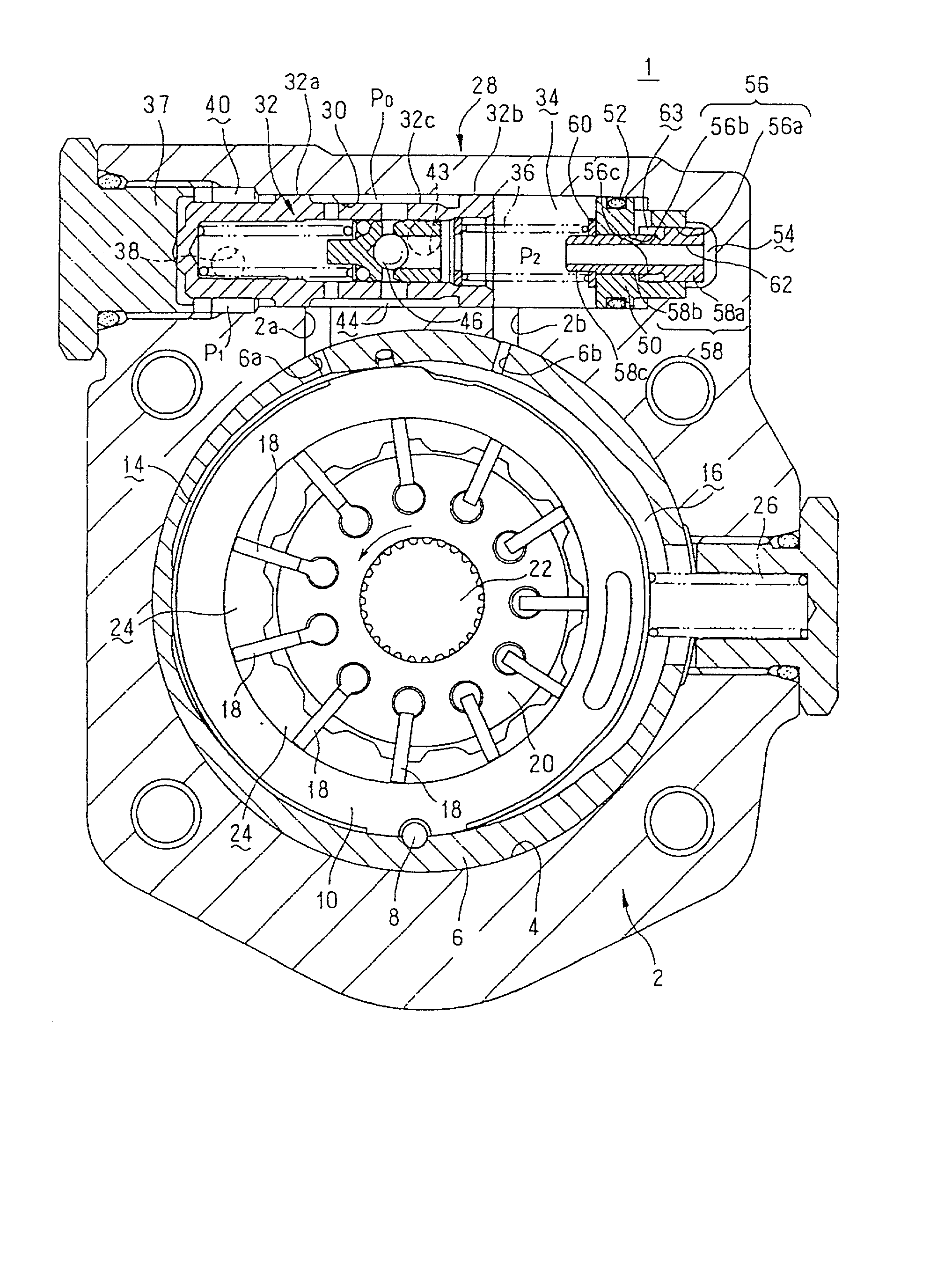

Variable displacement pump

A cam ring 10 is slidably supported within a pump body 2, and a rotor 20 is rotatably disposed inside the cam ring. The cam ring is eccentric to a rotation shaft 22 of the rotor. The rotor carries a plurality of vanes 18 that can be advanced or retreated, in which a pump chamber 24 is formed in a space between the cam ring and the rotor. The cam ring is formed with the first and second fluid pressure chambers 14 and 16 on both sides thereof, and biased in a direction where the displacement of the pump chamber is at maximum by a spring 26. A control valve 28 is provided in which a differential pressure across a metering orifice is applied on both ends of a spool 32 and a spring 36 is disposed on the side of an end face where a downstream fluid pressure is applied. The fluid pressures of the fluid pressure chambers 14 and 16 are controlled by means of the control valve, whereby the cam ring is swung. A piston 58 that is moved in accordance with an increase in working pressure of a power steering apparatus is provided. This piston 58 exerts an axial thrust to an end face of the spool on the spring side.

Owner:UNISIA JKC STEERING SYST

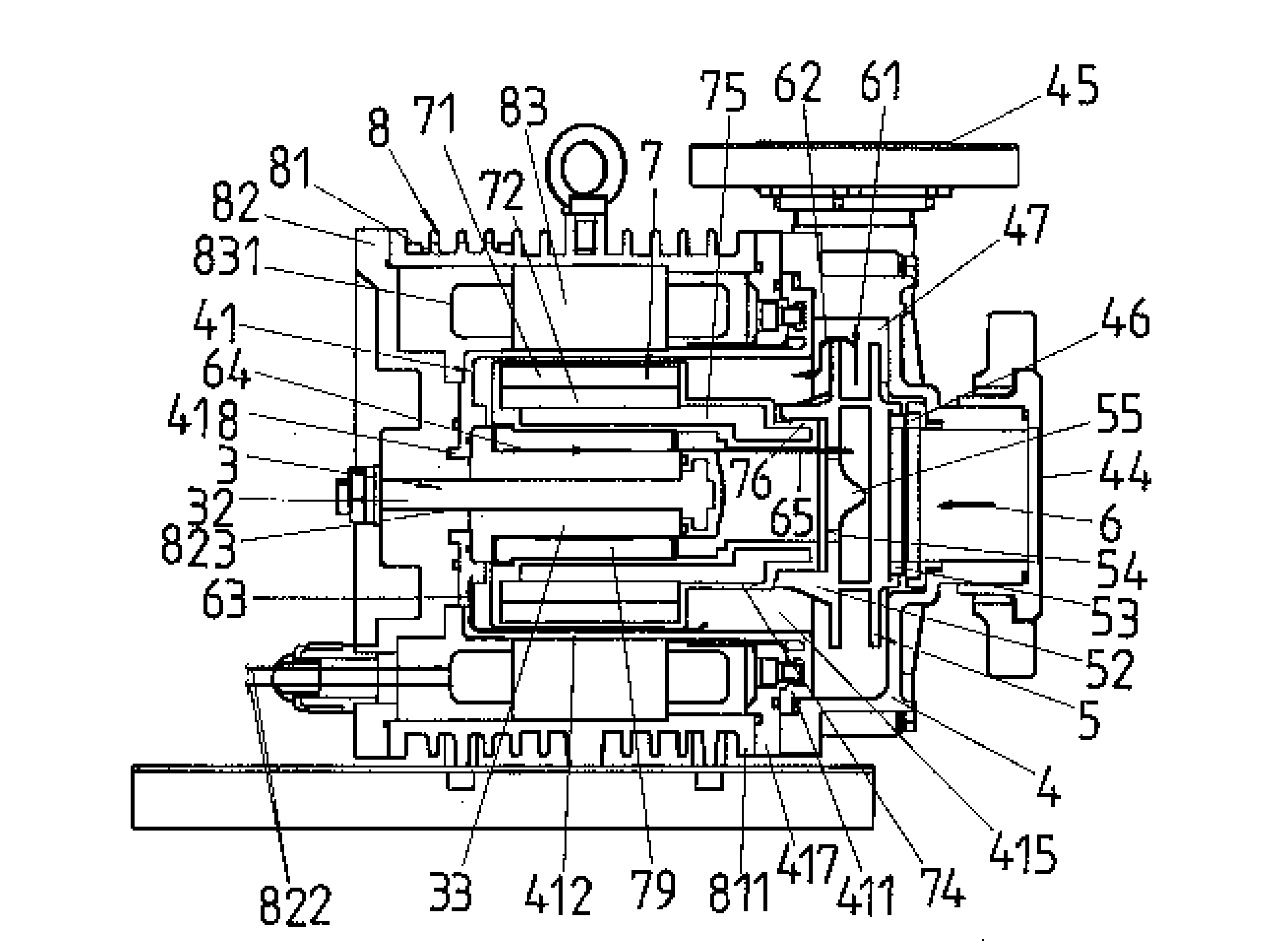

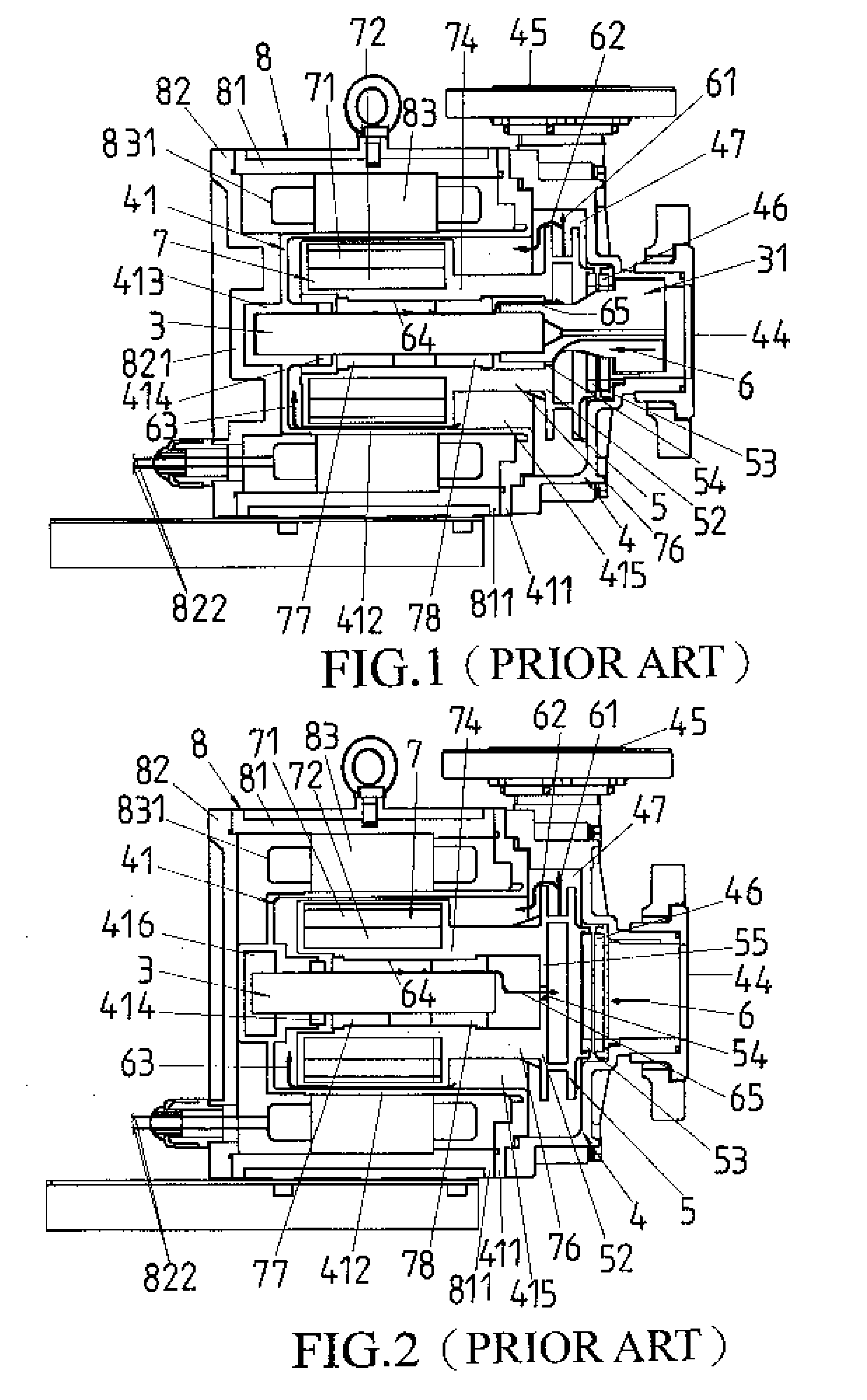

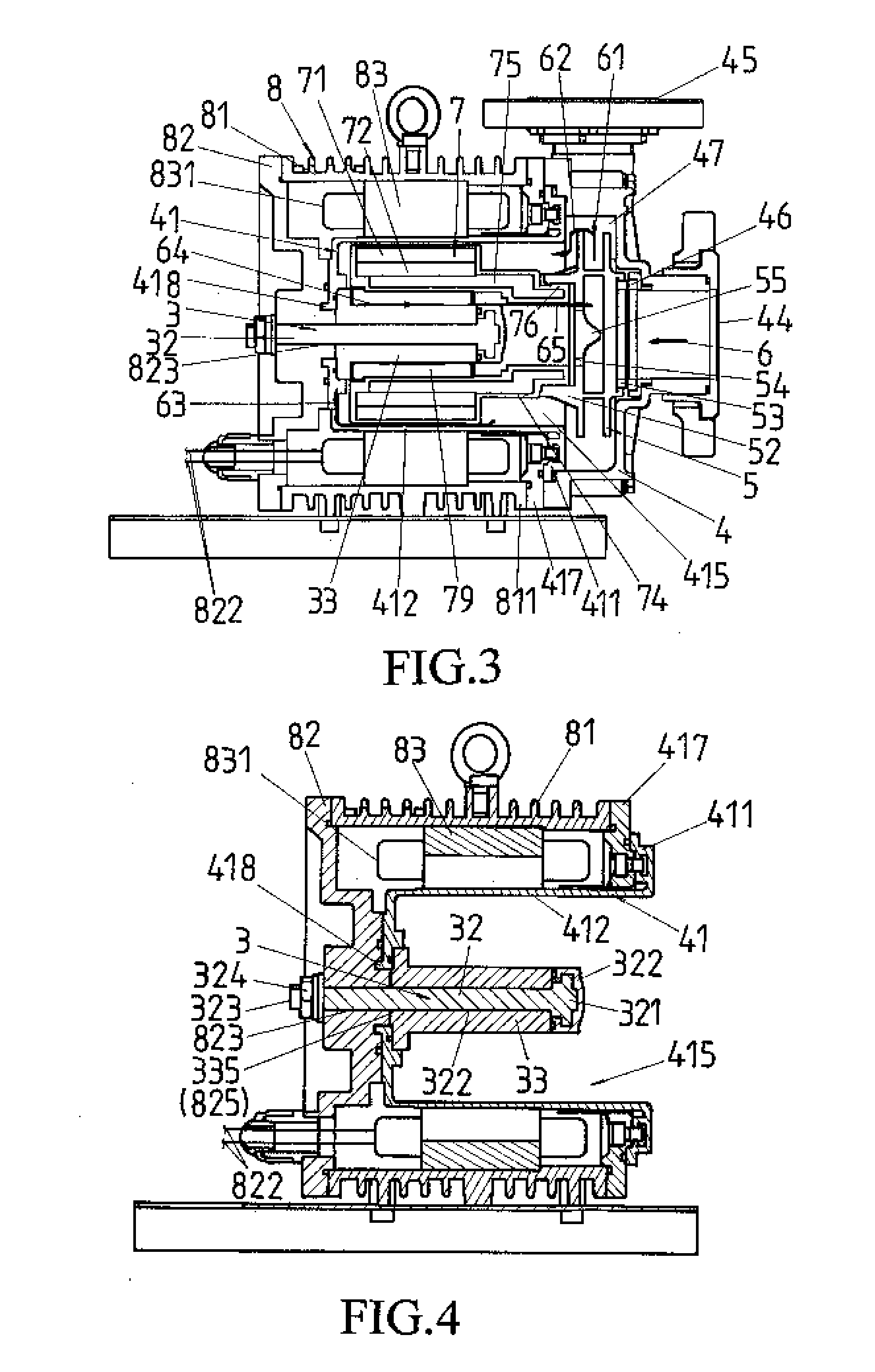

Structural improvement of a canned motor pump

ActiveUS20100272592A1Satisfies requirementImprove sealingPositive displacement pump componentsPiston pumpsInterior spaceAxial thrust

The present invention discloses structure improvement of a canned motor pump, and more particular to a canned motor pump which is a plastic pump or a pump with plastic lining to transfer chemical liquids, wherein a support structure of a rotor system is improved to provide a high-rigidity cantilever stationary shaft to satisfy all kinds of requirements. The high-rigidity cantilever stationary shaft of the present invention comprises a metal shaft, which is locked tightly at a motor rear casing with a nut to compress a ceramic shaft sleeve and the motor rear casing to form a complex cantilever stationary shaft; a ceramic shaft sleeve, which provides hydraulic bearing and an axial thrust bearing functions; a motor rear casing, which enhances the stiffness of the stationary shaft for supporting rotation of the motor rotor; a containment shell, which provides a sealing function to the ceramic sleeve, in addition, the containment shell is provided with a central hole allowing the metal shaft to pass through, and an inner space is used to hold the motor rotor and to provide a sealing function to a motor stator winding.

Owner:ASSOMA

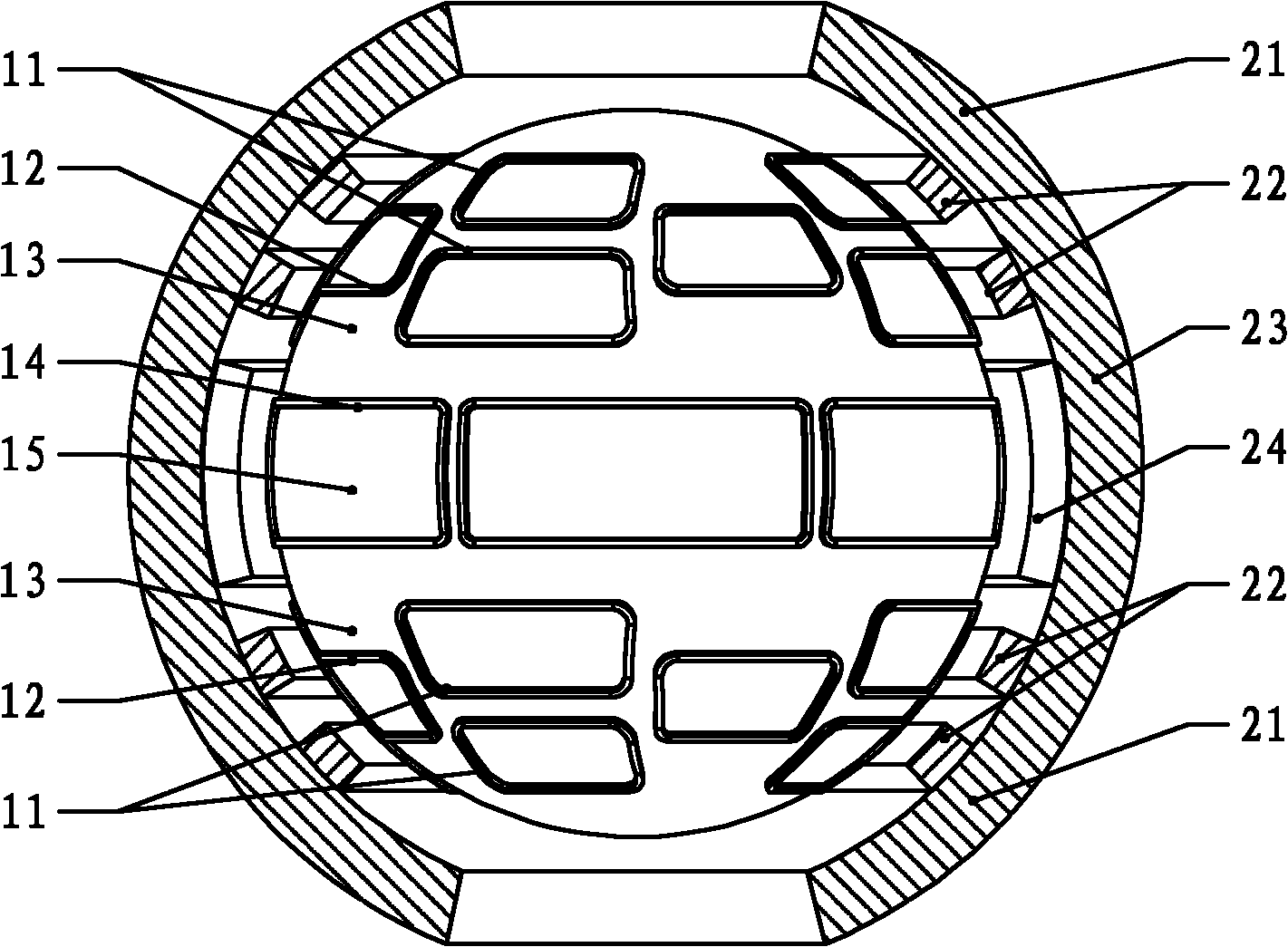

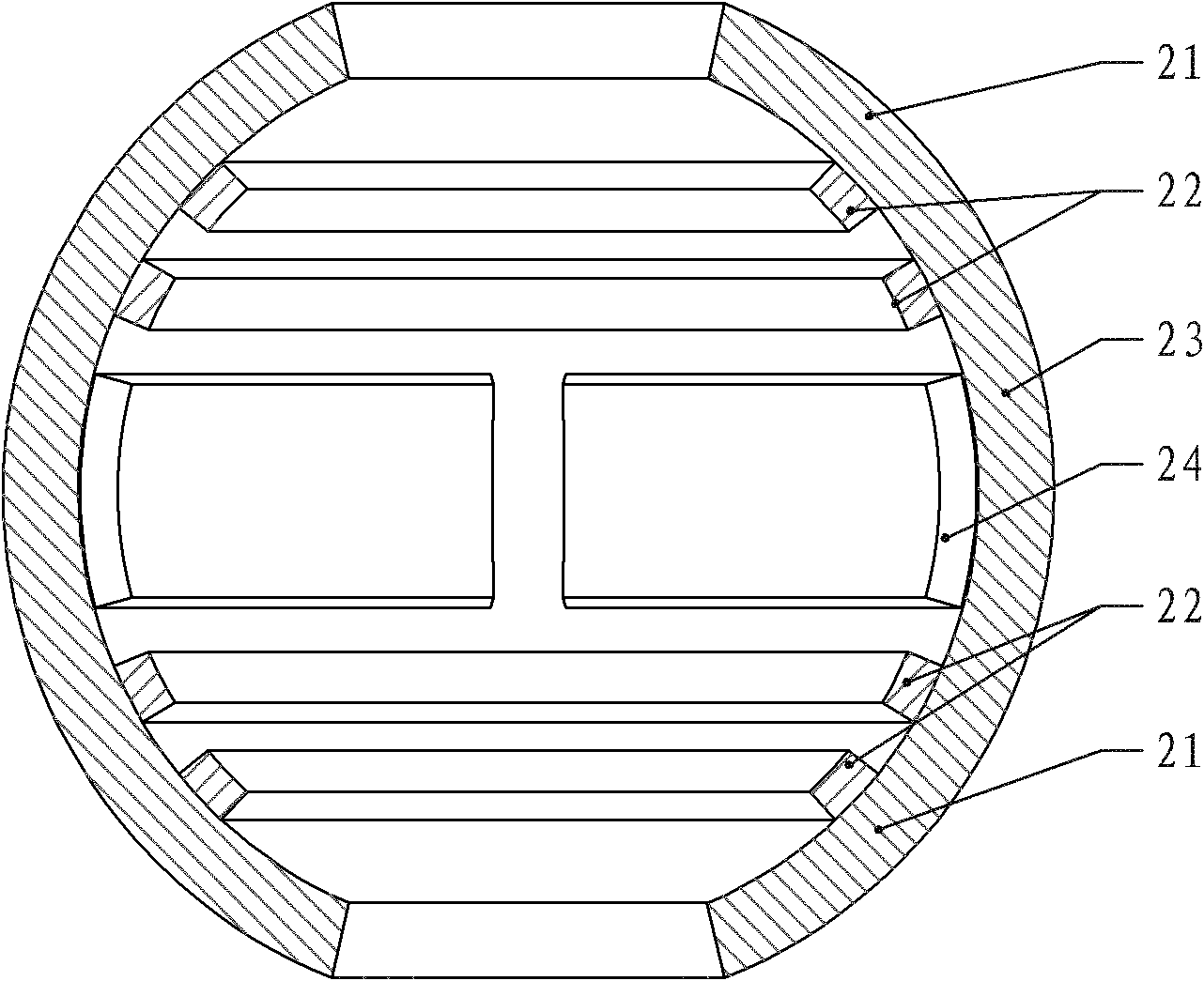

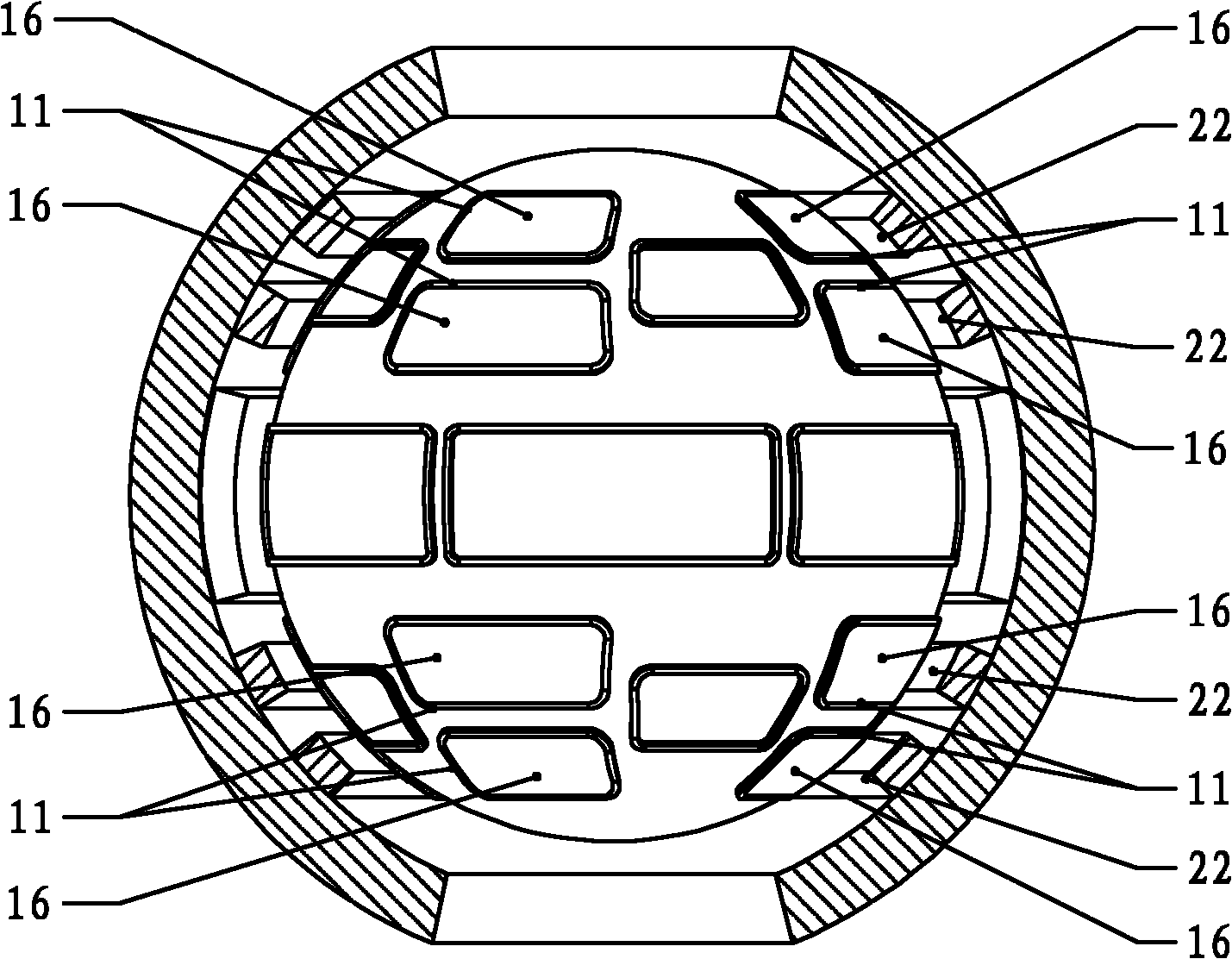

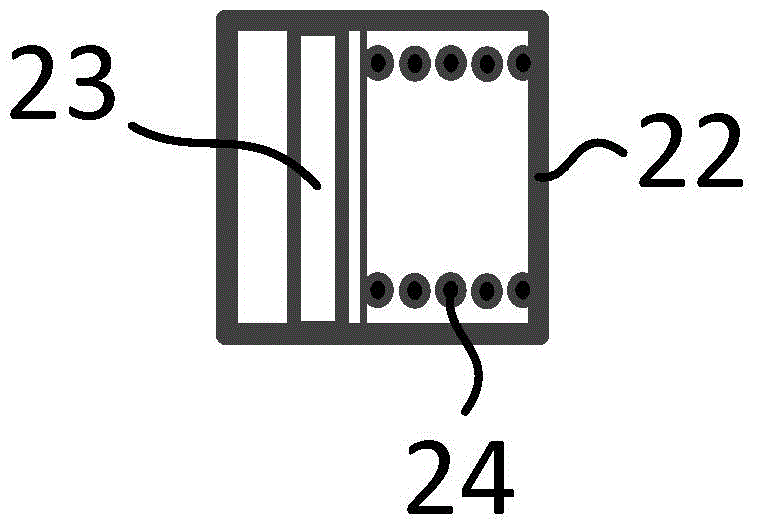

MDOF (multiple-degree-of-freedom) magnetic suspension motor

The invention provides an MDOF (multiple-degree-of-freedom) magnetic suspension motor, belonging to the technical field of motors. A magnetic suspension technology is combined with an MDOF motor technology to design the MDOF magnetic suspension motor. A spherical type MDOF magnetic suspension motor, a cylinder type MDOF magnetic suspension motor and a flat plate type MDOF magnetic suspension motor are provided, wherein a stator and a rotor of a rotating machine unit of the spherical type MDOF magnetic suspension motor are fixedly connected with a deflection motor unit and a suspension motor unit mainly by a primary structure and a secondary structure; a stator and a rotor of a rotating machine unit of the cylinder type MDOF magnetic suspension motor are fixedly connected with primary structures and secondary structures of an axial thrust and suspension motor unit respectively; and a primary structure and a secondary structure of a bilateral linear motor unit of the flat plate type MDOF magnetic suspension motor are fixedly connected with a primary structure and a secondary structure of an oriented suspension motor unit respectively. The MDOF control windings of the three motors are independent mutually and are not coupled; the same secondary structure is used for the suspension control and the deflection control, thereby being simple in structure; and the rotors are supported by adopting a magnetic suspension way, thus the friction does not occur, the speed is high and the service life is long.

Owner:HARBIN INST OF TECH

Bearing assembly for downhole mud motor

Owner:CIOCEANU NICU

Rolling element bearing cartridge with axial thrust damping and Anti-rotation assemblies

ActiveUS20130202432A1Prevent rotationLow costPump componentsBearing assemblyRolling-element bearingTurbocharger

To solve both axial and rotational constraint problems in turbochargers with rolling element bearings (REBs), a REB sleeve or outer race is mounted to the bearing housing in a way that is not axially and radially rigid, thus allowing for oil damping films both radially and axially. At the same time, the REB sleeve or outer race is held so that the REB sleeve or outer race does not rotate relative to the bearing housing. This dual purpose is achieved using an anti-rotation ring and a damping ring. The anti-rotation ring includes at least one anti-rotation feature for engaging the bearing housing and at least one anti-rotation feature for engaging the REB cartridge, preventing rotation of the REB cartridge sleeve or outer race. The damping ring axially locates the REB cartridge and dampens axial movement and cushions axial thrust.

Owner:BORGWARNER INC

Disk brake with a parking brake, mechanical thrust assembly, and method of assembling

ActiveUS20140158480A1Braking element arrangementsMechanically actuated brakesAxial thrustEngineering

An arrangement contains a brake piston for operating at least one disk brake pad and a nut-and-screw unit for producing an axial thrust, from the rear to the front, of the piston containing a nut arranged in the piston's interior, and secured thereto to prevent rotation, and mounted therein to slide axially, whose front axial end face interacts with an internal section facing the piston's front wall to push the piston axially towards the front when the screw is rotatably driven in the unscrewing direction, and the screw containing a front section screwed into the nut, an intermediate radial flange and a rear section, wherein the piston screw contain centering elements that interact with one another when the screw is in a predetermined front axial mounting position in relation to the piston in order to center the rear section of the screw radially in relation to the piston.

Owner:CHASSIS BRAKES INT BV

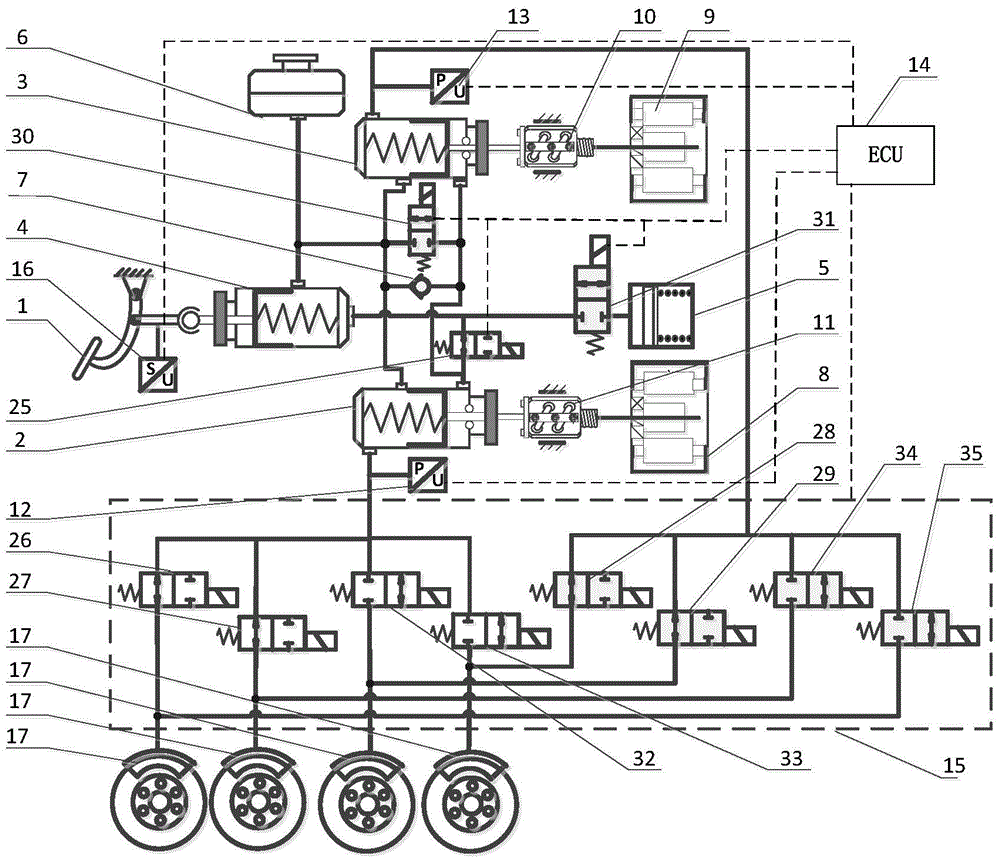

Dual-motor BBW (brake-by-wire) system with multiple working modes and voltage regulation modes

ActiveCN103552556AFeel adjustableWith active braking functionBraking action transmissionFoot actuated initiationsAxial thrustWheel cylinder

The invention discloses a dual-motor BBW system with multiple working modes and voltage regulation modes. A brake fluid in a manual cylinder flows into two main cylinders by means of a brake pedal, and brake pressure is generated; and meanwhile, output power torque of two motors is controlled, and axial thrust is overlaid to pistons of the two main cylinders through a transmission device, so that electric power brake is realized. Through control of output torque of the two motors, pressure of the two main cylinders is transmitted to wheel cylinders, brake by wire is realized, and a pedal travel simulator is used for providing force for the brake pedal. Under the condition that the brake pedal is not stepped, the output torque of the two motors is controlled, so that the two cylinders generate pressure which is transmitted to the wheel cylinders through a hydraulic control unit, and accordingly, the active brake is realized. The invention further discloses a structure of a hydraulic control system, and the structure has multiple voltage regulation modes. The dual-motor BBW system has the advantages as follows: the system has multiple braking modes and voltage regulation modes, the most appropriate braking mode and voltage regulation mode can be selected according to dynamic properties of the motors during implementation and application, the reliability is high, and the failure protection capacity is high.

Owner:南京经纬达汽车科技有限公司

Drive shaft assembly for a downhole motor

A drive shaft assembly for a downhole motor includes a drive shaft formed with convexly spherical bearing surfaces on each end, and end housings with concavely spherical bearing surfaces for mating contact with the spherical bearing surfaces of the drive shaft, thereby facilitating omni-directional articulation between the drive shaft and the end housings while transferring axial thrust loads between the drive shaft and end housings across the interface of the mating spherical bearing surfaces. Torque is transferred between the drive shaft and end housings through two or alternatively four swivelling drive keys mounted to each end of the drive shaft and engageable with complementary drive key slots in the end housings. Full and constant torque-transferring contact is thus provided between the swivelling drive keys and the end housings irrespective of any angular offset between the drive shaft and the end housings, resulting from omni-directional articulation of the drive shaft relative to the end housing. The omni- directional center of rotation at each end of the drive shaft coincides with the geometric centerpoint of the corresponding convexly spherical bearing surface, which corresponds to the intersection of the drive shaft's rotational axis, the end housing's rotational axis, and the drive key swivel axis.

Owner:DRECO ENERGY SERVICES ULC

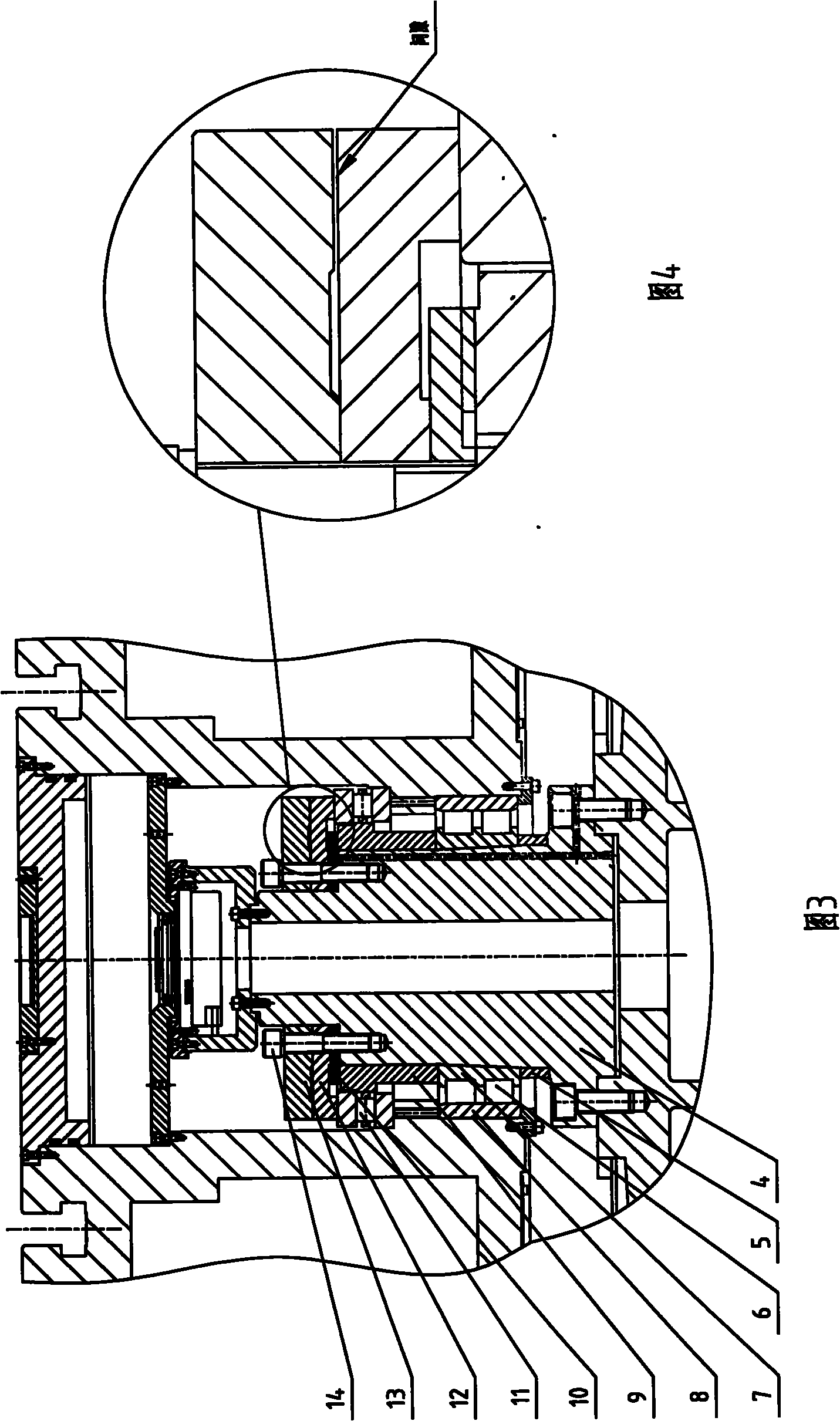

High-speed direct connection spindle

ActiveCN103737408AGuaranteed to workAvoid enteringLarge fixed membersChucksBody positionsEngineering

The invention relates to a high-speed direct connection spindle. The high-speed direction connection spindle comprises an engine body, a central spindle, a pull rod, a reset spring and an oil cylinder assembly, wherein the central spindle is pivoted in the engine body through an upper bearing and a lower bearing arranged at the upper end and the lower end of the engine body, and a conical hole is formed in the bottom end of the central spindle, wherein the diameter of the conical hole is increased from top to bottom in sequence; the lower end of the pull rod is connected with a pulling claw which is matched with the conical hole and used for fixing a cutter, and the upper end of the pull rod is fixedly provided with a cutter hitting disk; the reset spring is arranged between the central spindle and the pull rod; the oil cylinder assembly comprises a cylinder body positioned above the top of the engine body and a piston arranged at the interior of the cylinder body and used for propping against the cutter hitting disk downwards; the cylinder body is movably provided with a plurality of connecting pieces in a penetrating manner, the part, penetrating through the lower end of the cylinder body, of each connecting piece is fixedly connected to the engine body, and each connecting piece is connected with an elastic element in a sleeving manner. The cylinder body of the oil cylinder is arranged on the engine body in a floating manner, and the axial thrust applied to the central spindle when a cutter is assembled or disassembled on the oil cylinder can be counteracted, so that a bearing is protected from being damaged, and the service life of the bearing is prolonged.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com