Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23009 results about "Check valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A check valve, clack valve, non-return valve, reflux valve, retention valve or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, or inexpensive. Check valves work automatically and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal.

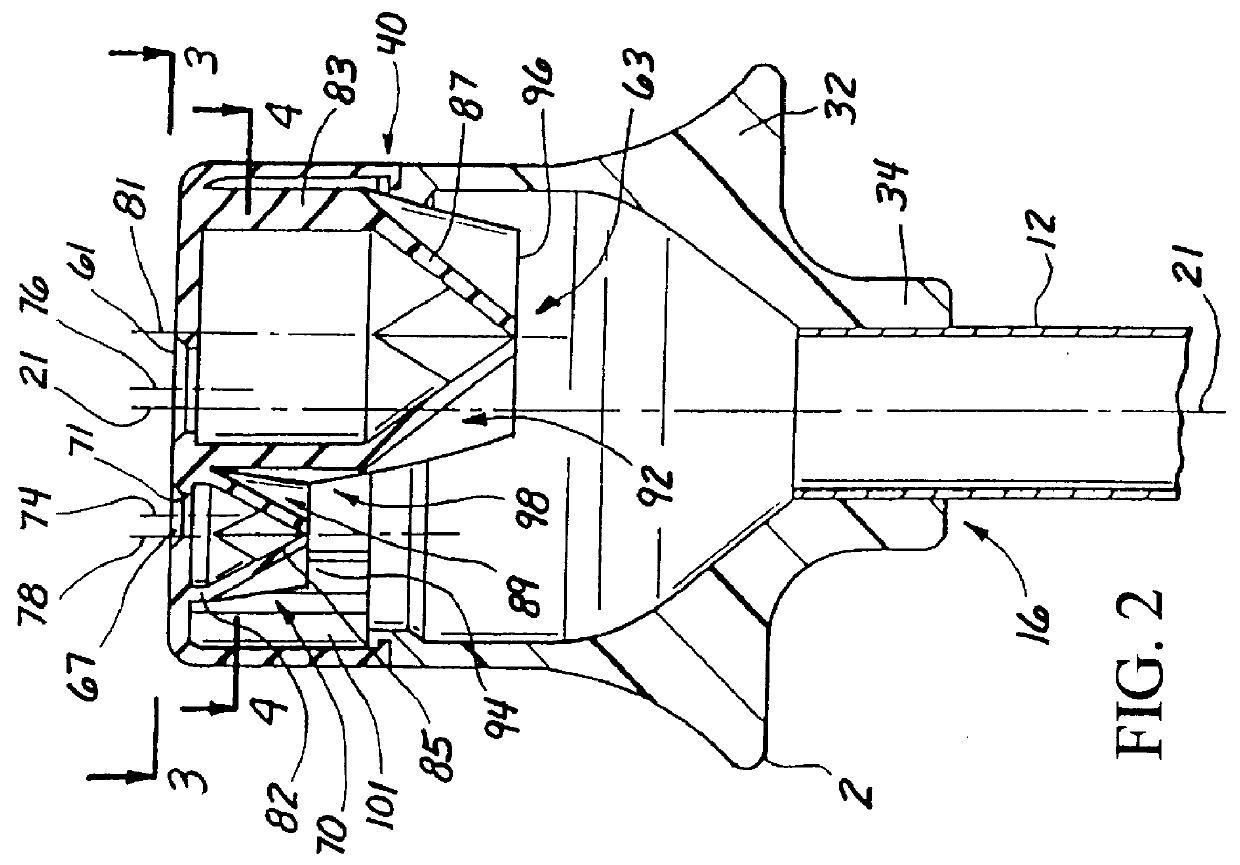

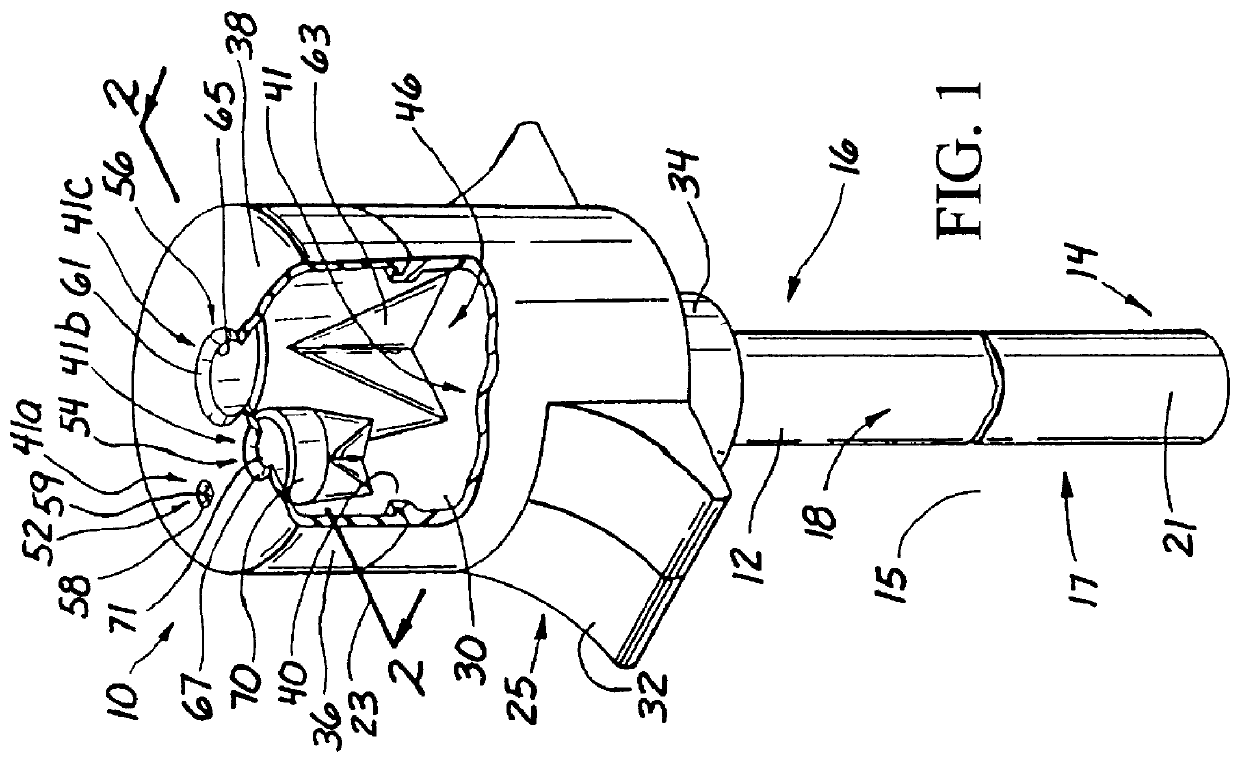

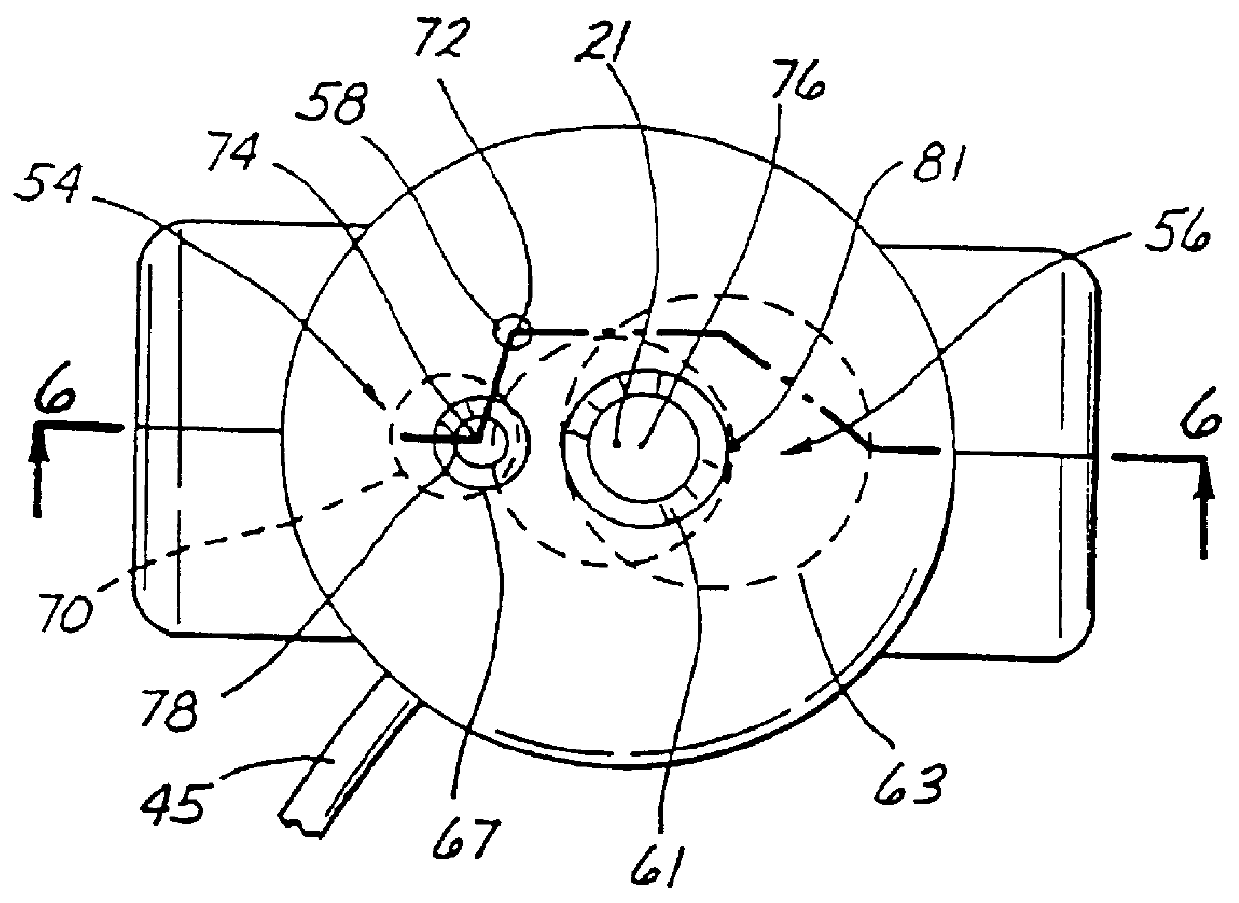

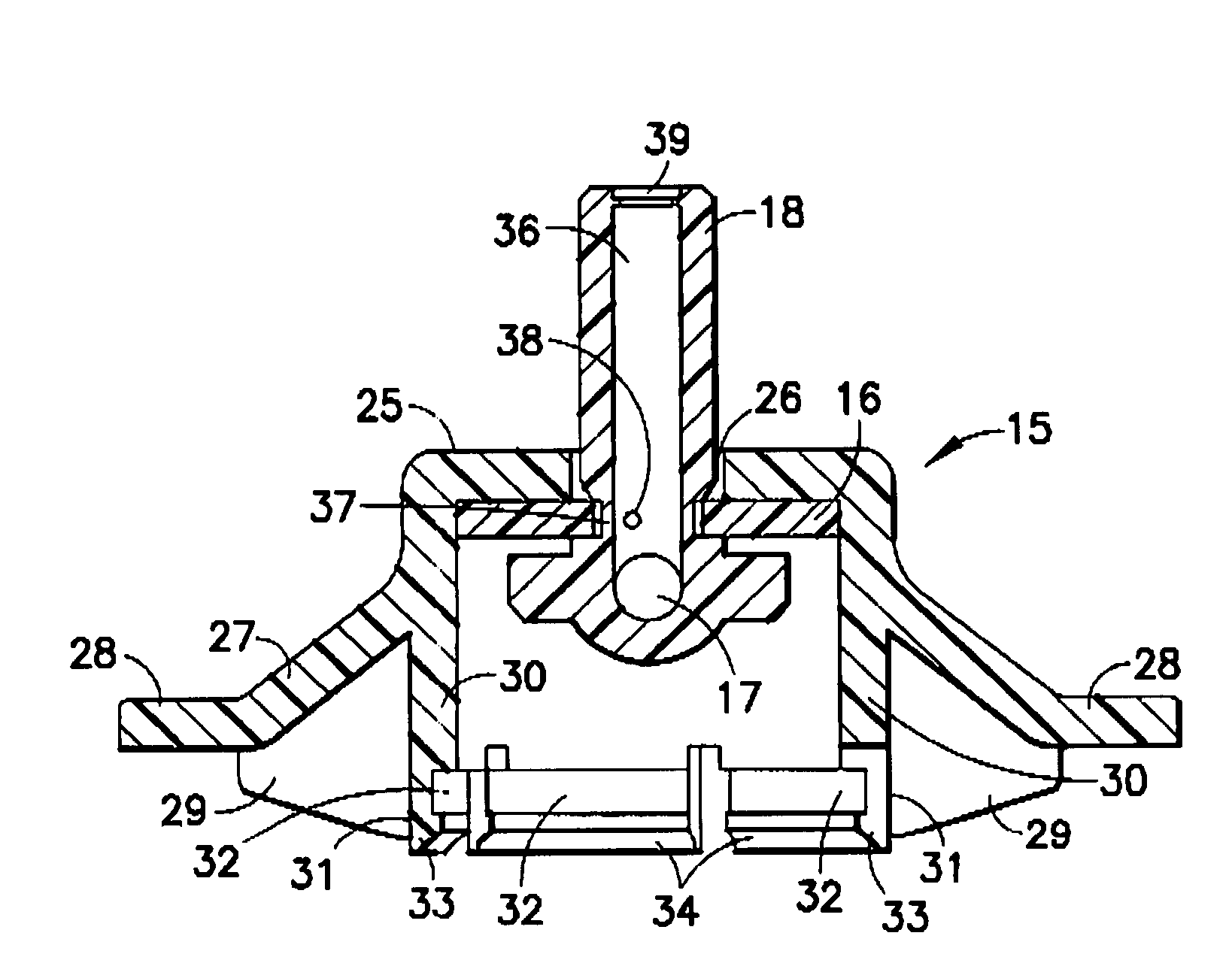

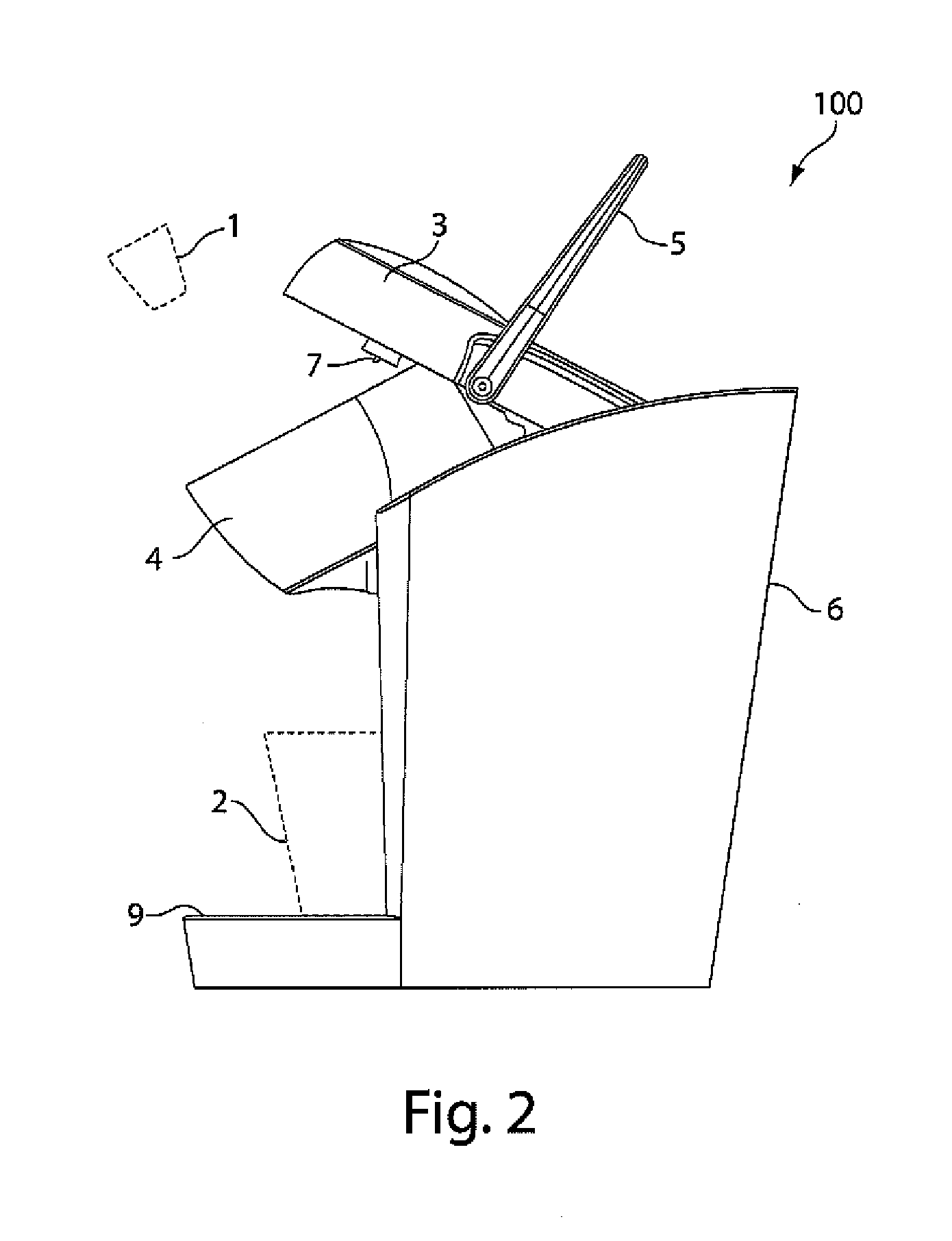

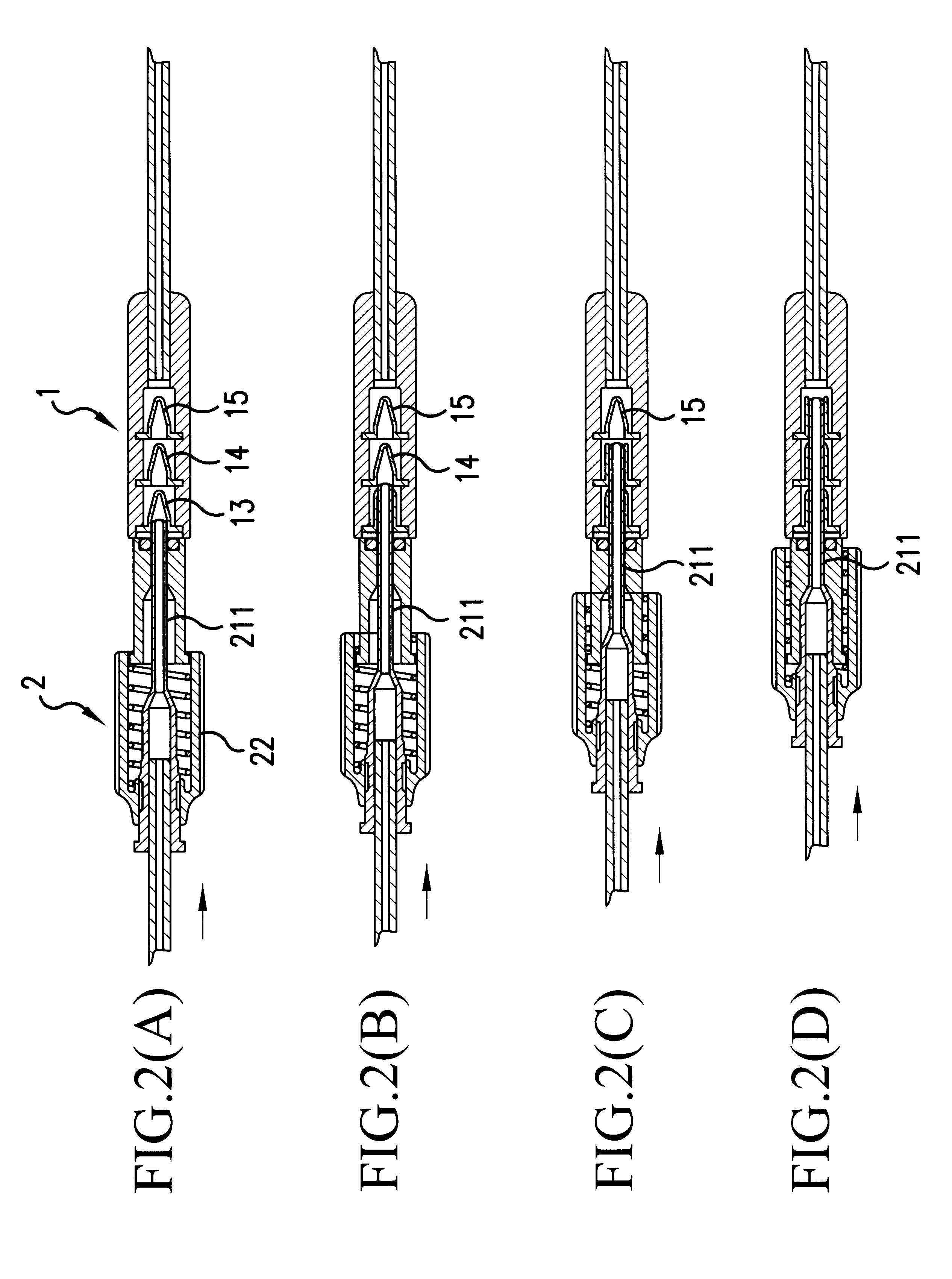

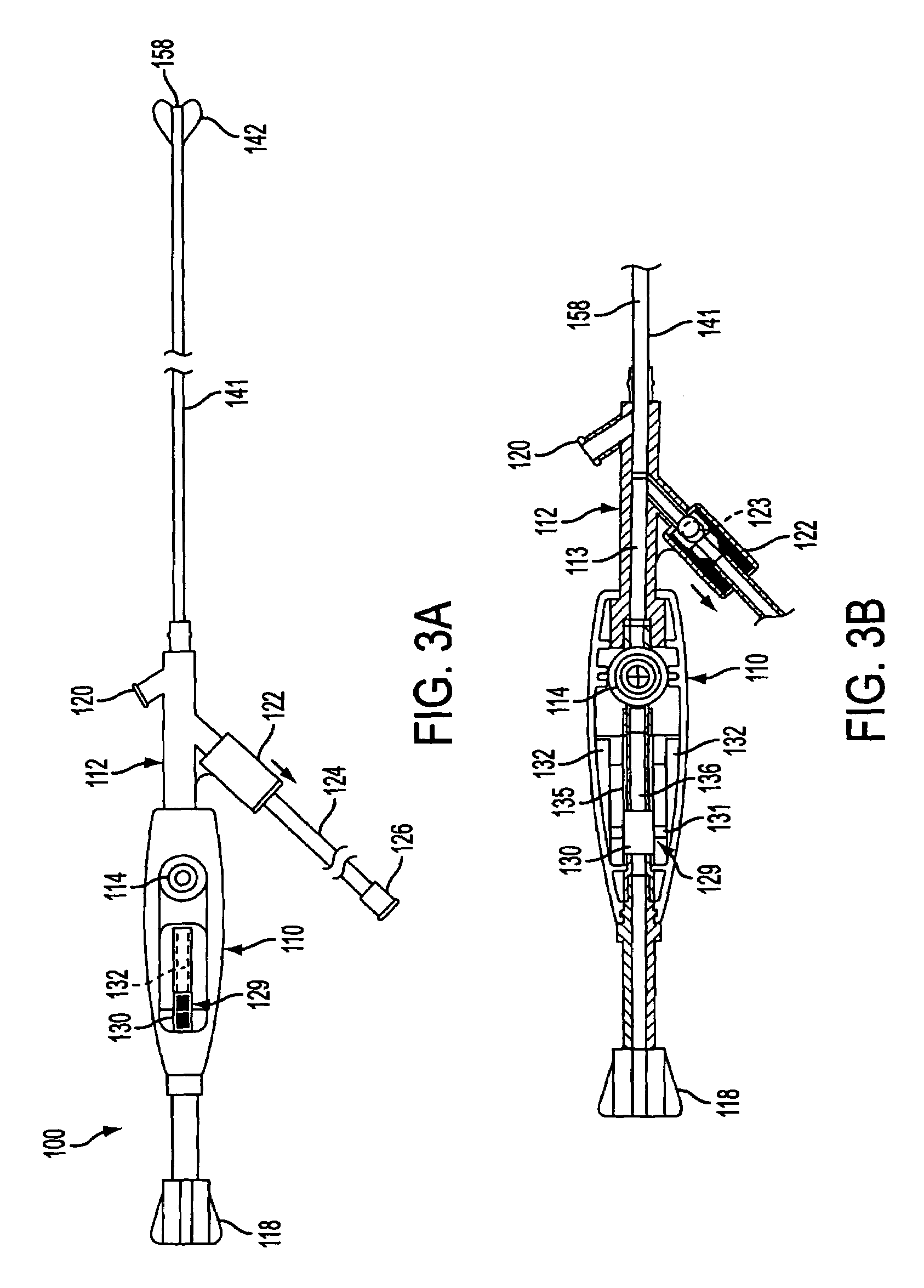

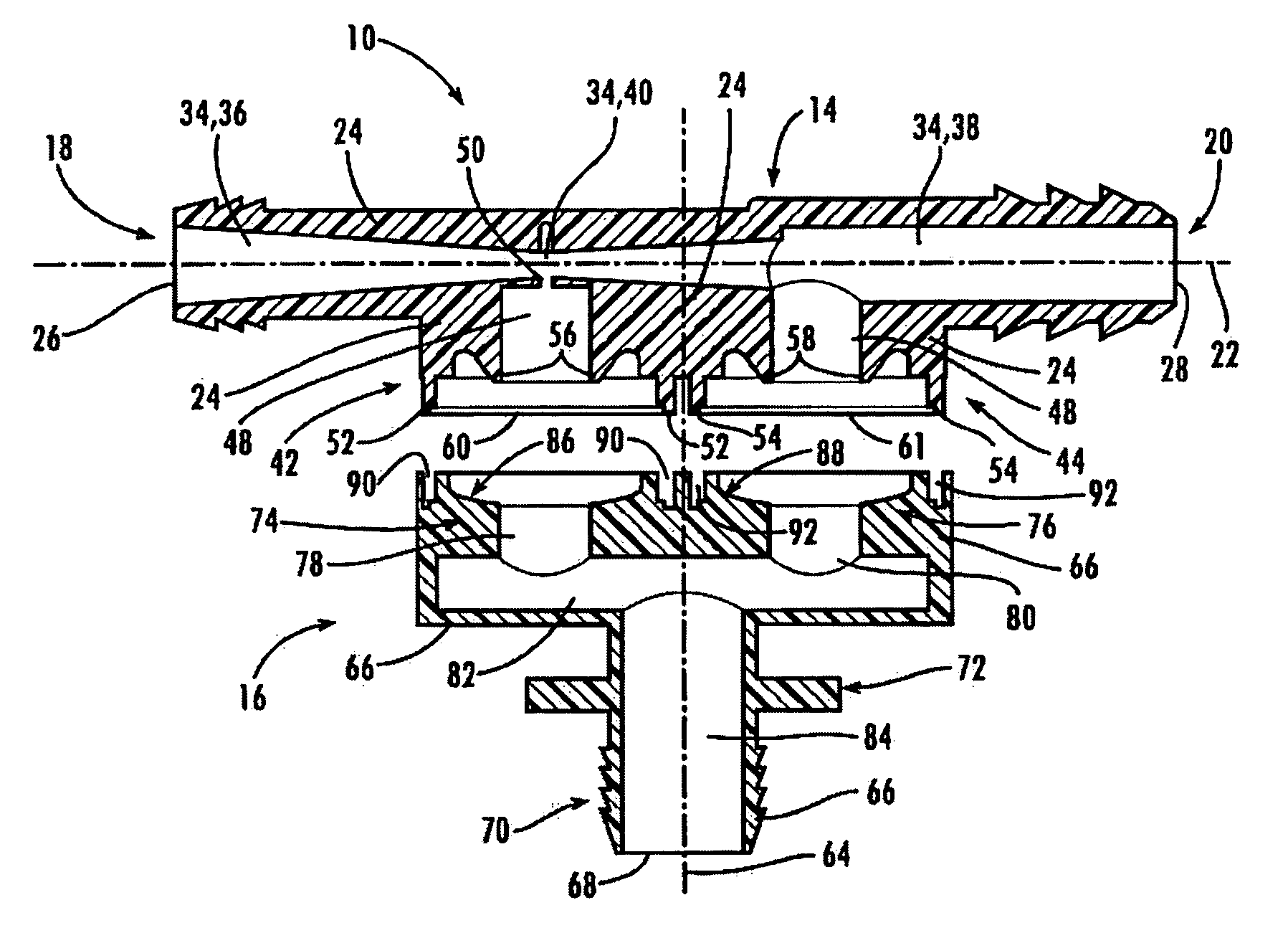

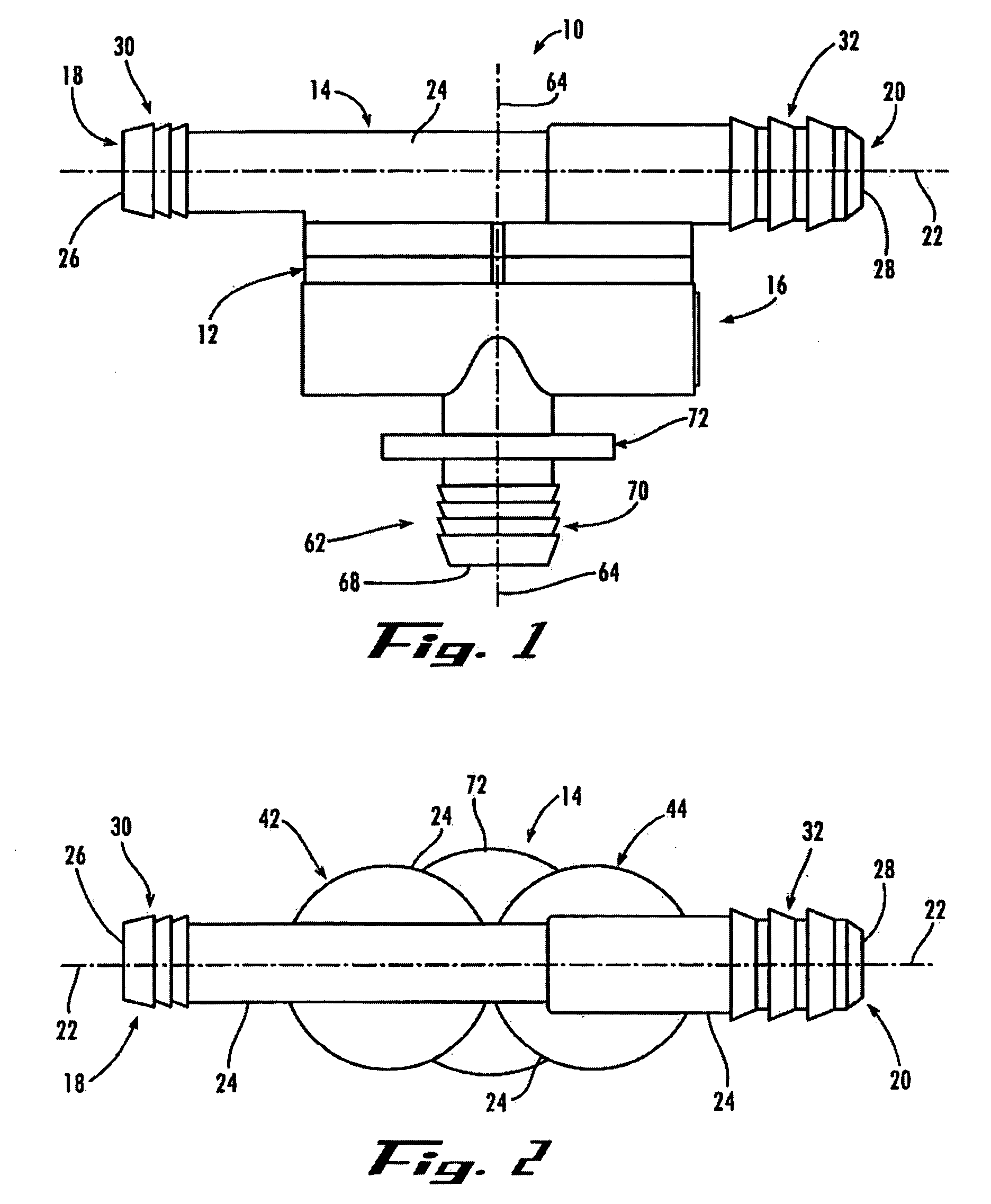

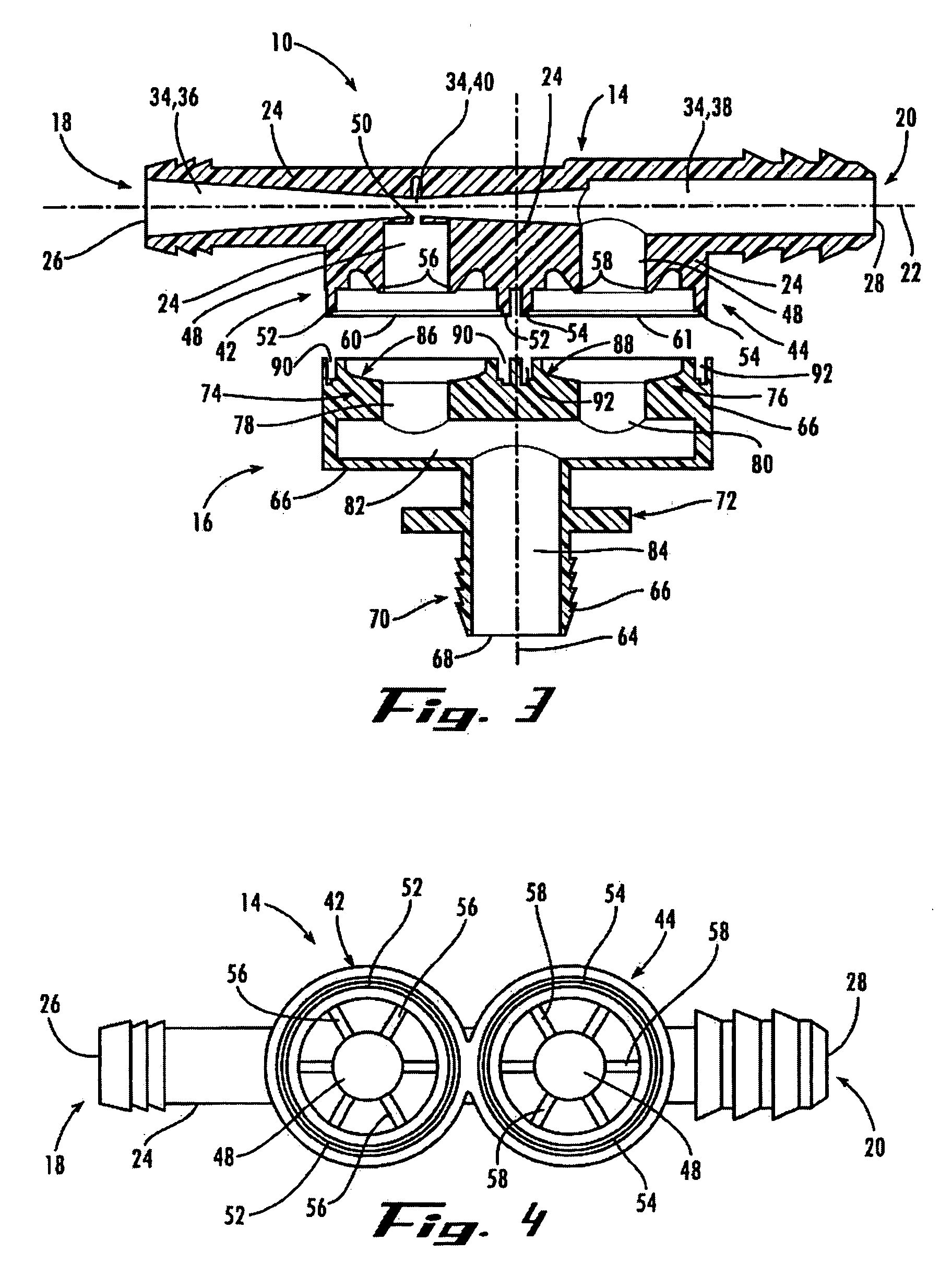

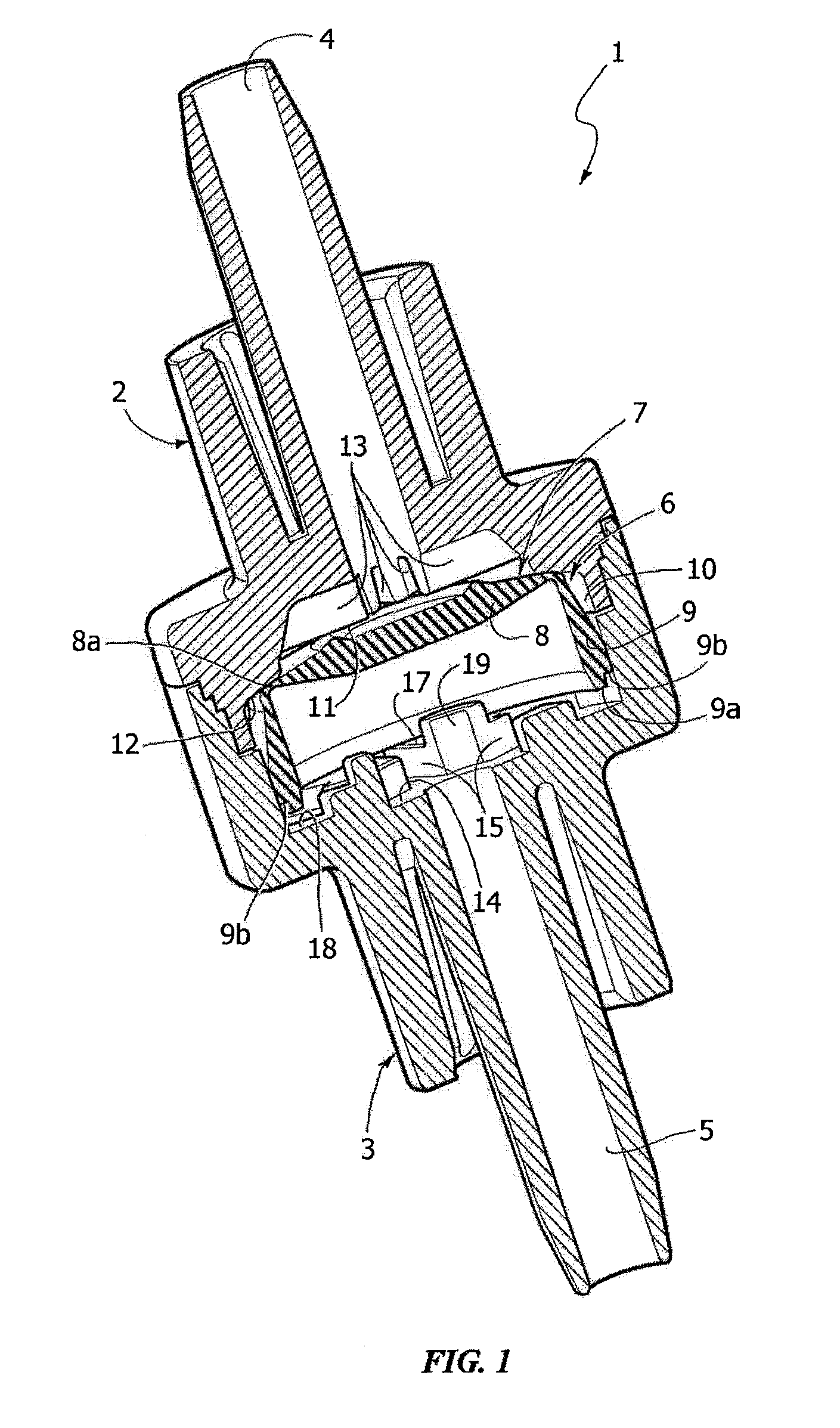

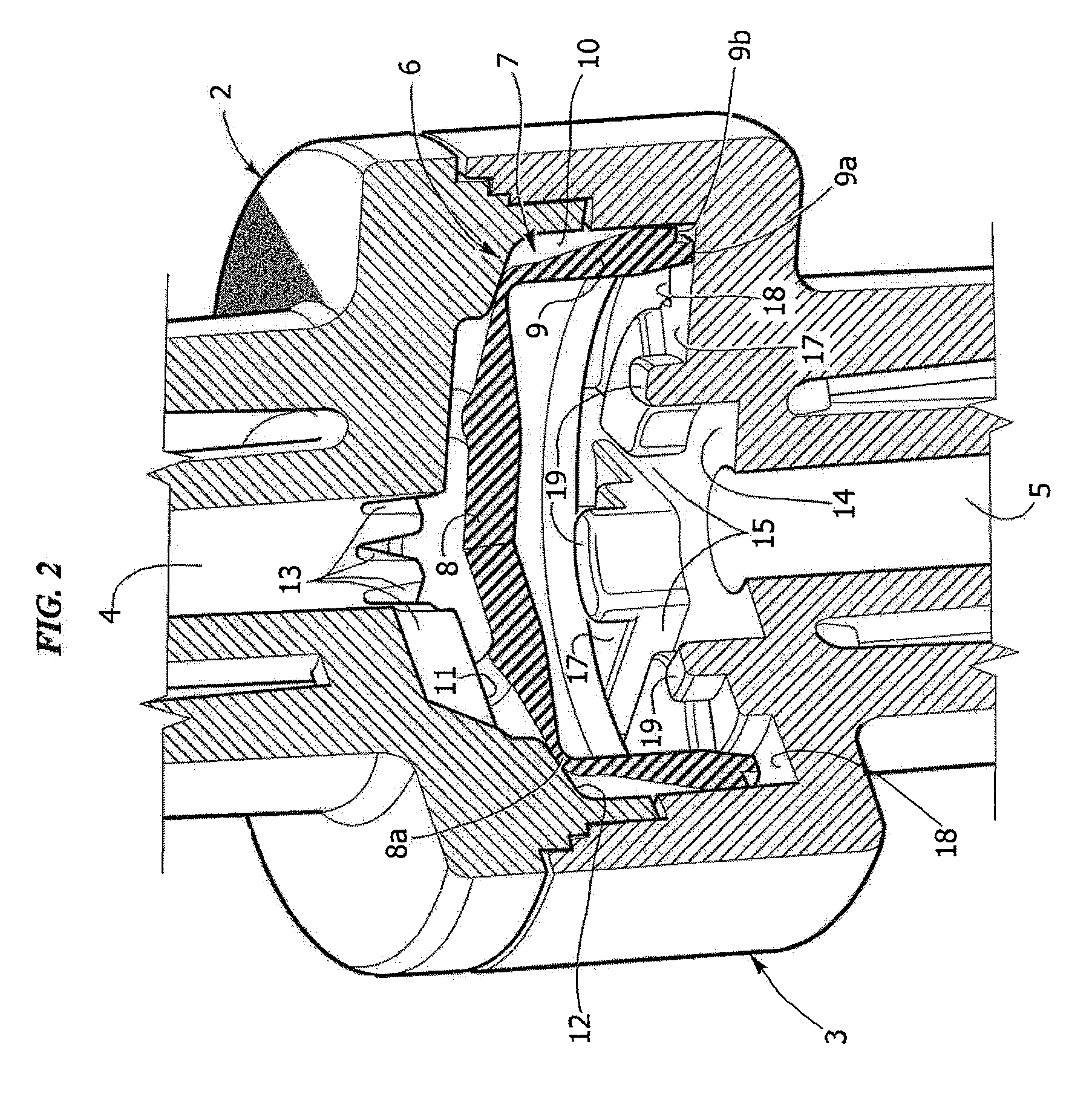

Multiport access device

A trocar having a cannula and a valve housing with a polygonal configuration, provides for a floating septum where the float is encouraged in a first direction and restricted in a second direction. The septum includes multiple septum valves which may function with a comnron zero-closure valve, or individually in a valve assembly with an associated zero-closure valve. Various seals can be configured to prevent blow-back. Cup valves, check valves, and reciprocating valves are contemplated, along with various skirt configurations for maintaining pressurized air within the trocar.

Owner:APPL MEDICAL RESOURCES CORP

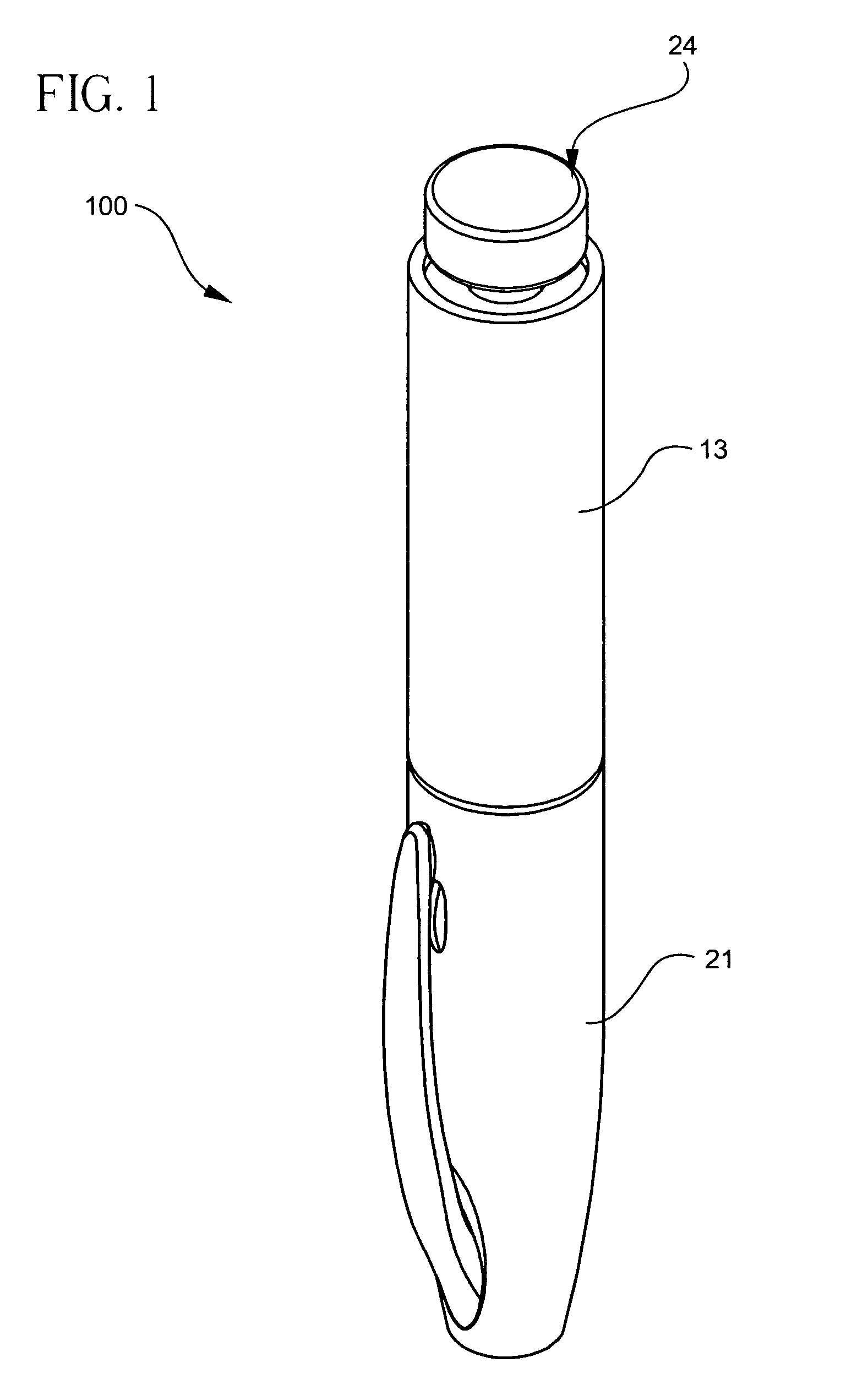

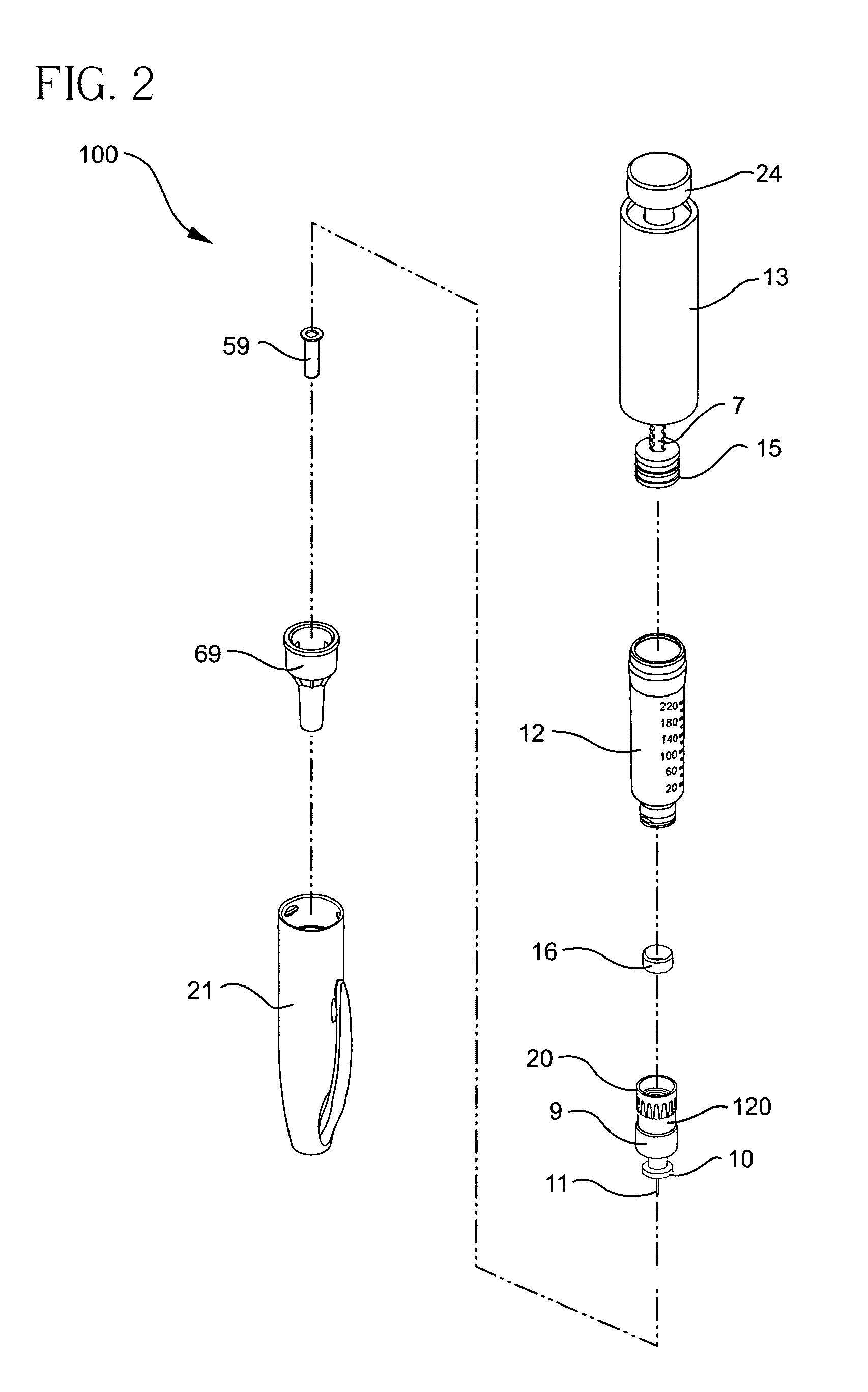

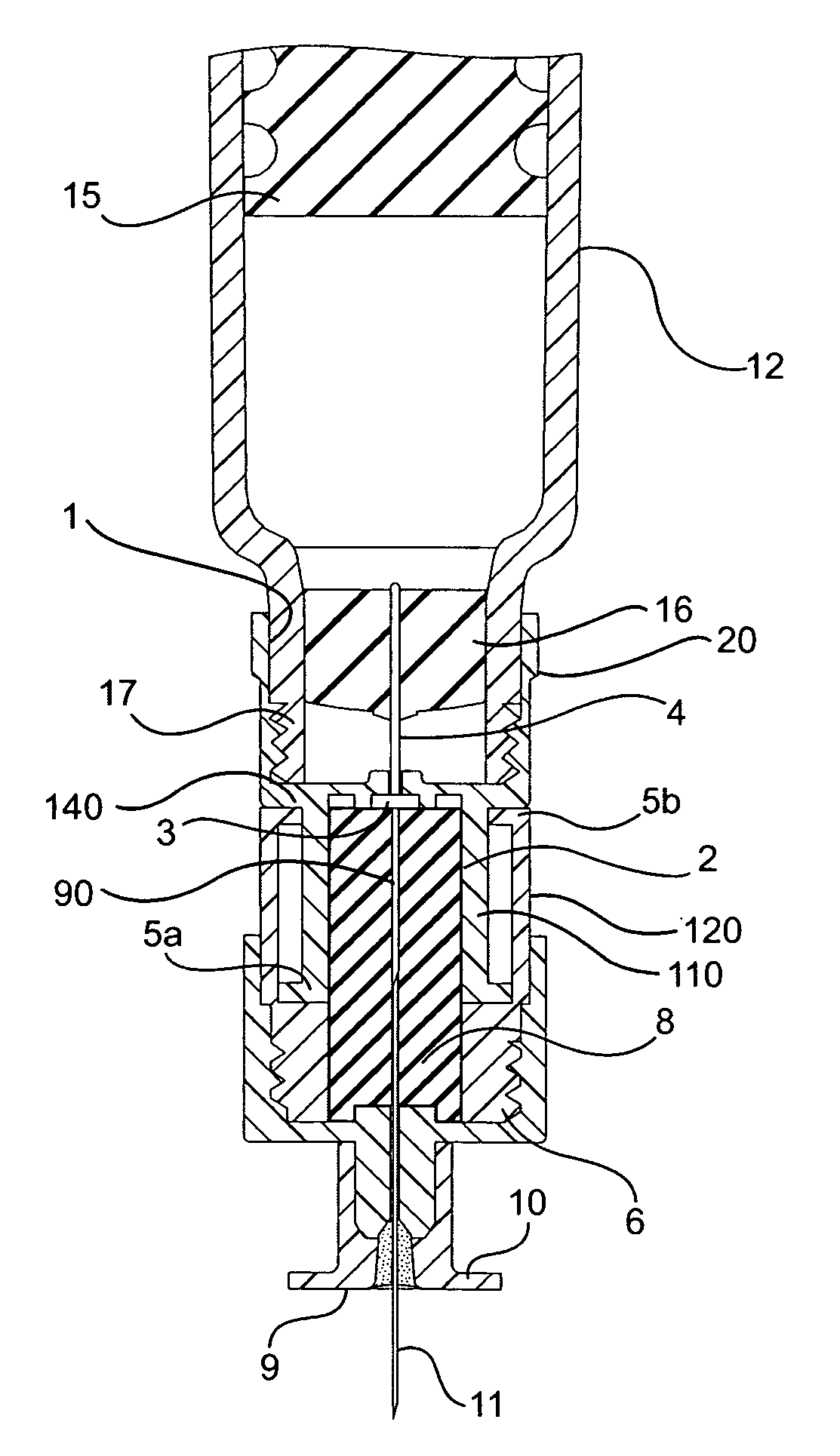

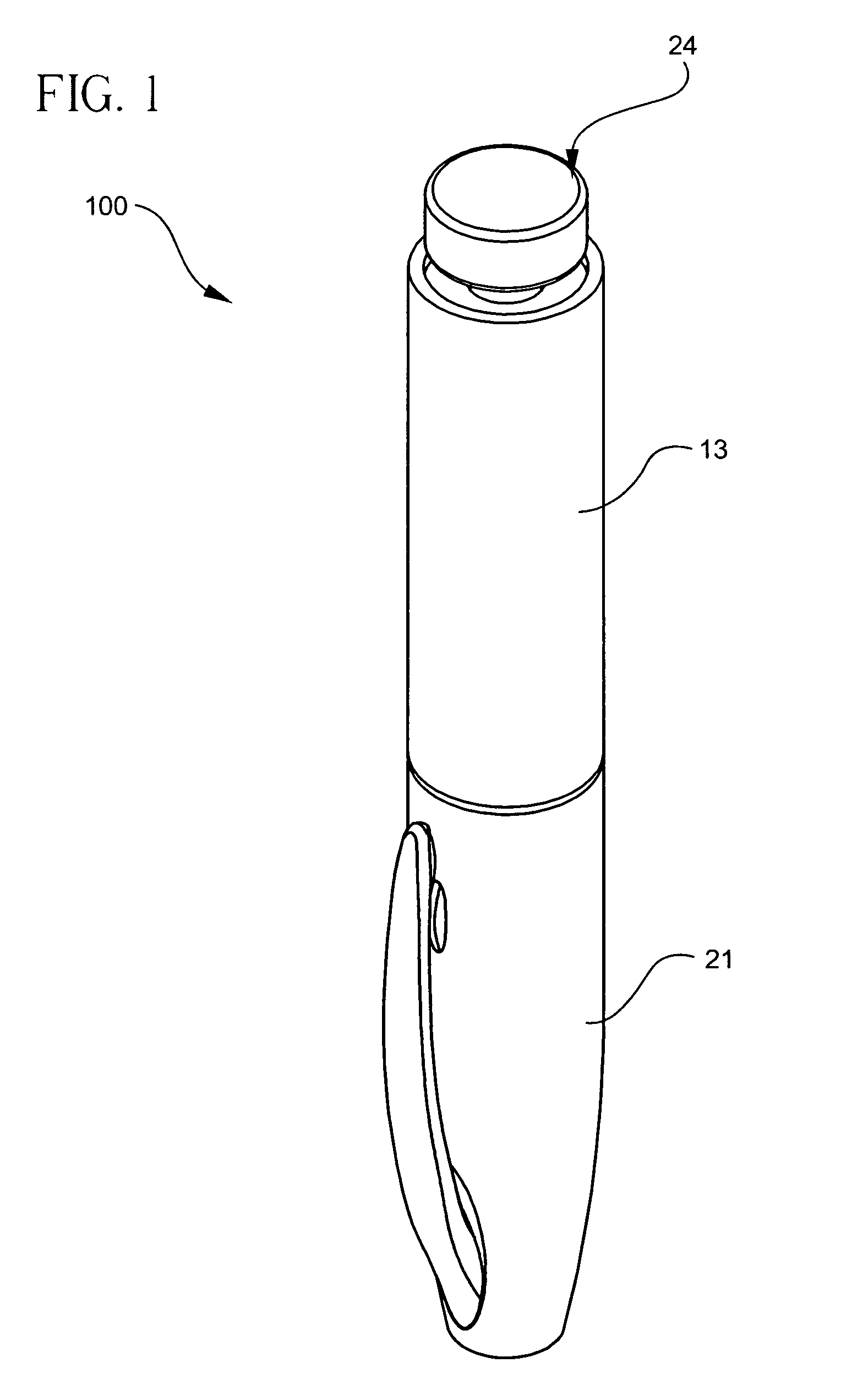

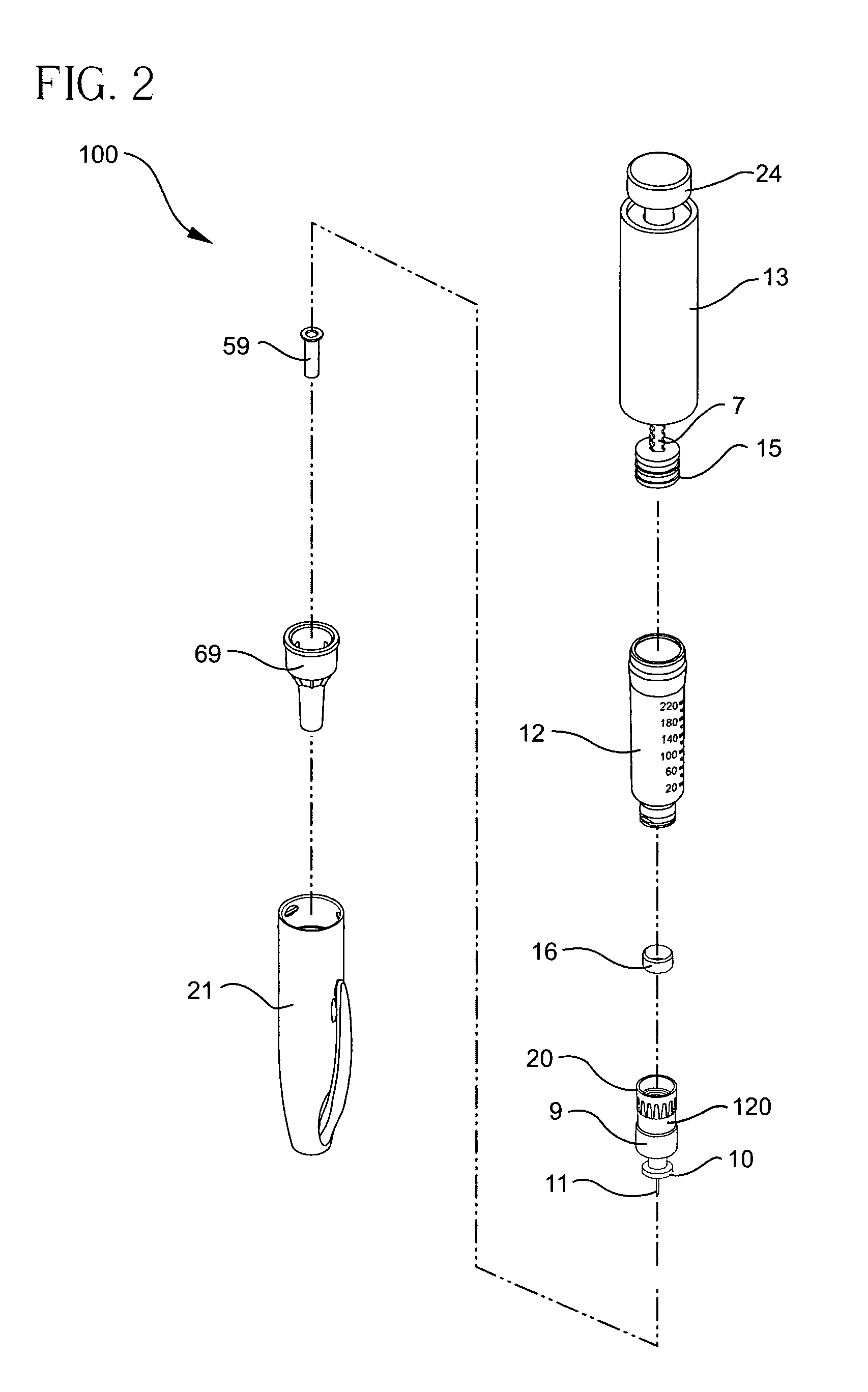

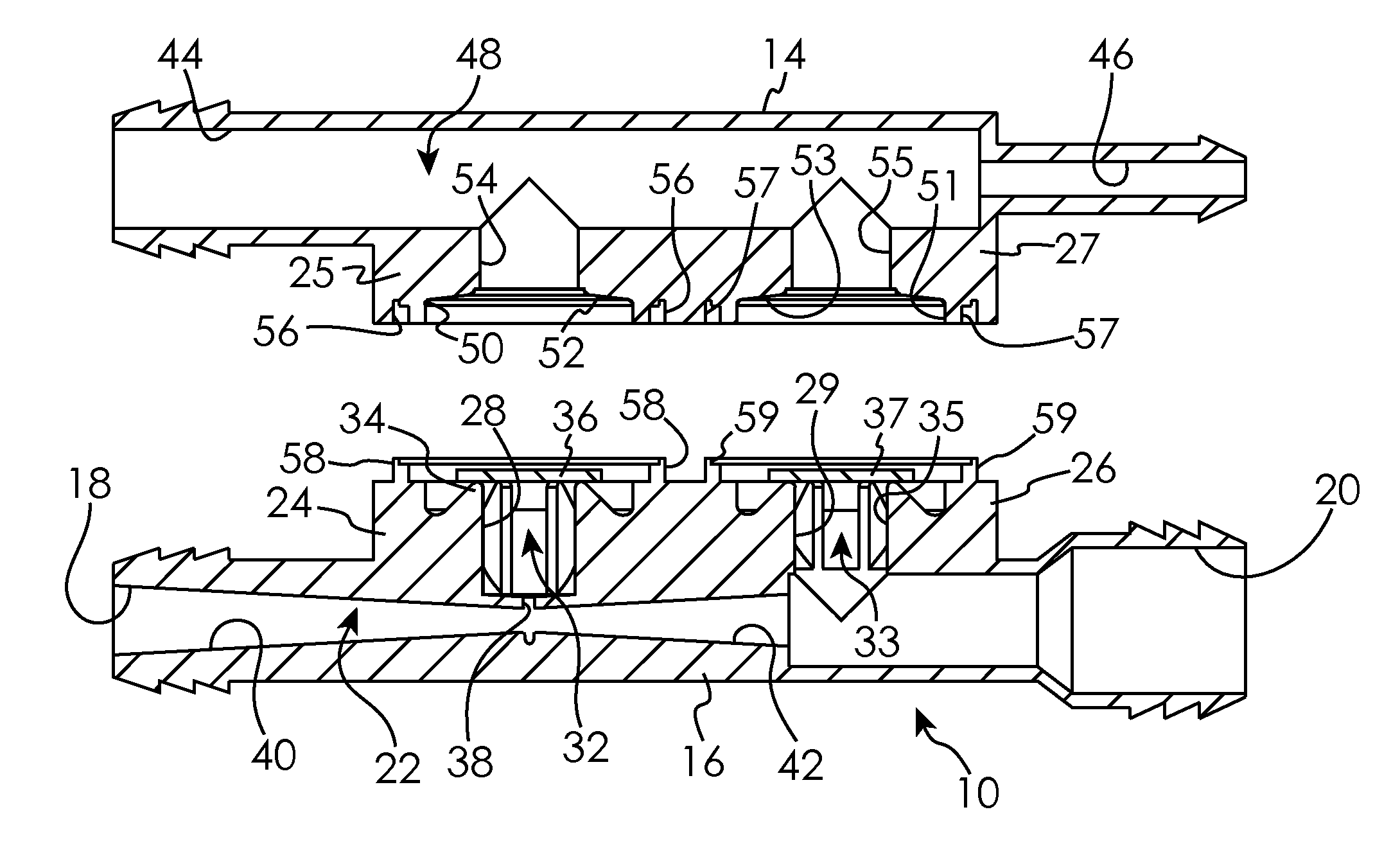

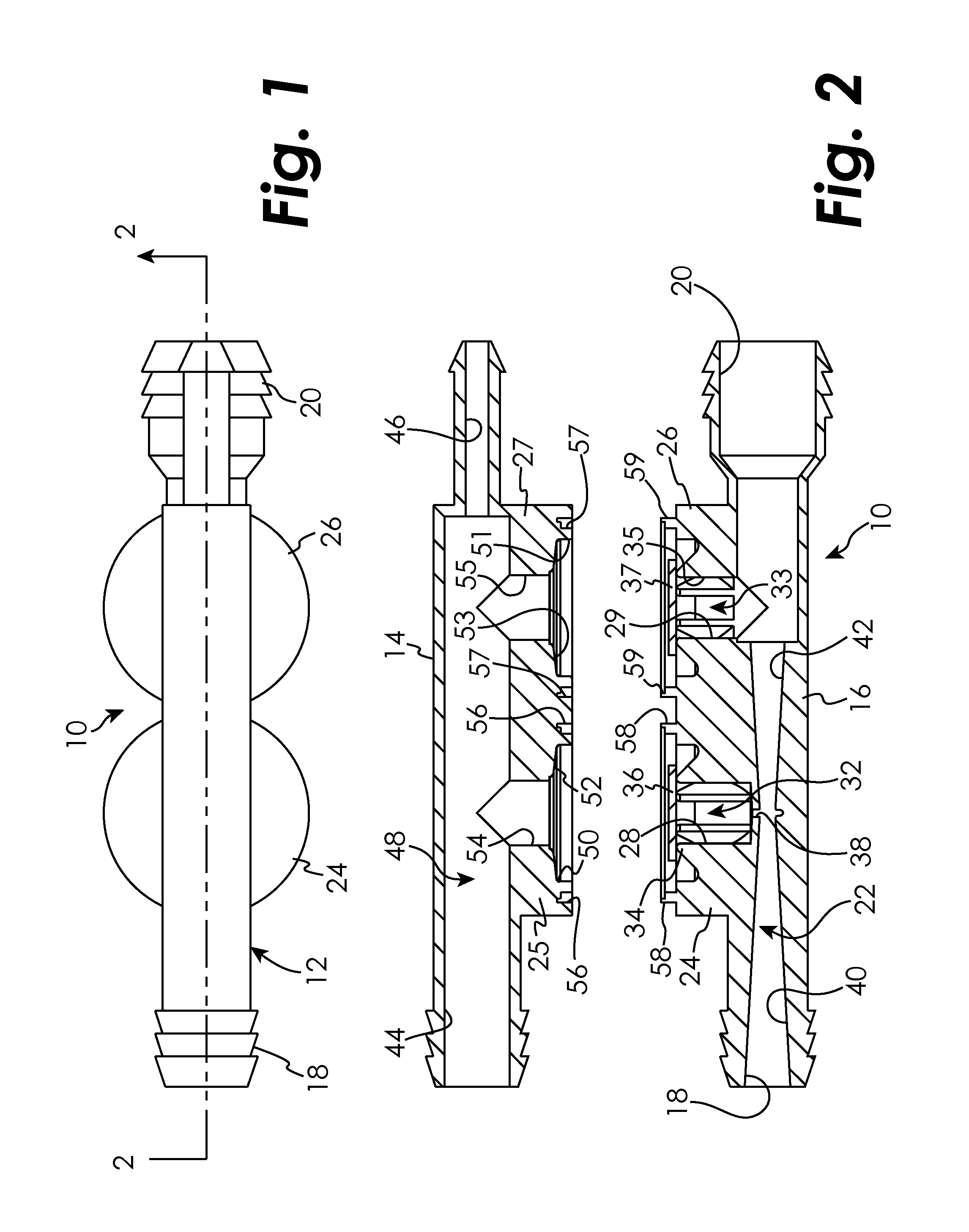

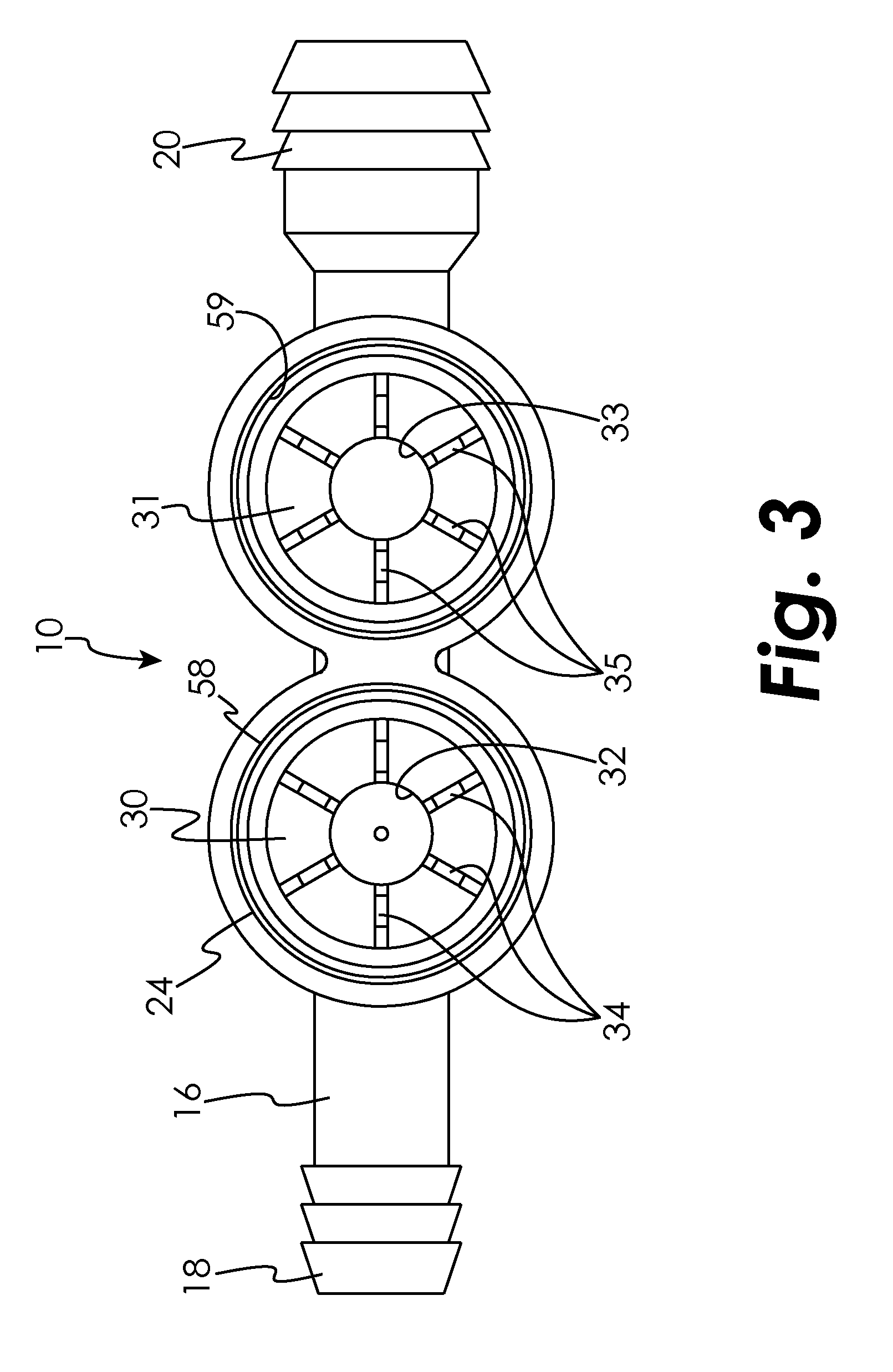

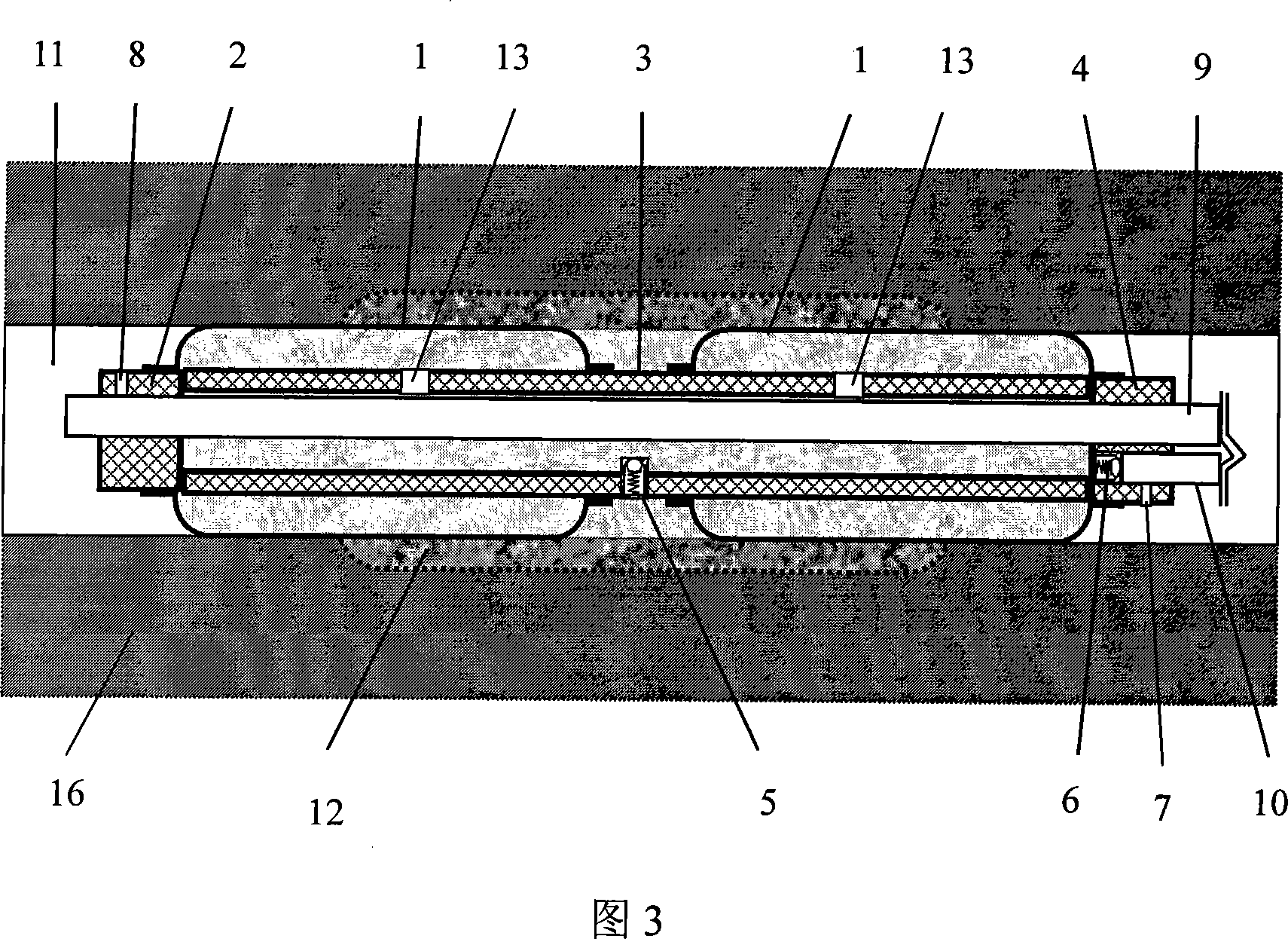

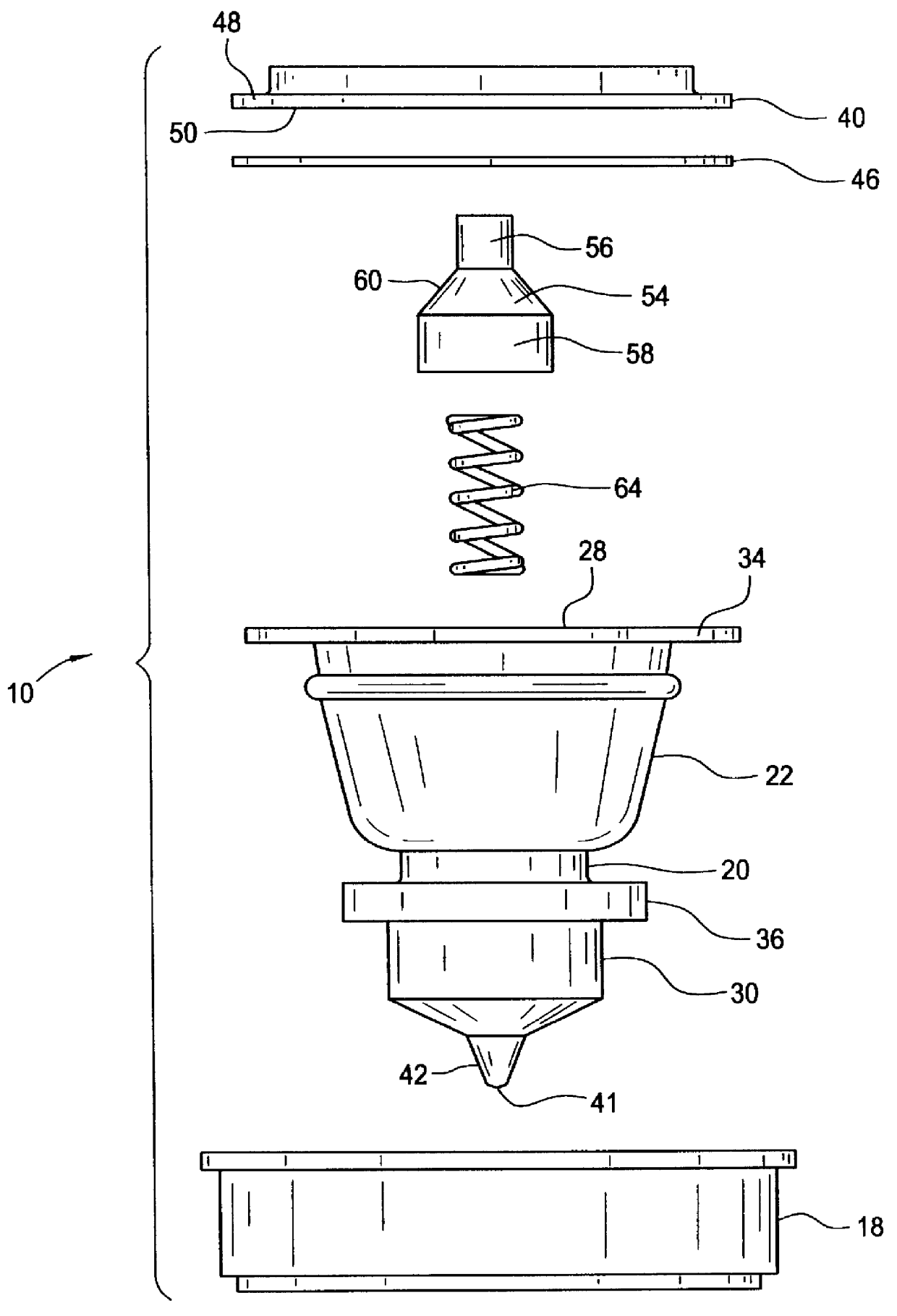

Injection device with secondary reservoir

A method and apparatus for injecting fluid into areas having high density tissue that creates a high backpressure resistance on the injection device is disclosed. The high backpressure resistance is overcome through a mechanical advantage achieved by using a secondary reservoir having a cross-sectional area smaller than the cross-sectional area of a primary reservoir. Exemplary injection device reservoir housings may comprise a primary reservoir, a secondary reservoir, a check valve, a septum penetrating cannula, travel limits, a pen needle connecting portion, sliding seal guide ribs, a sliding seal, a pen needle assembly, a needle stop, and a patient needle.

Owner:EMBECTA CORP

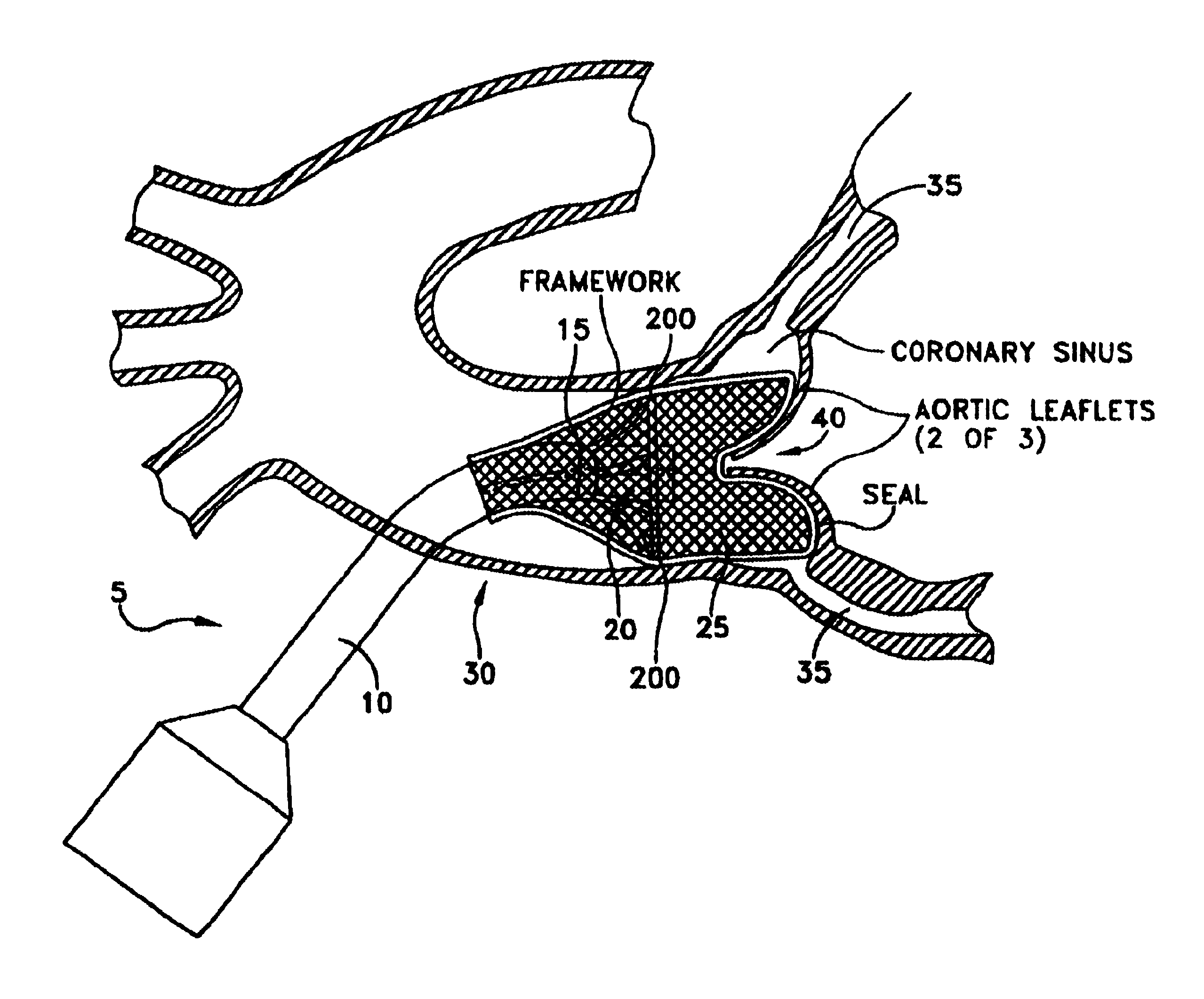

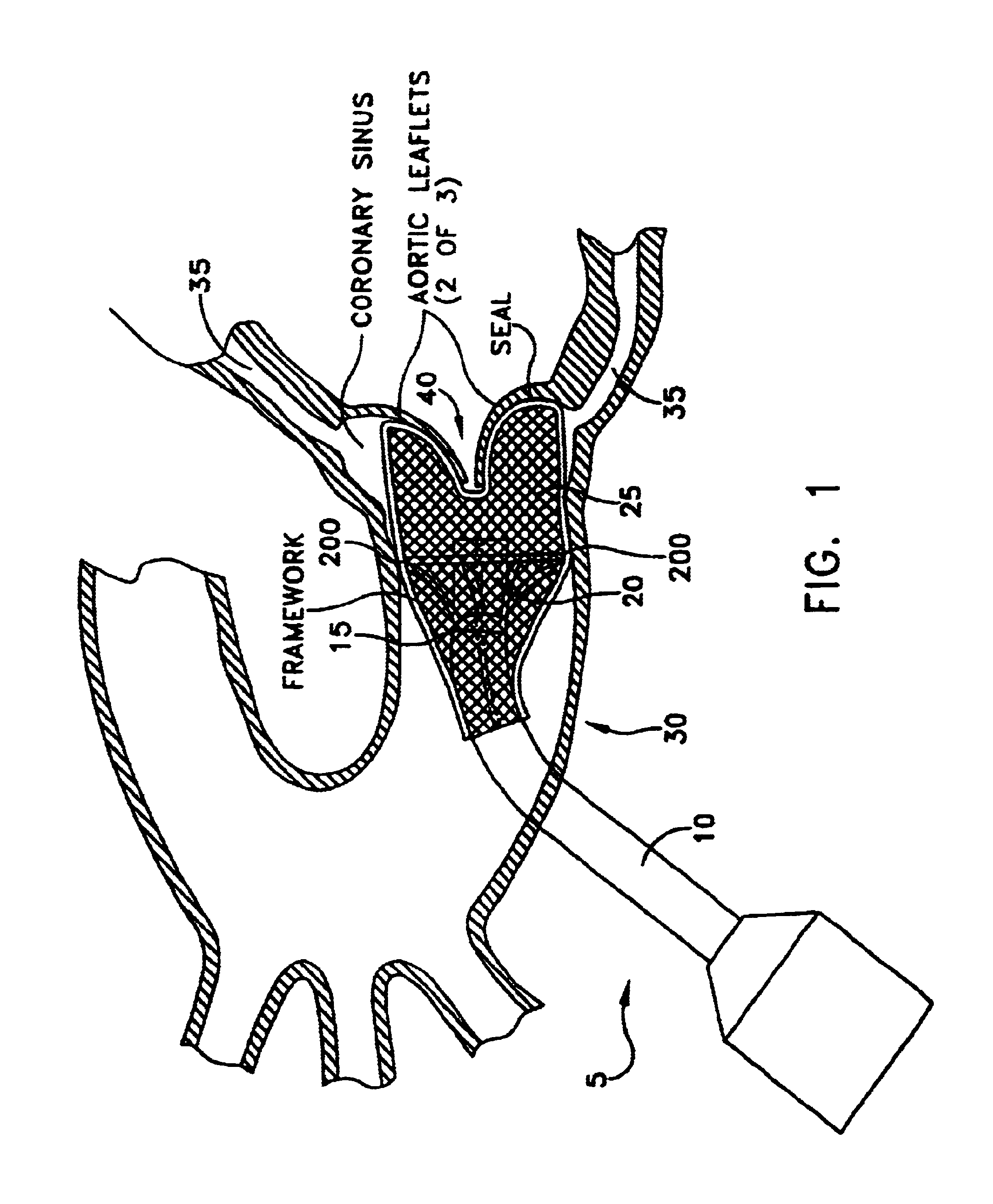

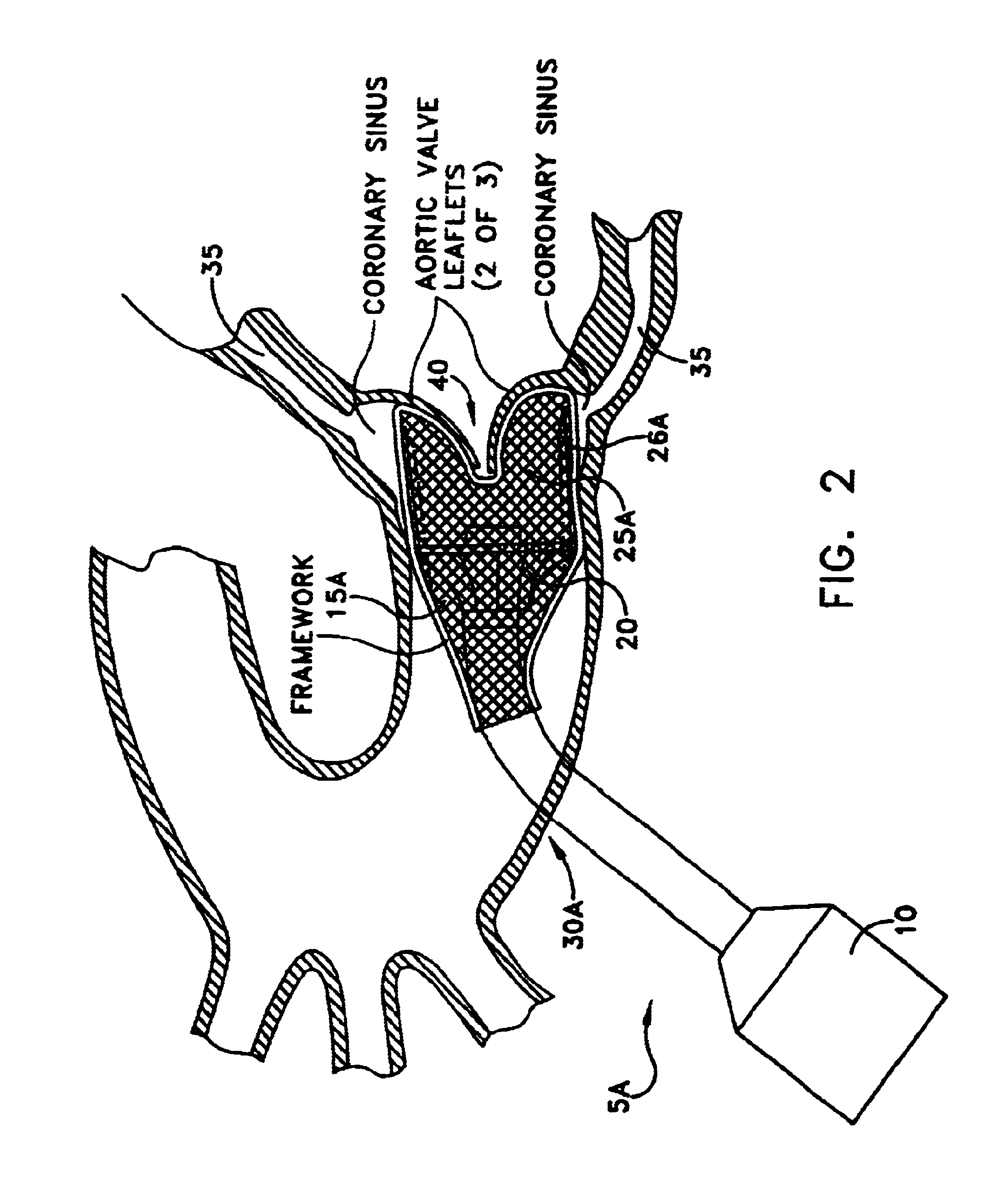

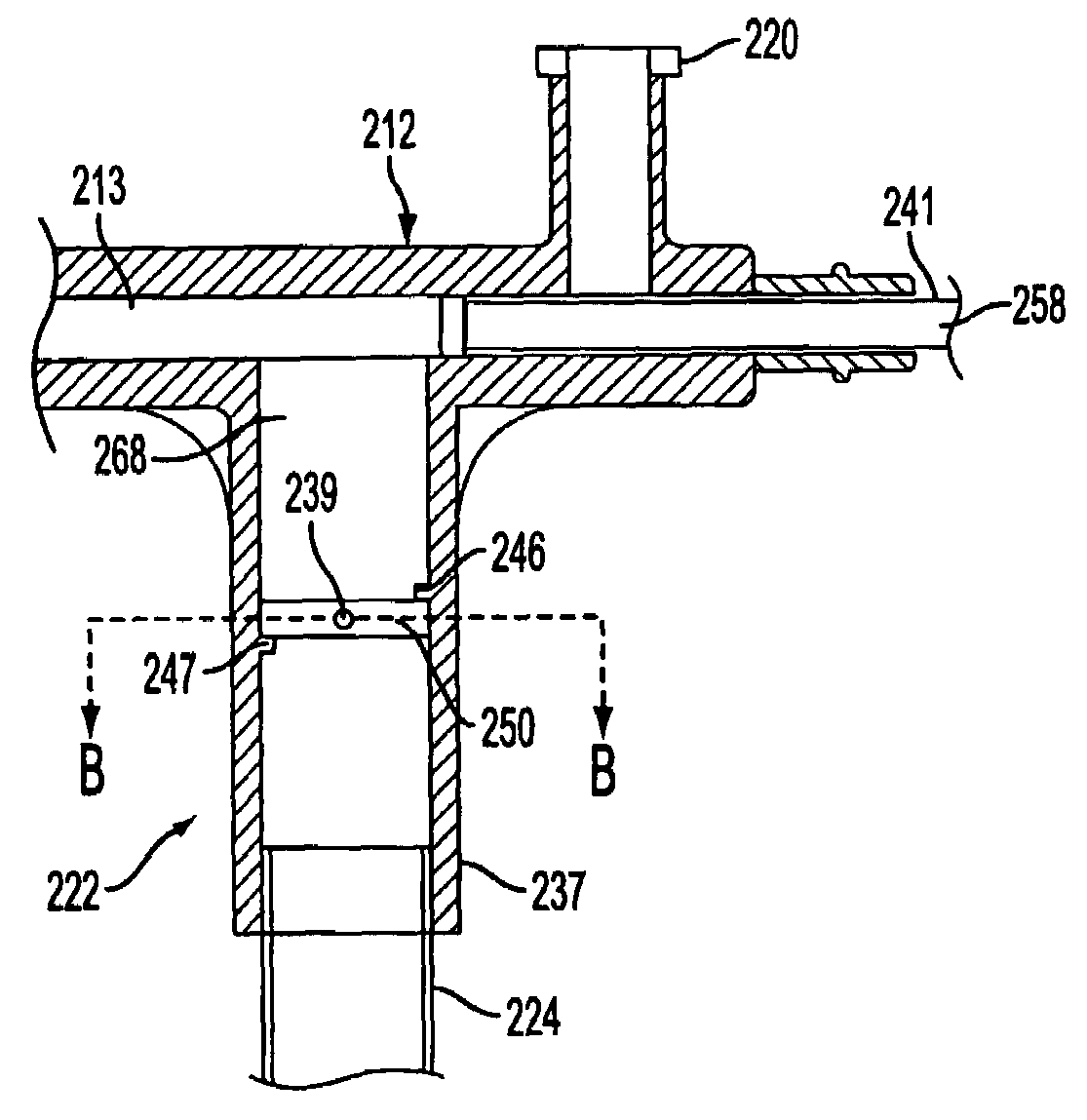

Apparatus and method for replacing aortic valve

Apparatus and methods are disclosed for performing beating heart surgery. Apparatus is disclosed comprising a cannula having a proximal end and a distal end; an aortic filter in connection with the cannula, the aortic filter having a proximal side and a distal side; a check valve in connection with the cannula, the check valve disposed on the distal side of the aortic filter; and a coronary artery filter in connection with the cannula, the coronary artery filter having a proximal end and a distal end, and the distal end of the coronary artery filter extending distally away from the distal end of the cannula. A method is disclosed comprising providing apparatus for performing beating heart surgery; deploying the apparatus in an aorta; performing a procedure on the aortic valve; and removing the apparatus from the aorta.

Owner:MEDTRONIC INC

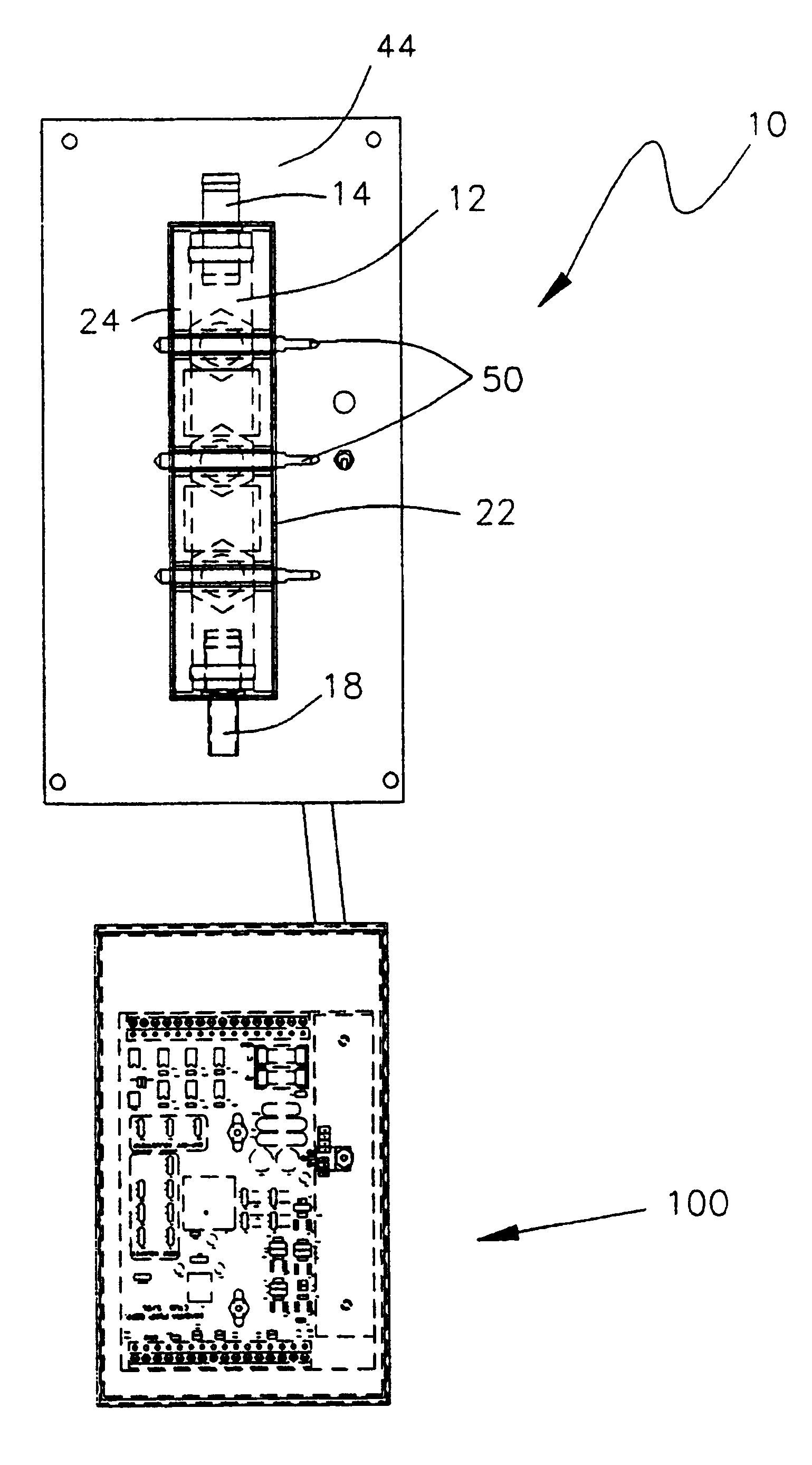

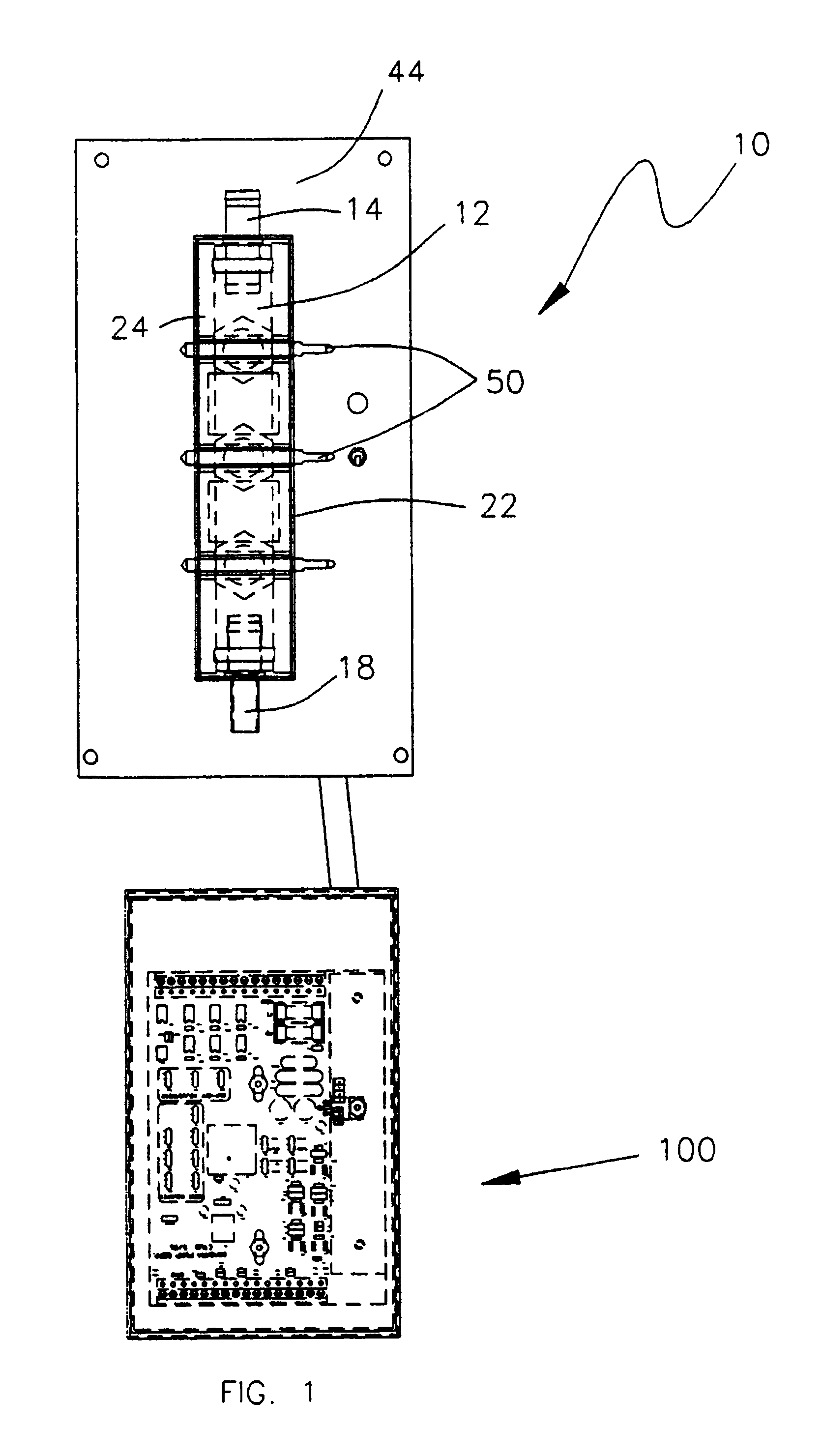

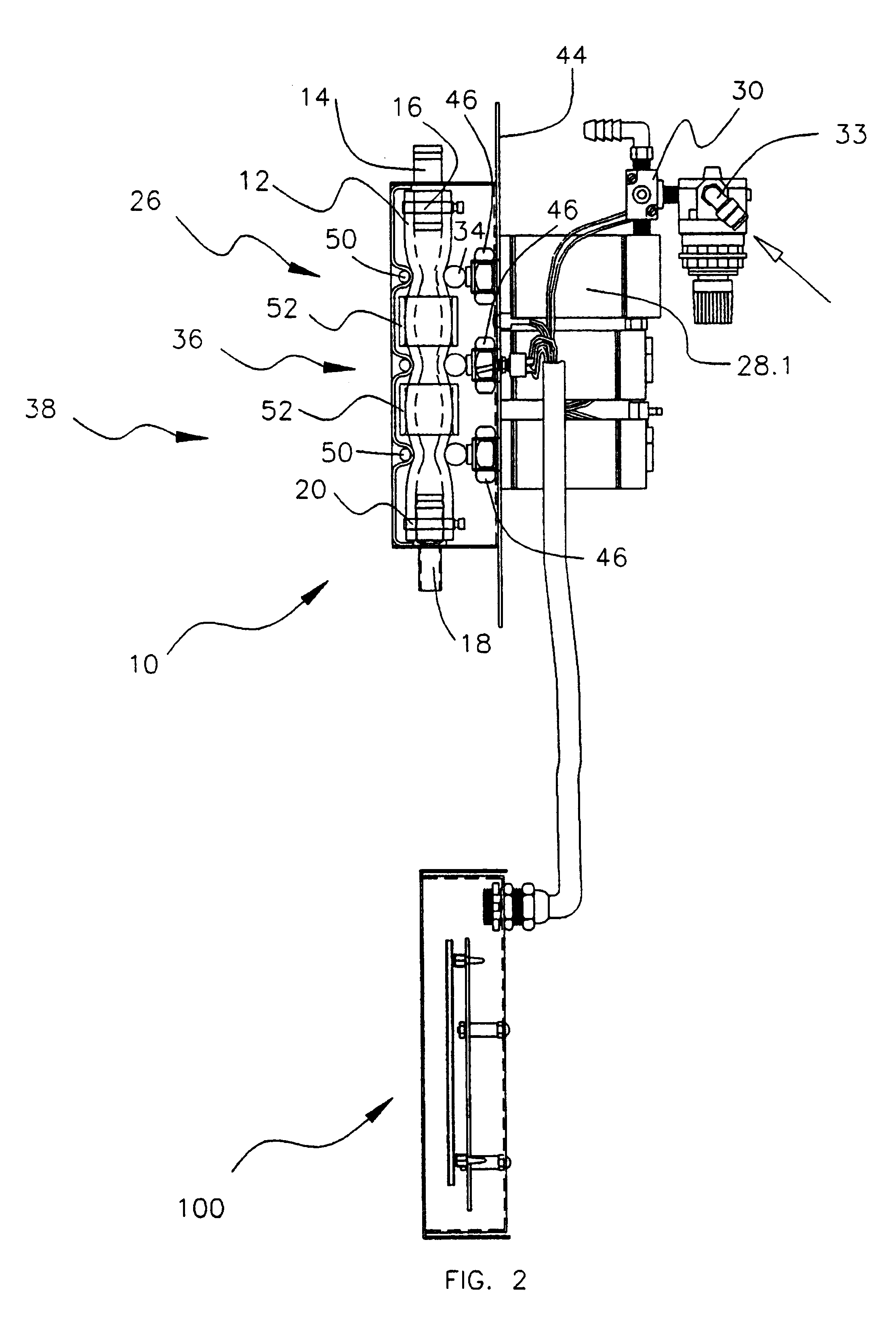

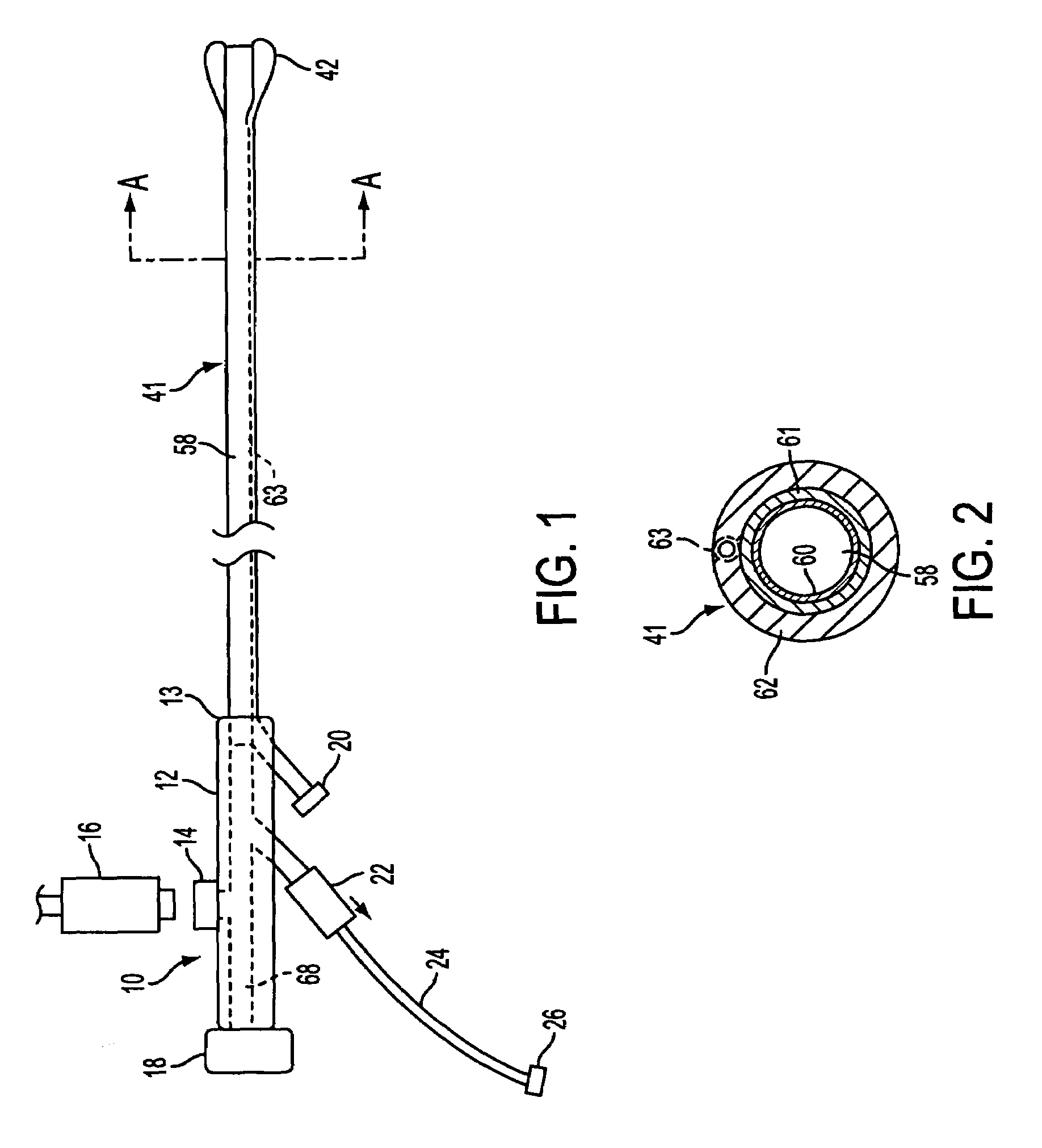

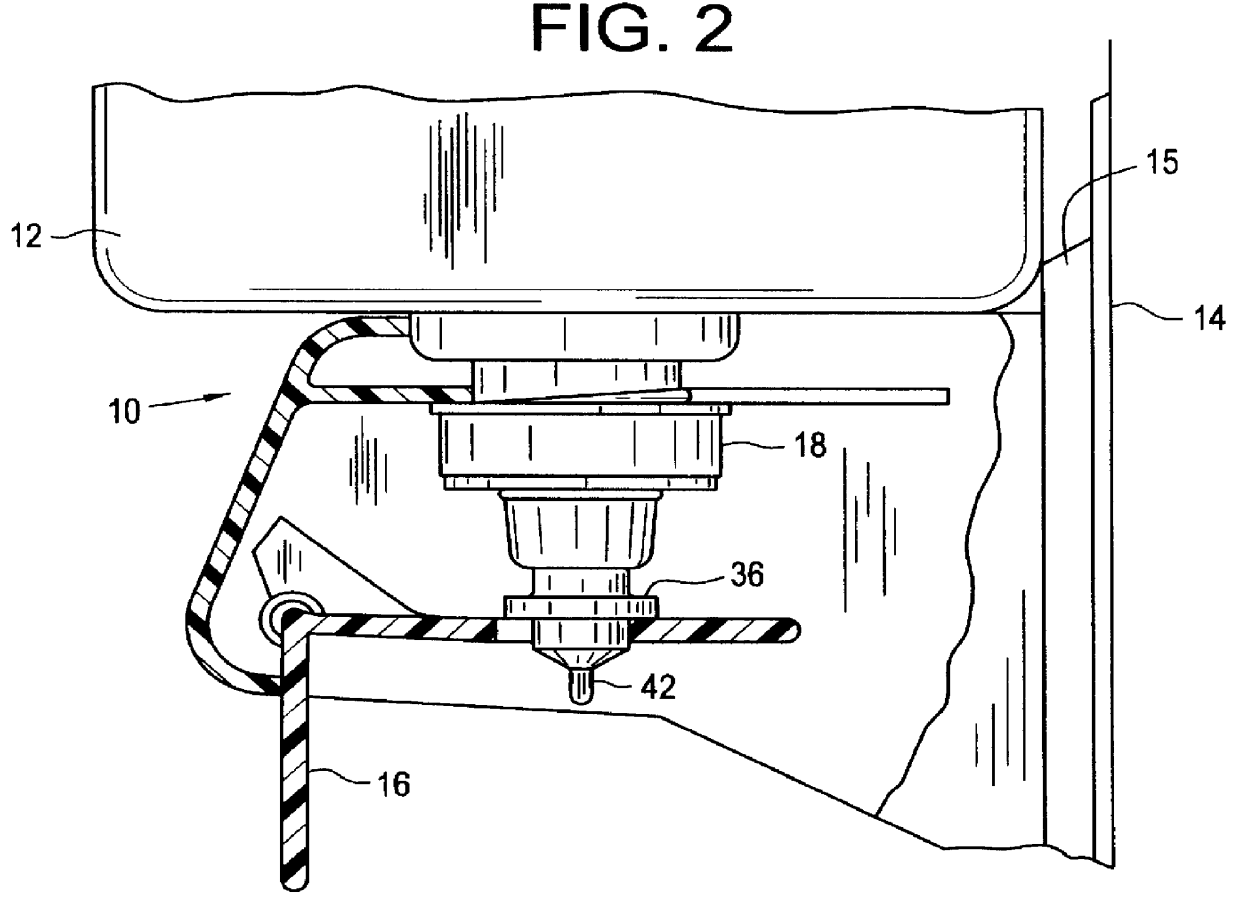

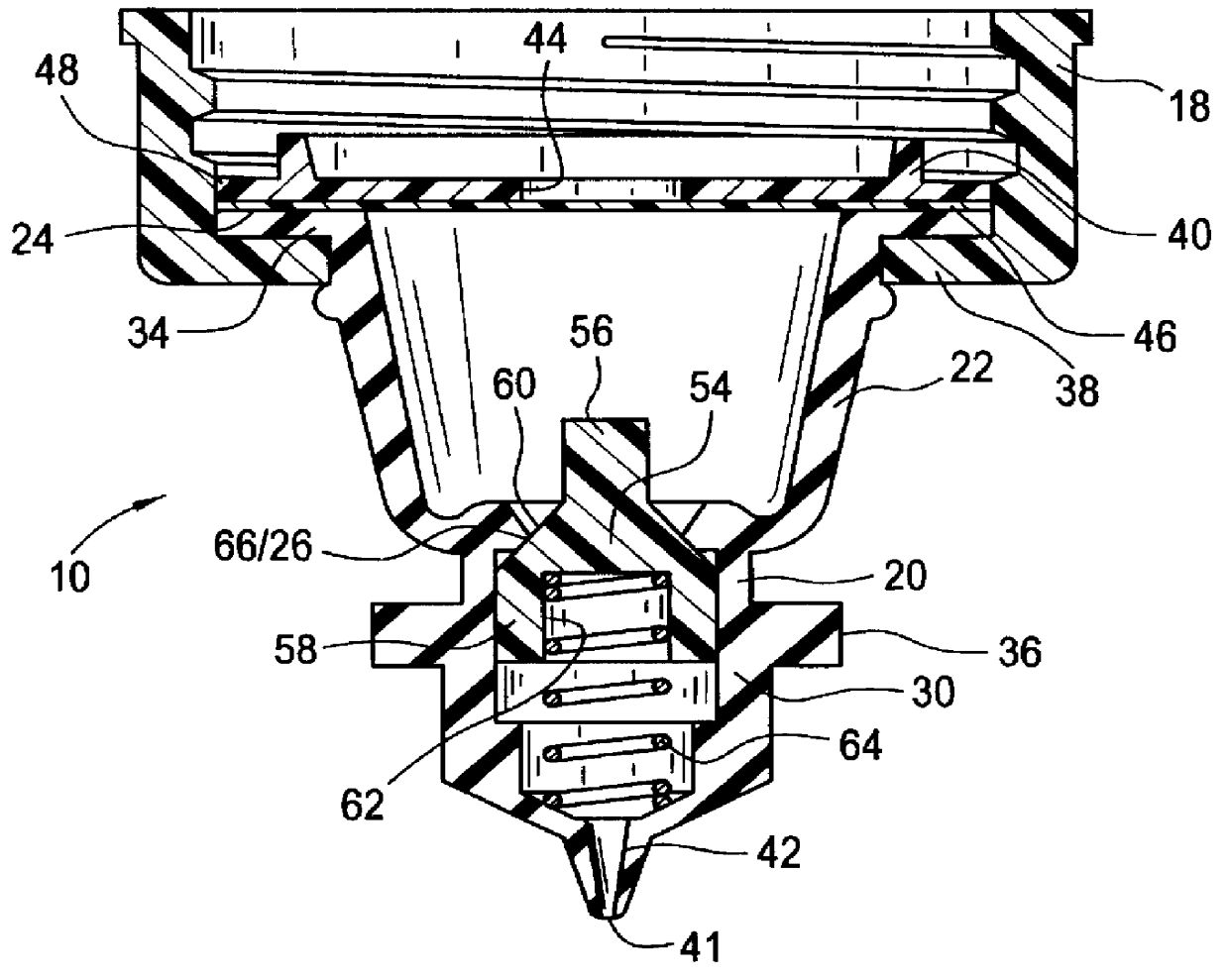

Linear peristaltic pump

InactiveUS6213739B1High liquid pumping pressureExtends useful pump tube lifeFluid parameterFlexible member pumpsPeristaltic pumpActuator

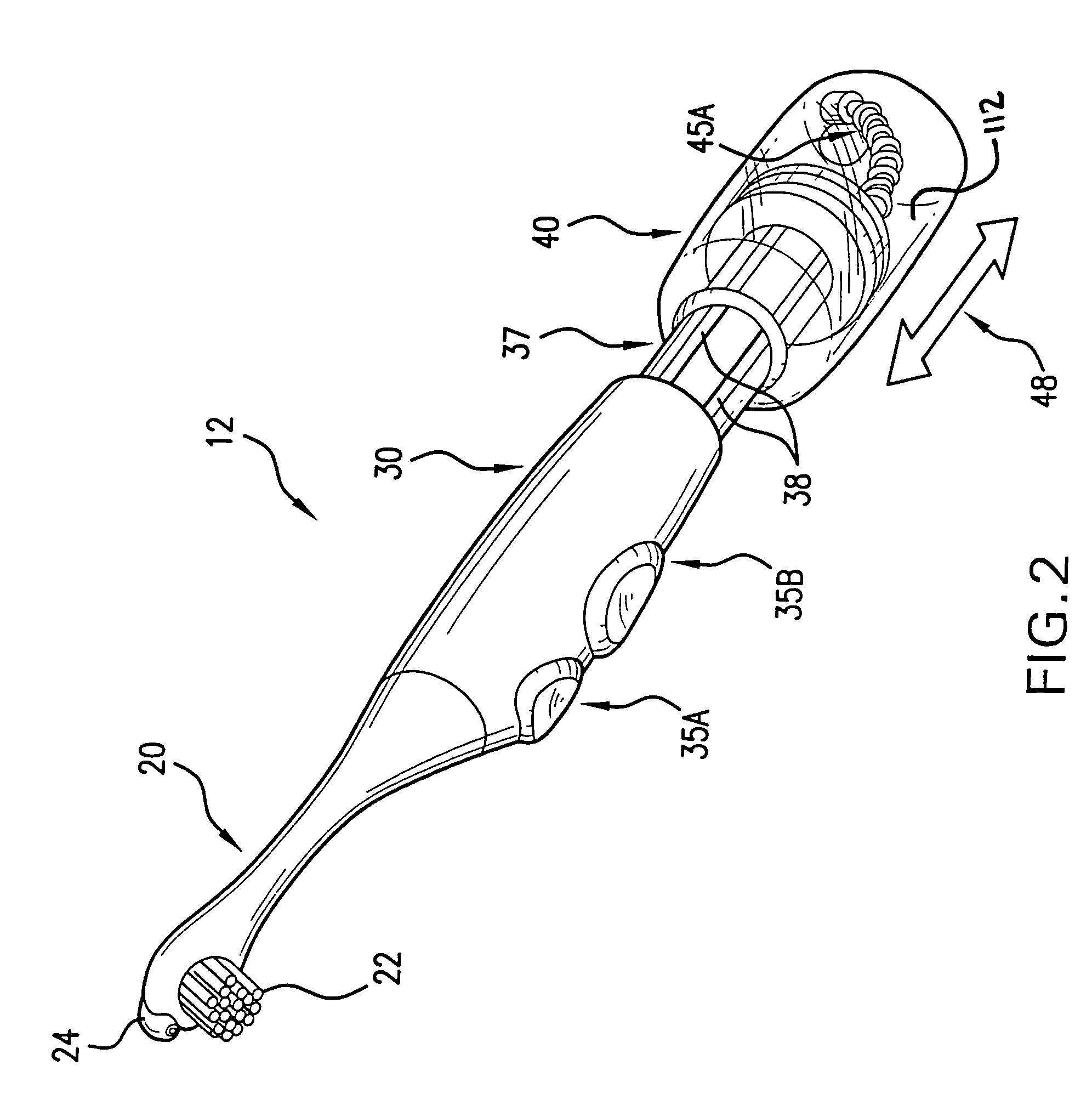

A liquid pumping apparatus for pumping liquids, more specifically a linear peristaltic pump apparatus. The apparatus consists of a high durometer compressible elastomeric liquid flow tube (12), an infeed valve assembly (26), an outfeed valve assembly (38), an extensible and retractable actuator anvil (34) having a round surface which engages the flow tube (12) at all times, an opposed anvil (24.1) having a round surface in engagement with the flow tube at all times, the flow tube being held between the anvils (34, 24.1) in a slightly compressed state when the anvil (34) is retracted, and a control assembly (100) for causing the movable anvil to be sequentially extended and retracted to cause flow within the flow tube (12) from the infeed valve assembly (26) to the outfeed valve assembly (38). With this apparatus the lumen of the flow tube (12) to the sides of the anvils is not completely reduced to zero volume during displacement compression whereby gas embolisms do not erupt or explode when discharged. Two principal embodiments are disclosed, one having infeed and outfeed check valves which oclude the flow tube, and the other having check valves.

Owner:NIAGARA PUMP CORP

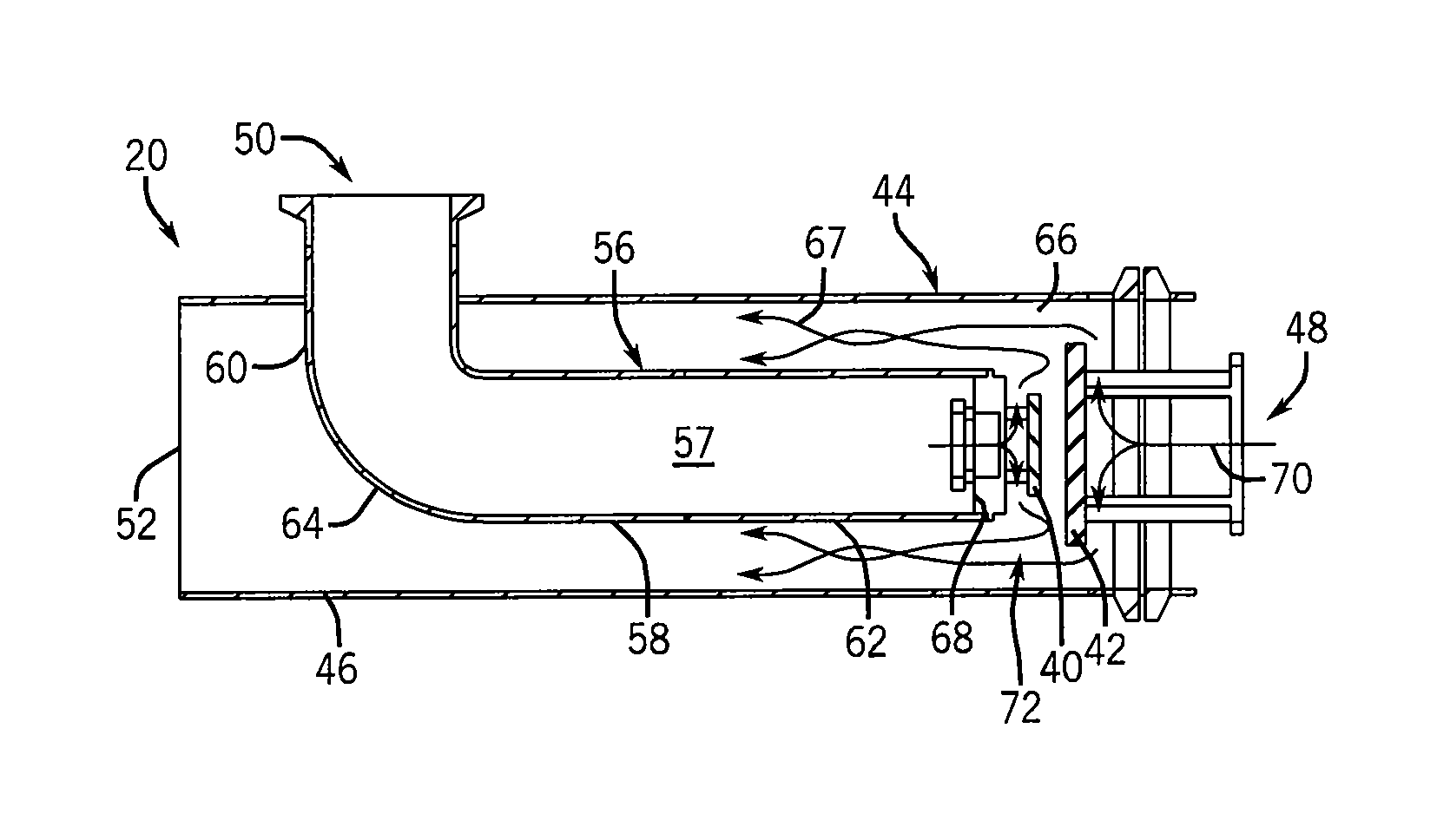

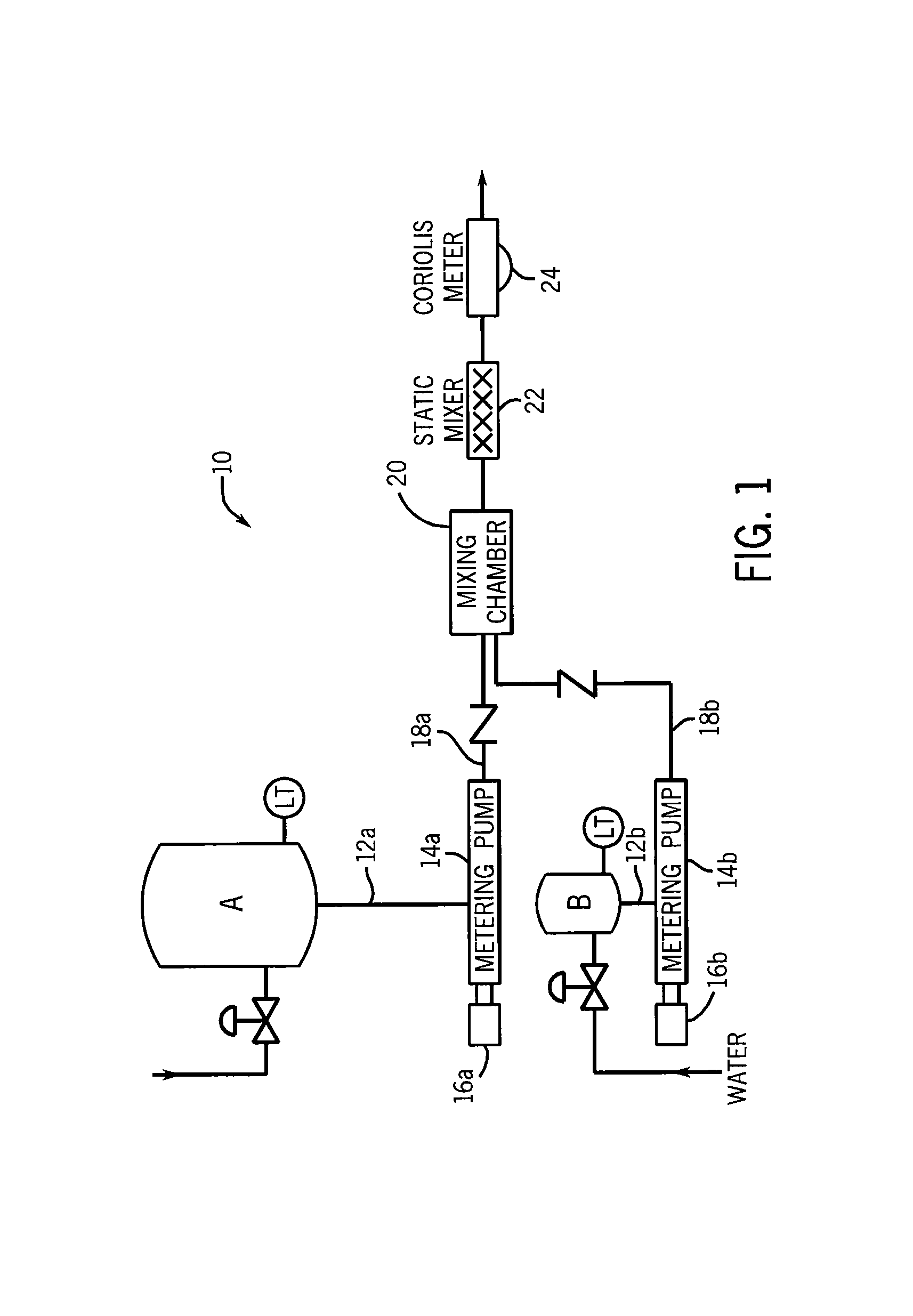

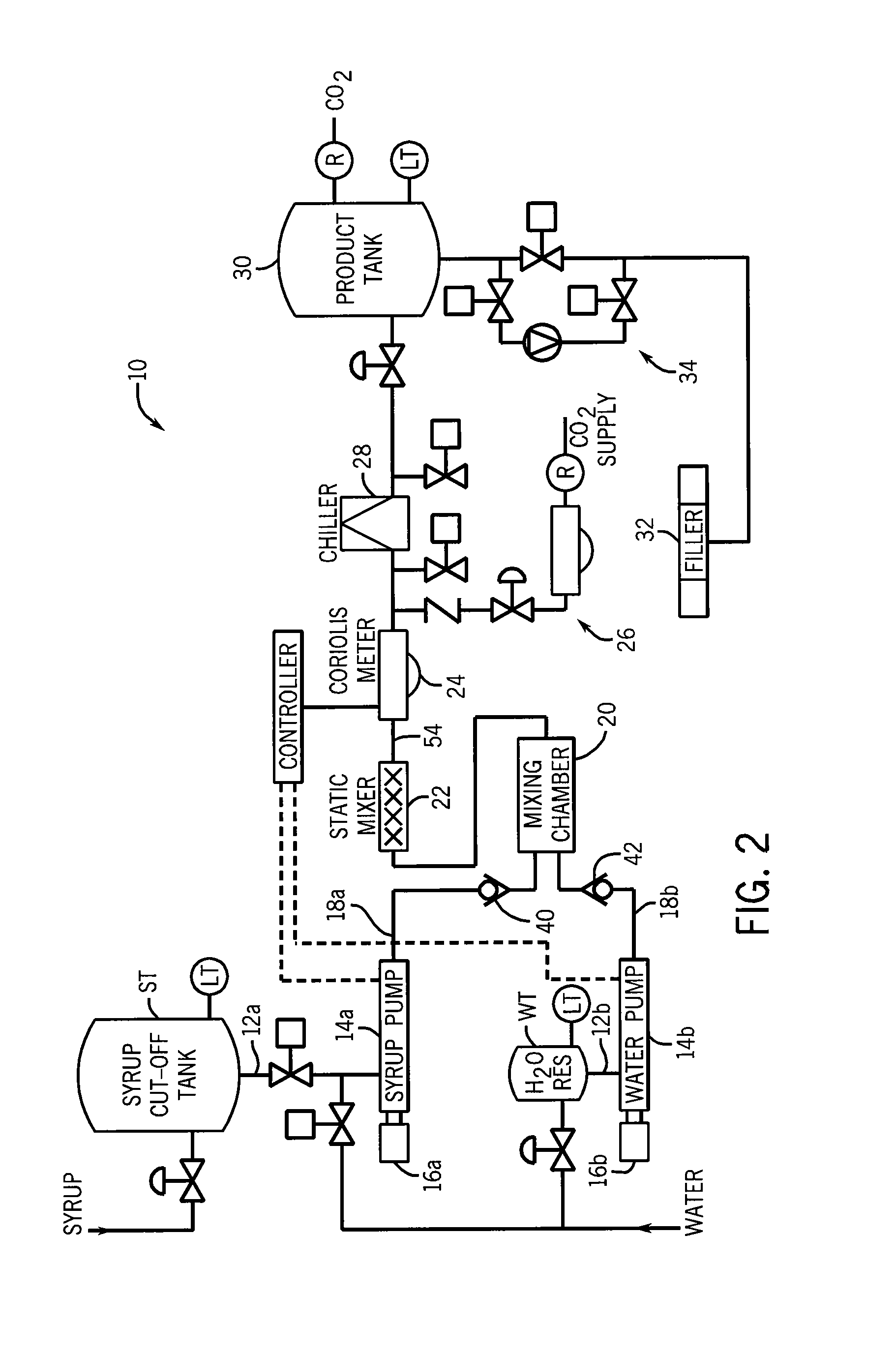

Fluid mixer using countercurrent injection

ActiveUS9004744B1Avoid many problemsEasy to controlFlow mixersTransportation and packagingEngineeringCheck valve

A method and apparatus for mixing fluids, such as beverage syrup and water, uses countercurrent injection to improve blending of the fluids. A mixing chamber has a first inlet through which a first fluid is fed to the mixing chamber, and a second inlet through which a countercurrent injection nozzle extends and is operative to inject a second fluid into a stream of the first fluid. The countercurrent injection nozzle is equipped with a check valve to control the flow of fluid into the mixing chamber. The mixing chamber may include additional inlets that may be fitted with countercurrent injection nozzles to permit the countercurrent injection of other fluid, such as flavorings, into the stream of the first fluid.

Owner:TECHNIBLEND LLC

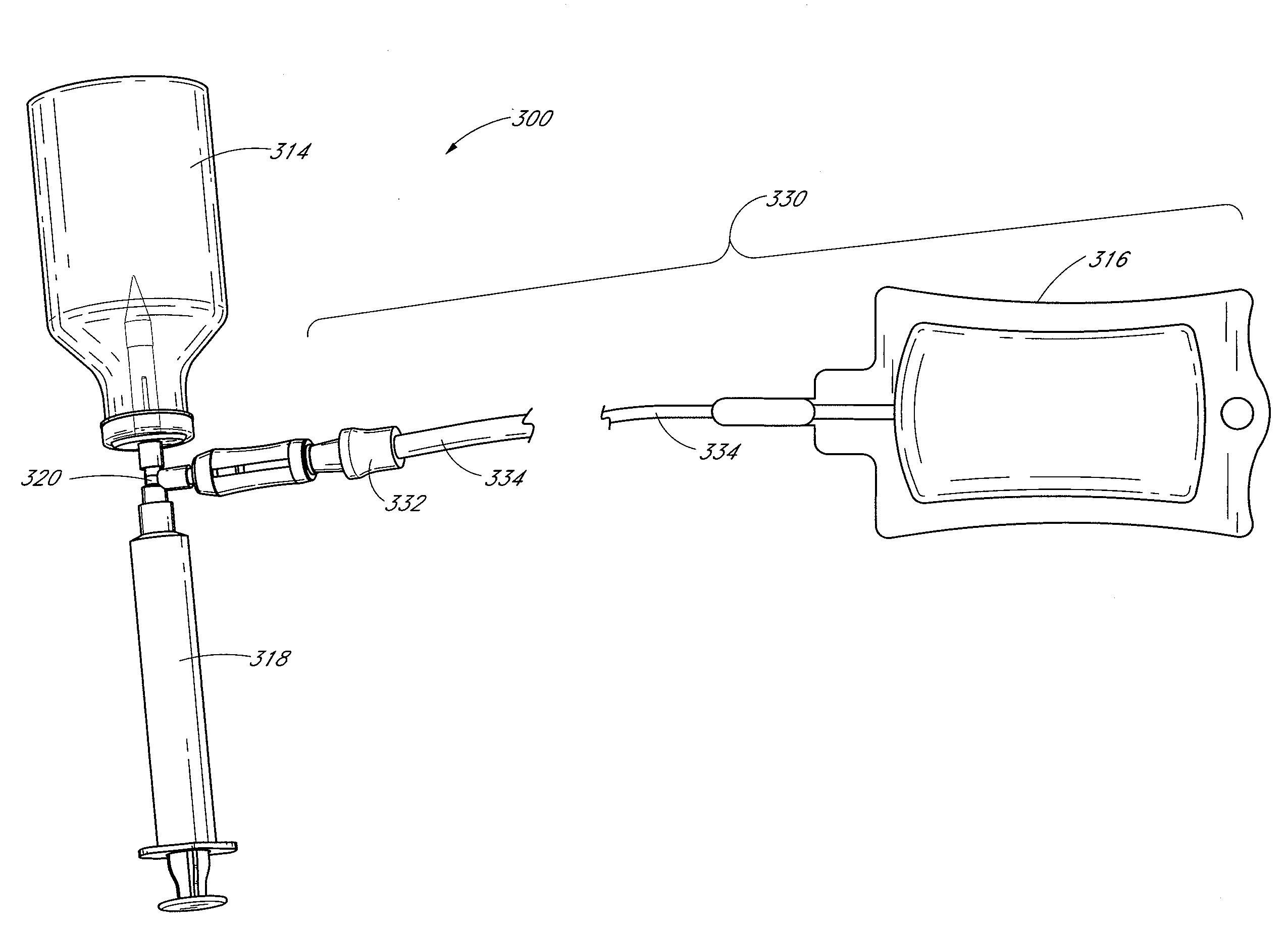

Fluid transfer devices and methods of use

Some embodiments disclosed herein related to a device for transferring precise amounts of fluid from at least one source container to a at least one target container. In some embodiments, the fluid is first transferred from the source container (e.g., a vial) through a connector to an intermediate measuring container (e.g., a syringe). In some embodiments air can pass through an air inlet and enter the vial to compensate for the volume of fluid withdrawn from the vial. An air check valve or a bag or a filter can prevent the fluid from escaping through the air inlet. The precisely measured amount of fluid can then be transferred from the intermediate measuring container to the target container (e.g., an IV bag). In some embodiments the connector can include a source check valve and a target check valve to direct fluid first from the source container to the intermediate measuring container and then from the intermediate measuring container to the target container. Some embodiments of the device can include a motor and a controller for automatically actuating a plunger of the syringe to transfer the desired amount of fluid.

Owner:ICU MEDICAL INC

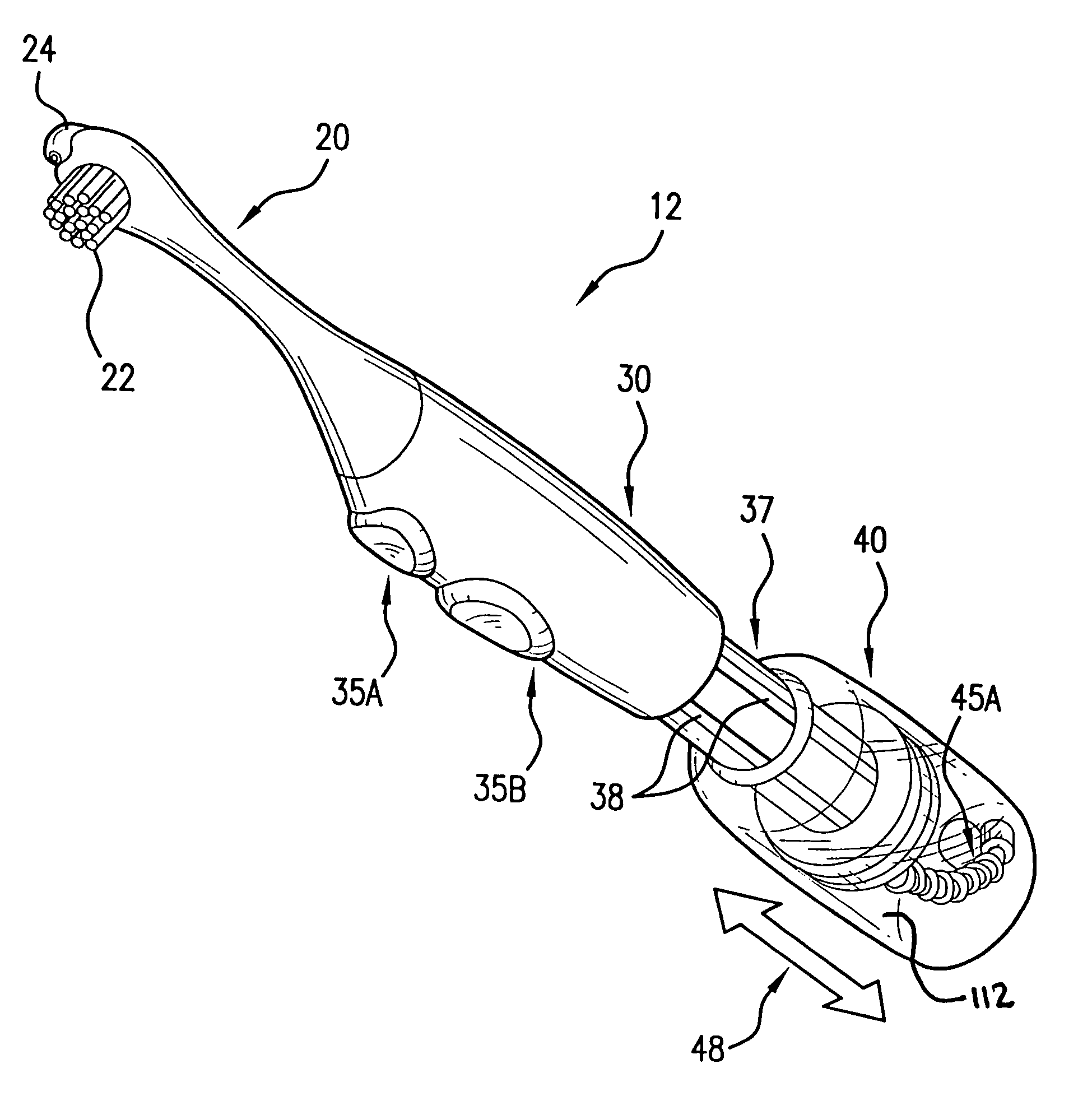

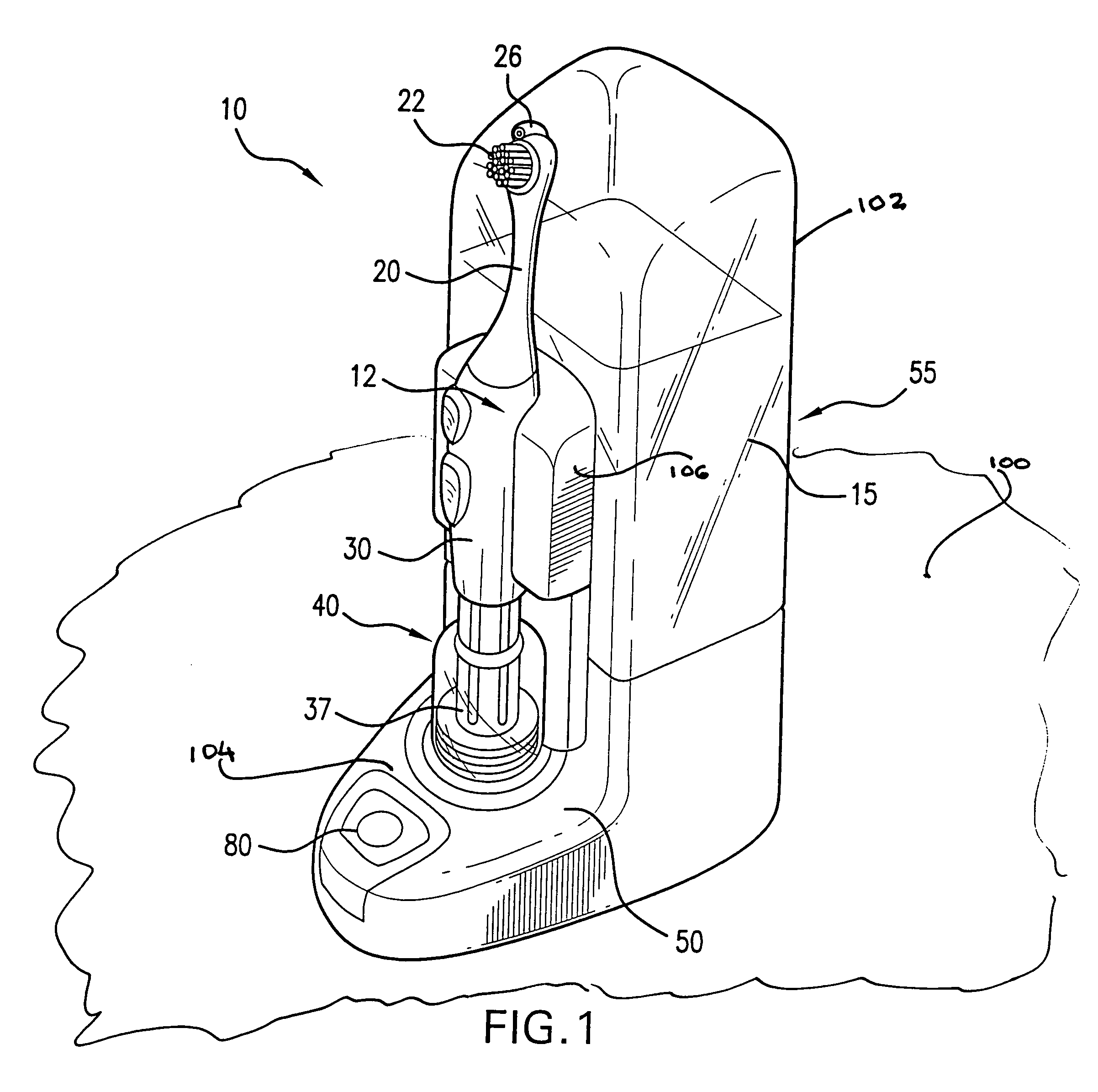

Dental hygiene device

InactiveUS7080980B2Minimal amount of maintenanceGum massageKitchenware cleanersDocking stationMotor drive

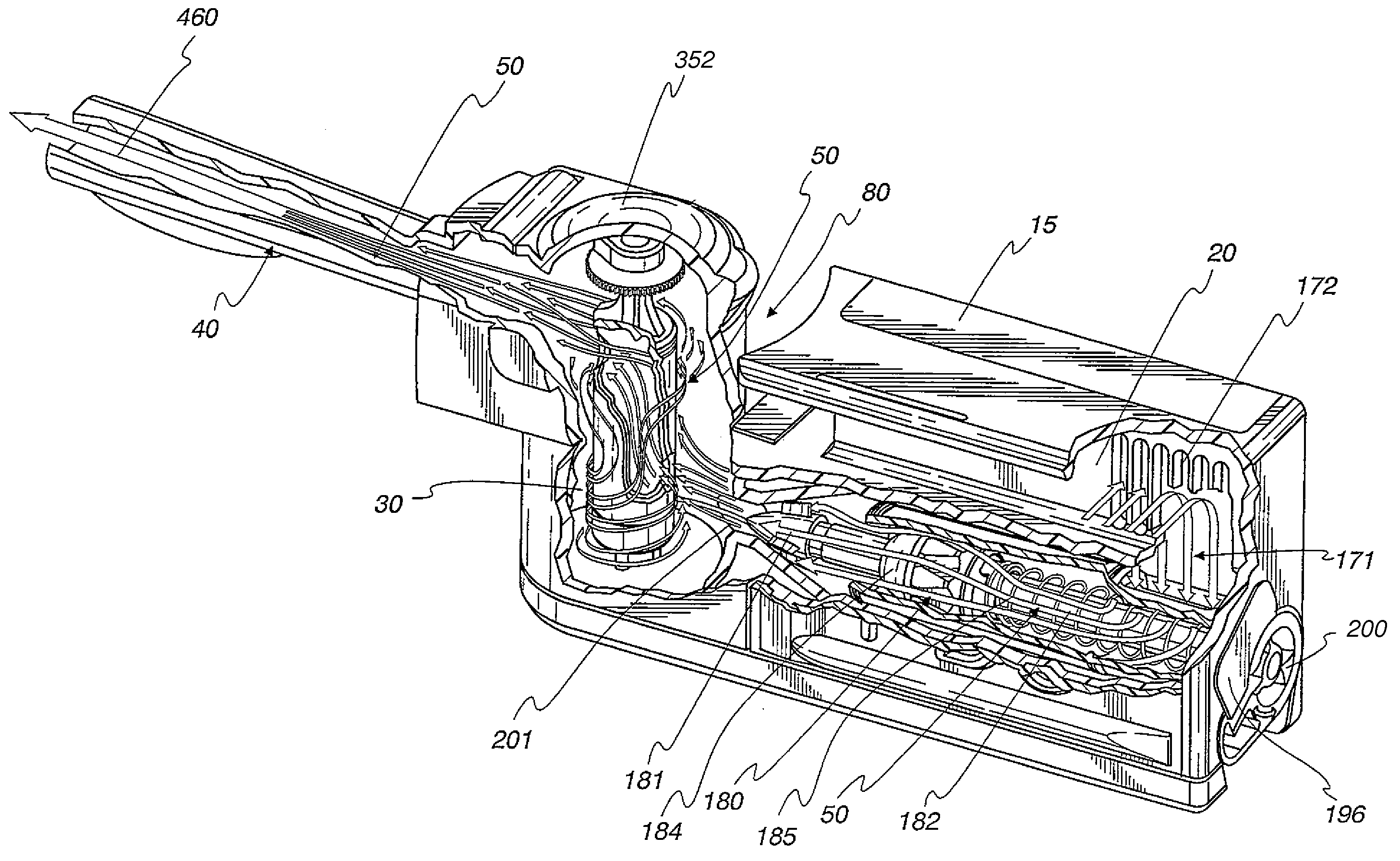

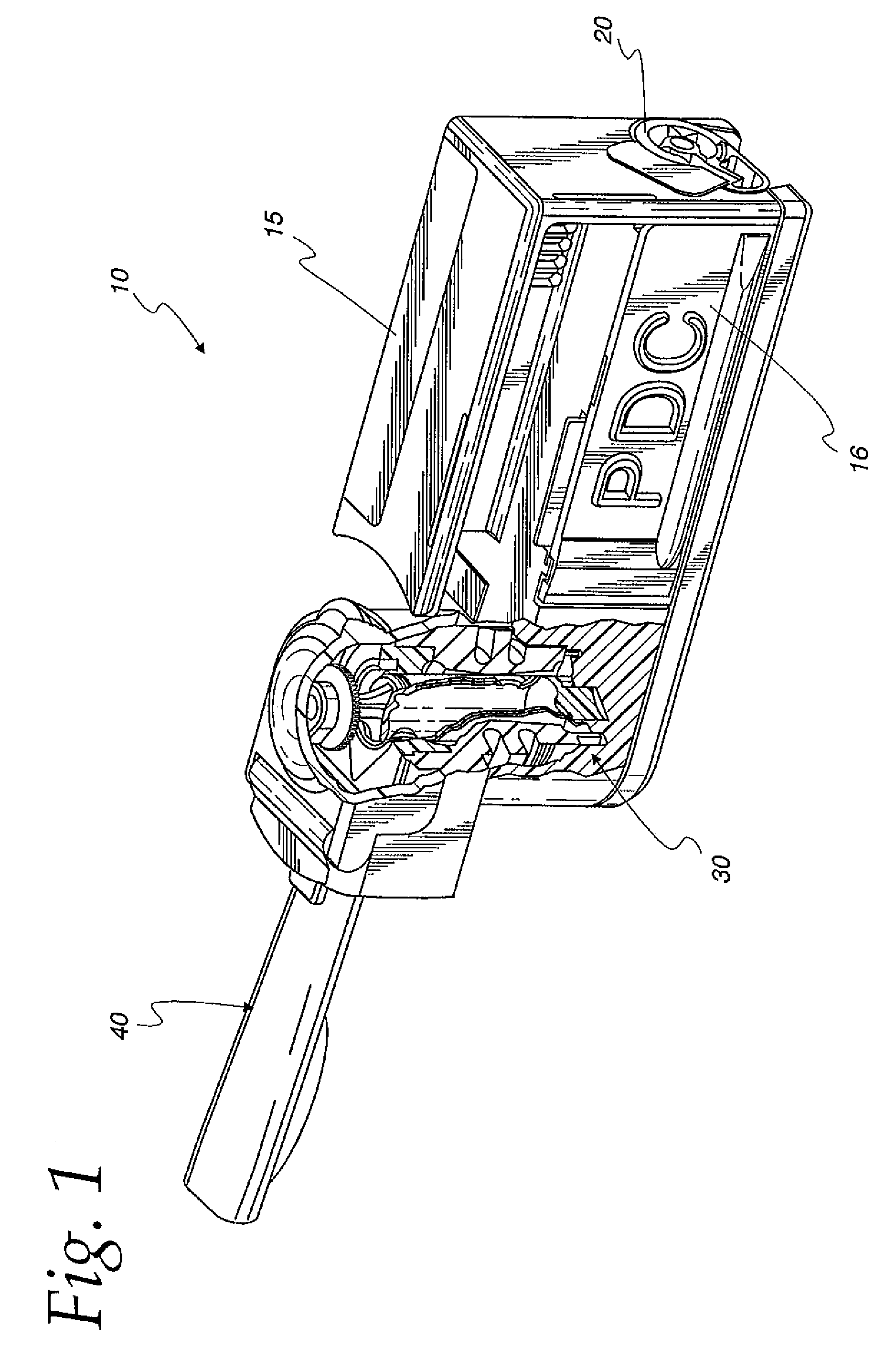

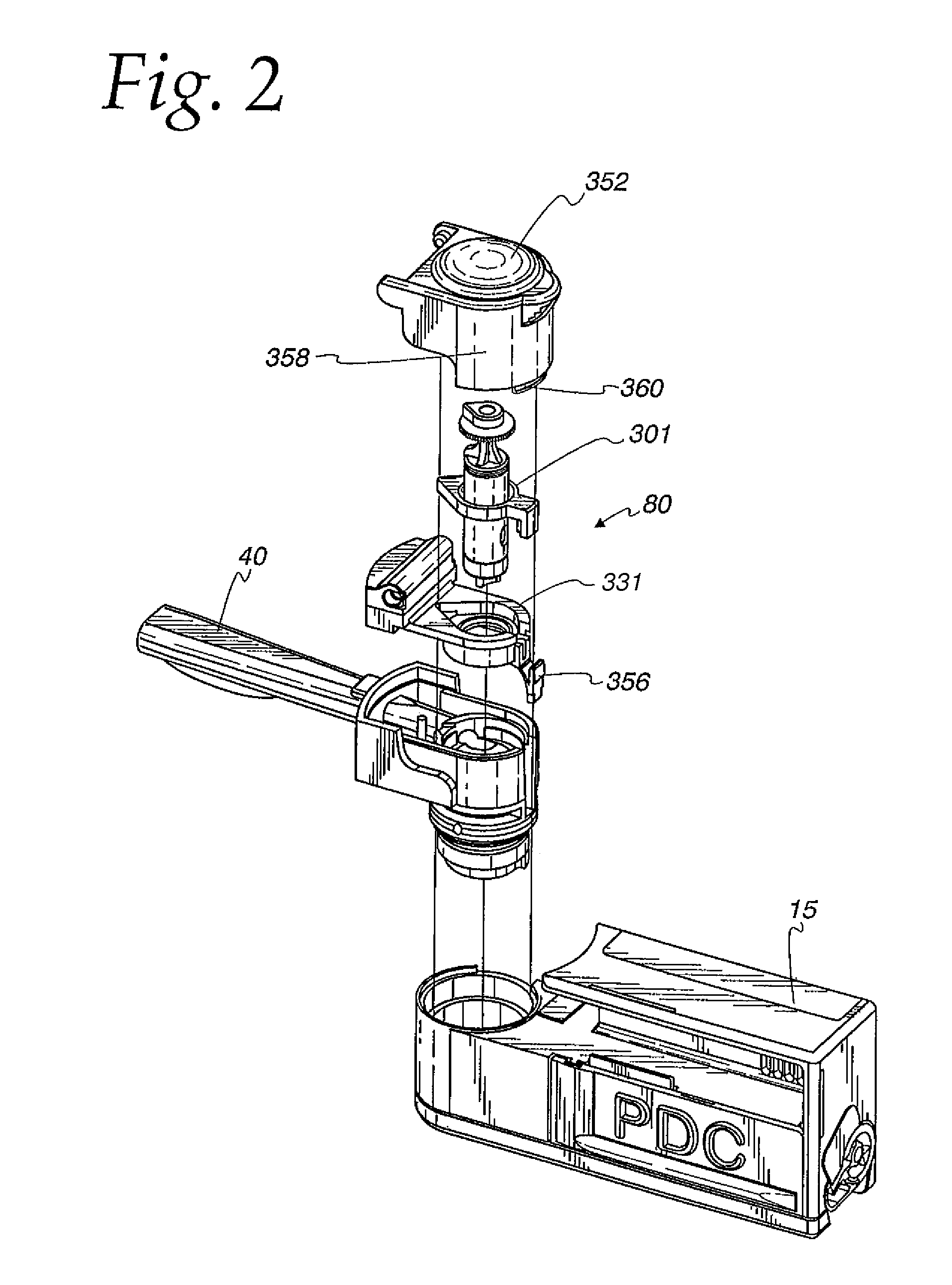

A dental hygiene system provided with interchangeable dental heads permits power-enhanced brushing and concurrent fluid irrigation to optimize a user's personal dental hygiene efforts. The system has a handle assembly with an irrigation nozzle in close proximity to displaceable bristles driven by a battery-operated handle motor. Pumping of irrigation fluid such as an antiseptic solution into the oral cavity is also motor driven. A telescoping chamber with irrigation fluid fits on the piston-like base end of the handle and is refilled by docking the handle assembly on a complementary docking station that includes a detachable fluid reservoir, microswitch controls and a base fluid pump. Docking of the handle assembly triggers the microswitches and opens a check valve in the bottom of the handle chamber, which activates the flow of fluid from the reservoir into the chamber. An optional fiberoptic subassembly illuminates the oral cavity.

Owner:KLUPT MICHAEL

Fluid pump

InactiveUS6109889ASimple structural designLow costFlexible member pumpsPositive-displacement liquid enginesPump chamberEngineering

PCT No. PCT / EP96 / 05382 Sec. 371 Date Jun. 3, 1998 Sec. 102(e) Date Jun. 3, 1998 PCT Filed Dec. 3, 1996 PCT Pub. No. WO97 / 21924 PCT Pub. Date Jun. 19, 1997A fluid pump has a pump body and a displacer, the displacer and the pump body being implemented such that a pump chamber is defined therebetween, the pump chamber having an inlet opening and an outlet opening, neither the inlet opening nor the outlet opening being provided with a check valve. A drive means is provided which positions the displacer periodically at a first and at a second end position. The displacer closes the outlet opening when it occupies its first end position and leaves the outlet opening free when it occupies its second end position and leaves the inlet opening free at both end positions thereof. The displacer, when moving from the first to the second end position, defines a flow-through gap which opens between the displacer and the pump body in the area of the outlet opening in dependence upon the movement, the flow-through gap being defined such that the flow through the outlet opening depends on the pressure in the pump chamber as well as on the respective opening degree of the flow-through gap.

Owner:EPPENDORF AG +1

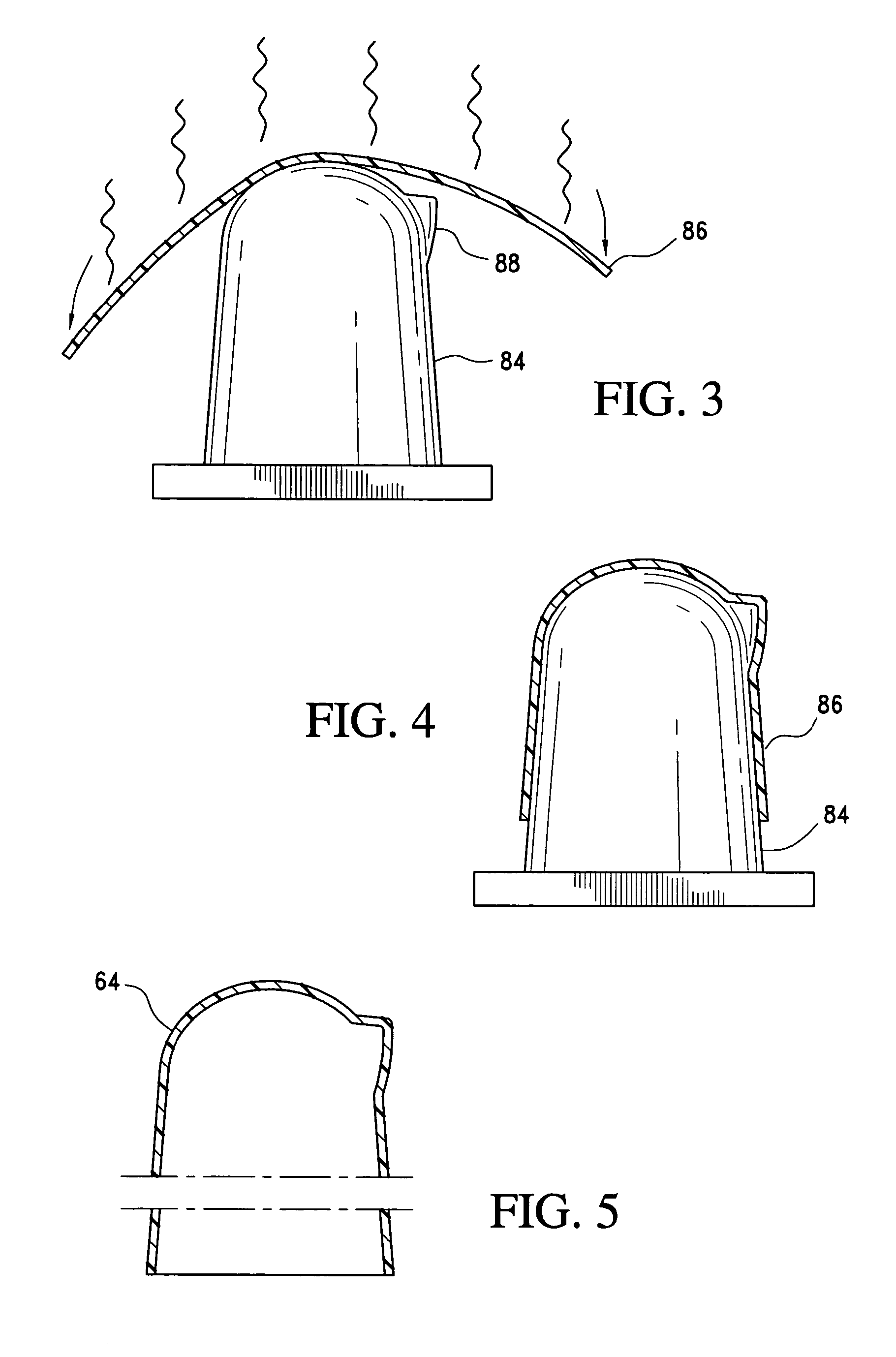

Unit dose cartridge and dry powder inhaler

InactiveUS7464706B2Broad inhalation tidal volume range of human breathMaintain good propertiesRespiratorsLiquid surface applicatorsMedicineCheck valve

A dry powder inhaler having improved aerodynamic properties for diluting, dispersing, and metering drug particles for increasing the efficiency of pulmonary drug delivery to a patient is described. The inhaler comprises, in general, a housing having an air intake, an air flow-control / check-valve, a mixing section and a mouthpiece. A cartridge loaded with a single dose of medicament can be installed in the mixing section.

Owner:MANNKIND CORP

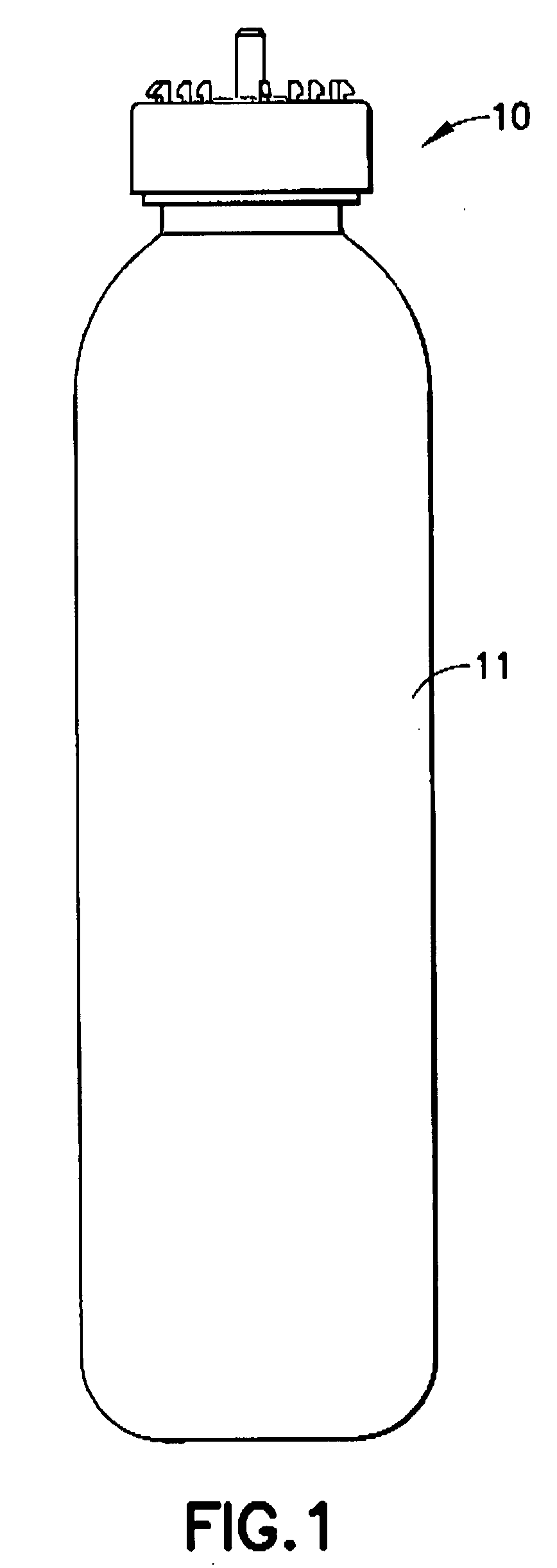

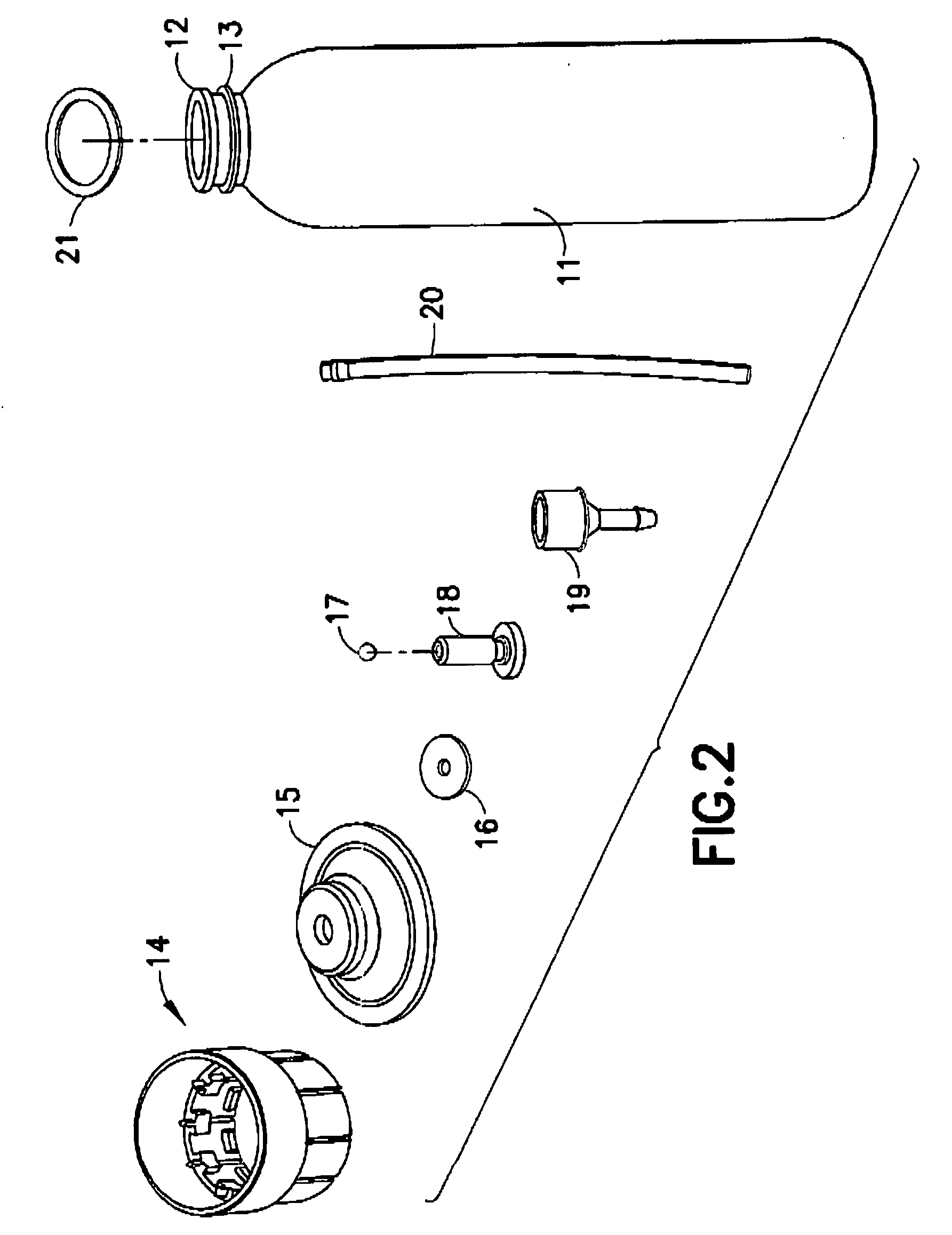

Plastic aerosol valve and method of assembly, mounting and retention

InactiveUS20090014679A1Guaranteed ease of operationShorten speedSingle-unit apparatusLiquid dispensingEngineeringBottle

A plastic aerosol valve with a plastic valve stem, plastic housing, plastic mounting cup, and plastic locking ring. The plastic valve is assembled into the mounting cup. The plastic housing is assembled into the plastic mounting cup by snap fittings. The plastic mounting cup has a peripheral portion that snap fits up into the plastic locking ring. The plastic locking ring has frangibly-connected upper and lower portions. The lower portion snap fits with the top of a plastic product bottle to mount the aerosol valve assembly on the bottle. The upper ring portion thereafter is telescoped downwardly over the lower ring portion to lock and retain the aerosol valve assembly on the pressurized bottle. The plastic mounting cup can be molded separately, or integrally with the plastic locking ring. A check valve may be contained in the valve stem.

Owner:PRECISION VALVE CORP

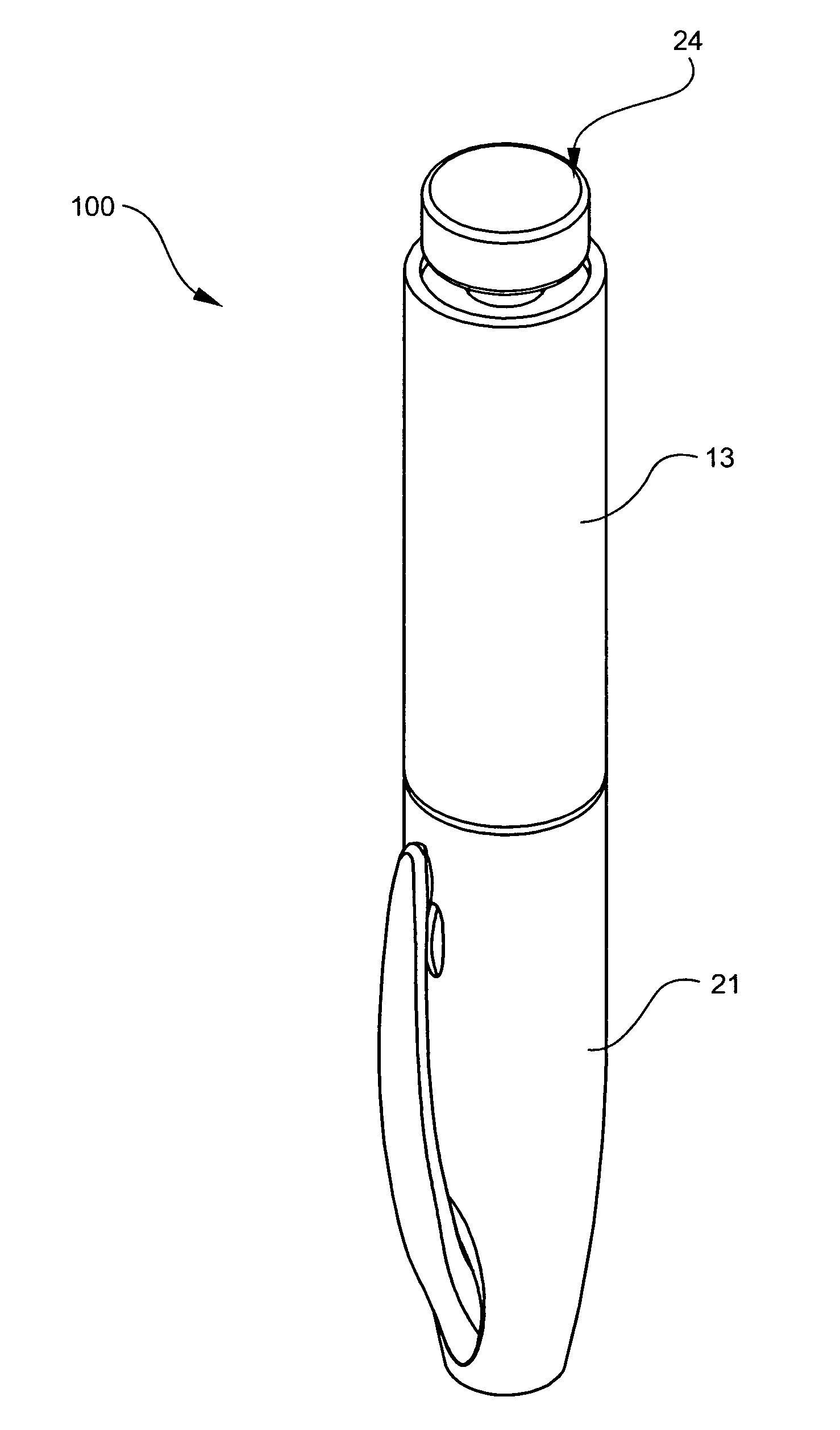

Injection device with secondary reservoir

A method and apparatus for injecting fluid into areas having high density tissue that creates a high backpressure resistance on the injection device is disclosed. The high backpressure resistance is overcome through a mechanical advantage achieved by using a secondary reservoir having a cross-sectional area smaller than the cross-sectional area of a primary reservoir. Exemplary injection device reservoir housings may comprise a primary reservoir, a secondary reservoir, a check valve, a septum penetrating cannula, travel limits, a pen needle connecting portion, sliding seal guide ribs, a sliding seal, a pen needle assembly, a needle stop, and a patient needle.

Owner:EMBECTA CORP

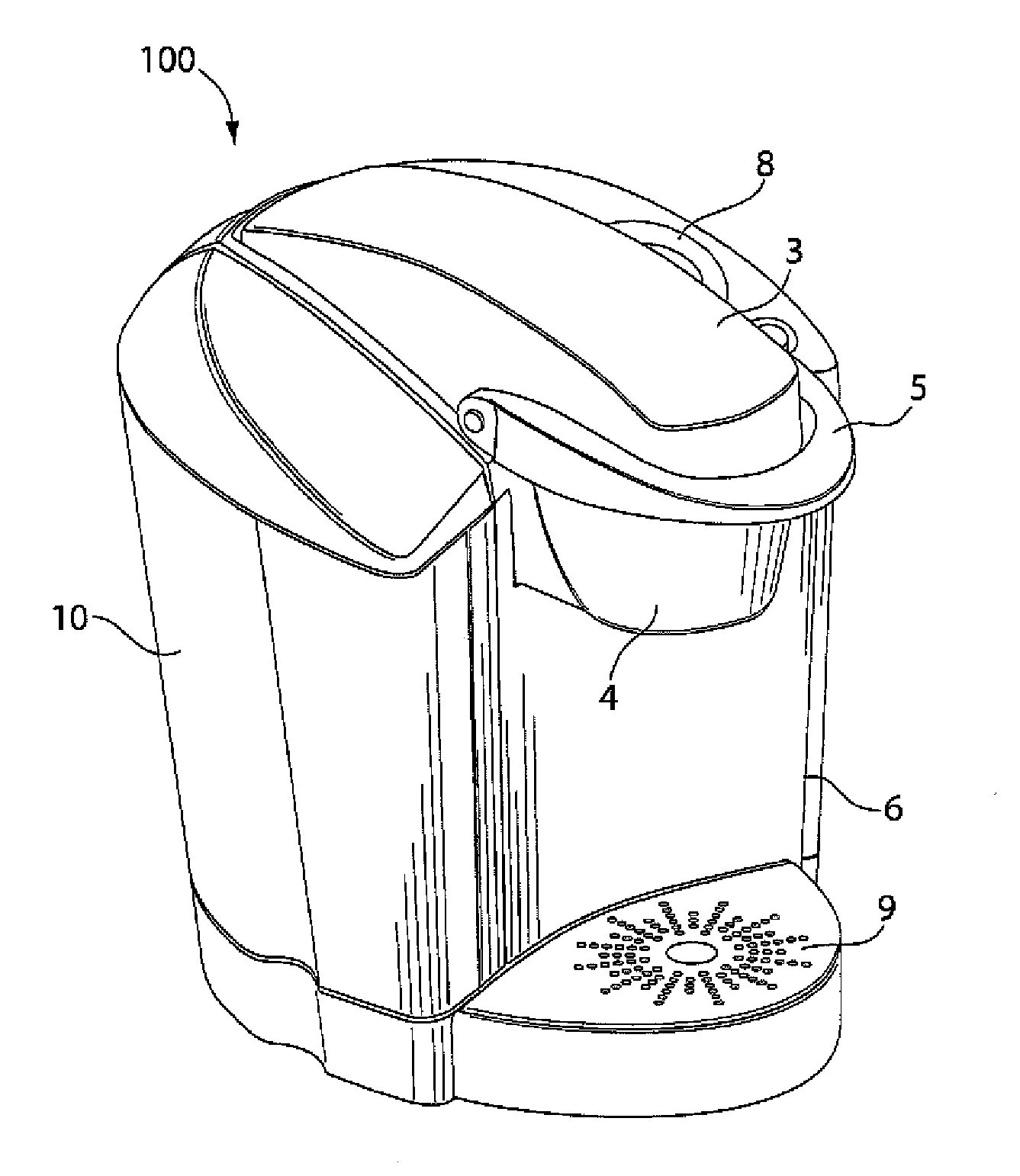

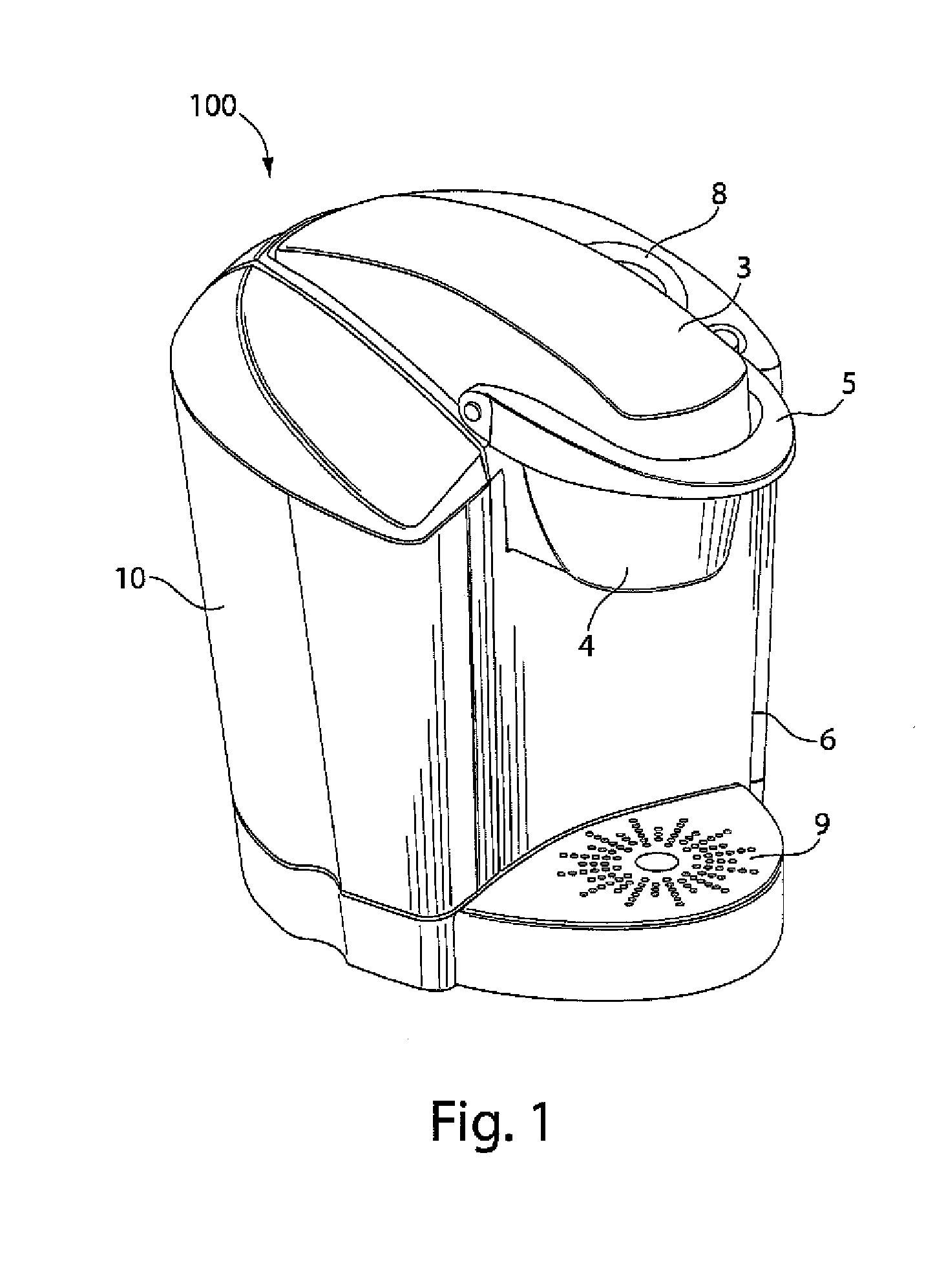

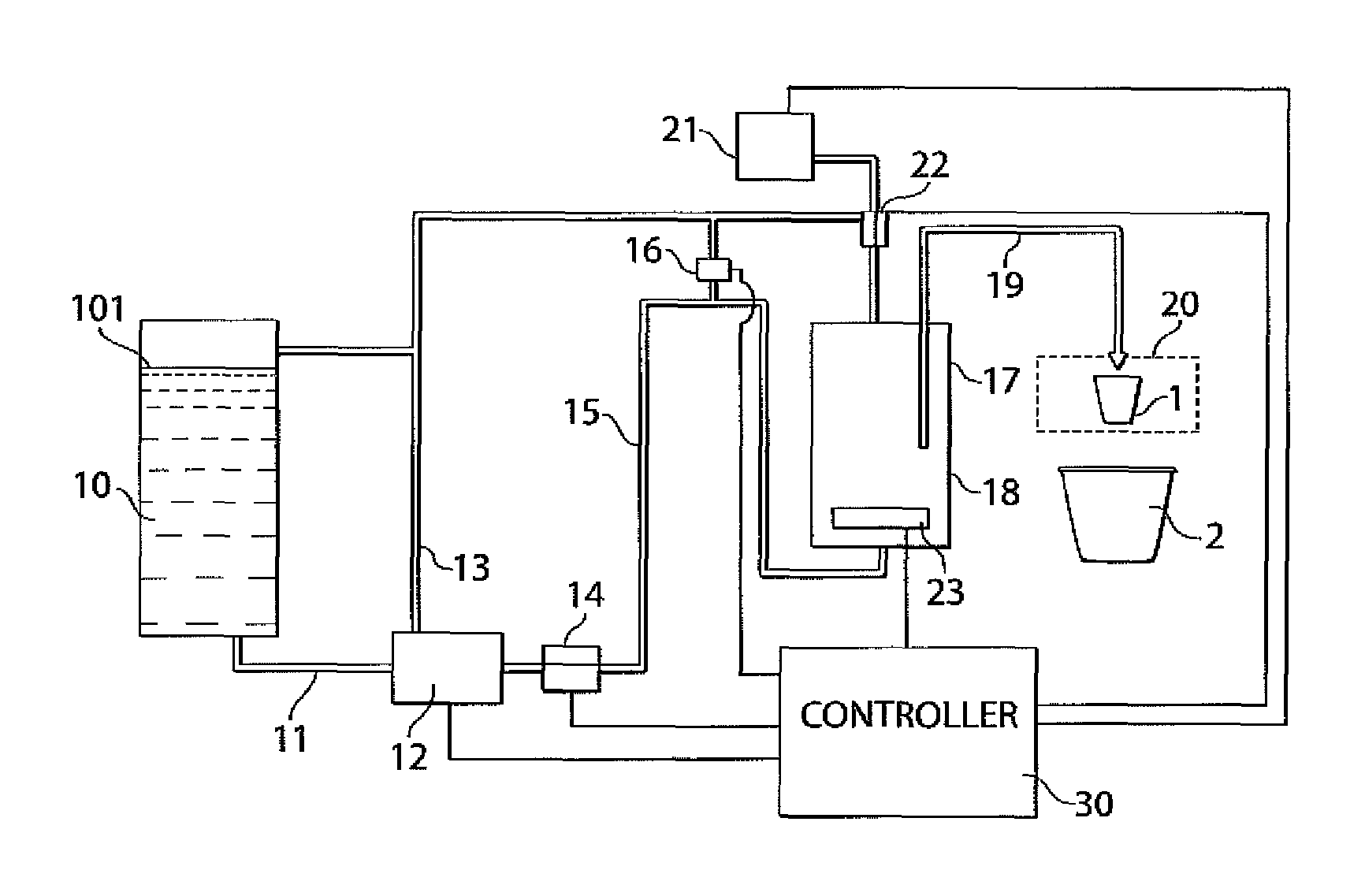

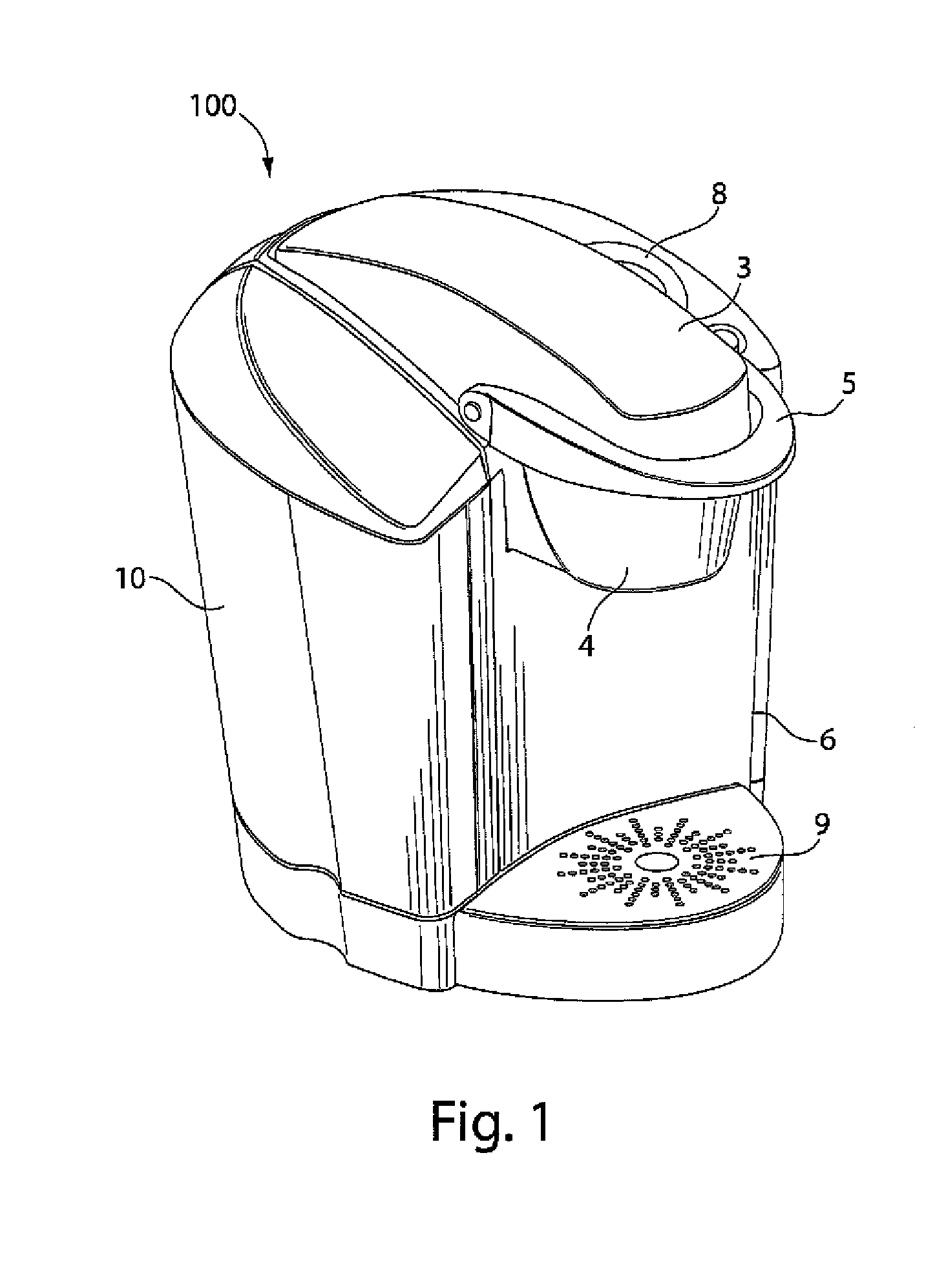

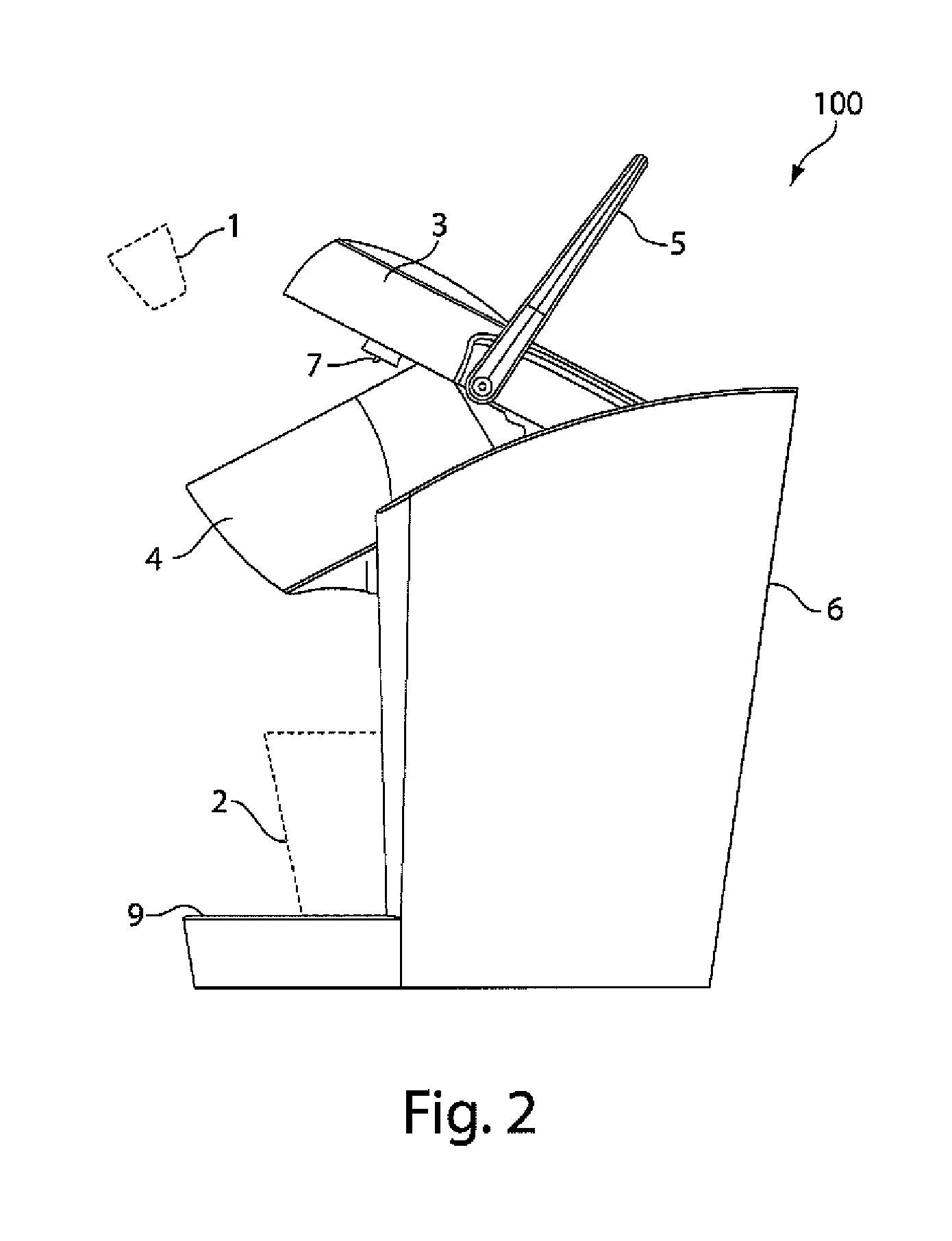

Beverage forming apparatus with centrifugal pump

ActiveUS20100024658A1Prevent substantial leakageAdequate flowBeverage vesselsFood preparationExhaust valveControl valves

A beverage forming apparatus includes a storage tank, and a centrifugal pump having an inlet connected to the storage tank by a supply conduit. The centrifugal pump may include a priming vent located below a full level of the storage tank and permit air to vent as liquid primes the pump. A metering tank may have an inlet connected to the centrifugal pump by a pump conduit, and an outlet connected to a brew chamber that forms a beverage using liquid received from the metering tank. In one embodiment, a flow control valve, such as a check valve, may be provided in the pump conduit to allow flow from the pump to the metering tank, but resist flow in reverse. In another embodiment, a vent valve in the pump conduit may be arranged to vent at least a portion of the pump conduit, e.g., to ambient air pressure.

Owner:KEURIG GREEN MOUNTAIN INC

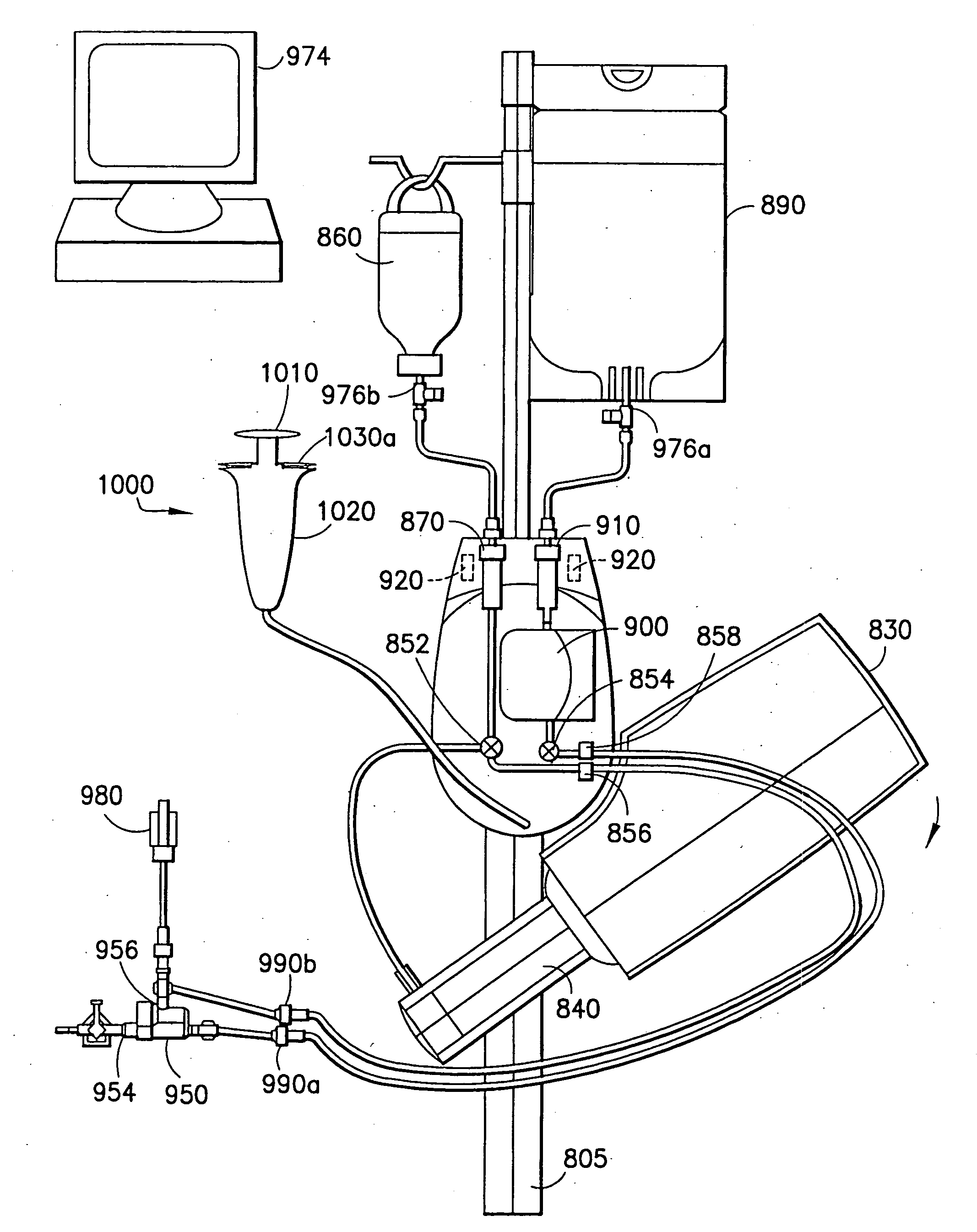

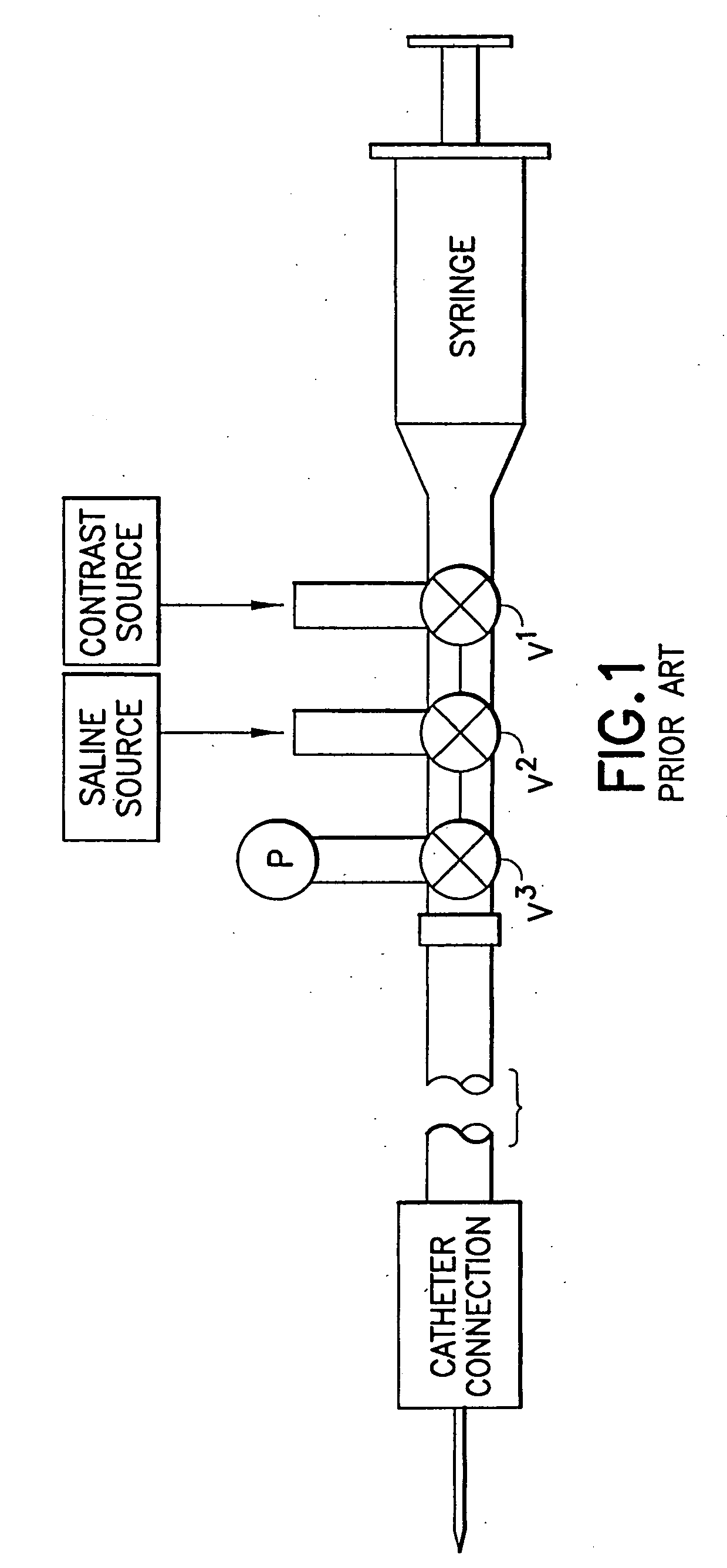

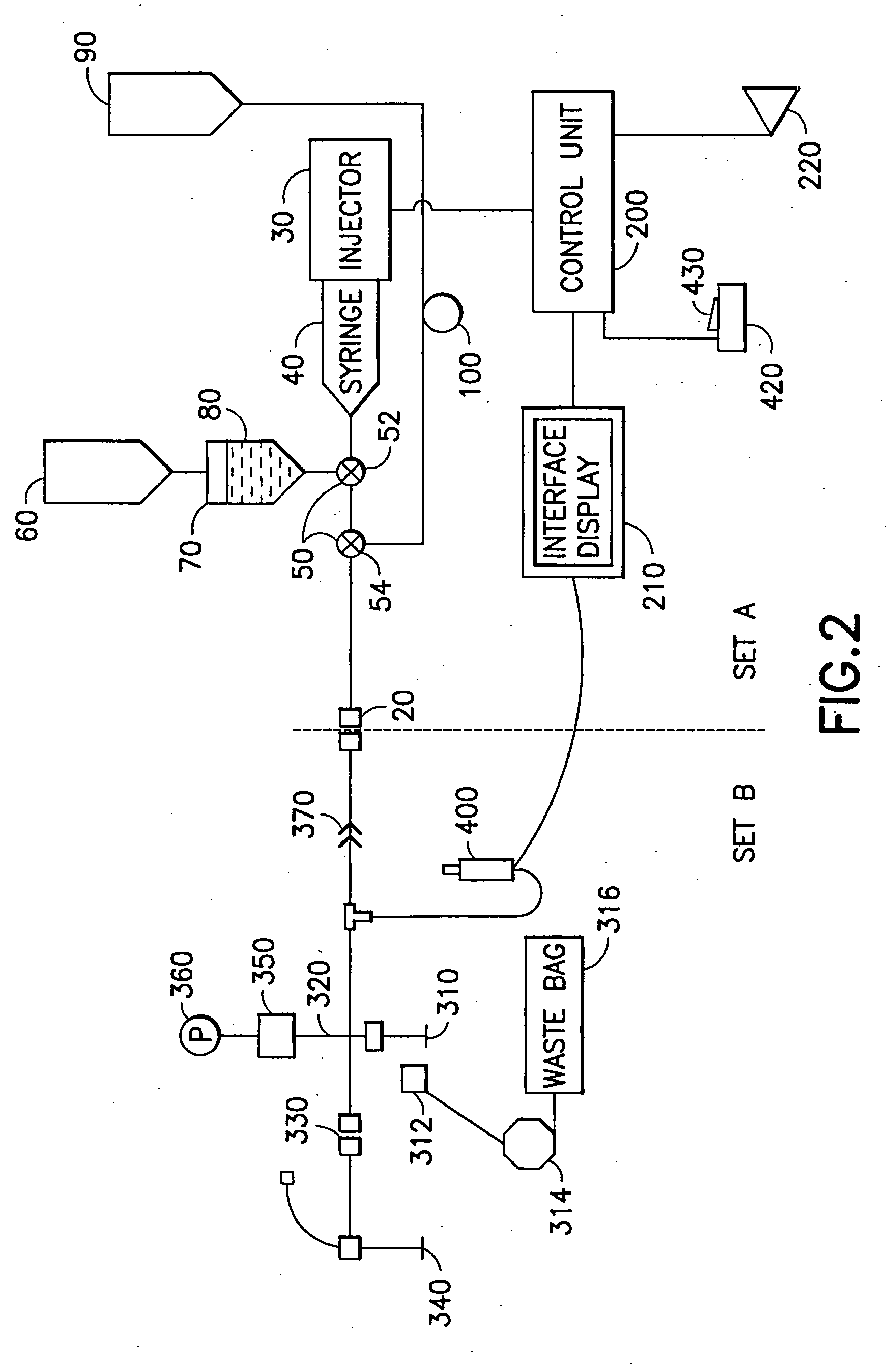

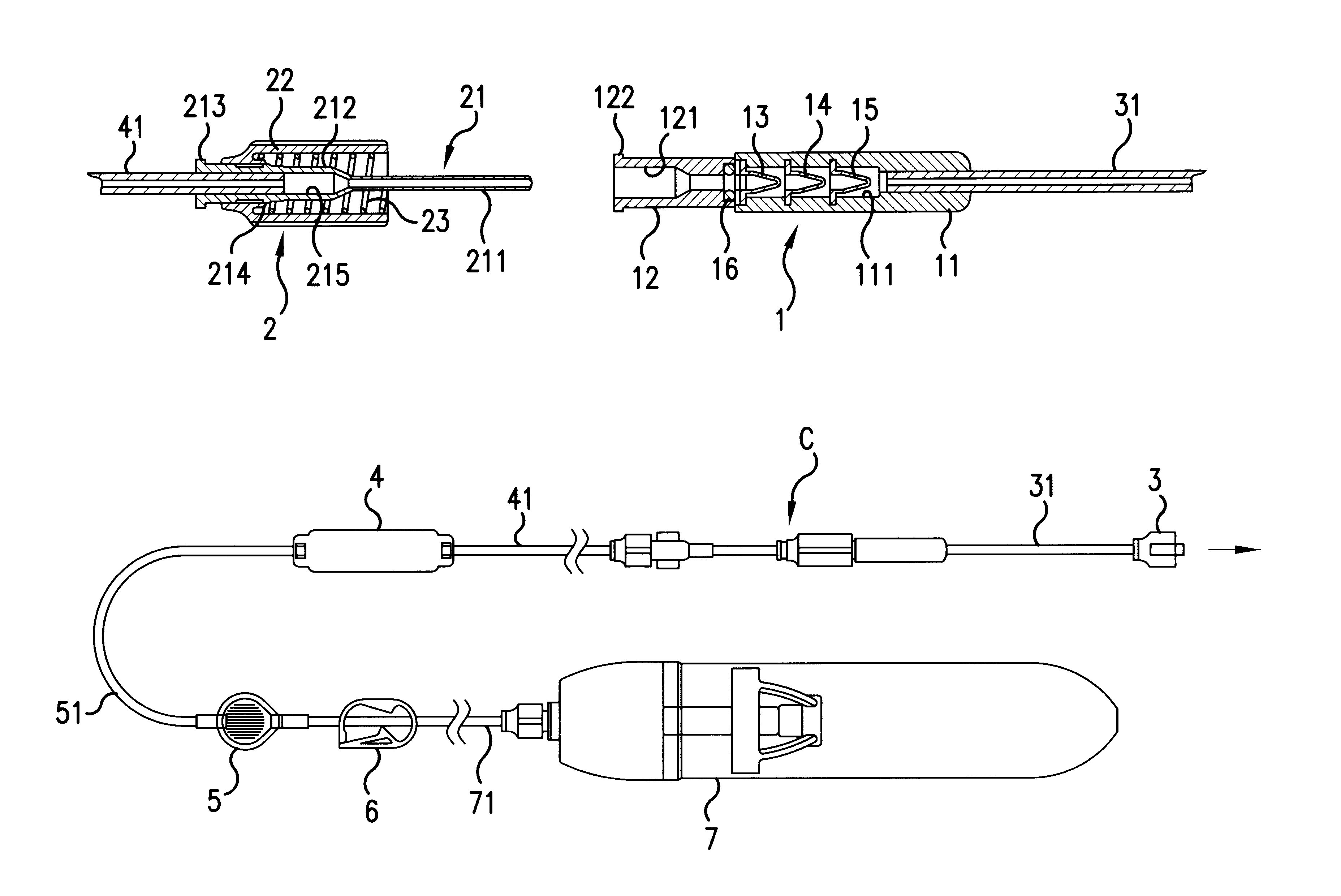

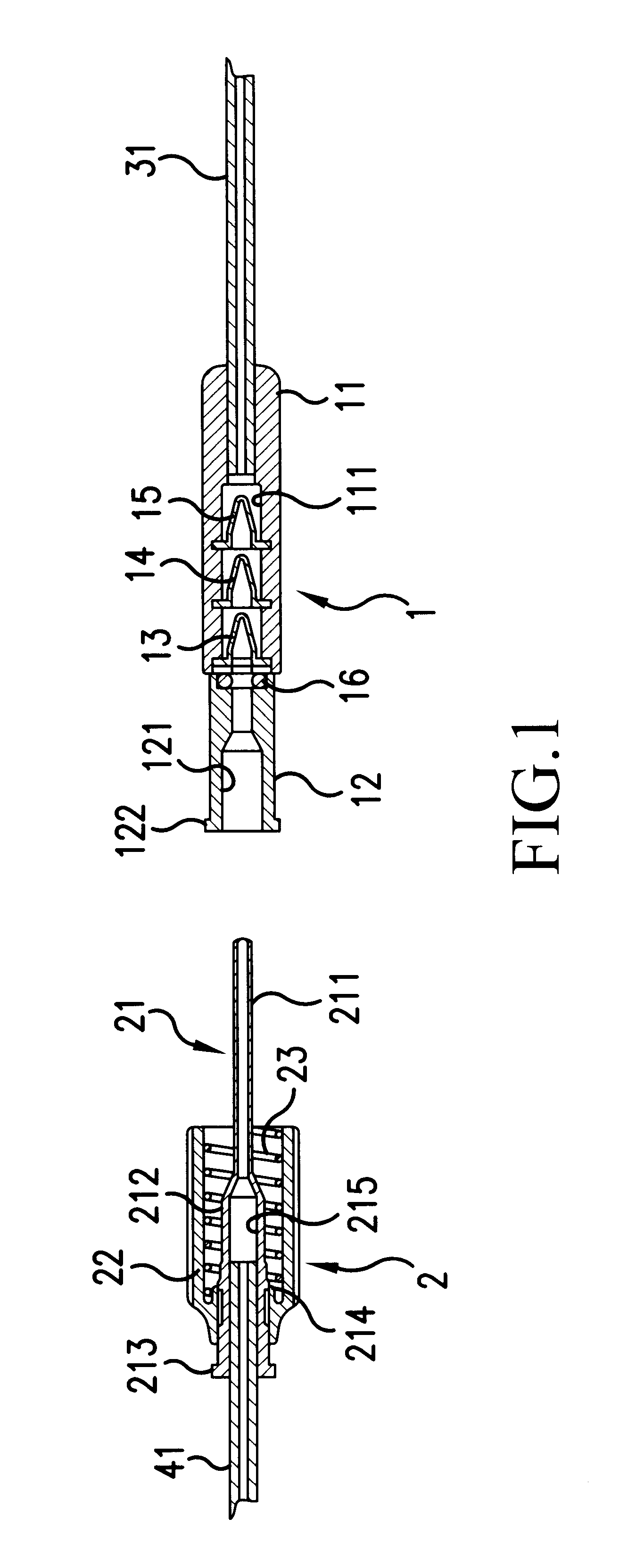

Fluid delivery system including a fluid path set with sterile check valve connector

ActiveUS20080086087A1Prevent leakageReduce and eliminate flowMedical devicesCatheterCheck valveDelivery system

The fluid delivery system includes a fluid path set with a first section adapted for connection to a syringe and to a source of fluid to be loaded into the syringe, and a second section that is removably connected to the first section. A connector removably connects the first and second sections. The connector includes a first connector member having a first luer member and a first annular member disposed about the first luer member. The connector further includes a second connector member having a second luer member and a second annular member disposed about the second luer member. A check valve arrangement is disposed in of one of the first and second connector members for limiting fluid flow to one direction through the connector. The first and second annular members are adapted to operably engage to securely and releasably connect the first and second connector members.

Owner:BAYER HEALTHCARE LLC

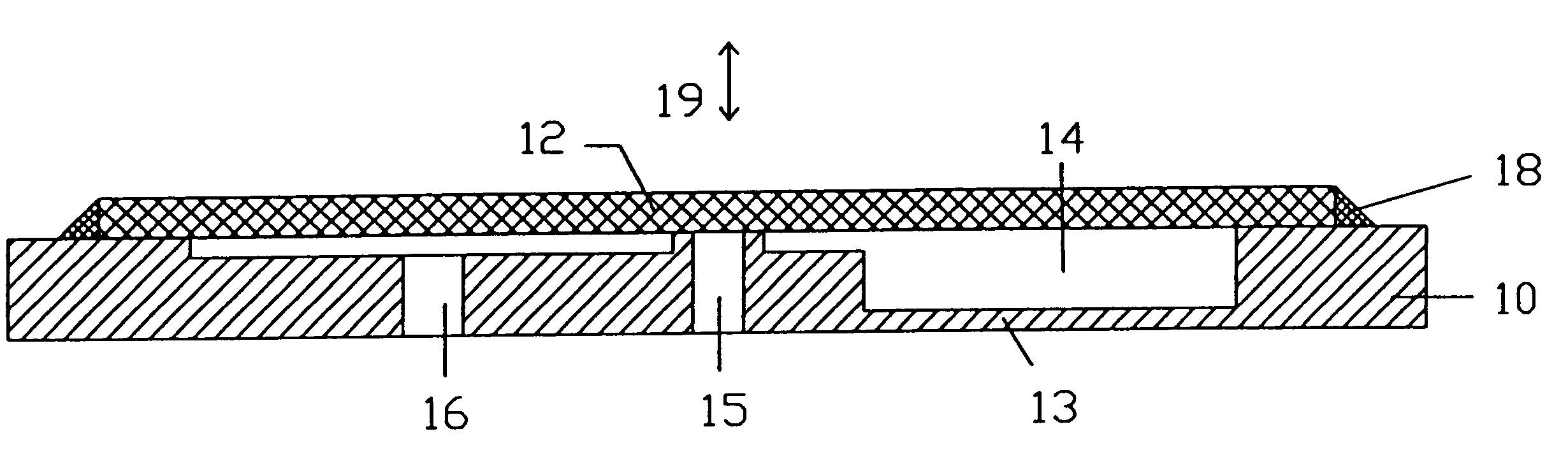

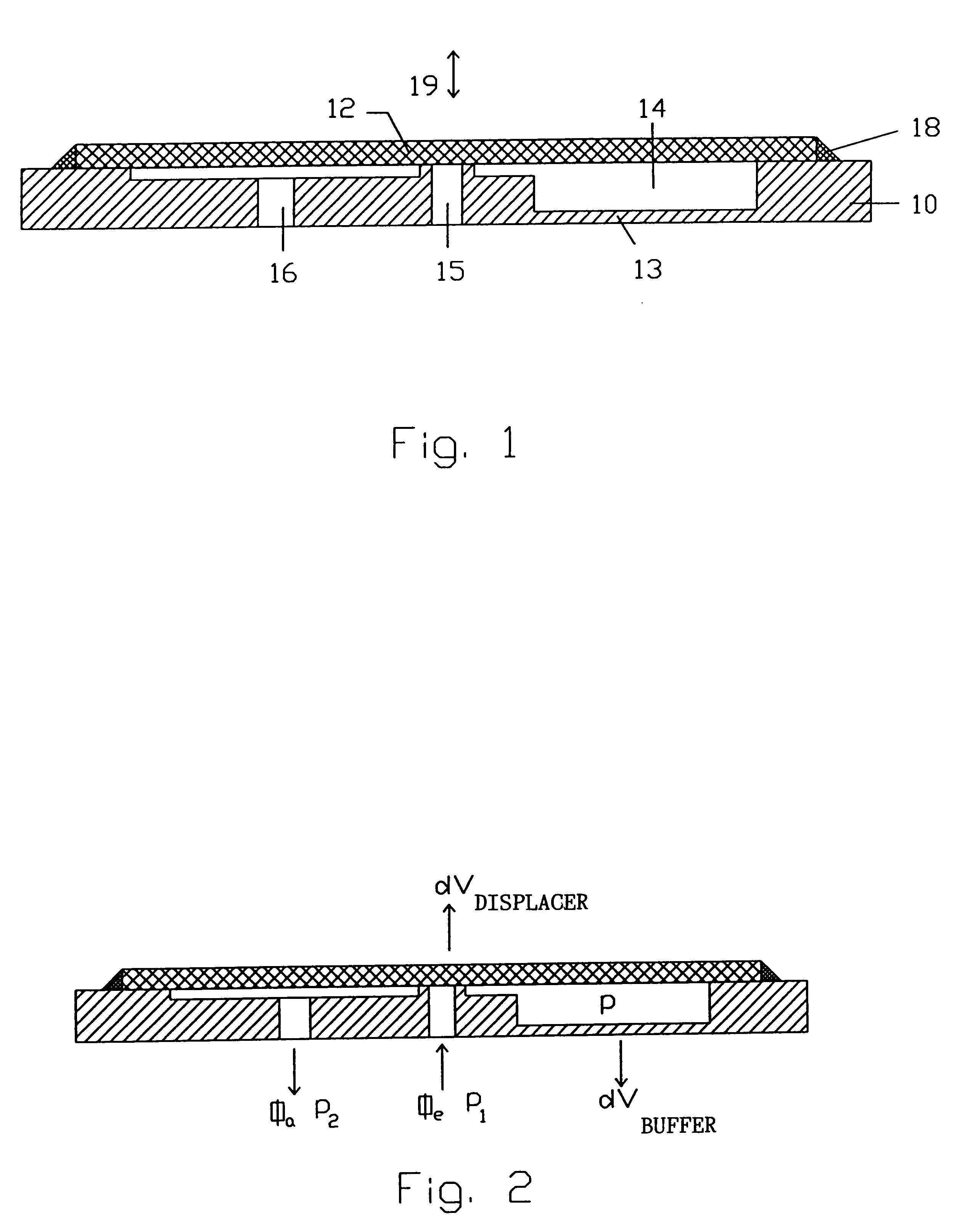

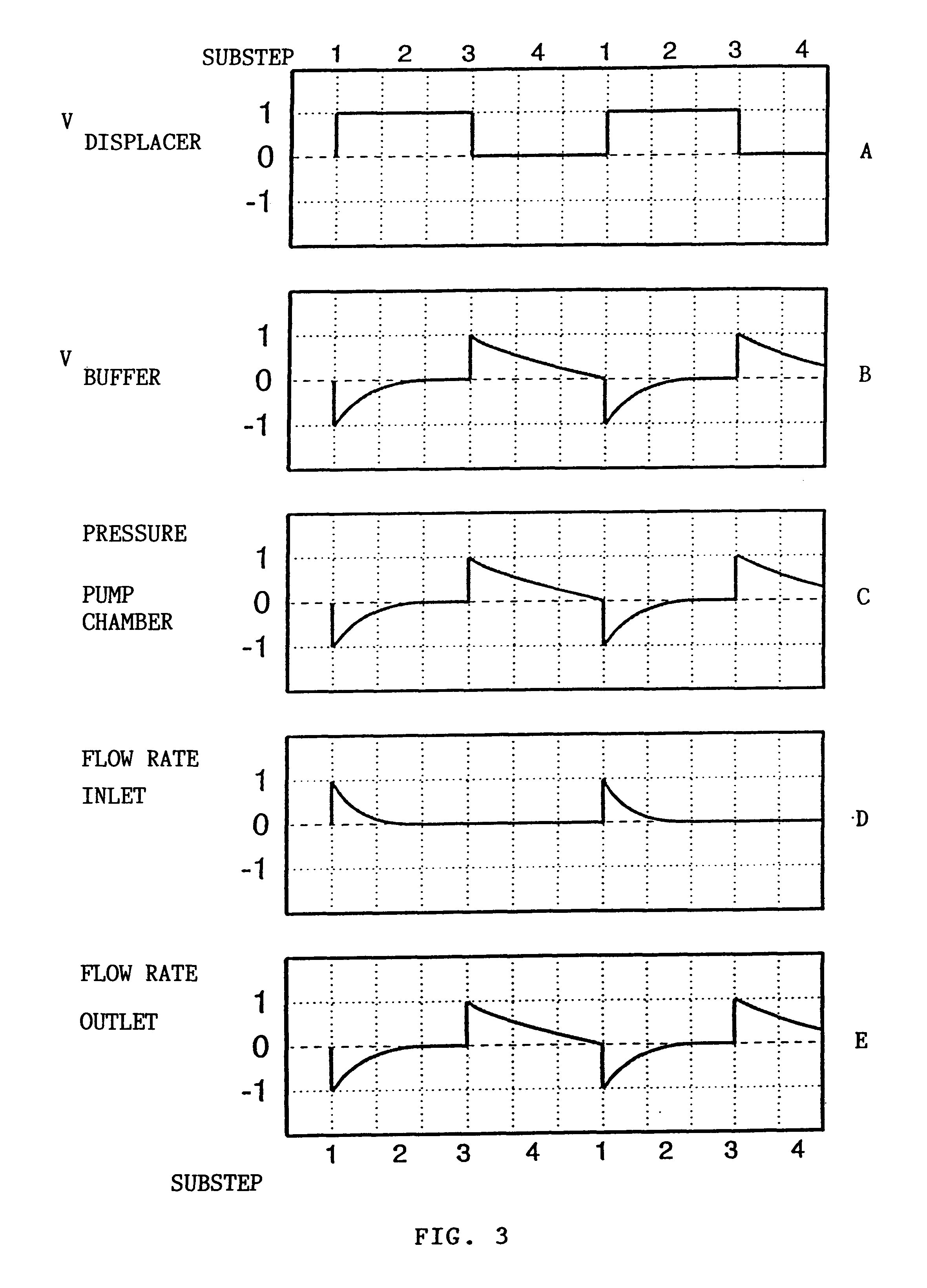

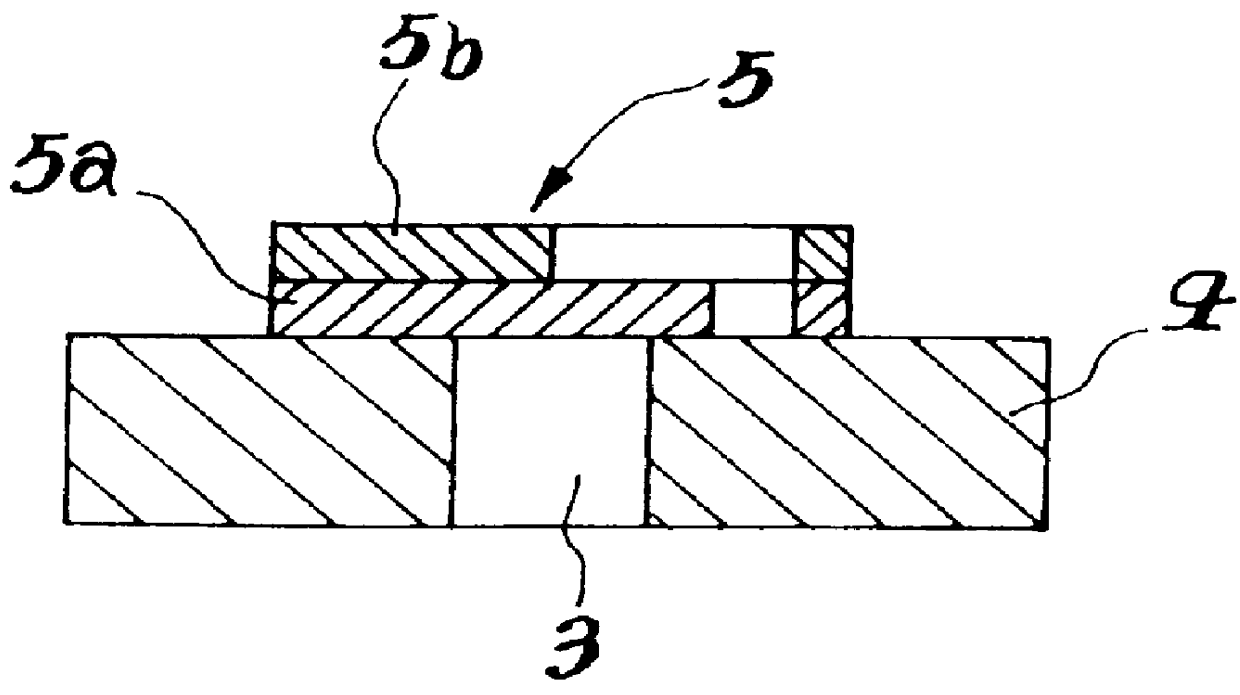

Fluid pump without non-return valves

InactiveUS6227824B1Reduce dead volumePositive displacement pump componentsFlexible member pumpsPump chamberEngineering

A fluid pump has a pump body and a displacer which is adapted to be positioned at a first and at a second end position by means of a drive, the displacer and the pump body being implemented such that a pump chamber is defined therebetween, and the pump chamber being adapted to be fluid-connected to an inlet and to an outlet via a first opening and a second opening which are not provided with check valves. An elastic buffer bordering on the pump chamber is provided. The displacer is implemented in the form of a plate which is secured to the pump body, and the pump body is provided with a recess defining the pump chamber. The drive acts on the displacer substantially in the area of the first opening. The displacer closes the first opening when it occupies its first end position and leaves the first opening free when it occupies its second end position. The drive means moves the displacer so abruptly from the second to the first end position that a deformation of the buffer means is caused by the movement of the displacer.

Owner:EPPENDORF AG

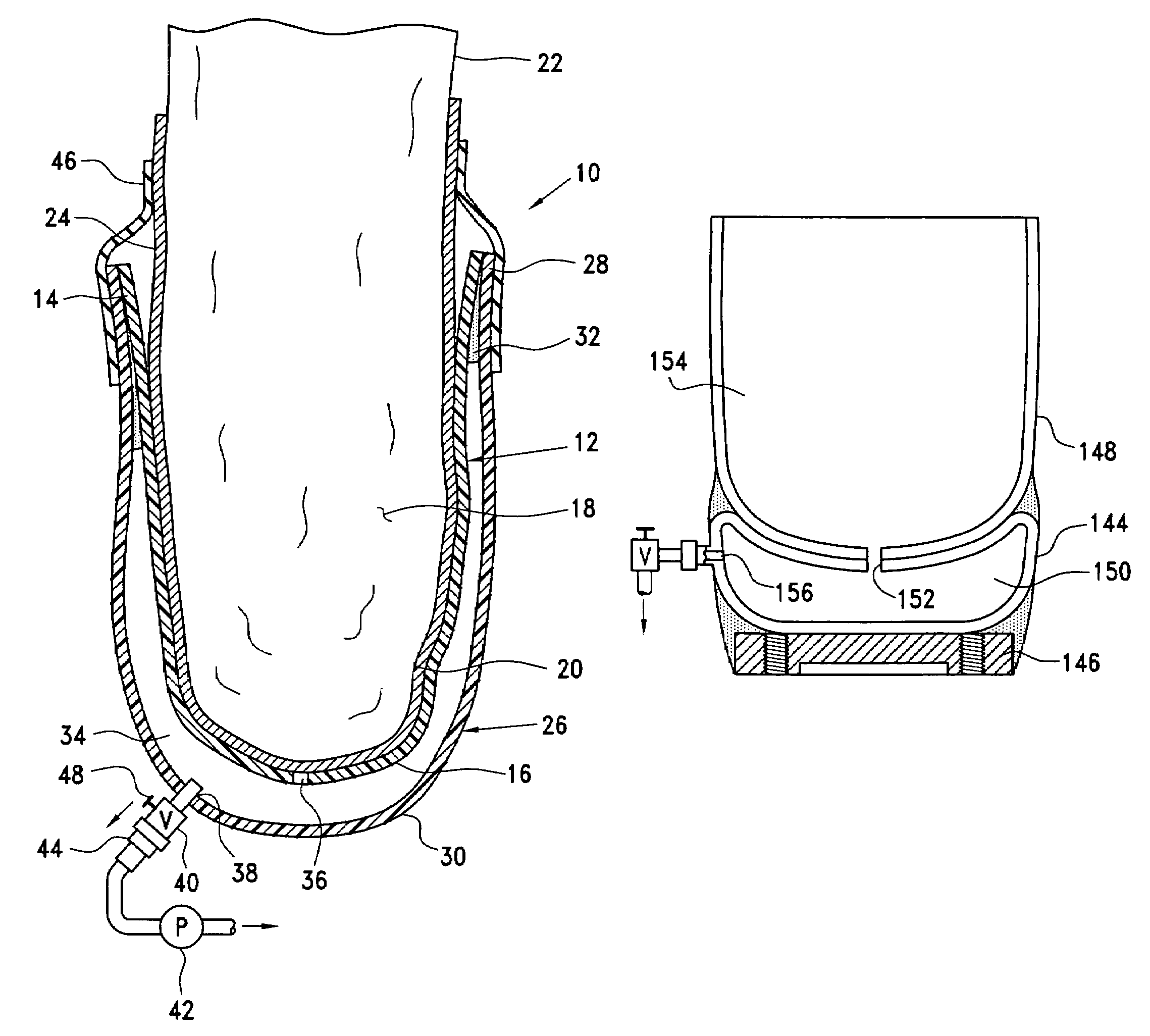

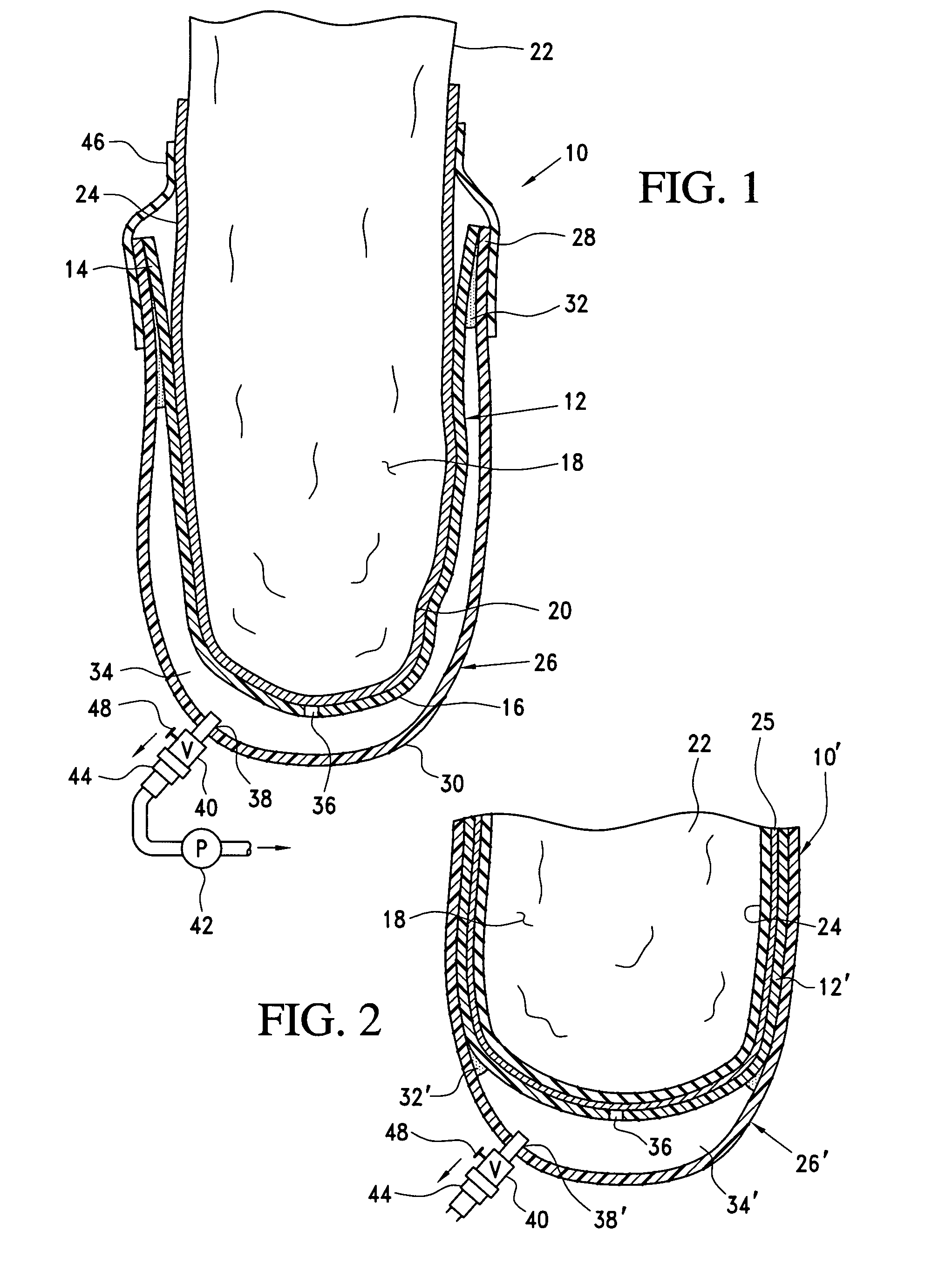

Prosthetic socket with self-contained vacuum reservoir

ActiveUS7427297B2Avoid substantial deflectionDomestic articlesProsthesisEngineeringLoad-bearing wall

Owner:OSSUR HF

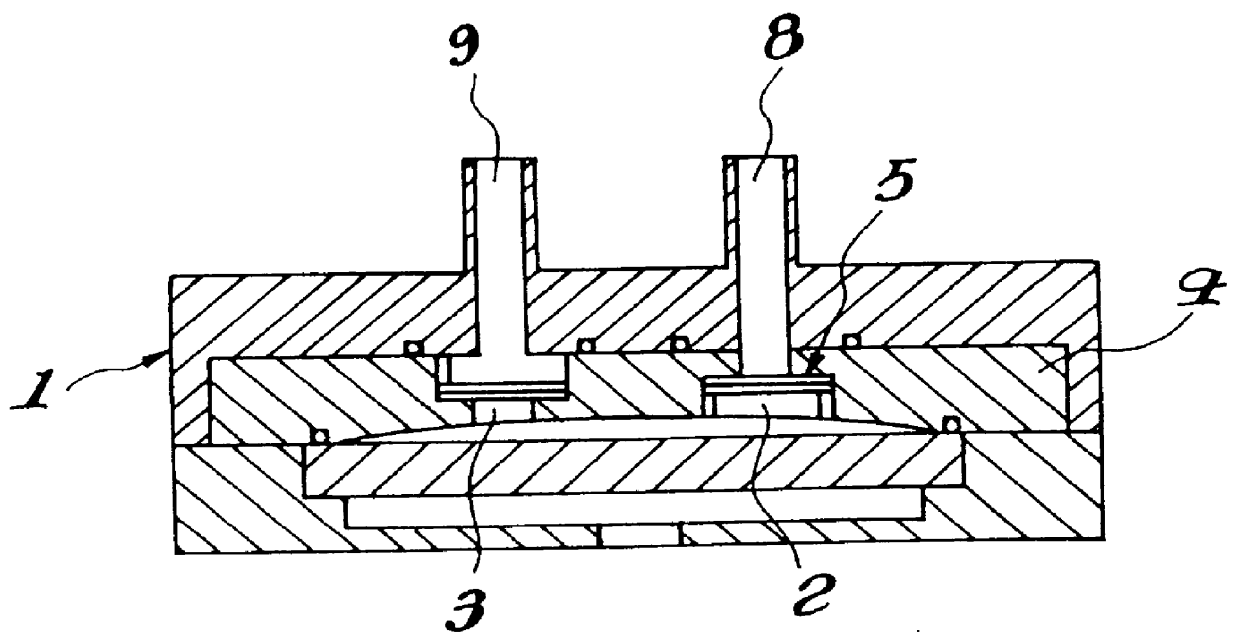

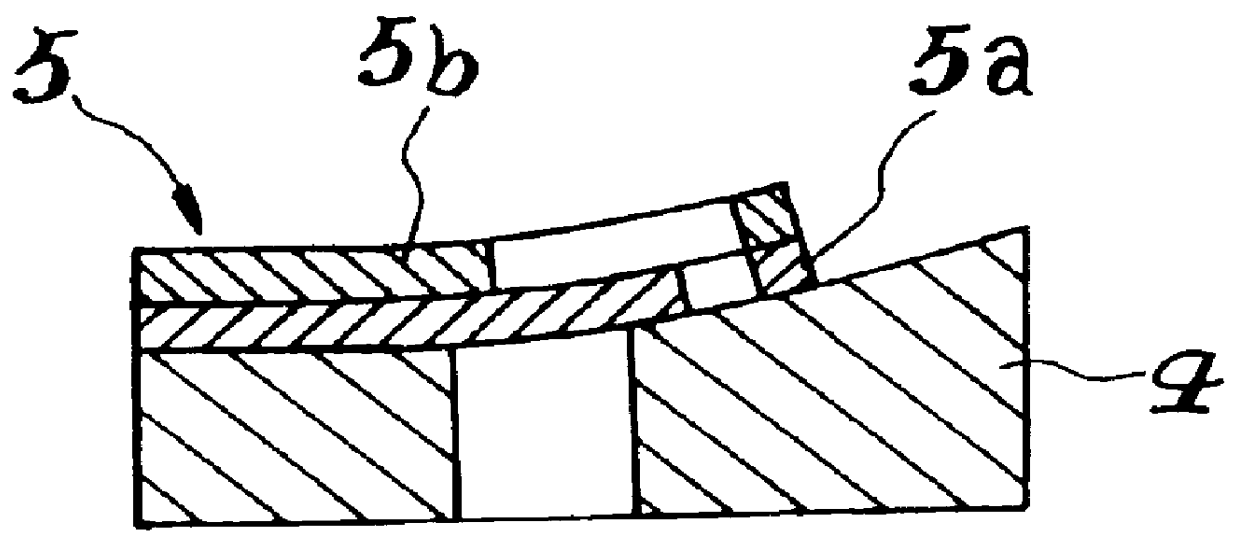

Reed valve for a pump

InactiveUS6116866APrevent backflowImprove sealingPositive displacement pump componentsFlexible member pumpsEngineeringReed valve

A reed valve is disclosed for use with a pump having a casing. A check valve unit is provided within the casing for preventing counterflow of fluids to be carried. A suction port communicates with a suction line into which the fluids to be carried flow, and a discharge port communicates with discharge line from which the fluids to be carried out are discharged. Reed valves are mounted on the suction port and on the discharge port of the check valve, respectively, in such a manner that the reed valves cover the suction port and the discharge port so as to be able to open and close. Each reed valve includes a first reed valve and second reed valve. The first reed valve is made of pliable material, and is formed to have a size capable of covering the entire respective suction port and discharge port. The second reed valve is smaller than first reed valve and is superposed on the first reed valve to engage the first reed valve such that the first reed valve can open and close, while enhancing sealability thereof.

Owner:NITTO KOHKI CO LTD

Check valve

InactiveUS20110186151A1Maximum vacuum boostIncrease airflowCheck valvesEqualizing valvesEngineeringInternal combustion engine

A check valve which is positioned in the vacuum air line of an internal combustion engine. The check valve includes a single-piece valve body having an outlet port and two or more inlet ports, with one outlet port located substantially in line with the inlet port and connected by a venturi tube. The second inlet port is separated from the main air flow line by the valve stem and a diaphragm which allows communication there between and prevents back pressure. The second inlet port communicates with the outlet port through the valve stem and a second venturi tube which provides a vacuum boost to a device, usually vehicle brakes, connected to the inlet. The use of seal diaphragms having a non-constant radius allows for faster recovery time for replenishment than prior art devices.

Owner:TECHNIPLAS US LLC

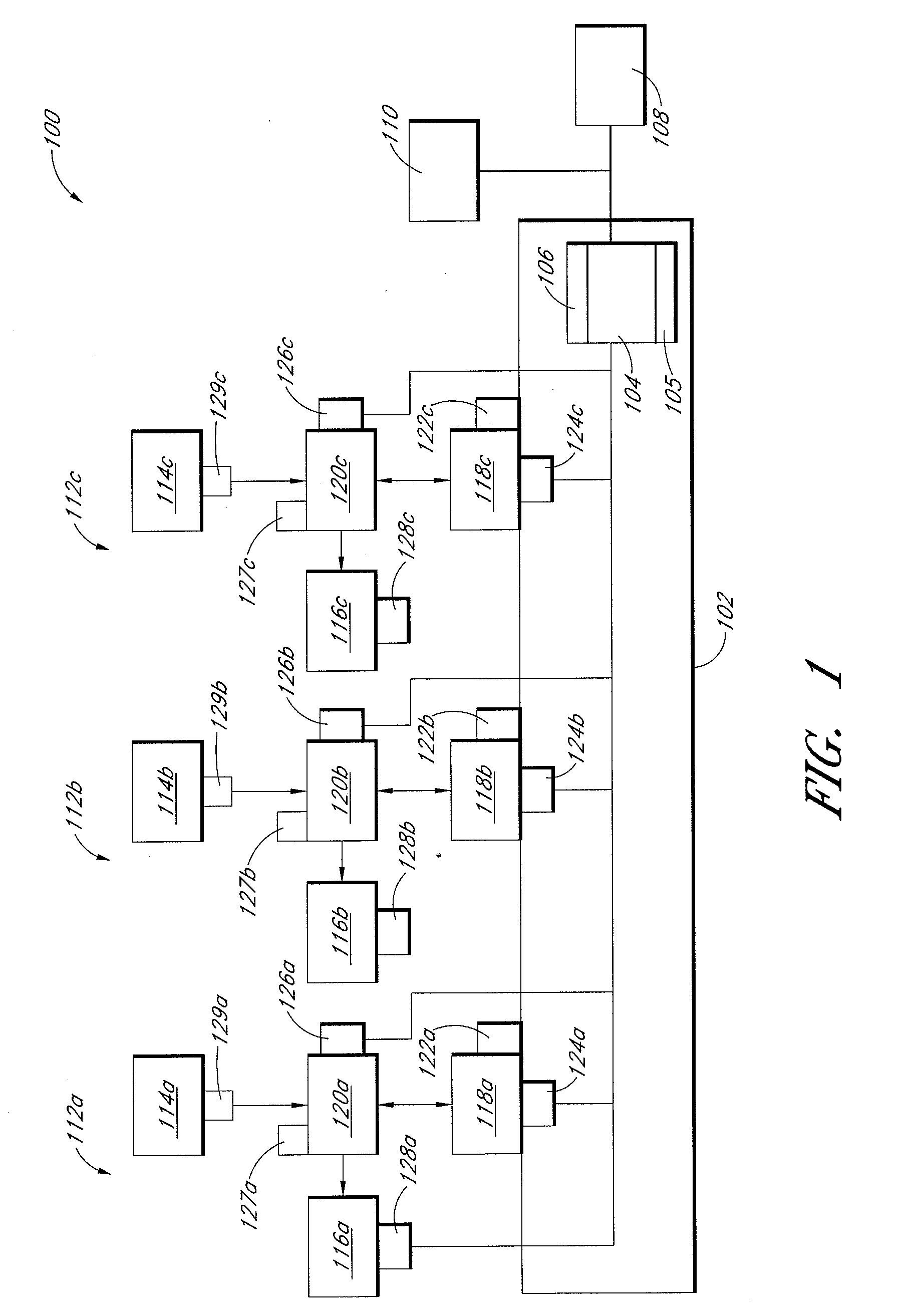

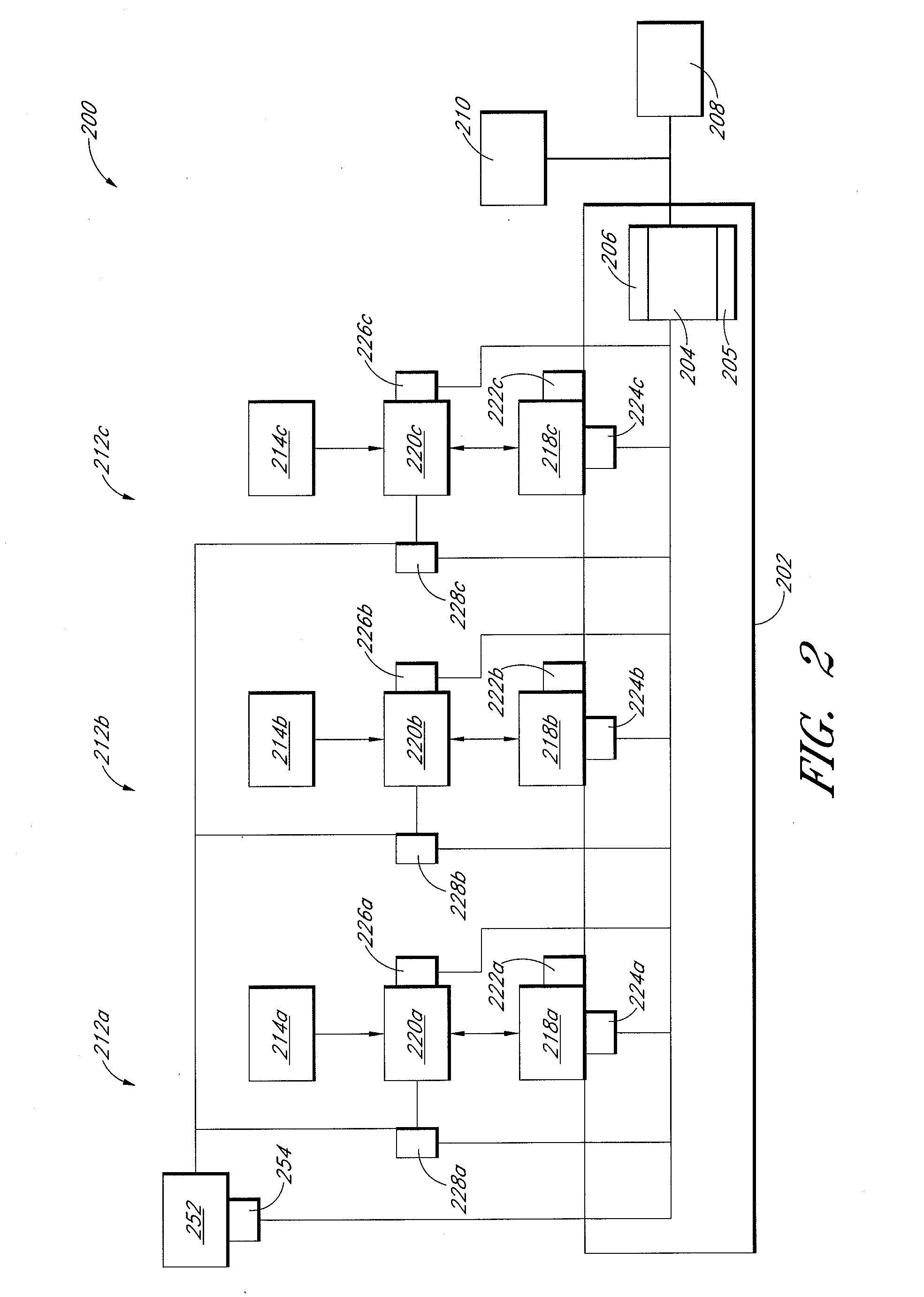

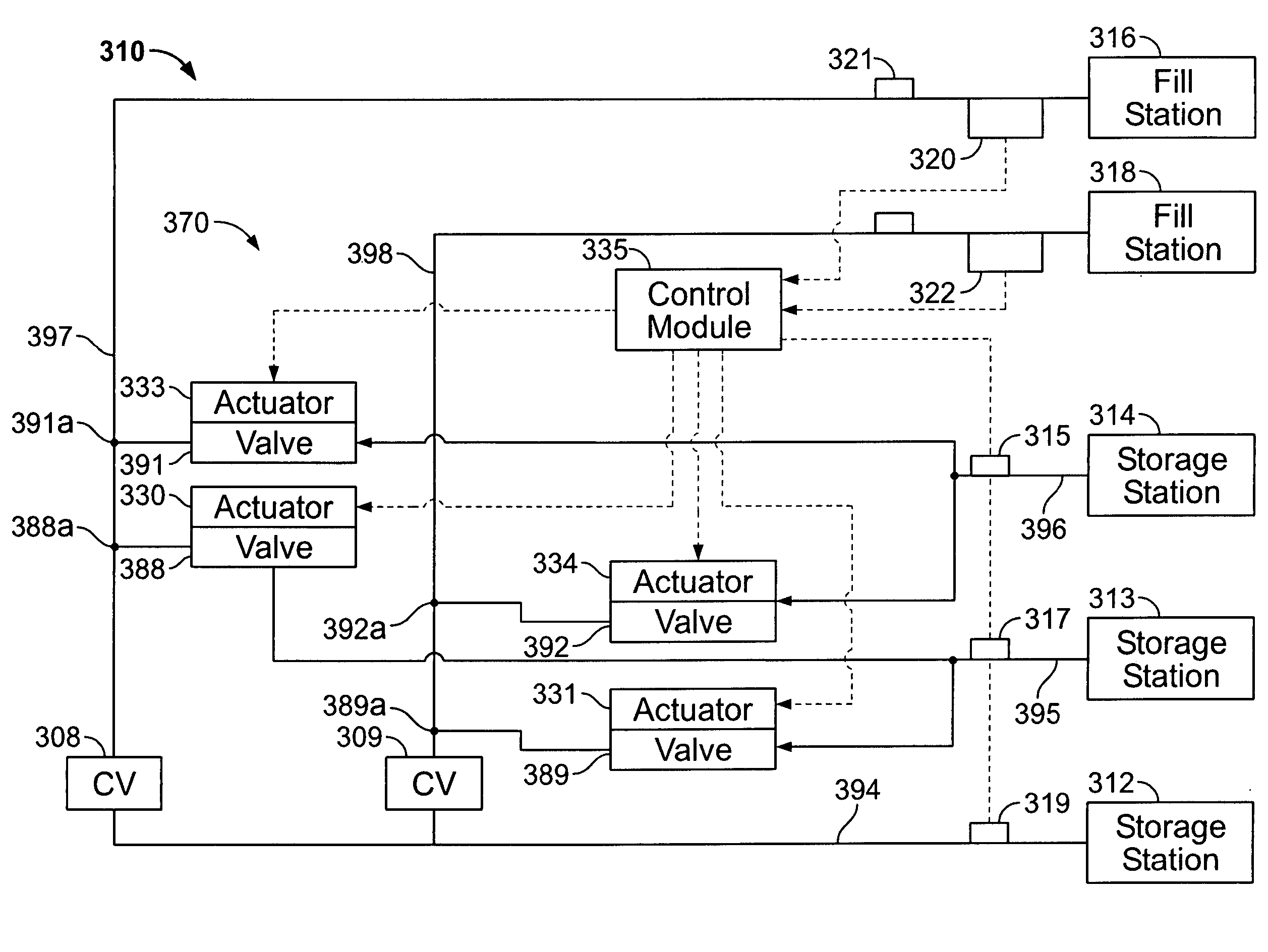

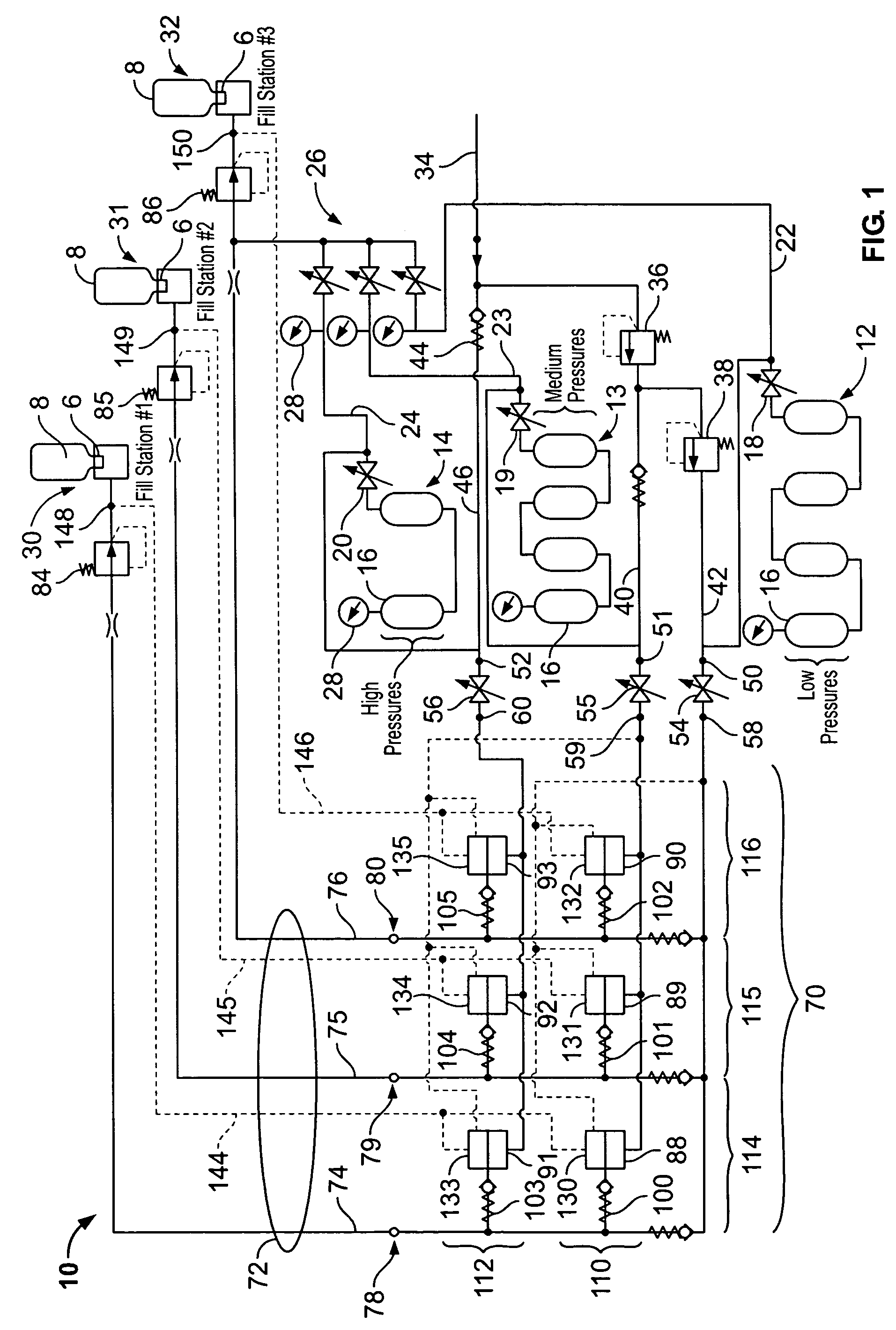

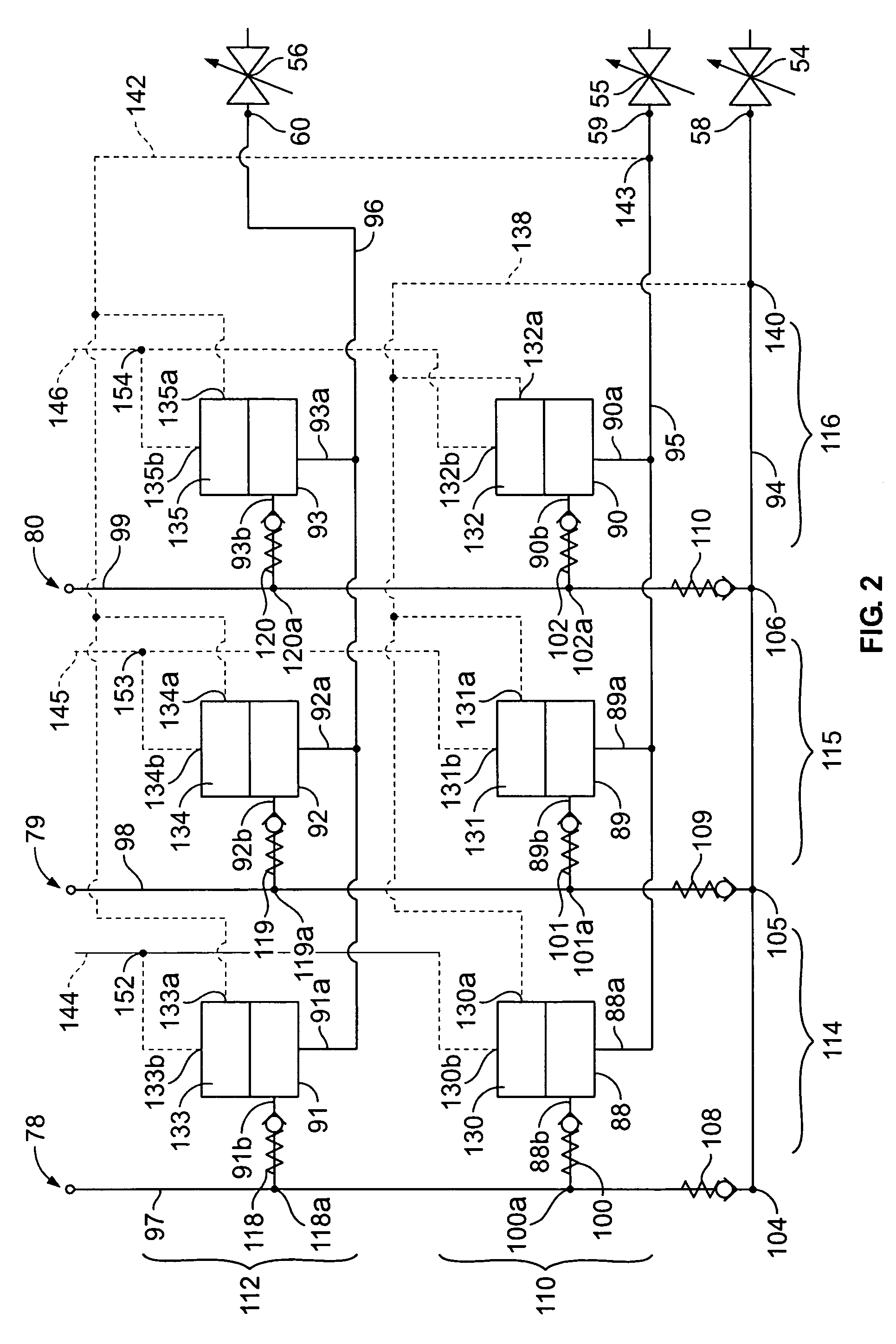

Method and system for independently filling multiple canisters from cascaded storage stations

A canister filling system is provided for independently filling multiple canisters from a common set of storage stations prioritized in a cascaded manner. The system includes first and second fill stations configured to receive and independently fill canisters with pressurized gas. First and second storage stations store gas at corresponding first and second charge pressures, respectively. A supply-chain joins each of the first and second fill stations to both of the first and second storage stations. First and second valve assemblies are provided in the supply-chain to monitor, independent of one another, the canister pressures at the corresponding first and second fill stations. The canister pressures represent the pressure within corresponding canisters. The first and second valve assemblies automatically open and close to permit and prevent discharge of gas from the first and second storage stations, independent of one another, to automatically switch between the first and second storage stations based on the canister pressures. In one embodiment, the valve assembly includes a combination of sequence valves and check valves. Alternatively, the valve assembly may be controlled by electronic sensors and electronic solenoids. The electronic sensors detect the canister pressures and the charge pressures at the storage stations. The electronic solenoids open and close the valves based on the sensed canister pressures.

Owner:SCOTT TECH INC

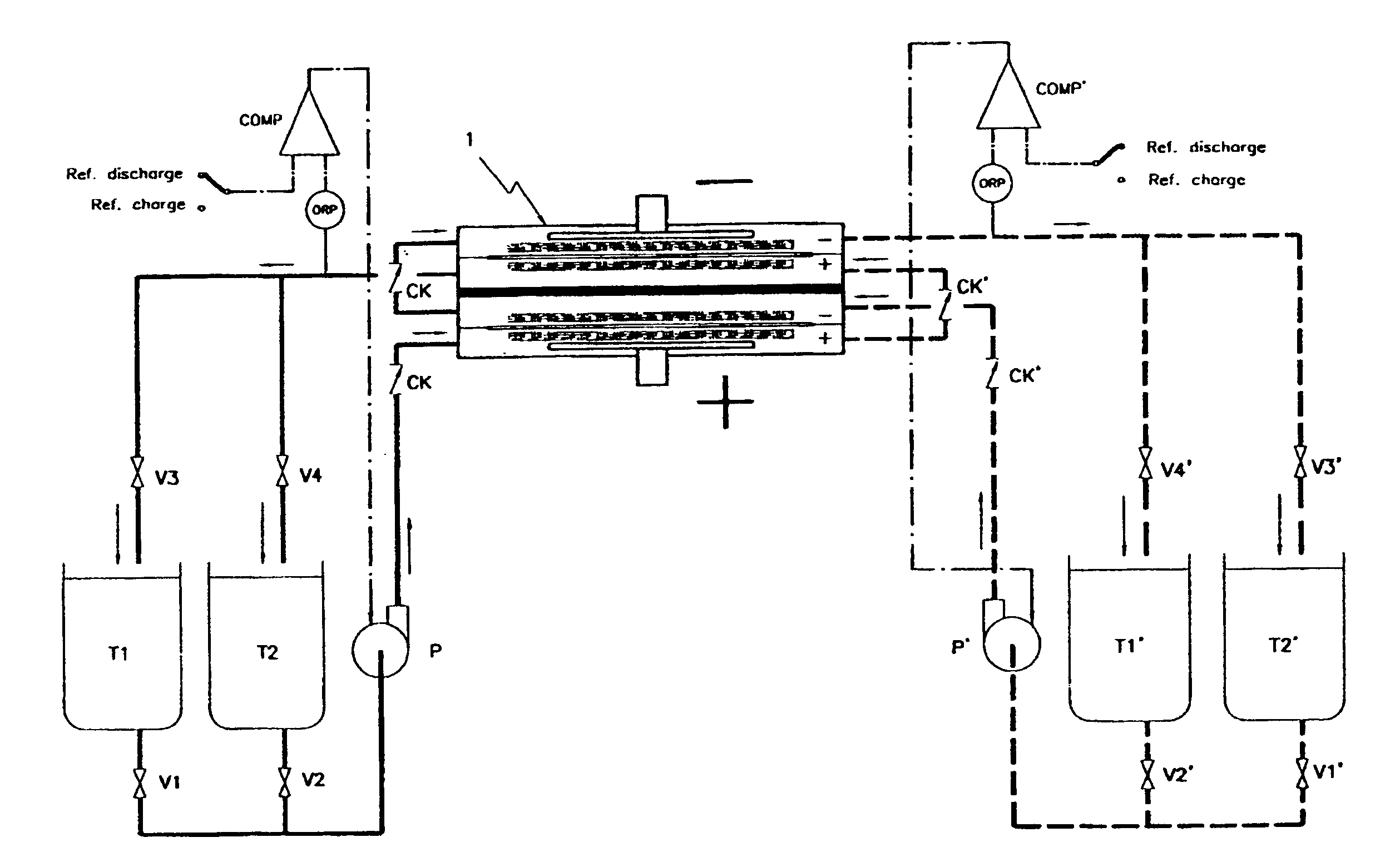

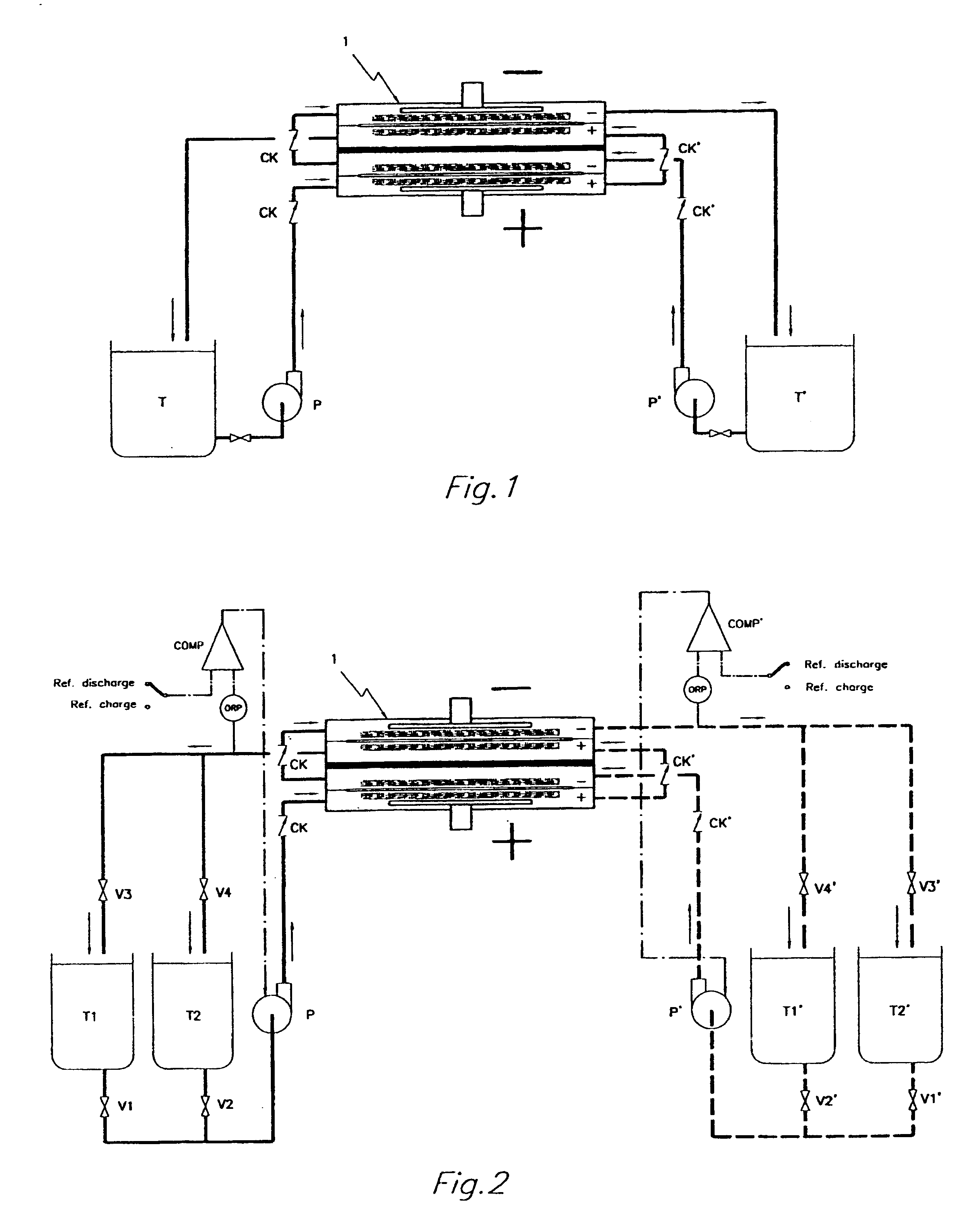

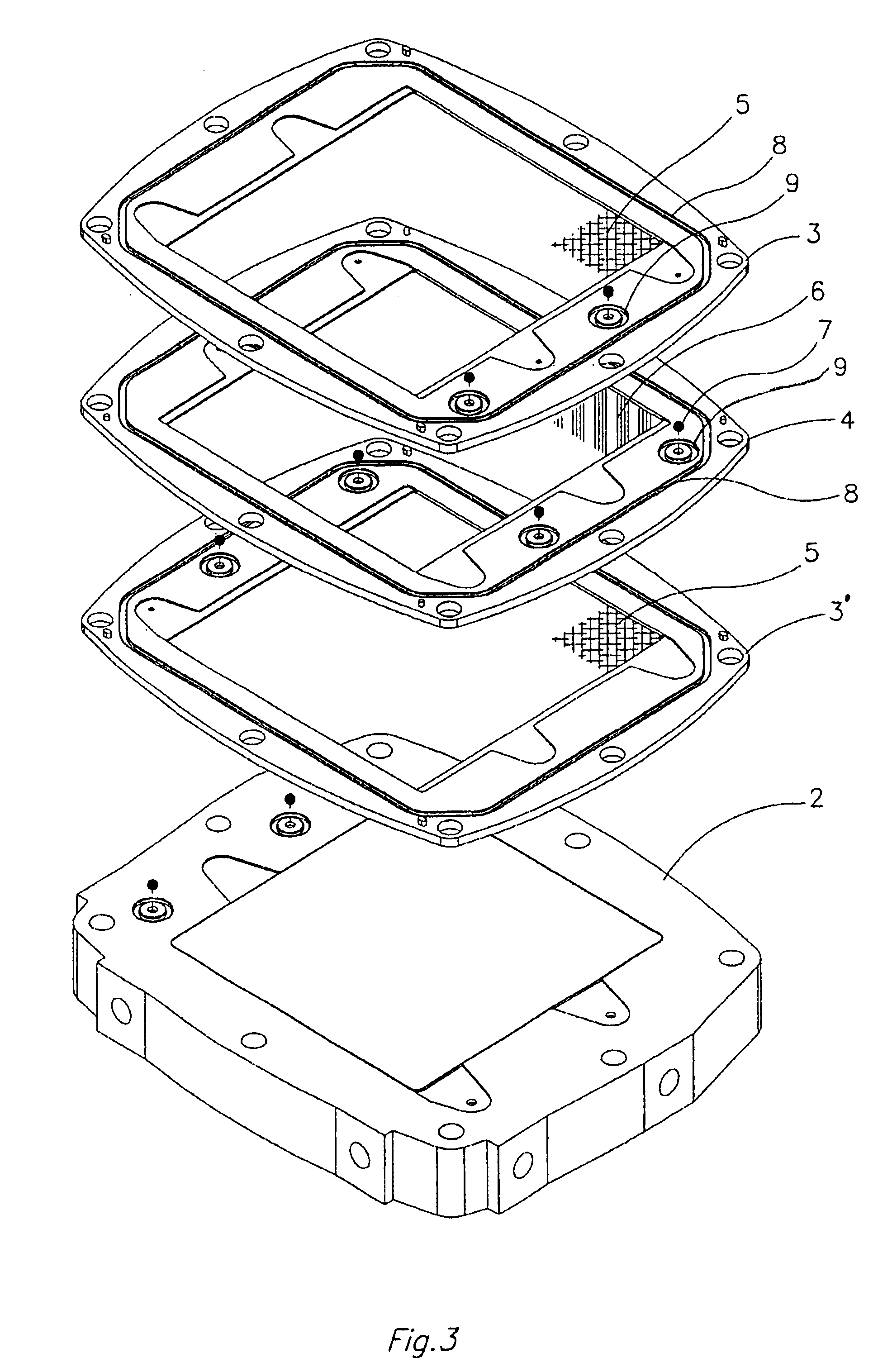

Redox flow battery and method of operating it

InactiveUS6692862B1Easy dischargeImprove efficiencyElectrolyte moving arrangementsFuel cells groupingWork cycleRedox

By realizing or installing check valve liquid vein interrupters in each compartment of the battery the phenomenon of slow discharge of the retained volumes of electrolytes during long periods of inactivity of a redox flow battery, with the electrolyte pumps stopped altogether, can be practically eliminated with the effect that the battery is perfectly ready to deliver electric power immediately upon request even after prolonged periods of inactivity. Moreover, the presence of liquid vein interrupters on each compartment in either an outlet or an inlet port substantially preventing by-pass current during a not pumping phase, permits to increase the by pumping the electrolytes through the compartments of a battery stack intermittently, in other words in a pulsed manner, with a certain duty-cycle. Relatively brief pumping phases at relatively high flow rate alternated to phases of not pumping provide for a volumetrically adequate refreshing of the electrolytes present in the battery compartments and contrast the formation of gradients in the bodies of electrolyte.

Owner:SQUIRREL HLDG

Infusion rate adjusting device for drug solution injector

Owner:NIPRO CORP

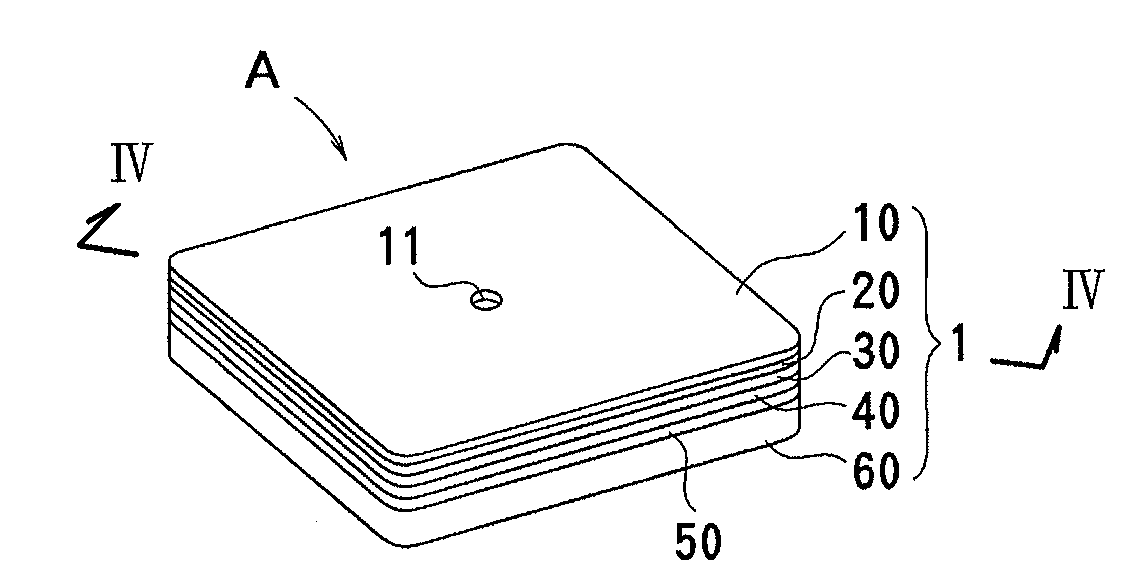

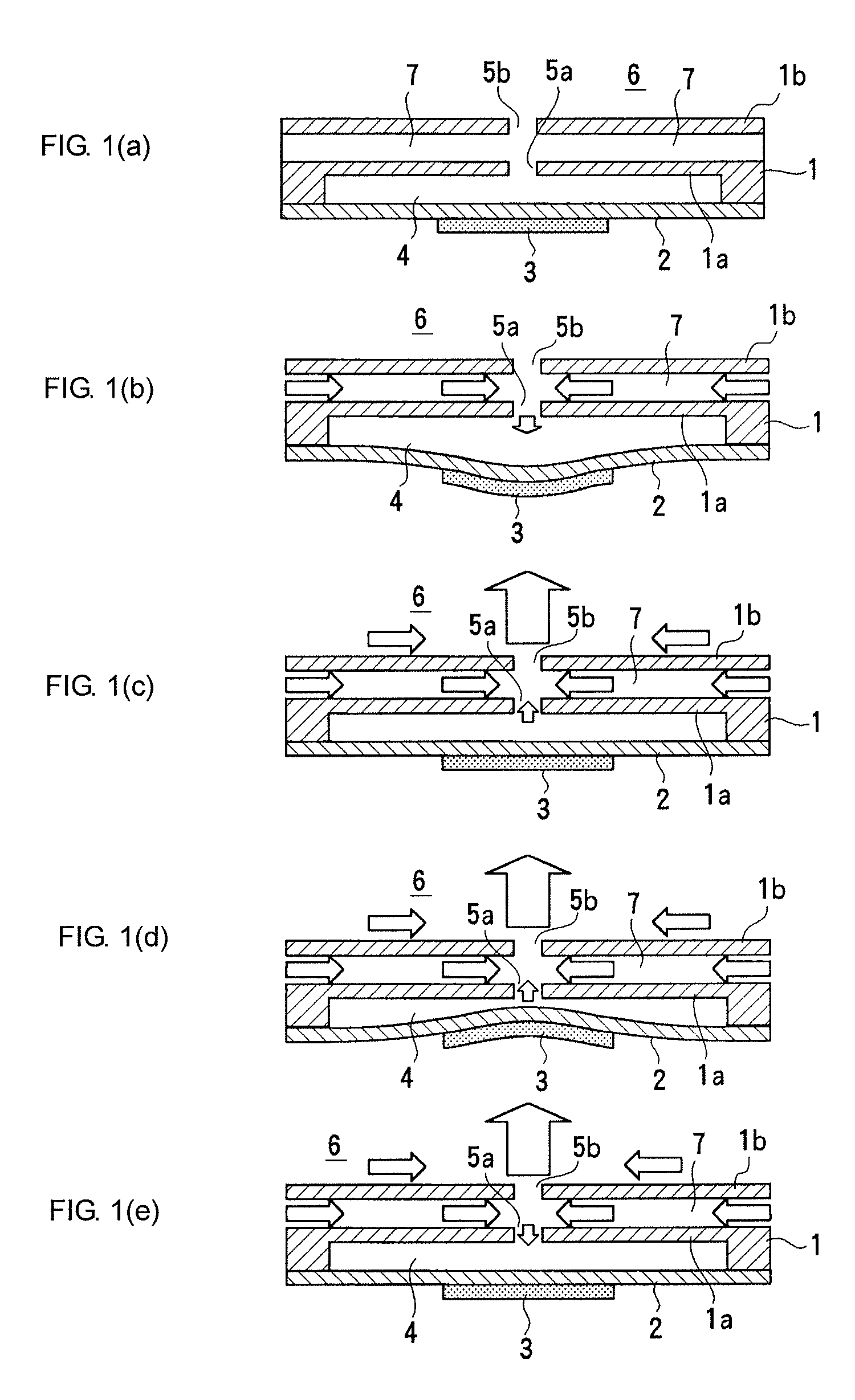

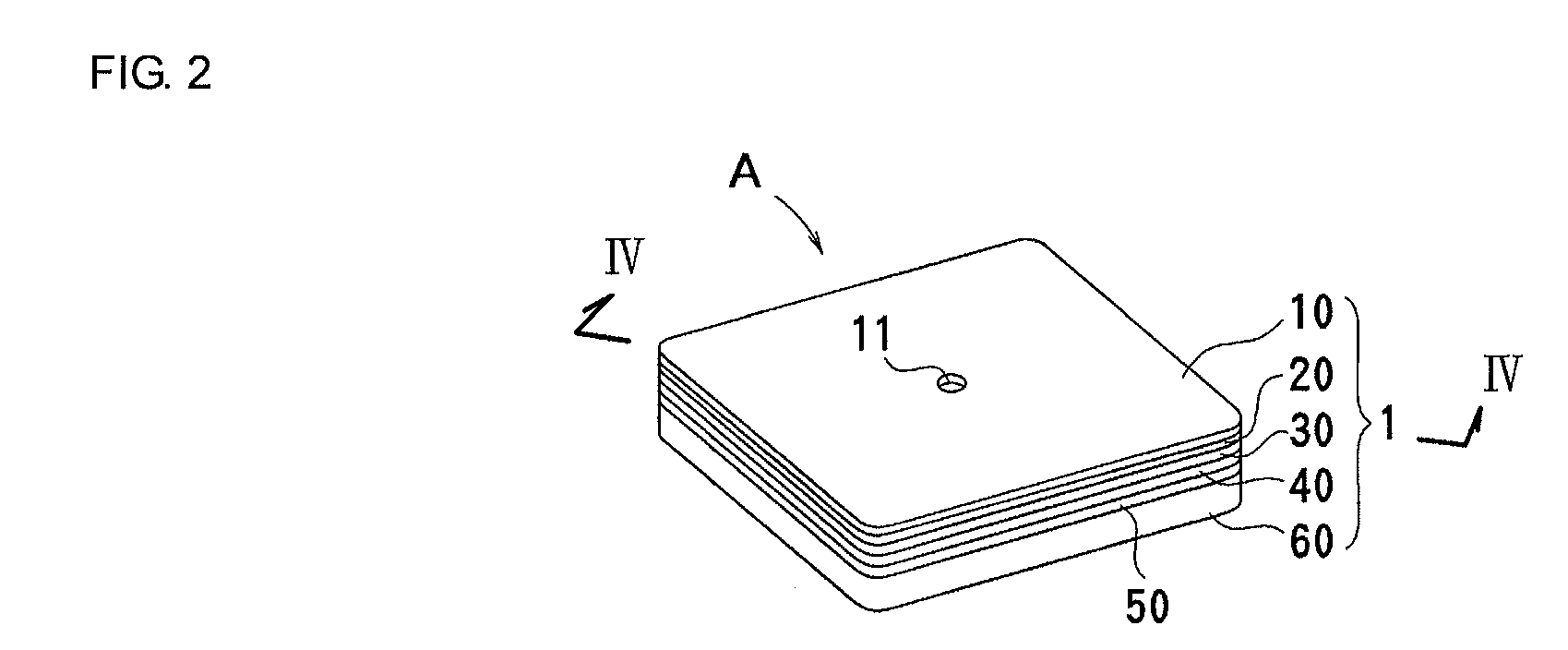

Piezoelectric micro-blower

ActiveUS20090232683A1Efficiently conveyedSufficient flow ratePositive displacement pump componentsFlexible member pumpsElectricityEngineering

A piezoelectric micro-blower capable of efficiently conveying compressive fluid without use of a check valve and ensuring a sufficient flow rate. The micro-blower has a blower body with a first wall and a second wall. Openings are formed in the respective walls and face a center of a diaphragm. An inflow path allowing the openings to communicate with the outside is formed between the walls. By applying a voltage to a piezoelectric element to cause the diaphragm to vibrate, a part of the first wall close to the first opening vibrates. Thus, gas can be drawn from the inflow path and discharged from the opening in the second wall.

Owner:MURATA MFG CO LTD

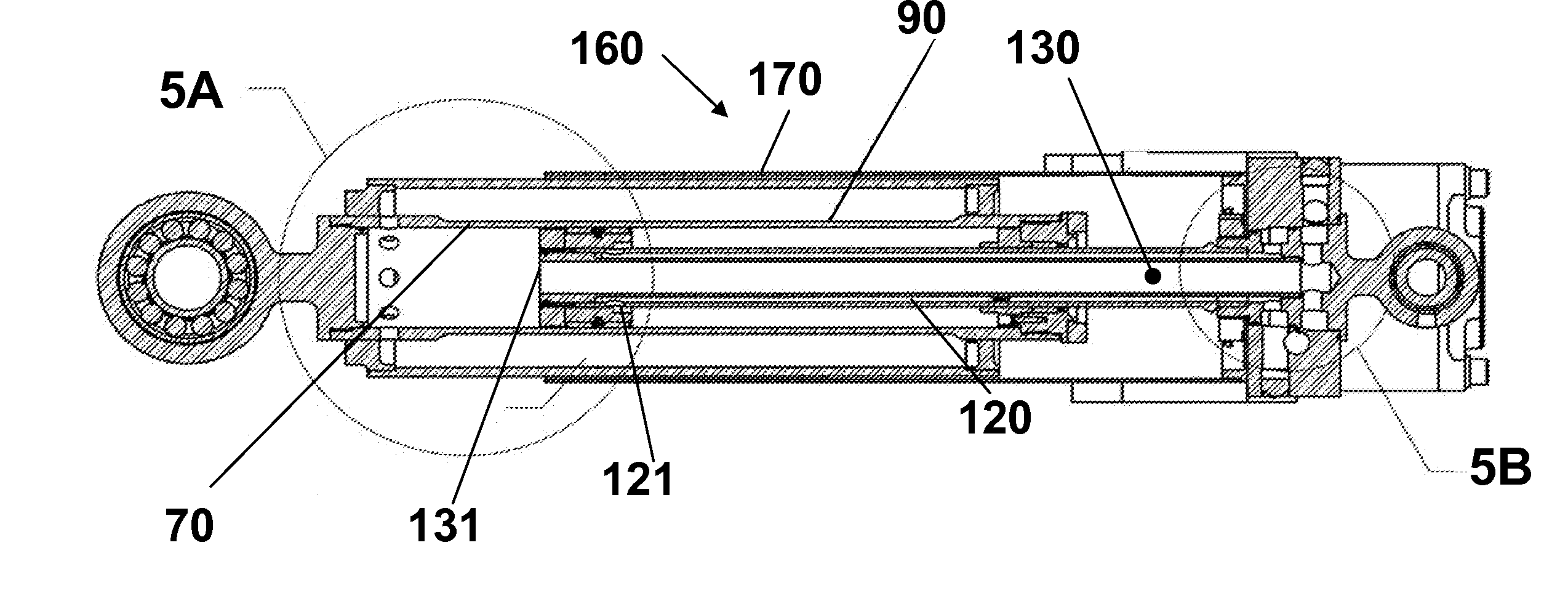

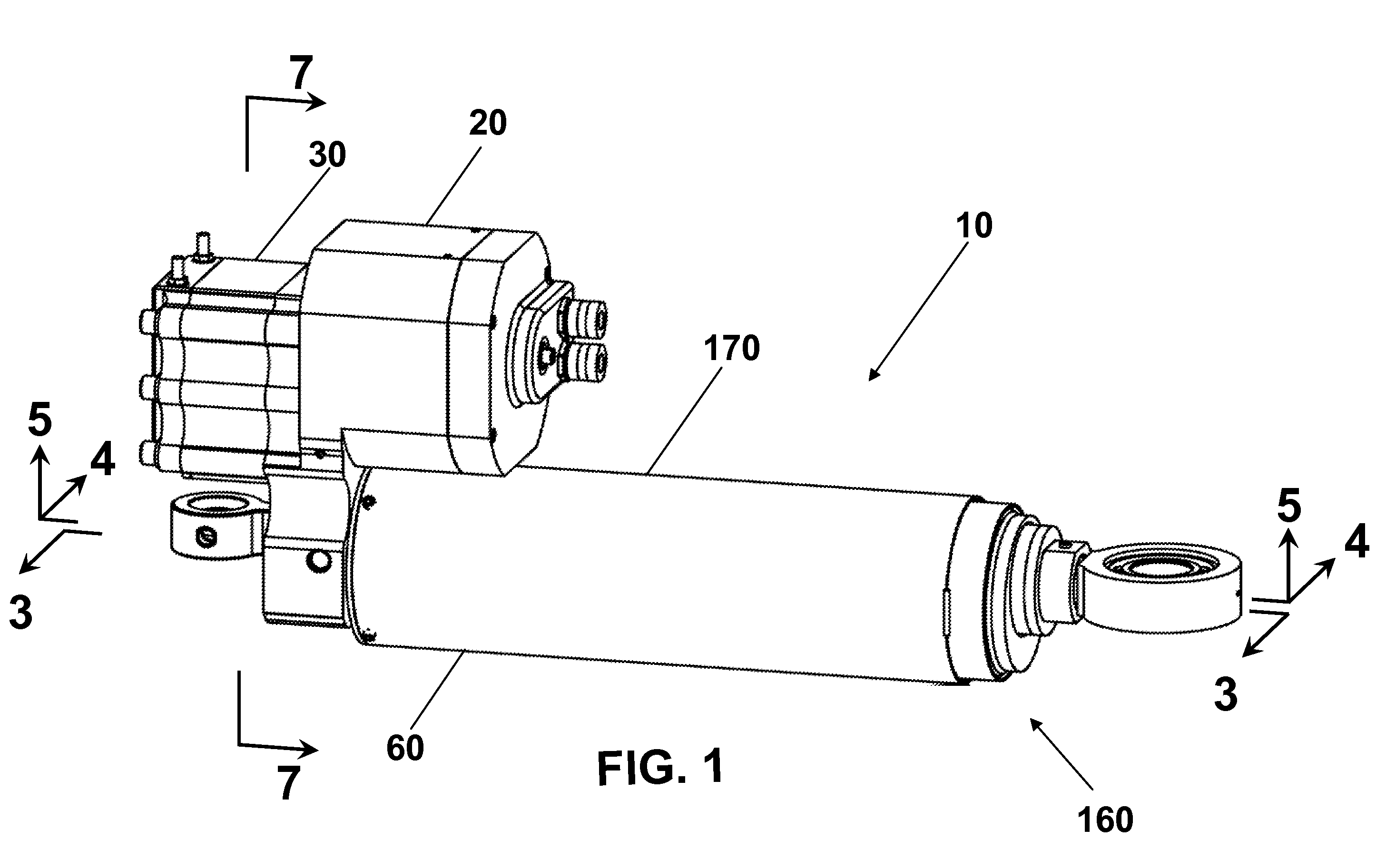

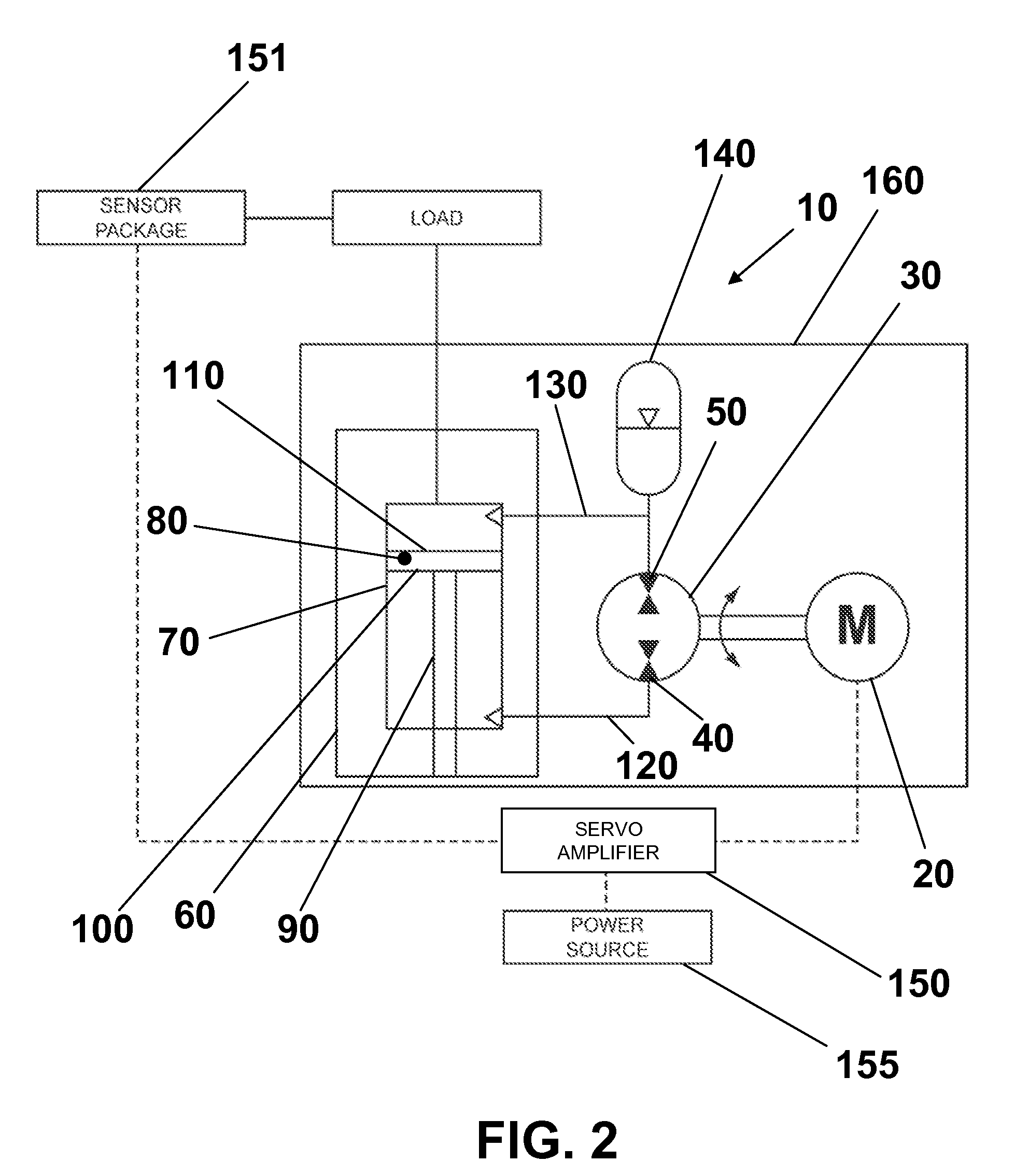

Actuators

Actuators suited for use with, for example, vehicular suspension systems. In some embodiments, the present actuators include a reversible hydraulic pump configured to produce variable hydraulic pressure; a hydraulic cylinder assembly having a cylinder bore, and a piston positioned within the cylinder bore that is axially movable relative to the cylinder bore; and a hydraulic circuit hydraulically coupling the reversible hydraulic pump to the hydraulic cylinder assembly. In these embodiments, actuated axial motion of the piston relative to the cylinder bore is accomplished without the use of check valves, pressure regulating valves, or actively controlled valves.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

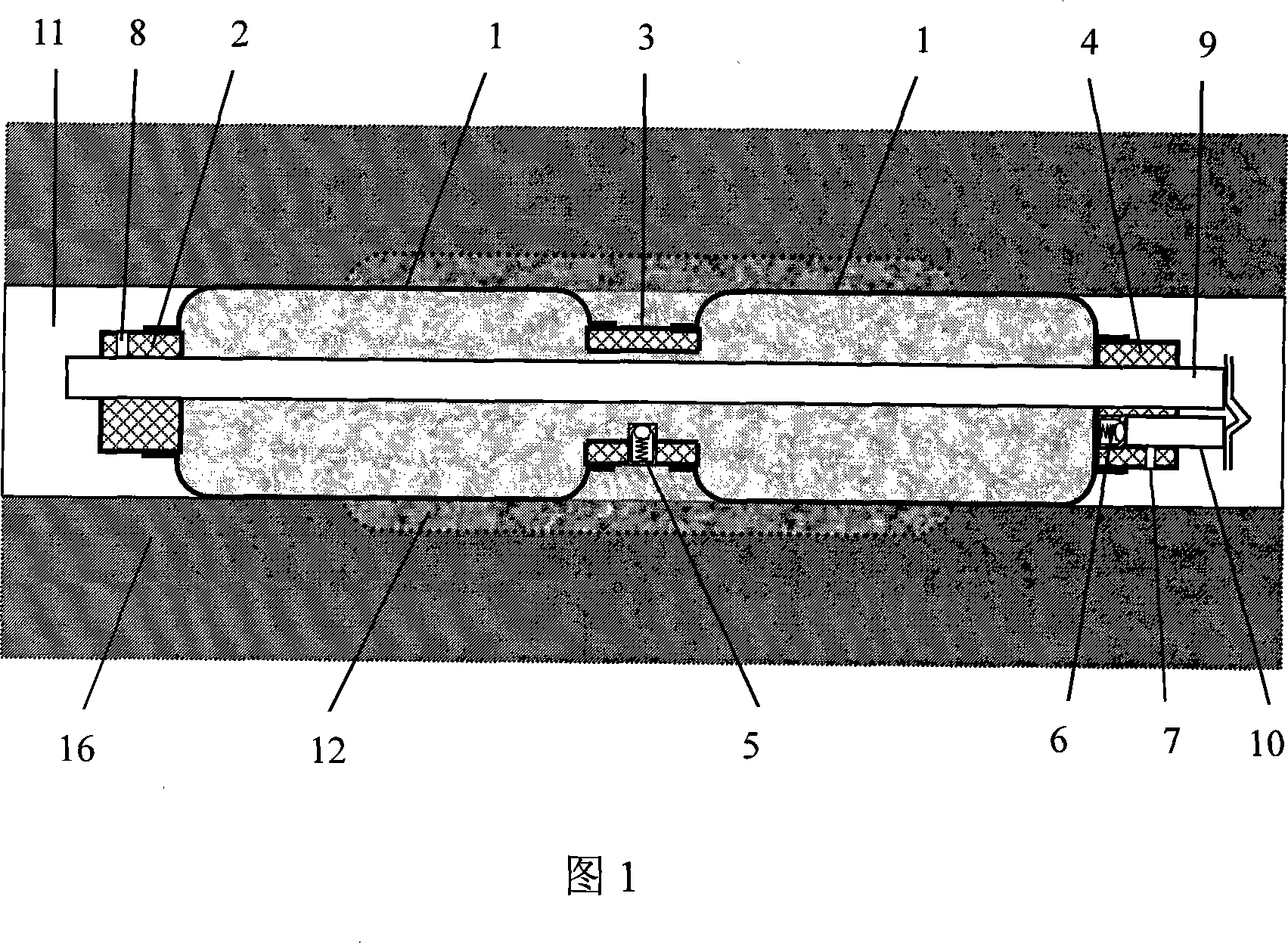

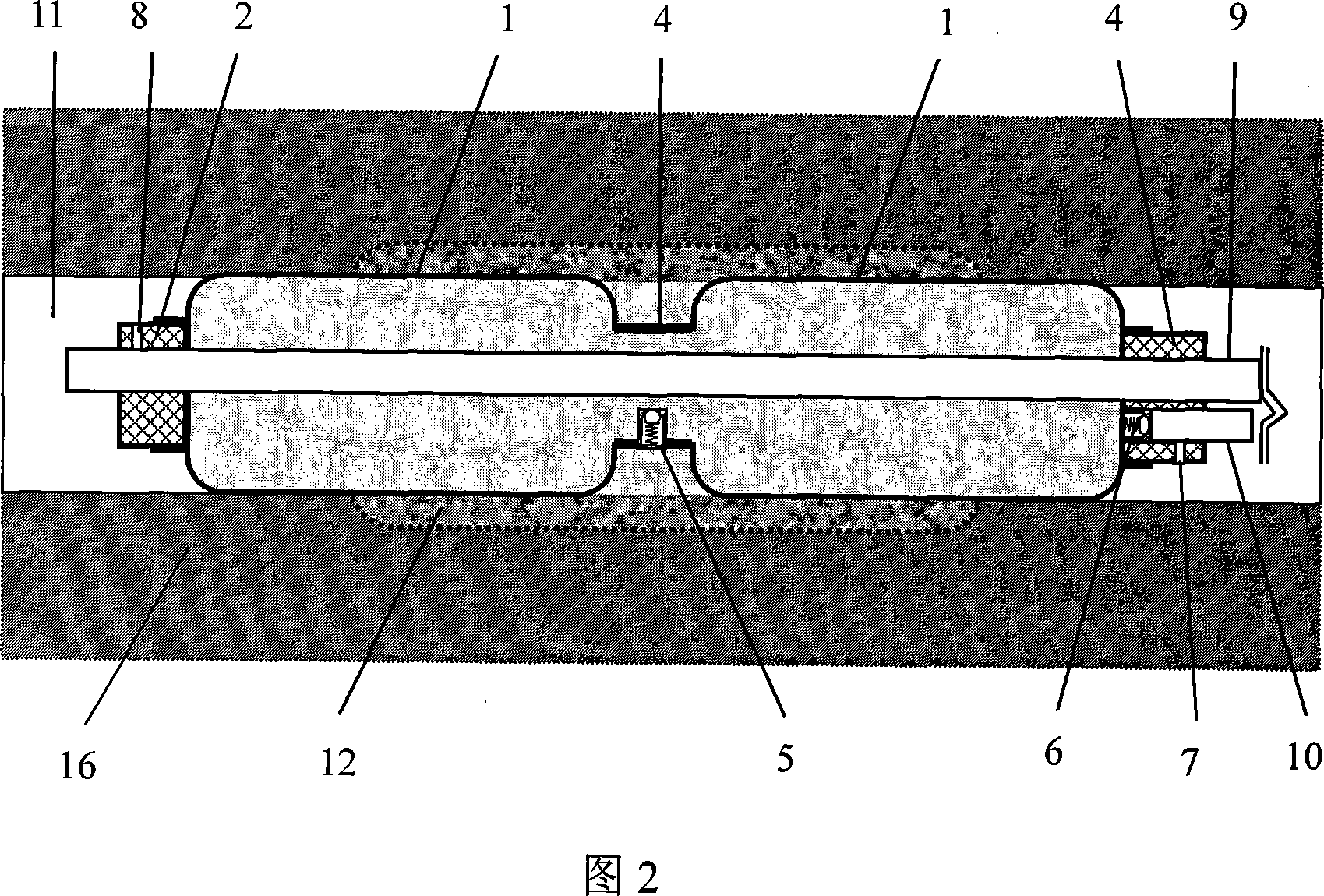

Bag type paste injection hole sealing device and its hole sealing method

InactiveCN101050696AGrouting and sealing are effectiveReduce air permeabilityGas removalSealing/packingSlurryControl valves

The present invention relates to a bag type paste-injecting hole-sealing equipment and its hole-sealing method. Said bag type paste-injecting hole-sealing equipment includes the following several portions: bag, internal end supporting component, middle portion supporting component, external end supporting component, paste injection control valve, reverse check valve and pressure control pin. Besides, said invention also provides the concrete steps of said hole-sealing method.

Owner:HENAN POLYTECHNIC UNIV

Proximal catheter assembly having a self-limiting aspiration valve

InactiveUS7004931B2Efficient removalIncrease chanceCatheterExcision instrumentsSelf limitingHigh rate

The present invention is directed to a proximal catheter assembly configured to facilitate natural or suction-assisted aspiration through a catheter lumen. The proximal catheter assembly comprises a multi-function valve configured to perform functions associated with conventional check valves and relief valves. The valve is configured to regulate the direction of fluid flow, and further configured to regulate the rate of suction-assisted aspiration provided through the lumen of the catheter. When the rate of suction-assisted aspiration exceeds a predetermined threshold, the valve opens to allow fluid to be drawn from tubing coupled to the proximal catheter assembly, thereby mitigating excessively high rates of aspiration imposed upon the patient's vessel.

Owner:WL GORE & ASSOC INC

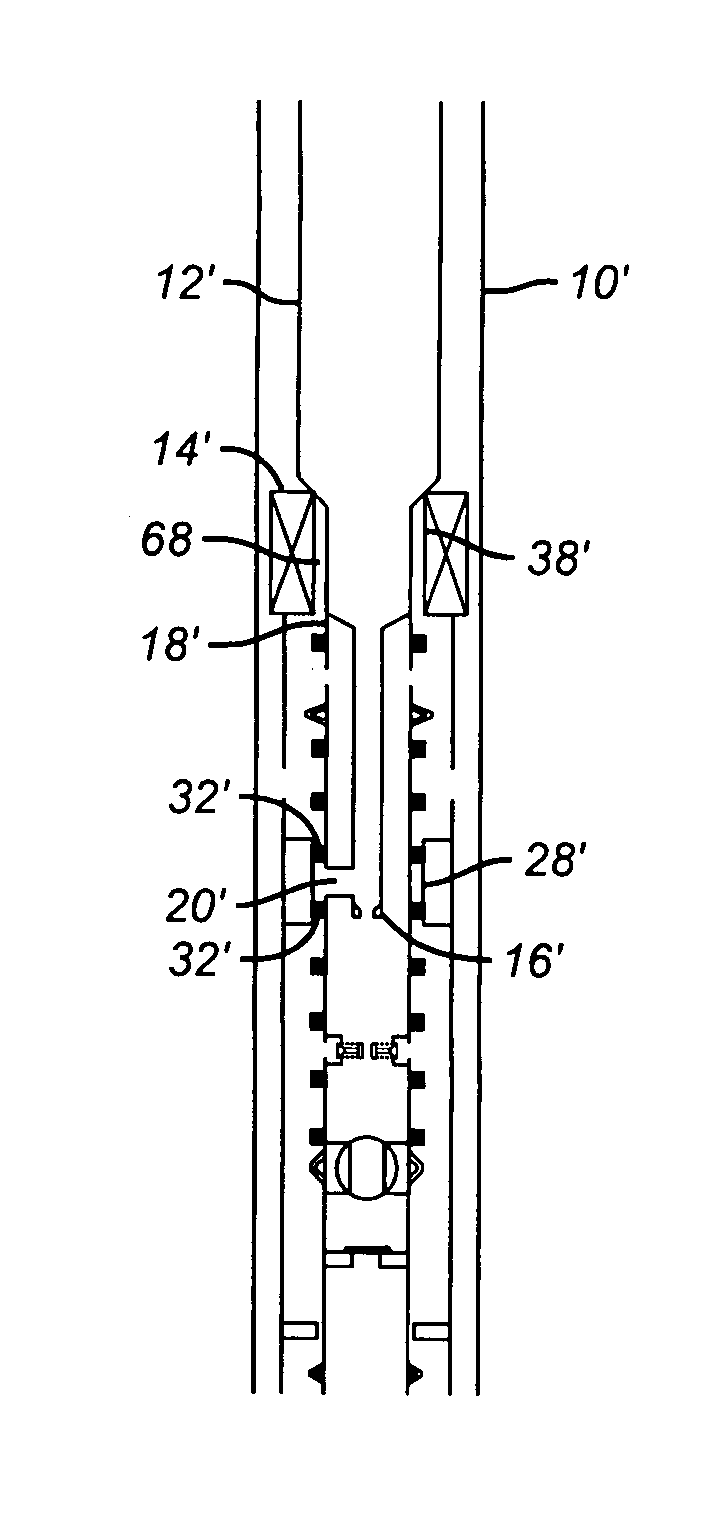

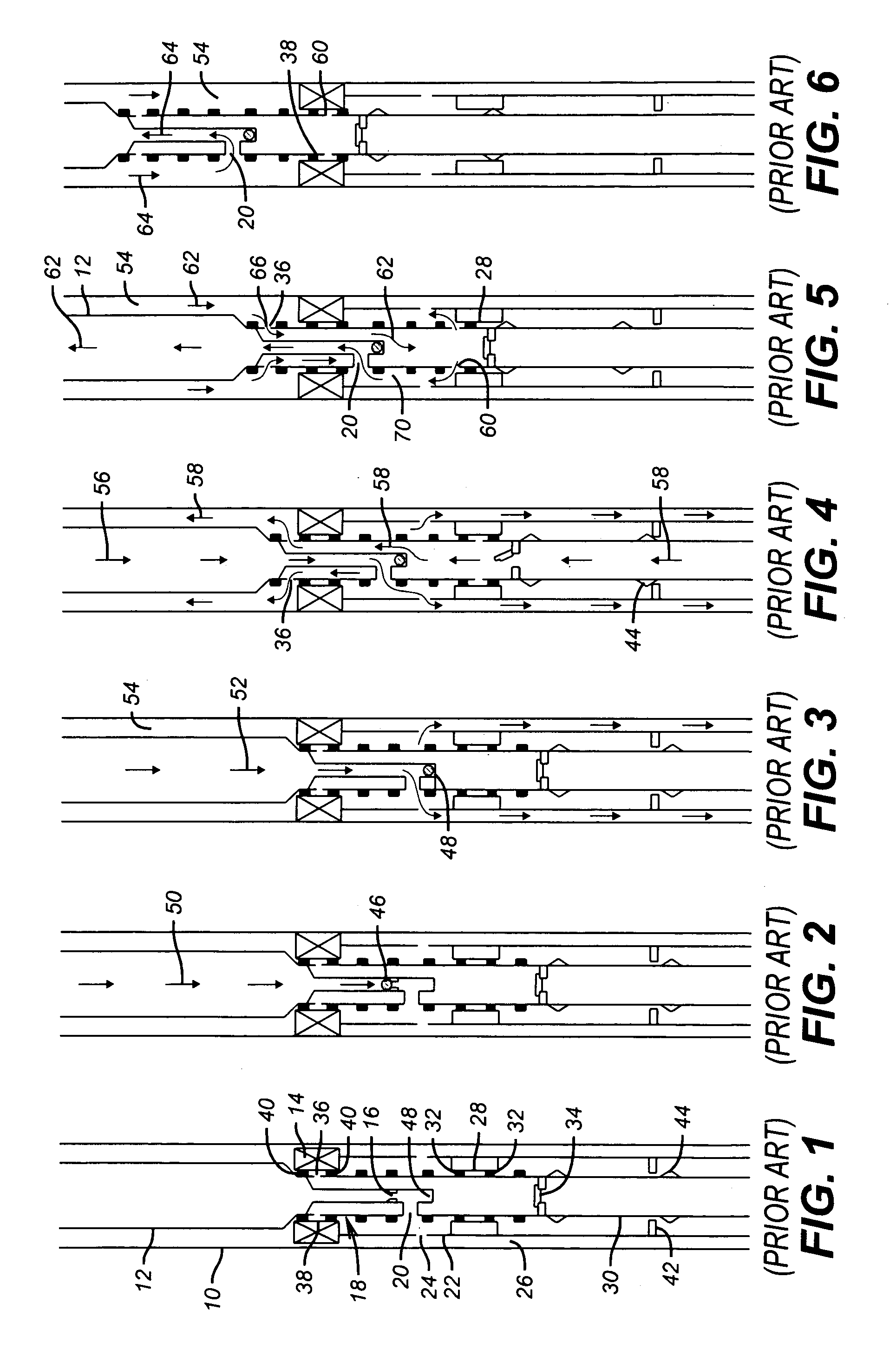

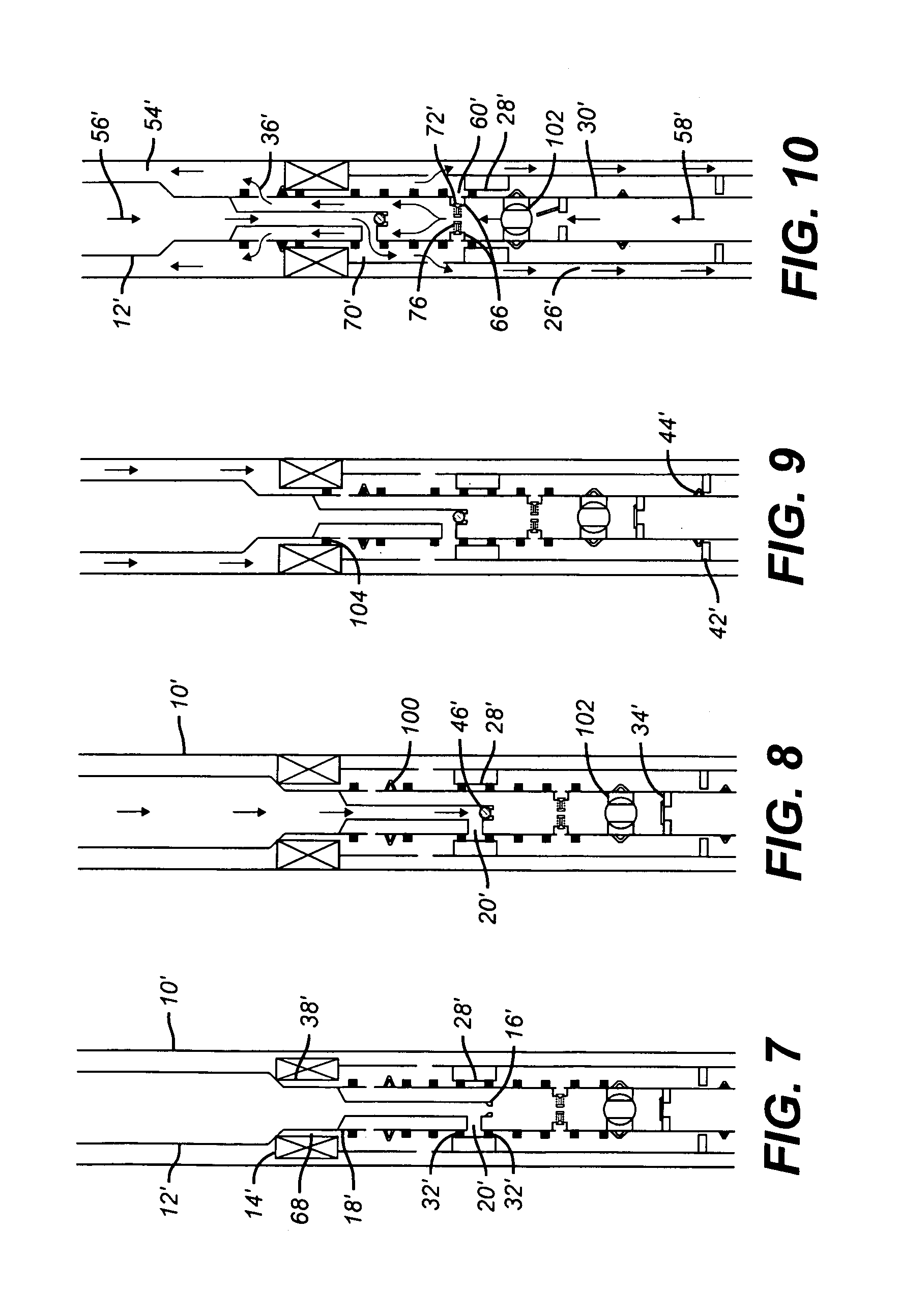

Gravel pack crossover tool with single position multi-function capability

Owner:BAKER HUGHES INC

Vacuum enhancing check valve

InactiveUS20060016477A1Reducing vehicle 's costReduce complexityBraking action transmissionRatio controlEngineeringCheck valve

A vacuum enhancing check valve for direct connection to a vehicle brake booster which increases the partial vacuum provided thereto and restricts possible air back flow into the brake booster. The valve comprises a venturi for reducing the pressure of air induced to flow between a first air inlet and an air outlet by a partial vacuum at a vehicle engine's intake manifold. By significantly reducing the air pressure, the valve enhances the partial vacuum available for provision to the brake booster. The venturi is also in air communication with a second air inlet directly attachable to the brake booster such that the air pressure at the second air inlet tends toward the enhanced partial vacuum within the venturi. A valve seat and seal member within the valve are cooperative to allow air flow from the second air inlet toward the venturi, but not in the reverse direction.

Owner:FORD GLOBAL TECH LLC

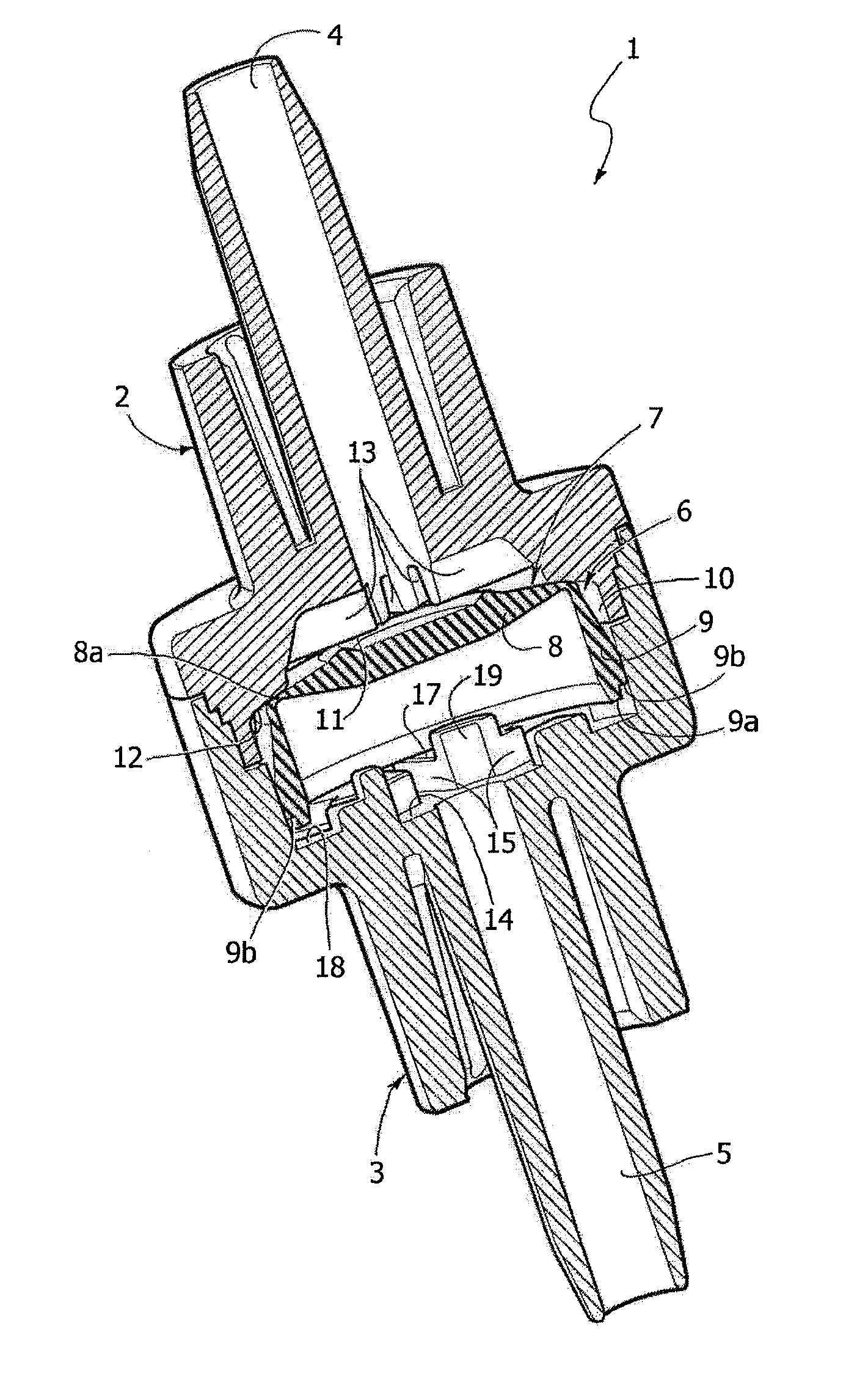

One-way valve for medical infusion lines and the like

A check valve for medical infusion lines and the like, includes a diaphragm made of elastic material set between a first tubular connector and a second tubular connector. The diaphragm includes an end wall of a cup-shaped element, having an outer peripheral edge of which is normally pressed in seal contact against an annular valve seat with a conical surface of the first tubular connector under an axial thrust exerted by a side wall of the cup-shaped element. A free edge of the side wall of the cup-shaped element is set resting against a transverse surface of the second tubular connector only in regions corresponding to angular portions of the latter separated by non-resting angular portions.

Owner:IND BORLA

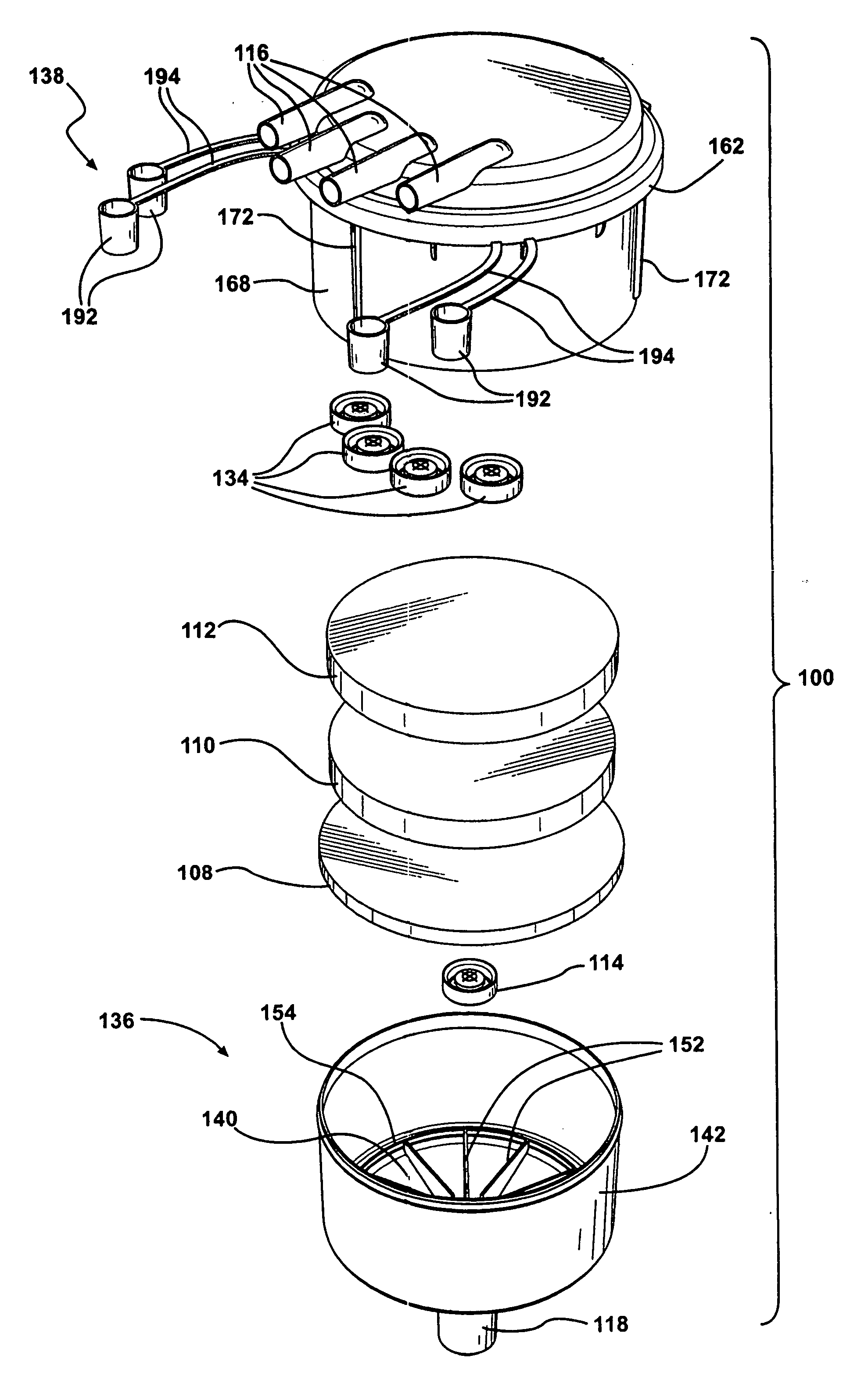

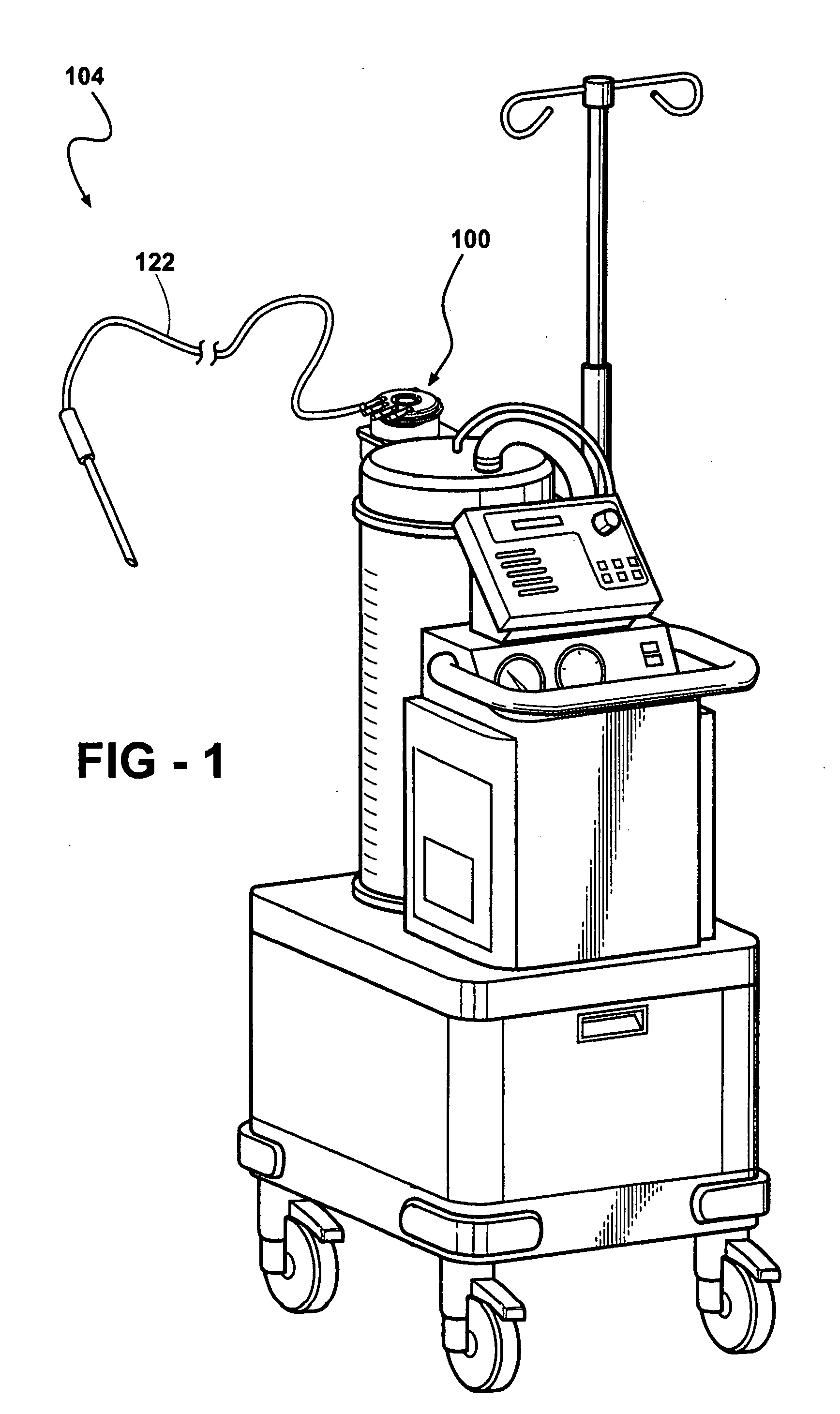

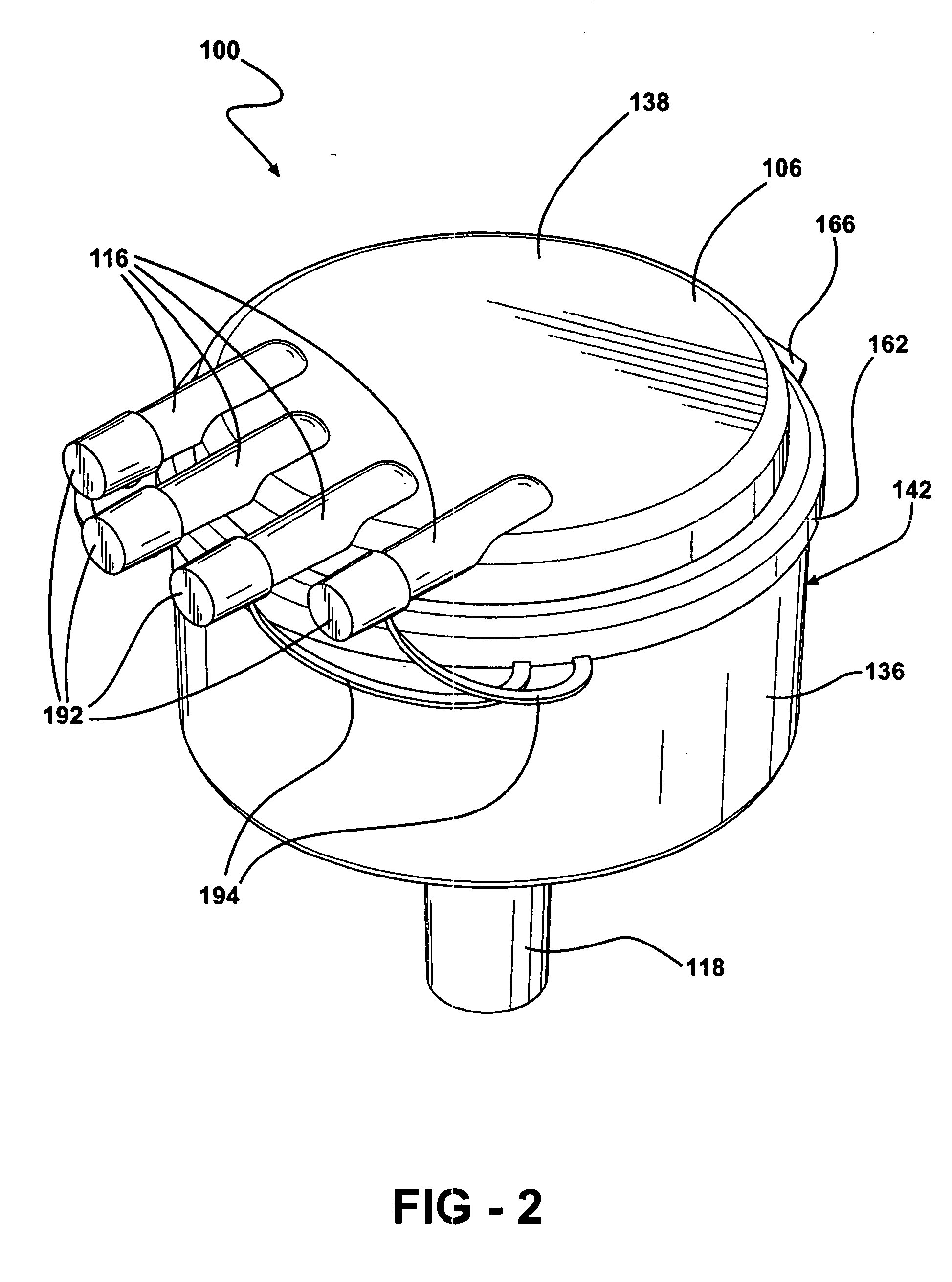

Manifold assembly

A manifold assembly (100) for directing and filtering material (102) from fluid flowing into a medical waste collection device (104) includes a plurality of inlet ports (116) and an outlet port (118) with a filter (108, 110, 112) disposed between the ports (116, 118) along a fluid path (120). An outlet check-valve (114) is disposed at the outlet port (118) for opening in response to a predetermined vacuum pressure applied to the outlet port (118) from the medical waste collection device (104).

Owner:STRYKER CORP

Fluid dispensing valve assembly

InactiveUS6053370AReduce manufacturing costEasy to useClosuresLiquid transferring devicesEngineeringCheck valve

A dispenser for dispensing charges of fluid from a container and applicable to a mouth of the container with the container in an inverted position and the mouth down. The dispenser includes a body formed of resilient elastomeric material having a hollow annular upper part having a flexible, resilient annular wall and an upper and lower end and constituting a bellows which is downwardly expansible and upwardly contractible by flexing of the annular wall. The body has integral with the bellows a lower part having a discharge port. The dispenser includes a first check valve at an entry end of the bellows operable for flow of fluid into the bellows on expansion thereof and operable to block flow of fluid from the pump member out of its upper end on contraction thereof. A second valve is operable for dispensing the charge of fluid from the bellows down into the outlet nozzle on contraction of the bellows and to block flow out of the bellows outlet on expansion of the bellows. The second check valve has a valve seat member at the intake of the bellows and outlet nozzle, has at least one outlet port below the valve and a spring biased to keep the poppet valve seated against the valve seat such that the fluid is expelled through the poppet valve, outlet nozzle, and outlet port on contraction of the pump member.

Owner:KOLLER ENTERPRISES +1

Beverage forming apparatus with centrifugal pump

ActiveUS8151694B2Adequate flowSufficient pressureBeverage vesselsFood preparationExhaust valveControl valves

Owner:KEURIG GREEN MOUNTAIN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com