Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19316 results about "Hydraulic pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydraulic pumps are used in hydraulic drive systems and can be hydrostatic or hydrodynamic. A hydraulic pump is a mechanical source of power that converts mechanical power into hydraulic energy (hydrostatic energy i.e. flow, pressure). It generates flow with enough power to overcome pressure induced by the load at the pump outlet. When a hydraulic pump operates, it creates a vacuum at the pump inlet, which forces liquid from the reservoir into the inlet line to the pump and by mechanical action delivers this liquid to the pump outlet and forces it into the hydraulic system. Hydrostatic pumps are positive displacement pumps while hydrodynamic pumps can be fixed displacement pumps, in which the displacement (flow through the pump per rotation of the pump) cannot be adjusted, or variable displacement pumps, which have a more complicated construction that allows the displacement to be adjusted. Hydrodynamic pumps are more frequent in day-to-day life. Hydrostatic pumps of various types all work on the principle of Pascal's law.

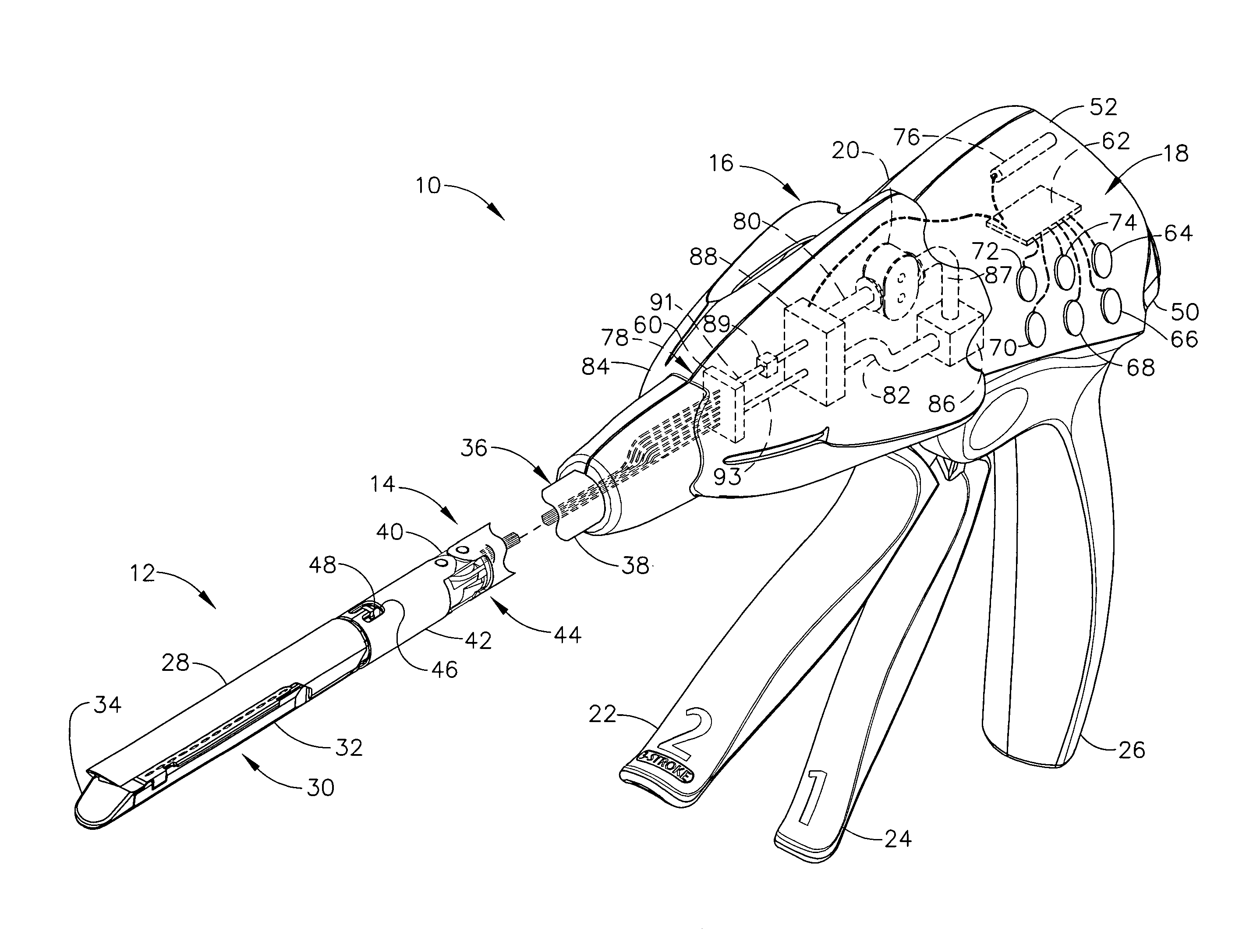

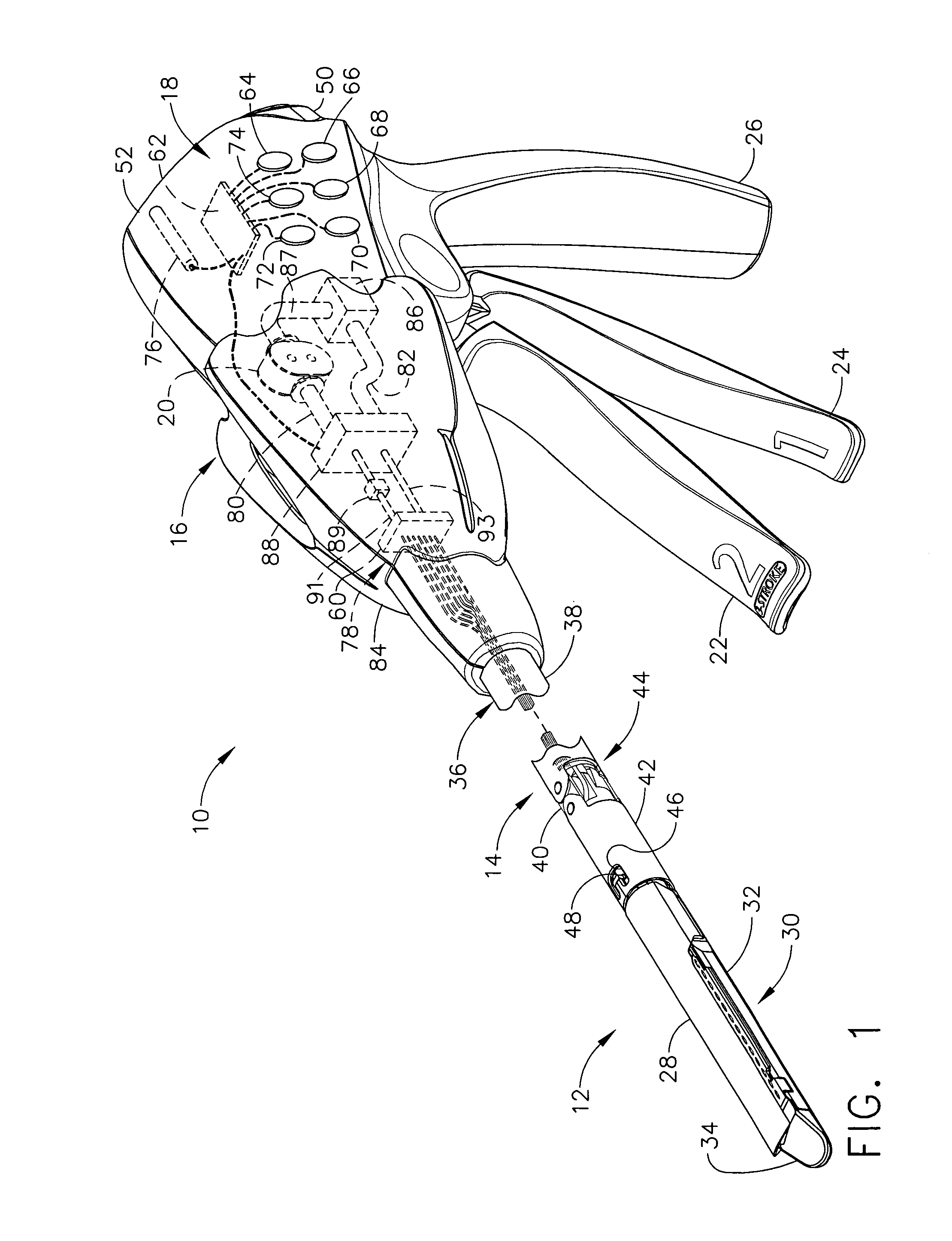

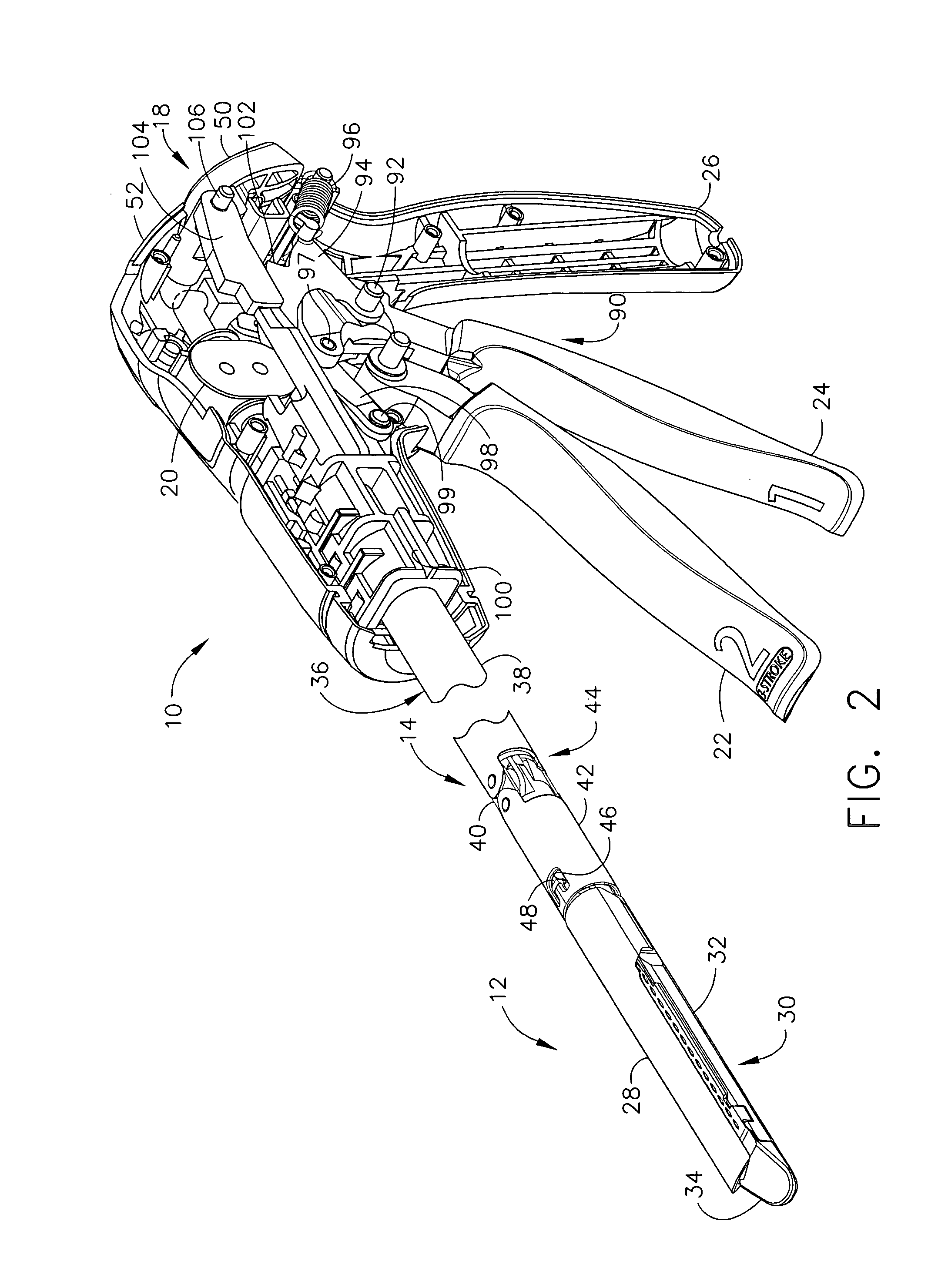

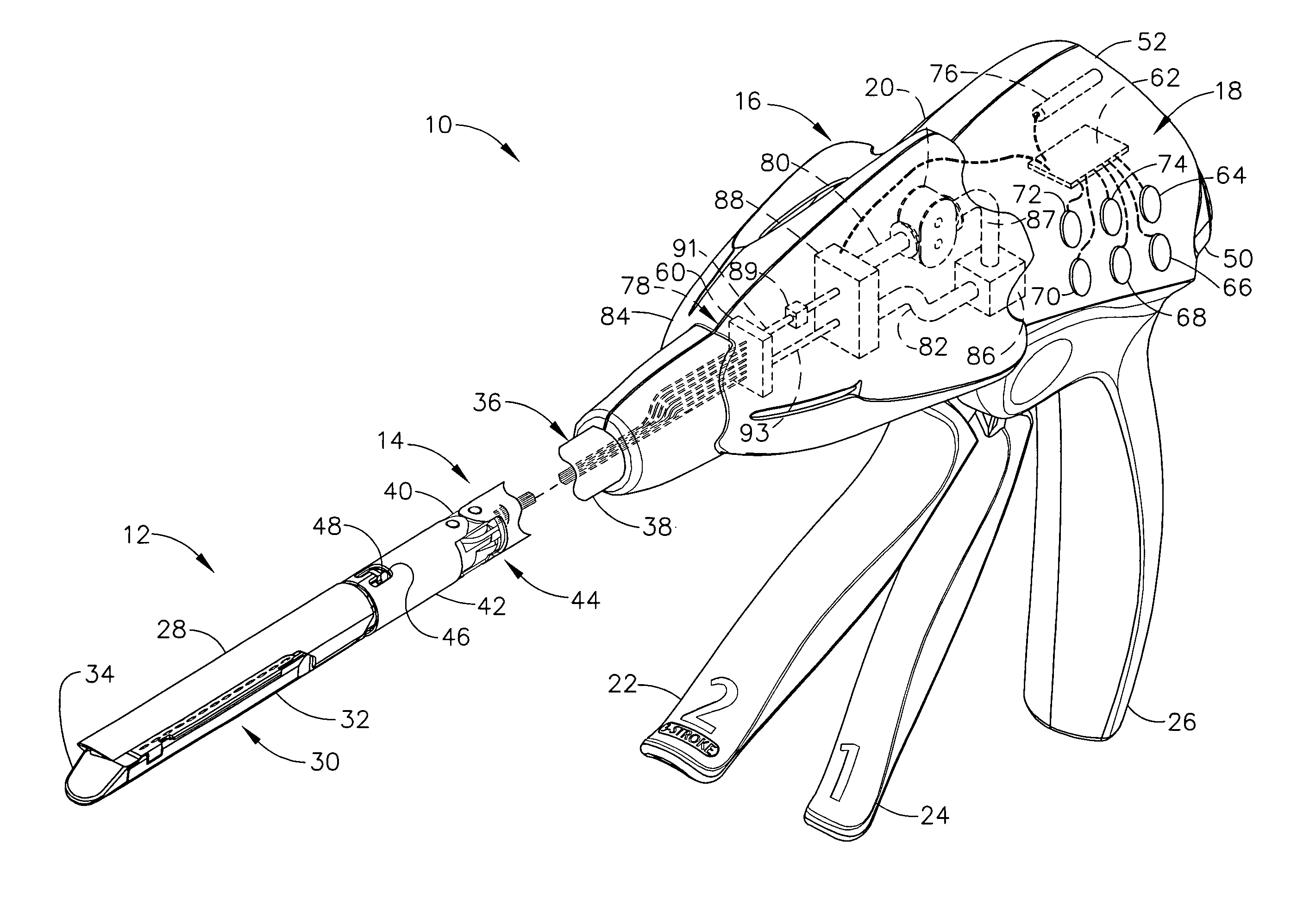

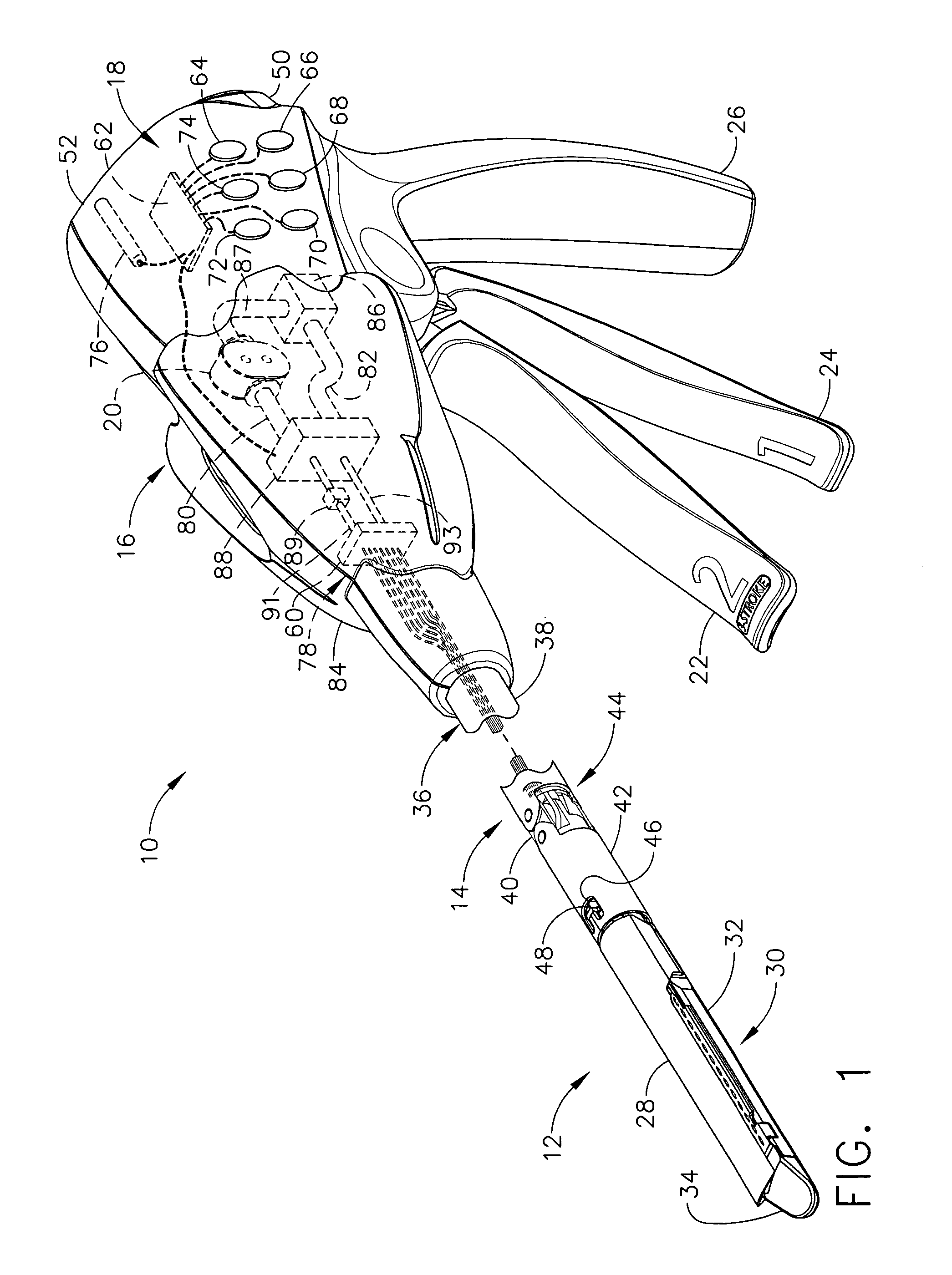

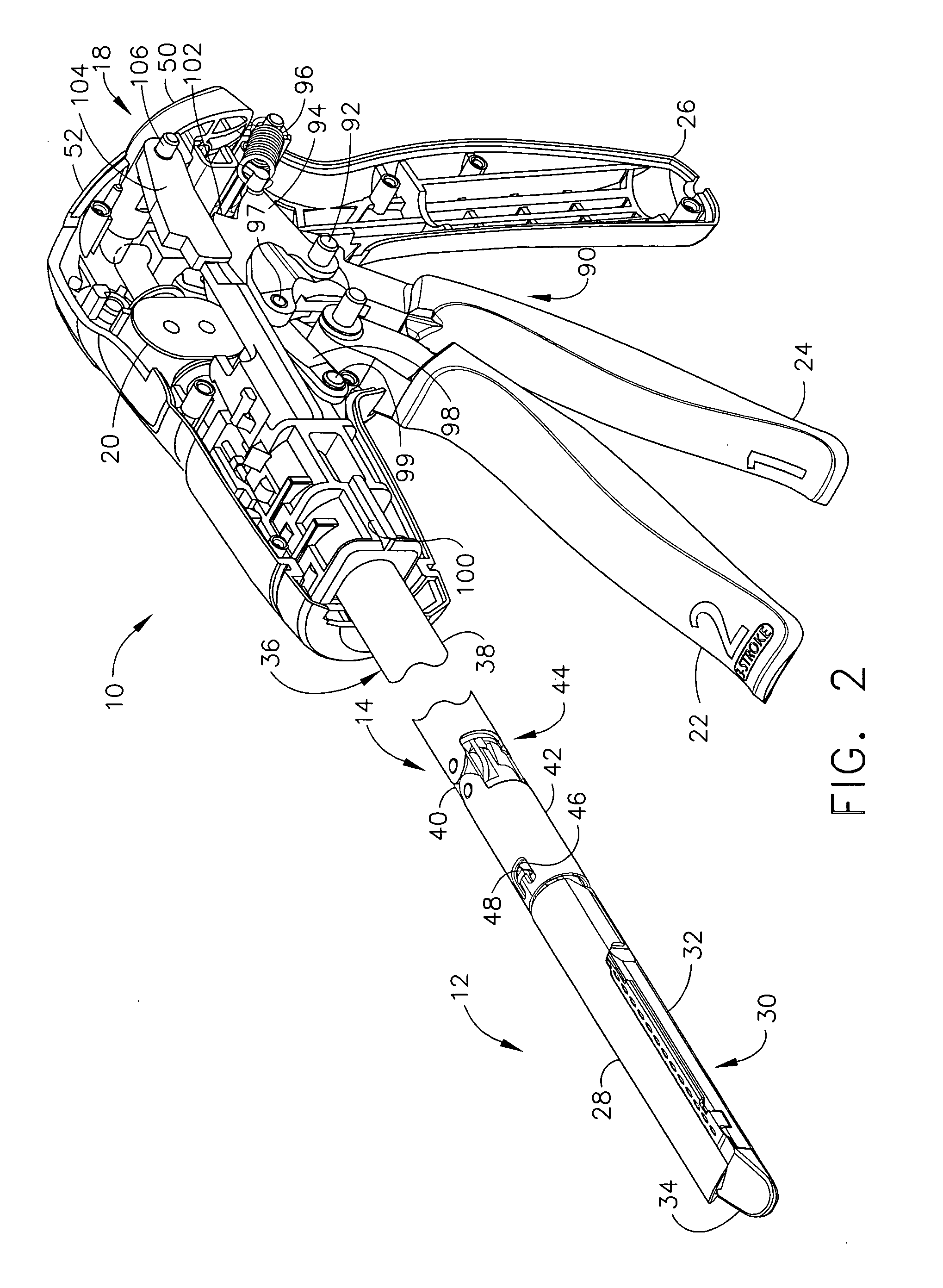

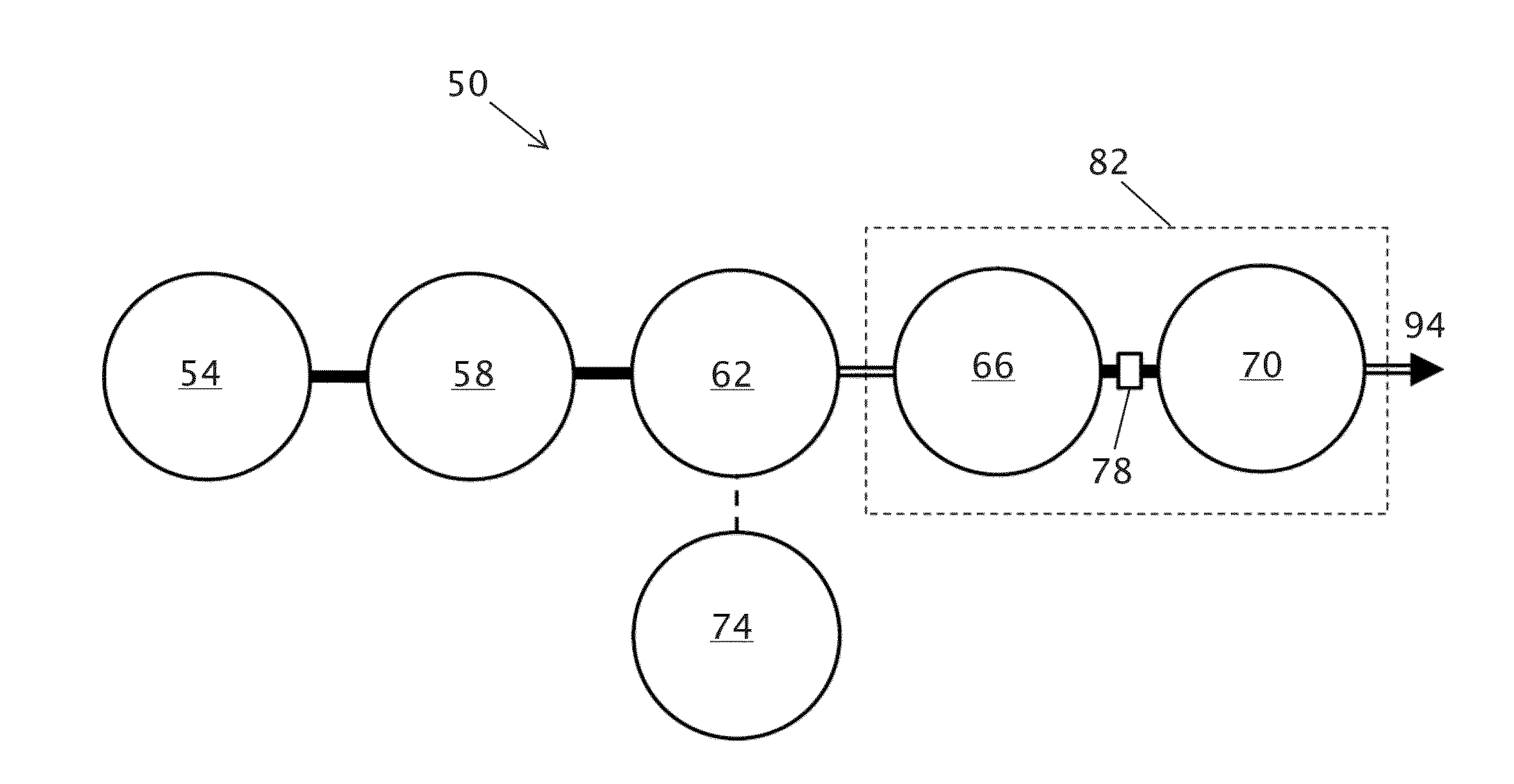

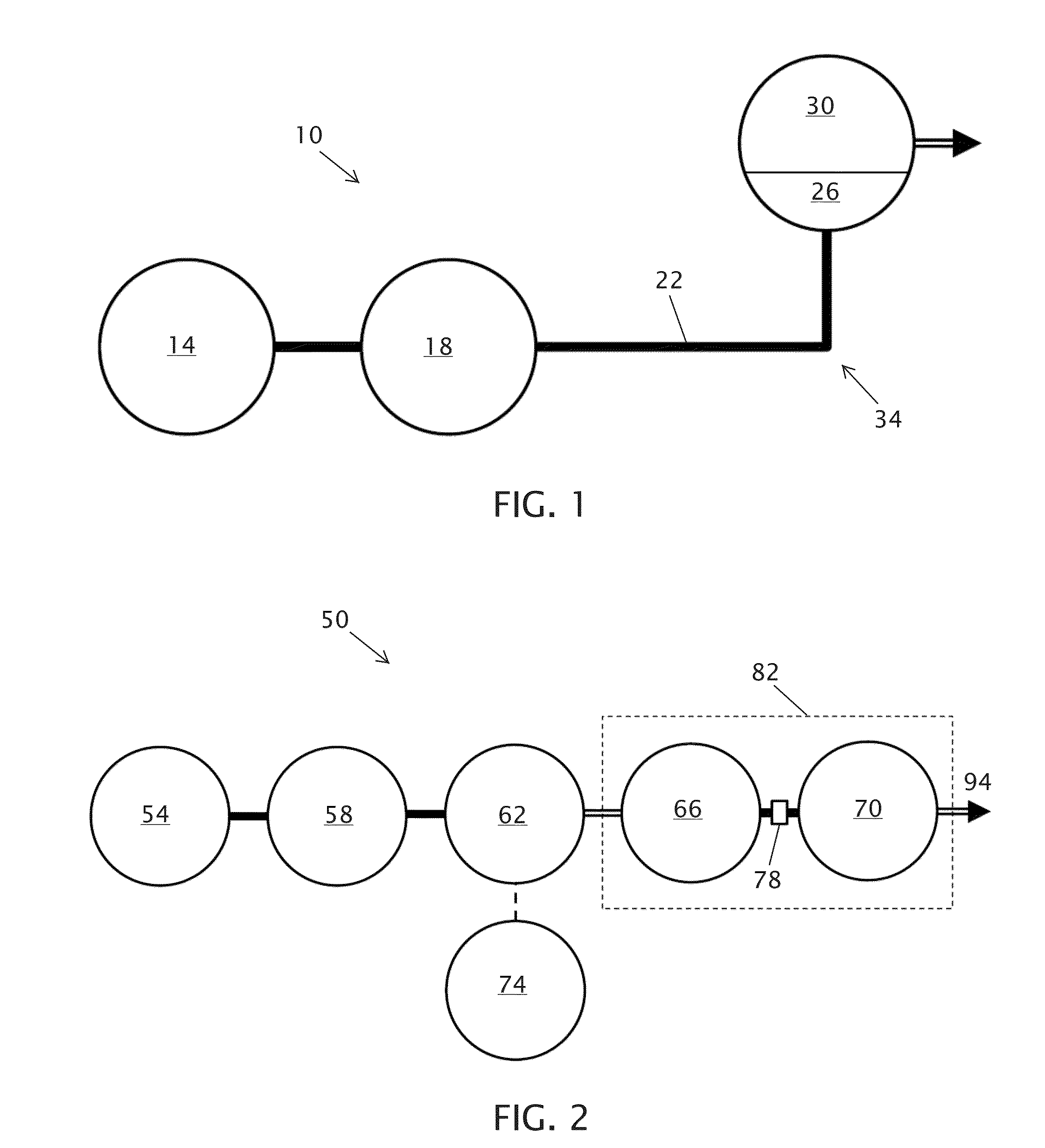

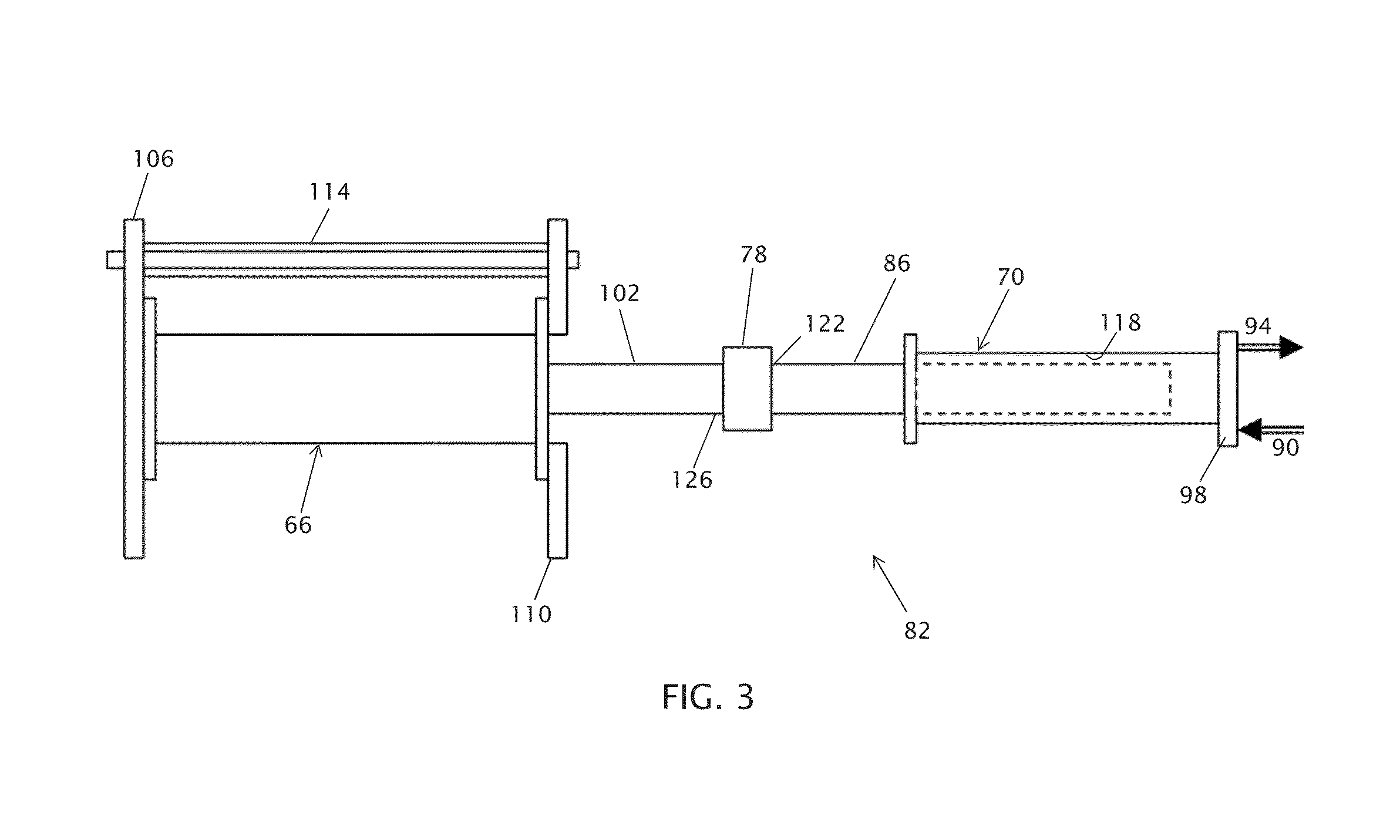

Rotary hydraulic pump actuated multi-stroke surgical instrument

A surgical instrument (e.g., endocutter, grasper, cutter, staplers, clip applier, access device, drug / gene therapy delivery device, and energy device using ultrasound, RF, laser, etc.) may benefit from having a plurality of hydraulically actuated subsystems (e.g., severing, stapling, articulation, locking / unlocking, lockout enabling / disabling, grasping, etc.) supplied with hydraulic power from a trigger actuated rotary pump (e.g., lobe pump, rotary gear pump, internal rotating gear pump, flexible vane rotor pump, rotary vane pump). Thereby, an available amount of mechanical advantage available at a firing trigger may be optimally distributed to various end effector components, perhaps sequenced by an electroactive polymer or piezoelelectrically actuated function switch block.

Owner:ETHICON ENDO SURGERY INC

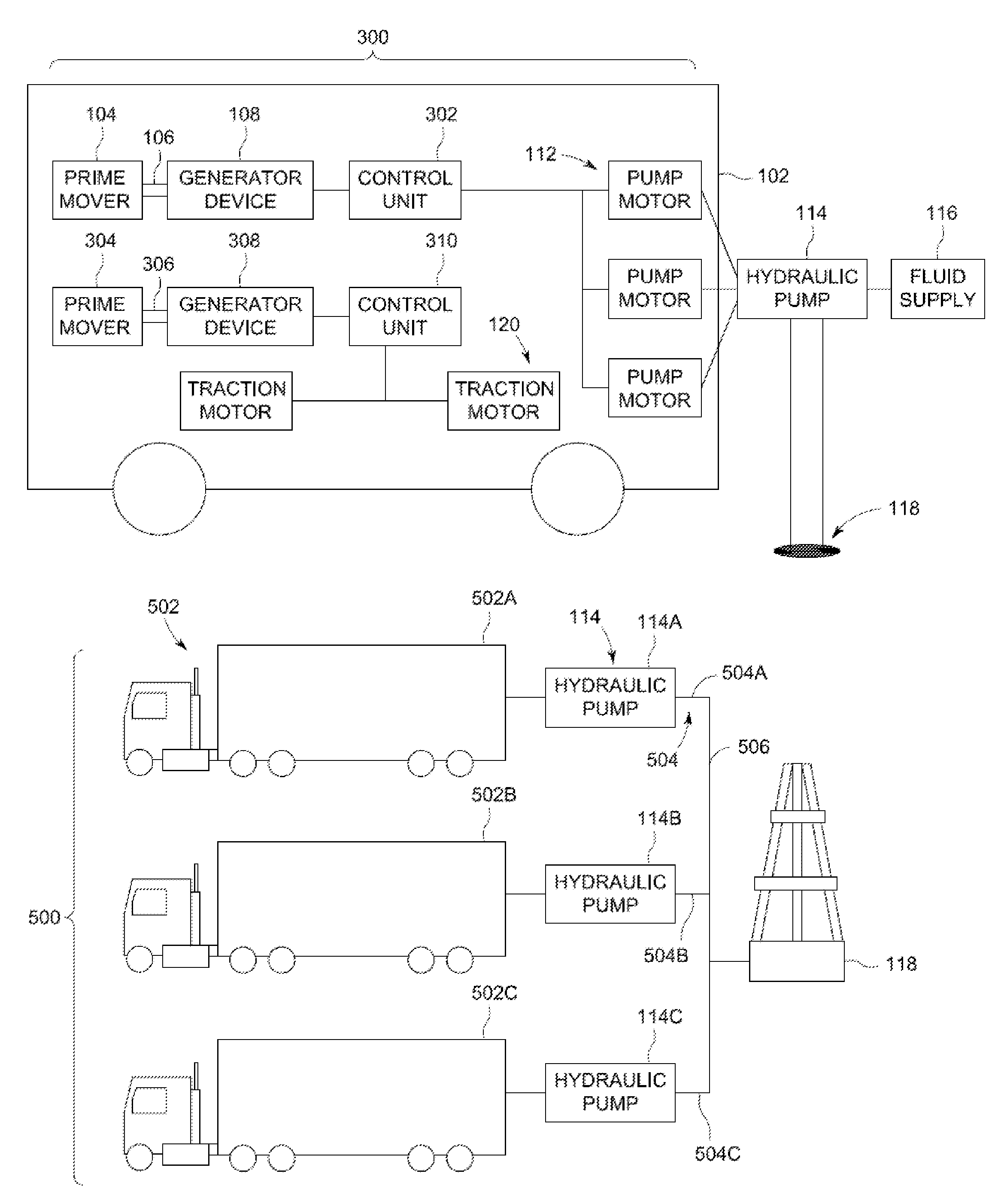

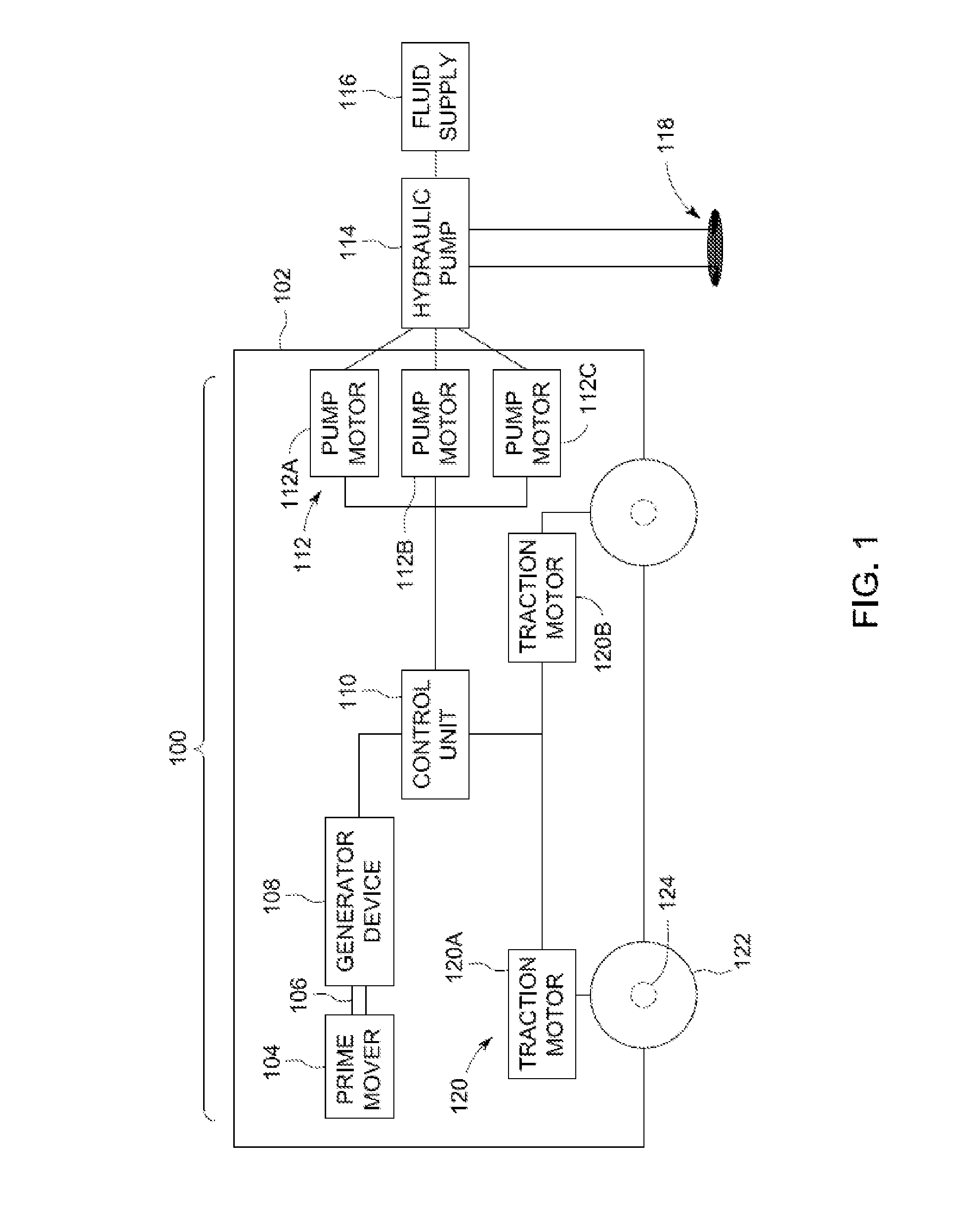

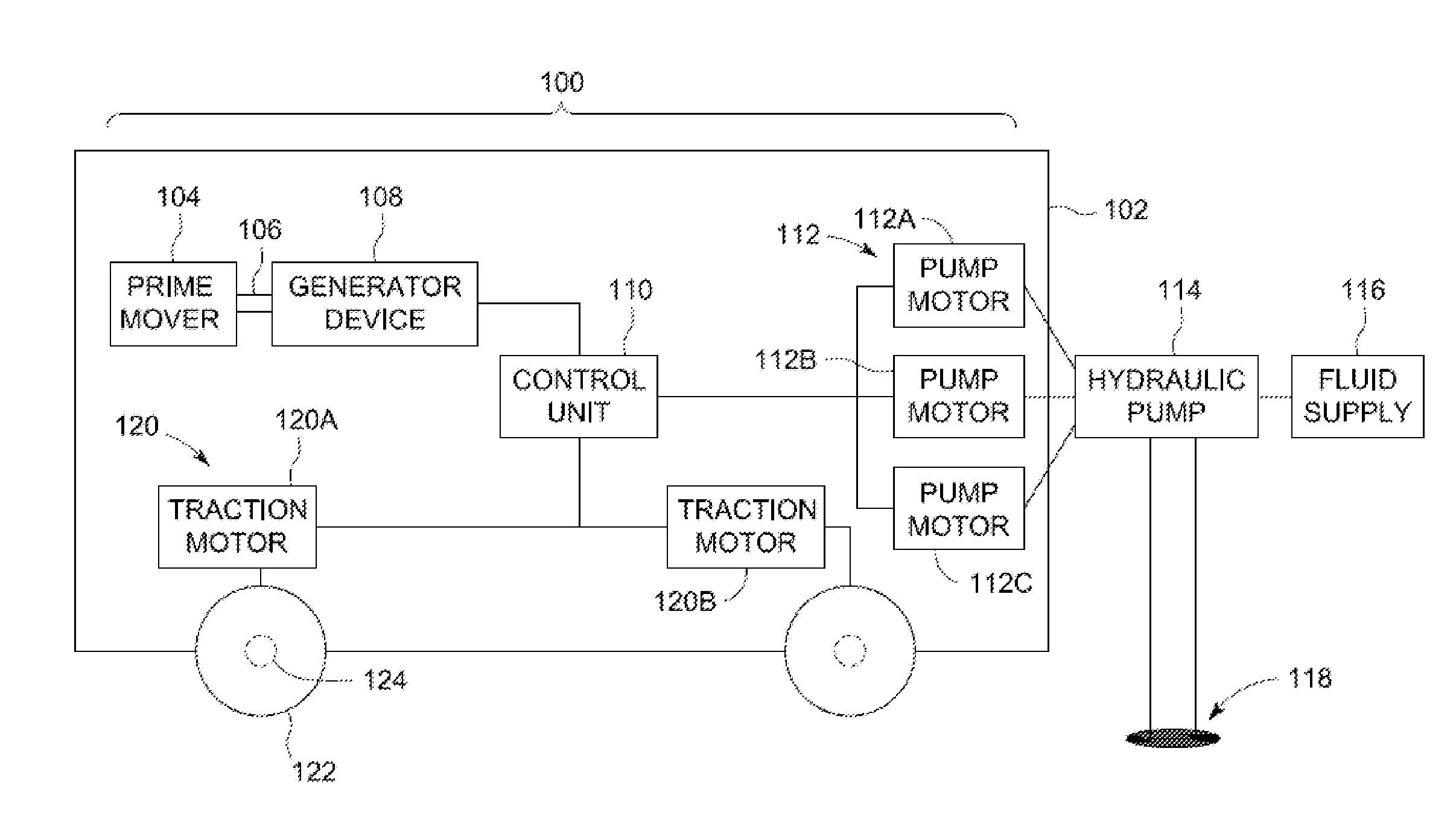

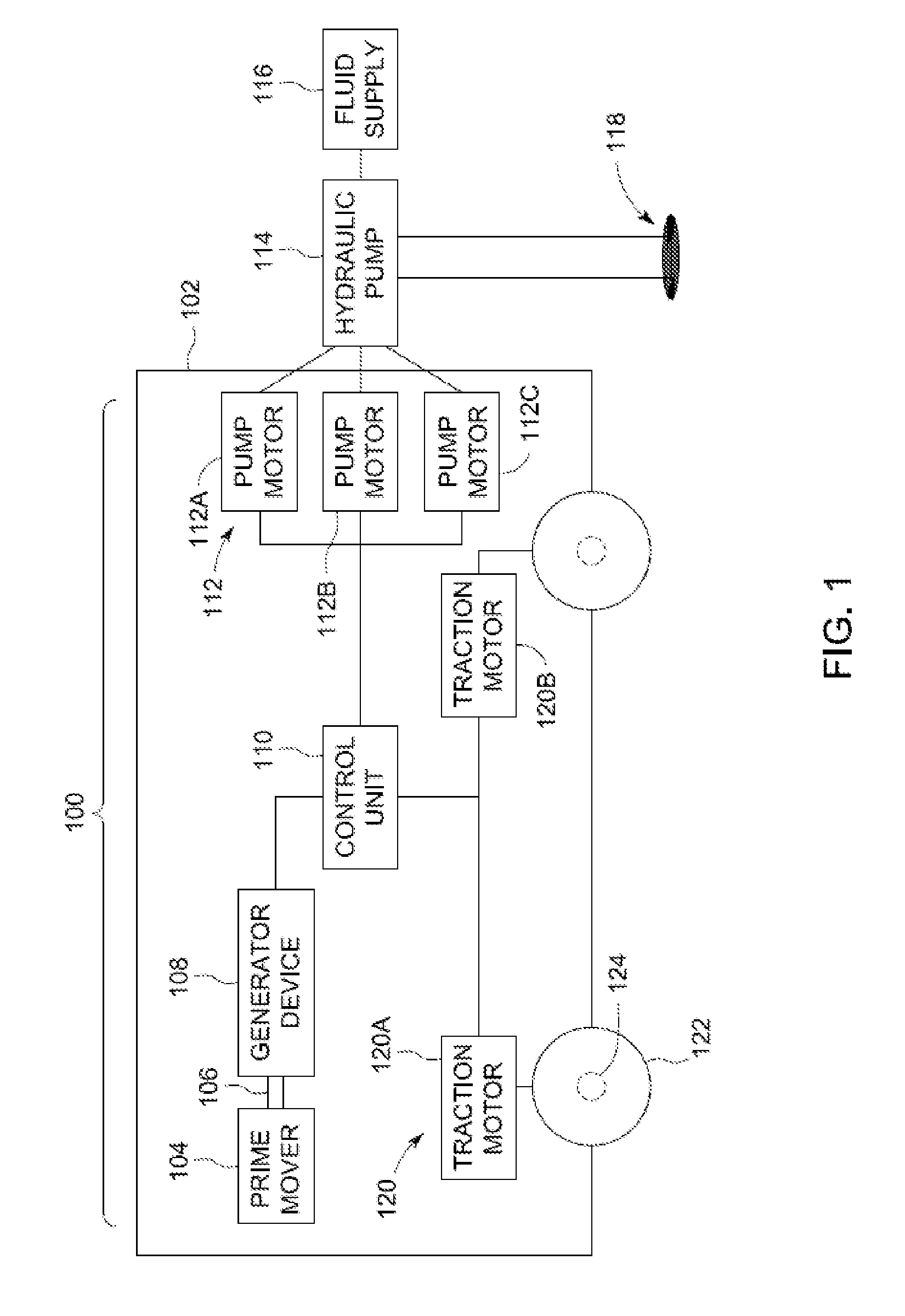

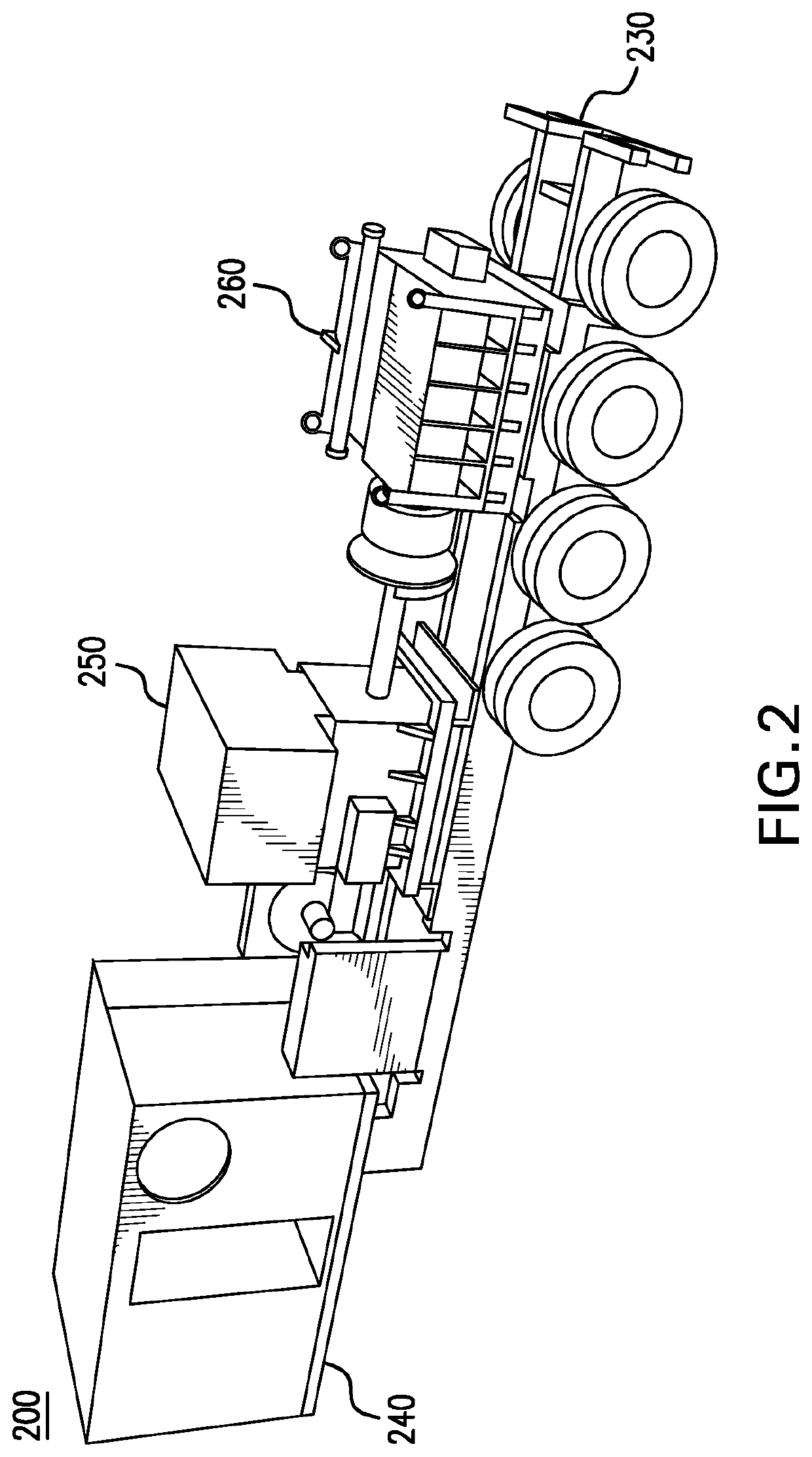

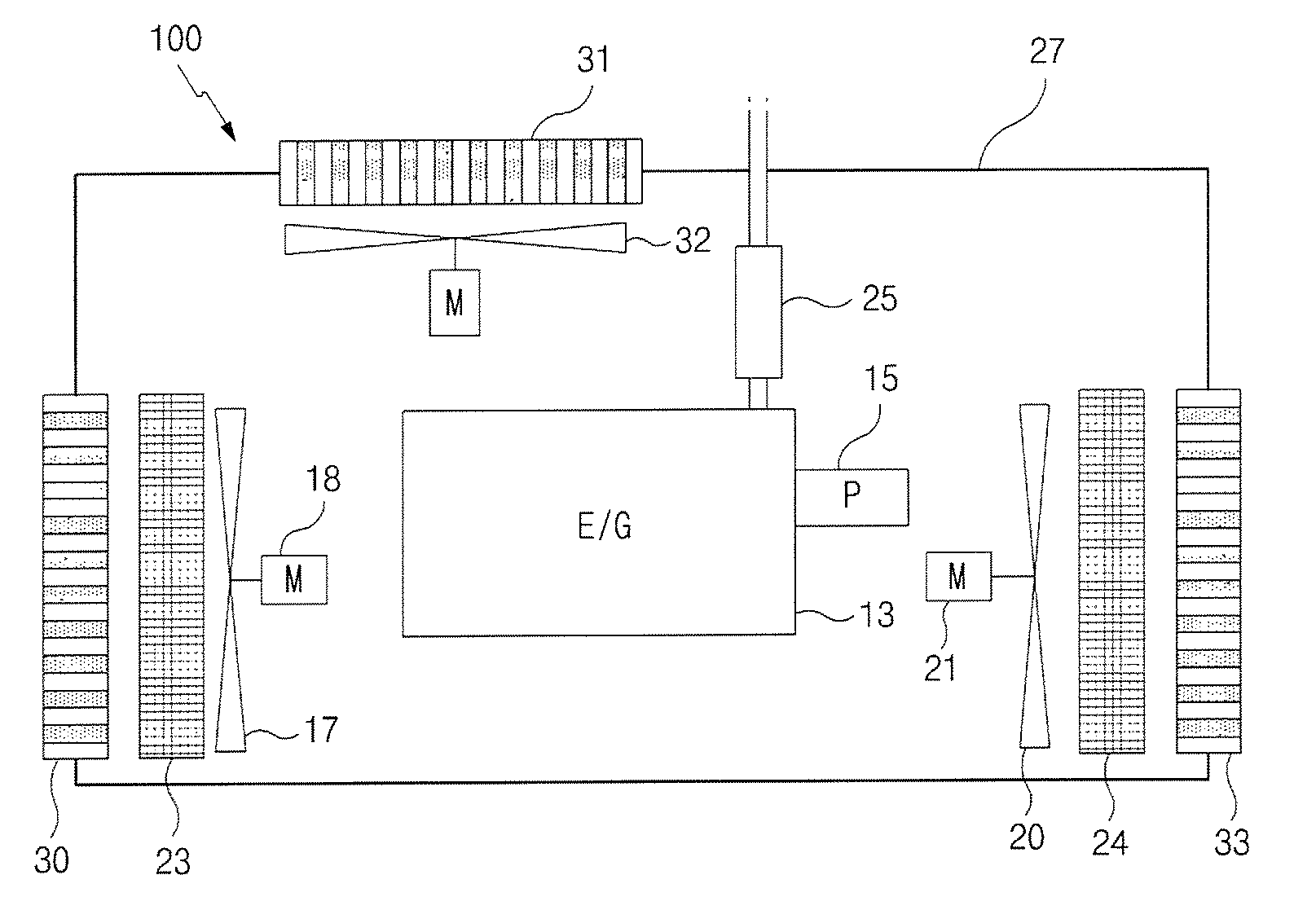

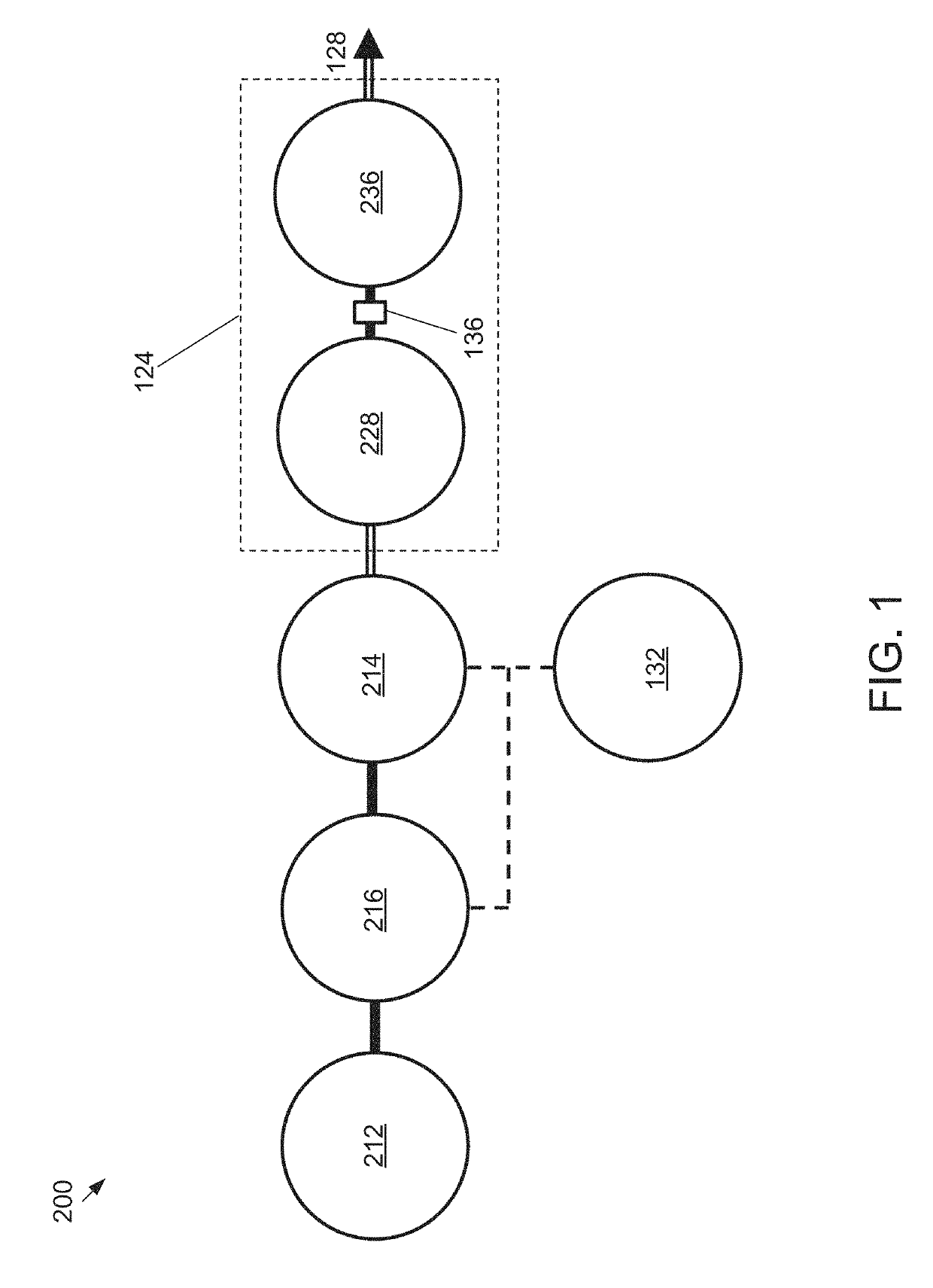

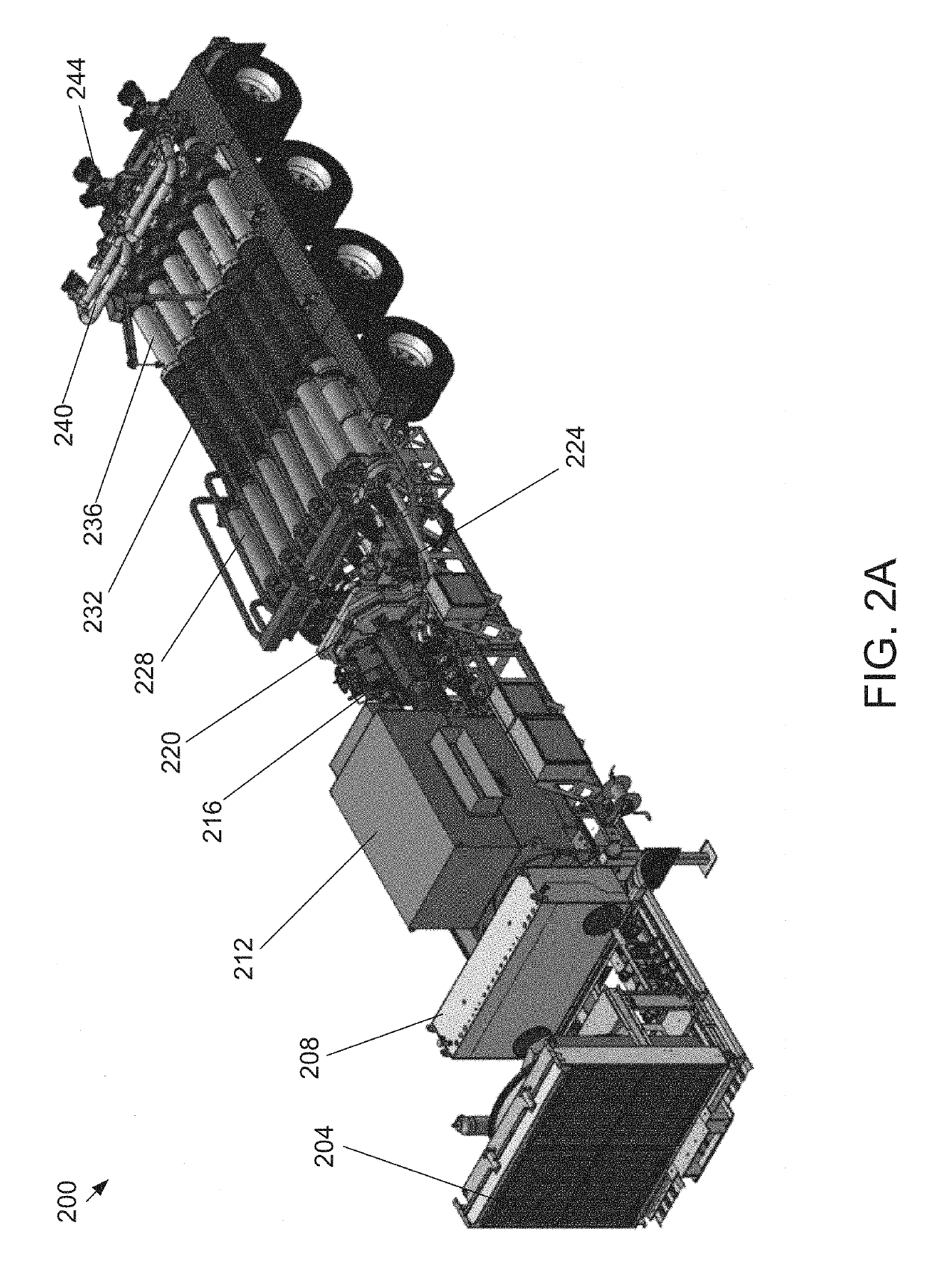

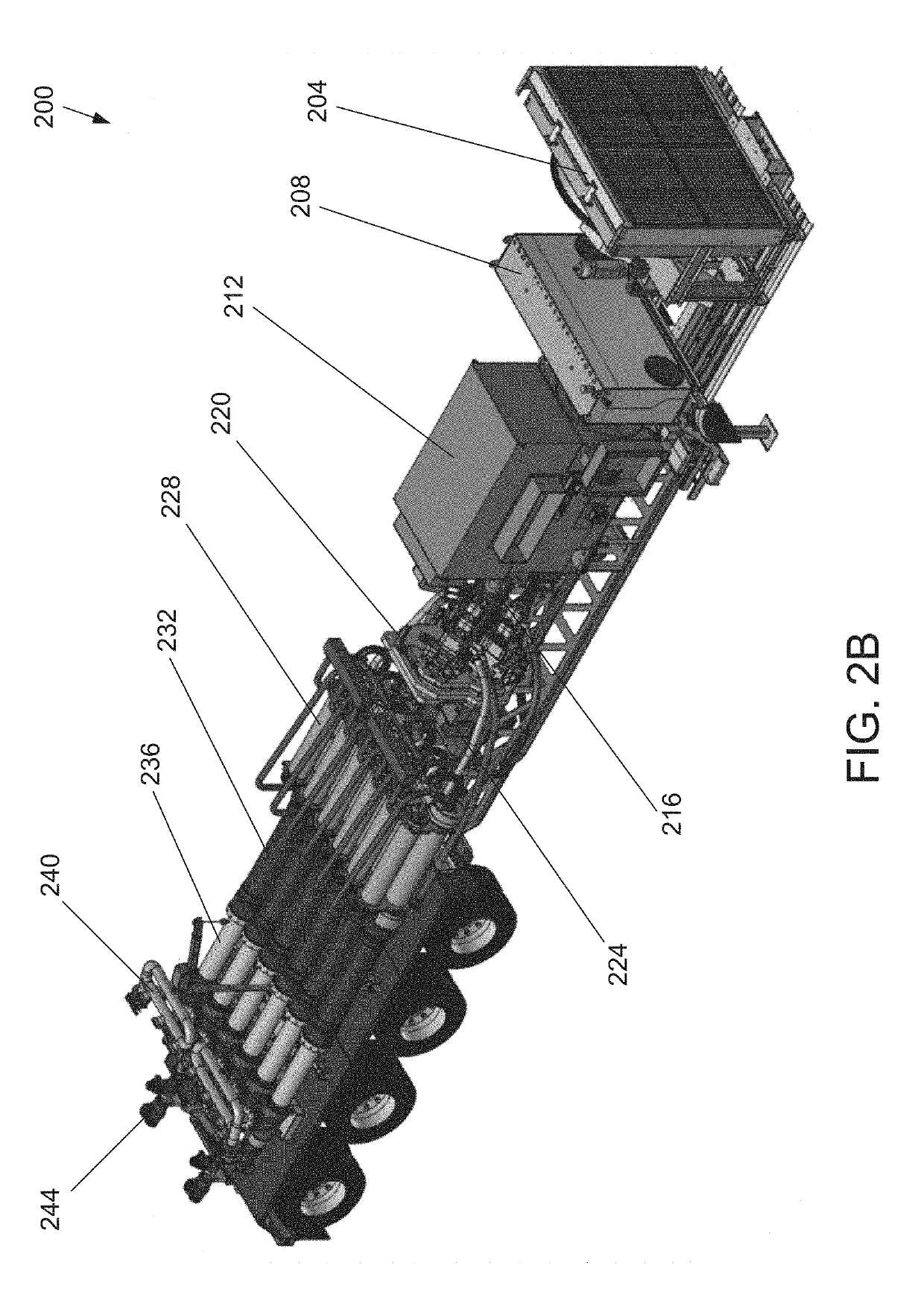

System and method for powering a hydraulic pump

A hydraulic pump powering system includes a mobile vehicle, a first electric current generator device, and one or more electric pump motors. The mobile vehicle has first and second prime movers. The first electric current generator device is disposed onboard the mobile vehicle and is configured to be mechanically coupled with the first prime mover to convert movement created by the first prime mover into first electric current. The one or more electric pump motors are configured to receive the first electric current to power a hydraulic pump. The second prime mover is configured to generate movement that is converted into a propulsive force that propels the mobile vehicle. The one or more electric pump motors are configured to receive the first electric current in order to power the hydraulic pump to pump a fluid into a pumping location located off-board the mobile vehicle.

Owner:GE GLOBAL SOURCING LLC

System and method for powering a hydraulic pump

A hydraulic pump powering system includes a mobile vehicle, a first electric current generator device, and one or more electric pump motors. The mobile vehicle has first and second prime movers. The first electric current generator device is disposed onboard the mobile vehicle and is configured to be mechanically coupled with the first prime mover to convert movement created by the first prime mover into first electric current. The one or more electric pump motors are configured to receive the first electric current to power a hydraulic pump. The second prime mover is configured to generate movement that is converted into a propulsive force that propels the mobile vehicle. The one or more electric pump motors are configured to receive the first electric current in order to power the hydraulic pump to pump a fluid into a pumping location located off-board the mobile vehicle.

Owner:GE GLOBAL SOURCING LLC

Rotary hydraulic pump actuated multi-stroke surgical instrument

A surgical instrument (e.g., endocutter, grasper, cutter, staplers, clip applier, access device, drug / gene therapy delivery device, and energy device using ultrasound, RF, laser, etc.) may benefit from having a plurality of hydraulically actuated subsystems (e.g., severing, stapling, articulation, locking / unlocking, lockout enabling / disabling, grasping, etc.) supplied with hydraulic power from a trigger actuated rotary pump (e.g., lobe pump, rotary gear pump, internal rotating gear pump, flexible vane rotor pump, rotary vane pump). Thereby, an available amount of mechanical advantage available at a firing trigger may be optimally distributed to various end effector components, perhaps sequenced by an electroactive polymer or piezoelectrically actuated function switch block.

Owner:ETHICON ENDO SURGERY INC

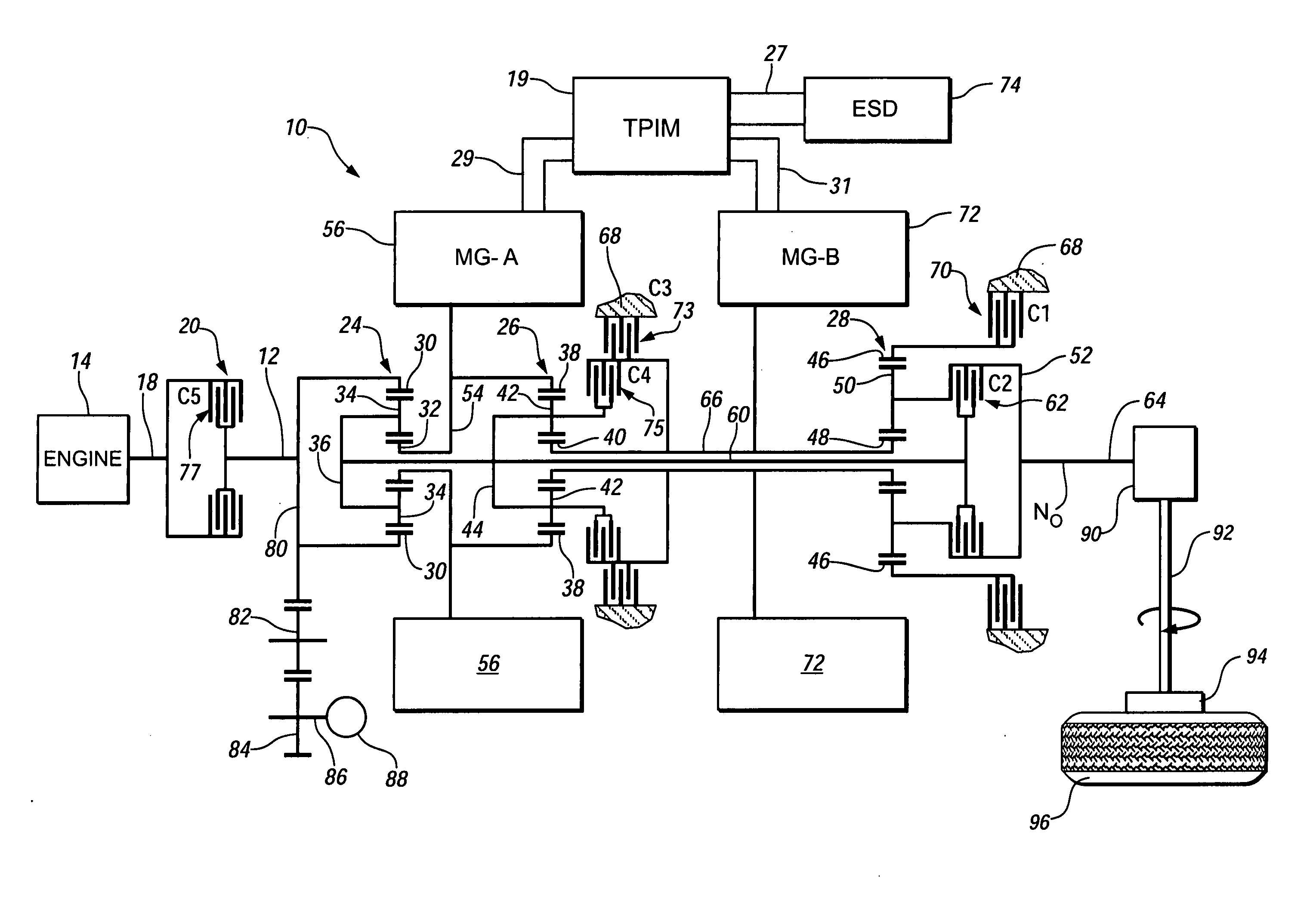

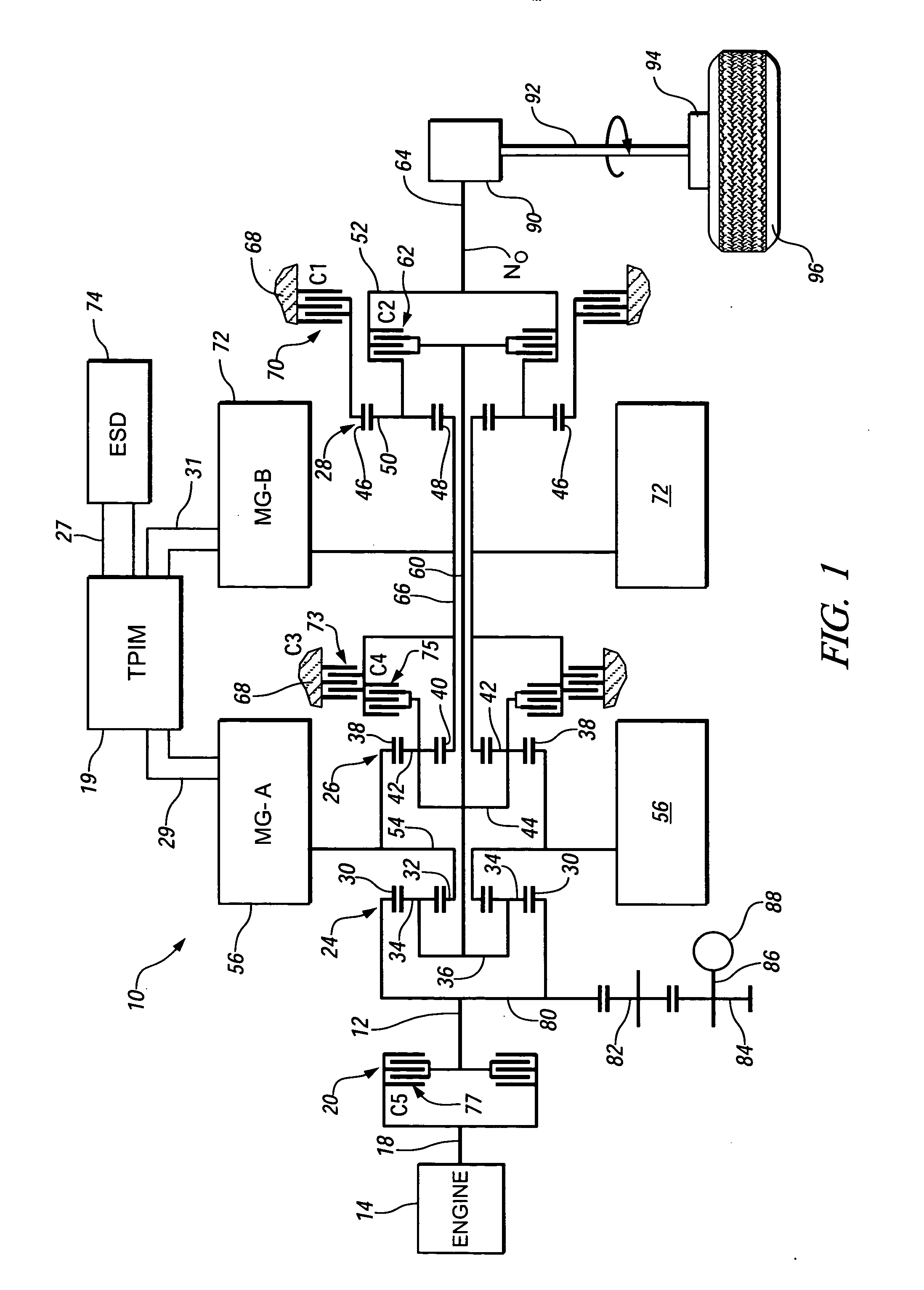

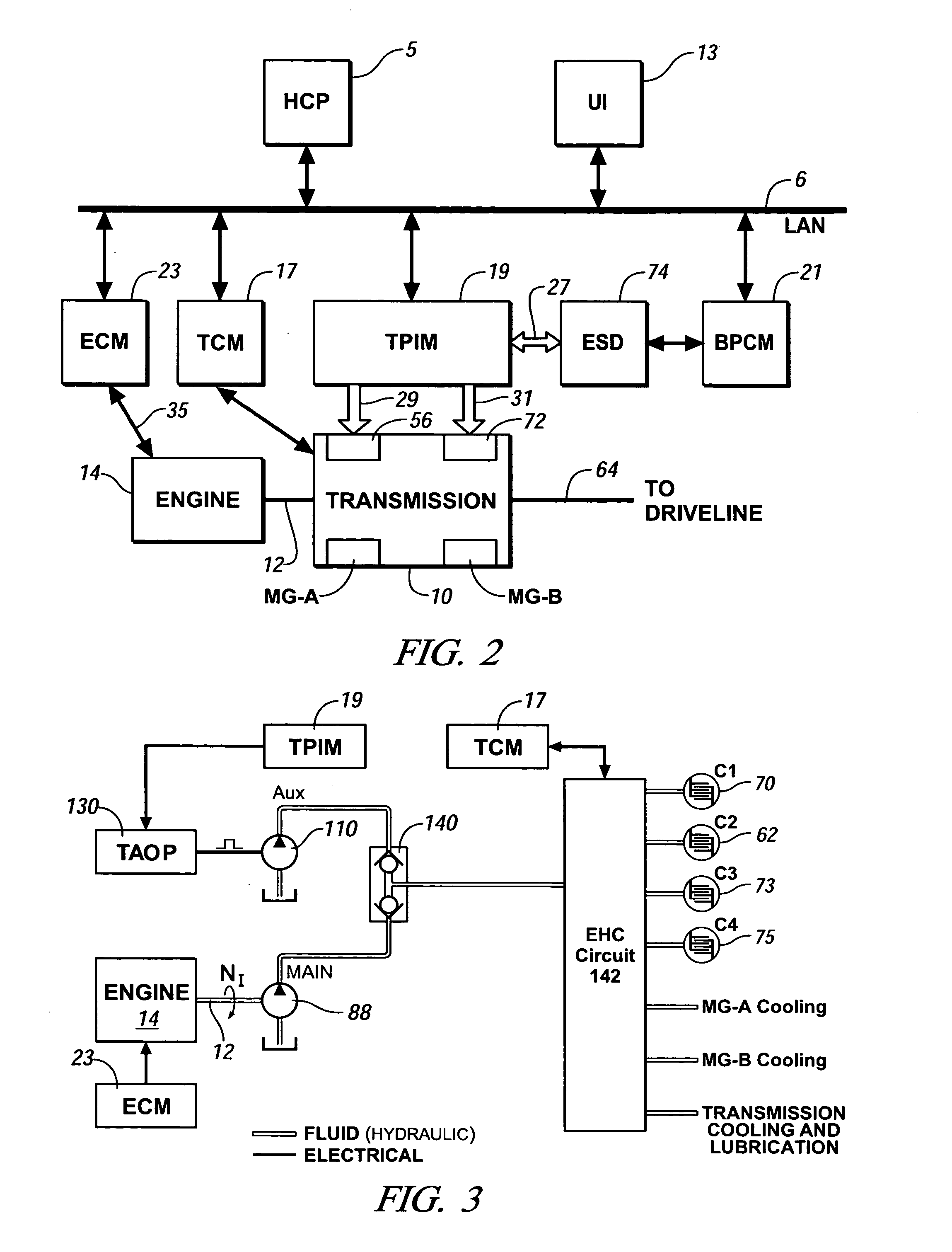

Method and apparatus to control hydraulic pressure in an electro-mechanical transmission

Owner:GM GLOBAL TECH OPERATIONS LLC

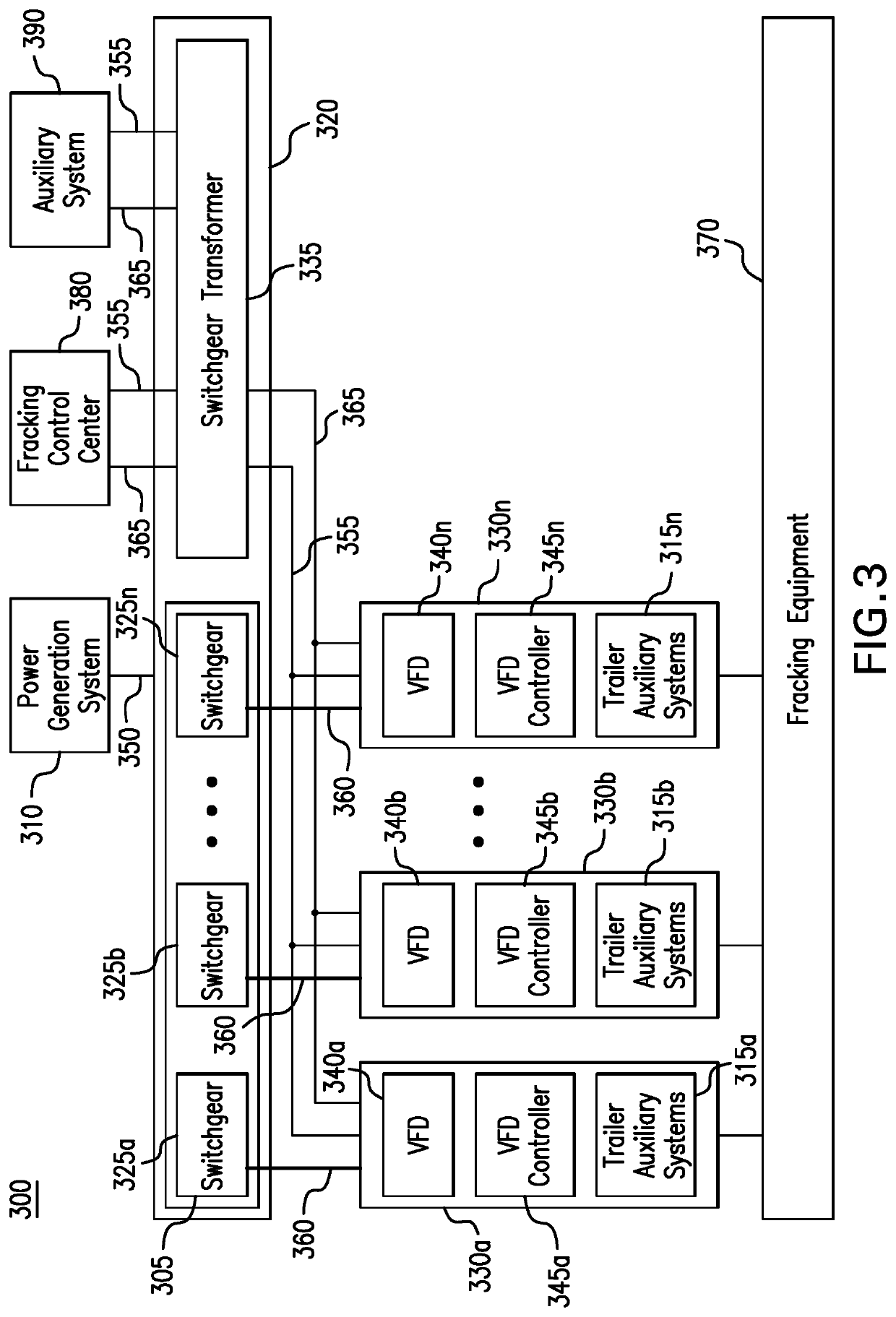

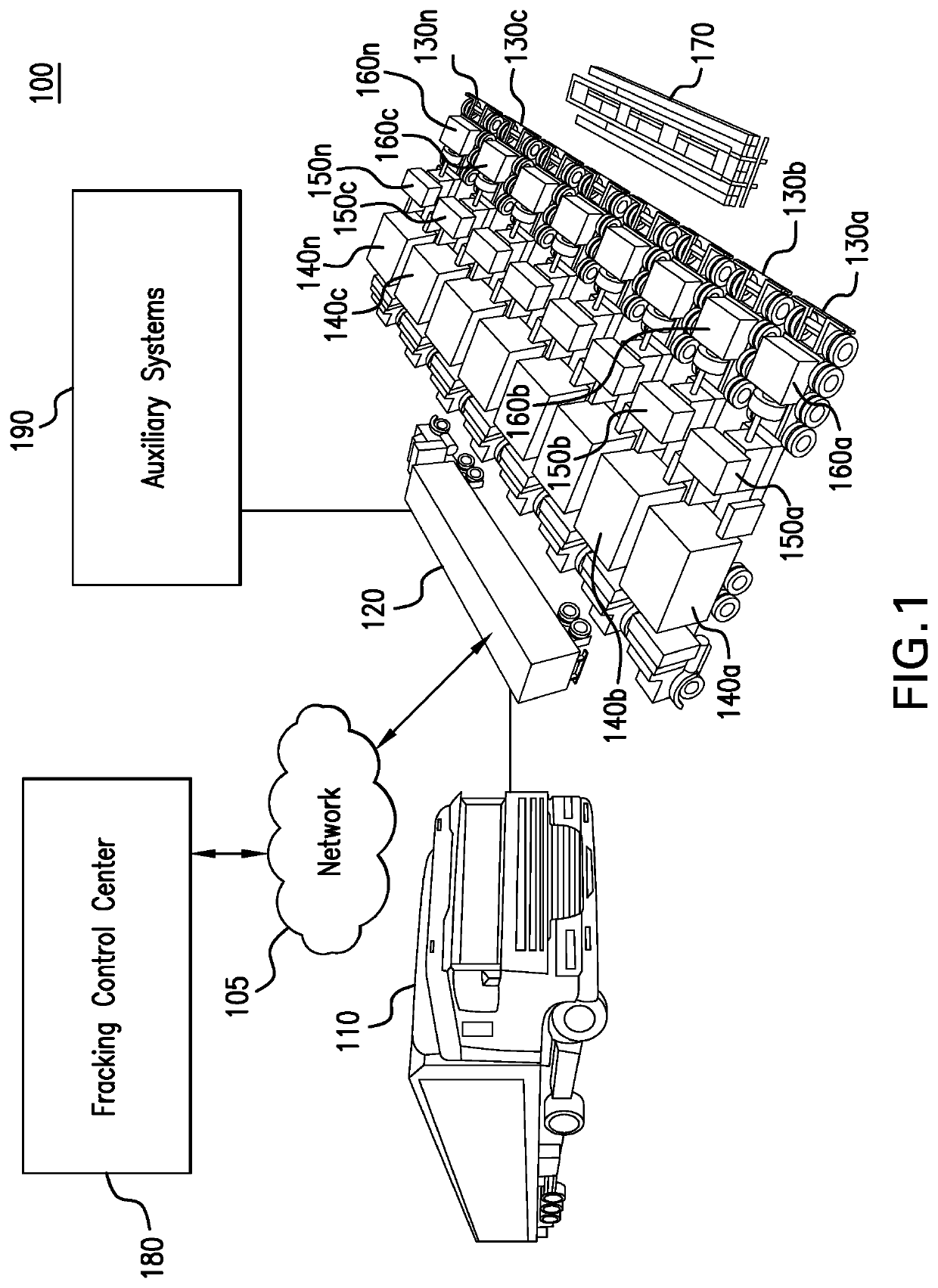

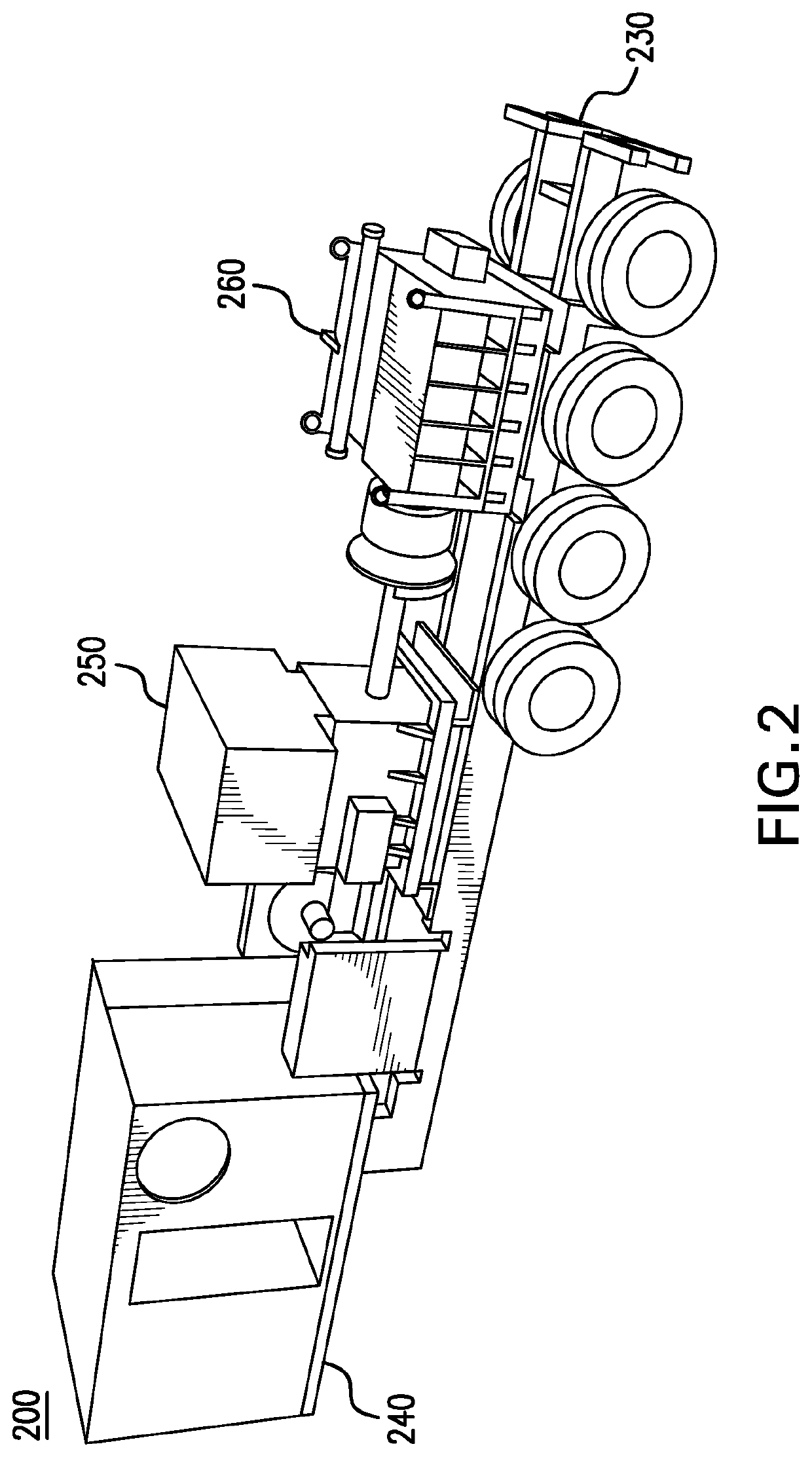

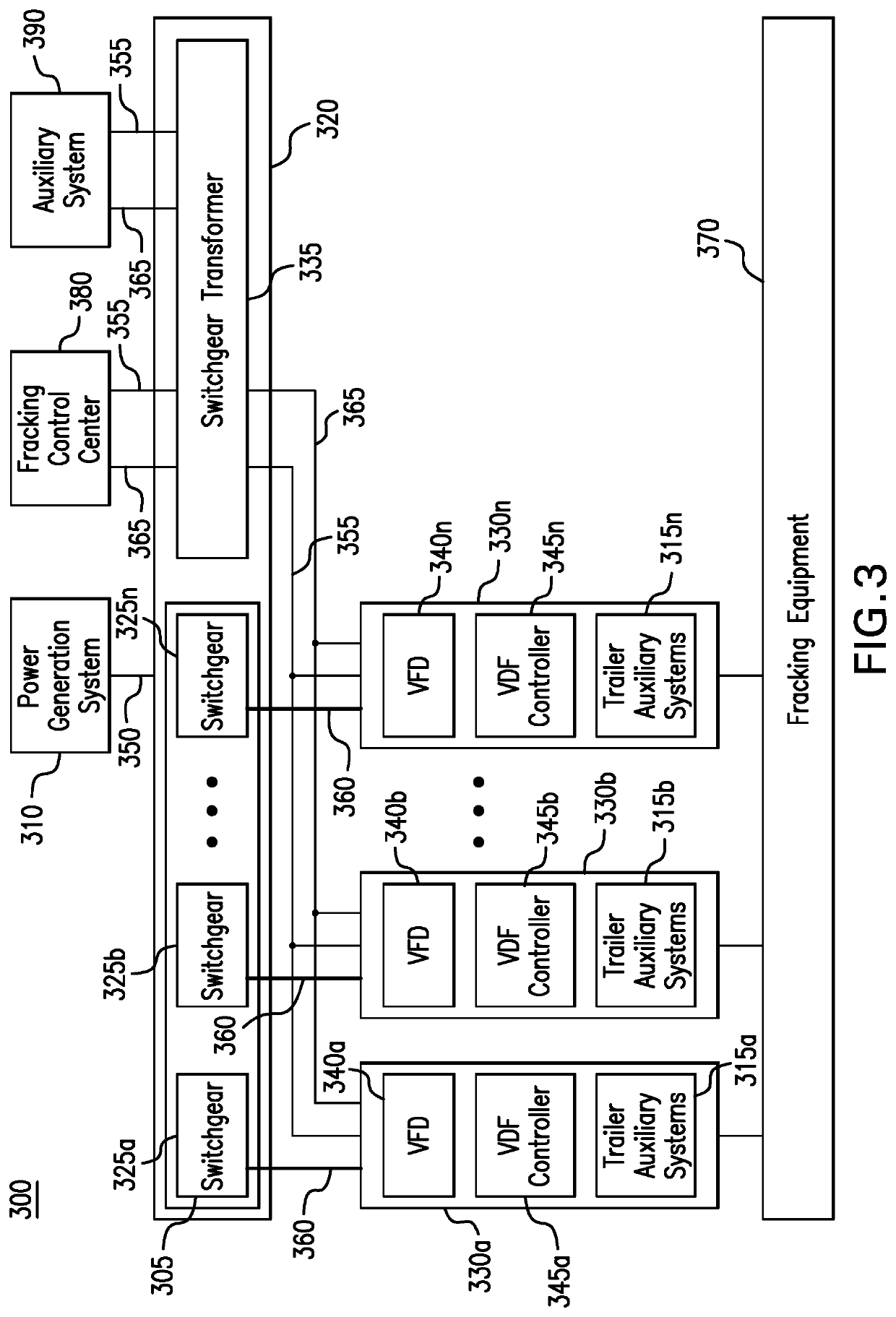

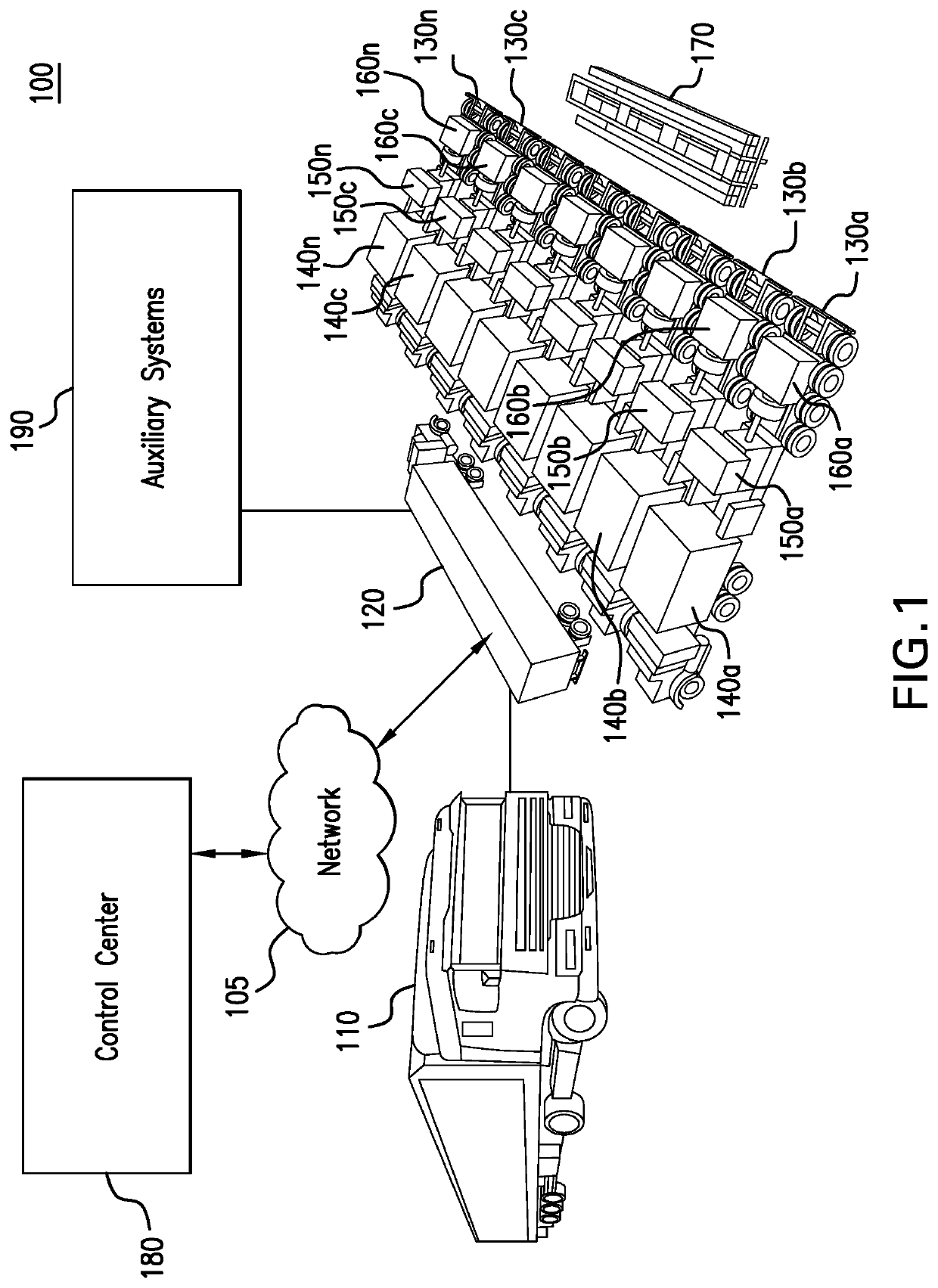

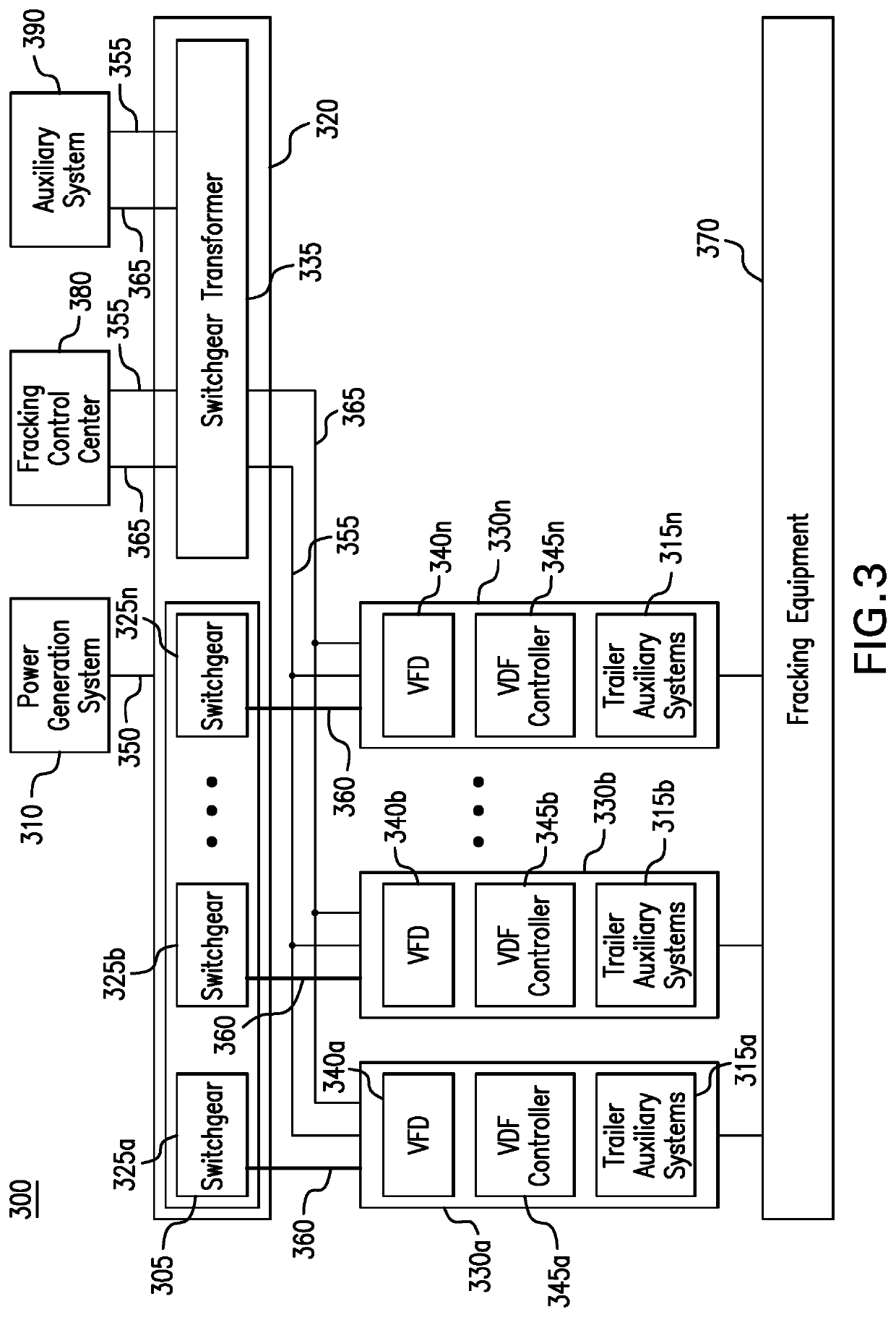

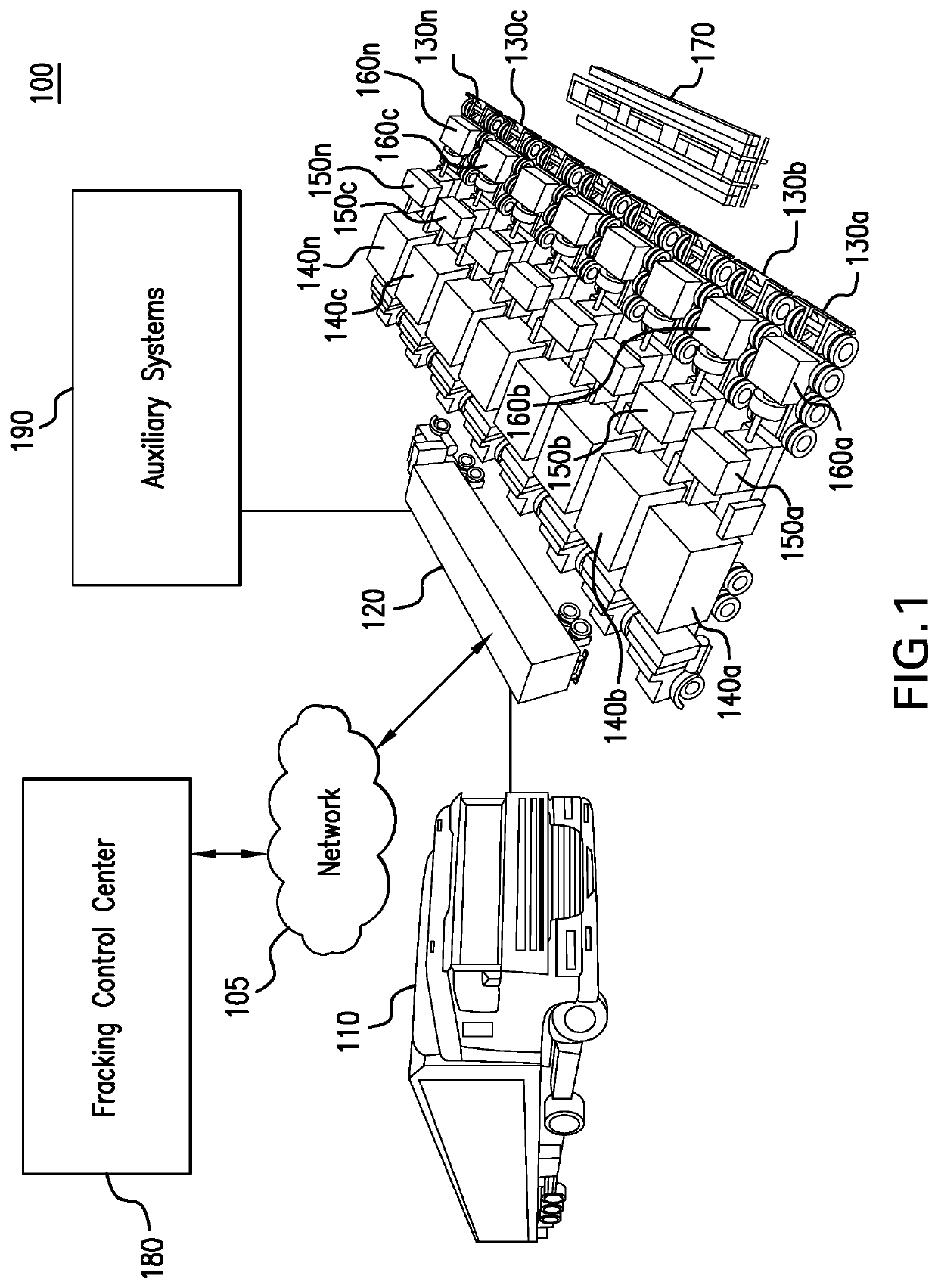

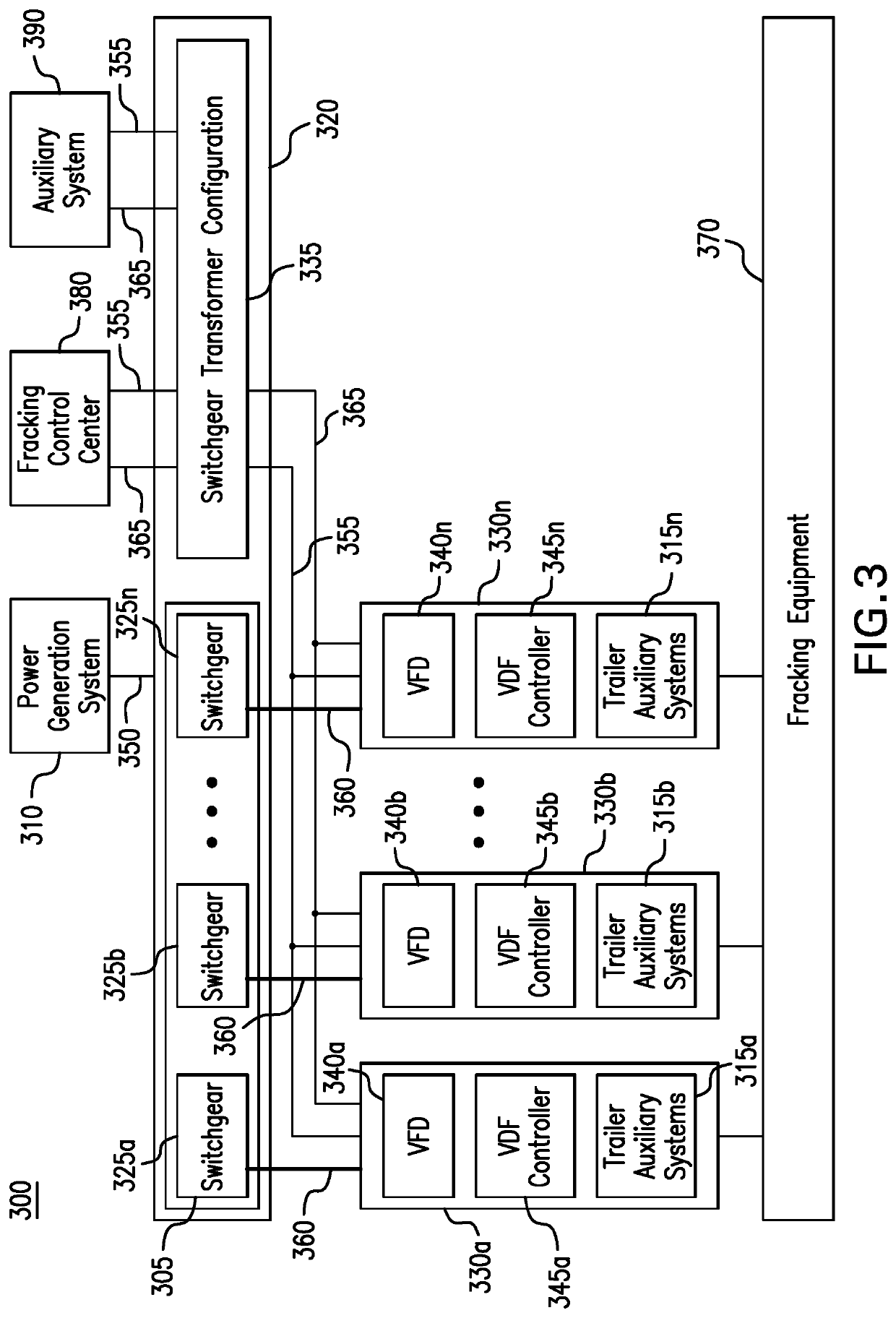

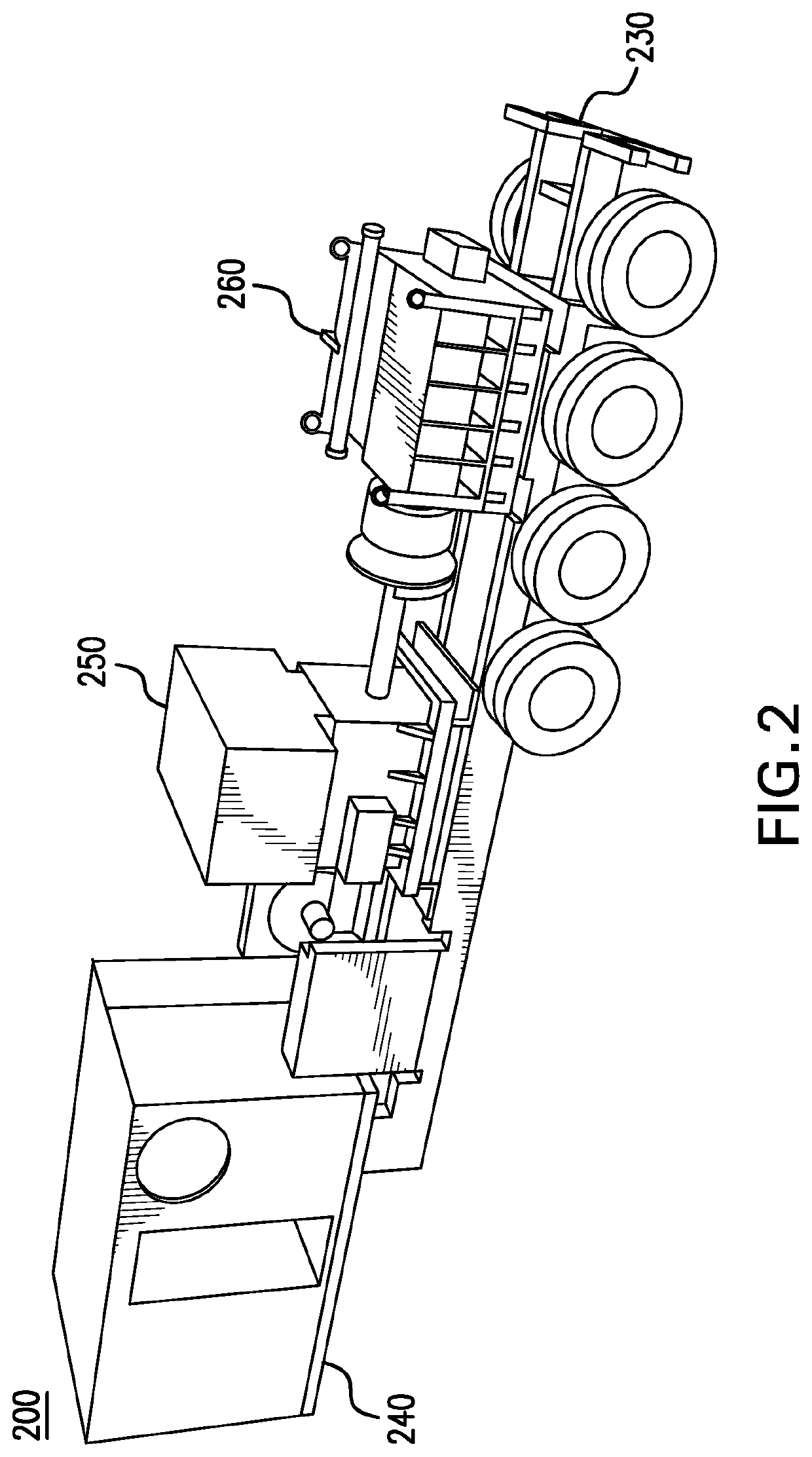

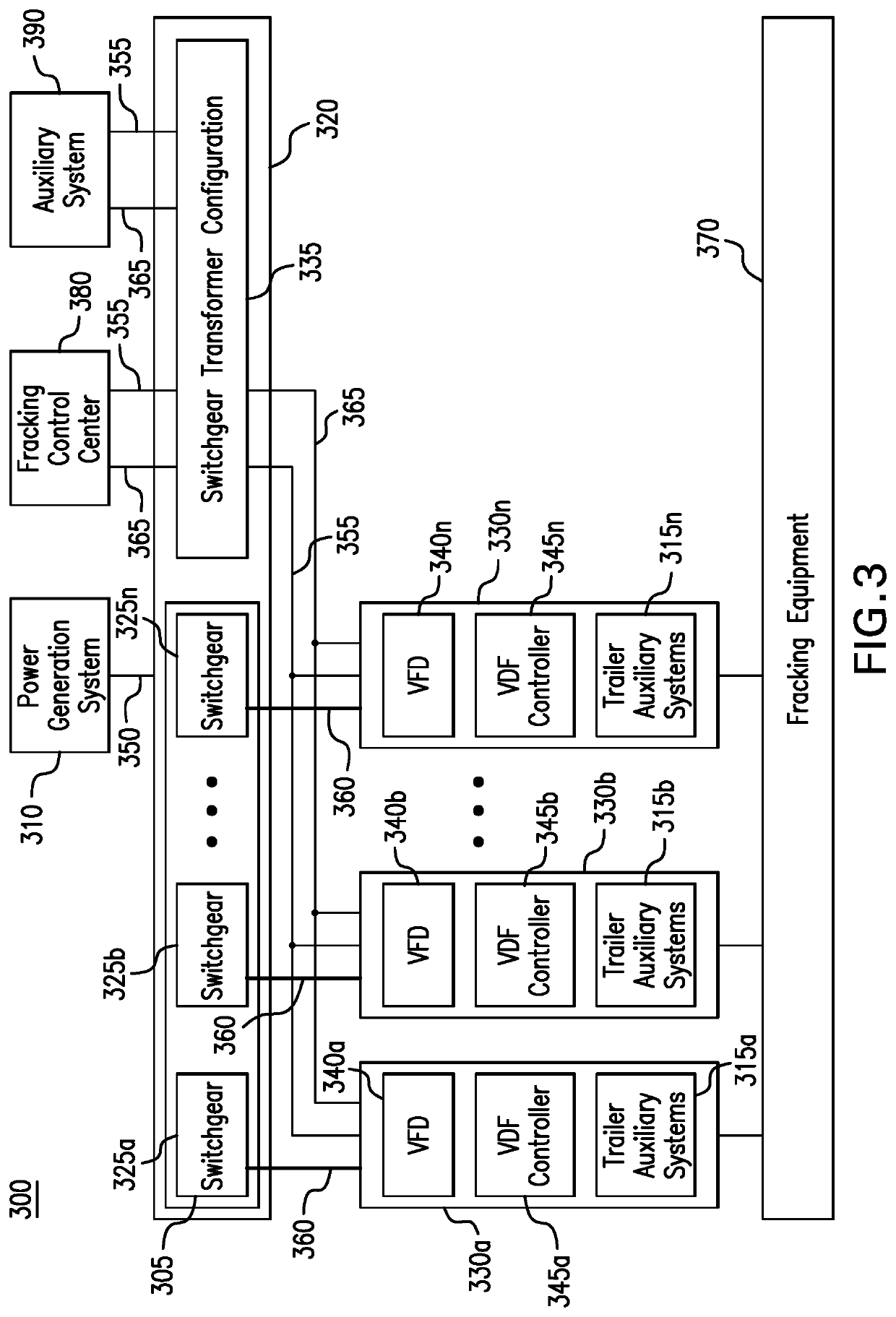

Power distribution trailer for an electric driven hydraulic fracking system

Owner:HALLIBURTON ENERGY SERVICES INC

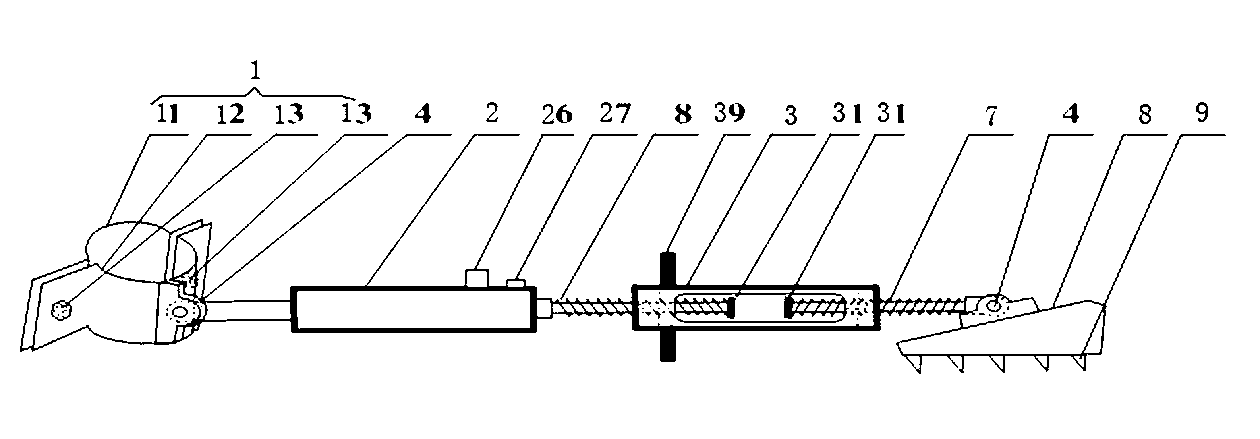

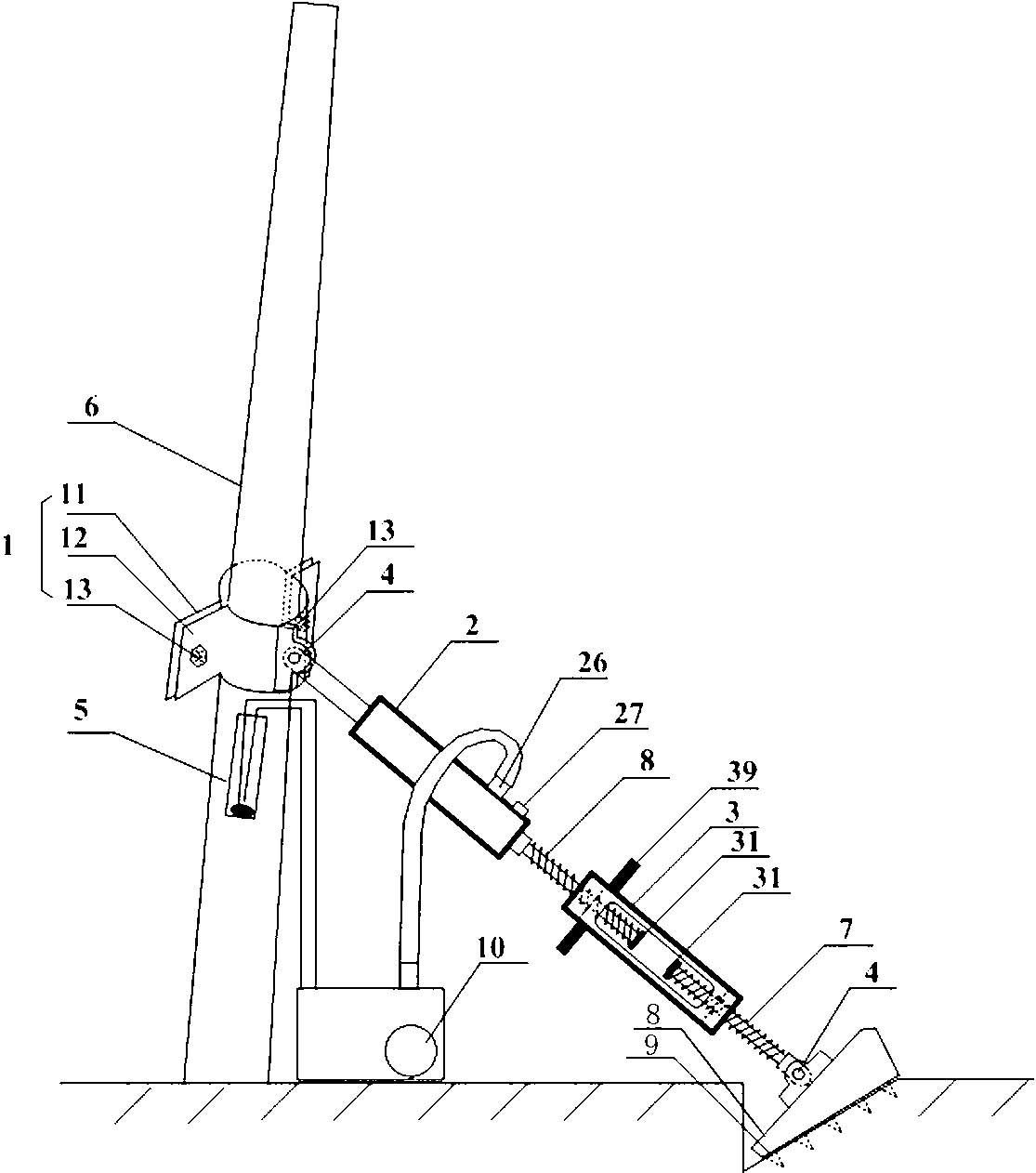

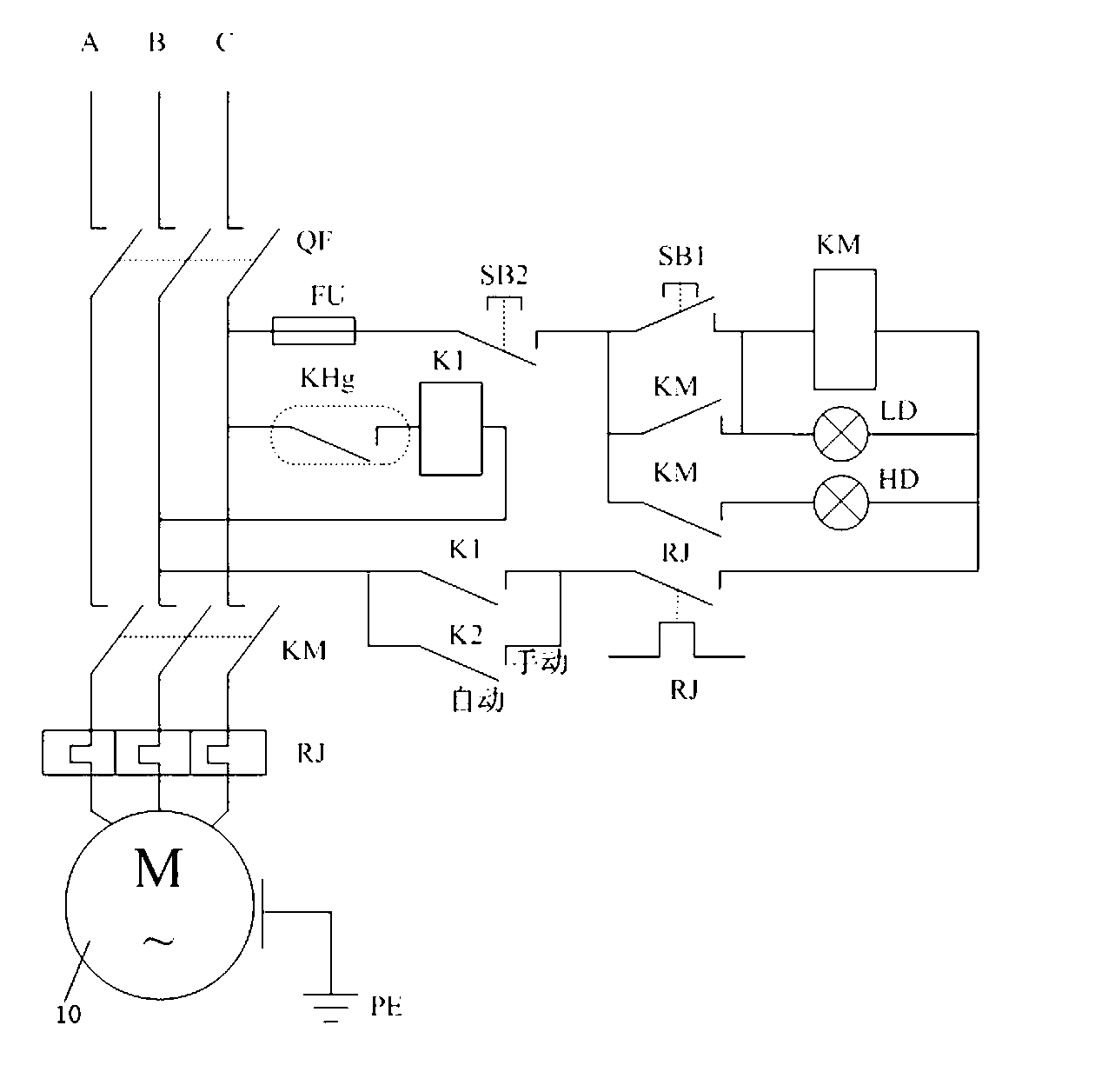

Full-automatic utility pole centralizer

InactiveCN103291117AEnsure power supply reliabilityImprove work efficiencyTowersHydraulic pumpEngineering

The invention relates to a full-automatic utility pole centralizer comprising a hoop, a hydraulic mechanism, a length adjuster, a connecting shaft, a right hand thread screw, a left hand thread screw, a base, a mercury switch and an electric hydraulic pump. The hoop is connected with the hydraulic mechanism through the connecting shaft. The hydraulic mechanism and the right hand thread screw are welded together. The right hand thread screw and the left hand thread screw are screwed in two ends of the length adjuster, respectively. A limit stopper is arranged at the end of each of the screws screwed into the length adjuster. The other end of the left hand thread screw is connected with the base through the connecting shaft. The hydraulic mechanism is provided with a relief valve and a hydraulic joint. The electric hydraulic pump is connected with the hydraulic joint through a high-pressure rubber pipe. The mercury switch is parallelly attached to a utility pole and is connected with the electric hydraulic pump through a circuit. The full-automatic utility pole centralizer has the advantages that when tilting, the utility pole can be automatically centralized with no power outage; power supply reliability is ensured, work efficiency is improved, and risks caused by power outage are reduced.

Owner:STATE GRID CORP OF CHINA +1

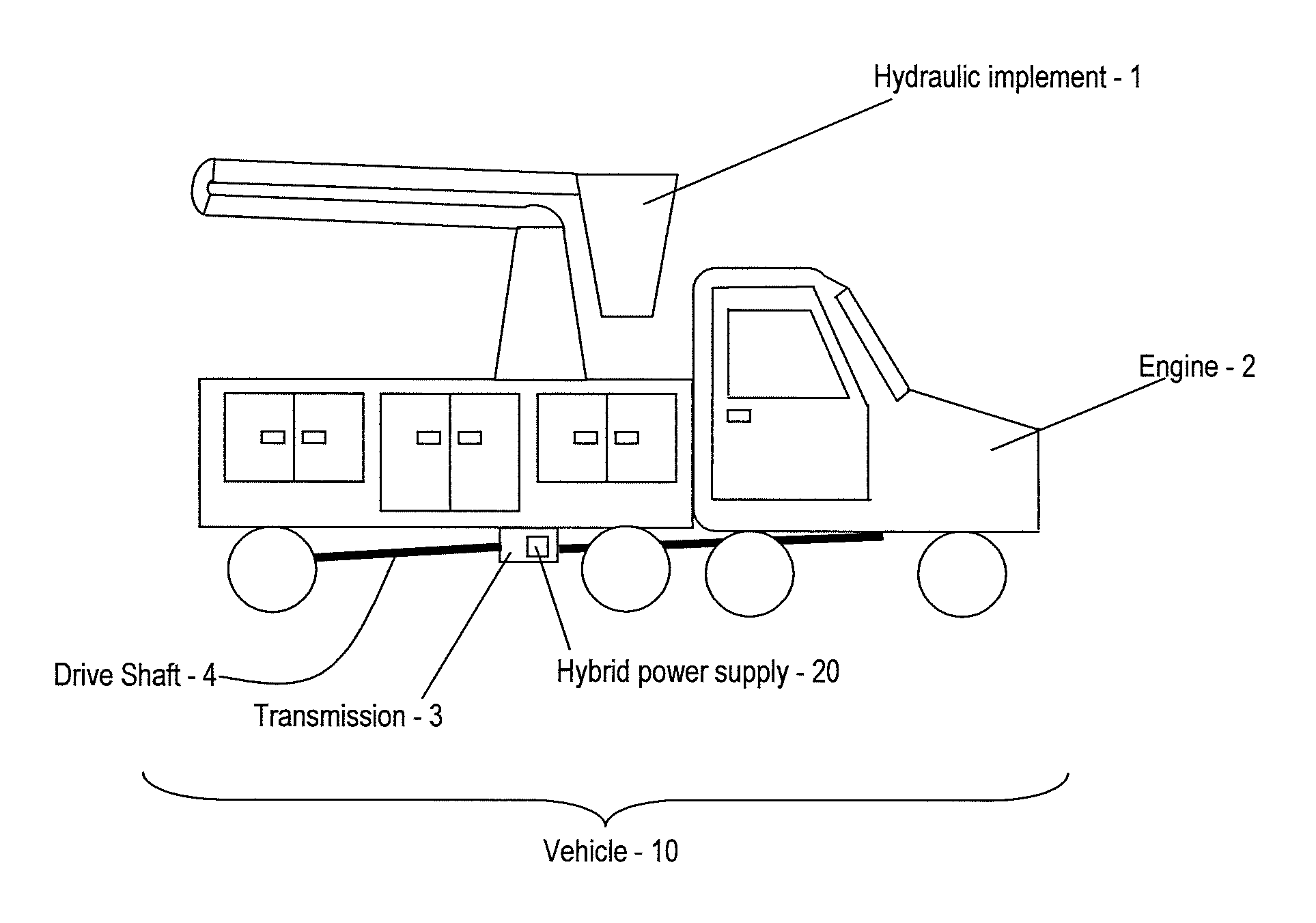

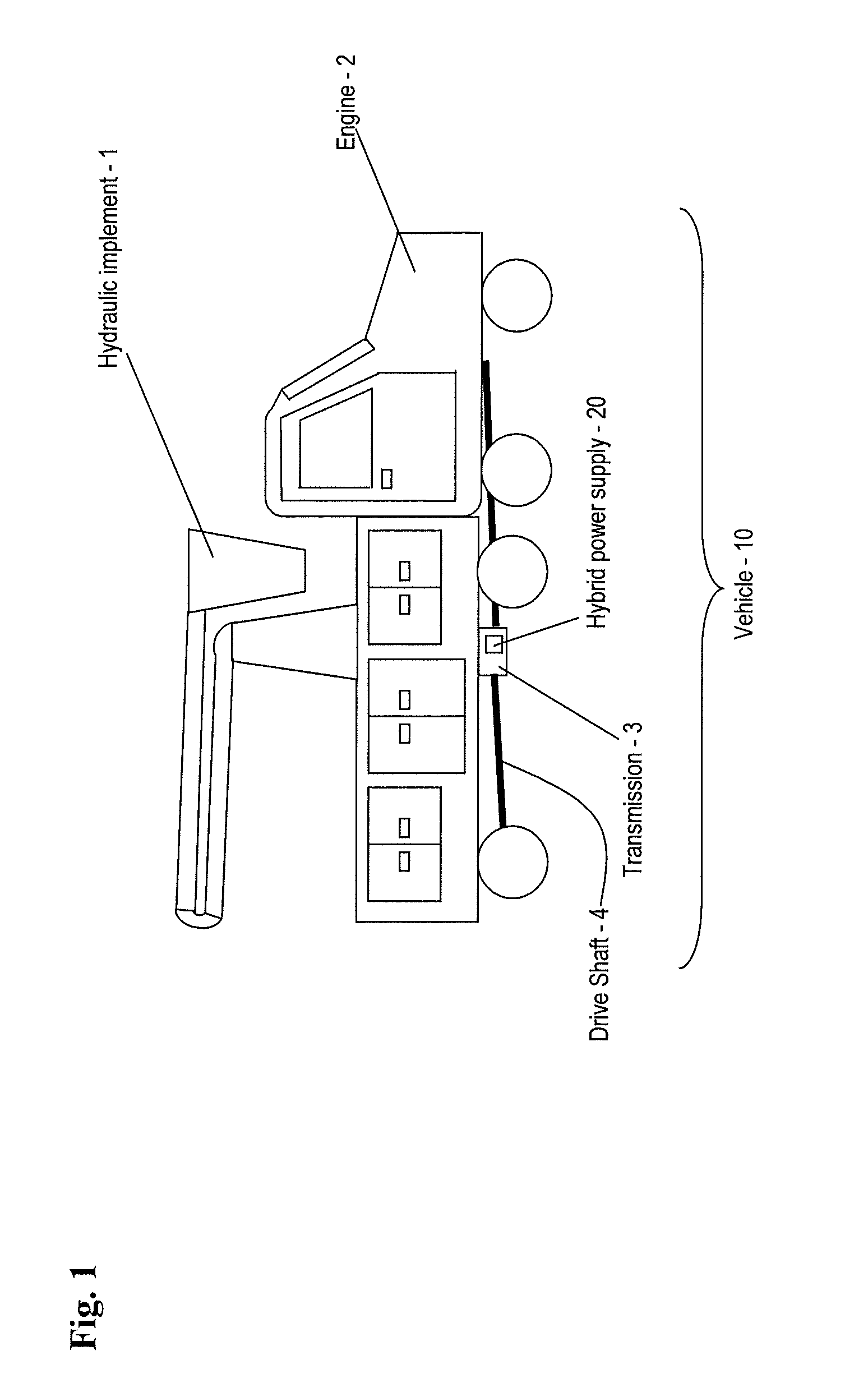

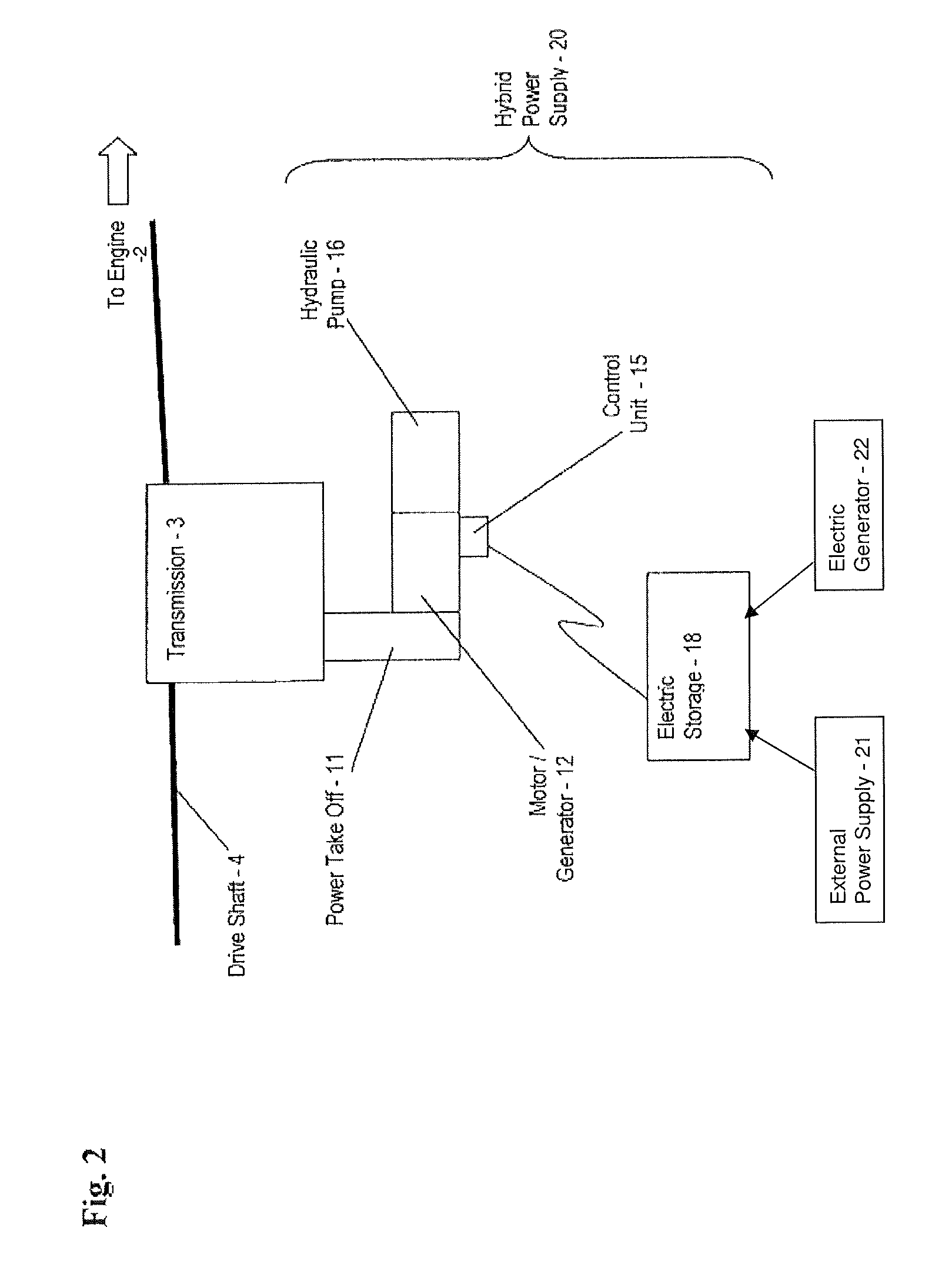

Hybrid drive for hydraulic power

A power supply for powering a hydraulic implement includes: an electric storage unit; an electric motor, an electric generator, a hydraulic pump and a control unit; the electric motor adapted for receiving electric power and driving the hydraulic pump to power the hydraulic implement; the electric generator adapted for translating mechanical energy into the electric power; the electric storage unit also being adapted for providing the electric power; and the control unit for selecting a source of the electric power from one of the generator and the electric storage unit. A method for operating the power supply and a vehicle are also provided.

Owner:TEREX SOUTH DAKOTA

Well Service Pump System

A well service pump system supplies high pressure working fluid to a well. The pump system is a linear design which incorporates a diesel engine, a hydraulic drive gear box, open loop hydraulic Pumps, hydraulic ram cylinders, controls for the hydraulic system hydraulic cylinders, working fluid end cylinders and a coupling to connect the hydraulic cylinders and the working fluid ends. The engine powers the hydraulic system which, in turn, provides hydraulic fluid to operate the hydraulic ram cylinders. Each of the polished rods of the hydraulic ram cylinders is connected axially to a plunger rod end of a working fluid end cylinder. There is no crankshaft or automatic transmission required. The linear design allows for a longer plunger stroke length while still allowing highway transport on a truck or skid.

Owner:AMERIFORGE GRP

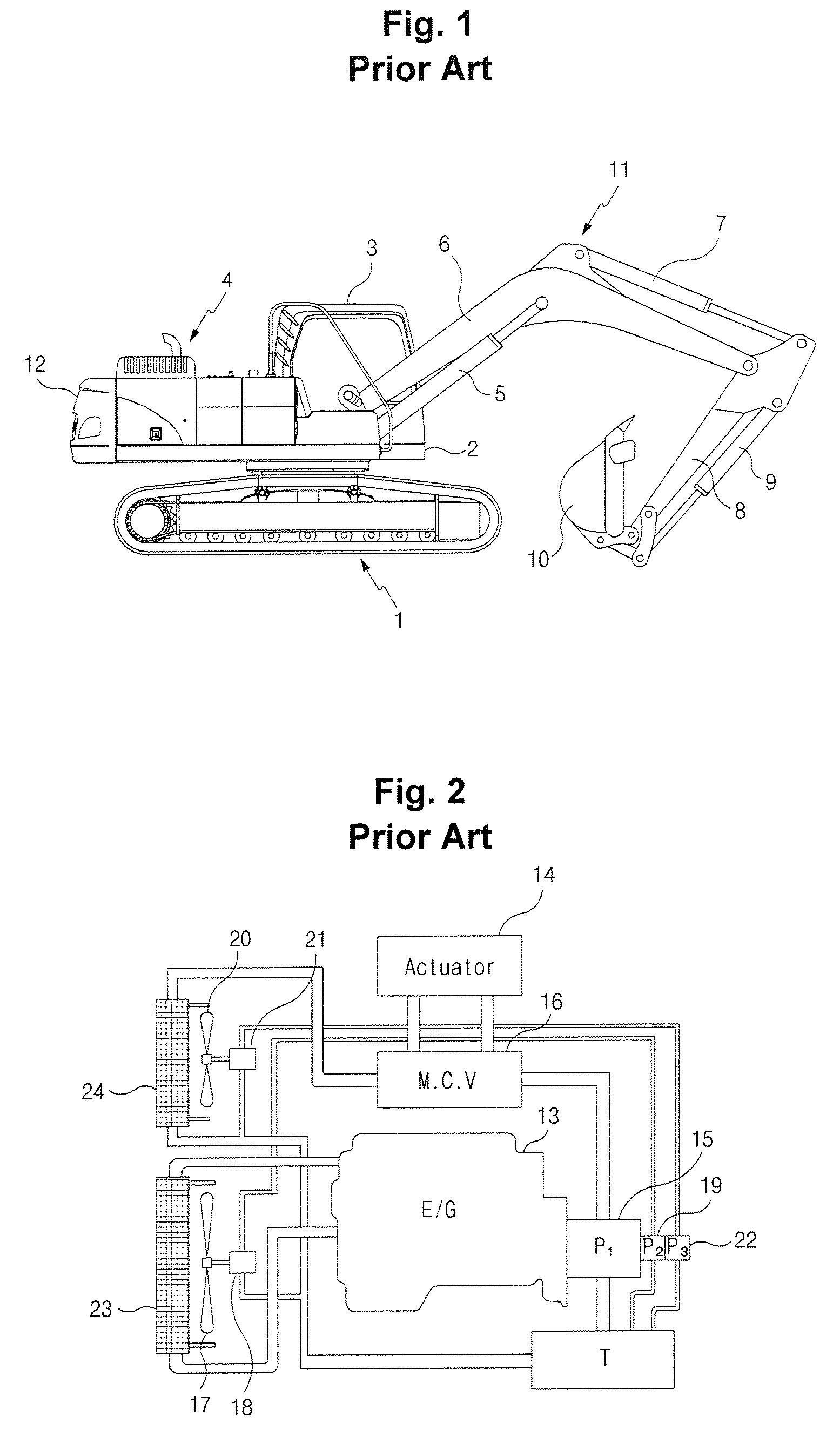

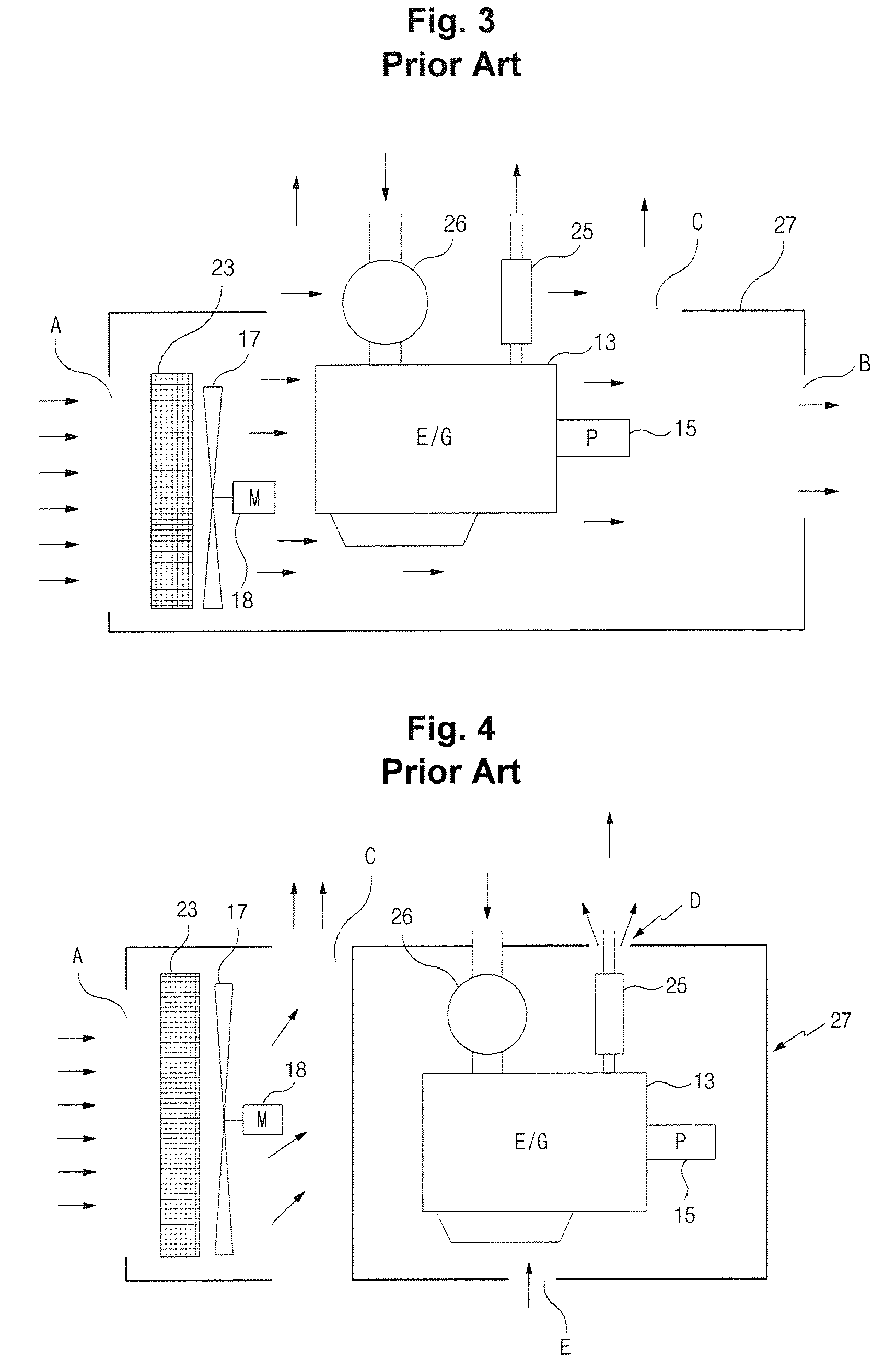

Engine room for construction equipment

InactiveUS8196555B2Reduce noiseAvoid componentsCoolant flow controlExhaust apparatusInhalationAtmospheric air

An engine room for construction equipment is provided, which can minimize emission of noise generated in an engine room due to driving of an engine and a ventilating fan to an outside of the engine room by absorbing the noise through a noise trap, and can improve the cooling performance of corresponding components by smoothing inhalation / discharge of an external air to / from the airtight engine room. The engine room for construction equipment includes a radiator cooling water for cooling the engine, a muffler discharging an exhaust gas from an engine to the atmosphere, a first noise trap installed in an inlet port to absorb noise generated in the engine room and emitted to an outside, a second noise trap installed in an outlet port to absorb the noise generated in the engine room and emitted to the outside, a radiator fan inhaling the external air through the first noise trap and making the inhaled external air pass through the radiator and the circumference of the engine, a discharge fan discharging the air in the engine room to the outside through the second noise trap, and an outer wall forming an airtight space for accommodating therein the engine, the muffler, the radiator fan, the hydraulic pump, and the discharge fan that generate the noise.

Owner:VOLVO CONSTR EQUIP HLDG SWEDEN AB

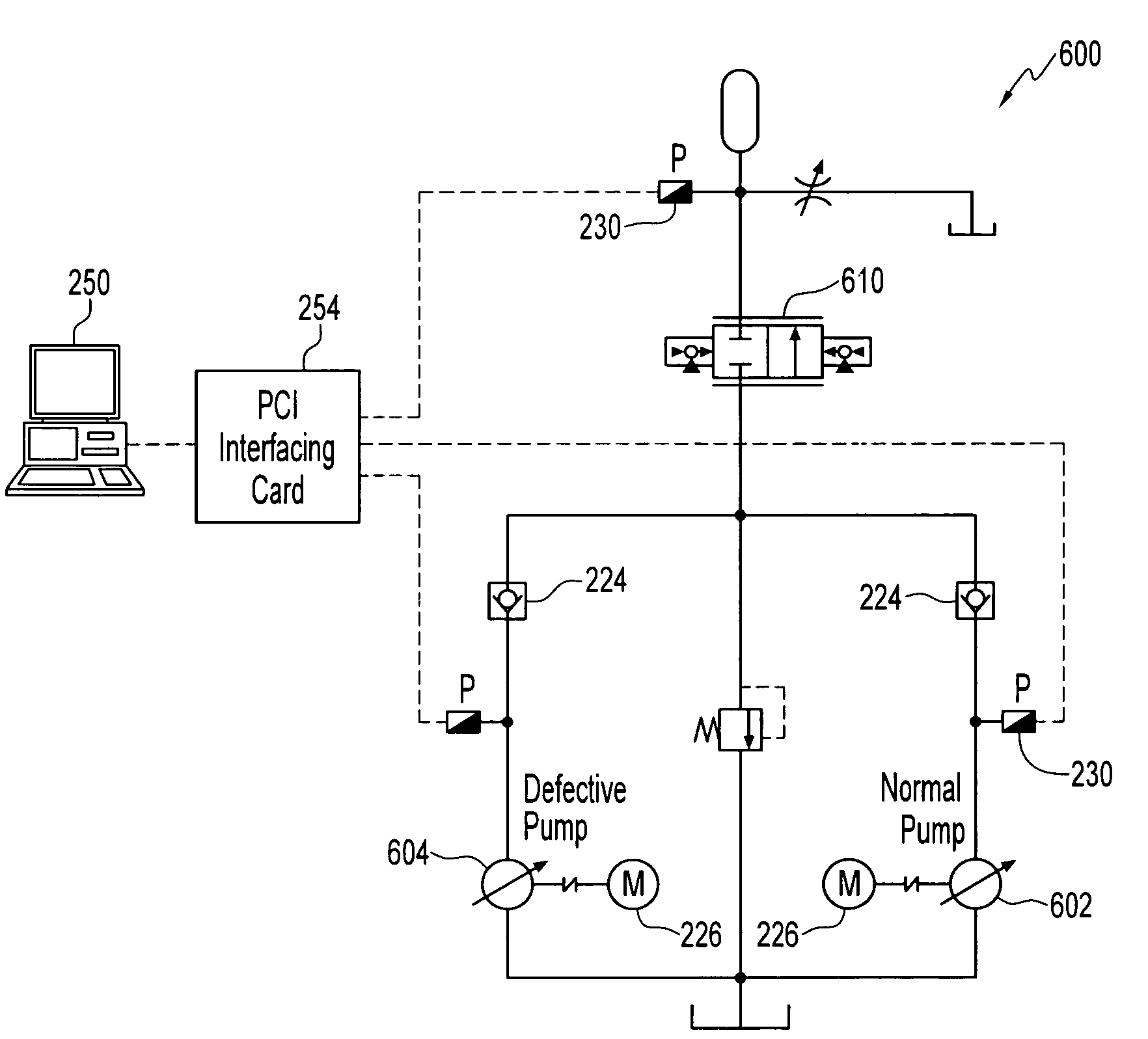

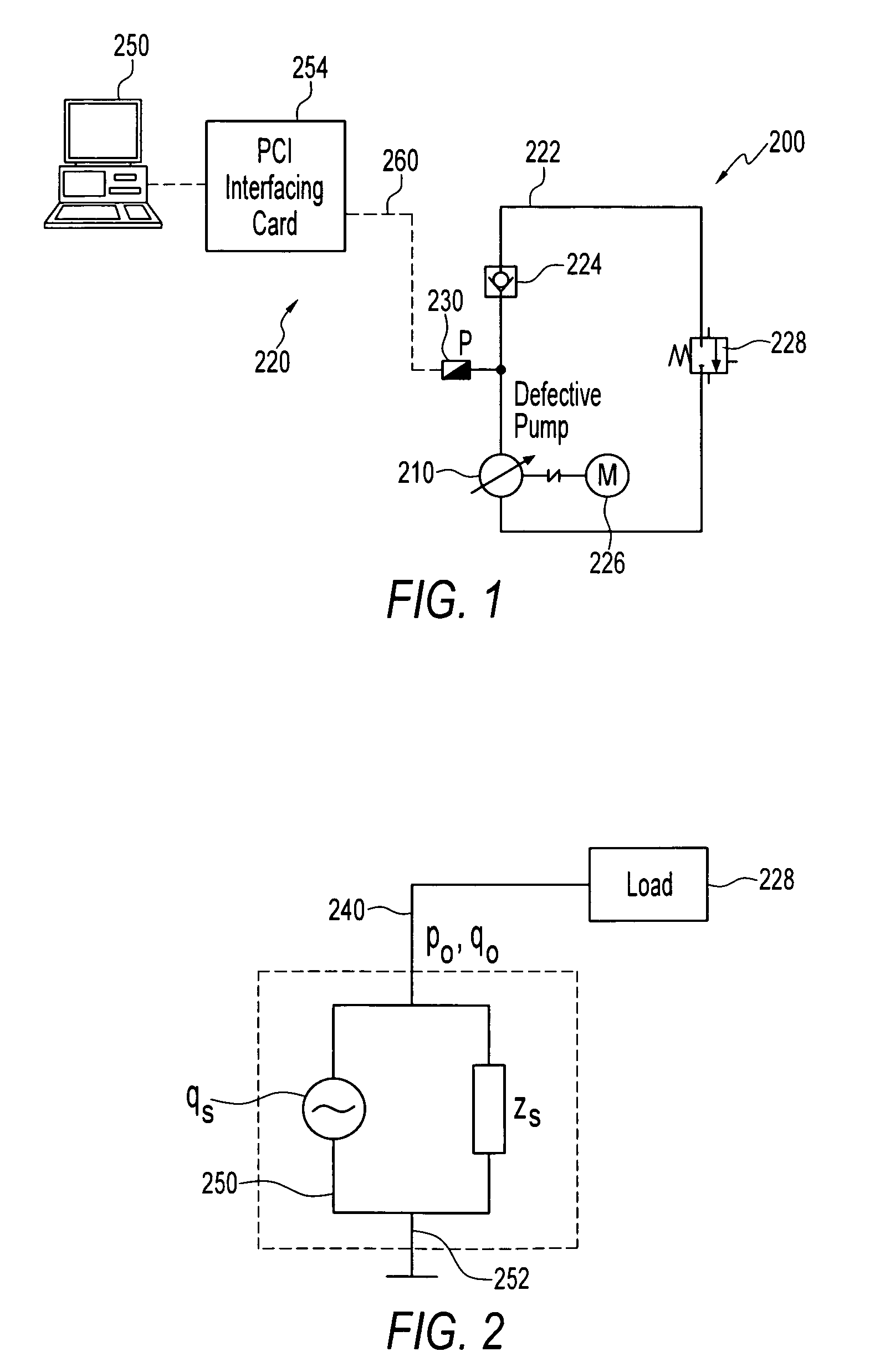

Method and apparatus for analyzing performance of a hydraulic pump

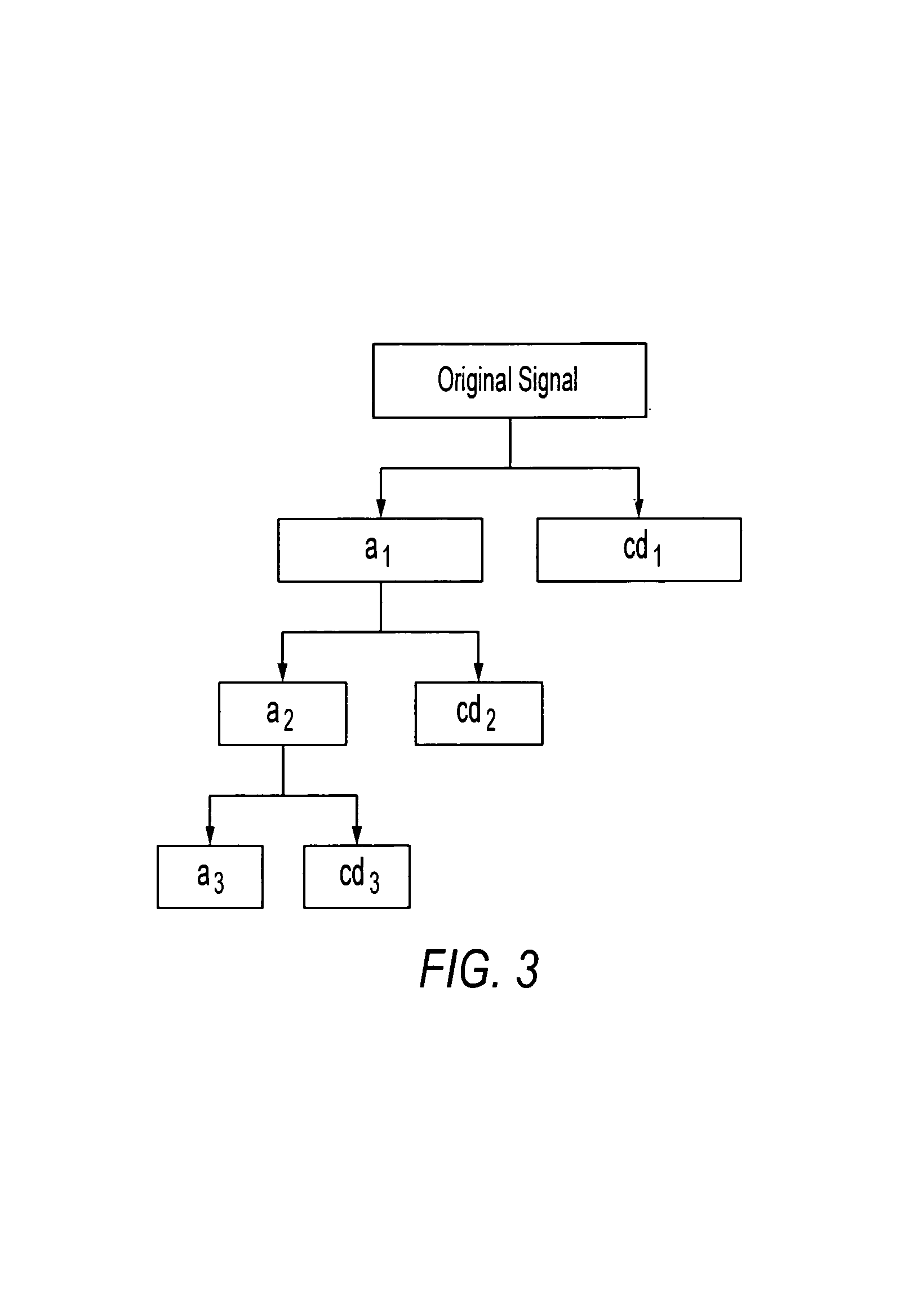

A method and apparatus for analyzing a hydraulic pump in real-time. A pressure signal is provided representing a discharge pressure of the hydraulic pump, and the pressure signal is decomposed into a plurality of levels. Each of the plurality of levels has at least one frequency band. A feature pressure signal is located in at least one of the frequency bands and compared to a reference wavelet to determine if a fault exists in the hydraulic pump and / or a type of defect in the hydraulic pump.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

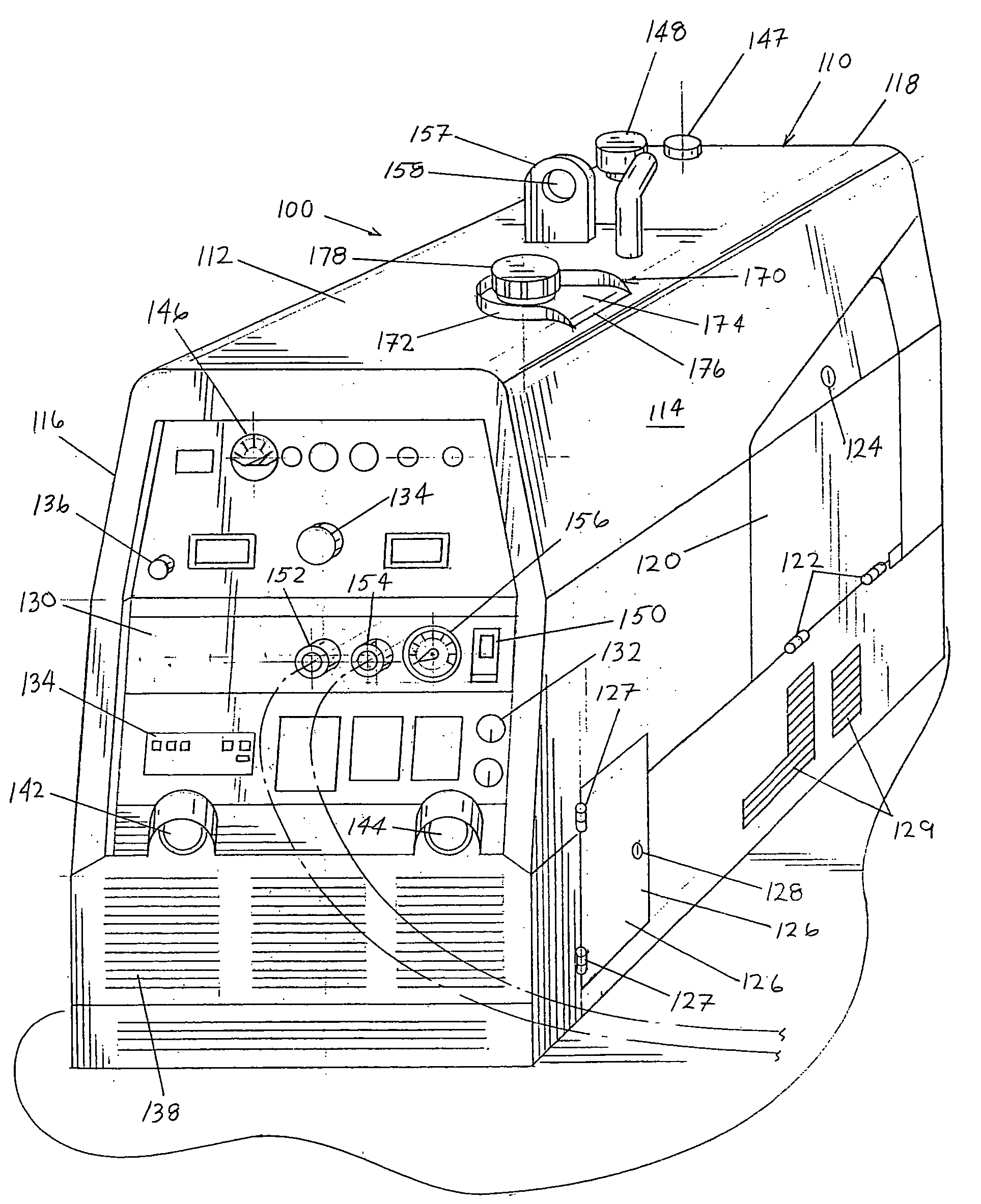

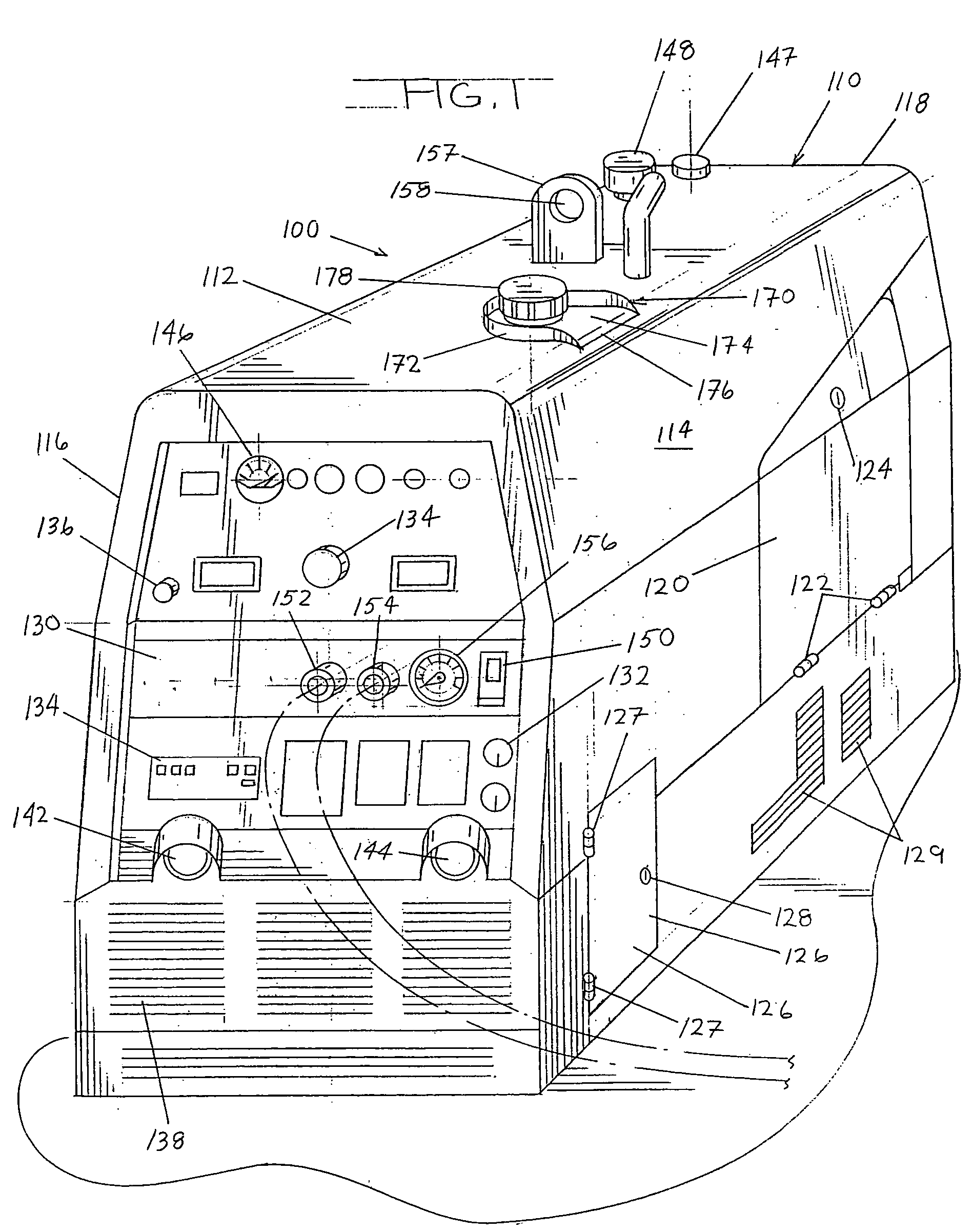

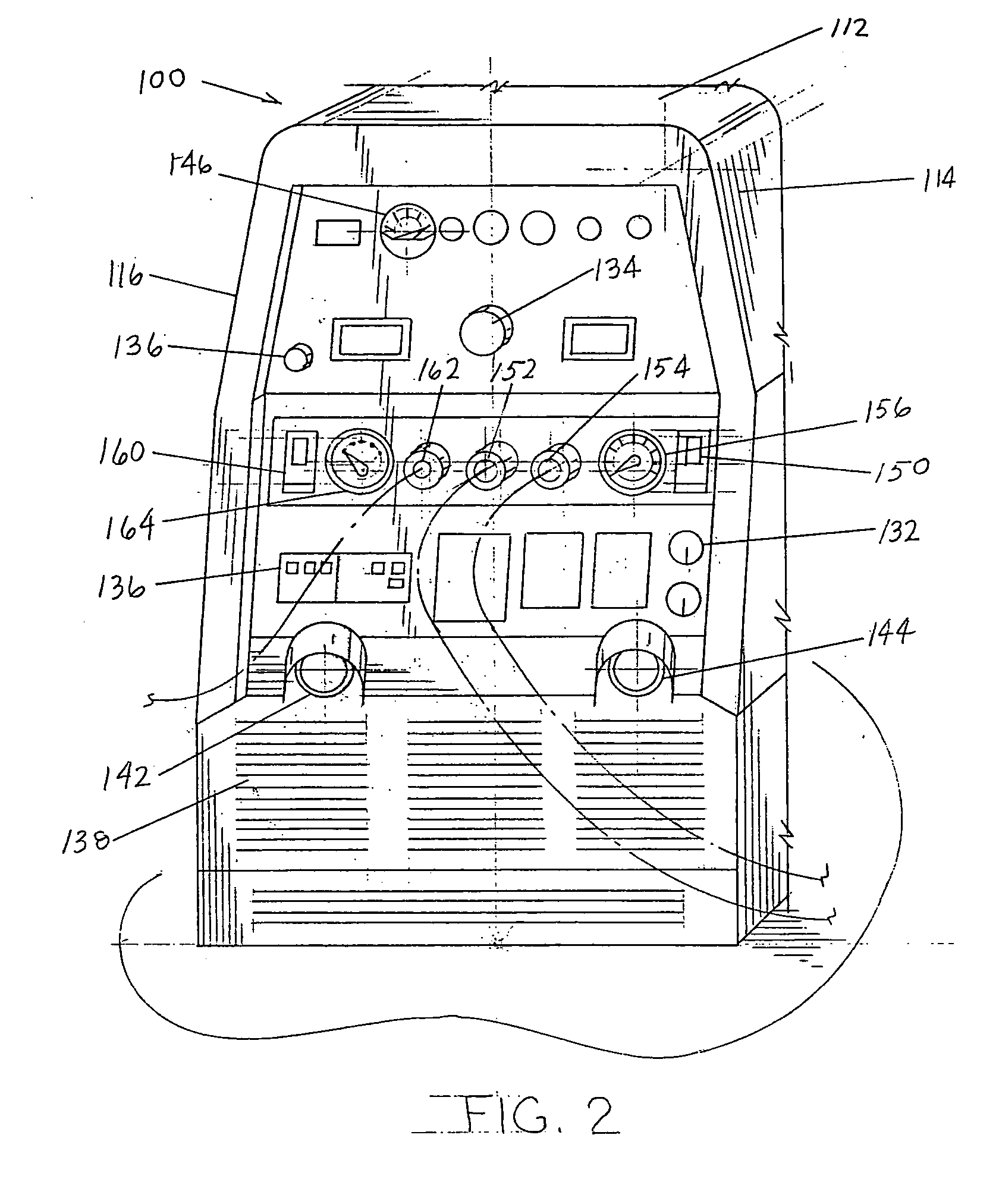

Integrated engine welder and hydraulic pump

InactiveUS20060027547A1Easy to transportImproves ease of designElectric discharge heatingWelding coupling meansHydraulic pumpAir compressor

An integrated welder, generator and hydraulic unit that includes a housing that at least partially contains components of a welder, generator and a hydraulic pump. An engine, an electric current generator, and a hydraulic pump are at least partially mounted in the housing. The electric current generator is at least partially connected to the engine to be at least partially driven thereby. The hydraulic pump can be at least partially powered by the electric current generator or the fuel powered engine during the operation of the engine. The integrated welder, generator and hydraulic unit can also include an air compressor.

Owner:LINCOLN GLOBAL INC

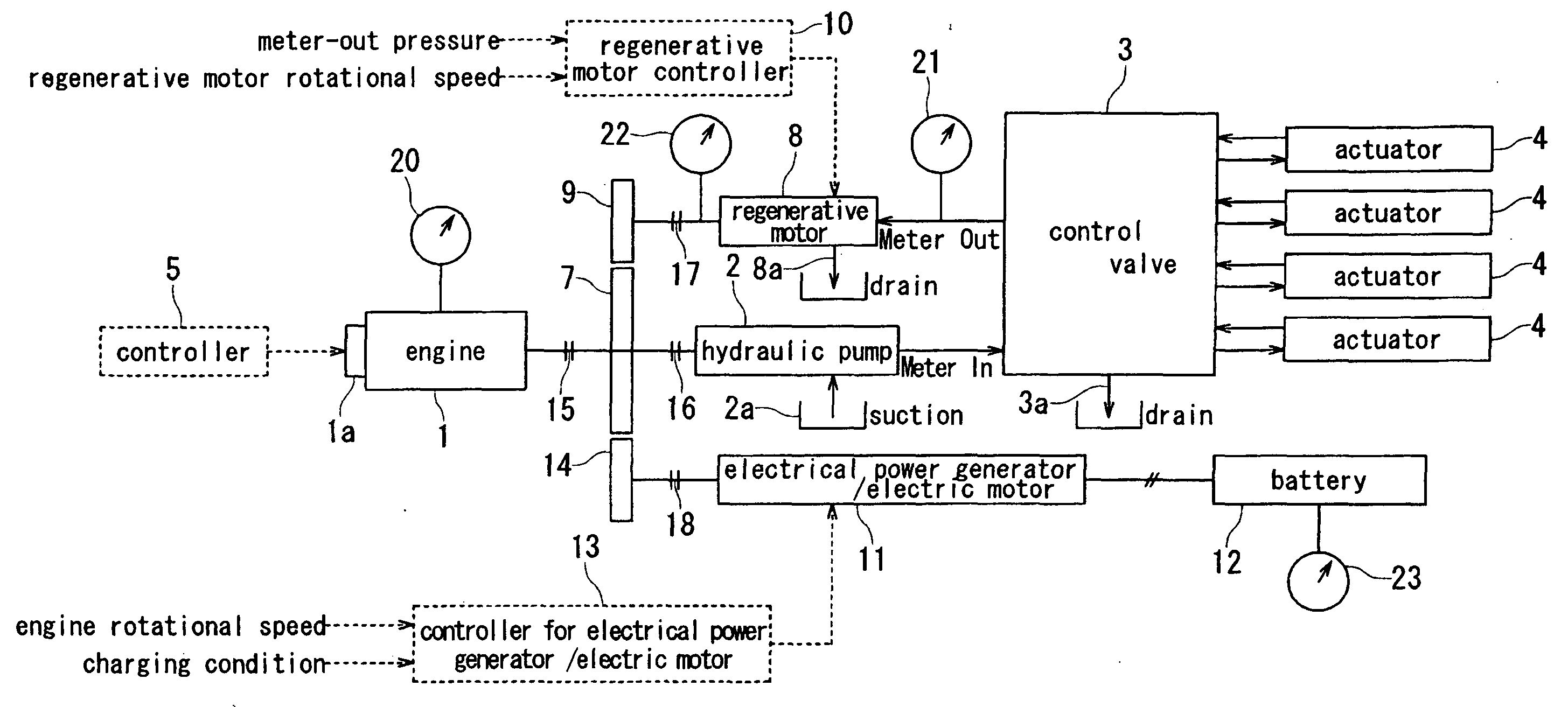

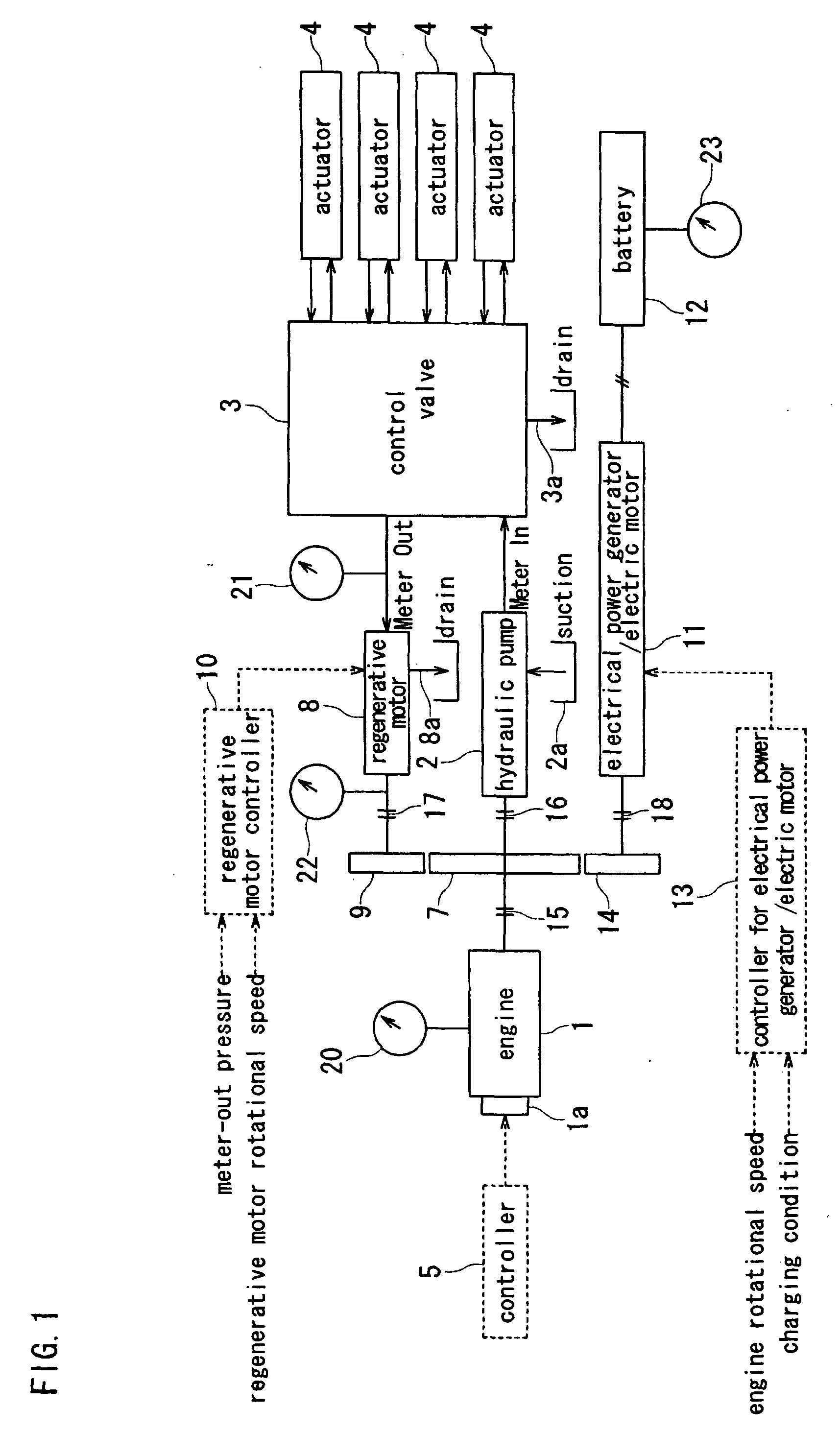

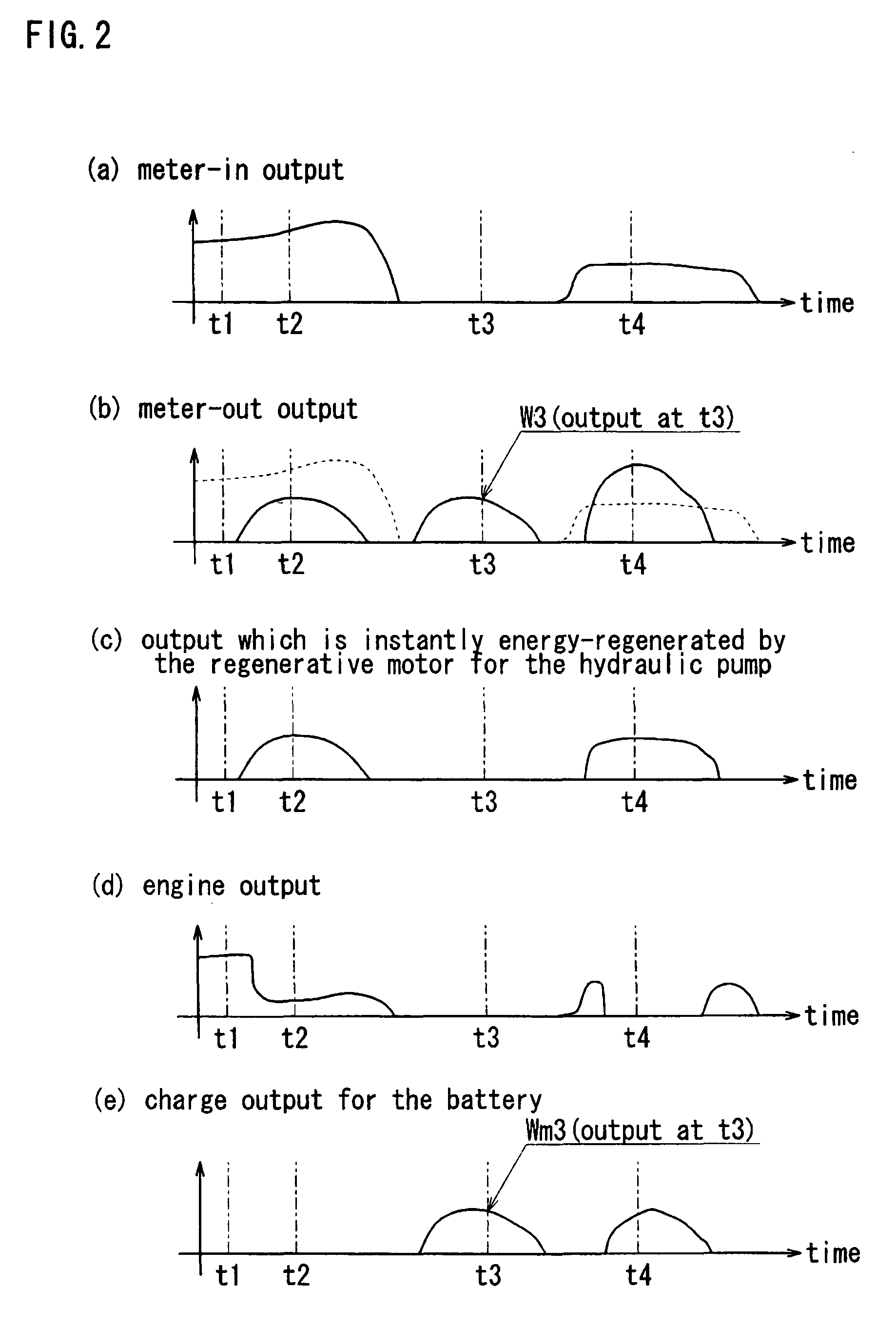

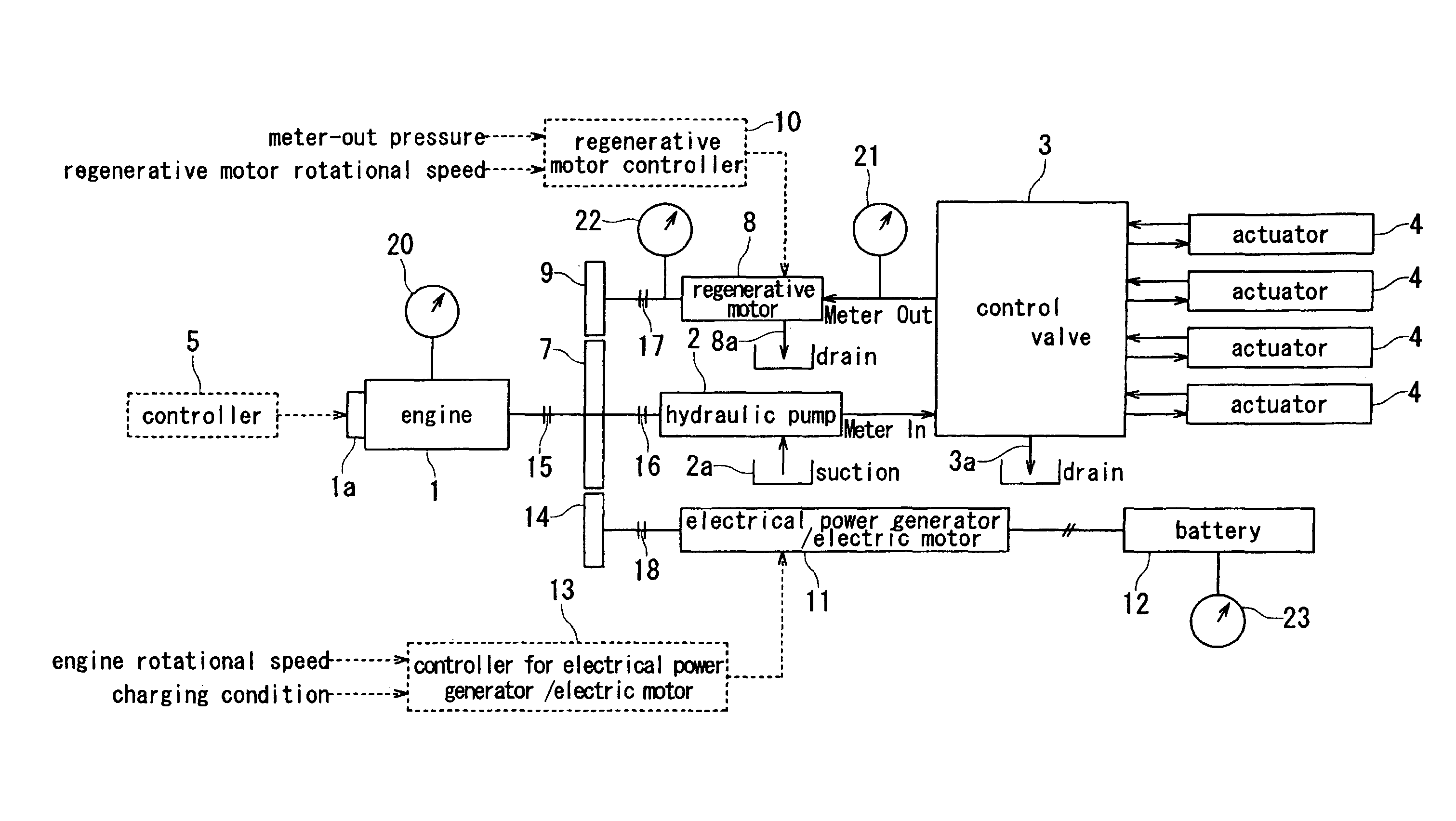

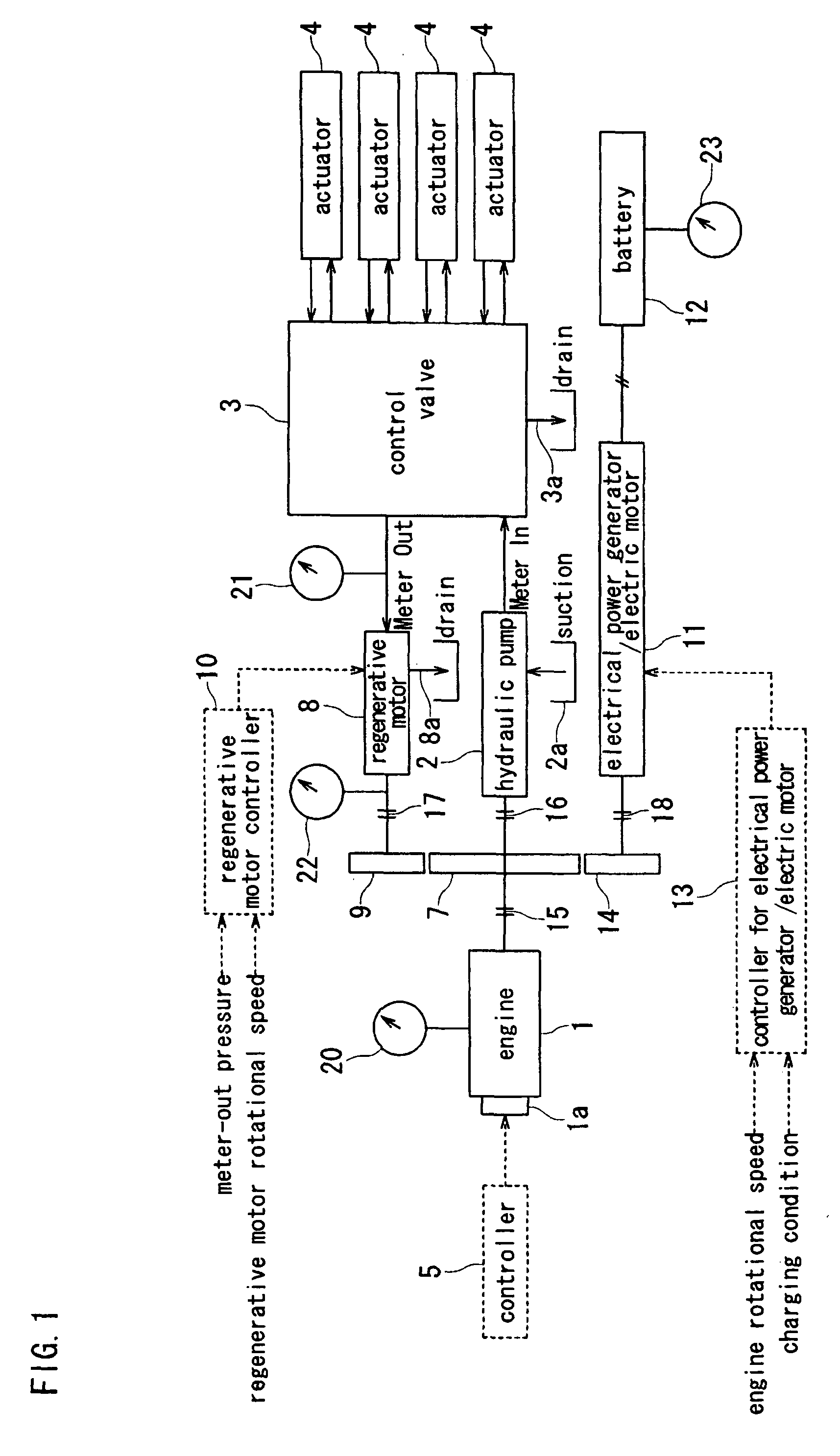

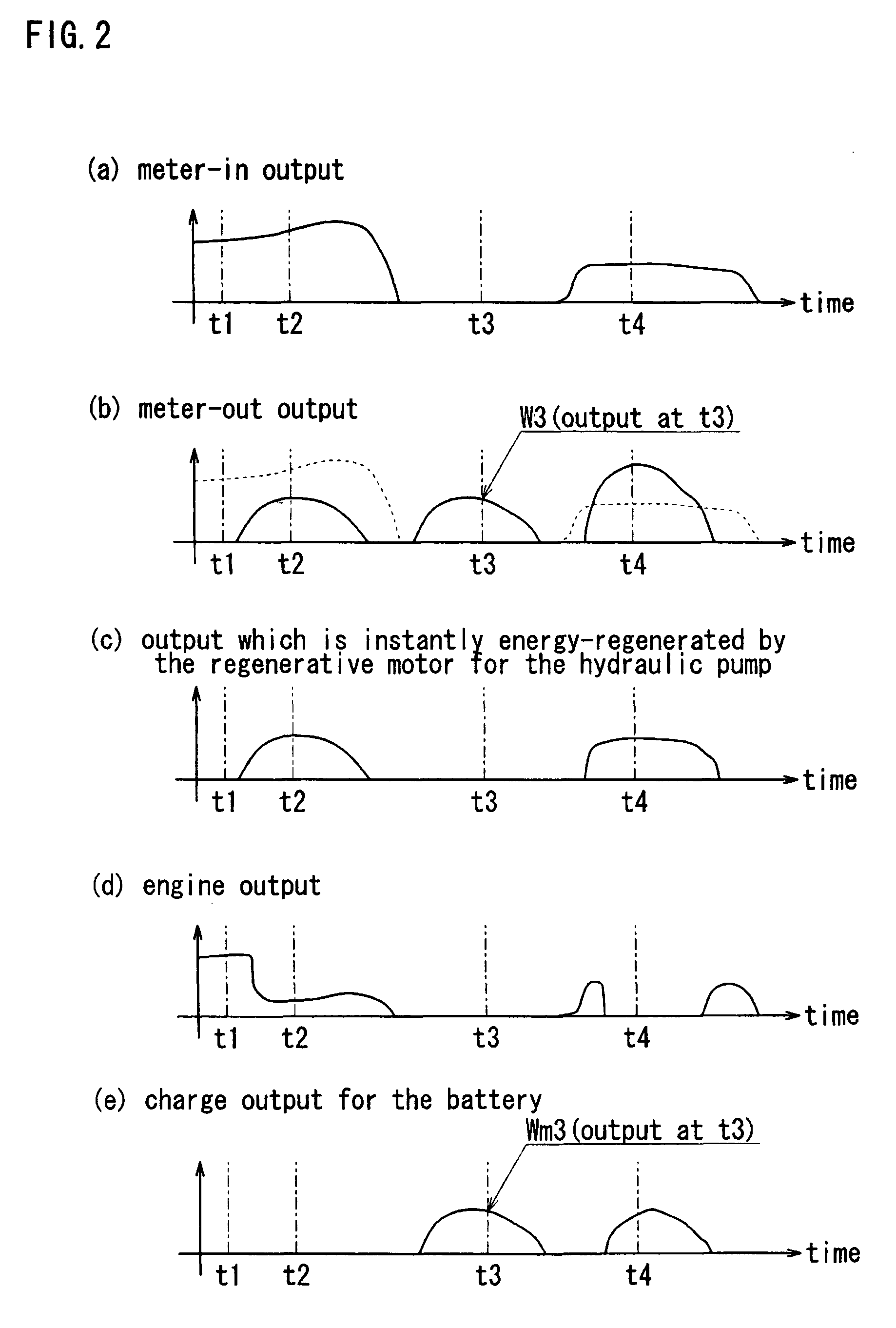

Construction machine

ActiveUS20050036894A1High electrical power generation efficiencyEfficient energy regenerationFluid couplingsMotor parameterElectricityHydraulic pump

In order to provide a construction machine by which energy regeneration can be performed reliably and battery and electrical power generator can be miniaturized, a construction machine has an engine, a hydraulic pump driven by the engine, and an actuator driven by discharge oil from the hydraulic pump, and a regenerative motor which rotates by return oil from the actuator is connected to the rotation shaft of the hydraulic pump. The hydraulic pump is driven by the engine and the regenerative motor when drive torque necessary in the hydraulic pump is larger than output torque generated by operation of the regenerative motor. Meanwhile, the hydraulic pump is driven by the regenerative motor when the drive torque of the hydraulic pump is smaller than output torque of the regenerative motor, and an electrical power generator connected to the rotation shaft of the hydraulic pump is operated to generate electricity by excess torque which has not been energy-regenerated in the hydraulic pump so that this generated electrical power is charged in a battery.

Owner:KOMATSU LTD

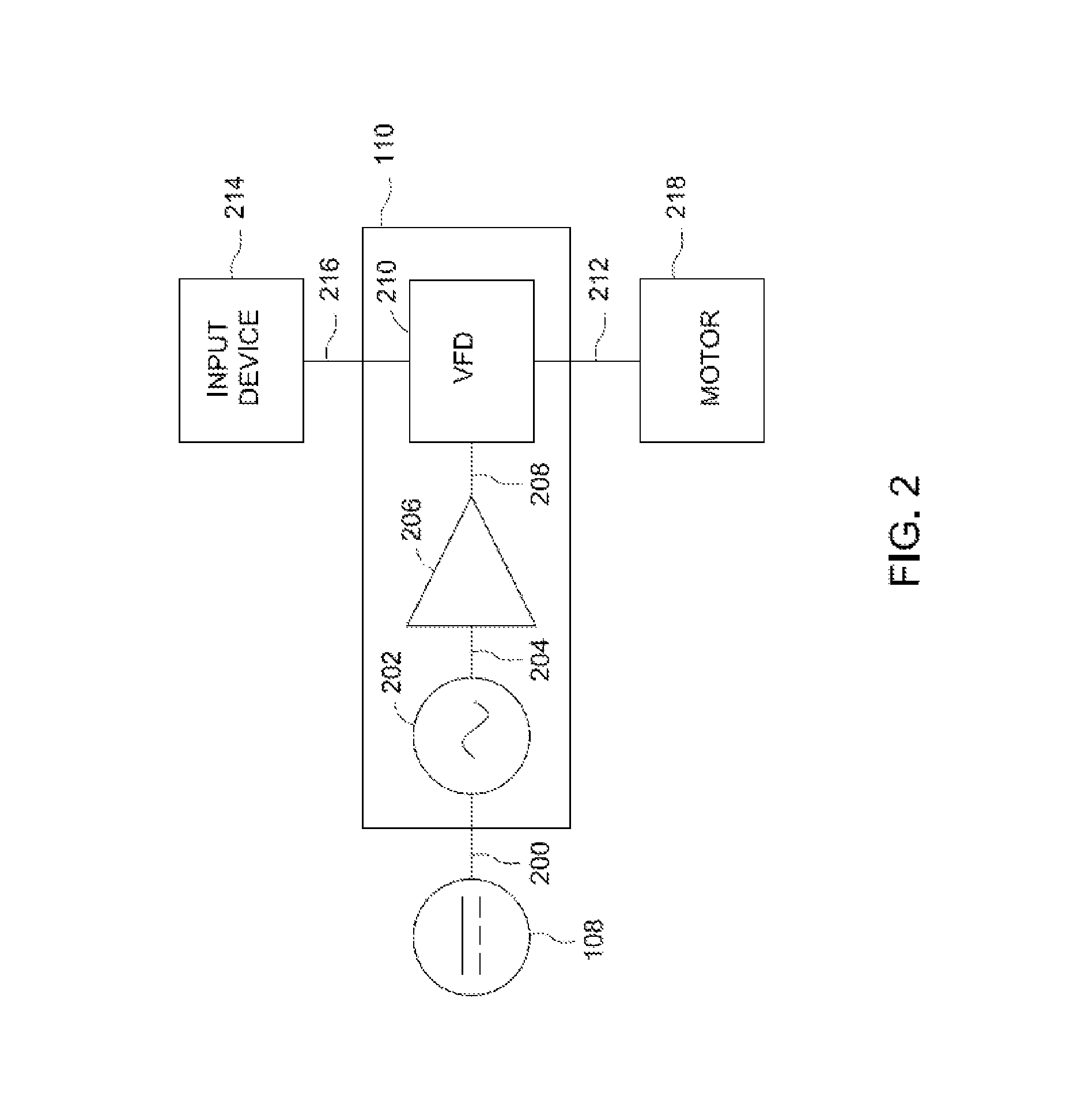

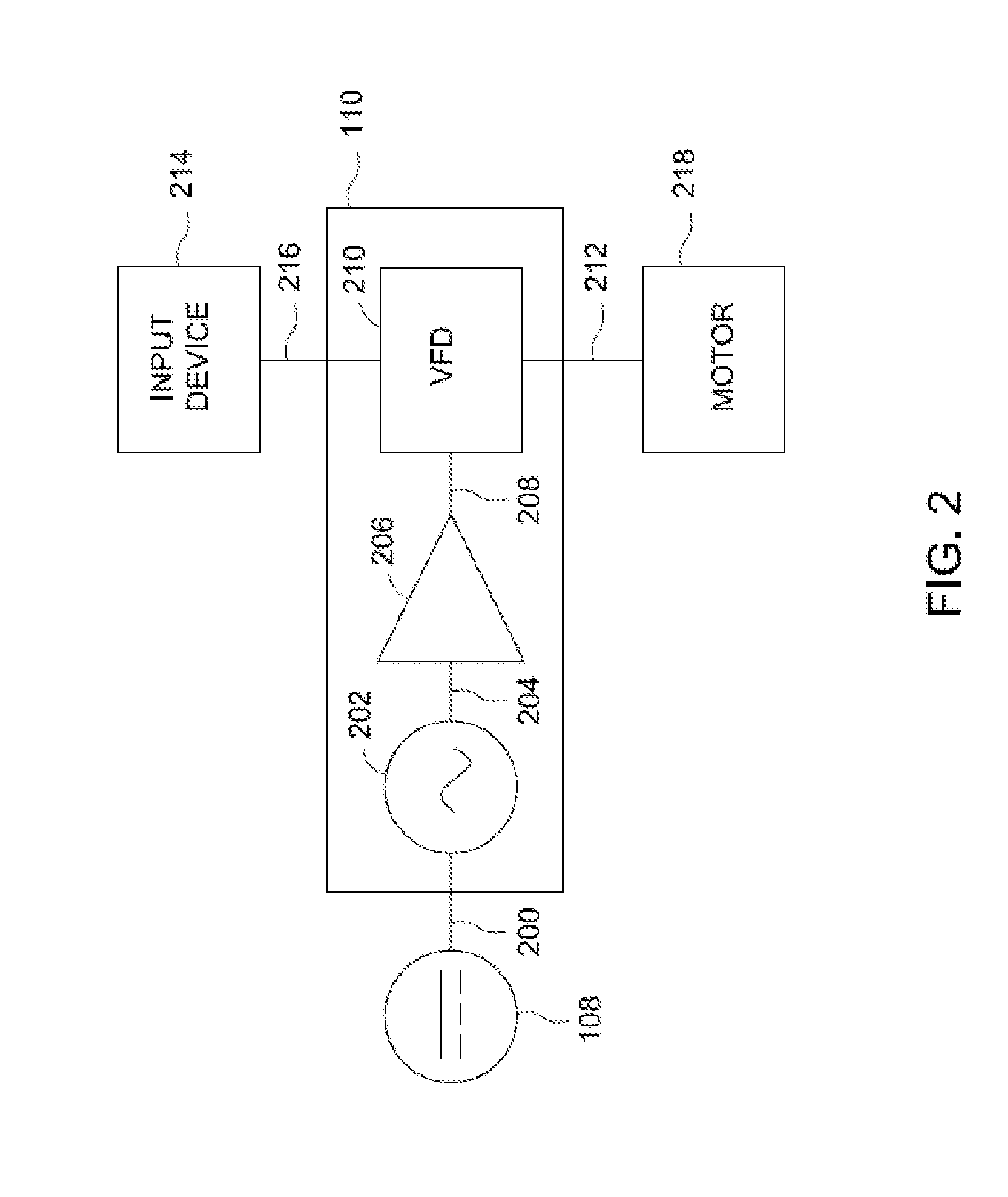

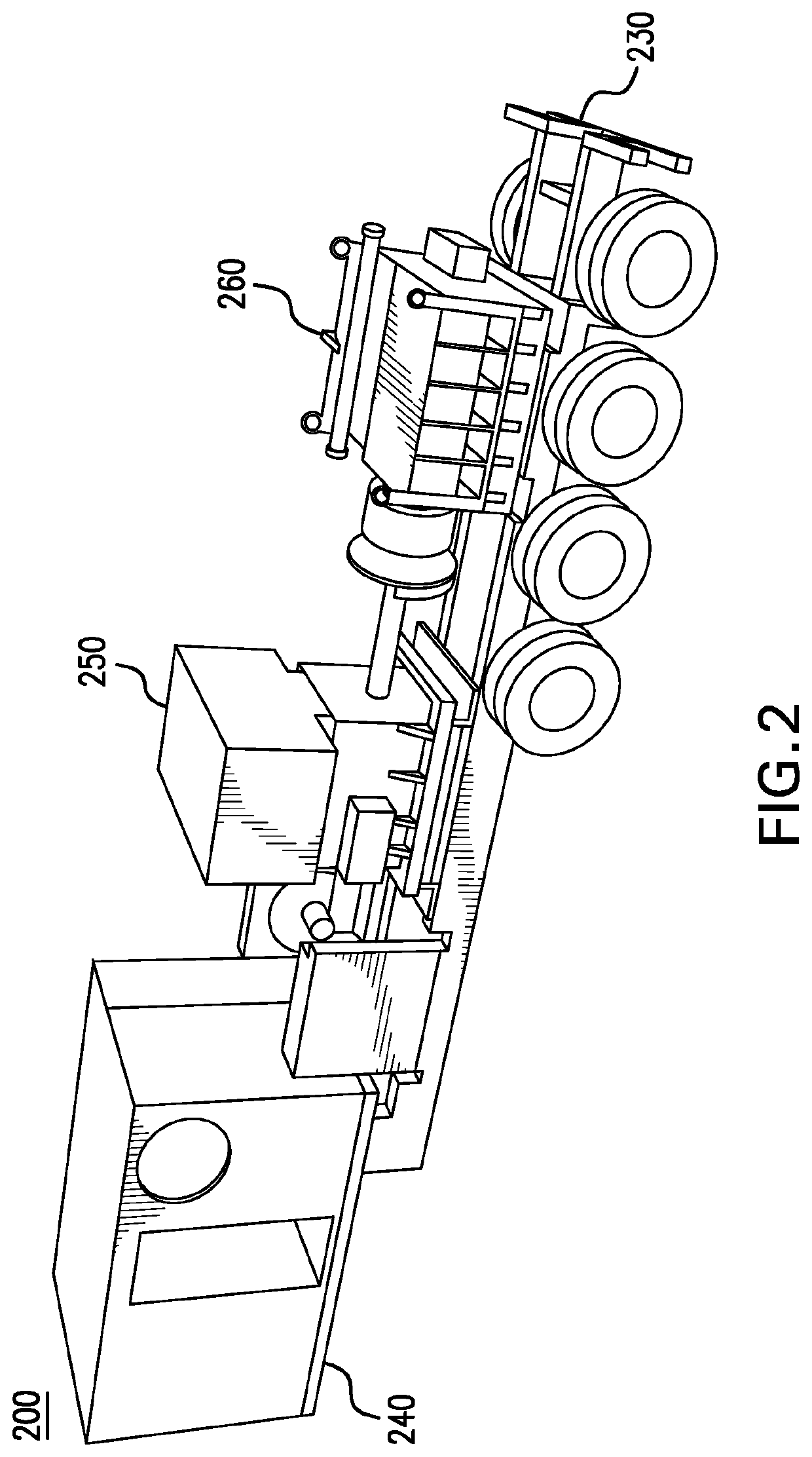

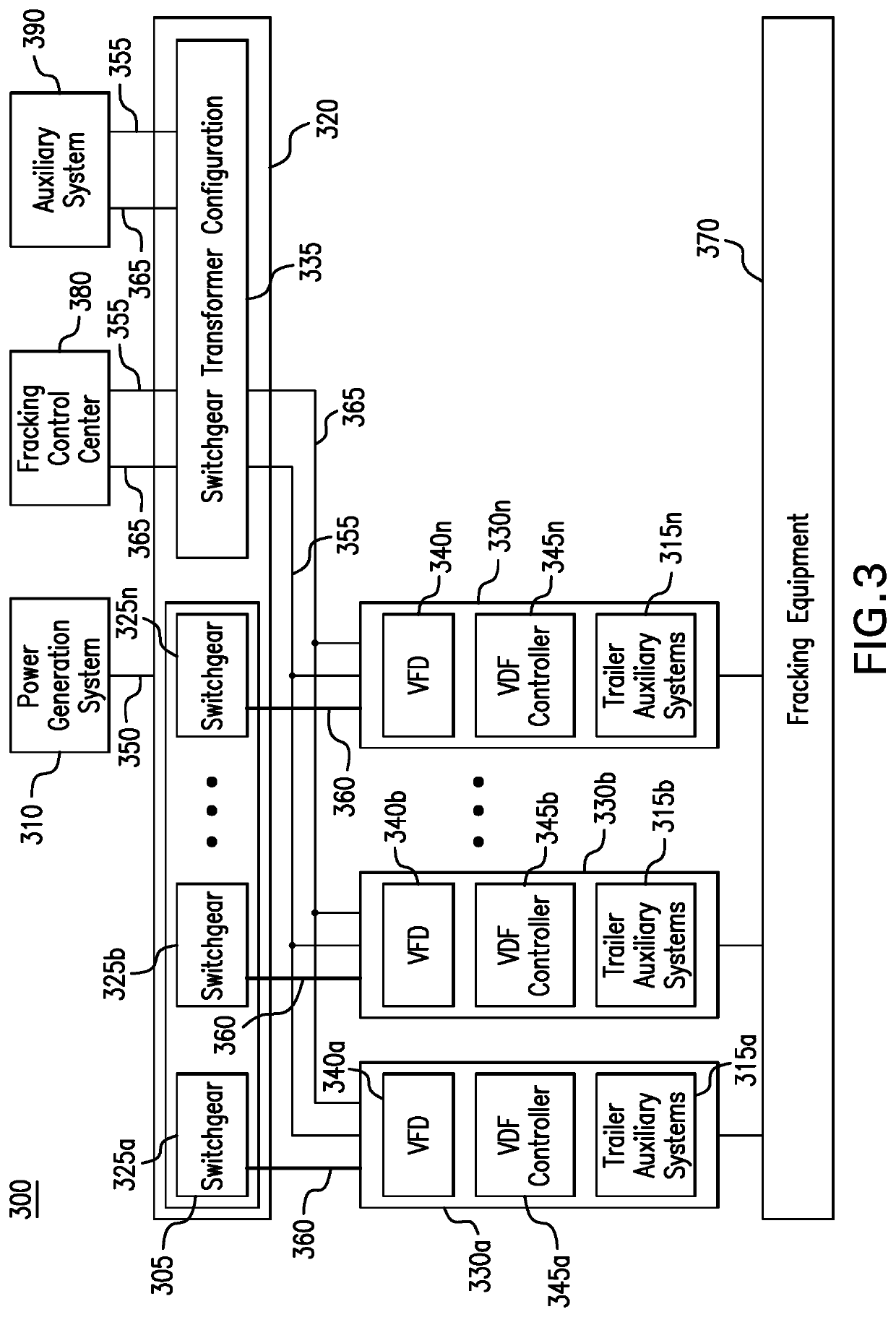

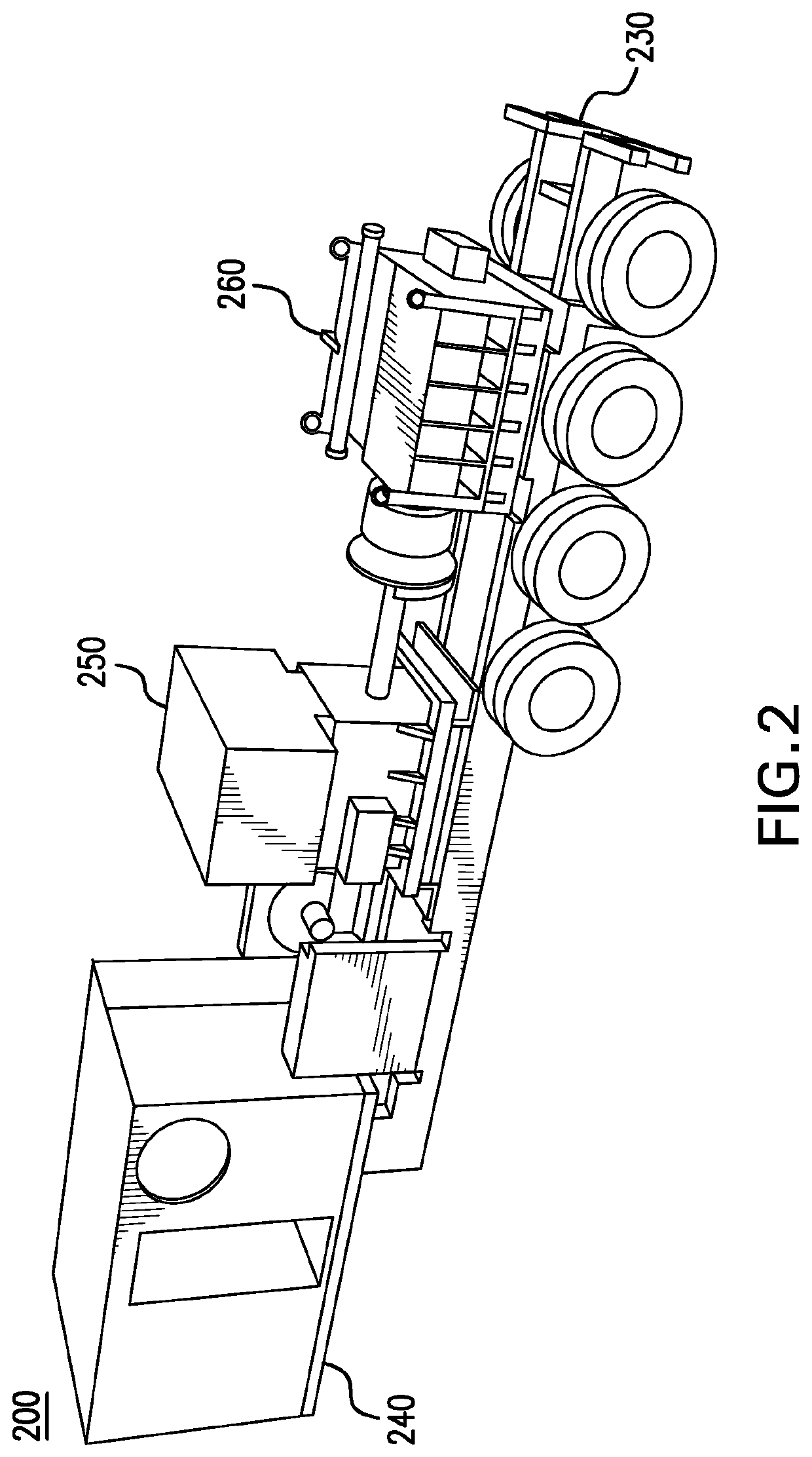

Parameter monitoring and control for an electric driven hydraulic fracking system

An electric driven hydraulic fracking system is disclosed. A pump configuration includes the single VFD, the single shaft electric motor, and the single hydraulic pump mounted on the single pump trailer. A controller associated with the single VFD and is mounted on the single pump trailer. The controller monitors operation parameters associated with an operation of the electric driven hydraulic fracking system as each component of the electric driven hydraulic fracking system operates to determine whether the operation parameters deviate beyond a corresponding operation parameter threshold. Each of the operation parameters provides an indicator as to an operation status of a corresponding component of the electric driven hydraulic fracking system. The controller initiates corrected actions when each operation parameter deviates beyond the corresponding operation threshold. Initiating the corrected actions when each operation parameter deviates beyond the corresponding operation threshold maintains the operation of the electric driven hydraulic fracking system.

Owner:HALLIBURTON ENERGY SERVICES INC

Parameter monitoring and control for an electric driven hydraulic fracking system

An electric driven hydraulic fracking system is disclosed. A pump configuration includes the single VFD, the single shaft electric motor, and the single hydraulic pump mounted on the single pump trailer. A controller associated with the single VFD and is mounted on the single pump trailer. The controller monitors operation parameters associated with an operation of the electric driven hydraulic fracking system as each component of the electric driven hydraulic fracking system operates to determine whether the operation parameters deviate beyond a corresponding operation parameter threshold. Each of the operation parameters provides an indicator as to an operation status of a corresponding component of the electric driven hydraulic fracking system. The controller initiates corrected actions when each operation parameter deviates beyond the corresponding operation threshold. Initiating the corrected actions when each operation parameter deviates beyond the corresponding operation threshold maintains the operation of the electric driven hydraulic fracking system.

Owner:NAT SERVICE ALLIANCE HOUSTON LLC

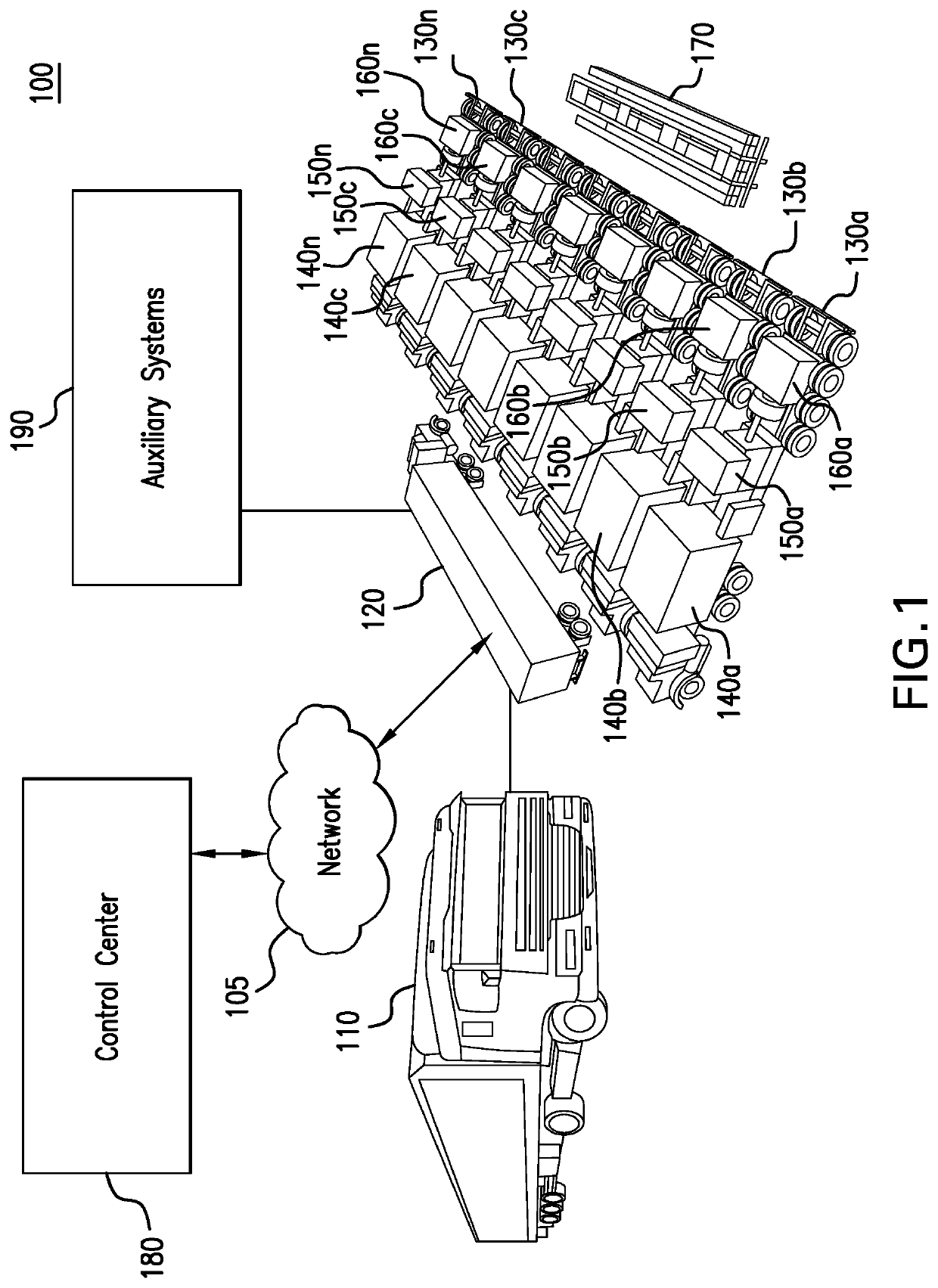

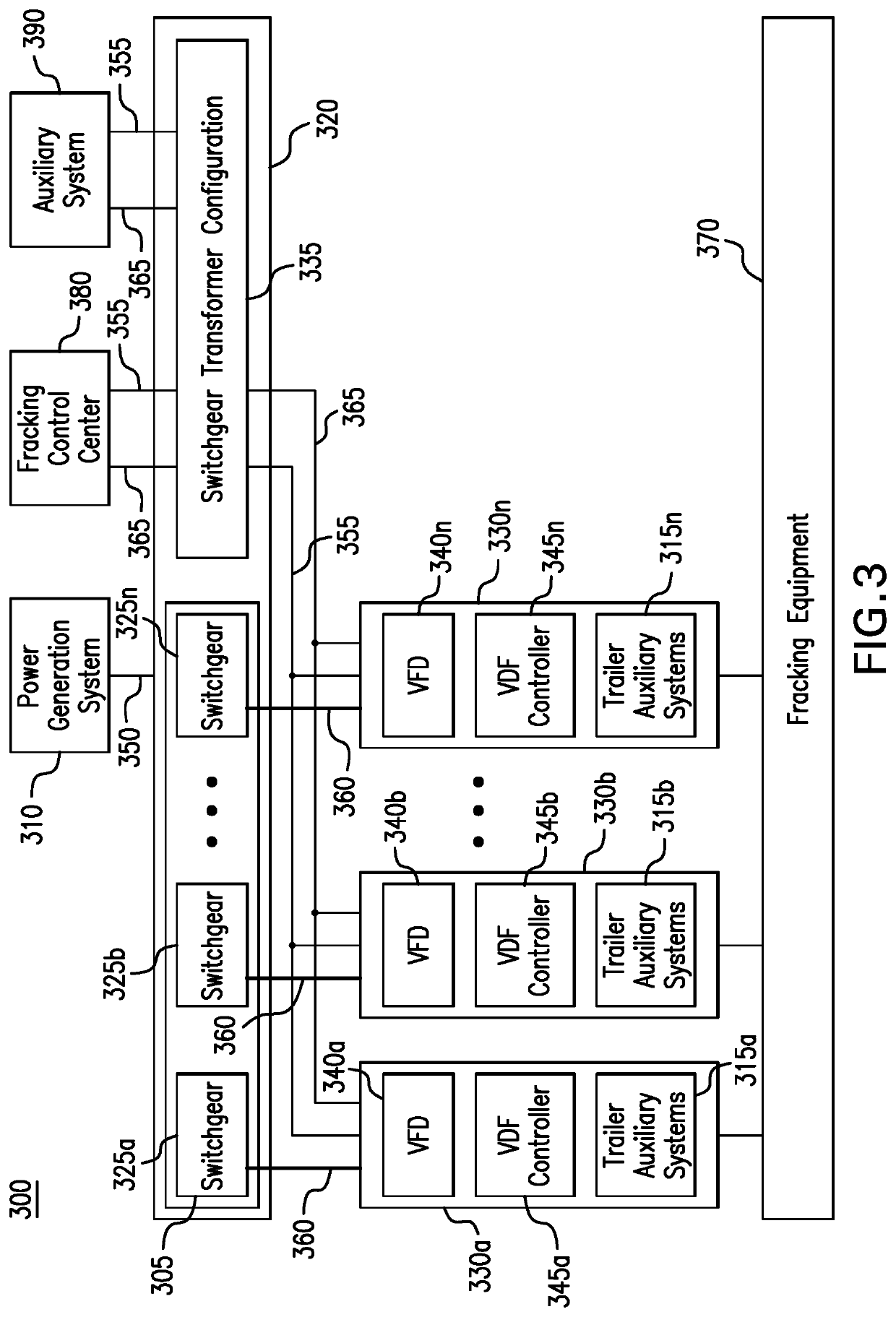

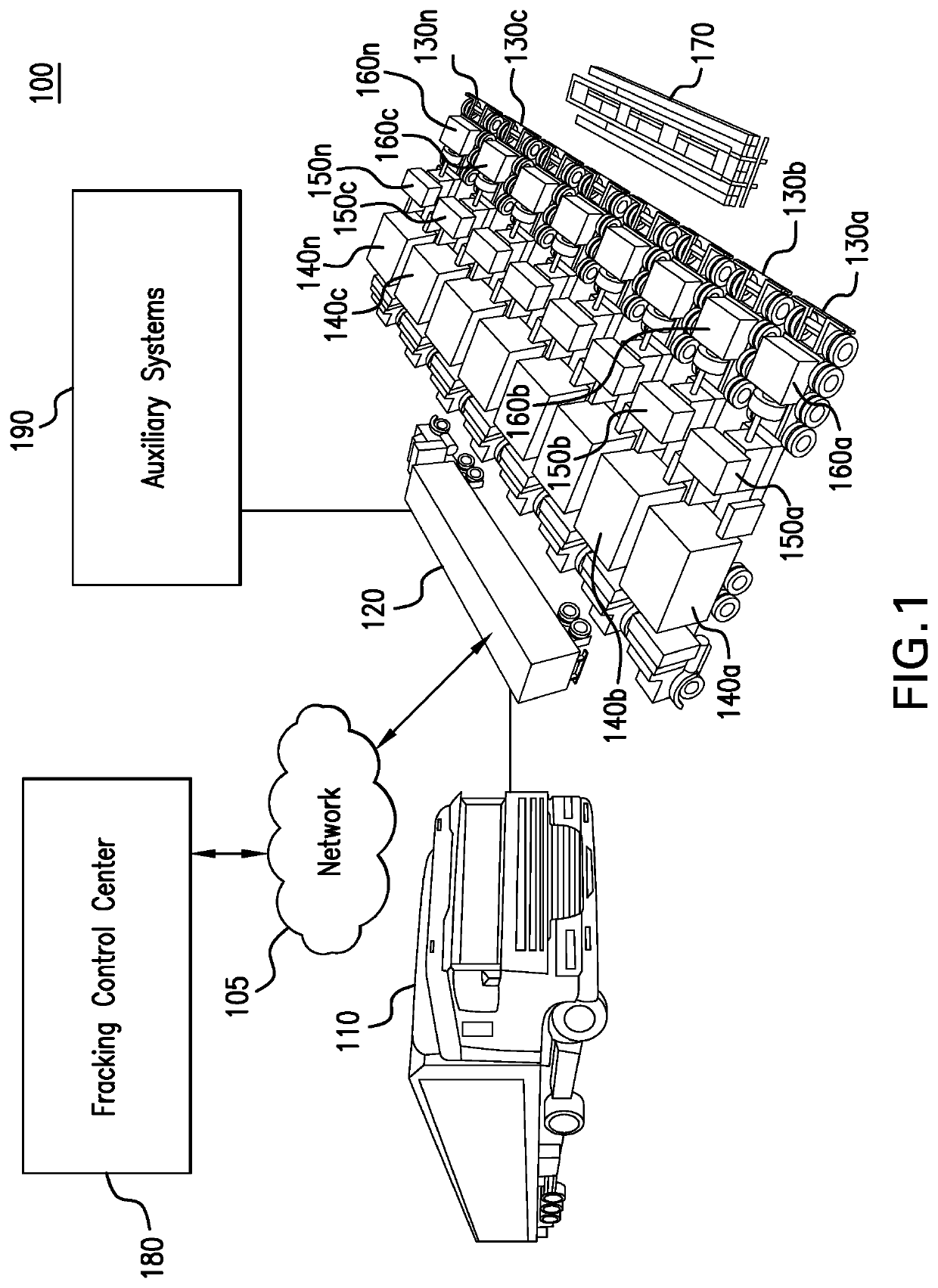

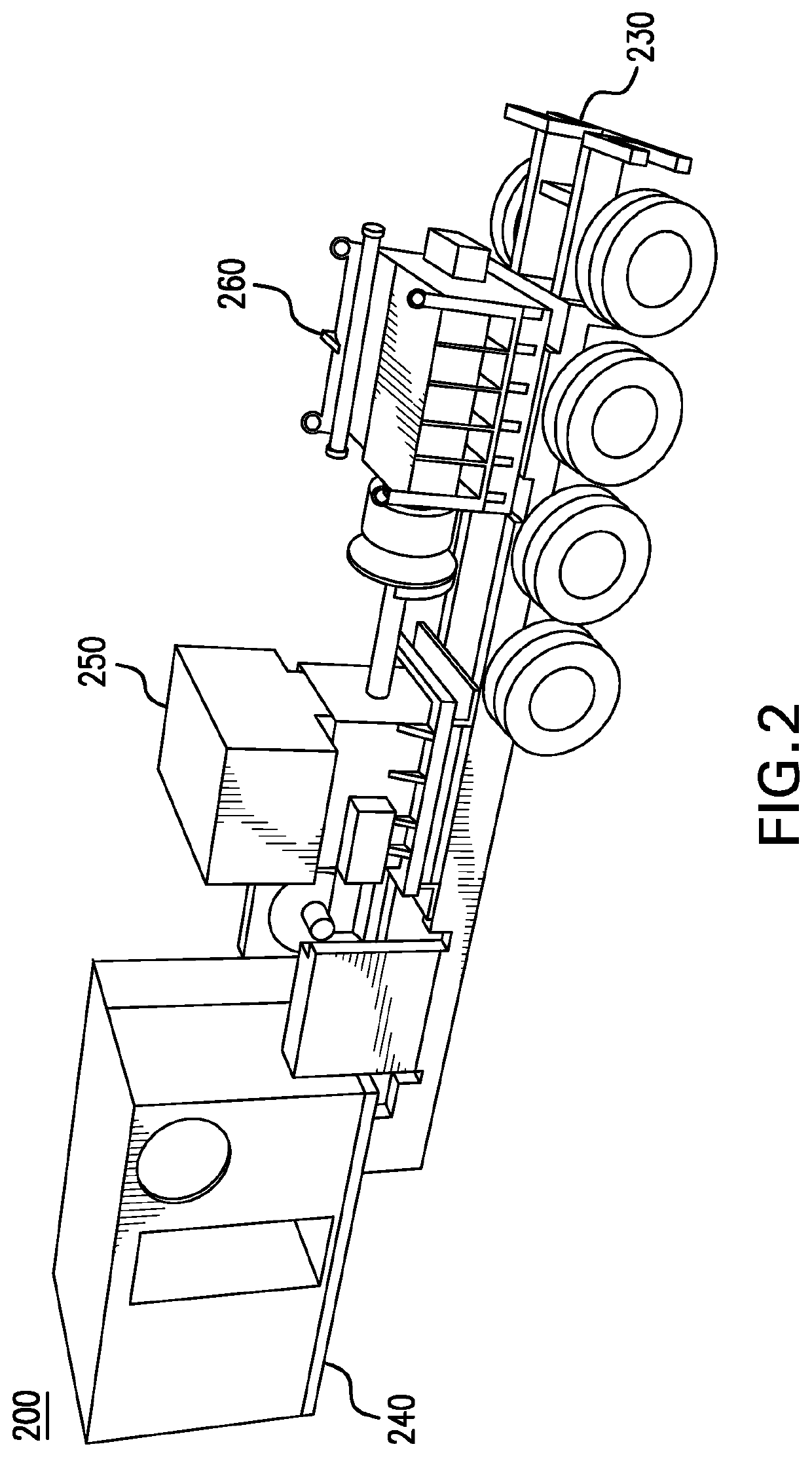

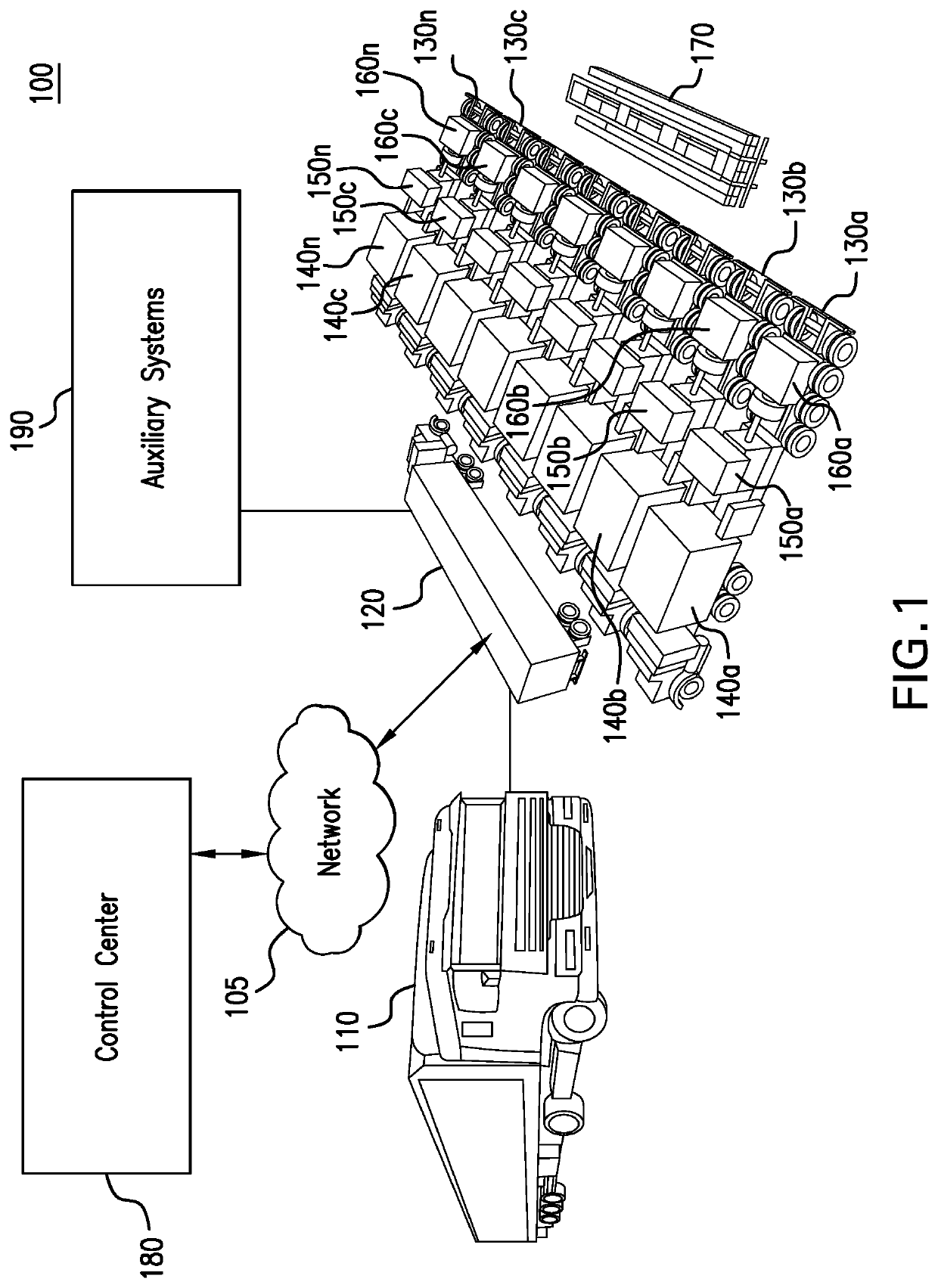

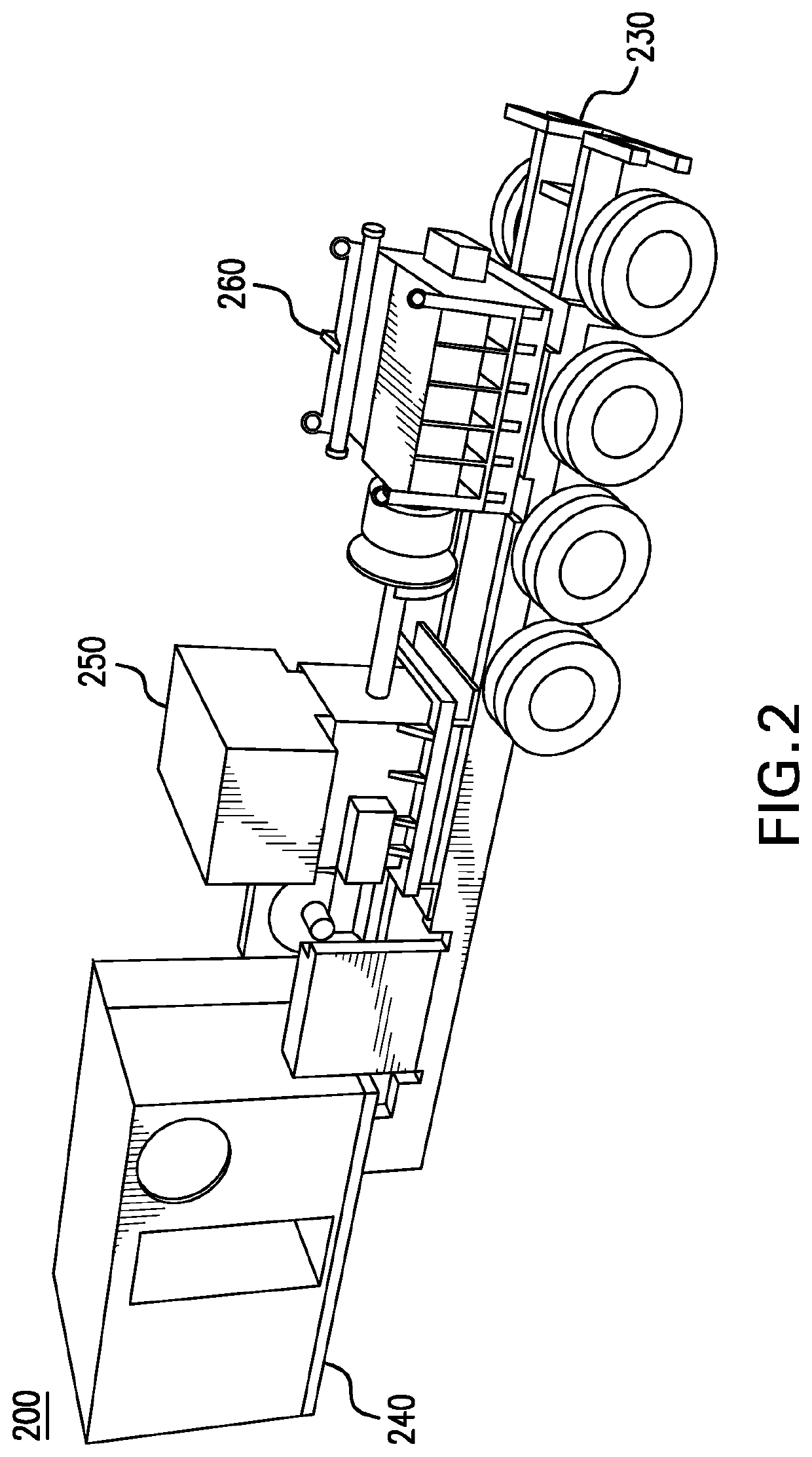

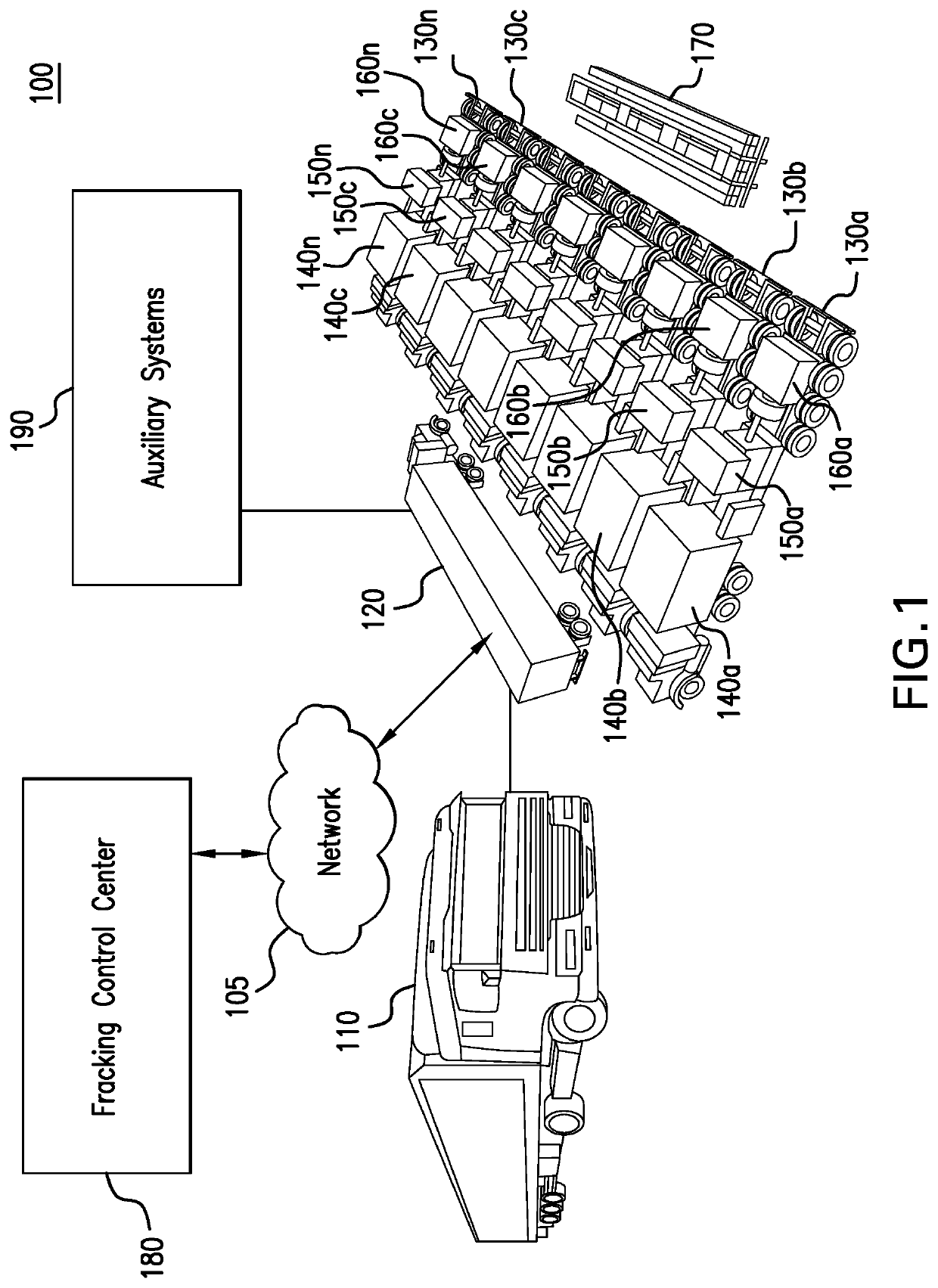

Variable frequency drive configuration for electric driven hydraulic fracking system

ActiveUS10753153B1Non-enclosed substationsSubstation/switching arrangement detailsHydraulic pumpElectric drive

An electric driven hydraulic fracking system is disclosed. A pump configuration that includes the single VFD, the single shaft electric motor, and the single hydraulic pump that is mounted on the single pump trailer. A pump configuration includes a single VFD configuration, the single shaft electric motor, and the single shaft hydraulic pump mounted on the single pump trailer. The single VFD configuration converts the electric power at the power generation voltage level distributed from the power distribution trailer to a VFD voltage level and drives the single shaft electric motor to control the operation of the single shaft electric motor and the single hydraulic pump. The VFD voltage level is a voltage level that is required to drive the single shaft electric motor. The VFD configuration also controls operation of the auxiliary systems based on the electric power at the auxiliary voltage level.

Owner:HALLIBURTON ENERGY SERVICES INC

Power distribution trailer for an electric driven hydraulic fracking system

ActiveUS20200263527A1Non-enclosed substationsSubstation/switching arrangement detailsHydraulic pumpElectro hydraulic

An electric driven hydraulic fracking system is disclosed. A pump configuration that includes the single VFD, the single shaft electric motor, and the single hydraulic pump that is mounted on the single pump trailer. A power distribution trailer distributes the electric power generated by the power generation system at the power generation voltage level to the single VFD and converts the electric power at a power generation voltage level to a VFD voltage level and controls the operation of the single shaft electric motor and the single hydraulic pump. The power distribution trailer converts the electric power generated by the power generation system at the power generation level to an auxiliary voltage level that is less than the power generation voltage level. The power distribution trailer distributes the electric power at the auxiliary voltage level to the single VFD that controls an operation of the of the auxiliary systems.

Owner:NAT SERVICE ALLIANCE HOUSTON LLC

Electric driven hydraulic fracking system

ActiveUS10738580B1Non-enclosed substationsSubstation/switching arrangement detailsHydraulic pumpElectro hydraulic

An electric driven hydraulic fracking system is disclosed. A pump configuration that includes the single VFD, the single shaft electric motor, and the single hydraulic pump that is mounted on the single pump trailer. The single VFD converts the electric power of at least 13.8 kV to a VFD rated voltage level of at least 4160V and drives the single shaft electric motor at the VFD voltage level of up to 4160V to control the operation of the single shaft electric motor and the single hydraulic pump. The single shaft electric motor drives the single hydraulic pump with the rotation at the rated RPM level of at least 750 RPM. The single hydraulic pump continuously pumps the fracking media into the well at the HP level of at least 5000 HP. The single hydraulic pump operates on a continuous duty cycle to continuously pump the fracking media at the HP level of at least 5000 HP.

Owner:NAT SERVICE ALLIANCE HOUSTON LLC

Electric driven hydraulic fracking system

Owner:HALLIBURTON ENERGY SERVICES INC

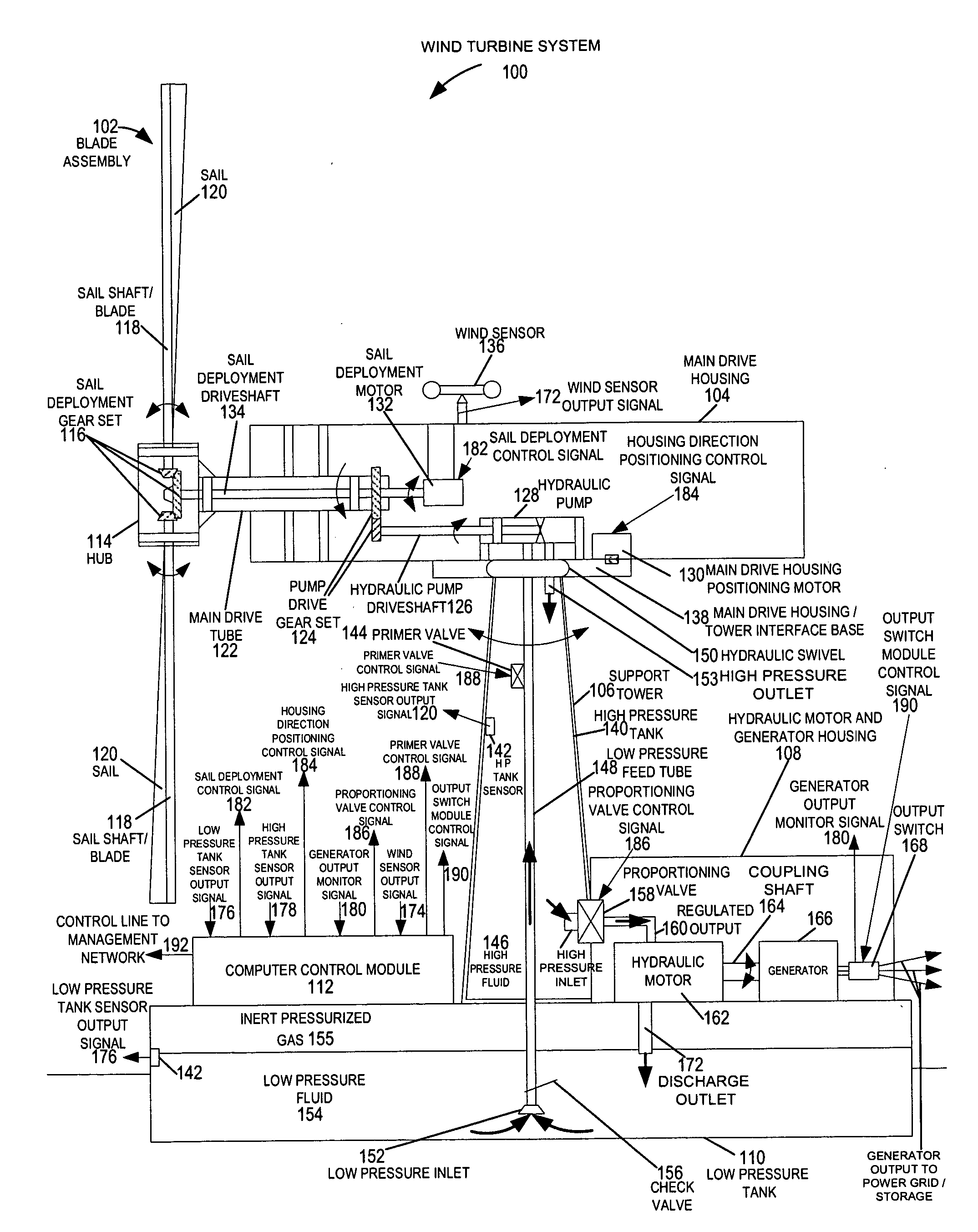

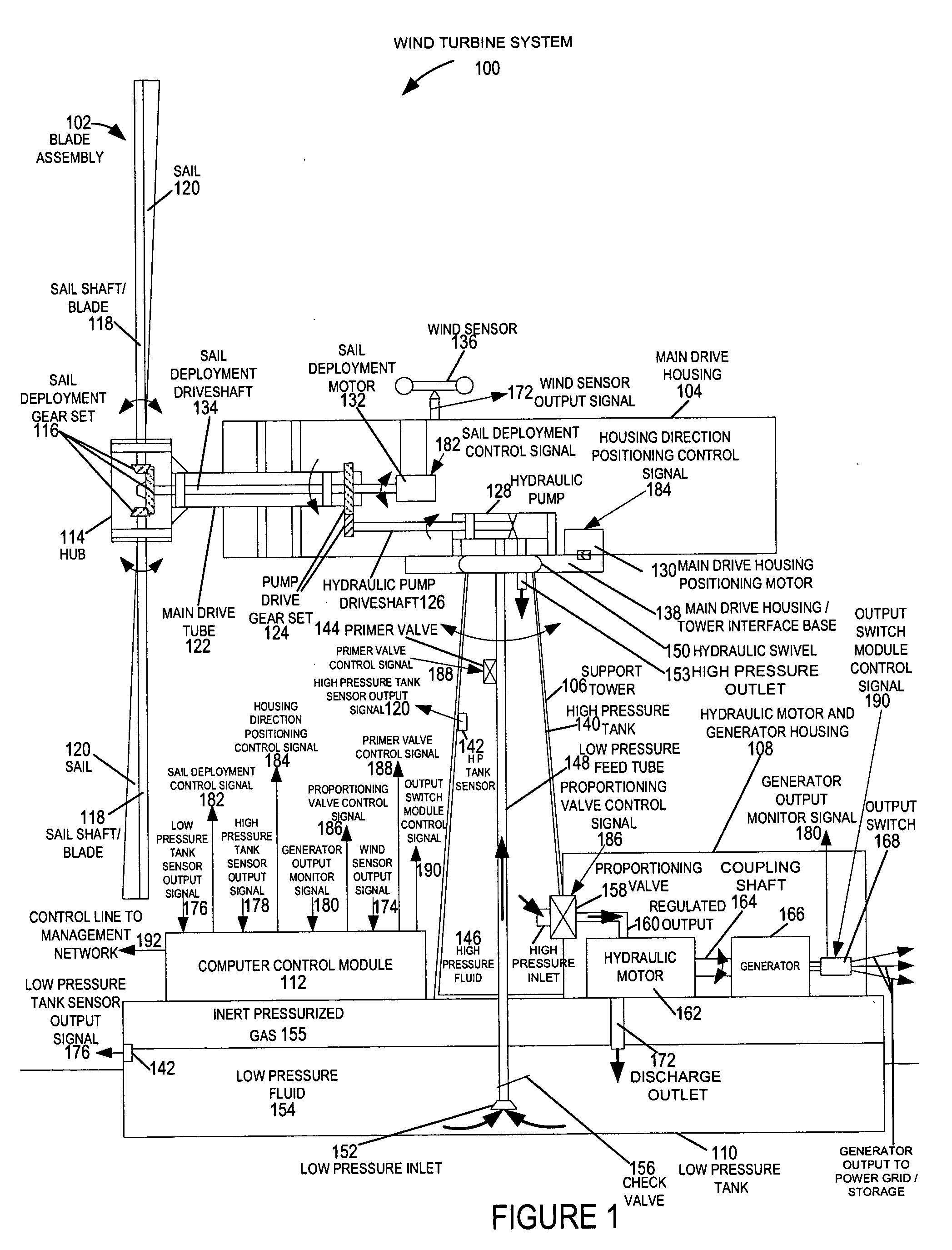

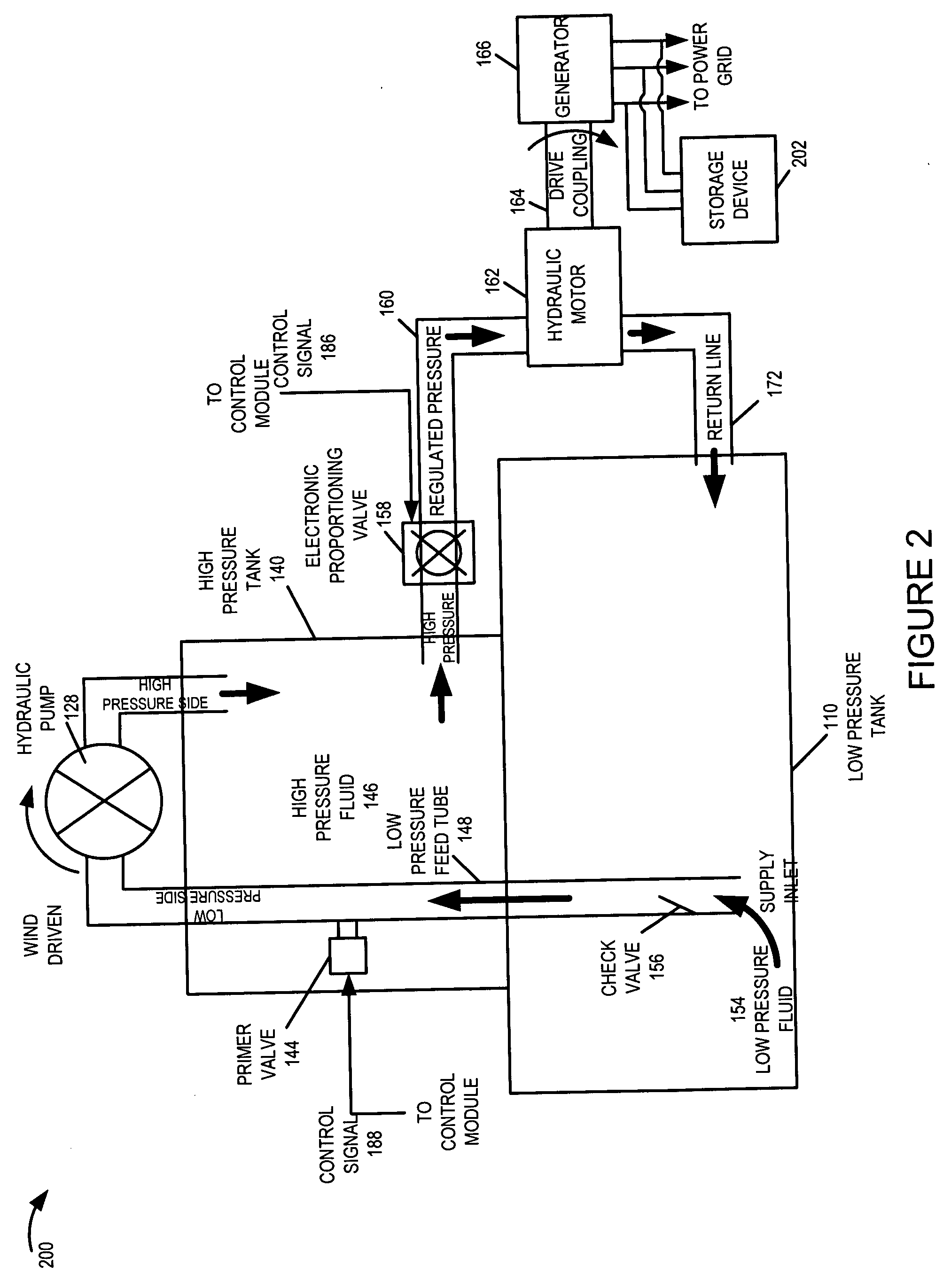

Methods and apparatus for advanced wind turbine design

ActiveUS20070024058A1Eliminate needReduced pressure levelWind motor controlEngine fuctionsHigh energyHydraulic pump

A wind turbine system includes a variable blade assembly including adjustable sails and wing shaped masts expanding the wind velocity capture envelope. The blade assembly turns a hydraulic pump, which pressurizes fluid and stores the pressurized fluid in a chamber in the support tower. Pressurized fluid is directed via an electronically controllable proportioning valve to a hydraulic motor which is coupled to an electric generator. A computer control module operates the proportioning valve regulating pressure to the hydraulic motor, maintaining generator rotational speed, and providing consistent output frequency to the power grid. Stored energy in the high pressure tank is used to continue generator operation after the winds cease, allowing early warning notification to the power management system of impending power loss. Residual pressure maintained in the high pressure tank allows restart operations via hydraulic pressure rather than power grid energy drain. On site high energy capacitors store additional energy.

Owner:MCCLINTIC FRANK

Well service pump power system and methods

A well service pump system supplies high pressure working fluid to a well. The pump system is a linear design which incorporates an electric motor, a variable frequency drive (VFD), a pump drive, closed loop variable flow rate hydraulic pumps, hydraulic ram cylinders, working fluid end cylinders, and a coupling to connect the hydraulic ram cylinders and the working fluid end cylinders. The electric motor powers the hydraulic system which, in turn, provides hydraulic fluid to operate the hydraulic ram cylinders. The VFD is connected to a single one of the hydraulic pumps at a time and applies power to the connected pump, via the pump drive, to drive the connected pump from a cold start to an operating speed. The VFD is connected sequentially, one pump at a time, to each of the hydraulic pumps and disconnected from each pump once the pump reaches the operating speed. Once the pump reaches operating speed, the pump is connected to receive power directly to the electric motor.

Owner:AMERIFORGE GRP

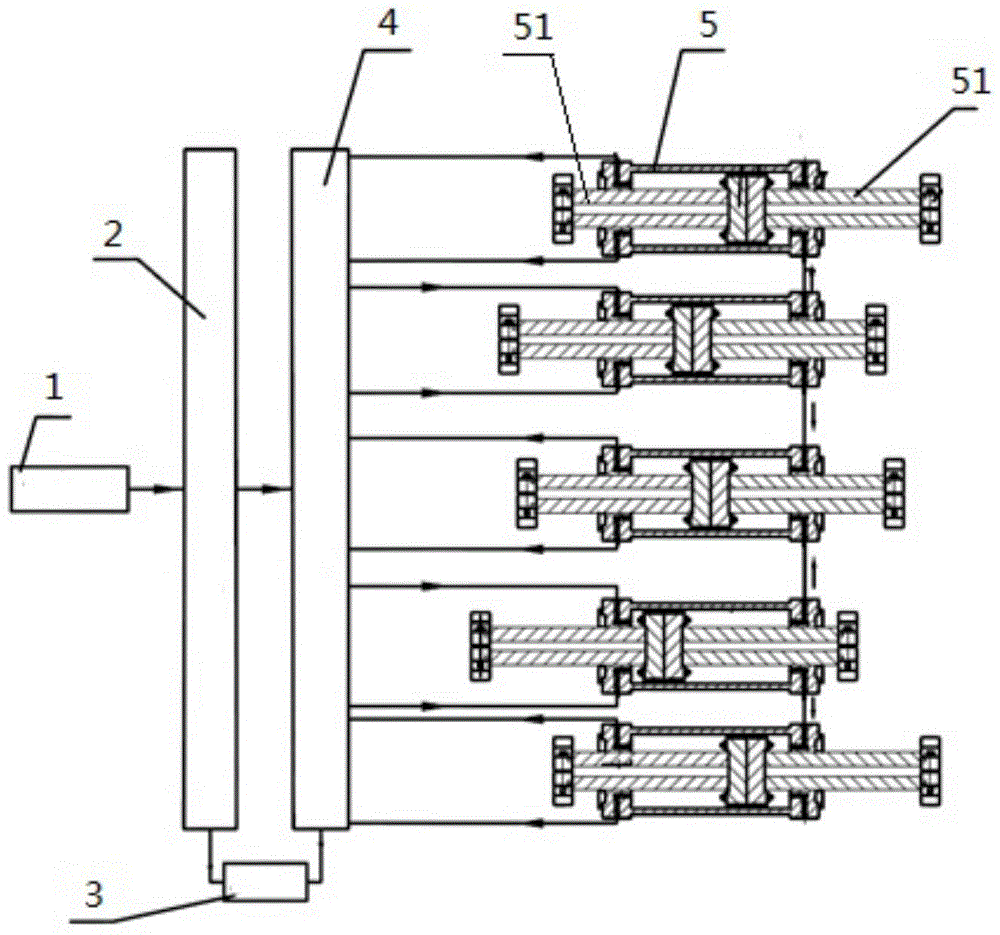

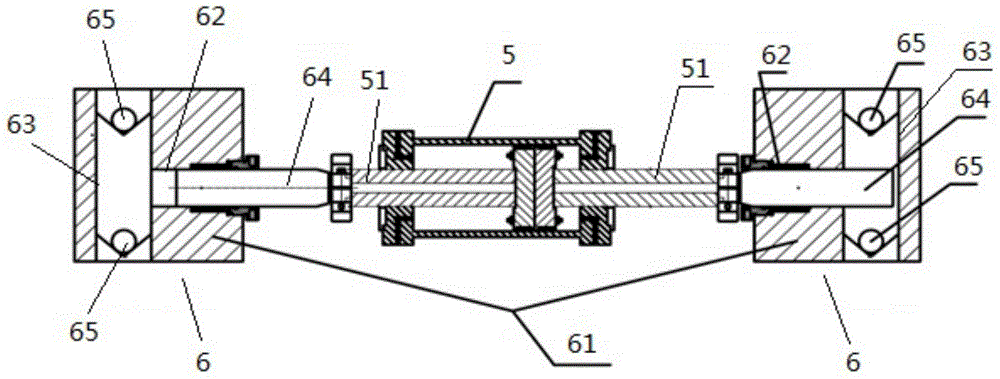

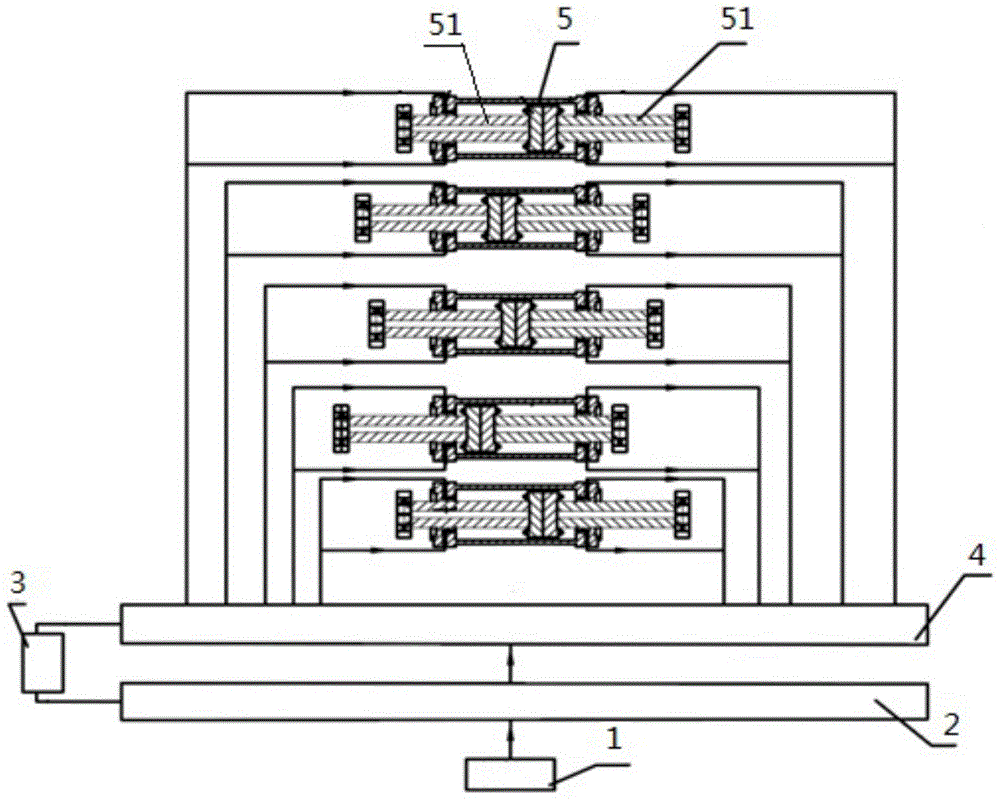

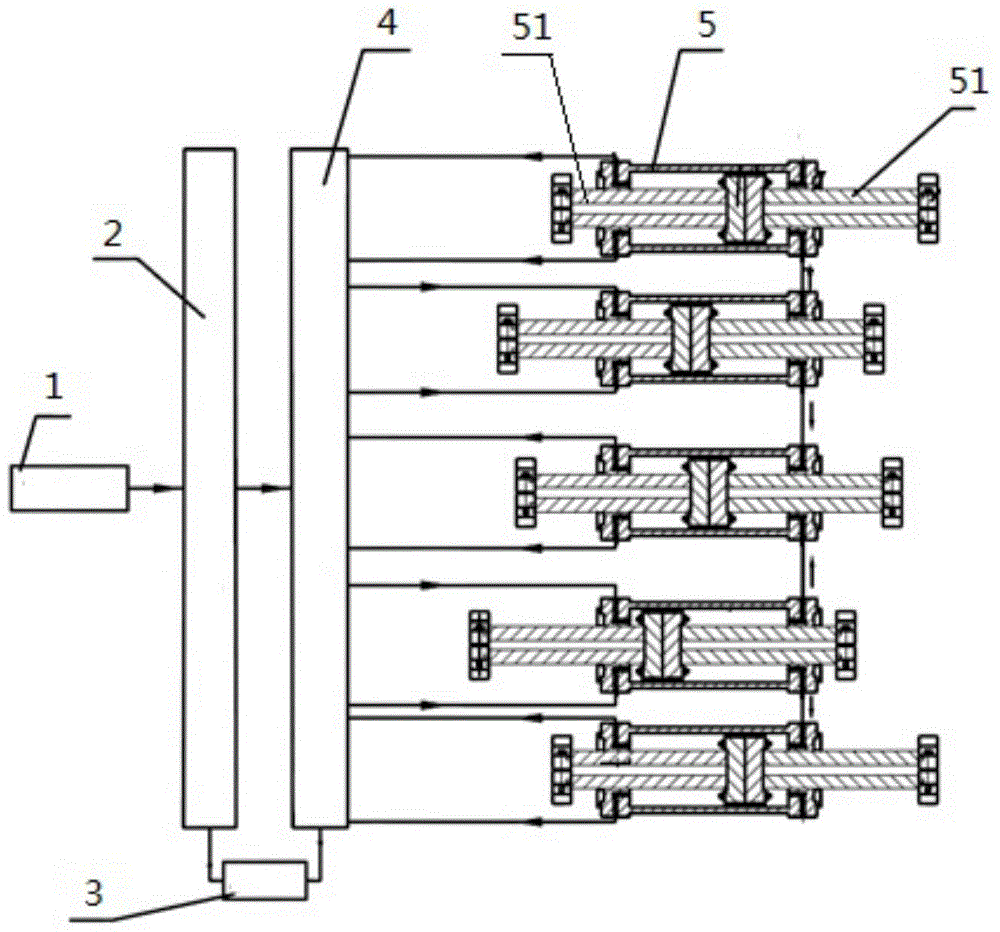

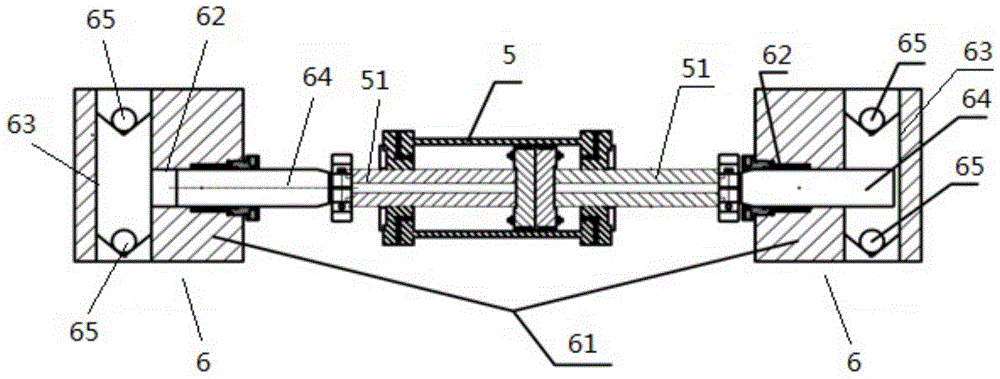

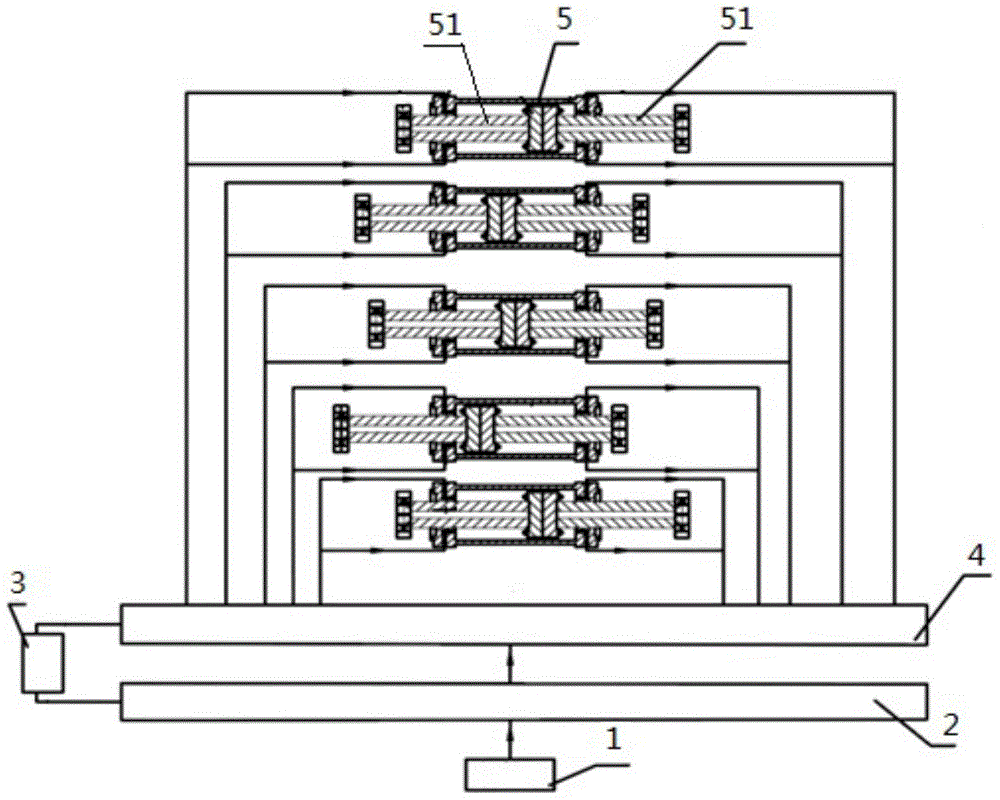

Hydraulic bidirectional pumping device

ActiveCN104612928AExtended service lifeImprove suction efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderMotor drive

The invention relates to a hydraulic bidirectional pumping device which comprises a prime motor, a hydraulic oil pump, a hydraulic oil tank, a control valve, a double-action hydraulic cylinder and plunger pumps. The prime motor drives the hydraulic oil pump. The hydraulic bidirectional pumping device utilizes the double-action hydraulic cylinder to drive the plunger pumps on both sides; the cylinder number is increased; stroke times are reduced; the service lives of easily damaged parts are prolonged; the coverage range of flow is effectively enlarged; suction efficiency of fracturing fluid is effectively improved; complexity of the integral structure is reduced; cost of manufacturing, maintenance and the like is reduced; the requirements on a lubricating system are lowered; the double-action hydraulic cylinder reciprocates to do work, so that working efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

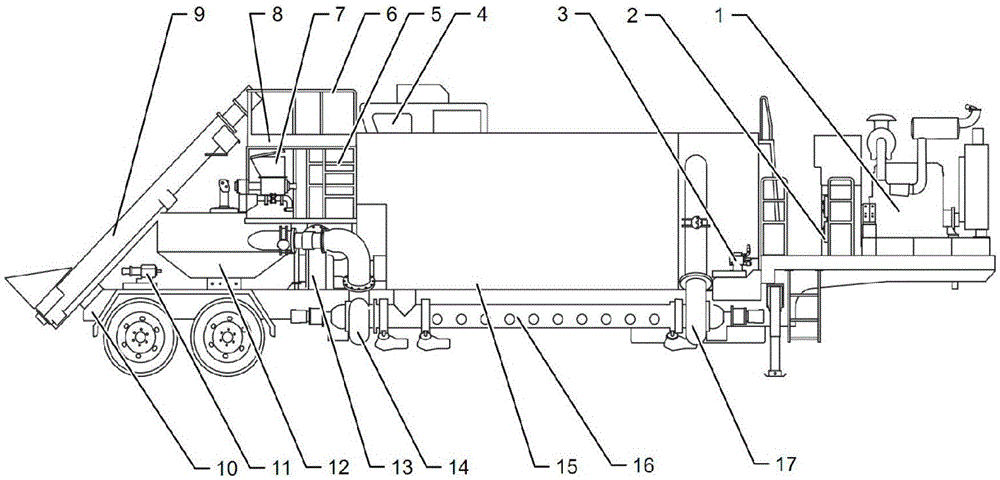

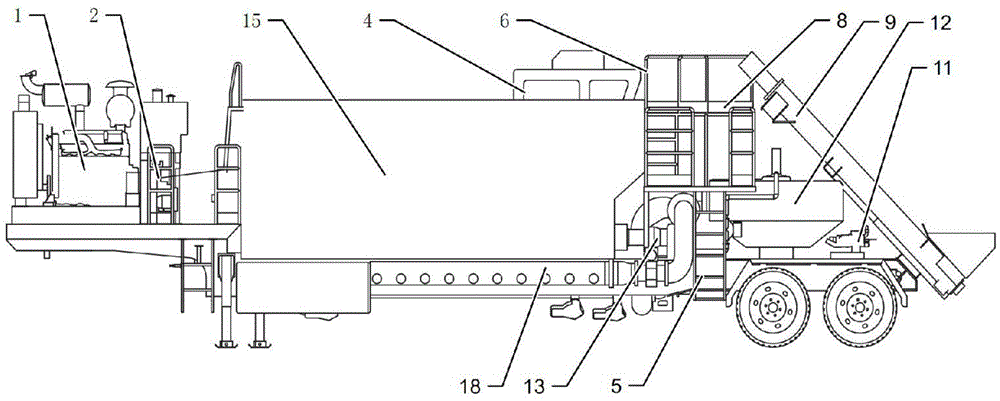

A fracturing fluid mixing sand mixing semi-trailer

ActiveCN103993869BReduce workloadLess supporting equipmentFluid removalTractor-trailer combinationsFracturing fluidHydraulic pump

The invention relates to a fracturing fluid and sand mixing semitrailer, and belongs to the field of fracturing devices for oil field work. The fracturing fluid and sand mixing semitrailer comprises a semitrailer body, a hydraulic system and an electrical control system. The hydraulic system comprises a hydraulic oil tank, at least one hydraulic pump and a hydraulic multi-way valve. An engine, the hydraulic system, the electrical control system, a lifting control chamber, a spiral conveyor, a clean water suction centrifugal pump, a fracturing fluid suction centrifugal pump, a stirring machine, a discharge centrifugal pump, a liquid adding pump, a dry powder adding device and a concentrated guanidine gum adding pump are integrated on the semitrailer body. The work steps of conducting glue solution mixing after fracturing liquid mixing is conducted and discharging the glue solution to a downward fracturing device can be conducted by operating the electrical control system to drive the hydraulic pump through an operator, and therefore work steps of oil field work are highly integrated, matched devices are reduced, workloads of working staff are reduced, and construction quality is ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Hydraulic double acting pumping unit

ActiveCN104612928BExtended service lifeImprove suction efficiencyPiston pumpsPositive-displacement liquid enginesHydraulic cylinderMotor drive

The invention relates to a hydraulic bidirectional pumping device which comprises a prime motor, a hydraulic oil pump, a hydraulic oil tank, a control valve, a double-action hydraulic cylinder and plunger pumps. The prime motor drives the hydraulic oil pump. The hydraulic bidirectional pumping device utilizes the double-action hydraulic cylinder to drive the plunger pumps on both sides; the cylinder number is increased; stroke times are reduced; the service lives of easily damaged parts are prolonged; the coverage range of flow is effectively enlarged; suction efficiency of fracturing fluid is effectively improved; complexity of the integral structure is reduced; cost of manufacturing, maintenance and the like is reduced; the requirements on a lubricating system are lowered; the double-action hydraulic cylinder reciprocates to do work, so that working efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

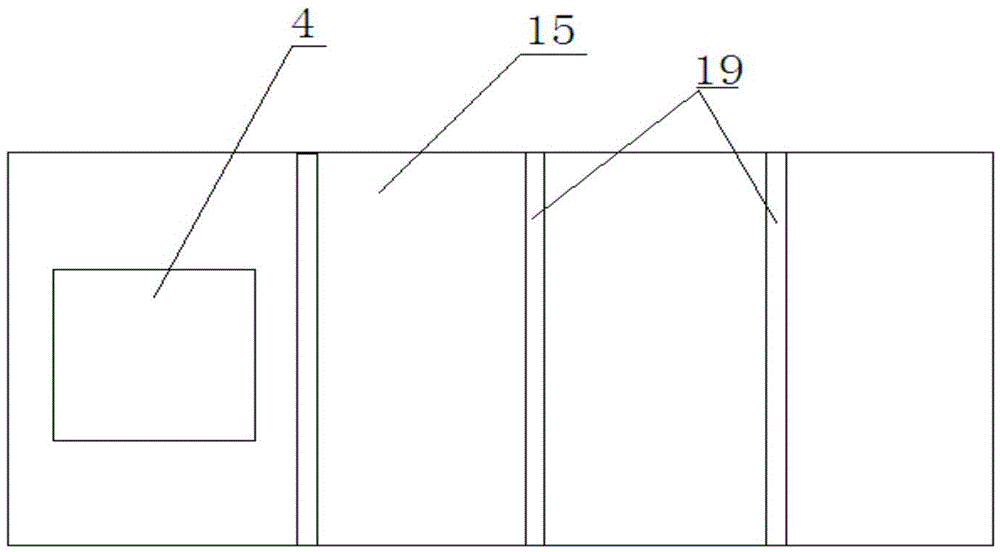

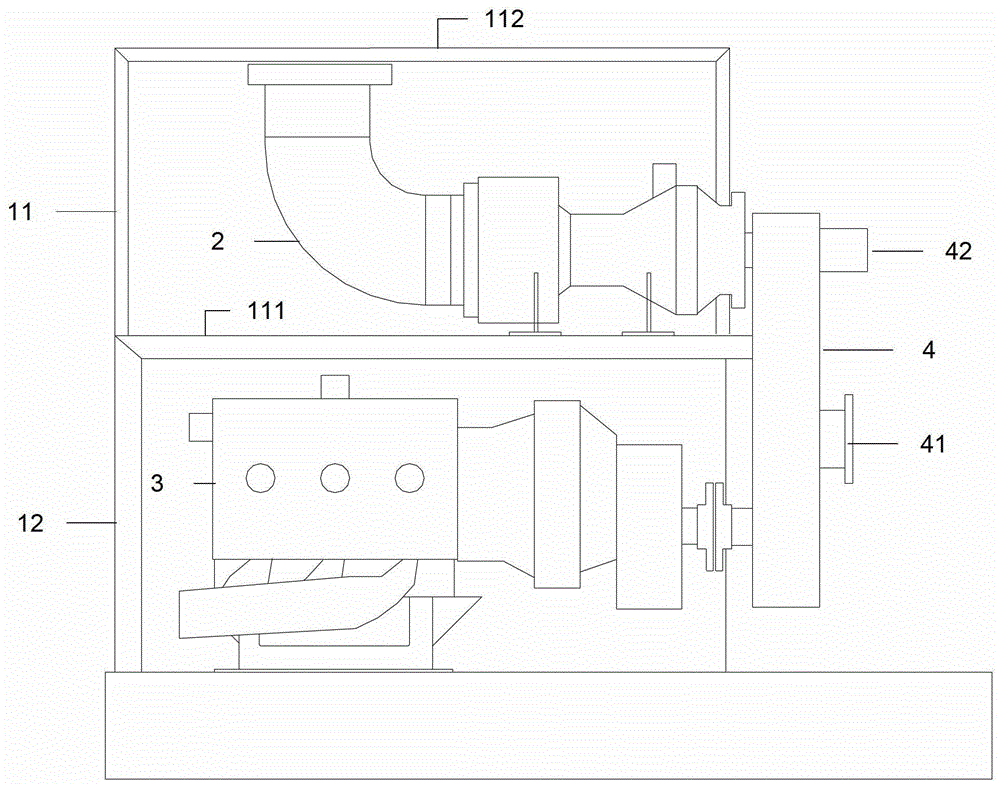

A high-pressure pumping integrated equipment

ActiveCN103277290BReduce volumeEasy to transportFlexible member pumpsPositive-displacement liquid enginesReduction driveHydraulic pump

The invention discloses integrated high-pressure pumping equipment. The integrated high-pressure pumping equipment comprises an engine, a high-pressure pump, a speed reducer and a frame, the frame comprises an upper frame body and a lower frame body, the engine is arranged in one of the upper frame body and the lower frame body, the high-pressure pump is arranged in the other one of the upper frame body and the lower frame body, the speed reducer is vertically arranged close to the frame, an input end of the speed reducer is connected with the engine, and an output end of the speed reducer is connected with the high-pressure pump. The engine and the high-pressure pump are vertically arranged in the integrated equipment, and the speed reducer is vertically arranged close to the frame, so that the size of the high-pressure pumping equipment is diminished greatly, the structure of entire equipment is compact, and transportation of the high-pressure pumping equipment in severe conditions such as in remote mountainous areas is facilitated.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP +1

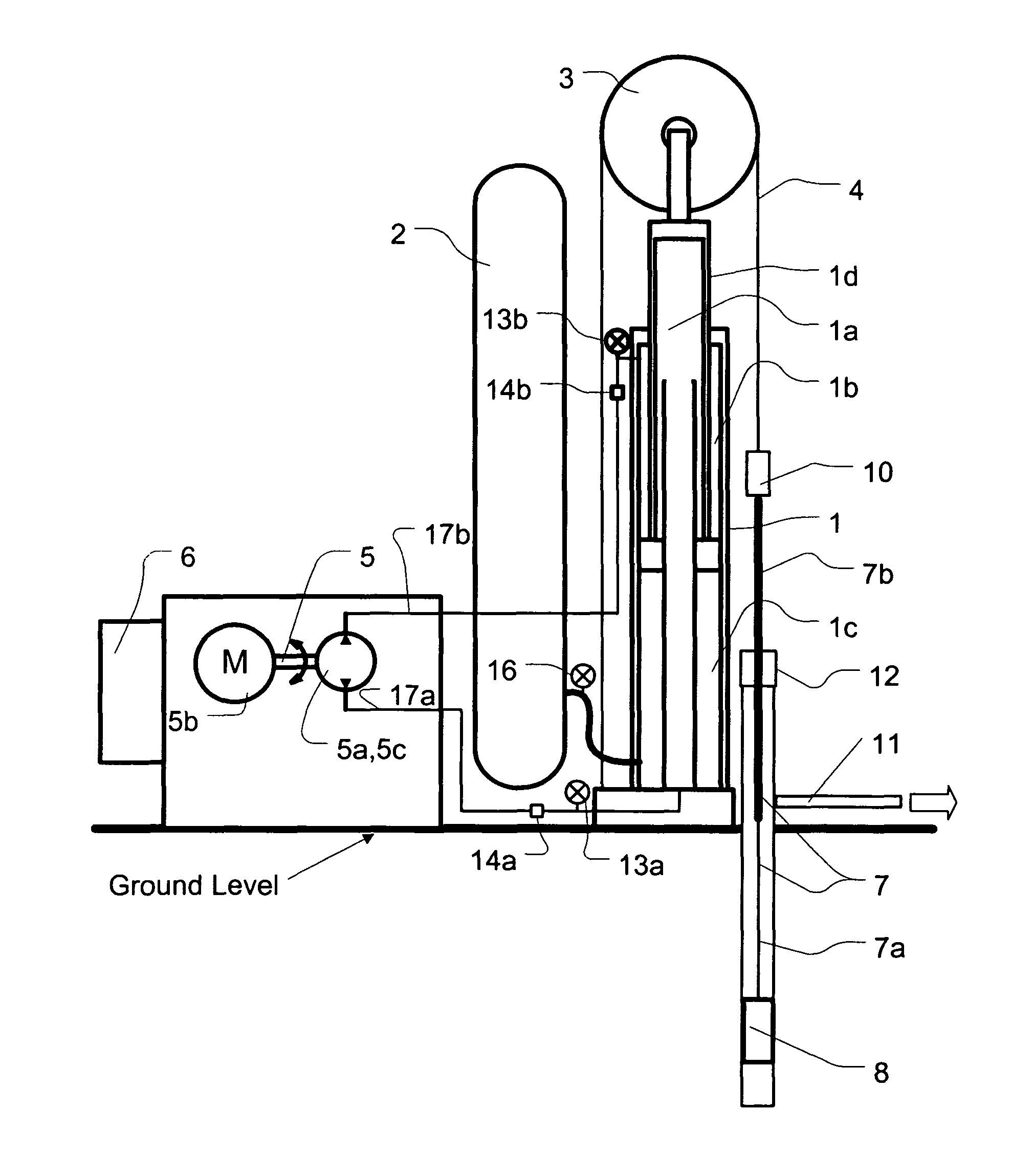

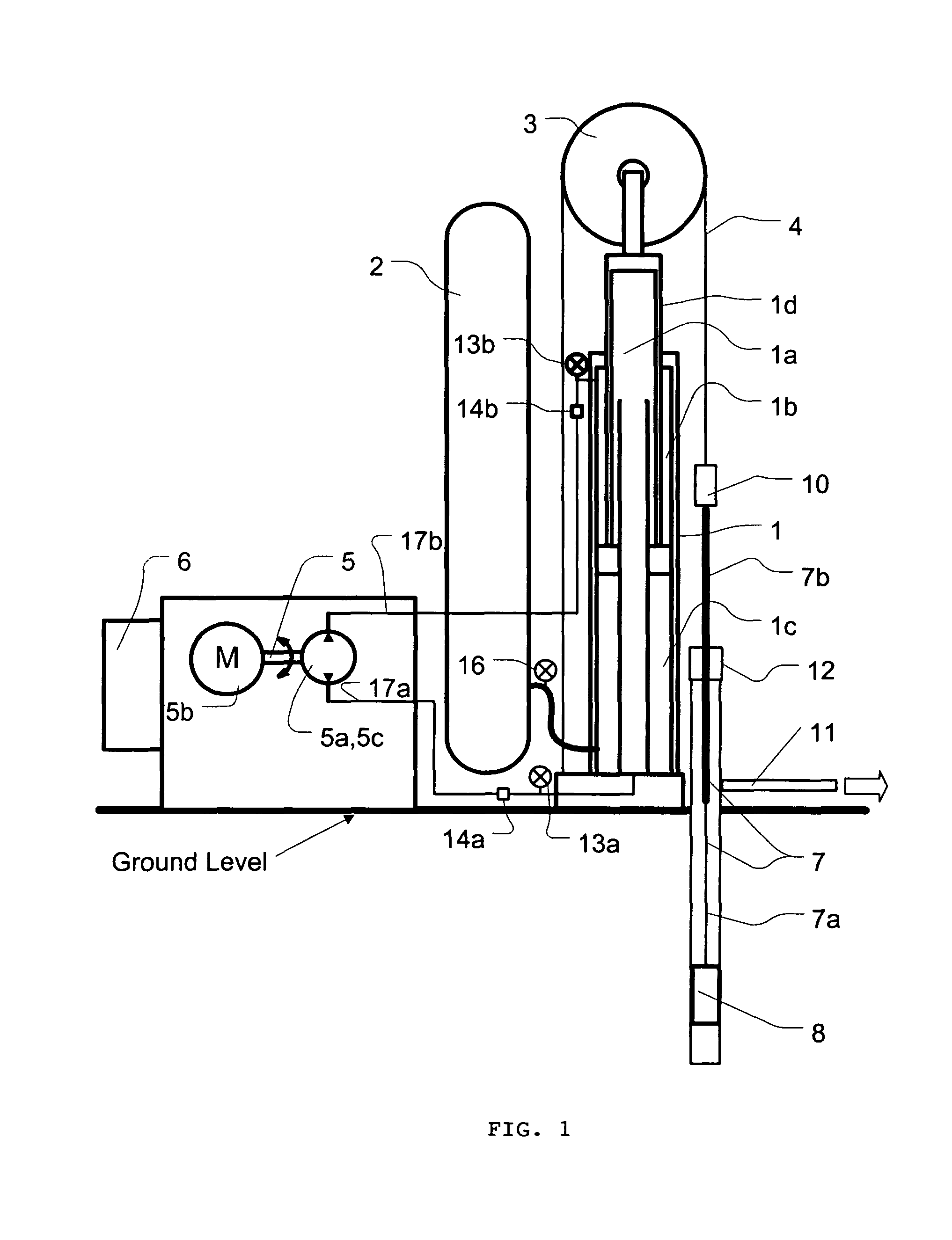

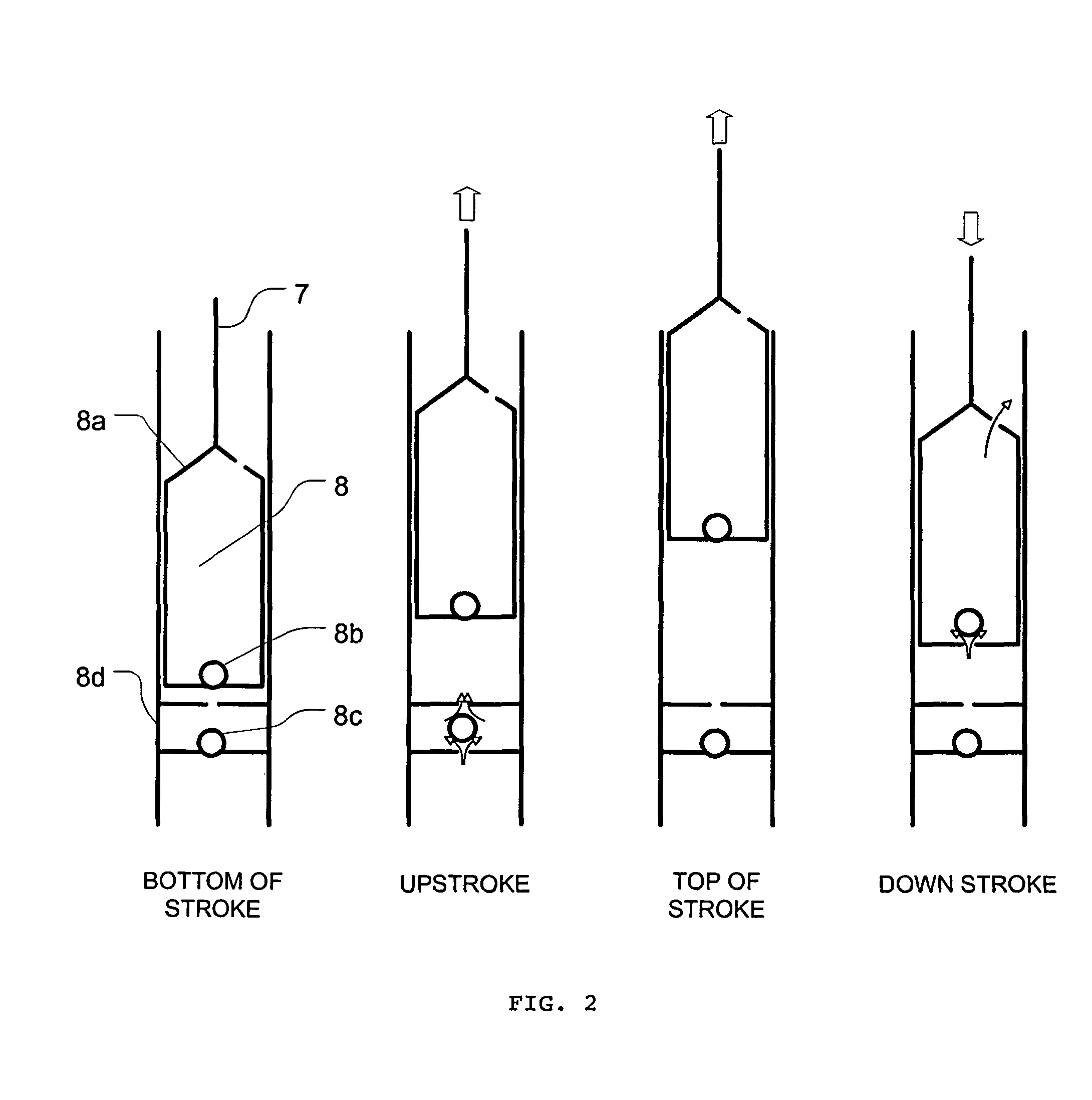

Adaptive control of an oil or gas well surface-mounted hydraulic pumping system and method

ActiveUS8851860B1Increase production capacityIncreased durabilityFluid parameterFlexible member pumpsControl systemSurface mounting

The disclosed invention provides intelligent adaptive control for optimization of production output, energy efficiency and safety of a linear reciprocating long stroke hydraulic lift system, for use at the surface of oil and gas wells to extract fluids or gas after free flowing stopped due to natural decline of reservoir pressure.The hydraulic pump and its adaptive control system introduced in this invention are capable of optimizing its production capacity by varying multiple operating parameters, including its stroking length and speed characteristics continuously and instantaneously at any point. Merits and benefits of this invention include significant increase in production efficiency, improved durability and longevity of the pumping equipment, significant power consumption savings and an ability to adapt effectively to changing well conditions.

Owner:DYNAPUMP INC +1

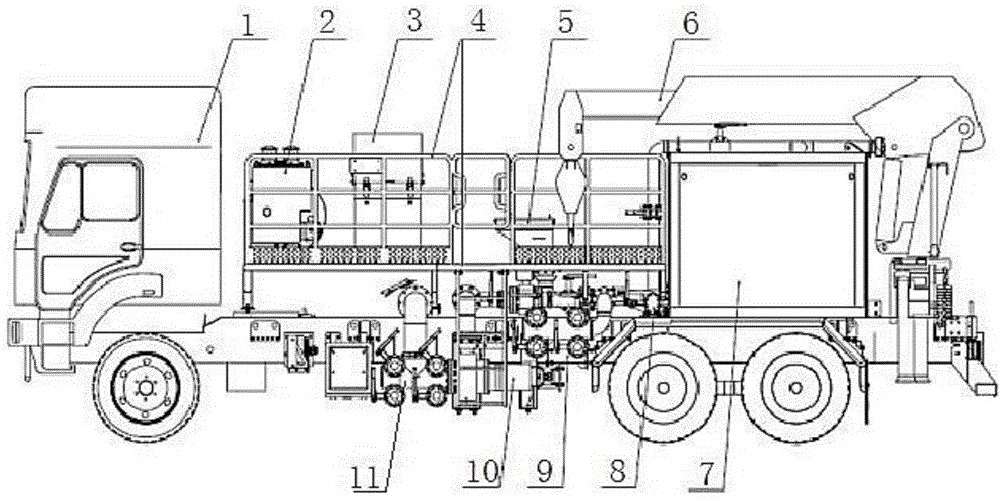

Multifunctional blending and liquid supplying vehicle

InactiveCN104057864AReduce labor costsAchieve mixingFluid removalItem transportation vehiclesControl systemElectrical control

The invention relates to a multifunctional blending and liquid supplying vehicle, which comprises a chassis, wherein an operation platform, a hydraulic oil tank, a dry powder feeder, an operation box for an electrical control system, a lorry-mounted crane and a liquid adding tank are fixedly arranged above the main beam of the chassis, wherein a centrifugal pump, an exhaust manifold and a suction manifold are arranged on each of two sides of the middle part of the main beam of the chassis, the exhaust manifold is communicated with the water outlet of the centrifugal pump, and the suction manifold is communicated with the water inlet of the centrifugal pump; the liquid adding pump is fixedly arranged on the side wall of the liquid adding tank, the water inlet of the liquid adding pump is communicated with the liquid adding tank, and the water outlet of the liquid adding tank is communicated with the exhaust manifold; a discharge opening in the lower end of the dry powder feeder is communicated with the exhaust manifold; the engine of the chassis is connected with a hydraulic pump, and the hydraulic pump is connected with the centrifugal pump, the lorry-mounted crane, the liquid adding tank and the liquid adding pump through a hydraulic multiway valve; the electrical control system is connected with the engine of the chassis, the hydraulic pump and the hydraulic multiway valve. The multifunctional blending and liquid supplying vehicle provided by the invention is low in cost, high in working efficiency, and can achieve various oil field operation functions.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Construction machine

InactiveUS7086226B2Reliable collectionReliable regenerationFluid couplingsMotor parameterElectricityEnergy regeneration

Owner:KOMATSU LTD

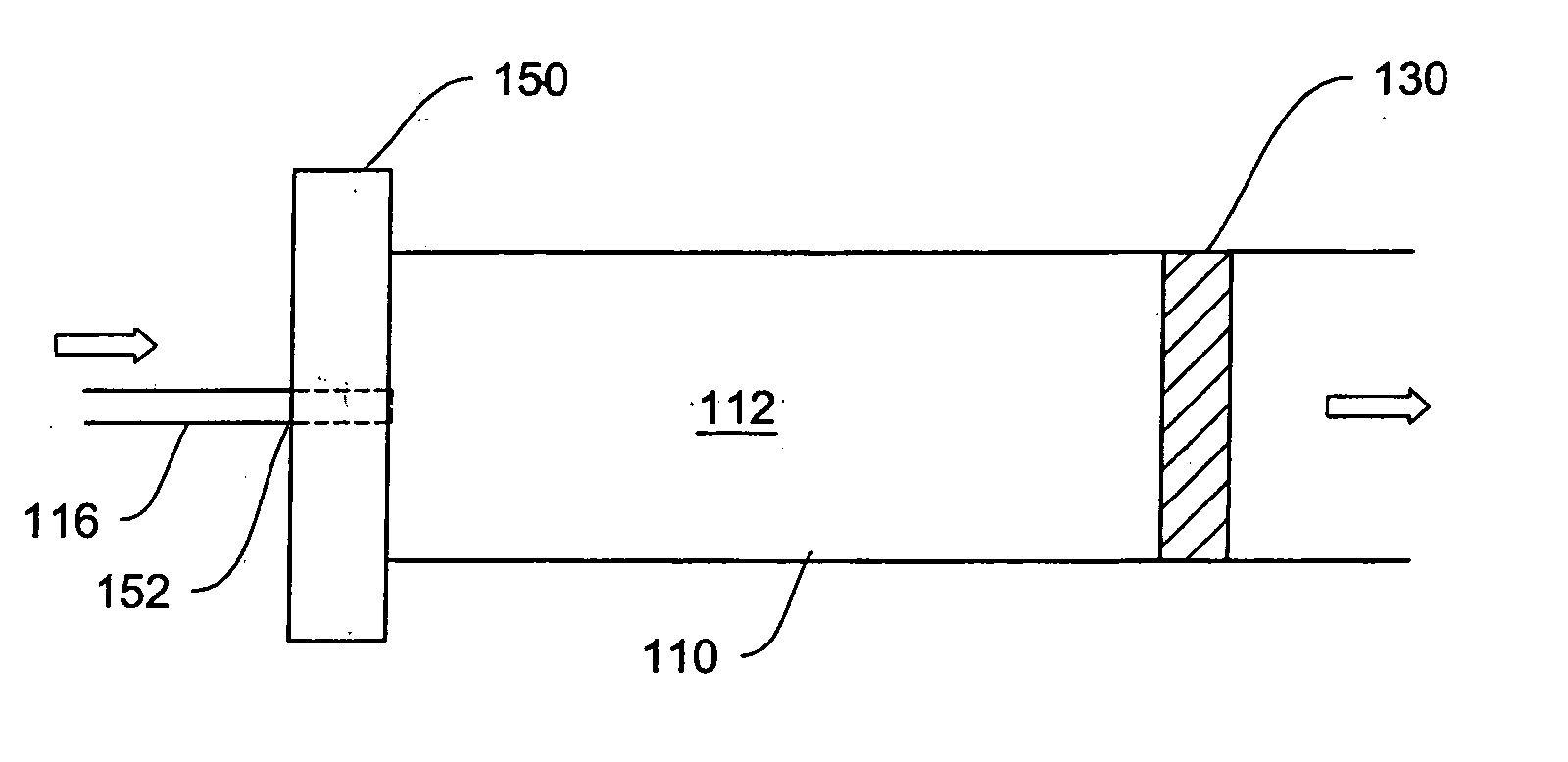

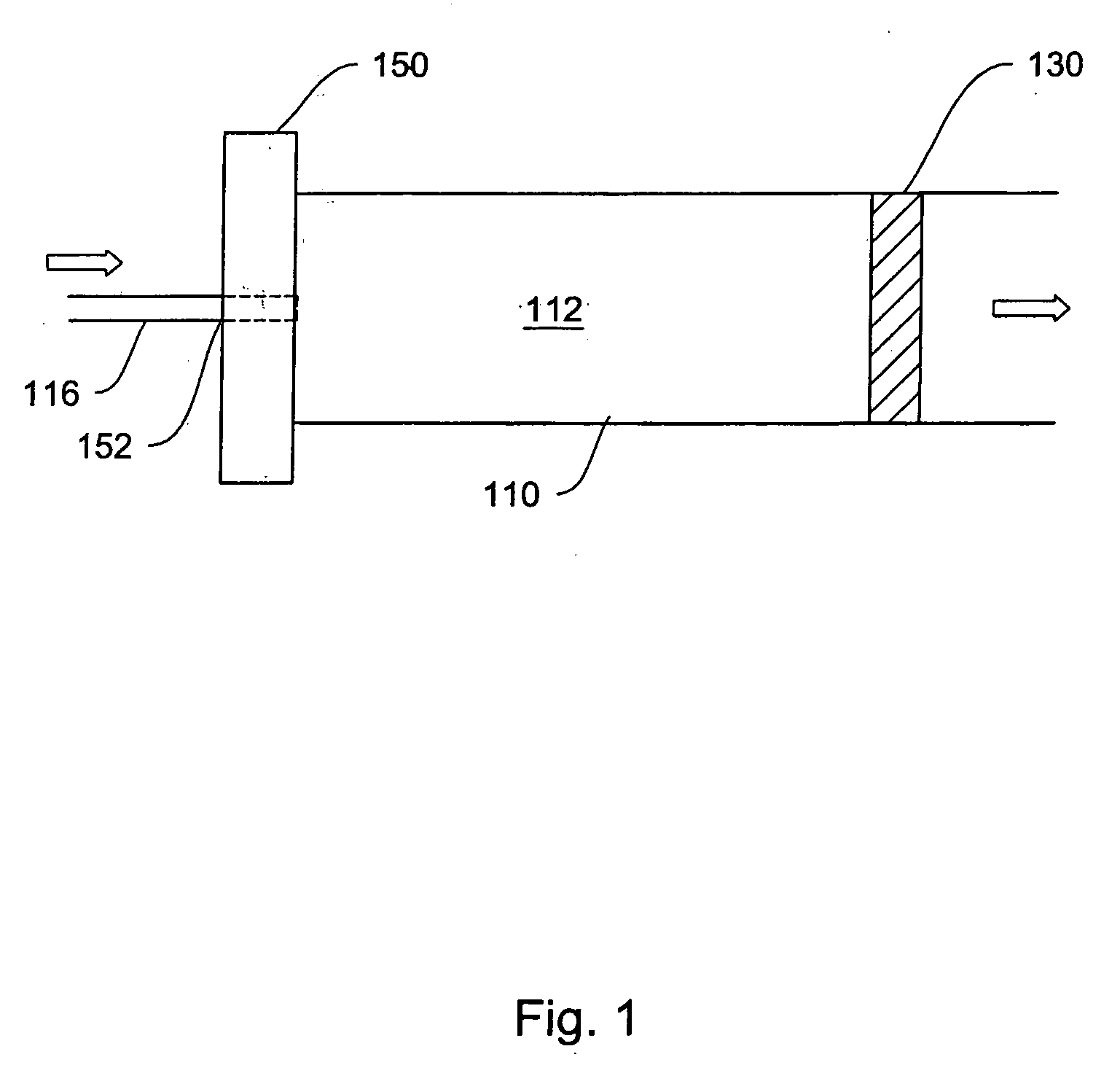

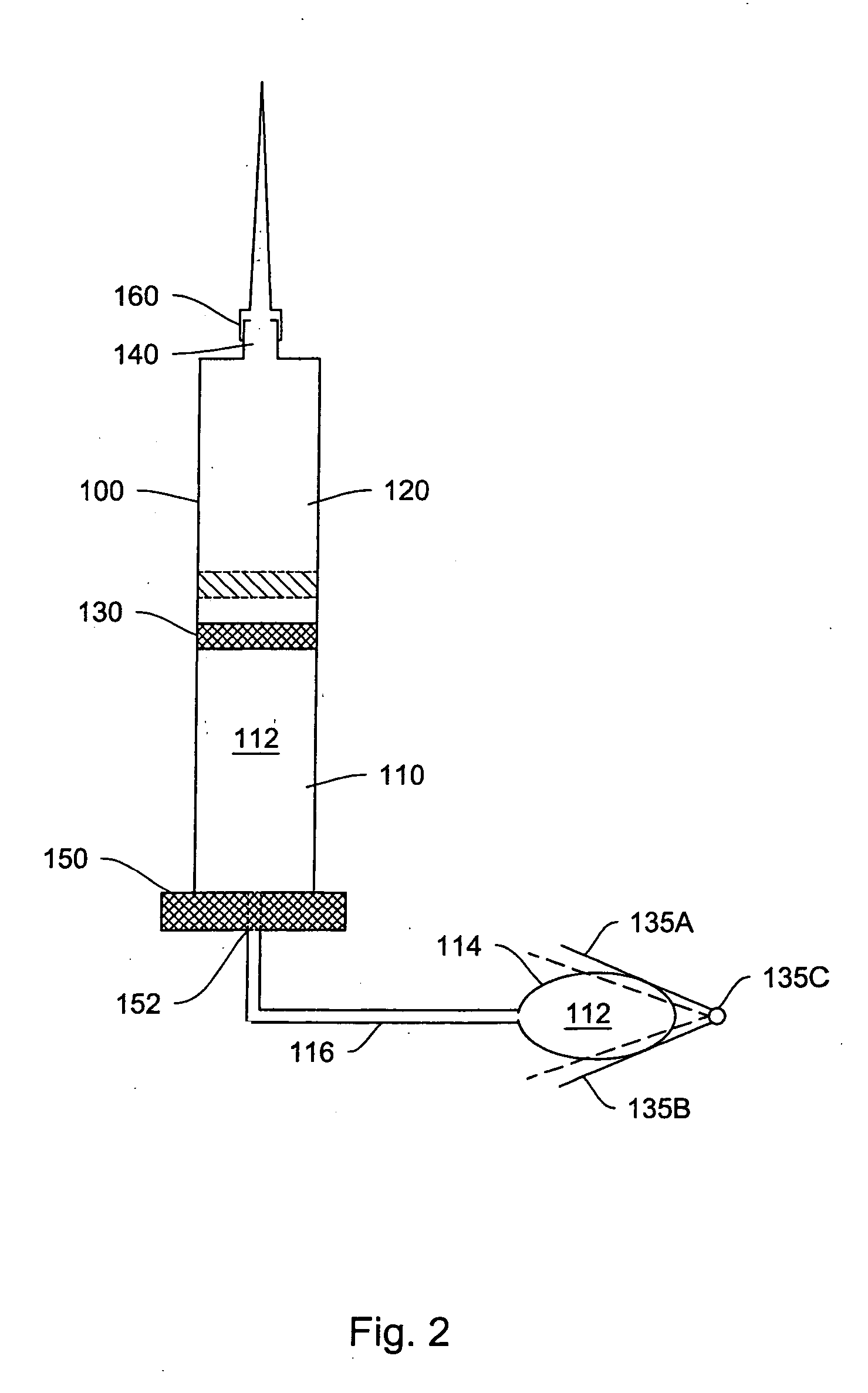

Hydraulically actuated pump for long duration medicament administration

ActiveUS20050119618A1Precise pressure regulationHigh viscosityPositive displacement pump componentsMicroneedlesHydraulic cylinderSingle-Use Device

Presently disclosed is a hydraulic pump device and its use thereof, especially in a fluid delivery system. In one embodiment, the fluid delivery system is an inexpensive, single-use device for slow dosing medicament applications. The fluid delivery system may employ a spring-compressed bellows crank or other combination of simple mechanisms operating according to the well-known peristaltic principle to force a volume of ultrapure bio-inert hydraulic fluid through an aperture, thereby expanding one chamber of a two chamber hydraulic cylinder. The second, fluid storage chamber, containing the medicament, is emptied through a conventional orifice in response to the expansion of the pump chamber. The medicament may thence flow through any suitable infusion set into a patient removeably attached thereto.

Owner:MANNKIND CORP

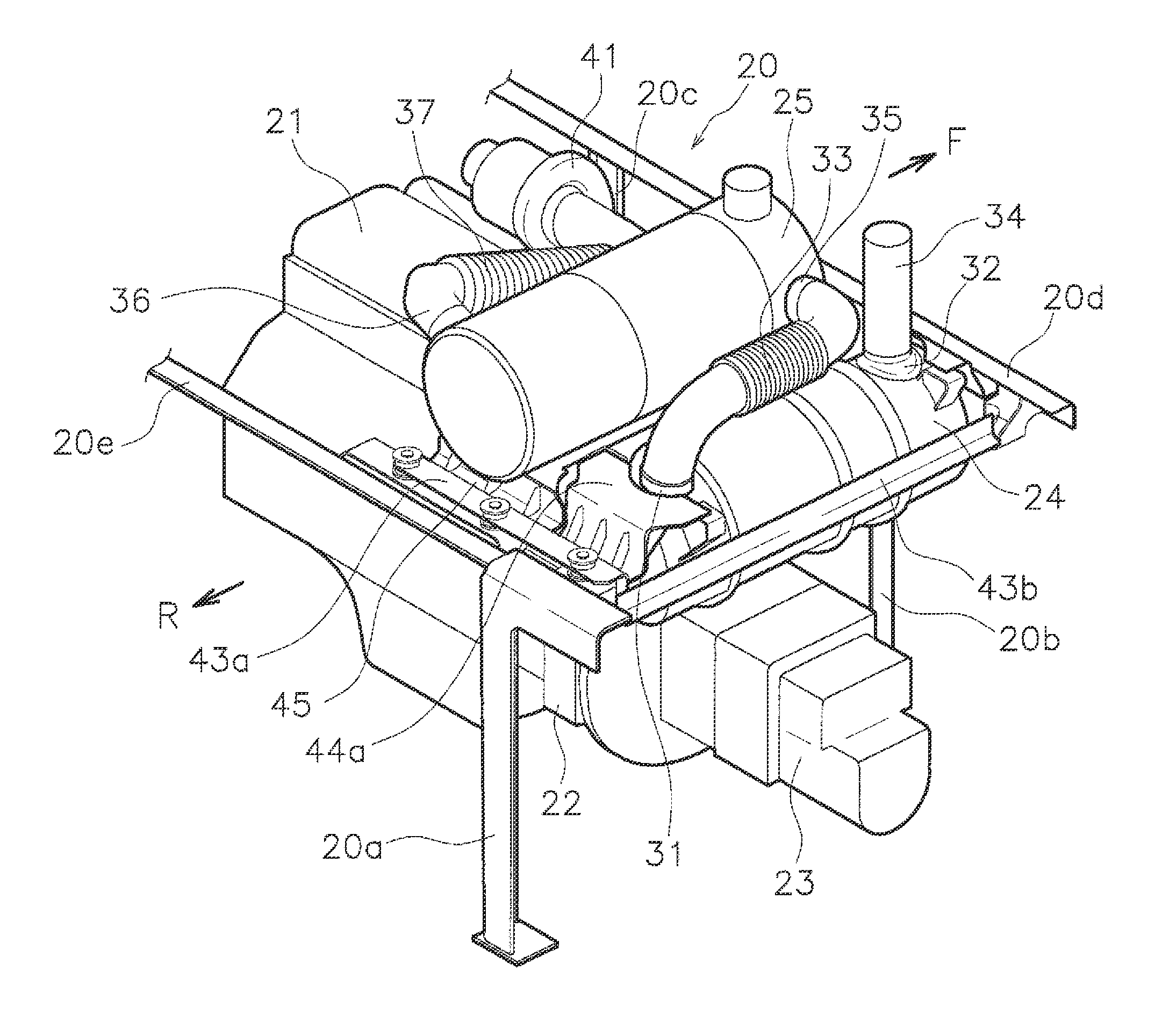

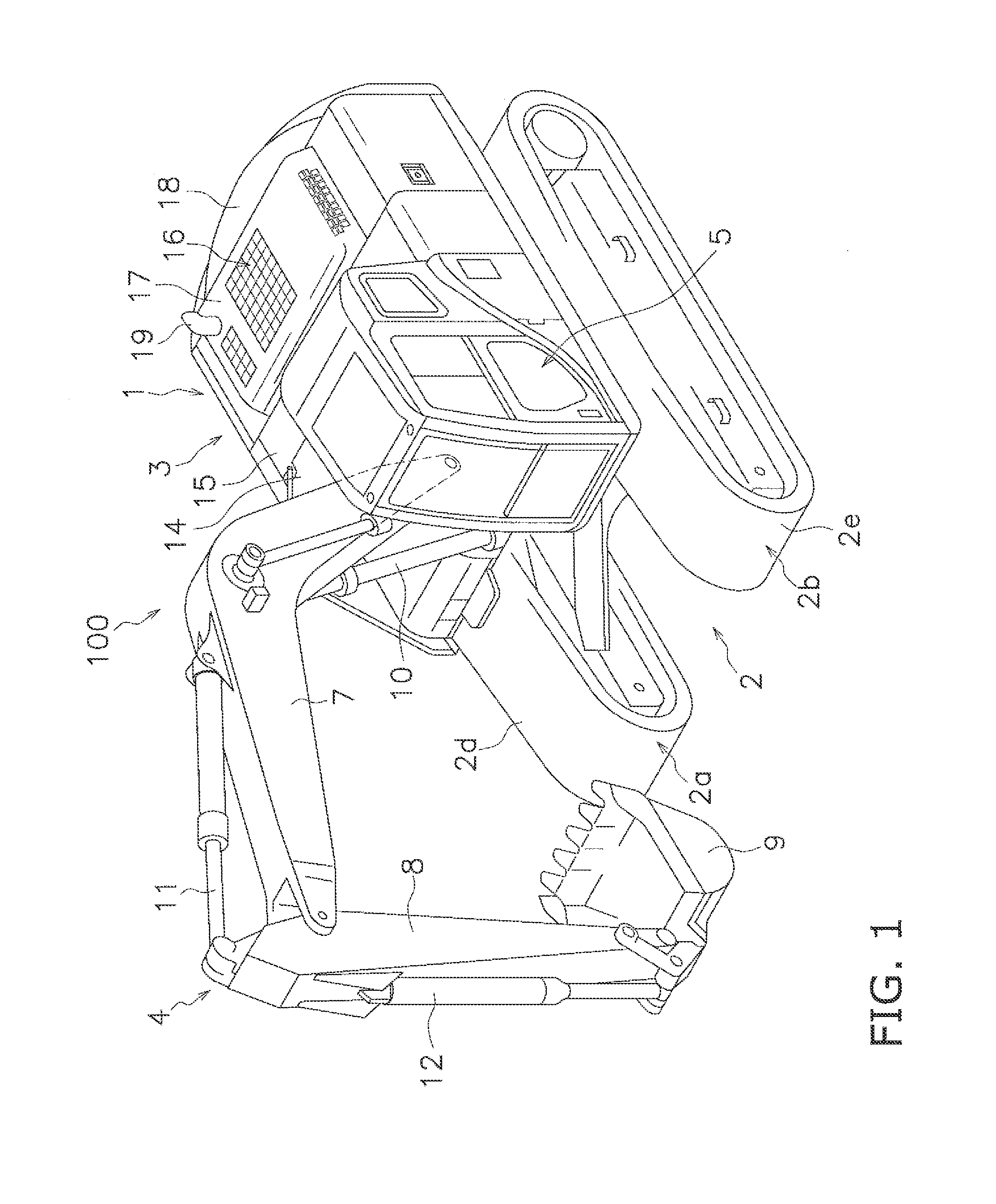

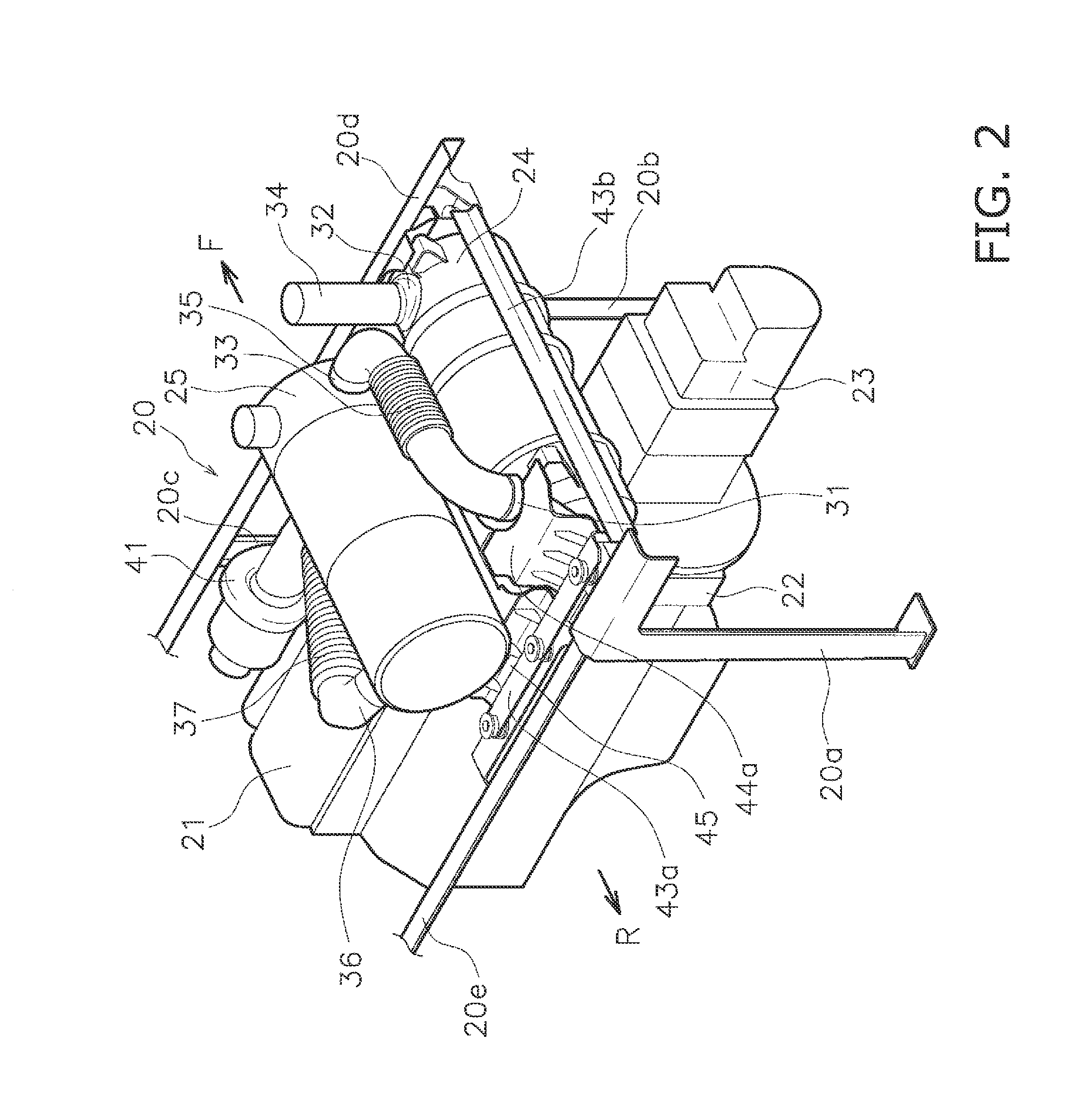

Work vehicle

ActiveUS20120247861A1Improve maintainabilityReduce spacingInternal combustion piston enginesExhaust apparatusHydraulic pumpEngineering

In a work vehicle, a second processing device, disposed over a hydraulic pump, is configured to process the hydraulic gas from an engine. A first processing device is disposed closer to the engine than the second processing device is Further, the first processing device is positioned higher the second processing device. The first processing device is partially overlapped with the second processing device in a top plan view.

Owner:KOMATSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com