Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1031 results about "Proportioning valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A proportioning valve is a valve that relies on the statics to supply a reduced pressure to an output line. A simple example is where spring load applies a reducing force so that the output pressure is reduced. Proportioning valves are frequently used in cars to reduce the brake fluid pressure to the rear brakes.

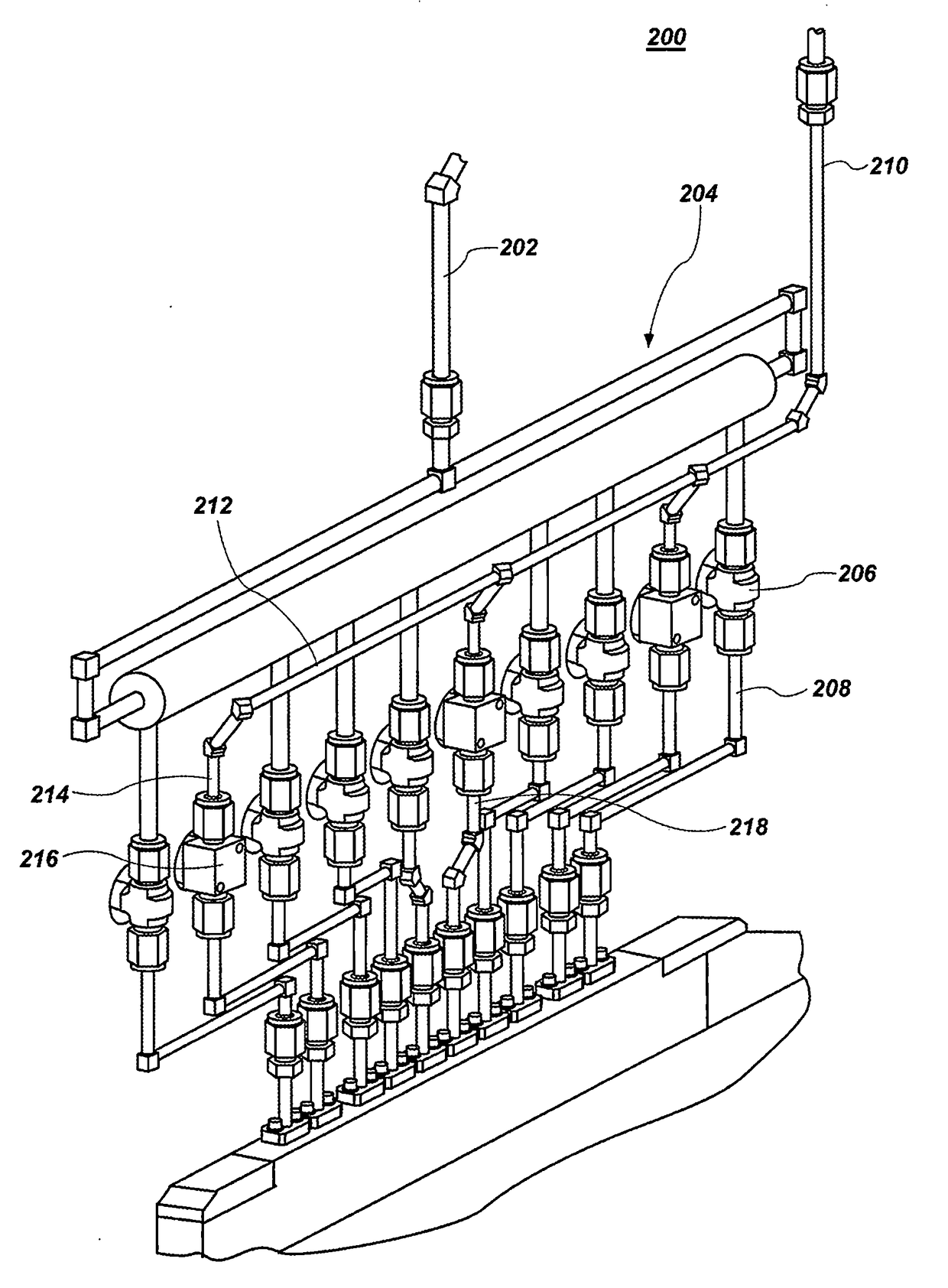

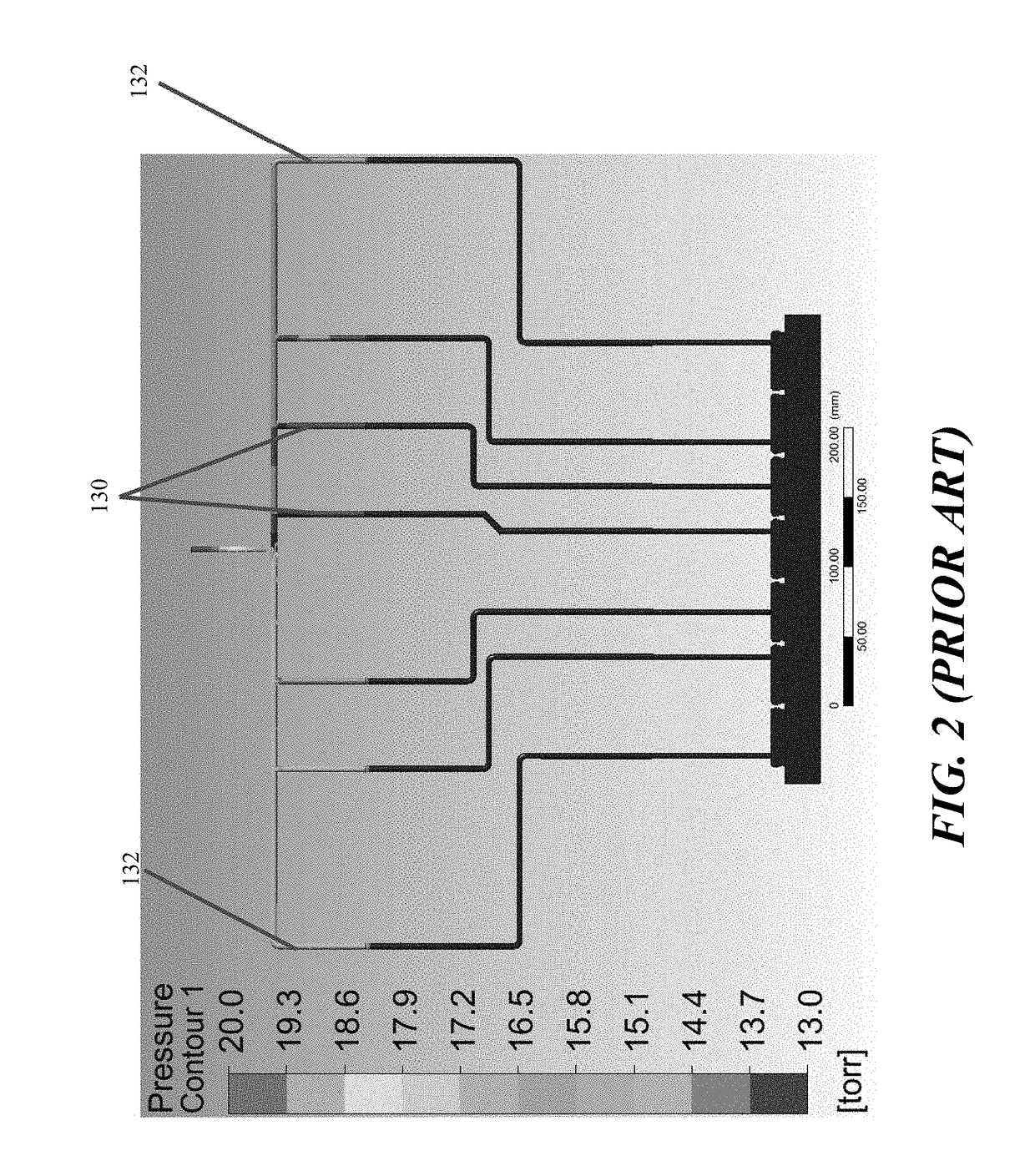

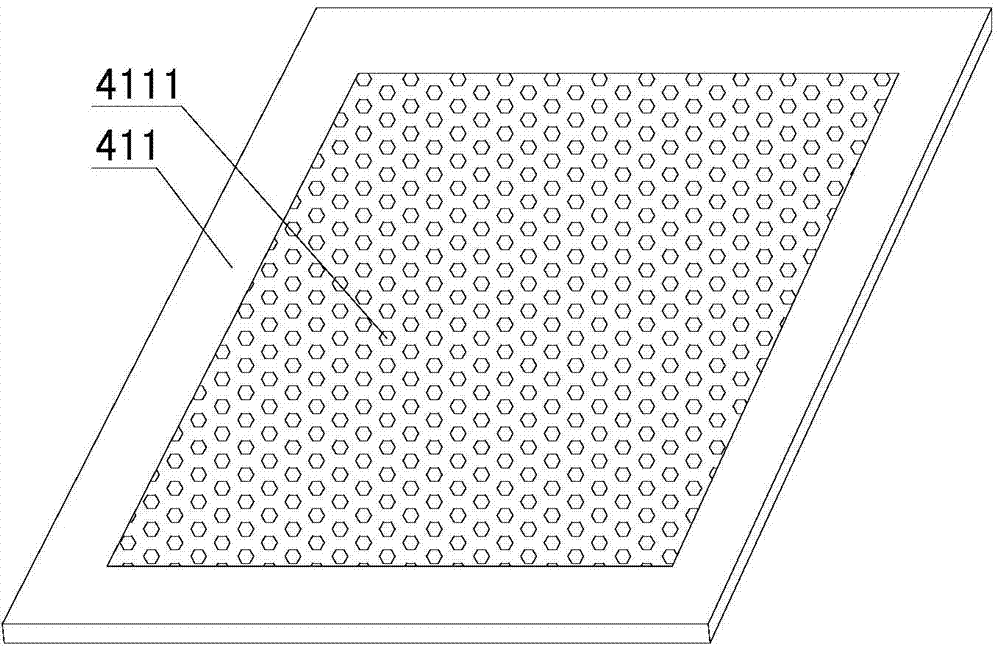

Gas distribution apparatus for improved film uniformity in an epitaxial system

ActiveUS20170260649A1Semiconductor/solid-state device manufacturingFrom chemically reactive gasesDistribution systemEngineering

A gas distribution system is disclosed in order to obtain better film uniformity on a wafer. The better film uniformity may be achieved by utilizing an expansion plenum and a plurality of, for example, proportioning valves to ensure an equalized pressure or flow along each gas line disposed above the wafer.

Owner:ASM IP HLDG BV

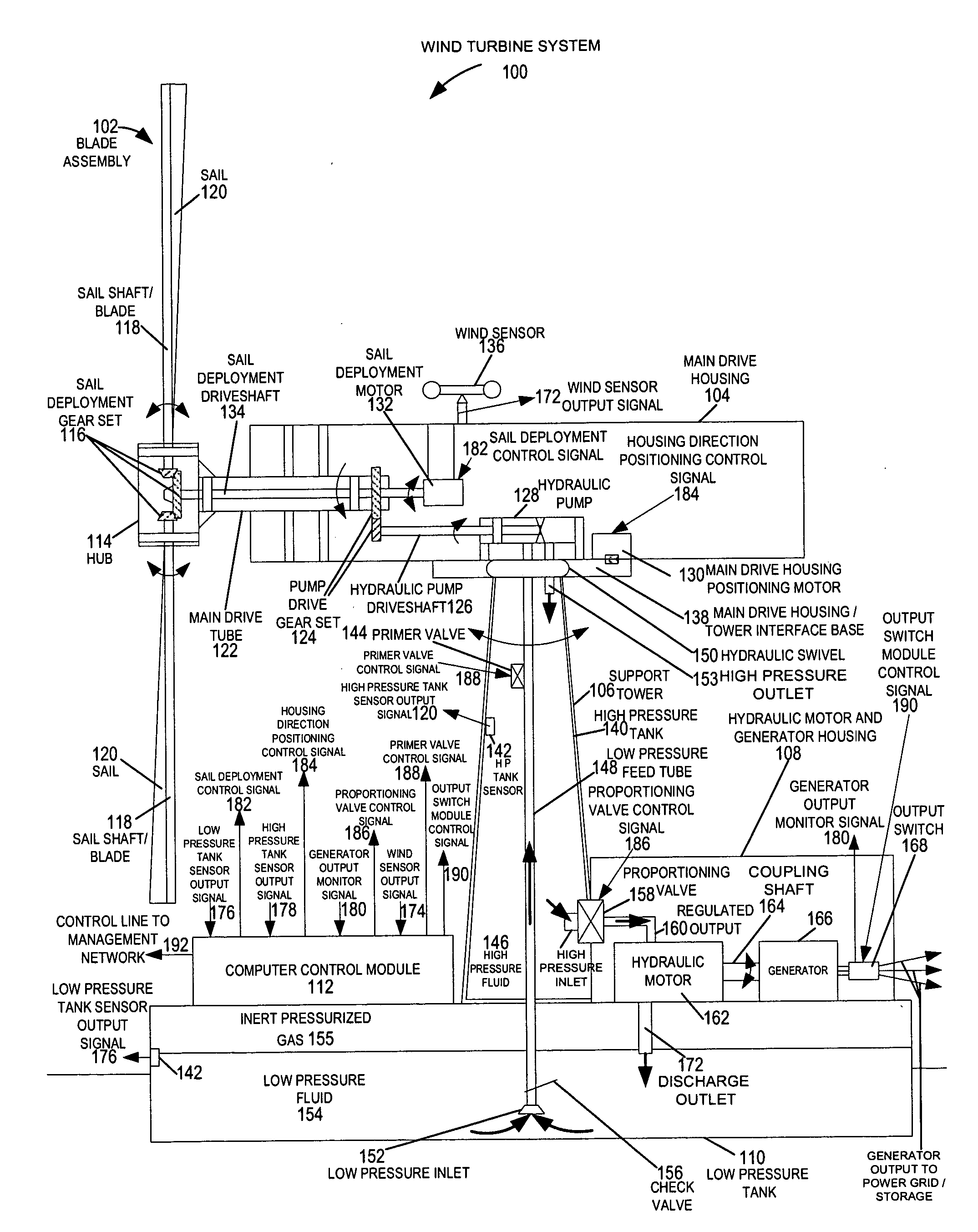

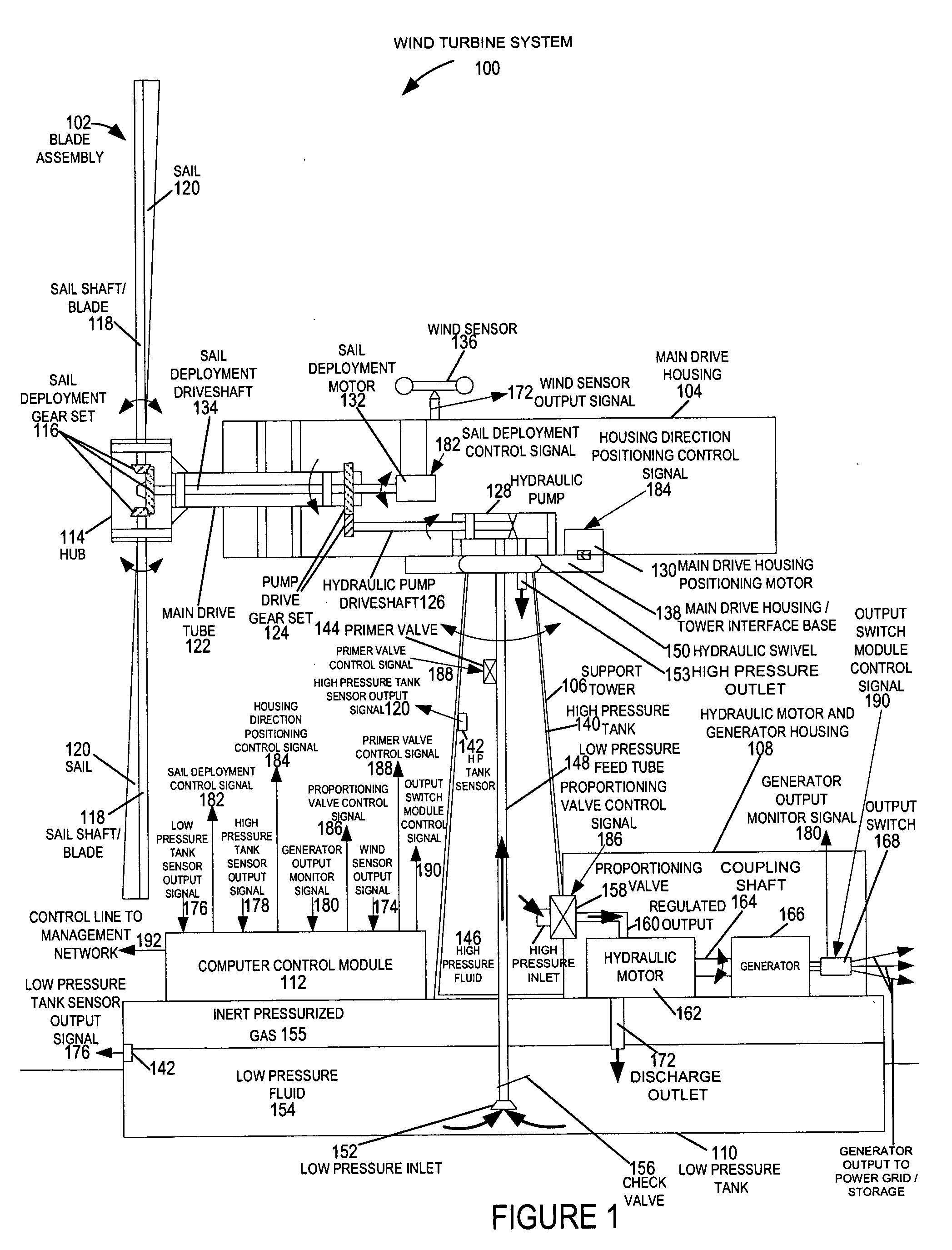

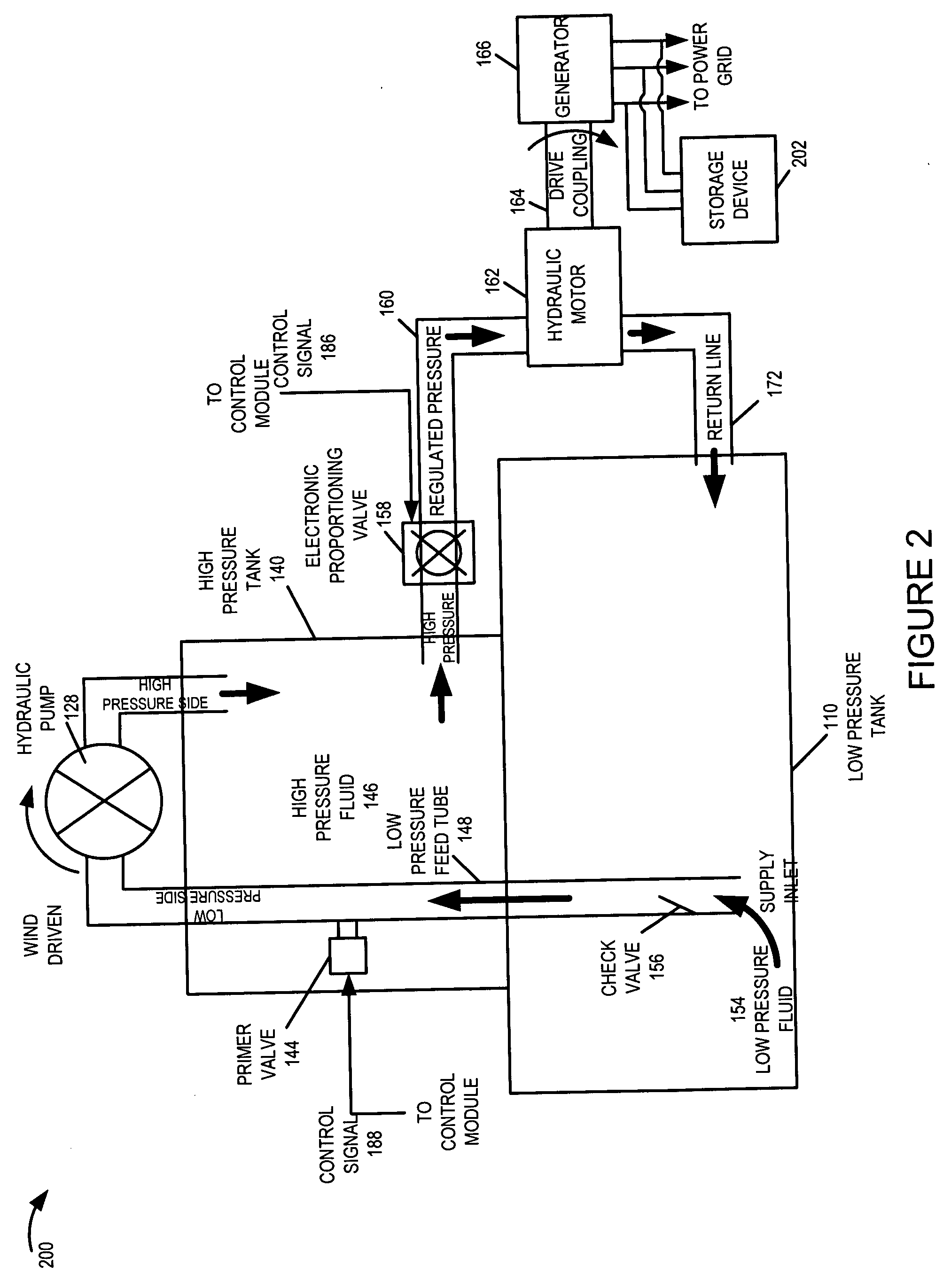

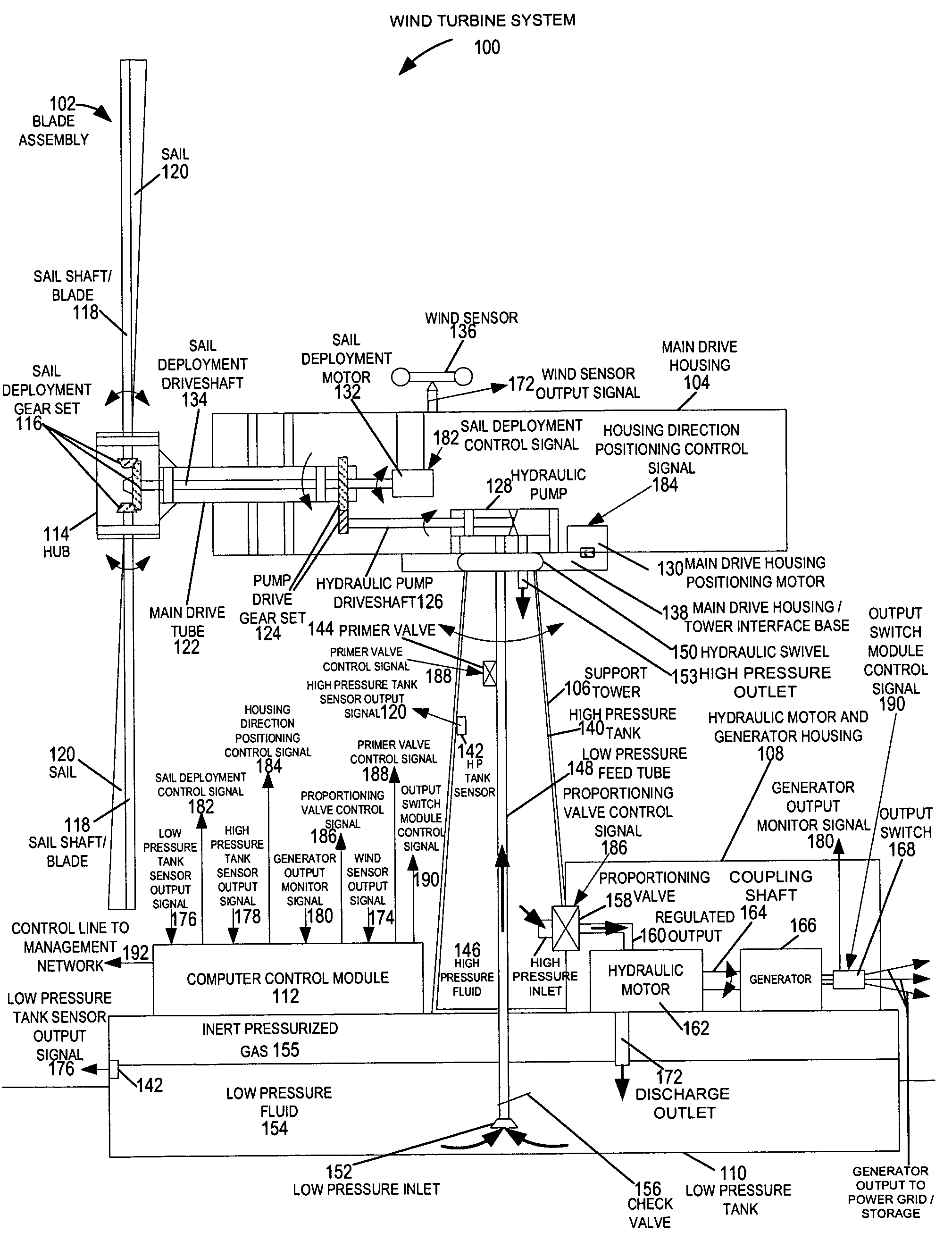

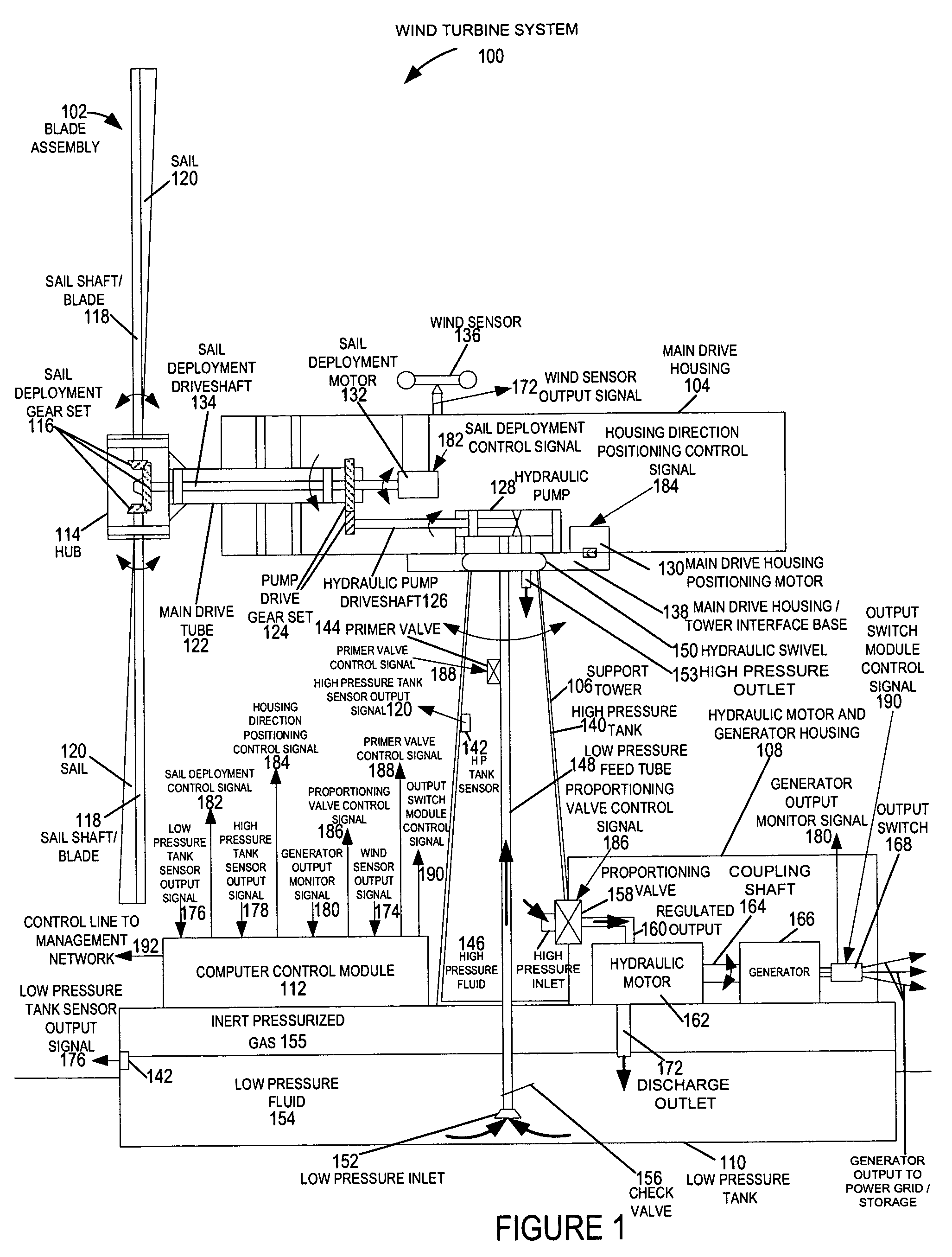

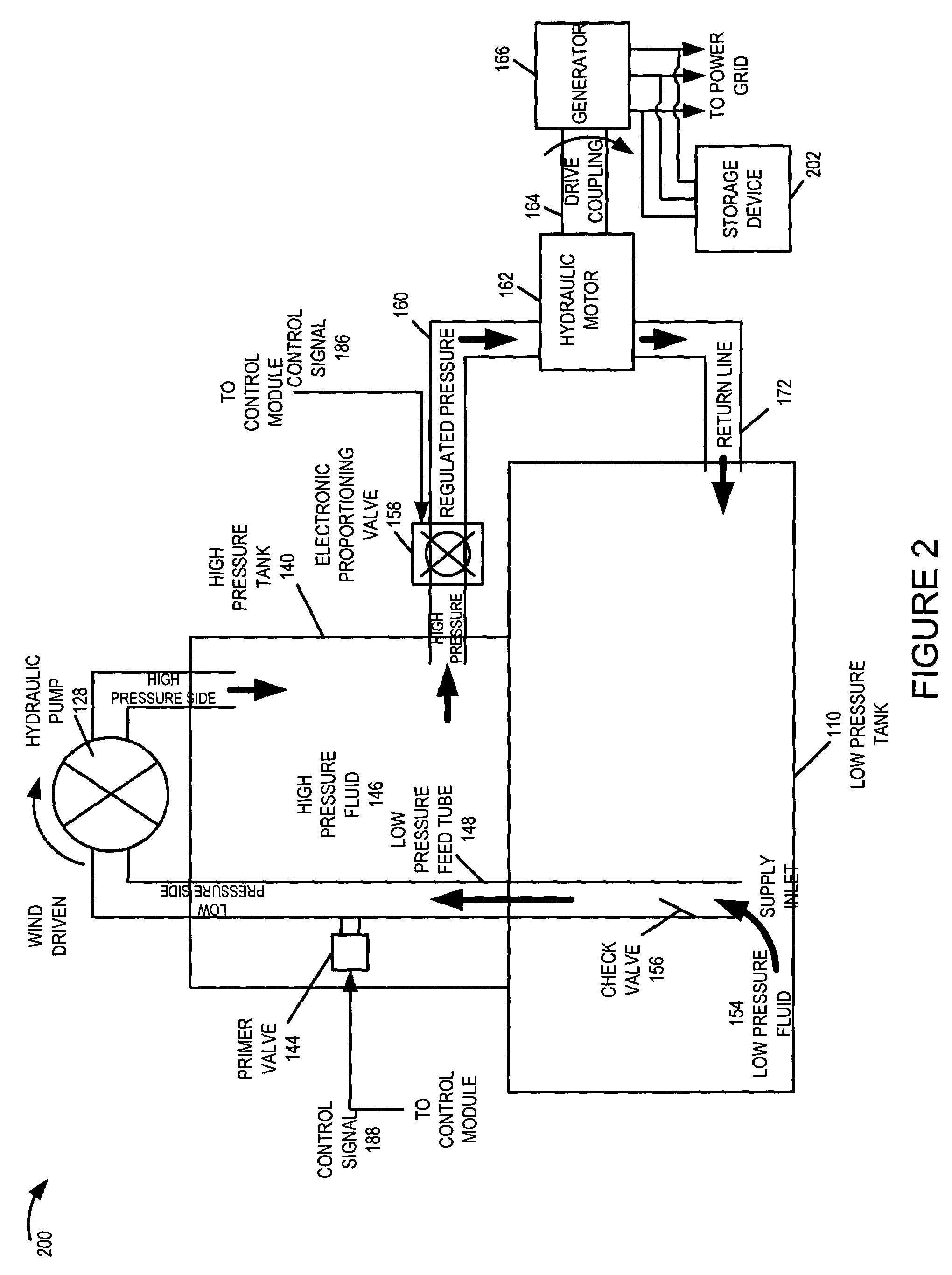

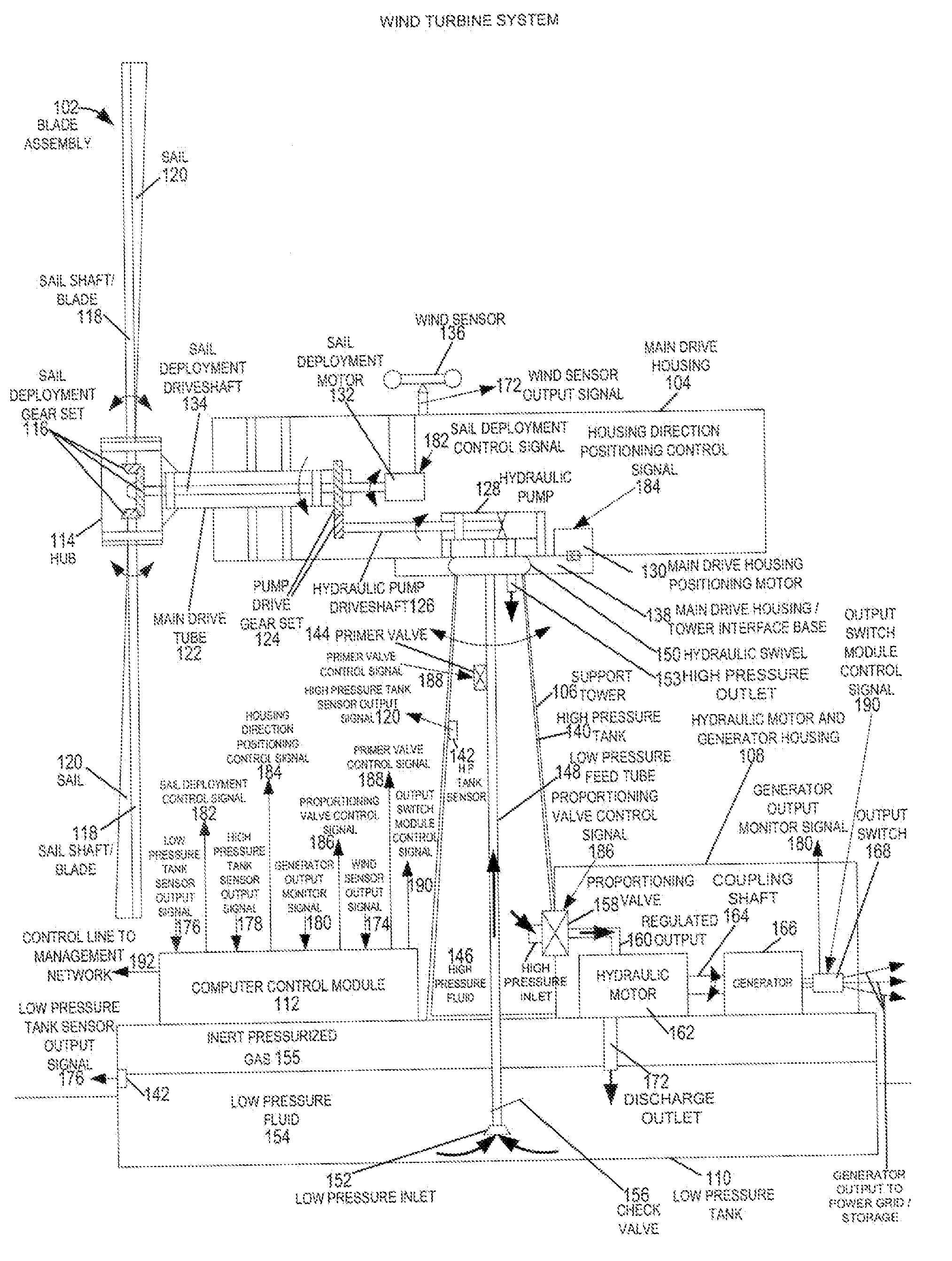

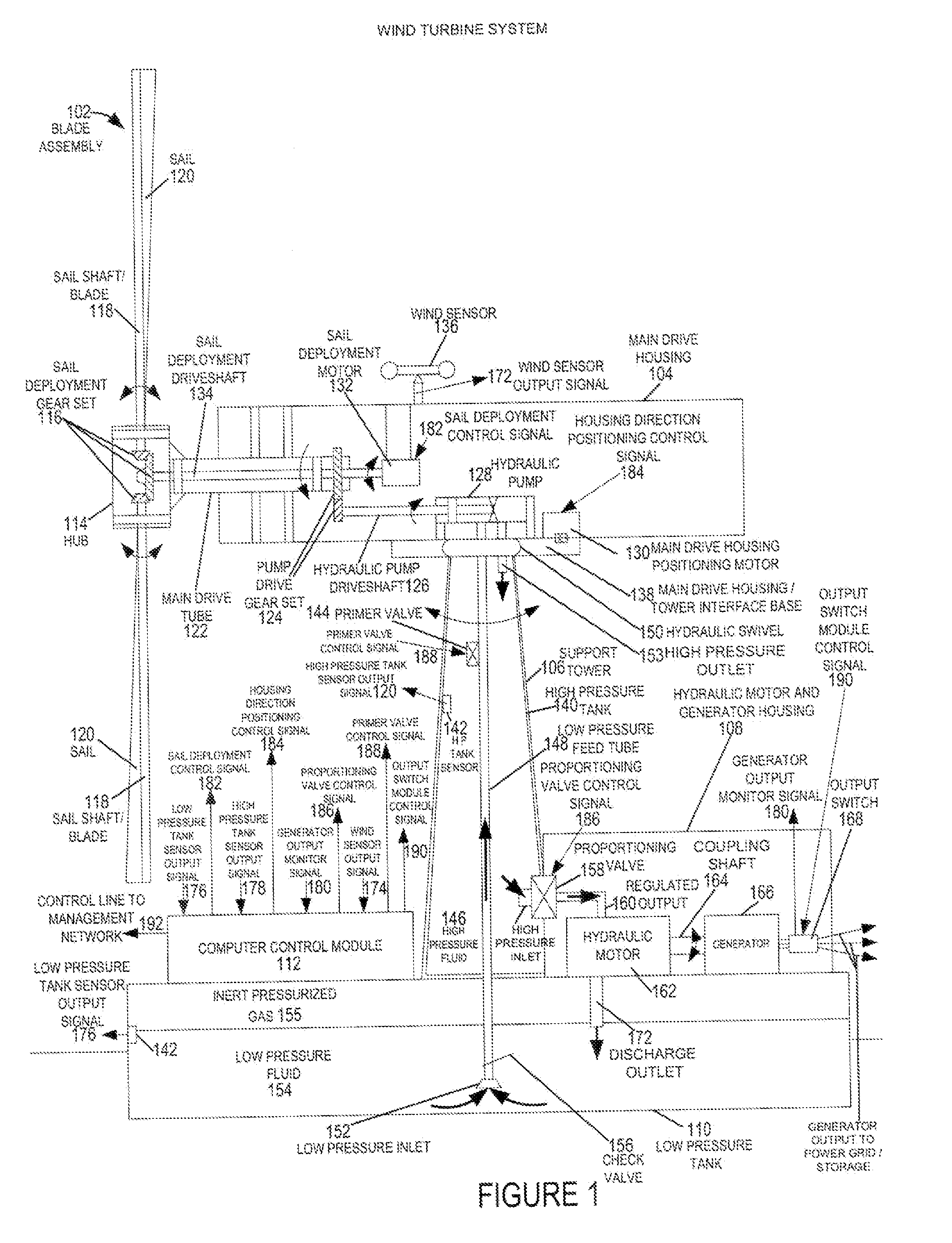

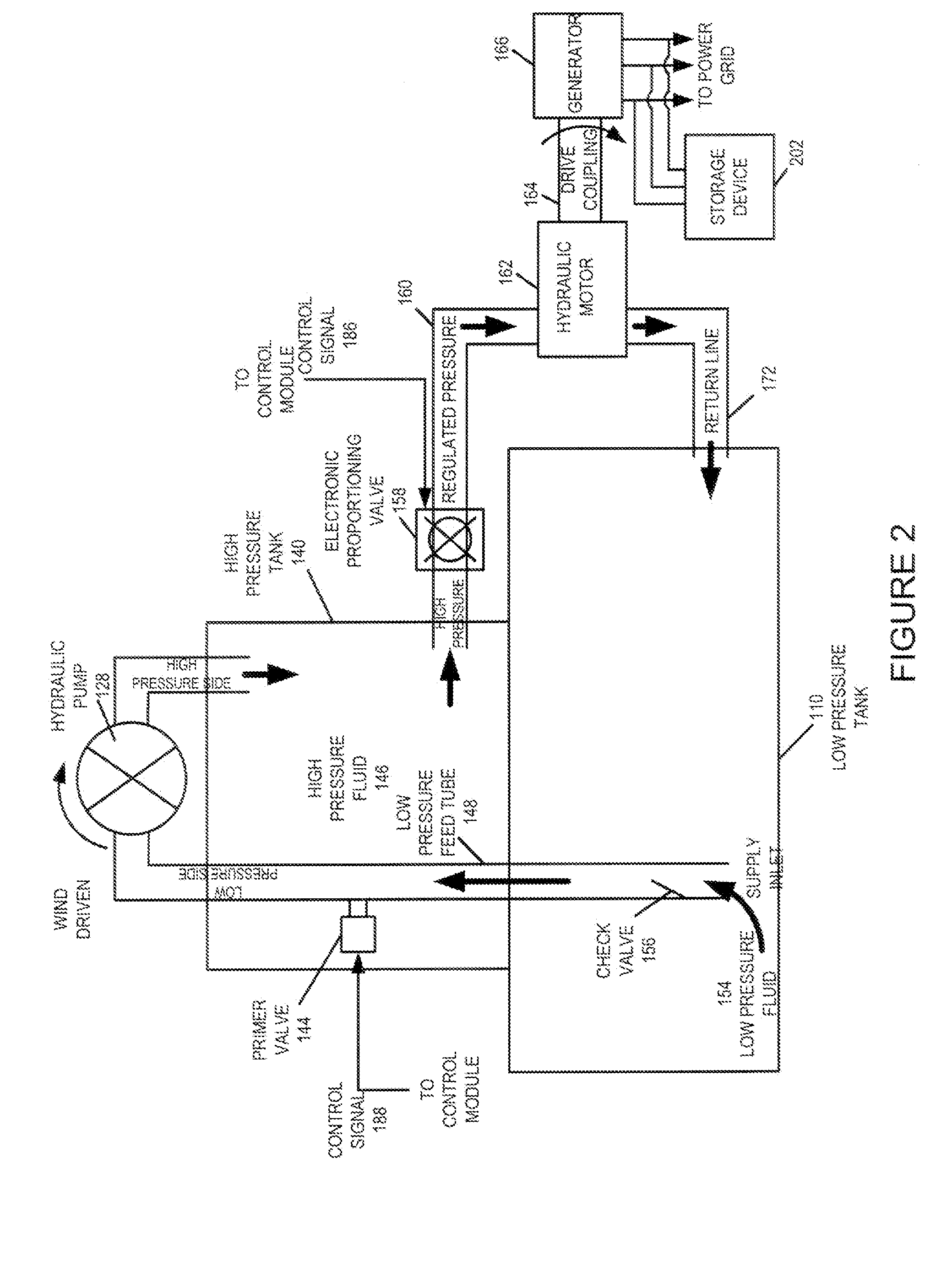

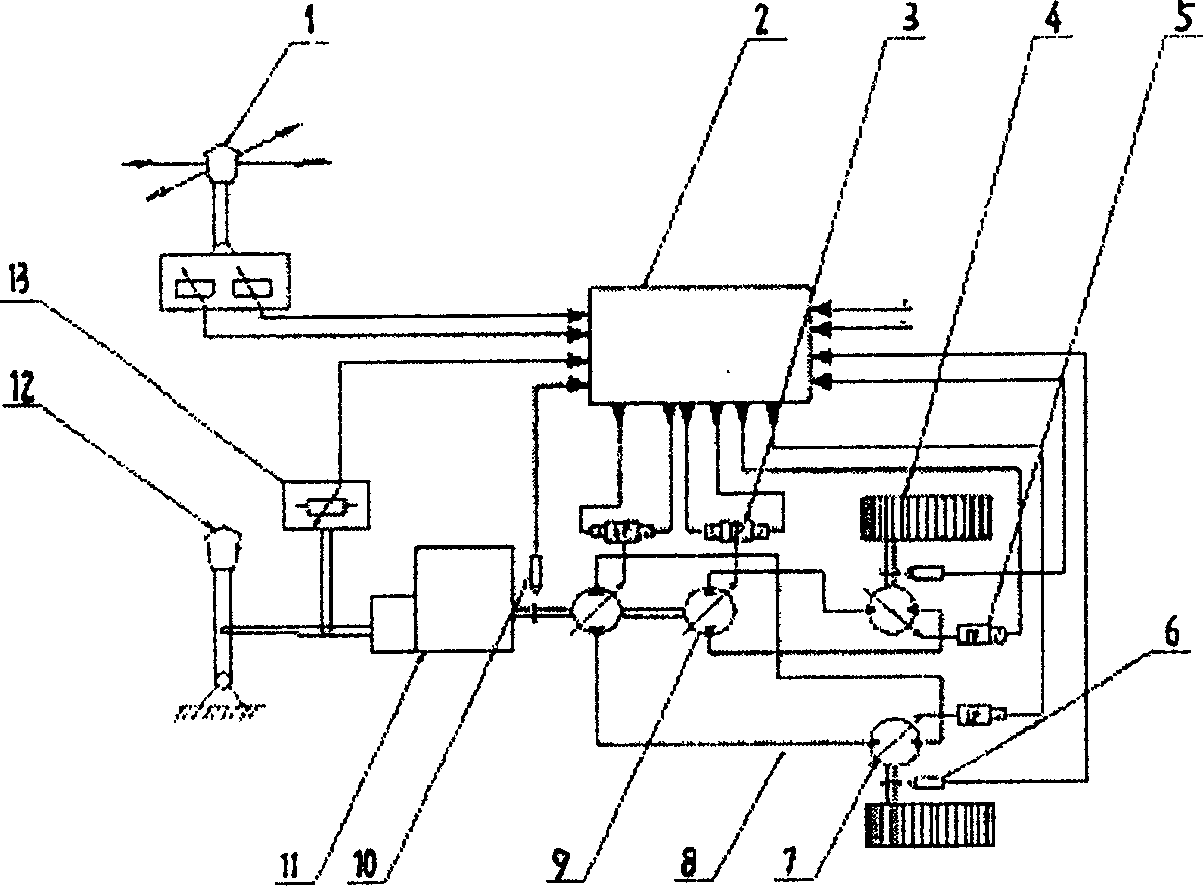

Methods and apparatus for advanced wind turbine design

ActiveUS20070024058A1Eliminate needReduced pressure levelWind motor controlEngine fuctionsHigh energyHydraulic pump

A wind turbine system includes a variable blade assembly including adjustable sails and wing shaped masts expanding the wind velocity capture envelope. The blade assembly turns a hydraulic pump, which pressurizes fluid and stores the pressurized fluid in a chamber in the support tower. Pressurized fluid is directed via an electronically controllable proportioning valve to a hydraulic motor which is coupled to an electric generator. A computer control module operates the proportioning valve regulating pressure to the hydraulic motor, maintaining generator rotational speed, and providing consistent output frequency to the power grid. Stored energy in the high pressure tank is used to continue generator operation after the winds cease, allowing early warning notification to the power management system of impending power loss. Residual pressure maintained in the high pressure tank allows restart operations via hydraulic pressure rather than power grid energy drain. On site high energy capacitors store additional energy.

Owner:MCCLINTIC FRANK

Methods and apparatus for advanced wind turbine design

ActiveUS7183664B2Eliminate needReduce pressureWind motor controlEngine fuctionsHigh energyHydraulic pump

A wind turbine system includes a variable blade assembly including adjustable sails and wing shaped masts expanding the wind velocity capture envelope. The blade assembly turns a hydraulic pump, which pressurizes fluid and stores the pressurized fluid in a chamber in the support tower. Pressurized fluid is directed via an electronically controllable proportioning valve to a hydraulic motor which is coupled to an electric generator. A computer control module operates the proportioning valve regulating pressure to the hydraulic motor, maintaining generator rotational speed, and providing consistent output frequency to the power grid. Stored energy in the high pressure tank is used to continue generator operation after the winds cease, allowing early warning notification to the power management system of impending power loss. Residual pressure maintained in the high pressure tank allows restart operations via hydraulic pressure rather than power grid energy drain. On site high energy capacitors store additional energy.

Owner:MCCLINTIC FRANK

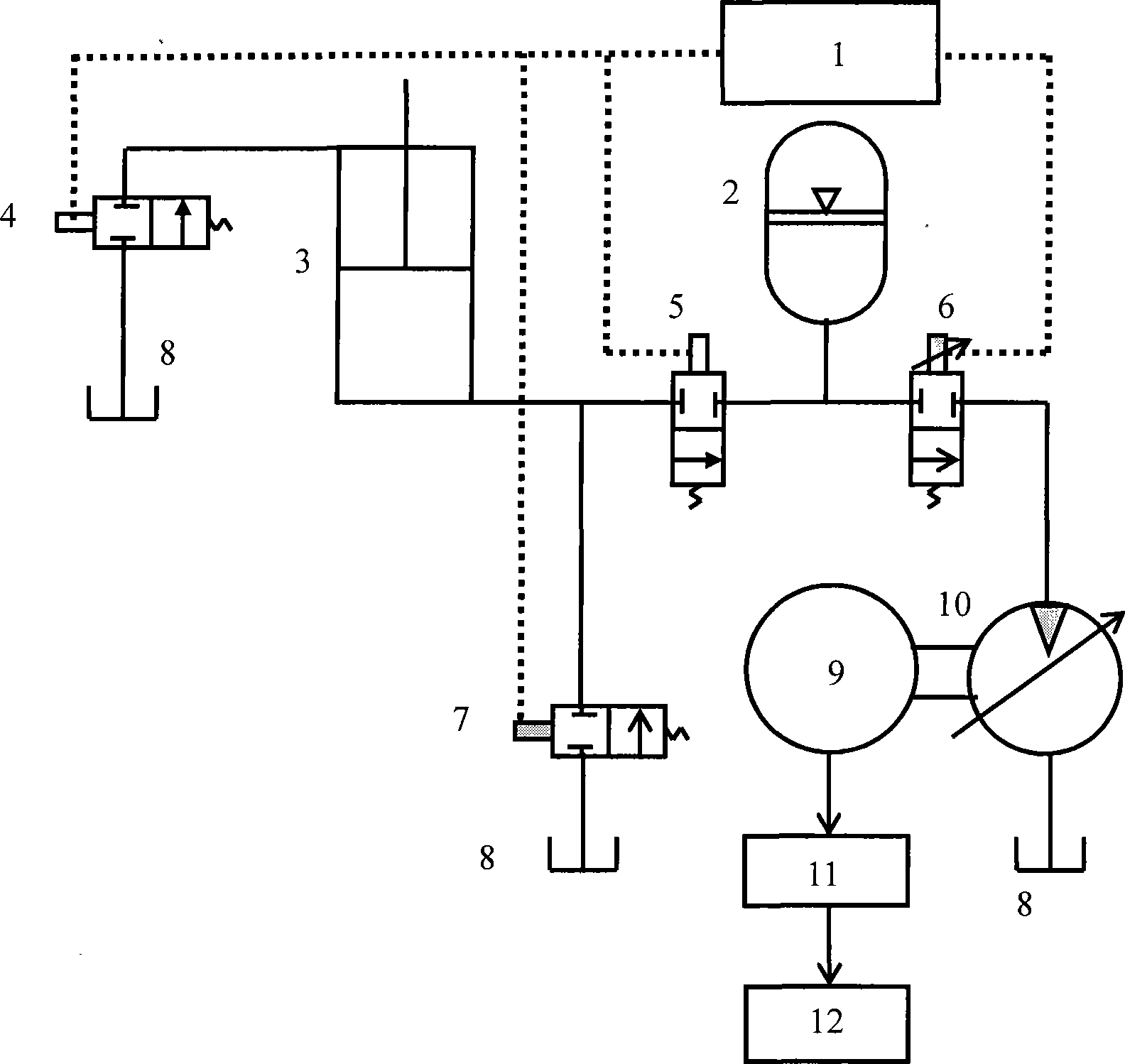

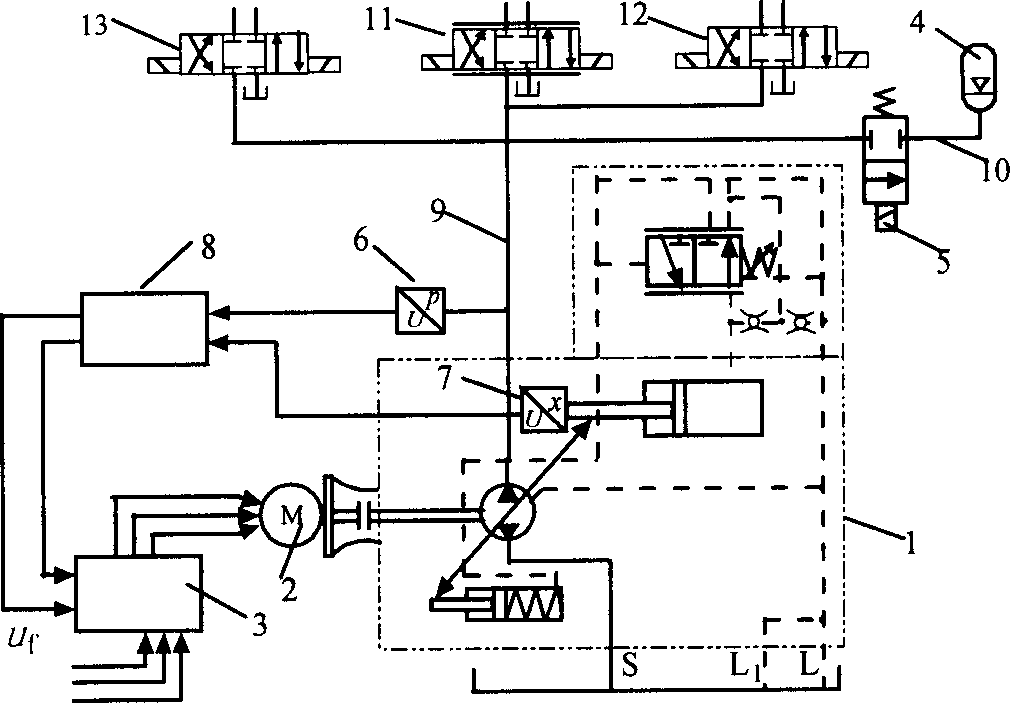

Movable arm potential energy recovery method and apparatus of hydraulic excavator

InactiveCN101435451ASmall pressure fluctuationsWorking speed adjustmentBatteries circuit arrangementsMechanical machines/dredgersRecovery methodThrottle control

The invention discloses a method for recovering potential energy of a movable arm of a hydraulic digging machine and a device thereof. The method comprises the following steps: firstly, the potential energy is stored through an energy accumulator in the retraction process of a hydraulic cylinder; and secondly the stored energy in the energy accumulator drives a generator to generate electricity, thereby realizing the recovery of the potential energy of the movable arm of the hydraulic digging machine. A mode for storing the potential energy is to convert the potential energy into pressure energy. The energy accumulator and the generator are connected through a proportioning valve so as to control the rotational speed of the generator. The method realizes high-efficiency recovery of the potential energy of the movable arm of the hydraulic digging machine; the principle of the method is to skillfully change the working time of hydraulic oil for power generation through the function of energy storage of the energy accumulator and provide effective buffering for recovering the potential energy; in addition, through the throttling control of the proportioning valve, the method reduces pressure fluctuation of the hydraulic oil in the power generation process, realizes the adjustment of the working rotational speed of the generator, improves the working efficiency of the generator and further improves the efficiency of energy recovery.

Owner:CENT SOUTH UNIV

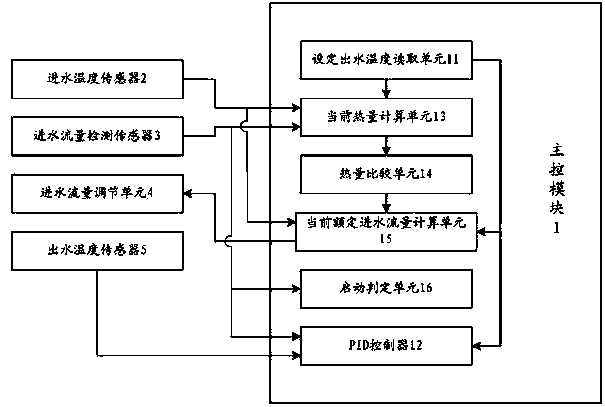

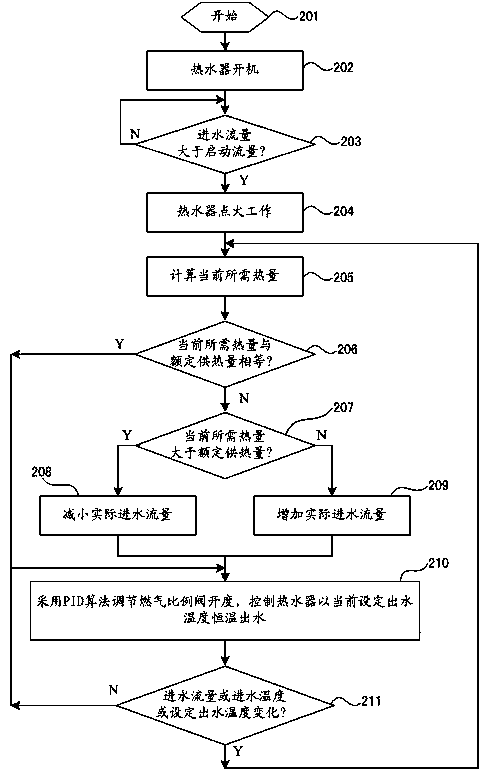

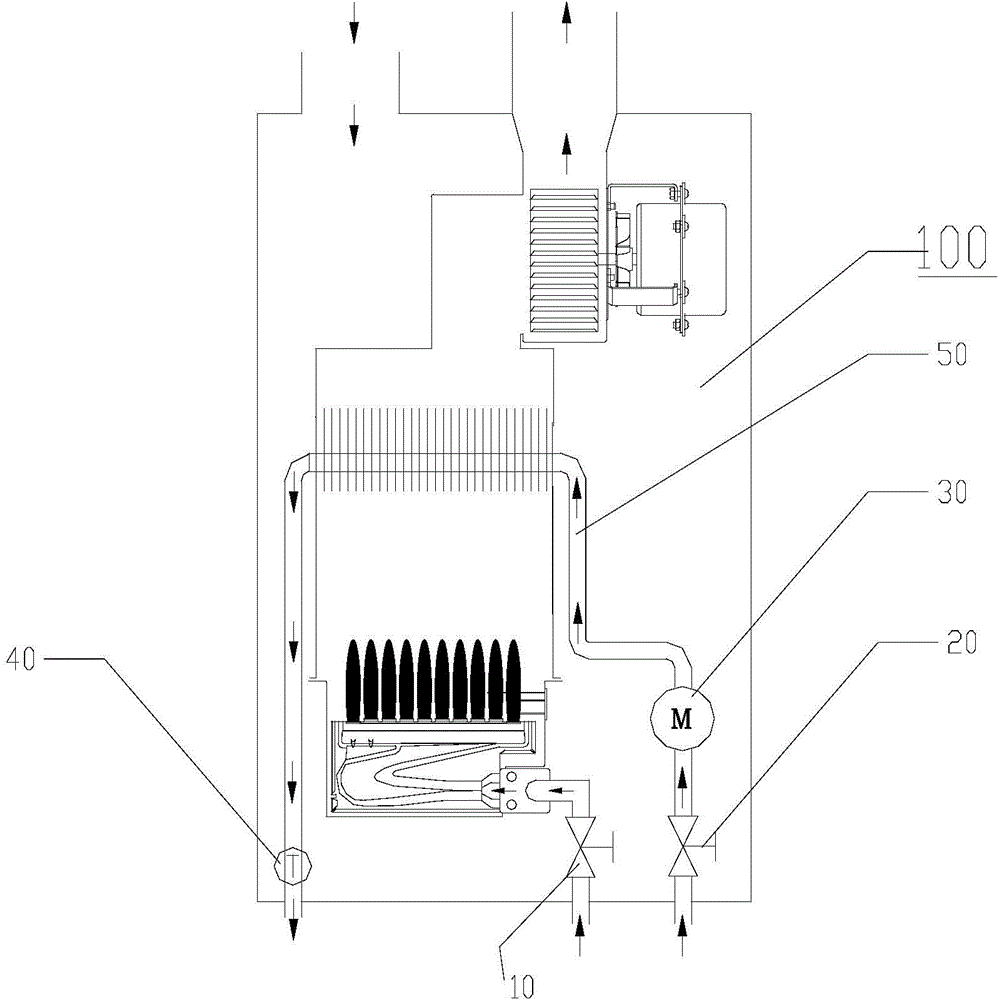

Control method and control device of constant-temperature gas water heater

ActiveCN104236109AImprove use comfort performanceRaise the water temperatureFluid heatersProportion integration differentiationEngineering

The invention discloses a control method and a control device of a constant-temperature gas water heater. The control method includes steps of detecting current water inlet temperature, current water inlet flow and current set water outlet temperature of the water heater and calculating current required heat; comparing the current required heat with rated heat supply of the heater; when the current required heat is higher than the rated heat supply, reducing practical water inlet flow of the heater, and when the current required heat is lower than the rated heat supply, increasing practical water inlet flow of the heater; adjusting opening of a gas proportion valve of the water heater by an PID (proportion integration differentiation) algorithm, and controlling the water heater so as to supply water at constant temperature by the current set water outlet temperature. By the control method and the control device of the constant-temperature gas water heater, the water heater is controlled, water outlet temperature reaches the set temperature, water outlet temperature can be quickly and stably adjusted, and service performance of the water heater is improved.

Owner:HAIER GRP CORP +1

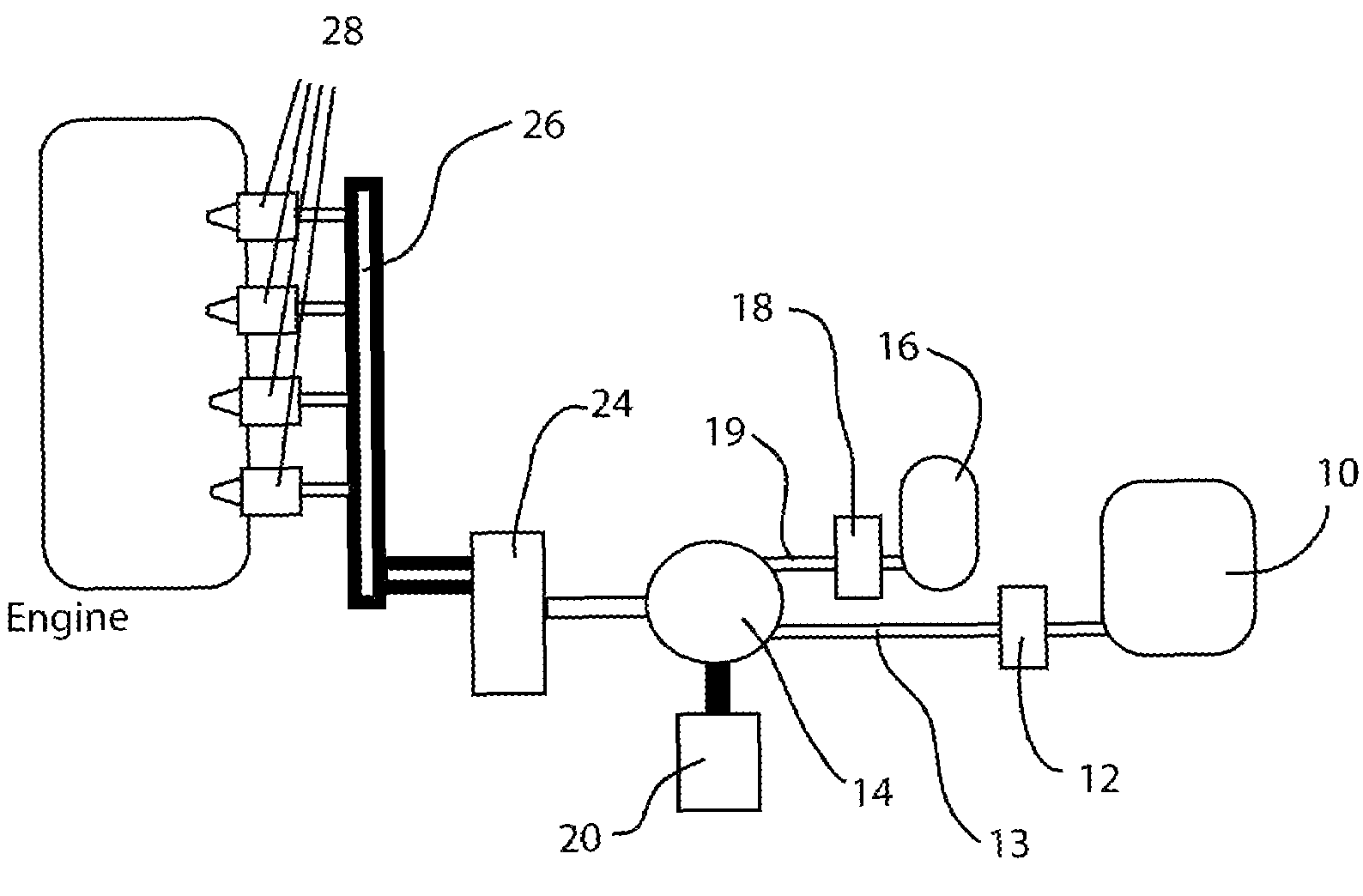

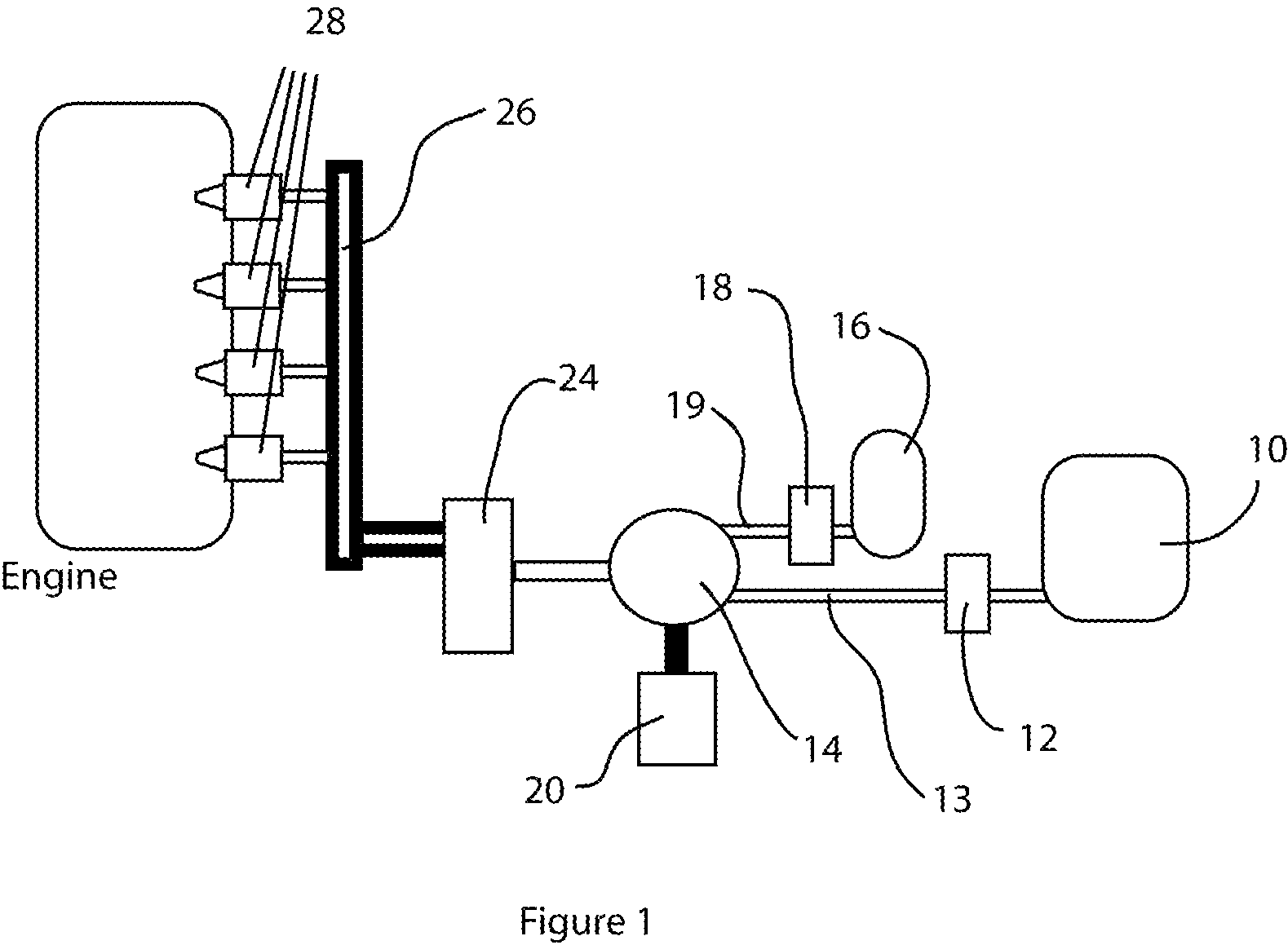

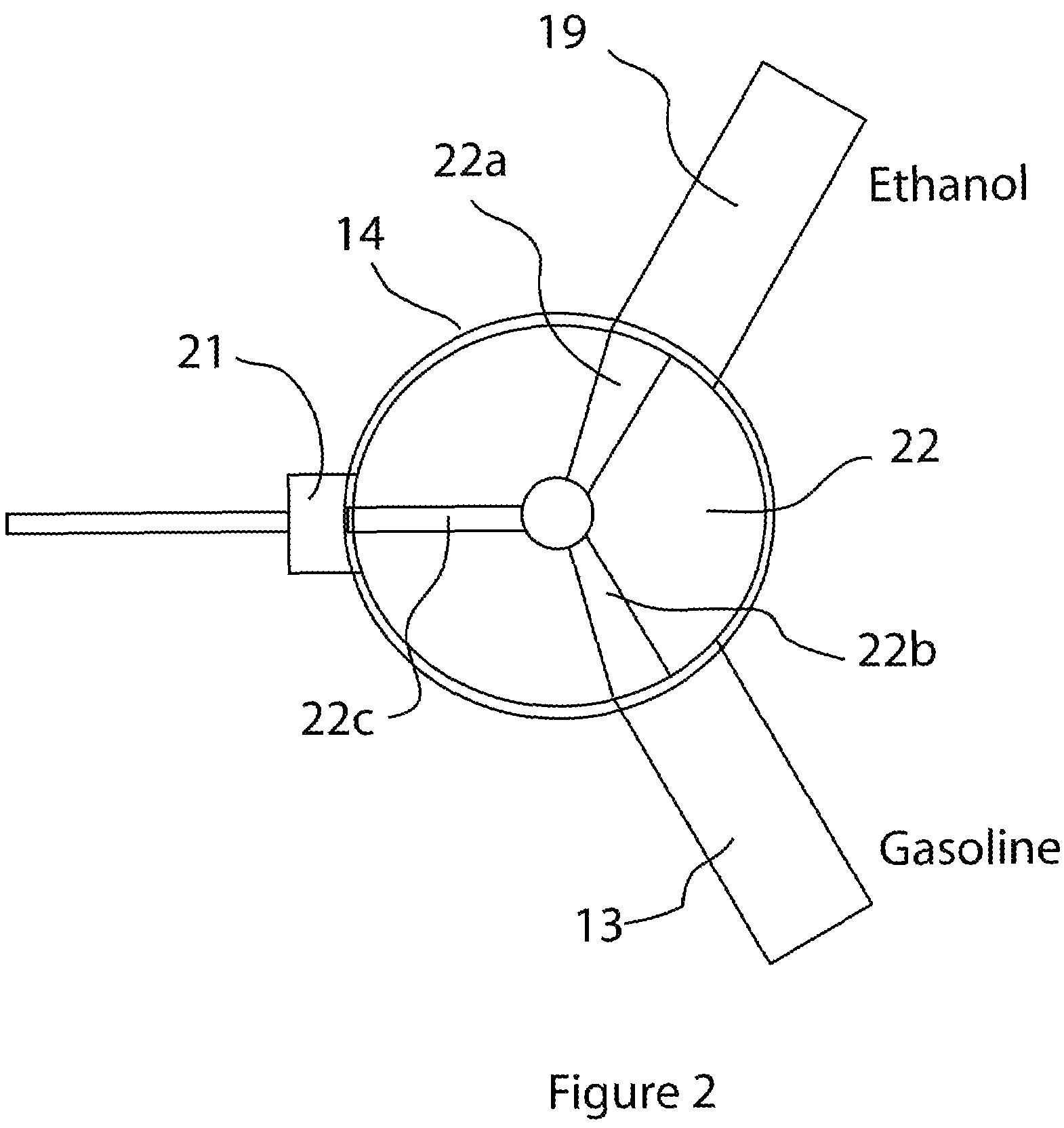

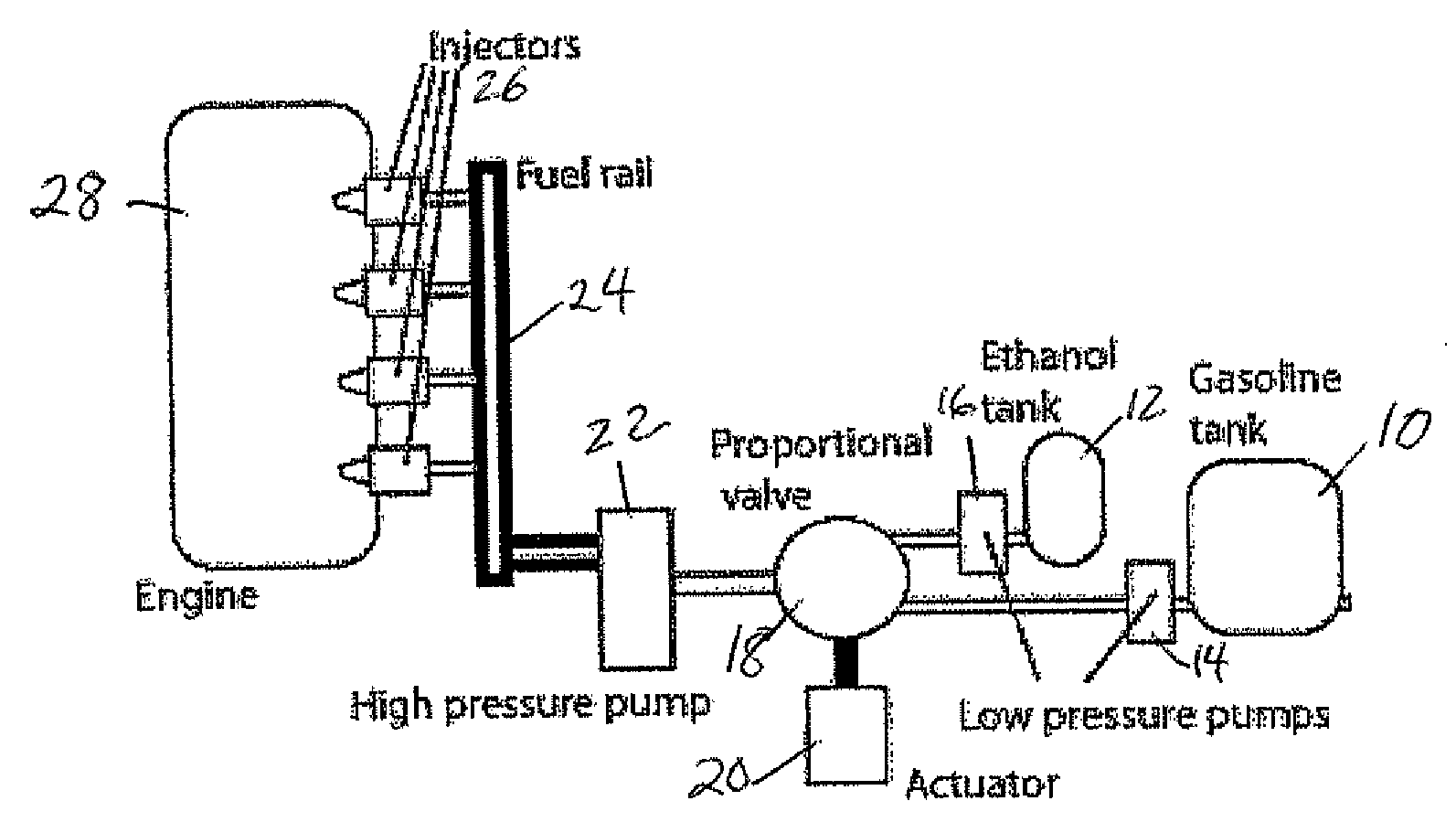

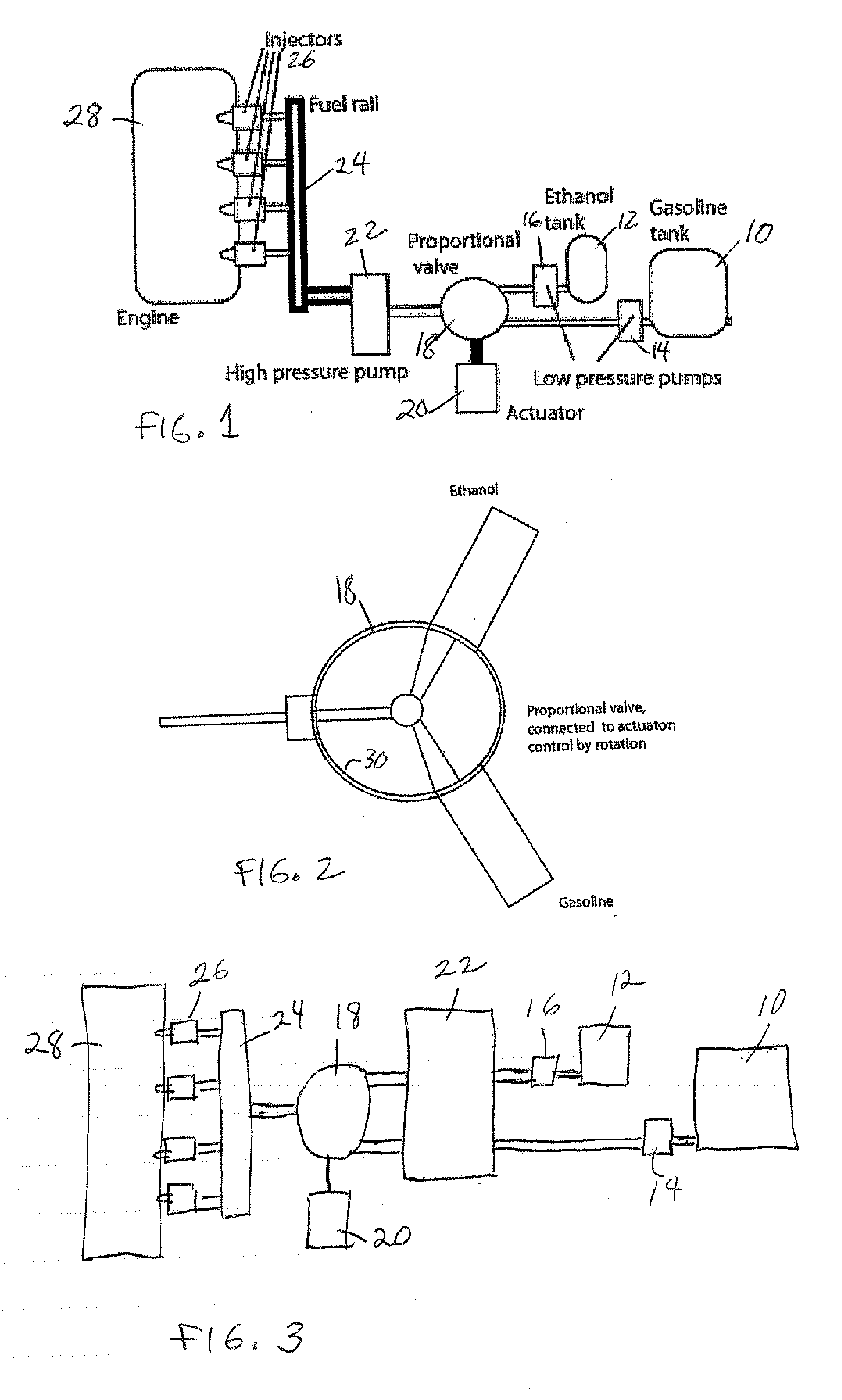

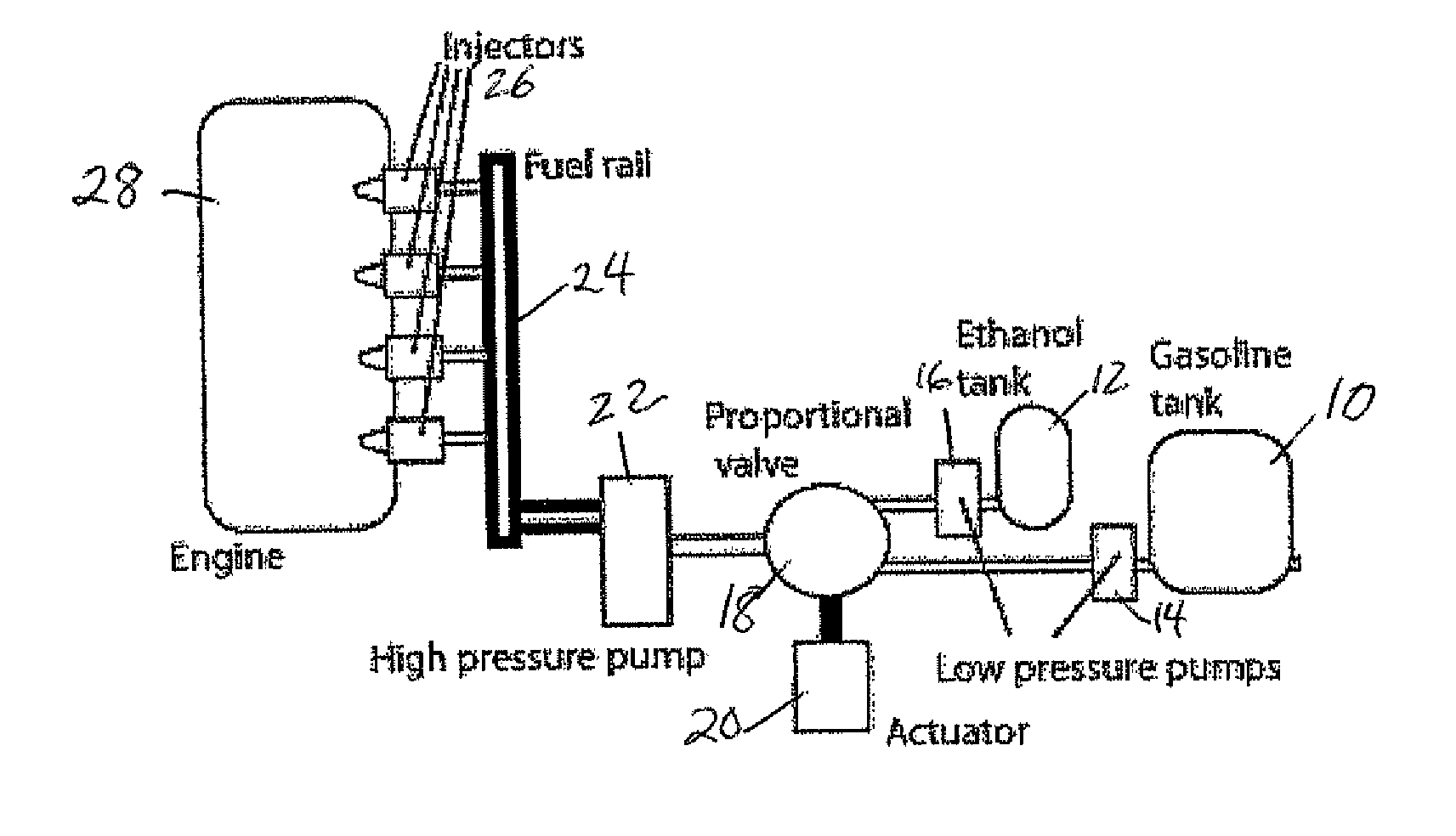

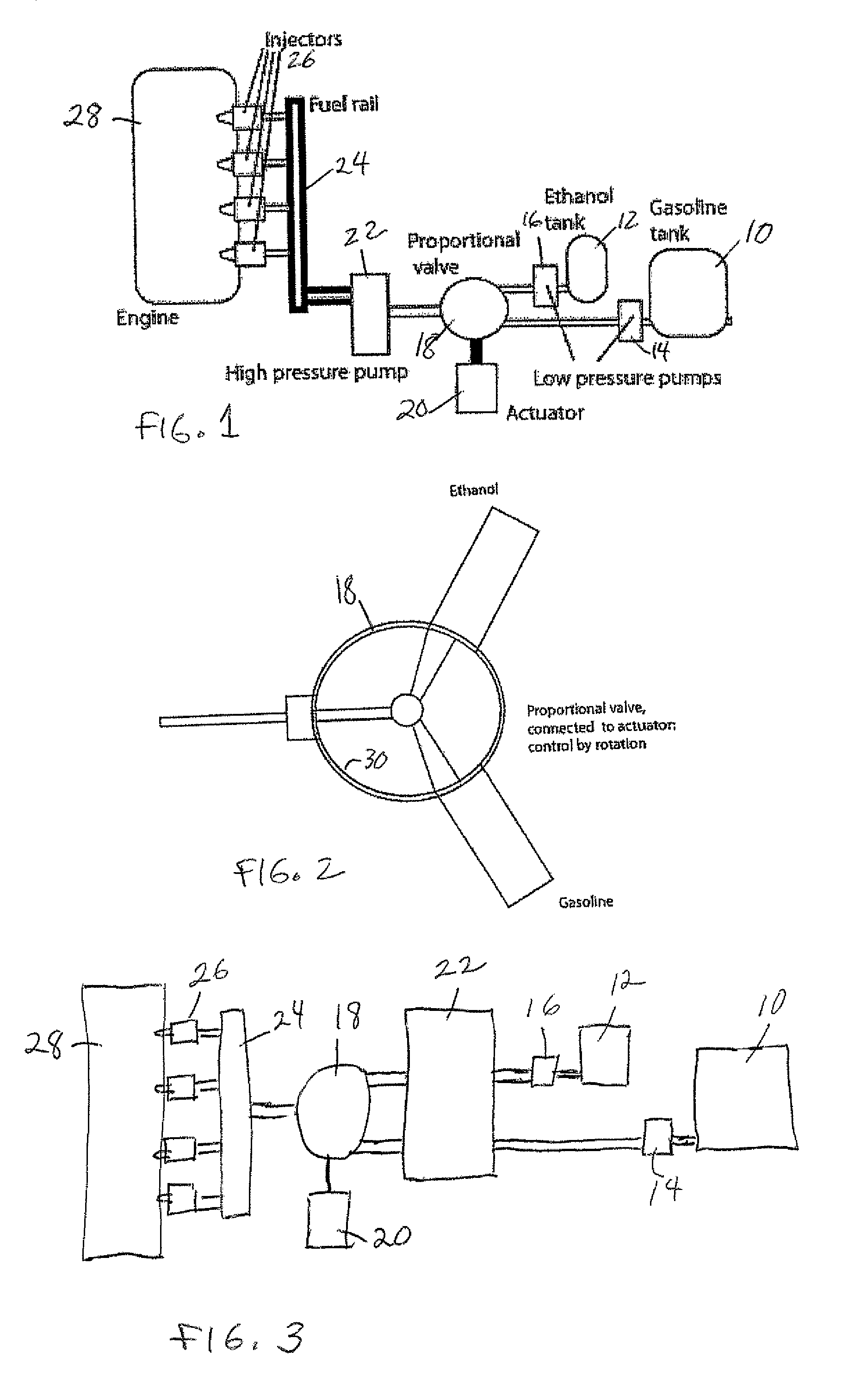

Single nozzle injection of gasoline and anti-knock fuel

InactiveUS7640913B2Improve transient performanceMinimized volumeAnalogue computers for vehiclesInternal combustion piston enginesControl systemGasoline

Fuel management system for operation of a spark ignition engine. The system includes a source of gasoline and a source of anti-knock fuel. A proportioning valve receives the gasoline and the anti-knock fuel to discharge a mixture having a controlled gasoline / anti-knock fuel ratio. A single high pressure pump receives the mixture and delivers the mixture to an injector. A fuel management control system controls the proportioning valve and the injector for injection of the mixture into a cylinder of the engine to control knock. A preferred anti-knock fuel is ethanol.

Owner:ETHANOL BOOSTING SYST LLC

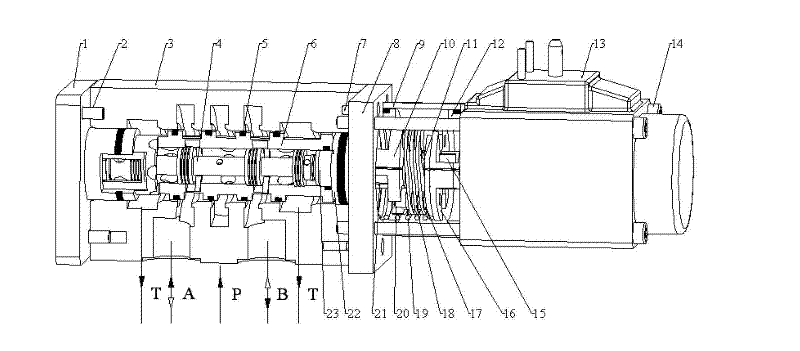

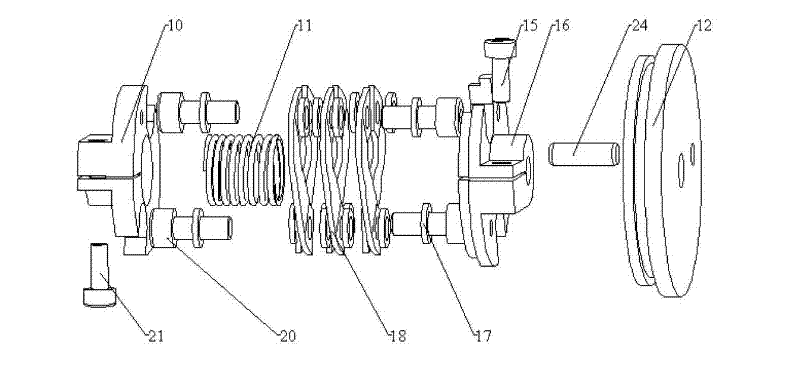

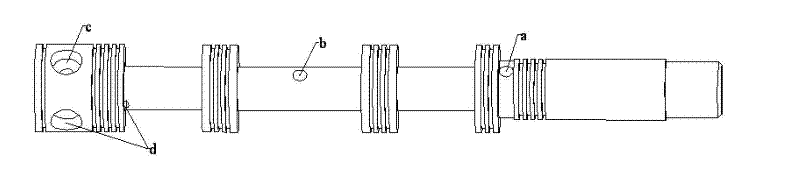

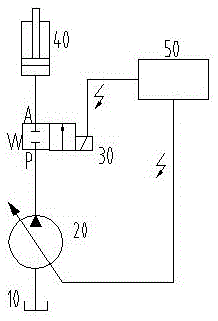

2D hydraulic-power-assisted electro-hydraulic proportional reversing valve

ActiveCN102650305AHigh precisionReduce adverse effectsServomotor componentsElectricityProportional control

The invention provides a 2D (2-dimensional) hydraulic-power-assisted electro-hydraulic proportional reversing valve, which comprises a valve body, a valve core, a valve sleeve, a linear electro-mechanical converter and a compressive-torsional coupling, wherein the valve core, the compressive-torsional coupling and the linear electro-mechanical converter are coaxially connected; an output shaft of the linear electro-mechanical converter is fixedly connected with an input end of the compressive-torsional coupling; an output end of the compressive-torsional coupling is fixedly connected with the right end of the valve core; a sensitive cavity is formed by the left end of the valve core, the valve sleeve and a left cover plate; a pair of axisymmetric high pressure holes and a pair of axisymmetric low pressure holes are respectively formed on the surfaces of shoulders of the valve core in the sensitive cavity; a pair of axisymmetric sensing channels are arranged on the inner surface of the valve sleeve outside the sensitive cavity; and one end of each receptive channel is communicated with the sensitive cavity, and the other ends of the receptive channels cover areas between adjacent high pressure holes and low pressure holes. The 2D hydraulic-power-assisted electro-hydraulic proportional reversing valve not only has the characteristics of high flow rate, high working pressure, and the like of an ordinary pilot-control type electro-hydraulic proportional valve, but also fulfils a proportional control function like a direct-actuated proportional valve under the circumstance of zero pressure (pressure loss).

Owner:ZHEJIANG UNIV OF TECH

Low idling energy consumption hydraulic power source

InactiveCN1821574AIncrease speedReduce volumePump controlPositive-displacement liquid enginesConstant powerSolenoid valve

The hydraulic power source with low idling energy consumption belongs to the field of fluid transmission and control technology, and is one oil supply device designed to lower the energy consumption in the non-work period and partial load work condition of hydraulic system. The present invention consists of hydraulic pump, motor, motor rotation speed controller, energy accumulator, solenoid valve, pressure sensor, displacement sensor, controller, pipeline, executor controlling proportion valve, direction valves and other parts. The present invention features that the hydraulic pump is one constant pressure variable capacity pump with displacement sensor for detecting the displacement of the pump, altering the rotation speed of the pump can reach the composite functions of making the power source possess constant pressure, constant flow and constant power, and lowering the rotation speed in the non-work period and partial load work condition of hydraulic pump can lower the power consumption of the system.

Owner:TAIYUAN UNIV OF TECH

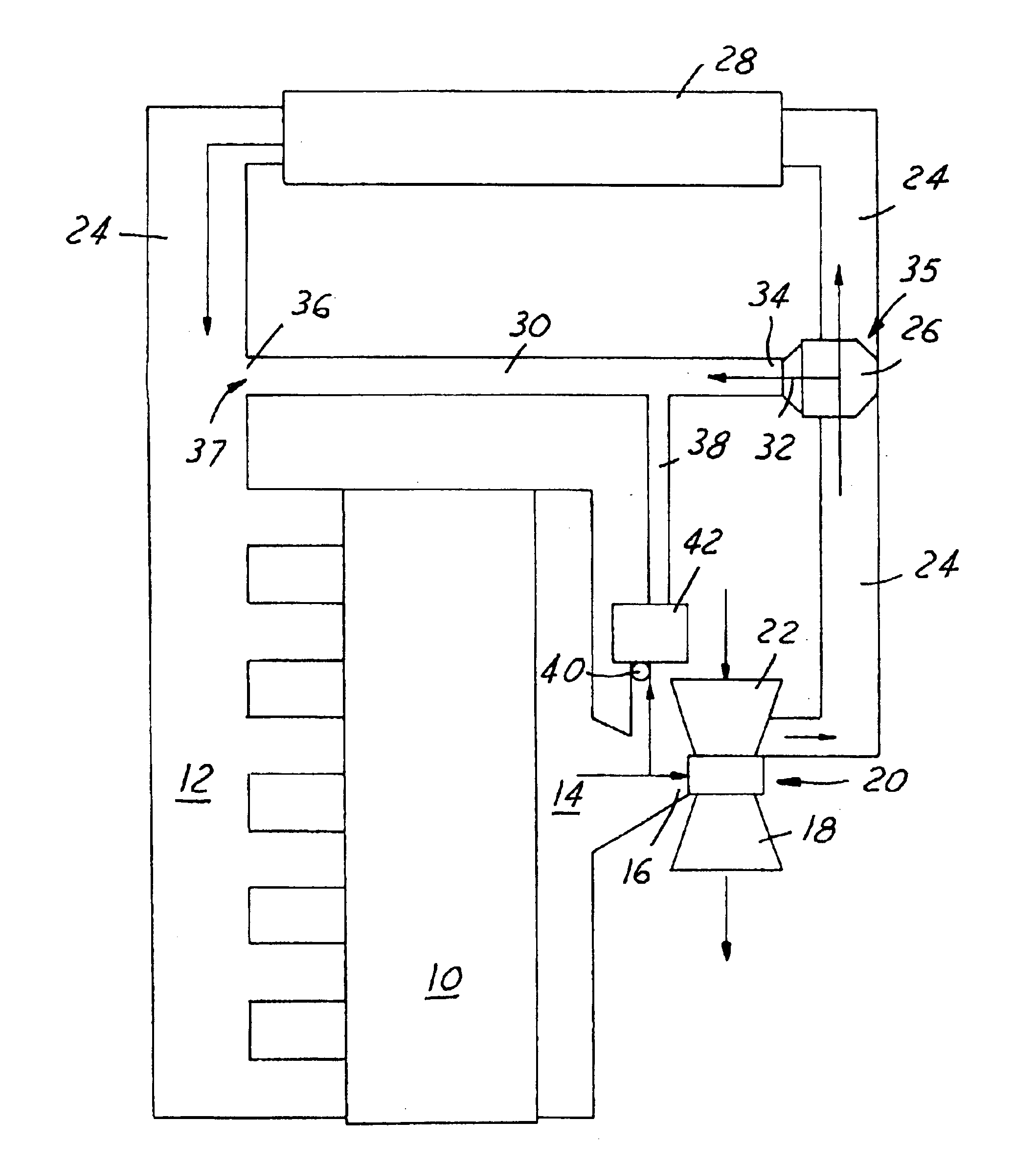

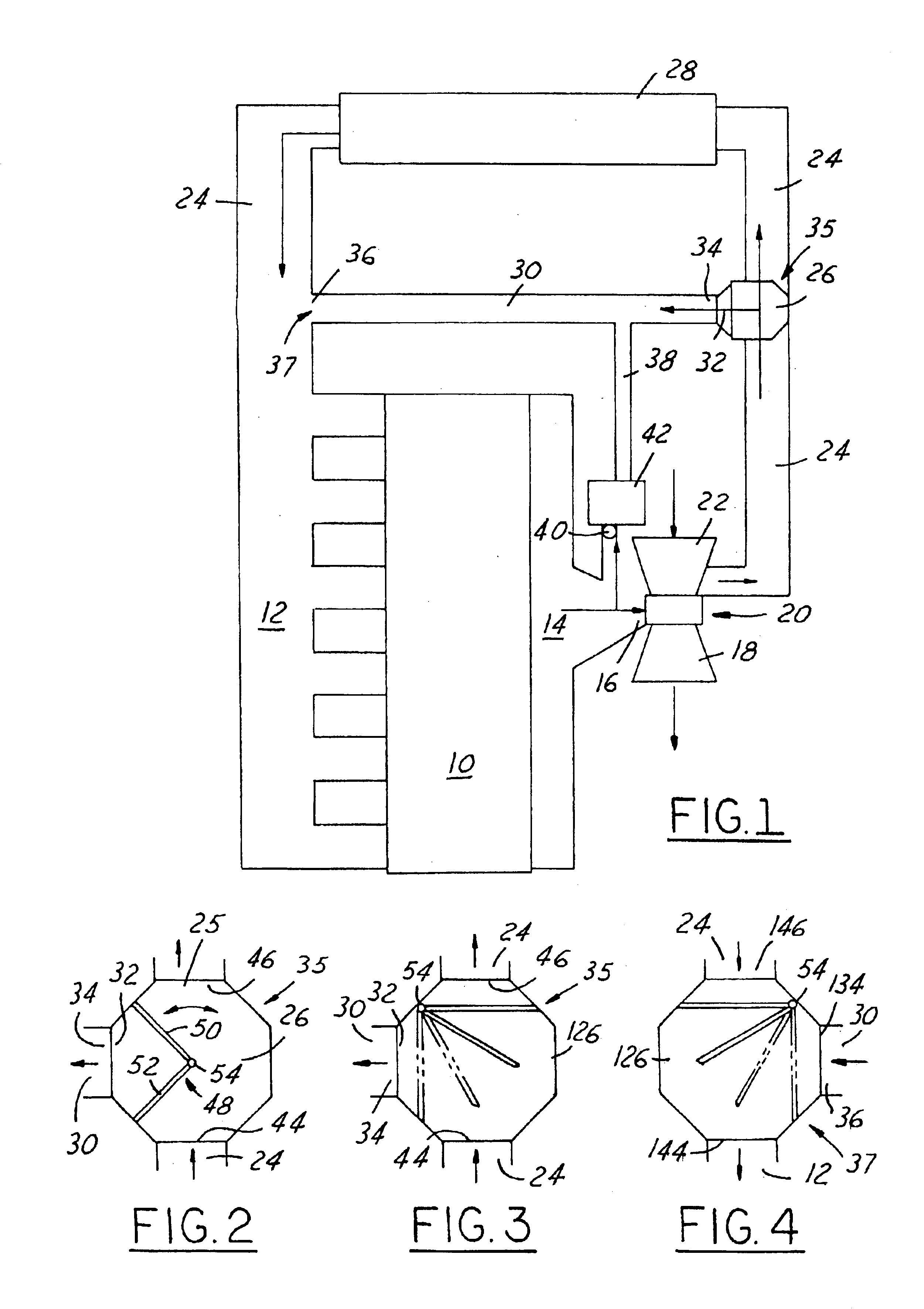

Charged air intake system for an internal combustion engine

InactiveUS6868840B2Increase air densityNon-fuel substance addition to fuelInternal combustion piston enginesDiesel engineExhaust manifold

A charge air intake system for a diesel engine (10) includes a first duct (24) and second bypass duct (30) having its upstream and downstream ends connected to the first duct and bypassing a charge air cooler (28) mounted in line with the first duct (24). An EGR conduit (38) leads from the exhaust manifold to the bypass duct (30). A turbo charger furnished charged air to the ducts where a proportioning valve (26) proportions air between the charge air cooler and the bypass duct.

Owner:DETROIT DIESEL CORP

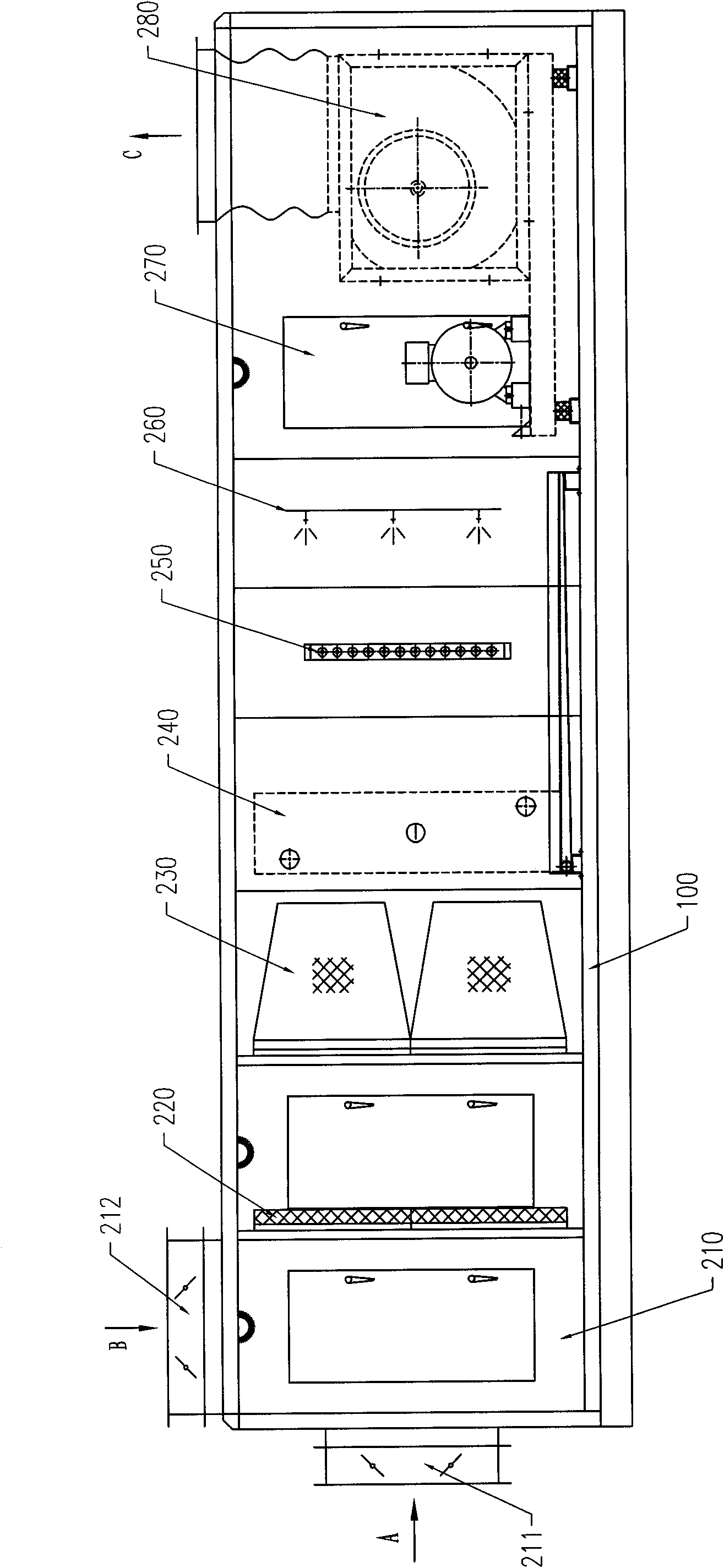

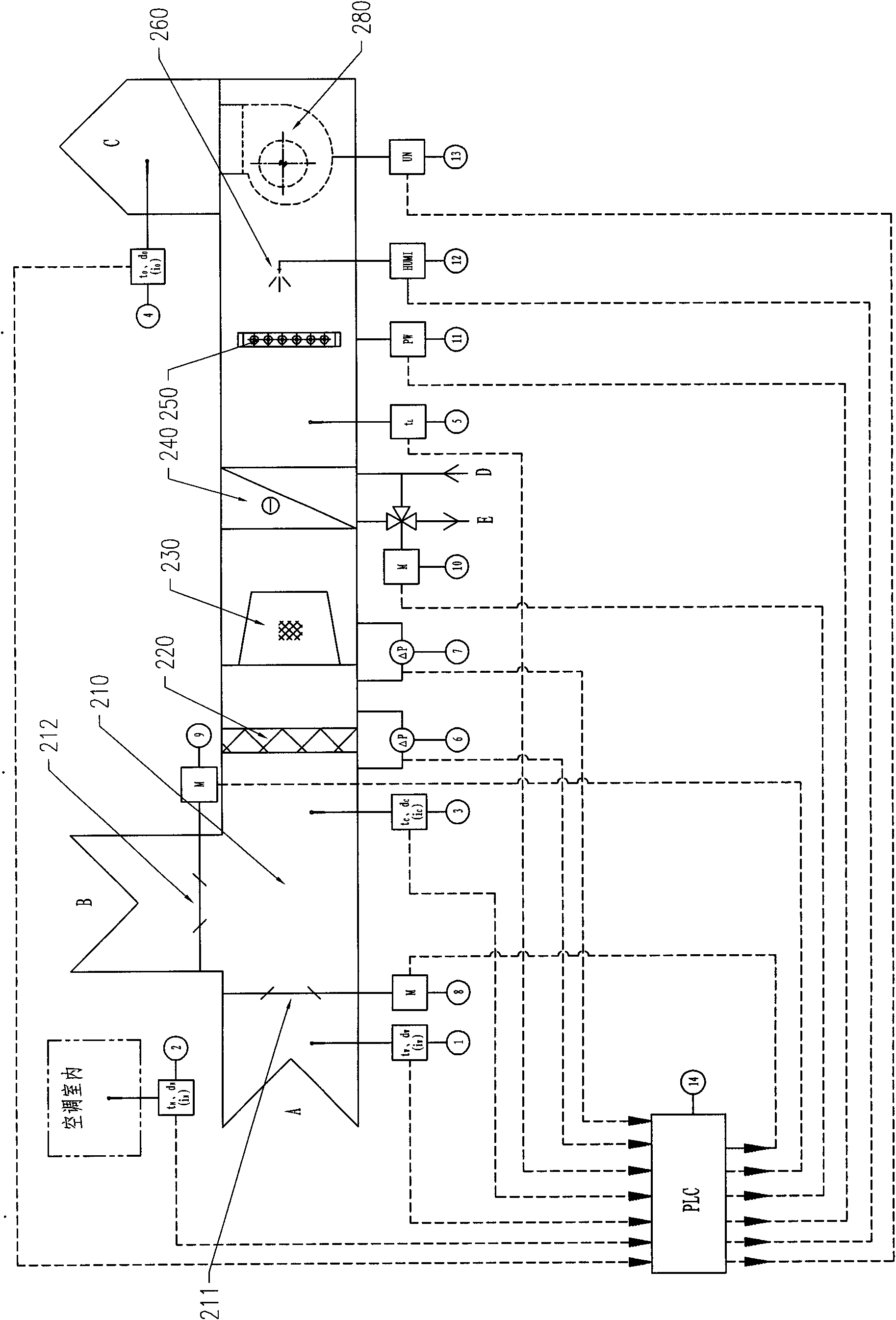

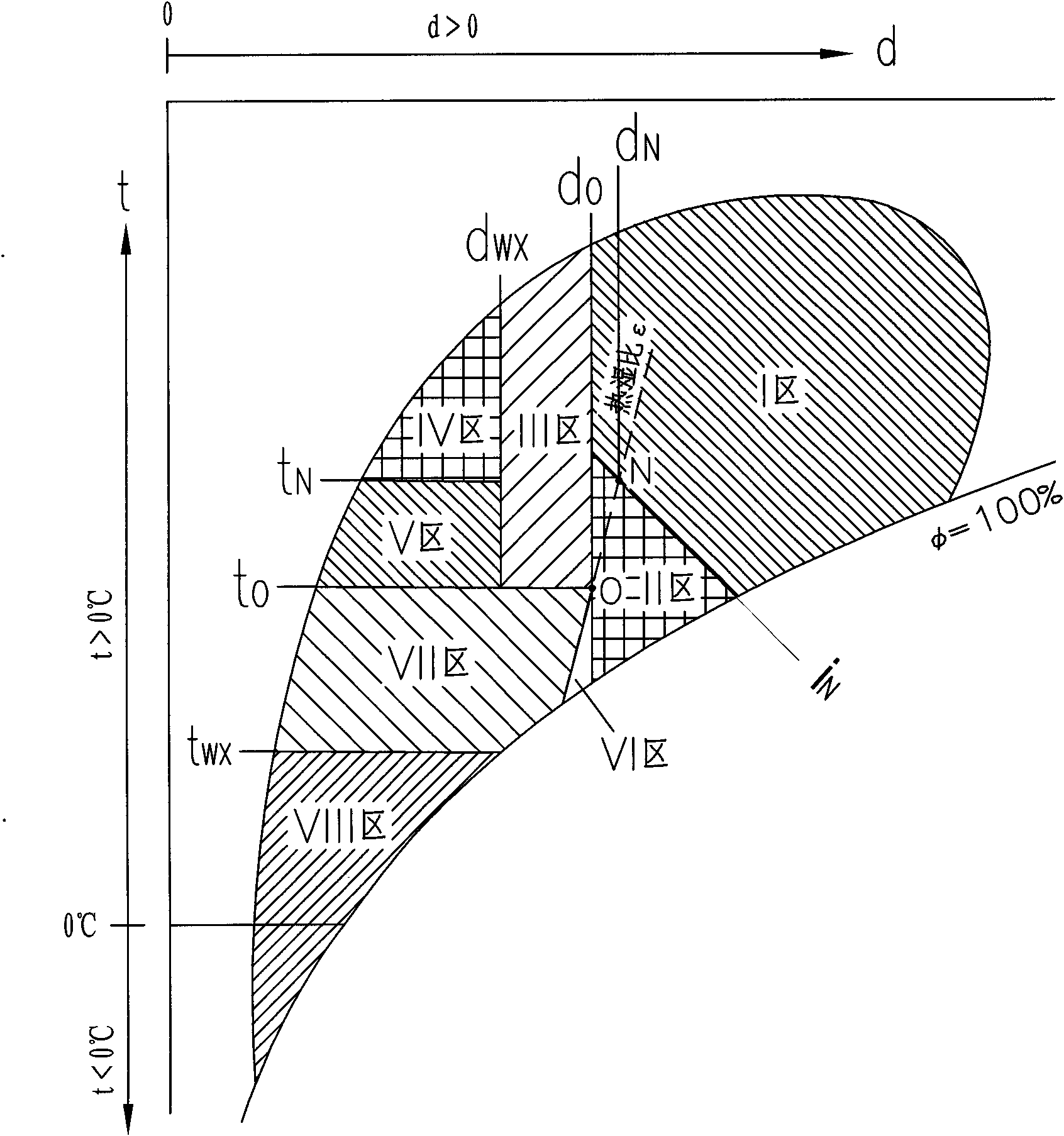

Multi-operating mode energy-saving controlled combined type thermostatic and humidistatic air conditioning unit with thermometal compound box body structure

ActiveCN101782263AReduce resistanceFully contactedSpace heating and ventilation safety systemsLighting and heating apparatusControl systemNuclear power

The invention relates to a multi-operating mode energy-saving controlled combined type thermostatic and humidistatic air conditioning unit with a thermometal compound box body structure special for nuclear power stations. The air conditioning unit comprises a control system and a box body structure, wherein a primary-efficiency filter, a medium-efficiency filter, a surface cooler, a heater, a humidifier and a blow-off device are sequentially arranged in the box body; the front side of the primary-efficiency filter is provided with a fresh air and return air mixing section, and inlets of fresh air and return air are respectively provided with a fresh air proportioning valve and a return air proportioning valve; the control system adopts a programmable logic controller (PLC) and adopts air conditioning multi-operating mode zone control to realize the energy-saving operation of the unit; the surface cooler adopts a large temperature difference cold water heat exchanging technology and can save the investment and operation expenses of a water system; and the box body adopts a double-layer compound structure and an anti-shock device to meet the special requirements on the nuclear power stations. The invention has the characteristics of high efficiency, energy saving, good tightness, strong anti-shock capacity, safety, reliability, long service life, and the like.

Owner:广东吉荣核电设备暖通技术有限公司

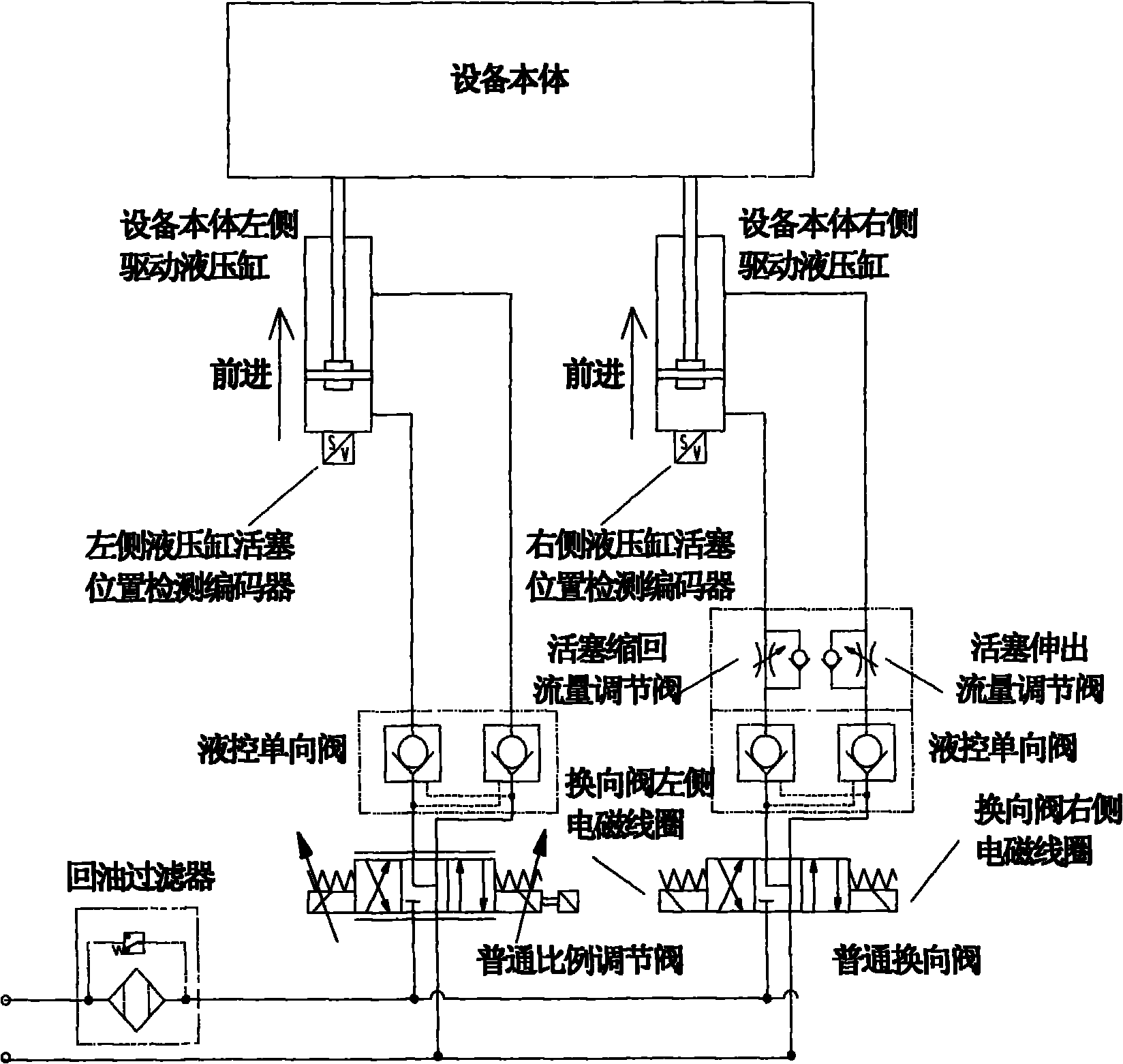

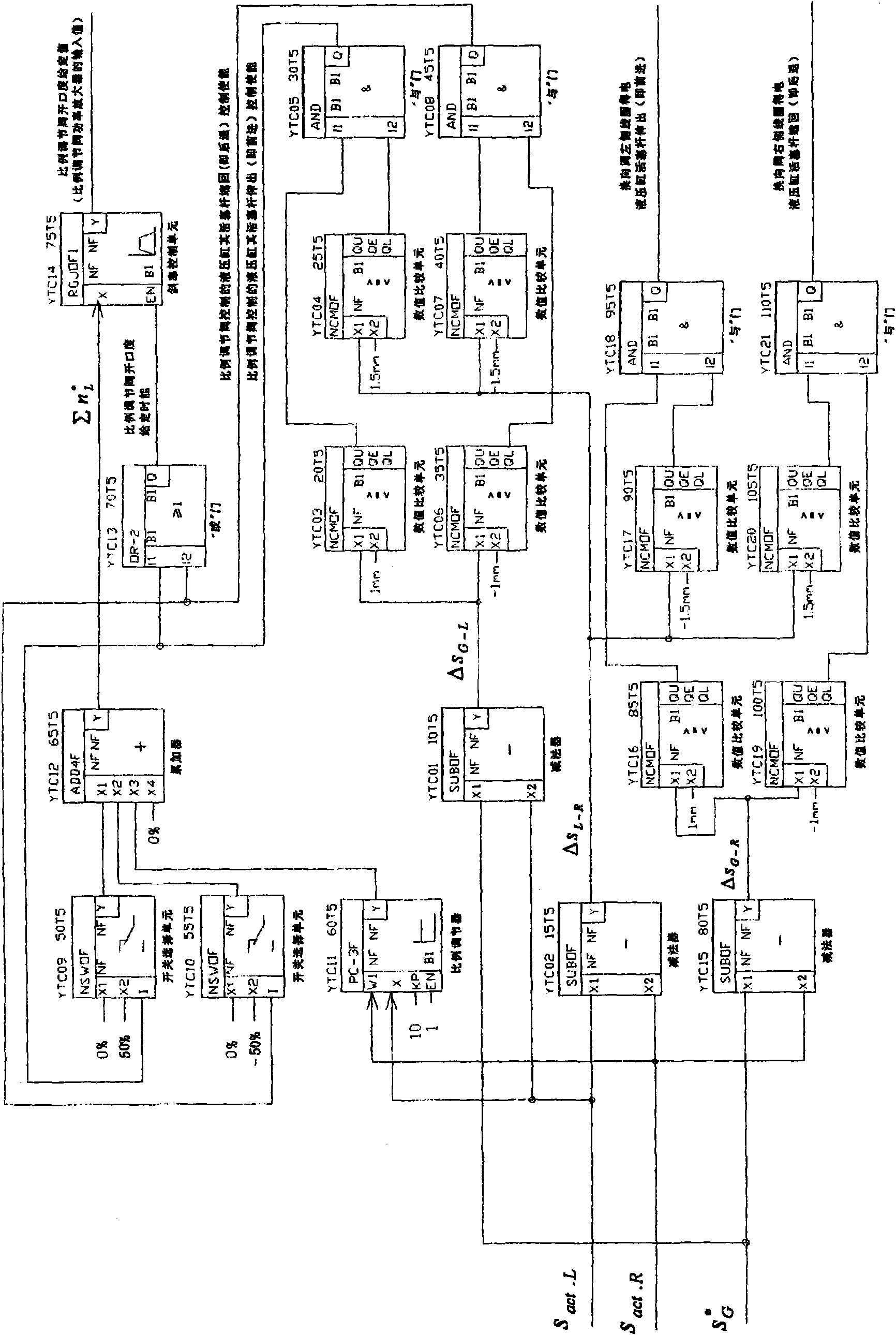

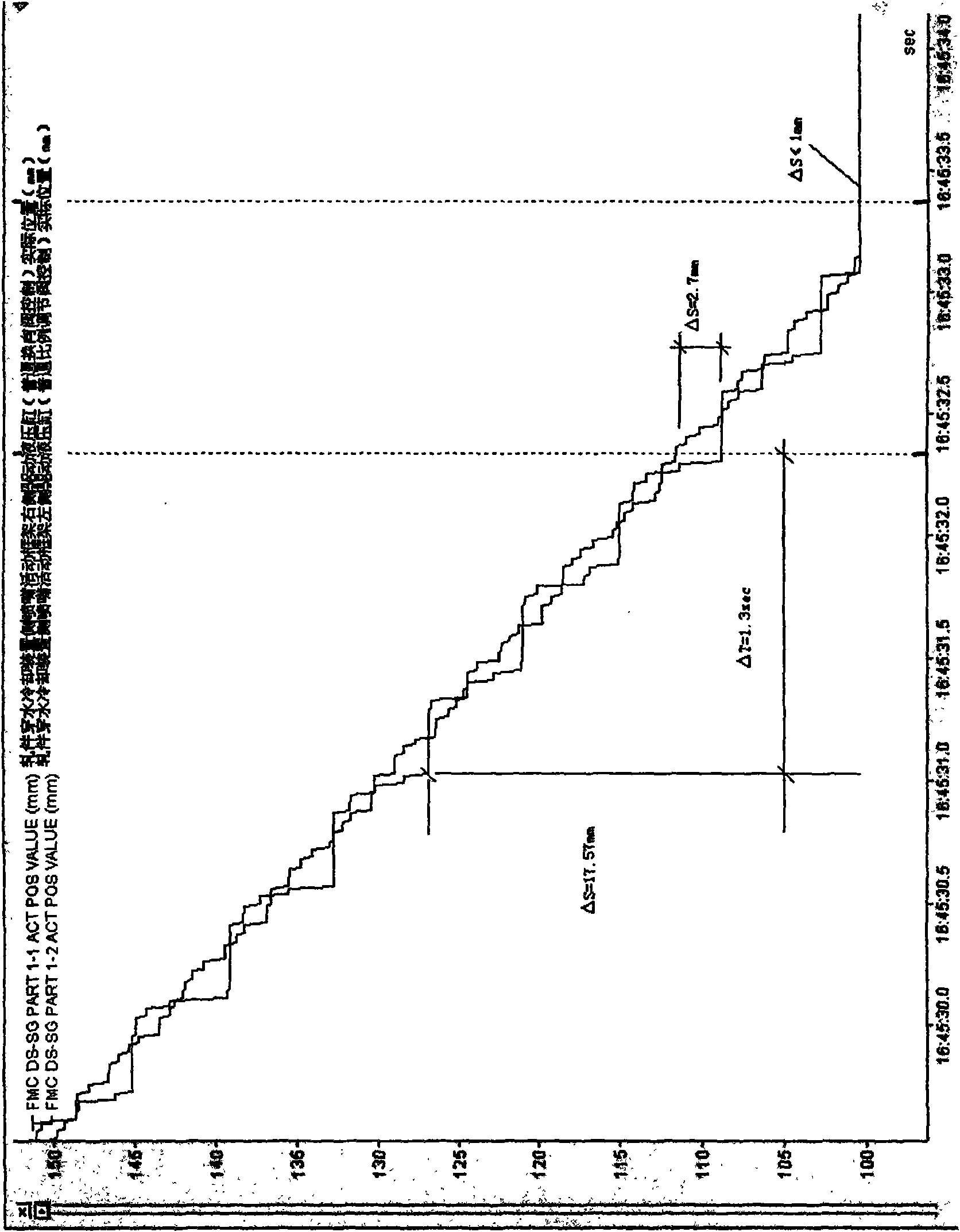

Synchronous control device for hydraulic cylinder and control method thereof

The invention relates to a synchronous control device for a hydraulic cylinder and a control method thereof. The device comprises a device body, an active hydraulic cylinder, n driven hydraulic cylinders, n+1 proportioning valves and n+1 hydraulic control one-way valves, wherein the active hydraulic cylinder is connected with all driven hydraulic cylinders and the device body and synchronously drives all the driven hydraulic cylinders and the device body; the active hydraulic cylinder and all the driven hydraulic cylinders are connected with a proportioning valve respectively and controlled by the proportioning valves; and each hydraulic control one-way valve is arranged on two pipelines behind each proportioning valve.

Owner:MAANSHAN IRON & STEEL CO LTD

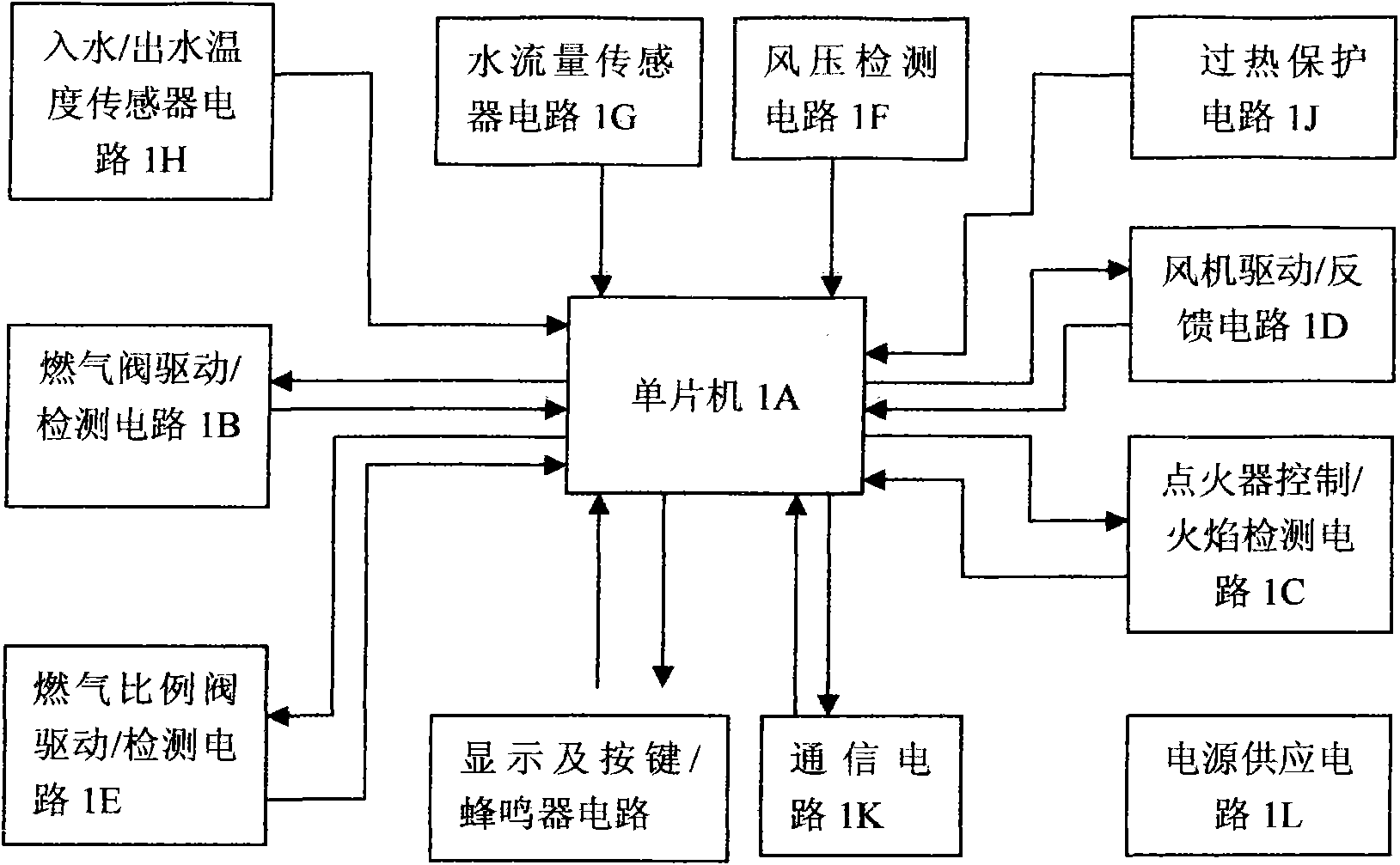

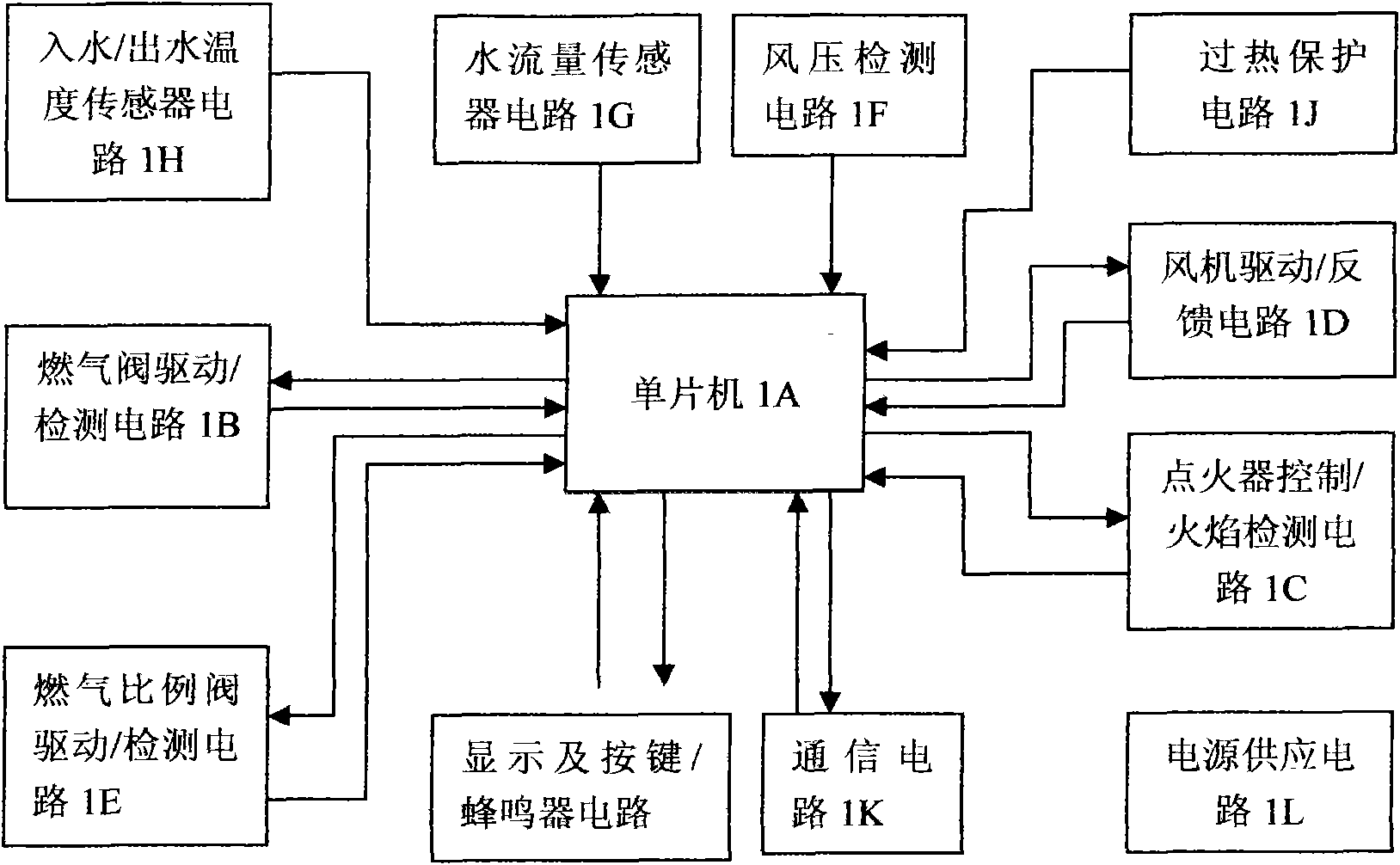

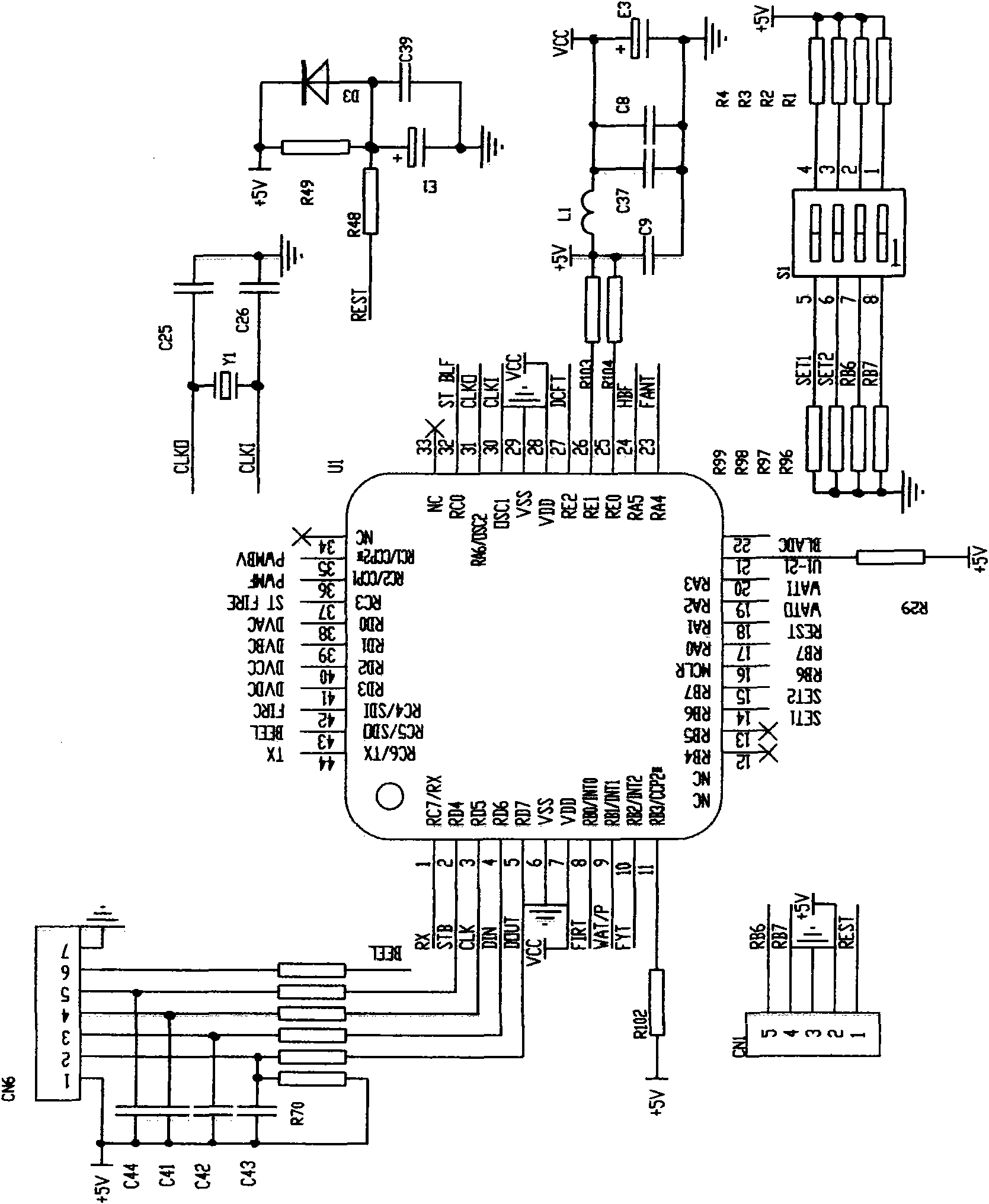

Thermostatic gas water heater controller

ActiveCN101813376AFast and precise control of outlet water temperaturePrecise control of outlet water temperatureFluid heatersFailure rateMicrocontroller

The invention discloses a thermostatic gas water heater controller, characterized by comprising a signlechip, a gas valve drive / detection circuit, an igniter control / flame detection circuit, a blower drive / feedback circuit, a gas proportion valve drive / detection circuit, an air pressure detection circuit, a water flow sensor circuit, a water inlet / outlet temperature sensor circuit and an overheat protection circuit. The gas valve drive / detection circuit also comprises a gas valve drive circuit and a valve detection circuit, and the igniter control / flame detection circuit further comprises an igniter control circuit and a flame detection circuit. The invention aims to overcome the shortcomings of low control accuracy, high failure rate and poor interference resistance of a traditional controller, and provide the thermostatic gas water heater controller with reliable control, low failure rate and no current surge.

Owner:VATTI CORP LTD

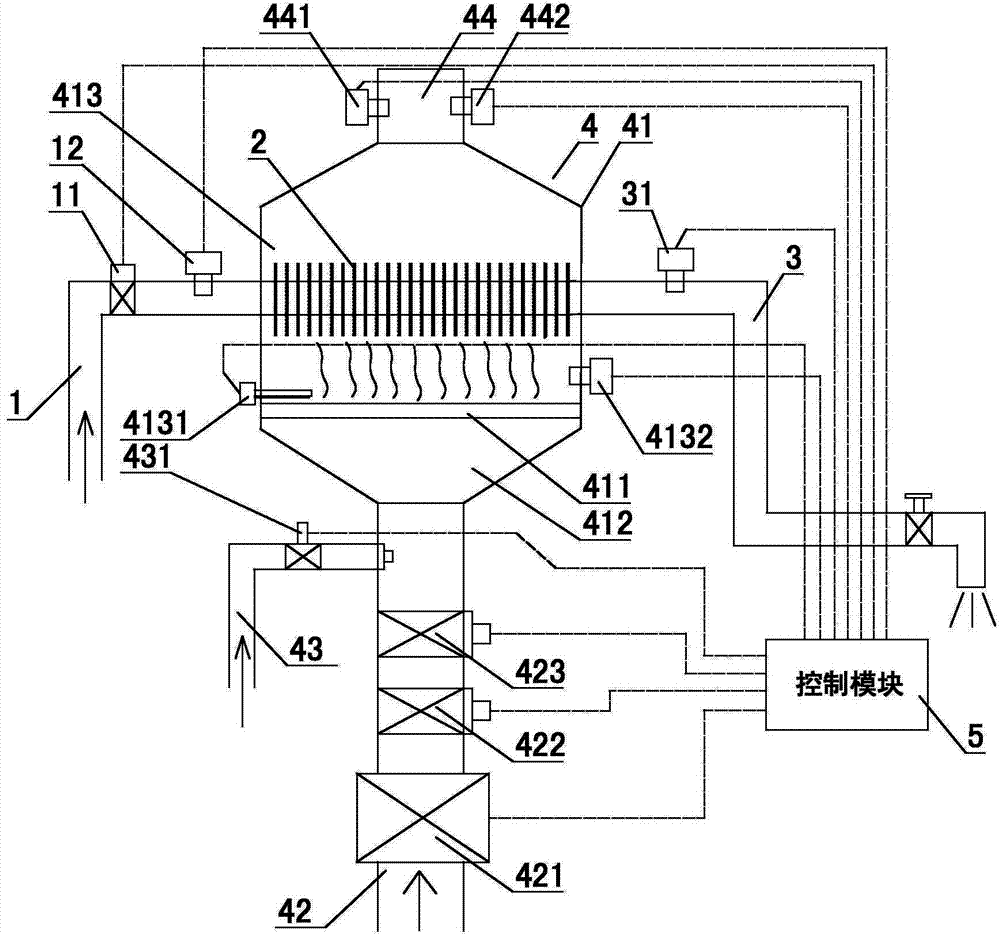

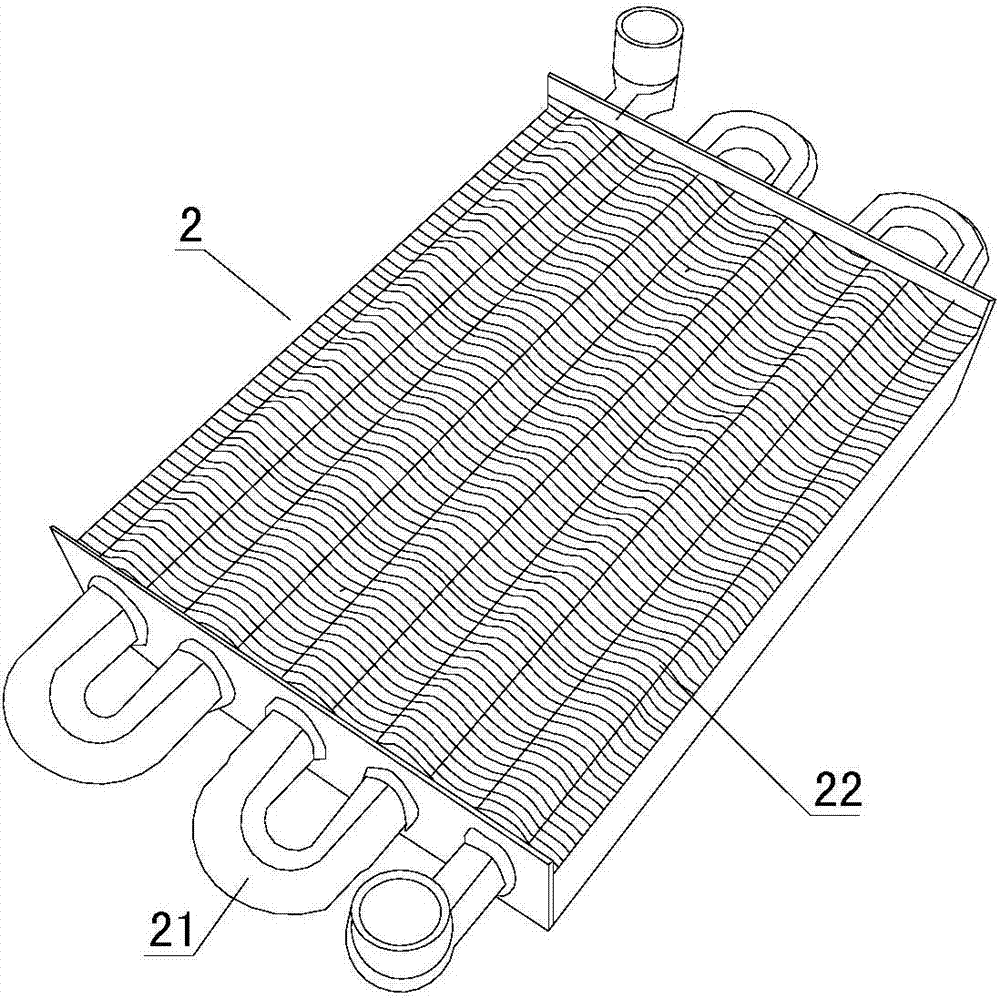

Combustion heating control device and method used for gas water heater

The invention discloses a combustion heating control device and method used for a gas water heater. The combustion heating control device comprises a water inlet pipe, a heat exchanger, a water outlet pipe, a heater and a control module. An air inlet pipe, a gas pipe and an exhaust pipe are arranged on a shell of the heater. An isolating and mixing bin and a combustion bin are arranged in the shell. A water inlet flow sensor and a water inlet temperature sensor are arranged on the water inlet pipe. A water outlet temperature sensor is arranged on the water outlet pipe. A vortex draught fan, an air proportional valve and an air flow sensor are arranged on the air inlet pipe. A gas proportion valve is arranged on the gas pipe. A tail gas temperature sensor and an air pressure sensor are arranged on the exhaust pipe. An igniter and an oxygen sensor are arranged in the combustion bin. The control module is connected with all the sensors, the vortex draught fan, the air proportion valve, the gas proportion valve and the igniter. An energy-saving control method of the combustion heating control device is included. The combustion heating control device has the advantages of being sufficient in gas combustion, low in manufacturing cost, concentrated in heat, and capable of saving gas, reducing carbon dioxide emission and reducing carbon monoxide poisoning.

Owner:广东奇林电气股份有限公司

Methods and apparatus for advanced wind turbine design

ActiveUS20070138798A1Eliminate needReduce pressureWind motor controlEngine fuctionsHigh energyHydraulic pump

A wind turbine system includes a variable blade assembly including adjustable sails and wing shaped masts expanding the wind velocity capture envelope. The blade assembly turns a hydraulic pump, which pressurizes fluid and stores the pressurized fluid in a chamber in the support tower. Pressurized fluid is directed via an electronically controllable proportioning valve to a hydraulic motor which is coupled to an electric generator. A computer control module operates the proportioning valve regulating pressure to the hydraulic motor, maintaining generator rotational speed, and providing consistent output frequency to the power grid. Stored energy in the high pressure tank is used to continue generator operation after the winds cease, allowing early warning notification to the power management system of impending power loss. Residual pressure maintained in the high pressure tank allows restart operations via hydraulic pressure rather than power grid energy drain. On site high energy capacitors store additional energy.

Owner:MCCLINTIC FRANK

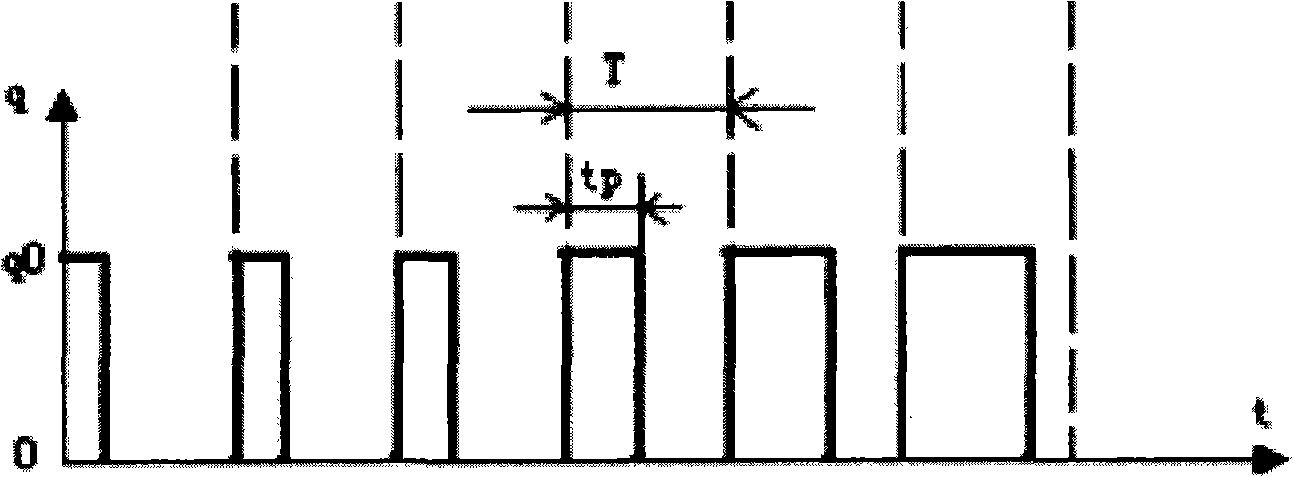

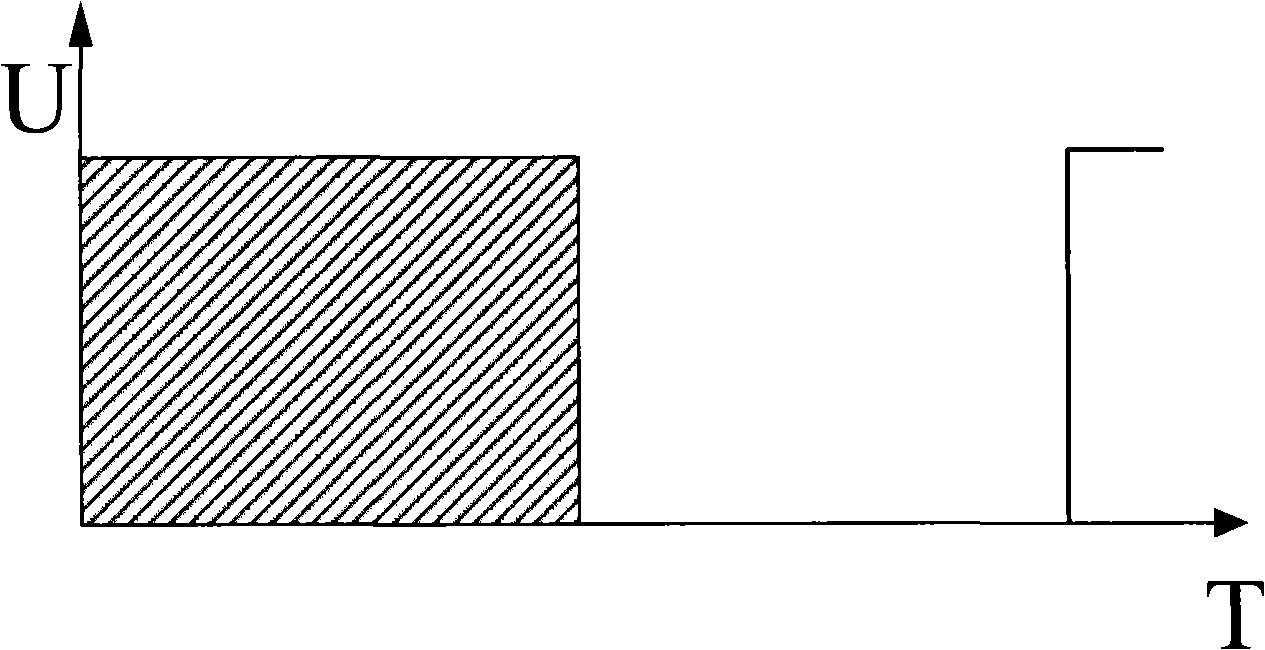

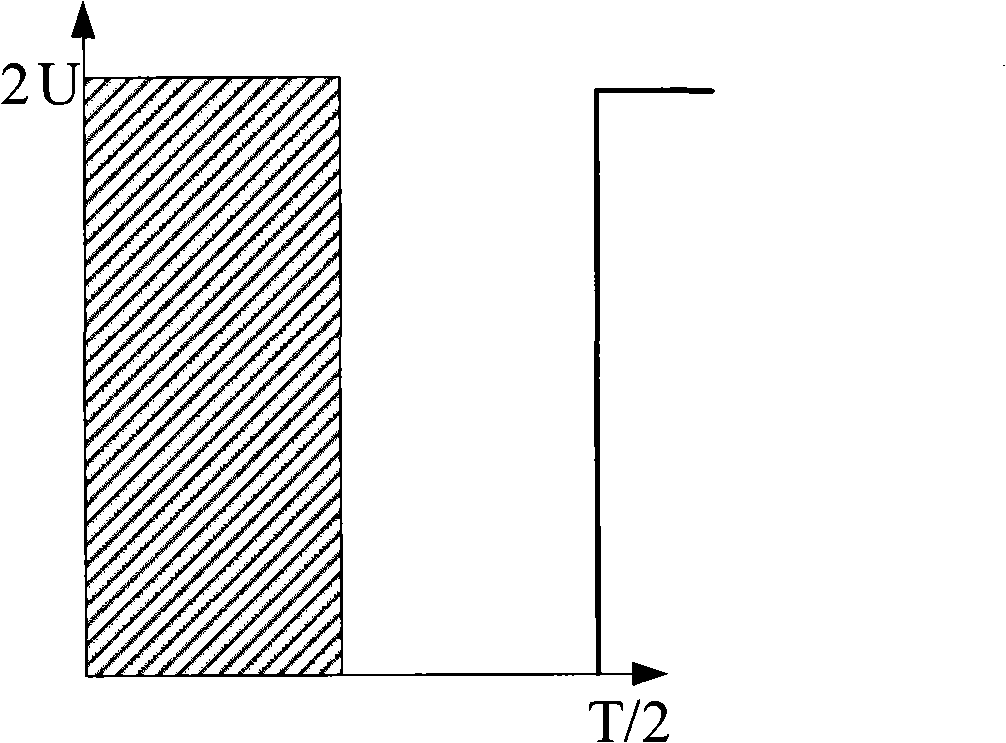

Control method and control system of proportion valve

InactiveCN101349358AGuaranteed reliabilityEasy to controlOperating means/releasing devices for valvesEqualizing valvesVoltage amplitudeProportional control

The invention relates to a control method of a proportional valve. The method comprises generating analogue signals and pulse signals of preset frequency and duty ratio, selecting the analogue signals corresponding to the pulse signals in the period of high level or low level, transmitting the selected signals to the proportional valve, and controlling the action of the proportional valve. The method also can obtain opening signals of the proportional valve, and adjusts voltage amplitude of generated analogue signals according to the opening signals of the proportional valve. Simultaneously, the invention discloses a control system of the proportional valve. When the control system of the proportional valve controls the opening of the proportional valve, vibration of the valve body of the proportional valve can be effectively avoided, thereby increasing the reliability of using the proportional valve.

Owner:SANY HEAVY IND CO LTD (CN)

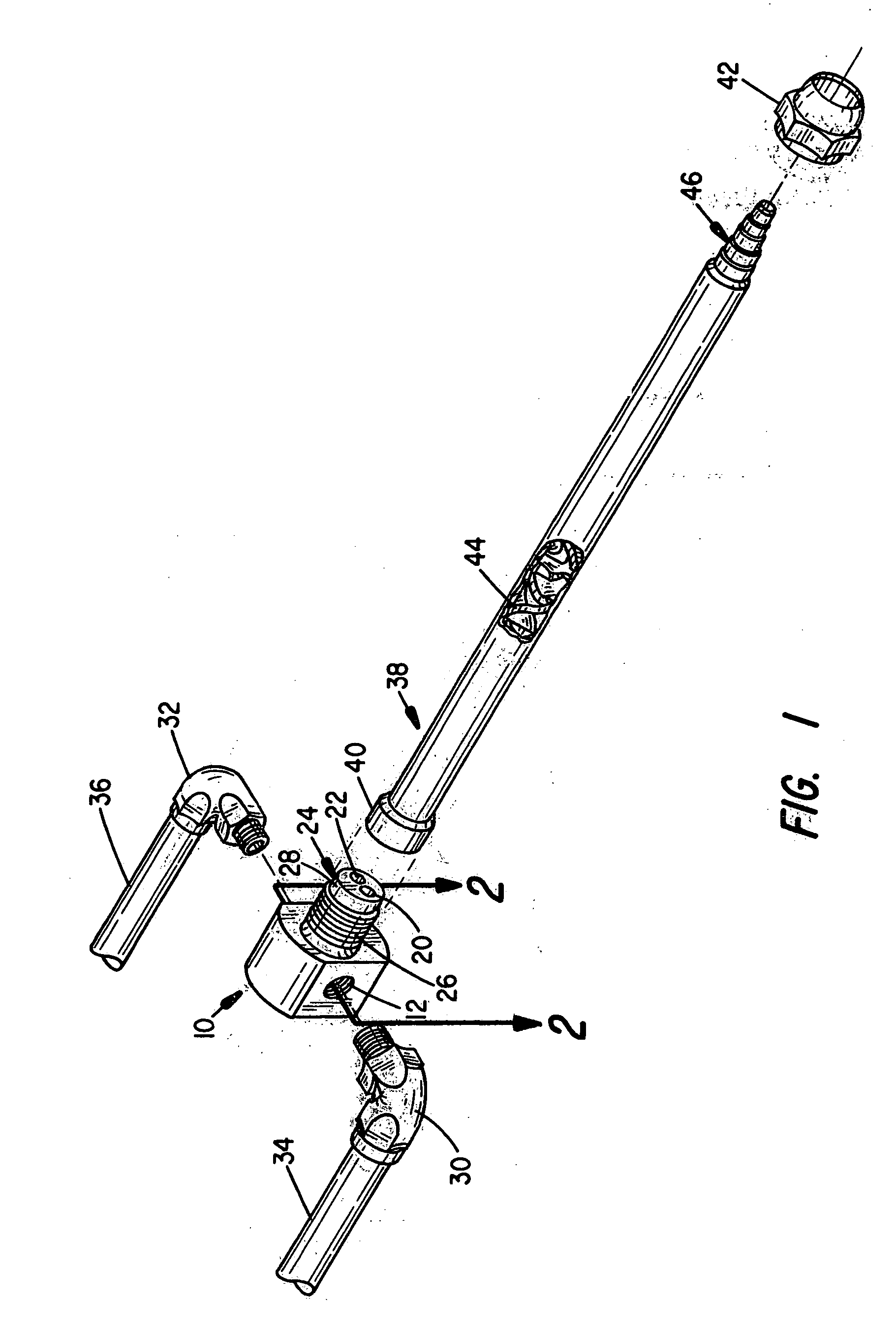

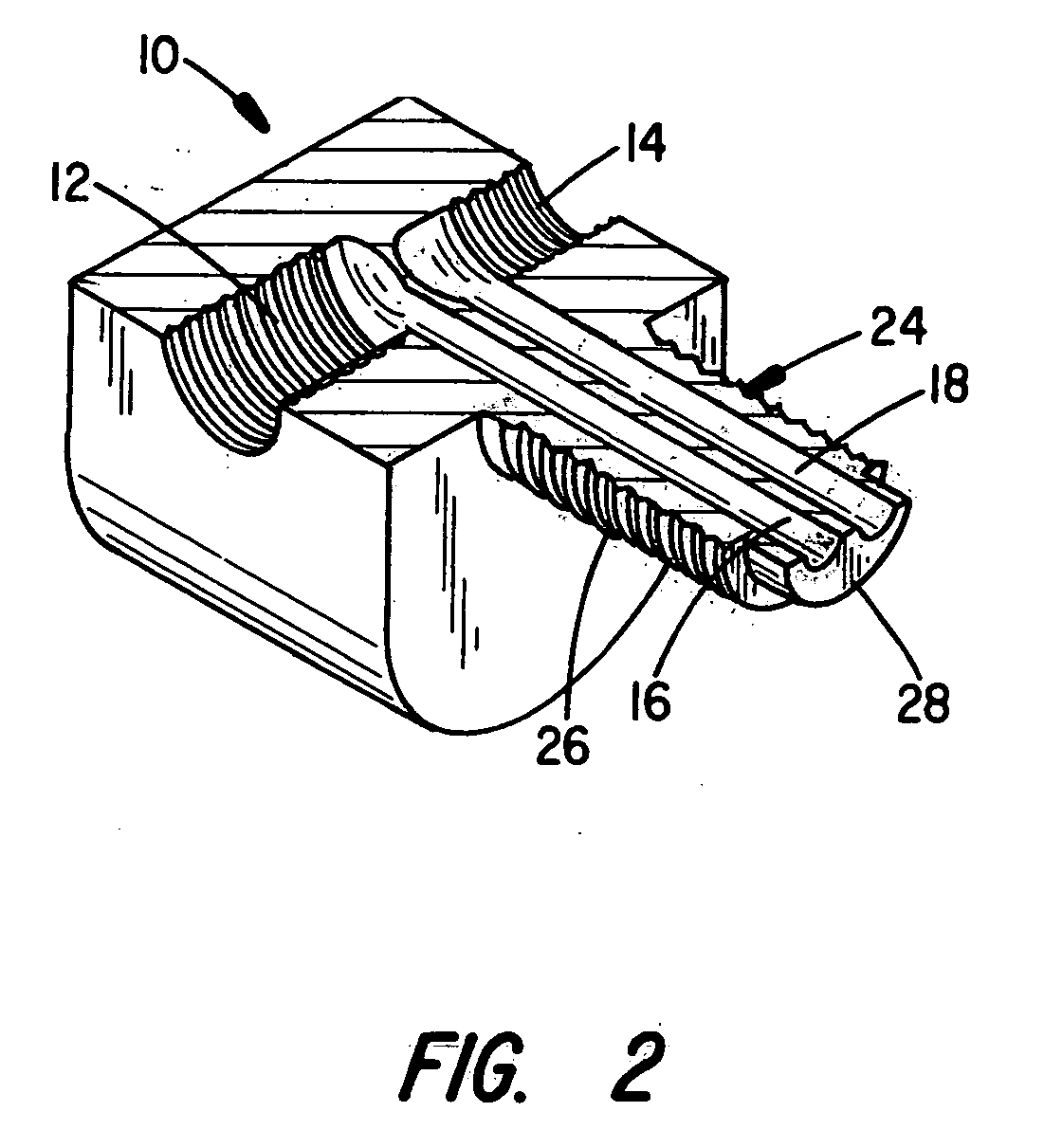

Applicator system

InactiveUS20070187434A1Liquid surface applicatorsLarge containersBiomedical engineeringProportioning valve

An applicator for combining and applying components of a multi-part curable system includes a proportioning valve having a body with a plurality of separate internal passageways, each communicating with a separate inlet recess and a separate outlet opening maintaining each component in separate condition in the valve. Each inlet recess is adapted to be connected to a source of one component of a multi-part curable system and the discharge openings discharge the two components separately from a common nose into an attached static mixing applicator nozzle.

Owner:MCNEILUS TRUCK & MFG INC

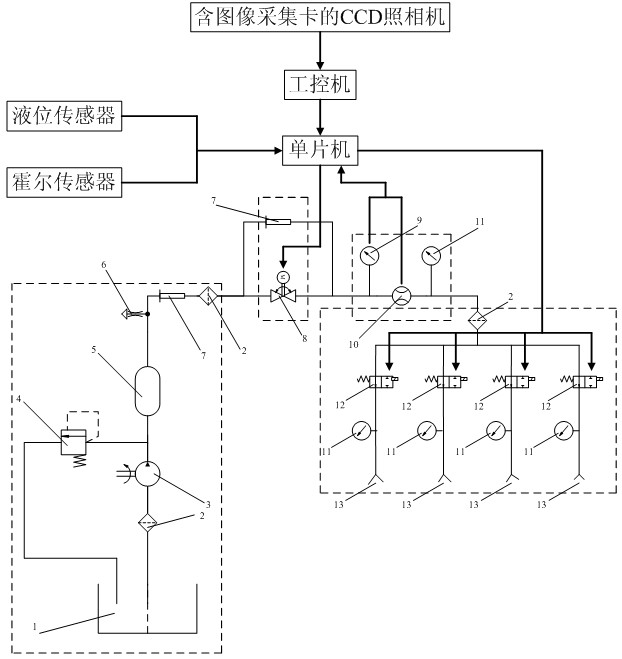

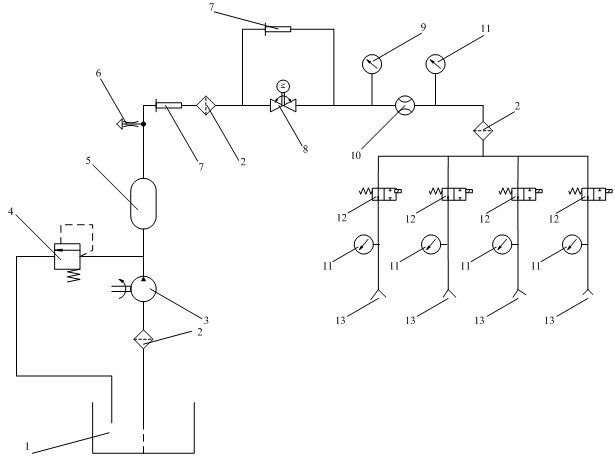

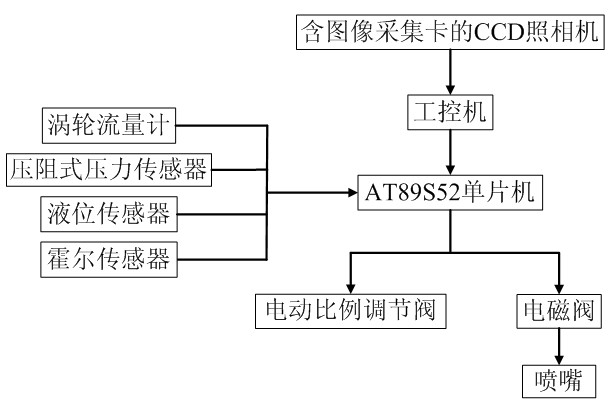

Toward-target variable spray tester

InactiveCN102669079AImprove effectivenessReduce wasteInsect catchers and killersMicrocontrollerMachine vision

The invention discloses a toward-target variable spray tester. The toward-target variable spray tester comprises a medicine feeding device, a variable spray controller, a variable spray detector, a medicine applying device and a machine vision toward-target device. The toward-target variable spray is realized according to the existence of a medicine spraying target, the size of a target crop area, and the change of the running speed of a spraying vehicle, so that the precision spraying of the crop can be realized, the effectiveness of the medicine liquid can be improved, and the waster of the medicine liquid and the pollution of the environment can be reduced. According to the tester, the spraying can be automatically completed, the corresponding control and adjustment can be carried out according to the real-time data, the spray tester ensures a spraying scheme and transmits to the spraying scheme to a singlechip according to an image acquired in the field and a preset image processing algorithm, the singlechip controls an electric proportioning valve to control the flow, an electromagnetic valve to control the length of the turning-off / on time, the toward-target variable spray is carried out, and the toward-target variable spray tester is multifunctional and convenient to operate. Meanwhile, the variable spray can be manually and automatically changed, so that the toward-target variable spray tester is convenient to select and use in the spraying field.

Owner:ZHEJIANG UNIV

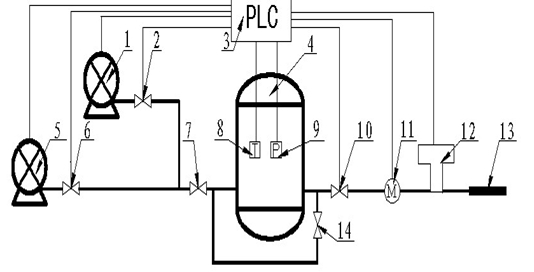

Device and method for detecting combustible gas leakage

The invention belongs to the field of oil and gas safety engineering and particularly relates to a device and a method for detecting the combustible gas leakage. The method belongs to a new method for realizing the fuel gas on-line detection and positioning in China, has the advantage of intermittent controllability and can also be used in process systems for gas taking detection and analysis on other gas. Through the arrangement of a first electromagnetic vacuum valve, a second electromagnetic vacuum valve, an automatic control proportion valve, a combustible gas detector and a gas pressure sensor, the goals of stable pressure in a continuous or intermittent control container and the combustible gas leakage detection are effectively realized. The device and the method have the advantages that the operation is convenient, the structure is simple, and the problems in two aspects including the on-line detection of the combustible gas and the stable pressure in a negative pressure container are mainly solved, and simultaneously, an automation control interface is also reserved for providing the possibility for the system full automation realization.

Owner:溧阳常大技术转移中心有限公司

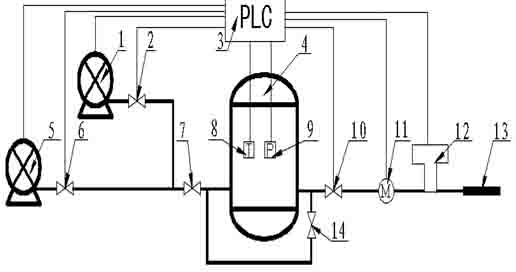

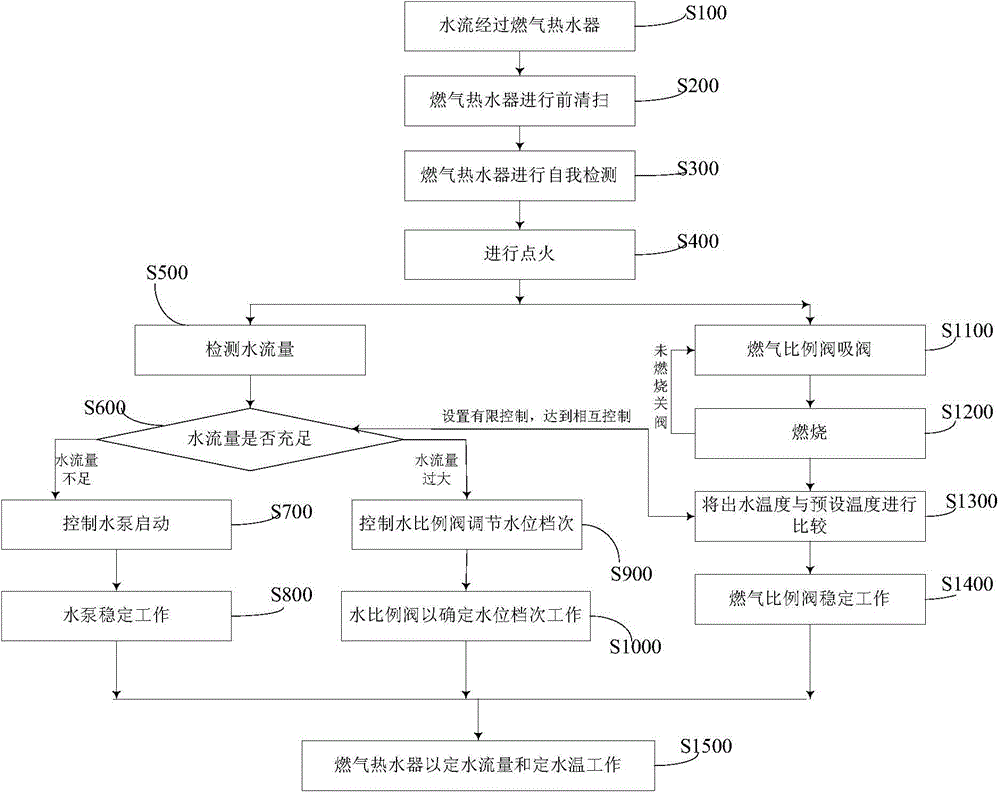

Gas water heater and control method thereof

The invention discloses a gas water heater comprising a gas ratio valve, a water ratio valve which adjusts the water level, a pump, a flow sensor, a temperature sensor and a controller. The pump is arranged on a water incoming pipeline of the gas water heater and is used for adjusting the flow; the flow sensor is used for detecting the incoming flow; the temperature sensor is used for detecting the discharged water temperature; the controller is used for controlling the water ratio valve, the gas ratio valve and the pump to adjust the temperature of flow of the discharged water according to the discharged water temperature and the incoming flow. The flow of the gas water heater can be adjusted, used water temperature is guaranteed, and comfort is improved. The invention further provides a control method of the gas water heater.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

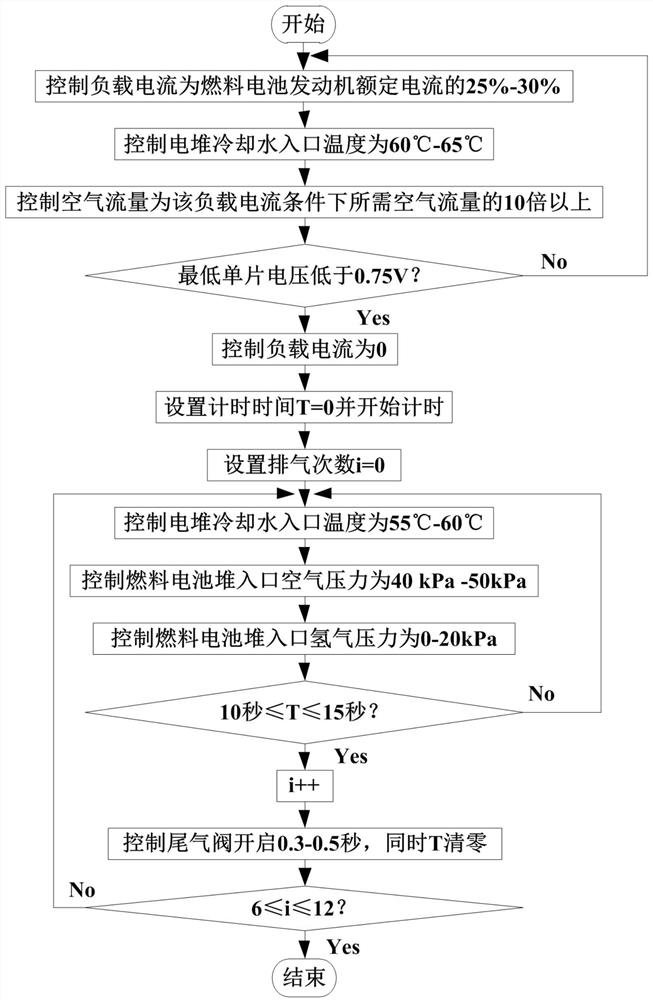

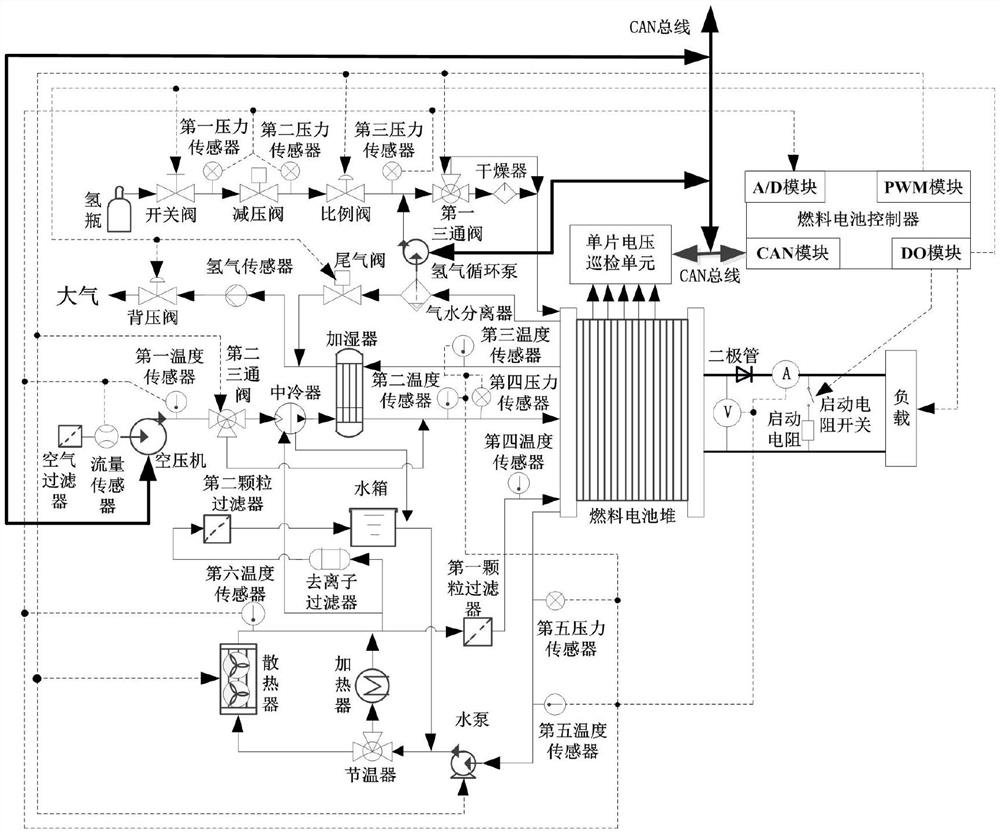

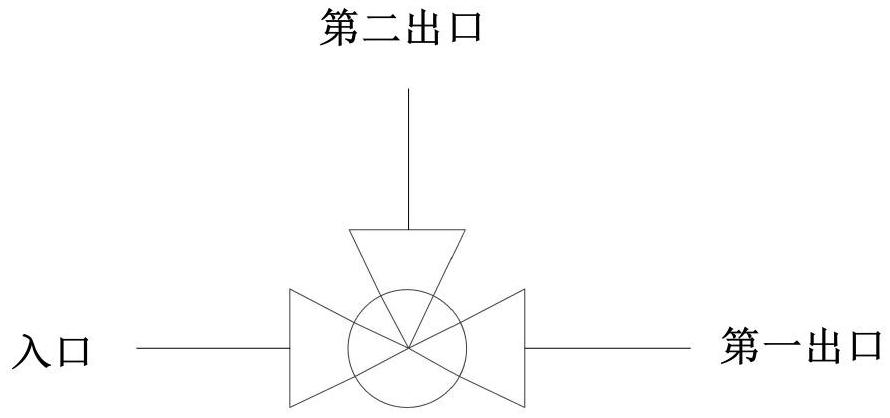

Low-temperature storage control method for purging and dewatering of fuel cell engine

InactiveCN111755720ALow temperature storage improvesImproved fast cold start performanceFuel cellsTemperature controlFuel cells

The invention relates to a low-temperature storage control method for purging and dewatering of a fuel cell engine. The low-temperature storage control method comprises the following steps of: 1) controlling load current, controlling a heater and a radiator to maintain the temperature of inlet cooling water of a fuel cell stack, controlling a rotating speed of an air compressor, and detecting thevoltage of each single cell of the fuel cell stack through a single voltage inspection unit; 2) controlling the load current by means of a fuel cell controller, controlling a heater and a radiator tomaintain the inlet cooling water temperature of the fuel cell stack, enabling air at an outlet of an air compressor to directly flow into an air inlet of the fuel cell stack without passing through anintercooler and a humidifier, controlling an inlet and outlet switching path of a first three-way valve in a hydrogen loop to enable hydrogen at an outlet of the proportional valve to directly flow into a hydrogen inlet of the fuel cell stack after passing through the dryer, and controlling the opening degree of the proportional valve to make air pressure at an inlet of the fuel cell stack to be0-20 kPa. The low-temperature storage control method does not depend on an internal resistance online test and humidity soft measurement instrument and method, and can accurately control the water content of the fuel cell engine stack.

Owner:HUBEI UNIV OF TECH

Single nozzle direct injection system for rapidly variable gasoline/Anti-knock agent mixtures

InactiveUS20080156303A1Decreased volumeLarge dynamic rangeInternal combustion piston enginesDigital data processing detailsEngineeringHigh pressure

Engine management system for operation of a direct injection spark ignition gasoline engine. The system includes a gasoline engine, a source of gasoline and a source of an anti-knock agent. Gasoline and anti-knock agent are introduced into a proportioning valve that delivers a selected mixture of gasoline / anti-knock agent to a high pressure pump. At least one injector receives the selected mixture from the high pressure pump and delivers the mixture into a cylinder of the engine. The engine management system provides a rapidly variable mixture of directly injected anti-knock agent and gasoline which prevents knock as the engine torque increases.

Owner:ETHANOL BOOSTING SYST LLC

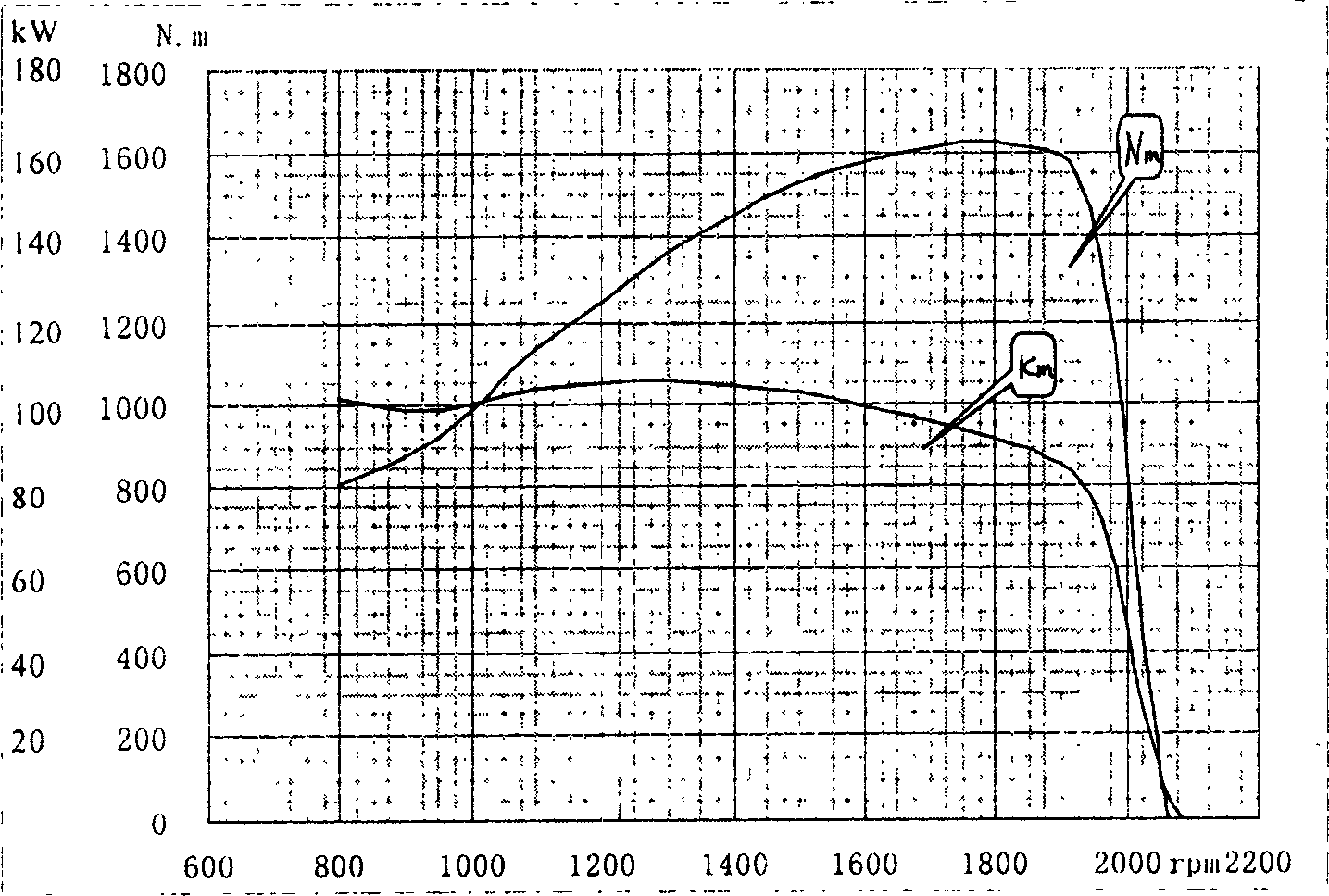

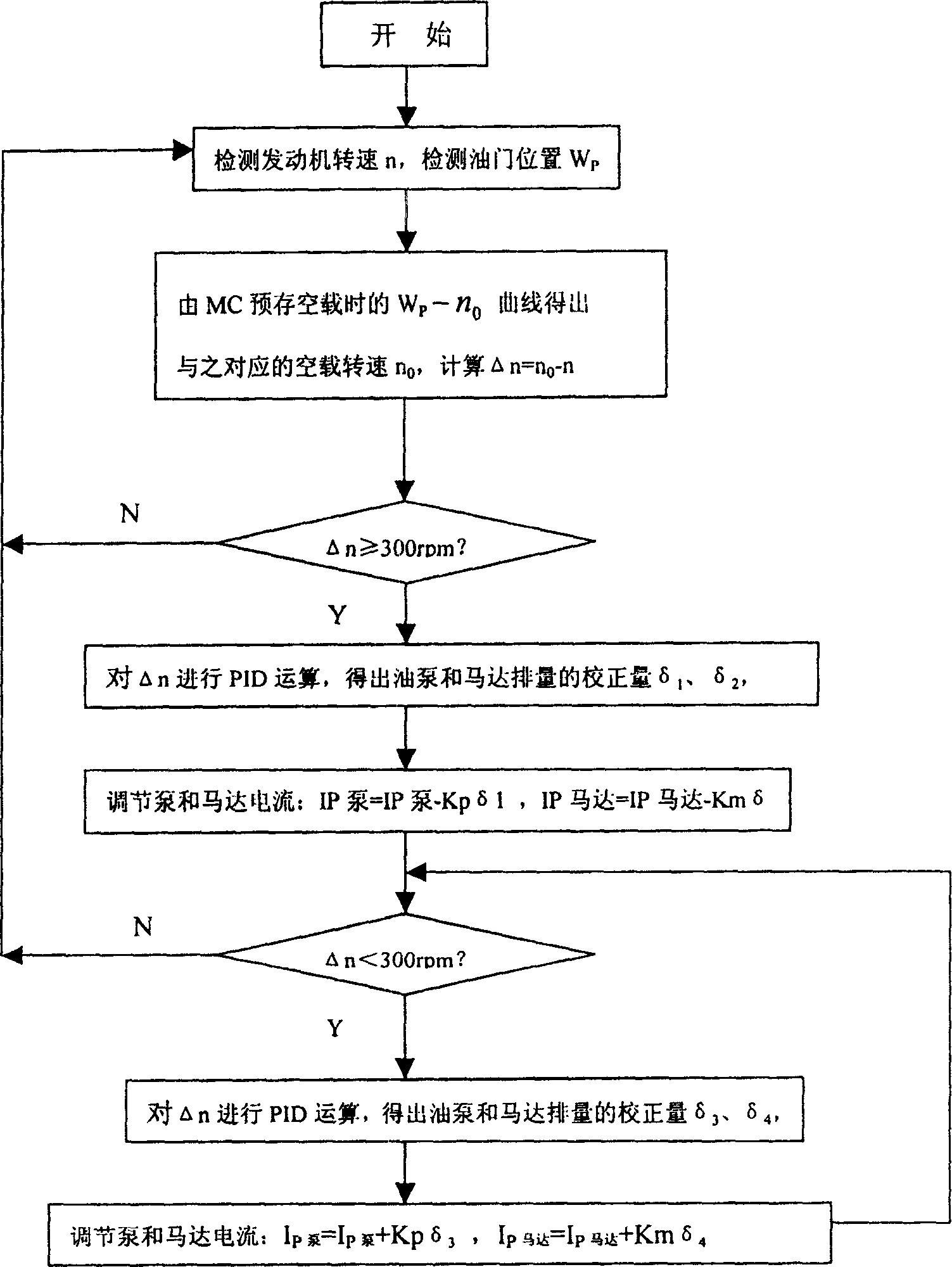

Limit load adjustment method of all hydraulic bulldozer and apparatus thereof

InactiveCN1558048AReduce in quantityNo pausesSoil-shifting machines/dredgersMotor speedPosition sensor

The present invention is limit load regulating method and apparatus for hydraulic bull dozer. The present invention features that by means of connecting the throttle valve sensor, the engine rotation speed sensor, walking motor rotation speed sensor and motor proportion valve to the micro controller (MC), connecting the engine to variable displacement oil pump and MC, the calculation in MC of the difference between practical rotation speed and the set value of the engine and the motor based on the signals from the sensors, the data processing and PID operation, the limit load regulating apparatus regulates the current of the electric proportion valve in the variable displacement oil pump and the current of the electric proportion valve in the motor to maintain the rotation speed of the engine in the constant value. The present invention makes the hydraulic bull dozer operate in optimal rotation speed with less fluctuation in high response speed.

Owner:SANY HEAVY IND CO LTD (CN)

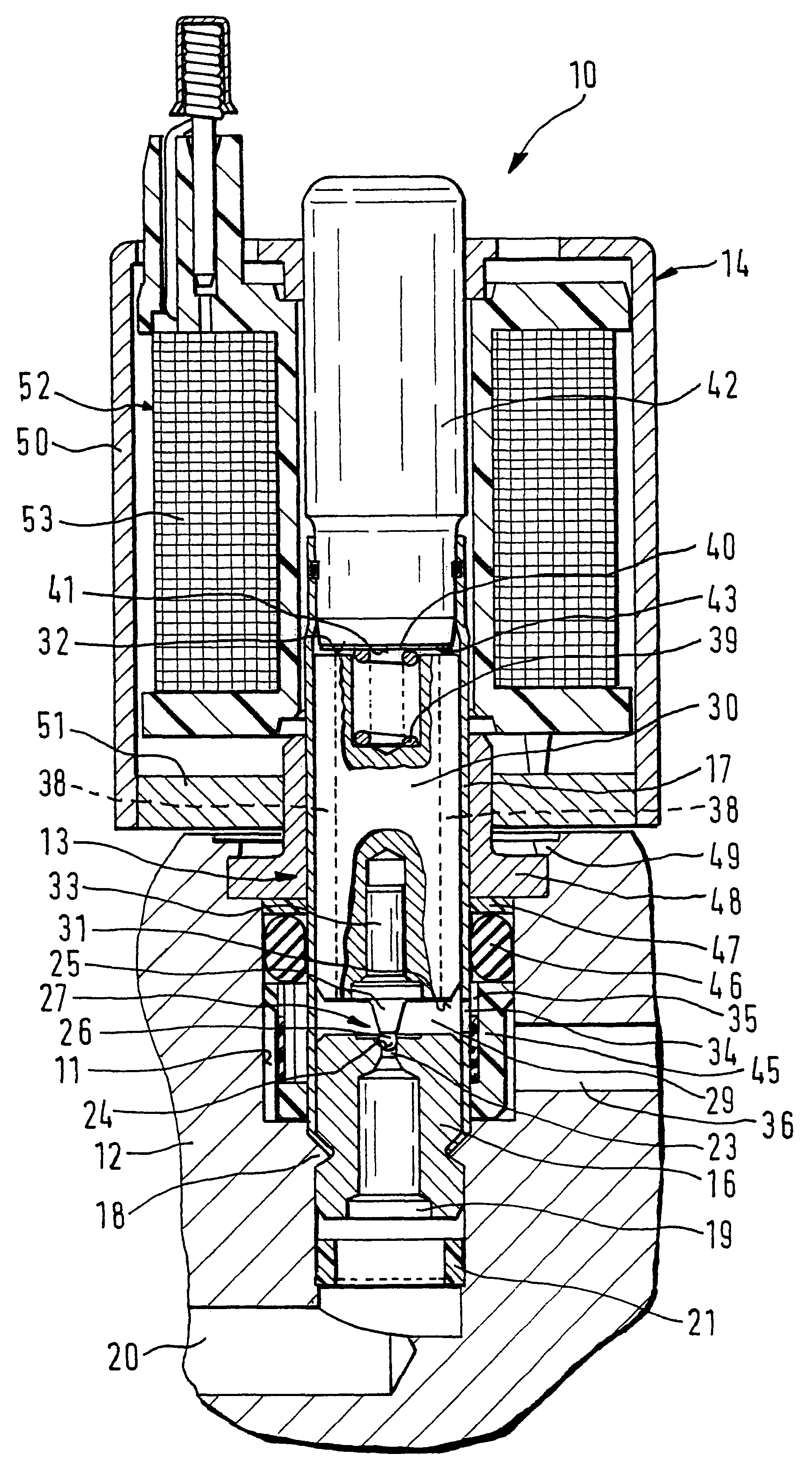

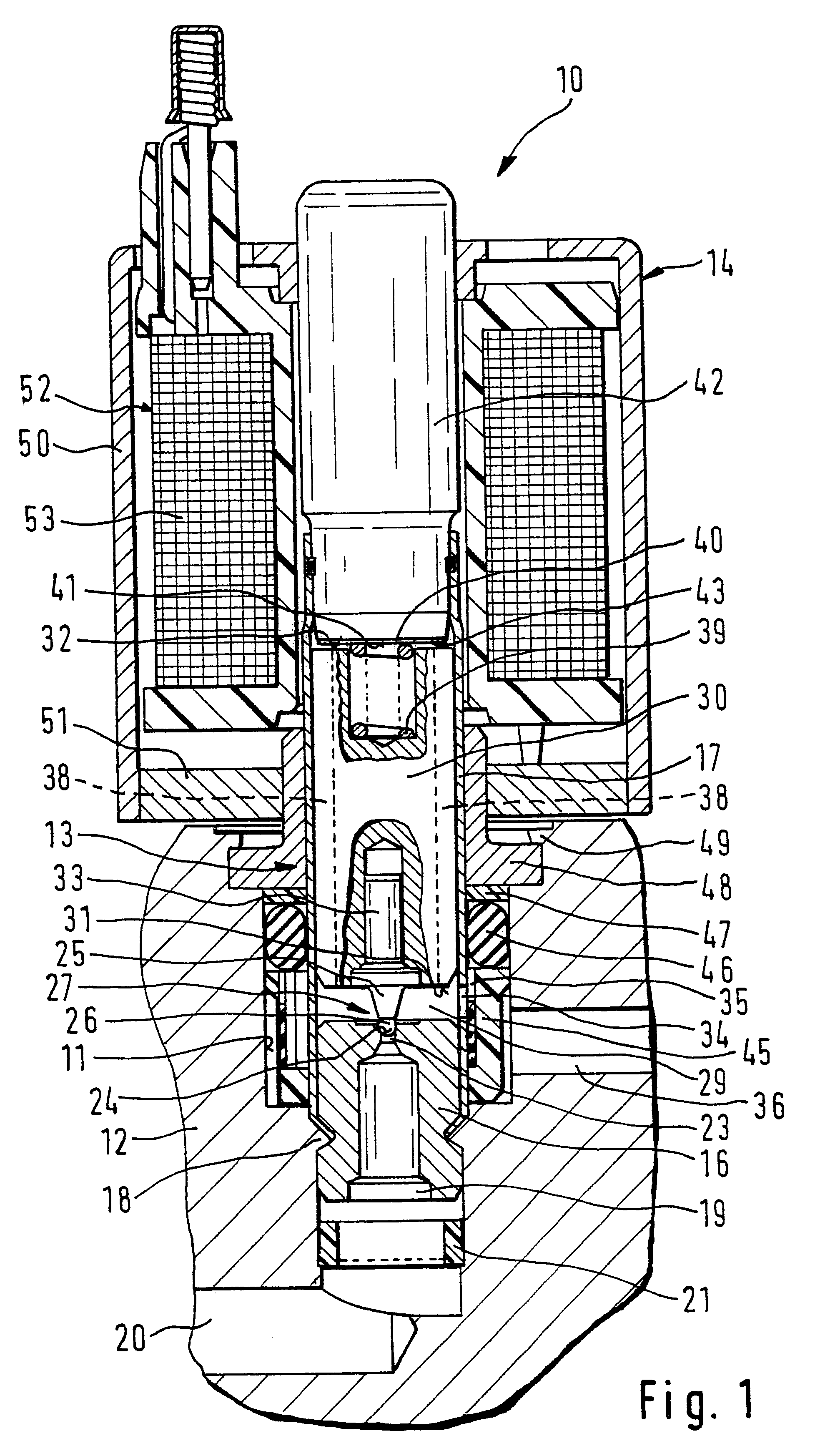

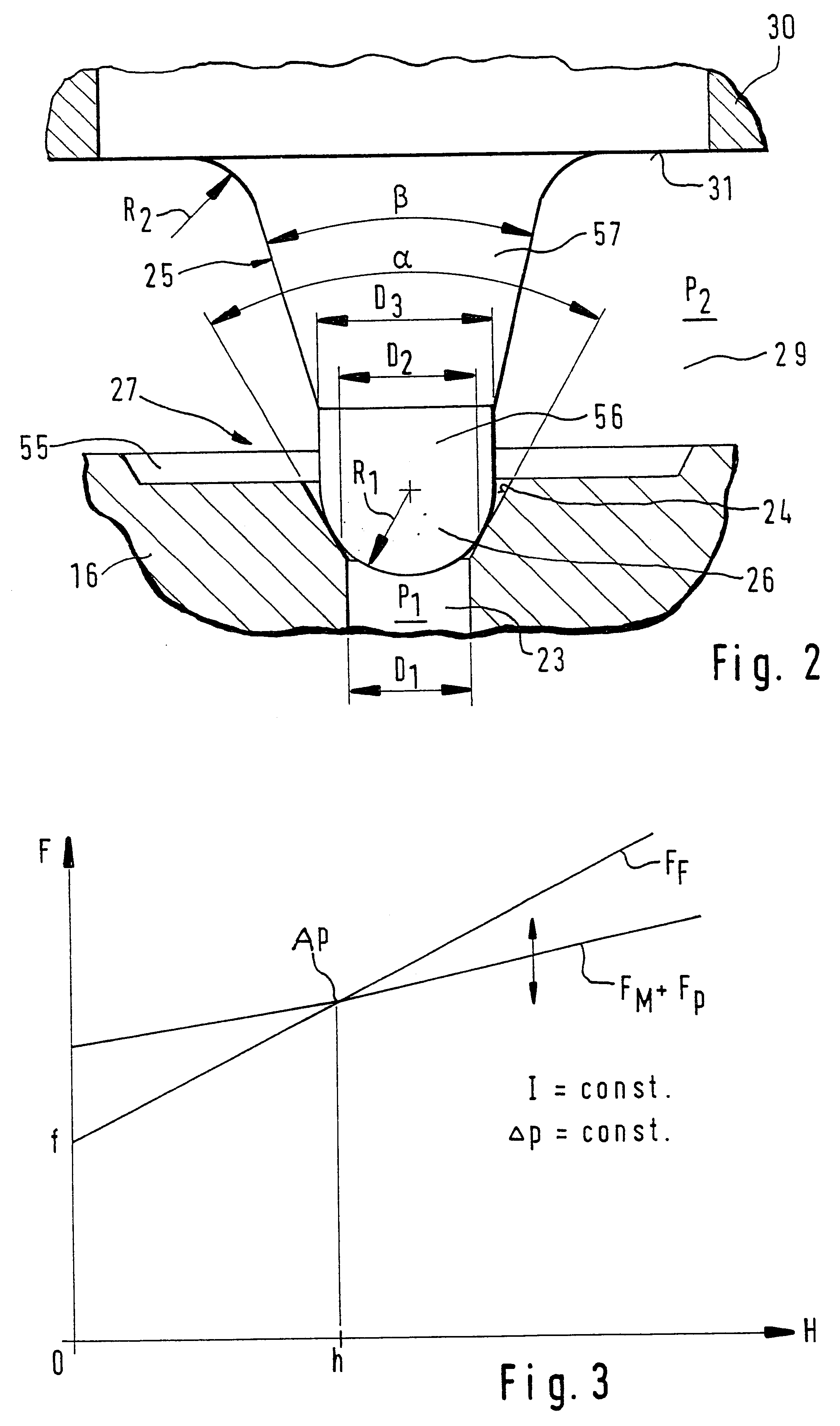

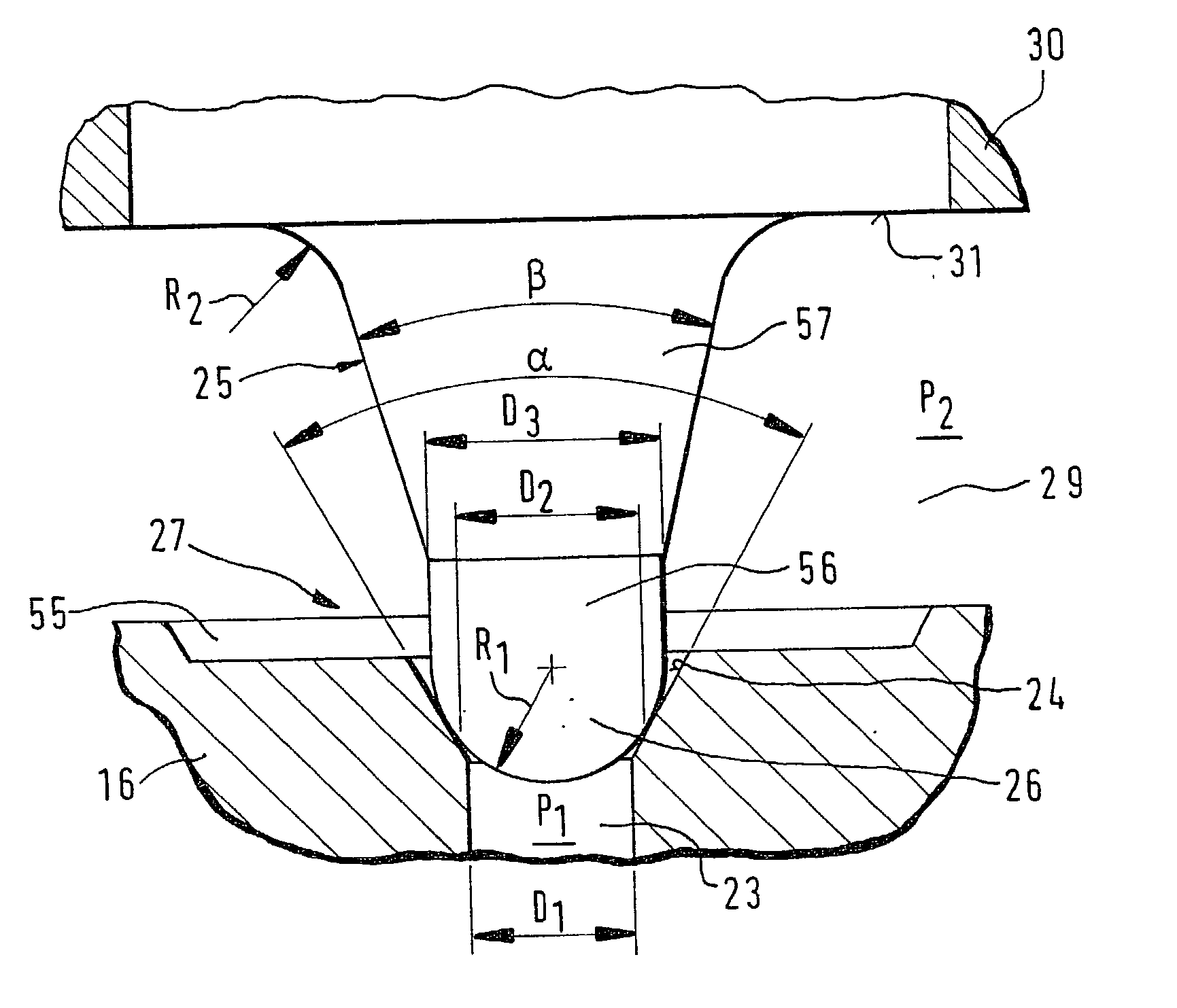

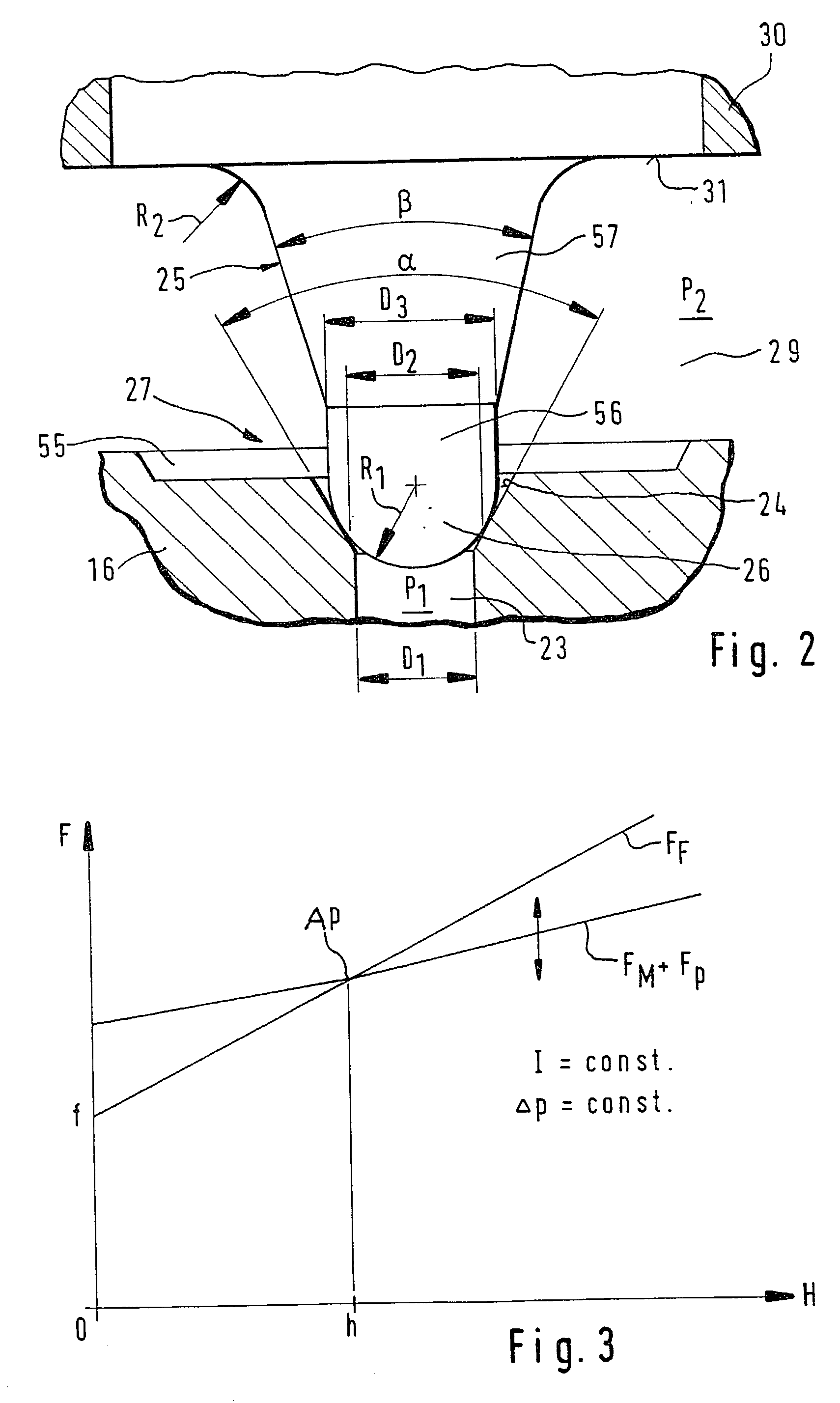

Electromagnetically actuated valve, especially for hydraulic braking systems in motor vehicles

InactiveUS6705589B2Simple designStable controlOperating means/releasing devices for valvesVehicle fittingsMobile vehicleMagnetic tension force

The valve (10) has a seat valve (27) comprising a hollow cone-shaped valve seat (24) and an hemispherical shutoff element (26). An afflux bore (23) having contact with a pressure-medium inlet (19) discharges centrically into the valve seat (24). A solenoid armature (30) acting upon the seat valve (27) in opening fashion grips a push rod (25) comprising the shutoff element (26). The solenoid armature cooperates with a pole body (42) according to the flat-type armature principle. A preloaded return spring (39) acting on the seat valve (27) in closing fashion is arranged between the pole body (42) and the solenoid armature (30). The valve (10) works as a proportioning valve, because, in addition to a suitable design of the seat valve (27) and push rod (25), the magnetic force is infinitely variable and, together with a hydraulic force, has a monotonously increasing course as the valve opening stroke increases, while the spring force-which also has a monotonously increasing course as the valve opening stroke increases-has a positive slope that is greater than that of the course of the magnetic and hydraulic force.

Owner:TECHLAND RES +1

Hydraulic cylinder synchronous control system and control method thereof

The invention relates to a hydraulic cylinder synchronous control system and a control method thereof. The system comprises an equipment body, more than one hydraulic cylinder, a common proportioning valve and a common reversing valve, wherein the hydraulic cylinders are connected and drive the equipment body. At least one of the hydraulic cylinders is connected with and controlled by the common proportioning valve and at least one of the left hydraulic cylinders is connected with and controlled by the common reversing valve.

Owner:MAANSHAN IRON & STEEL CO LTD

Electromagnetically actuated valve, especially for hydraulic braking systems in motor vehicles

InactiveUS20020179874A1Simple designStable control behaviorOperating means/releasing devices for valvesVehicle fittingsMobile vehicleMagnetic tension force

The valve (10) has a seat valve (27) comprising a hollow cone-shaped valve seat (24) and an hemispherical shutoff element (26). An afflux bore (23) having contact with a pressure-medium inlet (19) discharges centrically into the valve seat (24). A solenoid armature (30) acting upon the seat valve (27) in opening fashion grips a push rod (25) comprising the shutoff element (26), which said solenoid armature cooperates with a pole body (42) according to the flat-type armature principle. A preloaded return spring (39) acting on the seat valve (27) in closing fashion is arranged between the pole body (42) and the solenoid armature (30). The valve (10) works as a proportioning valve, because, in addition to a suitable design of the seat valve (27) and push rod (25), the magnetic force is infinitely variable and, together with a hydraulic force, has a monotonously increasing course as the valve opening stroke increases, while the spring force-which also has a monotonously increasing course as the valve opening stroke increases-has a positive slope that is greater than that of the course of the magnetic and hydraulic force.

Owner:TECHLAND RES +1

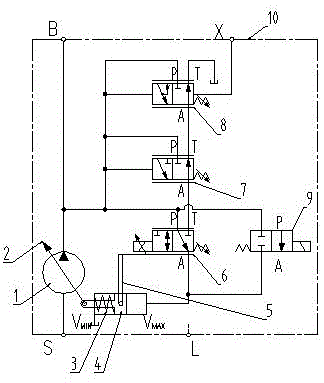

Composite variable pump and hydraulic control system using composite variable pump

ActiveCN105156391AGuaranteed non-interferenceReduce displacementServomotor componentsServomotorsThrottle controlControl system

The invention discloses a variable pump with load sensitive throttle control and volume control functions and a hydraulic control system using the composite variable pump. The composite variable pump comprises a shell, a pump body, a variable control hydrocylinder and an electromagnetic proportioning valve, wherein the electromagnetic proportioning valve is connected with a displacement valve in parallel; a constant-pressure control valve is connected between an oil outlet of the pump body and the electromagnetic proportioning valve; a flow control valve is connected between the oil outlet of the pump body and the constant-pressure control valve; and a control side of the flow control valve is connected with a load feedback oil port X. The hydraulic control system using the composite variable pump comprises a controller, the composite variable pump, a plurality of hydraulic actuating elements and a plurality of load sensitive valves. The composite hydraulic pump can enable the system to work in the volume control mode or load sensitive throttle control mode; the actions of the actuating mechanisms do not interfere with each other; and thus, the system has the advantages of higher efficiency and more energy saving.

Owner:XUZHOU COLLEGE OF INDAL TECH

Single nozzle direct injection system for rapidly variable gasoline/anti-knock agents mixtures

InactiveUS7703446B2Lower the volumeQuick changeInternal combustion piston enginesDigital data processing detailsEngineeringHigh pressure

Engine management system for operation of a direct injection spark ignition gasoline engine. The system includes a gasoline engine, a source of gasoline and a source of an anti-knock agent. Gasoline and anti-knock agent are introduced into a proportioning valve that delivers a selected mixture of gasoline / anti-knock agent to a high pressure pump. At least one injector receives the selected mixture from the high pressure pump and delivers the mixture into a cylinder of the engine. The engine management system provides a rapidly variable mixture of directly injected anti-knock agent and gasoline which prevents knock as the engine torque increases.

Owner:ETHANOL BOOSTING SYST LLC

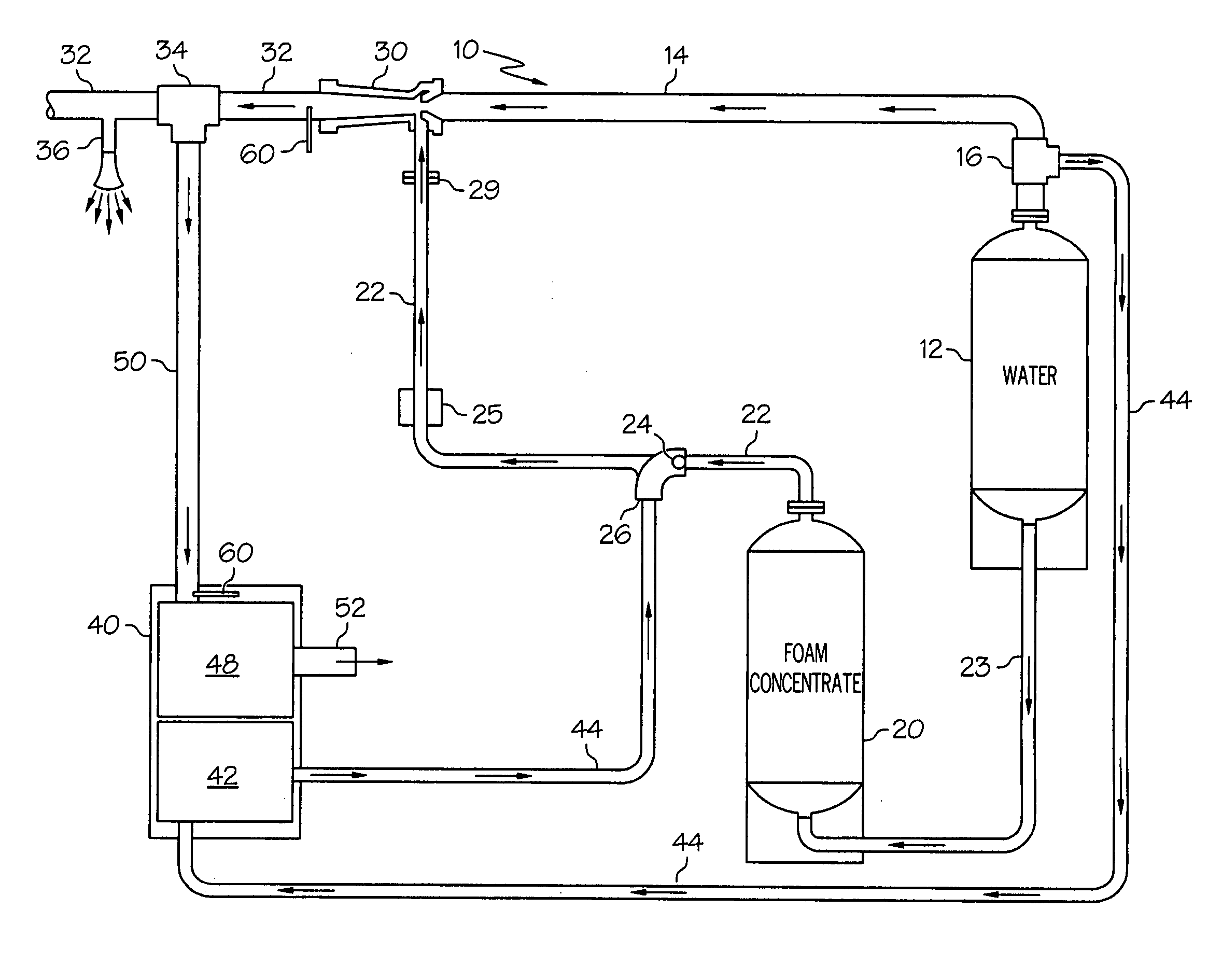

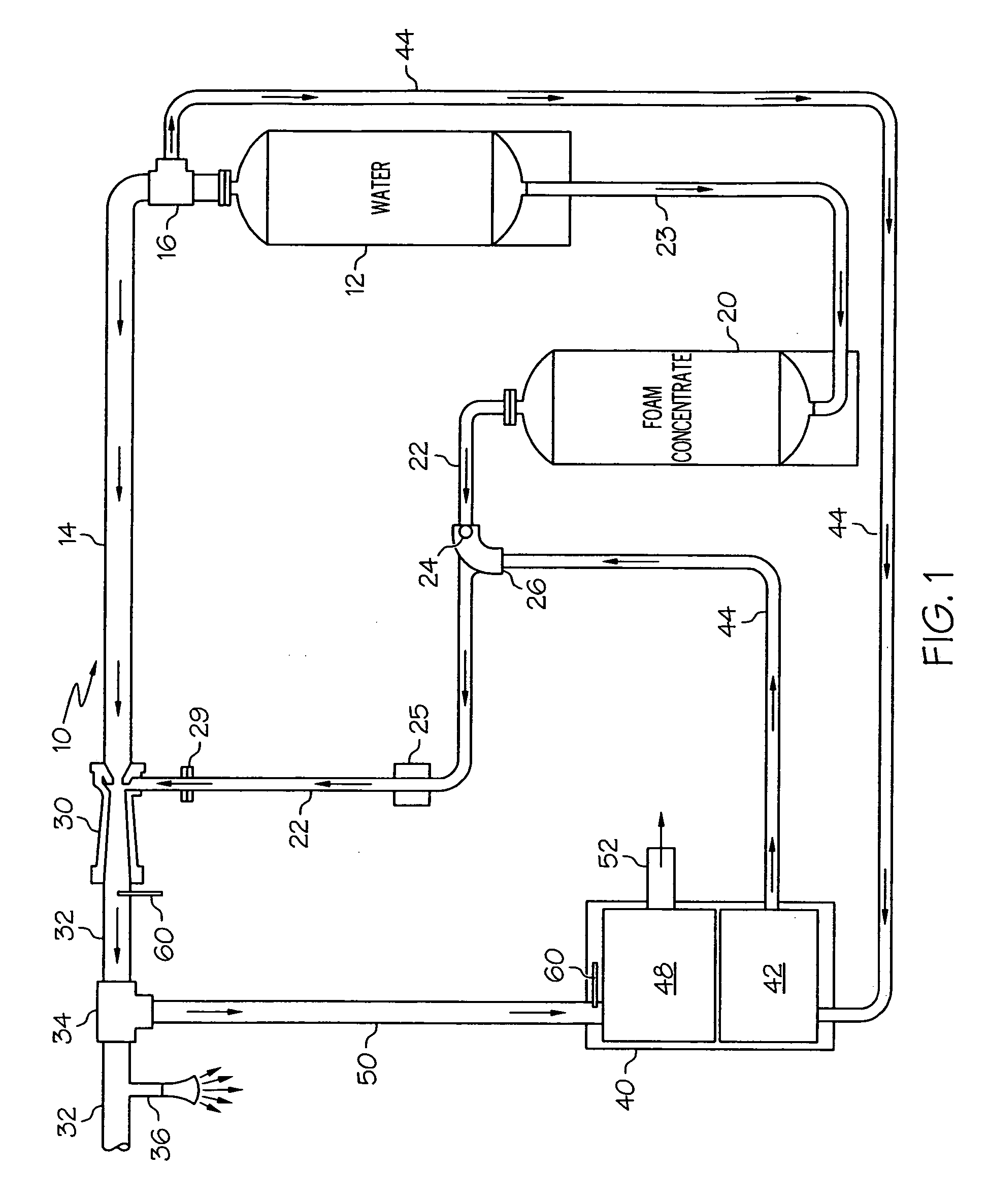

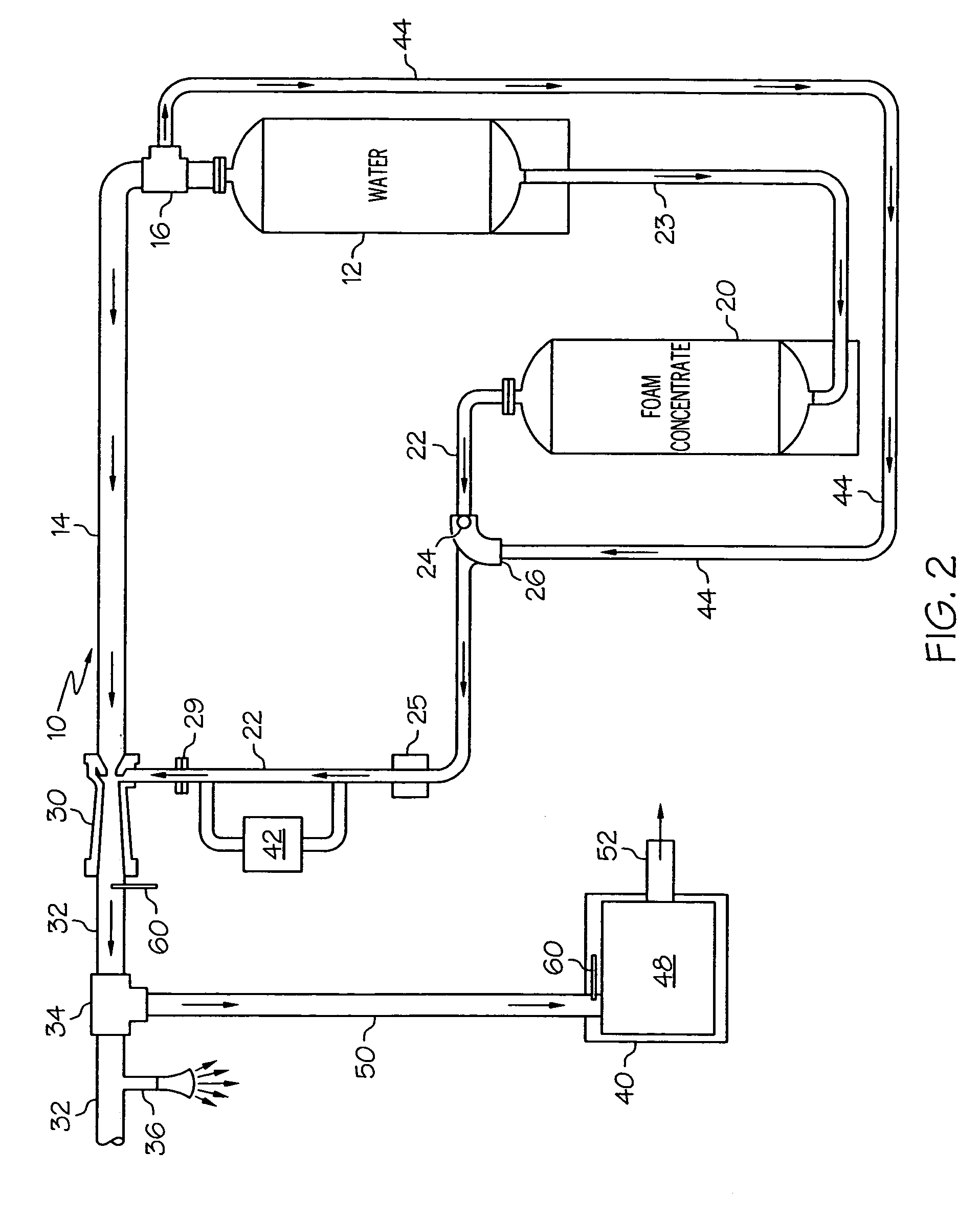

System and method for testing foam-water fire fighting and fire suppression systems

A test system for proportioning fire fighting and fire suppression systems is provided. This test system includes a foam-water proportioning system and at least one test apparatus connectable to or incorporated into the foam-water sprinkler system. In an exemplary embodiment, the foam-water proportioning system further includes: (i) at least one proportioning valve; (ii) at least one source of water; and (iii) at least one source of foam concentrate. The test apparatus further includes: (i) a means for bypassing the at least one source of foam concentrate; (ii) a first flow meter; and (iii) an optional second flow meter.

Owner:FOAM SOLUTIONS

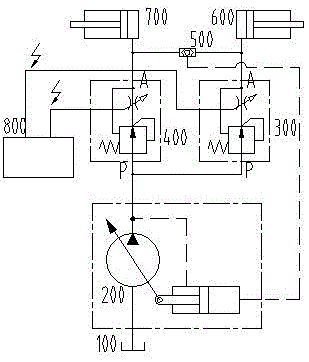

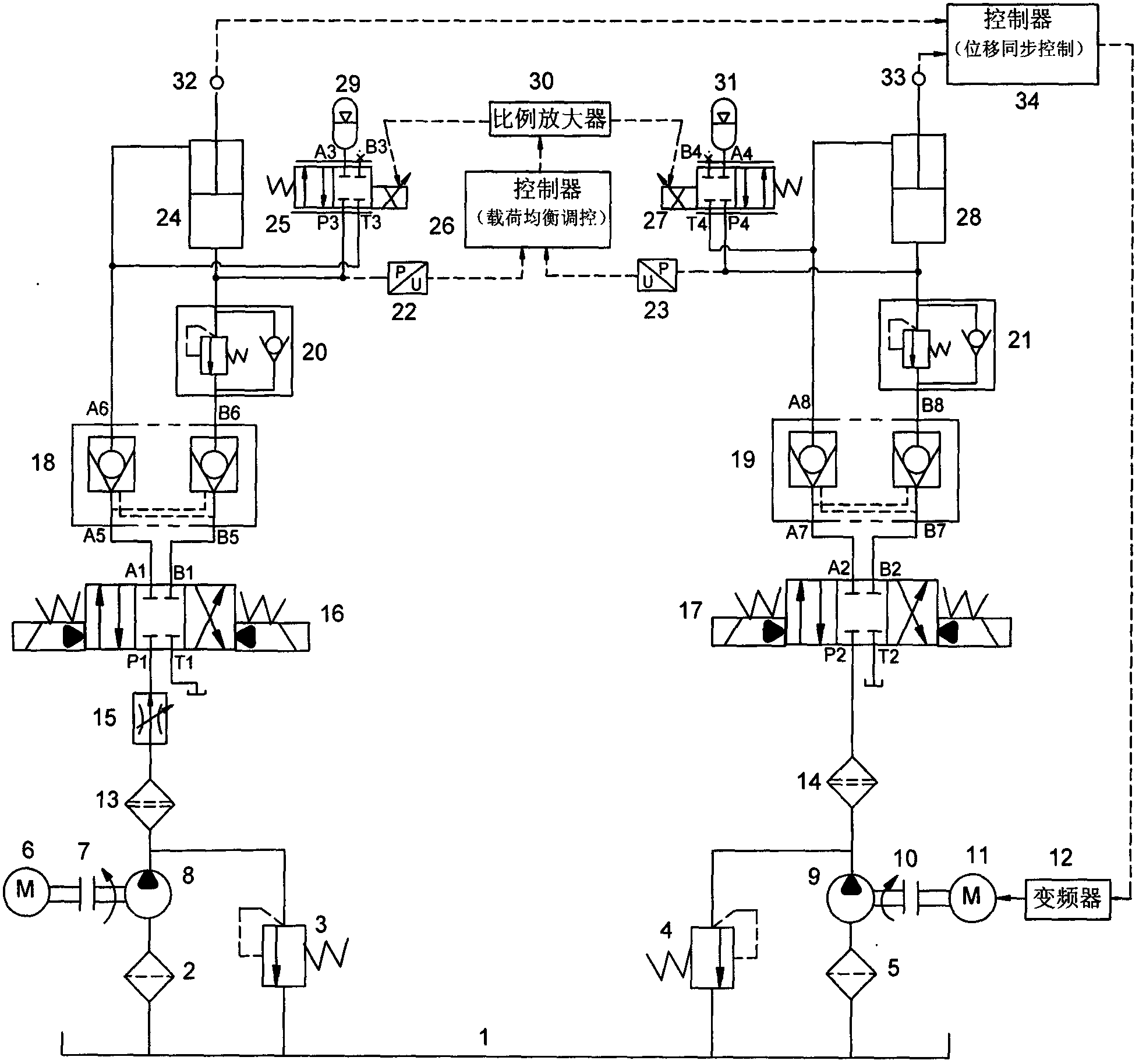

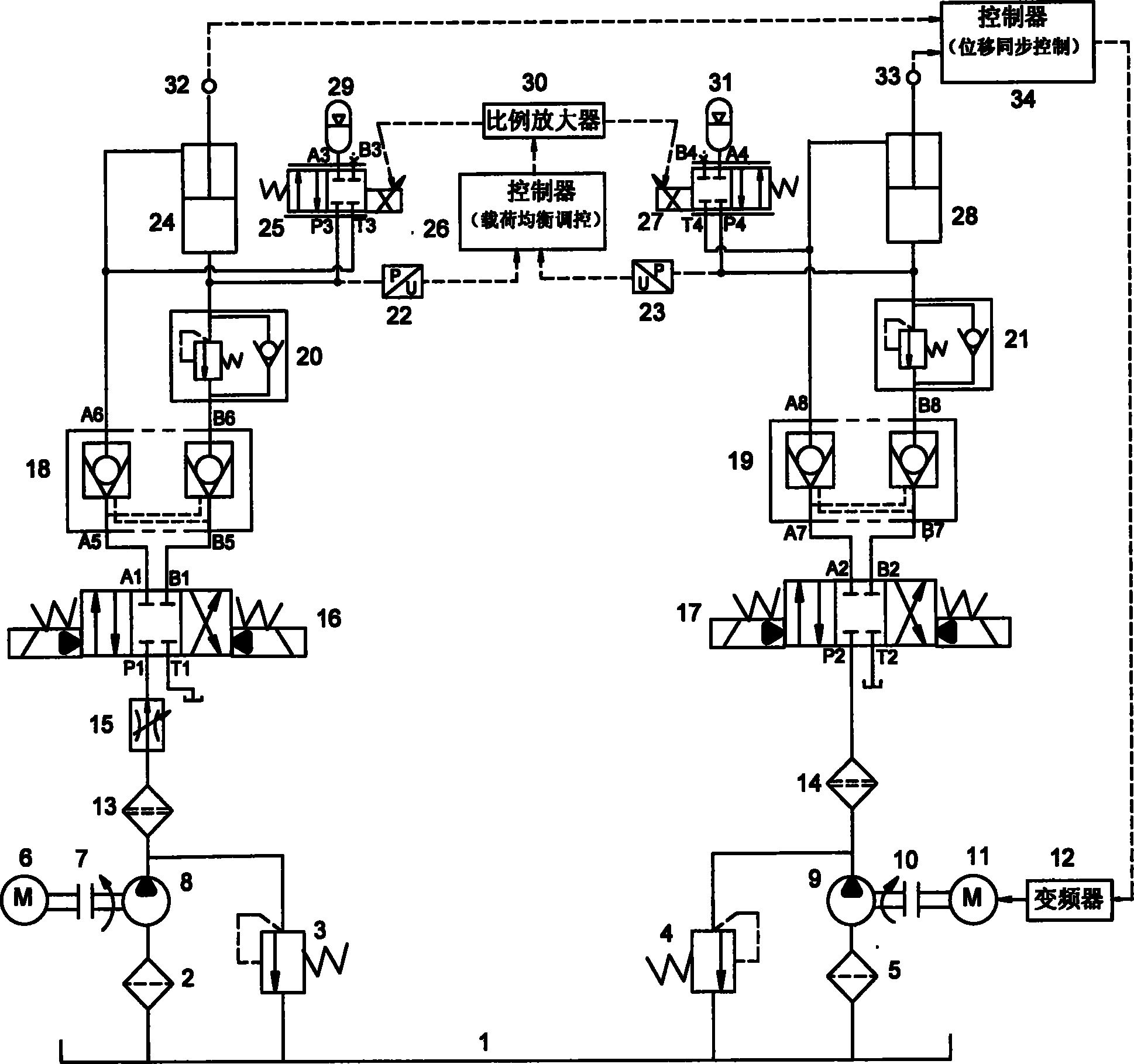

Hydraulic synchronous driving system for adjusting unbalanced load based on proportional valve controlled energy accumulator

InactiveCN102650304AThe output thrust is consistentReduce adverse effectsServomotorsFuel tankHigh pressure

The invention discloses a hydraulic synchronous driving system for adjusting unbalanced load based on a proportional valve controlled energy accumulator, comprising a hydraulic transmission loop and an electro hydraulic control system. The hydraulic synchronous driving system aims to realize synchronous movement with higher precision under the unbalanced load condition. The hydraulic transmission loop comprises an oil tank, oil absorption filters, overflowing valves, motors, shaft couplers, metering pumps, high-pressure filters, a speed adjusting valve, three-position four-way electro hydraulic reversing valves, hydraulic locks, balance valves, hydraulic cylinders, two-position four-way proportional reversing valves and energy storage devices. The electro hydraulic control system comprises a displacement synchronous control loop based on displacement feedback of the hydraulic cylinders and a load balancing adjusting and controlling circuit based on pressure feedback of rodless cavities of the hydraulic cylinders. Aiming at an unbalanced load working condition, the working pressure of the hydraulic cylinders is adjusted and controlled through the proportional valve controlled energy accumulator and the load balance between the different hydraulic cylinders is realized. Therefore, the bad influences on the synchronous precision by the unbalanced load are radically eliminated, the coordinated consideration of the displacement synchronization and the load balance is realized and higher synchronization precision is realized.

Owner:CENT SOUTH UNIV

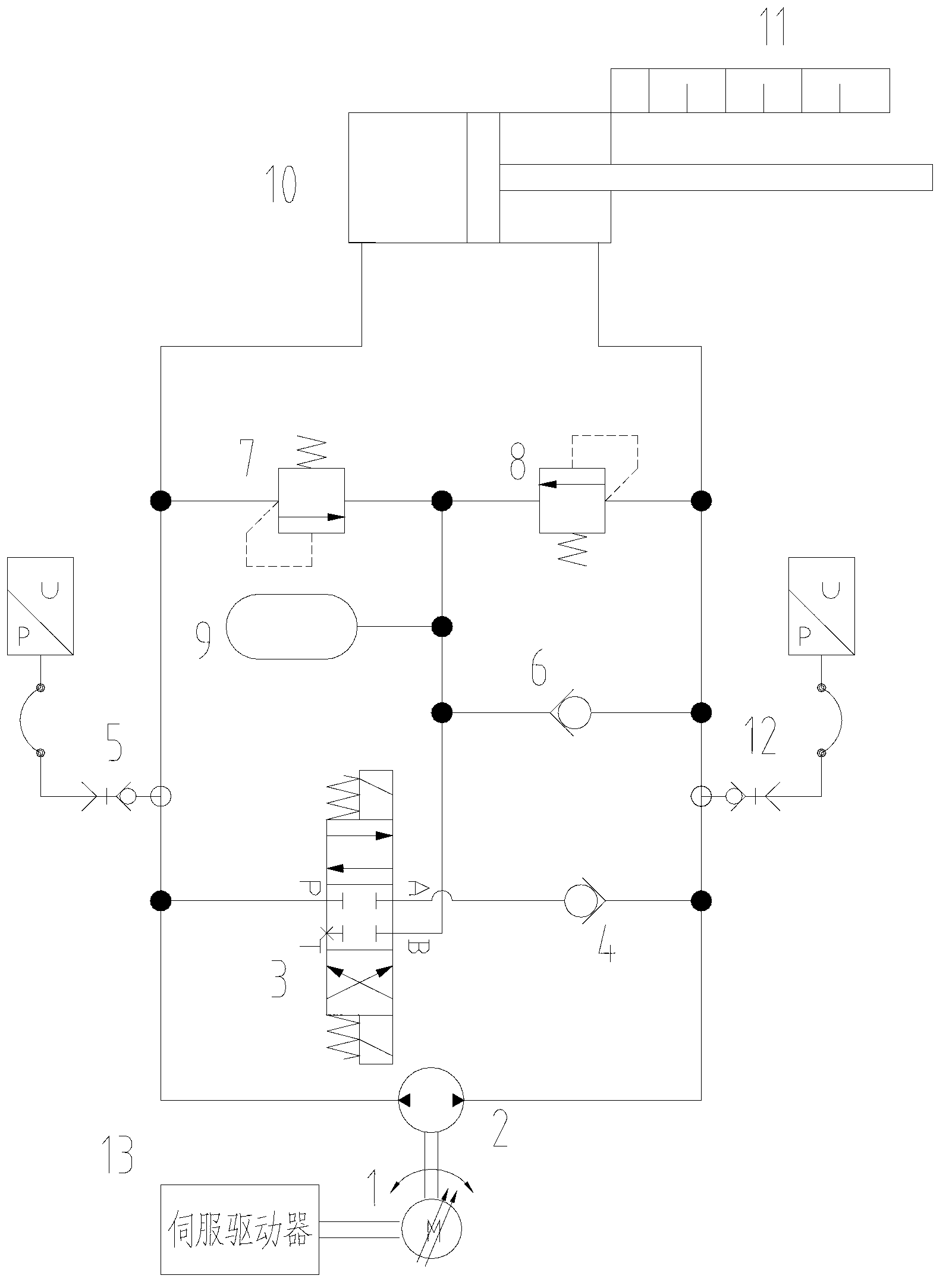

Direct drive type servo pump control electro-hydraulic combined driving hydraulic cylinder control system and control method

ActiveCN103307060AQuick responseExtend your lifeServomotorsFluid-pressure actuator componentsHydraulic cylinderDifferential pressure

The invention provides a direct drive type servo pump control electro-hydraulic combined driving hydraulic cylinder control system and a control method. The control system comprises a servo motor driver module, a pump controlled cylinder module and an auxiliary oil circuit module, wherein a servo driver controls a servo motor to drive a two-way pump for generating hydraulic energy, two oil circuits of the two-way pump are connected with a rod port and a head port of the hydraulic cylinder respectively, an oil tank is used for oil topping up and oil drainage when the flow quantity of the rod port and the head port is unbalanced, and the direction of motion of a piston rod of the hydraulic cylinder is controlled by the positive and negative rotation direction of the servo motor. The direct drive type servo pump control electro-hydraulic combined driving hydraulic cylinder control system provided by the invention has the advantages that the problem of asymmetric flow quantity existing in a pump control hydraulic control is solved effectively, the circulating oil consumption of the system and the pressure loss caused by oil flowing are reduced, the overall system is compact and easy to realize integration, and the pressure loss and heating of a conventional electro hydraulic servo system caused by the differential pressure discharge characteristic of a proportioning valve or a servo valve are reduced greatly.

Owner:NANJING ESTUN AUTOMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com