Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14986 results about "Programmable logic controller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

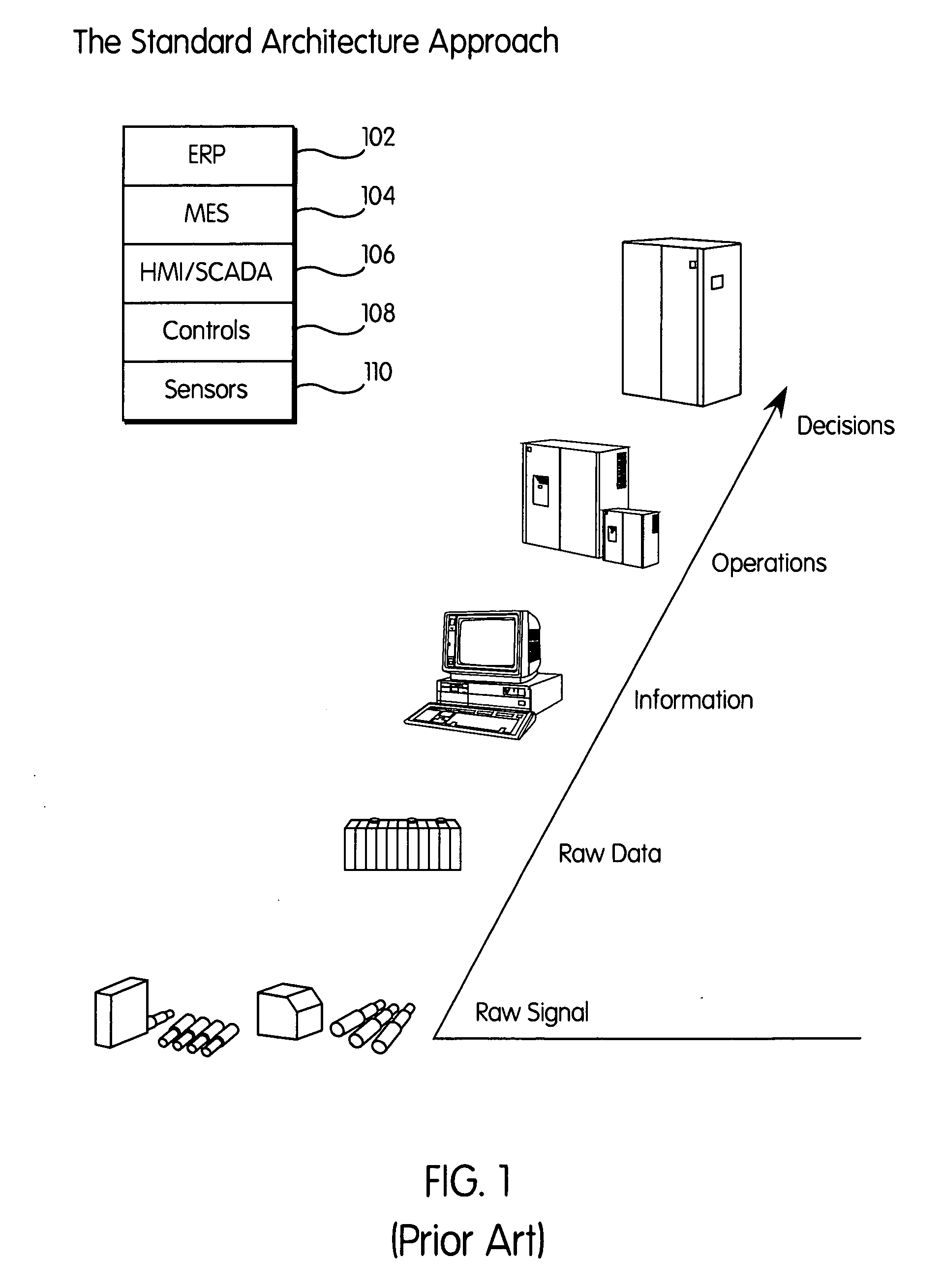

A programmable logic controller (PLC) or programmable controller is an industrial digital computer which has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, or robotic devices, or any activity that requires high reliability control and ease of programming and process fault diagnosis.

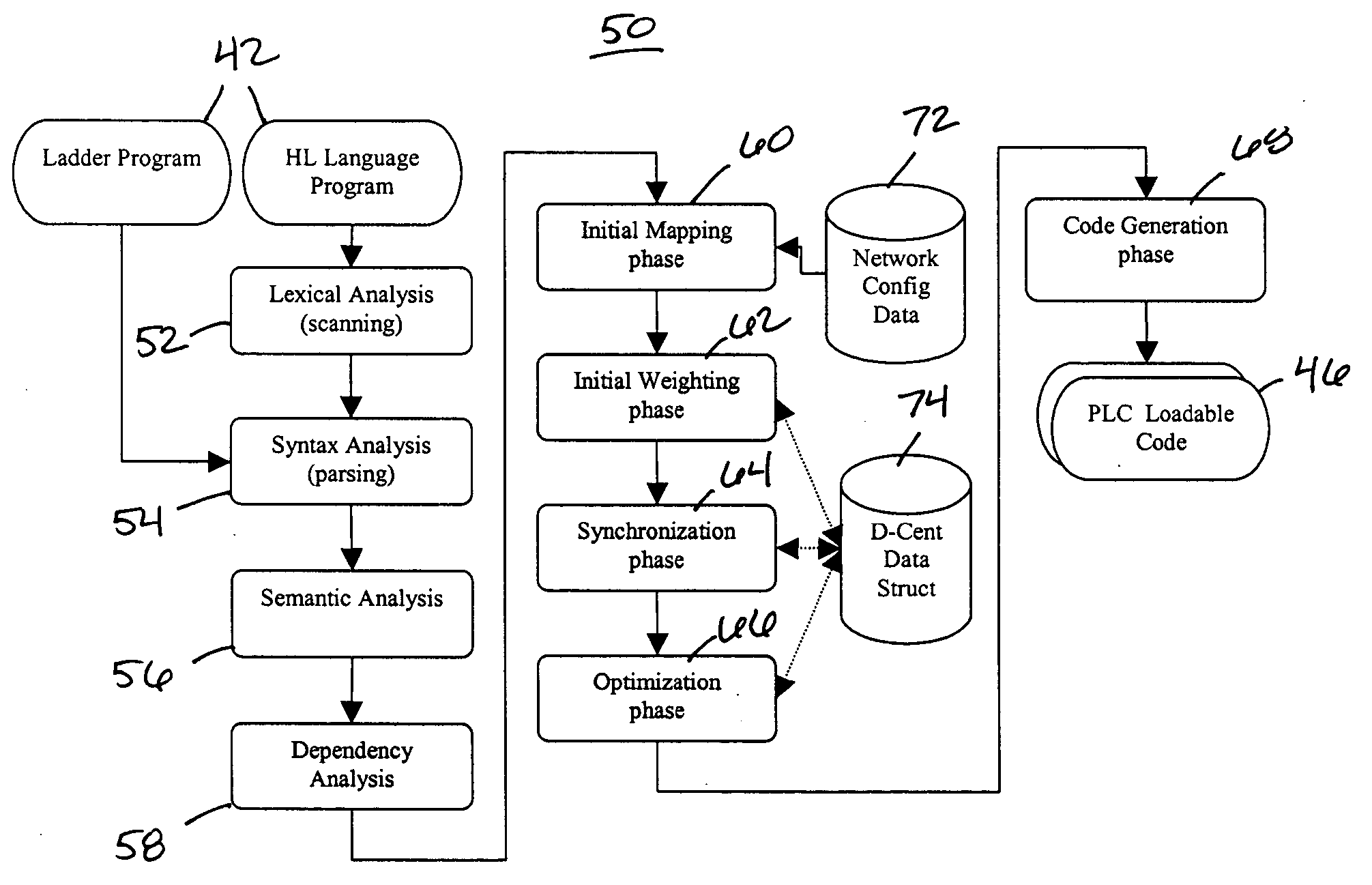

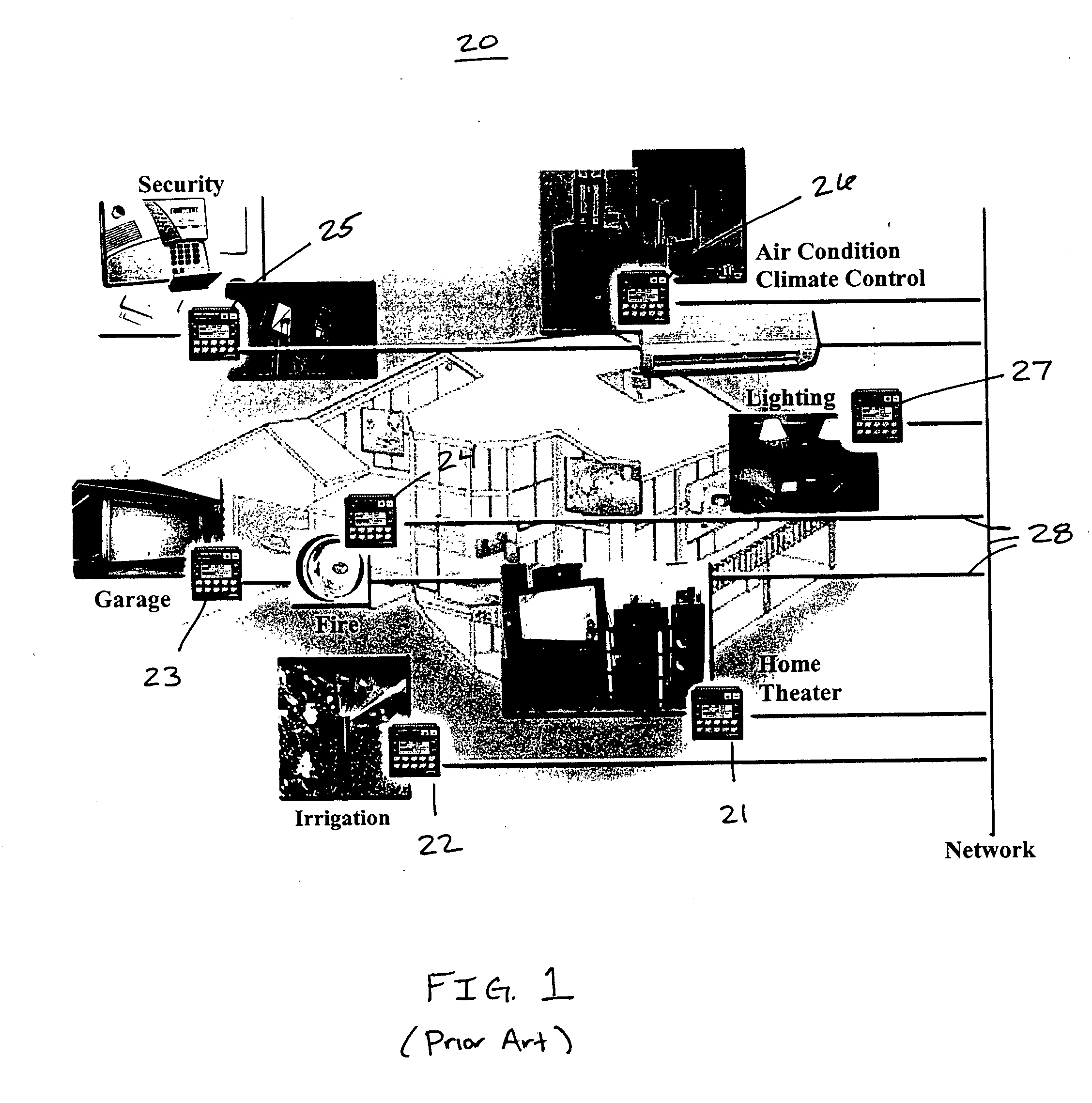

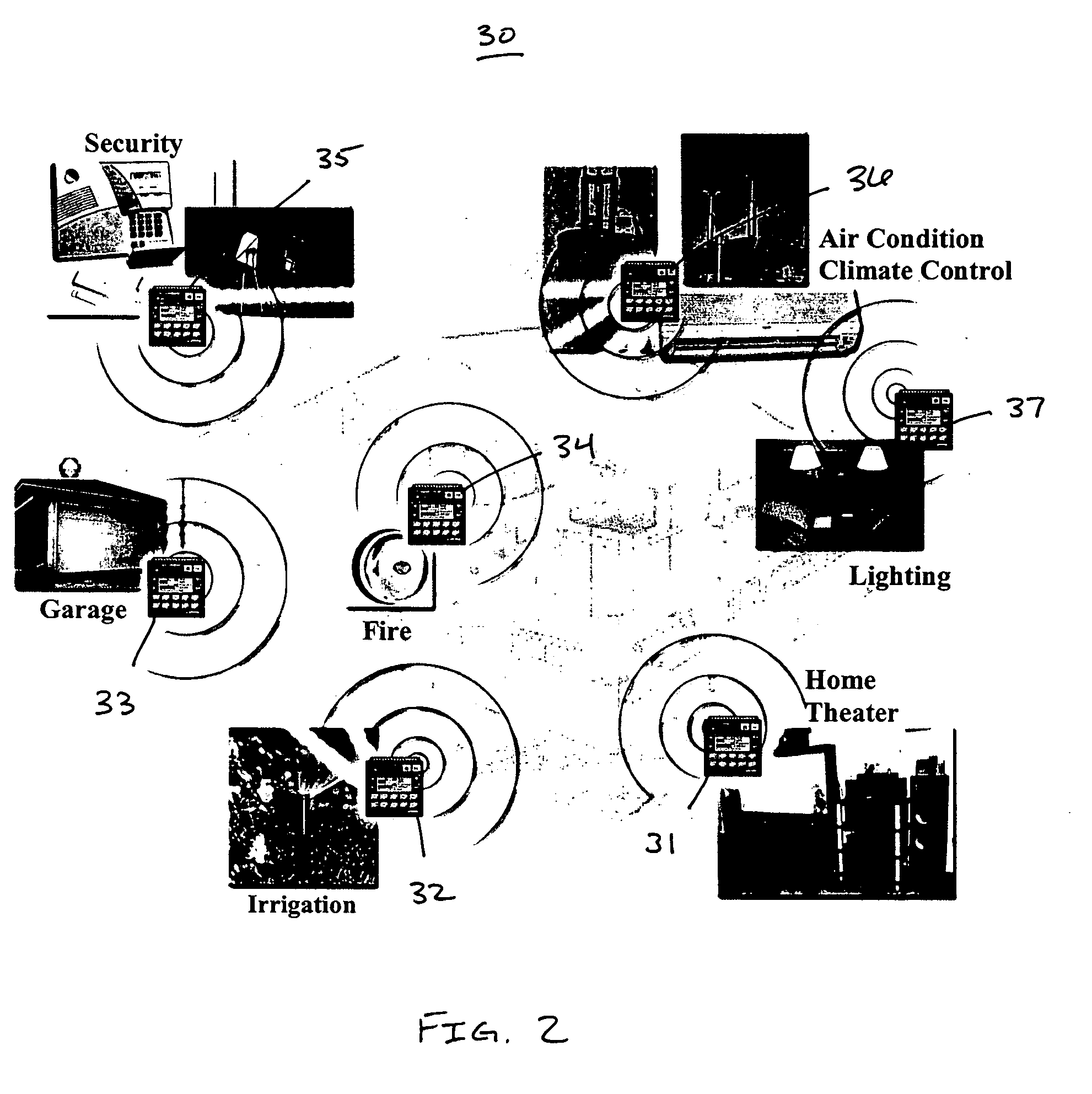

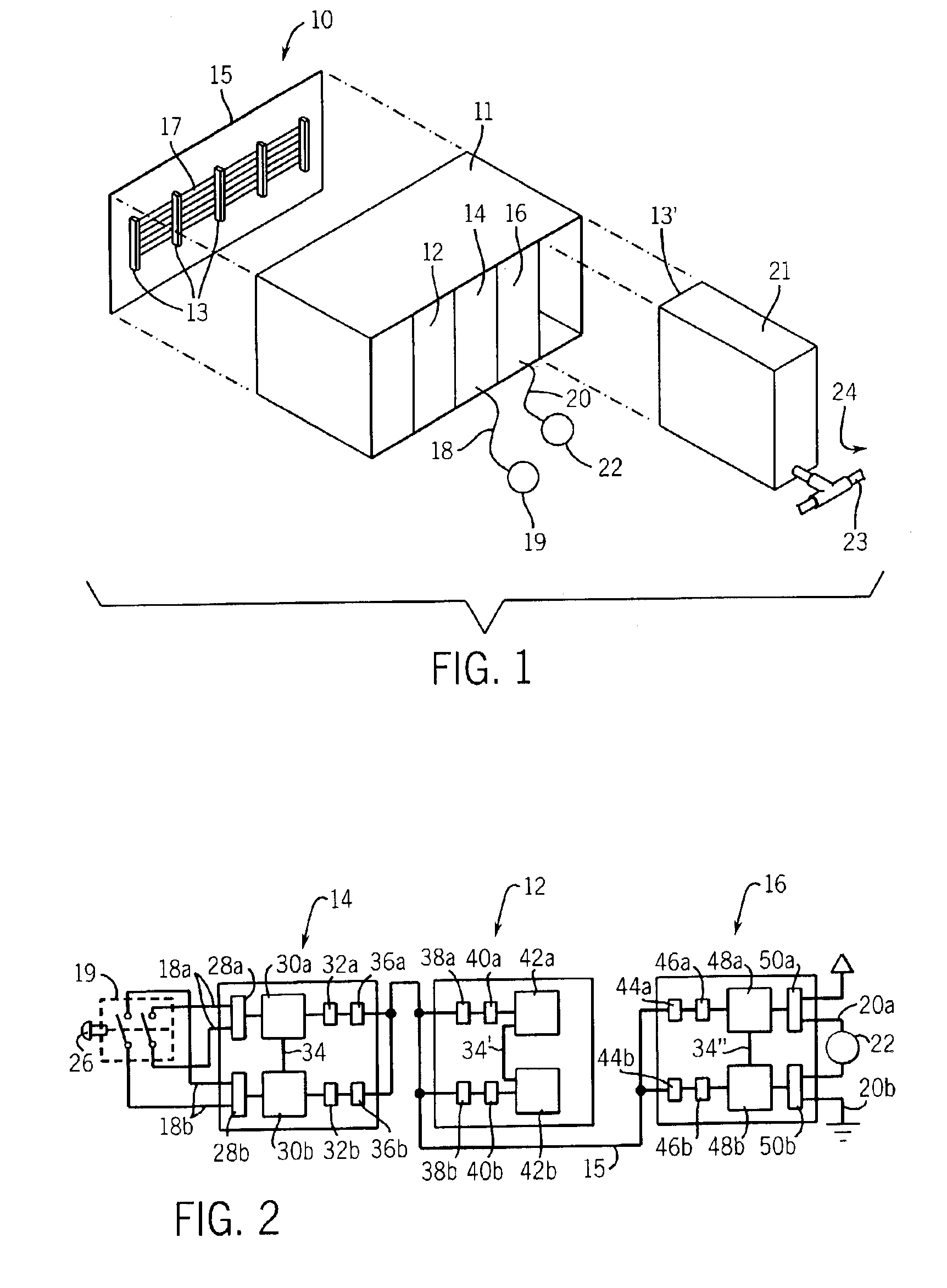

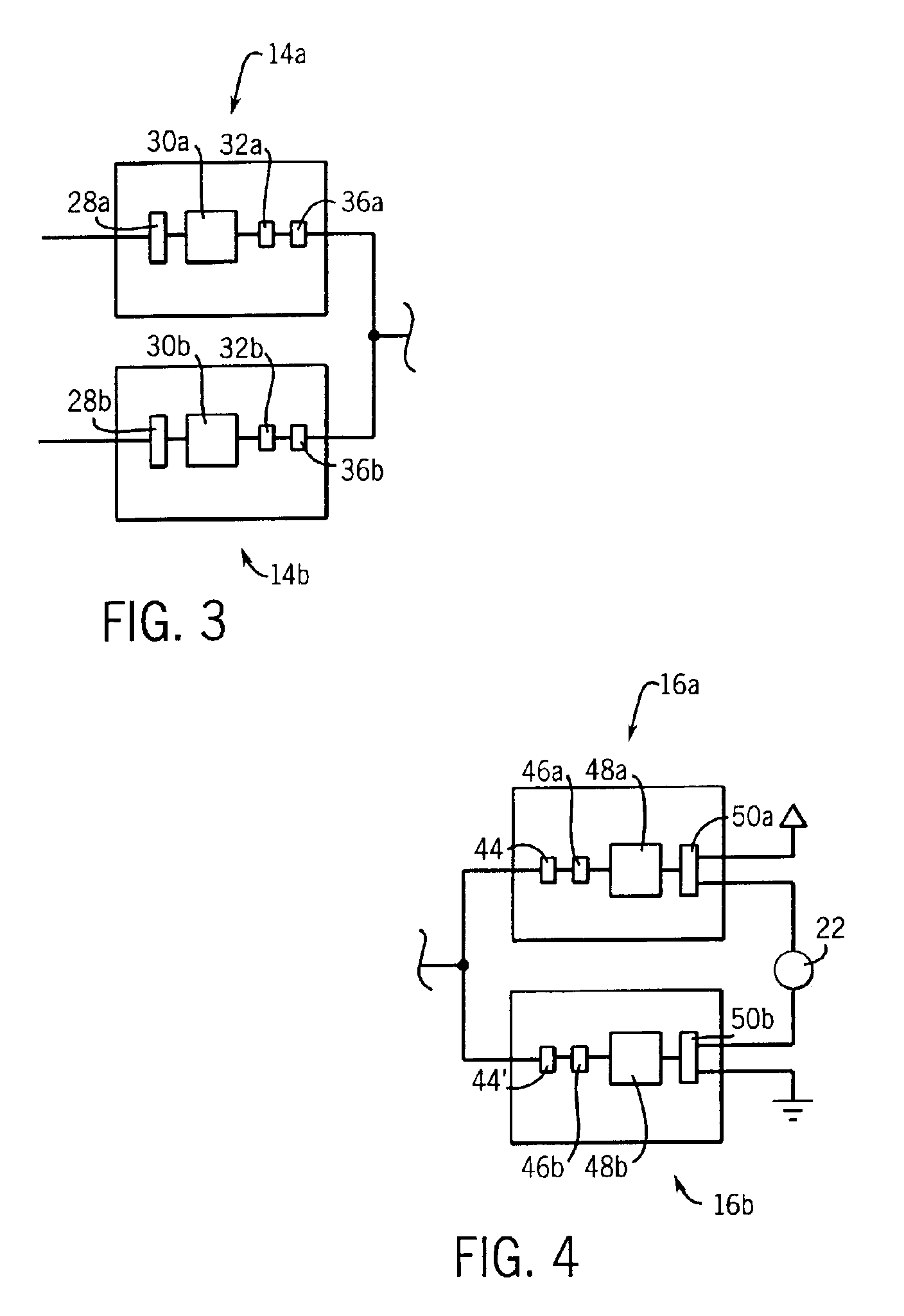

System and method for implementing logic control in programmable controllers in distributed control systems

ActiveUS7225037B2Easy to installEasy to modifyTemperatue controlStatic/dynamic balance measurementProgrammable logic controllerDistributed control system

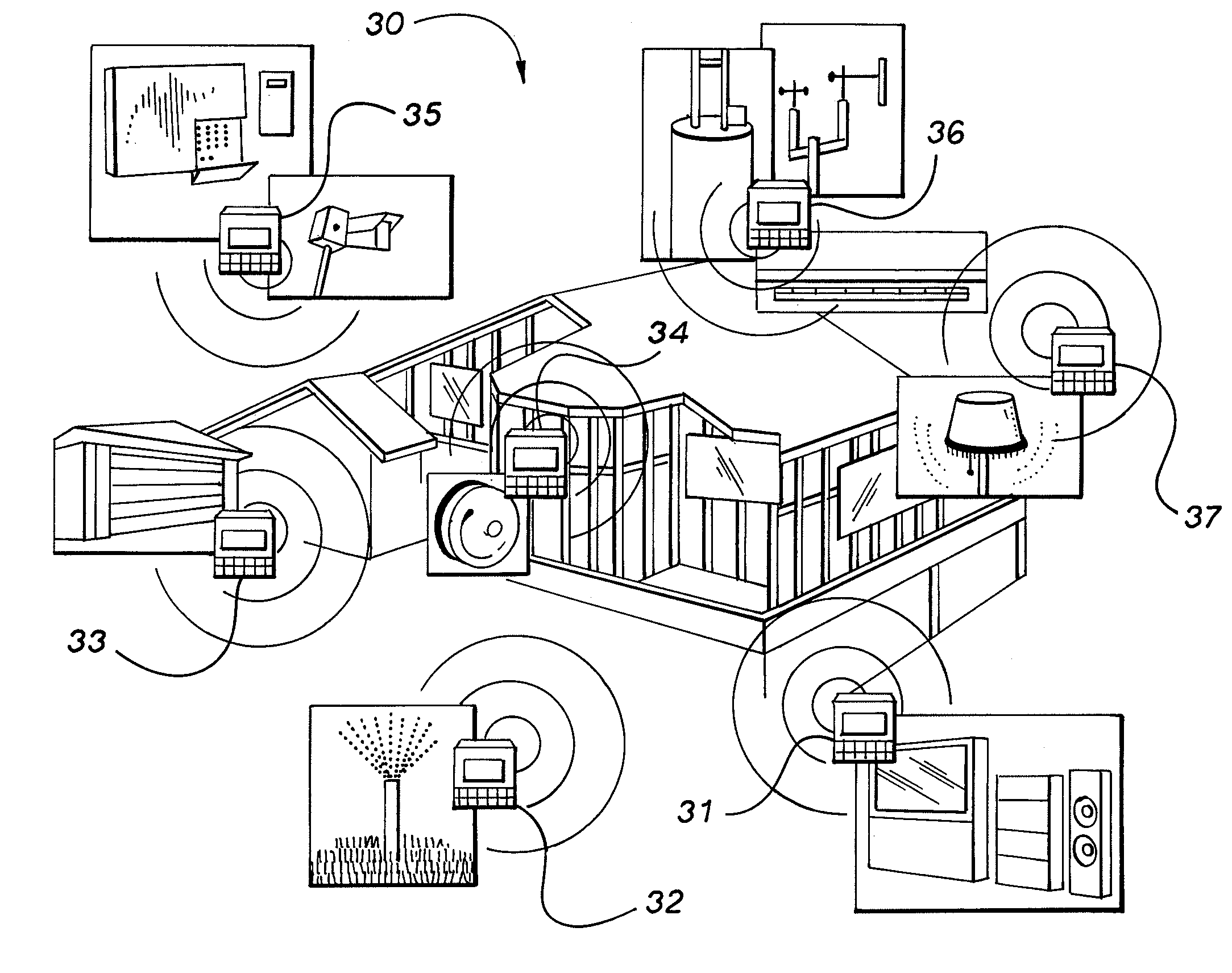

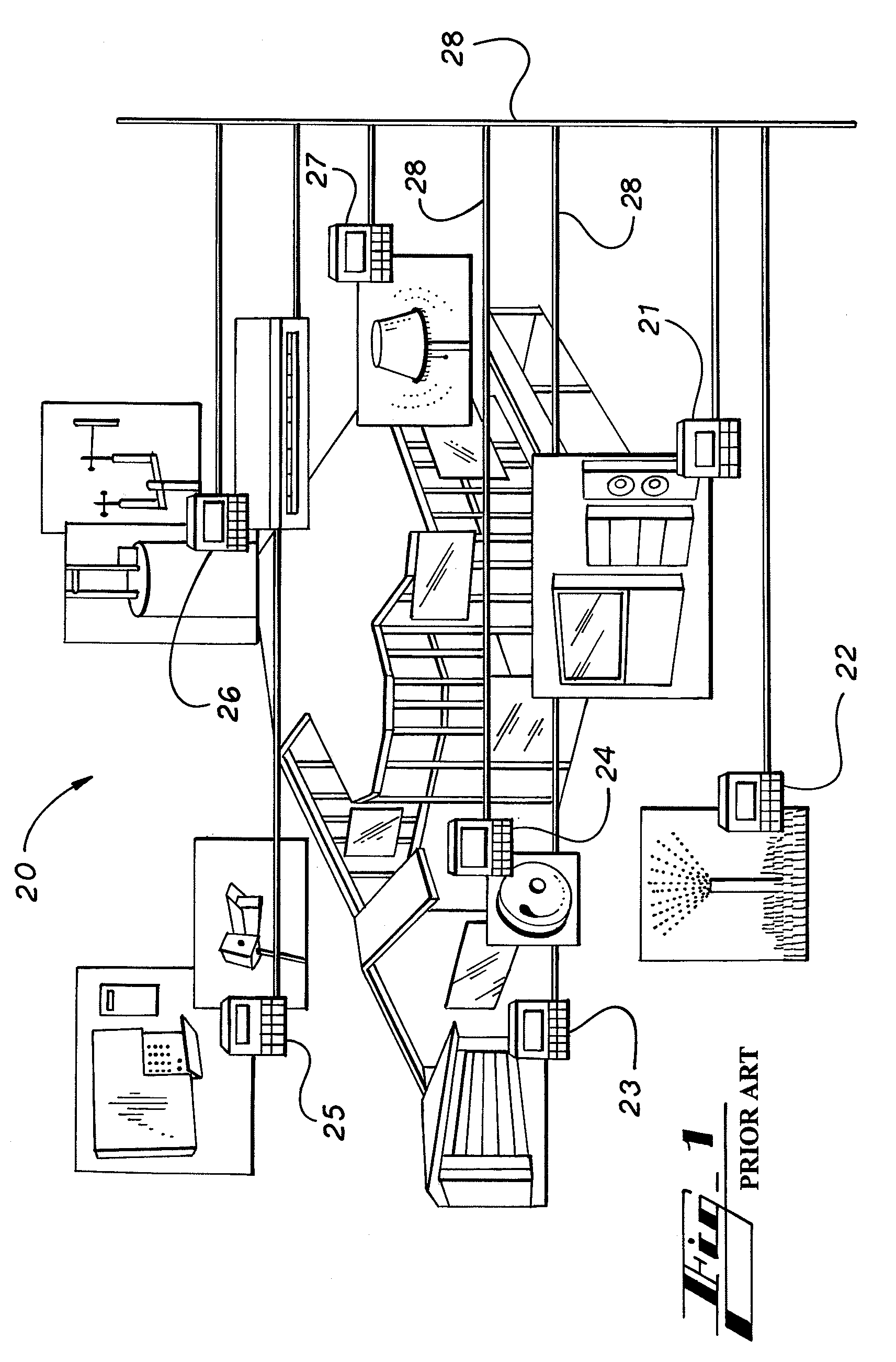

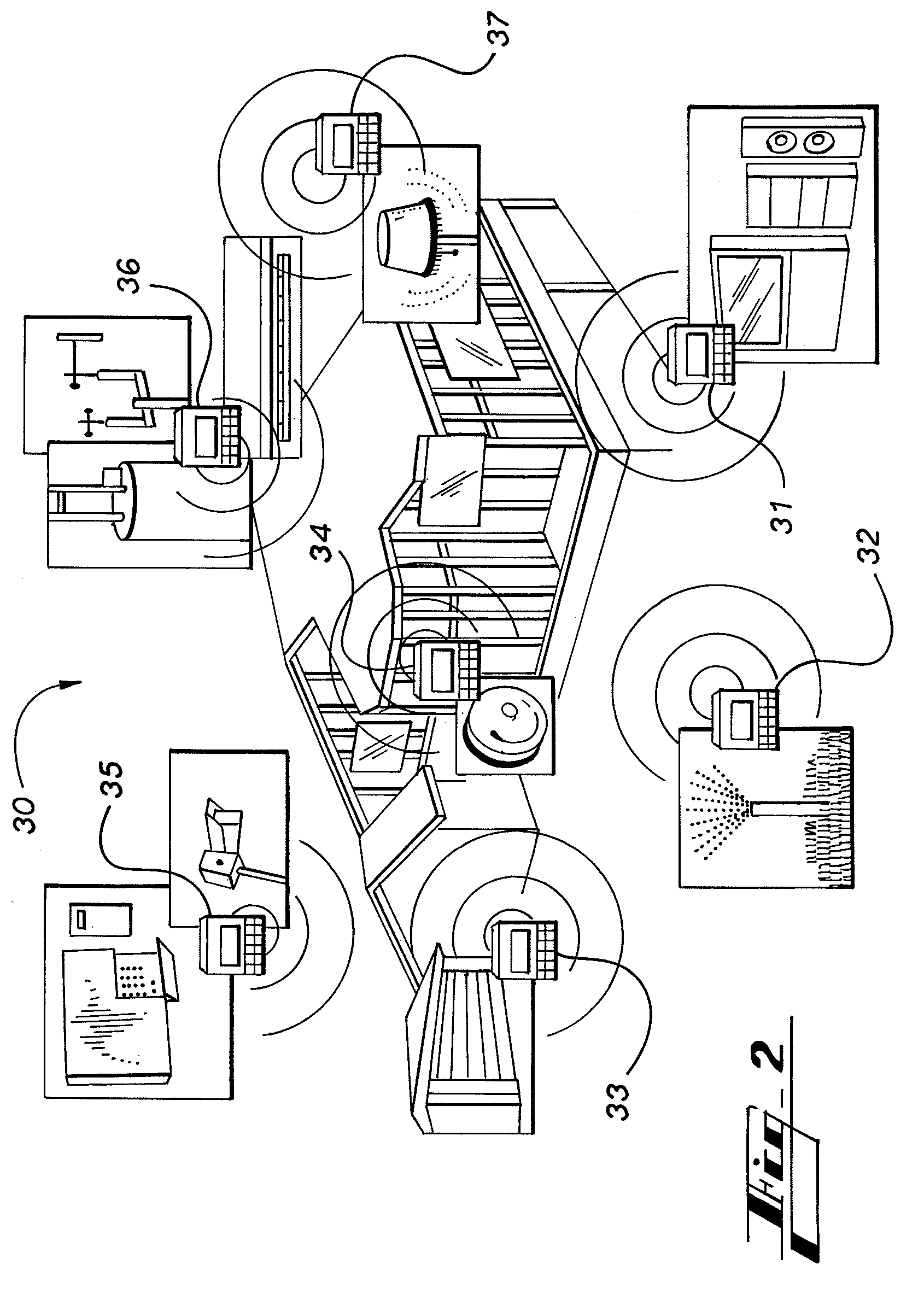

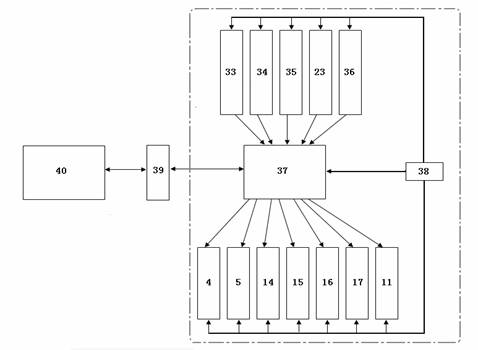

The present invention provides a system and method for implementing logic control in programmable controllers in distributed control systems using a wired or wireless network. A software application is used to define the configuration of the network. Based on the network configuration, a compiler engine automatically assigns each statement of the control program to at least one programmable logic controller in the network. Each statement is then transmitted over a data transmission medium to the programmable logic controller assigned to the statement.

Owner:UNITRONICS 1989 RG

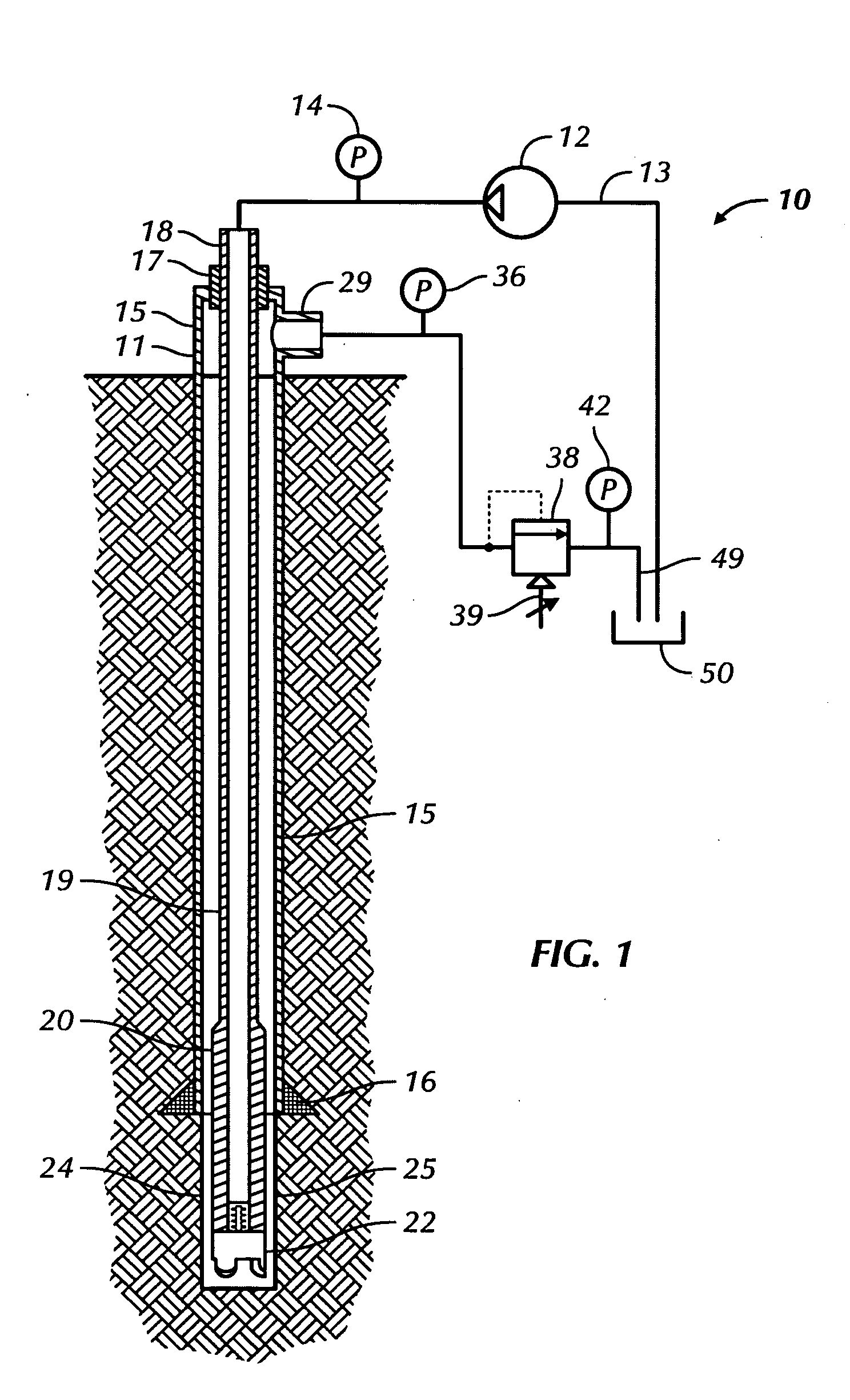

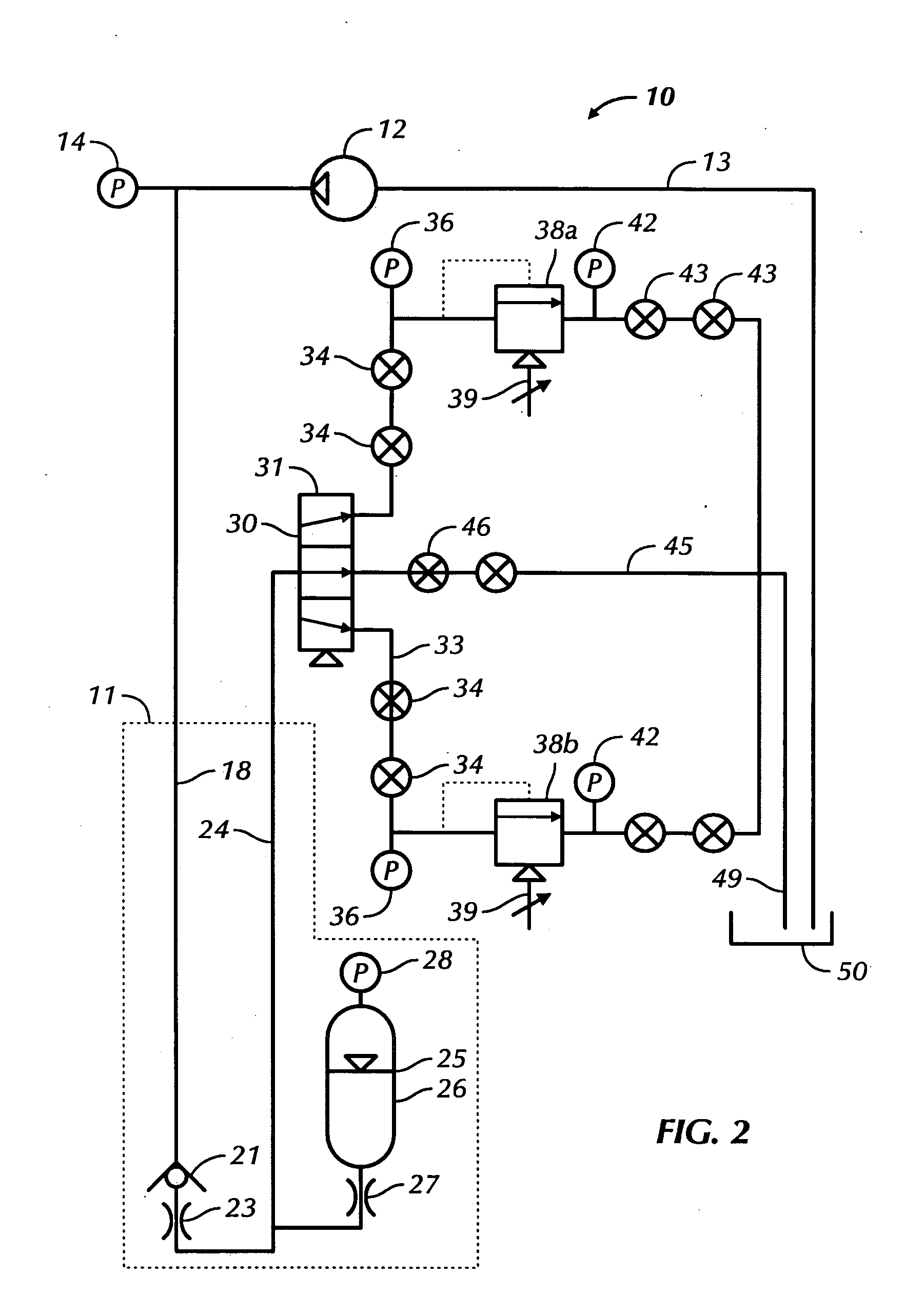

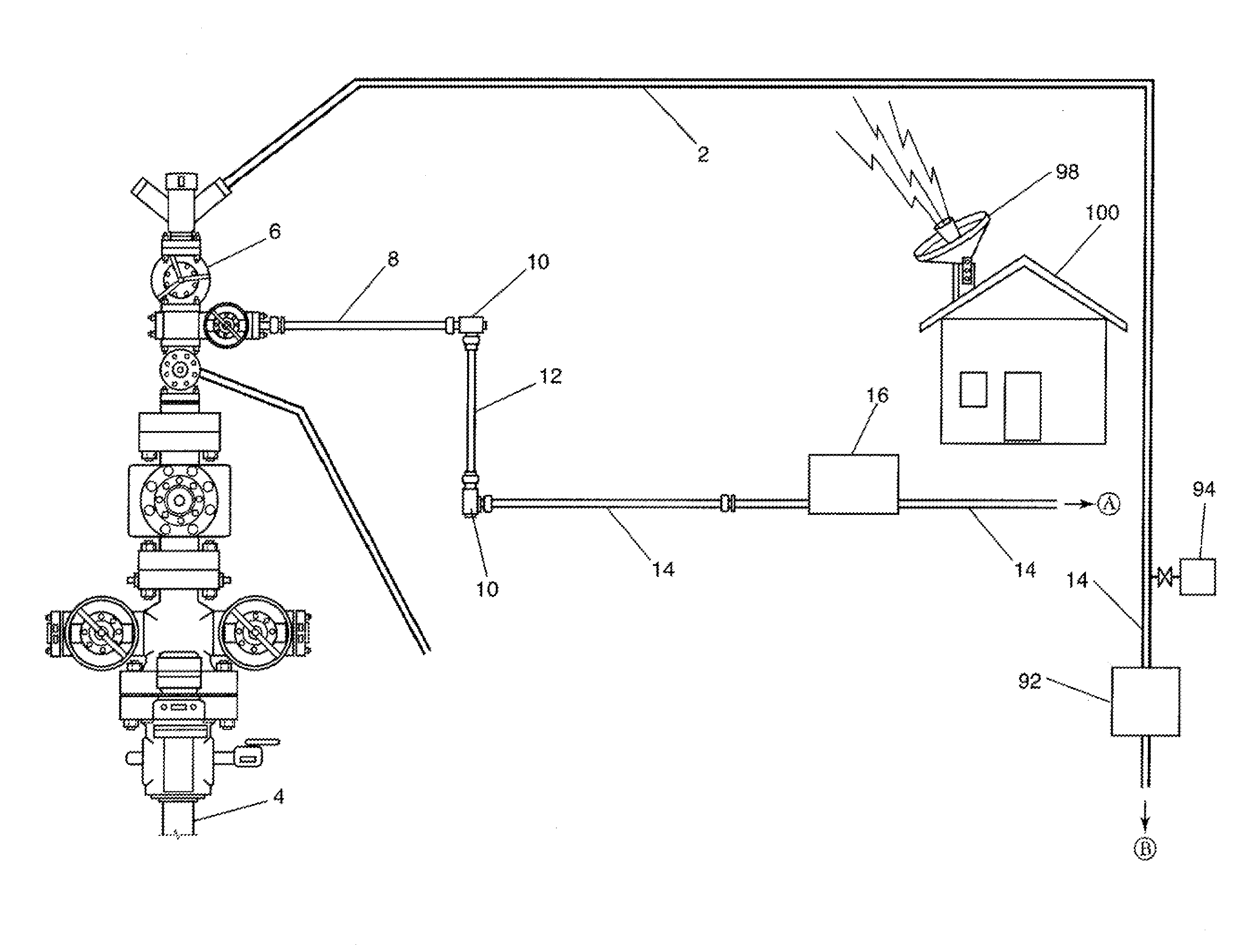

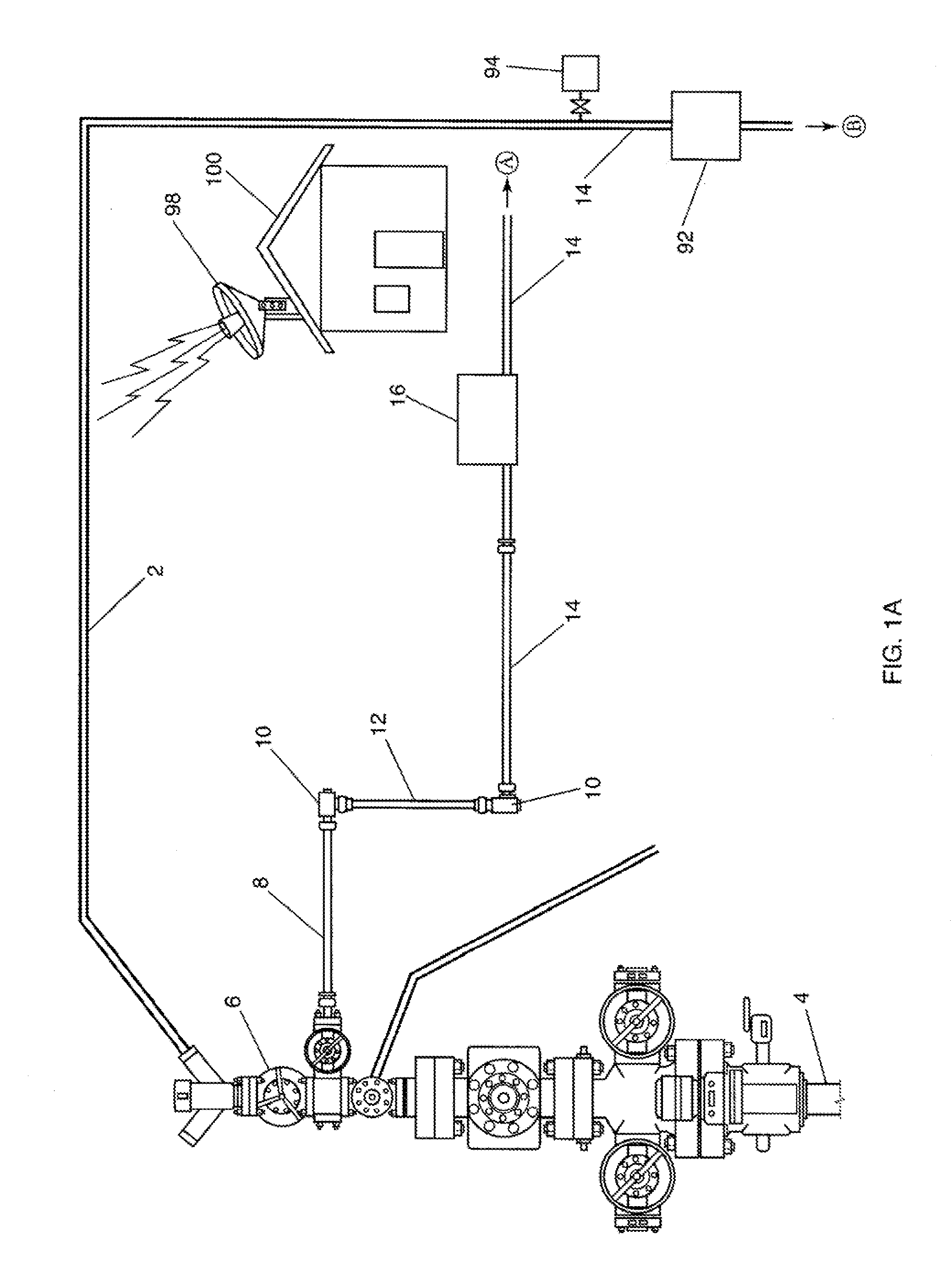

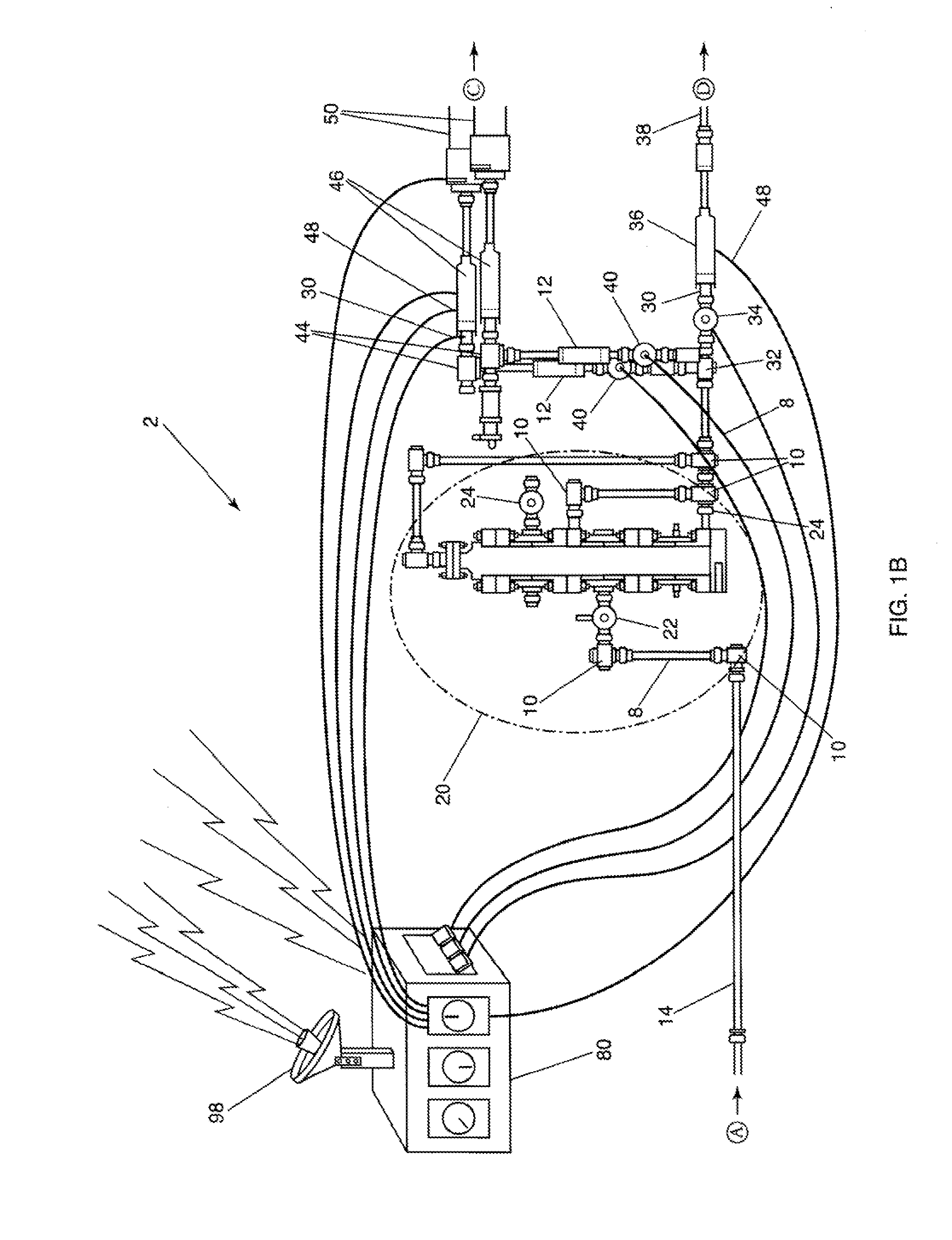

Well pressure control system

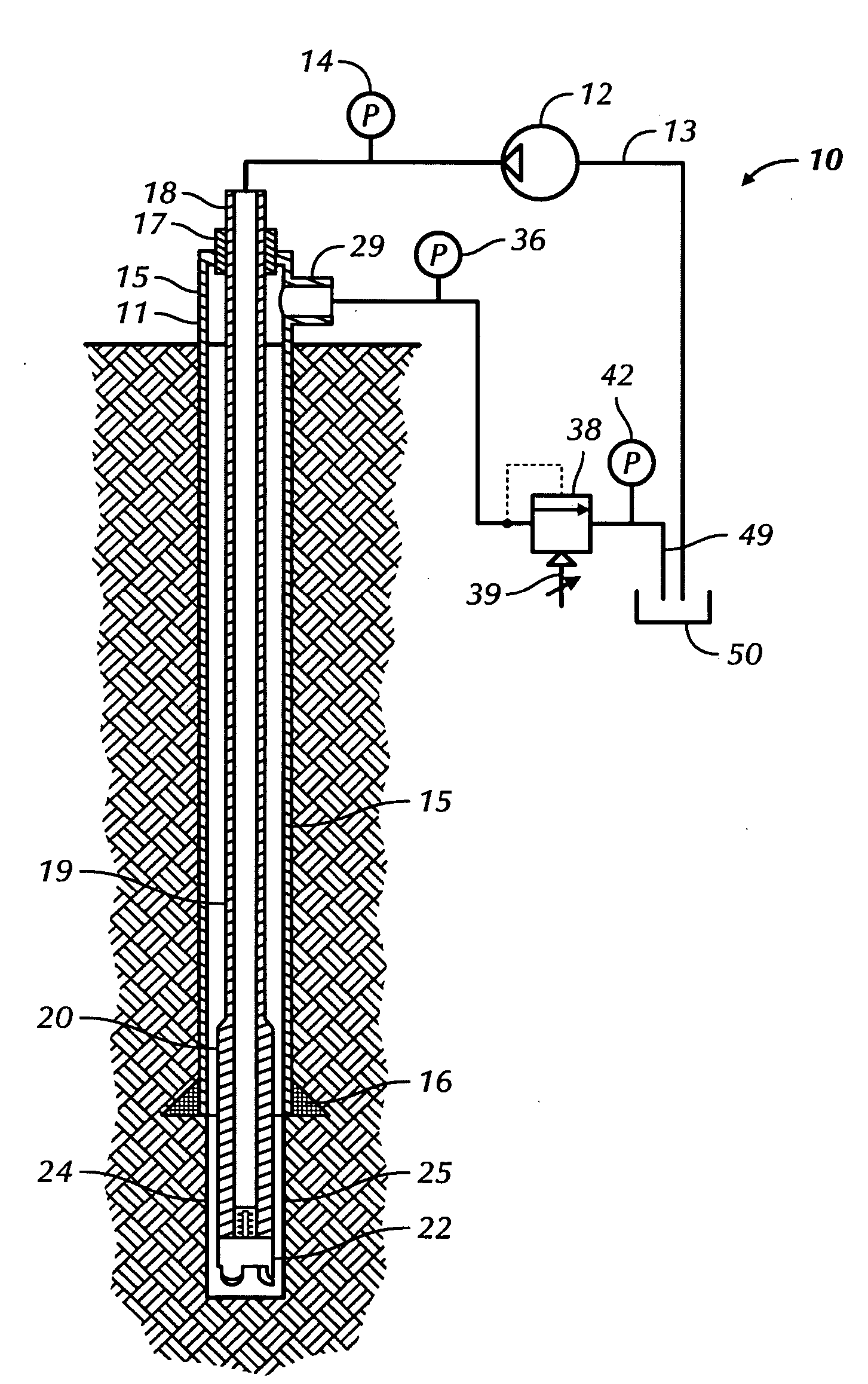

The present invention contemplates a choke control system that provides for local and off-site monitoring and control of the annulus flow pressure of a well. The choke control system includes a choke manifold connected to at least one choke and its associated actuator; a variety of instrumental drilling sensors, pump stroke counter switches, and choke position indicators; a local choke and hydraulic pressure control console; and a programmable controller in communication with the local choke and hydraulic pressure control console. The programmable controller handles the logical operations of the choke control system, including processing instrument measurements and operator input data to produce control signals for operating the choke, the choke actuator and the various valves associated with the choke manifold. The programmable controller is typically either an electronic digital computer and / or a programmable logic controller (PLC). The present invention further contemplates the two-way communication between the choke control system and the Internet via a satellite linkage.

Owner:EXPRO AMERICAS

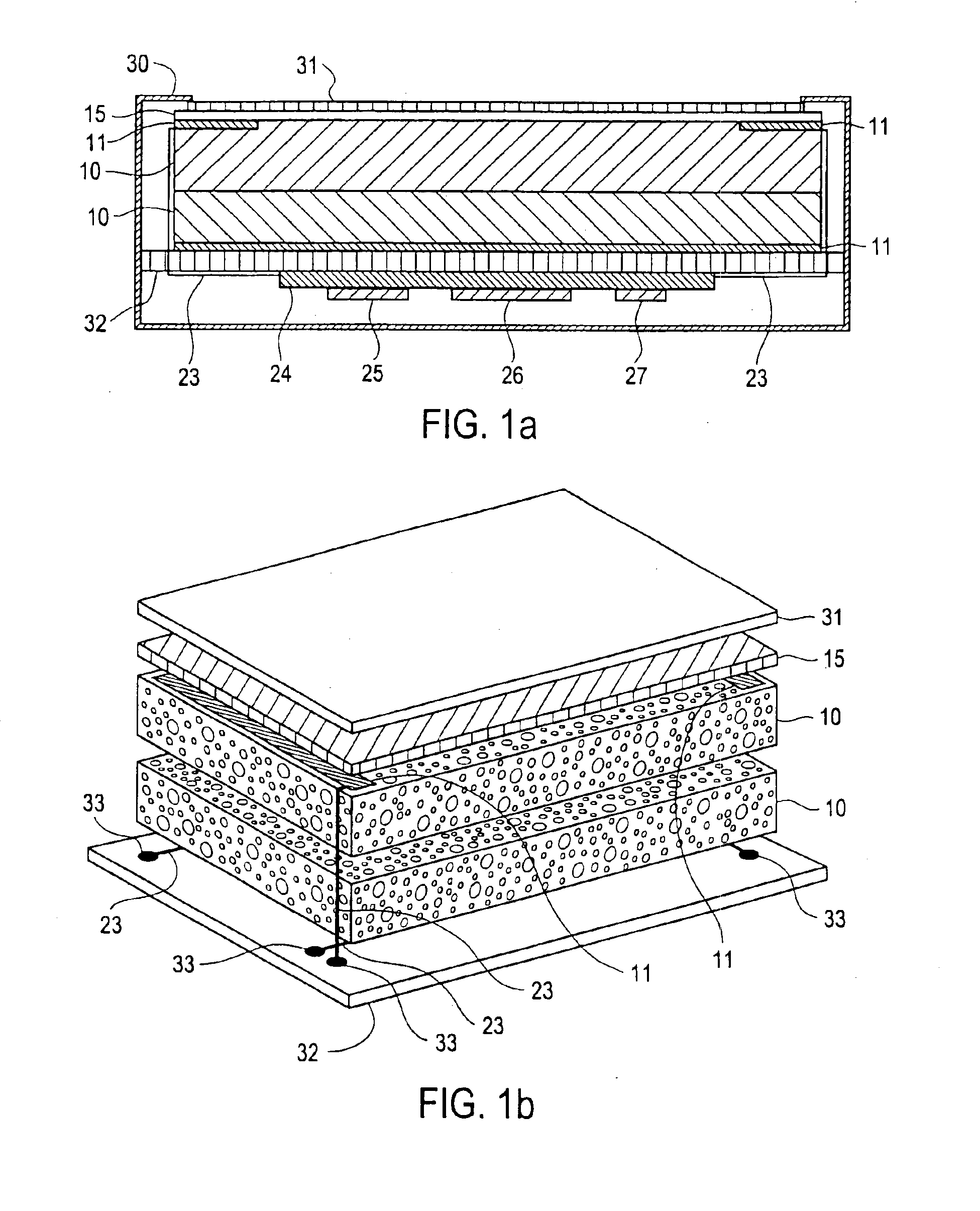

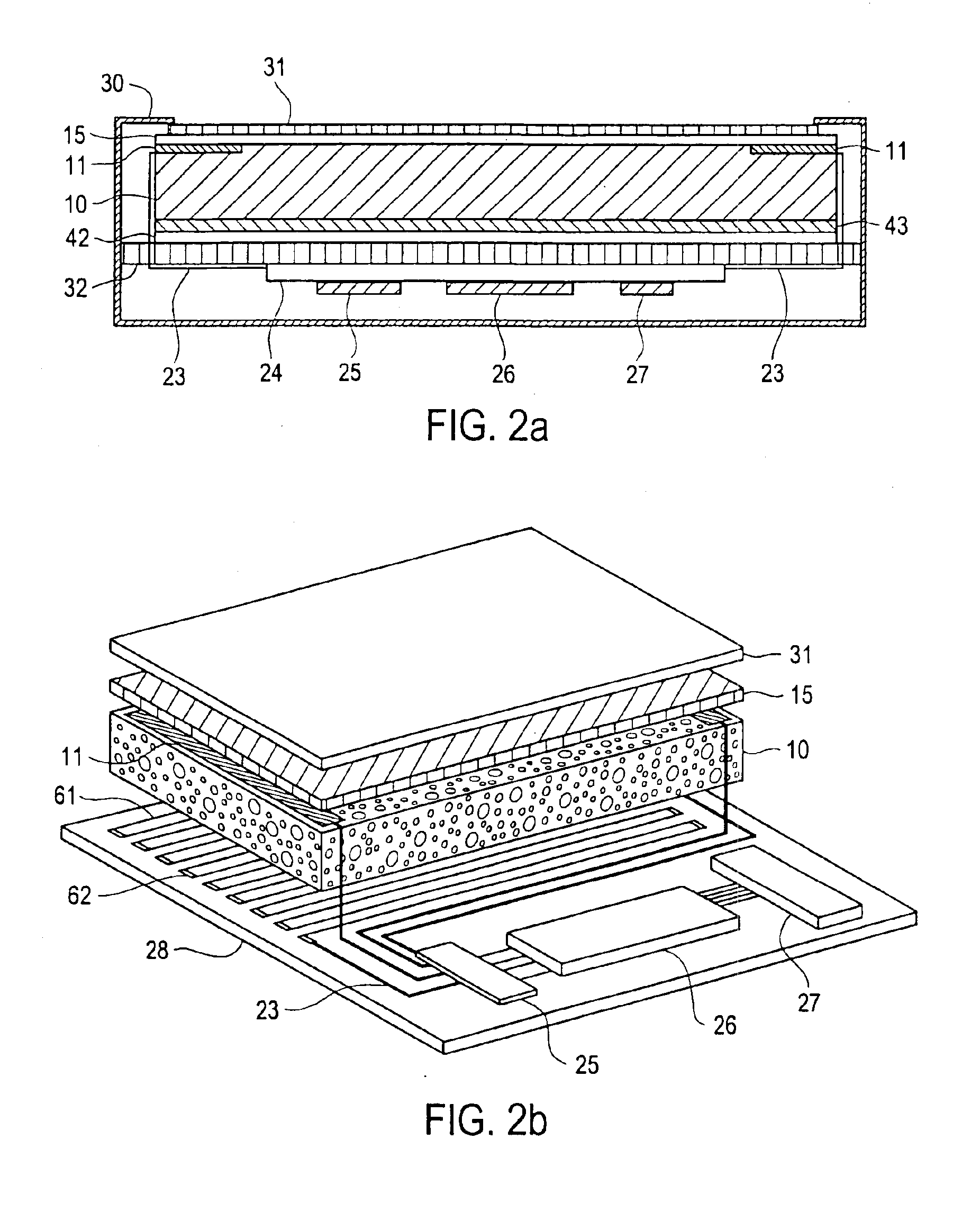

Configurable industrial input devices that use electrically conductive elastomer

InactiveUS6888537B2Inexpensive and easily and fully customizableInput/output for user-computer interactionCathode-ray tube indicatorsElastomerEngineering

A configurable operator panel that uses a tactile sensor with electrically conductive elastomer and appropriate electronics is disclosed herein. The device relies on a robust and inexpensive tactile sensor that senses the touch position (and may or may not sense touch pressure as well). The physical interface is easily configurable along with the electronics, which execute the desired function based on touch location and pressure. The configurable operator panel is designed to communicate with most industrial automation equipment, including but not limited to, motion control equipment, programmable logic controllers (PLC), personal computers, and can be made to control other types of machines requiring external analog or digital input.

Owner:SIEMENS CORP

System and method for implementing logic control in programmable controllers in distributed control systems

ActiveUS20050085928A1EliminateAchieve modularityTemperatue controlStatic/dynamic balance measurementProgrammable logic controllerDistributed control system

Owner:UNITRONICS 1989 RG

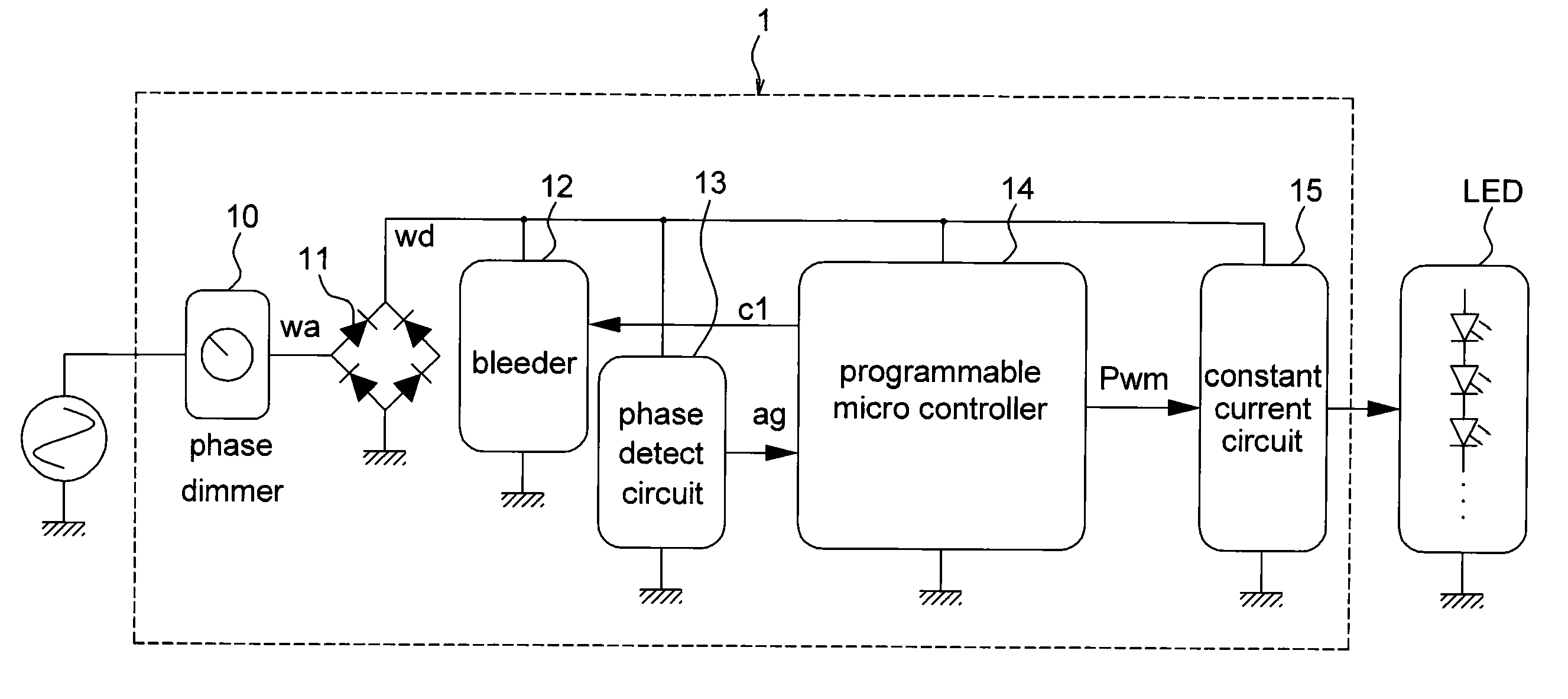

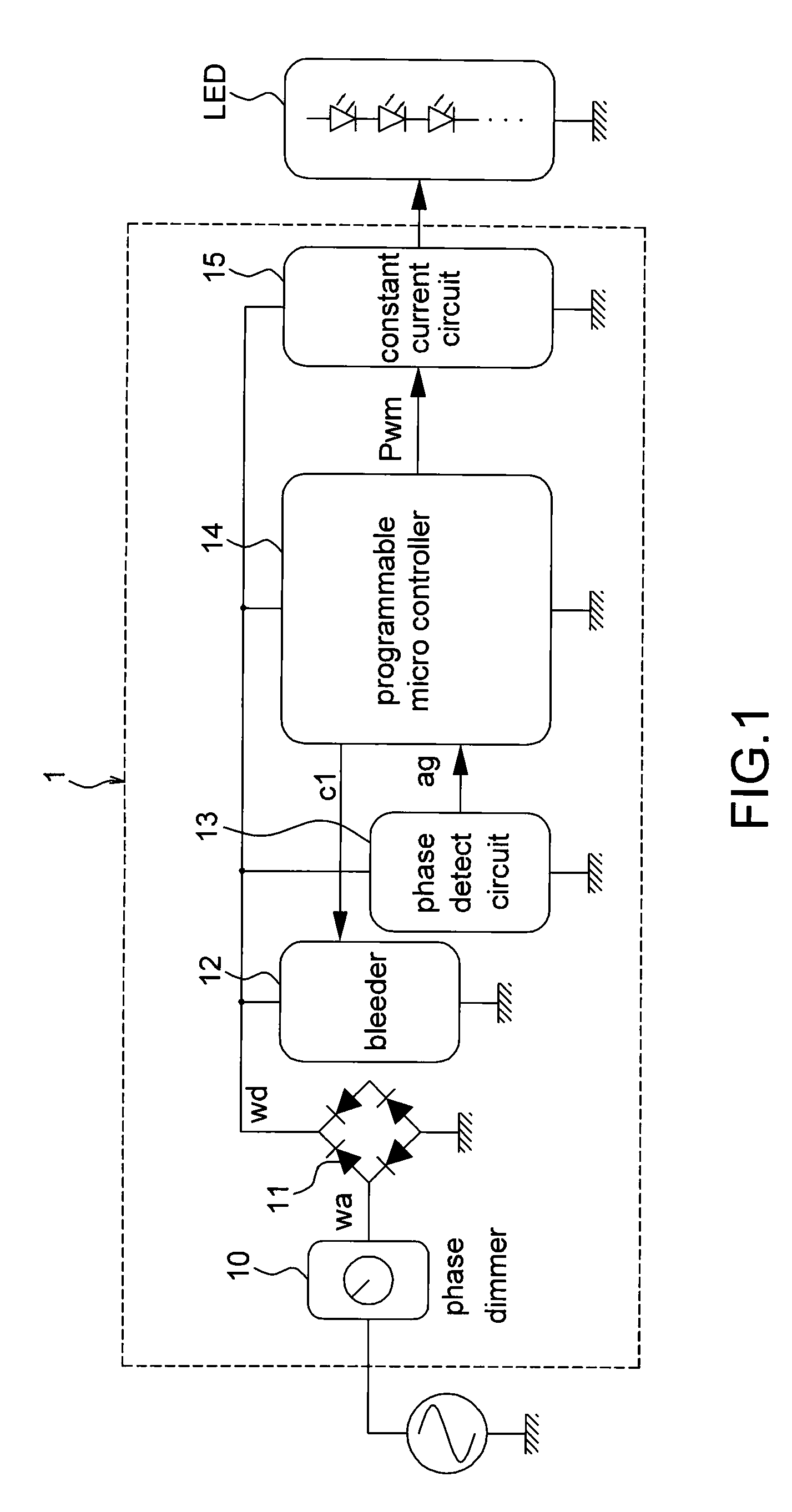

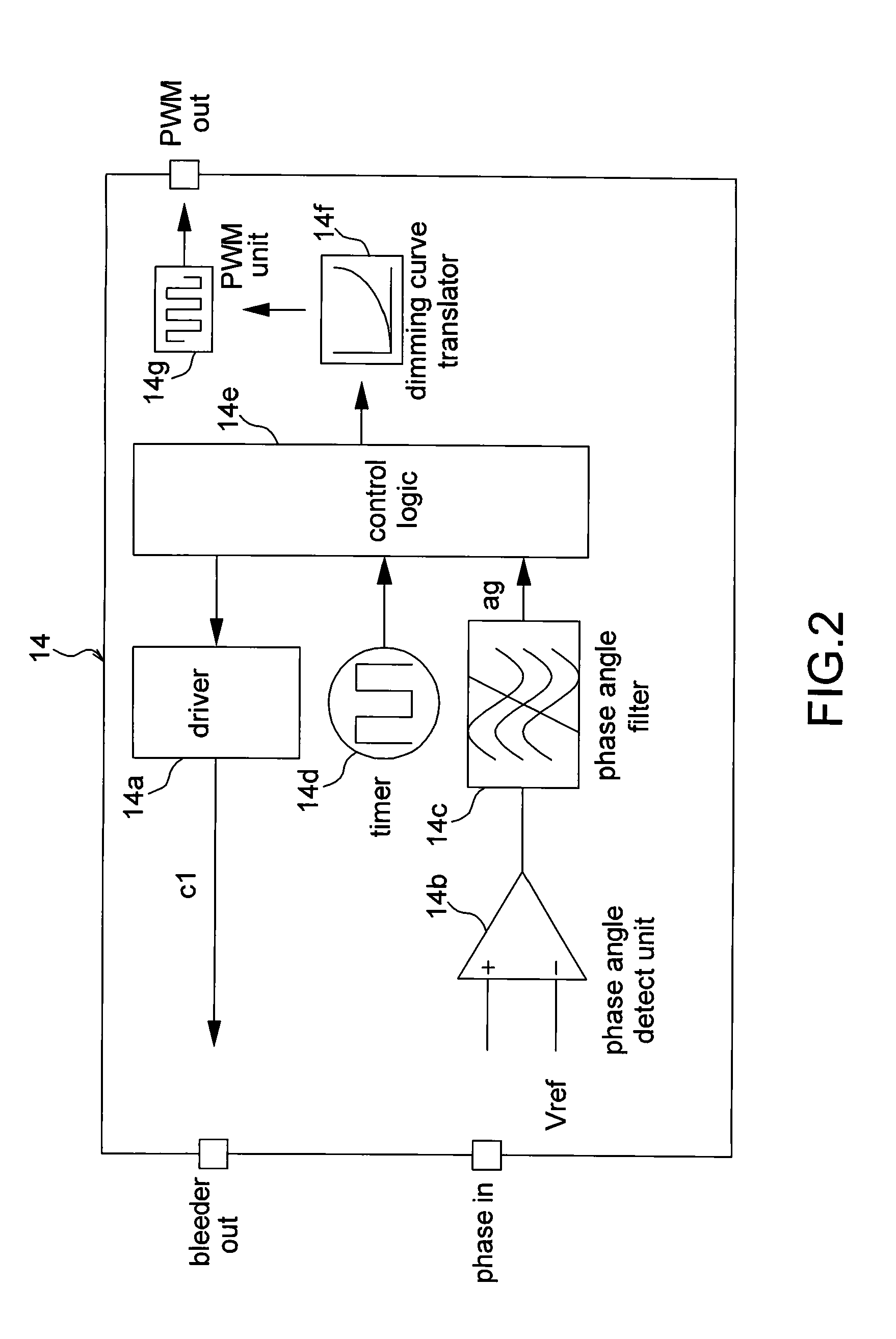

Dimmer circuit applicable for LED device and control method thereof

InactiveUS20110291583A1Improve efficiencyElectrical apparatusElectroluminescent light sourcesProgrammable logic controllerProgrammable Interrupt Controller

A dimmer circuit applicable for LED device and control method thereof is disclosed in the embodiments of the present invention. The dimmer circuit is applicable for controlling at least a LED device. The dimmer circuit includes a rectifier, a bleeder, a phase angle detect circuit, a constant current circuit and a programmable micro controller. The phase angle detect circuit couples to the programmable micro controller. The constant current circuit couples to the LED device The programmable micro controller generates a PWM signal according to the output signal of the phase angle detect circuit to adjust current of the constant current circuit.

Owner:UNITED POWER RES TECH CORP

Object-oriented programmable controller

InactiveUS6868538B1Good choiceProgramme controlComputer controlProgrammable logic controllerSoftware

An apparatus having a programmable processor and a memory for performing a plurality of user-selectable control functions includes a database for storing a plurality of items associated with each of the control functions. The items include, for each function, at least one procedure for performing an action associated with the control function and a specification of at least one state associated with the control function. The apparatus further includes software routines stored on the memory and adapted to be executed by the processor that facilitate selection of a procedure in the database, that access the database and cause performance of the selected procedure to achieve the state specified therein, and that monitor at least one resource associated with the action of the procedure and, based thereon, determine whether the specified state has been achieved.

Owner:FISHER-ROSEMOUNT SYST INC

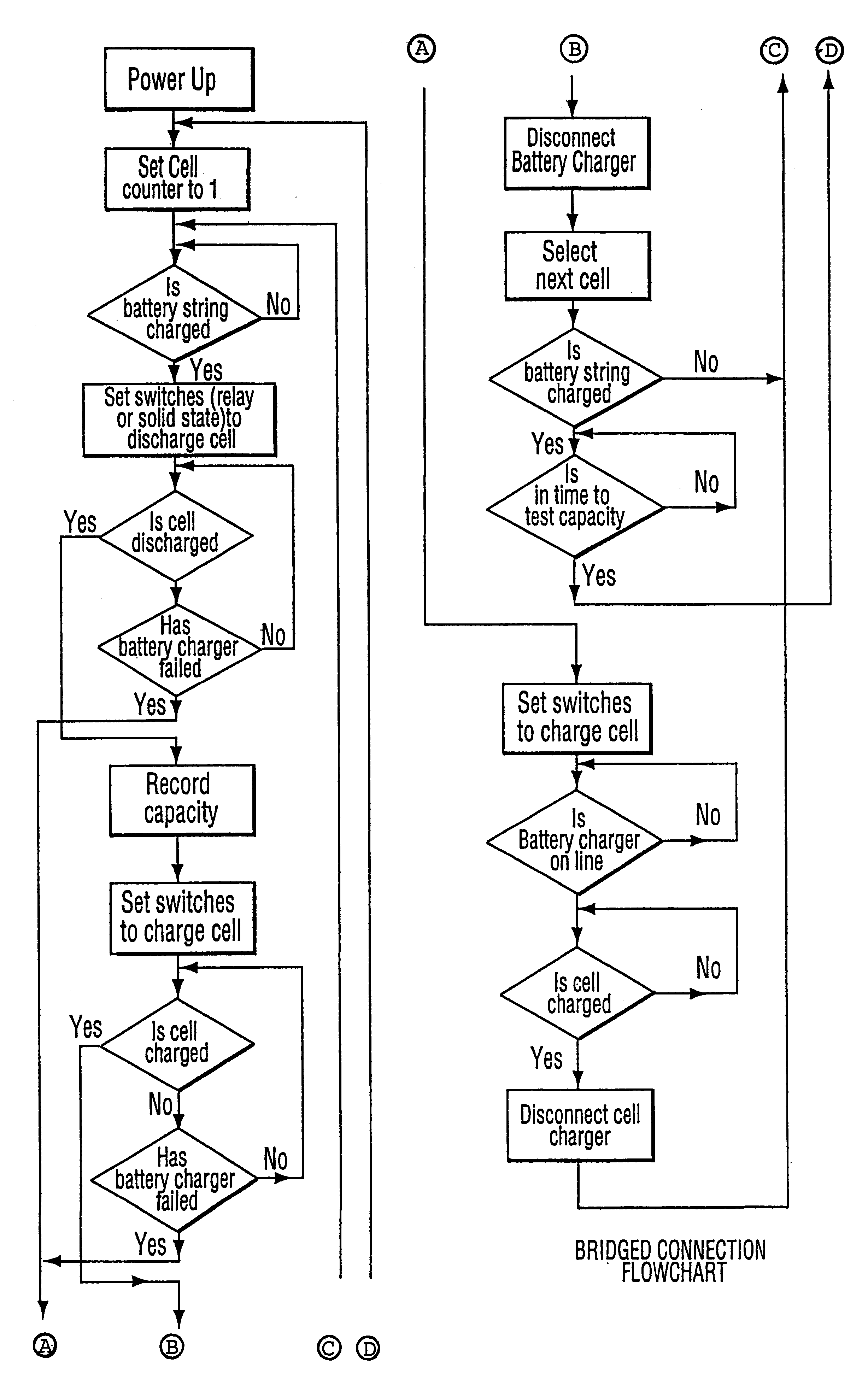

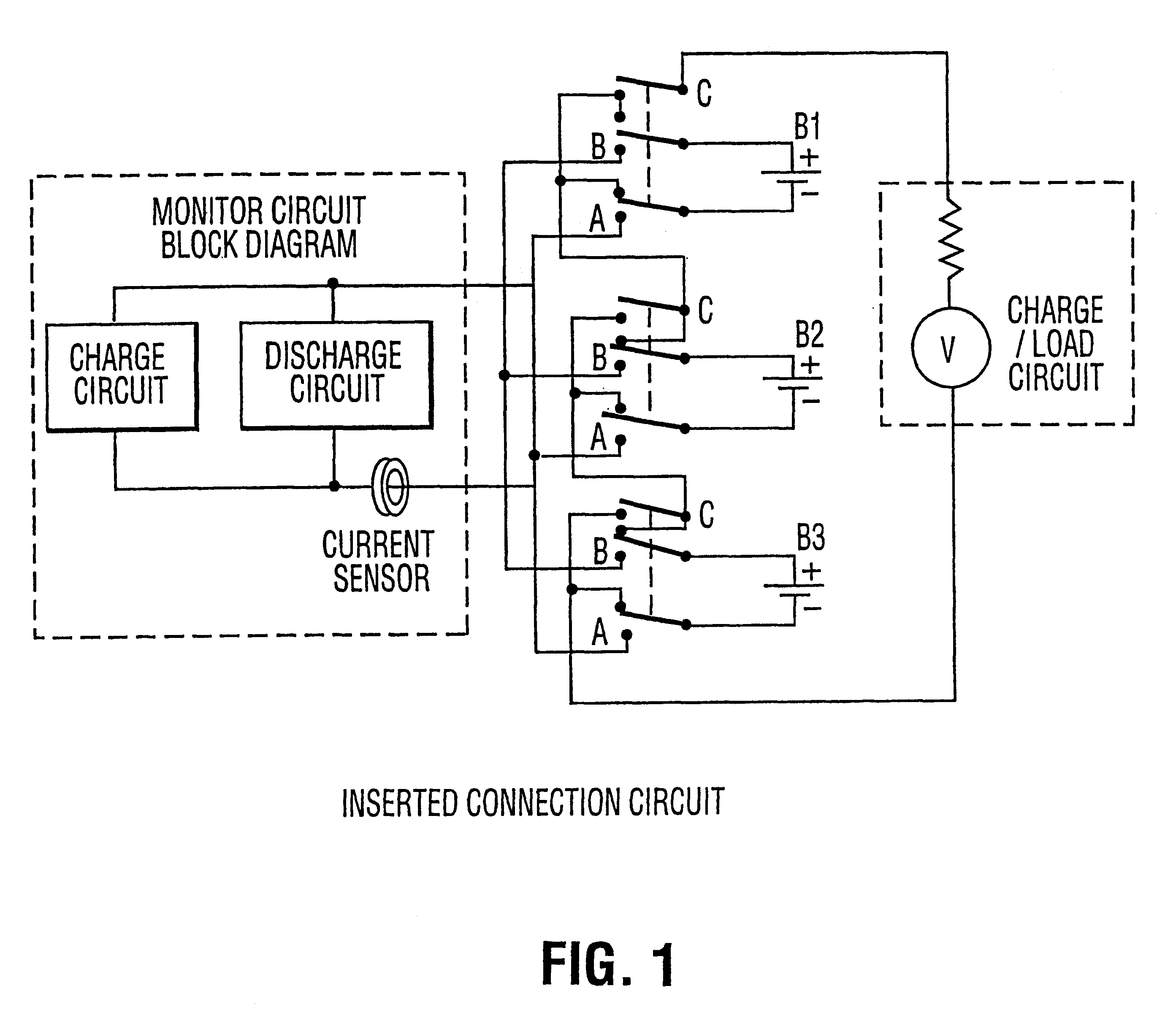

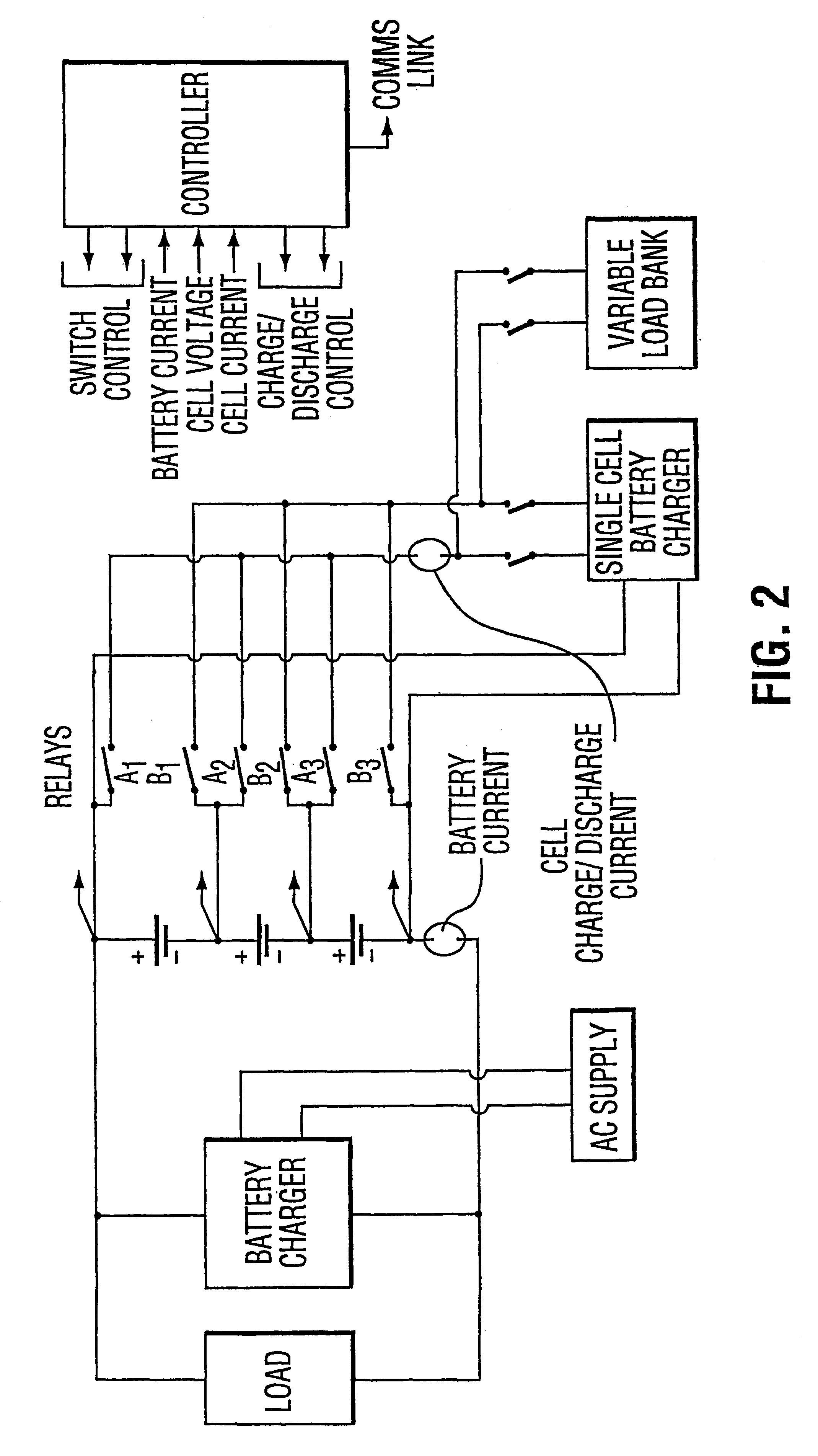

Device for managing battery packs by selectively monitoring and assessing the operative capacity of the battery modules in the pack

InactiveUS6239579B1Rejuvenate and boost healthCycle wellCharge equalisation circuitCircuit monitoring/indicationElectricityElectrical battery

The invention relates to a device for managing battery packs by measuring and monitoring the operating capacity of individual battery modules in a battery pack. A programmable logic controller directs the selective closing of relays to allow individual battery modules to be load-tested using a variable discharge load unit, without compromising useful battery pack capacity. A battery module whose useful capacity falls below a predefined threshold may be connected to a battery charger for replenishment and then electrically realigned with the remaining modules in the pack for continued operation. Alternatively, an alarm may be triggered which alerts the user that the module is due for replacement. This sequence of events is performed on all cells in the pack at a predetermined interval.

Owner:ESTCO ENERGY +1

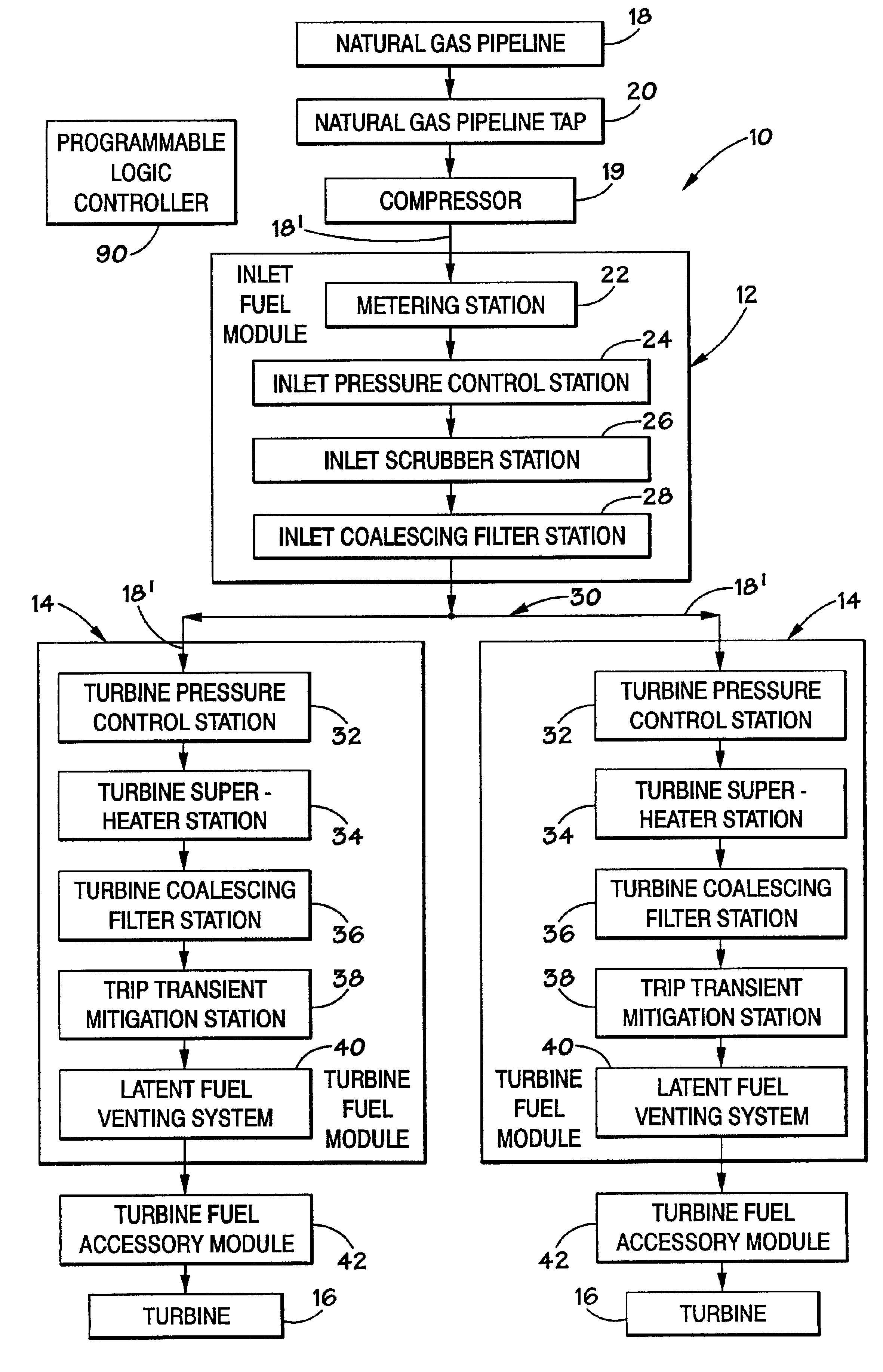

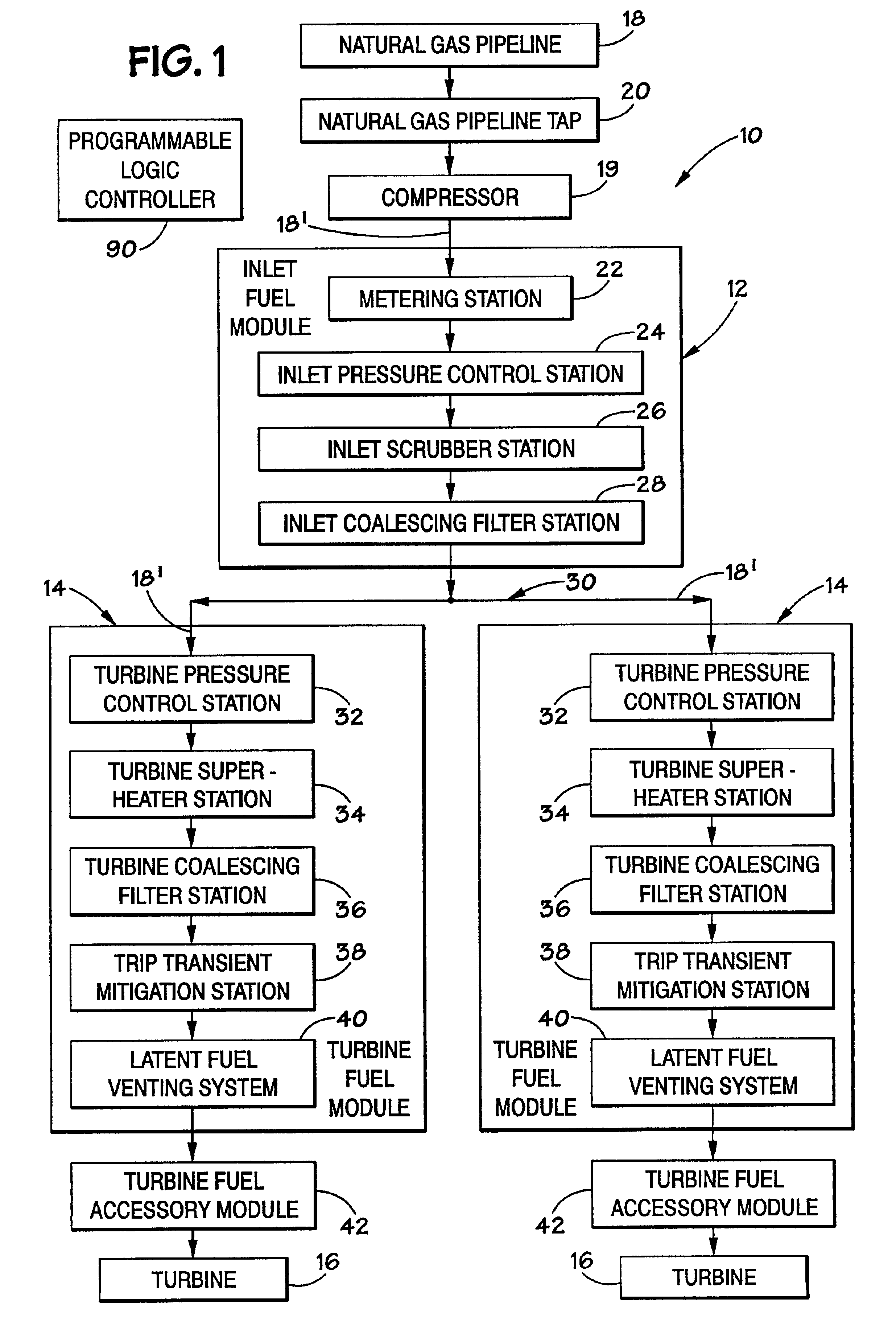

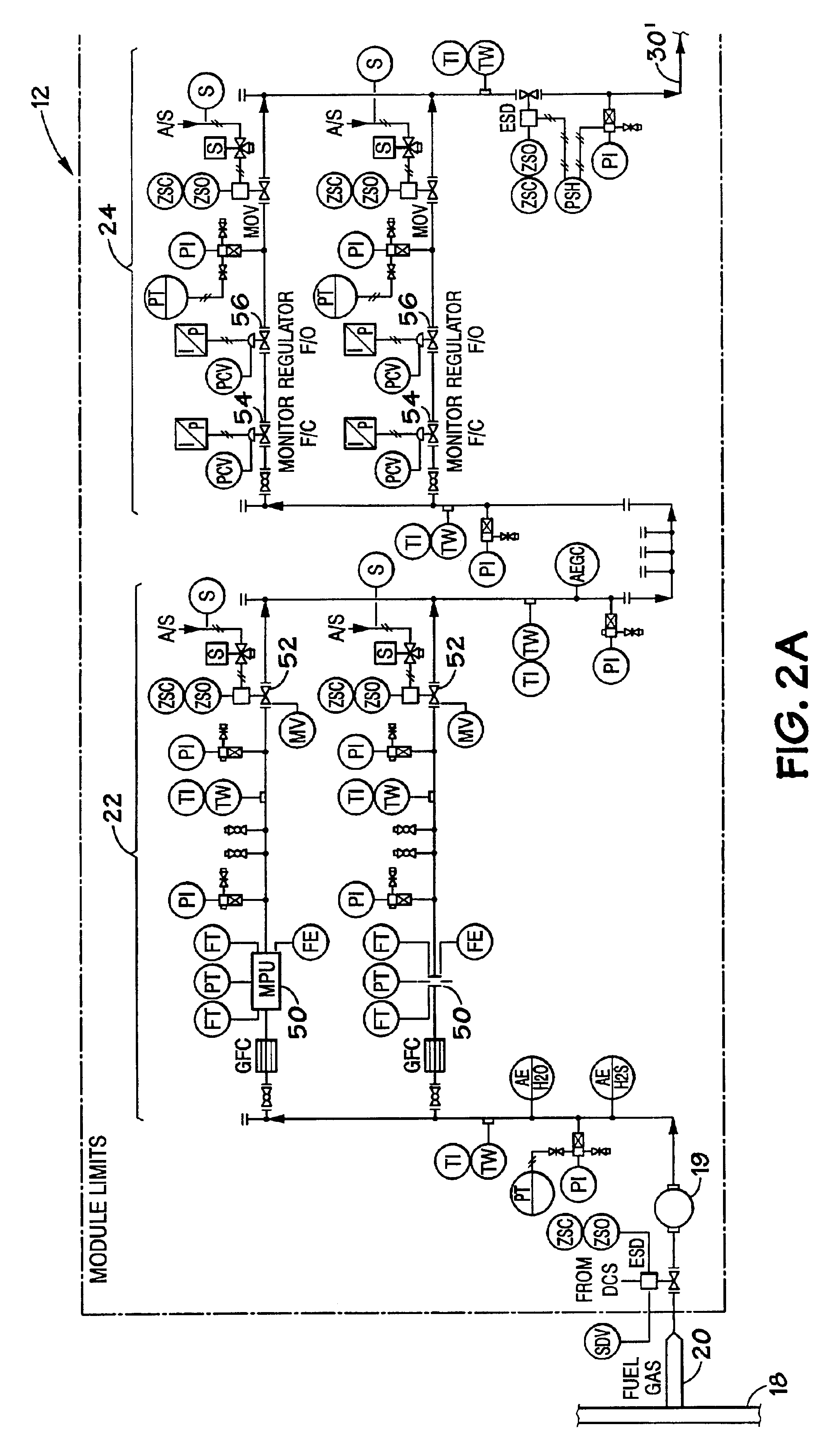

Modular fuel conditioning system

InactiveUS6901735B2Reduce pressureControl moreGas turbine plantsTurbine/propulsion fuel heatingProgrammable logic controllerModularity

A fuel conditioning system for a turbine plant may include an inlet fuel module followed by a turbine fuel module for each turbine, the modules being monitored and controlled by a programmable logic controller. The inlet fuel module may include a metering station, an inlet pressure control station, an inlet scrubber station, and an inlet coalescing filter station. Each turbine fuel module has a turbine pressure control station, a turbine super-heater station, and a turbine coalescing filter station. The fuel conditioning system may also include a trip transient mitigation system and a latent fuel venting system. The programmable logic controller collects data from all of the stations and systems as well as the turbine and then uses self-correcting algorithms to control the stations and systems. The programmable logic controller also stores the data collected and transmits the data to an off-site storage and verification center.

Owner:PIPELINE CONTROLS

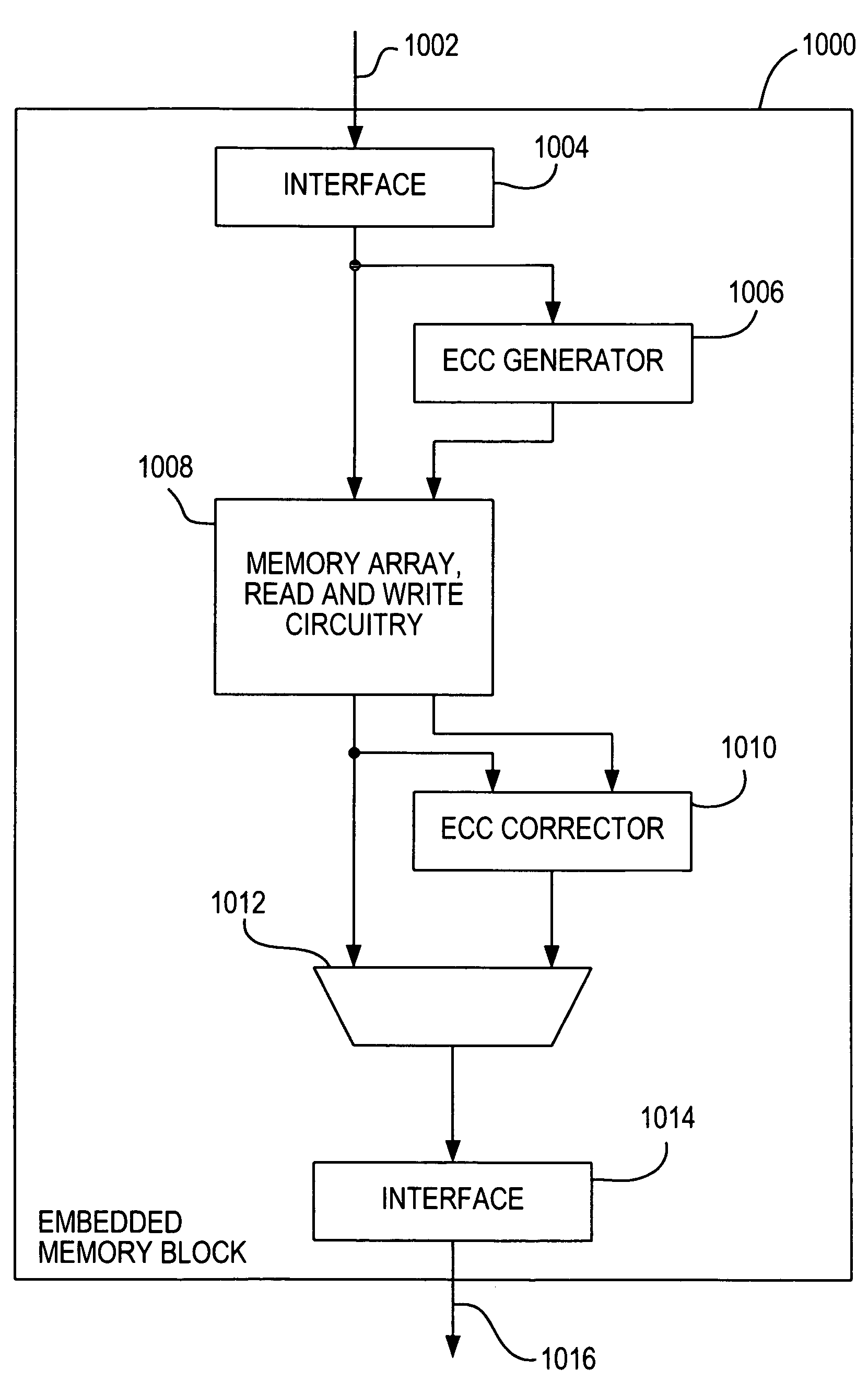

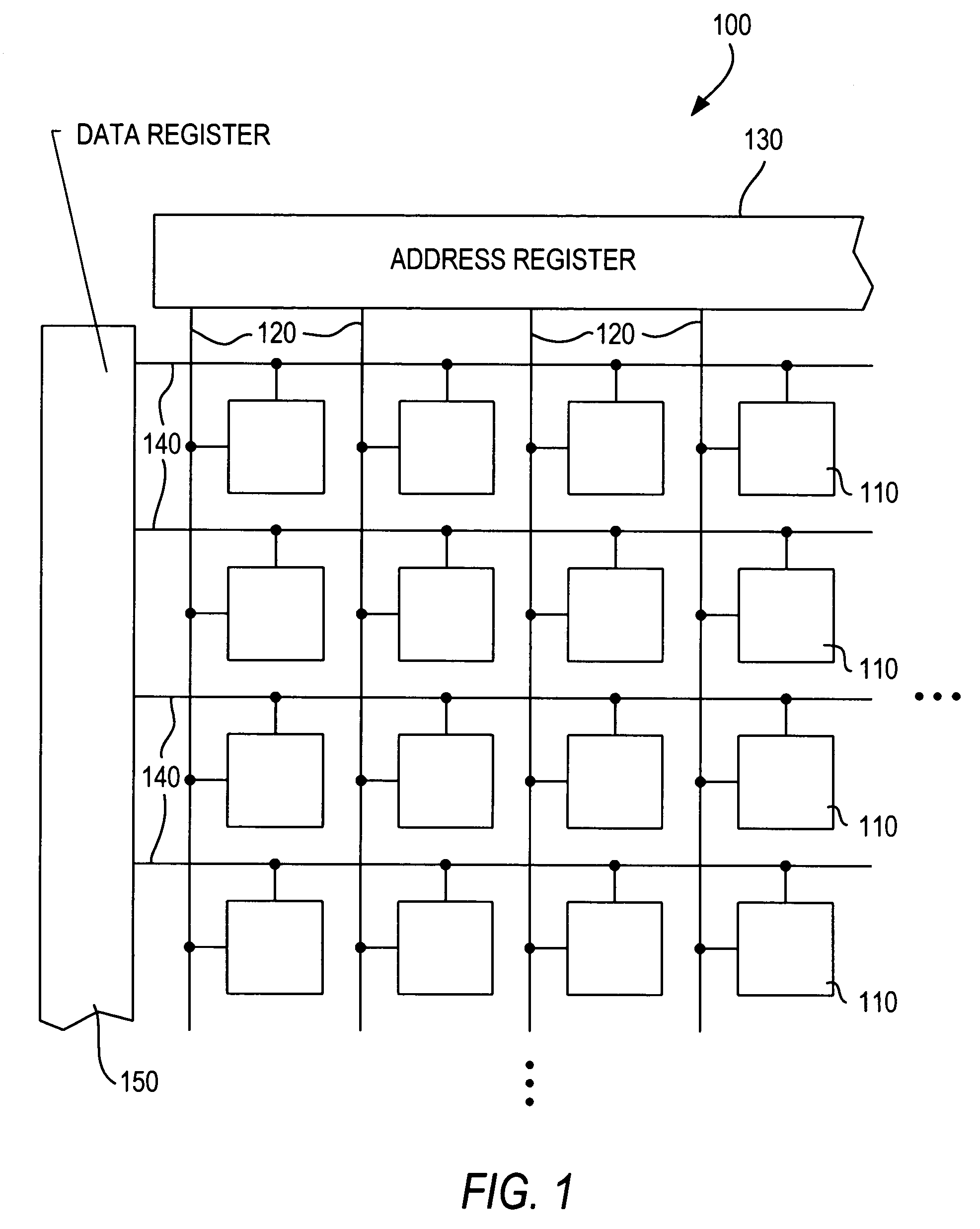

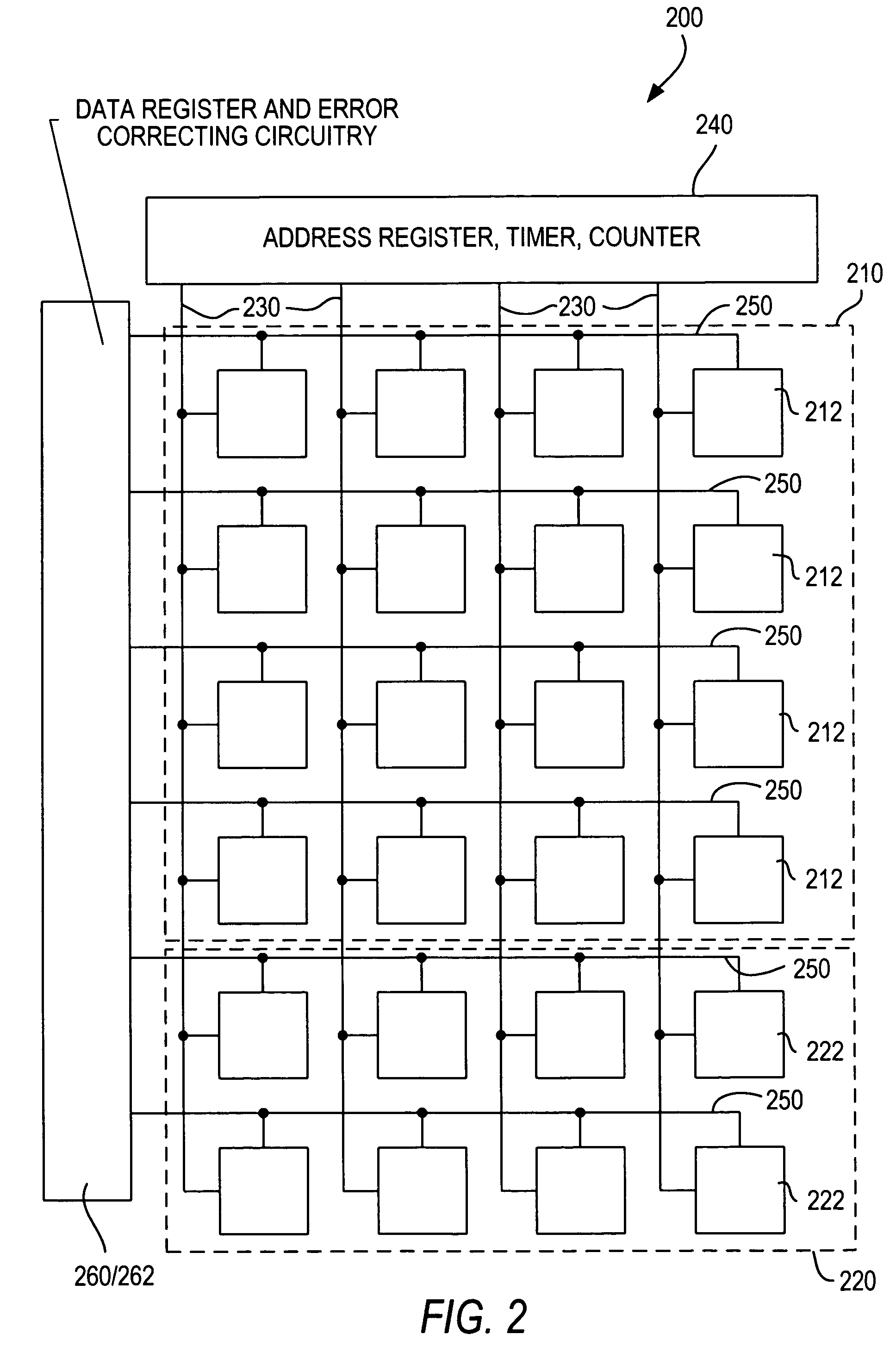

Error correction for programmable logic integrated circuits

InactiveUS7328377B1Increase delayReduces static hazardsError detection/correctionProgrammable logic controllerProgrammable logic device

Systems and methods for detecting and correcting errors in programmable logic ICs are provided. In one embodiment, a scrubber periodically reads the memory cells in a programmable logic IC, detects and corrects any errors, and writes the corrected contents back into the memory cell. In another embodiment, regions of memory cells in a programmable logic IC each have associated error correcting circuitry which operates to continuously detect and correct errors as they occur. Error correcting circuitry can further be designed to reduce static hazards. It may be more desirable to design programmable logic IC routing architectures that reduce the number of memory cells needed to implement a given function. Error correcting circuitry can be provided for configuration memory or for an embedded memory block on a programmable logic IC.

Owner:ALTERA CORP

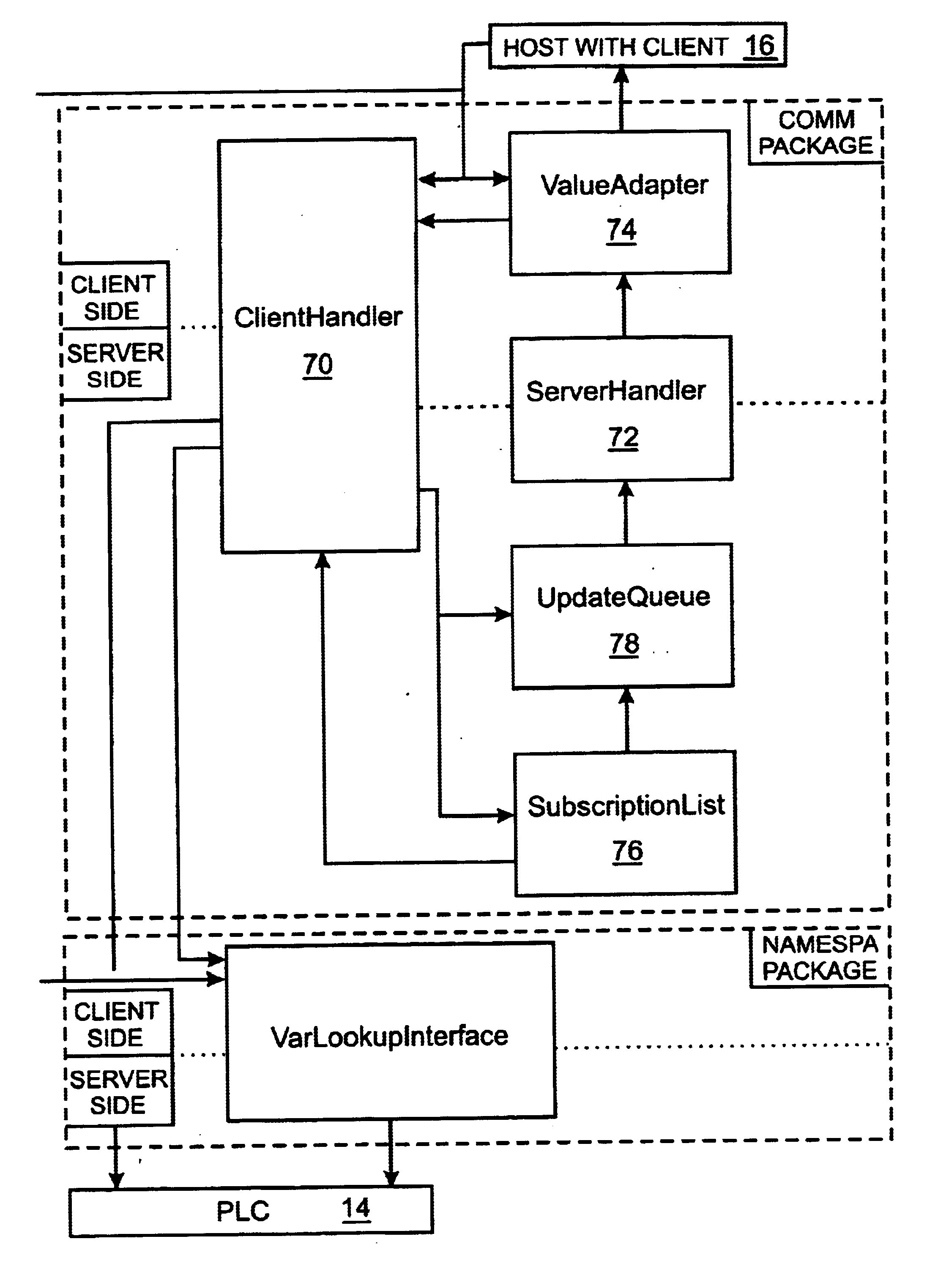

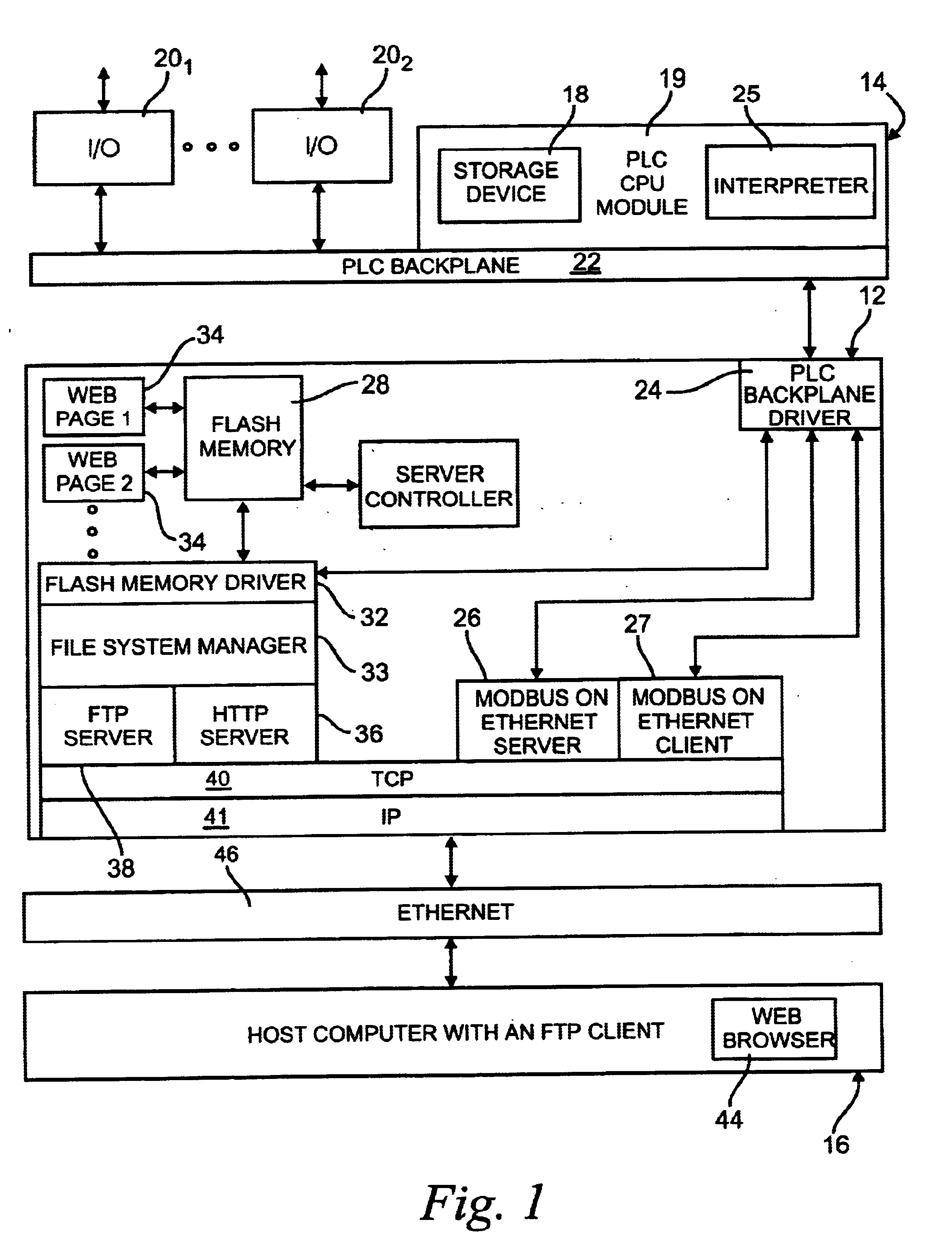

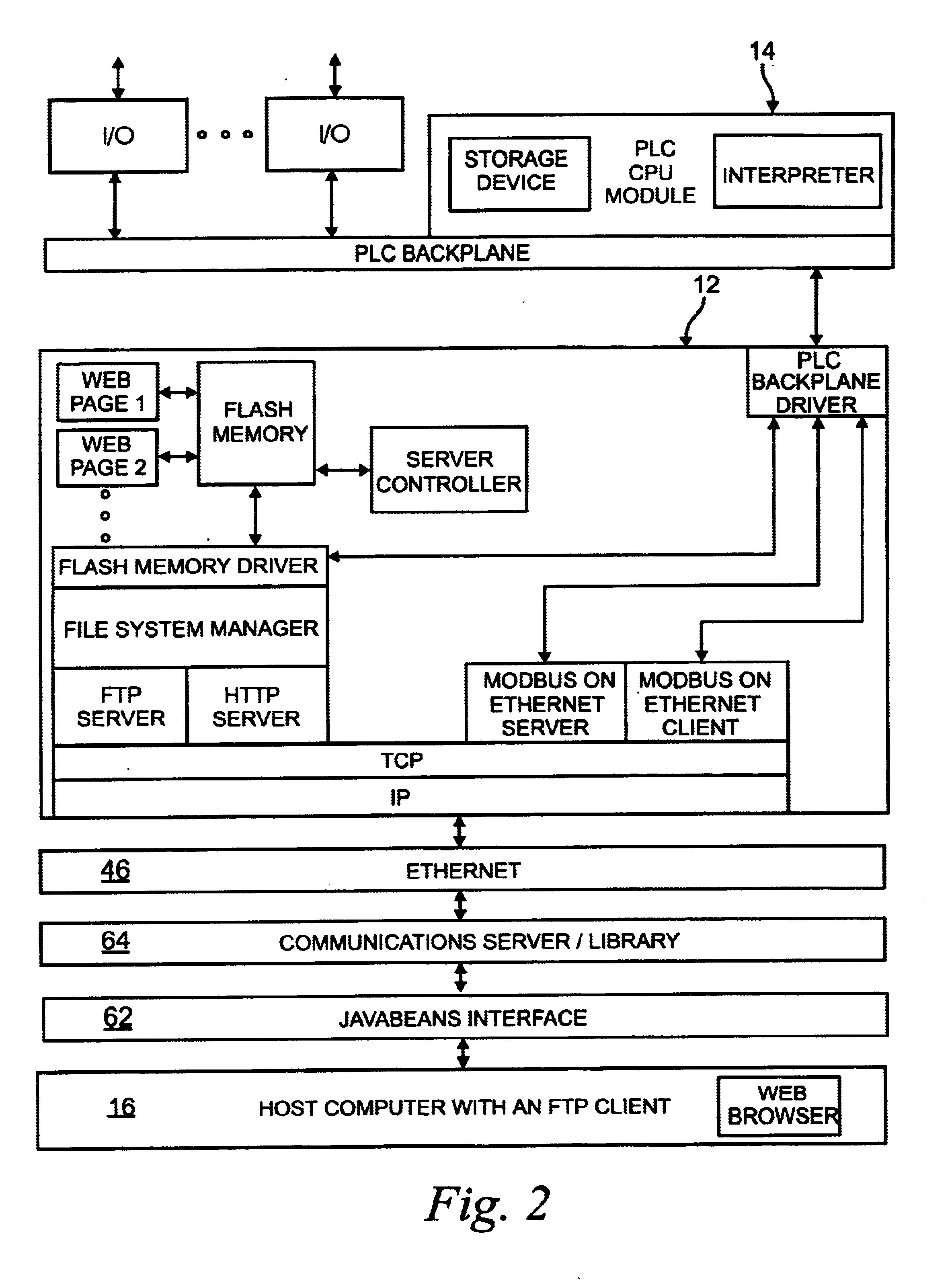

Interface to a programmable logic controller

An apparatus is provided for accessing, controlling and monitoring a programable logic controller with a network client having a conventional web browser. The apparatus includes an archive, an interface, and a library. The archive provides for compiling an application written in code supported by the web browser. The interface is responsive to the application for establishing a connection between the controller and the network client. Further, the library is responsive to the application for supporting communication between the controller and the network client upon establishing a connection therebetween.

Owner:SCHNEIDER AUTOMATION INC

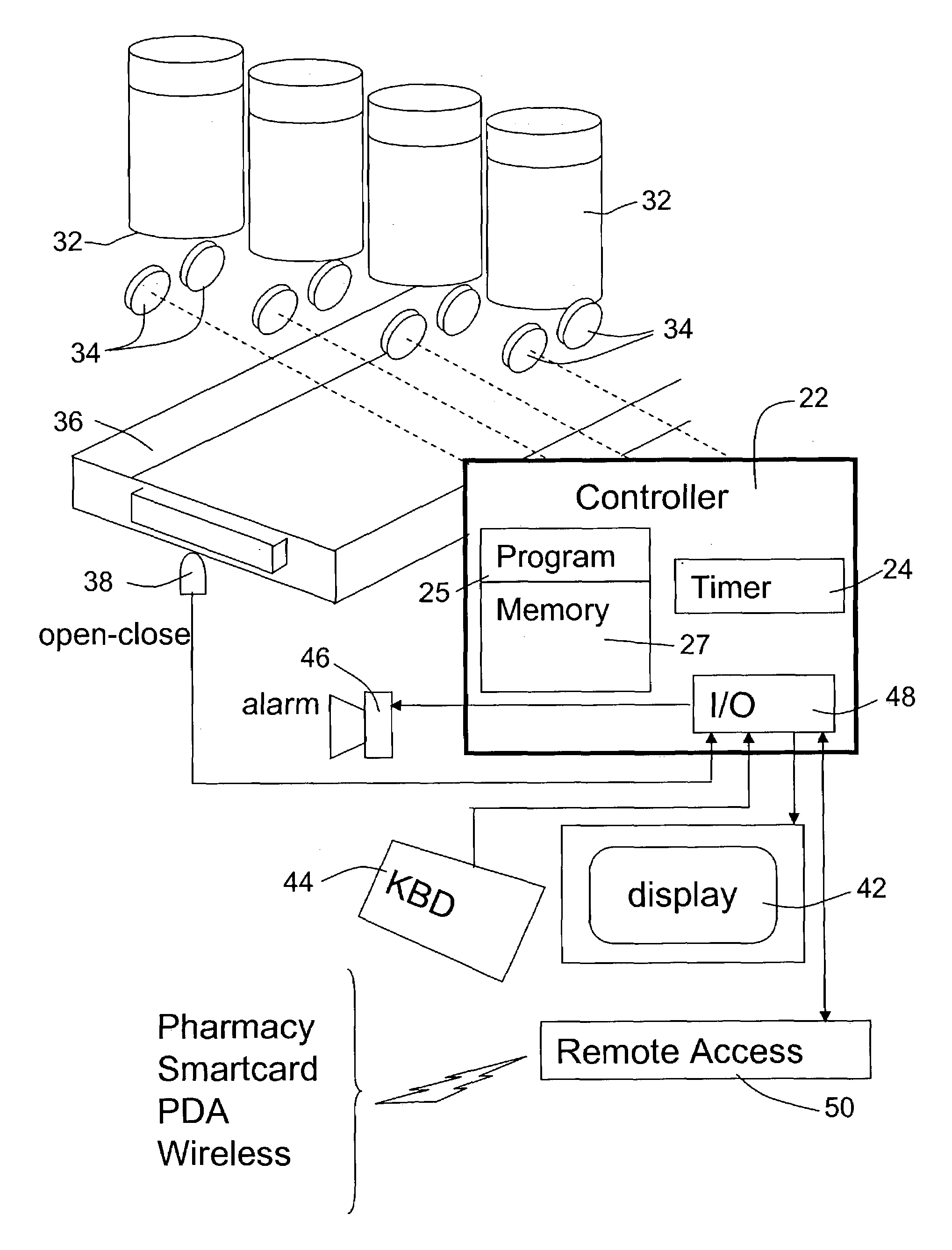

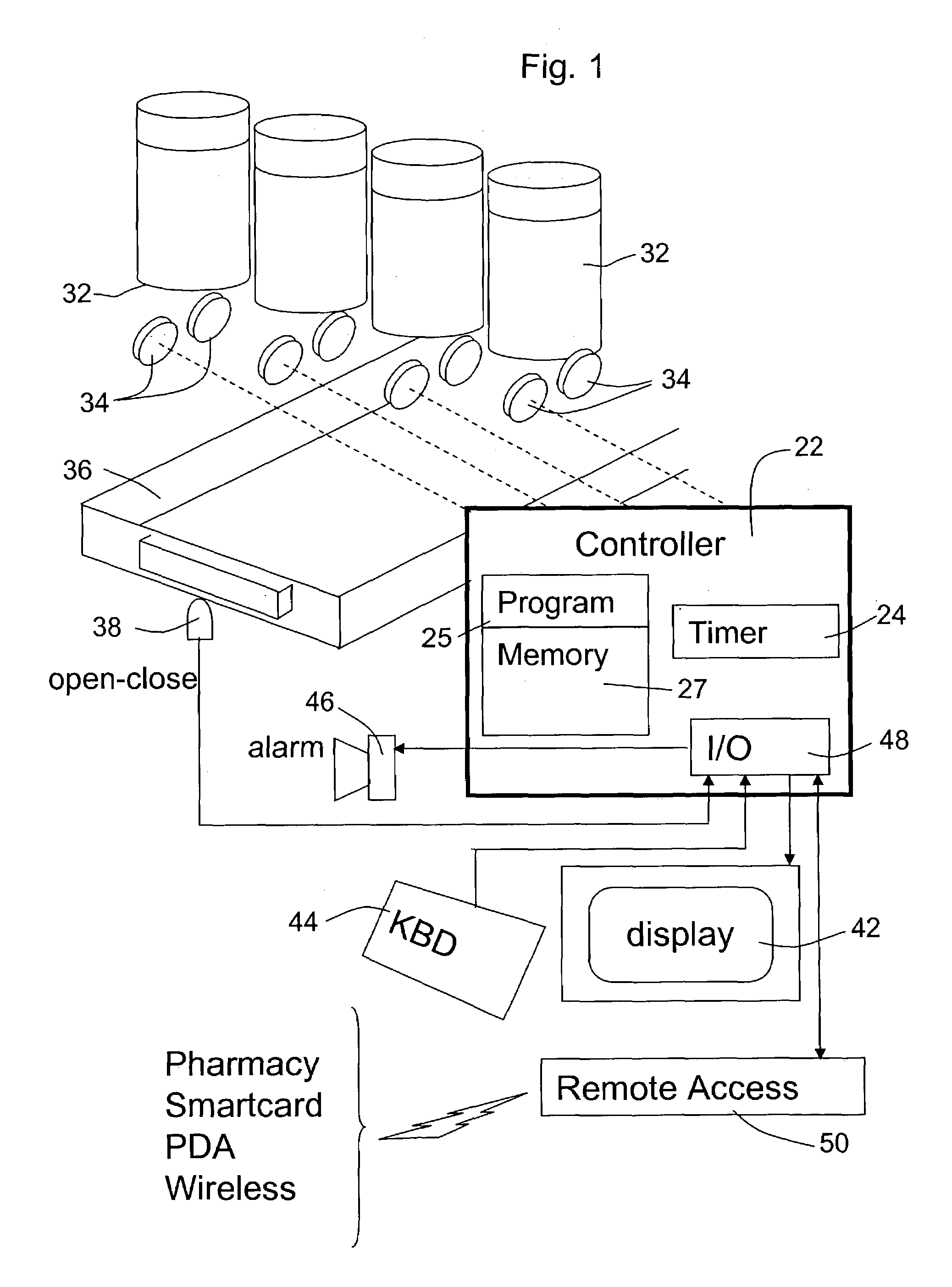

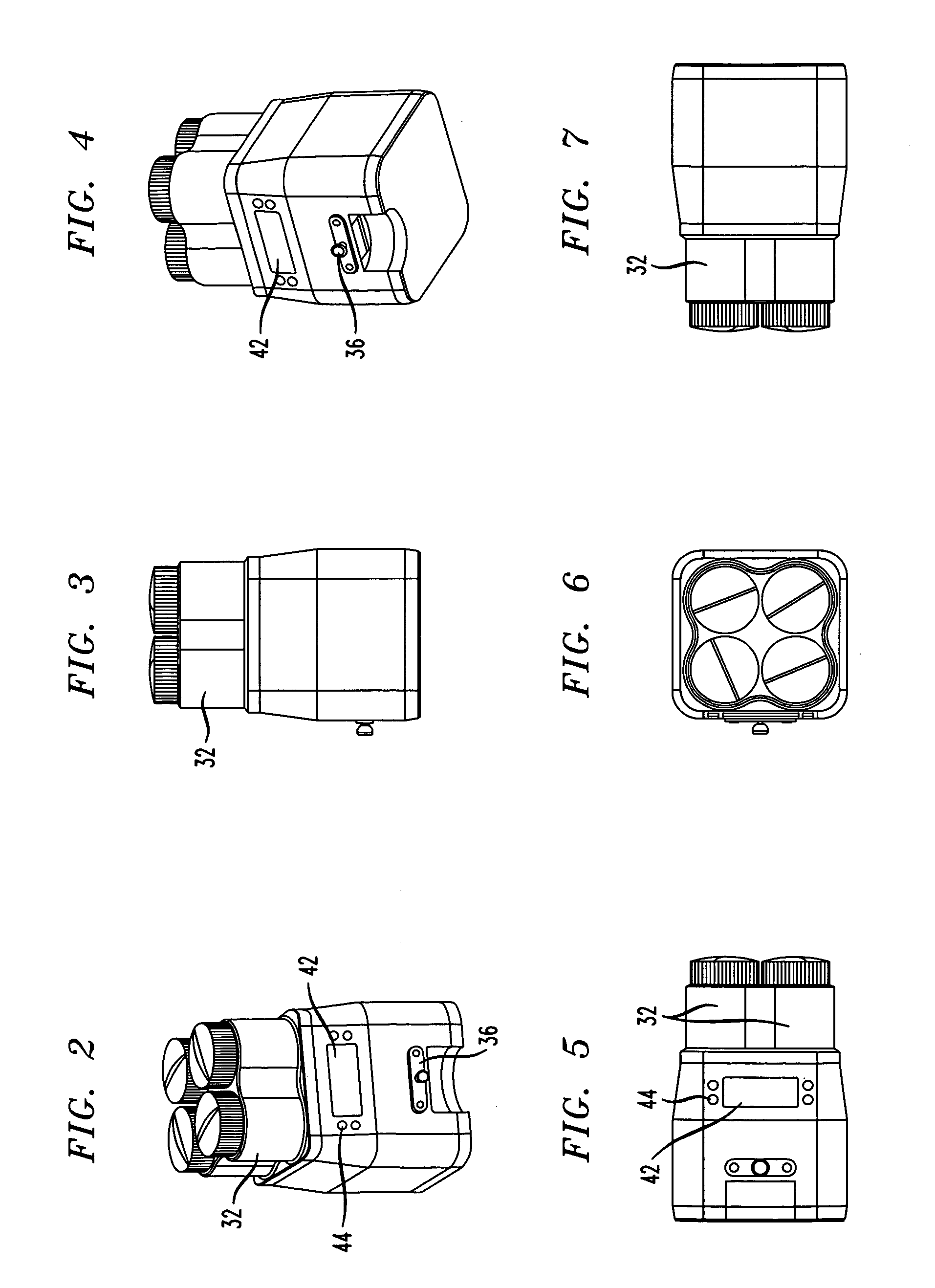

Personal medication dispenser

InactiveUS7048141B2Coin-freed apparatus detailsApparatus for meter-controlled dispensingPharmacyMedication Dispenser

An automated personal pill dispenser has at least two chambers, each for holding a supply of pills. A feed mechanism is associated with each of the chambers and is operable selectively to feed an incremental number of pills from a respective one of the chambers. A programmable controller is coupled to control and operate the feed mechanism to dispense pills from the chambers. The controller has a timer, a memory and an input means. The controller is operable programmably, by the user and / or by remote input from a smart card, PDA or network, for example with access to data from a pharmacy including instructions and warnings. The programming presets at least one of a time and a number of pills to be dispensed from each of said chambers. The controller operates an alarm to alert the user and operates the feed mechanism to feed pills from the chambers at the preset time and number, also detecting the user's access to obtain the dispensed pills.

Owner:ANTIOCH HLDG

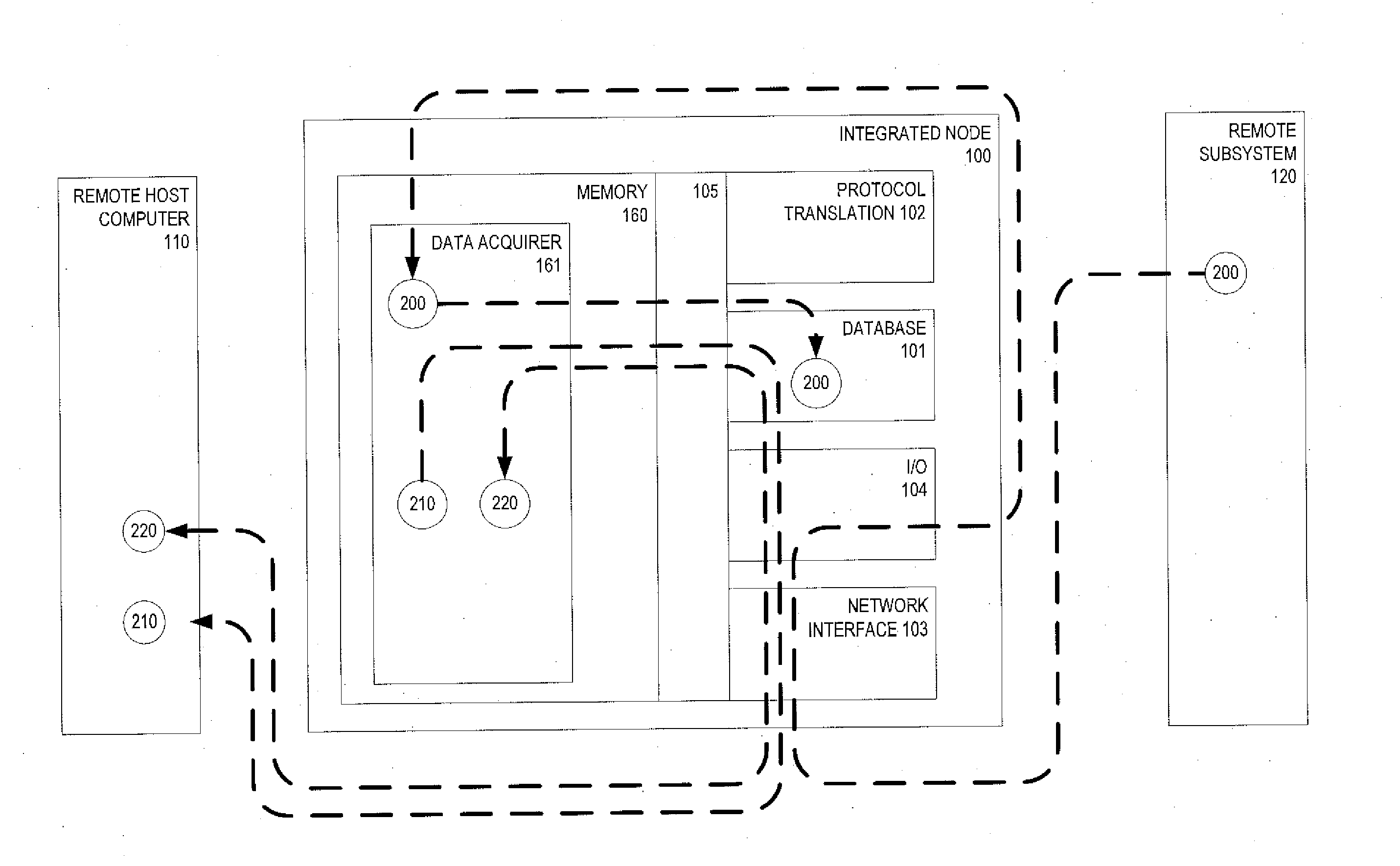

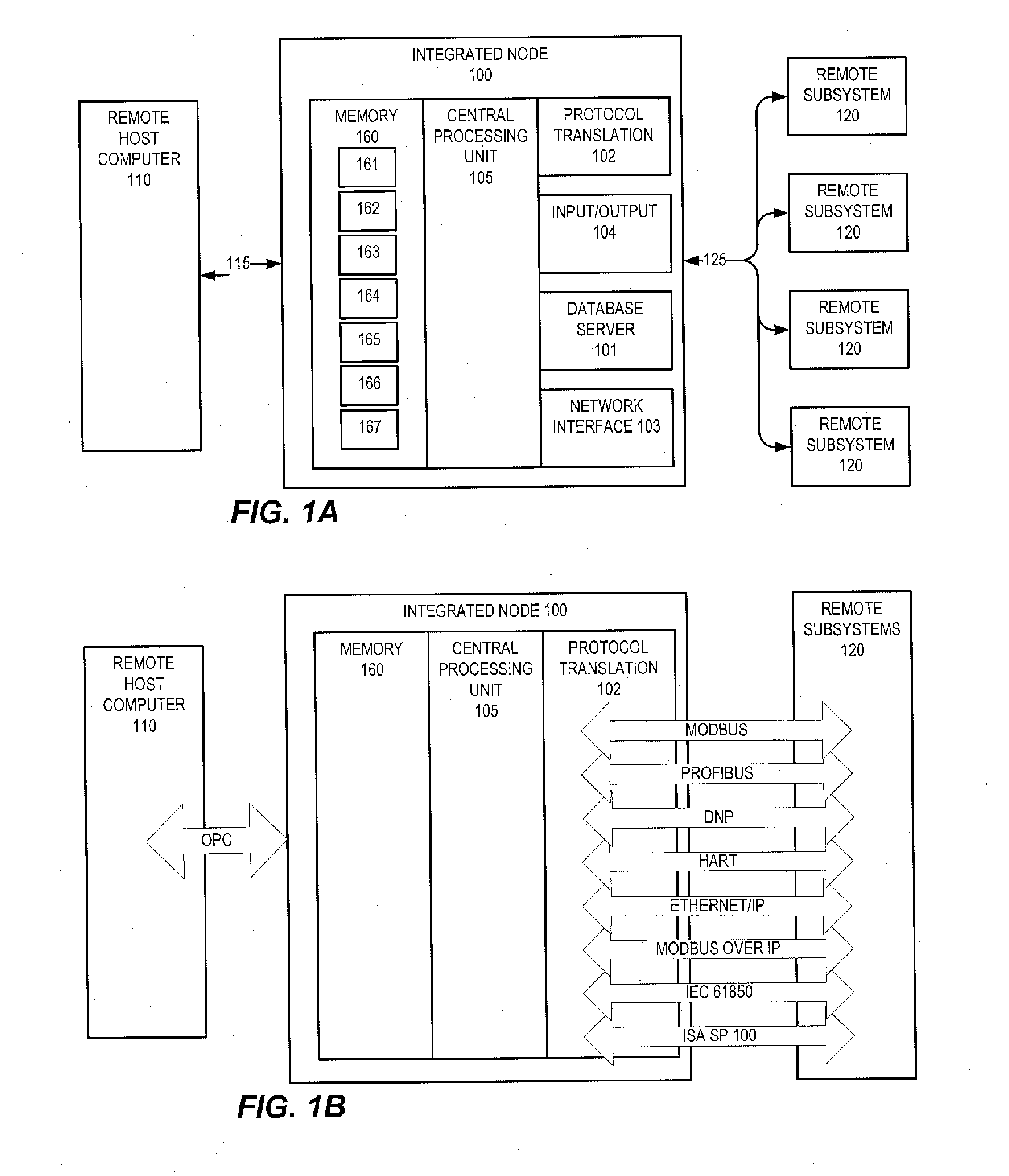

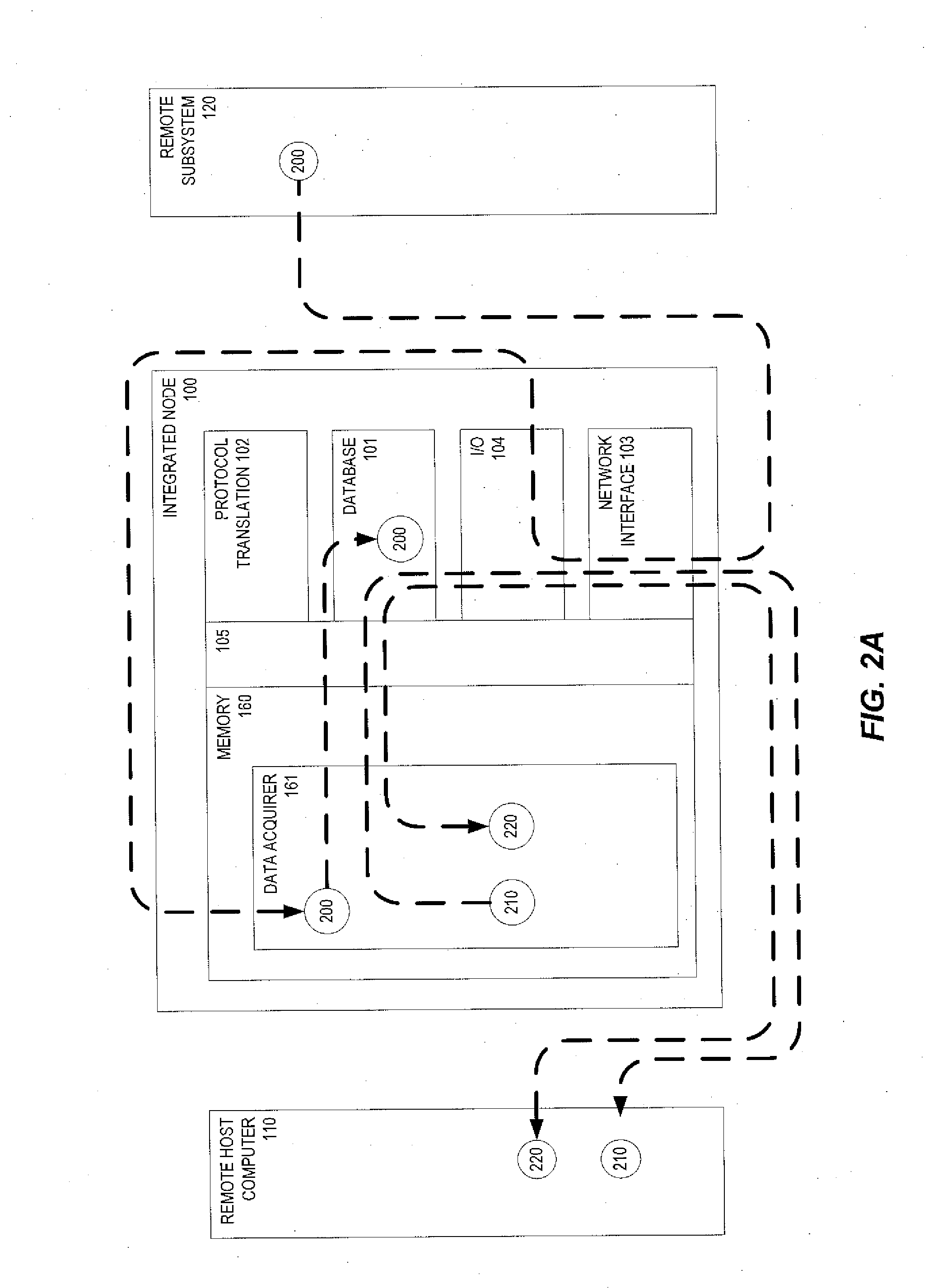

Machines, Computer Program Products, and Computer-Implemented Methods Providing an Integrated Node for Data Acquisition and Control

ActiveUS20120084400A1Uniform basis for collectionReduce in quantityProgramme controlError detection/correctionProgrammable logic controllerDatabase server

Embodiments of an integrated node, such as a programmable logic controller, are provided for process automation and seamless, flexible subsystem communications, allowing a remote host to interface with a plurality of remote and in-plant subsystems and services using a wired or wireless network interface and having a database server and a protocol translator or translation server to convert and manipulate various industrial interfaces and protocols. Embodiments of the integrated node time-synchronize the plurality of remote subsystems, acquire and archive time-stamped process data, report exceptions therein to the remote host, and extract and transmit time-stamped process data to the remote host. Embodiments of computer program products and computer implemented methods also are provided to detect a time of communication failure and a time of a corresponding recovery between a node and either a remote subsystem or a remote host.

Owner:SAUDI ARABIAN OIL CO

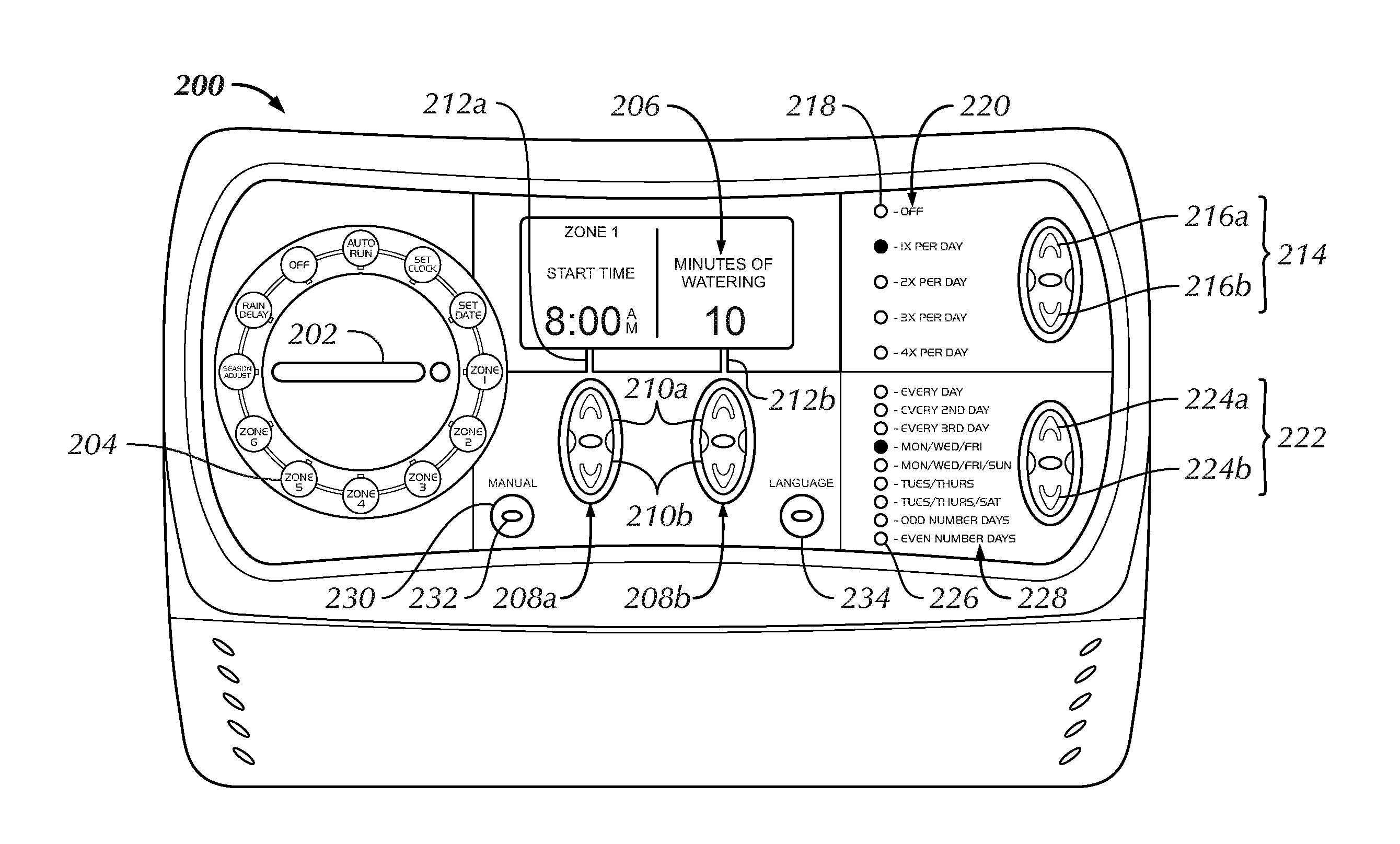

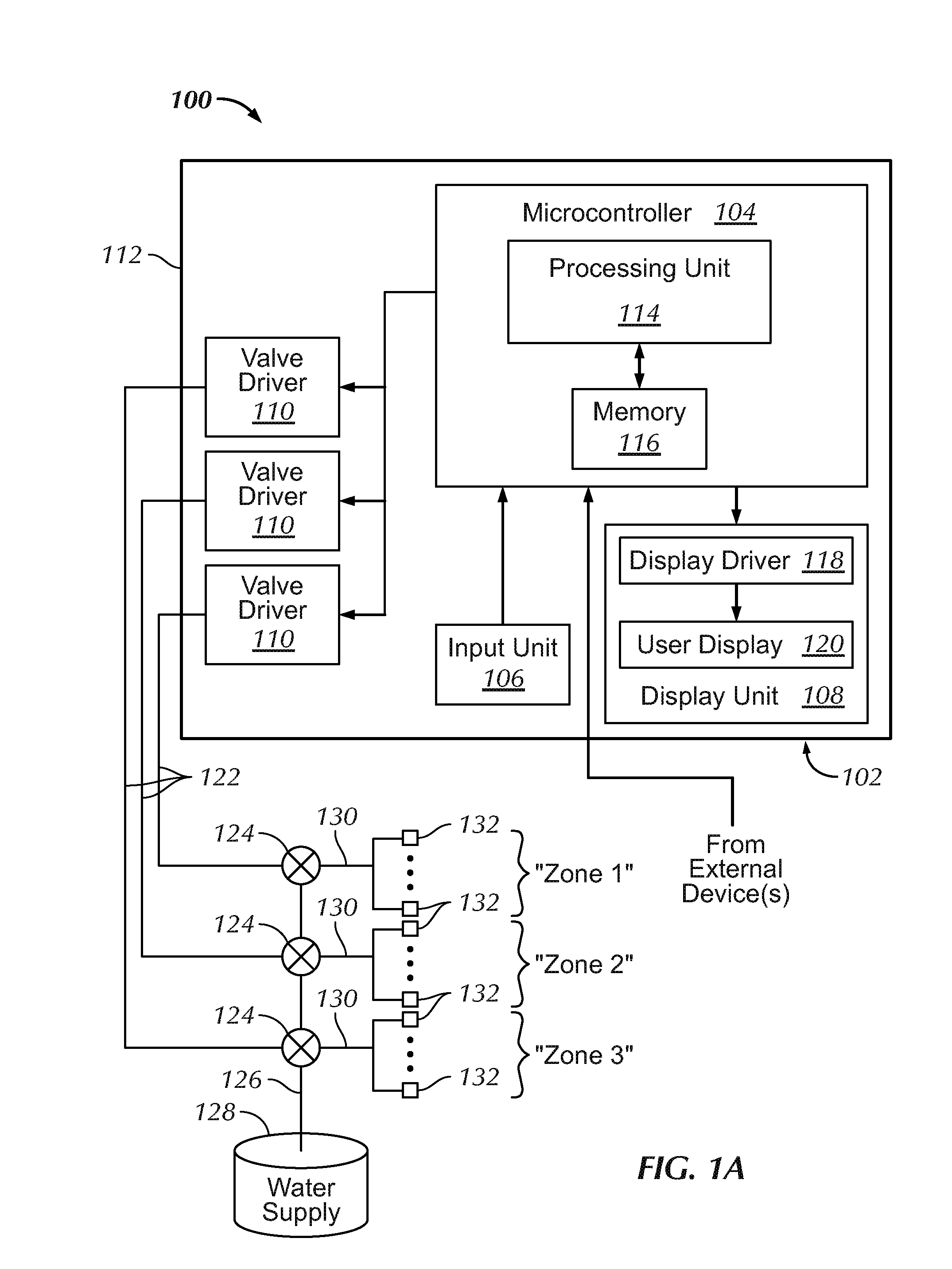

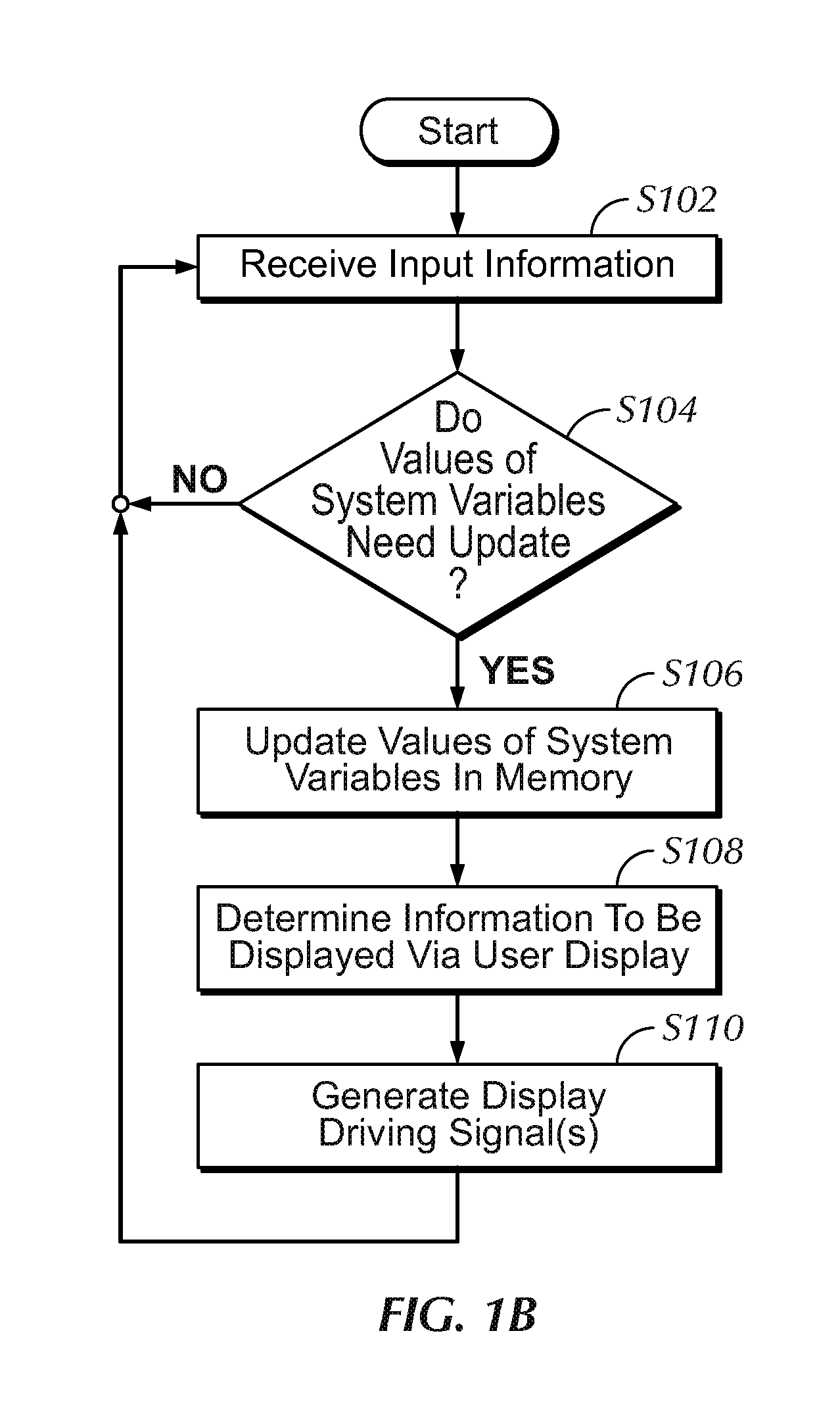

Programmable irrigation controller having user interface

ActiveUS8160750B2Digital variable displaySelf-acting watering devicesGraphicsProgrammable logic controller

An irrigation controller includes a user interface capable of presenting information to a user and allowing the programming of the controller in a simple and intuitive fashion. Information presented may include values of all programmable irrigation parameters associated with an irrigation zone. Information presented may include values of irrigation parameters associated with multiple irrigation zones. Information may also be presented graphically, in color, and / or in a plurality of languages.

Owner:RAIN BIRD CORP

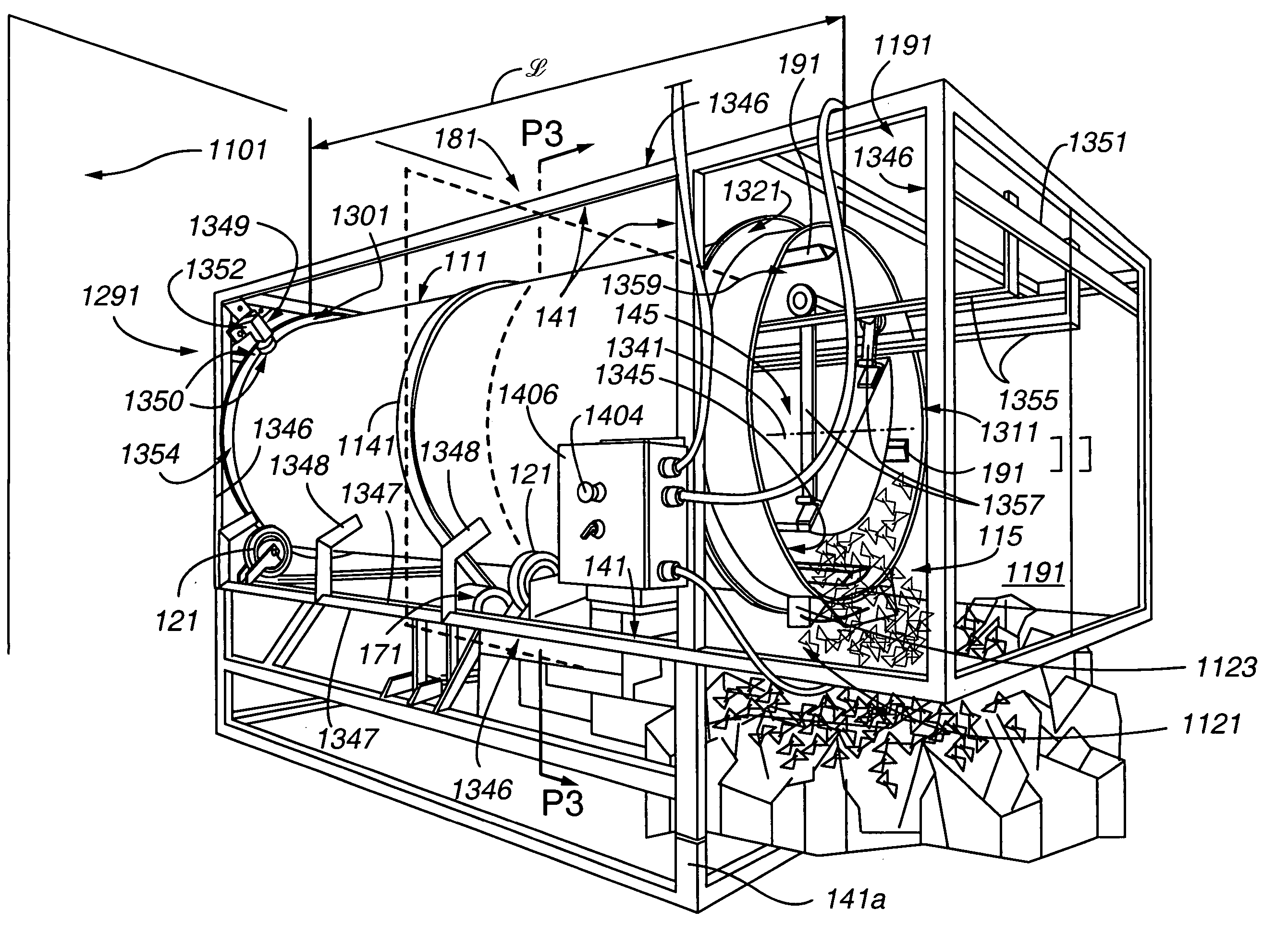

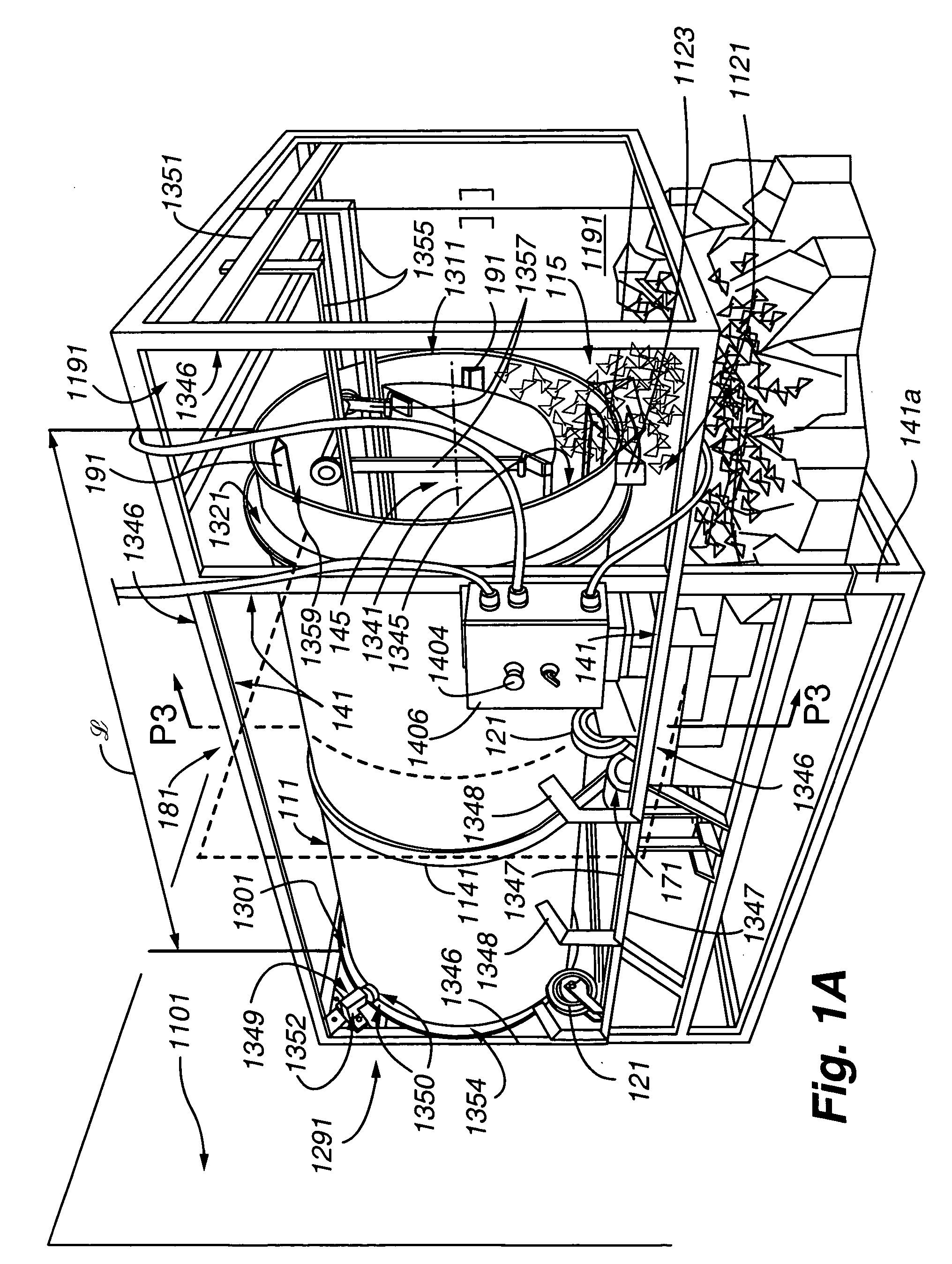

Food product surface sterilization apparatus and method

InactiveUS20040052702A1Increase temperatureReduce food product temperature changeFood preservationIndirect heat exchangersUnsafe conditionUltraviolet

An apparatus is disclosed for the micro-organism surface sterilization of foods using, a "germicidal" such as light waves (e.g., ultraviolet), and in some cases in combination with (or replaced by) one or more of sound waves and ozone. The surface sterilizer apparatus may include a plurality of germicidal (e.g., ultraviolet) emitters for surface sterilization of foods that are, e.g., rotated in a drum or rotated via a screw auger. Assemblies of emitters for the germicidal may be constructed to be watertight (i.e., withstand a high pressure, heated water spray), and movable relative to the drum or screw conveyor for easy cleaning and maintenance. The apparatus may also include a controller (e.g., programmable logic controller) for controlling the sterilization process so that the apparatus does not endanger personnel nearby, and so that the food is properly sterilized. The controller may vary the amount of germicidal used, the rate that food traverses the apparatus, the inclination of the apparatus, and terminate sterilization processing when an unsafe condition is detected. The apparatus may be used in-line with other food processing equipment for the real-time sterilization of food. The controller may also communicate with food processing components upstream of the apparatus for controlling the flow of food to the surface sterilizer

Owner:C & S EQUIP COMPANY

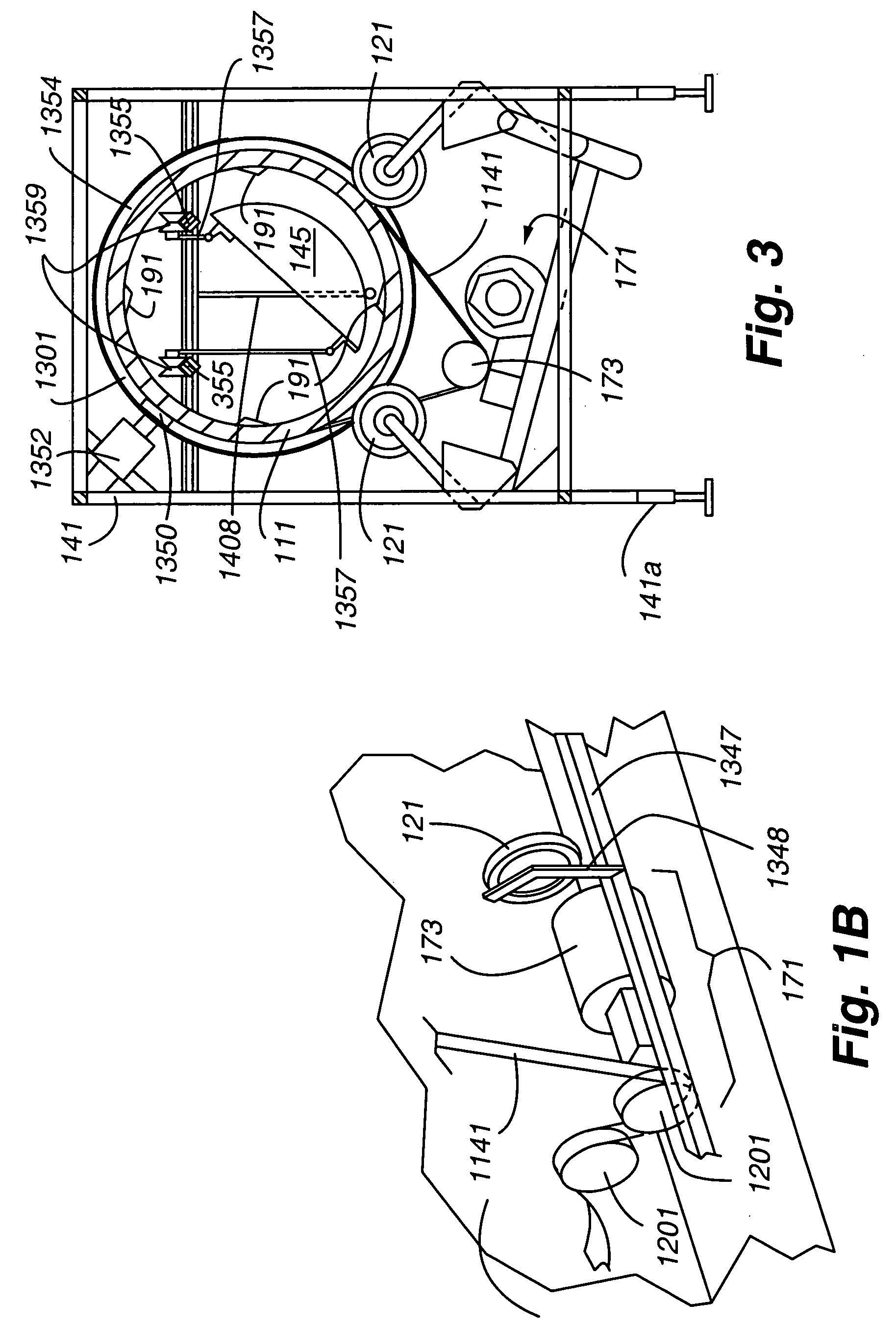

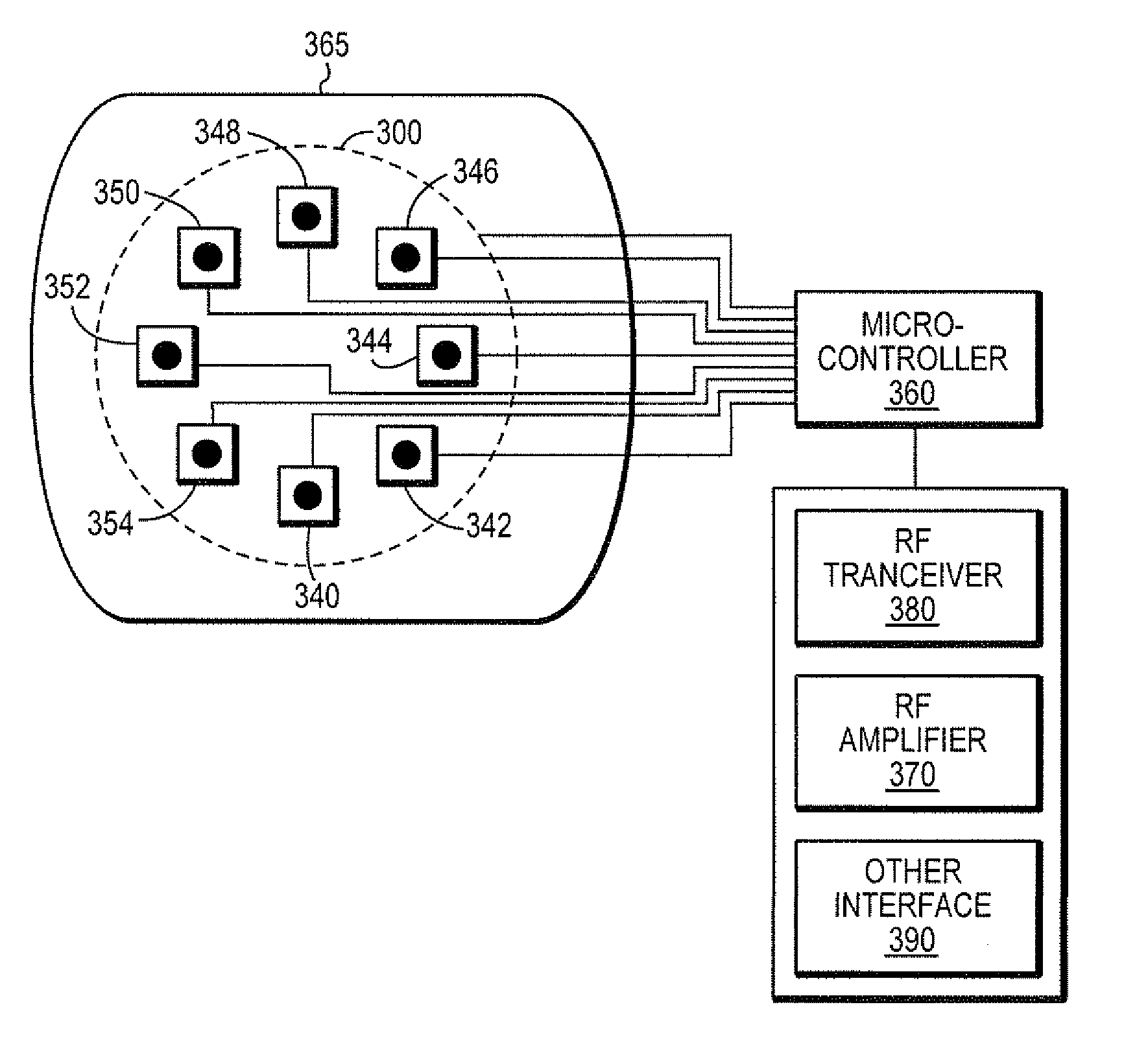

Remote control unit for a programmable multimedia controller

ActiveUS20080079604A1Facilitating detailed control absent bulky input deviceInput is hugeTelevision system detailsElectric signal transmission systemsRemote controlProgrammable logic controller

A remote control unit is provided that includes an annular touch sensor for manipulating an annular menuing system displayed on a display device. In response to a user gesturing by scrolling clockwise or counter-clockwise about the annular touch sensor, pressing firmly on the annular touch sensor, or tapping at a particular location on the annular touch sensor, the annular menuing system is manipulated to select particular items. The remote control unit is further configured to implement location-awareness features. Control is adapted to the location of the remote control unit and to the devices located nearby to this location. Similarly the remote control unit is further configured to implement user-awareness features, such that the control is adapted for the individual preferences of different users.

Owner:SAVANT SYST INC

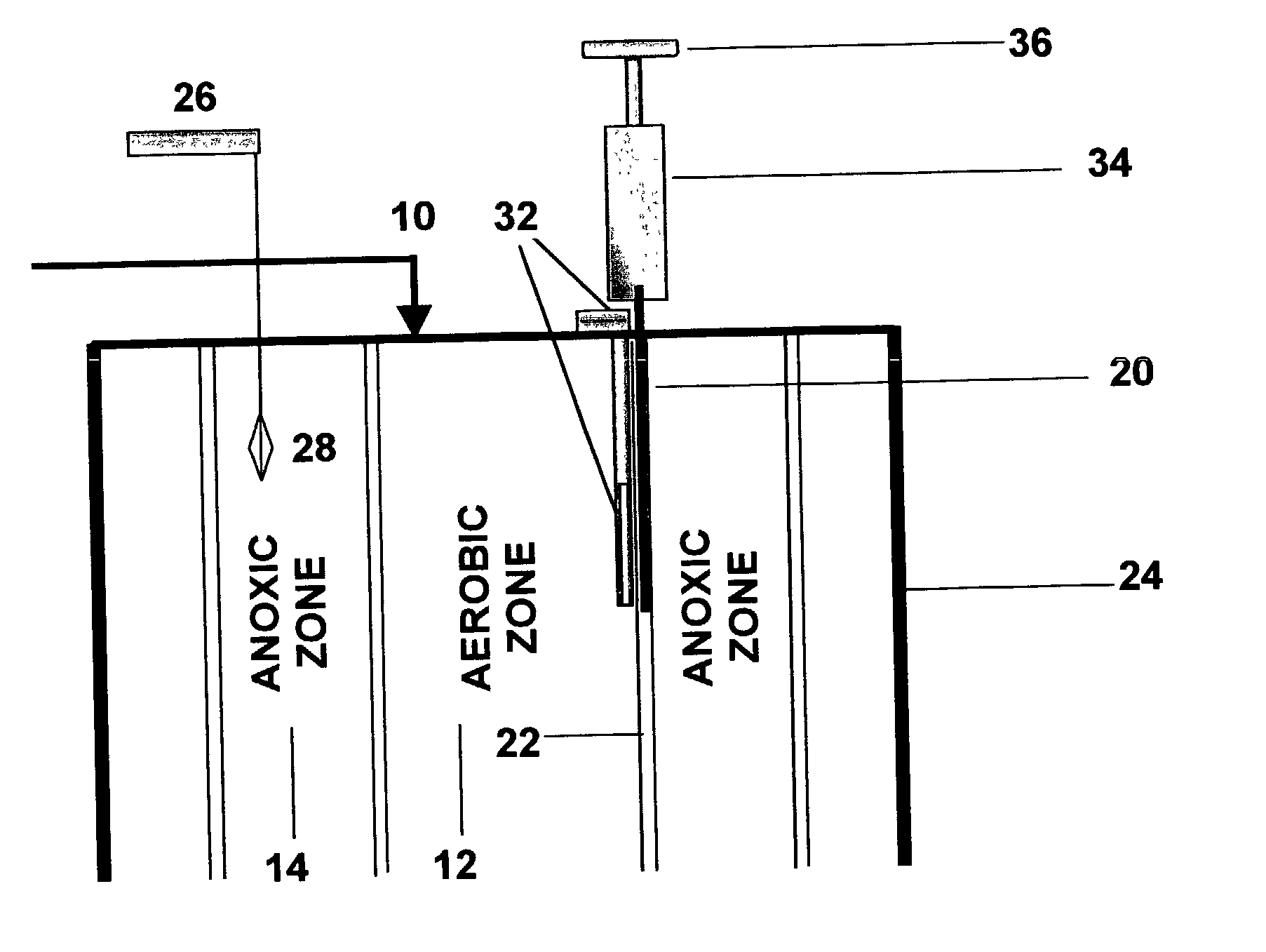

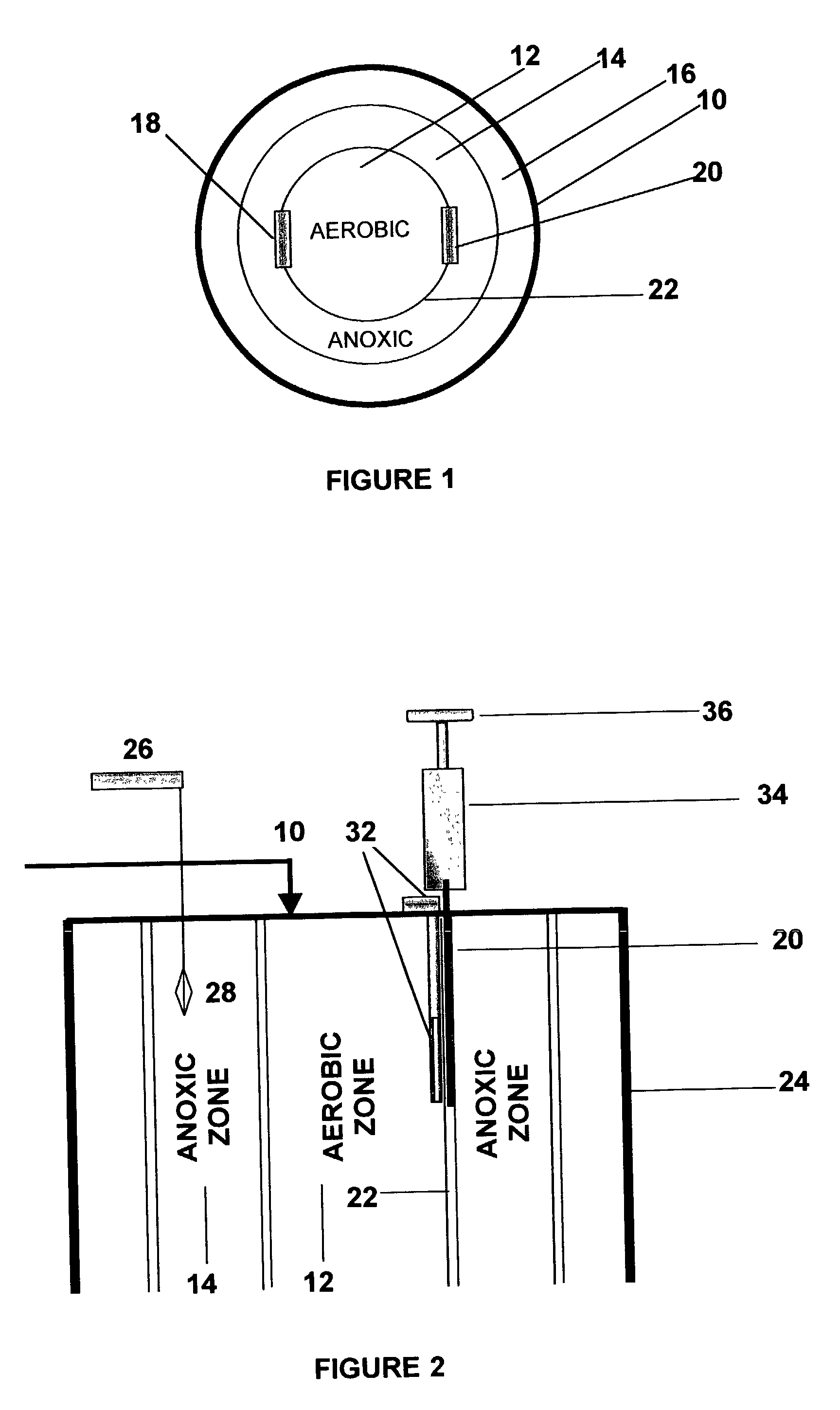

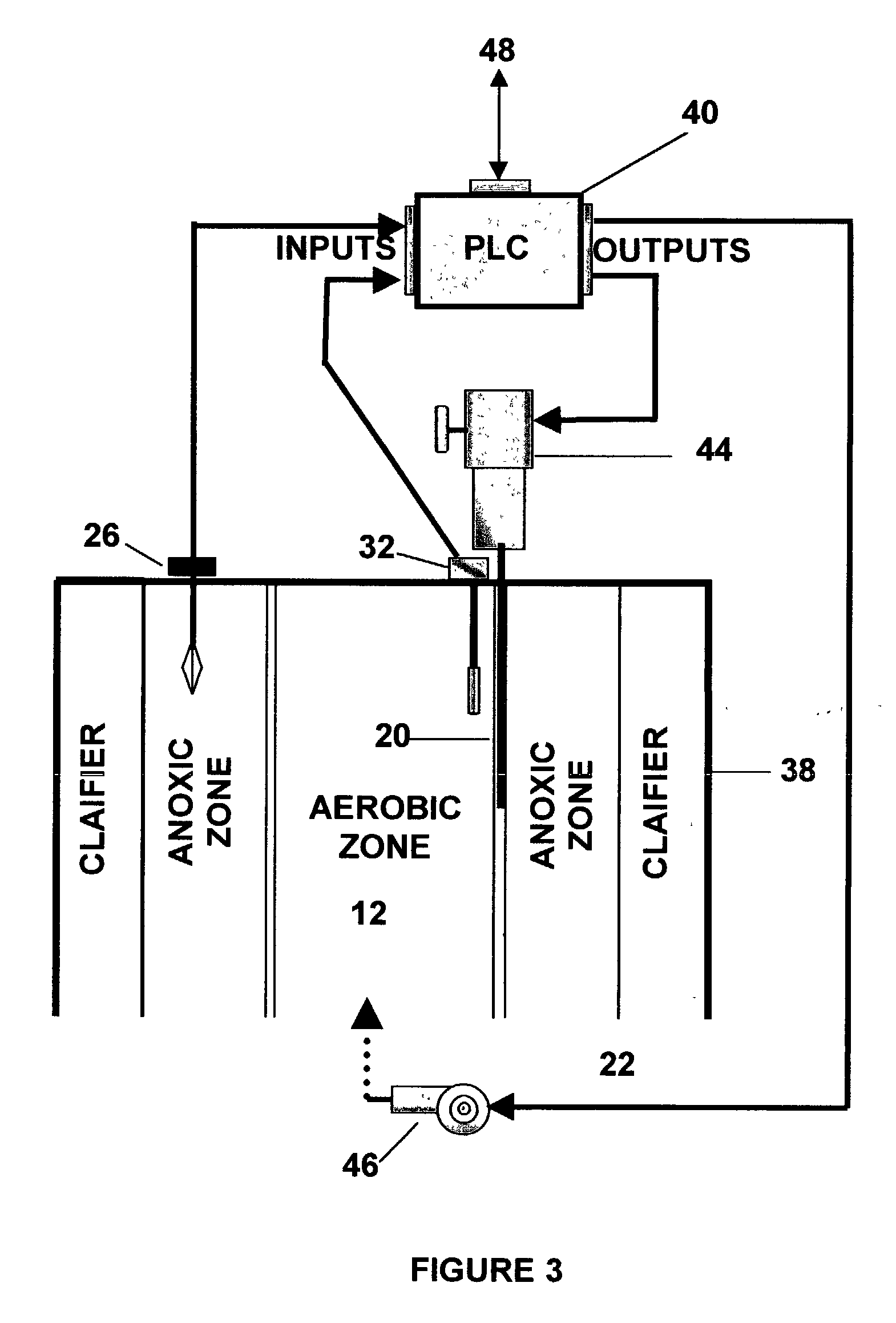

Dynamically responsive aerobic to anoxic inter-zone flow control system for single vessel multi-zone bioreactor wastewater treatment plants

InactiveUS20040035770A1Improve adaptabilityStable and fastLiquid separation auxillary apparatusWater treatment parameter controlProgram instructionProgrammable logic controller

An inter-zone aerobic to anoxic zone flow rate control system for single vessel multi-zone bioreactor plants for wastewater treatment is described herein. The system of the invention provides control of the relative treatment times of the mixed liquor in the horizontally disposed and adjacent aerobic and anoxic treatment zones of the bioreactor by providing one or more flow rate adjusting gates located between the aerobic and anoxic zones of the bioreactor. The opening of the gates is adjustable in accordance with sensed conditions in the treatment zones. An automated embodiment of the invention includes a programmable logic controller that provides control scripts for adjusting the opening of one or more flow control gates according to inputs from sensors and per programmed instructions. An automated and supervised embodiment of the invention includes a computer interfaced with a programmable automating controller. The computer provides status reports, commands to the programmable automating controller, storage and analysis of data, as well as a means of communicating to remote monitoring centers and networks.

Owner:ATARA ENVIRONMENTAL

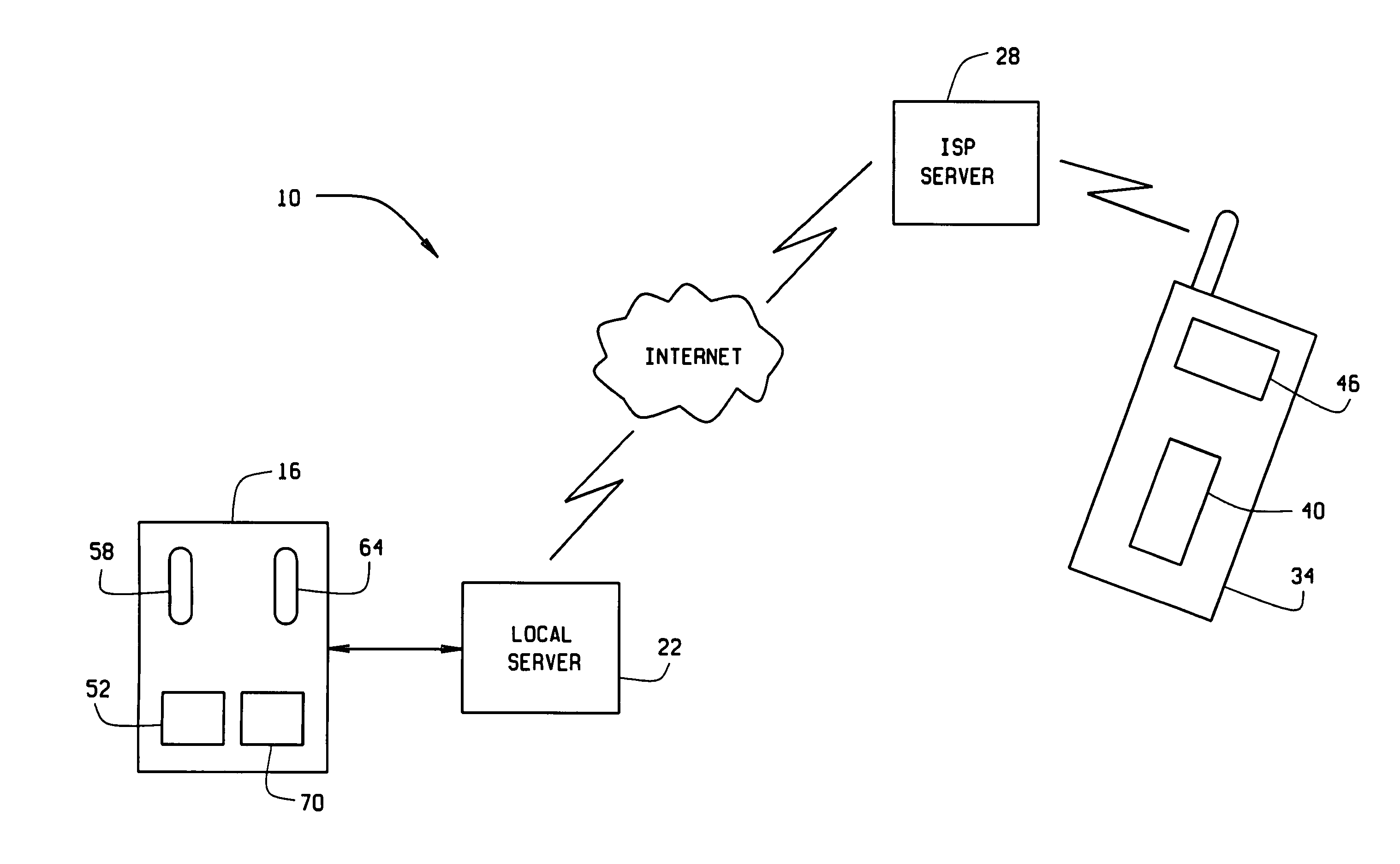

Method for using portable wireless devices to monitor industrial controllers

InactiveUS6965802B2Low costInput/output for user-computer interactionComputer controlService provisionProgrammable logic controller

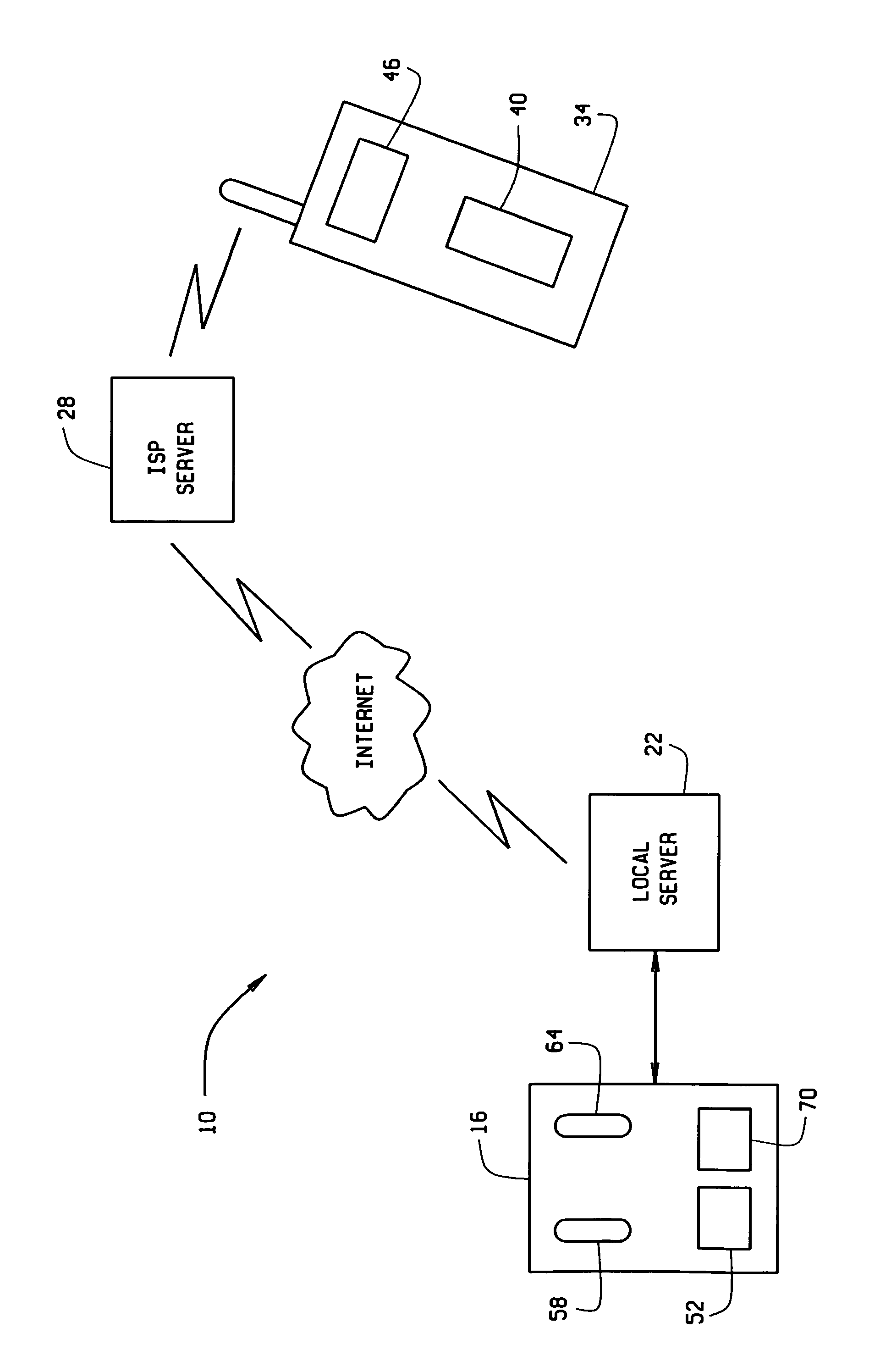

A system and method for controlling and monitoring an industrial controller using a portable wireless device. The system includes a programmable logic controller (PLC), a local server for exchanging communication with the PLC, a Internet Service Provider (ISP) server for exchanging communication with the local server using the Internet, and a wireless user communication device for exchanging communication with the ISP server. A user utilizes the Internet to monitor the operation of the PLC and input control commands to the PLC using the wireless user communication device.

Owner:GE FANUC AUTOMATION NORTH AMERICA INC

Apparatus and method for continuous depyrogenation and production of sterile water for injection

InactiveUS7122149B2Simple yet dependableReduce contact timeDialysis systemsTreatment involving filtrationDepyrogenationIon exchange

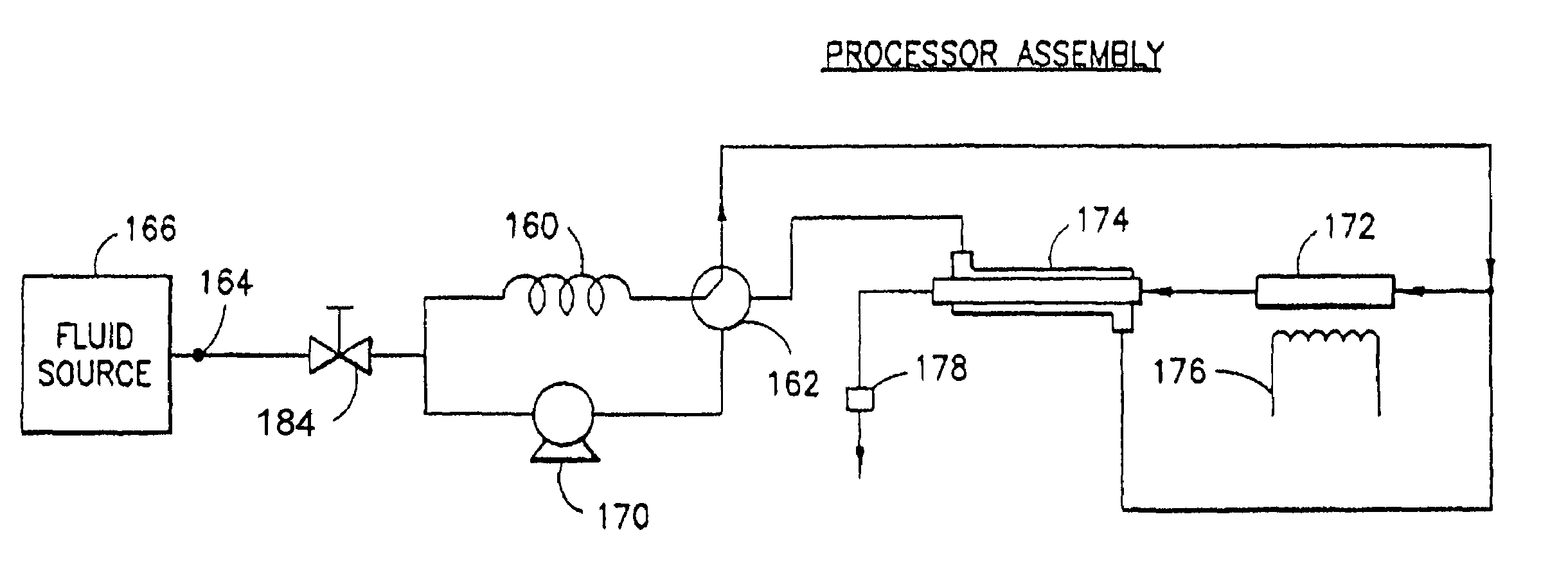

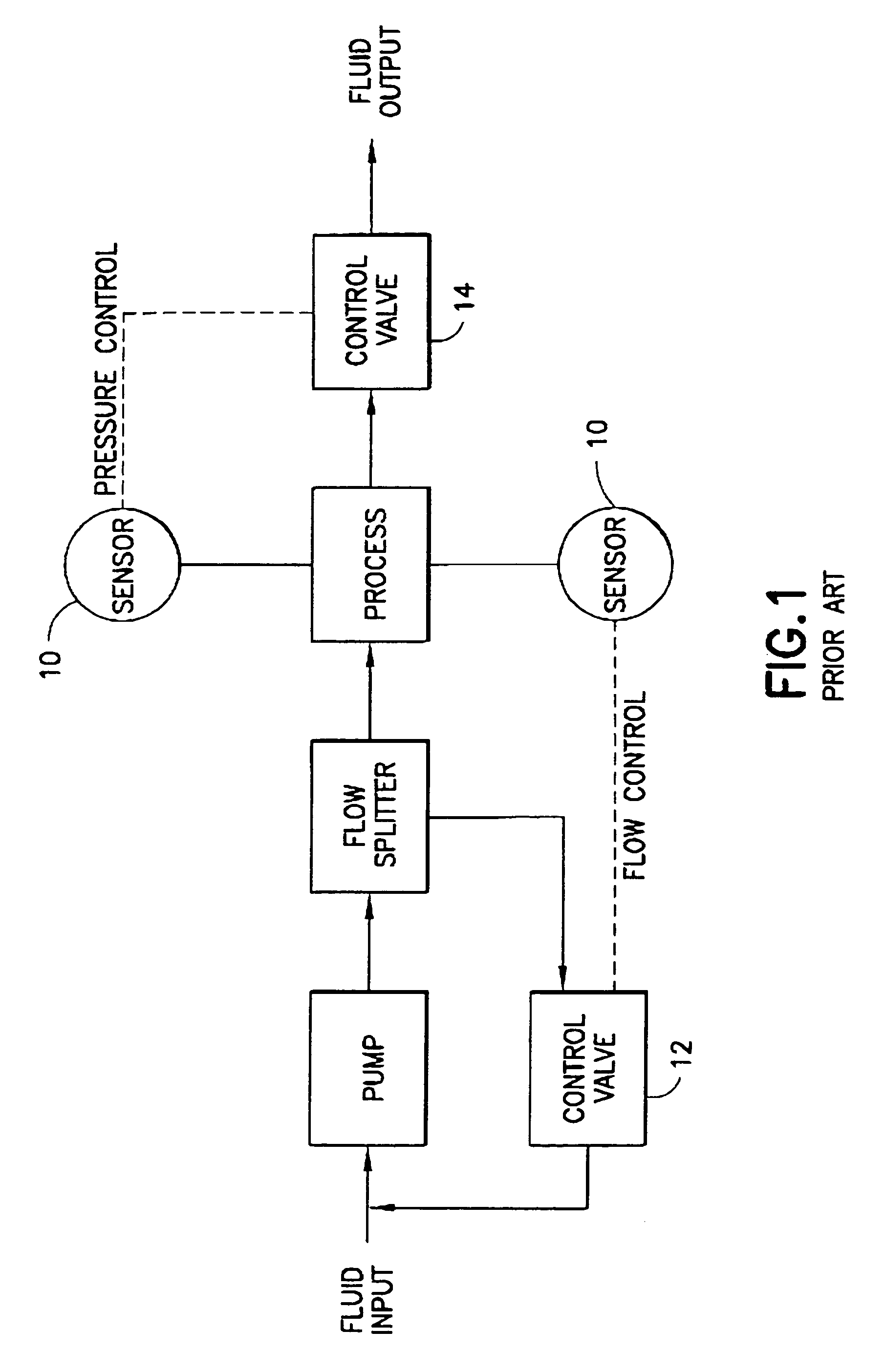

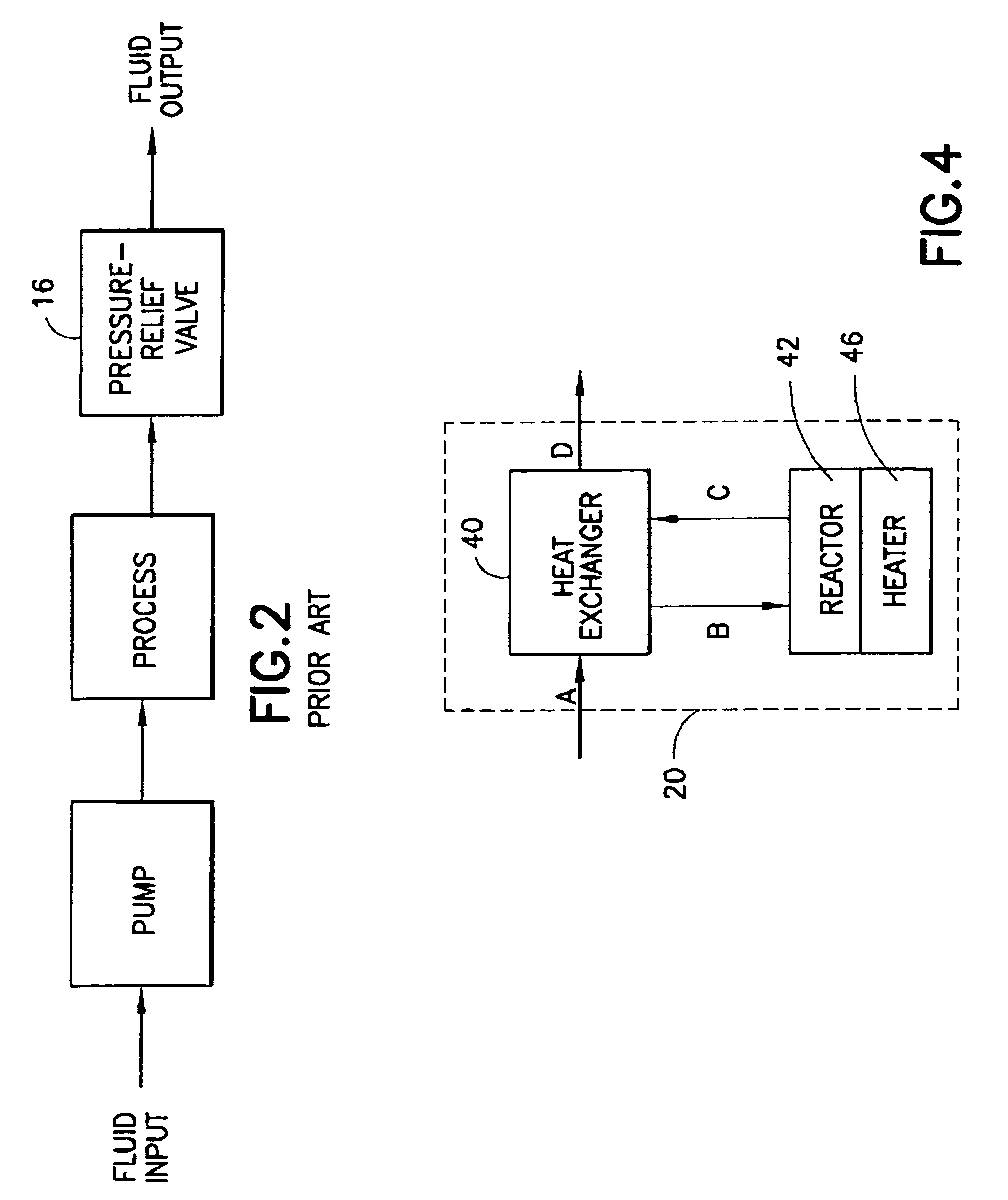

A fluid processor, suitable for the production of sterile water for injection, having a processor assembly and a process control system comprising a pump, a flow splitter, flow restrictors and a pressure relief valve. In a preferred embodiment, the processor assembly comprises a heat exchanger, a reactor and a heater arranged in a nested configuration. The preferred embodiment of the present invention also include a treatment assembly having a combination of filter, reverse osmosis and ion exchange devices and further incorporates an assembly and method allowing for the in situ sanitization of the fluid processor during cold start and shutdown to prevent bacteria growth during storage of the fluid processor. The fluid processor may include an electronic control system comprising a touch screen operator interface, a programmable logic controller and sensors for measuring temperature, pressure, flow rate, conductivity and endotoxin level.

Owner:APPLIED RES ASSOCS INC

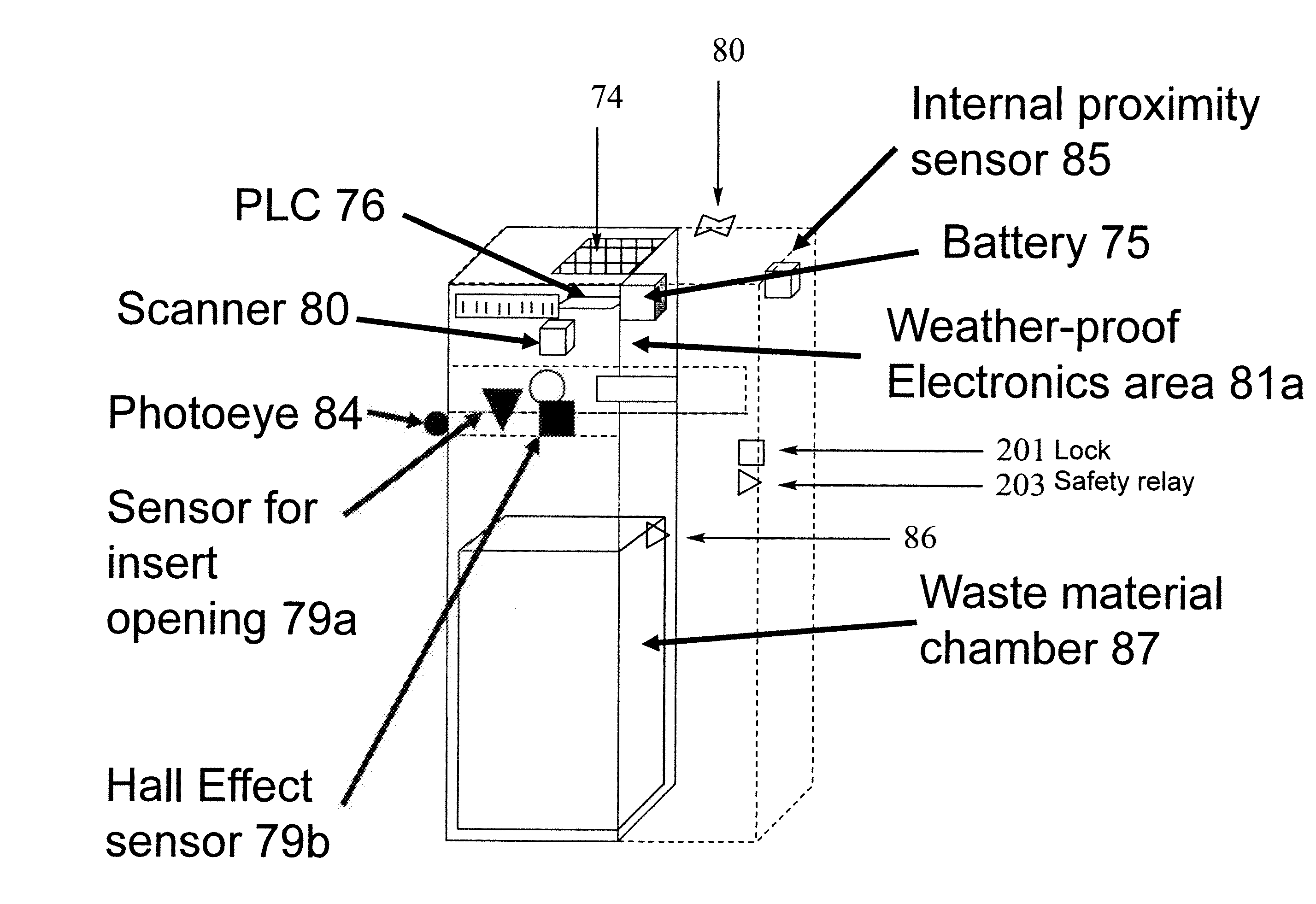

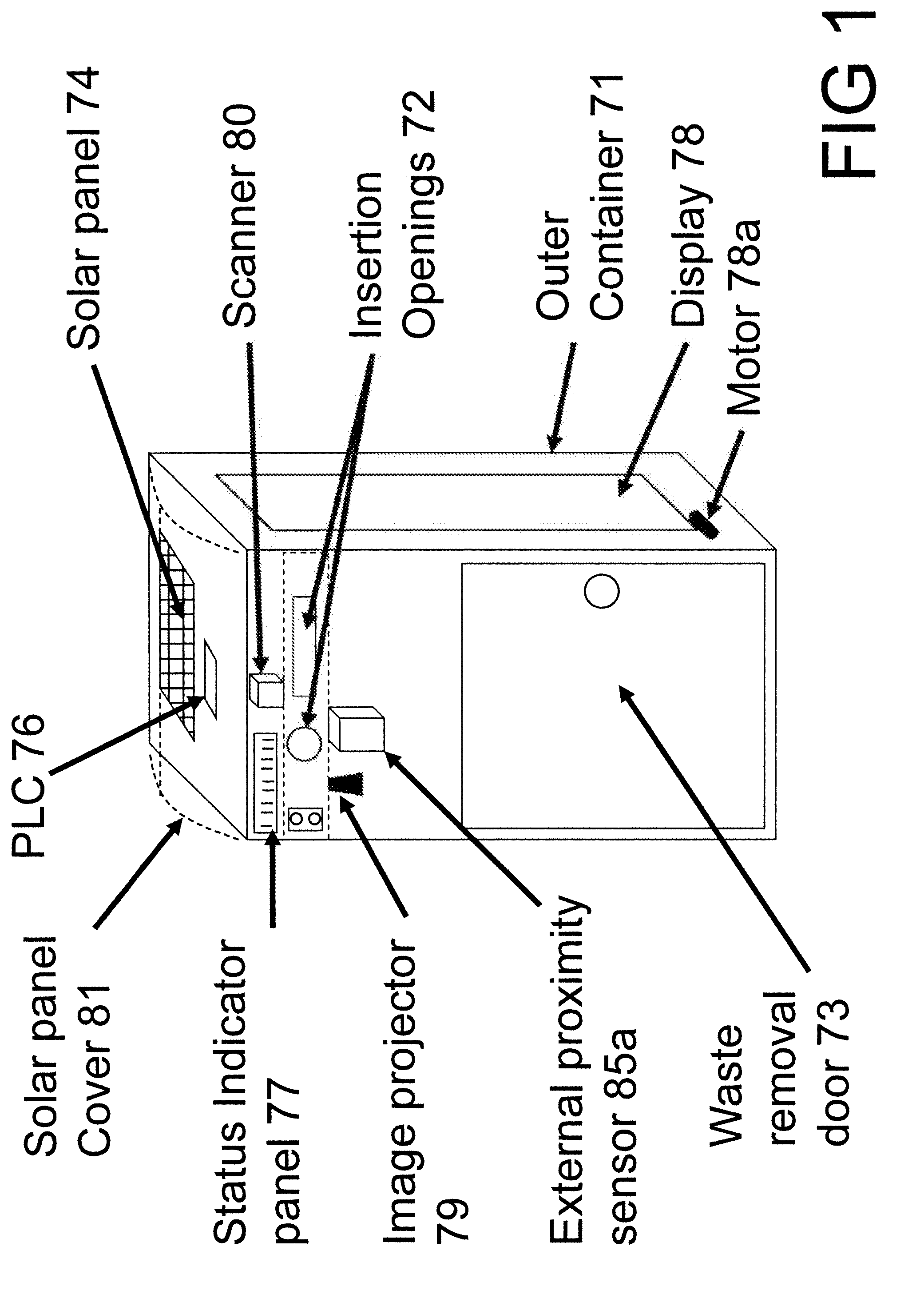

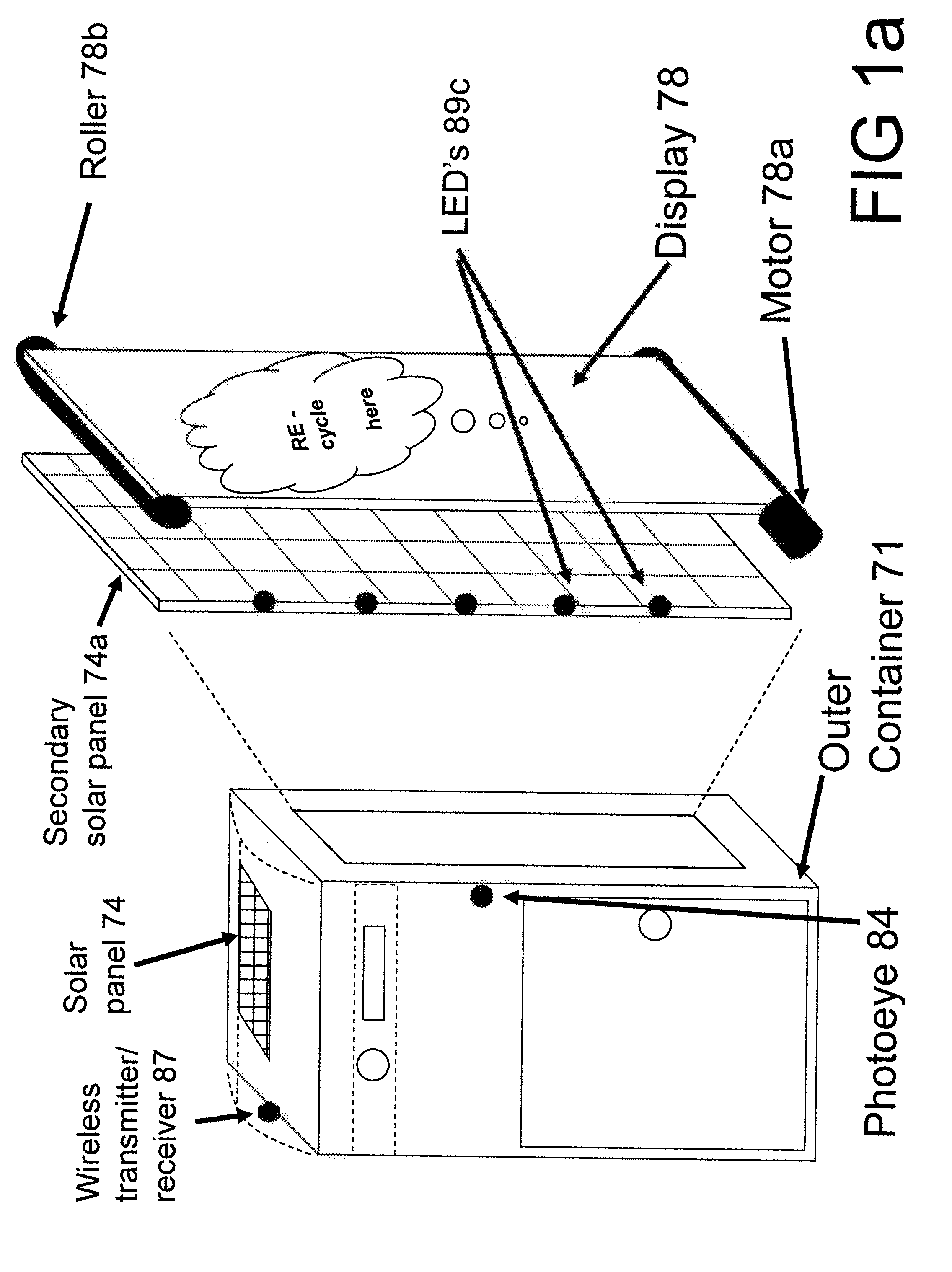

Electrically-powered programmable waste enclosure

ActiveUS20130278067A1Generate advertising revenueOffsetting costsOptical rangefindersWaste collection and transferProgrammable logic controllerElectric power

This invention is directed towards a waste enclosure device (“device”) comprising a waste enclosure employing operational functions including collection and monitoring capacity wherein said device includes one or more programmable logic controllers. Operational functions are performed by electrical components including sensors to determine waste deposits characteristics and contents. Said device operational functions are further adapted to send and receive data, optionally wirelessly, and configured and adapted to utilize solar derived electric power and, optionally, electric power from other sources.

Owner:BIG BELLY SOLAR

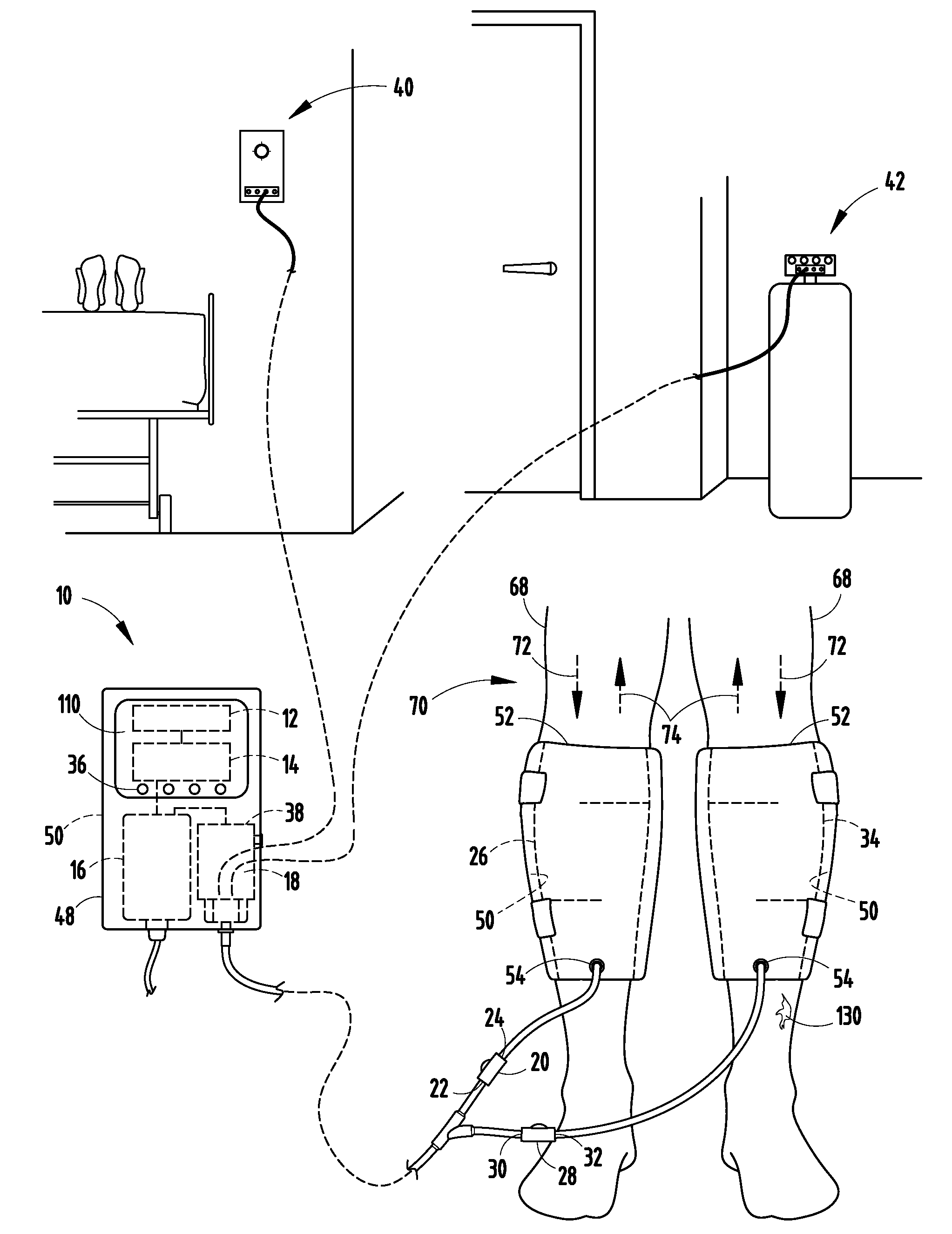

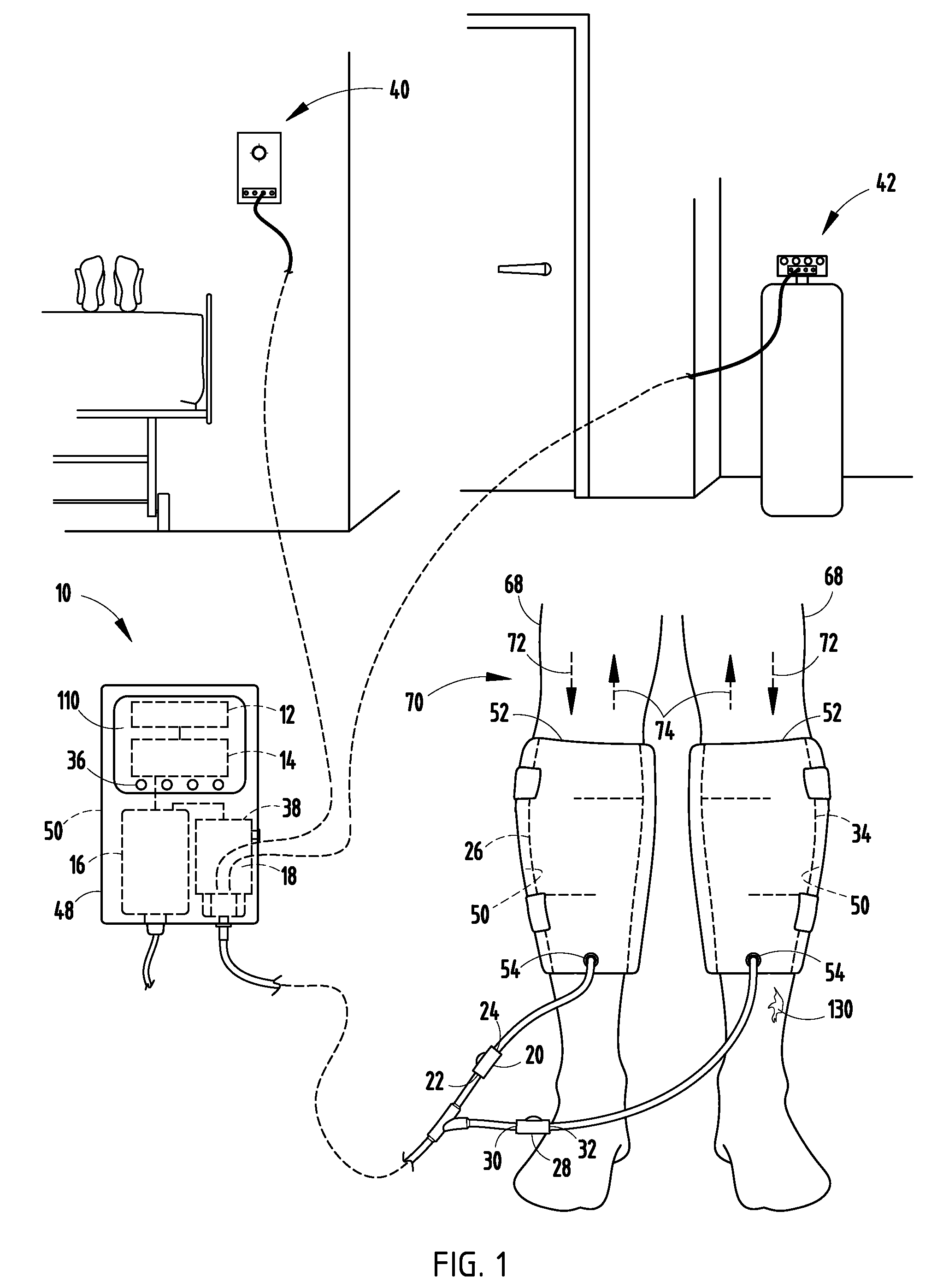

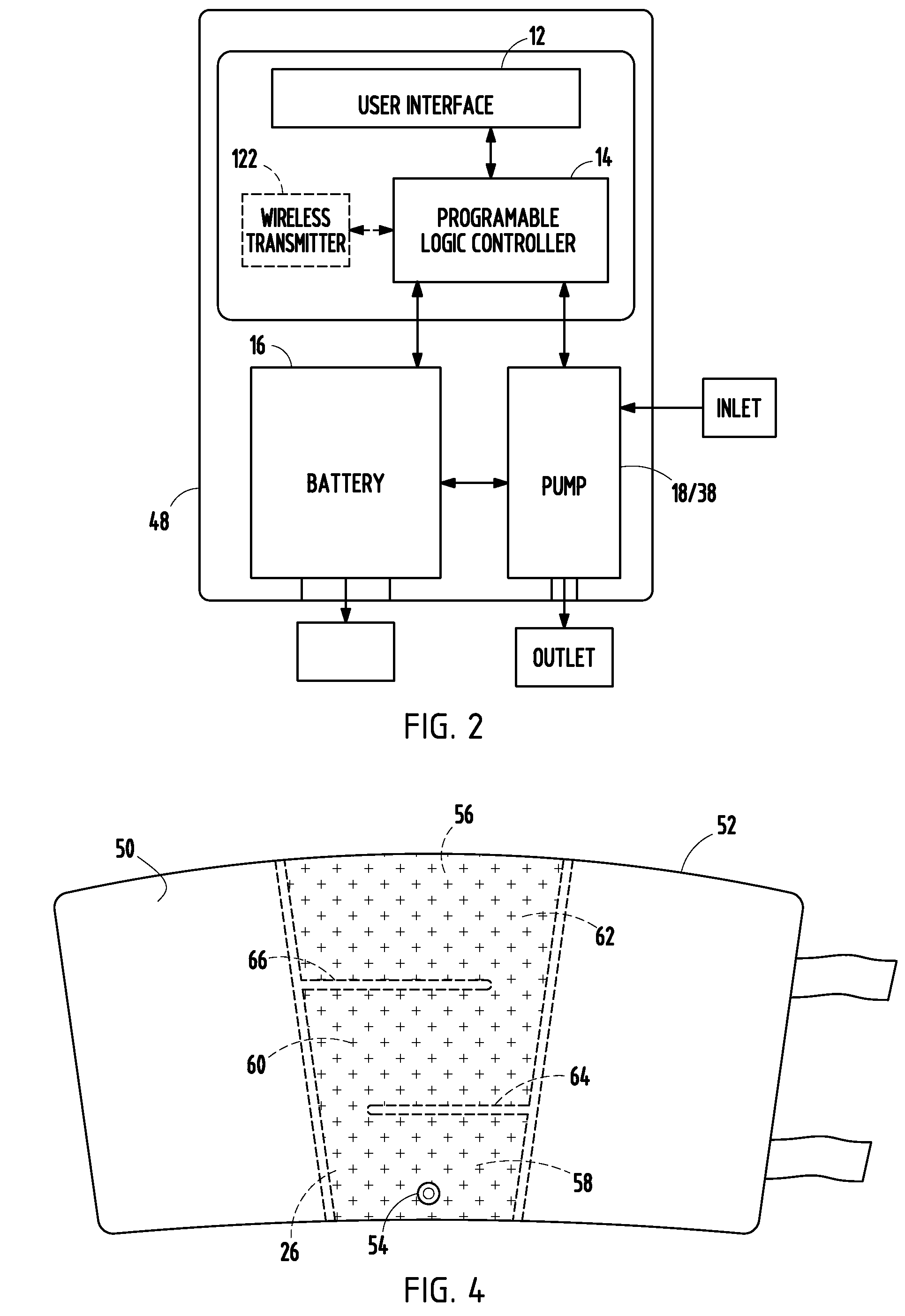

Compression device and control system for applying pressure to a limb of a living being

ActiveUS20100137764A1Prolong lifeWork lessPneumatic massageChiropractic devicesProgrammable logic controllerControl system

A device to compress the limb of a living being comprising a user interface, a programmable logic controller, a power source, a source of fluidic pressure, valves with ports in fluidic connection with the source of fluidic pressure, other valves, and a first and second inflatable bladders, wherein the programmable logic controller is programmed to cause the repeating sequence of inflating the first inflatable bladder by manipulating the ports of the valves, after a first preset period of time, deflating the first inflatable bladder and allowing the pressure within the first inflatable bladder to inflate partially the second inflatable bladder by manipulating the ports of the valves. The source of fluidic pressure can be a self-contained pump, a connection to fluidic pressure in a health care facility, or a pressurized canister. The power source can be a battery. The device has means to extend the life of the power source.

Owner:PARASOL MEDICAL

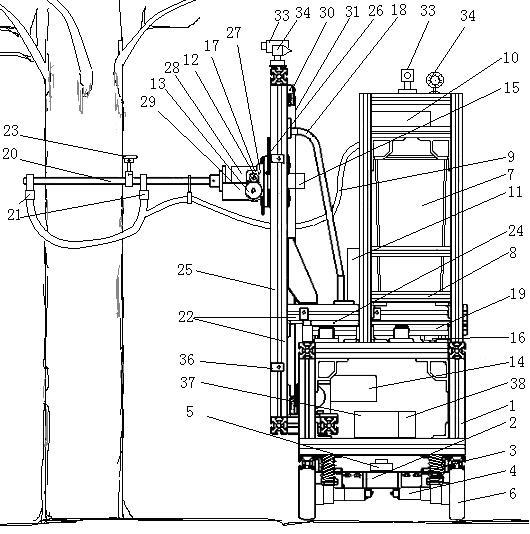

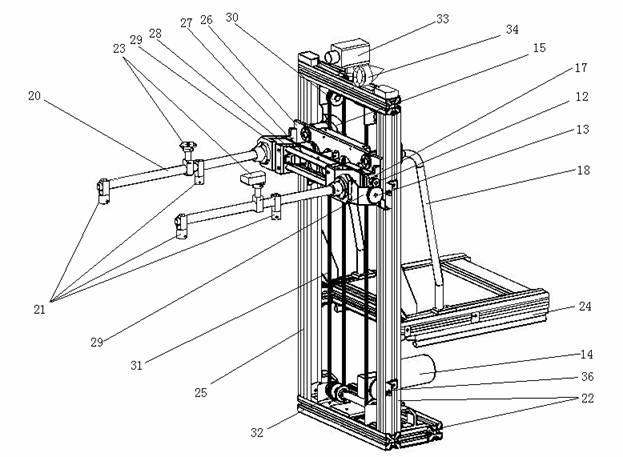

Intelligent tree trunk white paining robot

InactiveCN102151634AImprove work efficiencyQuality improvementLiquid spraying apparatusPlant protectionProgrammable logic controllerTree trunk

The invention discloses an intelligent tree trunk white painting robot and belongs to the related fields of urban and garden greening equipment. The intelligent tree trunk white painting robot comprises a machine frame system, a robot traveling system, a lime slurry supply system, an automatic white painting execution system and a real-time detection system. Adopting a spray painting mode for white painting of tree trunks, the robot can automatically walk along a side pavement and quickly and efficiently spray lime solution onto trees along the side pavement. In a real-time detection system, a digital compass, a laser sensor and a vision system are adopted to realize the semi-automatic searching of tree trunks and tree trunk automatic positioning, an ultrasonic transducer is adopted to realize automatic obstacle avoidance, and the whole-process real-time monitoring with a personal computer (PC) and a programmable logic controller (PLC) is realized. When the intelligent tree trunk white painting robot is used, coating is saved and the painting effect is optimized; and the robot automatically performs white painting of trees along the side pavement, the working efficiency is improved, labor force is saved, and the goals of intelligent control and green environmental sanitation are fulfilled.

Owner:SHANGHAI UNIV

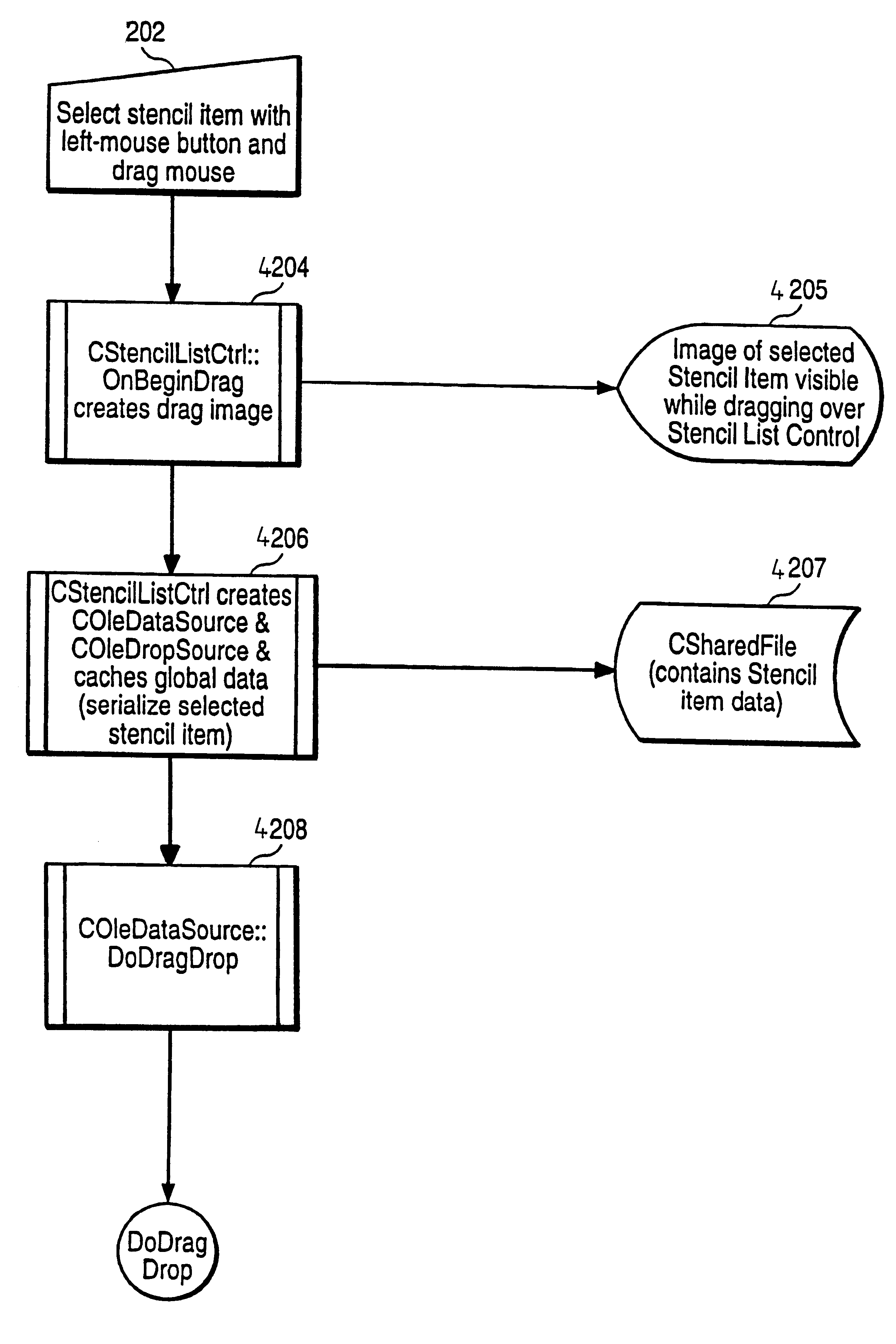

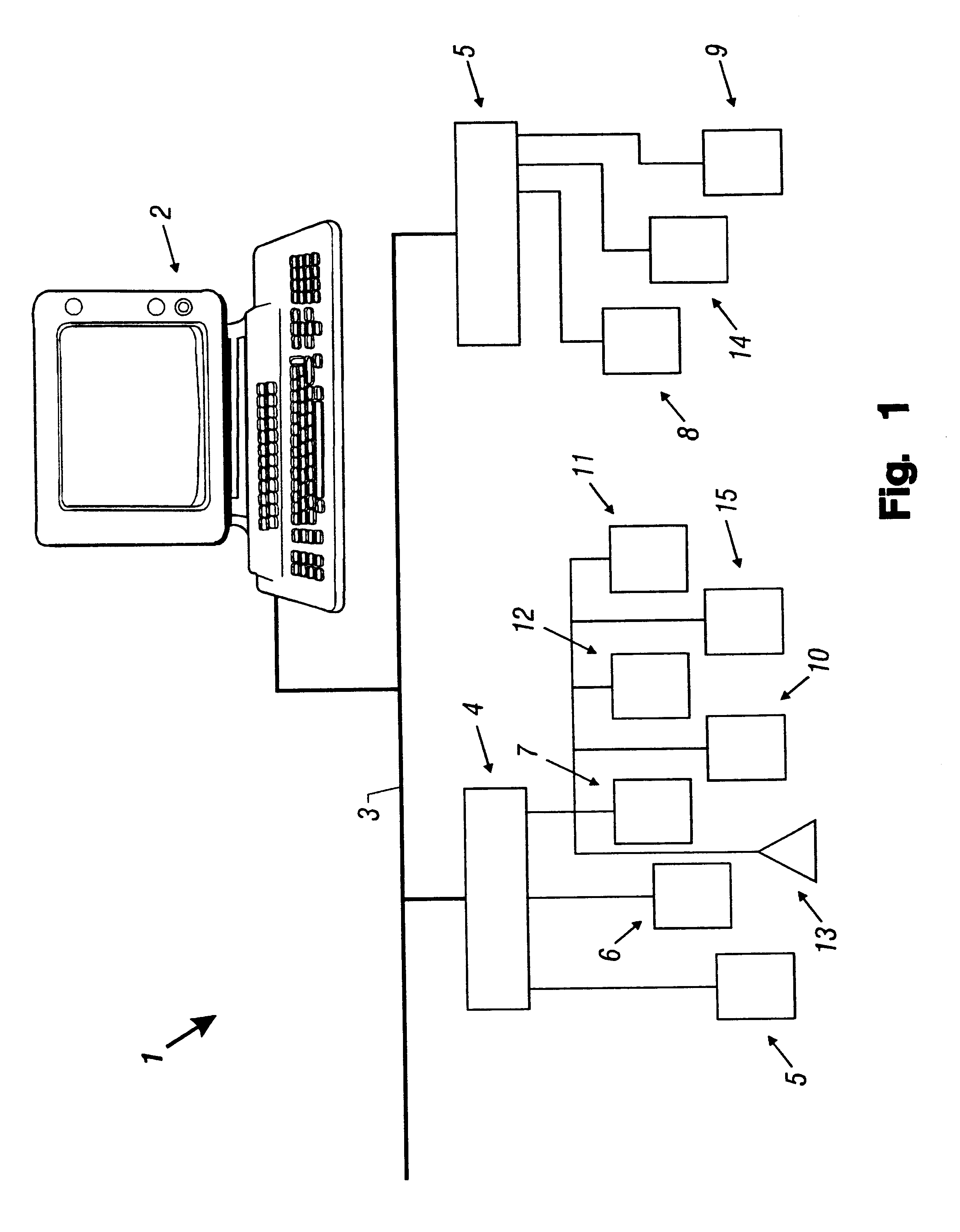

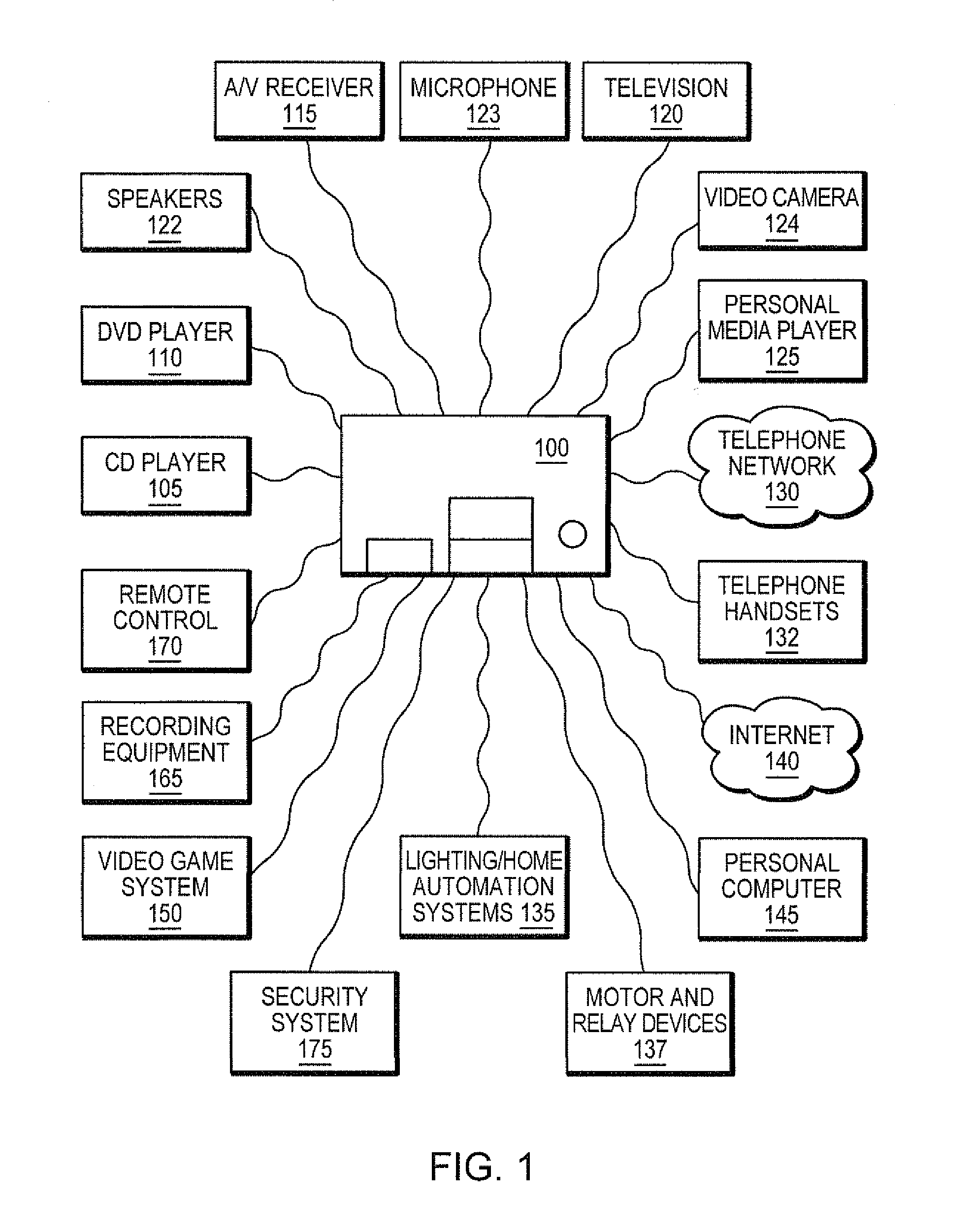

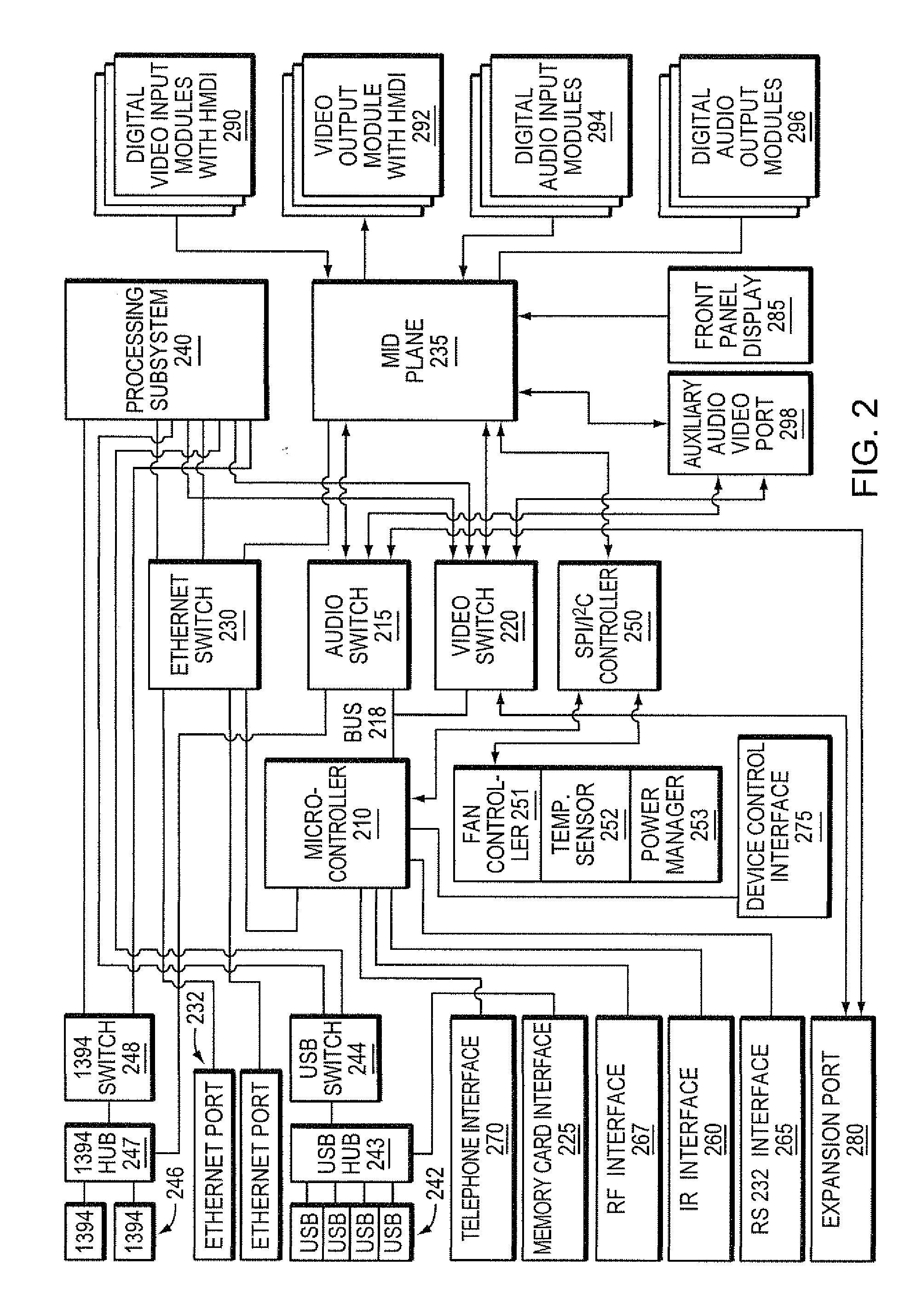

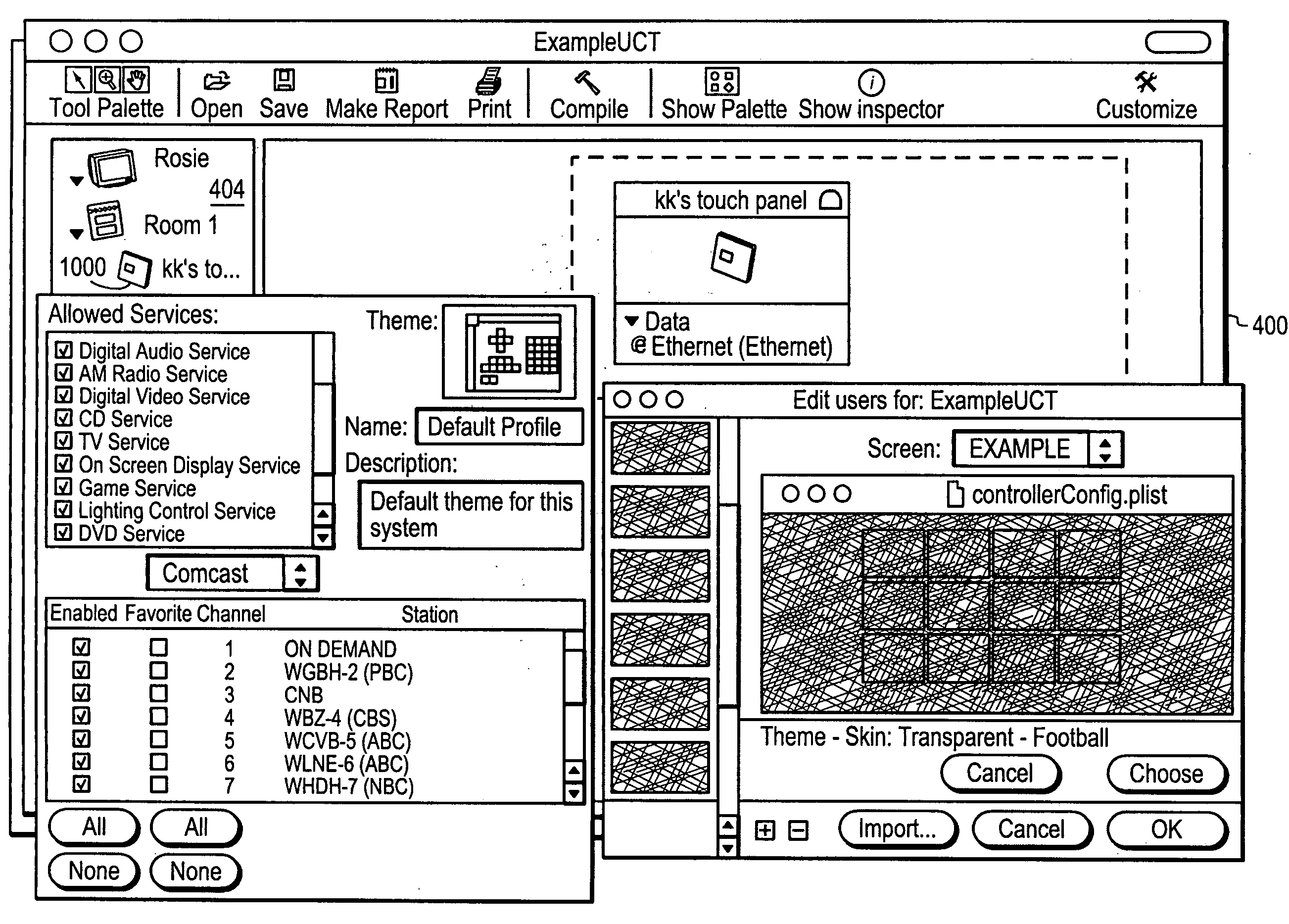

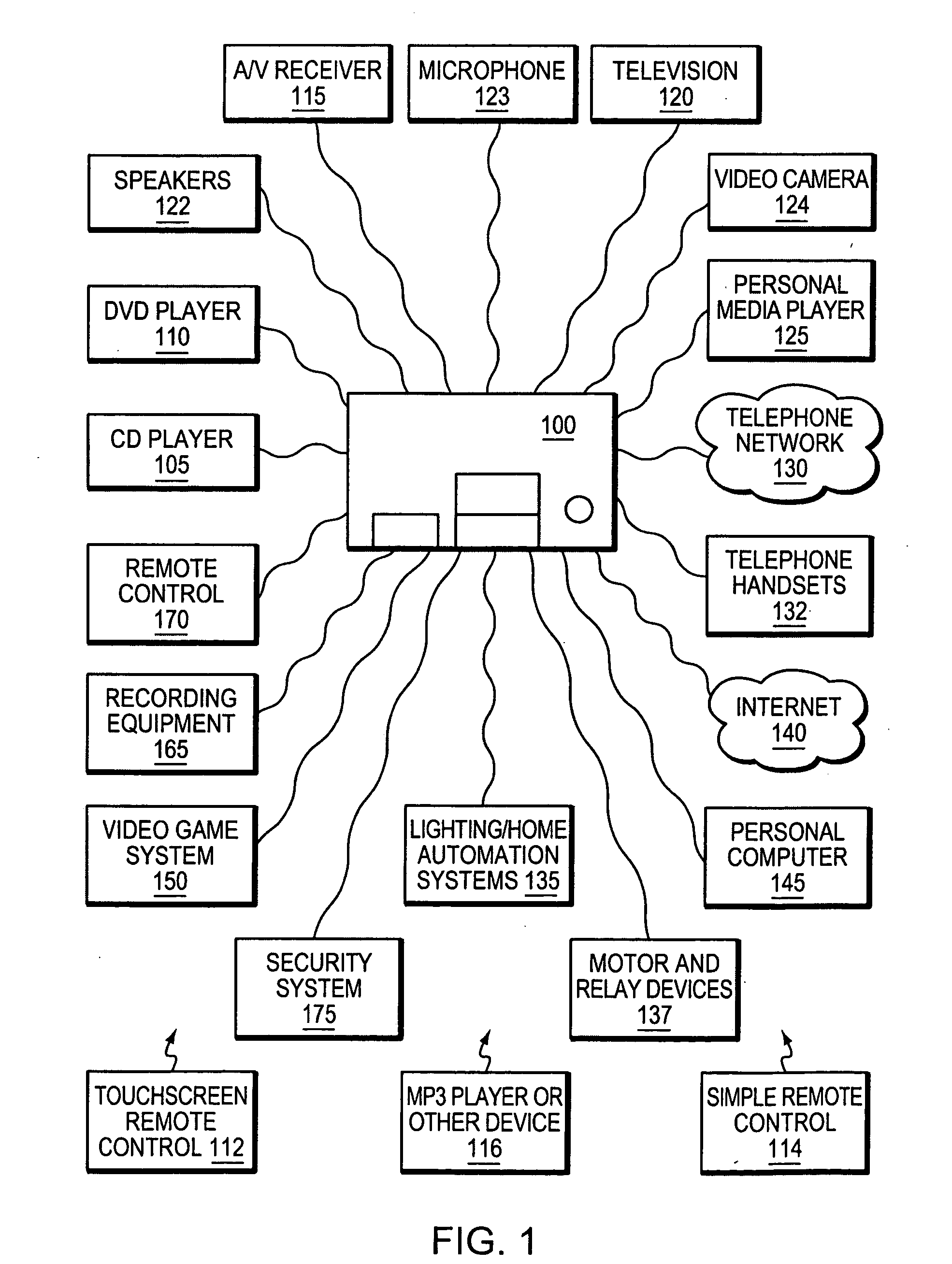

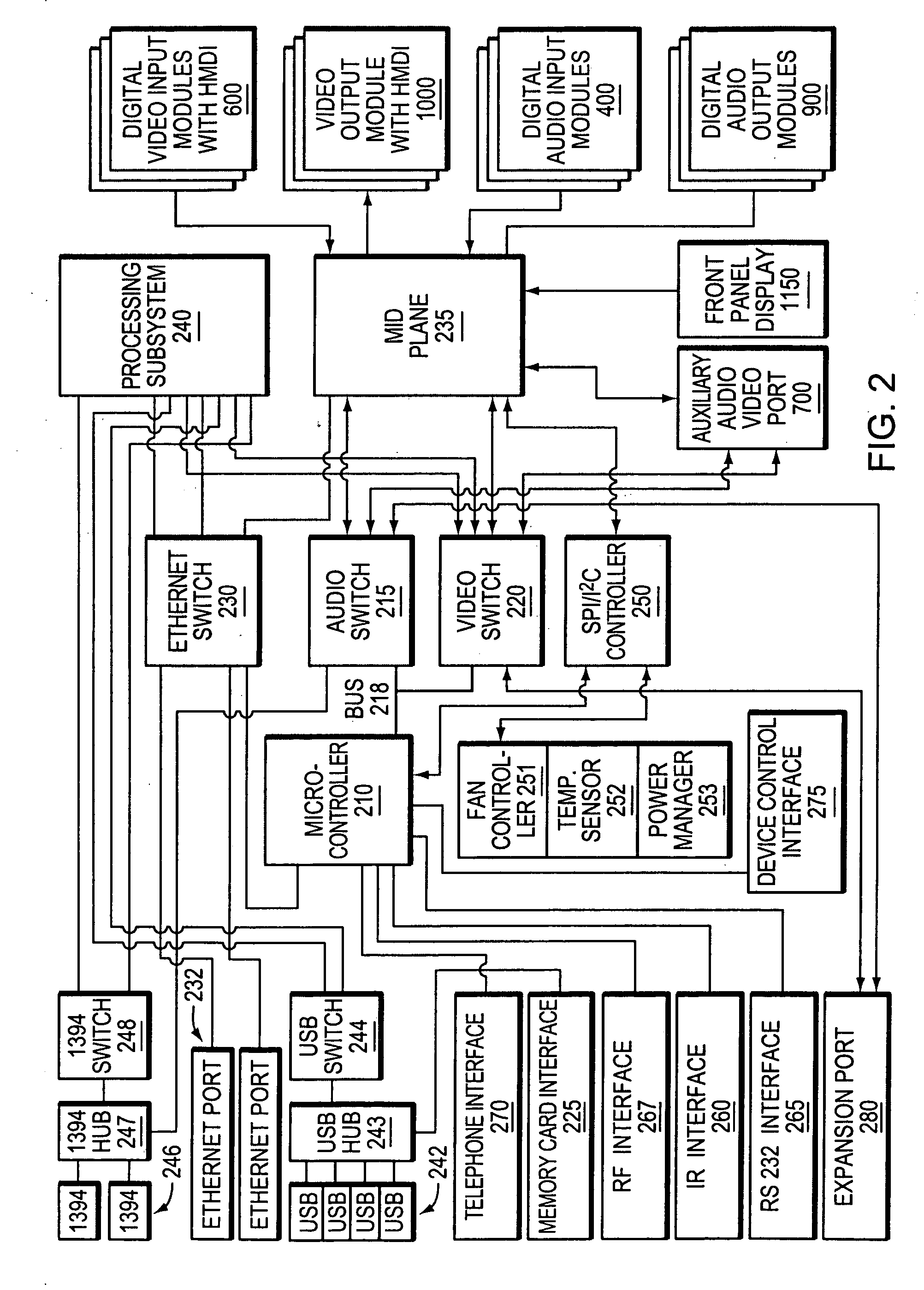

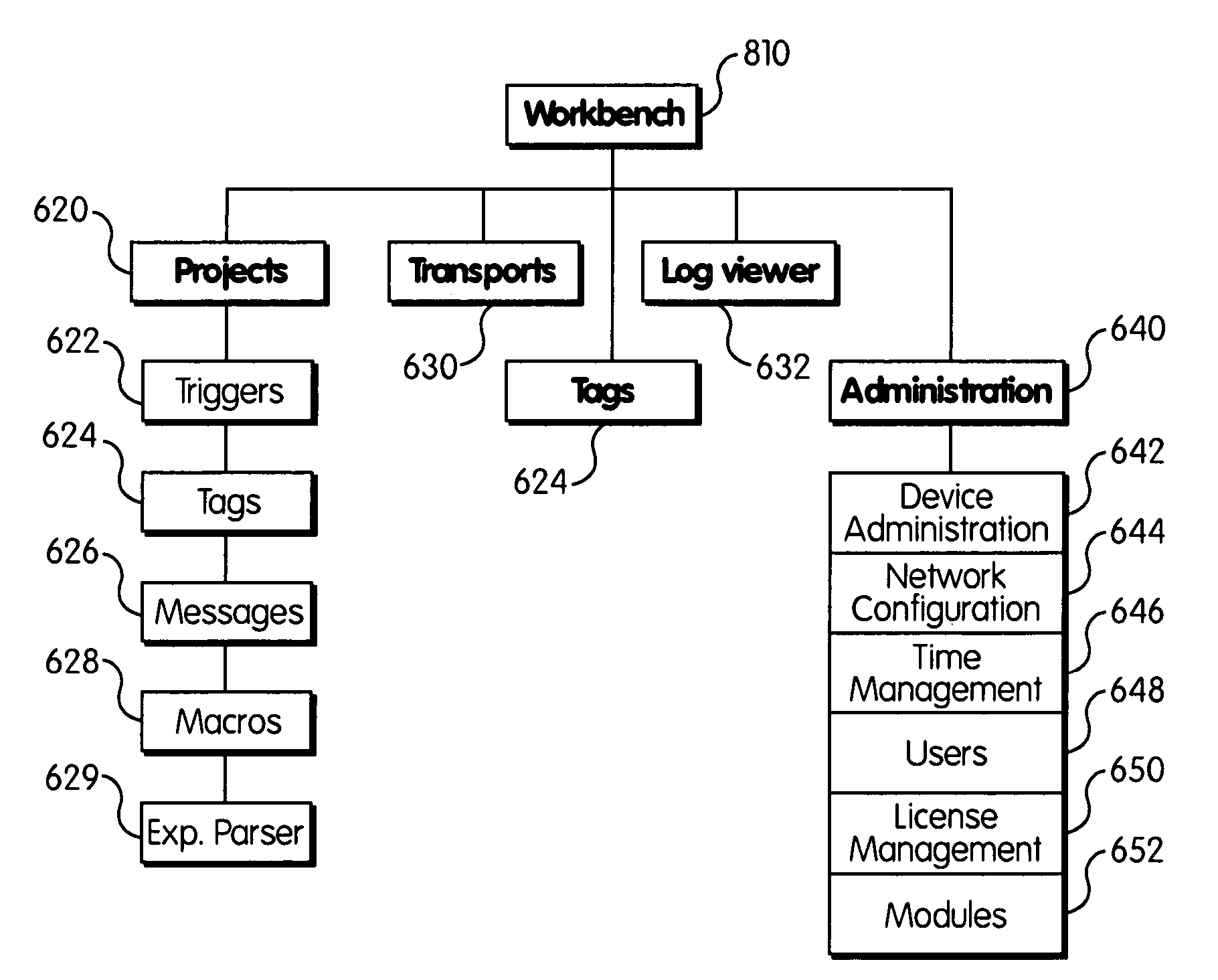

Programming environment and metadata management for programmable multimedia controller

ActiveUS20080127063A1Television system detailsTemperature control using digital meansGraphicsGraphical user interface

A multimedia controller, based on a general purpose computer, which is capable of interfacing with, controlling or managing a wide variety of audio, video, telecommunications, data communications or other devices. A configuration tool, based on a graphical user interface, provides a simple, schematic way to configure even highly complex systems having numerous components or devices which are to be interconnected with or interfaced to the multimedia controller. A user interface programming tool enables a user to customize the appearance and functionality of a graphical user interface to the multimedia controller. A metadata manager automatically collects metadata that is available within the multimedia controller, automatically detects the presence of new media and collects metadata from it, and may also access web resources to locate additional pertinent metadata.

Owner:SAVANT SYST INC

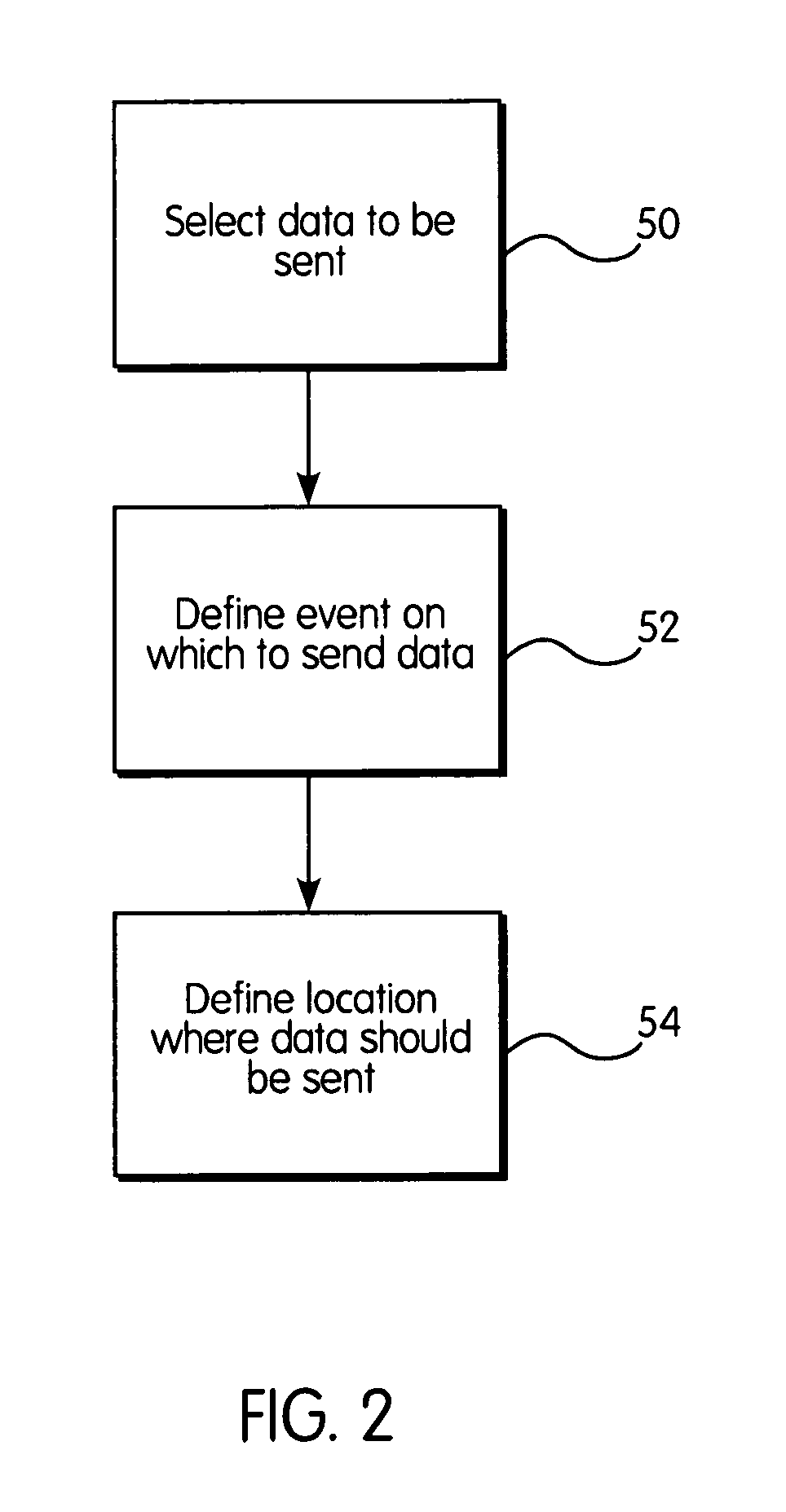

Model for communication between manufacturing and enterprise levels

ActiveUS20050267882A1Programme controlData processing applicationsProgrammable logic controllerEnterprise level

A device for communicating with low level controllers and sensors located on the production floor of an enterprise directly from the top level of the enterprise. The device comprises a controller which interfaces with programmable logic controllers (PLCs) via the backplane into which the PLCs are plugged. Users are able to define triggers that specify the circumstances under which data points within the PLCs are transported to the enterprise level where they may be stored in a database or sent directly to enterprise application via one of a number of possible transfer protocols. The invention also includes a software client which allows users to set up transfer triggers and view data points on the PLCs in real time.

Owner:TELIT TECH CYPRUS LTD

Automated closed loop flowback and separation system

InactiveUS20100206560A1Realize automatic adjustmentSurveyDrilling rodsAutomatic controlHuman–machine interface

An automated closed loop flowback and separation system that allows automated control and remote operation of a flowback operation from a safe distance without any fluid or gas release to the atmosphere. Four-phase separation tanks allow the transport gas, well bore cuttings, produced oil, and produced water to be automatically separated and transported through process piping for reuse or sale, eliminating the need for auxiliary equipment. Flow measurement instruments, pressure transmitters, and level transmitters work in conjunction with an automated blast choke to send data to a programmable logic controller for use in calculating the erosion status of the choke restriction and adjusting the choke to compensate. The programmable logic controller works with a touch-screen or similar human-machine interface to allow remote monitoring and control or automated control of the system. The automated blast choke can vary the choke restriction opening based on the pressure differential and flow rate conditions.

Owner:CANADIAN FRACMASTER

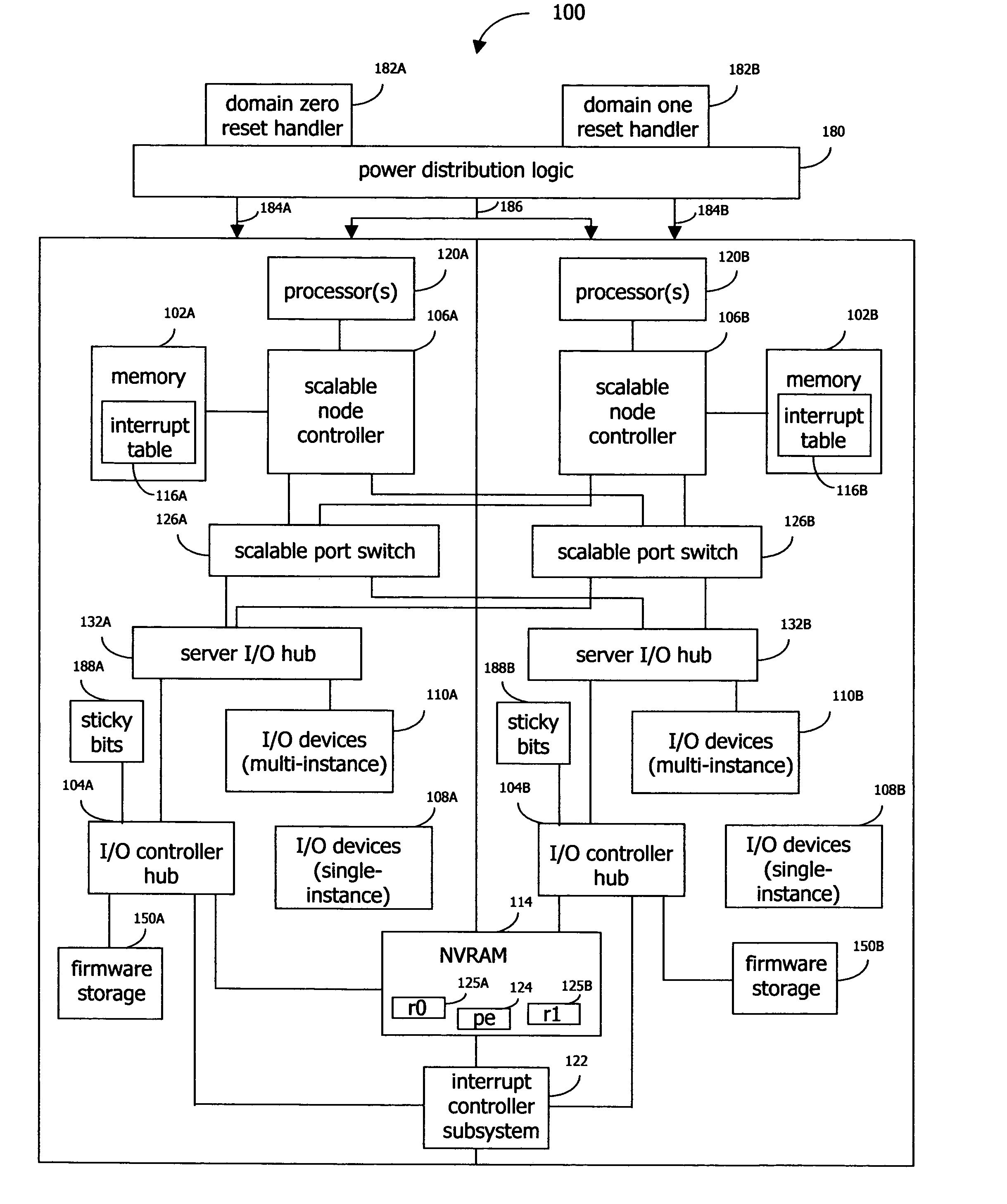

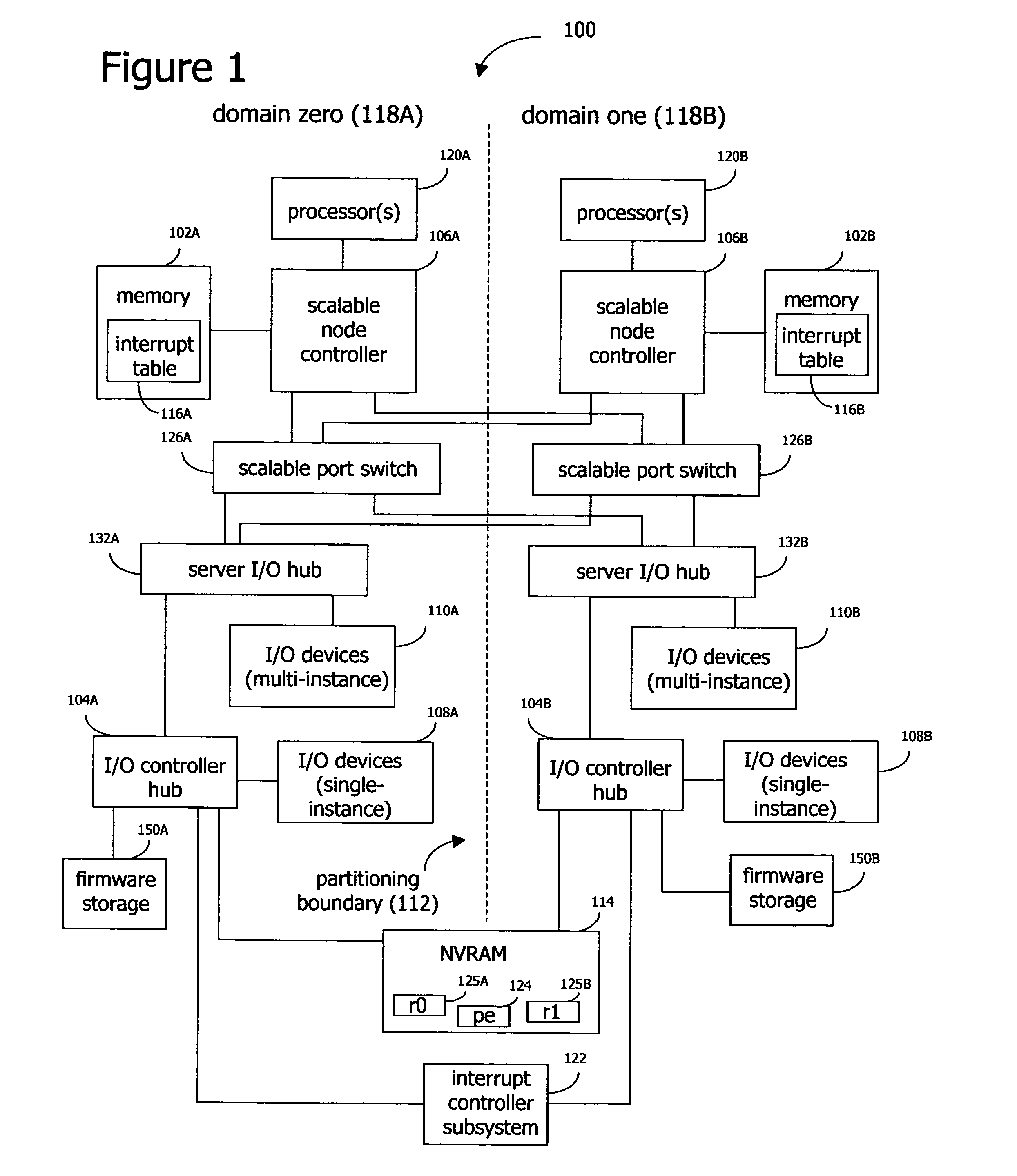

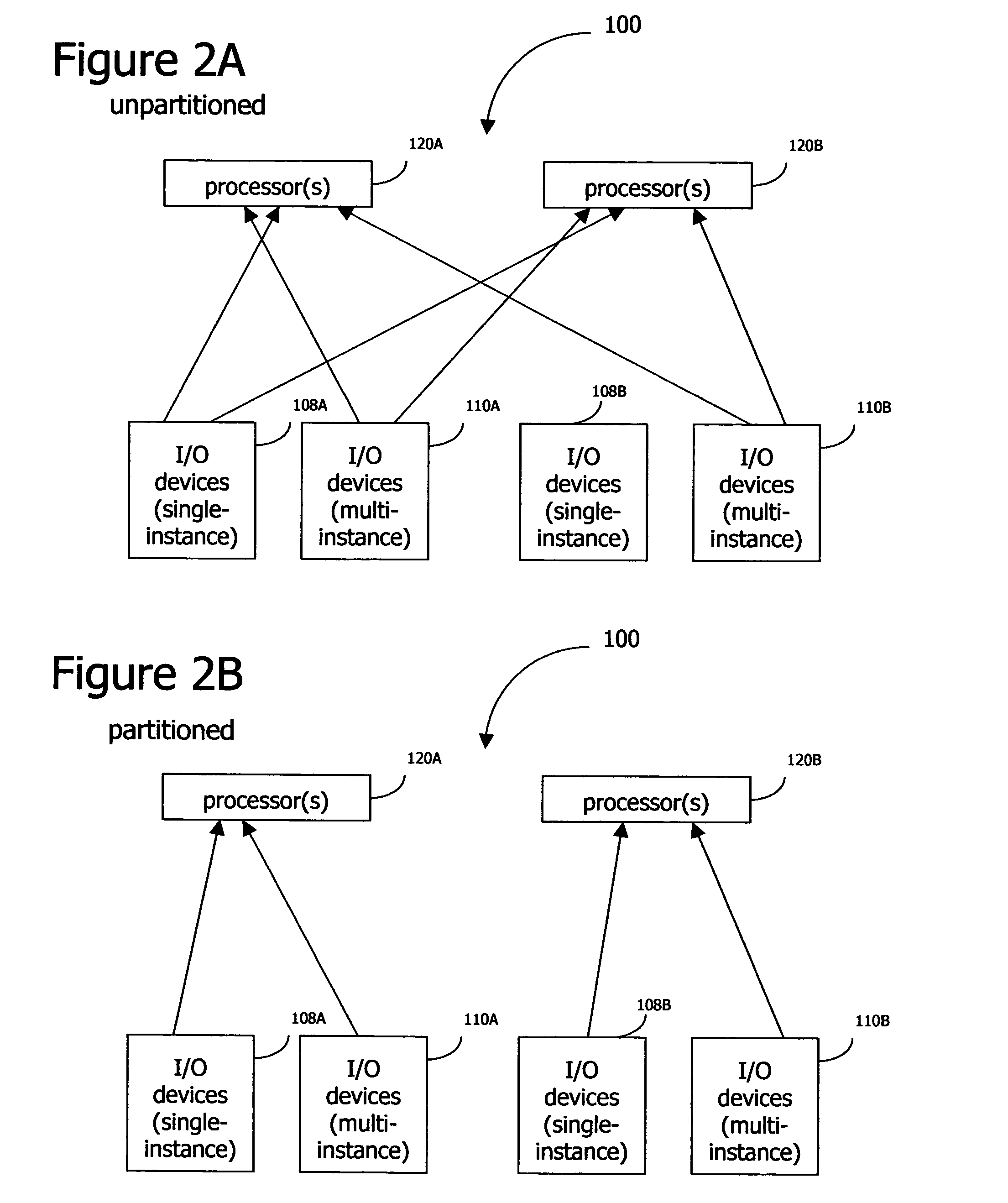

Partitionable multiprocessor system having programmable interrupt controllers

InactiveUS7162560B2General purpose stored program computerData resettingOperational systemMulti processor

A system that may optionally be partitioned into multiple domains is disclosed. Each domain is capable of independently powering on, executing a firmware program, and loading an operating system, including a legacy operating system, as well as running an application program that is distinct from programs running on another domain. Interrupts, including boot interrupts, reset handlers, and inter-chassis communications are initialized differently, depending on whether the system is to be partitioned or not. The cost of redundant hardware and / or firmware is substantially avoided, yet the system fully supports multiple domains.

Owner:INTEL CORP

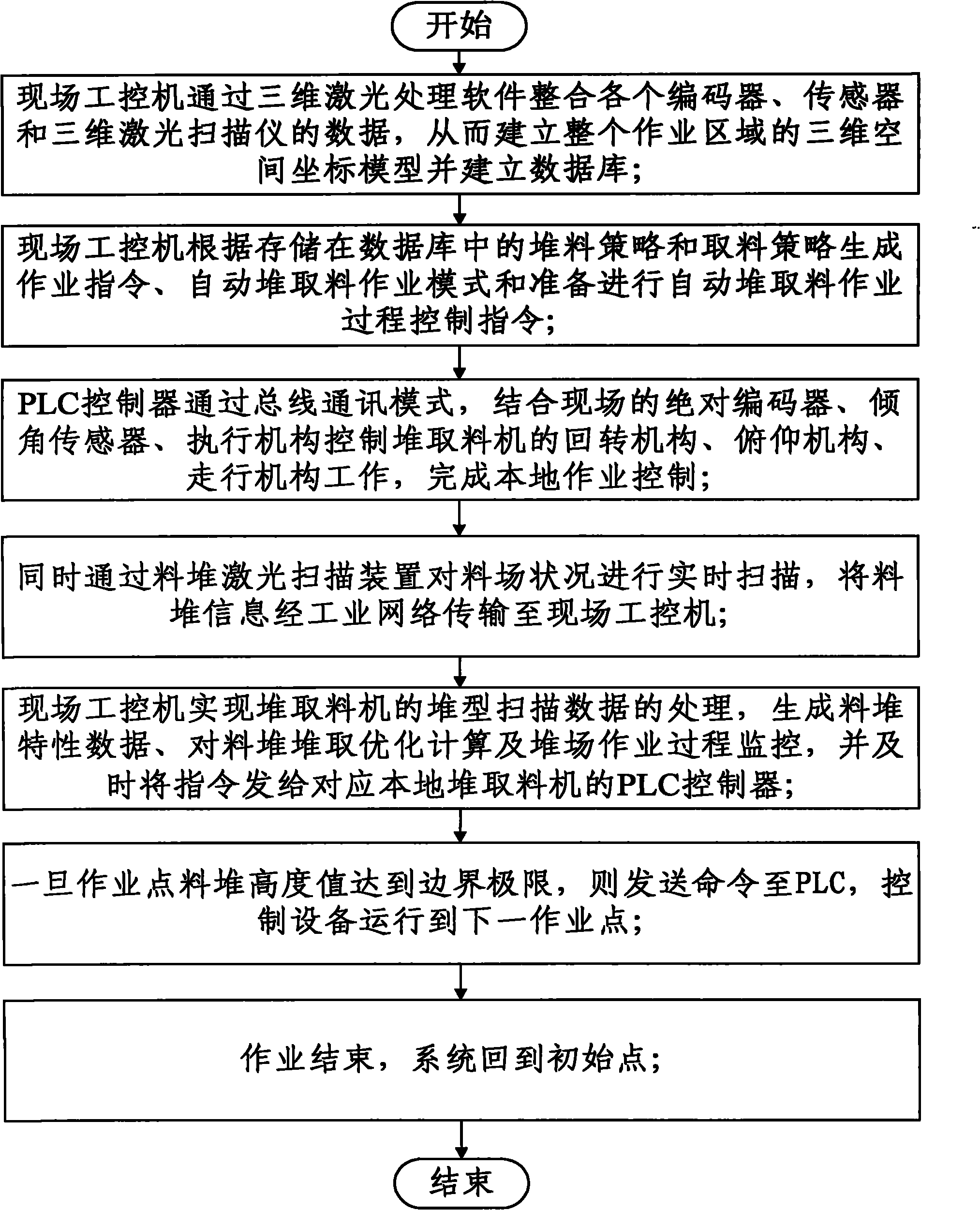

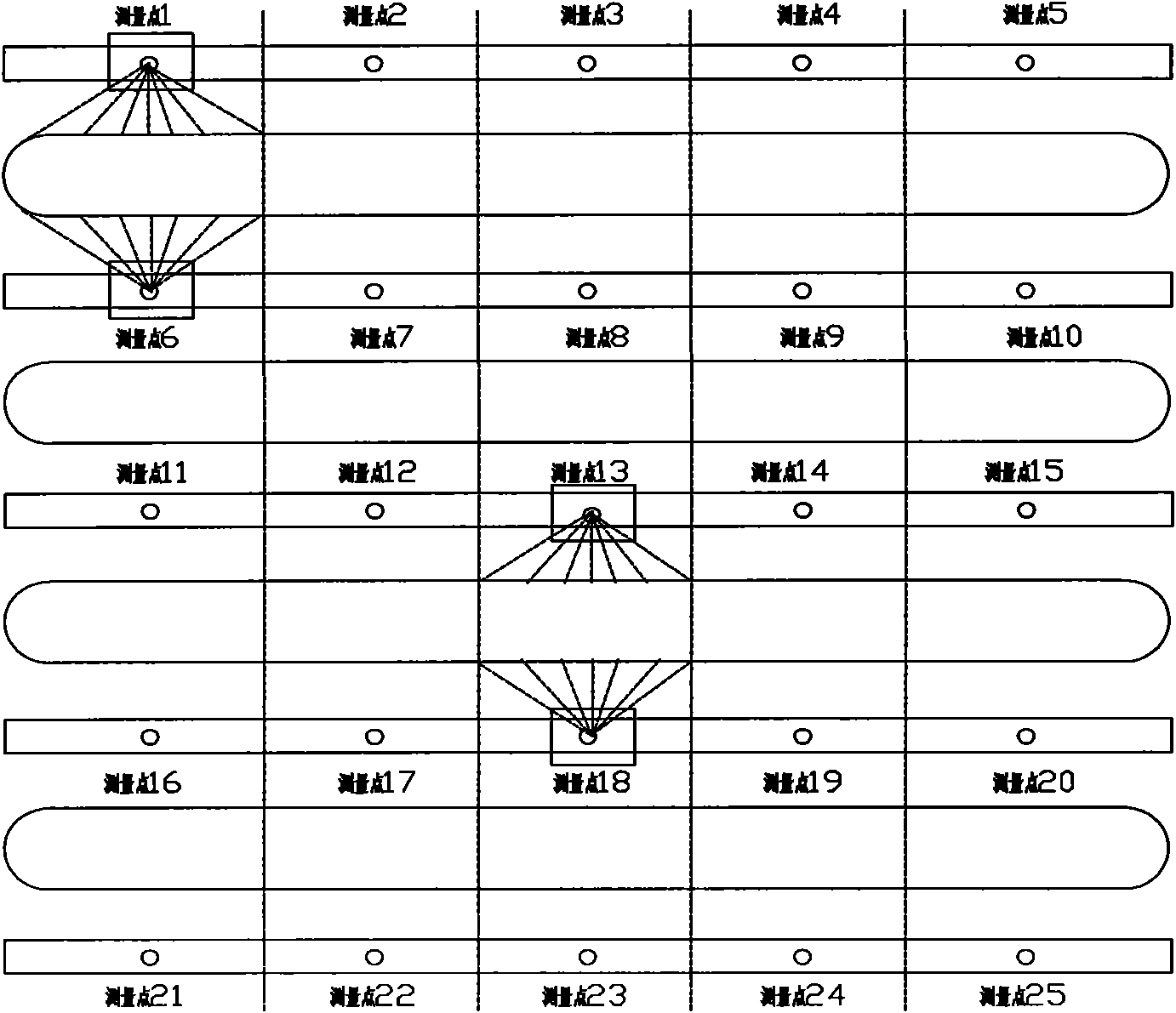

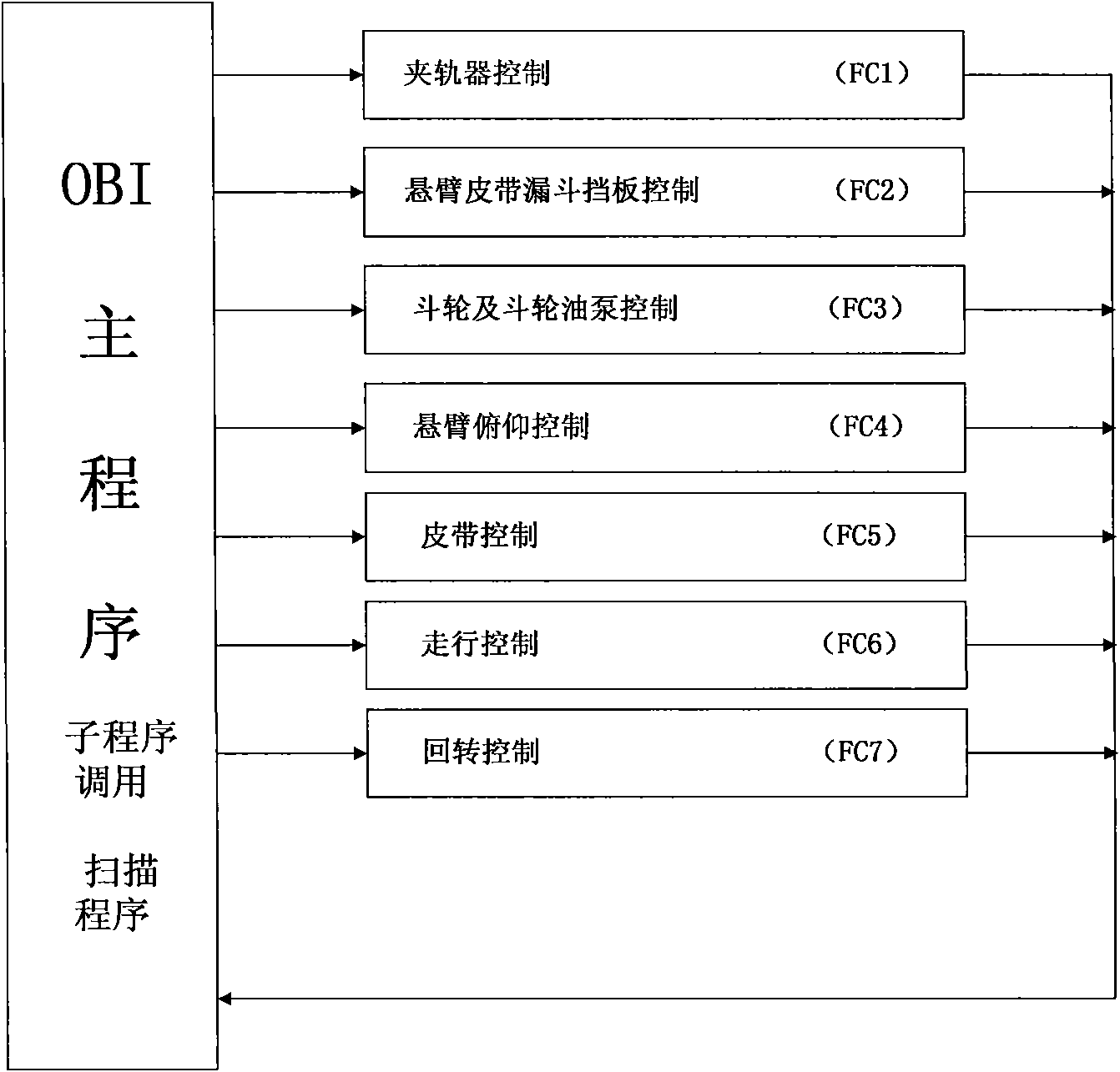

Full-automatic bulk cargo storage yard stacking and taking method

InactiveCN102336340AOvercoming automationOvercome labor intensityLoading/unloadingBulk cargoProgrammable logic controller

The invention relates to a full-automatic bulk cargo storage yard stacking and taking method applied to large port wharfs, truck stations and open storages. According to the method, when a stacking and taking machine works, an operating driver for operating and monitoring is not needed in a cab of the stacking and taking machine and a person for control and operation of the whole process is also not needed in a field industrial personal computer on the basis of fully ensuring the utilization rate of a stock yard and exerting the stacking and taking capacity and other functions of the stacking and taking machine. After the field industrial personal computer acquires an operation task from a management system, optimal calculation and security inspection are performed according to the condition of the stock yard and the state of the stacking and taking machine, and related stacking or taking mode information is automatically generated; and then the system automatically sends related control instructions to a programmable logic controller (PLC) corresponding to the local stacking and taking machine, and the stacking and taking machine performs unmanned automatic stacking and taking operation of the whole process. Therefore, the method overcomes the defects of low automation degree of the conventional bulk cargo storage yard, high labor intensity of operators, low working efficiency and low field utilization rate.

Owner:上海派恩科技有限公司

Safety communication on a single backplane

InactiveUS6909923B2Safety arrangmentsComputer controlProgrammable logic controllerProgrammable Interrupt Controller

Owner:ROCKWELL AUTOMATION TECH

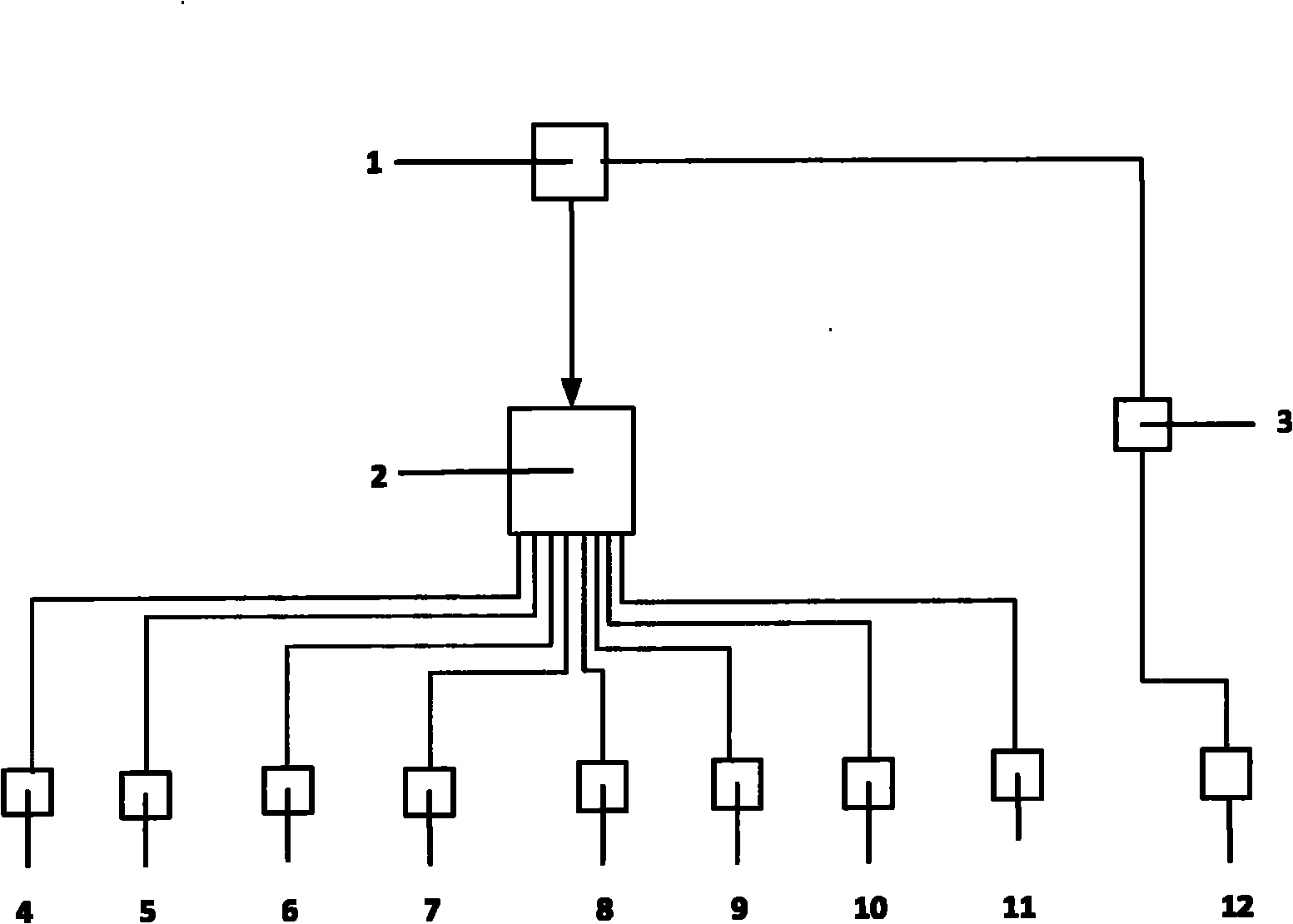

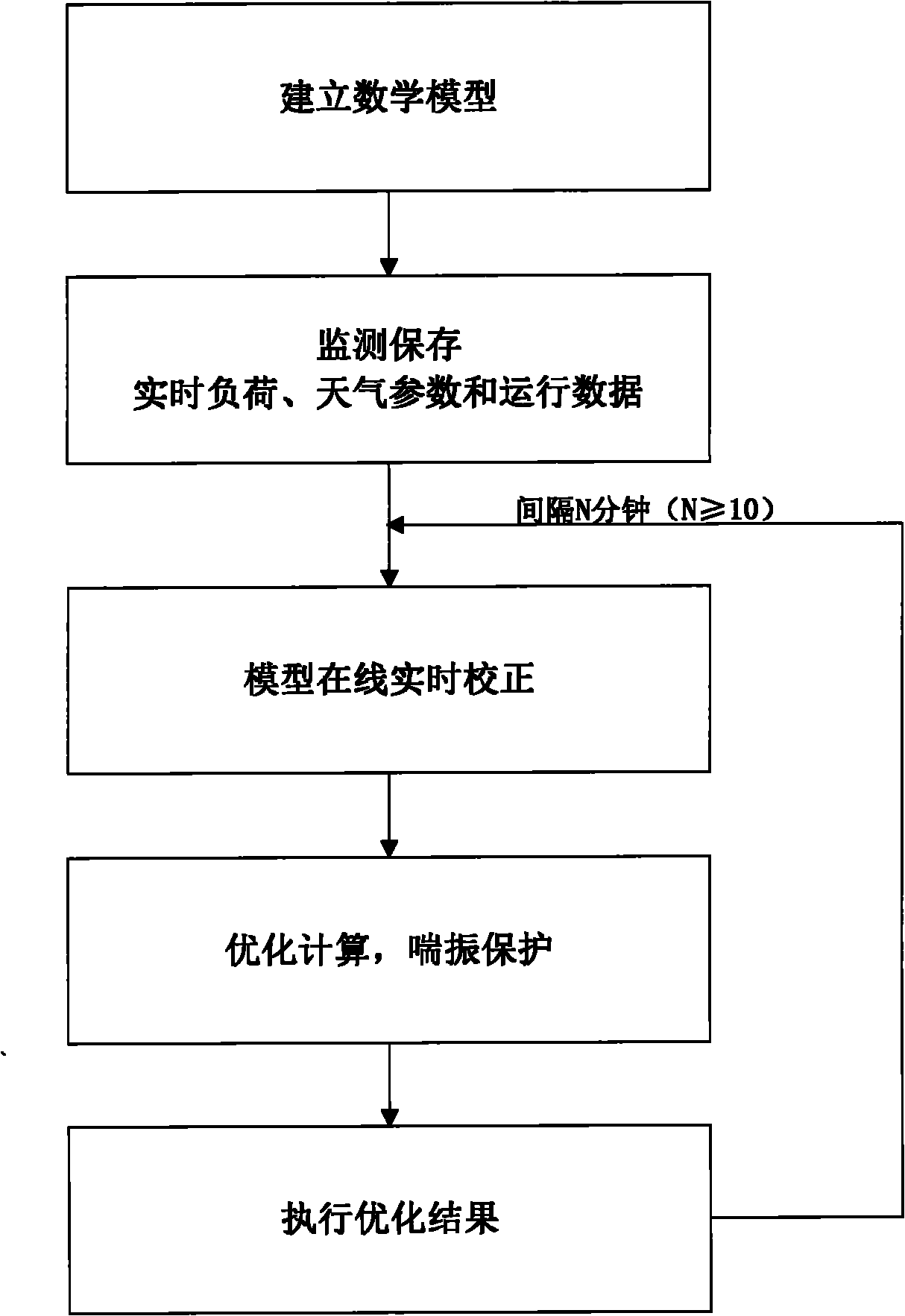

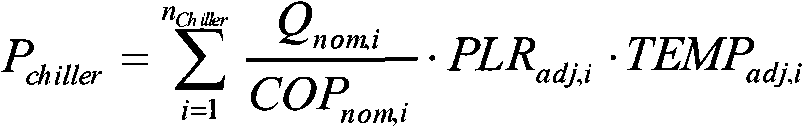

Energy-saving optimized control system and method for refrigerator room

ActiveCN101968250ASpace heating and ventilation safety systemsLighting and heating apparatusFrequency changerRefrigerator car

The invention relates to an energy-saving optimized control system and an energy-saving optimized control method for a refrigerator room. The energy-saving optimized control system comprises an industrial control computer, a flow sensor, a temperature sensor, an outdoor temperature and humidity sensor, a three-phase active power transmitter, a water pump frequency converter and a cooling tower fan frequency converter which are connected with a programmable logic controller respectively, wherein the programmable logic controller communicates with the industrial control computer through an industrial Ethernet; and an RS485 communication interface module is connected with a water cooling unit and communicates with the industrial control computer through a ModBus protocol. A mathematical model of relationships between the energy consumption and running parameters of each equipment in the refrigerator room is established to regulate the running state of each equipment in combination with real-time refrigeration loads and weather parameters, thereby fulfilling the aim of making the lowest running energy consumption of the whole refrigerator room at the premise of meeting the refrigeration loads.

Owner:WELDTECH TECH SHANGHAI

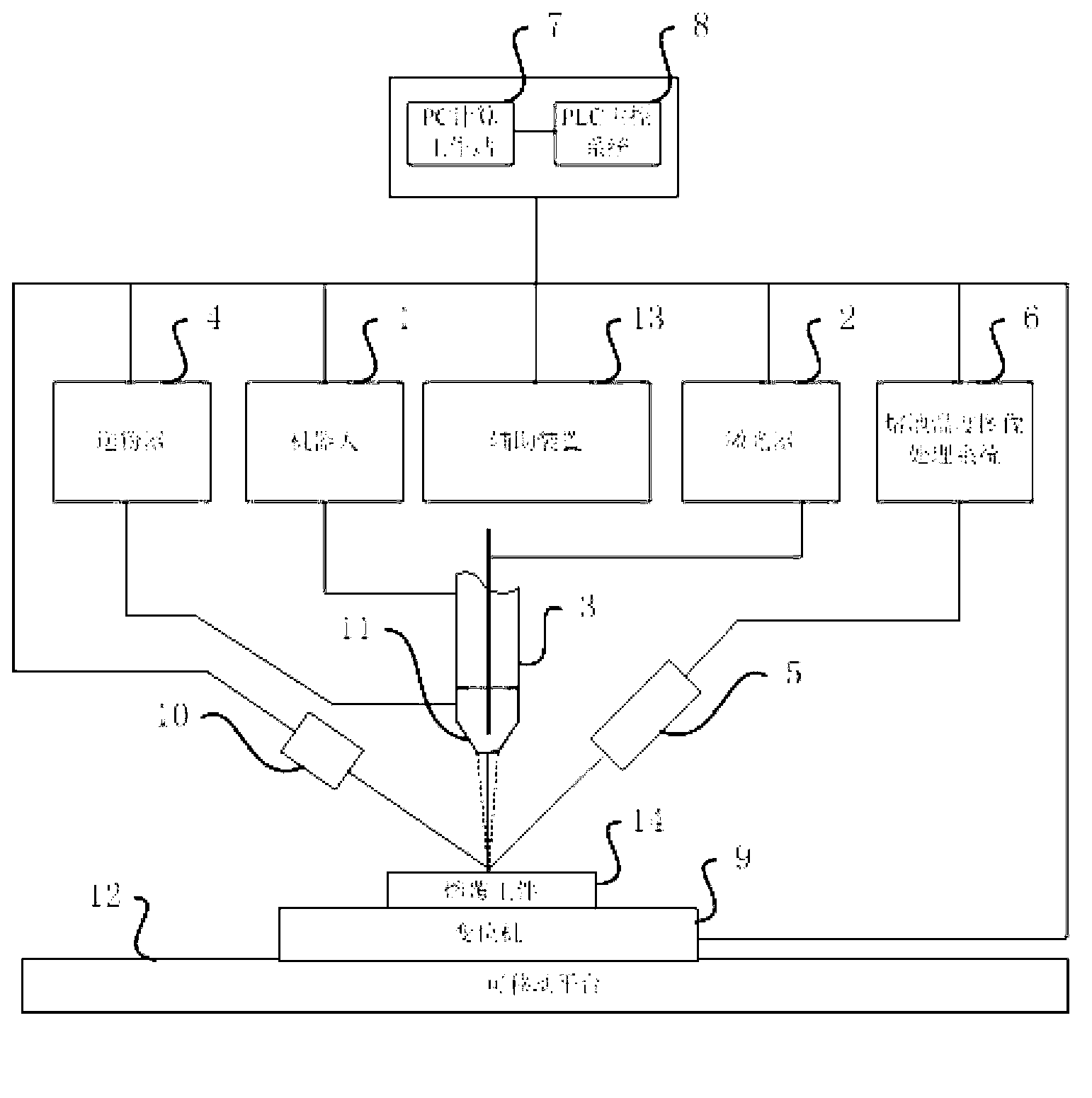

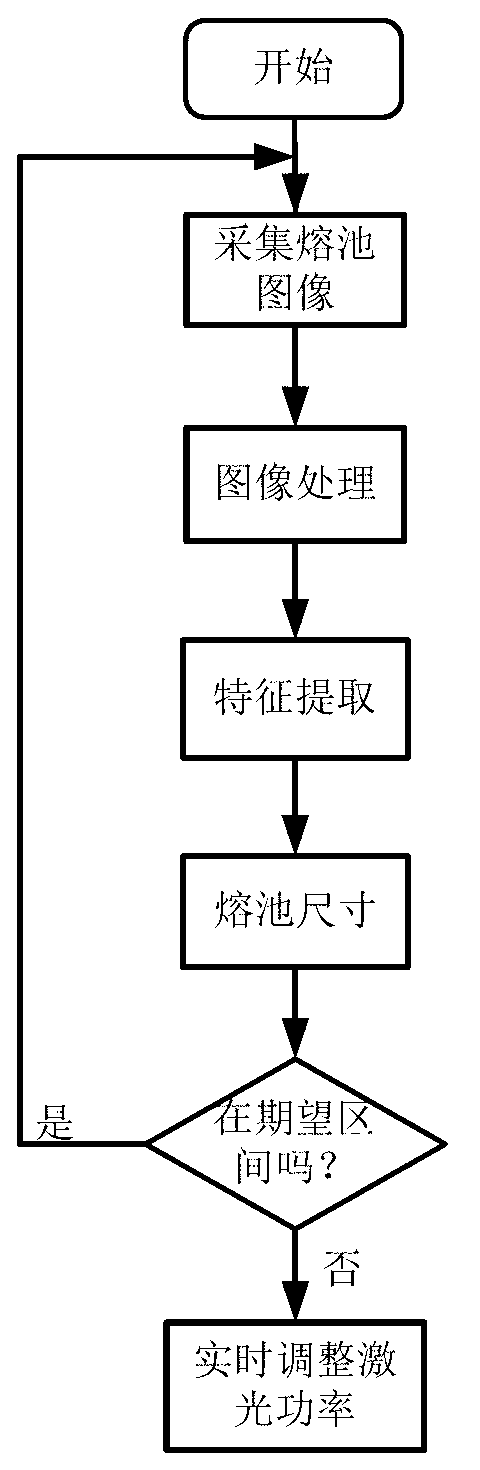

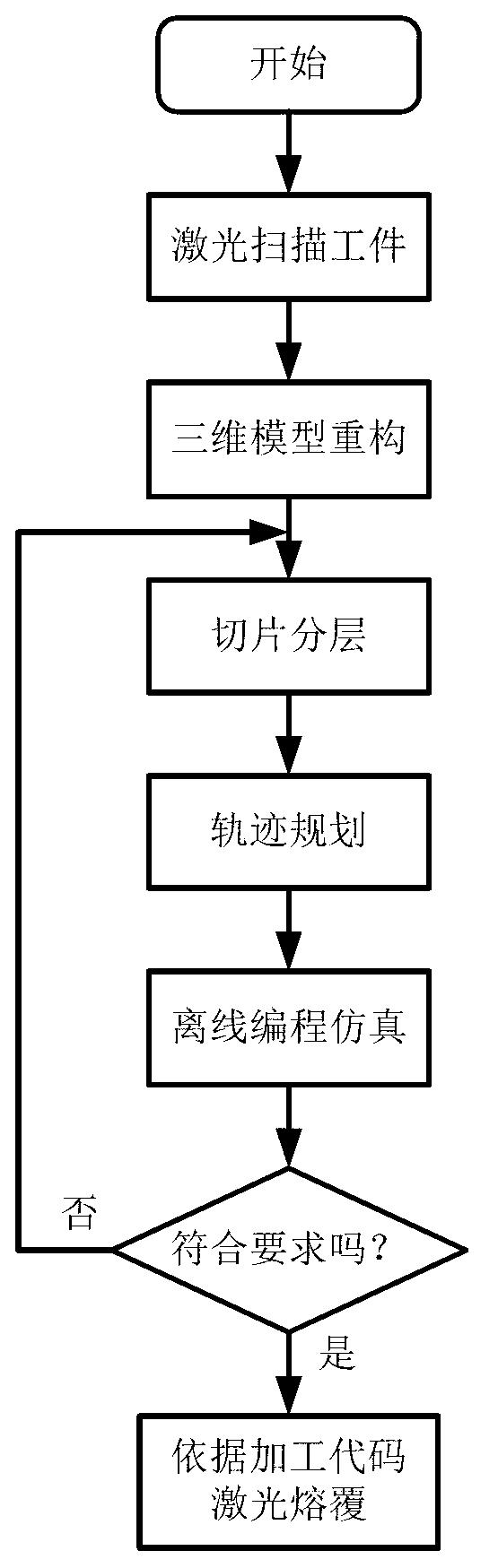

Movable laser cladding and repairing system

ActiveCN103074625AAchieve claddingAchieve fixMetallic material coating processesLaser scanningLaser sensor

The invention provides a movable laser cladding and repairing system in the field of laser cladding and repairing. The movable laser cladding and repairing system comprises a movable platform, wherein a laser, a robot, a position changing machine, a powder feeder, an image processing system, a control system (comprises a PLC (programmable logic controller) main control system, a PC (personal computer) computing workstation), a video camera, a three-dimensional laser scanning sensor, a laser processing head and a coaxial powder feeding head are fixedly arranged on the movable platform. The movable laser cladding and repairing system takes the robot as a moving body, controls the clad pool size, the temperature and other information by using an image acquiring and processing system, and scans a workpiece to slice, stratify and automatically clad a three-dimensional workpiece model based on the three-dimensional laser sensor; the movable laser cladding and repairing system is convenient and flexible, simplifies a repairing process, achieves precision and self-adaptive control of a cladding process, effectively improves the cladding quality, and facilitates field application of a large component through the movable platform.

Owner:SHANGHAI JIAO TONG UNIV

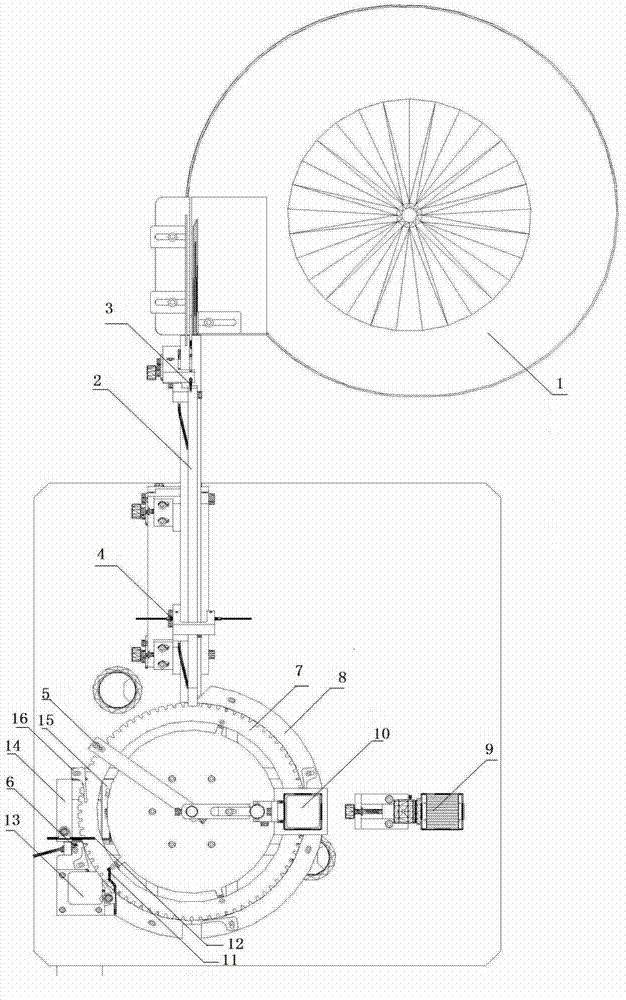

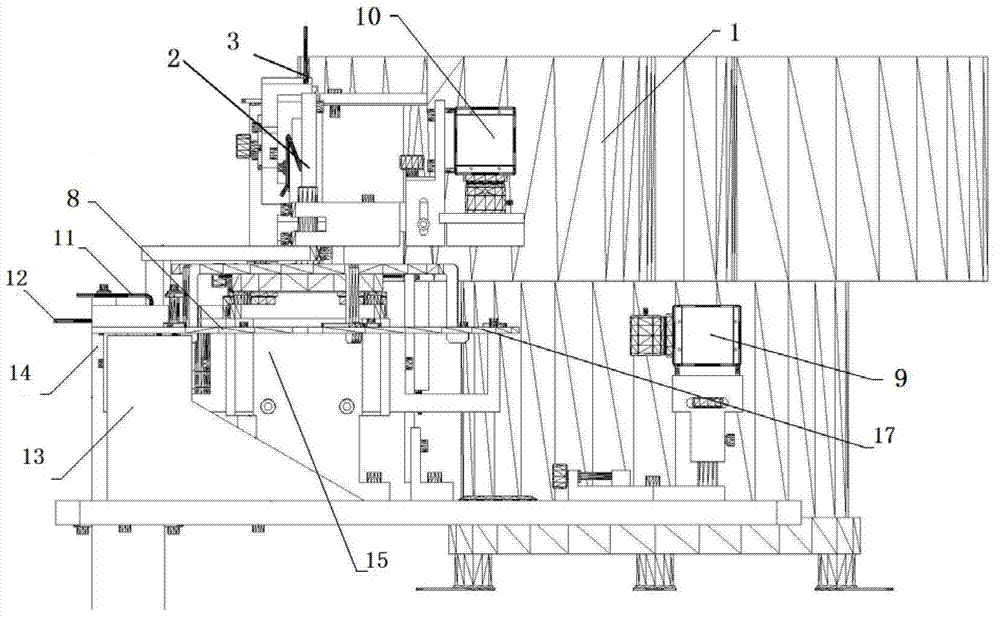

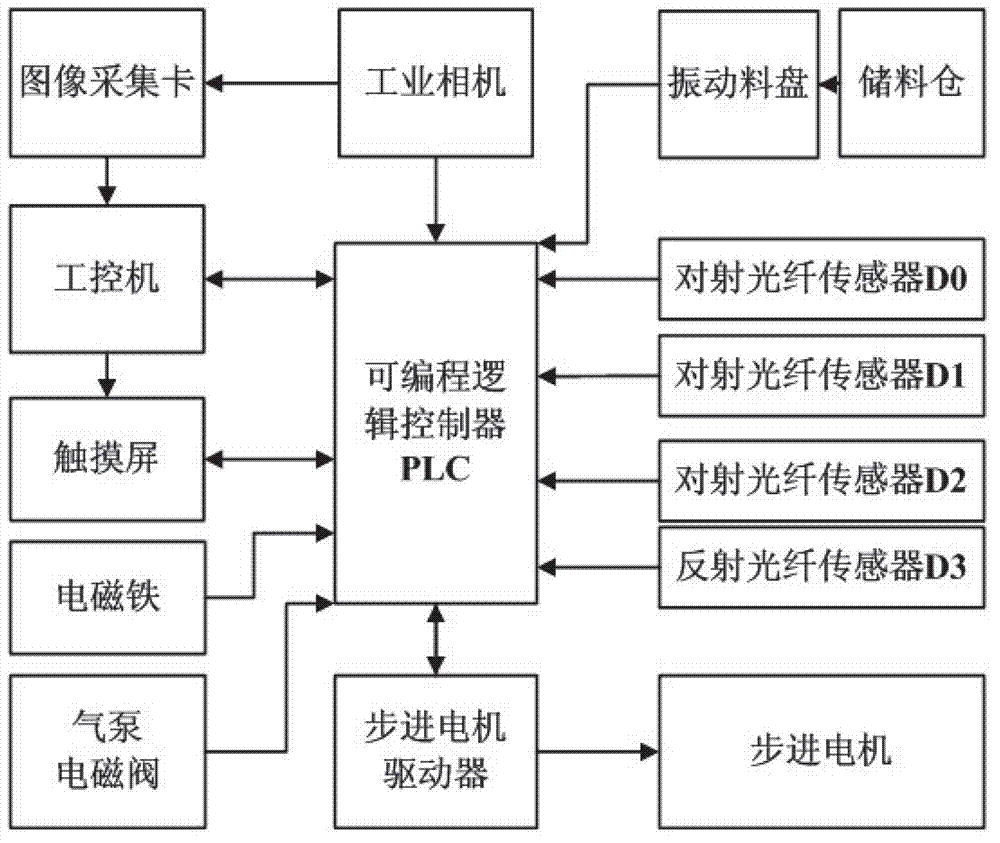

Machine vision automatic detection system for rivets

InactiveCN102829726AImprove the level ofReduce manual inspection costsUsing optical meansSortingVisual perceptionElectromagnetic valve

The invention discloses a machine vision automatic detection system for rivets. The machine vision automatic detection system for rivets comprises a PLC (programmable logic controller), two industrial cameras, a storage bin, a vibration feed plate, a linear rail, a mechanical rotary plate, a waste product blowing pipe, a waste product discharging trough, a salable product blowing pipe, a salable product discharging trough, discharging baffles, an image acquisition card, an industrial personal computer, a touch screen, an electromagnet, a pneumatic electromagnetic valve, an upper sensor, a lower sensor, a hole sensor, a count sensor, a stepping motor drive and a stepping motor. The detection precision of the machine vision automatic detection system for rivets is within + / -0.03mm, and the electromagnetic valve is controlled by the PLC to complete precise waste product blowing and realize separation of salable products from waste products. The final number of the salable products is accurately recorded by a counter, and a discharging port is closed according to time difference to prepare for a subsequent packaging procedure. In addition, all data are recorded in a database, and various production, client, analysis and CPK (complex processing capability index) report forms can be generated by one key.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com