Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3105 results about "Scrubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scrubber systems (e.g. chemical scrubbers, gas scrubbers) are a diverse group of air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams. The first air scrubber was designed to remove carbon dioxide from the air of an early submarine, the Ictineo I, a role for which they continue to be used today. Traditionally, the term "scrubber" has referred to pollution control devices that use liquid to wash unwanted pollutants from a gas stream. Recently, the term has also been used to describe systems that inject a dry reagent or slurry into a dirty exhaust stream to "wash out" acid gases. Scrubbers are one of the primary devices that control gaseous emissions, especially acid gases. Scrubbers can also be used for heat recovery from hot gases by flue-gas condensation. They are also used for the high flows in solar, PV, or LED processes.

Removal of carbon dioxide from air

InactiveUS20060051274A1Simple processReduce energy consumptionSemi-permeable membranesHydrogen sulfidesSolventCarbon dioxide binding

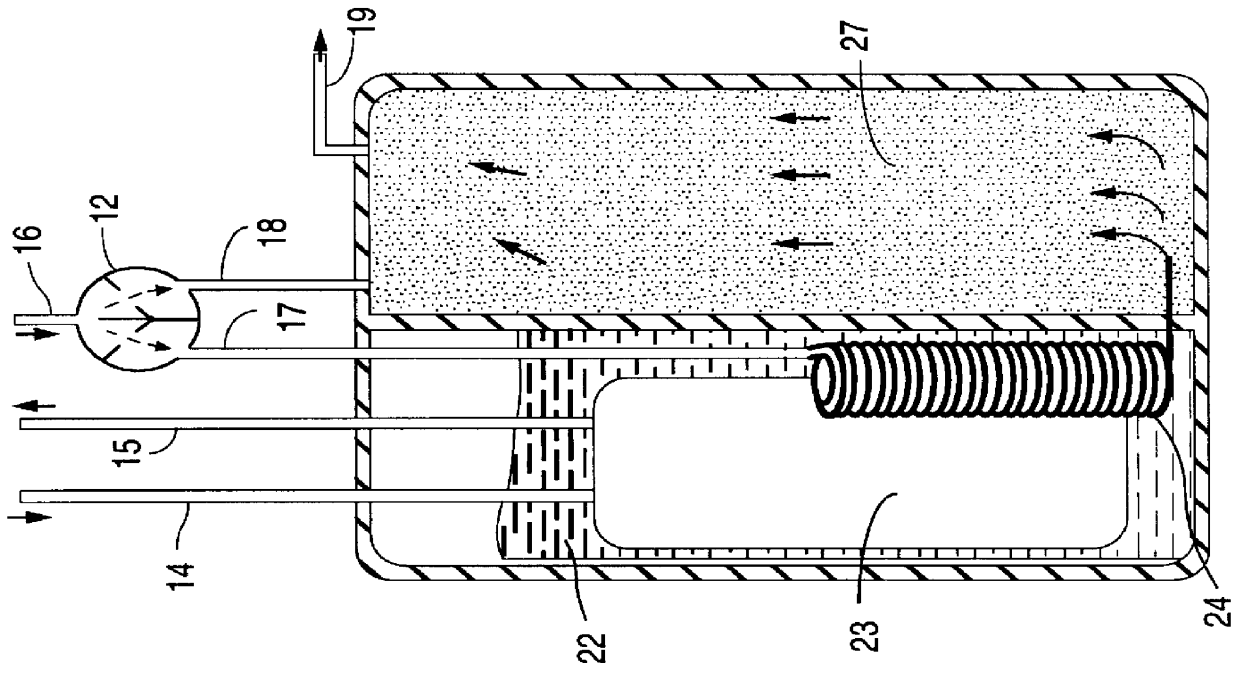

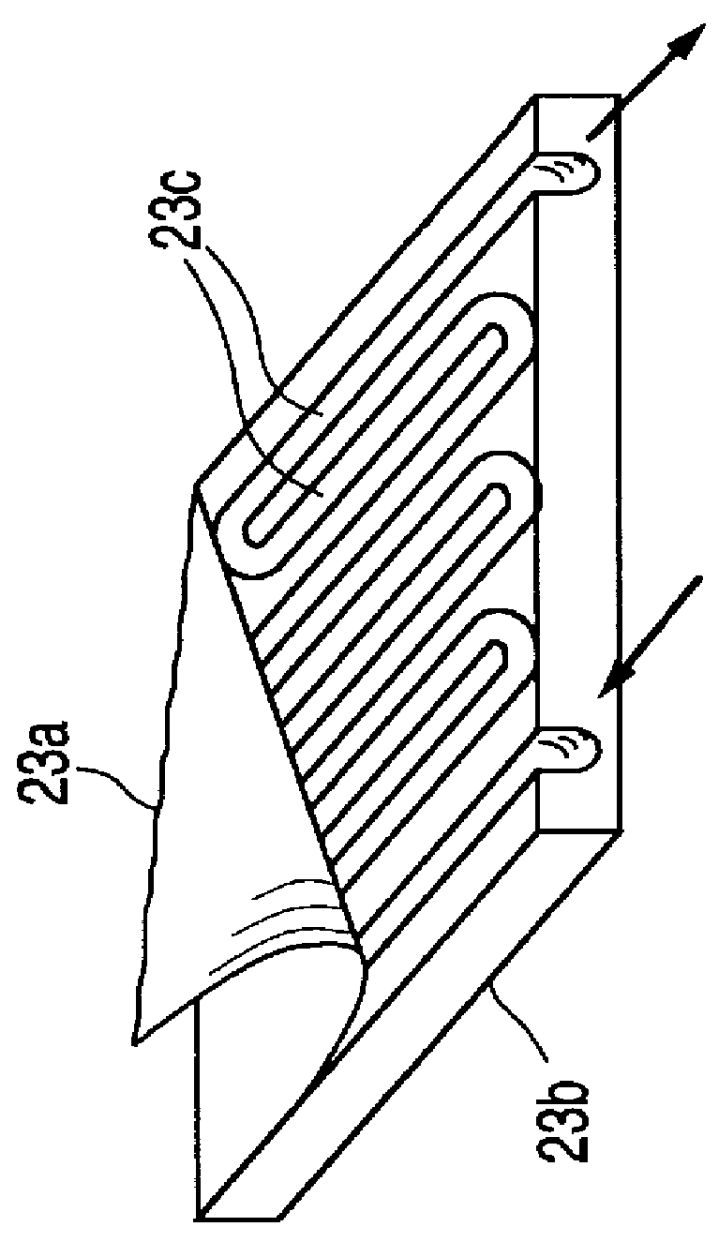

The present invention is directed to methods for removing carbon dioxide from air, which comprises exposing solvent covered surfaces to air streams where the airflow is kept laminar, or close to the laminar regime. The invention also provides for an apparatus, which is a laminar scrubber, comprising solvent covered surfaces situated such that they can be exposed to air stream. In another aspect, the invention provides a method and apparatus for separating carbon dioxide (CO2) bound in a solvent. The invention is particularly useful in processing hydroxide solvents containing CO2 captured from air.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK +2

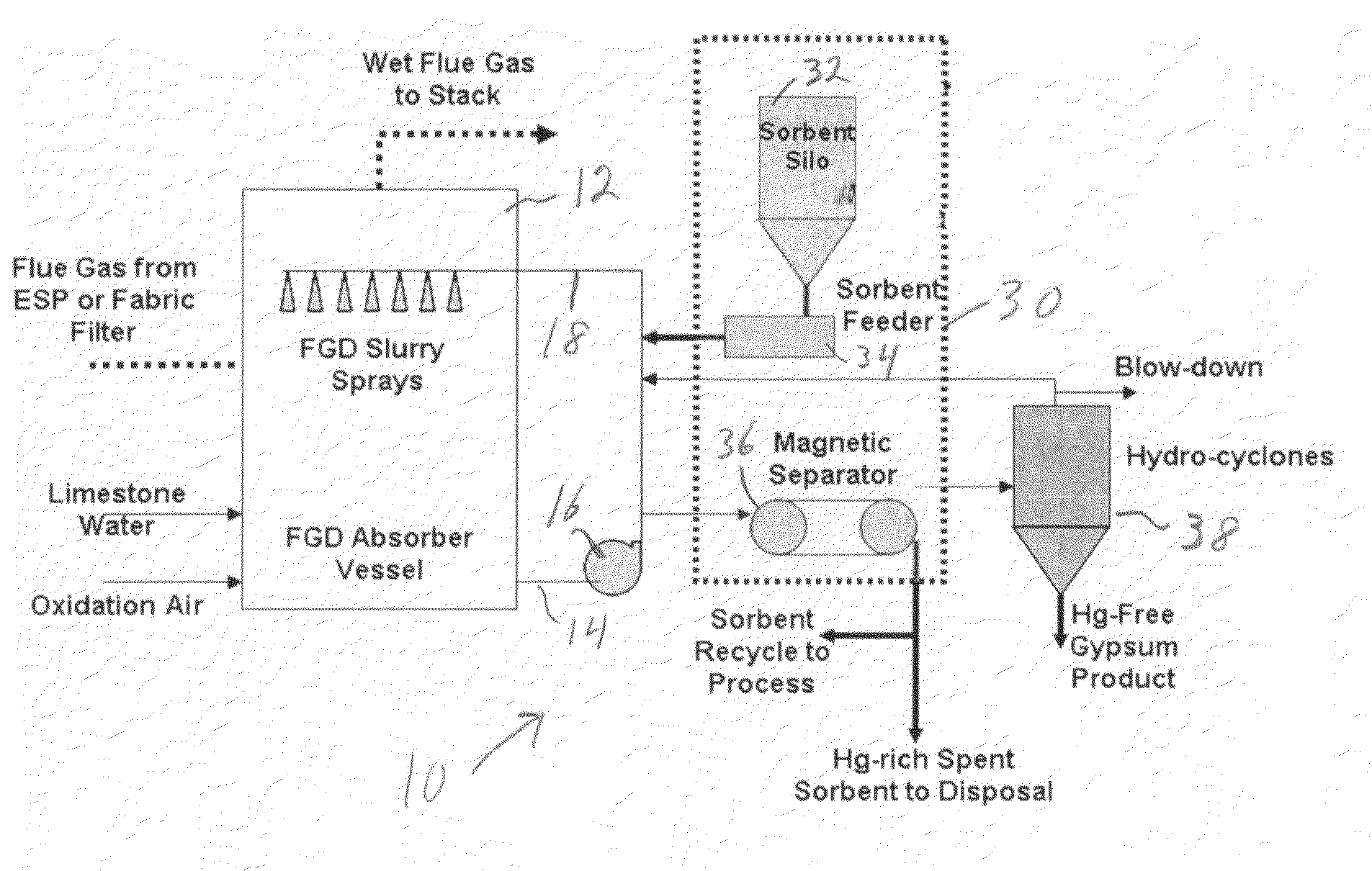

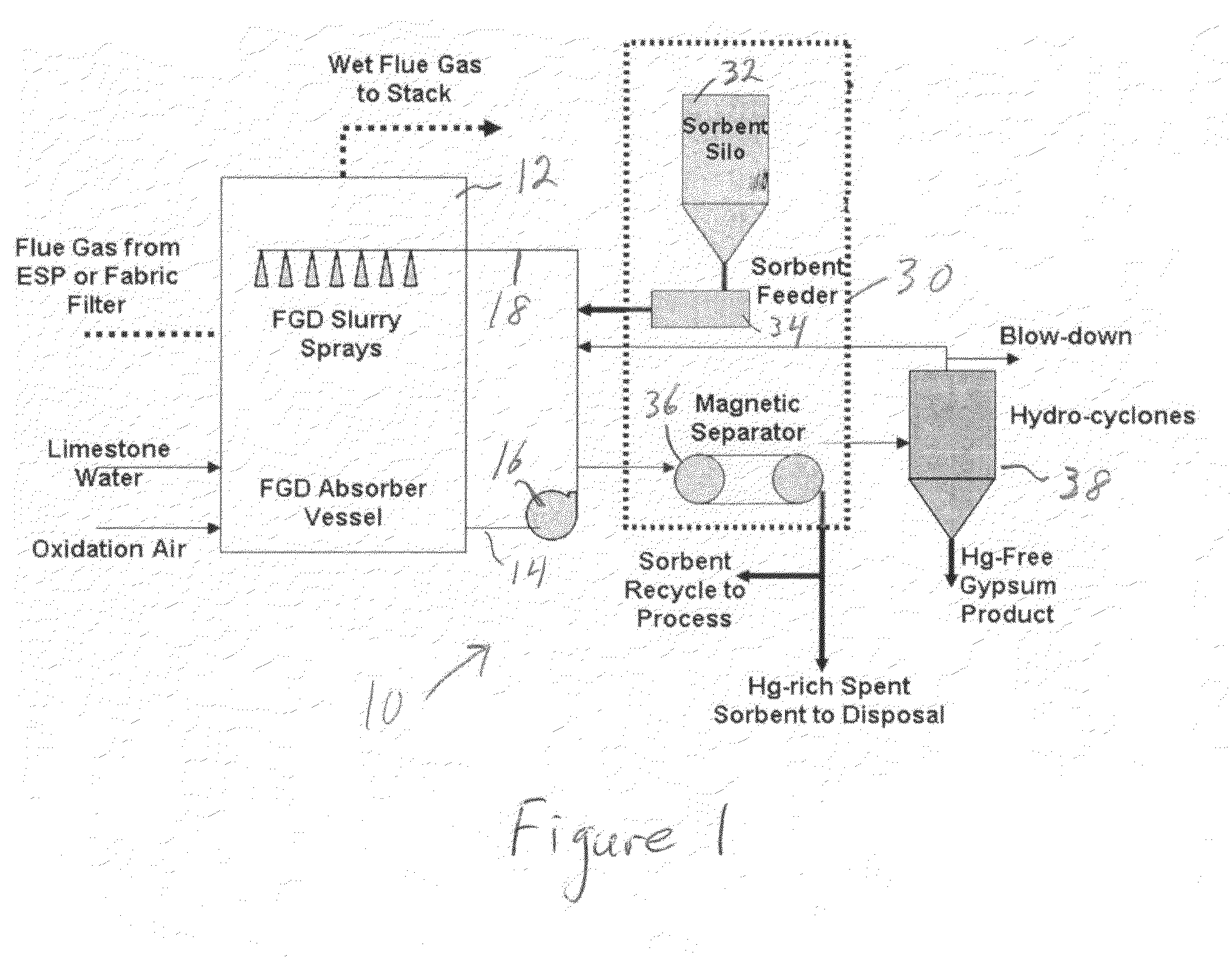

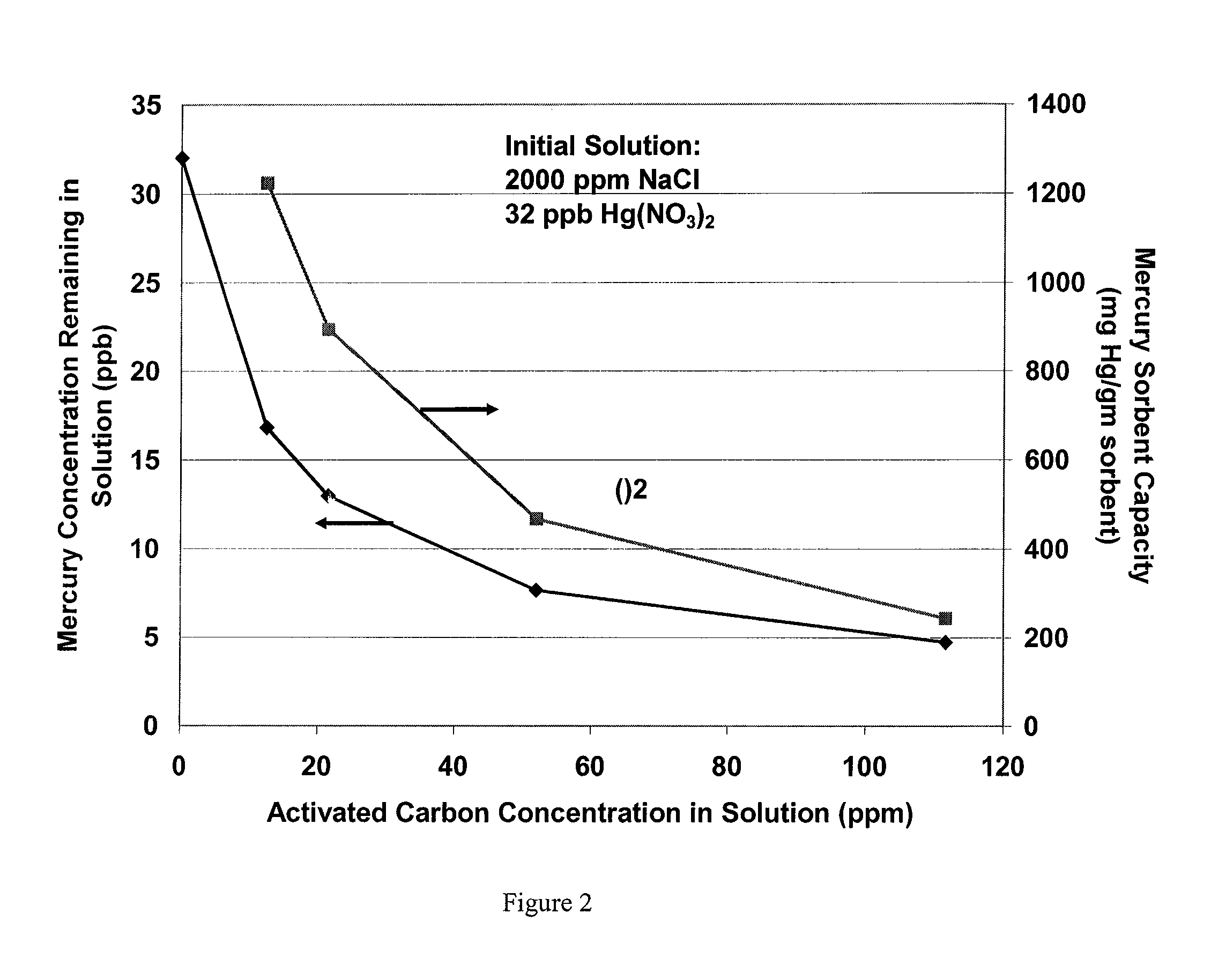

System and method for sequestration and separation of mercury in combustion exhaust gas aqueous scrubber systems

ActiveUS7722843B1Emission reductionMinimize re-emissionCombination devicesExhaust apparatusCombustionSorbent

A process, system and sorbent for removal of mercury from a combustion exhaust gas stream in a combustion exhaust gas purification scheme that includes a combustion exhaust scrubber system that uses an aqueous liquid to remove acid gases from the combustion exhaust gas. A powdered mercury sorbent is used. The sorbent is introduced into the aqueous scrubber liquid in the scrubber system. After introduction of the mercury sorbent into the scrubber liquid, at least some of the mercury sorbent is separated from the scrubber liquid.

Owner:SRINIVASACHAR SRIVATS

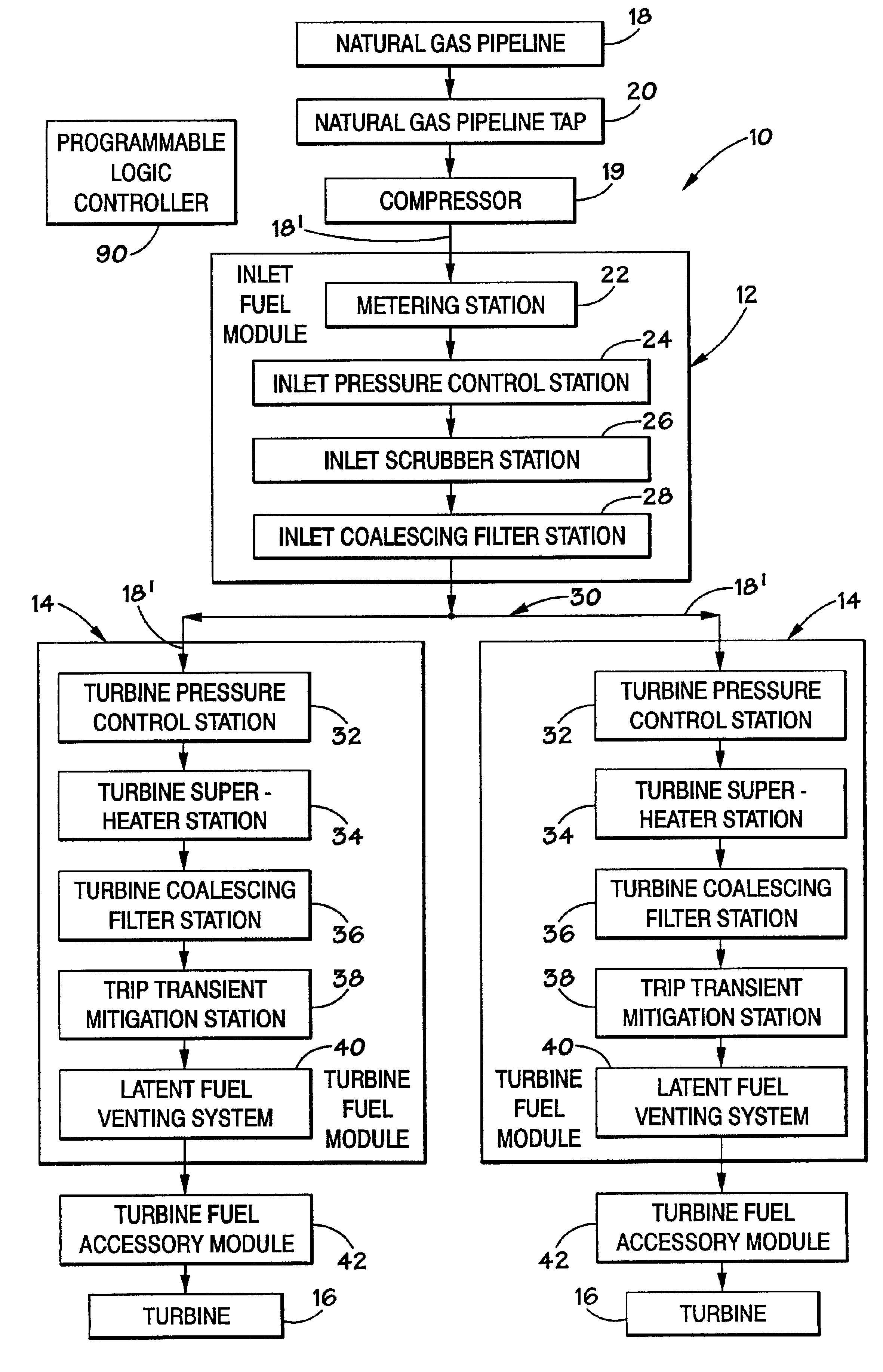

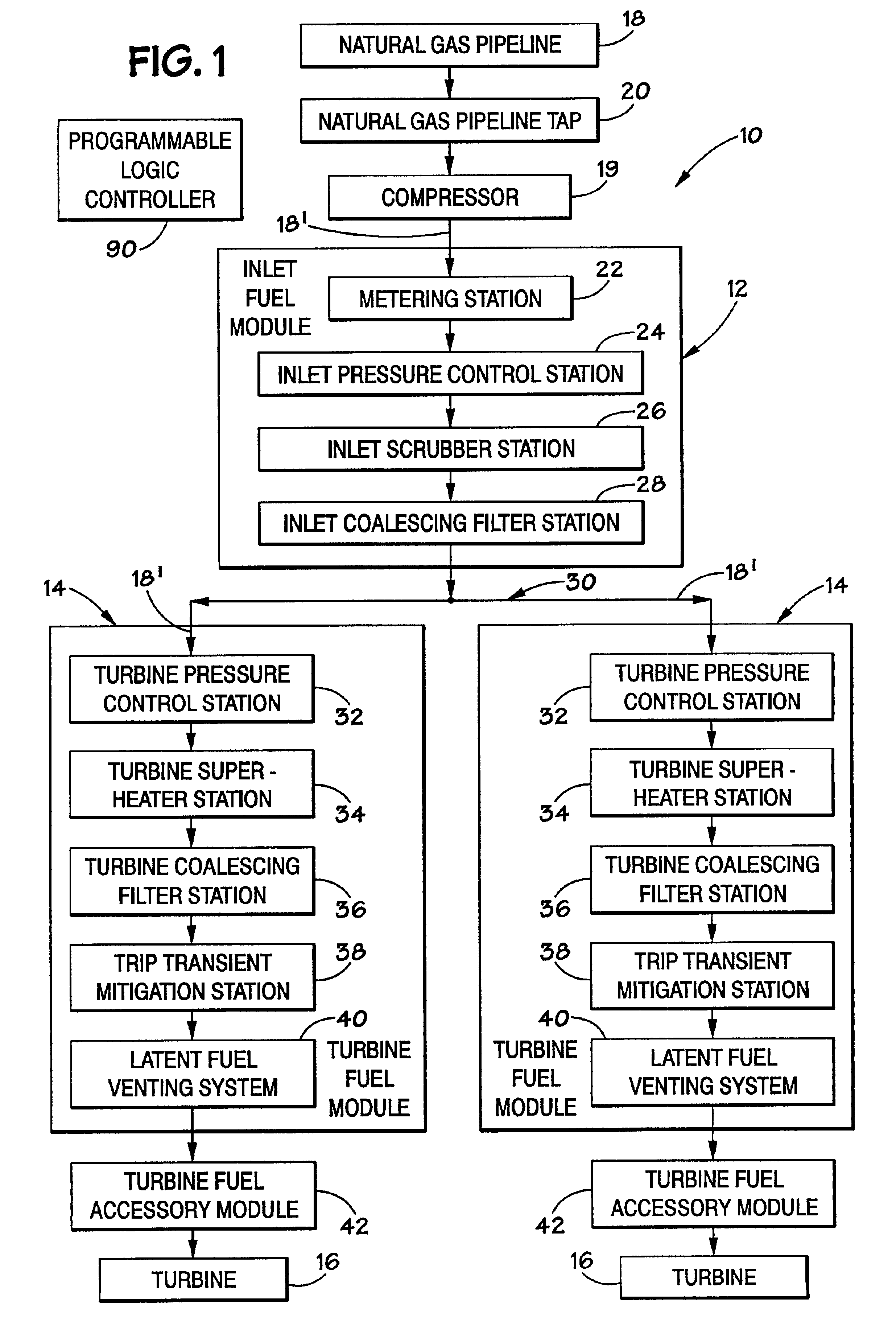

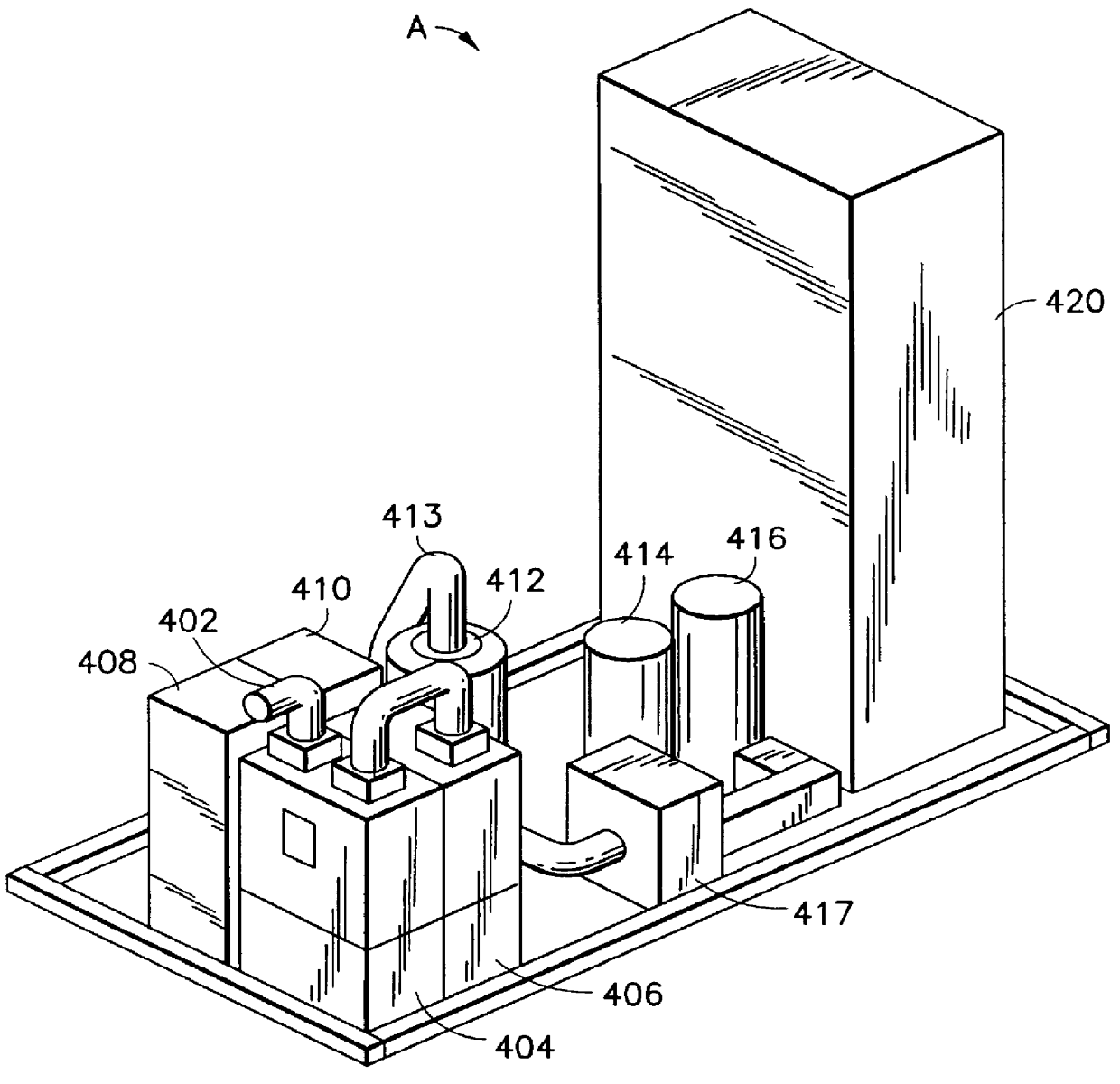

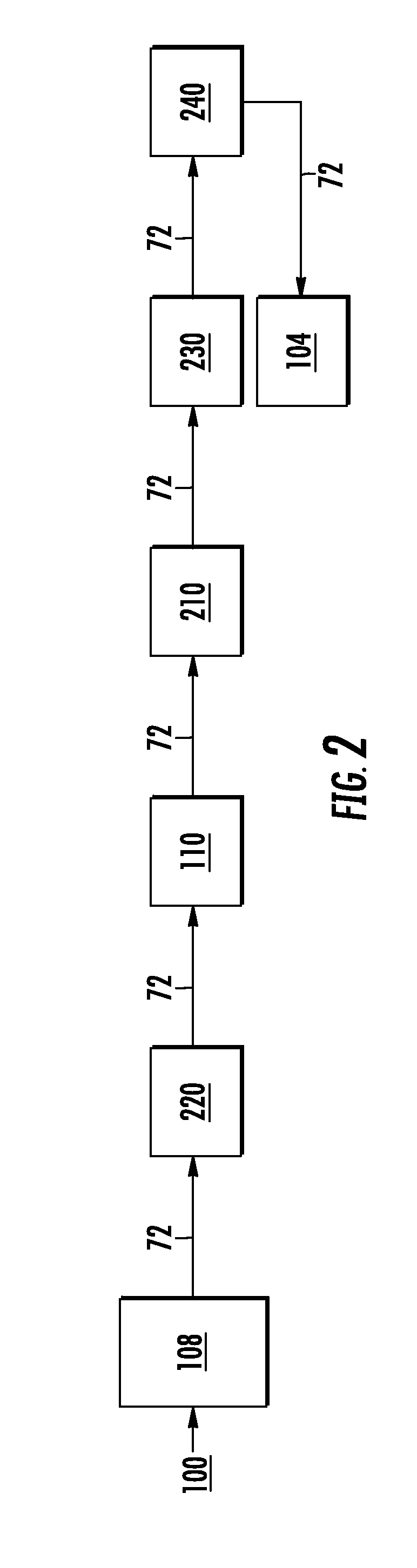

Modular fuel conditioning system

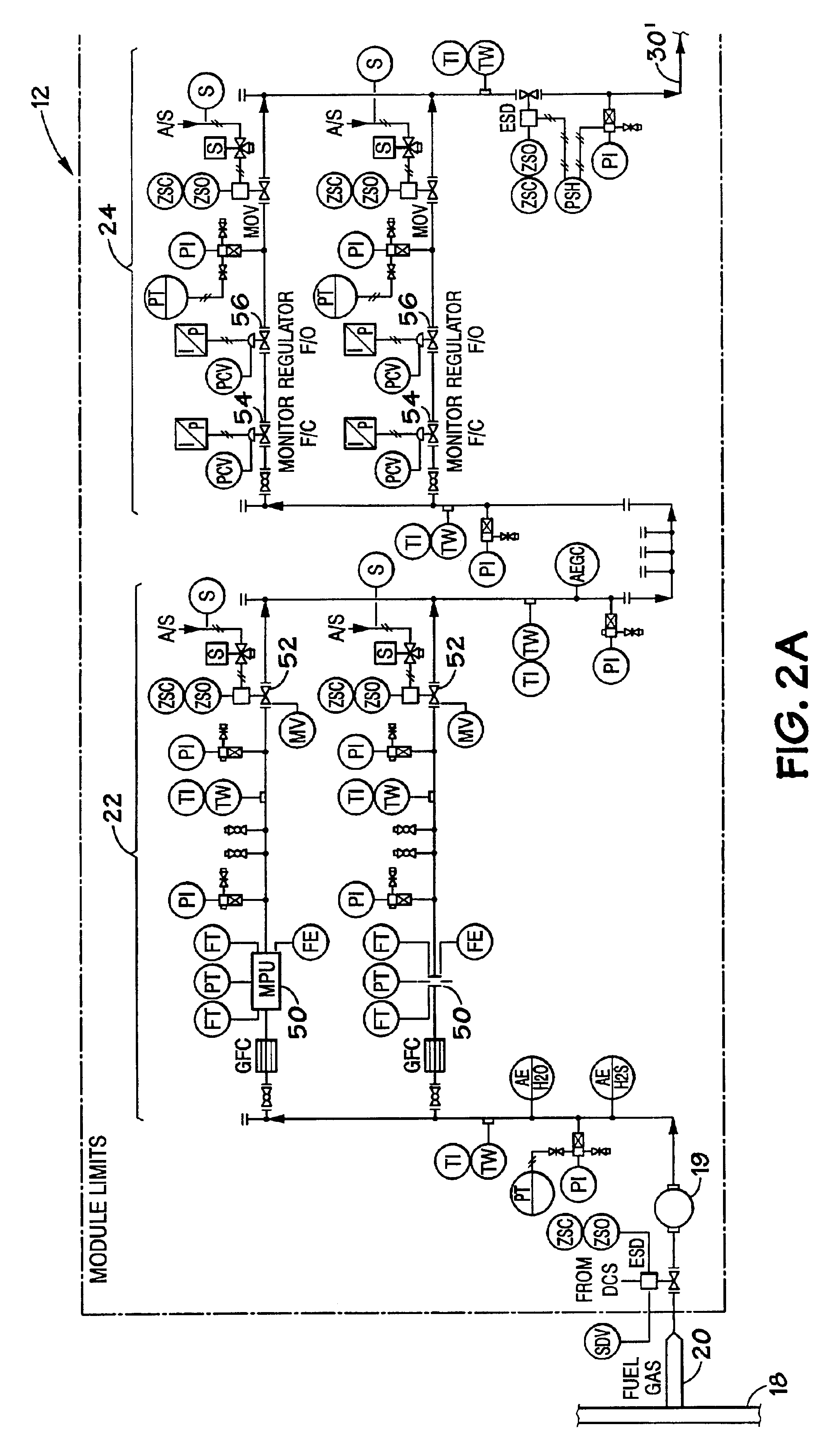

InactiveUS6901735B2Reduce pressureControl moreGas turbine plantsTurbine/propulsion fuel heatingProgrammable logic controllerModularity

A fuel conditioning system for a turbine plant may include an inlet fuel module followed by a turbine fuel module for each turbine, the modules being monitored and controlled by a programmable logic controller. The inlet fuel module may include a metering station, an inlet pressure control station, an inlet scrubber station, and an inlet coalescing filter station. Each turbine fuel module has a turbine pressure control station, a turbine super-heater station, and a turbine coalescing filter station. The fuel conditioning system may also include a trip transient mitigation system and a latent fuel venting system. The programmable logic controller collects data from all of the stations and systems as well as the turbine and then uses self-correcting algorithms to control the stations and systems. The programmable logic controller also stores the data collected and transmits the data to an off-site storage and verification center.

Owner:PIPELINE CONTROLS

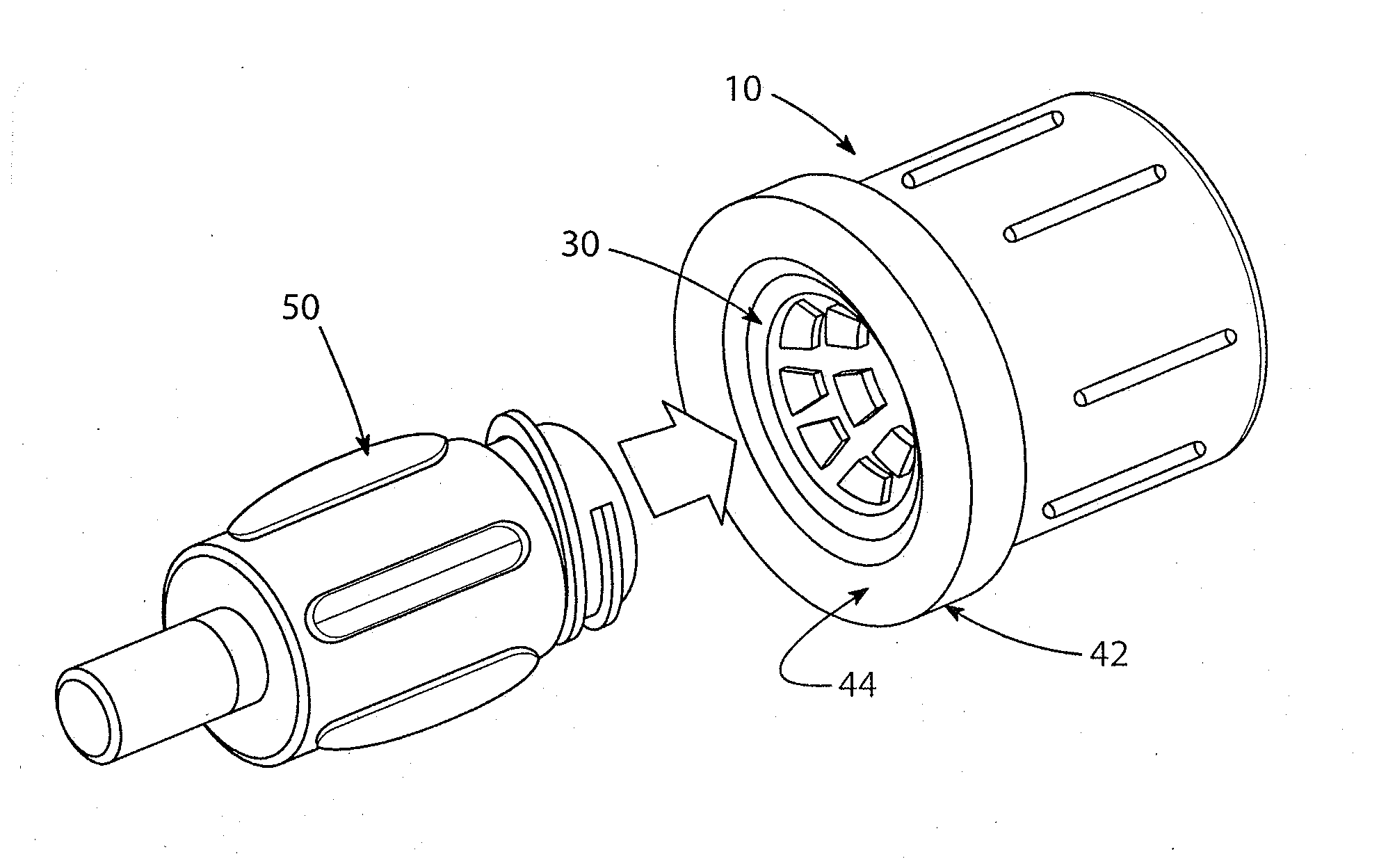

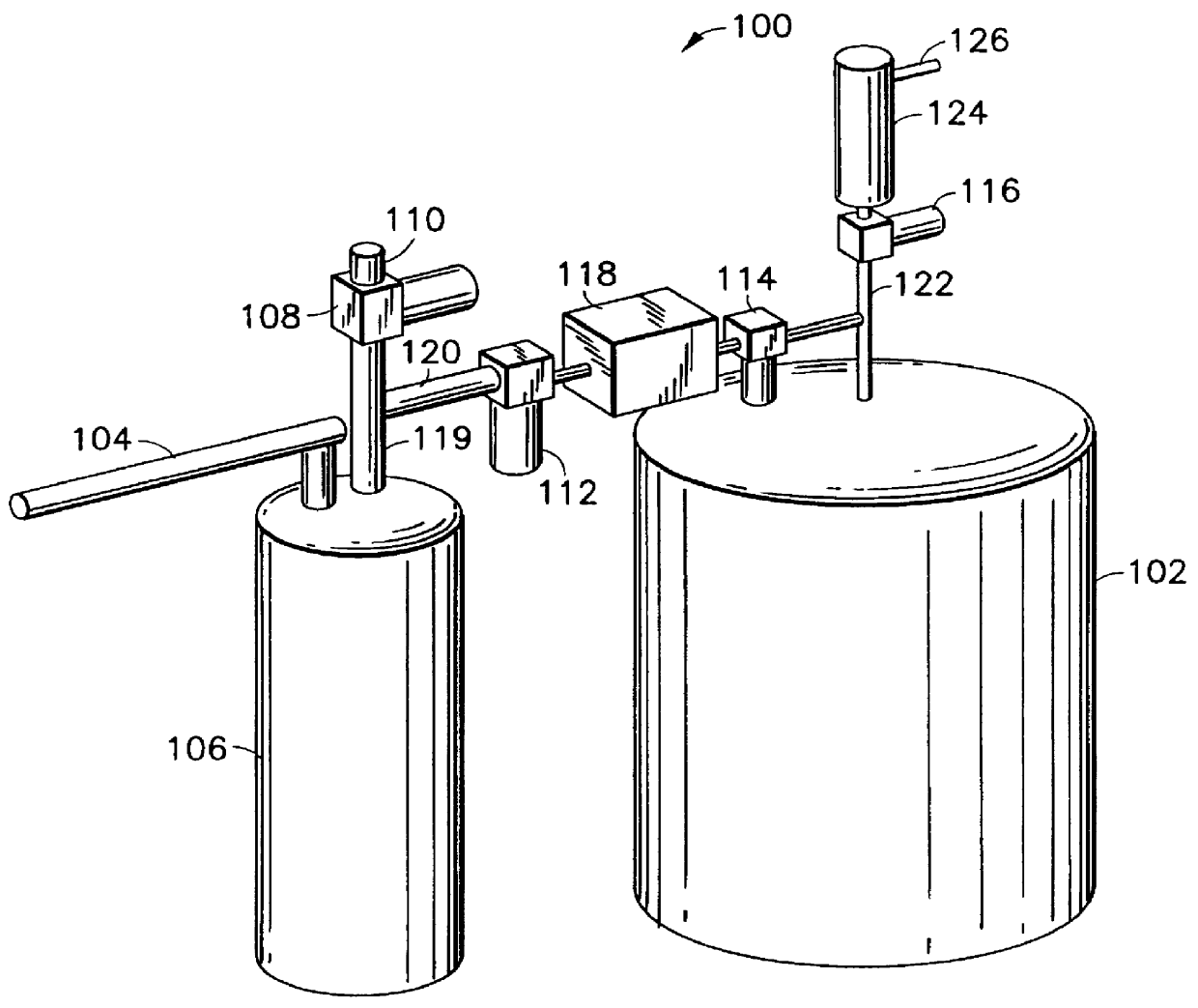

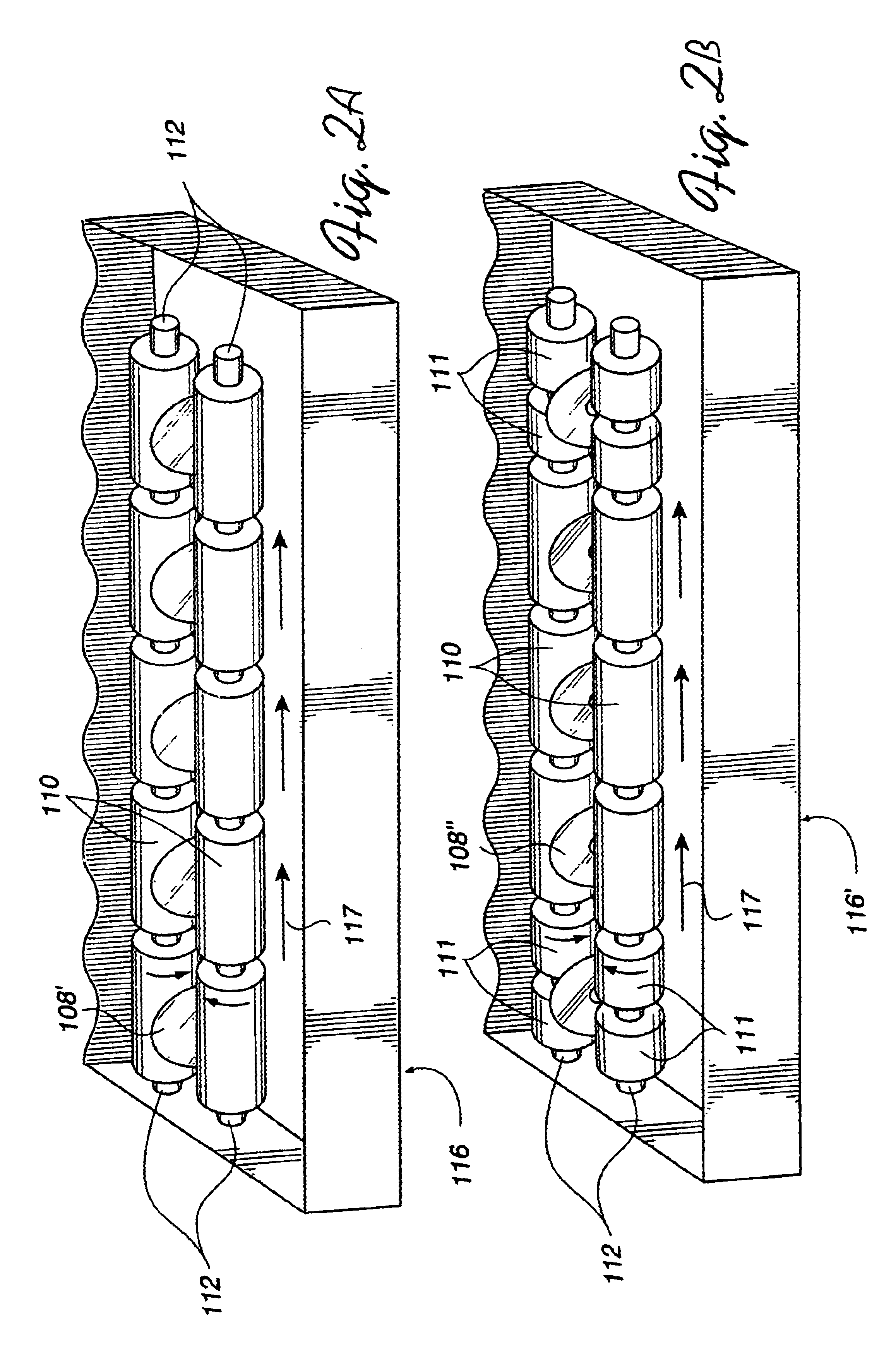

Luer Cleaner with Self-Puncturing Reservoir

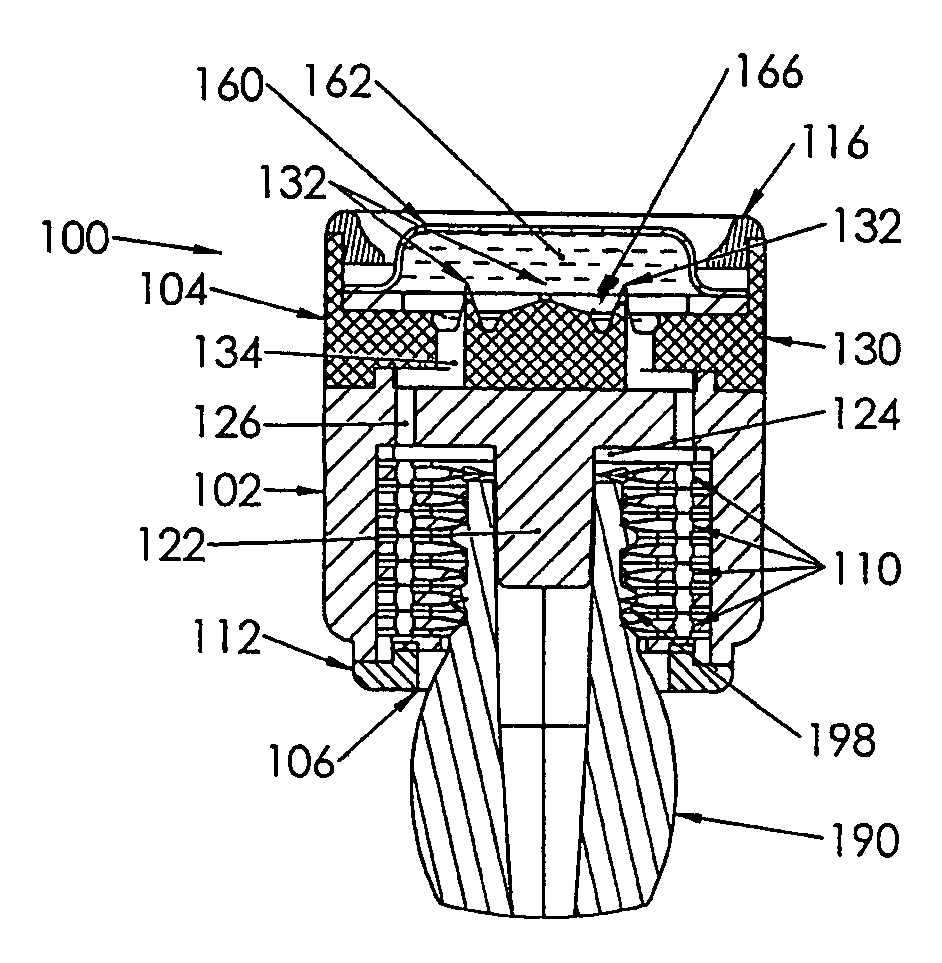

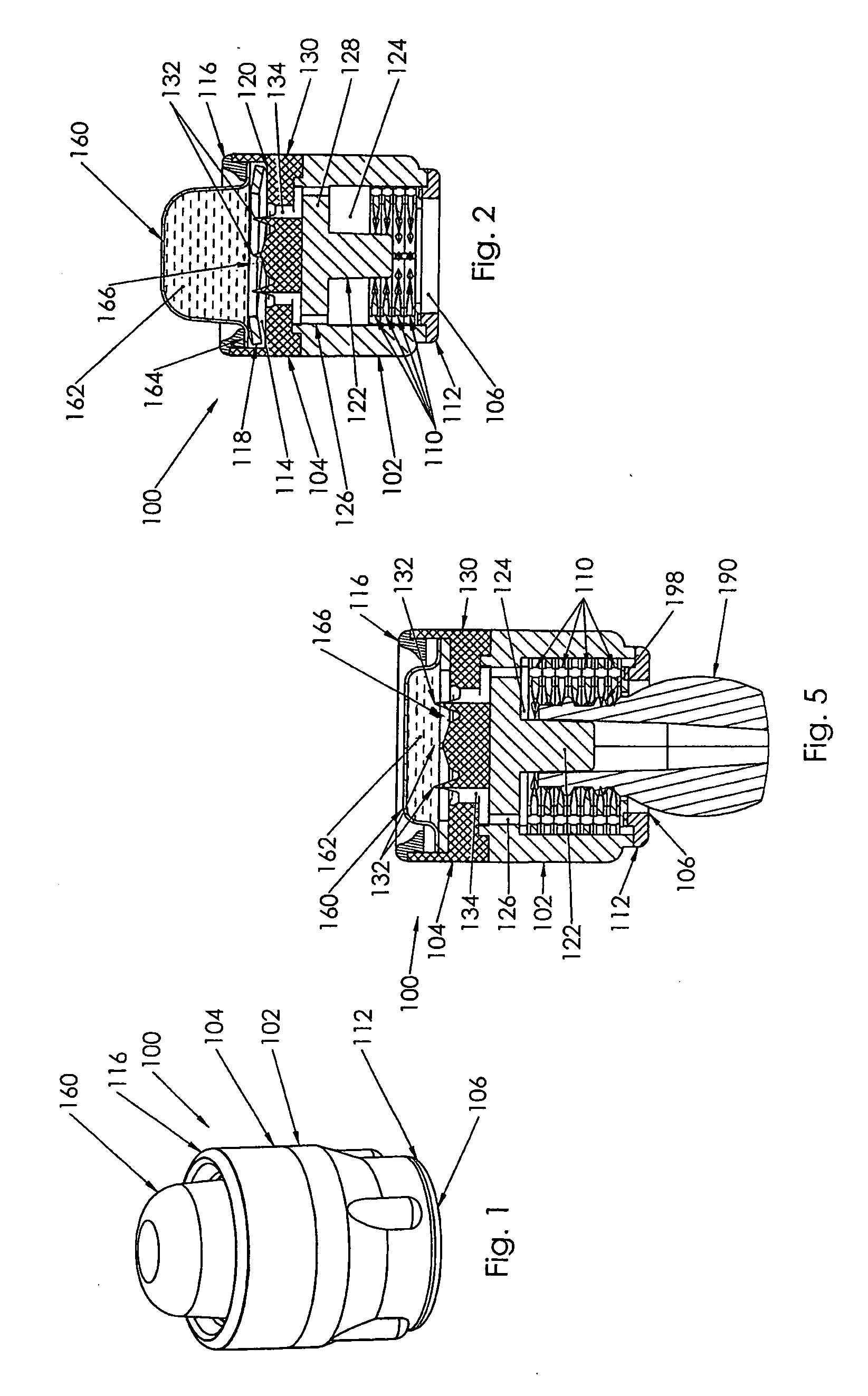

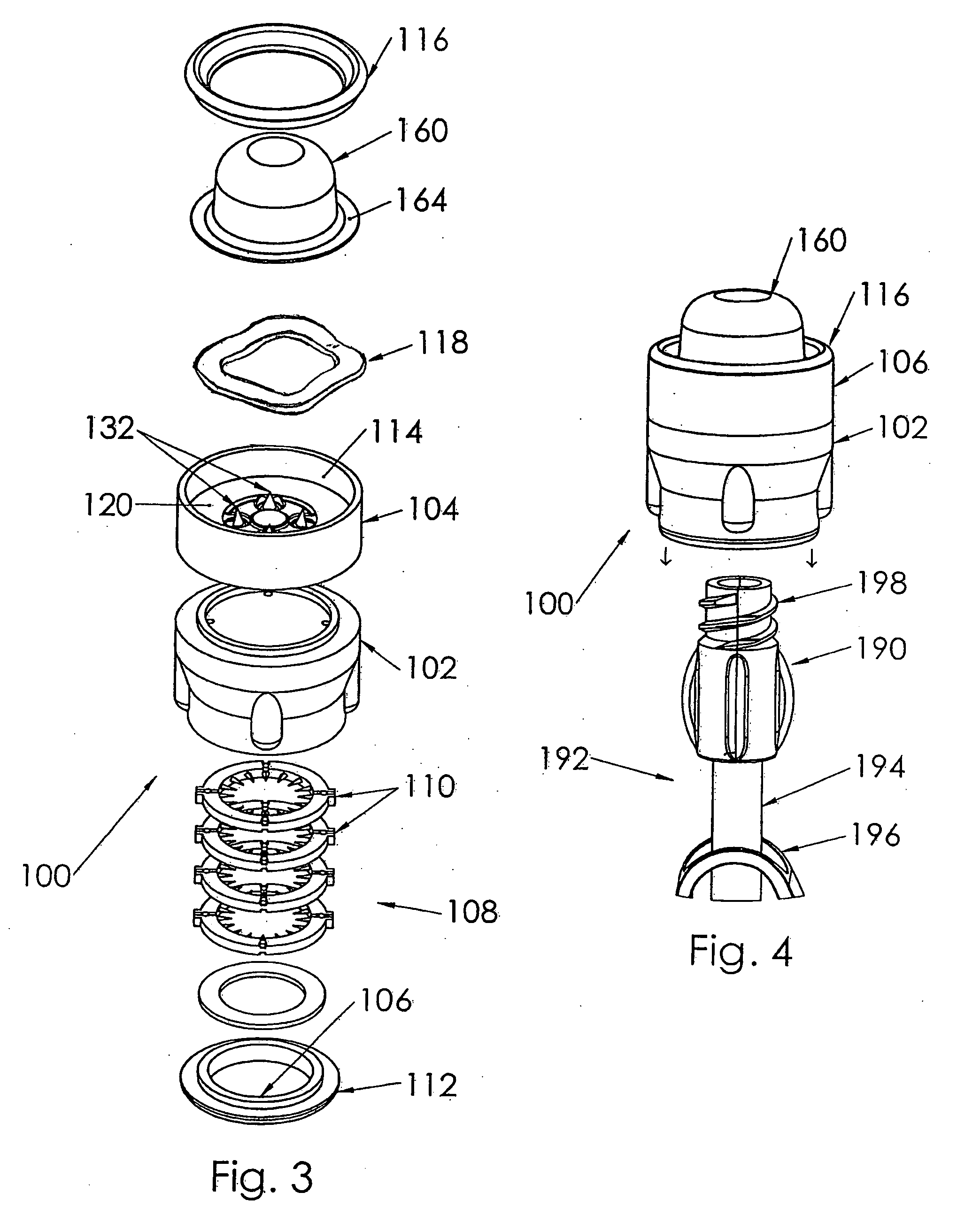

A luer cleaner assembly (100) for cleaning luer fittings (190) secured to proximal ends of medical tubing. The luer cleaner (100) includes a luer-receiving cavity (124) within which are contained scrubbers (110) that scrub exposed outer surfaces of a luer fitting inserted thereinto through an open distal end (106) of the luer cleaner housing (102). The luer cleaner includes at a proximal end a fluid reservoir (160) containing a cleaning fluid (162) such as isopropyl alcohol. The assembly further includes a reservoir-penetrating array of sharp pointed projections (132), such that during luer cleaning the reservoir (160) is pressed distally toward the luer fitting in the cavity for the array of projections to penetrate a distal cover (166) of the reservoir to access the cleaning fluid (162) which then flows distally through passageways (134,126) into the luer-receiving cavity and onto the scrubbers (110) and the outer surfaces of the luer fitting (190).

Owner:MEDICAL COMPONENTS INC

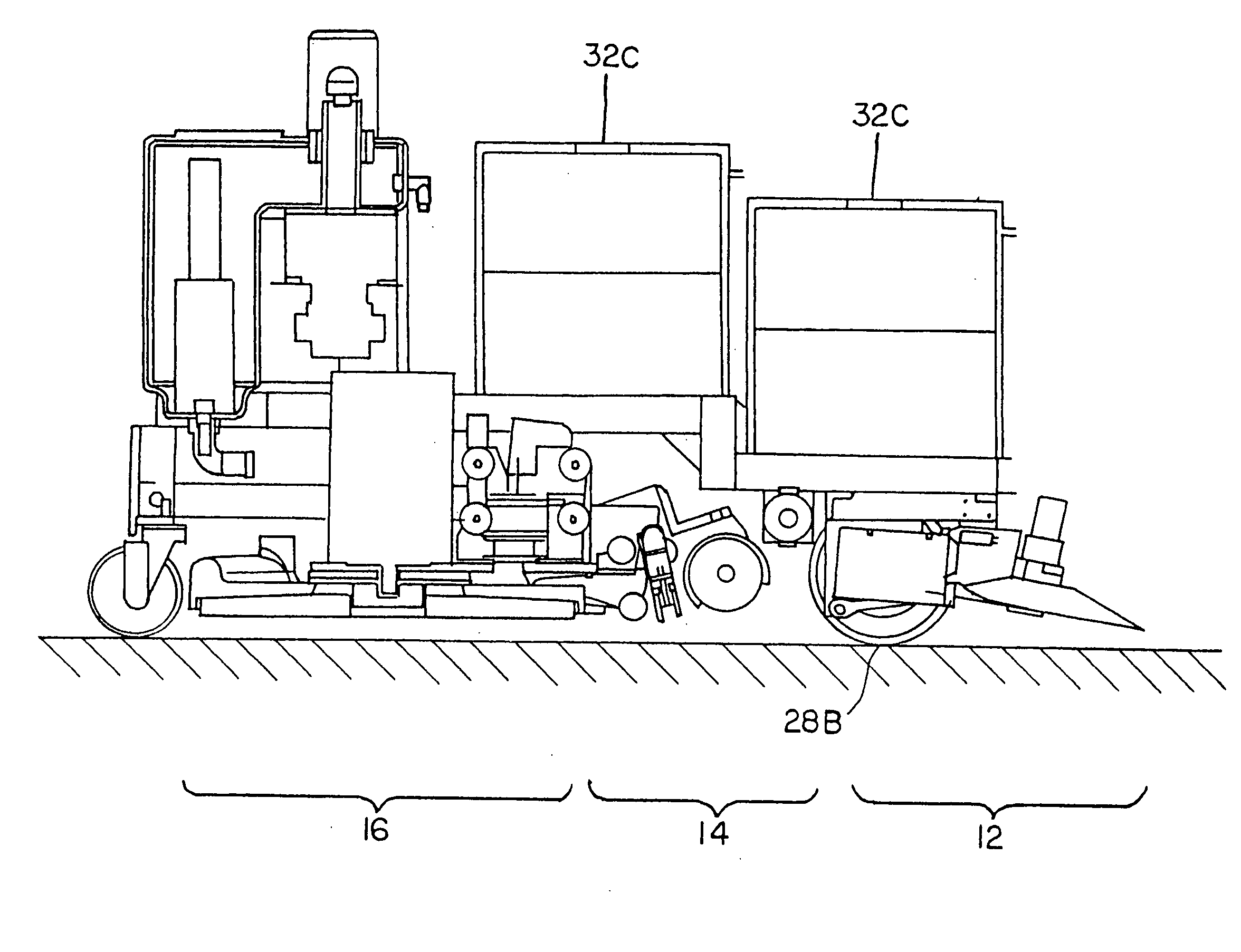

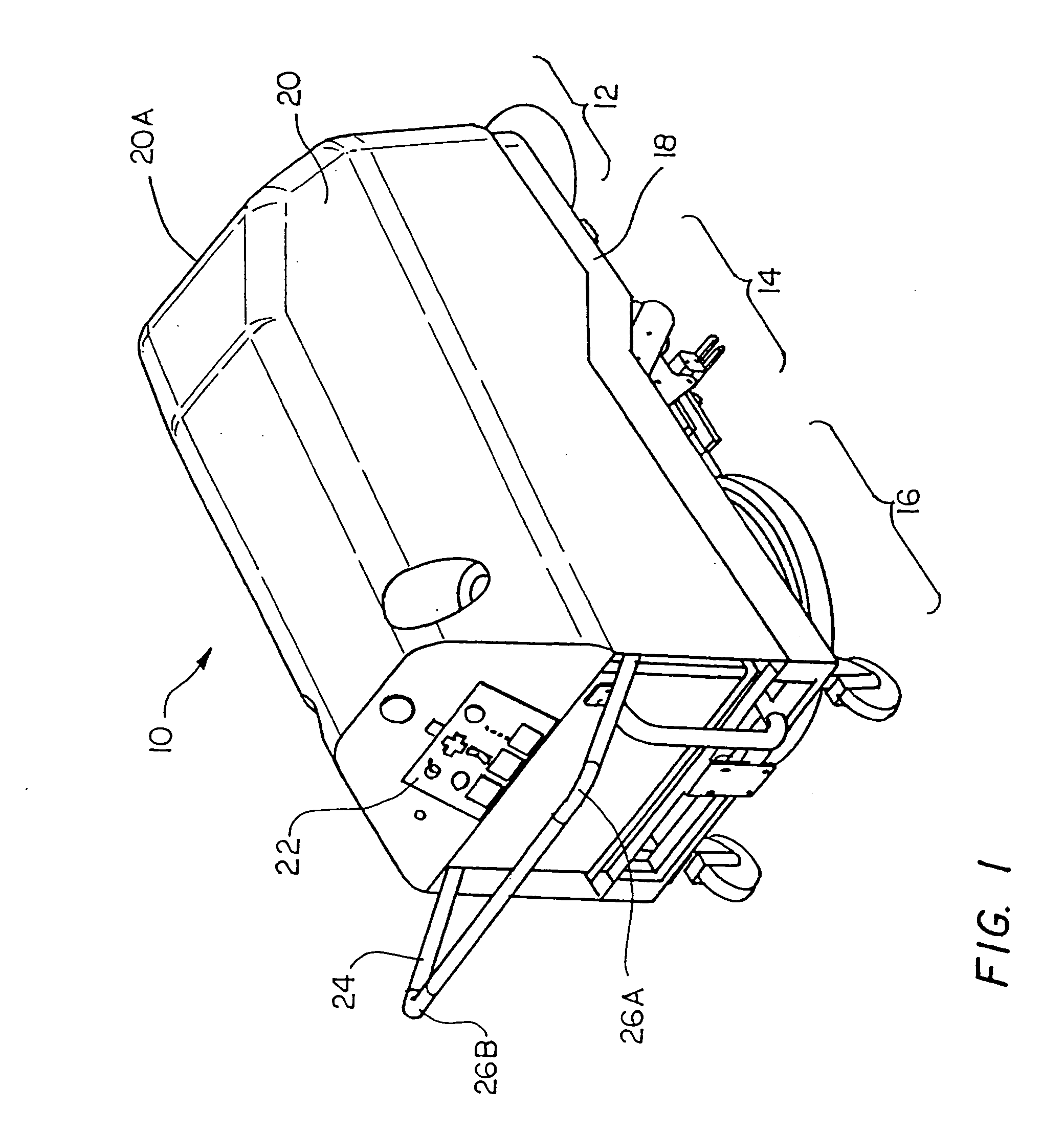

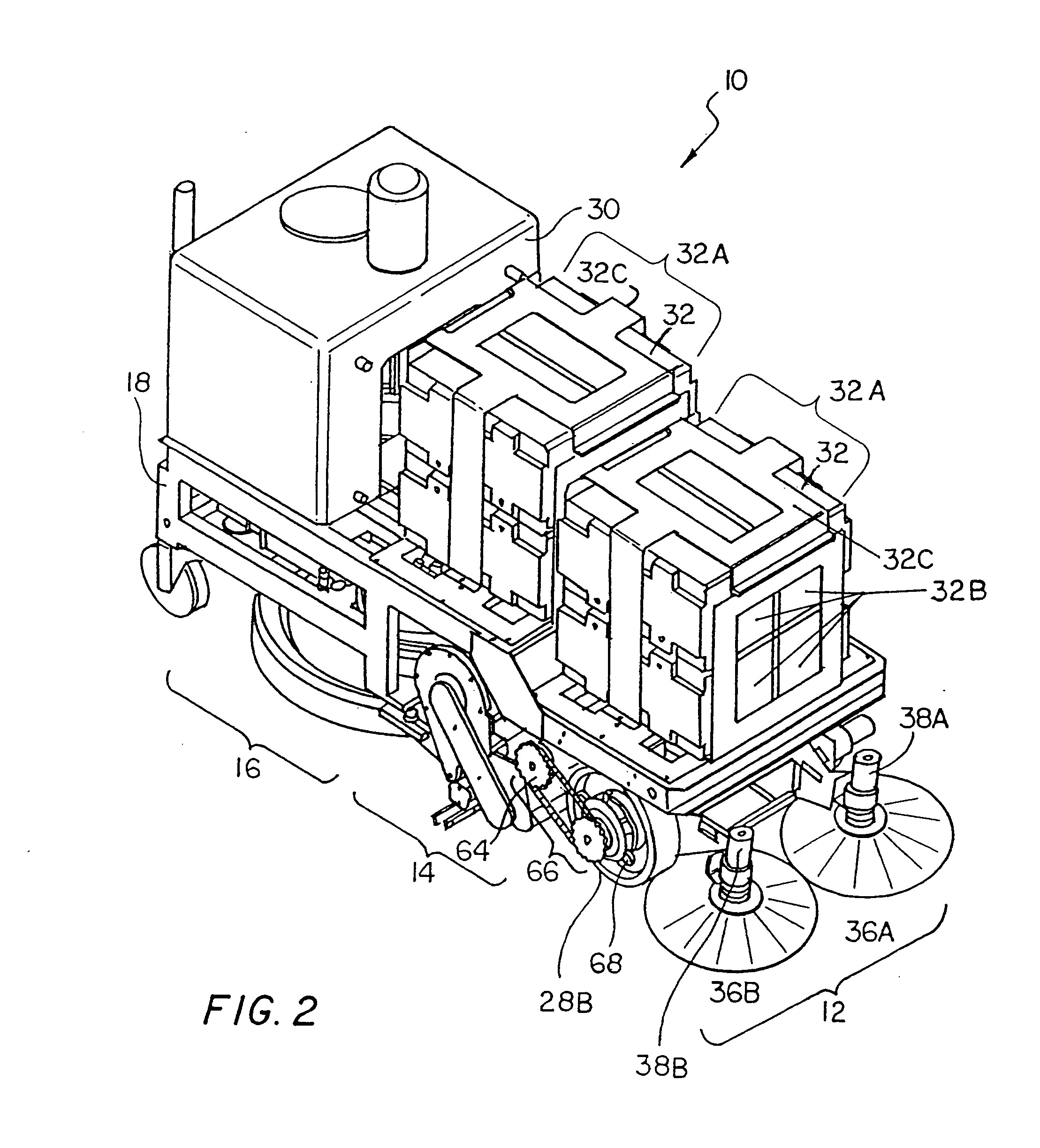

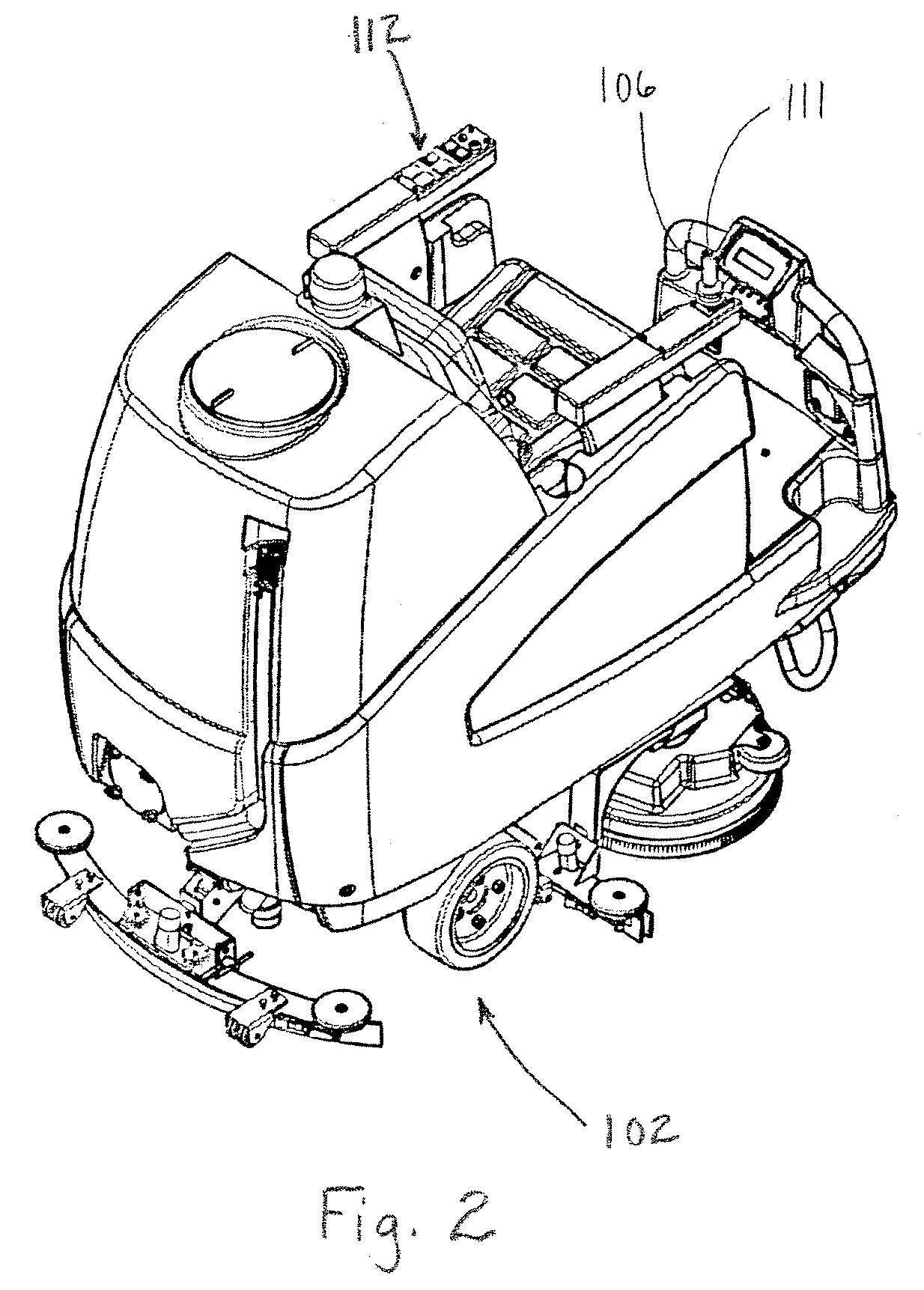

Floor cleaning apparatus with control circuitry

InactiveUS20050028316A1Easy to operateImprove performanceLiquid processingBrush bodiesEngineeringControl circuit

A floor cleaner is provided for cleaning a floor, where the floor cleaner has a front and a rear and includes: a sweeper for sweeping the floor; a scrubber, connected to the sweeper and located in the rear of the sweeper, for wetting and cleaning the floor; and a burnisher, connected to the scrubber and located in the rear of the scrubber, for burnishing the floor.

Owner:JOHNSONDIVERSEY INC

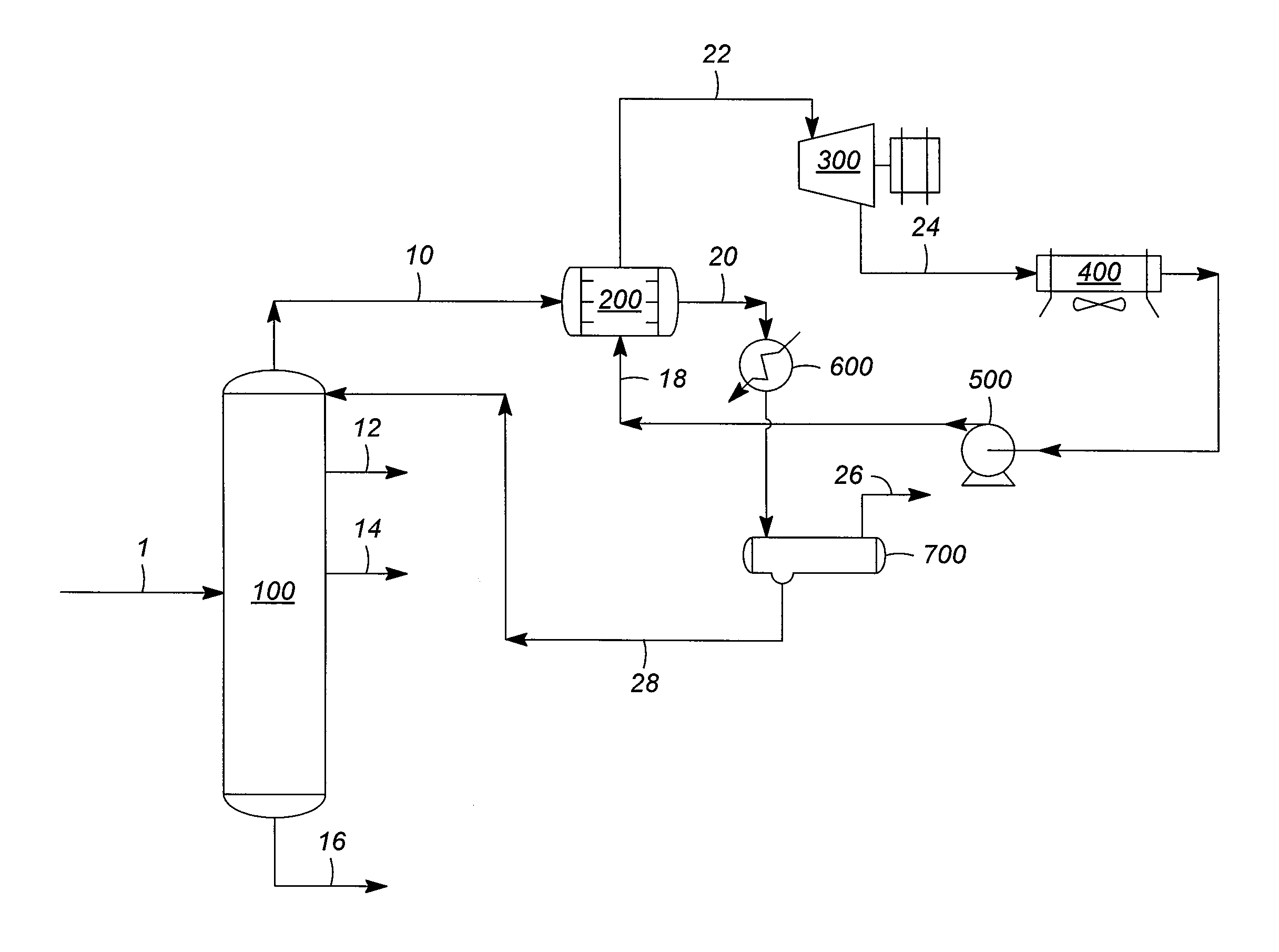

Low Grade Heat Recovery from Process Streams for Power Generation

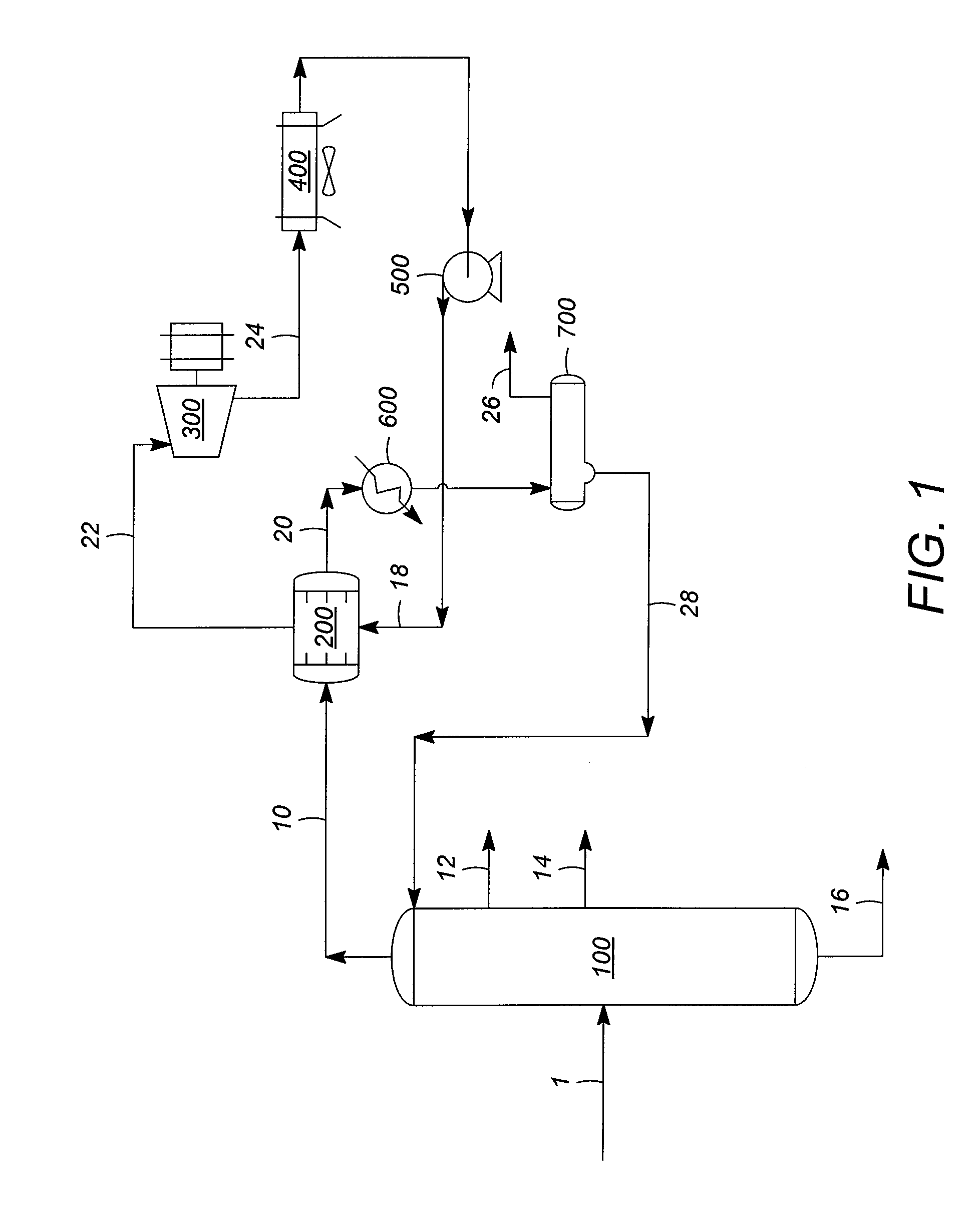

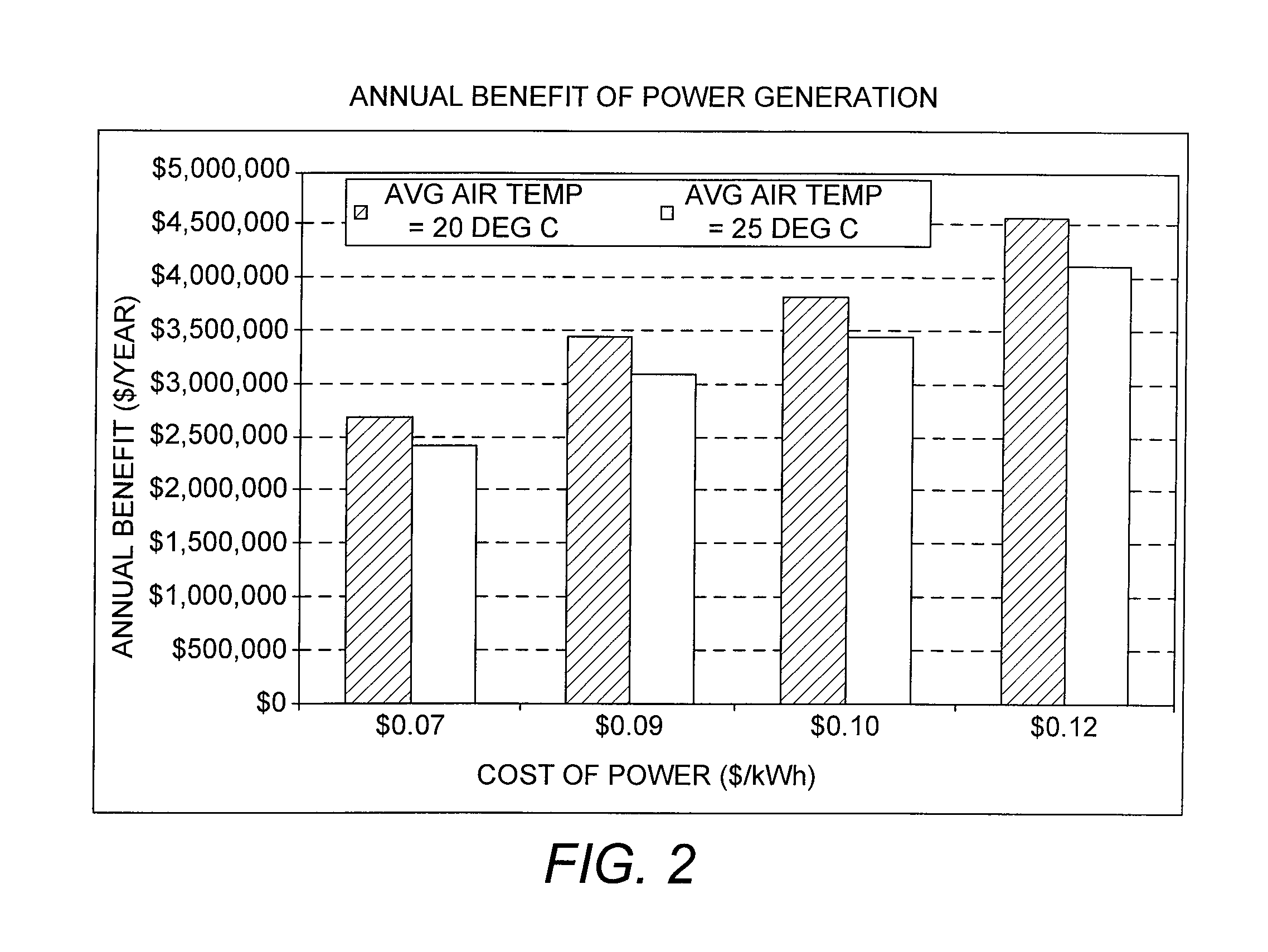

InactiveUS20120031096A1Improve efficiencyImproves flexibility in designFeed water supplySteam engine plantsVapor liquidWorking fluid

Methods are described for generating electrical power from low grade heat sources from refining and petrochemical processes, including overhead vapors from vapor-liquid contacting apparatuses such as distillation columns, absorbers, strippers, quenching towers, scrubbers, etc. In many cases, these overhead vapors exit the apparatuses at a temperature from about 90° C. (194° F.) to about 175° C. (347° F.). Rather than rejecting the low temperature heat contained in these vapors to cooling air and / or cooling water, the vapors may instead be used to evaporate an organic working fluid. The vapors of the working fluid may then be sent to a turbine to drive a generator or other load.

Owner:UOP LLC

Acid gas scrubbing apparatus and method

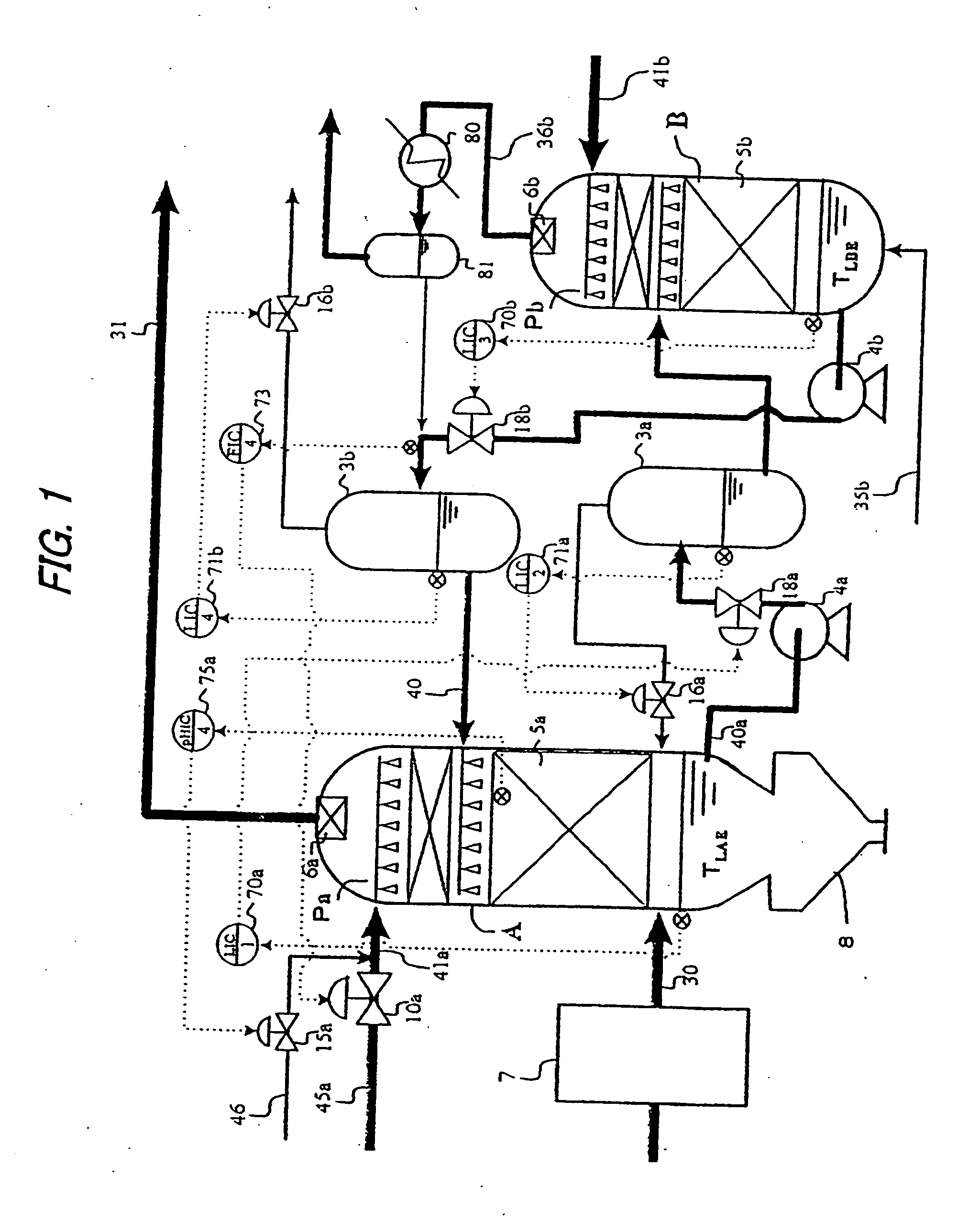

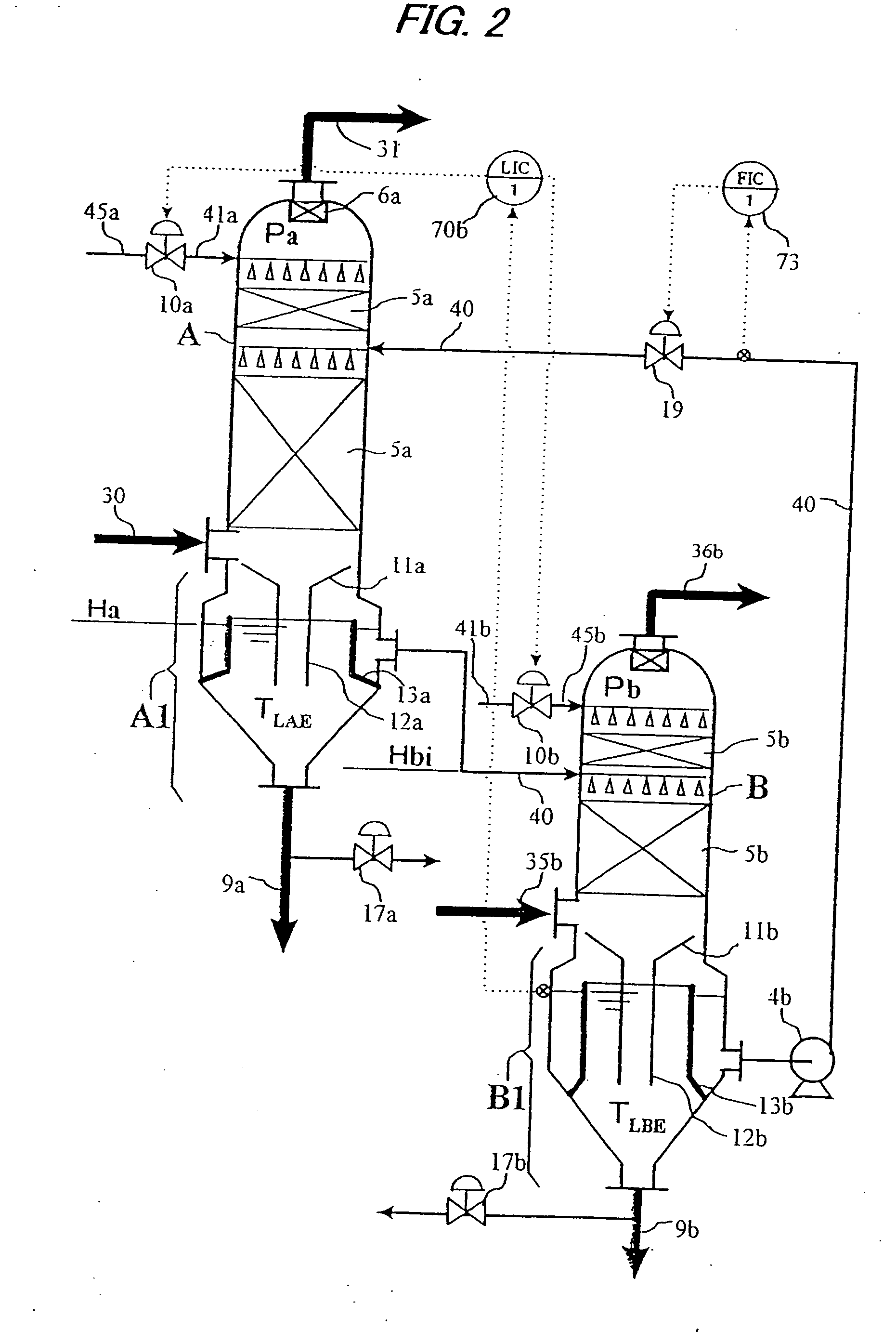

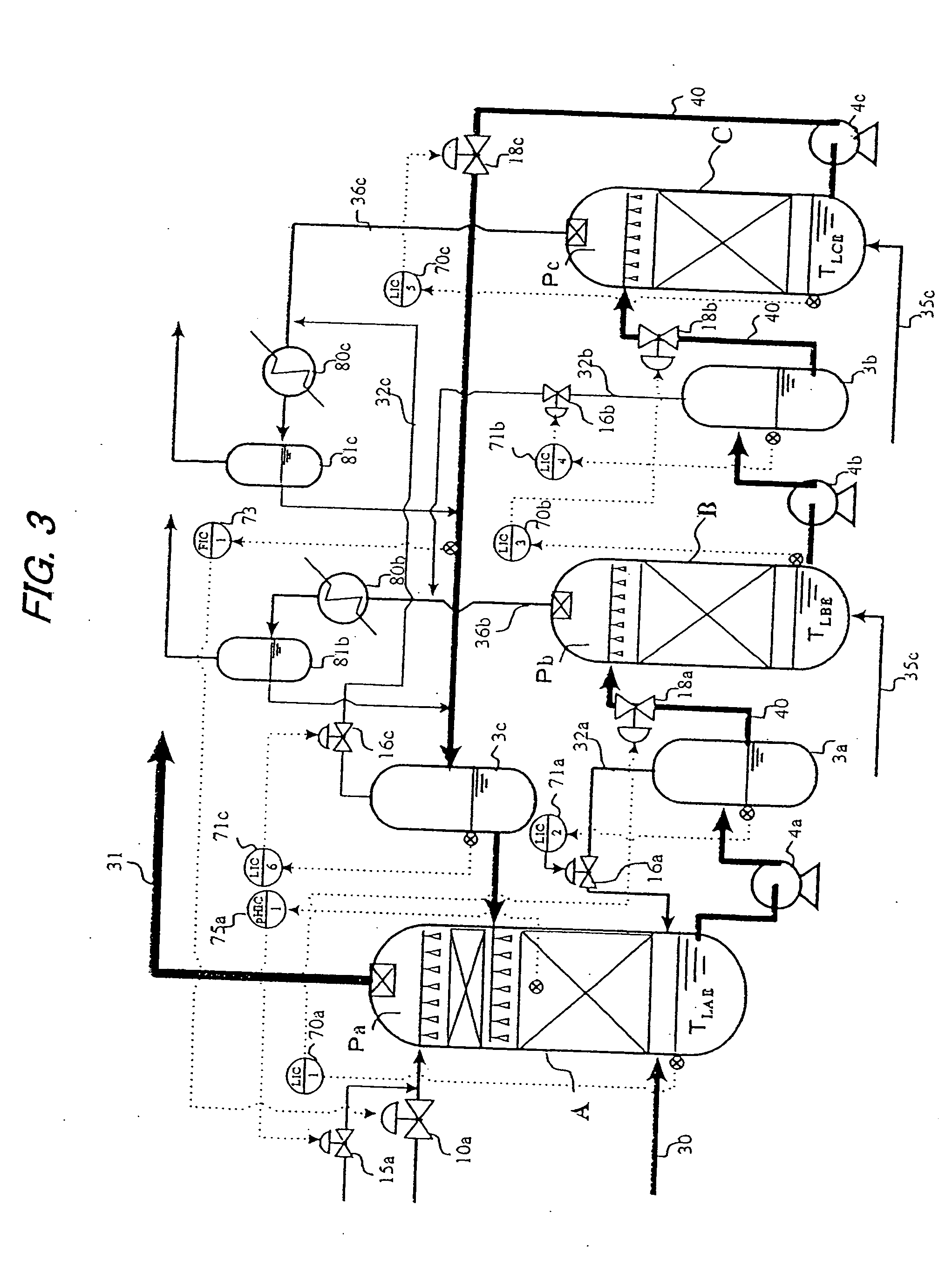

InactiveUS20050132883A1Improve energy efficiencyImprove acid gas removal capabilityUsing liquid separation agentCombustible gas catalytic treatmentScrubberCarbon dioxide

An acid gas scrubbing apparatus and method brings a gas, to be scrubbed, containing carbon dioxide into contact with a gas scrubbing liquid containing alkaline agent and cooled, and acid gases in the gas are removed. A gas scrubber removes acid gases in a gas, to be scrubbed, containing carbon dioxide by bringing the gas to be scrubbed into contact with a gas scrubbing liquid containing alkaline agent. A scrubbing liquid regenerator regenerates and cools the gas scrubbing liquid by bringing the gas scrubbing liquid into contact with a regenerating gas having components different from the gas scrubbing liquid and the gas to be scrubbed. A circulating device is provided between the gas scrubber and the scrubbing liquid regenerator for circulating the scrubbing liquid.

Owner:SU QINGQUAN +4

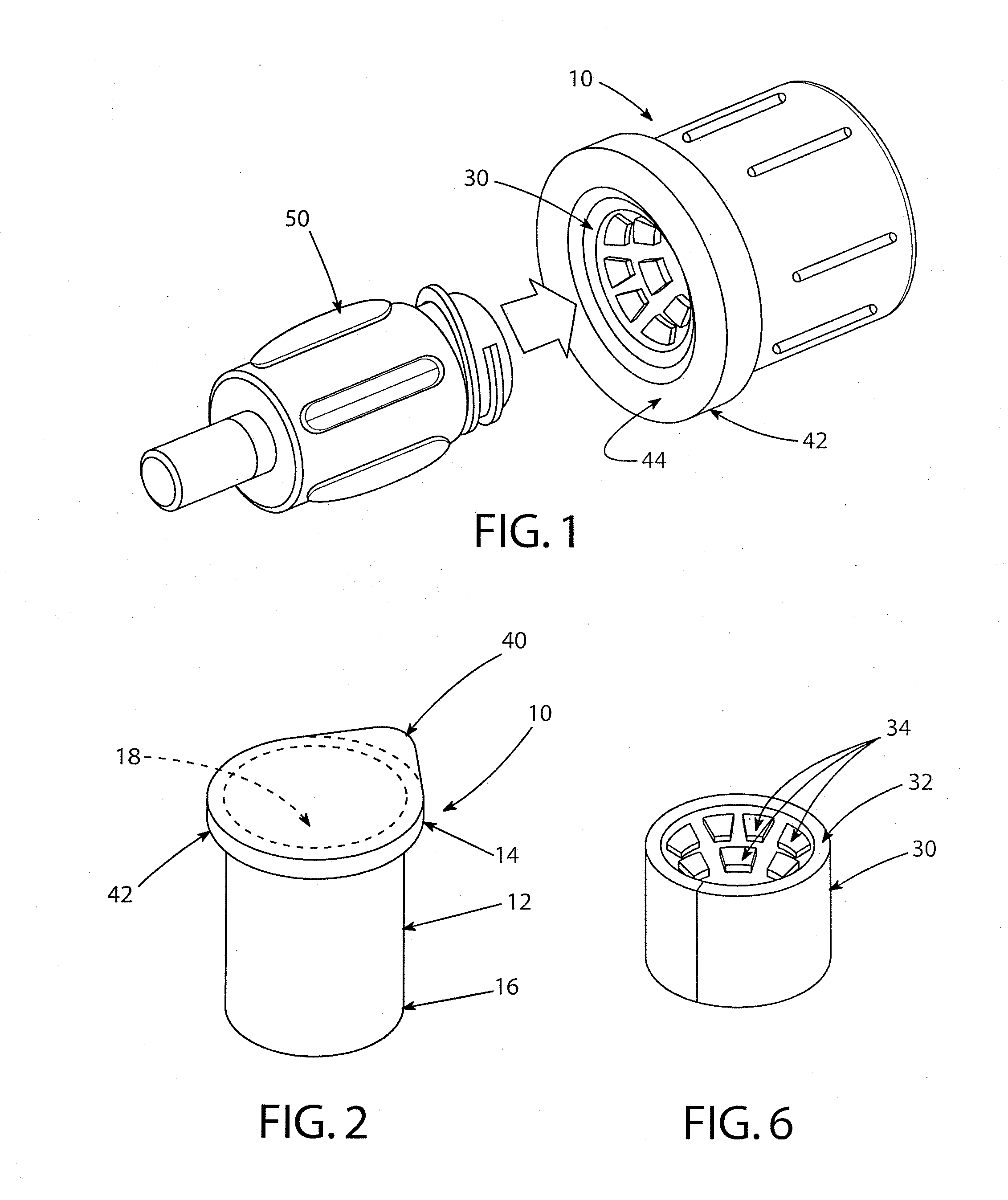

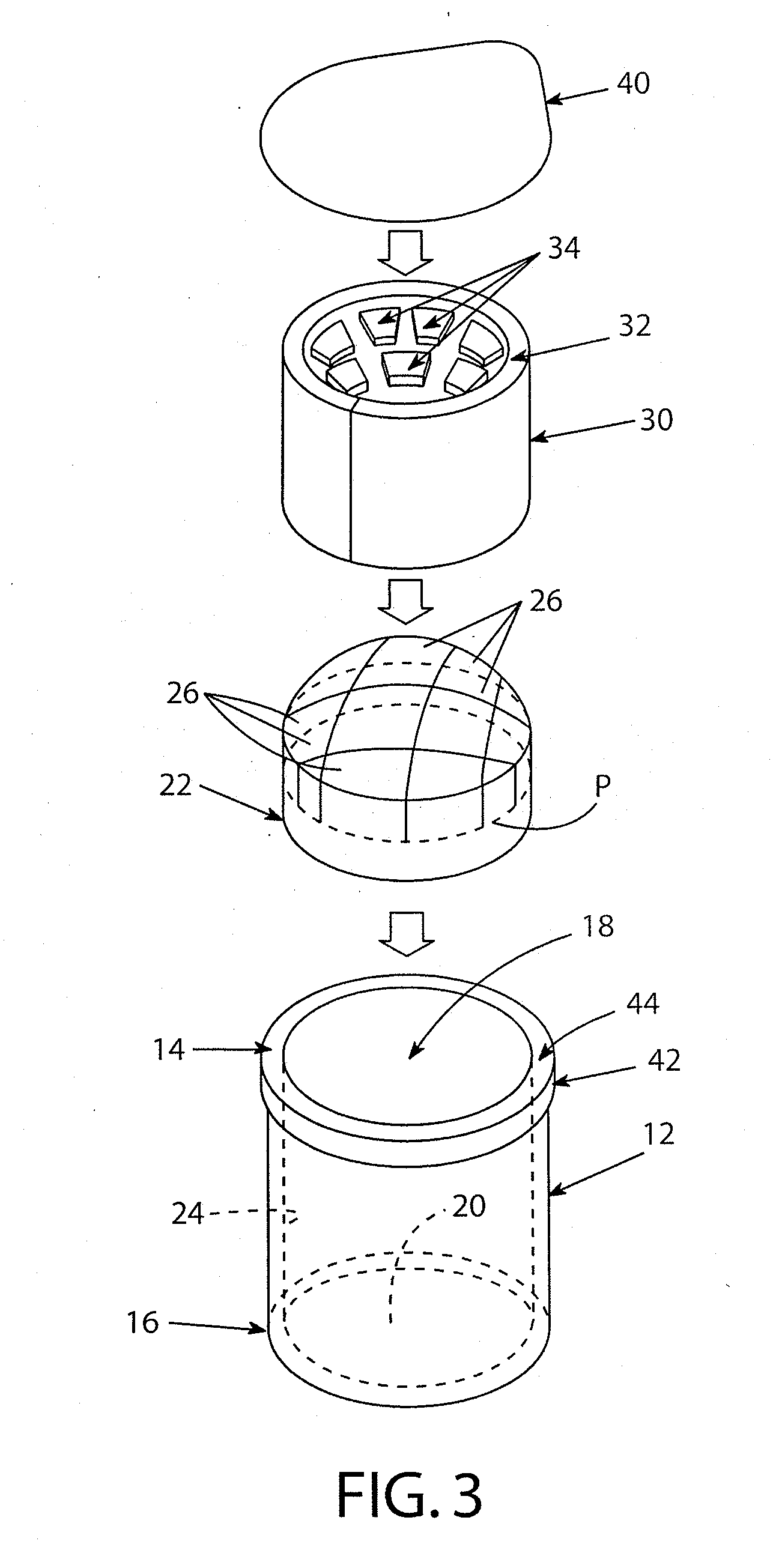

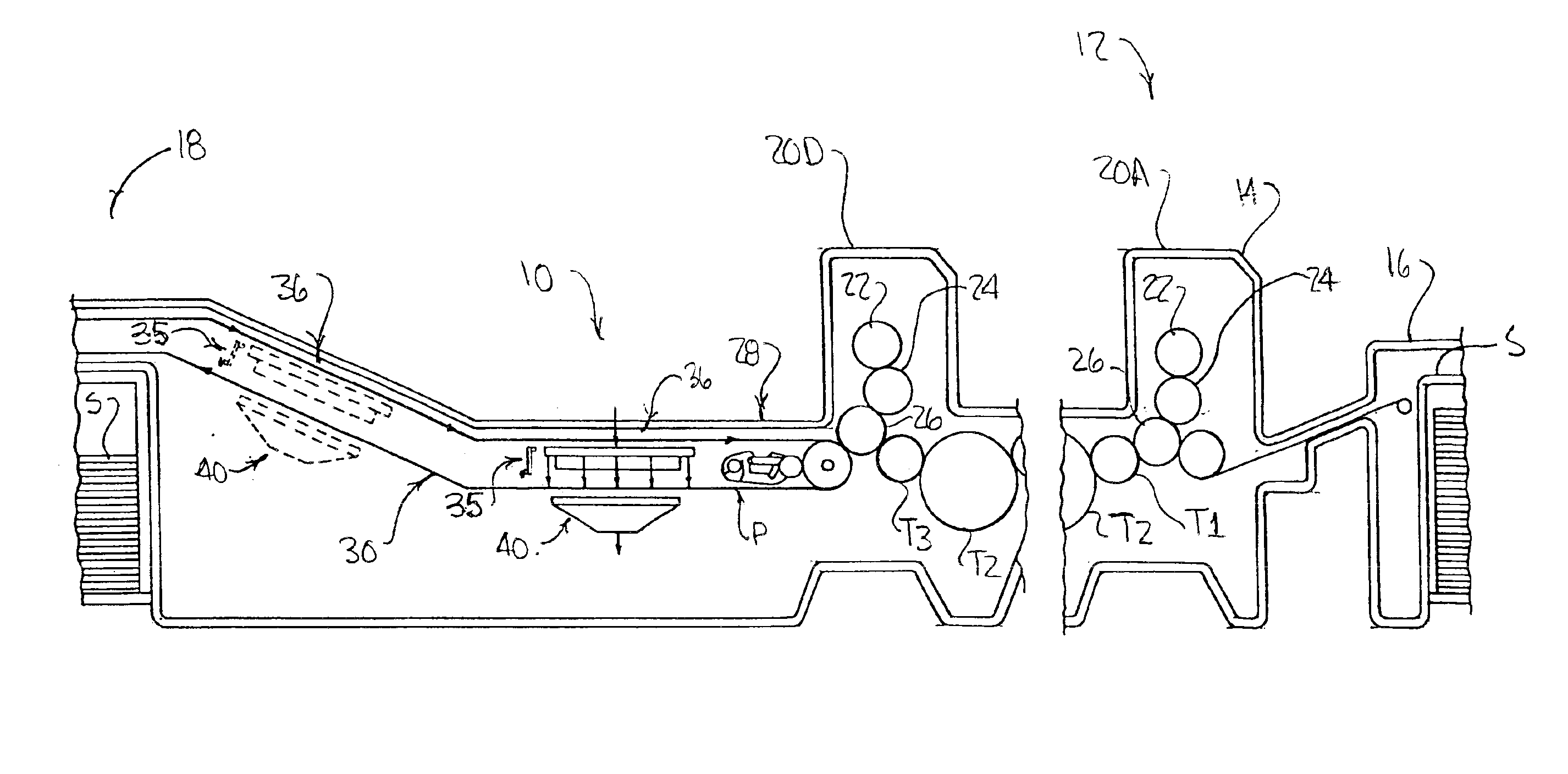

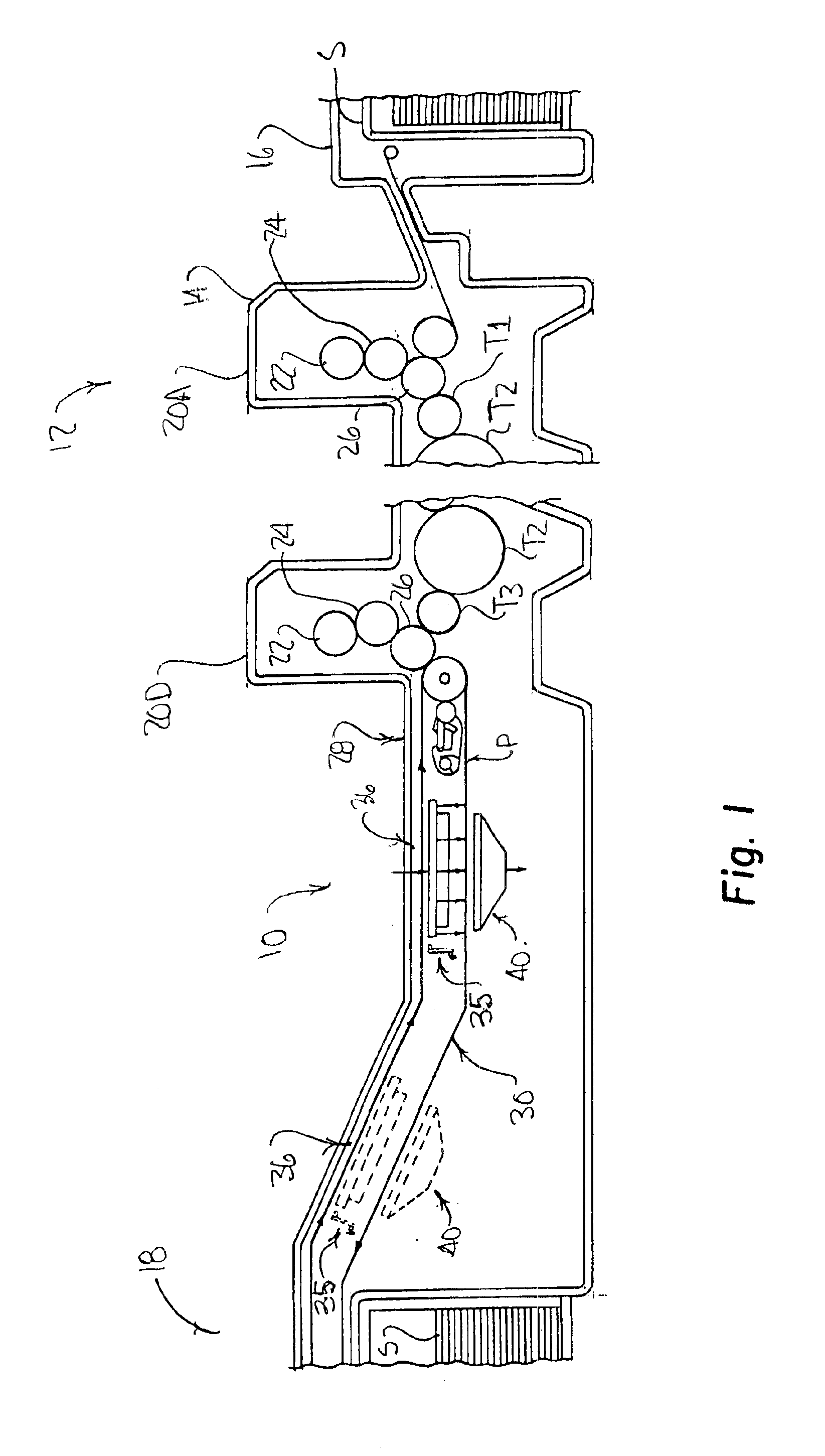

Cleaner for Medical Device

A cleaner assembly (10) for cleaning a medical device such as a luer connector. The assembly includes a cup-shaped housing (12) having a cavity (18) extending from an open first end (14) to a closed second end (16), and a first scrubber (22) affixed at the bottom and along side surfaces of the cavity (18) and saturated with antimicrobial fluid. The first scrubber (22) includes compressible fingers (26) co-extending toward the open first end (14) engageable by the medical device end portion inserted into the cavity whereupon the fingers (26) scrub the exterior and interior surfaces of the end of the device and applying the antimicrobial fluid thereto by being compressed by the device end. A second scrubber (30,30′) is affixed to cavity side walls (32) adjacent the open first end and has flexible projections (34 or 36) extending radially inwardly to scrub exterior surfaces of the device upon insertion.

Owner:MEDICAL COMPONENTS INC

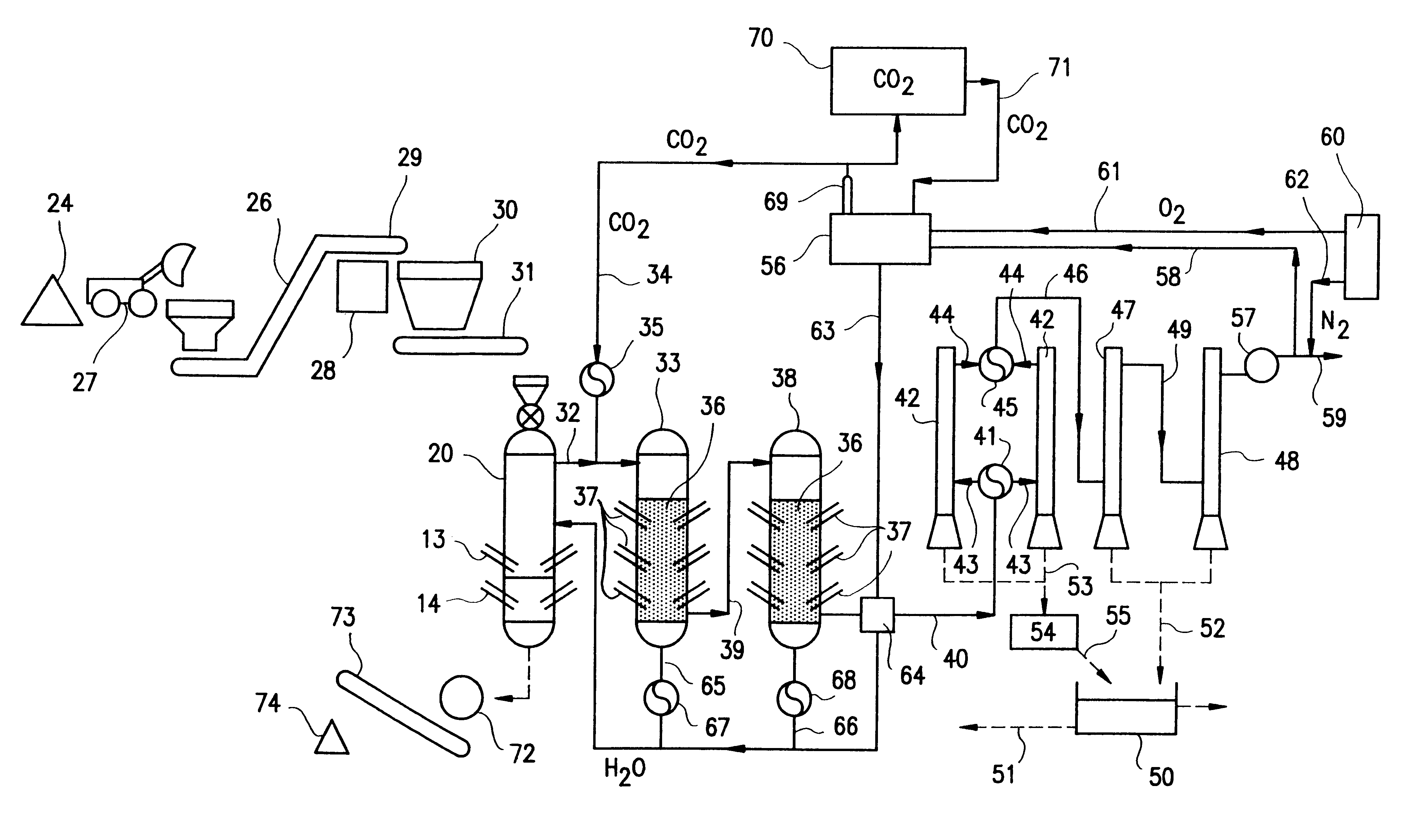

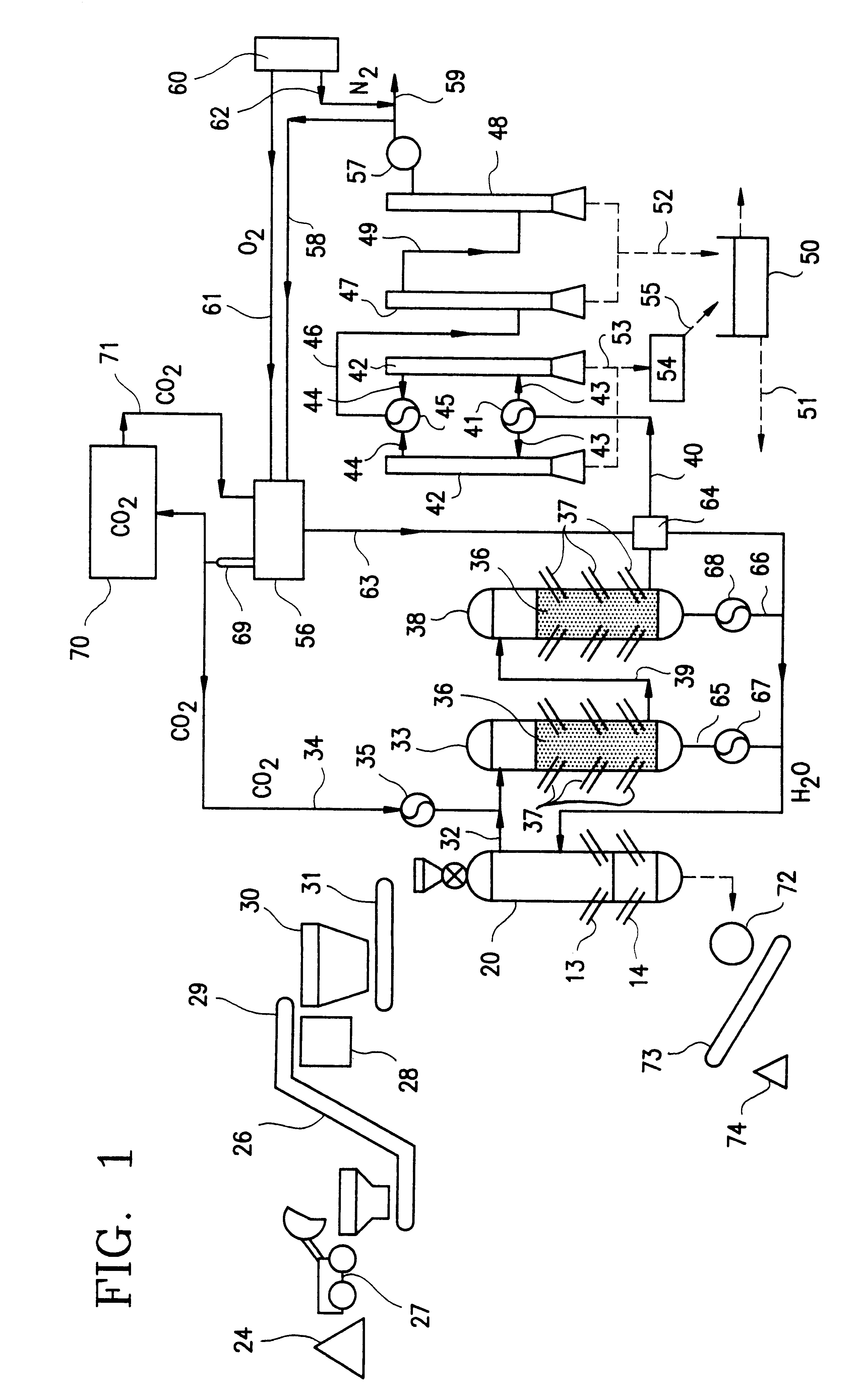

Synthesis gas production and power generation with zero emissions

InactiveUS6333015B1Avoid water pollutionEliminate needElectrical coke oven heatingGasifier electrodesClosed loopProduct gas

A process and apparatus for producing and burning synthesis gas. Carbonaceous waste material is pyrolytically decomposed in a primary reactor in the presence of steam to produce raw product gas containing H2 and CO. The raw product gas and CO2 is then introduced into a coke containing secondary reactor under pyrolyzing conditions, so that the CO2 and coke react to produce combustible gas having an increased CO content. The combustible gas is mixed with oxygen and CO2 to produce a combustible mixture which is burned as a fuel to produce heat, CO2 and H2O. A portion of the produced CO2 is recovered and used as the source of CO2 gas in the combustible mixture and as a source of CO2 gas for the secondary reactor. Preferably filters and scrubbers are used in a closed loop system to avoid undesirable emissions into the environment.

Owner:LEWIS GLORIA B

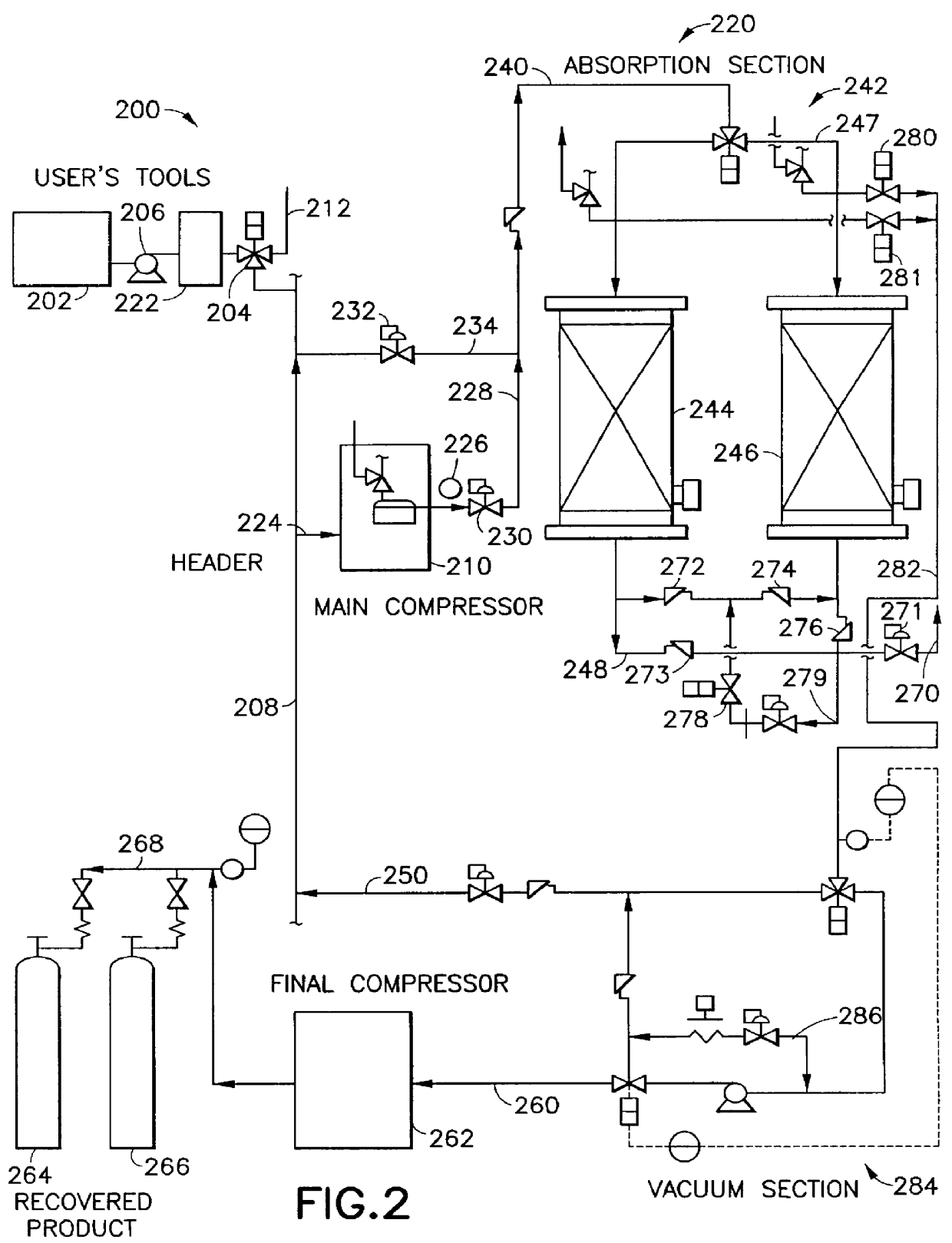

Process for removing and recovering halocarbons from effluent process streams

A process for recovery of fluorocompound gas from an effluent gas stream containing the fluorocompound gas and other gas components, in which at least one of the other gas components is removed, e.g., by oxidation or contacting of the effluent stream with a dry material such as an adsorbent or scrubber medium, to yield a first effluent gas mixture containing the fluorocompound gas. The fluorocompound gas is removed from the first effluent gas mixture and recovered as a concentrated fluorocompound gas, by a process such as cryogenic processing, membrane separation, and / or adsorption.

Owner:ADVANCED TECH MATERIALS INC

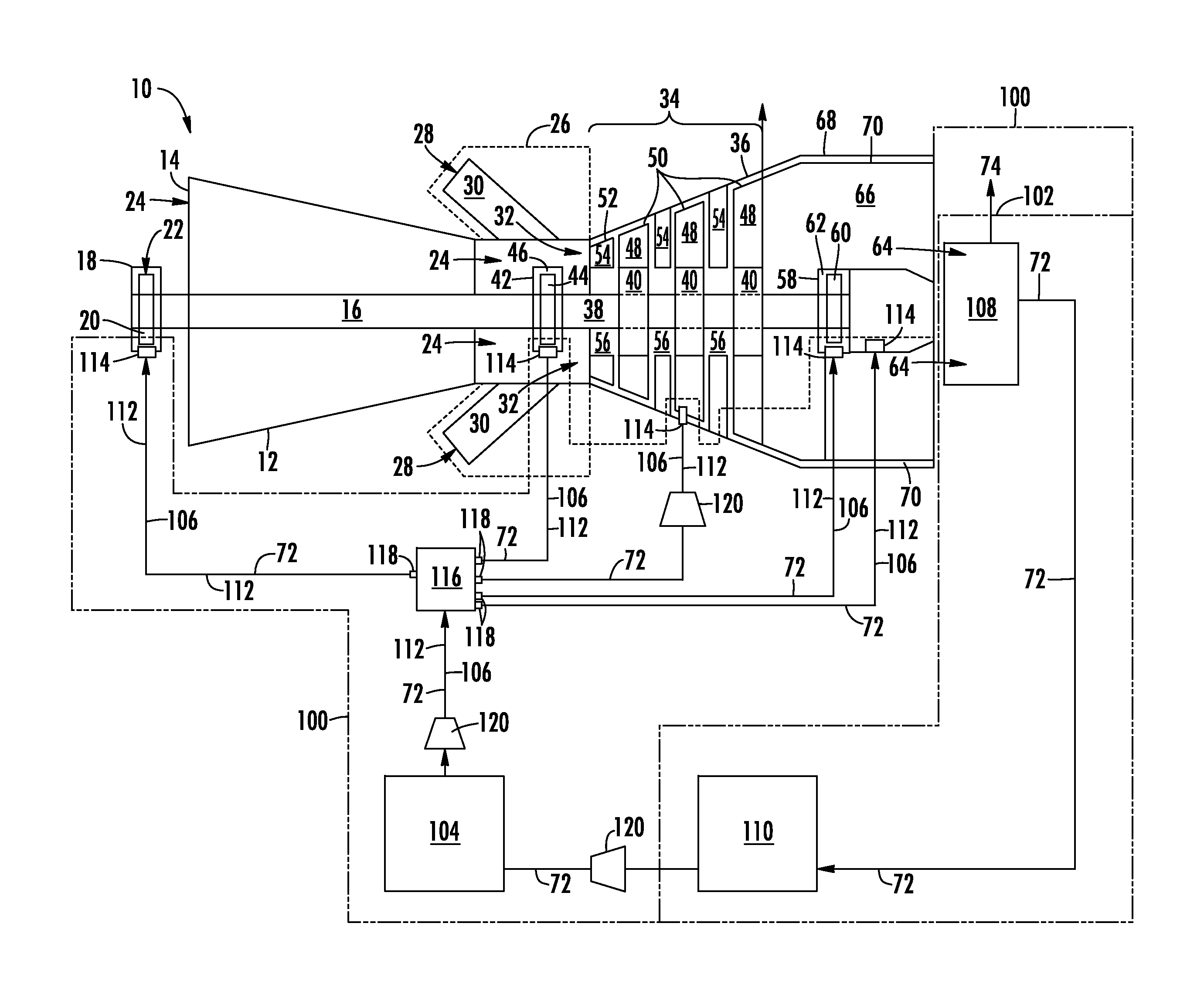

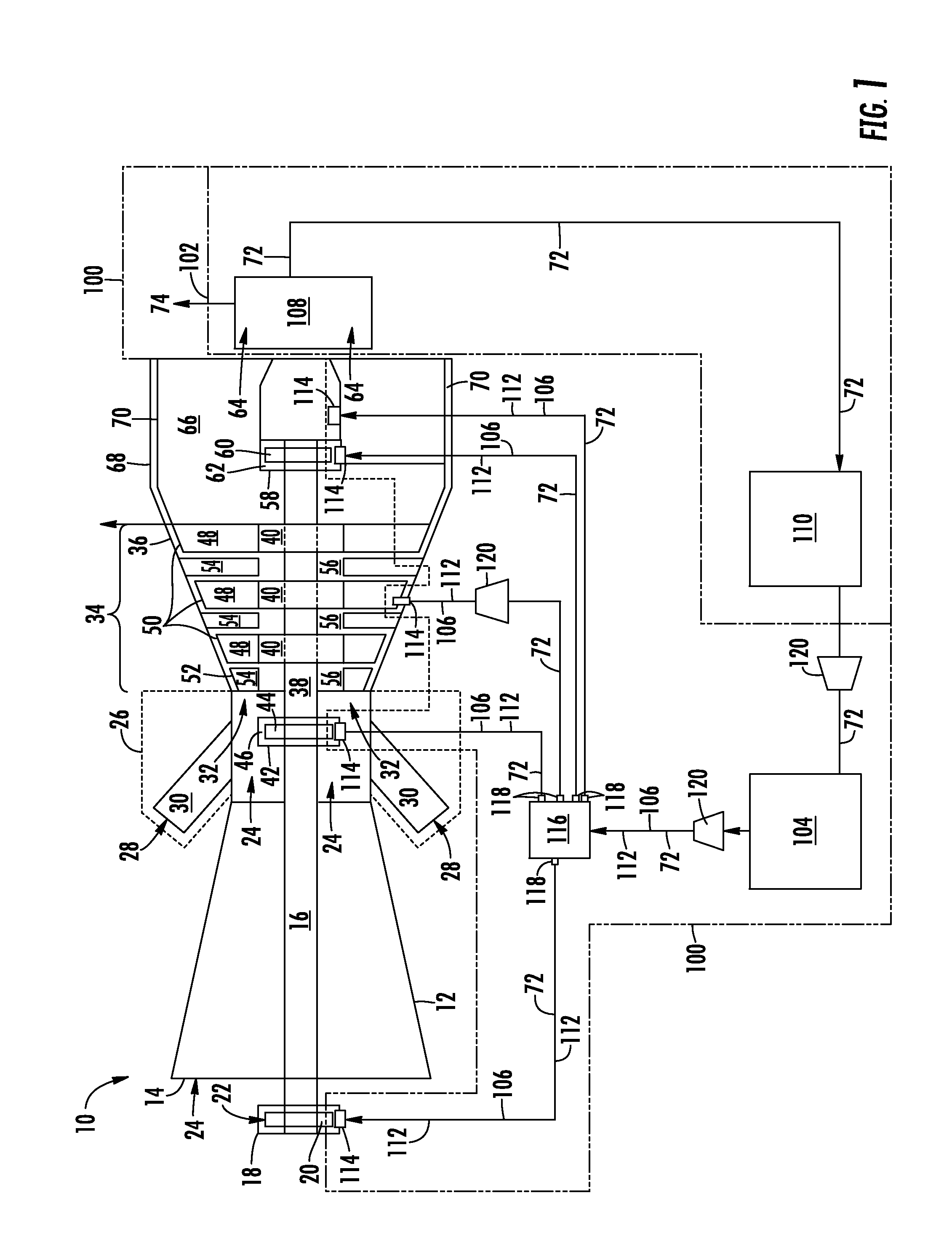

System and method for cooling a gas turbine with an exhaust gas provided by the gas turbine

ActiveUS20130283808A1Turbine/propulsion engine coolingGas turbine plantsExhaust fumesExhaust gas recirculation

A system for cooling a gas turbine with an exhaust gas provided by the gas turbine generally includes an exhaust gas recirculation system including an exhaust gas scrubber. The exhaust gas recirculation system is disposed downstream from the gas turbine and may receive at least a portion of the exhaust gas provided by the gas turbine. The system may also include a moisture separator located downstream from the exhaust gas recirculation system, and a cooling circuit configured to connect to one or more cooling circuit inlets. The one or more cooling circuit inlets may provide fluid communication between the cooling circuit and the gas turbine.

Owner:EXXONMOBIL UPSTREAM RES CO +1

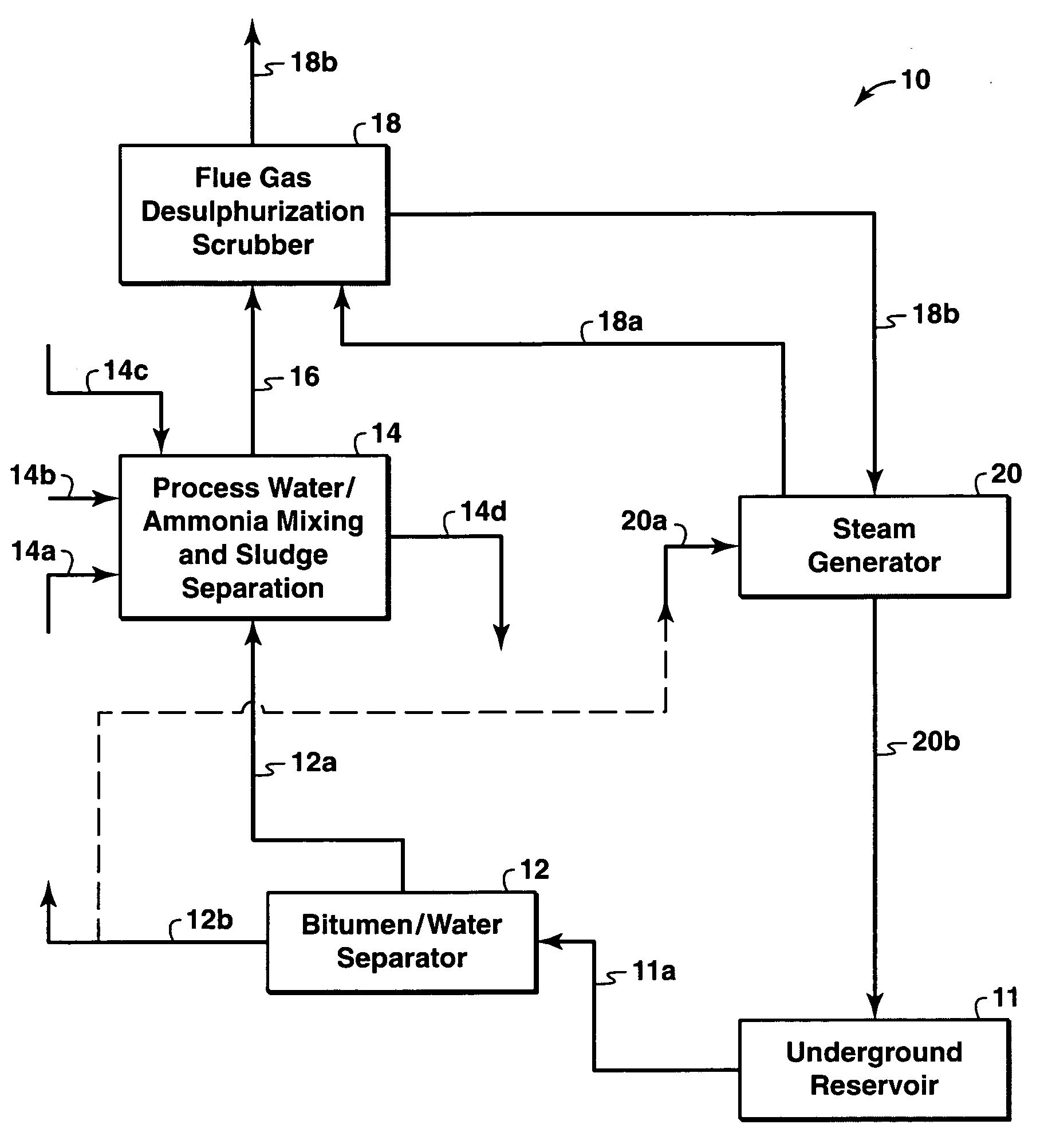

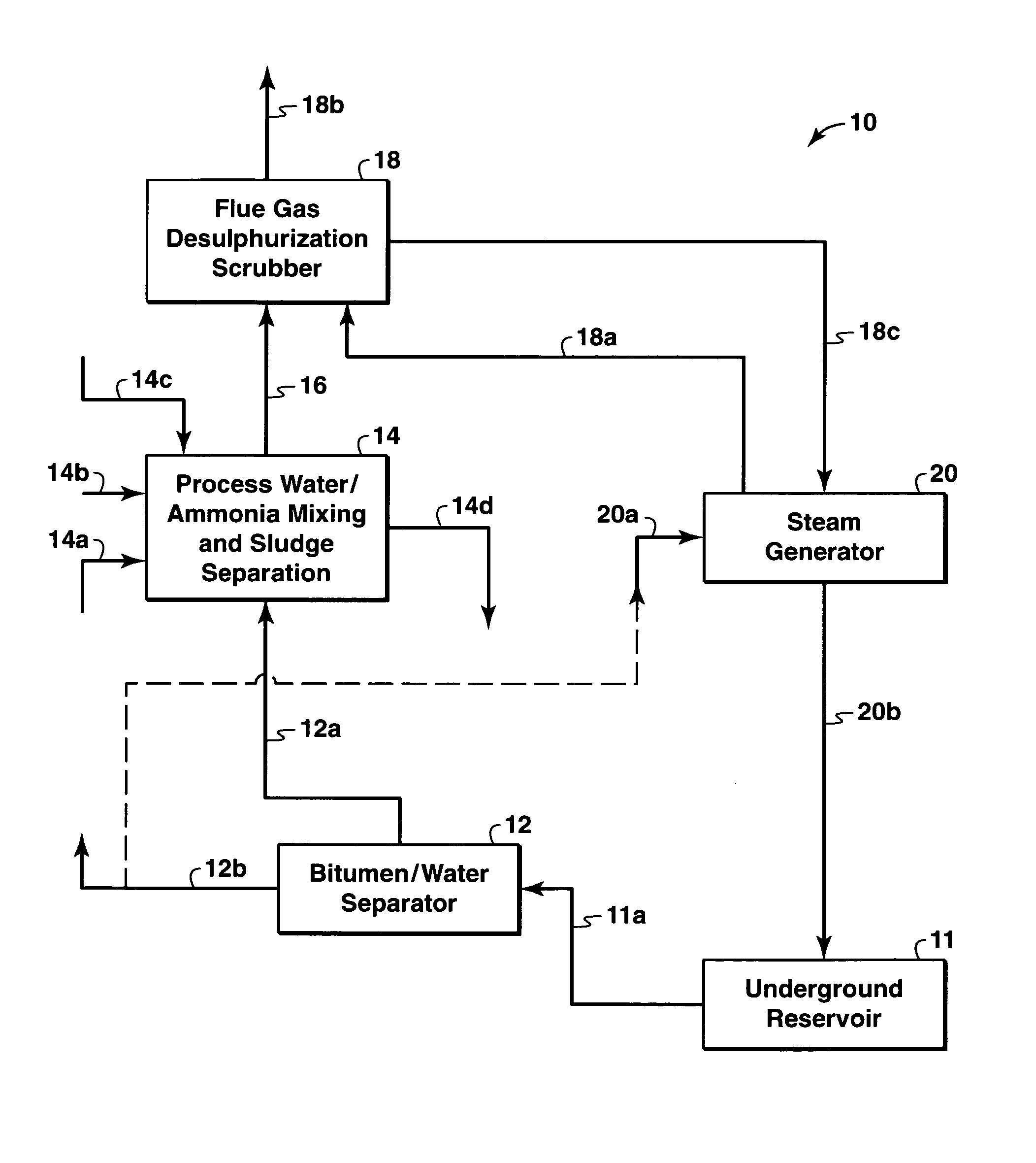

Integrated water treatment and flue gas desulfurization process

A water stream containing hardness minerals is subjected to a water treatment process using an alkali agent to precipitate the hardness minerals and to produce a softened water stream is used to create an integrated water treatment and flue gas desulfurization process. Thereafter, the softened, alkaline water stream is utilized in a scrubber to scrub a flue gas containing sulfur dioxide to produce a sulfur-lean flue gas. The invention may be applied to a steam-based bitumen recovery operation where bitumen, sour produced gas or other sulfur containing fuels are burned for producing steam for bitumen recovery. More specifically, the associated produced water from the bitumen recovery process may be softened for re-use and for utilization as a scrubbing agent for high-sulfur containing flue gas arising from the steam generators. The process provides an economically favorable process while minimizing waste disposal requirements.

Owner:EXXONMOBIL UPSTREAM RES CO

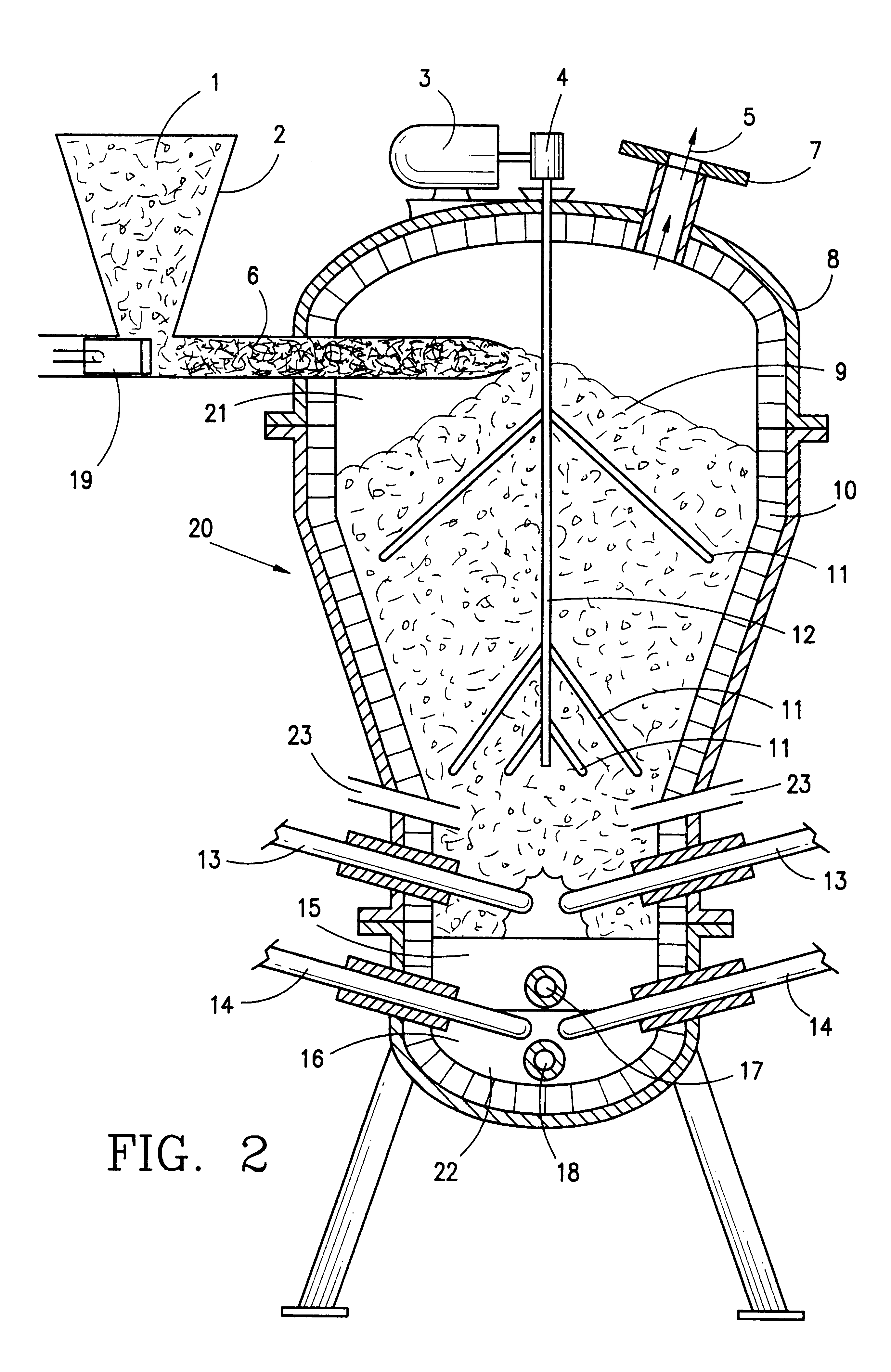

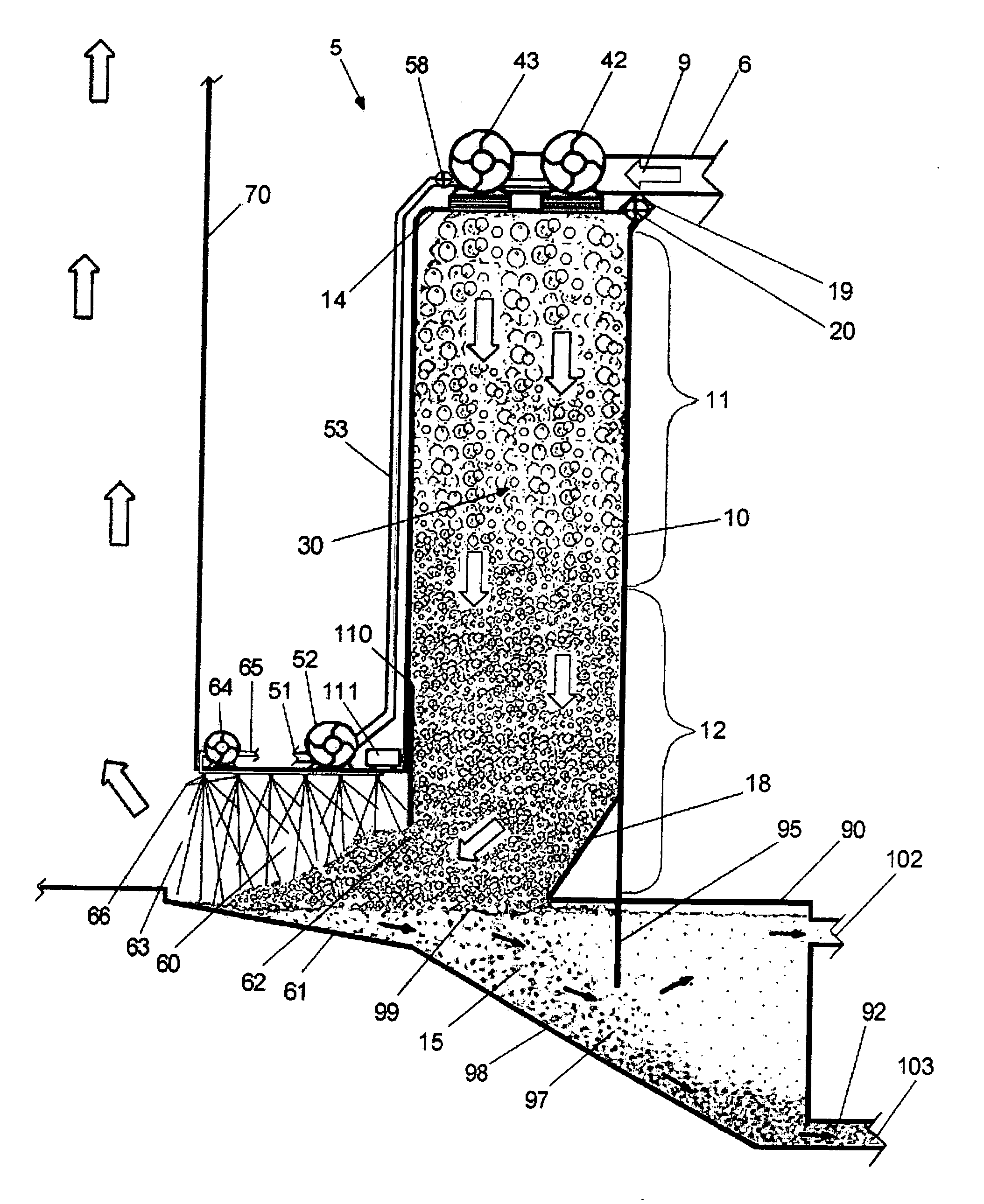

Method and means for capture and long-term sequestration of carbon dioxide

InactiveUS20090081096A1High heat of reactionHigh regeneration energyCombination devicesGas treatmentSolubilityAmbient pressure

The invention teaches a practical method of recovering CO2 from a mixture of gases, and sequestering the captured CO2 from the atmosphere for geologic time as calcium carbonate and provides a CO2 scrubber for carbon capture and sequestration. CO2 from the production of calcium oxide is geologically sequestered. A calcium hydroxide solution is produced from the environmentally responsibly-produced calcium oxide. The CO2 scrubber incorporates an aqueous froth to maximize liquid-to-gas surface area and time-of-contact between gaseous CO2 and the calcium hydroxide solution. The CO2 scrubber decreases the temperature of the liquid and the mixed gases, increases ambient pressure on the bubbles and vapor pressure inside the bubbles, diffuses the gas through intercellular walls from relative smaller bubbles with relative high vapor pressure into relative larger bubbles with relative low vapor pressure, and decreases the mean-free-paths of the CO2 molecules inside the bubbles, in order to increase solubility of CO2 and the rate of dissolution of gaseous CO2 from a mixture of gases into the calcium hydroxide solution.The CO2 scrubber recovers gaseous CO2 directly from the atmosphere, from post-combustion flue gas, or from industrial processes that release CO2 as a result of process. CO2 reacts with calcium ions and hydroxide ions in solution forming insoluble calcium carbonate precipitates. The calcium carbonate precipitates are separated from solution, and sold to recover at least a portion of the cost of CCS.

Owner:WESTEC ENVIRONMENTAL SOLUTIONS

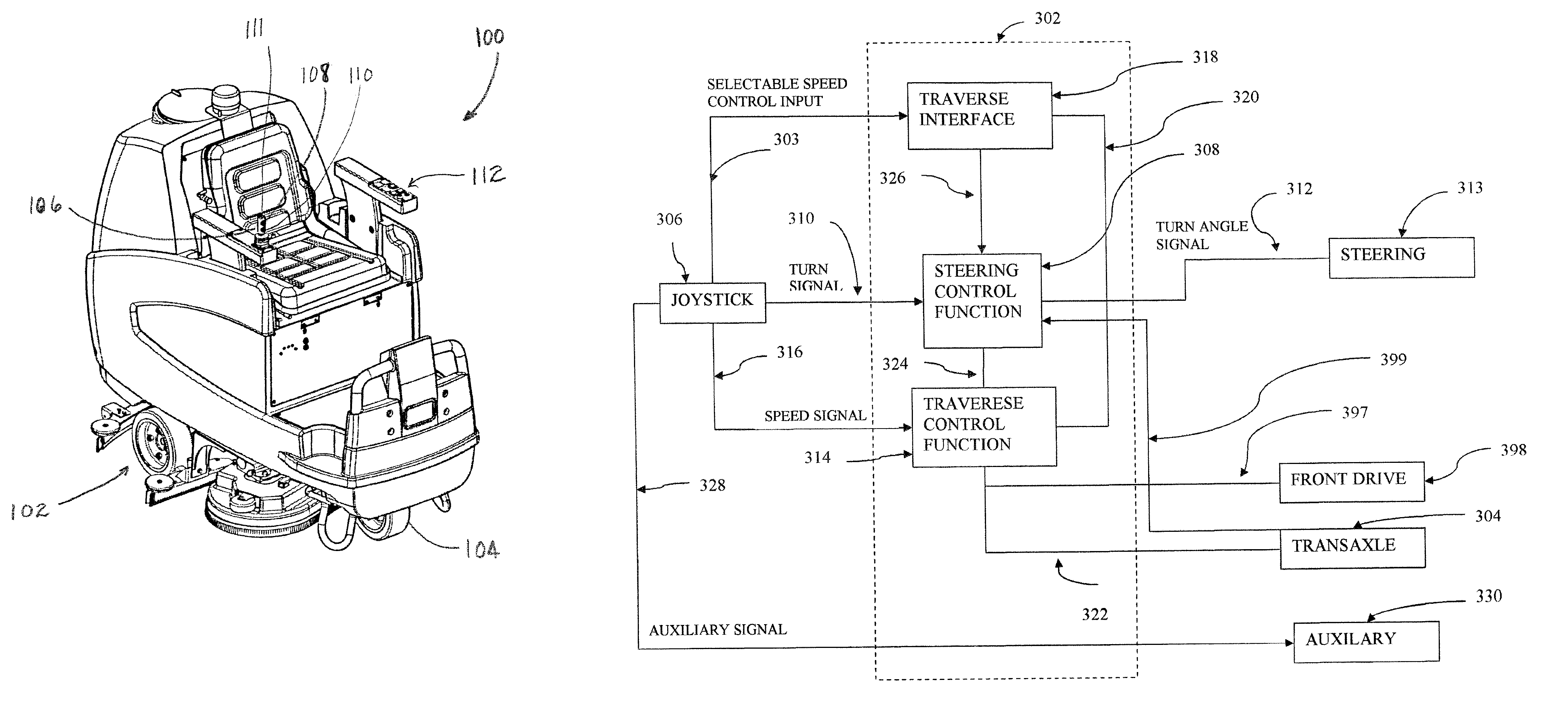

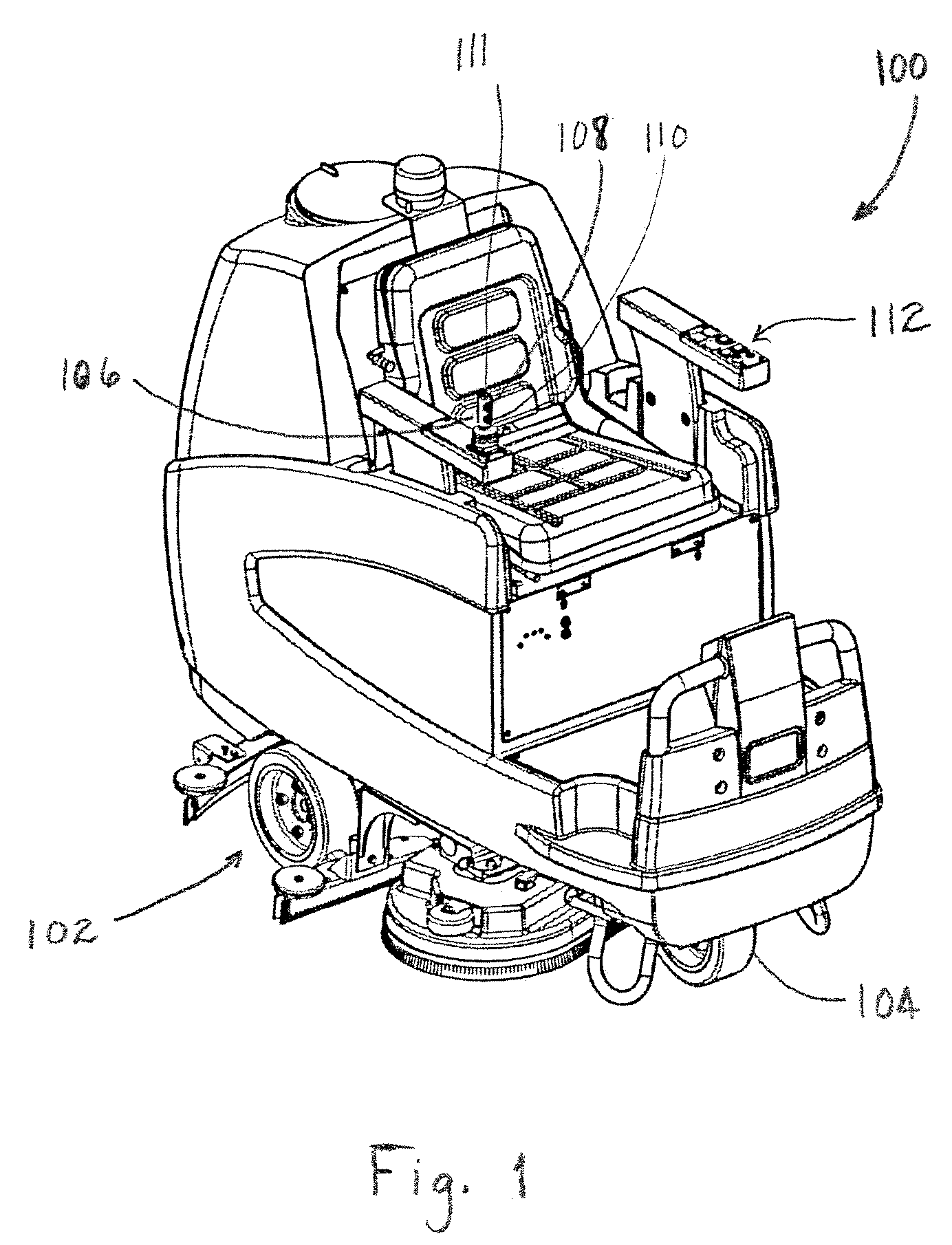

Joystick controlled scrubber

ActiveUS7041029B2Increase awarenessMaintenance safetyMotor/generator/converter stoppersDC motor speed/torque controlTurn angleJoystick

Owner:NILFISK

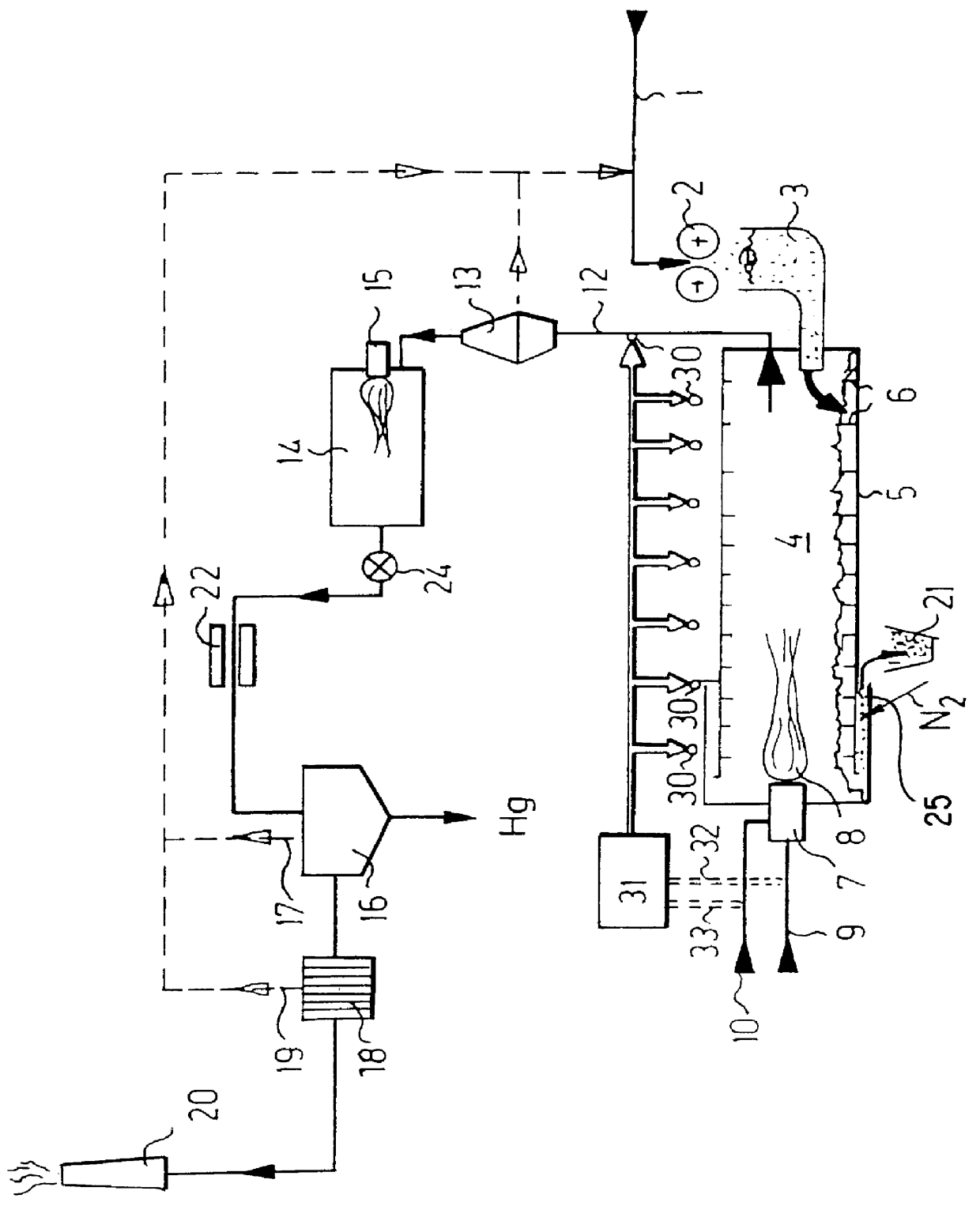

Process for removing mercury from mercury contaminated materials

PCT No. PCT / CH96 / 00252 Sec. 371 Date May 15, 1998 Sec. 102(e) Date May 15, 1998 PCT Filed Jul. 8, 1996 PCT Pub. No. WO97 / 02864 PCT Pub. Date Jan. 30, 1997Mercury-contaminated substances are fed through a shredder to a loader that loads a rotary tubular kiln, in which a mercury content is evaporated by a primary burner. A temperature of an unlined rotary kiln is monitored from an outside at various points over an entire length, by infrared sensors. The thus acquired data are supplied to a regulating unit that regulates fuel supply and primary air supply through various control lines. Burned gas is supplied through a duct to a cyclone separator in which solids are separated and returned to the process. The gaseous substances are fed through a postcombustion chamber of a quench to a washer in which mercury is removed. The residual gas reaches a chimney through an active coal filter. This process is particularly easy to control, economical and allows a particularly low residual mercury content to be reached, for example less than 0.1 ppm, in a residual combustion product.

Owner:DECO HANULIK

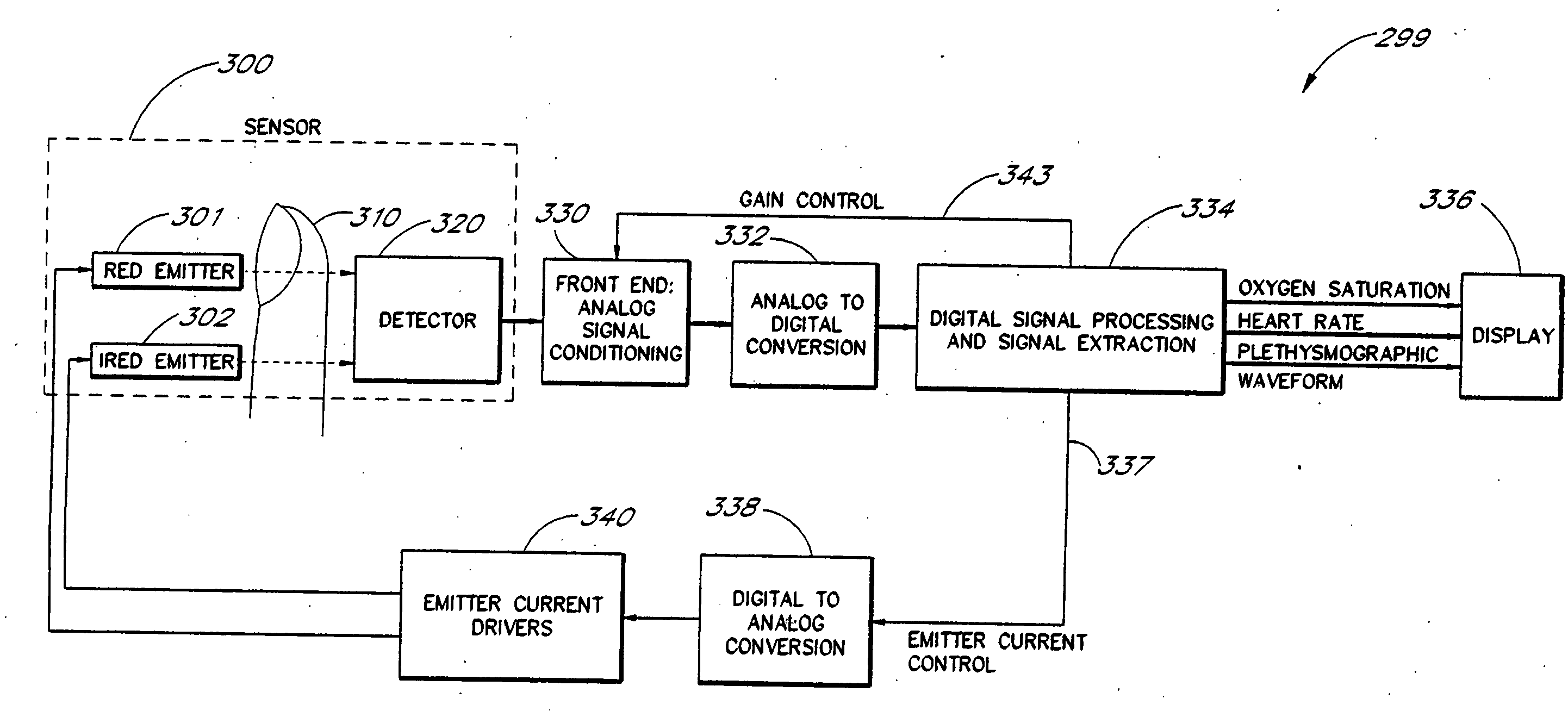

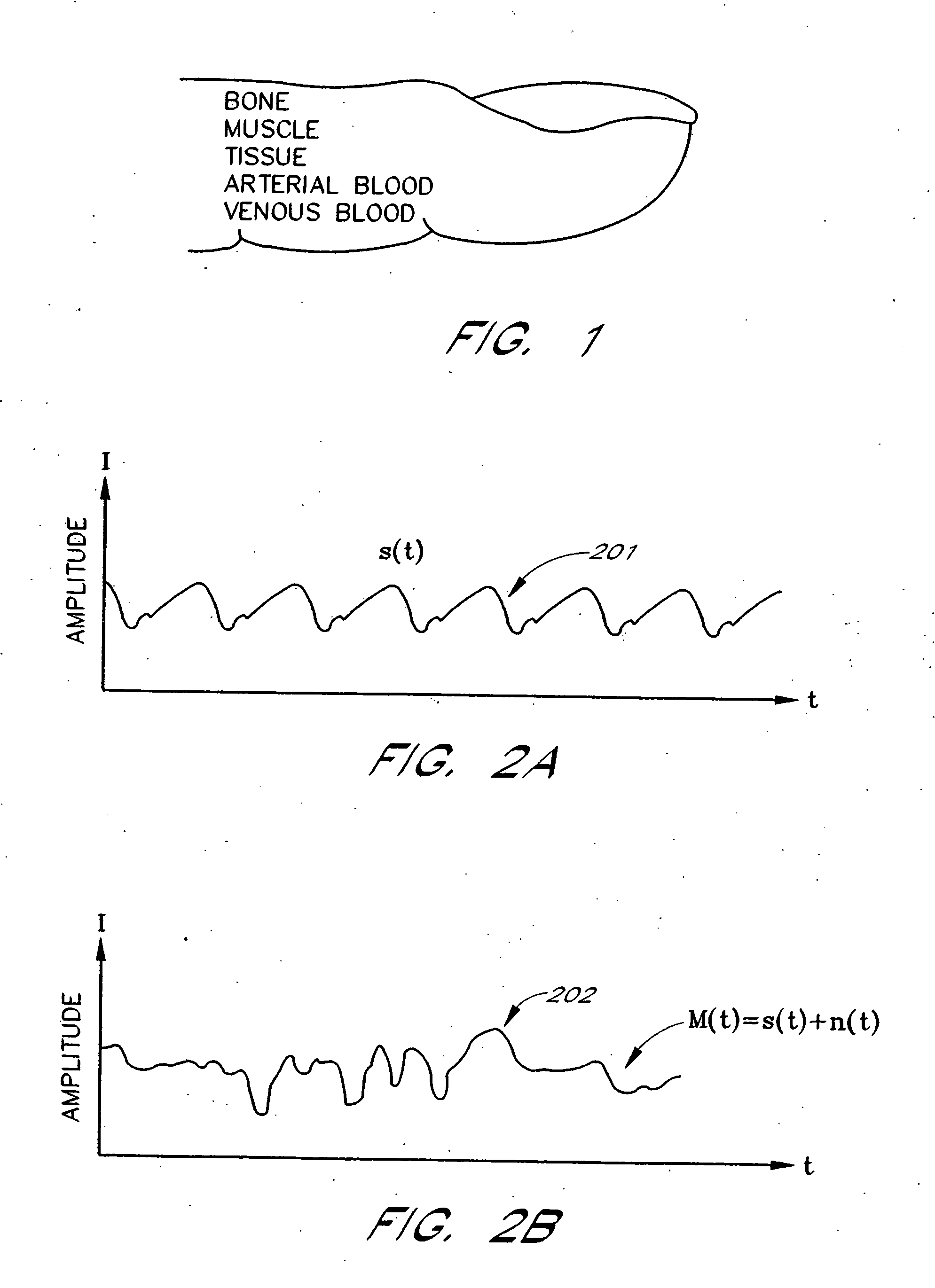

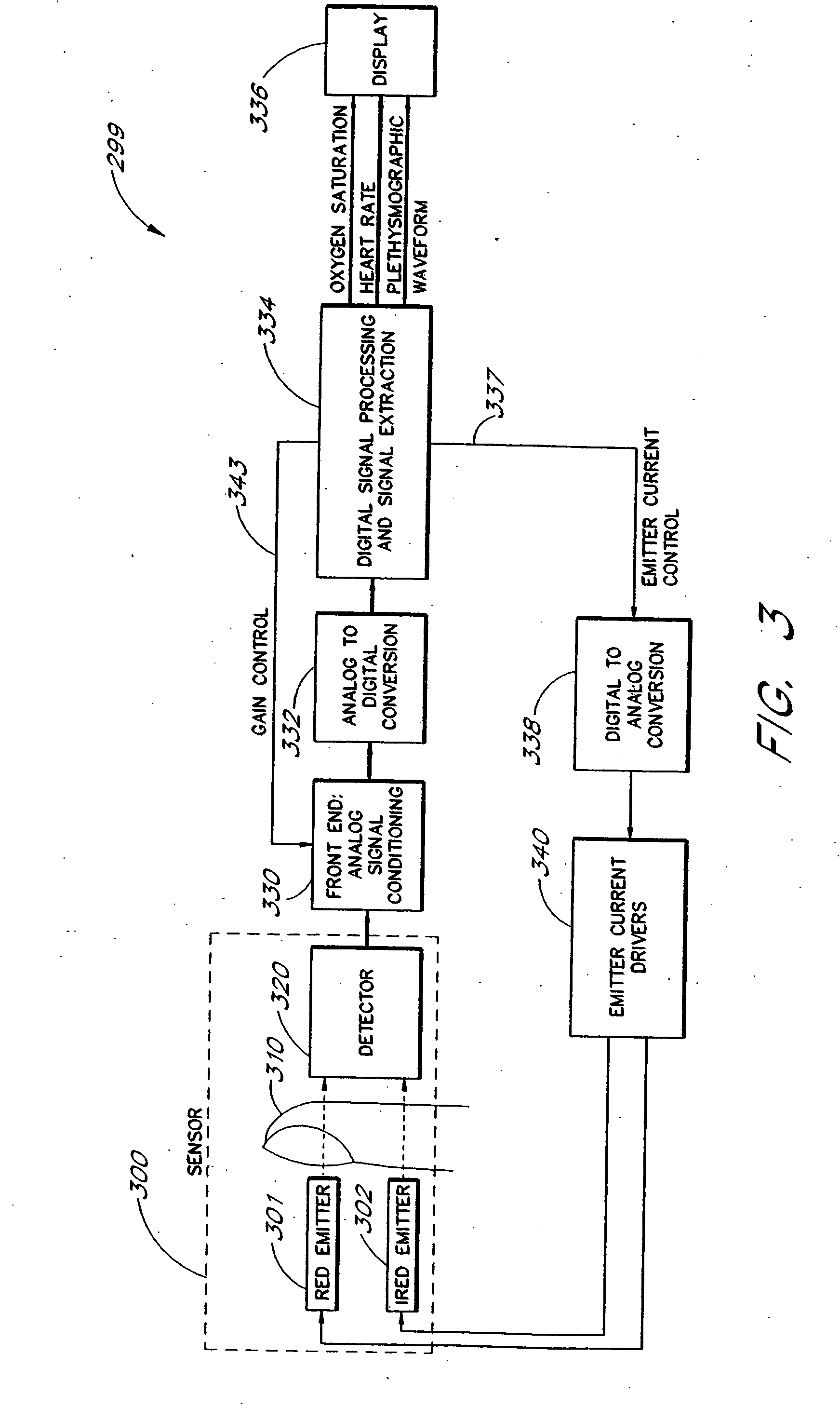

Signal processing apparatus and method

A method and an apparatus to analyze two measured signals that are modeled as containing desired and undesired portions such as noise, FM and AM modulation. Coefficients relate the two signals according to a model defined in accordance with the present invention. In one embodiment, a transformation is used to evaluate a ratio of the two measured signals in order to find appropriate coefficients. The measured signals are then fed into a signal scrubber which uses the coefficients to remove the unwanted portions. The signal scrubbing is performed in either the time domain or in the frequency domain. The method and apparatus are particularly advantageous to blood oximetry and pulserate measurements. In another embodiment, an estimate of the pulserate is obtained by applying a set of rules to a spectral transform of the scrubbed signal. In another embodiment, an estimate of the pulserate is obtained by transforming the scrubbed signal from a first spectral domain into a second spectral domain. The pulserate is found by identifying the largest spectral peak in the second spectral domain.

Owner:JPMORGAN CHASE BANK NA

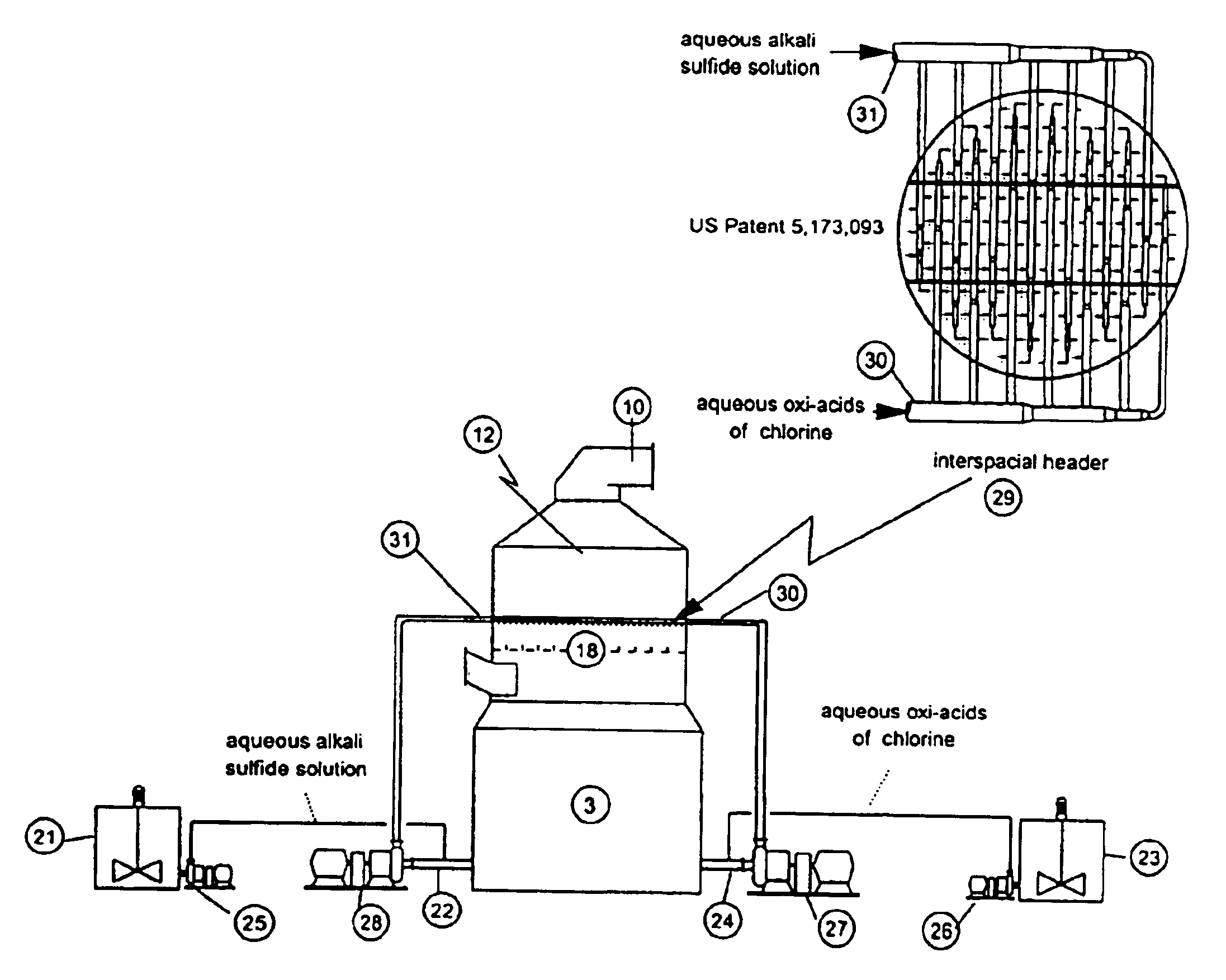

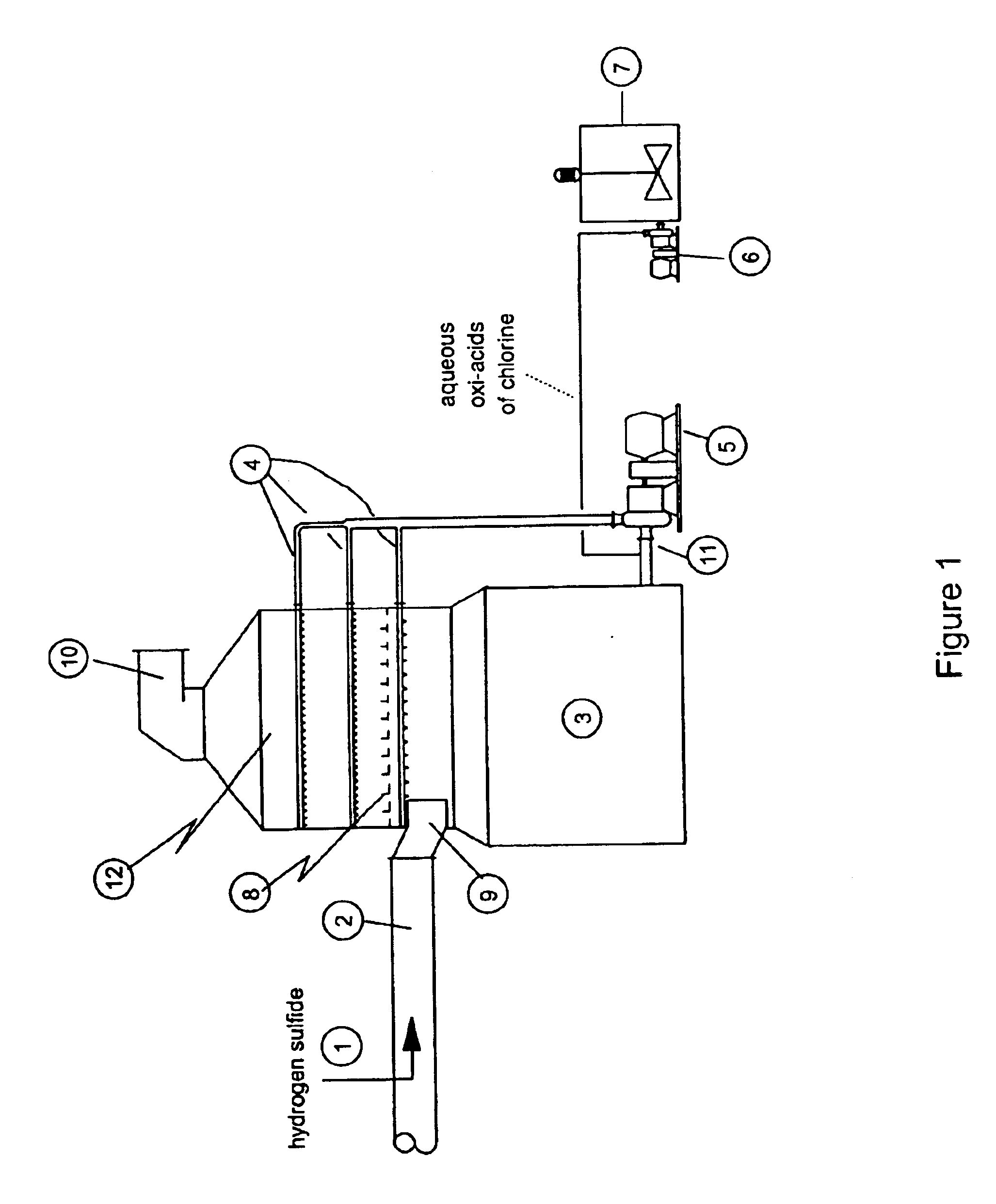

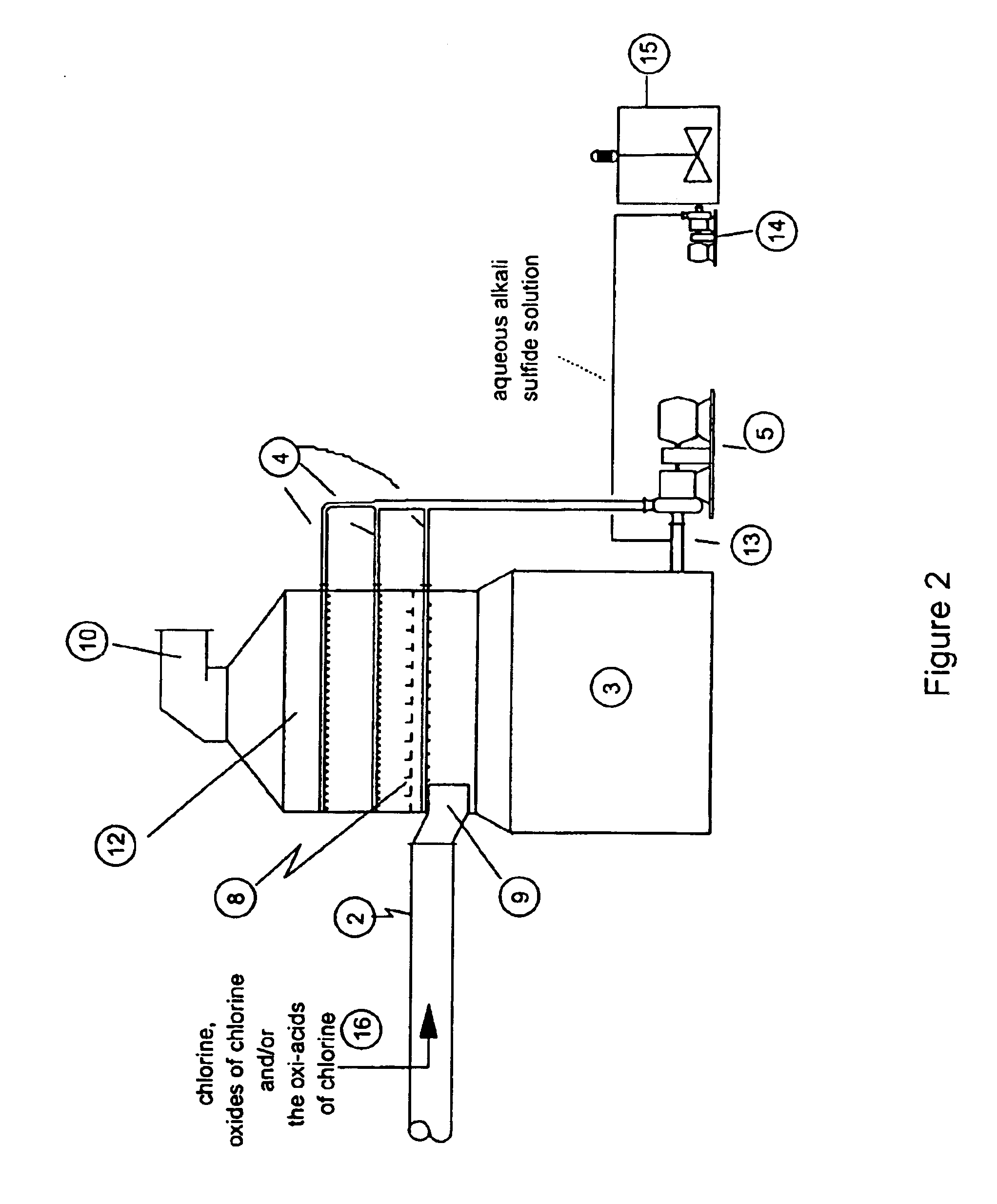

Method for controlling elemental mercury emissions

InactiveUS6855859B2Simple equipmentReduce oxidationGas treatmentExhaust apparatusElemental mercuryPrecipitation

Chlorine and sulfide species are separately introduced to a flue gas passing through a scrubber in order to remove the elemental and oxidized mercury from the gas through the precipitation of mercuric sulfide at near 100% efficiency.

Owner:THE BABCOCK & WILCOX CO

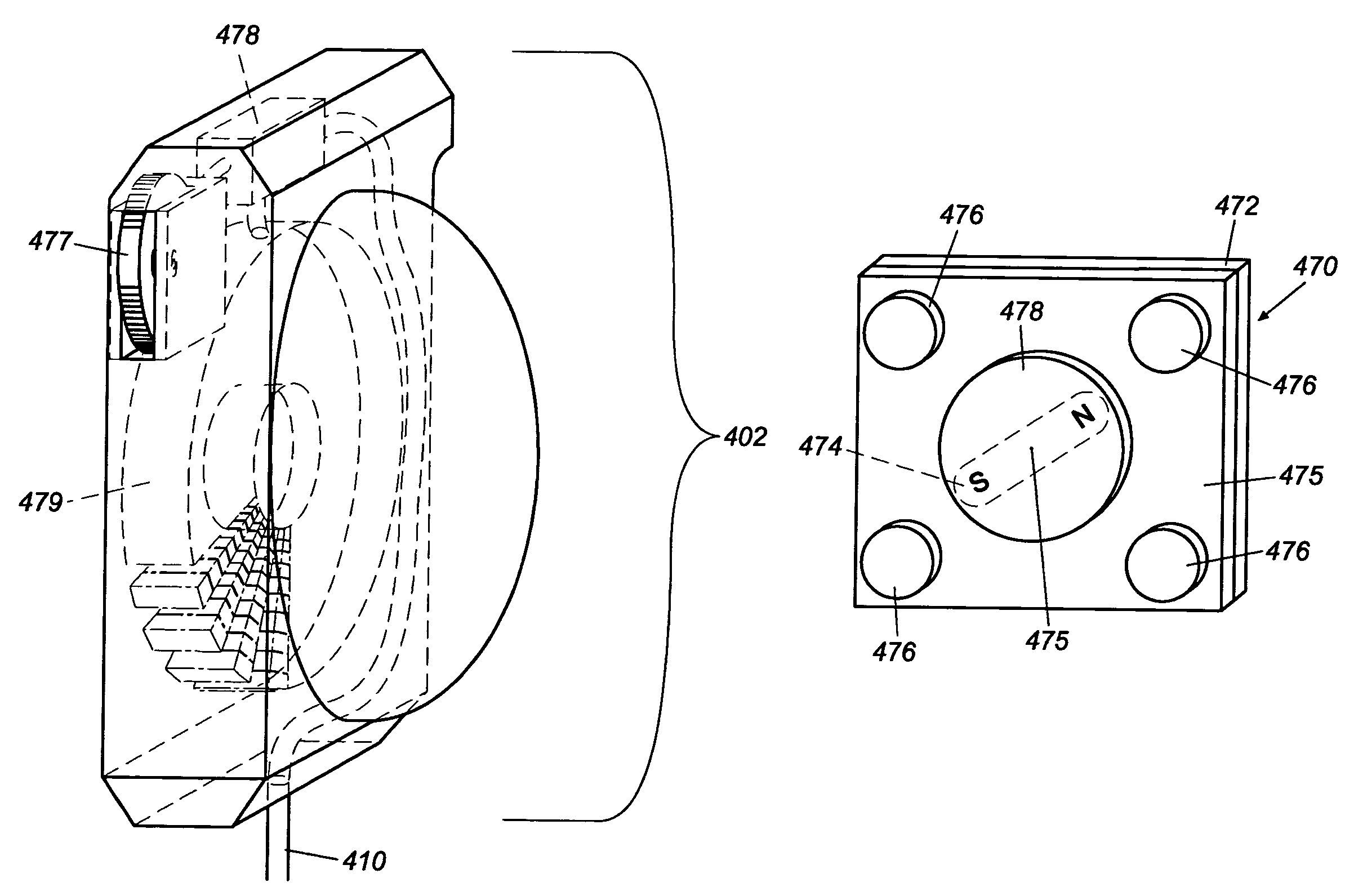

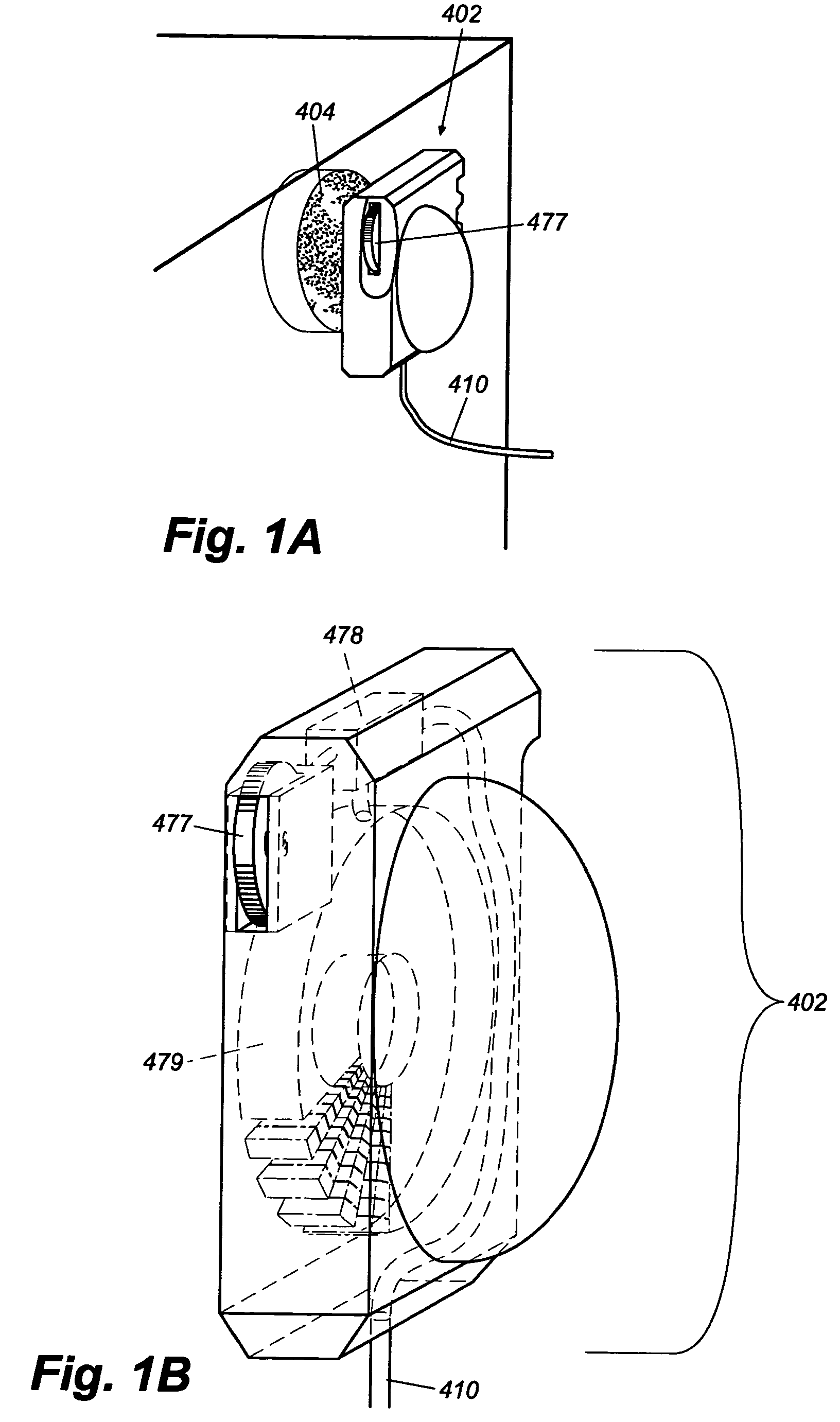

Induction liquid pump and magnetic tank scrubber

InactiveUS7313840B2Increase and decrease attractionLiquid processingKitchenware cleanersImpellerPower unit

An induction liquid pump includes a power unit and a circulation unit that are oppositely mountable to a tank with a plurality of fixation units. The liquid pump power unit includes a power induction unit to produce a variable magnetic field. The submersible liquid pump circulation unit includes an impeller unit to agitate or induce liquid flow in response to the variable magnetic field. A magnetic scrubber includes a power unit and a pad unit. The scrubber power unit produces a variable magnetic field in response to supplied power. When the scrubber power unit is held against a first surface of a tank, the scrubber pad unit is held oppositely against a second surface of the tank. The scrubber pad unit moves in response to the variable magnetic field to scrub the second surface of the tank.

Owner:WATKINS CHARLES E

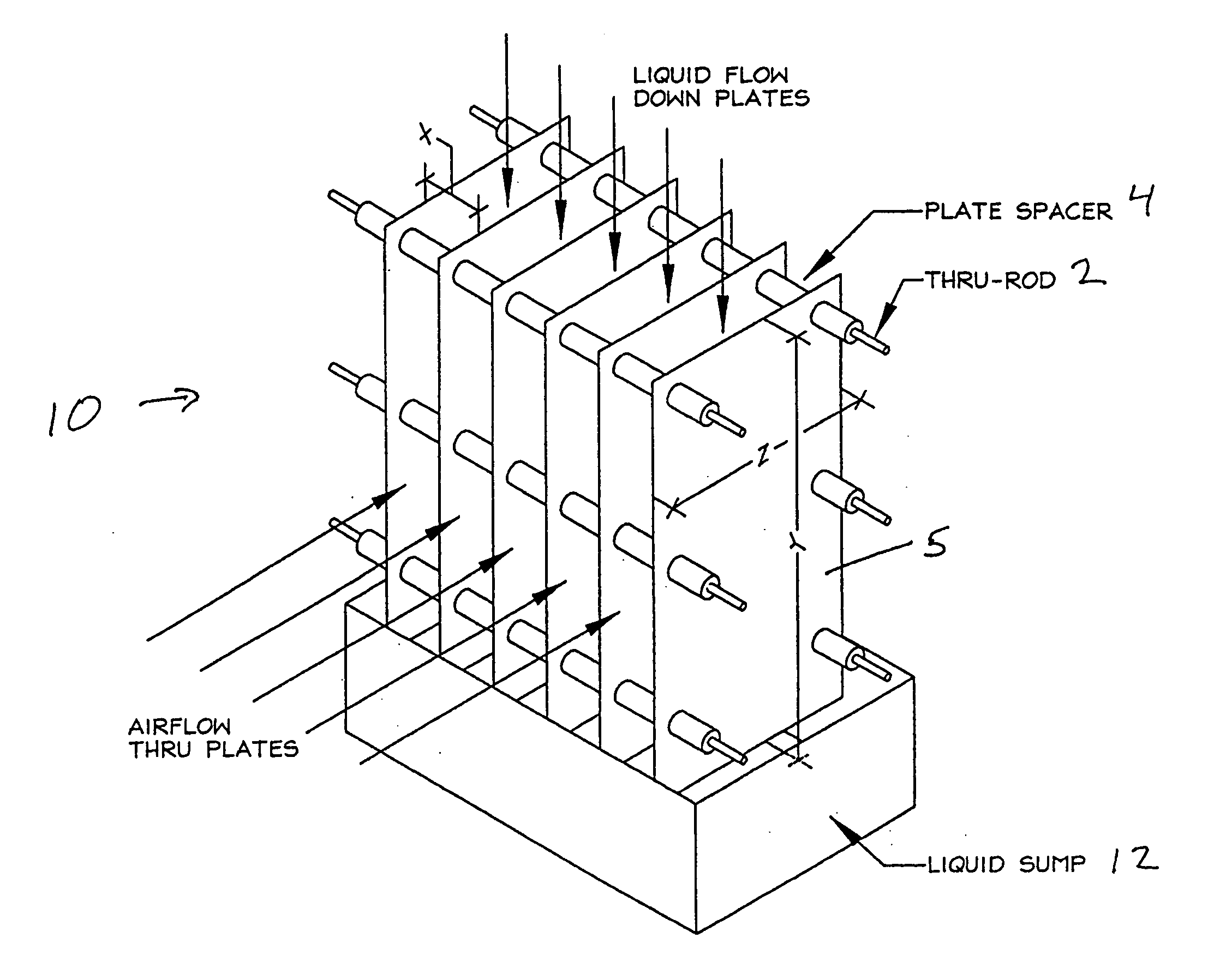

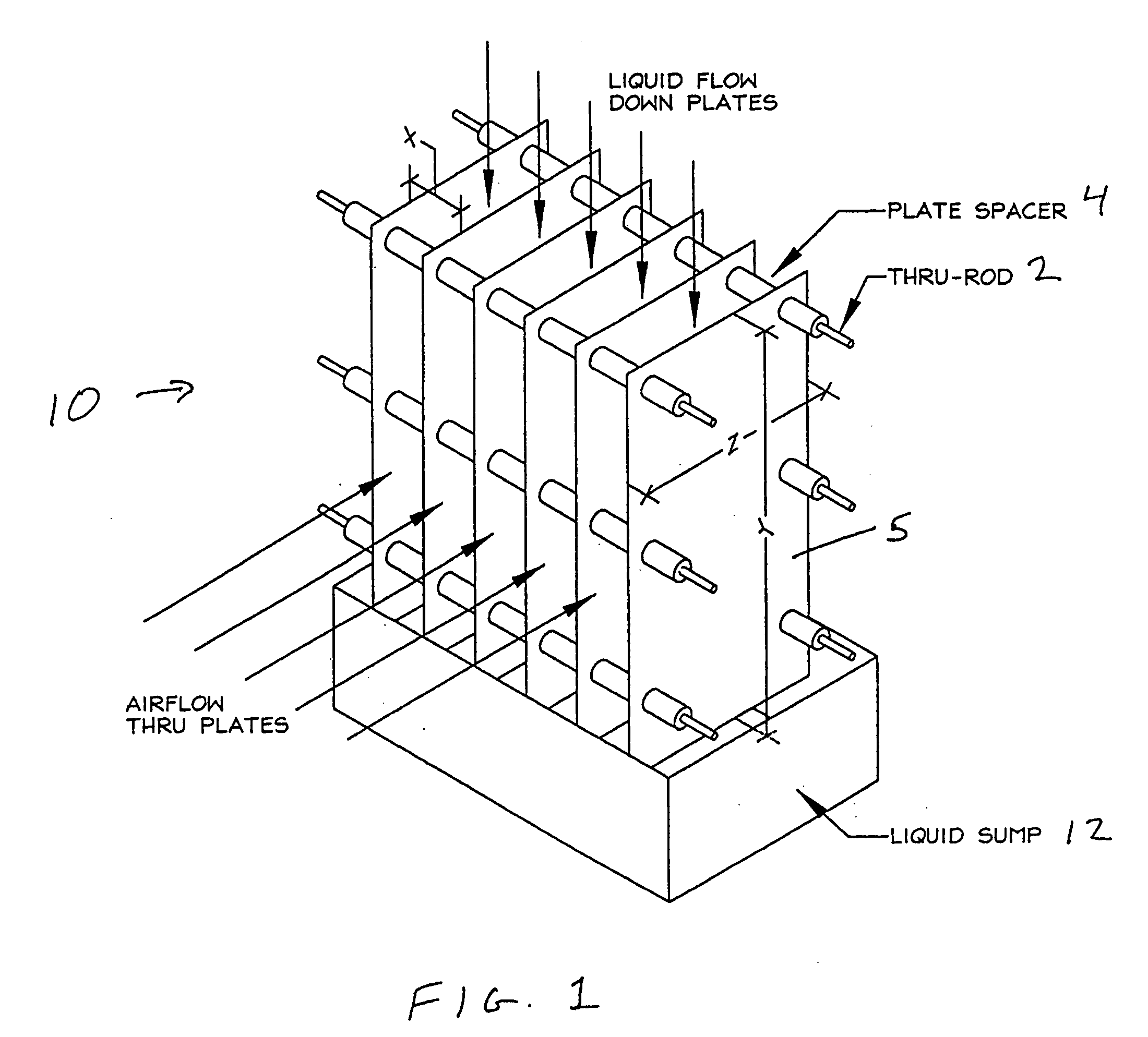

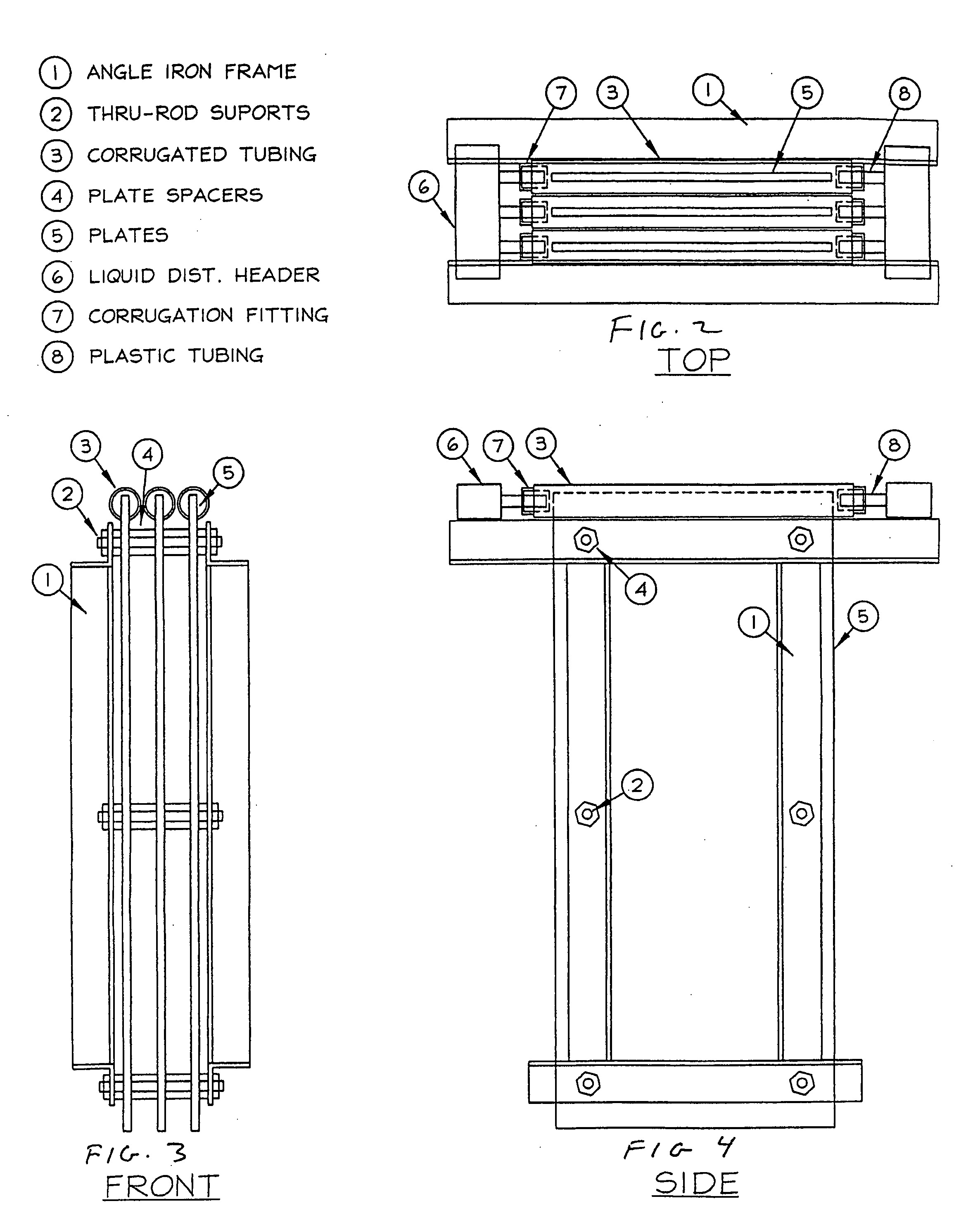

Laminar scrubber apparatus for capturing carbon dioxide from air and methods of use

The present invention is directed to methods for carbon dioxide from air, which comprises exposing solvent covered surfaces to air streams where the airflow is kept laminar, or close to the laminar regime. The invention also provides for an apparatus, which is a laminar scrubber, comprising solvent covered surfaces situated such that they can be exposed to air streams such that the airflow is kept laminar.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

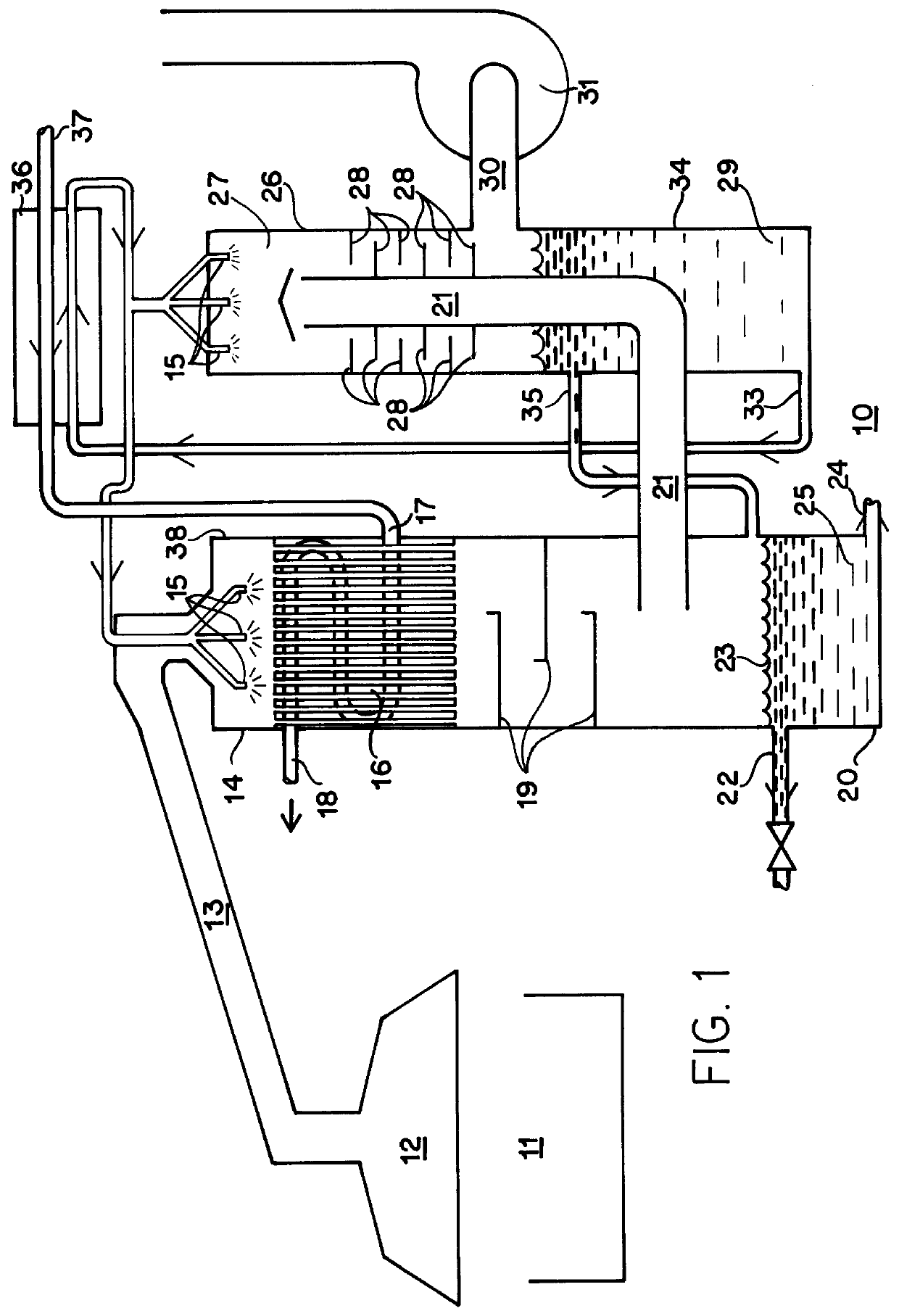

Apparatus and method for extracting heat from contaminated waste steam

InactiveUS6019819ALess energyHotter cooling water temperatureCombination devicesAuxillary pretreatmentAtmospheric airEngineering

Disclosed is a contaminated waste steam heat recovery apparatus 10 and method therefore which includes a primary condensing unit 38, a low pressure water washing unit 26, a liquid to liquid heat exchanger 36 and a vent fan 31. Waste gas is ducted from fryer 11 to a de-super-heating chamber 14 wherein superheated steam is converted to saturated steam by spraying water into the steam using spray nozzles 15. The gas is then introduced into a vertically disposed air to liquid heat exchanger 16 and is drafted downward therethrough. As heat is removed from the waste gas, water vapor in the steam condenses and in the process, collects some of the oil and hydrocarbons present. A plurality of condensate trays 19 are disposed below the bottom end of heat exchanger 16 in a cascading fashion to collect hold the condensate in the airflow path such that it will absorb some of the heat still present in the remaining waste gas. An oil outlet 22 is provided at the top of collection basin 22 for drawing off concentrated oil 23. The waste gas is pulled into a low pressure water washer 26 where it is washed by a second set of spray nozzles 15. Waste gas and water are sucked downward through a set of turbulence inducing baffles 28. The remaining waste gas is sucked out though exhaust tube 30, using vent fan 31, and vented to the atmosphere.

Owner:ALPHA ENGINEERS

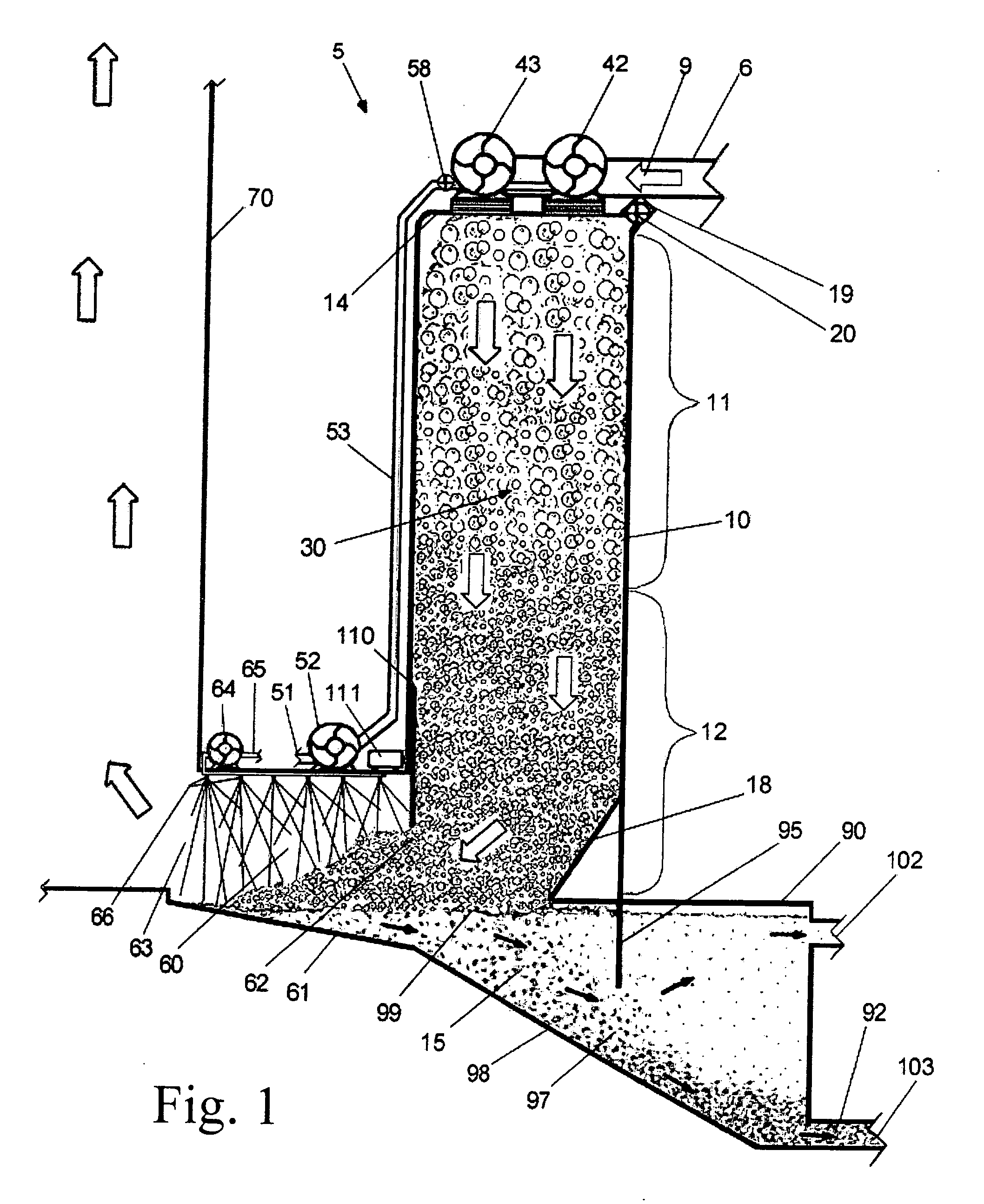

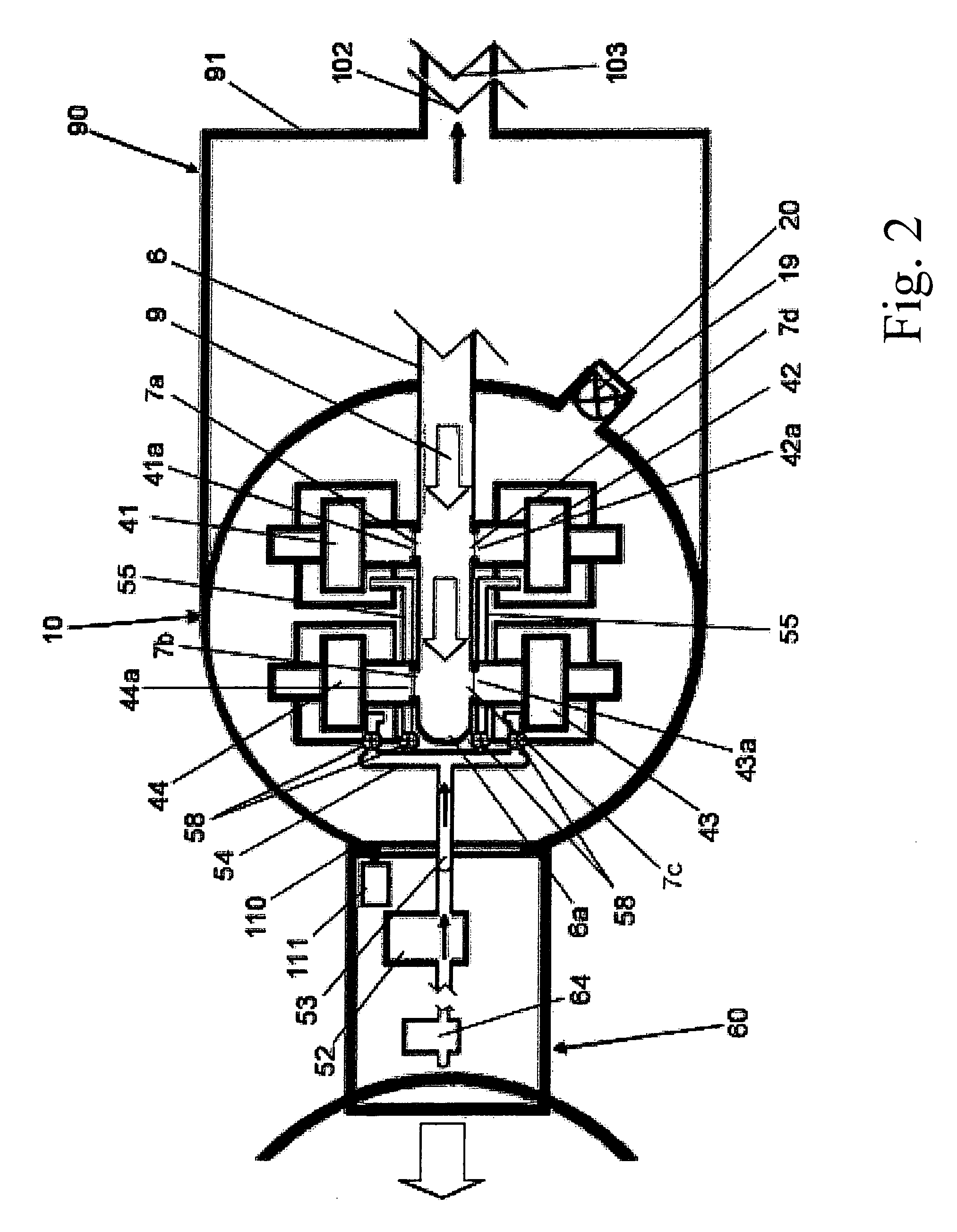

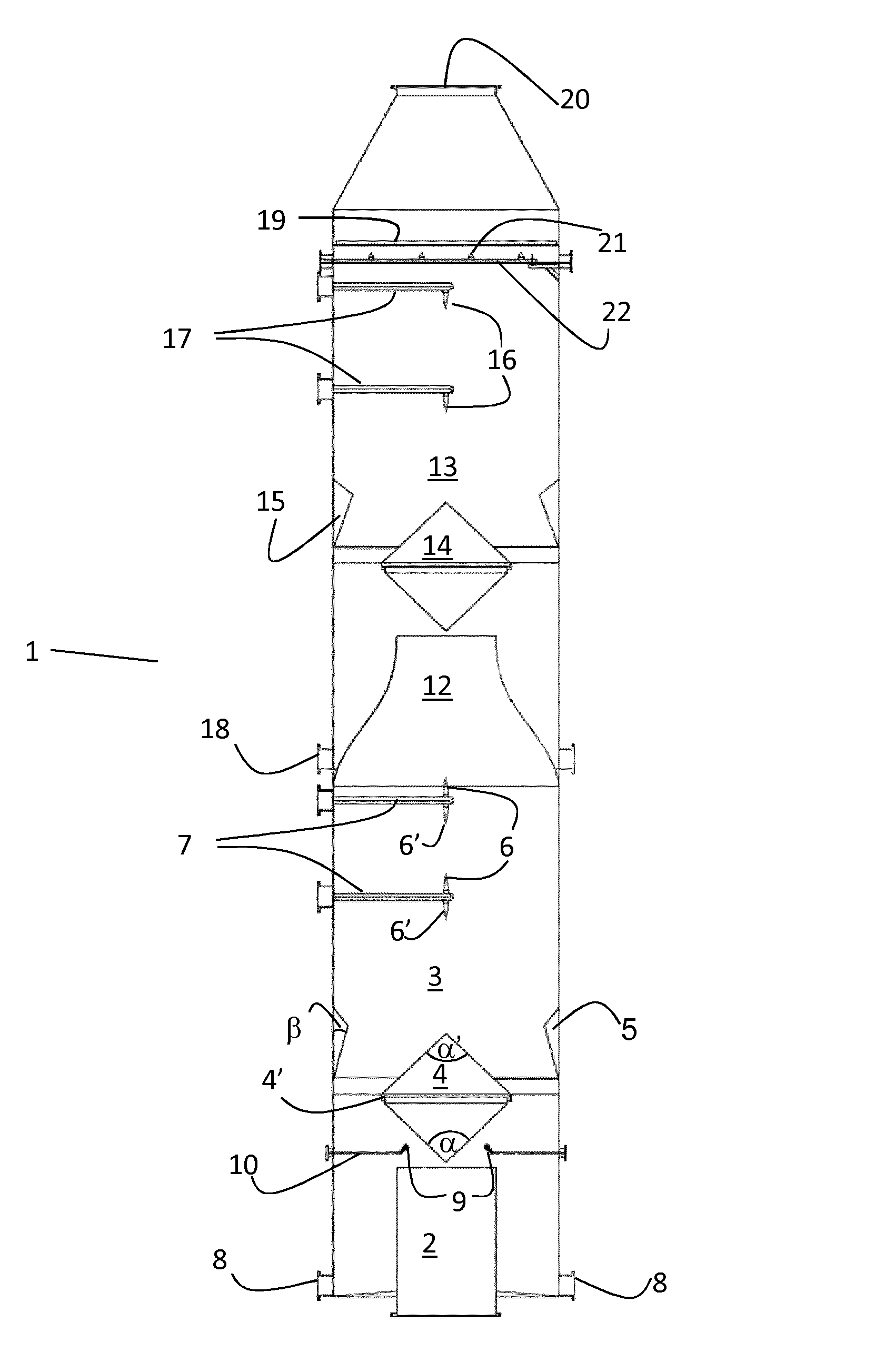

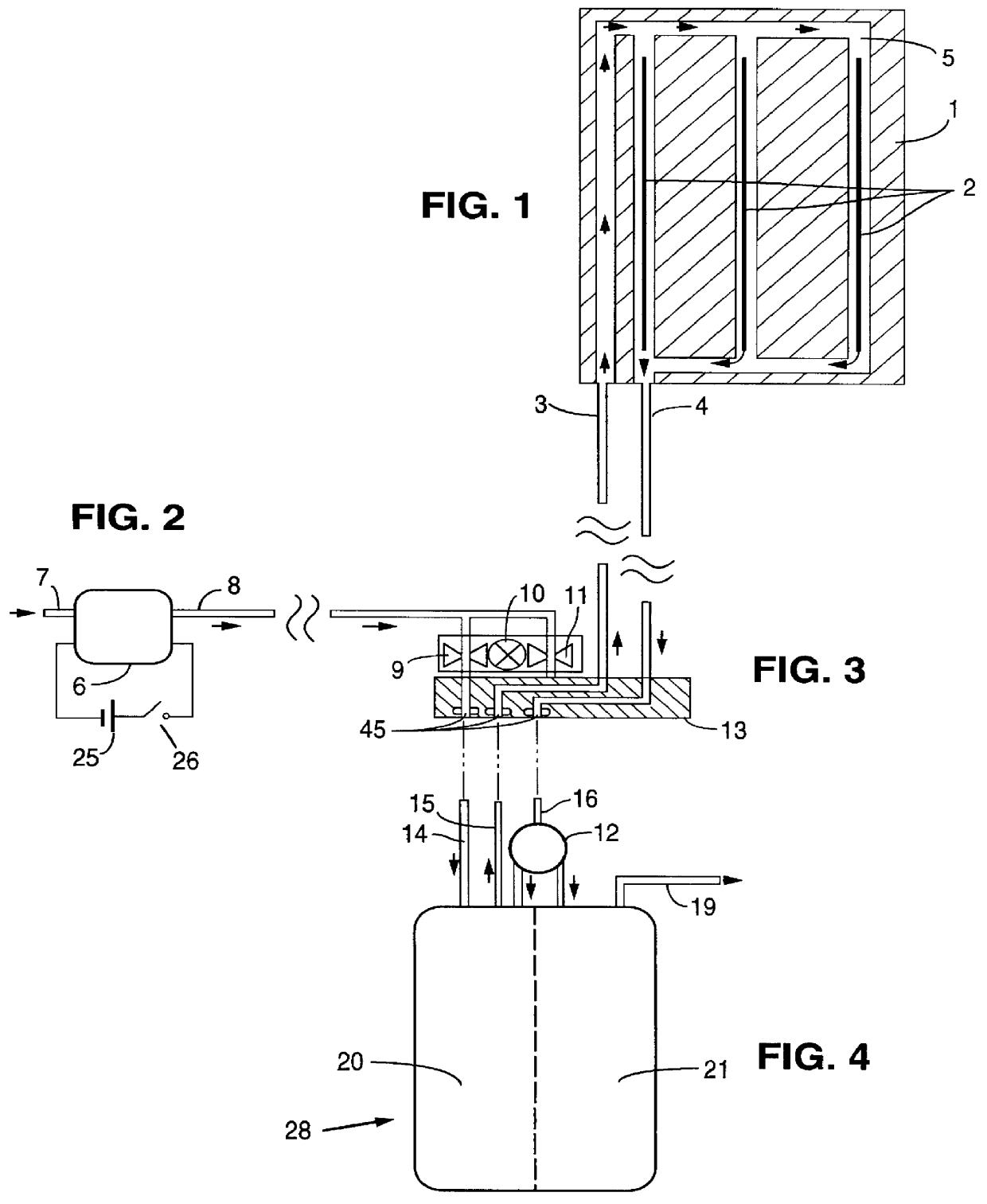

Marine exhaust gas scrubber

ActiveUS20160016109A1Easy constructionEffective dissolutionCombination devicesGas treatmentExhaust fumesEnvironmental engineering

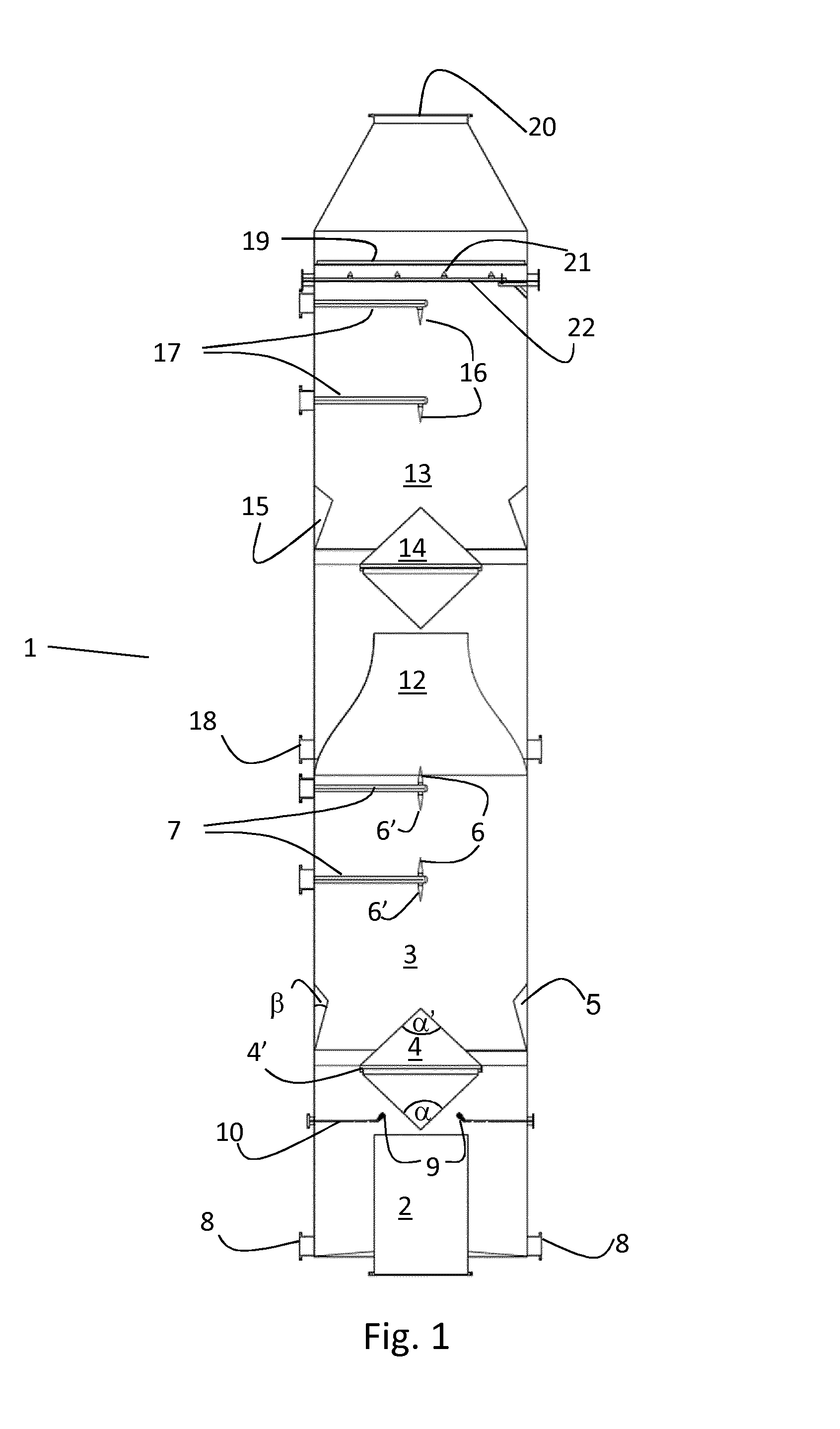

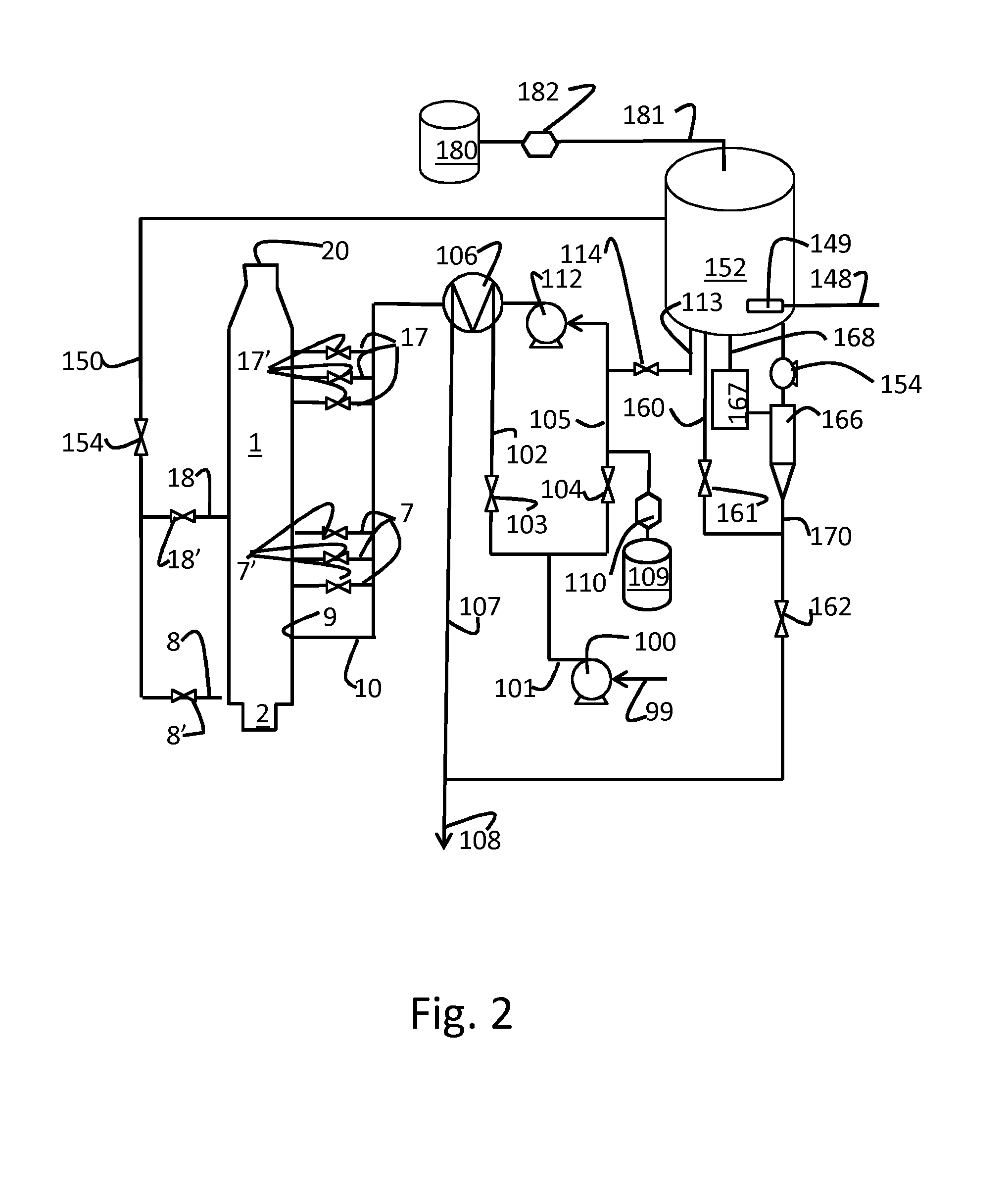

A vertical scrubber (1) for exhaust gas from a marine vessel is described. An exhaust gas tube (2) is substantially coaxially arranged through the bottom of a lower scrubbing chamber (3) and is released though an exhaust gas outlet (20) being coaxially arranged through the top of an upper scrubbing chamber (13). A lower scrubbing chamber deflection body (4) is arranged above the opening of the exhaust gas tube (2) for redirecting the exhaust gas towards the walls of the scrubber and create turbulent gas flow, where one or more lower chamber water injector(s) (6, 6′) is (are) arranged above the lower scrubbing chamber deflection body (4), to introduce scrubbing water, and where a lower chamber exhaust gas outlet (12) is arranged at the top of the lower scrubbing chamber (3) as a coaxial constriction, for withdrawing the partly scrubbed exhaust gas from the first scrubbing chamber and introducing the gas into the upper scrubbing chamber (13).

Owner:MARINE GLOBAL HLDG

Scrubber to Remove Personally Identifiable Information

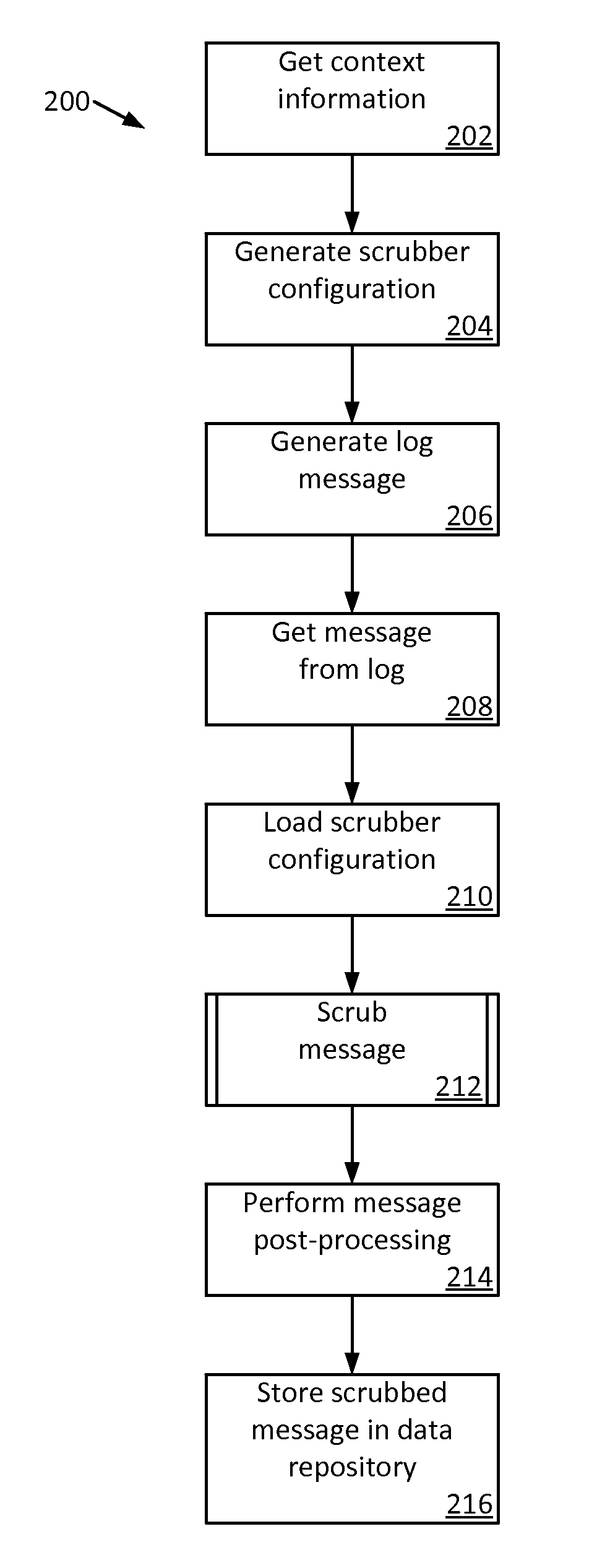

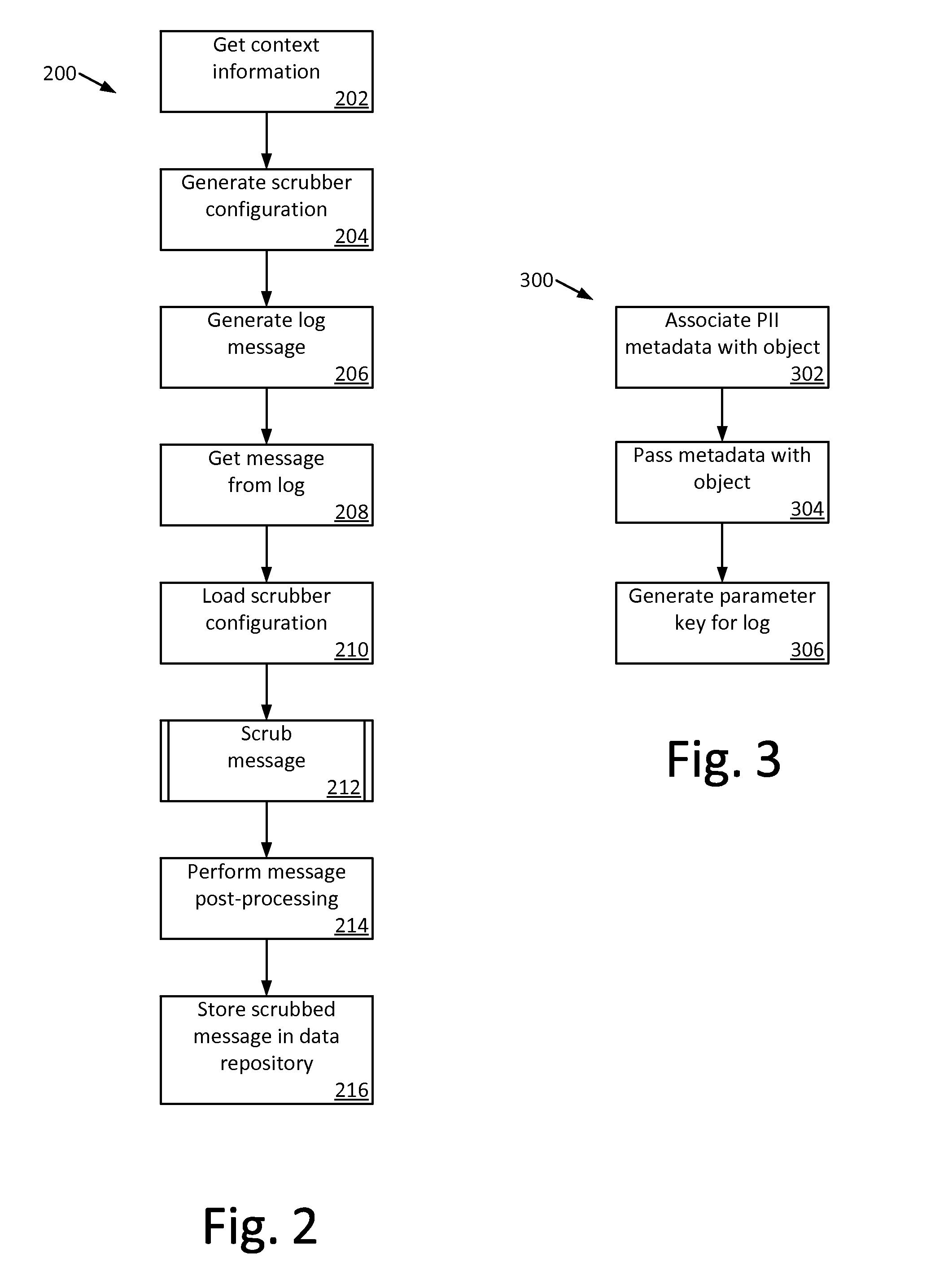

ActiveUS20150213288A1Quick and easy to createQuickly and easily and modifiedDigital data processing detailsAnalogue secracy/subscription systemsSurgical operationSurgical Scrubbing

A personally identifiable information (PII) scrubbing system. The PII scrubbing system surgically scrubs PII form a log based on a scrubber configuration corresponding to the log. The scrubber configuration includes context information about locations and types of PII in the log and rules specifying how to locate and protect the PII. Scrubber configurations are quickly and easily created or modified as scrubbing requirements change or new scenarios are encountered. The flexibility provided by the scrubber configurations allows only the PII to be scrubbed, even from unstructured data, without having to include surrounding data. Many consumers can use the scrubbed data without needed to expose the PII because less non-personal data is obscured. Surgical scrubbing also retains the usefulness of the underlying PII even while protecting the PII. Consumers can correlate the protected PII to locate specific information without having to expose additional PII.

Owner:MICROSOFT TECH LICENSING LLC

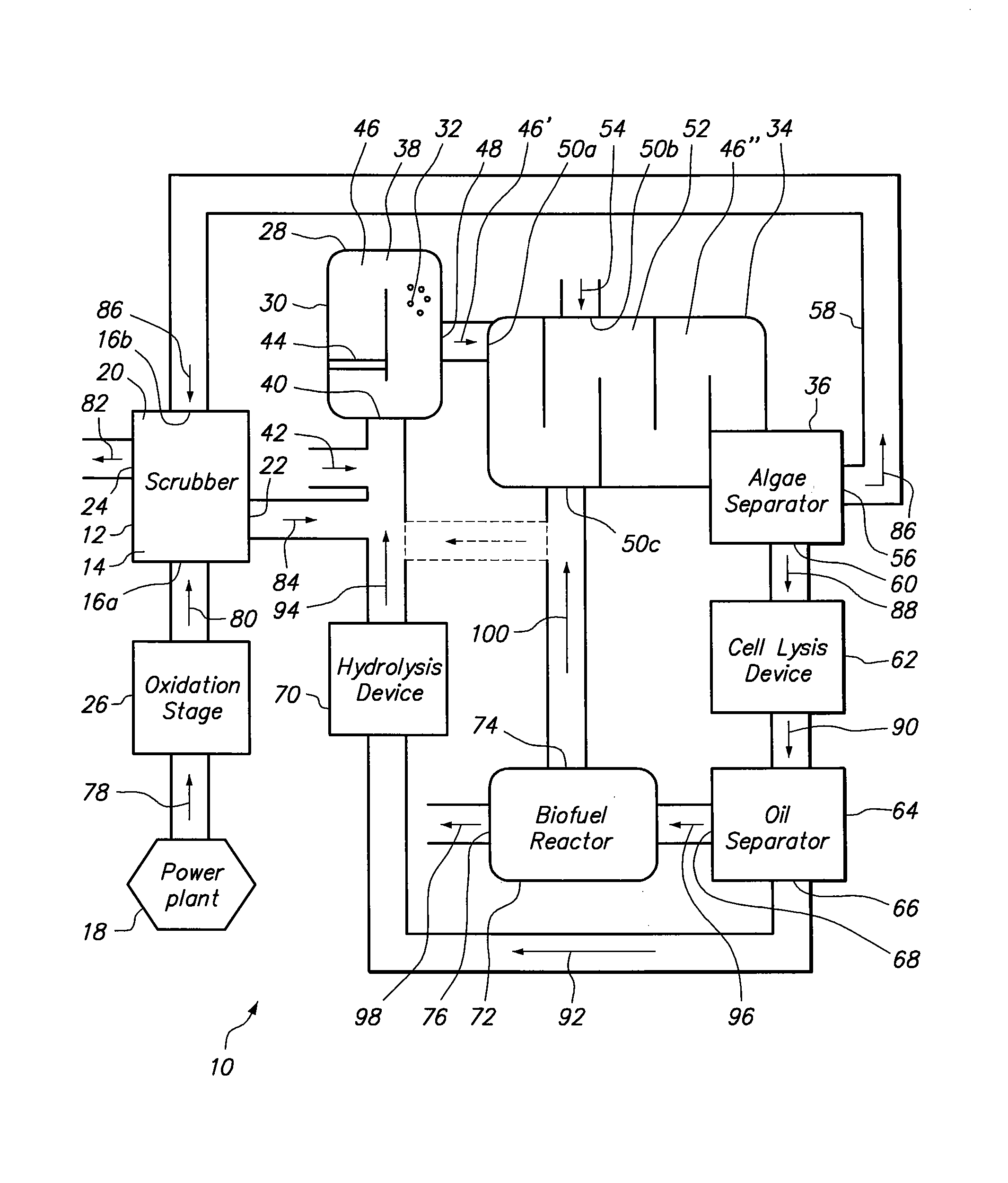

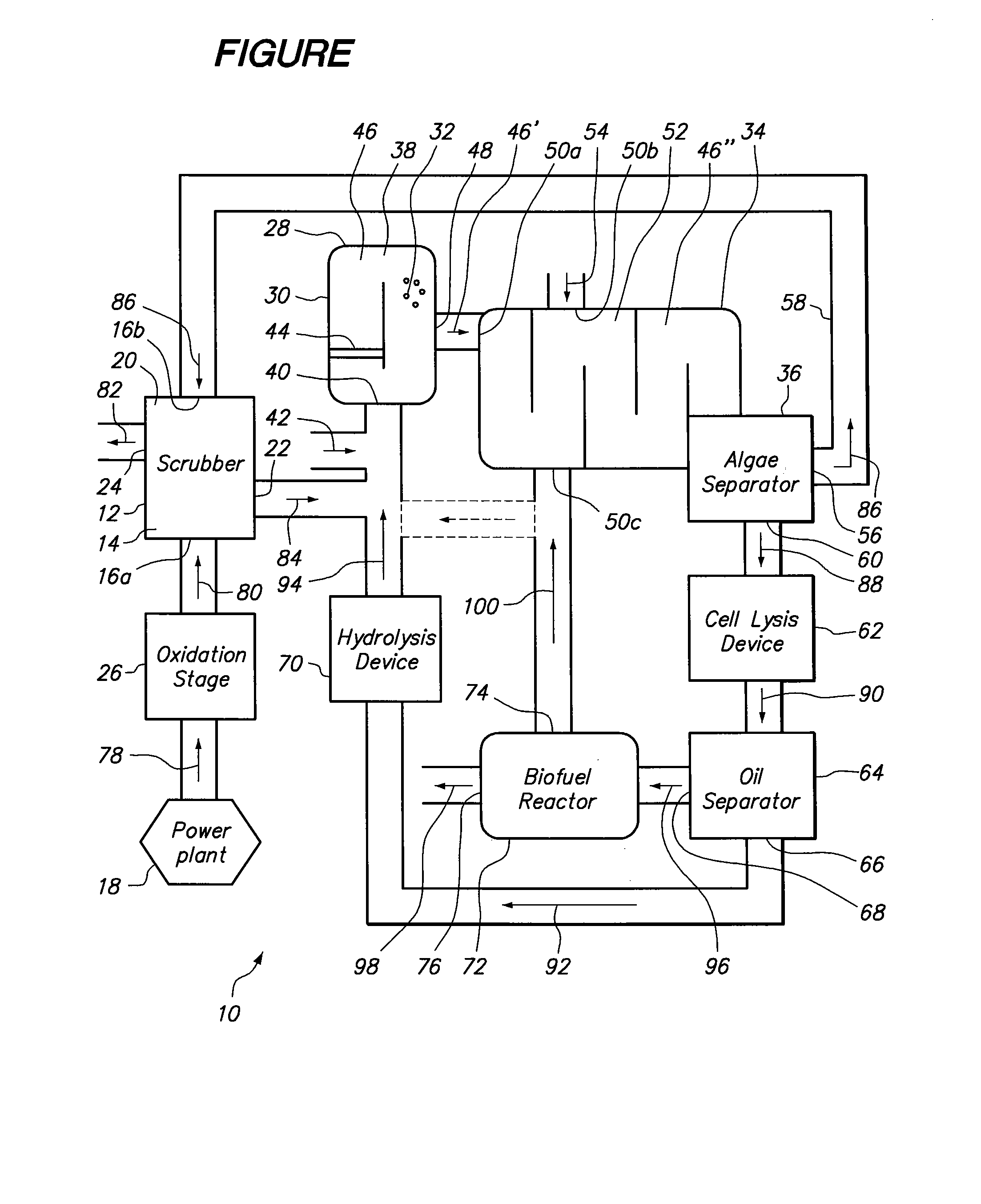

Photosynthetic carbon dioxide sequestration and pollution abatement

InactiveUS20080086938A1High oil contentBioreactor/fermenter combinationsBiological substance pretreatmentsBiofuelCell growth

A system and method for producing biofuel from pollutant-fed algae are disclosed. Specifically, the system includes a scrubber with a chamber for receiving a pollutant-contaminated fluid stream. Further, a scrubber solution is received in the chamber for scrubbing the pollutant-contaminated fluid stream. Also, the system includes a bioreactor that is provided with an input port to receive the scrubber solution with pollutants for use as nutrients to support algae cell growth. Further, the system includes an algae separator that removes the algae from the bioreactor and a device for processing the algae into biofuel. In order to recycle the scrubber solution, the algae separator is in fluid communication with the scrubber. With this arrangement, the effluence from the bioreactor may be recycled for use as the scrubber solution.

Owner:GENERAL ATOMICS

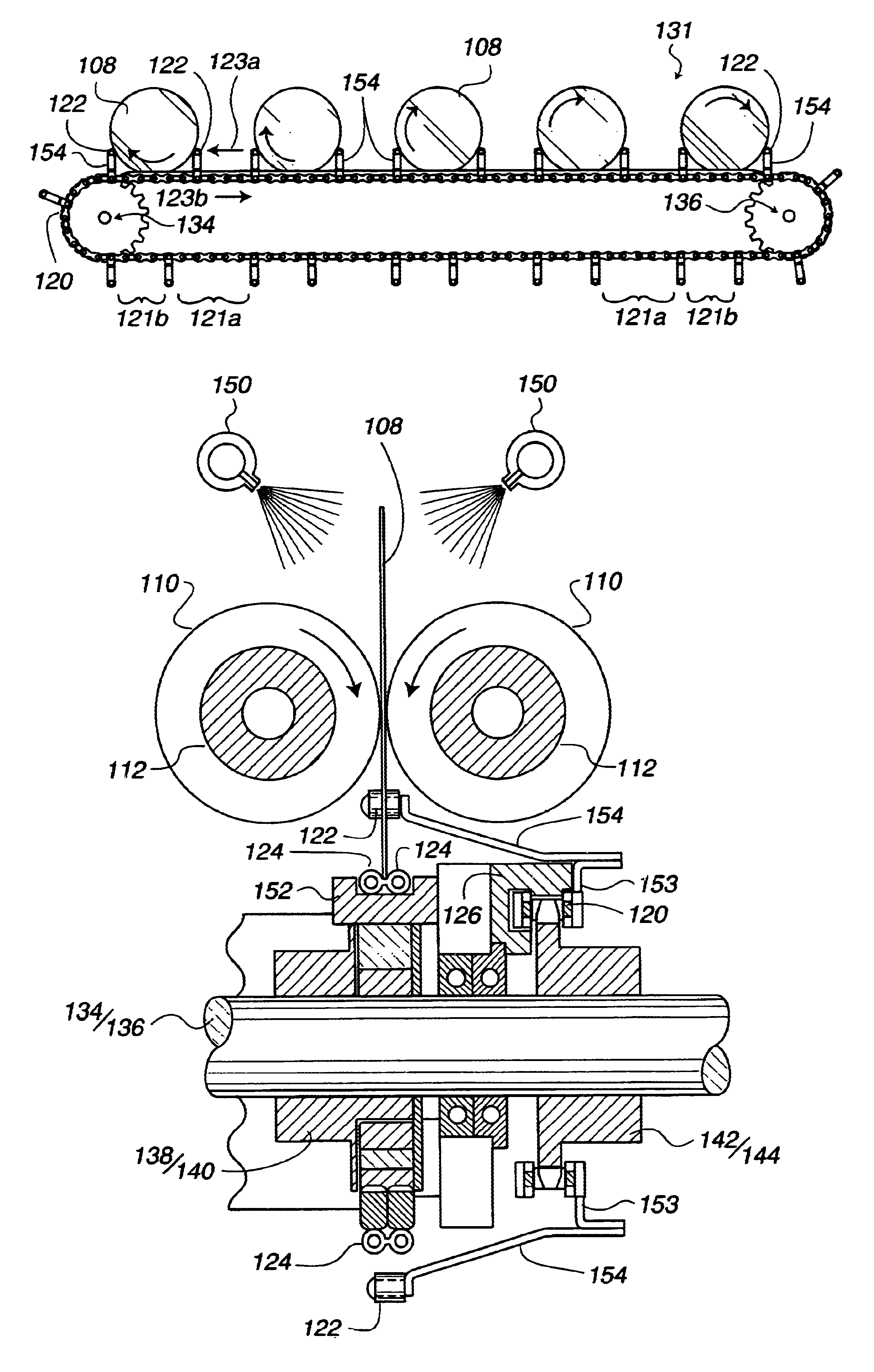

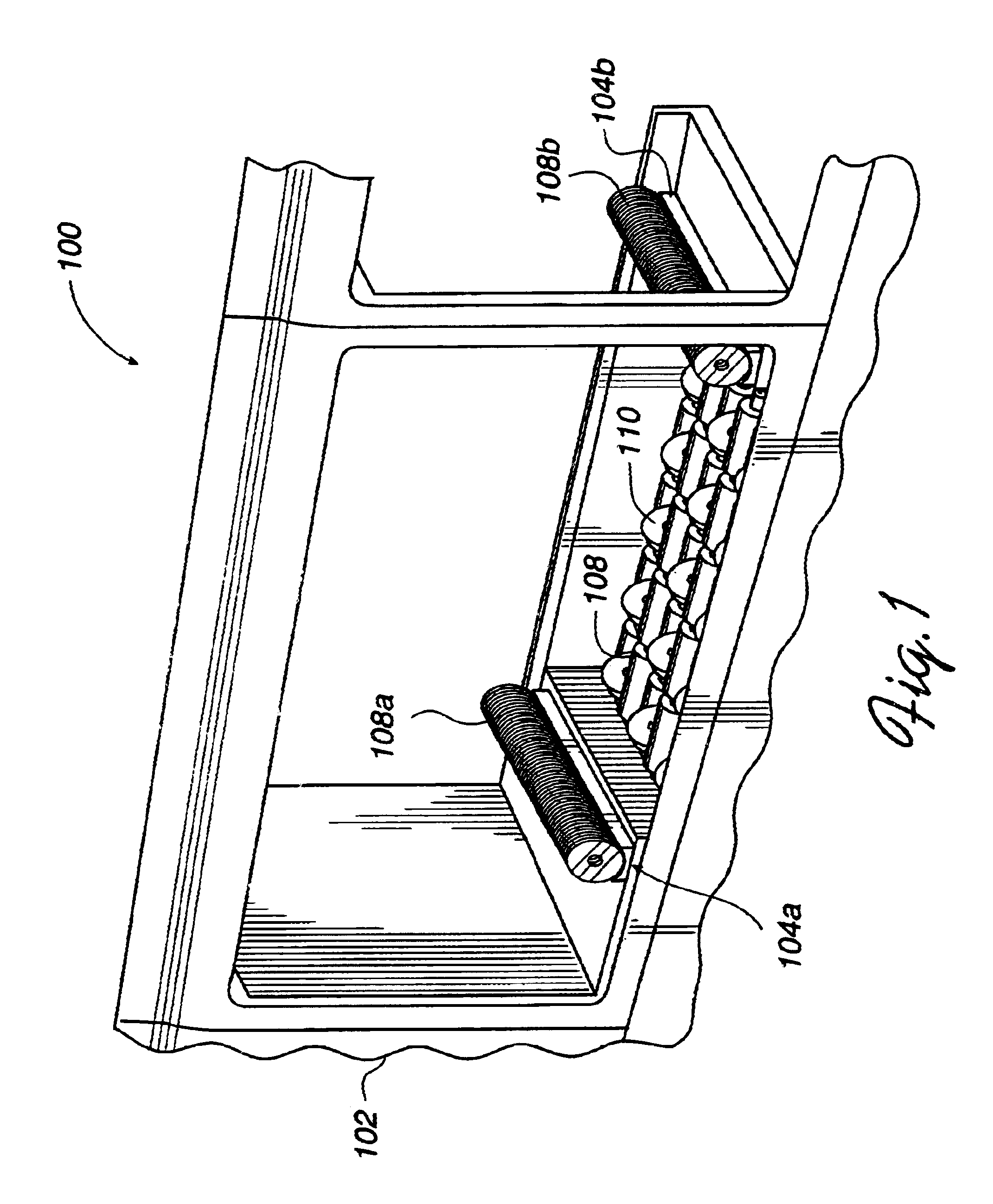

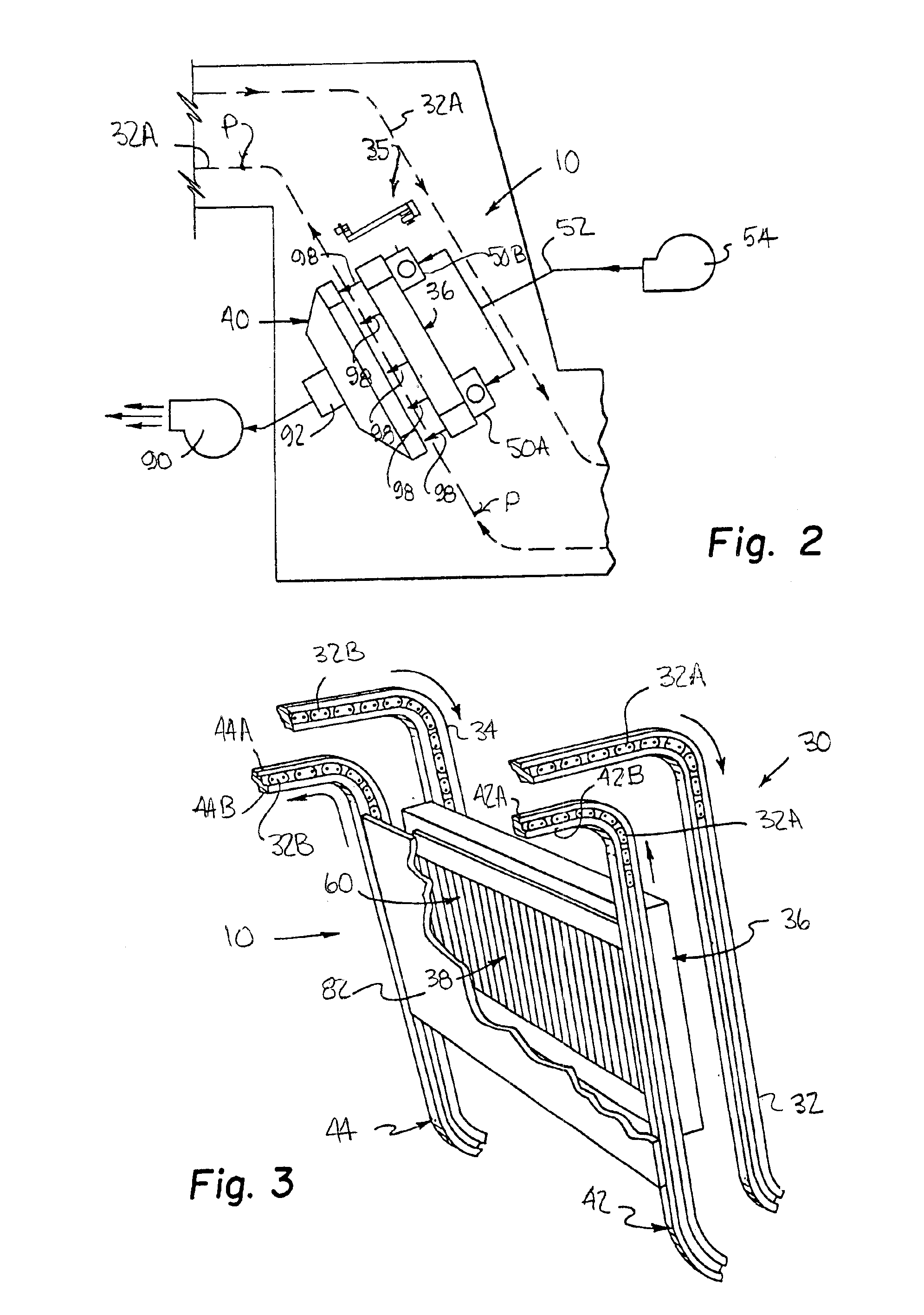

Disk cascade scrubber

A cascaded disk scrubbing system and method are provided. The cascaded disk scrubbing system includes an array of rows of brush pairs. Each row includes a plurality of counter-rotating brush pairs that are arranged horizontally and longitudinally, and configured to receive and process a disk in a vertical orientation through disk preparation zones defined by each pair of brushes. Below and between the pairs of brushes is a track that is configured to apply a rotation to the disk and to transition the disk in a vertical orientation through the brush pairs. Nozzles dispense fluids on and over the brush pairs, and the brush pairs are configured such that fluids are dispensed through the brush pairs. Nozzles dispense a curtain of fluid between each disk preparation zone, and the cascaded disk scrubbing system is configured to progress from dirtiest to cleanest as the disk transitions through each disk preparation zone.

Owner:LAM RES CORP +1

Power saving automatic zoned dryer apparatus and method

InactiveUS6877247B1Eliminates and greatly reduces needImprove paper qualityDrying solid materials with heatDrying gas arrangementsAuto regulationEngineering

A computer controlled power saving automatic zoned dryer for a printing press has a dryer head facing the substrate travel path, having a multiplicity of IR lamps connected individually or in groups to form a plurality of heating zones running longitudinally and each extending laterally side by side across the substrate travel path. The radiant heat output of each heating zone is controlled separately by means of a control unit connected to a power supply. The control unit individually regulates output of the heating zones. Unneeded zones are turned off to reduce cost of power and conserve energy. A plurality of heat sensors spaced laterally across the substrate path measure the surface temperature of substrate heated areas corresponding to the heating zones being operated and maintain an automatic set point temperature. The temperature of each individual heated area can be regulated automatically by adjusting the output of its heating zone whereby printed substrates having a more even temperature profile are delivered. In an alternate manual mode any zone can be set independently to operate at any percentage of full available power from zero to 100%. Separate high velocity air scrubbers and additional air extraction are used to enhance the total drying effect of the zoned dryer assembly.

Owner:PRINTING RES

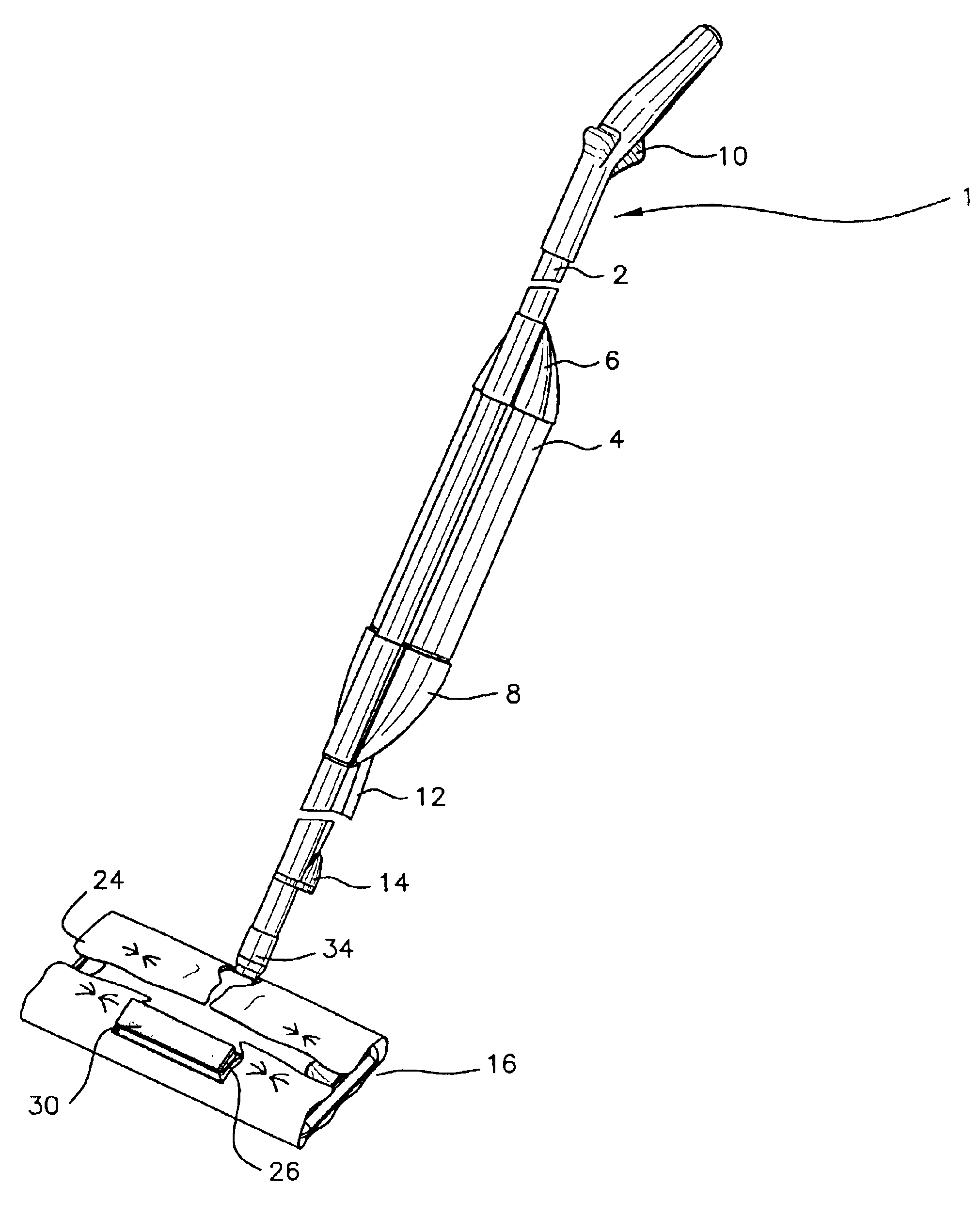

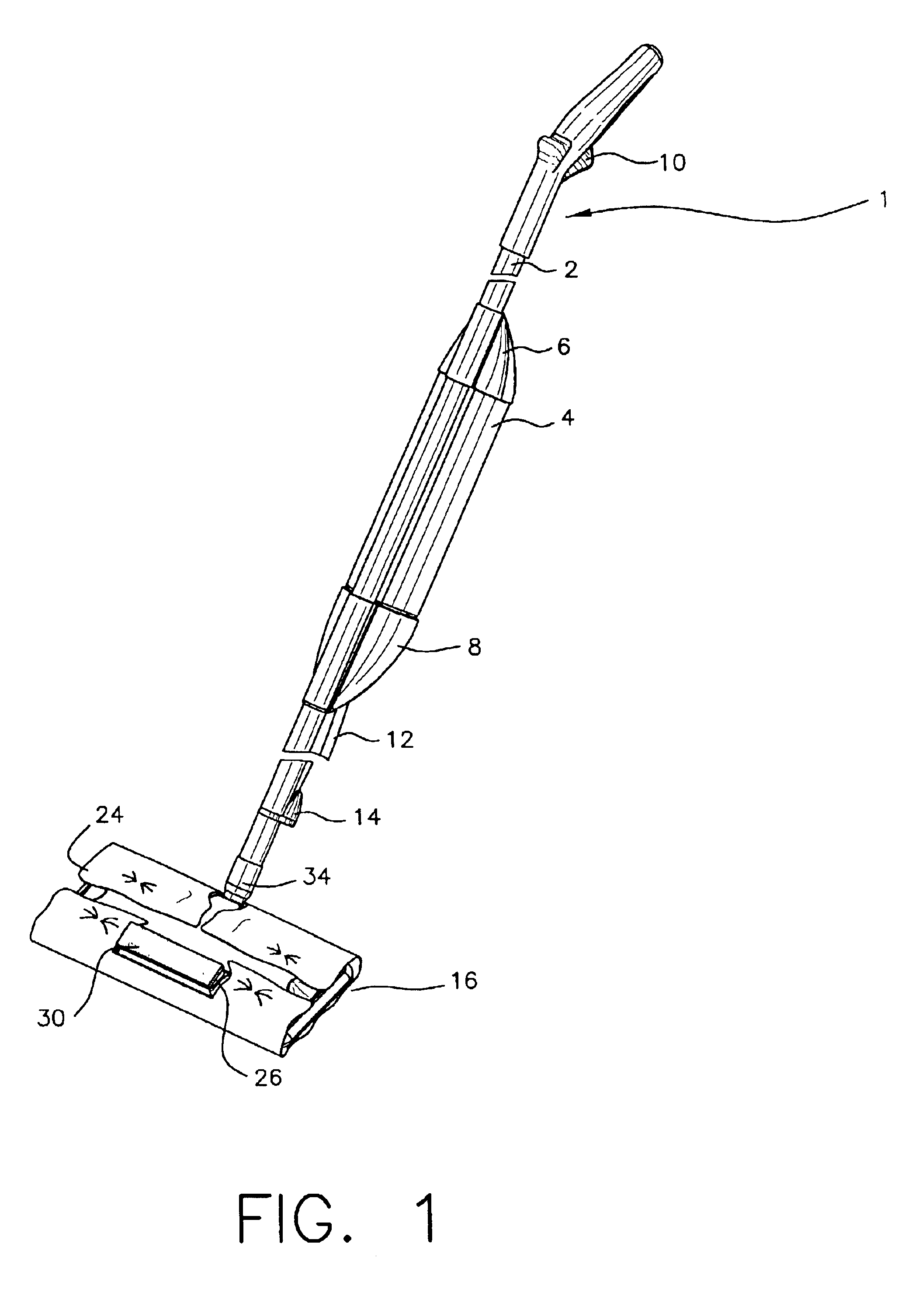

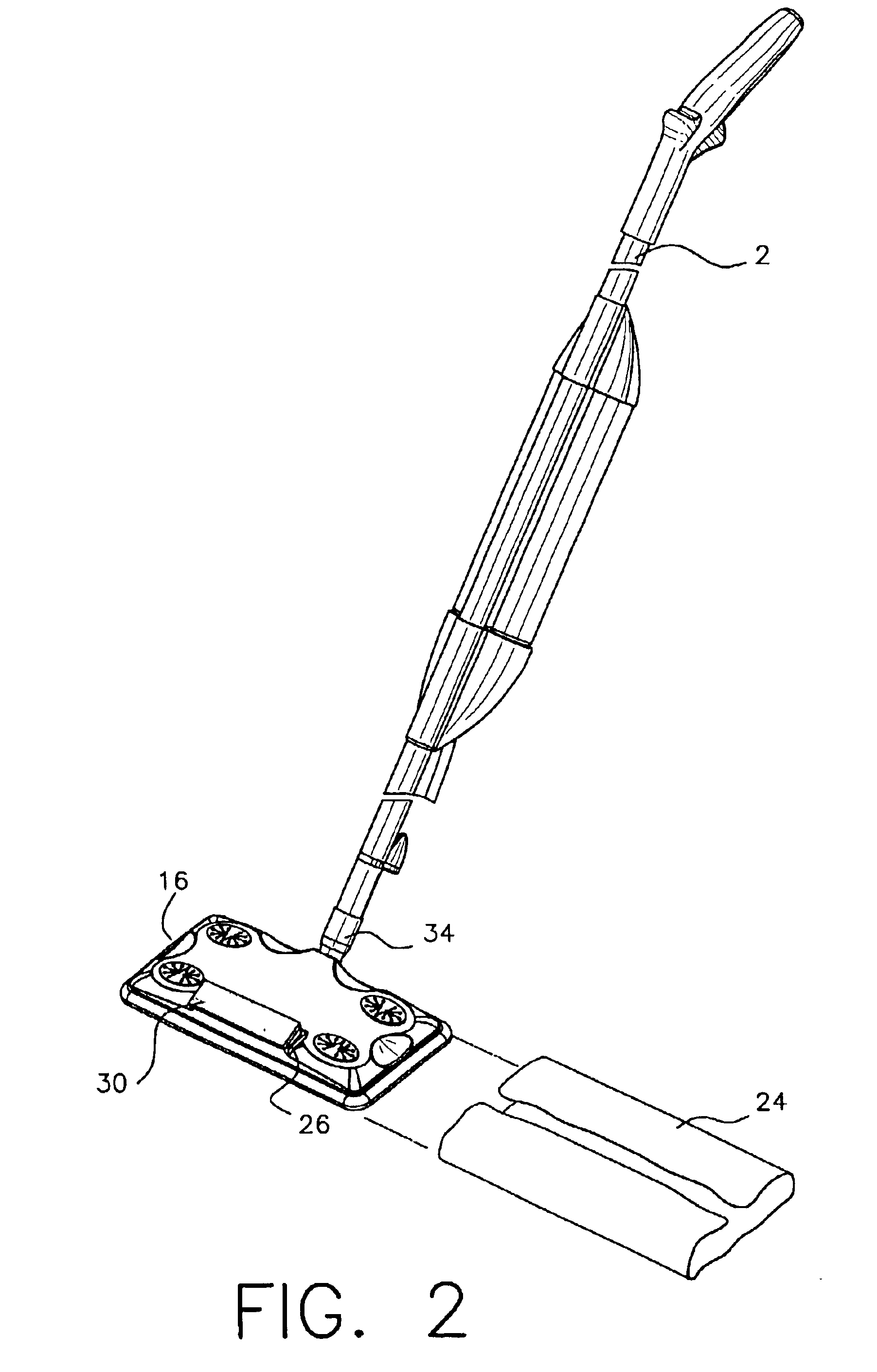

Mop with cleaning head member and scrubber

InactiveUS6871372B2Improve versatilityEasy to useBoard cleaning devicesCarpet cleanersMechanical engineeringScrubber

A mop with a platen-shaped cleaning head member, to be used for dry or wet applications, with or without cleaning sheets, suited to be used as a liquid dispensing mop. An abrasive scrubber support is integrally formed with and extends from the forward upper surface of the cleaning head member. An abrasive scrubber component is secured to the support. The cleaning head member is connected to the mop's handle by a swivel joint which permits easy and ready rotation of the cleaning head member, 360° in relation to the handle. This permits unencumbered positioning of the abrasive scrubber, for efficient and effective cleaning of ingrained soiled surfaces. After this cleaning is completed, the cleaning head member can easily be rotated back to its primary cleaning position.

Owner:QUICKIE MFG

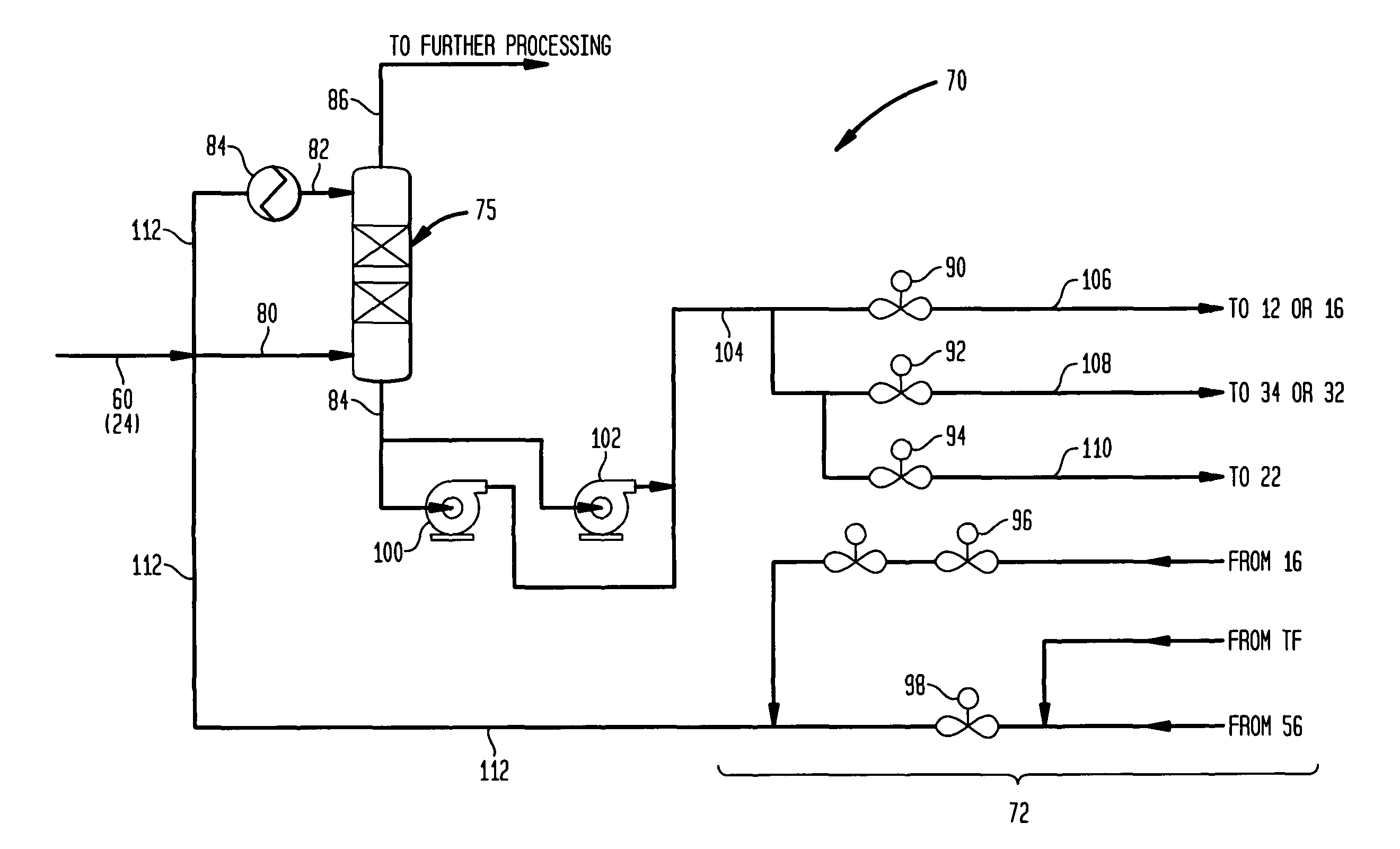

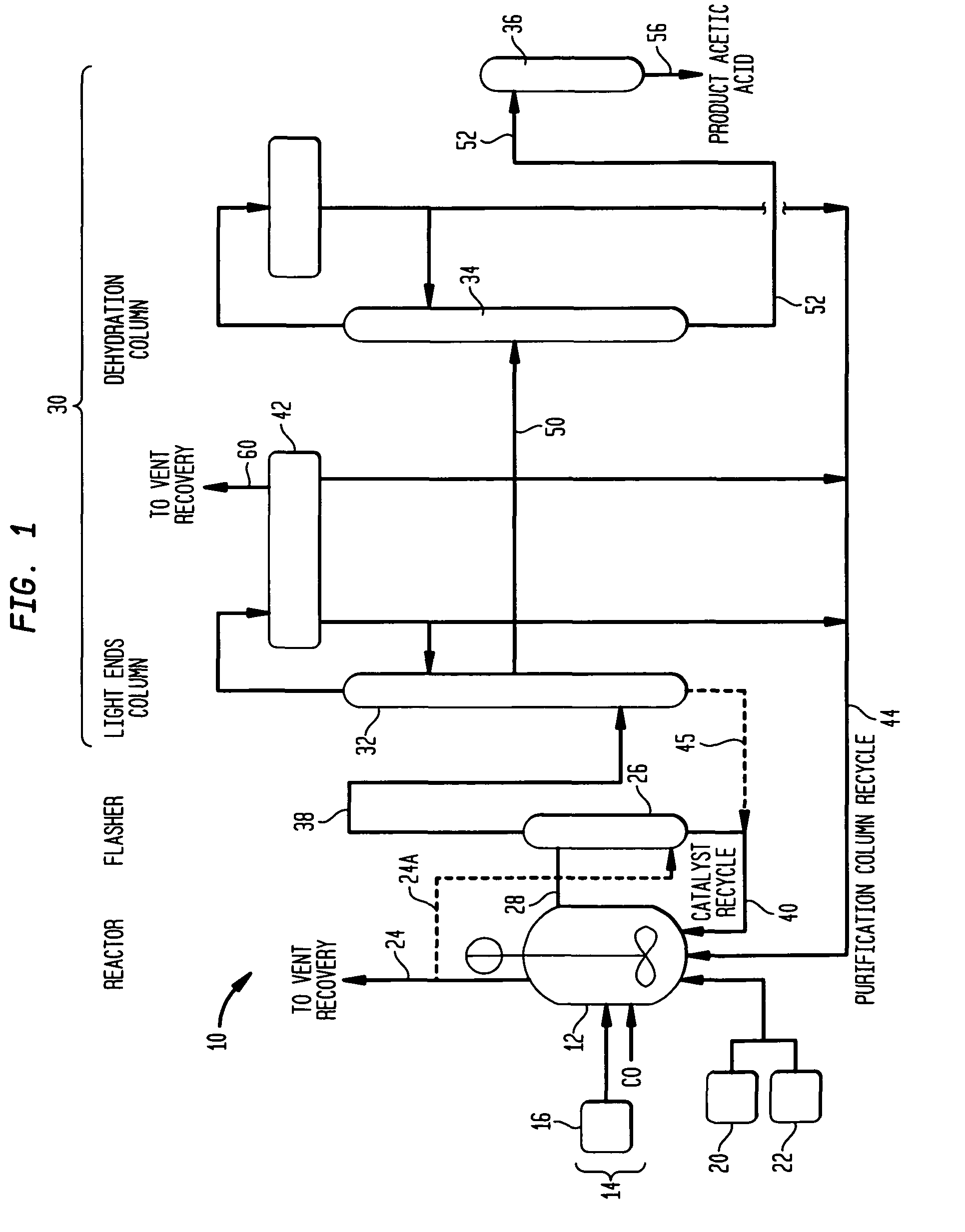

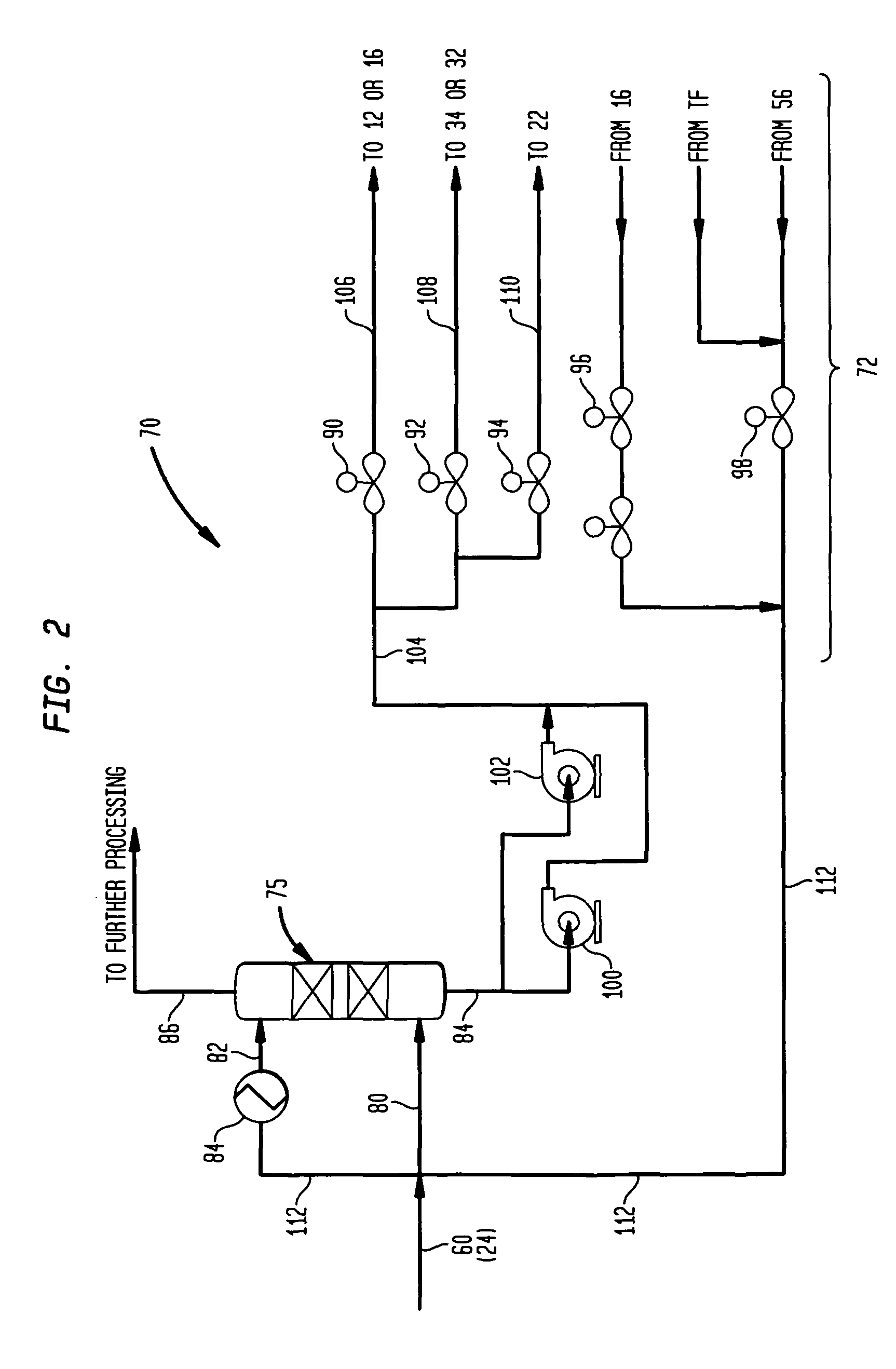

Methanol carbonylation system having absorber with multiple solvent options

A methanol carbonylation system 10 includes an absorber tower 75 adapted for receiving a vent gas stream and removing methyl iodide therefrom with a scrubber solvent, the absorber tower being coupled to first and second scrubber solvent sources 16, 56 which are capable of supplying different first and second scrubber solvents. A switching system including valves 90, 92, 94, 96, 98 alternatively provides first or second scrubber solvents to the absorber tower and returns the used solvent and sorbed material to the carbonylation system to accommodate different operating modes.

Owner:CELANESE INT CORP

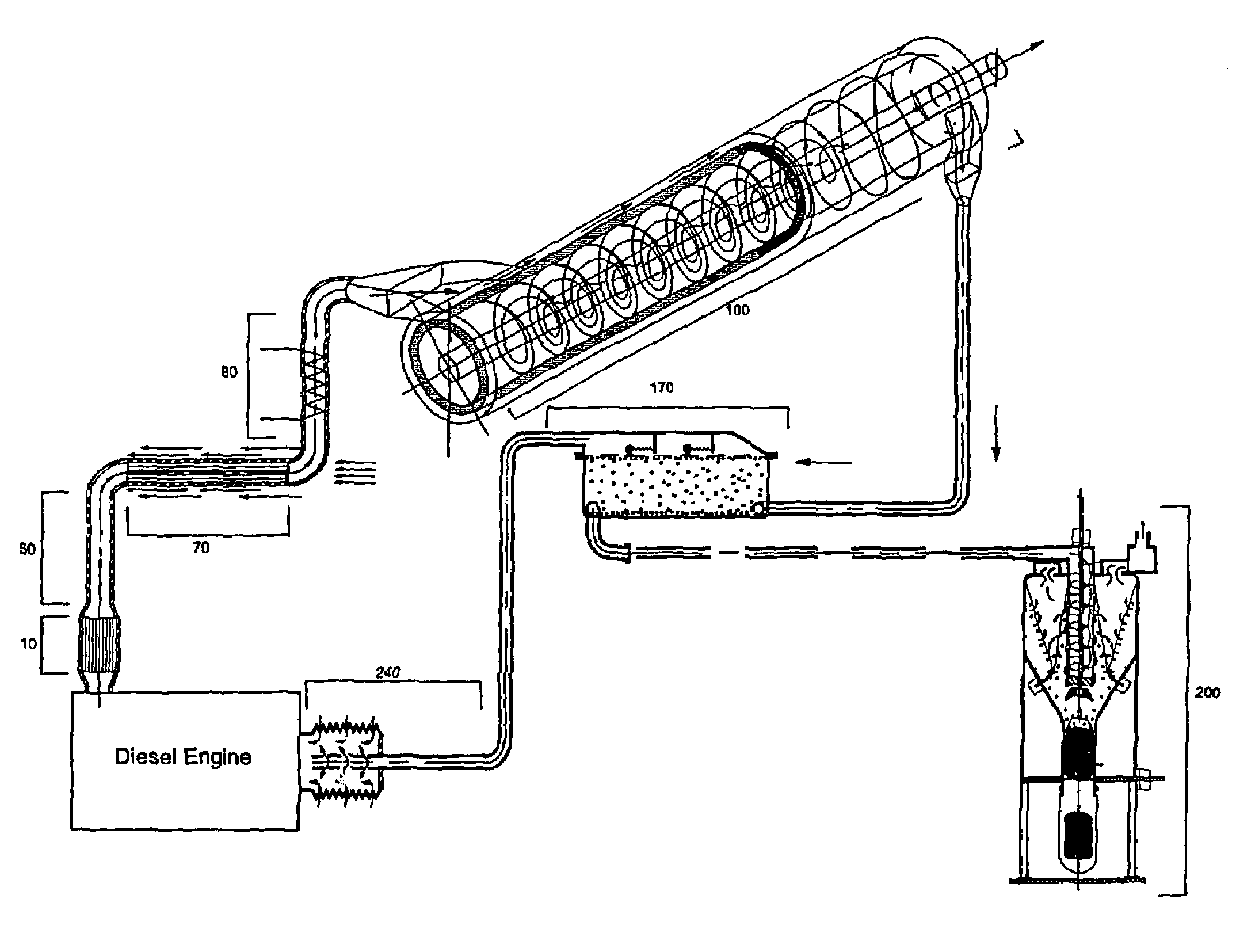

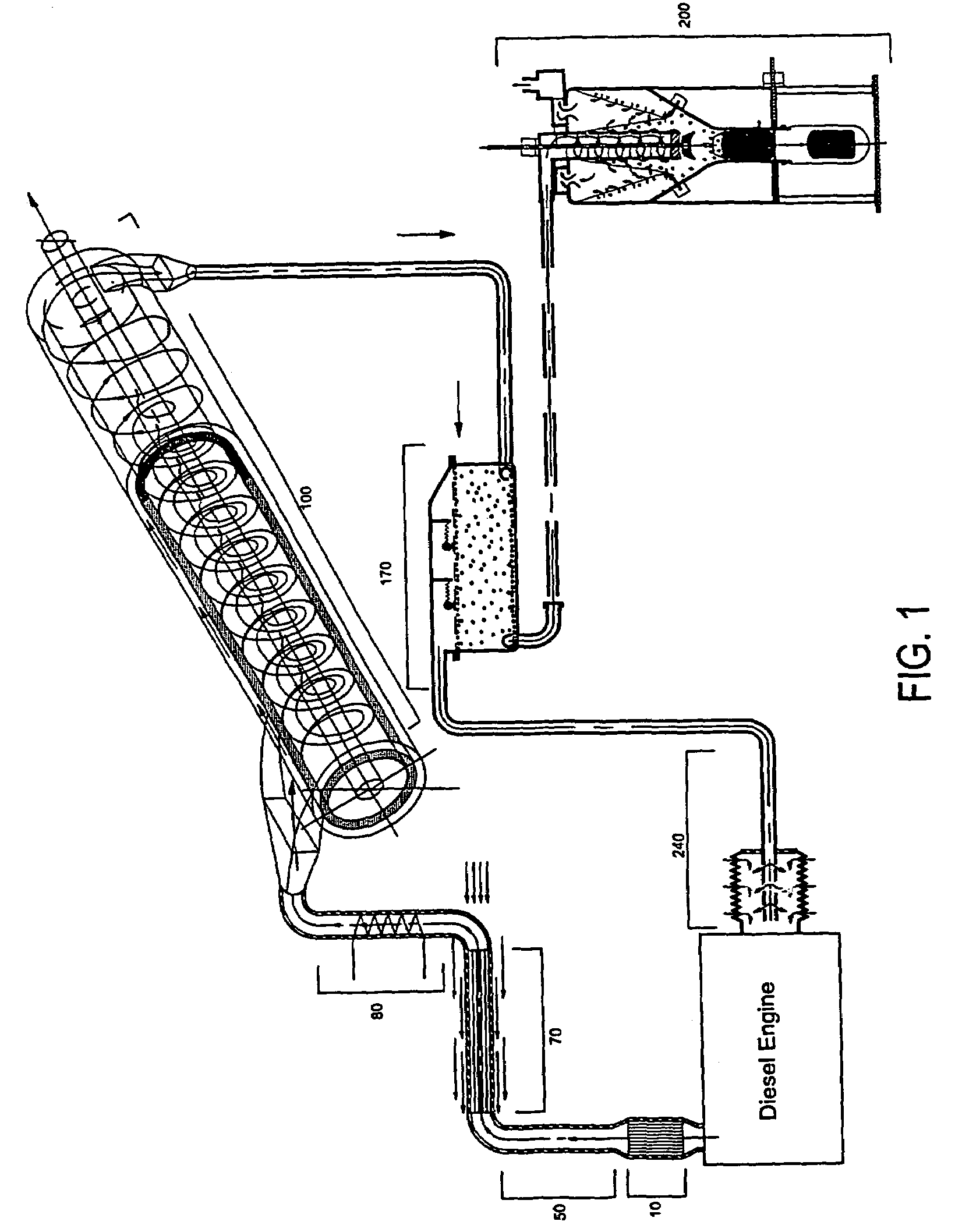

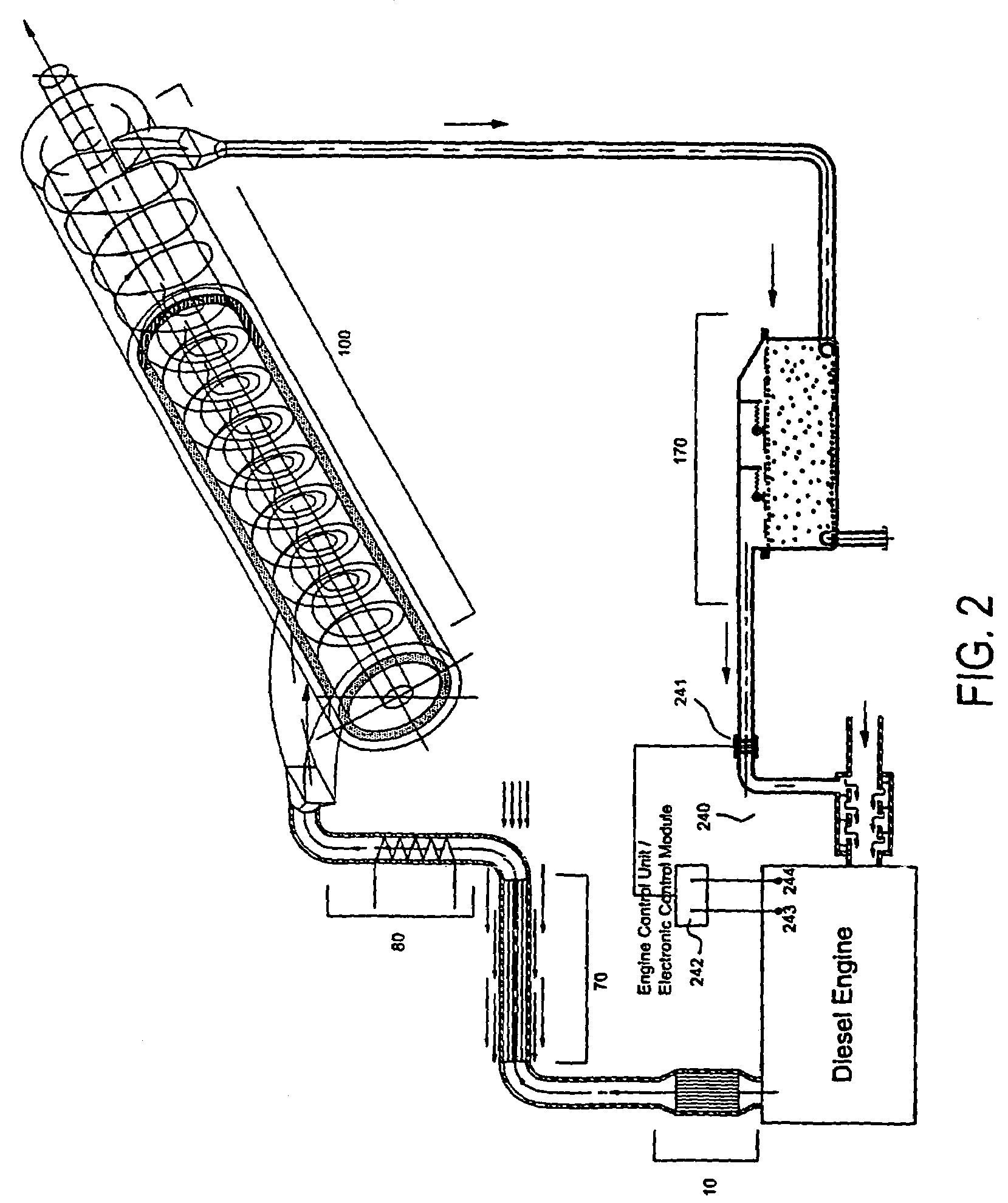

Exhaust after-treatment system for the reduction of pollutants from diesel engine exhaust and related method

InactiveUS7266943B2Easy to separateLower overall pressure dropCombination devicesInternal combustion piston enginesParticulatesAfter treatment

Exhaust after-treatment system for the reduction of particulate, NOx, HC, CO, VOCs, nano-particle count and sulfur dioxide from diesel exhaust. System employs diesel oxidation catalyst, exhaust cooling system, particulate converter, soot collection chamber, soot processing drum, EGR and water scrubber.

Owner:KAMMEL REFAAT

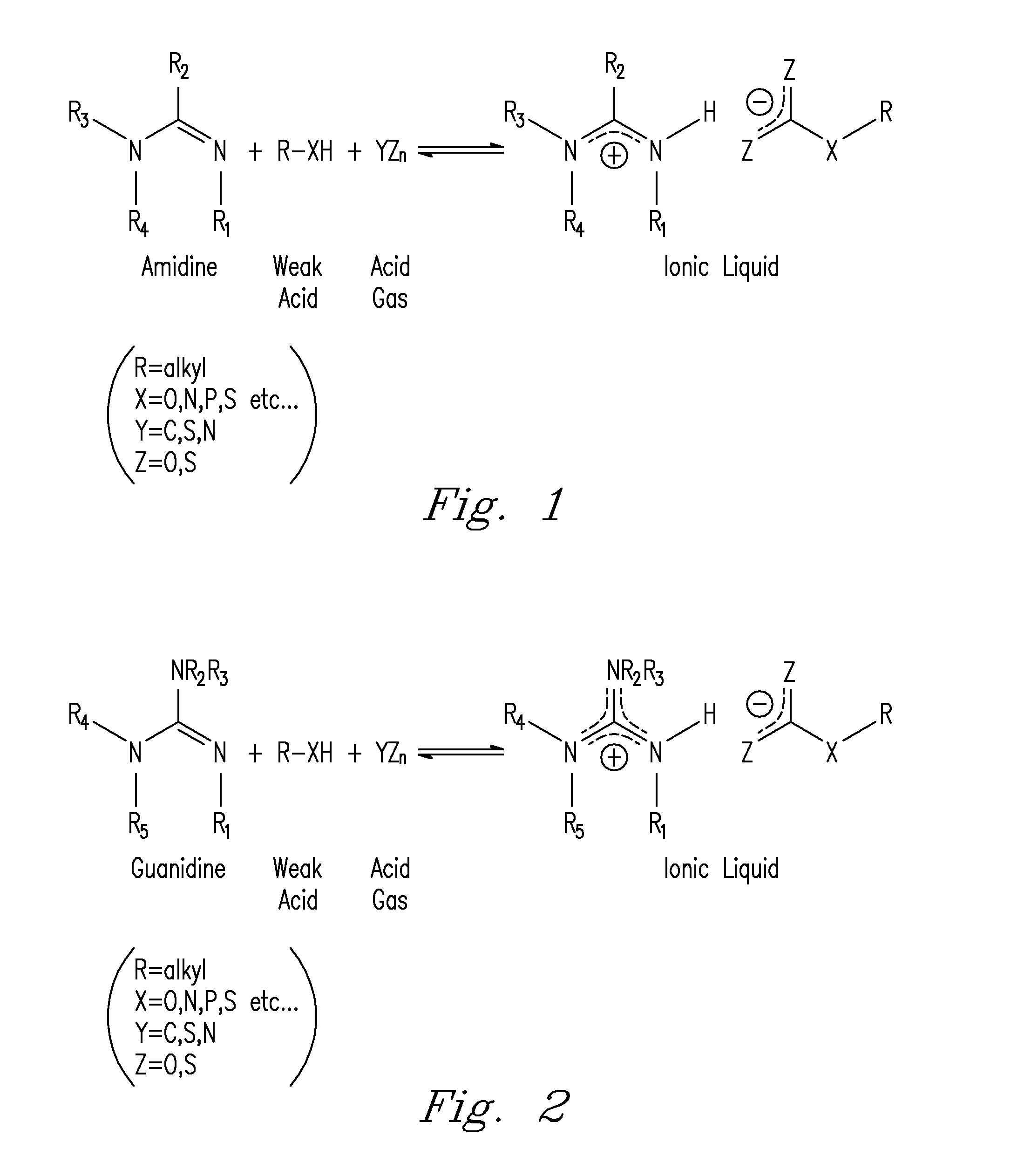

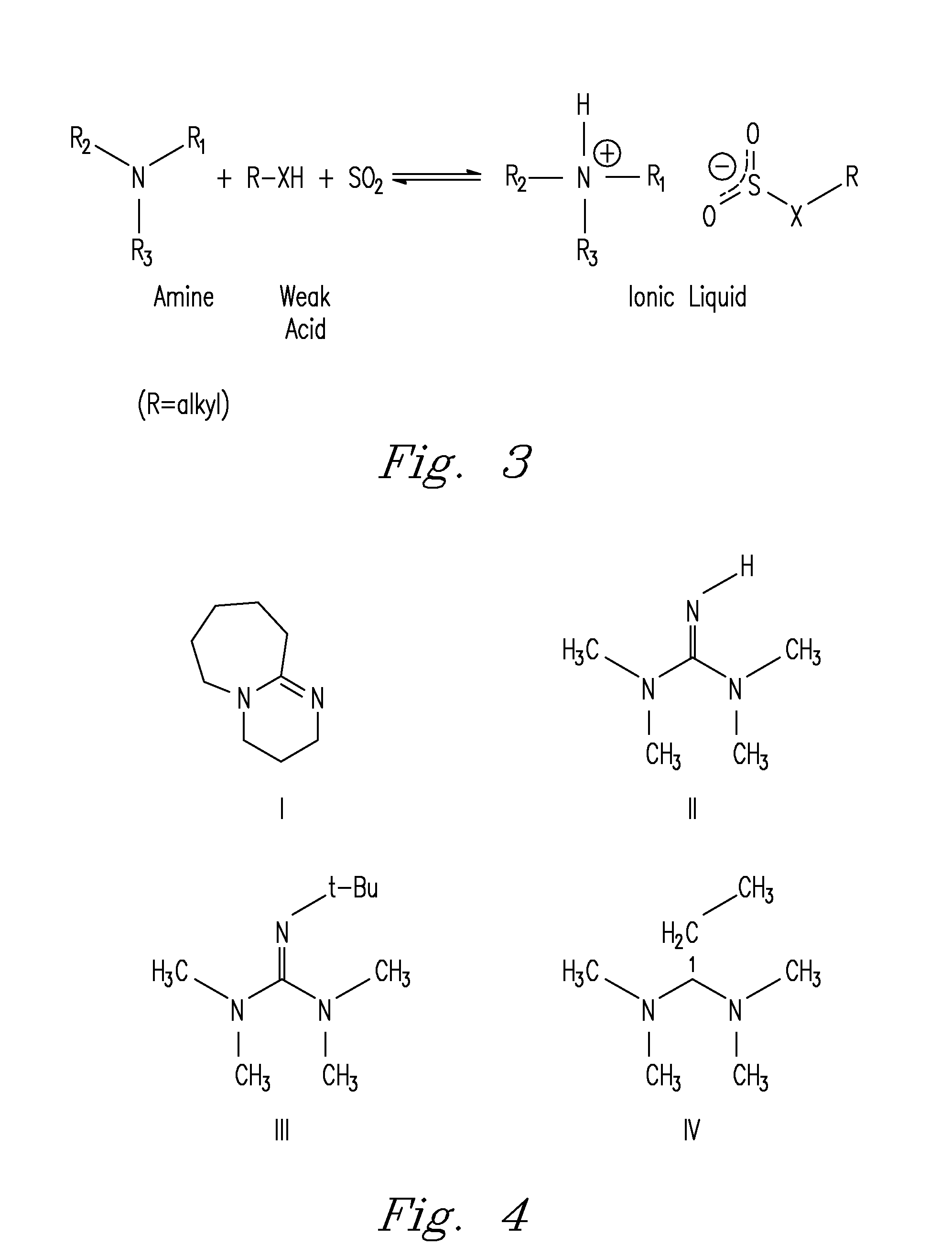

Capture and Release of Mixed Acid Gasses With Binding Organic Liquids

ActiveUS20090136402A1Reduced thermodynamic stabilityLess energy inputCombination devicesGas treatmentChemical reactionIonic liquid

Reversible acid-gas binding organic liquid systems that permit separation and capture of one or more of several acid gases from a mixed gas stream, transport of the liquid, release of the acid gases from the ionic liquid and reuse of the liquid to bind more acid gas with significant energy savings compared to current aqueous systems. These systems utilize acid gas capture compounds made up of strong bases and weak acids that form salts when reacted with a selected acid gas, and which release these gases when a preselected triggering event occurs. The various new materials that make up this system can also be included in various other applications such as chemical sensors, chemical reactants, scrubbers, and separators that allow for the specific and separate removal of desired materials from a gas stream such as flue gas.

Owner:BATTELLE MEMORIAL INST

Portable heat generating device

InactiveUS6062210APromotes spontaneous flameless combustionReduce necessityExothermal chemical reaction heat productionOther heat production devicesElastomerThermal energy

A portable heat generating device in which fuel vapor and an oxygen supply (e.g. air) are directed through channels contained within a thin, flexible and compliant elastomeric sheet of material. Elongated catalytic heat elements, placed strategically within the channels, spontaneously interact with the fuel-air stream liberating heat energy. Means and methods are defined that permit flameless catalytic combustion to be uniformly extended over the length of each heat element, lowering power density but maintaining the overall power generated, permitting the use of many types of low temperature materials like plastics, polymers, and elastomers in the construction of the heater. The heat generation process is started by pumping an air stream into a reservoir containing a fuel source (e.g. methanol) thereby saturating the air stream with fuel vapor. The fuel vapor is mixed with a another stream of air to achieve a particular fuel / air ratio and directed into channels within the elastomeric sheet, reacting with the catalytic heat elements to produce flameless combustion. The warm exhaust gas is directed to a thermally controlled diverter valve. The valve senses the temperature of the liquid fuel supply and diverts some or all of the warm exhaust gas, as necessary, to heat the fuel and keep its temperature within a specified range. Exhaust by-products are passed into a miniature scrubber module adjacent to the fuel module. The scrubber absorbs any noxious components in the exhaust stream that may occur during start-up or rapid changes in operating condition.

Owner:CLIFFORD G WELLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com