Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Improve paper quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

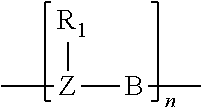

Dendritic Polymers With Enhanced Amplification and Interior Functionality

ActiveUS20070298006A1Reduced responseSizePowder deliveryOrganic active ingredientsCross-linkScavenger

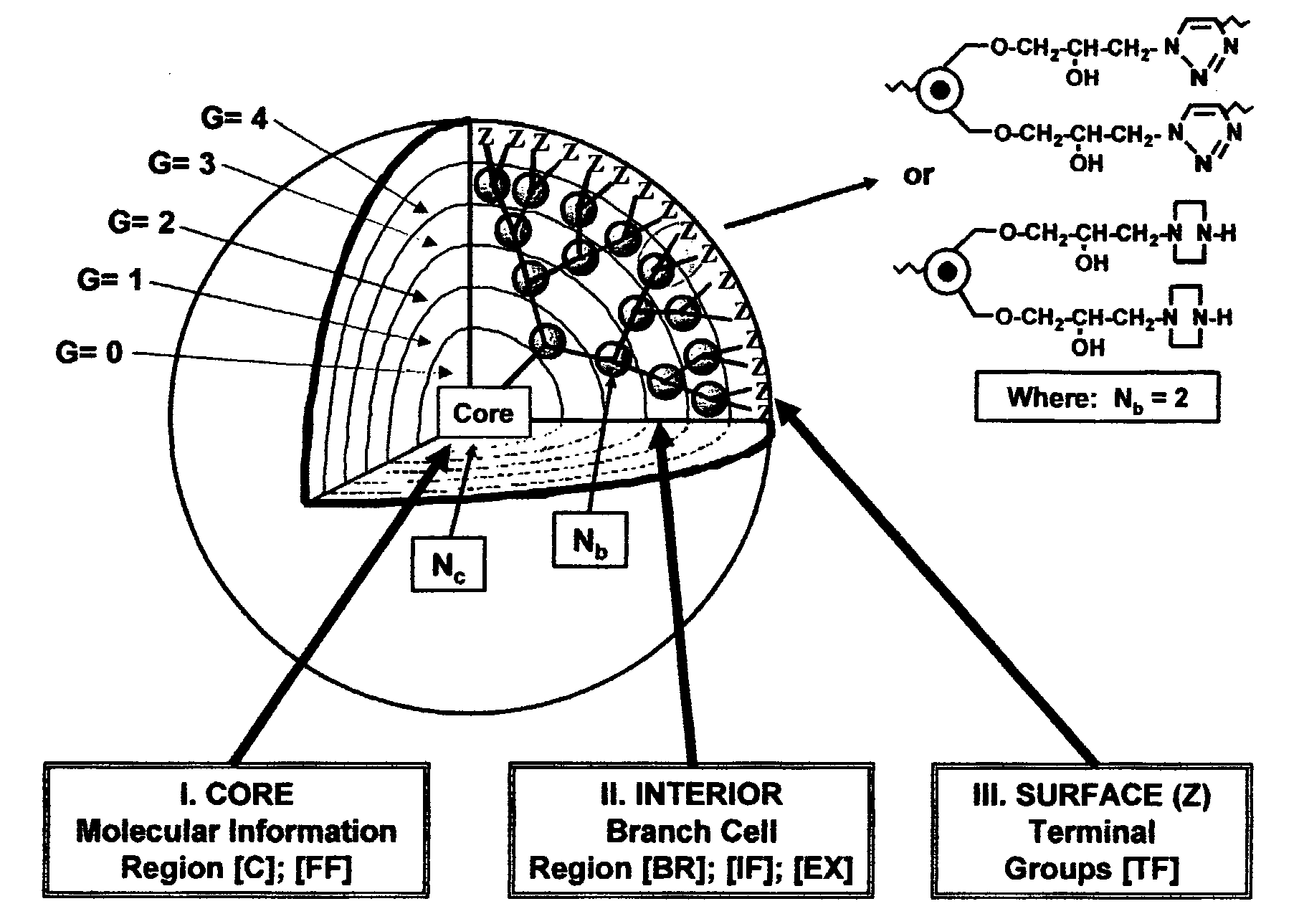

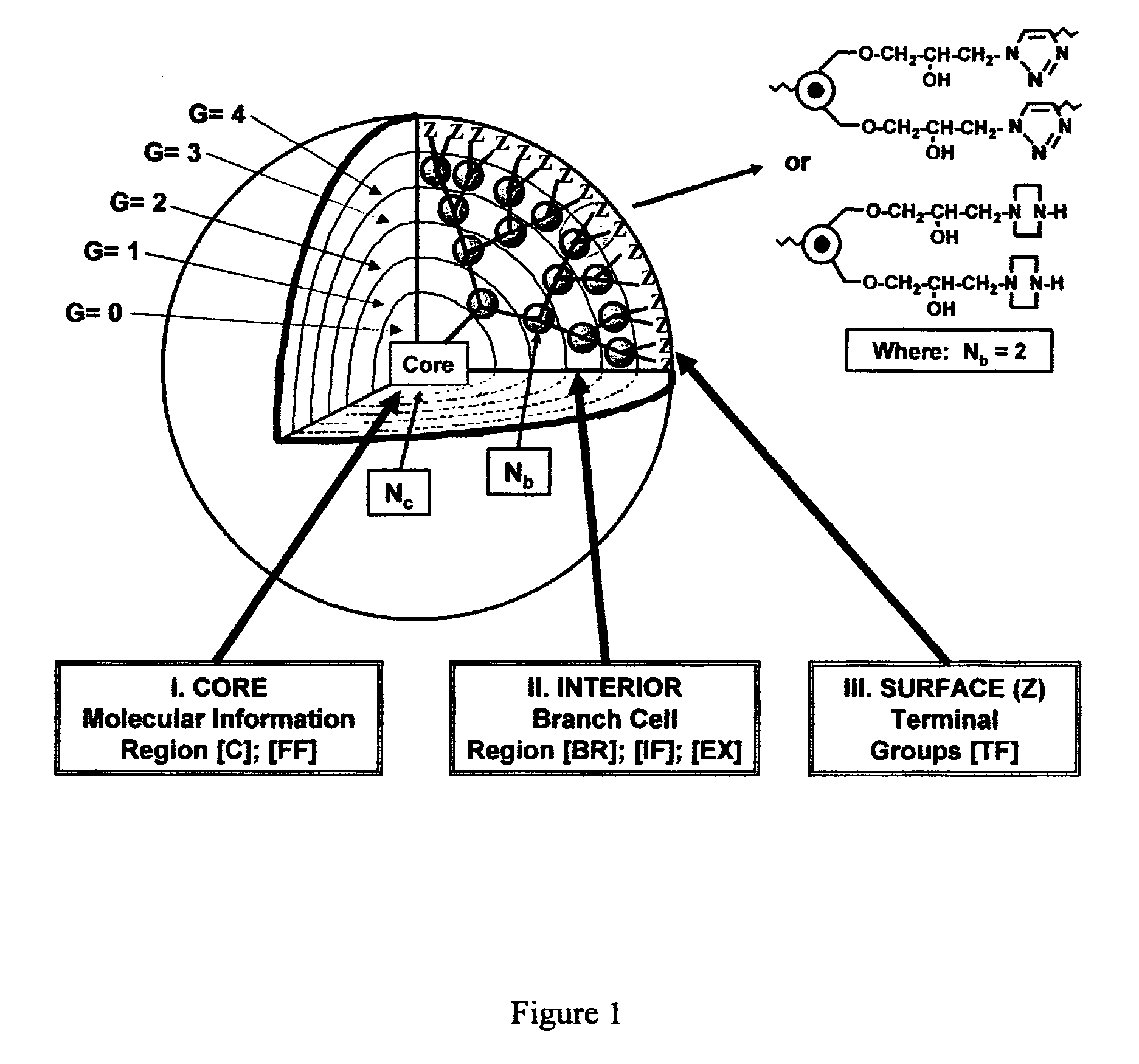

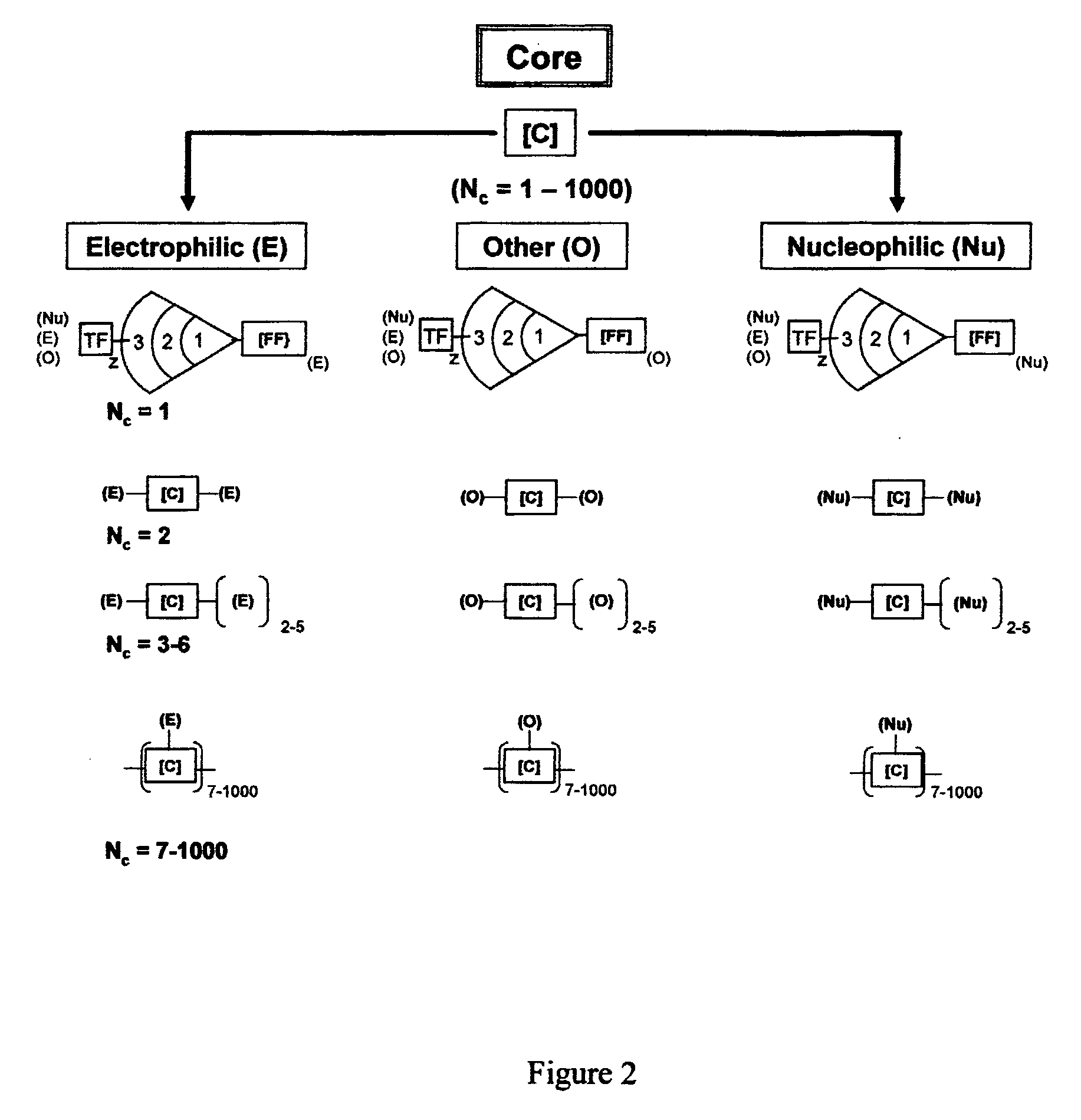

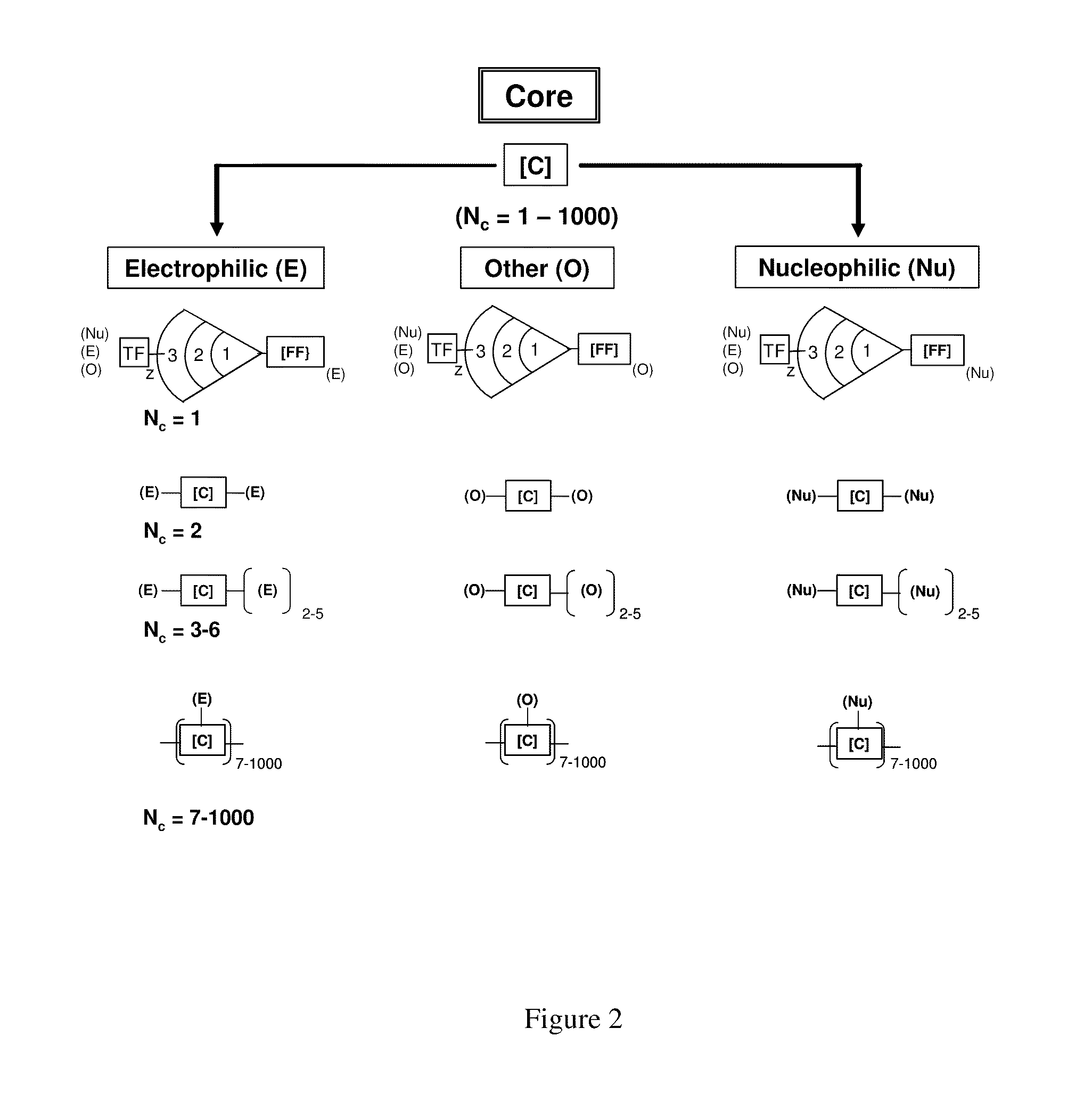

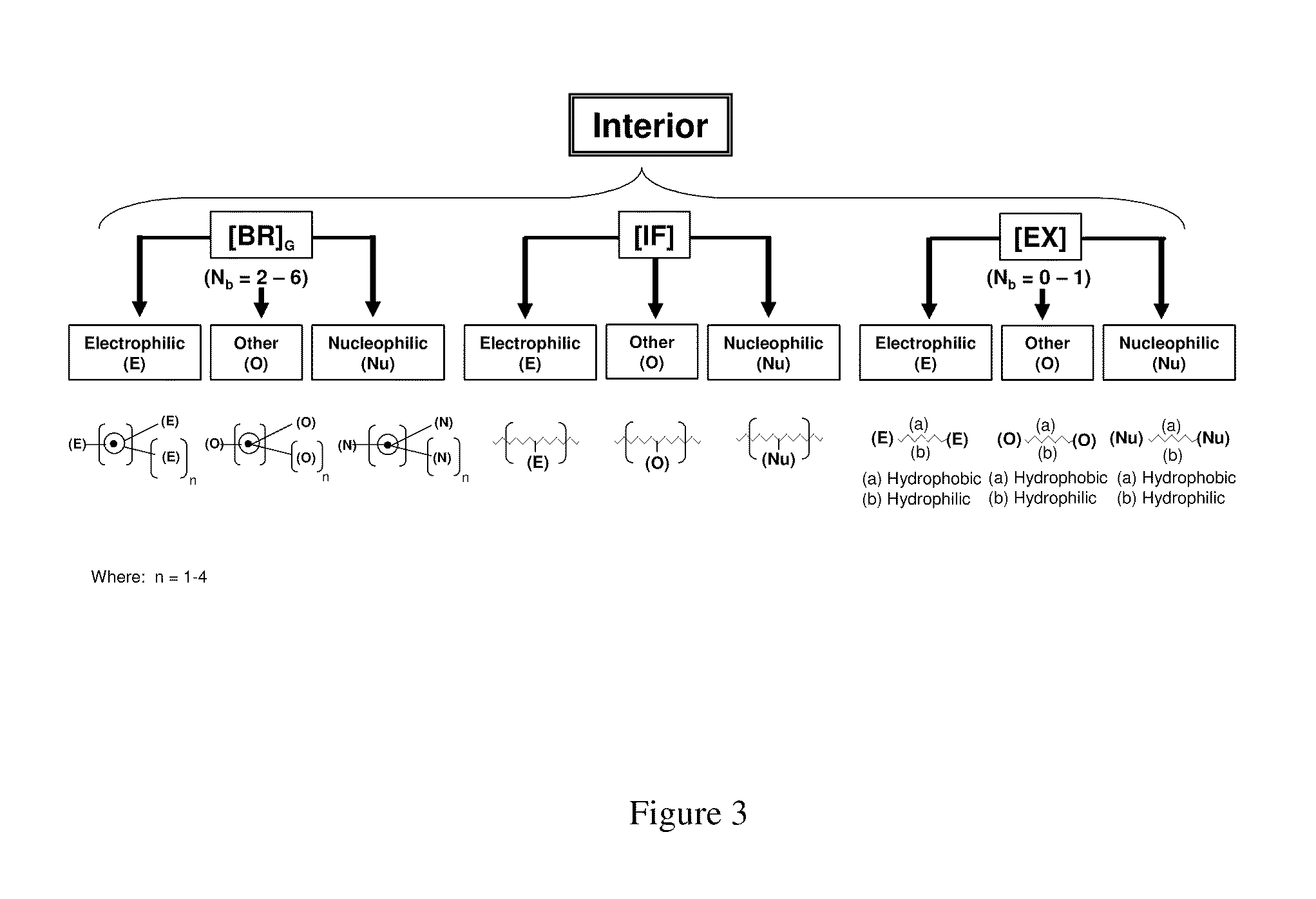

Dendritic polymers with enhanced amplification and interior functionality are disclosed. These dendritic polymers are made by use of fast, reactive ring-opening chemistry (or other fast reactions) combined with the use of branch cell reagents in a controlled way to rapidly and precisely build dendritic structures, generation by generation, with cleaner chemistry, often single products, lower excesses of reagents, lower levels of dilution, higher capacity method, more easily scaled to commercial dimensions, new ranges of materials, and lower cost. The dendritic compositions prepared have novel internal functionality, greater stability (e.g., thermal stability and less or no reverse Michael's reaction), and reach encapsulation surface densities at lower generations. Unexpectedly, these reactions of polyfunctional branch cell reagents with polyfunctional cores do not create cross-linked materials. Such dendritic polymers are useful as demulsifiers for oil / water emulsions, wet strength agents in the manufacture of paper, proton scavengers, polymers, nanoscale monomers, calibration standards for electron microscopy, making size selective membranes, and agents for modifying viscosity in aqueous formulations such as paint. When these dendritic polymers have a carried material associated with their surface and / or interior, then these dendritic polymers have additional properties for carrying materials due to the unique characteristics of the dendritic polymer, such as for drug delivery, transfection, and diagnostics.

Owner:DENDRITIC NANO TECH INC

Dendritic polymers with enhanced amplification and interior functionality

ActiveUS7985424B2Increase productionSimple materialPowder deliveryCosmetic preparationsCross-linkChemical reaction

Dendritic polymers with enhanced amplification and interior functionality are disclosed. These dendritic polymers are made by use of fast, reactive ring-opening chemistry (or other fast reactions) combined with the use of branch cell reagents in a controlled way to rapidly and precisely build dendritic structures, generation by generation, with cleaner chemistry, often single products, lower excesses of reagents, lower levels of dilution, higher capacity method, more easily scaled to commercial dimensions, new ranges of materials, and lower cost. The dendritic compositions prepared have novel internal functionality, greater stability (e.g., thermal stability and less or no reverse Michael's reaction), and reach encapsulation surface densities at lower generations. Unexpectedly, these reactions of polyfunctional branch cell reagents with polyfunctional cores do not create cross-linked materials. Such dendritic polymers are useful as demulsifiers for oil / water emulsions, wet strength agents in the manufacture of paper, proton scavengers, polymers, nanoscale monomers, calibration standards for electron microscopy, making size selective membranes, and agents for modifying viscosity in aqueous formulations such as paint. When these dendritic polymers have a carried material associated with their surface and / or interior, then these dendritic polymers have additional properties for carrying materials due to the unique characteristics of the dendritic polymer, such as for drug delivery, transfection, and diagnostics.

Owner:DENDRITIC NANO TECH INC

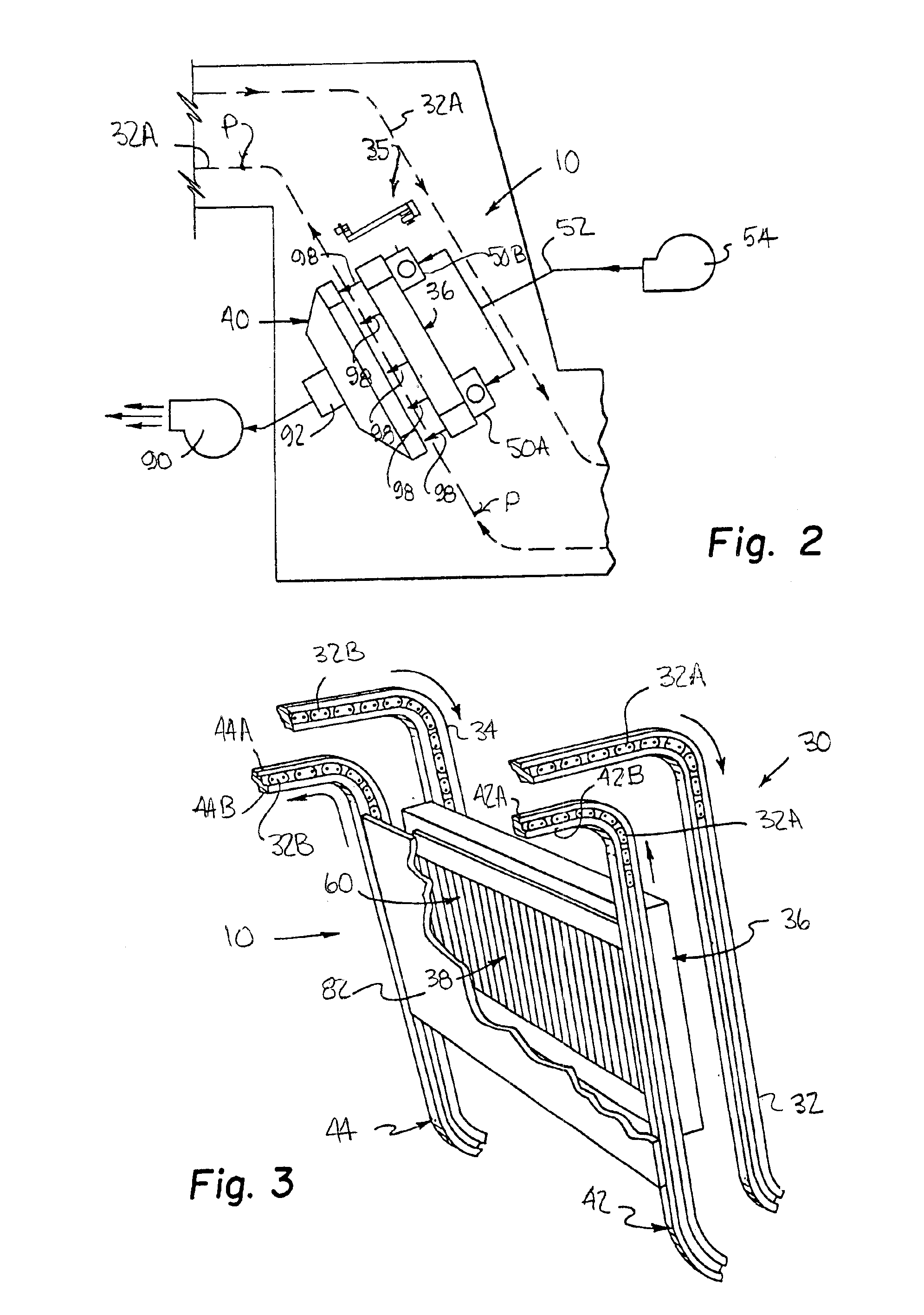

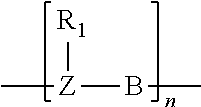

Power saving automatic zoned dryer apparatus and method

InactiveUS6877247B1Eliminates and greatly reduces needImprove paper qualityDrying solid materials with heatDrying gas arrangementsAuto regulationEngineering

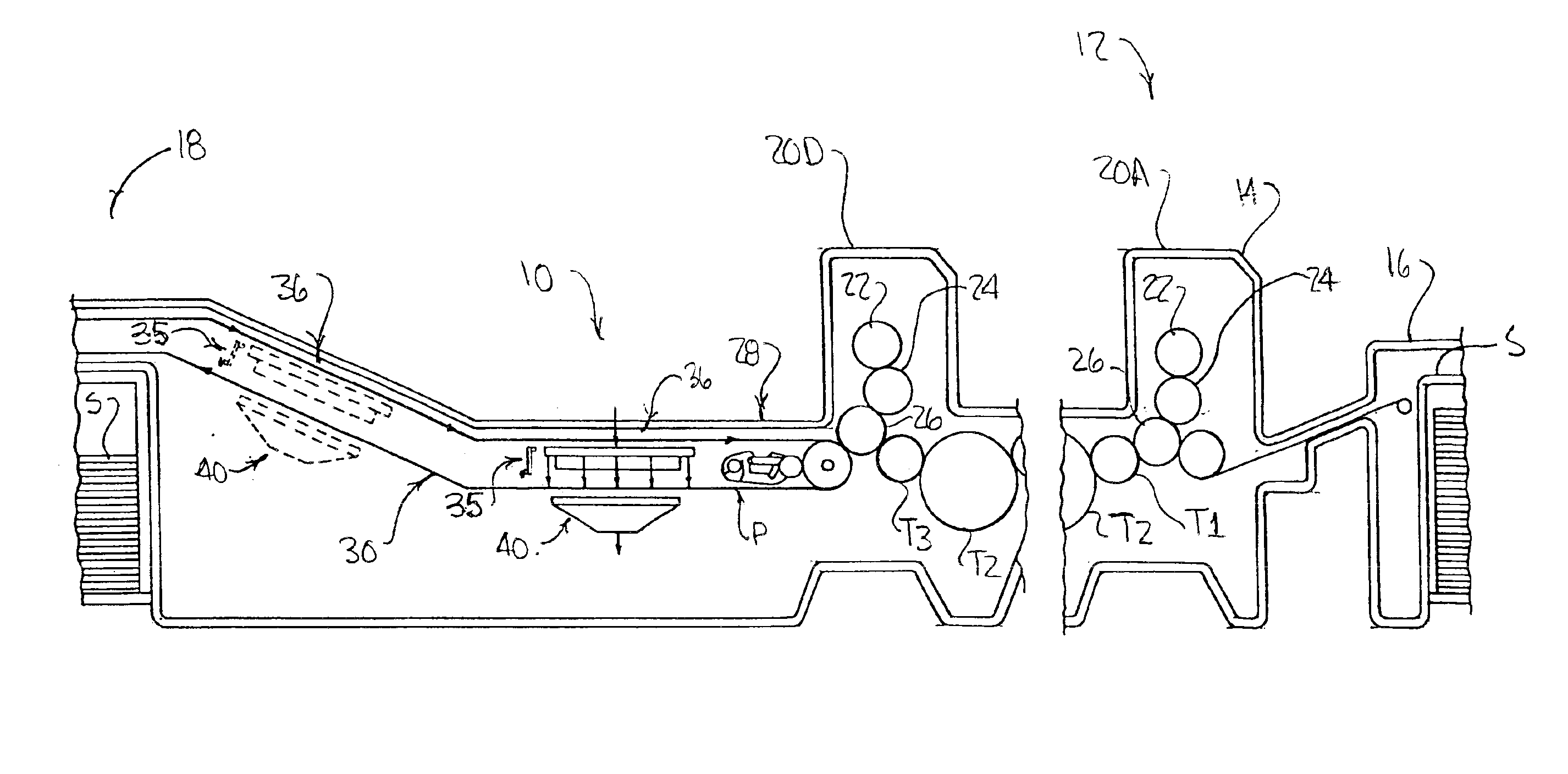

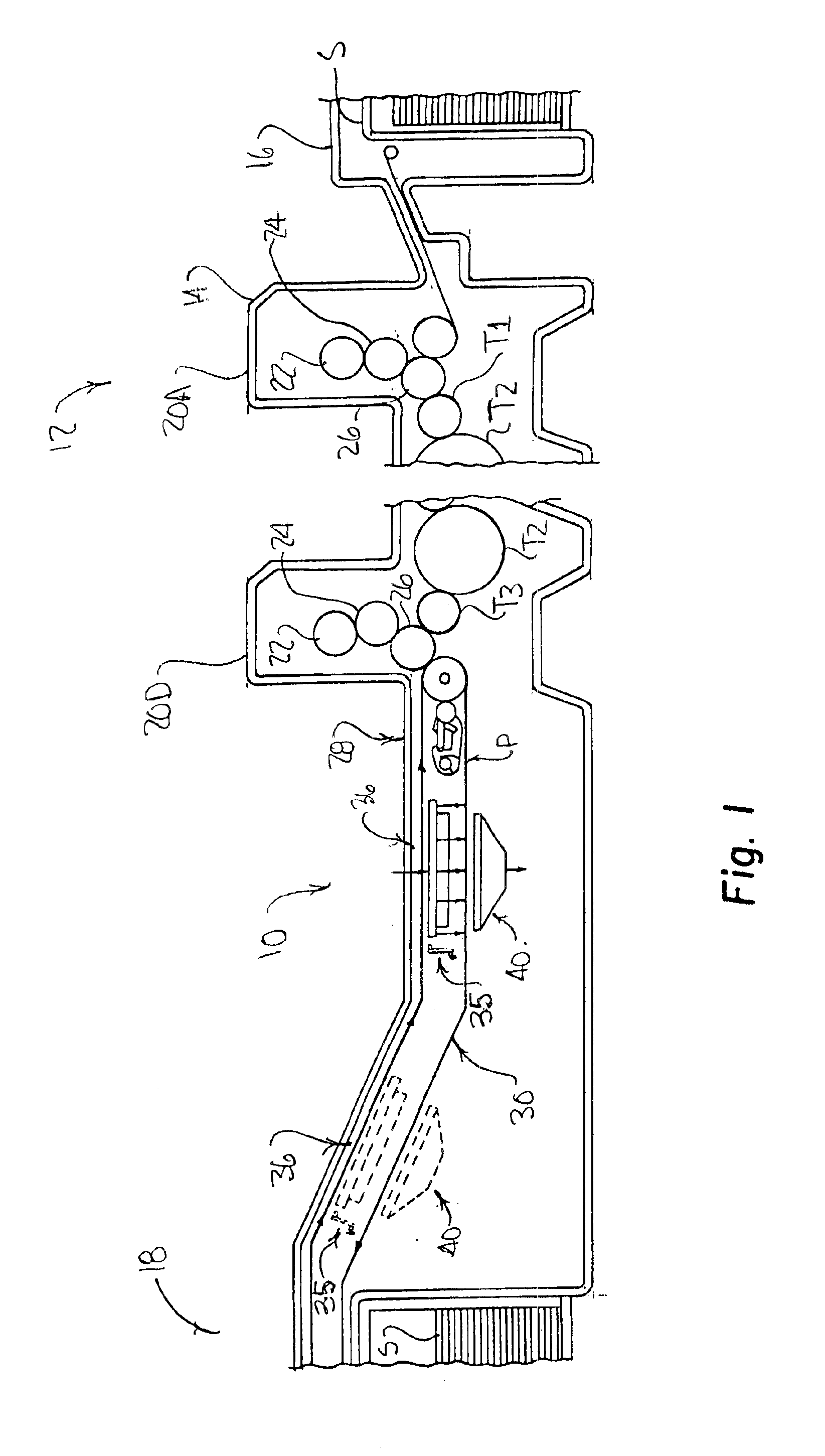

A computer controlled power saving automatic zoned dryer for a printing press has a dryer head facing the substrate travel path, having a multiplicity of IR lamps connected individually or in groups to form a plurality of heating zones running longitudinally and each extending laterally side by side across the substrate travel path. The radiant heat output of each heating zone is controlled separately by means of a control unit connected to a power supply. The control unit individually regulates output of the heating zones. Unneeded zones are turned off to reduce cost of power and conserve energy. A plurality of heat sensors spaced laterally across the substrate path measure the surface temperature of substrate heated areas corresponding to the heating zones being operated and maintain an automatic set point temperature. The temperature of each individual heated area can be regulated automatically by adjusting the output of its heating zone whereby printed substrates having a more even temperature profile are delivered. In an alternate manual mode any zone can be set independently to operate at any percentage of full available power from zero to 100%. Separate high velocity air scrubbers and additional air extraction are used to enhance the total drying effect of the zoned dryer assembly.

Owner:PRINTING RES

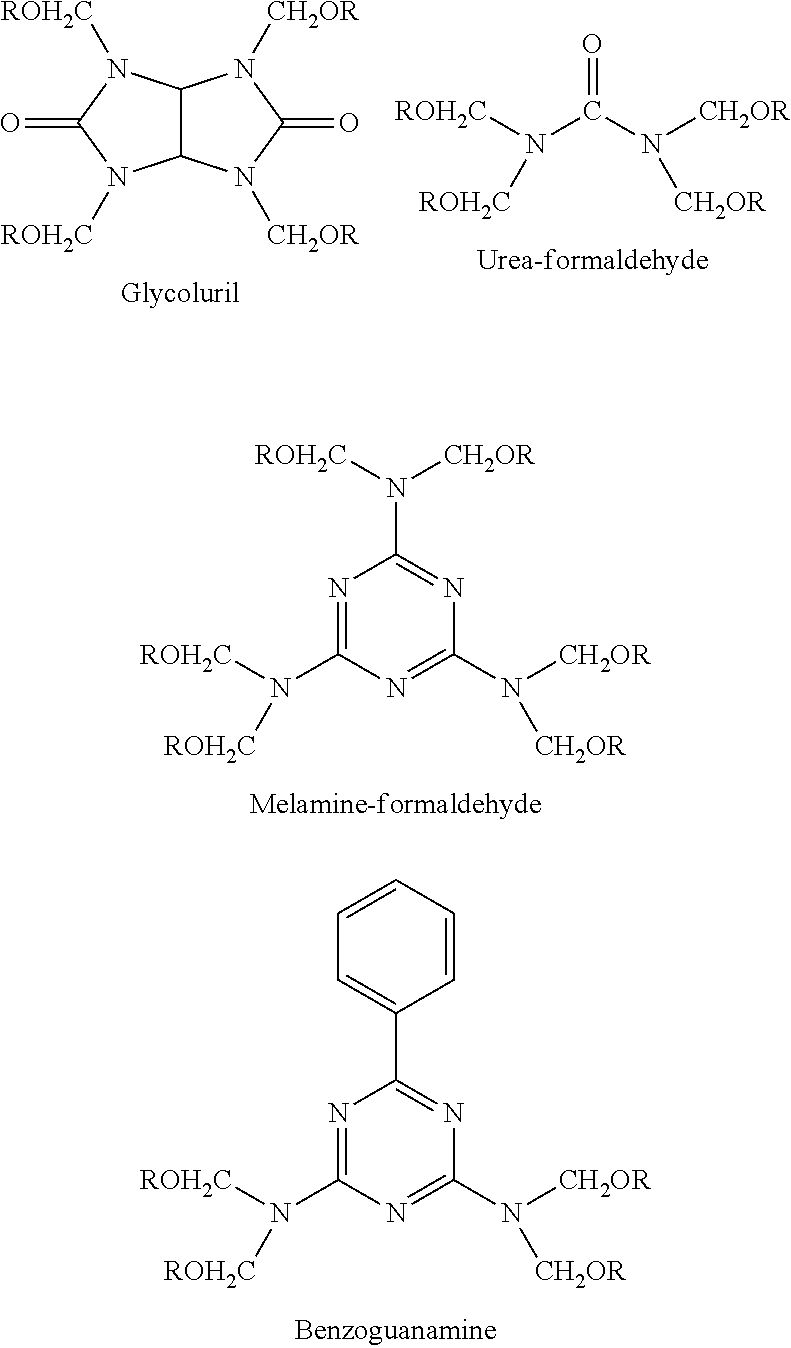

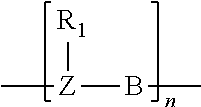

Method of controlling organic contaminants in pulp and paper making processes

InactiveUS20110094695A1Improve paper qualityLess hydrophobicNon-fibrous pulp additionNatural cellulose pulp/paperPollutantChemistry

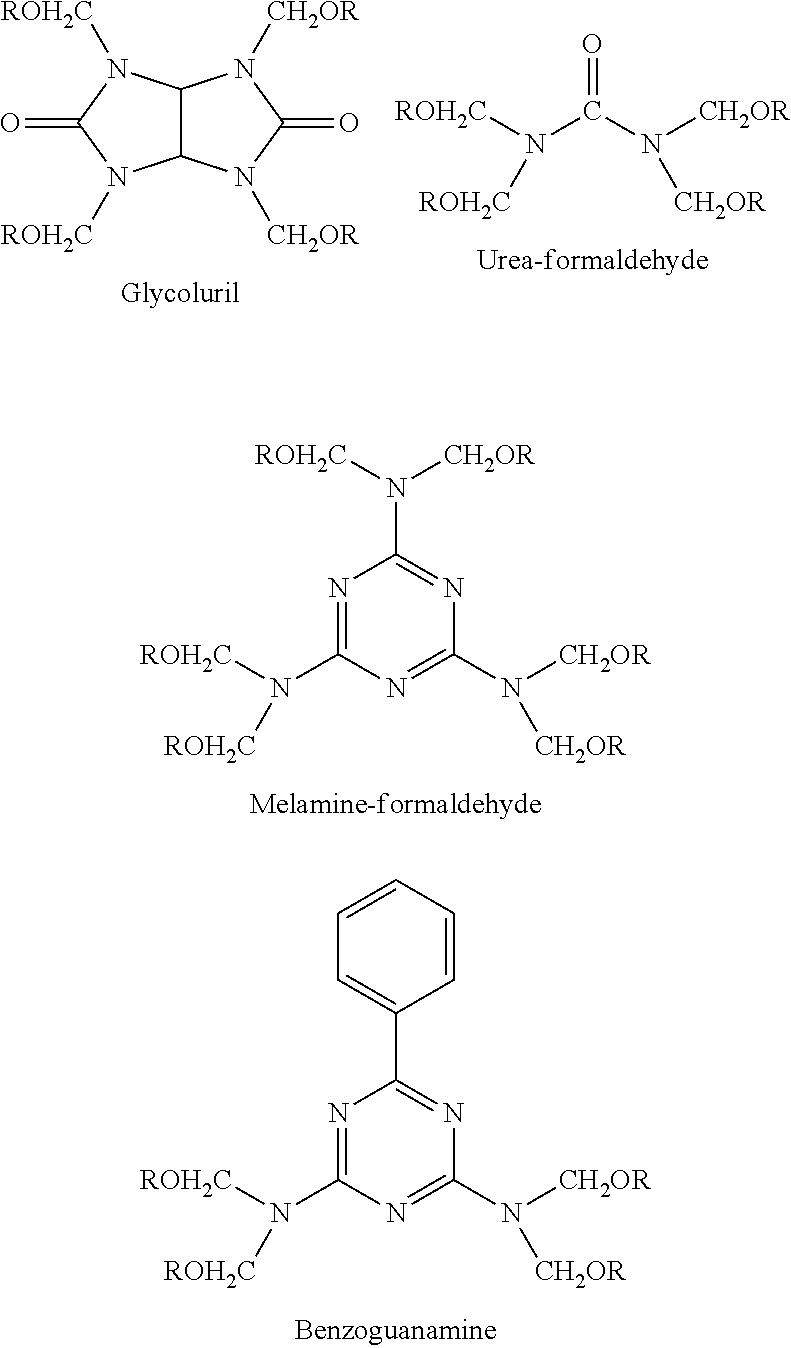

Method for controlling the deposition of organic contaminants from the pulp and papermaking systems using water soluble aminoplast ether copolymers is described herein. The aminoplast ether copolymer can be used alone or in combination with one or more additives. The pulps to be treated include mechanical, chemical, semi-chemical pulps; sulfide pulp; recycled old newspapers; mixed office wastes; corrugated boxes; and their combinations. The use of water soluble aminoplast ether copolymers to control or prevent pitch and stickies deposition improves down stream performance of papermaking equipment increasing mill efficiency and improving paper quality.

Owner:ENZYMATIC DEINKING TECH LLC

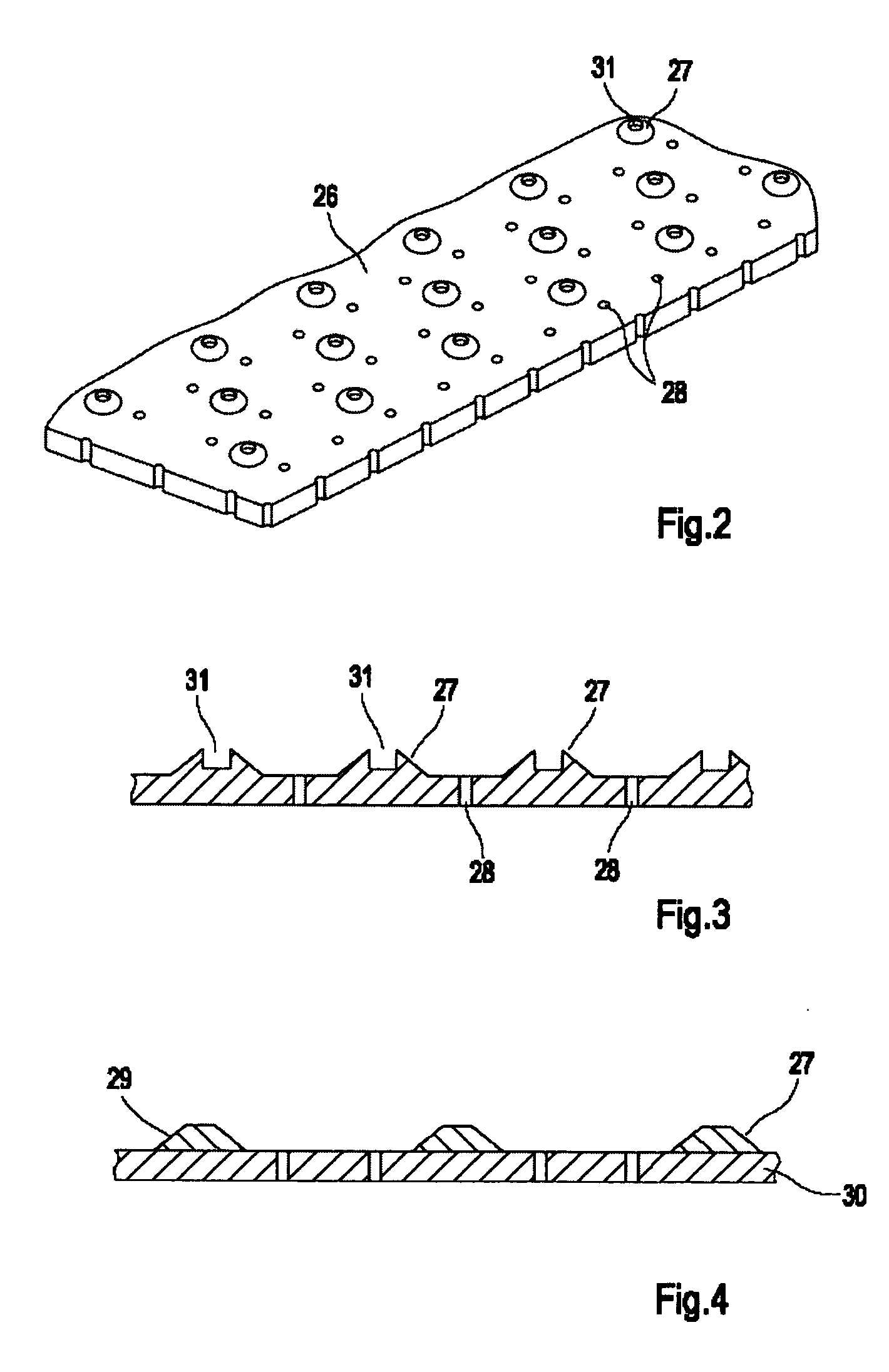

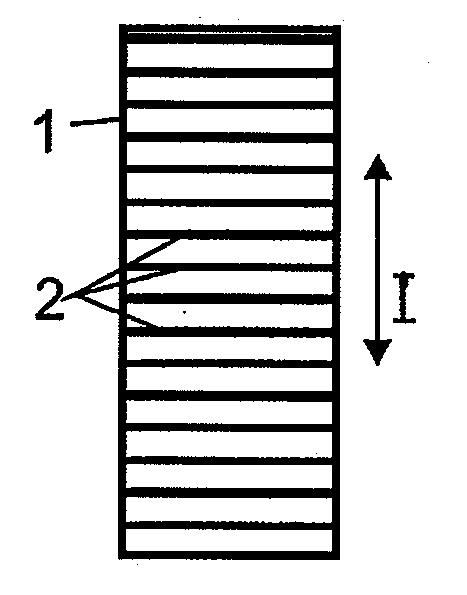

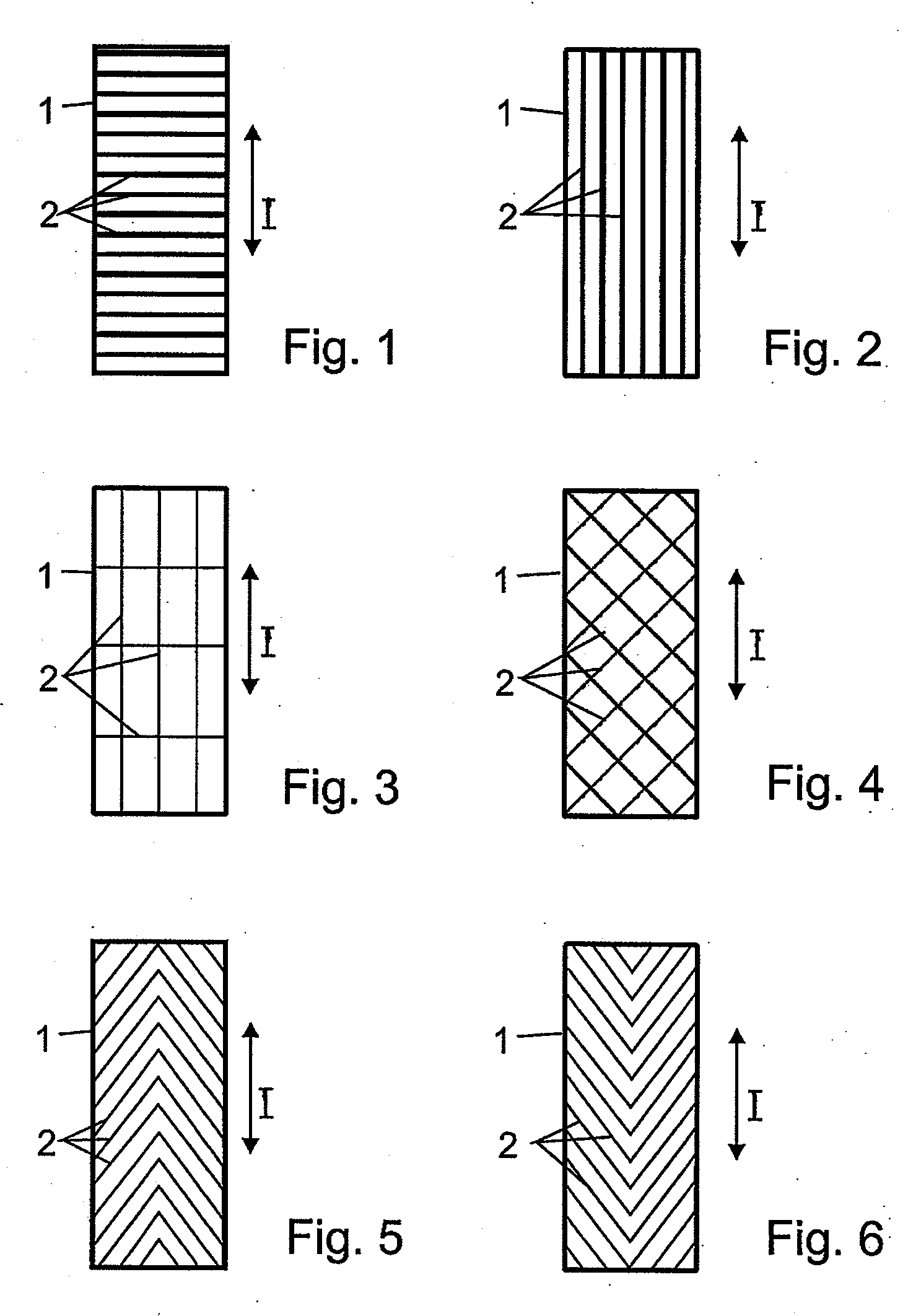

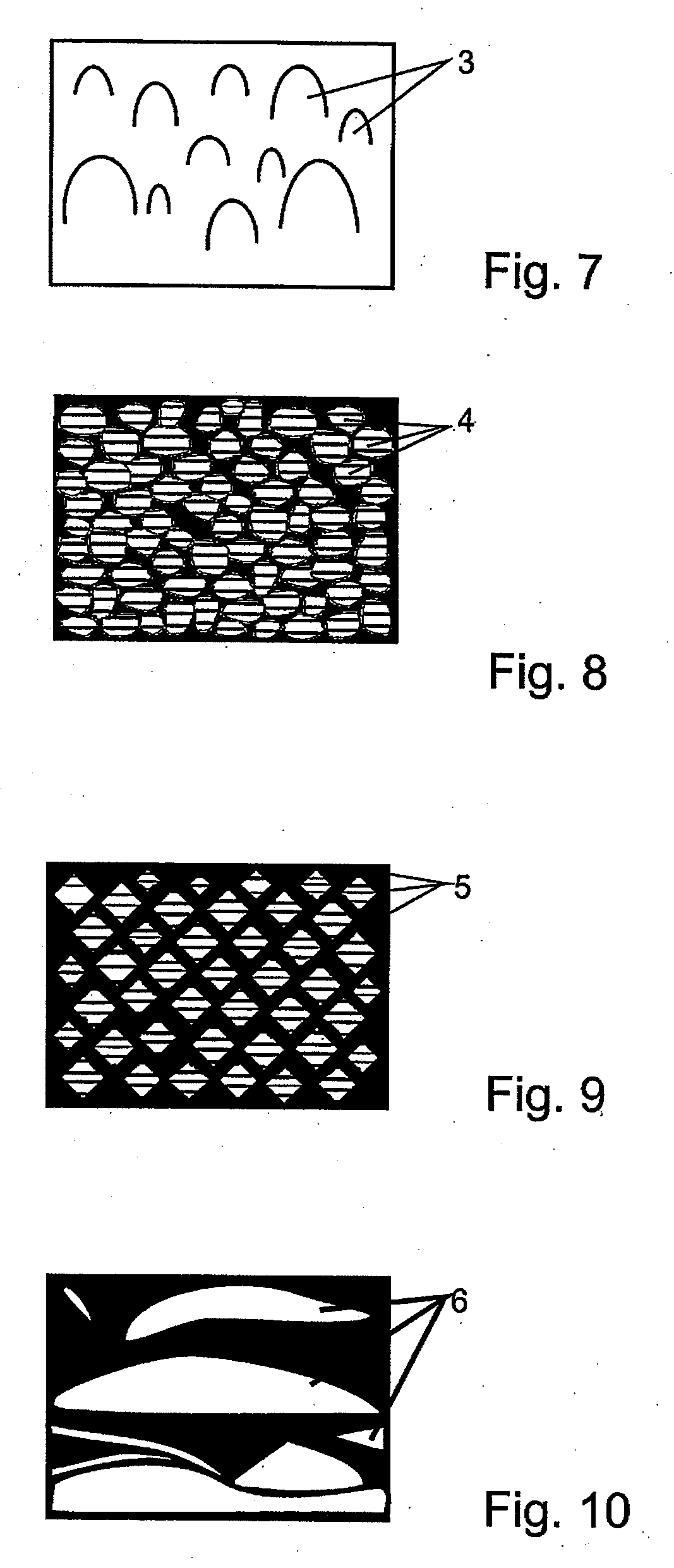

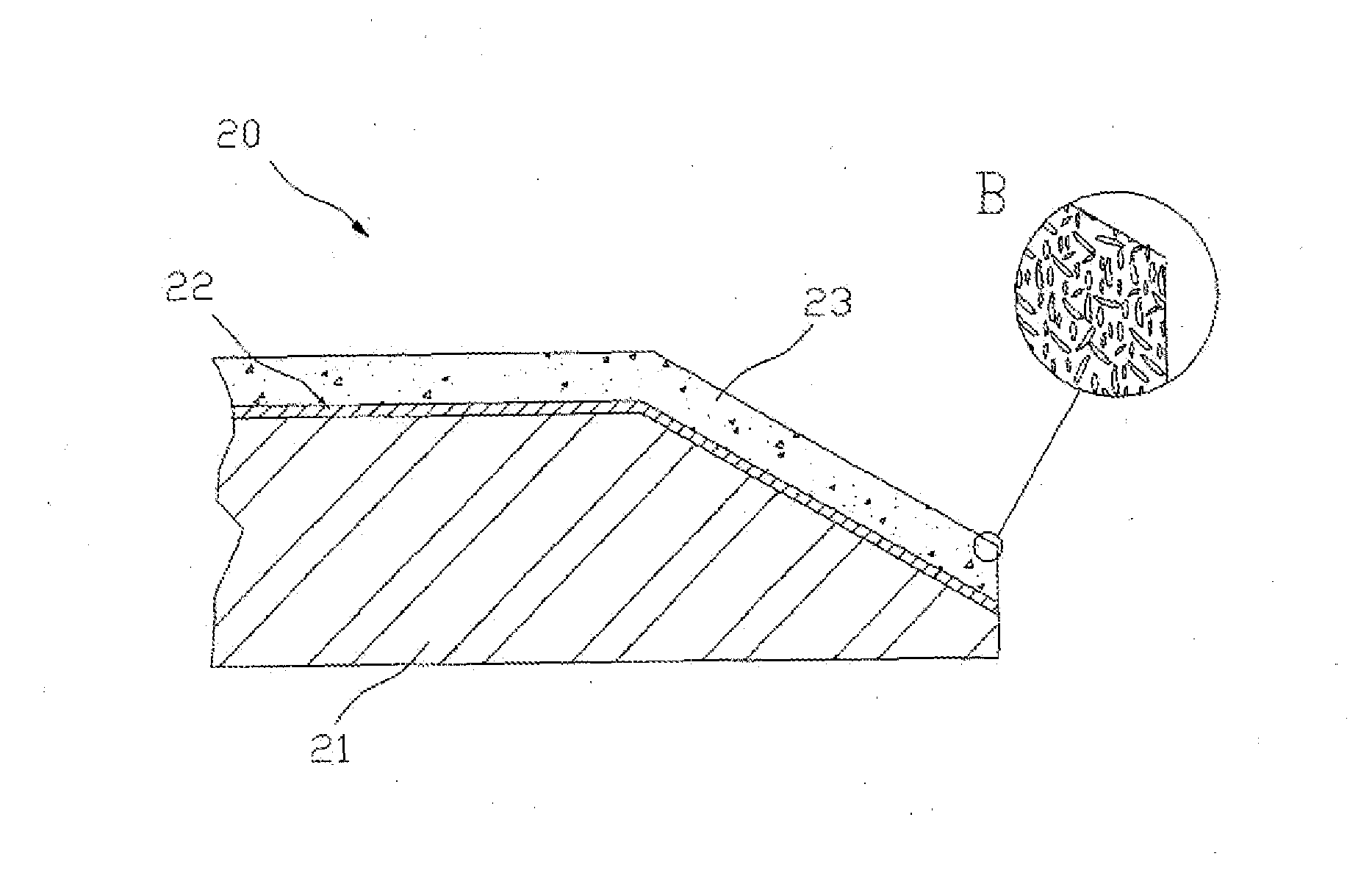

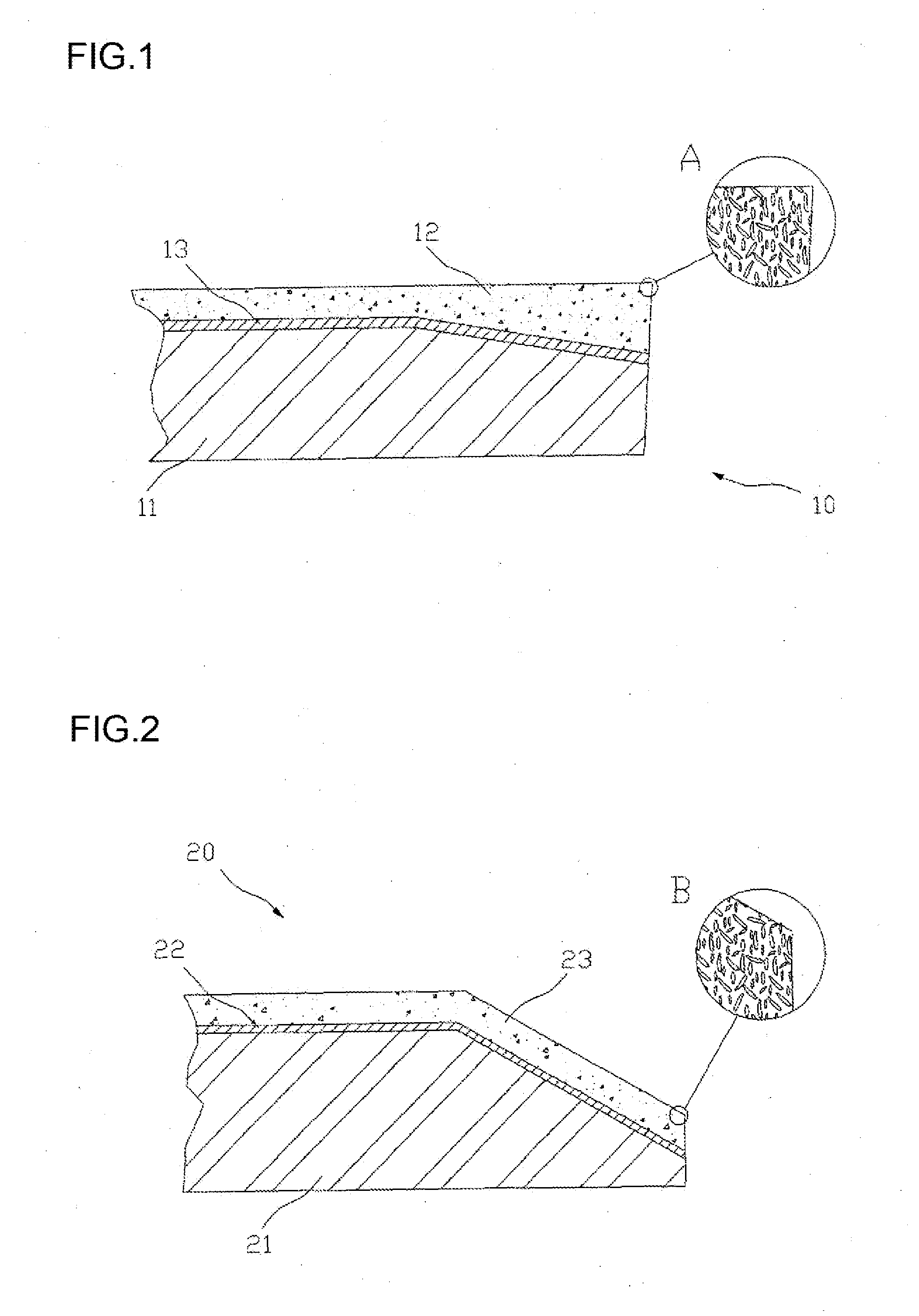

Papermachine clothing

InactiveUS7491297B2Improve paper qualityImprove printing qualityLayered productsPaper/cardboardFiberEngineering

Papermaching clothing for conveying a fibrous web in a machine for producing the fibrous web, whereby a fabric made of fibers which run in the machine direction and in the transverse direction, is disclosed having circular fibers, flat fibers or, as compared with the plane of the clothing formed by them, flattened fibers, such as fibers having an elliptical cross section.

Owner:VOITH PATENT GMBH

Method of controlling organic contaminants in pulp and paper making processes

InactiveUS8048268B2Less hydrophobicLess tackyNon-fibrous pulp additionNatural cellulose pulp/paperEtherWater soluble

Method for controlling the deposition of organic contaminants from the pulp and papermaking systems using water soluble aminoplast ether copolymers is described herein. The aminoplast ether copolymer can be used alone or in combination with one or more additives. The pulps to be treated include mechanical, chemical, semi-chemical pulps; sulfide pulp; recycled old newspapers; mixed office wastes; corrugated boxes; and their combinations. The use of water soluble aminoplast ether copolymers to control or prevent pitch and stickies deposition improves down stream performance of papermaking equipment increasing mill efficiency and improving paper quality.

Owner:ENZYMATIC DEINKING TECH LLC

'Dongba' paper used by 'Naxi' mationality and preparation method

InactiveCN1540092ALess impuritiesImprove paper qualityNon-fibrous pulp additionPulping with inorganic basesAqueous sodium hydroxideDigestion

A technology for making the Dongba paper of Naxi nationality with the paper mulberry bark and euphorbia root bark through proportioning, immersing in aqueous solution of sodium hydroxide, digestion, rinsing, adding aqueous solution of sodium hydroxide, stacking, digestion, removing hard wood, beating, mixing, shaping and drying in sun. Its advantages are high quality and preventing worm-eating.

Owner:李军

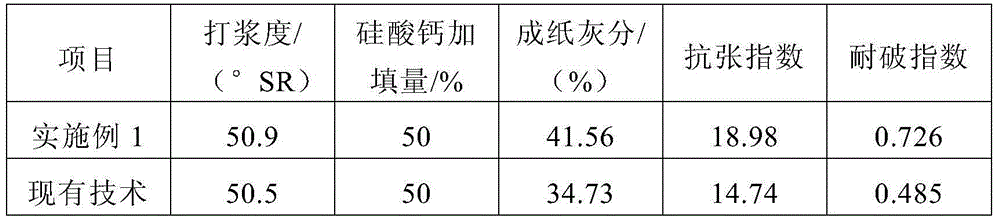

High-filler paper and production method thereof

InactiveCN102433796AHigh whitenessIncrease the addition ratioInorganic compound additionPulp material addition processesCalcium silicatePlant fibre

The invention discloses high-filler paper and a production method thereof. The high-filler paper contains 30 to 60 mass percent of filler, and the filler is active calcium silicate; in the step of adding the filler, after the active calcium silicate in an amount which is 40 to 70 percent of the total mass of the active calcium silicate and the pulp is fully stirred and dissolved to form emulsion,the emulsion is guided into a covered pulp storage tank or a pre-making pulp storage tank and fully stirred and mixed with plant fibers; the filler adding proportion of the high-filler paper is improved, so that the consumption of the plant fibers is greatly reduced at the same time of improving the performance of the paper; and according to the production method for the high-filler paper, the adding process of the papermaking filler is simplified, the filler and the plant fibers can be fully mixed uniformly, and the internal bonding force is increased, so that the performance of the paper isimproved.

Owner:GUONENG PAPER IND

Papermachine clothing

InactiveUS20060063451A1Suitable for useImprove paper qualitySynthetic resin layered productsMachine wet endFiberEngineering

Papermaching clothing for conveying a fibrous web in a machine for producing the fibrous web, whereby a fabric made of fibers which run in the machine direction and in the transverse direction, is disclosed having circular fibers, flat fibers or, as compared with the plane of the clothing formed by them, flattened fibers, such as fibers having an elliptical cross section.

Owner:VOITH PATENT GMBH

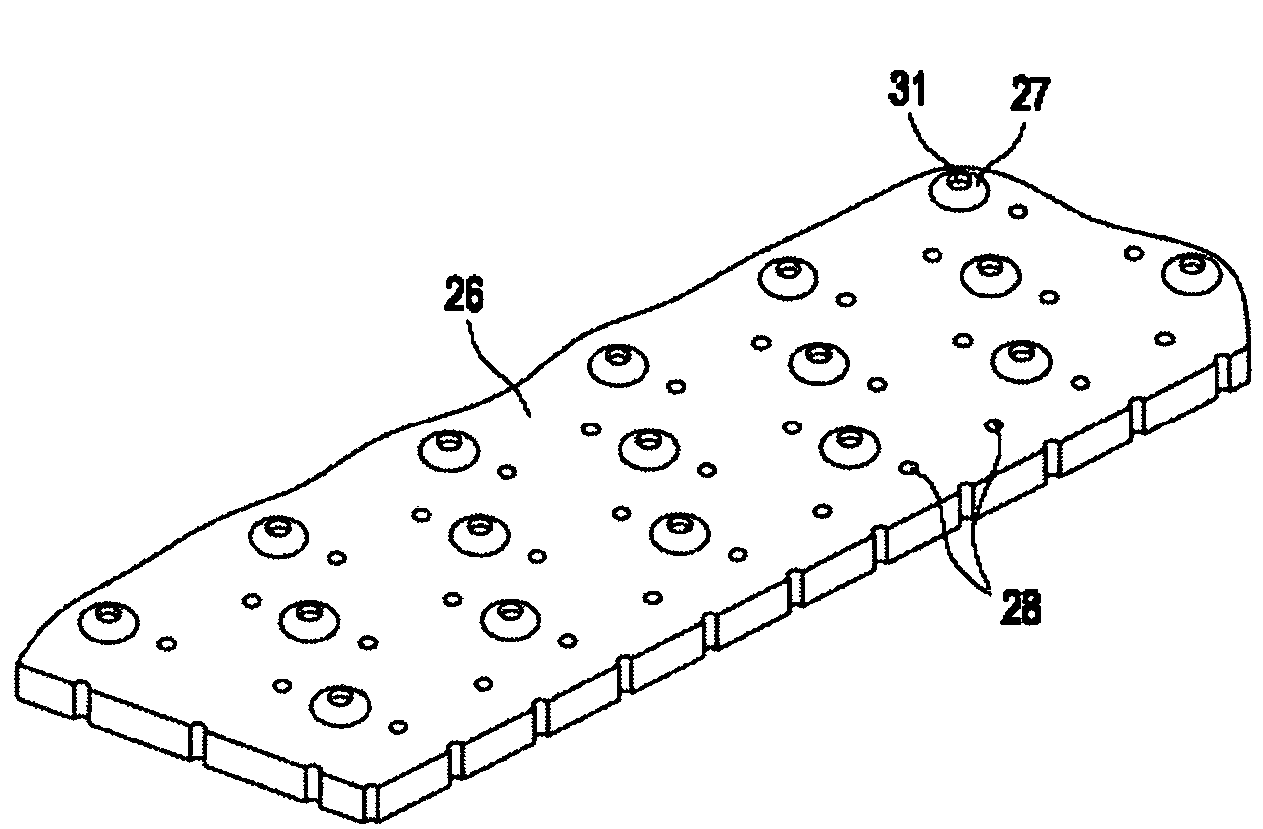

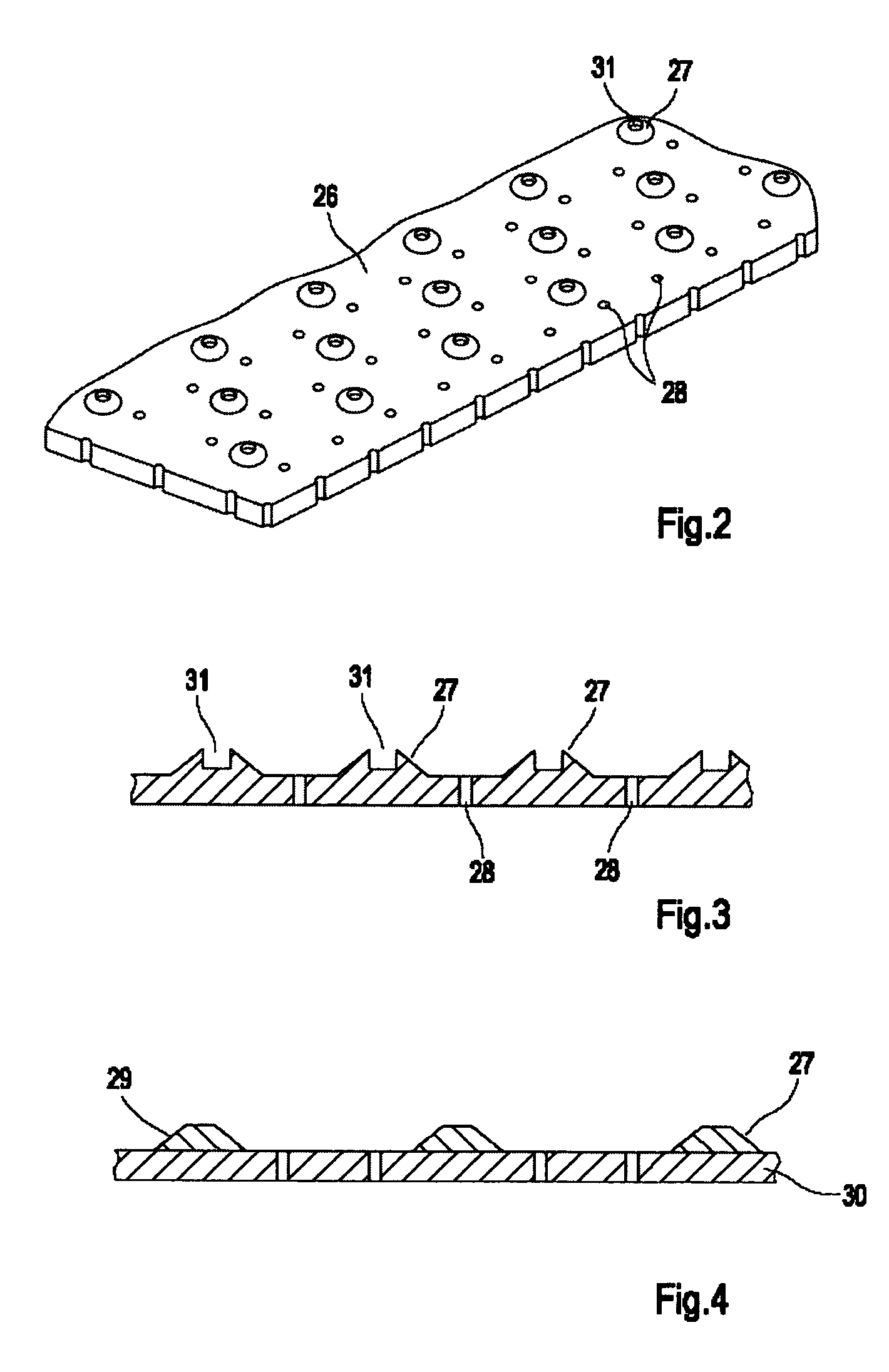

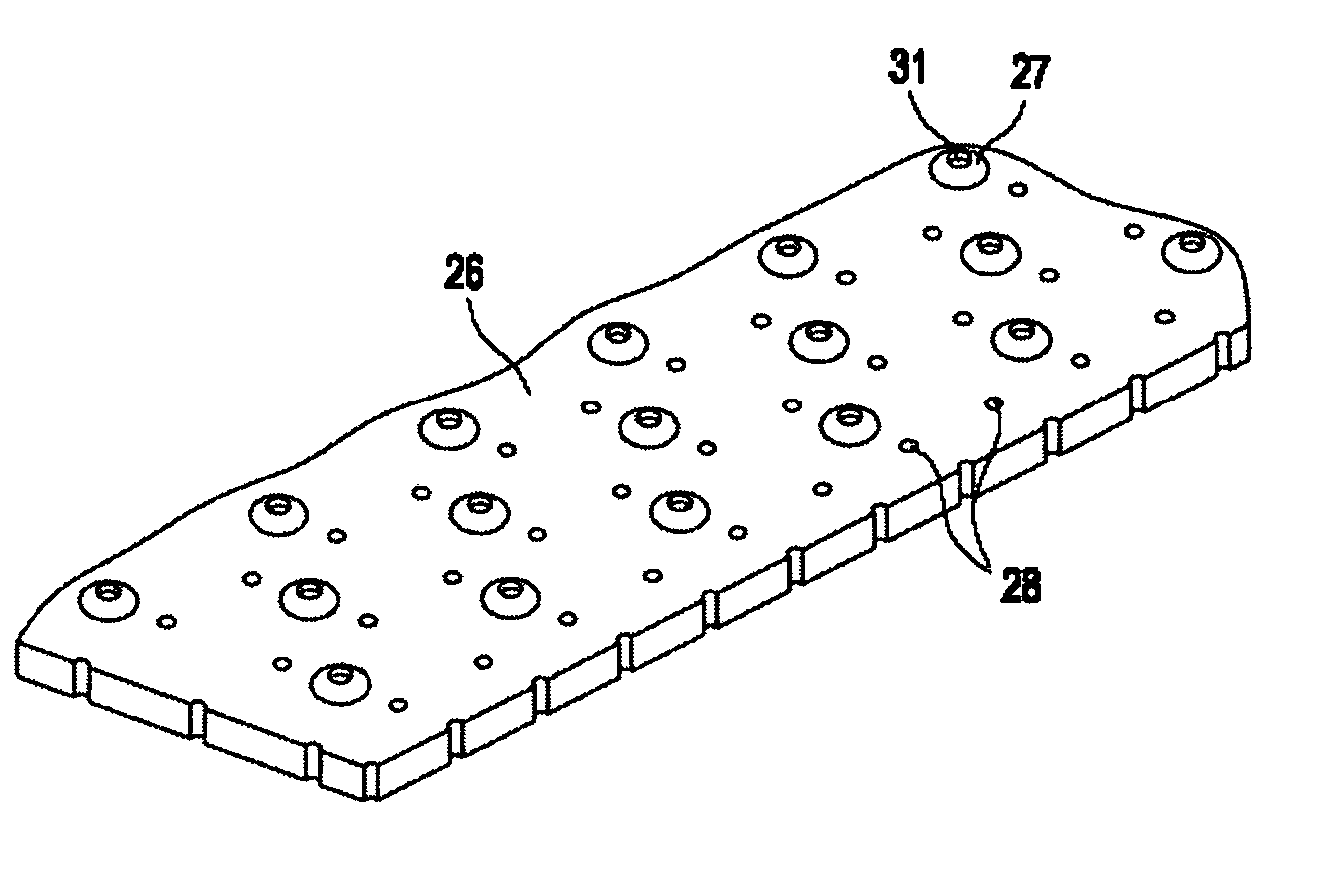

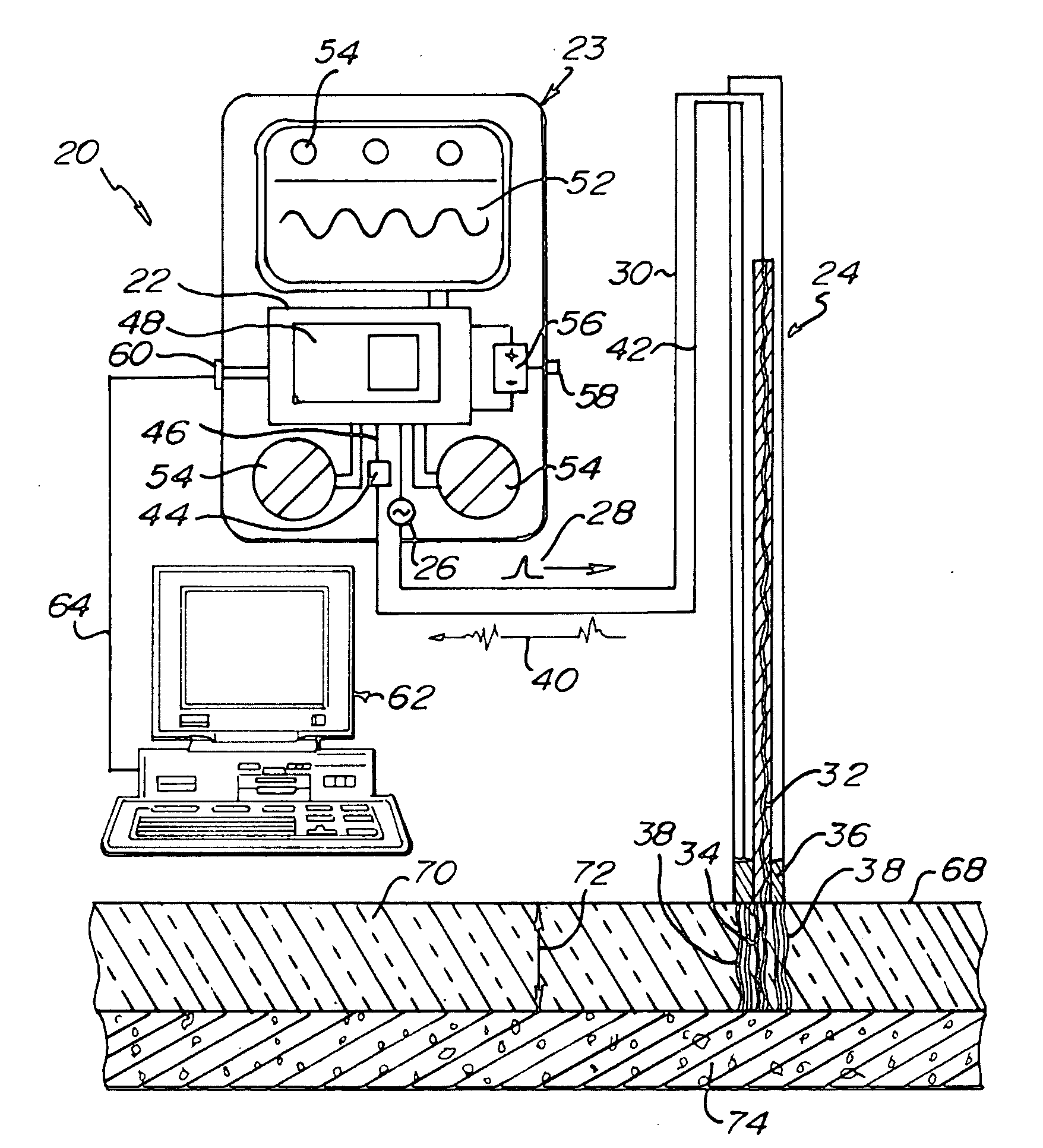

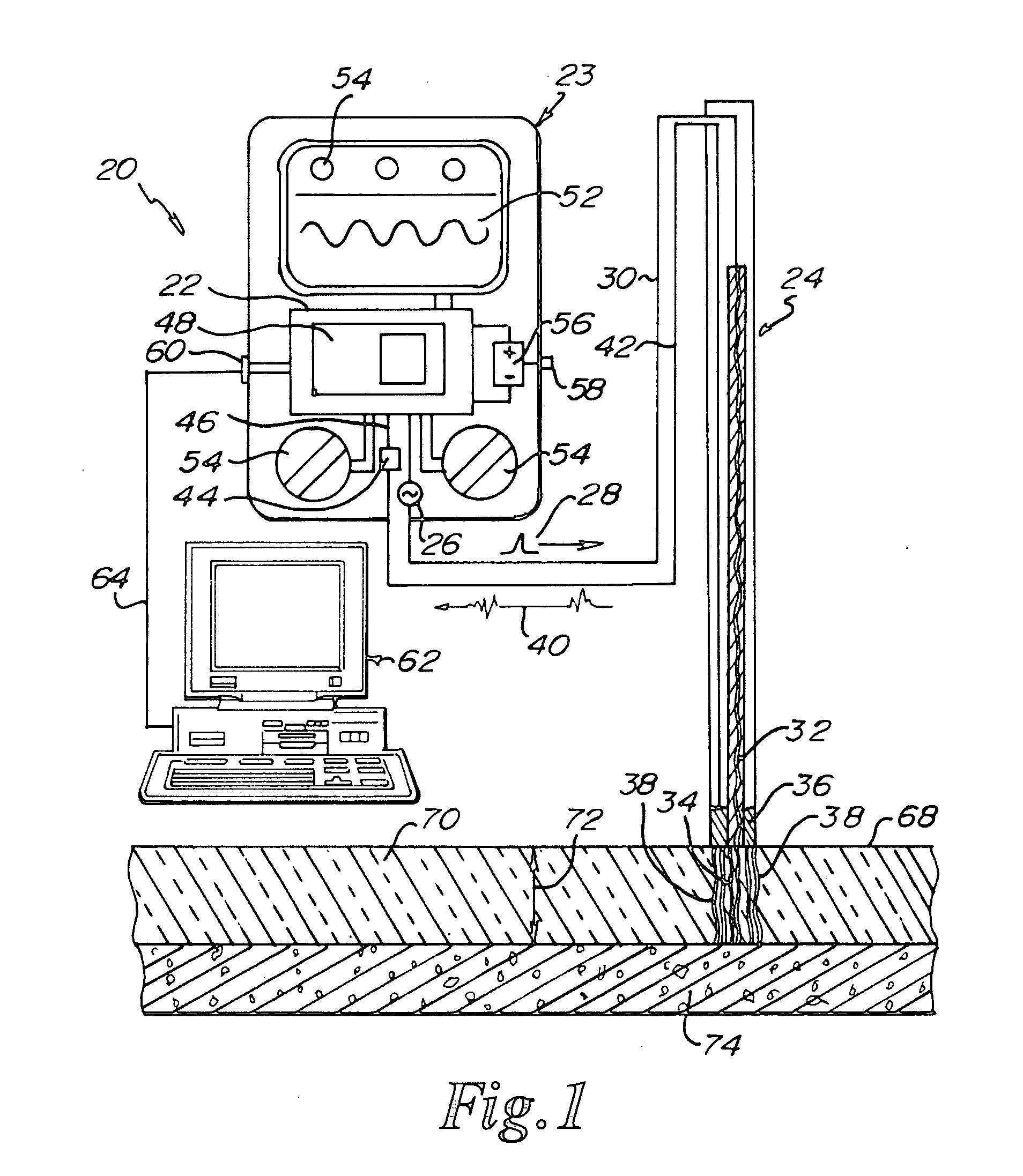

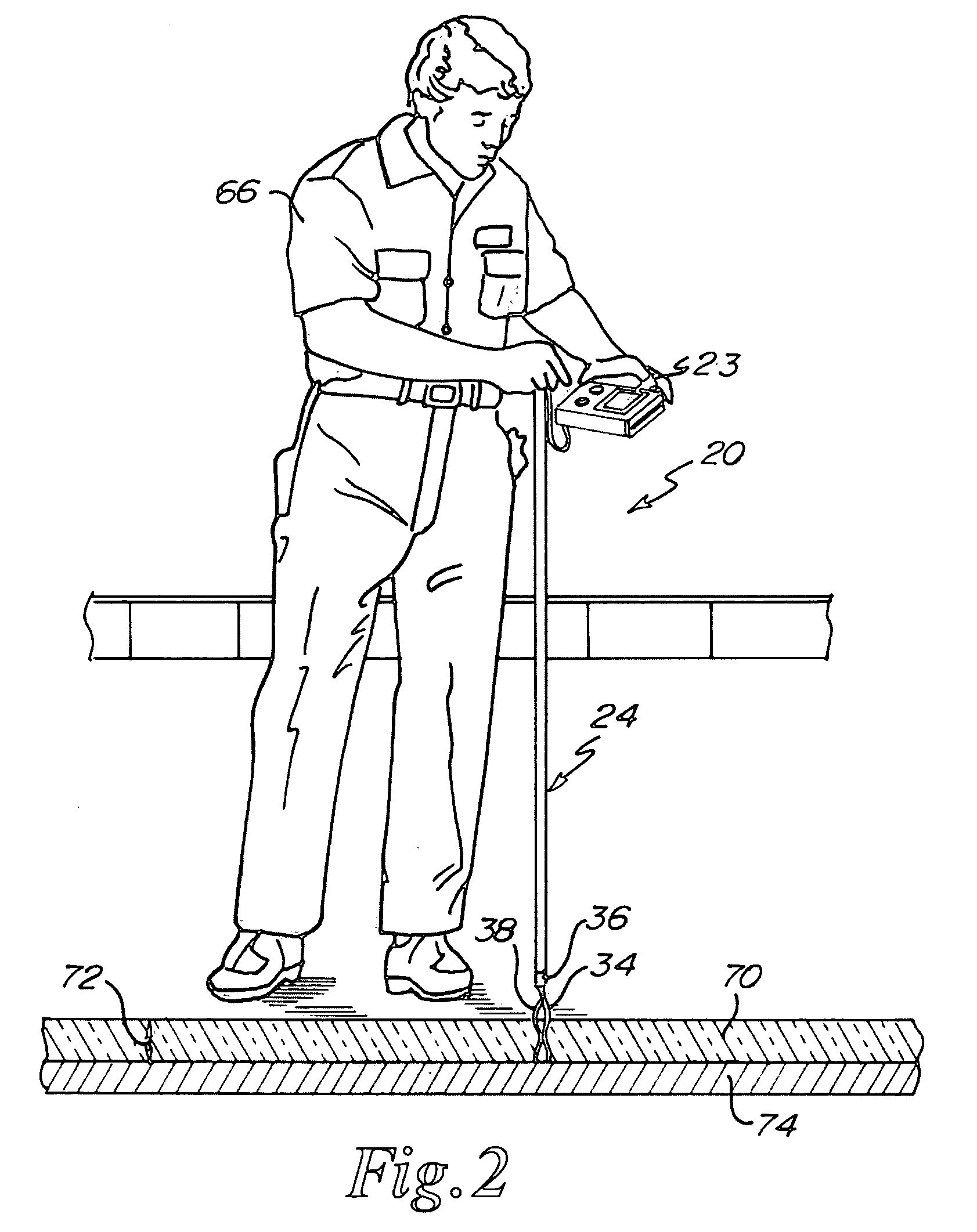

Ice thickness measuring system

InactiveUS20080295599A1Increase speedImprove accuracyMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidGraphicsGraphical user interface

An ice thickness measurement system for determining thicknesses of an ice sheet such as an ice rink that is positioned on a solid or granular substrate. The system determines the thickness of the ice sheet using an acoustic technique, is portable, and may include a display graphic or graphical user interface on the portable unit to direct operators of the unit where to conduct an array of measurements on the ice sheet. The system may also be compatible with a computer for downloading of data and uploading of graphical displays.

Owner:PRECICE TECH

Machine for producing a fibrous web

InactiveUS20060060321A1Suitable for productionImprove paper qualityMachine wet endFiberFiber suspension

Owner:VOITH PATENT GMBH

Preparation method of in-situ calcium silicate fiber pulp and calcium silicate high-filler pulp

InactiveCN104878649AHigh bonding strengthGood dispersionAlkaline-earth metal silicatesInorganic compound additionFiberCalcium silicate

The invention provides a preparation method of in-situ calcium silicate fiber pulp and calcium silicate high-filler pulp. The method comprises the following steps: adding coal ashes to a sodium hydroxide solution, and carrying out desilylation reaction to prepare a desilication liquid; burning limestone, and carrying out slaking reaction on the burnt limestone and water to prepare a lime milk; adding a fiber material to the desilication liquid, and carrying out defibering and pulping treatment, so as to prepare a pulp solution; and adding the lime milk into the pulp solution, and carrying out in-situ fiber hydrothermal synthesis reaction, so as to prepare the in-situ calcium silicate fiber pulp. According to the preparation method of the in-situ calcium silicate fiber pulp provided by the invention, the technical problems of low filler retention rate, relatively high chemical consumption and relatively high energy consumption in paper drying caused by relatively poor binding force of the calcium silicate and the fiber when the calcium silicate and the fiber are subjected to physical mixing, stirring and filling in the prior art are solved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

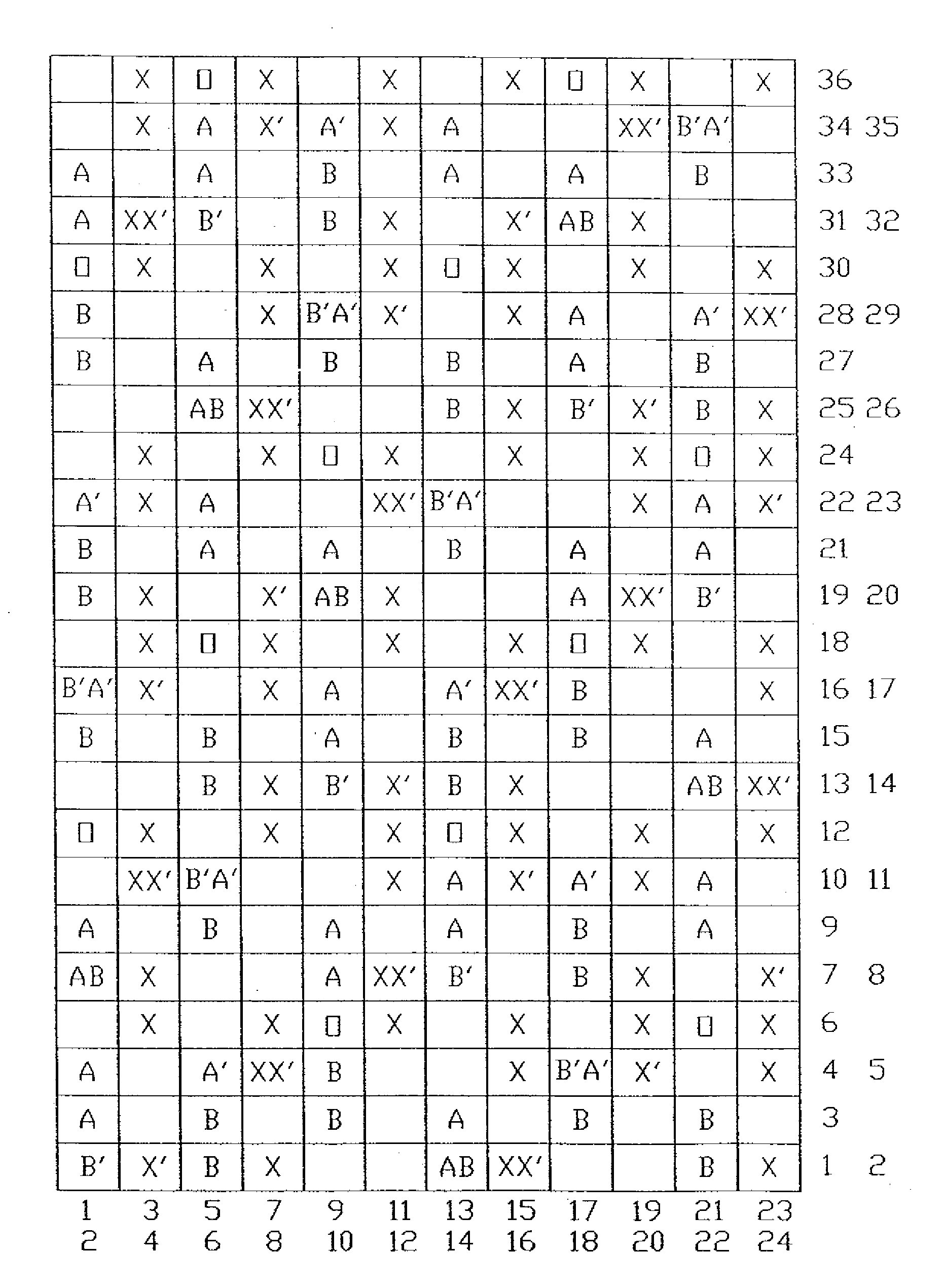

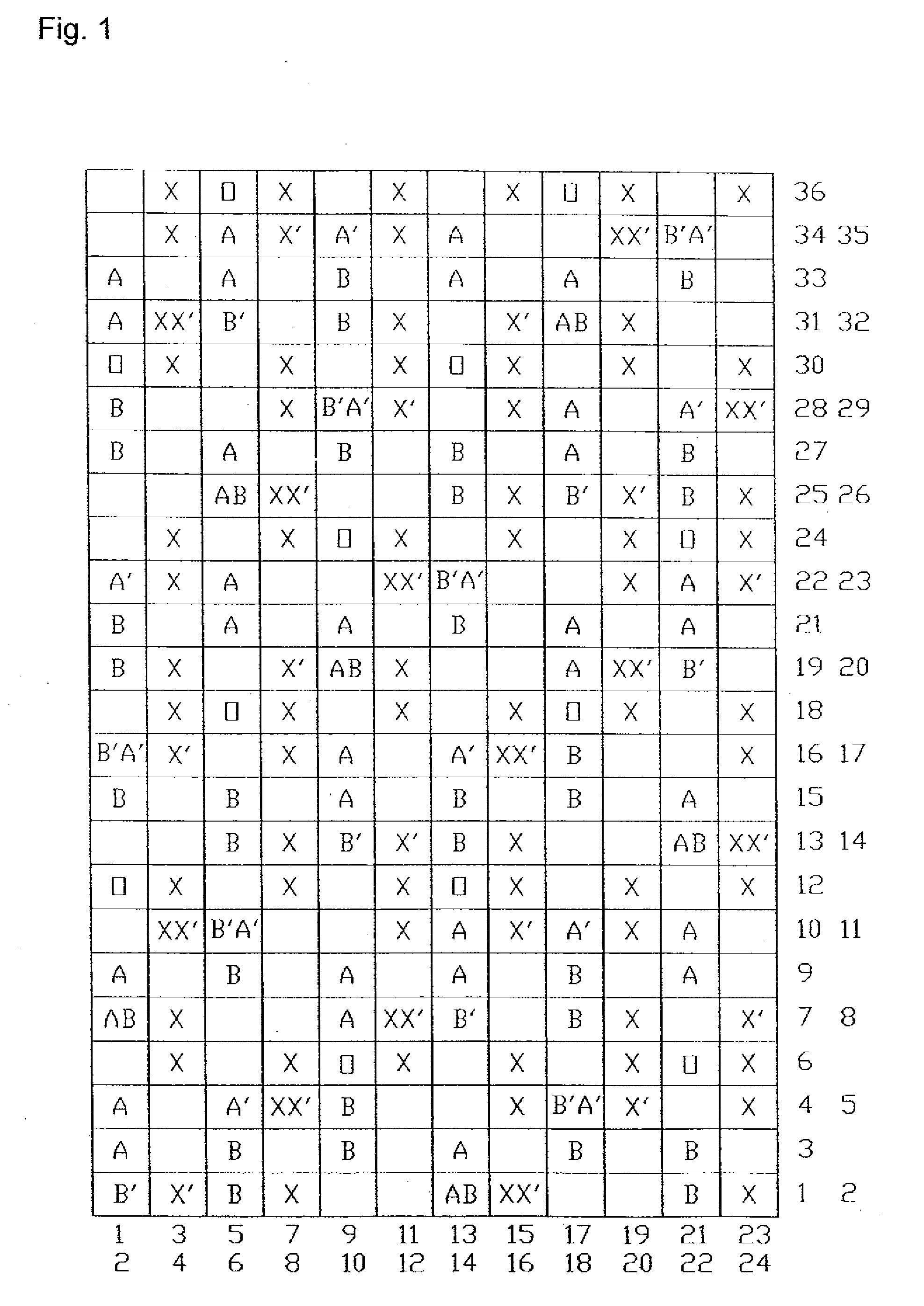

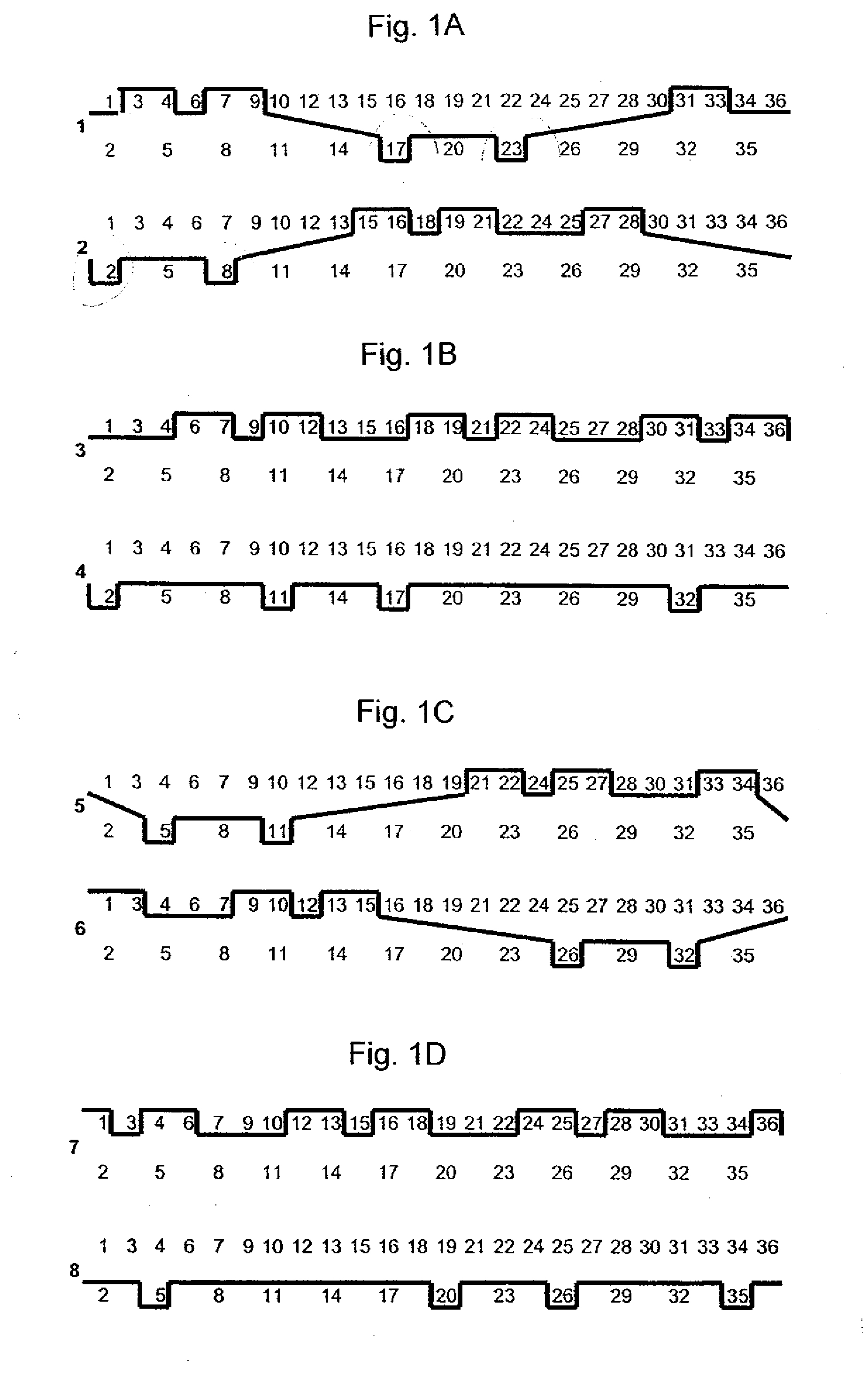

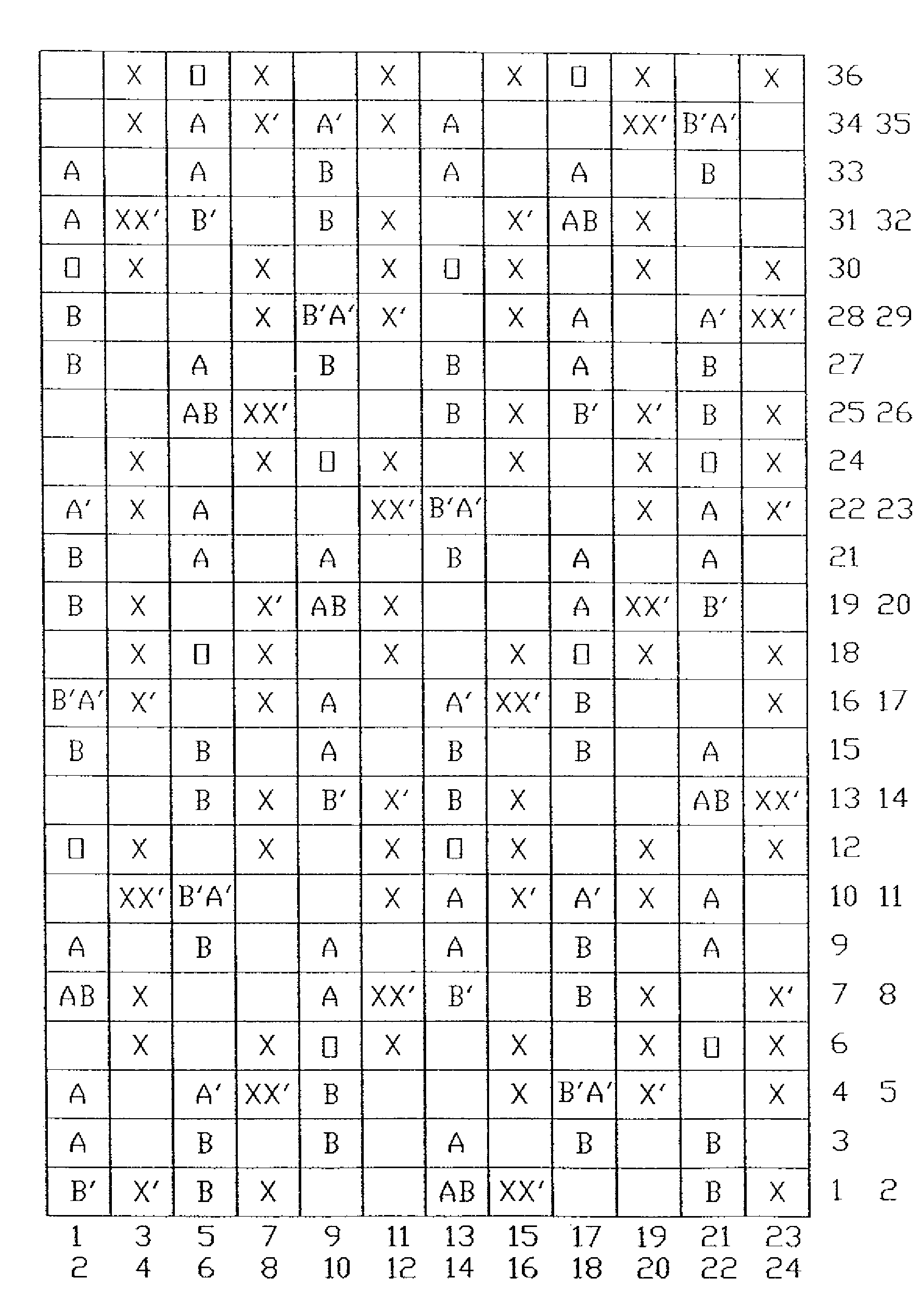

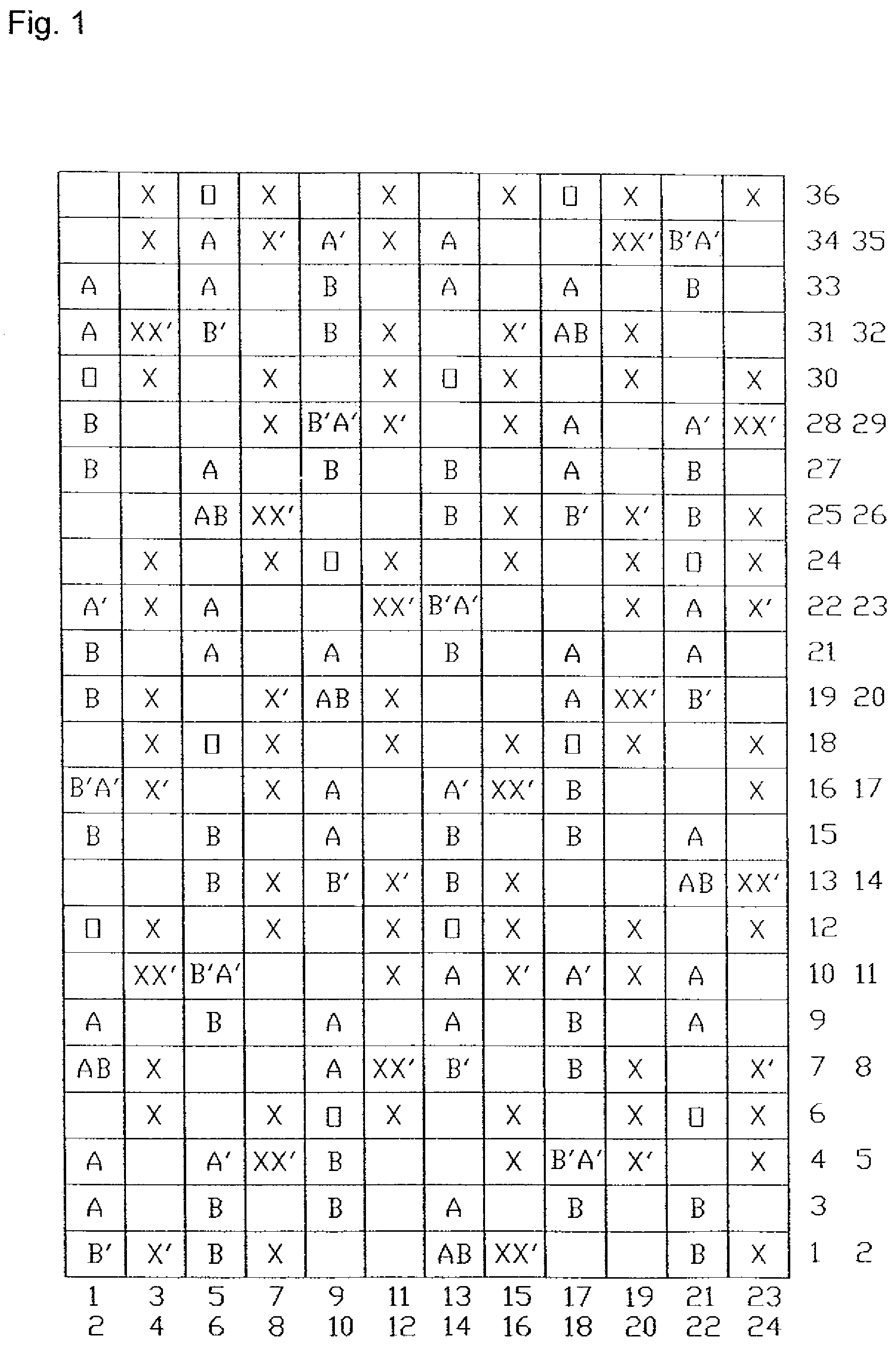

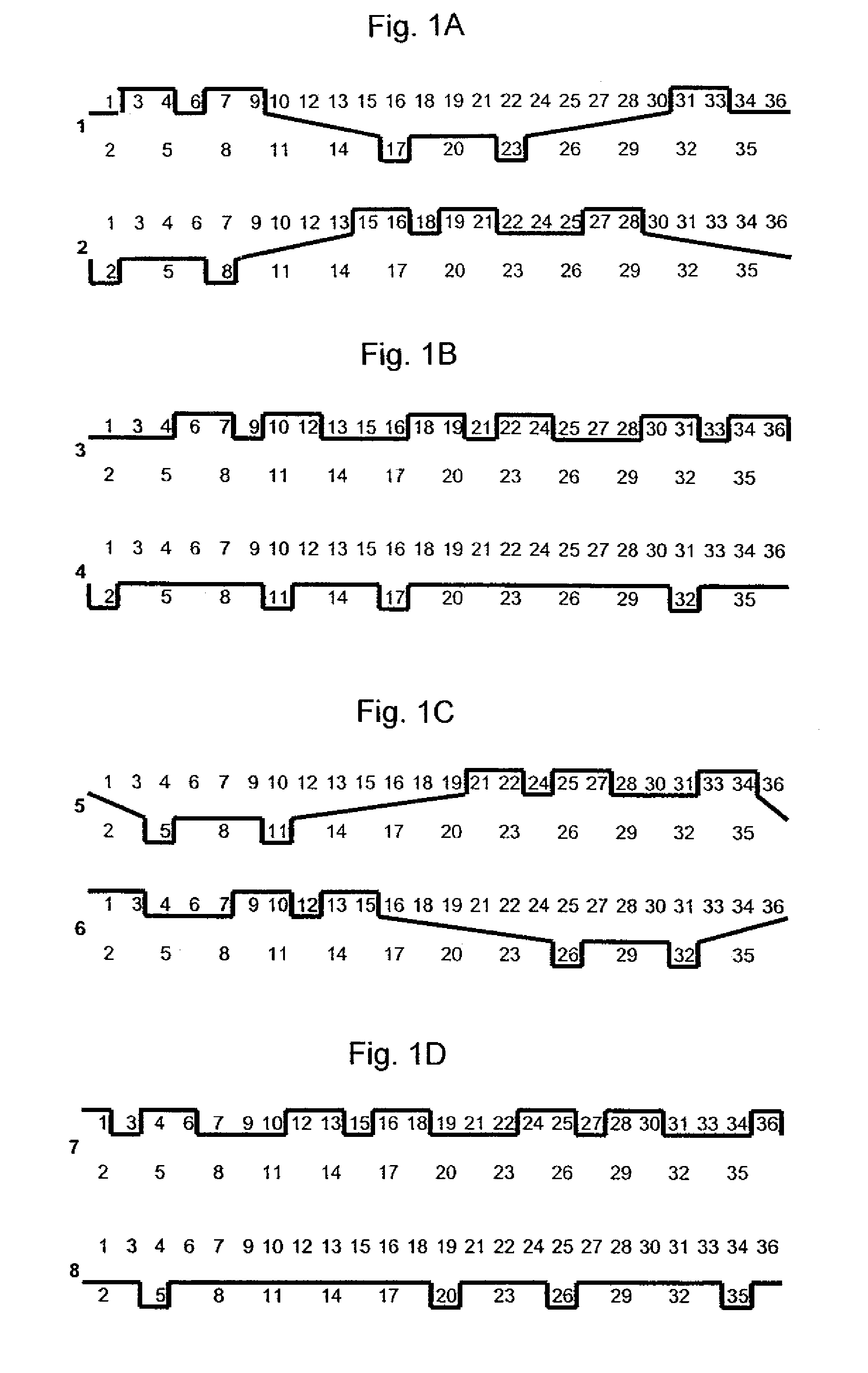

Forming fabric having offset binding warps

InactiveUS20080149213A1Easy to drainImprove joint strengthMachine wet endPress sectionPlain weaveWeft yarn

Forming fabric that includes a top layer having a plurality of first top warp yarns woven with a plurality of top weft yarns. A bottom layer includes a plurality of first bottom warp yarns woven with a plurality of bottom weft yarns. A plurality of second top warp yarns is woven with some of the plurality of top weft yarns and with some of the plurality of bottom weft yarns. A plurality of second bottom warp yarns is woven with some of the plurality of top weft yarns and with some of the plurality of bottom weft yarns. At least one of the plurality of second top warp yarns weaves to the bottom layer with a short plain weave. At least one of the plurality of second bottom warp yarns weaves to the bottom layer with a short plain weave.

Owner:VOITH PATENT GMBH

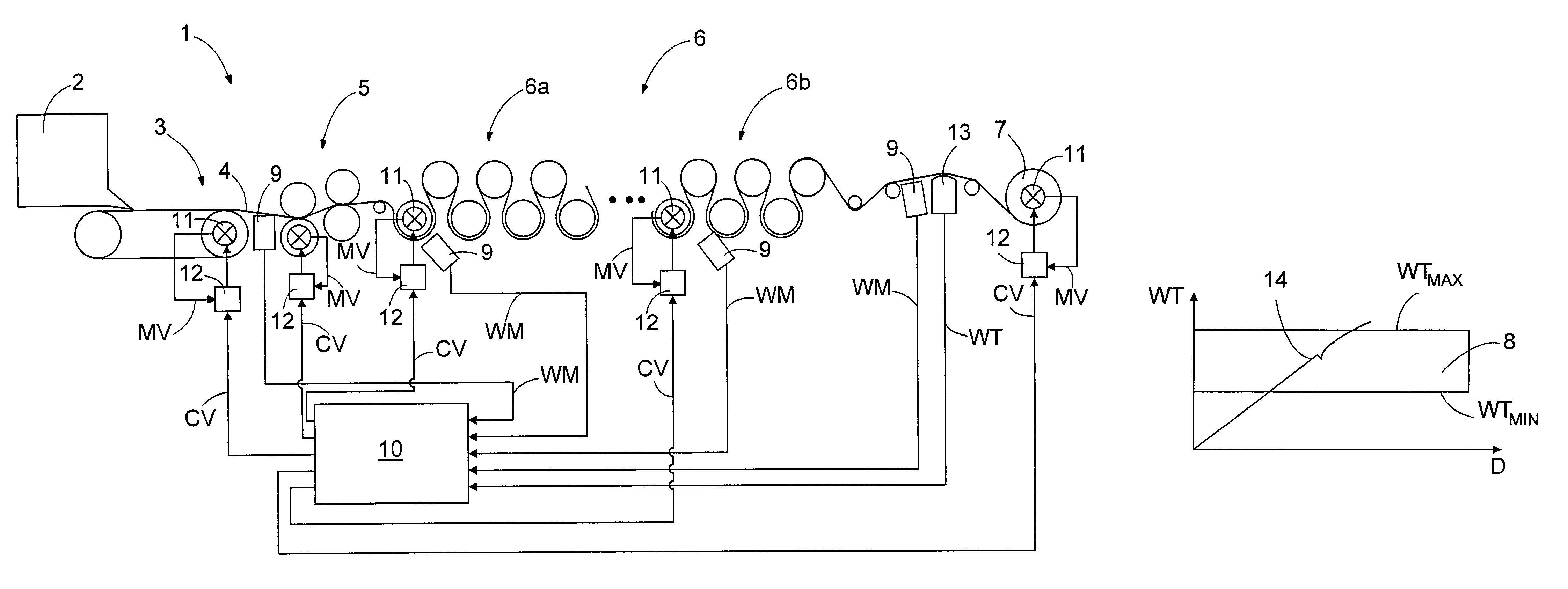

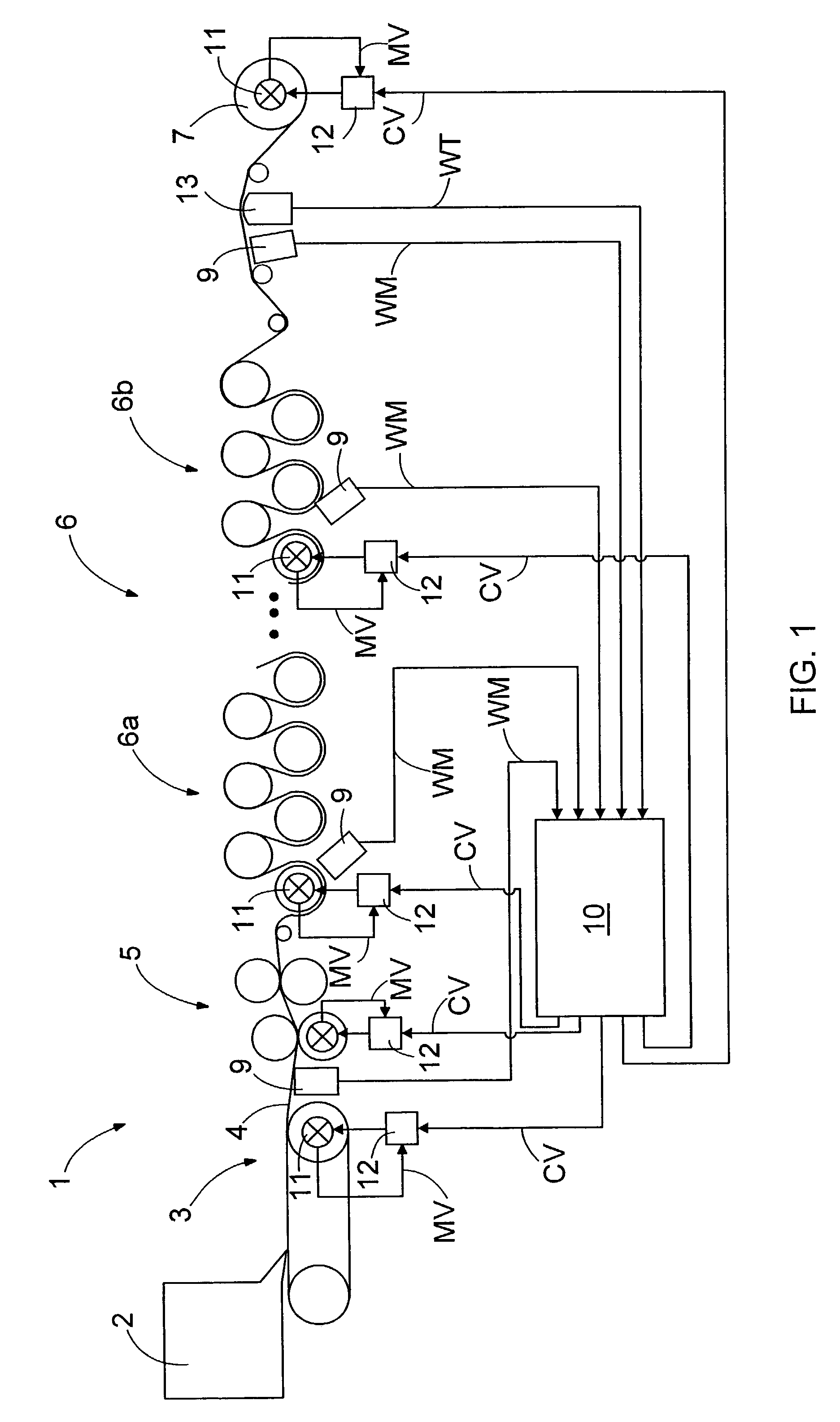

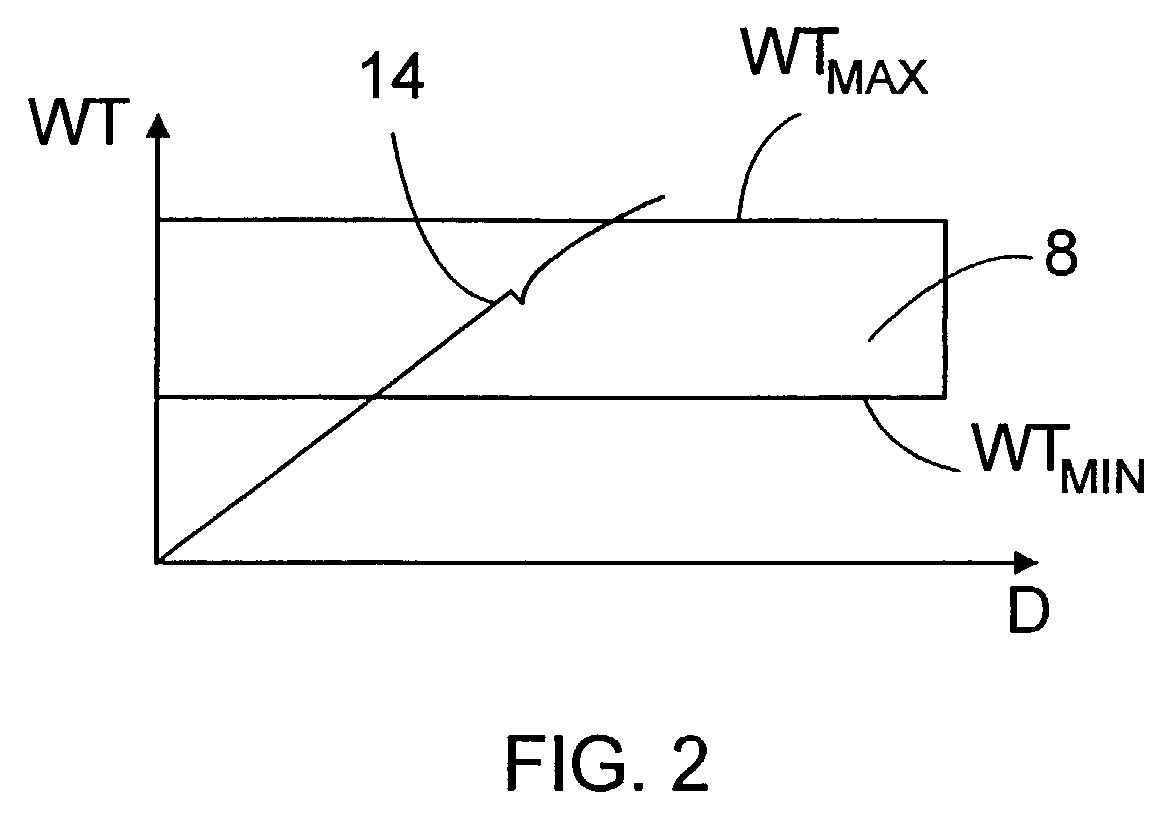

Method and equipment in connection with a paper machine or a paper web finishing apparatus

InactiveUS7067039B2Reduce breakageGuaranteed uptimeDrying solid materials with heatPaper/cardboard wound articlesMoisturePaper machine

A variable representing runnability of a paper web to be manufactured with a paper machine or processed with a finishing apparatus is measured and the speed difference between operational groups of the paper machine and / or the finishing apparatus is adjusted on the basis of the measurement of said variable such that the moisture profile of the paper web is measured substantially along the entire width of the paper web, the minimum and maximum values for moisture are defined on the basis of the moisture profile, a drawing window describing the allowable tension to be directed to the paper web is defined, the lower and upper limits of the drawing window being defined on the basis of the minimum and maximum values for moisture, and the speed difference between the operational groups is adjusted so that the paper web tension is within the range defined by the drawing window.

Owner:METSO AUTOMATION OY

Coated Paper for Sheet-Fed Offset Printing

InactiveUS20080261021A1Simple printing processShorter reprinting time timeCylinder pressesNon-fibrous pulp additionDusting powdersPrinting press

The specification pertains to a single or multiple coated printing sheet in particular but not exclusively for sheet-fed offset printing with an image receptive coating layer on a paper substrate. The printing sheet has the property that it can be printed in an offset printing process without spraying a fine powder, usually called offset powder or dust powder, on the sheet as it comes off the press to prevent the ink from transferring to the back side of the next sheet. Also irradiative (UV or IR) drying on the sheet fed press is not necessary and / or the use of overprint varnish is not required. In addition to that, unexpectedly short times until reprinting and converting can be achieved. Furthermore methods for making such a printing sheet and uses of such a printing sheet are disclosed.

Owner:SAPPI NETHERLANDS SERVICES

Method of controlling secondary gummy substances by using lipase

InactiveCN103061184AEliminate hazardsImprove the authenticity ratePaper recyclingWaste paper working-upPulp treatmentDe esterification

The invention discloses a method of using lipase to treat secondary gummy substances in paper pulp and white water produced in papermaking with waste paper. The lipase is alkaline lipase with a pH value of 7.5 to 9.0, enzyme activity of more than 100 U / mL, a hydrolysis rate of triglyceride of no less than 95% and transesterification and lipogenesis rates of less than 3%. A treating method for the paper pulp comprises steps consisting of adding the lipase accounting for 0.001 to 0. 5% of dry weight of the paper pulp into the paper pulp having a concentration adjusted to be 2 to 5%, carrying out treating and filtering, centrifuging and detecting the treated pulp. A treating method for the white water comprises steps consisting of adding the lipase accounting for 0.001 to 0. 5% of dry weight of the white water into the papermaking white water, carrying out treating and filtering, centrifuging and detecting the treated white water. According to the invention, the lipase is utilized to fundamentally degrade the gummy substances and mitigate deposition tendency of the gummy substances so as to remove the gummy substances, so the problem of pollution by secondary gummy substances is thoroughly overcome; and the method is simple to operate, has a substantial removal effect and enables the quality of papermaking with waste paper to be improved and production cost to be reduced.

Owner:TAIXING YIMING BIOLOGICAL PRODS

Forming fabric having offset binding warps

InactiveUS7604025B2Easy to drainImprove joint strengthMachine wet endPress sectionPlain weaveWeft yarn

Forming fabric that includes a top layer having a plurality of first top warp yarns woven with a plurality of top weft yarns. A bottom layer includes a plurality of first bottom warp yarns woven with a plurality of bottom weft yarns. A plurality of second top warp yarns is woven with some of the plurality of top weft yarns and with some of the plurality of bottom weft yarns. A plurality of second bottom warp yarns is woven with some of the plurality of top weft yarns and with some of the plurality of bottom weft yarns. At least one of the plurality of second top warp yarns weaves to the bottom layer with a short plain weave. At least one of the plurality of second bottom warp yarns weaves to the bottom layer with a short plain weave.

Owner:VOITH PATENT GMBH

High-energy paper pulp release agent and production method thereof

ActiveCN103774495AComprehensive ability to reduce pHBoosts pH synthesisNon-fibrous pulp additionSulfonateEmulsion

The invention provides a high-energy paper pulp release agent. The preparation method comprises the following steps: by taking cycloalkyl low viscosity base oil and Enable460M synthesized sodium sulfonate as fundamental research, treating through an advanced lubricating oil blending and filtering system; then compounding various additives such as a BK hexahydro-triazine bactericide, an MBM bactericide, T-405 vulcanized cottonseed oil and S2215C universal emulsified oil; stirring; finally adopting a triethanolamine to assist acid-base balance modulation so as to synthesize the high-energy paper pulp release agent. The product can be directly applied to paper pulp and further can be prepared to an emulsion for spraying a cylinder. The high-energy paper pulp release agent is low in cost, harmless to a human body and environment-friendly, and can be used for solving the problem of break, hair slip and powder fall of paper in the papermaking process in the paper industry, and reducing the cylinder adhering phenomenon in papermaking. The smoothness and glossiness of paper can be improved to a greater extent without affecting the strength of paper, and the paper quality is improved. Meanwhile, the high-energy paper pulp release agent has a good lubricating and protecting effect on a wrinkling scraper of a dryer, so that the service life of the scraper is prolonged.

Owner:广西飞日能源集团有限公司

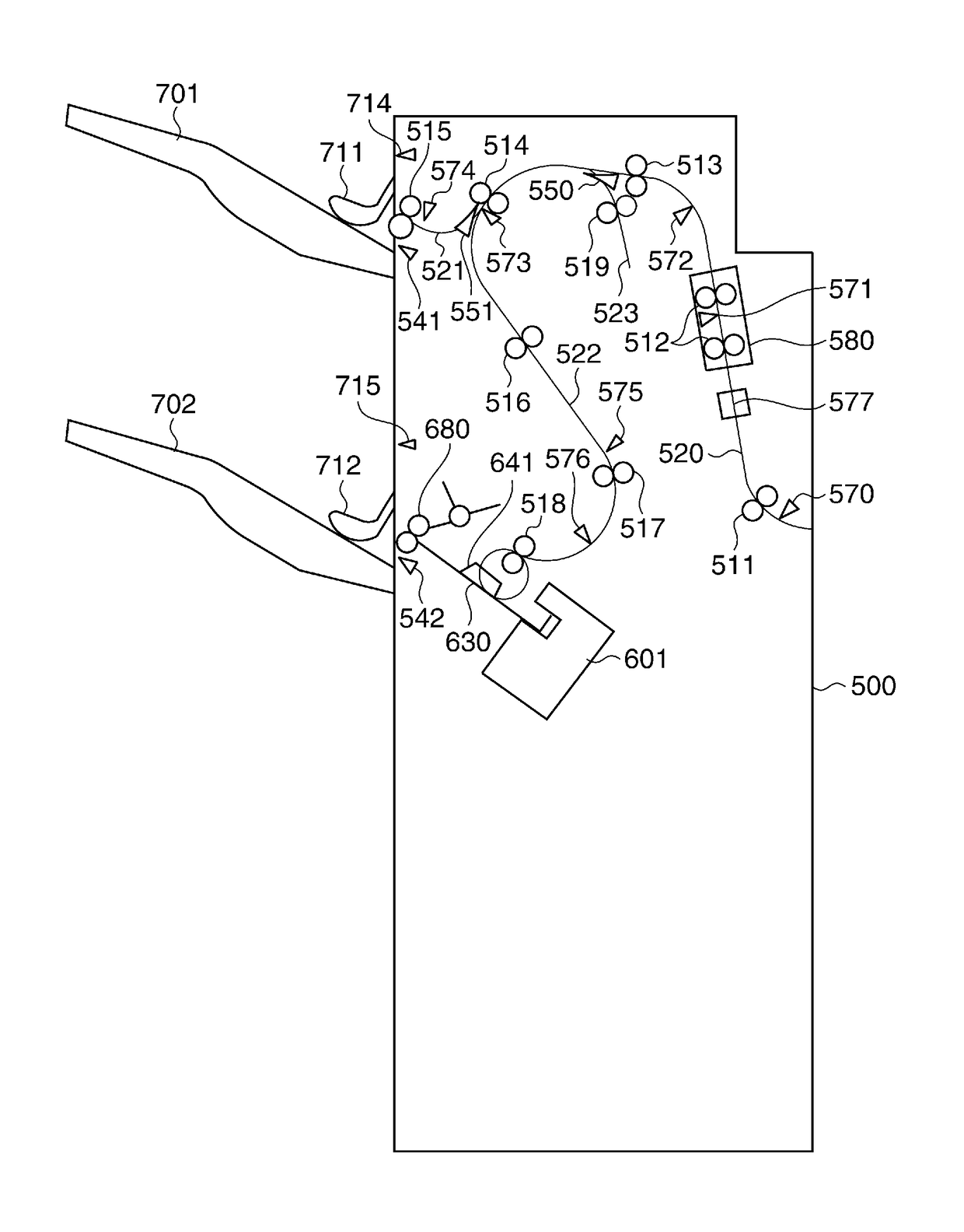

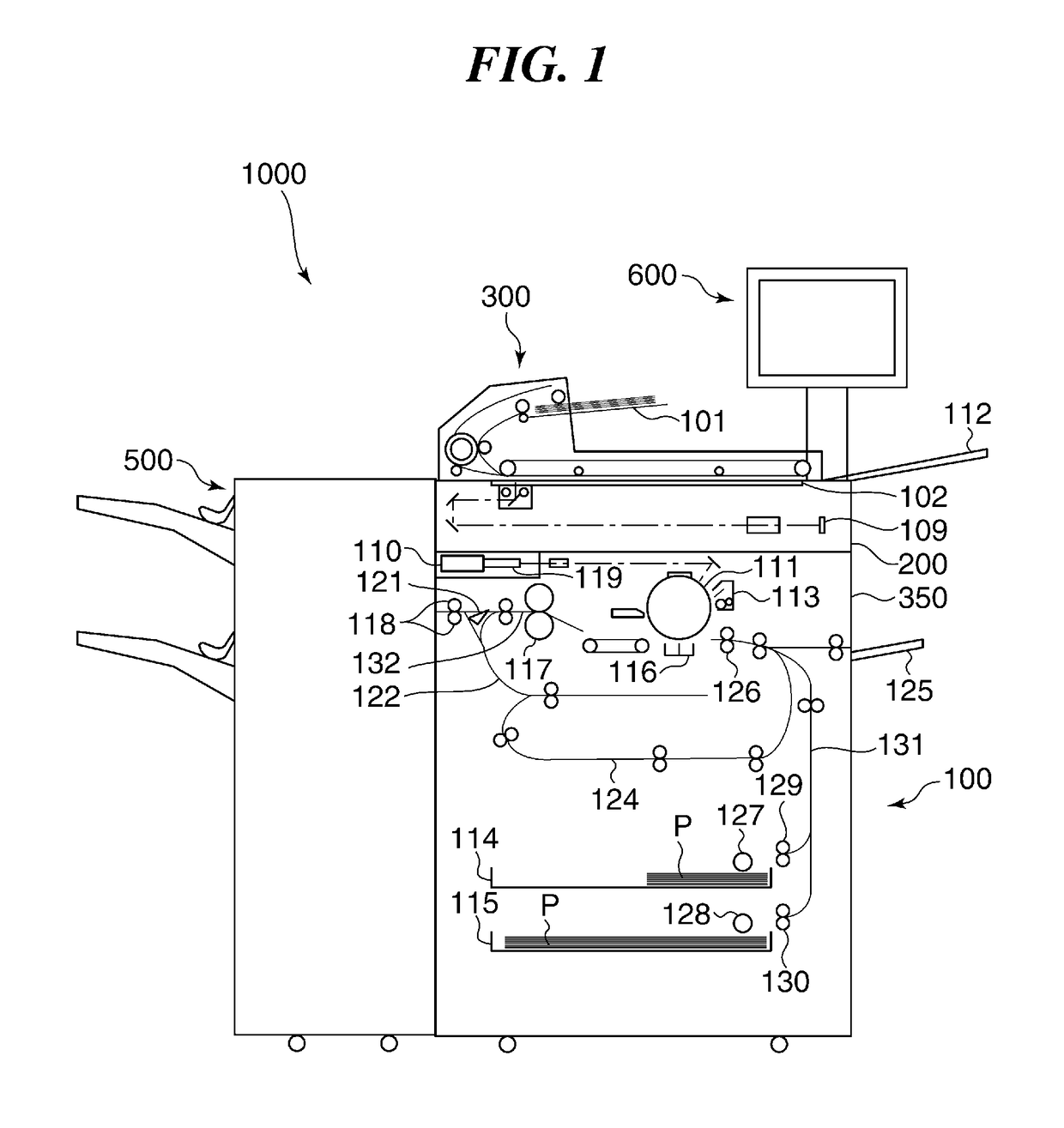

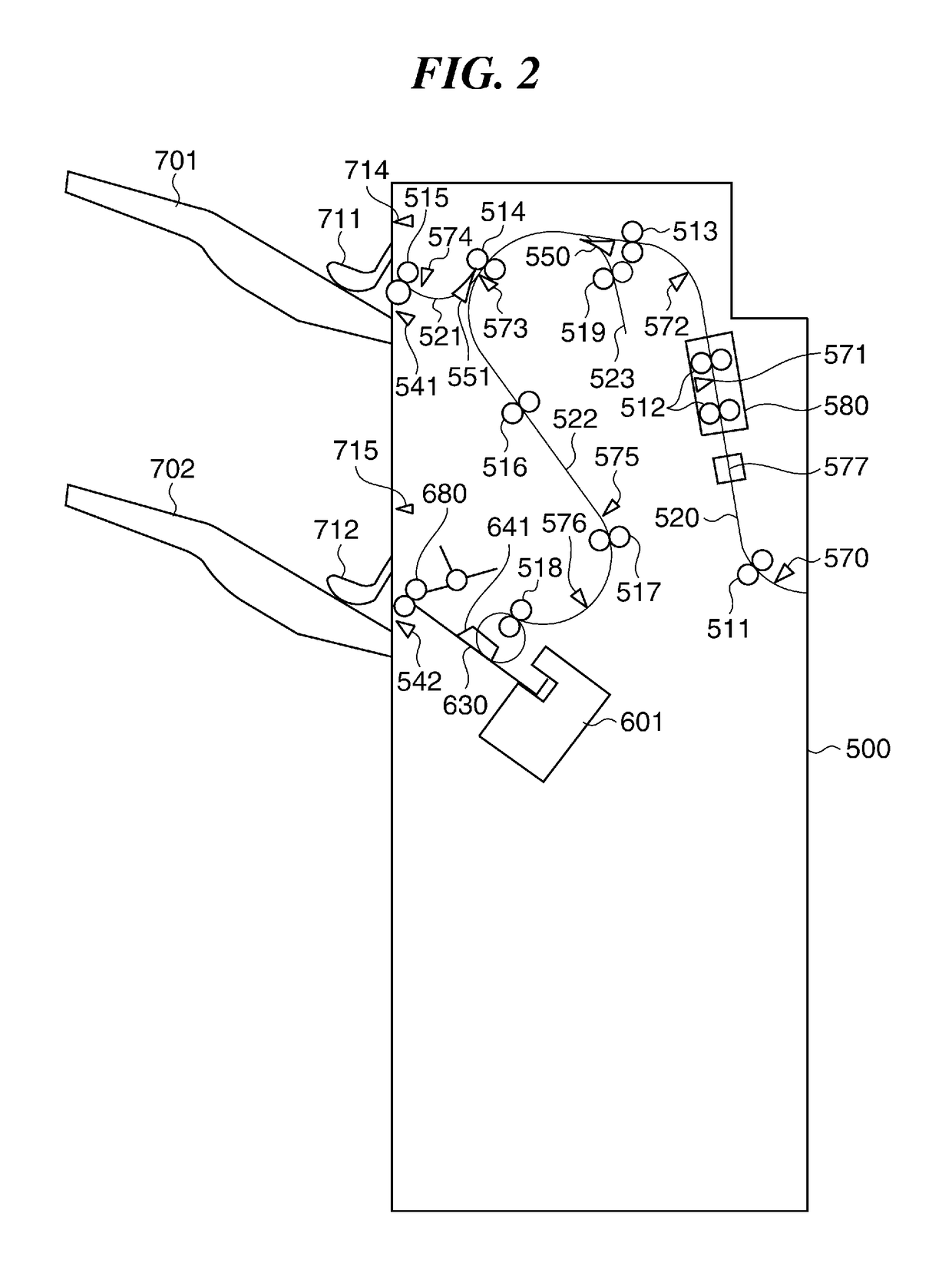

Sheet processing apparatus equipped with lateral displacement correction function

ActiveUS9809408B2Improve paper qualityLong distanceFunction indicatorsElectrographic process apparatusEngineeringAbutment

Owner:CANON KK

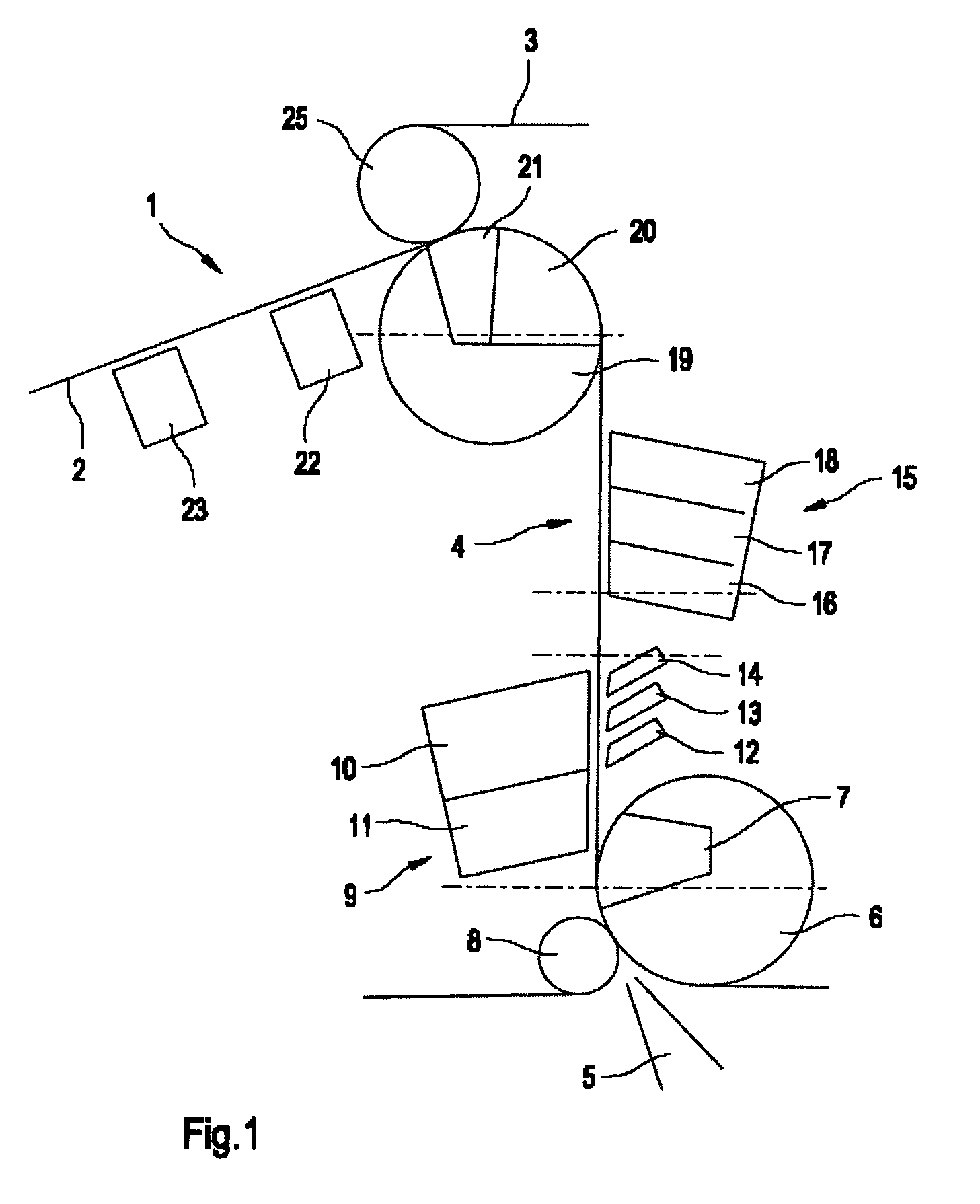

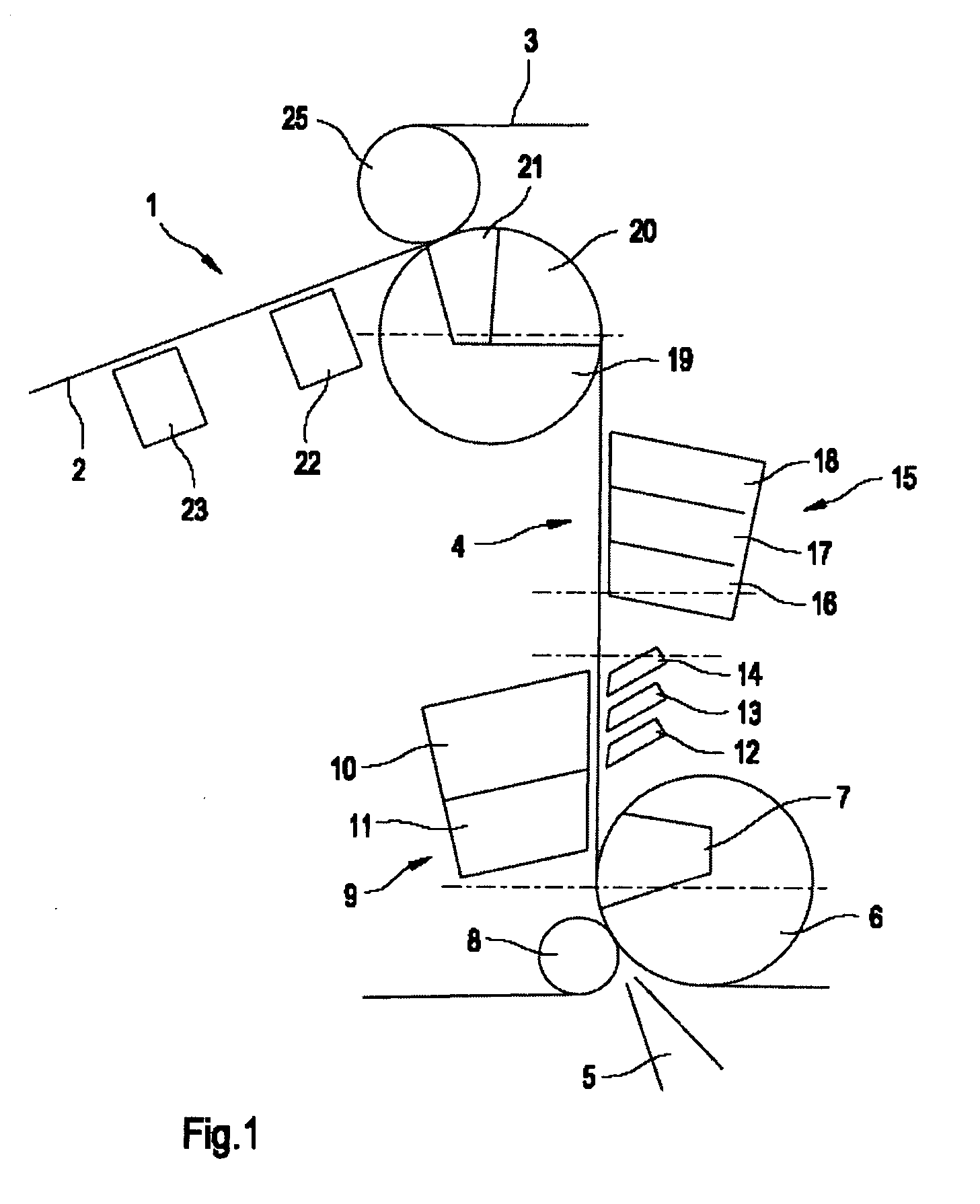

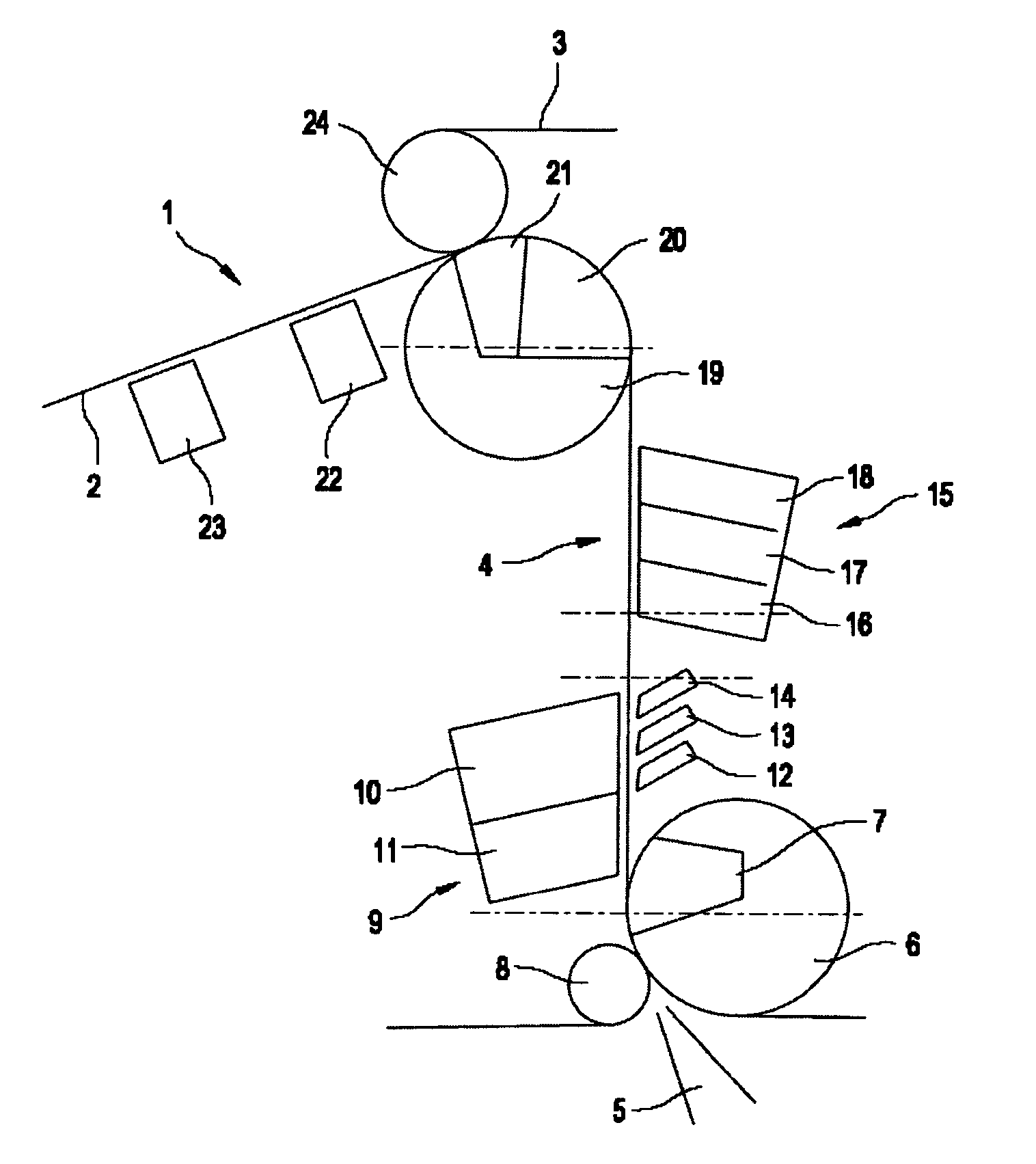

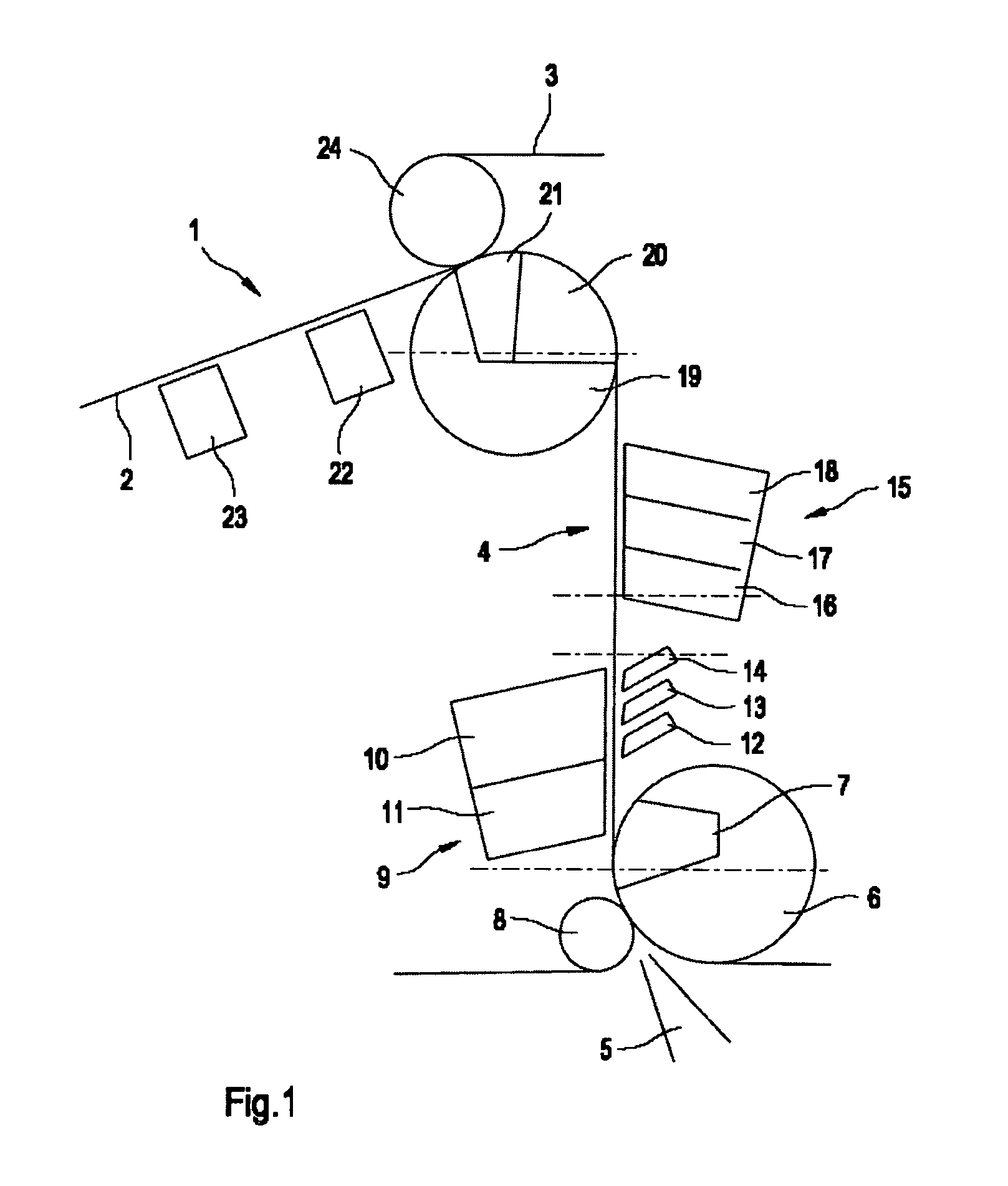

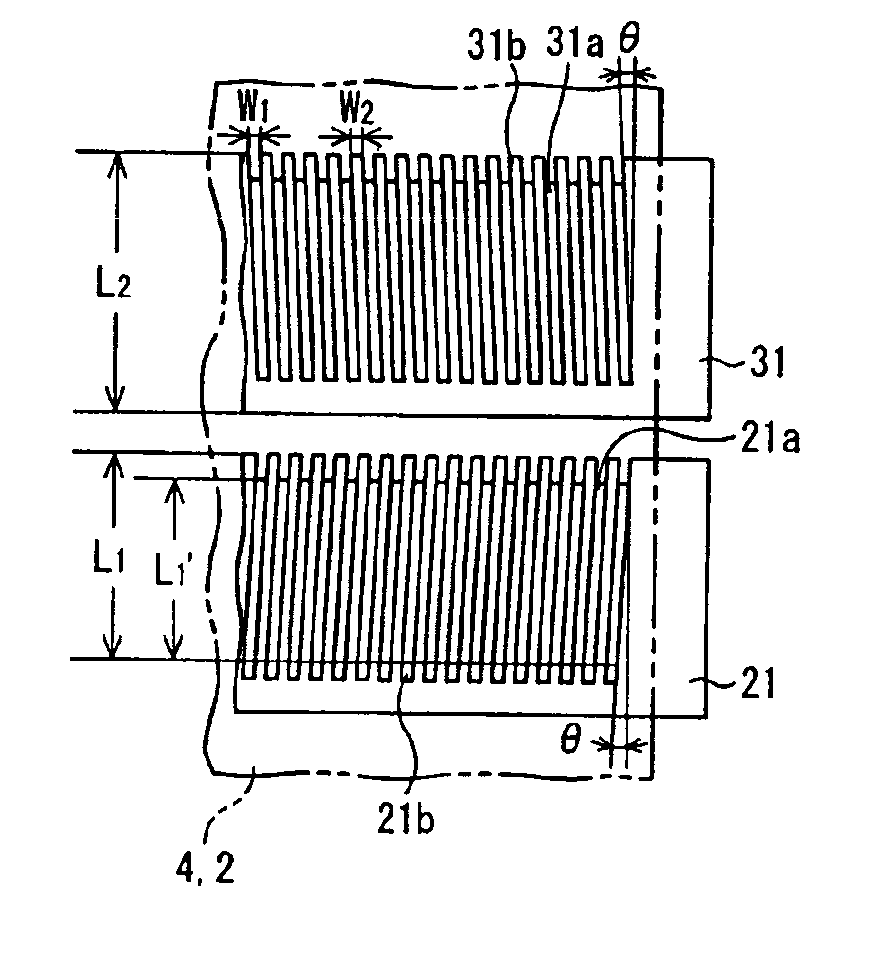

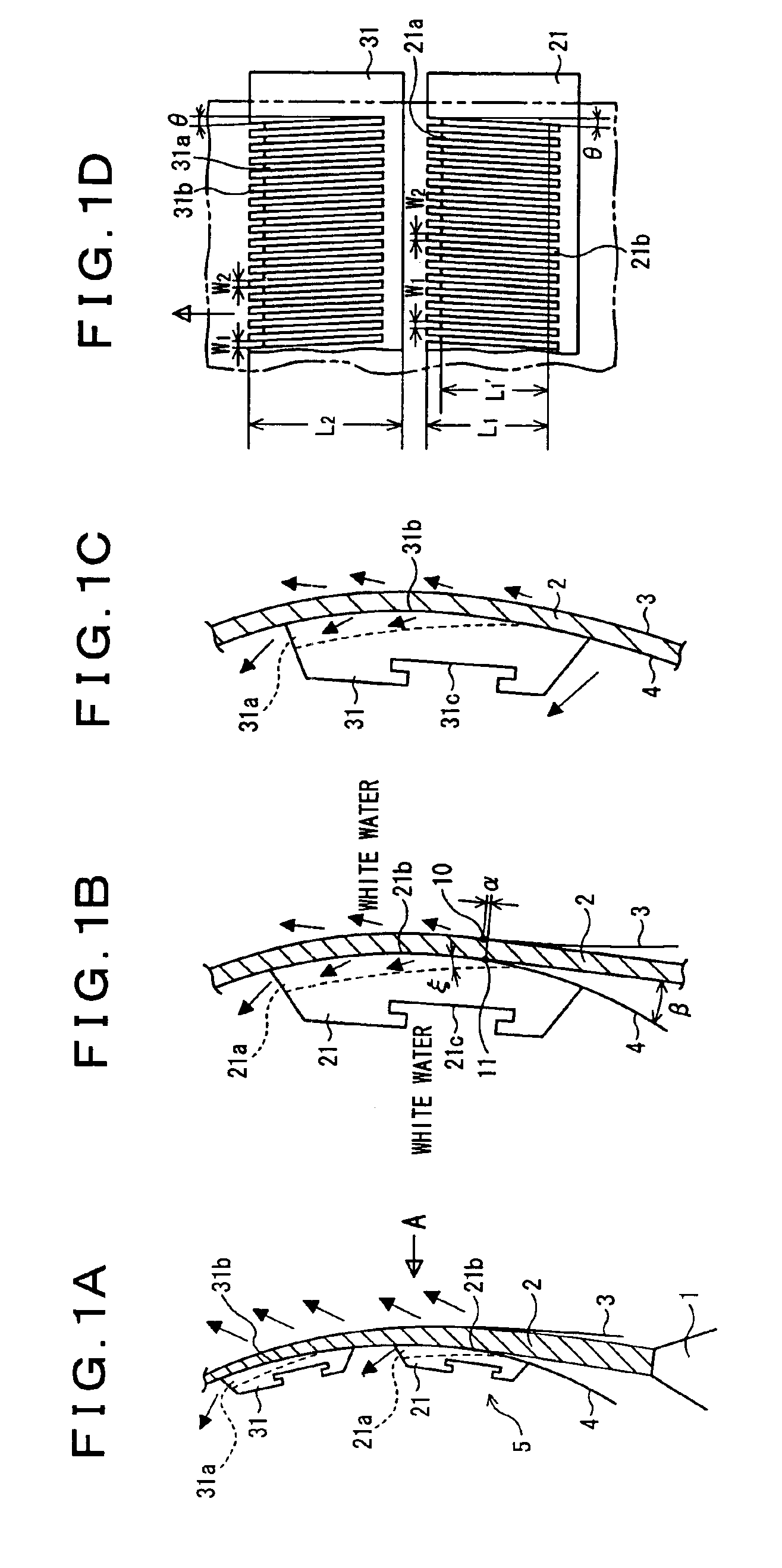

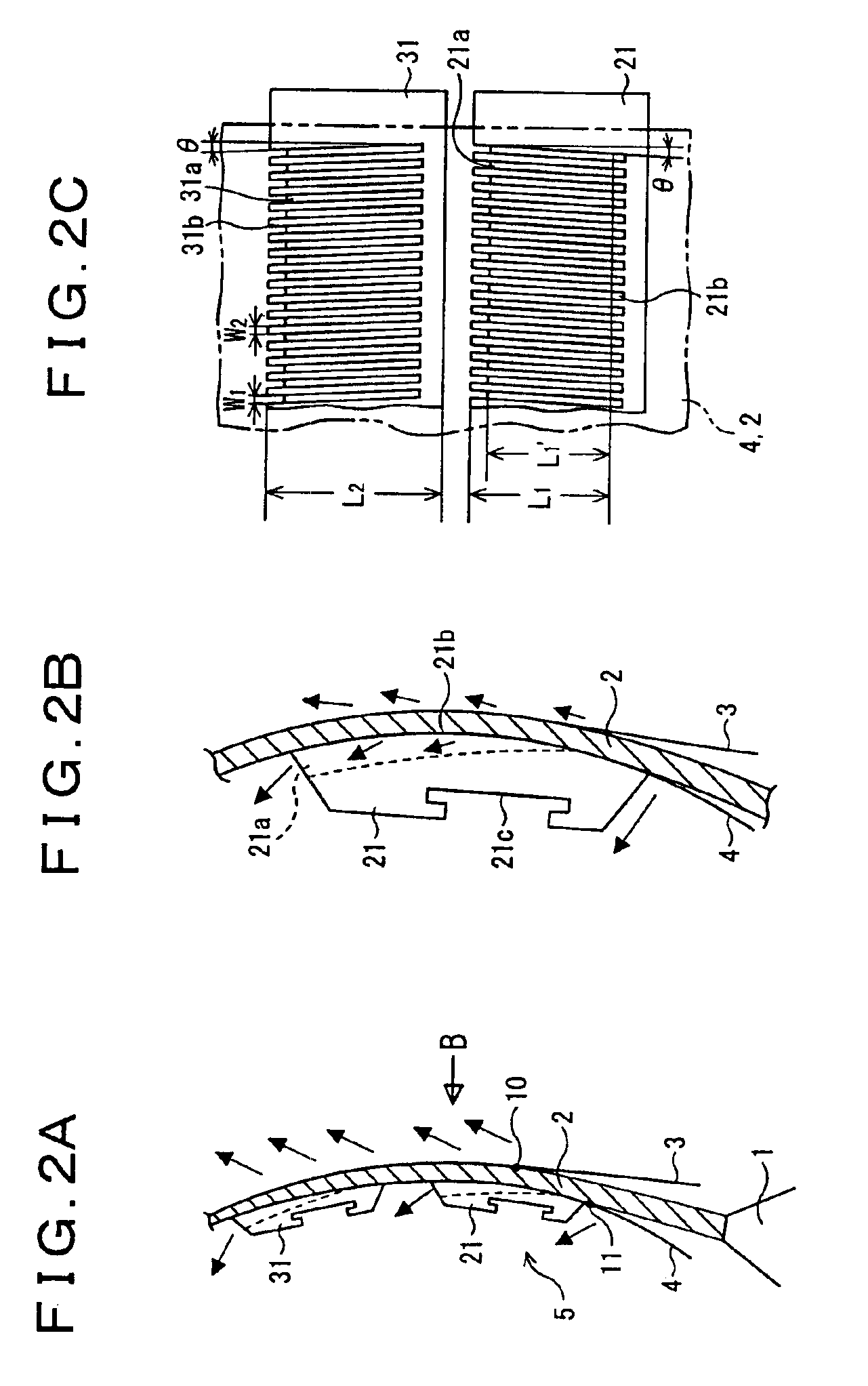

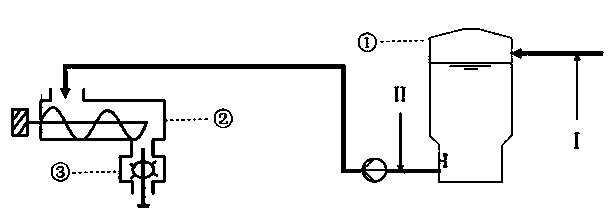

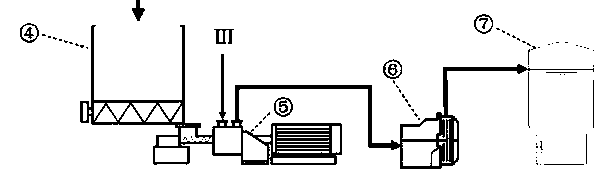

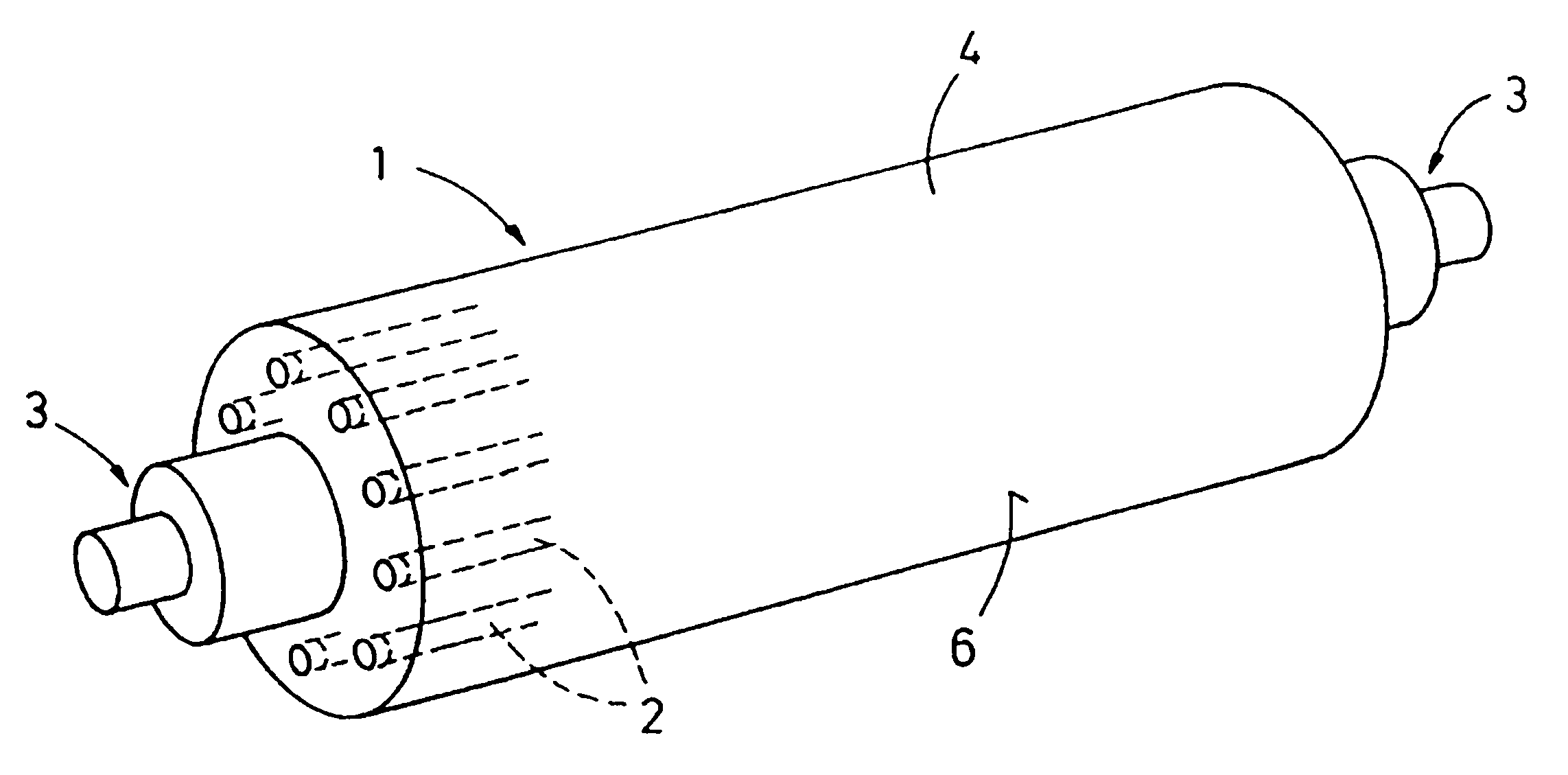

Former for use in paper production

InactiveUS6881302B2Suppression problemImprove paper qualityMachine wet endPaper productionEngineering

A paper former comprises two wires which converge for defining a paper production gap and a plurality of dewatering blades arranged in the paper production gap in a paper producing direction and brought into sliding contact with one of the two wires so that a stock is dehydrated while being conveyed in a state put in the paper production gap. Each of the plurality of dewatering blades is shaped into a convexly curved surface configuration bent along a traveling direction of the wires and equipped with a wire sliding contact surface brought into sliding contact with said wire for guiding the traveling of said wire, and grooves are made in said wire sliding contact surfaces as a moisture run-off opening for running off moisture developing through the dewatering from the wire side. This paper former thus constructed can suppress the occurrence of paper defects stemming from the landing of a material jet or paper defects stemming from the dewatering property, thus improving the paper quality.

Owner:VALMET TECH INC

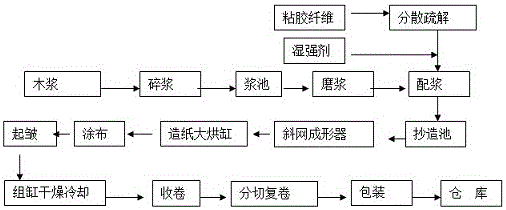

Production technology of crinkled wiping paper

ActiveCN106320084AImprove crease qualityGood flexibilityNon-fibrous pulp additionMechanical working/deformationViscosePulp and paper industry

The invention relates to a paper product processing method, in particular to a production technology of crinkled wiping paper, and belongs to the technical field of paper making and paper product processing and production. The production technology of the crinkled wiping paper includes the following steps that firstly, pure wood pulp is subjected to repulping through a hydraulic repulping machine, then millstone mill pulping is carried out, and pulp with the concentration of 3.5-4.0wt% and the SR beating degree of 18-20 is obtained; secondly, ultrashort viscose fibers are fluffed through a fluffer and then mixed with the pulp, and mixed pulp is obtained; thirdly, a softening agent, auxiliaries and a wet strength agent for paper are added into the mixed pulp and mixed evenly, the mixture is subjected to wet-process forming through an inclined-wire papermaking net part former, and the product is squeezed and dehydrated through a water absorption box and enters a vat to be pre-dried; fourthly, the body paper entering the vat is subjected to coating on the surface of the vat, the sizing amount is controlled to be within 2-5 g / m<2> according to paper requirements, crinkling occurs on the surface of the drying vat, and after vat-combined drying and finishing, cooling and rolling, rewinding and slitting, and packaging and warehousing, production of the product is completed.

Owner:杭州景森科技有限公司

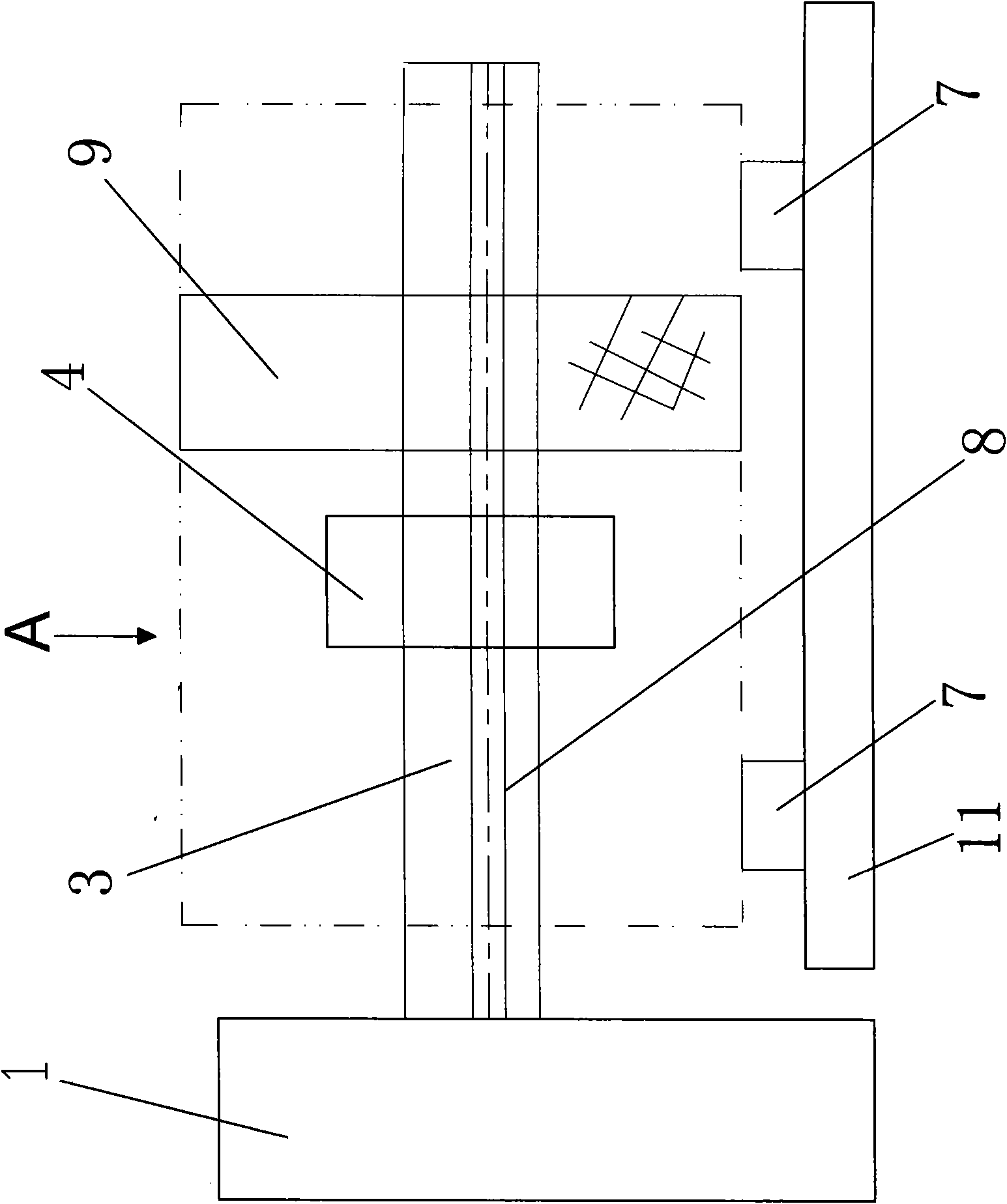

Grinding machine equipment for grinding internal surface of column

InactiveCN101683717AHigh movement precisionSmooth runningGrinding machine componentsRevolution surface grinding machinesMachine maintenanceControl system

The invention discloses grinding machine equipment for grinding the internal surface of a column. A machine head comprises a motor gear transmission system and a control system; a machine body comprises a first guiding rail and a second guiding rail; a feeding mechanism comprises a leading screw with external threads and a kinematic pair with internal threads, wherein the kinematic pair is sleeved on the leading screw by meshing the internal threads and the external threads; the feeding mechanism is also provided with a structure capable of moving forward and backward relative to processed pieces in a radial direction; a cutter lever mechanism comprises a grinding wheel frame and grinding wheels; a cooling liquid mechanism mainly comprises a liquid supply pipe and a liquid storage pool; roller frames comprise rollers and brackets, wherein the rollers are pivoted in the brackets; water liquid is stored in the brackets; the surfaces of the rollers are in contact with the water liquid; the first guiding rail and the second guiding rail are respectively provided with at least two roller frames at intervals; and the processed pieces are arranged on the surfaces of the rollers. The embodiment can ensure level internal surfaces of the processed pieces and uniform wall thickness, enhance roller movement precision, enable a paper making machine to stably run in a papermaking process, effectively enhance paper making quality and reduce machine maintenance cost.

Owner:JIANGSU HUADONG PAPER MACHINERY

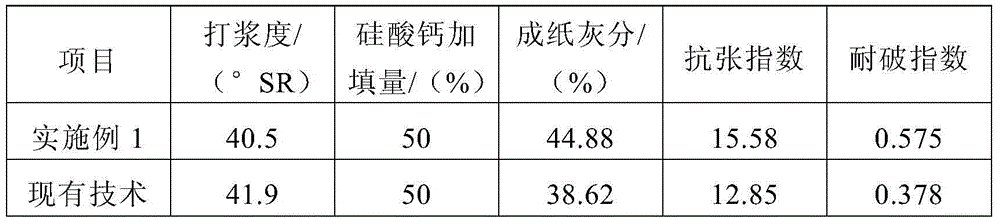

Fiber and filler mixed enzymatic defibrination method

The invention relates to a fiber and filler mixed enzymatic defibrination method which comprises the steps of high concentration and low concentration series beating, paste and filler premixed beating, and paste and beating enzyme premixed beating. Firstly, pre-treating fibers by beating enzyme, so as to enable the fibers to be soft and convenient to beat; secondly, adding fillers when concentrating the paste into a higher concentration through a press master; and conducting beating through a high consistency refiner. According to the method provided by the invention, fiber intensity is improved through three modes, tensile strength, bursting strength, folding endurance and cohesion of paper can be efficiently improved; identical paper strength can be maintained under the condition of improving 2 percent to 3 percent of paper ash, furthermore, beating energy consumption can be greatly decreased under the action of beating enzyme. Through the application of the method in a paper mill, macrofiber usage can be decreased, paper ash part can be improved, cost of a ton of paper can be greatly decreased, and product competitiveness can be improved.

Owner:HAINAN JINHAI PULP & PAPER

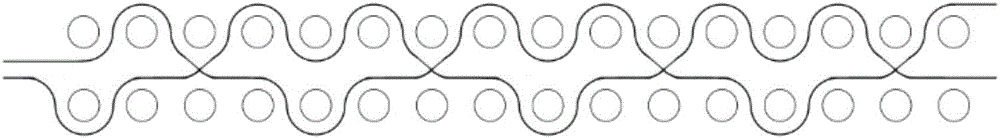

Microstructured monofilament and twined filaments

InactiveUS20070197334A1Reduce decreaseFrictionV-beltsRopes and cables for vehicles/pulleyPaperboardPulp and paper industry

An apparatus for the production of a fibrous web, in particular a paper web or paperboard web, having a belt formed from individual threads which are connected together, in particular woven together, whereby the surface of the threads is constructed to be structured in order to improve the paper quality and the production flow.

Owner:VOITH PATENT GMBH

Papermaking sterilizing preservative

InactiveCN103015266ARapid sterilizationDelay drug resistanceNon-fibrous pulp additionPaper/cardboardWater qualityPapermaking

The invention discloses a papermaking sterilizing preservative which comprises the following components in percentage by weight: 40-80% of 2, 2-dibromo-3-nitrilo-propanamide, 10-30% of ethylene glycol system organic solvent, 1-10% of polyhydric alcohols, 1-10% of cyclic nitrogen system sulfur system chemical compound, and 1-10% of organic nitrogen system sulfur system chemical compound. According to the papermaking sterilizing preservative provided by the invention, the bacterium can be quickly killed, the papermaking sterilizing preservative is low in drug resistance and wide in application range, the accumulation of dissolved matter and colloid in a white water system can be reduced, the cleanness of water quality can be kept, the use of the other chemical substances in the process of papermaking can be used, the papermaking cost can be reduced, and the quality of finished paper can be improved.

Owner:姜建明

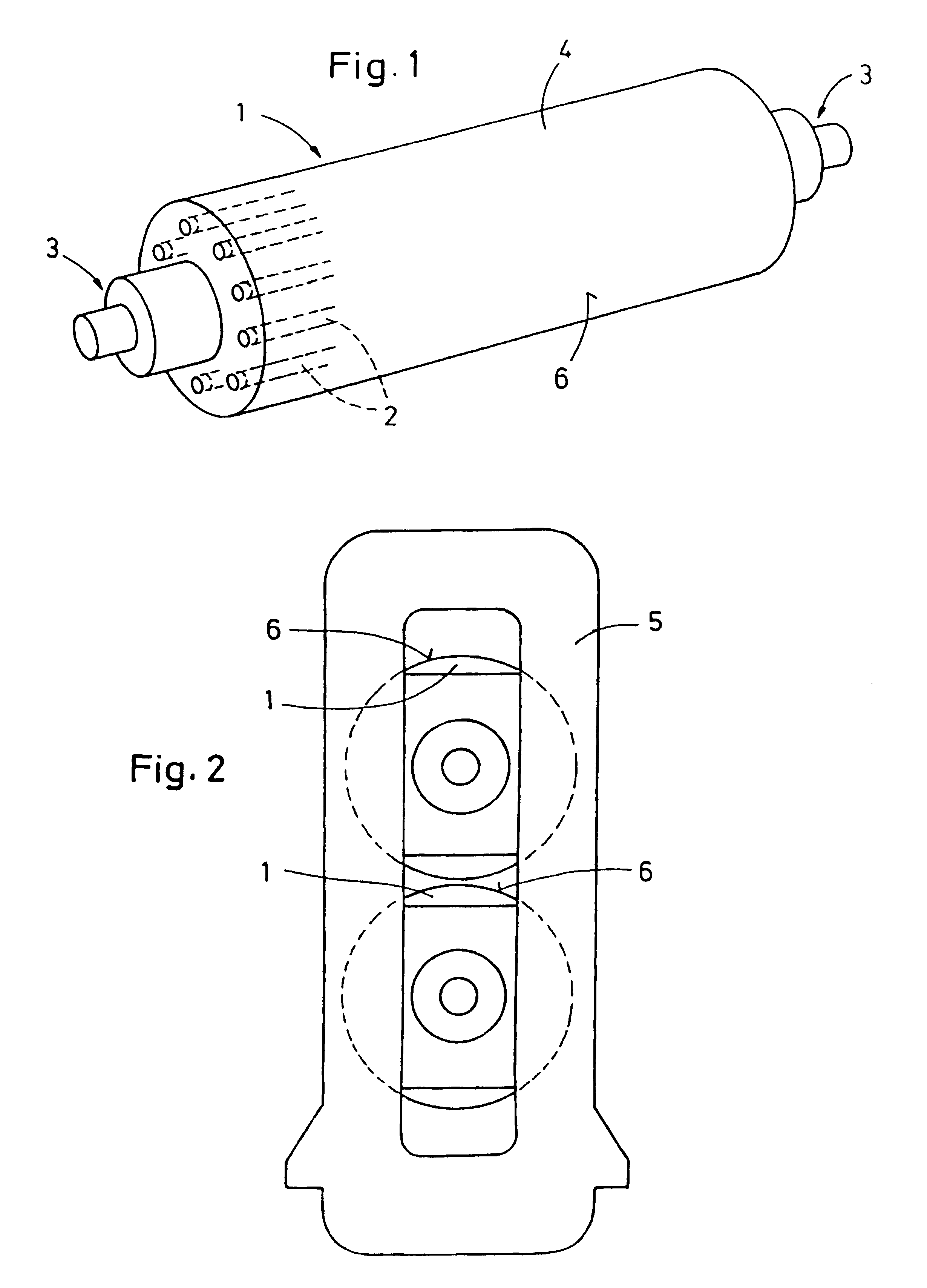

Roll, in particular, calender roll

InactiveUS7018512B2Inhibition of contractionIncrease working temperatureNon-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industryIncrease temperature

A paper processing roll for use in a calender of a paper-making machine which during operation can be exposed to increased temperatures is provided with a heat-treated surface which is produced by hot-grinding or hot-balancing or both.

Owner:WALZEN IRLE

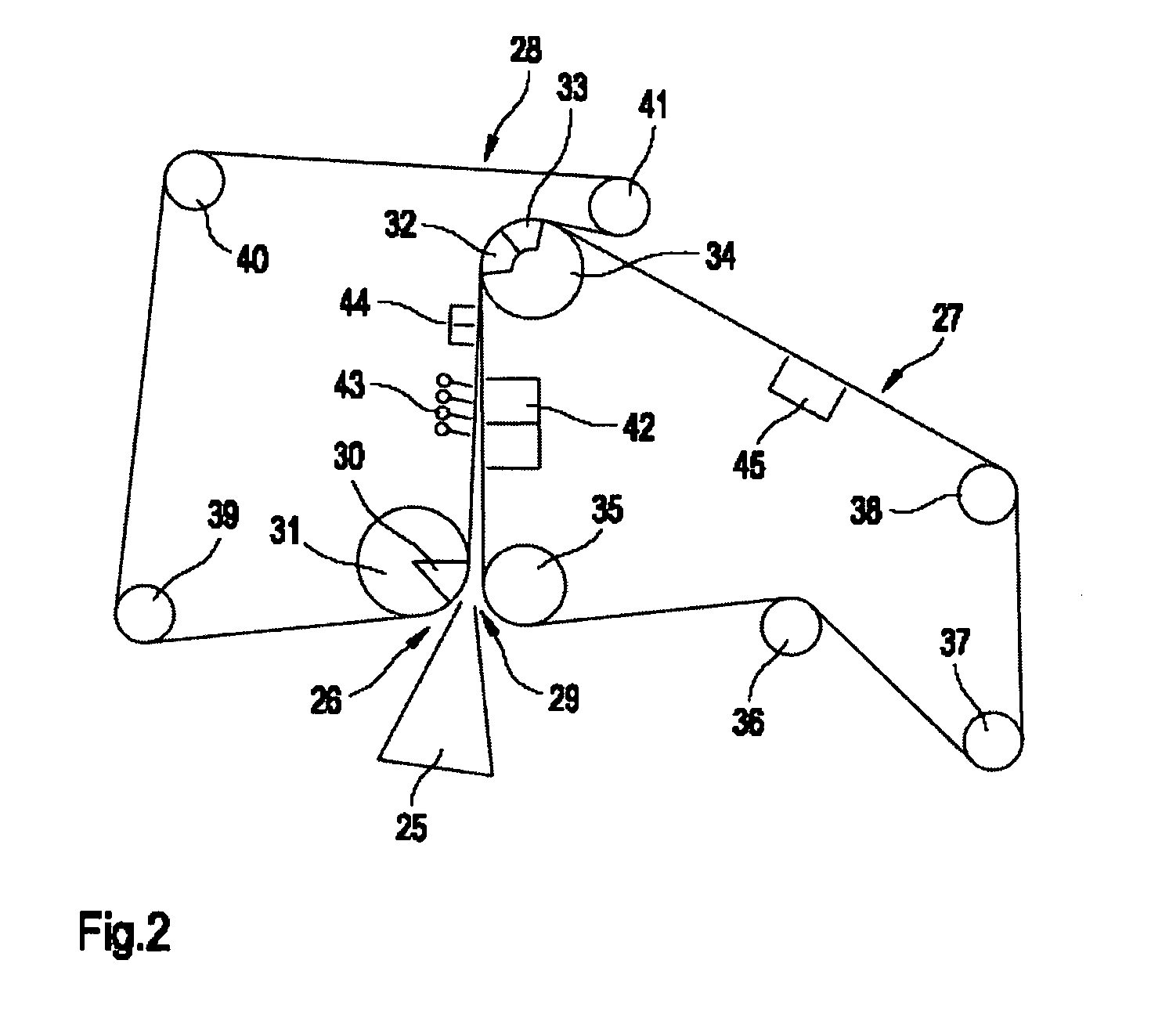

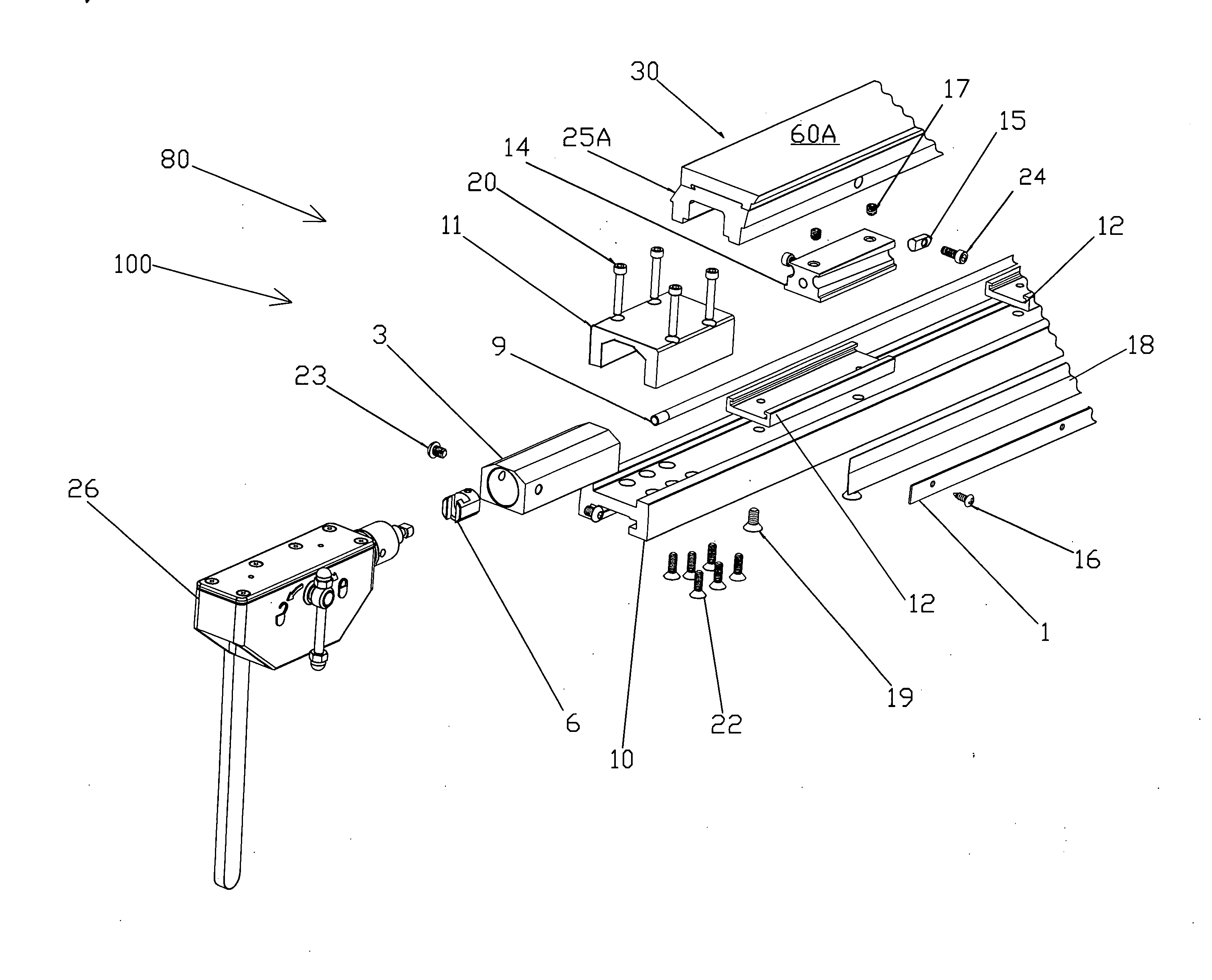

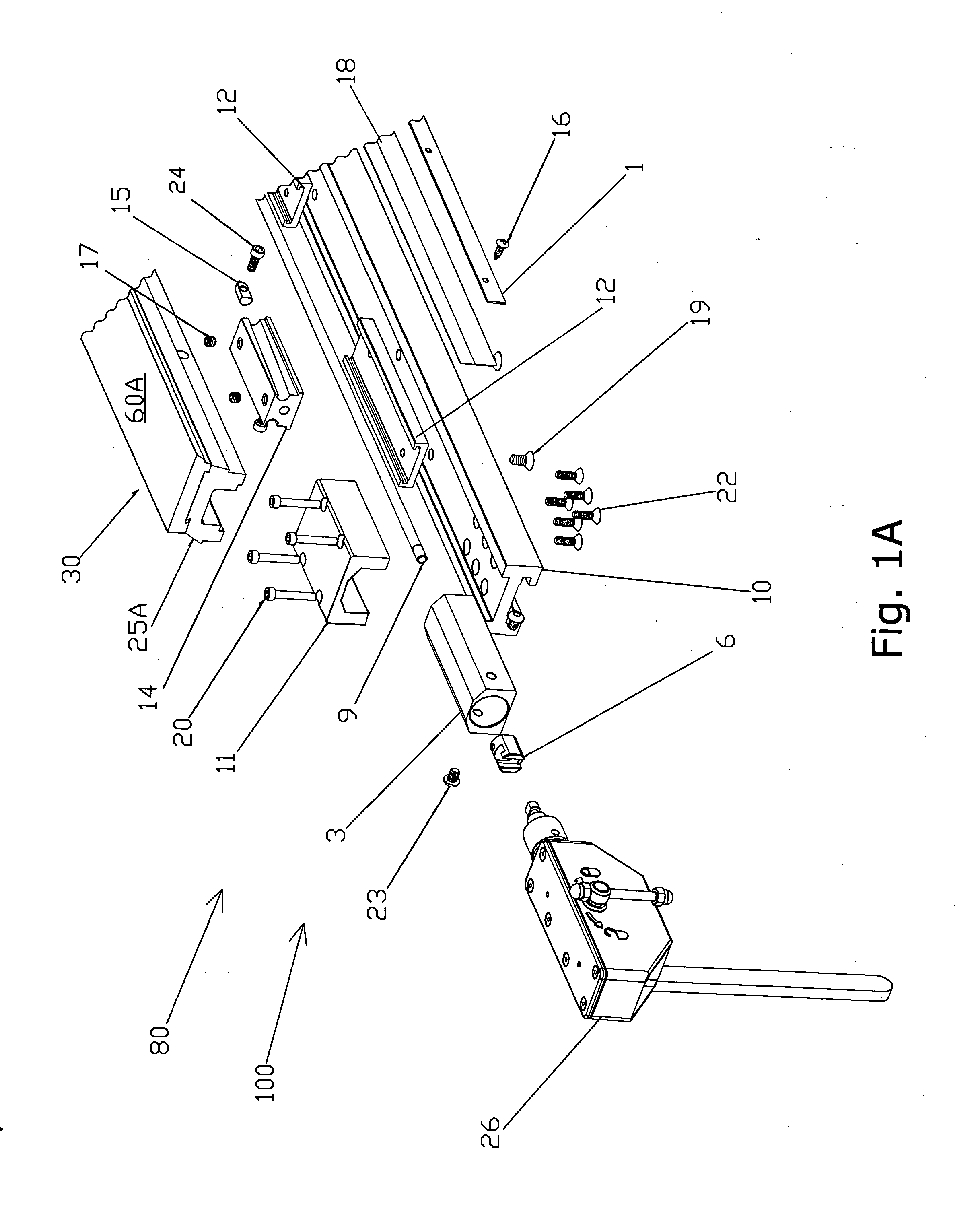

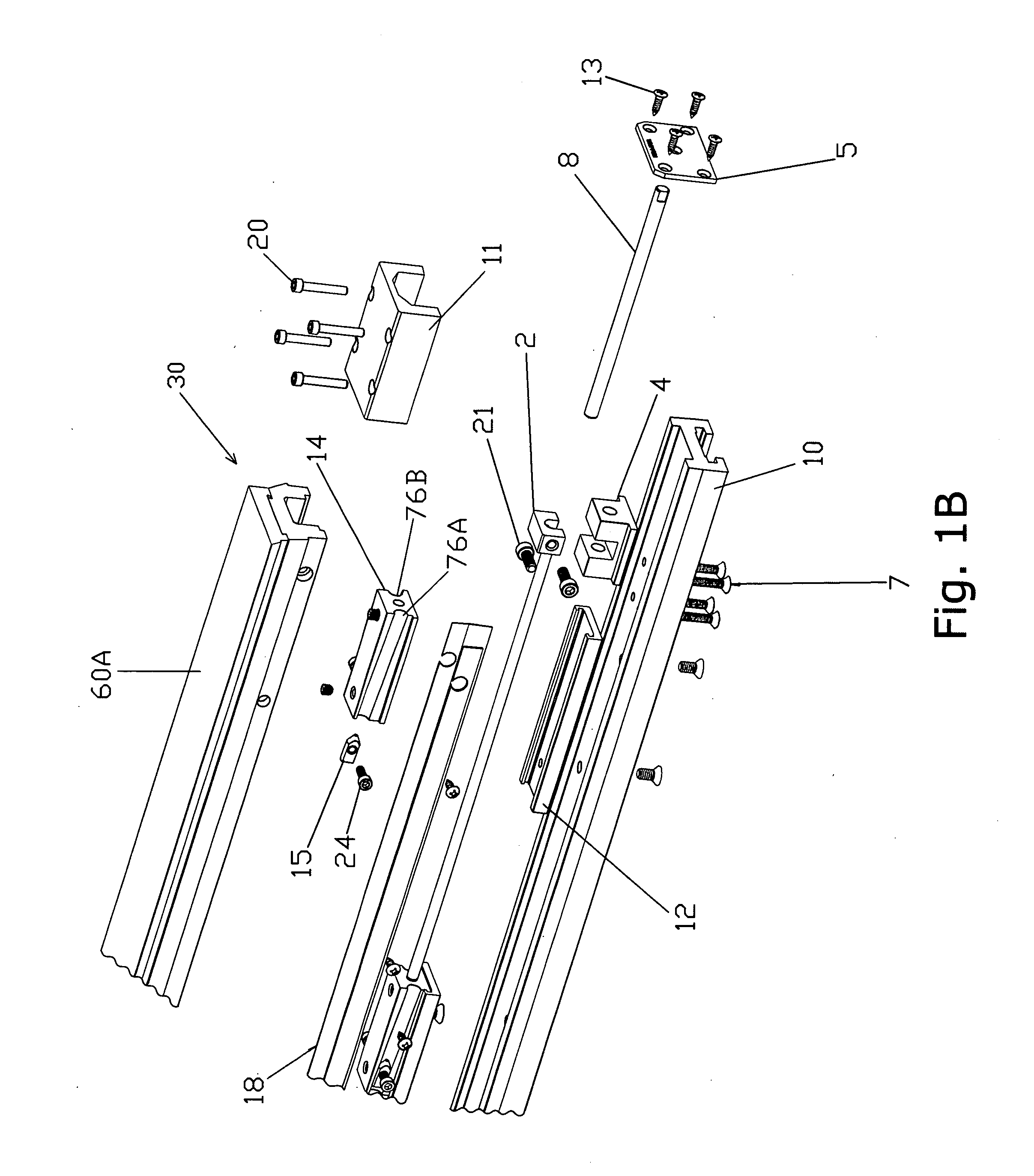

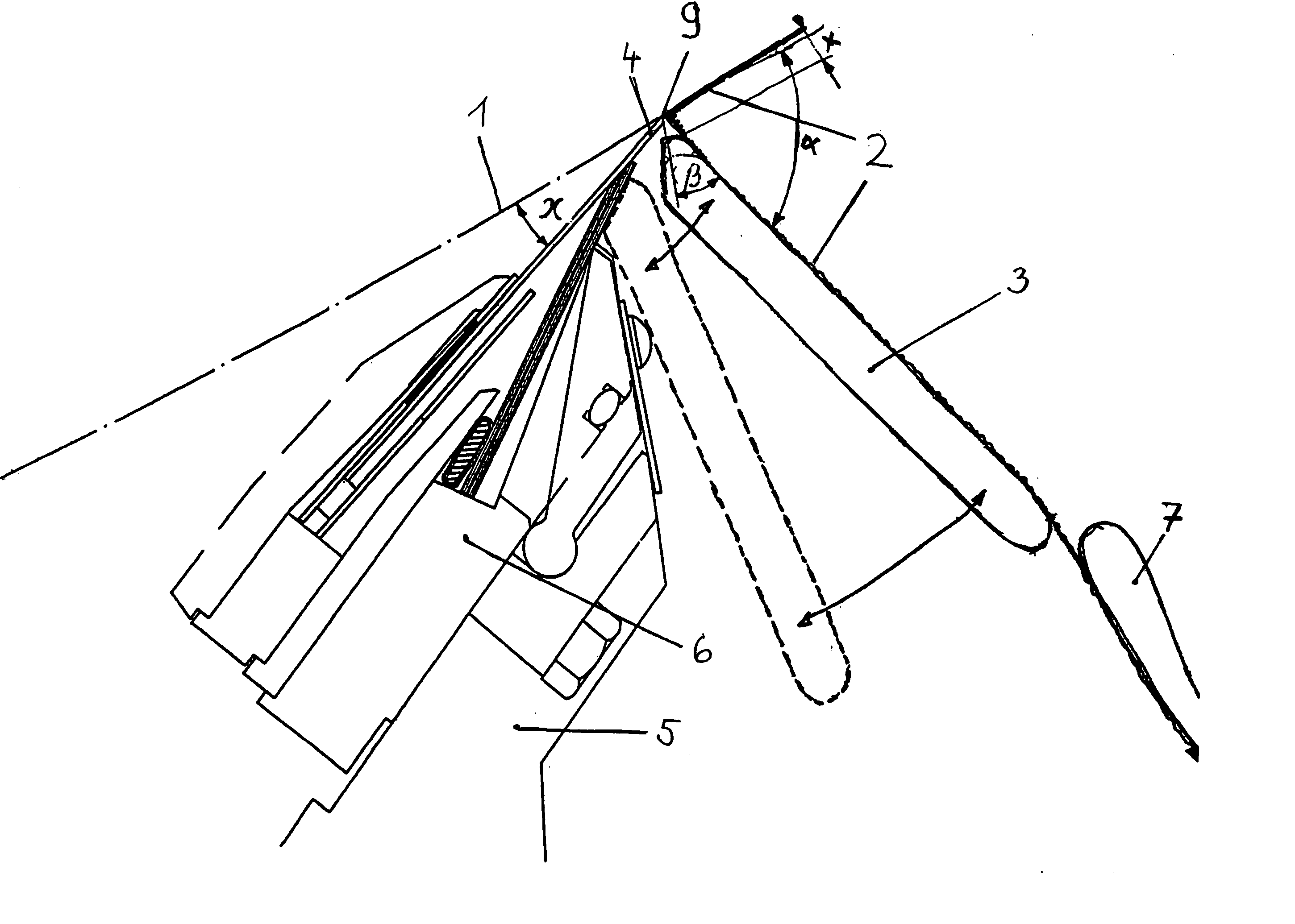

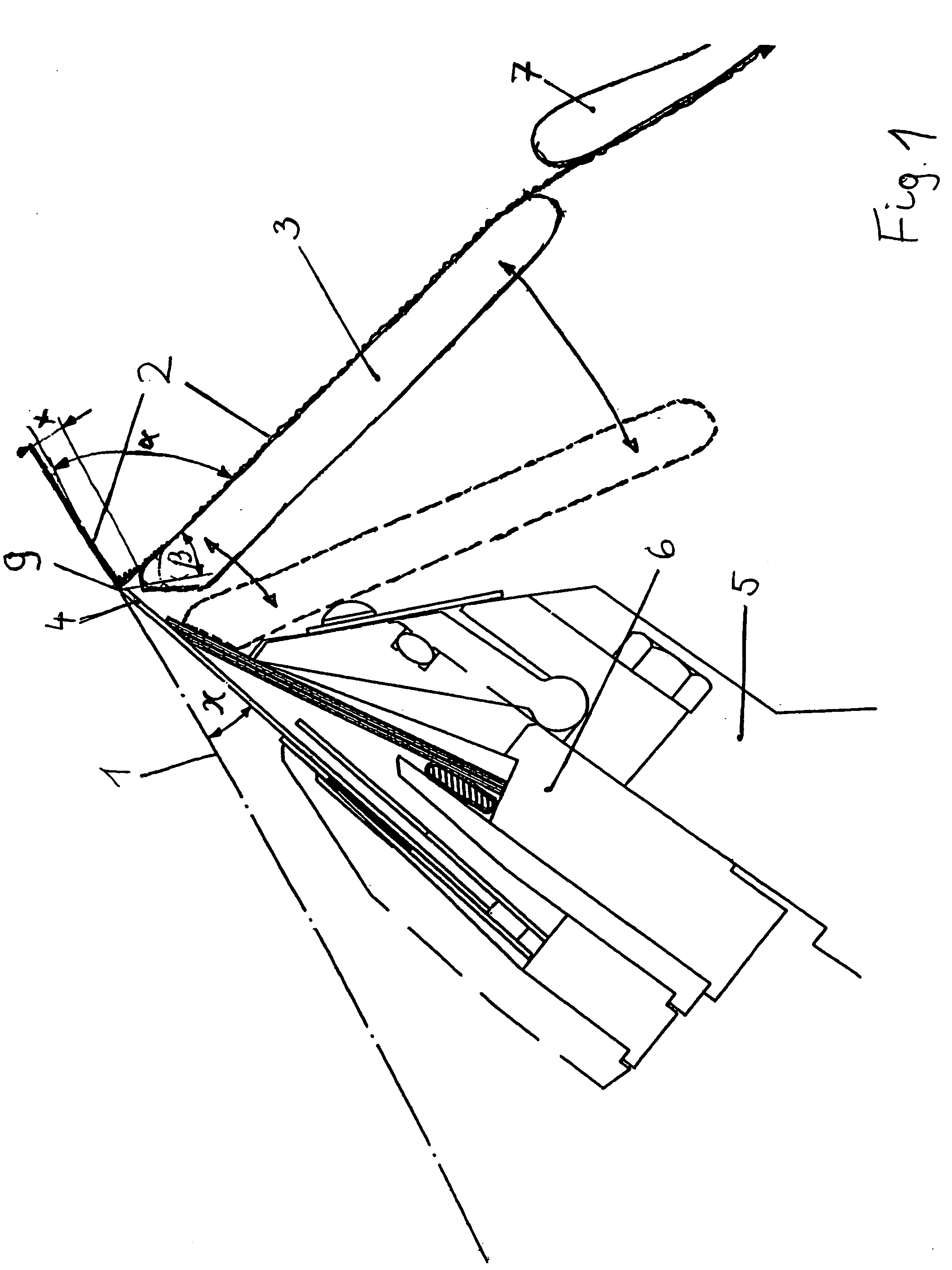

Angle and height control mechanisms in fourdrinier forming processes and machines

Improved height and angle adjustment mechanisms and methods for producing paper includes a plurality of height and angle adjustment mechanisms arranged in the forming or wet section of a Fourdrinier. Glide shoes and cam-blocks having sloped grooves are arranged to be driven within a recess of an upper pultrusion assembly to change the angle or height of a particular foil blade. Actuators extend or withdraw a connecting rod, coupled to the cam-blocks, to influence heights and angles of various foils blades.

Owner:IBS OF AMERICA

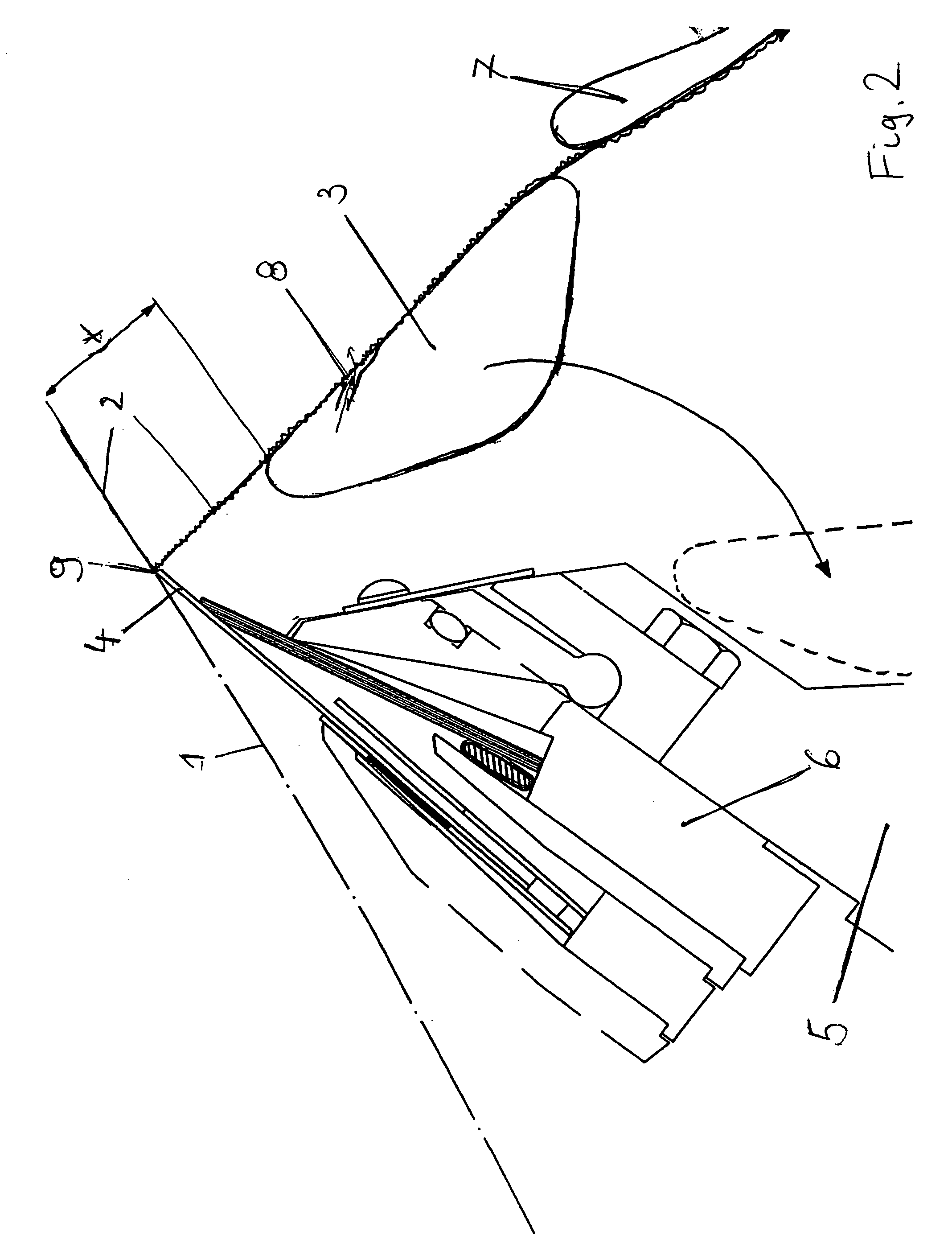

Device for stabilizing a paper web

InactiveUS20050161185A1Improve paper qualityIncrease production speedMechanical working/deformationDrying machines with non-progressive movementsAngle of incidencePulp and paper industry

The invention relates to a device for stabilizing a paper web, particularly a tissue web, with at least one (web) stabilizer (3, 7) after a drying cylinder (1), where the stabilizer (3) is located directly at the cylinder (1) under the paper web (2). It is mainly characterised by the angle of incidence α of the stabilizer (3) at the drying cylinder (1) being adjustable.

Owner:ANDRITZ AG

Weft self-binding forming net

InactiveCN106133239AImprove bindingLarge spanHeating/cooling textile fabricsMachine wet endSurface layerPulp and paper industry

The present invention discloses a weft self-binding forming net, which belongs to the technical field of net forming for papermaking. The forming net comprises a surface layer, a bottom layer and connection lines, wherein, the surface layer has a plain weave structure that is alternately intertwined with a surface warp and a surface weft; the bottom layer has a satin structure that is alternately intertwined with a bottom warp and a bottom weft; and the connection lines are set in pairs to connect the surface layer and the bottom layer in horizontal direction. The connection lines are intertwined between an upper net and a lower net reguraly, making the two nets connected; relative moving and sliding are prevented to avoid internal wear; the forming mesh has uniform mesh size and high paper quality; a longer service life is provided by preventing wear in a three-tier net.

Owner:许长云 +1

Impregnated blade coating

InactiveUS20130269897A1Good anti-adhesionImprove antifouling performanceMechanical working/deformationApplied substance rearrangementFiberMaterials science

A blade for treating fibrous nonwoven webs having a base body and a coating covering at least a part of the surface of the base body. The coating forms at least that part of the blade surface which is provided to come into contact with the fibrous nonwoven web. At the contact surface, the coating has an open-pored material, the pores of which are filled at least partly with a polymer.

Owner:VOITH PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com