Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

769results about "Alkaline-earth metal silicates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

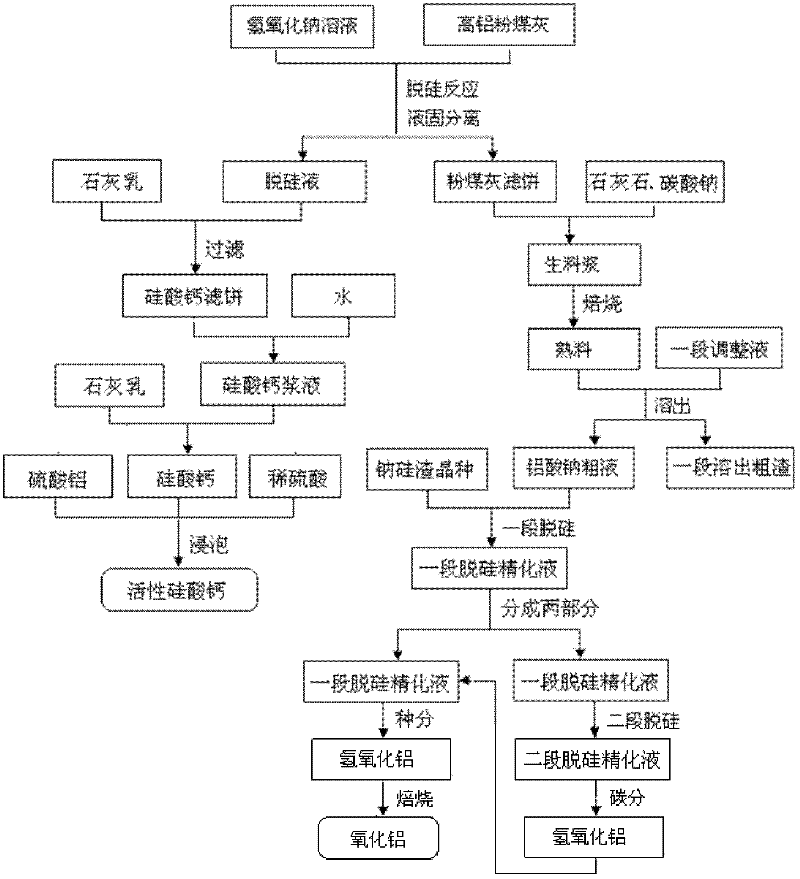

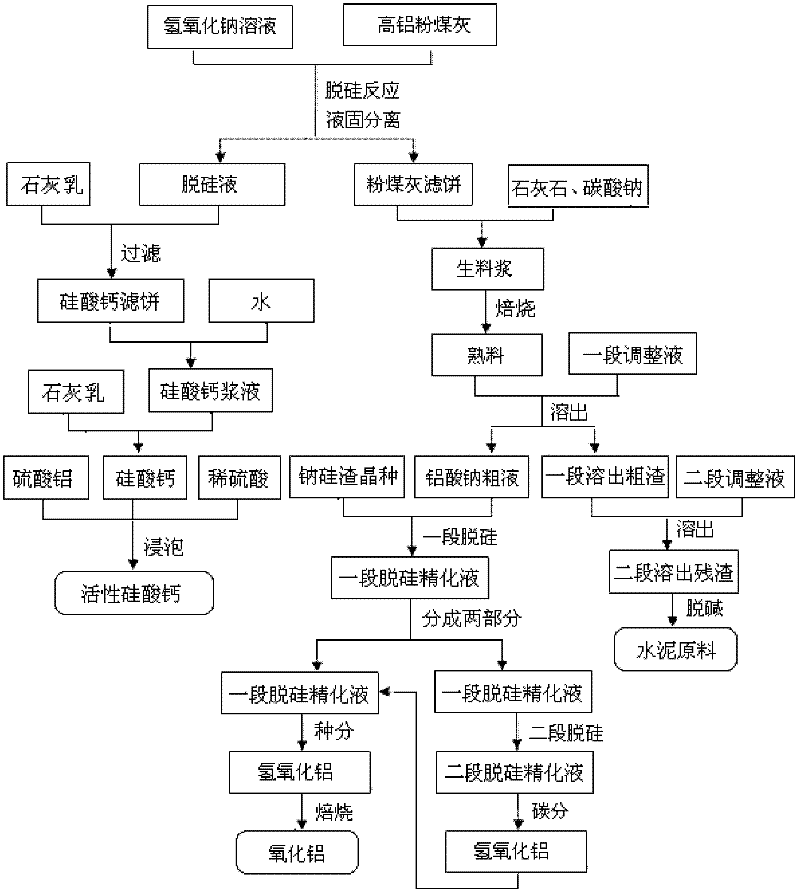

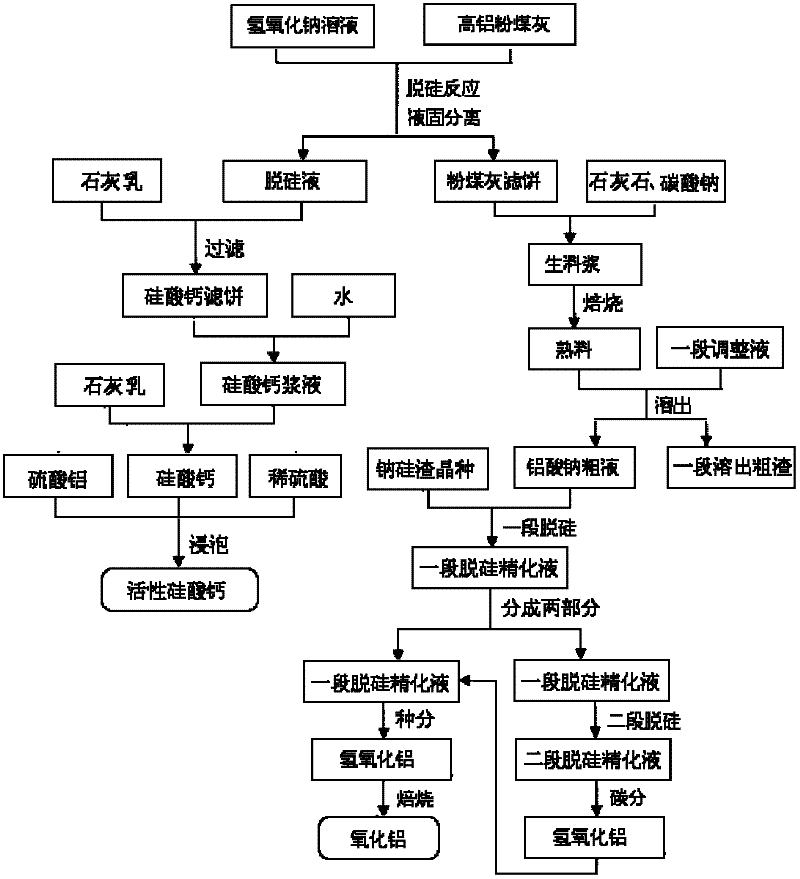

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253AExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateSodium aluminate

The invention provides a method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash. The method comprises the following steps that: the high-alumina fly ash firstly reacts with a sodium hydroxide solution to carry out pre-desilication to obtain a liquid-phase desiliconized solution and a solid-phase desiliconized fly ash; lime cream is added to the liquid-phase desiliconized solution to carry out a causticization reaction, the resulting solid phase is active calcium silicate which is prepared through carrying out filter pressing, flash evaporation and drying to obtain the finished product; limestone and a sodium carbonate solution are added to the desiliconized fly ash to blend qualified raw slurry, then the blend qualified raw slurry is subjected to baking into the clinker, the liquid phase generated from dissolution of the clinker is a crude solution of sodium aluminate; the crude solution of the sodium aluminate is subjected to processes of first-stage deep desilication, second-stage deep desilication, carbonation, seed precipitation, baking and the like to obtain the metallurgical grade aluminum oxide meeting requirements. According to the present invention, the defects in the prior art are overcome; purposes of less material flow and small amount of slaggling are achieved; energy consumption, material consumption and production cost are relative low; extraction rate of the aluminum oxide is high; the calcium silicate with high added value is co-produced; the method provided by the present invention can be widely applicable for the field of chemical engineering.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

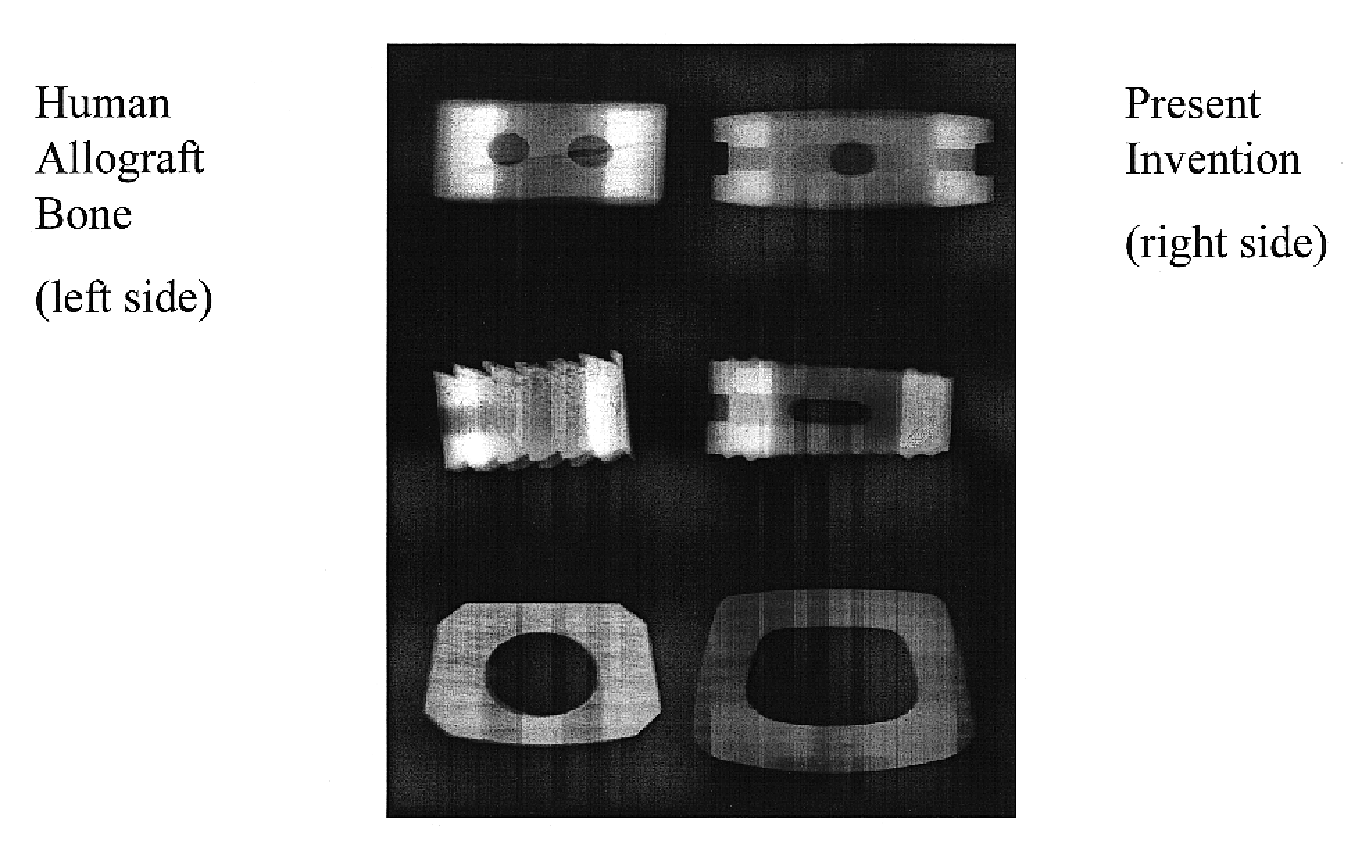

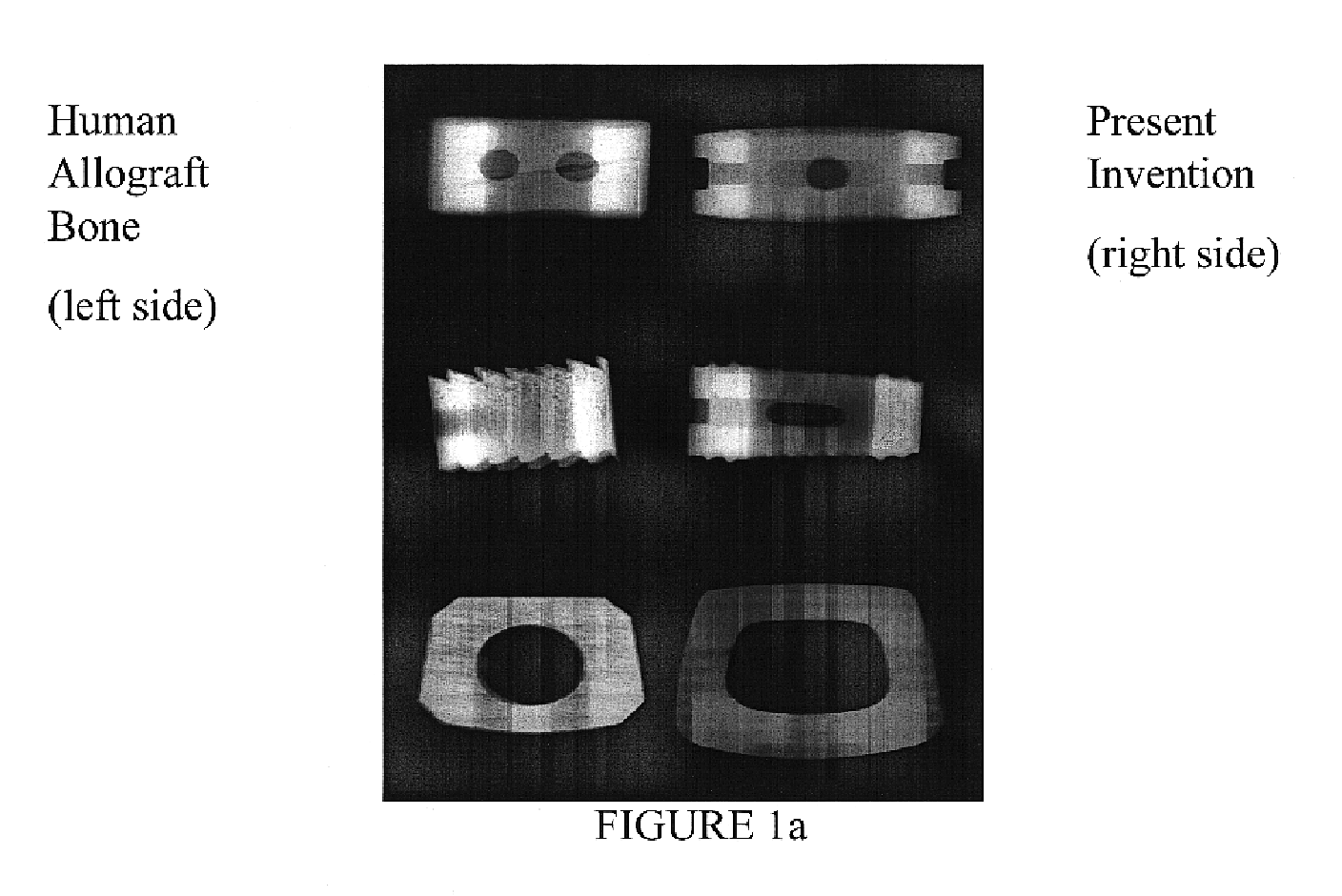

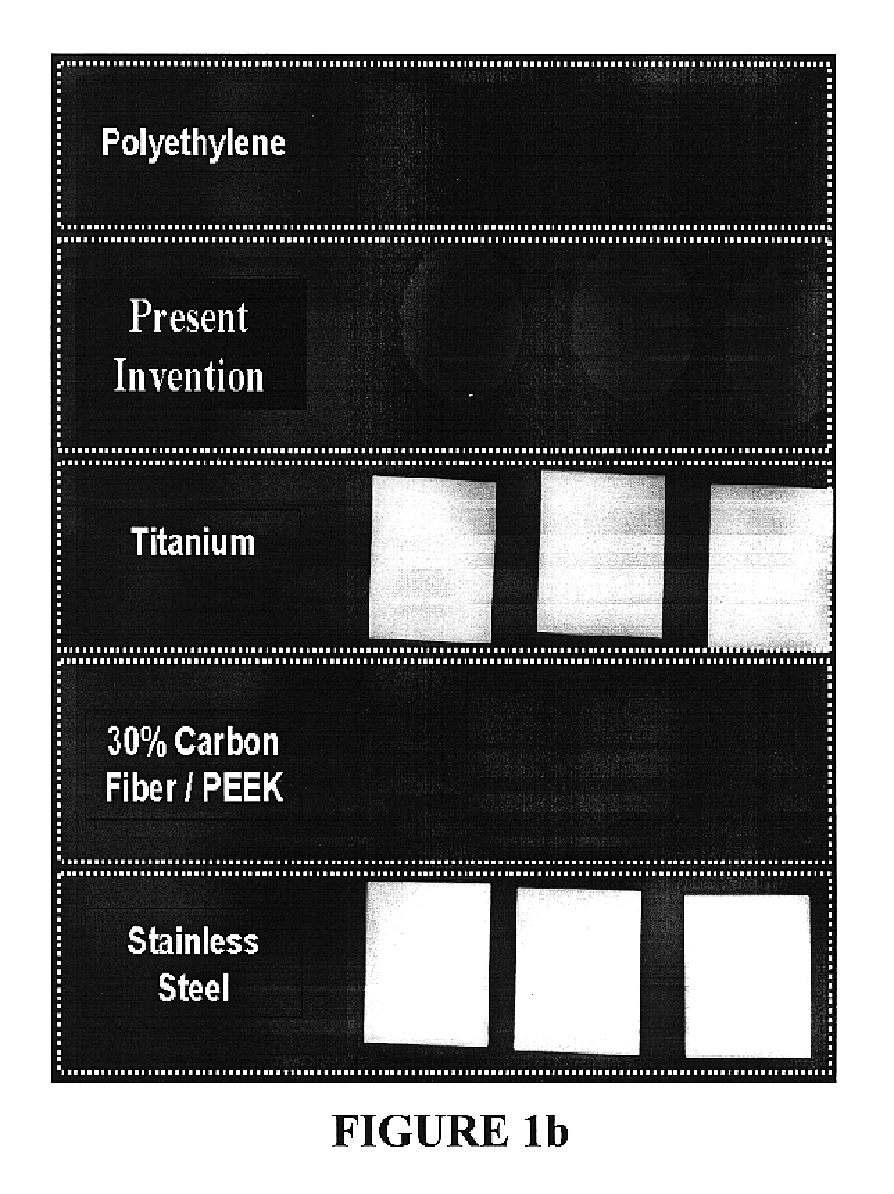

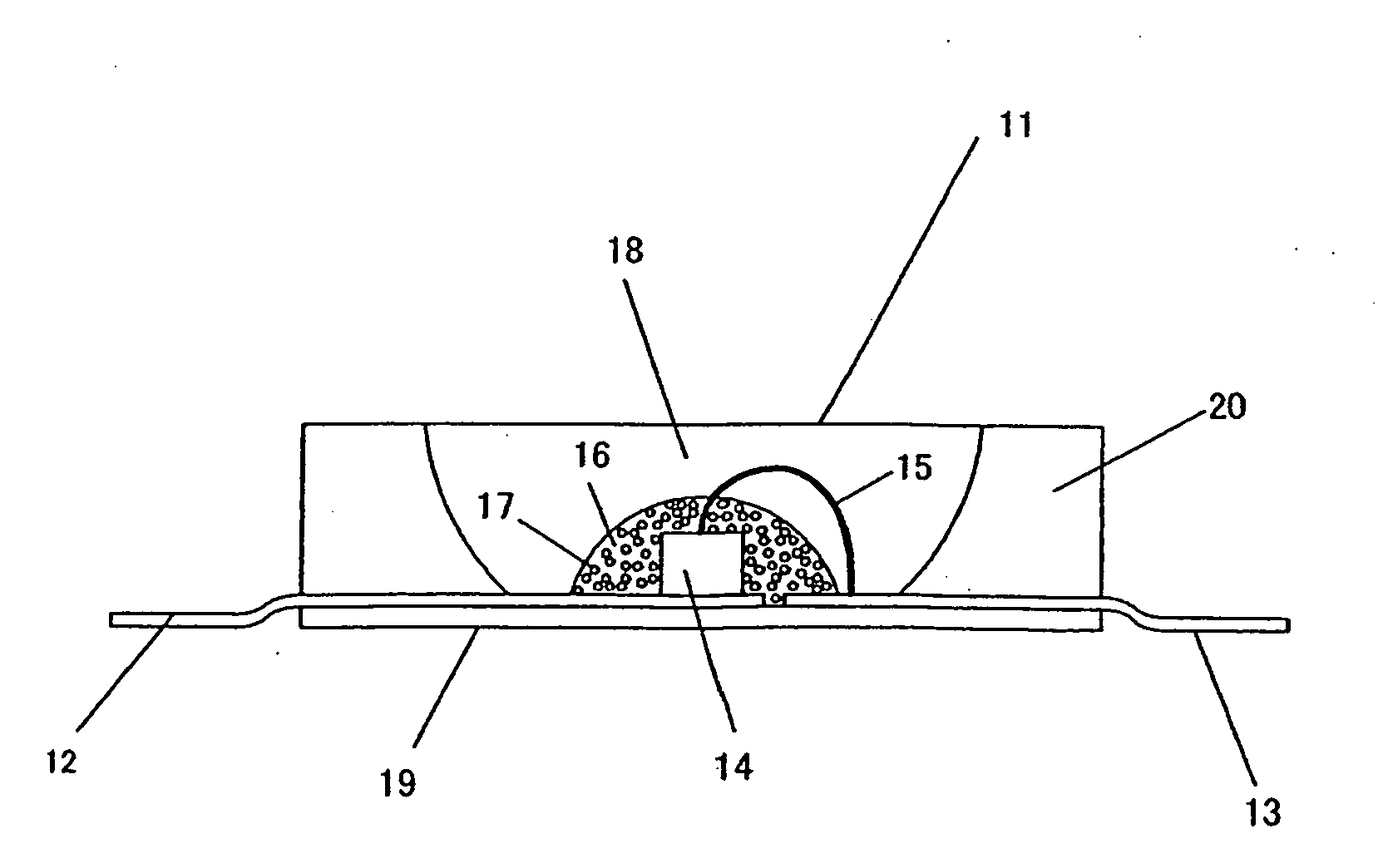

Bioactive spinal implant material and method of manufacture thereof

InactiveUS6987136B2High strengthGreat advantageImpression capsSurgical adhesivesMedicineSpinal implant

Bioactive spinal implant materials having optimized radiopacity, stiffness, and bioactivity properties for formulation of shaped bodies capable of withstanding large dynamic, compressive loads are provided. The invention also provides methods of making the optimized implant materials.

Owner:ORTHOVITA INC

Paint Compositions With Low- or Zero-VOC Coalescence Aids and Nano-Particle Pigments

InactiveUS20090149591A1High mechanical strengthDesirable blocking propertyOther chemical processesAlkaline-earth metal silicatesWater basedOrganic content

The invention is related to glossy, low- or zero-VOC aqueous paint compositions, comprising water based latex polymer, a hiding pigment, at least one low-VOC coalescence aid having a volatile organic content of less than 50 g / L, and a second inorganic pigment with particle size ranging from about 1 to 100 nanometers. The paint composition gives good block resistance and mechanical strength and can be adopted for paints with at least glossy and semi-gloss finishes.

Owner:COLUMBIA INSURANCE CO

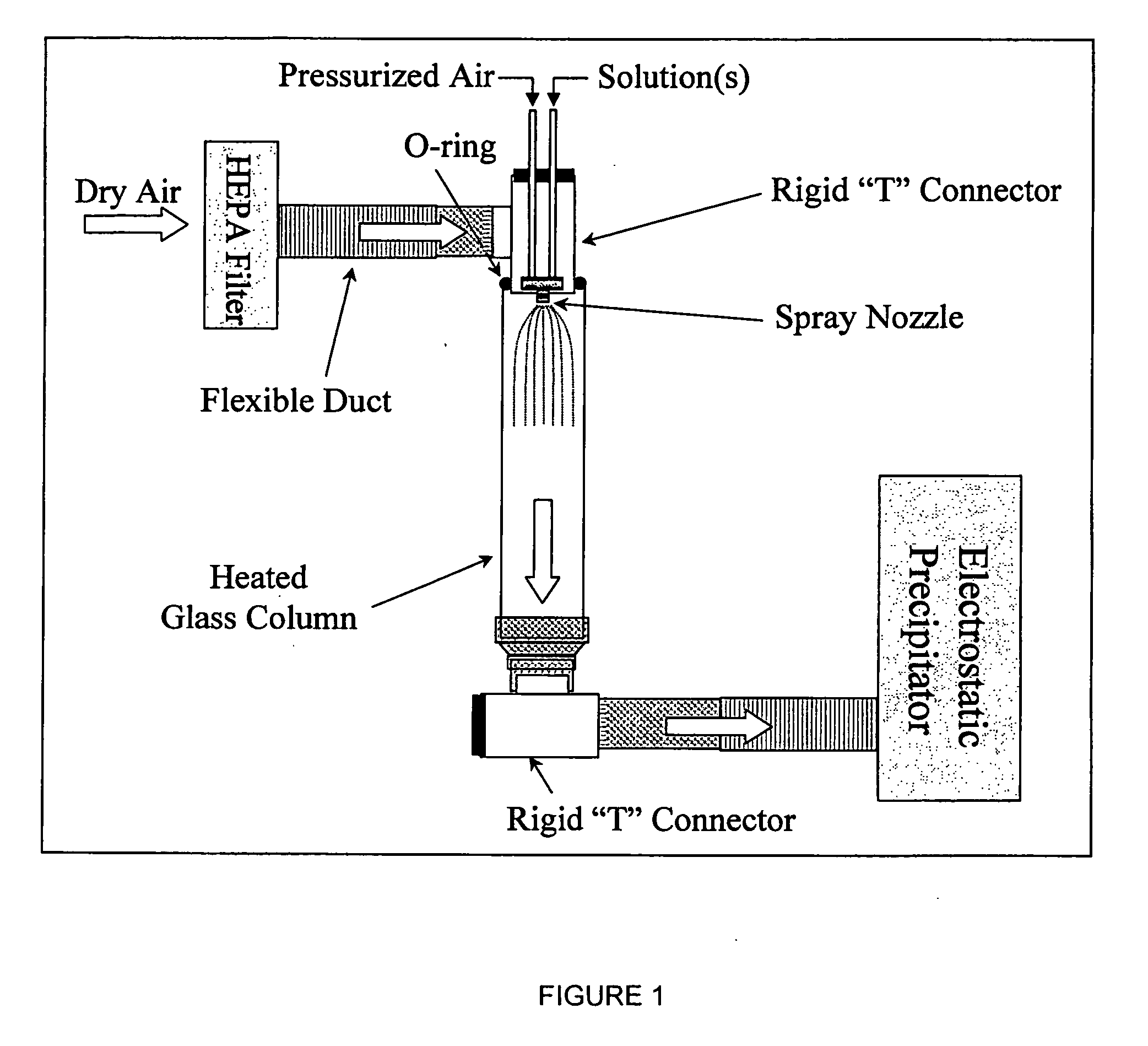

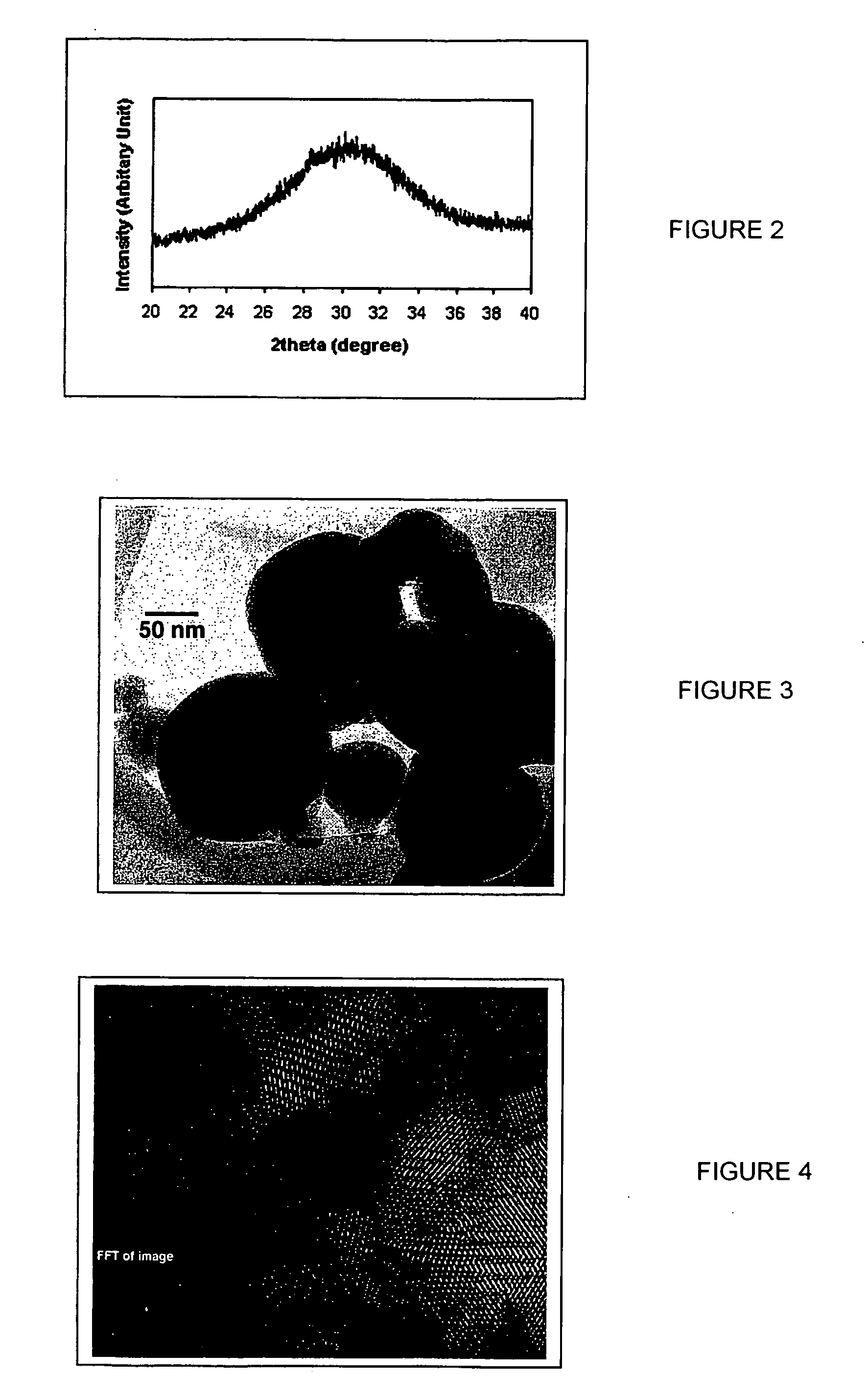

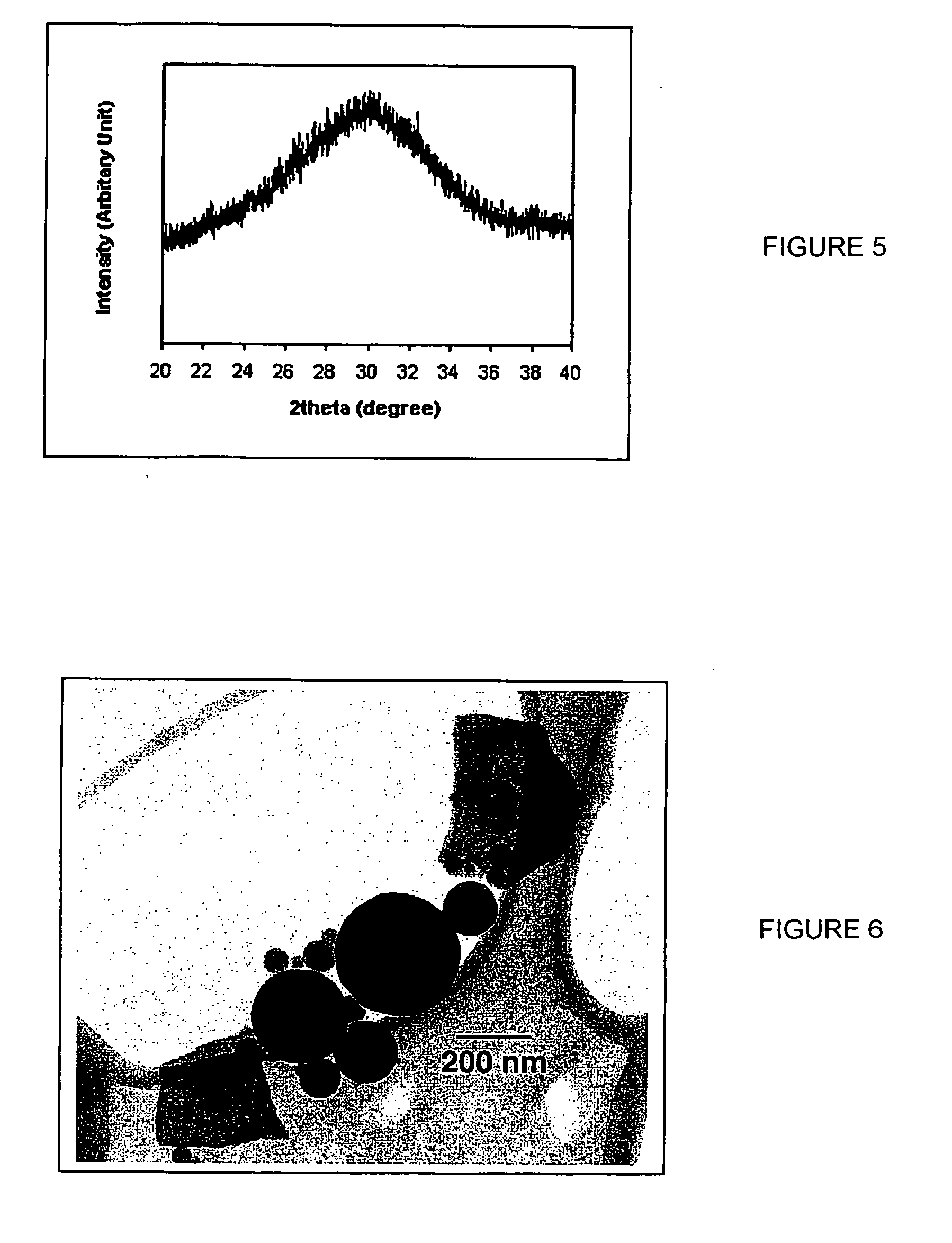

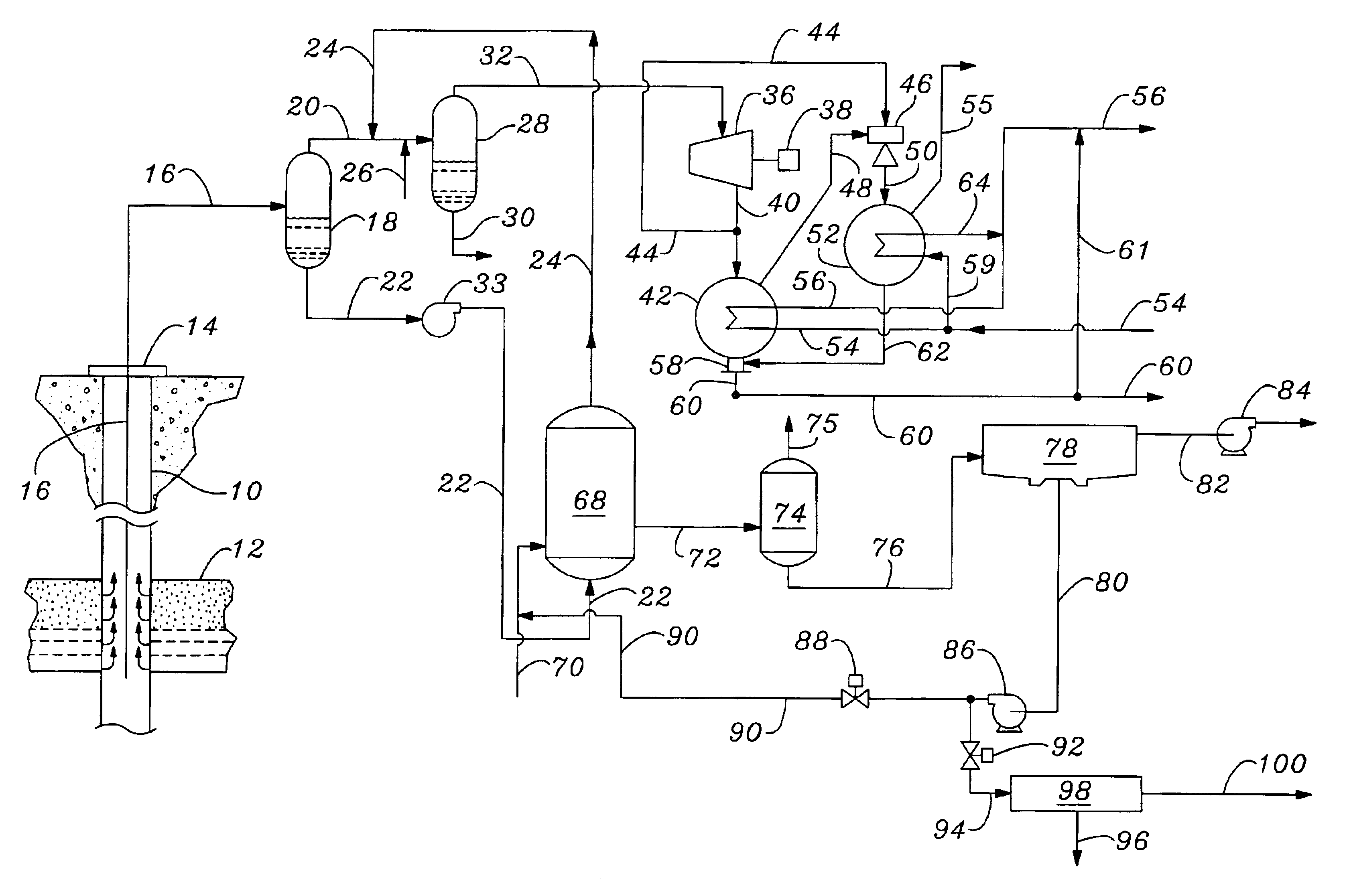

Nanostructured bioactive materials prepared by dual nozzle spray drying techniques

ActiveUS20060110306A1Easy to evaporatePromote formationMagnesium fluoridesImpression capsNanoparticleNanostructure

Nano-particles of calcium and phosphorous compounds are made in a highly pure generally amorphous state by spray drying a weak acid solution of said compound and evaporating the liquid from the atomized spray in a heated colunm followed by collection of the precipitated particles. Hydroxyapatite (HA) particles formed by such apparatus and methods are examples of particle manufacture useful in bone and dental therapies. Dual nozzle spraying etechniques are utilized for generally insoluble compounds.

Owner:ADA FOUND

Method for synthesizing crystalline magnesium silicates from geothermal brine

Crystalline magnesium silicates are synthesized from silica-containing brines, preferably spent geothermal brines, by mixing the brine with a magnesium-containing compound, adjusting the pH of the resultant mixture between 8.0 and 14, and crystallizing the magnesium silicate from the mixture at a temperature between 50° C. and 200° C. Kerolite is preferably synthesized from brine by adjusting the pH in a range between 9.5 and 10.5 and heating the mixture to between 100° C. and 170° C. to precipitate the crystalline kerolite. The brine remaining after the crystallization step is depleted in silica and can be further processed without significant problems caused by silica scaling.

Owner:UNION OIL OF CALIFORNIA

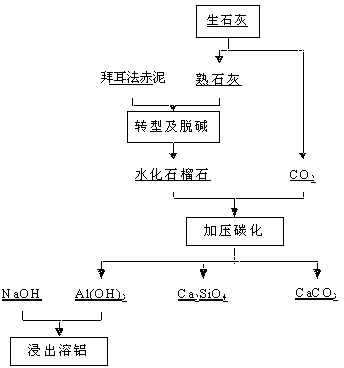

Method for dissolving Bayer process red mud

ActiveCN102757060AMeet industrial requirementsReduce sodiumCalcium/strontium/barium carbonatesSludge treatmentCalcium silicateAluminium hydroxide

The invention discloses a method for dissolving red mud. The method comprises the following specific steps of: mixing Bayer process red mud with white lime in the mass ratio of 1:(0.3-0.9); stirring at the temperature of 80-140 DEG C for reacting for 1-15 hours for calcifying, transforming and dealkalizing; mixing calcified, deformed and dealkalized Bayer process red mud with clear water or a low-concentration sodium aluminate solution in an enclosed container; introducing CO2 into the container to obtain calcified slag containing calcium silicate, calcium carbonate and aluminum hydroxide serving as main components; and extracting aluminum hydroxide from the calcified slag by using a sodium hydroxide solution or an aluminum hydroxide solution. In the method disclosed by the invention, the structure and composition of red mud are changed by adopting calcification transformation and pressurizing calcification transformation methods, so that dealkalization and extraction of aluminum can be realized; and iron is extracted properly, so that the structure and the composition of red mud can meet the requirements of cement production, and the aim of dissolving red mud on a large scale at low cost is fulfilled.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

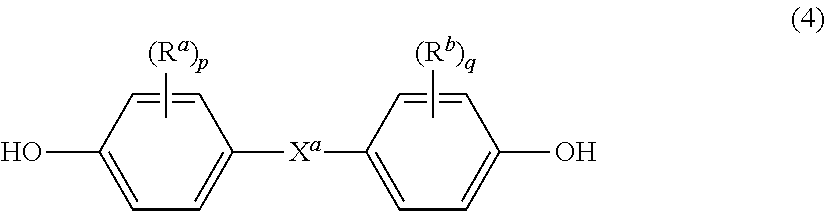

Polycarbonate compositions with thin-wall flame retardance

ActiveUS20050182165A1High strengthHigh impact strengthSemi-permeable membranesPlastic/resin/waxes insulatorsRoom temperaturePolycarbonate

Polycarbonate compositions containing a specific combination of additives achieve desirable flame retardance characteristics when used in thin wall polycarbonate articles. These compositions contain a polycarbonate / siloxane component, containing a polycarbonate siloxane copolymer, or a mixture of a polycarbonate siloxane copolymer and polycarbonate resin; a mineral filler; and a flame retardant. The composition contains at least 50% by weight of polycarbonate when the polycarbonate of the polycarbonate siloxane copolymer and any polycarbonate resin (linear or branched) are considered together; and the polycarbonate siloxane copolymer and the mineral filler are present in amounts effective to achieve a flex modulus of 29,000 kg / cm3 or greater, for example 30,000 kg / cm3 or greater, good flex-fold strength and good impact strength, for example a room temperature Notched Izod Impact Strength of 25 kgf-cm / cm or greater. The composition also includes a flame retardant to enable the composition to obtain a UL94 rating of V0 at test thicknesses of 1.2 mm.

Owner:SHPP GLOBAL TECH BV

Process for producing a prosthesis and a prosthesis material

A process for producing a dental prosthesis wherein an impression is taken of the patient's mouth, a working model is created, a base plate is applied to the working model, an insulating film is applied to the base plate, a tooth arrangement in wax is formed on the base plate, a framework of the teeth is then formed with an investment compound, the wax is then boiled out and replaced with a curable material which is subsequently hardened.

Owner:HERAEUS KULZER

Liquid crystalline polymer composition and moldings

InactiveUS6063848AReducing anisotropy characteristicLow coefficient of linear expansion without deteriorating mechanical propertiesAlkaline-earth metal silicatesLiquid crystallineParticulates

PCT No. PCT / JP96 / 03880 Sec. 371 Date Sep. 8, 1997 Sec. 102(e) Date Sep. 8, 1997 PCT Filed Dec. 27, 1996 PCT Pub. No. WO97 / 24404 PCT Pub. Date Oct. 7, 1997The present invention provides a liquid crystal polymer composition wherein the low coefficient of linear expansion is attained without significantly deteriorating mechanical properties by incorporating plural fibrous fillers or a fibrous filler and a particulate filler with liquid crystal polymer in a specified ratio.

Owner:POLYPLASTICS CO LTD

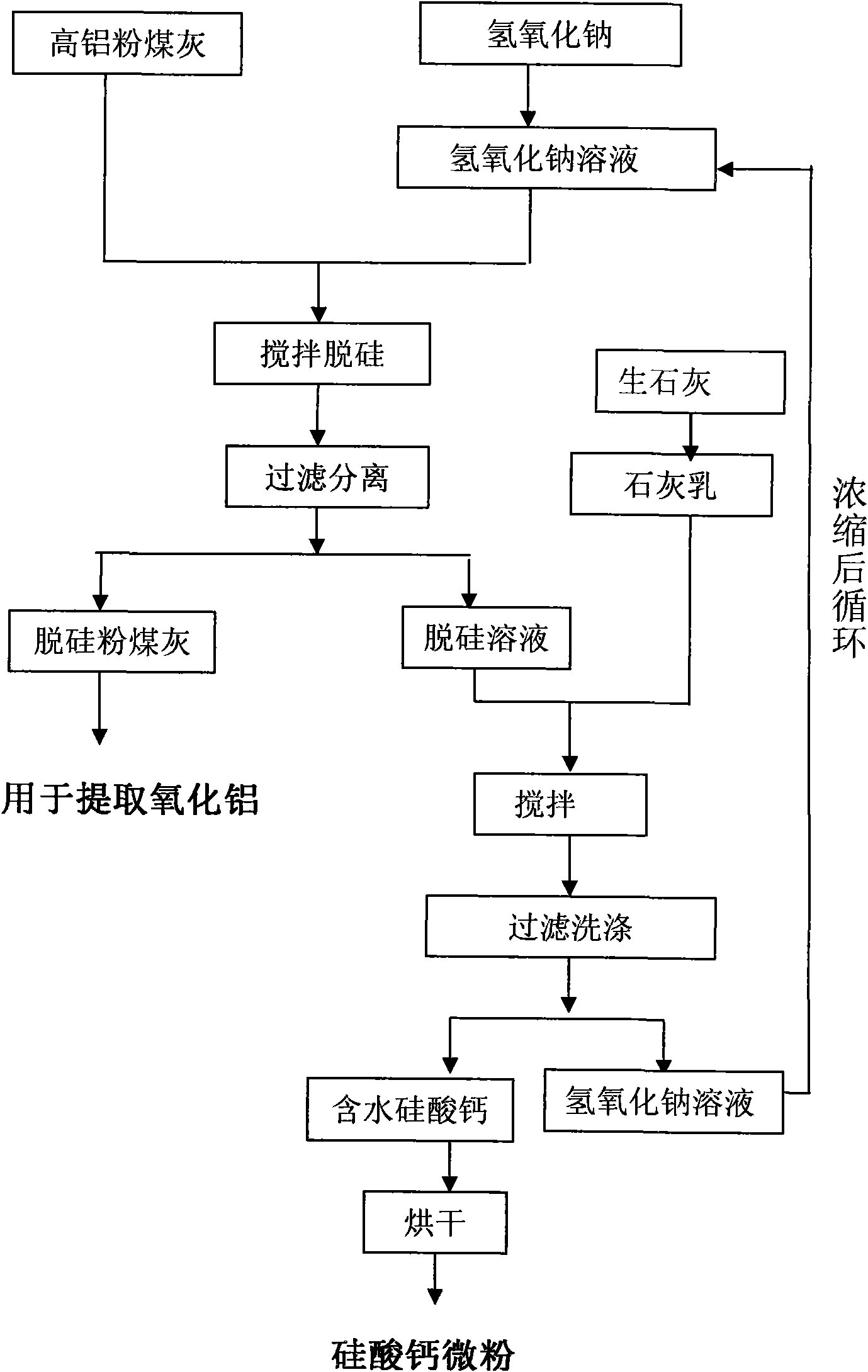

Method for preparing calcium silicate micro power by using high alumina fly ash

The invention discloses a method for preparing calcium silicate micro power by using high alumina fly ash, relating to the technical field of material and chemistry. The method comprises the steps as follows: 1. adding dry raw material high alumina fly ash into sodium hydroxide solution and stirring to carry out desiliconization reaction; 2. filtering and separating the mixture processed by desiliconization reaction, washing the filter cake to obtain desiliconized solution and desiliconized fly ash, and adding water to quicklime and stirring to obtain slurry lime cream; and 3. adding the lime cream into the desiliconized solution, stirring for reaction, filtering and washing to obtain watery calcium silicate and NaOH solution, drying the watery calcium silicate to obtain calcium silicate micro powder, and concentrating the NaOH solution for cycle use for step 1. Compared with the prior art, the method of the invention is simple in operation, low in investment, low in production cost and low in energy consumption, and the prepared calcium silicate micro power is uniform in physical and chemical performances, low in impurity content and extremely high in whiteness.

Owner:TONGFANG ENVIRONMENT

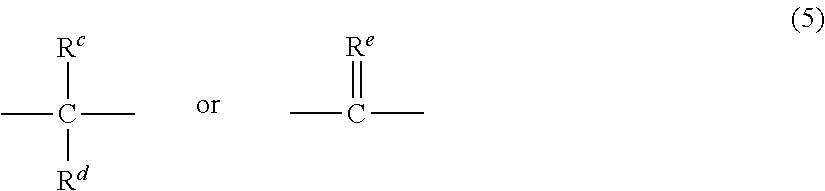

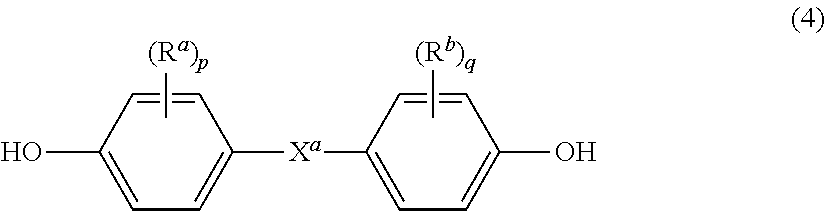

Modified Polyamides, Uses Thereof and Process for Their Preparation

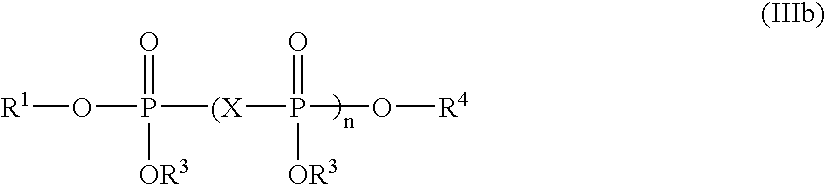

InactiveUS20090149590A1Conveniently addedImprove hydrolysis resistancePigmenting treatmentAlkaline-earth metal silicatesChemical LinkageAlcohol

A polymeric matrix having improved flowability and wettability is provided, as well as a process for making it. The matrix contains a polyamide and a polyhydric alcohol which is chemically bonded at least to a part of the polyamide, and it is suitable particularly for manufacturing fiber-reinforced polyamide articles exhibiting a very good surface appearance and excellent mechanical properties.

Owner:NILIT

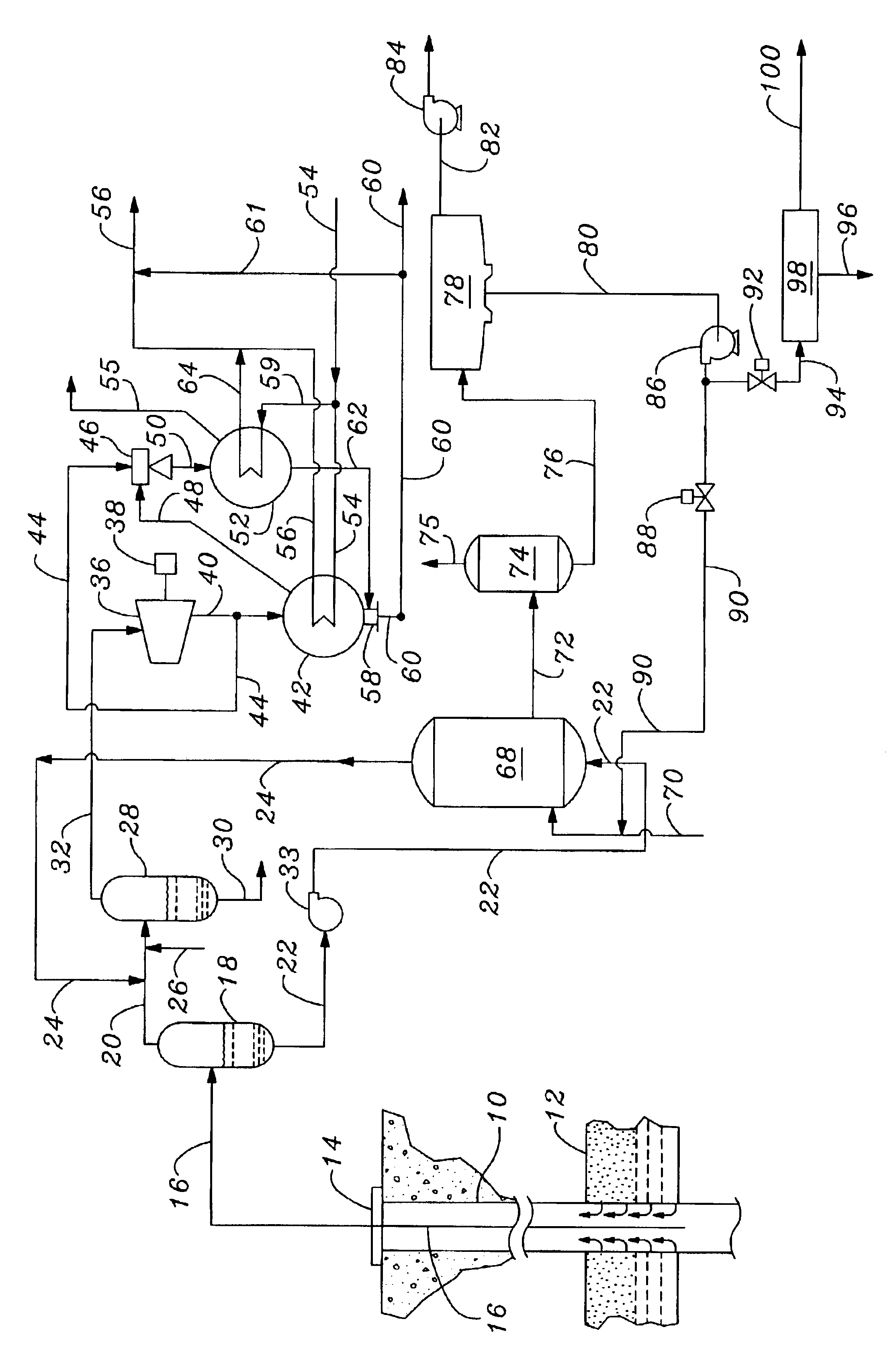

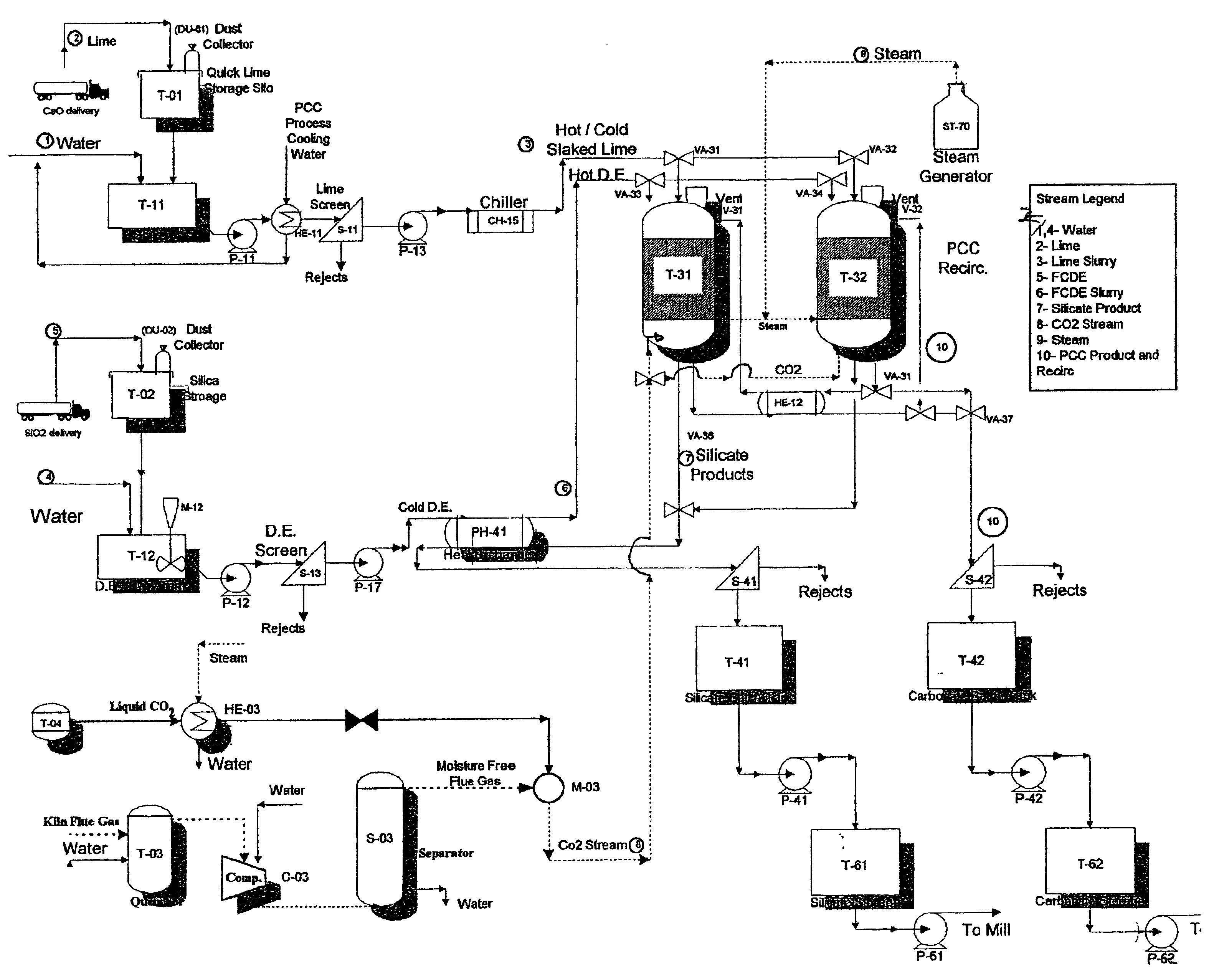

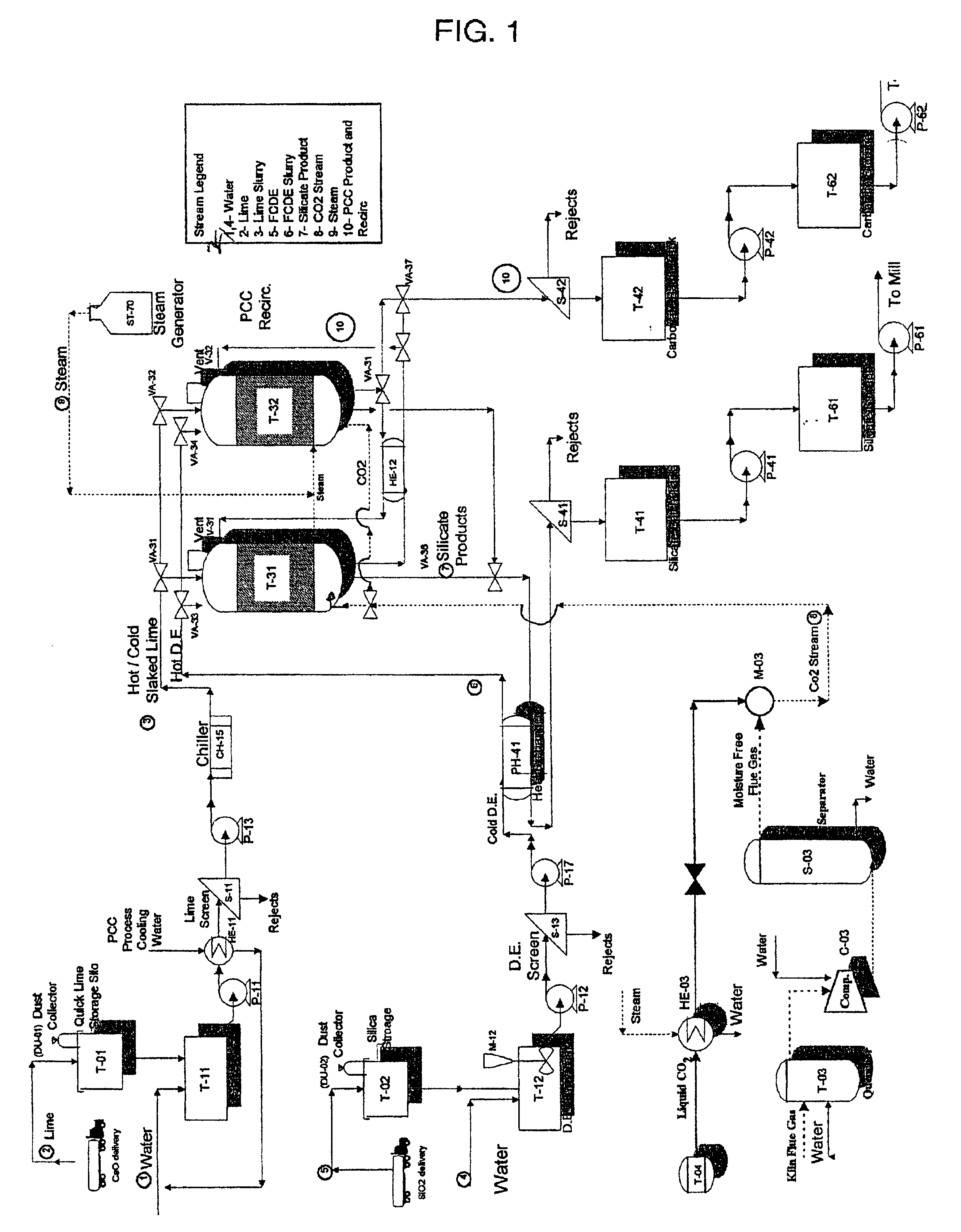

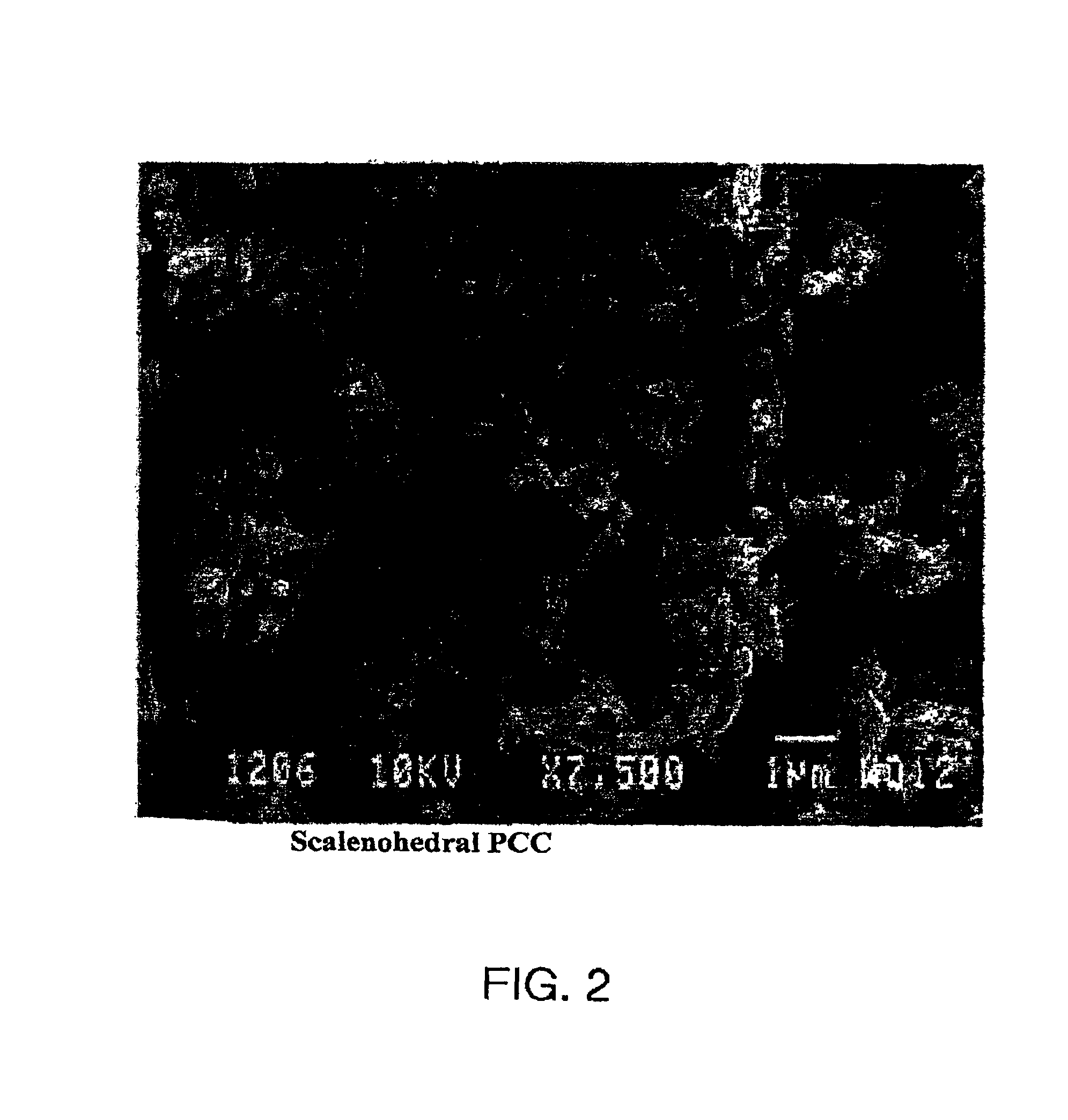

Method and apparatus for production of precipitated calcium carbonate and silicate compounds in common process equipment

InactiveUS7048900B2Increase brightnessHigh opacityCalcium/strontium/barium carbonatesPulp liquors combustionCalcium silicateProcess equipment

A method and apparatus for the production of calcium carbonate and calcium silicate in common superatmospheric reactors. Multiple reactors can be provided for switching production between reactors, and advantageously utilizing process waste heat. On site production of both PCC and Calcium Silicate Hydrates is thus achieved in a paper mill.

Owner:PACIFIC NANO PROD

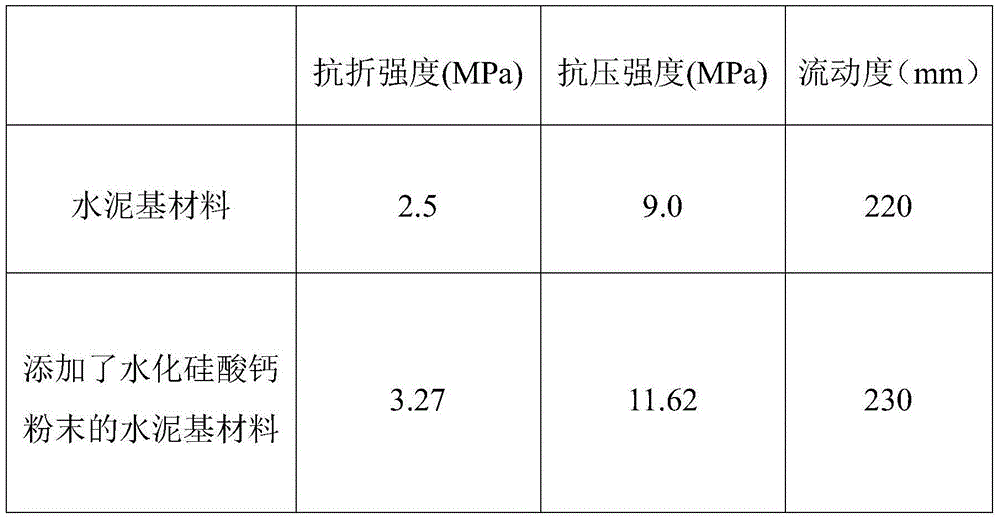

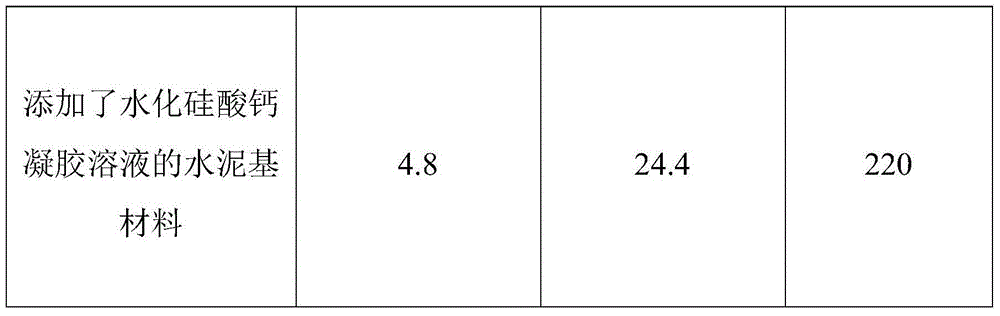

Calcium silicate hydrate gel solution early strength agent and preparation method thereof

ActiveCN104402009ALong term storageGood dispersionAlkaline-earth metal silicatesCalcium in biologyCalcium silicate

The invention discloses a calcium silicate hydrate gel solution early strength agent and a preparation method thereof, and relates to the technical field of construction material production. The early strength agent and the method are used for solving problems of complicated preparation process, high cost, storage difficulty, and poor early strength effect of traditional calcium silicate hydrate powder. The calcium silicate hydrate gel solution early strength agent comprises a calcareous material, a siliceous material, a gel dispersant, and water. A weight ratio of the calcareous material to the siliceous material is 0.3-3:1. A weight ratio of water to the total of the calcareous material and the siliceous material is 5-30:1. The mass percentage of the gel dispersant is 0.1-2.0%. The preparation method of the early strength agent comprises the following steps: reaction materials are weighed; a sodium silicate water solution and a calcium nitrate water solution are respectively prepared; the two are mixed and are subjected to a reaction, such that a gel mixture solution is obtained; suction filtration is carried out; and water and the dispersant are added for re-dispersion. The early strength agent is uniform and stable, and is convenient to store. The early strength agent is highly convenient to use, and has a good early strength effect. With the early strength agent, an alkali-aggregate reaction risk can be effectively reduced.

Owner:SHANGHAI CONSTRUCTION GROUP

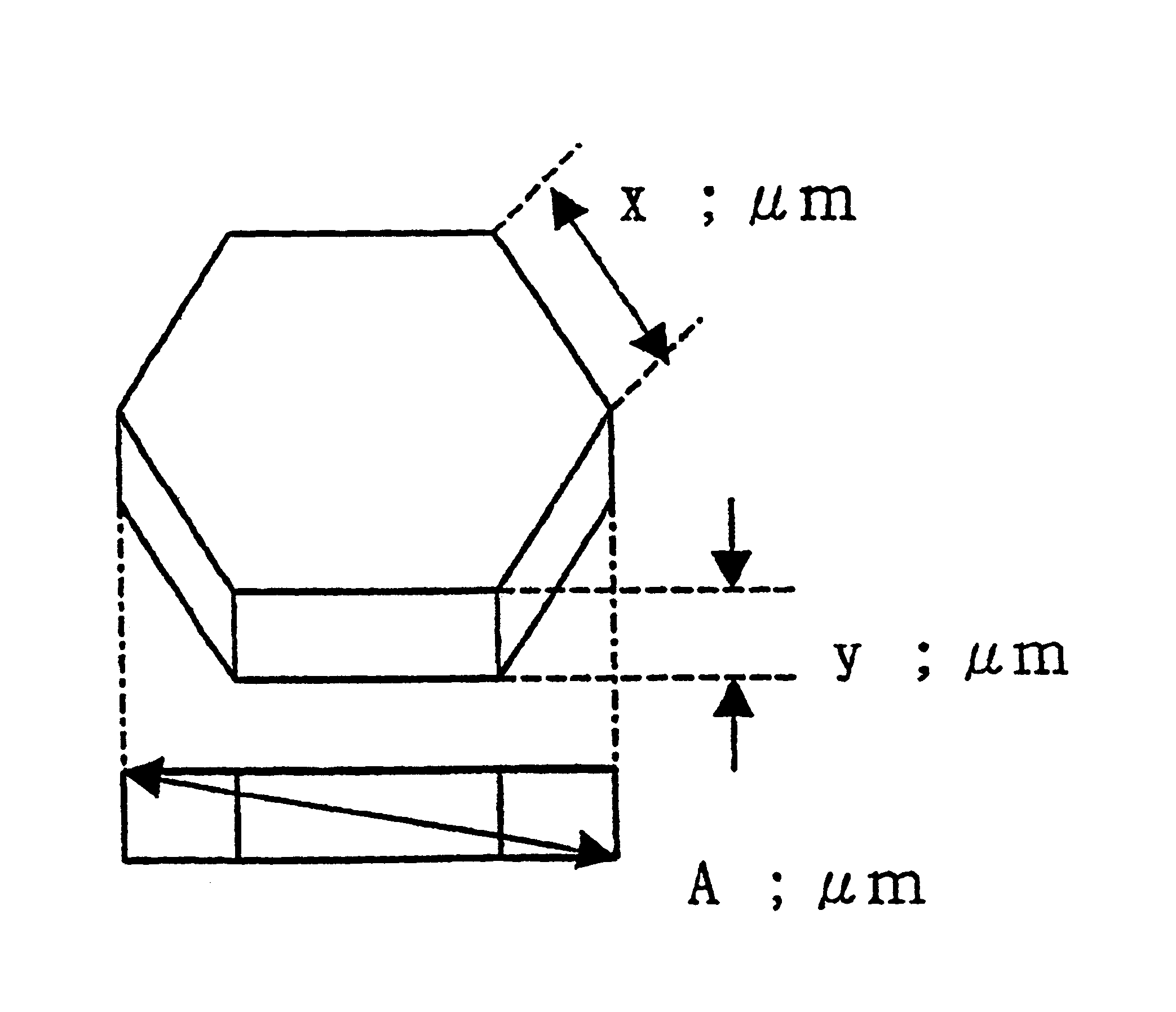

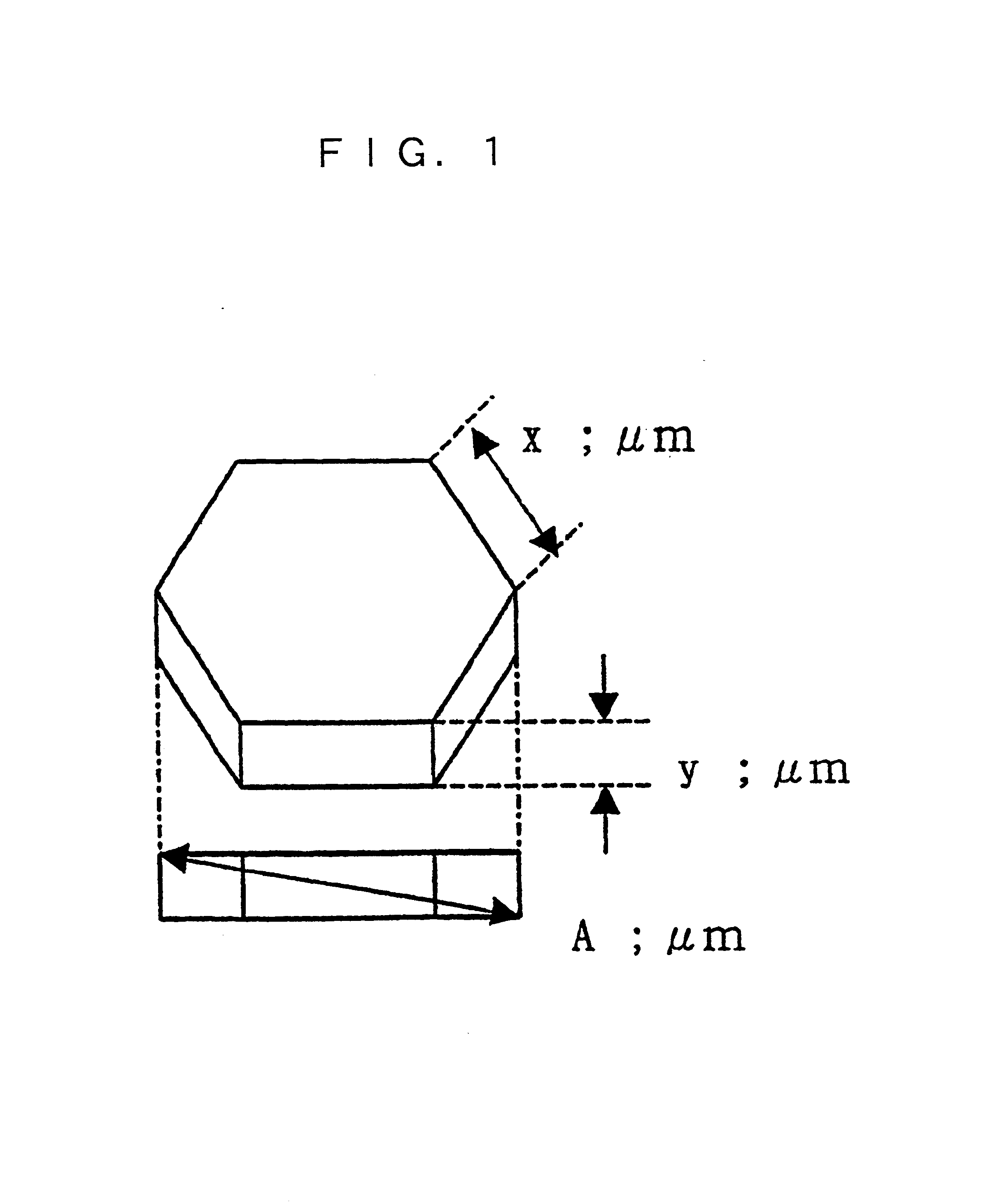

Magnesium hydroxide particles, process for producing the same, and resin composition containing the particles

InactiveUS6676920B1Maintain good propertiesOxide/hydroxide preparationSilicaShell moldingSingle crystal

Owner:KYOWA CHEM IND

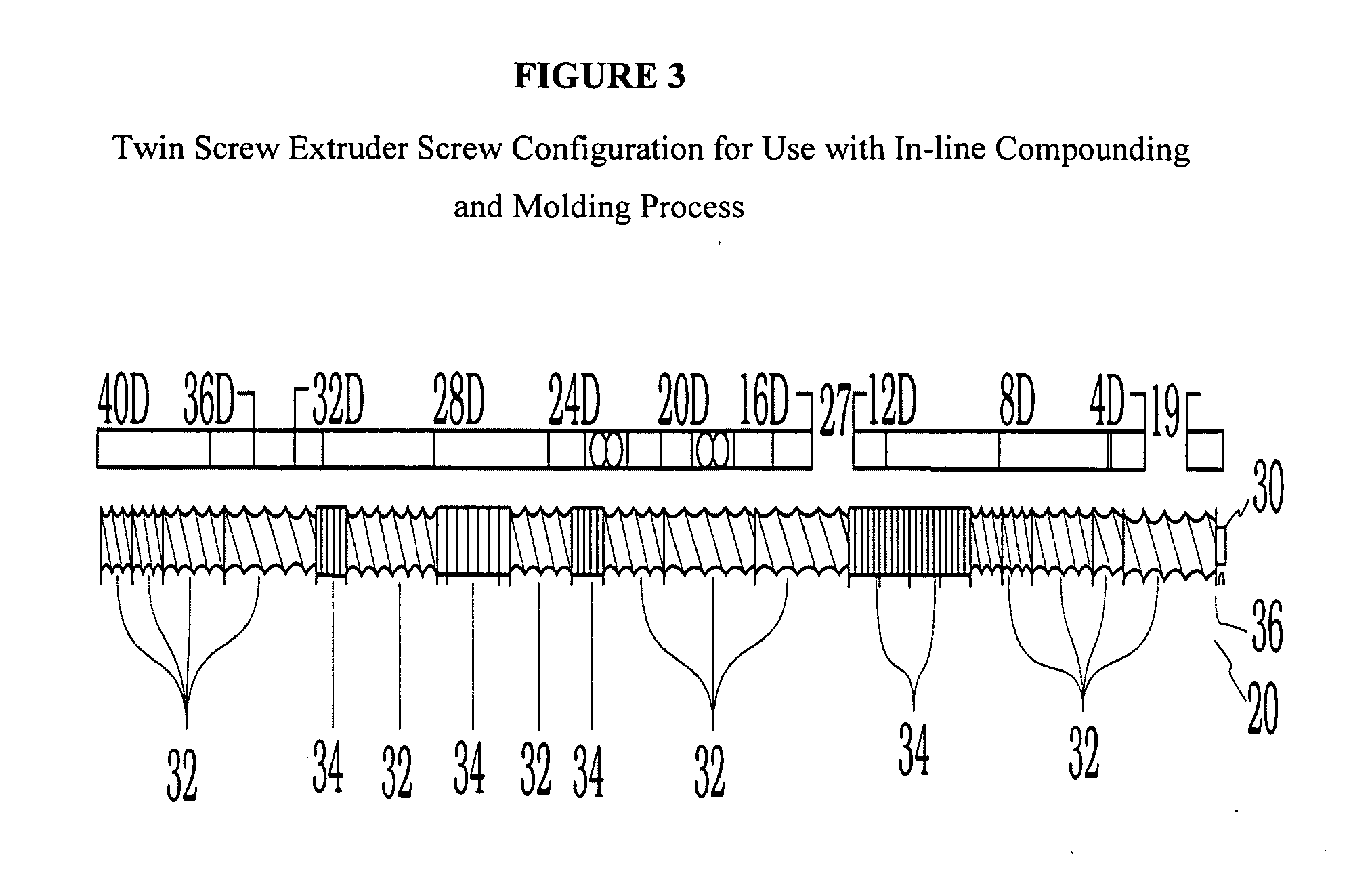

In-line compounding and molding process for making fiber reinforced polypropylene composites

InactiveUS20060264557A1Increase flexibilityHigh retention rateAlkaline-earth metal silicatesPolypropylene compositesPolymer science

The present invention is directed to an in-line compounding and molding process for making fiber reinforced polypropylene composite parts and articles that exhibit beneficial mechanical and aesthetic properties imparted by such process and compositions. The in-line compounding and molding process includes the steps of providing an in-line compounding and molding machine comprising a twin screw extruder fluidly coupled to an injection molder; extrusion compounding in the twin screw extruder a composition comprising at least 30 wt % polypropylene, from 10 to 60 wt % organic fiber, from 0 to 40 wt % inorganic filler, and from 0 to 0.1 wt % lubricant to form a melt extrudate; conveying the melt extrudate to the injection molder; and molding the melt extrudate in the injection molder to form a part or article. Fiber reinforced polypropylene articles formed from the in-line compounding and molding process have flexural modulus of at least 300,000 psi and exhibit ductility during instrumented impact testing. Fiber reinforced polypropylene articles formed from the process of the present invention are particularly suitable for making household appliances, automotive parts, and boat hulls.

Owner:LUSTIGER ARNOLD +1

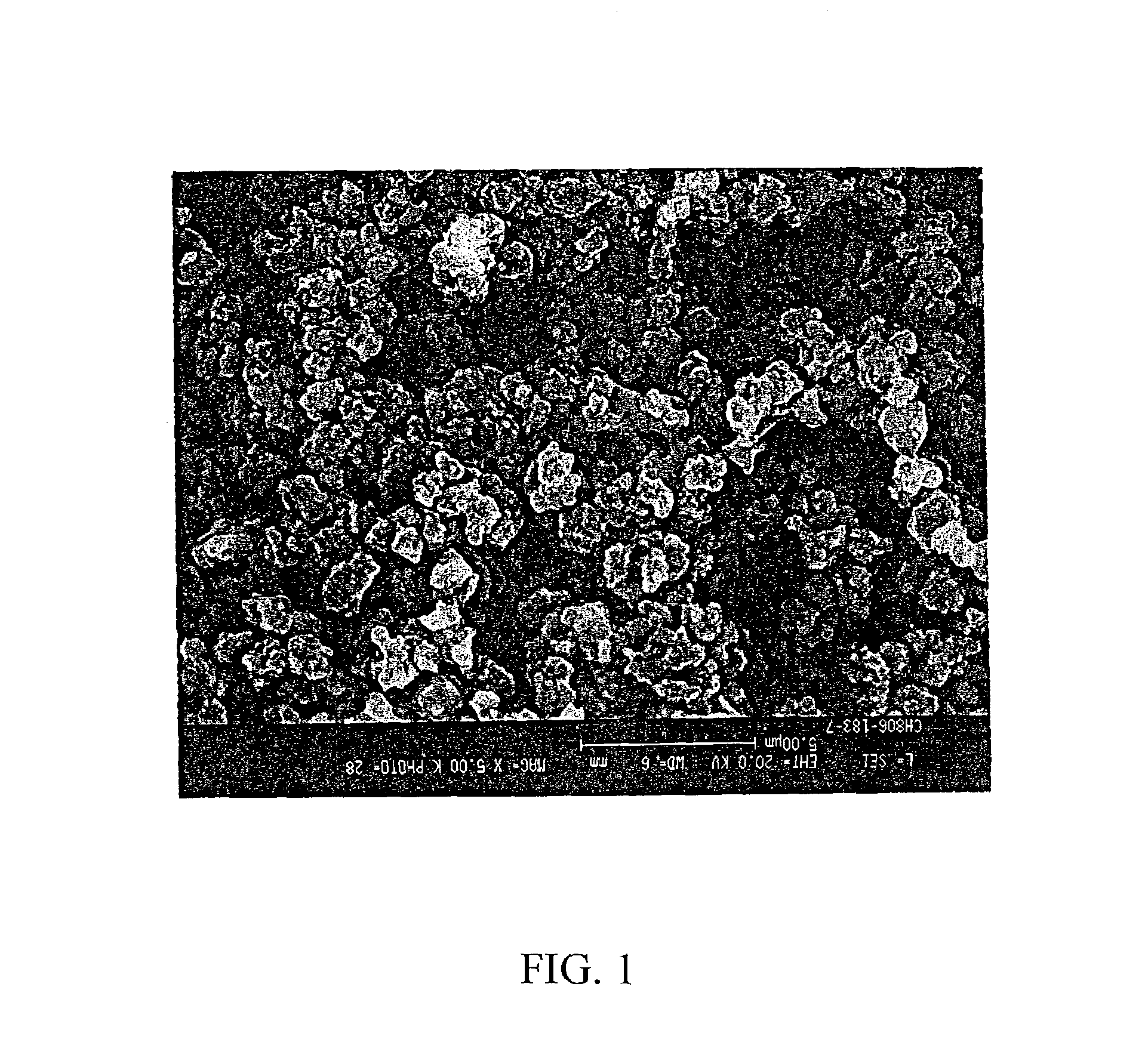

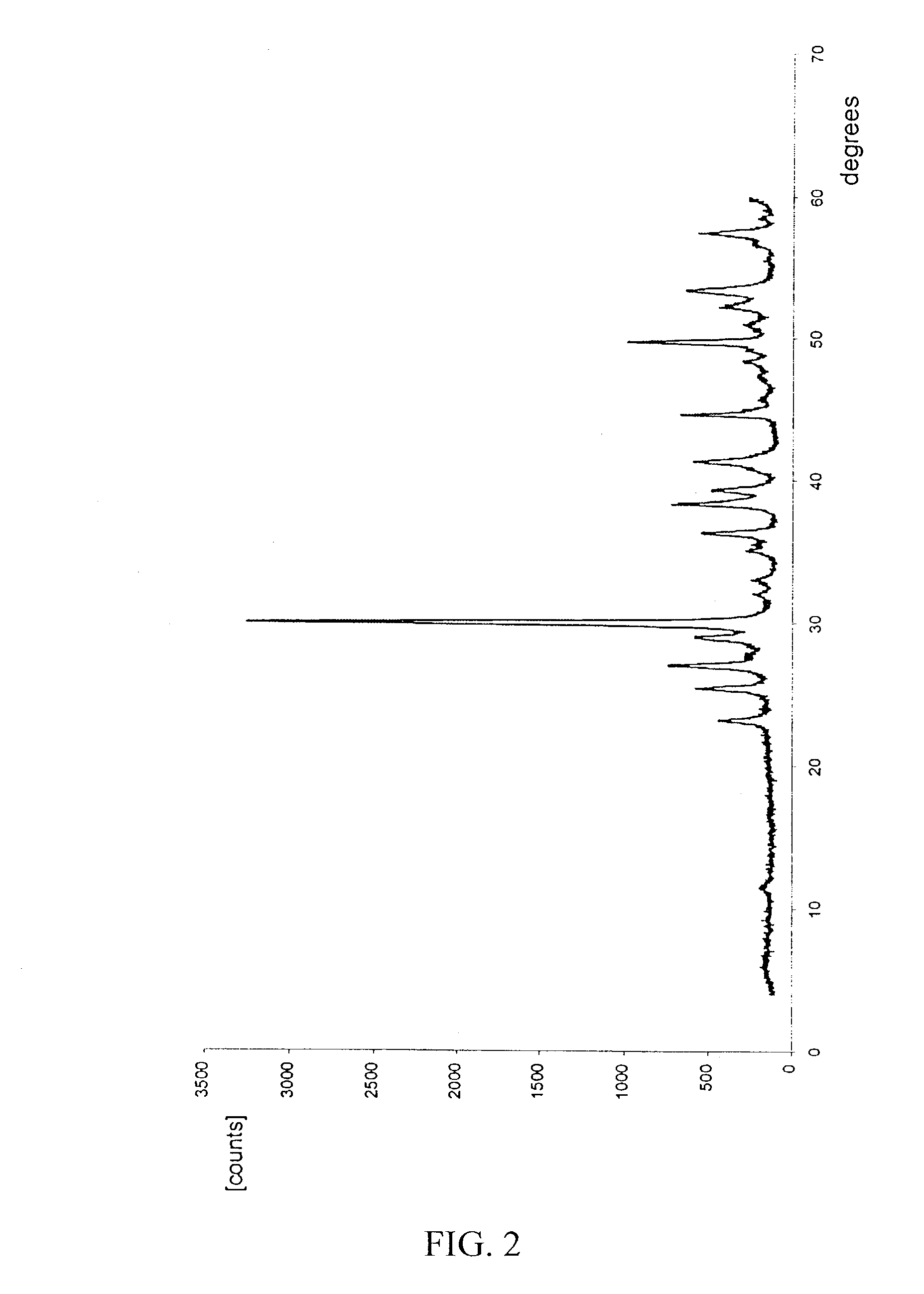

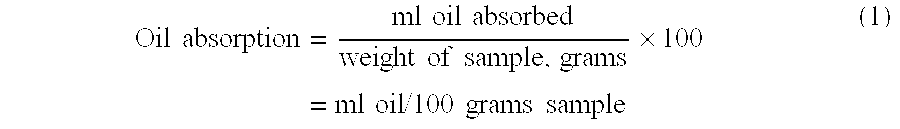

Oral care products comprising calcium metasilicates

Disclosed is an oral care composition comprising a calcium metasilicate having an aspect ratio (average major axial diameter / average minor axial diameter) of from about 1:1 to about 2.5:, and an oil absorption of from about 20 ml / 100 g to about 220 ml / 100 g. Also disclosed is an oral care composition comprising: a calcium metasilicate having an aspect ratio (average major axial diameter / average minor axial diameter) of from about 1:1 to about 2.5:, and an oil absorption of from about 20 ml / 100 g to about 220 ml / 100 g, a disintegration aid, an organoleptic enhancing agent, and an abrasive.

Owner:EVONIK OPERATIONS GMBH

High mineral content film for sealing

InactiveUS20100137493A1Improve biodegradabilityImprove moisture resistanceAlkaline-earth metal silicatesSpecial tyresPolyolefinPolymer chemistry

A composition used to form thermoplastic films and coatings comprising a thermoplastic polyolefin and a ground natural mineral material wherein a film or coating formed of said composition heat seals at or above 200 degrees F. with a dwell time exceeding approximately 0.5 seconds, has a TAPPI T-525 Whiteness % over 78, a TAPPI T-425 Opacity % over 78, a post corona treated ASTM D-2578 dyne level over 38, a minimum moisture barrier transmission rate of 4.0 g / mil / 100 sq. in. / 24 hrs. at 100 degrees F. at 90% relative humidity, and a minimum oxygen barrier of 350 cc / mil / 100 sq. in / 24 hrs. at 23 degrees C.

Owner:SMART PLANET TECH

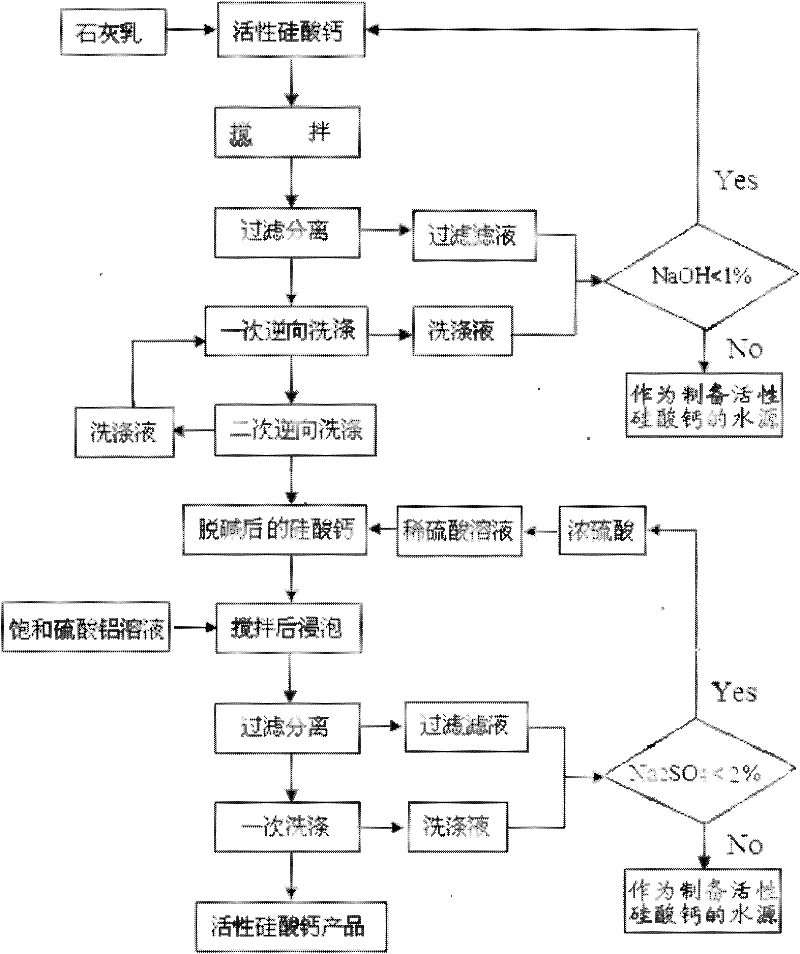

Method for lowering pH value of active calcium silicate

InactiveCN102190309AIncrease profitComply with environmental policyAlkaline-earth metal silicatesCalcium silicateDealkalization

The invention discloses a method for lowering the pH value of active calcium silicate. The method comprises the following steps of: adding lime milk to high-alkality active calcium silicate for dealkalization when the Na2O content (weight percent) in the high-alkality active calcium silicate is greater than or equal to 1%, and then carrying out acidification treatment; and directly carrying out acidification treatment on high-alkality active calcium silicate when the Na2O content (weight percent) in the high-alkality active calcium silicate is smaller than 1%. The invention overcomes the defects of the prior art, and realizes the advantages of wide raw material sources, low price, simple operation steps and low energy consumption. The pH value of high-alkality active calcium silicate treated by the method can be lowered to 8-10, thereby meeting the requirements on filler performance in the industries of plastic, rubber, paper making, paint and the like, and high-alkality active calcium silicate treated by the method can be used as a heat-insulation material.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Amorphous silica-alumina, a carrier combination and a hydrocracking catalyst containing the same, and processes for the preparation thereof

InactiveUS20020160906A1Increase surface areaLarge hole volumeMolecular sieve catalystsAluminium silicatesPtru catalystPhysical chemistry

Owner:CHINA PETROCHEMICAL CORP +1

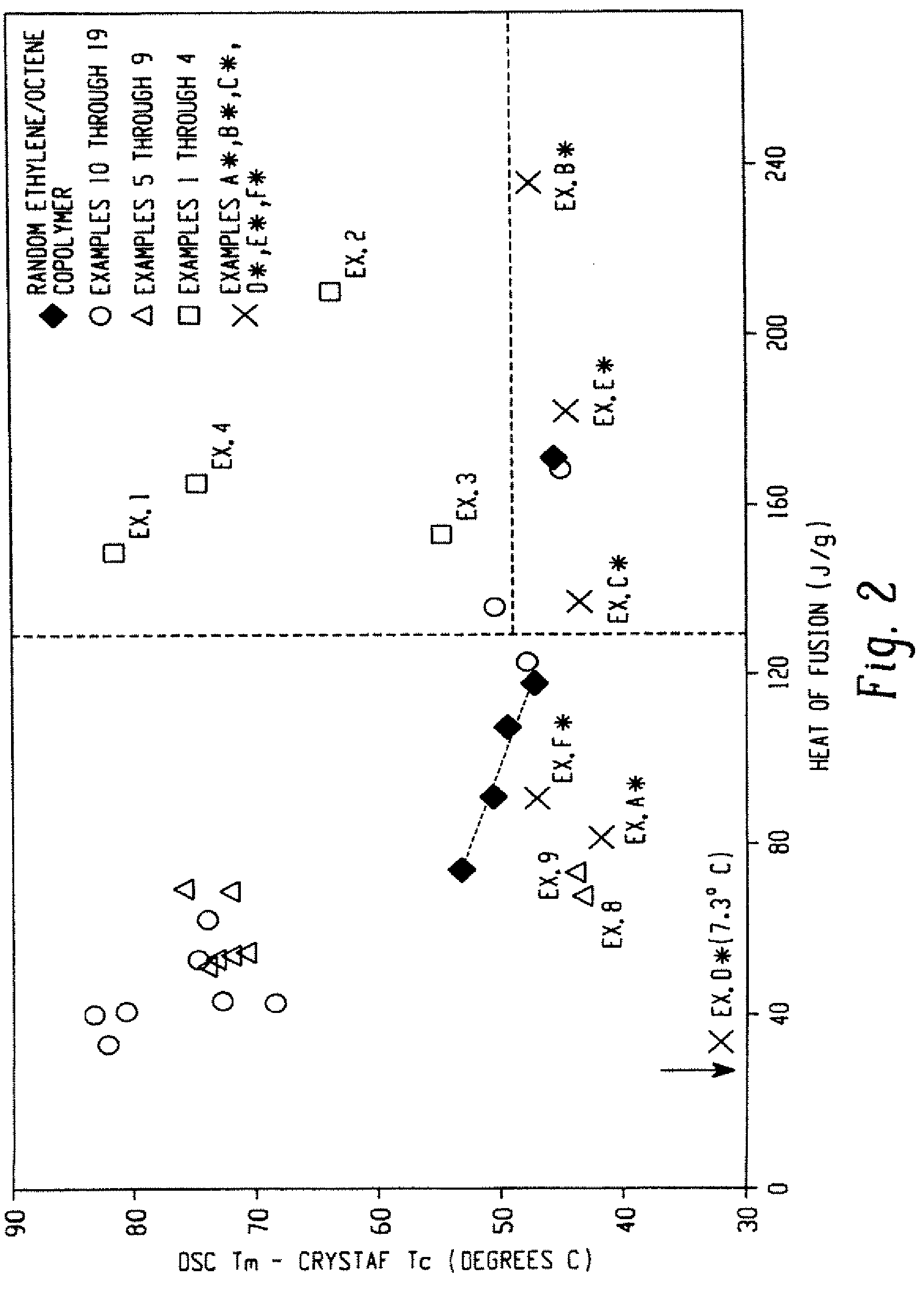

Thermoplastic olefin composition with improved heat distortion temperature

InactiveUS20090105374A1Reduce impactGood chemical resistancePigmenting treatmentOther chemical processesHeat deflection temperatureThermoplastic

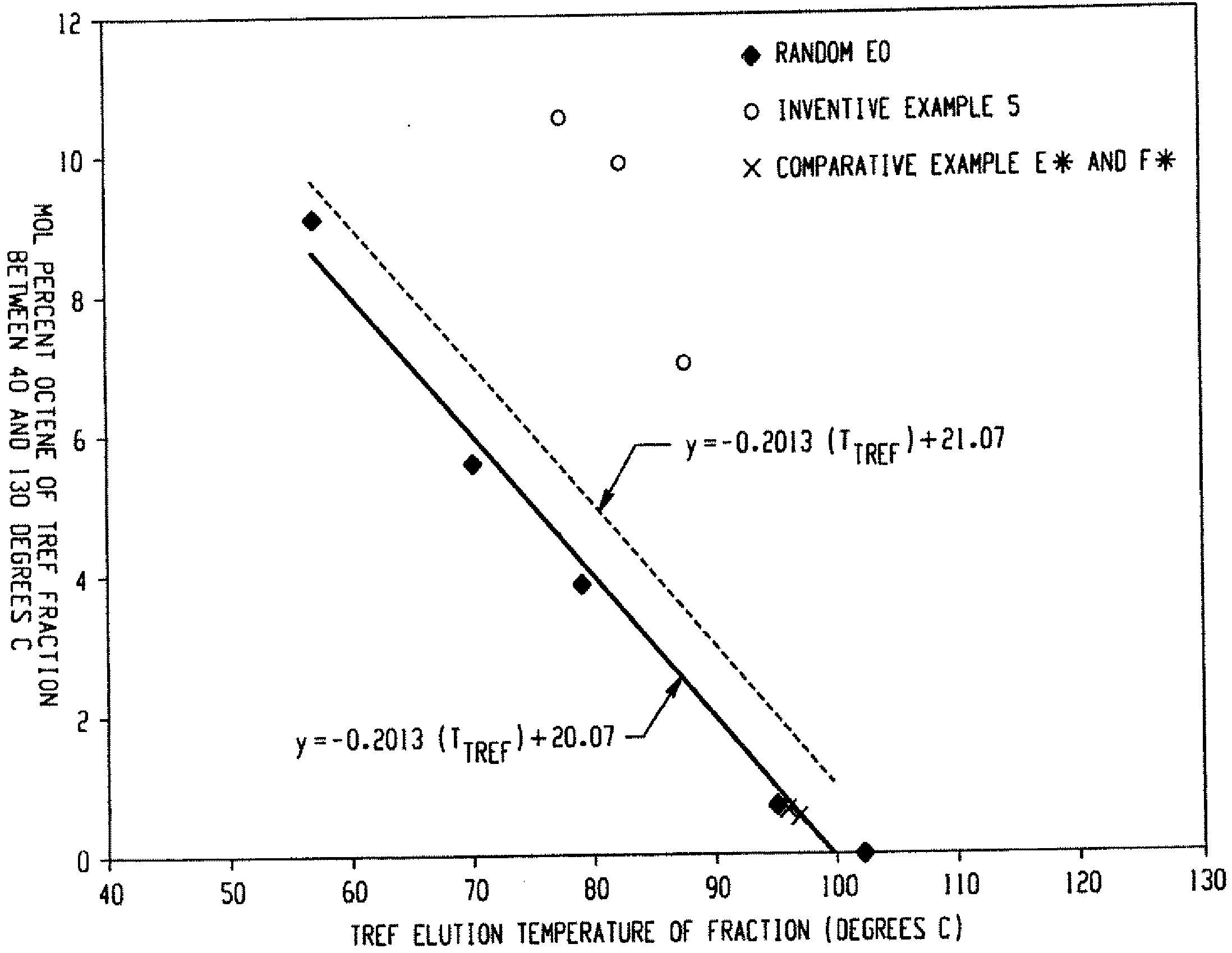

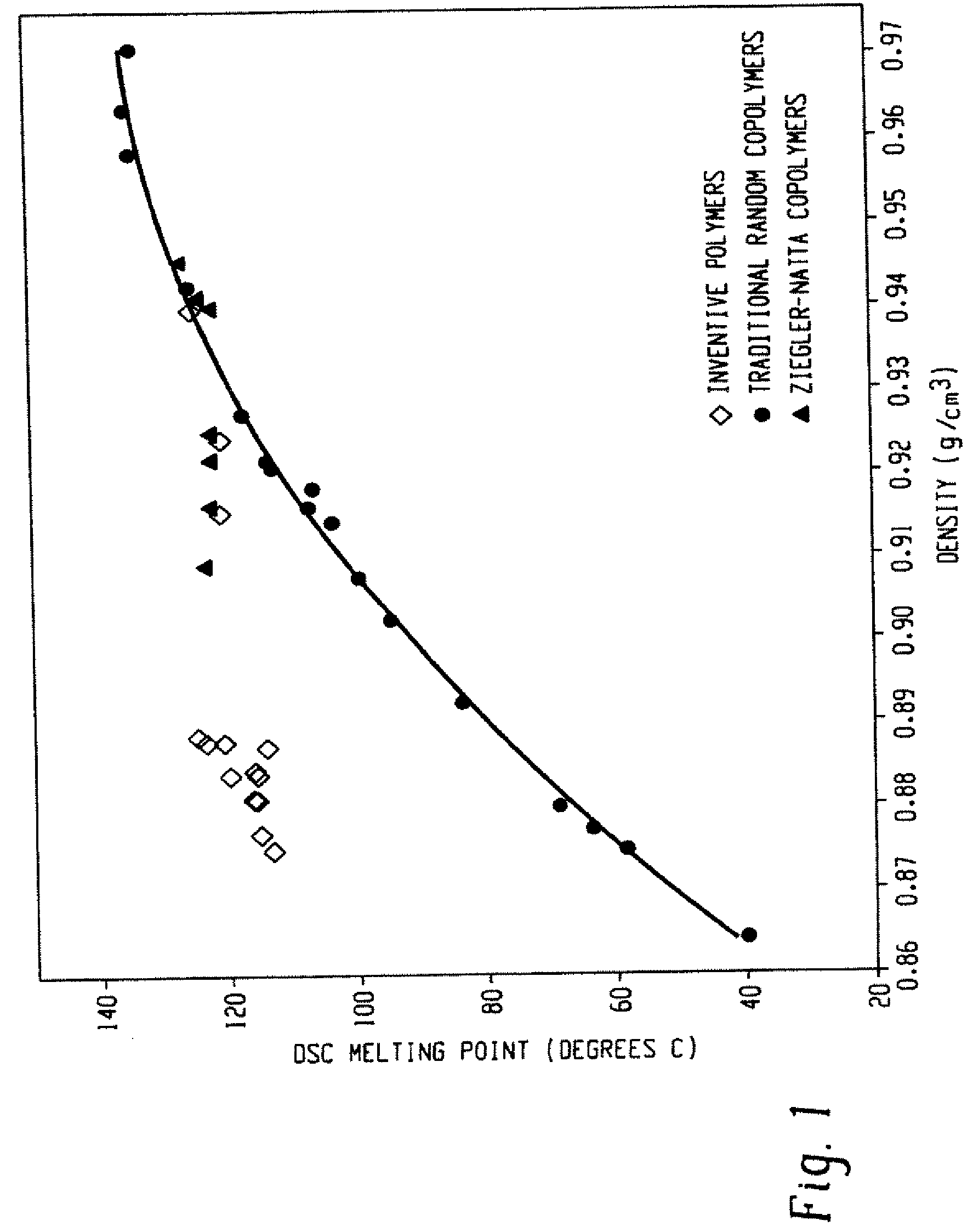

Compositions having good impact performance can be made from a thermoplastic (e.g., a polyolefin such as polypropylene or HDPE) and an ethylene multi-block copolymer. The compositions are easily molded and often have particular utility in making, for example, automotive facia, parts and other household articles.

Owner:DOW GLOBAL TECH LLC

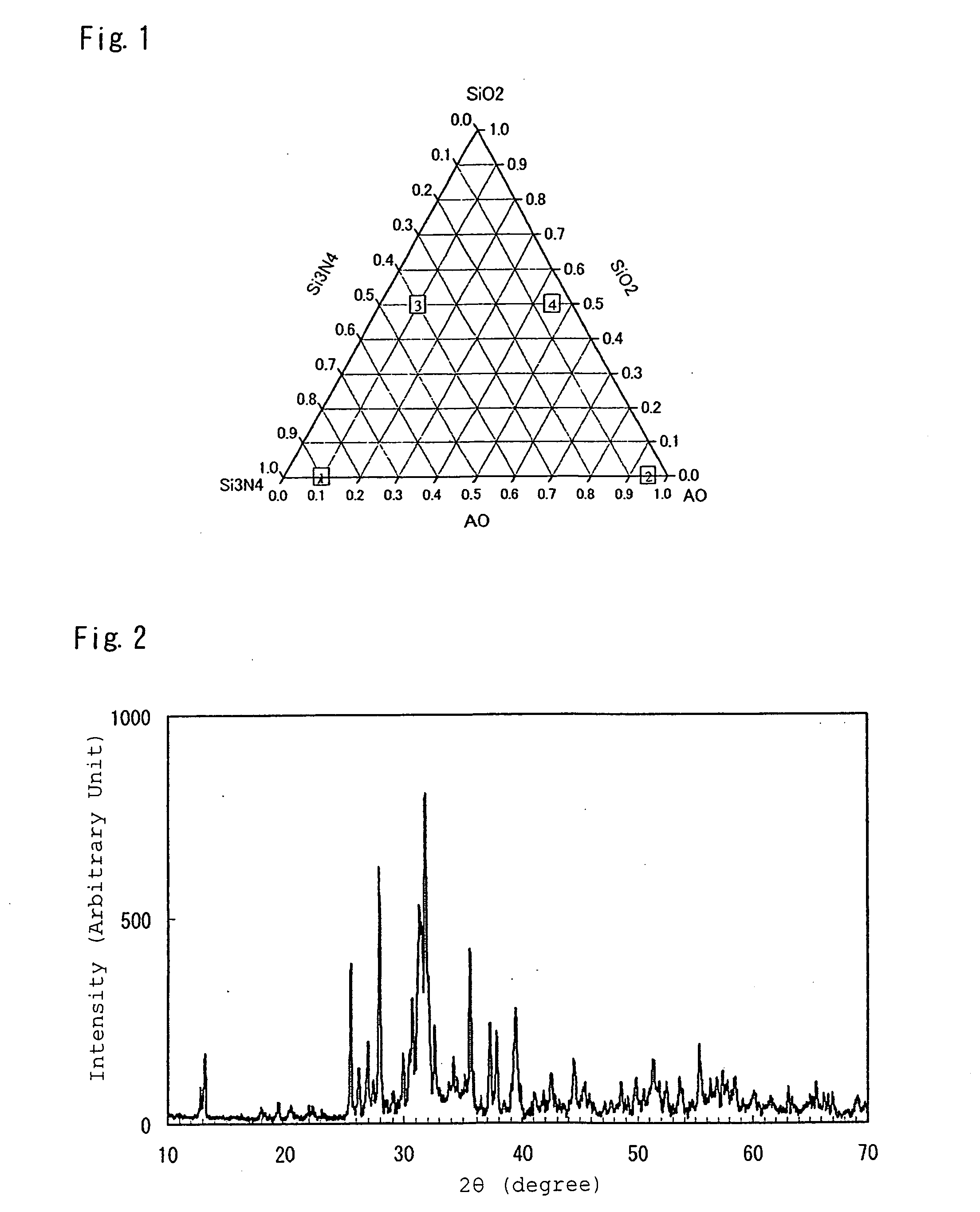

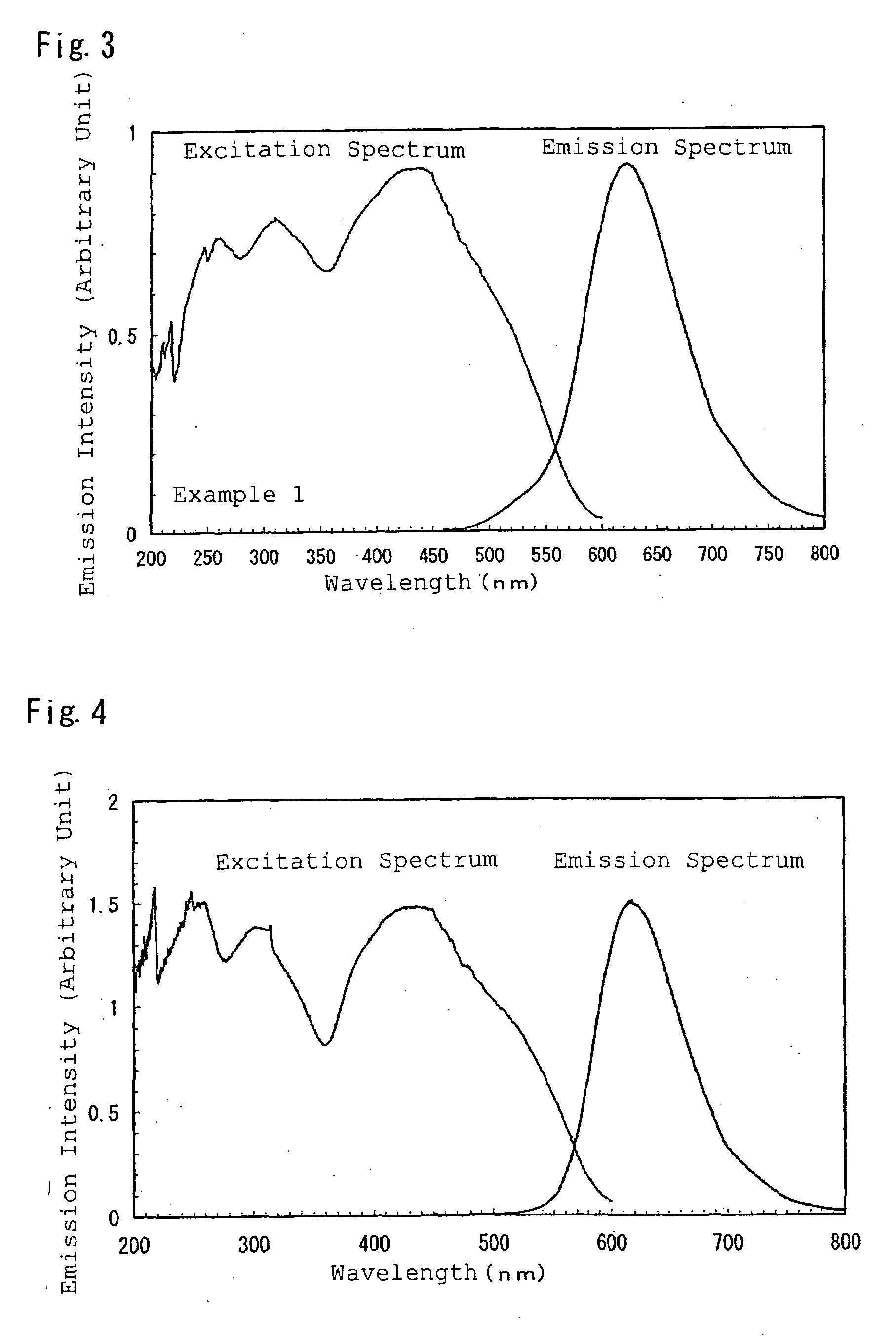

Phosphor, Production Method Thereof and Light Emitting Instrument

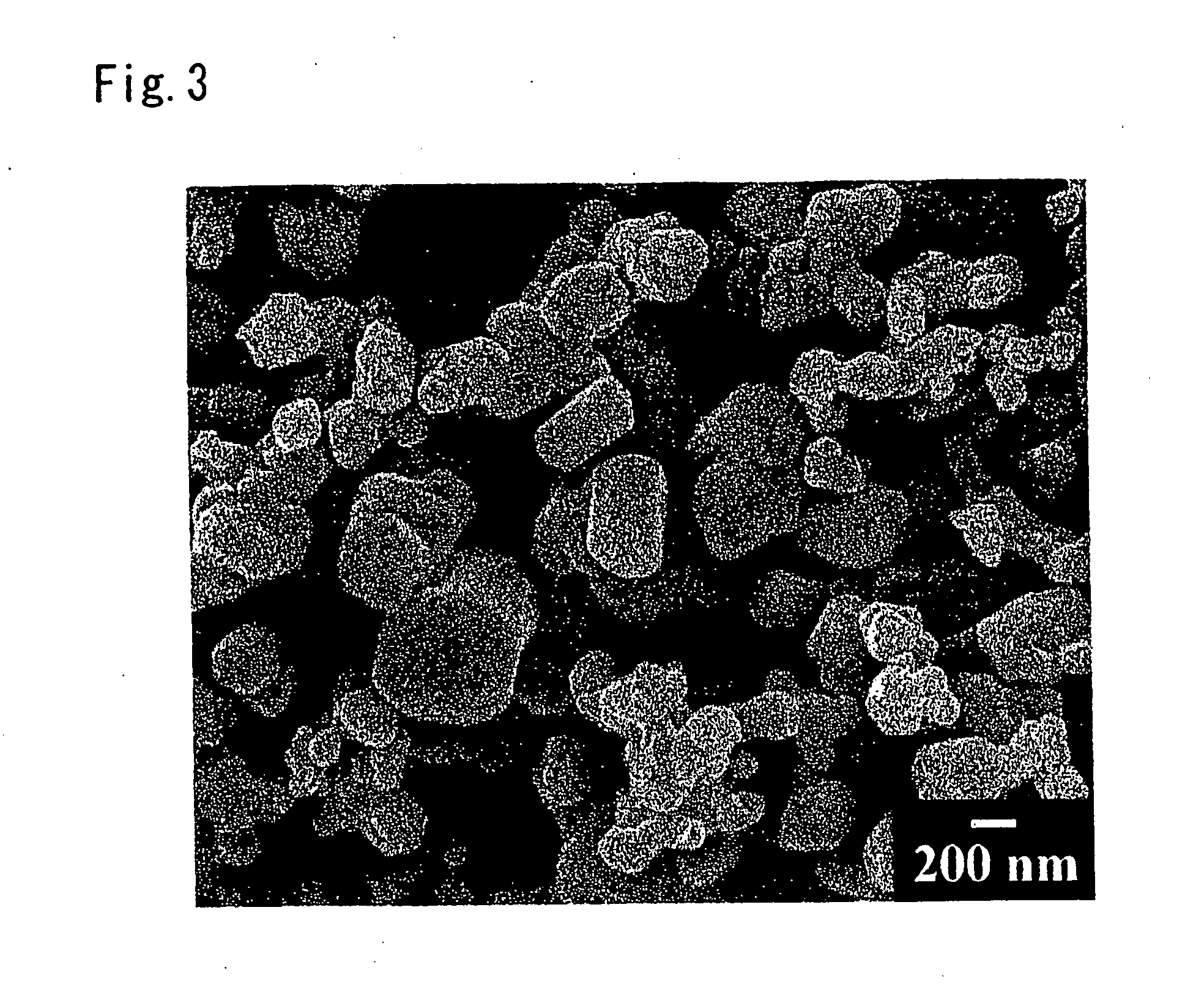

ActiveUS20080143246A1Without luminance deteriorationIncrease production capacityDischarge tube luminescnet screensCathode ray tubes/electron beam tubesAlkaline earth metalRare earth

The present invention aims at providing a chemically stabilized inorganic phosphor, among oxynitride phosphors including alkaline earths, which oxynitride phosphor emits orange or red light at longer wavelengths at higher luminance than conventional sialon phosphors activated by rare earths. The present invention further aims at providing a light emitting instrument based on the phosphor, for a lighting instrument excellent in color rendering property and for an image displaying apparatus excellent in durability.The solving means resides in provision of a fundamental phosphor comprising:a composition on a pseudo-ternary phase diagram including AO (A is one kind or two or more kinds of element(s) selected from Mg, Ca, Sr, and Ba; and AO is oxide of A), Si3N4, and SiO2 as end members, respectively, and satisfying all of the following conditions:in a composition formula, pAO-qSi3N4-rSiO2 (p+q+r=1),0.1≦p≦0.95, (1)0.05≦q≦0.9, and (2)0≦r≦0.5, and (3)at least a metallic element M (M is one kind or two or more kinds of element(s) selected from Mn, Ce, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm, and Yb) dissolved, in a solid state, in the composition.

Owner:NAT INST FOR MATERIALS SCI

Oxynitride powder and production method thereof

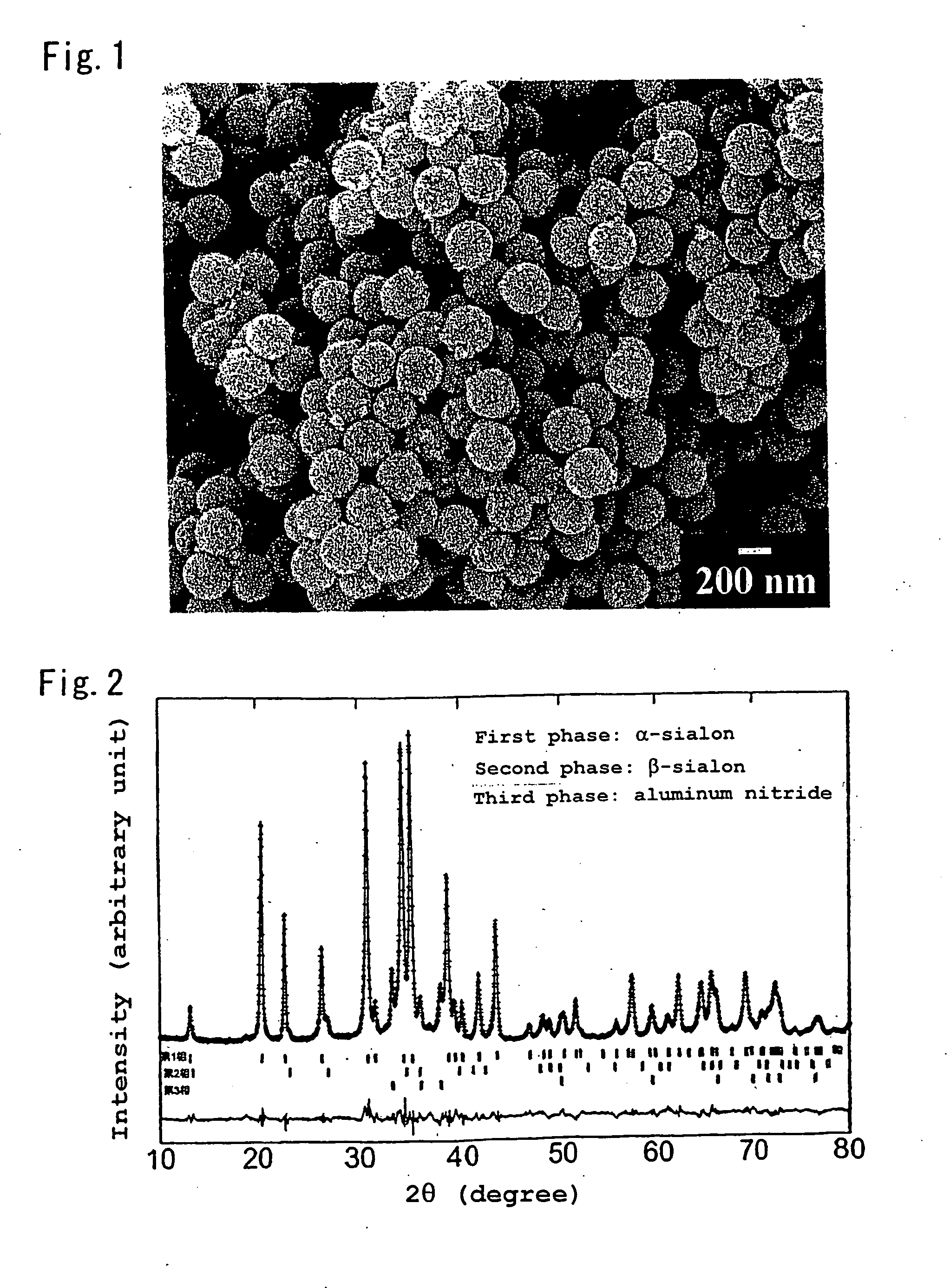

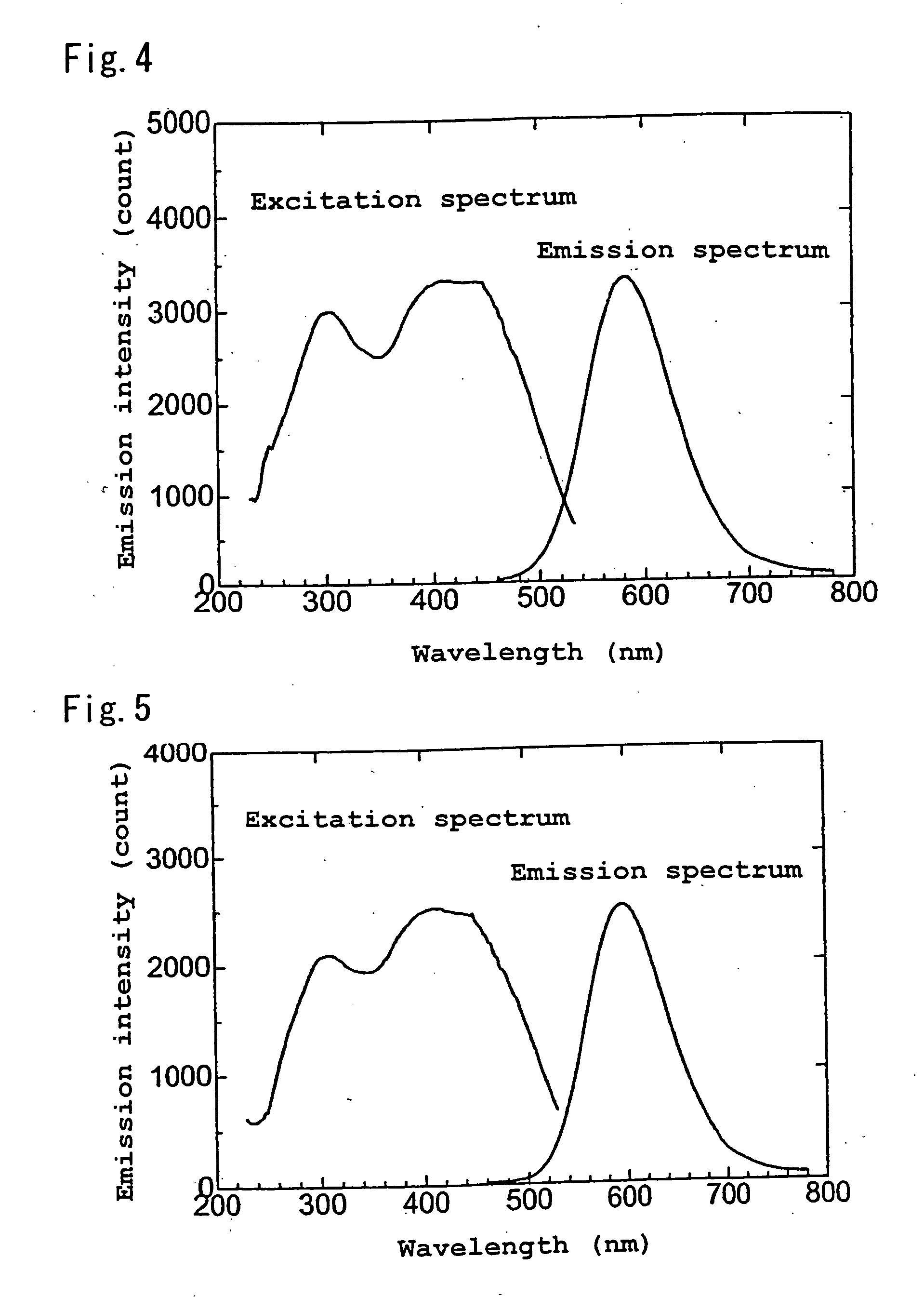

ActiveUS20070166218A1Low oxygenHigh nitrogen contentAluminium compoundsAluminium silicatesPhosphorNitrogen

It is aimed at providing an oxynitride powder, which is suitable for usage as a phosphor, is free from coloration due to contamination of impurities, and mainly includes a fine α-sialon powder. An oxynitride powder is produced by applying a heat treatment in a reducing and nitriding atmosphere, to a precursor compound including at least constituent elements M, Si, Al, and O (where M is one element or mixed two or more elements selected from Li, Mg, Ca, Sr, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu), thereby decreasing an oxygen content and increasing a nitrogen content of the precursor.

Owner:NAT INST FOR MATERIALS SCI

Process for the produciton of synthetic magnesium silicate compositons

InactiveUS20060147367A1Improved rheological propertiesShort reaction timeAlkaline-earth metal silicatesAlkali metal silicatesSynthetic magnesium silicateCrystal structure

A method for the preparation of a synthetic magnesium silicate having a crystal structure similar to natural hectorite, includes the steps of a) forming a precursor slurry, b) subjecting the precursor slurry to a continuous hydrothermal reaction in a pipe reactor at a temperature of from 210° C. to 400° C. and under a pressure of at least 20 10 bar for 10 seconds to 4 hours, and e) washing and filtering to remove water soluble salts formed in the preparation of the precursor slurry. The precursor slurry is not washed and filtered before it is subjected to the continuous hydrothermal reaction.

Owner:ROCKWOOD ADDITIVES

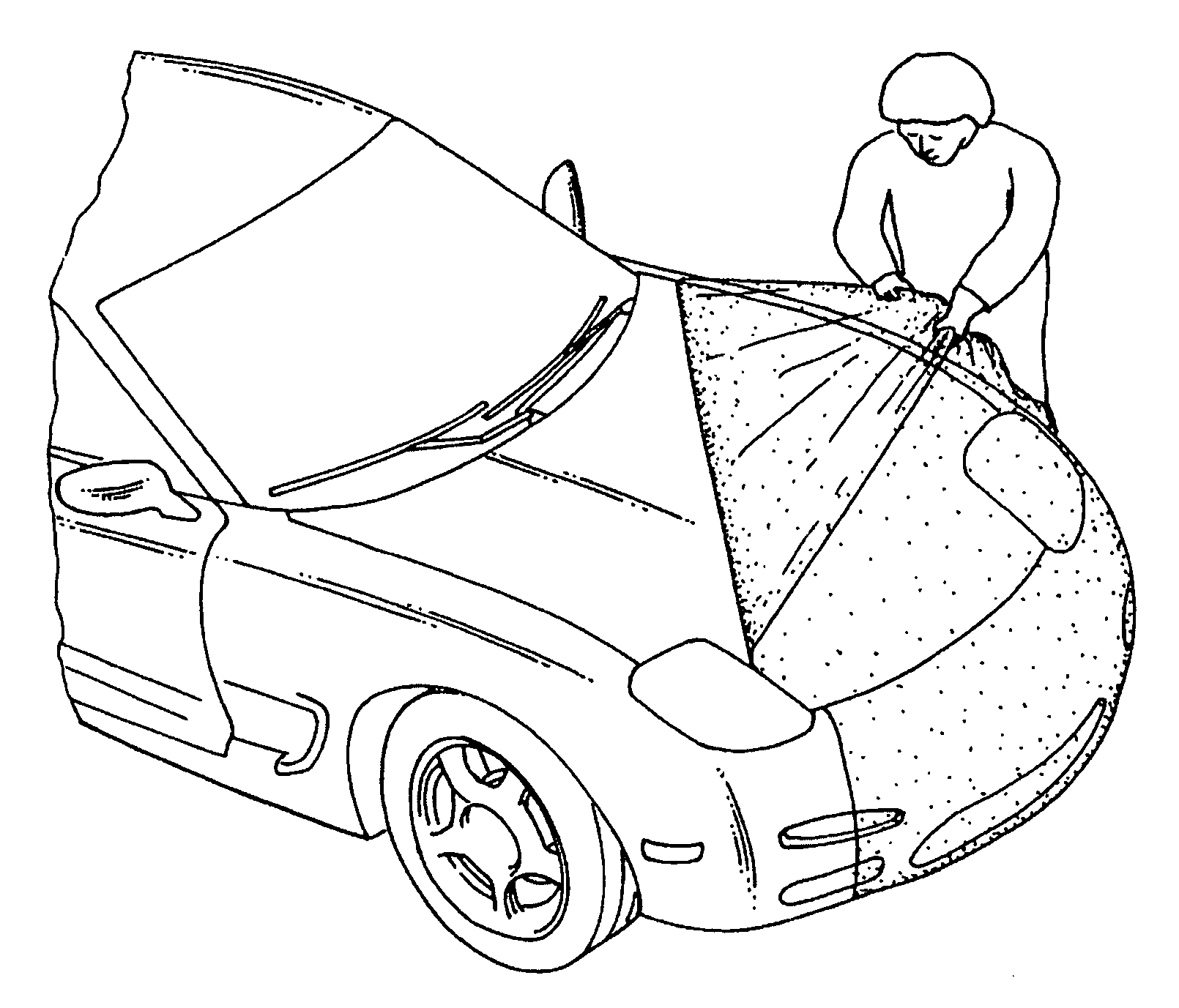

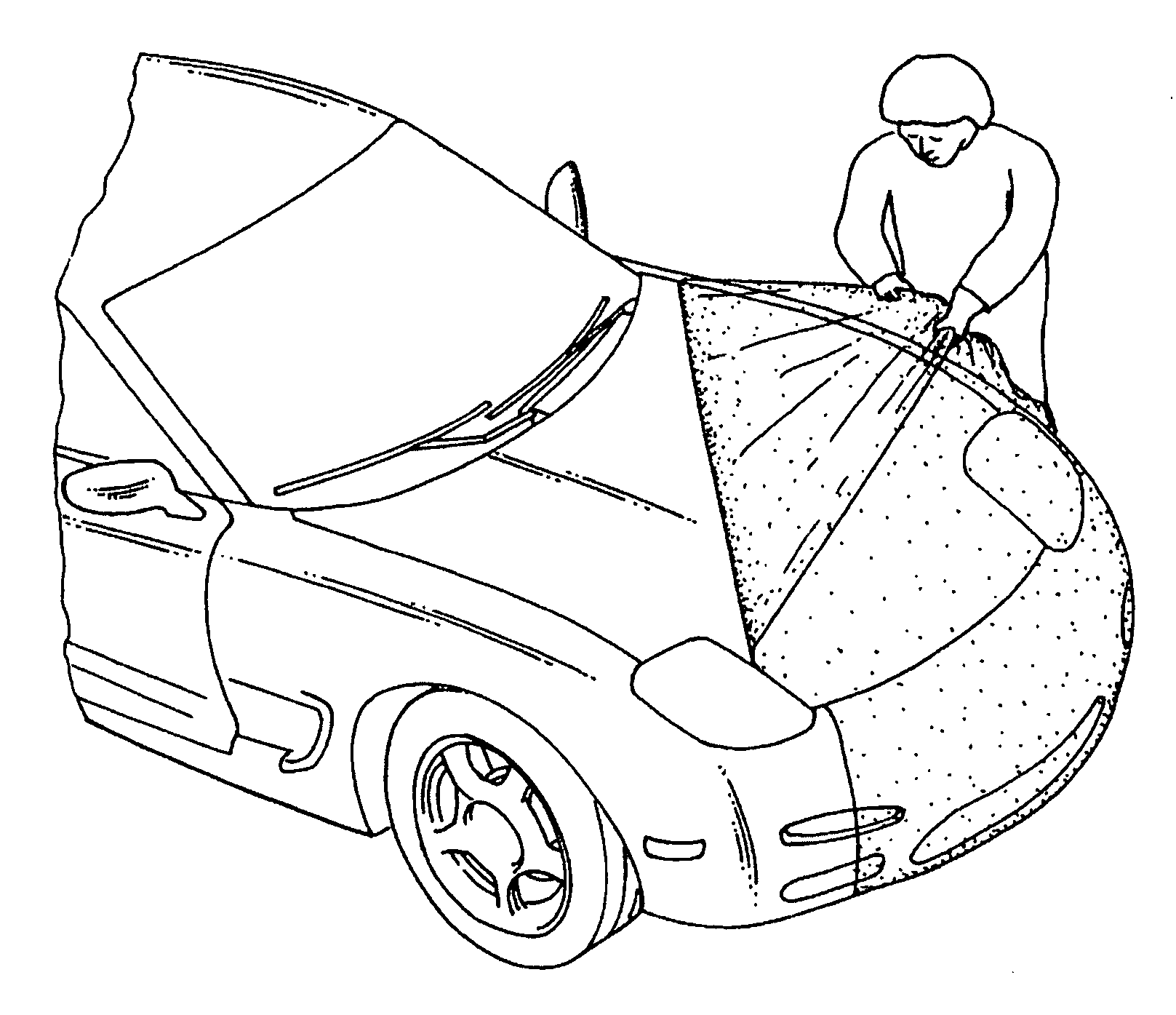

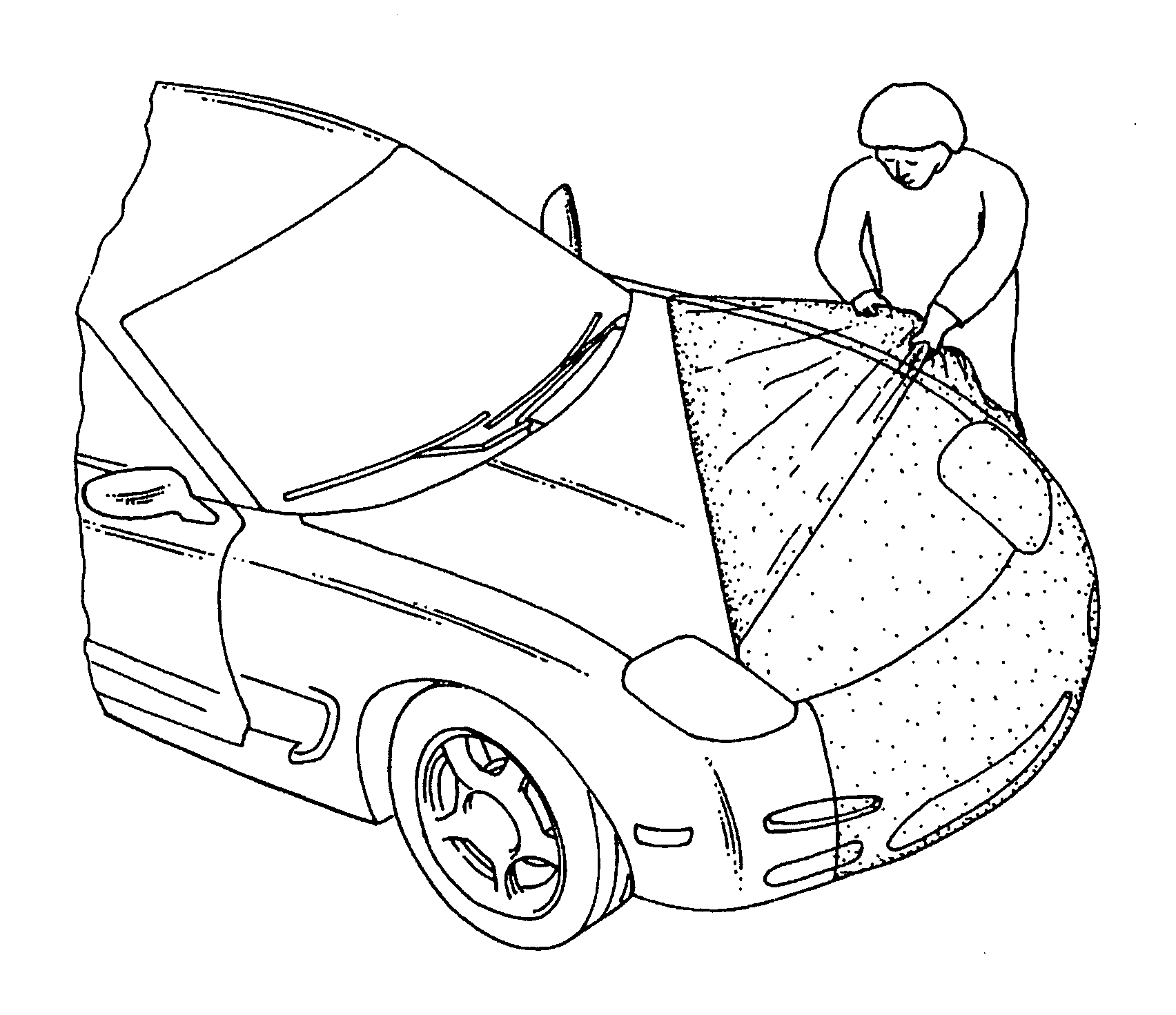

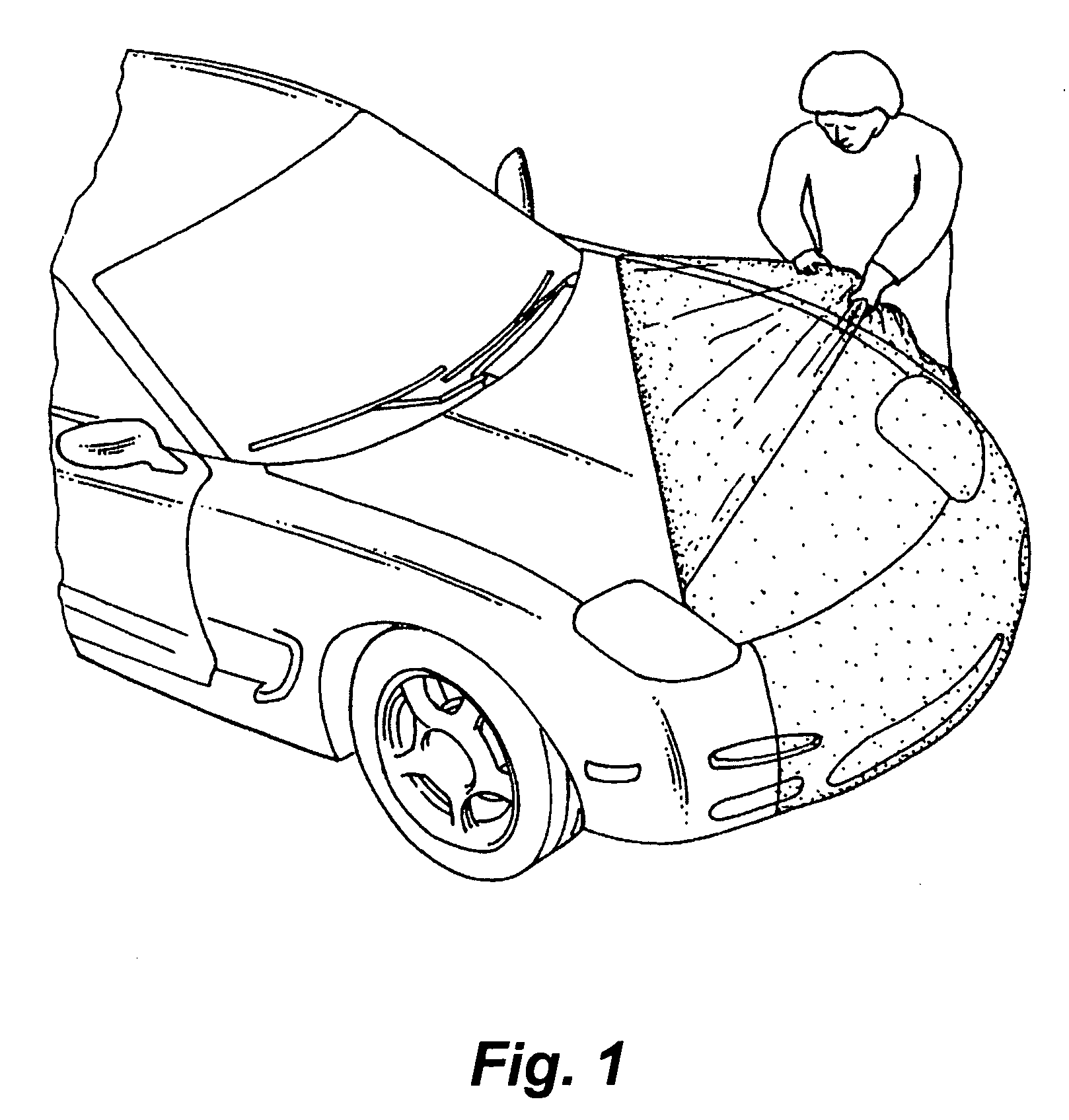

Peel-off coating compositions

ActiveUS8263231B2Easy to disassembleLow costNon-fibrous pulp additionAlkaline-earth metal silicatesEmulsionAcid rain

Methods and compositions are provided for protecting exterior surfaces of automobiles and other products, or components of products, against abrasion, abrasive dust, water, acid rain, etc. The methods involve applying to a surface a protective coating composition comprising a polyvinyl butyrate emulsion and a relatively inert extender. The emulsion is dried to form a water-resistant protective coating that can be removed from the underlying surface by peeling when no longer desired.

Owner:CAL WEST SPECIALTY COATINGS

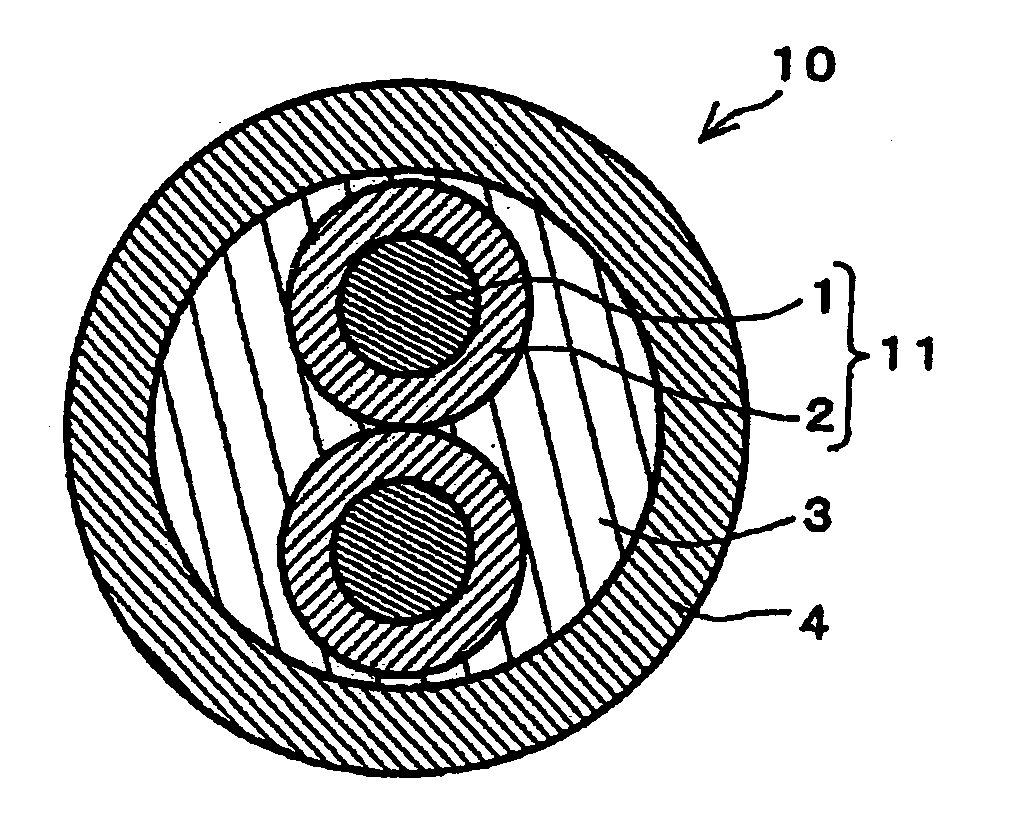

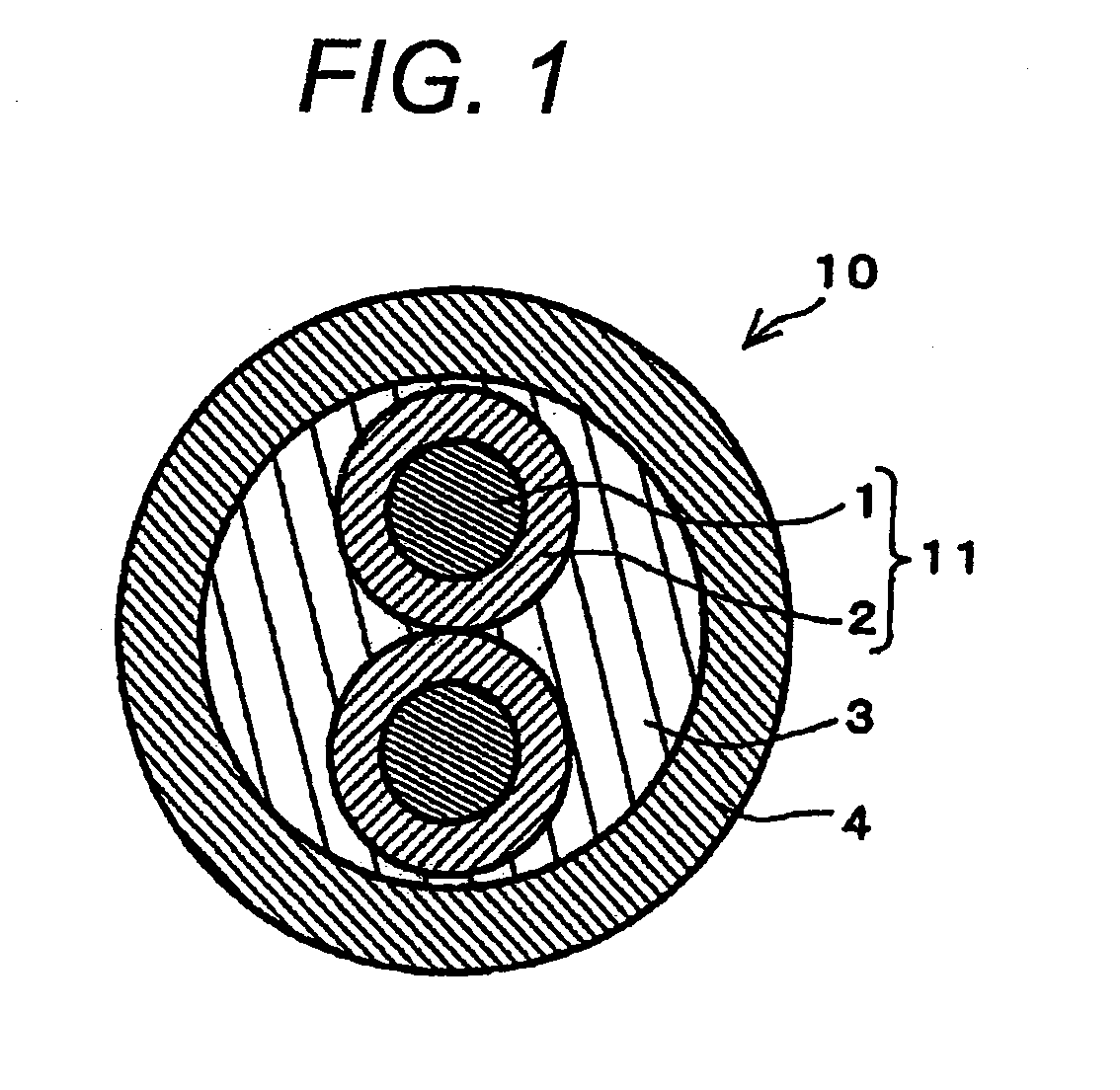

Non-halogen flame retardant resin composition and non-halogen flame retardant electric wire and cable

InactiveUS20080311328A1Improve flame retardant performanceExcellent mechanical propertiesAlkaline-earth metal silicatesLayered productsCarbon numberAlpha-olefin

An insulator 2 cladding the conductor 1 and / or a cable sheath 4 cladding the insulated electric wire 11 are formed by using a resin composition formed by mixing 100 to 250 parts by weight of silanized magnesium hydroxide together with 100 parts by weight of polymer composed of 50 to 80 parts by weight of ethylene-vinyl acetate copolymer, 10 to 30 parts by weight of polypropylene, and 10 to 20 parts by weight of magnesium hydroxide denatured with maleic acid obtained by denaturing copolymerized polymer with maleic anhydride, the copolymerized polymer being formed by copolymerizing ethylene and the co-monomer of alpha-olefin of carbon numbers 3 to 8.

Owner:HITACHI METALS LTD

Production method of active calcium silicate

InactiveCN103145136AEfficient removalReduce shipping costsAlkaline-earth metal silicatesAluminium oxides/hydroxidesCalcium silicateSlag

The invention provides a production method of active calcium silicate. The production method of the active calcium silicate is characterized by comprising the following steps of calcining limestone, cooling the limestone, screening the limestone to collect calcium oxide particles with the particle size of over 10 mm, conducting incineration to manufacture lime milk, wherein the concentration of the lime milk is 140-190g / L, conducting centrifugal sedimentation on the manufactured lime milk, collecting refined lime milk with the particle size less than 75 mu, filtering sodium silicate feed liquid of pre-desilication, wherein the content of seston in the sodium silicate feed liquid is enabled to be less than 0.1g / L, obtaining sodium silicate fine liquid, conducting a hydrothermal reaction on the manufactured refined lime milk and the sodium silicate fine liquid, conducting slag removal and washing on a product of the hydrothermal reaction, and obtaining the active calcium silicate. The production method of the active calcium silicate can effectively solve the problem that impurity content of the active calcium silicate serving as pack is high.

Owner:NORTHEASTERN UNIV +1

Flame-retardant reinforced polycarbonate compositions

ActiveUS8552096B2Increase stiffnessPlastic/resin/waxes insulatorsAlkaline-earth metal silicatesPolymer scienceFlexural modulus

A composition containing a polycarbonate, a polycarbonate-polysiloxane copolymer, an alicyclic hydrocarbon resin flow promoter, an inorganic filler, a flame retardant and an impact modifier. The compositions may include polycarbonate in an amount of 40% by weight or more of the combined weights of the polycarbonate, polycarbonate-polysiloxane copolymer, inorganic filler, flame retardant, flow promoter, and impact modifier compound wherein a molded sample of the thermoplastic composition is capable of achieving UL94 V0 rating at a thickness of 1.2 mm (±10%); wherein the polymer composition has a melt viscosity of 185 Pa·sec or less, when measured at 270° C. and 1500 sec−1; and wherein a molded sample of the thermoplastic composition has a flexural modulus determined in accordance with ASTM D790 within 3800-8000 MPa; and wherein a 3.2-mm thick molded NII bar comprising the composition has a notched Izod impact strength of 40 to 200 J / m determined in accordance with ASTM D256 at 23° C.

Owner:SHPP GLOBAL TECH BV

Peel-off coating compositions

ActiveUS20100167075A1High strengthAvoid lack of toughnessNon-fibrous pulp additionAlkaline-earth metal silicatesEmulsionWater resistant

Methods and compositions are provided for protecting exterior surfaces of automobiles and other products, or components of products, against abrasion, abrasive dust, water, acid rain, etc. The methods involve applying to a surface a protective coating composition comprising a polyvinyl butyrate emulsion and a relatively inert extender. The emulsion is dried to form a water-resistant protective coating that can be removed from the underlying surface by peeling when no longer desired.

Owner:CAL WEST SPECIALTY COATINGS

Flame-retardant reinforced polycarbonate compositions

ActiveUS20110028615A1Increase stiffnessPlastic/resin/waxes insulatorsAlkaline-earth metal silicatesFlexural modulusAlicyclic Hydrocarbons

A composition containing a polycarbonate, a polycarbonate-polysiloxane copolymer, an alicyclic hydrocarbon resin flow promoter, an inorganic filler, a flame retardant and an impact modifier. The compositions may include polycarbonate in an amount of 40% by weight or more of the combined weights of the polycarbonate, polycarbonate-polysiloxane copolymer, inorganic filler, flame retardant, flow promoter, and impact modifier compound wherein a molded sample of the thermoplastic composition is capable of achieving UL94 V0 rating at a thickness of 1.2 mm (±10%); wherein the polymer composition has a melt viscosity of 185 Pa·sec or less, when measured at 270° C. and 1500 sec−1; and wherein a molded sample of the thermoplastic composition has a flexural modulus determined in accordance with ASTM D790 within 3800-8000 MPa; and wherein a 3.2-mm thick molded NII bar comprising the composition has a notched Izod impact strength of 40 to 200 J / m determined in accordance with ASTM D256 at 23° C.

Owner:SHPP GLOBAL TECH BV

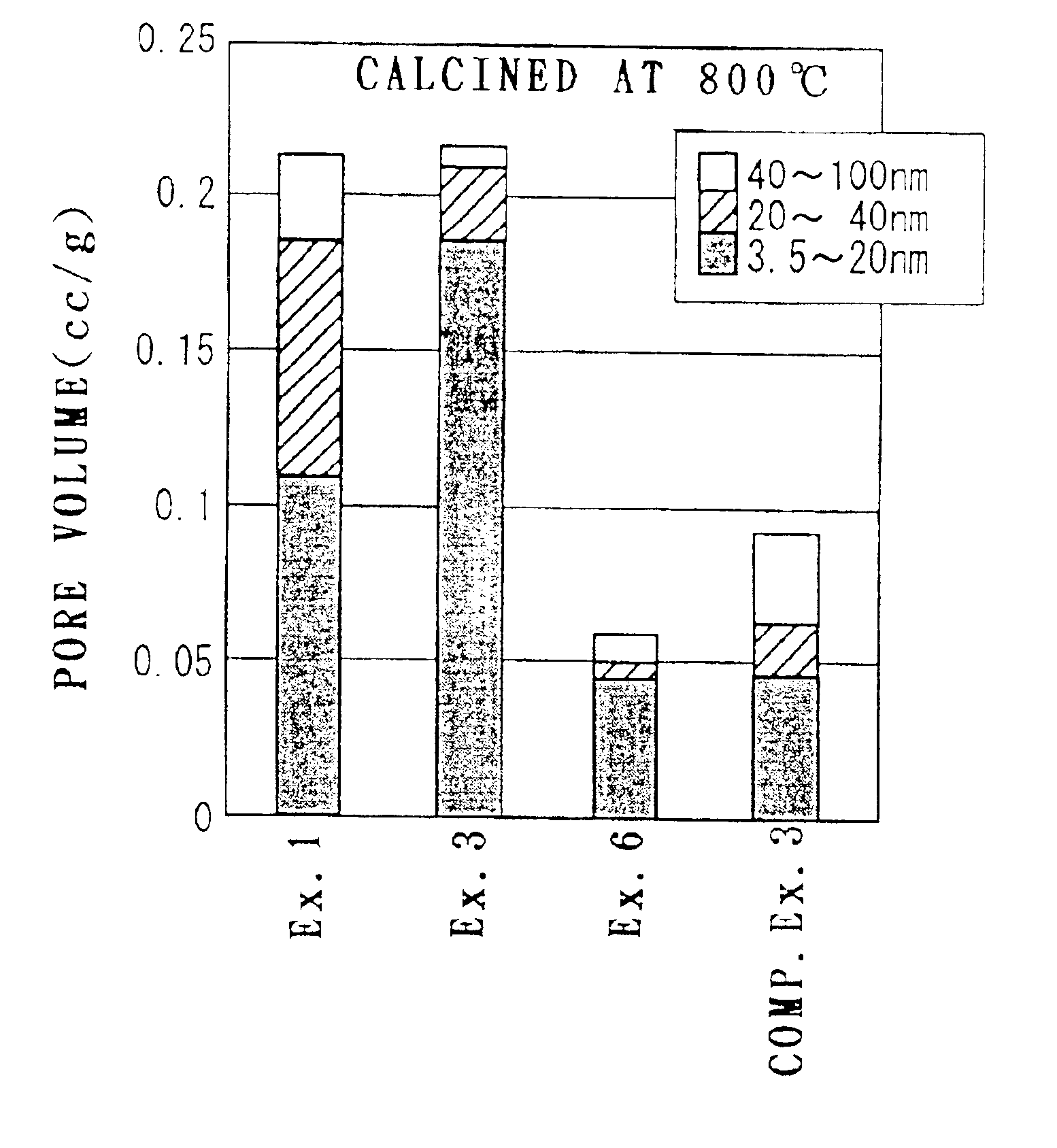

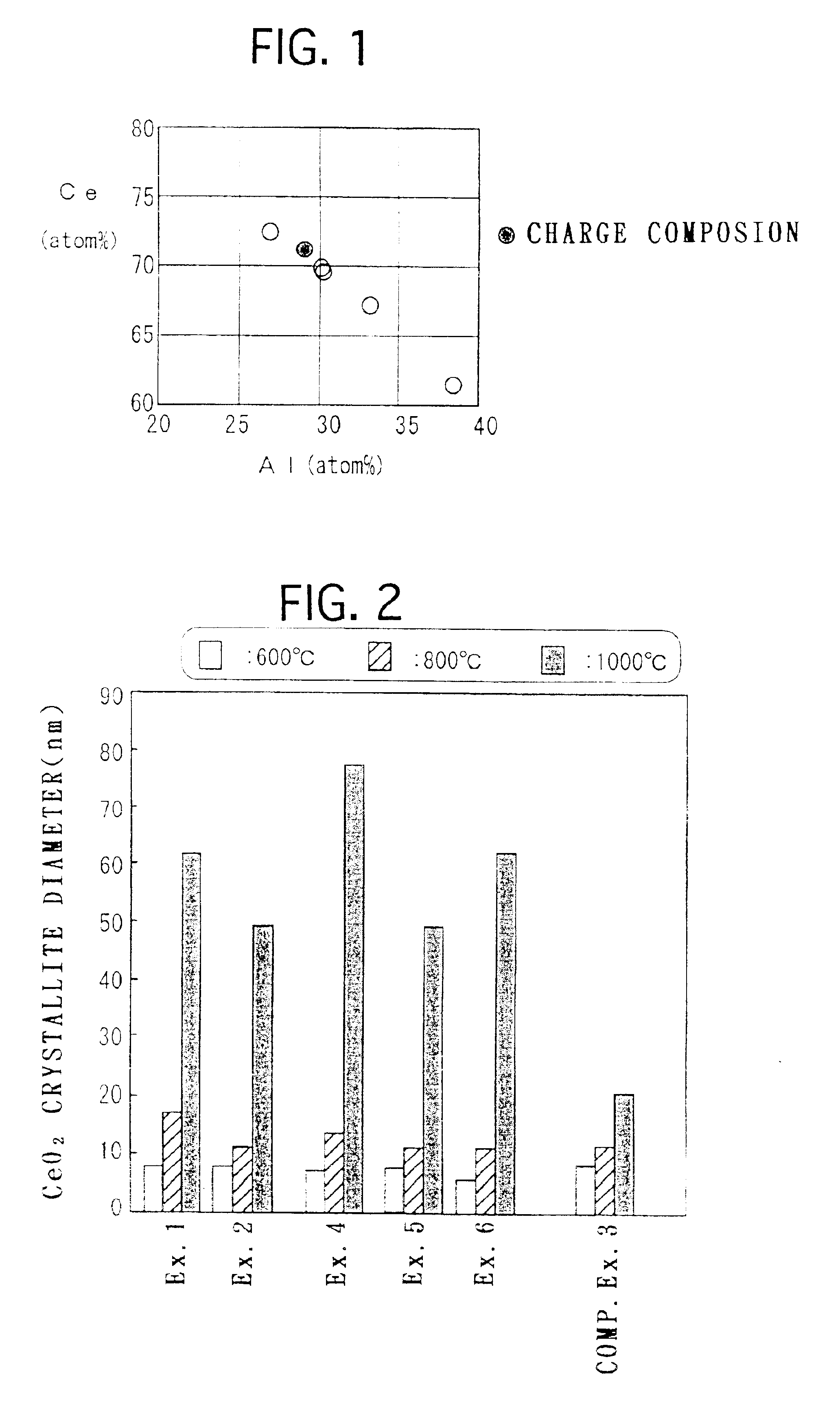

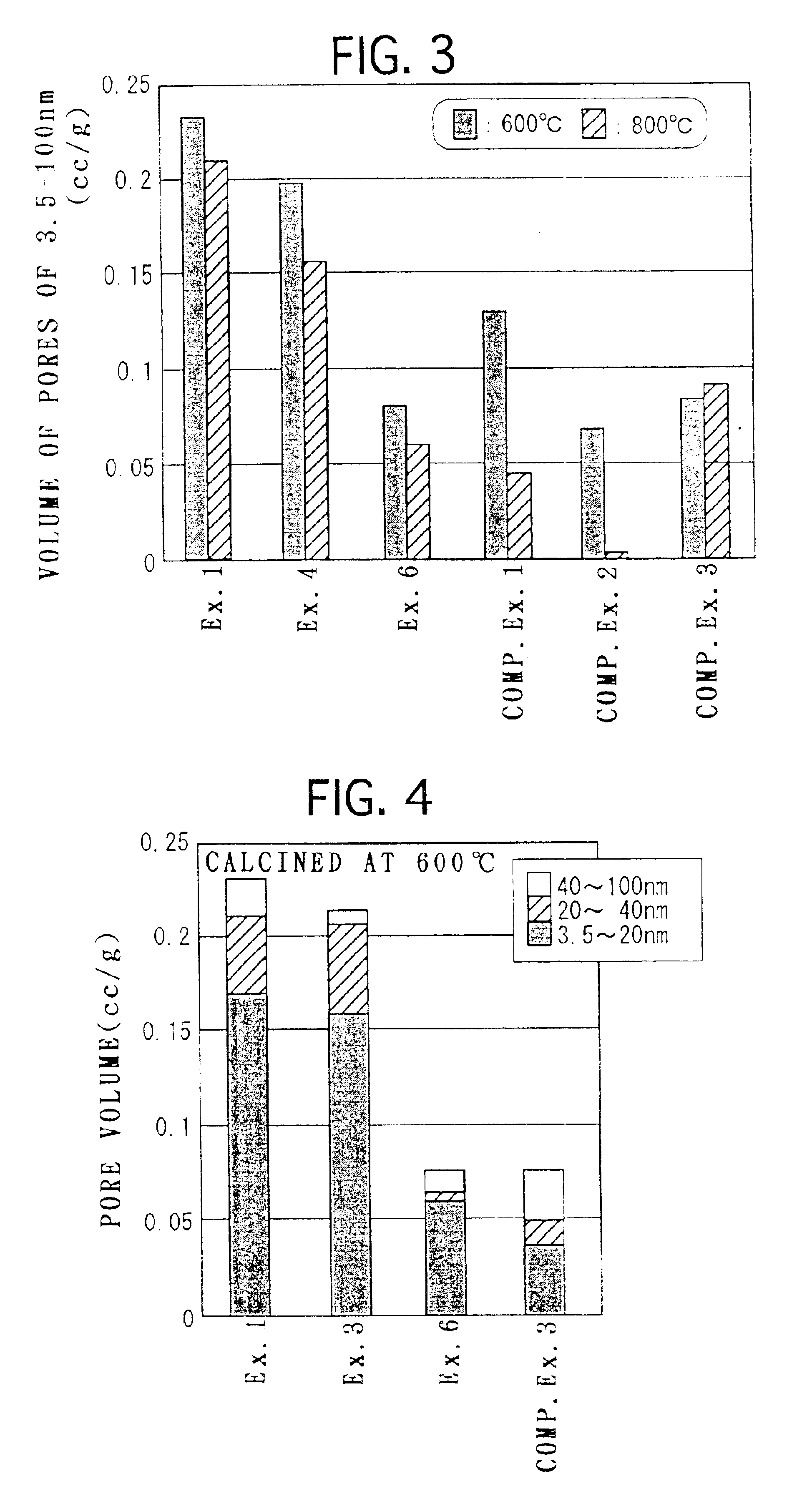

Composite oxide powder, a method for producing the same and a catalyst using the same

InactiveUS6933259B2Large pore volumeHigh catalytic activityInternal combustion piston enginesTitanium compoundsCrystalliteComposite oxide

This composite oxide powder can secure a large pore volume even after calcination at high temperature and, when a catalyst is formed by loading a noble metal on this composite oxide powder, noble metal grain growth can be suppressed. The composite oxide powder comprises particles of an oxide of a metal M1 and an oxide of a metal M2 which does not dissolve in the oxide of the metal M1, the oxide of the metal M1 and the oxide of the metal M2 being dispersed at the nanometer level. Since different oxides serve as a barrier to each other, sintering is suppressed. Therefore, in the case of composite oxide powder comprising Ce as a metal M1 and Al as a metal M2, grain growth is small even after exposed to high temperature and pores of 3.5-100 nm secure a volume of 0.07 cc / g or more after calcination at 600° C. for 5 hours and a volume of 0.04 cc / g or more after calcination at 800° C. for 5 hours.

Owner:TOYOTA CENT RES & DEV LAB INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com