Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Γ alumina" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

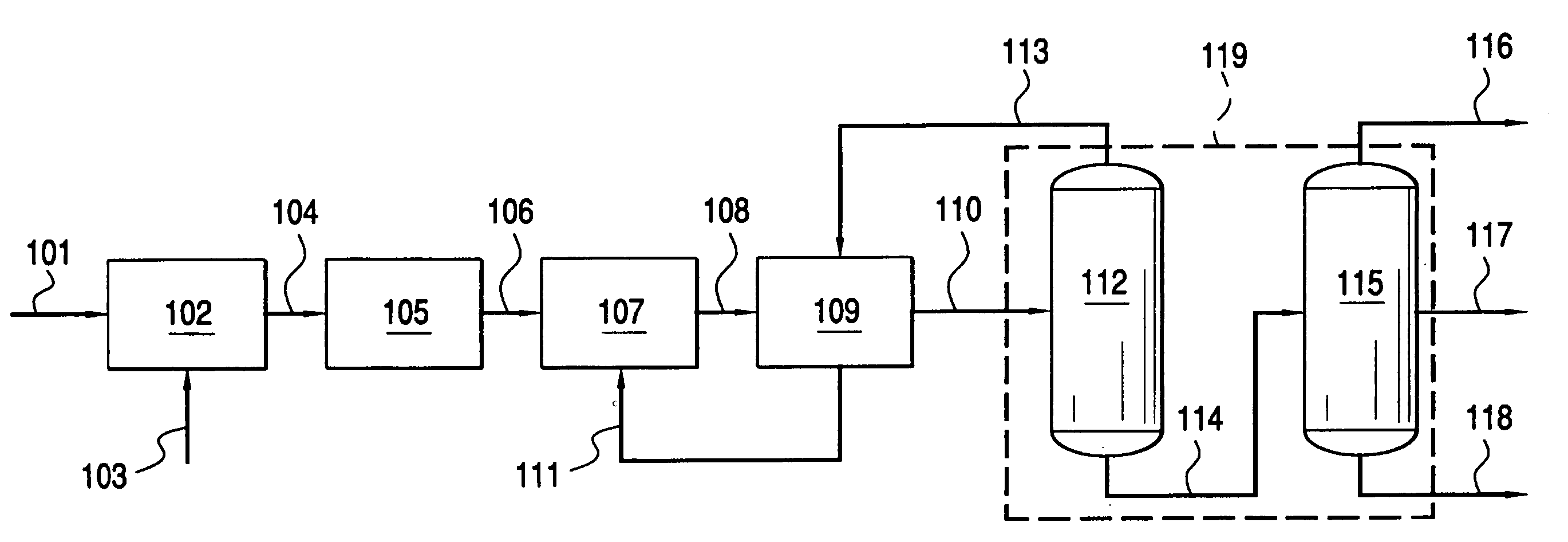

Processes for converting oxygenates to olefins at reduced volumetric flow rates

InactiveUS20060020155A1Reduction in effluent volumetric flow rateMolecular sieve catalystCatalystsSyngasMolecular sieve

This invention provides processes for forming light olefins from methanol and / or from syngas through a dimethyl ether intermediate. Specifically, the invention is to converting methanol and / or syngas to dimethyl ether and water in the presence of a first catalyst, preferably comprising γ-alumina, and converting the dimethyl ether to light olefins and water in the presence of a second catalyst, preferably a molecular sieve catalyst composition.

Owner:EXXONMOBIL CHEM PAT INC

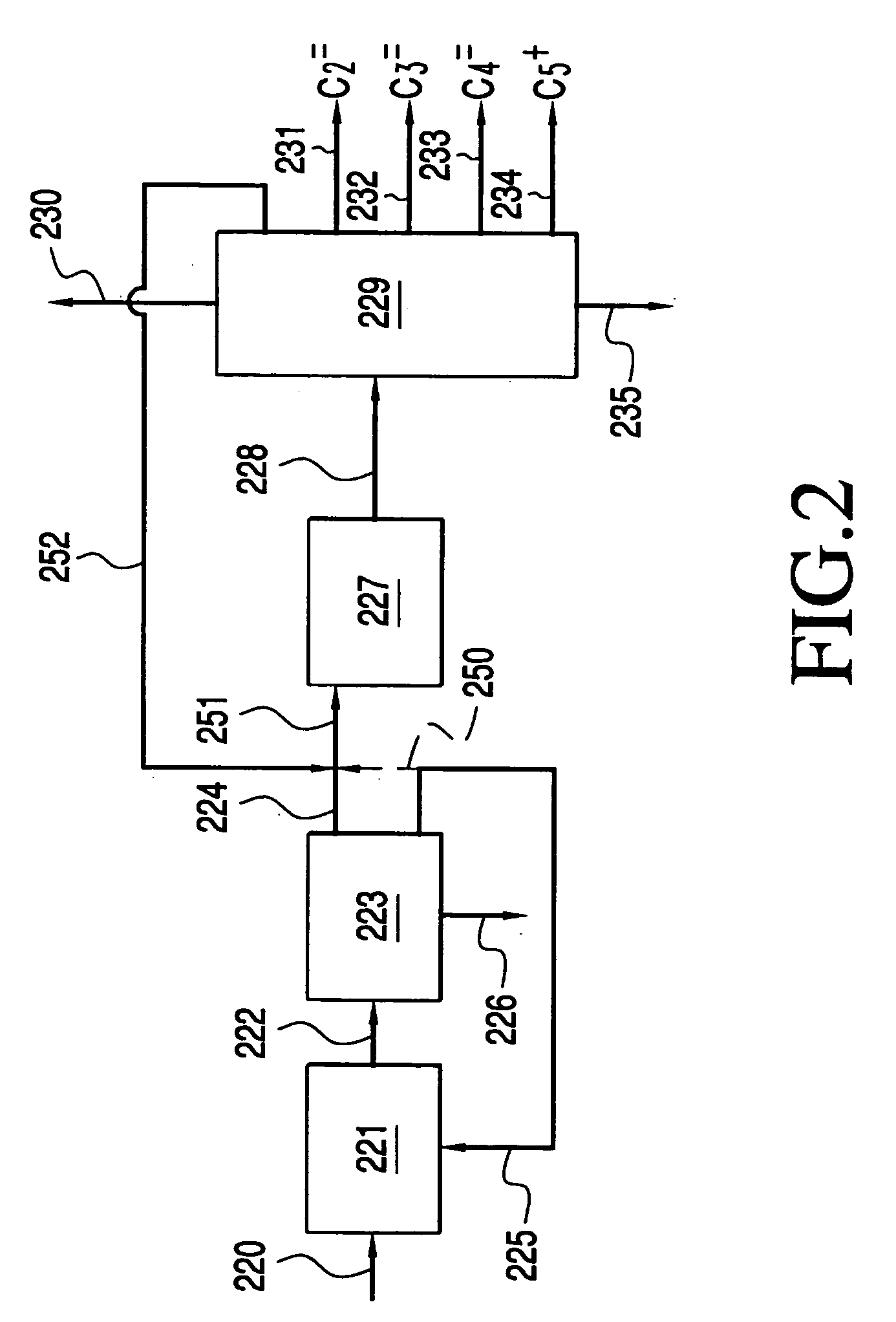

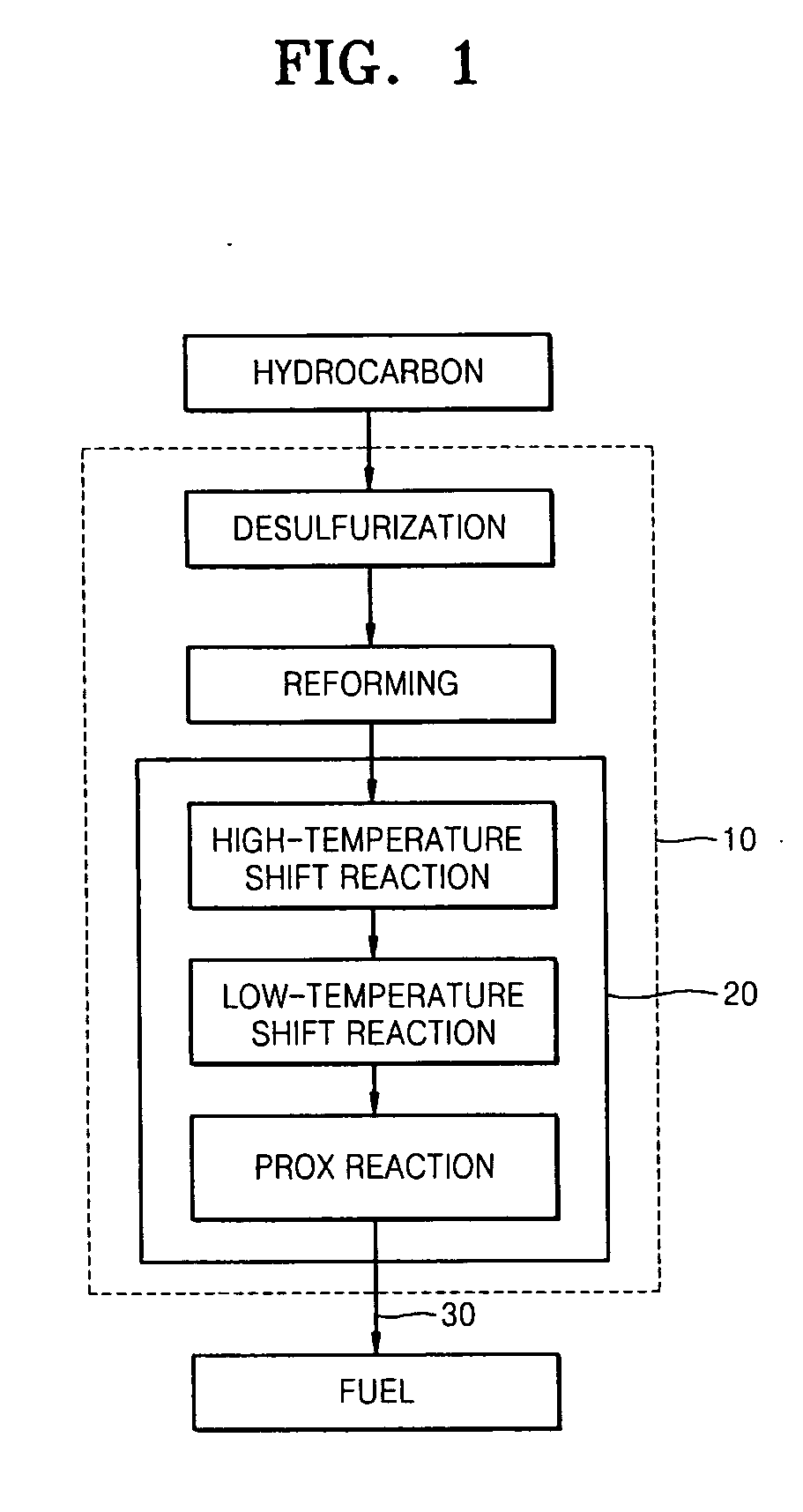

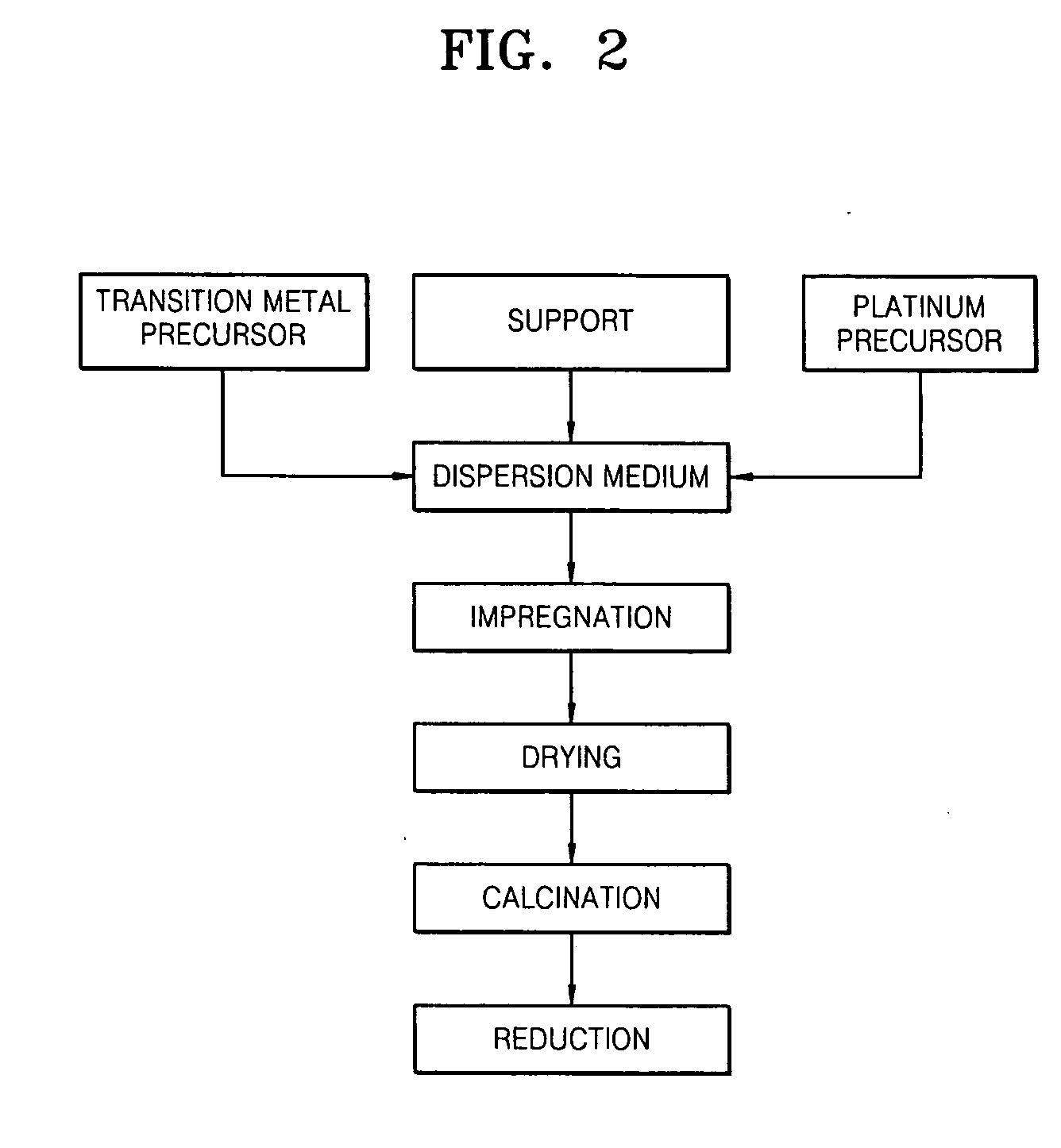

Catalyst for oxidizing carbon monoxide and method of manufacturing the same

InactiveUS20070092768A1Good reaction selectivityWide temperature rangeHydrogenOrganic-compounds/hydrides/coordination-complexes catalystsPlatinumMethanation

A catalyst that oxidizes carbon monoxide includes a bimetal consisting of platinum and a transition metal in a bimetallic phase that is loaded on γ-alumina support. The catalyst is manufactured by uniformly mixing a platinum precursor, a transition metal precursor, and γ-alumina (γ-Al2O3) in a dispersion medium to provide a mixture; drying the mixture; calcining the dried mixture; and reducing the calcined dried mixture. Since the catalyst that oxidizes carbon monoxide has high reaction activity even at low temperature and excellent reaction selectivity, and a methanation reaction and reoxidization do not occur, and the catalyst can effectively eliminate carbon monoxide in the fuel.

Owner:SAMSUNG SDI CO LTD

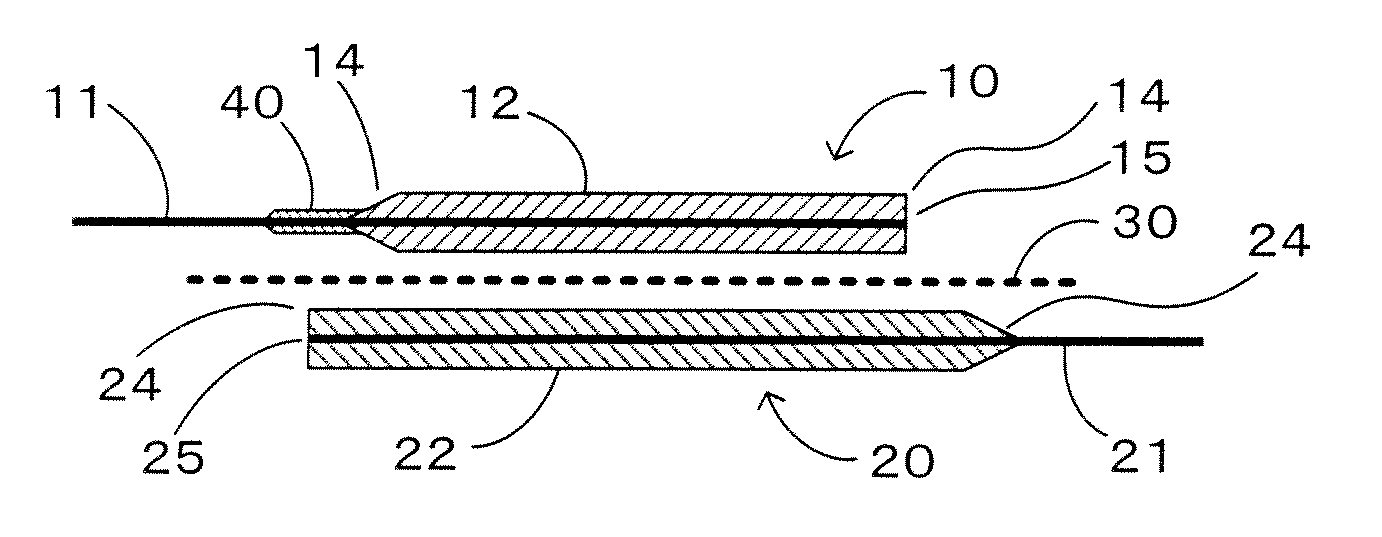

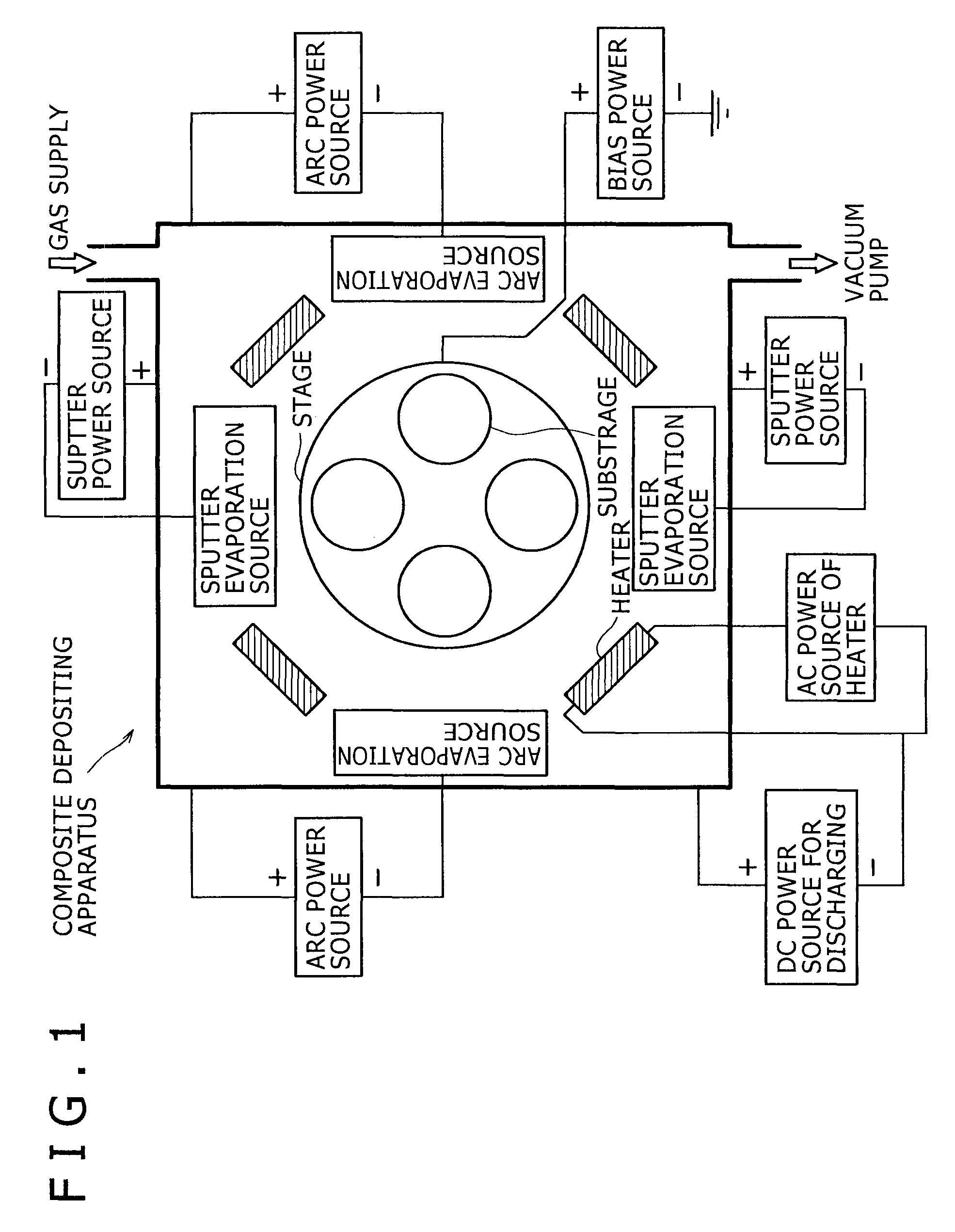

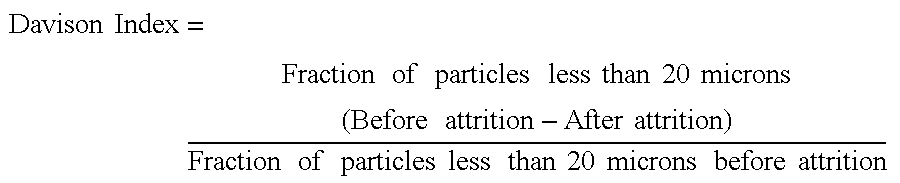

Battery

ActiveUS20120058375A1High bonding strengthTrend downMaterial nanotechnologyElectrode manufacturing processesEngineeringBond strength

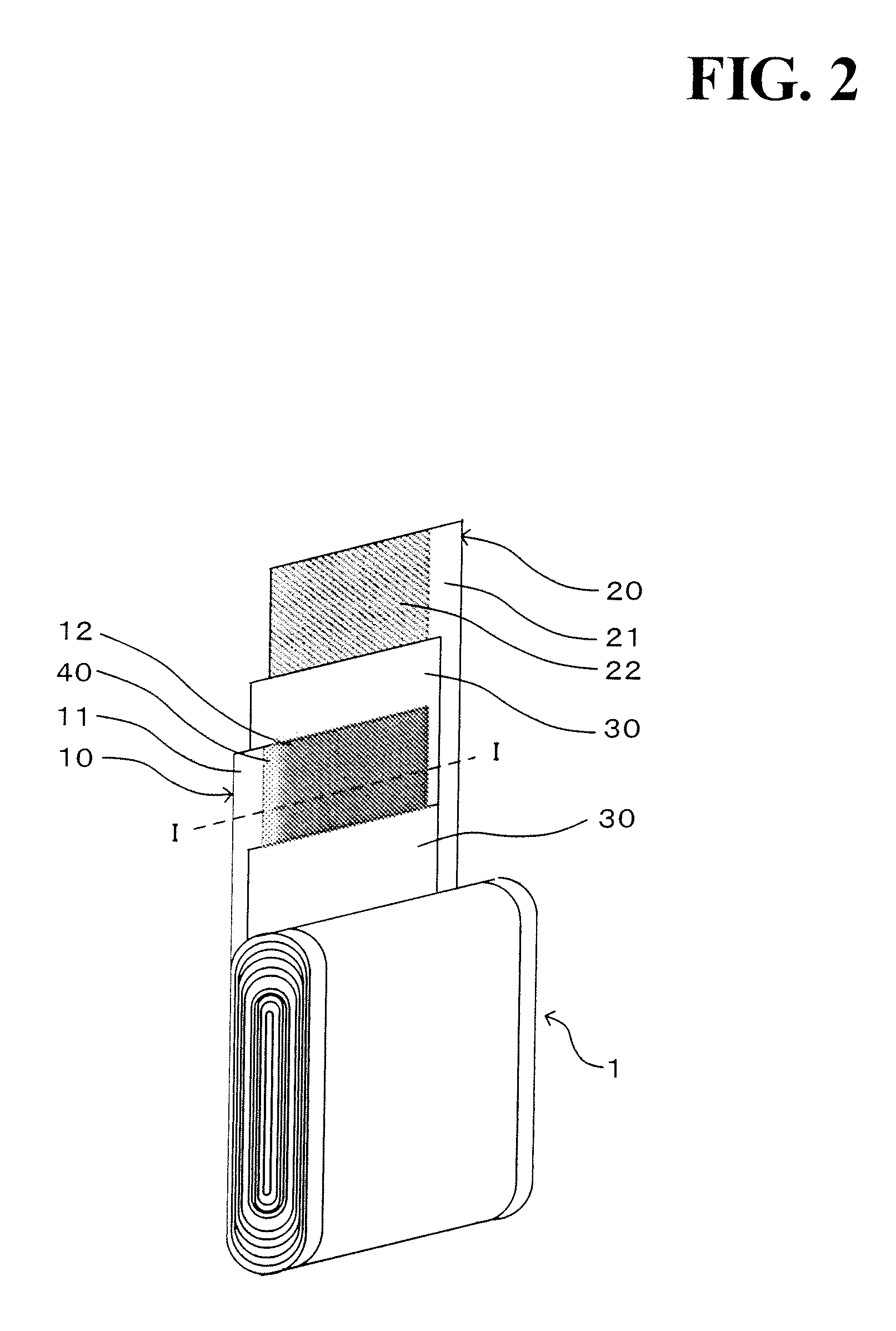

Provided is a battery which has less tendency to experience delamination or loss of short circuit prevention layer and / or active material layer during manufacture and use.A battery comprising a laminated electrode assembly in which a positive electrode, a negative electrode, and a separator are laminated together; wherein an alumina-containing layer containing γ-alumina particles is formed on at least one species selected from among the group consisting of the positive electrode, the negative electrode, and the separator. The fact that alumina-containing layer(s) is or are made to contain γ-alumina particles makes it possible to obtain high bond strength between alumina-containing layer(s) and electrode(s) comprising metal(s), current collector(s) and / or active material(s) making up electrode(s), and / or separator(s).

Owner:GS YUASA INT LTD

Cracking Catalyst and a Process for Preparing the Same

ActiveUS20080293561A1Increase lytic activityQuality improvementCatalytic crackingMolecular sieve catalystsMolecular sieveGasoline

A cracking catalyst, which contains alumina, phosphorus and molecular sieve, with or without clay, wherein said alumina is η-alumina or a mixture of η-alumina and χ-alumina and / or γ-alumina, and wherein the catalyst contains, on the basis of the total amount of the catalyst, 0.5-50 wt % of η-alumina, 0-50 wt % of χ-alumina and / or γ-alumina, 10-70 wt % of molecular sieve, 0-75 wt % of clay, and 0.1-8 wt % of phosphorus, measured as P2O5. The catalyst not only has higher cracking activity and higher cracking ability for cracking heavy oil, but also improves significantly quality and yield of gasoline, LCO and LPG in cracking products.

Owner:CHINA PETROCHEMICAL CORP +1

Method for preparing hydrogenation purification catalyst

InactiveUS6919294B2High mechanical strengthEasy to implementOther chemical processesManganese carbonylsPseudoboehmitePore diameter

A method for producing a hydrorefining catalyst is used to produce the hydrorefining catalyst which contains an inorganic oxide carrier and a hydrogenation-active metal and which has such a bimodal pore characteristic that pores having pore diameters of not more than 50 nm have a pore volume of not less than 0.4 cm3 / g, pores having pore diameters of not less than 50 nm have a pore volume of not less than 0.2 cm3 / g, and pores having pore diameters of not less than 1000 nm have a pore volume of not more than 0.1 cm3 / g. The method comprises the steps of mixing and forming a pseudo-boehmite powder having a dispersibility index of 0.13 to 0.28, and calcinating the formed pseudo-boehmite under a condition in which the pseudo-boehmite is converted into γ-alumina. The hydrorefining catalyst, which has the bimodal pore characteristic, can be produced easily at low cost.

Owner:JAPAN ENERGY CORP

Hydrodesulfurization catalyst for hydrocarbon oil, process of producing same and method for hydrorefining

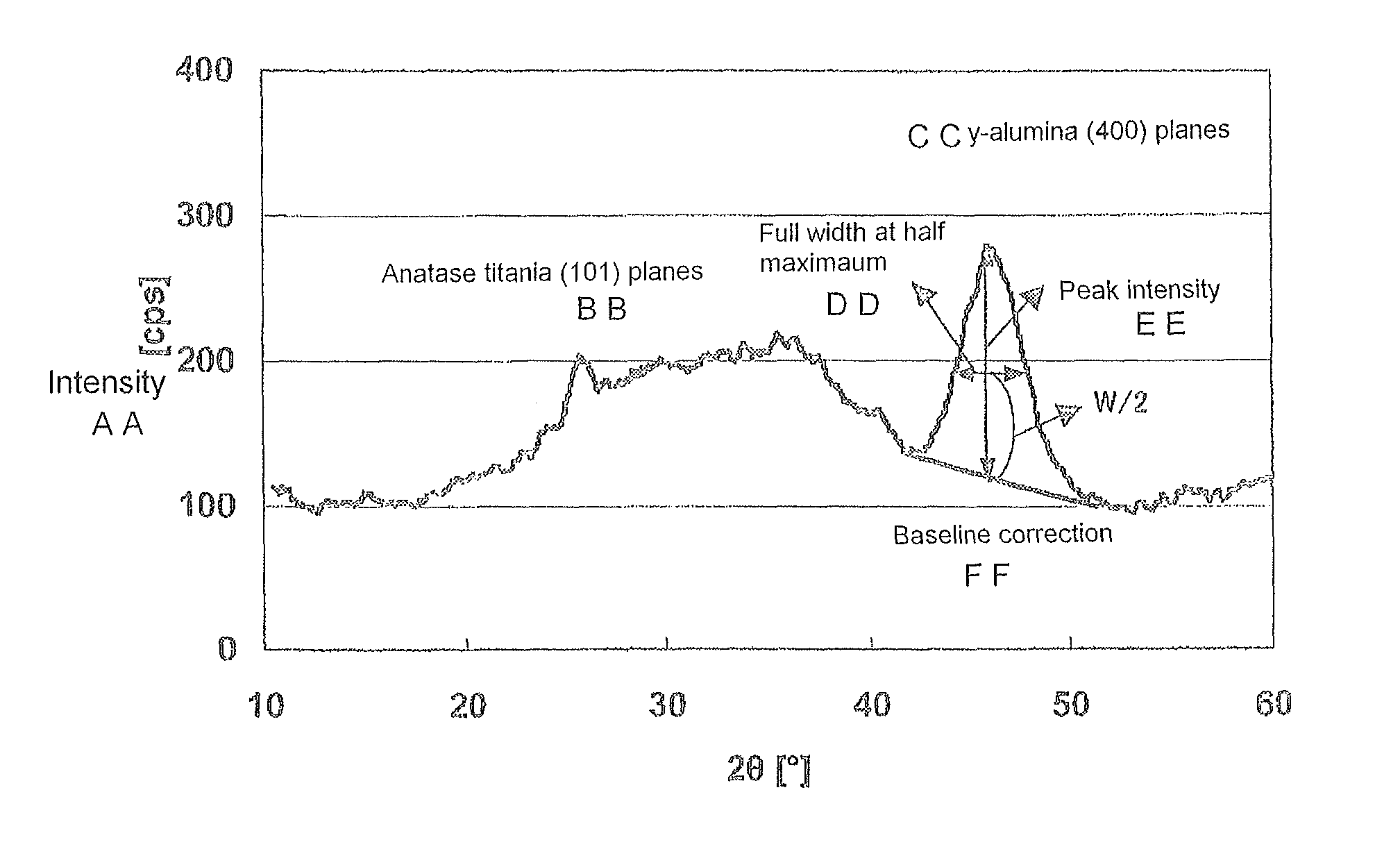

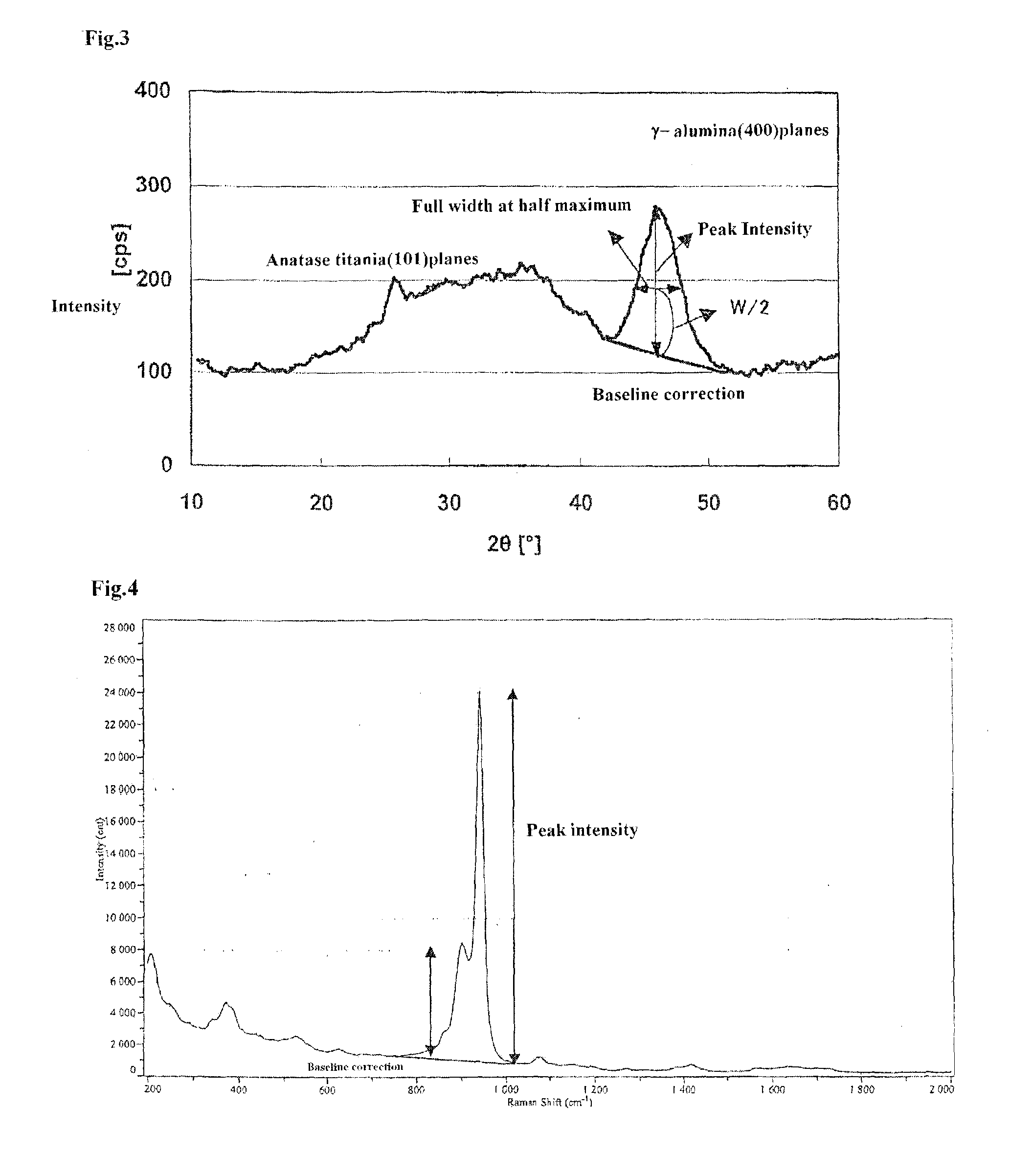

ActiveUS20120181219A1High desulfurization activityInexpensiveCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationX-ray

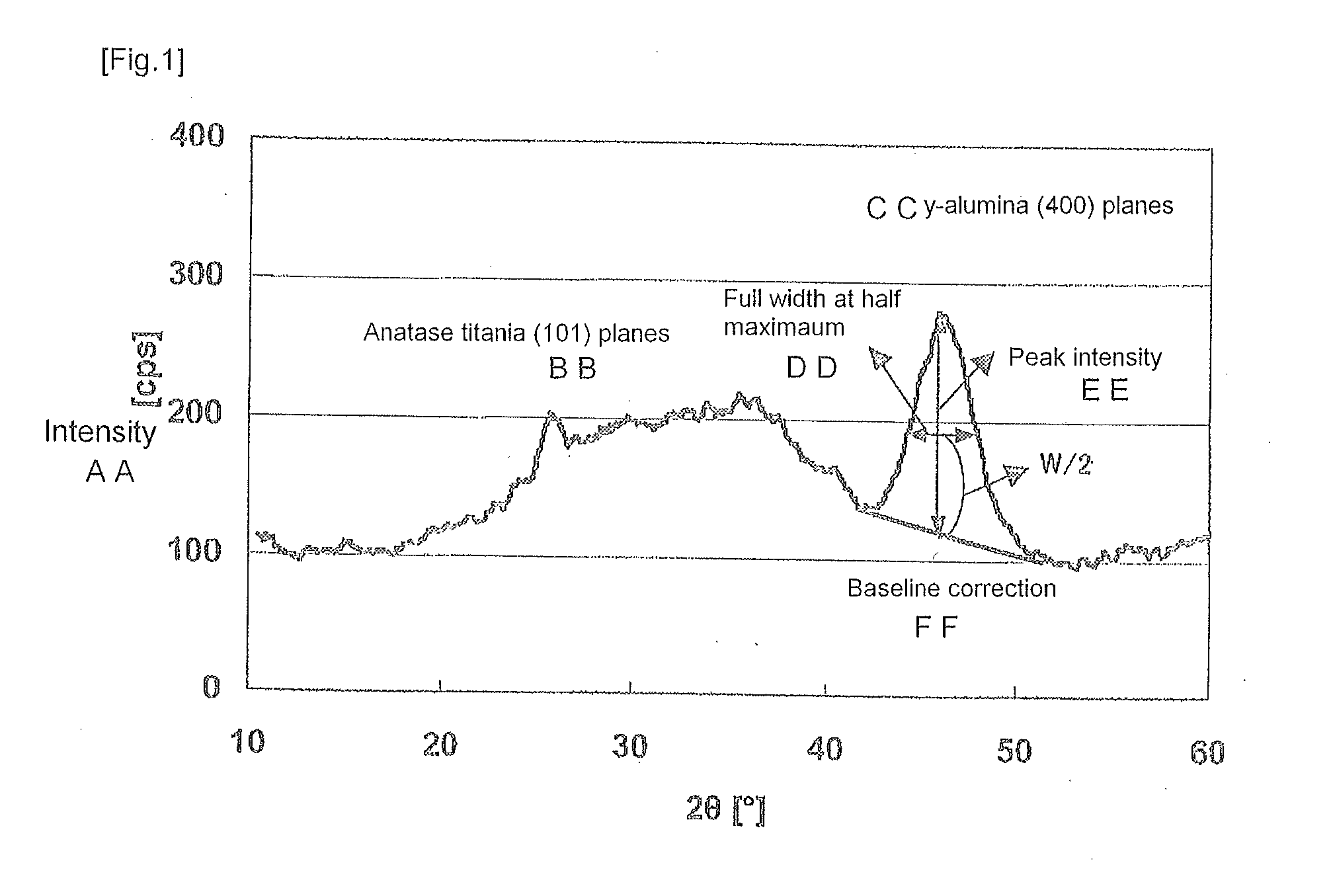

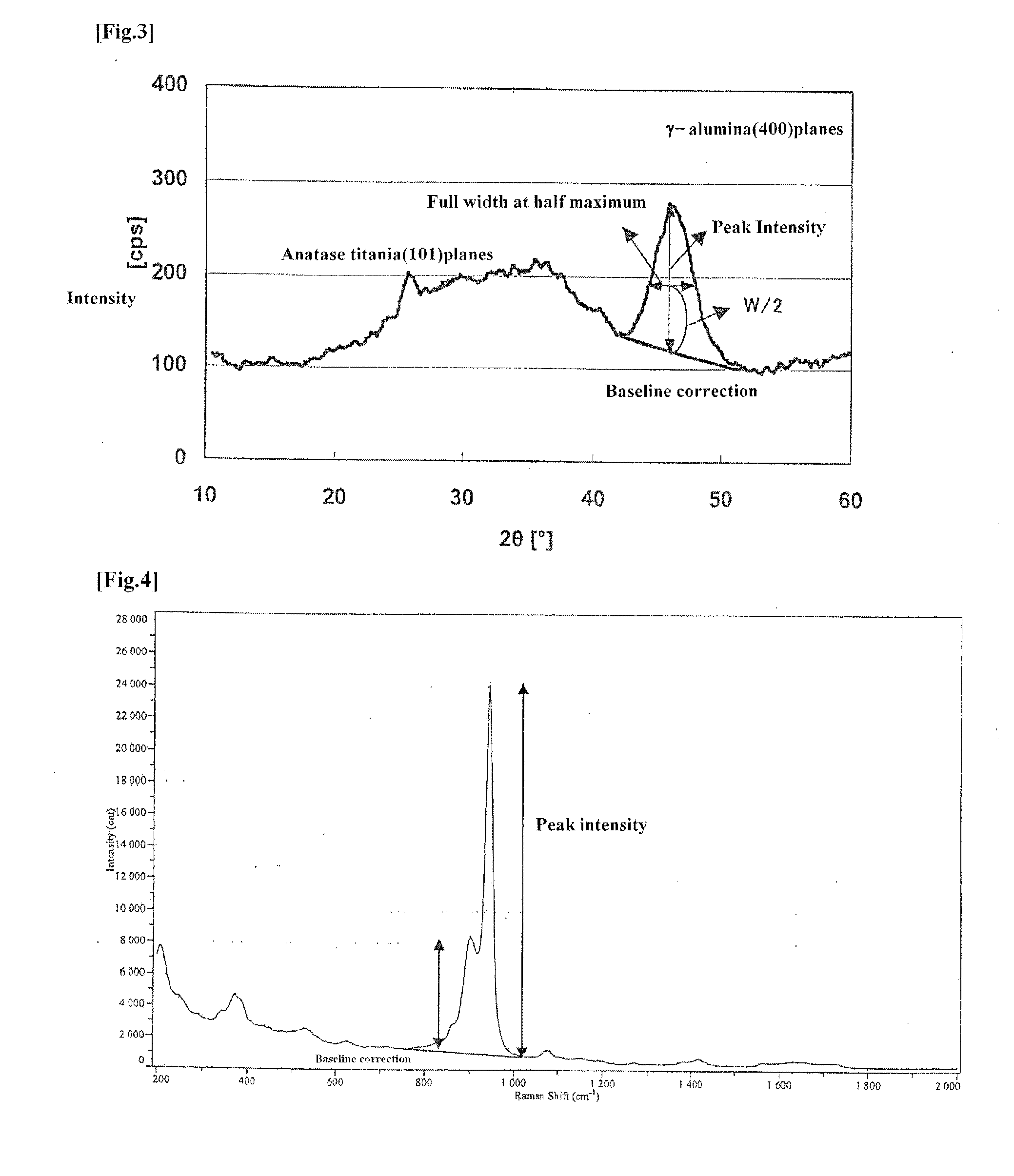

The present invention provides a hydrodesulfurization catalyst that exhibits a high desulfurization activity when used in hydrotreatment of hydrocarbon oil, in particular straight-run gas oil. The catalyst includes at least one type of metal component selected from Groups VIA and VIII in the periodic table, supported on a silica-titania-alumina support where the total of the diffraction peak area indicating the crystal structure of anatase titania (101) planes and the diffraction peak area indicating the crystal structure of rutile titania (110) planes is ¼ or less of the diffraction peak area indicating the aluminum crystal structure ascribed to γ-alumina (400) planes, as measured by X-ray diffraction analysis. The catalyst has (a) a specific surface area (SA) of 150 m2 / g or greater, (b) a total pore volume (PVo) of 0.30 ml / g or greater, (c) an average pore diameter (PD) of 6 to 15 nm (60 to 150 Å), and (d) the ratio of the pore volume (PVp) of pores having diameters within ±30 percent of the average pore diameter (PD) being 70 percent or greater of the total pore volume (PVo).

Owner:JX NIPPON OIL & ENERGY CORP +1

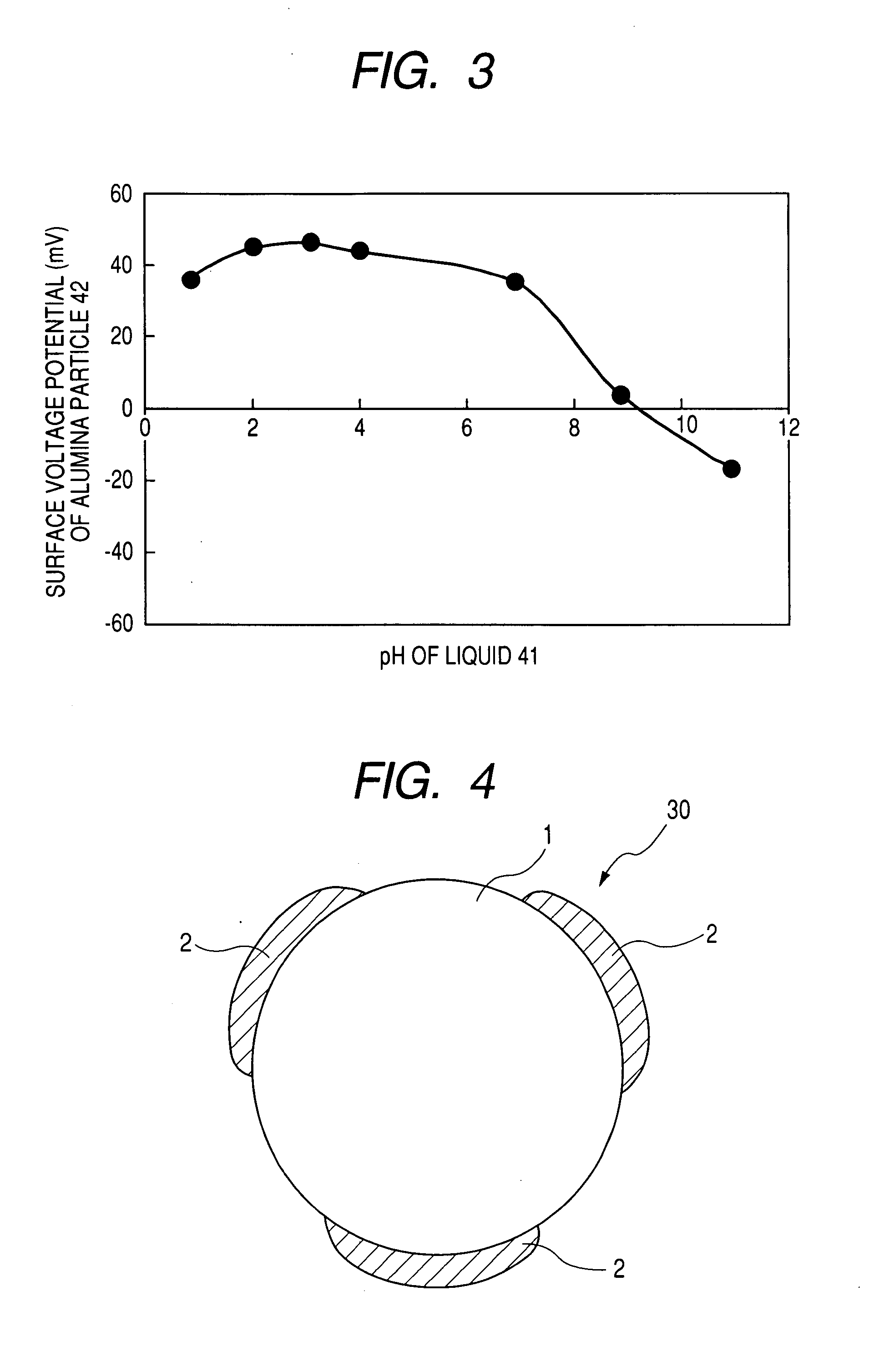

Chemical-mechanical polishing composition and method for using the same

InactiveUS20050211950A1Other chemical processesDecorative surface effectsTitanium nitrideNuclear chemistry

The invention provides a chemical-mechanical polishing composition comprising: (a) an abrasive comprising α-alumina, (b) about 0.05 to about 50 mmol / kg of ions of at least one metal selected from the group consisting of calcium, strontium, barium, and mixtures thereof, based on the total weight of the polishing composition, and (c) a liquid carrier comprising water. The invention also provides a chemical-mechanical polishing composition comprising: (a) an abrasive selected from the group consisting of α-alumina, γ-alumina, δ-alumina, θ-alumina, diamond, boron carbide, silicon carbide, tungsten carbide, titanium nitride, and mixtures thereof, (b) about 0.05 to about 3.5 mmol / kg of ions of at least one metal selected from the group consisting of calcium, strontium, barium, magnesium, zinc, and mixtures thereof, based on the total weight of the polishing composition, and (c) a liquid carrier comprising water. The invention further provides methods of polishing a substrate using each of the above-described chemical-mechanical polishing compositions.

Owner:CABOT MICROELECTRONICS CORP

Process for the preparation of phenol and cyclohexanone

InactiveUS20120157718A1EfficiencyGood choiceOxygen-containing compound preparationOrganic compound preparationCyclohexanoneCyclohexene

Process for the preparation of phenol and cyclohexanone which comprises:a. the synthesis of cyclohexylbenzene by the hydro-alkylation of benzene by contact with hydrogen or the alkylation of benzene with cyclohexene using Y zeolites;b. the selective aerobic oxidation of cyclohexylbenzene to the corresponding hydroperoxide catalyzed by N-hydroxy-derivatives in the presence of polar solvents; andc. the scission of the hydroperoxide of cyclohexylbenzene to phenol and cyclohexanone by homogeneous or heterogeneous acid catalysts;characterized in that the synthesis of cyclohexylbenzene takes place in the presence of a catalytic system comprising a Y zeolite and an inorganic ligand wherein the Y zeolite has a crystalline structure with openings consisting of 12 tetrahedra and the inorganic ligand is γ-alumina, and wherein said catalytic composition is characterized by a pore volume, obtained by adding the mesoporosity and macroporosity fractions, greater than or equal to 0.7 cm3 / g, wherein at least 30% of said volume consists of pores with a diameter greater than 100 nanometers.

Owner:POLIMERI EUROPA SPA

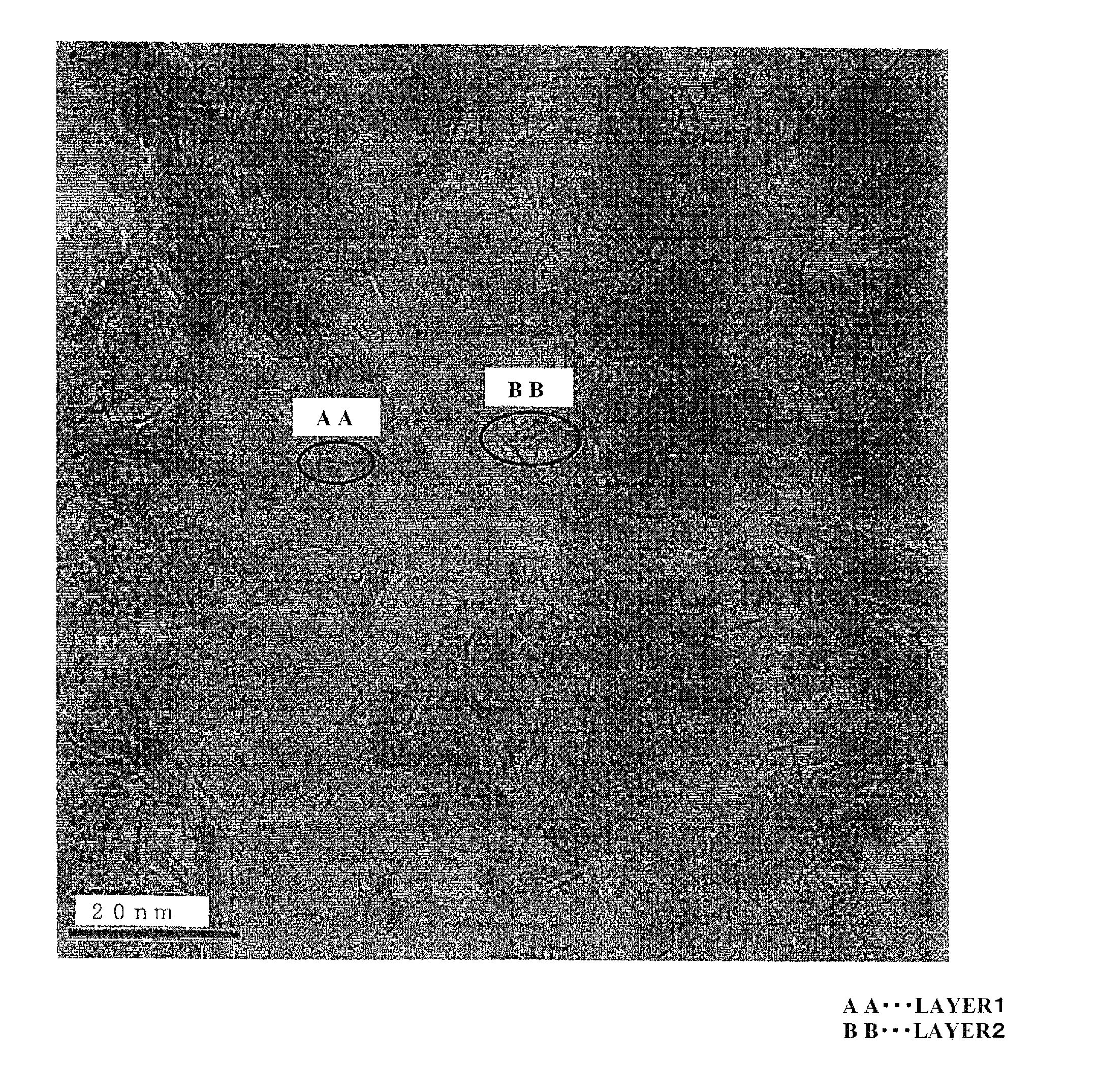

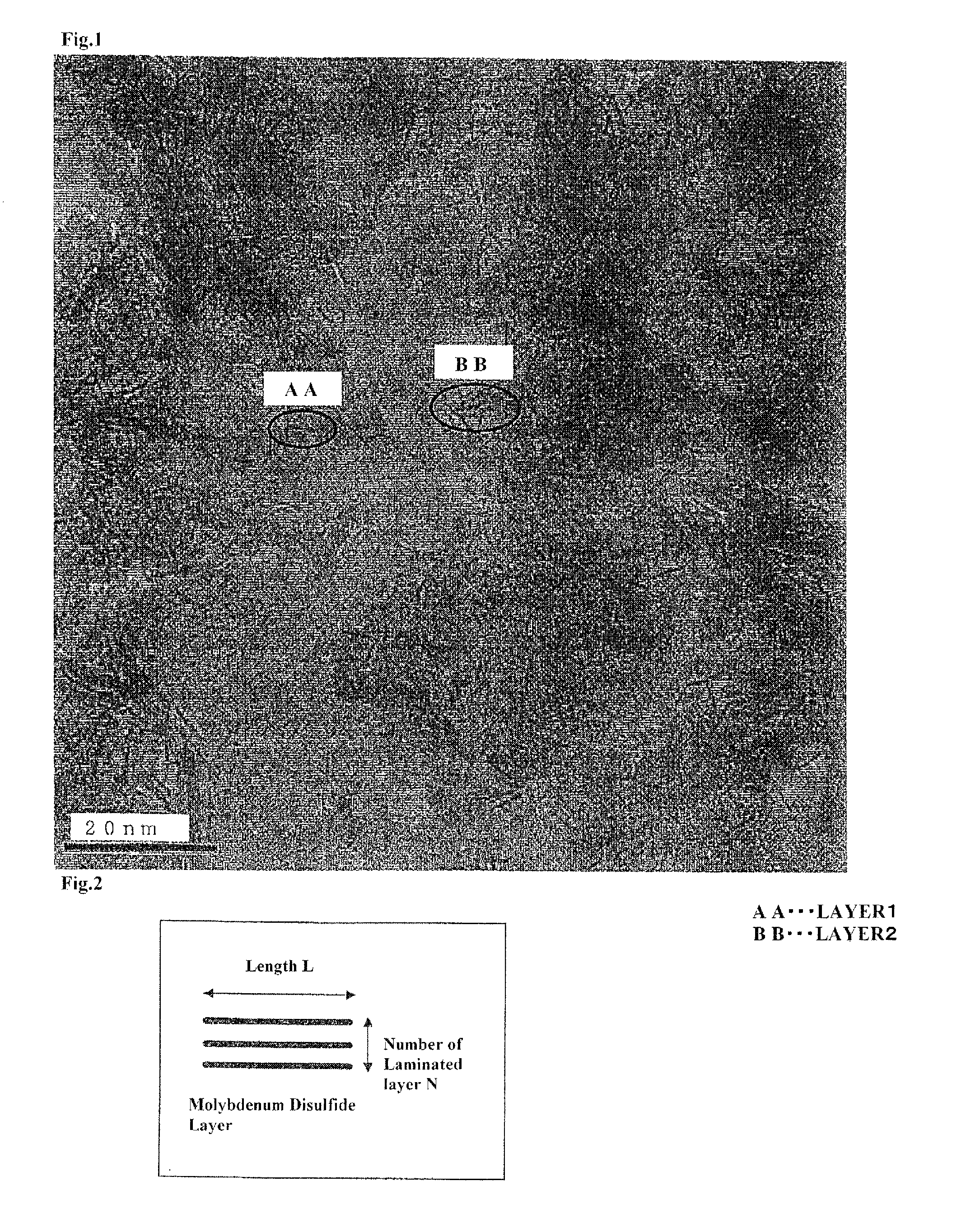

Hydrodesulfurization catalyst for hydrocarbon oil, process of producing same and method for hydrorefining

ActiveUS20130153467A1Improve desulfurizationImprove performanceCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationX-ray

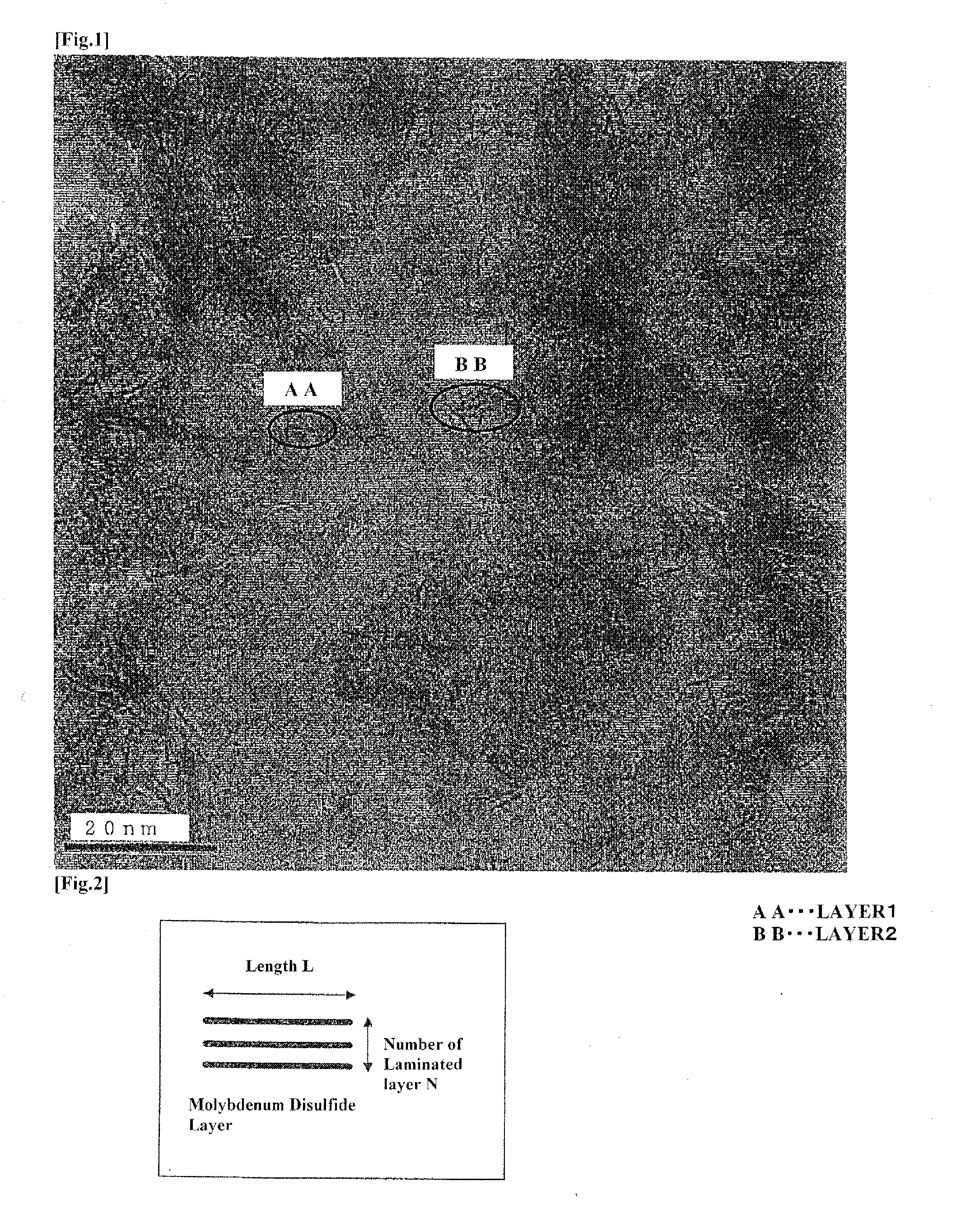

A hydrodesulfurization catalyst is produced by pre-sulfurizing a hydrodesulfurization catalyst Y including a support containing silica, alumina and titania and at least one metal component supported thereon and selected from VIA and VIII groups of the periodic table (comprising at least Mo), in which the total area of the diffraction peak area indicating the crystal structure of anatase titania (101) planes and the diffraction peak area indicating the crystal structure of rutile titania (110) planes in the support, measured by X-ray diffraction analysis being ¼ or less of the alumina diffraction peak area assigned to γ-alumina (400) planes. The molybdenum is formed into molybdenum disulfide crystal disposed in layers on the support by the pre-sulfurization, and having an average length of longer than 3.5 nm and 7 nm or shorter in the plane direction and an average number of laminated layers of more than 1.0 and 1.9 or fewer.

Owner:JX NIPPON OIL & ENERGY CORP +1

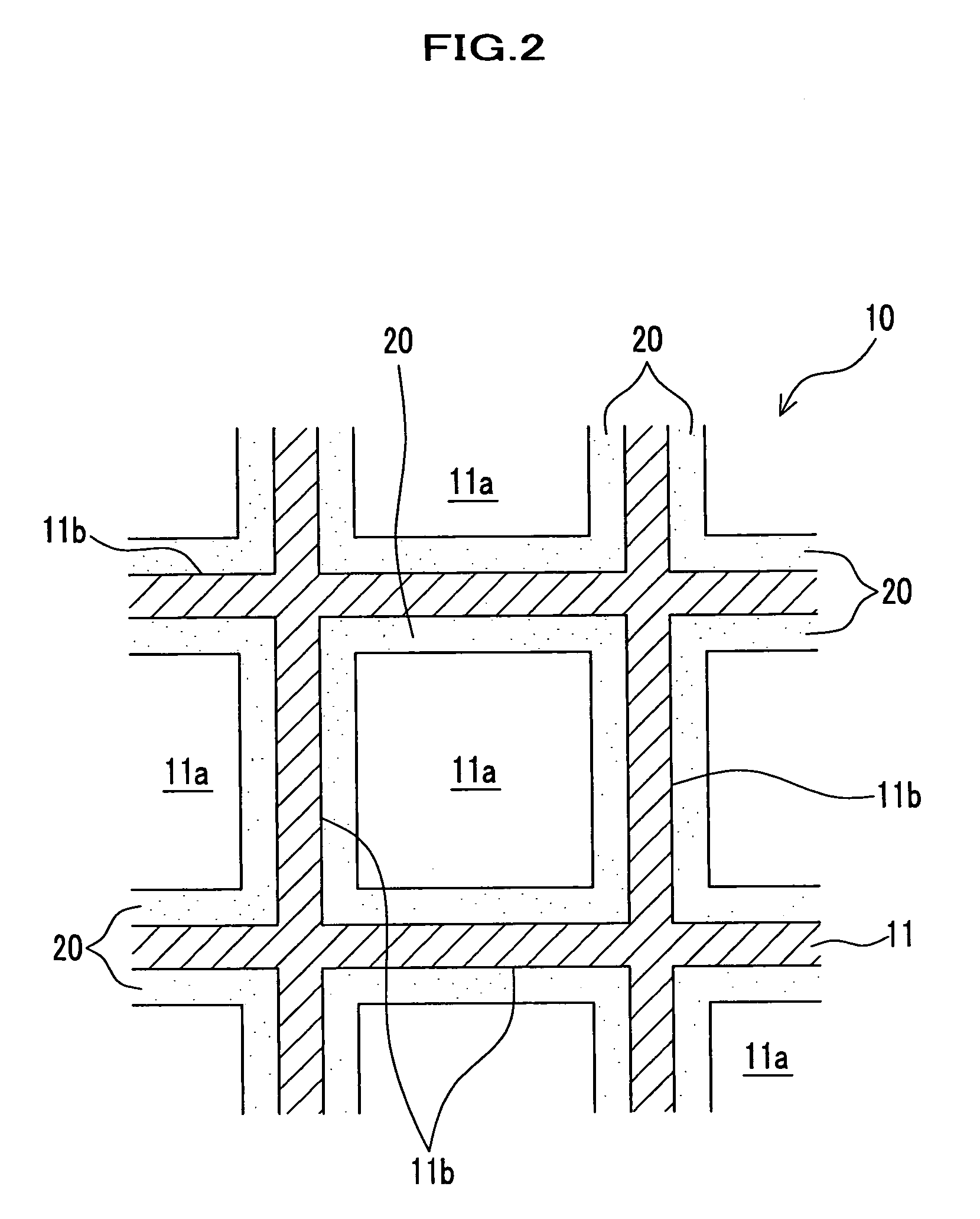

FORMED CATALYST FOR NOx REDUCTION

InactiveUS20100150801A1Reduce NOxNitrogen compoundsNoble gas compoundsCatalytic metalInorganic materials

The present invention provides a formed catalyst comprising a binder, a zeolite, and a catalytic metal disposed on a porous inorganic material. The zeolite domains in the formed catalyst are substantially free of the catalytic metal which is disposed on and or within the porous inorganic material. The formed catalyst is in various embodiments an extrudate, a pellet, or a foamed material. In one embodiment, the catalytic metal is silver and the porous inorganic material is γ-alumina. The formed catalysts provided are useful in the reduction of NOx in combustion gas streams.

Owner:GENERAL ELECTRIC CO

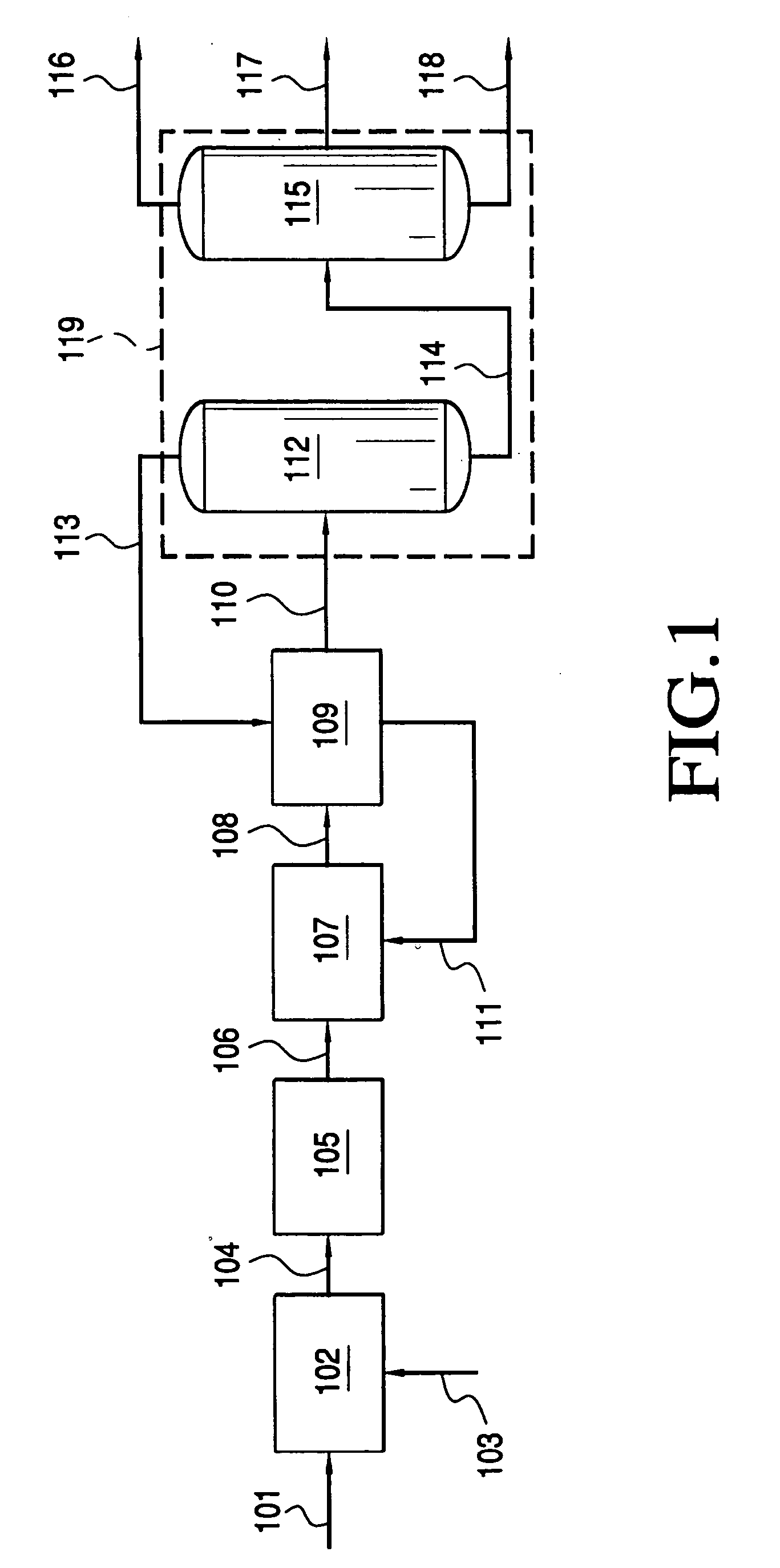

Process for preparing dimethyl ether from crude methanol in an adiabatic reactor

InactiveUS20090023958A1High yieldOrganic compound preparationEther preparation by compound dehydrationChemical industrySilicon dioxide

The present invention relates a process for preparing dimethyl ether from crude methanol in an adiabatic reactor(s) / and more particularly to a process for preparing dimethyl ether wherein crude methanol containing water is dehydrated by using (1) a catalytic system in which the reactant contacts a catalyst 1 of hydrophobic zeolite partially substituted by a specific metal cation and subsequently a catalyst 2 selected from γ-alumina or silica-alumina; and (2) an adiabatic reactor(s). In the present invention, the dehydration is accomplished effectively by avoiding the formation or byproducts and the deactivation of catalyst. Therefore, dimethyl ether useful as clean fuel and a raw material in chemical industry can be produced from crude methanol with an enhanced yield in an adiabatic reactor(s).

Owner:SK ENERGY CO LTD (KR)

Process for the hydrogenation of oxo aldehydes having high ester contents

InactiveUS7524997B2Low costHigh product yieldCatalyst protectionPreparation by oxo-reaction and reductionCobaltAldehyde formation

Owner:EVONIK DEGUSSA GMBH

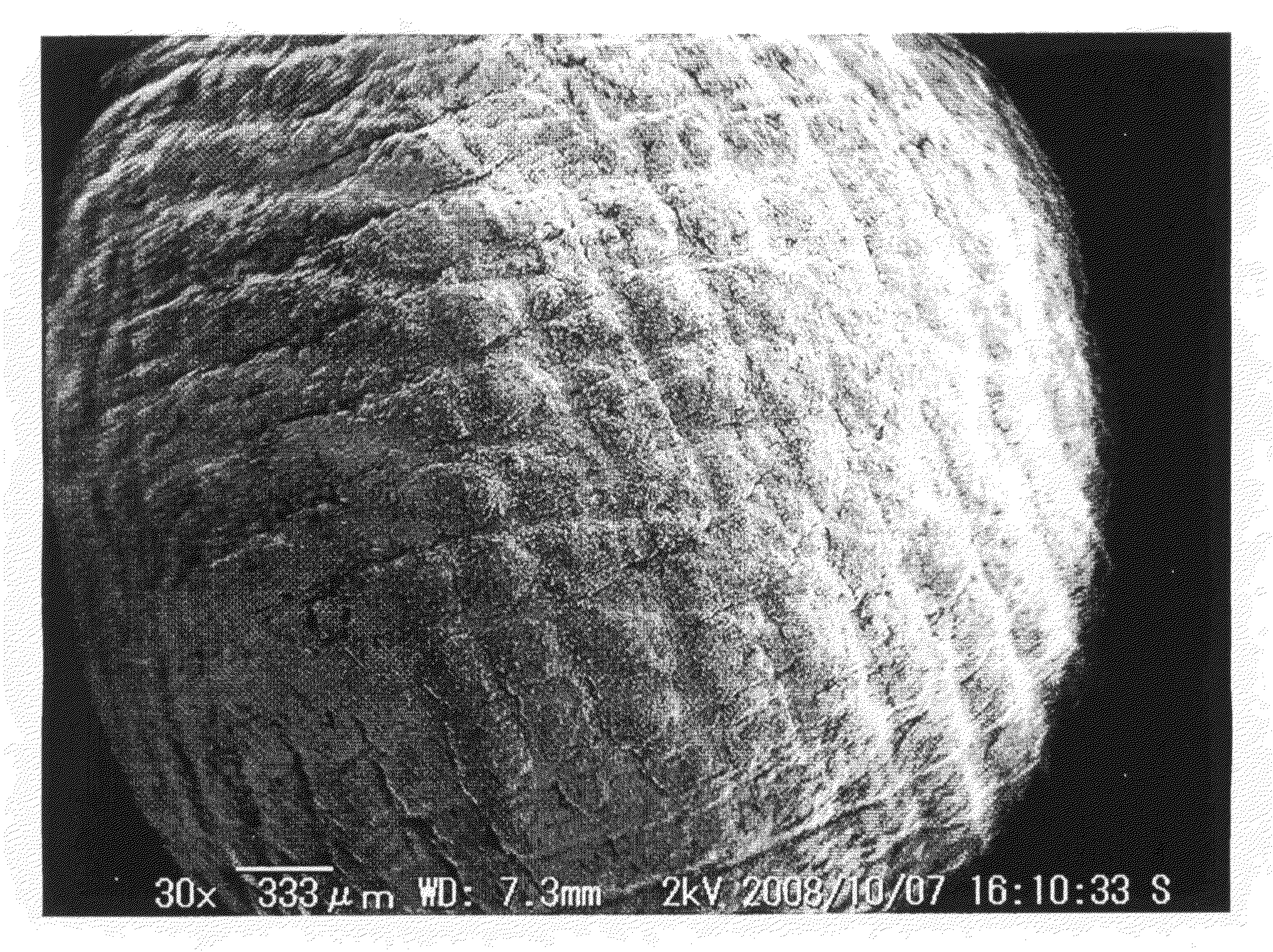

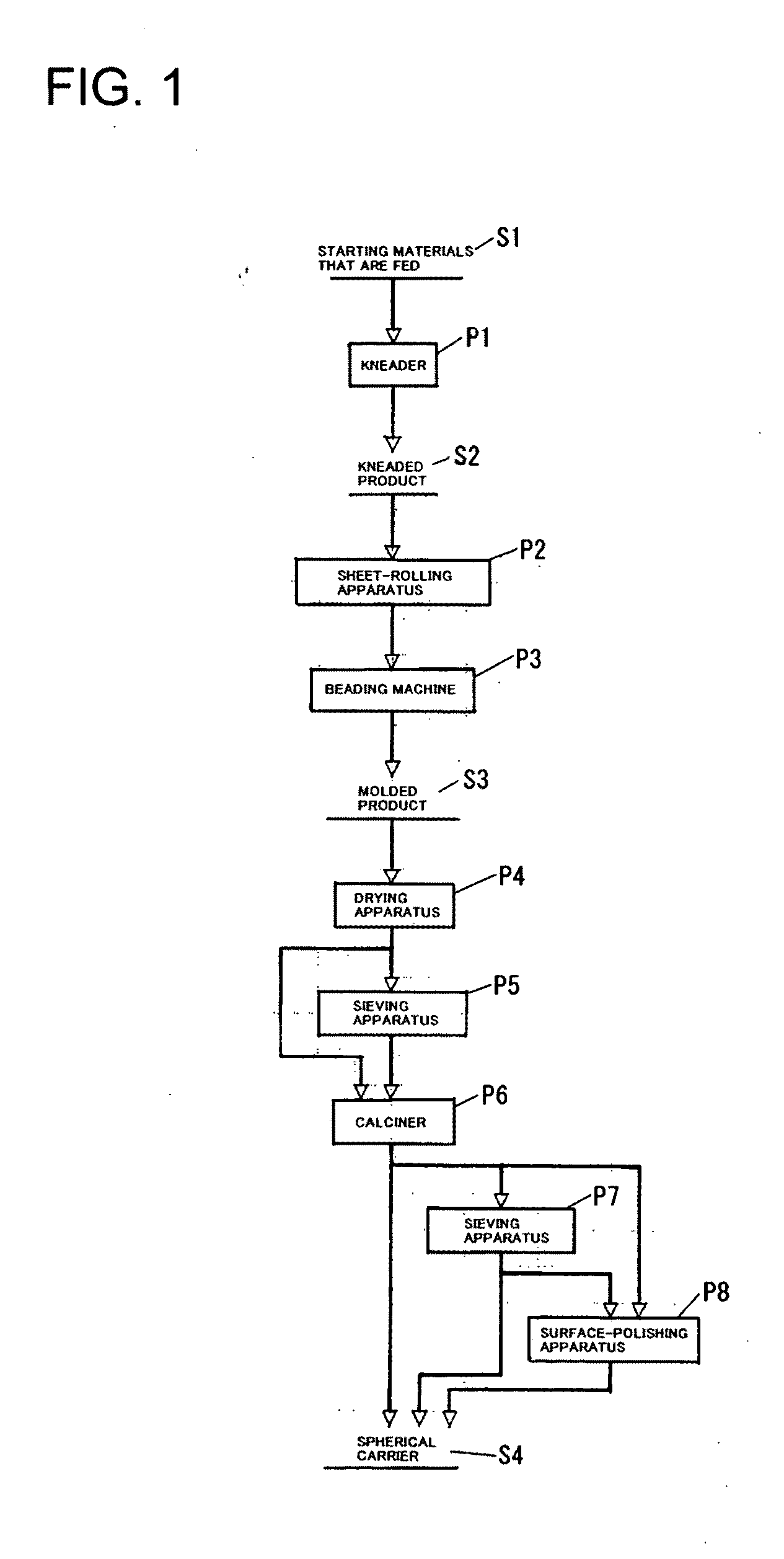

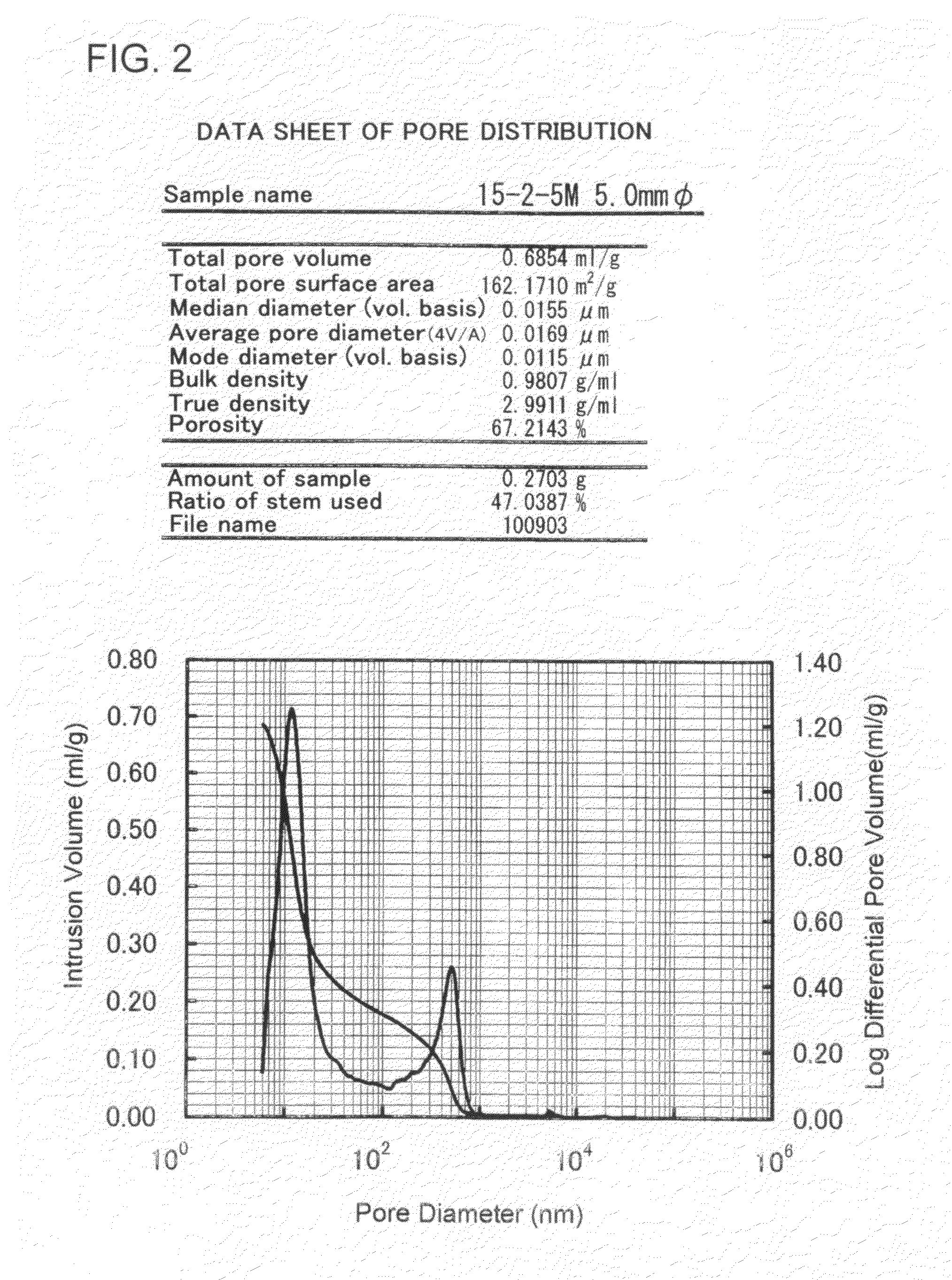

Carrier and method of producing the same

The method of producing a carrier of the invention includes a step of kneading the starting carrier components, solid binding agent, liquid binding agent and diluted nitric acid water. The starting carrier components comprise aluminum hydroxide, pseudoboehmite, γ-alumina, powdery silica gel, powdery natural silica and zeolite. The solid binding agent comprises a powder of α-starch (rice), α-starch (potato), α-starch (tapioca), funori (glue plant), crystalline cellulose and powdery cellulose. The liquid binding agent comprises colloidal alumina, colloidal silica and polyvinyl alcohol. As a de-firing agent, further, there are used wood powder, charcoal powder, rice flour, wheat flour, barley flour, buck wheat flour and corn. The carrier has a pore volume in a range of 0.52 to 0.84 cc / g and a side crushing strength in a range of 2.2 to 11.0 kgf / particle.

Owner:KUREHA YUSHI INDS +1

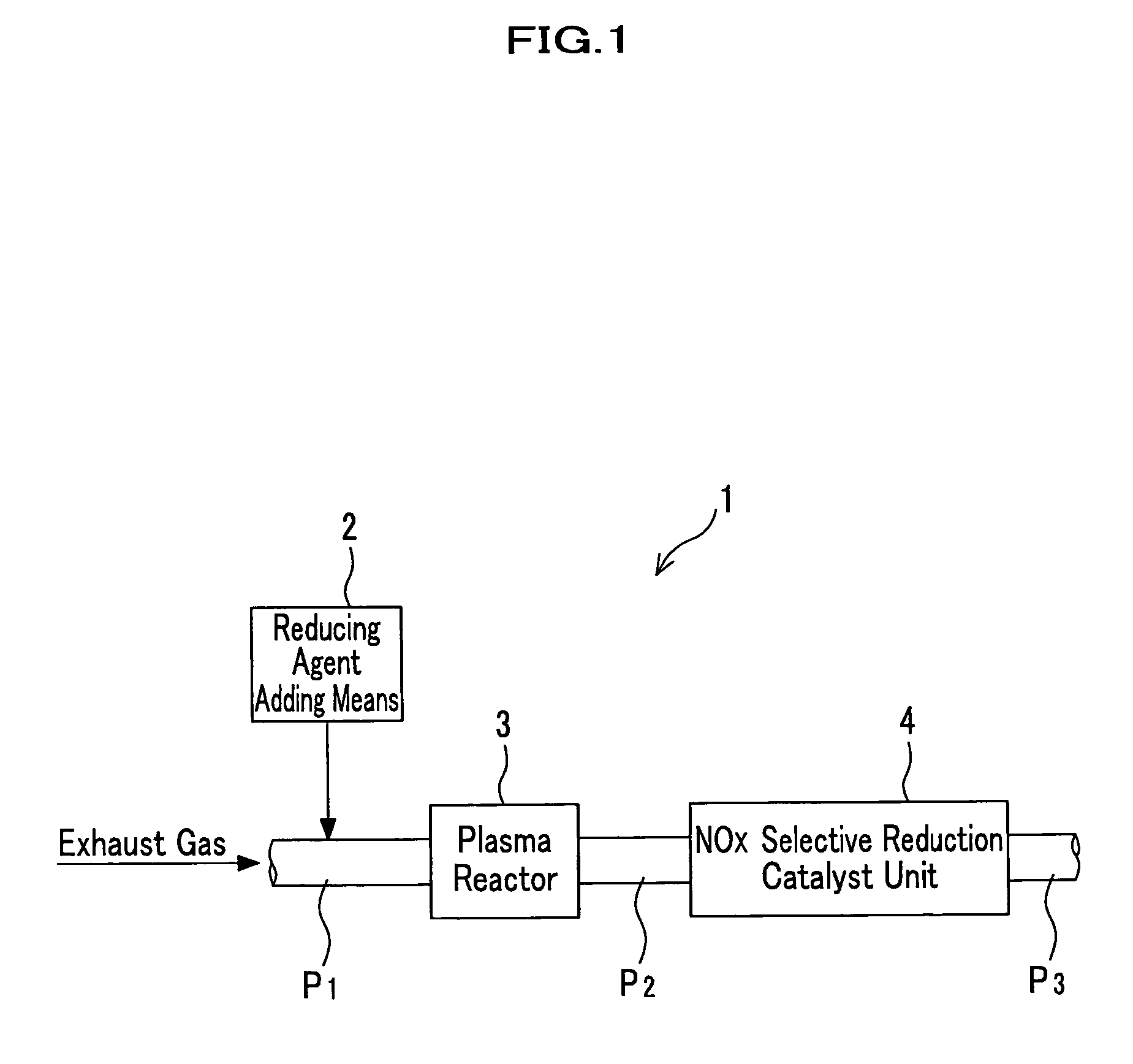

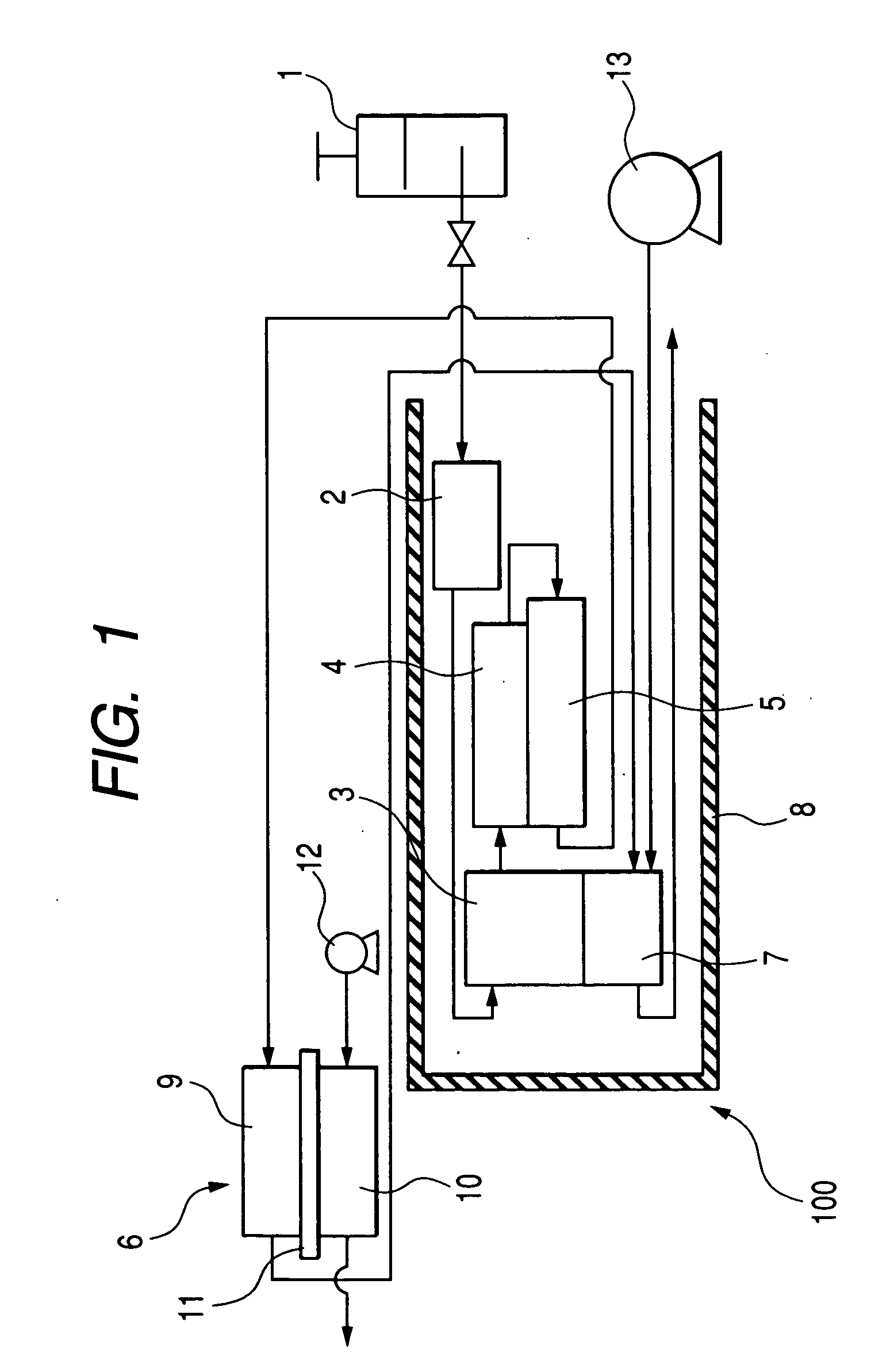

Exhaust gas purification system

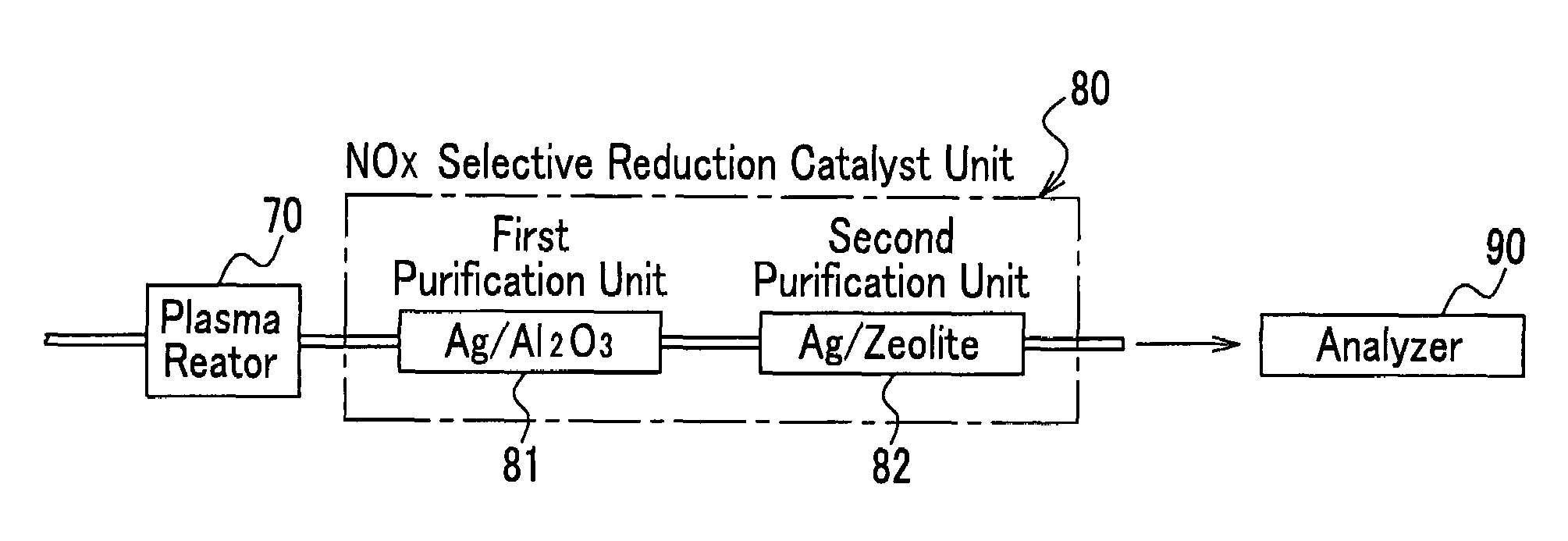

InactiveUS7374728B2Improve oxidation capacityShorten the purification processCombination devicesMolecular sieve catalystsExhaust fumesEnvironmental engineering

An exhaust gas purification system that is equipped, from an upstream side toward downstream side through which an exhaust gas flows, with a plasma reactor and a NOx selective reduction catalyst unit having a NOx selective reduction catalyst layer acting on the exhaust gas, and which system provides a reducing agent adding means adding a reducing agent to the exhaust gas at an upstream side of the plasma reactor, wherein the NOx selective reduction catalyst layer comprises nickel and a NOx selective reduction catalyst or wherein the NOx selective reduction catalyst layer contains γ-alumina that supports magnesium or wherein the NOx selective reduction catalyst unit comprises a first purification unit where an exhaust gas via the plasma reactor is introduced, and a second purification unit where an exhaust gas via the first purification unit is introduced.

Owner:HONDA MOTOR CO LTD

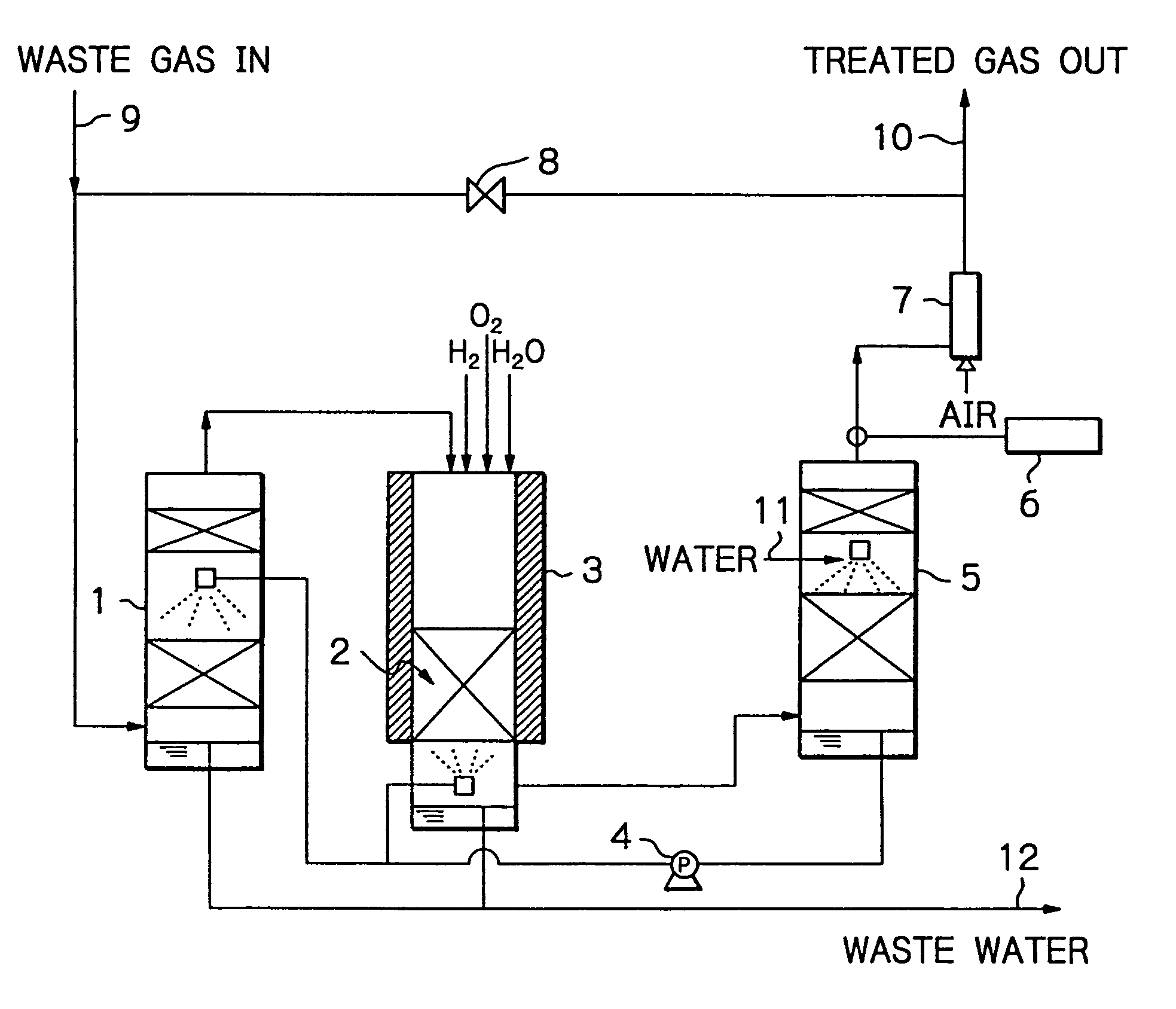

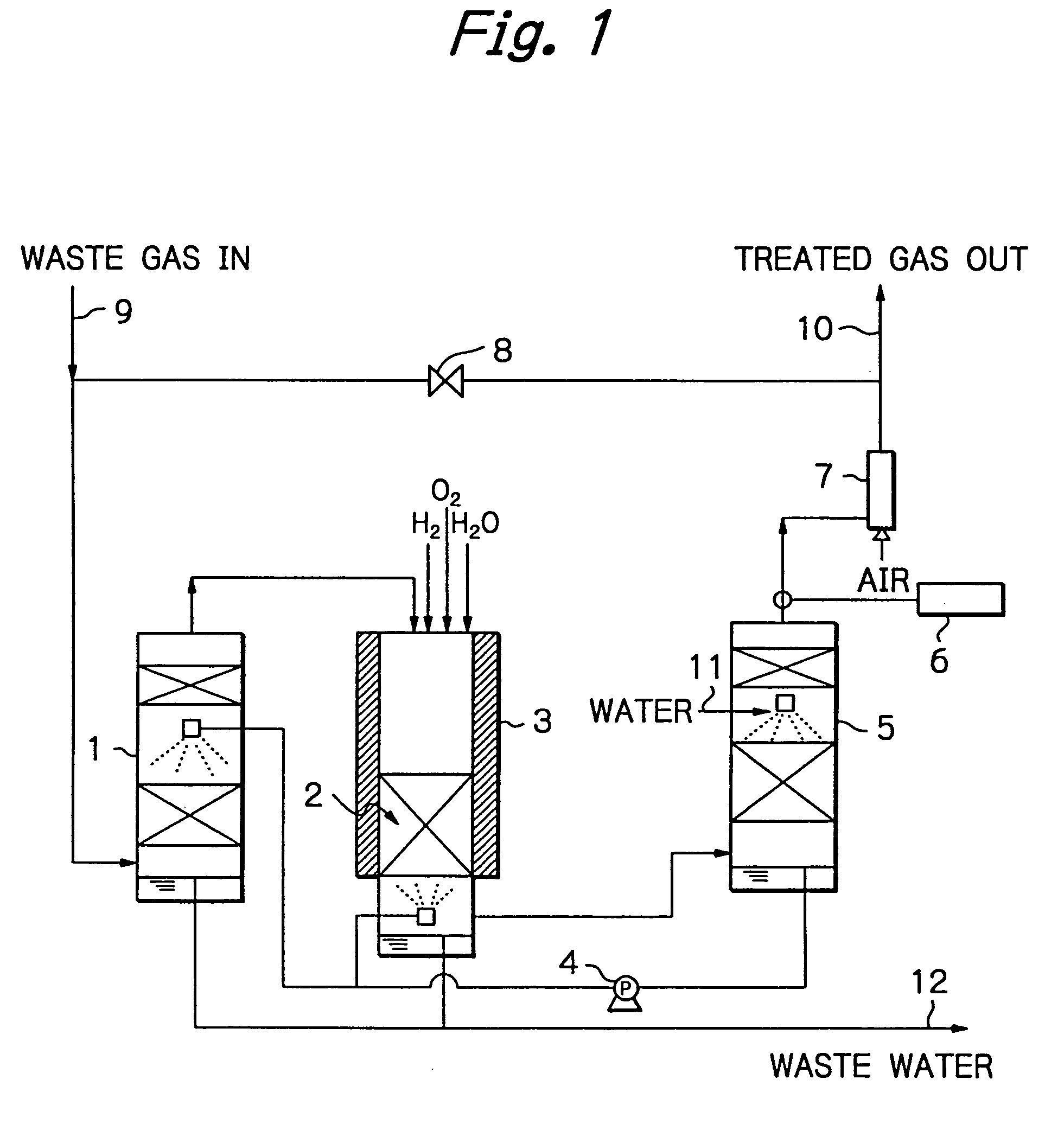

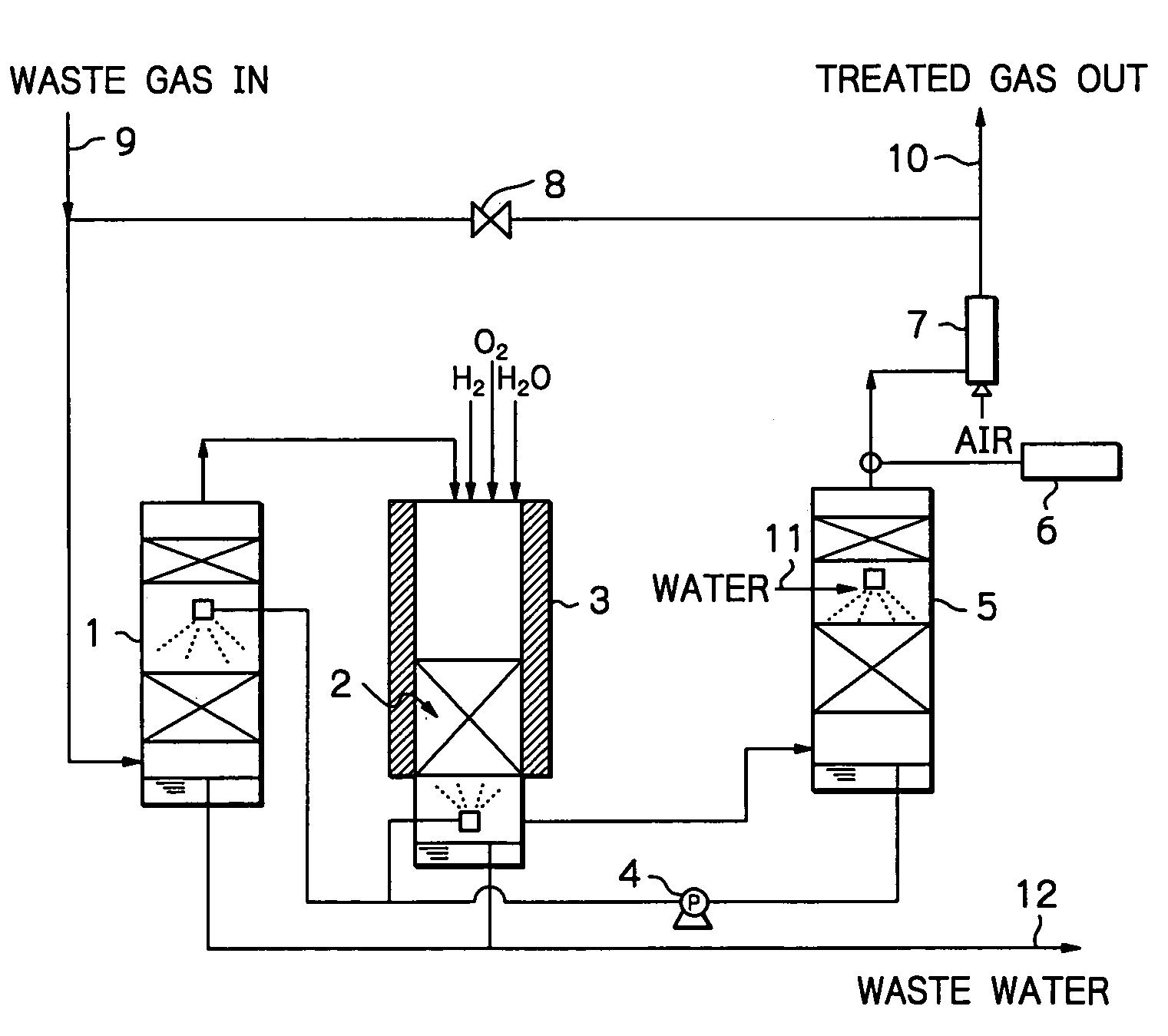

Method and apparatus for treating a waste gas containing fluorine-containing compounds

InactiveUS20050271568A1High percent decompositionEfficient removalCombination devicesGas treatmentInternal pressureDecomposition

An apparatus for treatment of a waste gas, containing fluorine-containing compounds, comprises: a solids treating device for separating solids from the waste gas; an addition device for adding H2 and / or H2O, or H2 and / or H2O and O2, as a decomposition assist gas to the waste gas leaving the solids treating device; a thermal decomposition device that is packed with γ-alumina heated at 600-900° C., and which thermally decomposes the waste gas to which the decomposition assist gas has been added; an acidic gas treating device for removing acidic gases from the thermally decomposed waste gas; and channels or lines for connecting these devices in sequence. The apparatus preferably includes an air ejector which is capable of adjusting an internal pressure of the apparatus.

Owner:MORI YOICHI +2

Ink jet recording sheet

InactiveUS20050179759A1High transparencyHigh print densityDuplicating/marking methodsCoatingsPolyvinyl alcoholRecording layer

This invention is an inkjet recording sheet having a high gloss cast coating recording layer containing a pigment and a binder comprising mainly polyvinyl alcohol on a support having air permeability, wherein the pigment is a mixture comprising alumina (A) and silica (B) having an average particle diameter of 100˜500 nm, blended in the proportion of A:B=95:5˜50:50 in terms of weight ratio. The silica (B) is preferably a silica to which cationic properties have been imparted, and the alumina (A) is preferably γ-alumina. Due to this, the gloss of a silver halide photograph together with excellent ink absorption properties and print density can be obtained.

Owner:NIPPON PAPER IND CO LTD

Method and apparatus for treating a waste gas containing fluorine-containing compounds

InactiveUS6949225B1High percent decompositionEfficient removalCombination devicesGas treatmentInternal pressureDecomposition

An apparatus for treatment of a waste gas, containing fluorine-containing compounds, comprises: a solids treating device for separating solids from the waste gas; an addition device for adding H2 and / or H2O, or H2 and / or H2O and O2, as a decomposition assist gas to the waste gas leaving the solids treating device; a thermal decomposition device that is packed with γ-alumina heated at 600–900° C., and which thermally decomposes the waste gas to which the decomposition assist gas has been added; an acidic gas treating device for removing acidic gases from the thermally decomposed waste gas; and channels or lines for connecting these devices in sequence. The apparatus preferably includes an air ejector which is capable of adjusting an internal pressure of the apparatus.

Owner:EBARA CORP

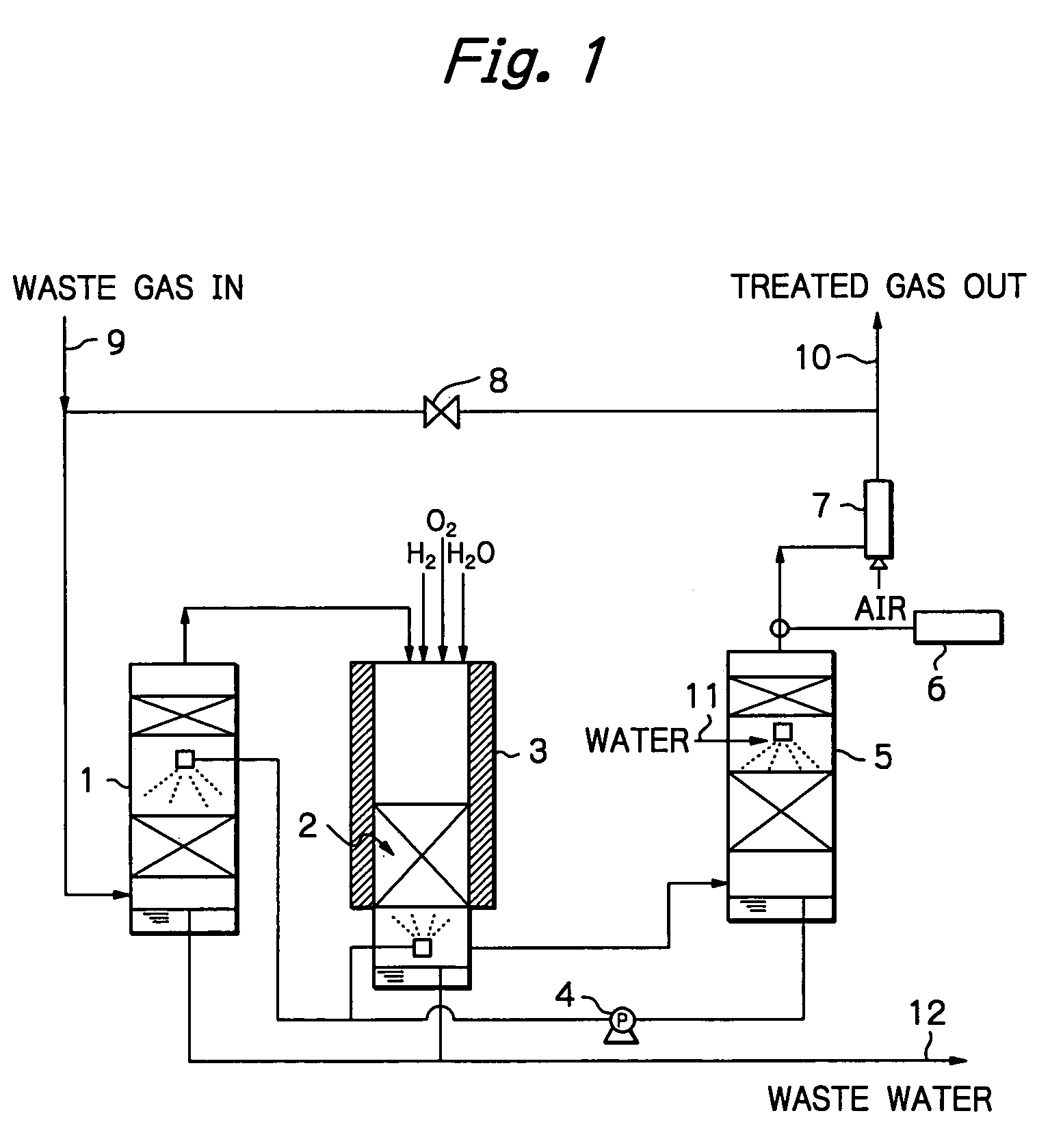

Wear-resistant member with hard coating

InactiveUS8003231B2Improve wear resistanceImprove adhesionPigmenting treatmentOther chemical processesWear resistantHeat resistance

A member with alumina-based hard coating formed there-on wherein said hard coating contains nitrogen and has a composition represented by the formula (1) below:Al1-xMx(O1-yNy)z (1)(0≦x≦0.5, 0<y≦0.5, z>0)where, M denotes at least one species of elements selected from those belonging to Group 4, Group 5, and Group 6 (excluding Cr), and such elements as Y, Mg, Si, and B.The hard coating based on γ-alumina, which is formed at temperatures no higher than 1000° C., is superior in wear resistance and heat resistance.

Owner:KOBE STEEL LTD

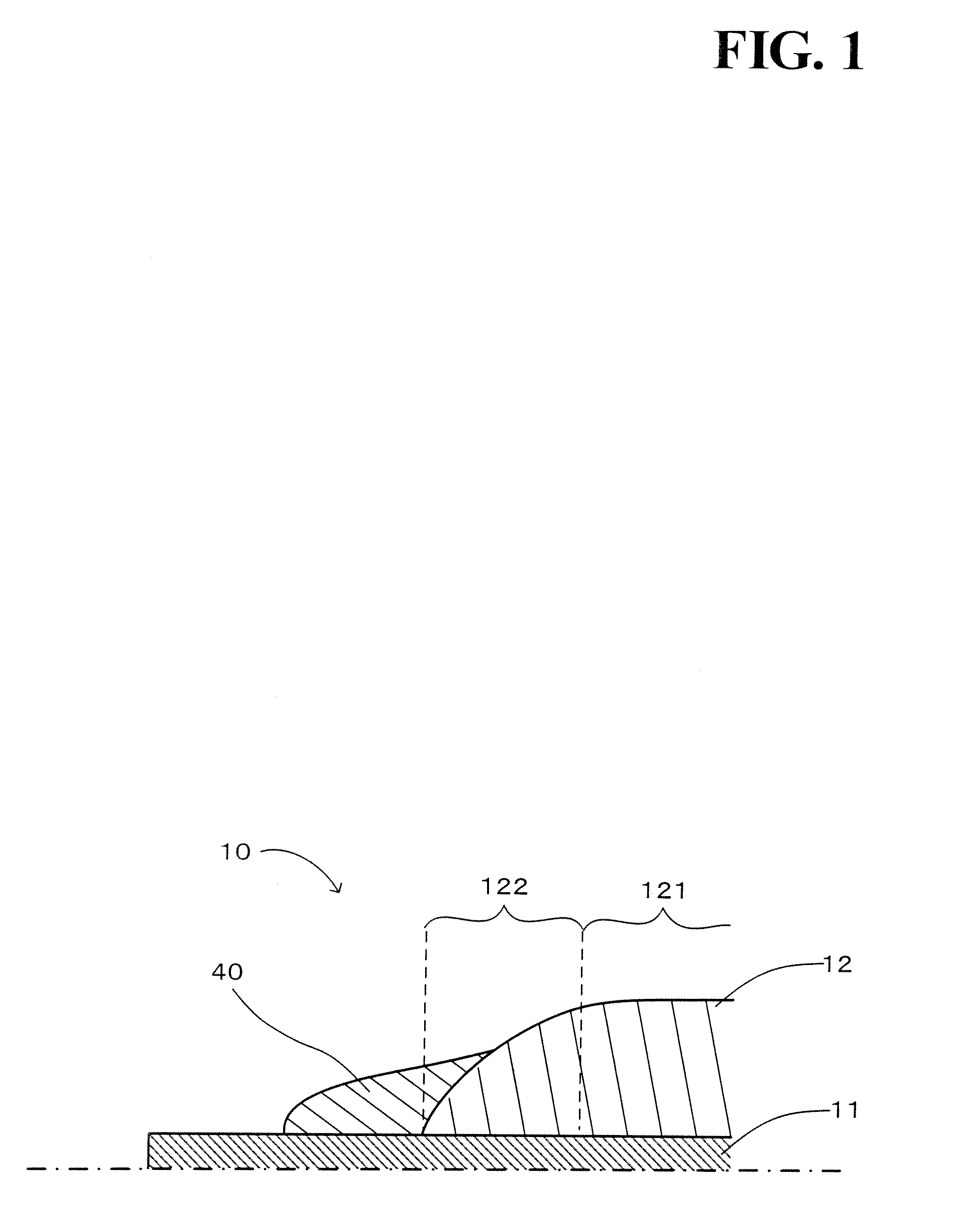

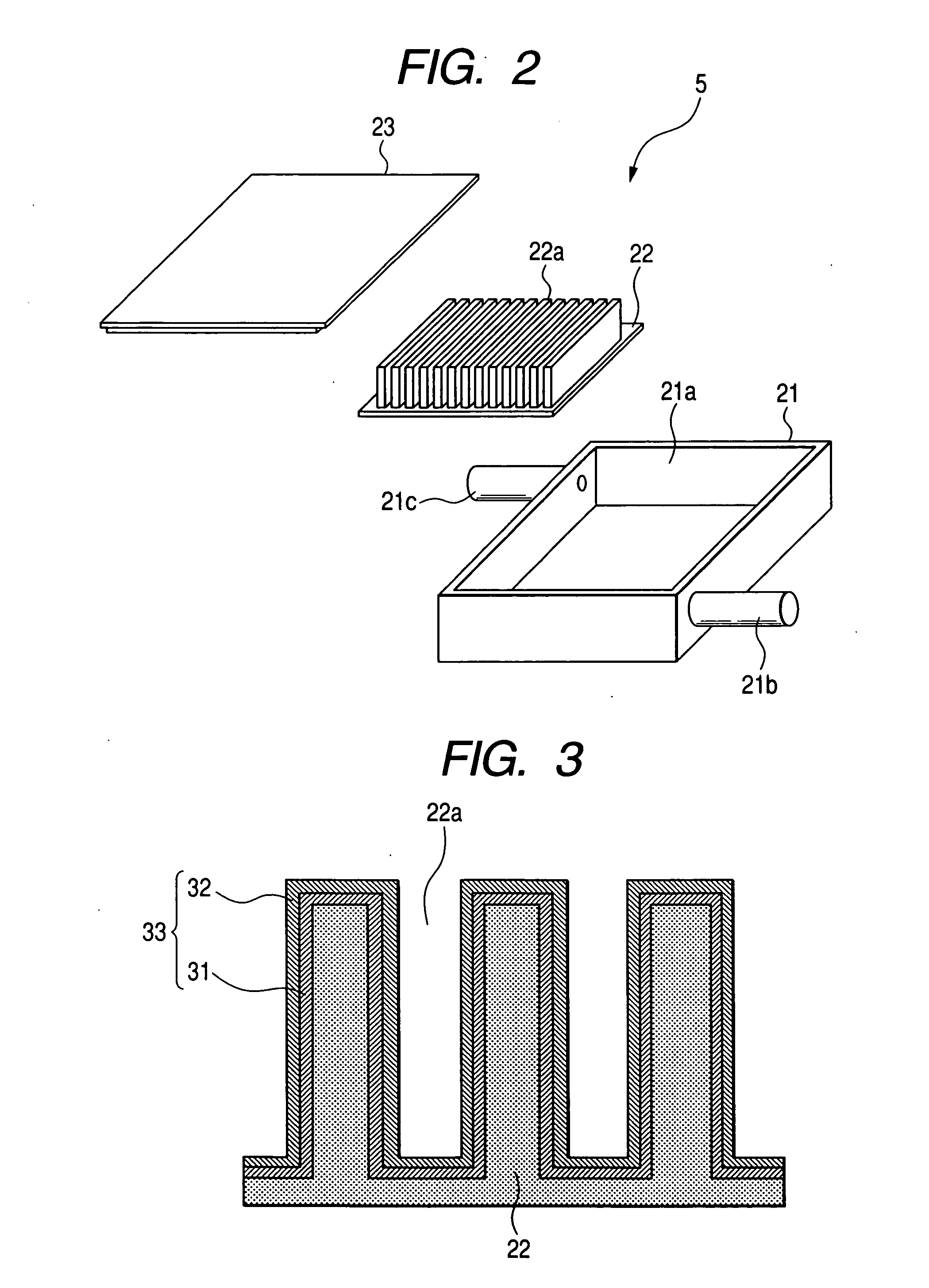

Carbon monoxide removing method, carbon monoxide removing apparatus, method for producing same, hydrogen generating apparatus using same, and fuel cell system using same

A hydrogen generating apparatus and a fuel cell system, which can be reduced in size, are provided. The hydrogen generating apparatus and the fuel cell system each has a CO removing portion. A catalyst portion formed by aluminum is provided on the surface of a CO removing portion for accelerating the methanation reaction of a part of carbon monoxide contained in a reformed gas. The catalyst portion includes a catalyst layer having ruthenium supported on γ-alumina formed by the anodization of the surface thereof. Heating is effected such that the temperature of the catalyst portion reaches 250° C. or more.

Owner:KK TOSHIBA

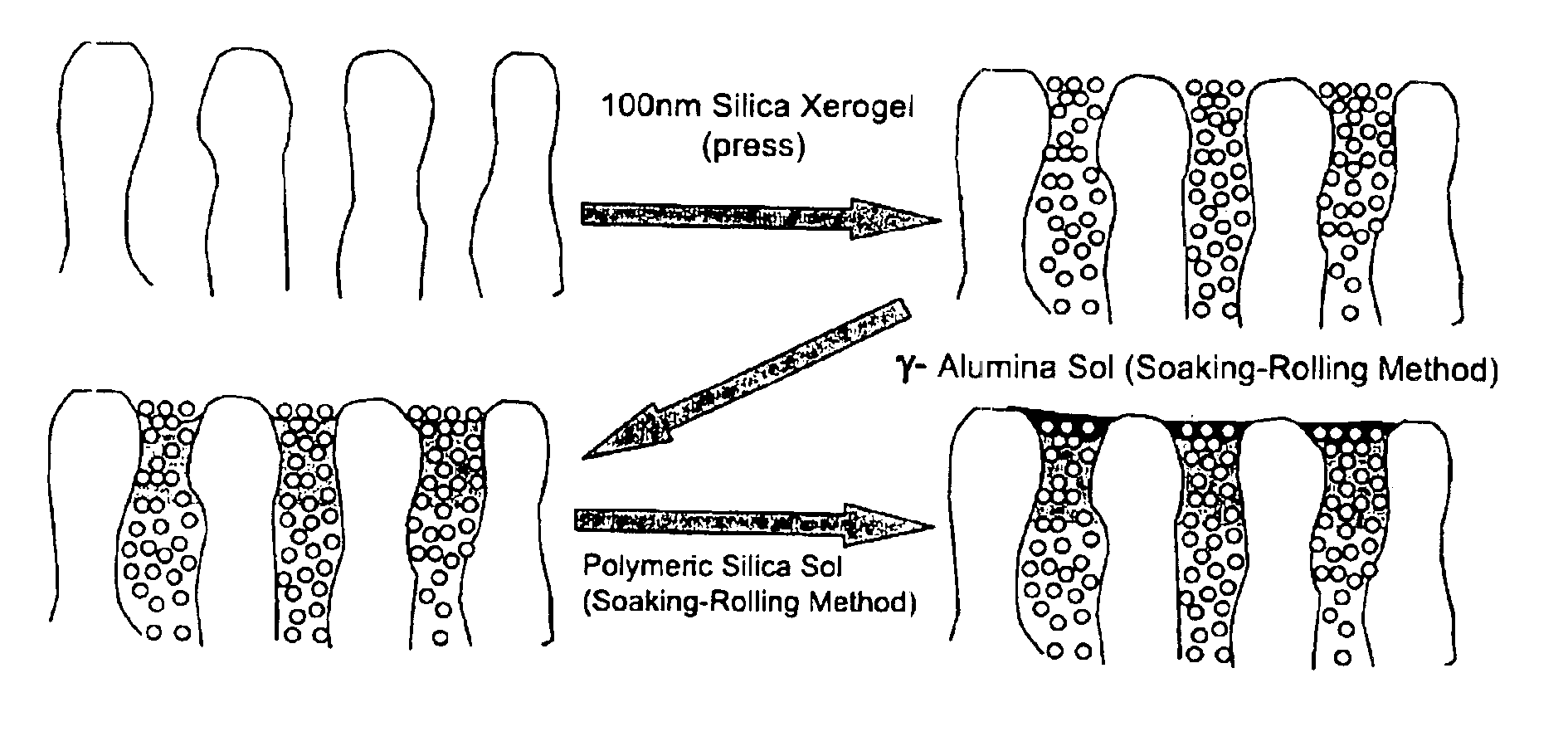

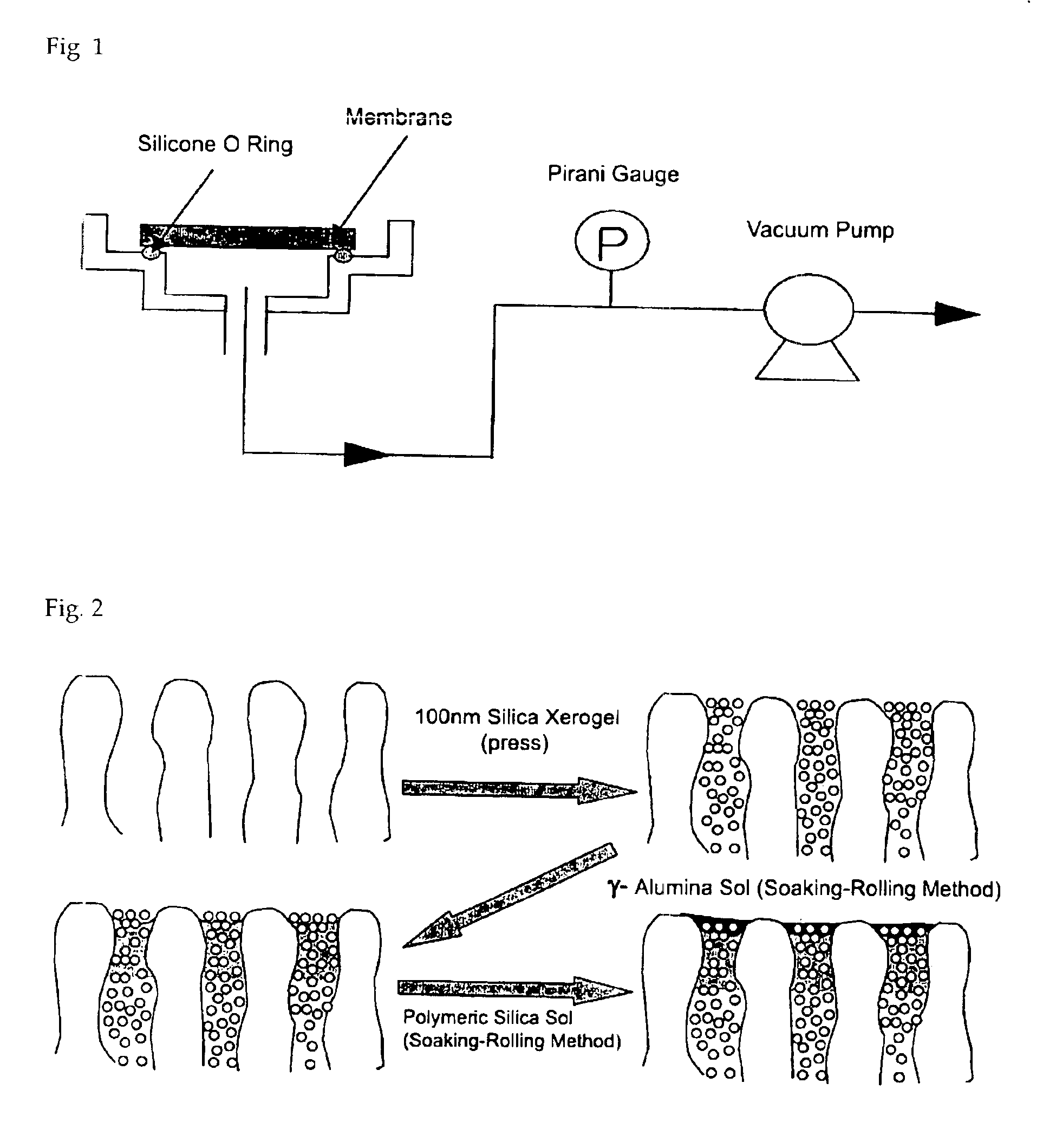

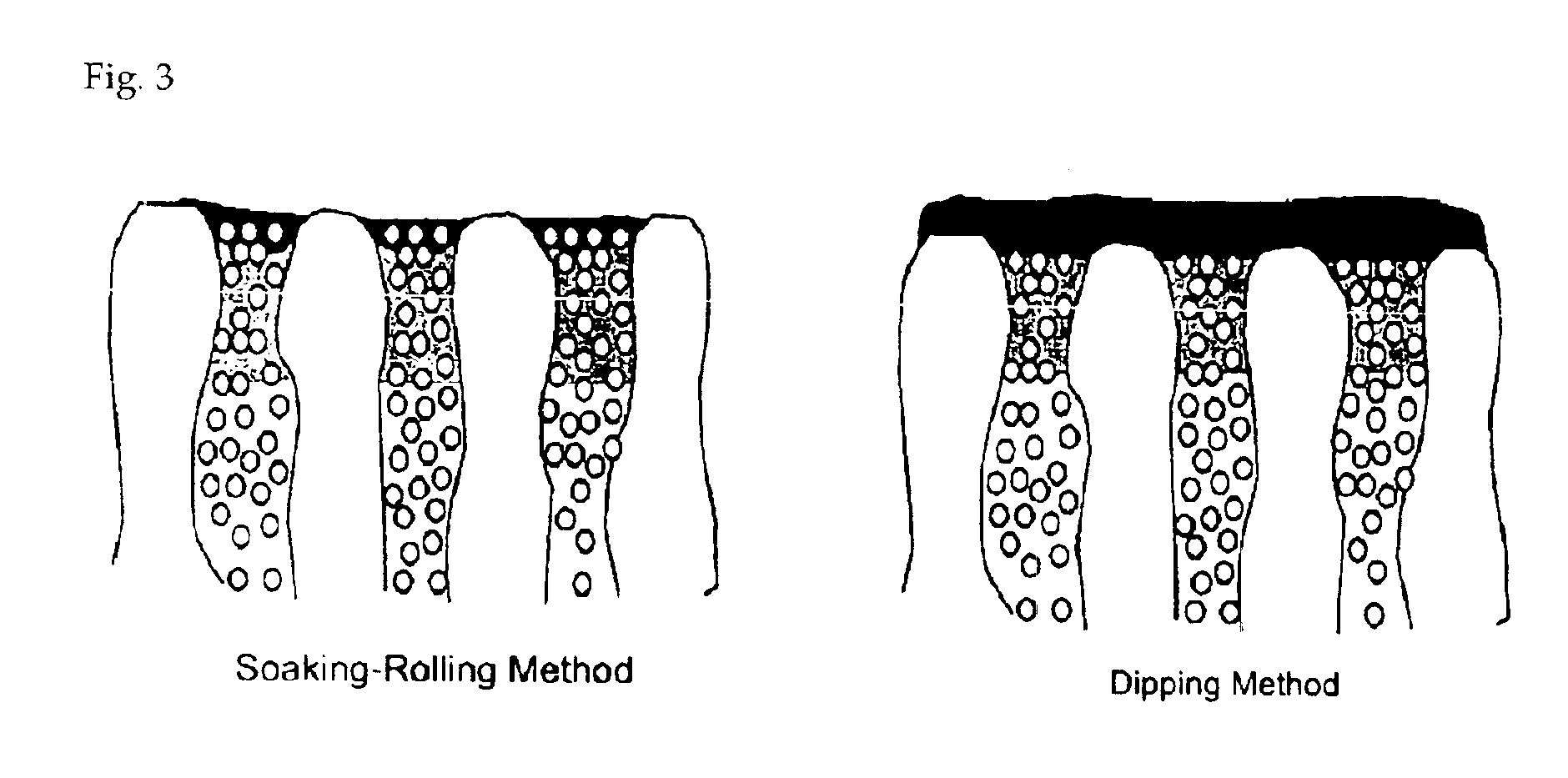

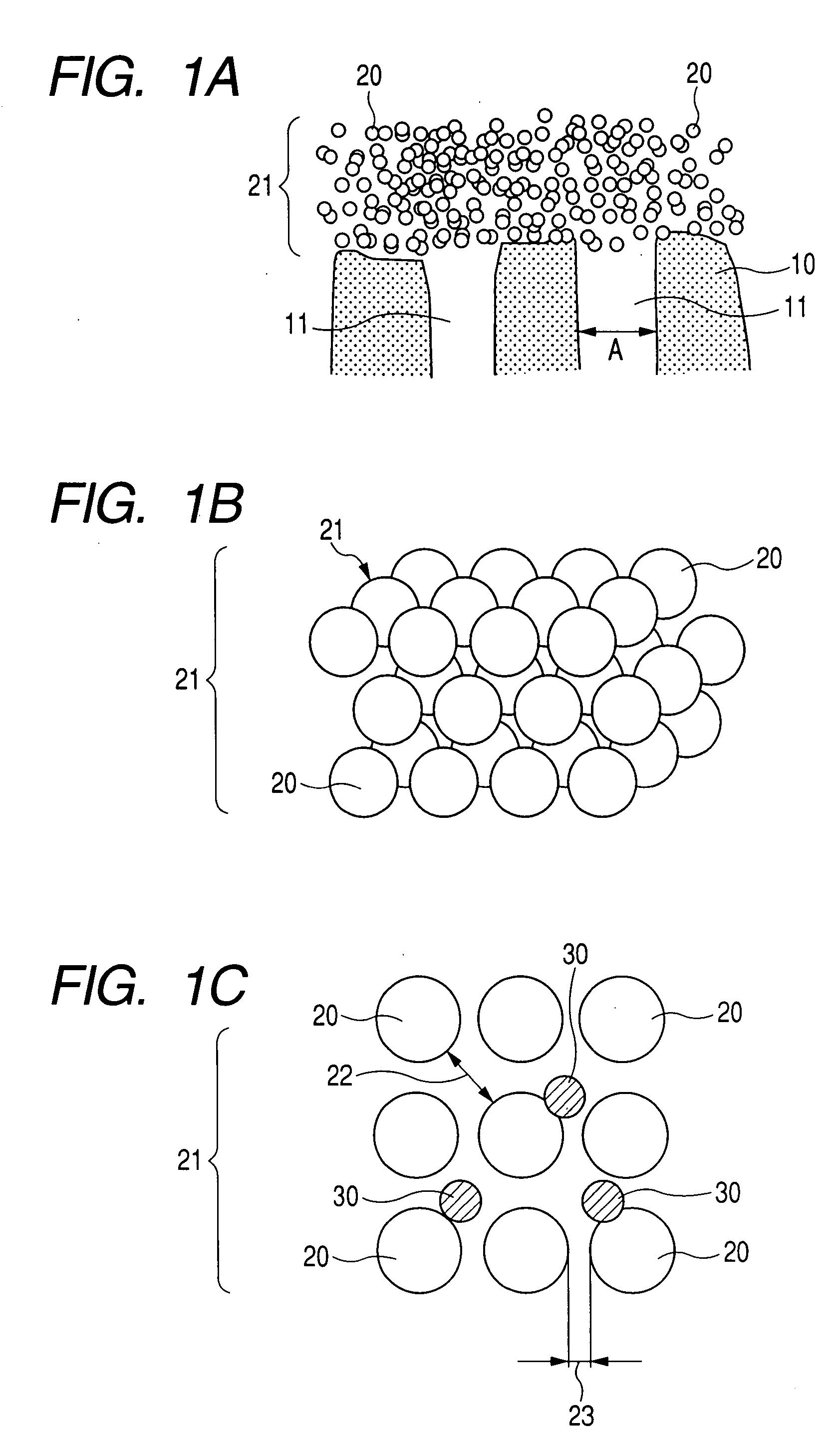

Preparation of composite silica membranes with thermal stability by a soaking-rolling method

InactiveUS6958137B2Improve thermal stabilitySemi-permeable membranesMembranesThermal stabilitySilicon dioxide

The present invention relates to a method for preparing a composite silica membrane with thermal stability by a soaking-rolling method, and more particularly to a method for preparing a composite silica membrane with improved thermal stability by rolling the surface of a porous support with silica xerogel, soaking-rolling the surface with γ-alumina, coating, drying, and sintering the porous support surface, thereby forming a fine coating membrane on the porous support surface.

Owner:KOREA RES INST OF CHEM TECH

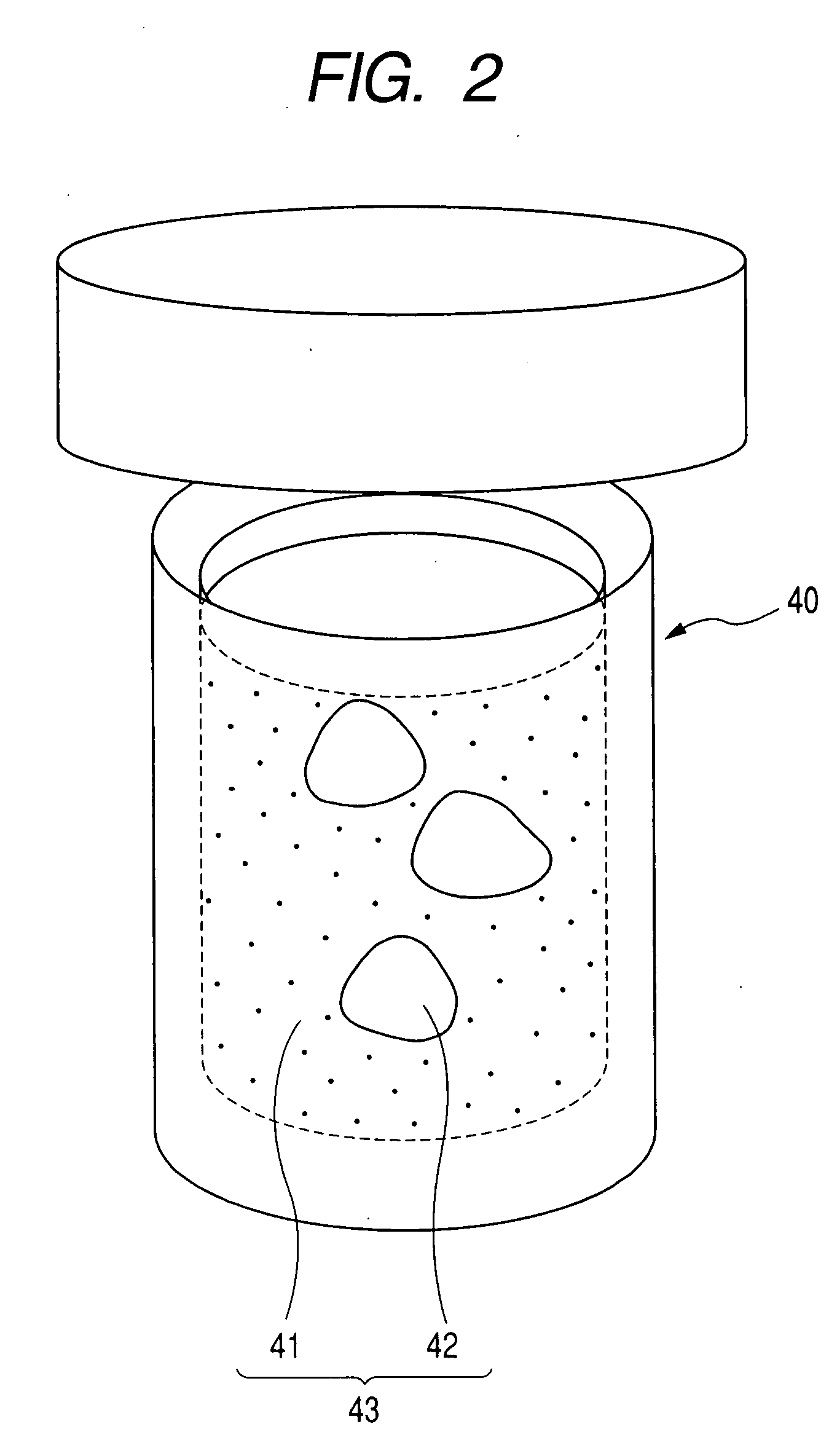

Fischer-tropsch catalysts

ActiveUS20130199966A1Quantity minimizationIncrease resistanceHydrocarbon from carbon oxidesMolecular sieve catalystsAluminateSpinel

A method of producing an aluminium oxide supported catalyst for use in a Fischer-Tropsch synthesis reaction, which comprises: spray-drying a slurry of γ-alumina and a source of a spinel forming metal to form a solid precursor material; calcining the precursor material to form a modified support material including a metal aluminate spinel; impregnating the modified alumina support material with a source of cobalt; calcining the impregnated support material, and activating the catalyst.

Owner:GTL F1

Method of producing catalyst support particles and a catalyzer using the catalyst support particles

InactiveUS20070281856A1Slow changeImprove heat resistanceMaterial nanotechnologyAluminium compoundsHeat resistanceHeat treated

Catalyst support particles and a catalyzer are produced by using γ-alumina particles or alumina precursor particles treated in advance by hydrothermal treatment in an autoclave. Performing the hydrothermal treatment improves the thermal resistance of the alumina particles because of suppressing deformation of the alumina particles when used at a high temperature such as 1000° C.

Owner:DENSO CORP

Hydrodesulfurization catalyst for hydrocarbon oil, process of producing same and method for hydrorefining

ActiveUS9067191B2High desulfurization activityCatalyst is relatively cheapCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationX-ray

The present invention provides a hydrodesulfurization catalyst that exhibits a high desulfurization activity when used in hydrotreatment of hydrocarbon oil, in particular straight-run gas oil. The catalyst includes at least one type of metal component selected from Groups VIA and VIII in the periodic table, supported on a silica-titania-alumina support where the total of the diffraction peak area indicating the crystal structure of anatase titania (101) planes and the diffraction peak area indicating the crystal structure of rutile titania (110) planes is ¼ or less of the diffraction peak area indicating the aluminum crystal structure ascribed to γ-alumina (400) planes, as measured by X-ray diffraction analysis. The catalyst has (a) a specific surface area (SA) of 150 m2 / g or greater, (b) a total pore volume (PVo) of 0.30 ml / g or greater, (c) an average pore diameter (PD) of 6 to 15 nm (60 to 150 Å), and (d) the ratio of the pore volume (PVp) of pores having diameters within ±30 percent of the average pore diameter (PD) being 70 percent or greater of the total pore volume (PVo).

Owner:JX NIPPON OIL & ENERGY CORP +1

Hydrodesulfurization catalyst for hydrocarbon oil, process of producing same and method for hydrorefining

InactiveUS9061265B2Inexpensive but high performance catalystReduce interactionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationX-ray

Owner:JX NIPPON OIL & ENERGY CORP +1

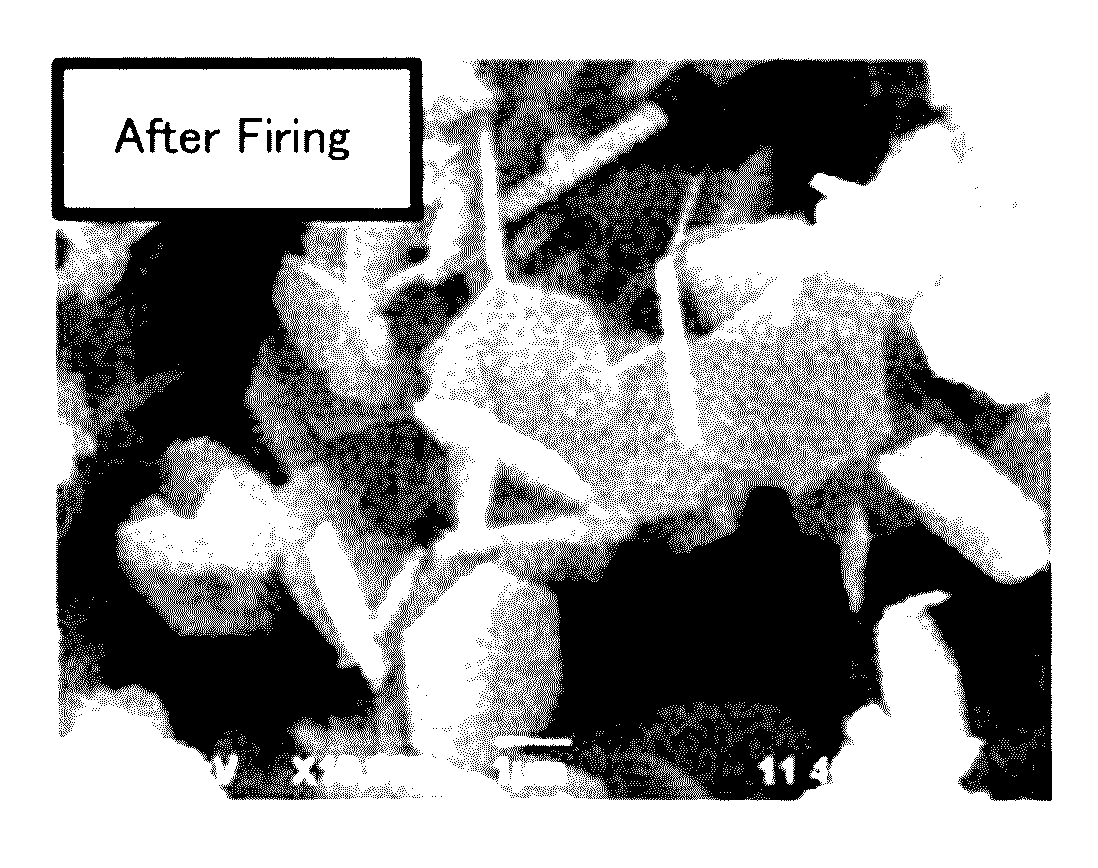

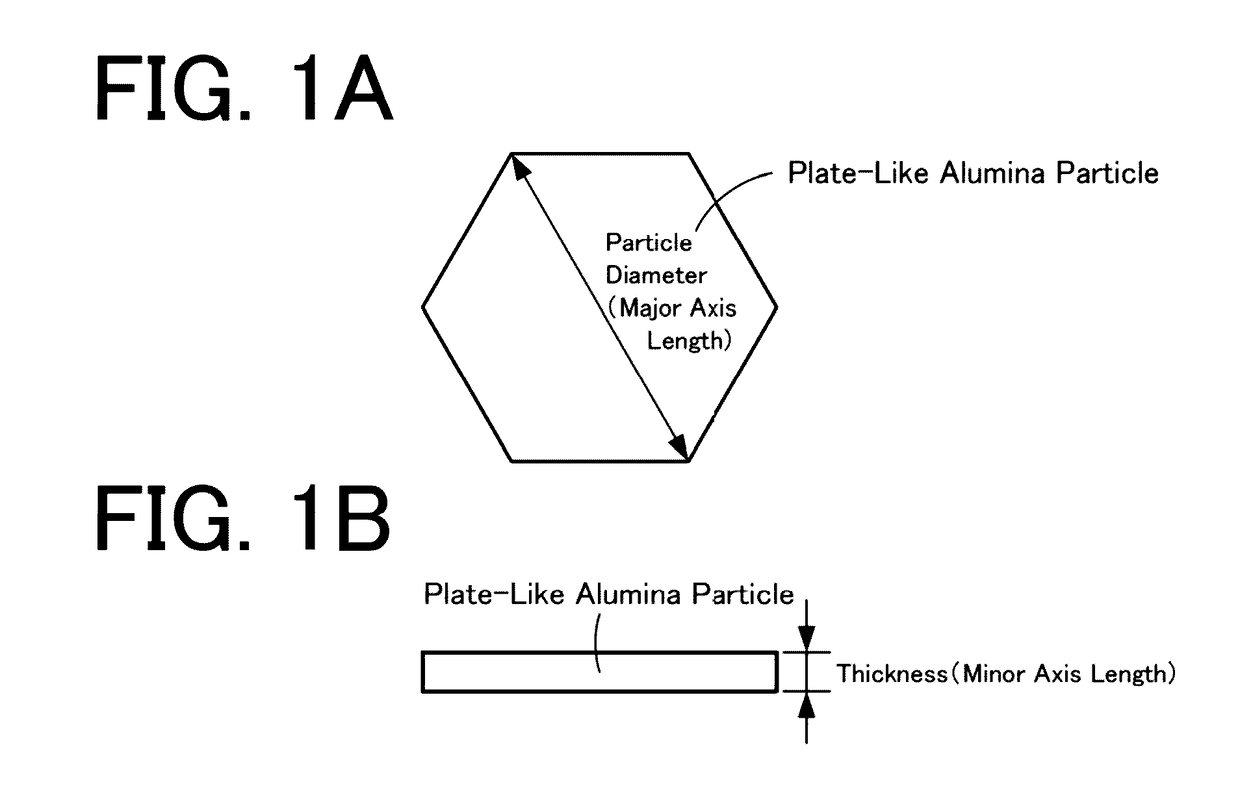

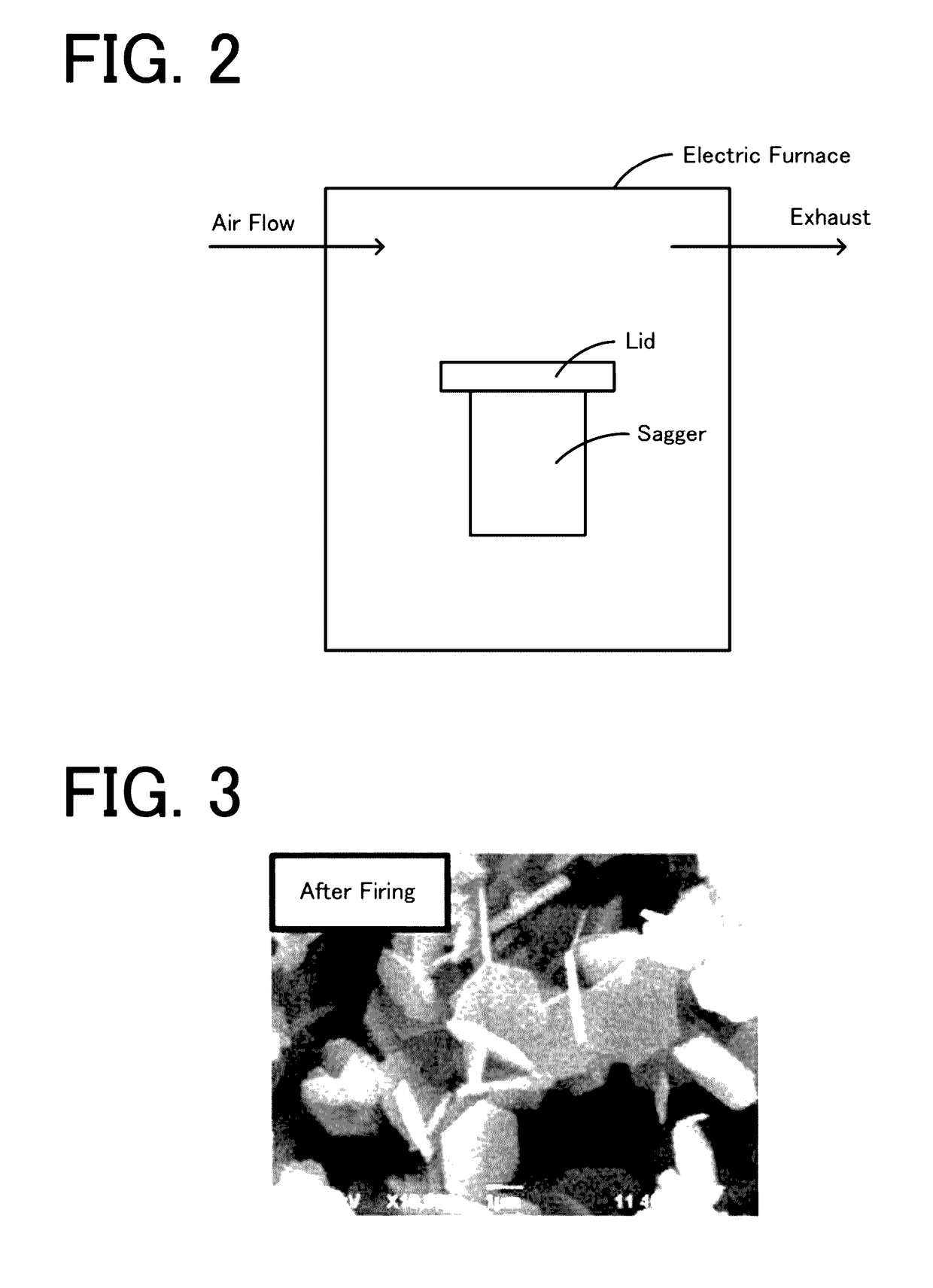

Method for manufacturing plate-like alumina powder and plate-like alumina powder

ActiveUS20170166454A1Highly oriented aluminaPolycrystalline material growthFrom solid stateSeed crystalImpurity

96 parts by mass of a γ-alumina powder, 4 parts by mass of a an AlF3 powder, and 0.17 parts by mass of an α-alumina powder as a seed crystal were mixed by a pot mill. The purities of each raw material were evaluated, and it was found that the mass ratio of each impurity element other than Al, O, F, H, C, and S was 10 ppm or less. In a high-purity alumina-made sagger having a purity of 99.9 percent by mass, 300 g of the obtained mixed powder was received, and after a high-purity alumina-made lid having a purity of 99.9 percent by mass was placed on the sagger, a heat treatment was perforated at 900° C. for 3 hours in an electric furnace in an air flow atmosphere, so that an alumina powder was obtained. The value of AlF3 mass / container volume was 0.016 g / cm3.

Owner:NGK INSULATORS LTD

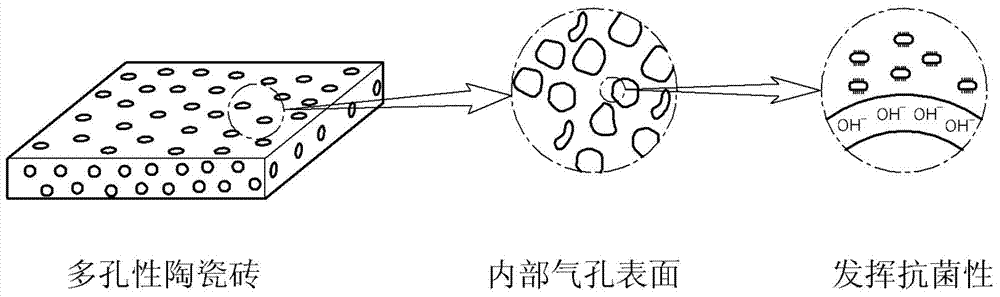

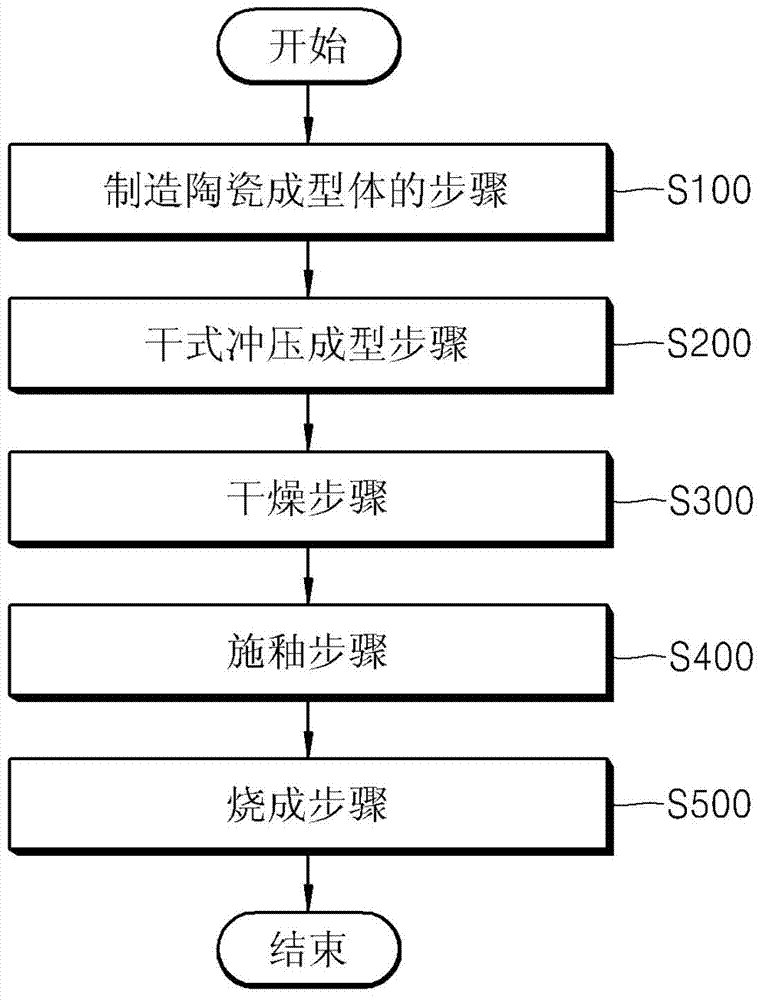

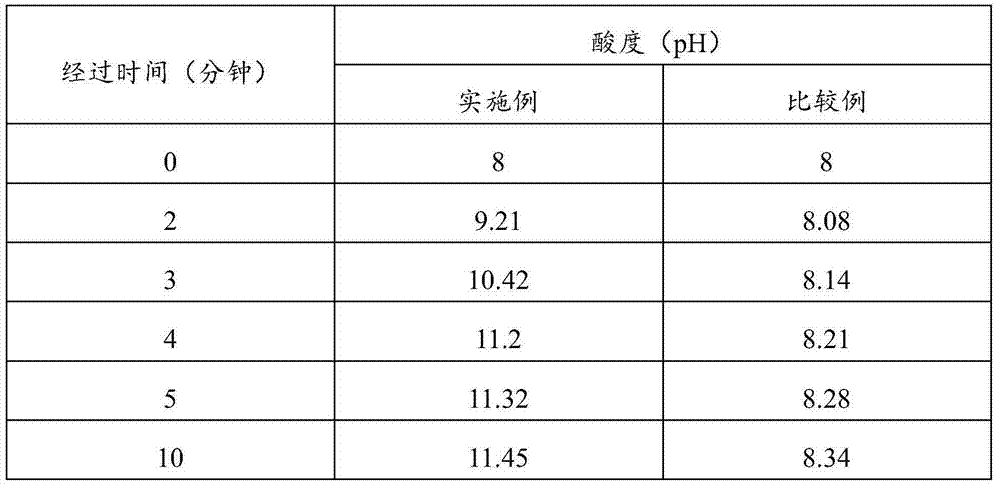

Antibacterial porous ceramic tile, and preparation method therefor

ActiveCN104781210AInhibition of reproductionComfortable indoor environmentCeramicwareClaywaresBrickMetallurgy

A porous ceramic tile comprising γ-alumina and an antibacterial active material is provided. Provided is a method for preparing a porous ceramic tile, comprising the steps of: forming a ceramic molded product by mixing γ-alumina and an antibacterial active material; preparing a porous ceramic tile by dry press molding the ceramic molded product; drying the molded porous ceramic tile; applying a glaze to the dried porous ceramic tile; and thermally decomposing and firing the glaze-applied porous ceramic tile.

Owner:LG HAUSYS LTD

Process for the hydrogenation of oxo aldehydes having high ester contents

InactiveUS20070027346A1Reduce energy consumptionIncreased space-time yieldCatalyst protectionPreparation by oxo-reaction and reductionCobaltMetallic Nickel

A hydrogenation catalyst is used for the catalytic hydrogenation of an ester-containing aldehyde mixture and the catalyst contains a γ-alumina having a BET surface area of from 70 to 350 m2 / g as support material, and at least one component having hydrogenation activity and being selected from the group consisting of nickel, cobalt and mixtures thereof.

Owner:EVONIK DEGUSSA GMBH

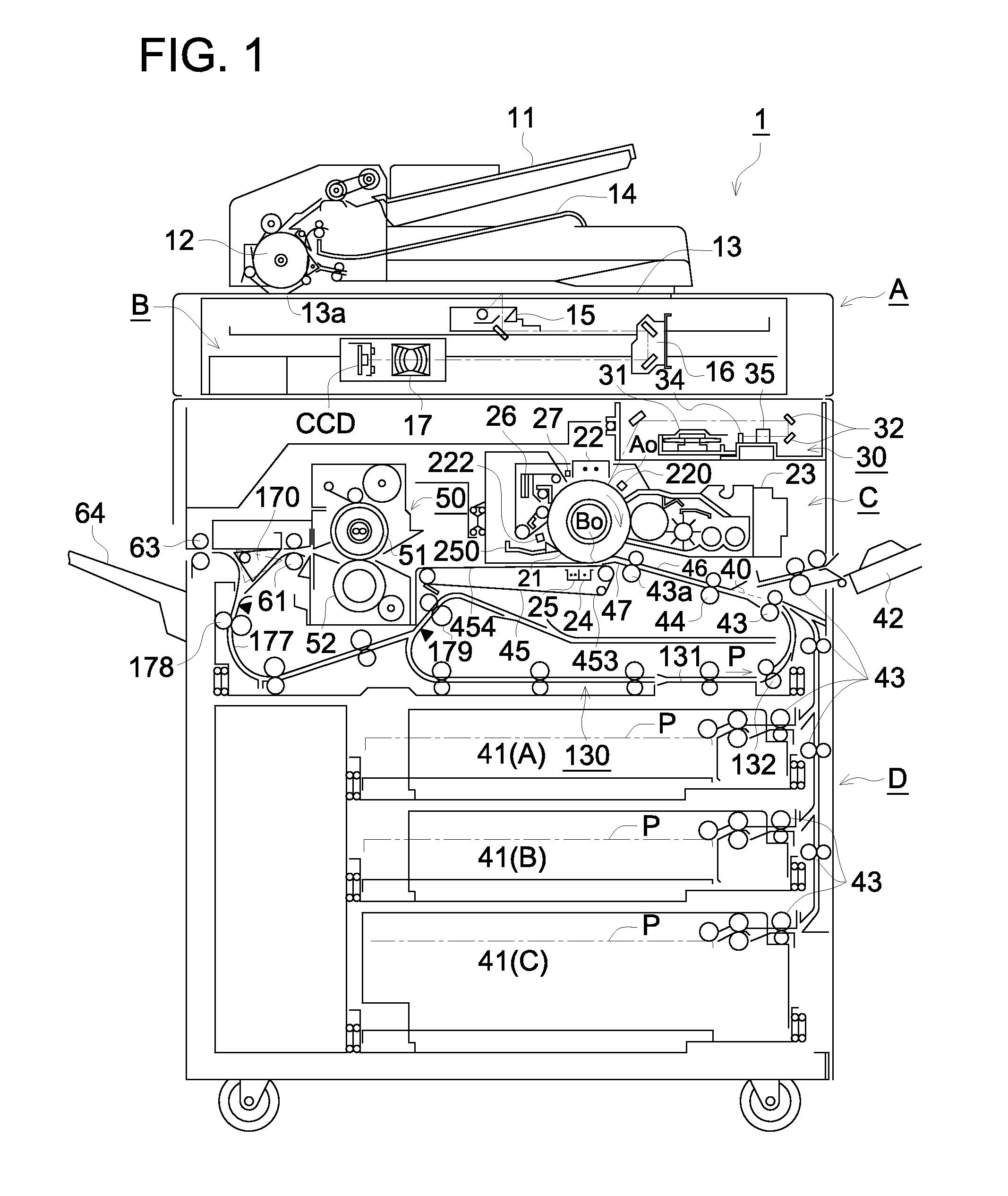

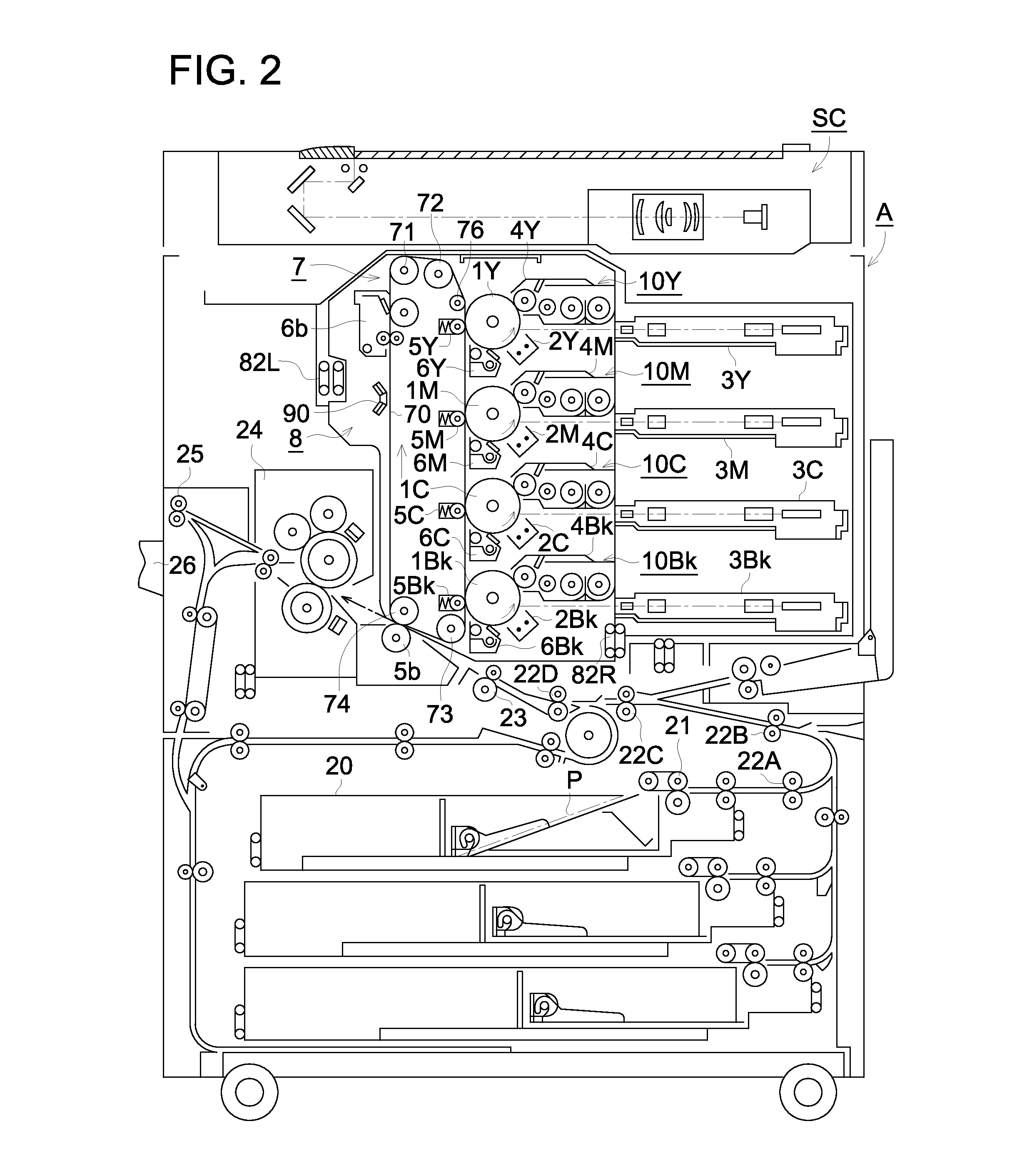

Organic photoreceptor and manufacturing method thereof

ActiveUS8298735B2Improve surface strengthIncreased durabilityElectrographic process apparatusΓ aluminaChemistry

Disclosed is an organic photoreceptor, which is composed of a photosensitive layer and a protective layer, provided on an electric conductive support, and the protective layer contains a composition obtained by hardening reaction of γ-alumina particles treated with a compound having a reactive functional group with a hardenable compound. A manufacturing method thereof is also disclosed.

Owner:KONICA MINOLTA BUSINESS TECH INC

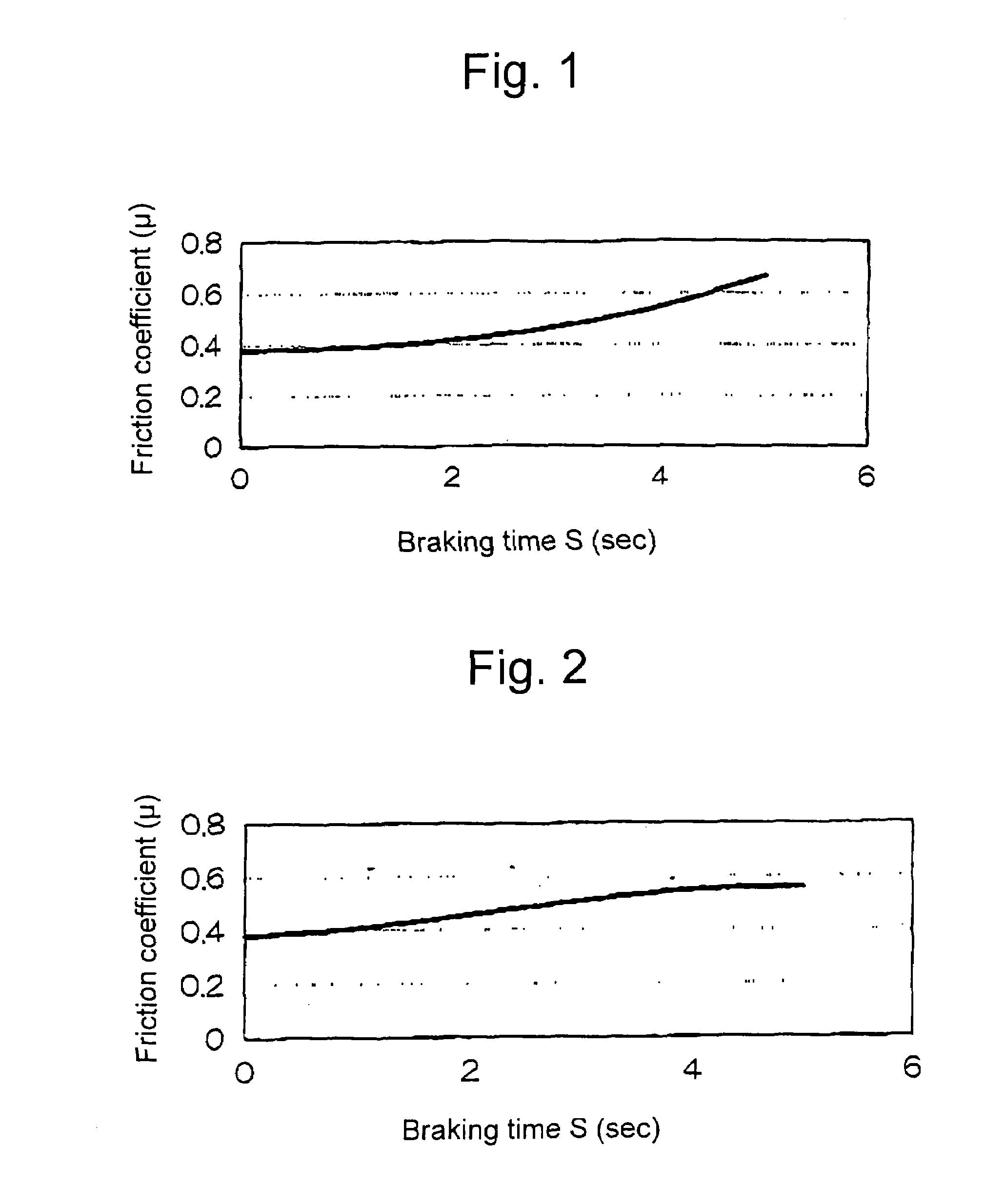

Friction material composition and friction material using the same

InactiveUS7338987B2Increase volumeEffectivenessBraking element arrangementsOther chemical processesFiberSilicon

There are disclosed a friction material composition which comprises a fibrous material except for asbestos, an inorganic friction regulator, an organic friction regulator and a binder, part of the inorganic friction regulator is α alumina and γ alumina in combination, a weight ratio of the α alumina and the γ alumina, α alumina:γ alumina, is in the range of 1:20 to 1:5, and part or whole part of the binder is a silicon-containing phenol resin, and a friction material obtained by molding the friction material composition under heating and pressure.

Owner:HITACHI CHEM CO LTD +1

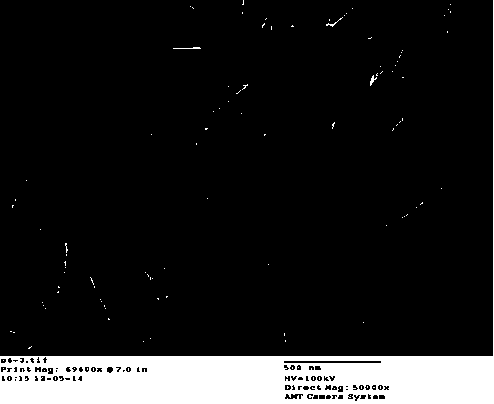

A kind of preparation method of leaf-shaped nanometer gamma-alumina

ActiveCN106276992BReduce concentrationReduce exposureCatalyst carriersNanotechnologyHydrogenHigh pressure

The present invention discloses a method of producing an paddle nano γ- alumina, including the following: (1) an inorganic aluminum salt and urea in water to give a clear solution by dissolving, the solution was transferred to an autoclave; (2) the introduced into the autoclave hydrogen, to maintain constant the reaction pressure and temperature; after (3) the reaction, the reaction mass was filtered, washed and dried to give boehmite precursor obtained after calcination paddle nano γ- alumina. This method is not neutralized, cumbersome aging step, the process is simple, less reaction steps and so on. Synthesis of high surface area nano-γ- alumina support of the present invention can be obtained are lobed structure, large specific surface area γ- alumina powder for metal supported catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com