Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2125results about How to "Trend down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

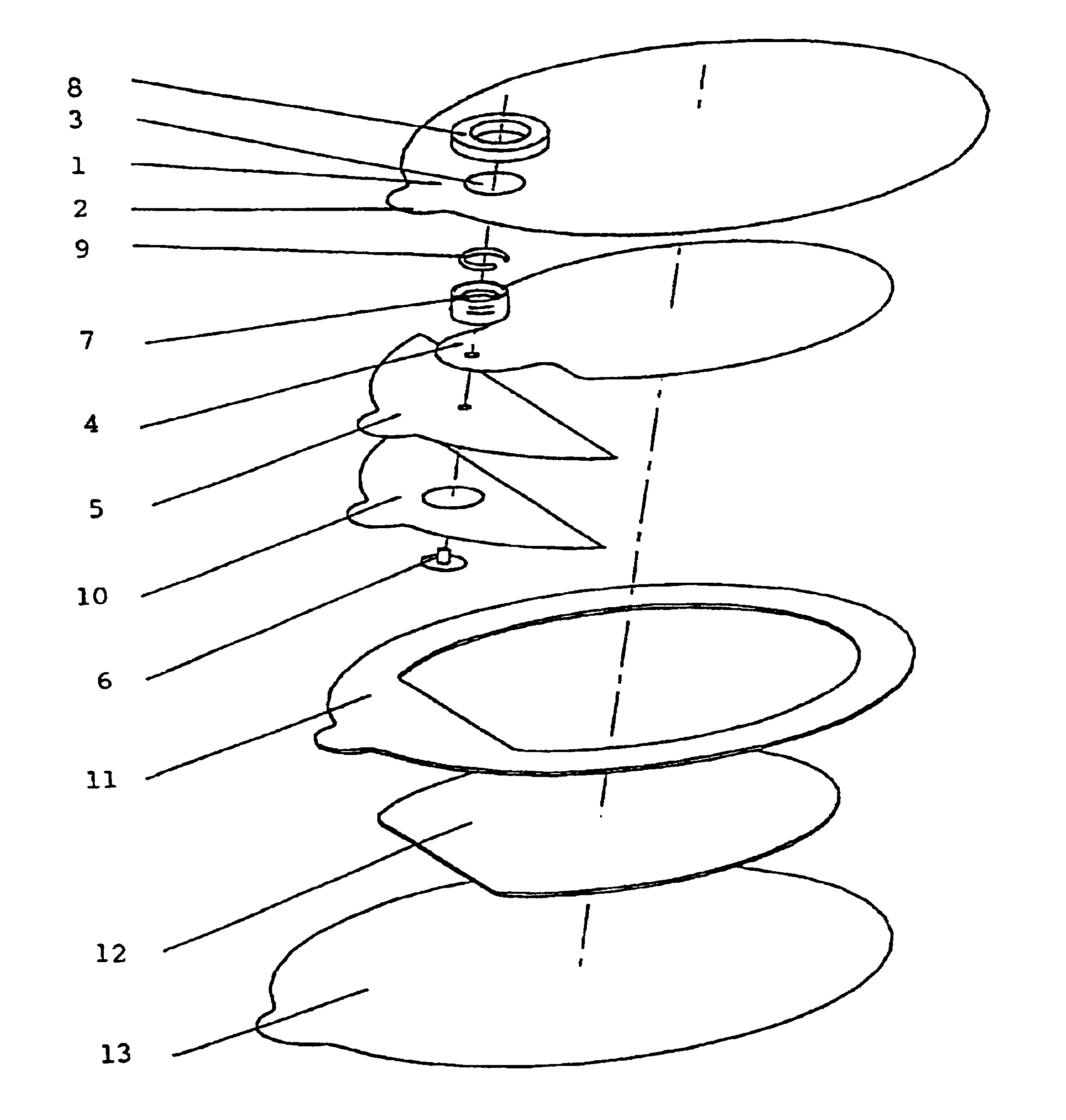

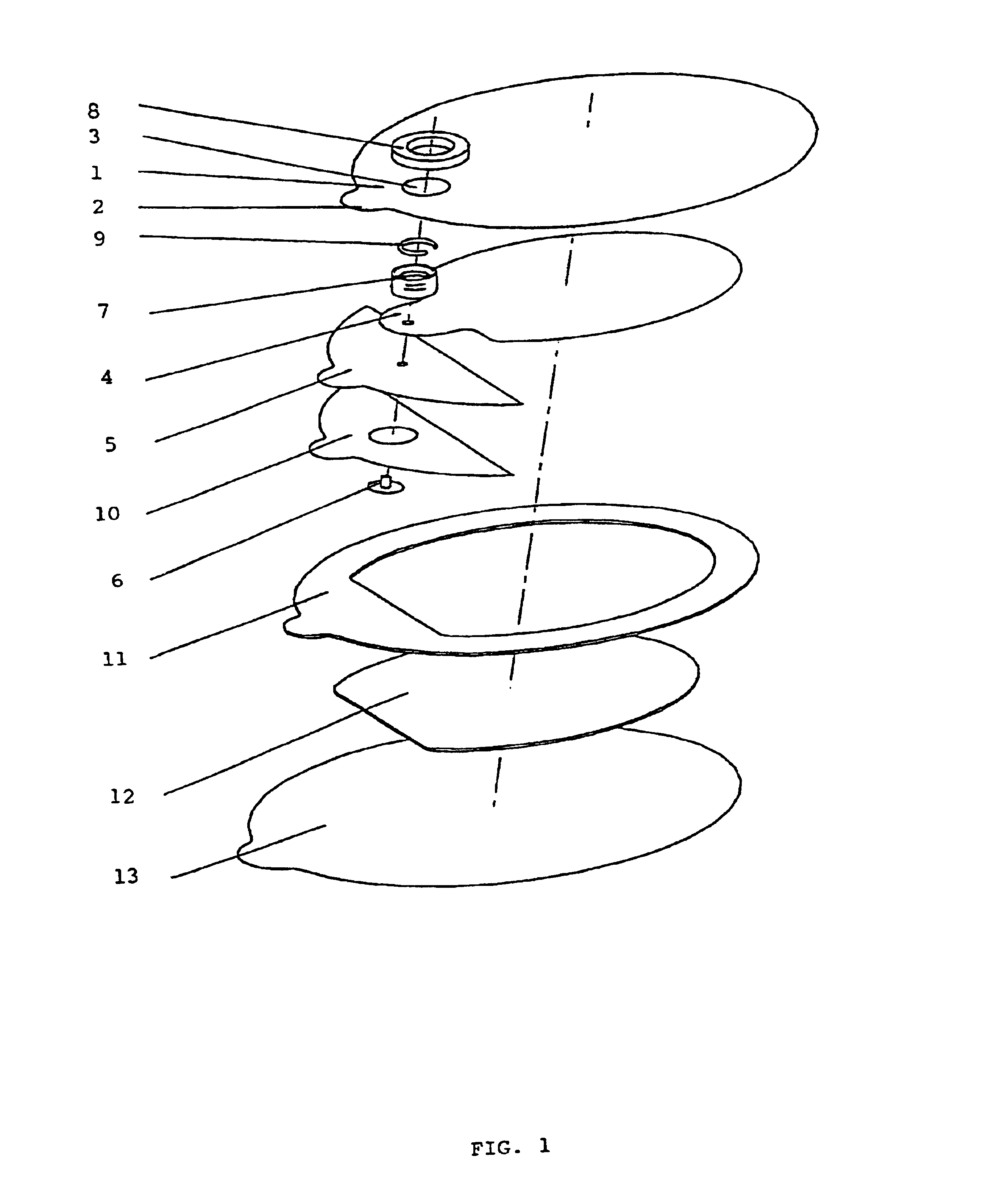

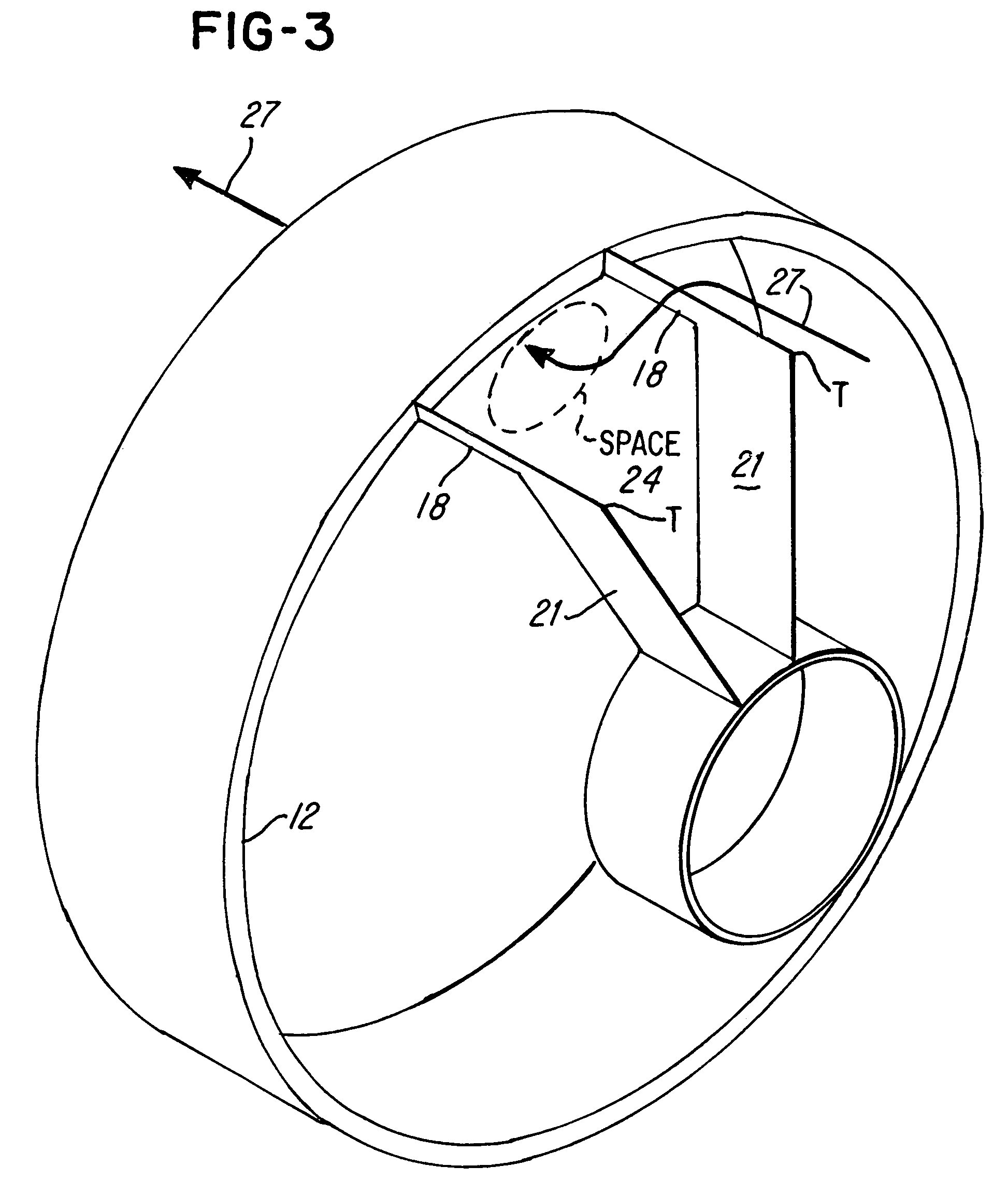

Surgical device

InactiveUS7695485B2Easy to separateReduction tendencyIncision instrumentsSurgical scissorsSurgical deviceGeneral surgery

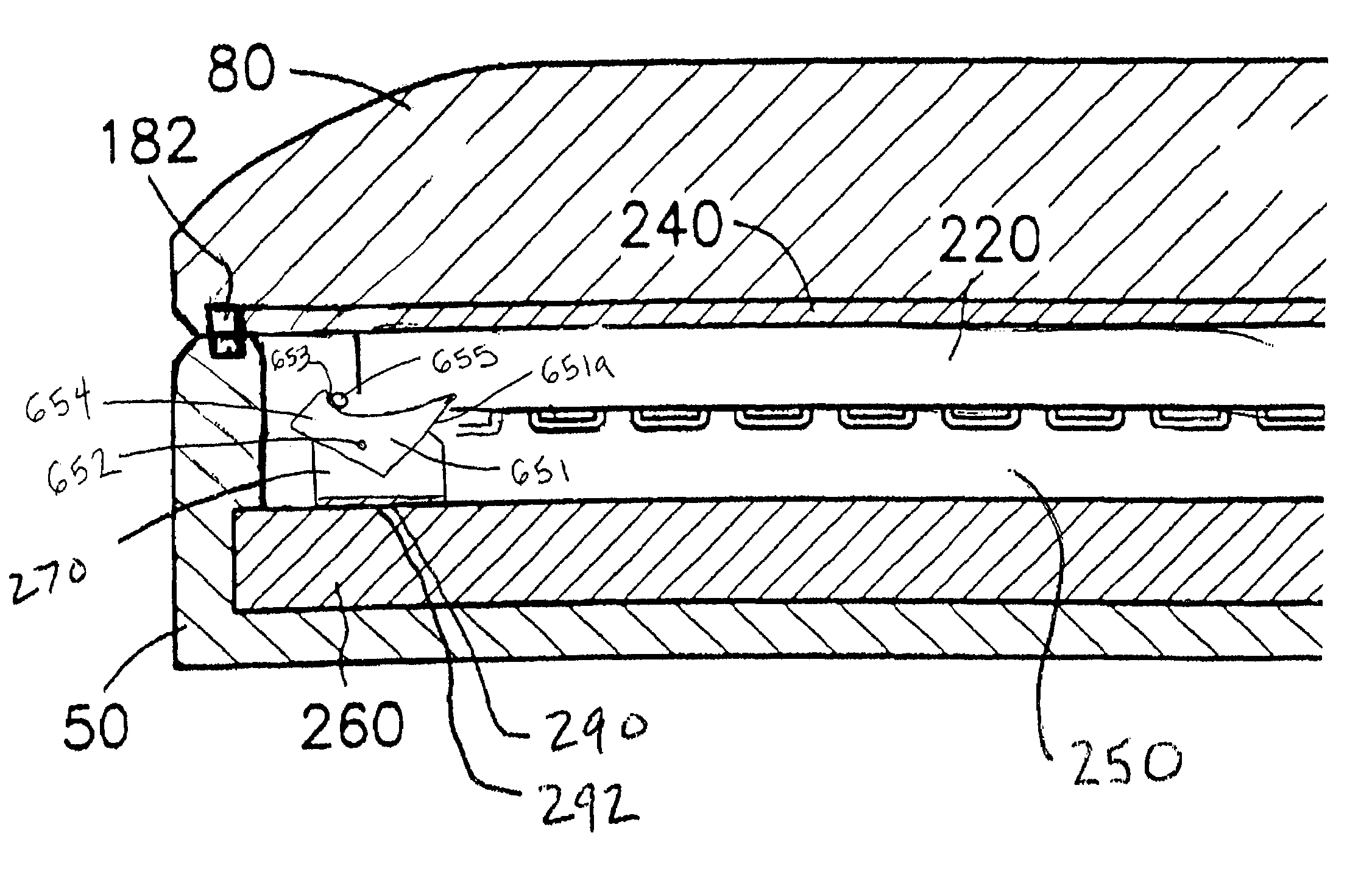

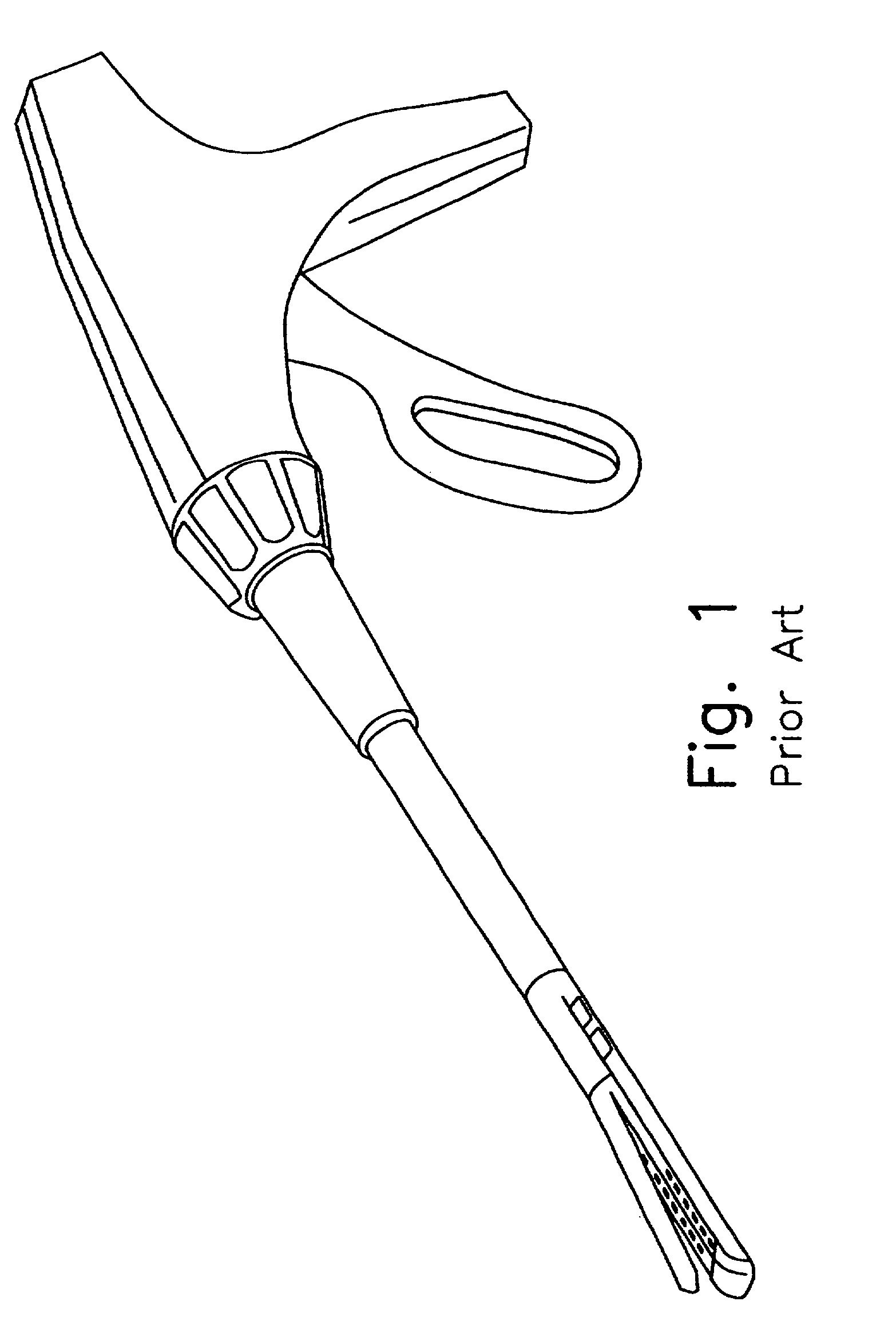

A surgical device includes a first jaw and a second jaw disposed in opposed correspondence with the first jaw. The second jaw is mechanically coupled to the first jaw at a proximal end opposite a distal end. A cutting element is disposed within the second jaw, and a first driver is configured to move the cutting element proximally from the distal end toward the proximal end of the second jaw to cut a section of tissue disposed between the first and second jaws. The device may also include a stapling element disposed within the second jaw. The cutting element and the stapling element may be contiguous so as to define a cutting and stapling element, such as a wedge having a blade disposed thereon. As the wedge is moved proximally from the distal end of the second jaw to the proximal end, the wedge pushes a plurality of staples against a plurality of opposing staple guides disposed in the first jaw in order to staple a section of tissue while cutting the section of tissue.

Owner:DORROS GERALD M D

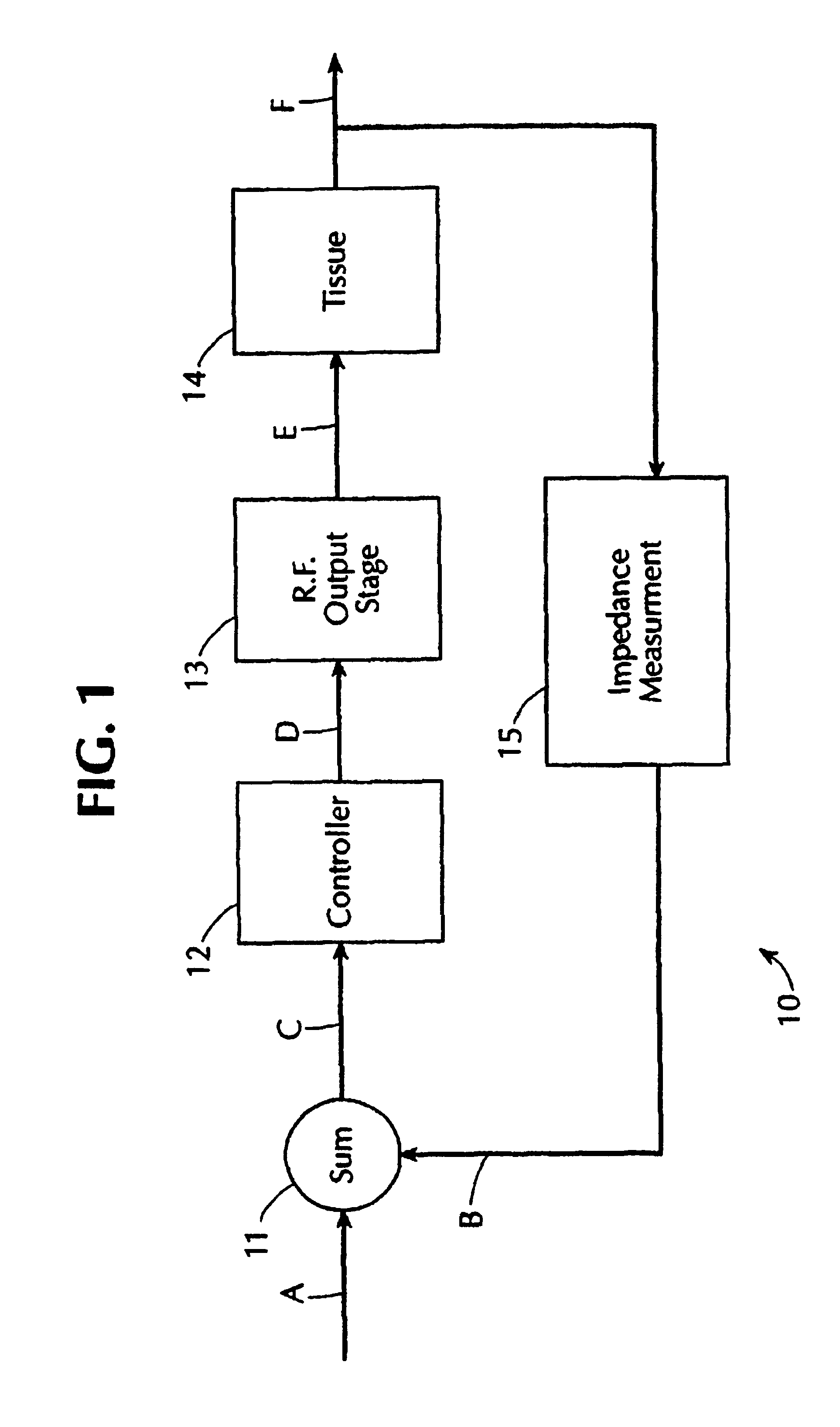

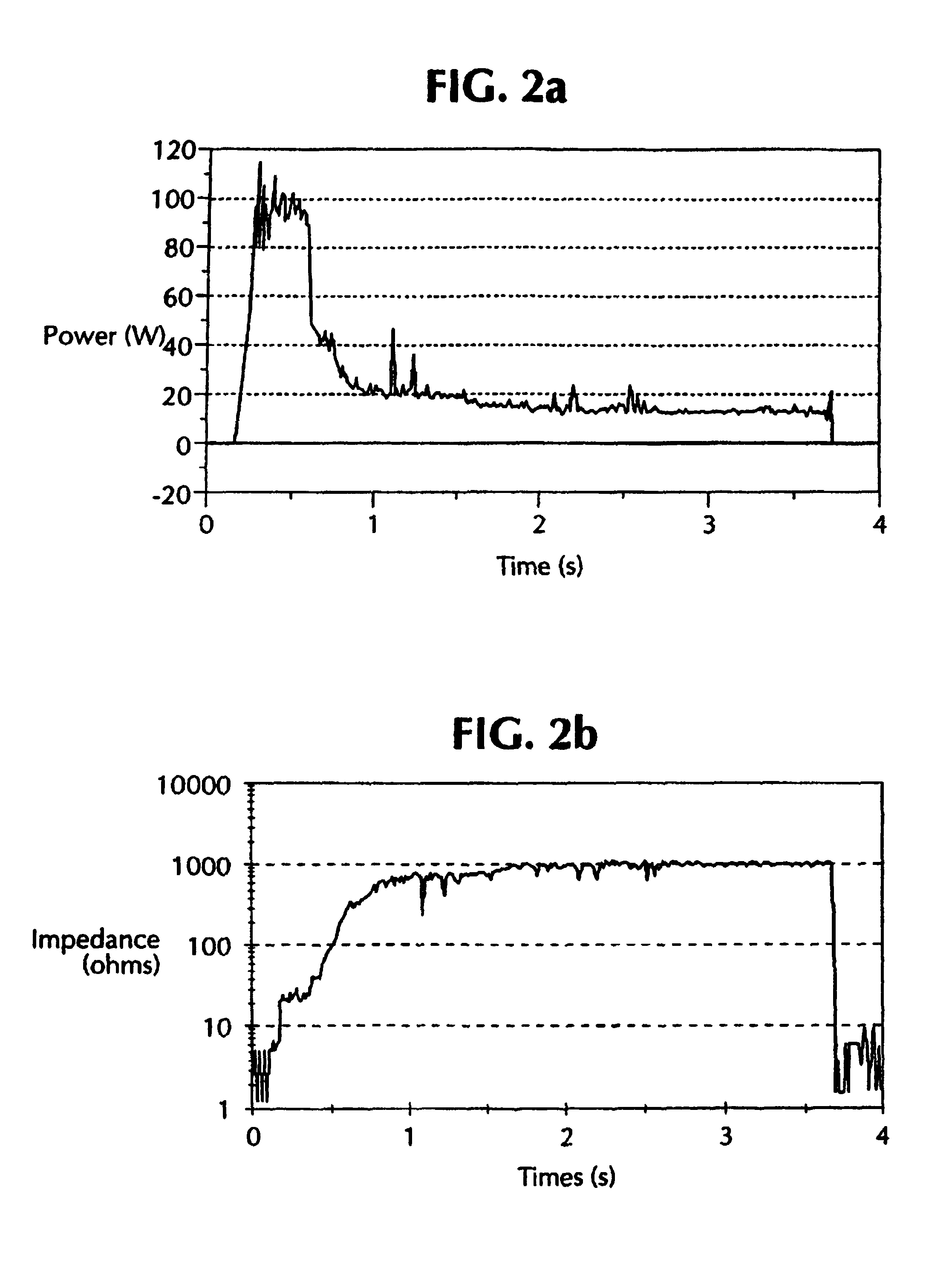

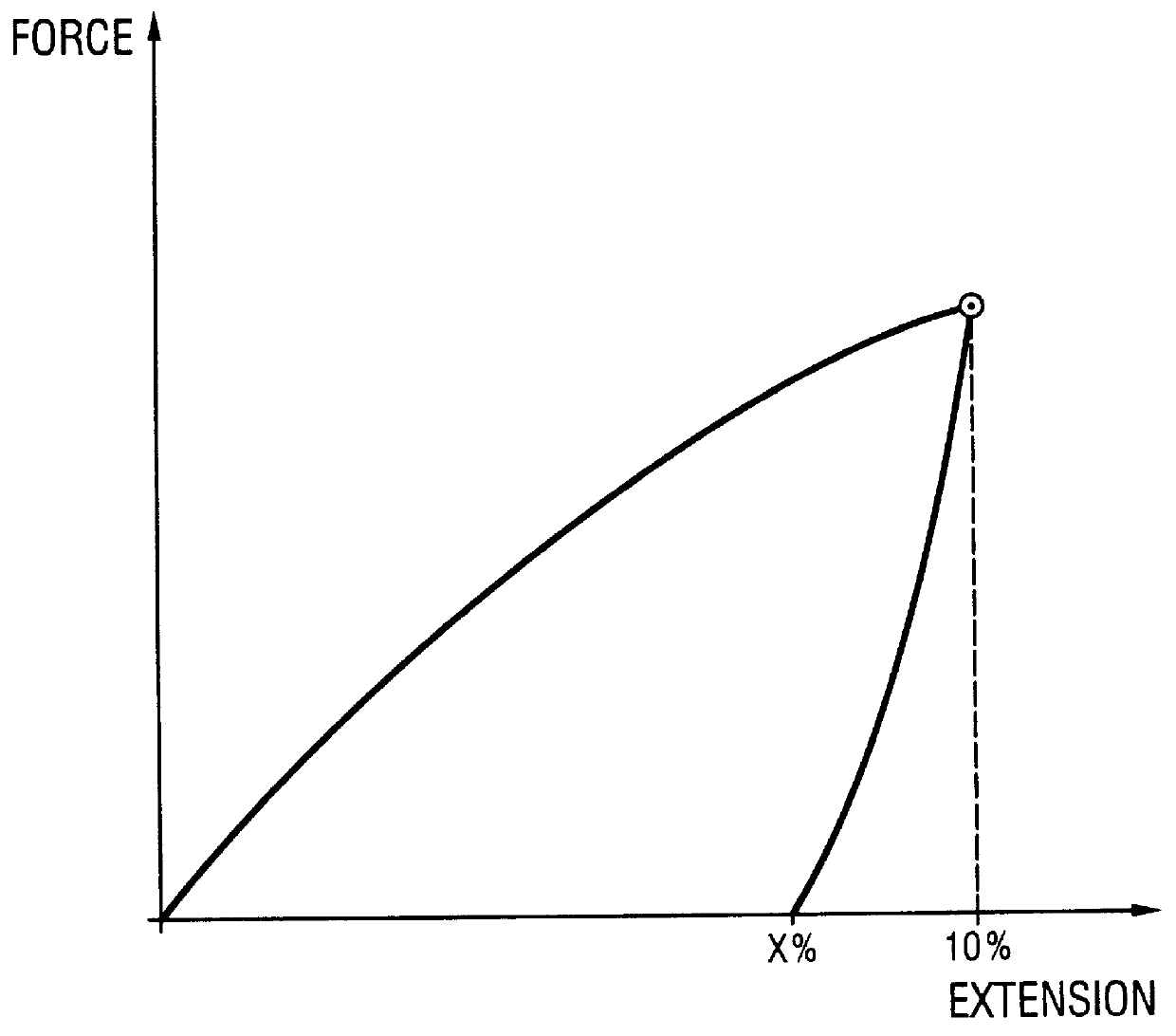

Electrosurgical generator with adaptive power control

InactiveUSRE40388E1Lower Level RequirementsImproved tissue sealing characteristicPulse automatic controlSurgical instruments for heatingThermal energyVessel sealing

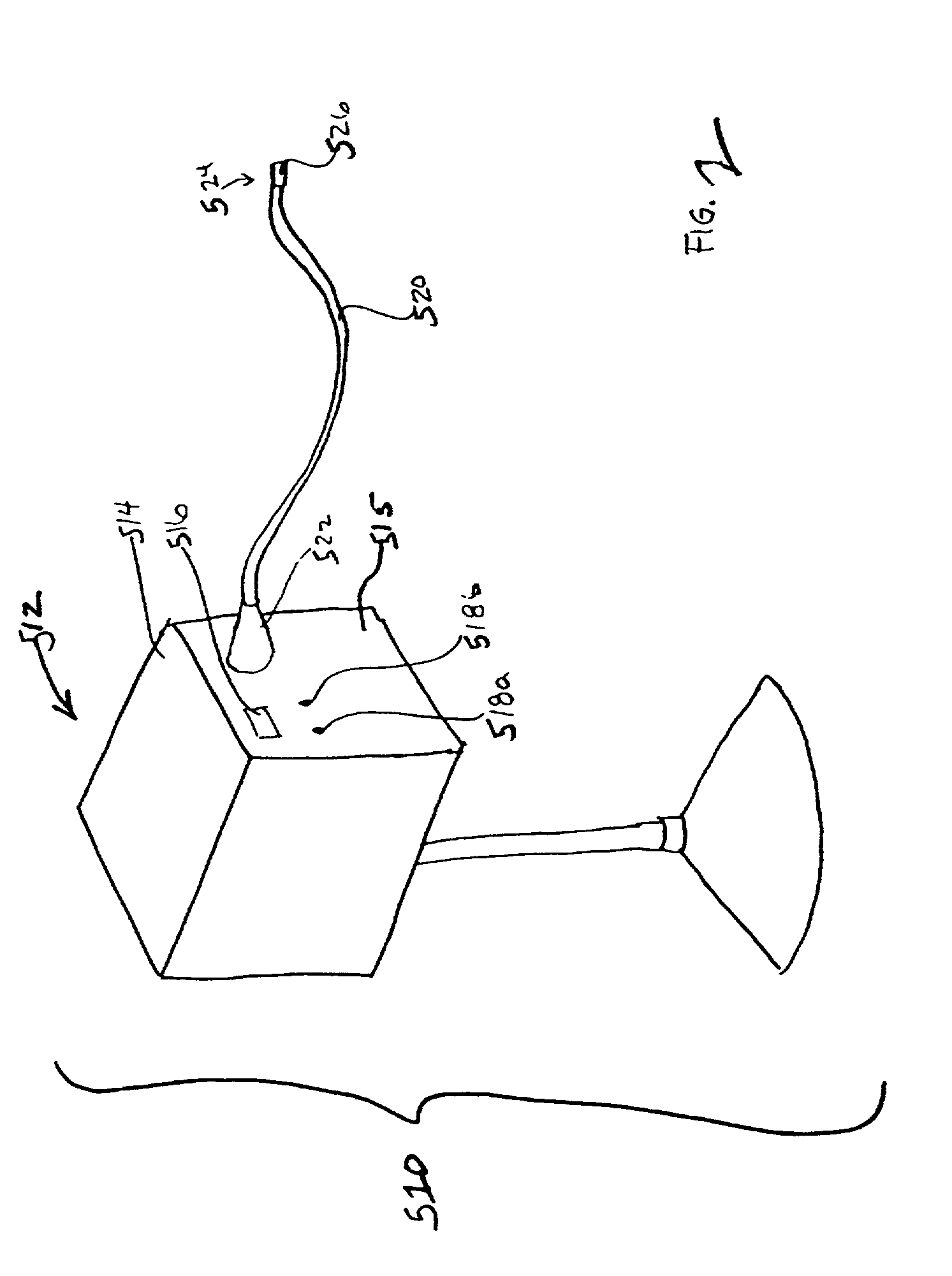

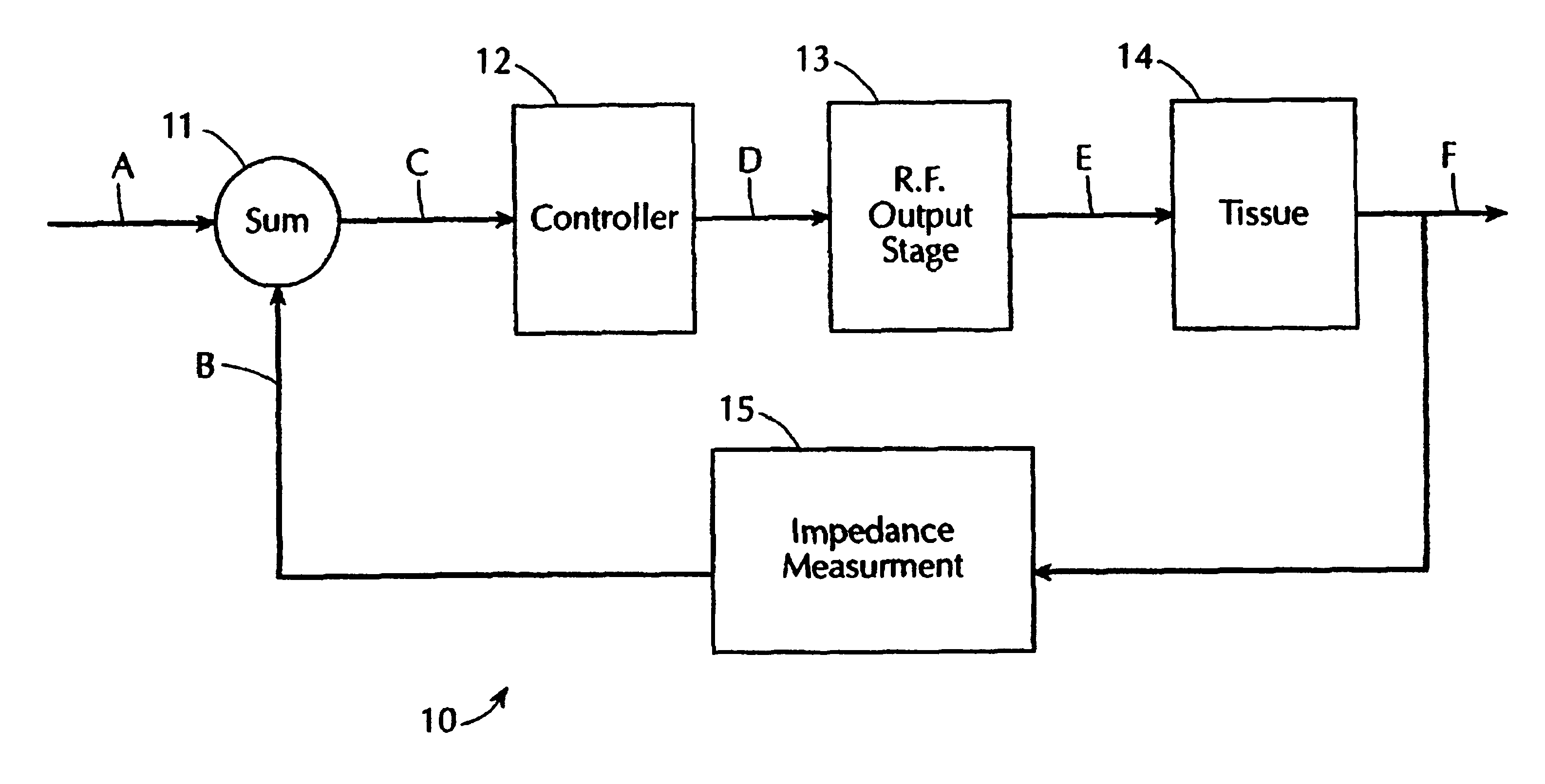

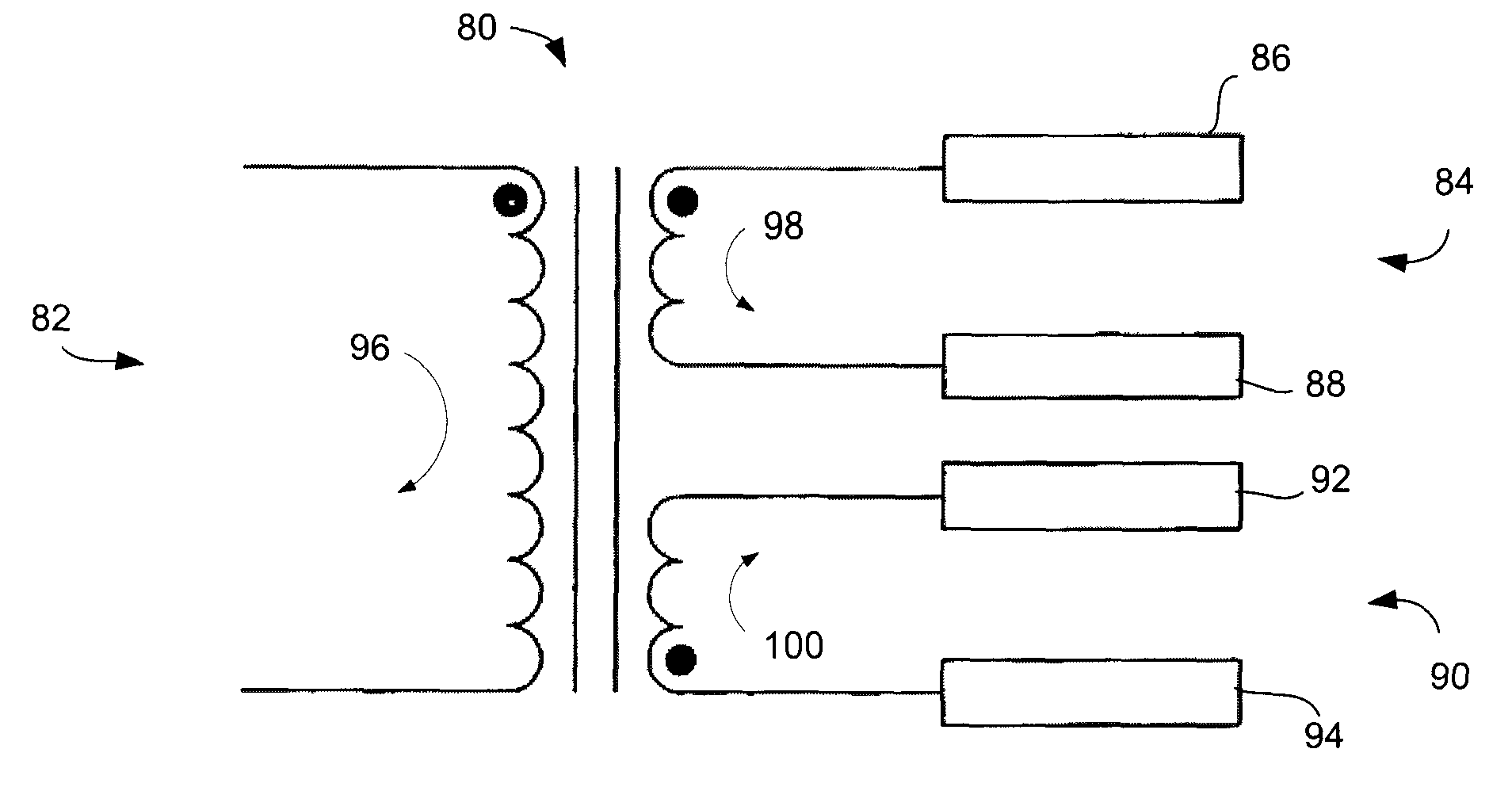

An electrosurgical generator has an output power control system that causes the impedance of tissue to rise and fall in a cyclic pattern until the tissue is desiccated. The advantage of the power control system is that thermal spread and charring are reduced. In addition, the power control system offers improved performance for electrosurgical vessel sealing and tissue welding. The output power is applied cyclically by a control system with tissue impedance feedback. The impedance of the tissue follows the cyclic pattern of the output power several times, depending on the state of the tissue, until the tissue becomes fully desiccated. High power is applied to cause the tissue to reach a high impedance, and then the power is reduced to allow the impedance to fall. Thermal energy is allowed to dissipate during the low power cycle. The control system is adaptive to tissue in the sense that output power is modulated in response to the impedance of the tissue.

Owner:COVIDIEN AG

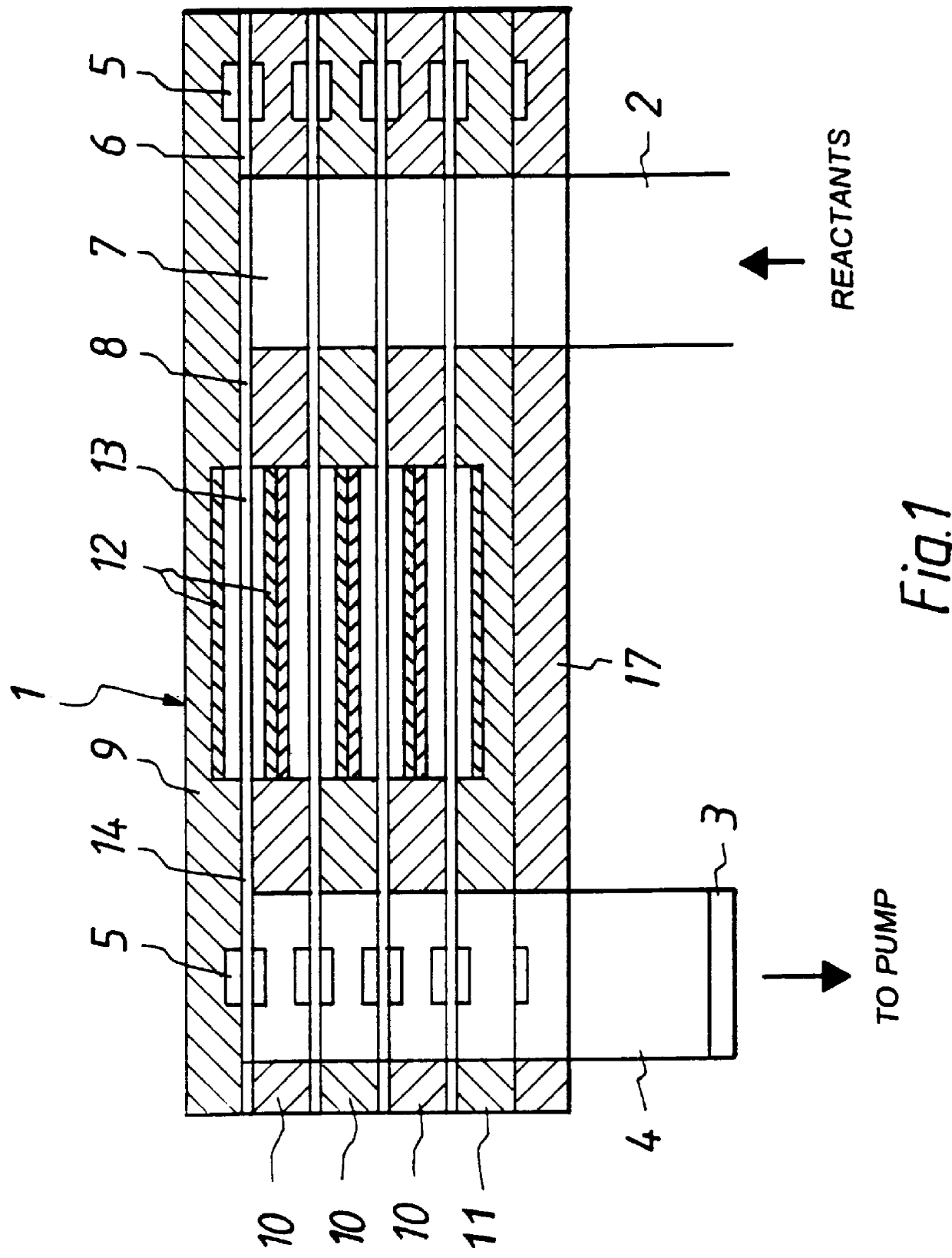

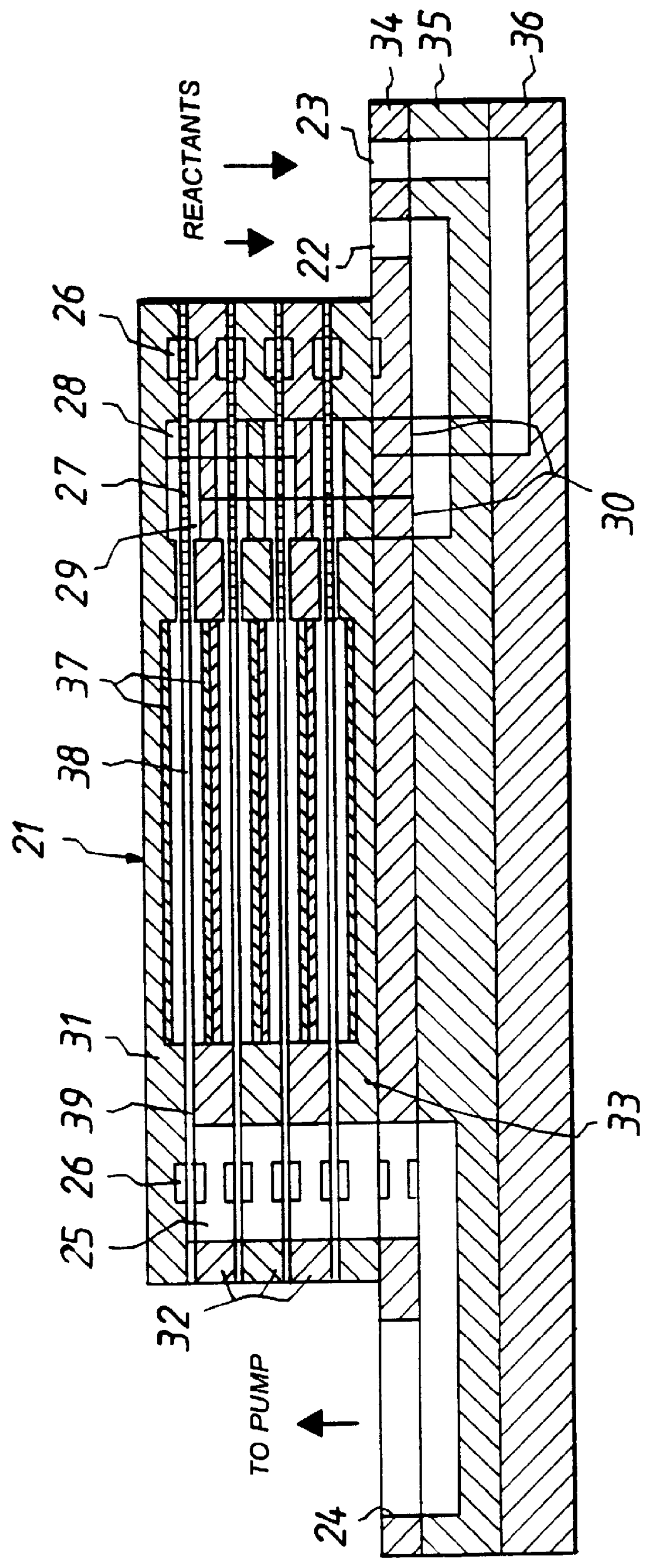

Method for growing thin films

InactiveUS6015590AMinimized volumeTrend downAfter-treatment apparatusPolycrystalline material growthChemistryVapor phase

PCT No. PCT / FI95 / 00658 Sec. 371 Date Sep. 25, 1996 Sec. 102(e) Date Sep. 25, 1996 PCT Filed Nov. 28, 1995 PCT Pub. No. WO96 / 17107 PCT Pub. Date Jun. 6, 1996A method for growing a thin film on a substrate. A substrate is placed in a reaction space. The substrate is subjected to at least two vapor phase reactants in the form of vapor phase pulses, repeatedly and alternately. Gas within the reaction space is purged between two successive vapor phase pulses essentially entirely by use of a pump connected to the reaction space. The reaction space is purged between two successive vapor phase pulses such that less than 1% of the residual components from the first vapor phase pulse remains prior to the inflow of the second vapor phase pulse.

Owner:ASM AMERICA INC

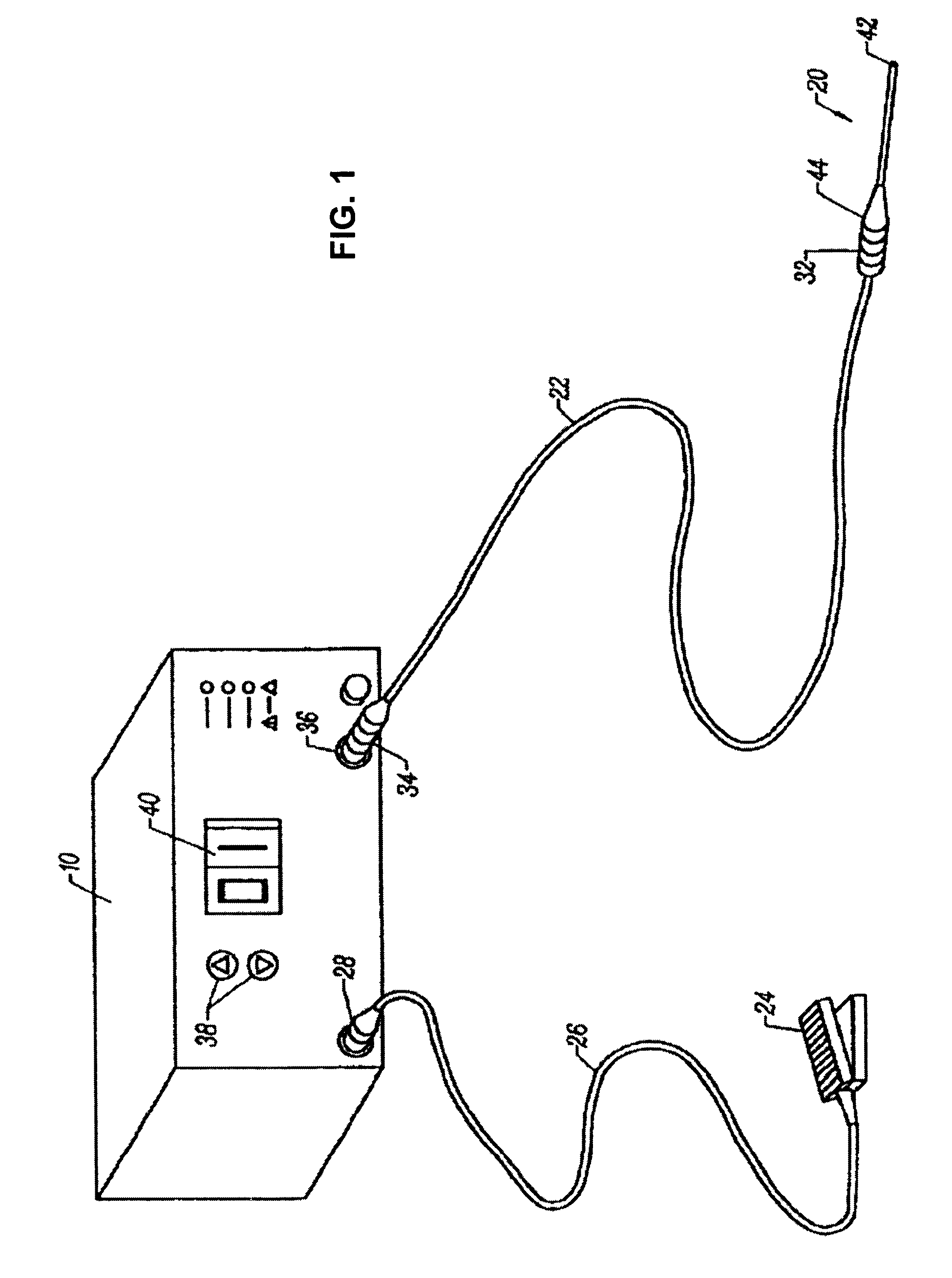

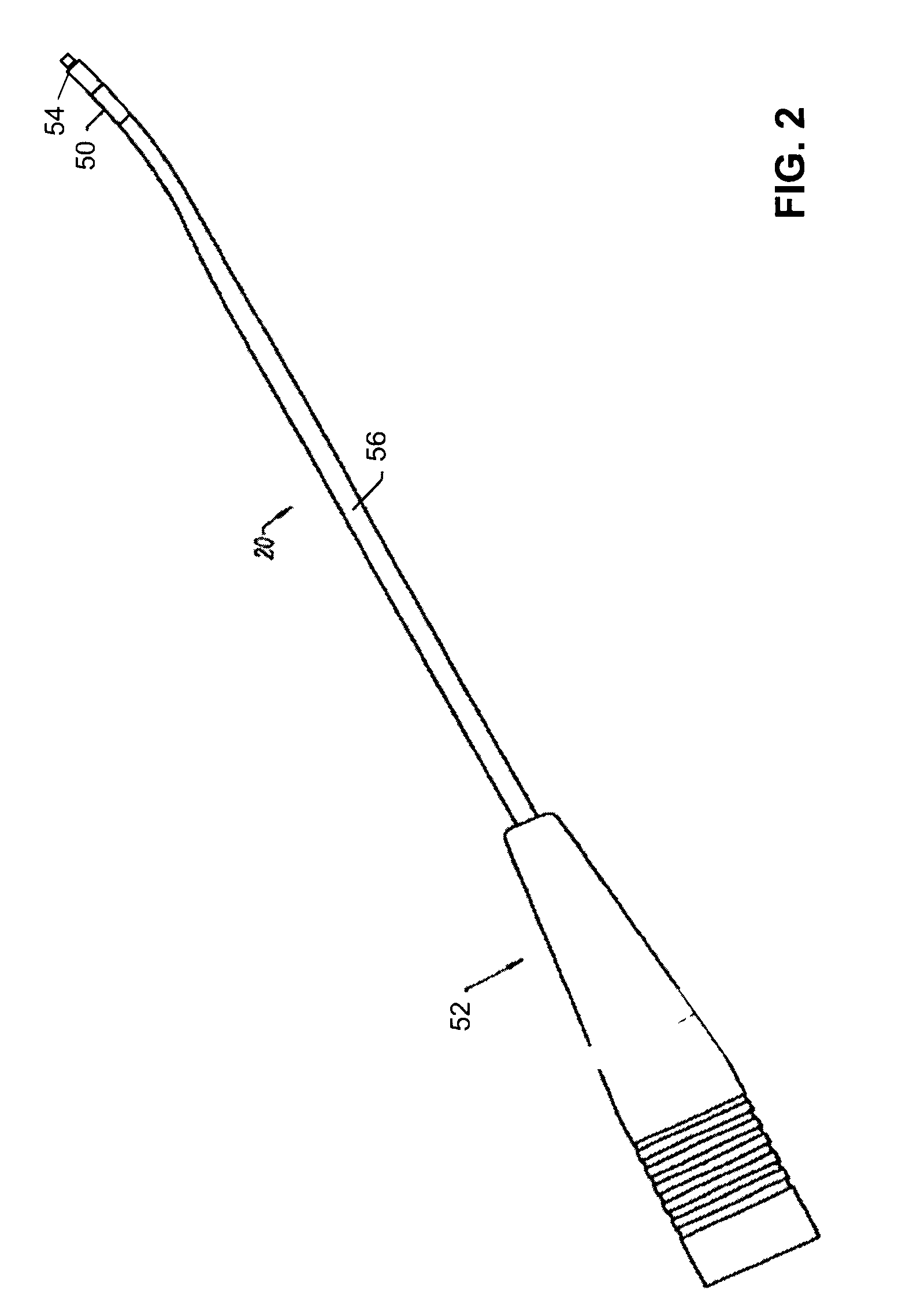

Ablation apparatus having reduced nerve stimulation and related methods

InactiveUS7862560B2Mitigating and eliminating undesired electrical stimulationTrend downSurgical instruments for heatingSurgical instruments for irrigation of substancesSacral nerve stimulationPhysical therapy

Apparatus and methods for reducing nerve stimulation in electrosurgical instruments utilizing electrically isolated pairs of electrodes are disclosed. At least two pairs of electrodes may be configured to create at least two opposing currents which effectively cancel one another such that a net current flow is inhibited from developing within surrounding tissue structures to mitigate or eliminate undesired electrical stimulation of the tissue.

Owner:ARTHROCARE

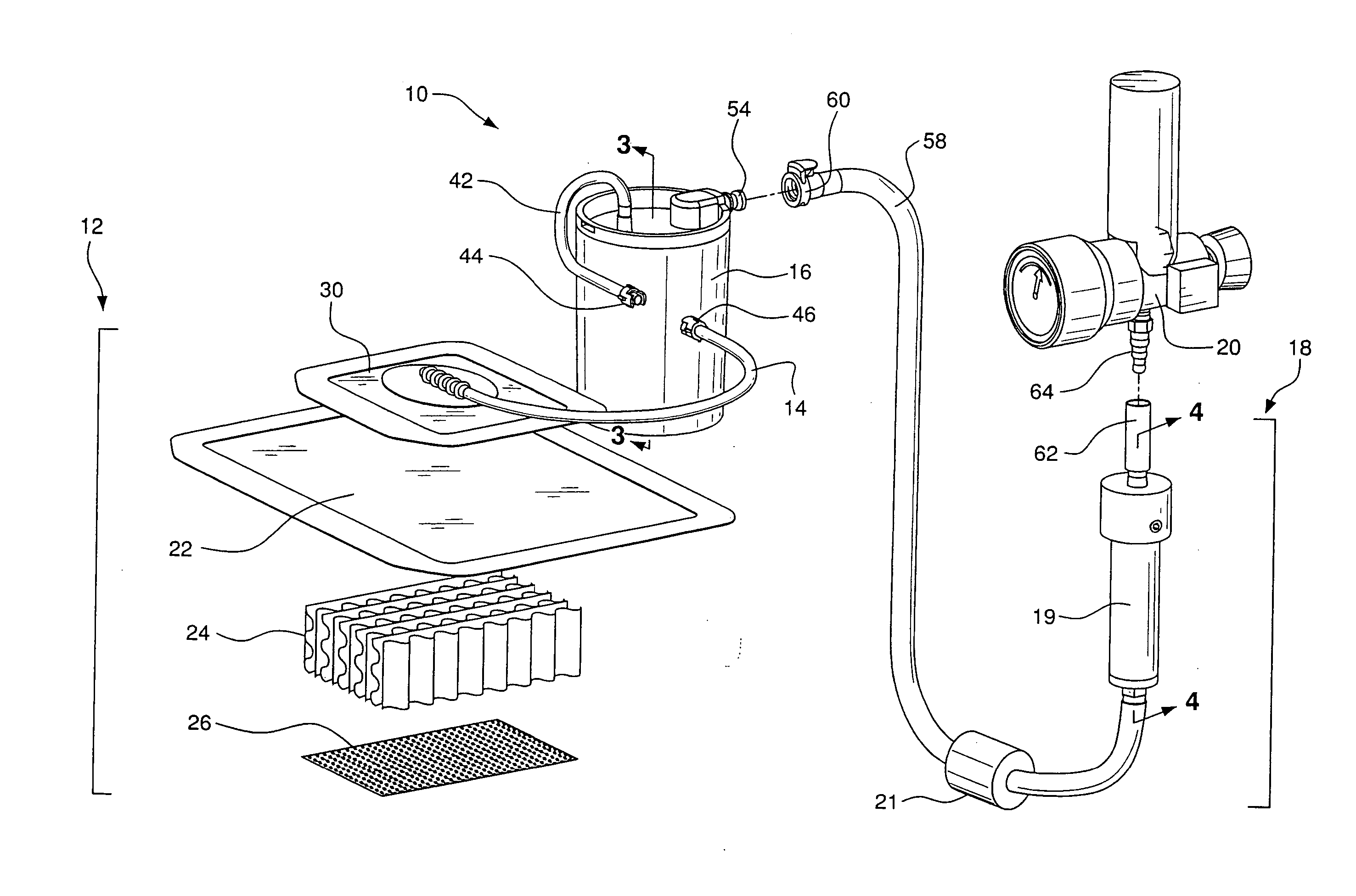

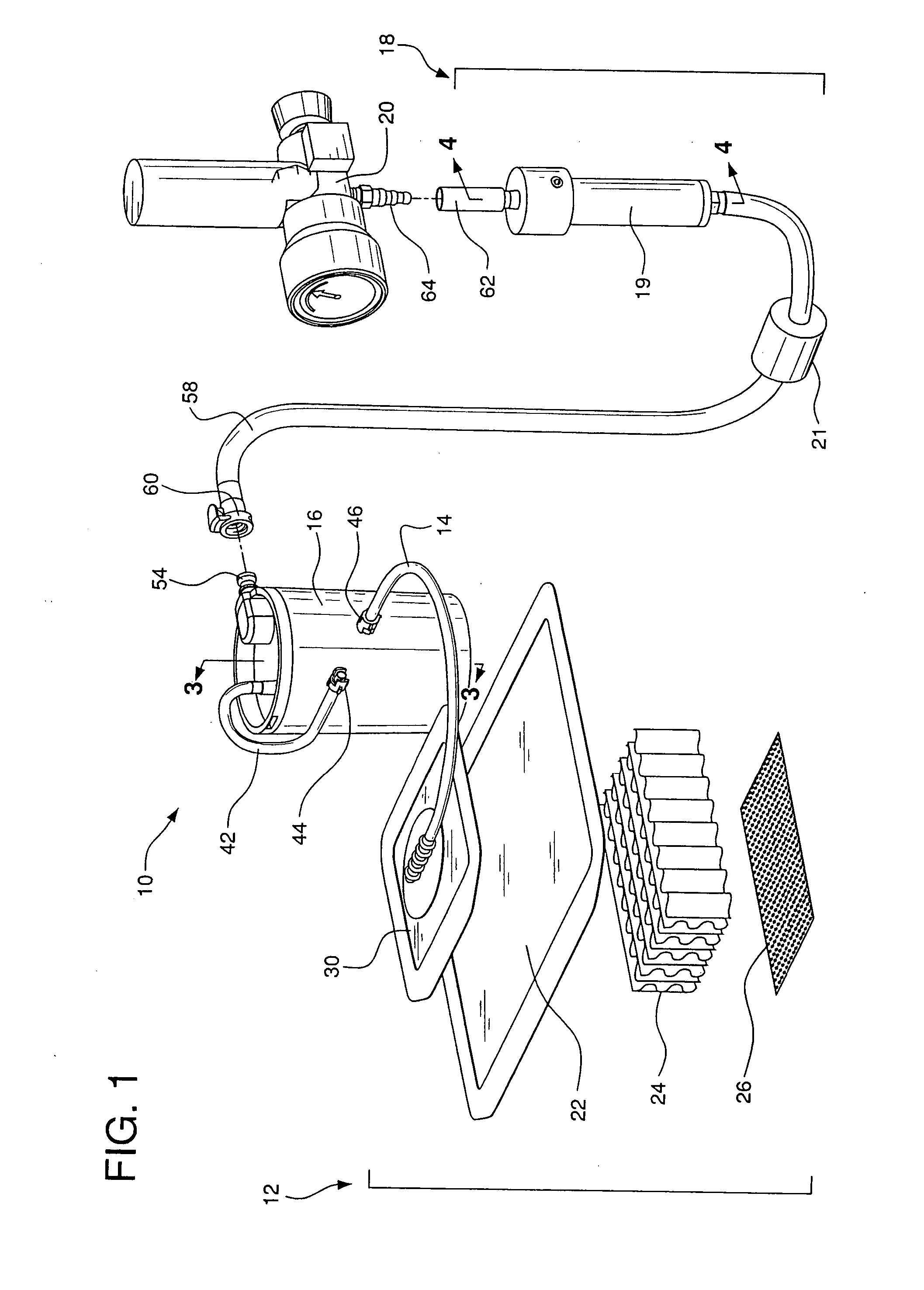

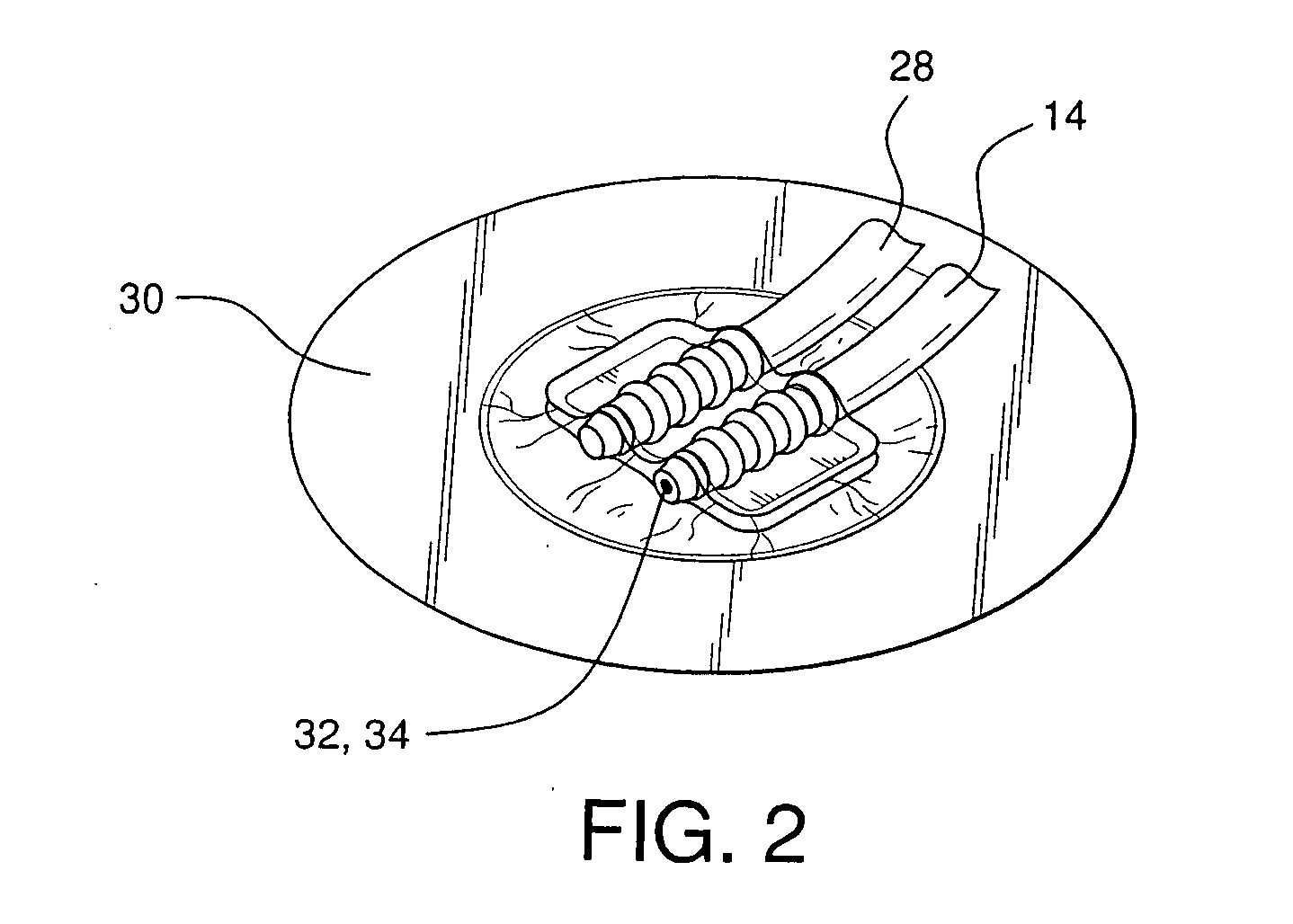

Pump system for negative pressure wound therapy

ActiveUS20070219532A1Reduce the possibilityTrend downWound drainsMedical devicesLevel sensorEngineering

A pump system for applying negative pressure to a wound, including a flow monitor capable of detecting a deviation from a reference airflow rate provided by a controlled leak to determine whether the system is operating normally or abnormally, and a flow status annunciator to indicate a normal operating condition or whether an abnormal condition is a leak or an occluded line in the system. The pump system further includes a pressure controller for regulating operation of a pump to control pressure in the system at a range around a user-selected setpoint. The pump system may also include a waste collector and a level sensor for detecting when the collector is full.

Owner:PAUL HARTMANN AG

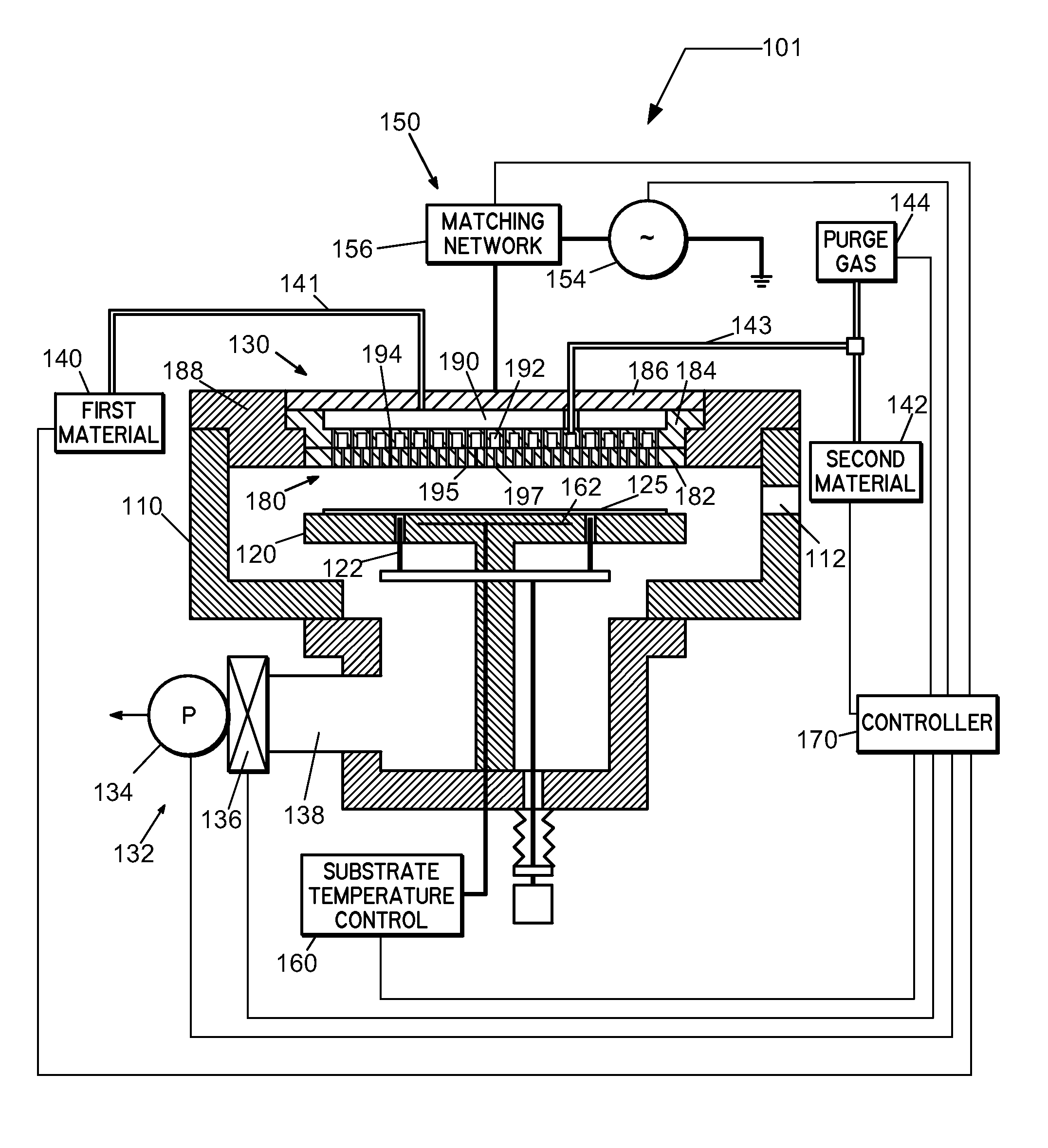

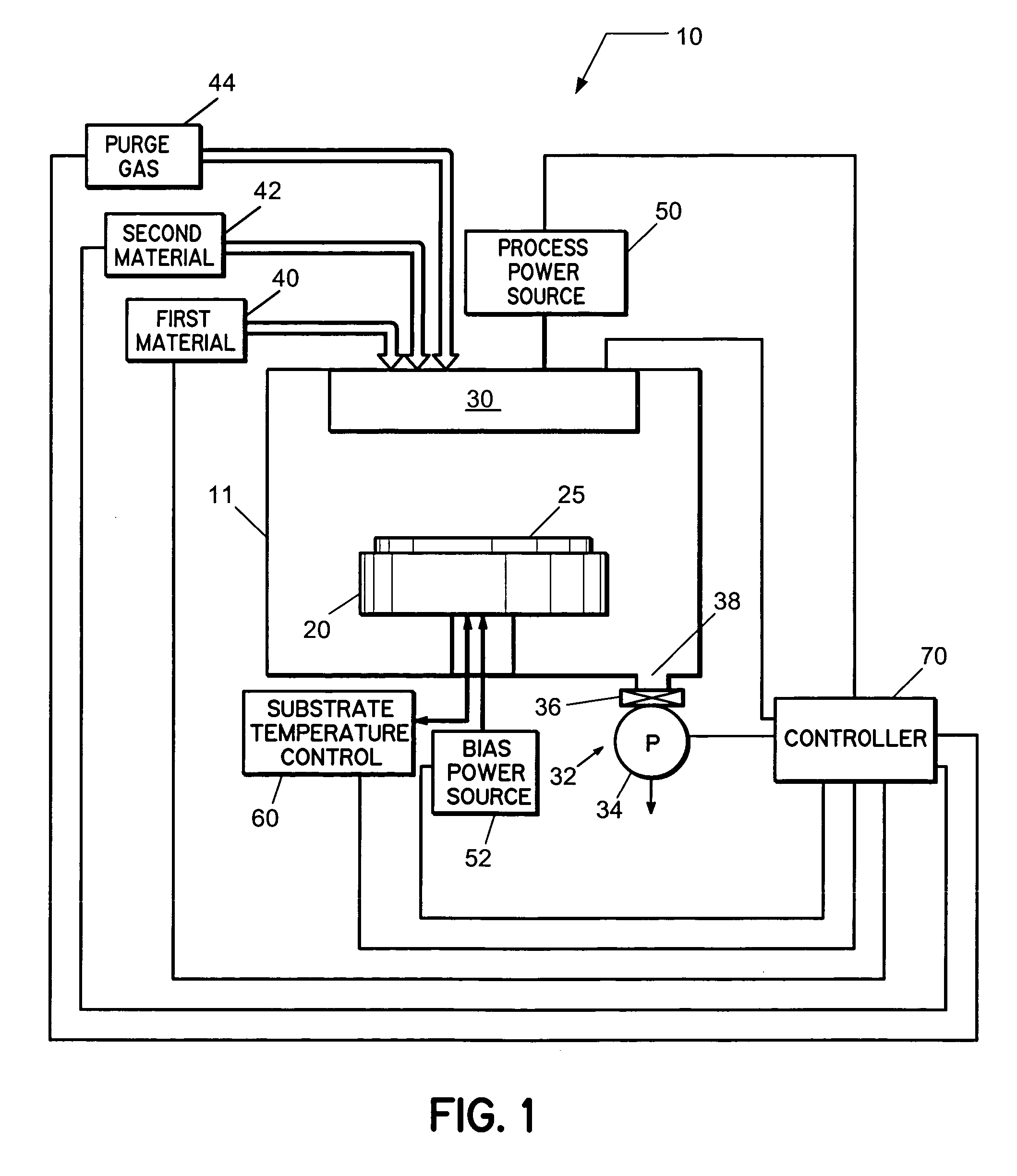

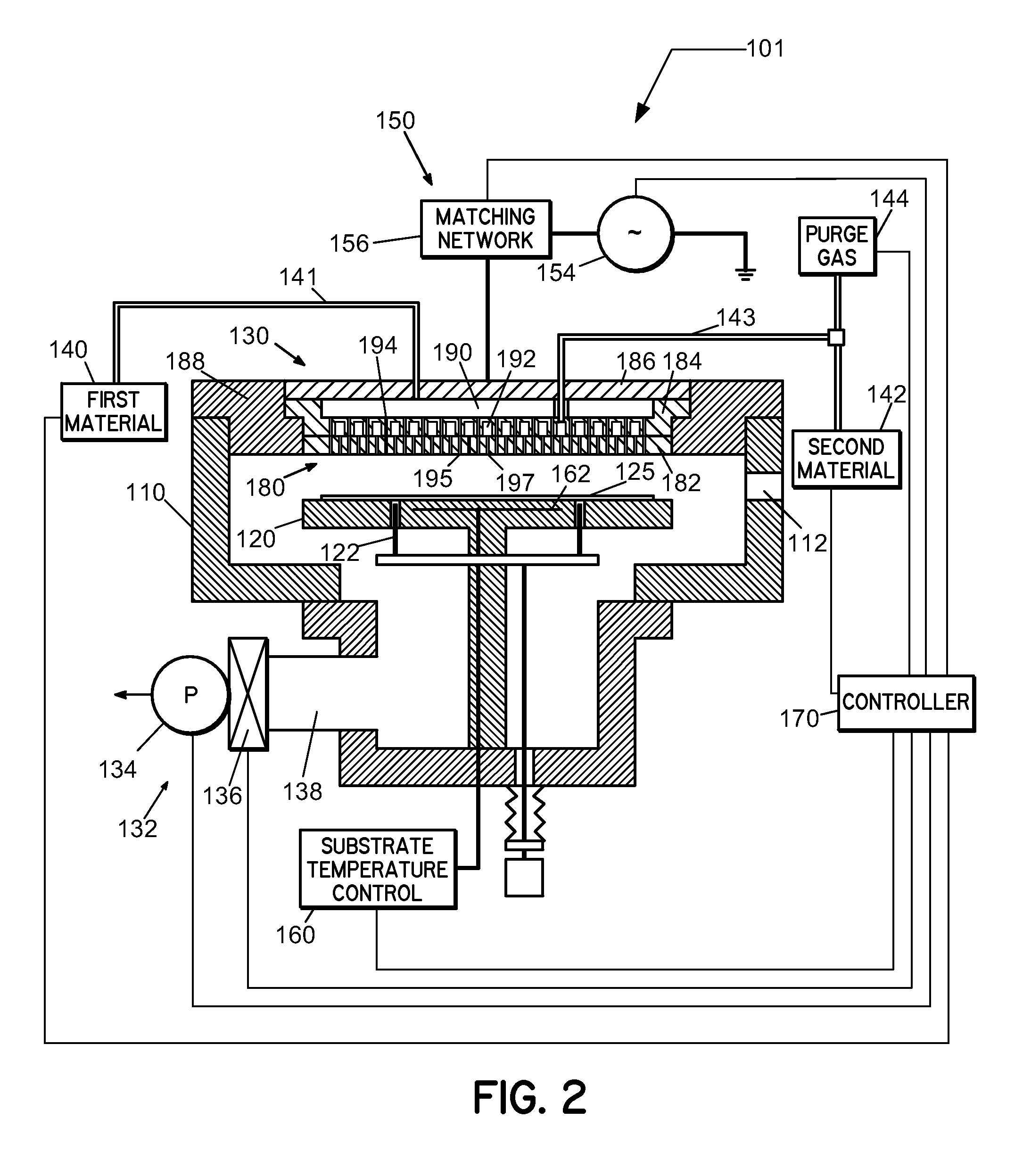

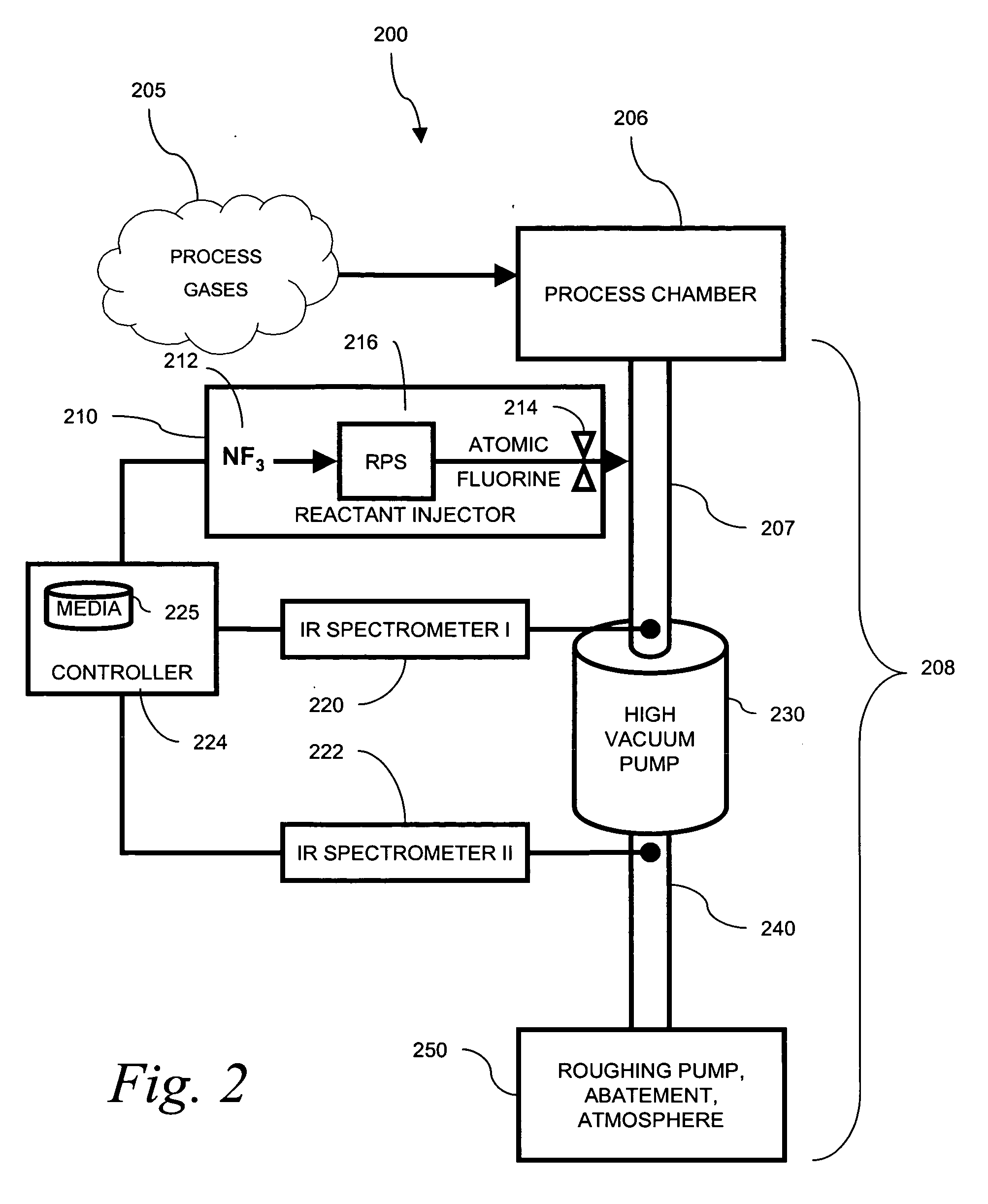

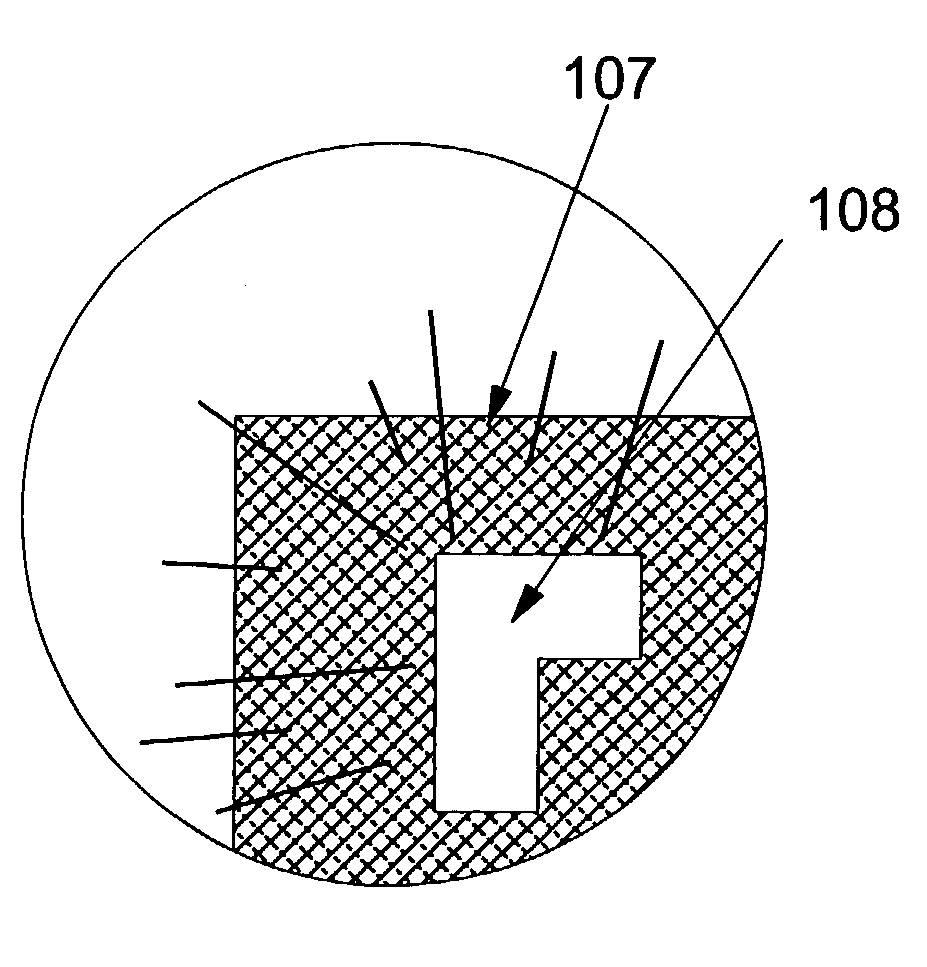

Plasma enhanced atomic layer deposition system having reduced contamination

ActiveUS7422636B2Reduce pollutionEnhance layeringLiquid surface applicatorsSemiconductor/solid-state device manufacturingAtomic layer depositionContamination

A plasma enhanced atomic layer deposition (PEALD) system is described, wherein the system comprises a processing space and a high vacuum, ultra-clean transfer space. During processing, the substrate to which the thin conformal film is formed is exposed to the processing space. During substrate transfer, the substrate is exposed to the high vacuum space. Processing gases are introduced sequentially and alternately to the process chamber and the pressures and gas flows within, to and from, and between the process chamber and the high vacuum transfer space are controlled to keep the transfer space ultra-clean.

Owner:TOKYO ELECTRON LTD

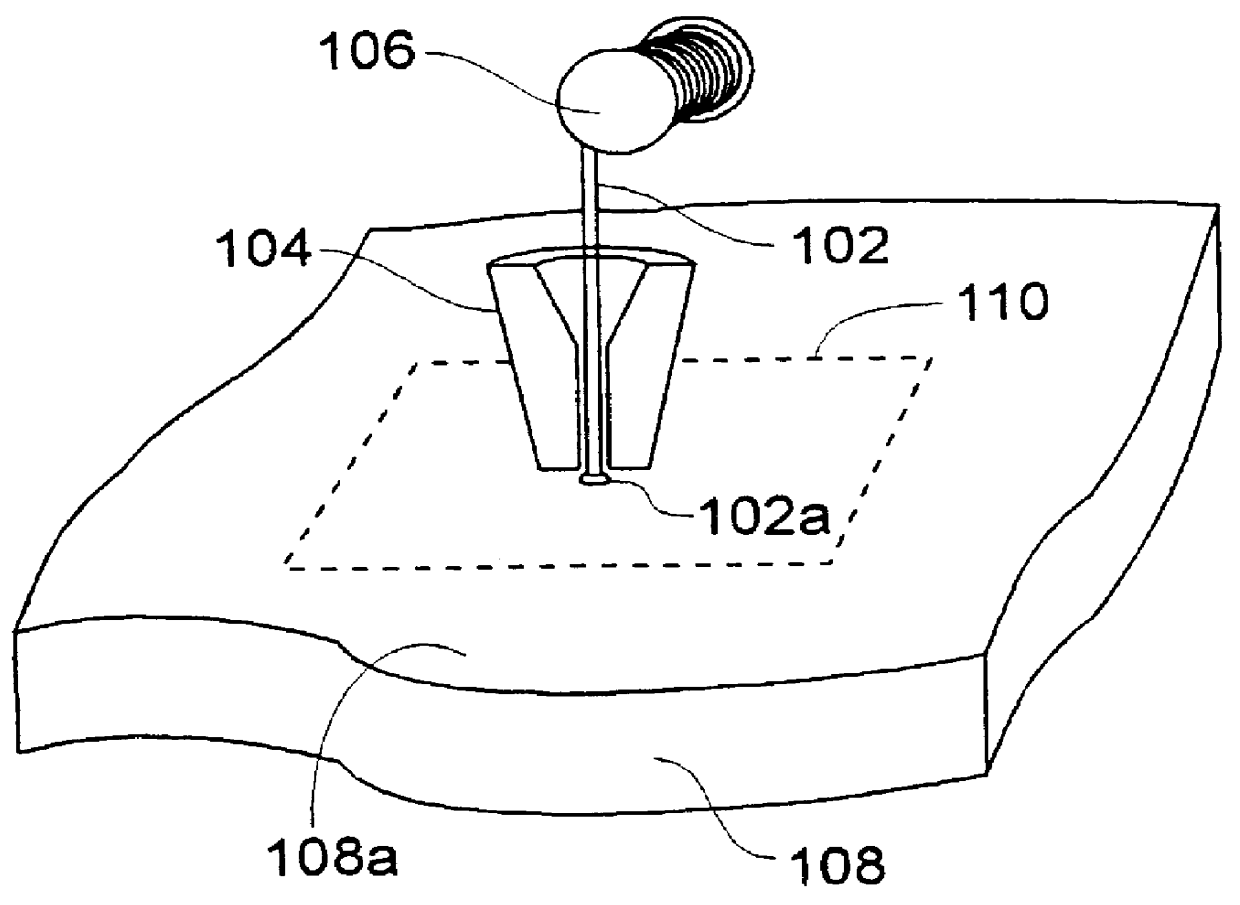

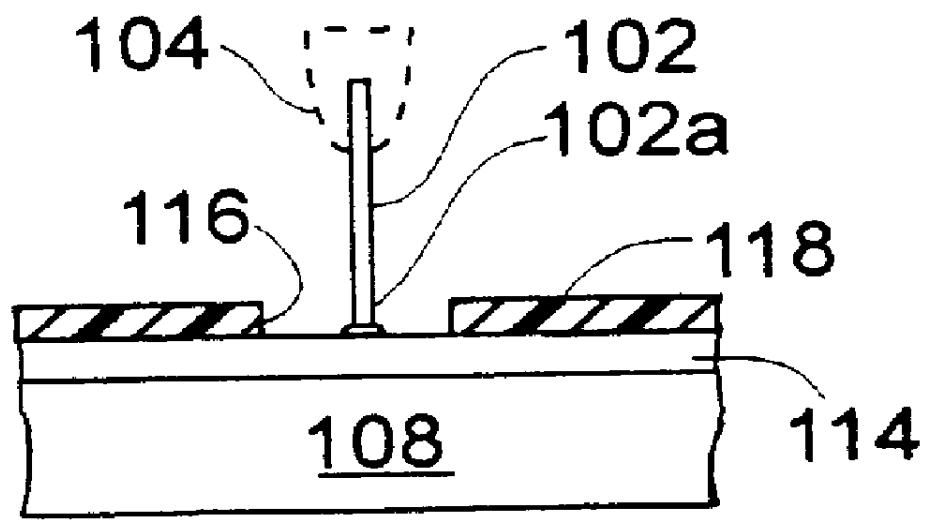

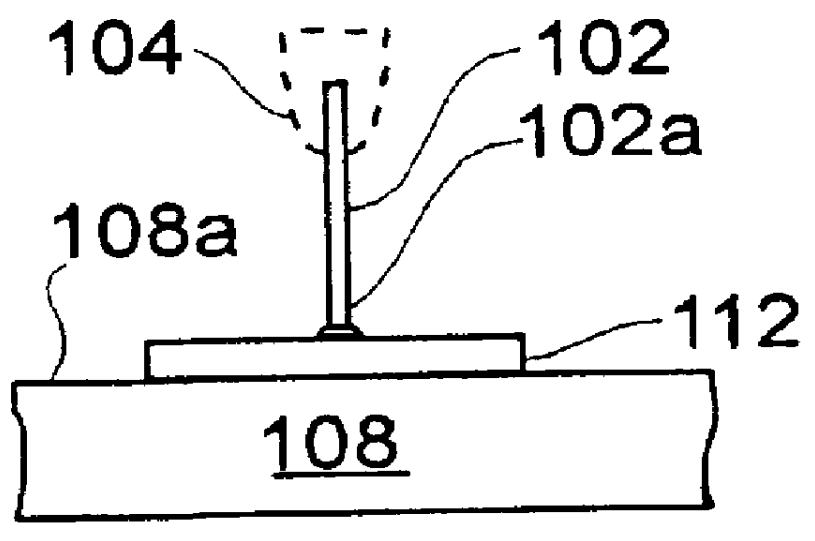

Method of modifying the thickness of a plating on a member by creating a temperature gradient on the member, applications for employing such a method, and structures resulting from such a method

InactiveUS6110823ASimple technologyTrend downSemiconductor/solid-state device testing/measurementFinal product manufactureEngineeringElectronic component

Contact structures exhibiting resilience or compliance for a variety of electronic components are formed by bonding a free end of a wire to a substrate, configuring thw wire into a wire stem having a springable shape, serving thw wire stem, and overcoating the wire stem with at least one layer of a material chosen primarily for its structural (resiliency, compliance) characteristics. A variety of techniques for configuring, serving, and overcoating the wire stem are disclosed. In an exemplary embodiment, a free end of a wire stem is bonded to a contact area on a substrate, the wire stem is configured to ahve a springable shape, the wire stem is served to be free-standing by an electrical discharge, and the free-standing wire stem is overcoating by plating.

Owner:FORMFACTOR INC

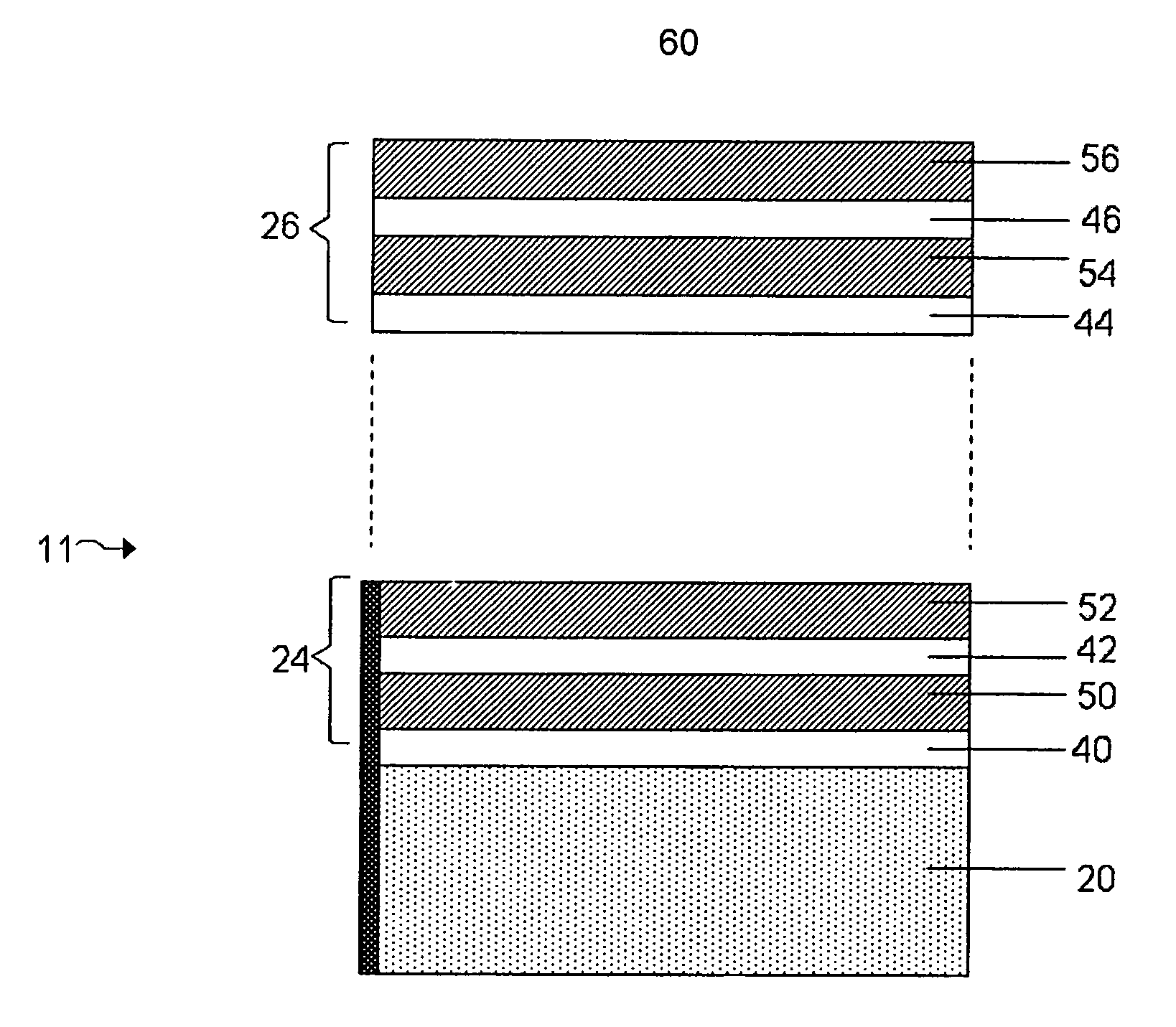

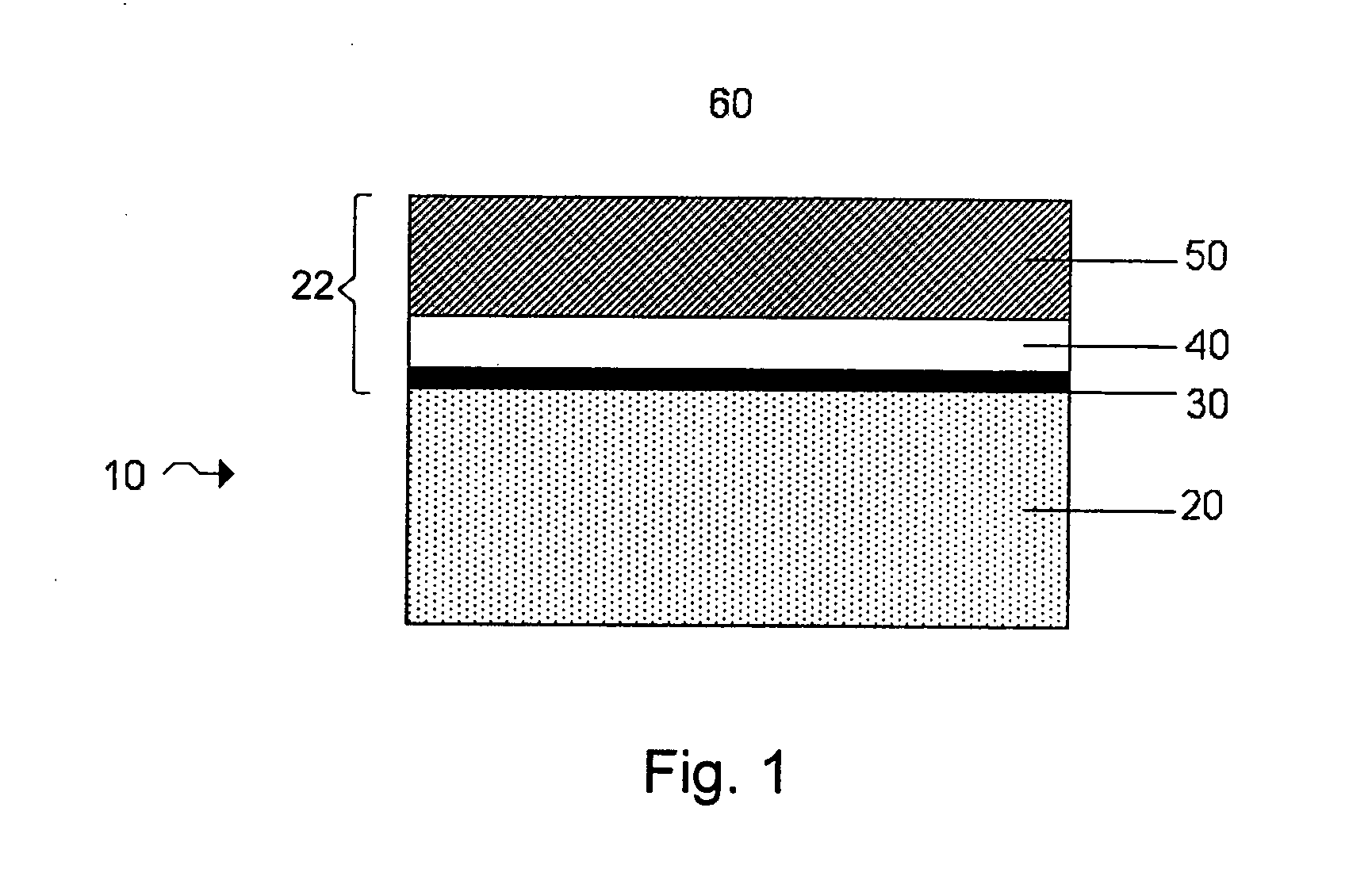

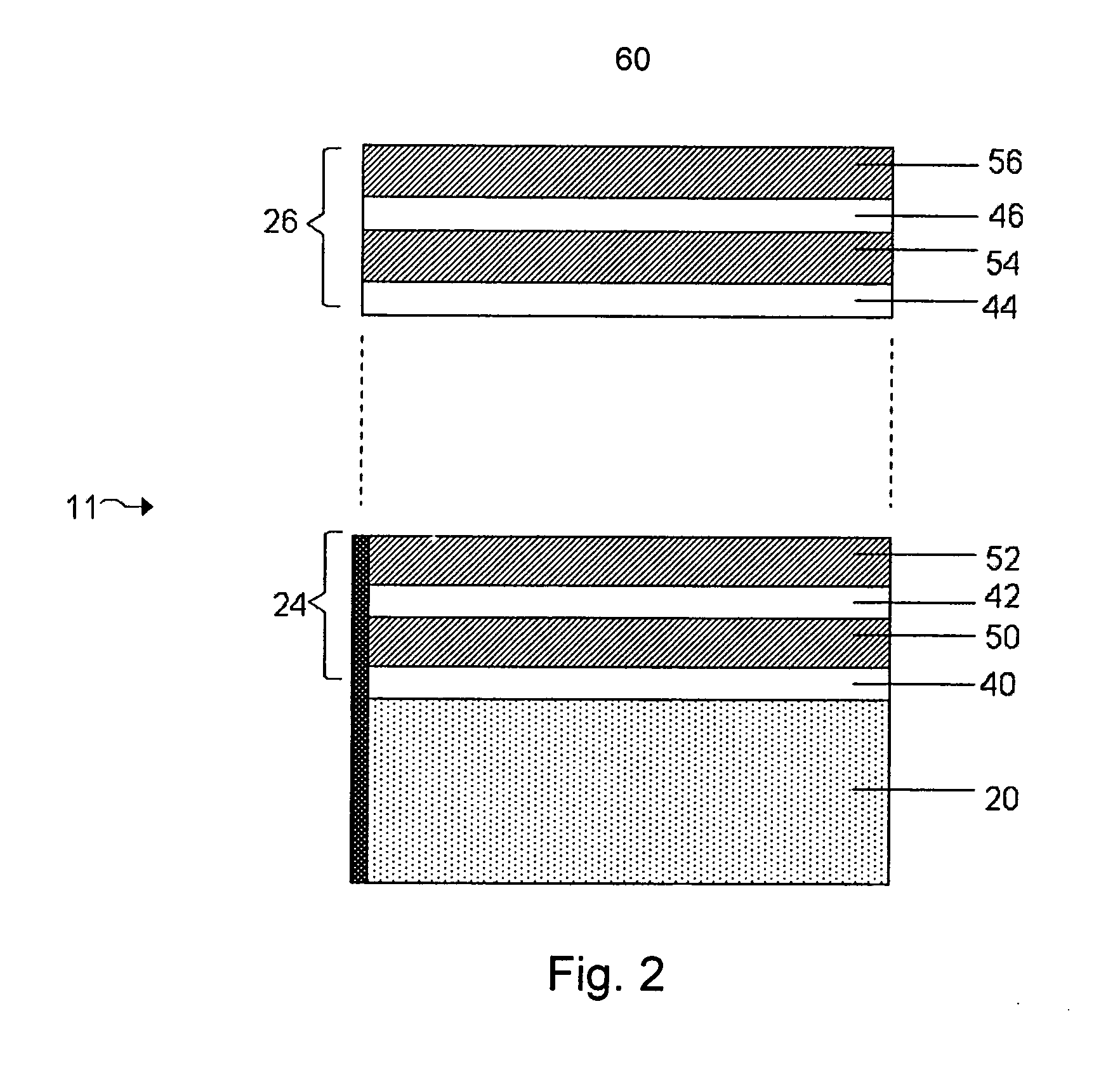

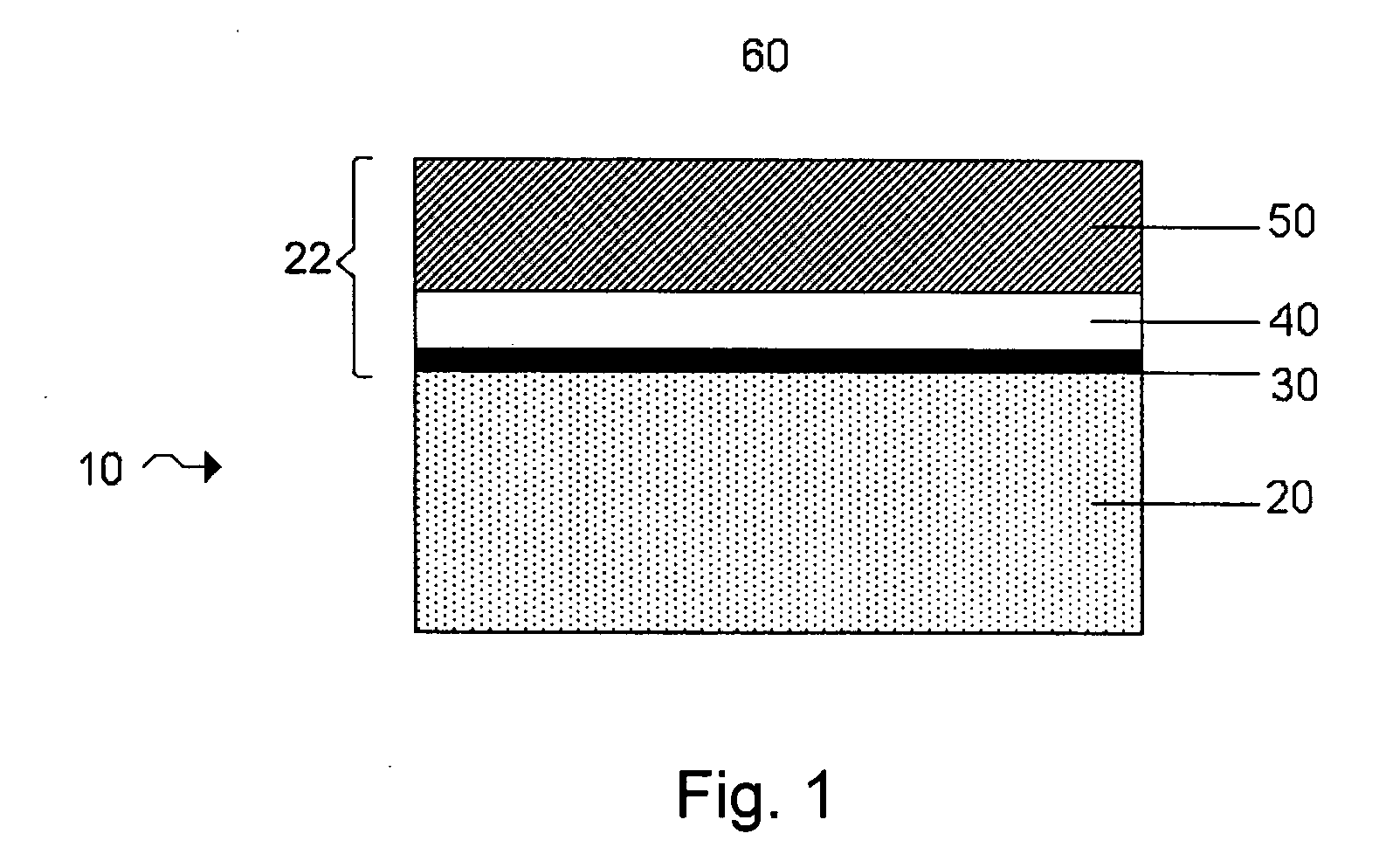

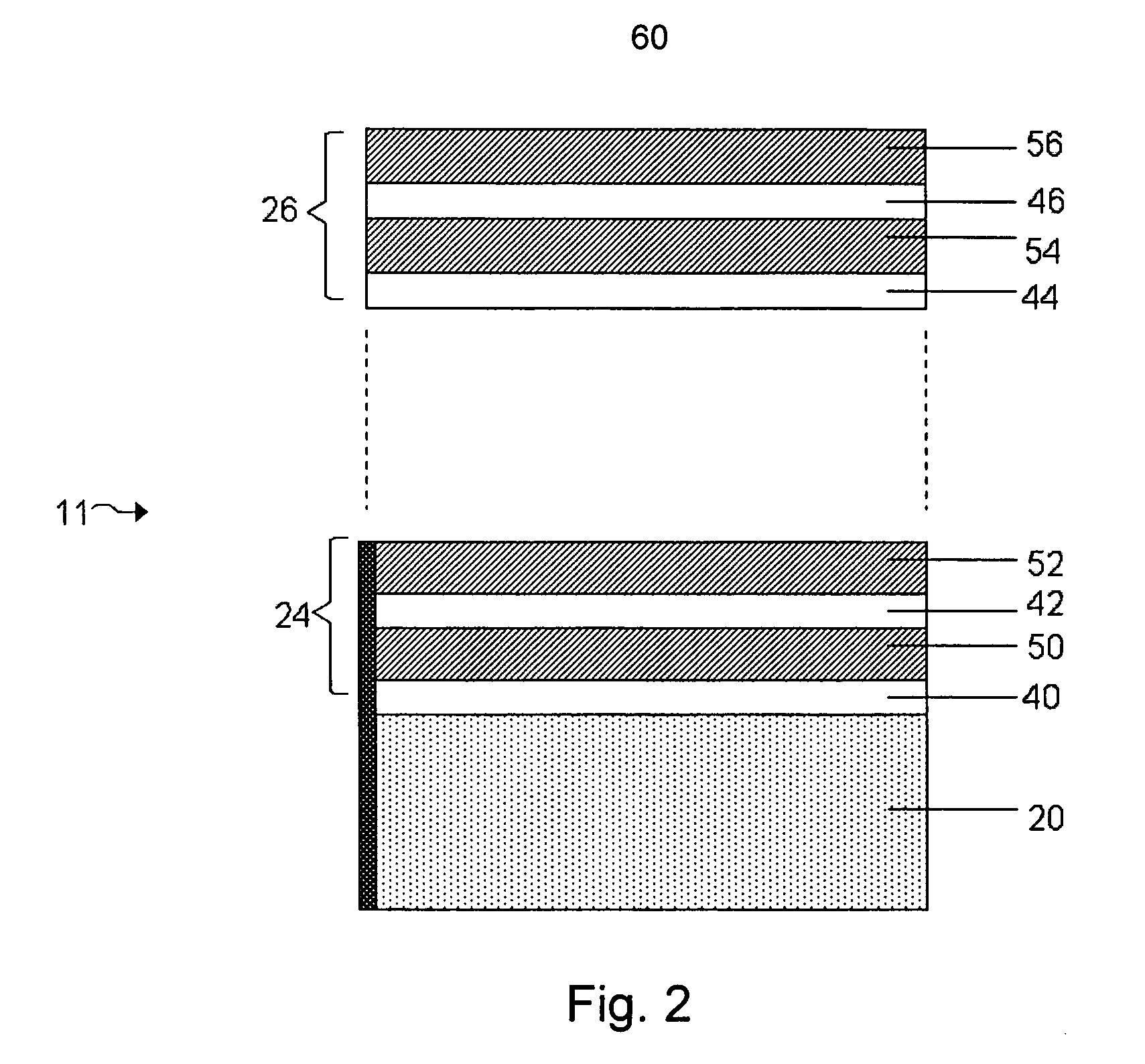

Rechargeable lithium/water, lithium/air batteries

InactiveUS20070221265A1Improve protectionEasy to controlFinal product manufacturePV power plantsHigh energyOptoelectronics

Electrochemical cells, and more specifically, rechargeable batteries comprising lithium anodes for use in water and / or air environments, as well as non-aqueous and non-air environments, are presented. In one embodiment, an electrochemical cell includes an anode comprising lithium and a multi-layered structure positioned between the anode and an electrolyte of the cell. A multi-layered structure can include at least a first single-ion conductive material layer (e.g., a lithiated metal layer), and at least a first polymeric layer positioned between the anode and the single-ion conductive material. The invention also can provide an electrode stabilization layer positioned within the electrode, i.e., between one portion and another portion of an electrode, to control depletion and re-plating of electrode material upon charge and discharge of a battery. Advantageously, electrochemical cells comprising combinations of structures described herein are not only compatible with environments that are typically unsuitable for lithium, but the cells may be also capable of displaying long cycle life, high lithium cycling efficiency, and high energy density.

Owner:SION POWER CORP

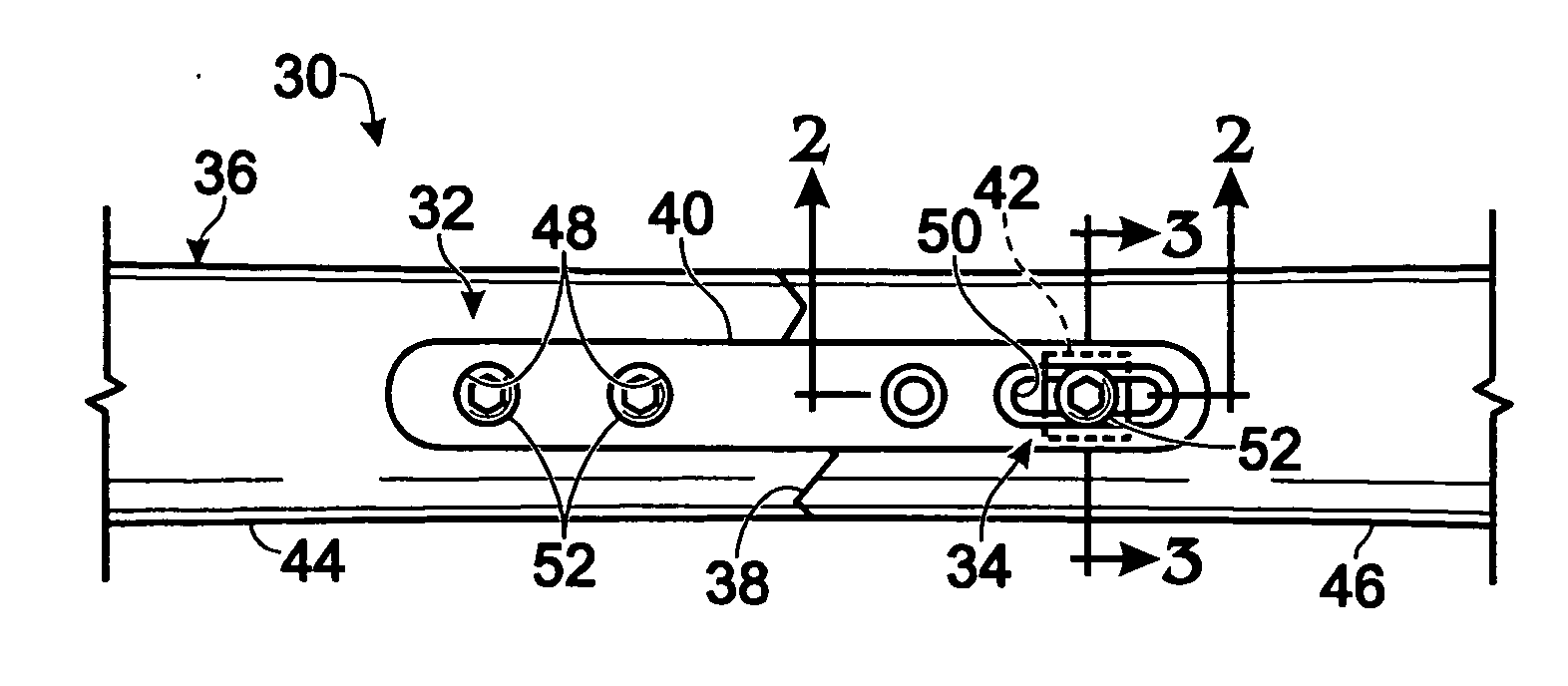

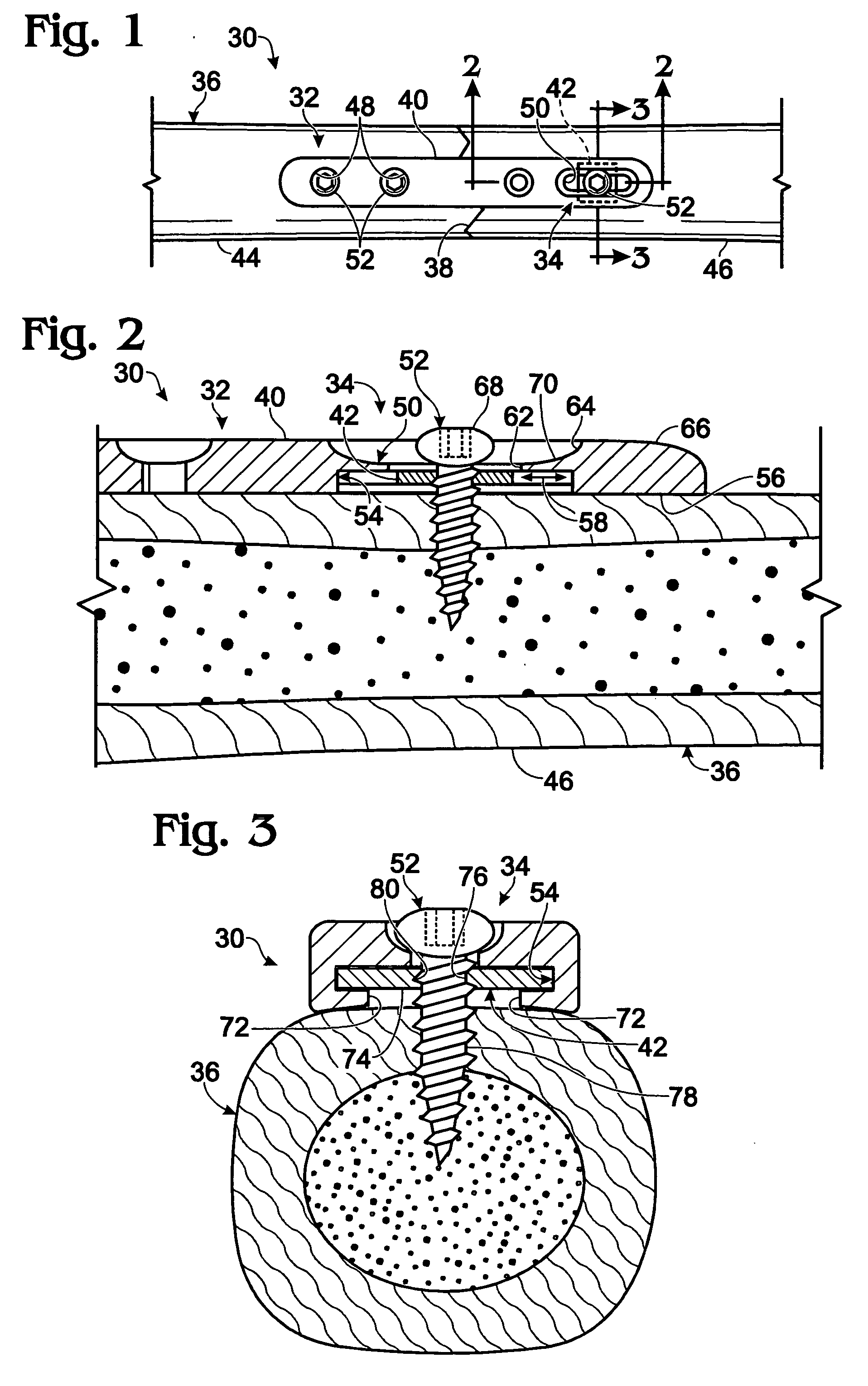

Bone plates with movable locking elements

ActiveUS20070055251A1Reduce discontinuityReduce chanceJoint implantsBone platesEngineeringMechanical engineering

System, including methods, apparatus, and kits, for fixing bones with bone plates having movable locking elements.

Owner:ACUMED

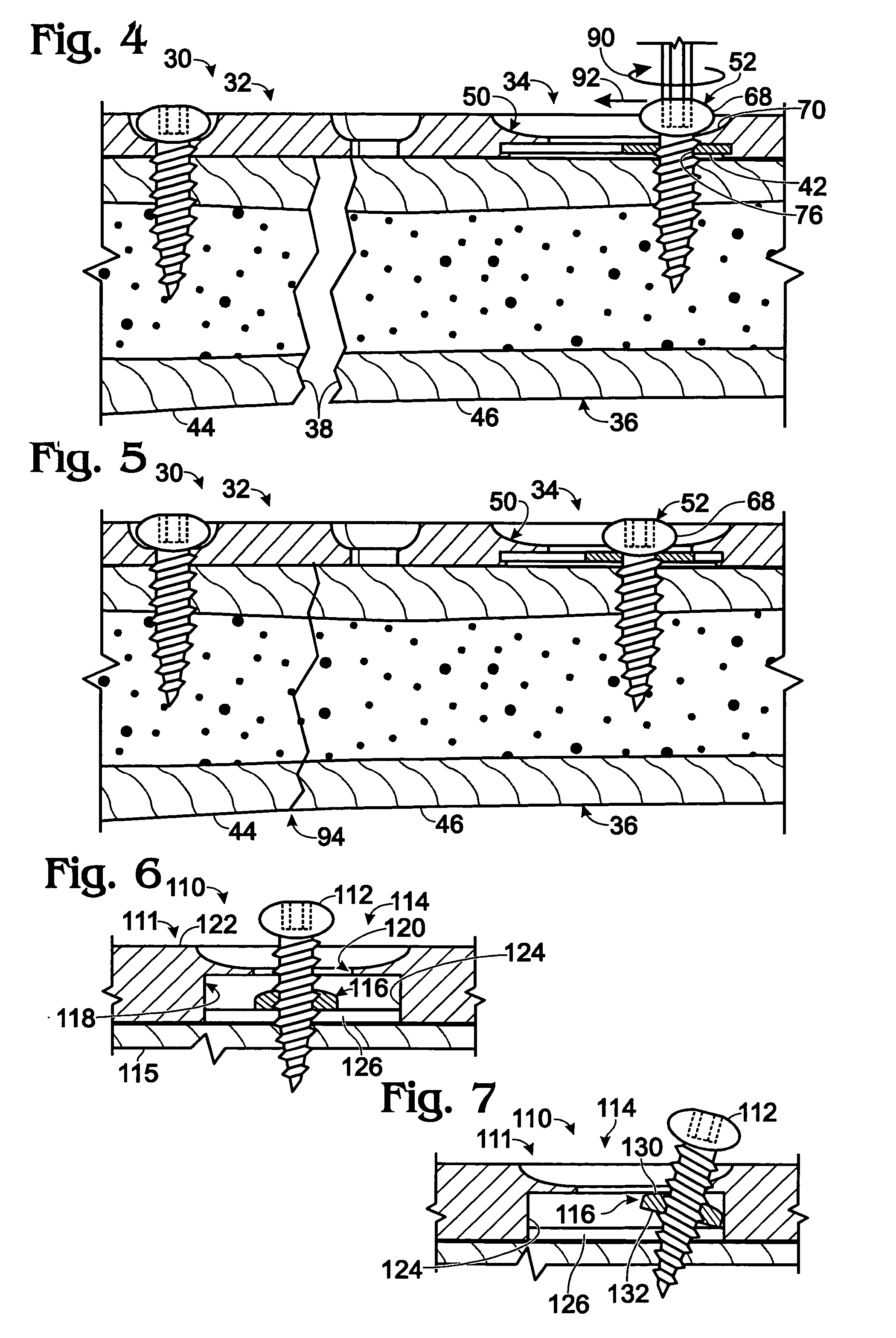

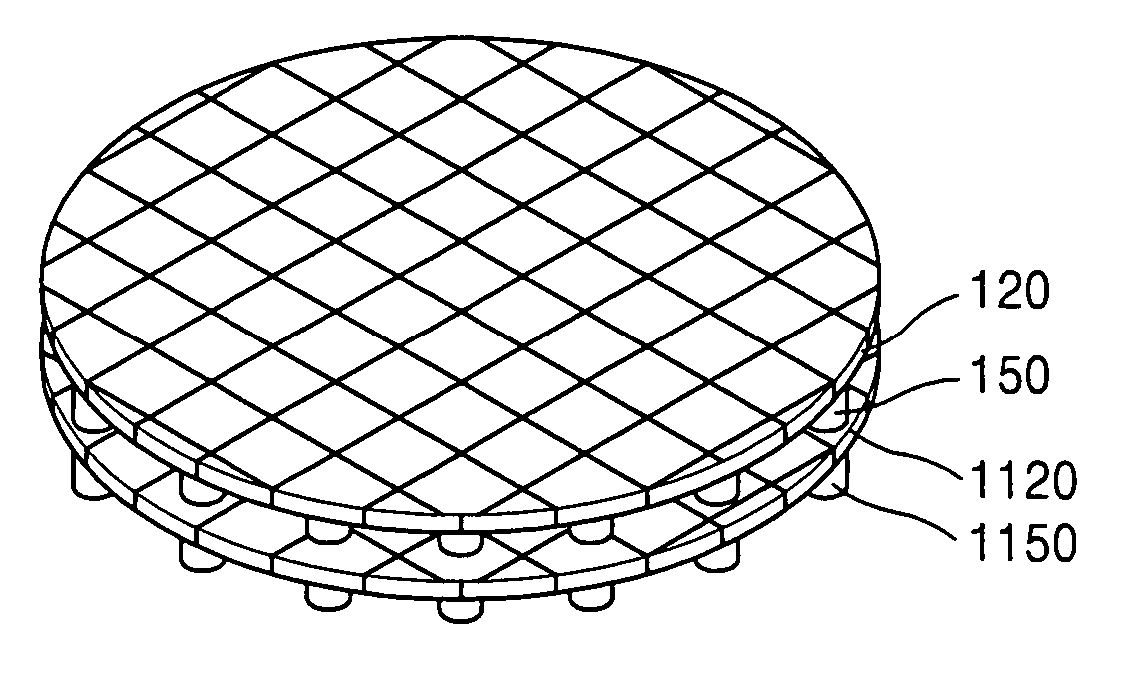

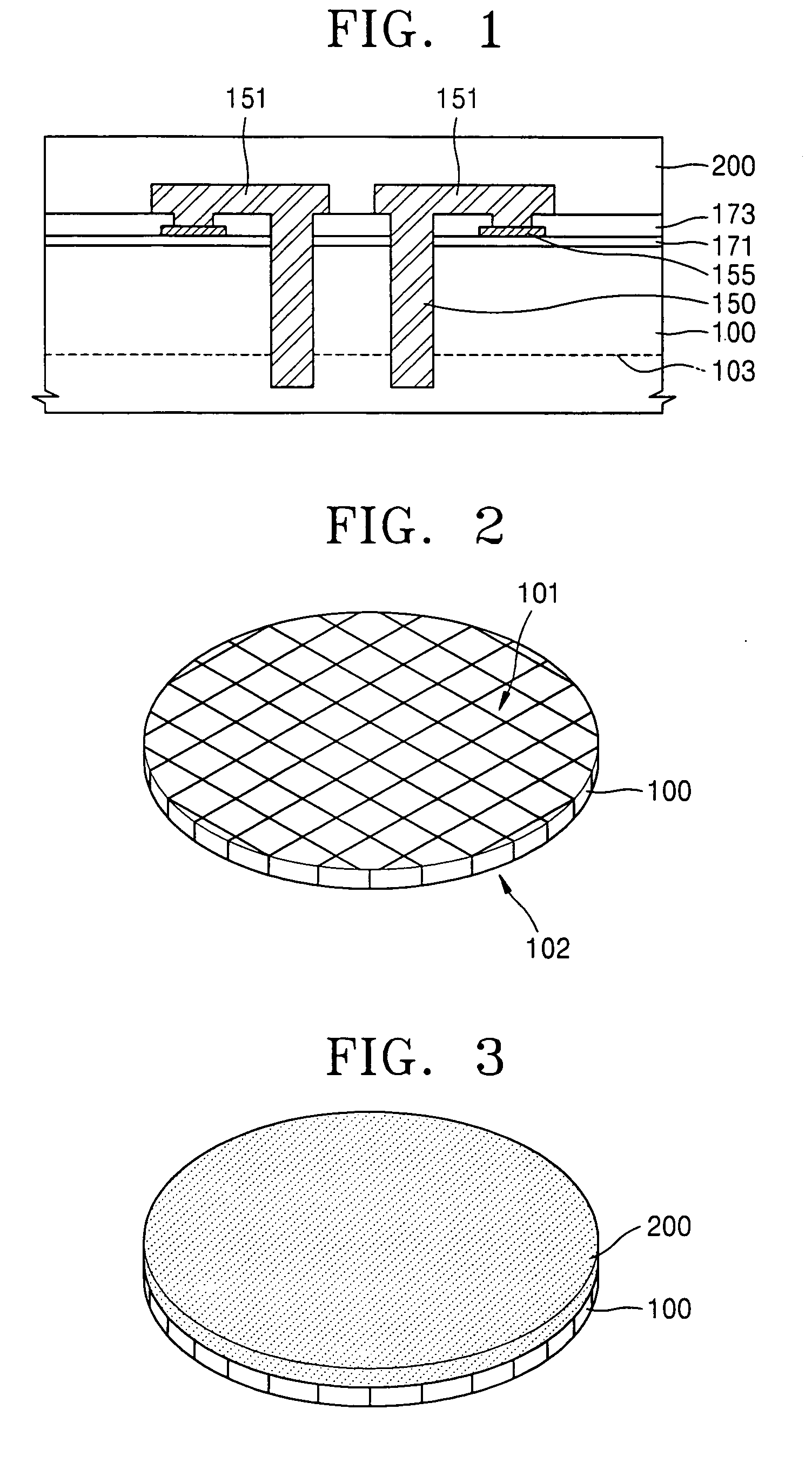

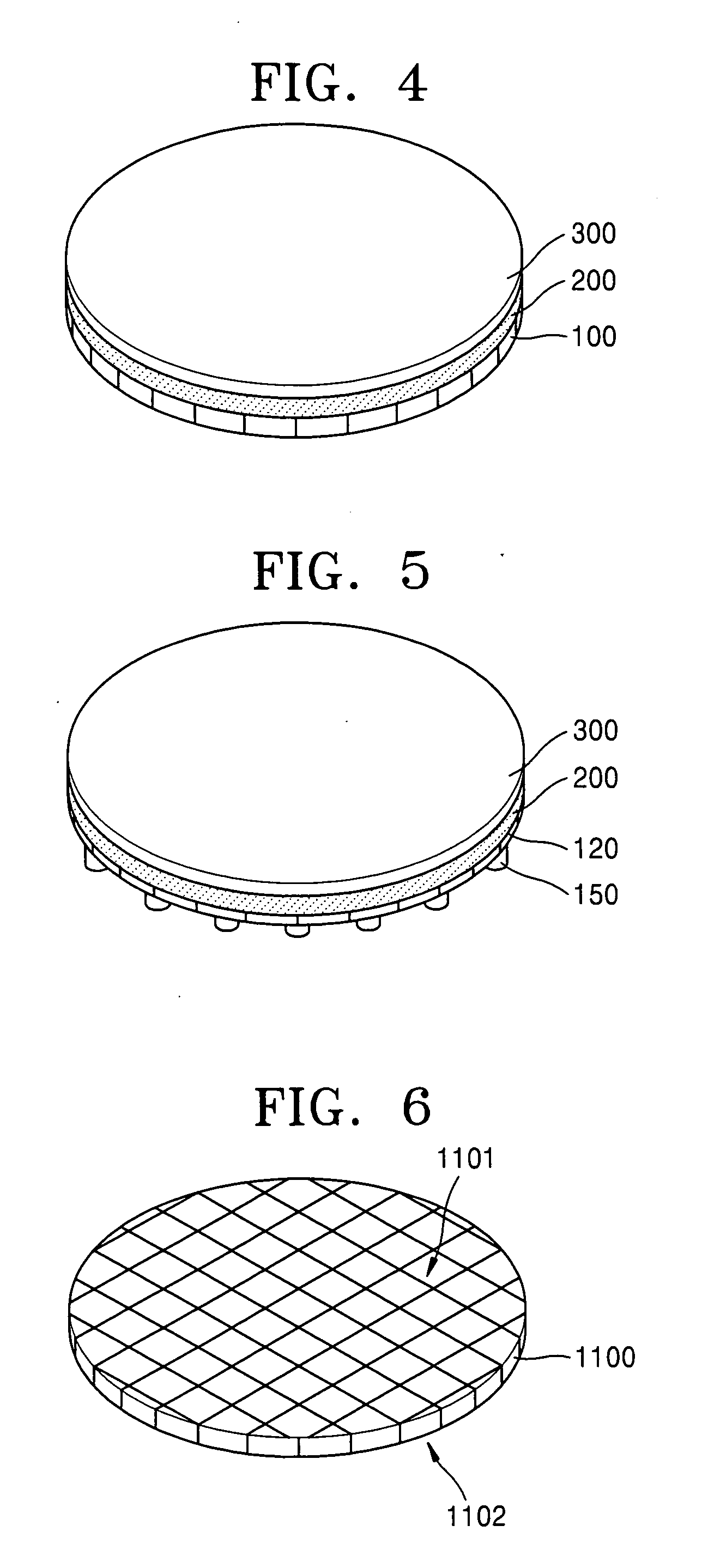

Method of forming a thin wafer stack for a wafer level package

InactiveUS7494845B2Reduce warpageTrend downSemiconductor/solid-state device detailsSolid-state devicesWaferingUltraviolet

A method of forming a stack of thin wafers provides a wafer level stack to greatly reduce process time compared to a method where individually separated chips are stacked after a wafer is sawed. A rigid planar wafer support member stabilizes and planarizes each wafer while it is thin or its thickness is reduced and during subsequent wafer processing. Thinned wafers are stacked and the external support members are removed by applying heat or ultraviolet (UV) light to an expandable adhesive layer between the support members and the thin wafers. The stacked wafers then can be further processed and packaged without thin-wafer warping, cracking or breaking. A wafer level package made in accordance with the invented method also is disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

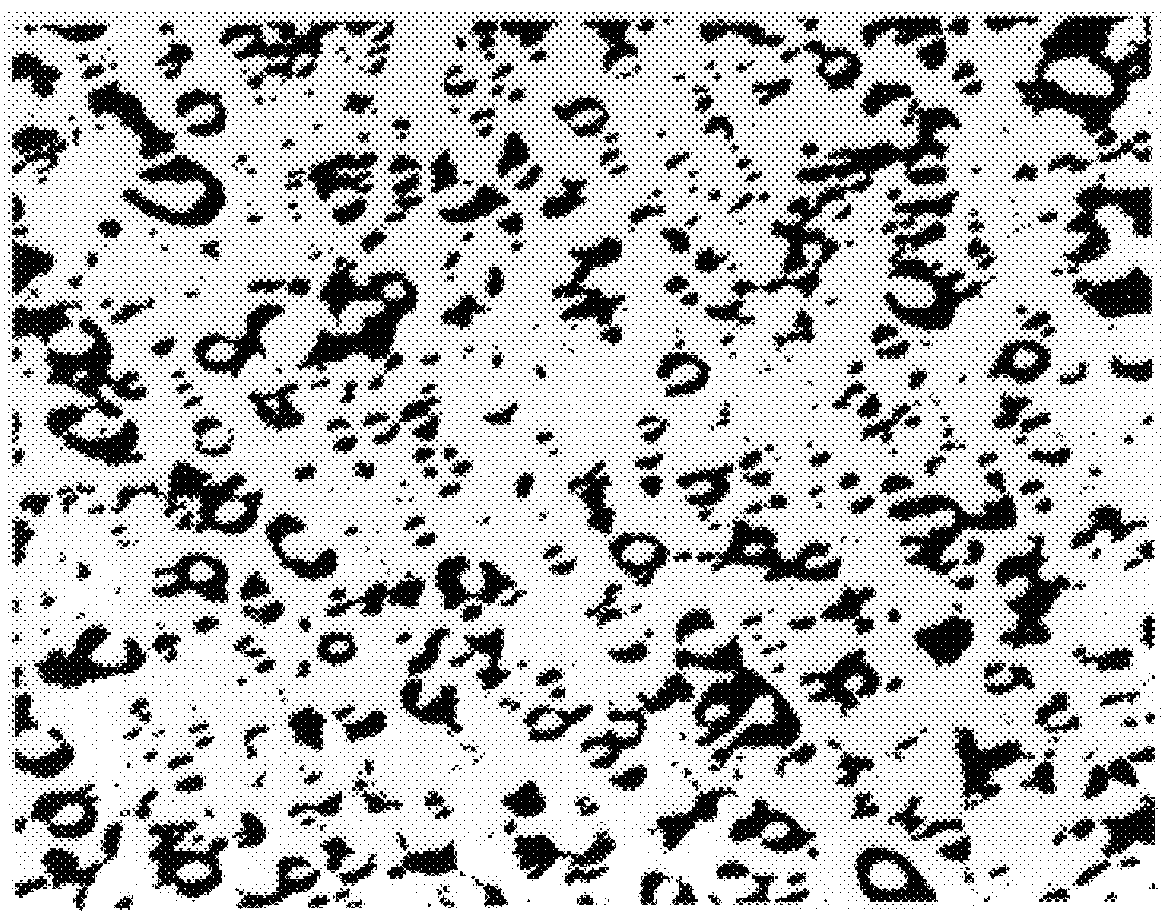

Particulate material containing thermoplastics and methods for making and using the same

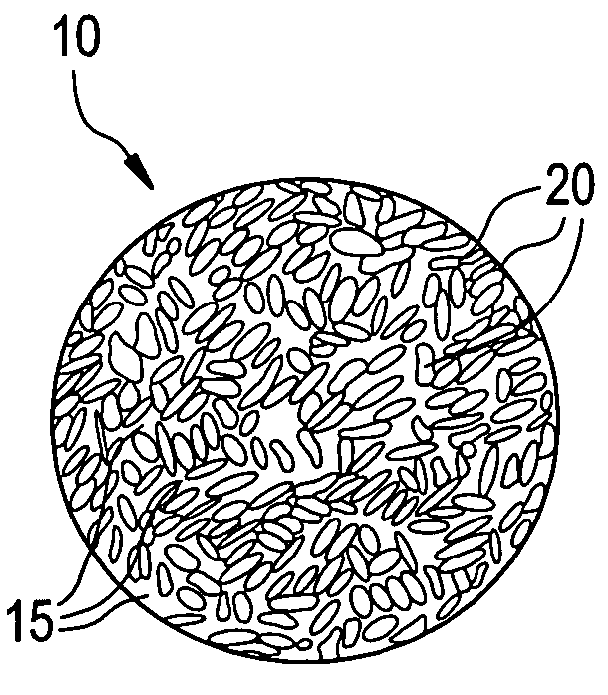

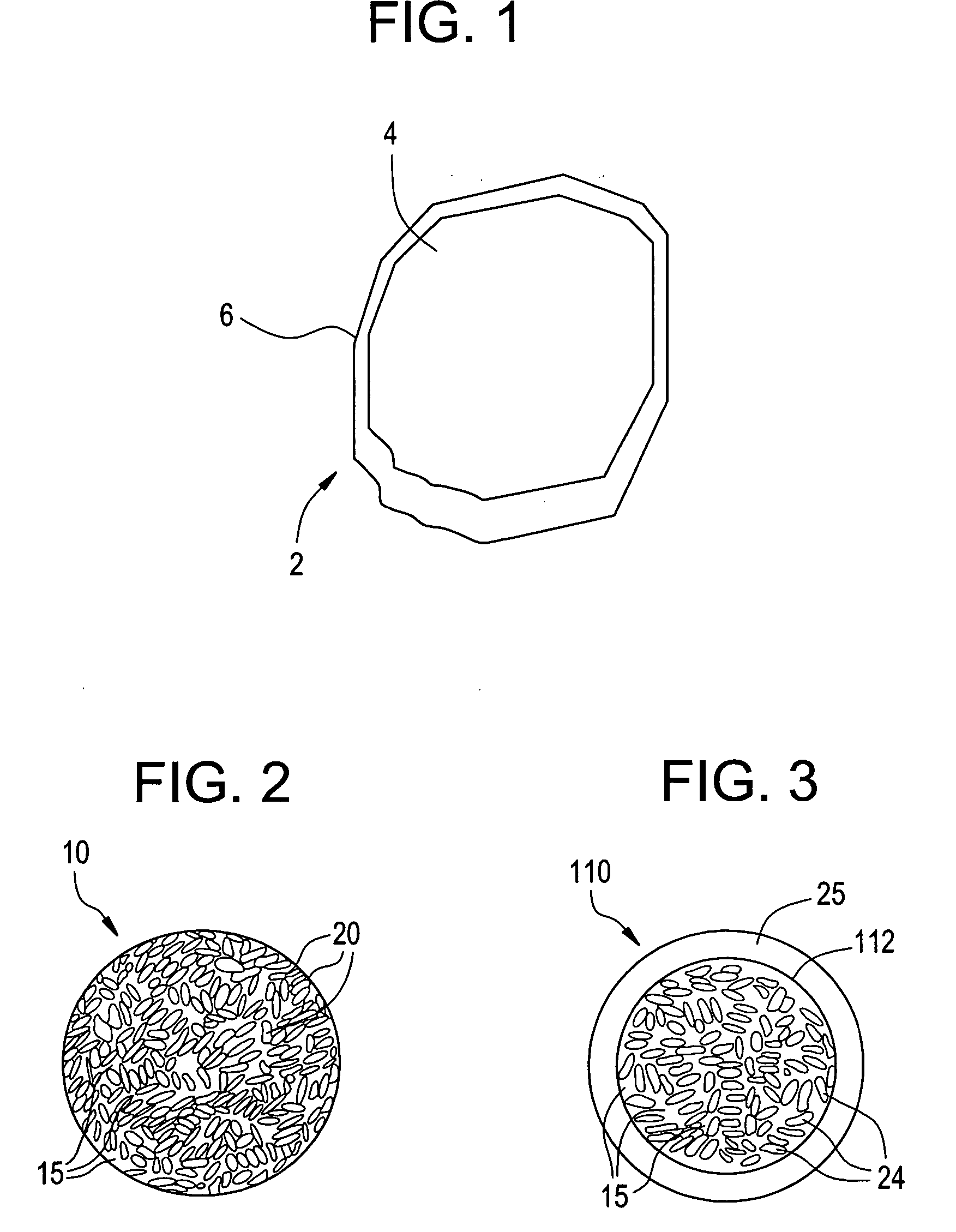

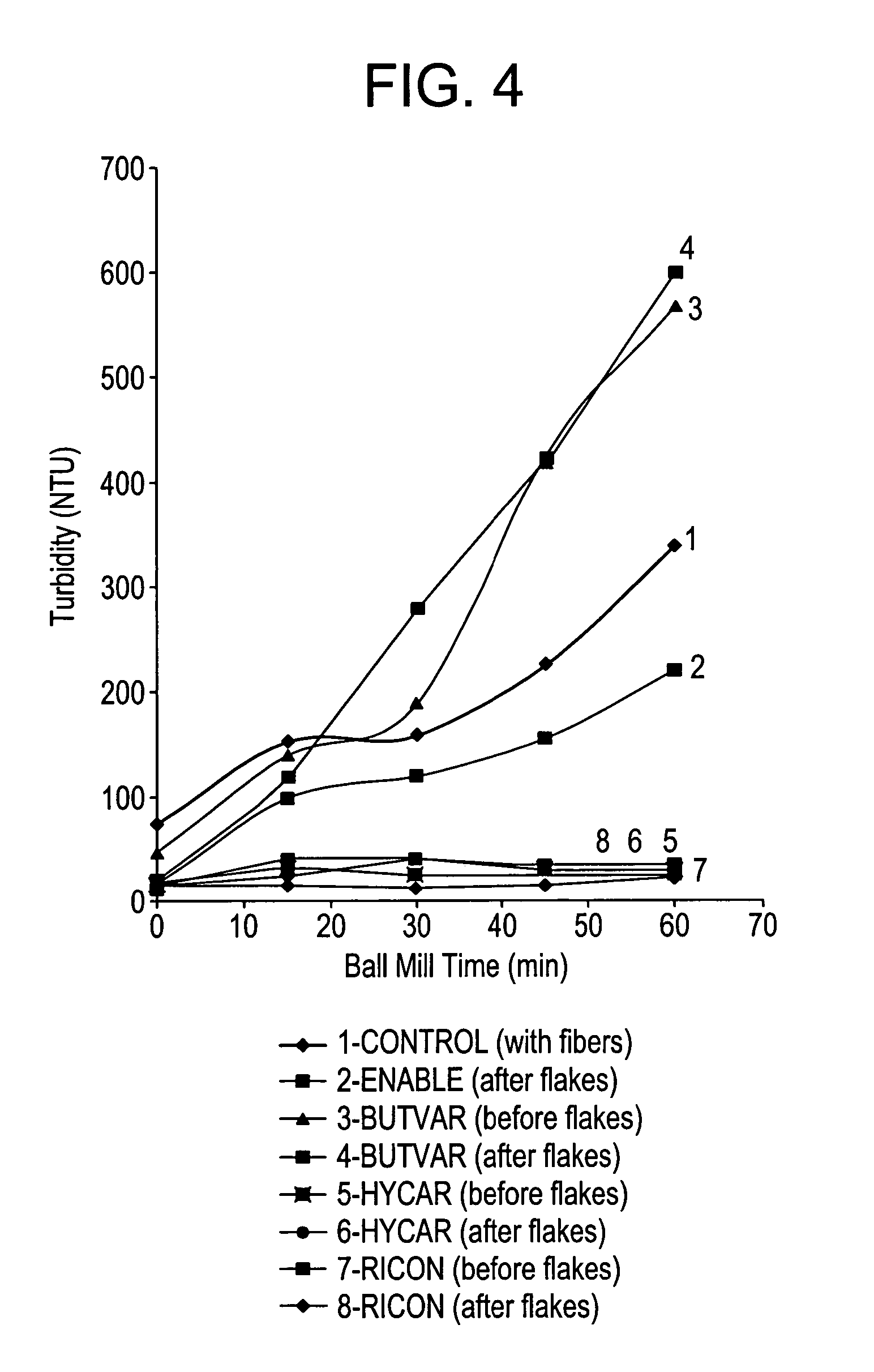

ActiveUS20050019574A1Retain and enhance proppant propertyReducing dust formationPretreated surfacesDrilling compositionThermoplasticPolymer chemistry

Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer present on or in the substrate as an amount sufficient to improve the dust suppression of the particle above that which would occur if the thermoplastic elastomer was absent. Disclosed herein is a particle comprising a particulate substrate; and a thermoplastic elastomer, wherein the particle has a compressive strength retention of greater than about 50% as measured by a UCS test and a turbidity of about 10 to 200 NTU after a one hour ball mill test.

Owner:HEXION INC

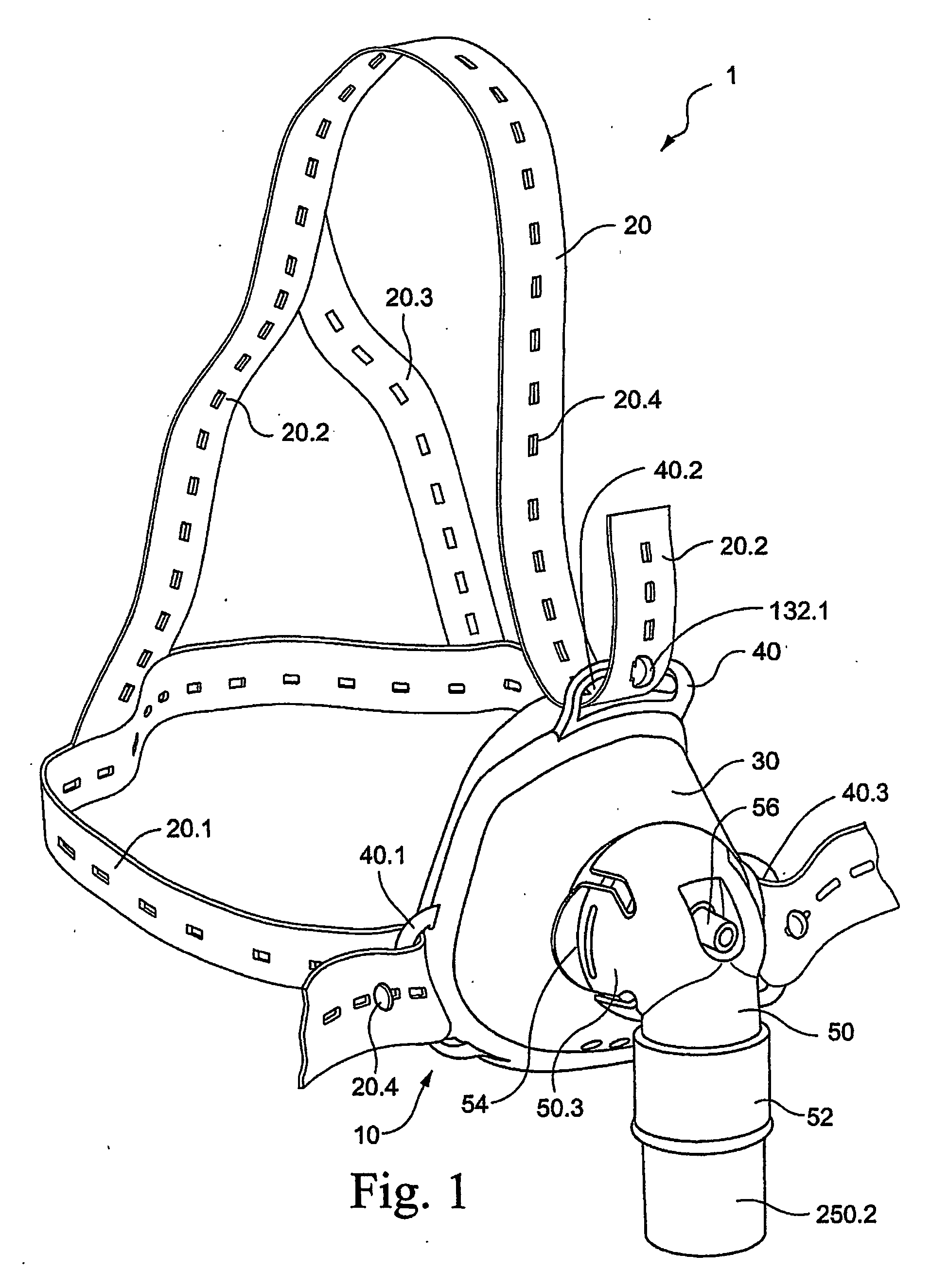

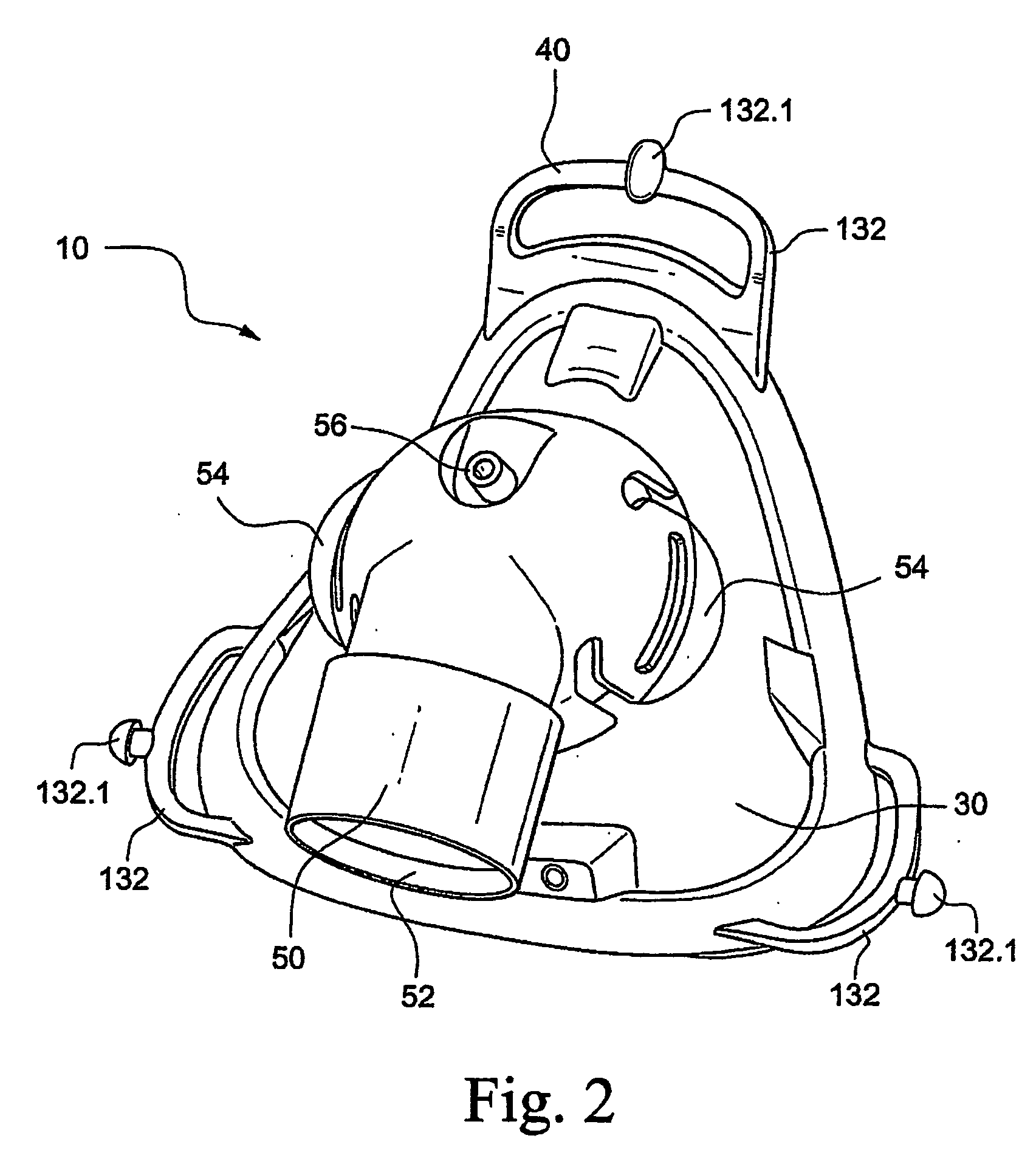

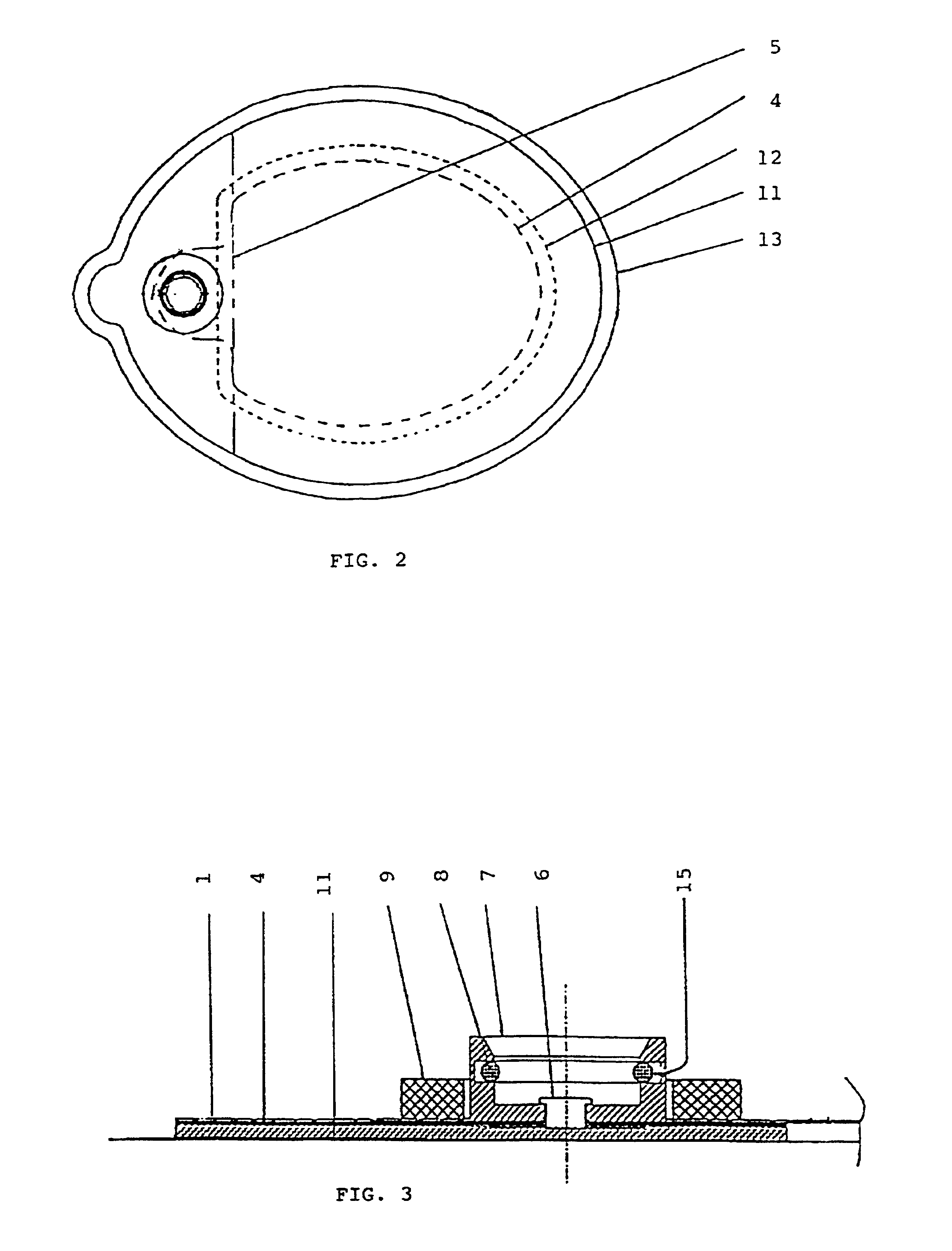

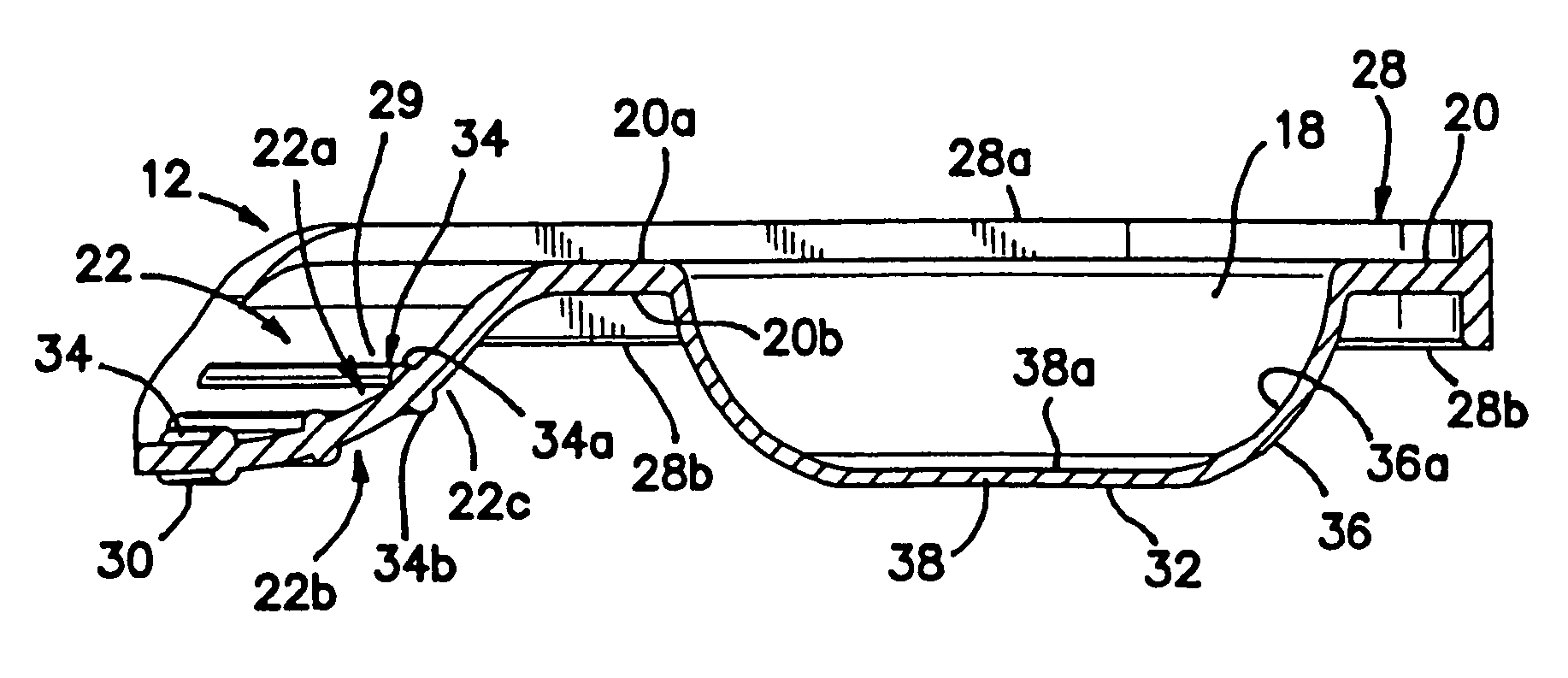

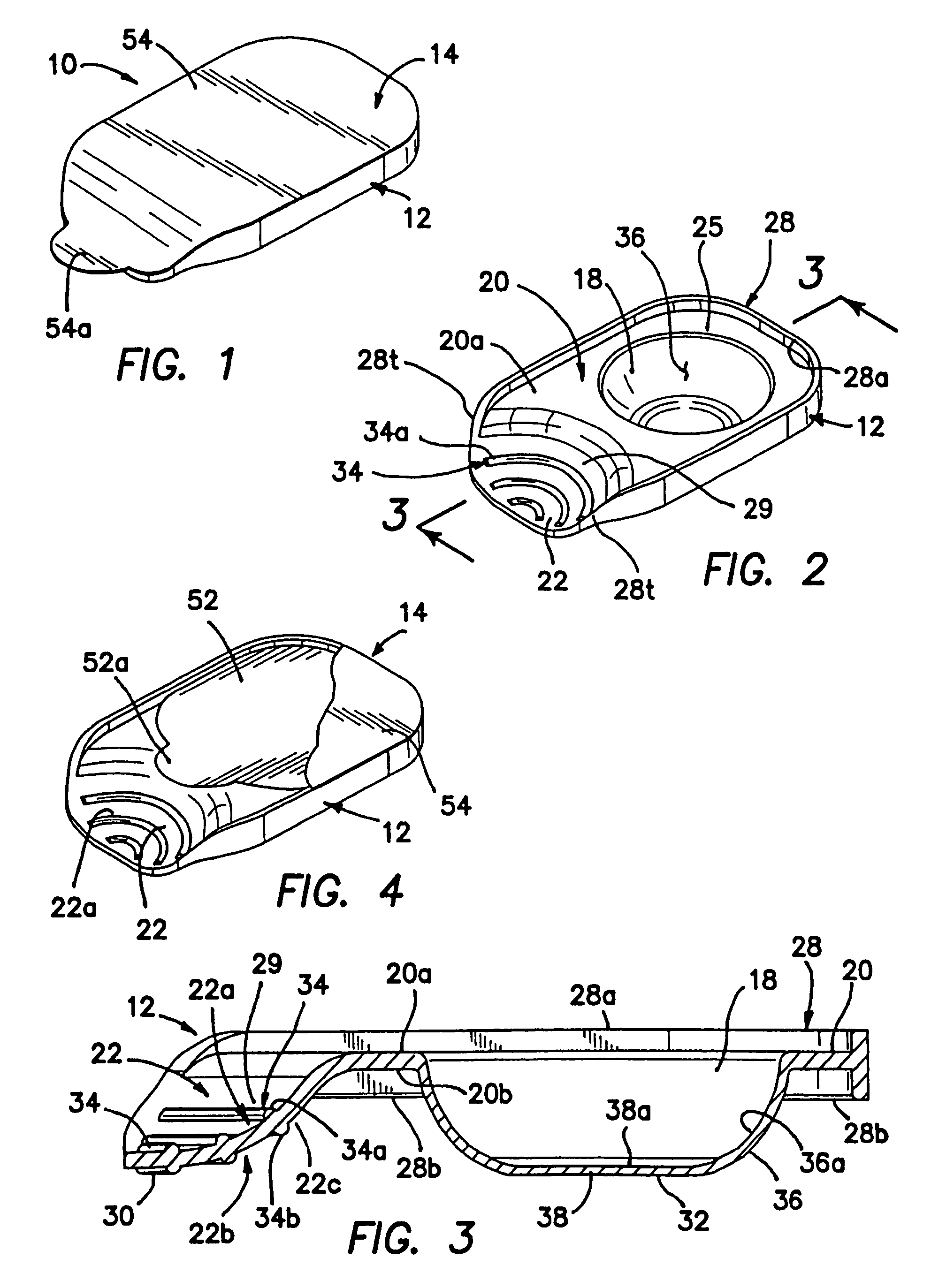

Mask system

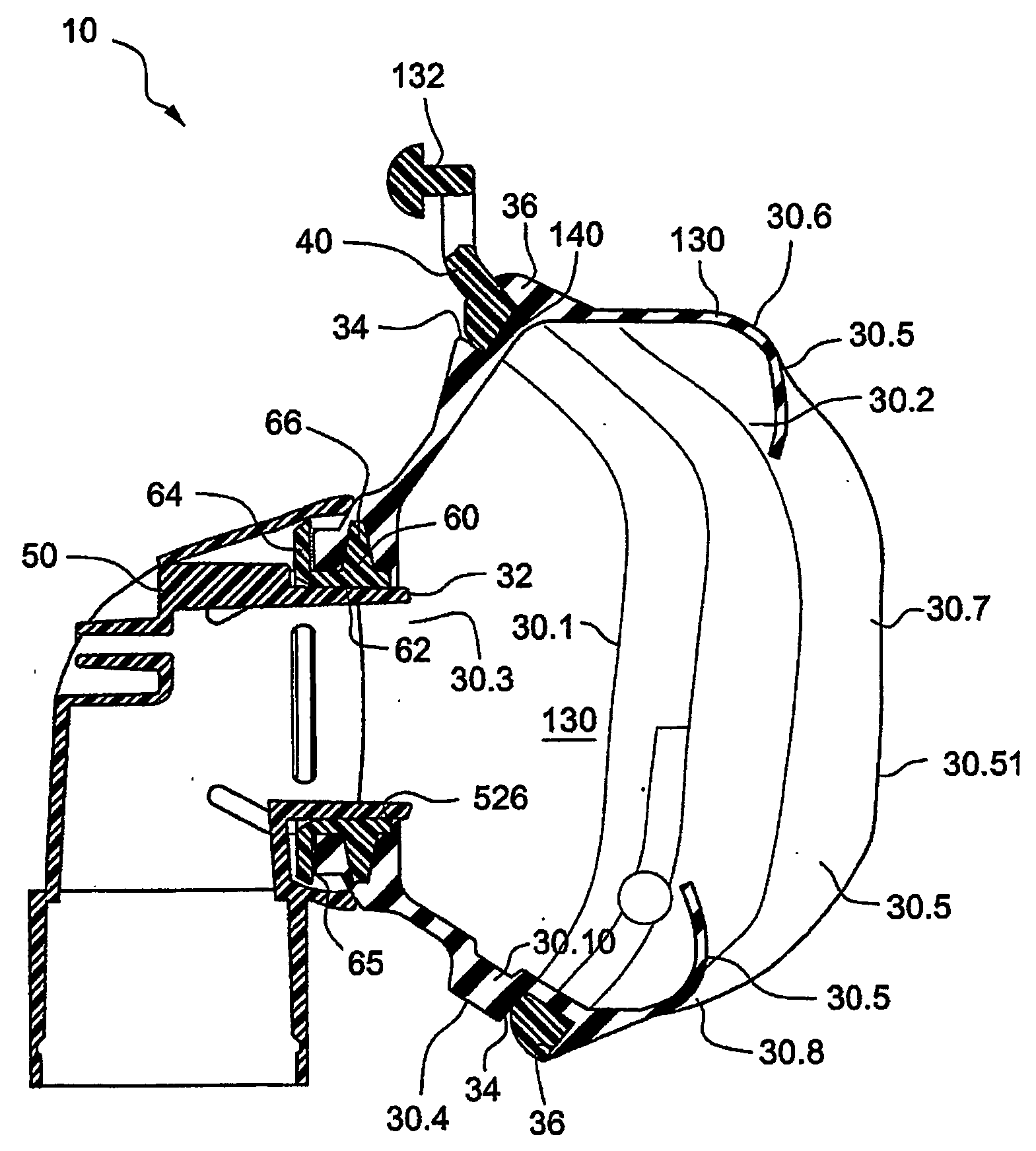

ActiveUS20060201514A1Low costTrend downOperating means/releasing devices for valvesRespiratory masksSleep disordered breathingEngineering

A mask system for treating sleep disordered breathing, comprising headgear, a shell / cushion including a channel adjacent a front aperture, a frame, an elbow including at least one undercut on a proximal end, a retaining ring including a rear flange adapted to be retainably insertable in the channel of the shell / cushion, and a front flange adapted to retainably engage with the at least one undercut of the elbow.

Owner:RESMED LTD

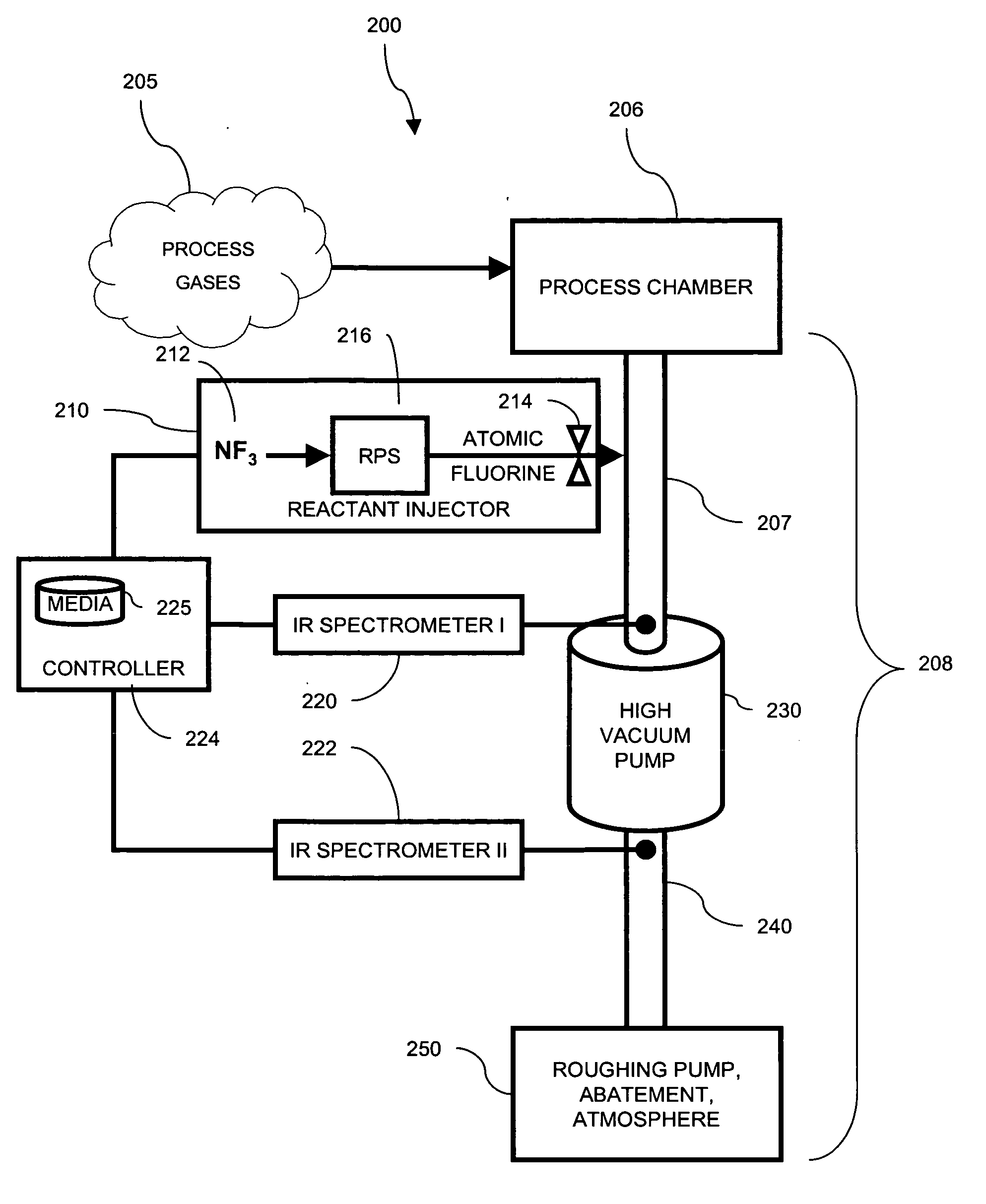

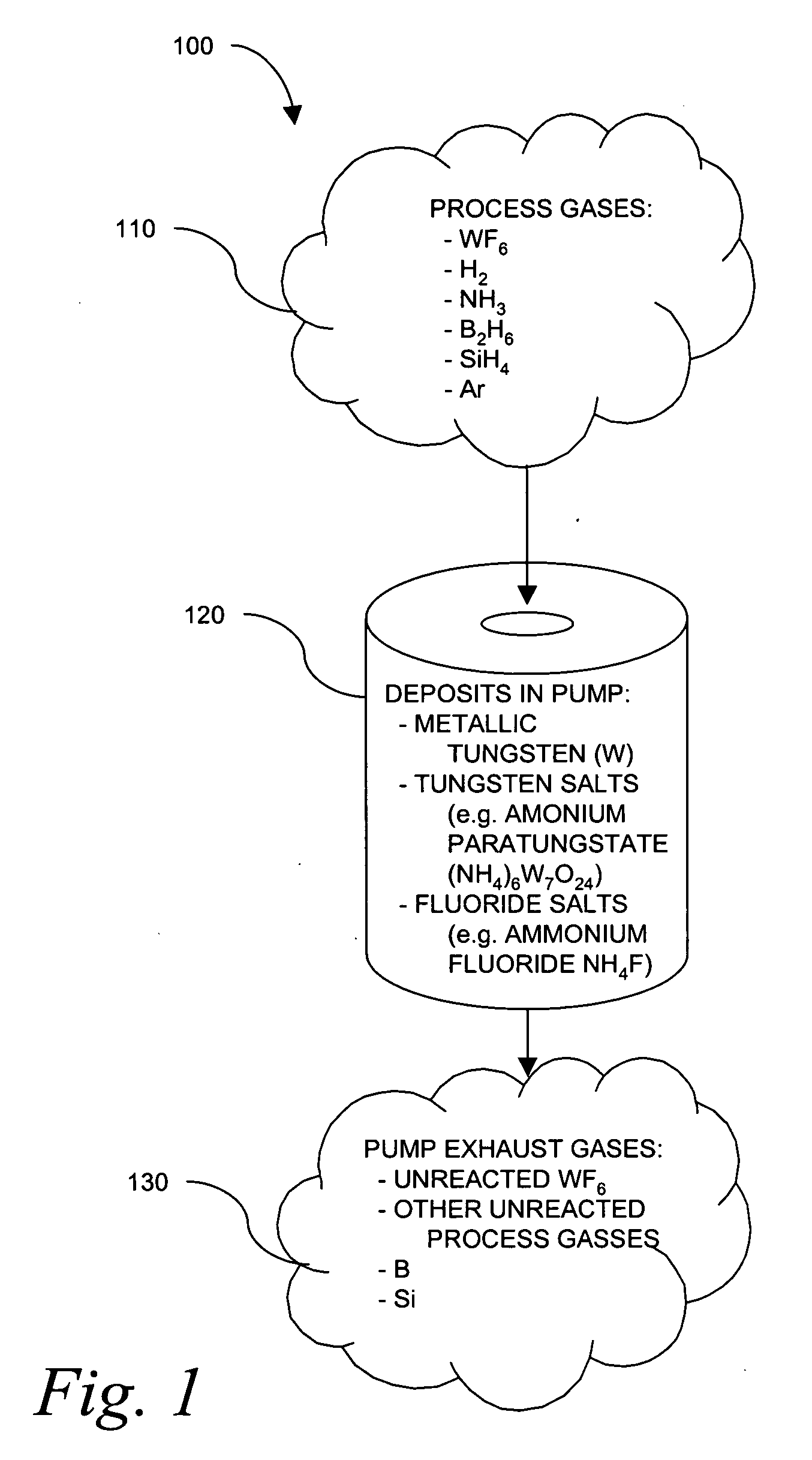

Use of spectroscopic techniques to monitor and control reactant gas input into a pre-pump reactive gas injection system

ActiveUS20090320881A1Produce some attenuationTrend downRotary/oscillating piston combinations for elastic fluidsHollow article cleaningGas phaseReactive gas

The present invention relates to vacuum processing systems in which process gases are introduced in a process chamber and are exhausted through a vacuum processing system exhaust path. Deposits made by the exhausted gas are reduced or eliminated by introducing a reactive gas upstream of the device affected by deposits. The amount of introduced reactive gas is controlled by measuring gas phase concentrations of exhausted gas components upstream and downstream of the affected device, and, from those measurements, determining whether the components are being consumed in deposits on the affected device.

Owner:EDWARDS VACUUM LLC

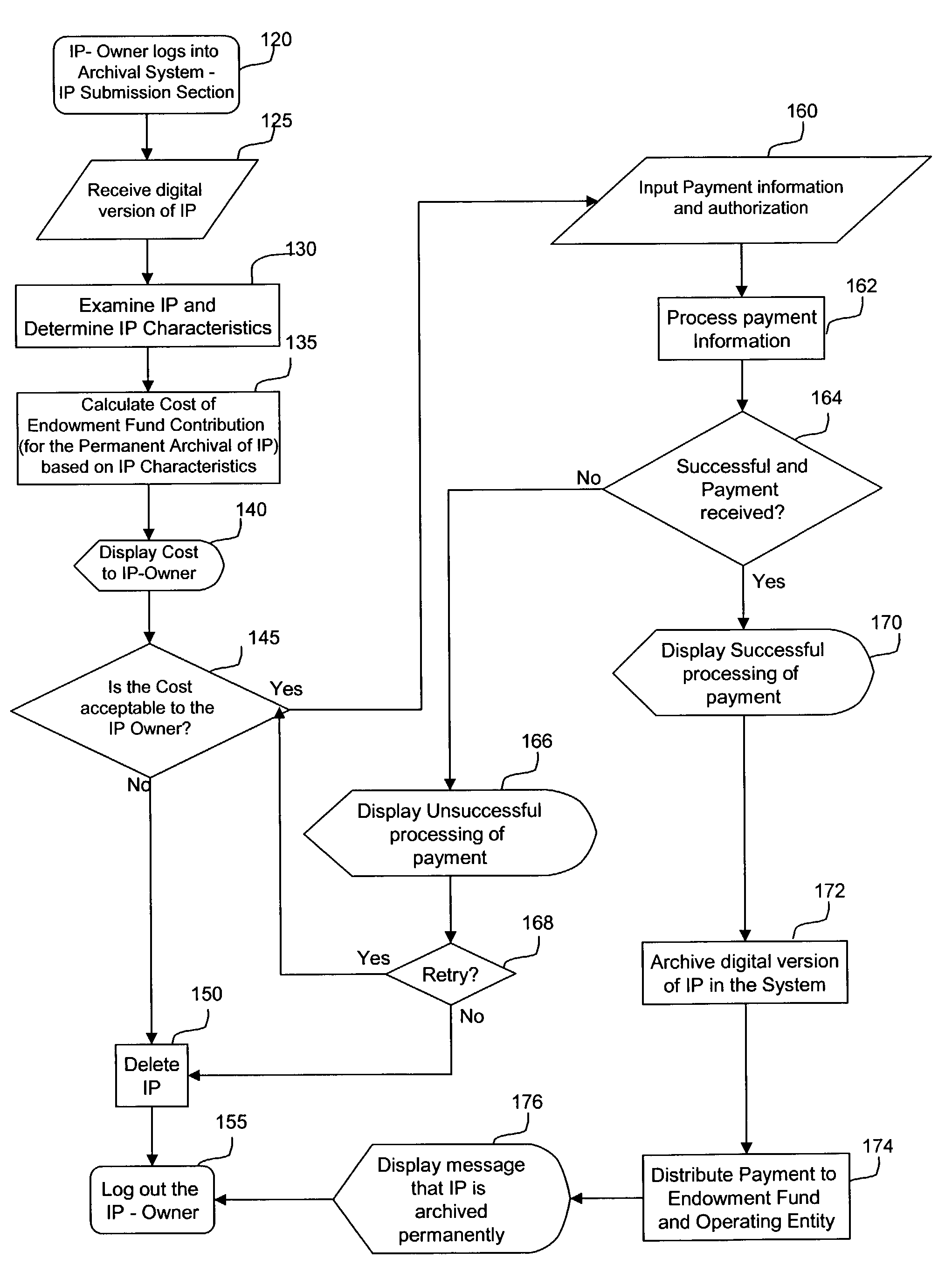

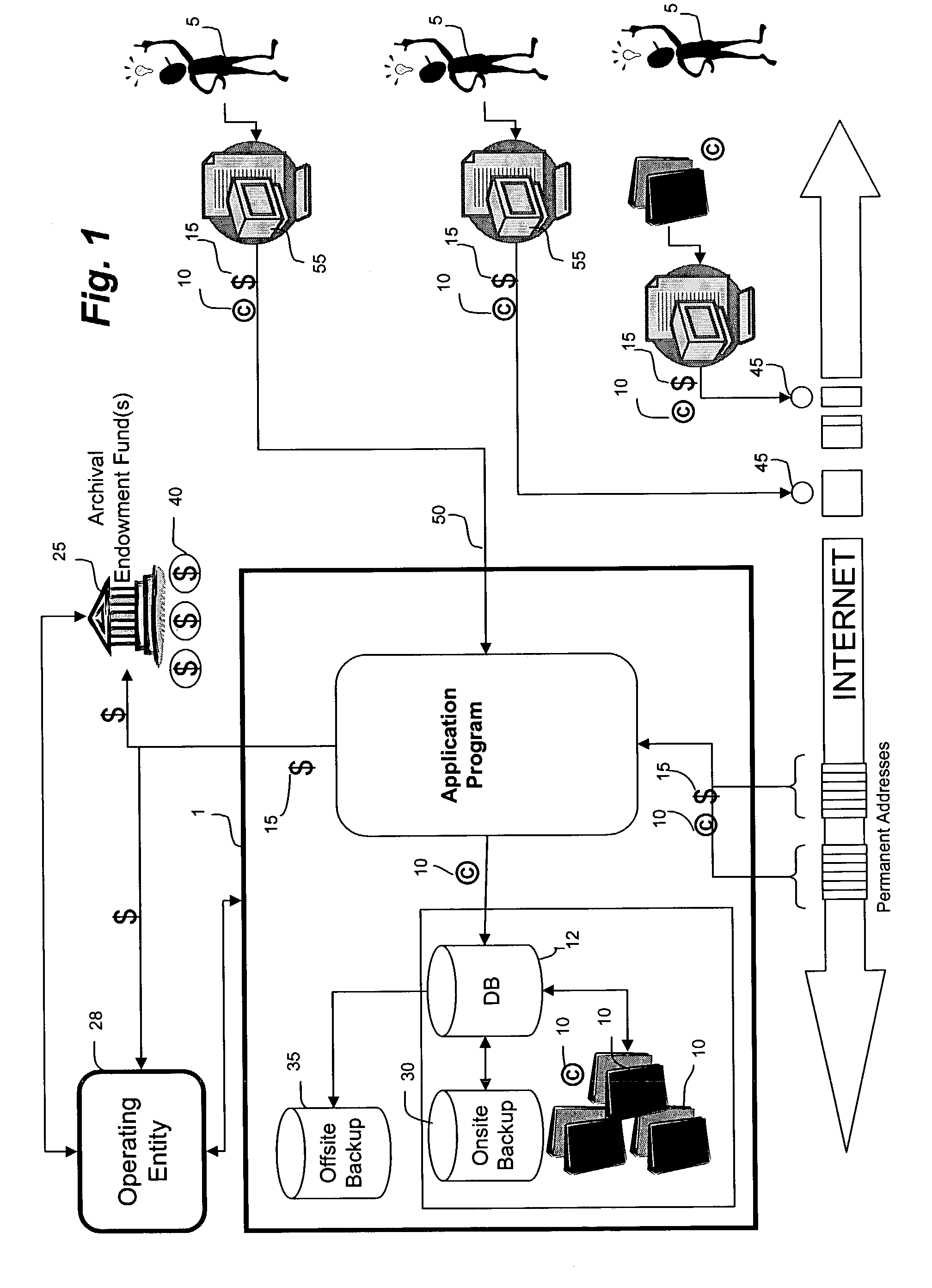

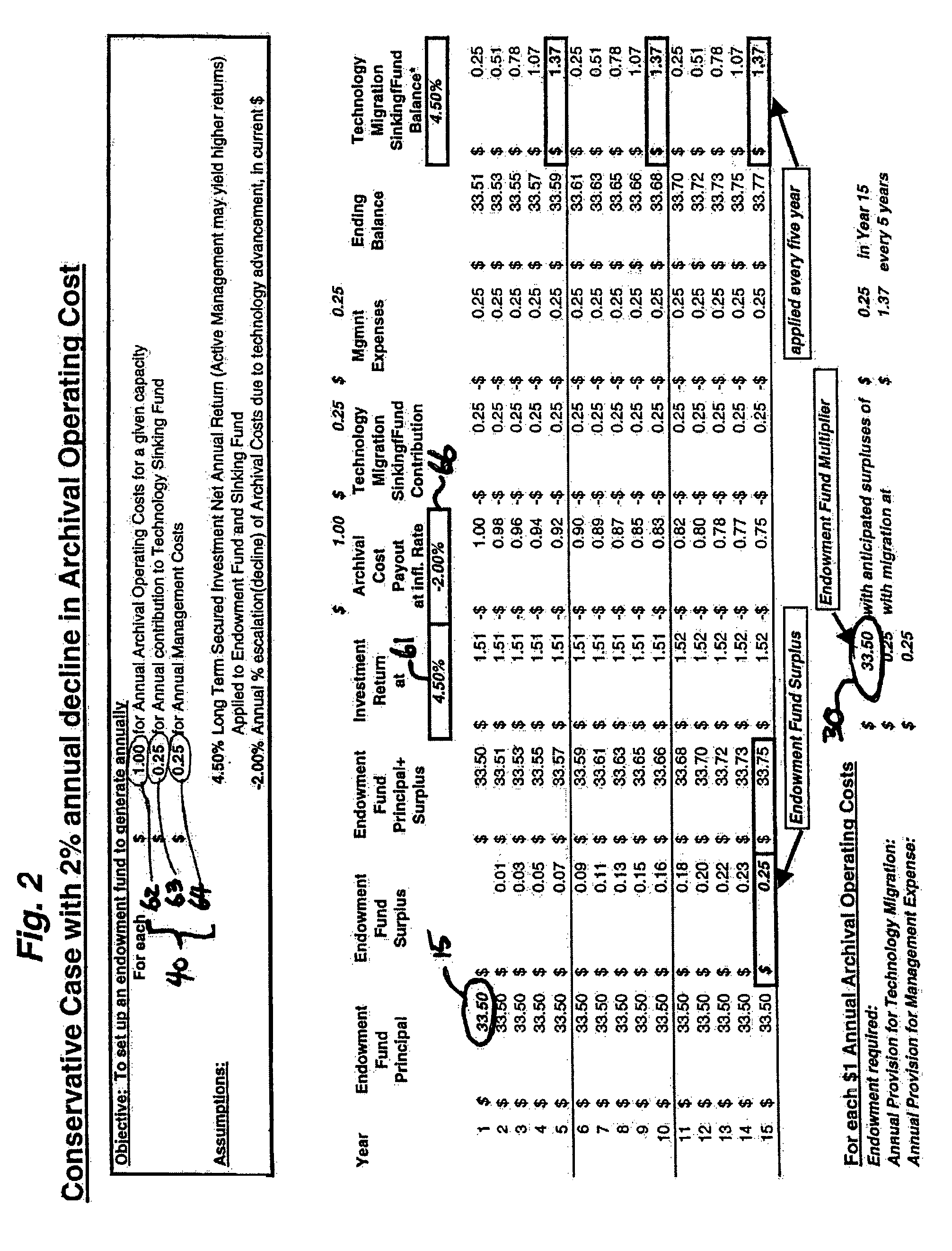

Assured archival and retrieval system for digital intellectual property

ActiveUS7856414B2Economy of scaleImprove integrityFinanceDigital data processing detailsIntellectual propertyDigital rights management

A system and method of use for permanently archiving intellectual properties (IP) in a digital archival system. An owner contributes each IP with an initial financial contribution including a discrete archival endowment which is sufficient to fund archival of the IP for an assured archival period. A plurality of discrete archival endowments can be pooled into one or more archival endowment funds, jointly managed for the maintenance of each archived IP. The endowment funds can be managed by a trustee separate from the management of the digital archive. Retrieval can be funded through retrieval fees or an endowment maintained separate from the archival endowment fund. Digital rights management can remunerate owners and revenue tracking can capitalize the value of each IP. Access to the archive system is preferably through a variety of membership options including owners, users, and partners.

Owner:ZEE CHRISTOPHER

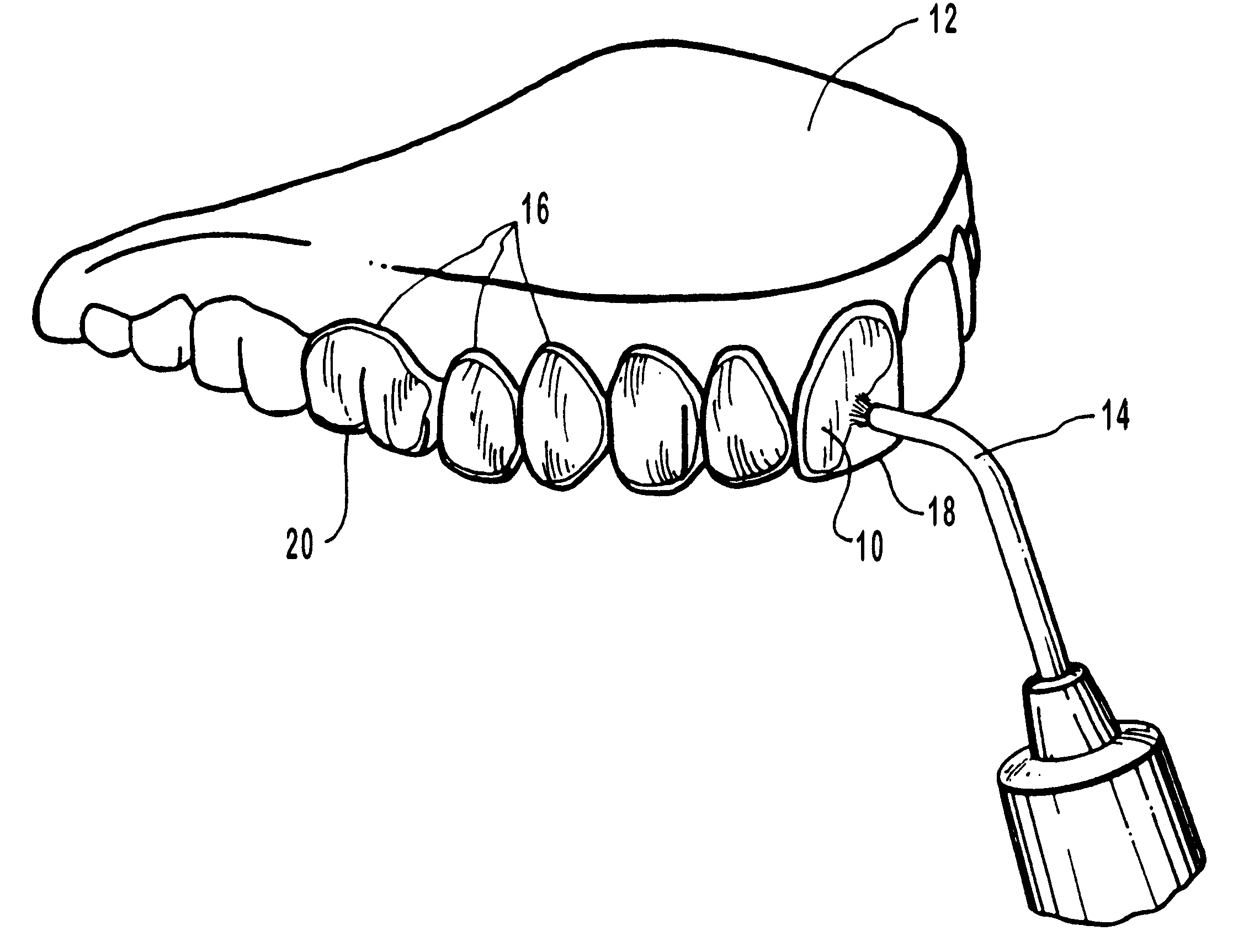

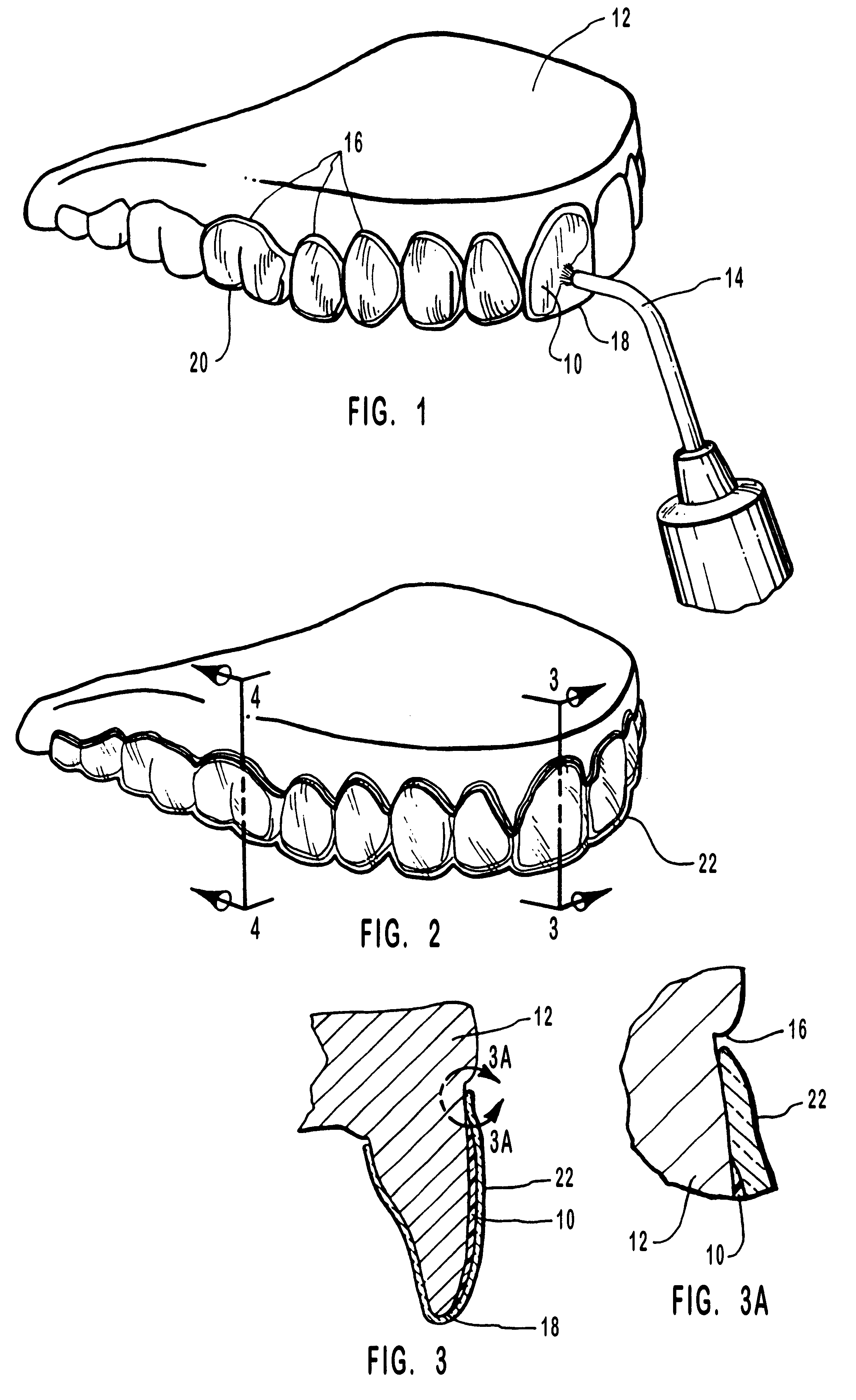

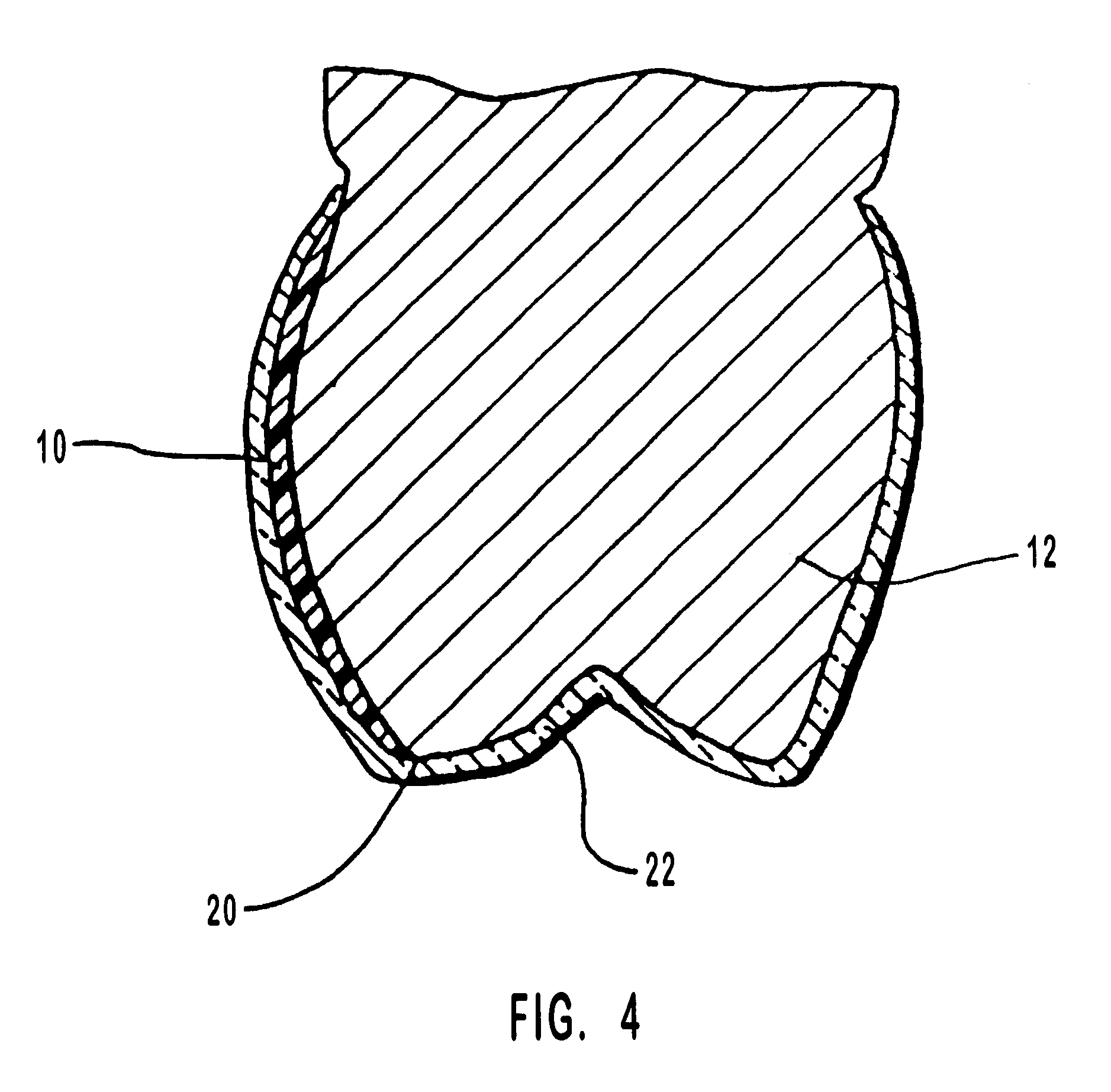

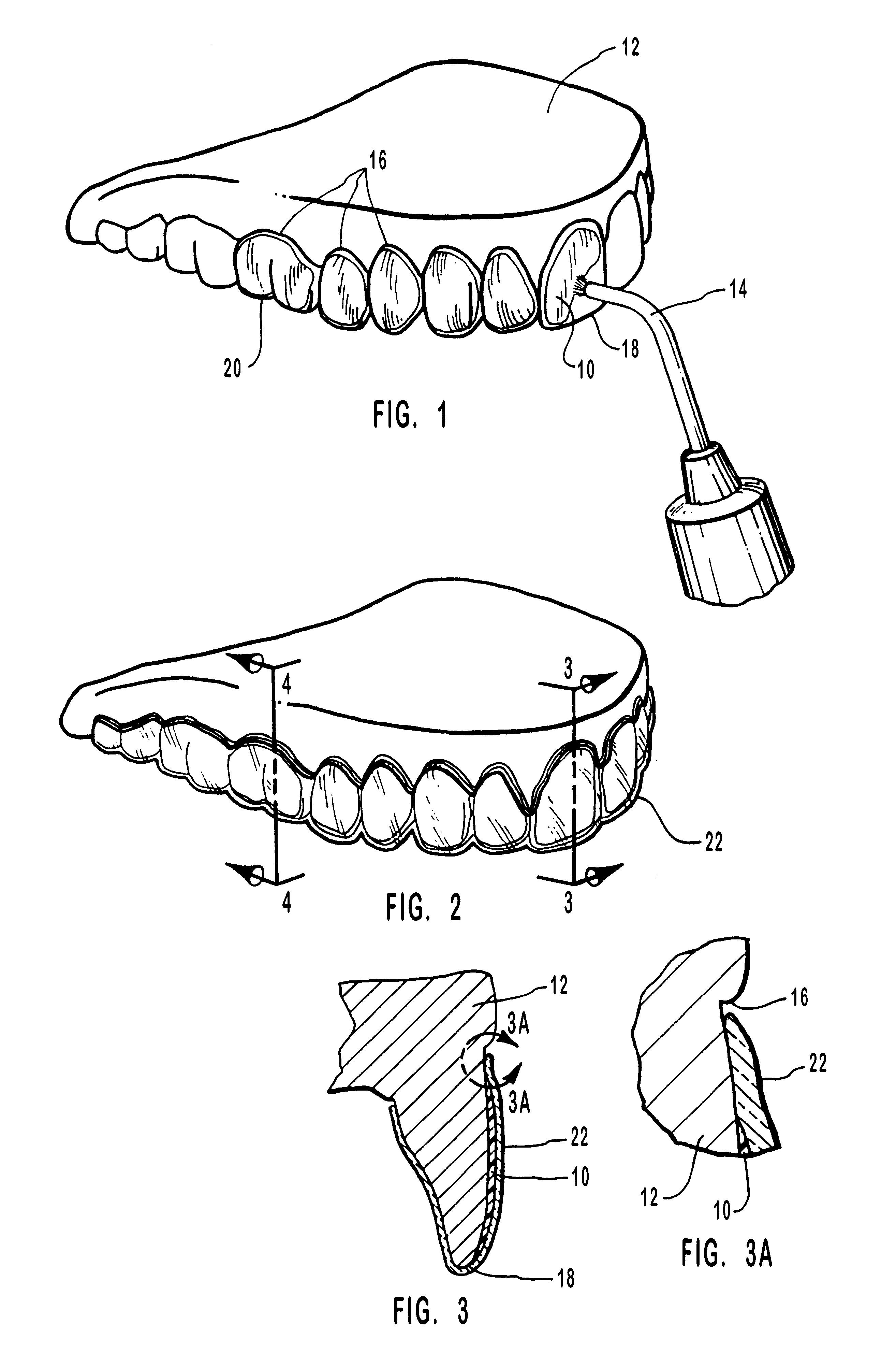

Methods for bleaching, opacifying and desensitizing teeth

InactiveUS6368576B1Trend downReduce sensitivityCosmetic preparationsTeeth fillingPotassium nitrateCarbamide peroxide

Owner:ULTRADENT PROD INC

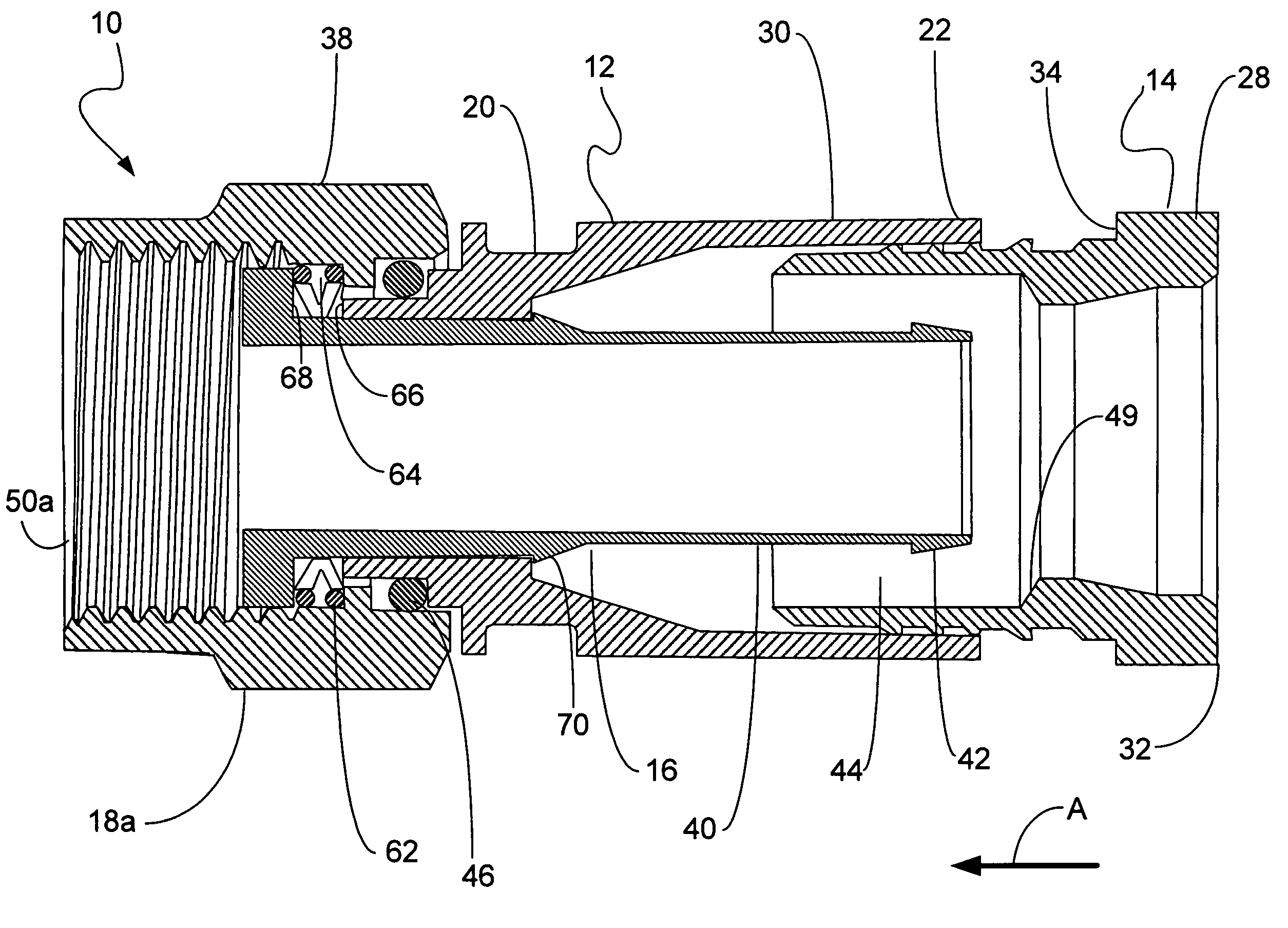

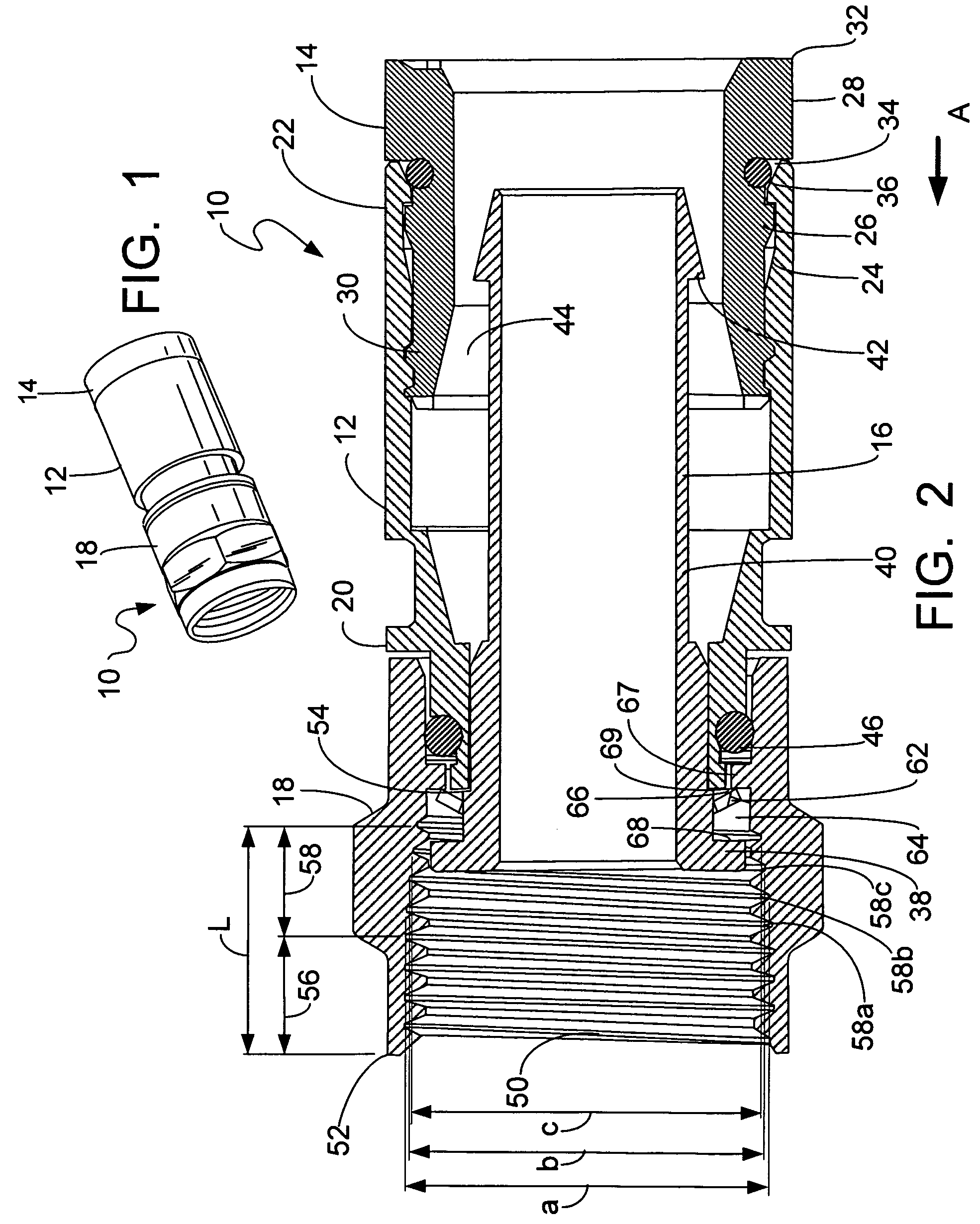

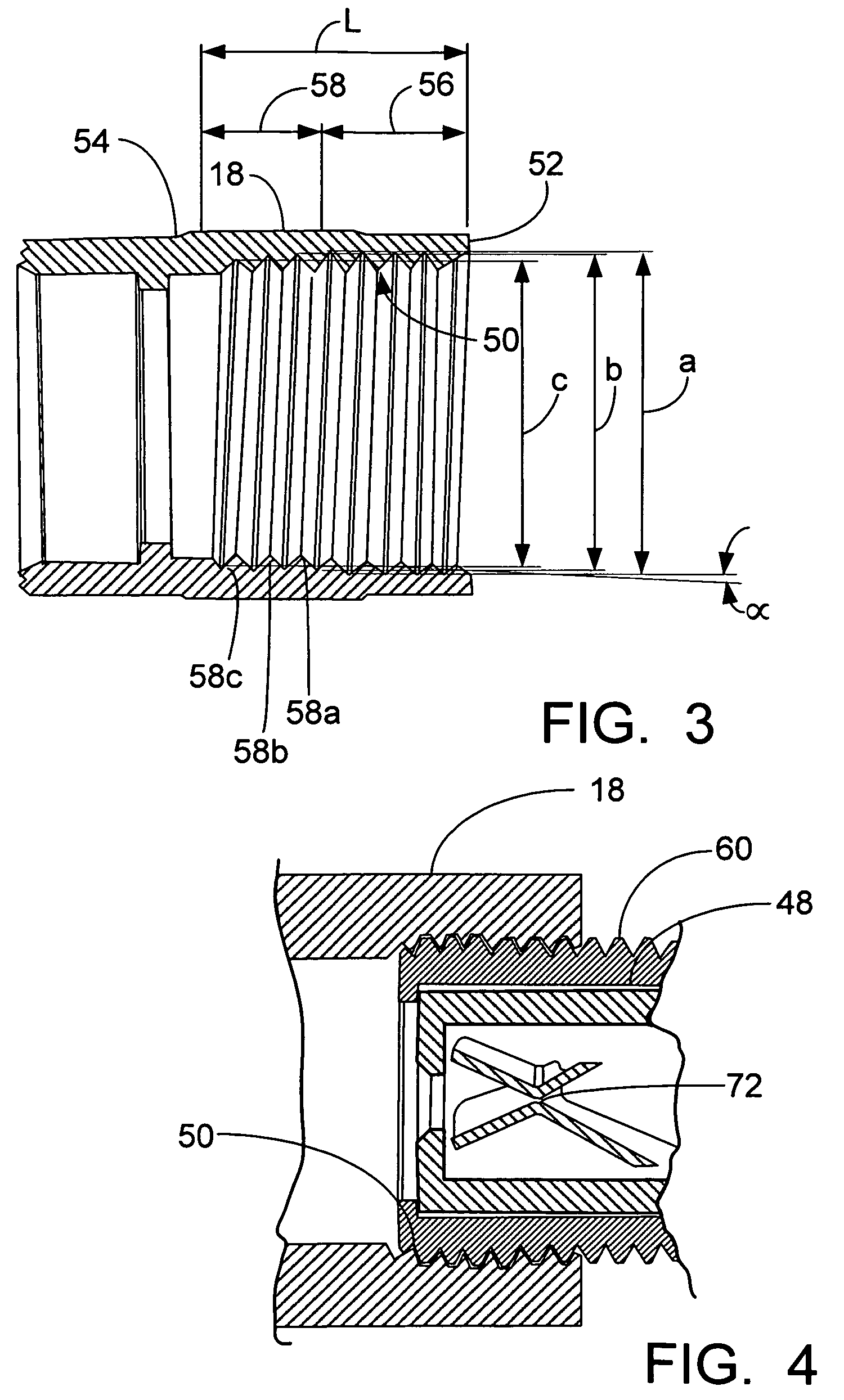

Constant force coaxial cable connector

ActiveUS7566236B2High retention rateTrend downEngagement/disengagement of coupling partsTwo pole connectionsInterference fitMating connection

Owner:PPC BROADBAND INC

Skin electrode

InactiveUS6845272B1Reduced shelf lifeExtended shelf lifeElectrocardiographySensorsMaterials scienceMetal

An electrode for establishing electrical contact with the skin is disclosed, said electrode having a low impedance and comprising an electrically conductive metallic layer (4) and an electrically conductive gel (12) attached to said metallic layer, wherein the pH of the electrically conductive gel (12) is chosen so as to provide a corrosion of the metallic layer (4).

Owner:MEDICOTEST SYSTR

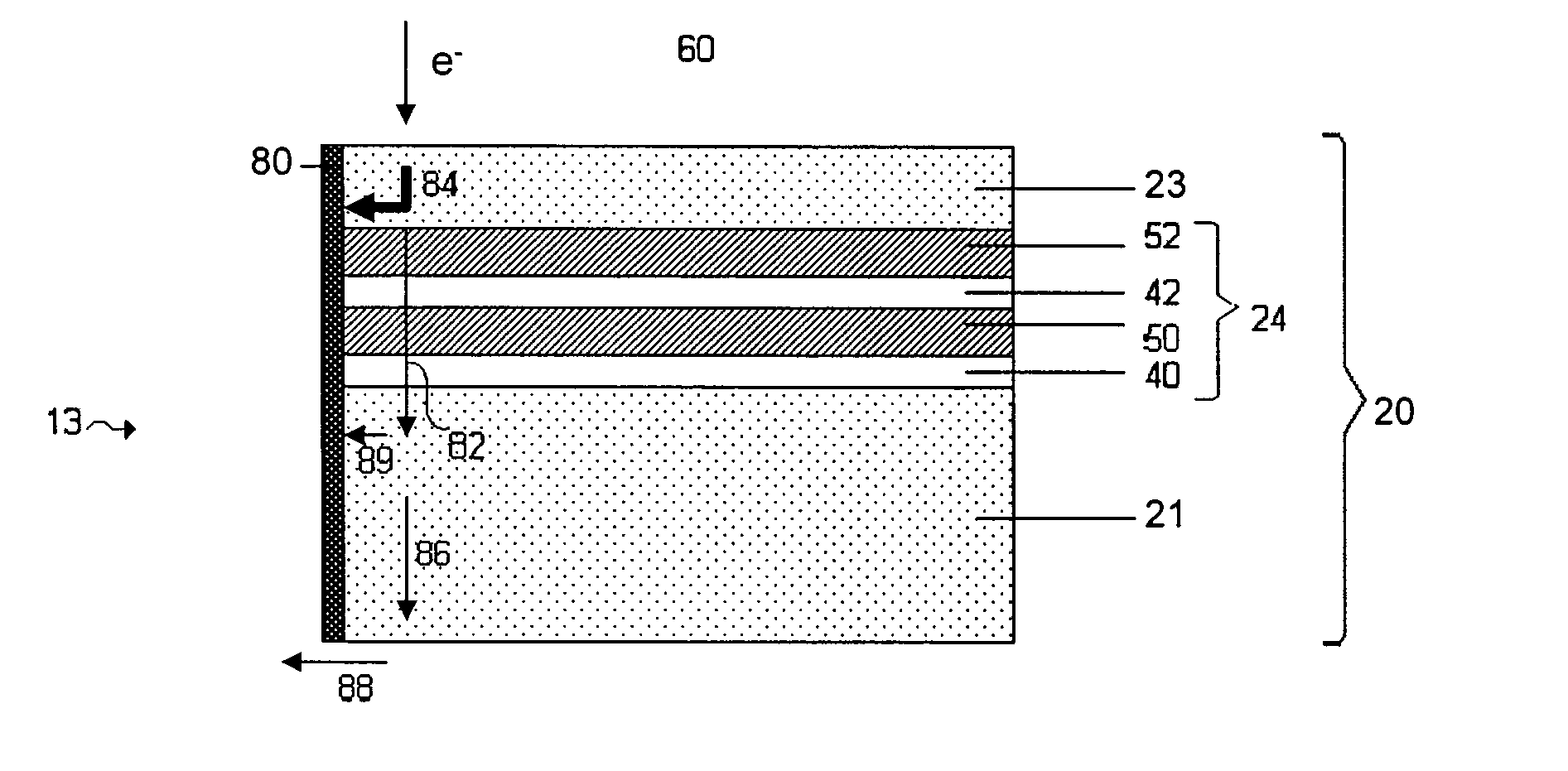

Electrode protection in both aqueous and non-aqueous electrochemical cells, including rechargeable lithium batteries

ActiveUS20070224502A1Preventing electronic communicationAvoid communicationFinal product manufactureElectrode carriers/collectorsHigh energyConductive materials

Electrode protection in electrochemical cells, and more specifically, electrode protection in both aqueous and non-aqueous electrochemical cells, including rechargeable lithium batteries, are presented. In one embodiment, an electrochemical cell includes an anode comprising lithium and a multi-layered structure positioned between the anode and an electrolyte of the cell. A multi-layered structure can include at least a first single-ion conductive material layer (e.g., a lithiated metal layer), and at least a first polymeric layer positioned between the anode and the single-ion conductive material. The invention also can provide an electrode stabilization layer positioned within the electrode, i.e., between one portion and another portion of an electrode, to control depletion and re-plating of electrode material upon charge and discharge of a battery. Advantageously, electrochemical cells comprising combinations of structures described herein are not only compatible with environments that are typically unsuitable for lithium, but the cells may be also capable of displaying long cycle life, high lithium cycling efficiency, and high energy density.

Owner:SION POWER CORP

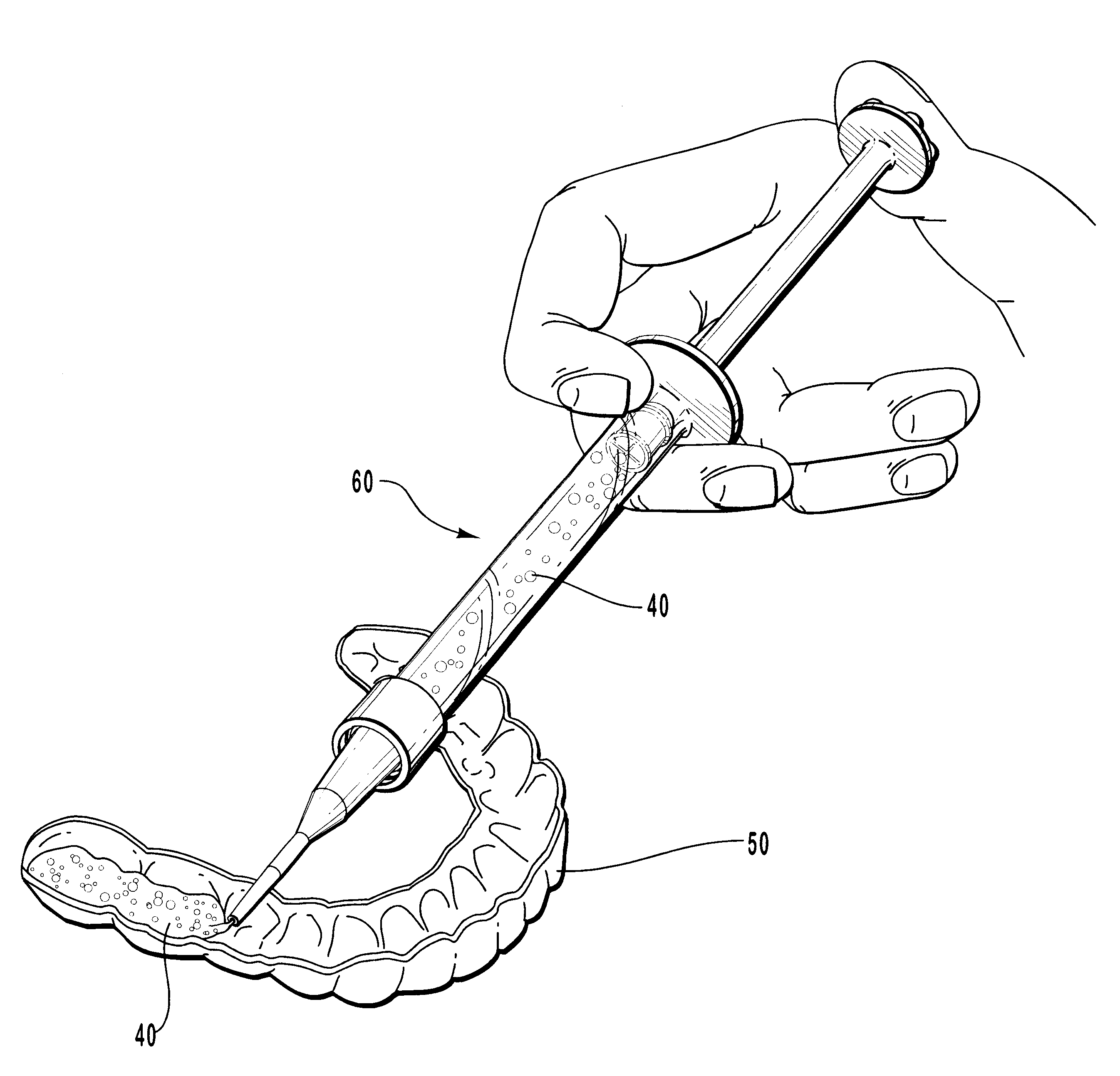

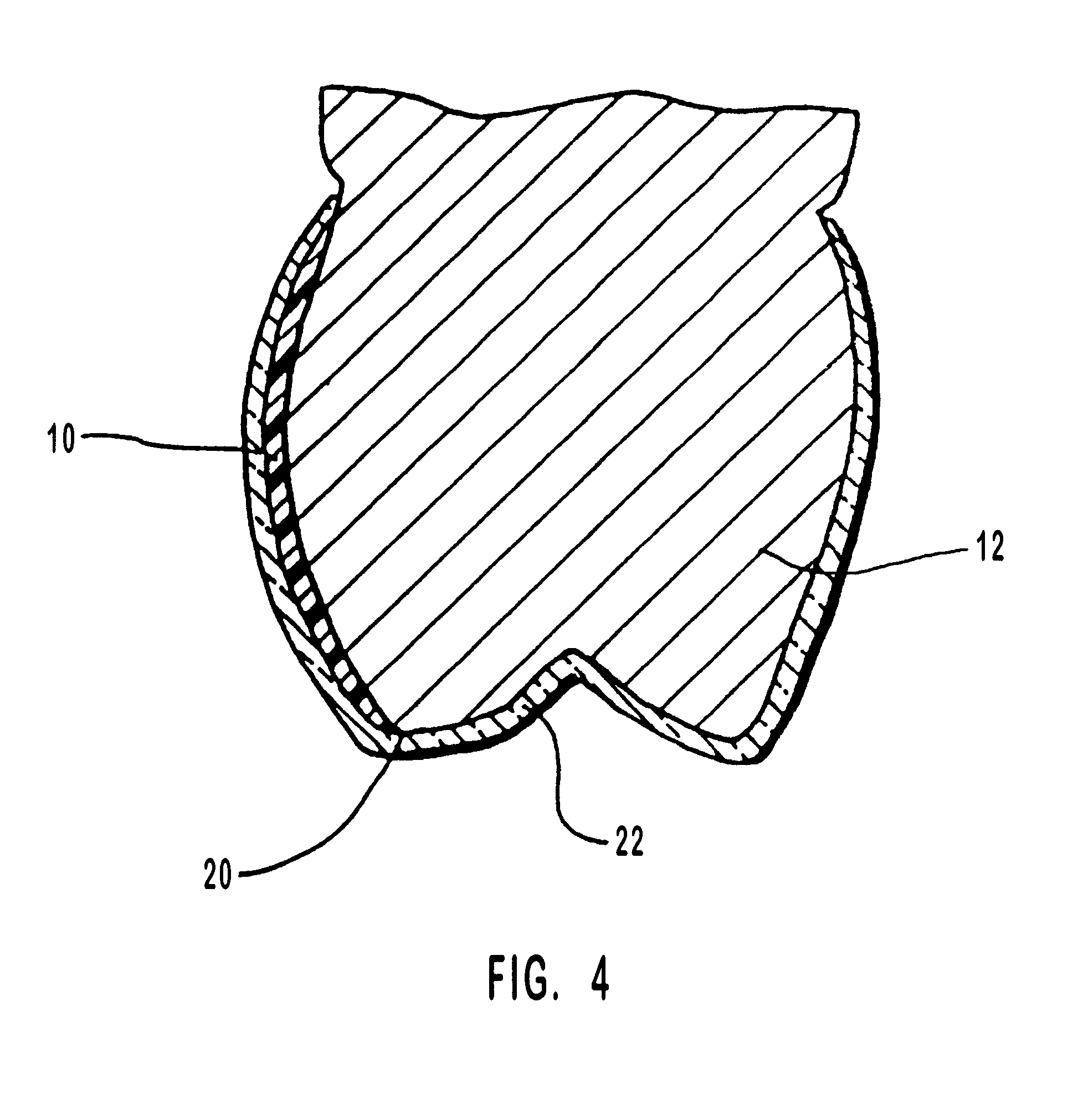

Compositions and methods for whitening and desensitizing teeth

InactiveUS6306370B1Reduce sensitivityTrend downCosmetic preparationsImpression capsPotassium nitrateMedicine

Composition and methods that include potassium nitrate for whitening and / or reducing tooth sensitivity. The dental compositions may optionally include a dental bleaching agent, such as hydrogen peroxide or carbamide peroxide. The dental compositions may be applied directly to the person's teeth, or they may be loaded into a comfortable fitting, flexible, thin-walled dental tray and placed over the person's teeth. In that case, the dental compositions will include a tackifying agent, such as carboxypolymethylene, which assists the composition in retaining the dental tray over the person's teeth as a result of the adhesive properties of the dental composition rather than due to mechanical interlocking of the tray over the person's teeth. The dental compositions may further include anticariogenic and antimicrobial agents.

Owner:ULTRADENT PROD INC

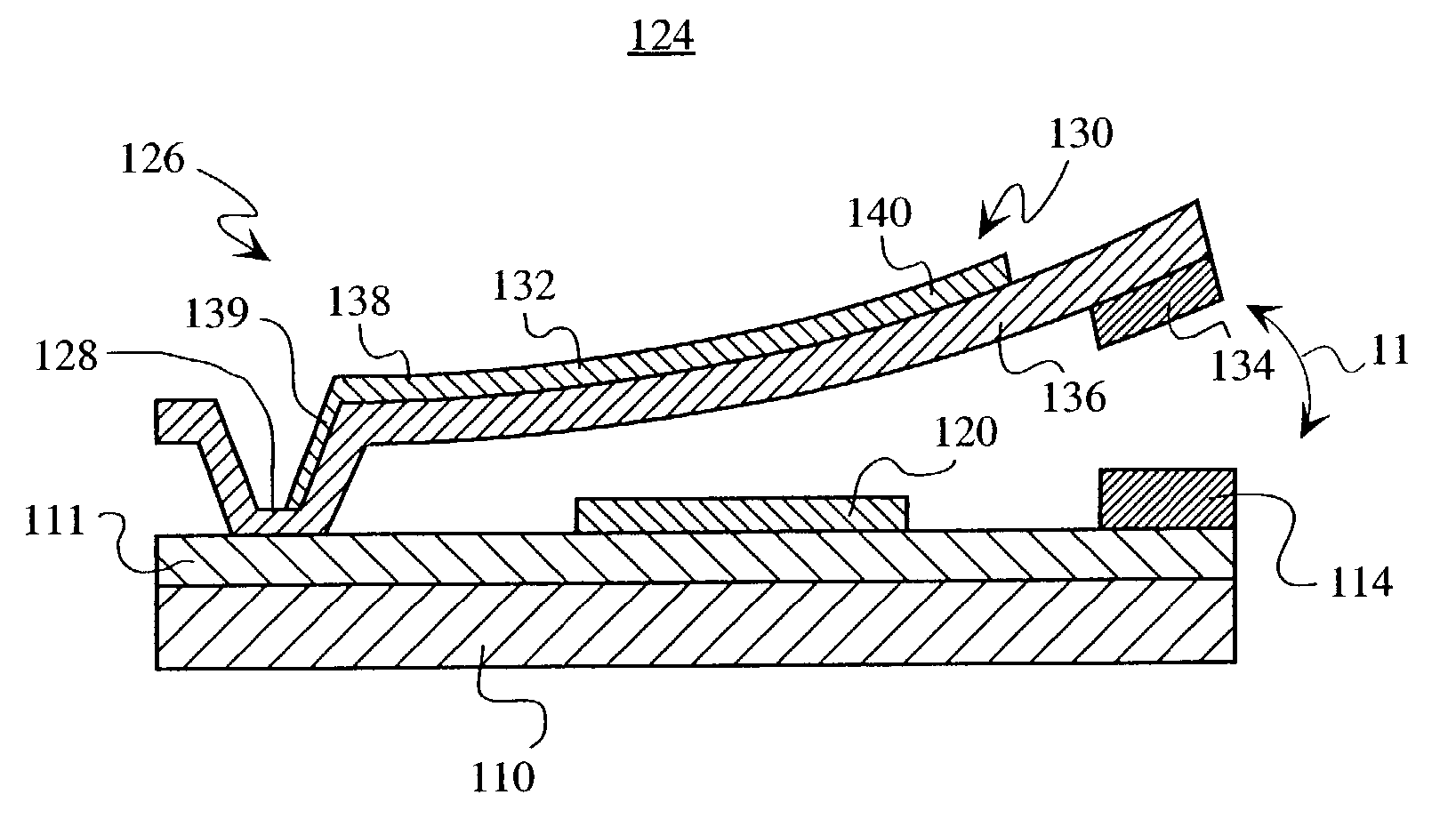

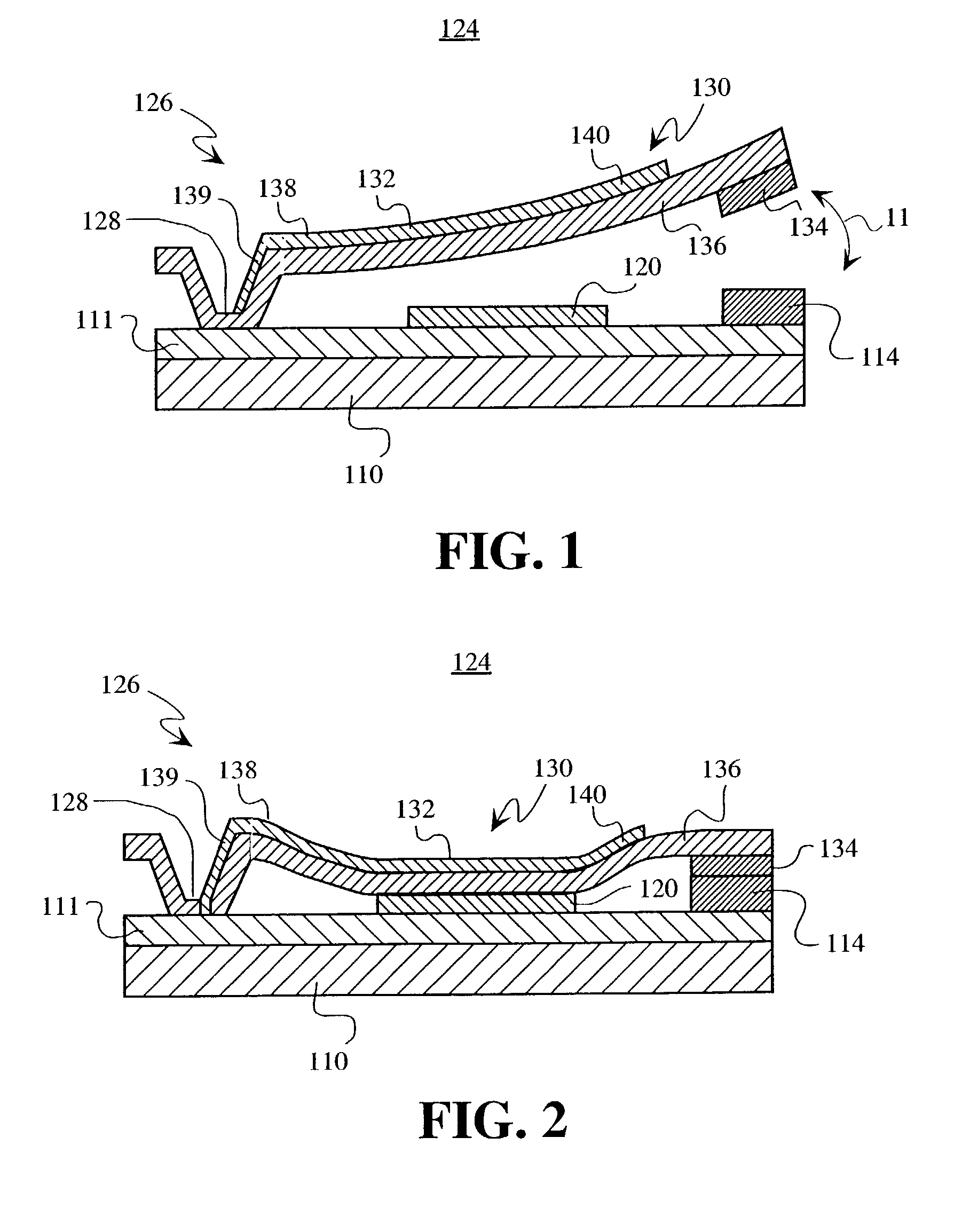

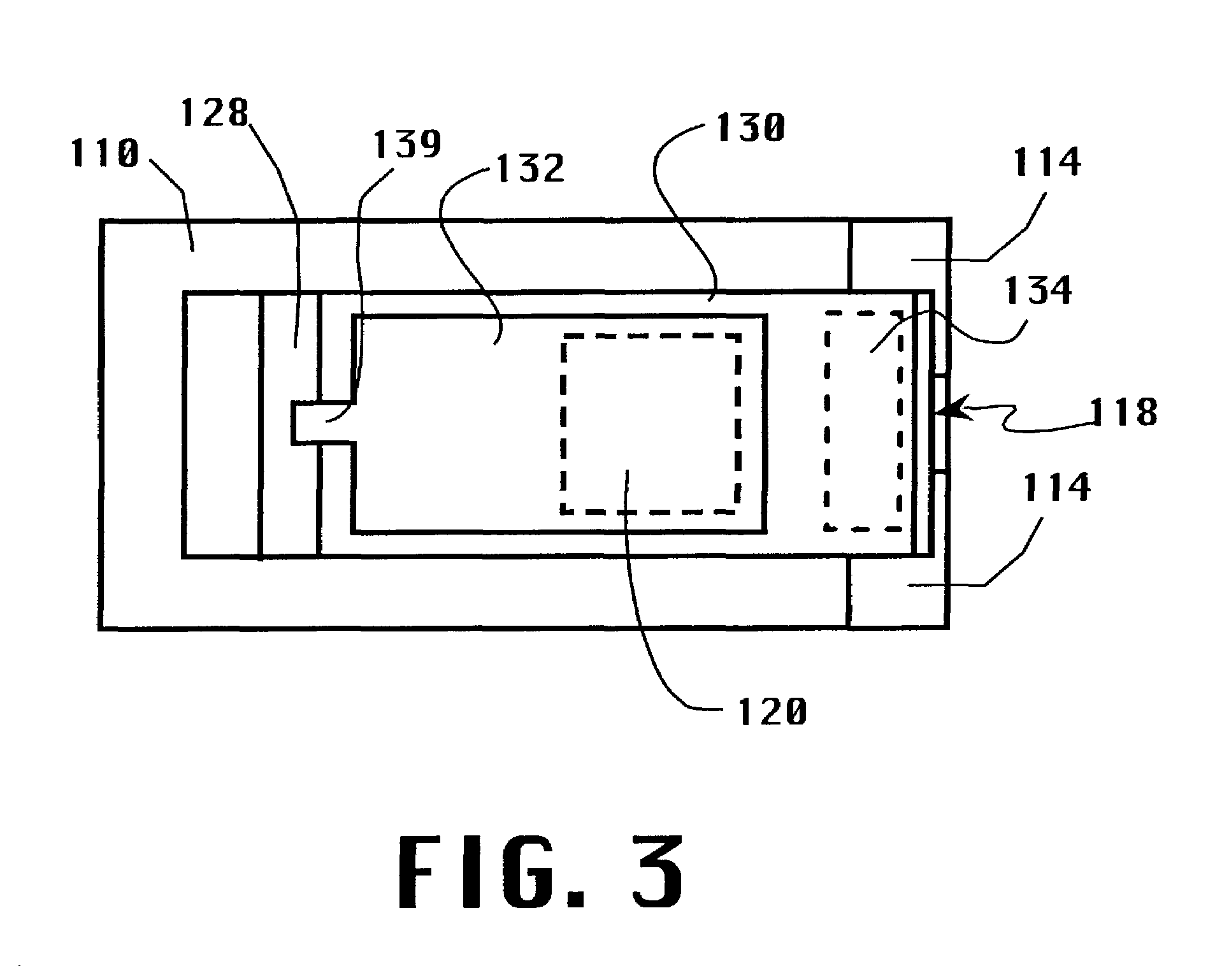

Stress bimorph MEMS switches and methods of making same

InactiveUS7053737B2Reduce capacitanceMinimize OFF-state capacitanceElectrostatic/electro-adhesion relaysCapacitor with electrode distance variationEngineeringCantilever

A micro-electromechanical system (MEMS) switch formed on a substrate, the switch comprising a transmission line formed on the substrate, a substrate electrostatic plate formed on the substrate, and an actuating portion. The actuating portion comprises a cantilever anchor formed on the substrate and a cantilevered actuator arm extending from the cantilever anchor. Attraction of the actuator arm toward the substrate brings an electrical contact into engagement with the portions of the transmission line separated by a gap, thus bridging the transmission line gap and closing the circuit. In order to maximize electrical isolation between the transmission line and the electrical contact in an OFF-state while maintaining a low actuation voltage, the actuator arm is bent such that the minimum separation distance between the transmission line and the electrical contact is equal to or greater than the maximum separation distance between the substrate electrostatic plate and arm electrostatic plate.

Owner:HRL LAB +1

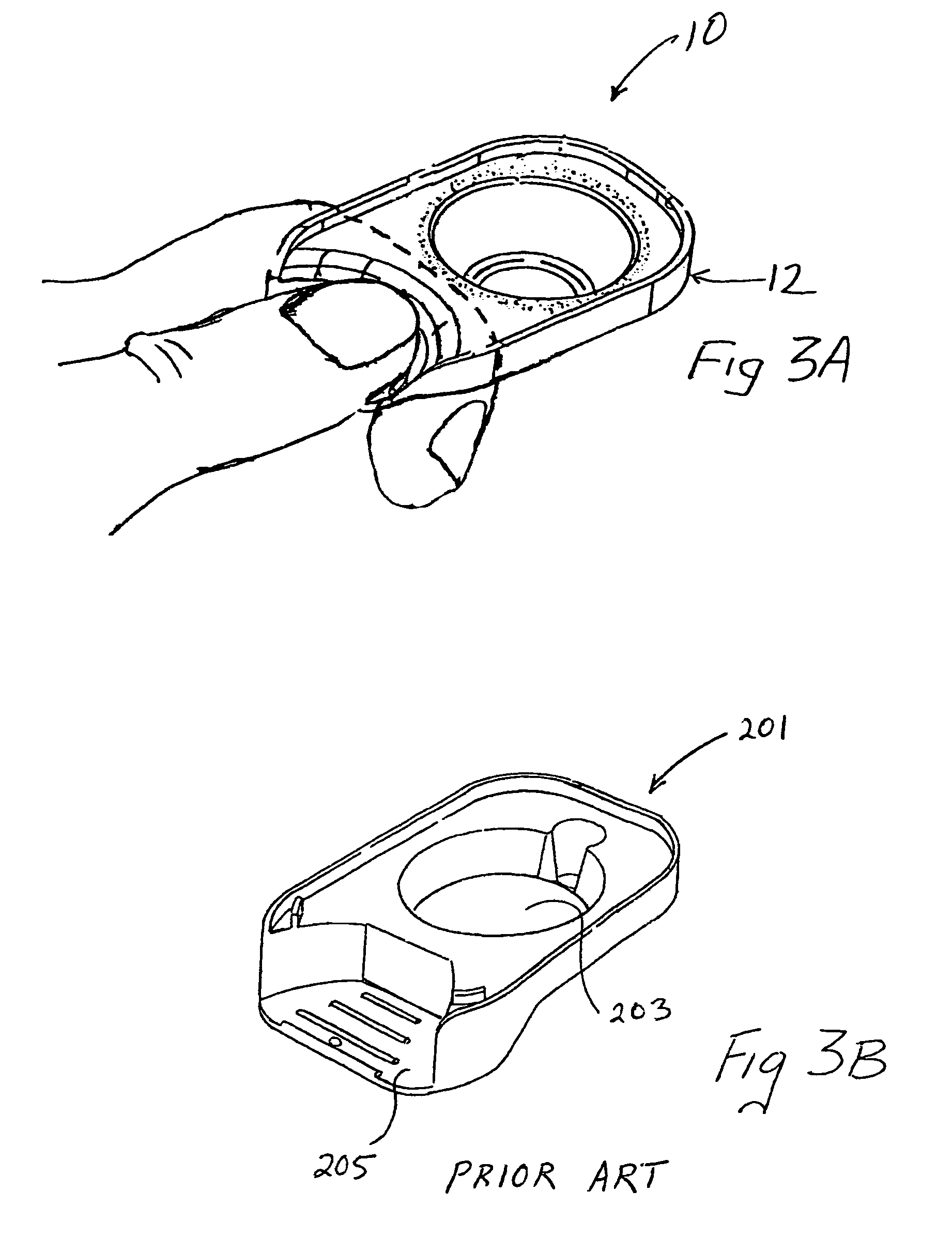

Contact lens package

ActiveUS7426993B2Reduced tendency to stick togetherReduce effortOther accessoriesContainer/bottle contructionLiquid mediumEngineering

Owner:COOPERVISION INT LTD

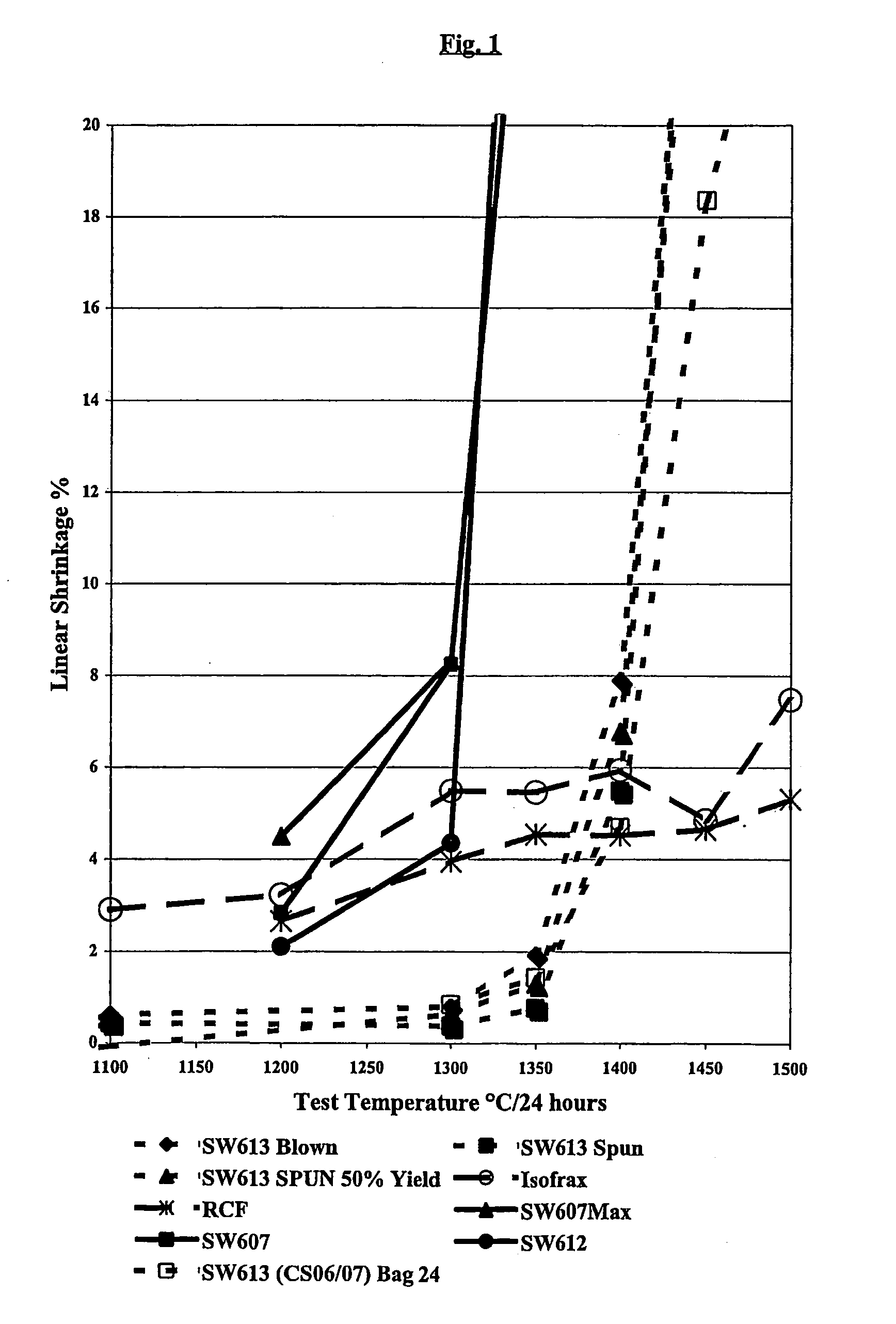

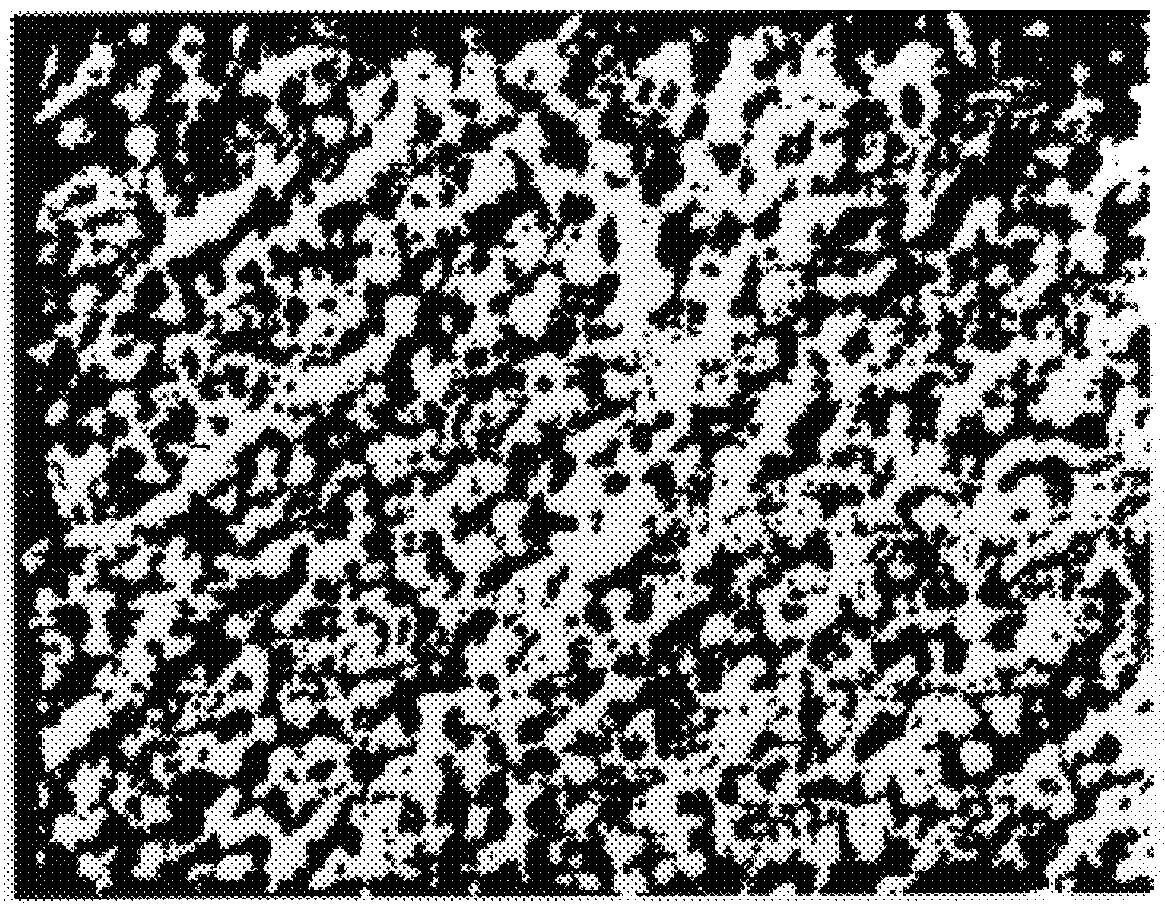

Saline soluble inorganic fibres

InactiveUS7153796B2Improve fiber qualityMinimise reduction is solubilityInorganic material artificial filamentsHeat proofingFiberThermal insulation

Thermal insulation is provided for use in applications requiring continuous resistance to temperatures of 1260° C. without reaction with alumino-silicate firebricks, the insulation comprises fibers having a composition in wt %65%<SiO2<86%MgO<10%14%<CaO<28%Al2O3<2%ZrO2<3%B2O3<5%P2O5<5%72%<SiO2+ZrO2+B2O3+5*P2O5 95%<SiO2+CaO+MgO+Al2O3+ZrO2+B2O3+P2O5 Addition of elements selected from the group Sc, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y or mixtures thereof improves fiber quality and the strength of blankets made from the fibers.

Owner:THE MORGAN CRUCIBLE CO PLC

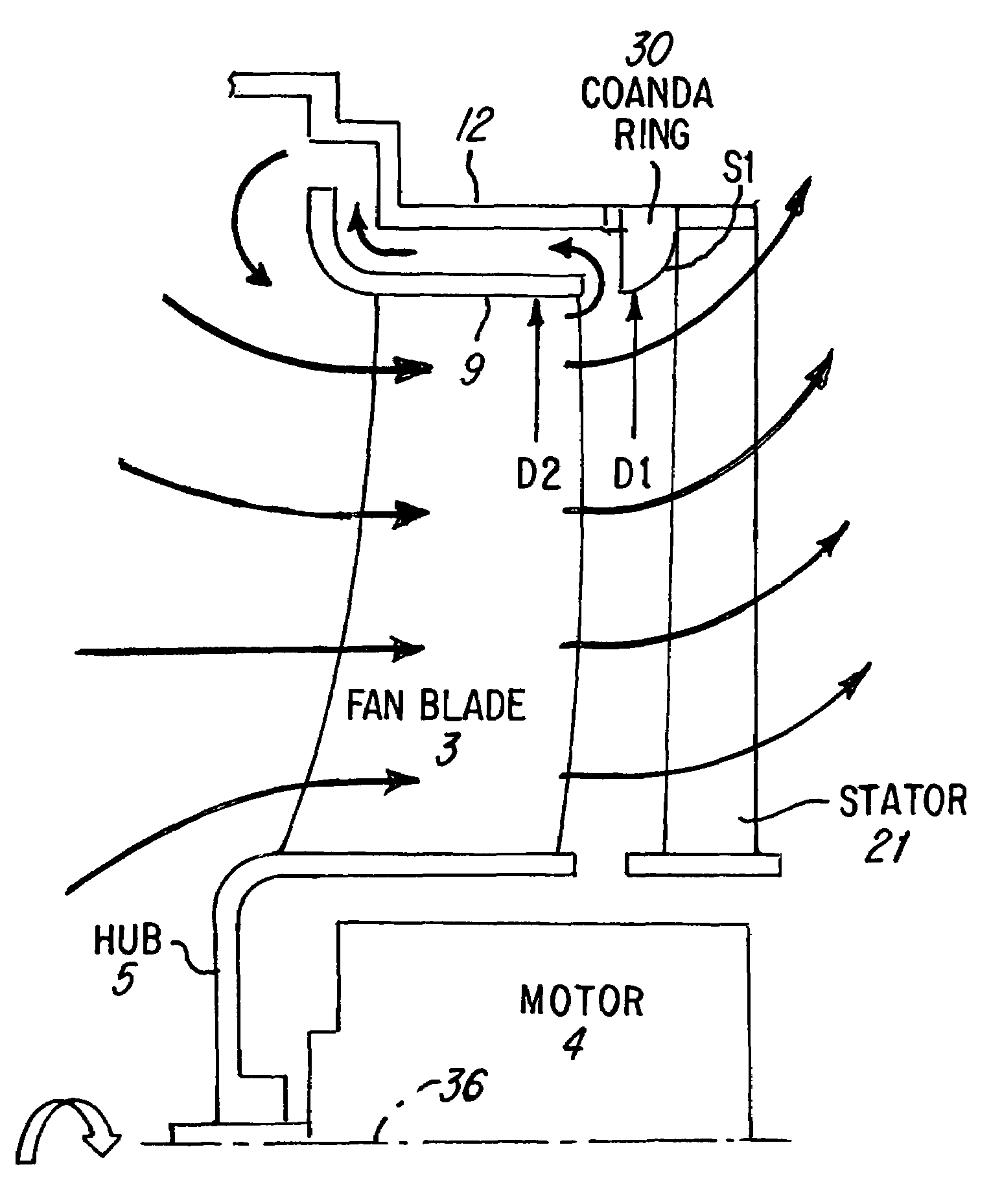

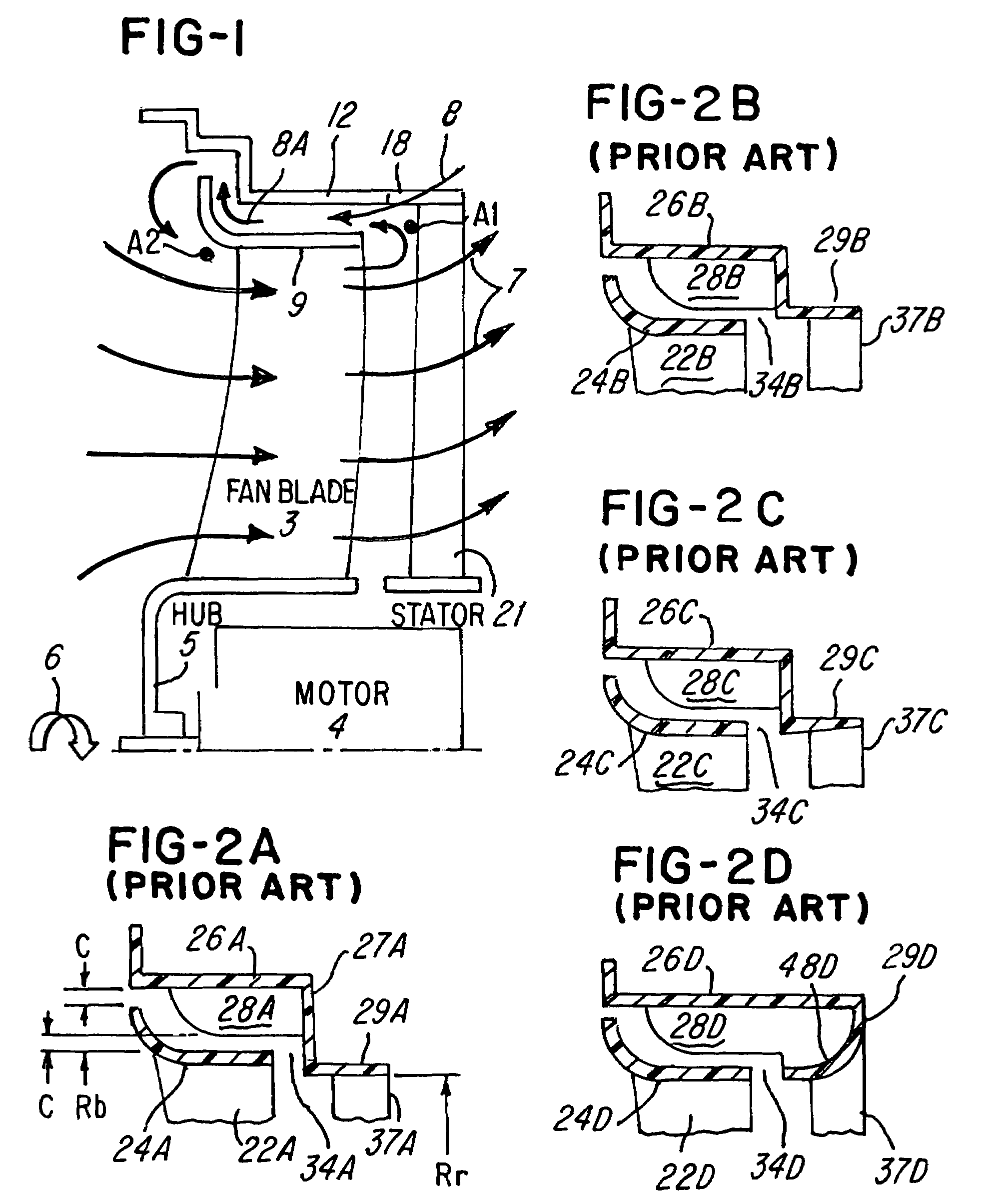

Cooling fan using Coanda effect to reduce recirculation

ActiveUS7478993B2Trend downIncrease the cross-sectional areaPump componentsReaction enginesEngineeringFan blade

Owner:VALEO INC

Thermally applied coating for piston rings, consisting of mechanically alloyed powders

InactiveUS20030180565A1Minimize negative affectConstant sliding wearPiston ringsMolten spray coatingBearing surfaceWear resistant

The invention relates to a wear-resistant coating used for bearing surfaces and flanks of piston rings in internal combustion engines. The wear-resistant inventive coating is obtained by mechanically alloying powders which form a metallic matrix with hard material dispersoids and lubricant material dispersoids. The coating is then thermally applied to the workpieces, especially by means of high velocity oxygen fuel spraying (HVOF). The workpieces coated are bearing surfaces and parts of flanks pertaining to piston rings in internal combustion engines.

Owner:FEDERAL MOGUL BURSCHEID

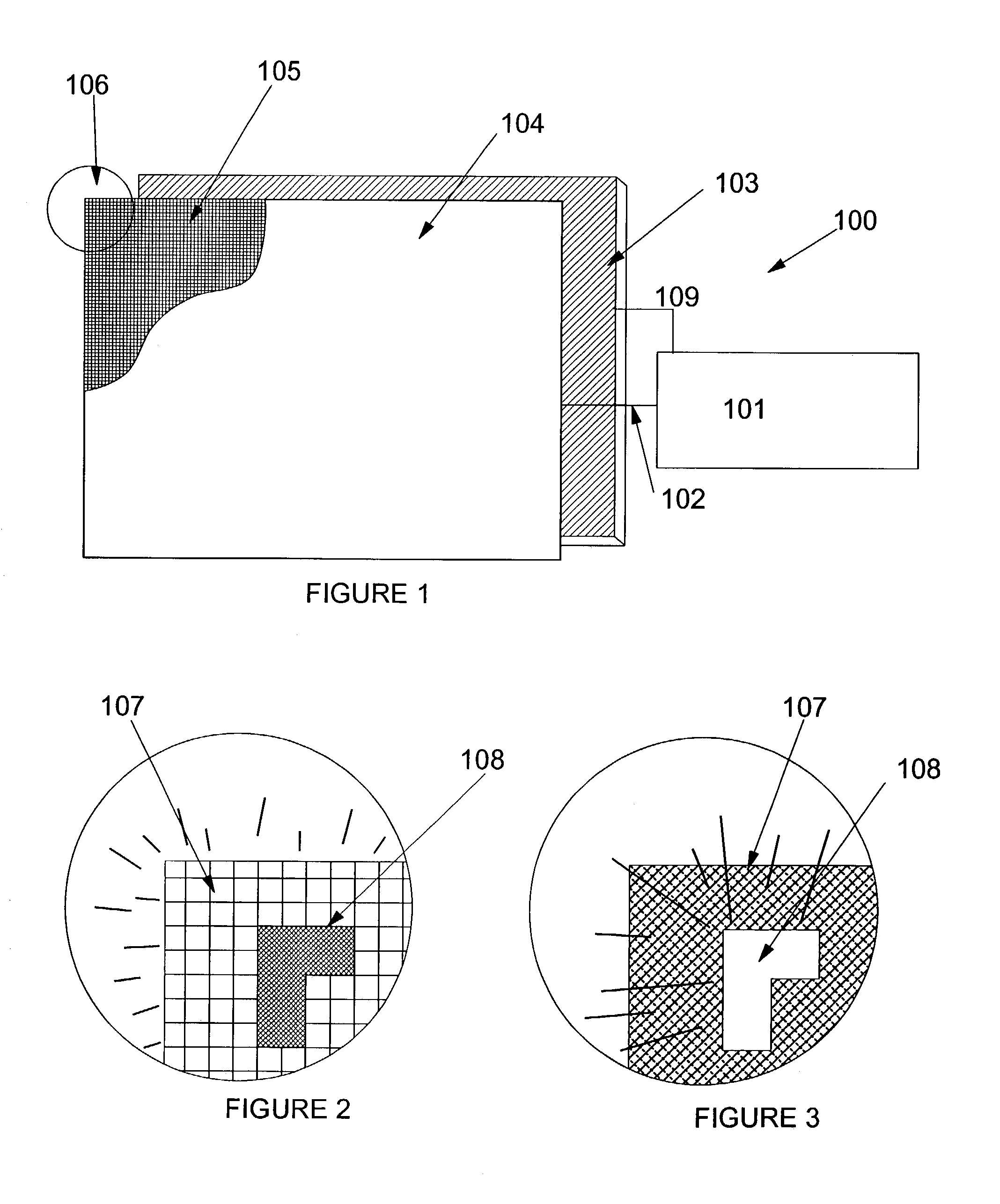

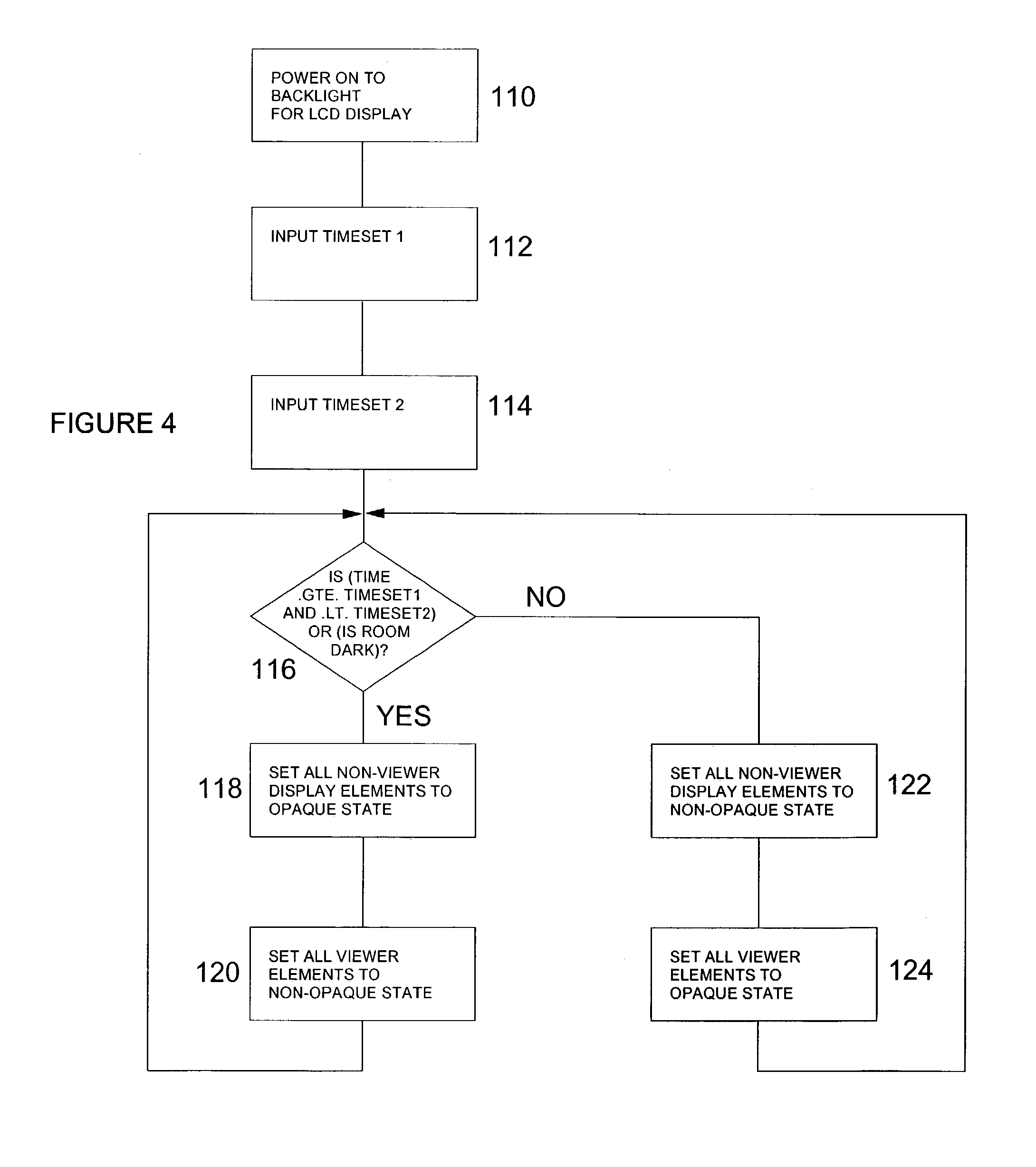

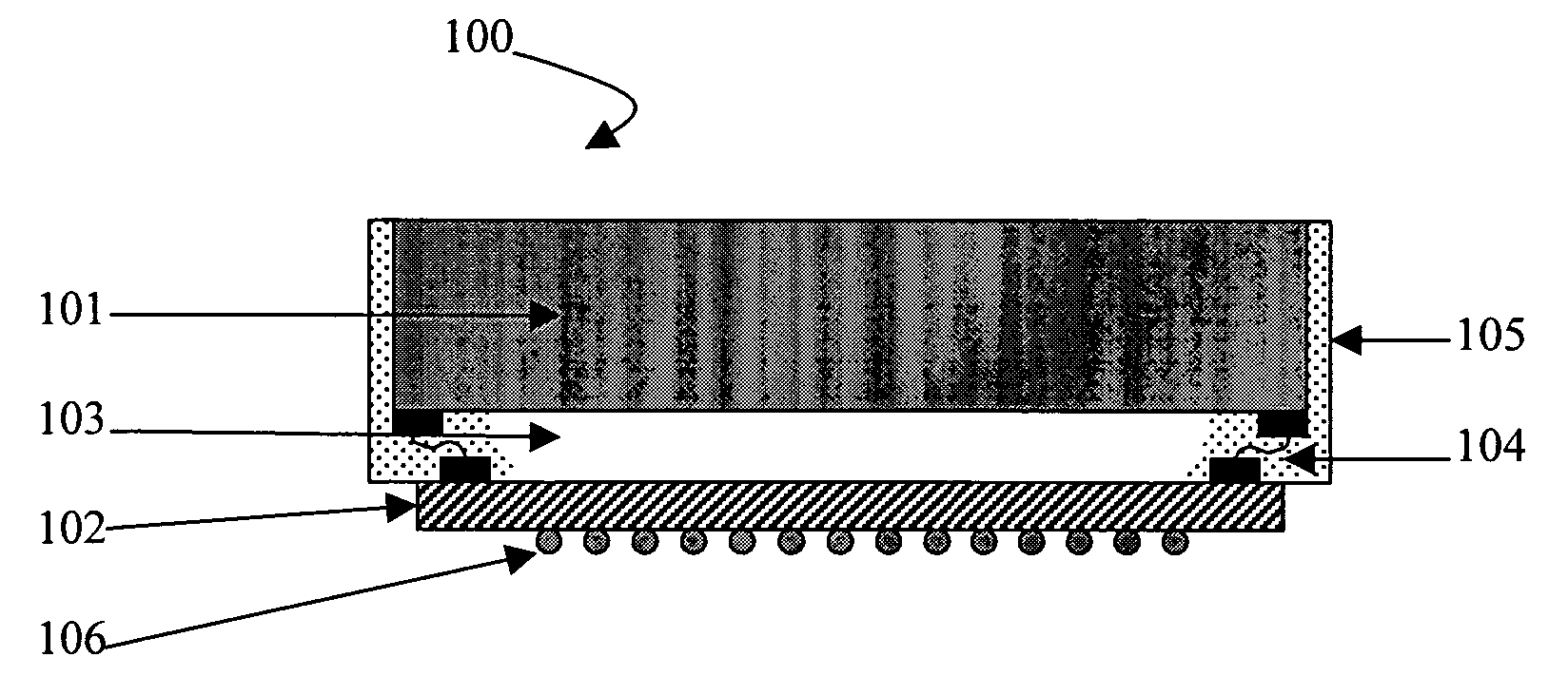

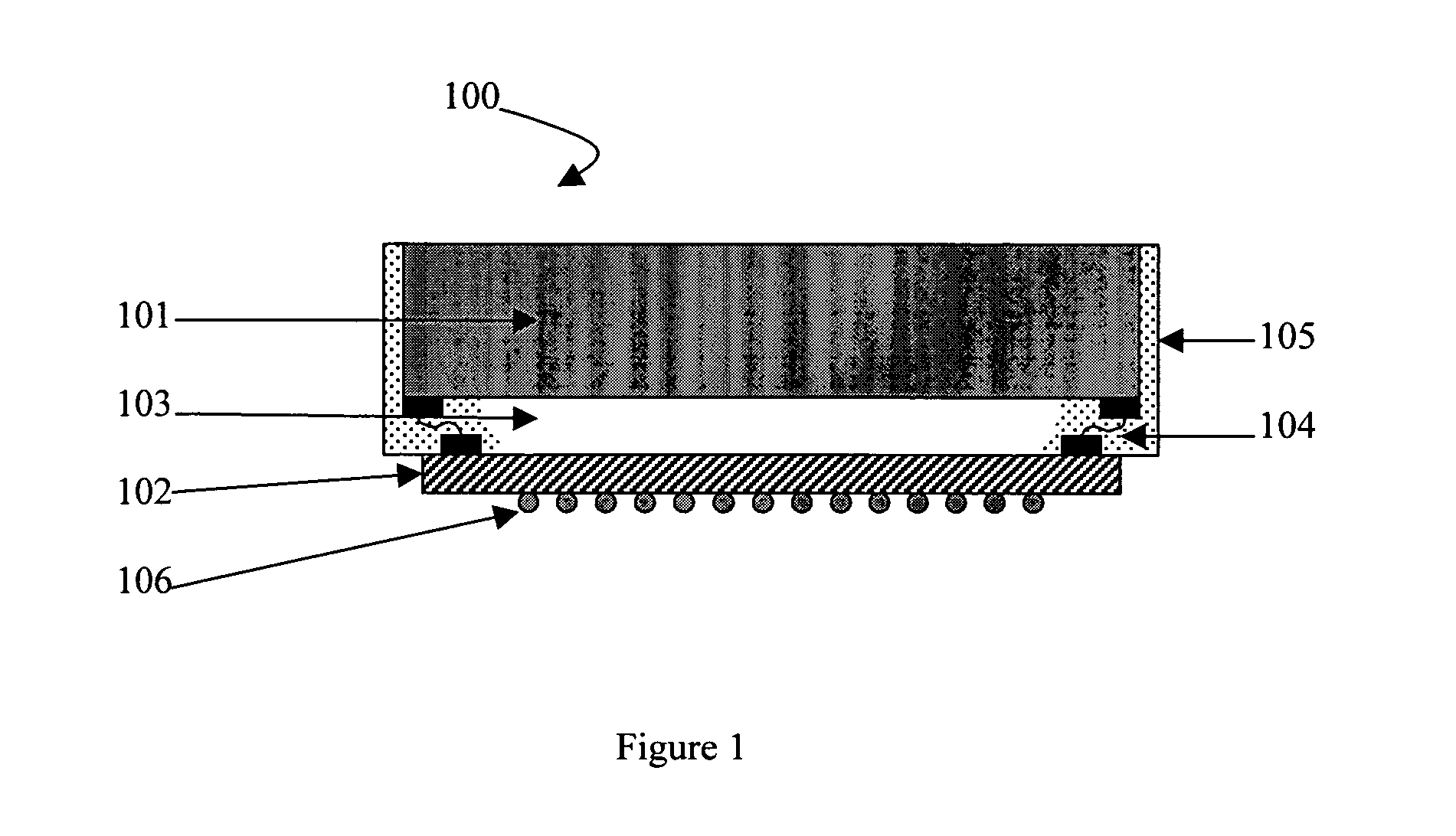

Reverse images in a dot matrix LCD for an environmental control device

ActiveUS7050026B1Easy to seeAccurate distinctionStatic indicating devicesTemperatue controlDot matrixProgrammable thermostat

The present invention is a method for operating a backlighted dot matrix type LCD for displayed outputs from a programmable environmental control device, such as a programmable thermostat. The LCD is operated so that viewer elements of a displayed data item are non-opaque when a room where the LCD is located is darkened and the surrounding display elements are partially or completely opaque. Selected elements can also change from opaque to non-opaque to display an active condition.

Owner:ROSEN TECH LLC

Silicones having improved chemical resistance and curable silicone compositions having improved migration resistance

InactiveUS20050038188A1Improve the immunityTrend downMouldsSemiconductor/solid-state device detailsHydrogenHydrogen atom

A composition is prepared by mixing components including: (I) a polyorganosiloxane having an average of at least two unsaturated organic groups per molecule, with the proviso that component (I) is free of fluorine atoms; optionally (II) an organohydrogenpolysiloxane having an average of at least two silicon-bonded hydrogen atoms per molecule, with the proviso that component (II) is free of fluorine atoms; (III) a hydrosilylation catalyst; (IV) a fluoroorganosilicone, with the provisos that (1) component (IV) has at least one functional group reactive with component (I), component (II), or both, (2) when component (II) is not present, then component (IV) has an average of at least two silicon-bonded hydrogen atoms per molecule, and (3) component (IV) is added to the composition in an amount sufficient to provide chemical resistance to a cured product of the composition; and (V) an adhesion promoter.

Owner:DOW CORNING CORP

Polyolefin film containing cycloolefin polymer, process for the production thereof, and the use thereof

InactiveUS6068936AHigh strength valueGood barrier effectFlexible coversWrappersPolymer sciencePolyolefin

A polyolefin film which includes at least one layer containing polyolefin and cycloolefin polymer (COP), where the cycloolefin polymer is amorphous and has a mean molecular weight Mw in the range from 200 to 100,000, and this mean molecular weight Mw of the cycloolefin polymer is at most 50% of the mean molecular weight Mw of the polyolefin, and the cycloolefin polymer is a homopolymer or a copolymer containing at most 20% by weight of comonomer.

Owner:TICONA GMBH

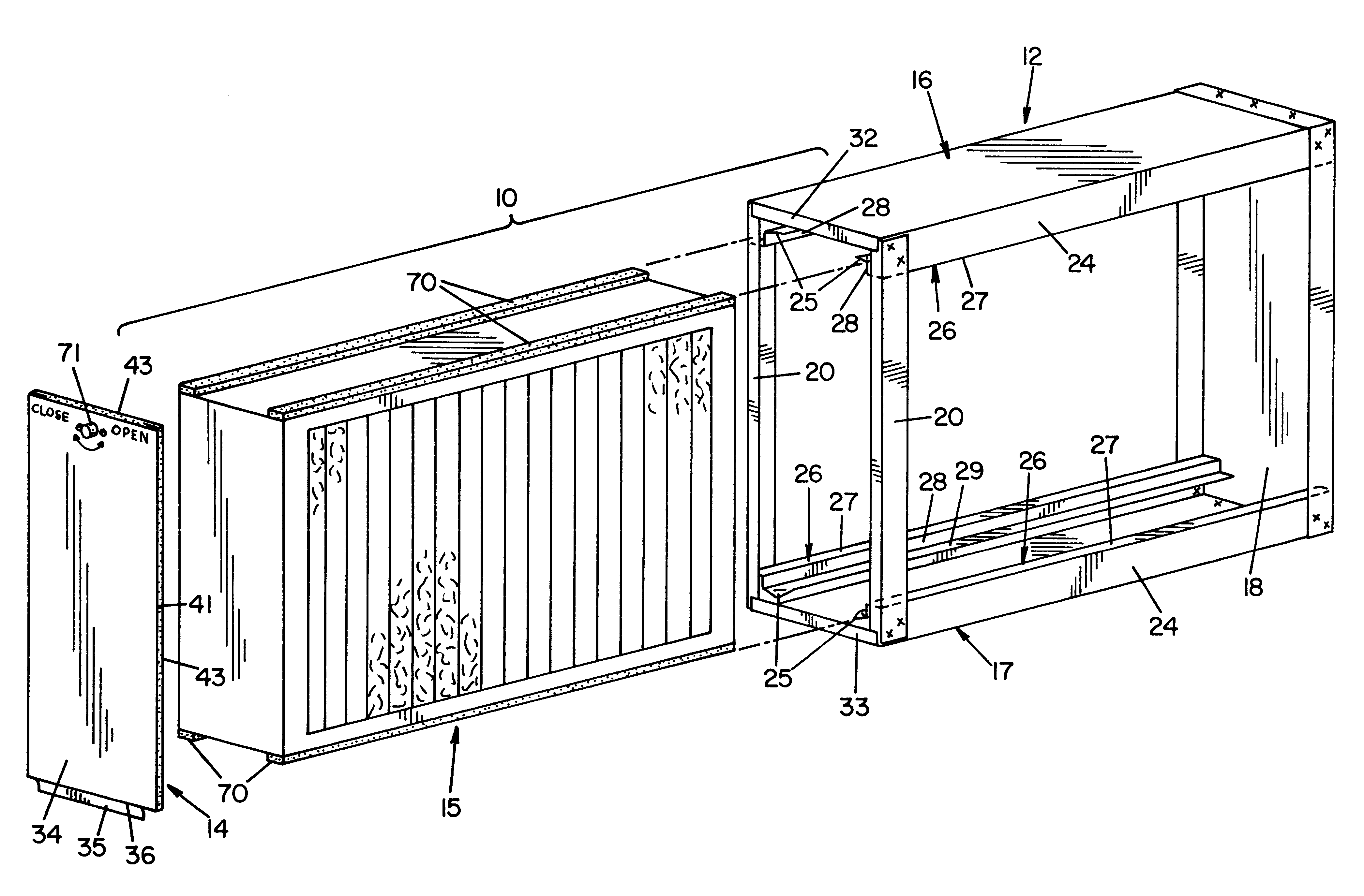

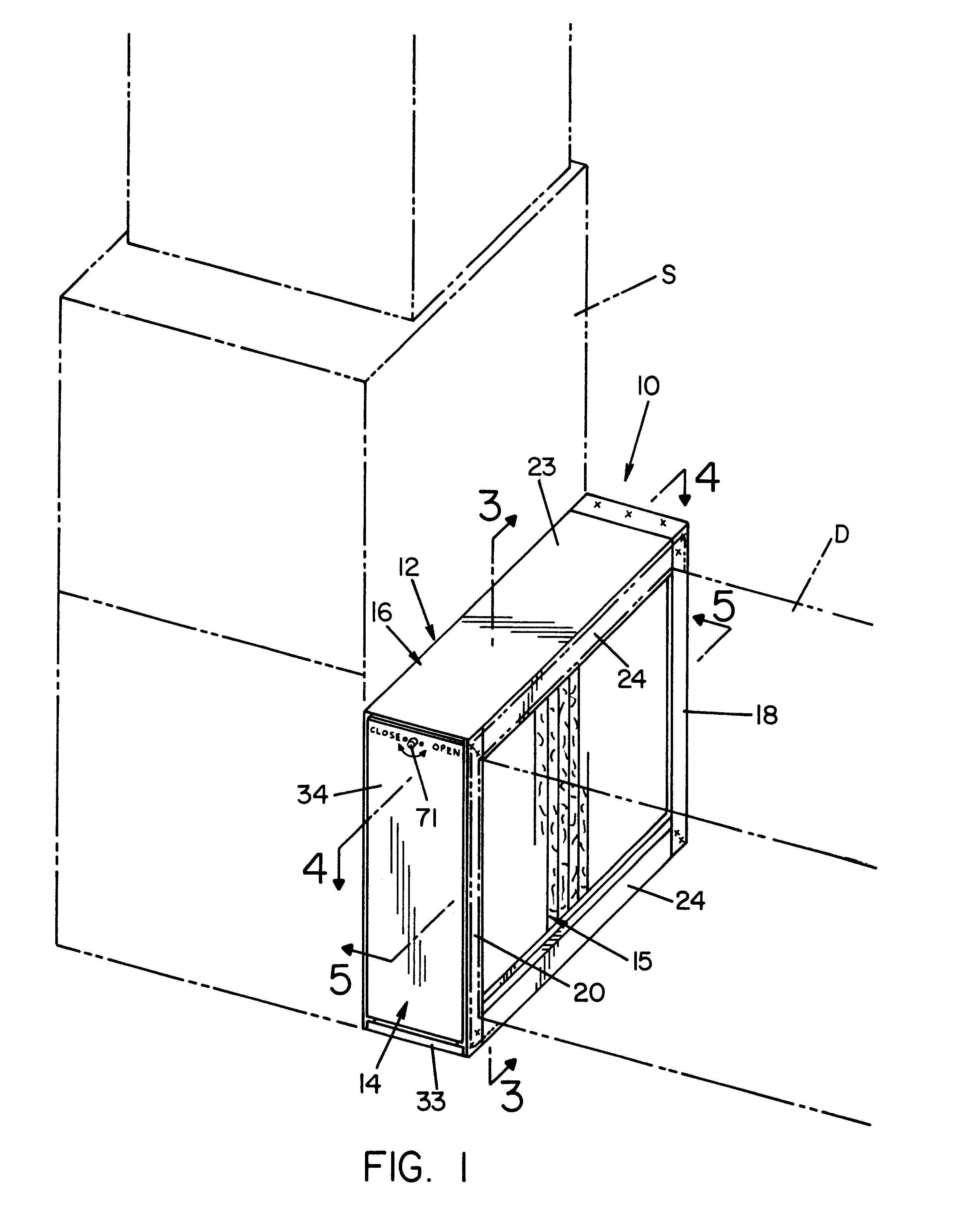

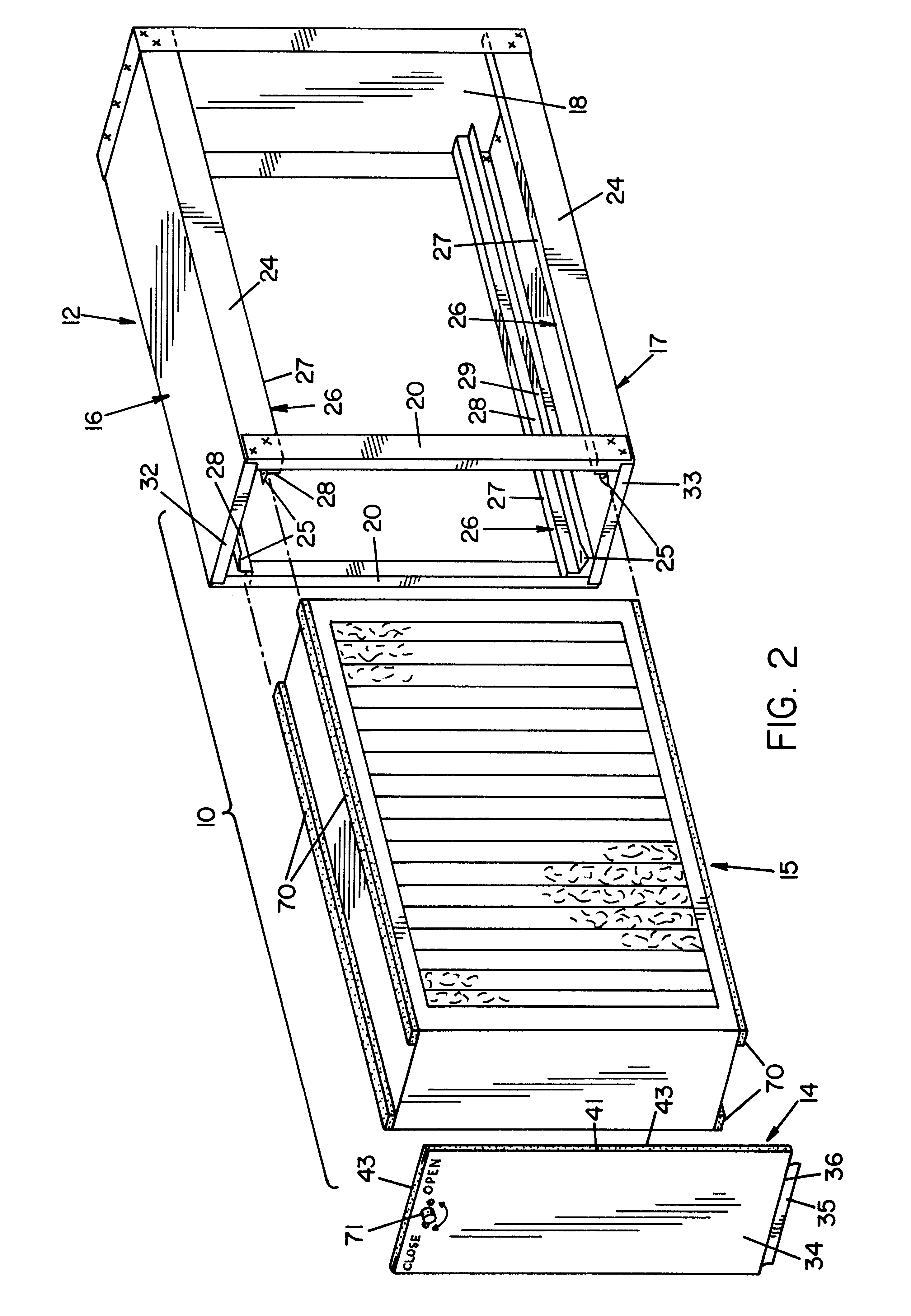

Media filter assembly having replaceable filter element

InactiveUS6264713B1Substantial structural integrityImprove sealingCombination devicesDispersed particle filtrationEngineeringMedia filter

A filter assembly is provided having a housing and a cover that communicate to retain a filter element. The housing has a top and a bottom spaced apart from each other, and a first pair of guide members is maintained beneath the top while a second pair of guide members is maintained above the bottom. The filter element is retained in the housing between the first and second pair of guide members thereby defining a first cavity between the top and the filter element and a second cavity between the bottom and the filter element. Fasteners, such as screws, rivets, nails and the like, may communicate with the cavities without damaging the filter element. The first and second pair of guide members allow for access to the internal surface area of the top and bottom of the housing such that fasteners or other installment means can be employed from the inside of the housing outwardly to the duct work or framework to which the filter assembly is to be attached.

Owner:SKUTTLE MFG

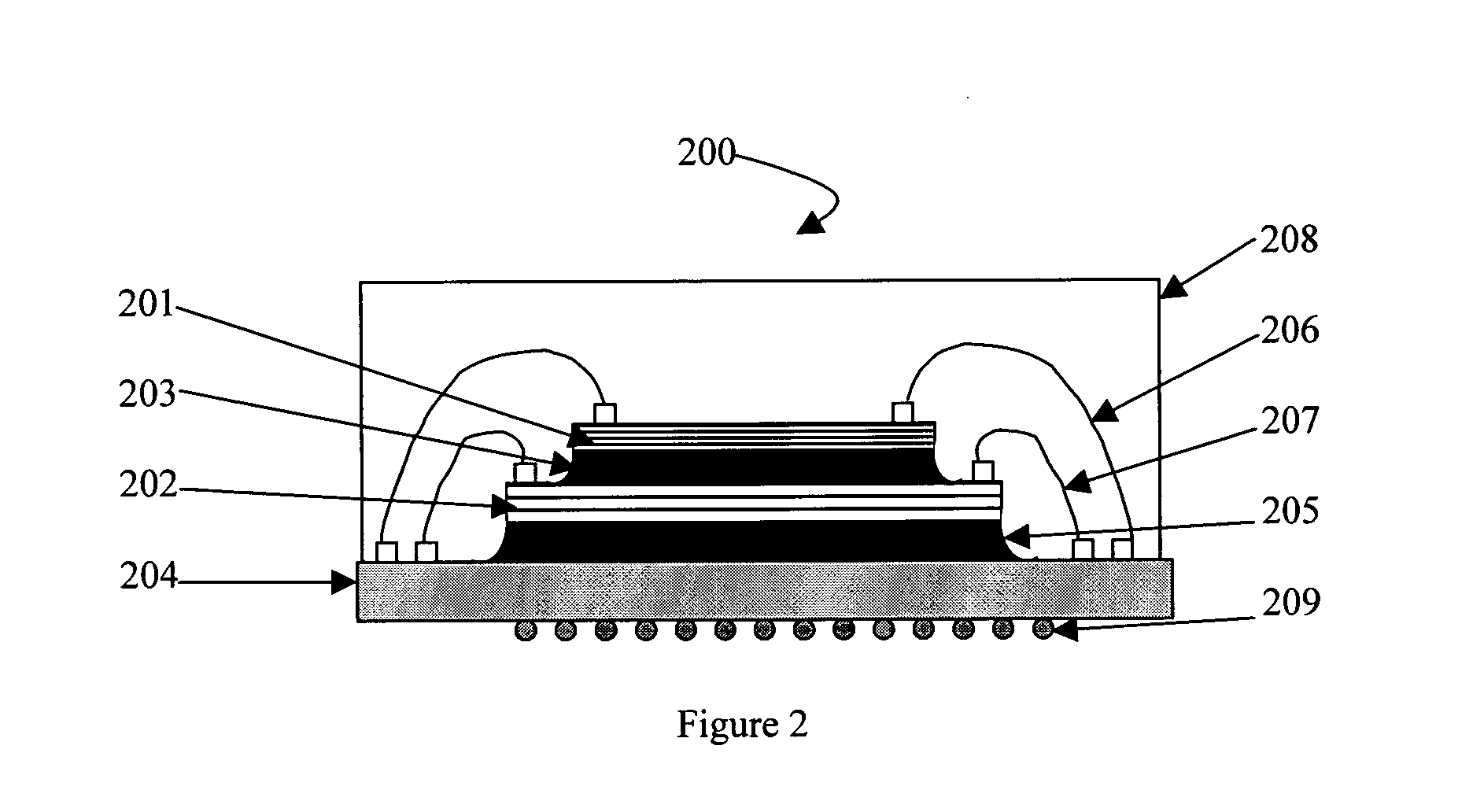

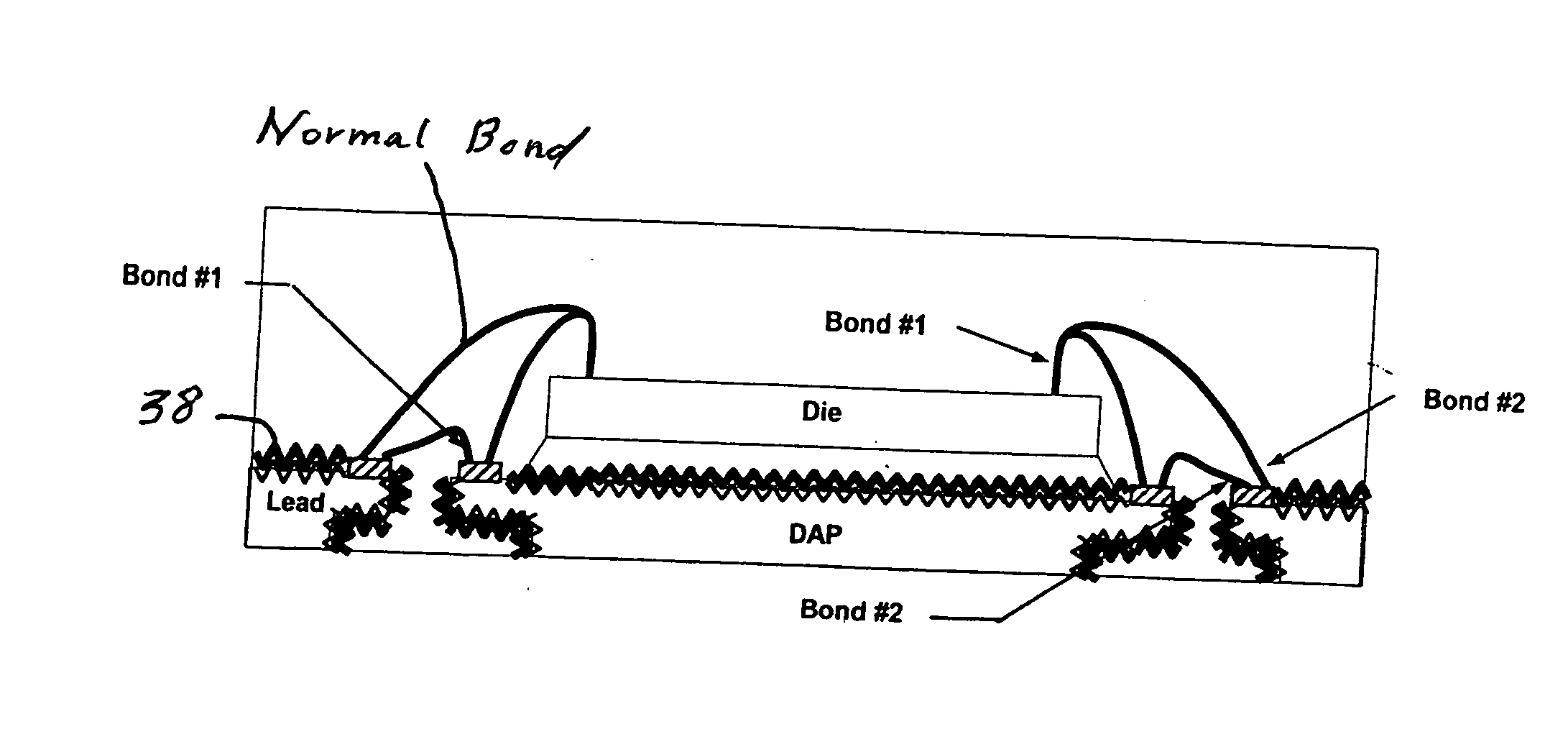

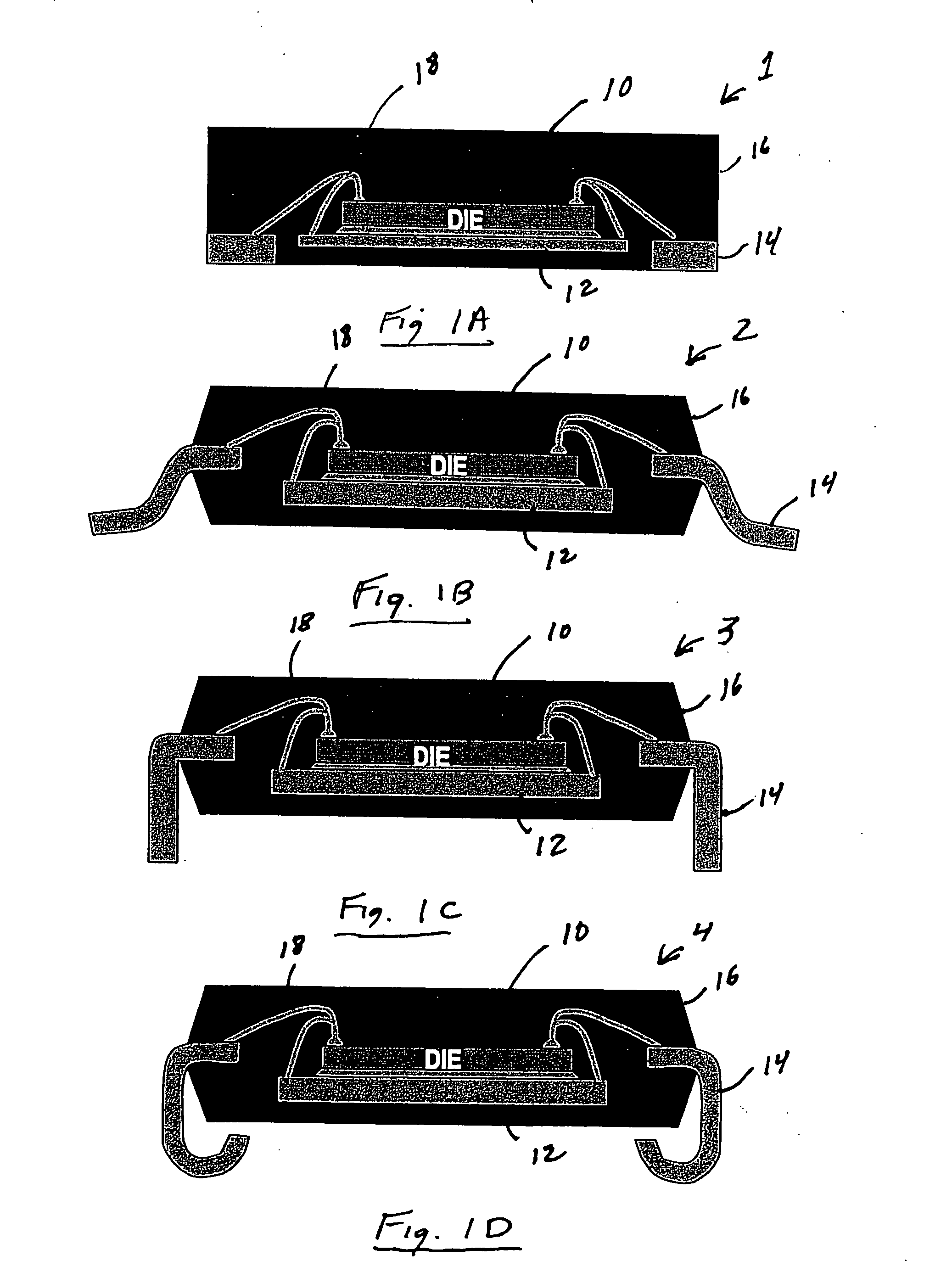

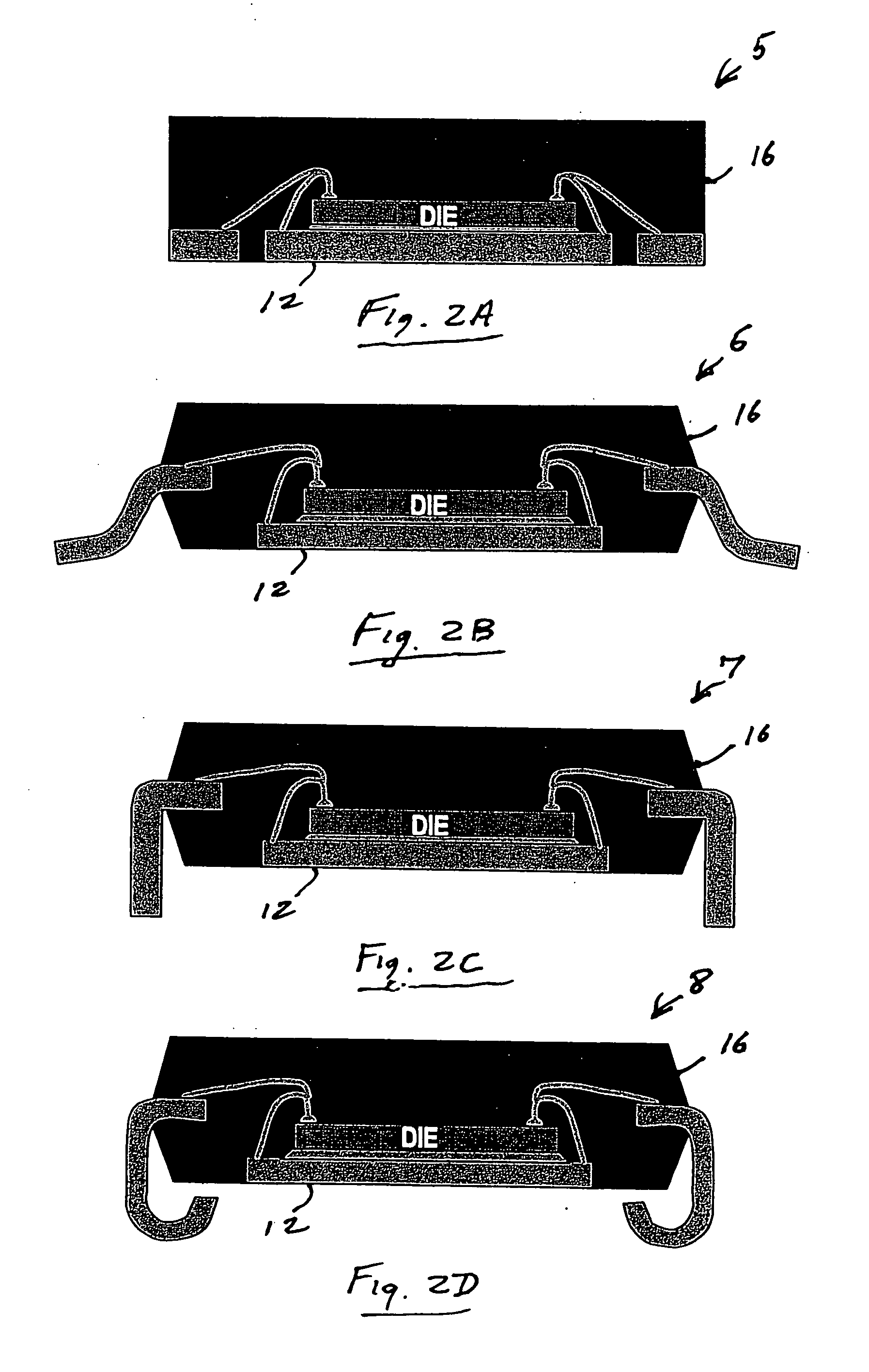

Semiconductor package including leadframe roughened with chemical etchant to prevent separation between leadframe and molding compound

InactiveUS20060097366A1Improve adhesionTrend downSemiconductor/solid-state device detailsSolid-state devicesCompound aSemiconductor package

A semiconductor package contains a metal leadframe that has been specially treated by roughening it with a chemical etchant. The roughening process enhances the adhesion between the leadframe and the molten plastic during the encapsulation of the leadframe and thereby reduces the tendency of the package to separate when exposed to moisture and numerous temperature cycles. In one embodiment, the leadframe made of copper is roughened with a chemical etchant that contains sulfuric acid and hydrogen peroxide.

Owner:UTAC HEADQUARTERS PTE LTD

Method of forming a thin wafer stack for a wafer level package

InactiveUS20050282374A1Wafer thickness reductionAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesEngineeringWafer stacking

A method of forming a stack of thin wafers provides a wafer level stack to greatly reduce process time compared to a method where individually separated chips are stacked after a wafer is sawed. A rigid planar wafer support member stabilizes and planarizes each wafer while it is thin or its thickness is reduced and during subsequent wafer processing. Thinned wafers are stacked and the external support members are removed by applying heat or ultraviolet (UV) light to an expandable adhesive layer between the support members and the thin wafers. The stacked wafers then can be further processed and packaged without thin-wafer warping, cracking or breaking. A wafer level package made in accordance with the invented method also is disclosed.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com