Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22532 results about "Fan blade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

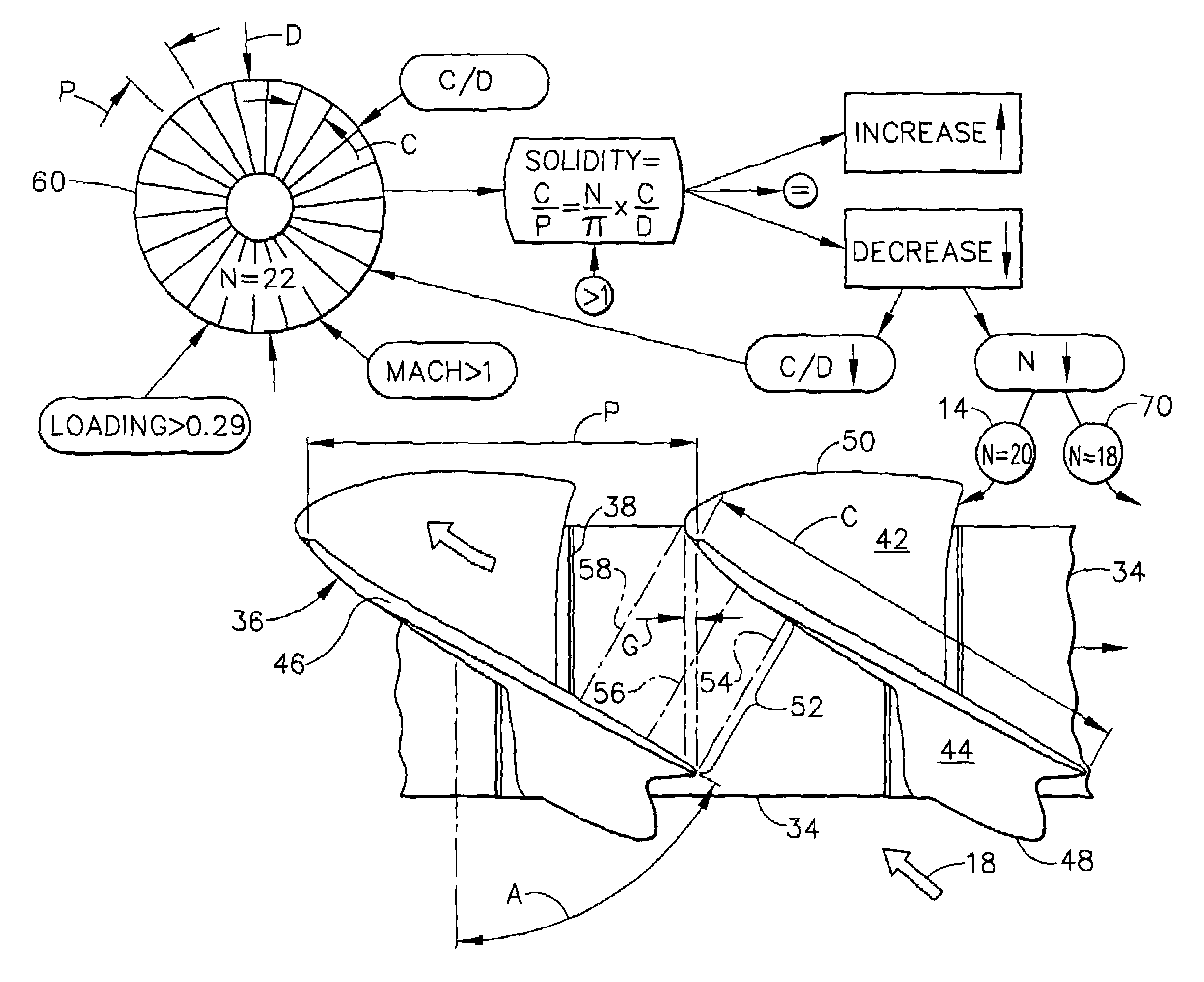

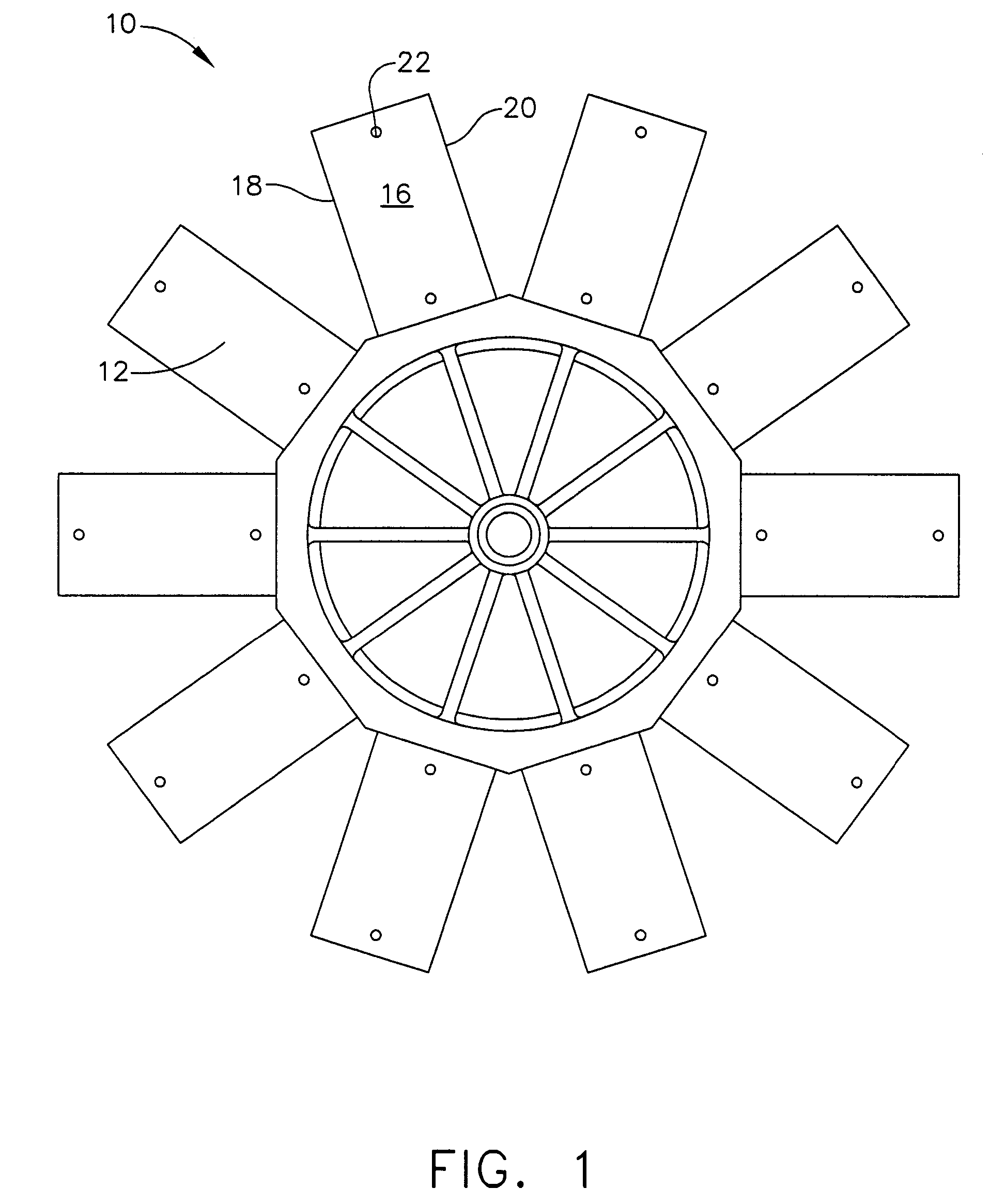

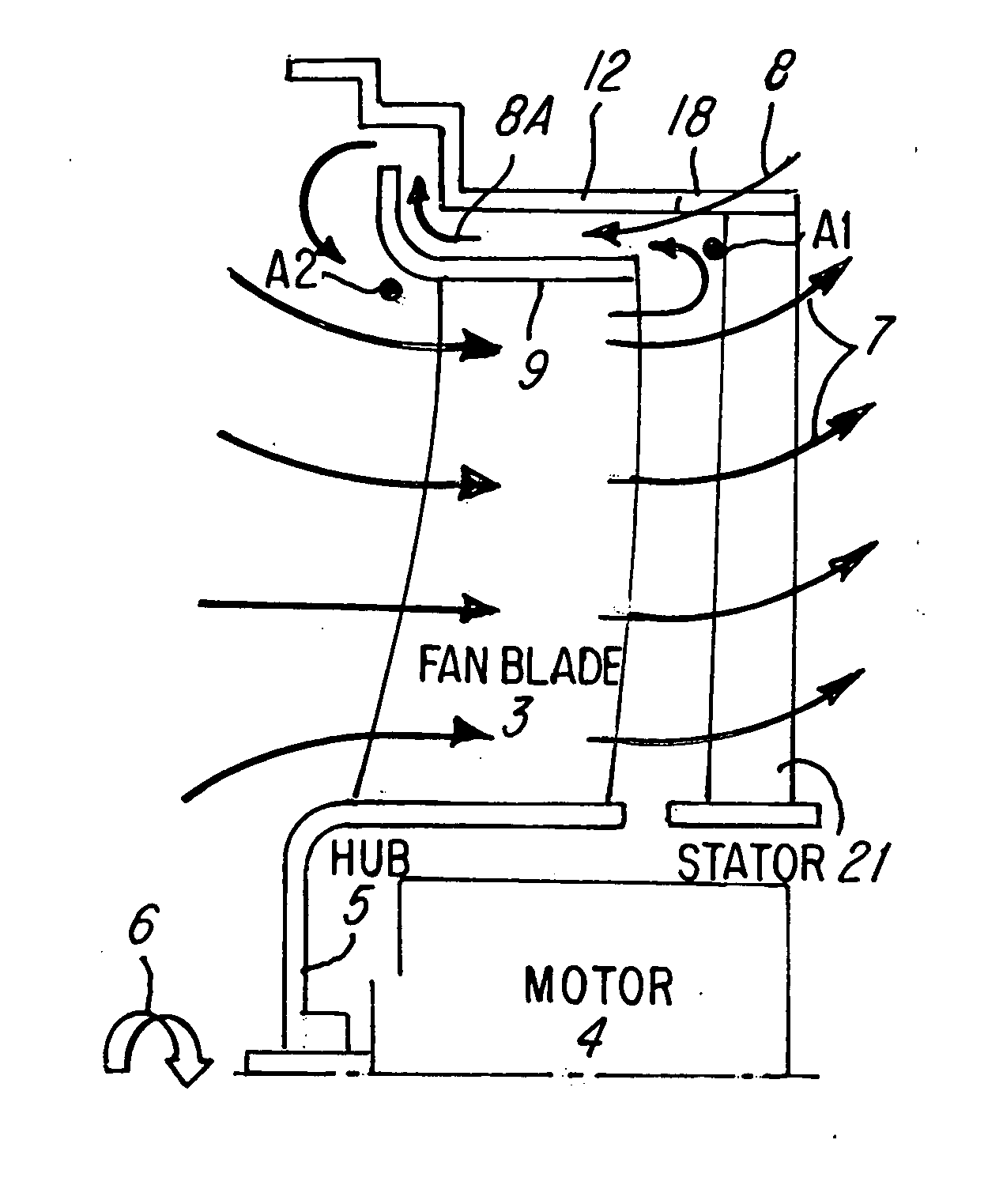

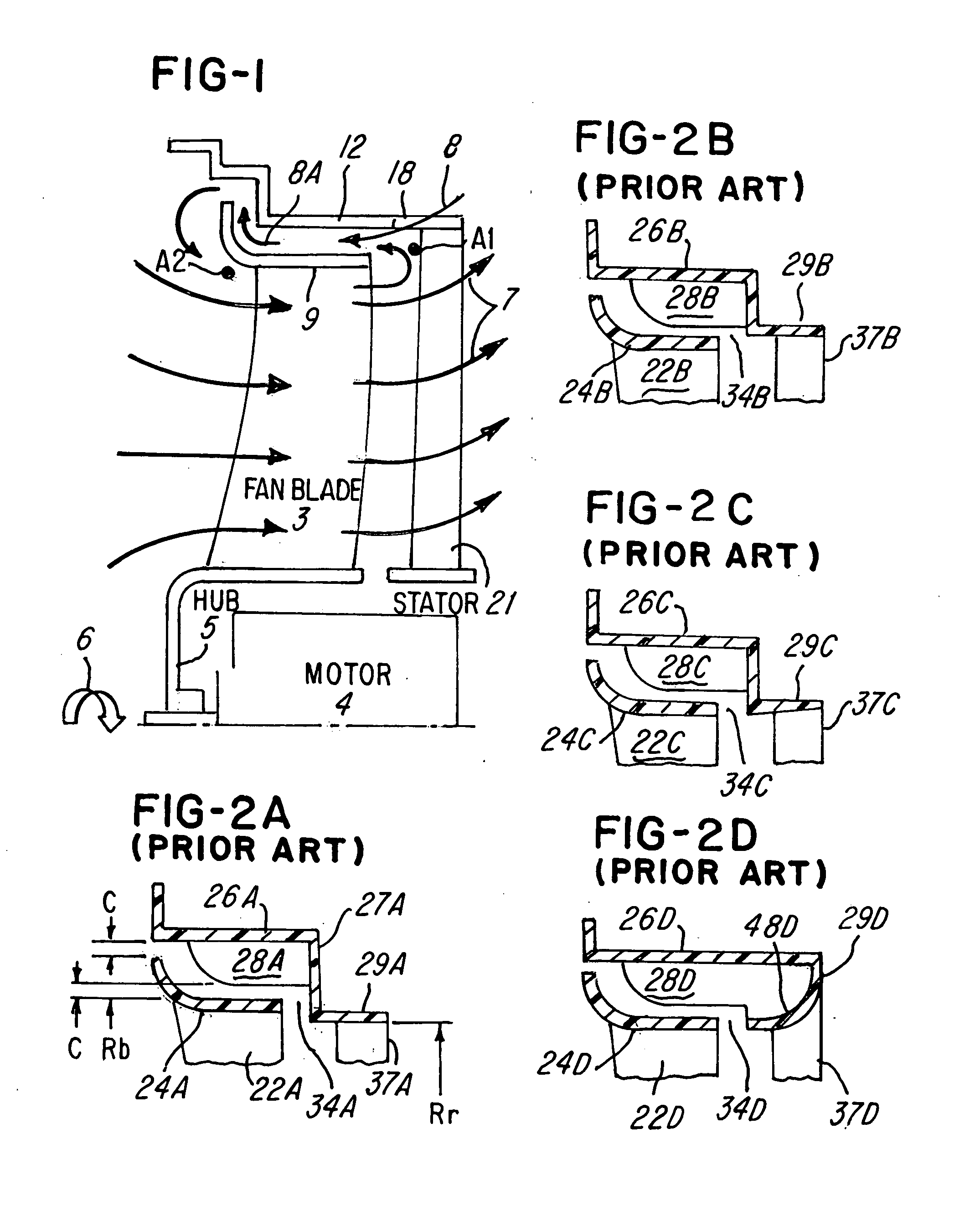

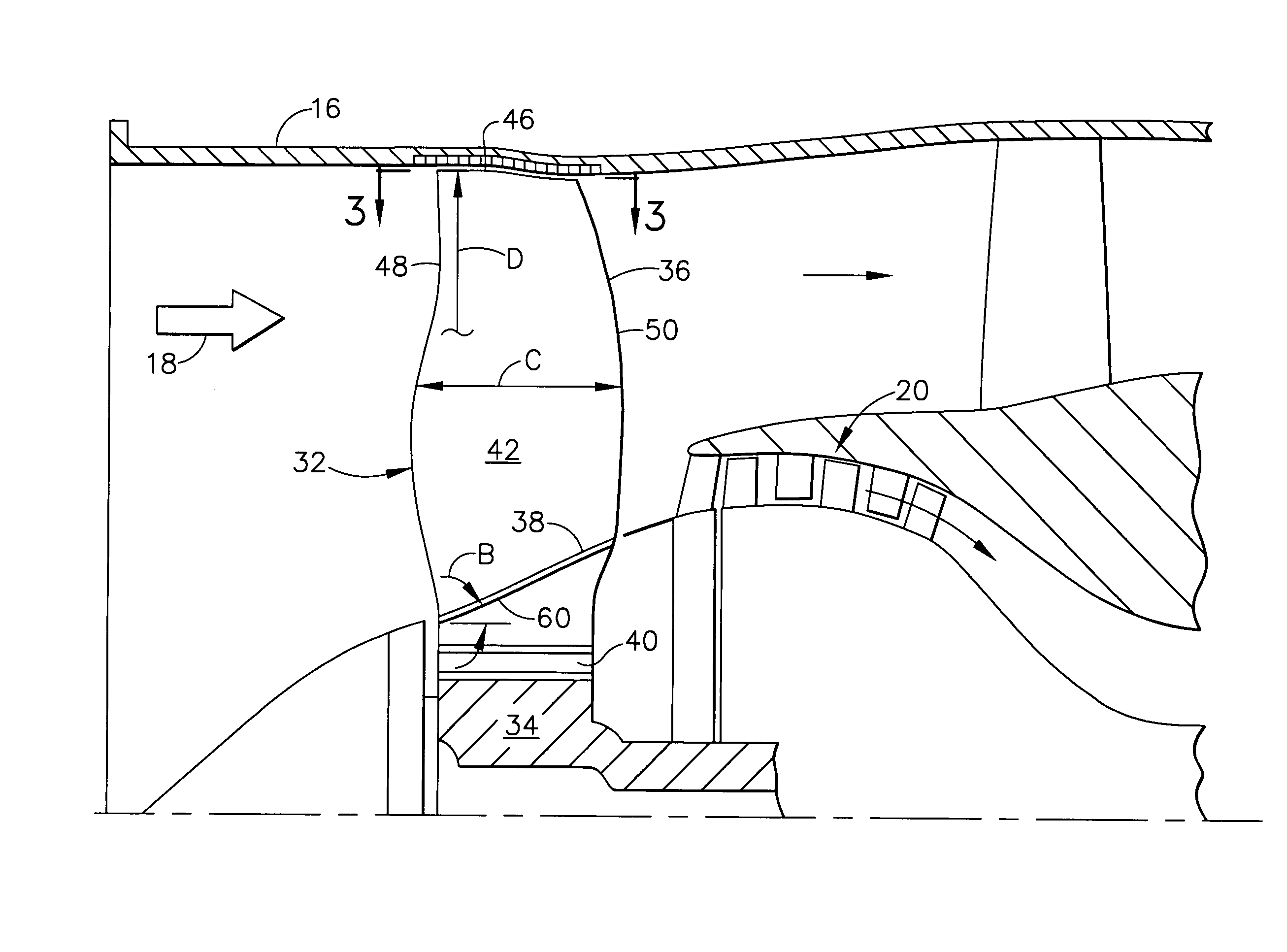

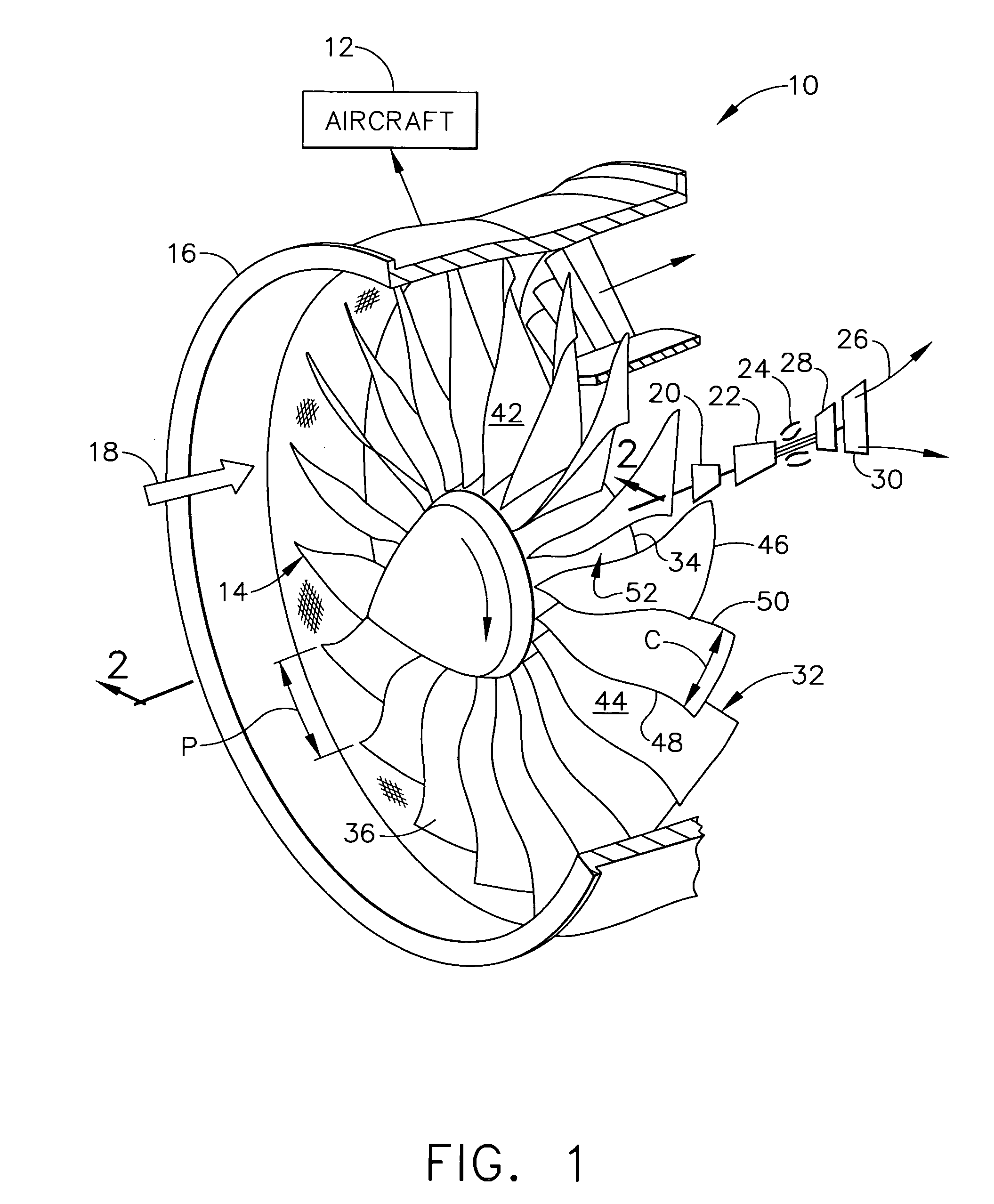

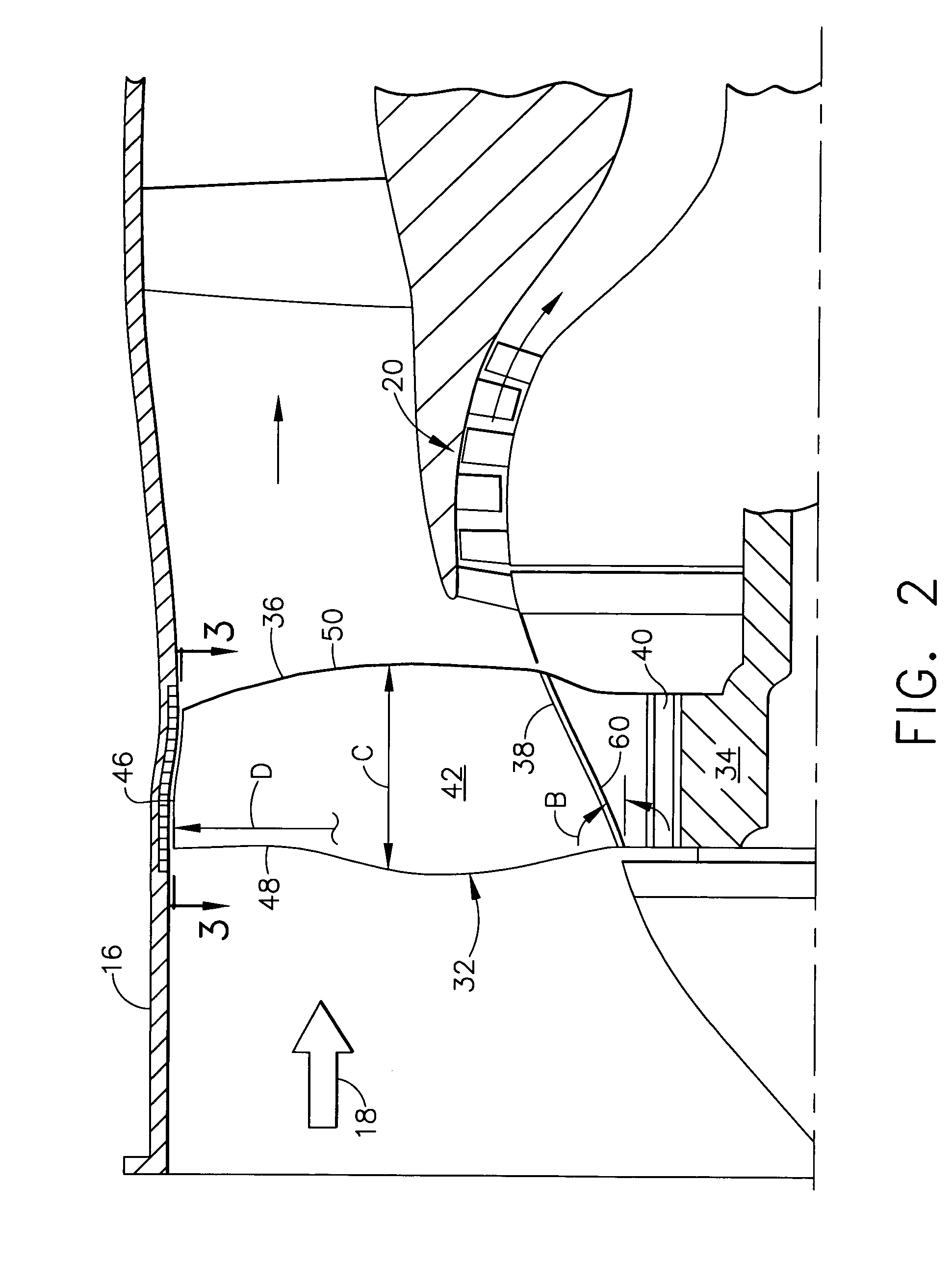

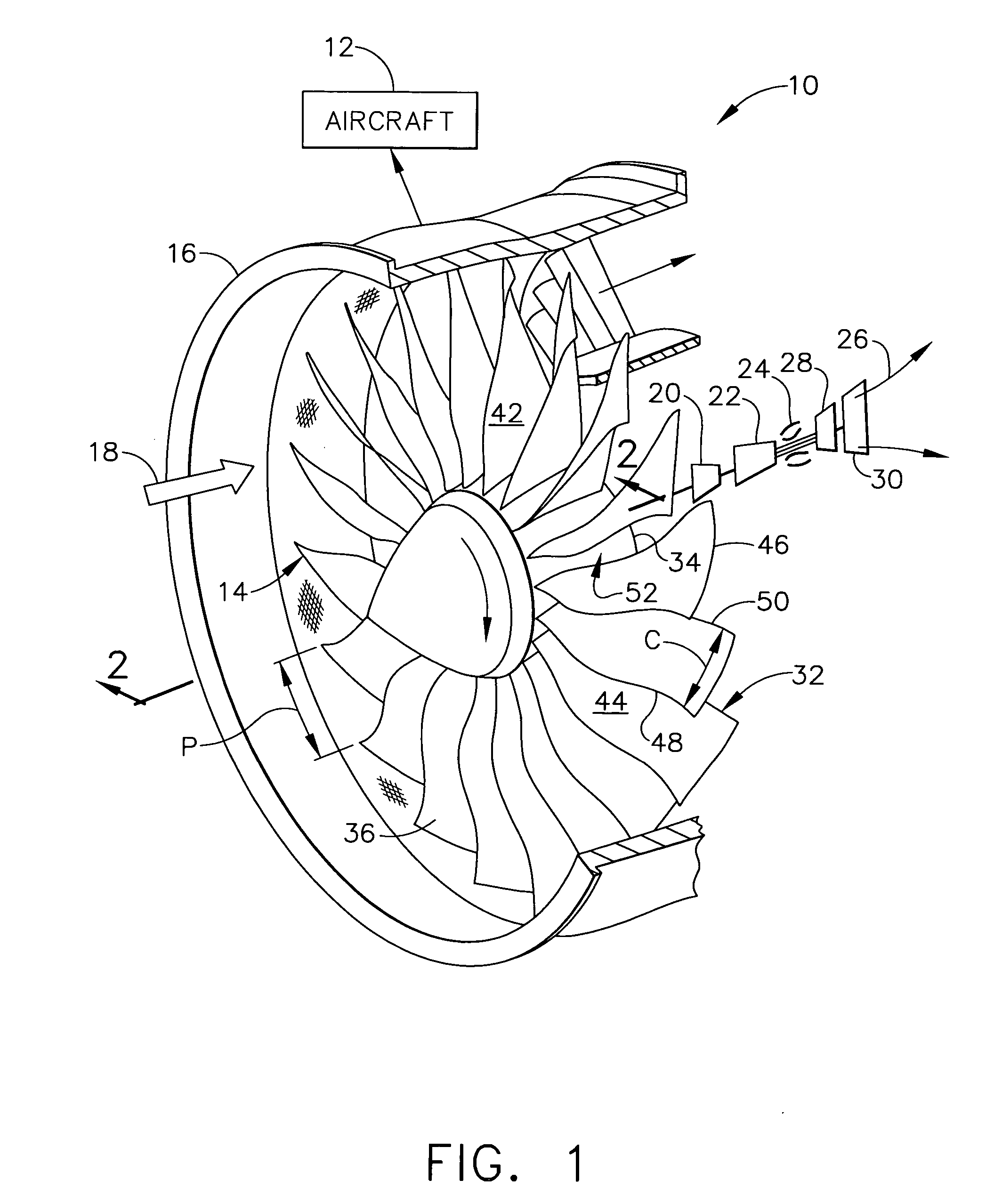

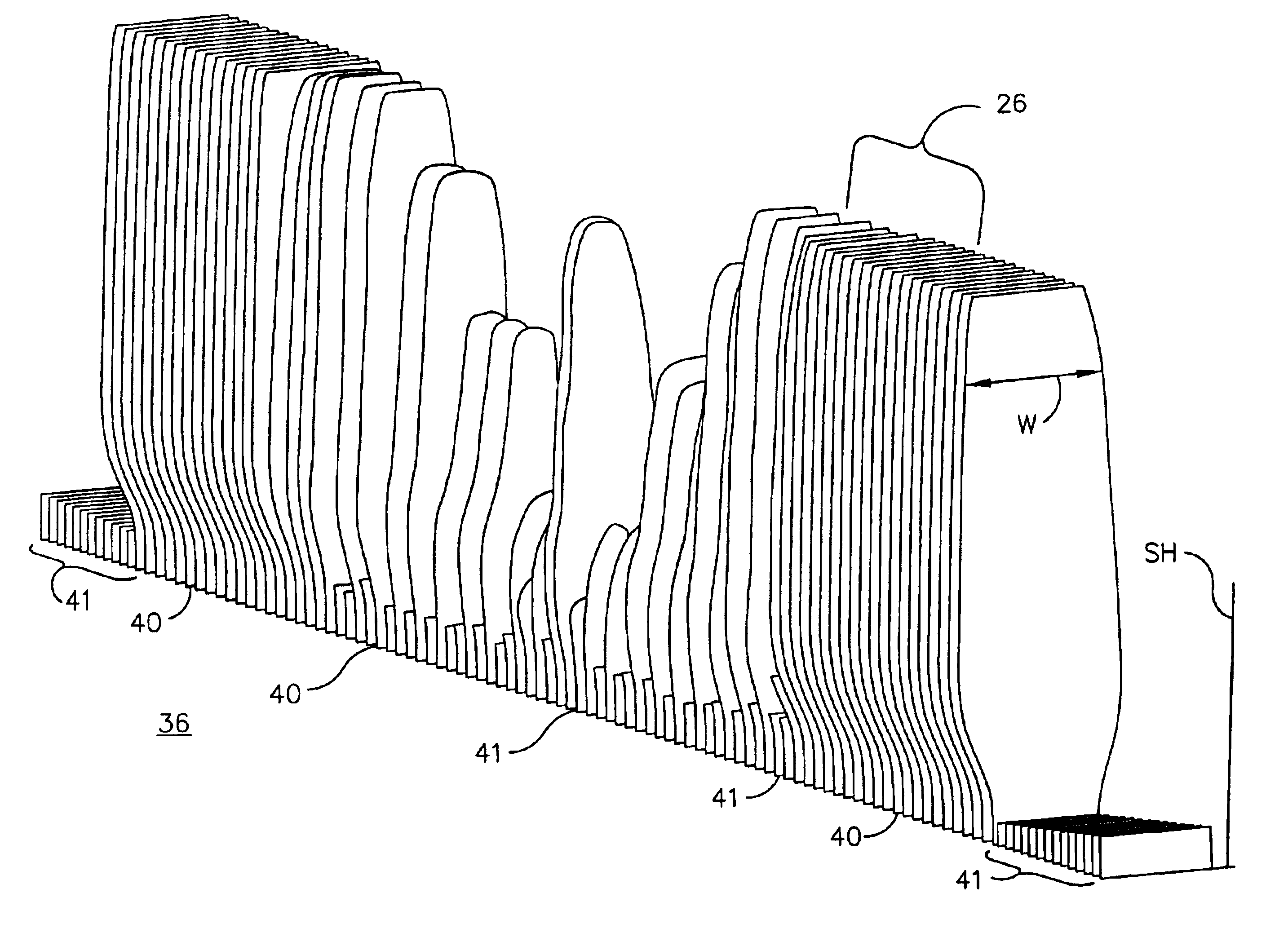

Low solidity turbofan

A turbofan includes a row of fan blades extending from a supporting disk inside an annular casing. Each blade includes an airfoil having opposite pressure and suction sides extending radially in span between a root and tip and axially in chord between leading and trailing edges. Adjacent airfoils define corresponding flow passages therebetween for pressurizing air. Each airfoil includes stagger increasing between the root and tip, and the flow passage has a mouth between the airfoil leading edge and the suction side of an adjacent airfoil and converges to a throat aft from the mouth. The row includes no more than twenty fan blades having low tip solidity for increasing the width of the passage throat.

Owner:GENERAL ELECTRIC CO

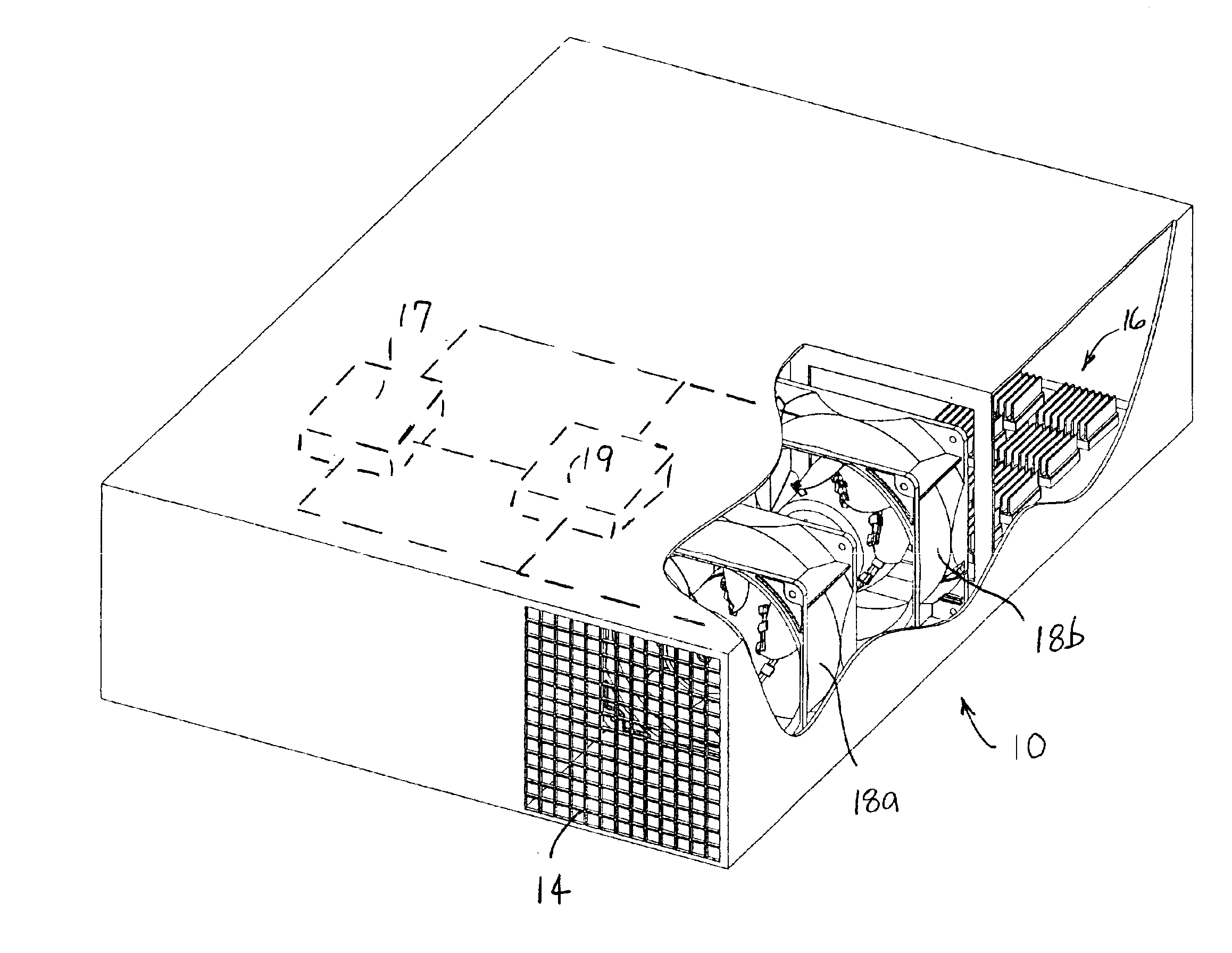

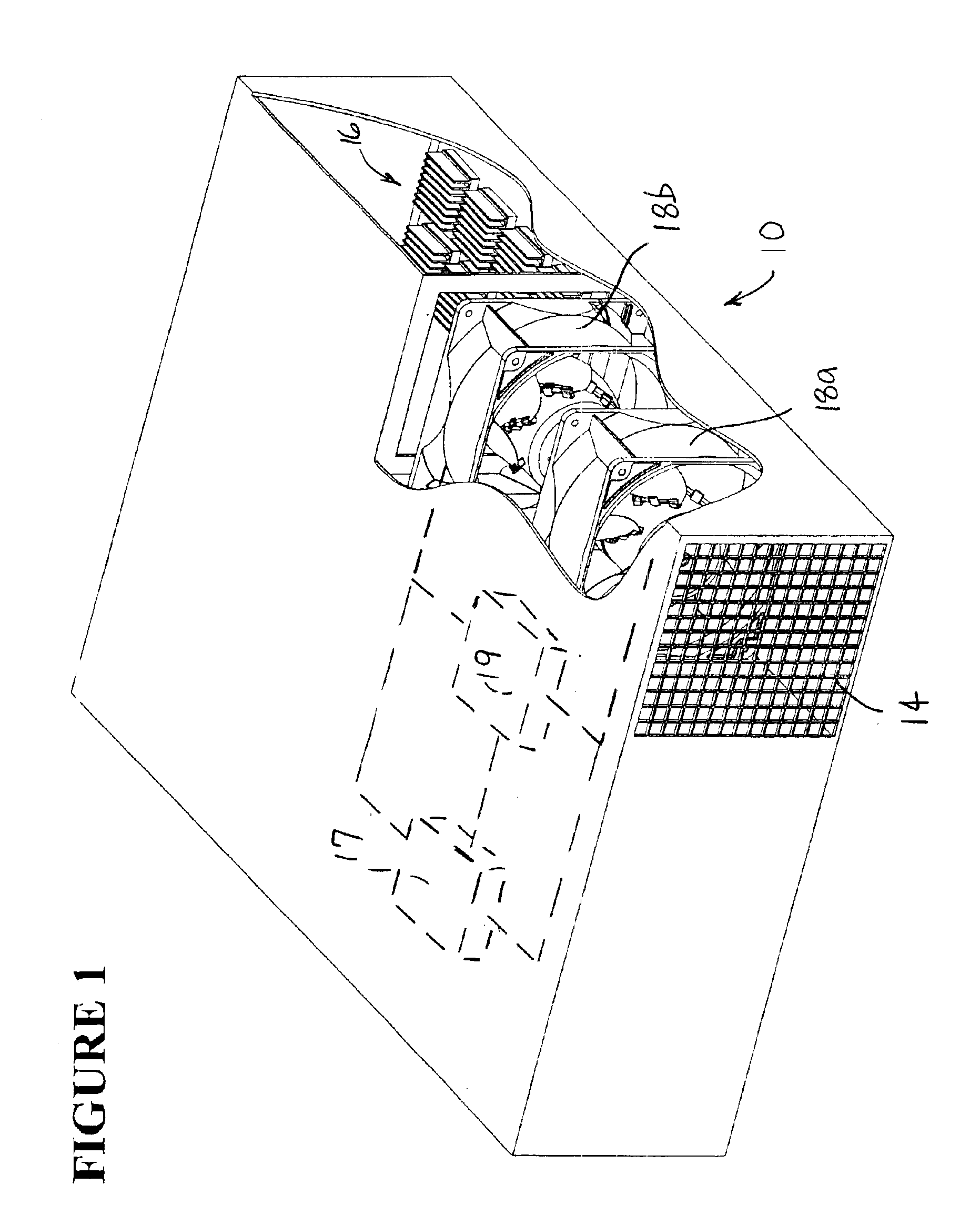

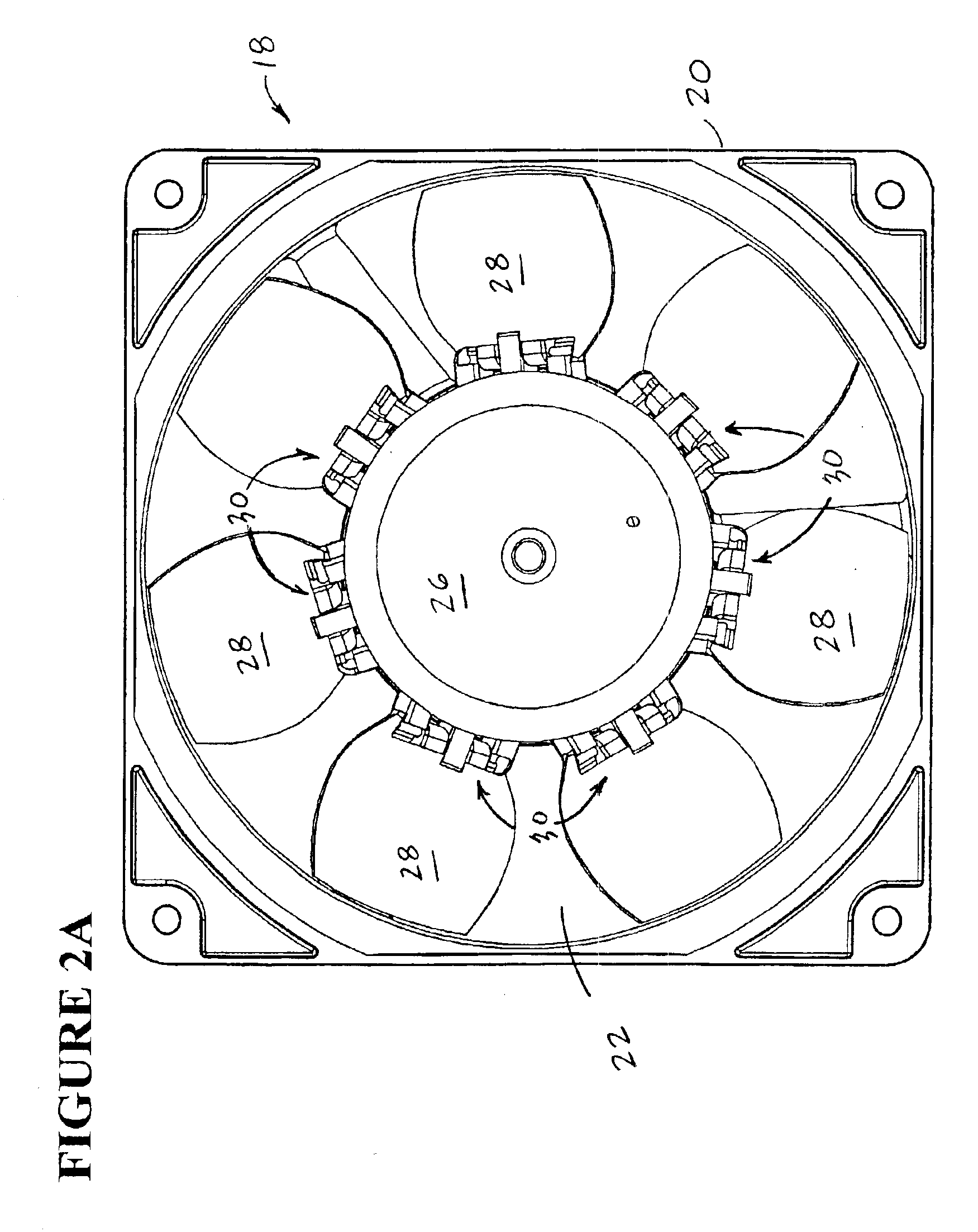

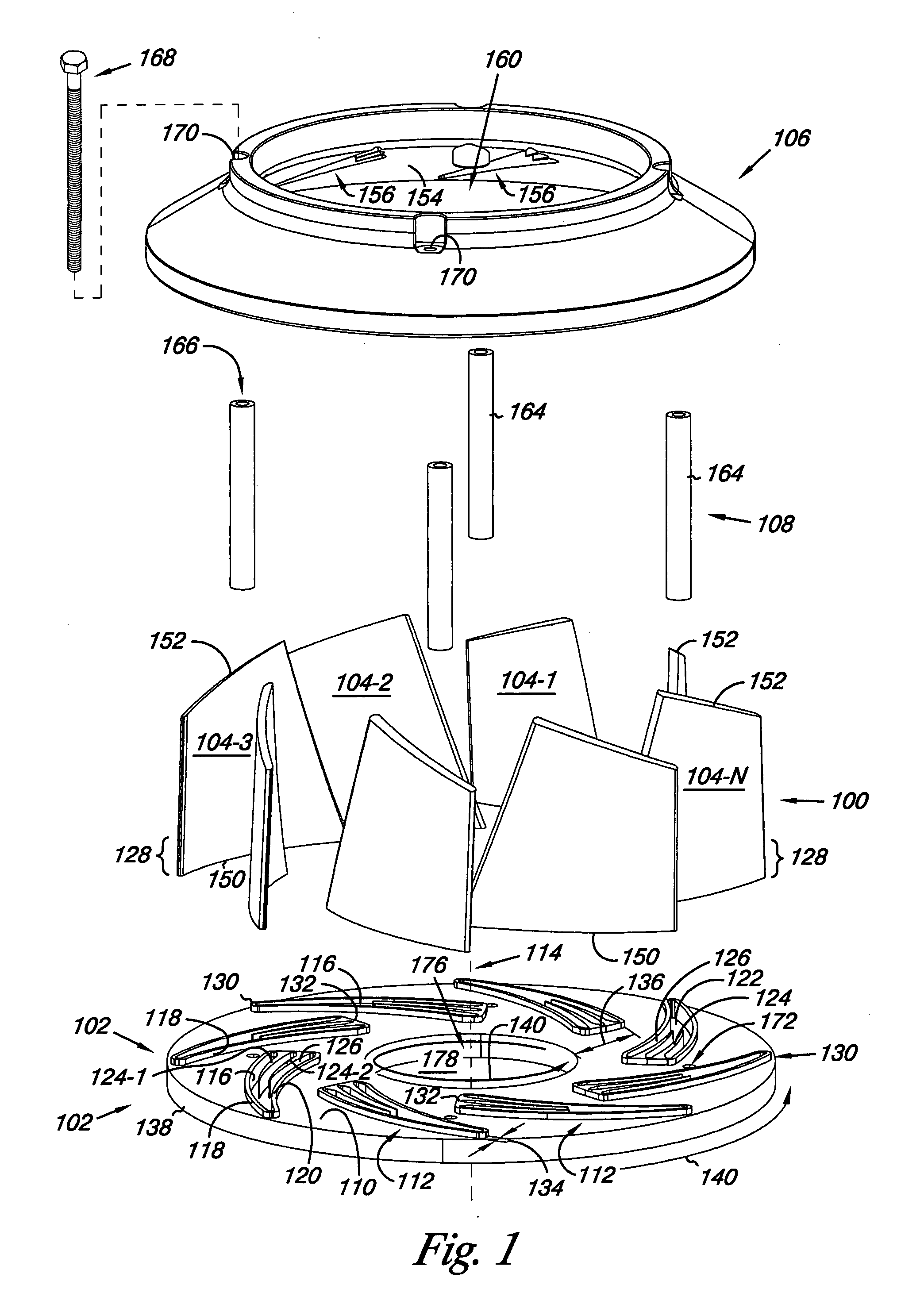

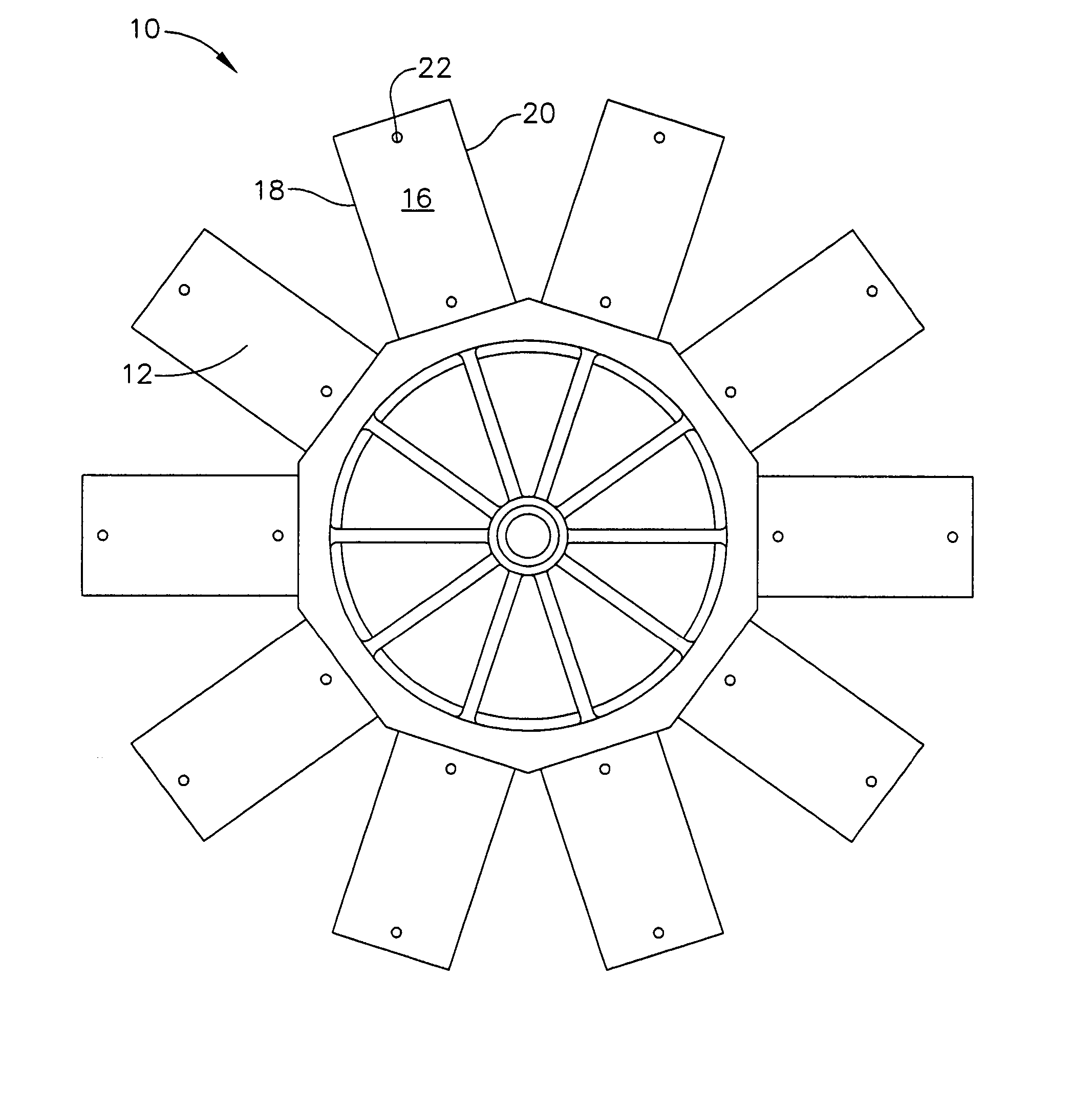

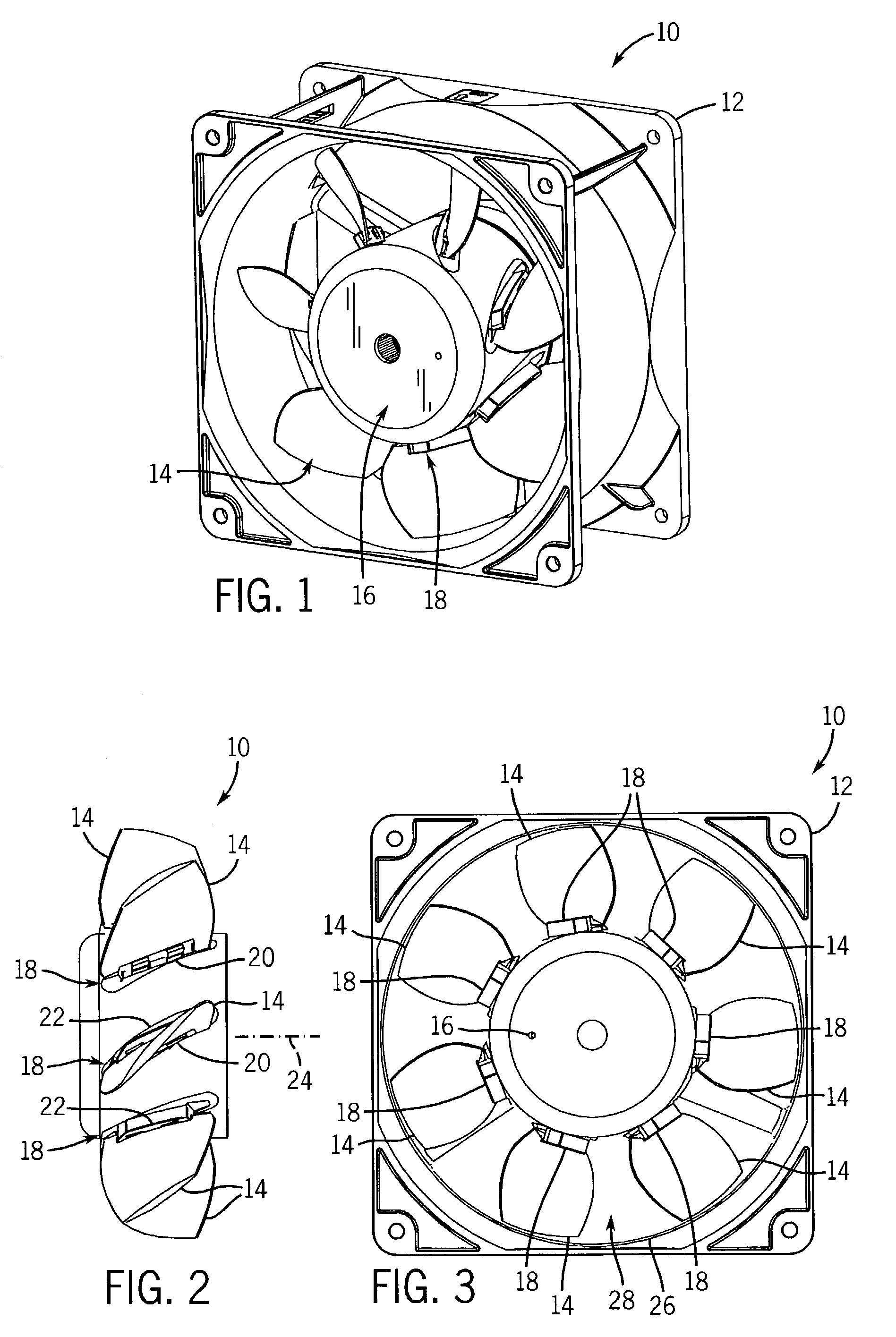

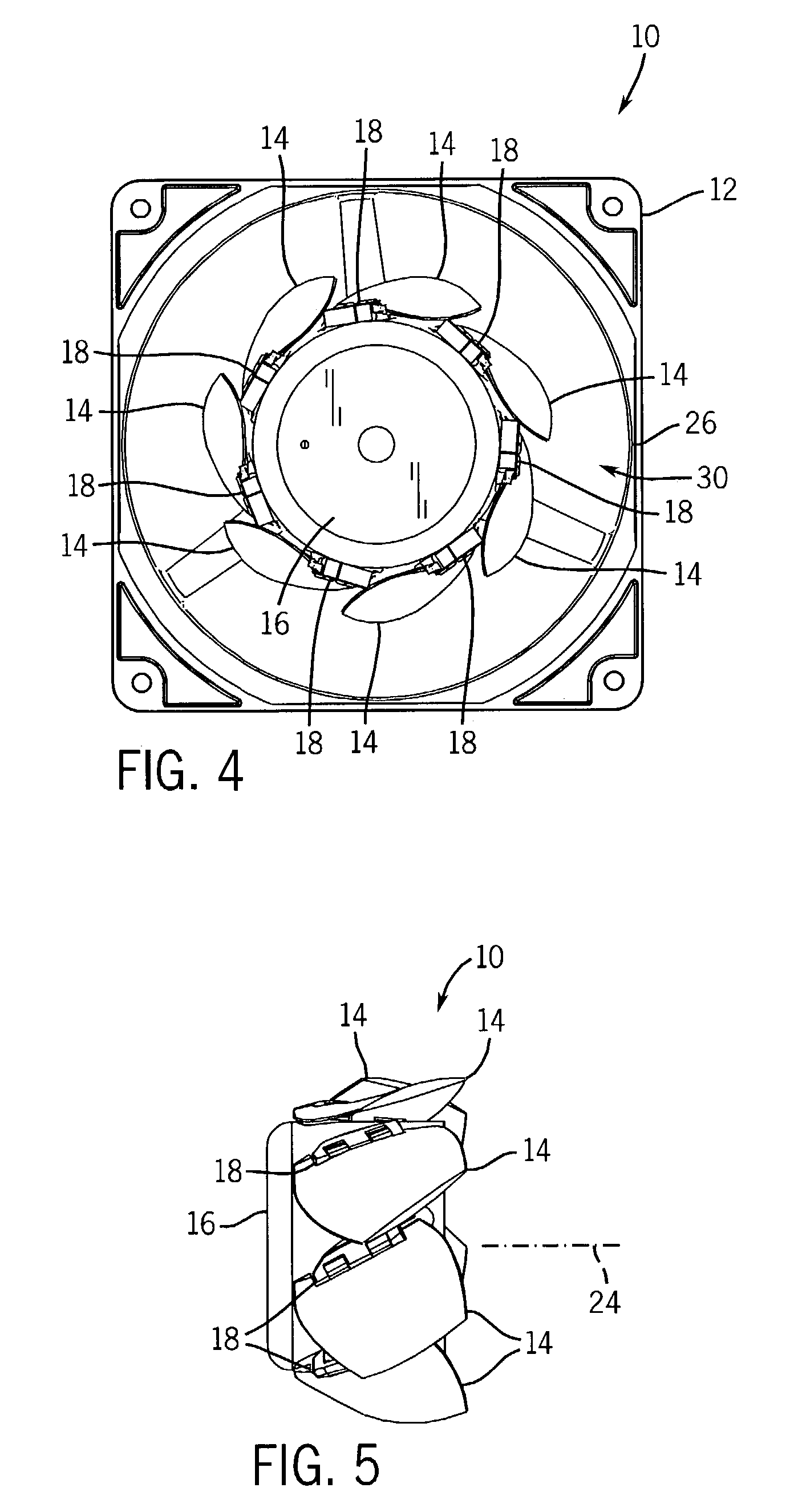

Fan with collapsible blades, redundant fan system, and related method

InactiveUS6860713B2Reduces fan inefficiencyPrevent undesirable blockagePropellersPump componentsFan bladeAirflow

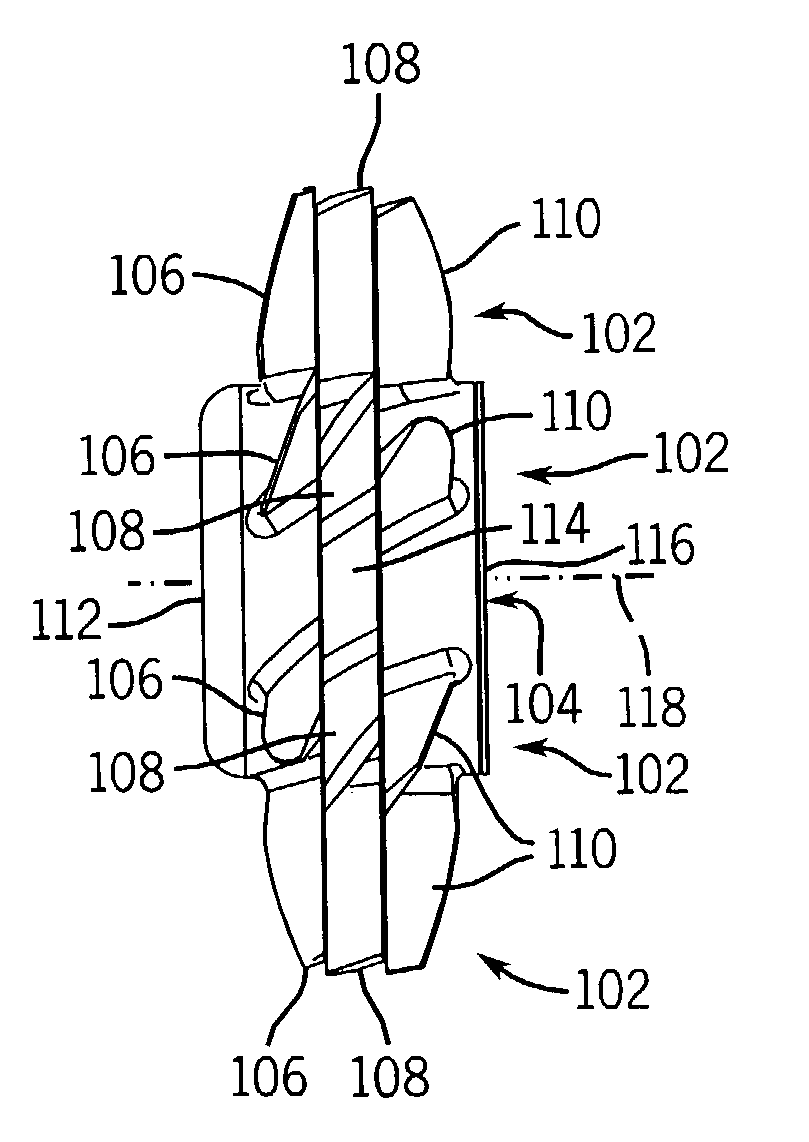

A redundant fan system for a computer includes two fans installed in series with at least one of the fans having collapsible blades. A fan system of this type reduces the fan inefficiency caused when one fan in a series mounted pair is not operating, either because it is free-wheeling or in a locked rotor condition. When non-operational, the fan blades of the collapsible fan fold inward due to airflow generated by the operational fan over the collapsible blades. The ability of the blades to fold reduces the inefficiency of the operational fan, having less of an effect on fan life. Also, because the flow of air is less restricted, proper airflow can be maintained, thus preventing overheating of the computer.

Owner:NIDEC AMERICA CORP

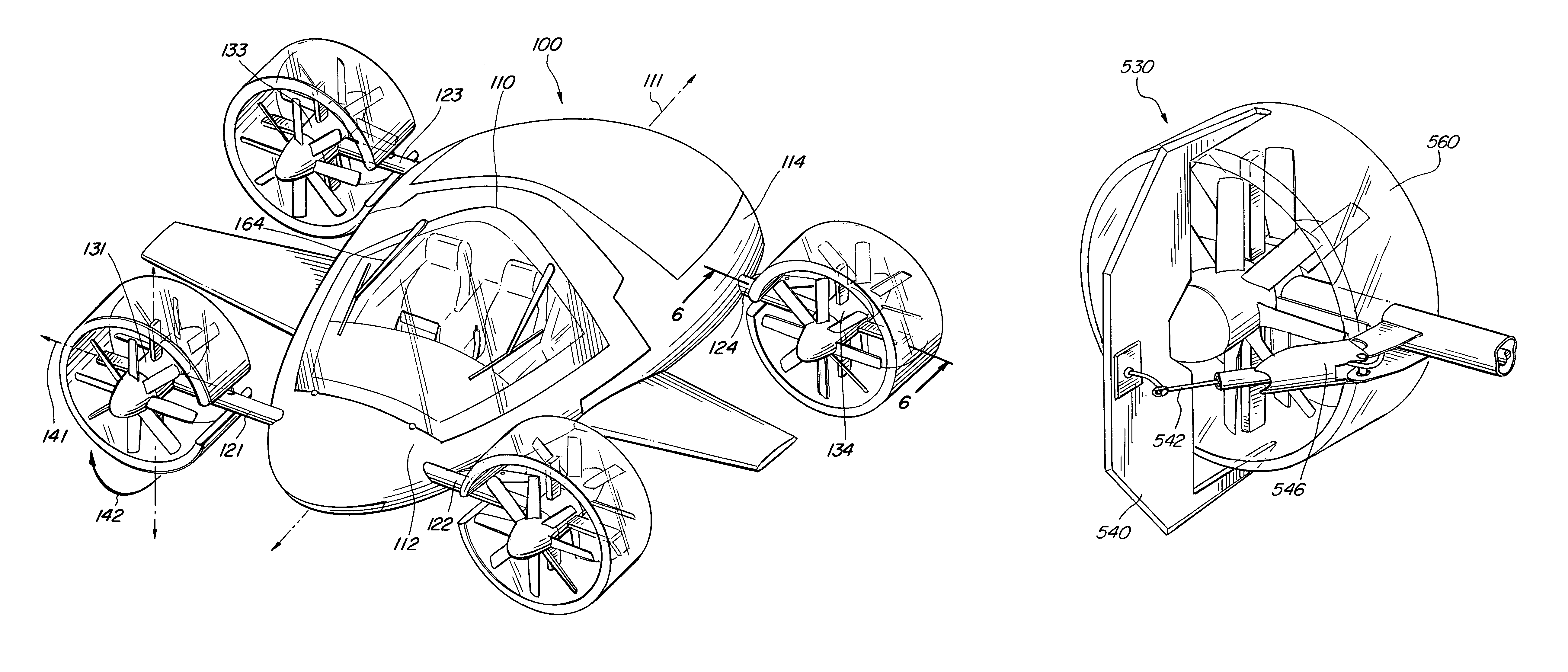

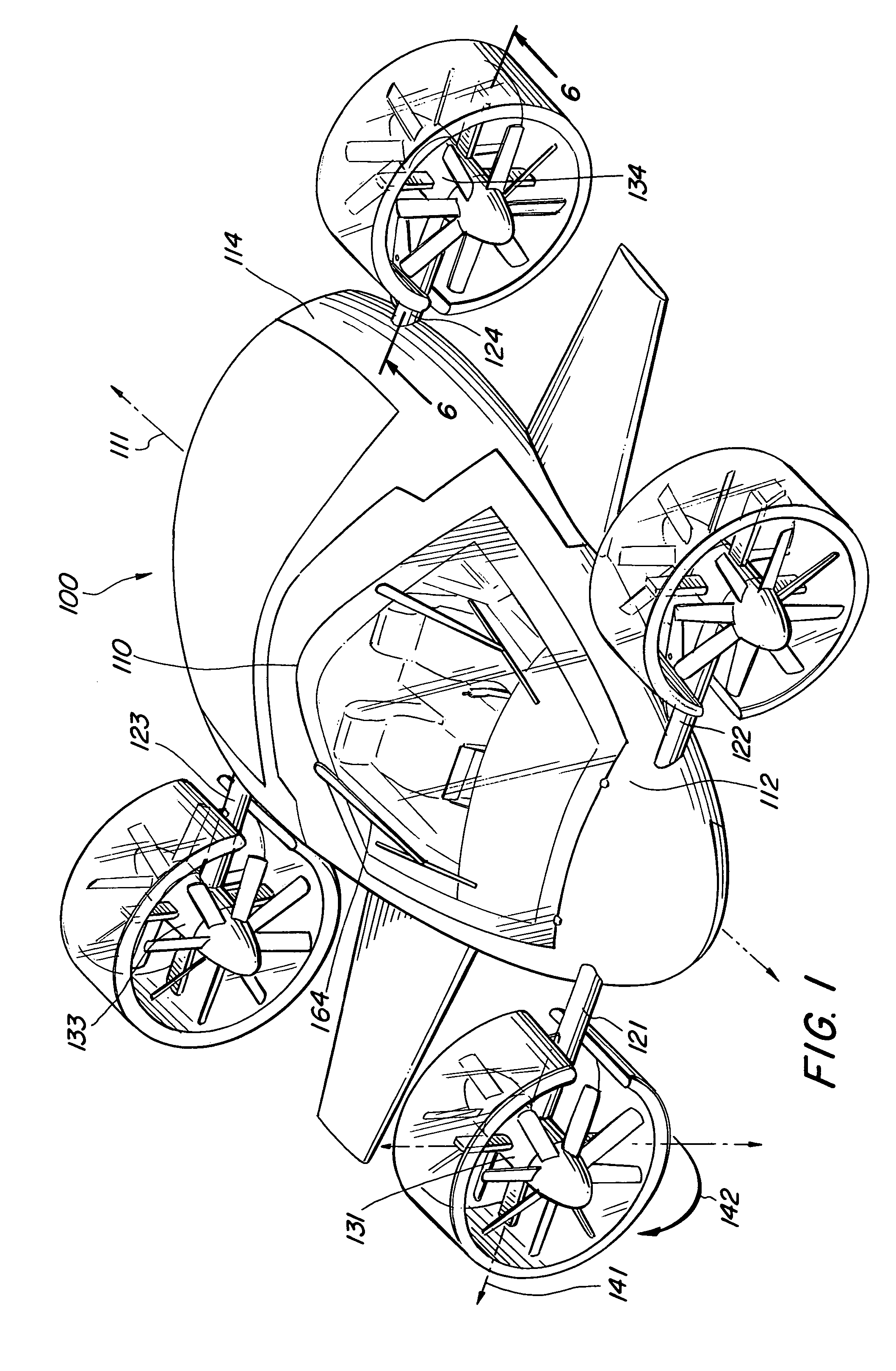

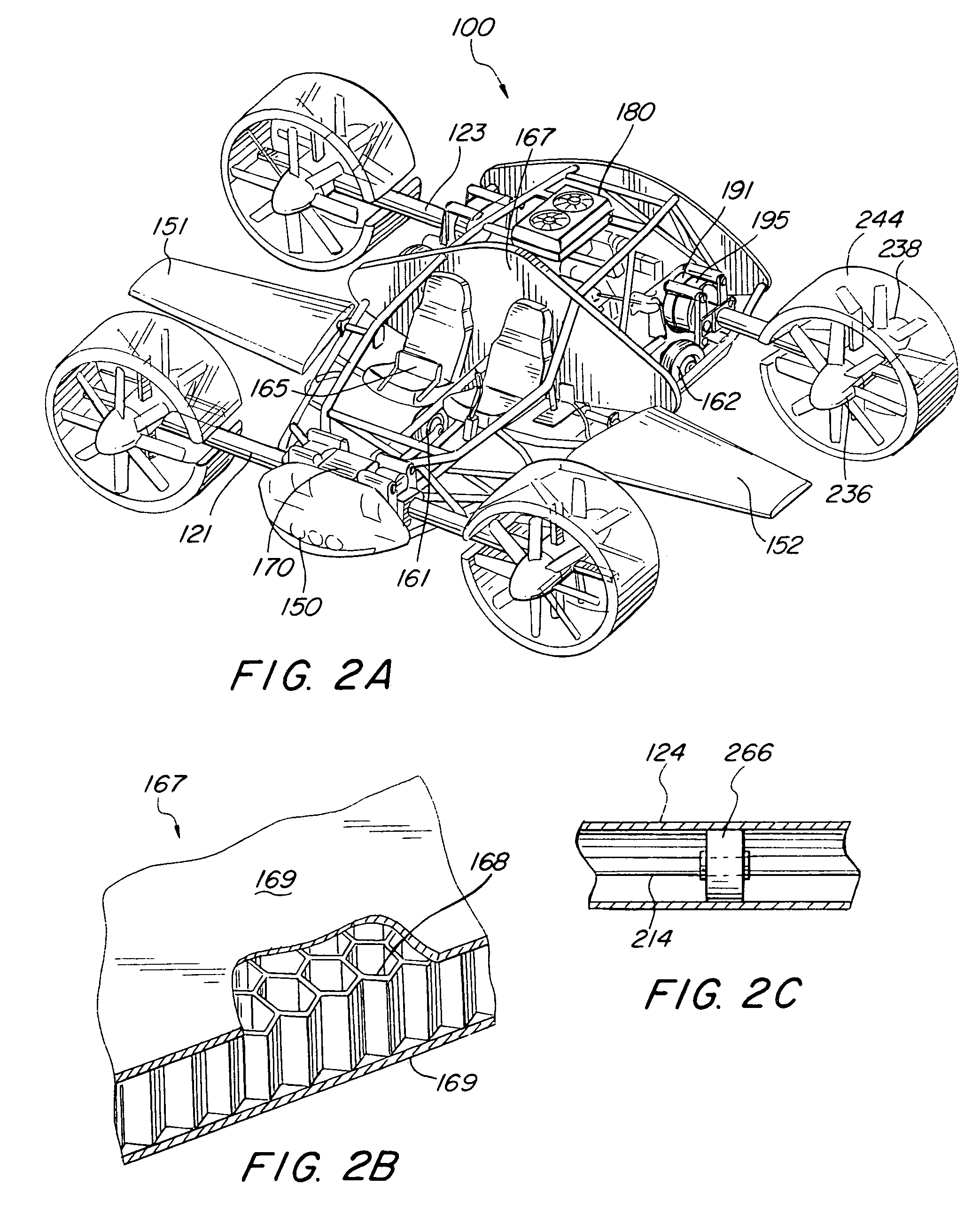

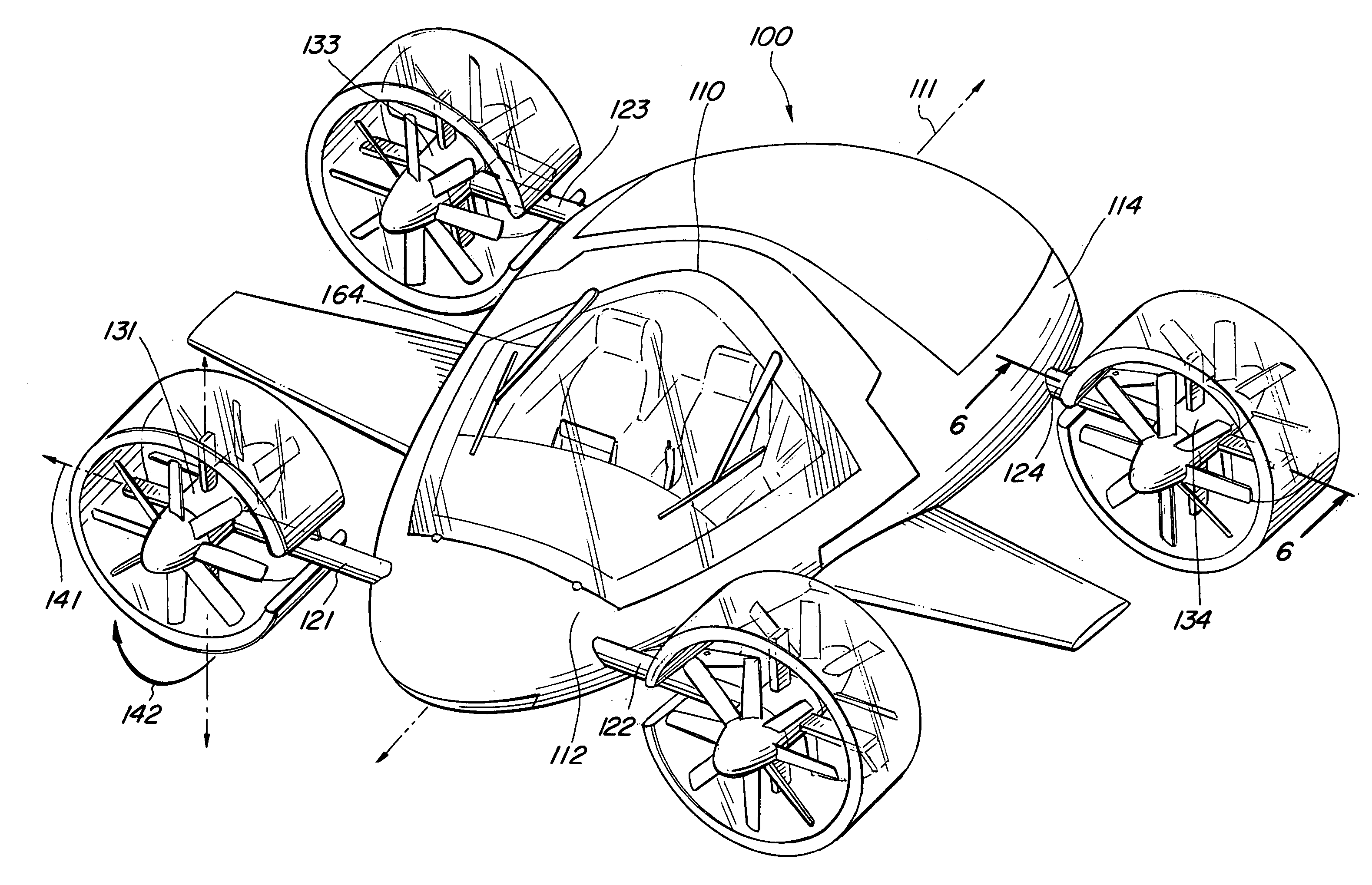

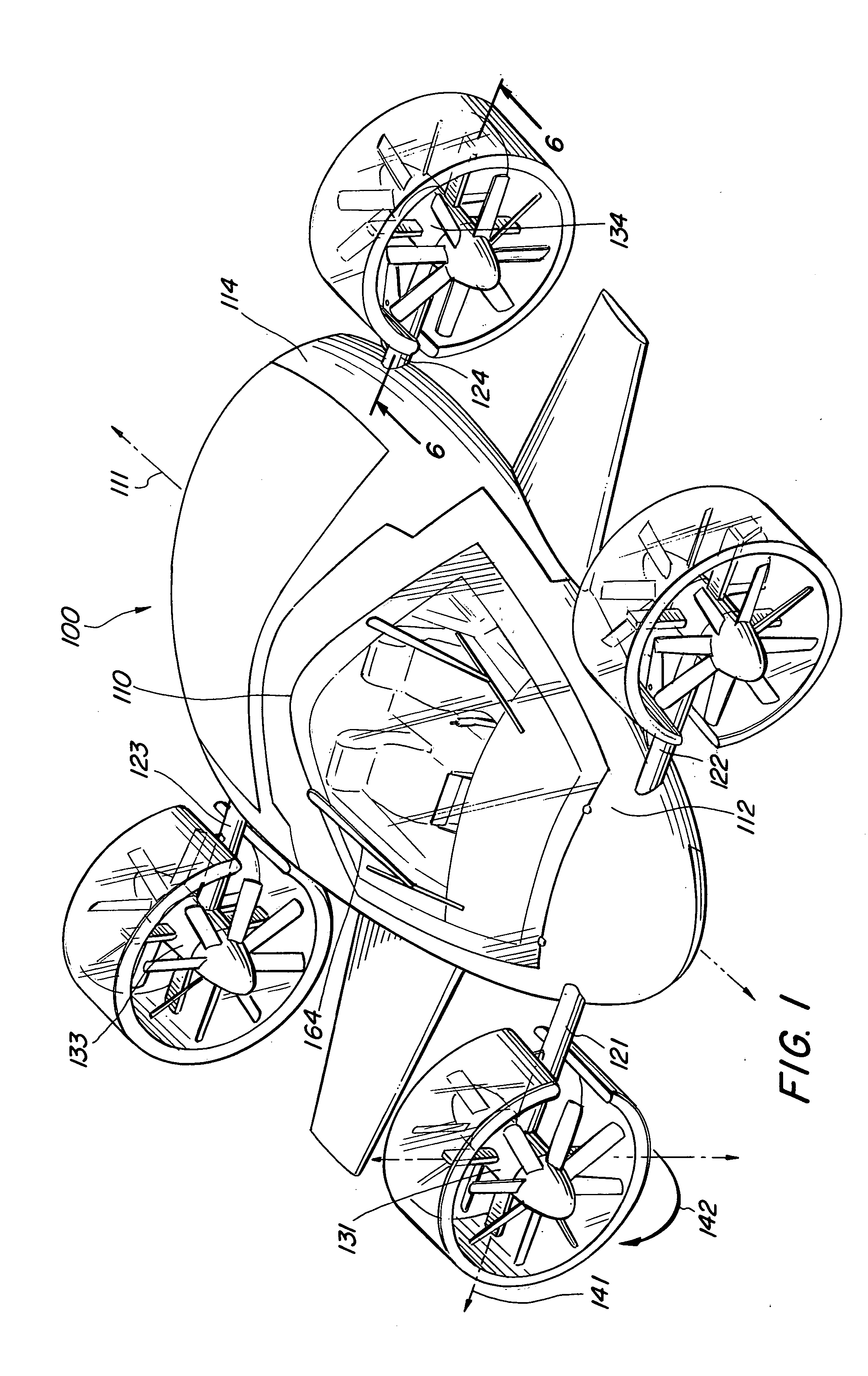

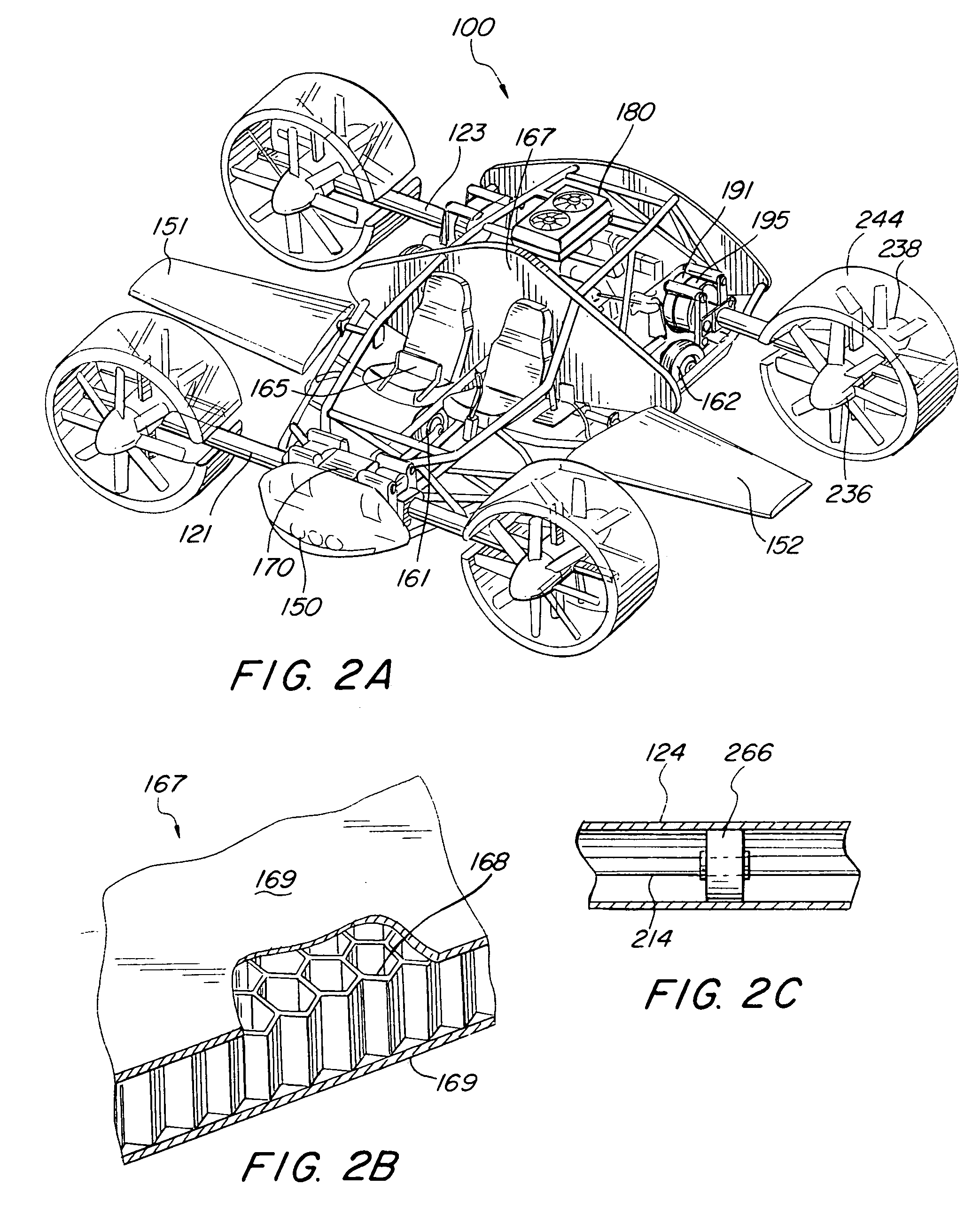

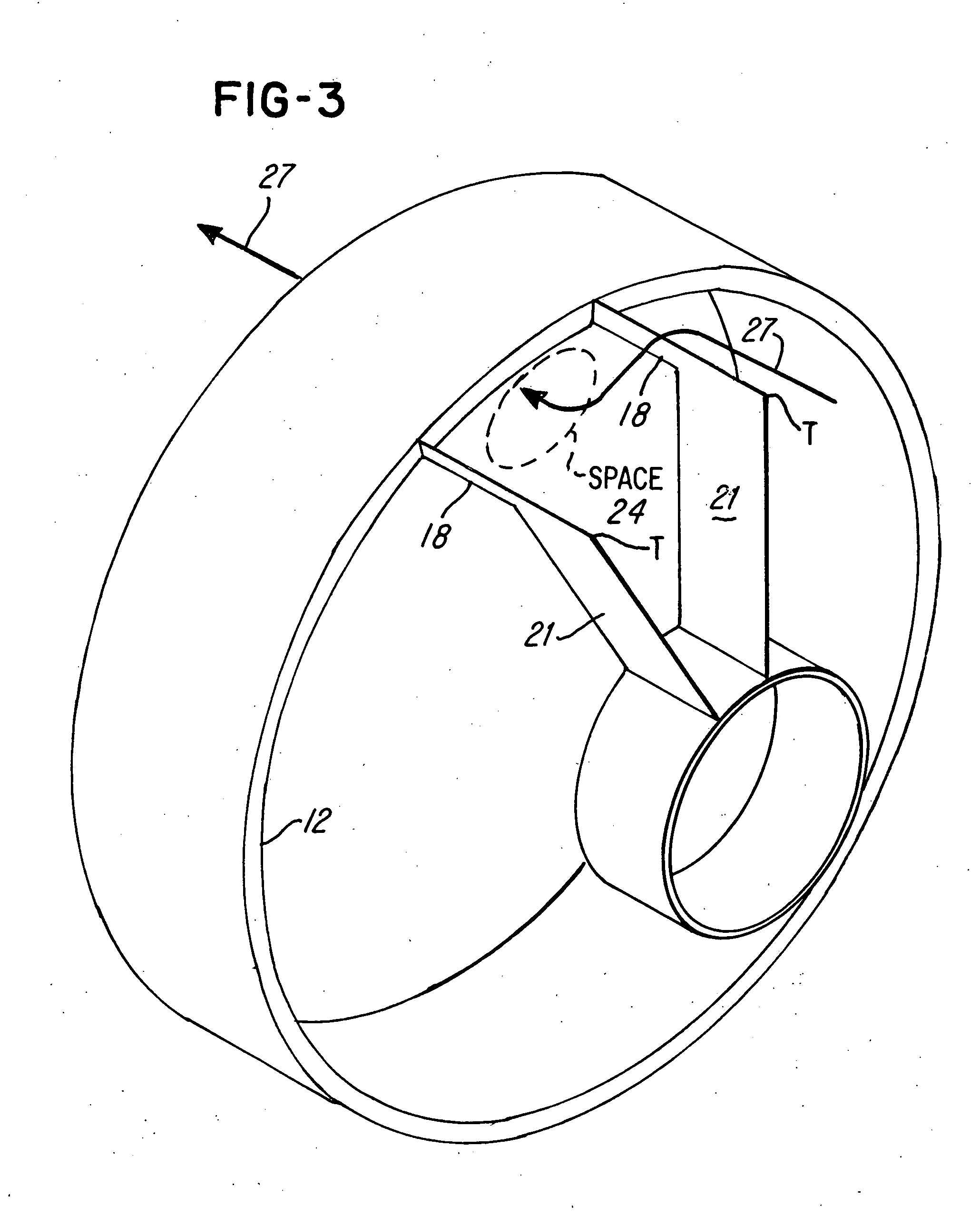

Sky hopper

InactiveUS7472863B2Increase shaft powerAircraft navigation controlToy aircraftsSkyExternal combustion engine

A vertical takeoff and landing (VTOL) aircraft design particularly suitable as a full-sized aircraft or remote controlled (RC) model aircraft is disclosed. The invention employs lightweight, high strength materials to reduce the power requirements of the propulsion plant. A preferred system of the invention comprises one internal combustion engine able to spit shaft power to four fan units. The fan units further employ counter rotating fan blades for stability. Separate horizontal and vertical tilting mechanisms delivered to the fan units are additionally disclosed. A variation in design is further included wherein electric motors provide the necessary shaft power.

Owner:PAK STEVE

Sky hopper

InactiveUS20060016930A1Increase shaft powerAircraft navigation controlToy aircraftsSkyRemote control

A vertical takeoff and landing (VTOL) aircraft design particularly suitable as a full-sized aircraft or remote controlled (RC) model aircraft is disclosed. The invention employs lightweight, high strength materials to reduce the power requirements of the propulsion plant. A preferred system of the invention comprises one internal combustion engine able to spit shaft power to four fan units. The fan units further employ counter rotating fan blades for stability. Separate horizontal and vertical tilting mechanisms delivered to the fan units are additionally disclosed. A variation in design is further included wherein electric motors provide the necessary shaft power.

Owner:PAK STEVE

Fan blades

Owner:DELTA T

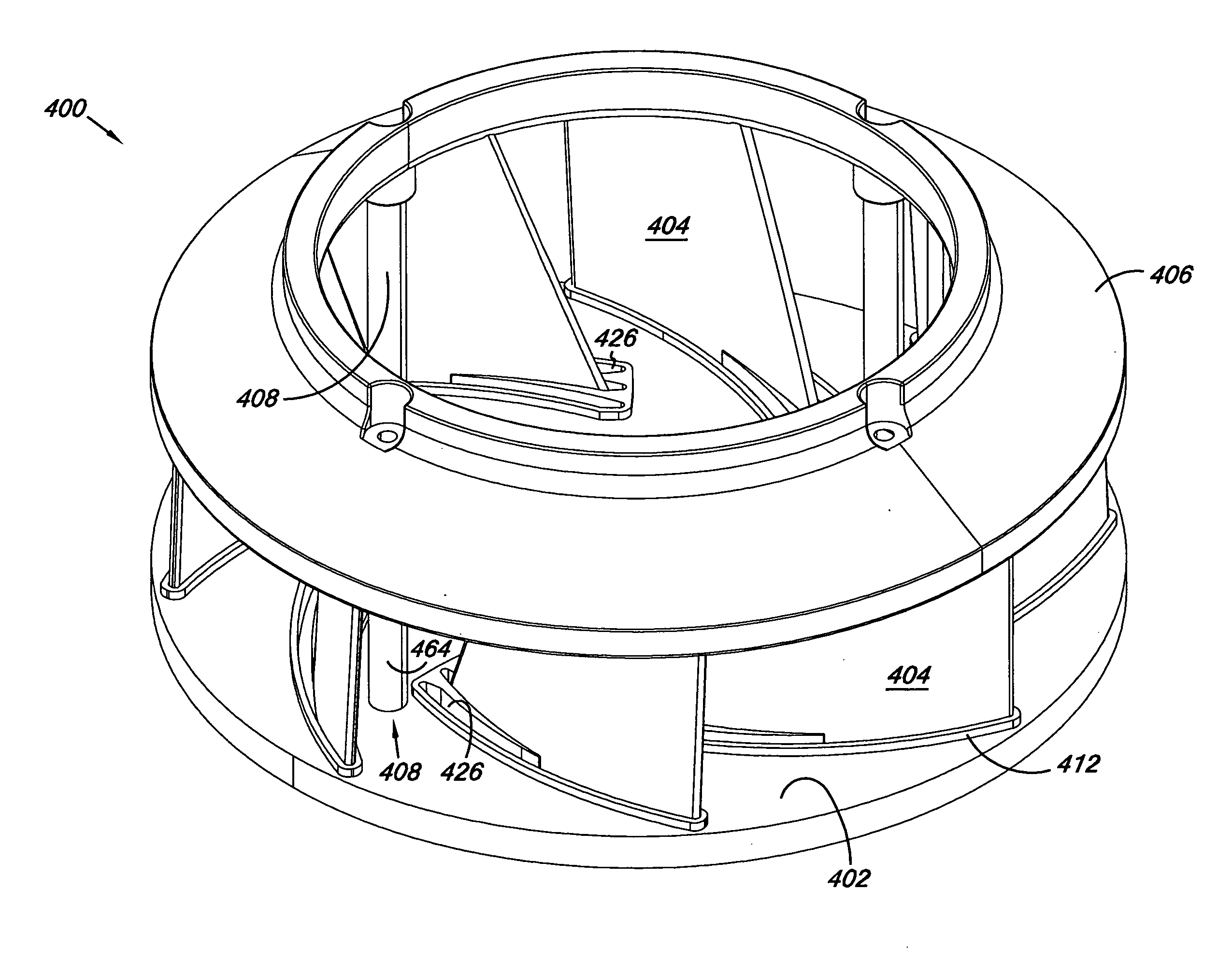

Fan impeller

A fan impeller having fan blades, a base plate, a support ring and fasteners to releasably hold the fan blades between the base plate and the support ring. The base a plate includes channels each having two or more sockets that receive and releasably seat at least a portion of the fan blade. The position of the fan blade relative the axis of rotation of the impeller can be selected from the two or more sockets. The support ring includes grooves in which at least a portion of the fan blade releasably seats to hold the fan blades static relative the base plate and the support ring. The fasteners can extend between the base plate and the support ring to releasably hold the two or more blades.

Owner:KURZ KASCH

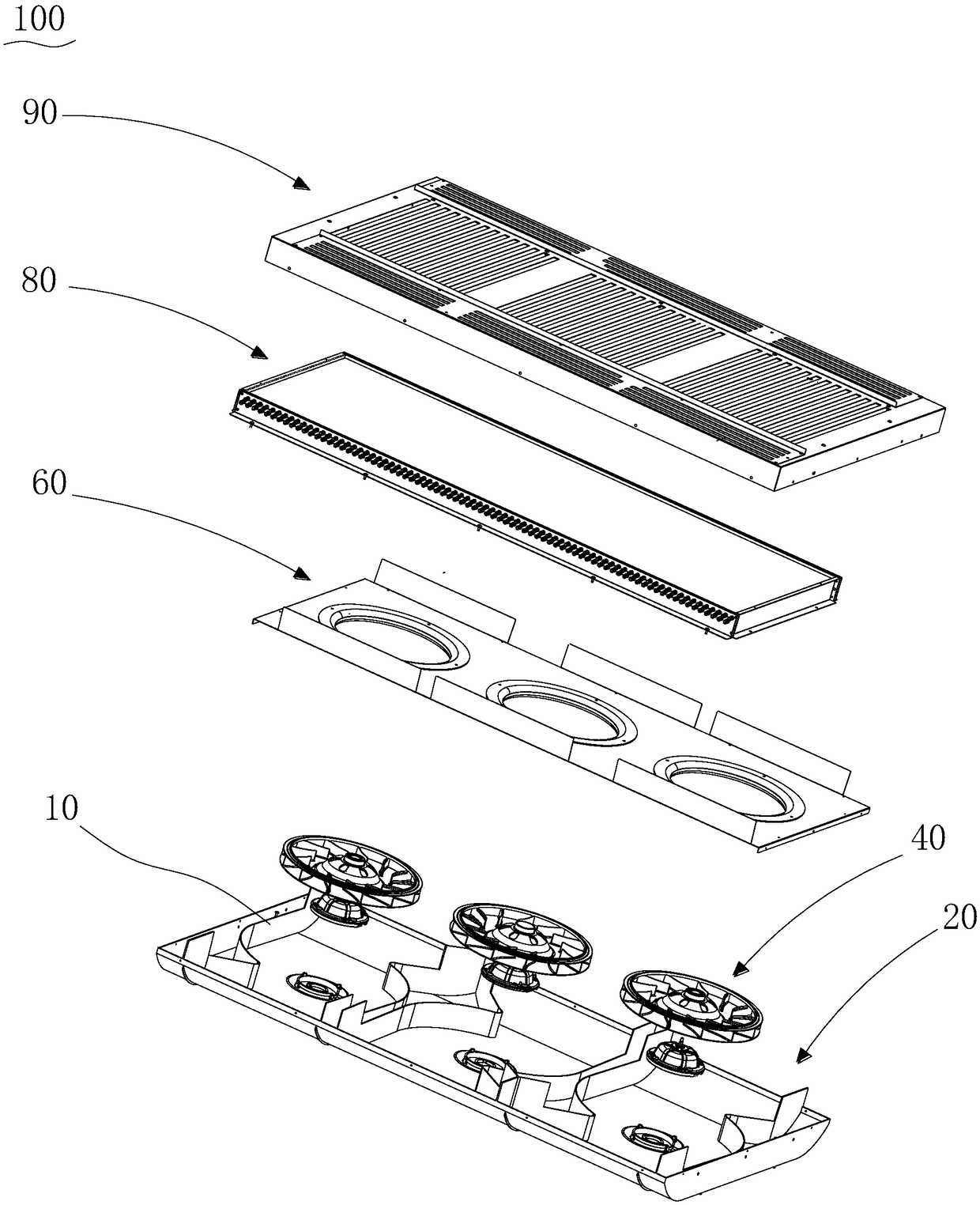

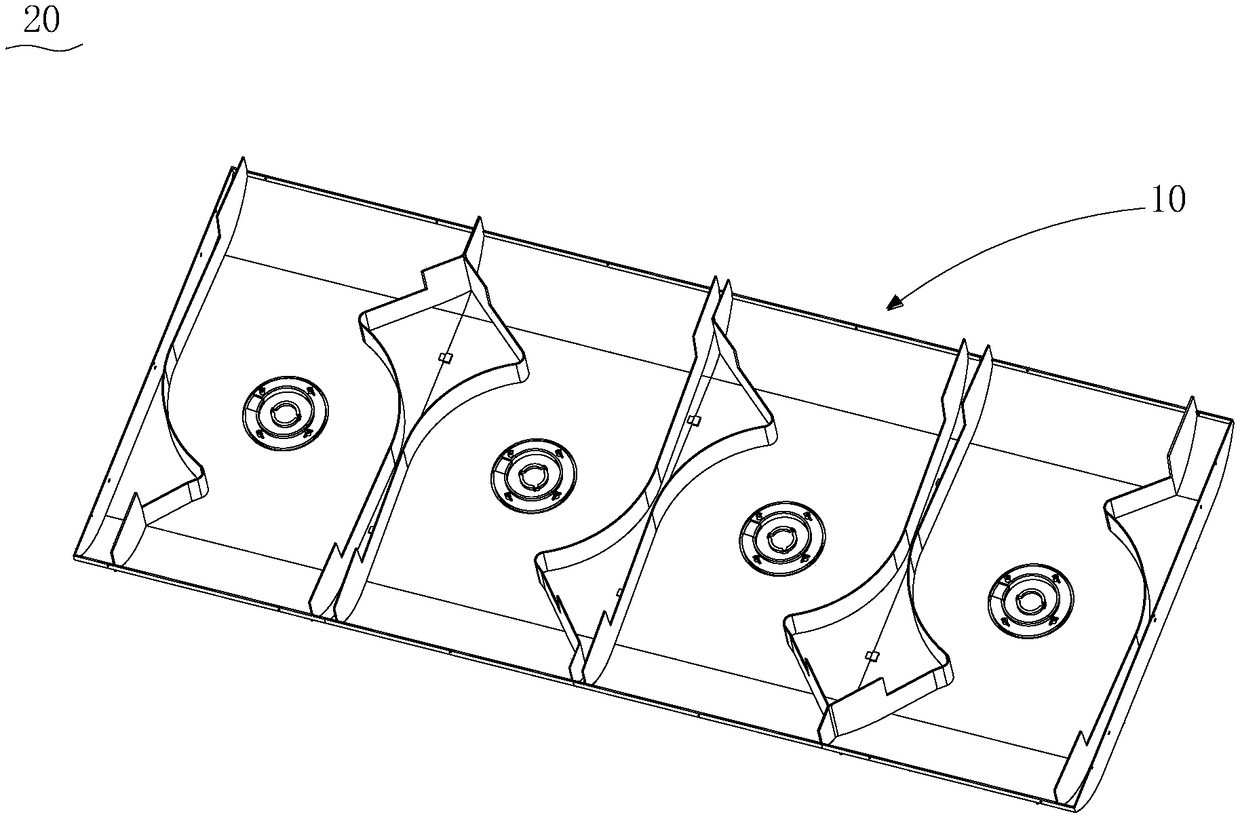

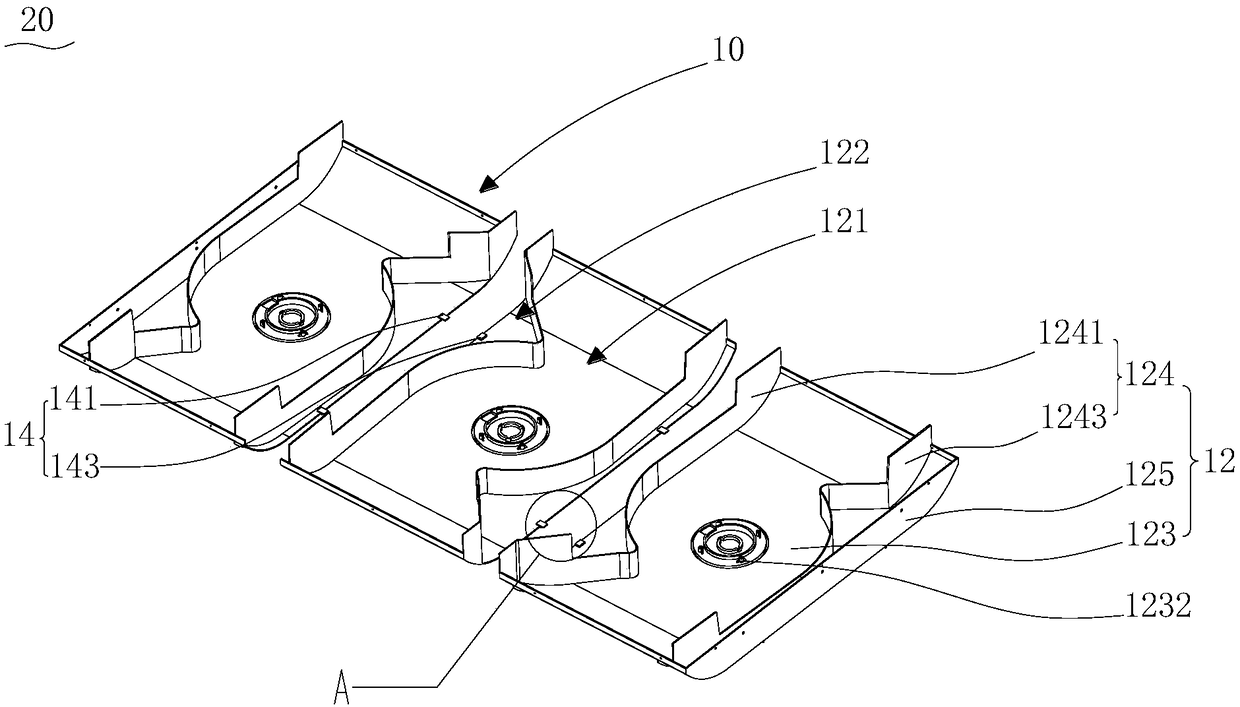

Air channel module and air channel structure with air channel module and air conditioner

InactiveCN109000352AReduce design costReduce manufacturing costDucting arrangementsLighting and heating apparatusEngineeringFan blade

The invention relates to an air channel module and an air channel structure with the air channel module and an air conditioner. The air channel module comprises an air channel main body and a connecting assembly, wherein the air channel main body comprises an air field area in which an airflow air channel is formed, and the airflow air channel is provided with two opposite air outlets; the connecting assembly is arranged on the air channel main body; and a plurality of air channel modules can be connected with each other by virtue of respective connecting assemblies so as to form the air channel structure with a plurality of air field areas. According to the air channel module, different number of air channel modules can form different air channel structures so as to install different number of fan blades, so that the air channel module can be applied to series of products with different heat transfer periods, and the different air channel structures do not need to be independently designed and manufactured according to the products with the different heat transfer periods, so that the design and production cost is effectively reduced, and the production cycle is shortened.

Owner:GREE ELECTRIC APPLIANCES INC

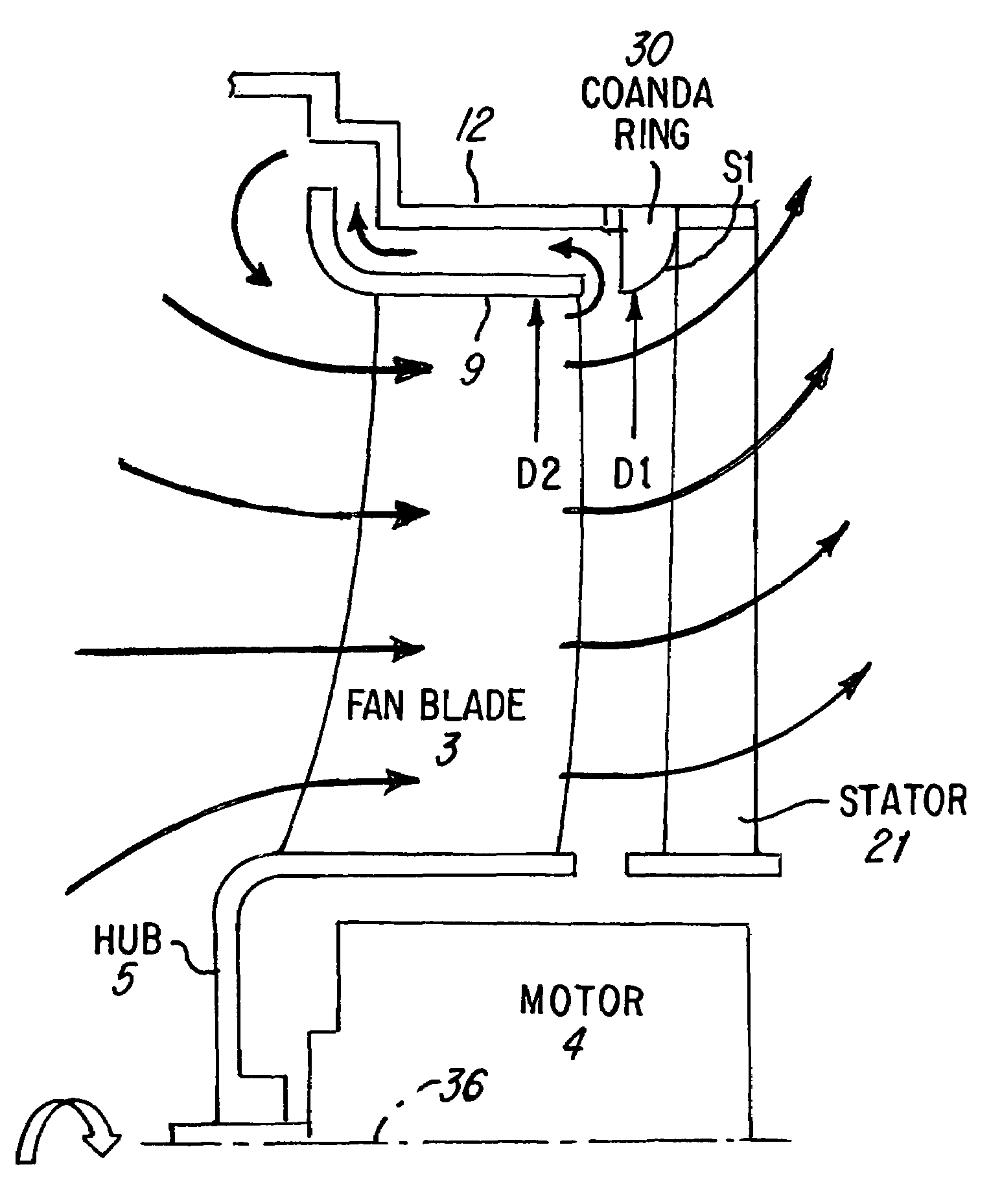

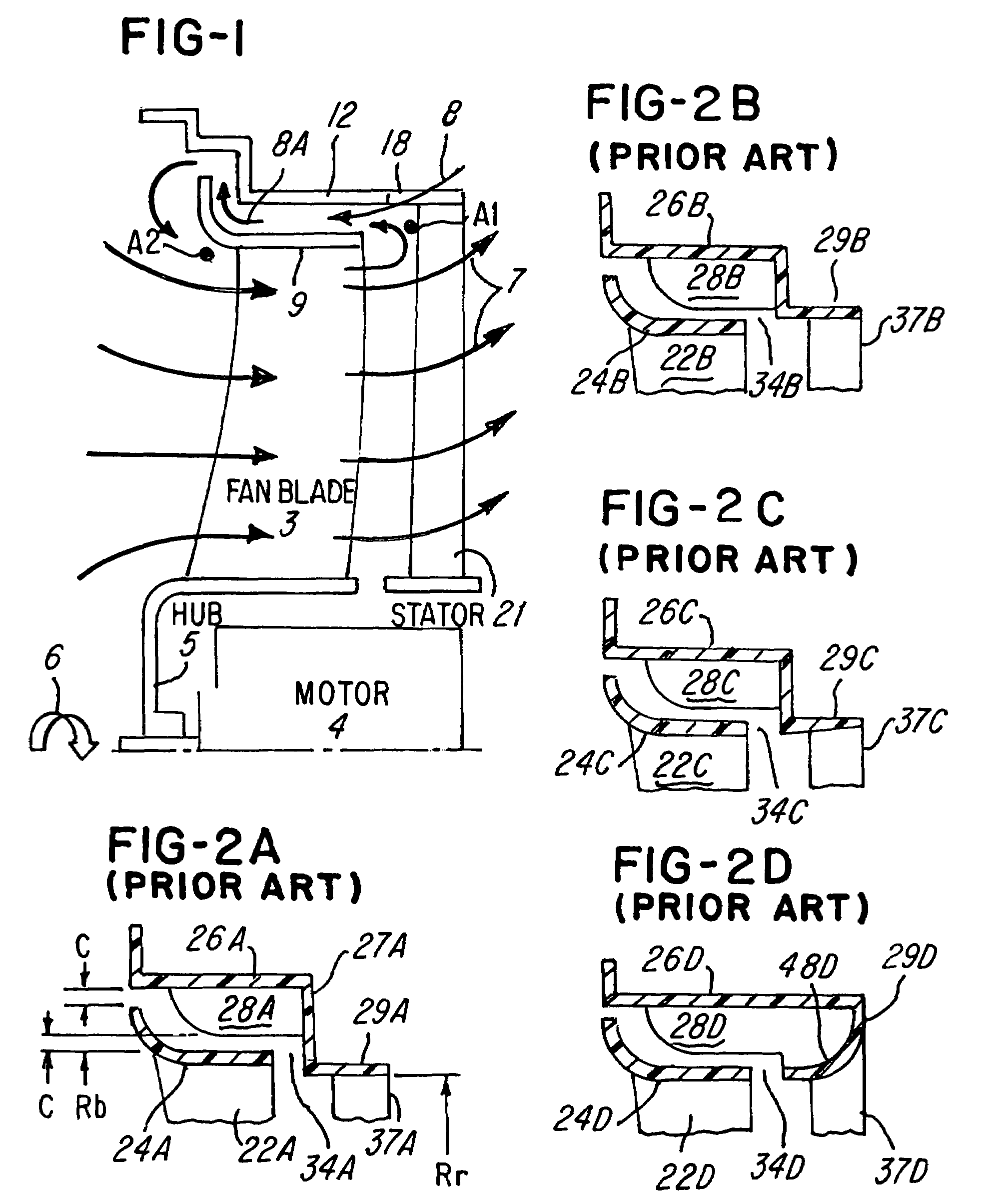

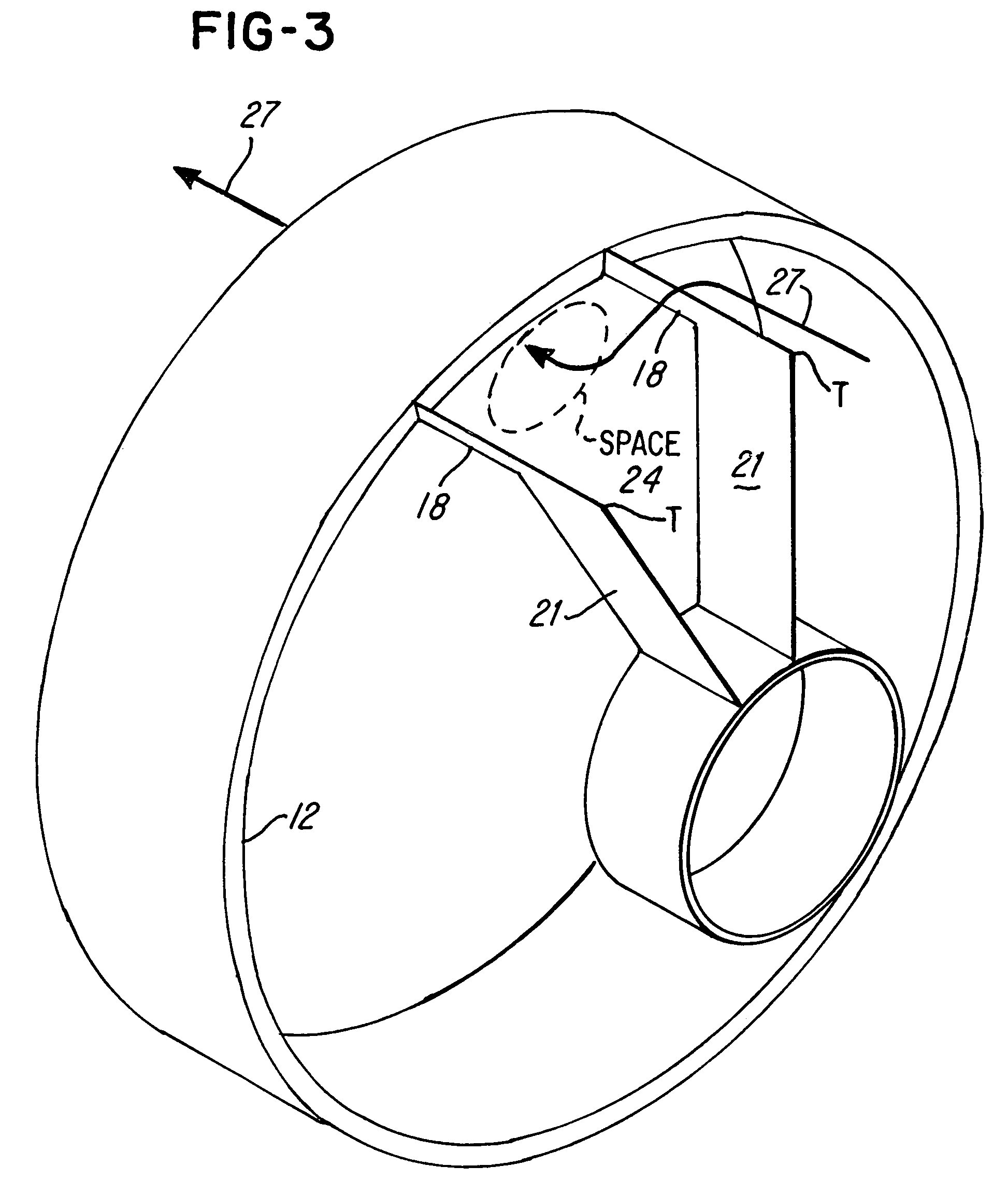

Cooling fan using Coanda effect to reduce recirculation

ActiveUS7478993B2Trend downIncrease the cross-sectional areaPump componentsReaction enginesEngineeringFan blade

Owner:VALEO INC

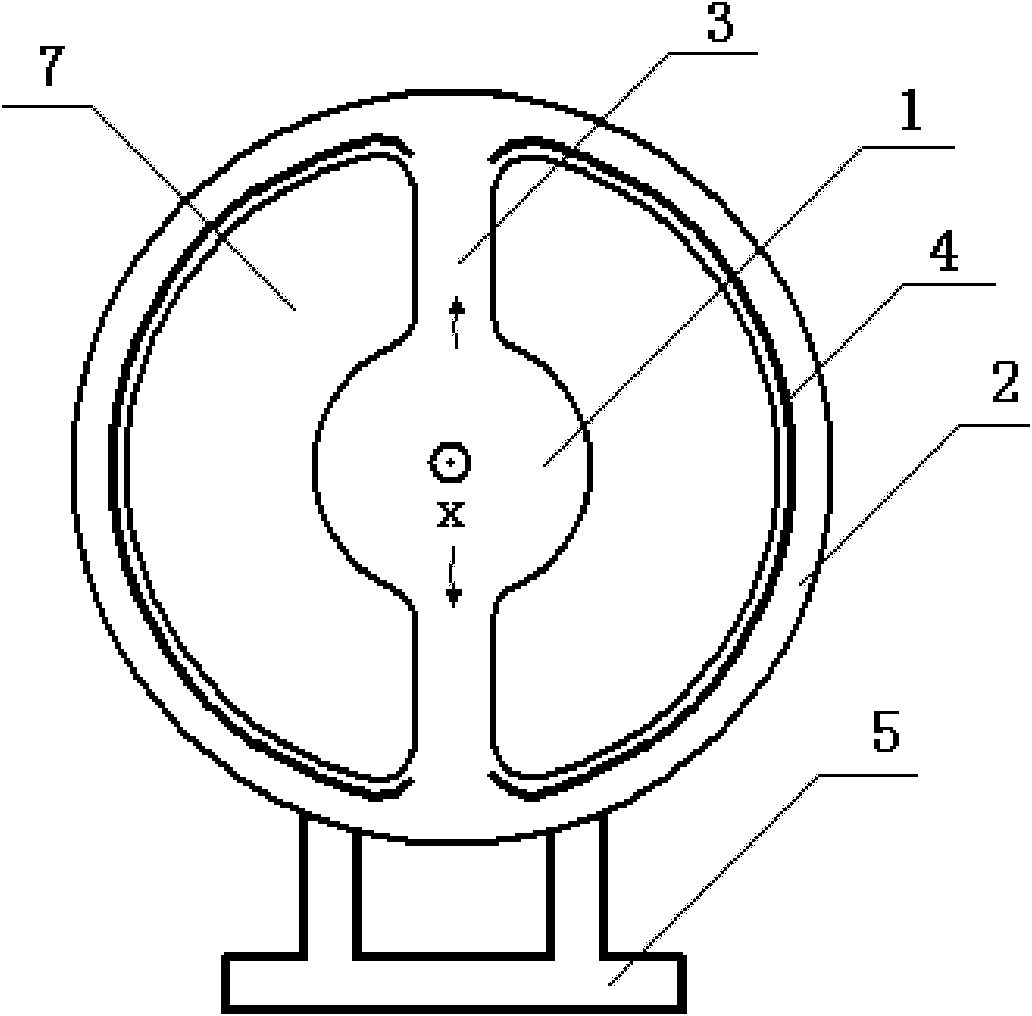

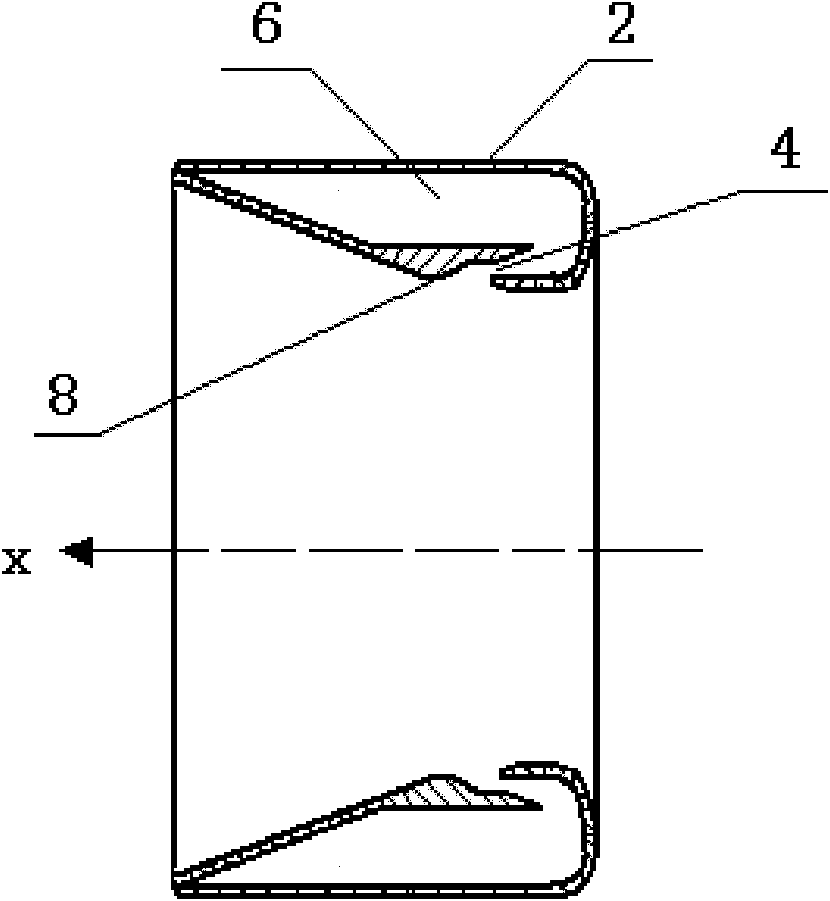

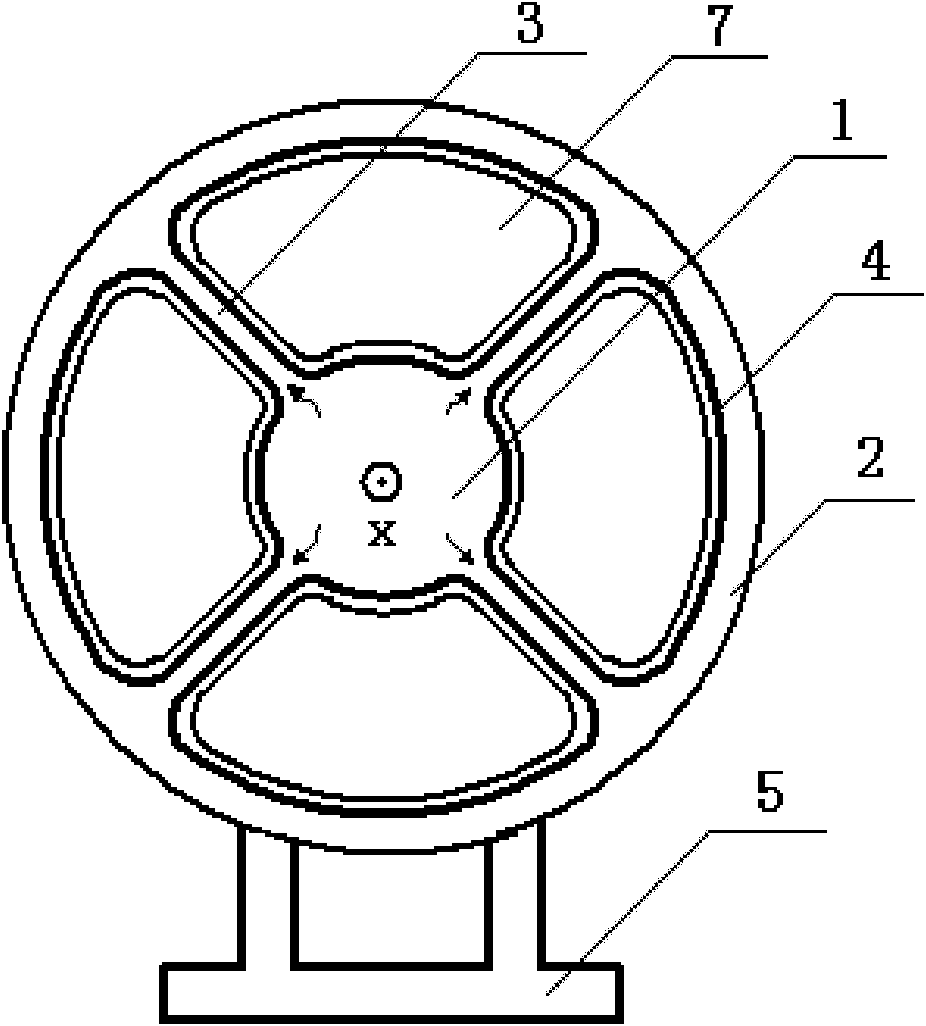

Fan without fan blades

The invention discloses a fan without fan blades and relates to a fan device, which is characterized by comprising an airflow generating device (1), a nozzle (2) and a connecting pipe (3), wherein the nozzle comprises an internal channel (6), an exhaust port (4) and a closed loop, the airflow generating device is used for producing high-pressure airflow, at least part of the airflow generating device is positioned in the closed loop of the nozzle, and the connecting pipe is connected between the airflow generating device and the nozzle, thereby being a channel for circulation of the high-pressure airflow from the airflow generating device to the nozzle. The device has compact structure and low noise and can provide the airflow with uniform flow rate.

Owner:任文华

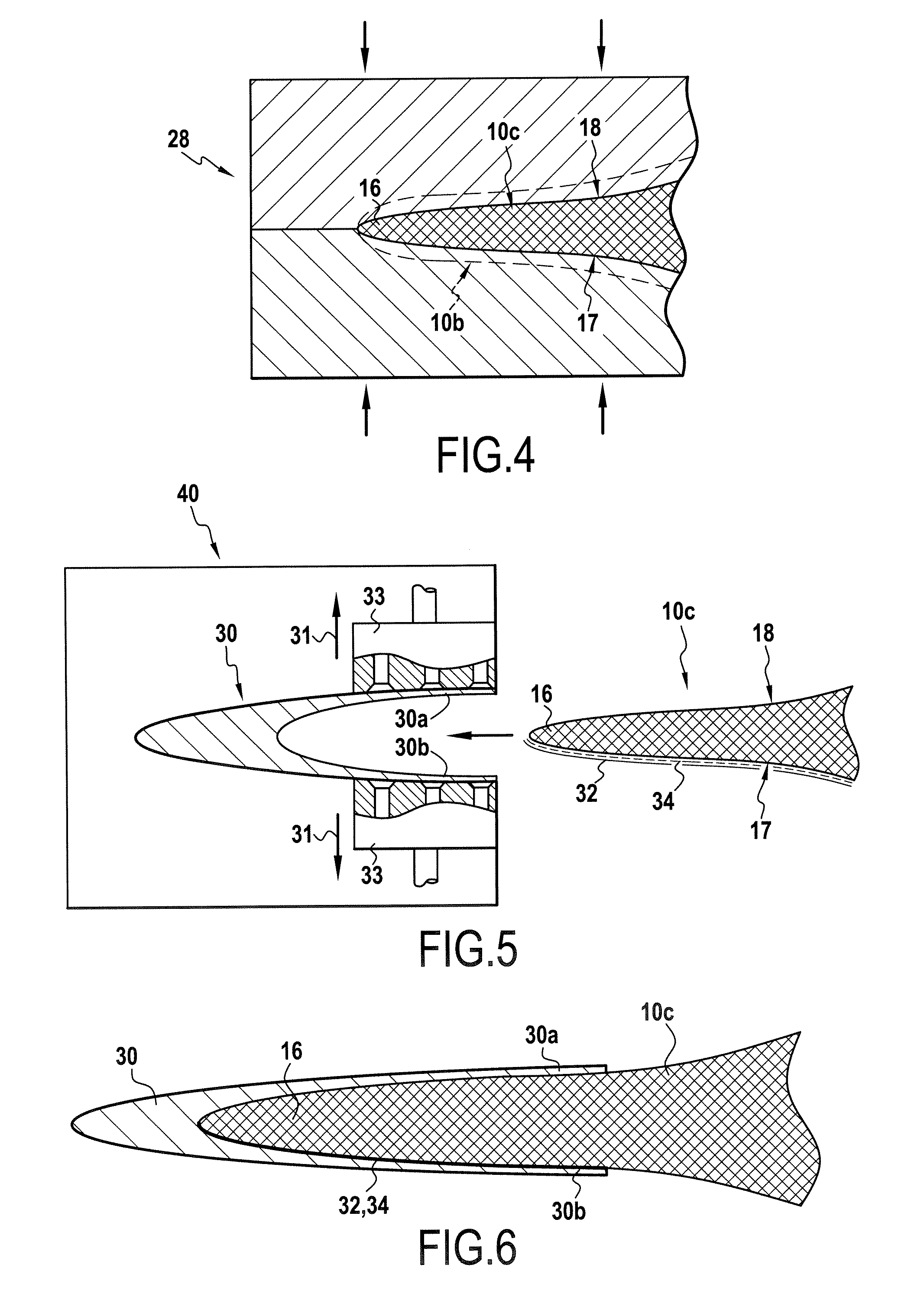

Turbomachine blade, in particular a fan blade, and its method of manufacture

The composite turbomachine blade of the present invention comprises a preform made of yarns or fibers woven in three dimensions and a binder maintaining the relative disposition between the yarns of the preform. Said preform is made up of warp yarns and of weft yarns, the direction of the warp yarns forming the longitudinal direction of the preform. In characteristic manner, said preform comprises at least a first portion made using a first weave forming the airfoil of the blade, and a second portion made using a second weave forming the root of the blade, and the first and second portions are united by a transition zone in which the first weave is progressively modified to end up with the second weave, thereby obtaining a reduction at least in the thickness of the blade between the second portion and the first portion. The invention is applicable to making a fan blade for a turbojet.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Fan blade modifications

Owner:DELTA T

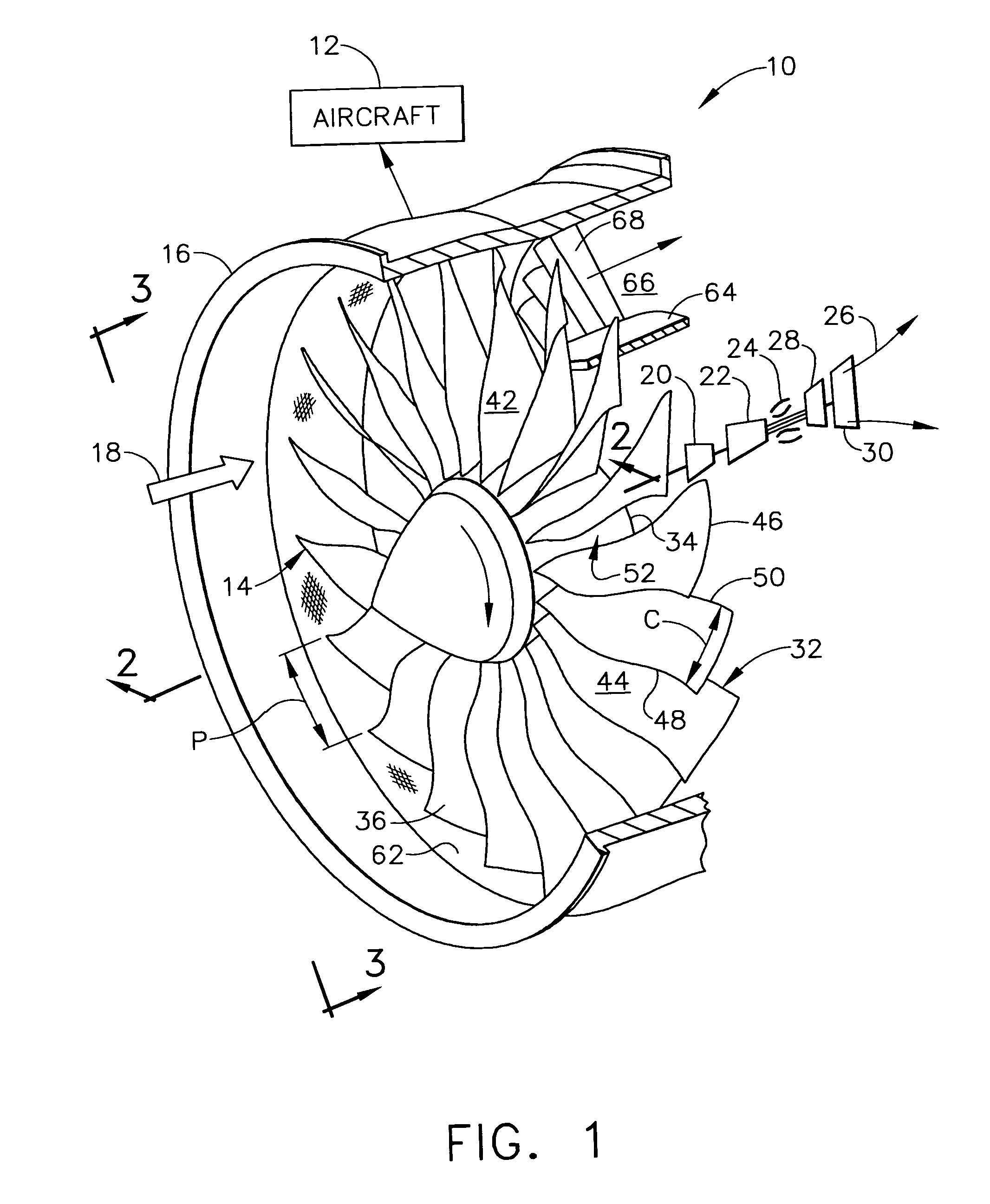

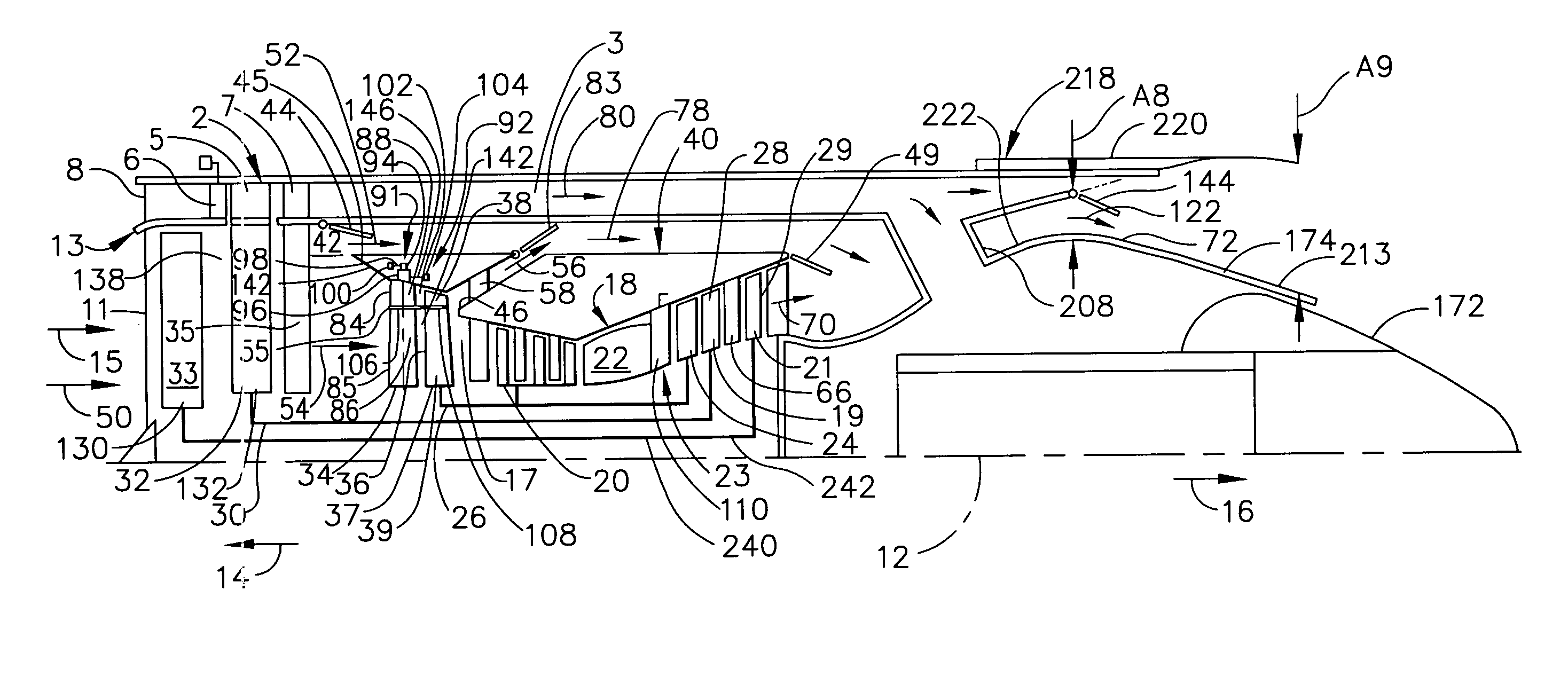

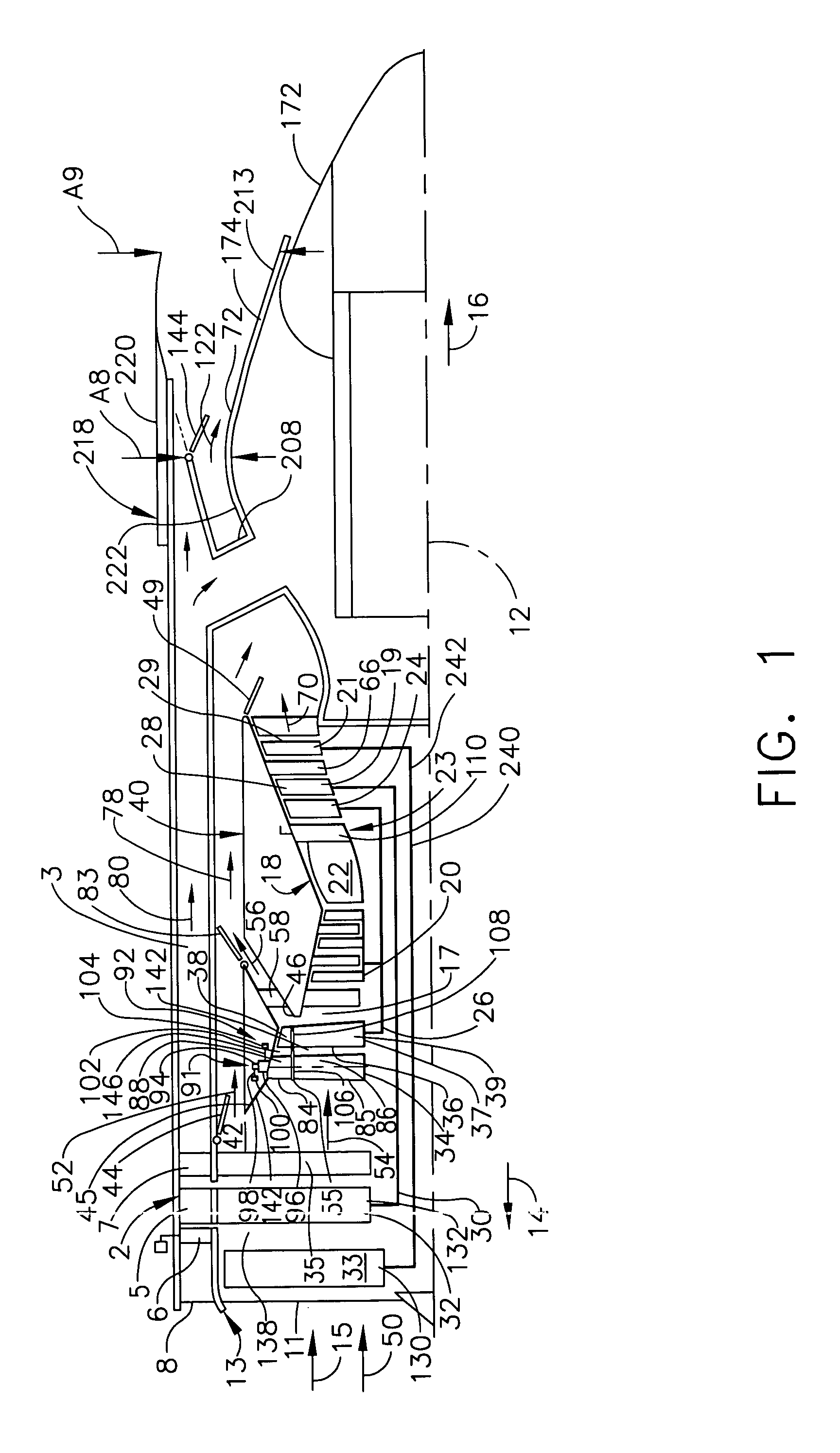

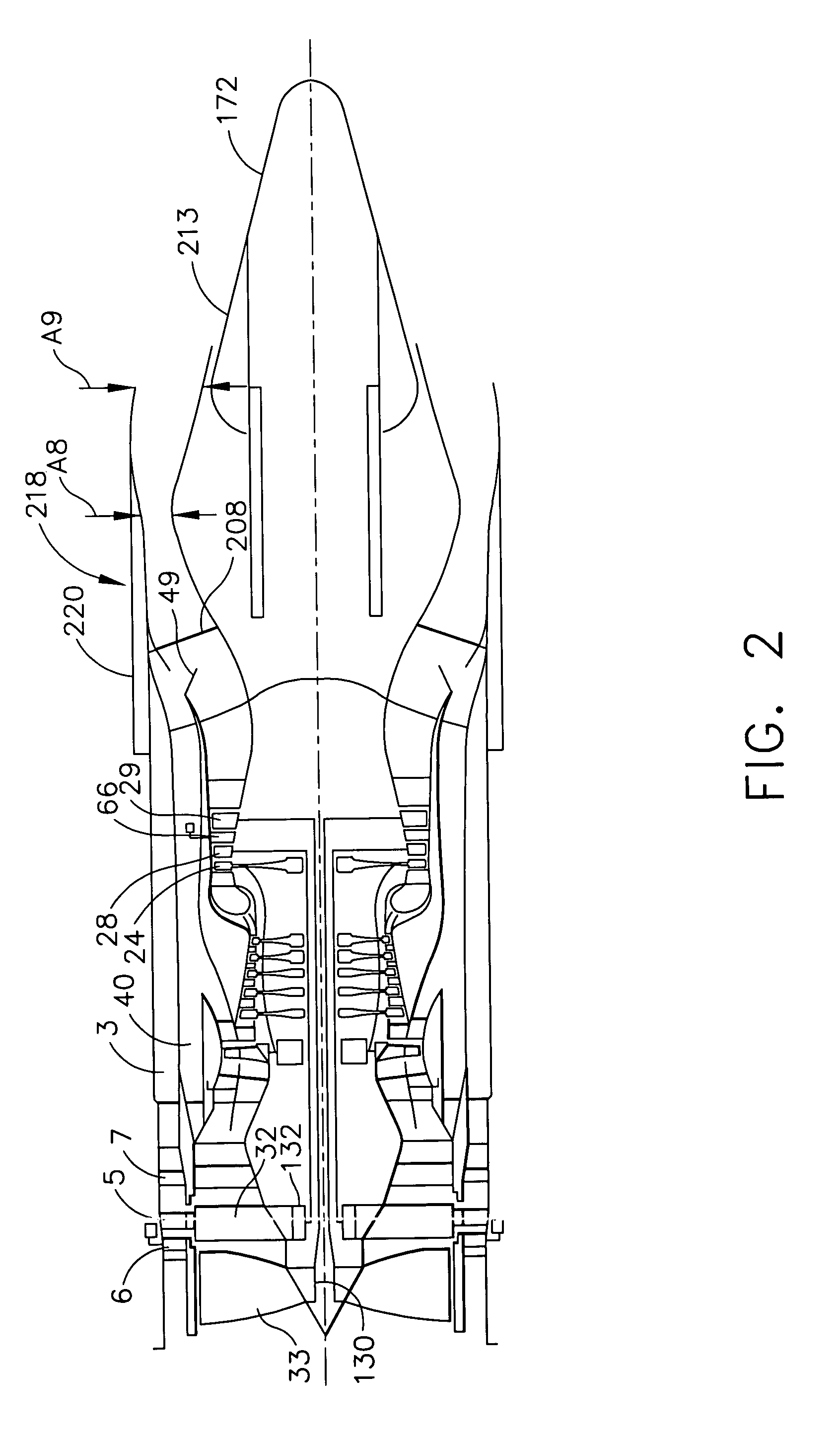

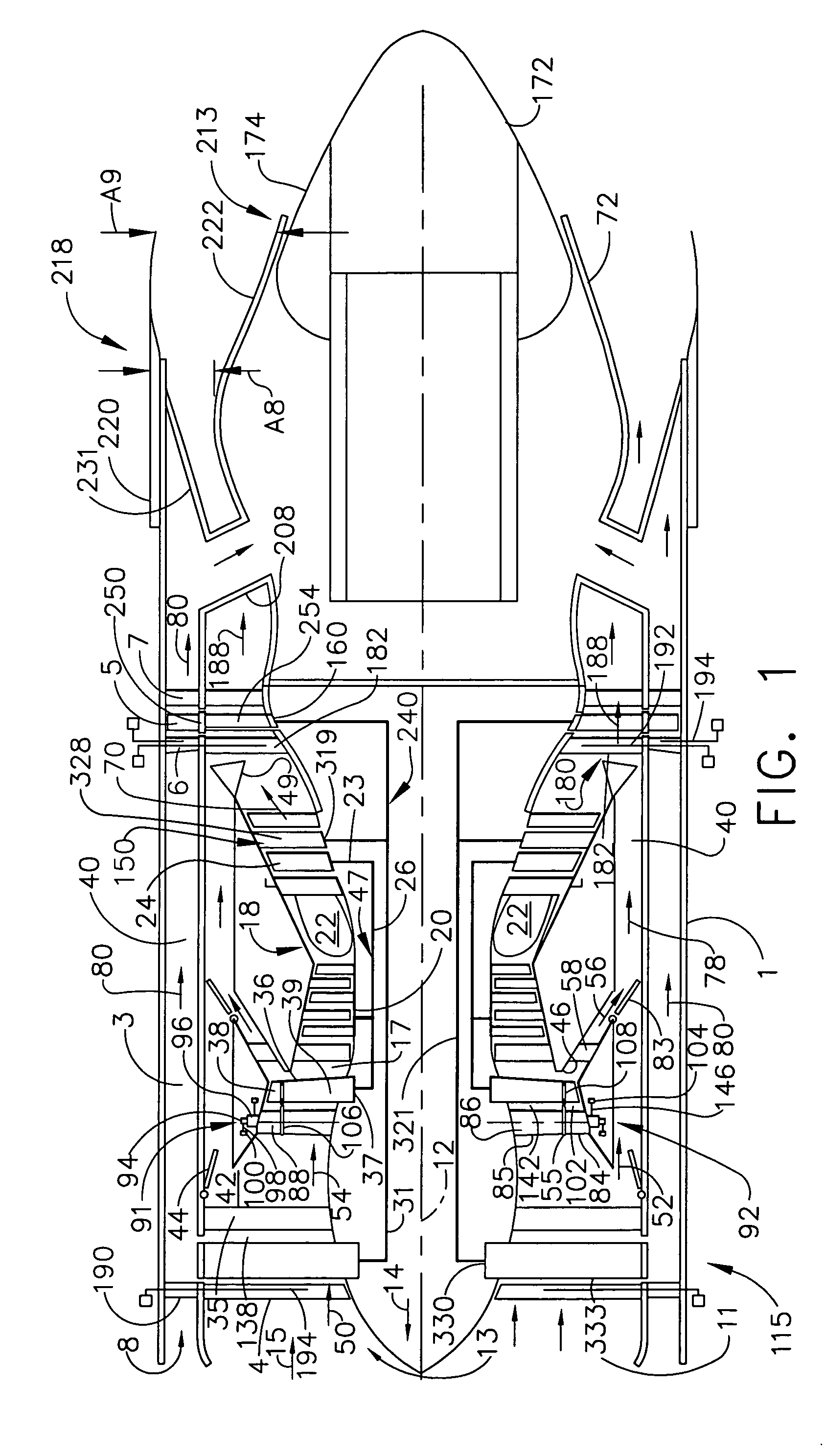

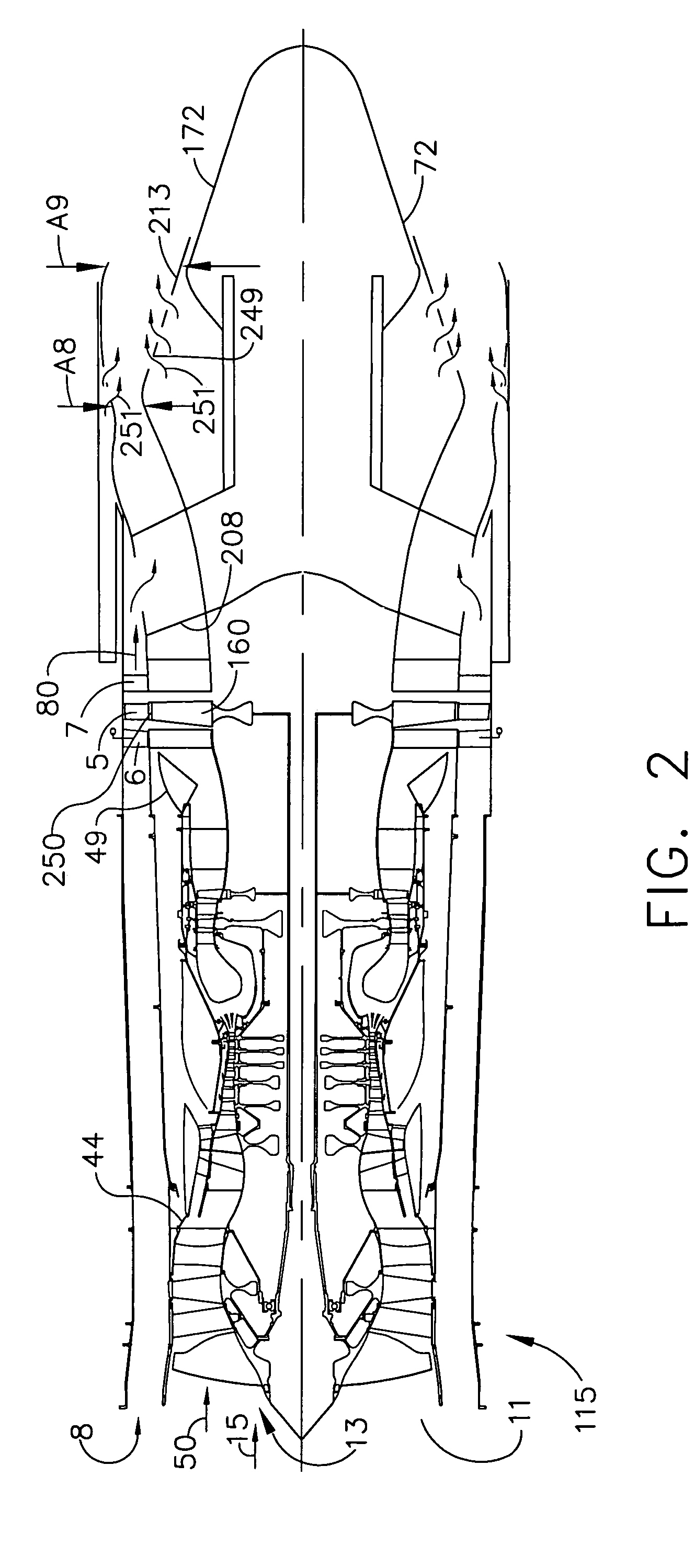

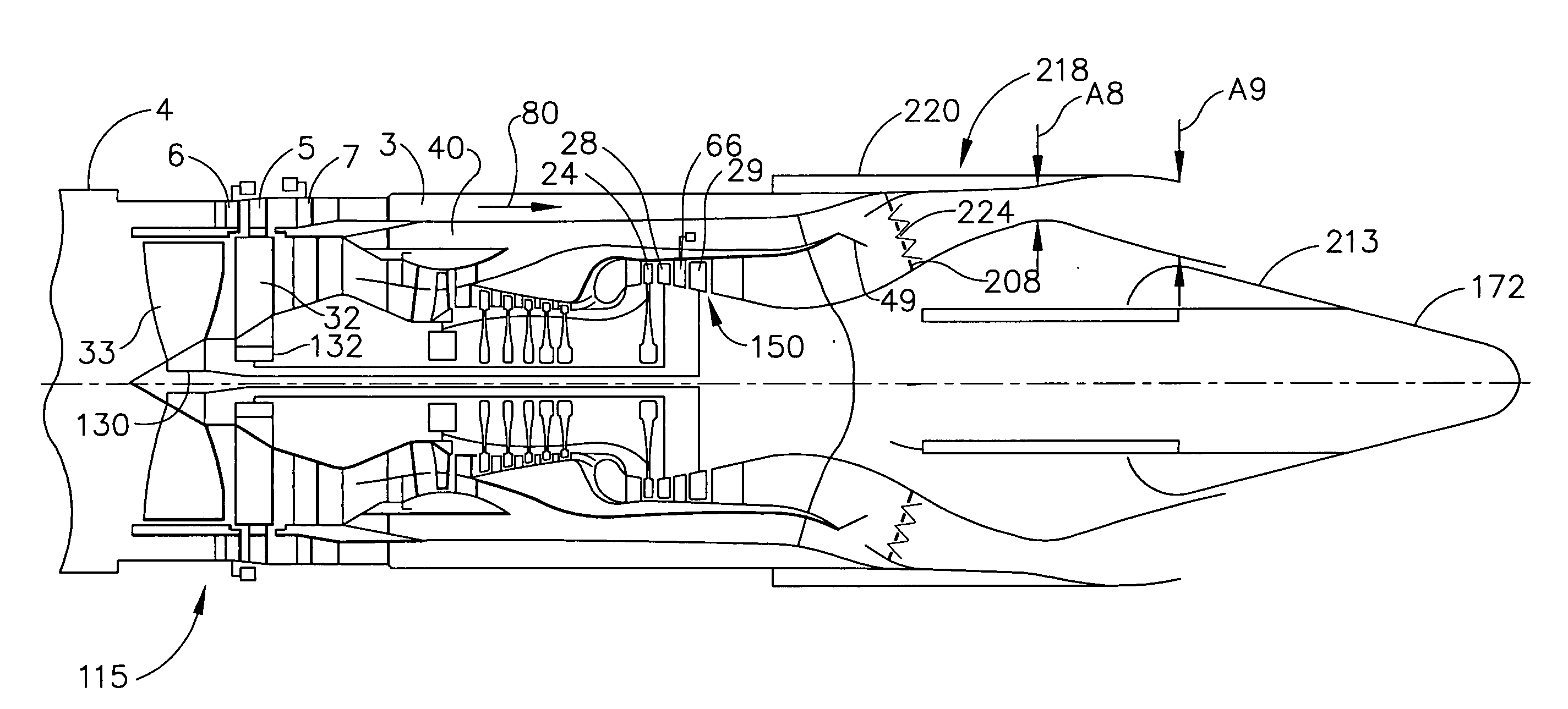

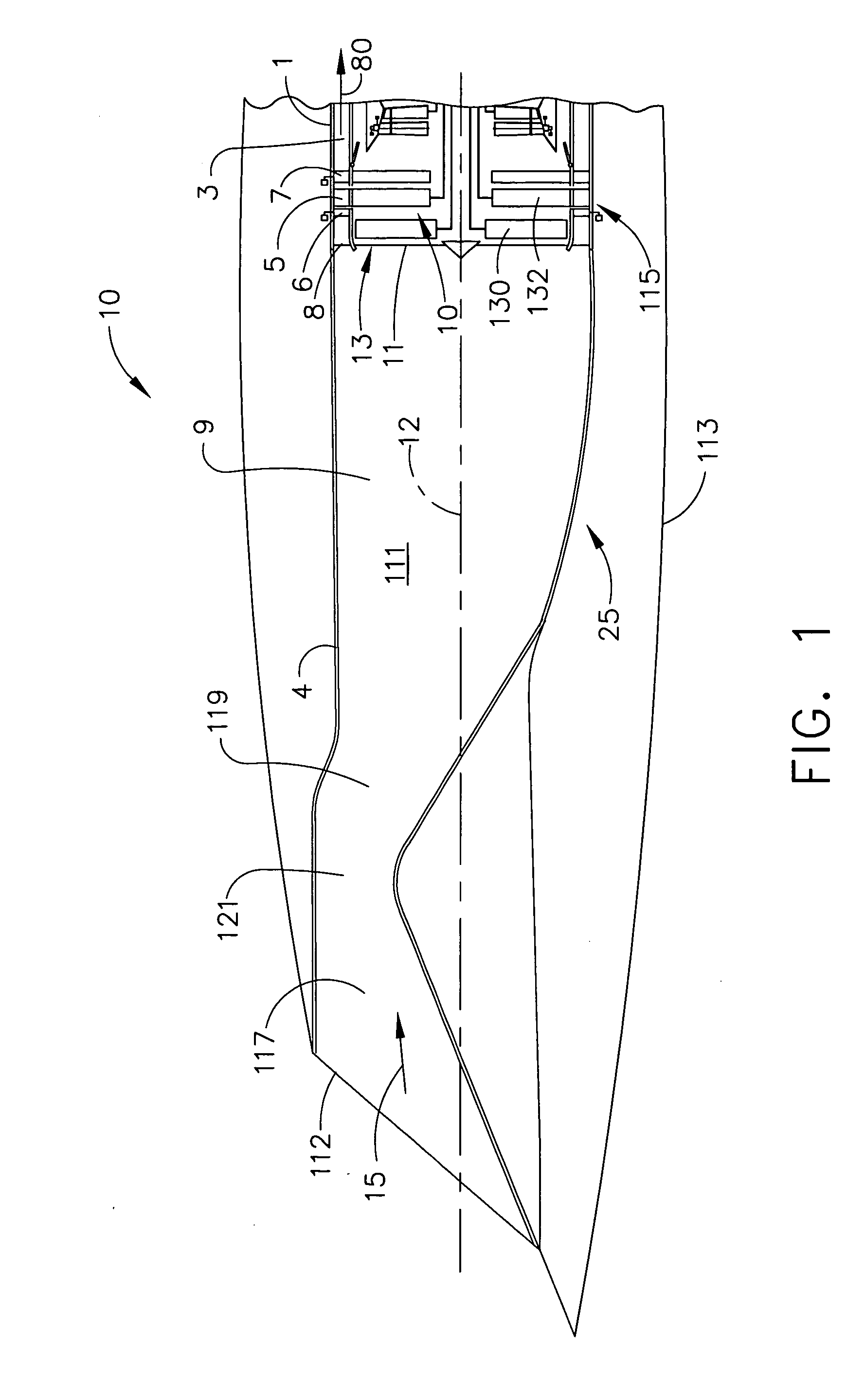

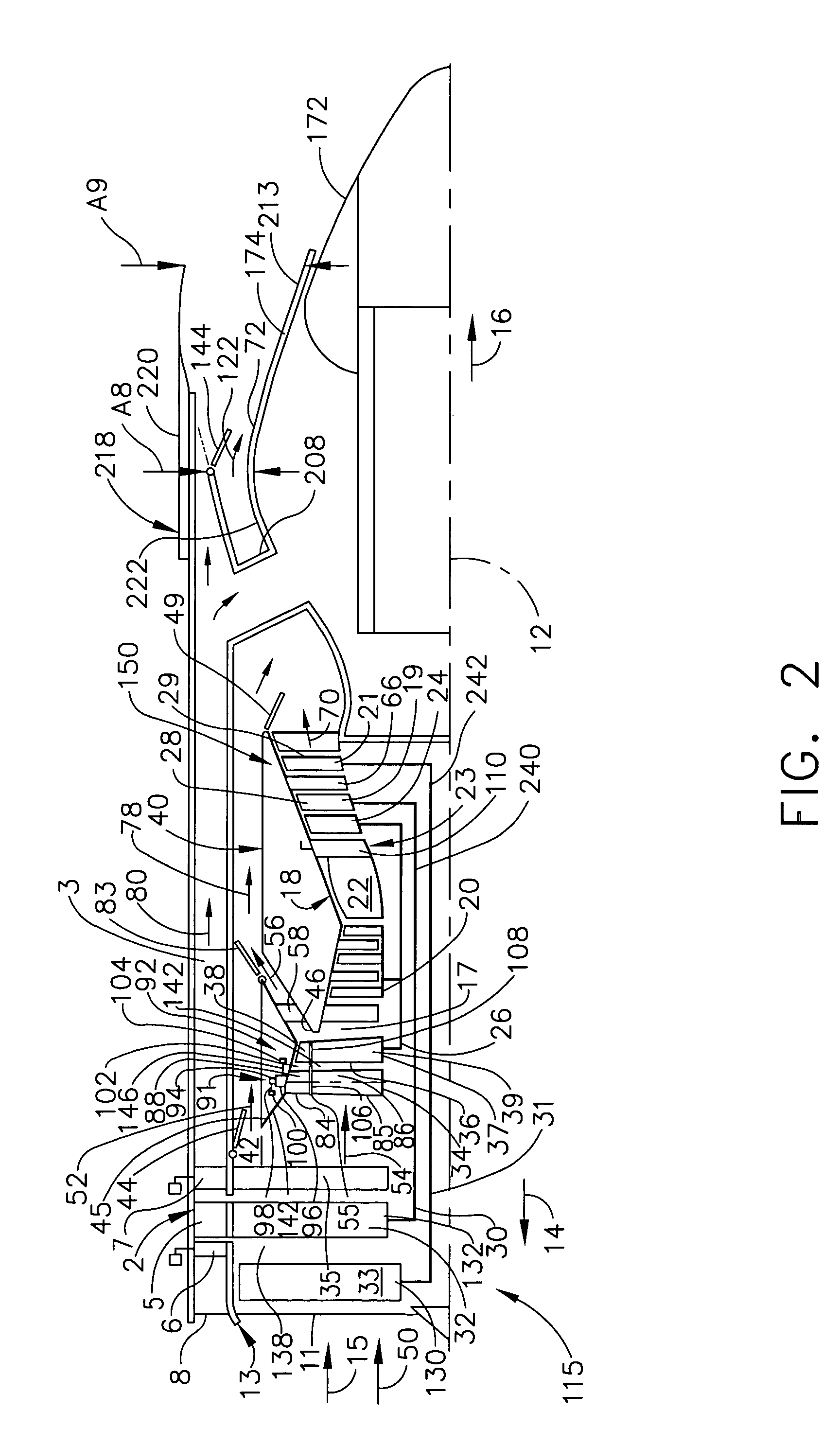

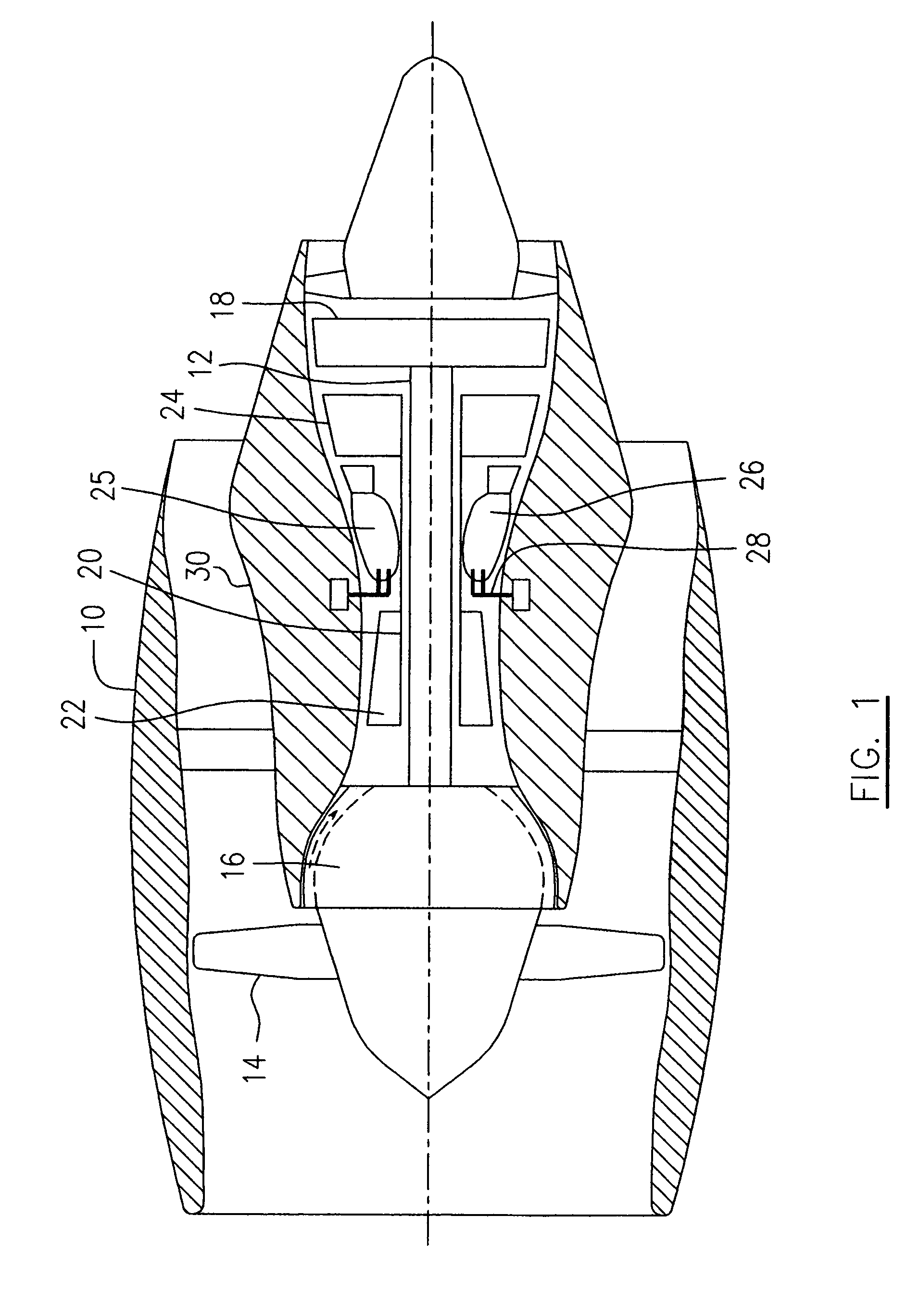

FLADE gas turbine engine with counter-rotatable fans

An exemplary embodiment of a FLADE counter-rotating fan aircraft gas turbine engine includes at least one row of FLADE fan blades disposed radially outwardly of and drivingly connected to one of axially spaced-apart first and second counter-rotatable fans. A core engine located downstream and axially aft of the first and second counter-rotatable fans is circumscribed by a fan bypass duct downstream and axially aft of the first and second counter-rotatable fans. The row of FLADE fan blades radially extend across a FLADE duct circumscribed about the first and second counter-rotatable fans and the fan bypass duct. A second low pressure turbine is drivingly connected to the first counter-rotatable fan and a first low pressure turbine is drivingly connected to the second counter-rotatable fan.

Owner:GENERAL ELECTRIC CO

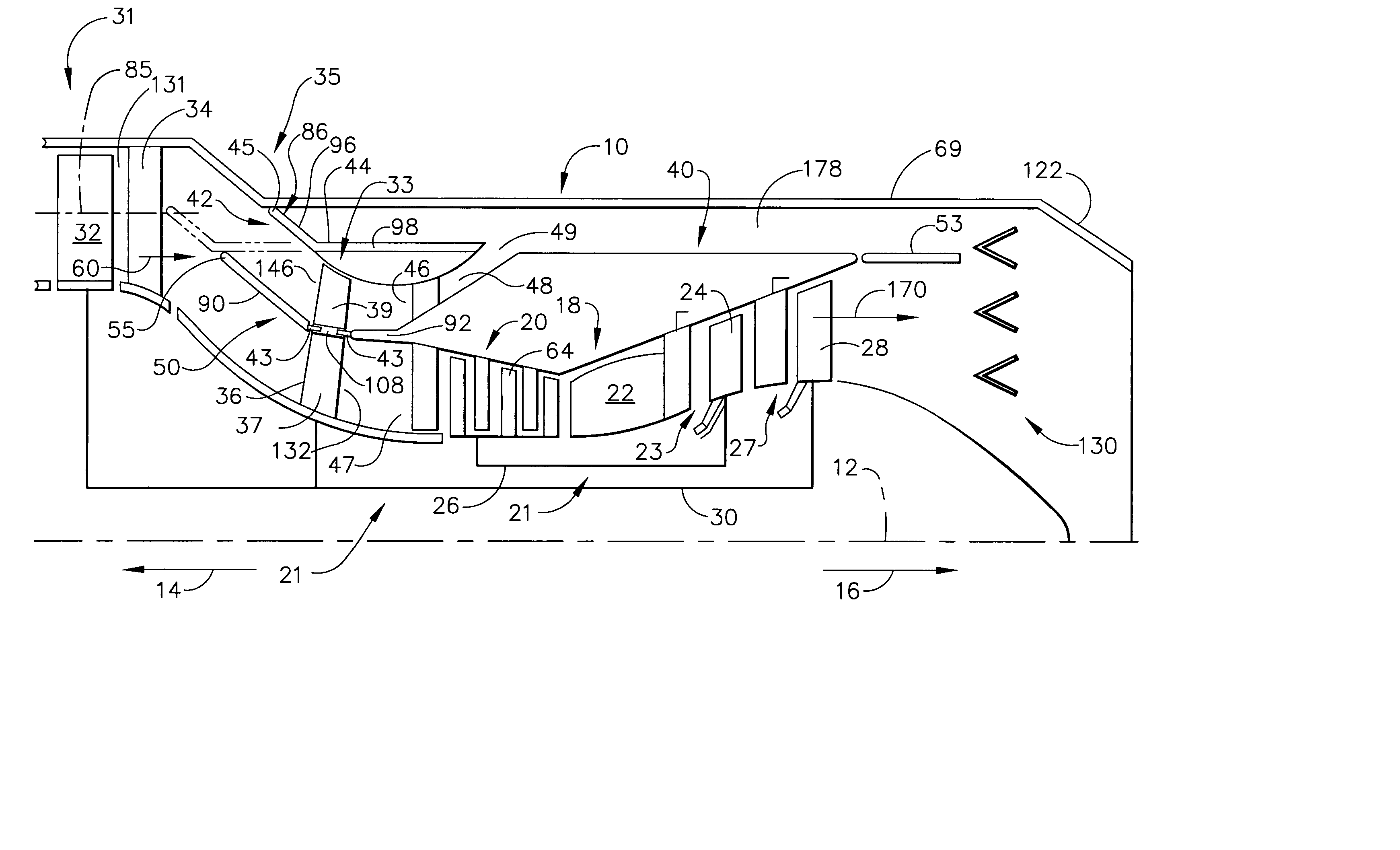

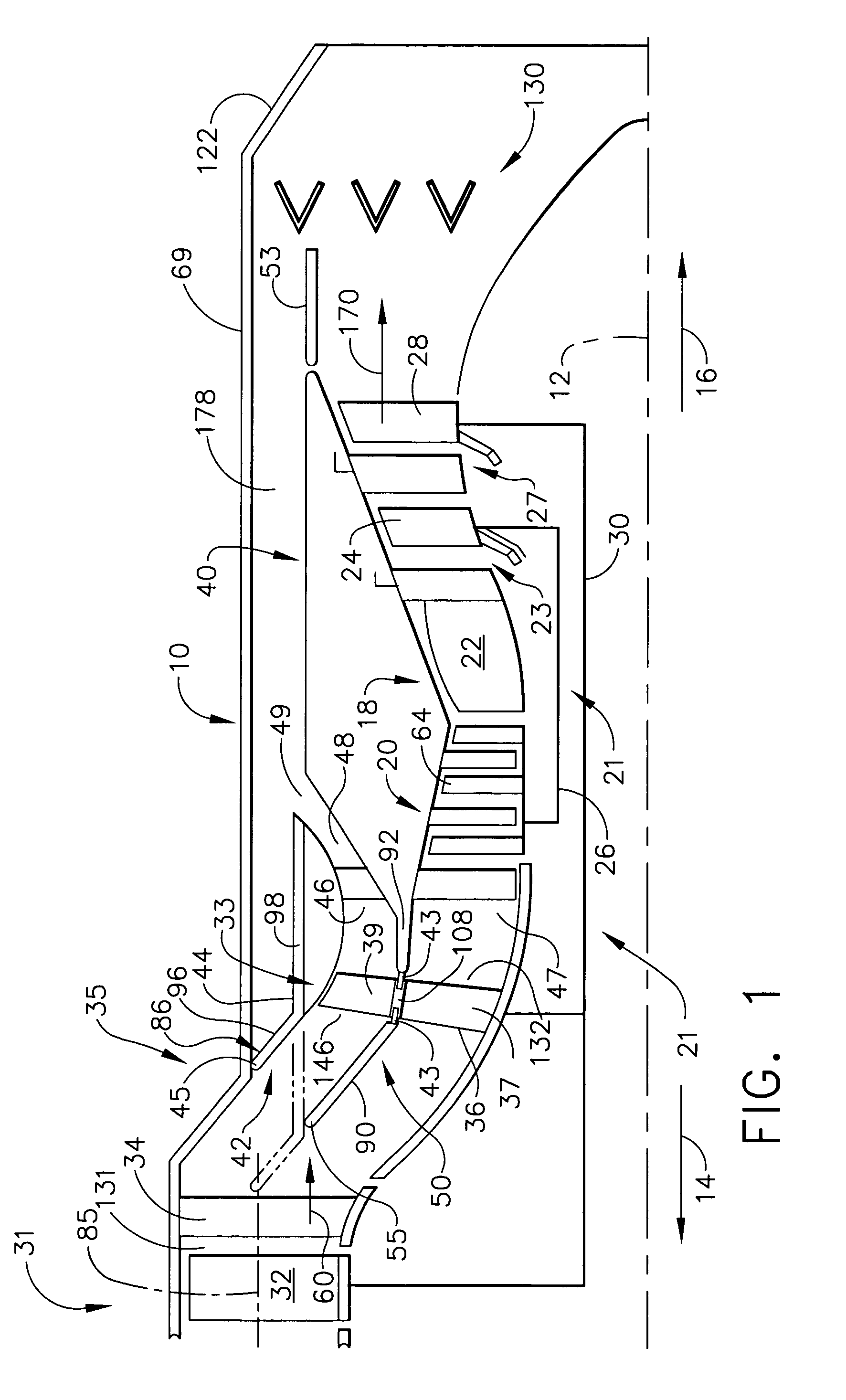

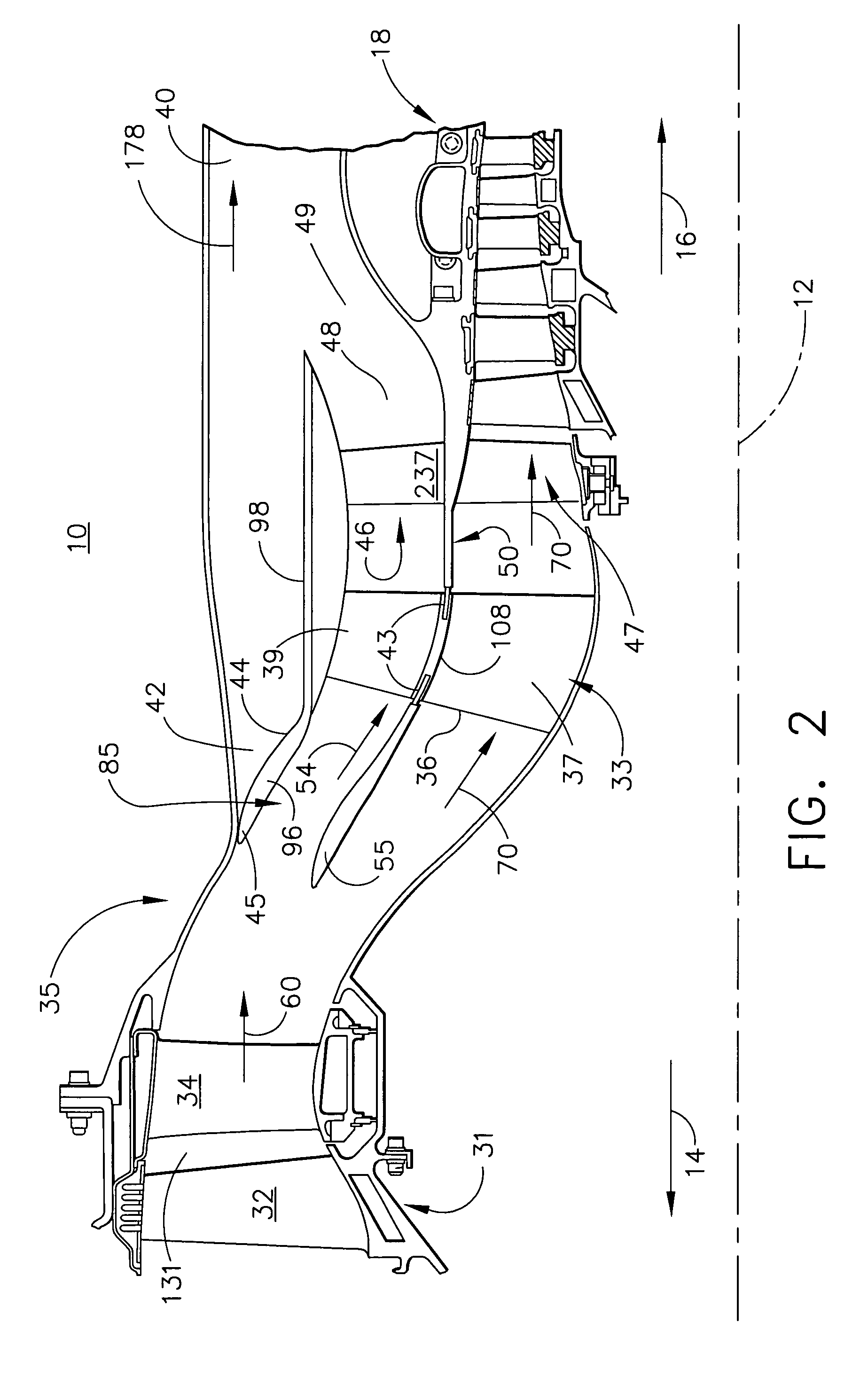

Aft FLADE engine

ActiveUS7216475B2Increase pressureEasy to demonstrateEngine manufactureJet propulsion plantsFan bladePower extraction

An aft FLADE gas turbine engine includes a fan section drivenly connected to a low pressure turbine section, a core engine located between the fan section and the low pressure turbine section, a fan bypass duct circumscribing the core engine and in fluid communication with the fan section, and a mixer downstream of the low pressure turbine section and in fluid communication with the fan bypass duct, and an aft FLADE turbine downstream of the mixer. At least one row of aft FLADE fan blades disposed radially outwardly of and connected to the aft FLADE turbine and radially extending across a FLADE duct circumscribing the fan bypass duct. The aft FLADE turbine may be a free turbine or connected to and rotatable with the low pressure turbine section. A power extraction apparatus may be disposed within the engine and drivenly connected to the aft FLADE turbine.

Owner:GENERAL ELECTRIC CO

Cooling fan using coanda effect to reduce recirculation

ActiveUS20070224044A1Increase the cross-sectional areaTrend downPump componentsReaction enginesFan bladeAerospace engineering

Owner:VALEO INC

Turbomachine blade, in particular a fan blade, and its method of manufacture

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Cooling fan with reinforced blade

InactiveUS6939108B2Simple structureIncreased downward thrustPropellersPump componentsTrailing edgeFan blade

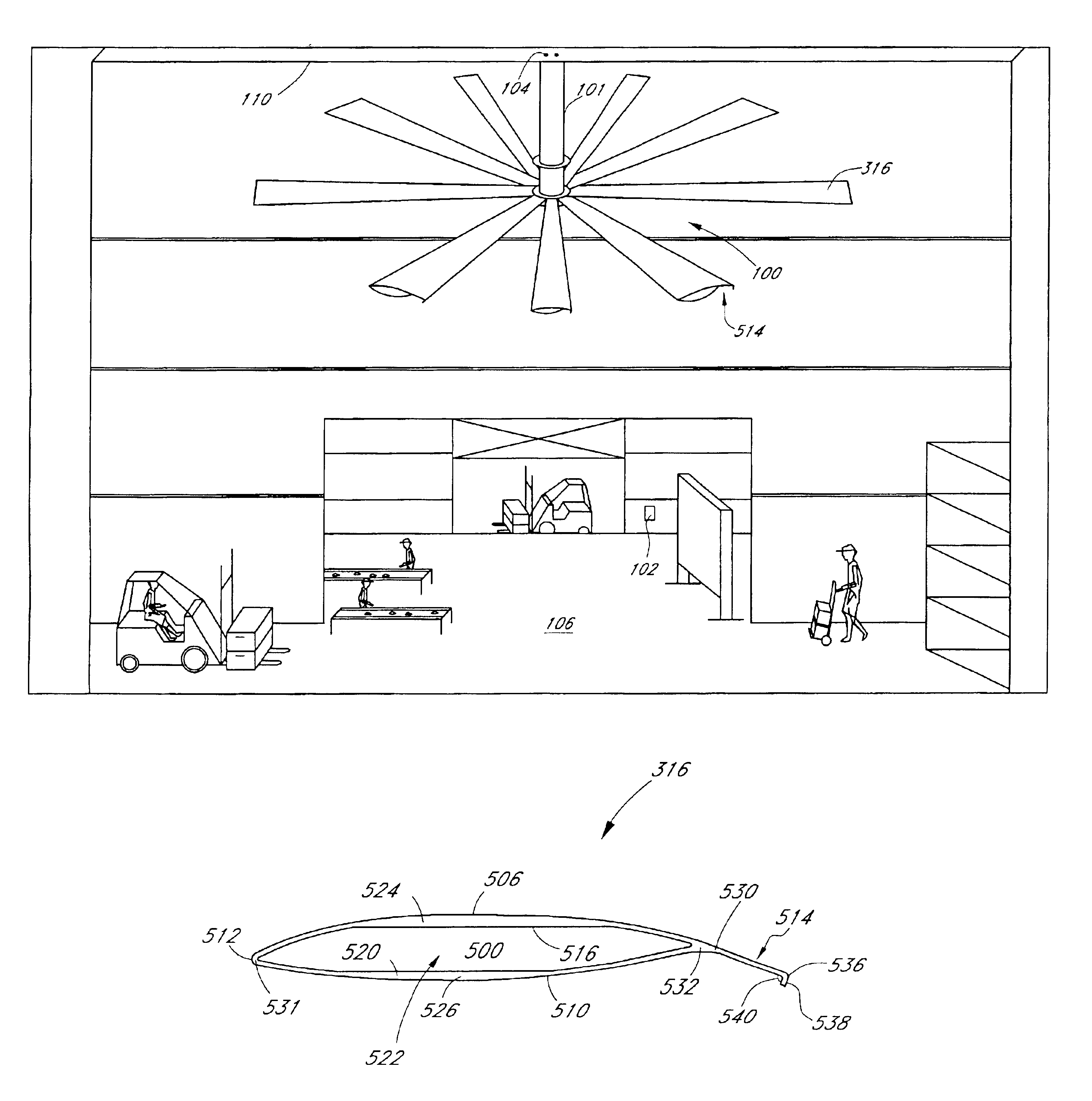

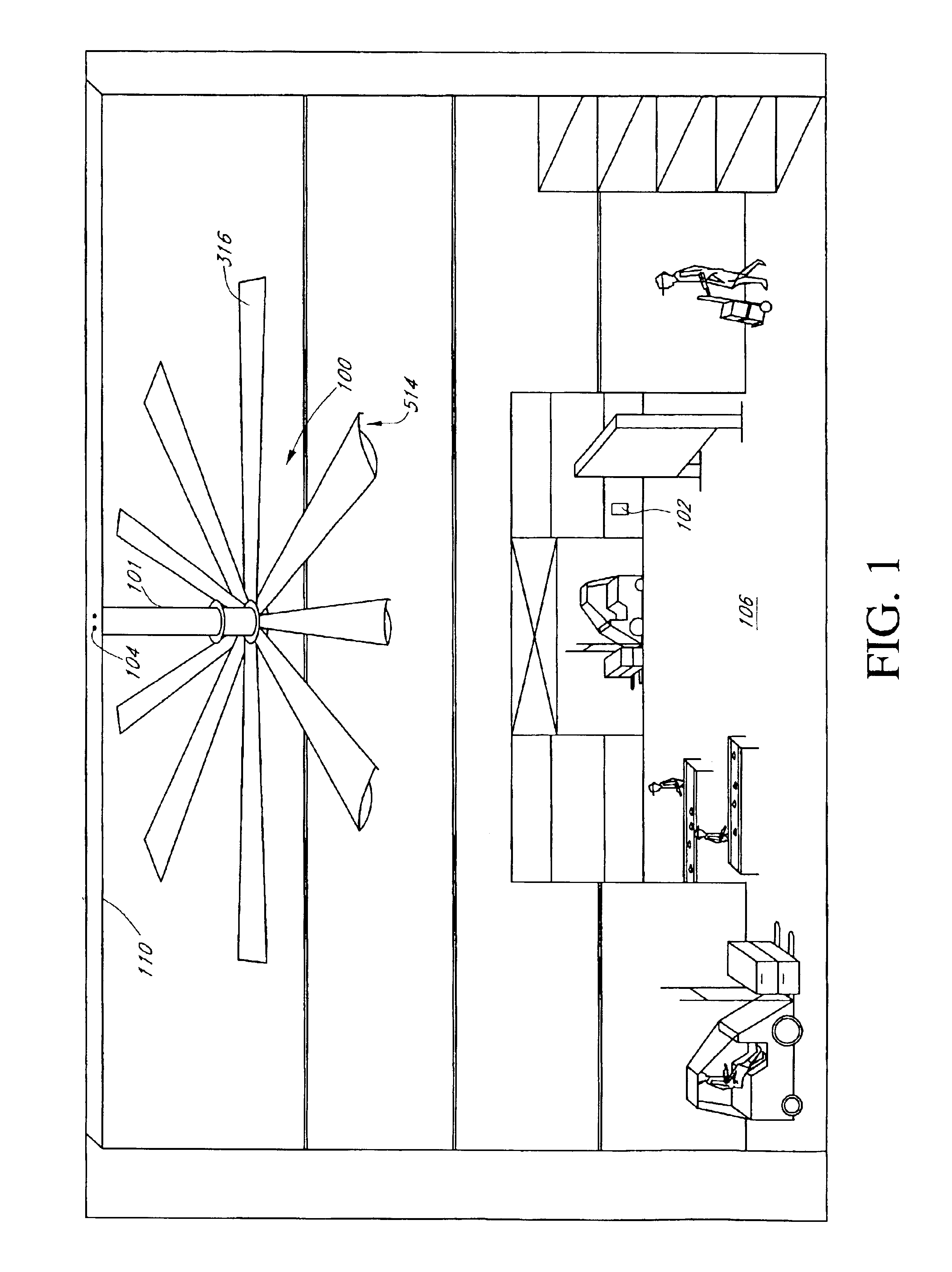

A circulatory device comprising a large diameter fan having reinforced fan blades with a tapered airfoil shape is disclosed. The fan blades may be formed using an extrusion method of fabrication, wherein each fan blade may comprise a reinforced trailing edge with a downwardly extending flange. The benefit of forming each fan blade with a reinforced trailing edge of the present invention results in improved structural characteristics such that the trailing edge of each fan blade may be fabricated longer so as to improve aerodynamic performance. Also, the reinforced trailing edge resists tearing that may occur during extrusion by adding the bent flanged region to at least one distal end of the trailing edge. For example, the bent portion of the trailing edge tends to rigidly orient the extruded material in a stabilized position more readily during formation. Also, the bent portion provides added strength by providing supporting forces in two dimensions that relatively parallel and perpendicular to its length so as to neutralize the adverse effects of pressure forces acting on the trailing edge of the fan blade during extrusion.

Owner:DELTA T

Collapsible fan and system and method incorporating same

A collapsible fan. The collapsible fan may be disposed in parallel or series with one or more other fans. If the collapsible fan becomes inactive or non-operable, such as by malfunction or failure, then its fan blades collapse to a less restrictive flow configuration allowing the remaining fans to operate more effectively. The fan blades may have any suitable expansion and contraction mechanism, such as a hinge, a pivot joint, or a multi-section inner or outer support structure having different sections of the fan blades.

Owner:HTC CORP

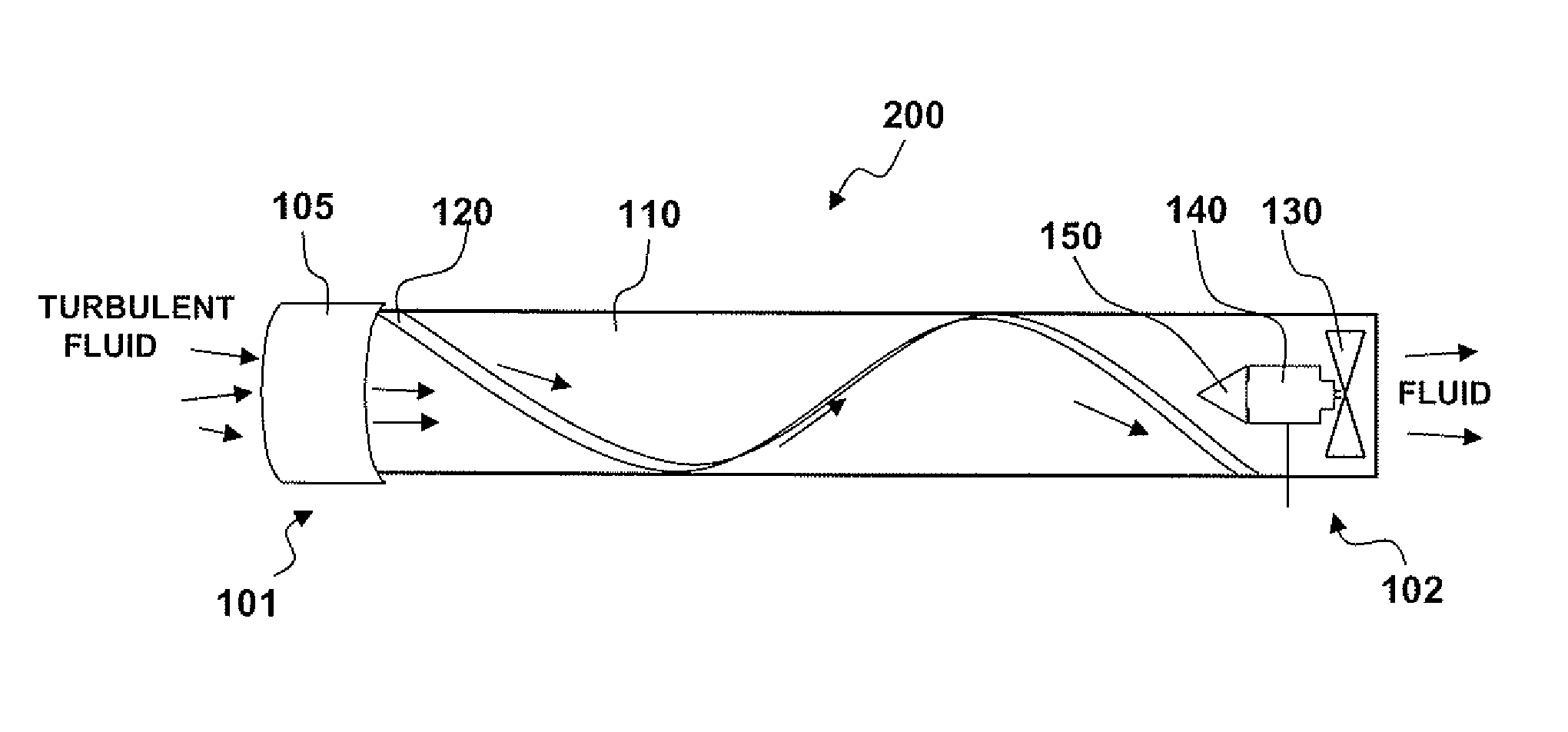

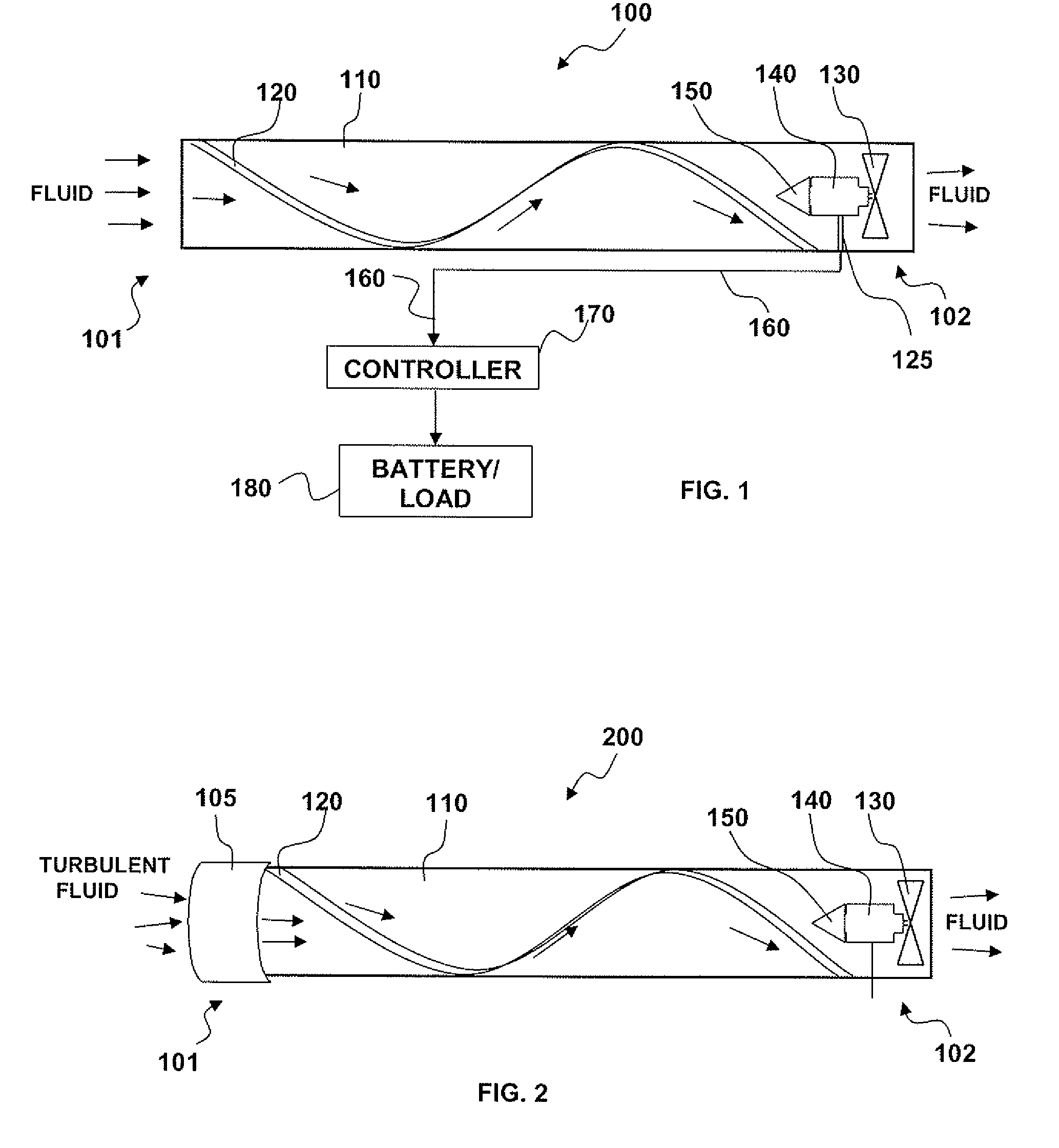

Fluid driven electric power generation system

ActiveUS20080238105A1Scalable in sizeGood effectWind motor controlWind motor supports/mountsAlternatorHelical blade

A tubular housing includes at least one fixed helical vane formed onto the inner surfaces of the tubular housing in a spiral and adapted to direct fluid into a spiraled flow and focus fluid onto a fan blade assembly associated with an alternator system and located within the tubular housing before a system exhaust. A generator cone can be mounted near the center and front of the fan blade assembly facing fluid passing through the tubular housing. As fluid passes over the generator cone it experiences compression between the generator cone and housing resulting in increased pressure and velocity of the fluid, thereby increasing rotational speed of the generator blades and generator as the compressed, spiraled fluid passes through the blades and exits the tubular housing. The system can be used for fixed or mobile applications in water, wind and manually induced air flow.

Owner:MDL ENTERPRISES

Centrifugal fan with low noise

InactiveUS20070160458A1Reduce noiseReduce transmissionPump componentsBlade accessoriesImpellerLow noise

A centrifugal fan with low noise includes a housing, a fan wheel and a recess unit. The fan wheel has a hub and a plurality of fan blade extending outward from the hub radially. The housing has a chamber therein to receive the fan wheel and has a recess unit at the surface thereof. The recess unit is composed of a projection part and a recess part for reducing noise transmission greatly.

Owner:YEN JUN CHIEN

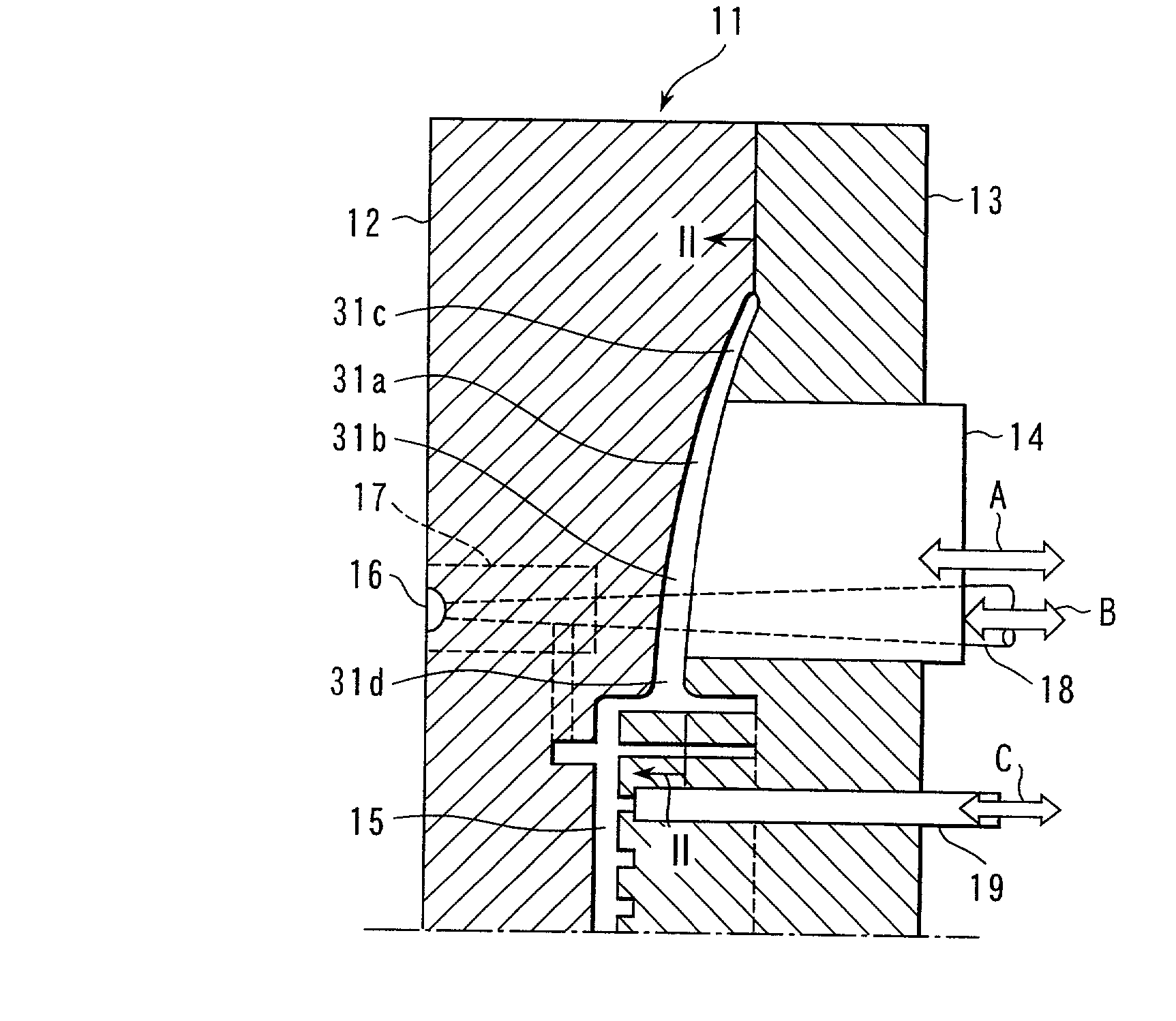

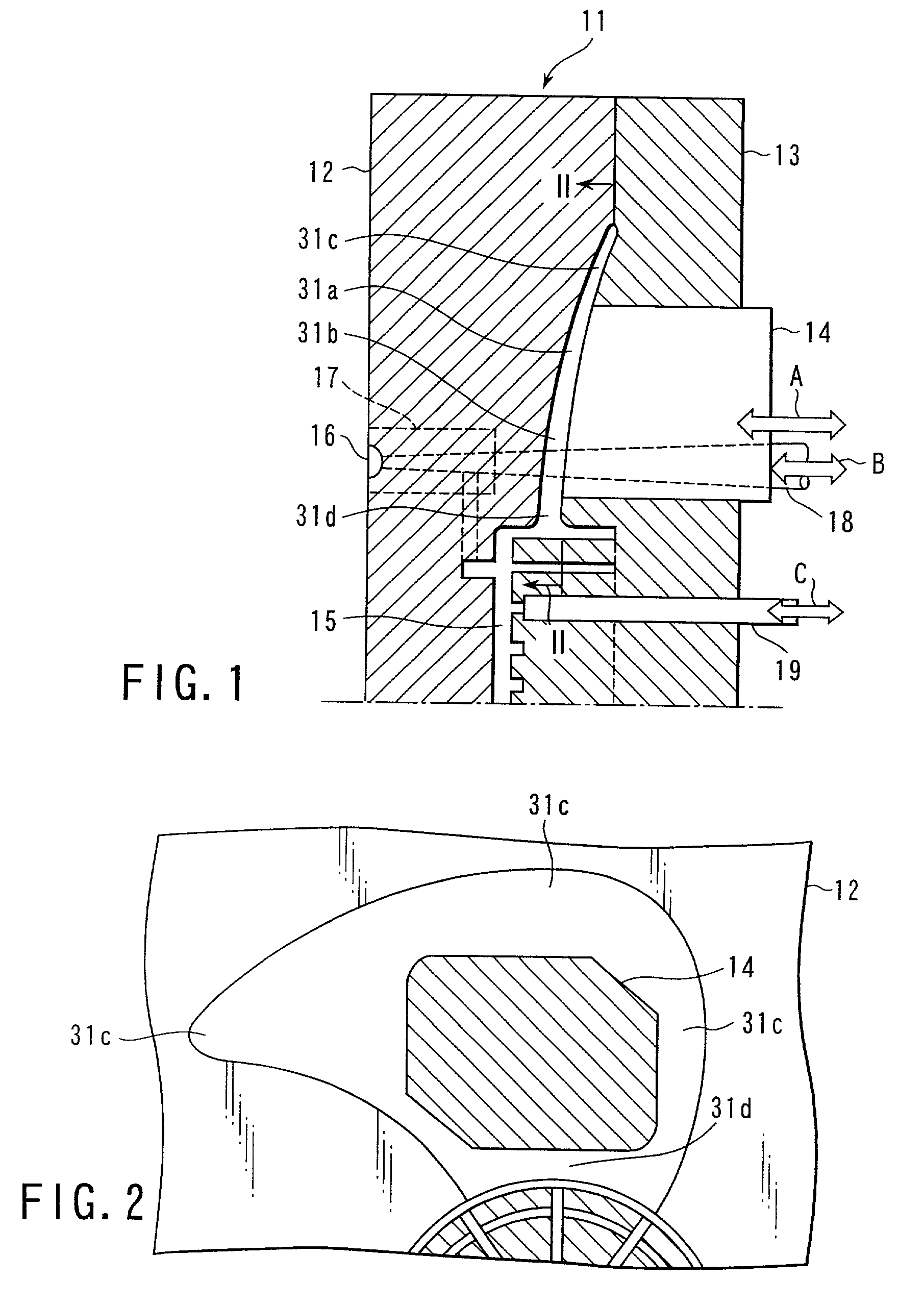

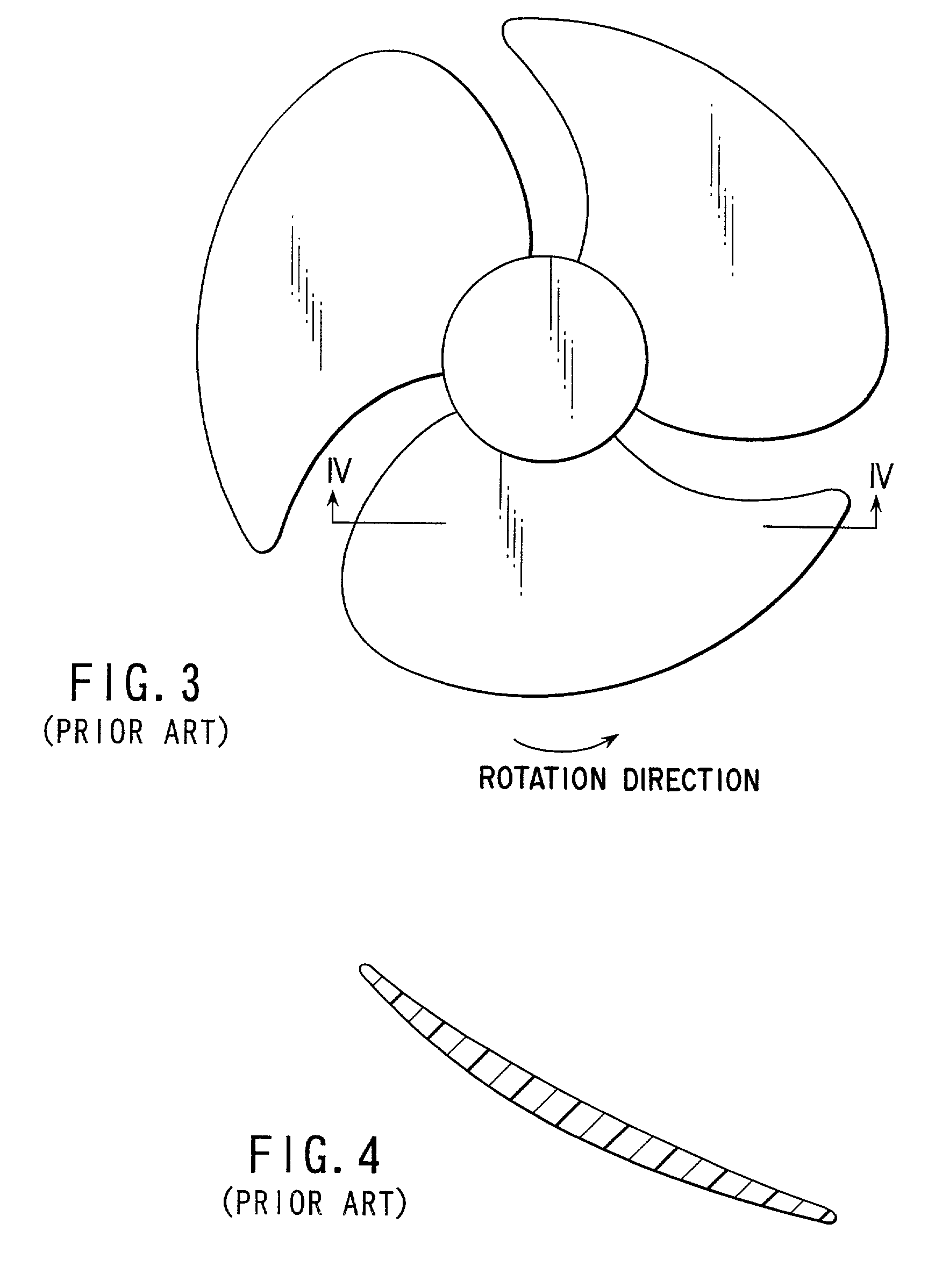

Method for injection-molding a propeller fan

InactiveUS20020089078A1Low amount of unbalanceReduce the amount requiredDomestic articlesPropellerEngineering

A method for injection-molding a plastics propeller fan by using a fixed-side mold section and movable-side mold section, comprises the steps of providing a movable core at an area corresponding to a thicker portion of a blade section of the propeller fan; after a predetermined amount of plastics material has been injected into a blade space of a mold cavity defined by the fixed-side mold section, movable-side metal section and movable core and conforming to the propeller fan, pushing out the movable core into the mold cavity and, after this step, bringing the movable core back to a normal position conforming to a mold shape defining the blade space and forming a proper fan.

Owner:IDEMITSU KOSAN CO LTD +2

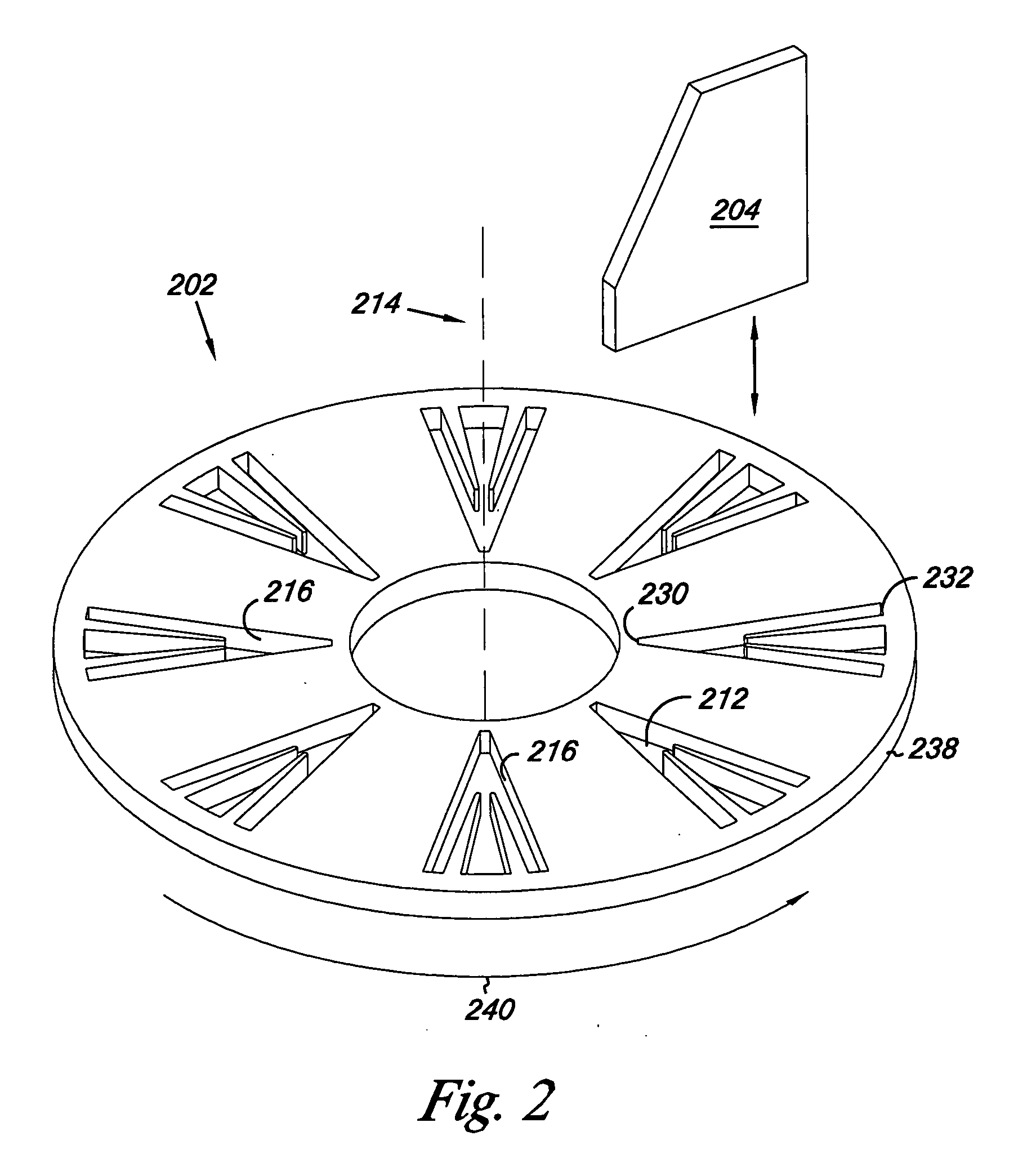

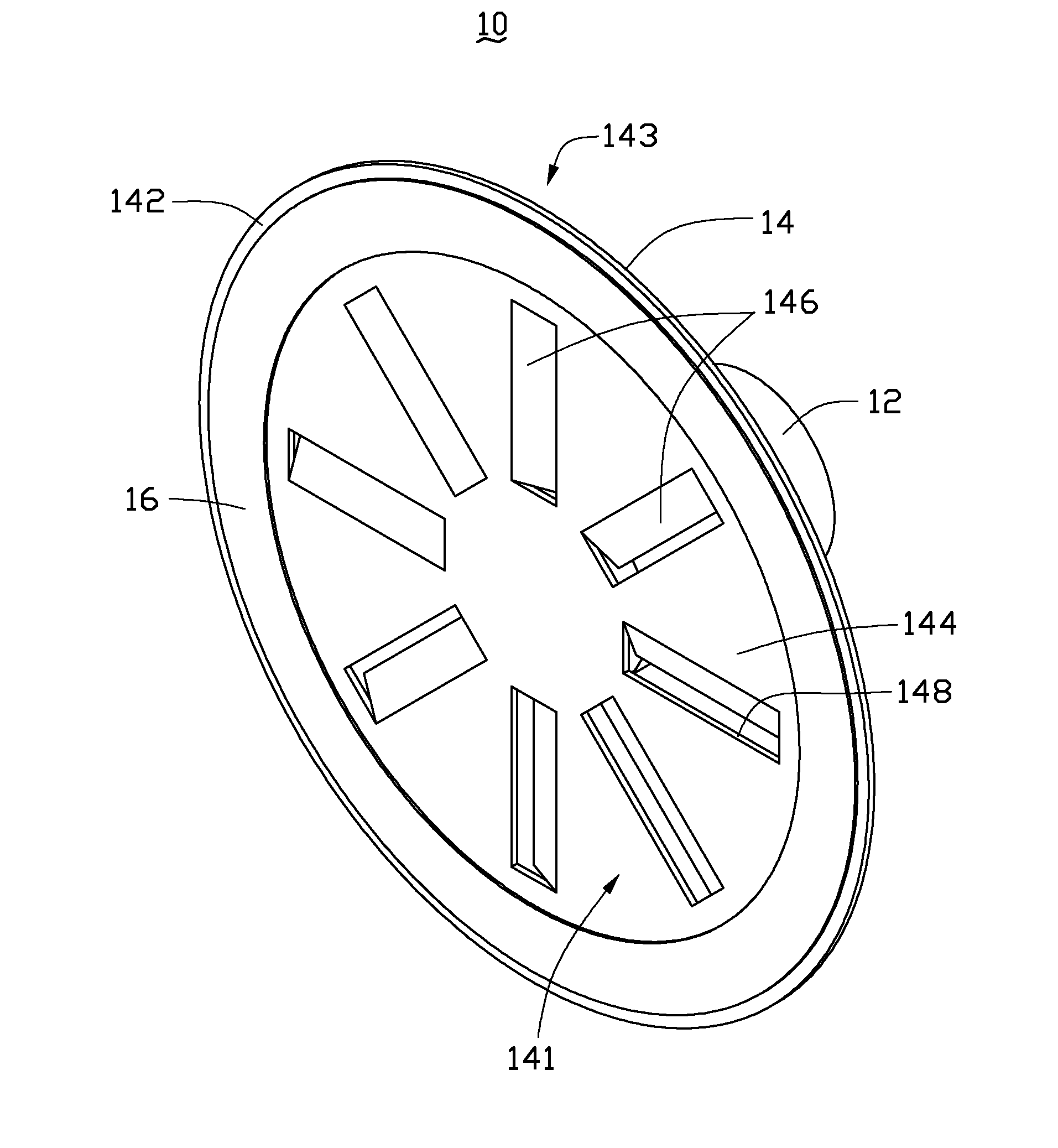

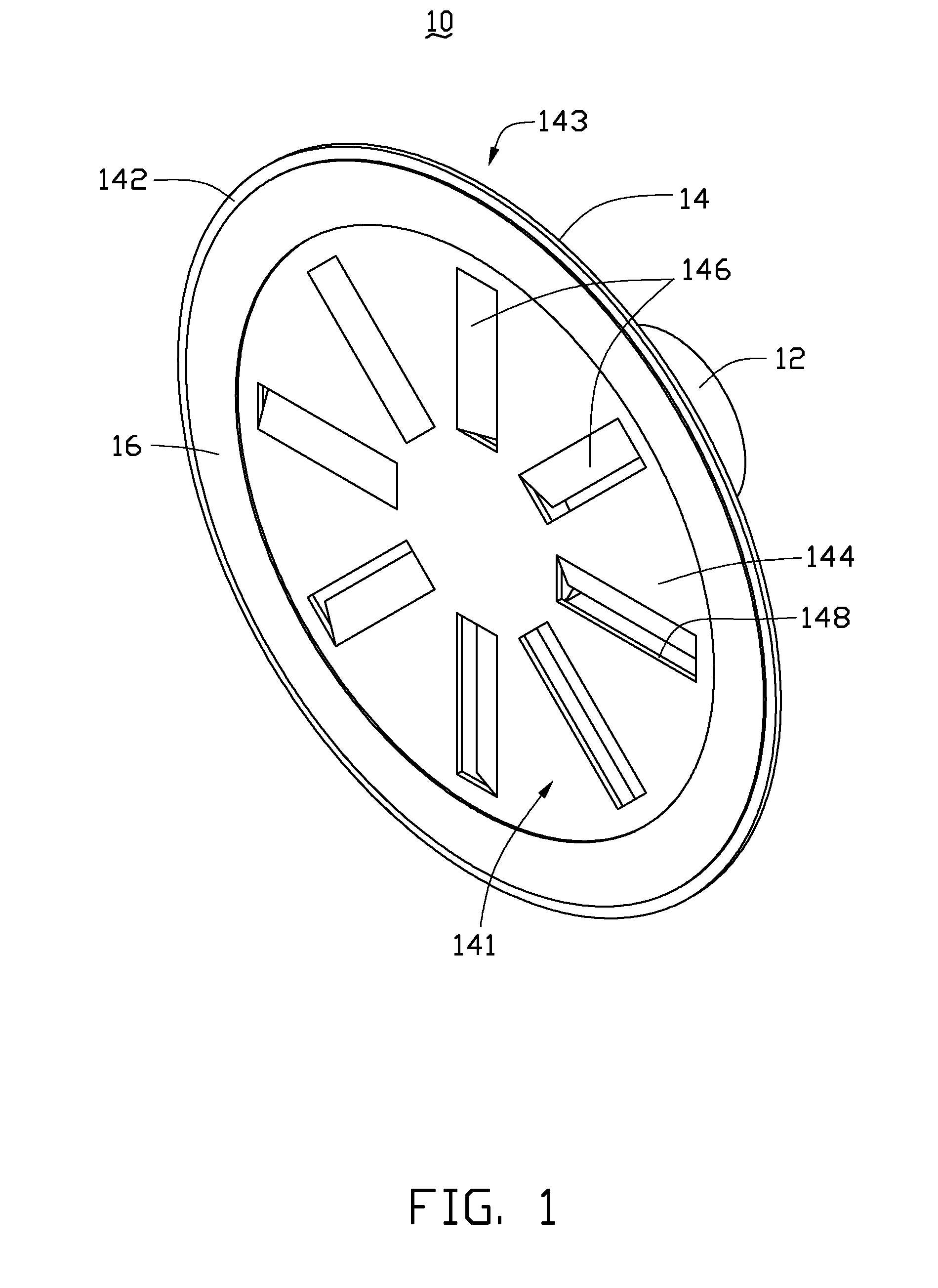

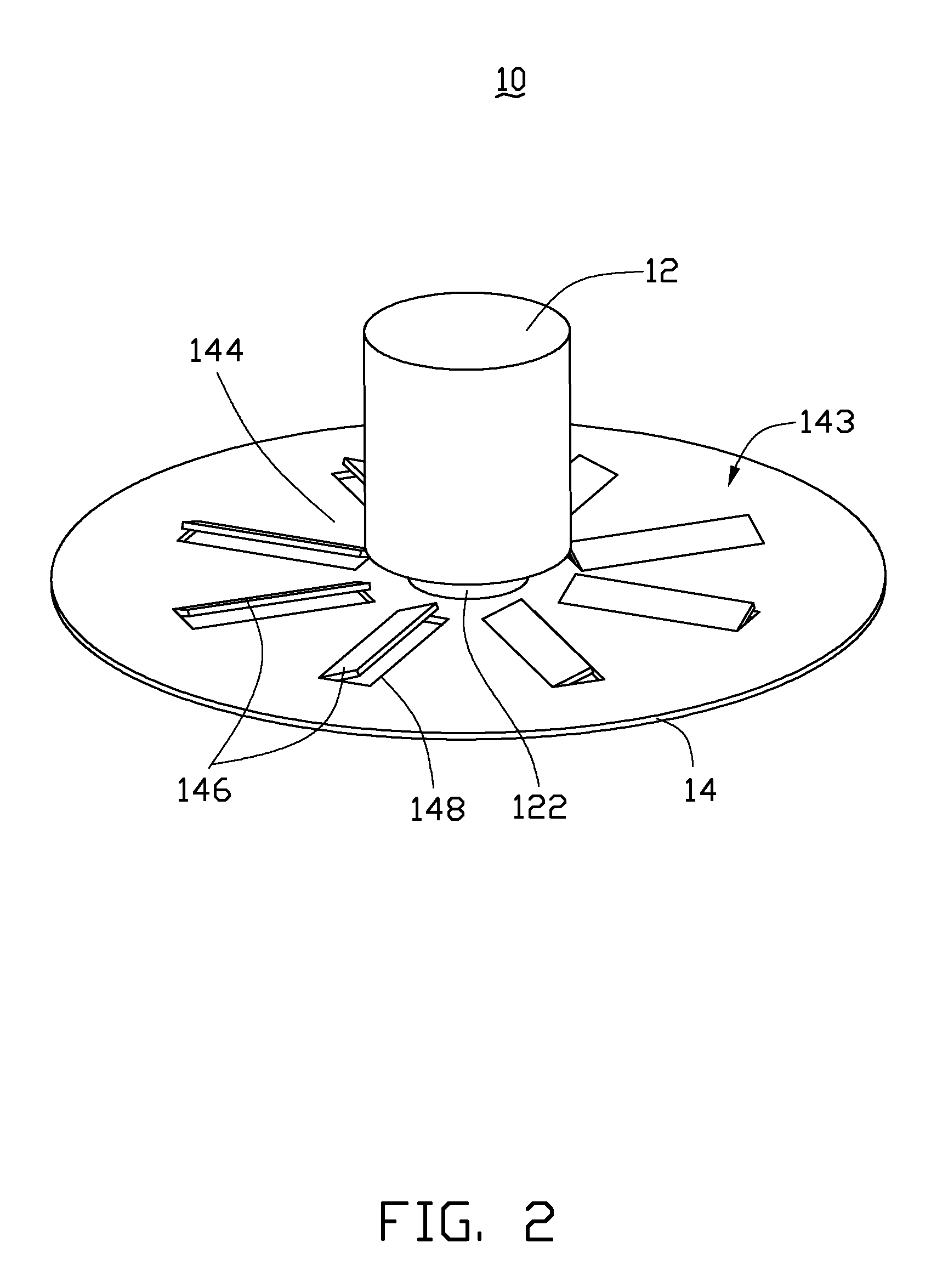

Color wheel with fan blade

A color wheel unit of a projector includes a motor and a color wheel. The color wheel is synchronized with the rotating motion of the motor. The color wheel has a light-irradiated area and a non-irradiated area. The light-irradiated area is positioned in an outer margin of the color wheel and at least a phosphor layer is located on the light-irradiated area. The non-irradiated area is positioned at the inner portion of the color chip. A number of fan blades are located in the non-irradiated area. The fan blades are synchronized with the rotating motion of the color wheel that generates air flow to enhance heat dissipation efficiency of the color wheel.

Owner:HON HAI PRECISION IND CO LTD

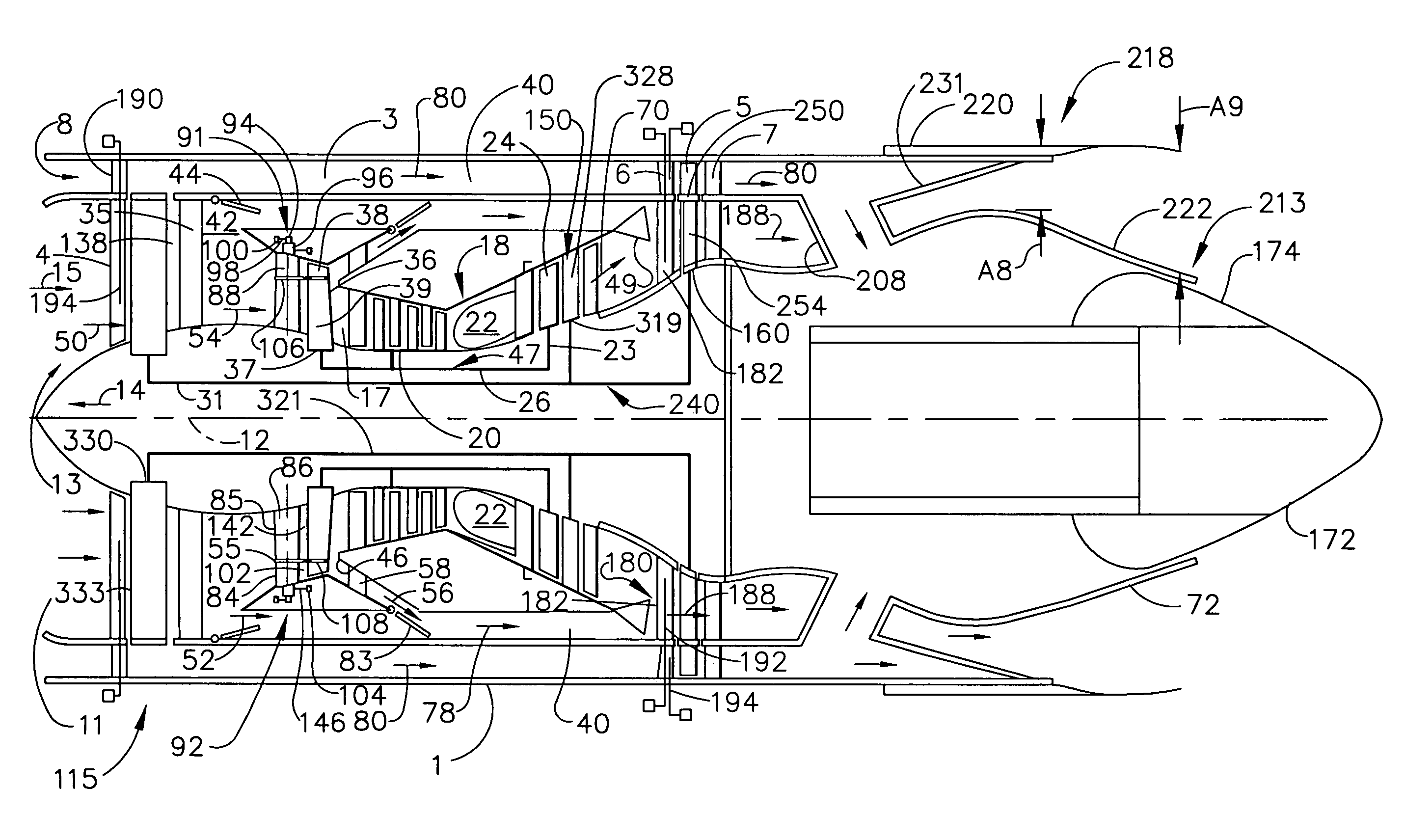

Gas turbine engine with variable pressure ratio fan system

InactiveUS6901739B2High specific thrustReduce consumptionEngine componentsJet propulsion plantsFan bladeTurbofan

A multiple bypass turbofan engine includes axially spaced-apart first and second stage fans of the engine fan connected in driving engagement to a low pressure shaft. A fan bypass duct circumscribes the second stage fan. A first bypass inlet to the fan bypass duct is disposed axially between the first and second stage fans and a second bypass inlet is axially disposed between the second stage fan and an annular core engine inlet. A fan shroud divides the second stage fan blades into radially inner and outer fan hub and tip sections, respectively. The tip sections are radially disposed in a fan tip duct. An axially translatable deflector is positioned to close the fan tip duct when it opens the first bypass inlet and open the fan tip duct when it closes the first bypass inlet.

Owner:GENERAL ELECTRIC CO

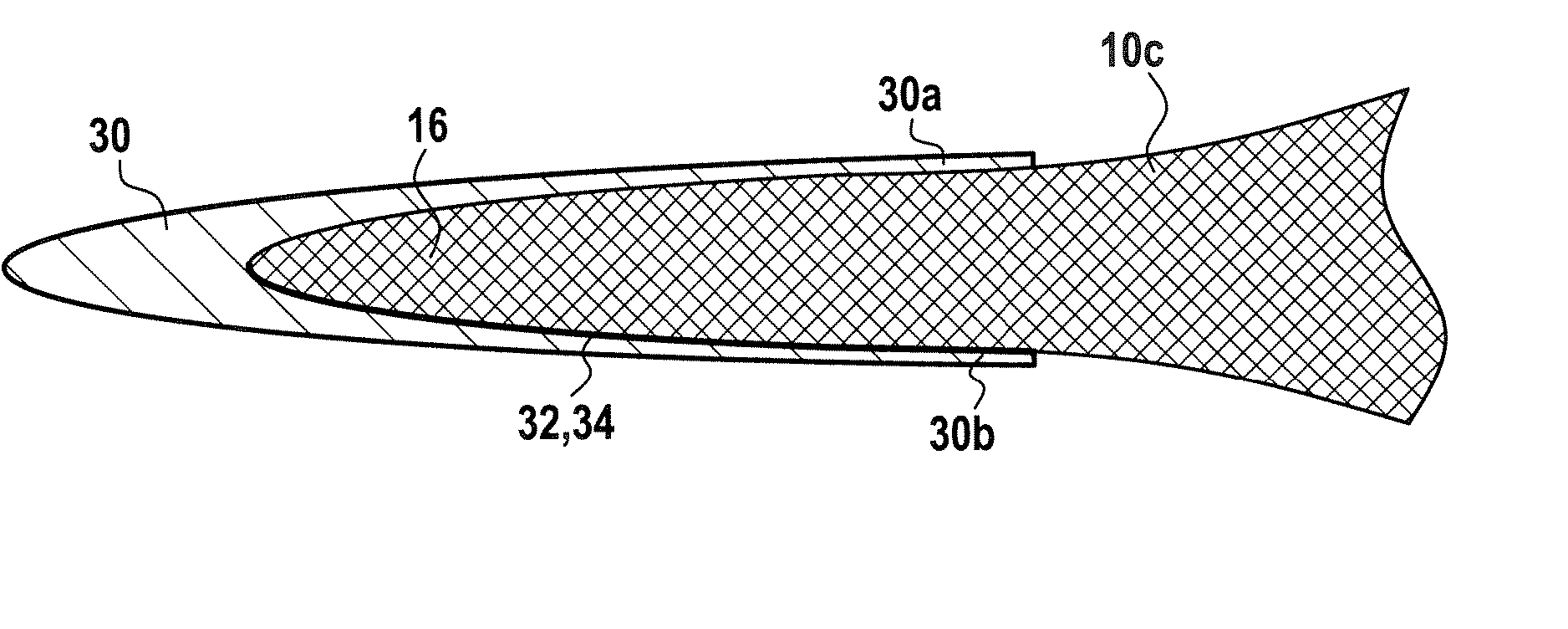

Method of manufacturing a composite turbomachine blade, and a blade obtained by the method

The invention relates to a method of manufacturing a composite turbomachine blade, the method comprising the following steps: a) making a preform by three-dimensionally weaving yarns including tracer yarns disposed at least at the surface of the preform; b) cutting out said preform so as to leave intact a series of tracer yarns situated along a reference face of the preform; c) pre-deforming said cut-out preform; d) compacting and stiffening said pre-deformed preform; e) providing an injection mold in which said stiffened preform is placed; f) heating said injection mold; g) injecting a binder into said injection mold, the binder comprising a thermosettable resin; and h) extracting from the mold a composite molded part presenting substantially the shape and the dimensions of said blade. The invention is applicable to a making fan blade.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Flade gas turbine engine with fixed geometry inlet

ActiveUS20050081509A1Low costAvoid weightTurbine/propulsion engine coolingTurbine/propulsion air intakesFan bladeGas turbines

An aircraft propulsion system includes a gas turbine engine having a fan section, at least one row of FLADE fan blades disposed radially outwardly of and drivingly connected to the fan section, the row of FLADE fan blades radially extending across a FLADE duct circumscribing the fan section, an engine inlet including a fan inlet to the fan section and an annular FLADE inlet to the FLADE duct. A fixed geometry inlet duct is in direct flow communication with the engine inlet. The fan section may include only a single direction of rotation fan or alternatively axially spaced apart first and second counter-rotatable fans in which the FLADE fan blades are drivingly connected to one of the first and second counter-rotatable fans. The row of FLADE fan blades may be disposed between rows of variable first and second FLADE vanes.

Owner:GENERAL ELECTRIC CO

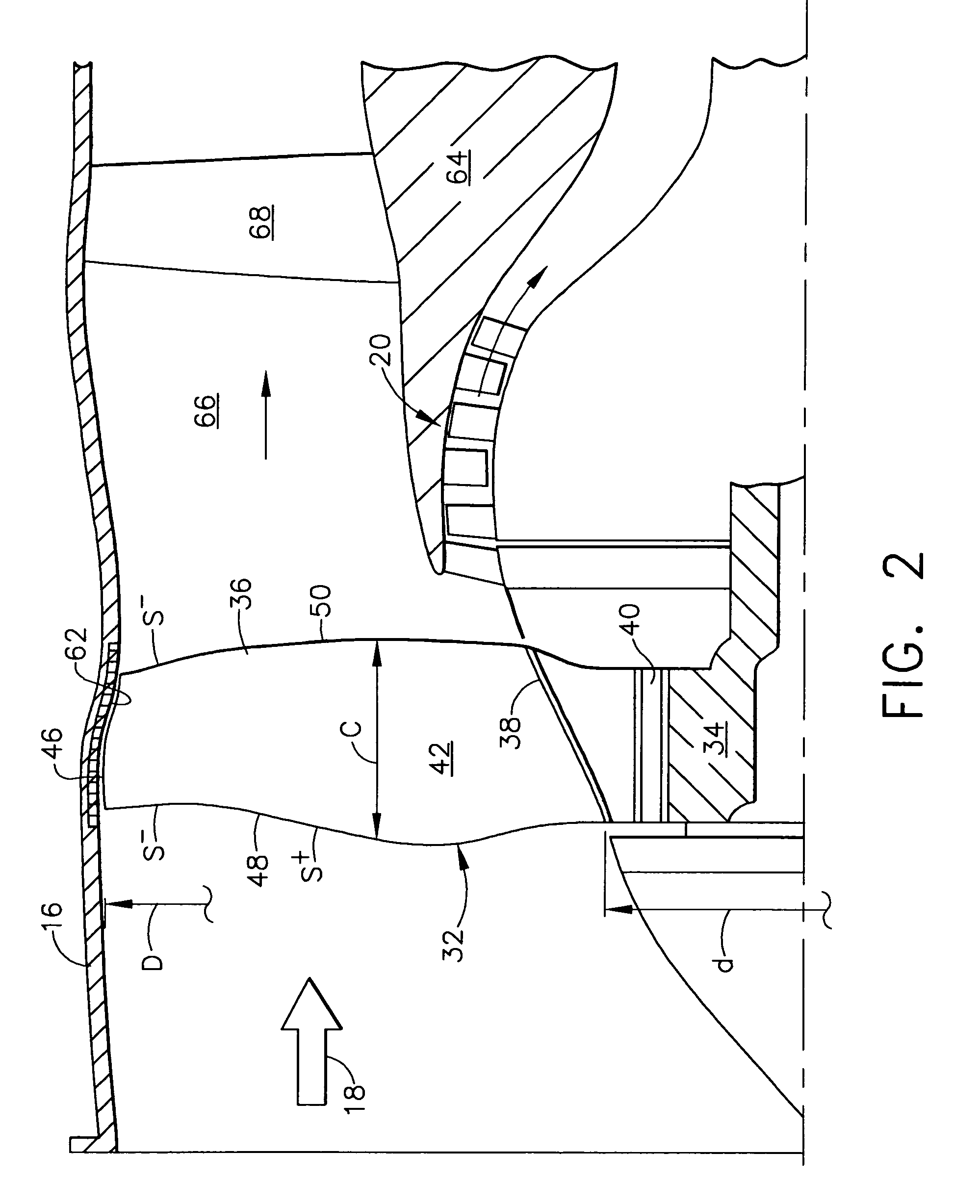

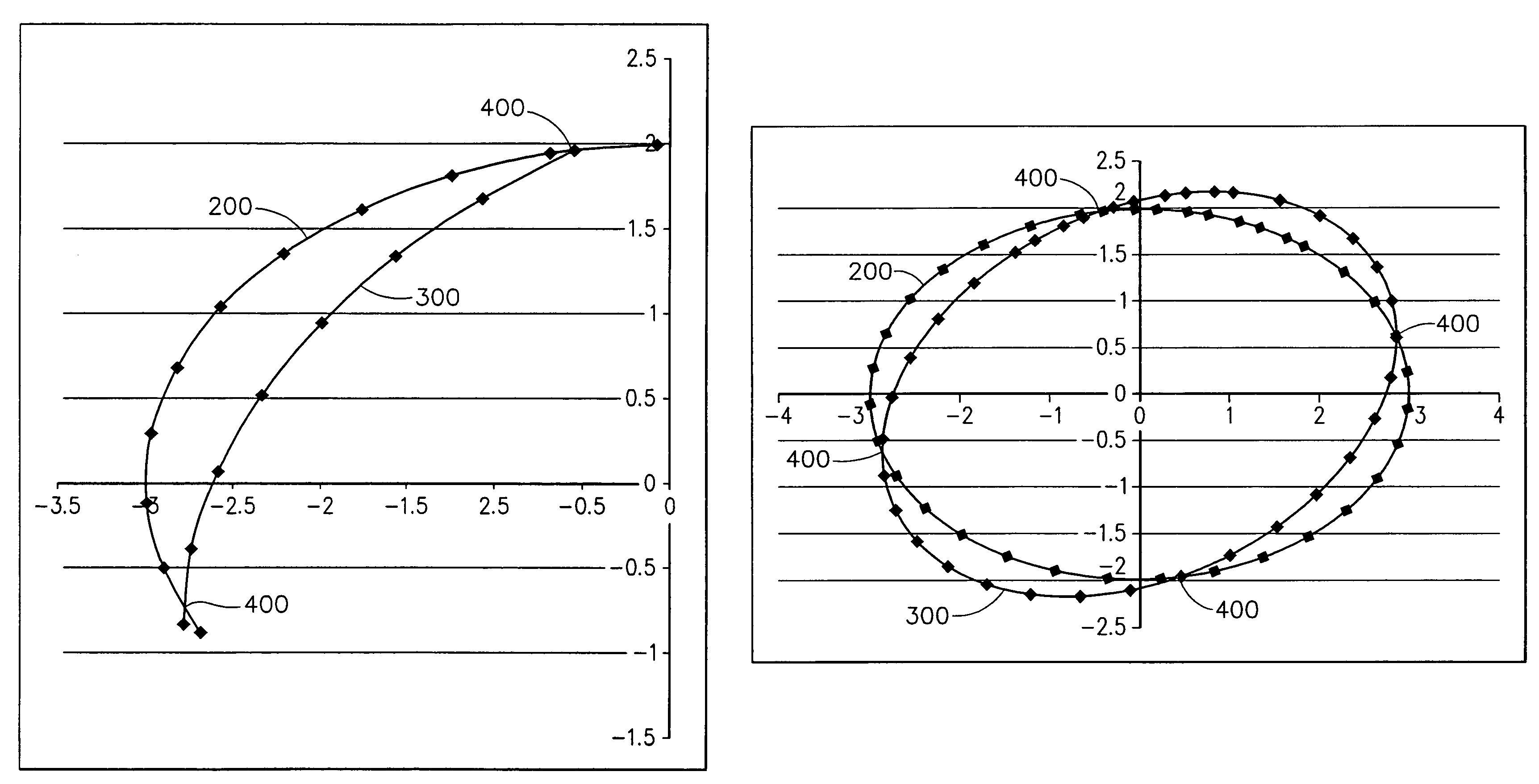

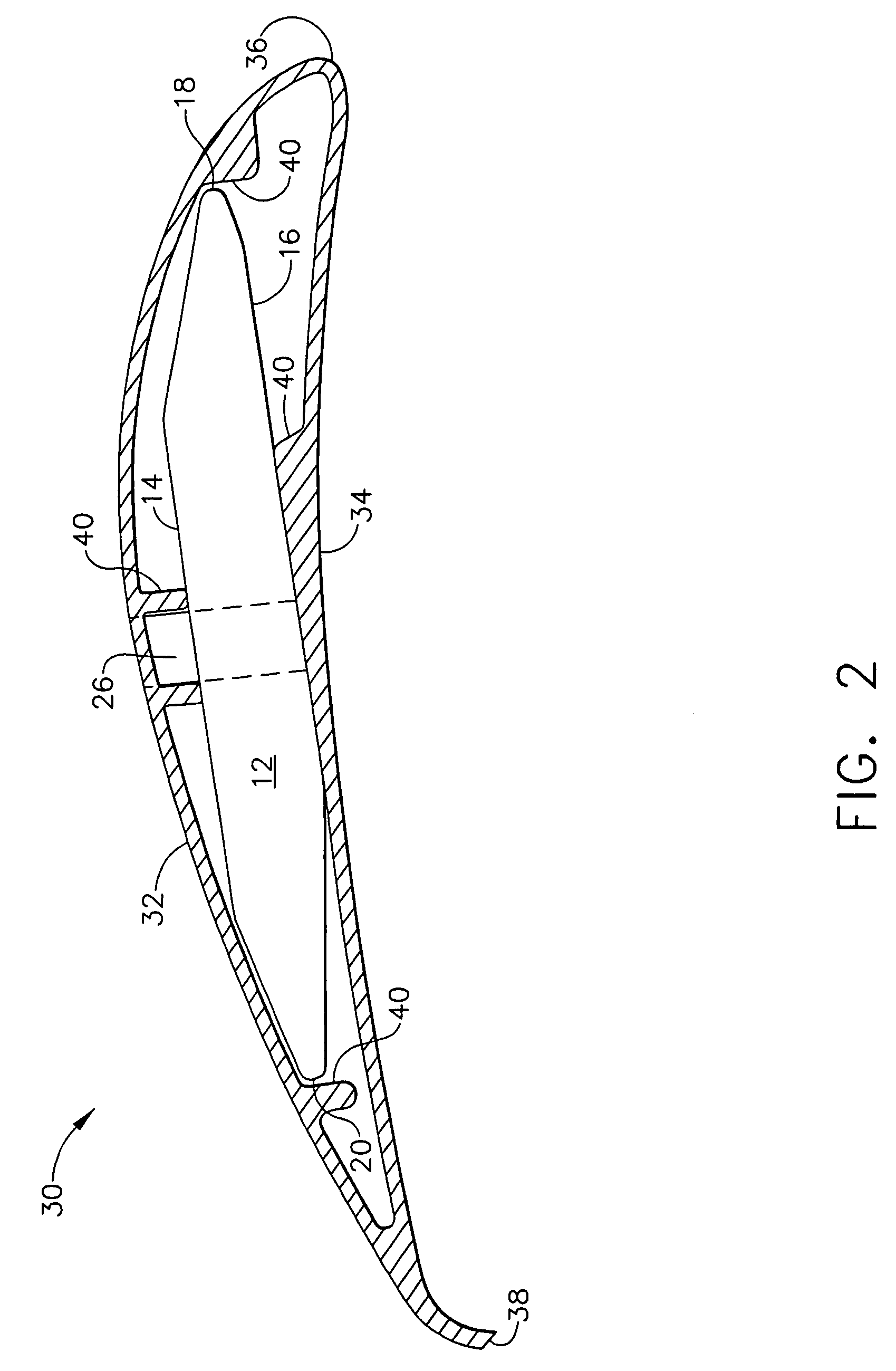

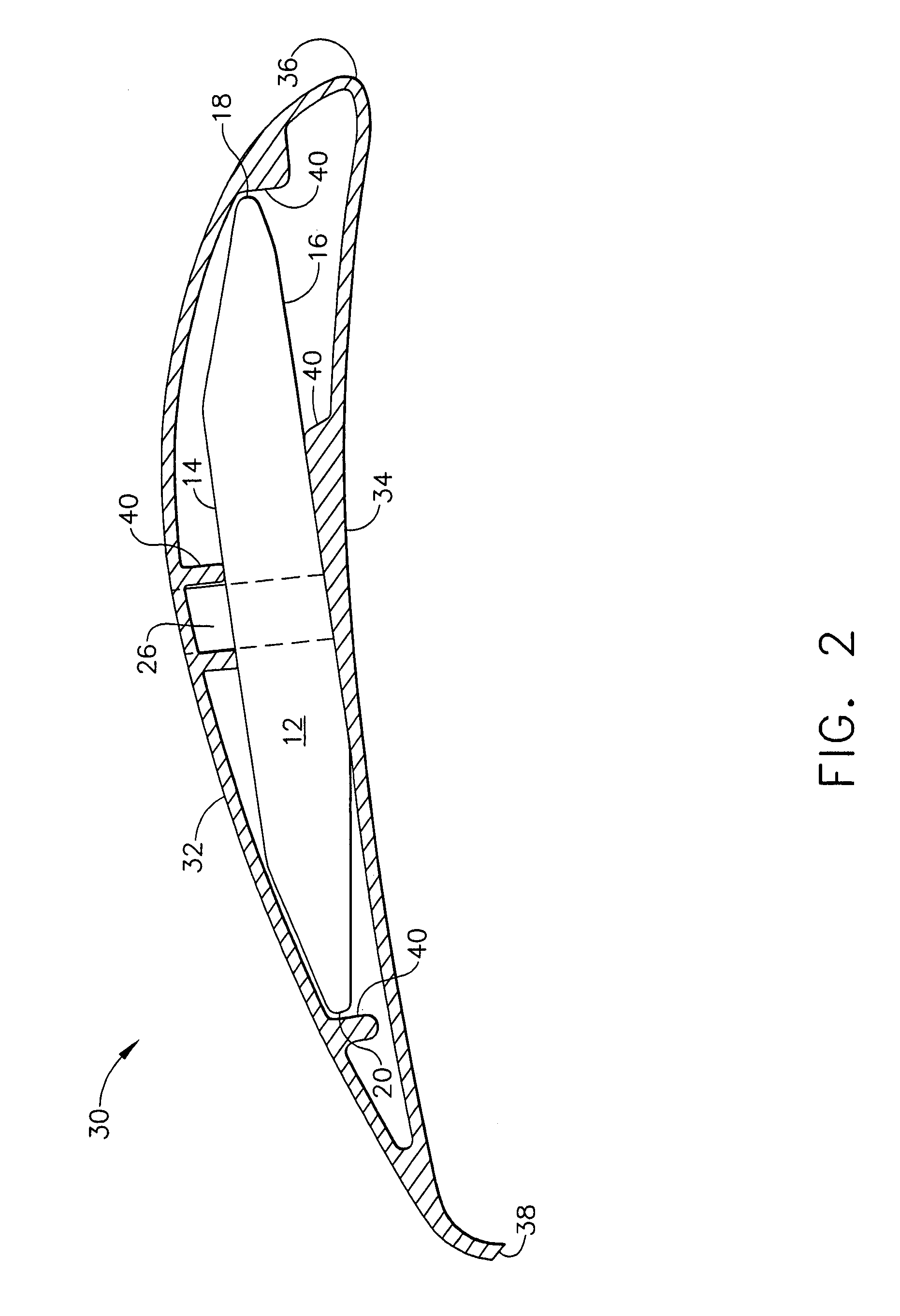

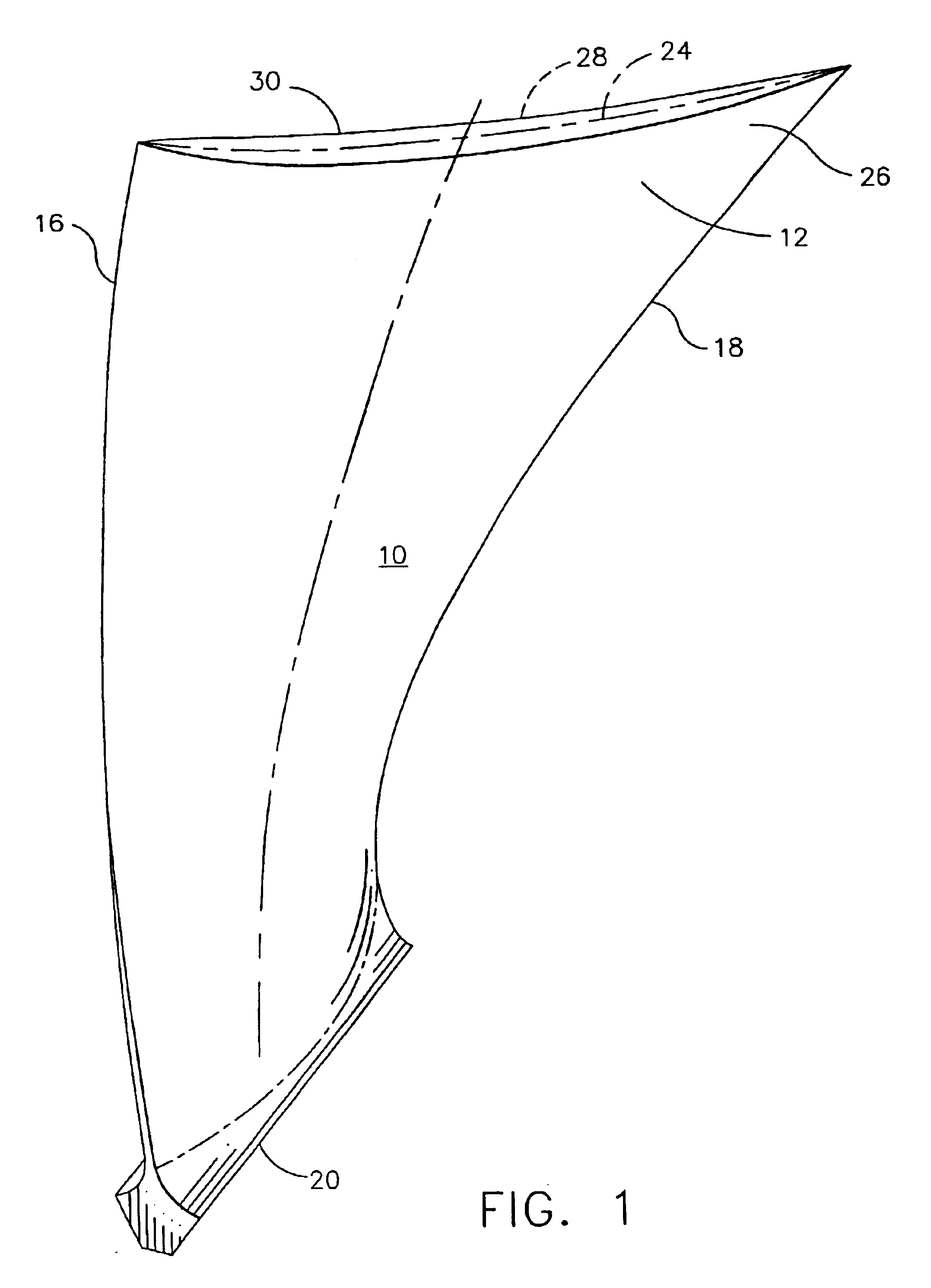

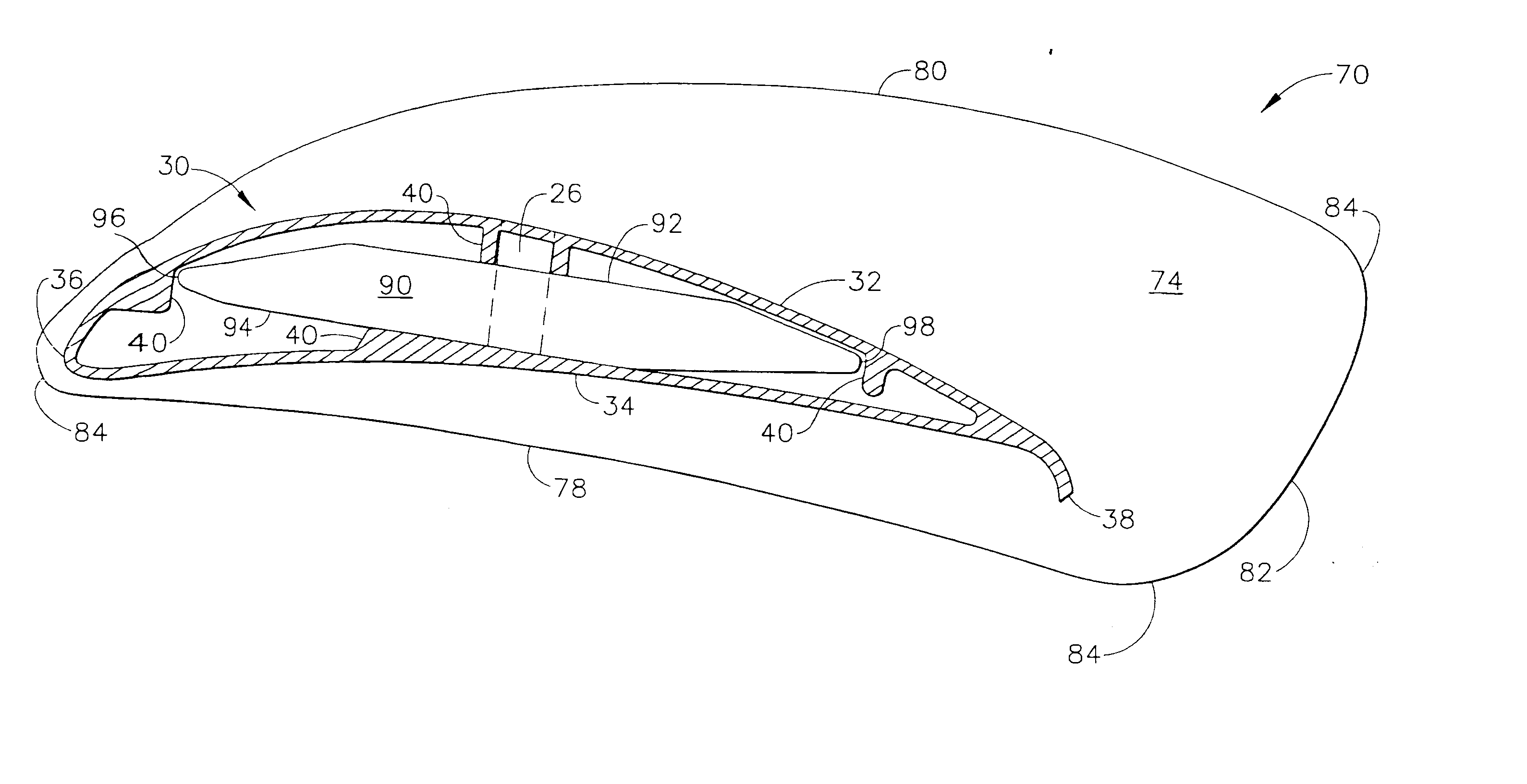

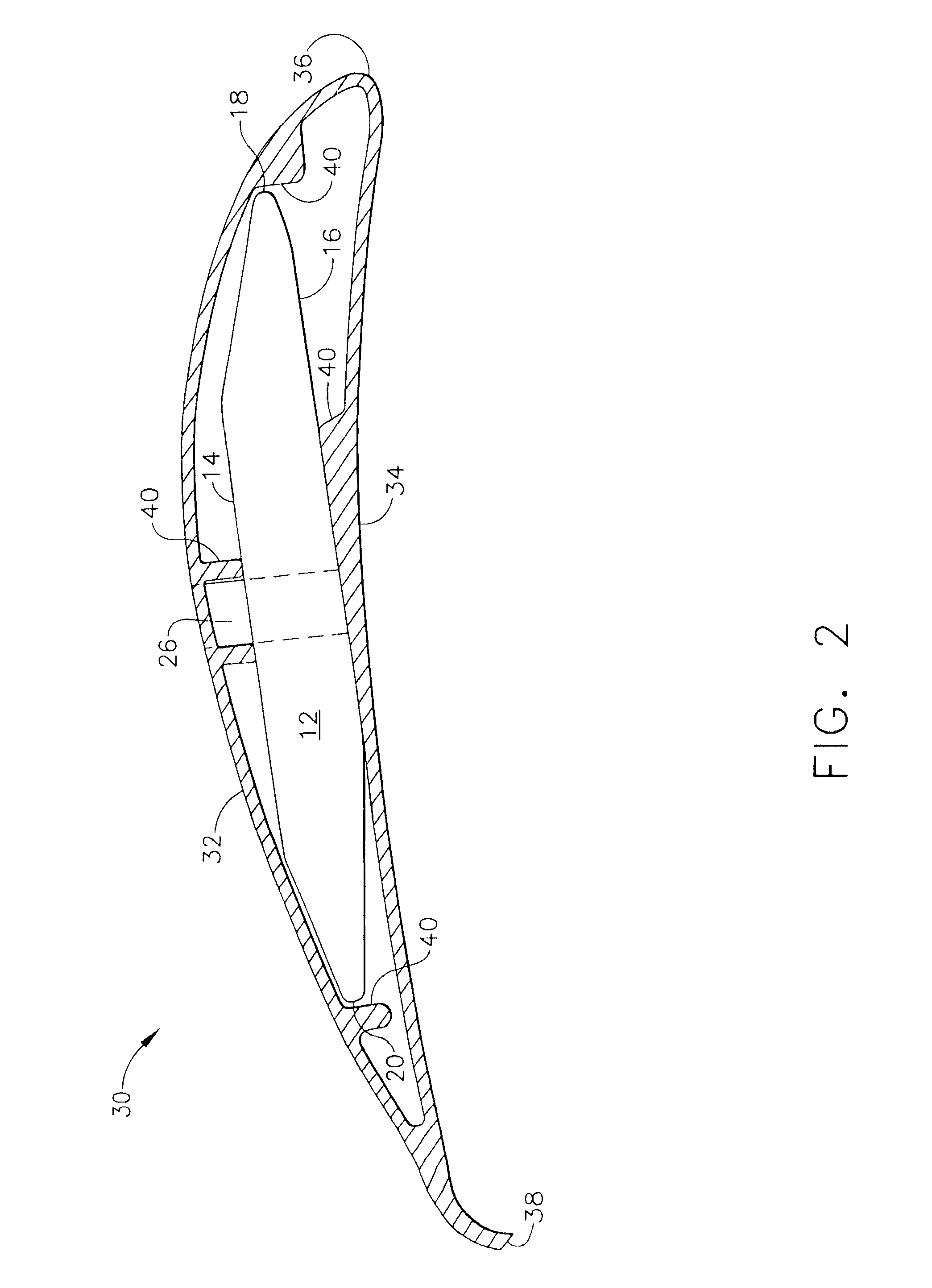

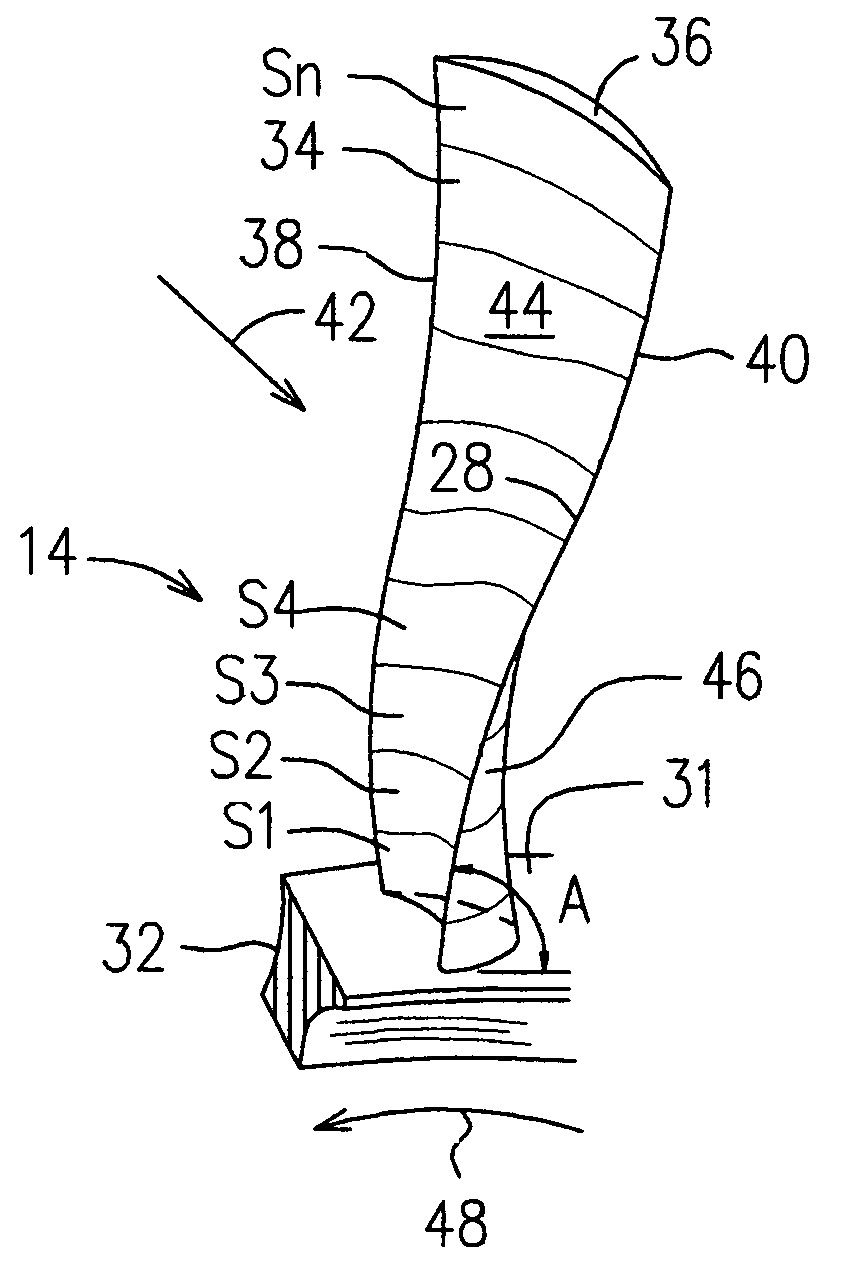

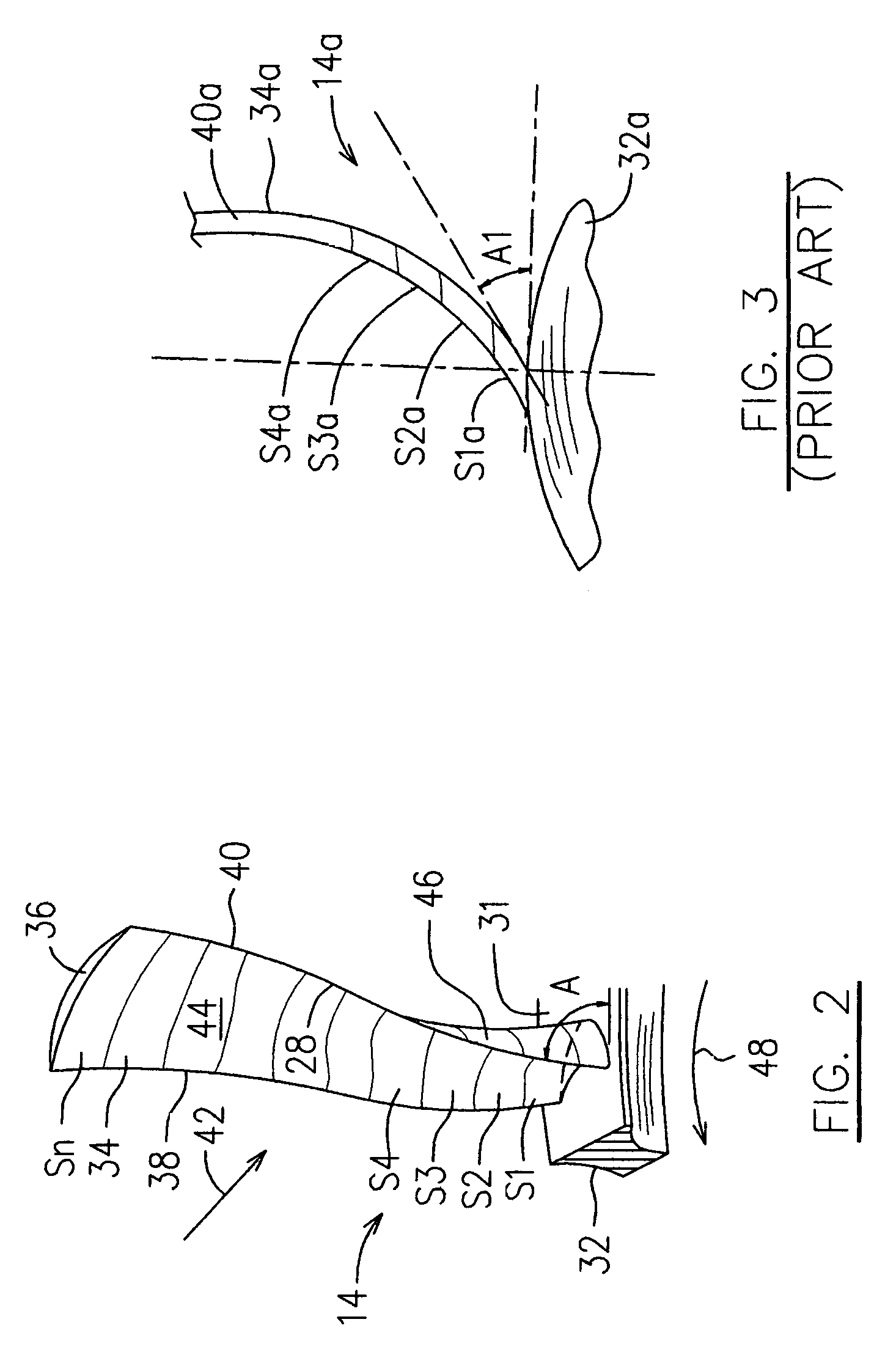

Tip cambered swept blade

ActiveUS7476086B2Increasing staggerReduce camberPropellersEngine manufactureLeading edgeTrailing edge

A fan blade includes an airfoil having opposite pressure and suction sides extending in span between a root and tip, and extending in chord between opposite leading and trailing edges. From root toward tip, the airfoil includes increasing stagger and decreasing camber, and increasing chord length to barrel the airfoil along both the leading and trailing edges. The airfoil further includes forward aerodynamic sweep at the tip, and non-forward aerodynamic sweep between the maximum barrel and the root.

Owner:GENERAL ELECTRIC CO

Tip cambered swept blade

ActiveUS20070243068A1Increasing staggerReduce camberPropellersEngine manufactureLeading edgeEngineering

A fan blade includes an airfoil having opposite pressure and suction sides extending in span between a root and tip, and extending in chord between opposite leading and trailing edges. From root toward tip, the airfoil includes increasing stagger and decreasing camber, and increasing chord length to barrel the airfoil along both the leading and trailing edges. The airfoil further includes forward aerodynamic sweep at the tip, and non-forward aerodynamic sweep between the maximum barrel and the root.

Owner:GENERAL ELECTRIC CO

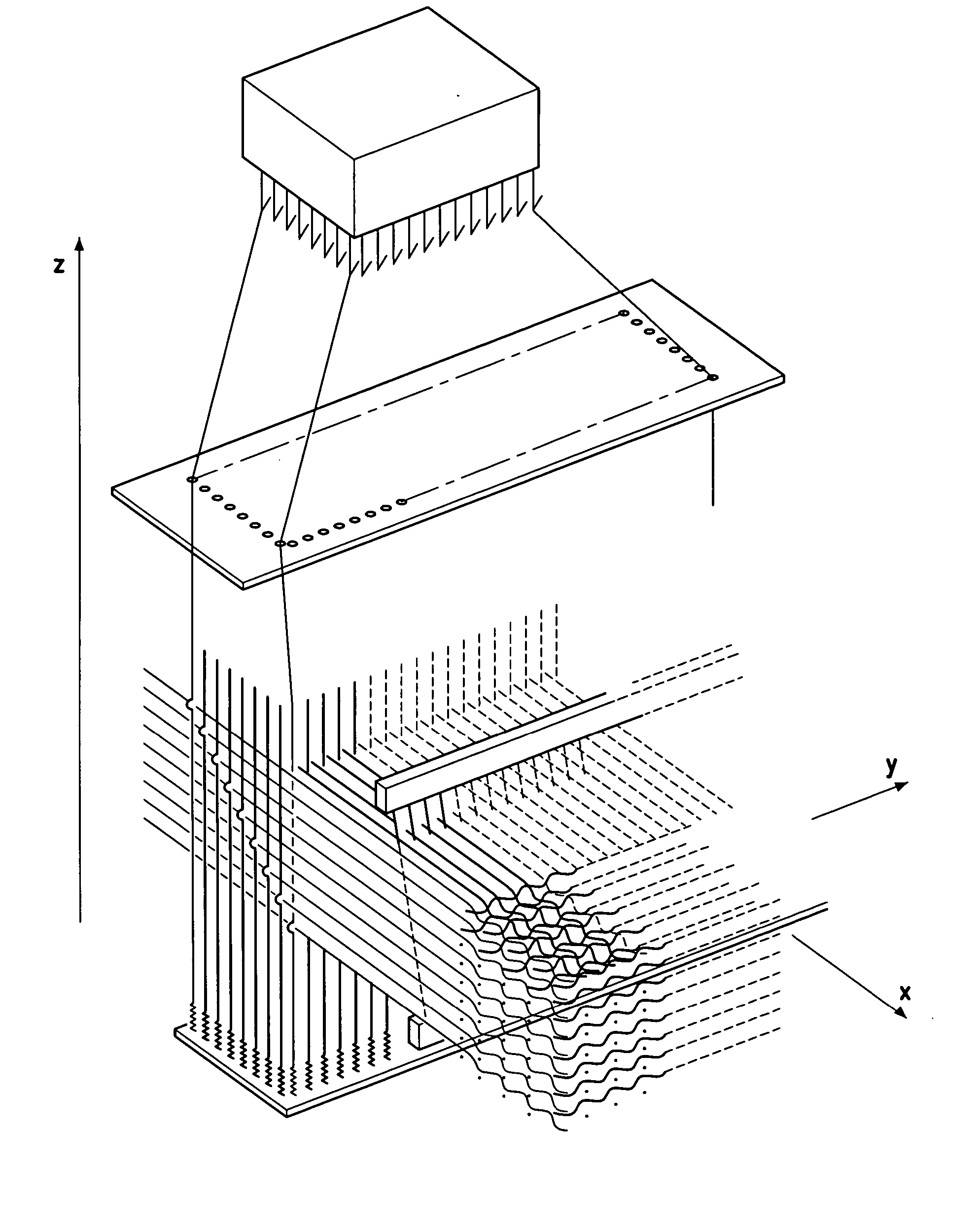

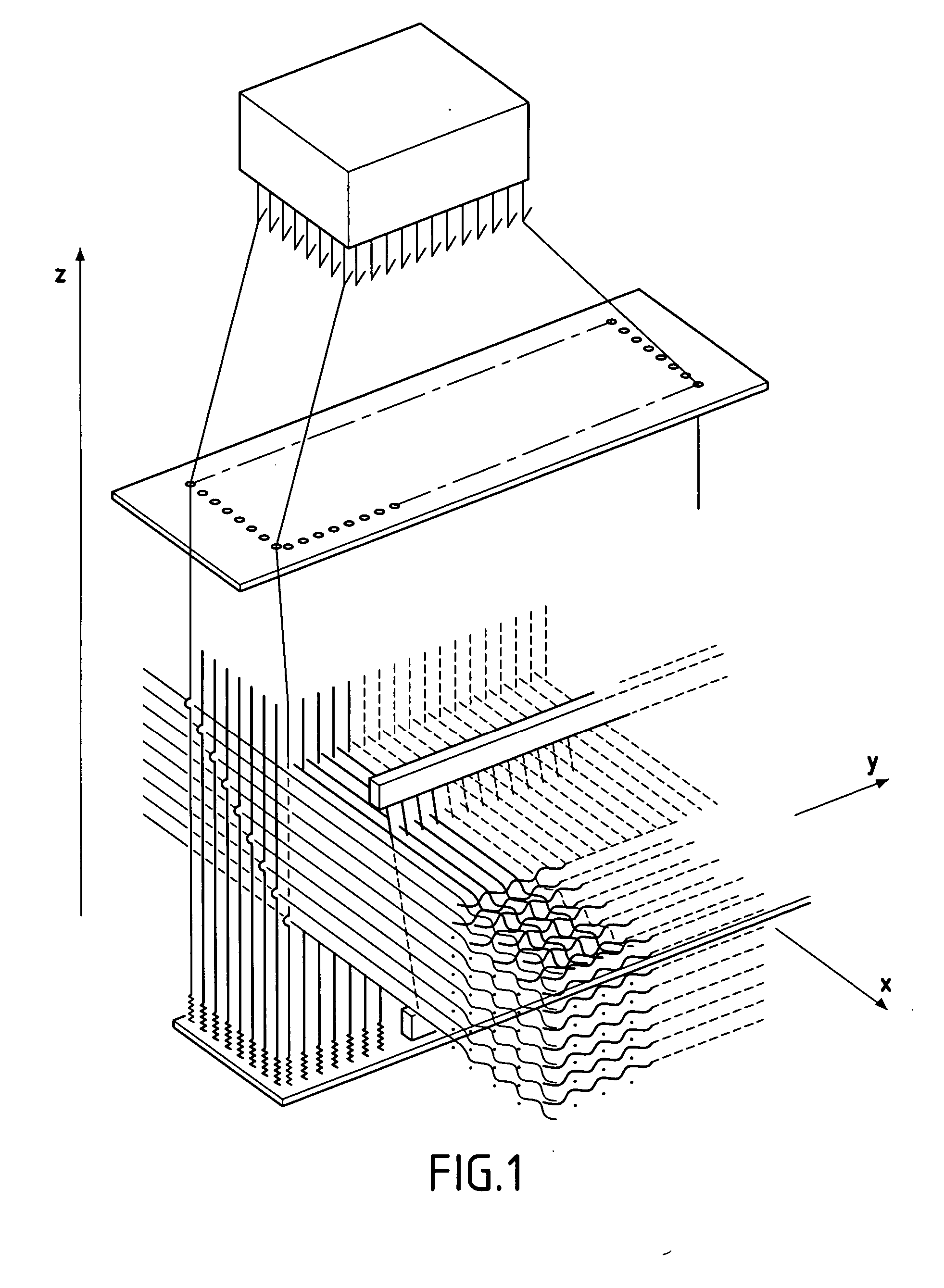

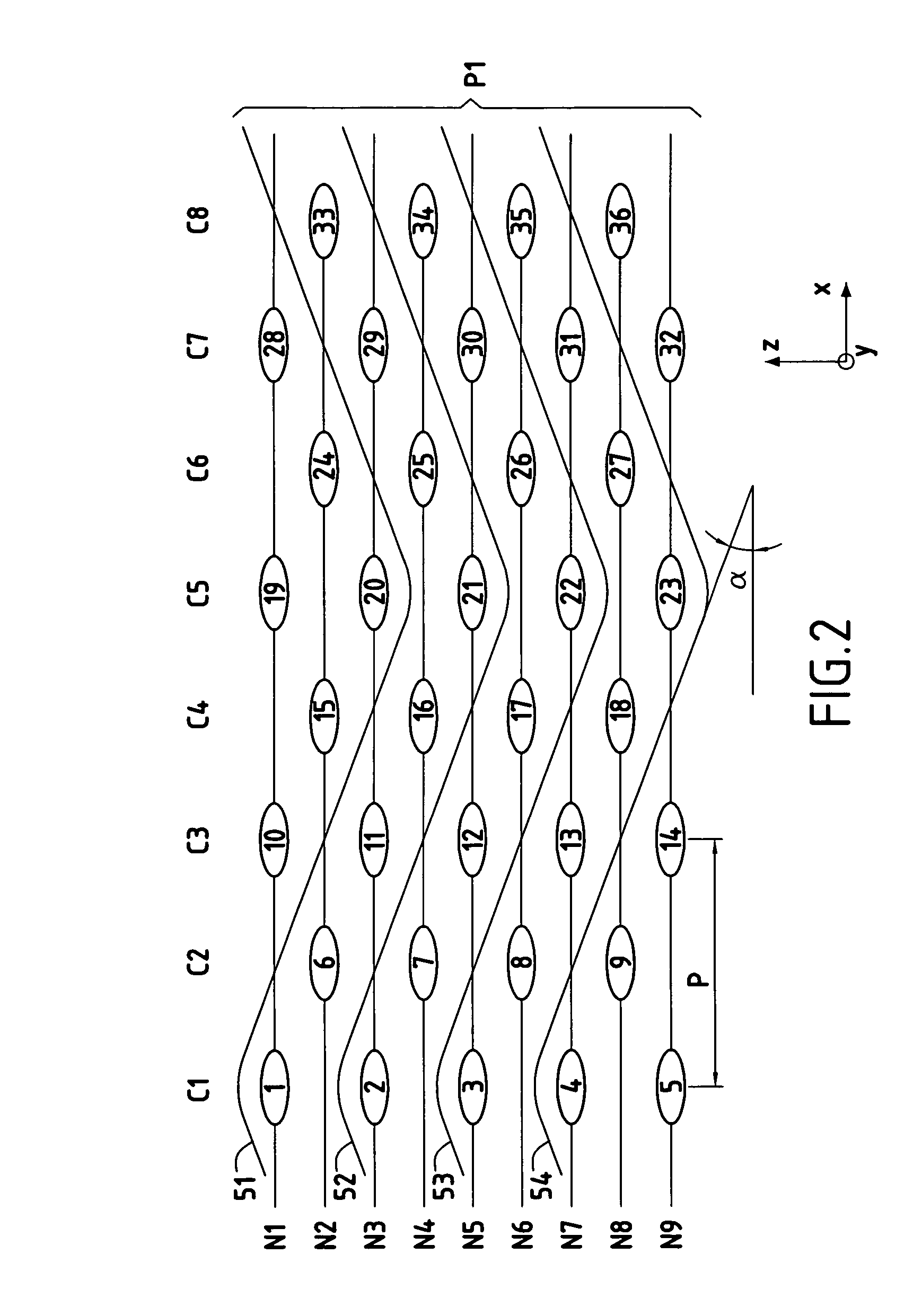

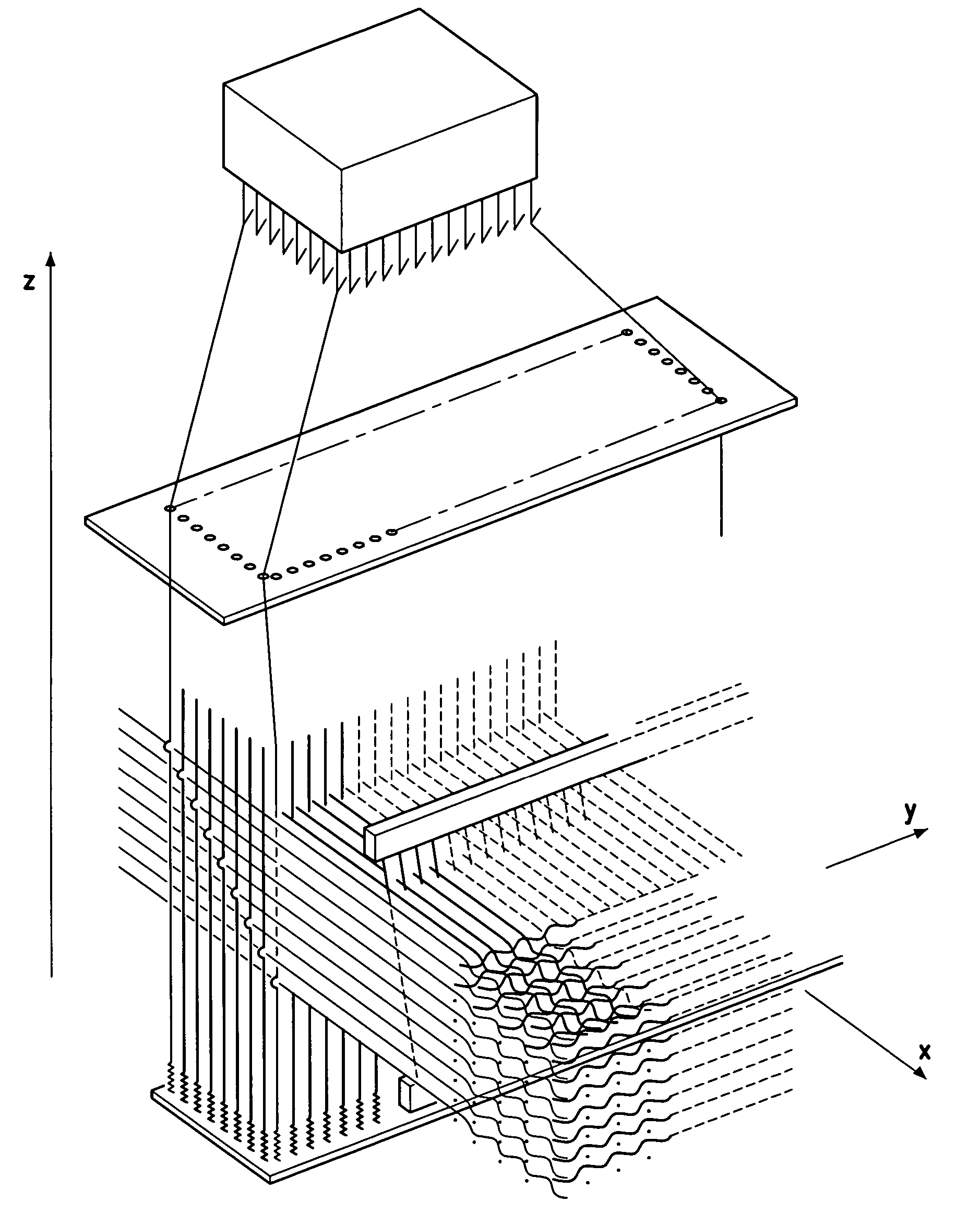

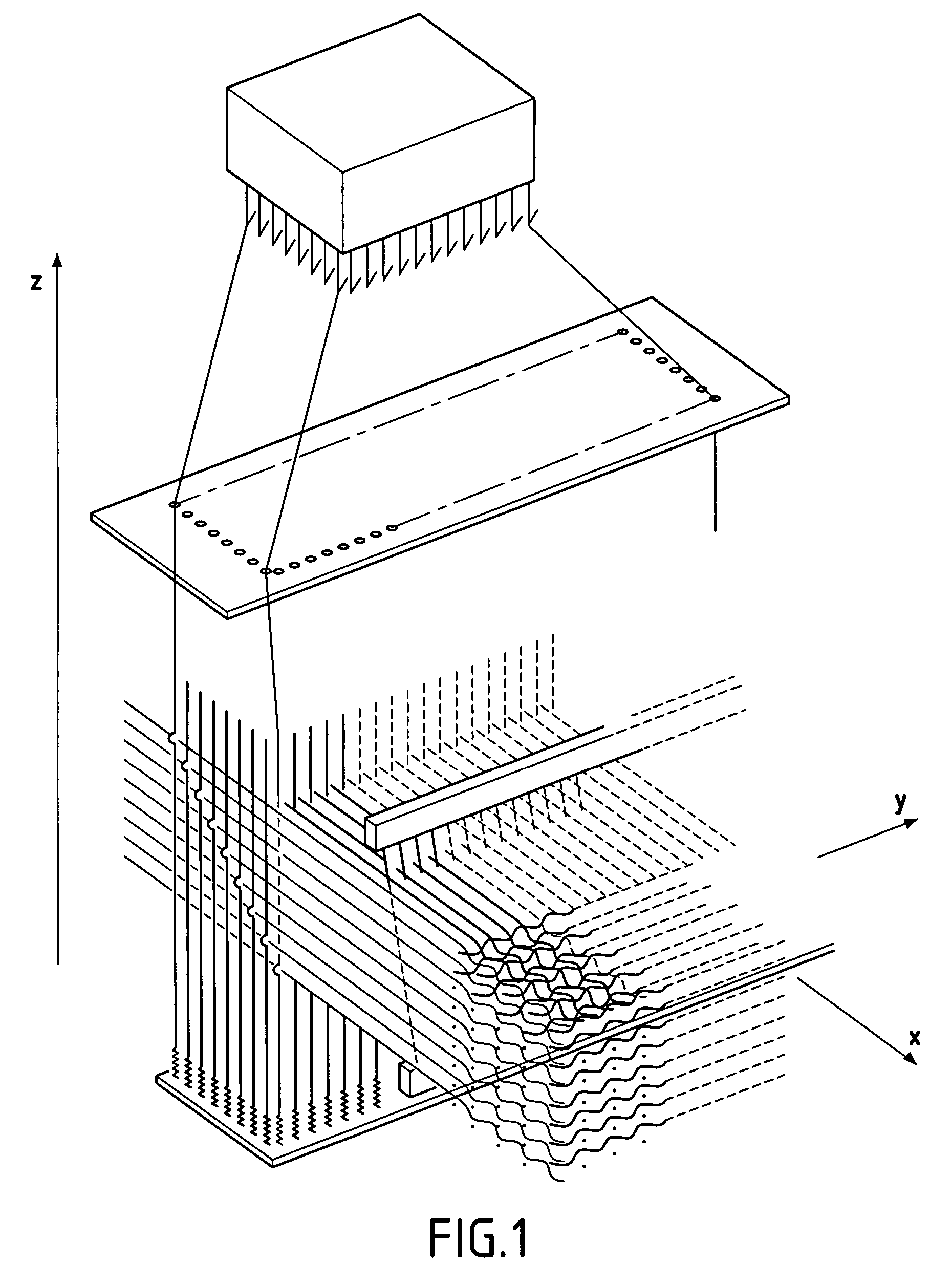

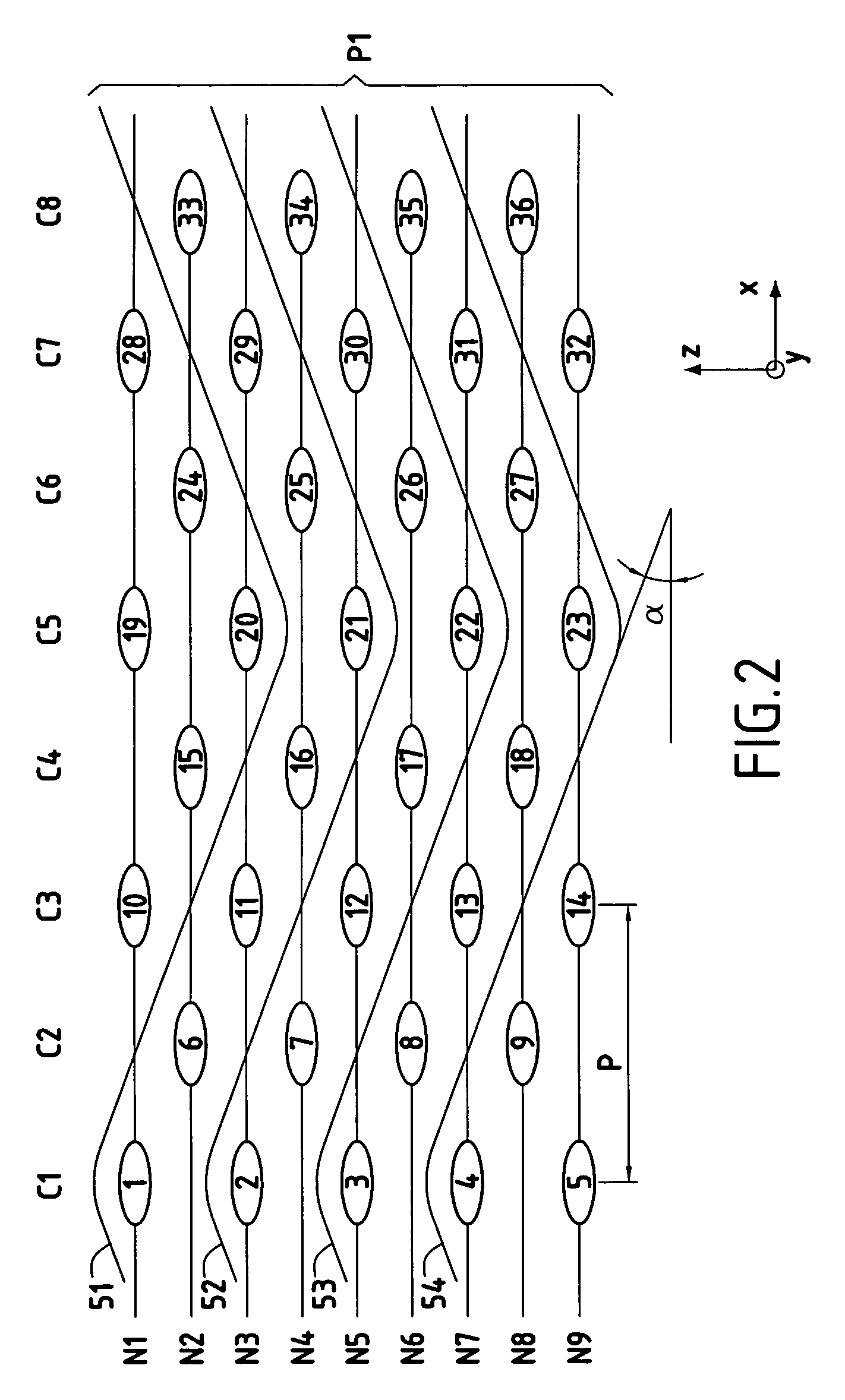

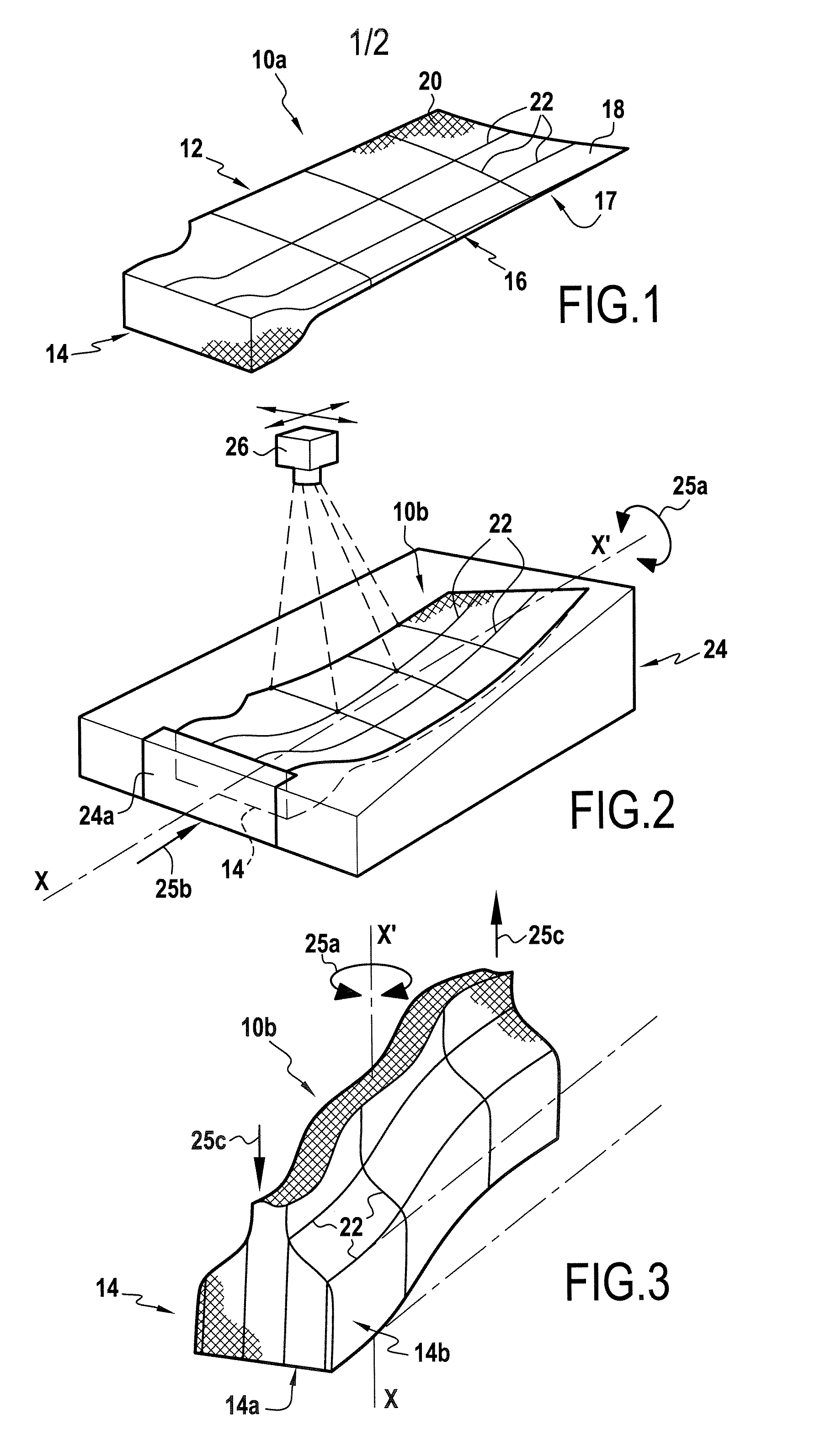

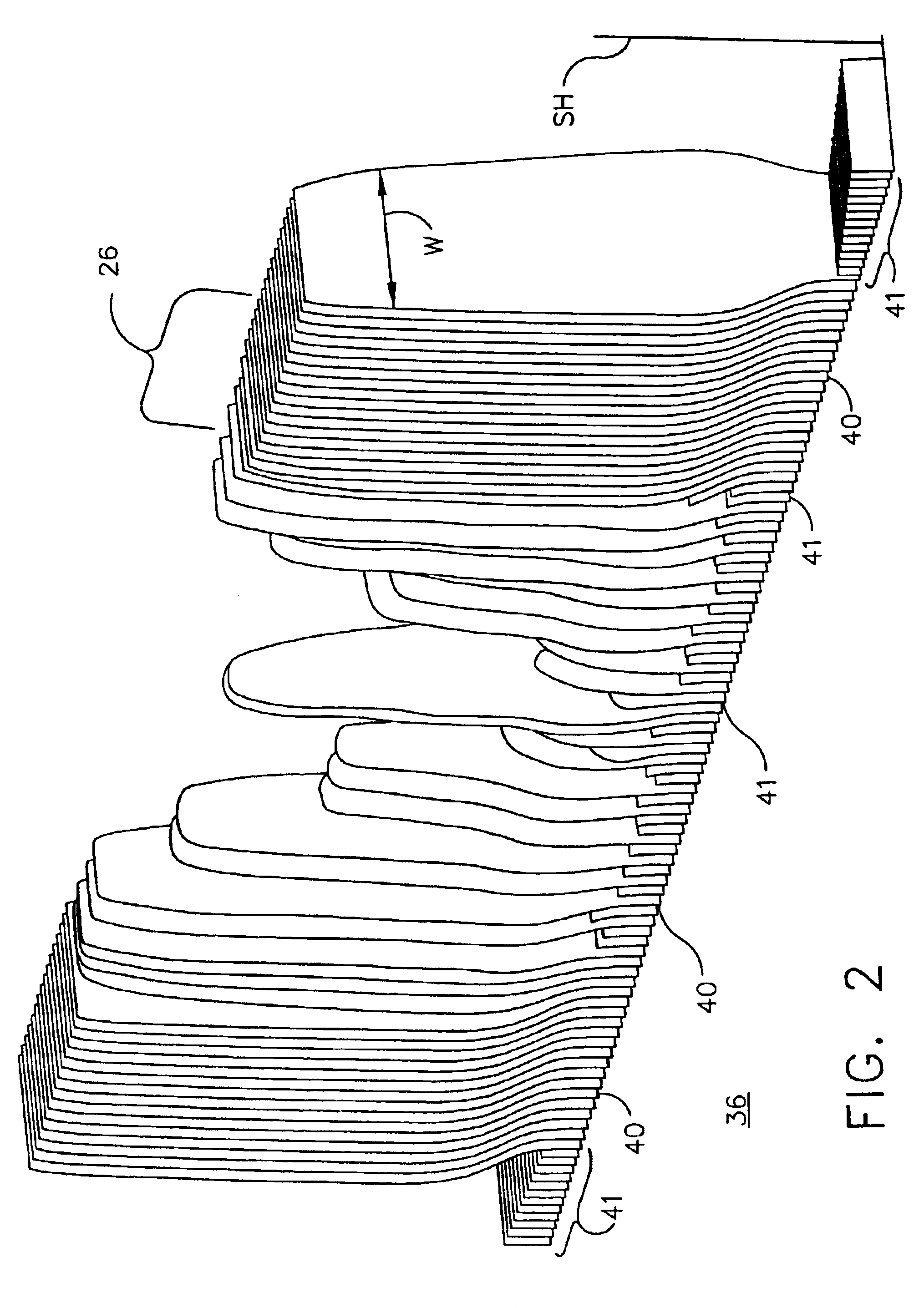

Laser projection system to facilitate layup of complex composite shapes

InactiveUS6843565B2Increased ply lay-up speedReduce morbidityBlade accessoriesProjectorsData setComposite laminates

The present invention provides a process for the lay-up of a composite laminate article, the article produced by this process, and the apparatus used to produce the composite laminate article. The composite laminate article may be, for example, an airfoil, particularly useful as a fan blade in a large high bypass ratio turbofan engine, wherein the blade is generally regarded as large and having a high degree of twist. In a preferred embodiment, the present invention provides a process for laying up a composite laminate article comprising a) reading a data set to enable the projection of an image of a ply section onto a work surface, the image indicating a ply section target point; b) laying up a ply section of composite laminating material within the image, wherein the ply section first contacts the work surface at the target point; and c) repeating steps (a)-(b) until the composite laminate article is complete. In a second preferred embodiment, the present invention provides for a lamination apparatus for use in making a composite laminate article comprising a work surface for receiving, in a predetermined sequence, a plurality of ply sections of composite laminating material; a laser projection system using predetermined projection points for outlining an image of a ply section onto the work surface, the image further indicating a ply section target point for making first contact of the ply section with the work surface; and a data set for providing the predetermined projection points to the laser projection system.

Owner:GENERAL ELECTRIC CO

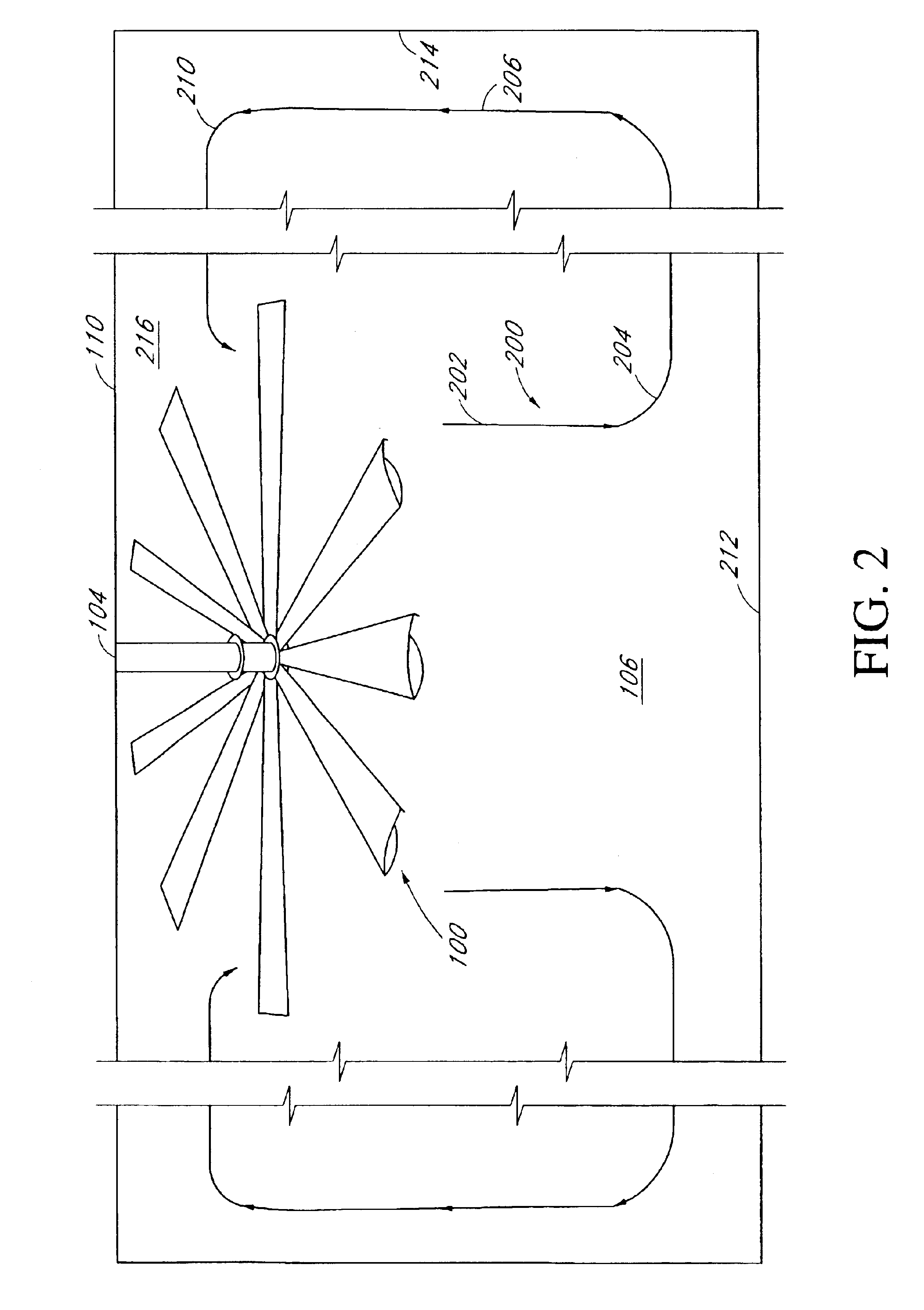

Cuffed fan blade modifications

A winglet includes a vertical member and a mounting member. The mounting member is configured to facilitate the mounting of the winglet to the tip of a fan blade. The vertical member is configured to extend perpendicularly relative the tip of a fan blade. A cuff extends from the vertical member to substantially cover at least a portion of the interface between the end of a fan blade and the vertical member. Adding winglets to fan blades may improve the aerodynamics of the fan blades, and thereby increase efficiencies of a fan.

Owner:DELTA T

Fan blade curvature distribution for high core pressure ratio fan

ActiveUS7204676B2Enhance the imageSpeed up the descentPropellersEngine manufactureEngineeringTrailing edge

A method for reducing vortex promotion of a rotor blade used in high core PR fans comprises shifting a curvature distribution of a blade section immediately adjacent to the hub such that a major turning of the suction side of the section is located near a trailing edge of the blade.

Owner:PRATT & WHITNEY CANADA CORP

Method and apparatus for washing objects

A wash apparatus includes a harness assembly comprising a coupling device a coupling device for connecting one or more fluid supply lines to one or more fluid delivery lines; one or more fluid delivery lines removably attached at one end to the coupling device's first portion and positioned for delivering washing fluid directly into the gas turbine engine core as the engine is cranked; one or more fluid supply lines removably attached to the coupling device's second portion for supplying washing fluid to the harness assembly and remaining in a static position relative to the rotating fluid delivery lines; one or more harness rings attached to the one or more fluid delivery lines for spacing, stabilizing, and positioning the fluid delivery lines relative to the fan blades; and a connector for removably attaching the harness assembly directly onto the fan hub.

Owner:ECOSERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com