Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1713results about "Turbine/propulsion air intakes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of generating energy in a power plant comprising a gas turbine, and power plant for carrying out the method

InactiveUS20050028529A1Small sizeLow costContinuous combustion chamberDispersed particle separationPower stationCombustor

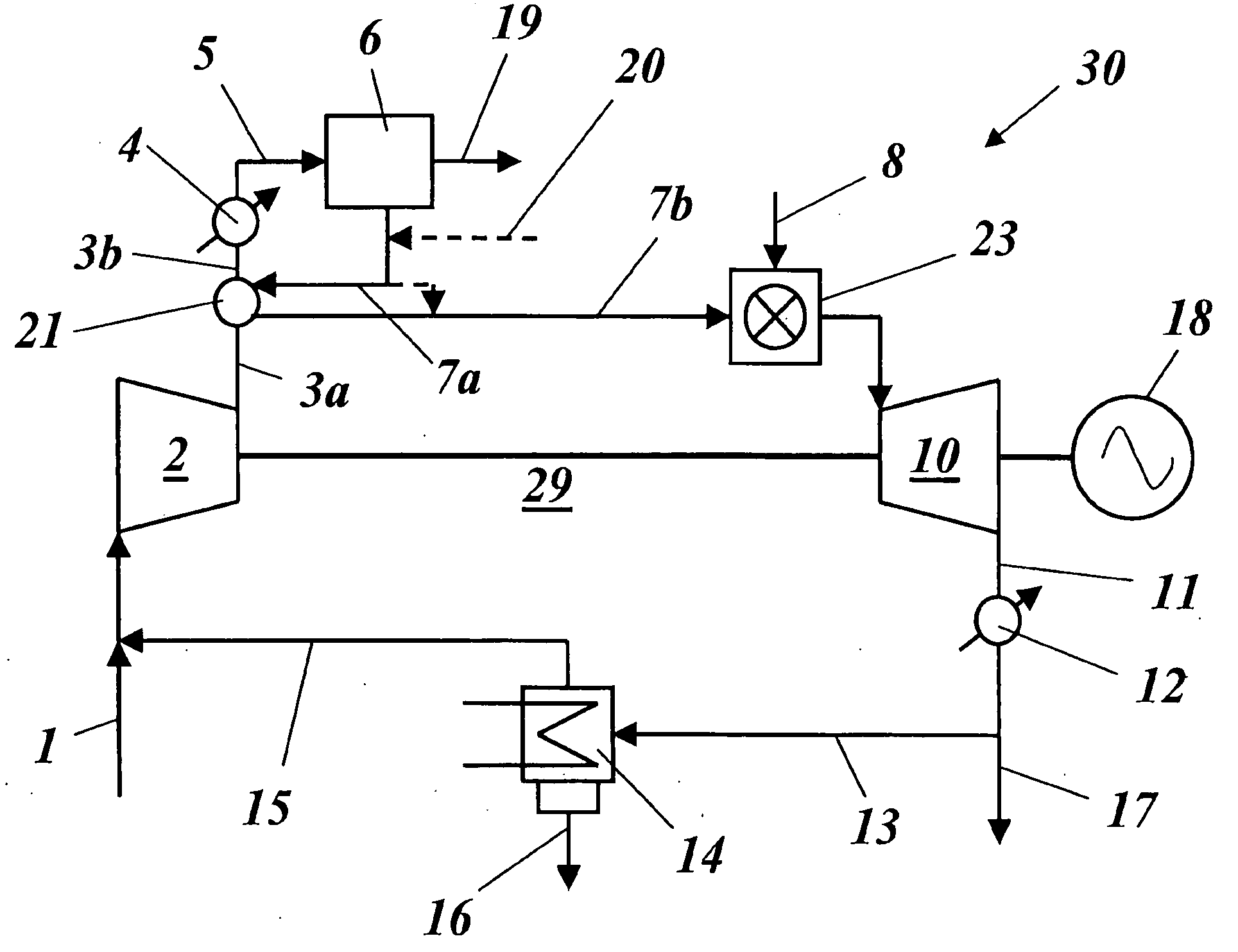

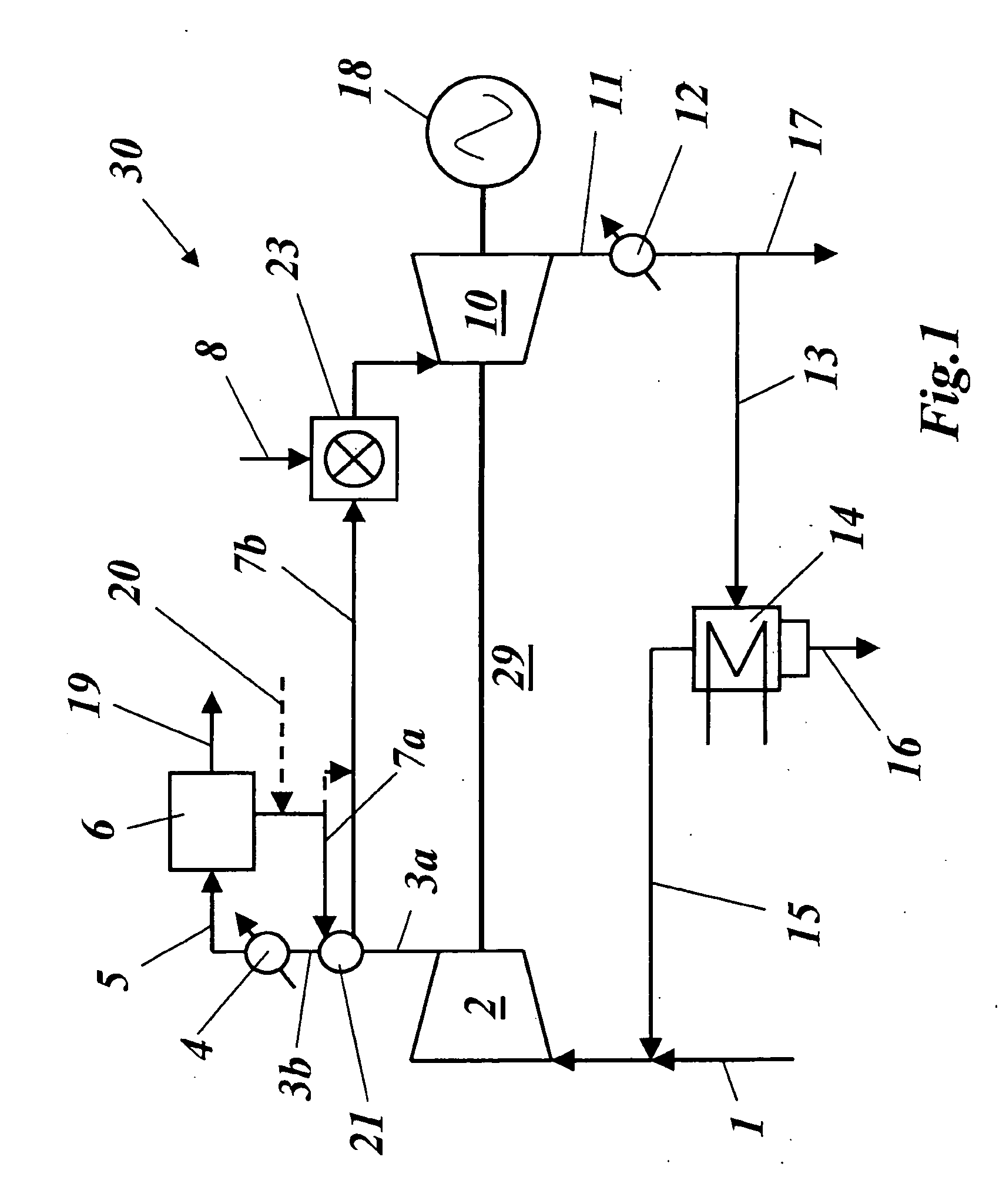

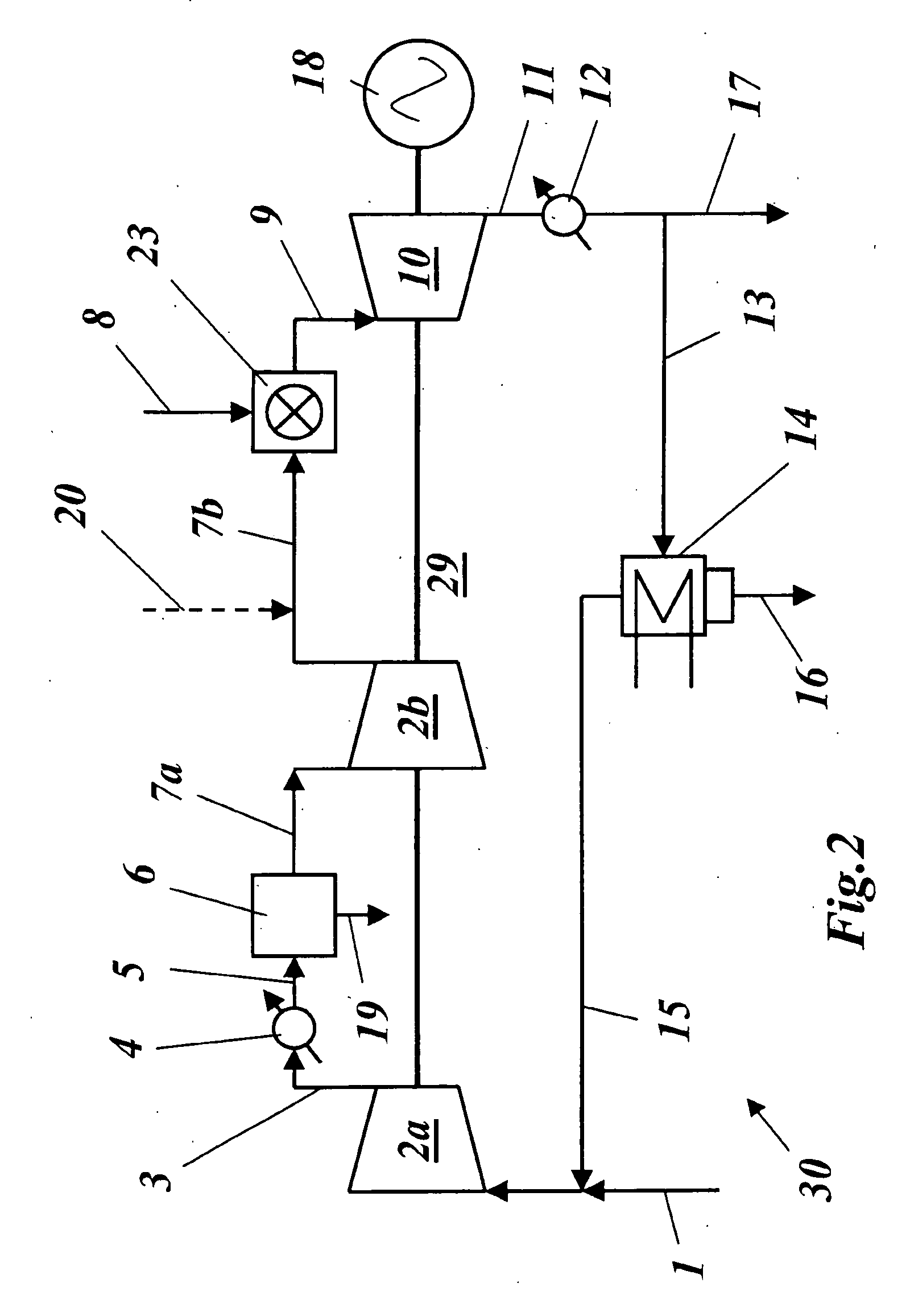

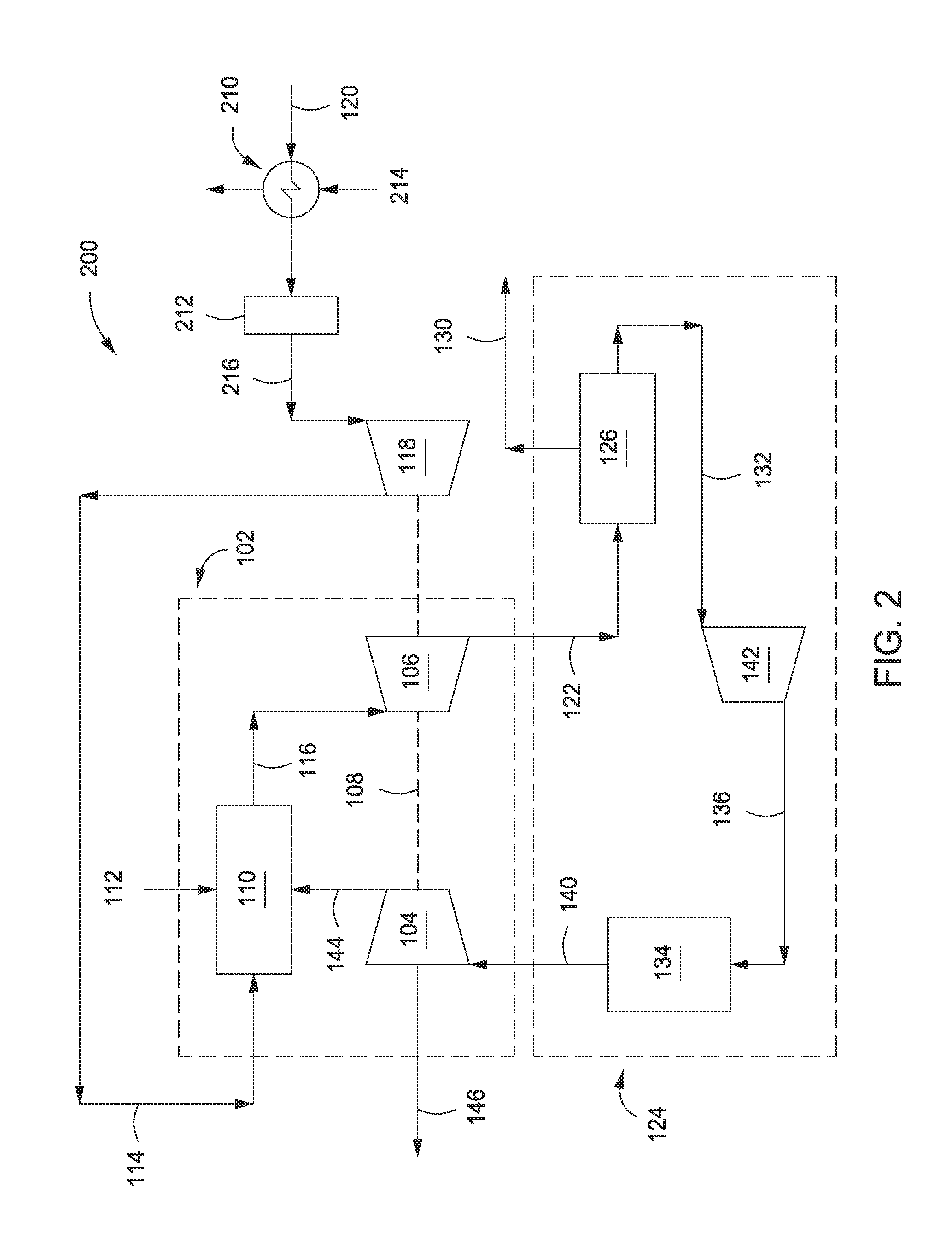

A method of generating energy in a power plant (30) having a gas turbine (29), includes a first step a gas containing air (1) is compressed in a first compressor (2) of the gas turbine (29), a second step the compressed gas (3, 3a, 3b; 5; 7a, 7b) is fed to a combustion process with the addition of fuel (8) in a combustor (23), a third step the hot flue gas (9) from the combustor (23) is expanded in an expander or a turbine (10), driving a generator (18), of the gas turbine (29) while performing work, and a fourth step a partial flow of the expanded flue gas (11) is recirculated to the inlet of the first compressor (2) and admixed with the gas containing air (1). Carbon dioxide (CO2) is separated from the compressed gas (3, 3a, 3b; 5; 7a, 7b) in a CO2 separator (6) before the third step. In such a method, the overall size and energy costs are reduced by virtue of the fact that, to permit increased CO2 concentrations in the CO2 separator (6), not more than about 70% of the carbon dioxide contained in the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b) is removed from the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b).

Owner:ALSTOM TECH LTD

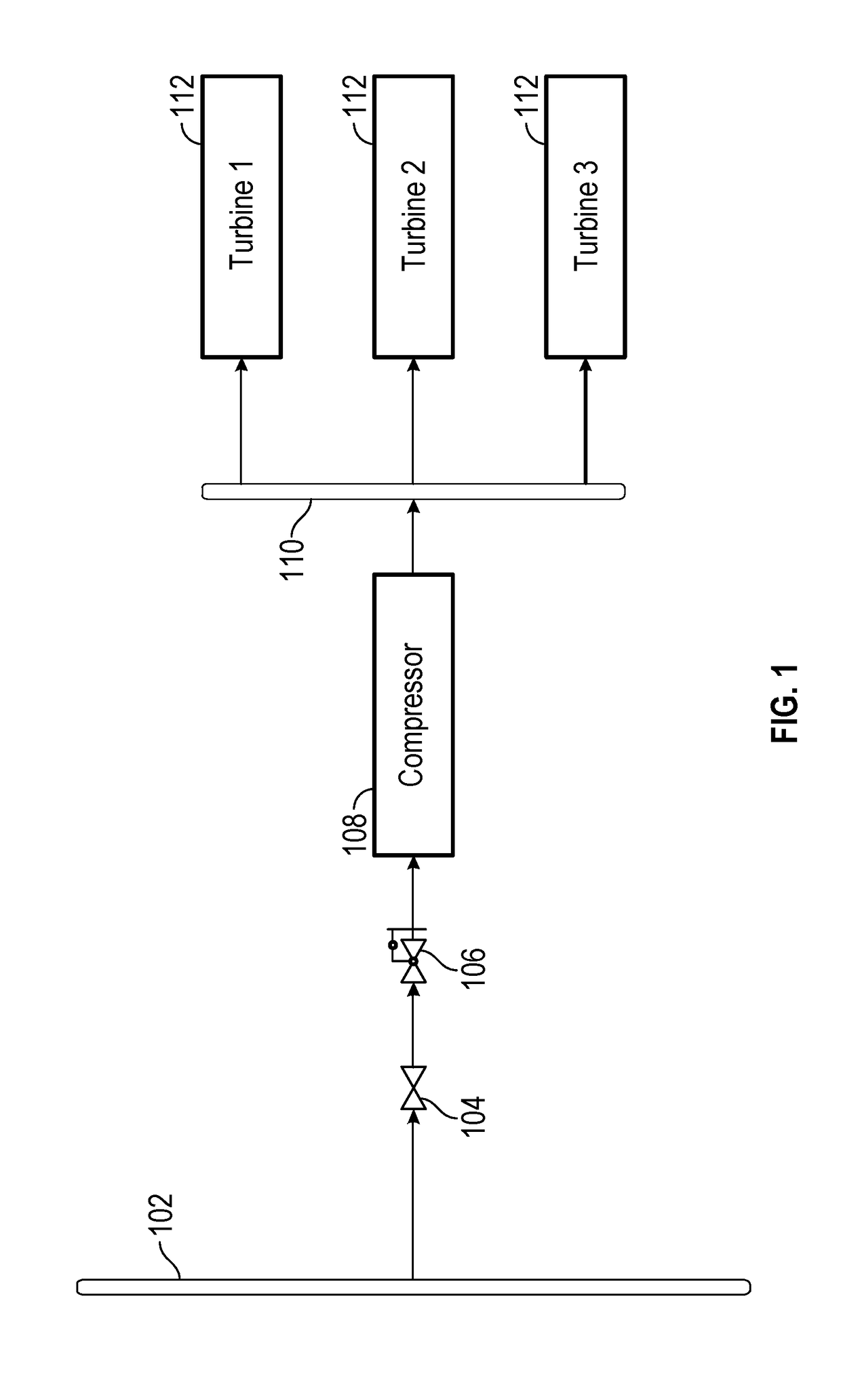

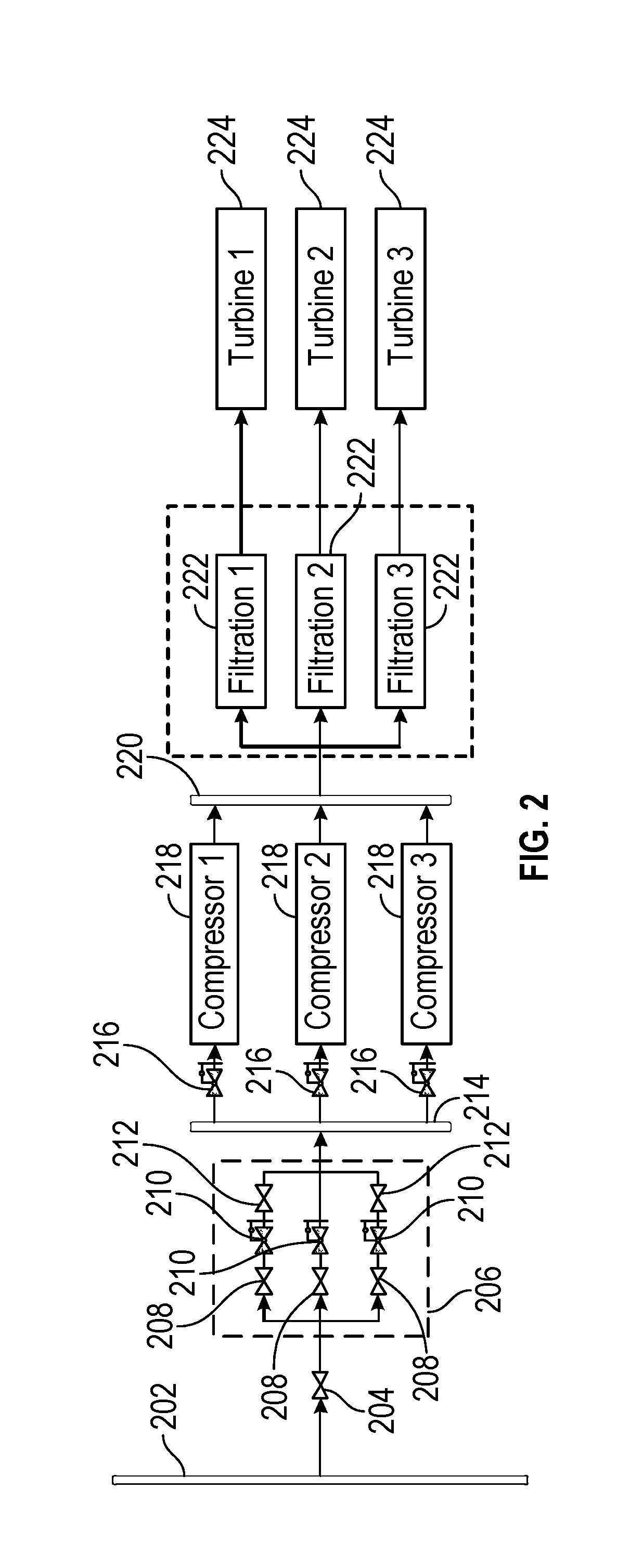

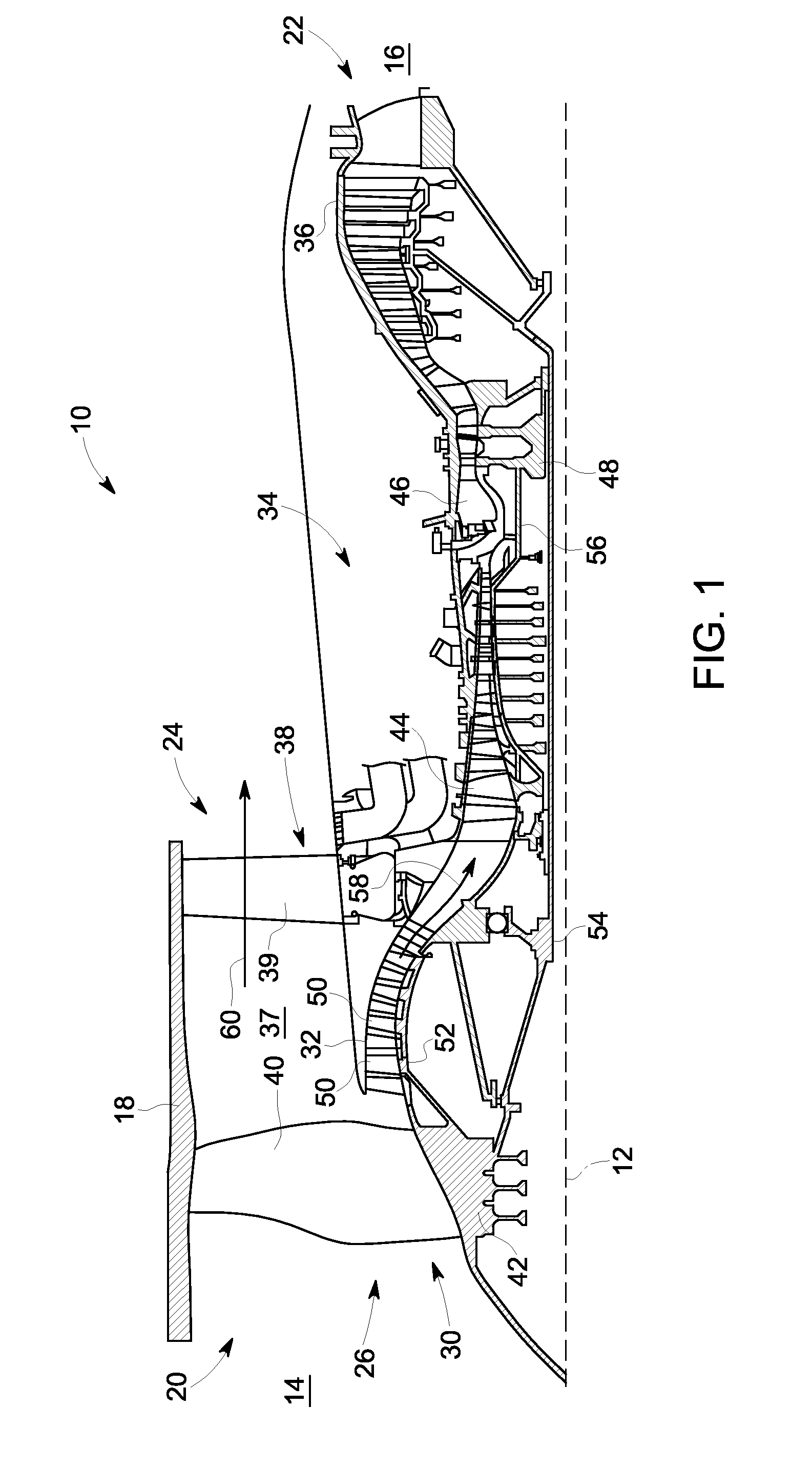

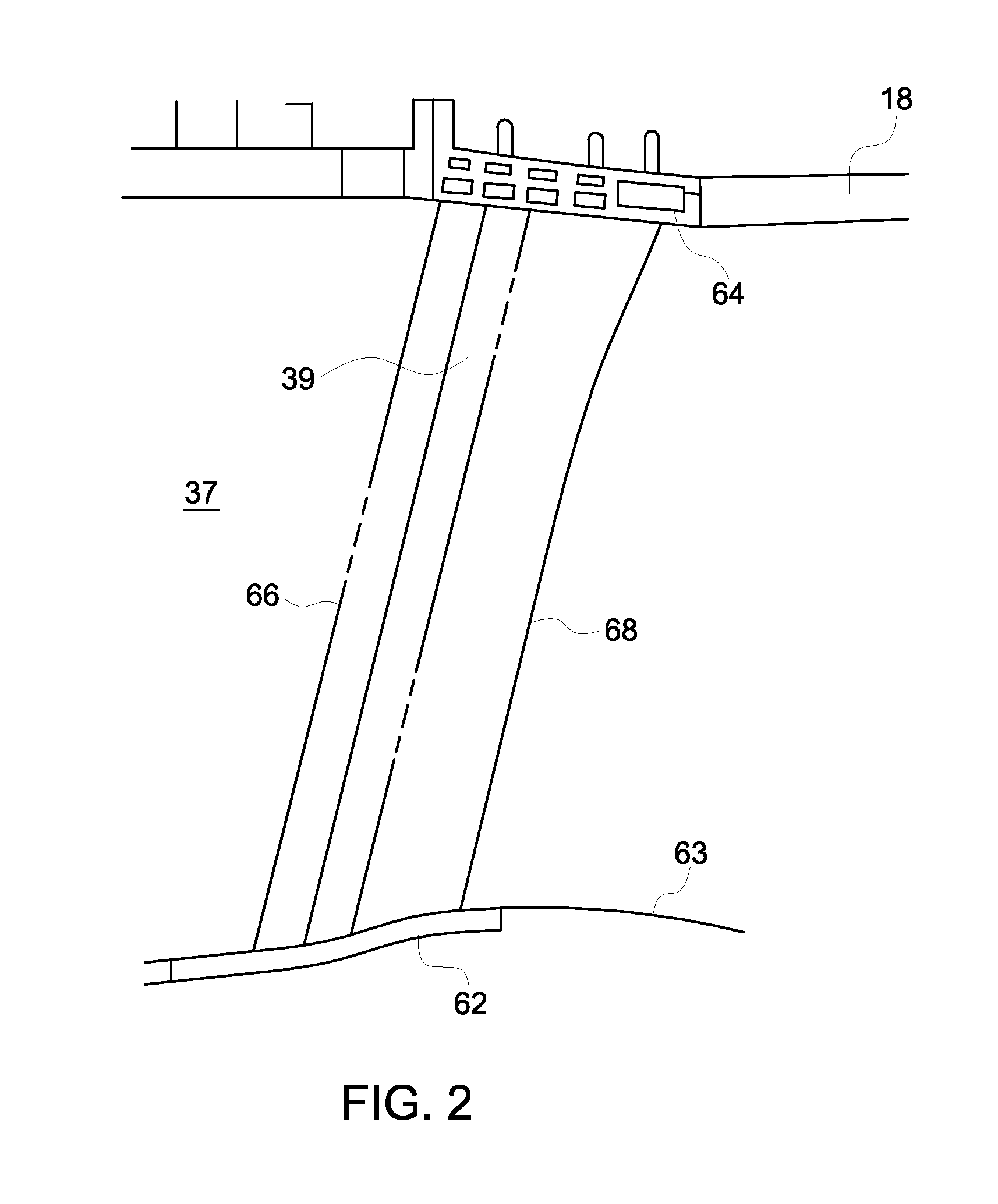

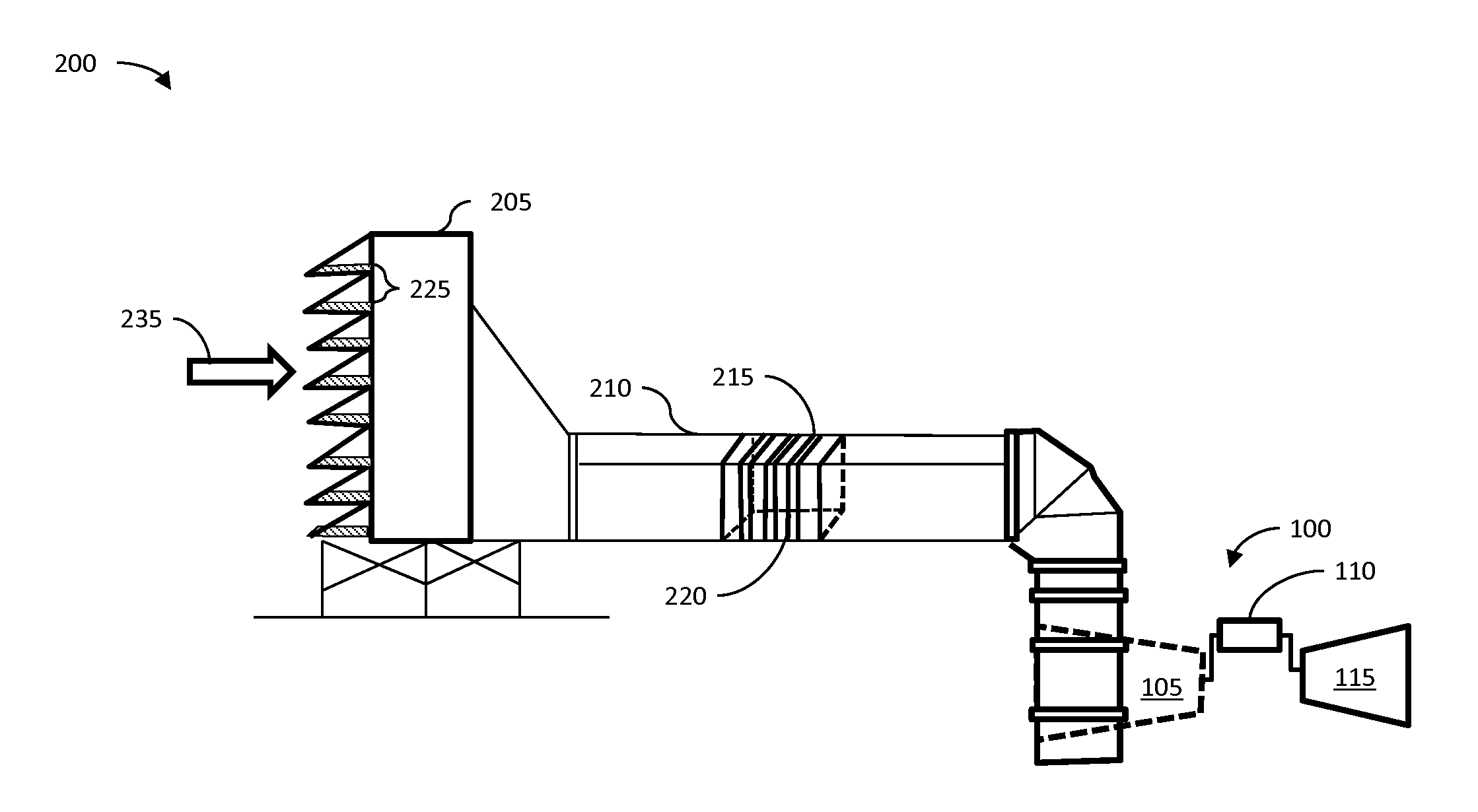

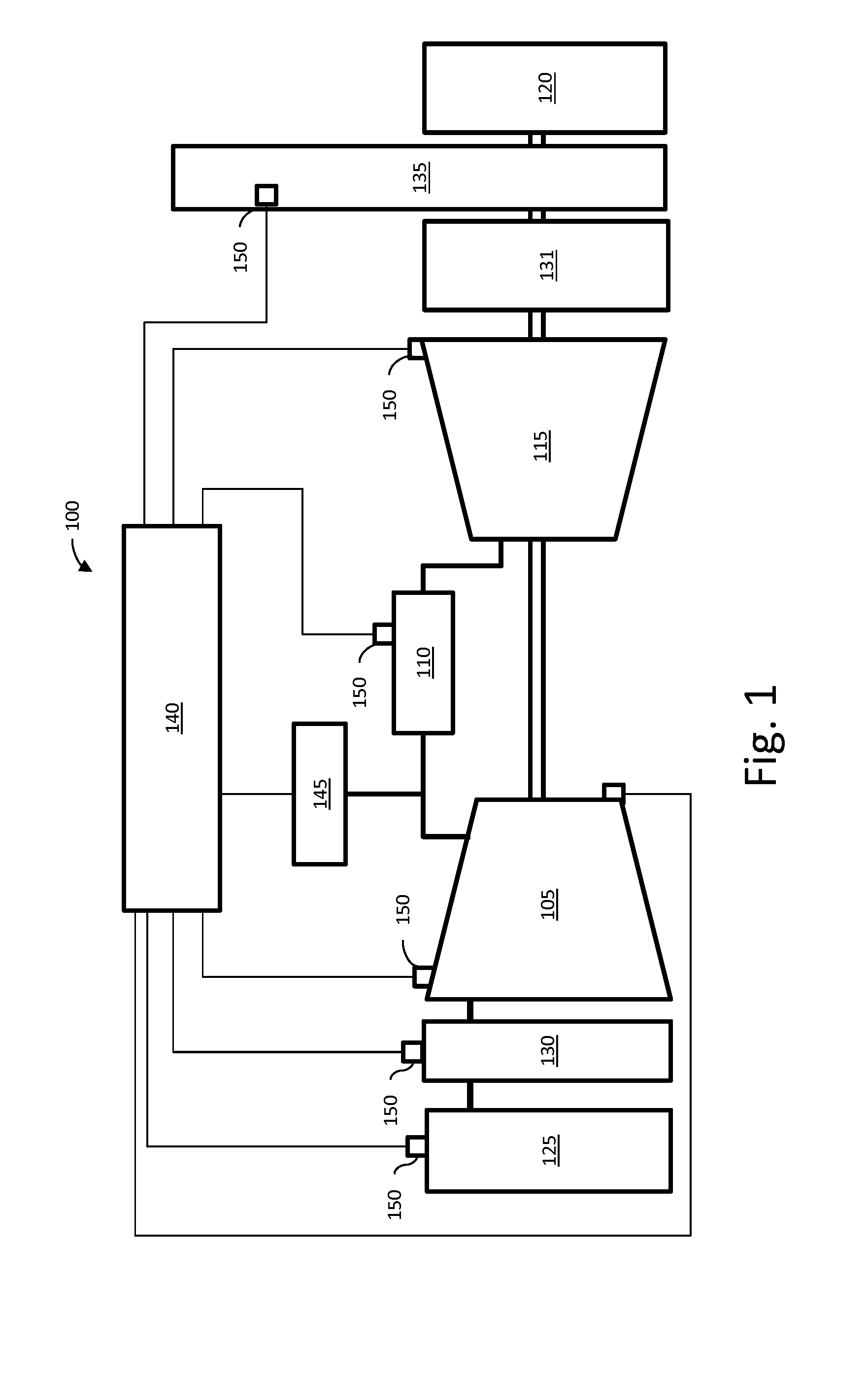

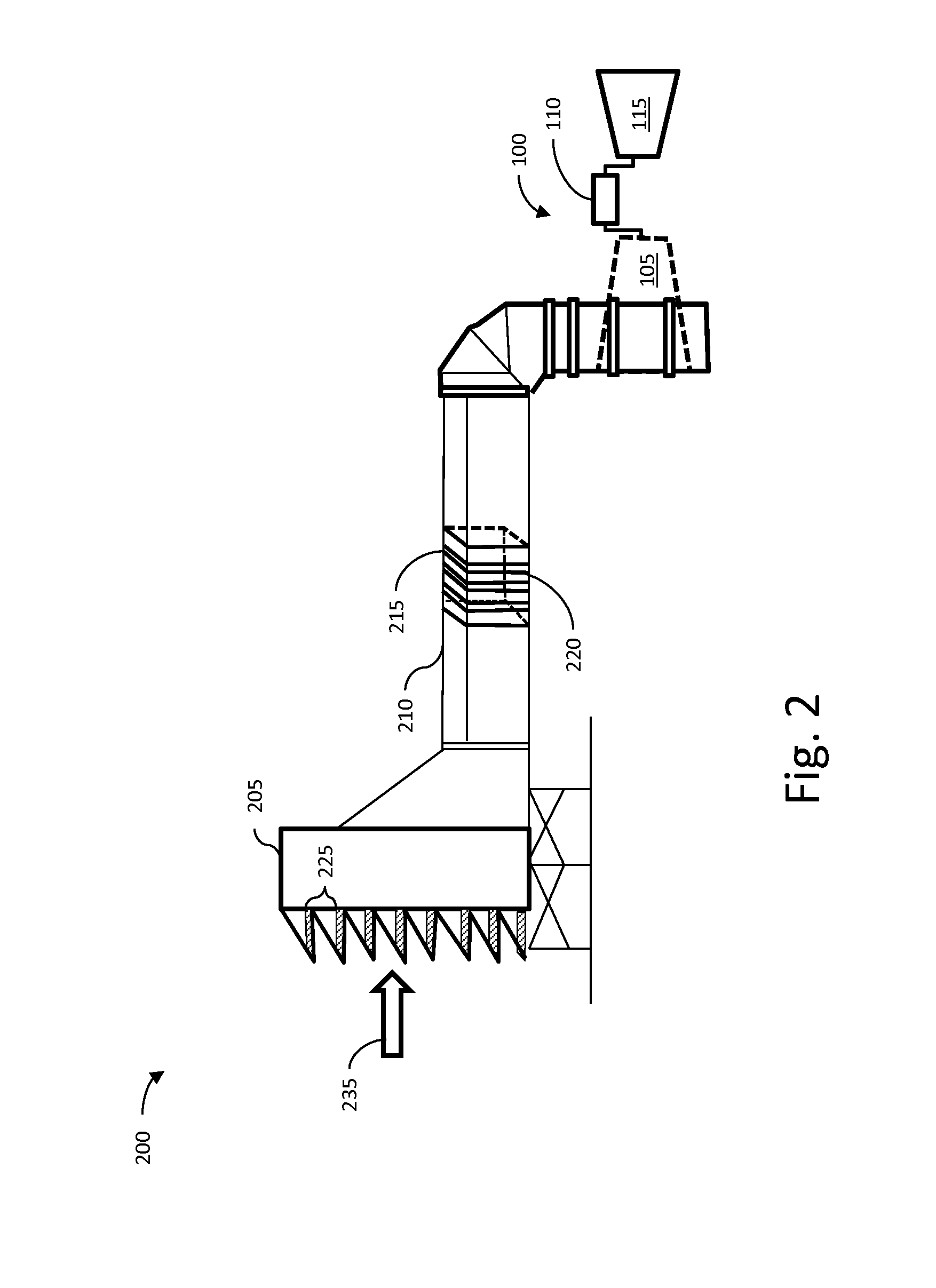

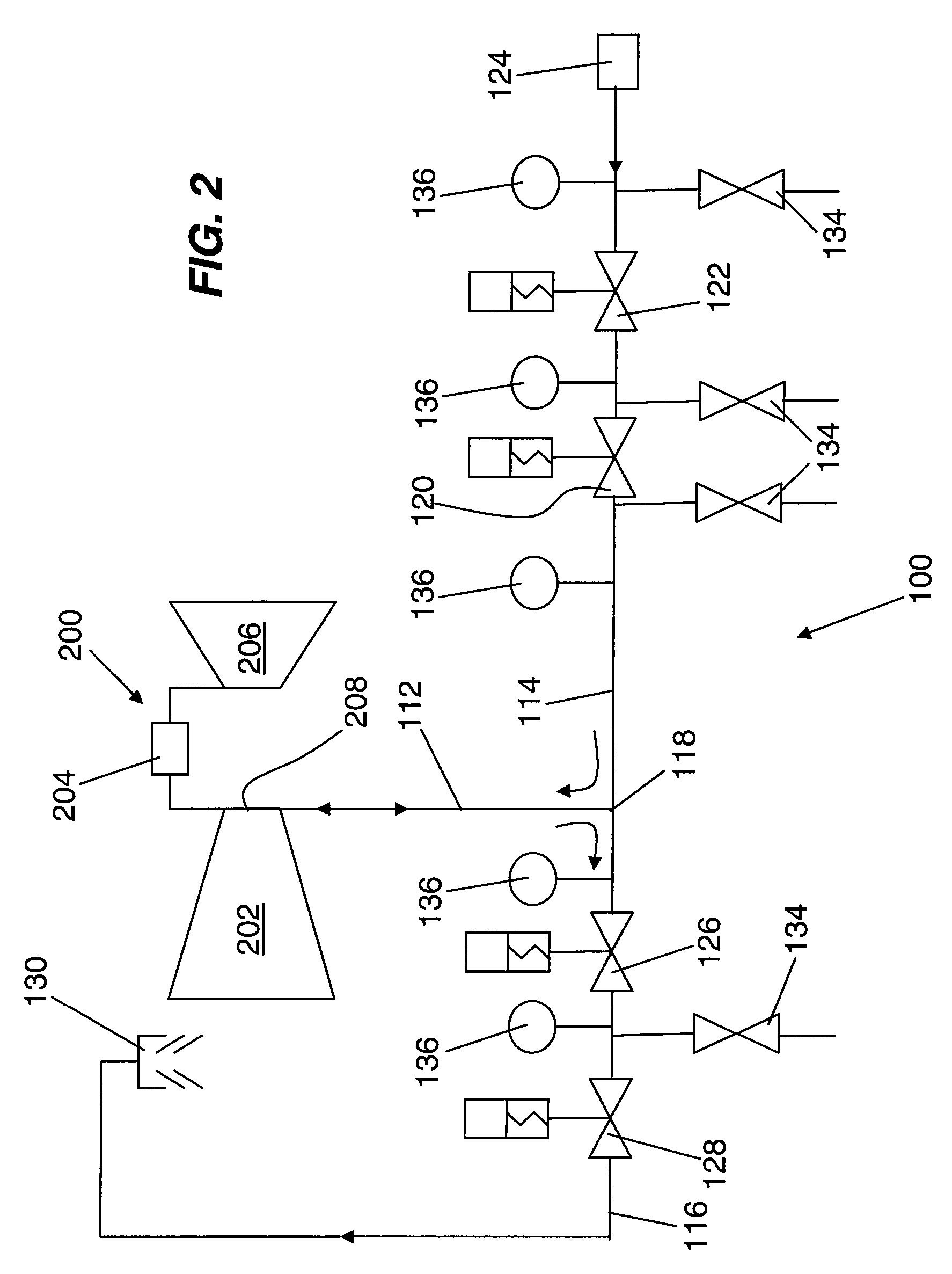

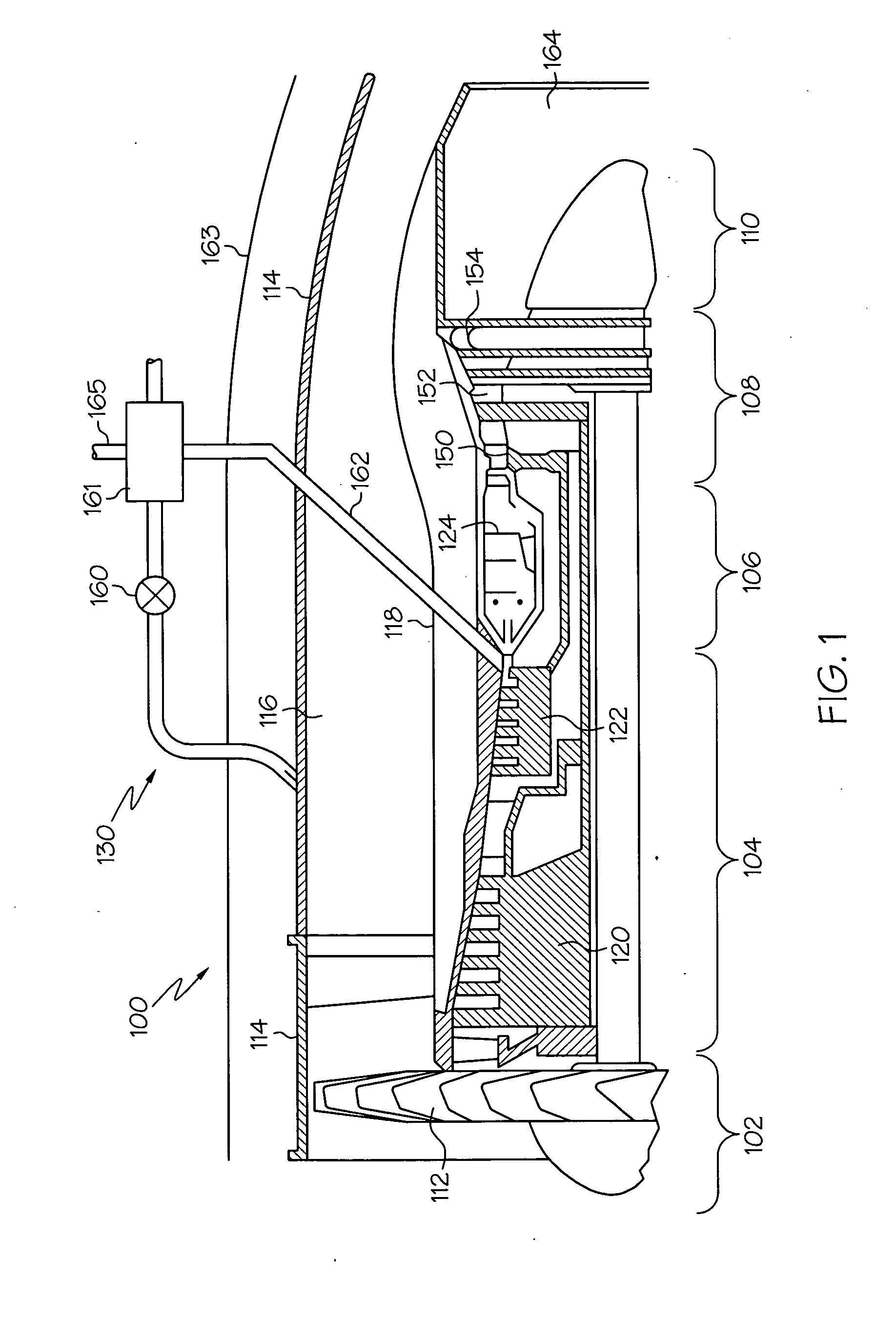

System for gas compression on electric hydraulic fracturing fleets

PendingUS20170145918A1Reduce pressureTurbine/propulsion fuel supply systemsGas turbine plantsElectricityGas compressor

Embodiments relate to hydraulic fracturing equipment powered by one or more natural gas turbine generators. Natural gas from a supply line is released via a valve into a turbine gas line. The turbine gas line includes one or more regulators to reduce the pressure of the natural gas stream in the turbine gas line to a pressure or pressure range optimum for one or more gas compressors. The gas compressors increase the pressure of the natural gas stream, which is then directed to one or more natural gas turbine generators. The natural gas turbine generators combust the natural gas to produce electricity, which powers electric hydraulic fracturing equipment.

Owner:US WELL SERVICS LLC

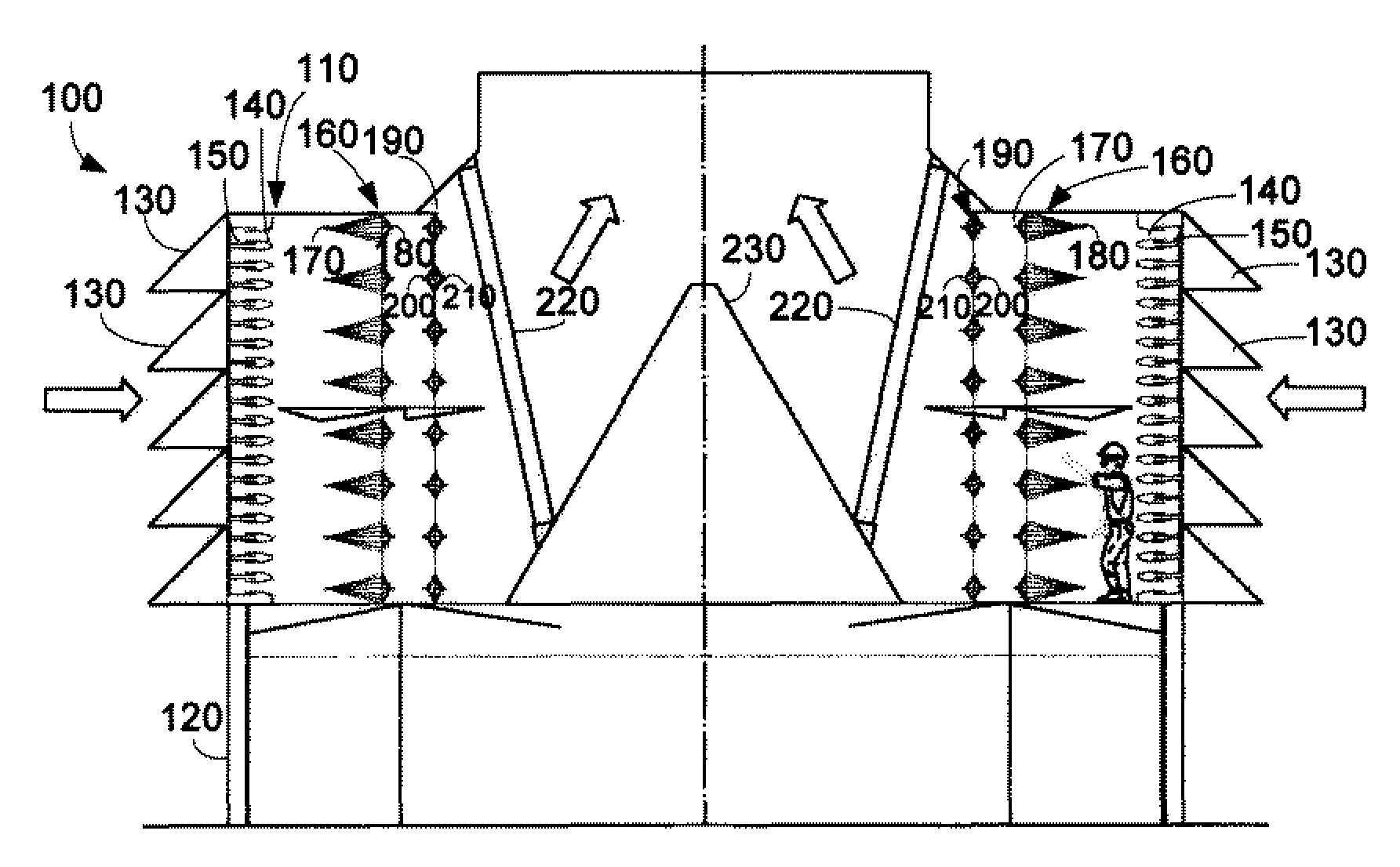

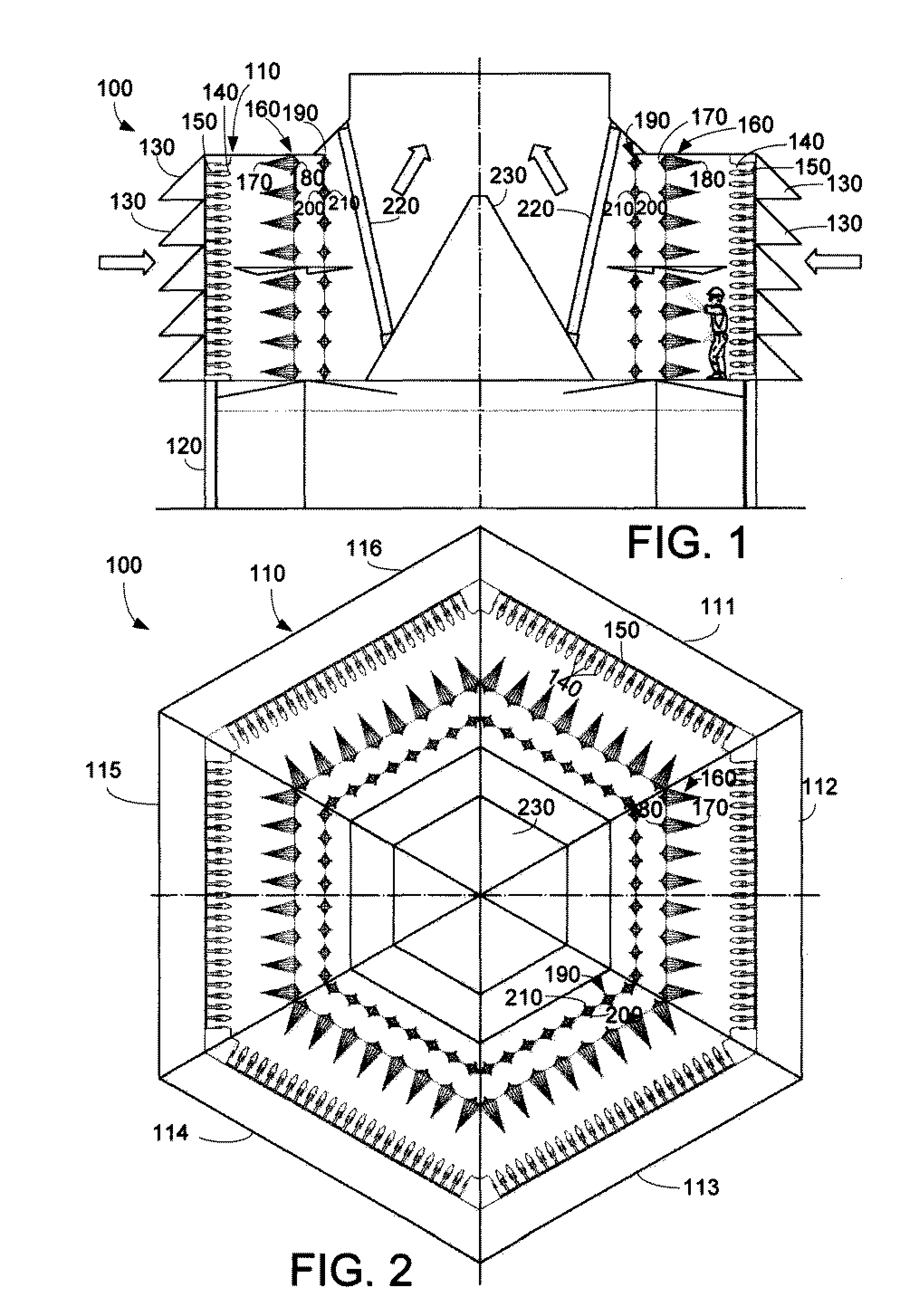

Turbine inlet air treatment apparatus

An inlet air treatment system. The inlet air treatment system includes a housing with more than two symmetric sides. Each of the sides includes a number of air filters and a number of spray arrays. A central air deflector is positioned within the housing.

Owner:GENERAL ELECTRIC CO

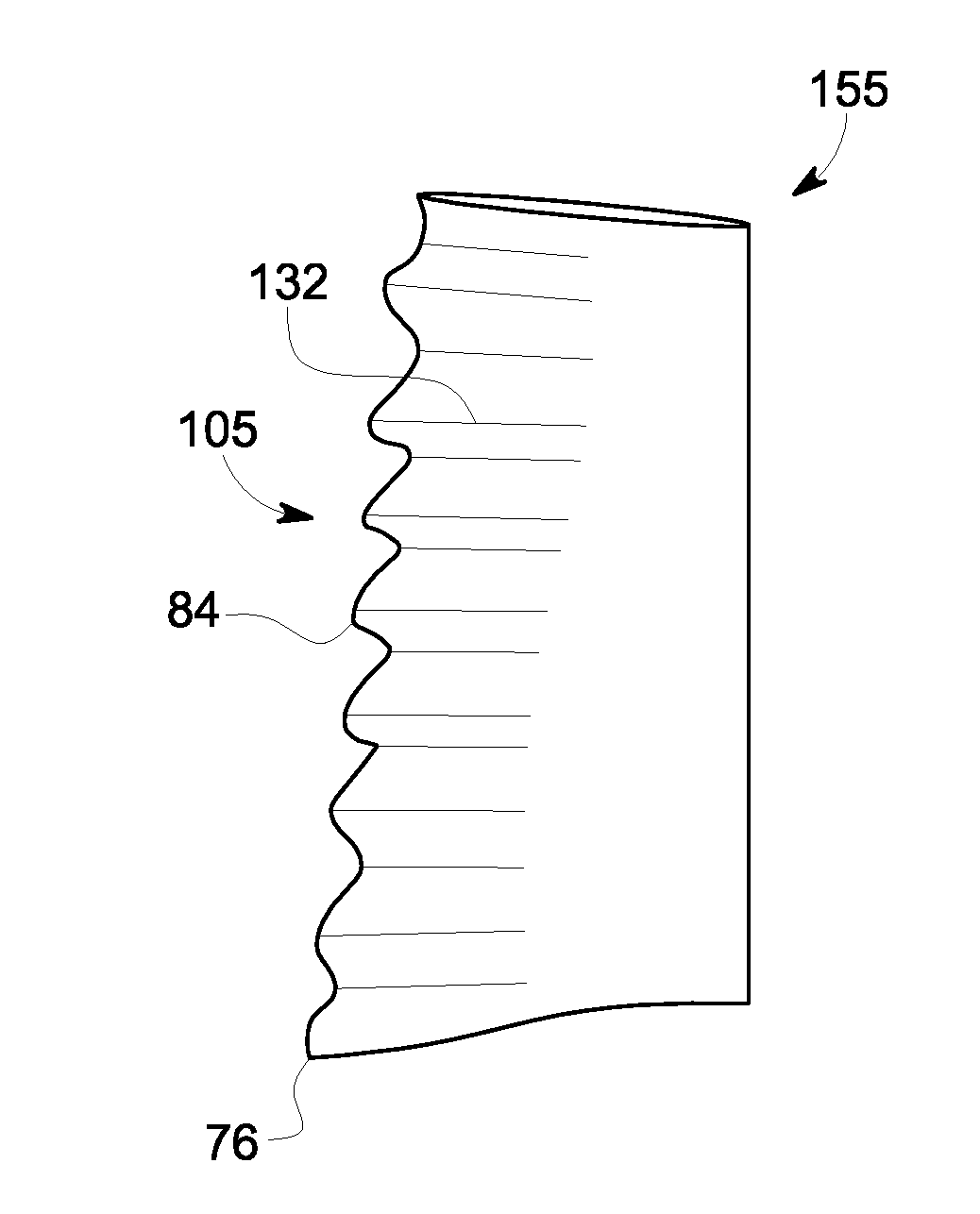

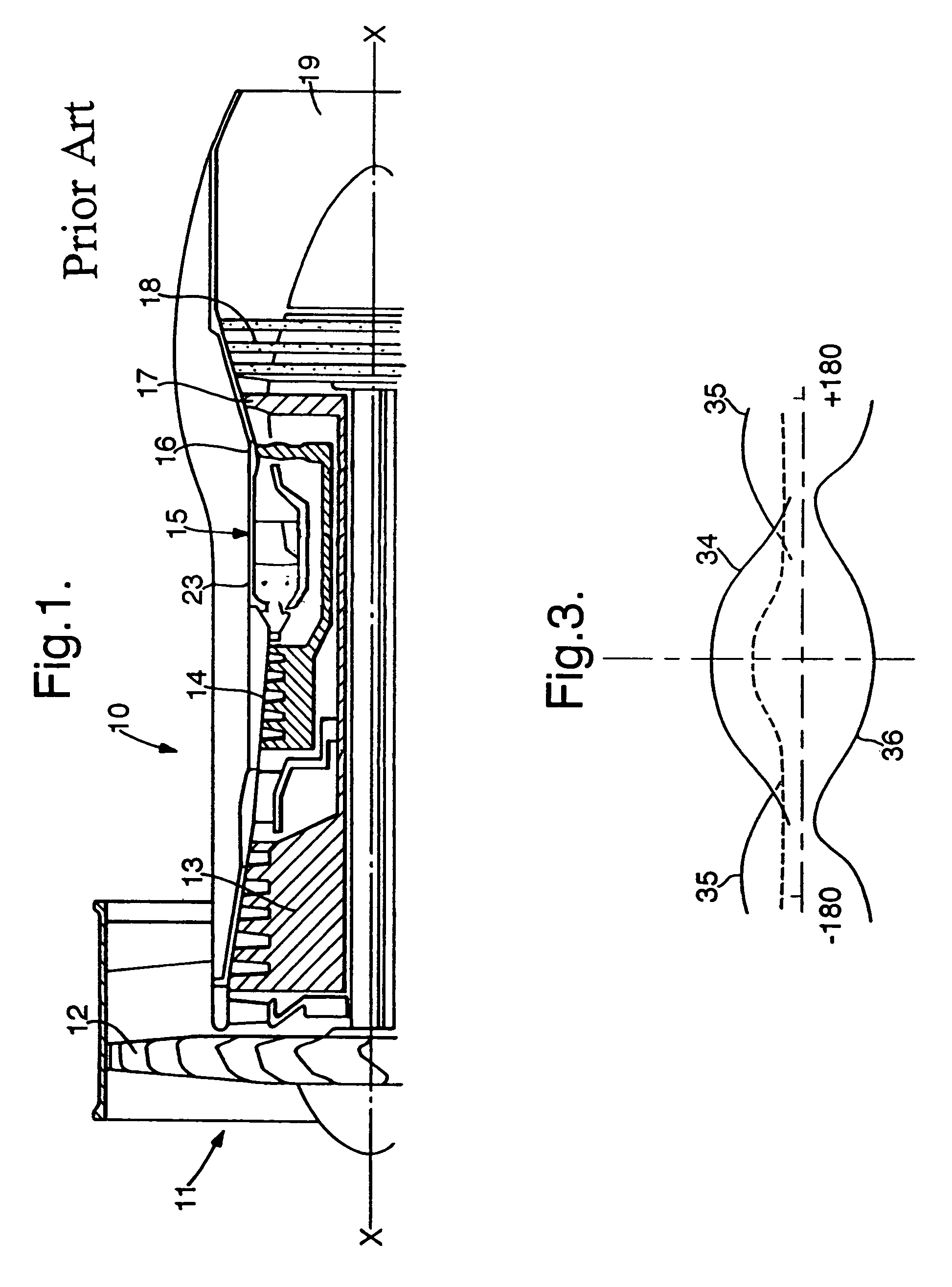

Airfoils for wake desensitization and method for fabricating same

ActiveUS20130164488A1Reducing desensitizationEngine manufacturePump componentsLeading edgeTrailing edge

An airfoil and method of fabricating an airfoil including a first and a second side coupled together at a leading and a trailing edge and extending there between. The airfoil includes a plurality of first chord sections having a first chord length and extending outward from one of the first side or second side of the airfoil at the leading edge and a plurality of second chord sections having a second chord length and extending outward from the one of the first side or the second side of the airfoil at the leading edge. The leading edge including spaced-apart wave-shaped projections defining a waveform. The configuration defining a three-dimensional crenulated airfoil configured to facilitate desensitization of an airfoil unsteady pressure response to at least one impinging upstream generated wake or vortex by decorrelating spatially and temporally and reducing in amplitude an unsteady pressure caused by interaction of the airfoil with the upstream generated wake or vortex.

Owner:GENERAL ELECTRIC CO

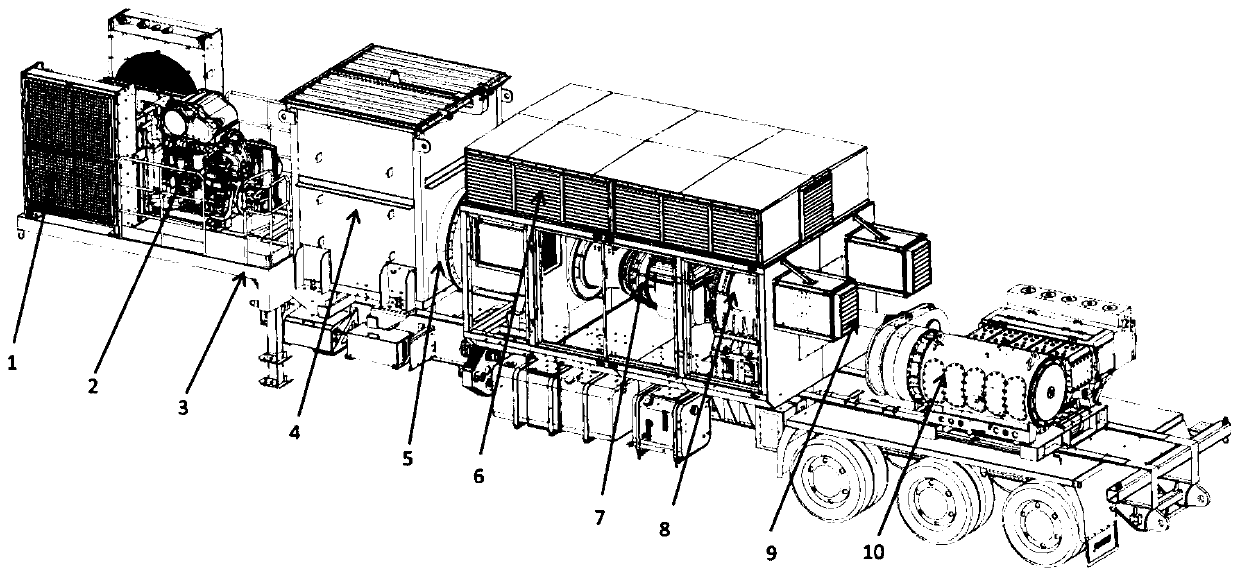

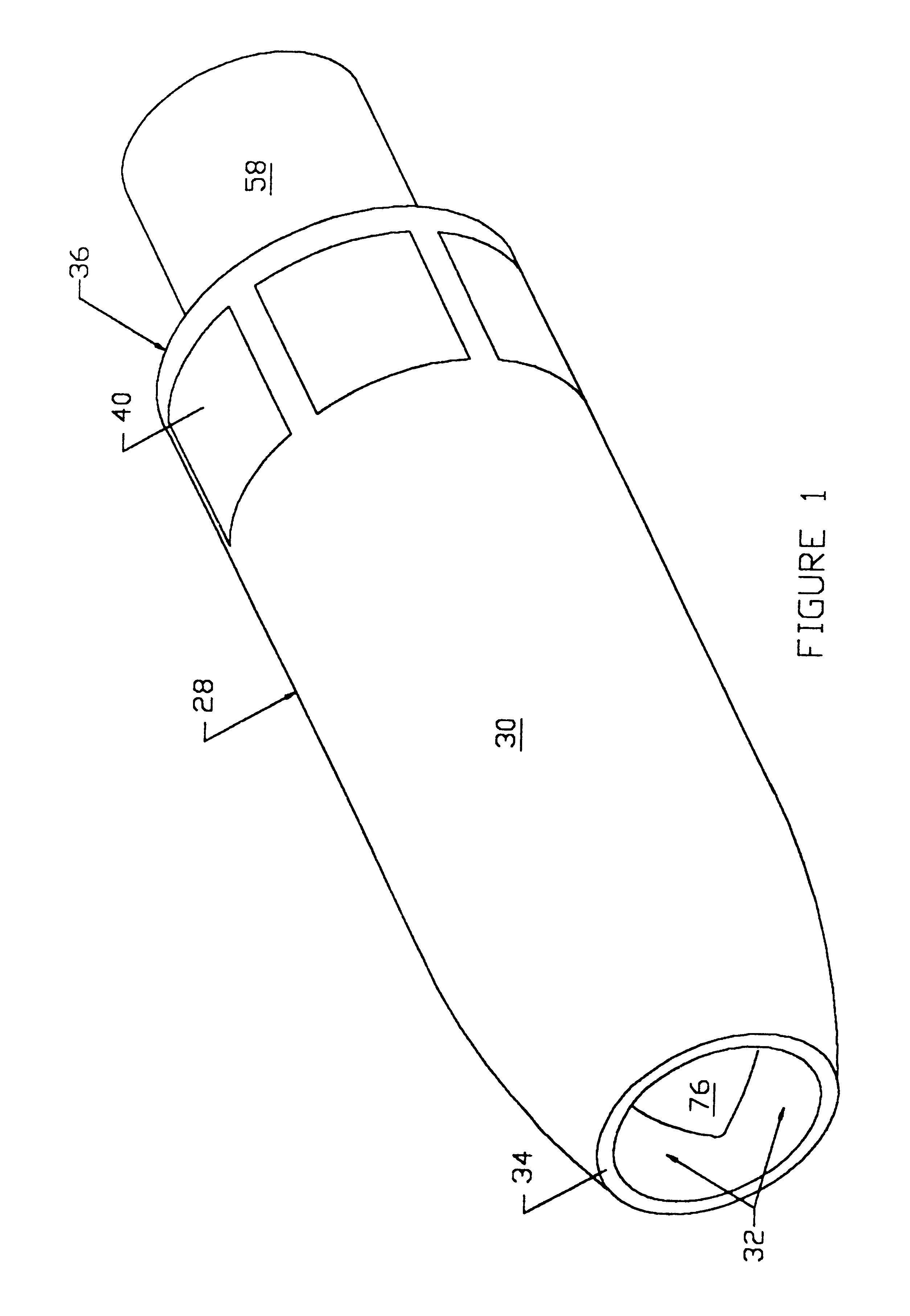

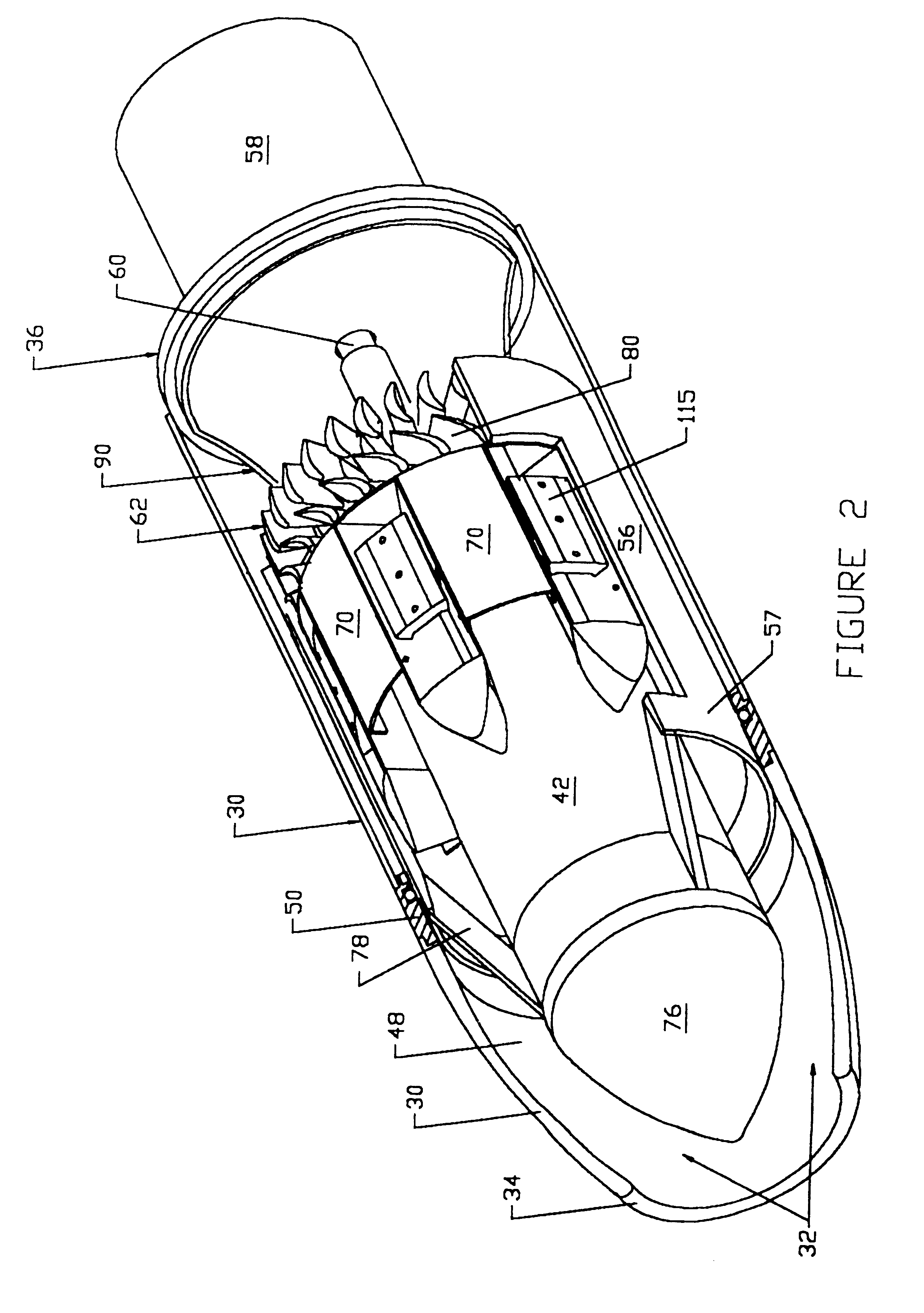

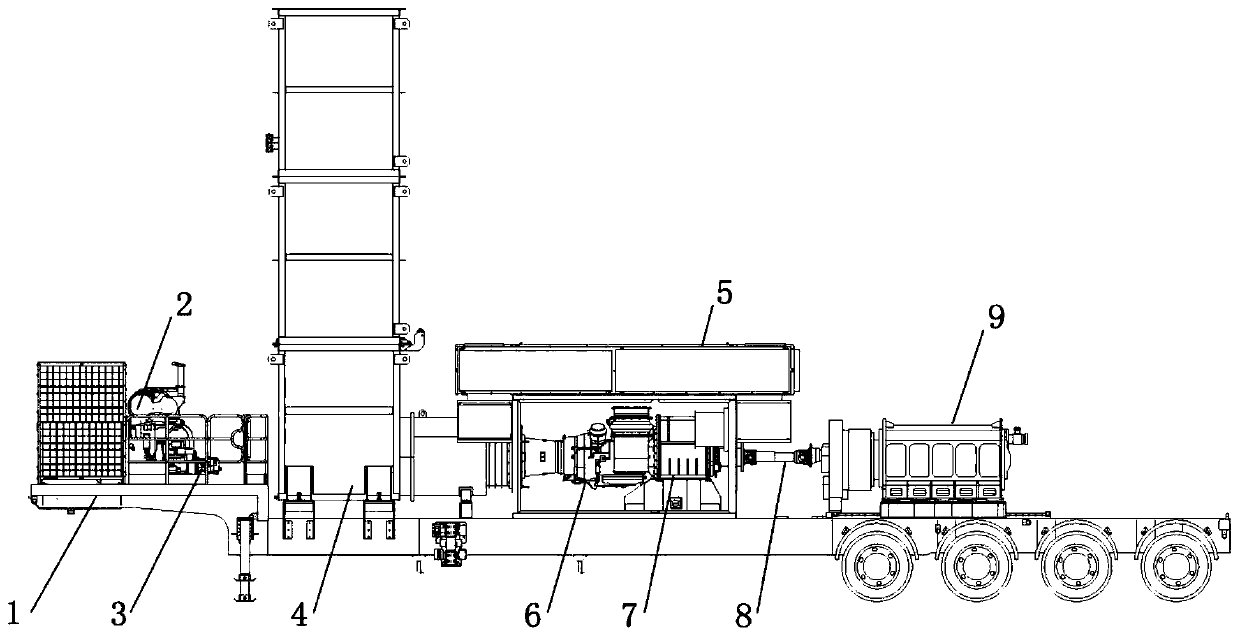

Turbine fracturing semitrailer

PendingCN110485983AReduce volumeReduce weightEngine manufactureEngine fuctionsTransmission lossFailure risk

The invention discloses a turbine fracturing semitrailer. The turbine fracturing semitrailer comprises a semitrailer body, a turbine engine, a reduction gearbox, a transmission mechanism and a plungerpump; the turbine engine, the reduction gearbox, the transmission mechanism and the plunger pump are arranged on the semitrailer body, the output end of the turbine engine is connected with the reduction gearbox, and the reduction gearbox is connected with the plunger pump through the transmission mechanism in a transmission mode. The turbine fracturing semitrailer has the beneficial effects thatthrough linear connection of the turbine engine, the reduction gearbox, the transmission mechanism and the plunger pump in the power-transmission direction, excessive transmission loss can be avoided, and efficient transmission performance is guaranteed; and the whole semitrailer is small in size, light in weight, low in the use cost, and low in failure risks.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

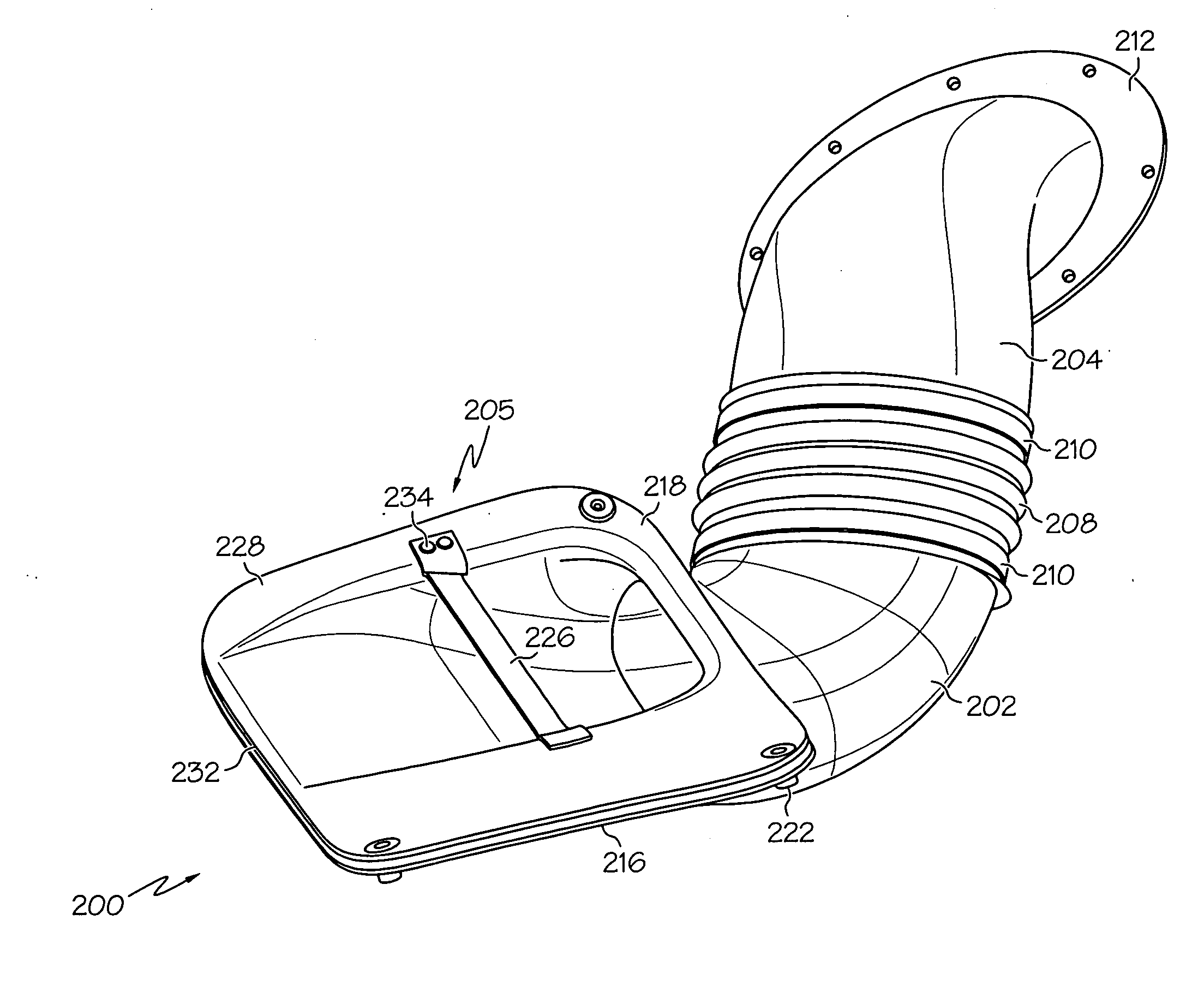

Systems and Methods for Bypassing a Coalescer in a Gas Turbine Inlet

A system including an air intake subsystem having a housing is provided. A coalescer having a frame is disposed inside the housing. The system includes a mounting bracket, and a release mechanism coupled to the frame and the mounting bracket. The release mechanism is adapted to selectively release the frame.

Owner:BHA ALTAIR

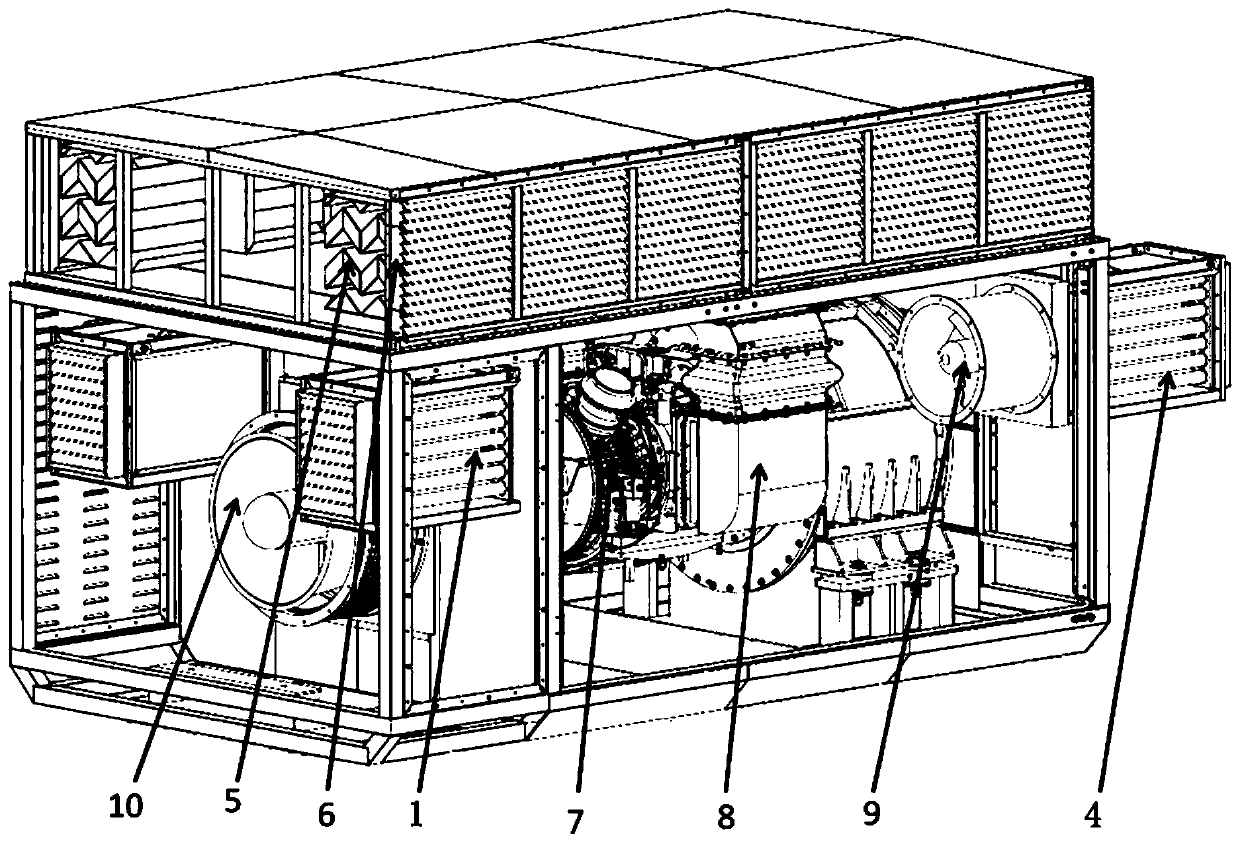

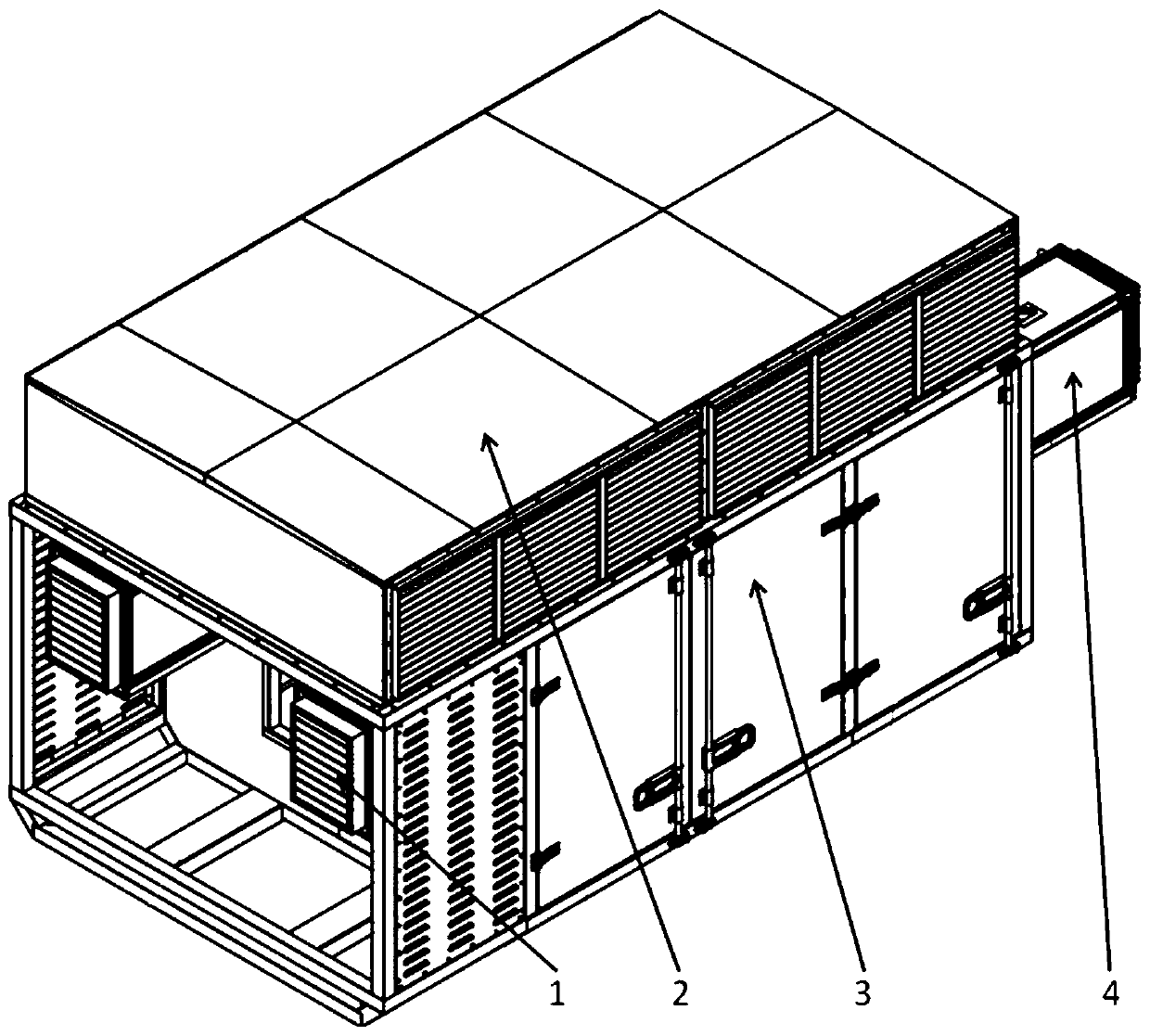

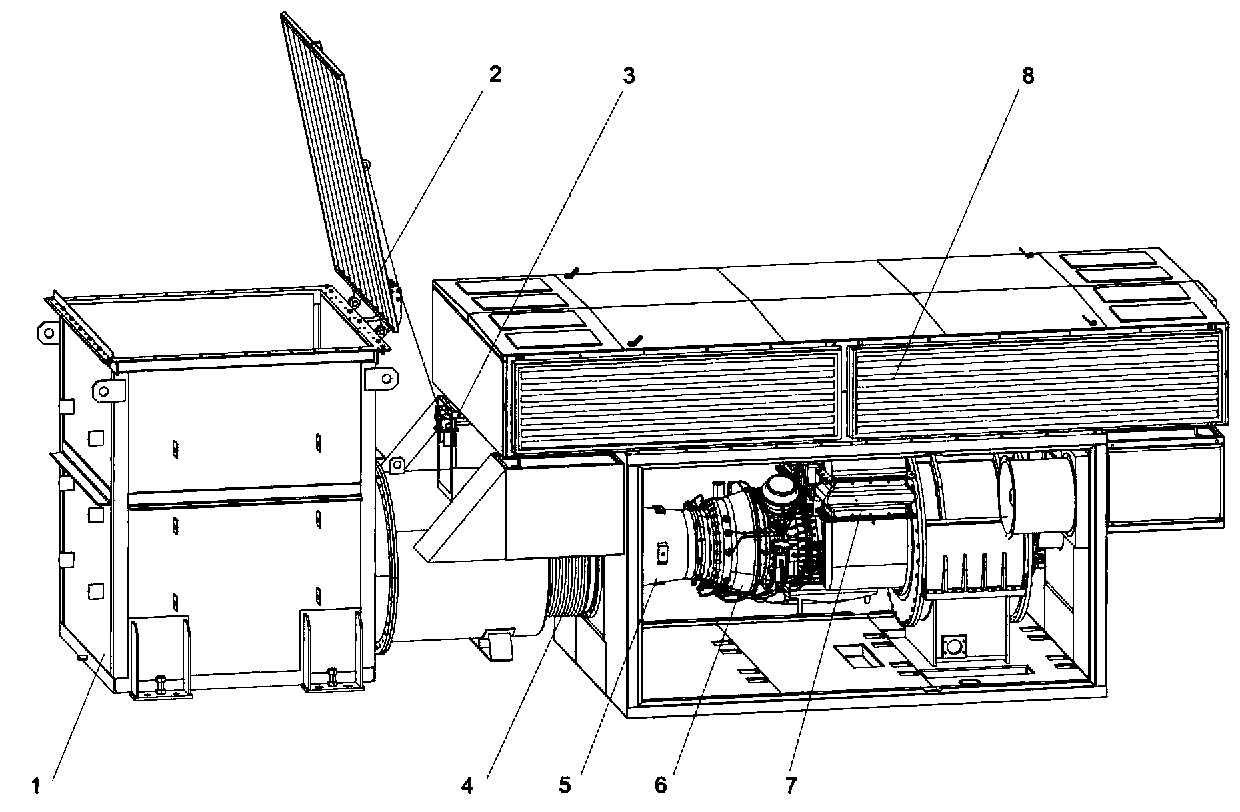

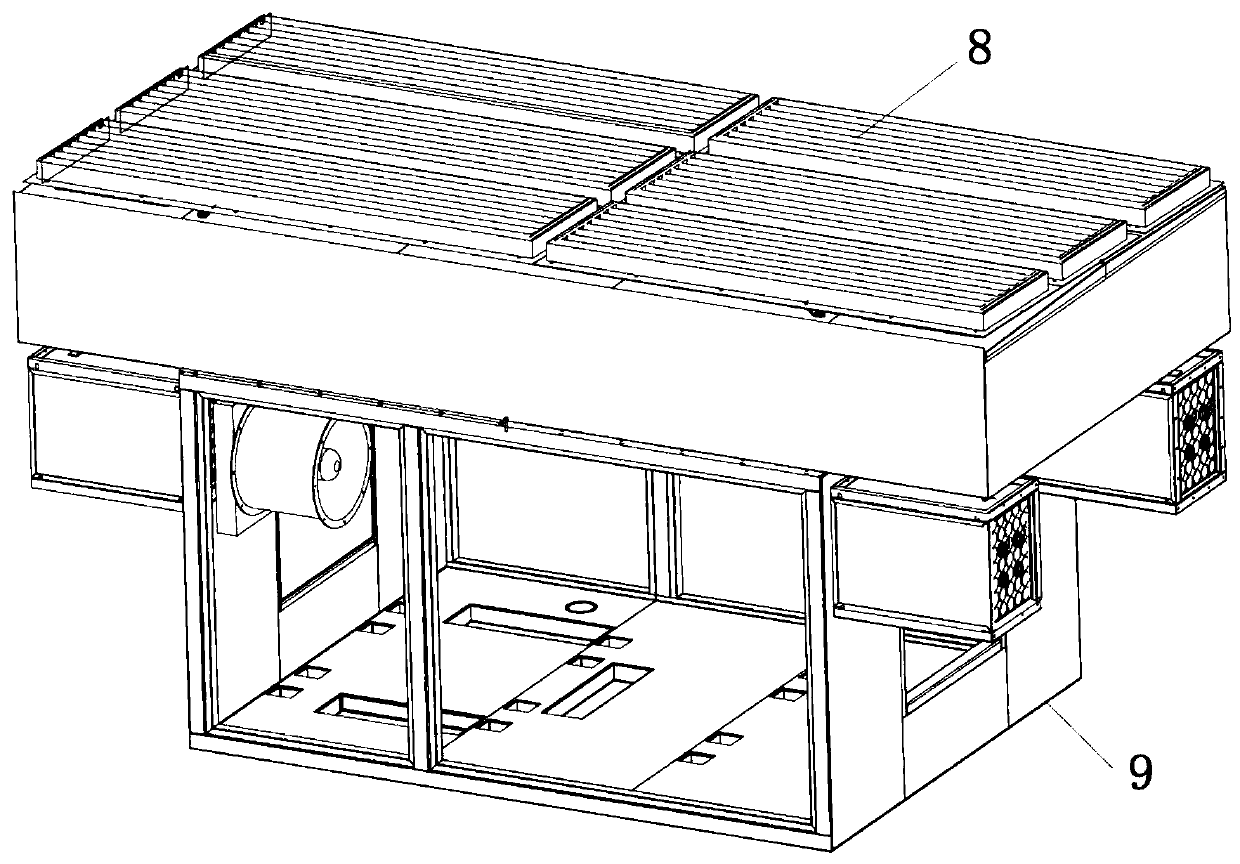

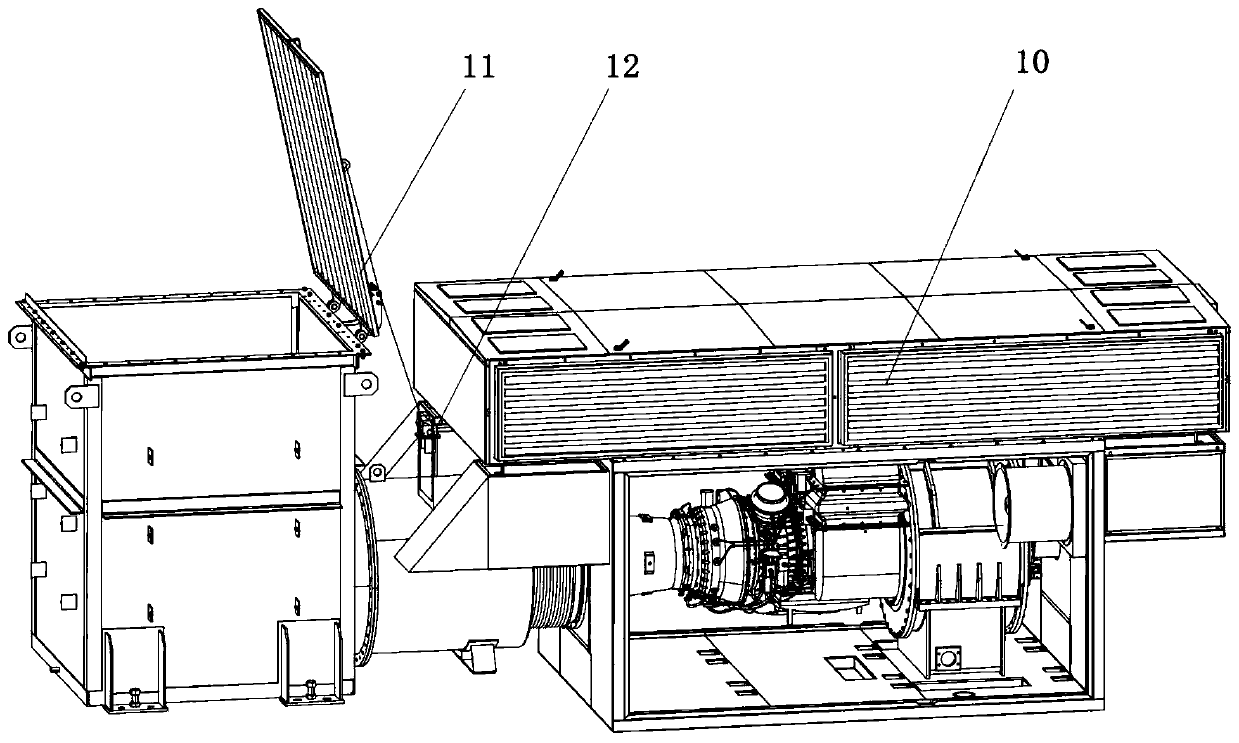

Sound insulation cabin of turbine engine

PendingCN110454285AAchieve noise reductionAchieve ventilationTurbine/propulsion engine coolingEngine fuctionsEngineeringNoise reduction

The invention discloses a sound insulation cabin of a turbine engine. The sound insulation cabin is arranged on the turbine engine in a sleeving mode, and comprises a cabin body, an intake noise reduction unit and a ventilation noise reduction unit; the intake noise reduction unit and the ventilation noise reduction unit are arranged on the cabin body, and the periphery of the cabin body is filledwith sound insulation materials; and the intake noise reduction unit is used for intake noise reduction of the turbine engine, and the ventilation noise reduction unit is used for noise reduction ofa ventilation system of the turbine engine. The sound insulation cabin has the beneficial effects that the intake noise reduction unit is additionally arranged at an air inlet of the turbine engine, and intake noise reduction of the turbine engine is achieved; the ventilation noise reduction unit is additionally arranged in the transmission direction of the turbine engine, and the ventilation andcooling noise reduction for the turbine engine is achieved; the periphery of the cabin body is filled with the sound insulation materials, and the overall noise reduction for the periphery of the turbine engine is achieved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

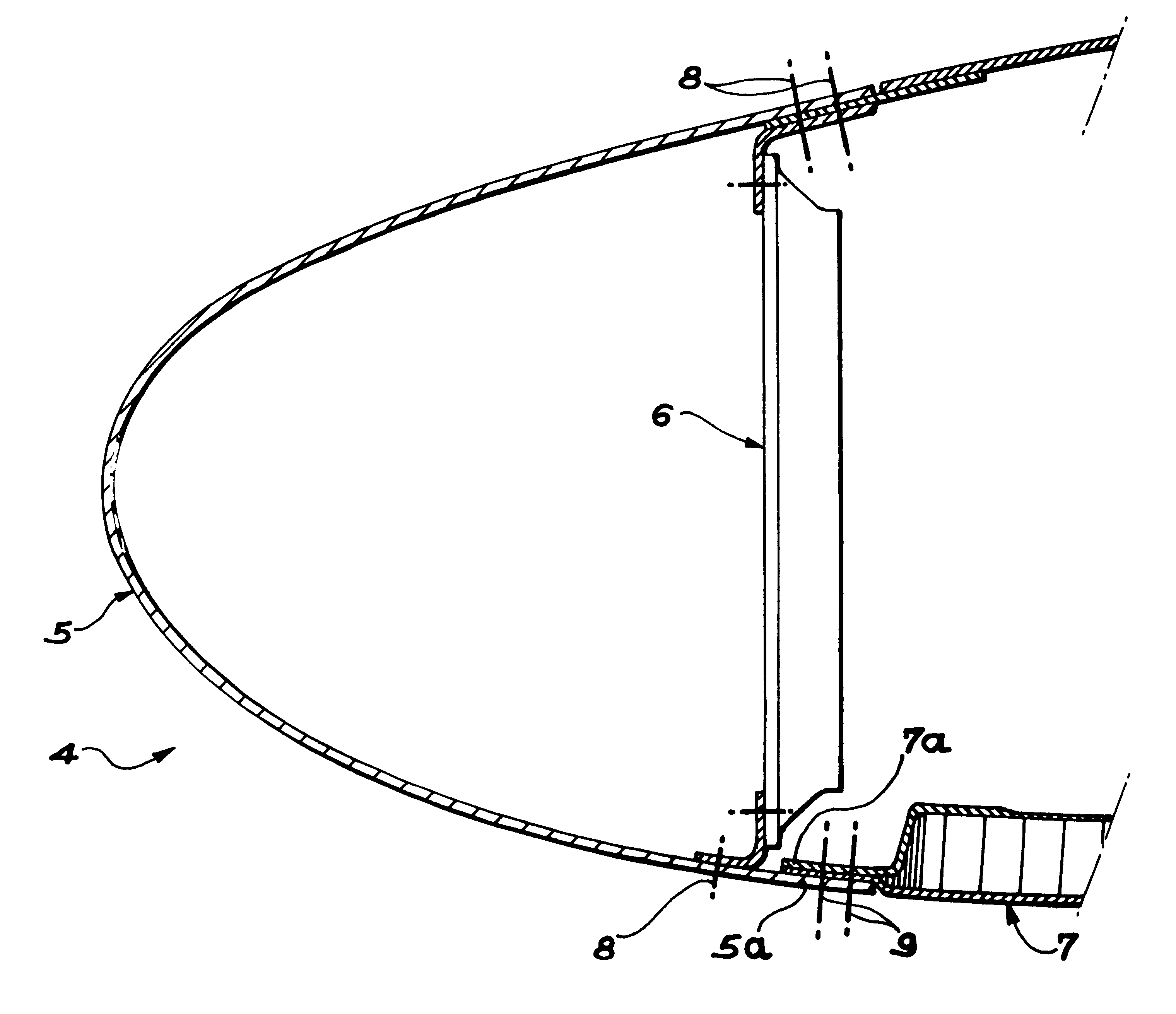

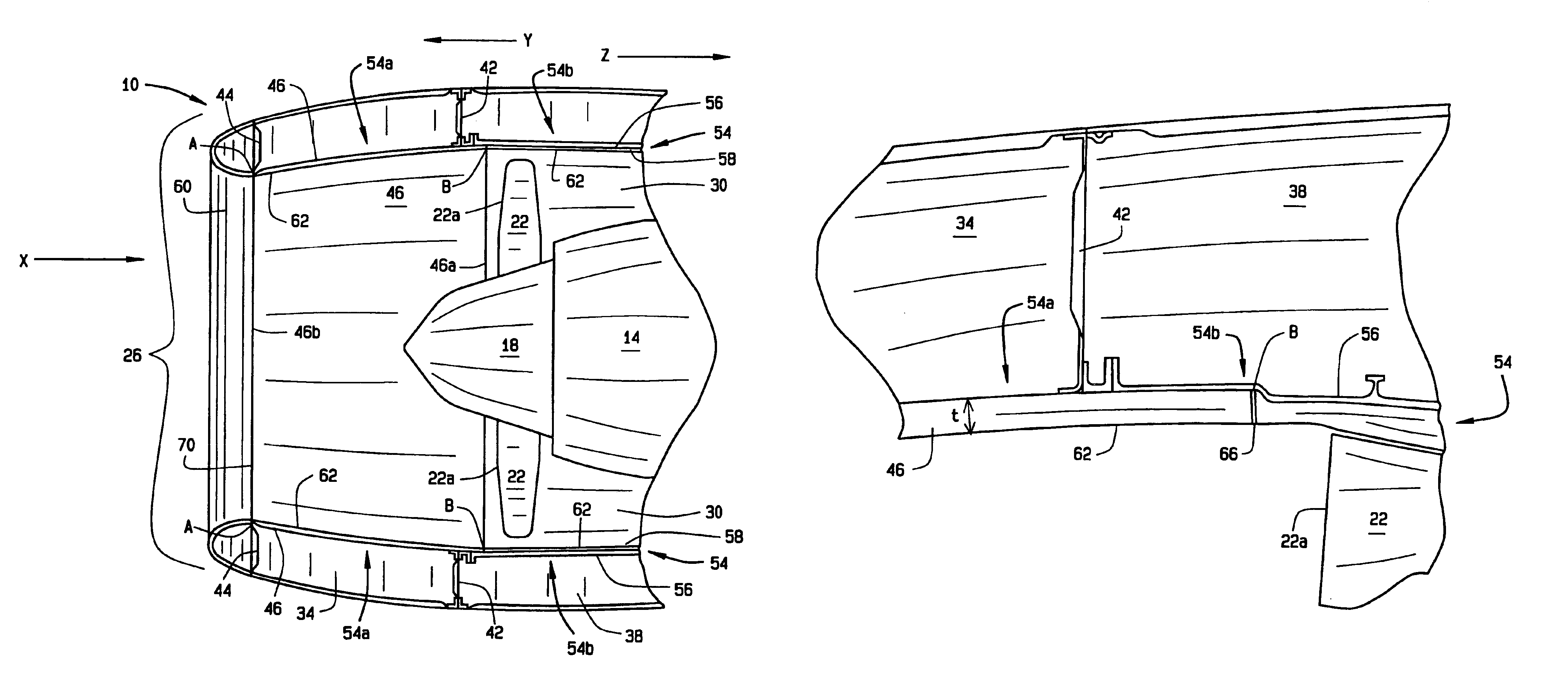

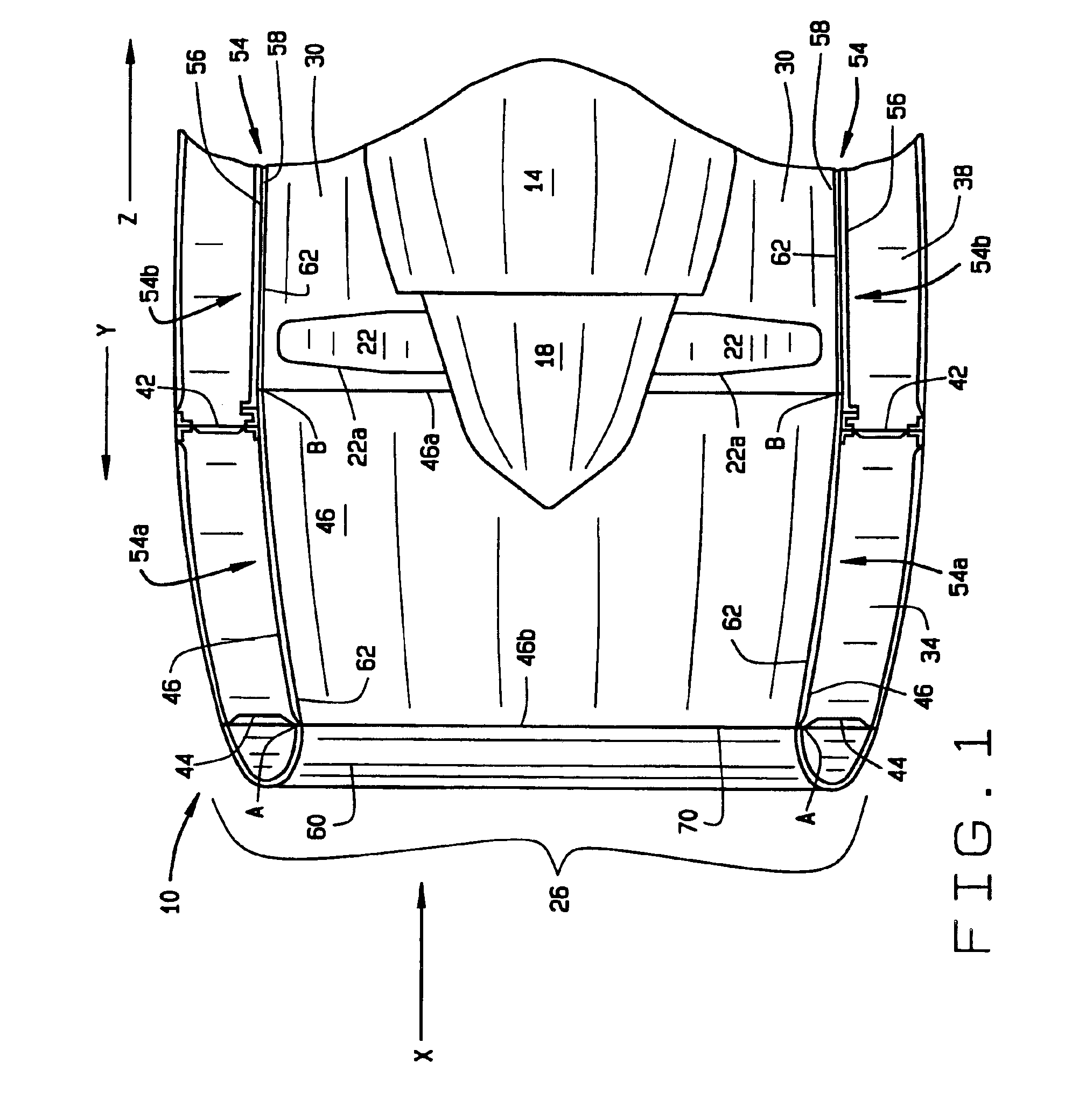

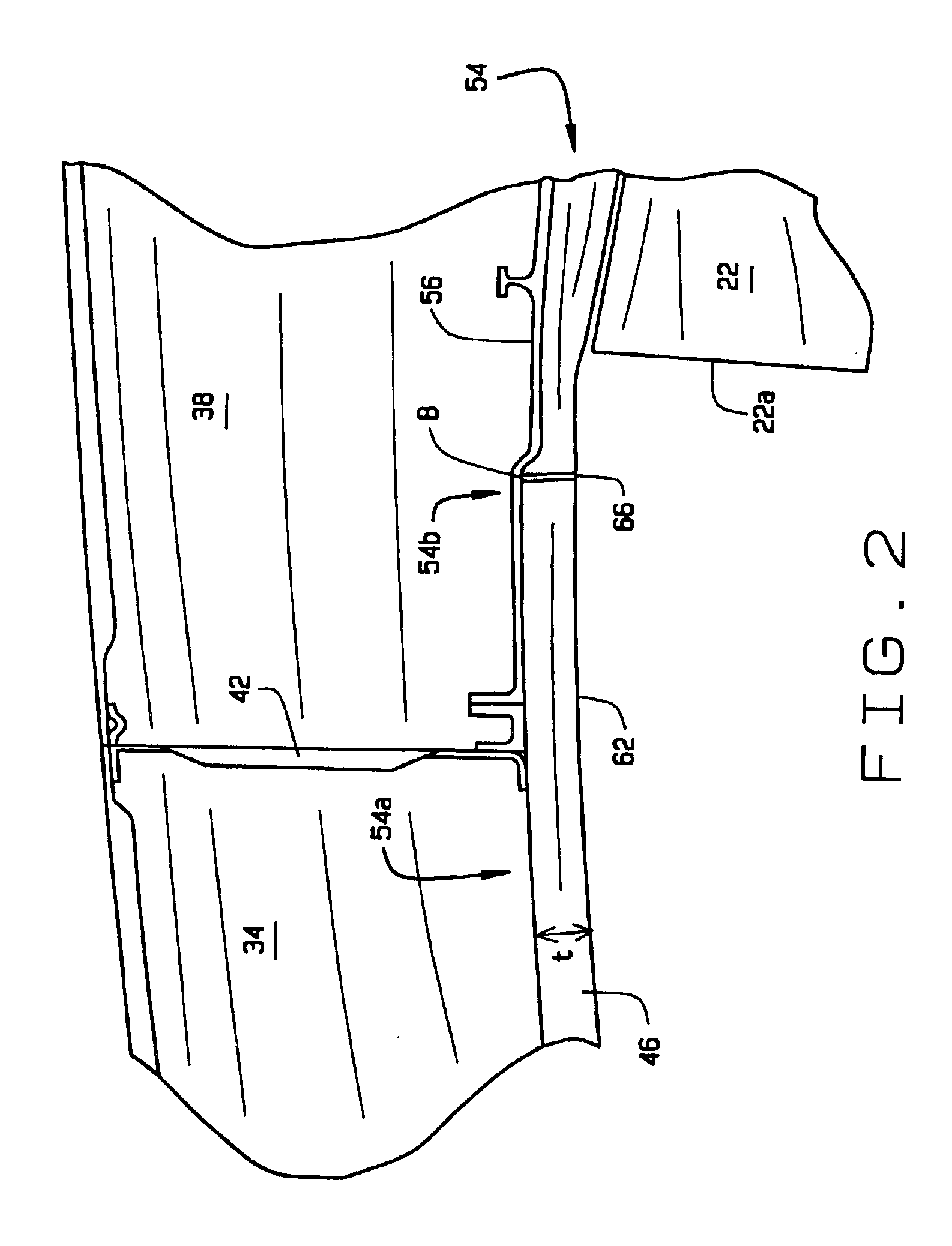

Air intake structure for aircraft engine

InactiveUS6328258B1Aircraft power plant componentsEfficient propulsion technologiesAirplaneEngine room

Owner:AEROSPATIALE MATRA

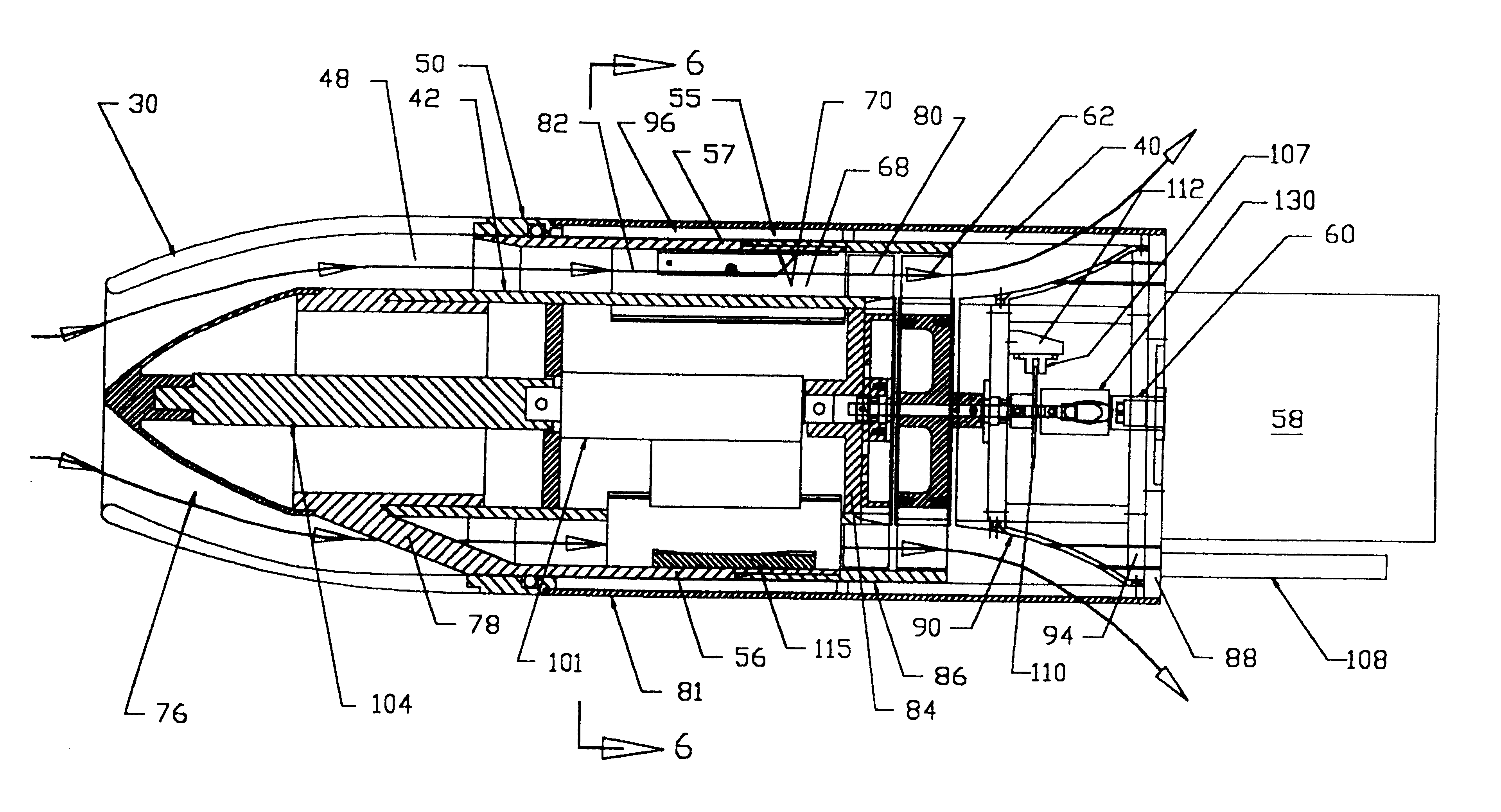

Low drag ducted Ram air turbine generator and cooling system

InactiveUS6270309B1Efficient extractionEnergy efficiencyPump componentsWind motor controlRam air turbineElectric generator

A low drag ducted ram air turbine generator and cooling system is provided. The ducted ram air turbine generator and cooling system has reduced drag while extracting dynamic energy from the air stream during the complete range of intended flight operating regimes. A centerbody / valve tube having an aerodynamically shaped nose is slidably received in a fairing and primary structure to provide a variable inlet area. An internal nozzle control mechanism attached to the valve tube positions nozzle control doors to provide variable area nozzles directing air flow to the turbine stator and rotor blades to maintain optimum generator efficiency. An alternate embodiment includes an annular internal nozzle having interleaved panels to modulate the air flow to the turbine.

Owner:GHETZLER AERO POWER CORP

Intake and exhaust system of turbine engine

PendingCN111206994AMeet air intake needsAvoid damageGas turbine plantsTurbine/propulsion air intakesAir filterExhaust fumes

The invention discloses an intake and exhaust system of a turbine engine. The intake and exhaust system of the turbine engine comprises an intake system and an exhaust system, wherein the intake system is connected with an intake port of the turbine engine, the exhaust system is connected with an exhaust port of the turbine engine, the intake system comprises an intake filter and an intake pipeline, the intake filter is connected with the intake pipeline, the intake filter adopts a V-shaped structure, and a rain shielding cap is arranged at the exhaust tail end of the exhaust system. The intake and exhaust system of the turbine engine has the beneficial effects that the air inlet area is large, the air inlet flow speed is lower, the service life of an air filter is long, the rain shieldingcap additionally arranged at the exhaust port avoids the rainwater deposition in an exhaust silencer, the condition that rainwater possibly flows backwards is avoided and damages the turbine engine,and an opening of the rain shielding cap is away from the intake port, so that exhausted waste gas is prevented from being sucked by the intake port, and the quality of inlet air is ensured.

Owner:美国杰瑞国际有限公司

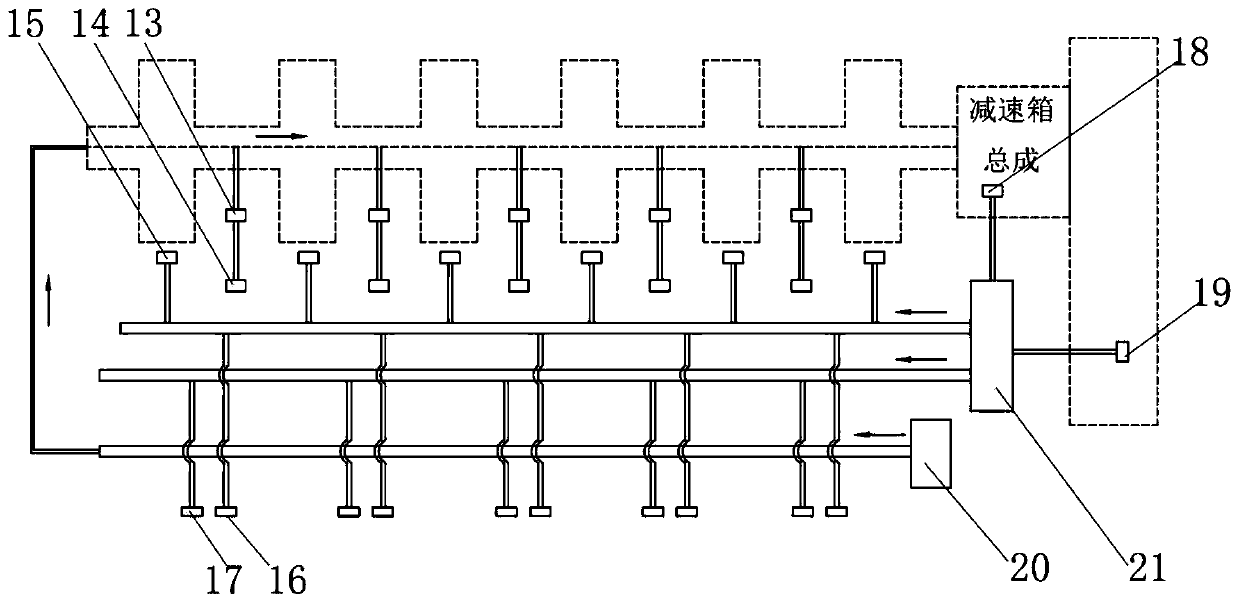

Continuous large-power turbine fracturing equipment

PendingCN111206992AStable and efficient transmissionStable working platformPositive displacement pump componentsGear lubrication/coolingDrive shaftControl engineering

The invention discloses continuous large-power turbine fracturing equipment. The large-power turbine fracturing equipment comprises a turbine engine, a reduction box, a transmission shaft and a plunger pump, wherein the turbine engine and the reduction box are arranged on the same straight line; the reduction box is connected to the plunger pump through a transmission shaft; and an angle of the transmission shaft ranges from 2 degrees to 4 degrees. The continuous large-power turbine fracturing equipment has the beneficial effects that: a chassis T1 material is selected, so that a stable working platform is provided for the equipment; the turbine engine and the reduction box are on the same straight line, the transmission shaft is arranged between the reduction box and the plunger pump, andthe angle of the transmission shaft ranges from 2 degrees to 4 degrees, so that stable and efficient transmission of the turbine engine is guaranteed, and a fault occurrence rate is reduced; a lubricating system driven by an auxiliary power system guarantees that the turbine engine, the reduction box and the plunger pump work under a proper environment; dual lubricating systems guarantee that theplunger pump realizes continuous operation under power of 5000 HP or higher; and the technical means finally can meet continuous large-power operation requirements of the fracturing equipment.

Owner:美国杰瑞国际有限公司

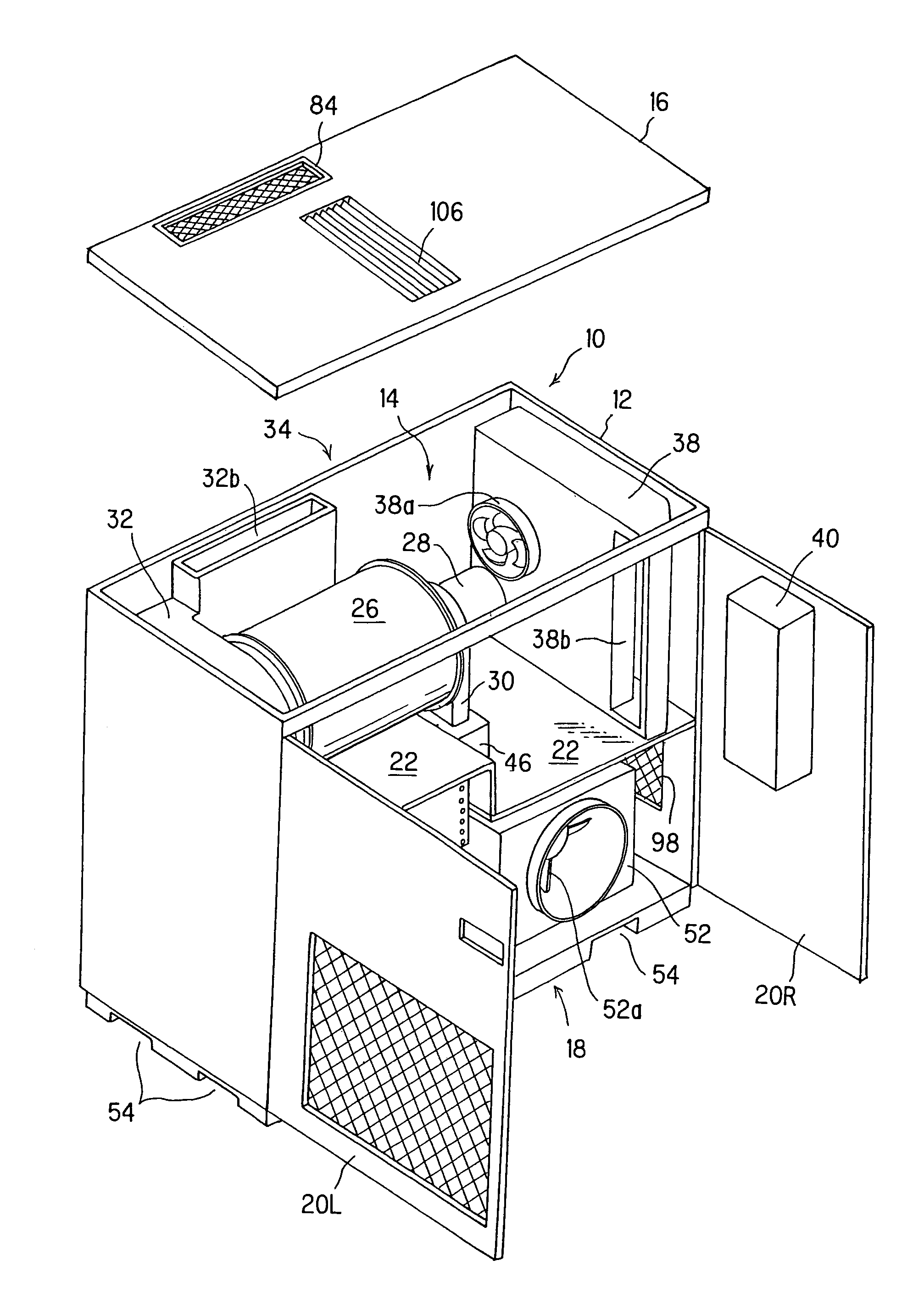

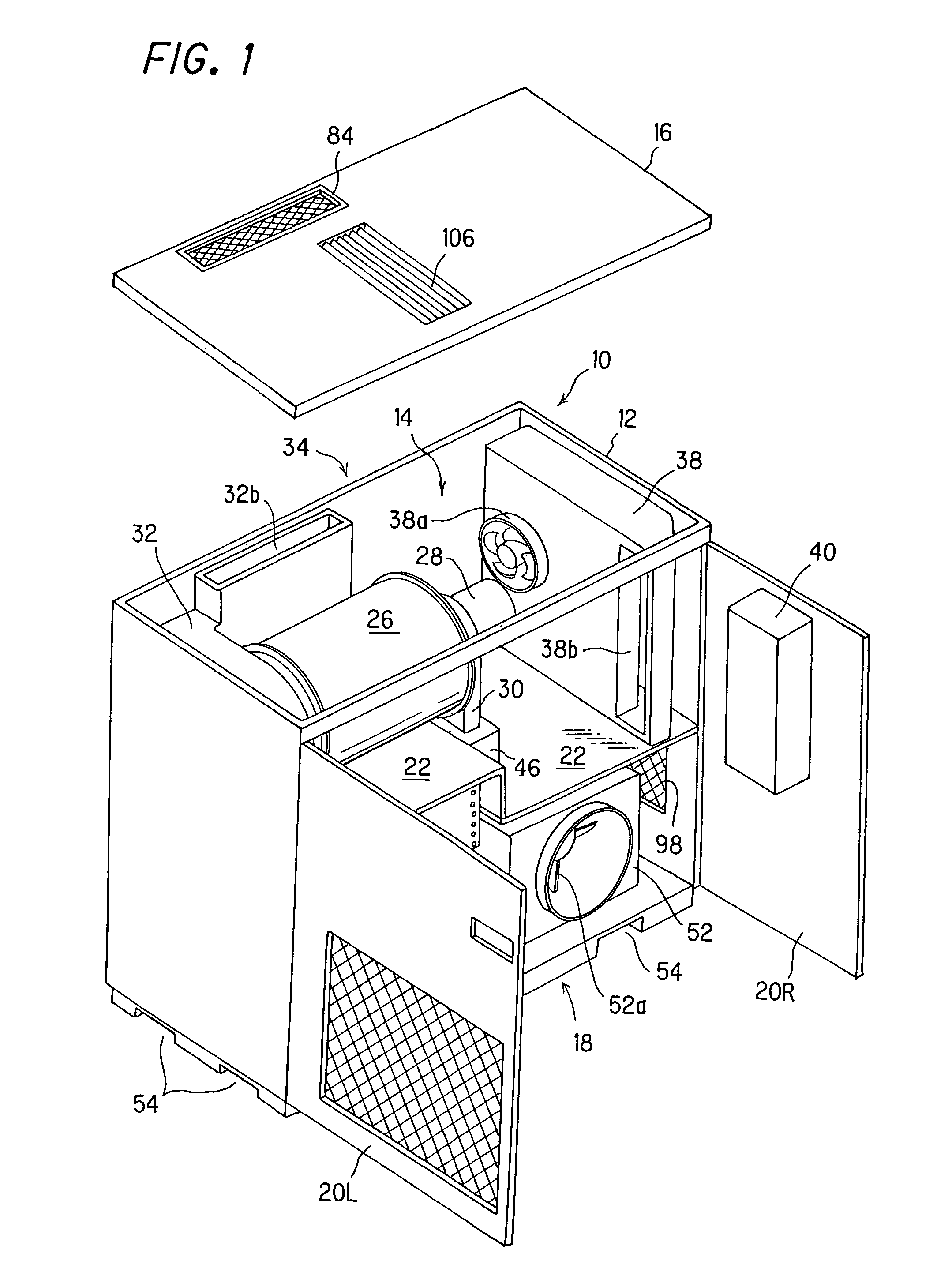

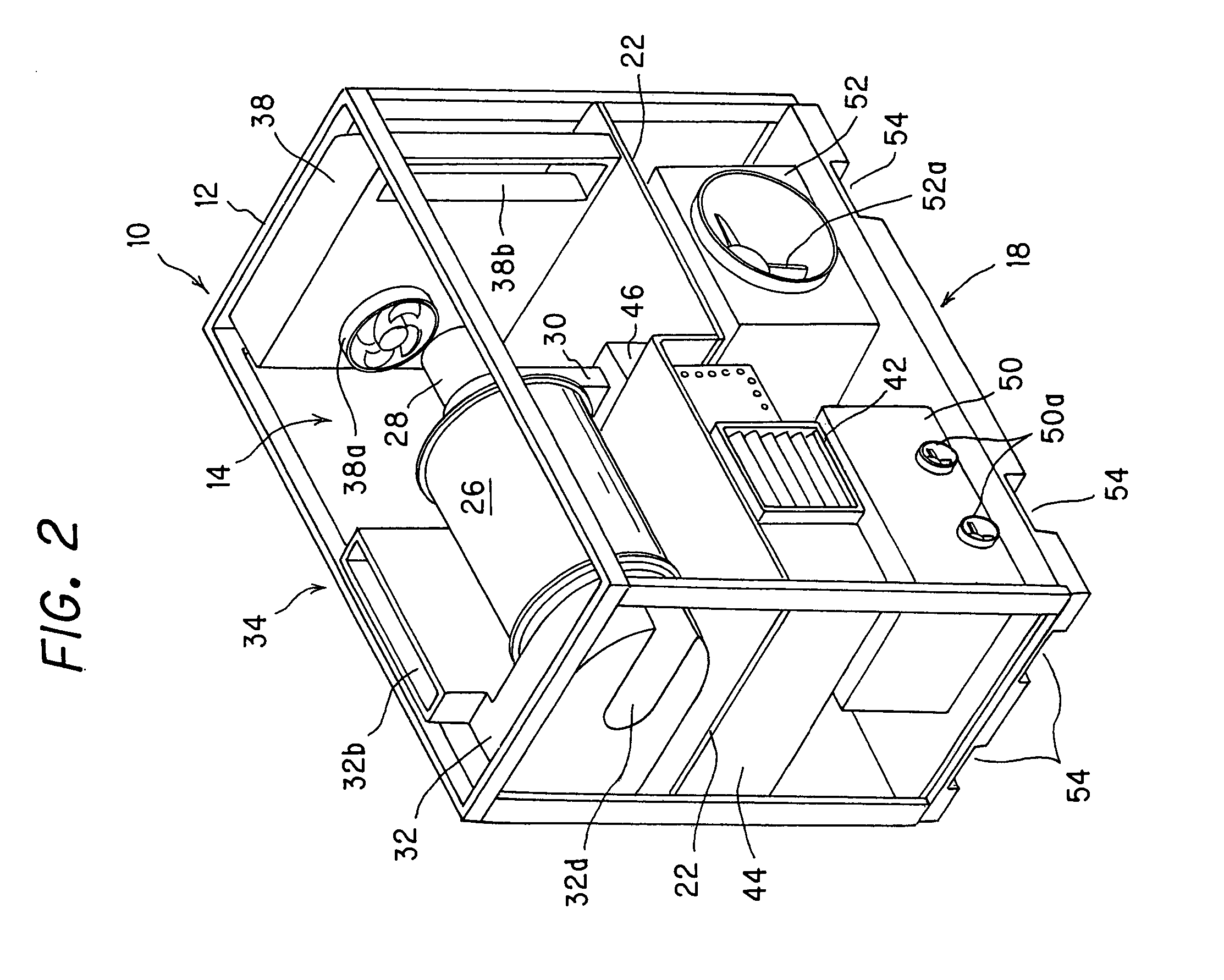

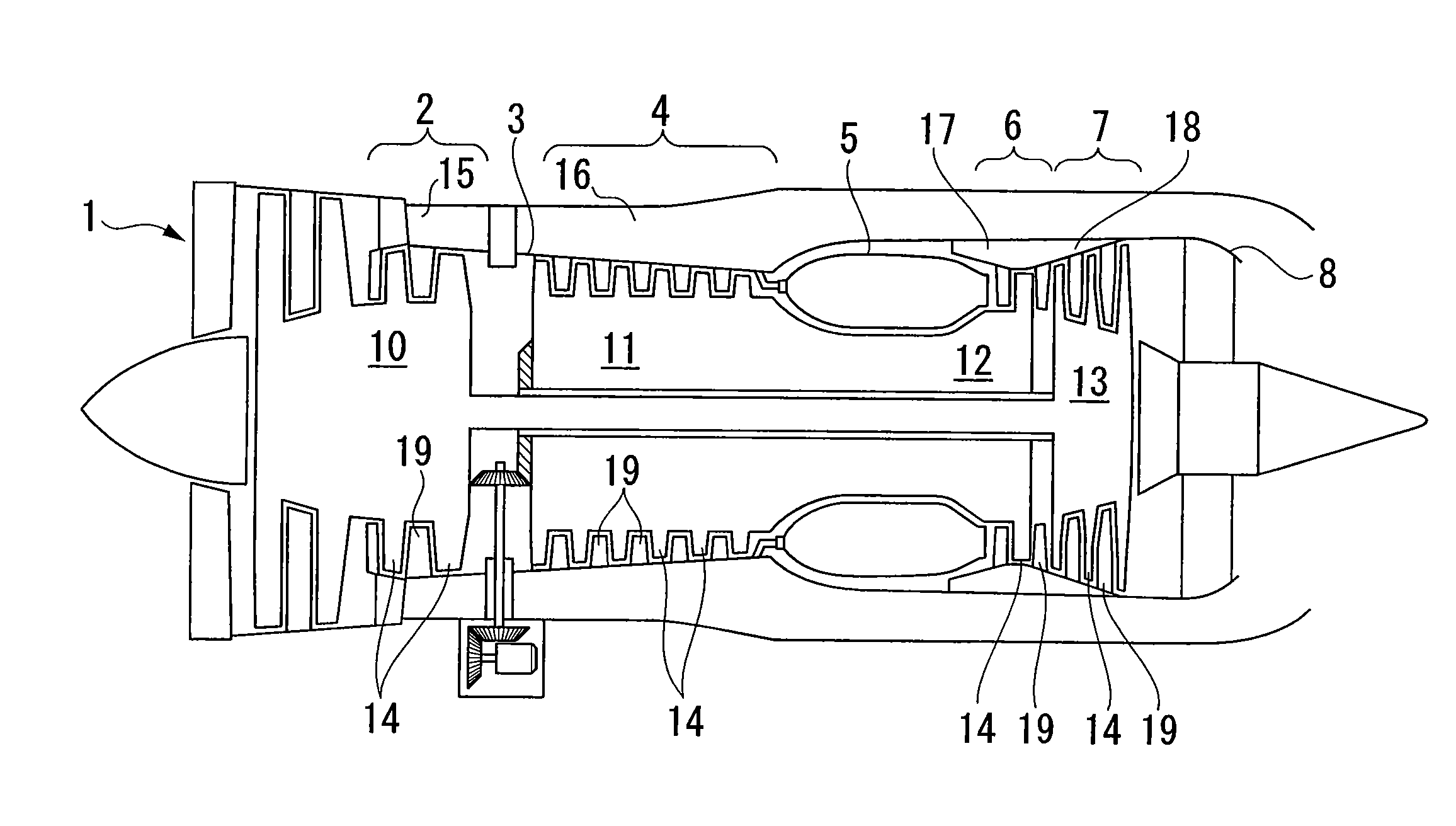

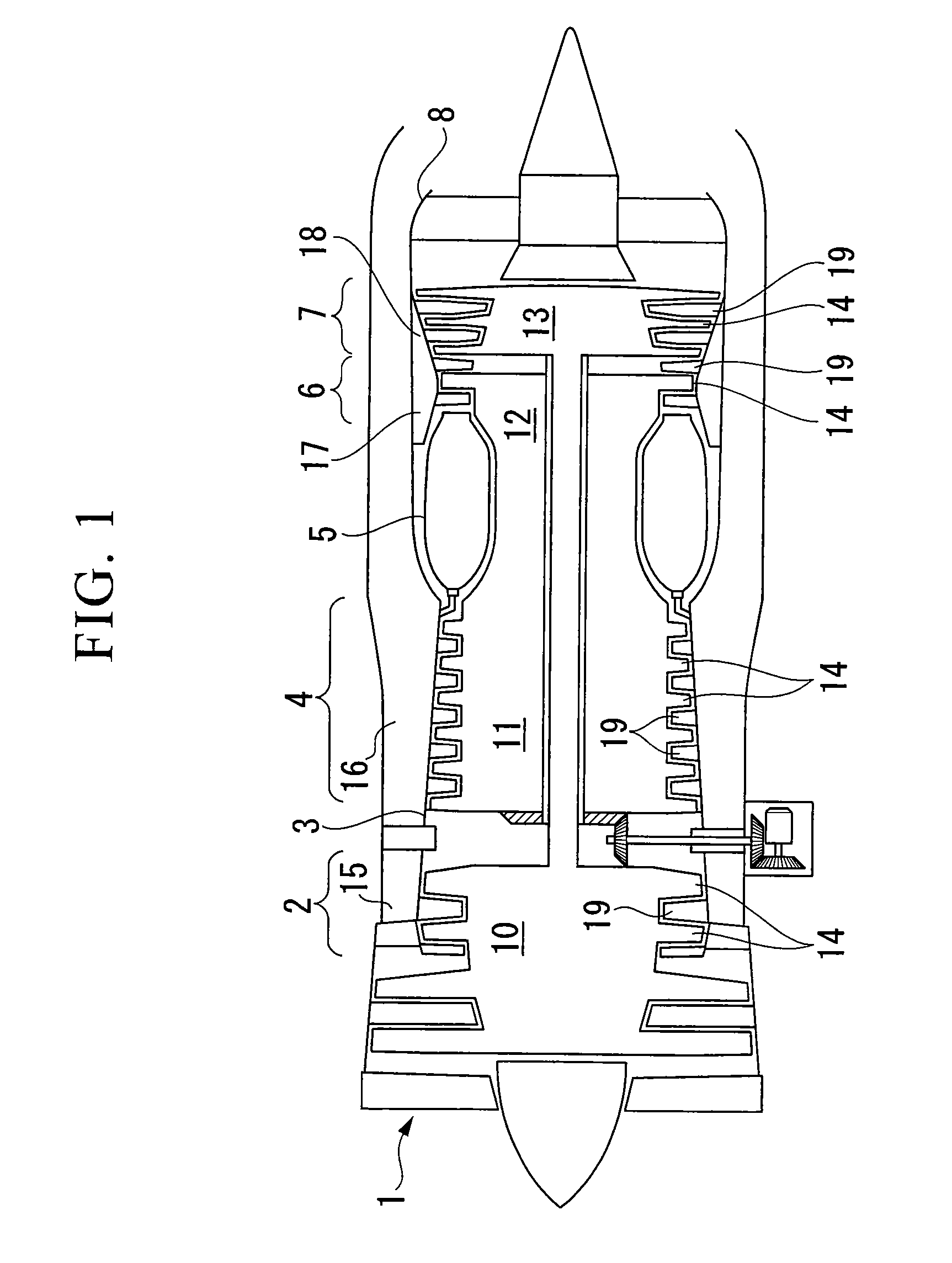

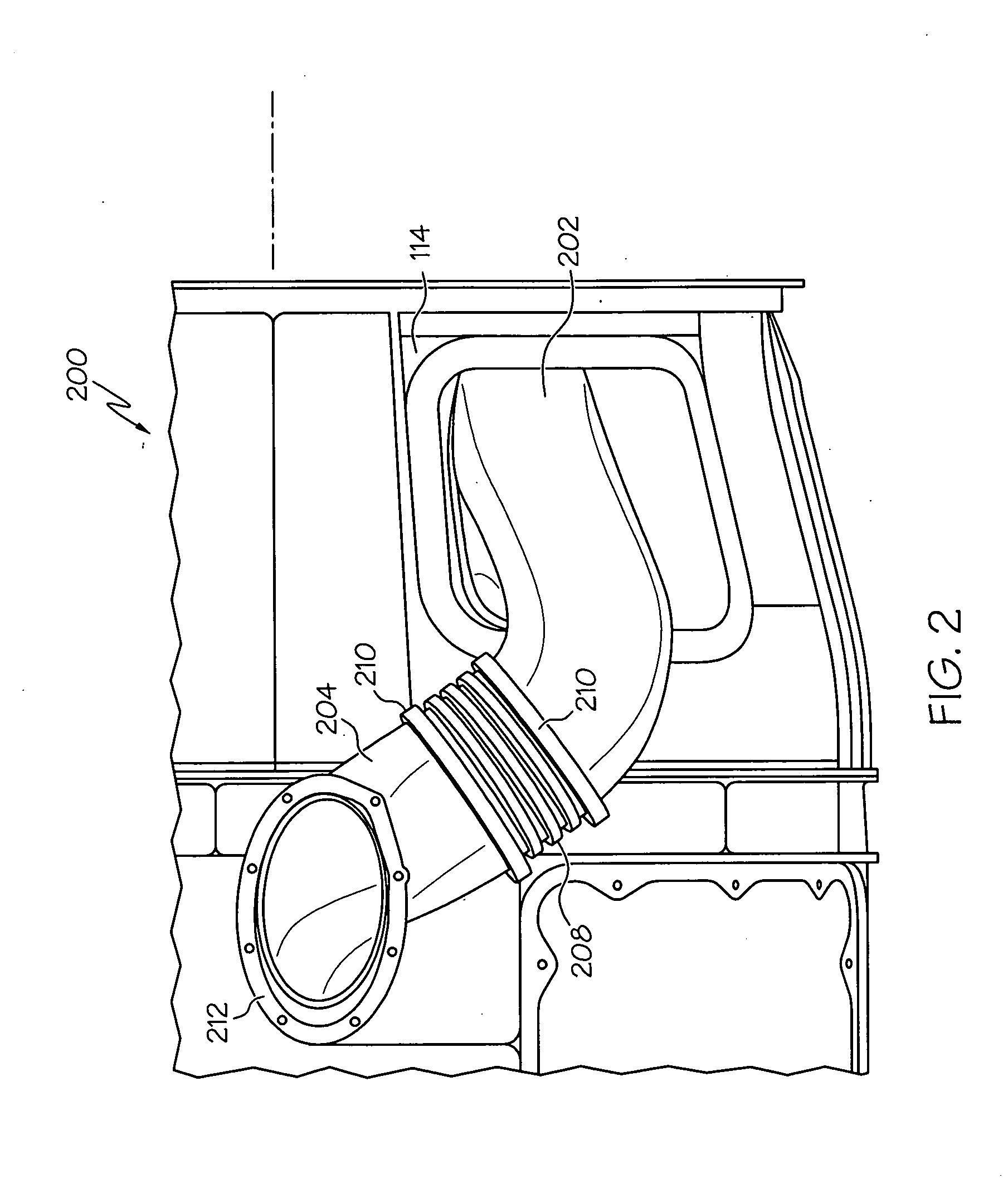

Gas turbine power generation system

InactiveUS6962057B2Reduce dedicated installation spaceFacilitate air filter replacementPortable framesMagnetic circuitInterior spaceAir filter

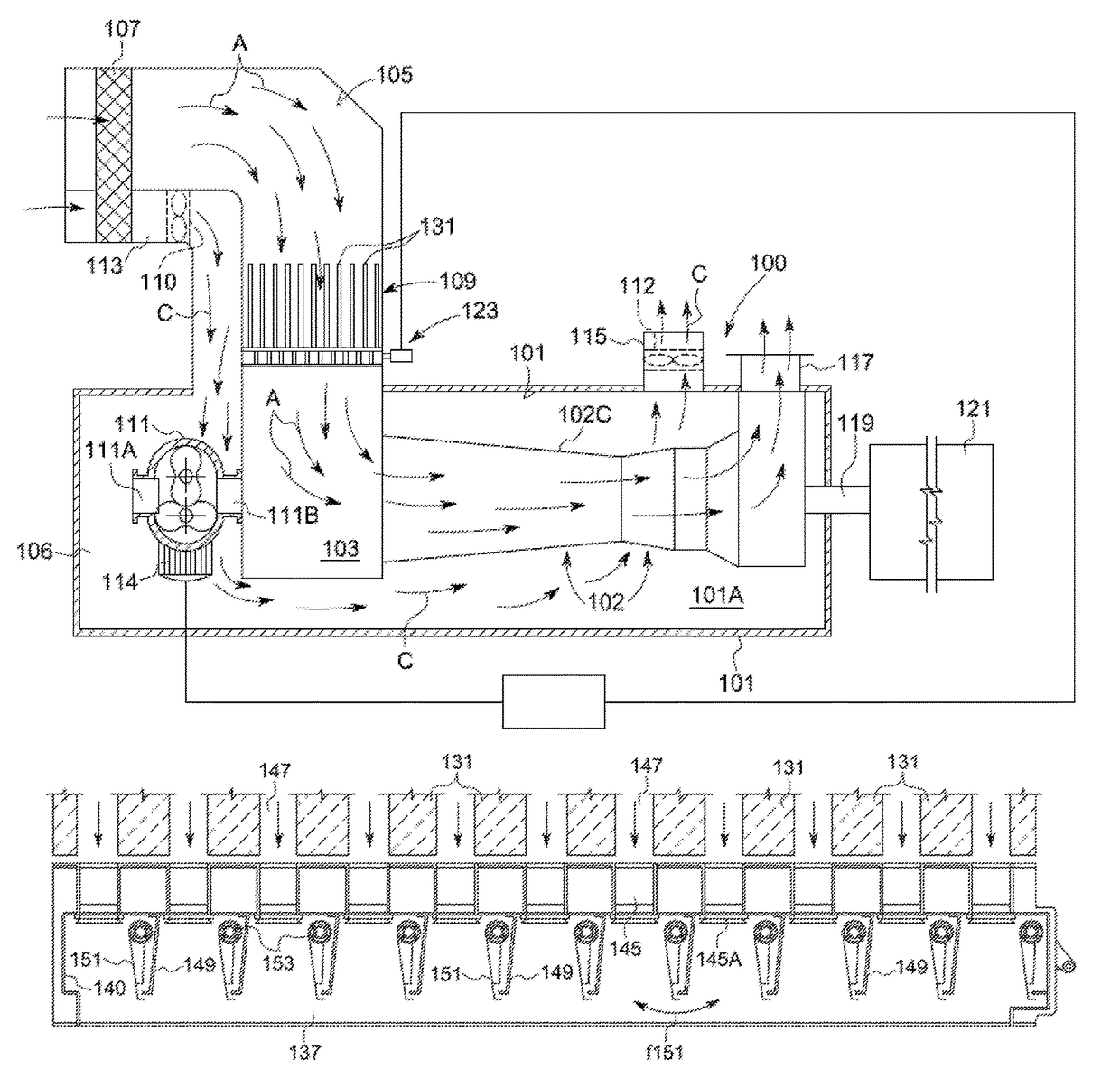

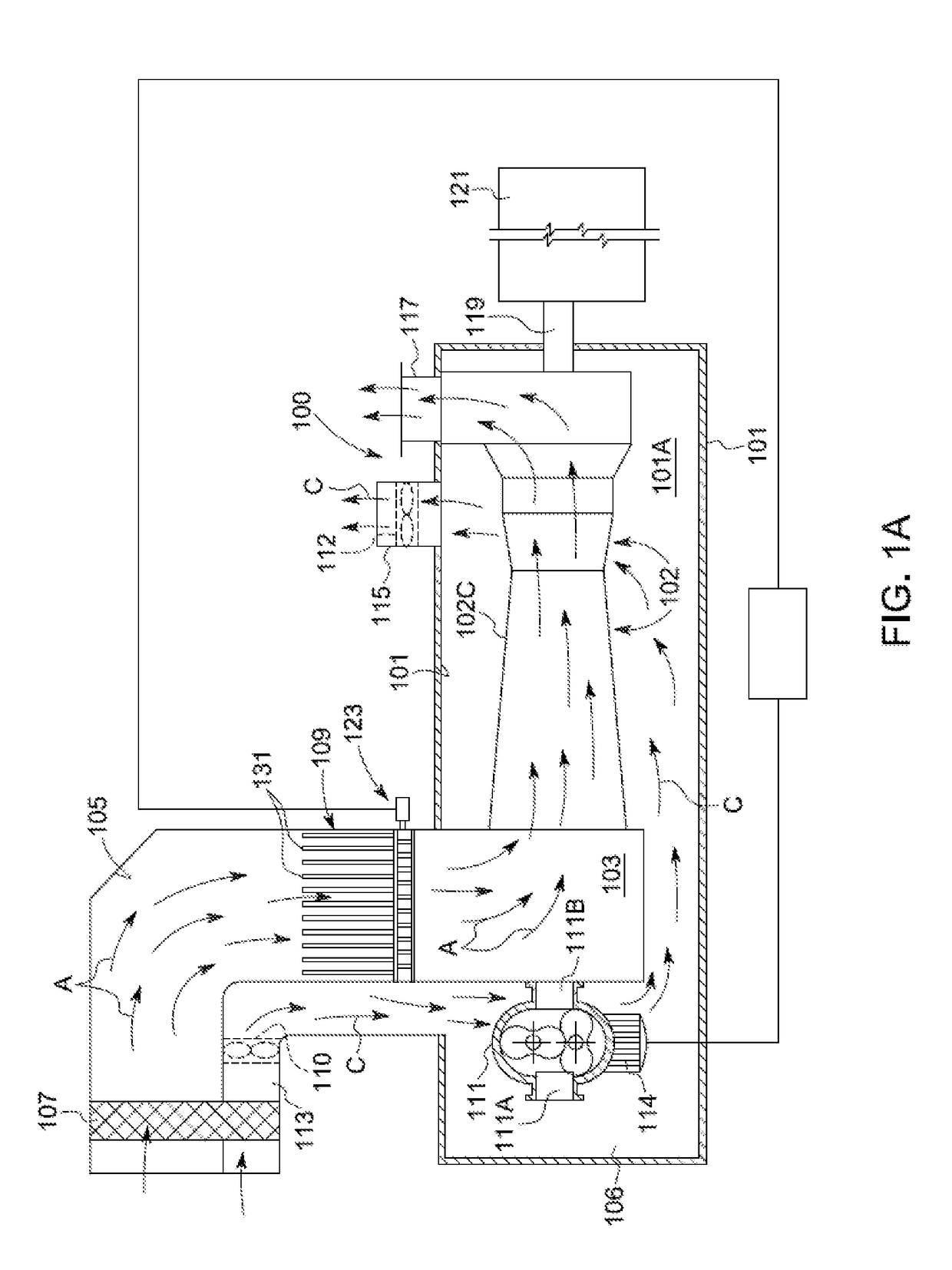

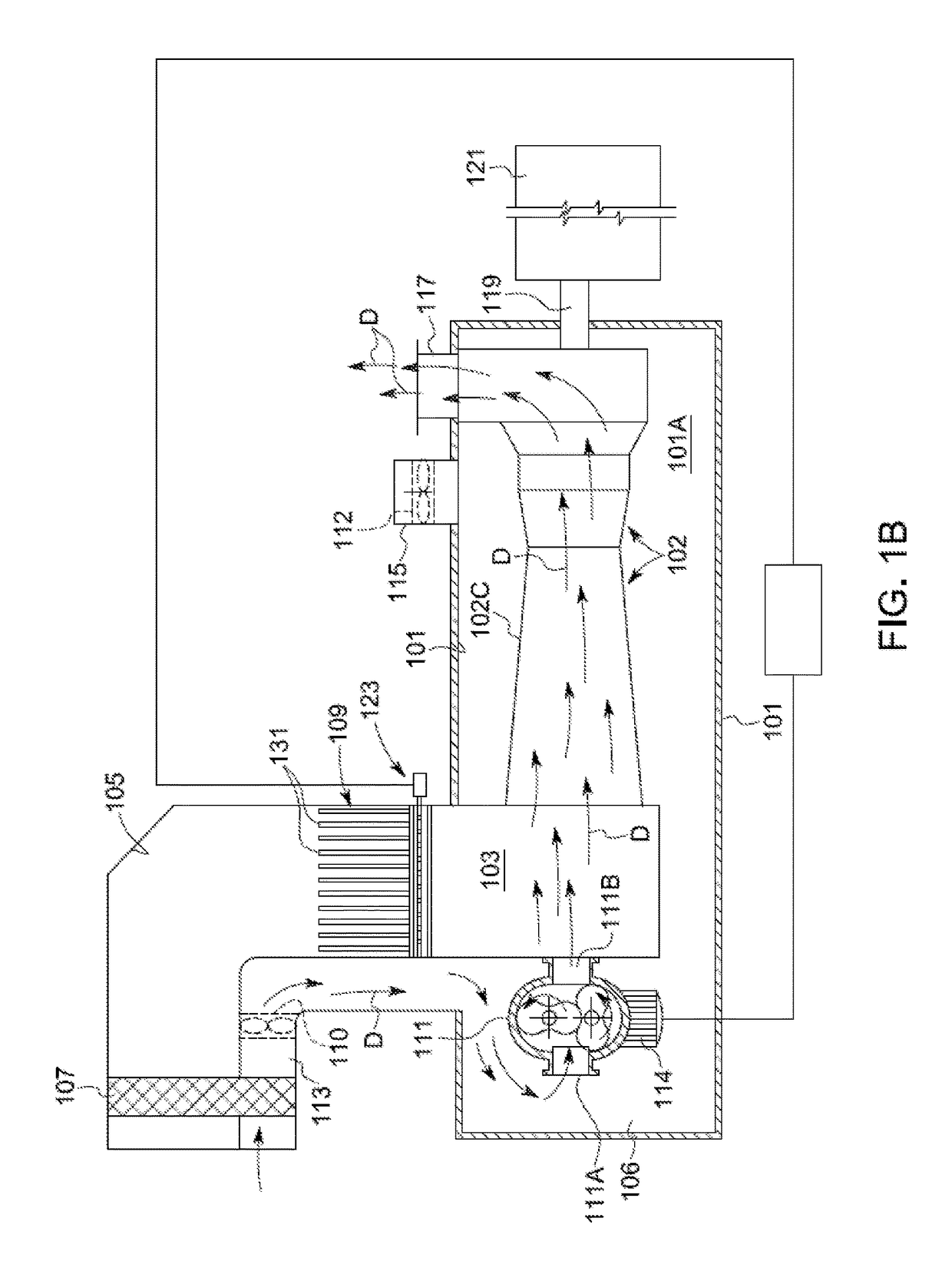

In a gas turbine power generation system having a gas turbine engine and a generator connected to the engine, maintenance ease is enhanced by forming the housing to have openable maintenance faces at two of its faces. Installation space is reduced and a compact configuration is achieved by providing a partition that divides the interior space of the housing into two regions into an upper bay and a lower bay, mounting the engine in the upper bay and mounting air intake duct in the lower bay at a location directly under the engine. Noise is reduced by using a partition to define two separate spaces (bays) and mounting the engine and the air intake duct in the upper and lower bays. Noise is also reduced by preventing engine rotation noise from escaping to the outside through the air intake duct. Moreover, it achieves a reduction in the amount of dedicated space required by constituting the air intake duct of a duct section having an air inlet at a plane coincident with that of the maintenance opening and a filter-housing section for removably housing an air filter, thereby enabling a common space to be utilized for that required in front of the maintenance opening and the air inlet.

Owner:HONDA MOTOR CO LTD

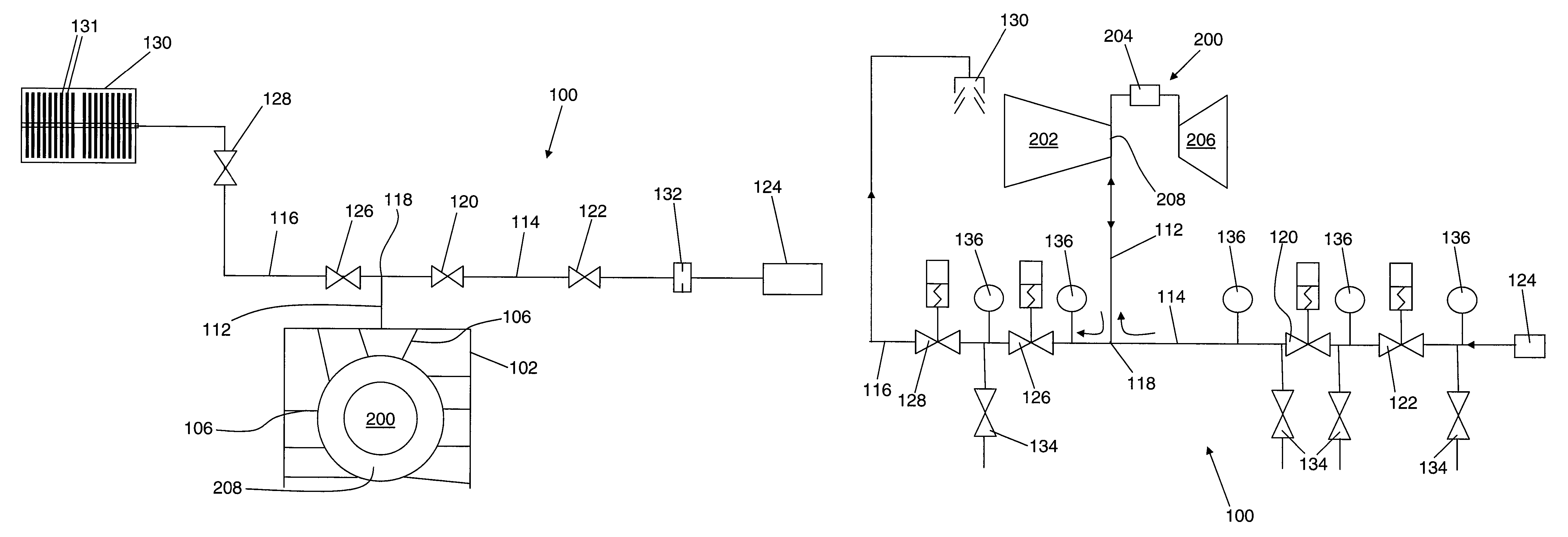

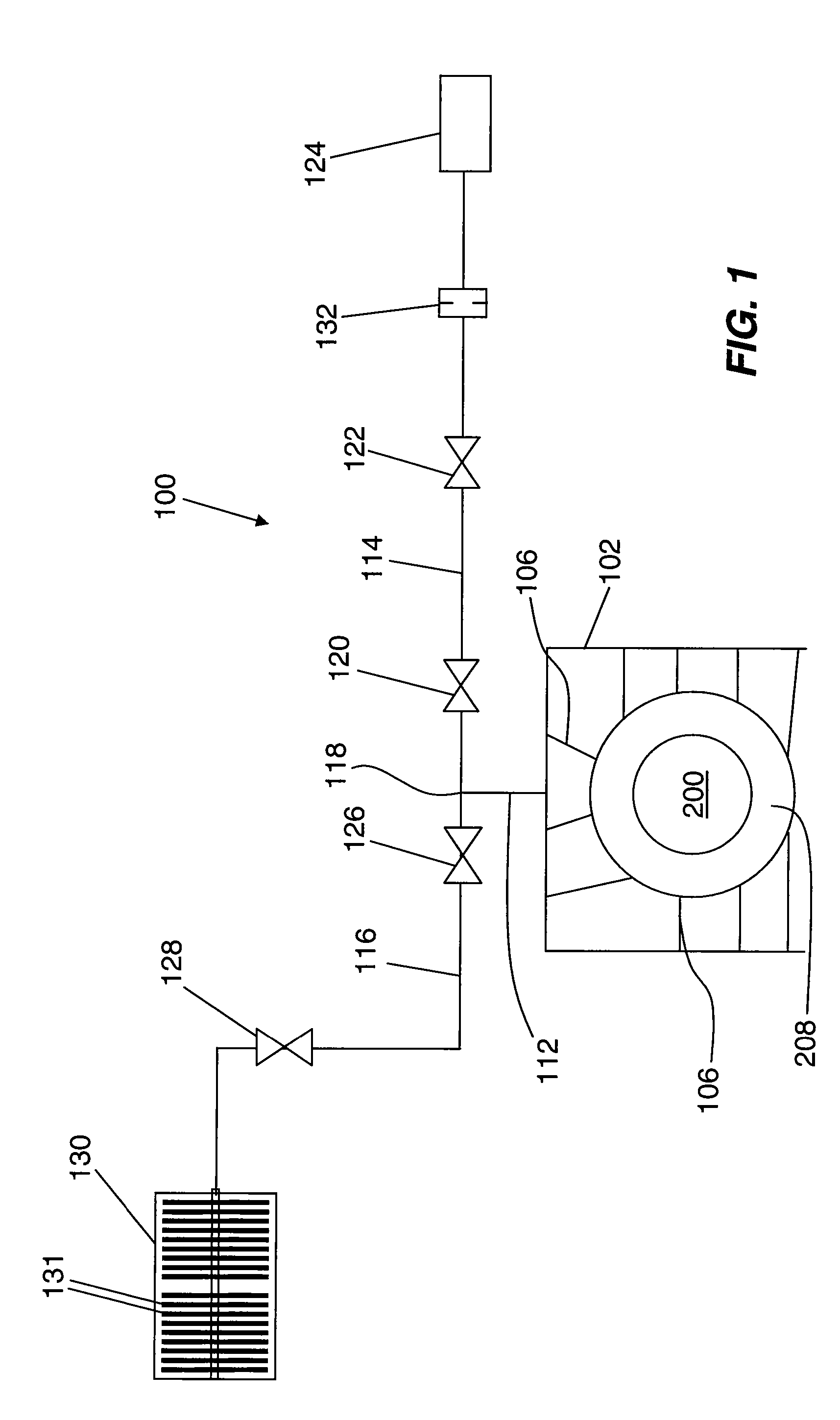

Inlet bleed heat and power augmentation for a gas turbine engine

ActiveUS7841186B2Gas turbine plantsTurbine/propulsion air intakesProcess engineeringAugmentation system

An inlet bleed heat and power augmentation system utilizing a bi-directional and common piping arrangement is disclosed. The piping arrangement includes a plurality of feed tubes arranged to communicate either steam to a compressor discharge plenum or compressed air from the compressor discharge plenum. Various embodiments of the invention are discussed including operation methods.

Owner:ANSALDO ENERGIA SWITZERLAND AG

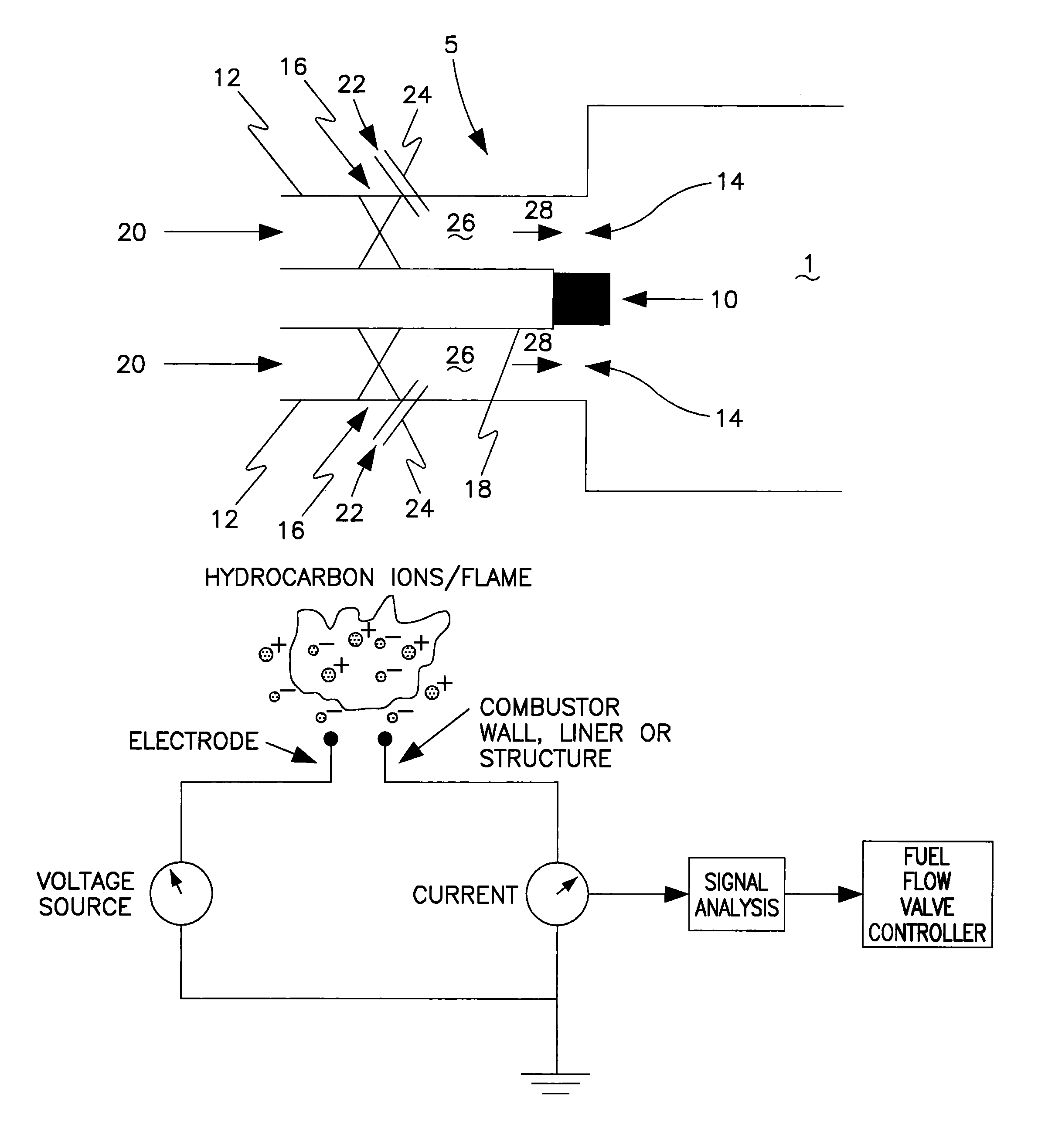

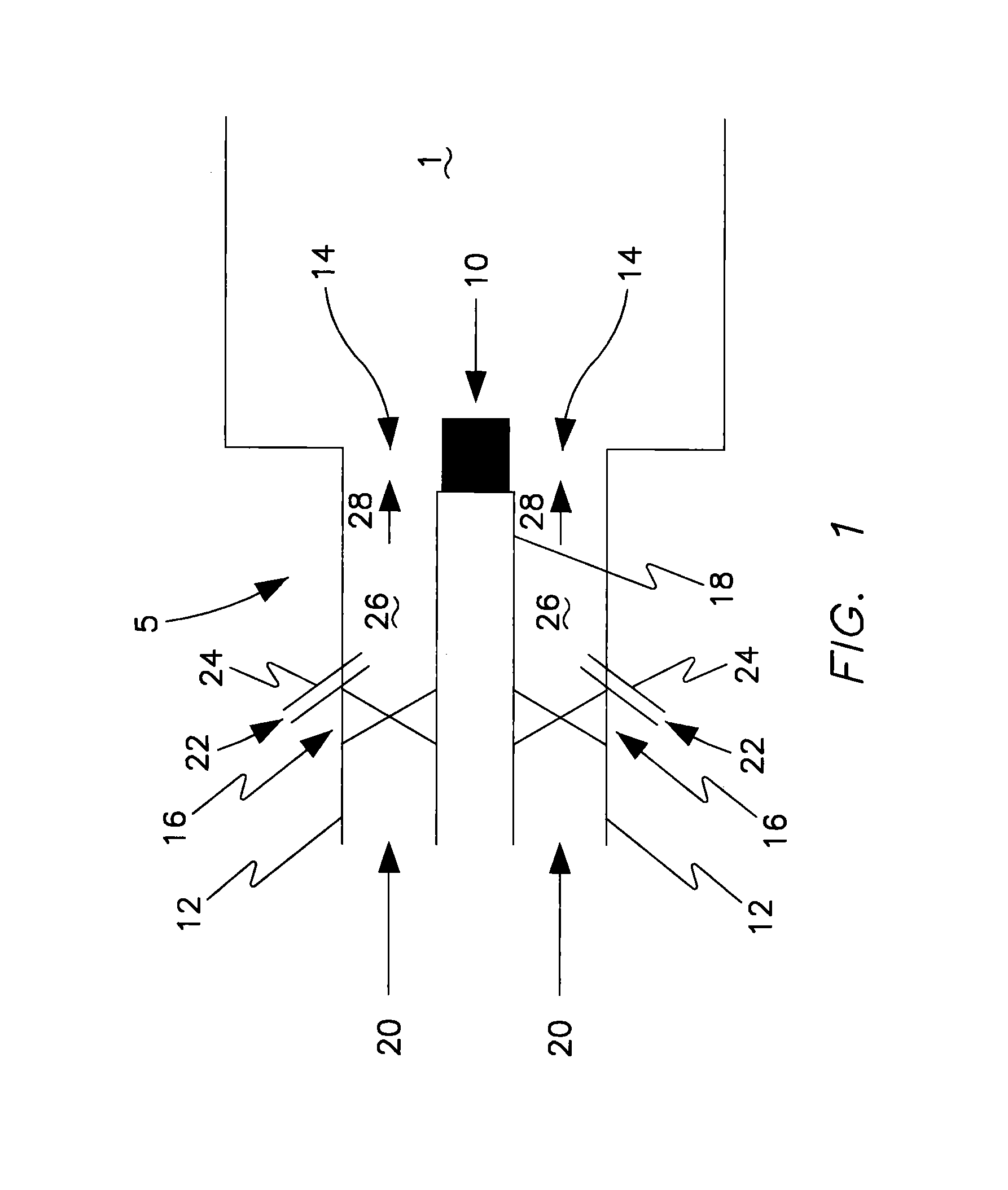

Lean blowoff detection sensor

InactiveUS7197880B2Readily incorporated into burnerMinimal modificationTurbine/propulsion engine ignitionTurbine/propulsion engine startersCombustionEngineering

Apparatus and method for detecting incipient lean blowoff conditions in a lean premixed combustion nozzle of a gas turbine. A sensor near the flame detects the concentration of hydrocarbon ions and / or electrons produced by combustion and the concentration monitored as a function of time are used to indicate incipient lean blowoff conditions.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

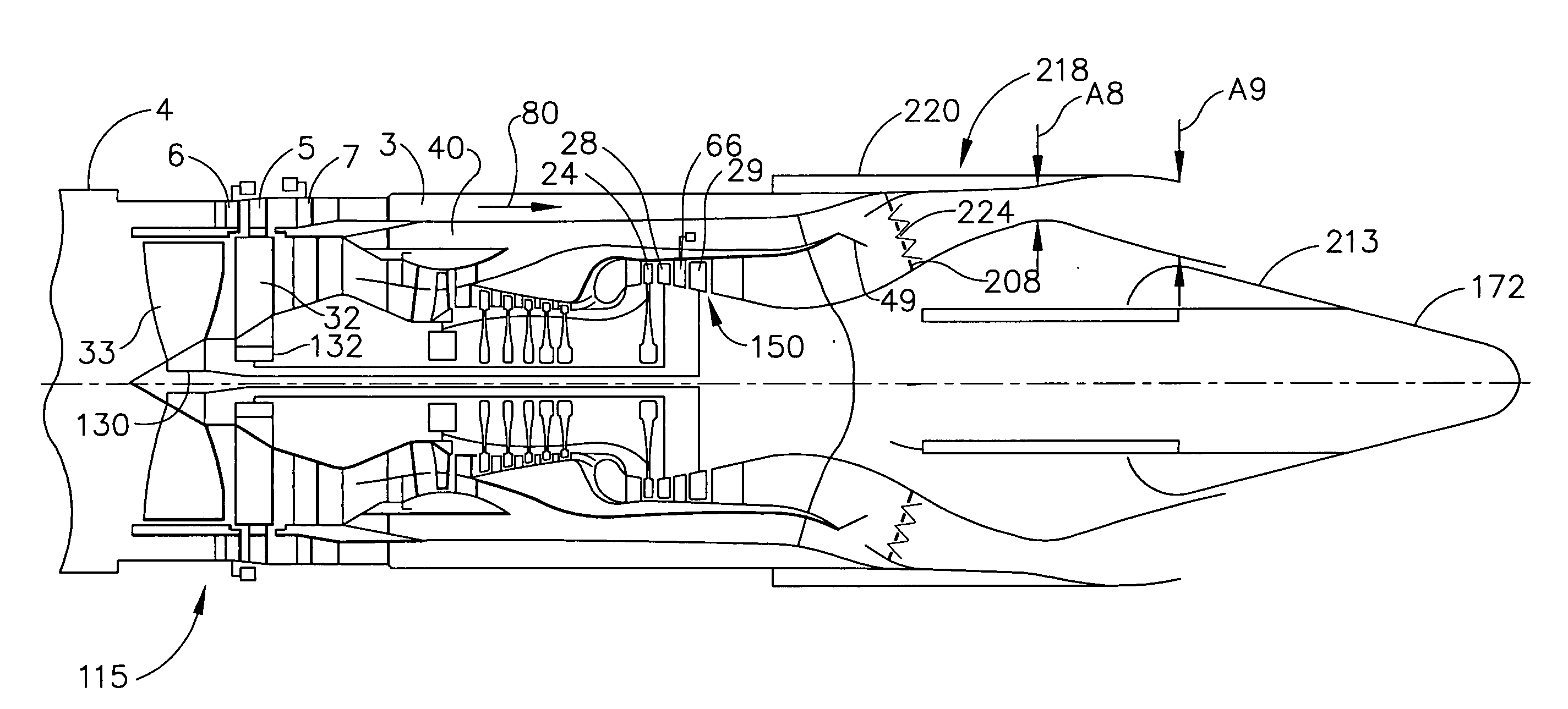

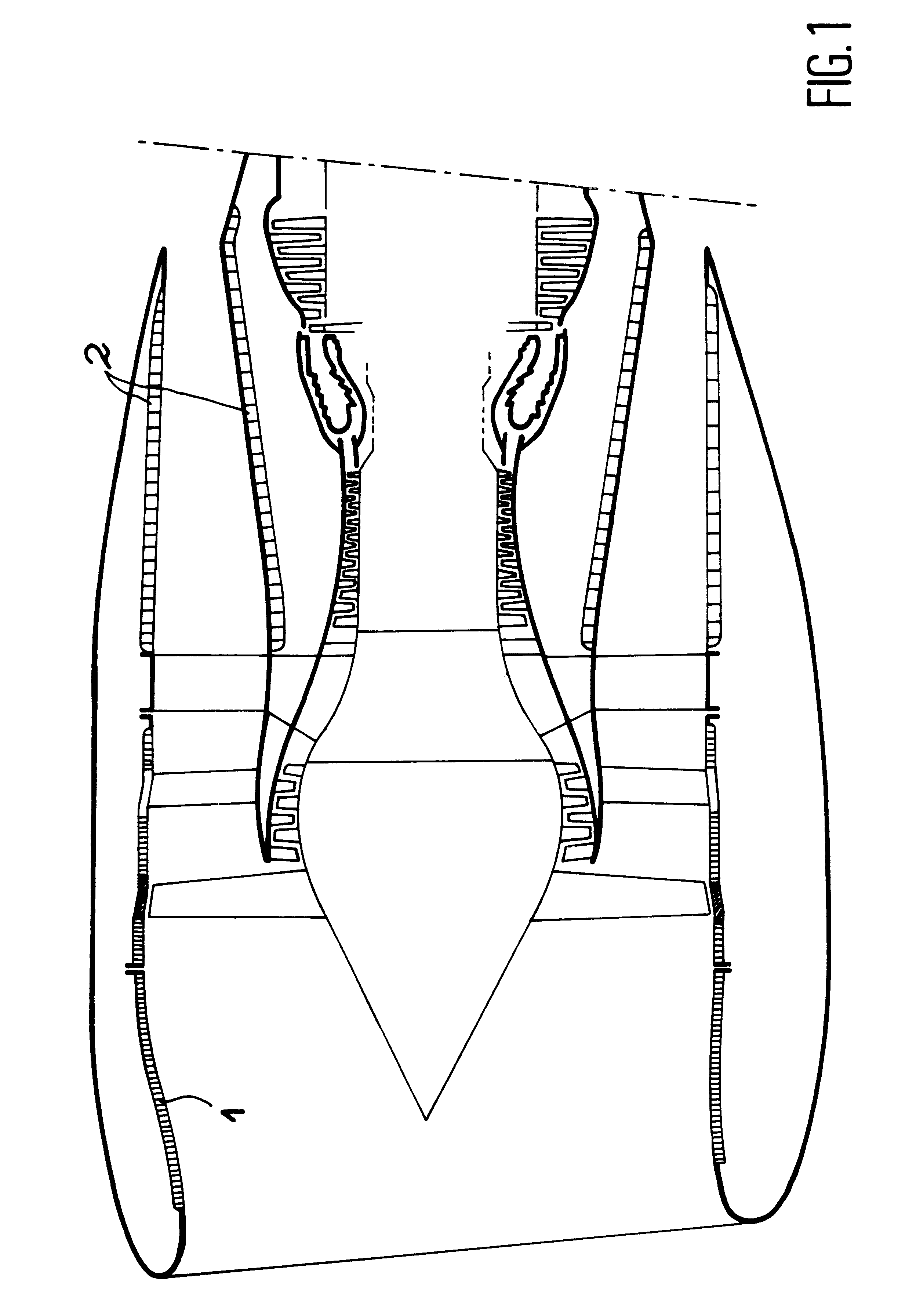

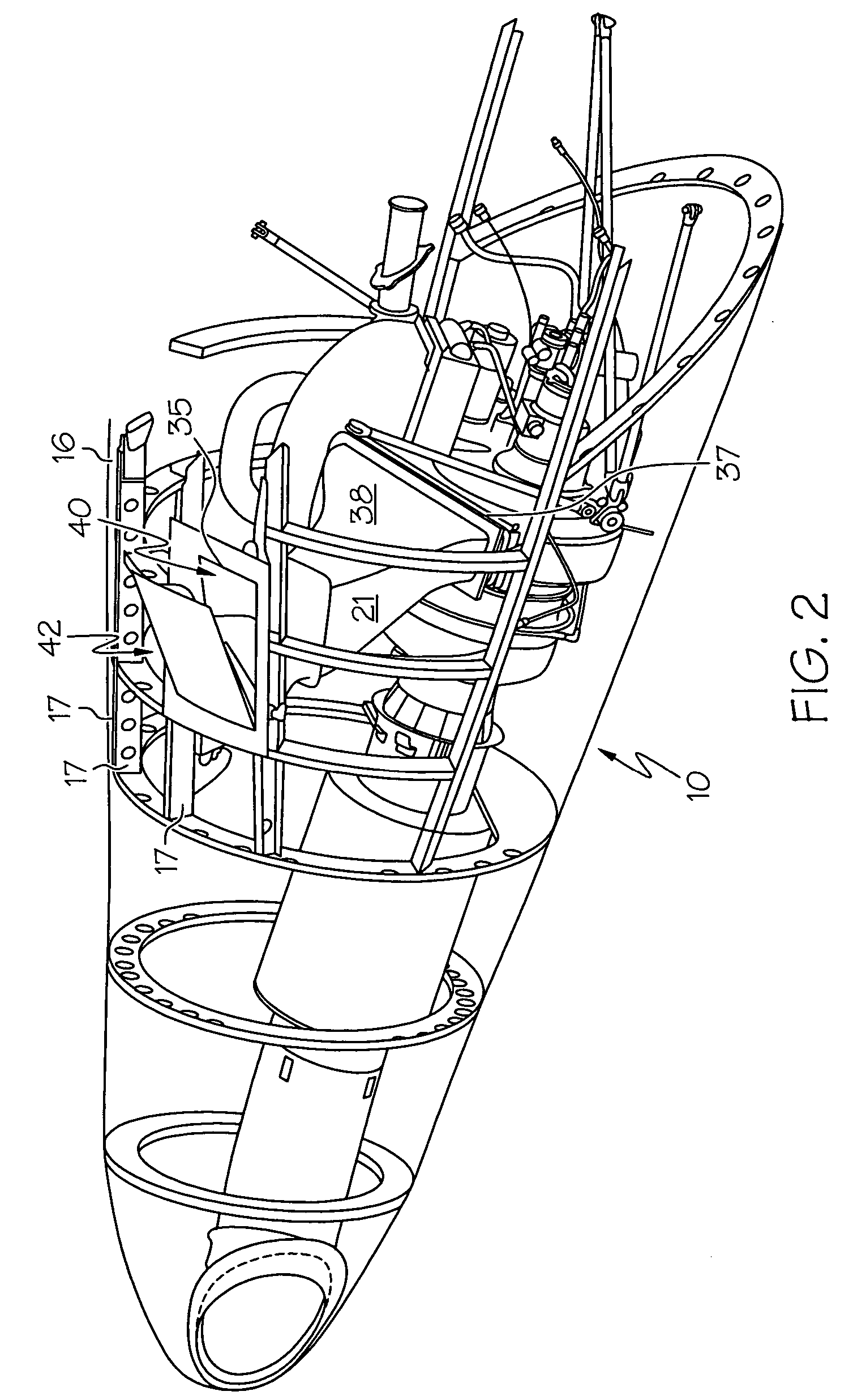

Flade gas turbine engine with fixed geometry inlet

ActiveUS20050081509A1Low costAvoid weightTurbine/propulsion engine coolingTurbine/propulsion air intakesFan bladeGas turbines

An aircraft propulsion system includes a gas turbine engine having a fan section, at least one row of FLADE fan blades disposed radially outwardly of and drivingly connected to the fan section, the row of FLADE fan blades radially extending across a FLADE duct circumscribing the fan section, an engine inlet including a fan inlet to the fan section and an annular FLADE inlet to the FLADE duct. A fixed geometry inlet duct is in direct flow communication with the engine inlet. The fan section may include only a single direction of rotation fan or alternatively axially spaced apart first and second counter-rotatable fans in which the FLADE fan blades are drivingly connected to one of the first and second counter-rotatable fans. The row of FLADE fan blades may be disposed between rows of variable first and second FLADE vanes.

Owner:GENERAL ELECTRIC CO

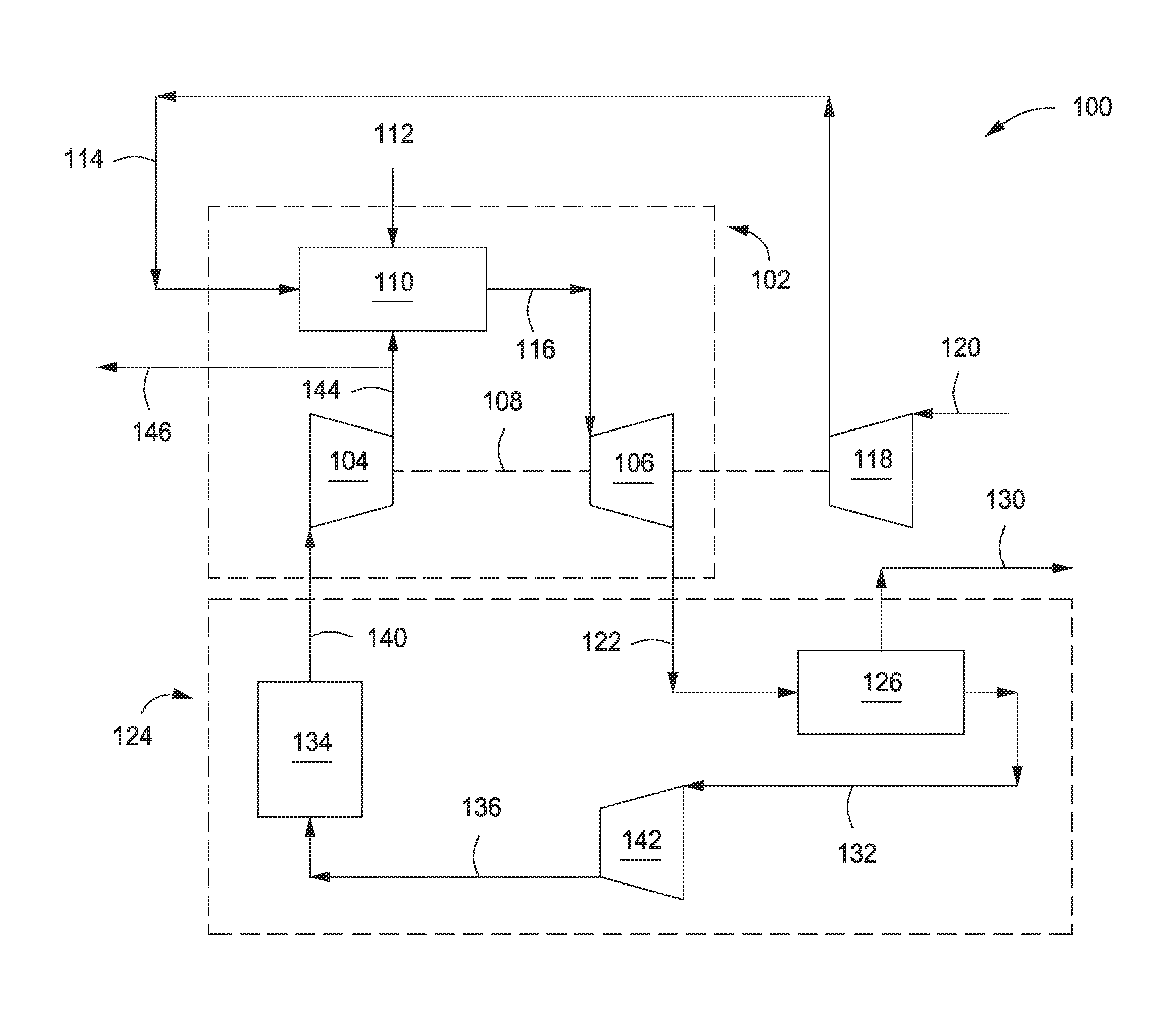

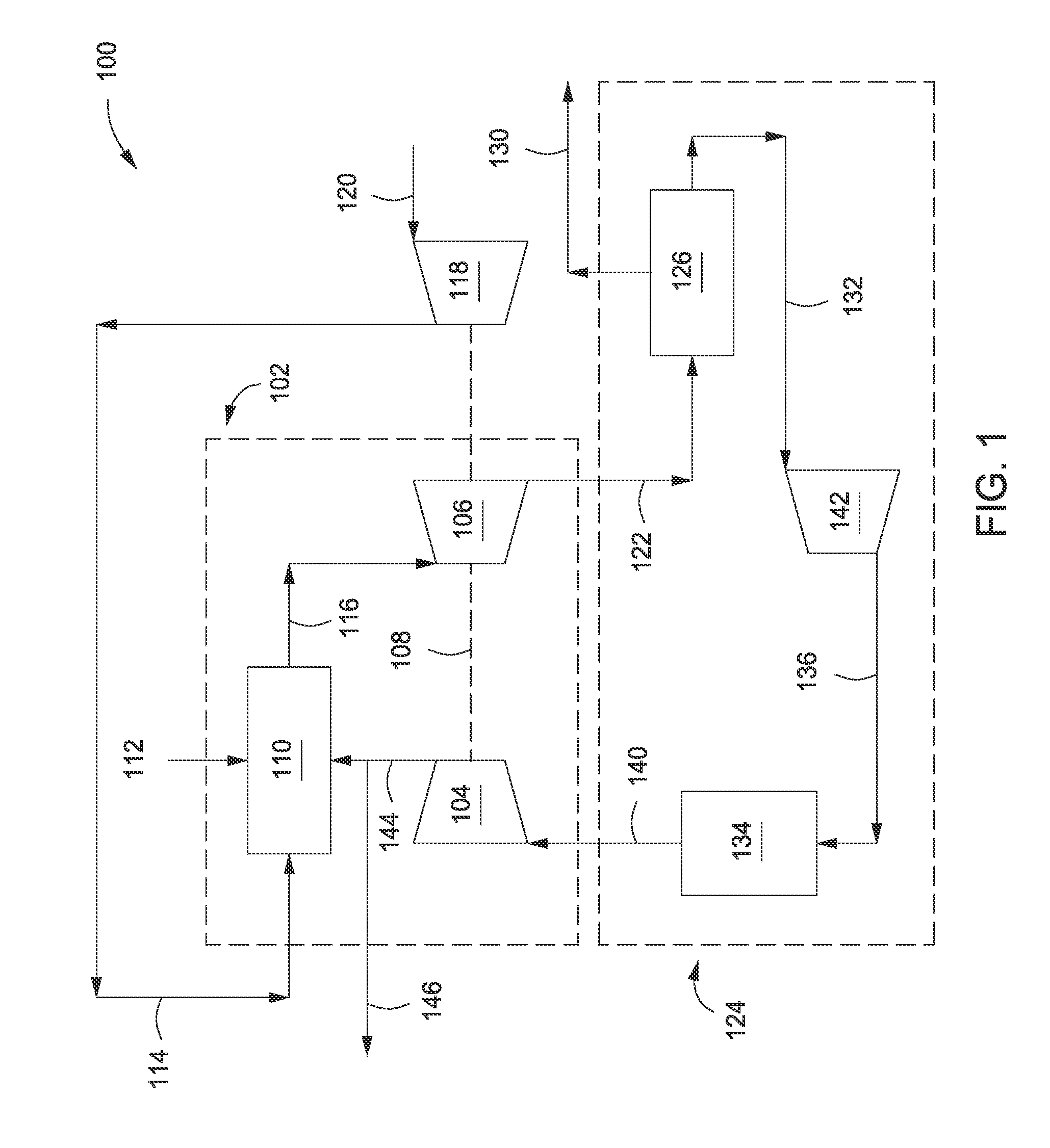

Low Emission Turbine Systems Incorporating Inlet Compressor Oxidant Control Apparatus And Methods Related Thereto

InactiveUS20140000273A1Promote recoveryEfficient propulsion technologiesGas turbine plantsCombustion chamberTurbine

Systems, methods, and apparatus are provided for controlling the oxidant feed in low emission turbine systems to maintain stoichiometric or substantially stoichiometric combustion conditions. In one or more embodiments, such control is achieved through methods or systems that ensure delivery of a consistent mass flow rate of oxidant to the combustion chamber.

Owner:MITTRICKER FRLIN F +4

Device and method for gas turbine unlocking

ActiveUS9845730B2Shorten the timeReduce downtimePump componentsTurbine/propulsion engine coolingAviationCombustor

An aeroderivative gas turbine including an air intake plenum; a compressor with a compressor air intake in fluid communication with the air intake plenum; a combustor; a high pressure turbine; a power turbine. A forced air-stream generator is arranged in fluid communication with the air intake plenum. A shutter arrangement is provided in a combustion-air flow path, arranged and controlled to close the combustion-air flow path for pressurizing said air intake plenum by means of the forced air-stream generator to a pressure sufficient to cause pressurized air to flow through the aeroderivative air turbine.

Owner:NUOVO PIGNONE TECH SRL

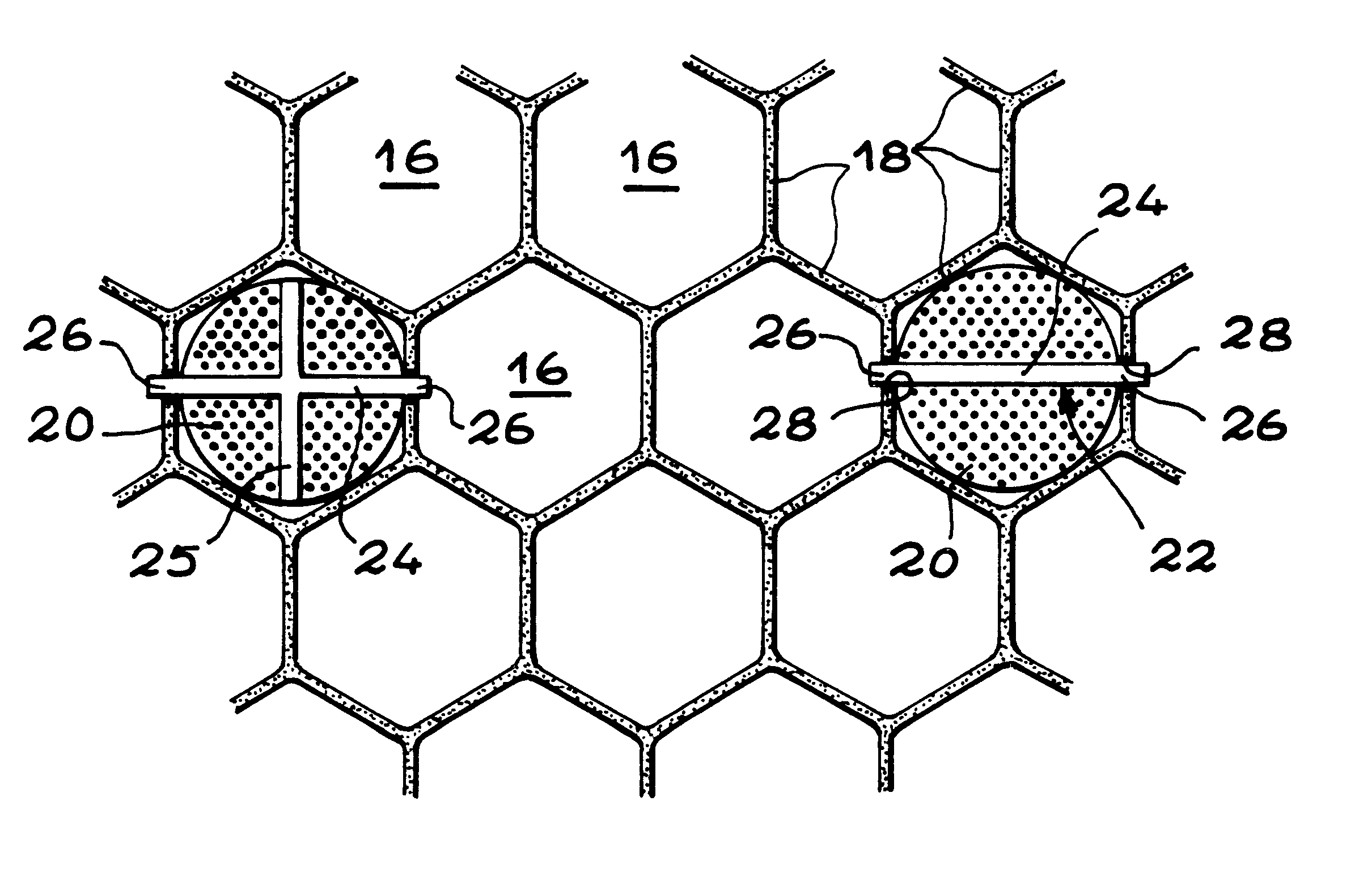

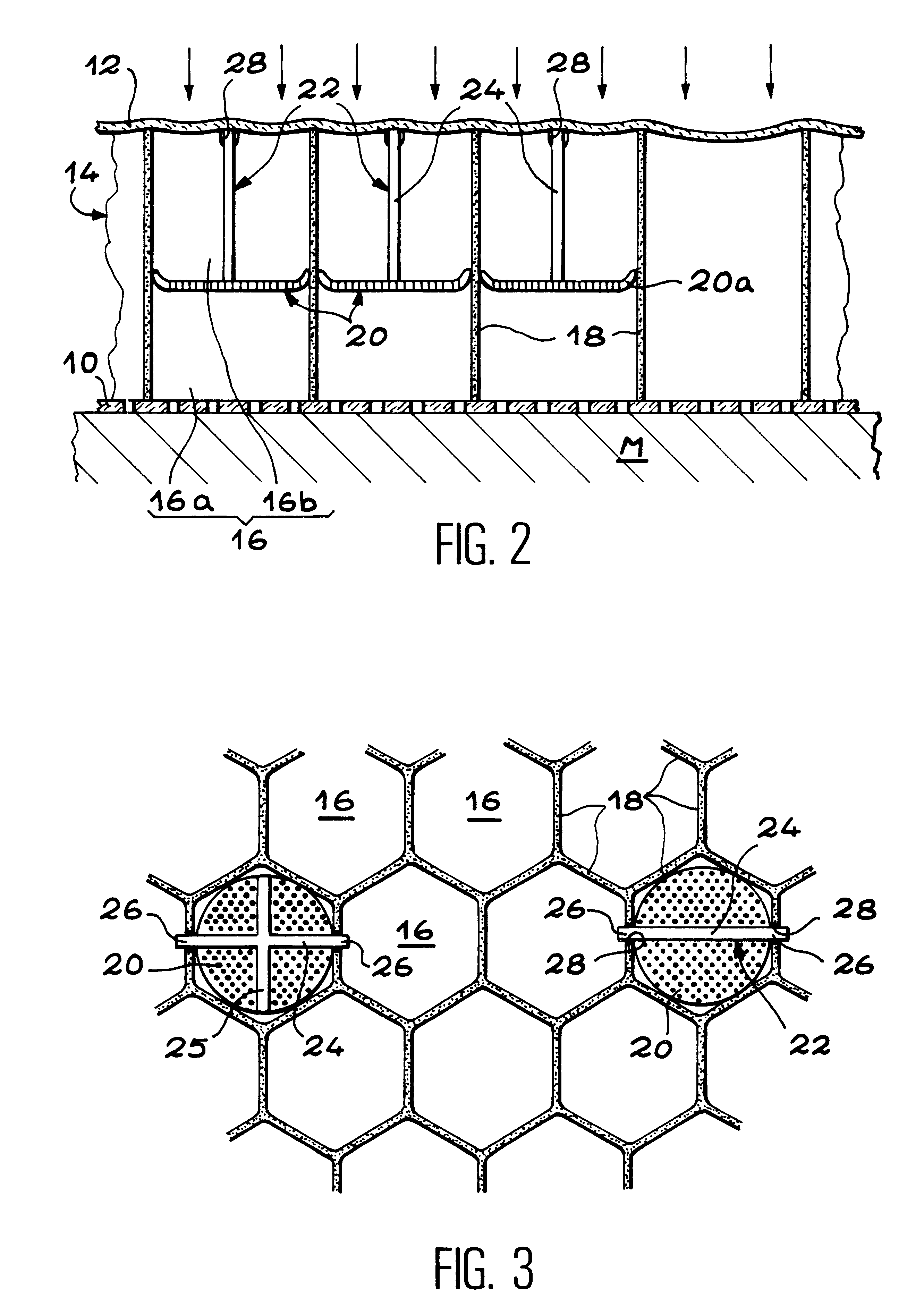

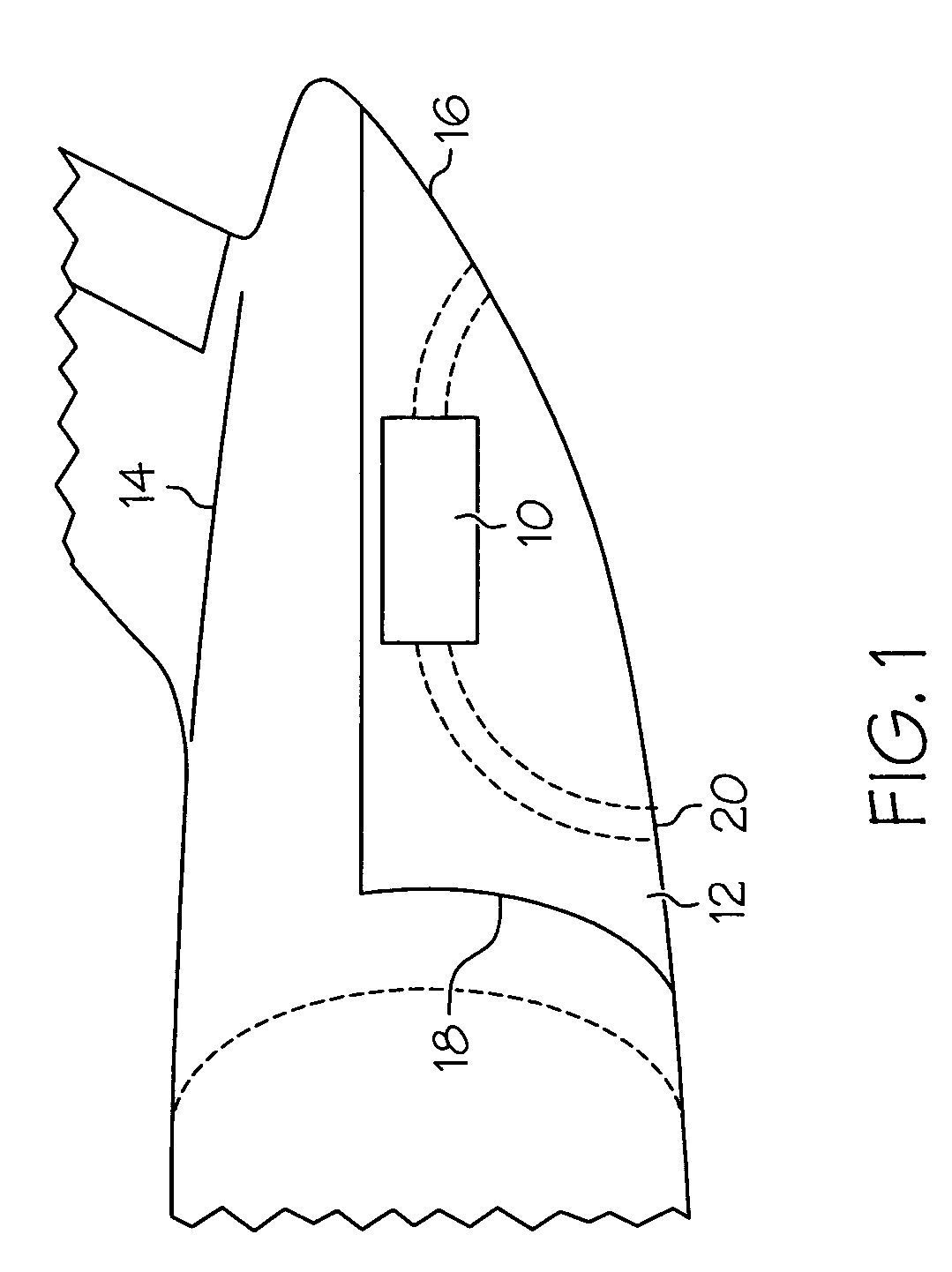

Noise reduction sandwich panel, notably for aircraft turbojet engine

InactiveUS6536556B2Improve suppression propertiesEasy to installCeilingsLayered productsRelative displacementJet engine

Noise reduction sandwich panel, notably for an aircraft turbojet engine.In order to produce a noise reduction sandwich panel having a structure with two degrees of freedom, inserted separative components (20) are placed into the hexagonal cells (16) of the unique waffle core of the panel. More specifically, the separative components (20) have an substantially circular external peripheral edge, which allows them to be easily assembled, in spite of the deformations of the walls (18) of the cells (16) due to manufacturing tolerances and to the optional forming of the waffle core. Advantageously, several separative components (20) are supported by a same positioning unit (22), which then allows relative displacement between the separative components.

Owner:AIRBUS OPERATIONS (SAS)

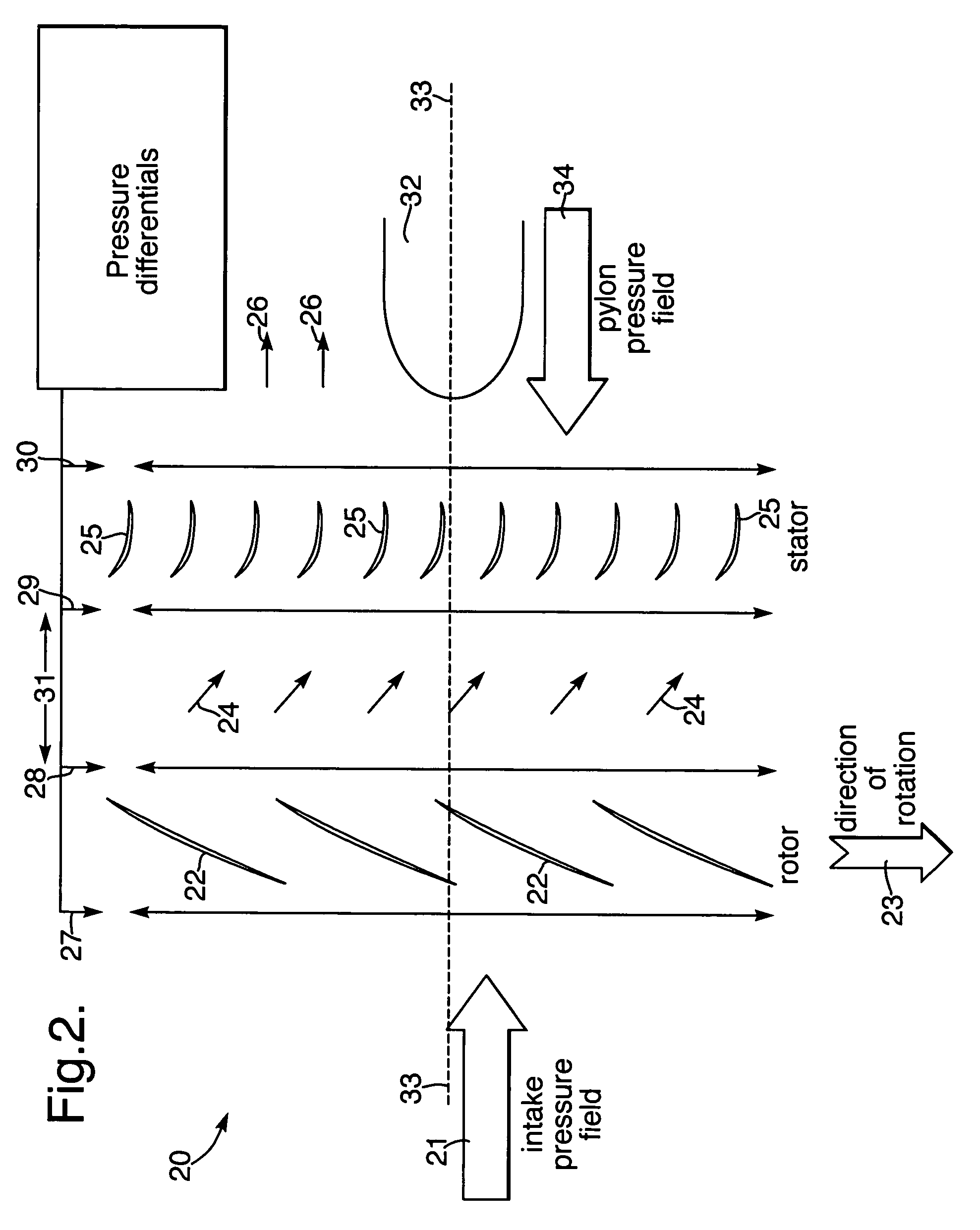

Gas turbine engine including stator vanes having variable camber and stagger configurations at different circumferential positions

Within an intake for a gas turbine engine provision is provided through stator vanes 25, 45 in the stator whereby back pressure from a necessary obstruction 34, 46 can be utilised to balance forward pressure variations caused by intake droop or crosswinds in order to reduce those forward pressure detriments for more efficient engine operation according to a desired objective regime. Typically the flow through the intake 20 is analysed and then an appropriate positioning of the stator vanes 25, 45 determined in order to provide approximate balance between the forward pressures and back pressures. Normally, a combination of camber variation of stator vanes 45a and stagger variation of stator vanes 45b are utilised in order to achieve a desired momentum balance around the circumference of the intake 20. It will be understood that both the forward pressures and the back pressures are differentially variable about the circumference such that one opposes the other.

Owner:ROLLS ROYCE PLC

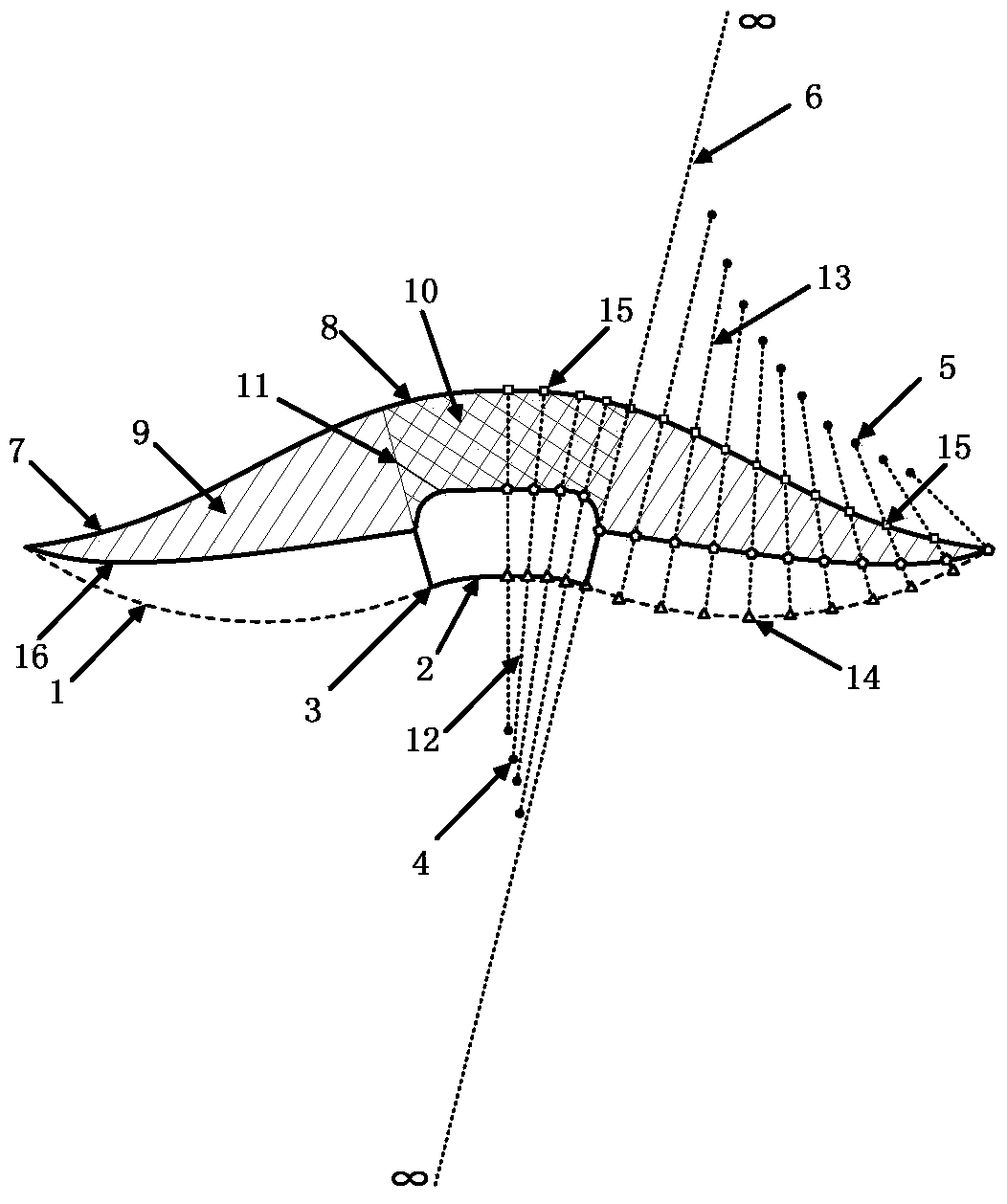

Wall Configuration of Axial-Flow Machine, and Gas Turbine Engine

ActiveUS20070258810A1Reduce lossesImprove performanceEngine manufacturePump componentsLeading edgeEngineering

A wall configuration of an axial-flow machine which can reduce the secondary flow loss is provided. A trough is formed between a blade and another blade in the blade row and extends in at least an axial direction of the blade row. The region where the trough is formed is axially between a leading edge and a trailing edge of the blade. A center line of the trough has a curvature in the same direction as a camber line of the blade. A maximum amplitude of the trough is located adjacent to an axial center of the blade or located axially between the axial center and the leading edge of the blade.

Owner:IHI CORP

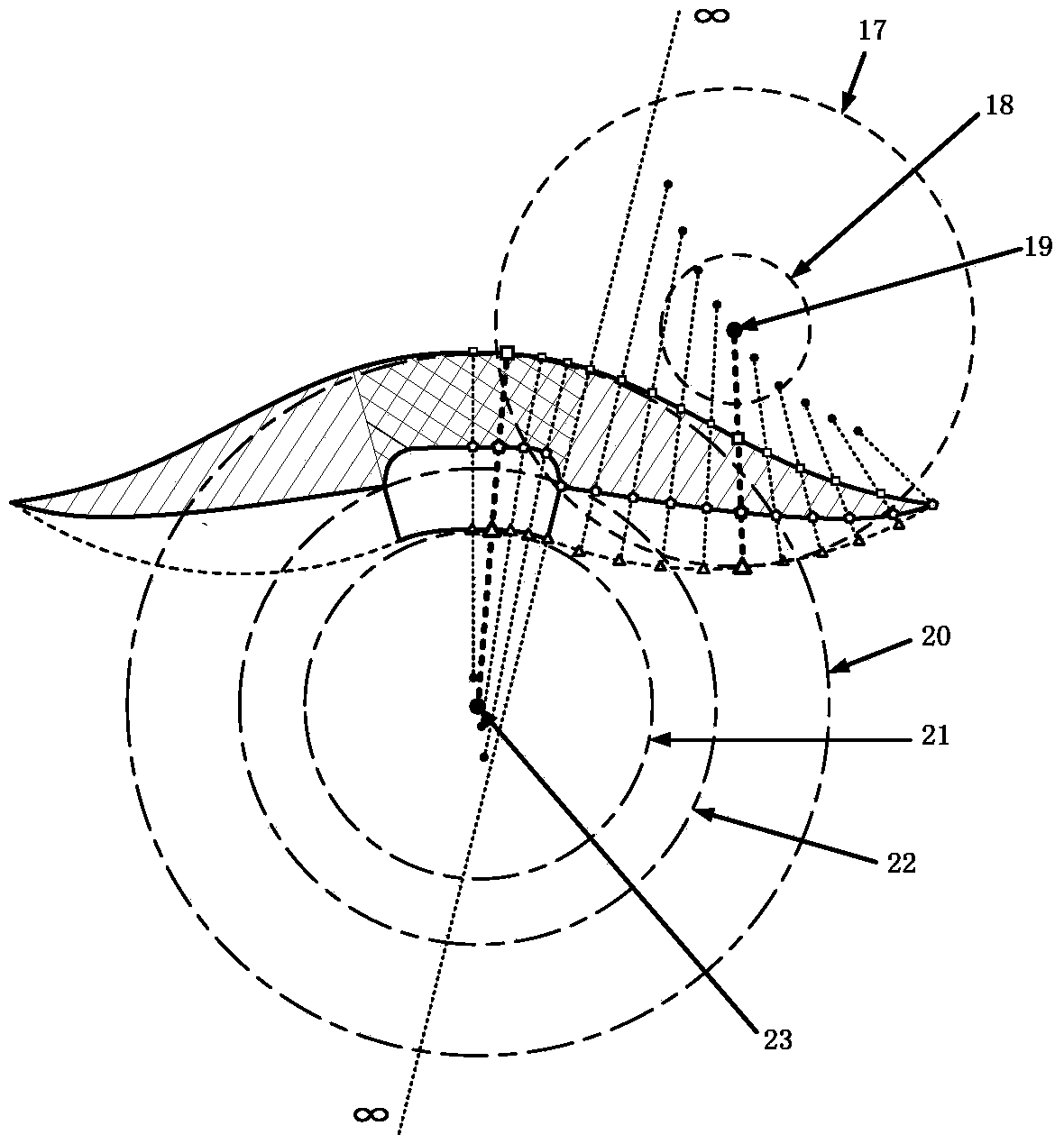

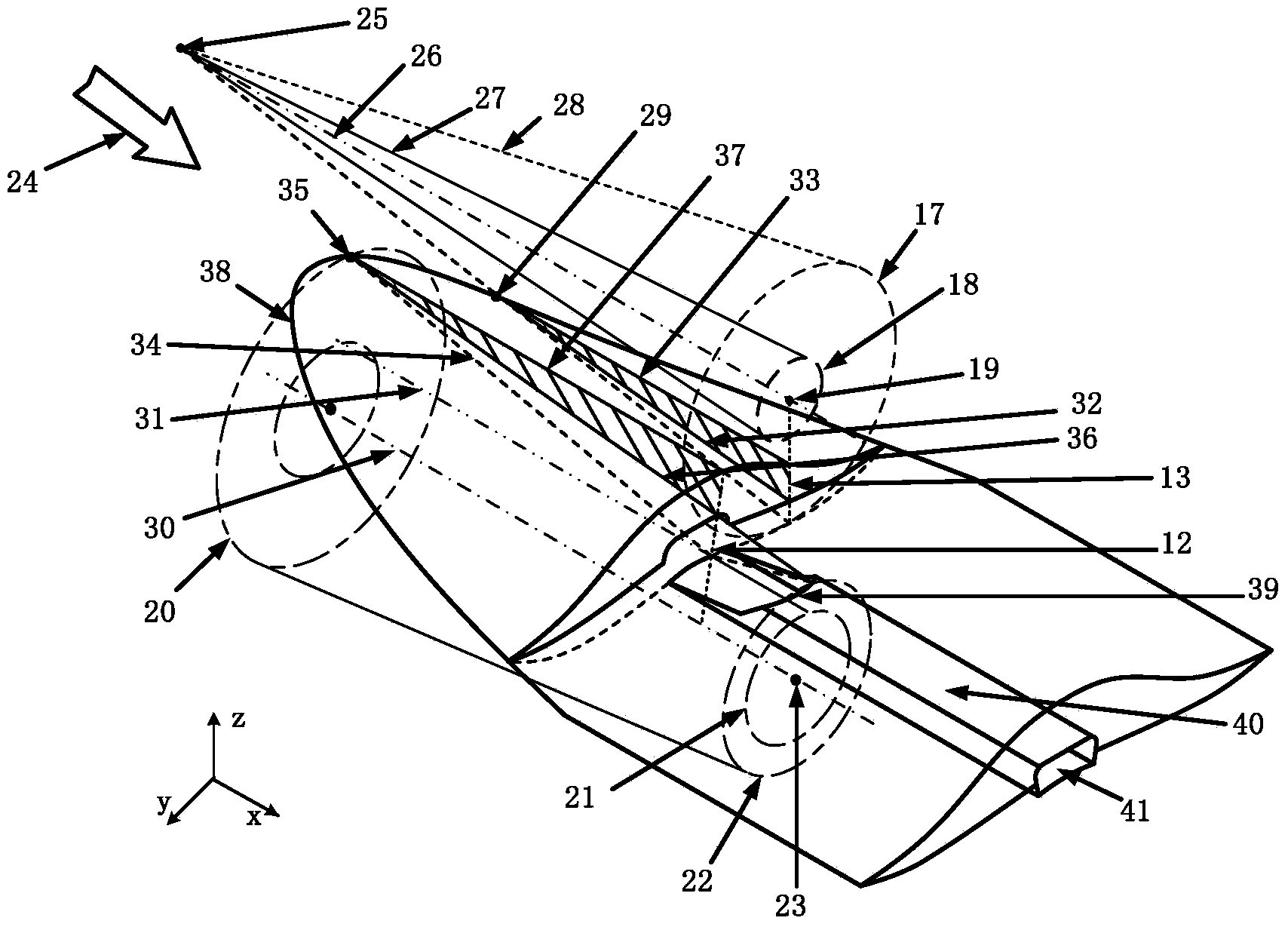

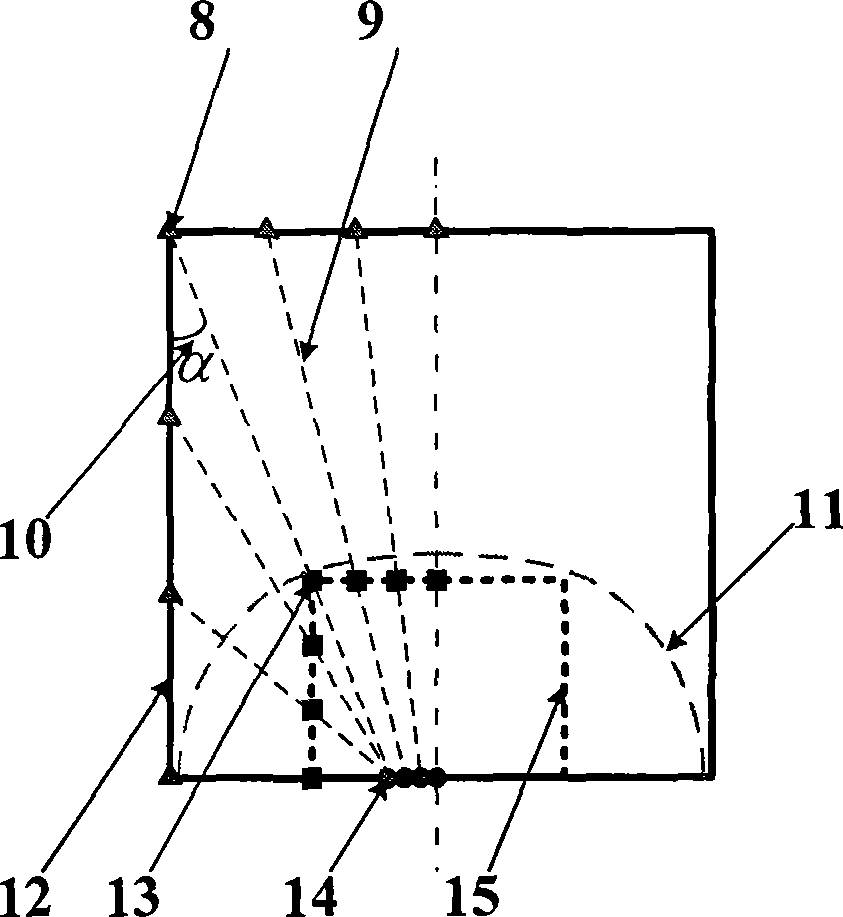

Hypersonic aerocraft and air inlet internal and external waverider integrated design method

ActiveCN103662087ARealize seamless dockingRealize integrated designTurbine/propulsion air intakesGround installationsShock waveRadial position

The invention discloses a hypersonic aerocraft and air inlet internal and external waverider integrated design method, and relates to a near space aerocraft. An aerodynamics characteristic is firstly appointed, and then a design scheme meeting the characteristic is inferred backwards; a three-dimensional shock wave curved surface in a complex shape is appointed, the change rule of the transverse curvature center is obtained, and a series of basic flow fields meeting the needs of the waverider design are inferred backwards according to the change rule; flow lines of different curvature centers and different radial positions are traced in every basic flow field in the circumferential direction; a waverider device capable of producing the appointed complex three-dimensional shock wave curved surface is obtained finally, namely the integrated design scheme is obtained. The advantages of a waveriders and an internal waverider air inlet are kept, the integrated design of the two high-performance devices is achieved, the waverider model with high lift-drag ratio and the scheme of the air inlet with full-flow capture can be obtained at the same time, and accordingly the overall performance of the aerocraft is improved.

Owner:XIAMEN UNIV

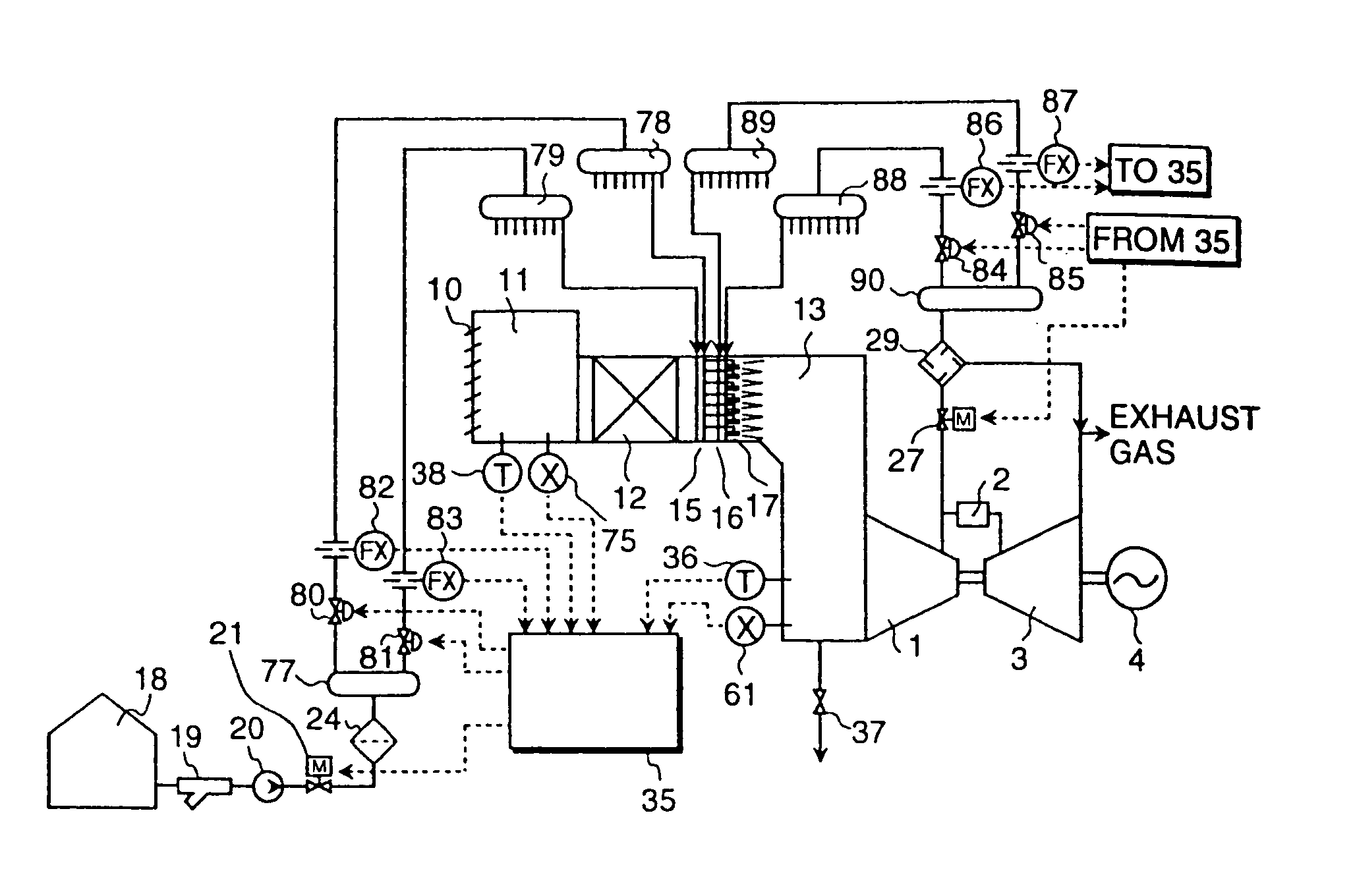

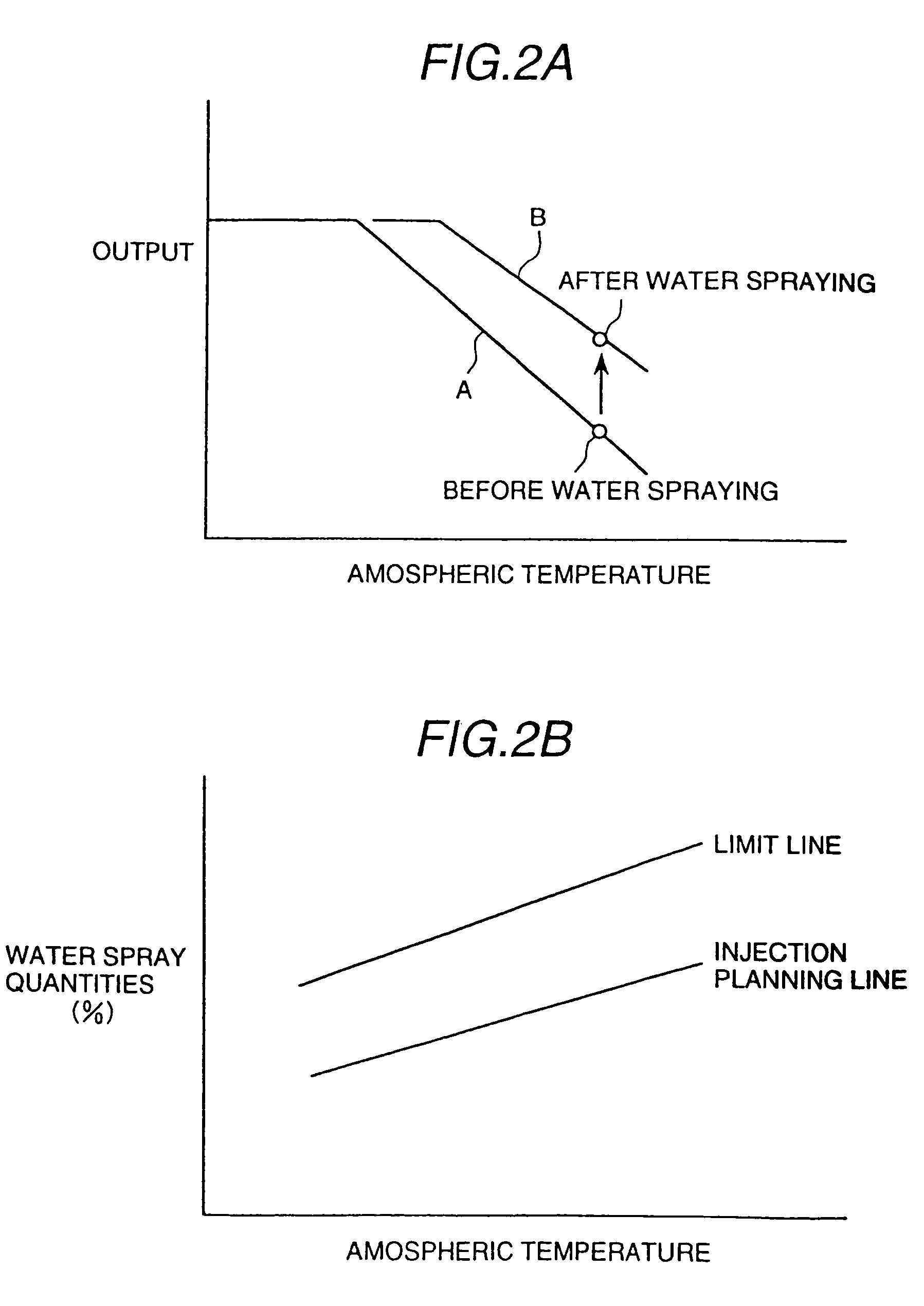

Gas turbine having water injection unit

InactiveUS7040083B2Low temperature of airIncrease productionTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionCombustorAtmospheric temperature

A gas turbine comprises a compressor for compressing a gas supplied therein and discharging the compressed gas, a combustor in which the discharged gas from the compressor and a fuel are combusted, a turbine to be driven by a combustion gas from the combustor, and a water injection unit which injects water into the gas to be supplied to the compressor, thereby lowering the temperature of the gas to be introduced into the compressor to a temperature lower than the atmospheric temperature, and causing water droplets having been injected in the gas and within the compressor to be vaporized while flowing down therein, wherein the quantity of water spray injection is controlled while monitoring operational conditions of the gas turbine.

Owner:HITACHI LTD

Annular acoustic panel

InactiveUS6920958B2Reduce noiseIncreasing noise absorption qualityNoise reduction installationsEngine fuctionsNacelleEngineering

An aircraft engine assembly is provided that is adapted to reduce noise produced by an engine included in the engine assembly. The engine assembly includes a nacelle having an inlet section and a main section that is houses the engine and fan assembly associated with the engine. The inlet section is coupled to the main section at a main bulkhead junction between the inlet section and the main section. A one piece annular acoustic panel is located within a recess in an internal wall of the nacelle. The annular acoustic panel extends from a forward portion of the inlet section to a forward portion of the main section such that the bulkhead is covered by the annular acoustic panel.

Owner:THE BOEING CO

Flush inlet scoop design for aircraft bleed air system

ActiveUS20100126182A1Reduction of Helmholtz resonanceEfficient propulsion technologiesGas turbine plantsHelmholtz resonatorBleed air

Owner:HONEYWELL INT INC

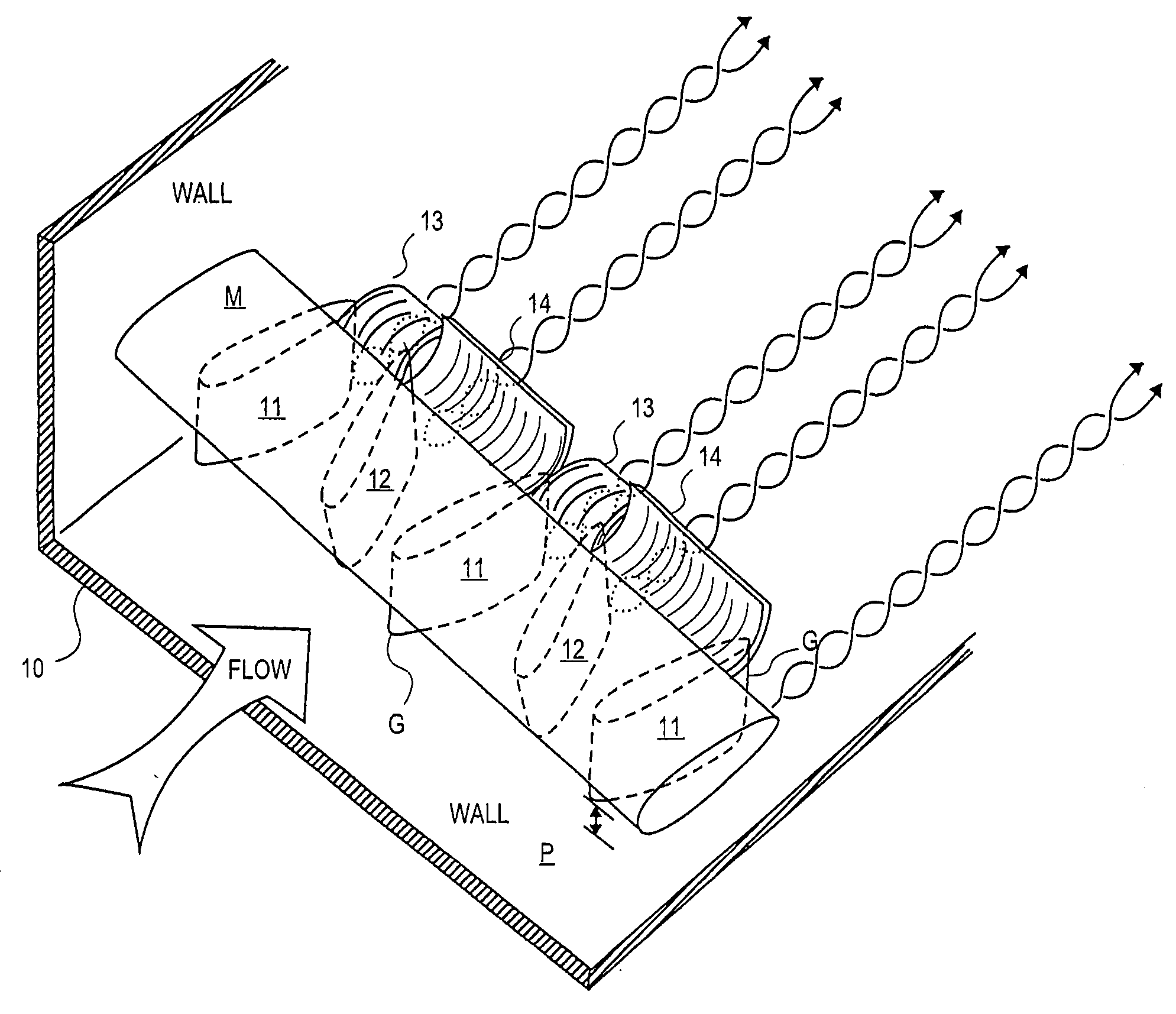

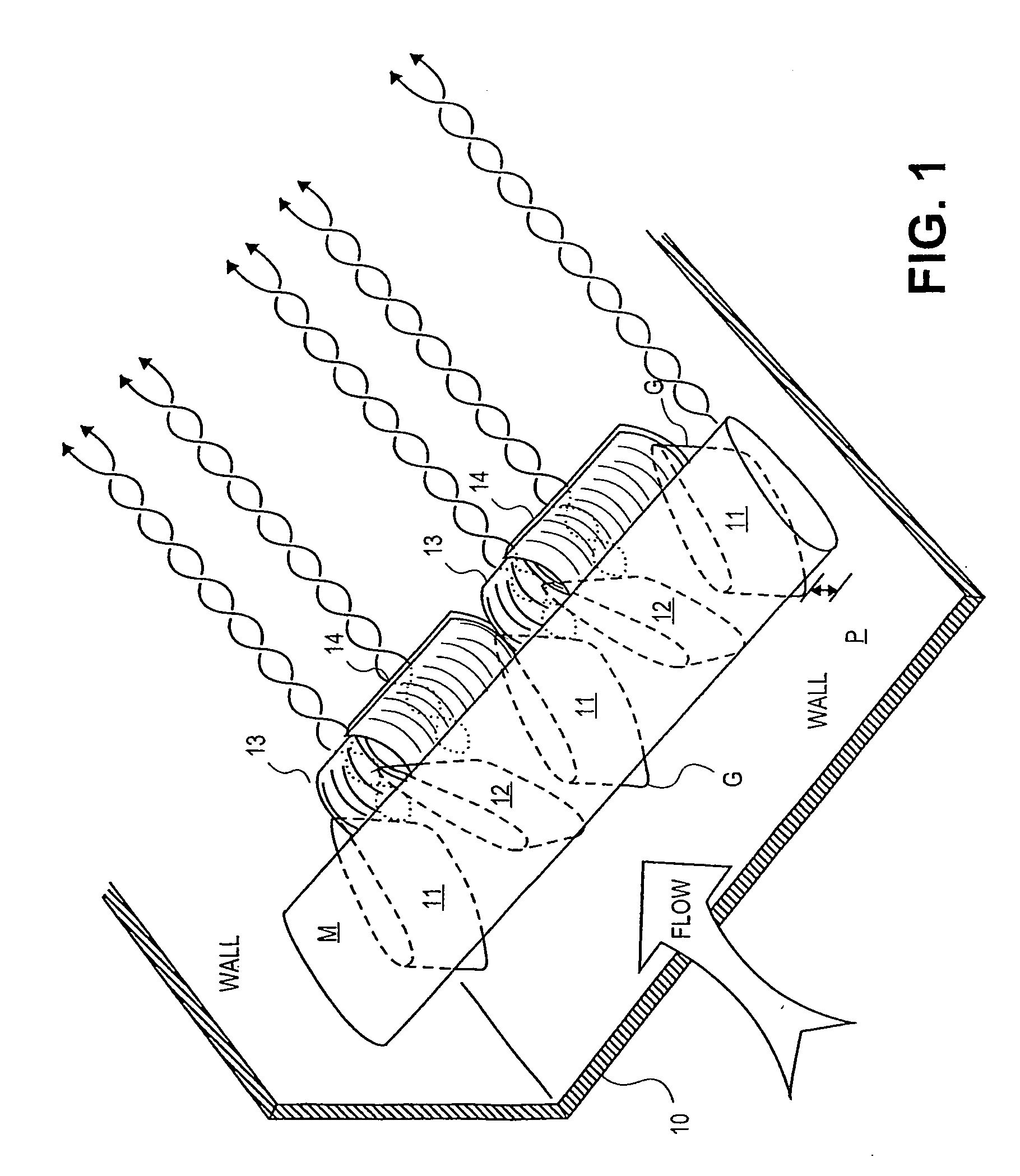

Externally Mounted Vortex Generators for Flow Duct Passage

InactiveUS20080121301A1Inhibition formationReduce the overall heightEngine manufacturePump componentsEngineeringJet stream

Owner:NORRIS THOMAS R

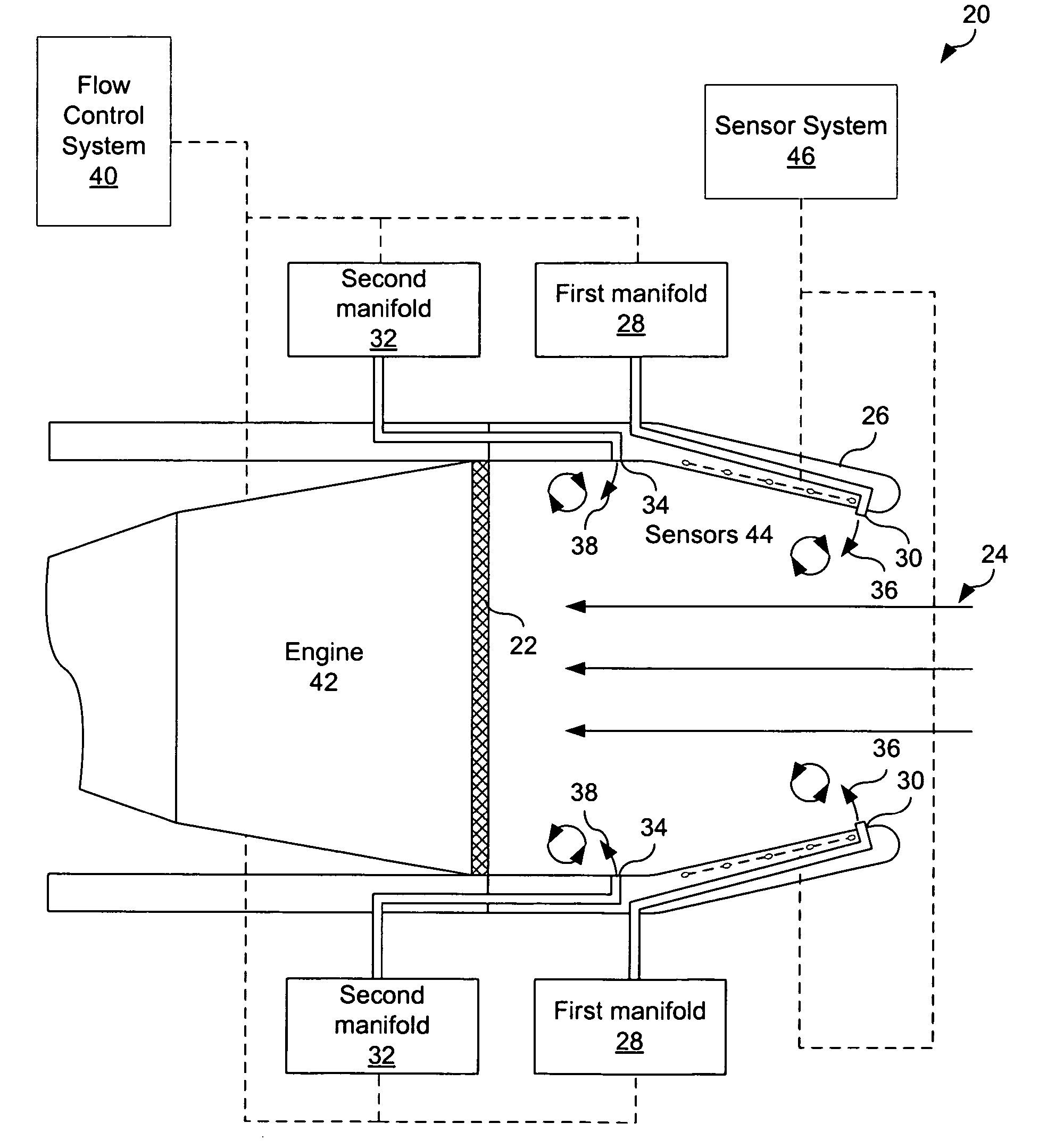

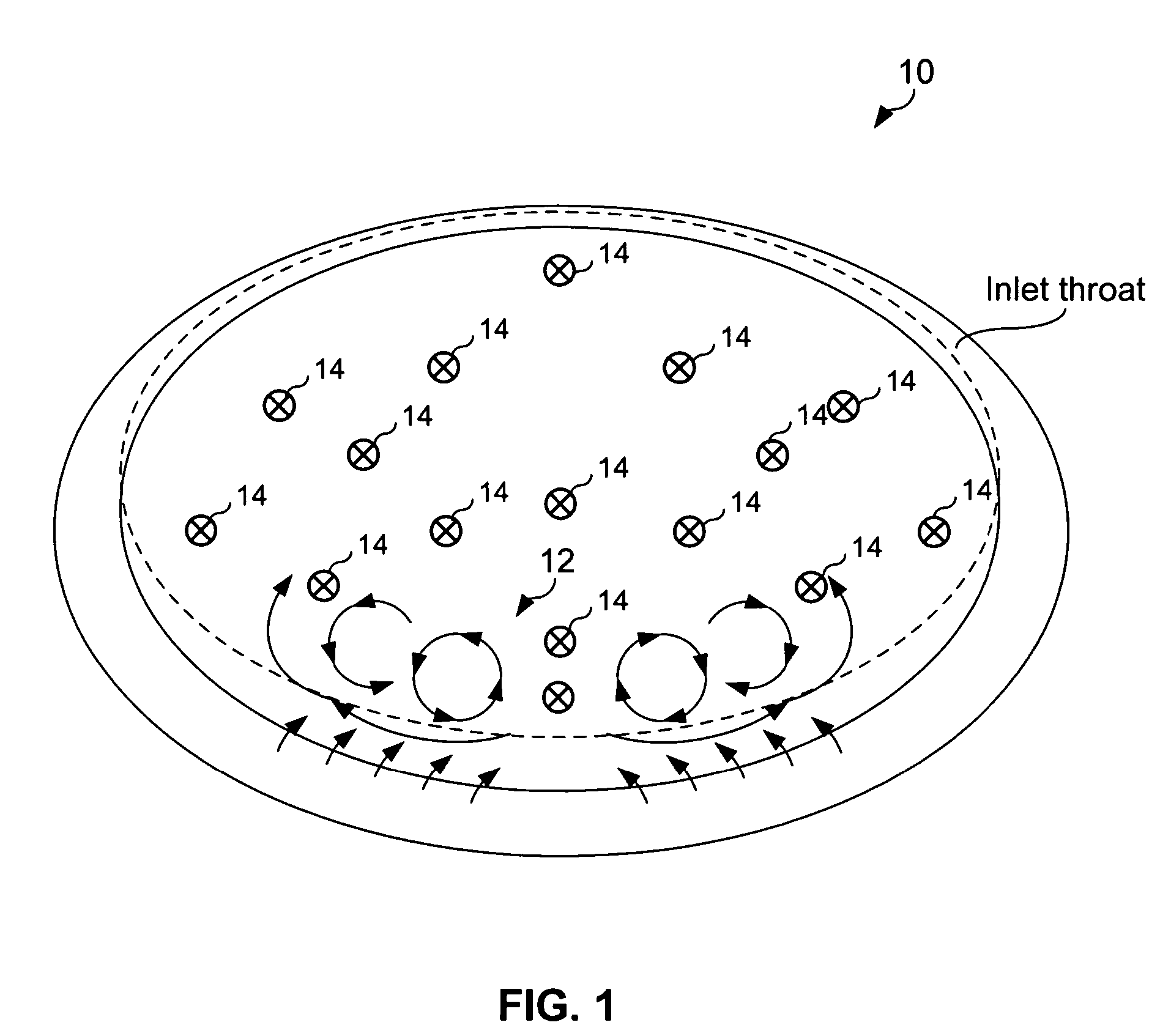

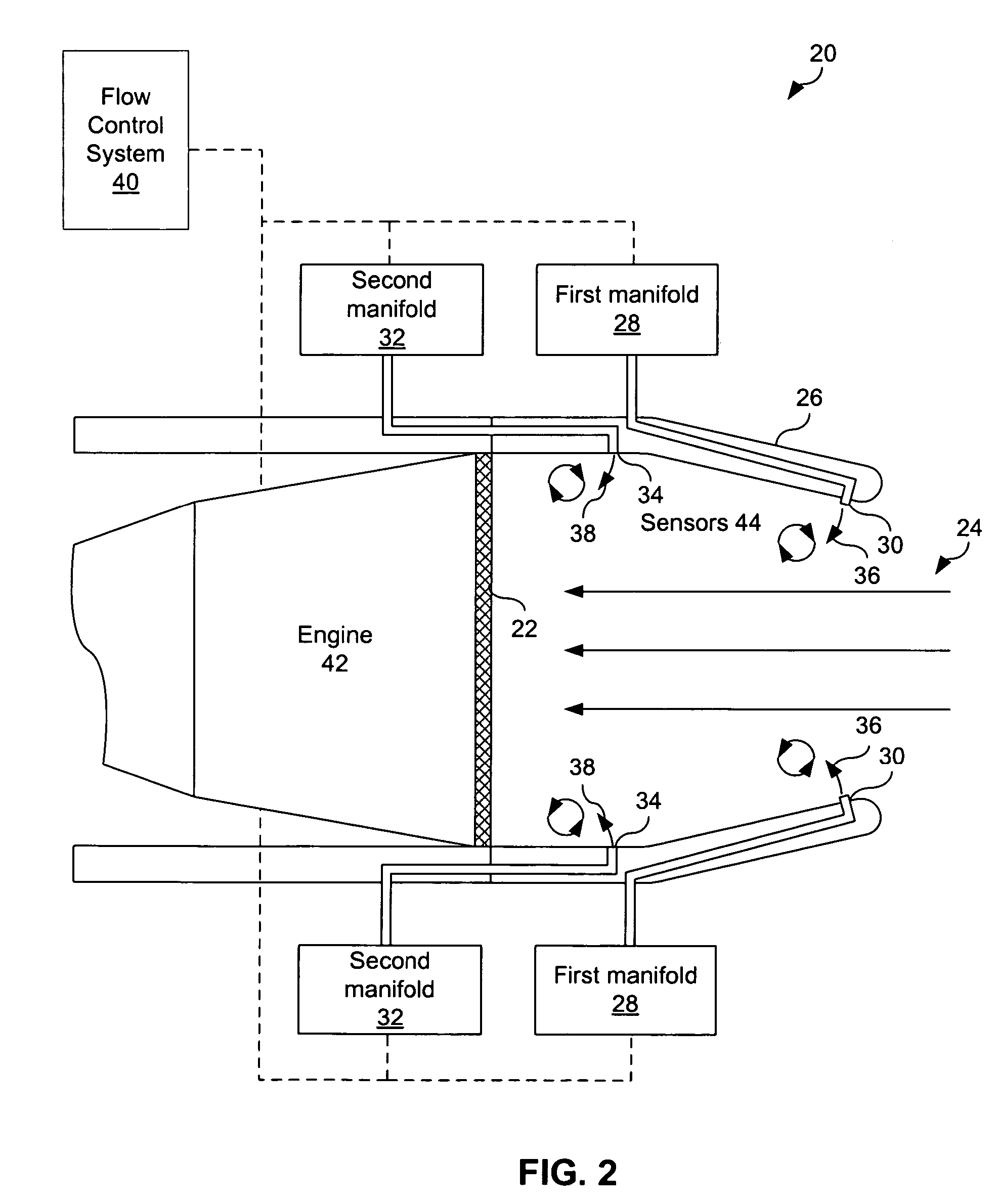

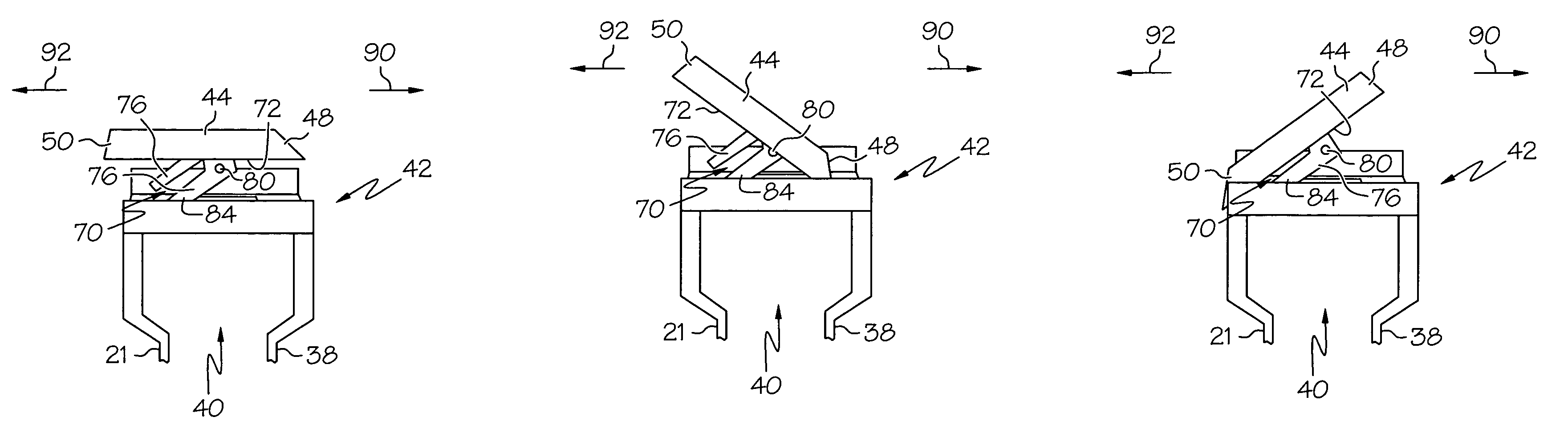

Flow control redistribution to mitigate high cycle fatigue

ActiveUS7617670B2Improve distortionPromote recoveryCombustion enginesGas turbine plantsEngineeringLow-cycle fatigue

A method operable to improve pressure recovery and / or distortion within engine inlet is disclosed. A first fluid flow is provided to primary jet vortex generator(s) operable to inject fluid at a first injection rate into a boundary layer of a primary fluid flow within the inlet. A secondary fluid flow is injected by secondary jet vortex generator(s) at a second injection rate into the boundary layer of the primary fluid flow, The fluid injected at the first injection rate and second injection rate is operable to induce secondary flow structures within the boundary layer. These secondary close structures are then operable to improve or manipulate the pressure recovery of the inlet. At specific engine conditions, this method may redistribute the ratio of the first injection rate and second injection rate in order to improve pressure recovery and / or distortion of the inlet when the particular engine conditions.

Owner:LOCKHEED MARTIN CORP

Dual action inlet door and method for use thereof

InactiveUS7014144B2Reduce noiseReducing APU noisePower installationsEngine fuctionsDual actionEngineering

An inlet door assembly and method for reducing noise from an auxiliary power unit (APU) contained within an aircraft housing is provided. The inlet assembly includes an inlet duct, an actuator, and a door. The inlet duct is configured to extend from the auxiliary power unit to the aircraft housing and has a sidewall that defines a flow passage through which APU noise propagates. The actuator is disposed at least partially within the inlet duct. The door coupled to the actuator. The actuator is also configured to selectively rotate the door between at least a first position, in which at least a portion of the door deflects APU noise in a first direction, and a second position, in which at least a portion of the door deflects the APU noise in a second direction.

Owner:HONEYWELL INT INC

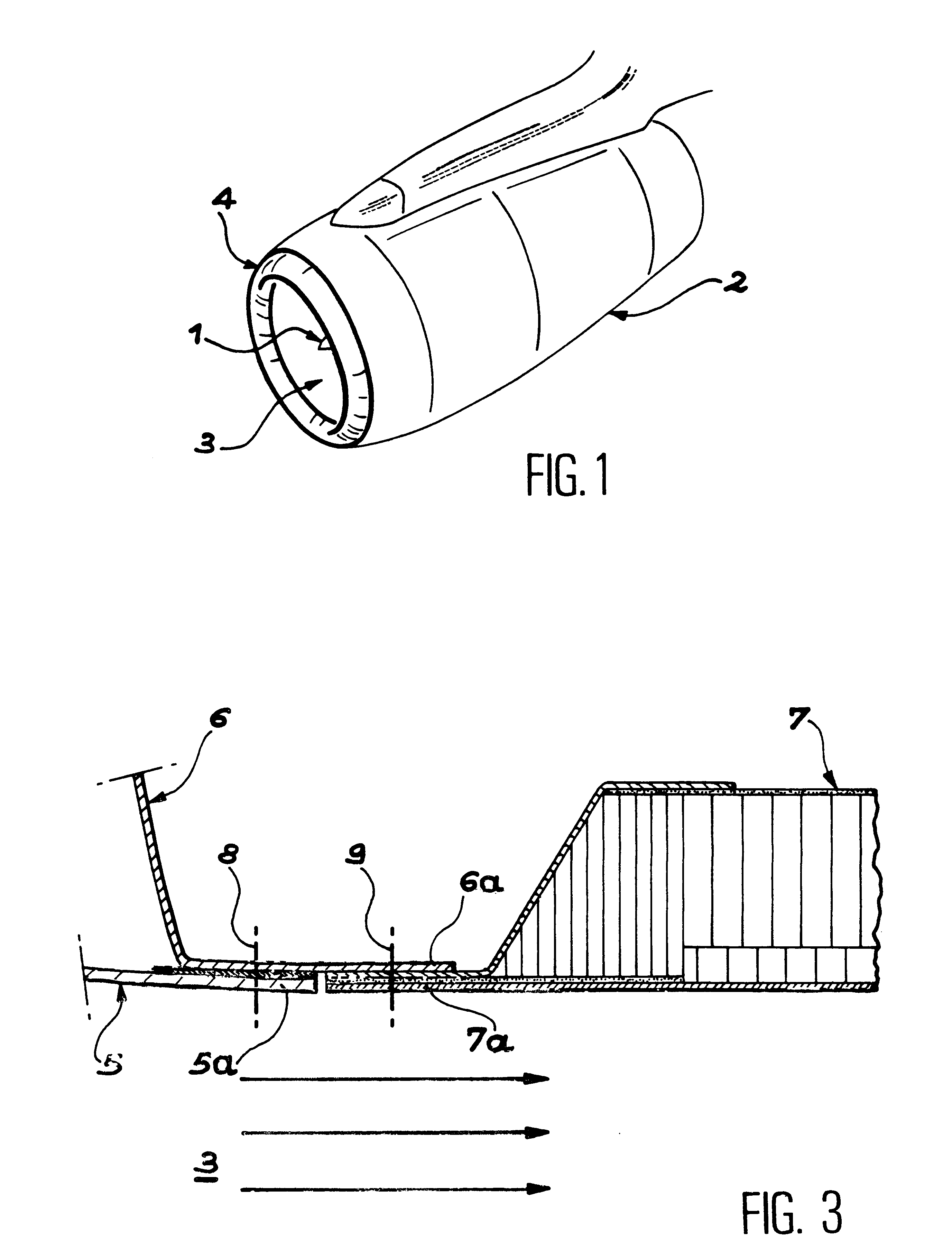

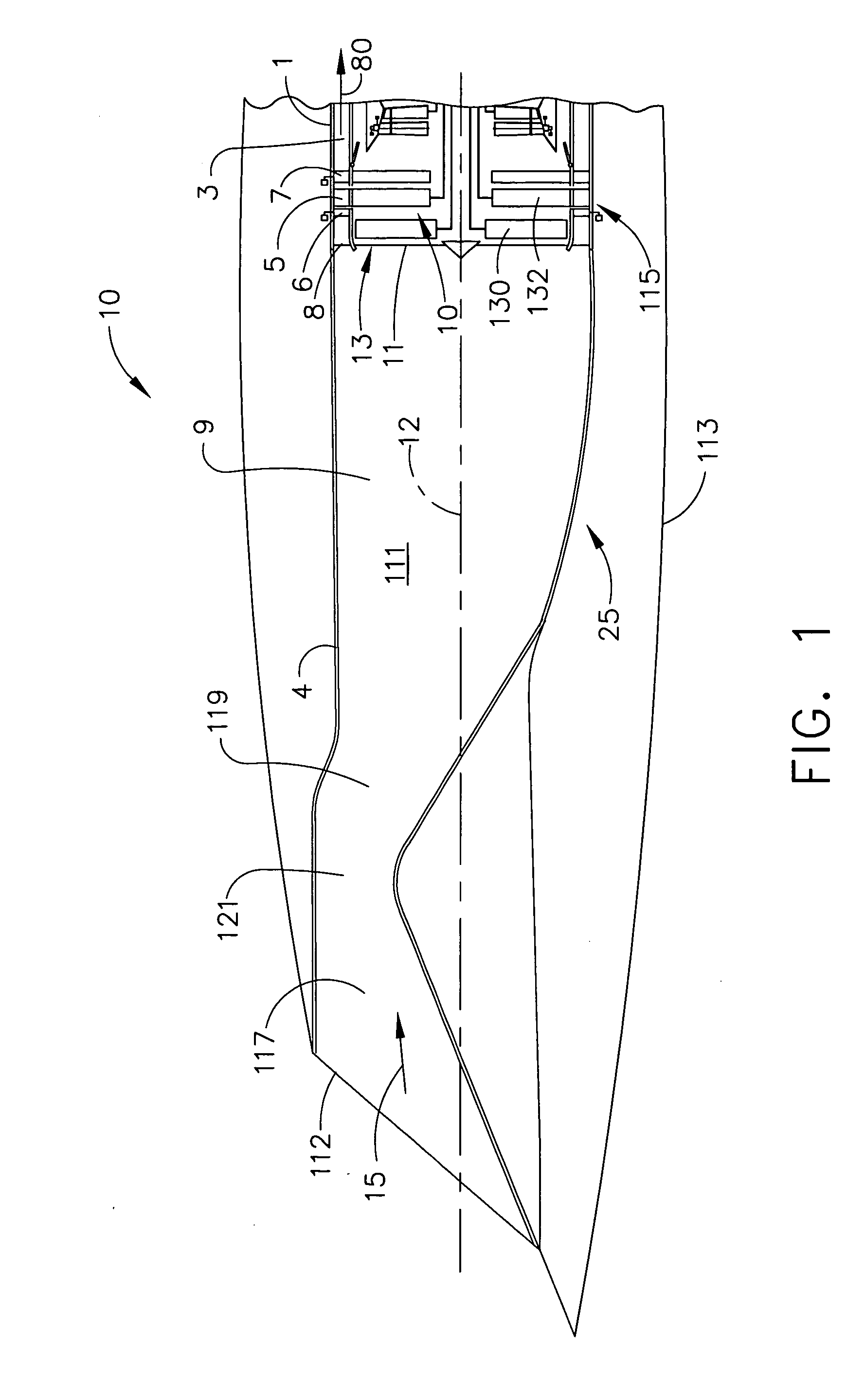

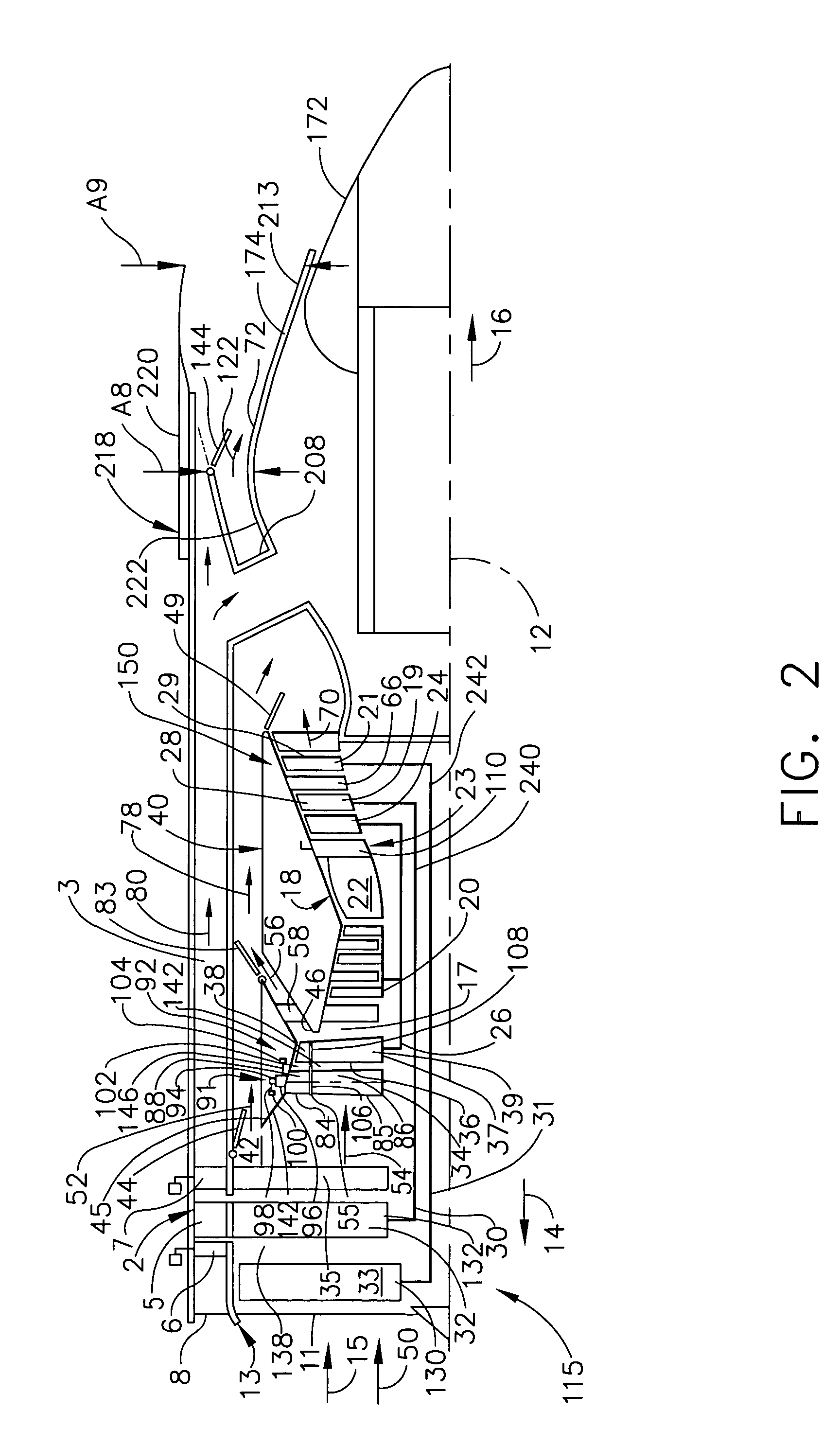

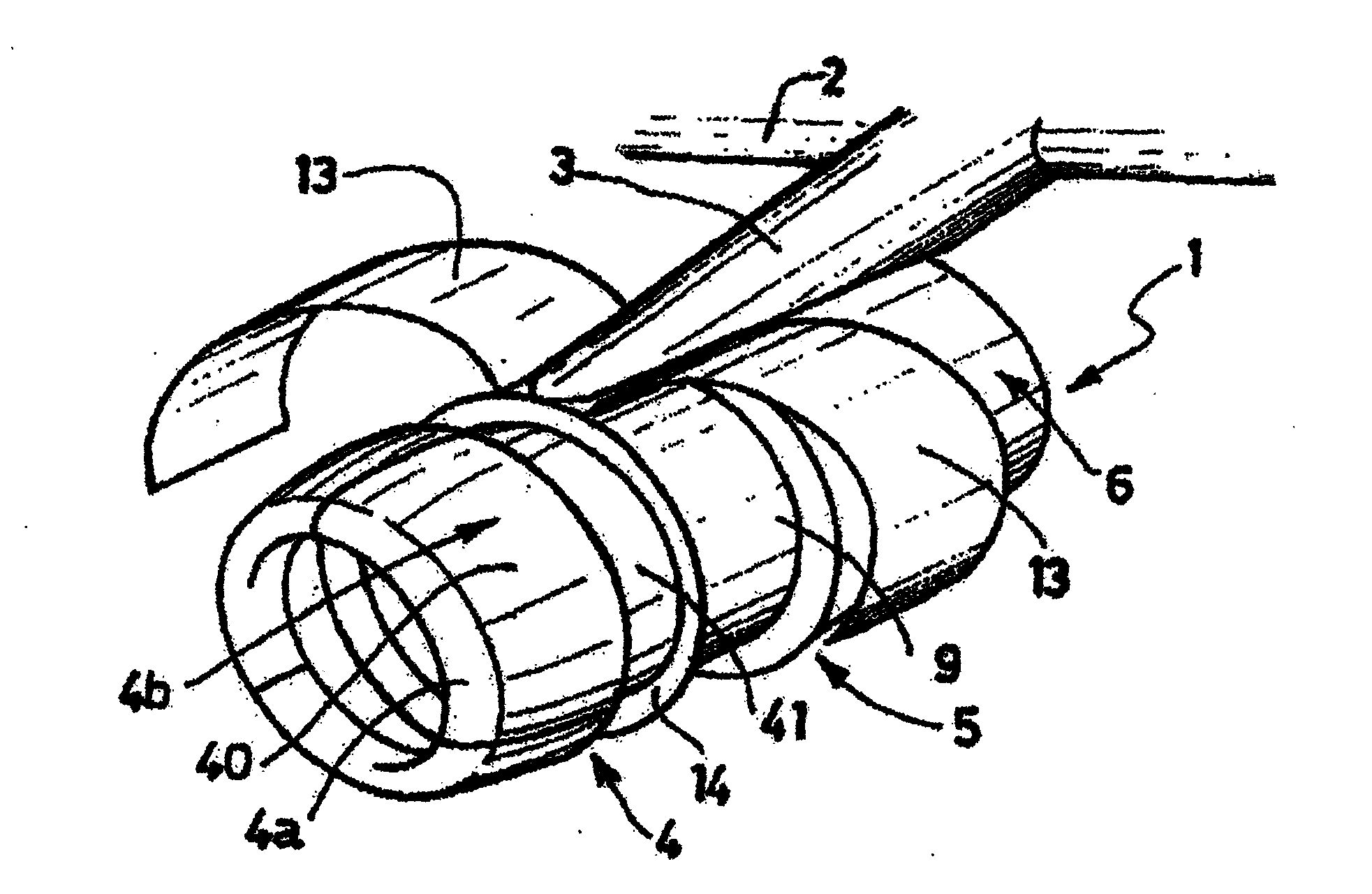

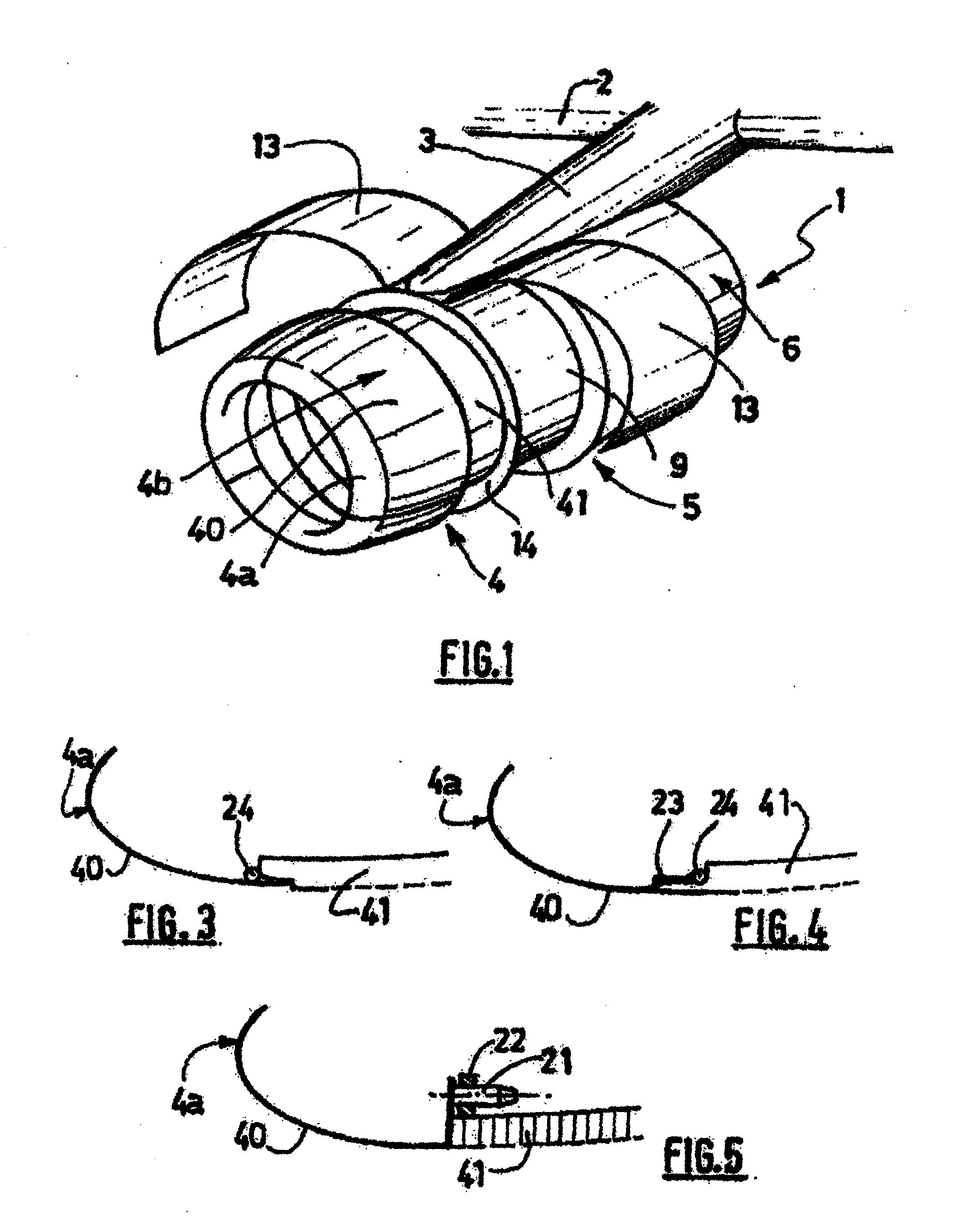

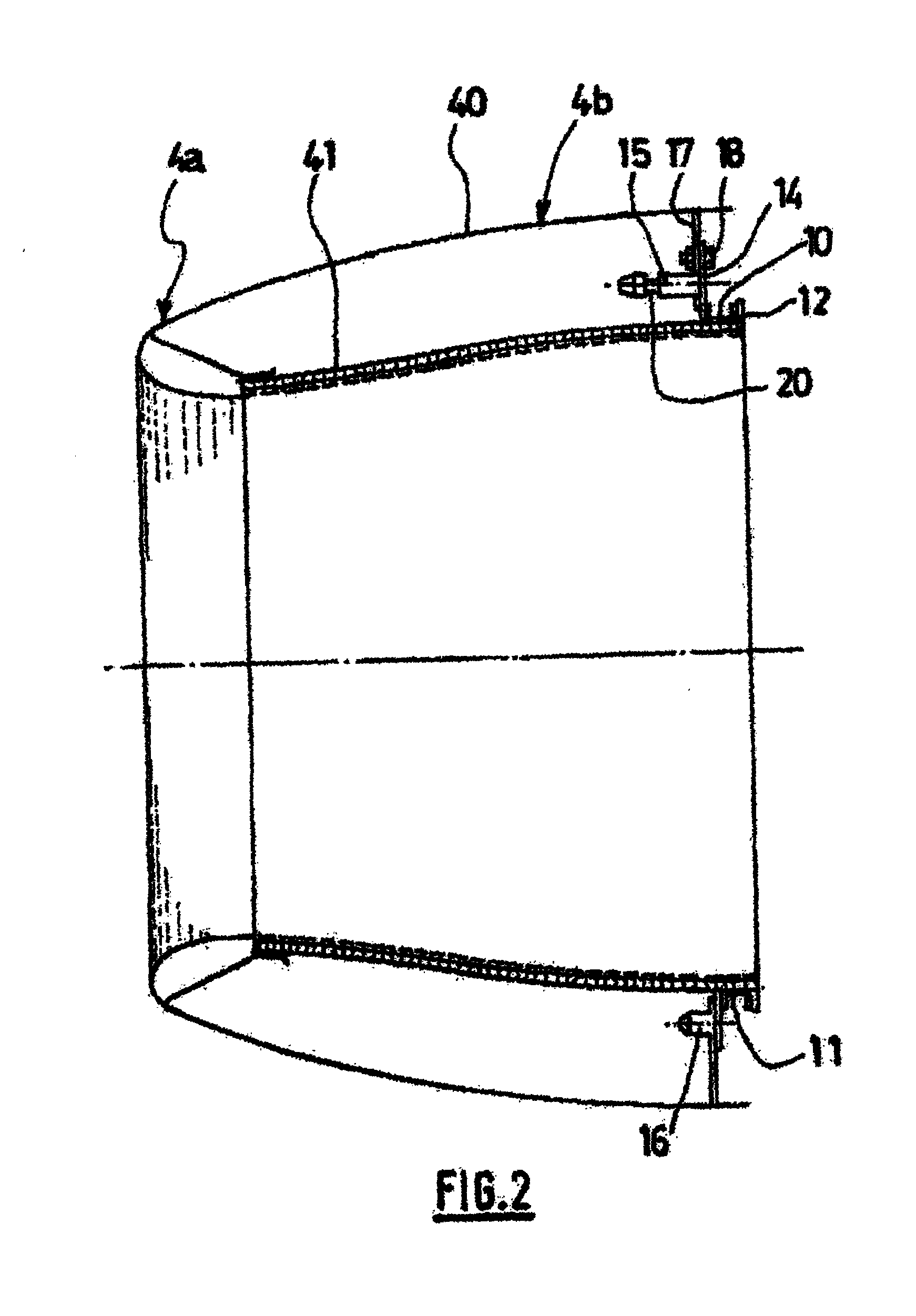

Removable air intake structure for turbojet engine nacelle

ActiveUS20100084507A1Improve outer aerodynamic lineEasy to disassemblePower plant inspection panelsEfficient propulsion technologiesNacelleTurbojet engine

The present invention relates to a nacelle (1) for a turbojet engine comprising an air intake structure (4) capable of ducting a flow of air towards a fan and a central structure (5) intended to surround the said fan and to which the air intake structure is attached, the central structure comprising a casing (9) intended to surround the fan and an external structure (13), characterized in that the air intake structure comprises, on the one hand, at least one internal panel (41) attached to the central structure via the casing and therewith forming a fixed structure and, on the other hand, at least one longitudinal external panel (40) attached removably to the fixed structure and incorporating an air intake lip (4a), the said external panel being removable between an operating position in which the external panel is aerodynamically continuous with the external structure of the central section and the air intake lip provides aerodynamic continuity with the internal panel of the air intake structure, and a maintenance position in which the external panel is separated from the external structure of the central section and the air intake lip is separated from the internal panel of the air intake structure.

Owner:SAFRAN NACELLES

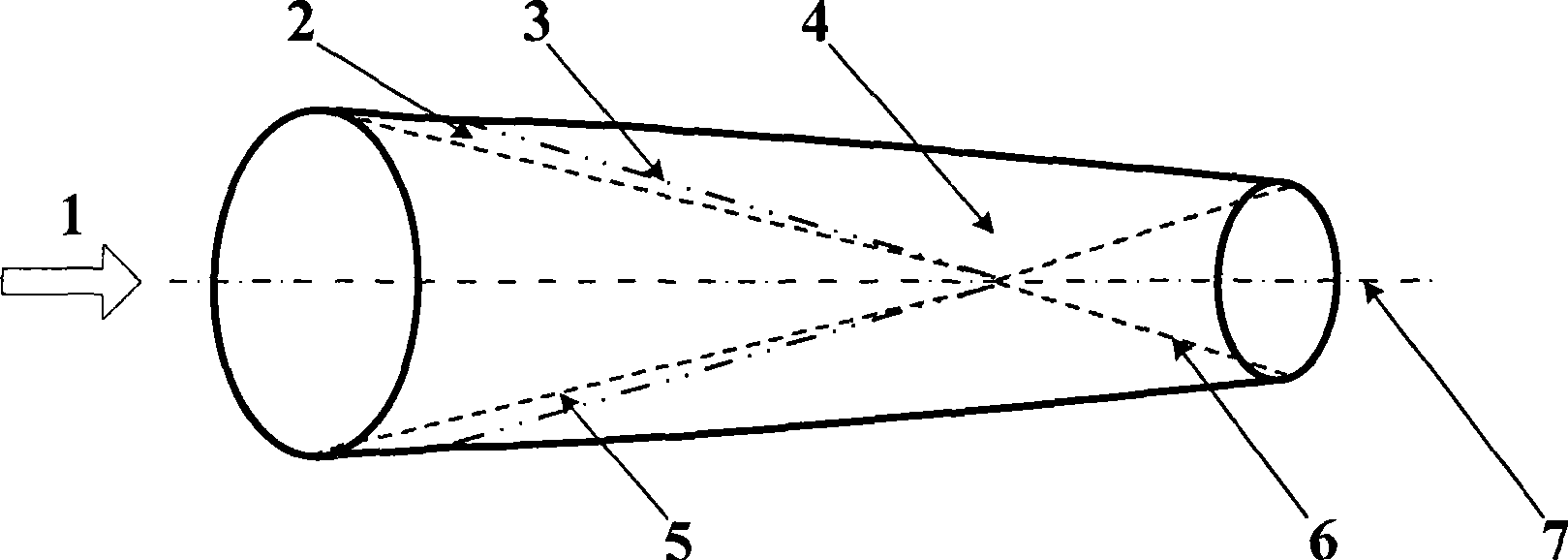

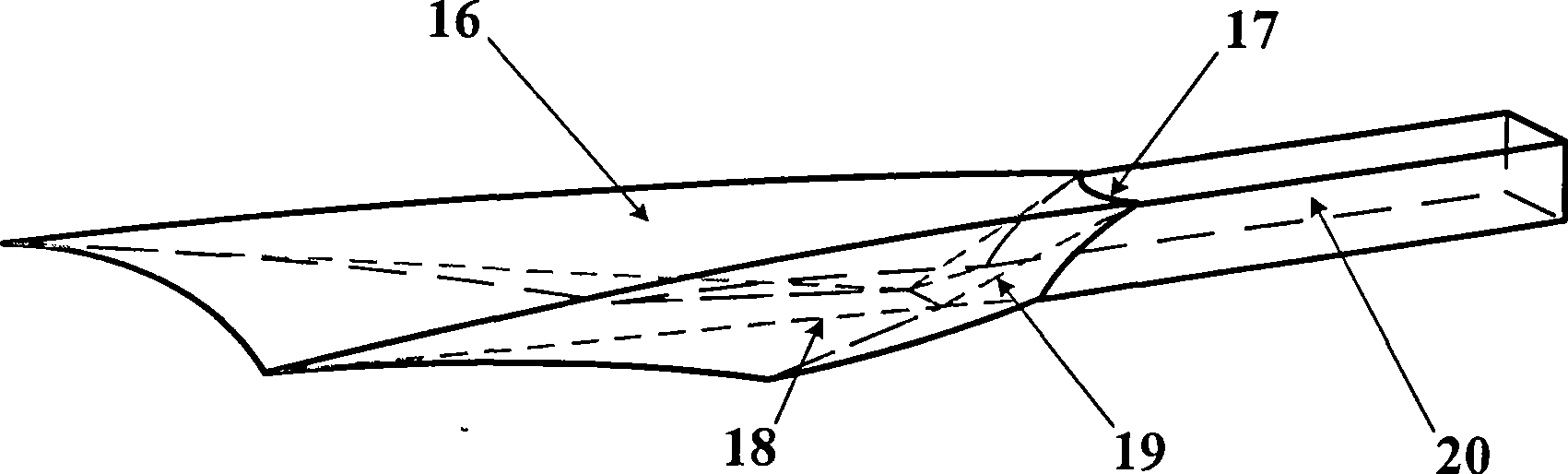

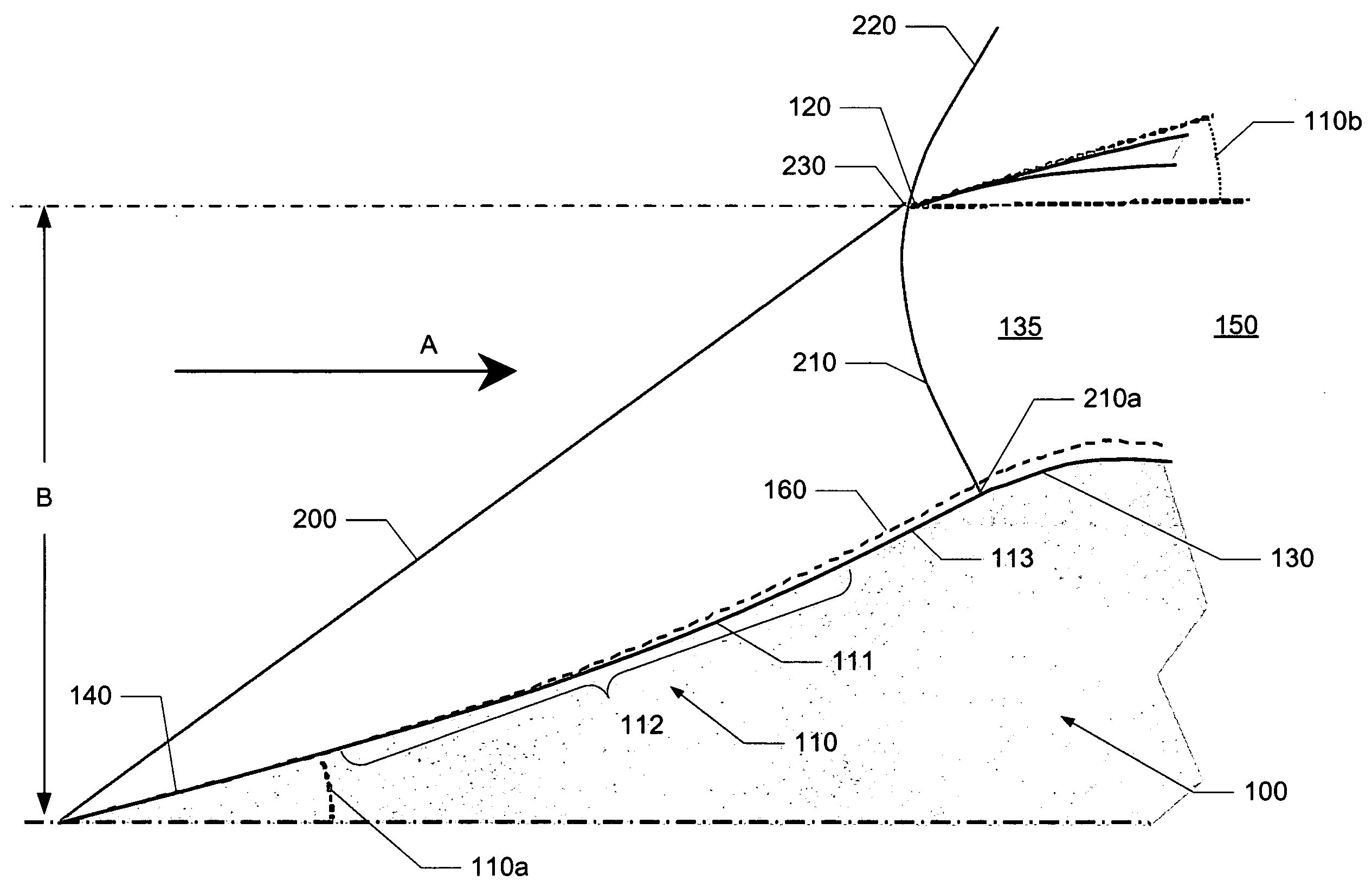

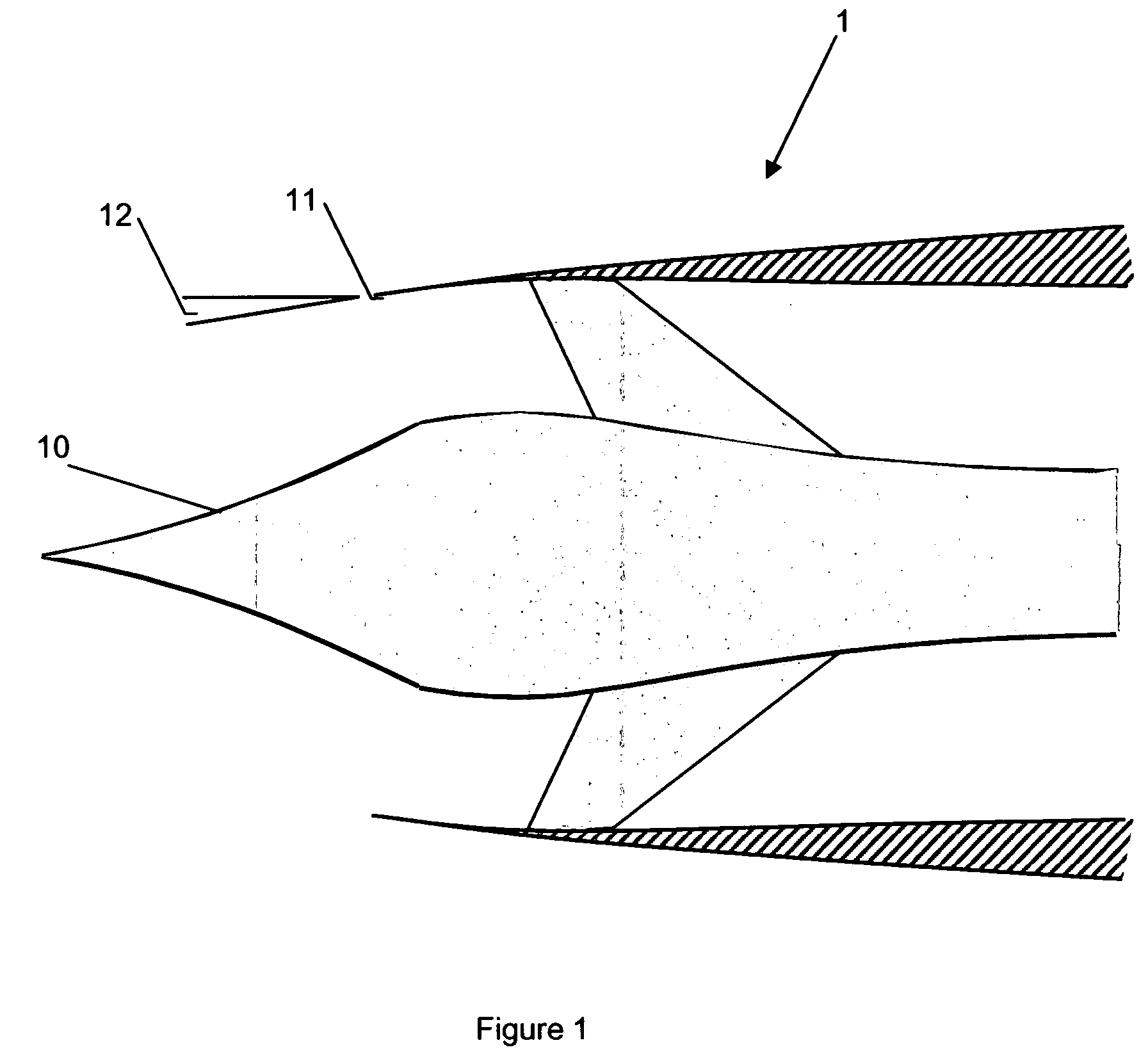

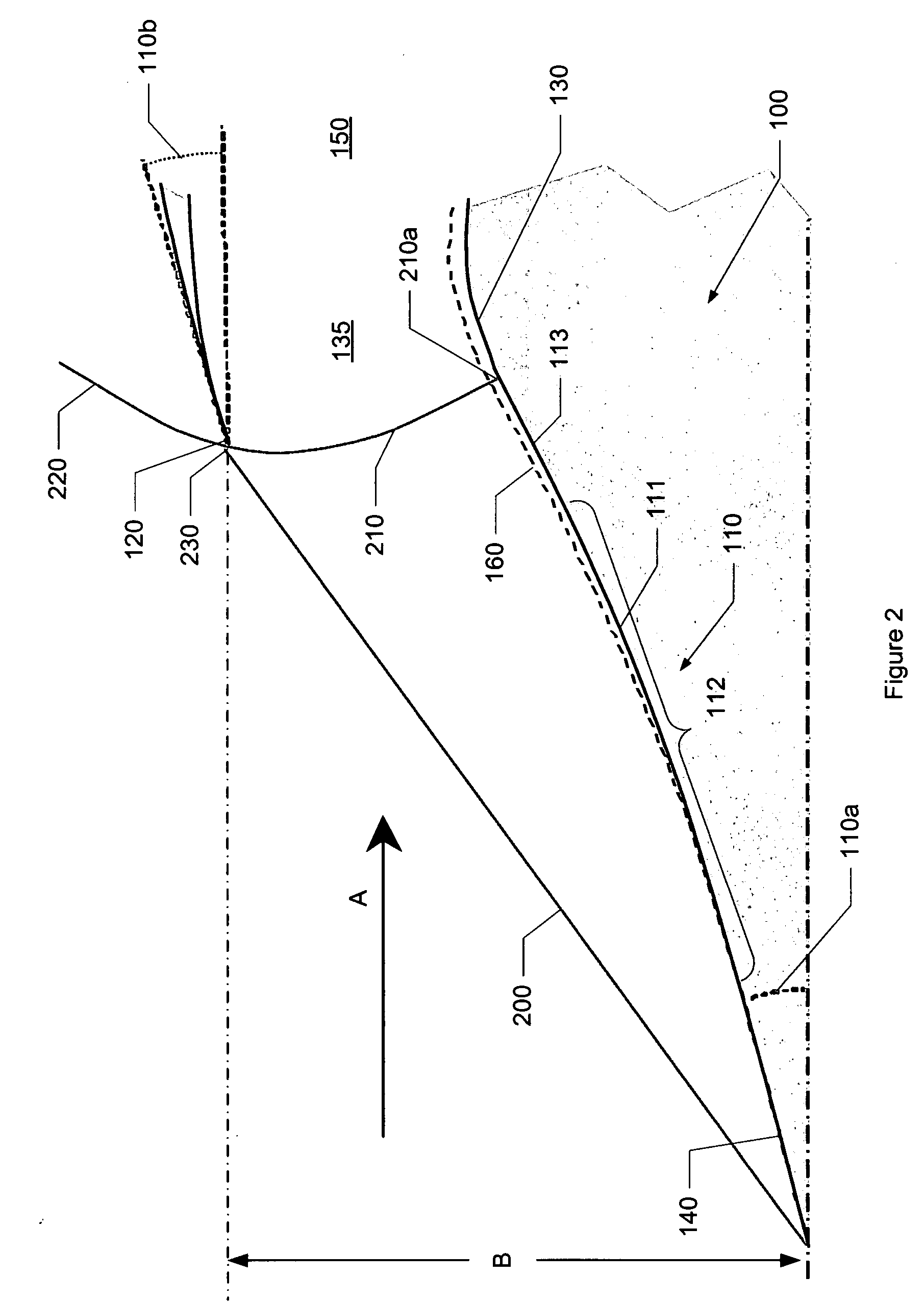

Internal waverider hypersonic inlet and design method based on random shock form

InactiveCN101392685AImprove export aerodynamic performanceReduce windward external resistanceTurbine/propulsion air intakesShock waveRadial position

The invention provides an internal waverider-derived hypersonic inlet based on arbitrary shockwave shape and a design method thereof. The structure of the internal waverider-derived hypersonic inlet comprises an inlet contraction section and an inlet insulation section; wherein the inlet contracting section is inward contracted in three-dimension; hypersonic velocity incoming flow forms irregular initial incident three-dimensional shockwave at the inlet; and the shockwave closes the three-dimensional inlet surface completely. The design method comprises the following steps: an internally contracted axisymmetric basic flow field used as a base is formed by the combination of ICFA flow field and partial Buesemann flow field; and after shapes of shockwave sections with different centers of curvature and directions of curvature are appointed, flown line tracing of the basic flow field with different centers and different radial positions is carried out on a plane in each circle of the hypersonic inlet to obtain the internal waverider-derived hypersonic inlet based on arbitrary shockwave shape. The internal waverider-derived hypersonic inlet and the method have the advantages of ensuring that the hypersonic inlet captures the incoming flow in full flow, increasing thrust force of an engine while reducing overflow resistance, improving pneumatic performance of an outlet of the hypersonic inlet, reducing windward external resistance of the hypersonic inlet, and improving starting performance of low-mach number of the hypersonic inlet.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Low shock strength inlet

ActiveUS20090107557A1Power plant exhaust arrangementsAircraft power plant componentsNacelleUltimate tensile strength

Embodiments of the invention relate to a supersonic inlet having a cowl lip configured to capture the conic shock and exhibit a zero or substantially zero cowl angle. The inlet may be configured to employ a relaxed isentropic compression surface and an internal bypass. The nacelle bypass may prevent flow distortions, introduced by the capture of the conic shock, from reaching the turbomachinery, thereby allowing the cowl angle to be reduced to zero or substantially zero. Such a cowl angle may reduce the inlet's contribution to the overall sonic boom signature for a supersonic aircraft while allowing for an increase in engine pressure recovery and a subsequent improvement in generated thrust by the engine.

Owner:GULFSTREAM AEROSPACE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com