Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1222 results about "Sandwich panel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sandwich panel is any structure made of three layers: a low-density core, and a thin skin-layer bonded to each side. Sandwich panels are used in applications where a combination of high structural rigidity and low weight is required.

Prepreg fabric and honeycomb sandwich panel

InactiveUS6429157B1Good self-adhesiveReduce porositySynthetic resin layered productsPaper/cardboard layered productsPorosityHoneycomb

A woven fabric prepreg comprising at least [A] a woven fabric as reinforcing fibers, [B] a thermosetting resin or thermosetting resin composition and [C] fine particles of a resin and having a cover factor of 95% or more, and a honeycomb sandwich panel, comprising skin panels fabricated by said woven fabric prepreg and [D] a honeycomb core can be obtained. The woven fabric prepreg little changes in tackiness with the lapse of time and has moderate drapability, being excellent in self adhesiveness to the honeycomb core when used as skin panels of a honeycomb sandwich panel. Furthermore, the honeycomb sandwich panel obtained has a small porosity in the skin panels fabricated by the cured prepreg and has excellent surface smoothness with few pits and depressions on the surfaces of the skin panels.

Owner:TORAY IND INC

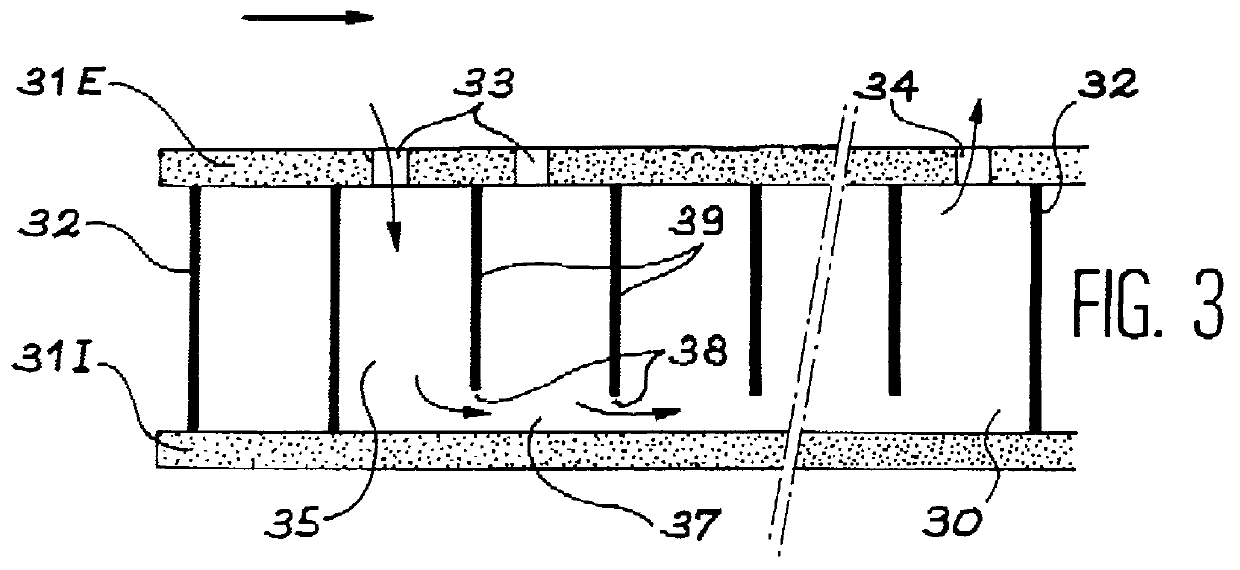

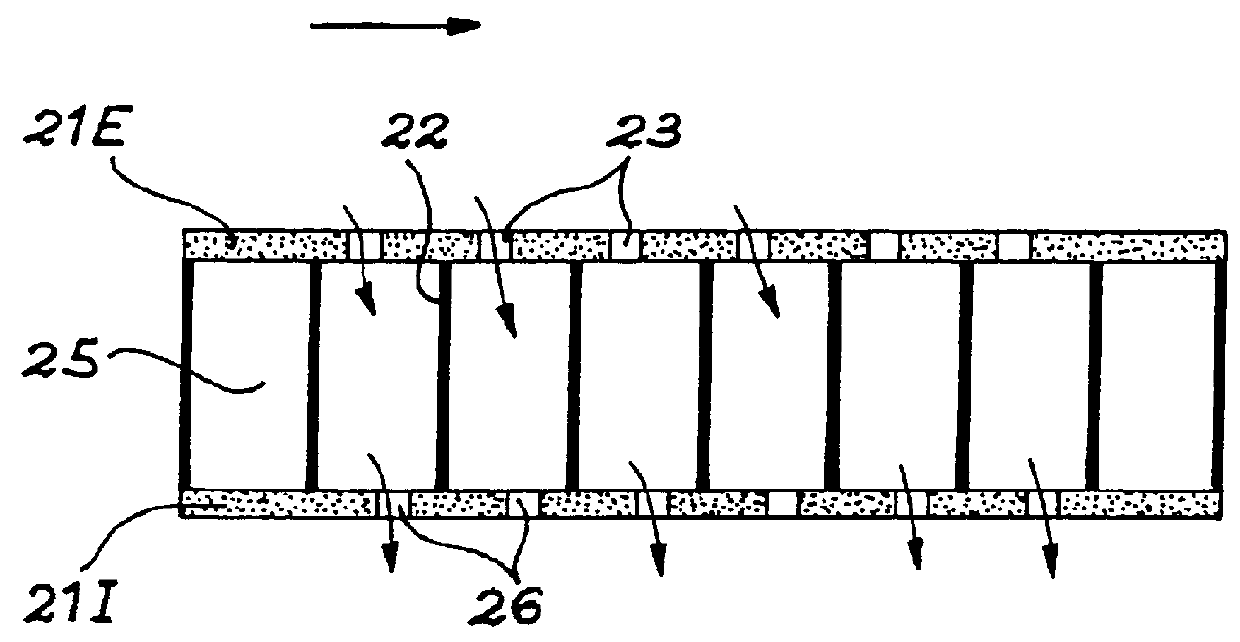

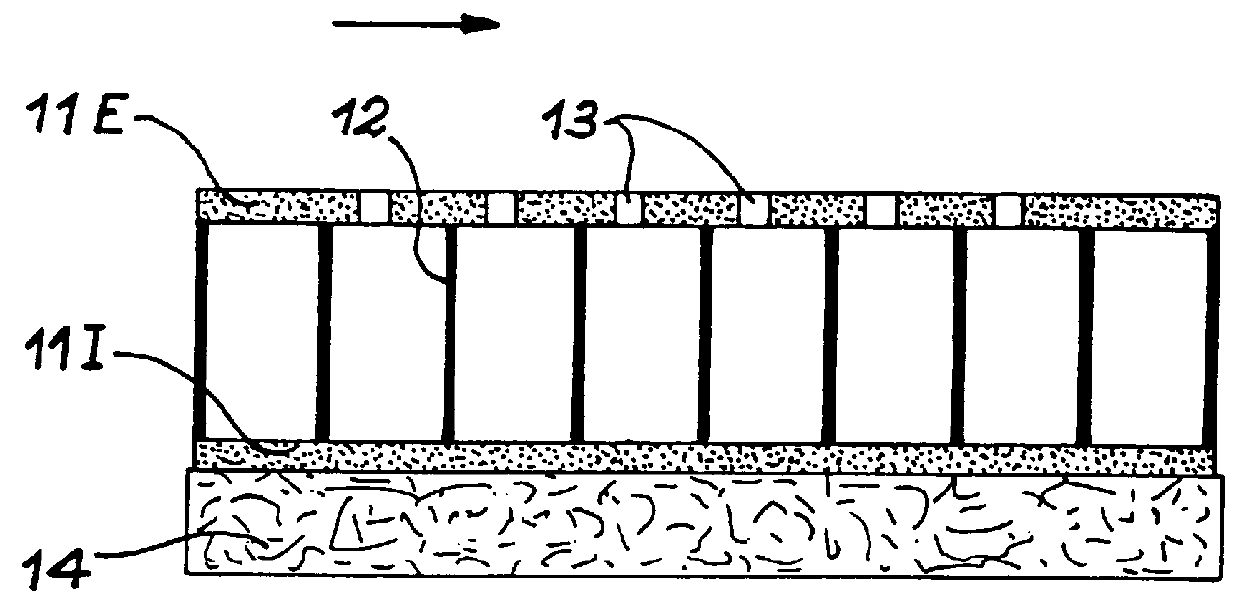

Ventilated honeycomb cell sandwich panel and ventilation process for such a panel

InactiveUS6122892AEasy to shapeSpeed up the flowEngine manufactureLayered productsCells panelHoneycomb

A cell panel for thermal ventilation including a first wall having raised portions which define openings; a second wall; partition walls connected to the first and second walls and that define cells. The openings in the first wall are located upstream of an air flow flowing outside the first wall. The first wall may further include raised portions which define other openings located downstream of the air flow. The second wall may also include raised portions which define openings located downstream of the air flow. The partition walls may define communication holes between adjacent cells.

Owner:SOC HISPANO SUIZA AEROSTRUCTURES

Resin compositions for fiber-reinforced composite materials and processes for producing the same, prepregs, fiber-reinforced composite materials, and honeycomb structures

InactiveUS6045898ASufficient self adhesivenessReduce porosityLayered productsNon-woven fabricsPorosityFiber-reinforced composite

PCT No. PCT / JP97 / 00250 Sec. 371 Date Jan. 5, 1998 Sec. 102(e) Date Jan. 5, 1998 PCT Filed Jan. 31, 1997 PCT Pub. No. WO97 / 28210 PCT Pub. Date Aug. 7, 1997The present invention provides a prepreg having an excellent self adhesiveness to a honeycomb core, a low porosity when used as skin panels, an excellent surface smoothness due to a low surface porosity, and good tackiness and drapability. This invention also provides a honeycomb sandwich panel having a skin panel peel strength, an excellent impact resistance and an excellent hot water resistance, and a composition for a fiber reinforced composite material made from the prepreg and honeycomb sandwich panel. The fiber reinforced composite material made from the prepreg of the present invention can be used for airplanes, automobiles and other industrial applications, particularly as structural materials of airplanes, because of its excellent mechanical properties.

Owner:TORAY IND INC

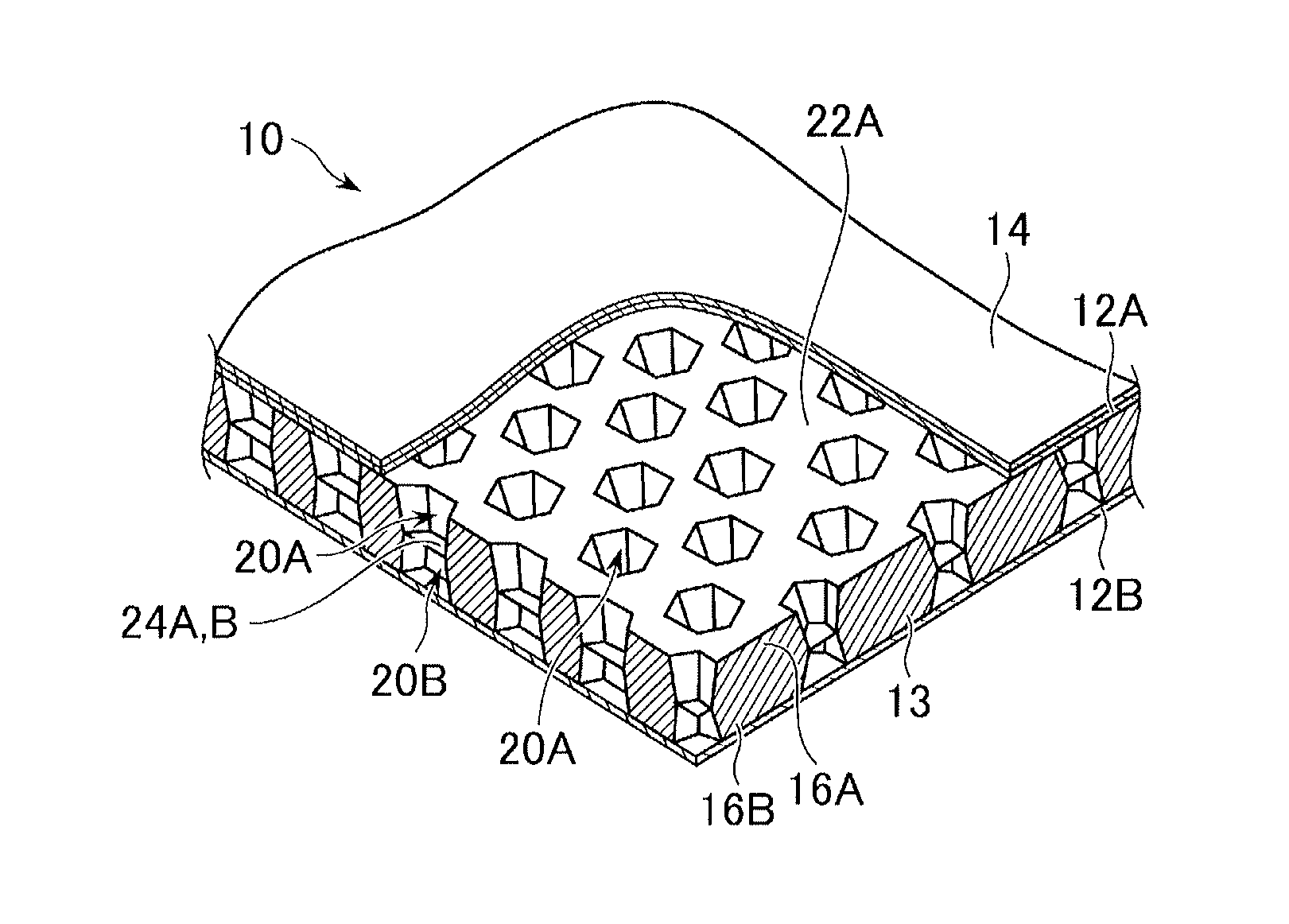

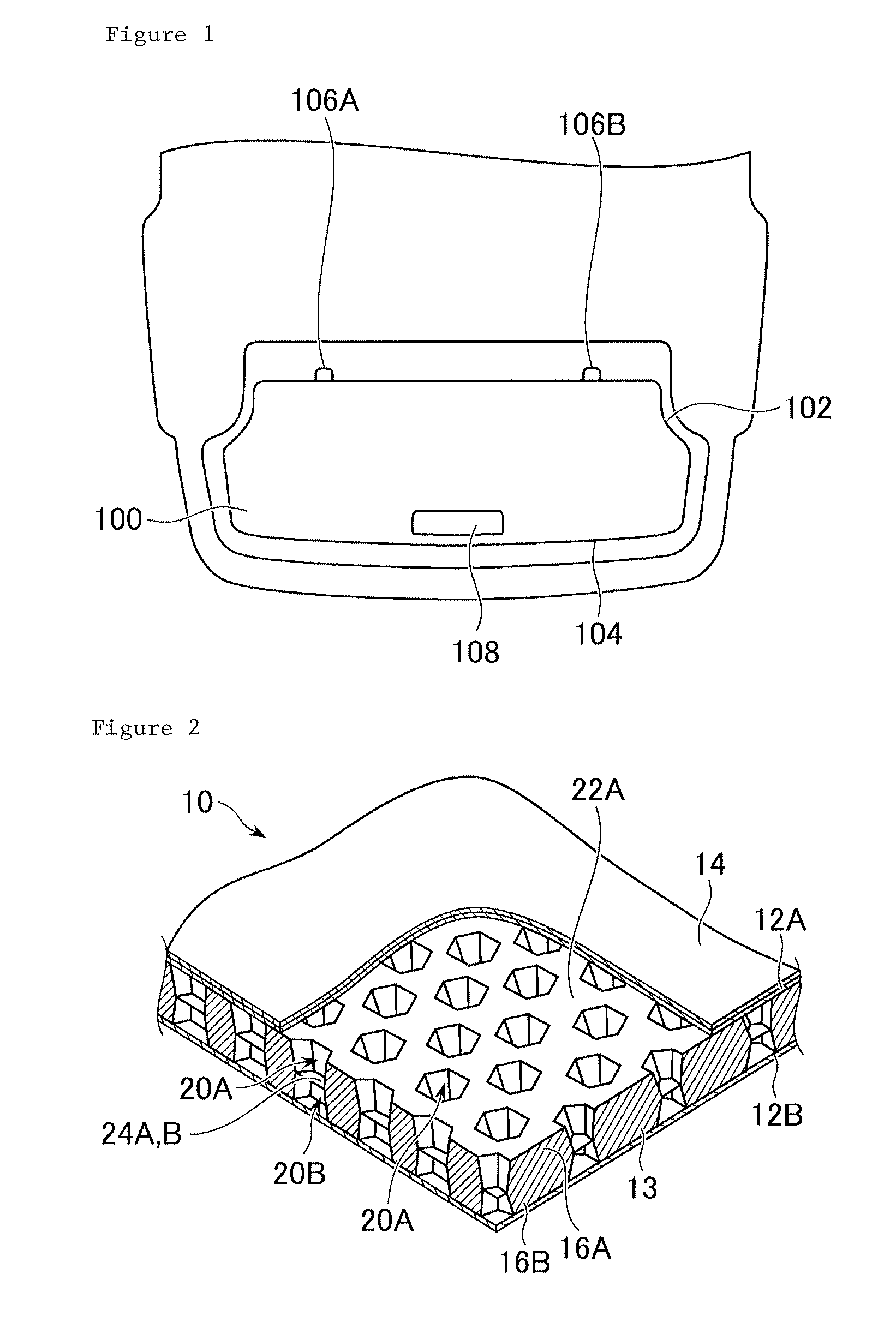

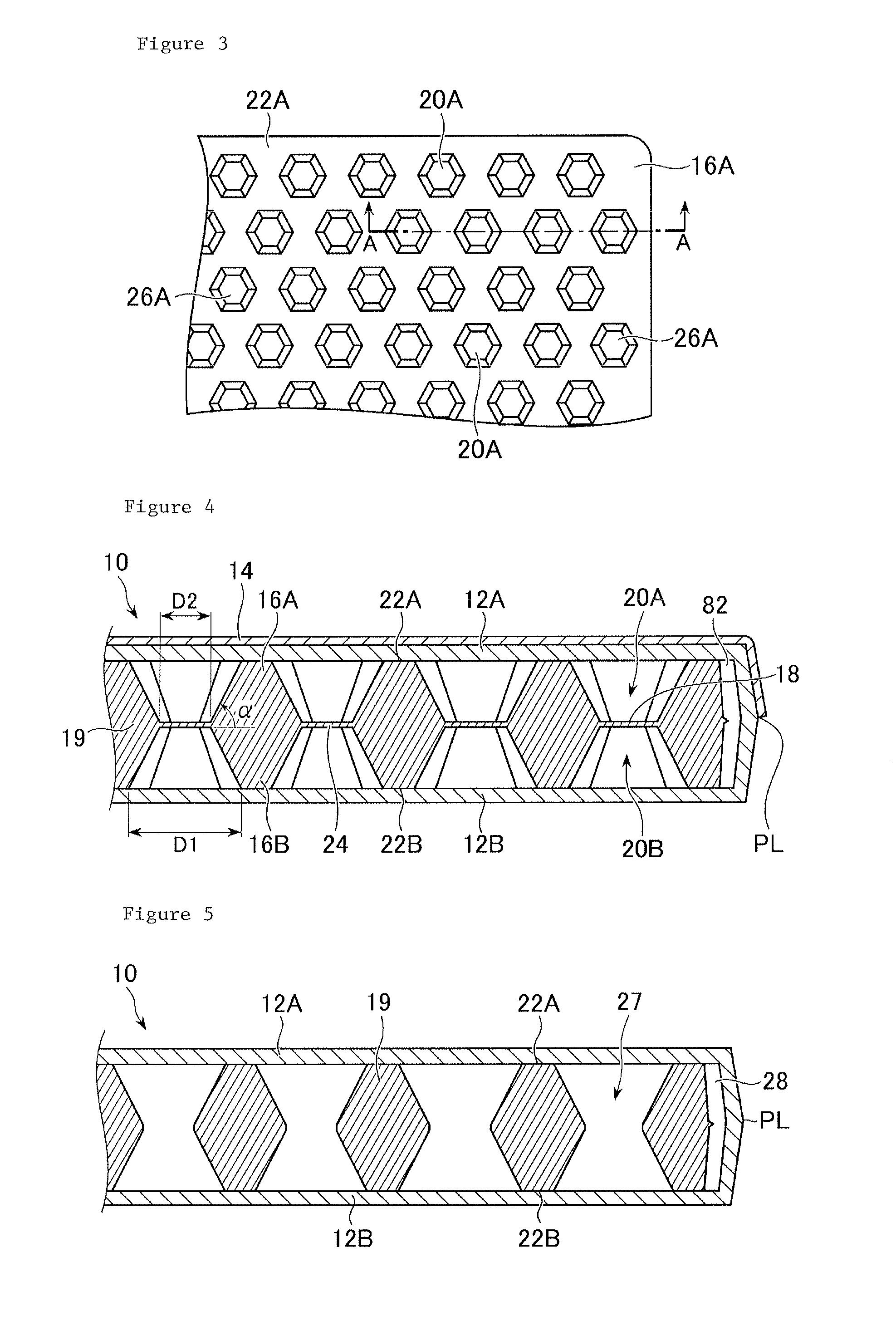

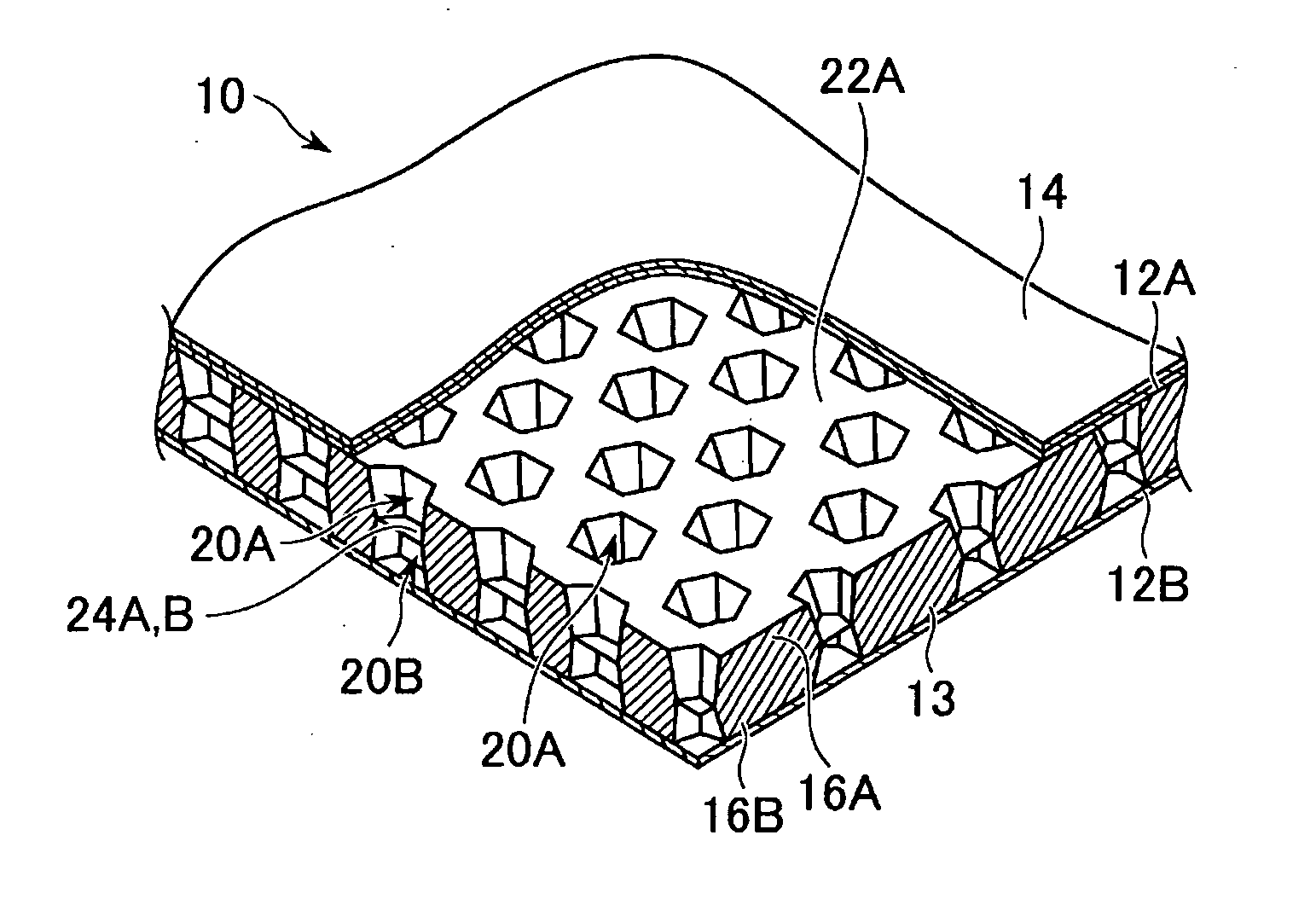

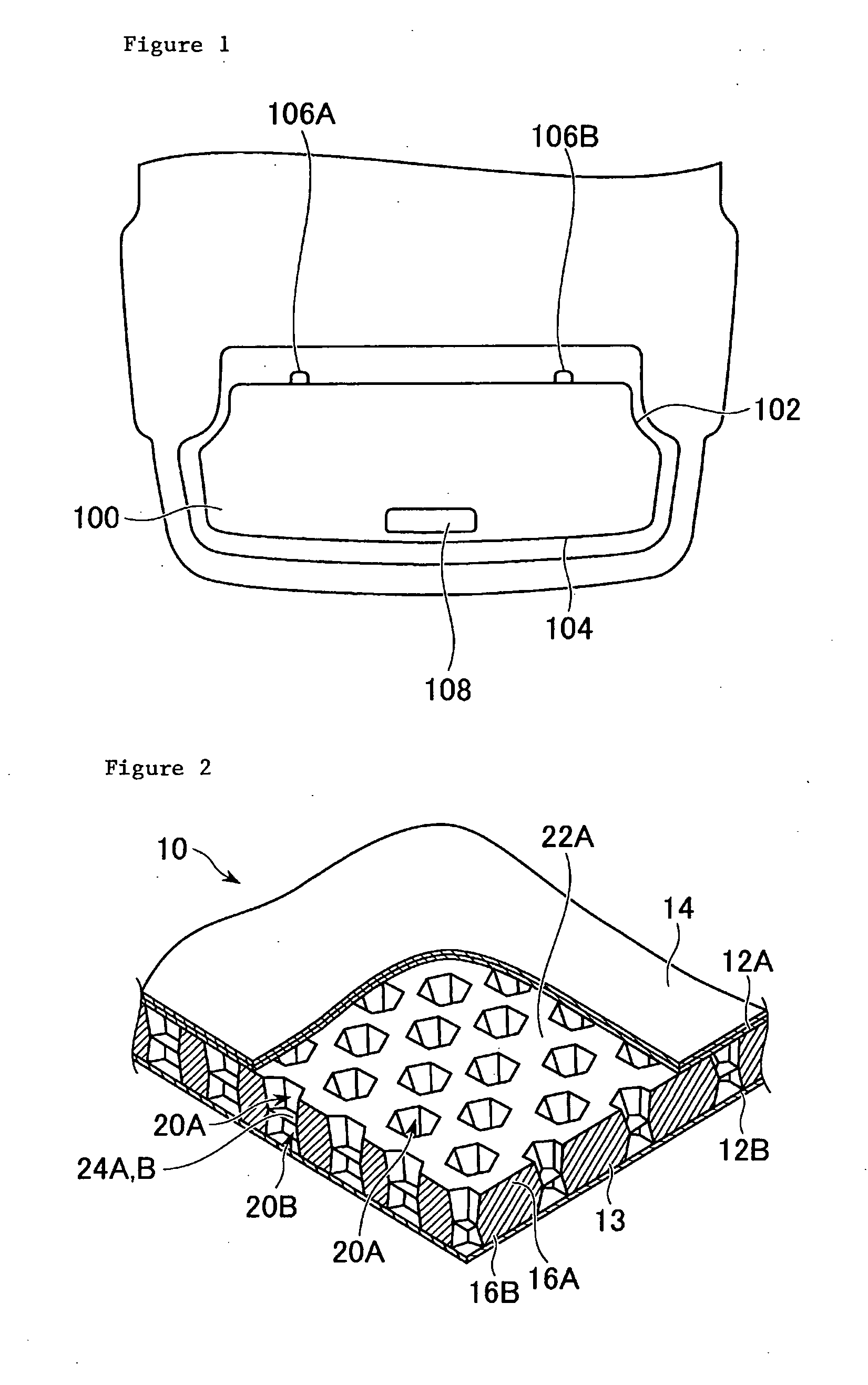

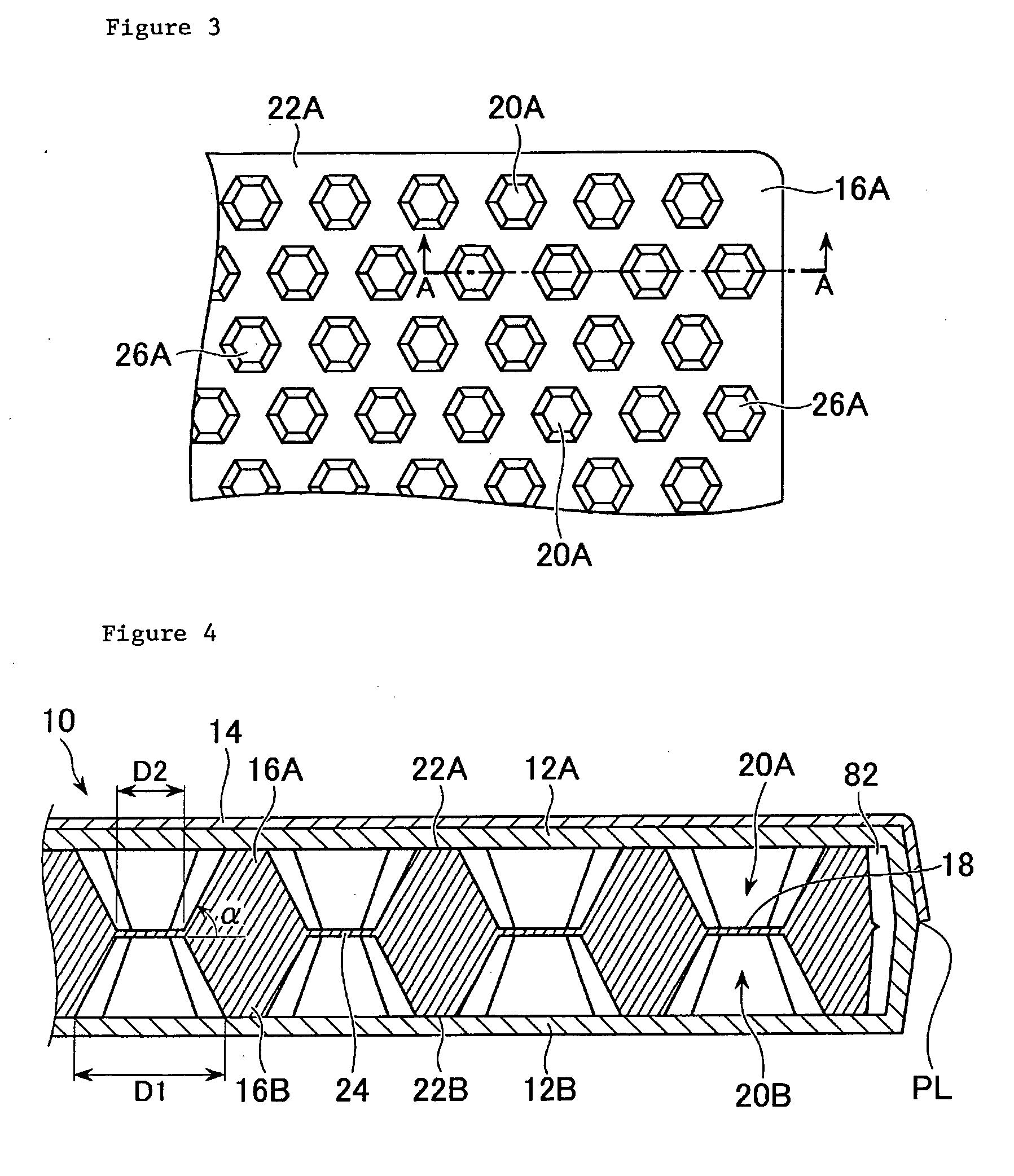

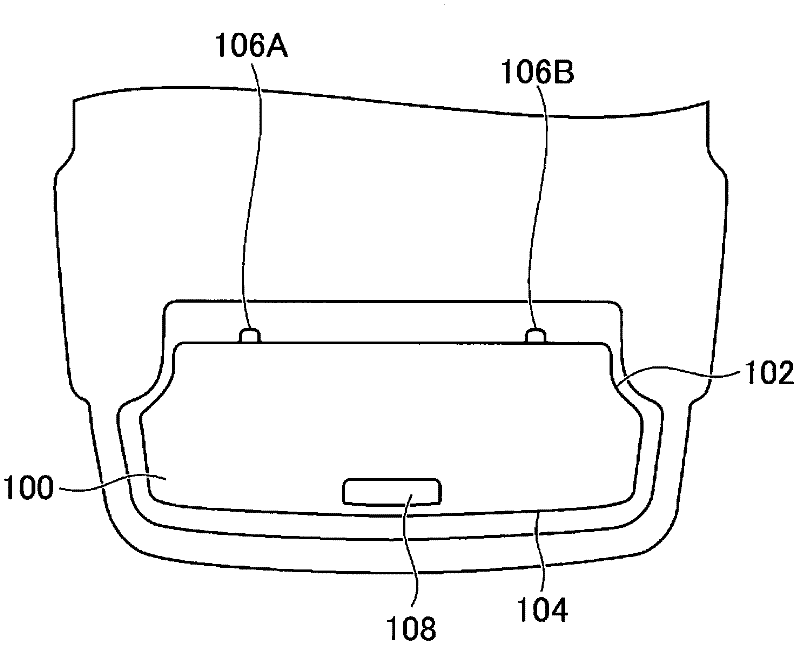

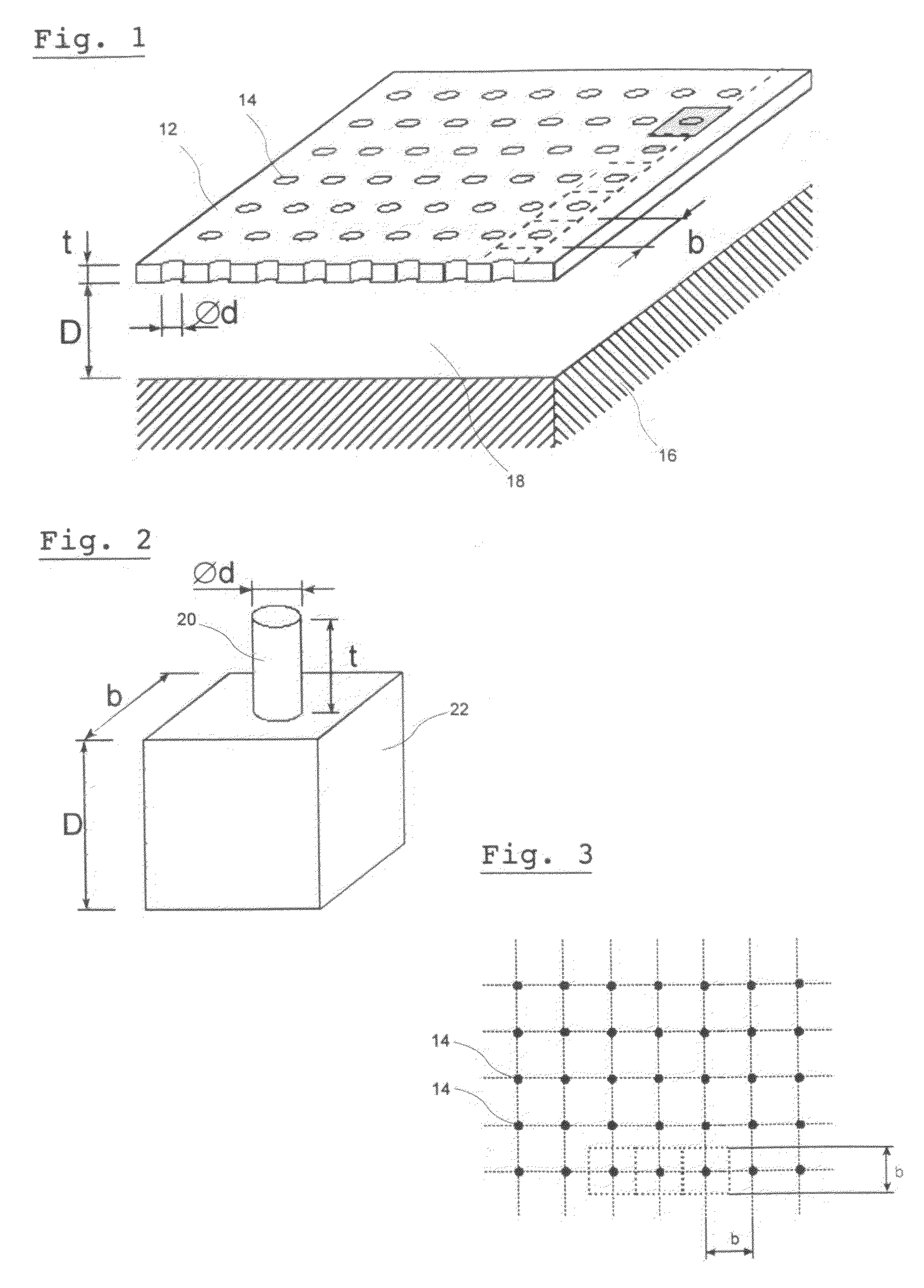

Sandwich panel, method of forming core material for sandwich panel, and method of forming sandwich panel

ActiveUS20110250384A1Increase weightLamination ancillary operationsSynthetic resin layered productsEngineeringSandwich panel

Owner:KYORAKU CO LTD

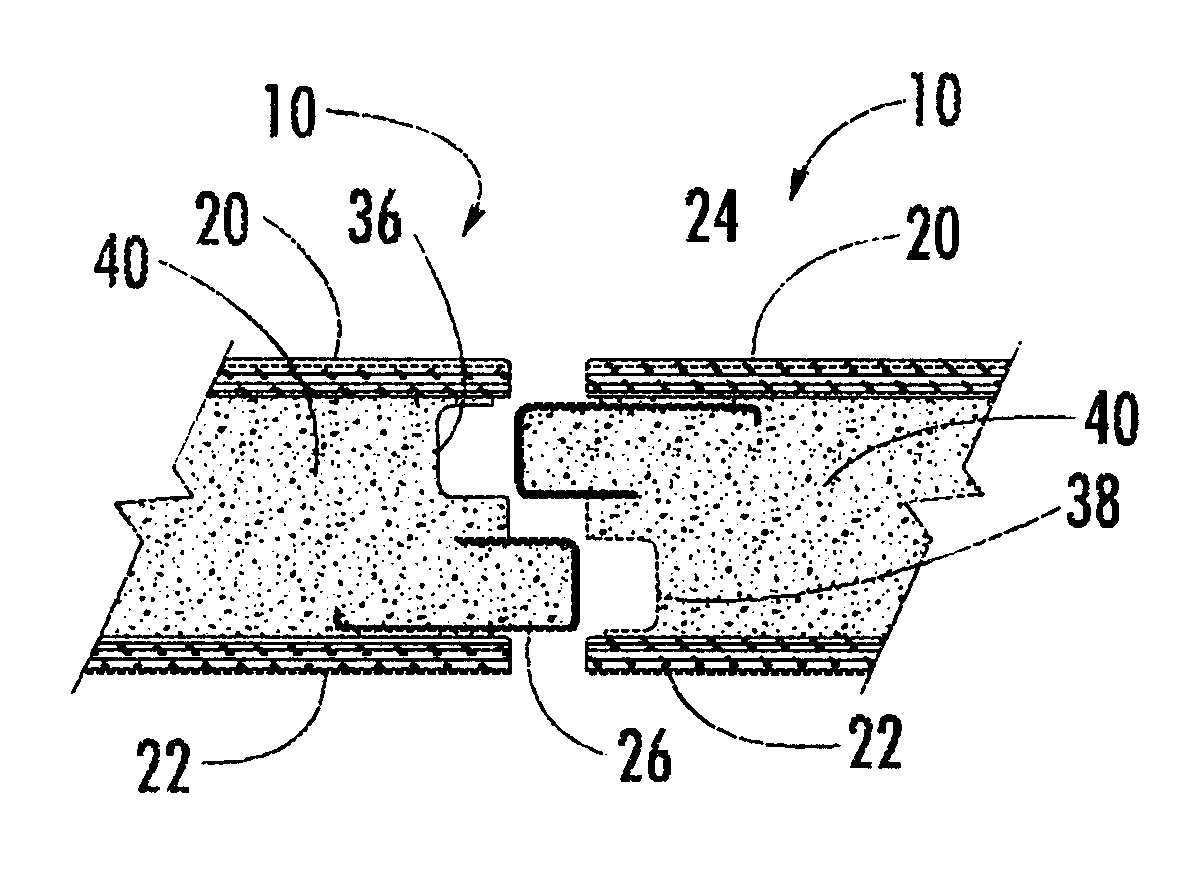

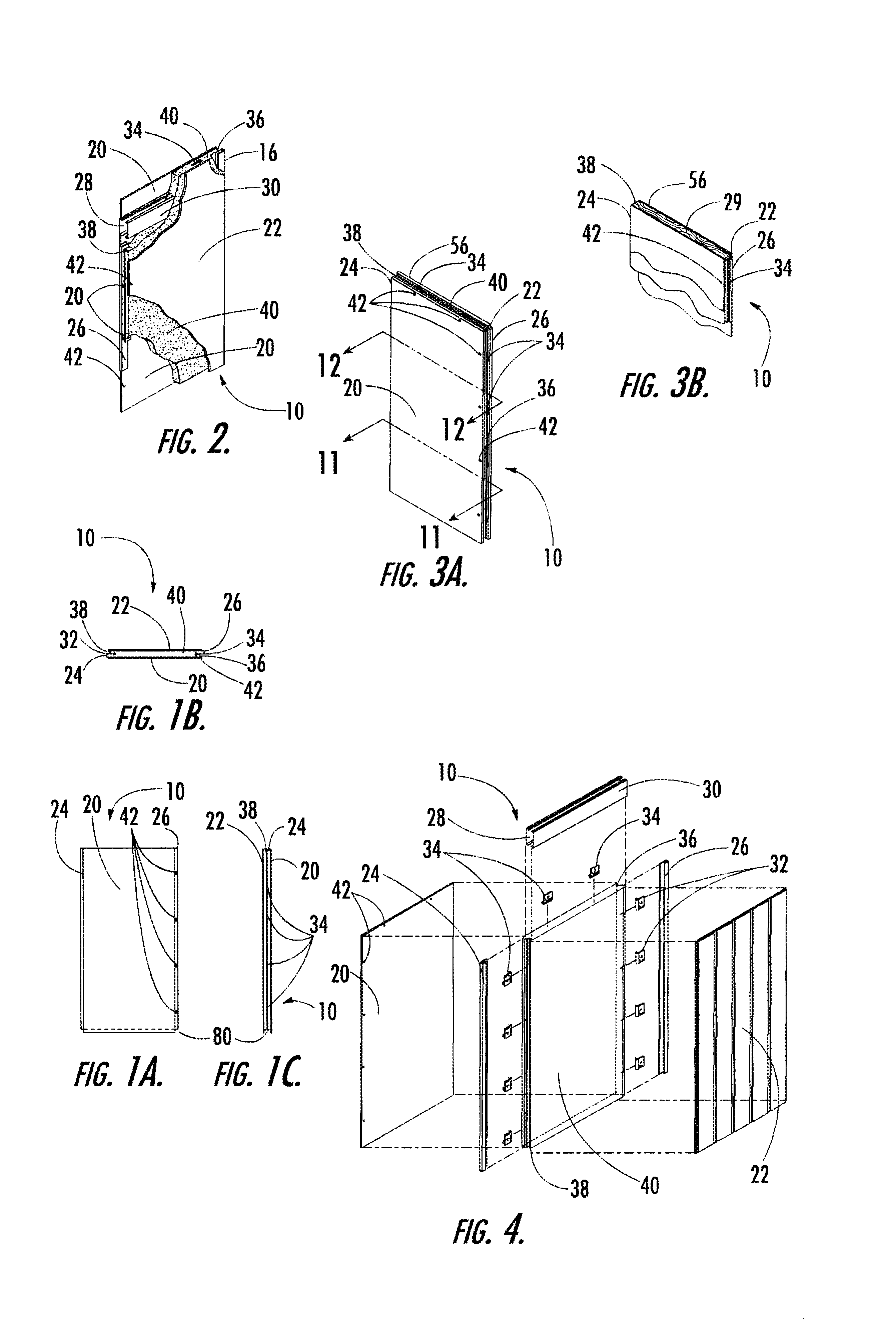

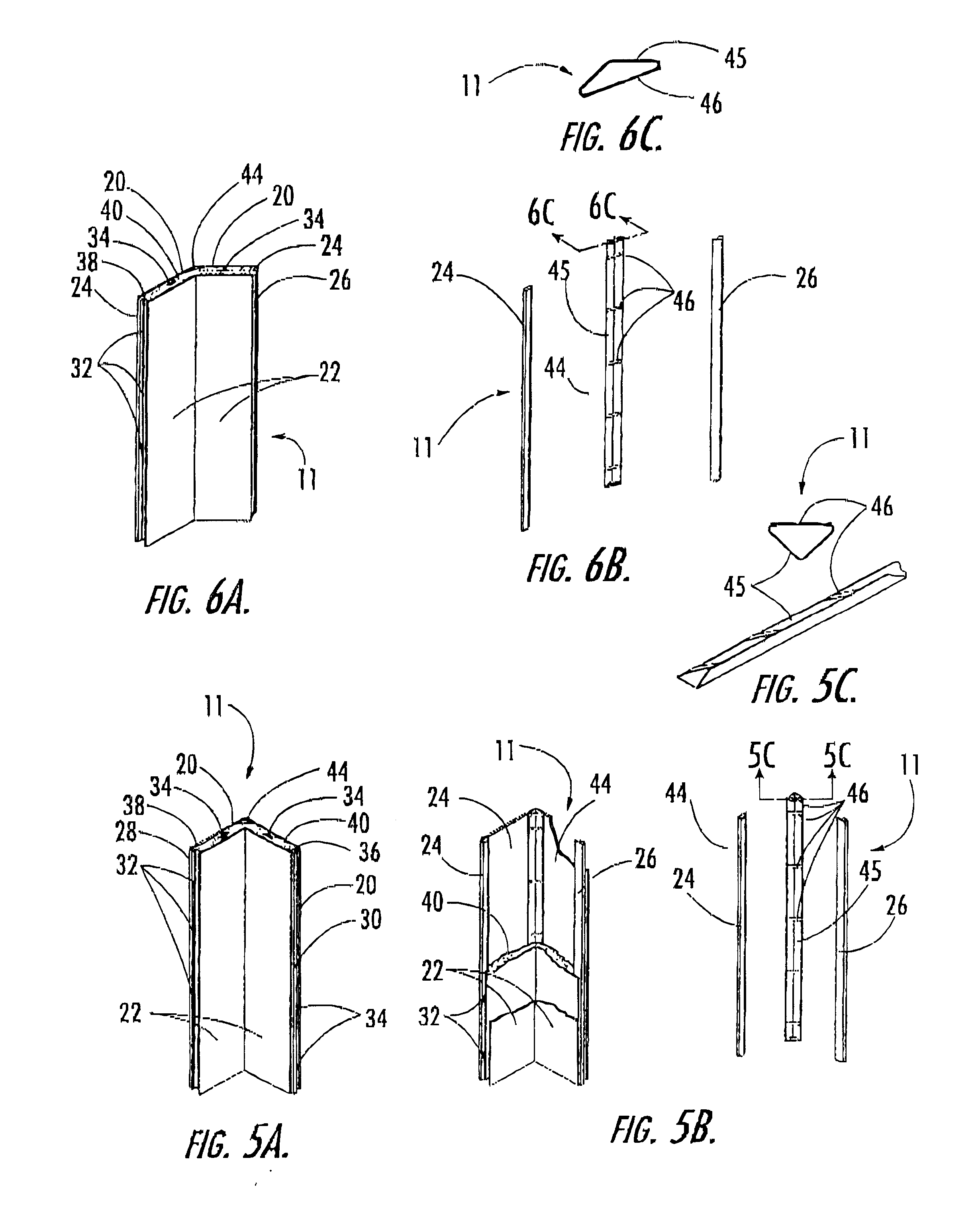

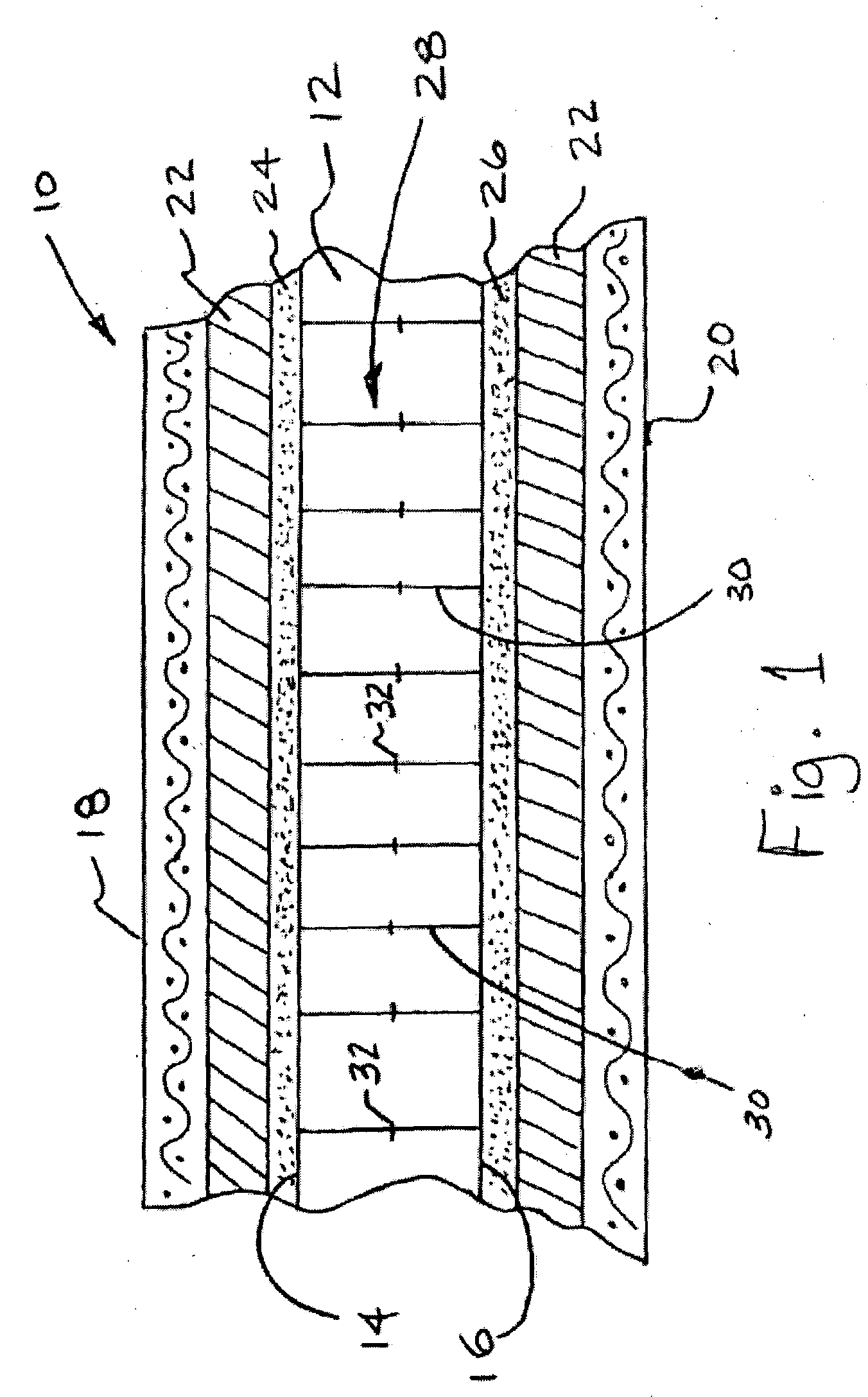

Structural sandwich panels and method of manufacture of structural sandwich panels

Rigid structural members, profiles, joints, and forms added to structural sandwich panels to provide higher strength, integral joining joint, and single facing sheet manufacturing. Facing sheets (20) and (22), rigid structural members (24) and (26), latch side and pin side cam-locks (34) and (32), fabricated wire truss assembly (48), and rigid structural headers (28) and (30) and an integrated top plate (29) are positioned into containment form assembly (58) in the proper position. Facing sheets (20) and (22) are placed in position in the containment form assembly (58) forming a structural sandwich panel assembly. A foam resin core material (40) is injected into the structural sandwich panel assembly and allowed to cure. The resultant structural sandwich panel includes rigid structural members (24) and (26) and elongated recesses (36) and (38) which also form a joint for joining abutting structural sandwich panels together and cam-locks (32) and (34) used to secure adjoining panels together. Comer and angle panels have a comer rigid structural assembly (44).

Owner:BROWN PAUL A +1

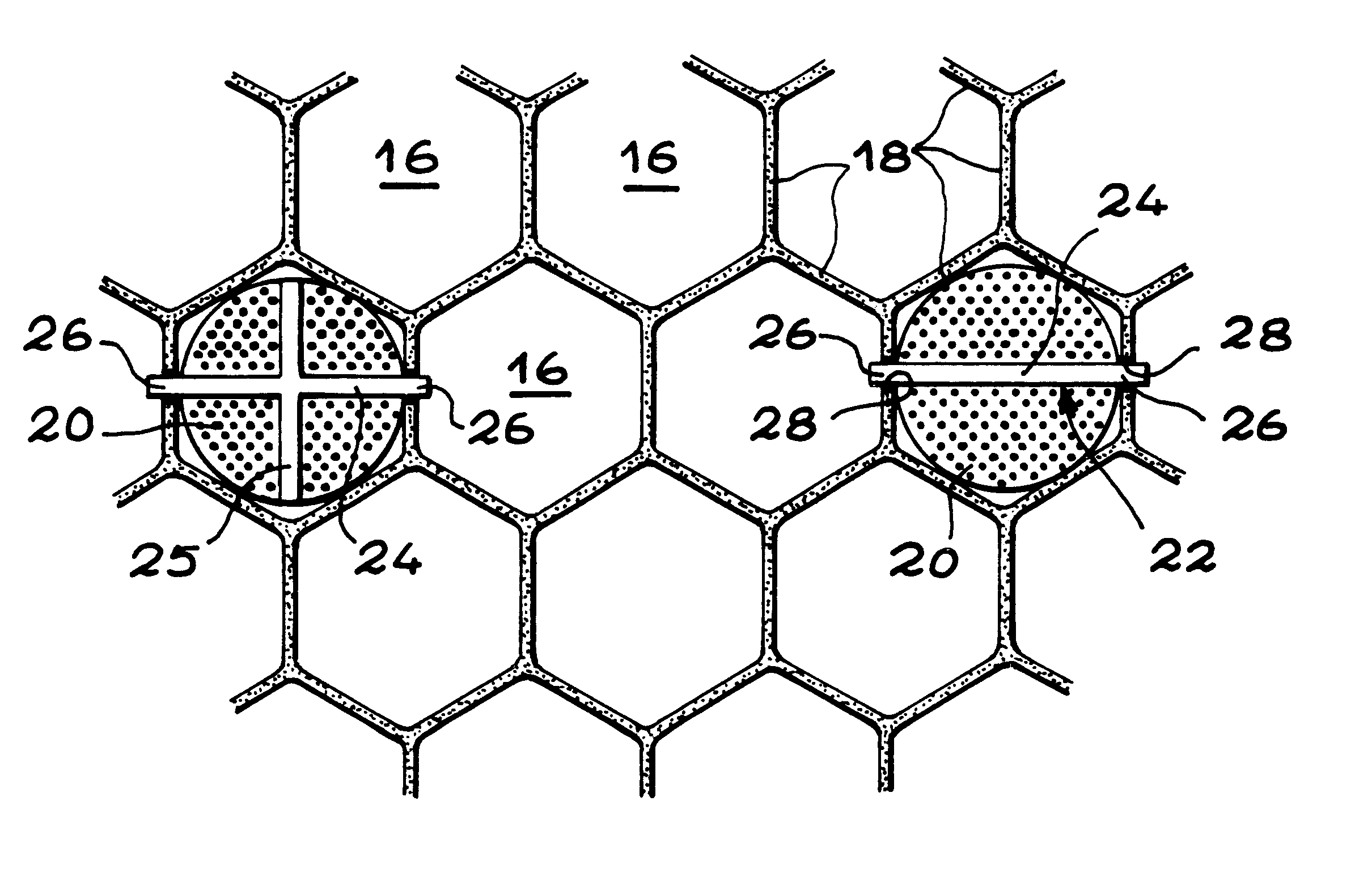

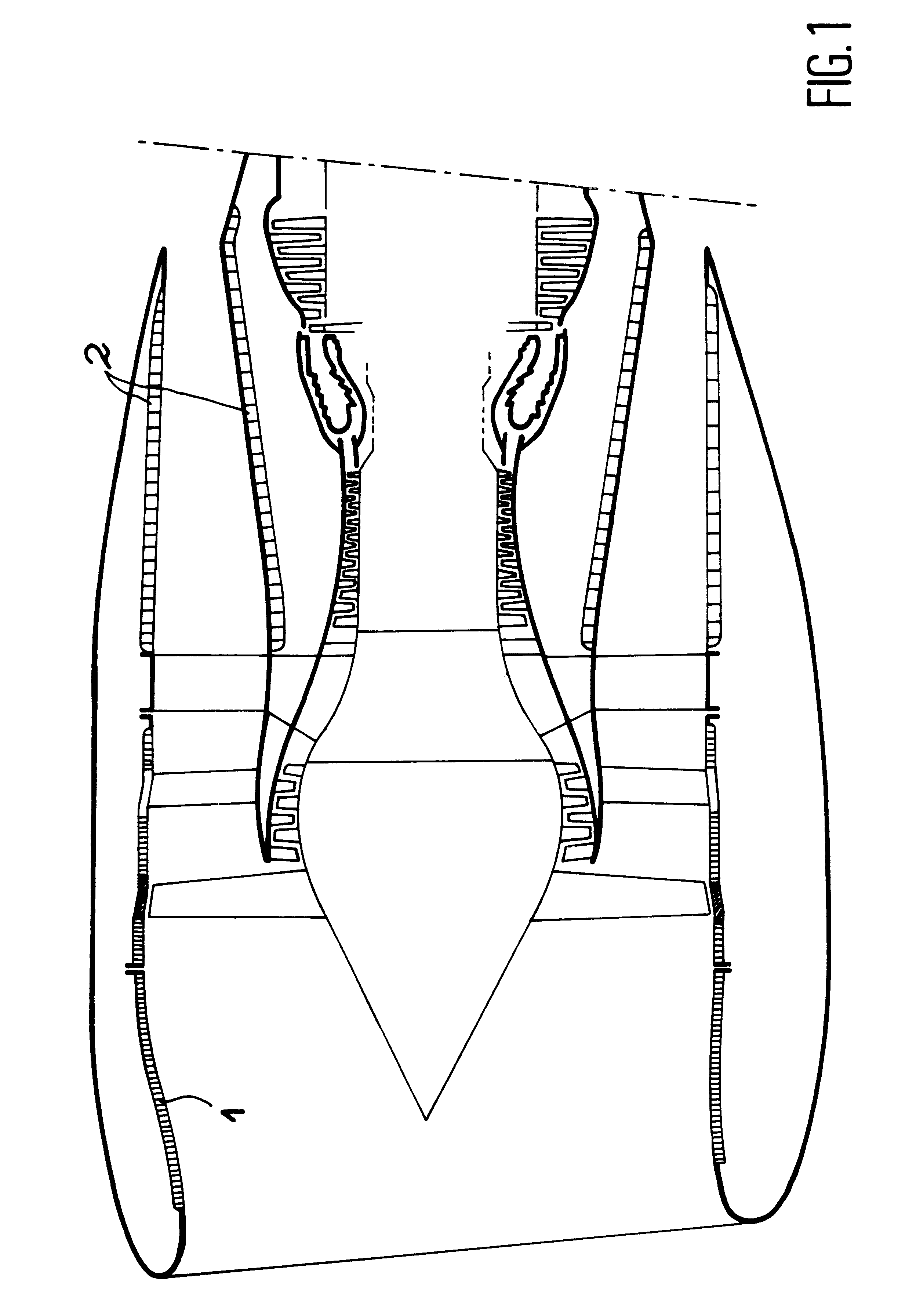

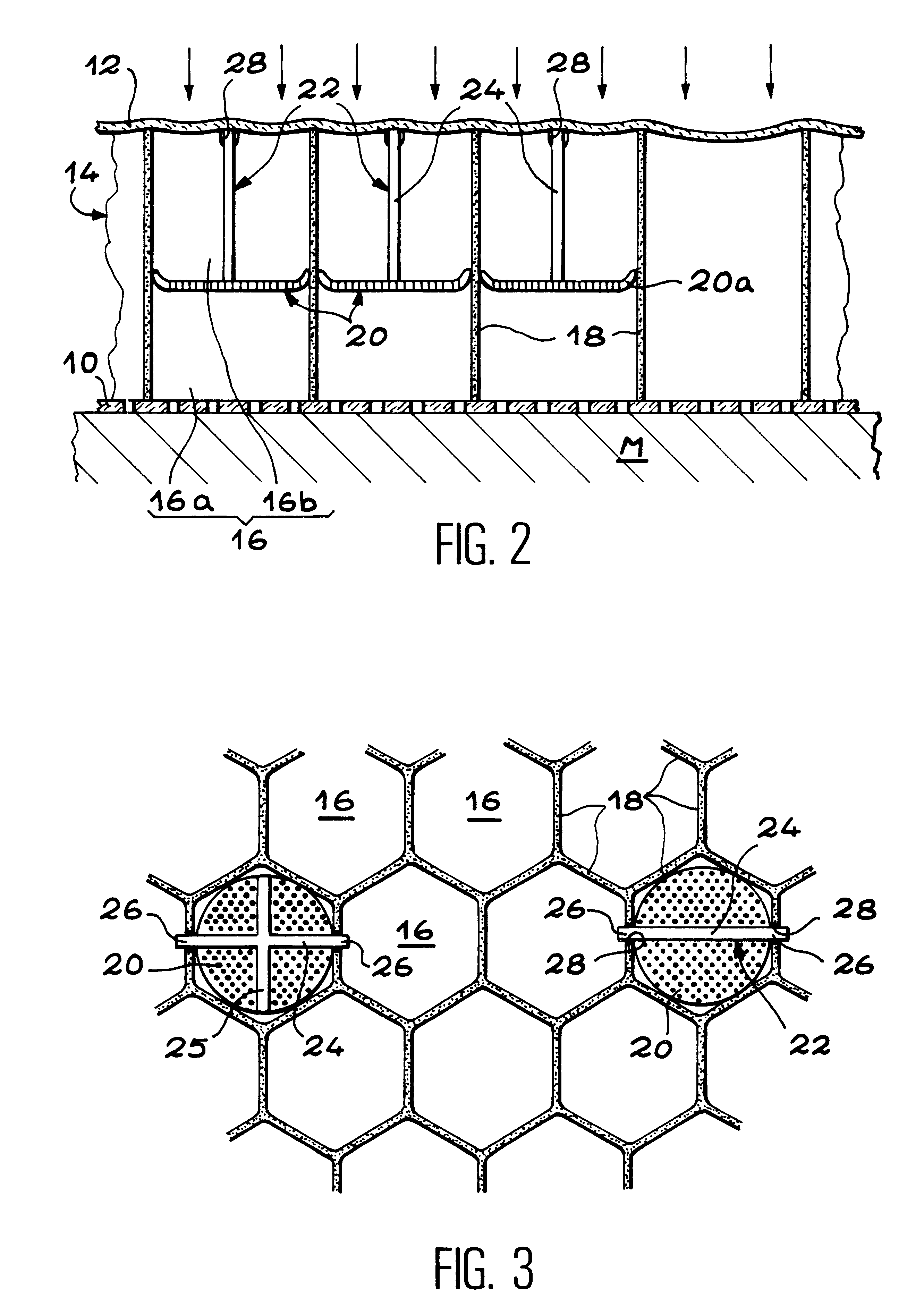

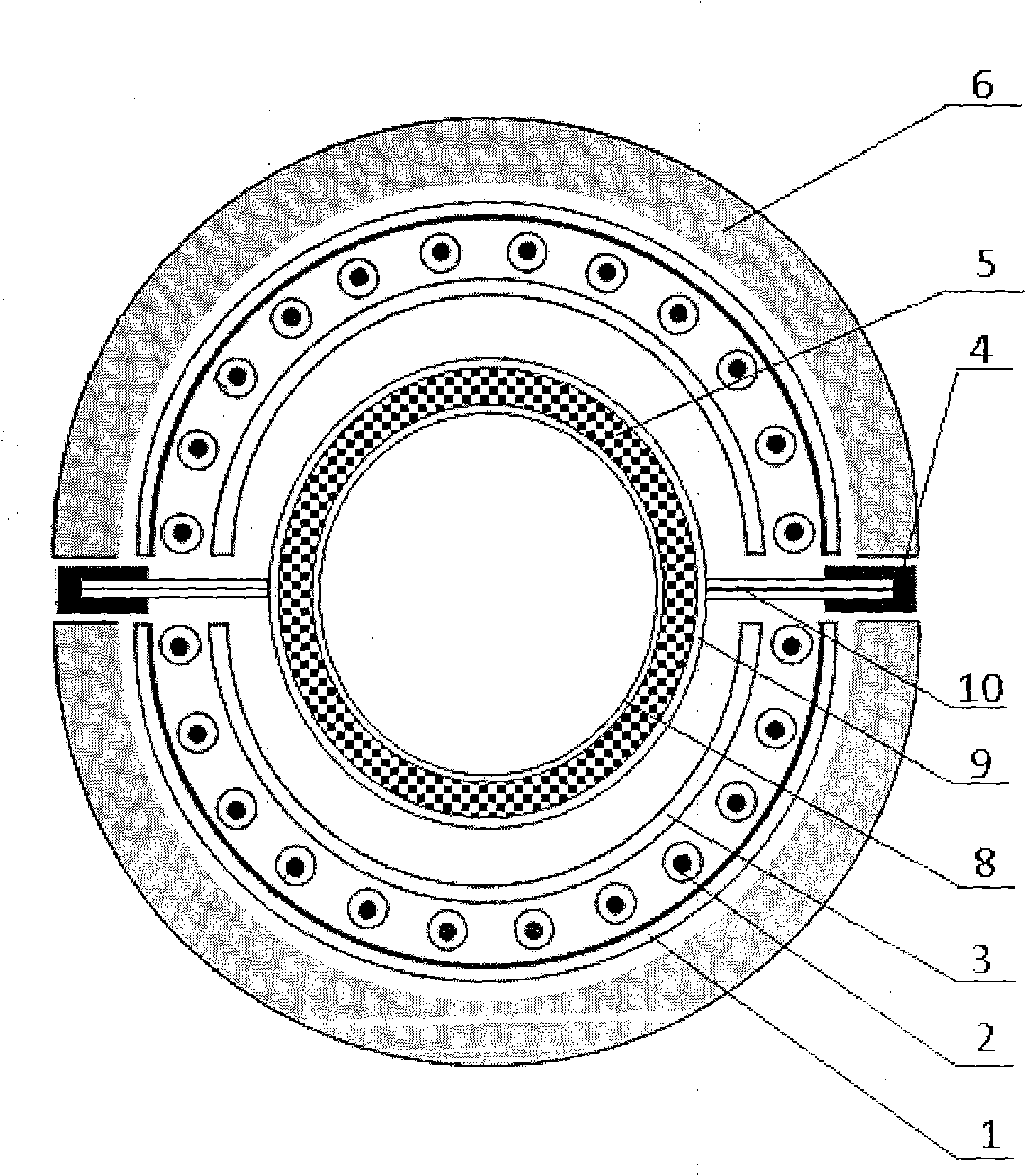

Noise reduction sandwich panel, notably for aircraft turbojet engine

InactiveUS6536556B2Improve suppression propertiesEasy to installCeilingsLayered productsRelative displacementJet engine

Noise reduction sandwich panel, notably for an aircraft turbojet engine.In order to produce a noise reduction sandwich panel having a structure with two degrees of freedom, inserted separative components (20) are placed into the hexagonal cells (16) of the unique waffle core of the panel. More specifically, the separative components (20) have an substantially circular external peripheral edge, which allows them to be easily assembled, in spite of the deformations of the walls (18) of the cells (16) due to manufacturing tolerances and to the optional forming of the waffle core. Advantageously, several separative components (20) are supported by a same positioning unit (22), which then allows relative displacement between the separative components.

Owner:AIRBUS OPERATIONS (SAS)

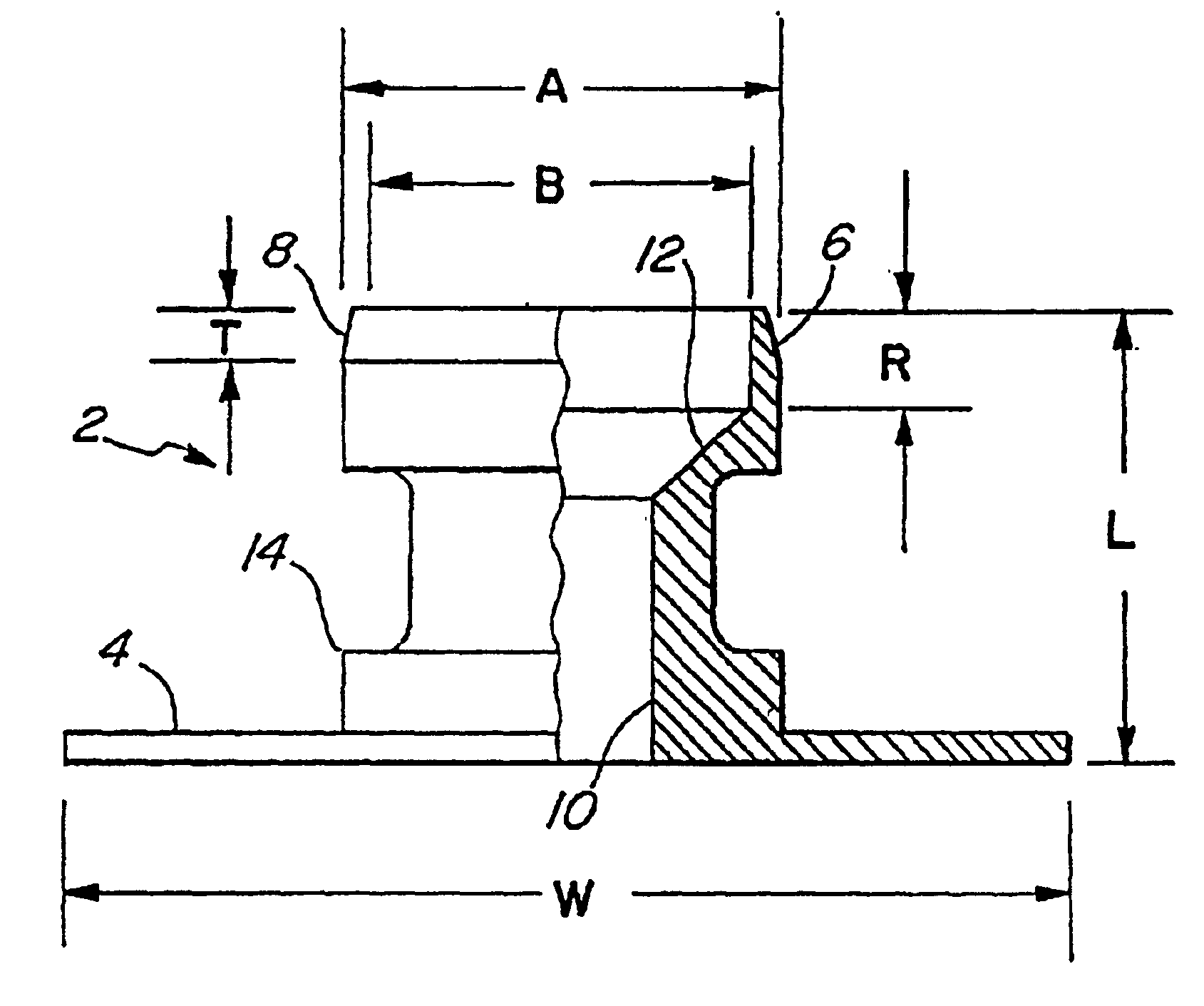

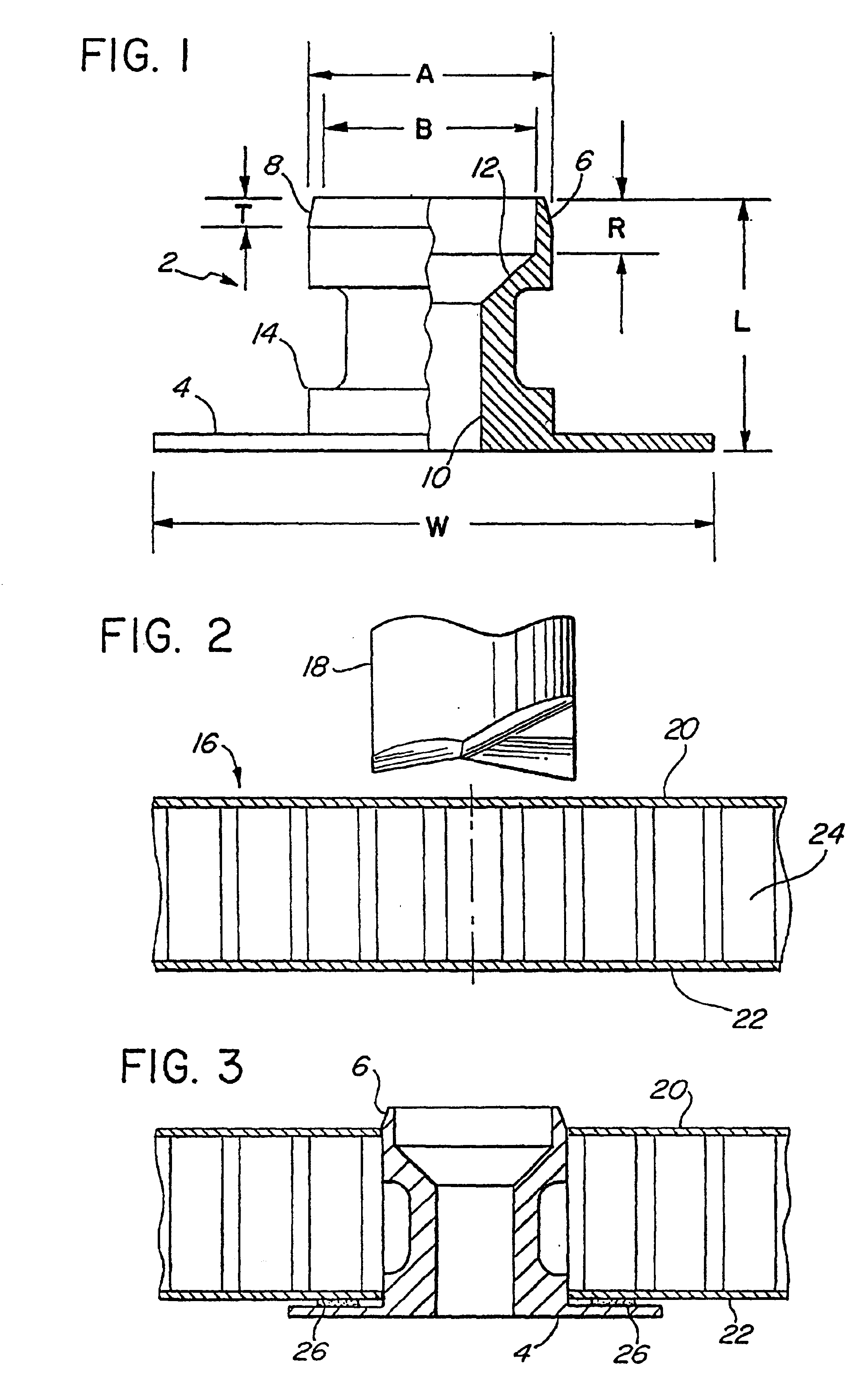

Flush panel spacer and method and apparatus of installing the same

InactiveUS6862863B2Large inner diameterEasy to installSheet joiningBuilding componentsSealantSandwich panel

A method of installing an insert in a sandwich panel for mounting a fastener includes making a hole in the panel and inserting a spacer having a height greater than the thickness of the panel. An entrance rim of the spacer extends above an upper surface of the panel and a setting tool exerts a force on the entrance rim to force it into the hole and to position an upper edge of the entrance rim flush with the panel surface. The spacer can include an annular groove on an interior wall of the entrance rim to facilitate the cold working deformation during an installation in the panel and a hole engaging surface to align and maintain the spacer within the hole. An outer exterior surface of the entrance rim can be indented and coated with a first sealing compound to ensure a watertight seal with the panel. A second sealant material can be provided within the entrance rim for sealing with a head of any fastener extending through the spacer. An improved floor panel with spacer is accordingly provided for aircraft.

Owner:SPS TECH LLC

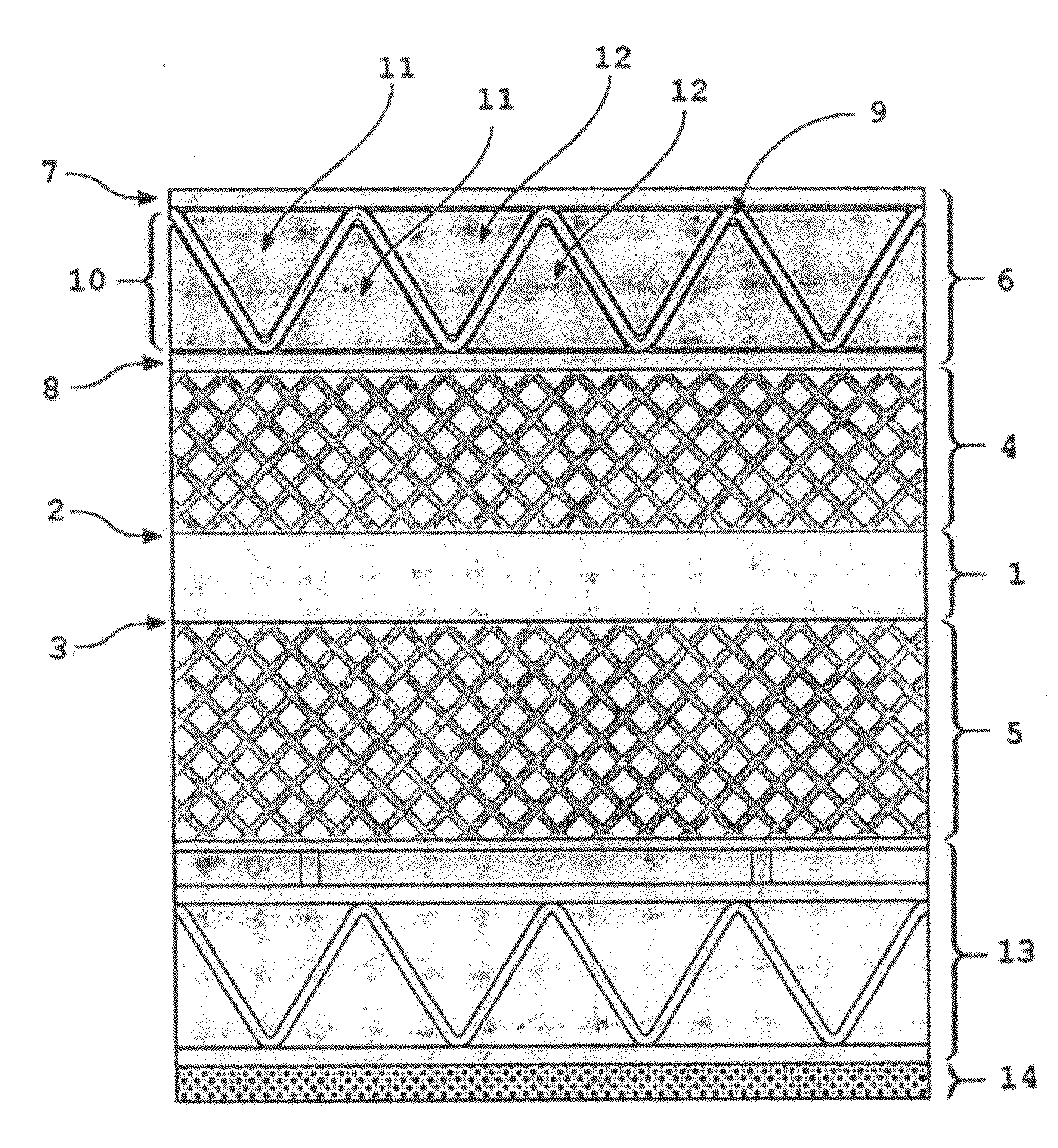

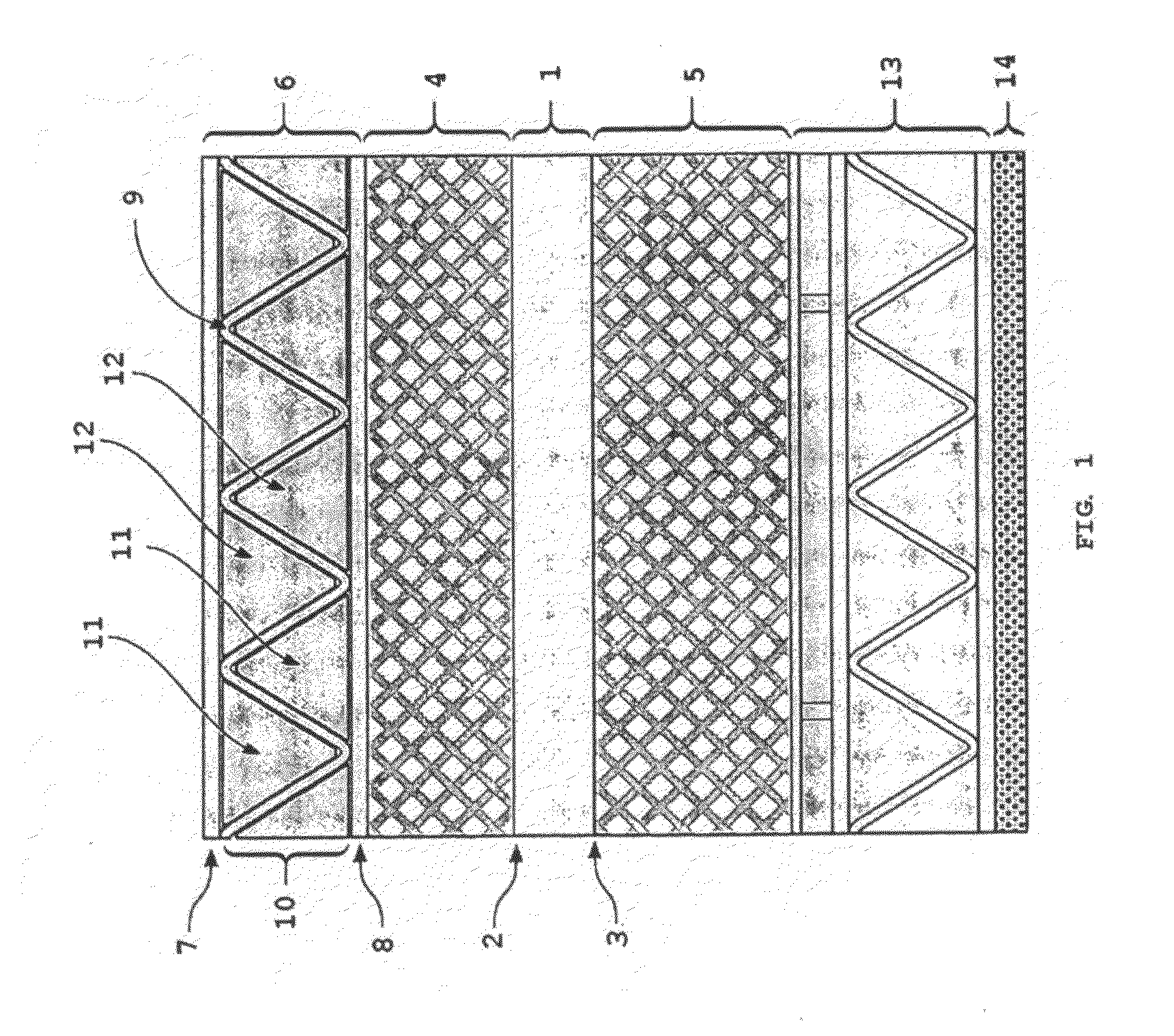

Synergistically-Layered Armor Systems and Methods for Producing Layers Thereof

The armor system according to the present invention also exploits synergistic multi-layering to provide different properties as a function of depth within a sandwich panel. Various embodiments of the invention include a combination of composite sandwich topology concepts with hard, strong materials to provide structures that (i) efficiently support static and fatigue loads, (ii) mitigate the blast pressure transmitted to a system that they protect, (iii) provides very effective resistance to projectile penetration, and (iv) minimizes shock (stress wave) propagation within the multi-layered armor sandwich structure. By using small pieces of highly constrained ceramic, the concept has significant multi-hit potential.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

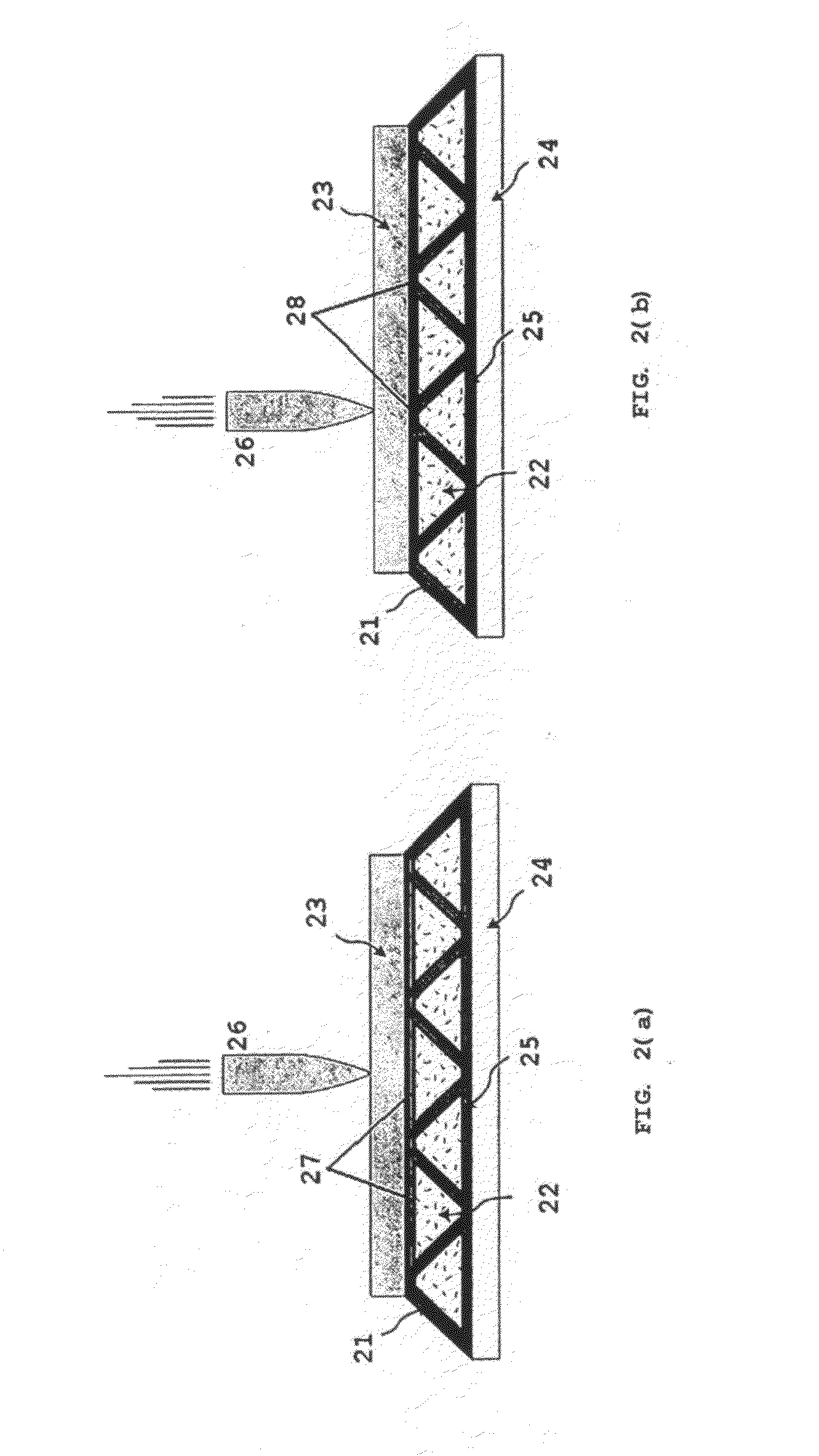

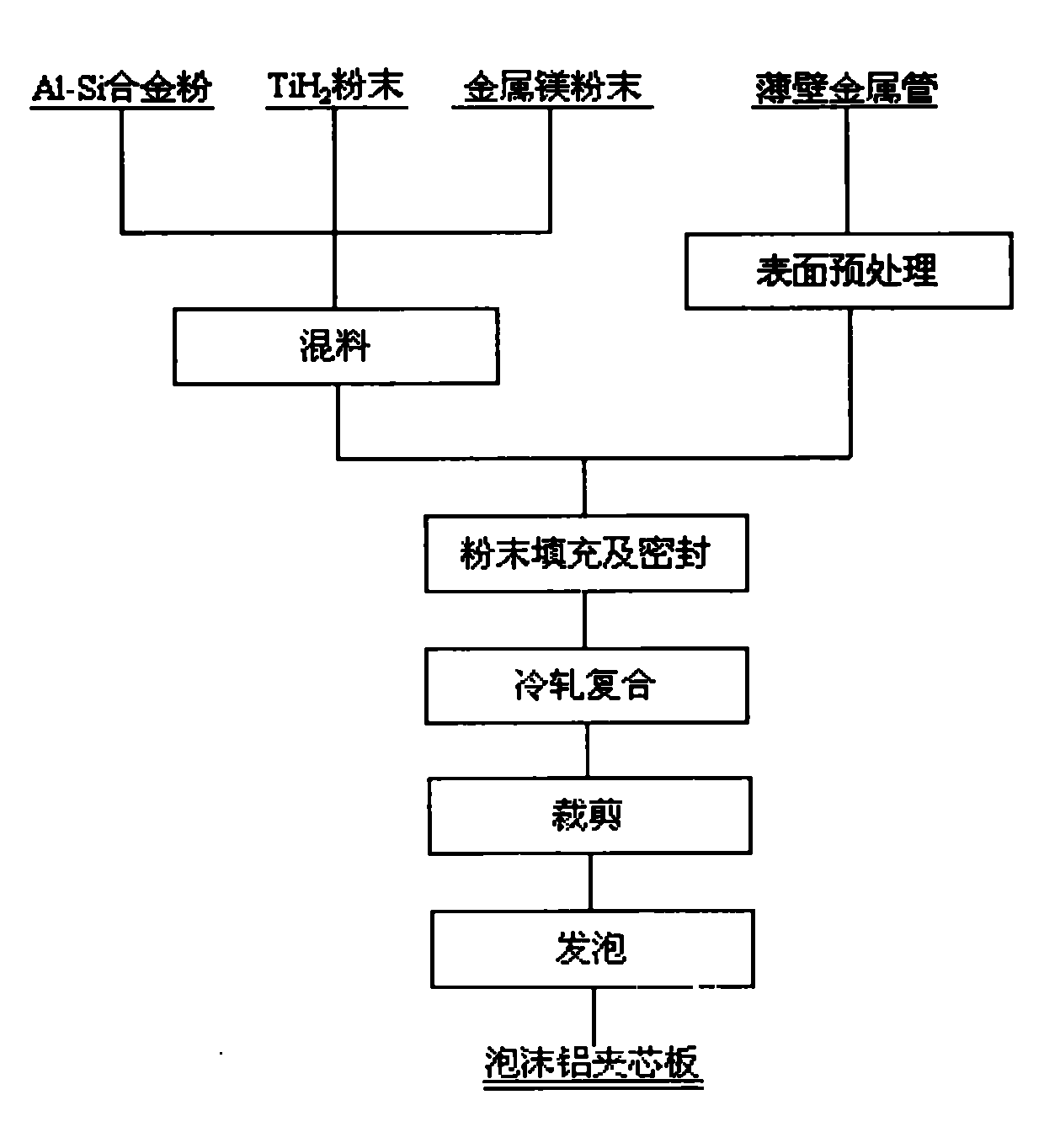

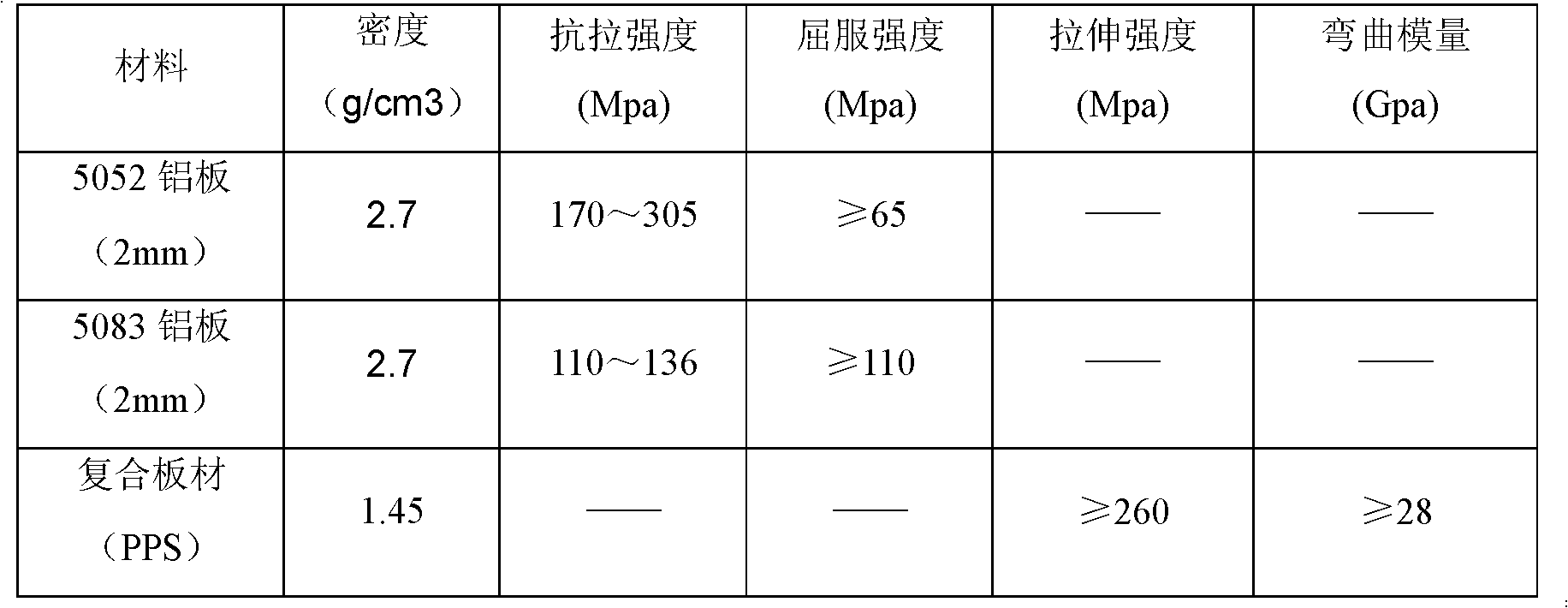

Method for manufacturing foamed aluminum sandwich plate

The invention relates to a method for manufacturing a foamed aluminum sandwich plate, which belongs to the field of porous foam metal and laminar composite materials. The method comprises the following steps of: uniformly mixing aluminum-silicon alloy powder prepared by an atomization method, and foaming agent titanium hydride powder and metal magnesium powder in a certain ratio; filling the powder into a thin-wall steel (or aluminum alloy) tube with one sealed end; sealing the other end of the tube after powder filling and preparing a rolled blank; rolling and compounding at a slow speed on a cold rolling mill; trimming an obtained composite plate and cutting a foamed preformed blank according to the size of a foaming mold; foaming the preformed blank in a steel mold in a limited way; adjusting foaming temperature and foaming time as required; and foaming at a high temperature for a short period of time to obtain a high-quality foamed aluminum sandwich plate with a uniform foam structure in a core layer, good interface bonding, high thickness accuracy and excellent plate profile. The method has the outstanding characteristics of low equipment requirement, high plate profile accuracy of a product, high three-point bending strength and the like and is advantaged technology suitable for mass industrial production of foamed aluminum sandwich structural materials.

Owner:NORTHEASTERN UNIV

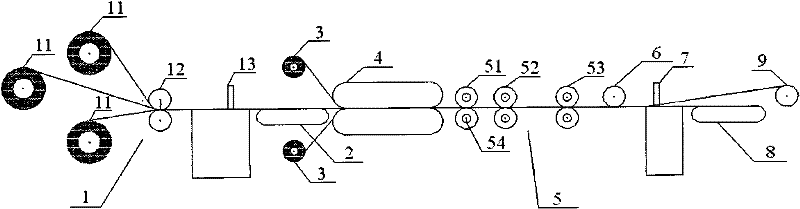

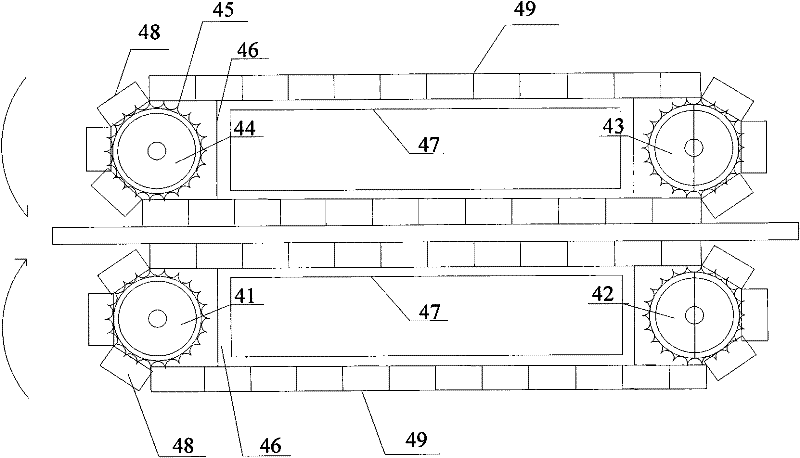

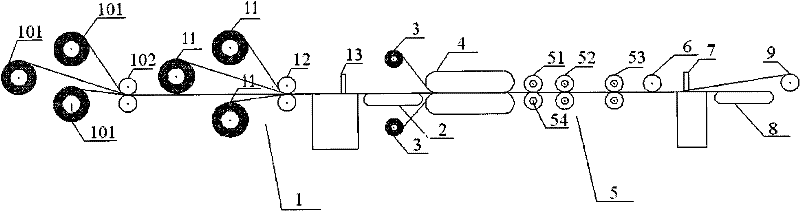

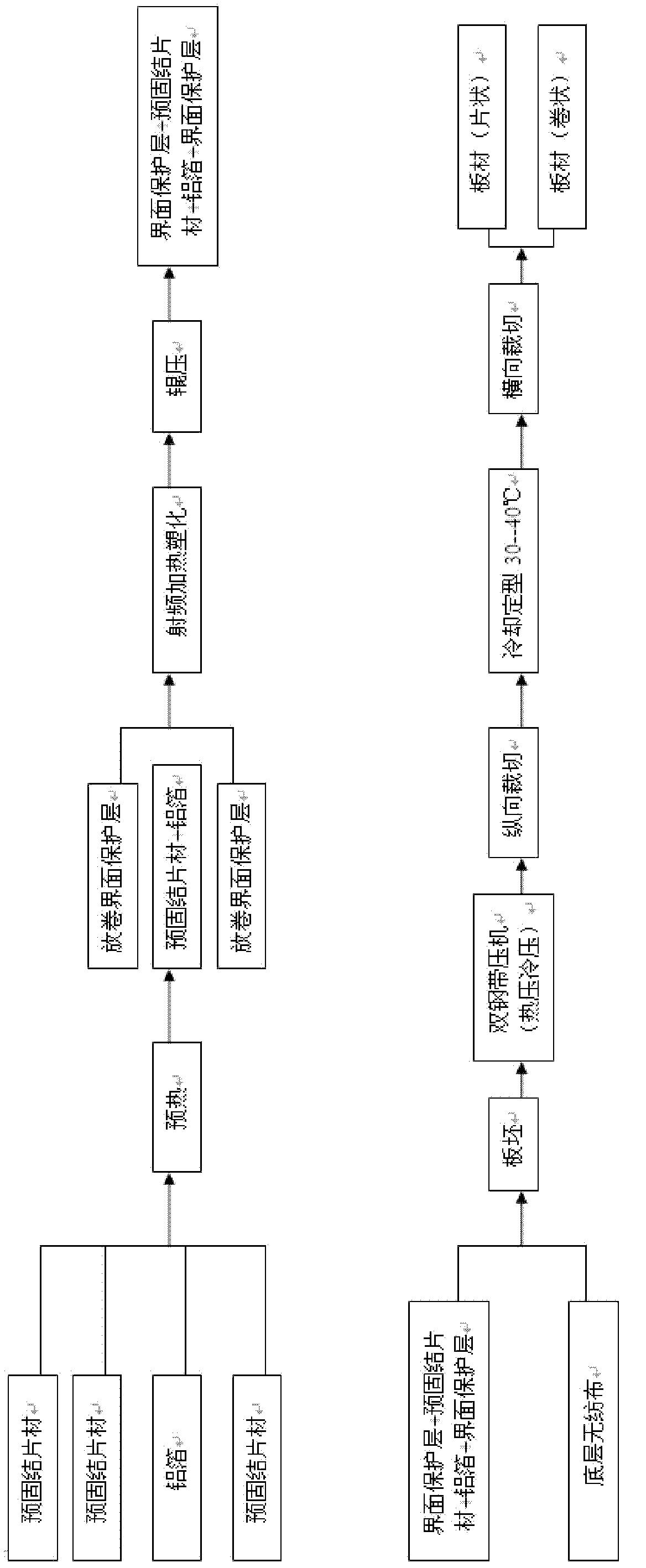

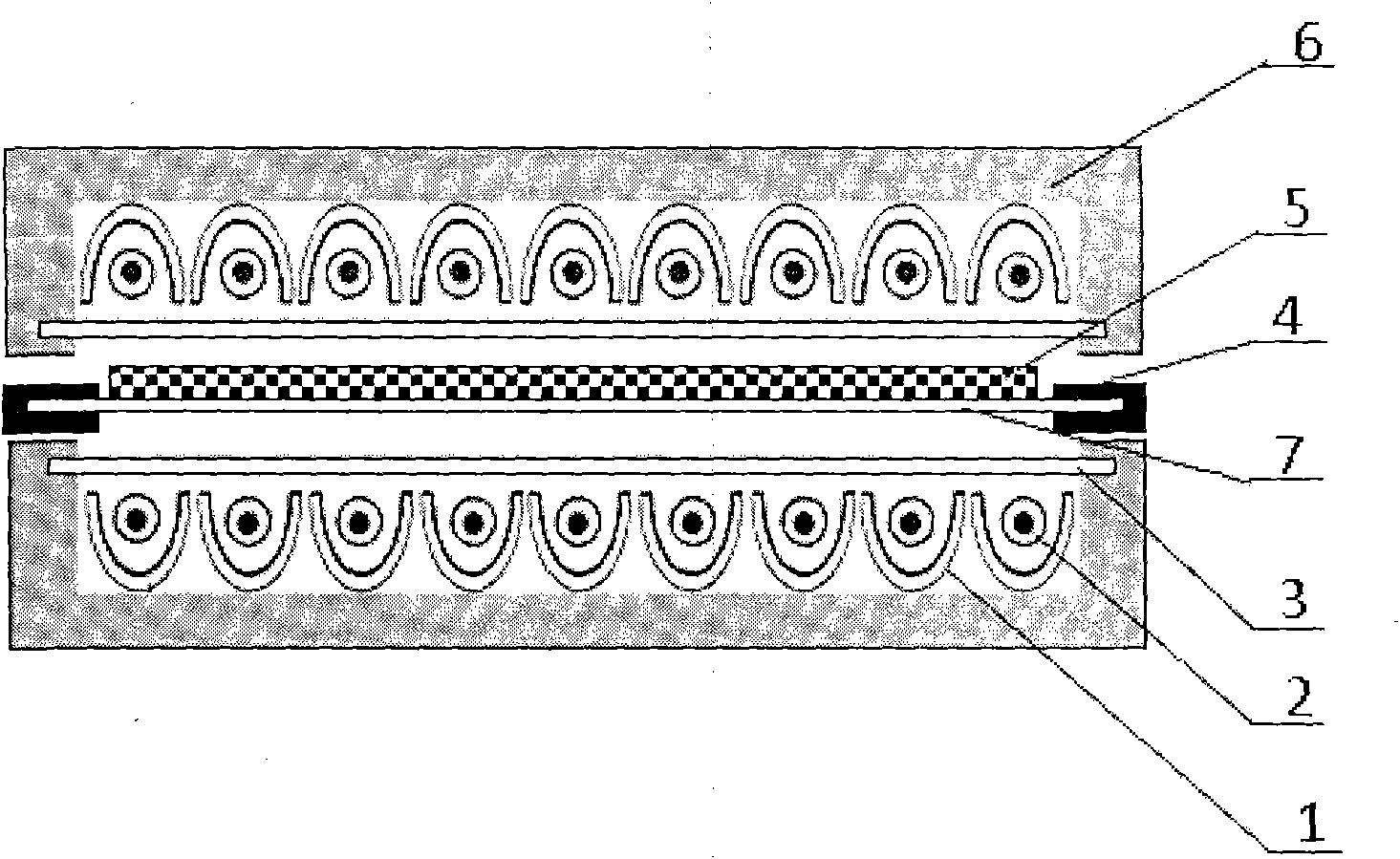

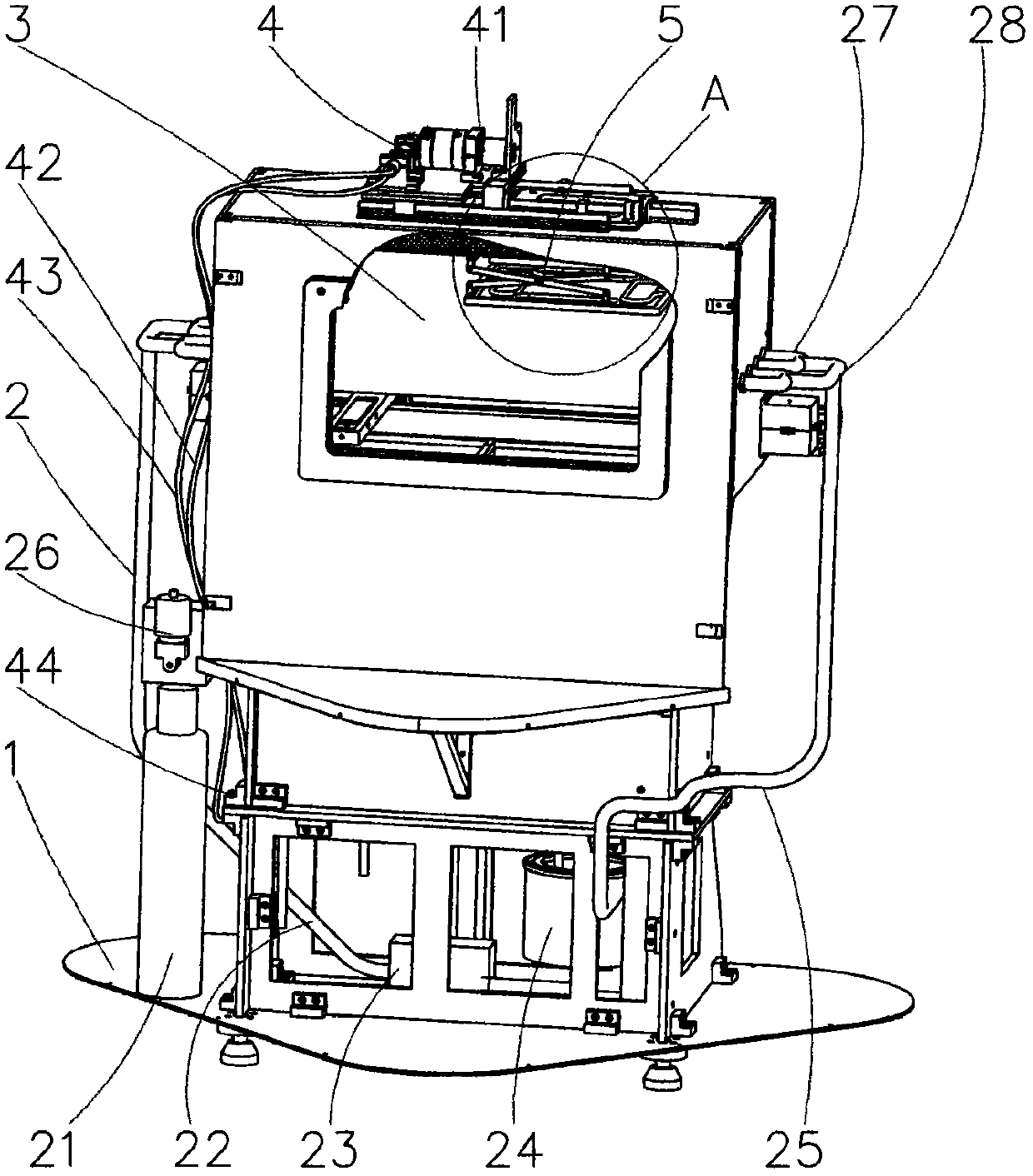

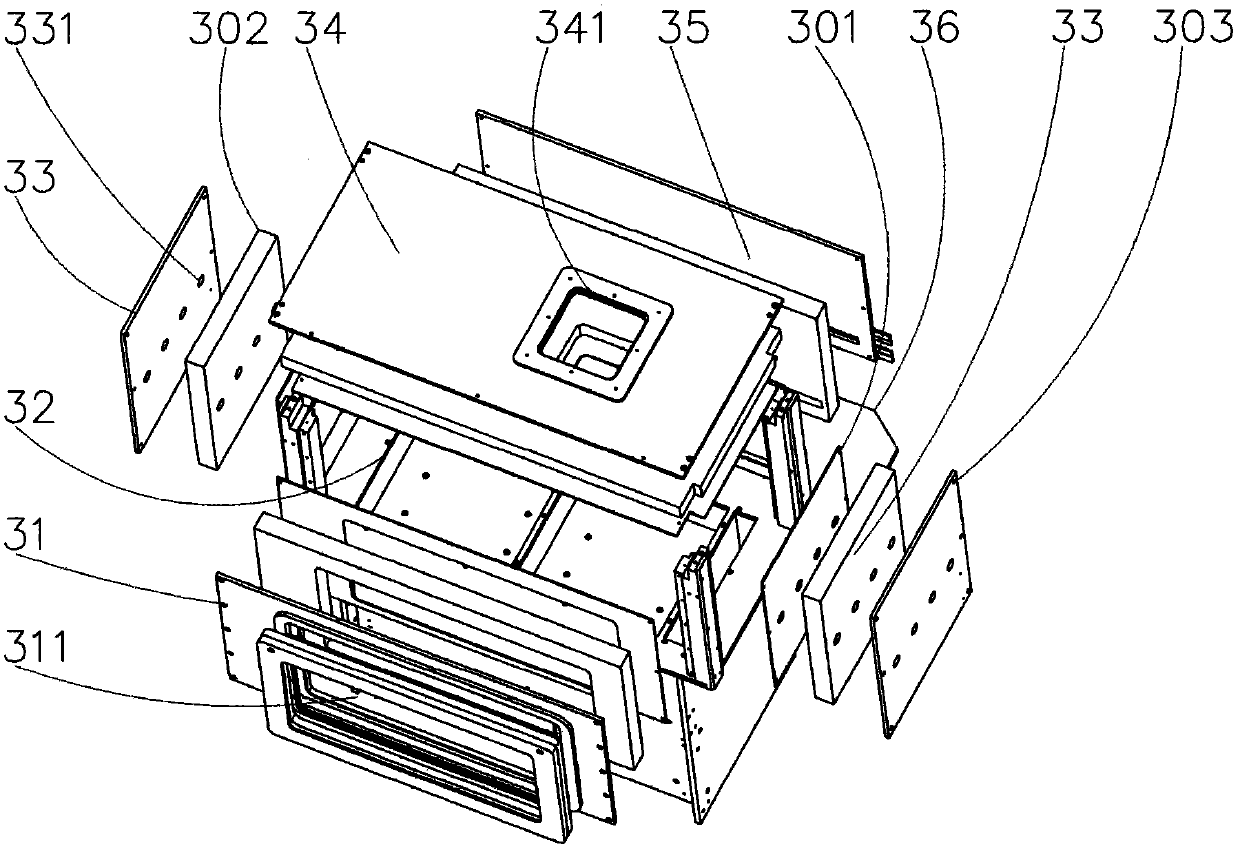

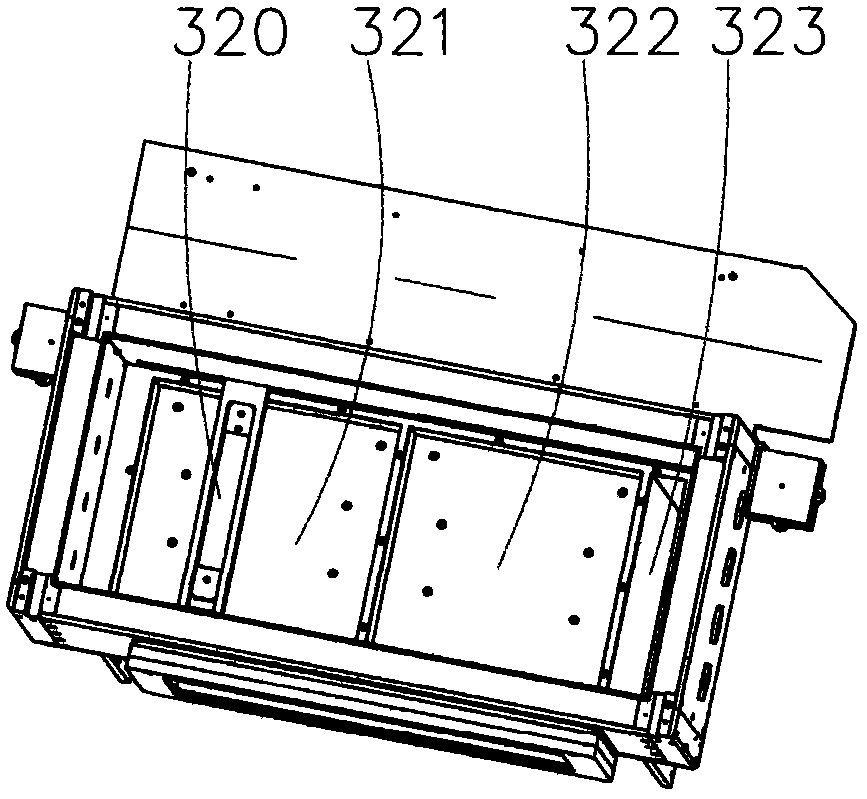

Production equipment for continuous fiber reinforced thermoplastic structural panel

ActiveCN102452209AEasy dischargeHigh degree of production automationLamination ancillary operationsLaminationThermoplasticCompression molding

The invention relates to production equipment for a continuous fiber reinforced thermoplastic structural panel. In the molding process of the panel, a continuous fiber reinforced thermoplastic prepreg tape and a sandwich material are conveyed to a panel compositing place by an automatic conveyer and performed with compression molding by crawler-type hot pressing compositing, and cold pressing molding by a roll shaft. The mode of heating is electromagnetic heating. Compared with prior art, the invention has simple process and high production efficiency and is able to produce continuous panels and large area composite panels. The equipment is suitable for use in sandwich panels formed by the continuous fiber reinforced thermoplastic structural panel and continuous fiber reinforced thermoplastic plastic and composite panels formed by continuous fiber reinforced thermoplastic plastic and metals such as aluminum foil and the like.

Owner:LIAONING LIAOJIE SCI & TECH

Composite Sandwich Panel

InactiveUS20120058299A1Increase resistanceSynthetic resin layered productsLaminationHigh strength concreteHigh intensity

Constructional panel having a front side suitable to be exposed to outside weather conditions, comprising a front side element, a rear side element and an insulating material arranged between said front and rear side elements, where the front side element is made from a high strength concrete, and where the insulating material is adhered to the rear side of said front and rear side elements.

Owner:CONNOVATE

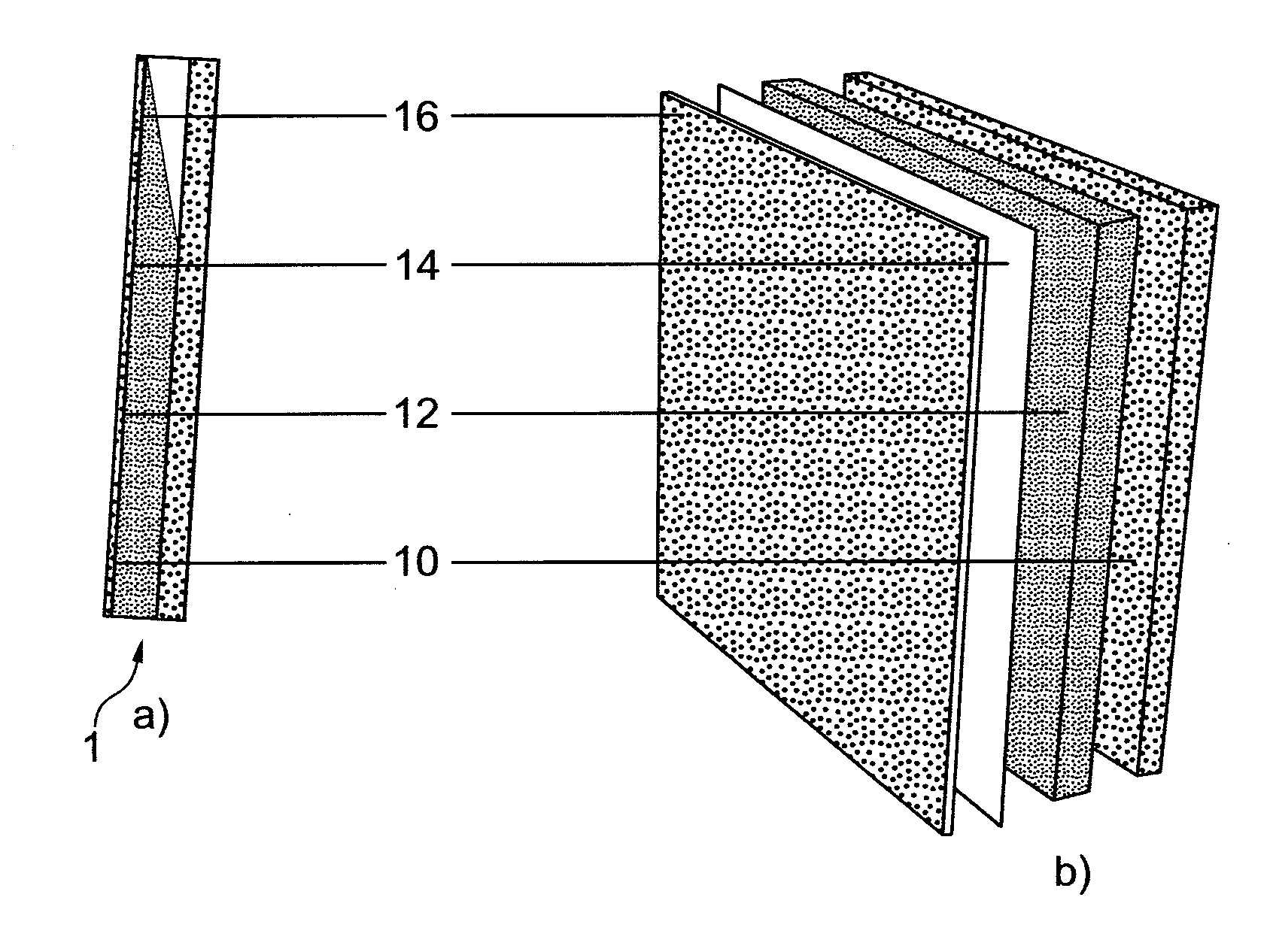

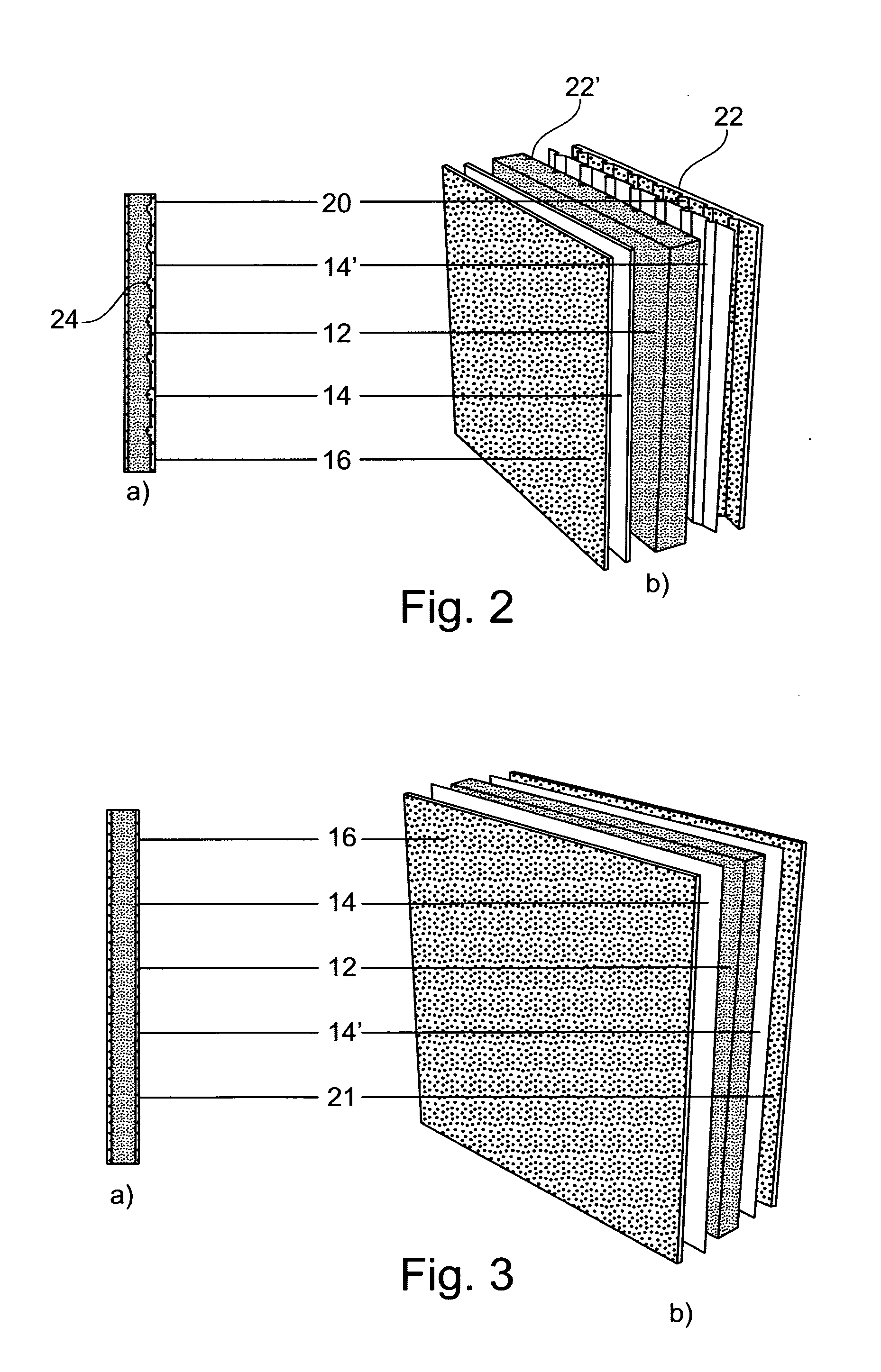

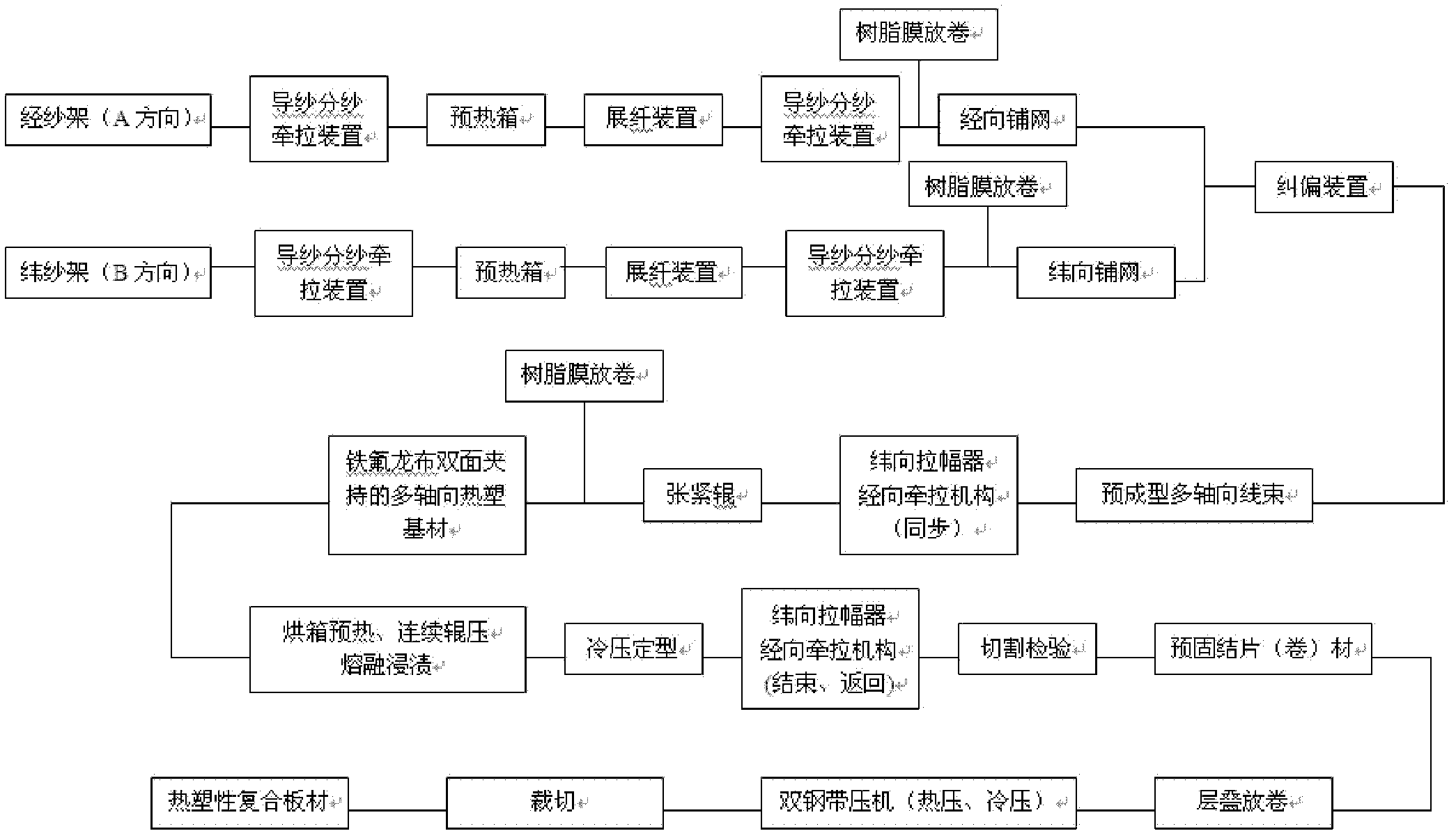

Method for preparing continuous fiber multiaxial fabric reinforced thermoplastic composite material

InactiveCN102218828AGuaranteed to be straightAvoid breakingSynthetic resin layered productsLaminationAviationHoneycomb

The invention discloses a method for preparing a continuous fiber multiaxial fabric reinforced thermoplastic composite material. The prepared continuous fiber multiaxial reinforced thermoplastic preconsolidating material is taken as a base material of the composite board, and combined with other functional materials for forming a novel material system which can be used for producing multiaxial fabric reinforced thermoplastic composite materials for different industries and solving the technical bottleneck that different materials have different composite bonding difficulties. According to the invention, the prepared composite material is constructed by continuous fiber multiaxial direaction; materials have the characteristics of resilience and uniform stressing on different directions. In addition, light sandwich panel formed by a honeycomb core material provides higher impact strength of materials, which is suitable for preparing structural parts and interior decorative parts in the field of railway car containers of navigation and aviation. The product of light-weight flame retardant can be recovered and used, and is more suitable for industrialization scale production of the warp knitting industry organization.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

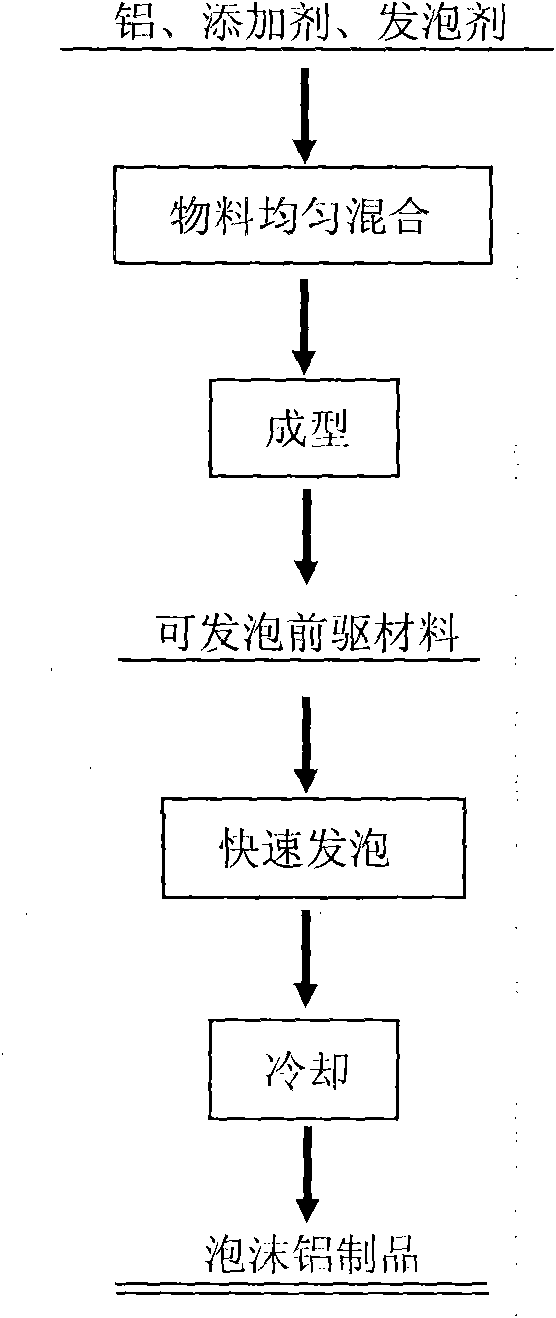

Preparation method and device of metal foam material

The invention discloses a preparation method and a device of a metal foam material. The preparation method comprises the following steps: mixing 93-99 wt% of aluminium matrix, 0.5-5 wt% of additive and 0.5-2 wt% of foaming agent uniformly to form a shaped foamable precursor material, putting the foamable precursor material in a foaming furnace with infrared heating to foam the foamable precursor material fast under infrared radiation, then taking the foam material out from the foaming furnace and cooling, wherein, the aluminium matrix is pure aluminium, aluminium powder or aluminium alloy, the foaming agent is titanium hydride, zirconium hydride, or calcium carbonate, and the additive is calcium, carborundum powder, or alumina powder. The device is a foaming furnace with infrared heating,has the advantages of fast foaming the precursor material, eliminating the hole gradient, easily controlling the foaming and cooling process, making the product have reproducibility and maneuverability, and improving cellular uniformity. According to the invention, metal foam sandwich panels can be prepared directly, and the mechanical properties of the aluminium-based foam material are improved.

Owner:NORTHEASTERN UNIV

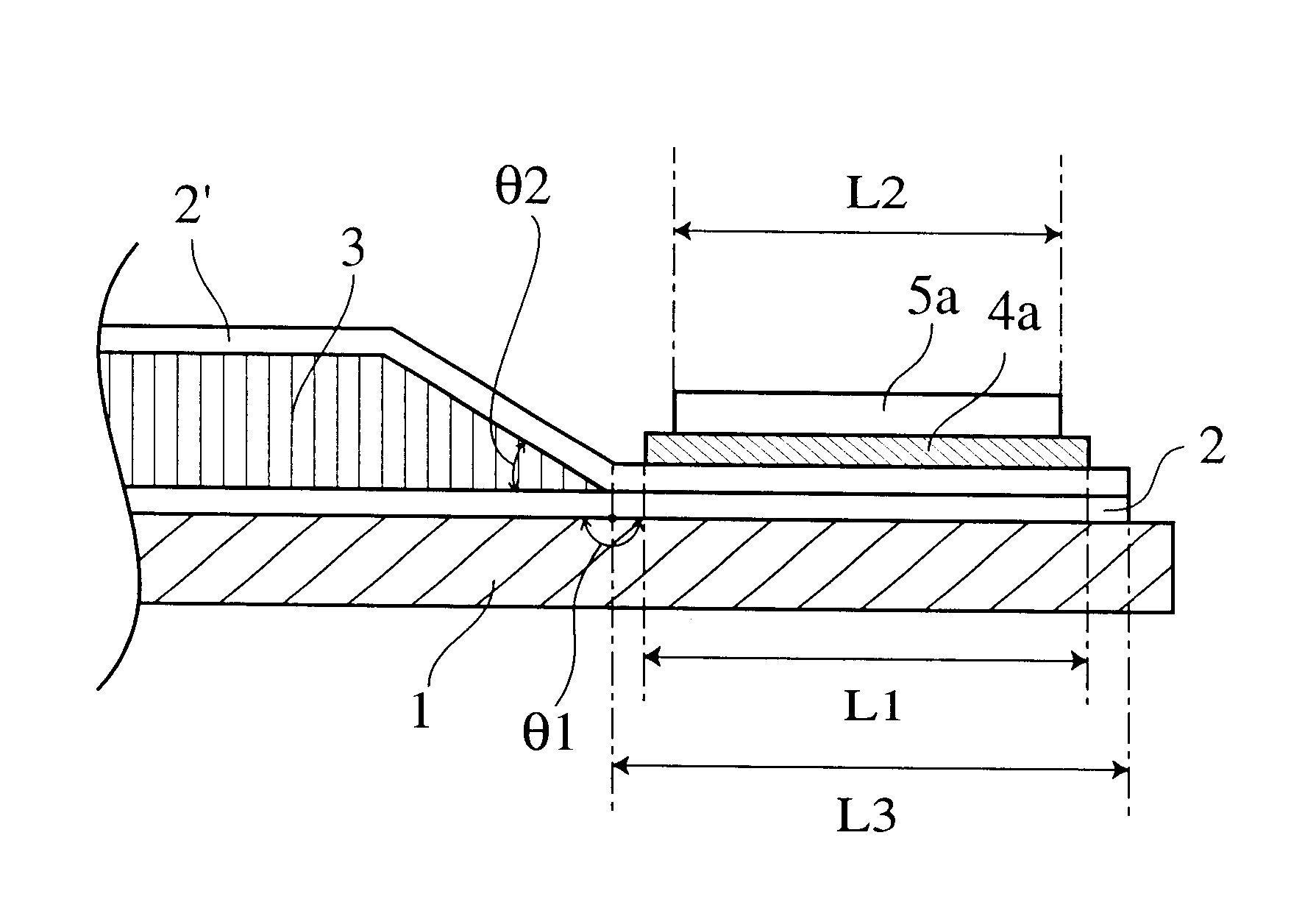

Method for producing honeycomb sandwich panel

A honeycomb sandwich panel is produced by (a) mounting a honeycomb core on a lower prepreg laminate skin placed on a forming die, (b) superimposing thereon an upper prepreg laminate skin to cover the honeycomb core, (c) mounting flat plate-shaped elastic jigs on a portion of the resulting assembly where the lower prepreg laminate skin and the upper prepreg laminate skin are overlapping each other, (d) superimposing flat plate-shaped press jigs on the elastic jigs, and (e) heating the assembly under pressure for adhesion forming.

Owner:HONDA PATENTS & TECH NORTH AMERICA

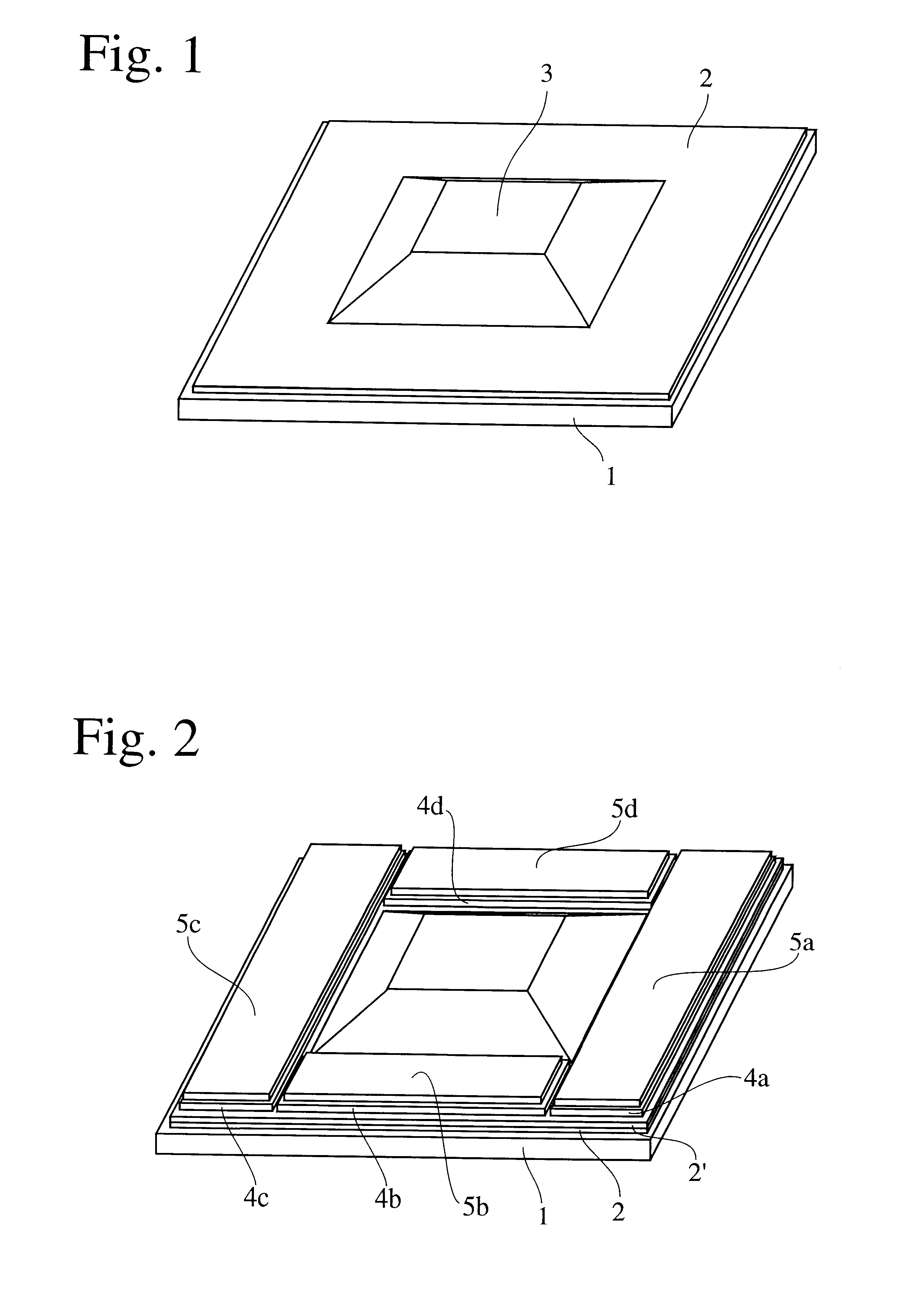

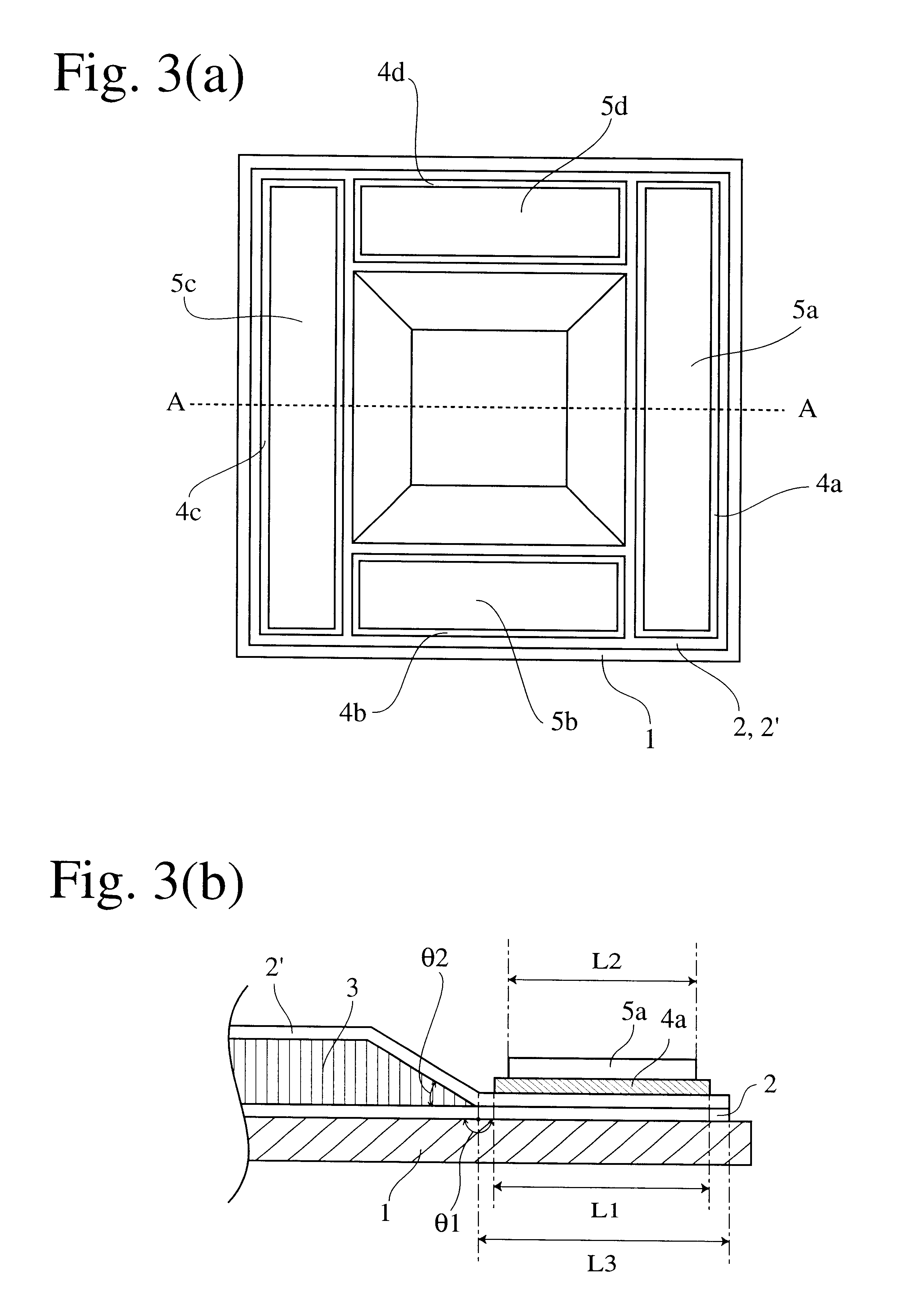

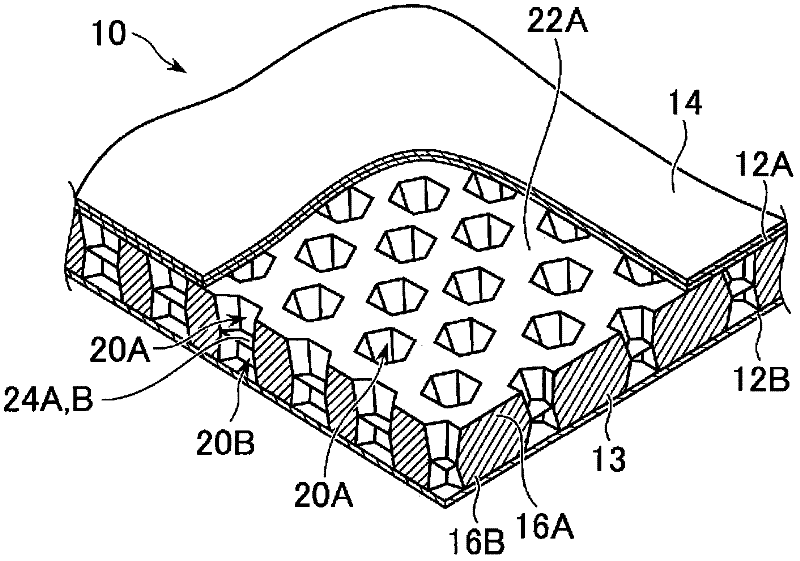

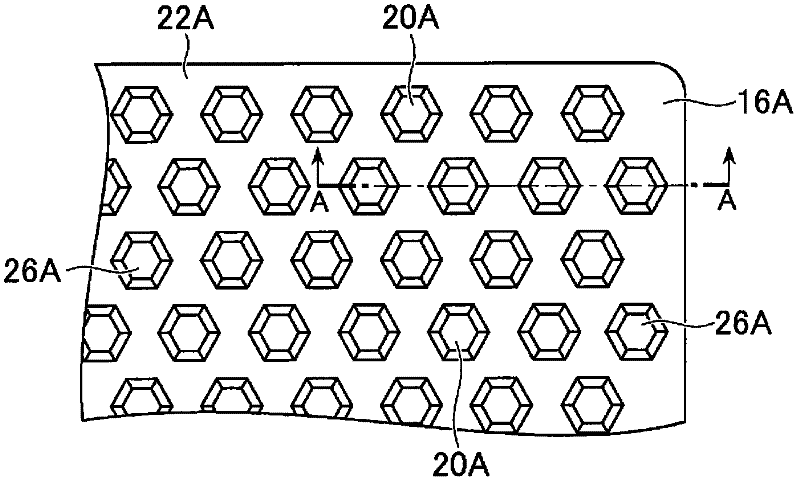

Core material for sandwich panel, method of molding core material for sandwich panel, sandwich panel, and method of molding sandwich panel

ActiveUS20110135862A1High strengthLabelling non-rigid containersLayered productsSandwich boardEngineering

An object of the present invention is to provide a core member for a sandwich panel and a method of forming the core member for the sandwich panel which are capable of attaining a desired profile, a desired pattern on its surface, and a desired inner structure in accordance with an application of the sandwich panel. According to an aspect of the invention, there is provided a thermoplastic resin core member interposed between two resin skin sheets comprising a closed hollow portion located to be inside of a desired position in accordance with an application of the sandwiched panel, and it is formed by clamping parison of a molten thermoplastic resin positioned to be between two split molds so as to exhibit a desired profile and / or a surface shape, two surfaces against each of which the molten parison is pressed to form an adhesive surface on which the corresponding resin skin sheet is formed.

Owner:KYORAKU CO LTD

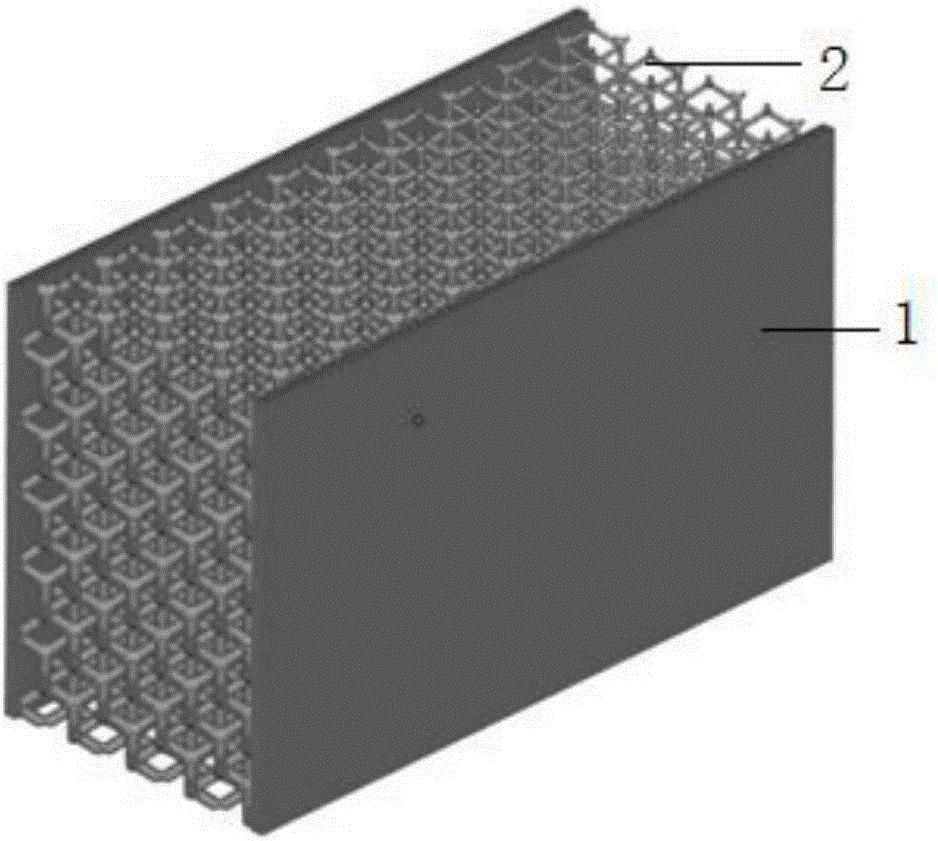

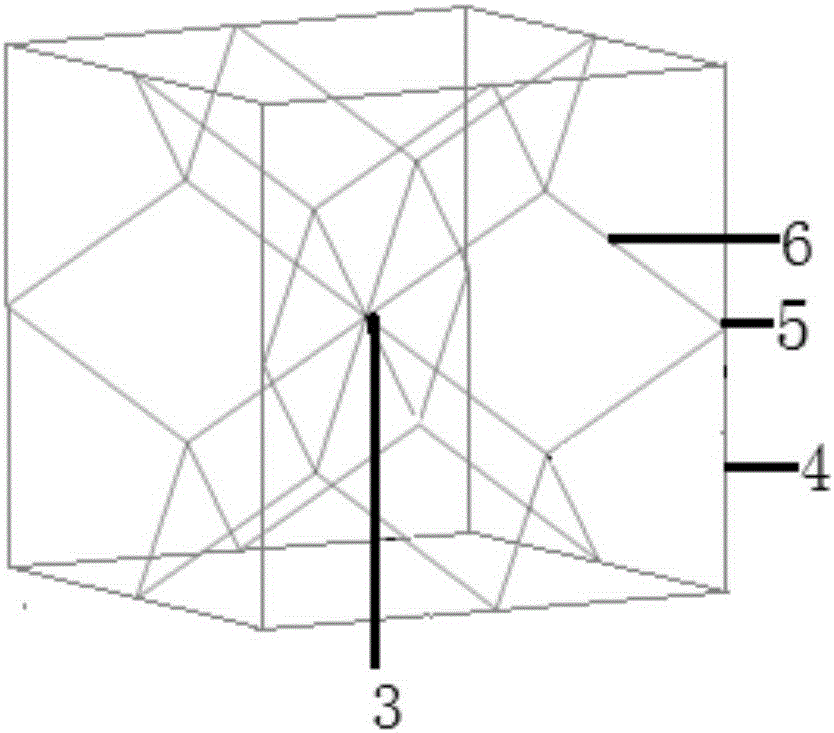

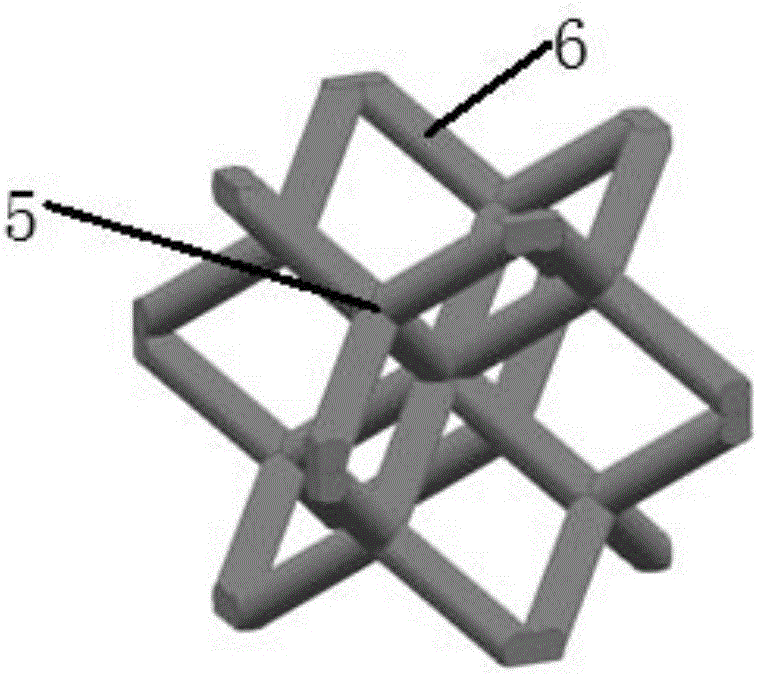

Hollowed-out lattice sandwich layer with gradient functionality and manufacturing method of hollowed-out lattice sandwich layer

ActiveCN106694884ALightweight structureHigh specific strengthAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSandwich board

The invention discloses a hollowed-out lattice sandwich layer with gradient functionality. The hollowed-out lattice sandwich layer with gradient functionality comprises two cladding plates, wherein a core sandwich layer is arranged between the cladding plates and comprises a plurality of hollowed-out lattice filling units which are connected with one another; and each hollowed-out lattice filling unit consists of a plurality of tiny dense hollowed-out base cells. The hollowed-out sandwich layer is formed by the hollowed-out lattice filling units, and is light in structure weight and high in specific strength, the maximum weight reduction benefit can reach 85% or above, and meanwhile, the hollowed-out lattice sandwich layer has functional benefits such as heat insulation and sound insulation; comprehensive benefits of structure light weight and functionalization are improved, property mismatching of a sandwich board with the single structure in the application field under various working conditions is avoided, and finally, the gradient function is fulfilled; and meanwhile, a selective laser melting technology is adopted, the risk of reduction of strength of a connecting region between a traditional sandwich layer and an outer cladding plate and complicated multi-process flow can be avoided, and therefore, the use value is quite high.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

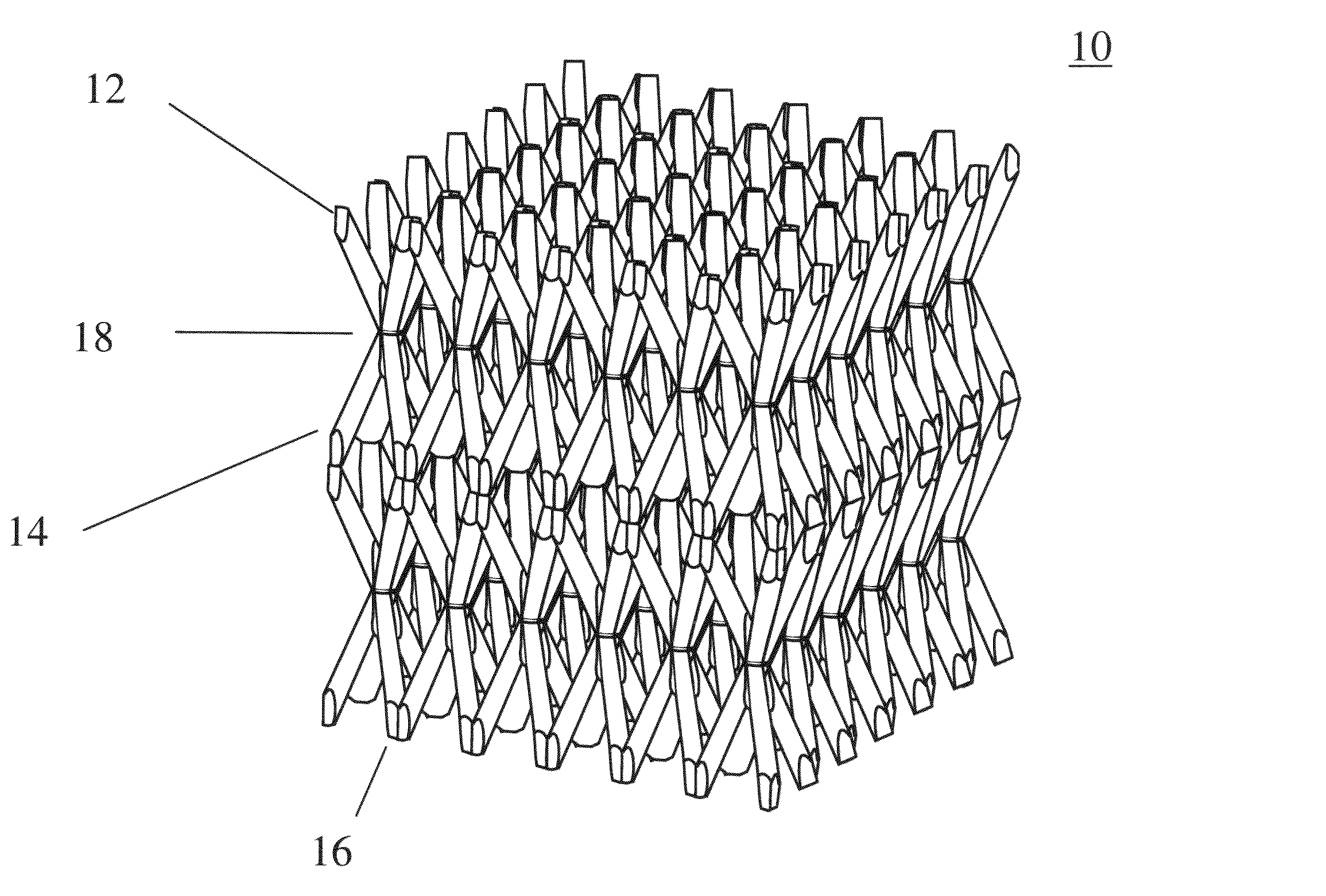

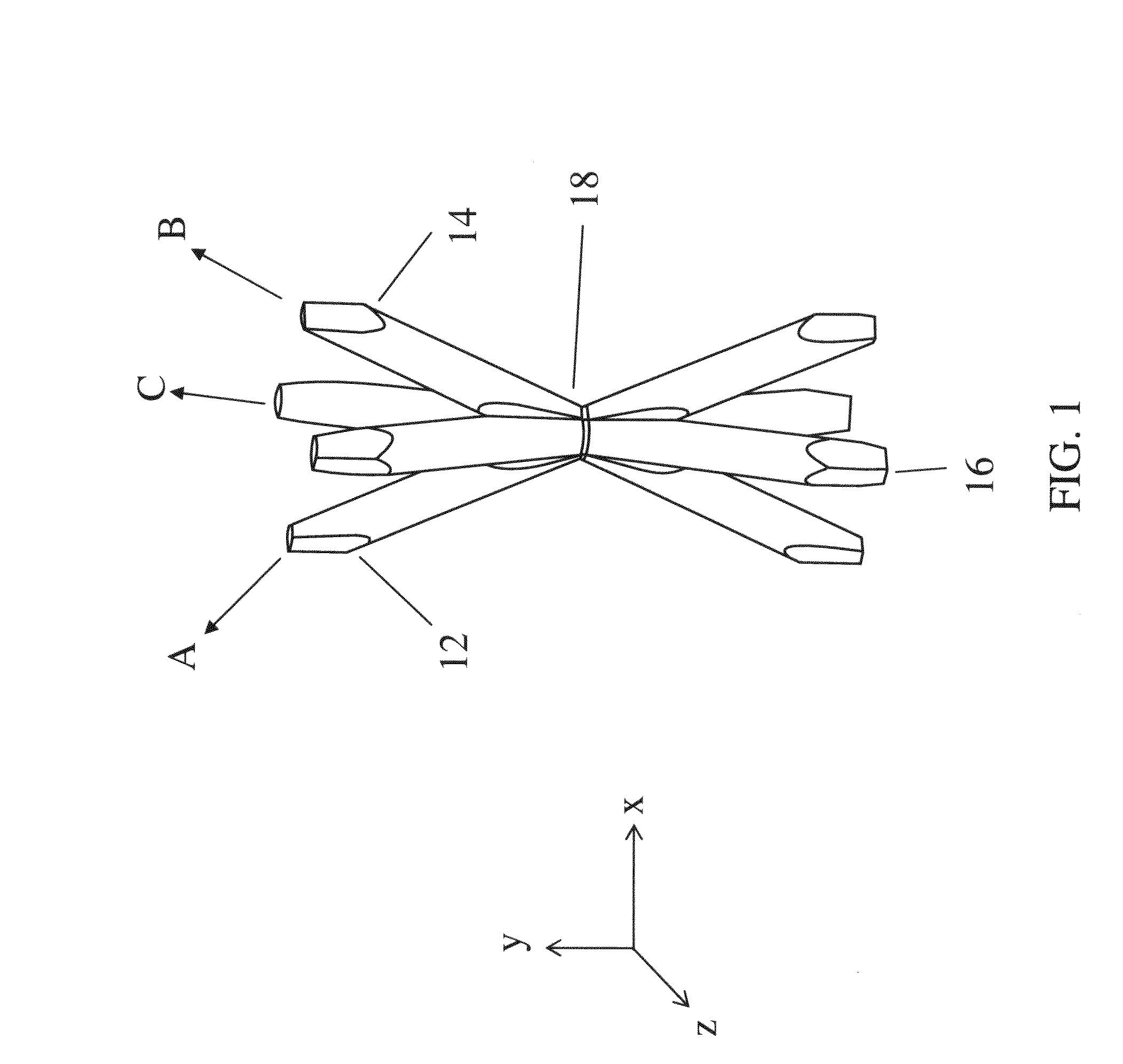

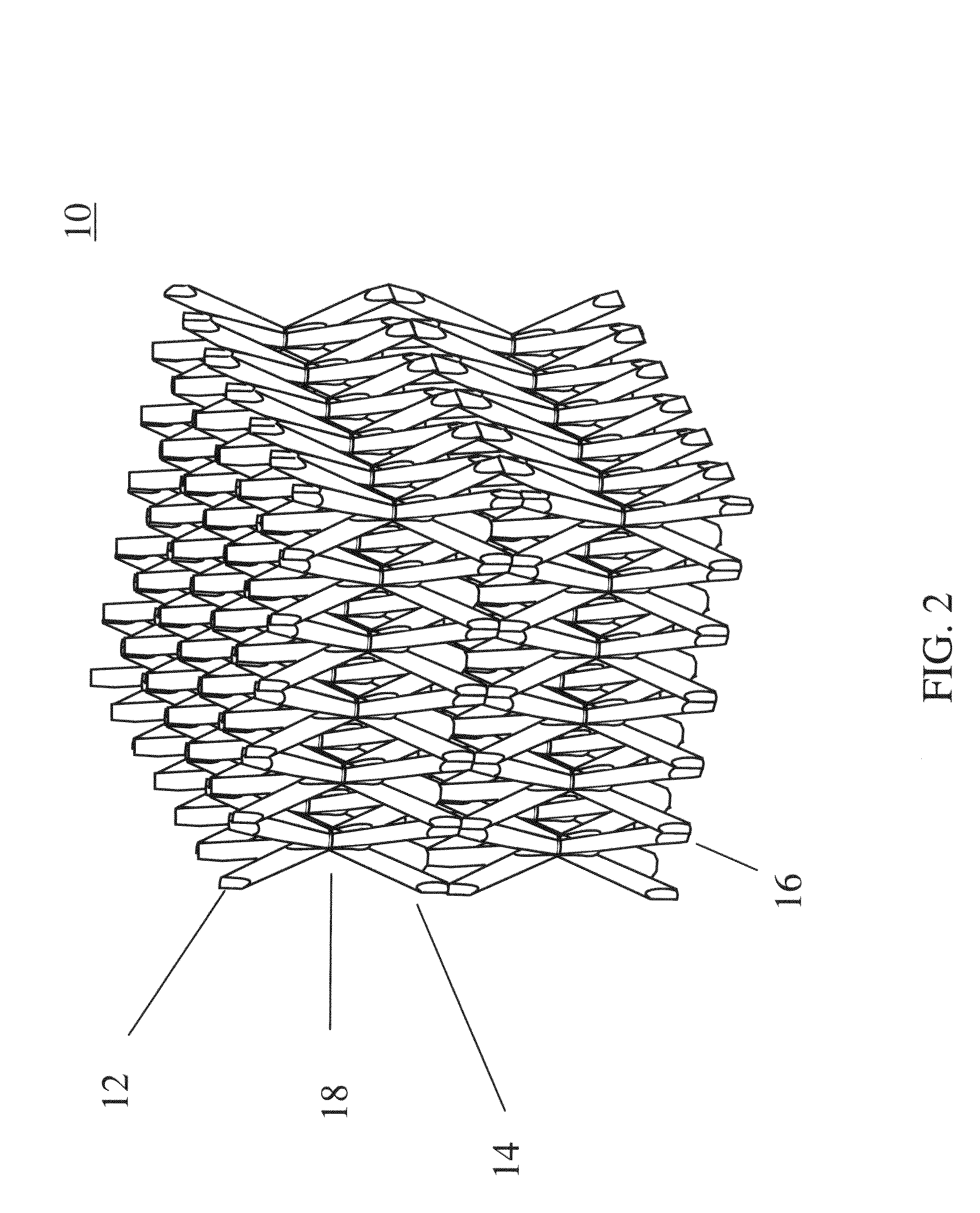

Lightweight sandwich panel heat pipe

ActiveUS8579018B1Easy to manufactureLarge diameterIndirect heat exchangersHeat transfer modificationWorking fluidGas phase

A sandwich panel heat pipe with a three-dimensional ordered open-cellular micro-truss core and a method creating the same. In one embodiment, the sandwich panel heat pipe includes a first face sheet, a second face sheet, the three-dimensional ordered open-cellular micro-truss core between the first face sheet and the second face sheet, and a working fluid in the ordered open-cellular micro-truss core. Here, the three-dimensional ordered open-cellular micro-truss core includes a vapor region and a liquid region, the vapor region is for transporting a vapor phase portion of the working fluid to the liquid region, and the liquid region is for transporting a liquid phase portion of the working fluid to the vapor region.

Owner:HRL LAB

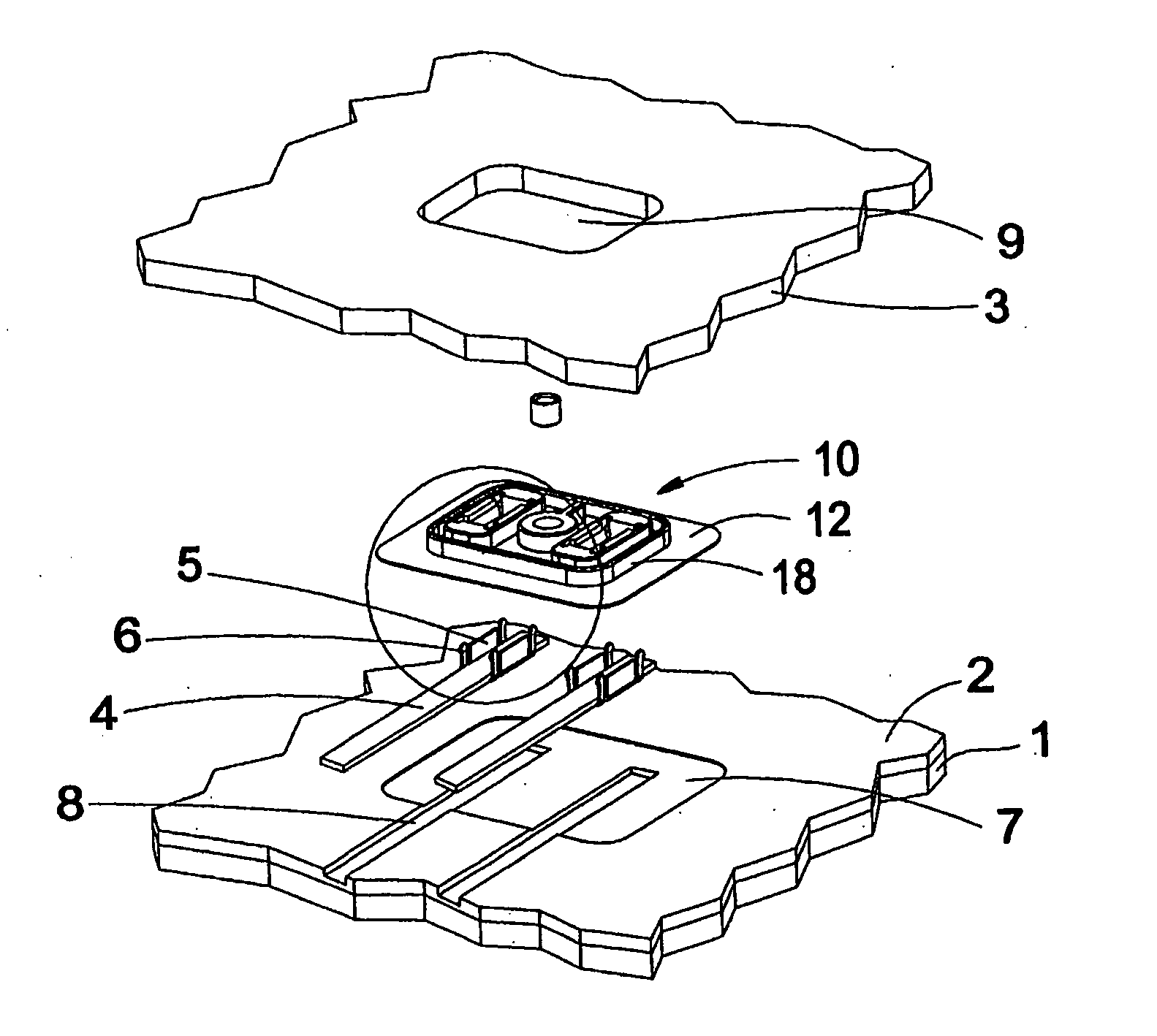

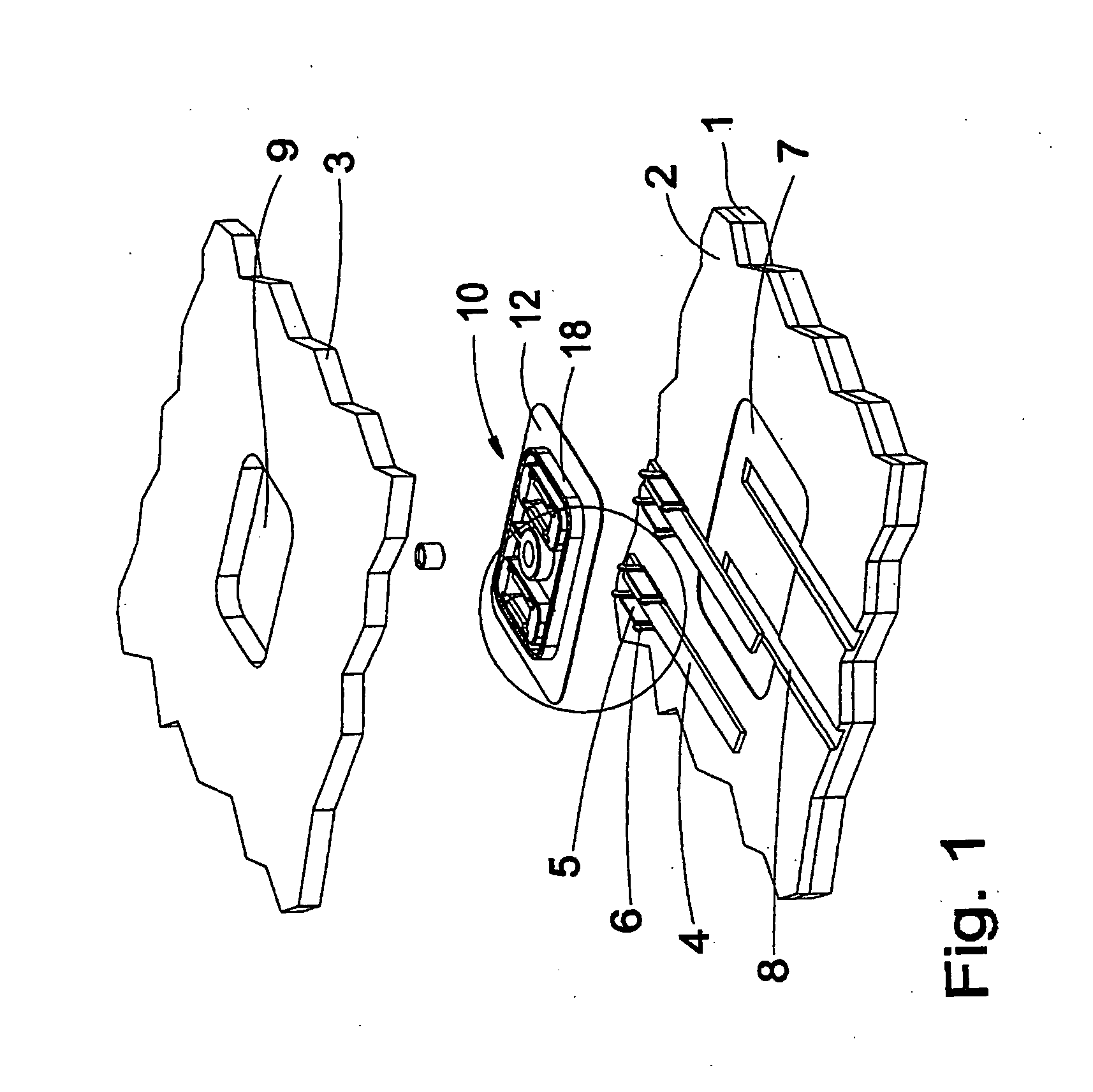

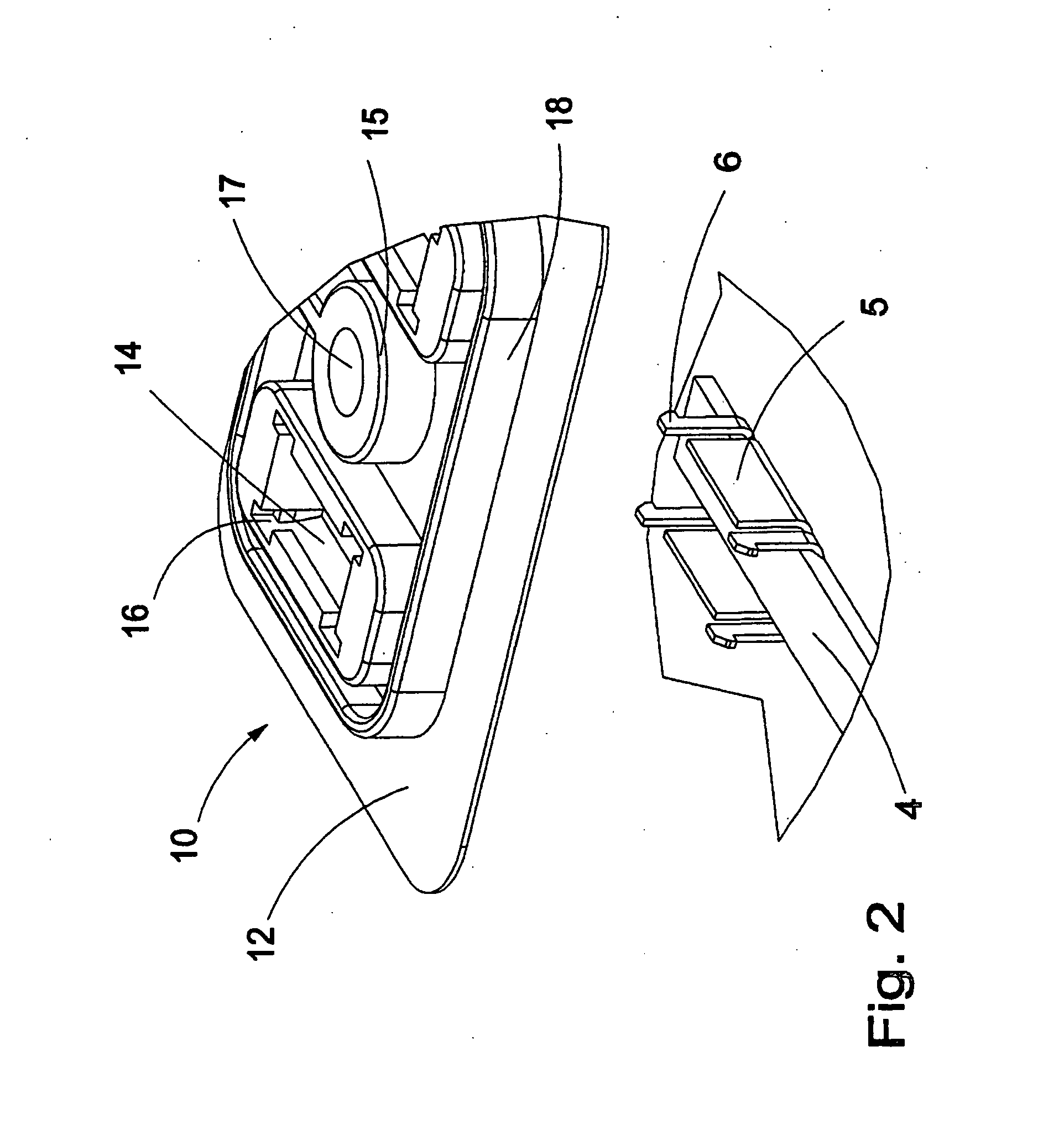

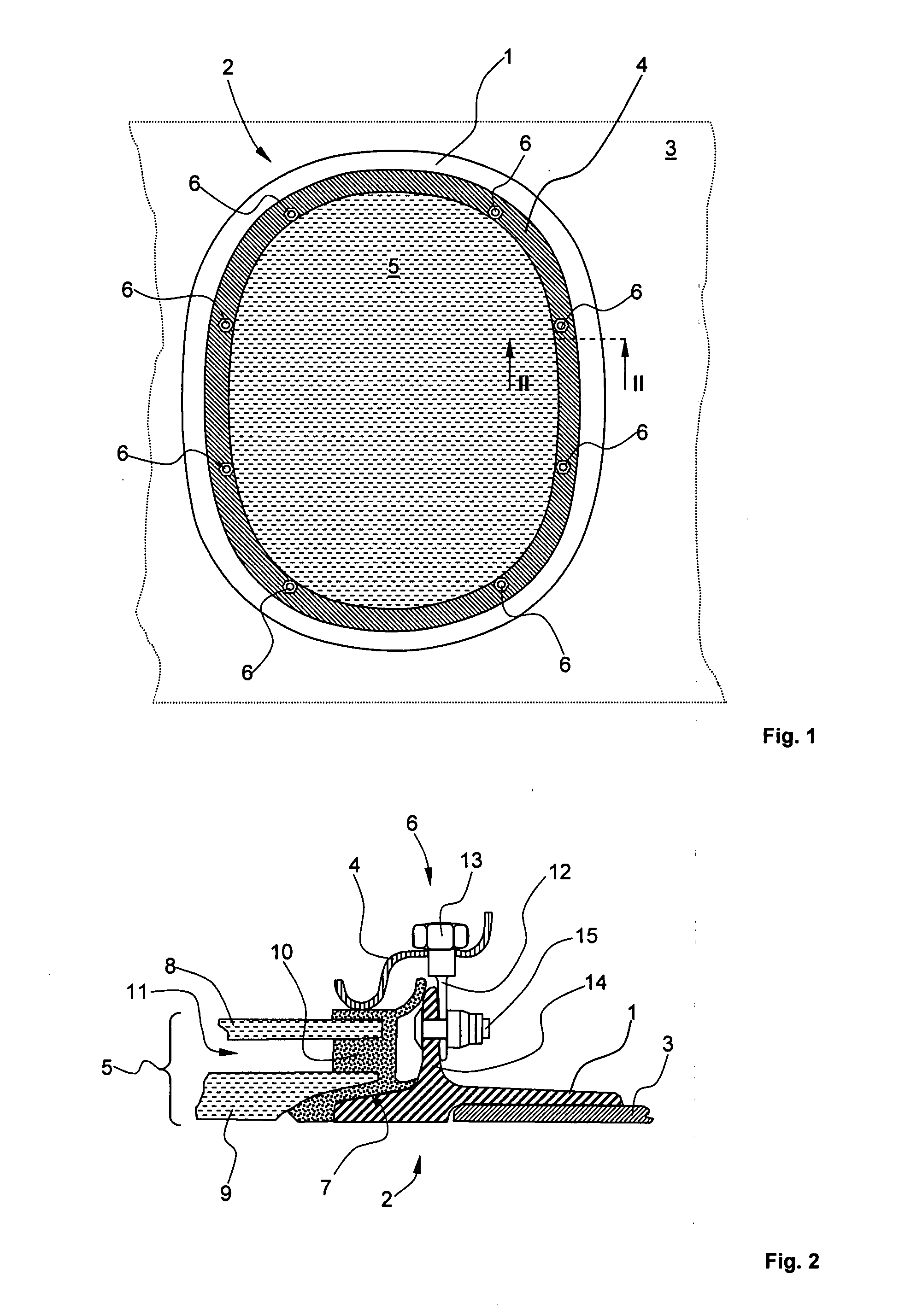

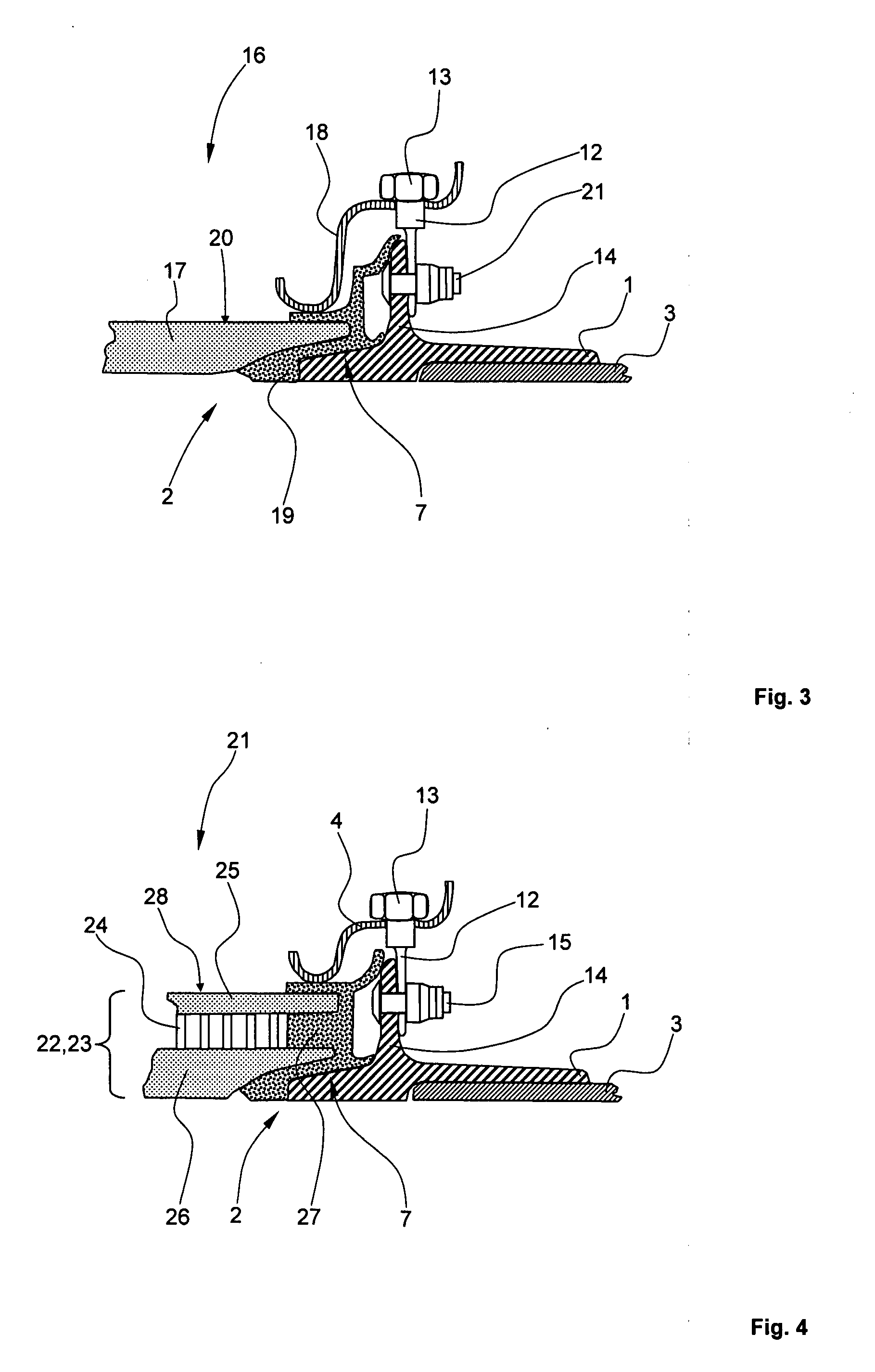

Connector for a solar module

InactiveUS20050022859A1Easy and inexpensive to produceIncorrect coupling preventionPV power plantsPhotovoltaic solar energyContact element

In order to deliver the current generated by means of photovoltaic solar elements, the invention proposes a connector for a solar module that is accommodated in a connector housing and can be connected to the solar elements. The solar elements are interconnected by means of flat connecting lines and embedded in a translucid sandwich panel. The current is delivered through an opening in one of the sheets of the sandwich panel by means of springable contact elements that are in electric contact with the connecting lines of the solar elements.

Owner:HARTING ELECTRIC GMBH & CO KG

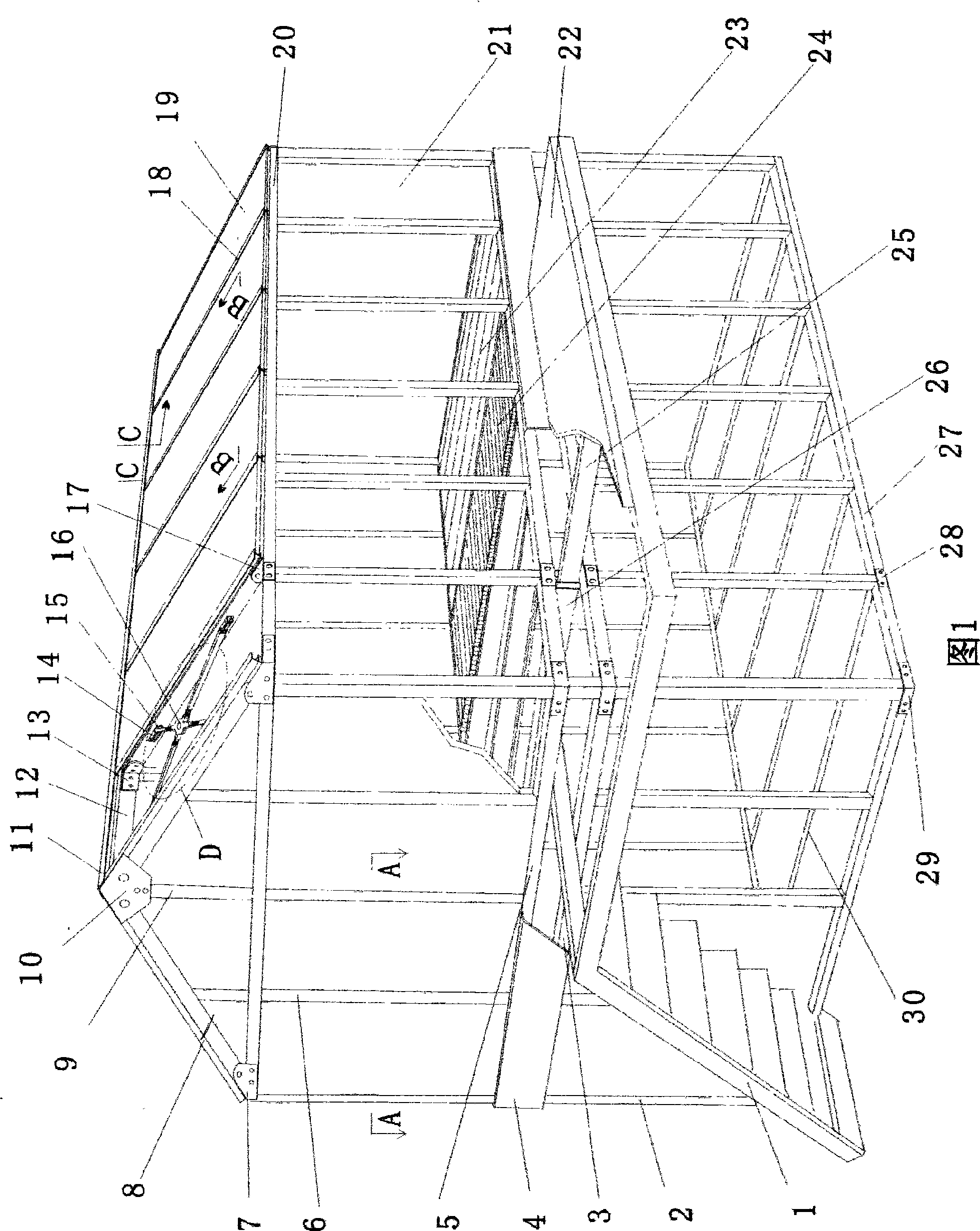

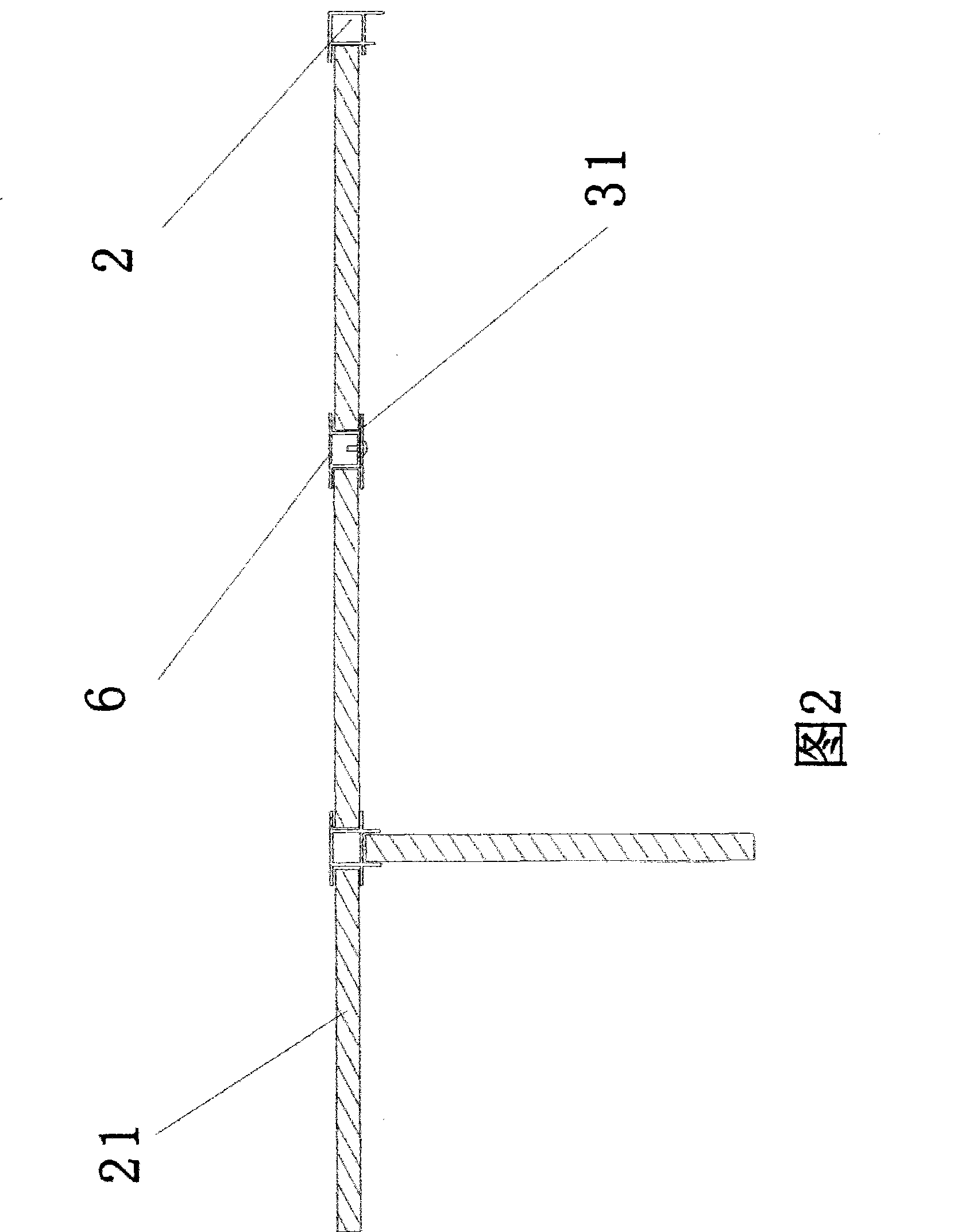

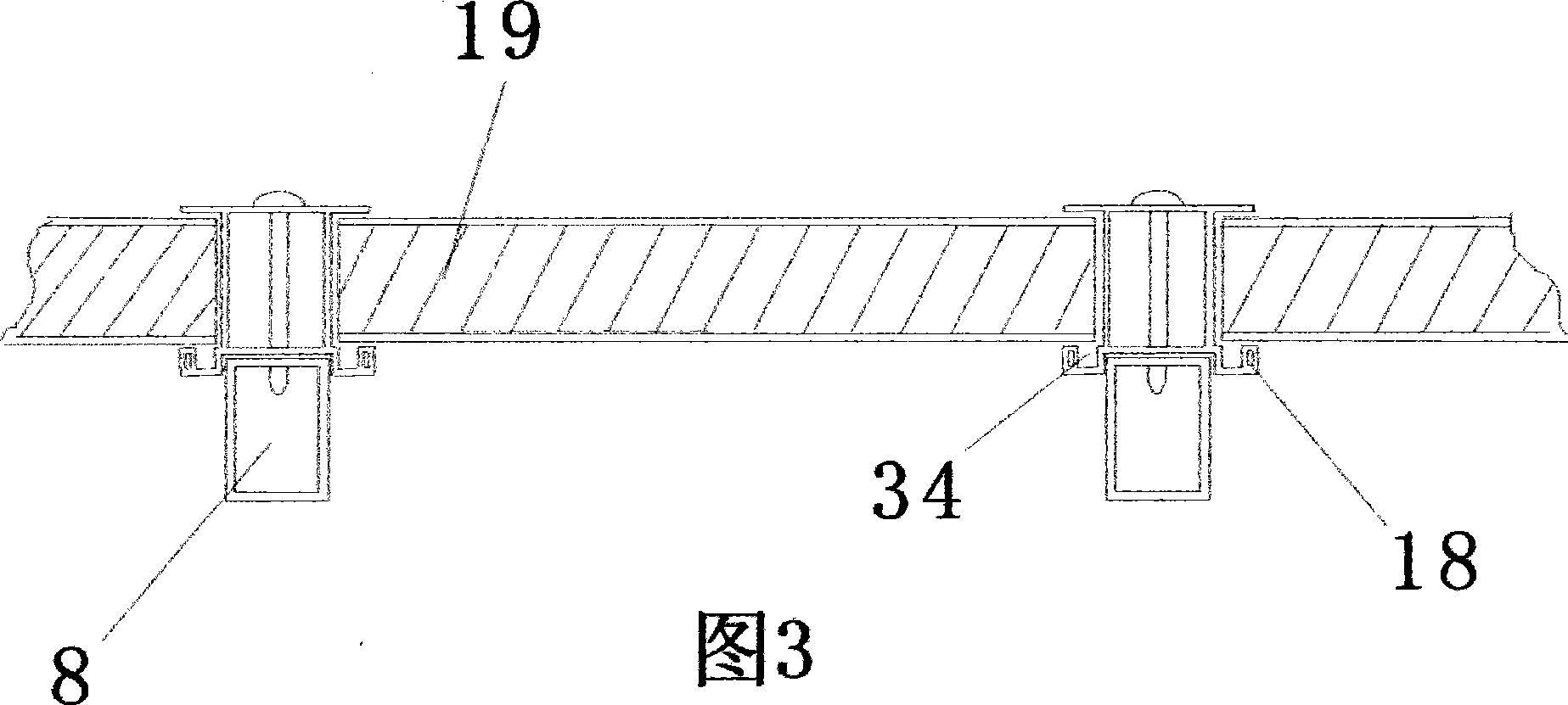

Combined light steel structure house and mounting method thereof

InactiveCN101418592AHigh degree of factoryReduce the ratio of output value to energy consumptionBuilding constructionsFloor slabSandwich panel

The invention relates to a combined lightweight steel structure building and an assembling method thereof. The combined lightweight steel structure building comprises ground beams, angular upright posts, upright posts, ring beams, sandwich panels, a roof, staircases, doors and windows. The key technical points of the combined lightweight steel structure building are as follows: a plurality of floor bottom girders in parallel are arranged on the ground; four ground beams are arranged on the circumference of each floor bottom girder in turn; bolt fastening sheets which are connected with the ground beams and the ring beams are arranged on joints of upper ends and lower ends of each angular upright post and each upright post respectively; limit baffle plates of wall panels are arranged on angular upright posts and upright posts near the outside of the building; bolt fastening limit treadle bars of the wall panels are arranged on upright posts near the inside of the building; the wall panels comprise wall panels provided with door bodies or wall panels provided with window bodies; metal section supporting layers which are suitable to be connected with balcony bottom girders or / and corridor bottom girders are uniformly distributed between two adjacent floors; metal floor slabs are laid on the metal section supporting layers; and the roof is as follows: a waterproof ridge section is arranged on the upper part of a ridge main girder; the edge of a roof slab is embedded into the ridge section; and a roof slab slot section provided with a drainage channel is arranged on the upper part of a ramp beam of the roof.

Owner:官木喜

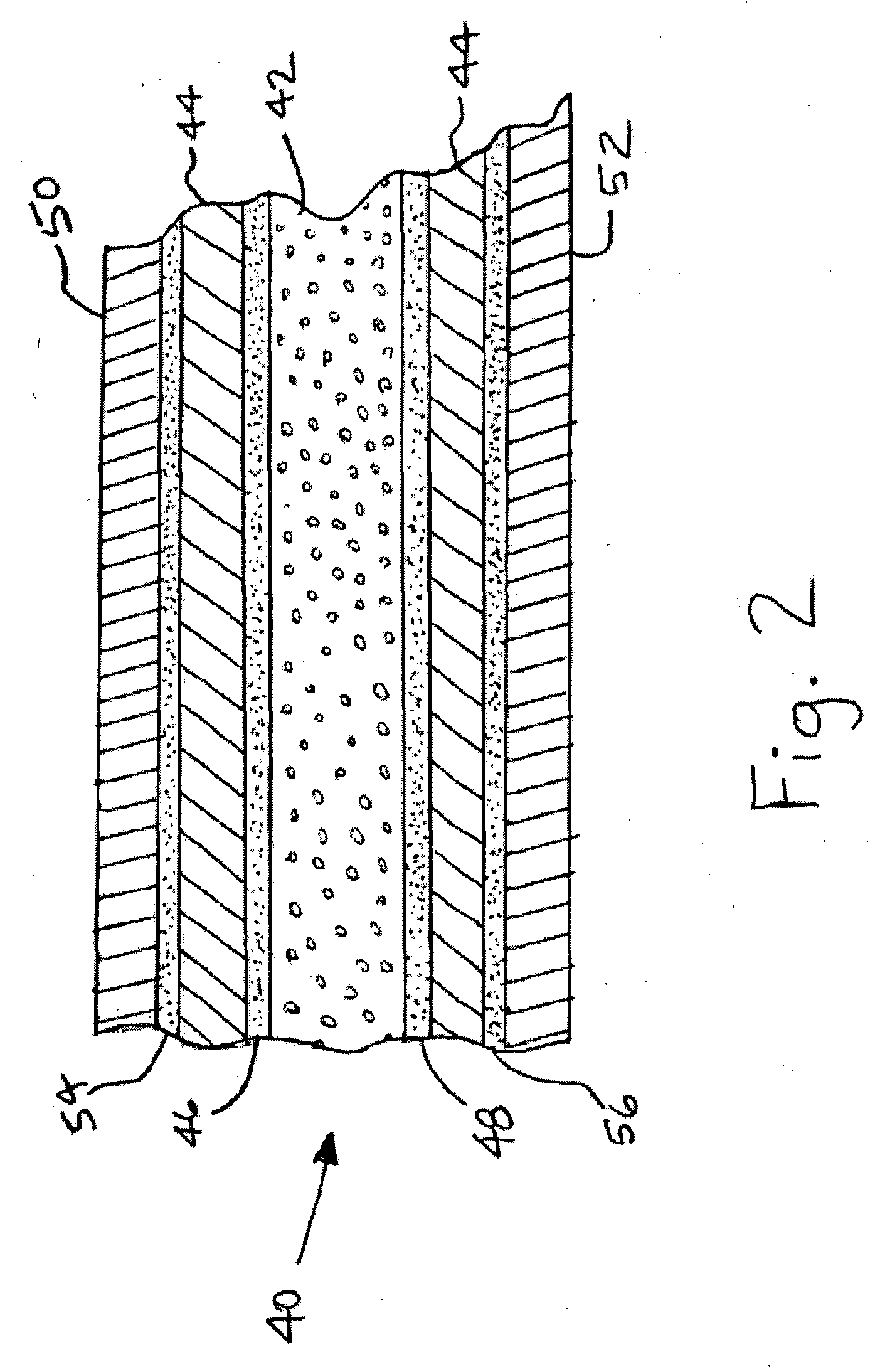

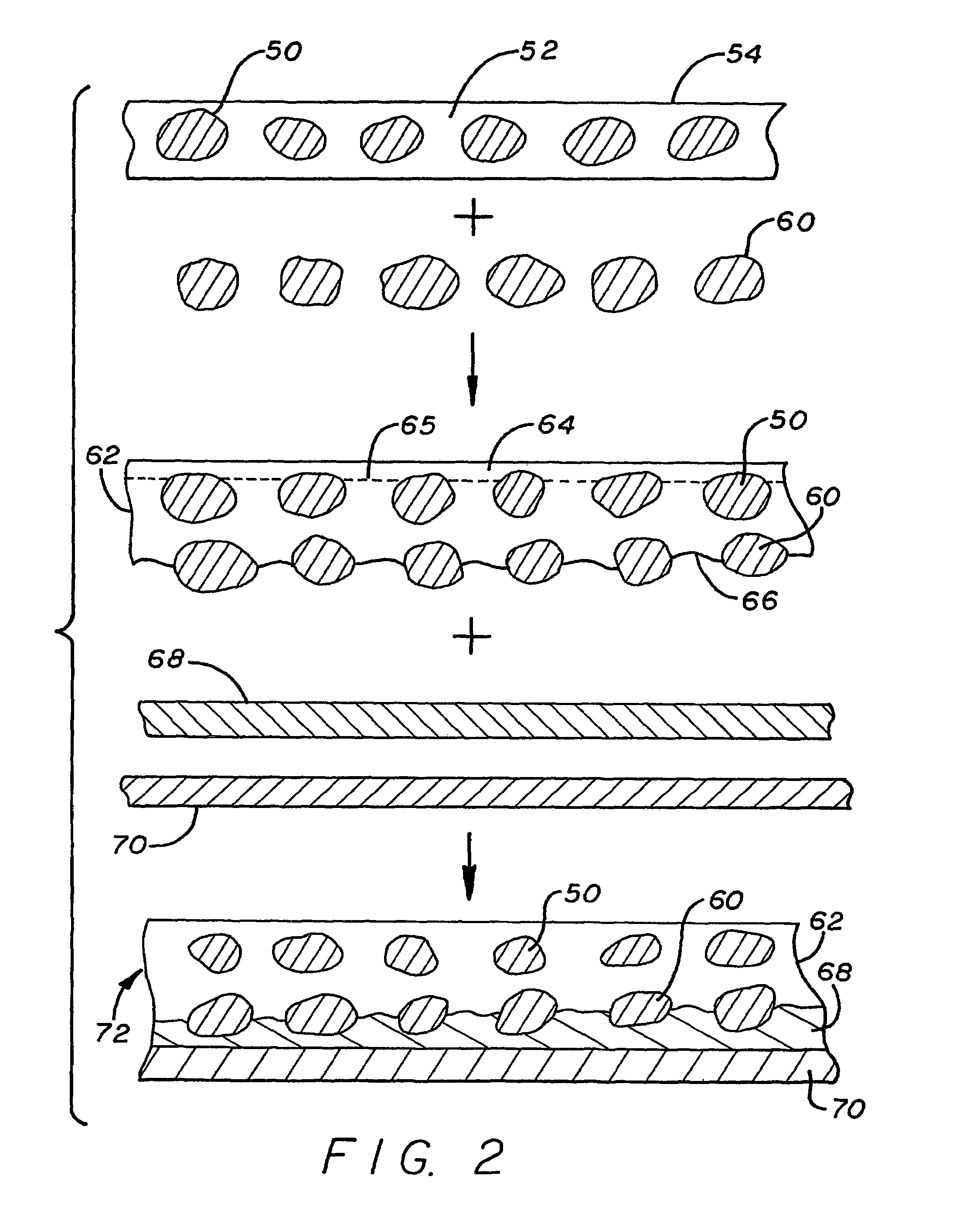

Sandwich panel with interior barrier

InactiveUS20050025929A1Reducing of other imperfectionReducing amount of void and other imperfectionLabelling non-rigid containersLaminationSurface finishCounter pressure

Composite sandwich panels that include a core having a permeable body that is sandwiched between two skins. An internal barrier is located between the skins and the core to provide an impermeable chamber surrounding the permeable core. The chamber is pressurized during formation of the panel to provide an interior counter pressure against the mold / press used to form the panel. The counter pressure applied by the chamber reduces the amount of voids in the skins and improves the surface finish of the skins. In addition, the impermeable material remains within the finished panel to provide an internal barrier surrounding the core.

Owner:HEXCEL

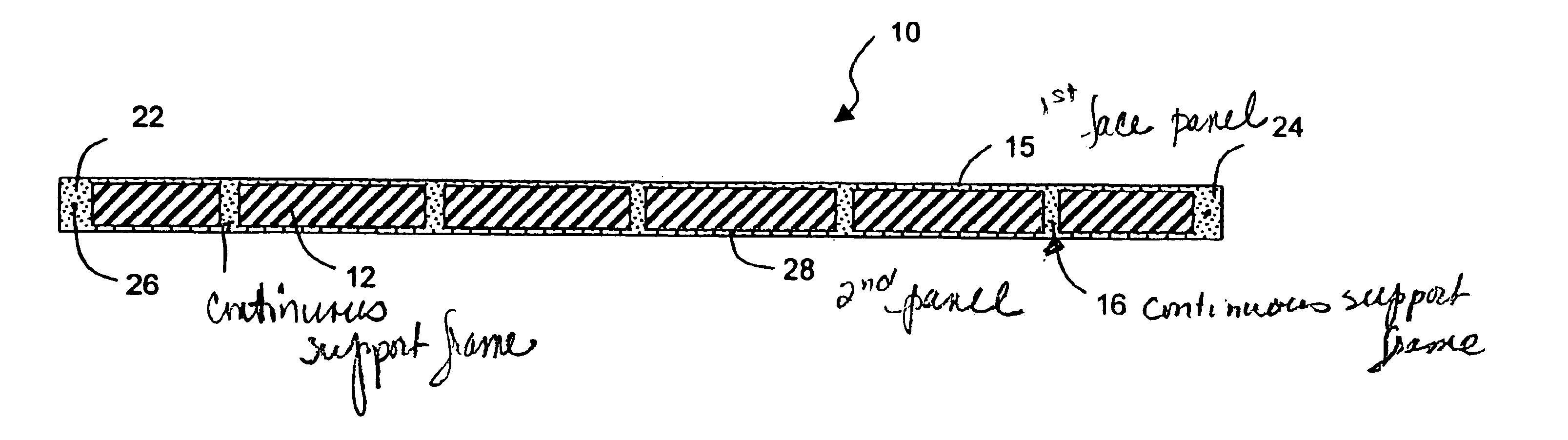

Fiber-reinforced sandwich panel

The present invention may be embodied in a sandwich panel having first and second face panels each having a first predetermined thickness and being formed of a fiber-reinforced cementitious material. The sandwich panel further includes support frame for supporting the first and second face panels in a spaced apart configuration. The support frame is formed of a fiber-reinforced cementitious material that is continuous with the cementitious material of the first and second face panels. Blocks of rigid insulation are embedded in the sandwich panel for defining a structure of the support frame.

Owner:ECO BUILDING SYST INC DBA ECOCRETE INC +1

Modification and innocuous treatment method of phosphogypsum

The invention discloses a modification and innocuous treatment method of phosphogypsum, comprising the following steps: (1) cleaning, (2) neutralizing, (3) dehydrating, (4) calcining, and (5) packaging. The modified phosphogypsum prepared by the invention is a raw material for building material, can be used for preparing a phosphogypsum high strength cement fiberboard. The modified phosphogypsum sandwich panels prepared by the phosphogypsum high strength cement fiberboard can be applied in wall material, floor and roof panel, and has the advantages of good antifreezing performance, thermal insulation performance, heat shielding performance, corrosion resisting performance, fireproof performance, high intensity, light specific gravity, easiness in installation and the like. According to the invention, the waste residue phosphogypsum of phosphorus chemical enterprises are recycled through modification treatment and can be used for producing building materials after recycling, so that the national energy saving policy and the development direction of circular economy are satisfied; even temporarily unable use occurs because of investment or other reasons, the modified phosphogypsum can be stored in long term without environmental hazard, so that the harmlessness is realized.

Owner:GUIYANG PENGHONG HIGH NEW TECH DECORATION MATERIAL

Sandwich panel, method of forming core material for sandwich panel, and method of forming sandwich panel

ActiveCN102202881ALamination ancillary operationsSynthetic resin layered productsEngineeringPolyresin

Owner:KYORAKU CO LTD

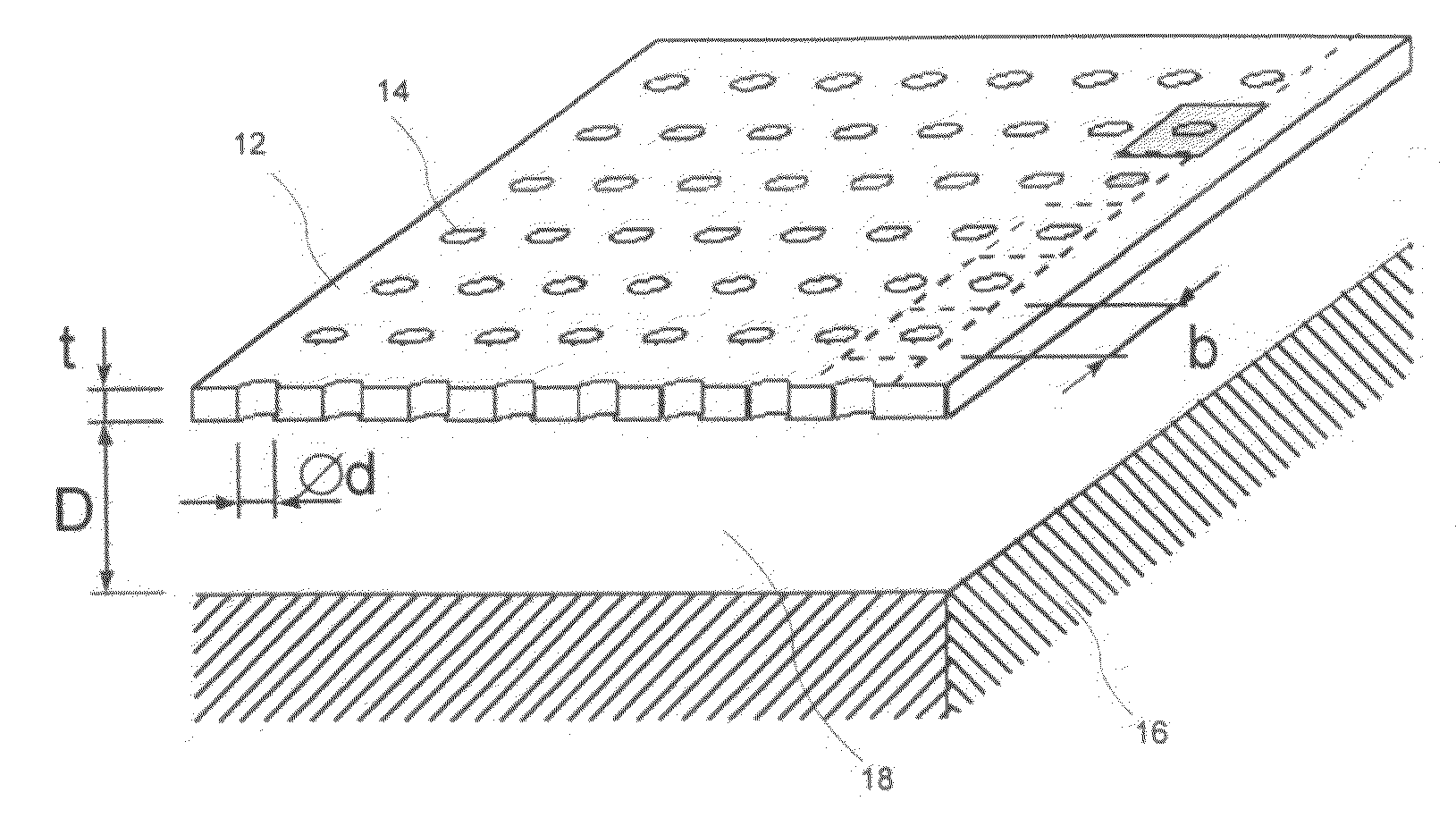

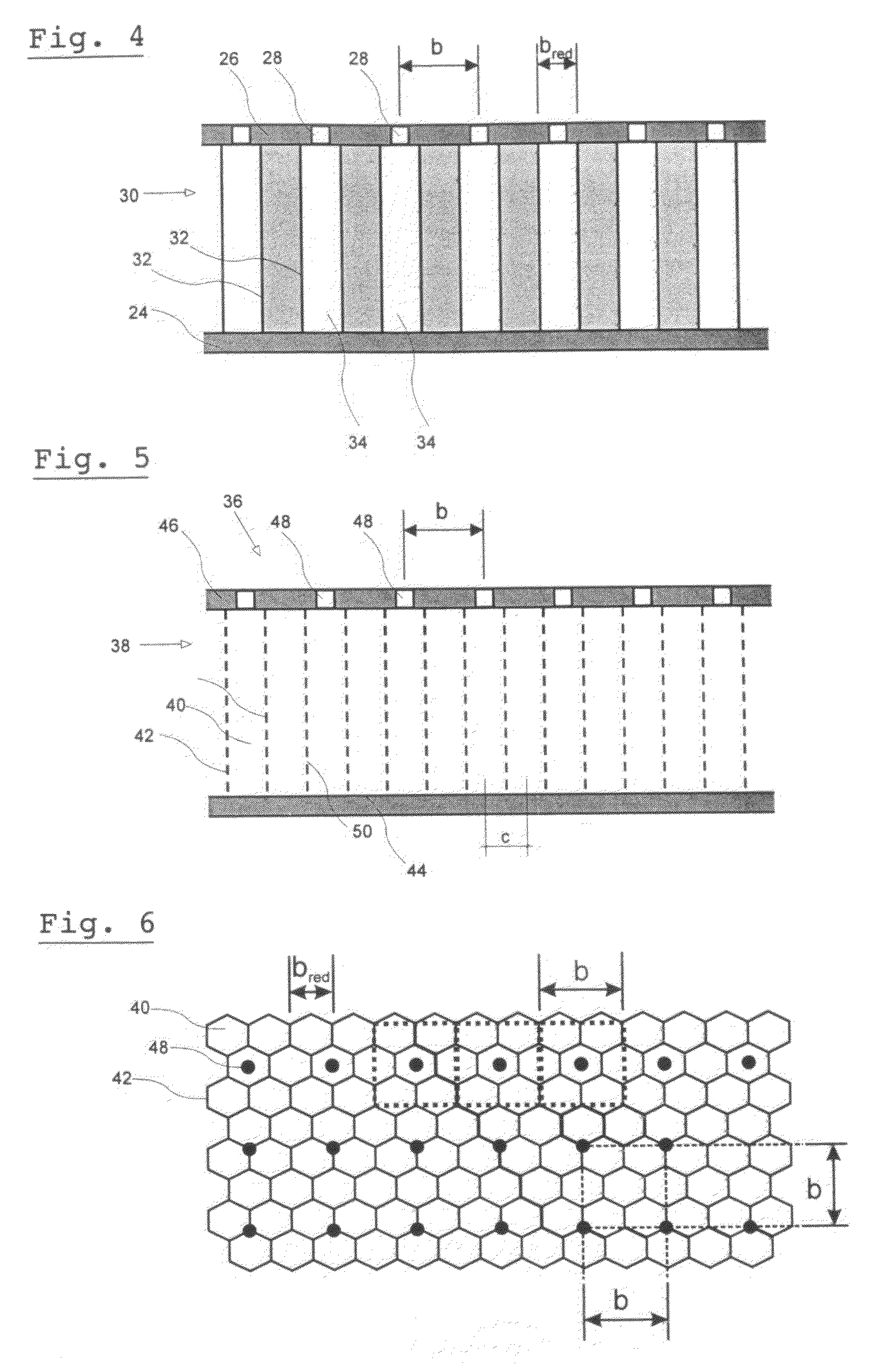

Sandwiich panel for sound absorption

ActiveUS20090166127A1Large space volumeReduce weightPump componentsBlade accessoriesSandwich boardEngineering

An aircraft cabin panel for sound absorption, with a sandwich construction, comprising a core layer that comprises a plurality of tube-like or honeycomb-like cells that extend in an open manner across the thickness of the core layer and that are separated from each other by cell walls and that are uniform in design. A first cover layer faces away from the sound field, as well as a second cover layer that faces towards the sound field and that comprises a plurality of perforation holes and adjacent cells are interconnected by way of apertures in the cell walls. The perforation of the second cover layer comprises a distance (b) between holes, which distance exceeds the opening width (c) of the cells of the core layer, wherein the first cover layer is closed and wherein the cell walls comprise a perforation so that they are acoustically transparent in the direction parallel to the cover layers.

Owner:AIRBUS OPERATIONS GMBH

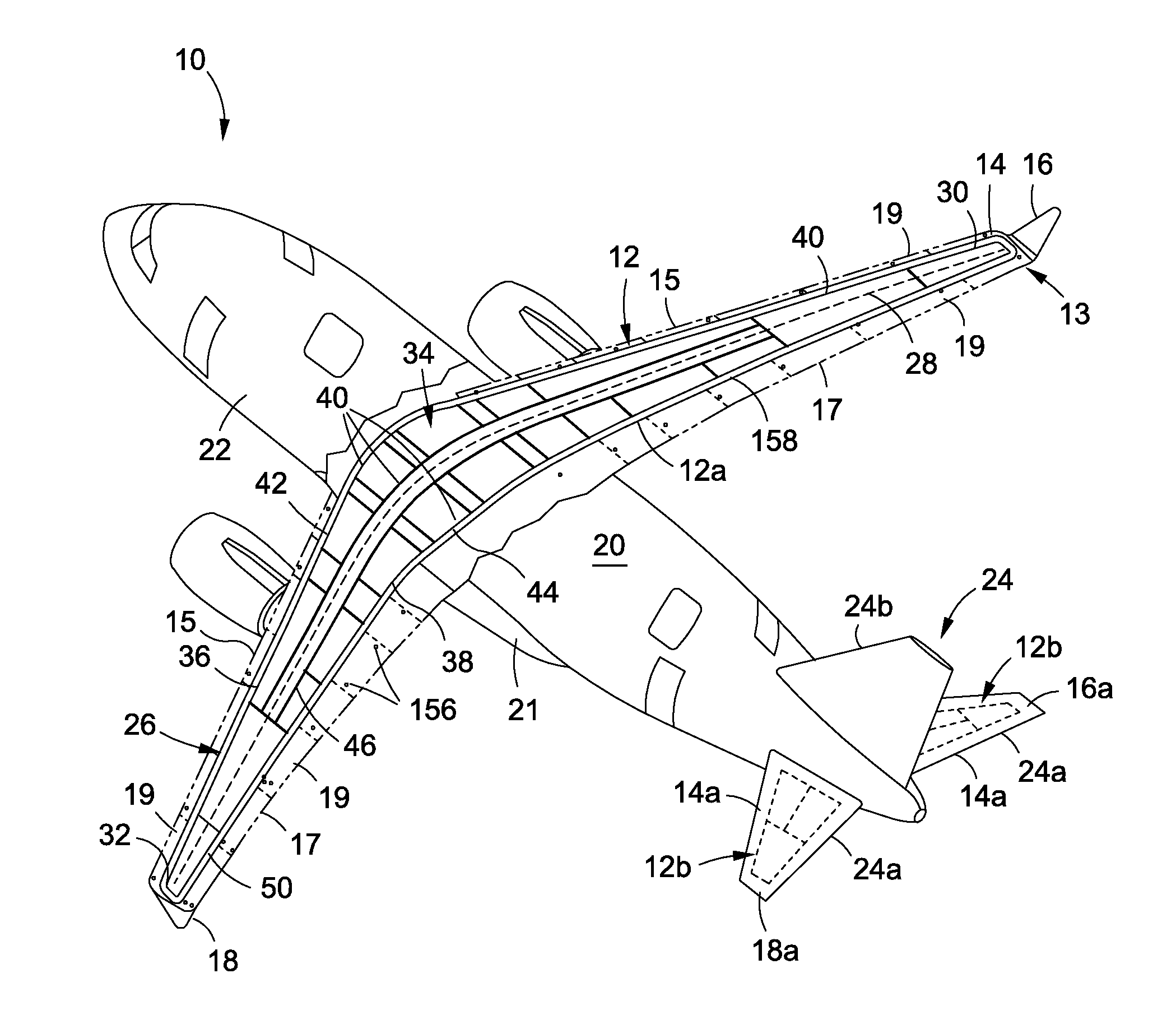

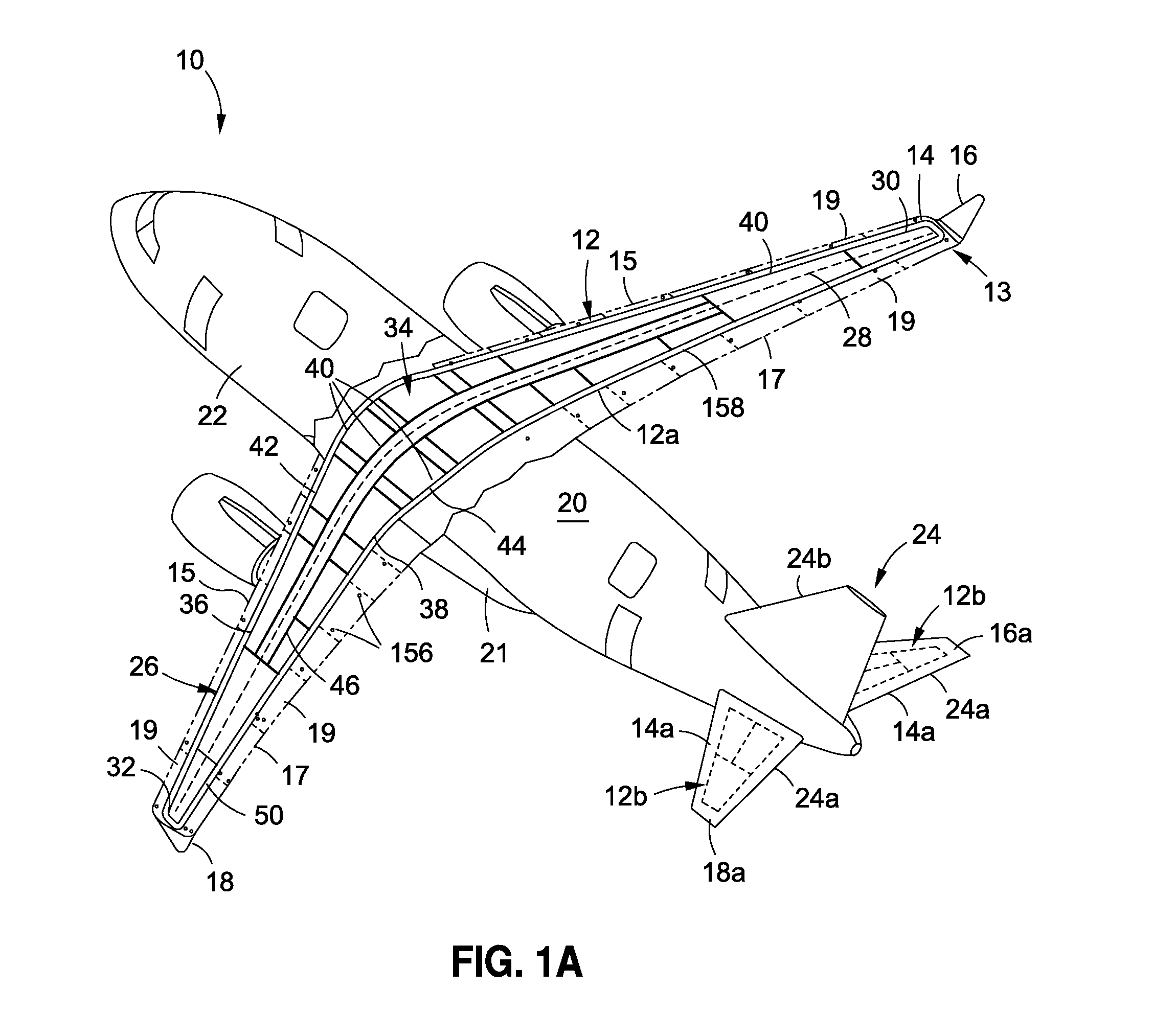

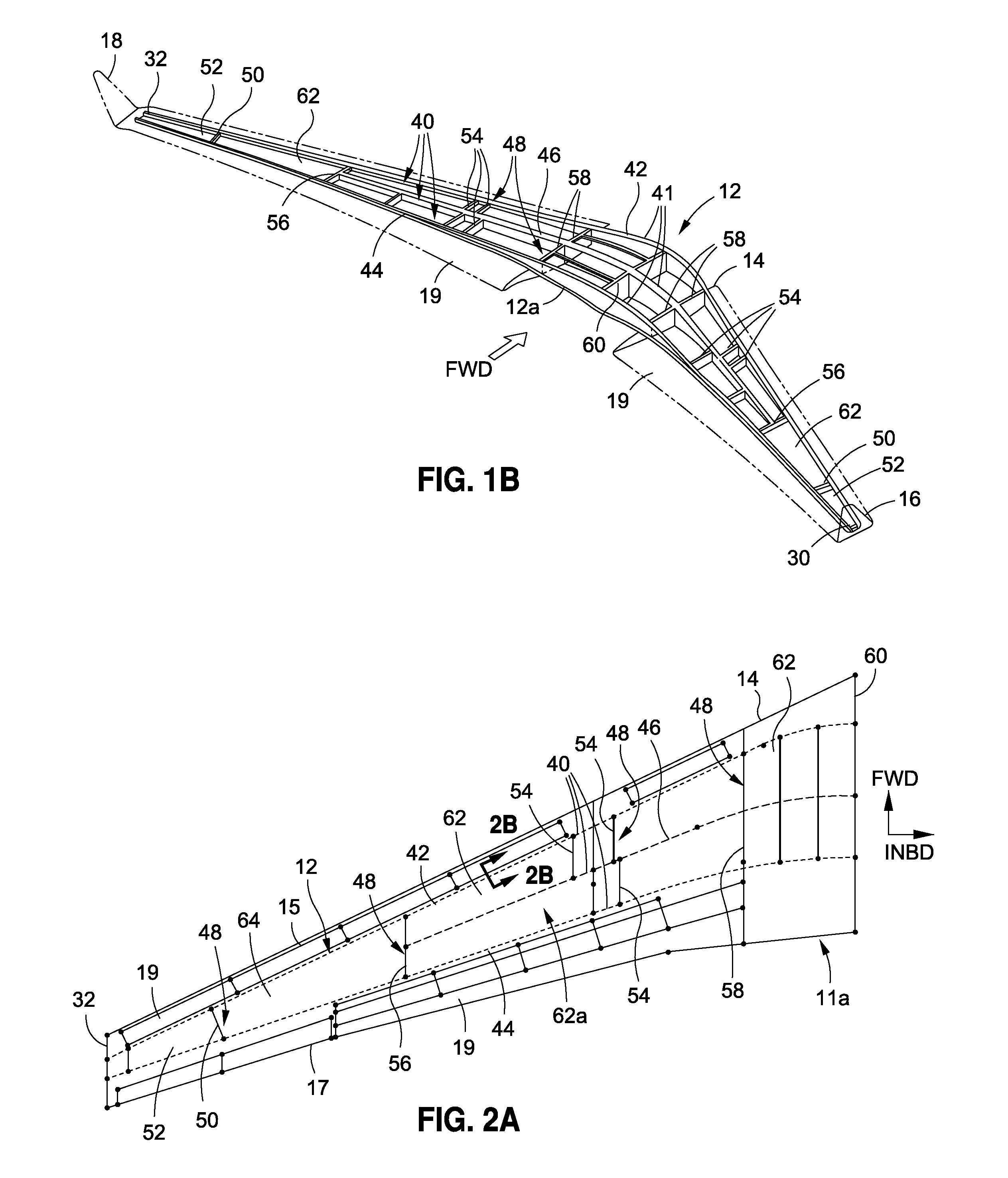

Box Structures for Carrying Loads and Methods of Making the Same

Owner:THE BOEING CO

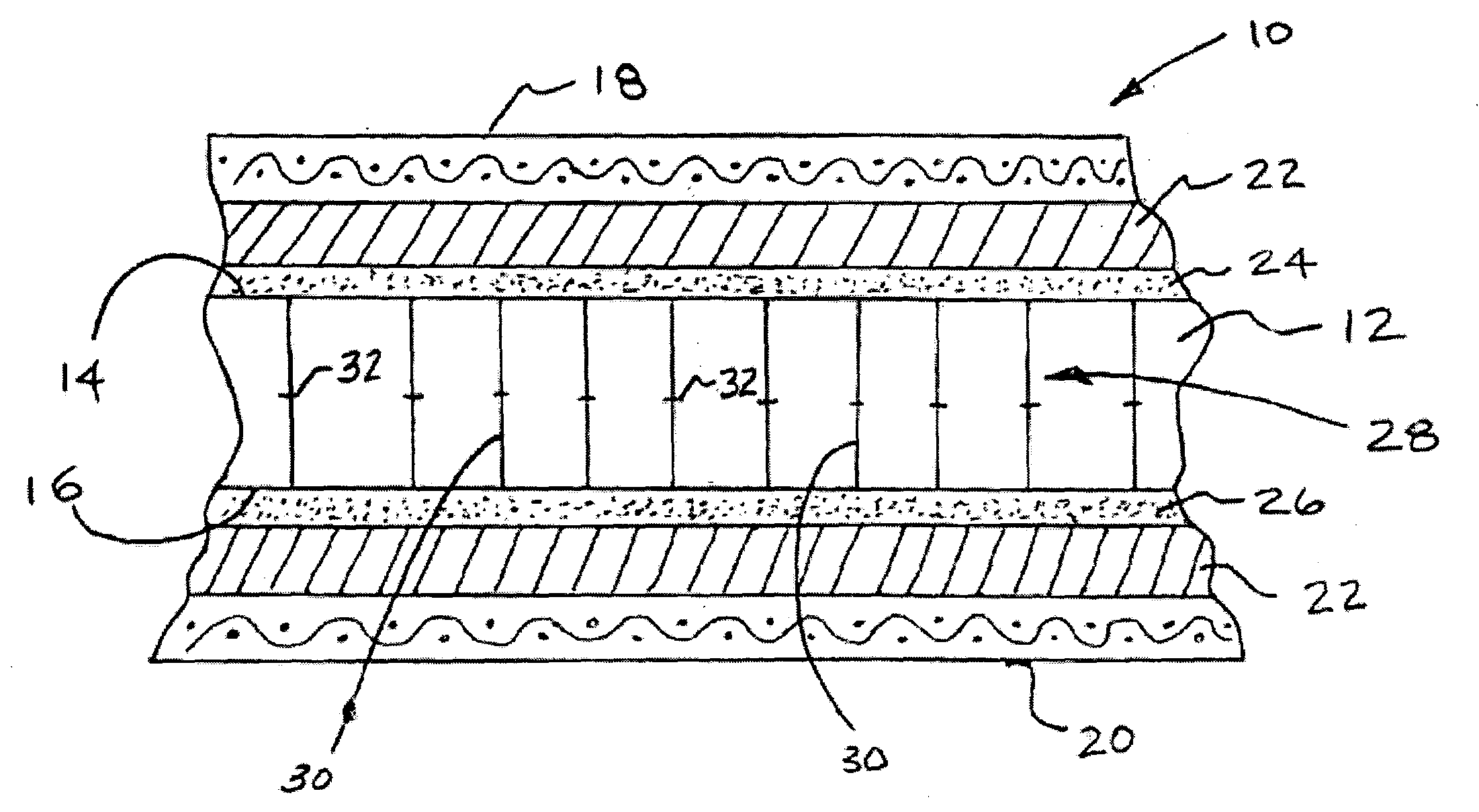

Composite panel with fire resistant face sheets

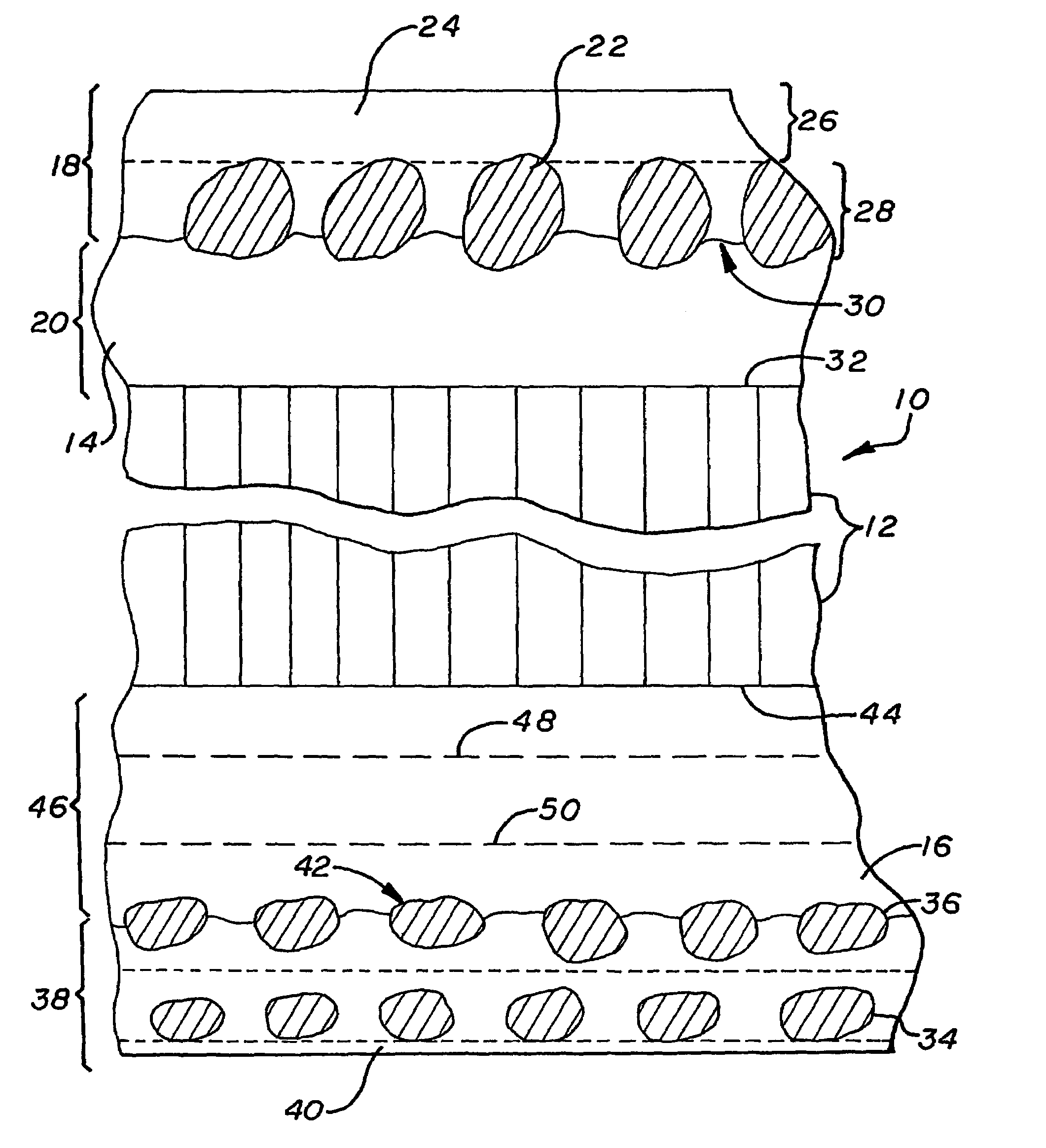

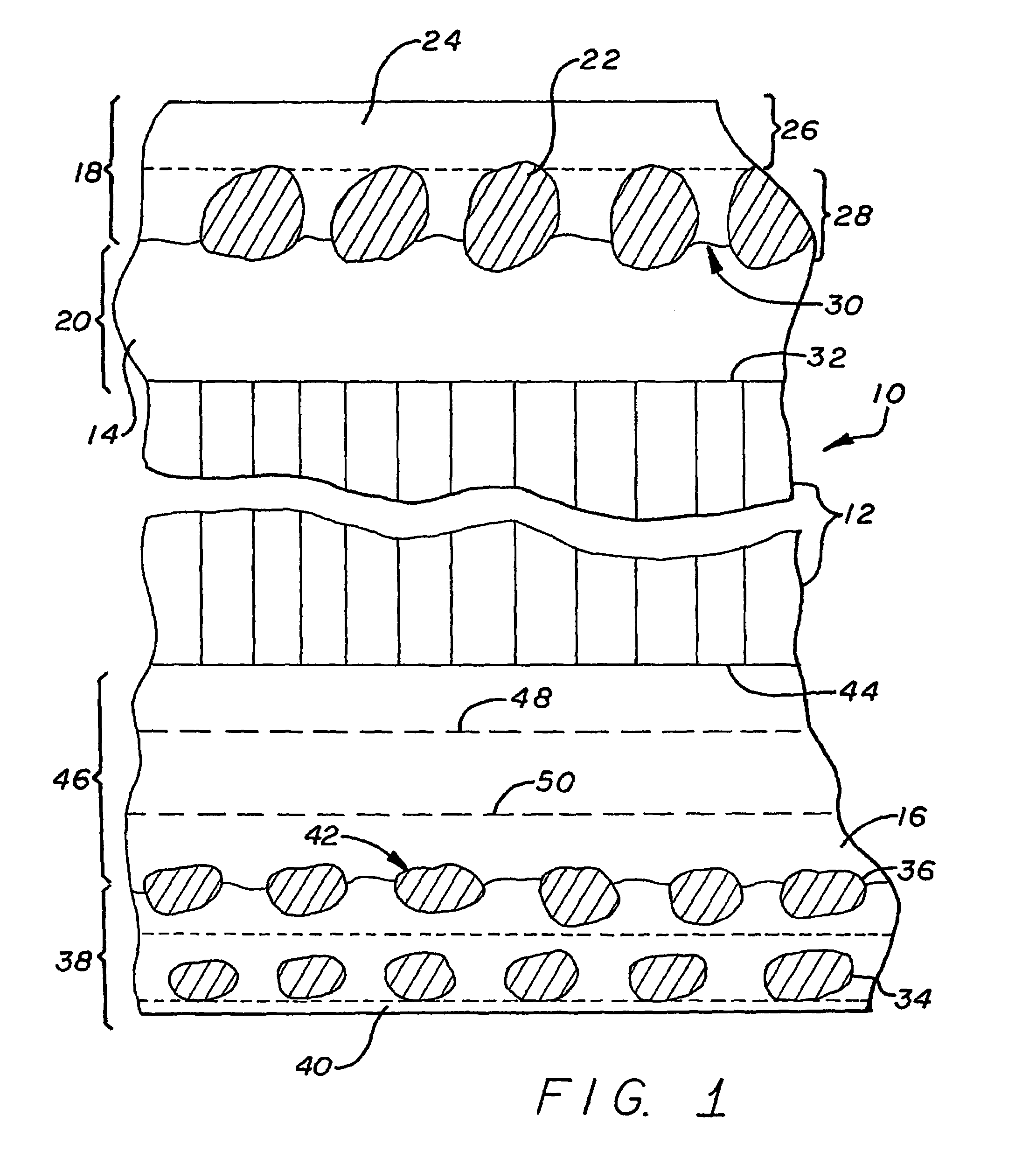

InactiveUS6992027B1Poor adhesionReduce adhesionSynthetic resin layered productsGlass/slag layered productsFiberFire protection

A fire resistant laminate for application to a core structure (12) to form a sandwich panel (10) having fire resistant face sheets (14&16). The laminate includes a fire protection (18) in which at least one layer of fibers (22) is embedded within a cured inorganic polymer matrix (24). The laminate further includes an adhesive layer (20) for bonding to the core structure.

Owner:HEXCEL COMPOSITES LTD (GB)

Manufacturing equipment of laser additive

ActiveCN103737933AReduce in quantityReduce lossesIncreasing energy efficiencyEngineeringProtection system

The invention provides manufacturing equipment of a laser additive. The manufacturing equipment comprises a frame, a work cavity, a laser system, an atmosphere protection system and a preheating system, wherein the work cavity is a sealed cavity defined by a heat insulation sandwich panel; a scanning galvanometer of a laser system is arranged at the top of the external part of the work cavity; the preheating system is a three-dimensional flexible heating system, and has a plurality of radiation heating layers with adjustable interlayer spaces arranged at the top inside the work cavity; an air feed pipe and an air return pipe of the atmosphere protection system are divided into a plurality of passages to be respectively connected with two sides of the work cavity through U-shaped tee joints, so that the circulation of inactive gas inside the work cavity is achieved. By adopting the manufacturing equipment of the laser additive, the space can be effectively saved, the heat loss is reduced, the heating efficiency is improved, the energy consumption is reduced, the temperature inside the work cavity is relatively even in distribution, the protective effect on the processing process caused by an internal atmosphere is obvious, different types of materials (metal, macromolecule and the like) can be molded, the processing deformation is reduced, and the excellent quality of molded spare parts is ensured.

Owner:GUANGZHOU OGGI3D ELECTROMECHANICAL

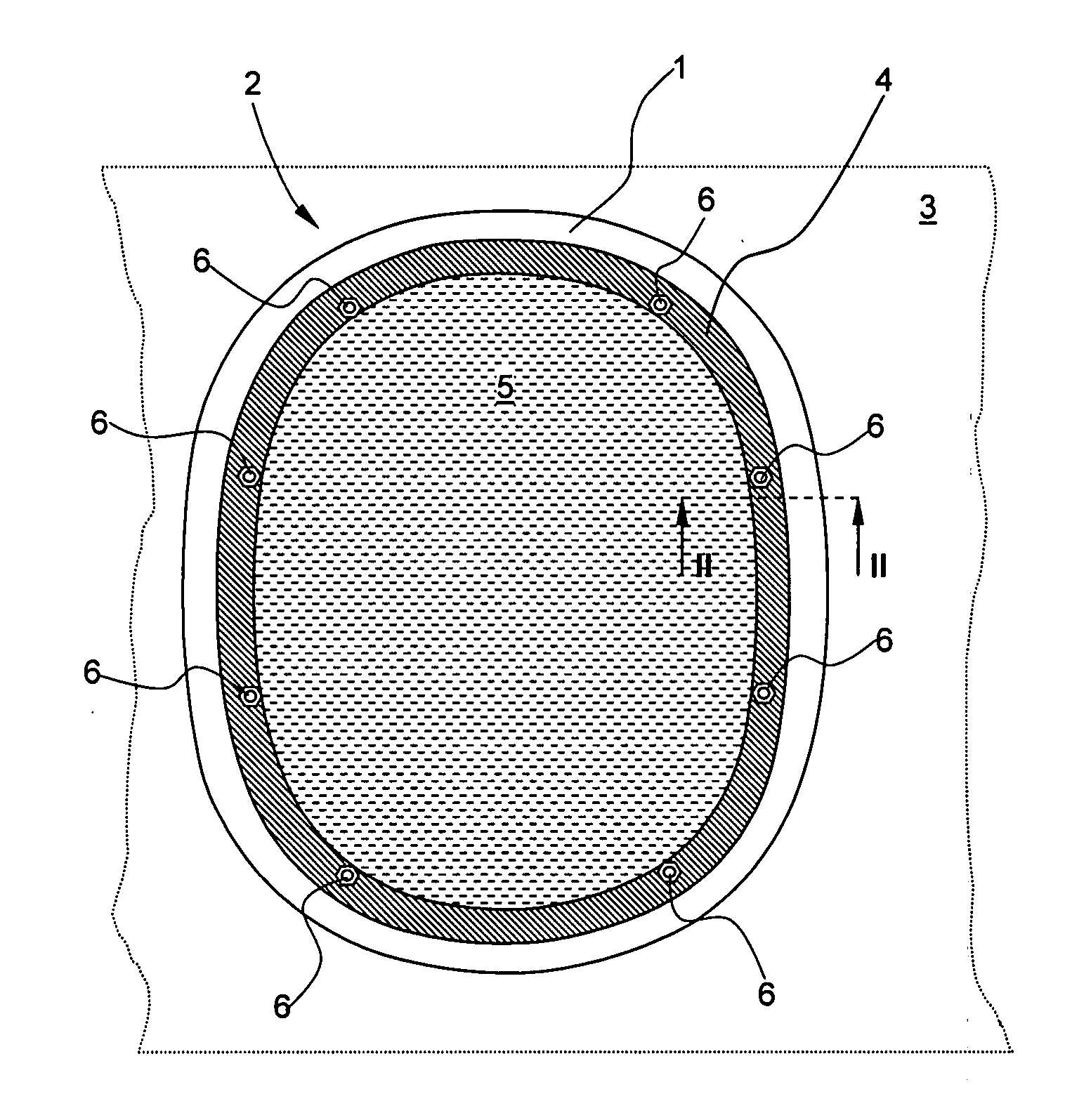

Window replacement for filling a window frame

ActiveUS20080067288A1Avoid disadvantagesFuselage bulkheadsAircraft floorsSynthetic materialsMetallic materials

The invention relates to a window replacement for filling a window frame in an aircraft, in particular a passenger aircraft, the window replacement being fixable by means of a retainer in the window frame in place of the window assembly when the window assembly is removed. According to the invention, the window replacement comprises a panel-shaped element with at least a single curvature, the panel-shaped element, being made of a synthetic material. In one configurational variant, the window replacement according to the invention is formed by a monolithic panel-shaped element. In a second configurational variant, the panel-shaped element of the window replacement is formed by a sandwich panel. Both embodiments allow a weight reduction in comparison with a window replacement of a metallic material.

Owner:AIRBUS OPERATIONS GMBH

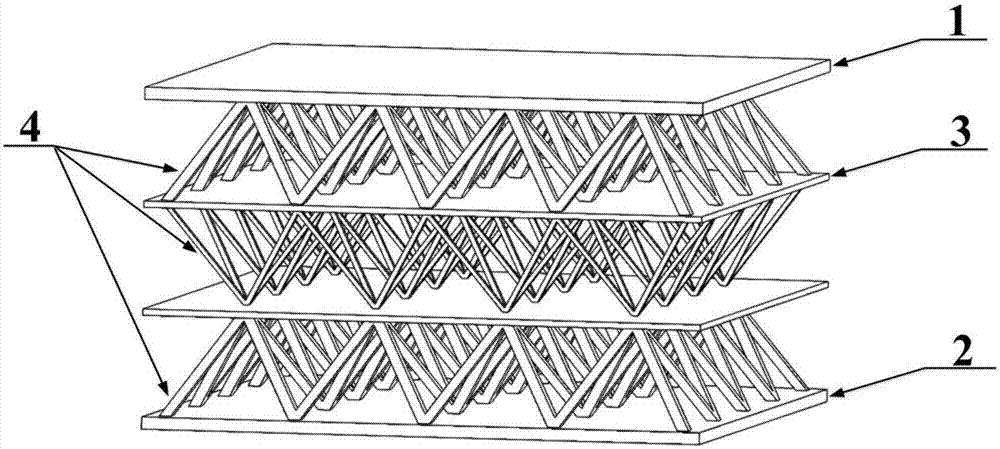

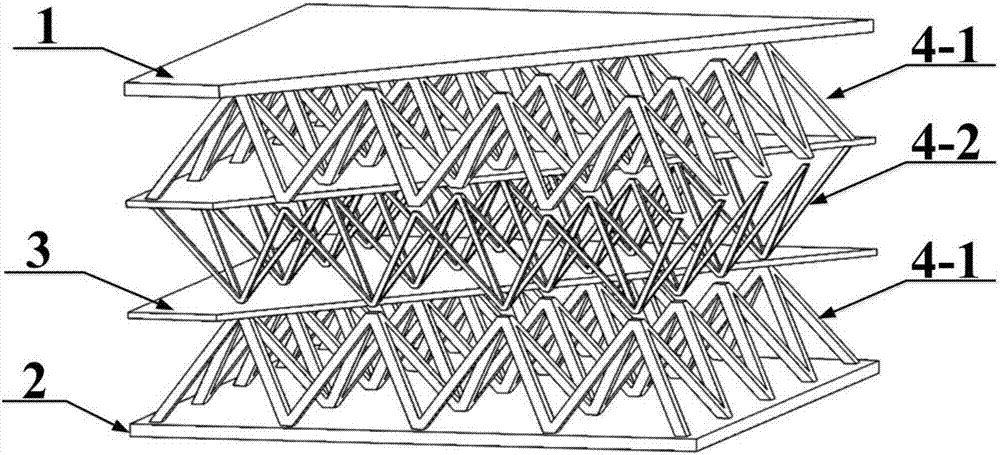

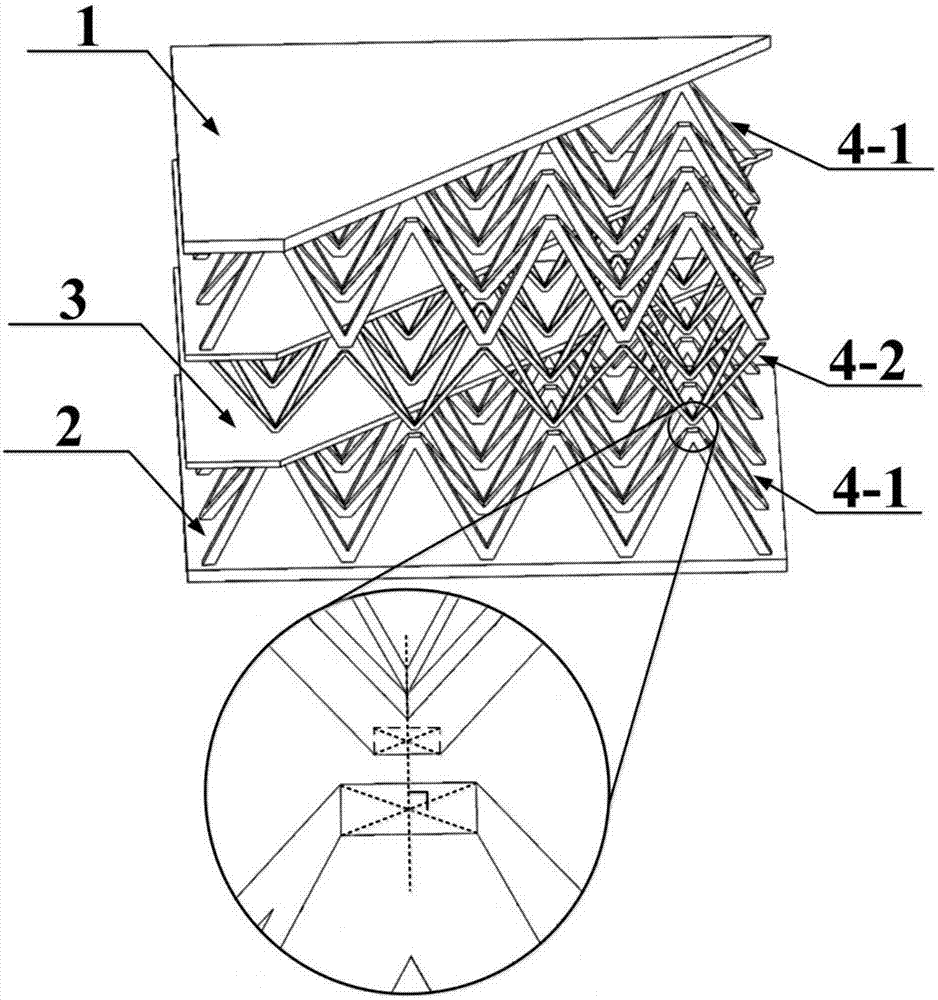

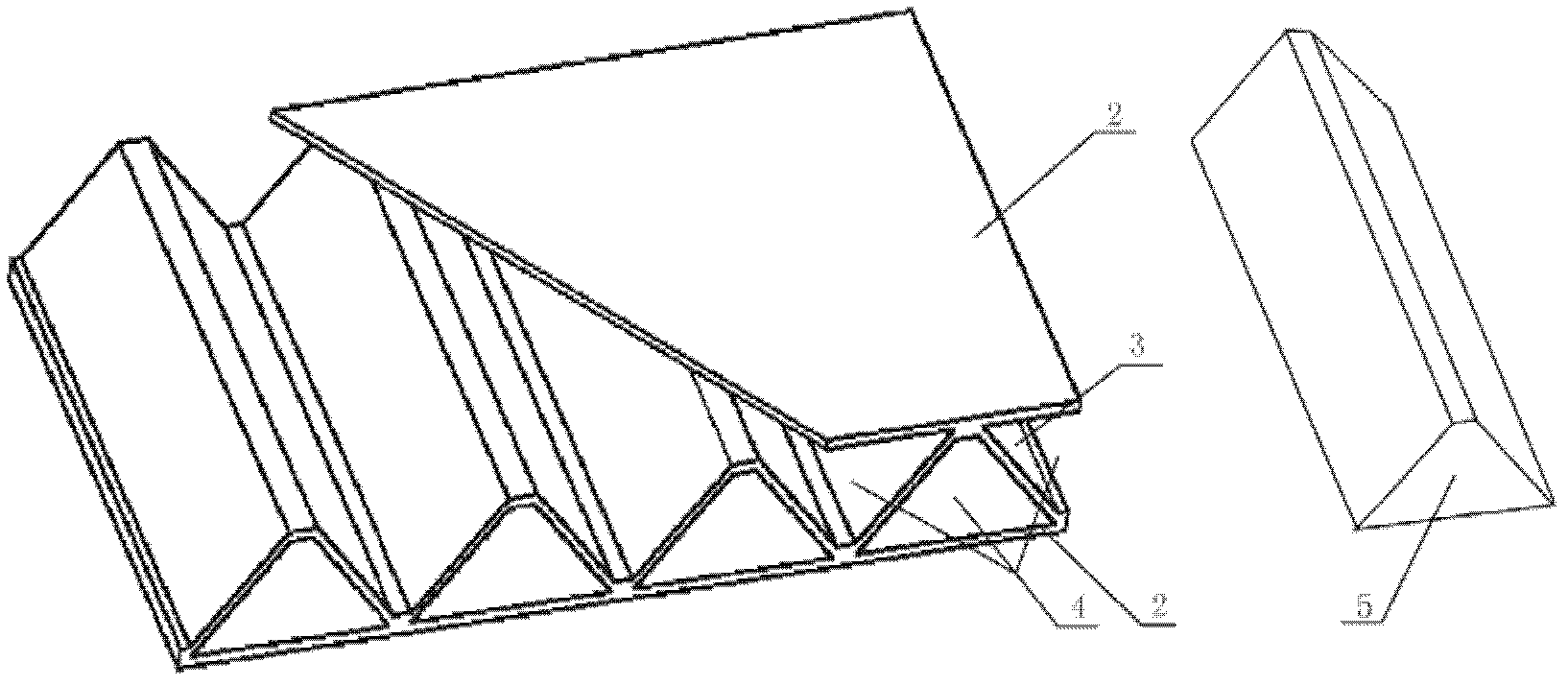

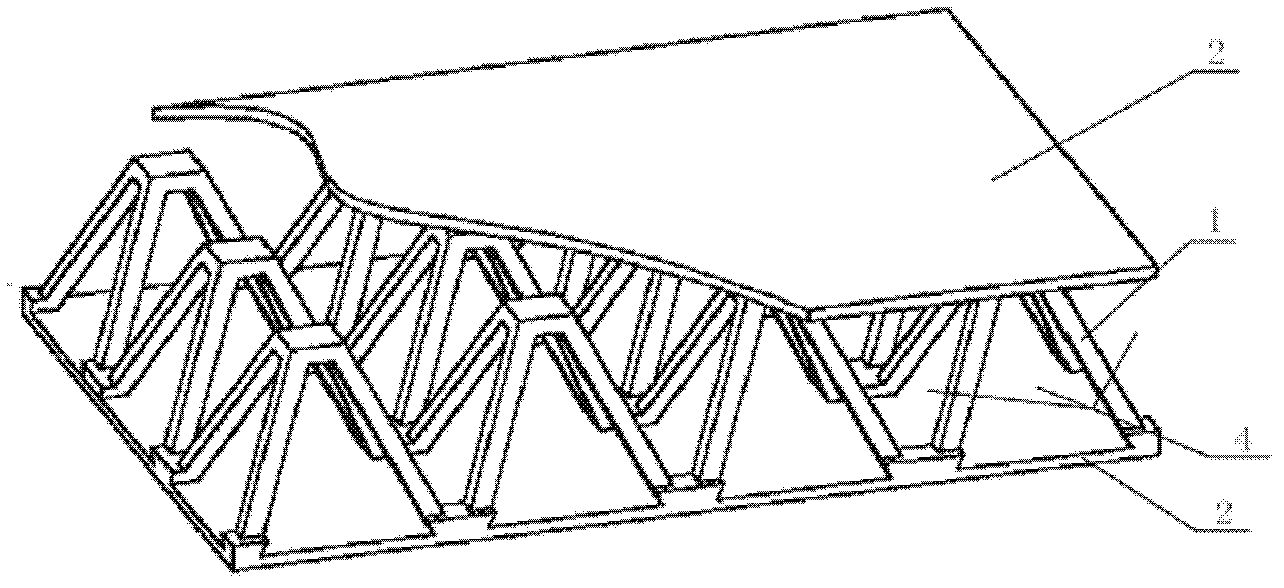

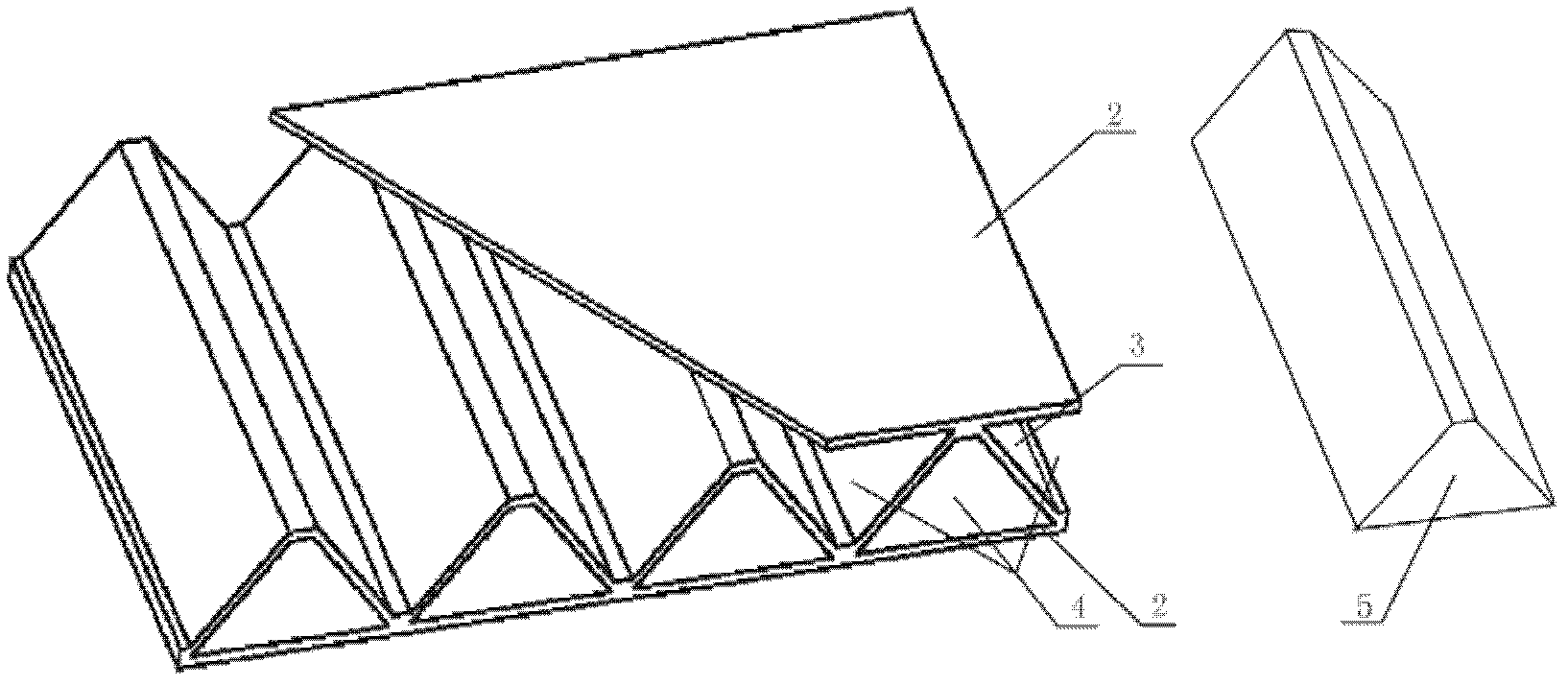

Multilayer gradient lattice sandwich panel and preparation method thereof

The invention discloses a multilayer gradient lattice sandwich panel and a preparation method thereof. Two punched diamond plates with different thicknesses are treated with mold pressing and folding technologies, two pyramid lattice core layers with different core rod part side lengths are prepared, the two core layers are welded with metal panels or partition boards in a circularly interphase distribution form, and the multilayer gradient lattice sandwich panel is obtained. Compared with a non-gradient multilayer lattice structure, the multilayer gradient lattice structure has the advantages that deformation difference among different core layers under the explosion load is greatly reduced, buckling deformation of the core layers are sufficiently utilized, influence of the rear panel by explosion shock is reduced by 50%, and a better protection function is realized. Besides, the characteristic of high porosity of the lattice structure is reserved, and further function composite is facilitated. The sandwich panel has broad application prospects in the fields of safety protection, military and the like by means of the excellent energy adsorption mechanism, low density, high specific strength and specific stiffness and multifunctional composite potentials.

Owner:三亚哈尔滨工程大学南海创新发展基地

Lattice metal-foamed aluminium composite material and preparation method thereof

InactiveCN102416714AGood mechanical propertiesImprove performanceMetal layered productsMetallic materialsHigh intensity

The invention discloses a preparation method of a lattice metal-foamed aluminium composite material, characterized by cementing a lattice metal material (including ripple structure and pyramid structure) and cut foamed aluminium to obtain a multifunctional composite porous material. The lattice metal-foamed aluminium composite sandwich panel disclosed herein has a wide application prospect in the fields of transportation, mechanical manufacturing, and military, can effectively reduce the structure weight, improves the performances of impact deformation and magnetic shield, especially brings the performances of high intensity, high rigidity and excellent damping capacity into play in the field of mechanical manufacturing, and has the advantage of low production cost.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com