Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49996 results about "Aluminium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium alloys (or aluminum alloys; see spelling differences) are alloys in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. About 85% of aluminium is used for wrought products, for example rolled plate, foils and extrusions. Cast aluminium alloys yield cost-effective products due to the low melting point, although they generally have lower tensile strengths than wrought alloys. The most important cast aluminium alloy system is Al–Si, where the high levels of silicon (4.0–13%) contribute to give good casting characteristics. Aluminium alloys are widely used in engineering structures and components where light weight or corrosion resistance is required.

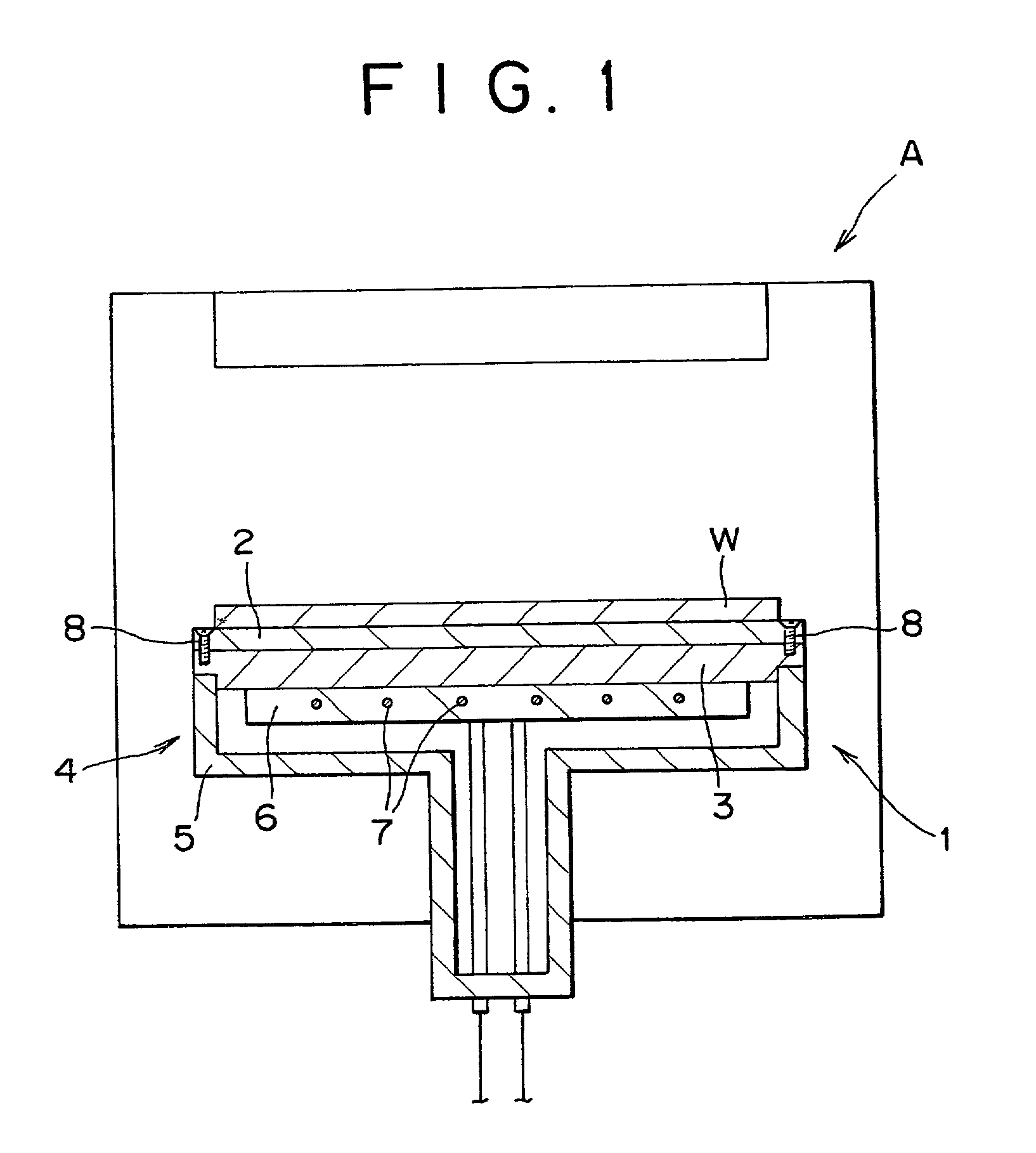

Chamber material made of Al alloy and heater block

InactiveUS20010019777A1Not be restrictElectric discharge tubesSemiconductor/solid-state device manufacturingHigh-temperature corrosionContamination

A chamber material made of Al alloy excellent in thermal cracking resistance and chemical and / or physical corrosion resistance and capable of reducing contamination excellently and further having excellent and wide applicable brazing property in a high temperature corrosive circumstance, in which the substrate aluminum material for the chamber material made of Al alloy having an anodized film comprises 0.1 to 2.0% Si, 0.1 to 3.5% Mg, 0.02 to 4.0% Cu on the mass % basis and the balance of Al and impurity element with Cr in the impurity elements being less than 0.04%. Preferably, Fe is 0.1% or less and Mn is 0.04% or less in the impurity element and, further, the total sum of impurity elements other than Cr and Mn being restricted to 0.1$ or less. This invention can be utilized suitably to various materials used in high temperature corrosive circumstance, particularly, in high temperature corrosive gas or plasma atmosphere.

Owner:KOBE STEEL LTD

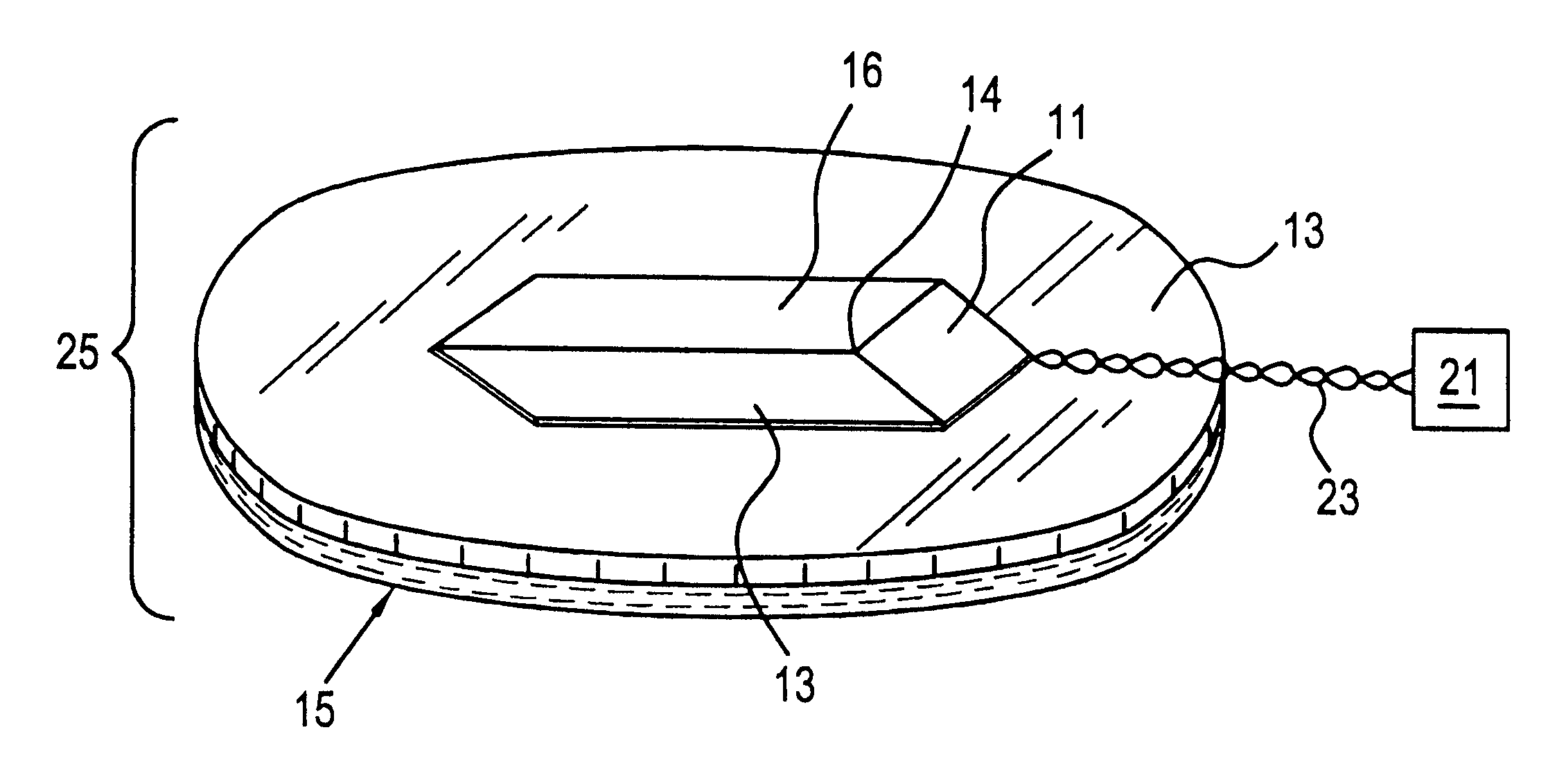

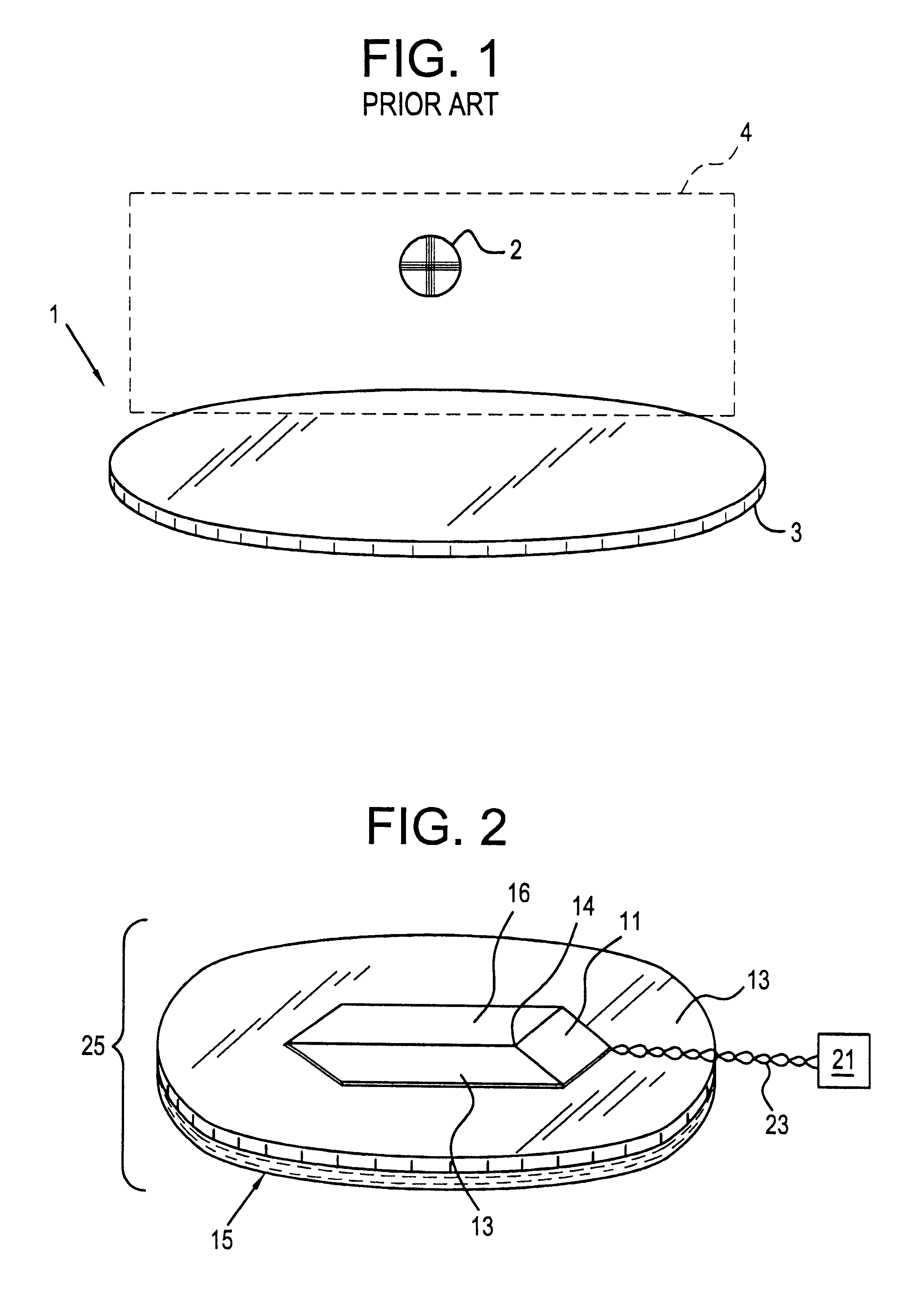

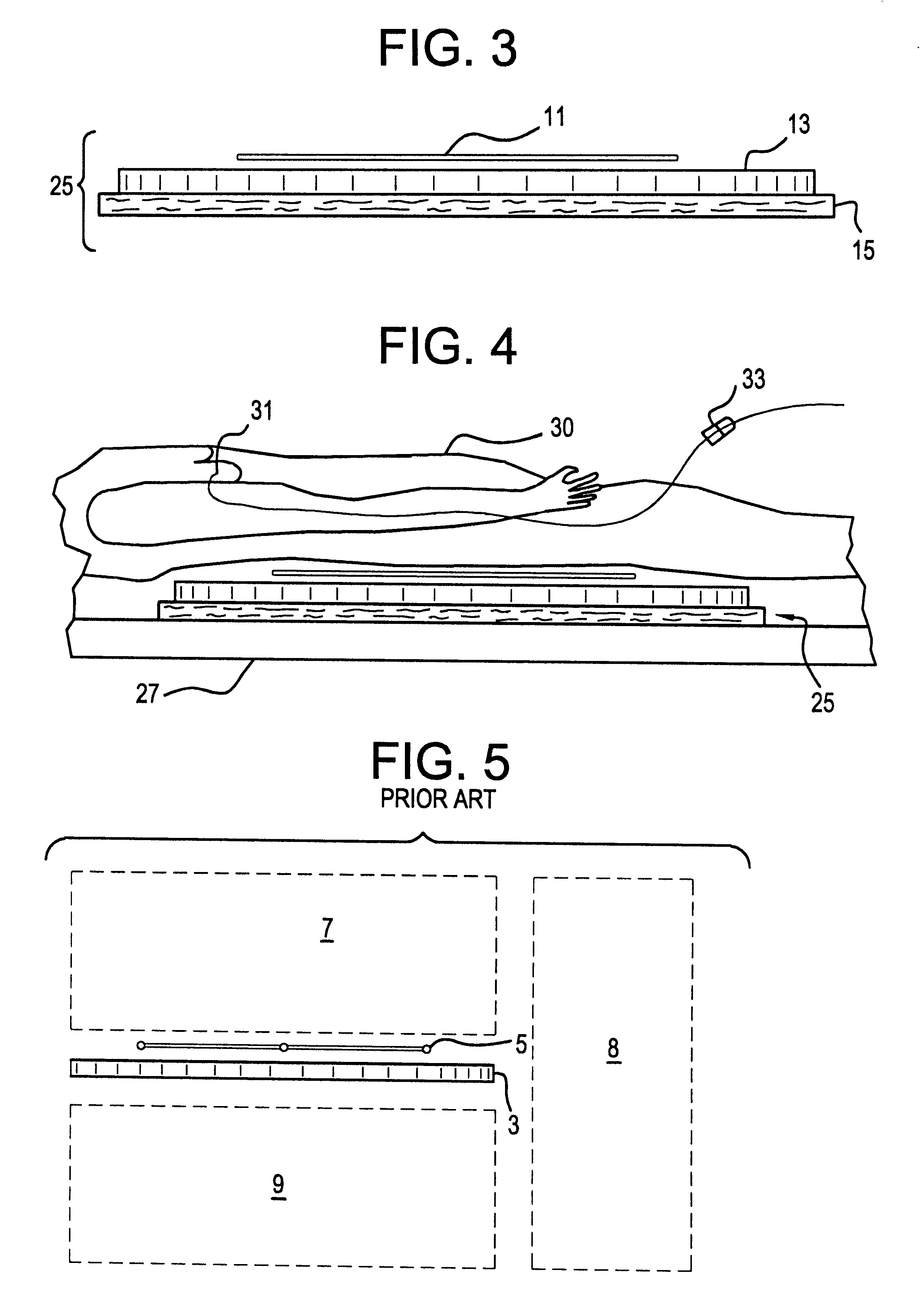

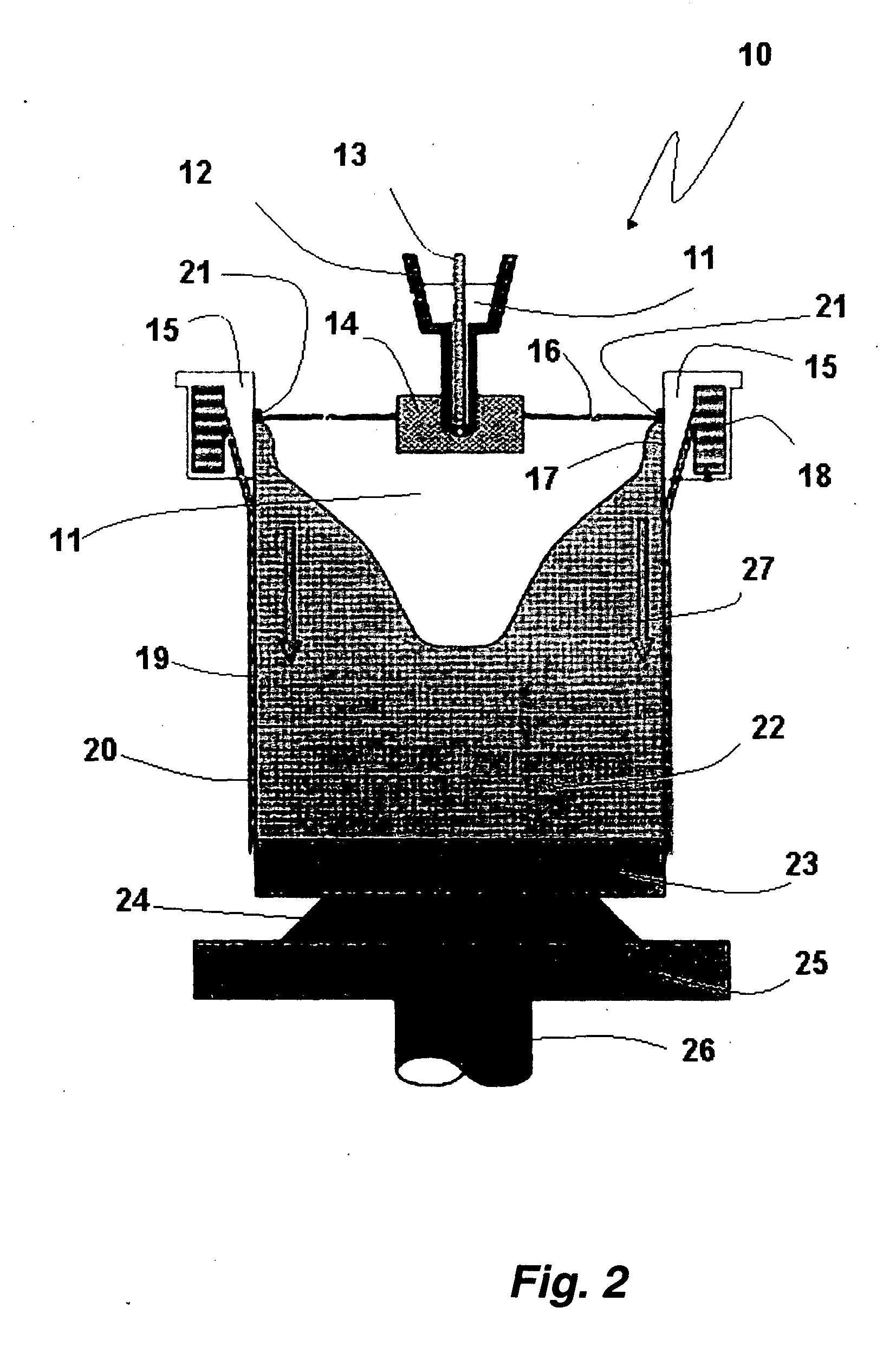

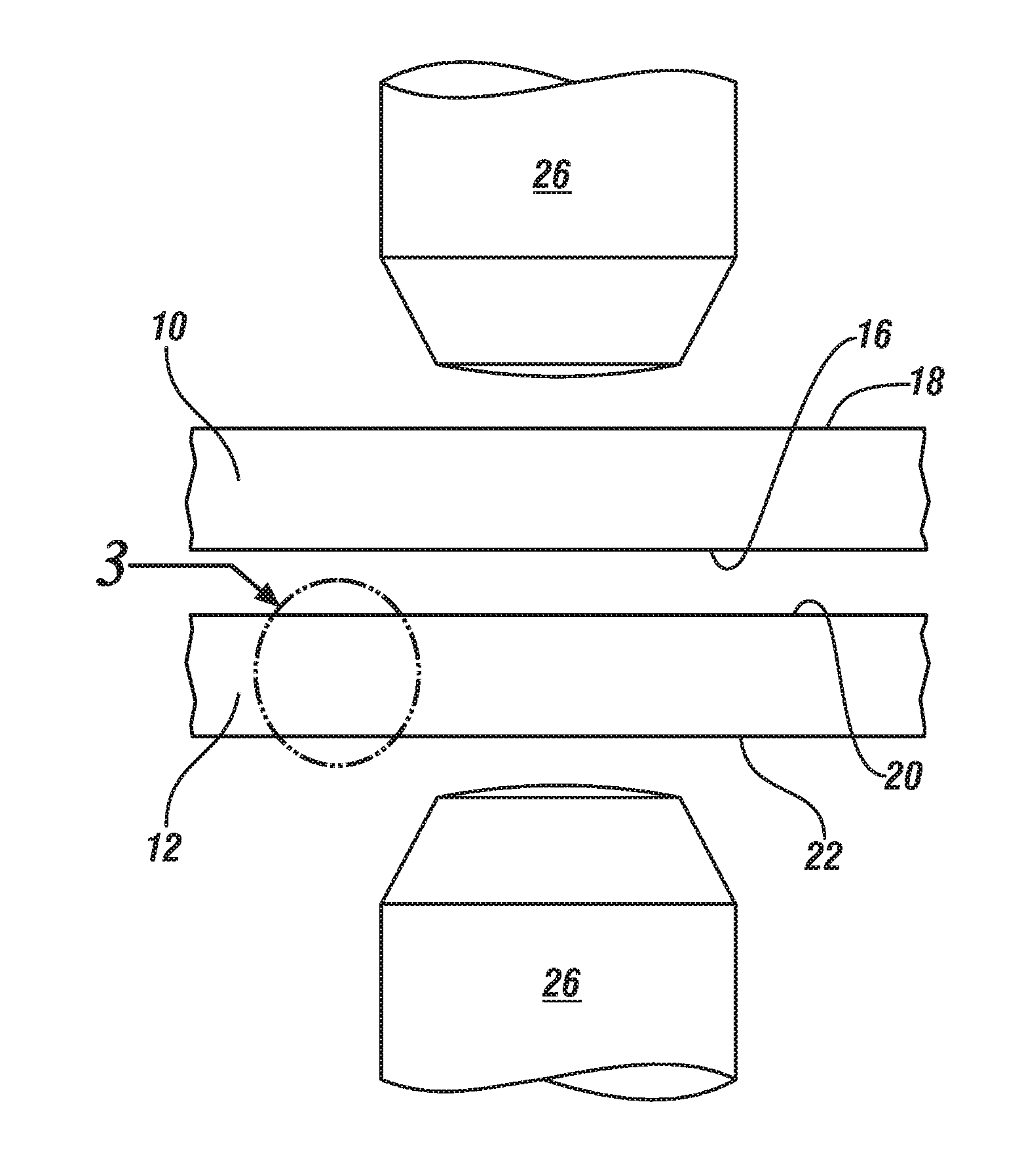

Magnetic field permeable barrier for magnetic position measurement system

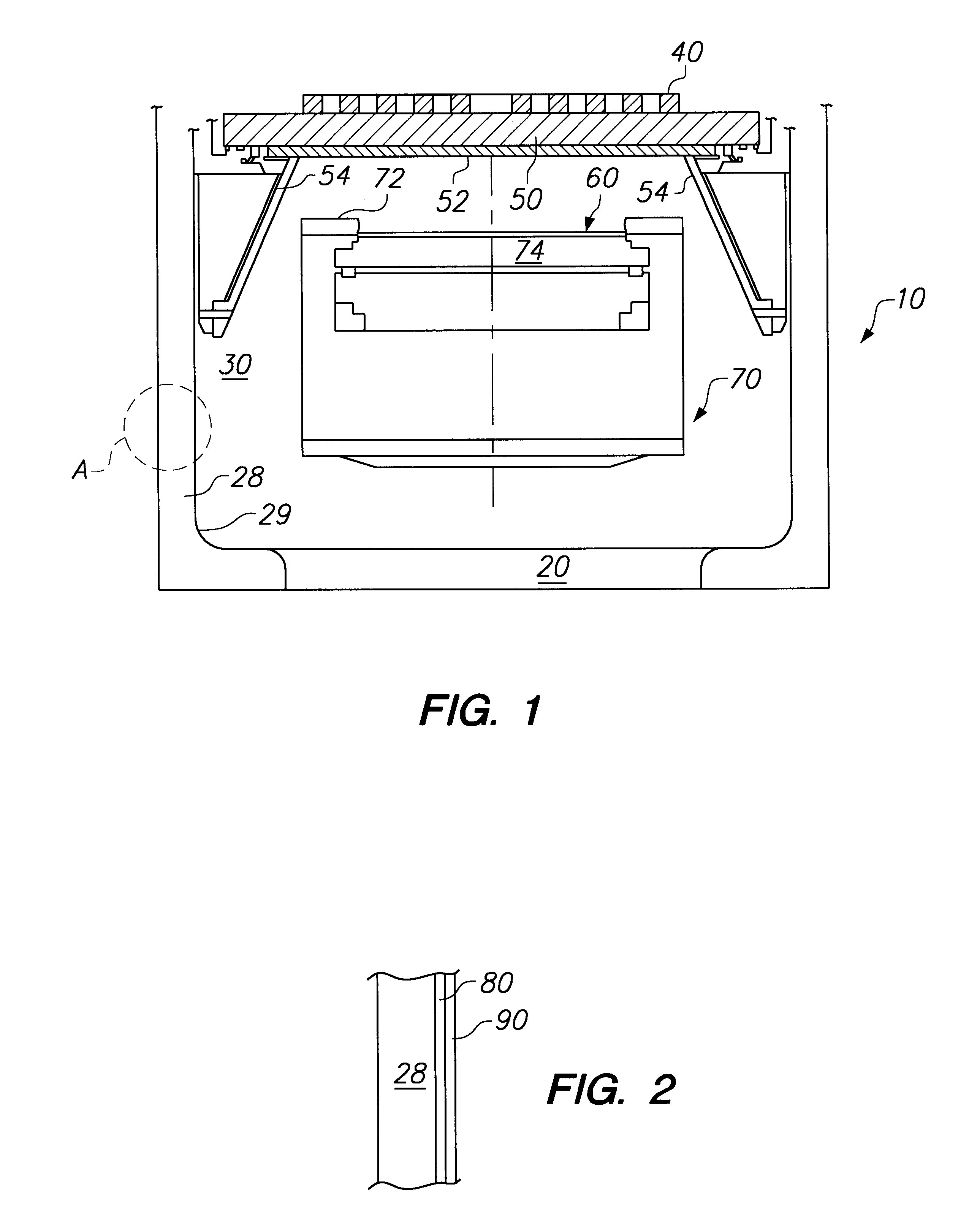

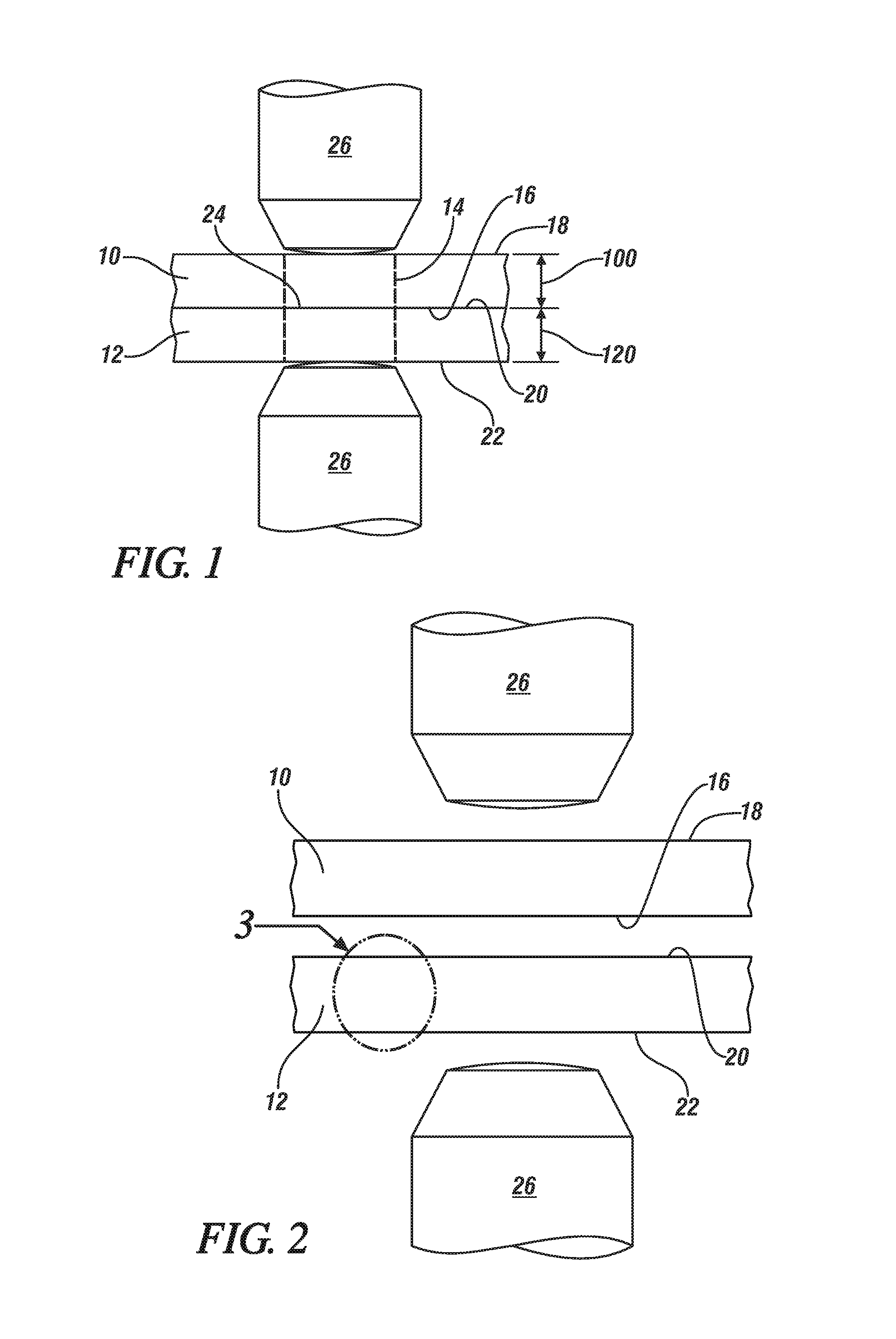

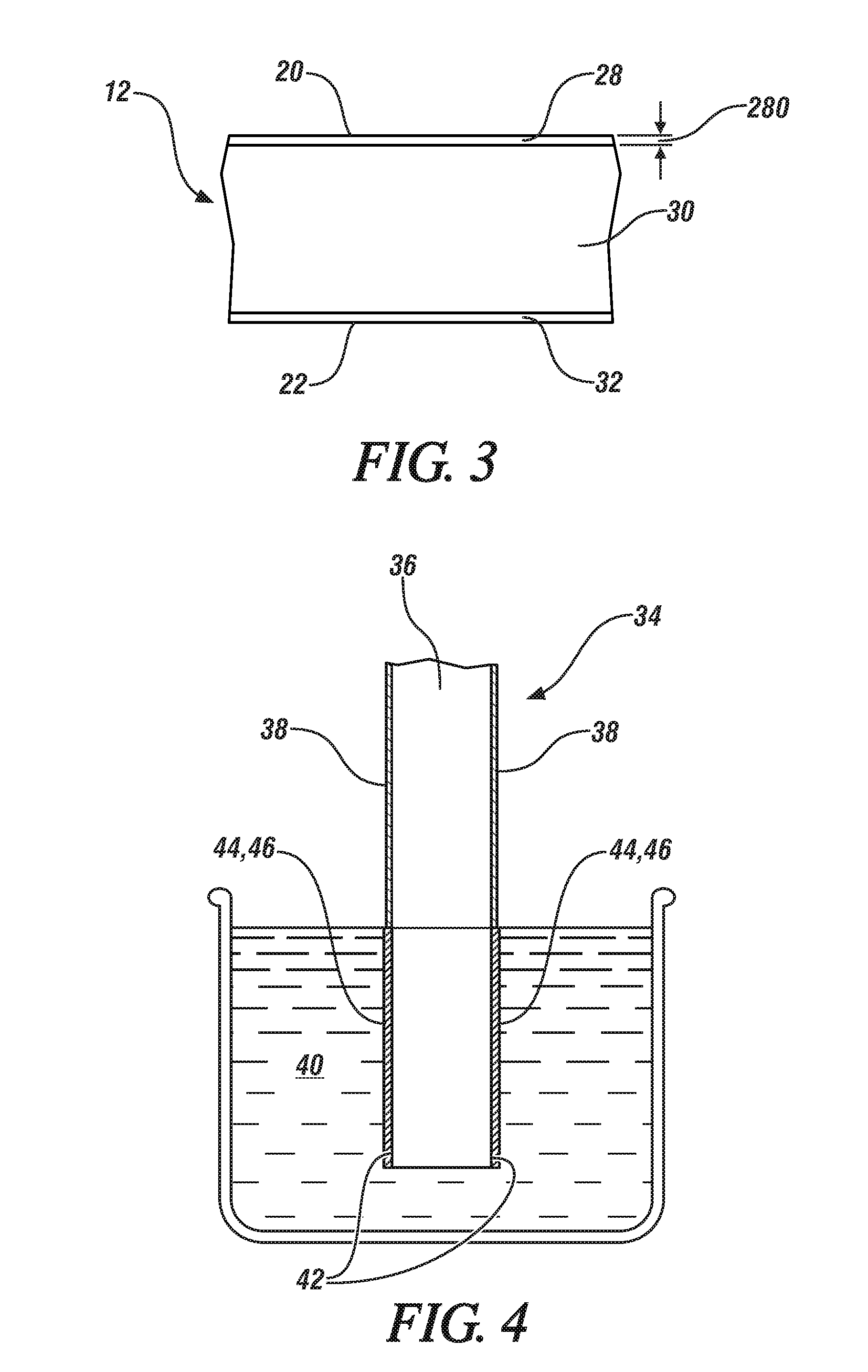

InactiveUS6246231B1SurgeryElectric/magnetic position measurementsOrientation measurementMetallic Object

A magnetic field position and orientation measurement system contains, confines and re-directs the magnetic field from one or more transmitters such that the fields are attenuated in areas outside of the operating volume in areas where metallic objects are commonly found. A thin barrier made of a highly permeable material such as ferrite or mumetal is placed on top of a conductive plate. The thickness of the permeable layer is from 0.01 inches to 0.25 inches while the conductive plate, preferably made of an aluminum alloy, may preferably be from {fraction (3 / 16)} of an inch to ¼ inch in thickness. On top of the permeable barrier, a rhombic three axis transmitter is placed. In the preferred embodiment, the transmitter consists of a PC board carrying the transmitter. PC boards having thicknesses varying from 0.03125-0.125 inches may be employed. Thus, the entire "stack" including the transmitter, the permeable barrier and the conductive plate may only be from ½ inch to ⅝ of an inch in thickness. The permeable barrier may have a flat, planar configuration. Alternatively, it may be made to resemble, in cross-section, a cake pan having a flat central region with uplifted peripheral edges. Alternatively, the permeable barrier may have a generally flat configuration with peripheral edges that taper outwardly from the top surface thereof to the bottom surface thereof with the taper making an angle with the bottom surface in the range of, preferably, 30° to 85°.

Owner:ASCENSION TECH

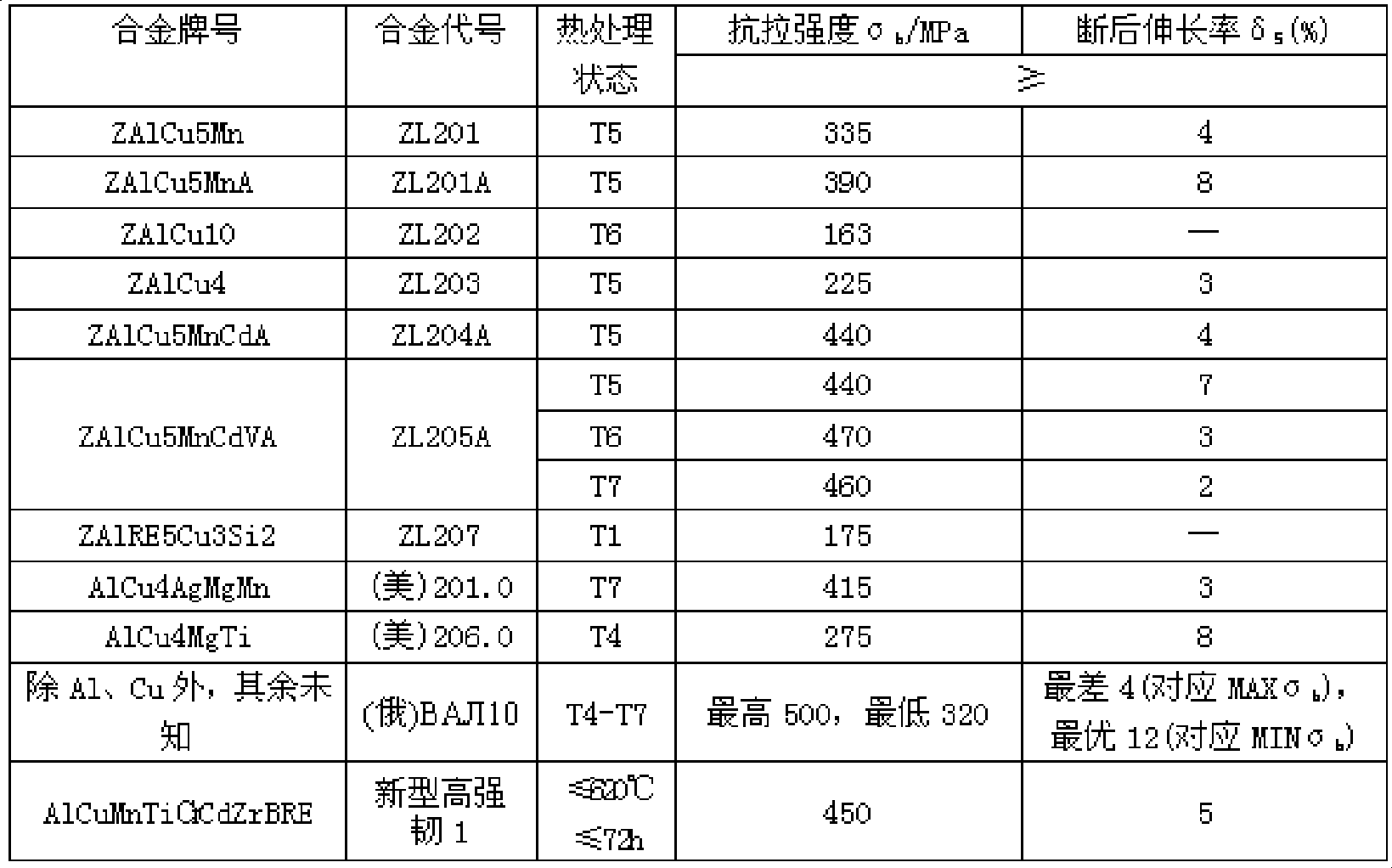

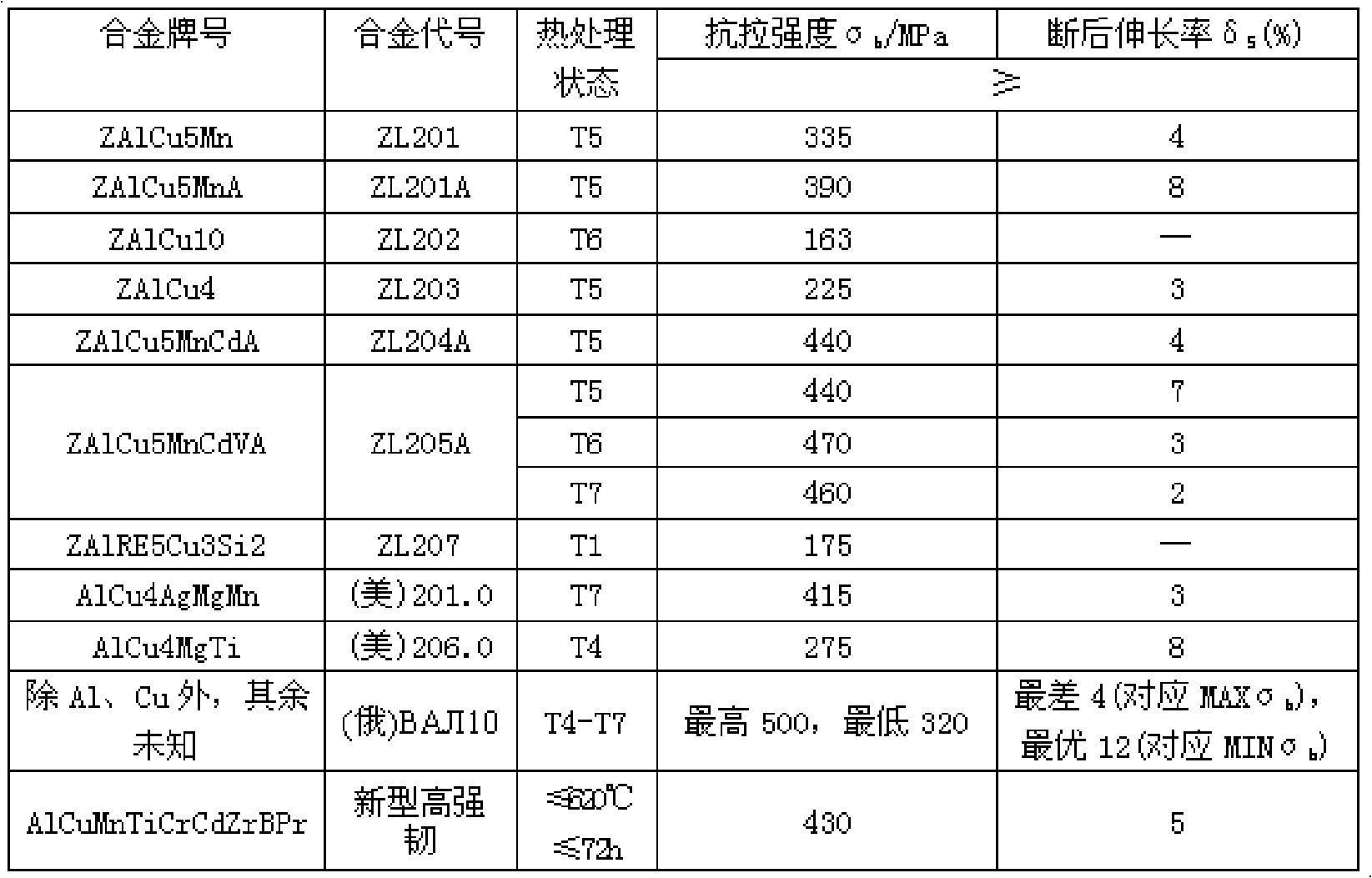

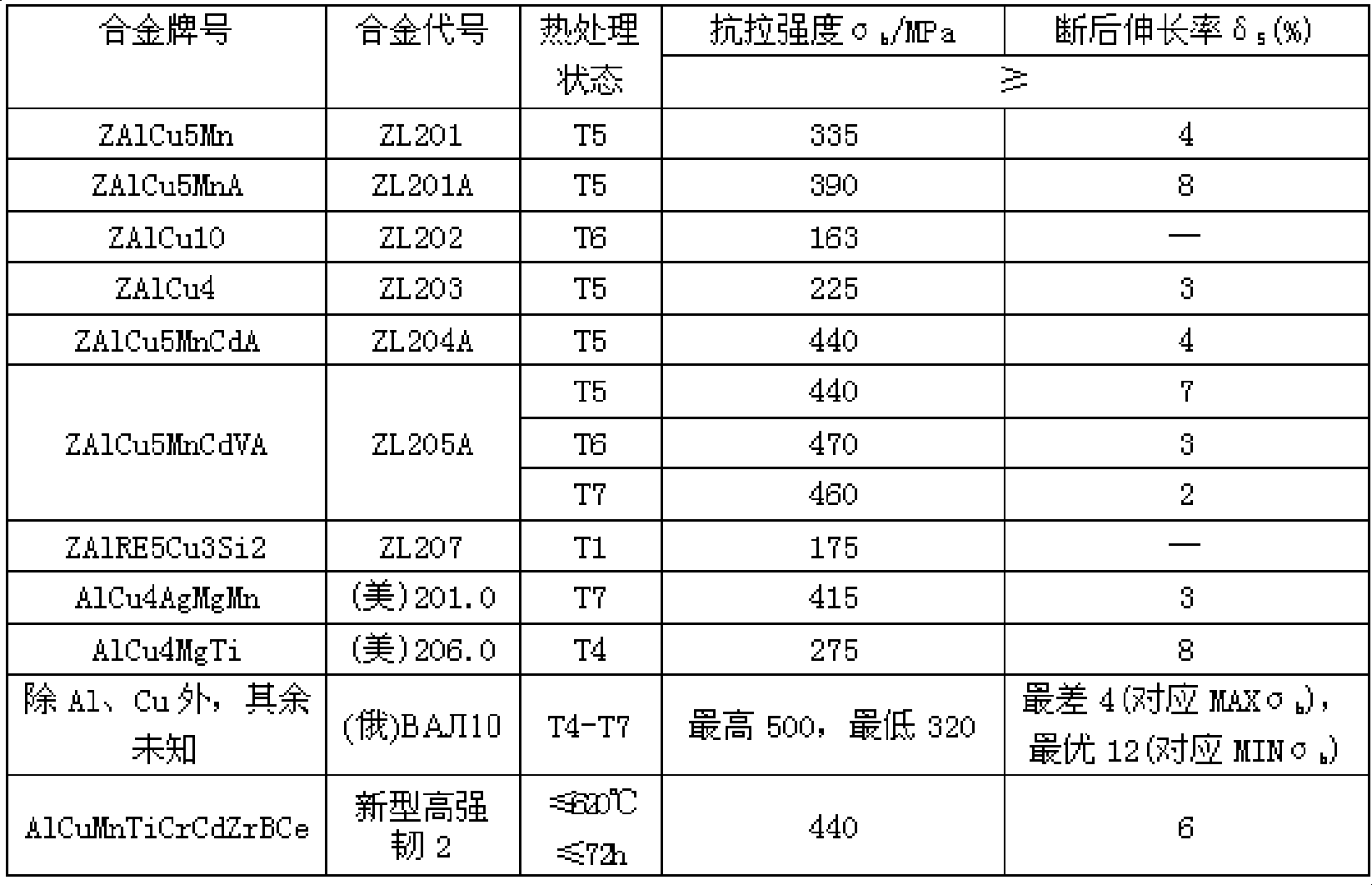

High-strength cast aluminium alloy material

The invention discloses a high-strength cast aluminum alloy material which comprises the following components by weight percentages: 2.0-6.0% of Cu, 0.05-1.0% of Mn, 0.01-0.5% of Ti, 0.01-0.2% of Cr, 0.01-0.4% of Cd, 0.01-0.25% of Zr, 0.005-0.04% of B, 0.05-0.3% of mixed rare earth RE, Al and microimpurity elements. The material adopts the advanced design of alloy components and the microalloying design. Based on the Al-Cu-Mn as the major components, rational microalloy elements (the Ti, the Cr, the B, the Zr, the mixed rare earth, etc.) are found and the ranges thereof are determined, which can realize the function of substituting the precious rare metals Ag, V, and the like, thus lowering the formula cost by 5-10%.

Owner:GUIZHOU UNIV +2

High-strength cast aluminium alloy material

The invention discloses a high strength casting aluminum alloy material. The alloy comprises the following compositions in weight percent: 2.0 to 6.0 percent of Cu, 0.05 to 1.0 percent of Mn, 0.01 to 0.5 percent of Ti, 0.01 to 0.2 percent of Cr, 0.01 to 0.4 percent of Cd, 0.01 to 0.25 percent of Zr, 0.005 to 0.04 percent of B, 0.05 to 0.3 percent of Pr, the balance being Al and trace impurity elements. The invention adopts the advanced alloy composition design and the micro alloying design. Based on taking Al-Cu-Mn as main compositions, the material finds reasonable micro alloy elements (Ti, Cr, B, Zr and rare earth, etc.), determines the ranges of compositions of the micro alloy elements, is capable of realizing the function of replacing precious and rare metals such as Ag and V, etc., and lowers the formula cost by 5 to 10 percent.

Owner:GUIZHOU UNIV +2

High-strength cast aluminium alloy material

The invention discloses a high-strength aluminum casting alloy material which comprises the following components by weight percentages: 2.0-6.0% of Cu, 0.05-1.0% of Mn, 0.01-0.5% of Ti, 0.01-0.2% of Cr, 0.01-0.4% of Cd, 0.01-0.25% of Zr, 0.005-0.04% of B, 0.05-0.3% of Ce, Al and other microimpurity elements. The material adopts the advanced design of alloy components and microalloying design. Based on the Al-Cu-Mn as the major components, rational microalloy elements (the Ti, the Cr, the B, the Zr, mixed rare earth, etc.) are found and the ranges thereof are determined, which can realize the function of substituting the precious rare metals Ag, V, and the like, thus lowering the formula cost by 5-10%.

Owner:贵州铝厂有限责任公司 +2

High-strength cast aluminium alloy material

The invention discloses a high-strength aluminum casting alloy material which comprises the following components by weight percentages: 2.0-6.0% of Cu, 0.05-1.0% of Mn, 0.01-0.5% of Ti, 0.01-0.2% of Cr, 0.01-0.4% of Cd, 0.01-0.25% of Zr, 0.005-0.04% of B, 0.05-0.3% of La, Al and other microimpurity elements. The material adopts the advanced design of alloy components and microalloying design. Based on the Al-Cu-Mn as the major components, rational microalloy elements (the Ti, the Cr, the B, the Zr, mixed rare earth, etc.) are found and the ranges thereof are determined, which can realize the function of substituting the precious rare metals Ag, V, and the like, thus lowering the formula cost by 5-10%.

Owner:贵州铝厂有限责任公司 +2

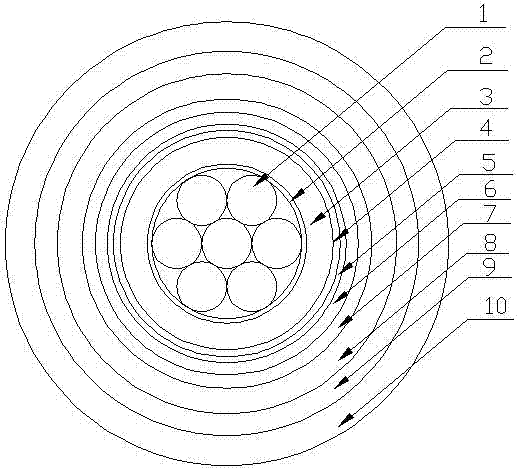

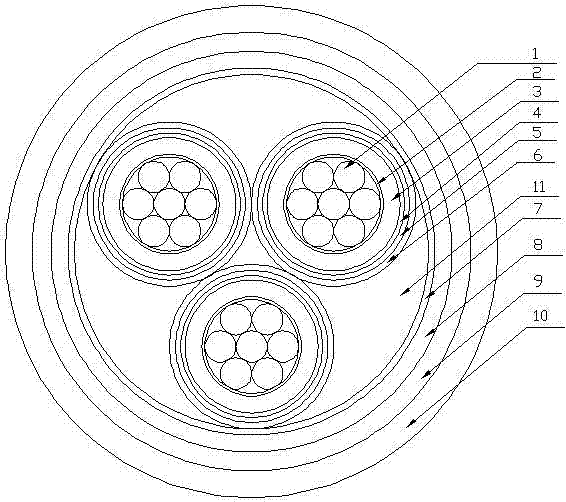

Water-blocking medium voltage aluminum alloy power cable

InactiveCN103700442AWith water blocking functionGood vertical water resistanceClimate change adaptationPower cables with screens/conductive layersElectrical conductorMemory effect

The invention discloses a water-blocking medium voltage aluminum alloy power cable which comprises an insulating cable core and an outer wrapping layer, wherein one or more insulating cable cores are provided; the insulating cable core is wrapped by the outer wrapping layer so as to form the water-blocking medium voltage aluminum alloy power cable. The cable is characterized in that each insulating cable core comprises an inner aluminum alloy conductor core (1), an inner shielding layer (2), an insulating layer (3), an outer shielding layer (4), a semiconductor resistor water-blocking zone (5) and a seamless metal sleeve (6) from inside to outside in sequence; the outer wrapping layer comprises a winding and wrapping layer (7), an inner protective layer (8), an armored layer (9) and an outer protective layer (10) from inside to outside The aluminum alloy power cable disclosed by the invention is made of an aluminum alloy material, the inner aluminum alloy conductor core is high in yield strength, small in resilience value, free of memory effect and easy to install, and compared with a copper core cable of the same mass, the cable is small in resistance, and the cost of the alloy material is smaller than that of copper.

Owner:江苏南瑞淮胜电缆有限公司 +1

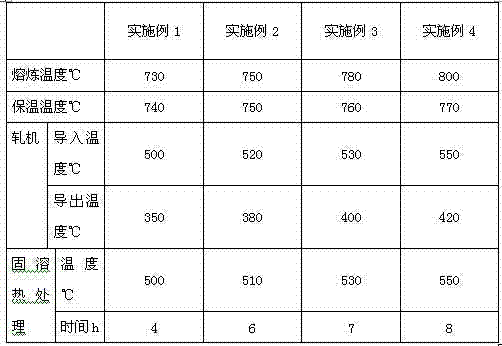

A kind of aluminum alloy material and preparation method thereof

The invention relates to an aluminum alloy material which is characterized in that the aluminum alloy material comprises the following components by weight percent: 0.16-1.2% of Fe, 0.001-0.8% of Cu, 0.001-0.8% of Mg, 0.001-0.8% of Zn, 0.001-0.8% of Ca, 0.001-1.0% of rare-earth elements, a trace amount of strontium, titanium, boron, nickel, chromium, zirconium, vanadium, beryllium, cobalt, lead, tin, bismuth, molybdenum, silver, indium, niobium and barium and the balance of aluminum. The alloy has excellent mechanical strength, processing performance and corrosion resistance and is suitable for the cable armored sheath.

Owner:GUANGDONG XINYI ALUMINUM ALLOY CABLE

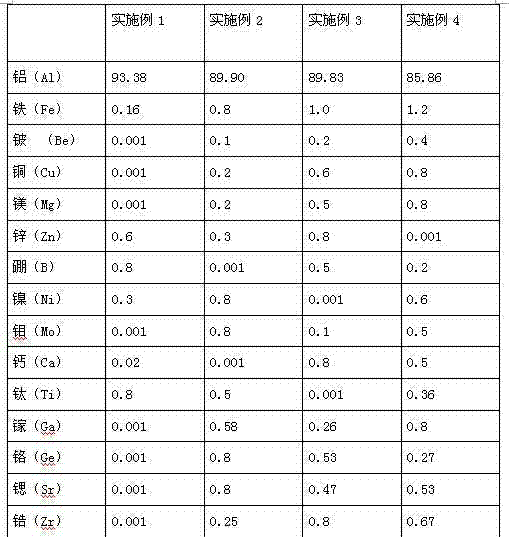

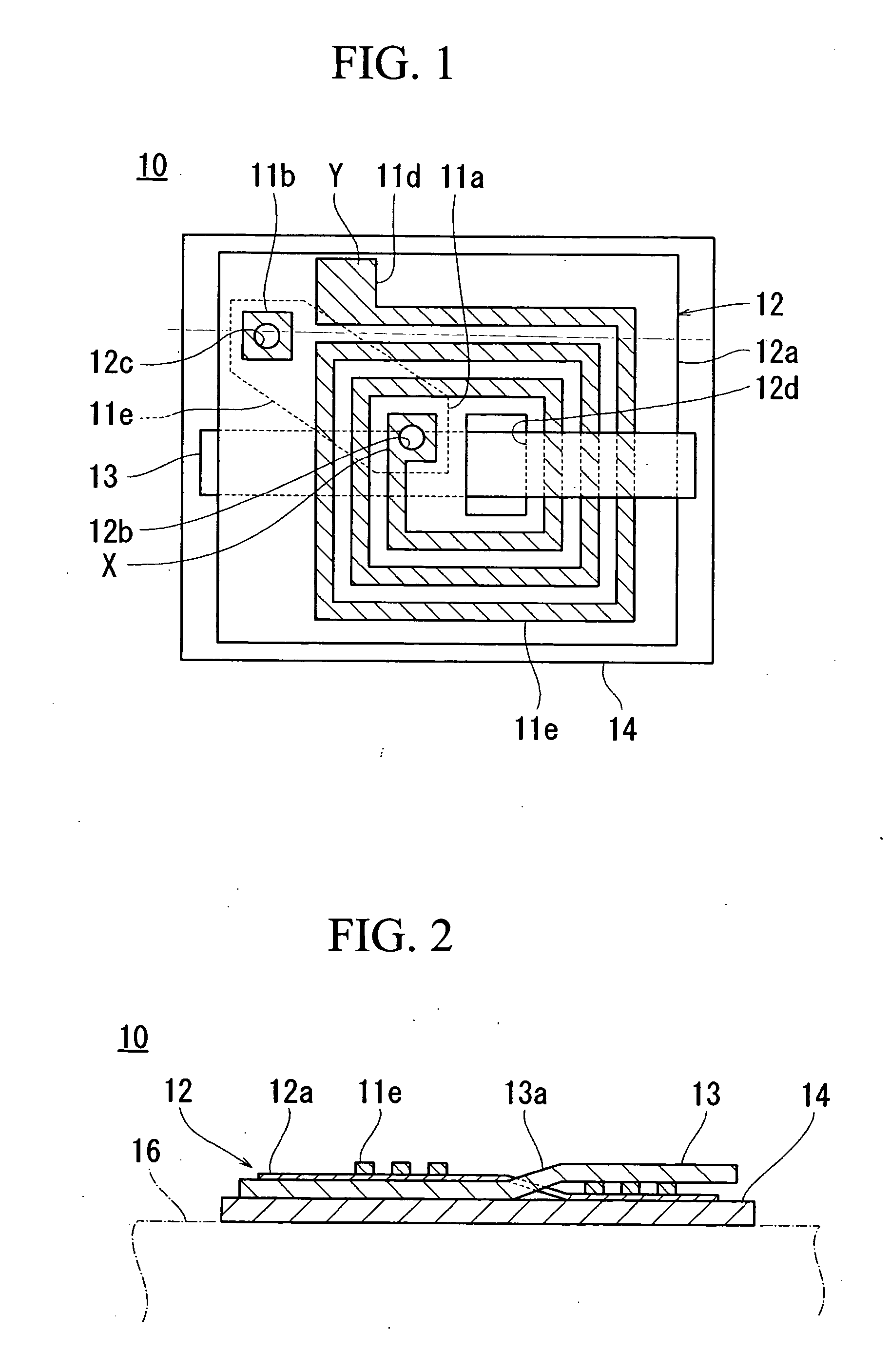

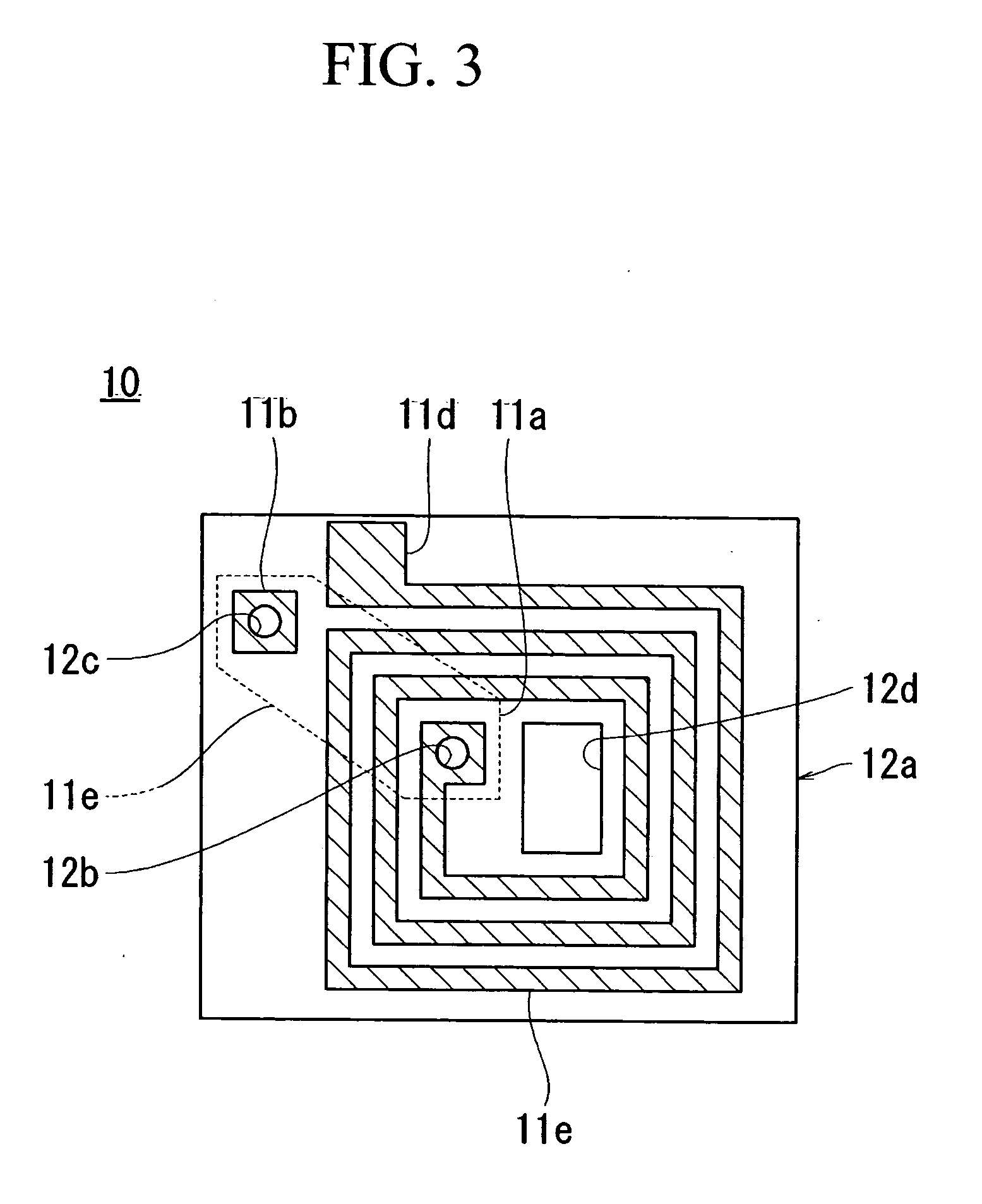

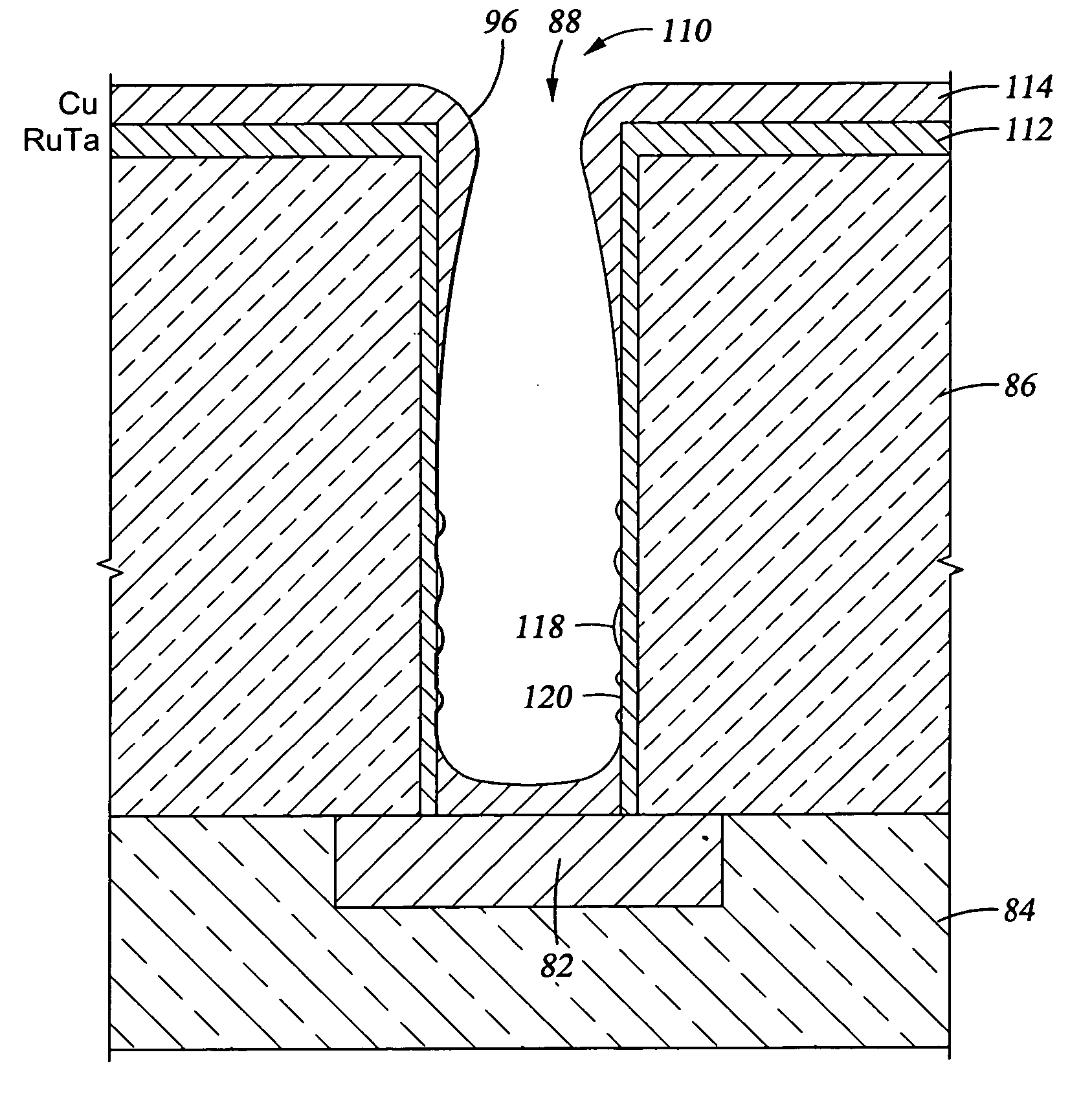

Antenna coil and rfid-use tag using it, transponder-use antenna

InactiveUS20050007296A1Improve rigidityHigh frequencyLoop antennas with ferromagnetic coreOther printing matterAir coreNon magnetic

An antenna coil includes an air-core coil wound helically in a plane and a plate magnetic core member inserted in the air-core coil to be approximately parallel with a plane of the air-core coil. The magnetic core member is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member is a magnetic coating formed by applying and drying the composite member. A non-magnetic conductive plate that has a conductivity is layered on a surface of the air-core coil through which the magnetic core member is inserted. The conductive plate is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. The antenna coil is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

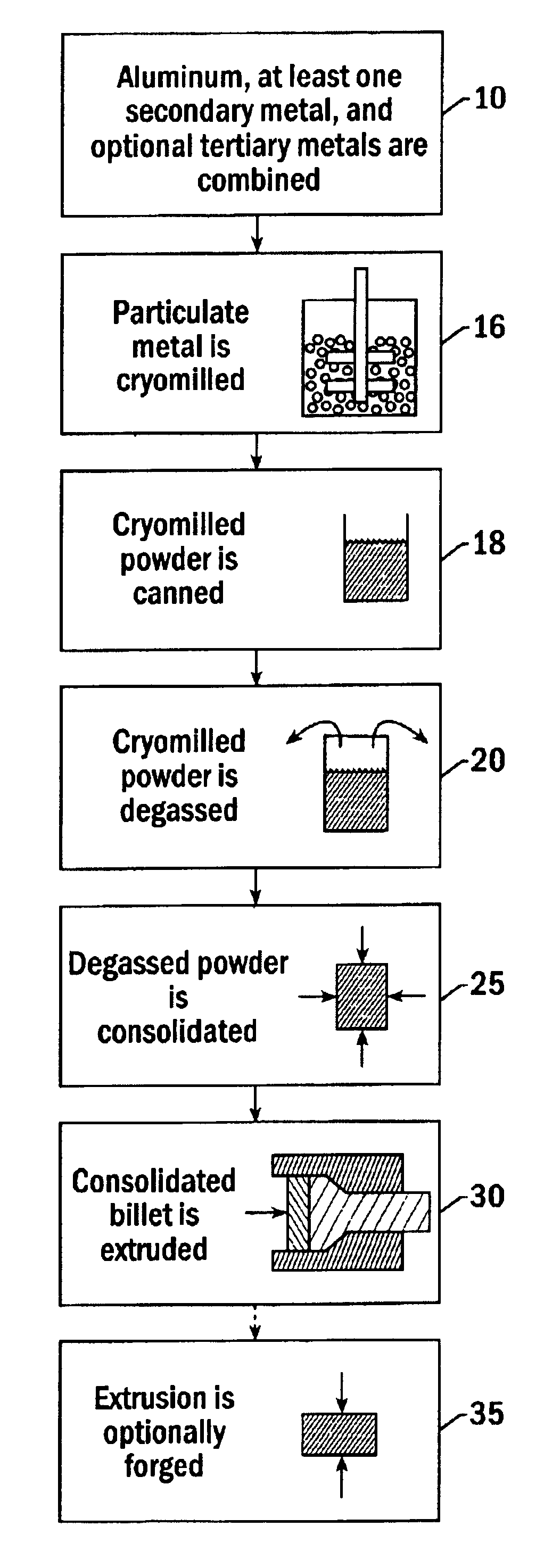

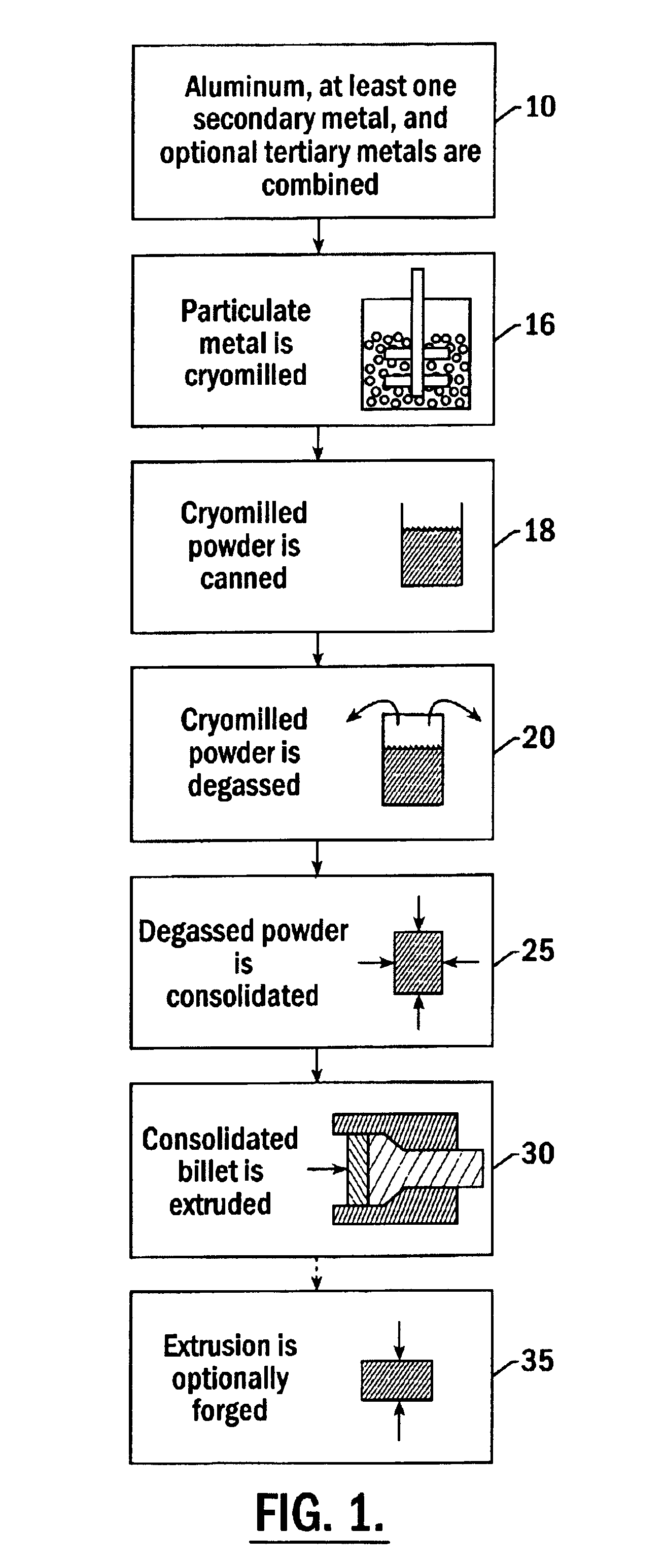

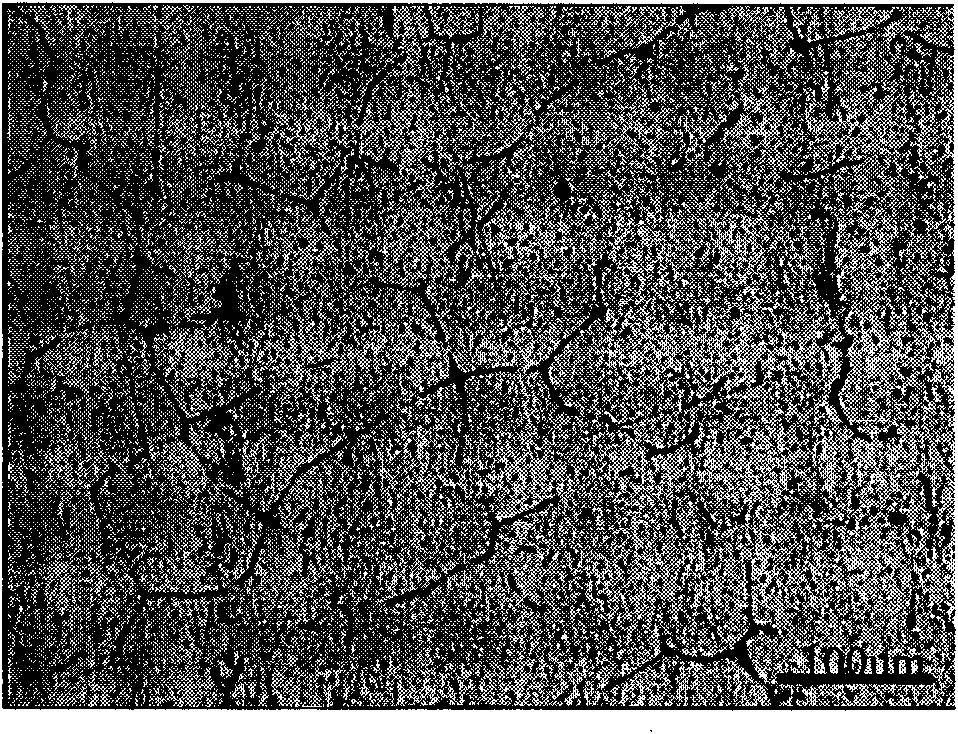

Method for preparing cryomilled aluminum alloys and components extruded and forged therefrom

InactiveUS6902699B2Stable structureHigh strengthTransportation and packagingMetal-working apparatusNanostructureAluminium alloy

High strength aluminum alloy powders, extrusions, and forgings are provided in which the aluminum alloys exhibit high strength at atmospheric temperatures and maintain high strength and ductility at extremely low temperatures. The alloy is produced by blending about 89 atomic % to 99 atomic % aluminum, 1 atomic % to 11 atomic % of a secondary metal selected from the group consisting of magnesium, lithium, silicon, titanium, zirconium, and combinations thereof, and up to about 10 atomic % of a tertiary metal selected from the group consisting of Be, Ca, Sr, Ba, Ra, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Y, Nb, Mo, Tc, Ru, Rh, Pd, Ag, Cd, W, and combinations thereof. The alloy is produced by nanostructure material synthesis, such as cryomilling, in the absence of refractory dispersoids. The synthesized alloy is then canned, degassed, consolidated, extruded, and optionally forged into a solid metallic component. Grain size within the alloy is less than 0.5 μm, and alloys with grain size less than 0.1 μm may be produced.

Owner:THE BOEING CO

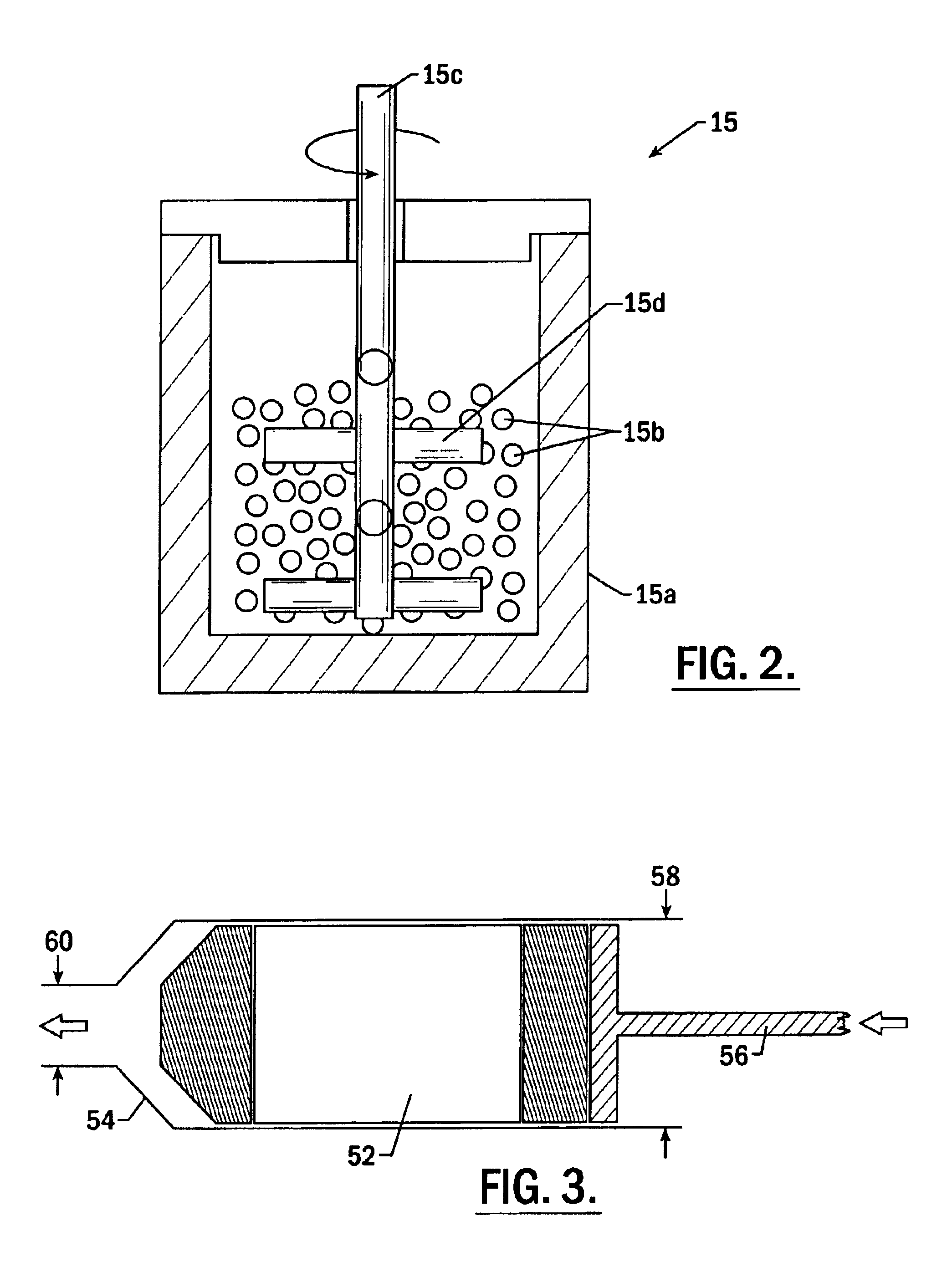

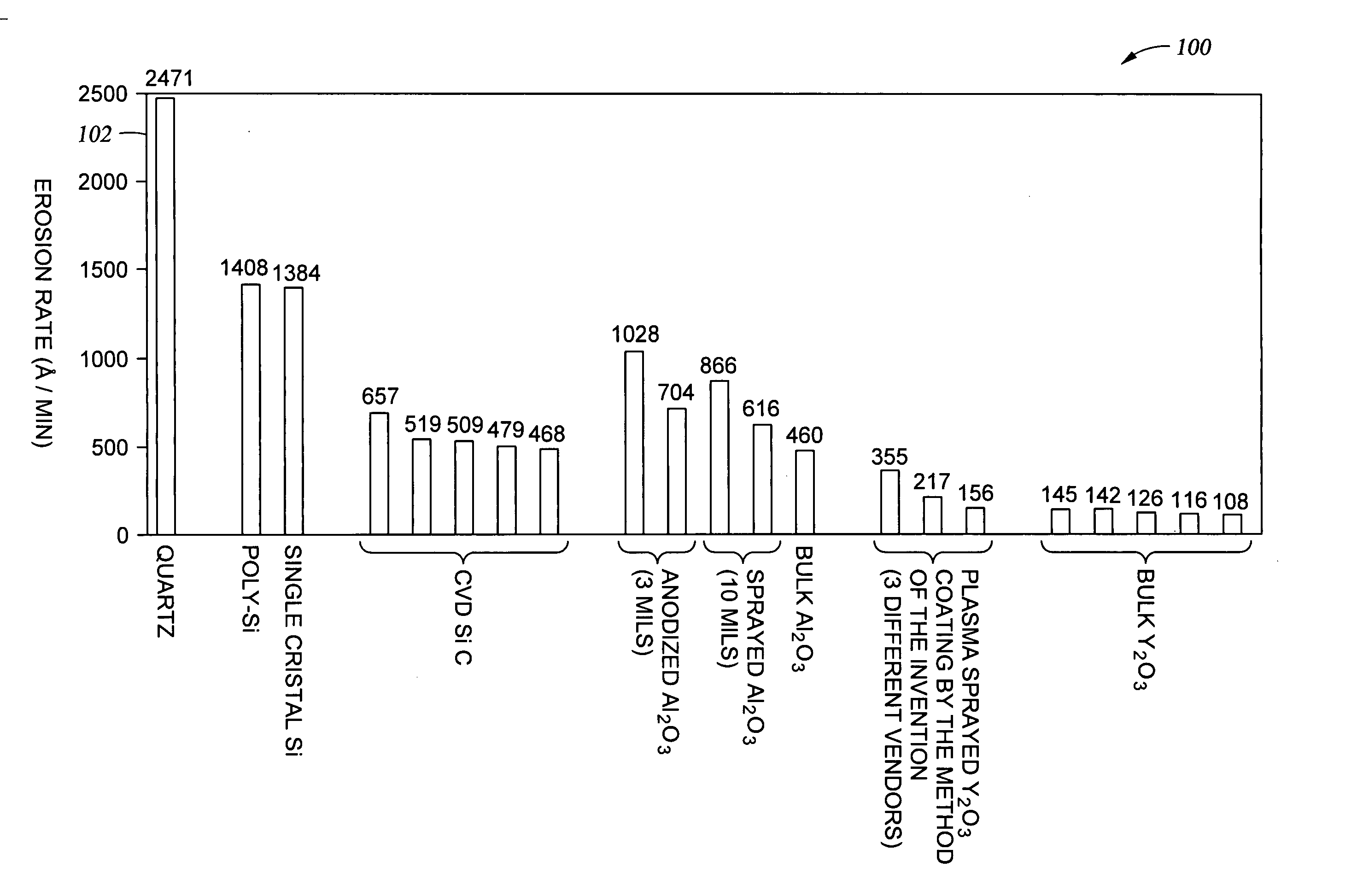

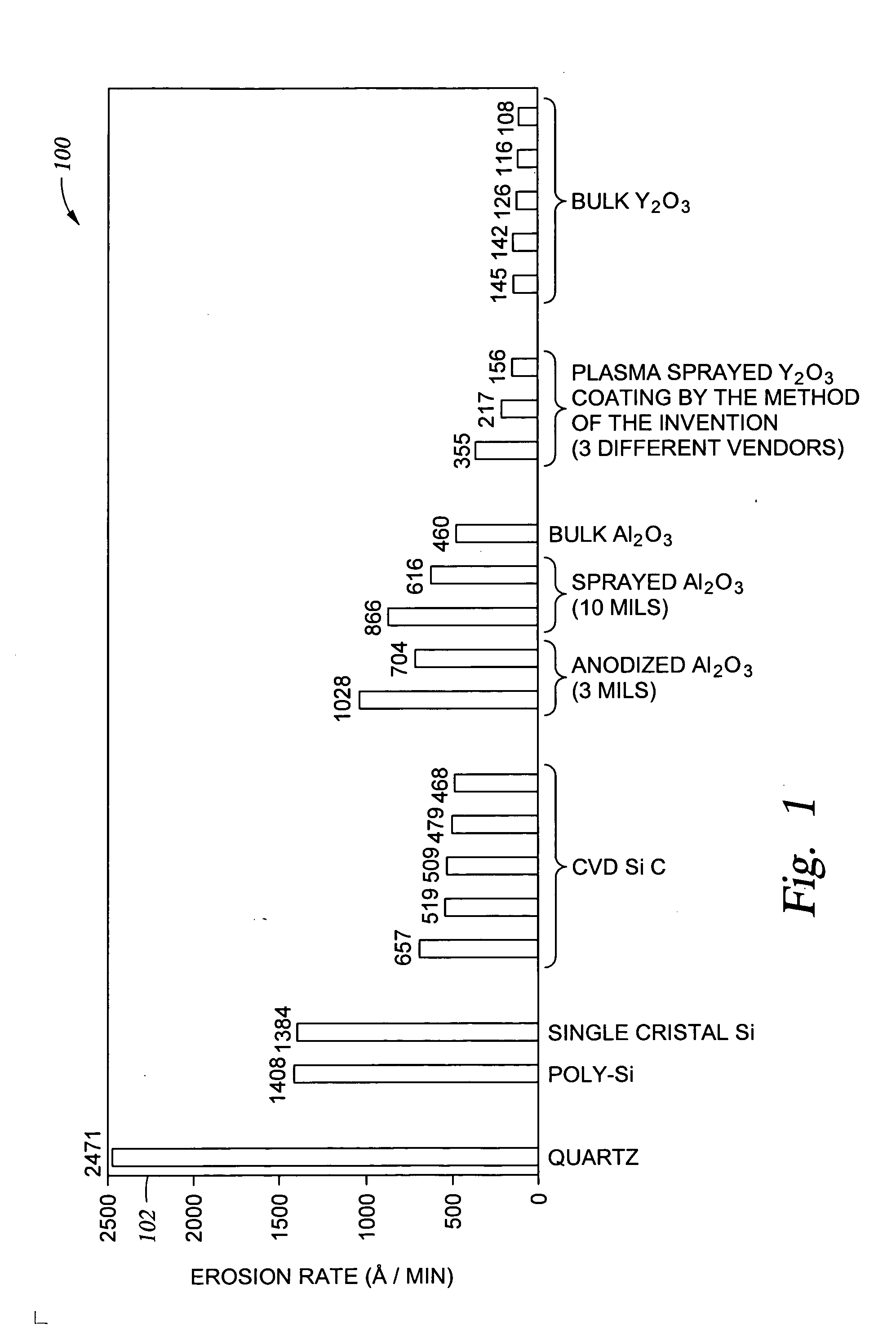

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

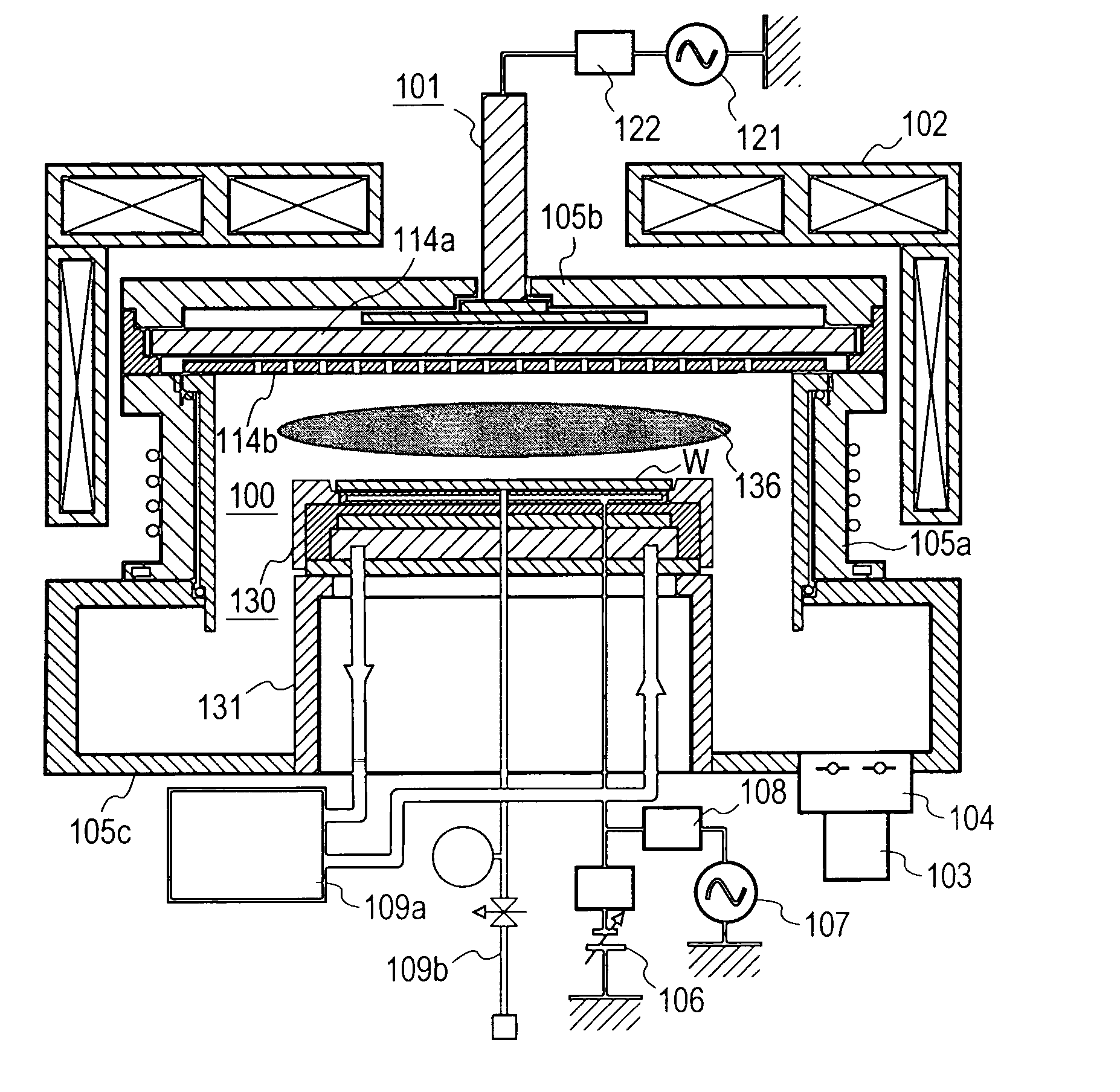

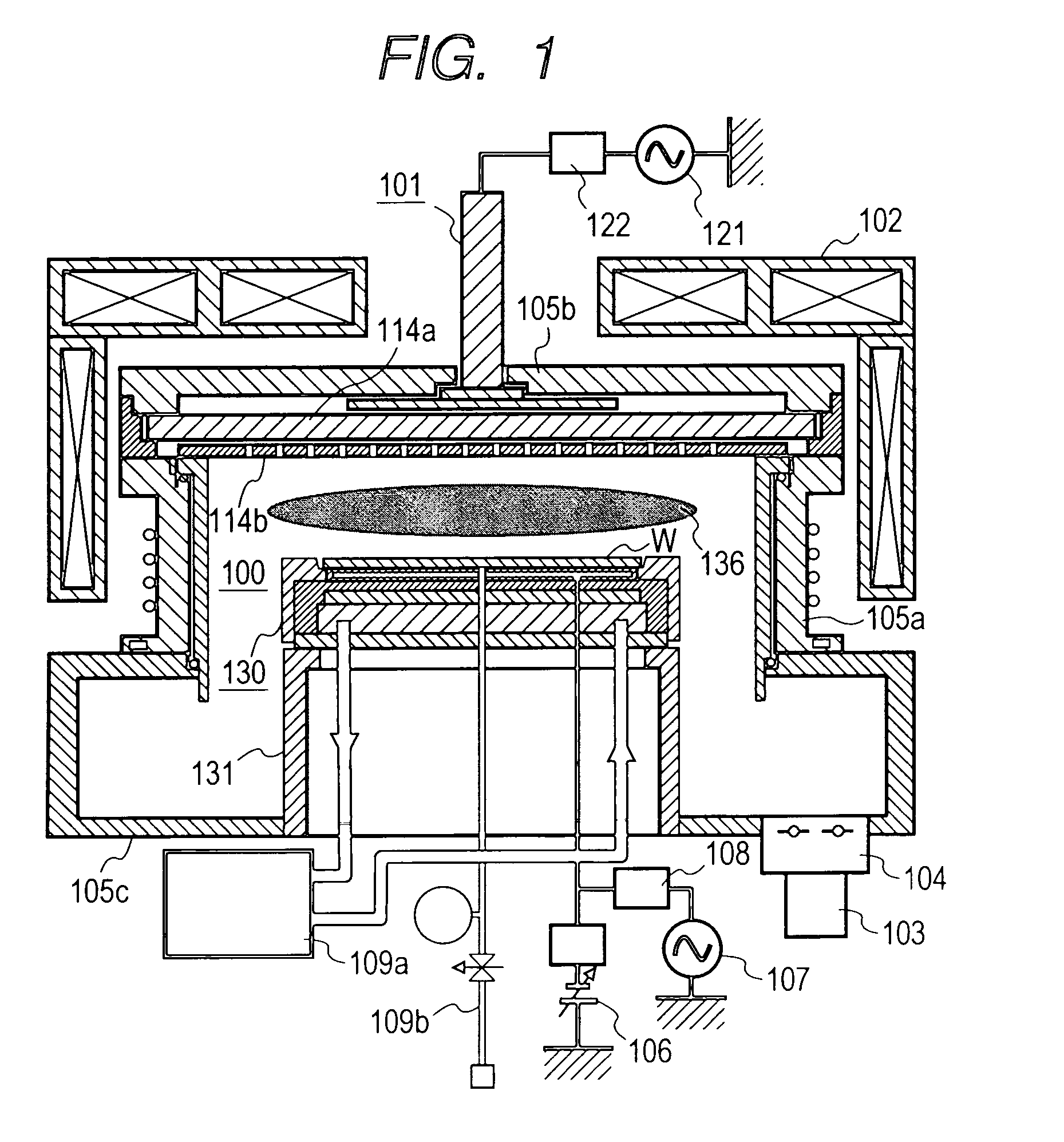

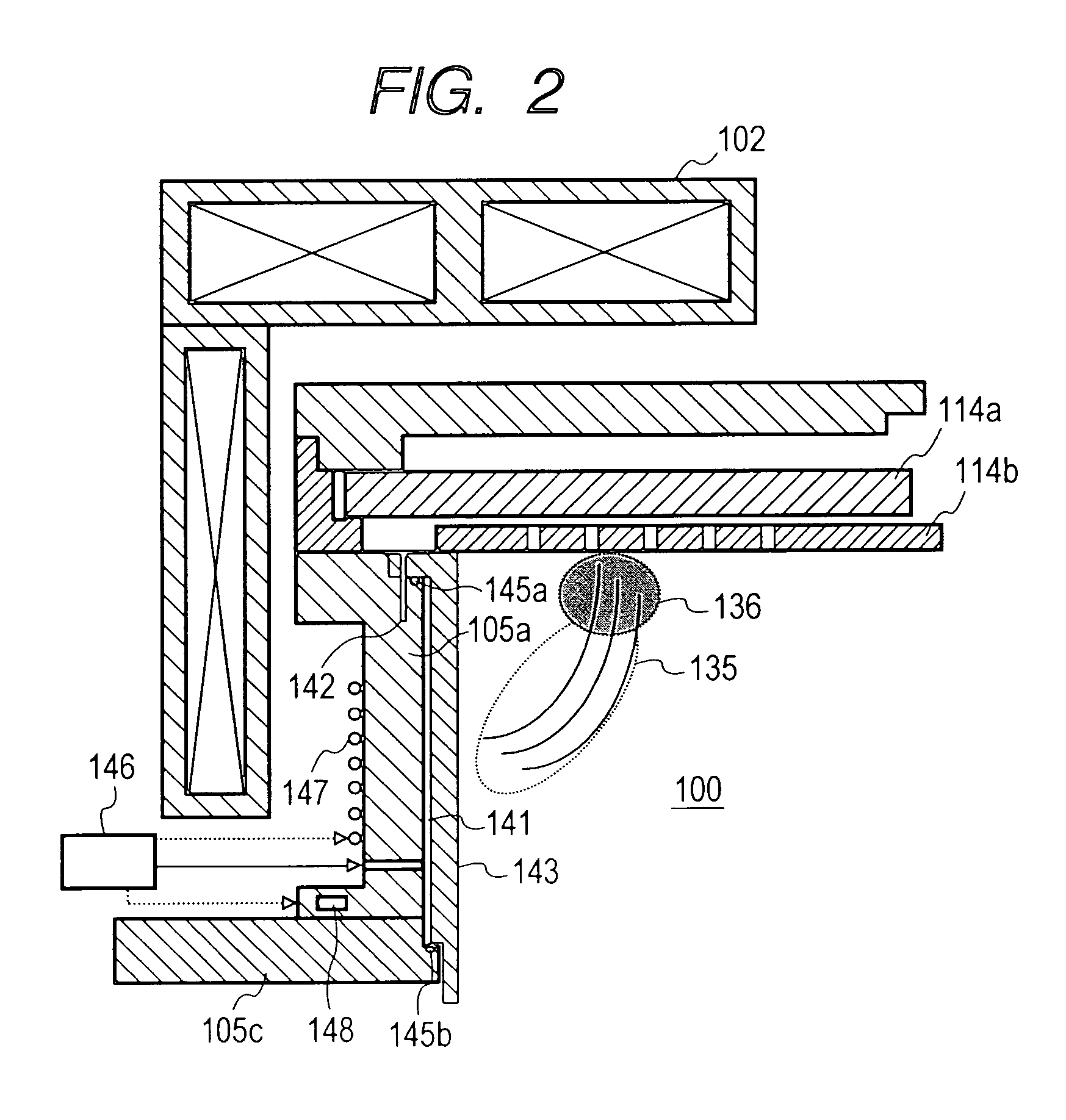

Plasma etching apparatus and method for forming inner wall of plasma processing chamber

InactiveUS20070215278A1Reduce corrosionDecreasing amountElectric discharge tubesSemiconductor/solid-state device manufacturingProduction rateHeat resistance

A plasma etching apparatus is provided which can prevent corrosion of an aluminum substrate constituting an etching processing chamber or an inside component thereof, thereby avoiding a reduction in productivity due to scattering of a sprayed coating. In the plasma etching apparatus, an anodic oxide film is disposed between a ceramic sprayed coating with excellent resistance to plasma, and the etching processing chamber and the inside component thereof made of aluminum alloy. The anodic oxide film has a thickness of 5 μm or less to have heat resistance.

Owner:HITACHI HIGH-TECH CORP

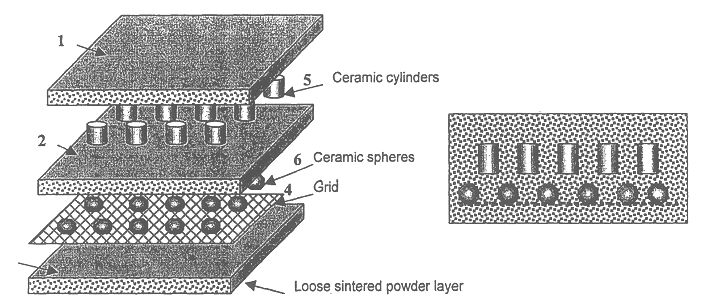

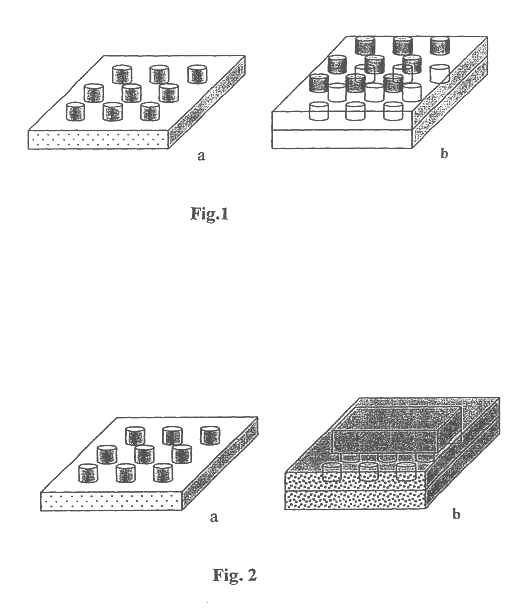

Bulletproof lightweight metal matrix macrocomposites with controlled structure and manufacture the same

InactiveUS6635357B2Stop crack propagation after bullet orPromote reproductionMilitary adjustmentWelding/cutting media/materialsPorosityMetal insert

The lightweight bulletproof metal matrix macrocomposites (MMMC) contain (a) 10-99 vol. % of permeable skeleton structure of titanium, titanium aluminide, Ti-based alloys, and / or mixtures thereof infiltrated with low-melting metal selected from Al, Mg, or their alloys, and (b) 1-90 vol. % of ceramic and / or metal inserts positioned within said skeleton, whereby a normal projection area of each of said inserts is equal to or larger than the cross-section area of a bullet or a projectile body. The MMMC are manufactured as flat or solid-shaped, double-layer, or multi-layer articles containing the same inserts or different inserts in each layer, whereby insert projections of each layer cover spaces between inserts of the underlying layer. The infiltrated metal contains 1-70 wt. % of Al and Mg in the balance, optionally, alloyed with Ti, Si, Zr, Nb, V, as well as with 0-3 wt. % of TiB2, SiC, or Si3N4 sub-micron powders, to promote infiltrating and wetting by Al-containing alloys. The manufacture includes (a) forming the permeable metal powder and inserts into the skeleton-structured preform by positioning inserts in the powder followed by loose sintering in vacuum to provide the average porosity of 20-70%, (b) heating and infiltrating the porous preform with molten infiltrating metal for 10-40 min at 450-750° C., (c) hot isostatic pressing of the infiltrated composite, and (d) re-sintering or diffusion annealing.

Owner:ADVANCED MATERIALS PRODS

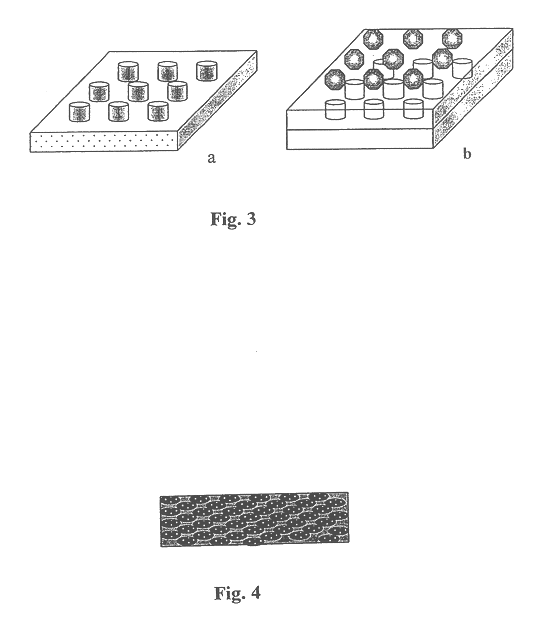

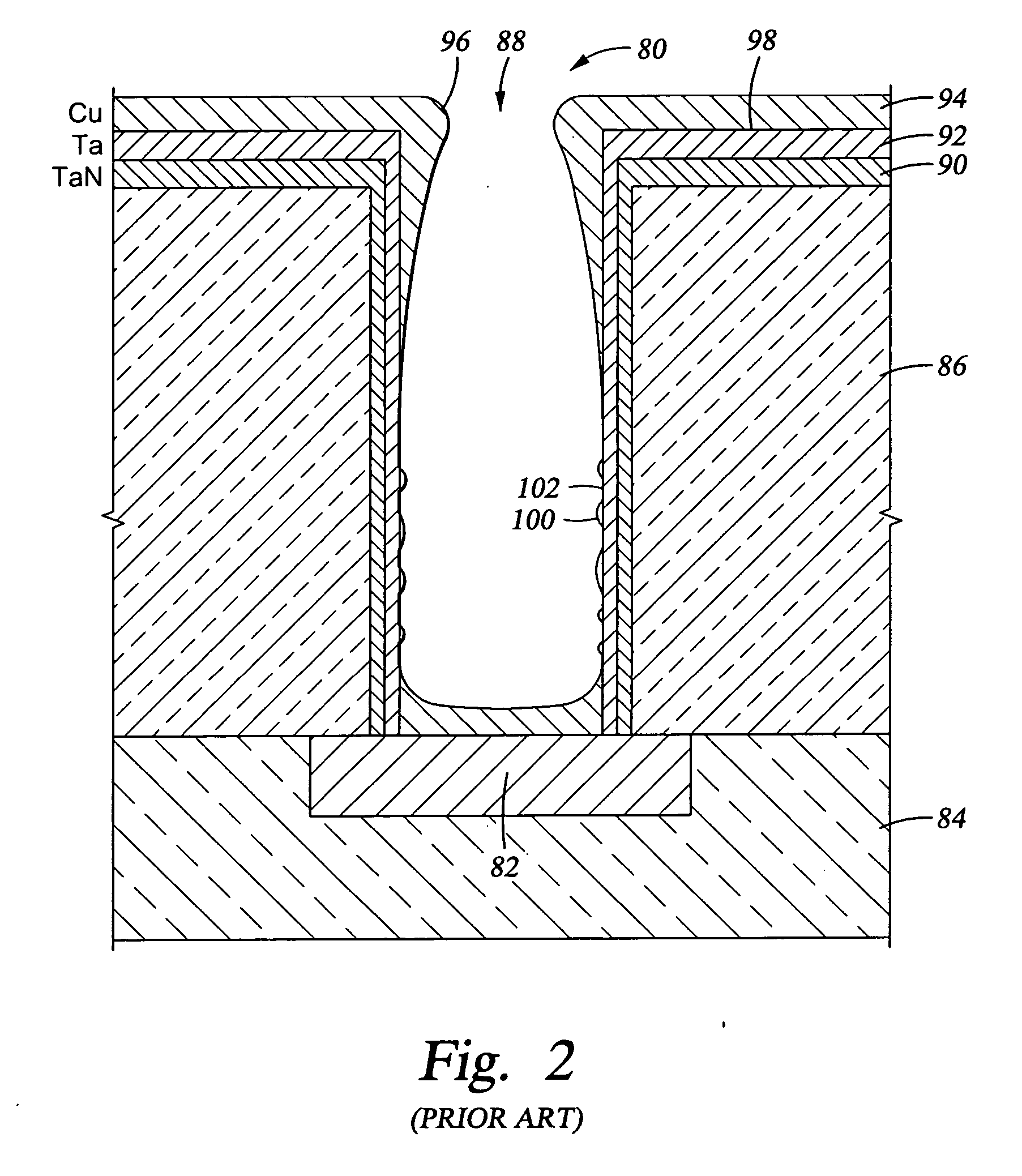

Integrated process for sputter deposition of a conductive barrier layer, especially an alloy of ruthenium and tantalum, underlying copper or copper alloy seed layer

InactiveUS20070059502A1Effective interfacial barrierGood suitSemiconductor/solid-state device detailsVacuum evaporation coatingMoisture barrierRefractory metals

A fabrication method and a product for the deposition of a conductive barrier or other liner layer in a vertical electrical interconnect structure. One embodiment includes within a a hole through a dielectric layer a barrier layer of RuTaN, an adhesion layer of RuTa, and a copper seed layer forming a liner for electroplating of copper. The ruthenium content is preferably greater than 50 at % and more preferably at least 80 at % but less than 95 at %. The barrier and adhesion layers may both be sputter deposited. Other platinum-group elements substitute for the ruthenium and other refractory metals substitute for the tantalum. Aluminum alloying into RuTa when annealed presents a moisture barrier. Copper contacts include different alloying fractions of RuTa to shift the work function to the doping type.

Owner:APPLIED MATERIALS INC

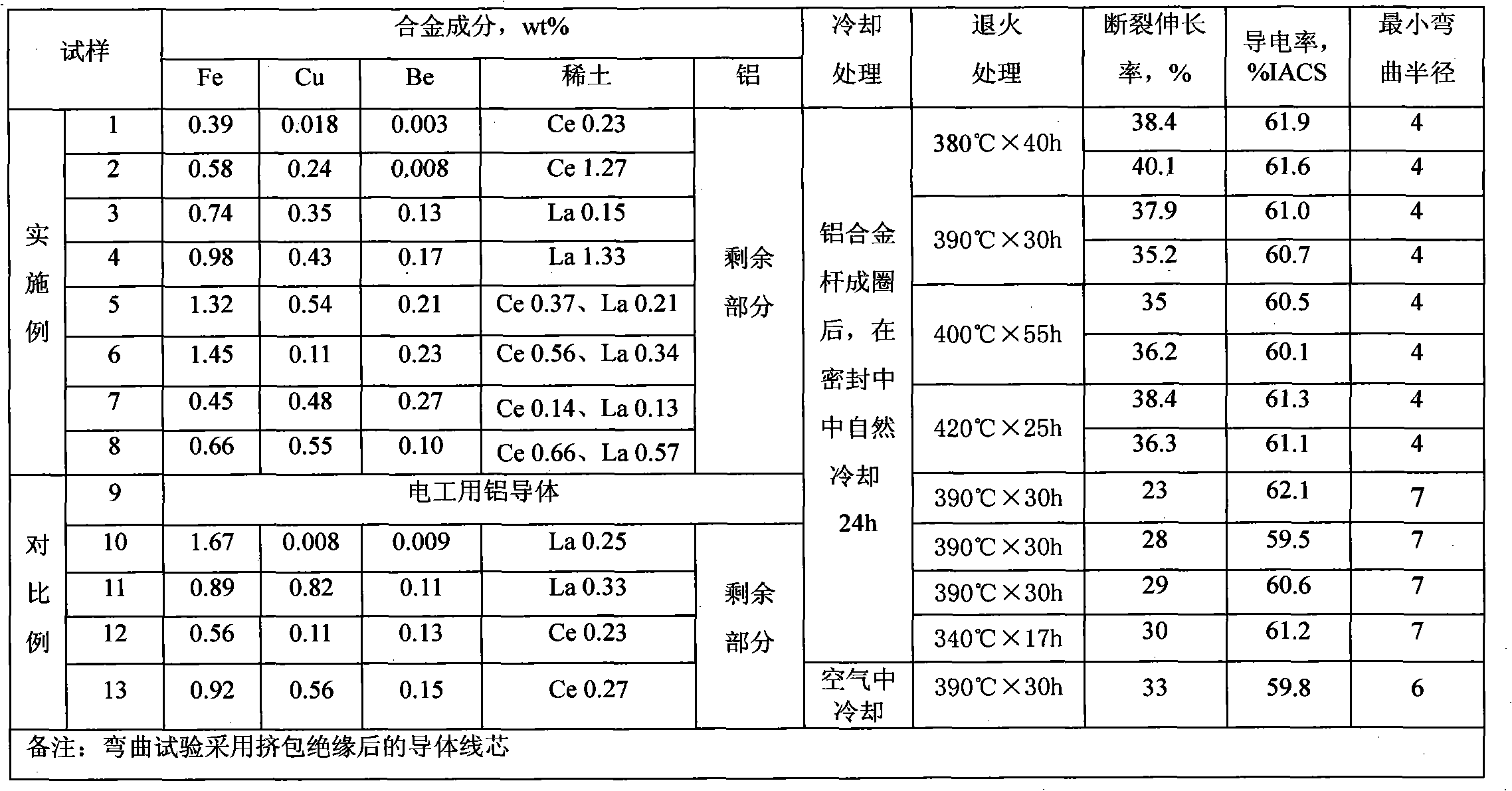

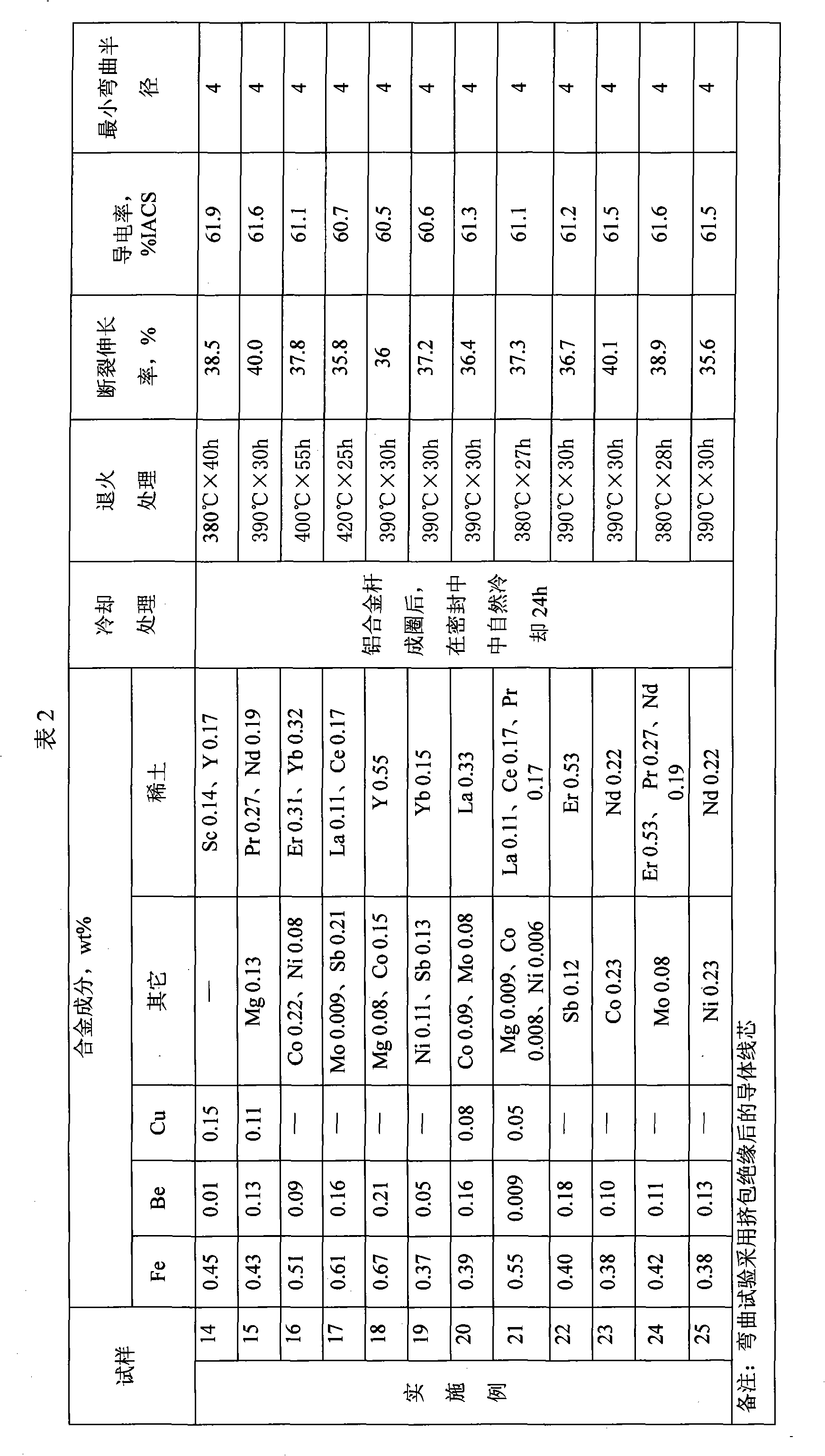

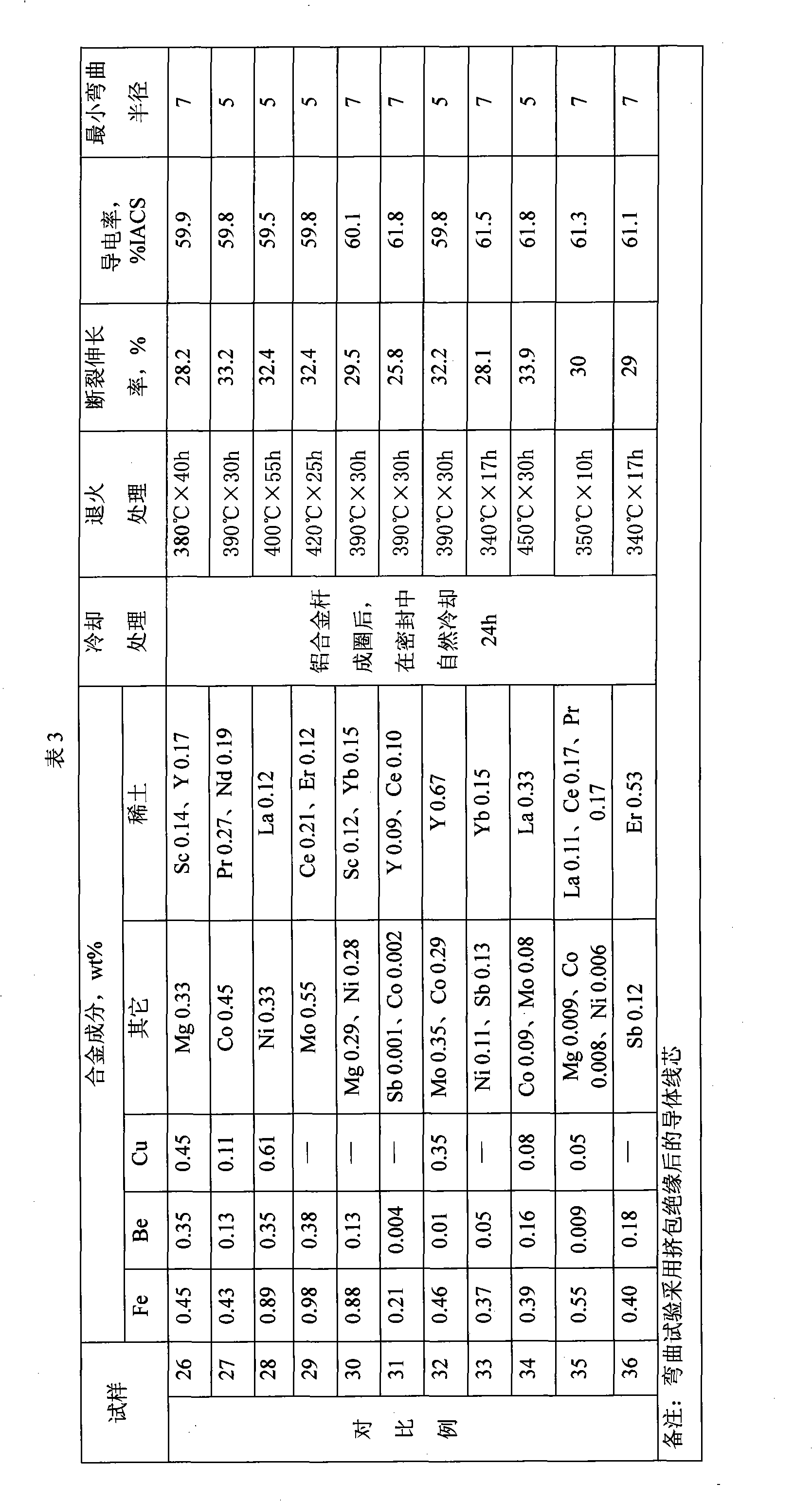

Super-soft aluminum alloy conductor and preparation method thereof

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

Corrosion resistant component of semiconductor processing equipment and method of manufacturing thereof

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber includes a metal surface such as aluminum or aluminum alloy, stainless steel, or refractory metal coated with a phosphorus nickel plating and an outer ceramic coating such as alumina, silicon carbide, silicon nitride, boron carbide or aluminum nitride. The phosphorus nickel plating can be deposited by electroless plating and the ceramic coating can be deposited by thermal spraying. To promote adhesion of the ceramic coating, the phosphorus nickel plating can be subjected to a surface roughening treatment prior to depositing the ceramic coating.

Owner:LAM RES CORP

Surface anti-corrosion sol for aeronautic aluminum alloy material and treatment method thereof

The invention discloses surface anti-corrosion sol for an aeronautic aluminum alloy material and a treatment method thereof in the technical field of aluminum alloy surface treatment. The sol comprises the following components in percentage by weight: 1-15 percent of organosiloxane, 45-93 percent of organic solvent, 0.1-10 percent of additive, 0.5-10 percent of rare earth salt, 5-50 percent of deionized water and 0.1-5 percent of catalyst. In the invention, a coating with a compact netlike crosslinking structure is formed on the surface of an aluminum alloy matrix and has high chemical stability and thermal stability, so that influence of an external acidic and alkaline environment and temperature variation on the coating can be resisted; and the coating has higher mechanical strength, rain washing resistance, friction resistance and scratch resistance. The technical method is simple, is easy and convenient to operate, does not have high requirement on equipment and is environmentally-friendly and pollution-free.

Owner:SHANGHAI JIAO TONG UNIV +1

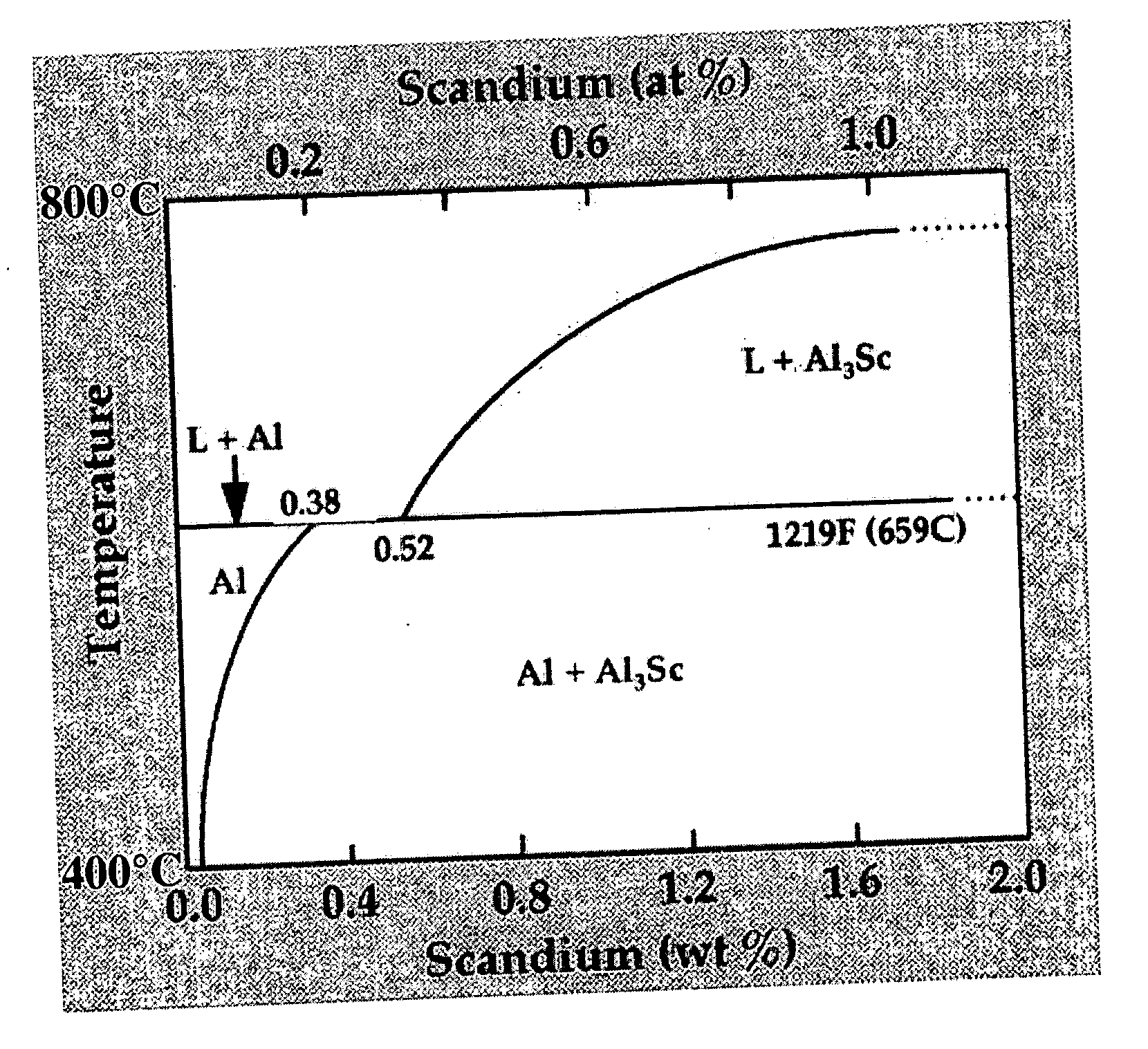

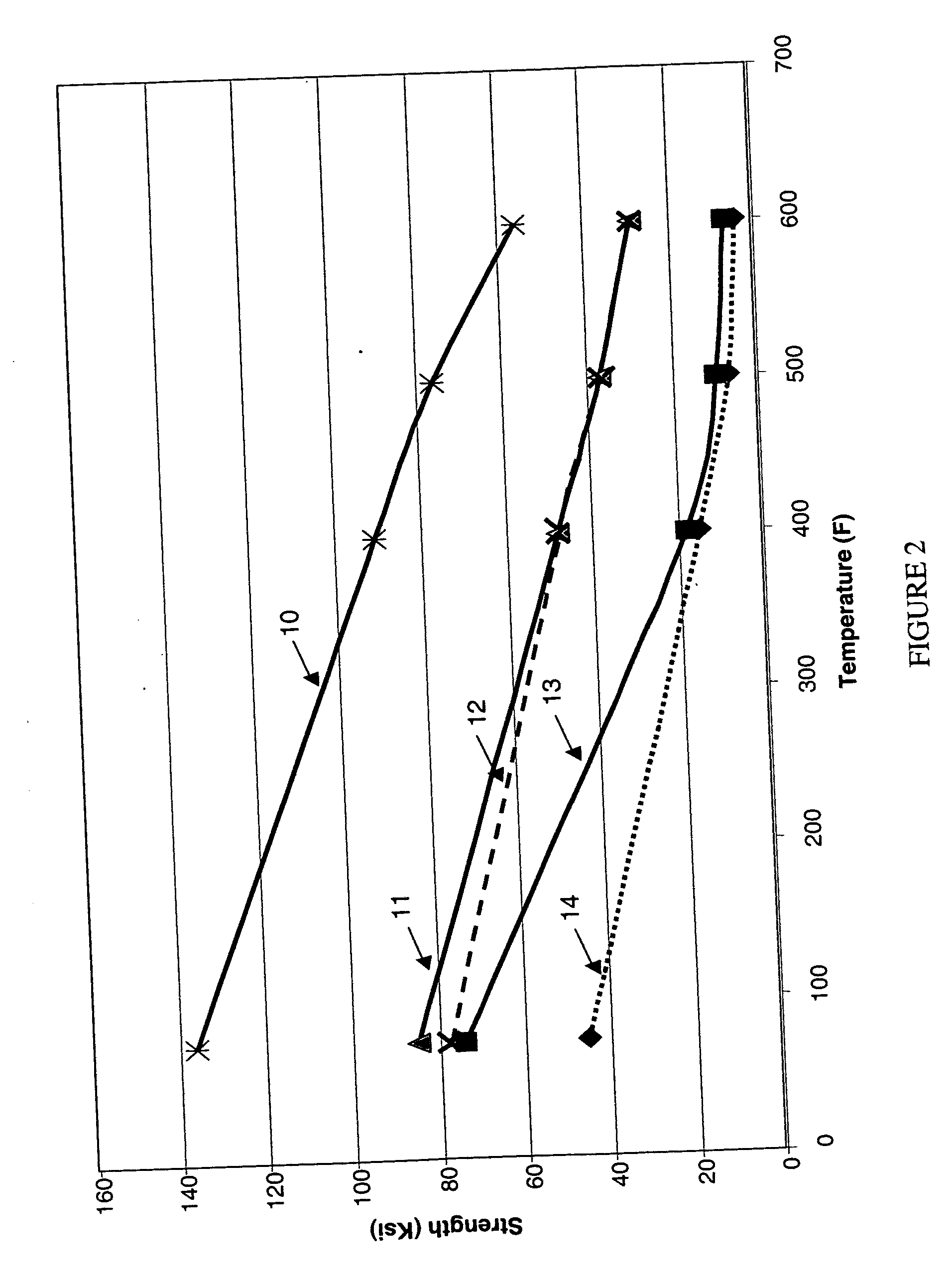

High temperature aluminum alloys

High temperature aluminum alloys that can be used at temperatures from about −420° F. (−251° C.) up to about 650° F. (343° C.) are described herein. These alloys comprise aluminum; scandium; at least one of nickel, iron, chromium, manganese and cobalt; and at least one of zirconium, gadolinium, hafnium, yttrium, niobium and vanadiuim. These alloys comprise an aluminum solid solution matrix and a mixture of various dispersoids. These alloys are substantially free of magnesium.

Owner:RTX CORP

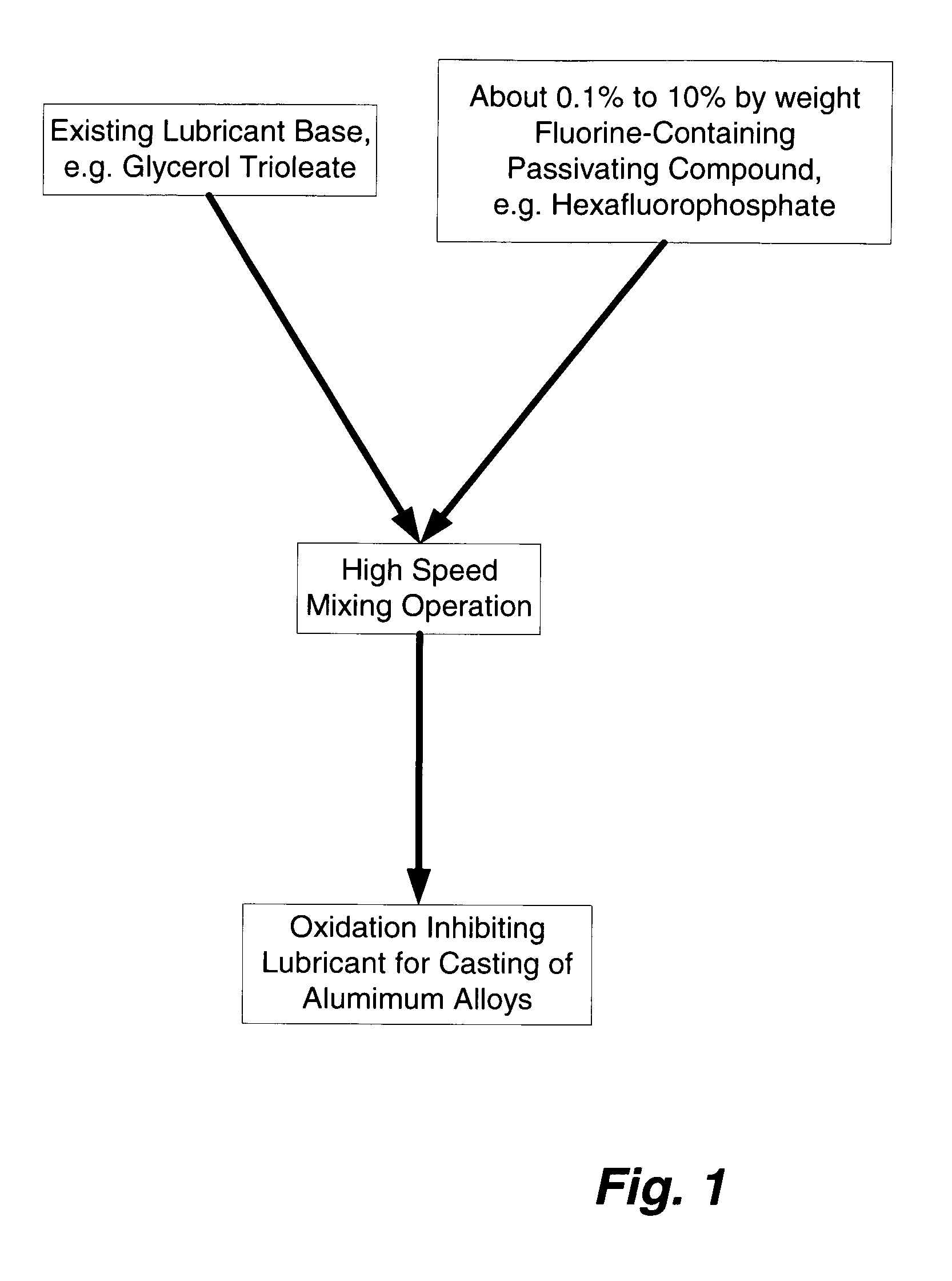

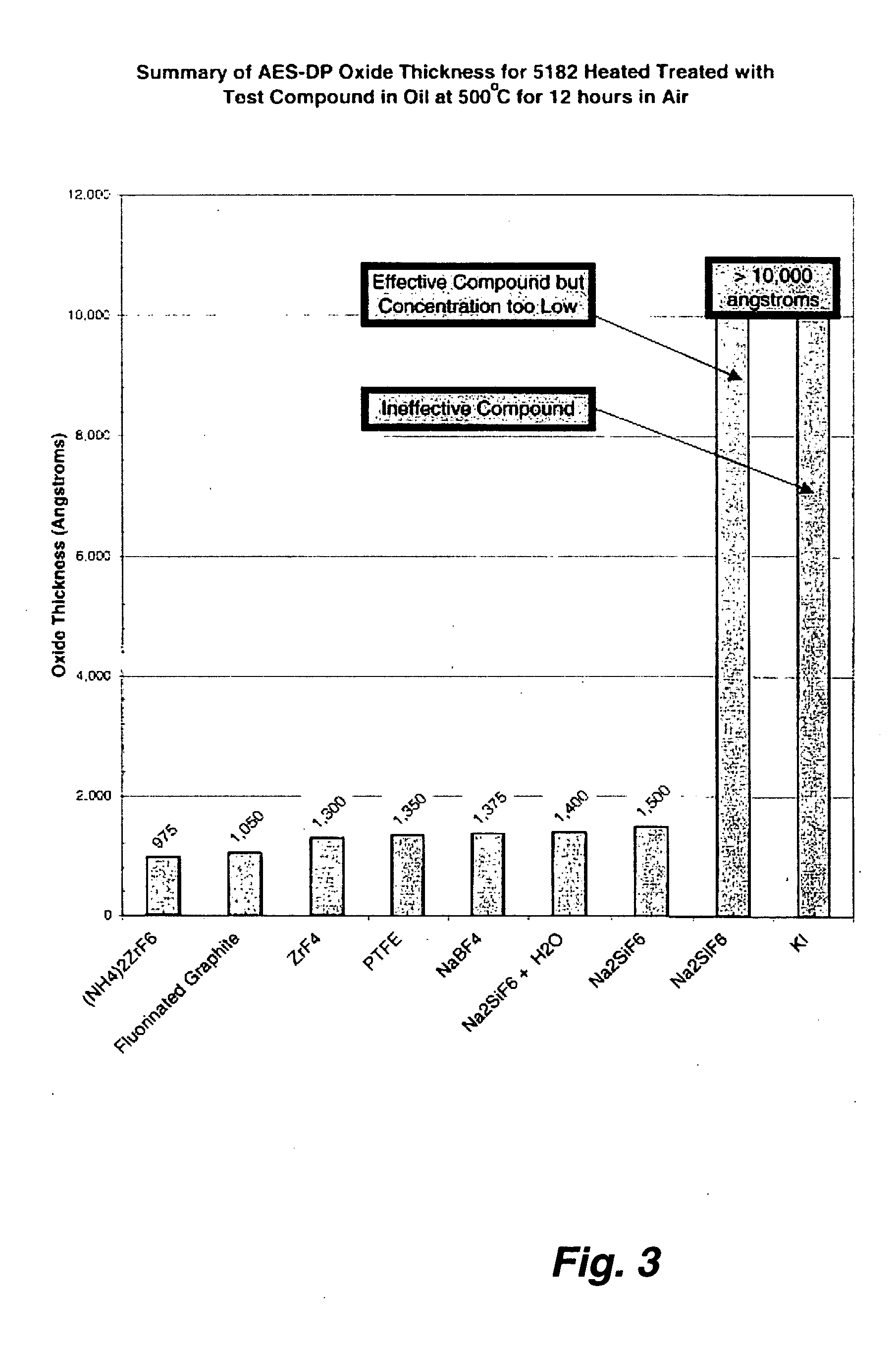

Lubricant for improved surface quality of cast aluminum and method

InactiveUS20050043189A1Reduce oxidationProtect the surfaceSnowboard bindingsSkisEmulsionOxidation resistant

In an oxidation inhibiting lubricant composition suitable for use in the manufacture of aluminum alloys comprising lubricant base selected from the group consisting of solid lubricants, liquid lubricants, grease lubricants, emulsion lubricants, and dispersion lubricants, the improvement wherein the lubricant composition further comprises: an effective amount of a fluorine-containing passivating compound.

Owner:ARCONIC INC

Golf club head with center of gravity adjustability

ActiveUS8956244B1Optimize locationIncrease heightGolf clubsRacket sportsMetallic materialsEngineering

A golf club head comprising an adjustable weighting feature including a tube extending from the crown to the sole of the golf club head is disclosed herein. More specifically, a golf club head formed from three pieces, namely a first piece comprising a face, a crown portion, a sole portion, and a hosel, a second piece comprising a rear end, a crown portion, and a sole portion, and a tube, wherein these pieces are welded to one another, is disclosed herein. Each of these pieces may be separately cast, forged, or formed from a metal material such as stainless steel, titanium alloy, and aluminum alloy.

Owner:TOPGOLF CALLAWAY BRANDS CORP

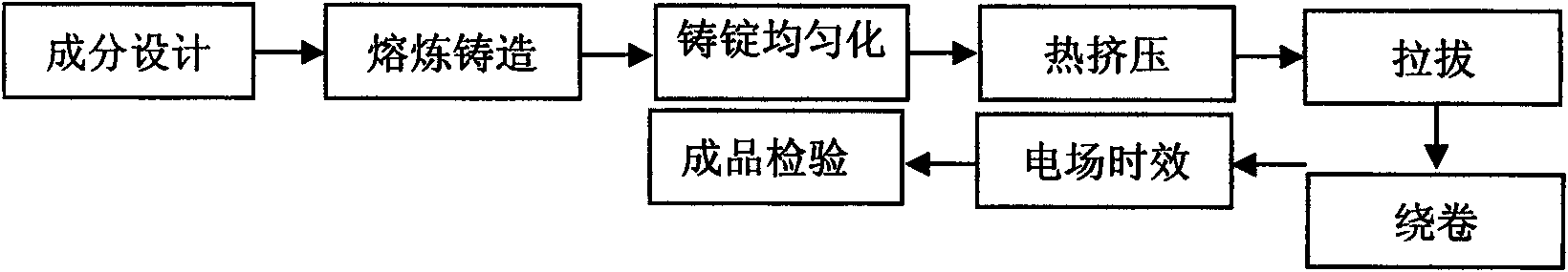

Aluminum alloy lead with lanthanon yttric and preparation method thereof

ActiveCN101587757AImprove conductivityHigh strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare earthTime effect

The invention discloses an aluminum alloy lead with lanthanon yttric and preparation method thereof. The specific component and weight percentage of the invention are Si0.5%-0.7%, Mg0.6%-0.9%, Fe 0.1%-0.2%, Y 0.2%-0.8%, Al residue. The preparation method is following: preparing the elements according to the alloy design to prepare aluminum alloy wire material via melting, casting, homogenization, extrusion and wire drawing, preparing the cables via winding to obtain the aluminum alloy lead with great intensity and conduction via the electric field time effect heat treatment. The aluminum alloy lead with high intensity of the invention adds the lanthanon yttric to purify the melting body and reduce the silicon quantity in the alloy further enhance the conductive rate of the melting on the one hand; on another hand to thin the crystal grain and enhance intensity of the alloy wire; the generatrix intending intensity is 260MPa and the conductive rate can achieve 57% IACS.

Owner:HUNAN XIANGNENG ELECTRIC WORKS

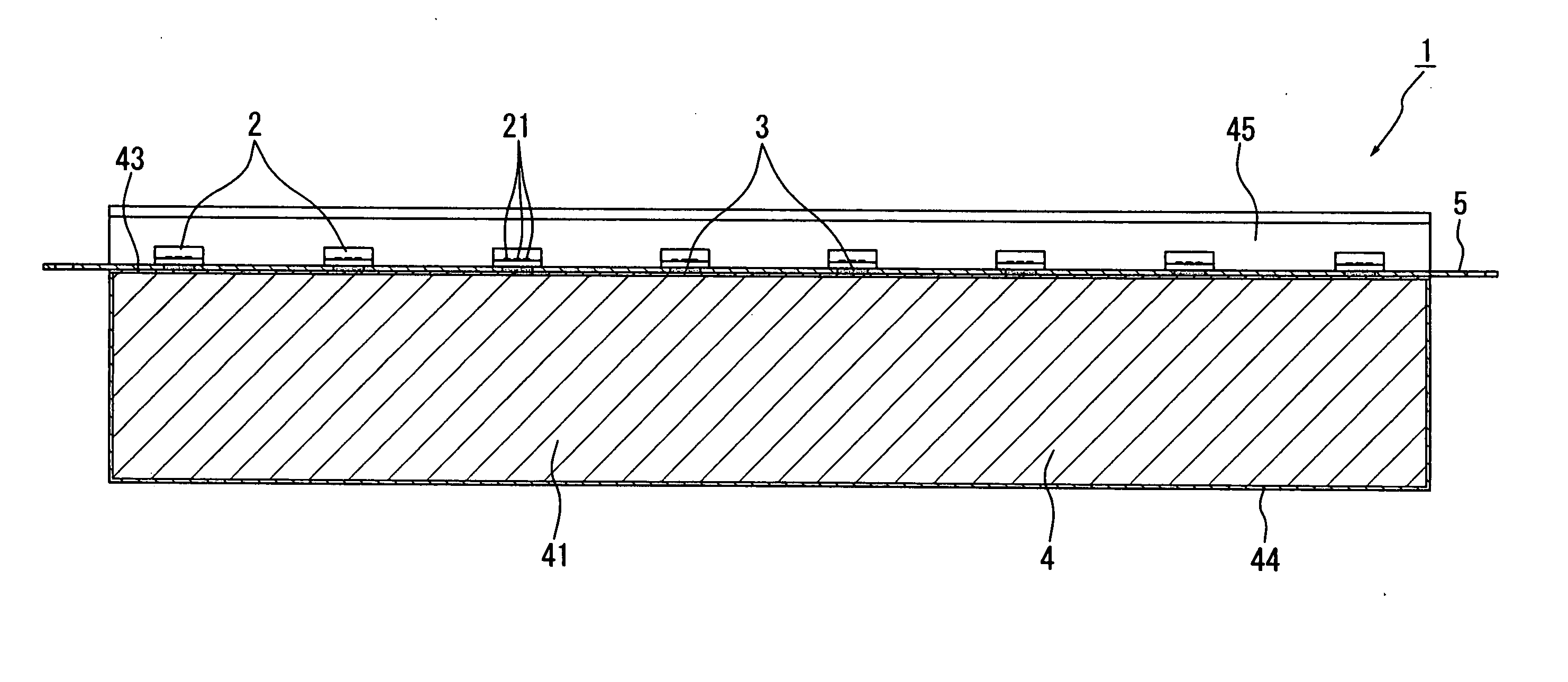

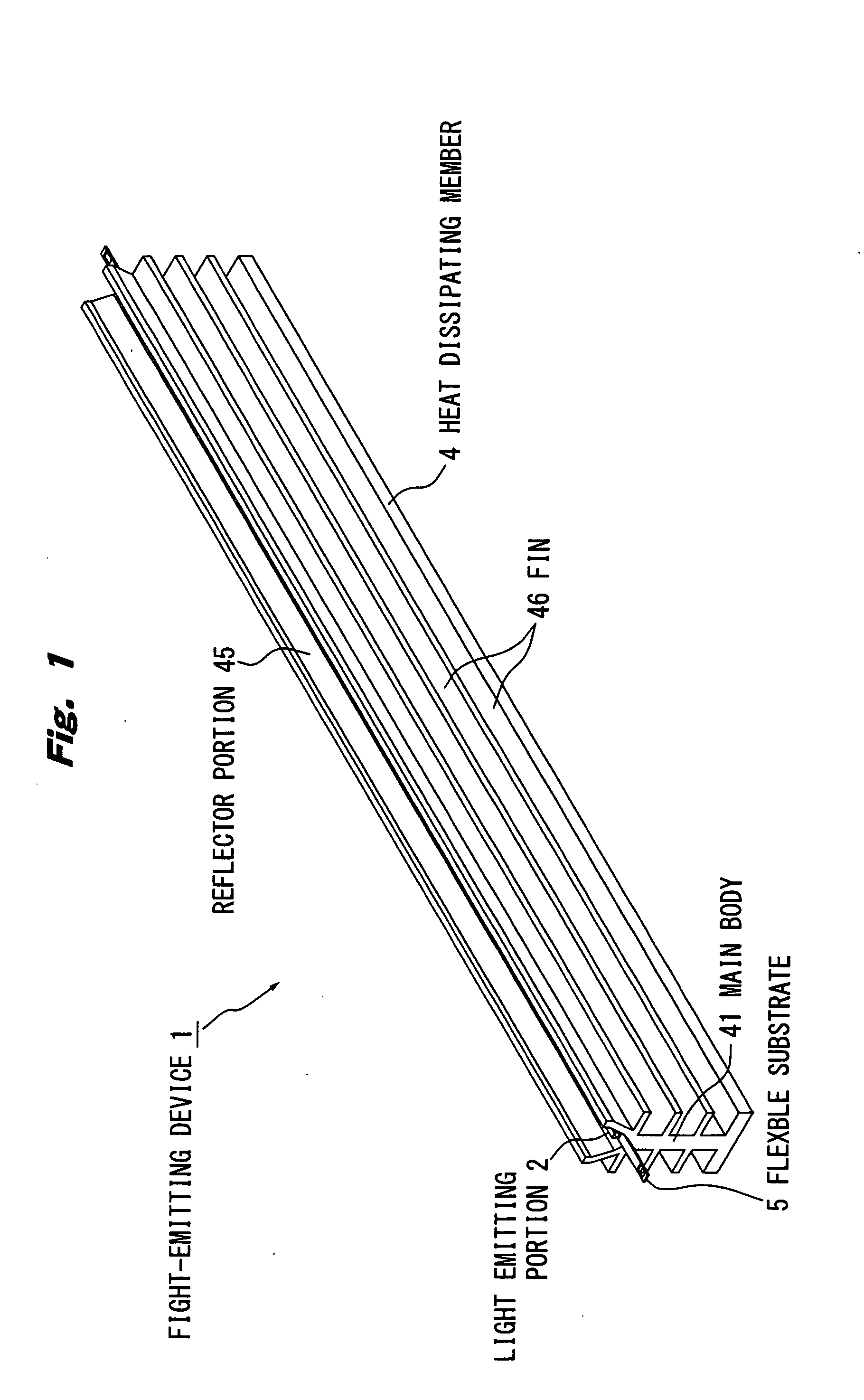

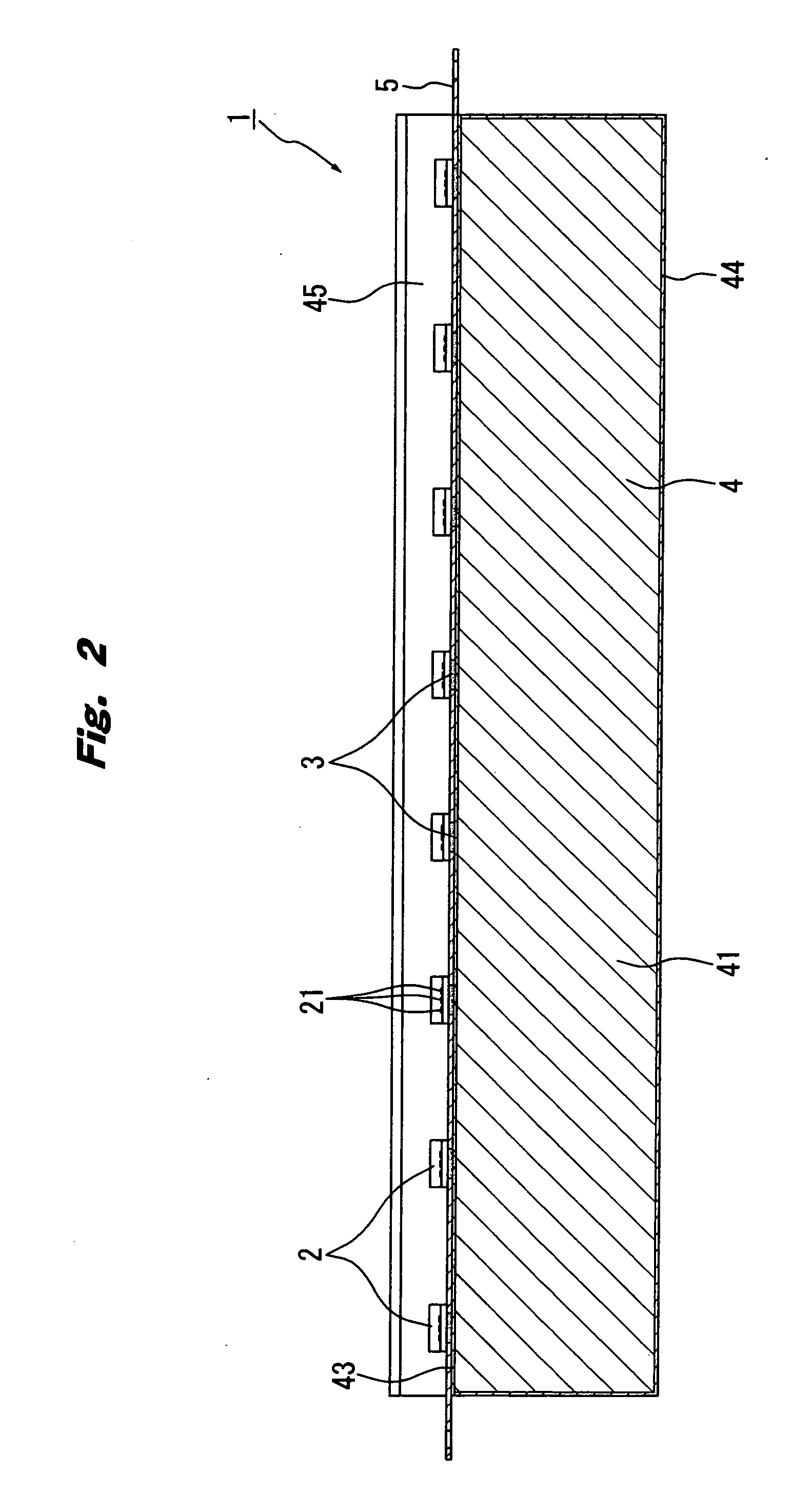

Light-emitting device and method of manufacturing the same

InactiveUS20100214777A1Increase the number ofImprove cooling efficiencyLighting support devicesPoint-like light sourceLight emitting deviceSemiconductor

A light-emitting device includes a light emitting portion comprising a substrate having a mounting surface for mounting a LED element and a metal portion formed on a surface of the substrate opposite to the mounting surface, the substrate comprising ceramic or a semiconductor and the metal portion being bondable to a solder material and a heat dissipating member comprising aluminum, aluminum alloy, magnesium or magnesium alloy, and having, on a surface thereof, a junction treated so as to be bondable to the solder material and a heat dissipating film formed in a periphery of the junction, wherein the metal portion of the light emitting portion is bonded to the junction of the heat dissipating member by the solder material.

Owner:TOYODA GOSEI CO LTD

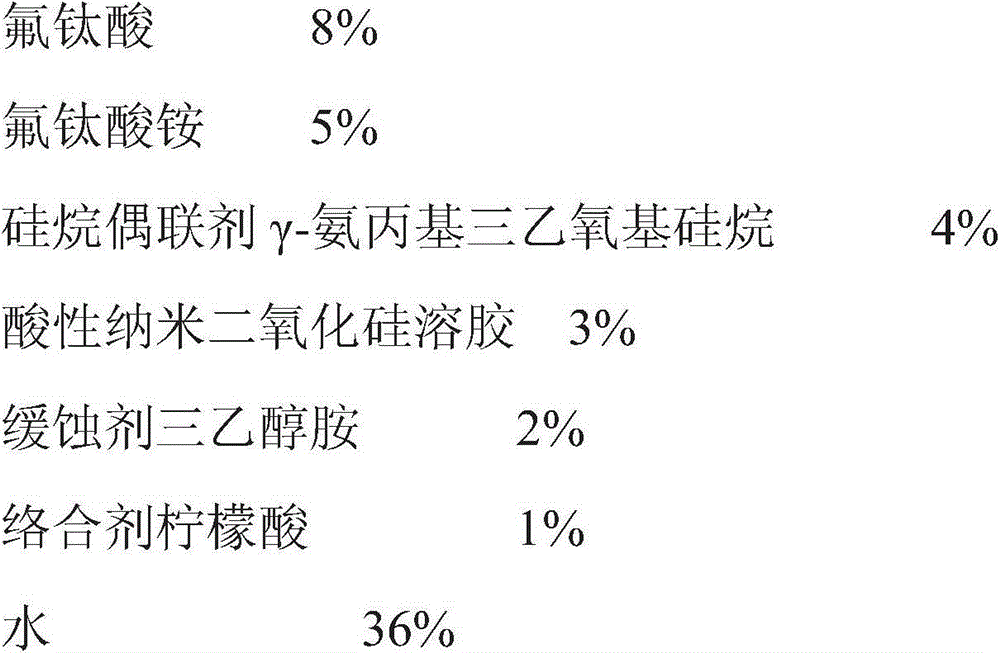

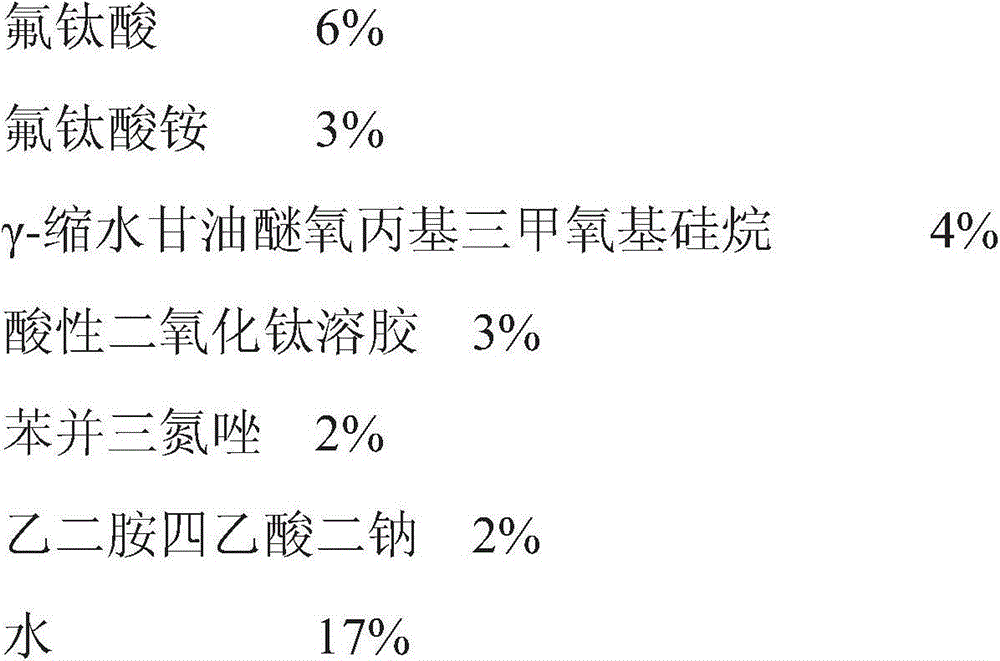

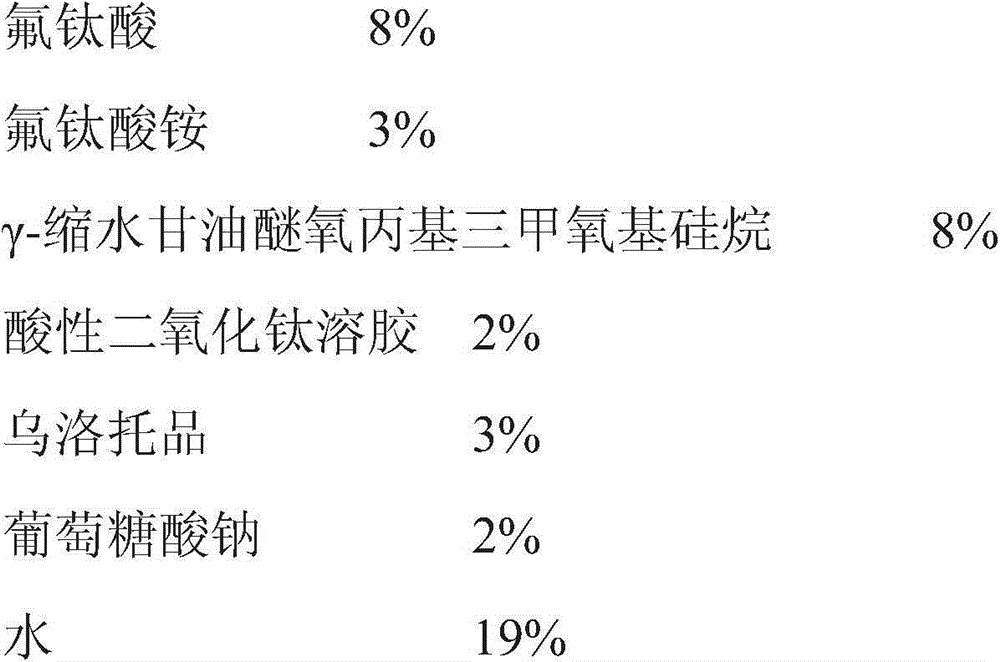

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

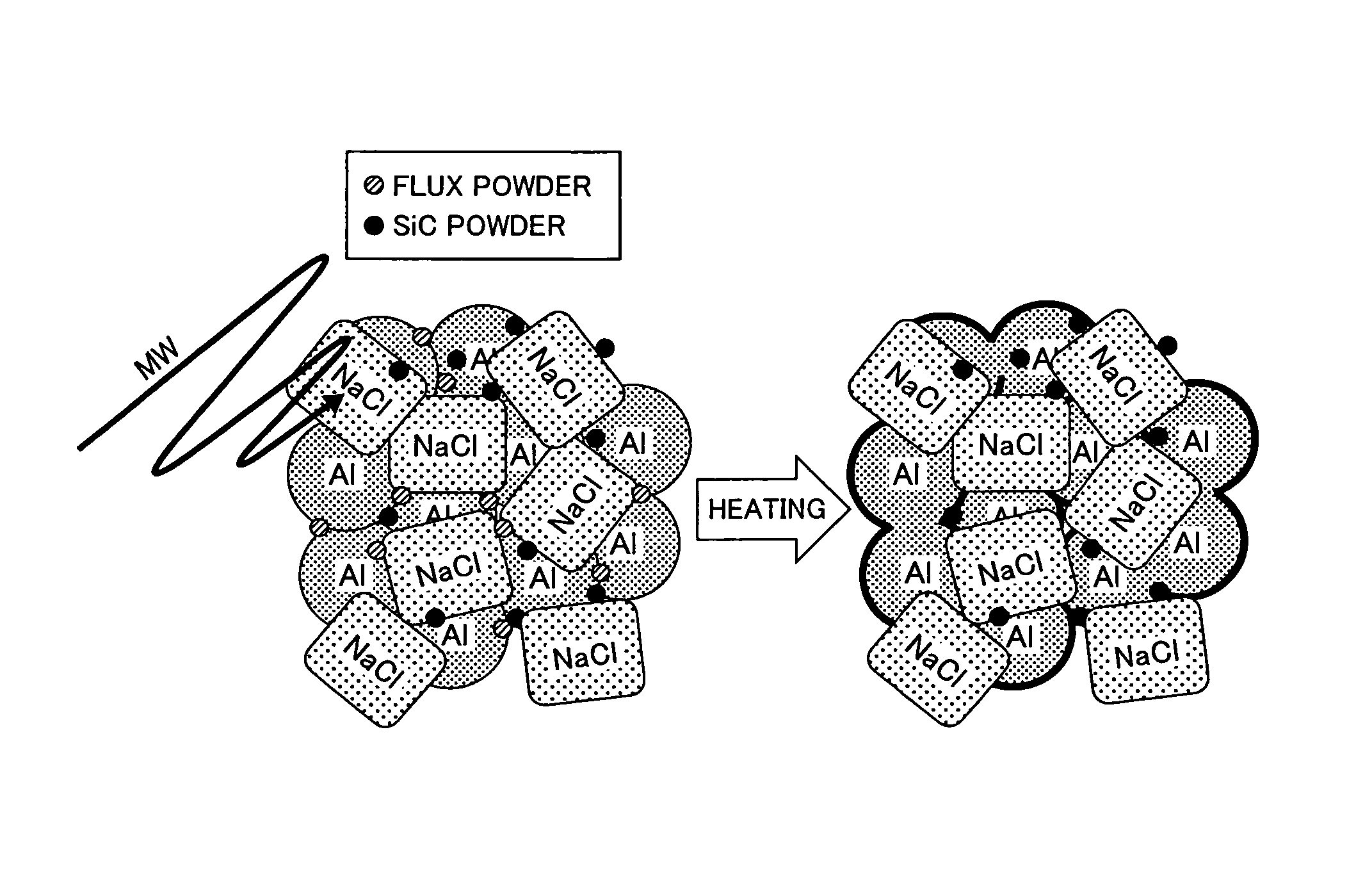

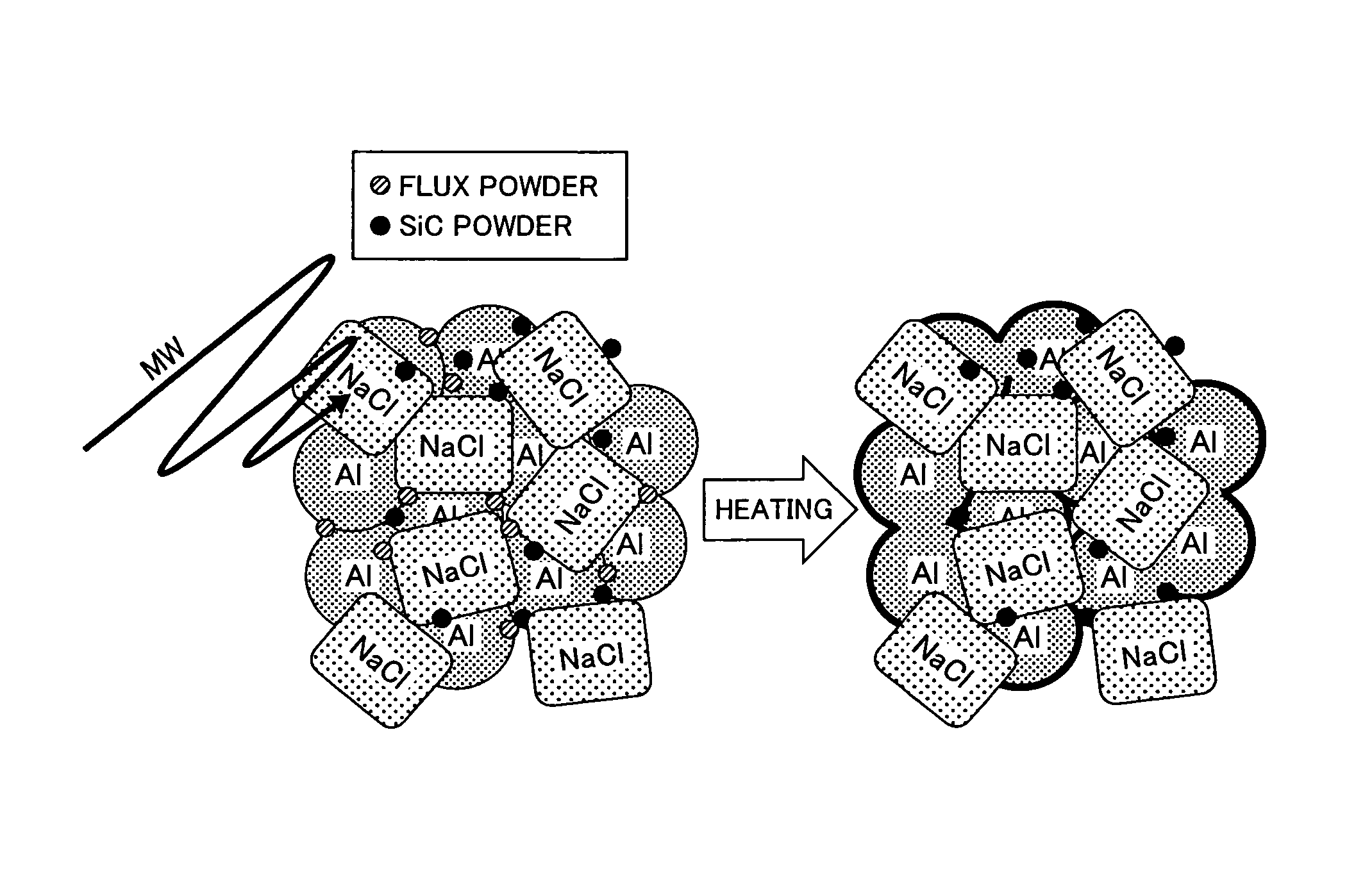

Aluminum porous body and fabrication method of same

It is an objective of the present invention to provide an aluminum porous body which is formed of a pure aluminum and / or aluminum alloy base material and has excellent sinterability and high dimensional accuracy without employing metal stamping. There is provided an aluminum porous body having a relative density of from 5 to 80% with respect to the theoretical density of pure aluminum, in which the aluminum porous body contains 50 mass % or more of aluminum (Al) and from 0.001 to 5 mass % of at least one selected from chlorine (Cl), sodium (Na), potassium (K), fluorine (F), and barium (Ba). It is preferred that the aluminum porous body further contains from 0.1 to 20 mass % of at least one selected from carbon (C), silicon carbide (SiC), iron (II) oxide (FeO), iron (III) oxide (Fe2O3), and iron (II,III) oxide (Fe3O4).

Owner:HITACHI LTD

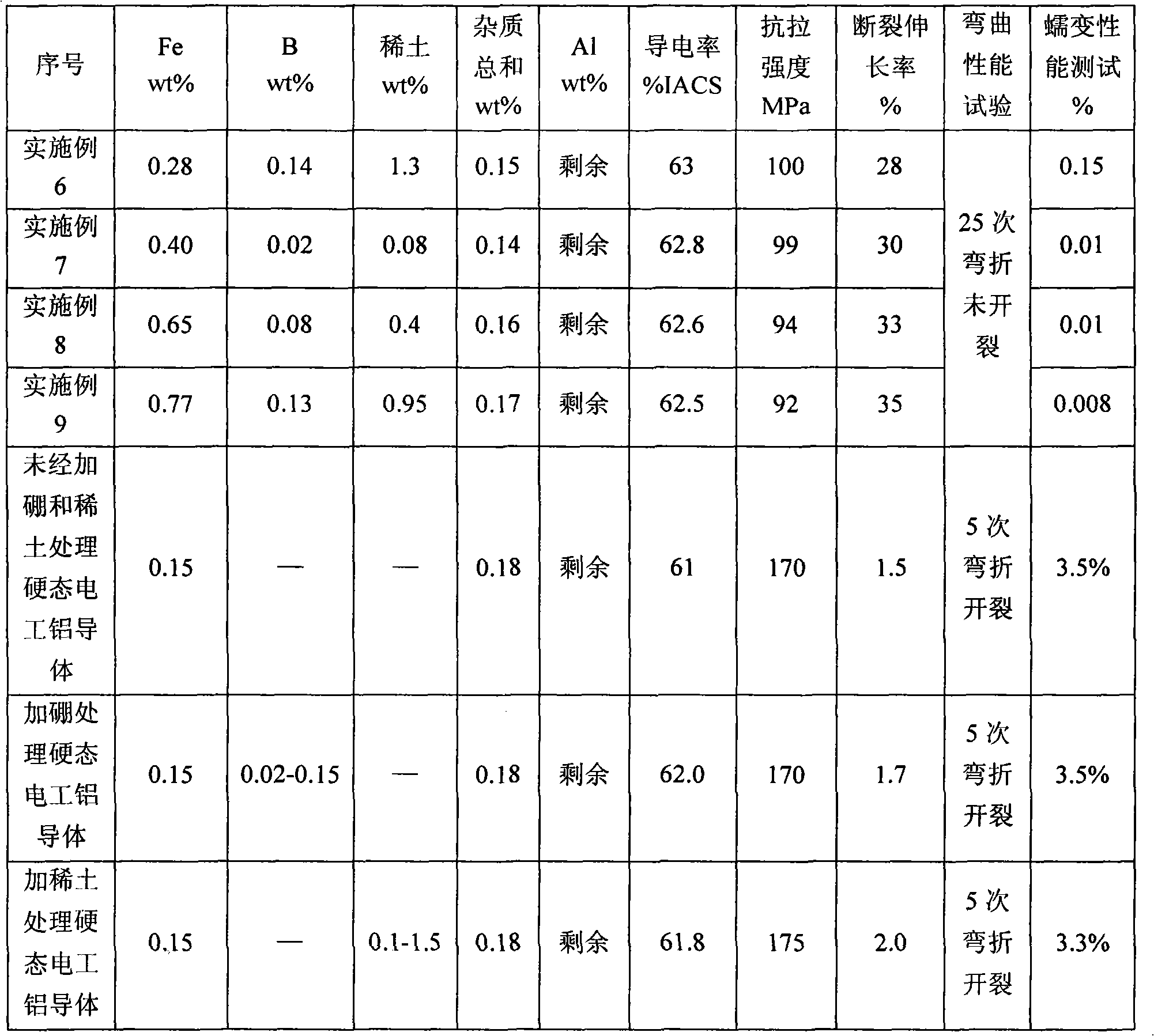

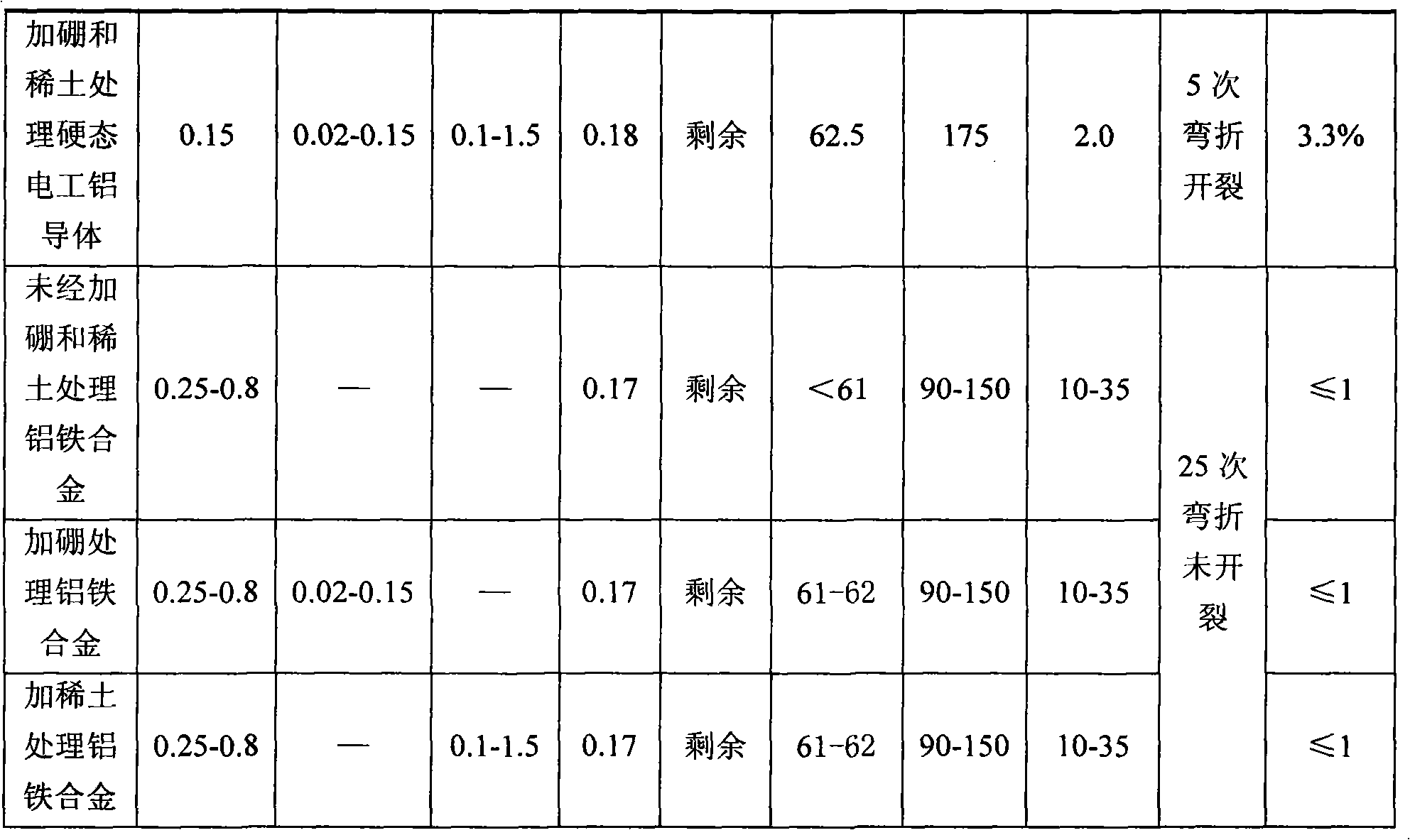

High-conductivity aluminum alloy material for cable and preparation method thereof

InactiveCN101886198ALittle impact on electrical performanceEasy to stretchMetal/alloy conductorsRare-earth elementPliability

The invention relates to a high-conductivity aluminum alloy material for a cable and a preparation method thereof. The aluminum alloy material comprises the following components in percentage by weight: 0.25-0.80 percent of iron element, 0.02-0.15 percent of boron element, 0.1-1.5 percent of rare earth element and the balance of aluminum and inevitable impurities. The aluminum alloy is formed by adding an aluminum alloy intermediate alloy, an aluminum-boron alloy and an aluminum-rare earth intermediate alloy into an aluminum ingot of which the purity is more than 99.80 percent by weight and carrying out a casting process and annealing treatment on the mixture. Compared with a common electric aluminum conductor, the prepared aluminum alloy conductor has more excellent conductive performance and the conductivity reaching or exceeding 62.5 percent IACS (International Annealed Copper Standard); the aluminum alloy conductor treated by using a special process has excellent flexibility and creep resistance; and compared with a common electric aluminum conductor, the prepared aluminum alloy material used as a cable extrusion insulating lead core is more energy-saving and safer.

Owner:ANHUI JOY SENSE CABLE

Resistance spot welding of steel to pre-coated aluminum

ActiveUS20140360986A1Low melting pointImprove the immunityWelding/soldering/cutting articlesResistance welding apparatusTitanium zirconiumConversion coating

Resistance spot welding of a steel workpiece to an aluminum or an aluminum alloy workpiece can be facilitated by replacing the refractory aluminum oxide-based layer(s) on at least the faying surface of the aluminum or aluminum alloy workpiece with a protective coating that is more conducive to the spot welding process. The protective coating may be a metallic coating or a metal oxide conversion coating. In a preferred embodiment, the protective coating is a coating of zinc, tin, or an oxide of titanium, zirconium, chromium, or silicon.

Owner:GM GLOBAL TECH OPERATIONS LLC

Emulsification type metal cutting liquor composition

InactiveCN101240218AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsPhenolCutting fluid

Disclosed is an emulsifying metal-cutting-fluid composition comprising base oil or oily agent, mixed alcohol-amine, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative and the like. The invention has a strong general usability, suitable for metal processing, particularly aluminum alloy metal processing with advantages of excellent lubricity, corrosion resistance, a low cost and being free of toxic or harmful substances such as nitrites and phenols, so as to keep the environment and operators away from harmfulness.

Owner:河北九熙新材料科技有限公司

7000 series aluminum alloy material and preparation method thereof

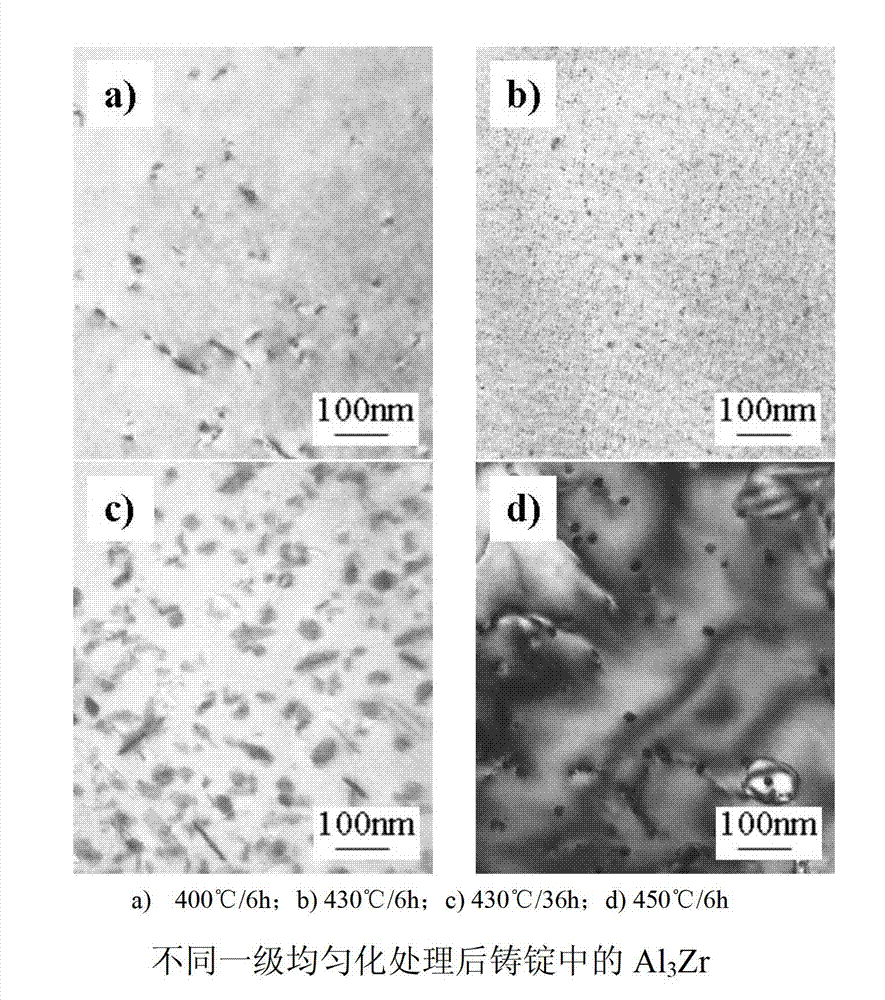

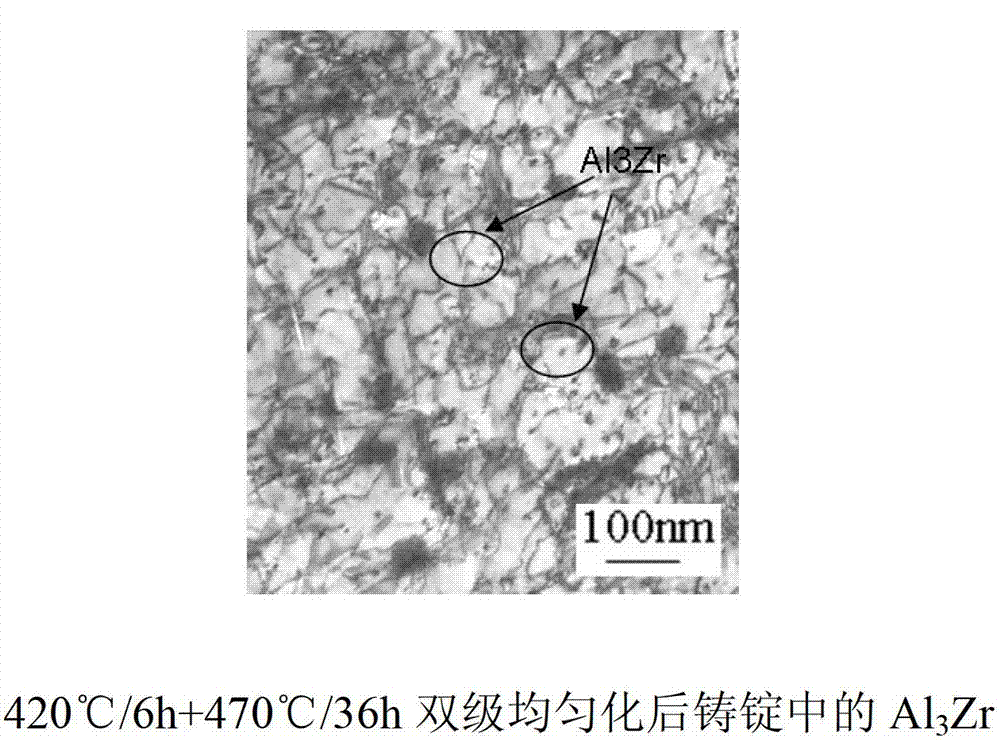

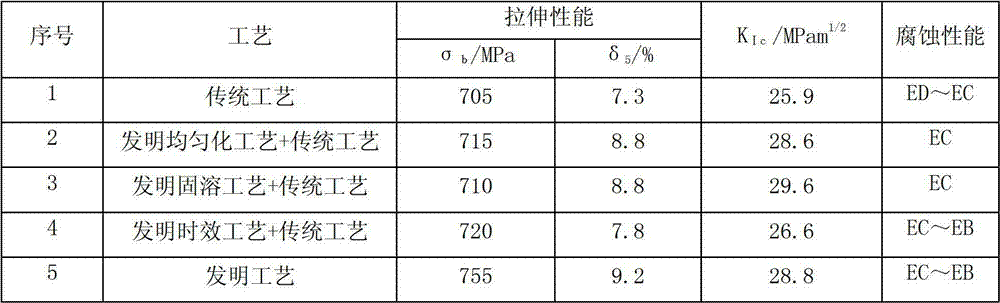

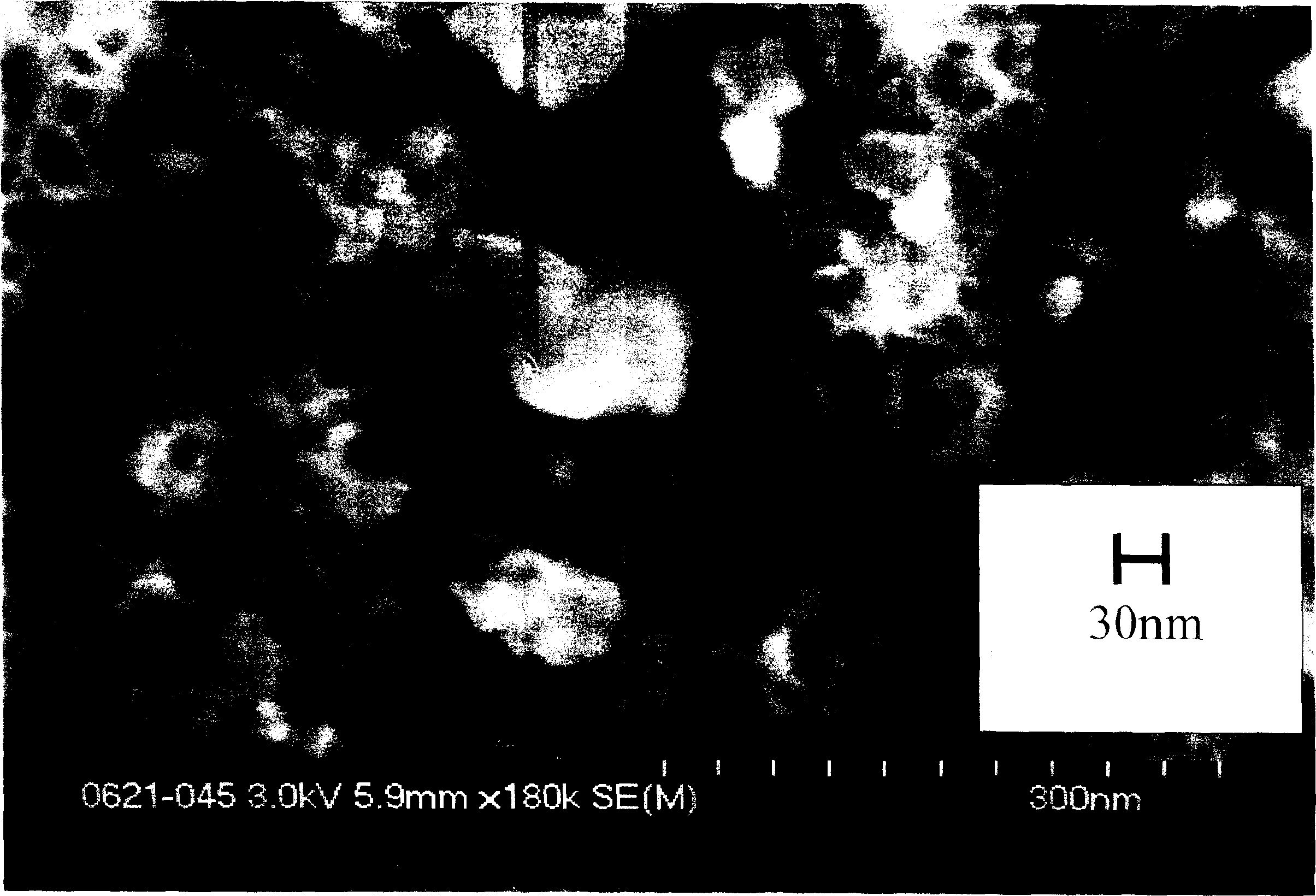

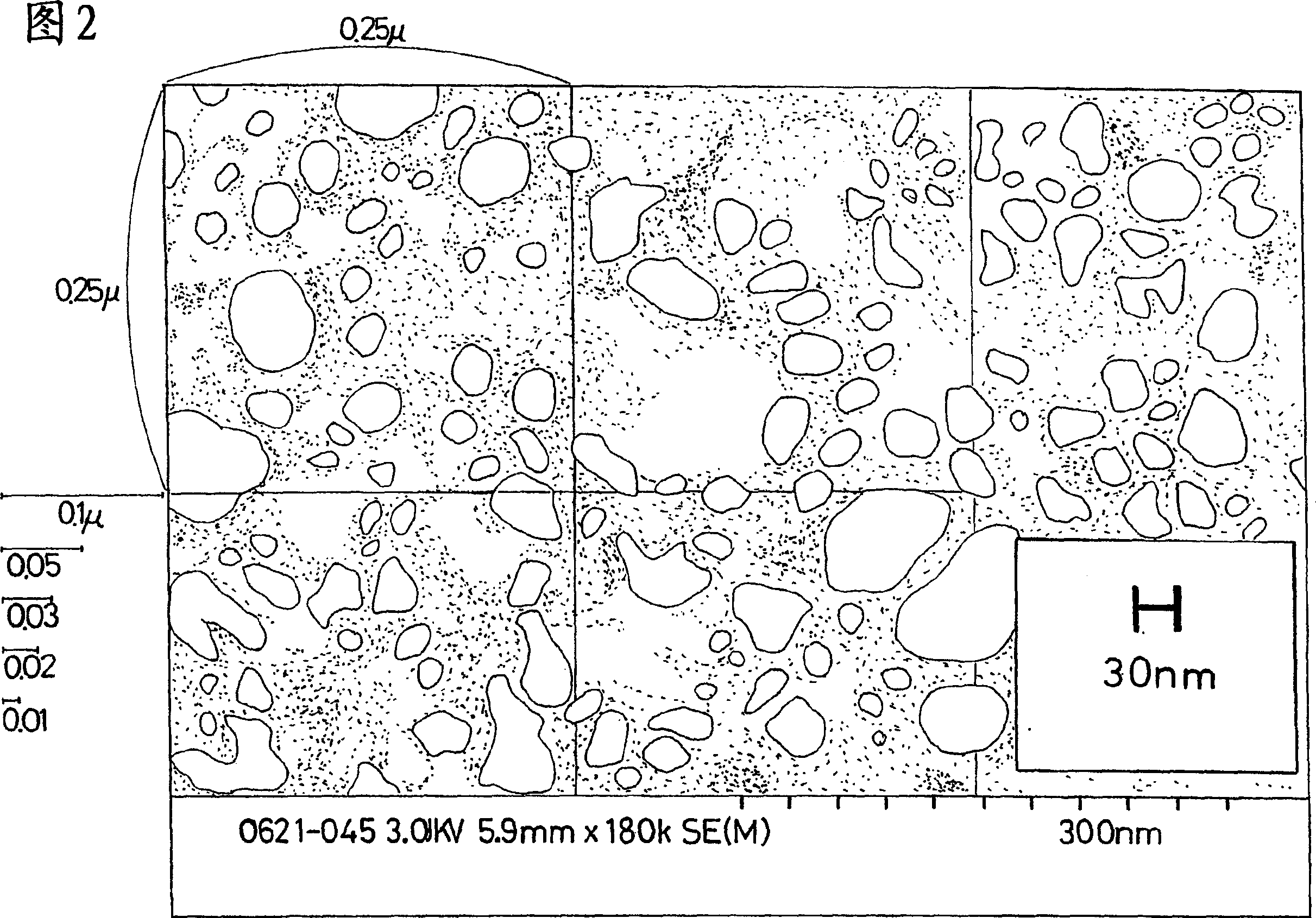

The invention relates to a 7000 series aluminum alloy material and a preparation method thereof. The aluminum alloy material has alloy components of, by weight: 7.6-11.0% of Zn, 1.2-3.0% of Mg, 1.3-2.6% of Cu, 0.04-0.30% of Zr, 0.10-0.60% of Cr, no more than 0.08% of Si, no more than 0.10% of Fe, no more than 0.10% of Ti, no more than 0.15% of total other impurities (wherein the content of single other impurity is no more than 0.05%), and balance of Al. The alloy elements Zr and Cr can be added optionally or simultaneously. The materials are prepared according to the alloy composition; the raw materials are molten; in-furnace refining and standing are carried out; and the material is cast into alloy ingots with required specifications. The alloy ingots are subjected to a preferable graded uniformization process, and is forged or extruded, such that the alloy ingots are molded; the molded materials are subjected to graded solid solution treatment, and are quenched; and artificial forced aging is carried out, such that the material can be processed into parts. The microstructures of the material are uniform, and the property of the material is stable. The ultimate tensile strength of the material can be more than 750MPa. The extensibility of the material is higher than 10%. The T-L direction KIc of the material reaches 28MPam1 / 2.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Composite of aluminum alloy and resin composition and process for producing the same

InactiveCN1717323ASynthetic resin layered productsThin material handlingPolytetramethylene terephthalateSurface roughness

The invention relates to a complex, which is characterized in that the complex consists of an aluminium alloy shape and a thermoplastic resin combination; the roughness of surface of the complex is more than 5 to 50 Mu m; the surface is provided with the aluminium alloy shape with minute recessed parts or raised parts, the diameter of which is less than 1 Mu m; the aluminium alloy shape is fixed through the recessed parts or raised parts; with the longitudinal and transverse average coefficientof linear expansion ranging from 2X<-5> DEG C<-1> to 4X<-5> DEG C<-1>, the thermoplastic resin combination is primarily made of polybutylene terephthalate resin or polyphenyl thioether; as the thermoplastic resin combination is not peeled off easily from the aluminium alloy shape, the invention has the advantages of metal enclosers and synthetic resin structures in electronic machines and electric appliances. The production efficiency is high, and the complex can be produced on large scale with shape and structure to be designed freely.

Owner:TAISEI PLAS CO LTD

Cast aluminum alloys

ActiveUS20120000578A1Improve mechanical propertiesImprove corrosion resistanceAngiosperms/flowering plantsRare-earth elementIndium

Aluminum alloys having improved properties are provided. The alloy includes about 0 to 2 wt % rare earth elements, about 0.5 to about 14 wt % silicon, about 0.25 to about 2.0 wt % copper, about 0.1 to about 3.0 wt % nickel, approximately 0.1 to 1.0% iron, about 0.1 to about 2.0 wt % zinc, about 0.1 to about 1.0 wt % magnesium, 0 to about 1.0 wt % silver, about 0.01 to about 0.2 wt % strontium, 0 to about 1.0 wt % scandium, 0 to about 1.0 wt % manganese, 0 to about 0.5 wt % calcium, 0 to about 0.5 wt % germanium, 0 to about 0.5 wt % tin, 0 to about 0.5 wt % cobalt, 0 to about 0.2 wt % titanium, 0 to about 0.1 wt % boron, 0 to about 0.2 wt % zirconium, 0 to 0.5% yttrium, 0 to about 0.3 wt % cadmium, 0 to about 0.3 wt % chromium, 0 to about 0.5 wt % indium, and the balance aluminum. Methods of making cast aluminum parts are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com