Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1739 results about "Tin Element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tin (Sn), a chemical element belonging to the carbon family, Group 14 (IVa) of the periodic table. It is a soft, silvery white metal with a bluish tinge, known to the ancients in bronze, an alloy with copper.

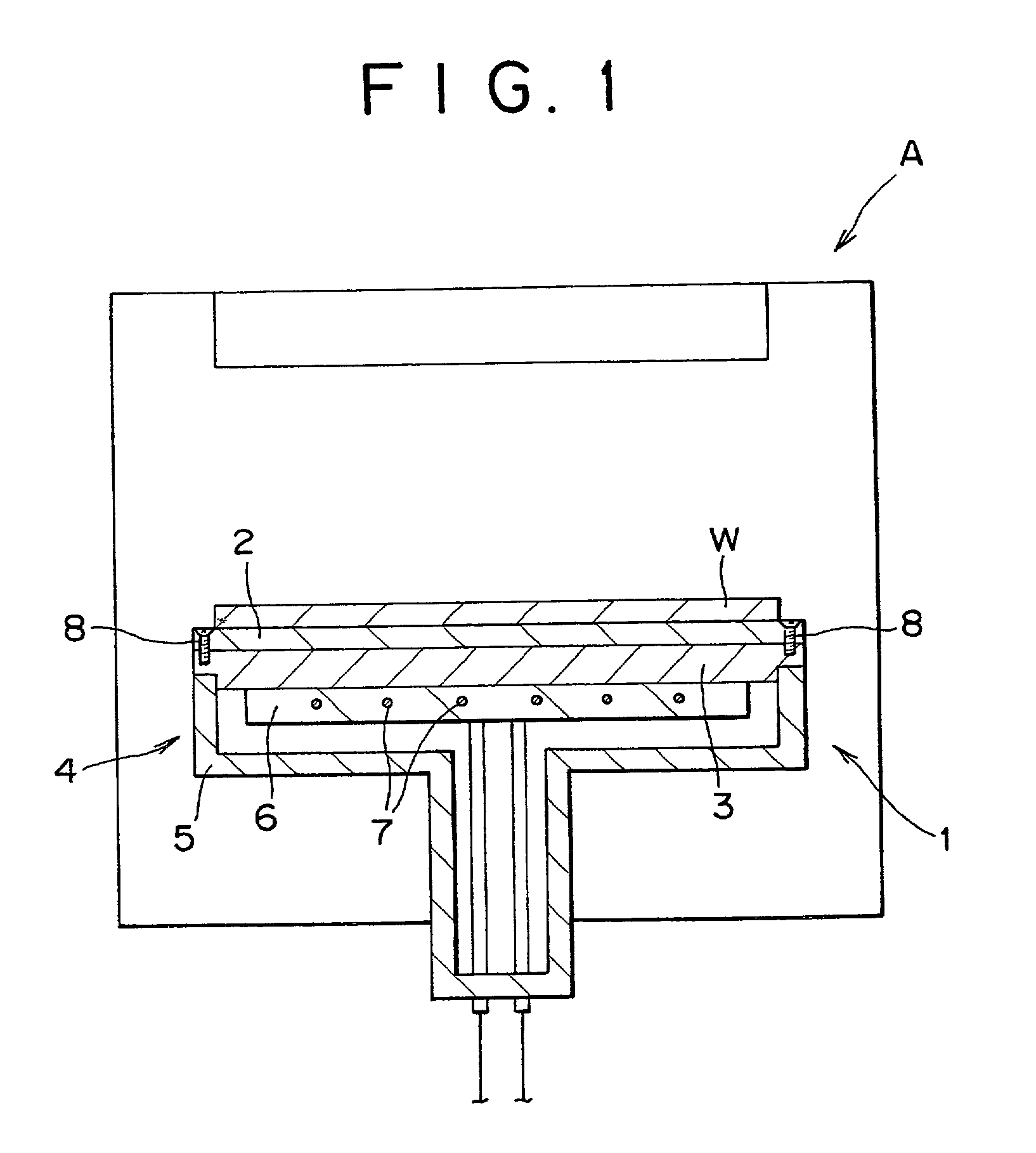

Chamber material made of Al alloy and heater block

InactiveUS20010019777A1Not be restrictElectric discharge tubesSemiconductor/solid-state device manufacturingHigh-temperature corrosionContamination

A chamber material made of Al alloy excellent in thermal cracking resistance and chemical and / or physical corrosion resistance and capable of reducing contamination excellently and further having excellent and wide applicable brazing property in a high temperature corrosive circumstance, in which the substrate aluminum material for the chamber material made of Al alloy having an anodized film comprises 0.1 to 2.0% Si, 0.1 to 3.5% Mg, 0.02 to 4.0% Cu on the mass % basis and the balance of Al and impurity element with Cr in the impurity elements being less than 0.04%. Preferably, Fe is 0.1% or less and Mn is 0.04% or less in the impurity element and, further, the total sum of impurity elements other than Cr and Mn being restricted to 0.1$ or less. This invention can be utilized suitably to various materials used in high temperature corrosive circumstance, particularly, in high temperature corrosive gas or plasma atmosphere.

Owner:KOBE STEEL LTD

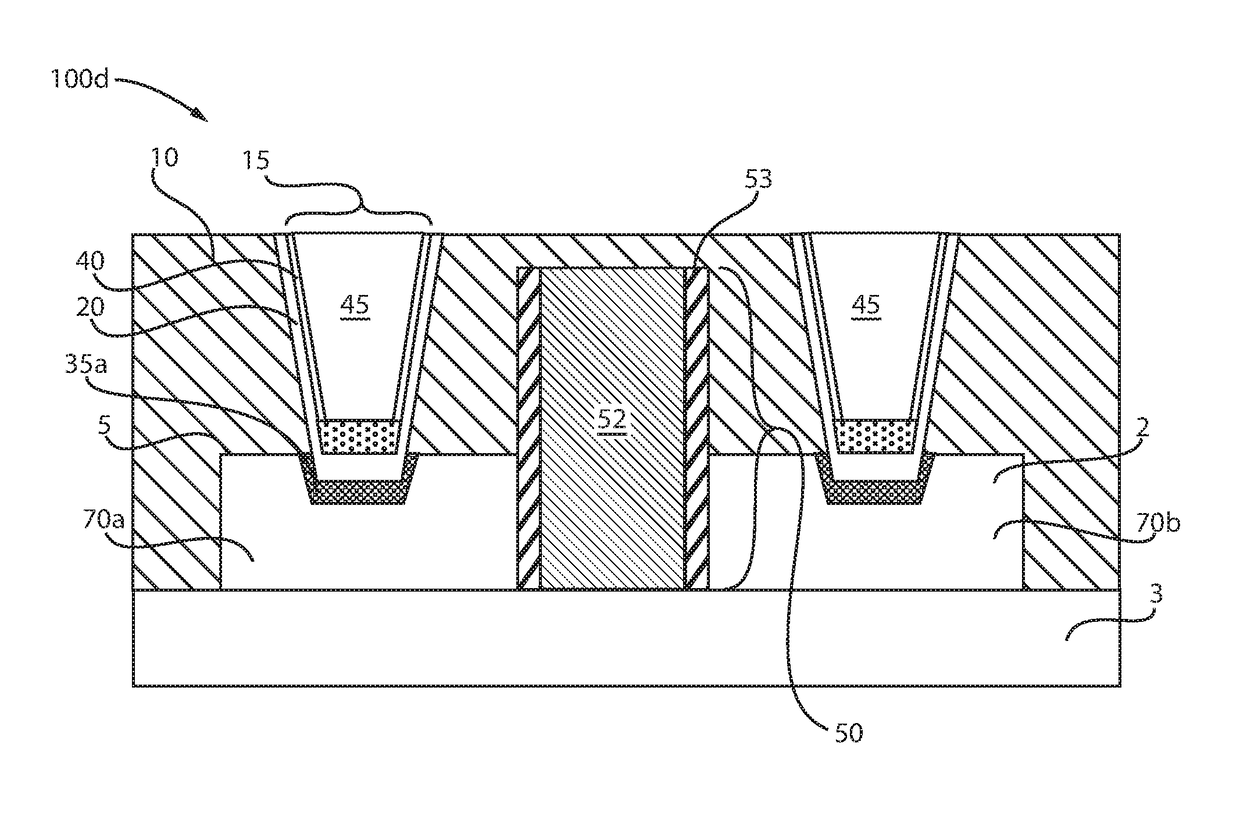

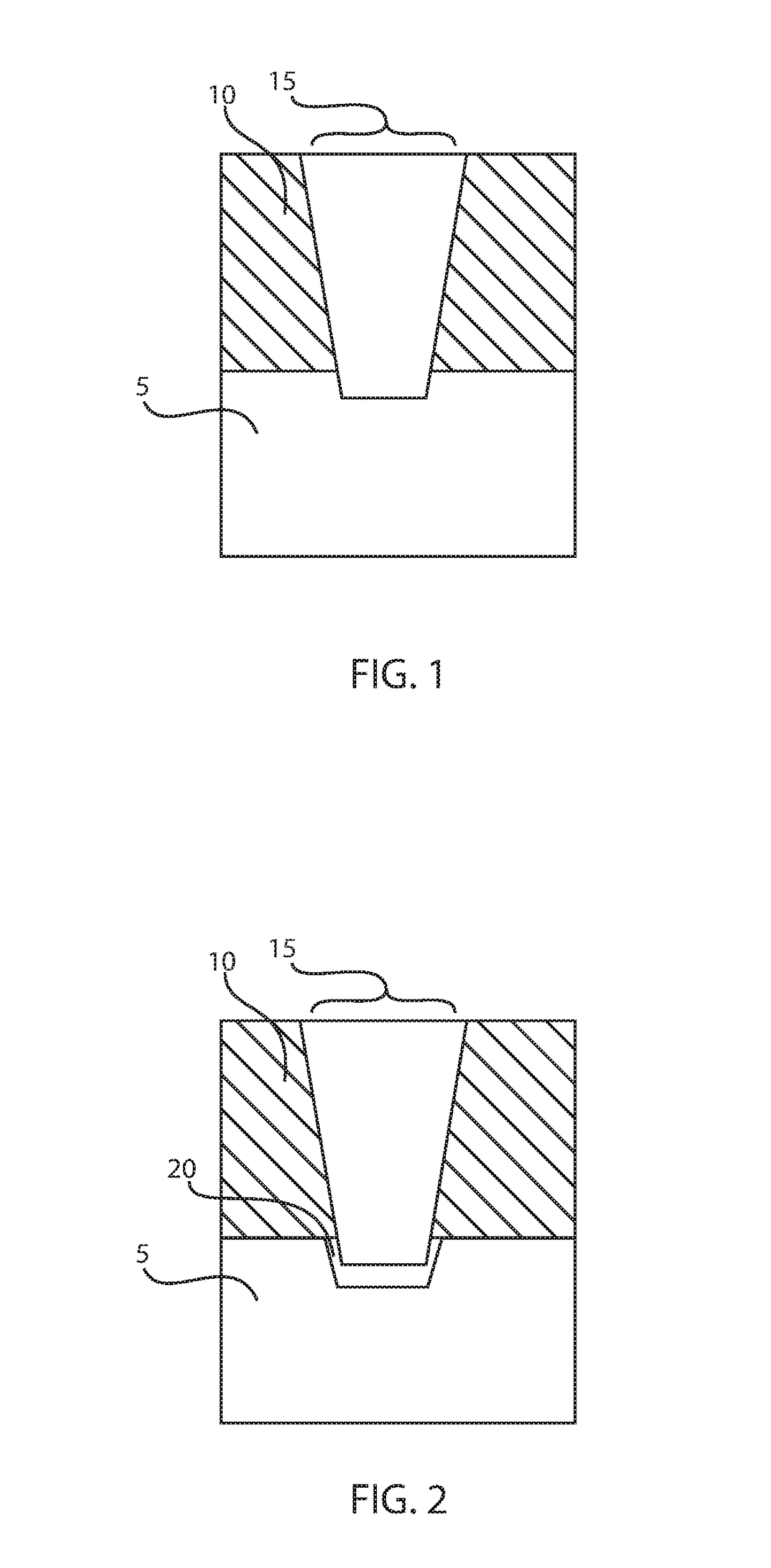

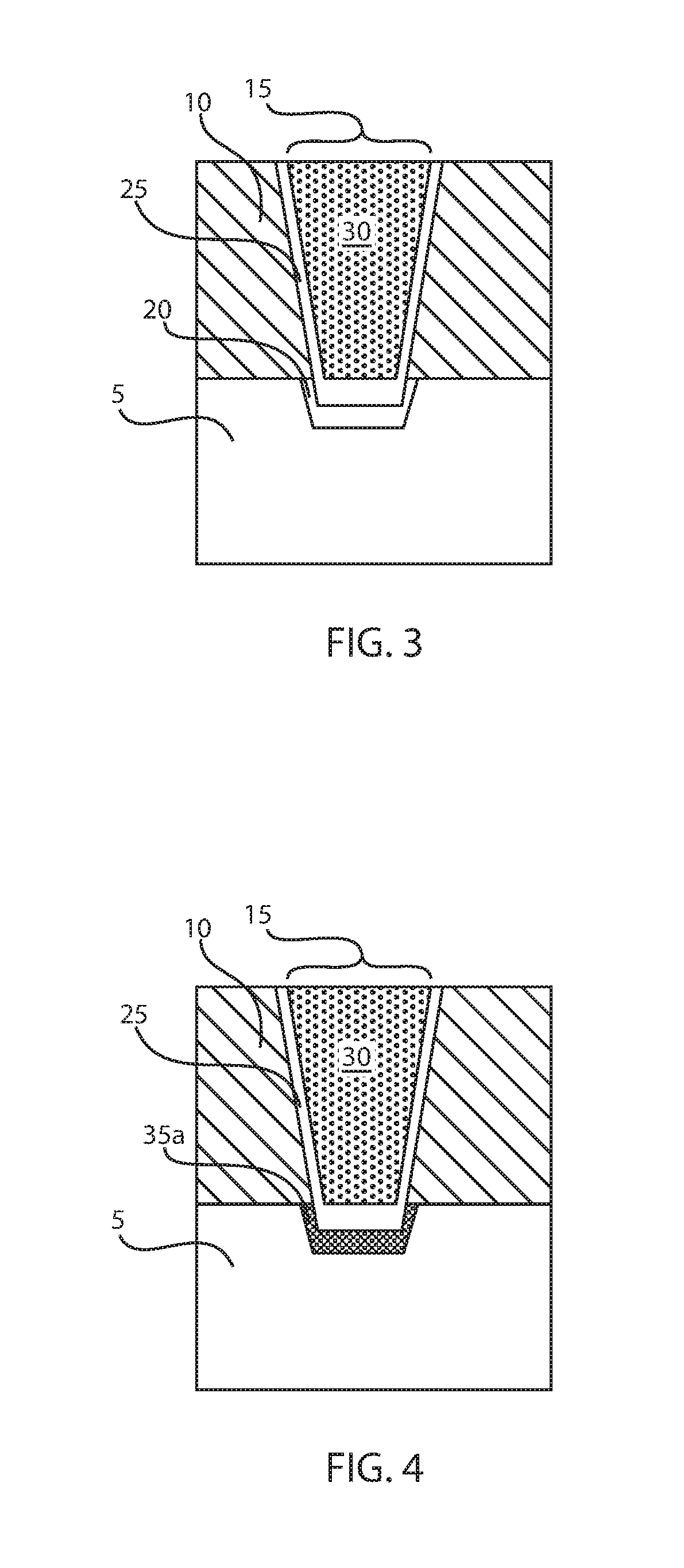

Low resistance contacts including intermetallic alloy of nickel, platinum, titanium, aluminum and type iv semiconductor elements

ActiveUS20180068950A1Semiconductor/solid-state device detailsSolid-state devicesPlatinumSemiconductor materials

A method of forming a contact to a semiconductor device is provided that forms an alloy composed of nickel (Ni), platinum (Pt), aluminum (Al), titanium (Ti) and a semiconductor material. The methods may include forming a nickel and platinum semiconductor alloy at a base of a via. A titanium layer having an angstrom scale thickness is deposited in the via in contact with the nickel platinum semiconductor alloy. An aluminum containing fill is deposited atop the titanium layer. A forming gas anneal including an oxygen containing atmosphere is applied to the structure to provide a contact alloy comprising nickel, platinum, aluminum, titanium and a semiconductor element from the contact surface of the semiconductor device.

Owner:IBM CORP

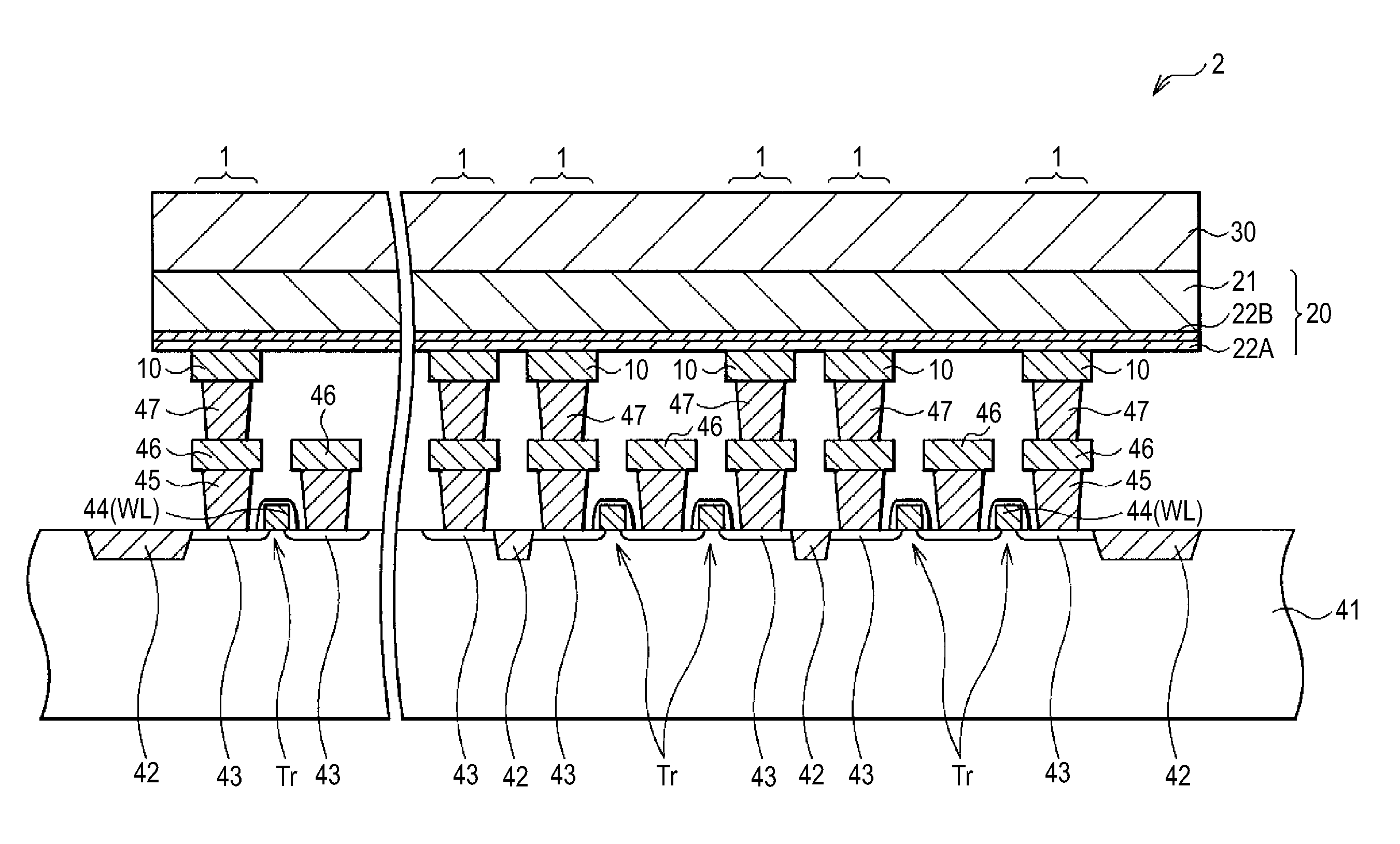

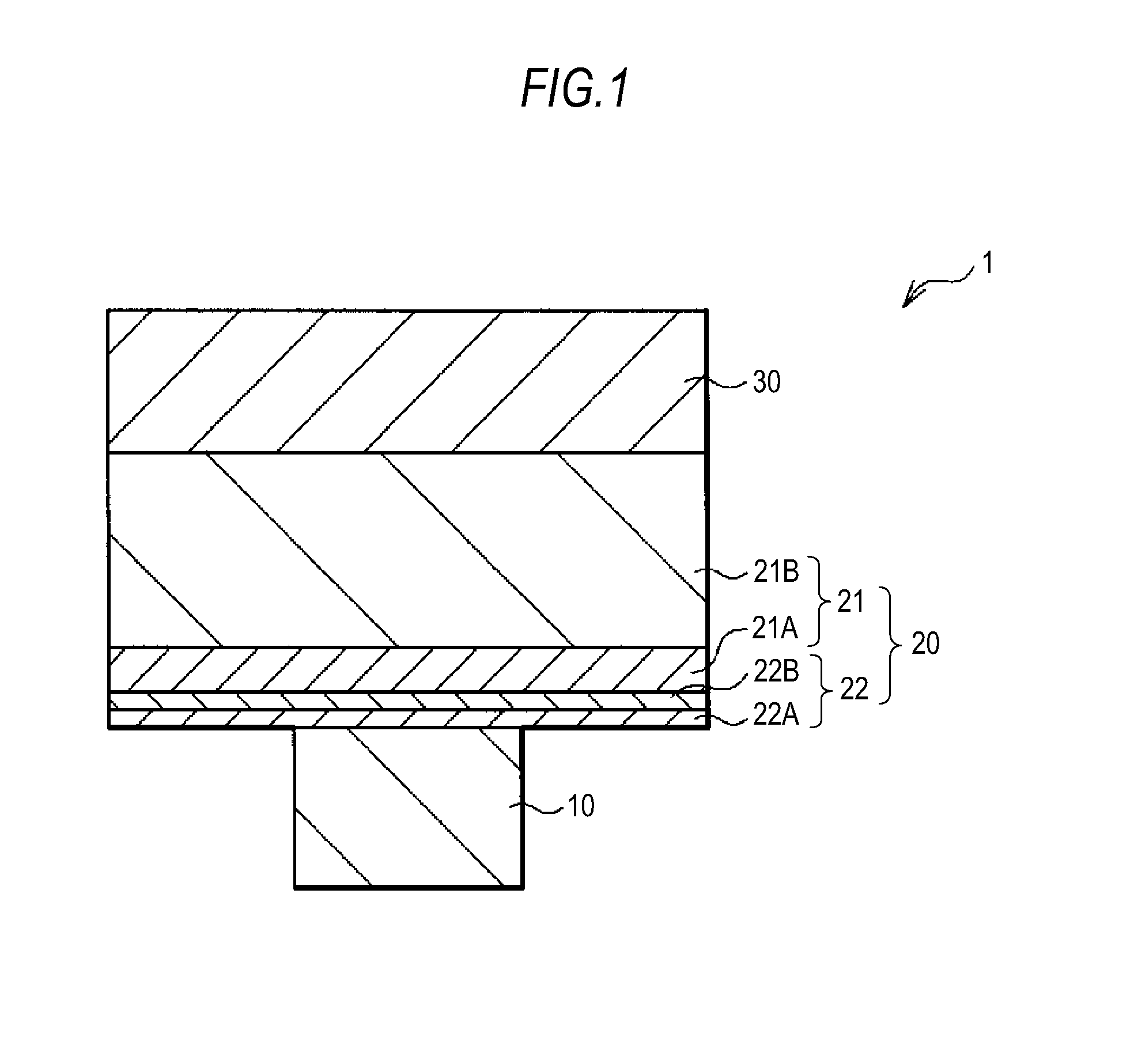

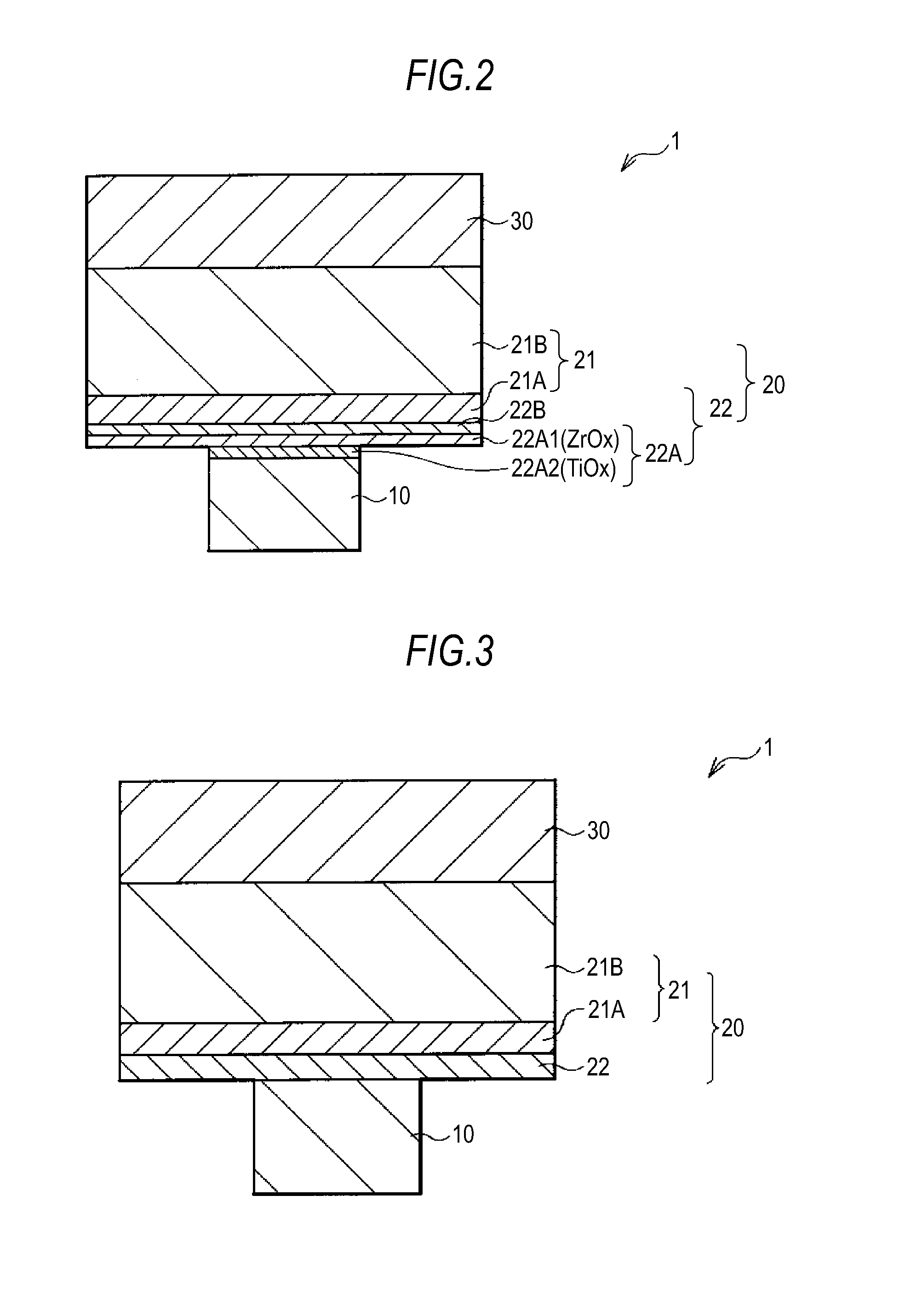

Memory component, memory device, and method of operating memory device

InactiveUS20110194329A1Avoid reactionImprove repetition durabilitySolid-state devicesDigital storageLow resistanceTellurium

A memory component includes: a first electrode; a memory layer; and a second electrode which are provided in that order, wherein the memory layer includes an ion source layer containing aluminum (Al) together with at least one chalcogen element selected from the group consisting of tellurium (Te), sulfur (S), and selenium (Se), and a resistance variable layer provided between the ion source layer and the first electrode and containing an aluminum oxide and at least one of a transition metal oxide and a transition metal oxynitride having a lower resistance than the aluminum oxide.

Owner:SONY SEMICON SOLUTIONS CORP

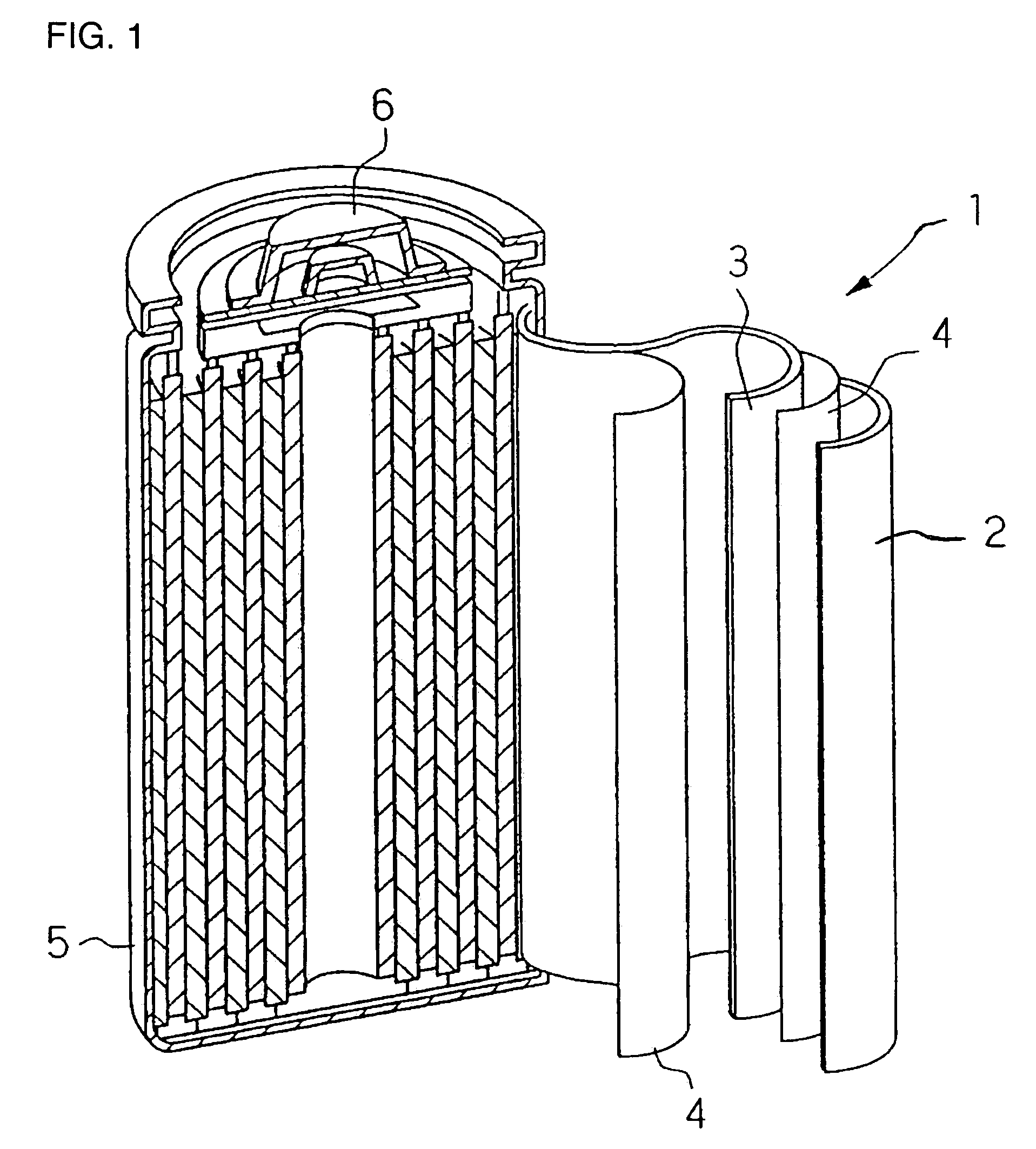

Active material for positive electrode used in lithium secondary battery and method of manufacturing same

InactiveUS6372385B1Easy to implementEvenly dispersedElectrode thermal treatmentActive material electrodesLithium-ion batteryMetal

Disclosed is active material for a positive electrode used in lithium secondary batteries of Formula 1 below and a method manufacturing the same, a surface of the active material being coated with metal oxide. The method includes the steps of producing a crystalline powder or a semi-crystalline powder of Formula 1; coating the crystalline powder or the semi-crystalline powder with metal alkoxide sol; and heat-treating the powder coated with the metal alkoxide sol.where 0<x<=0.3, 0<=y<=0.01, andA is an element selected from the group consisting of Ni, Co and Mn; B is an element selected from the group consisting of Ni, Co, Mn, B, Mg, Ca, Sr, Ba, Ti, V, Cr, Fe, Cu and Al; and C is an element selected from the group consisting of Ni, Co, Mn, B, Mg, Ca, Sr, Ba, Ti, V, Cr, Fe, Cu and Al.

Owner:SAMSUNG ELECTRONICS DEVICES CO LTD

Method for preparing positive active material for rechargeable lithium battery and positive active material prepared by same

ActiveUS7326498B2Inhibiting high-temperature swellingElectrode manufacturing processesNon-aqueous electrolyte accumulatorsRare-earth elementAlkaline earth metal

Disclosed is a method of preparing a positive active material for a rechargeable lithium battery including adding first and second compounds to a solvent to prepare an acidic solution with a pH from 0.01 to 3, the first compound including an element that is capable of forming a double bond with an oxygen of a lithium metal oxide, and the second compound including at least one element selected from the group consisting of alkali metals, alkali earth metals, group 13 elements, group 14 elements, transition metals and rare-earth elements; adding a lithium-containing compound to the acidic coating solution to coat the lithium-containing compound; and heat-treating the coated lithium-containing compound to form a surface-treatment layer comprising a compound represented by the formula MXOk where M is an element selected from the group consisting of alkali metals, alkali earth metals, group 13 elements, group 14 elements, transition metals, rare-earth elements and combinations thereof; X is an element that is capable of forming a double bond with oxygen; and k is an integer from 2 to 4.

Owner:SAMSUNG SDI CO LTD

Silver-free tin-bismuth-copper leadless solder and preparation method

ActiveCN1927525AGood solder wettabilityImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaShielding gasIngot

The invention relates to a tin-base leadless solder without silver, and relative production. Wherein, it comprises Bi at 7.5-60% (without 7.5%), Cu at 0.1-3.0%, and the left is tin; and it also can contain Zn, Ni, P, Ge, Ga, In, Al, La, Ce, Sb, Cr, Fe, Mn, or Co while the total amount of micro alloy element is not higher than 1.0%. And the production comprises that in protective gas or vacuum, smelting middle alloy Sn-Cu10; then smelting into leadless solder alloy ingot which can be used as solder directly or be made into bar band, wire plate or powder. The inventive solder has low cost while its fusion point can be controlled between 140 and 230Deg. C. And it has strong anti-oxidization and anti-corrosion properties.

Owner:BEIJING COMPO ADVANCED TECH

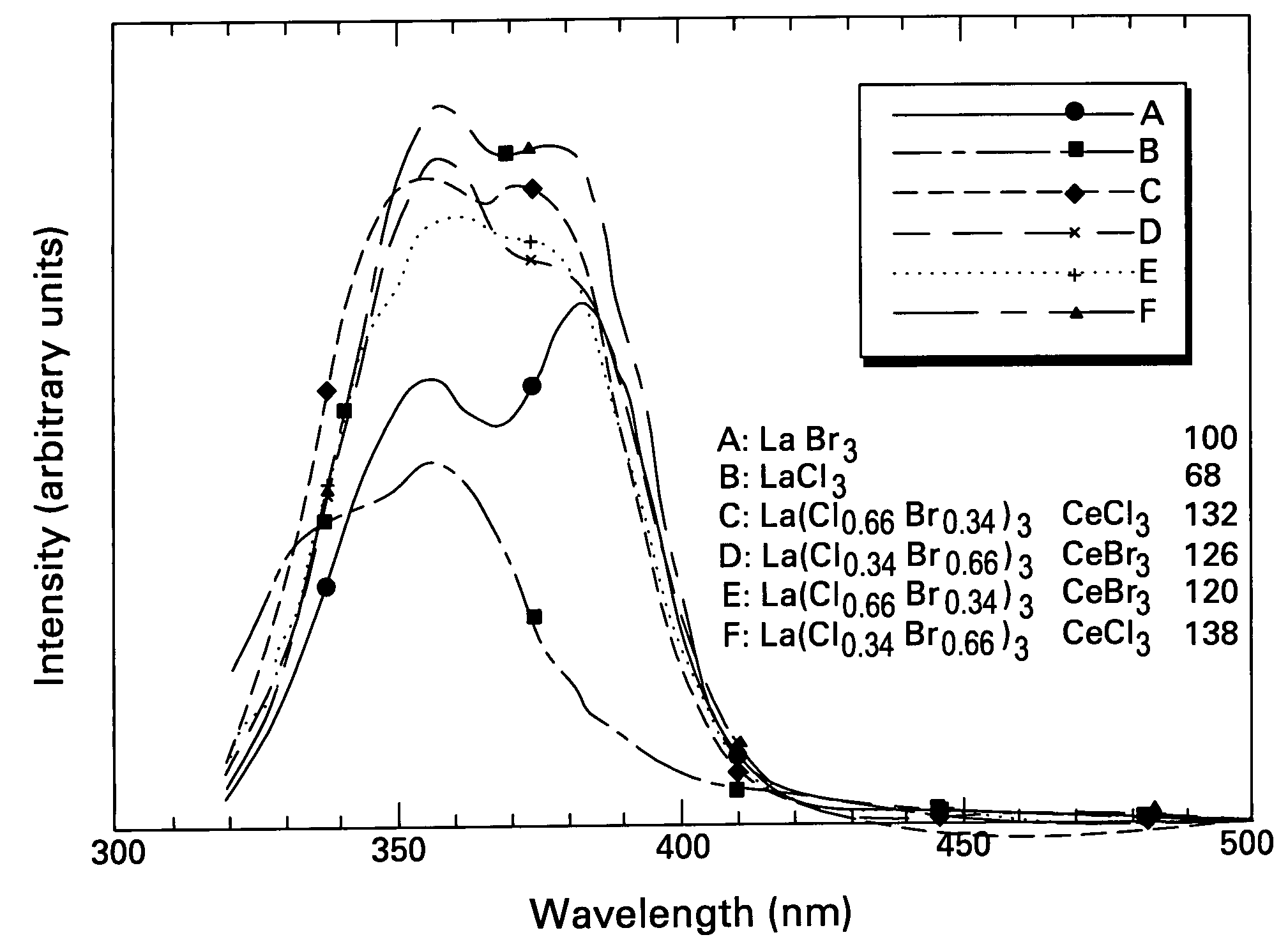

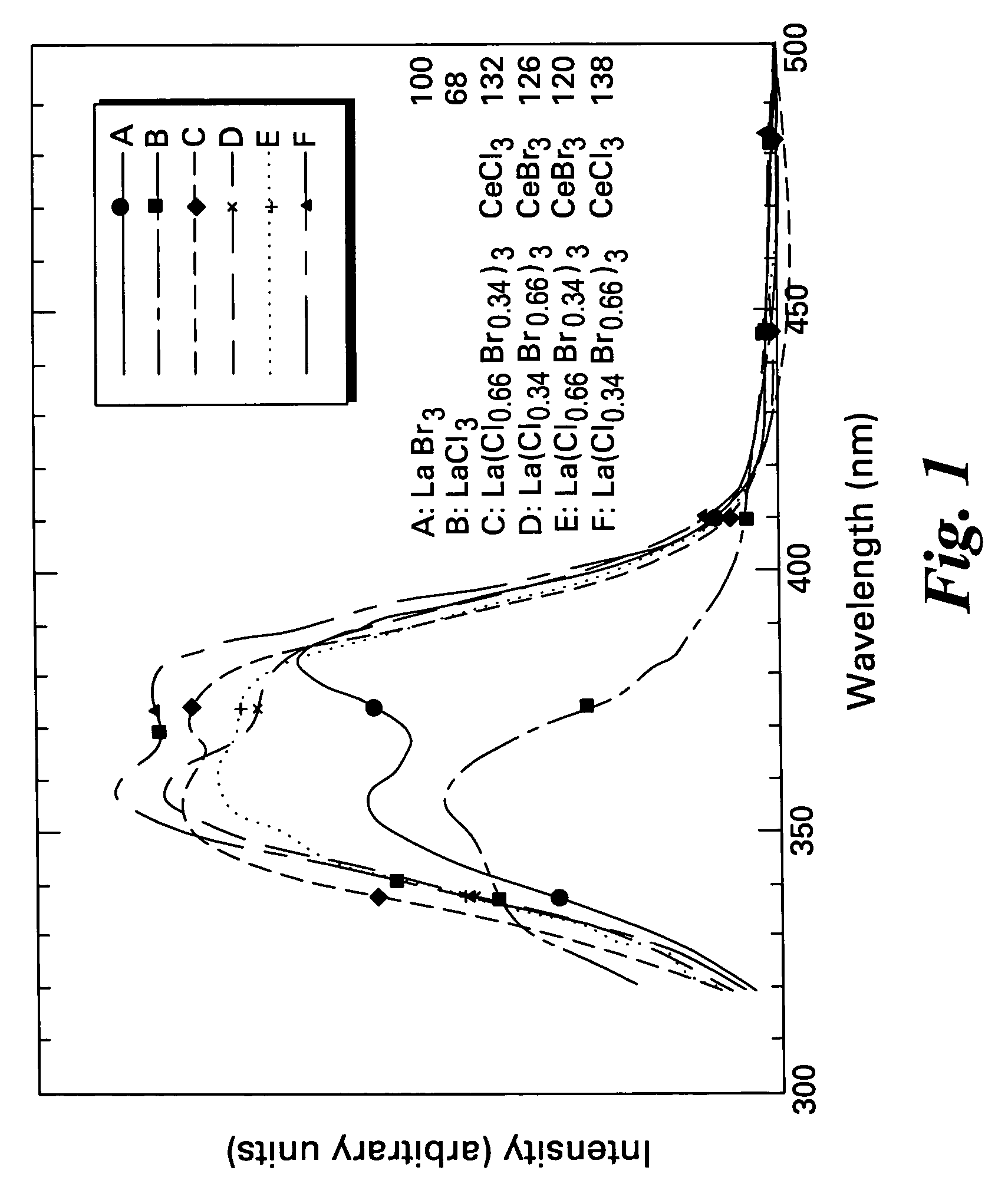

Scintillator compositions, and related processes and articles of manufacture

ActiveUS7084403B2Excellent and reproducible scintillation responseImprove performanceMaterial analysis by optical meansLuminescent compositionsHigh energyIodide

Scintillator materials based on certain types of halide-lanthanide matrix materials are described. In one embodiment, the matrix material contains a mixture of lanthanide halides, i.e., a solid solution of at least two of the halides, such as lanthanum chloride and lanthanum bromide. In another embodiment, the matrix material is based on lanthanum iodide alone, which must be substantially free of lanthanum oxyiodide. The scintillator materials, which can be in monocrystalline or polycrystalline form, also include an activator for the matrix material, e.g., cerium. Radiation detectors that use the scintillators are also described, as are related methods for detecting high-energy radiation.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

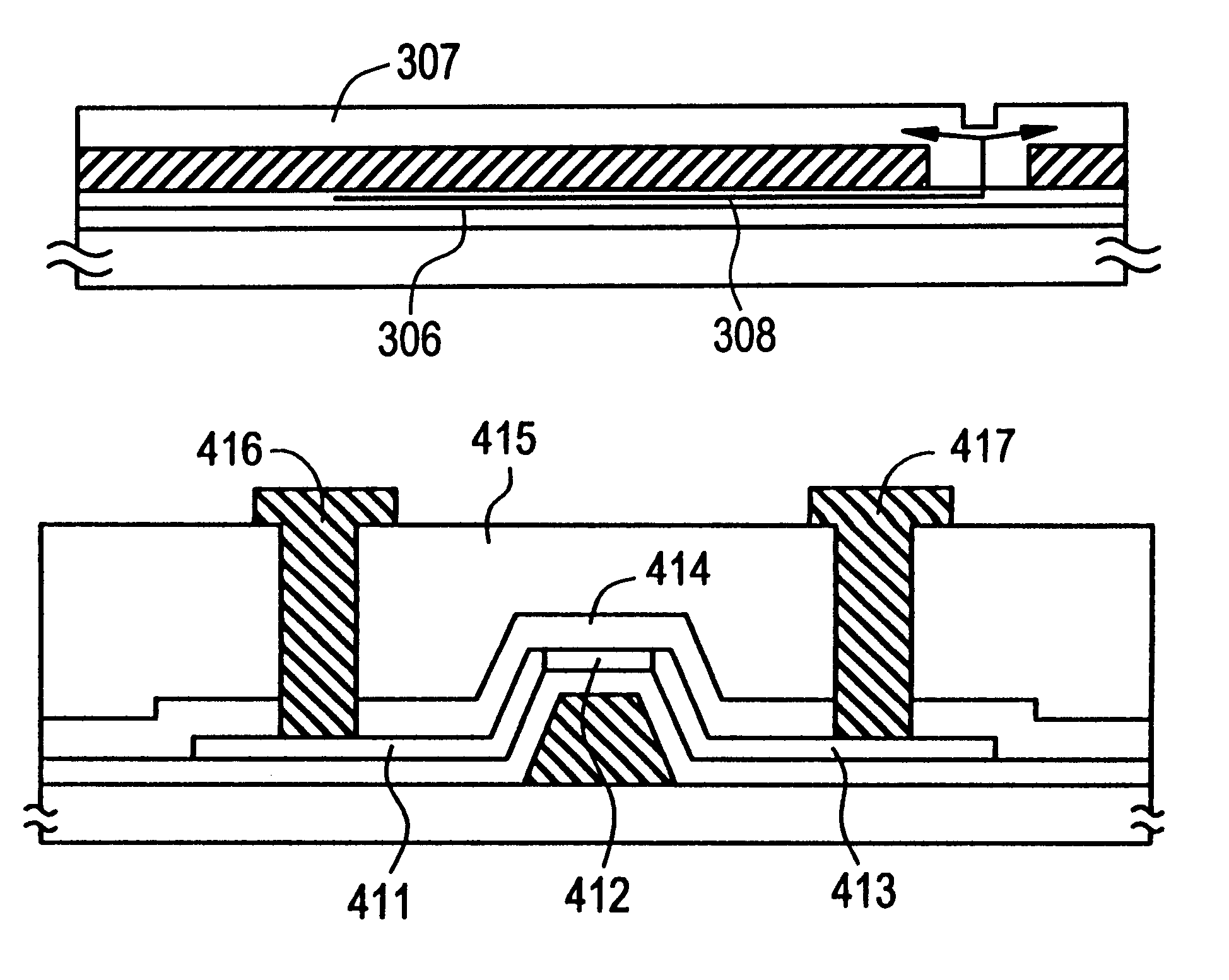

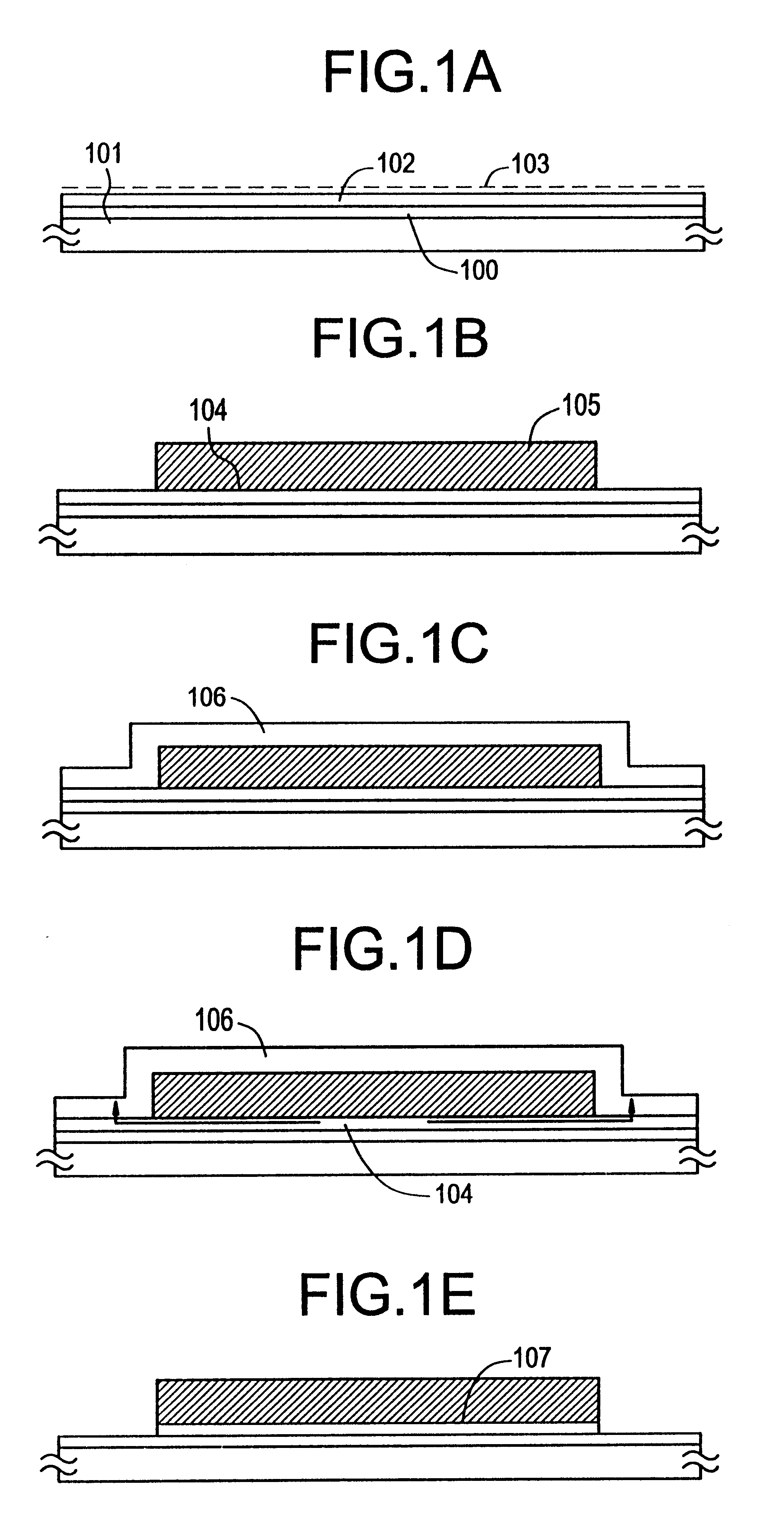

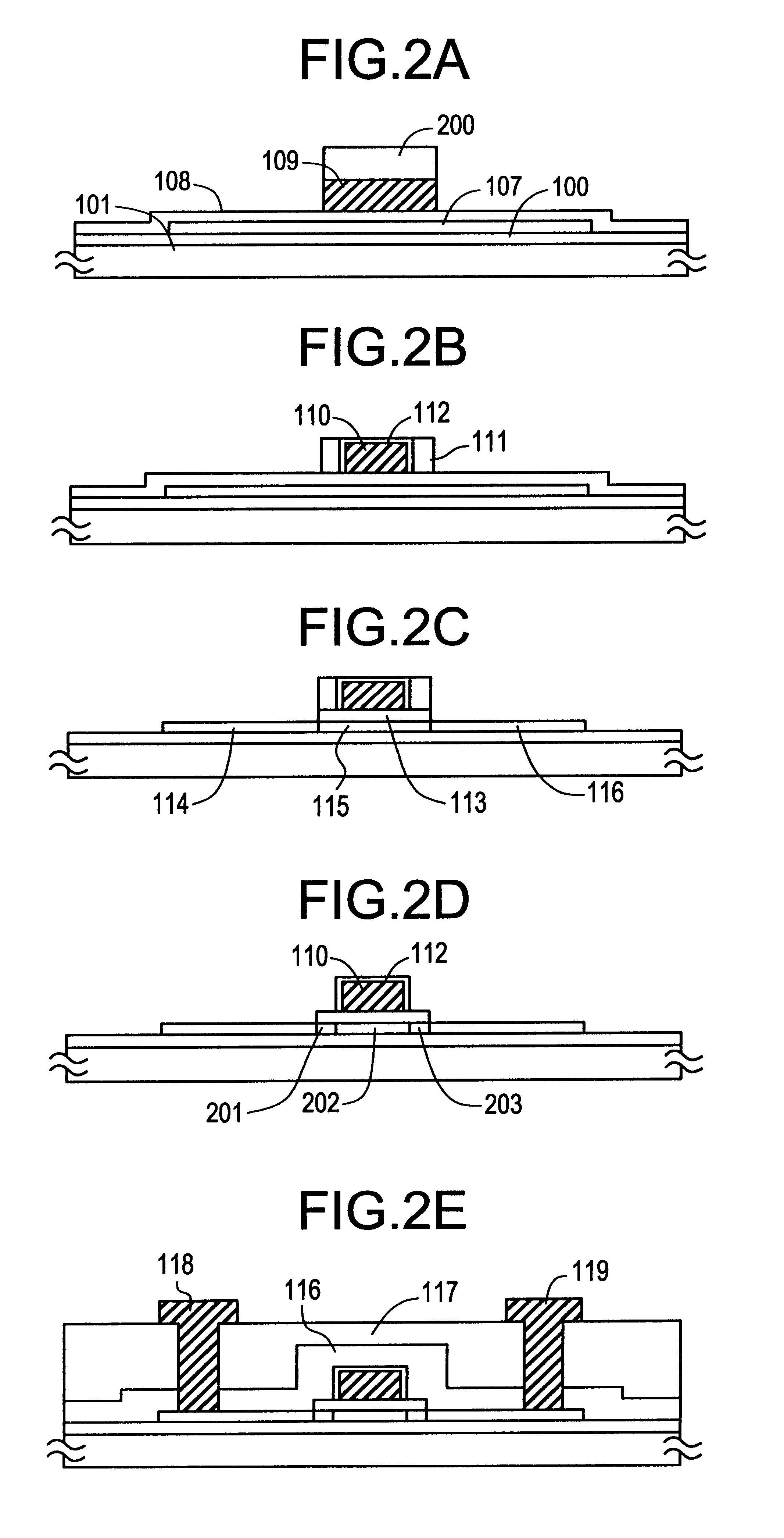

Method of forming a TFT by adding a metal to a silicon film promoting crystallization, forming a mask, forming another silicon layer with group XV elements, and gettering the metal through opening in the mask

InactiveUS6242290B1TransistorSemiconductor/solid-state device manufacturingSilicon membraneAmorphous silicon

There is disclosed a method of fabricating TFTs using a silicon film crystallized with the aid of nickel. The nickel is removed from the crystallized silicon film. The method starts with maintaining nickel in contact with the surface of an amorphous silicon film. Then, a heat treatment is performed to form a crystalline silicon film. At this time, nickel promotes the crystallization greatly, and nickel diffuses into the film. A mask is formed. A silicon film heavily doped with phosphorus is formed. Thereafter, a heat treatment is performed to move the nickel from the crystalline silicon film into the phosphorus-rich silicon film. This reduces the concentration of nickel in the crystalline silicon film.

Owner:SEMICON ENERGY LAB CO LTD

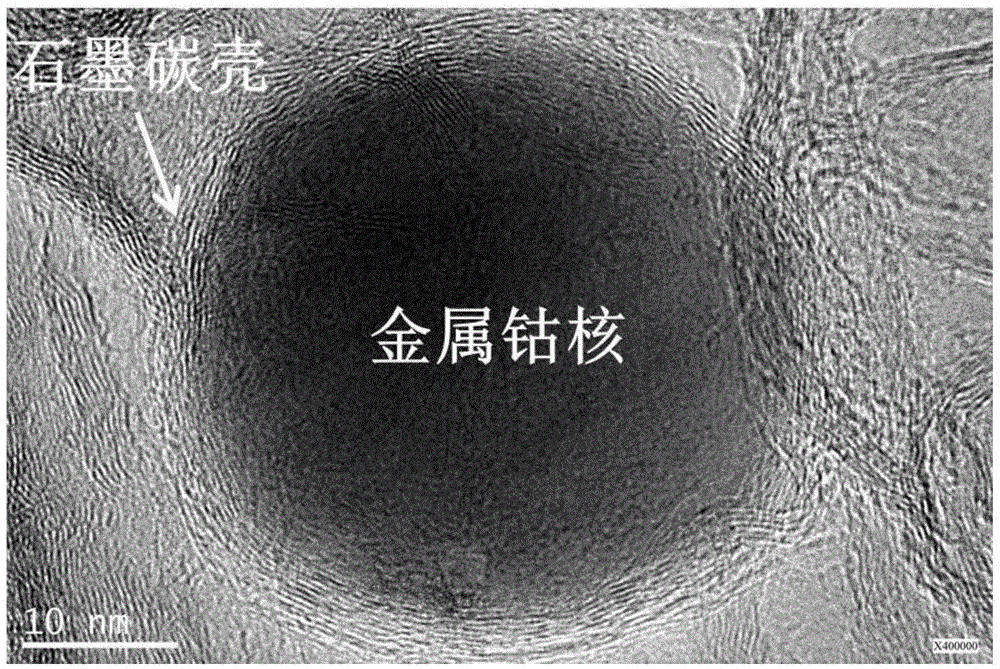

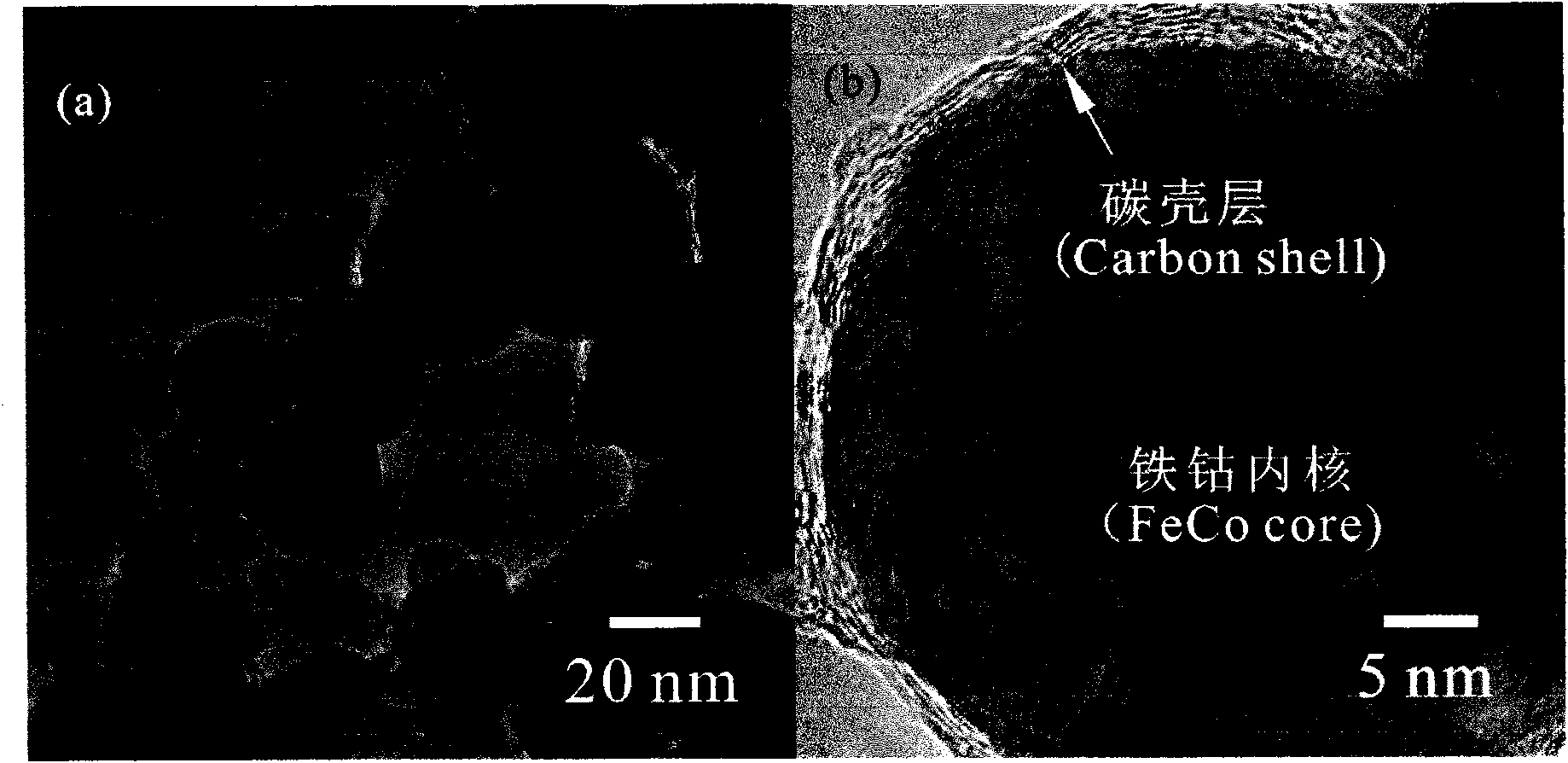

Method for preparing non-metallic element doped carbon coated metal nanoparticle magnetic composite

ActiveCN105478755AGood dispersionHigh purityTransportation and packagingMetal-working apparatusDispersityCyanamide compound

The invention discloses a method for preparing a non-metallic element doped carbon coated metal nanoparticle magnetic composite. The method comprises the steps that water-soluble metal divalent salt, a cyanamide compound and a nitrogen or boron or sulfur containing non-metallic compound are added into a methanol solution to be mixed, dissolved, dried and ground, and obtained homogeneous-phase powder is subjected to roasting pyrolysis under the protection of inert gas; and a pyrolysis product is subjected to acid pickling, washing, drying and grinding, and a target product is obtained. According to the whole preparing process of the method, metal ion reduction, metal nanoparticle coating and doping of nitrogen / boron / sulfur and other non-metallic elements are achieved in one step. The composite prepared through the method is high in degree of graphitization, good in dispersity between particles and high in purity, and the preparing method has the advantages that the cost is low, the process is simple, and large-quantity synthesis can be easily achieved.

Owner:合肥庐阳科技创新集团有限公司

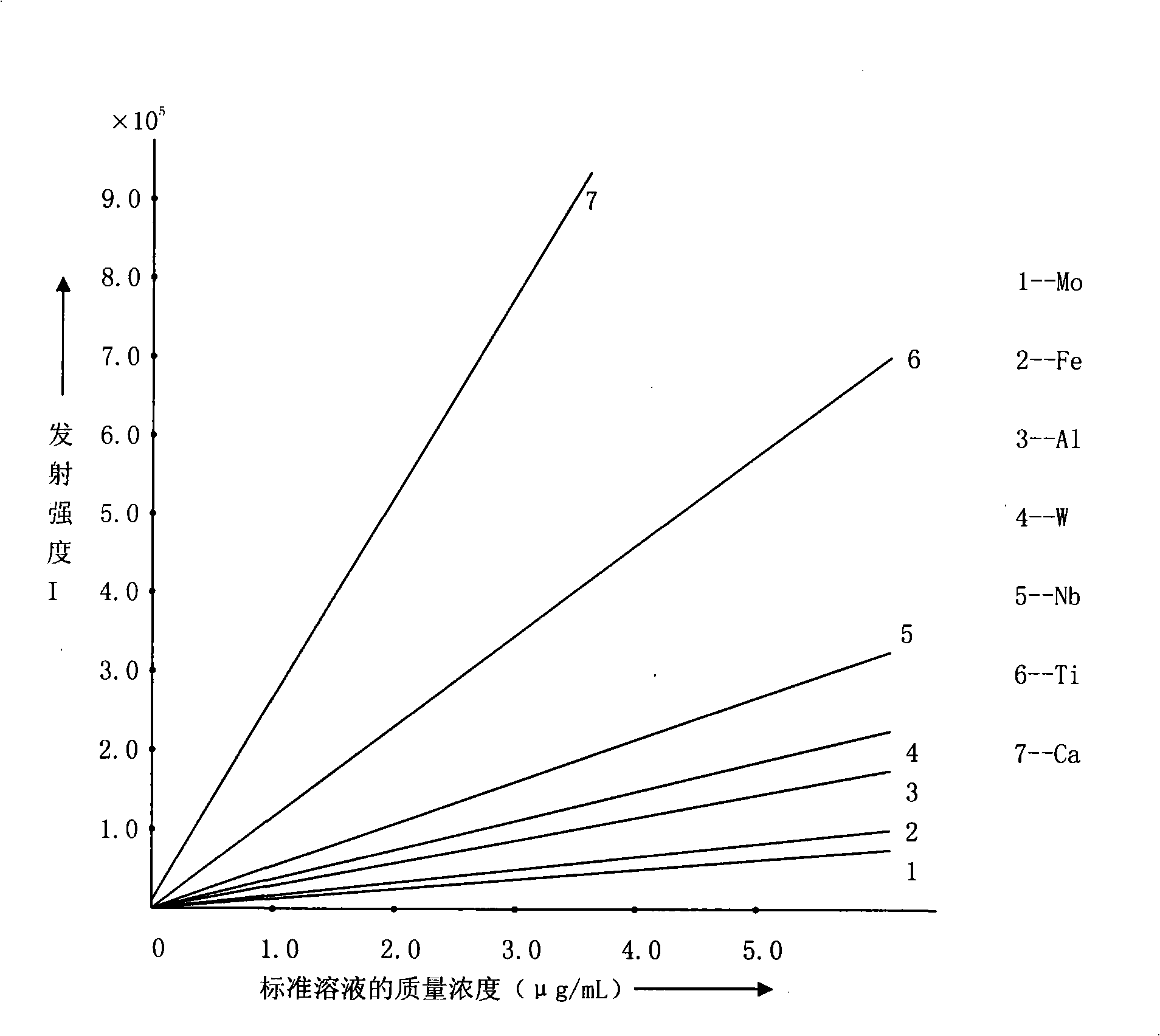

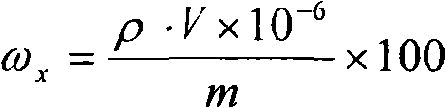

Analyses testing method of aluminum, calcium, iron, molybdenum, niobium, titanium, tungsten impurity elements in chromium carbide

ActiveCN101303307ASolve difficult technical problemsImprove measurement accuracyPreparing sample for investigationAnalysis by thermal excitationNiobiumDecomposition

The invention discloses an analysis and detection method for impurity elements such as aluminum, calcium, ion, molybdenum, niobium, titanium, tungsten and the like in chromium carbide. The method comprises adding a chromium carbide sample into a dissolving cup, adding hydrofluoric acid, sulphuric acid and nitric acid sequentially, stirring, charging into a sealed high-pressure jar; putting the sealed high-pressure jar into a microwave extinguishing instrument for two times of microwave extinguishment; taking the high-pressure jar out of the microwave extinguishing instrument for cooling, transferring the dissolved chromium carbide liquid sample into a volumeric flask, diluting to a predetermined index, stirring; preparing a chromium substrate matched mixed standard solution series of aluminum, calcium, iron, molybdenum, niobium, titanium and tungsten; measuring element emission power of aluminum, calcium, iron, molybdenum, niobium, titanium, tungsten or the like in a blank liquid sample, a chromium carbide liquid sample and the prepared series mixed standard solution by an inductively coupled plasma atomic emission spectrometer in the same time, obtaining the analysis result by checking a standard working curve or by linear equation calculation. The invention adopts two times of microwave extinguishment using the mixed acid, solves the problem of hardness in chromium carbide decomposition, having a measurement range from 0.010% to 1.00%, which is high in accuracy, and good in precision.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

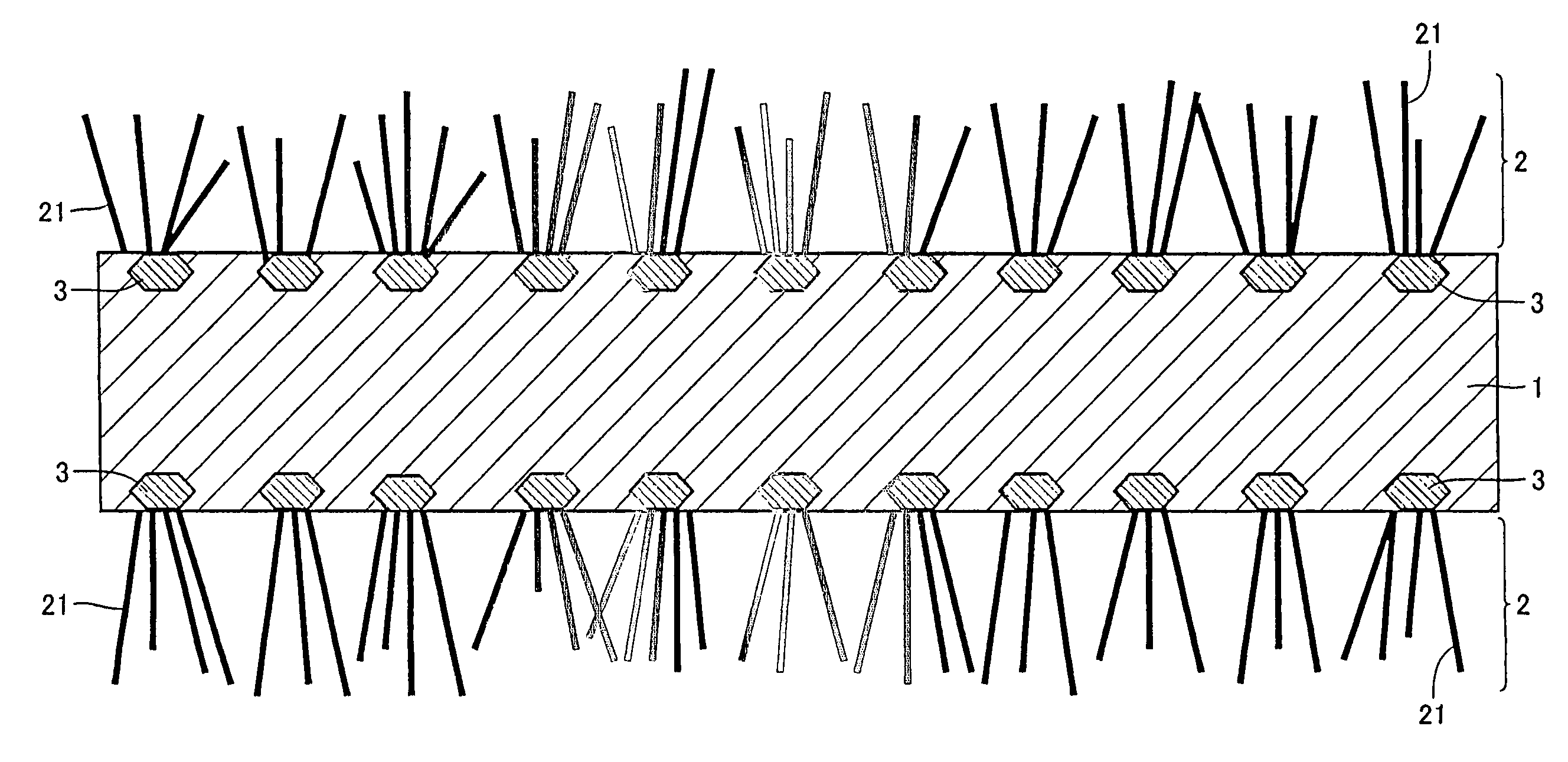

Carbon-coated aluminum and method for producing same

ActiveUS7327556B2Improve adhesionHybrid capacitor electrodesElectrode carriers/collectorsCarbon coatedHydrocarbon

Owner:TOYO ALUMINIUM KK

Method of making material alloy for iron-based rare earth magnet

InactiveUS6695929B2Good reproducibilityUniform structureNanomagnetismInorganic material magnetismRare-earth elementRare-earth magnet

A melt of an iron-based rare earth material alloy, represented by (Fe1-mTm)100-x-y-zQxRyMz, is prepared, wherein T is Co and / or Ni; Q is B and / or C; R is selected from Y (yttrium) and the rare earth elements; M is selected from Al, Si, Ti, V, Cr, Mn, Cu, Zn, Ga, Zr, Nb, Mo, Ag, Hf, Ta, W, Pt, Au and Pb; 10<=x<=30 at %; 2%<=y<10 at %; 0<=z<=10 at % and 0<=m<=0.5. The melt is fed onto a guide to form a flow of the melt thereon and move the melt onto a melt / chill roller contact region, where the melt is rapidly cooled by the chill roller to make a rapidly solidified alloy. An oxygen concentration of the melt yet to be fed onto the guide is controlled at about 3,000 ppm or less in mass percentage.

Owner:SUMITOMO SPECIAL METAL CO LTD

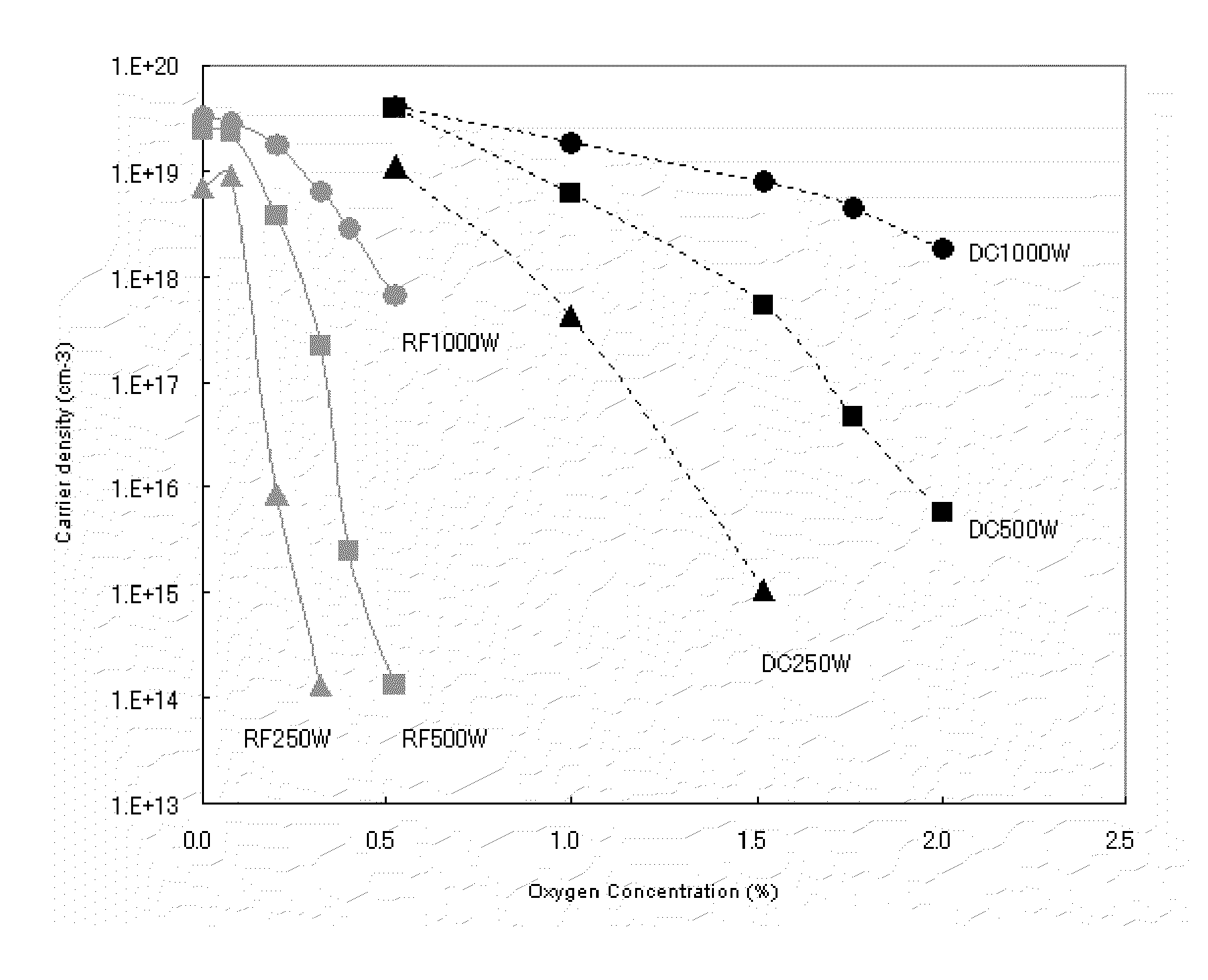

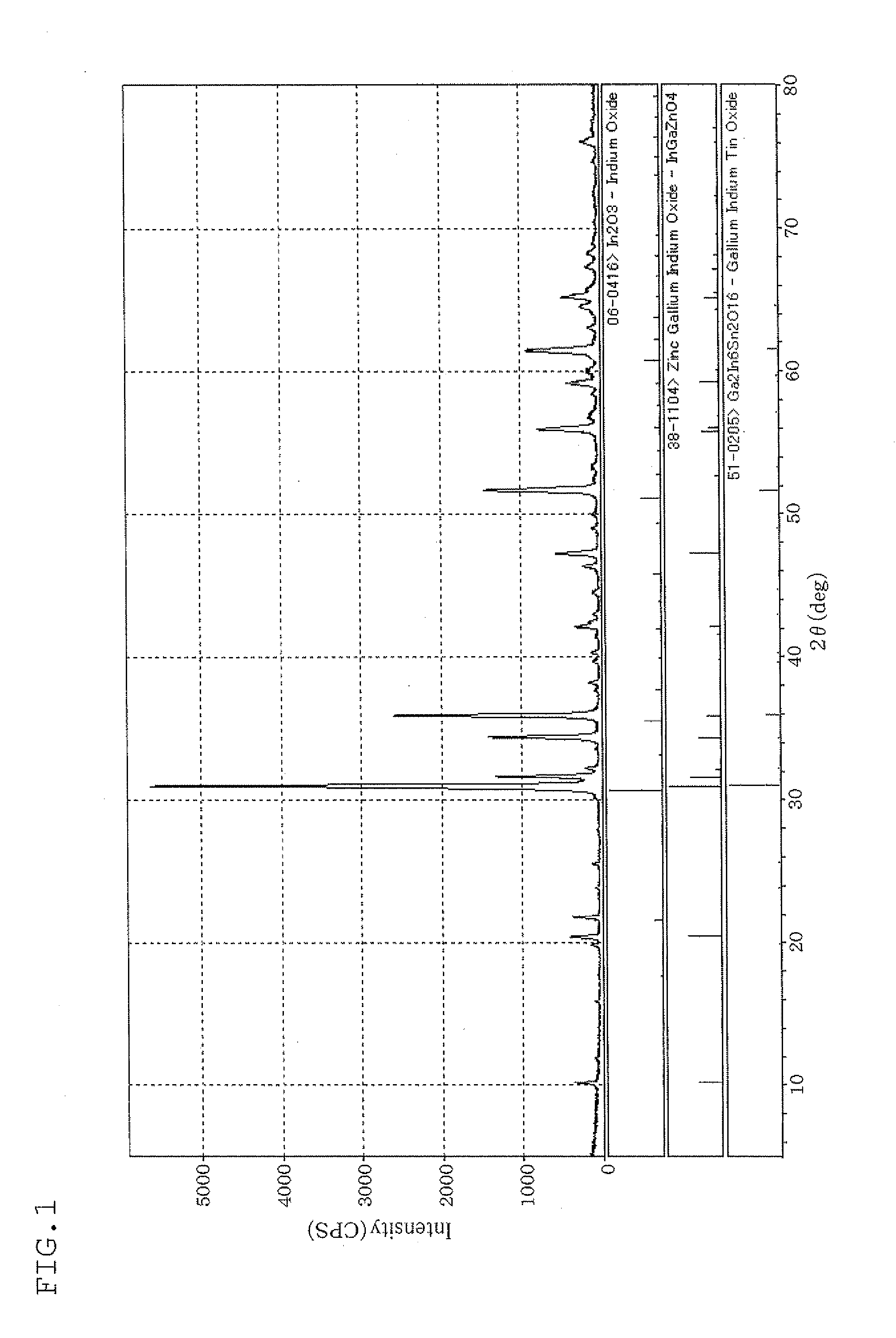

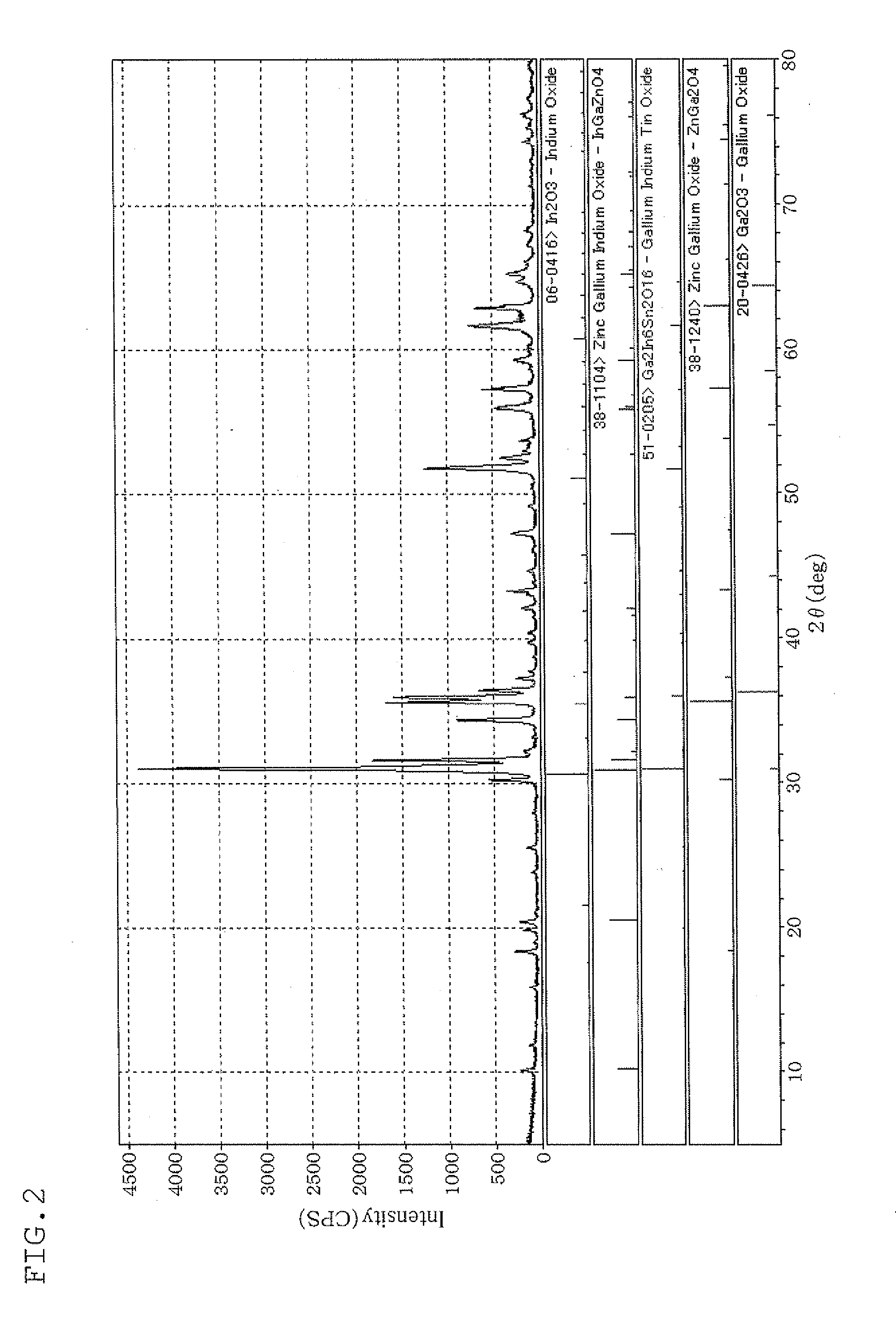

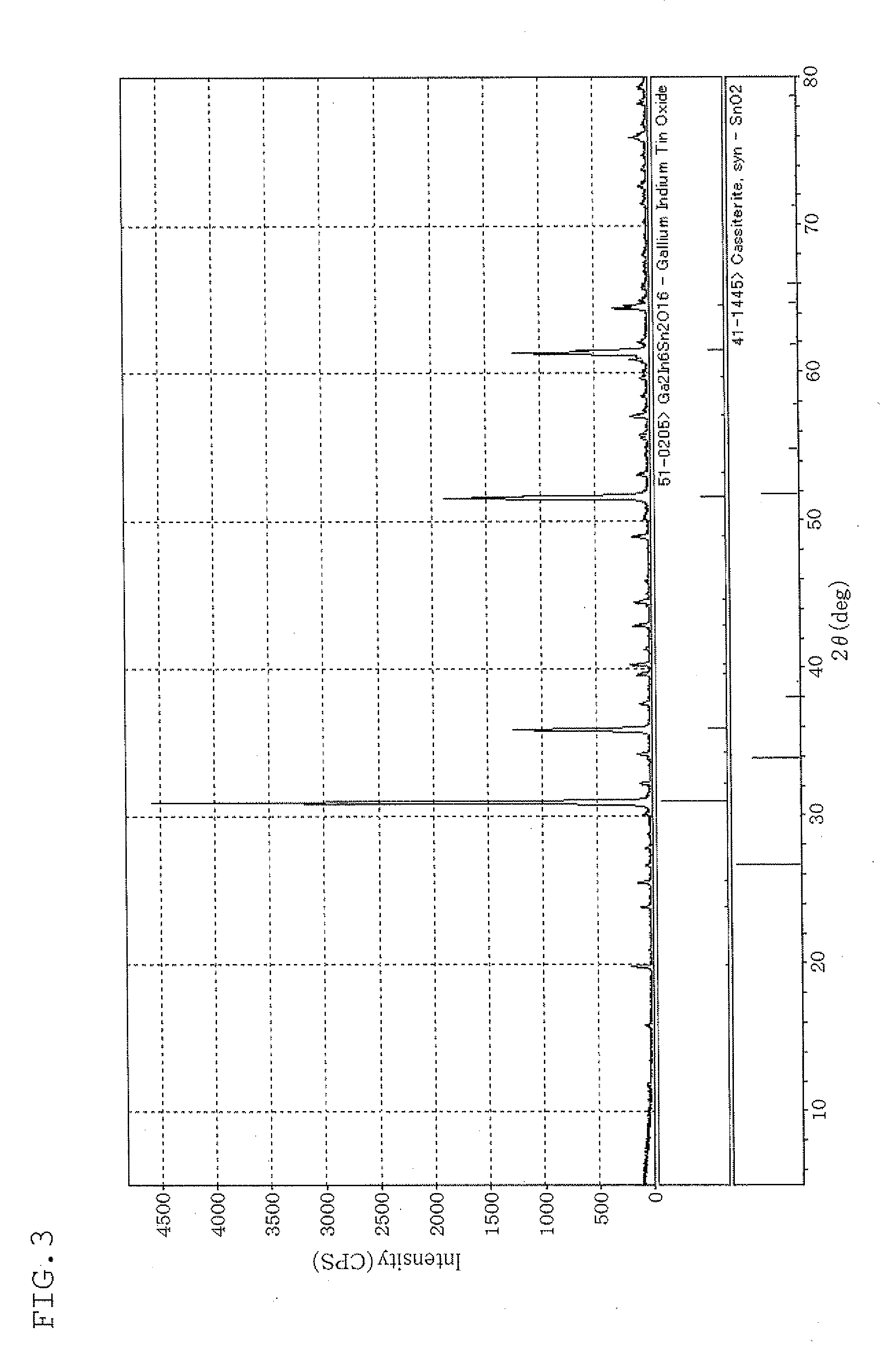

Method for producing a-IGZO oxide thin film

ActiveUS8148245B2Good reproducibilityImprove quality stabilityCellsSynthetic resin layered productsSputteringIndium

There is provided a method for producing an a-IGZO oxide thin film by sputtering, which can control the carrier density of the film to a given value with high reproducibility. The method is an amorphous In—Ga—Zn—O based oxide thin film production method including: providing a sintered oxide material consisting essentially of indium (In), gallium (Ga), zinc (Zn), and oxygen (O) as constituent elements, wherein the ratio [In] / ([In]+[Ga]) of the number of indium atoms to the total number of indium and gallium atoms is from 20% to 80%, the ratio [Zn] / ([In]+[Ga]+[Zn]) of the number of zinc atoms to the total number of indium, gallium and zinc atoms is from 10% to 50%, and the sintered oxide material has a specific resistance of 1.0×10−1 Ωcm or less; and producing a film on a substrate by direct current sputtering at a sputtering power density of 2.5 to 5.5 W / cm2 using the sintered oxide material as a sputtering target.

Owner:JX NIPPON MINING & METALS CORP

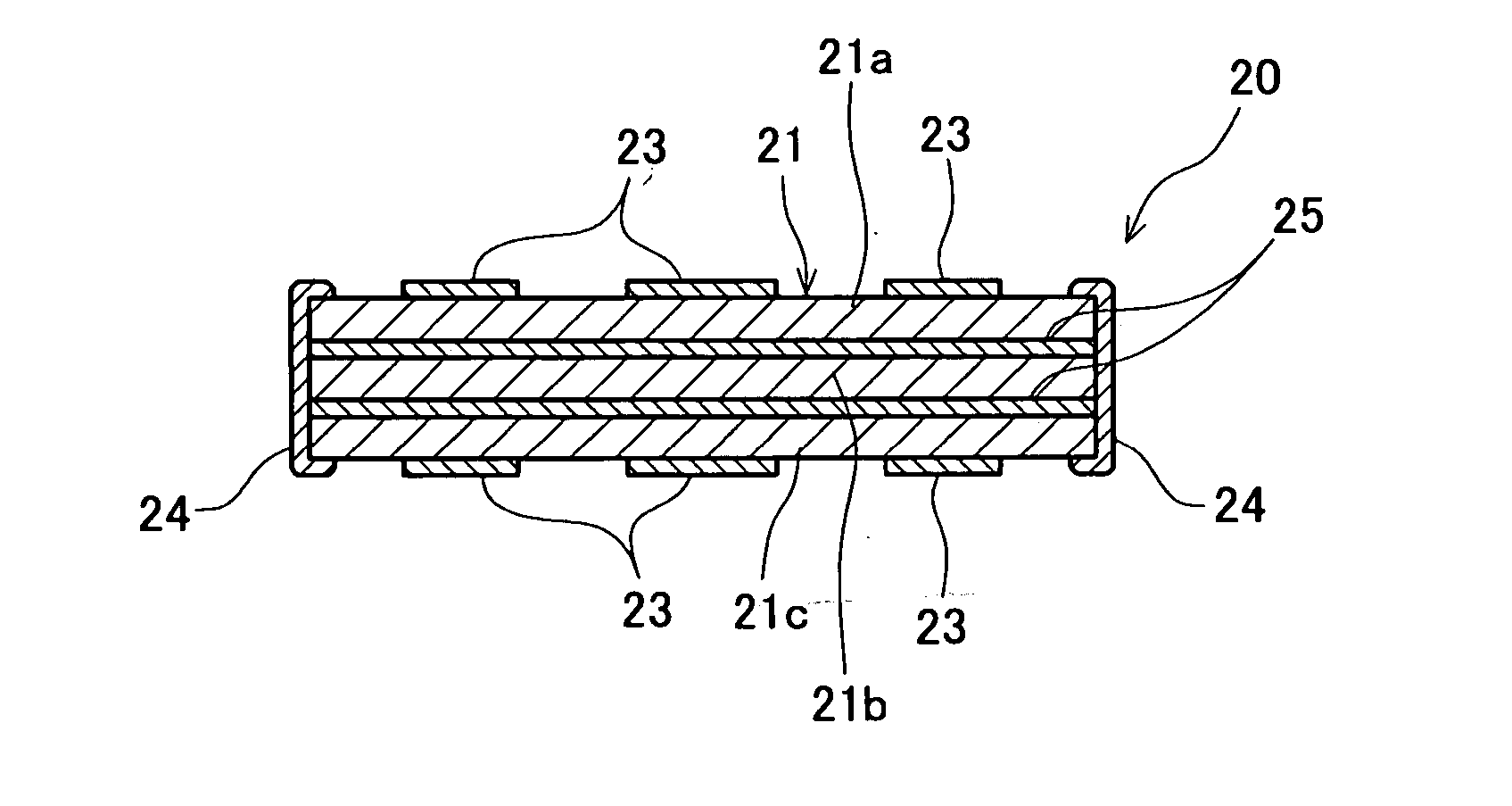

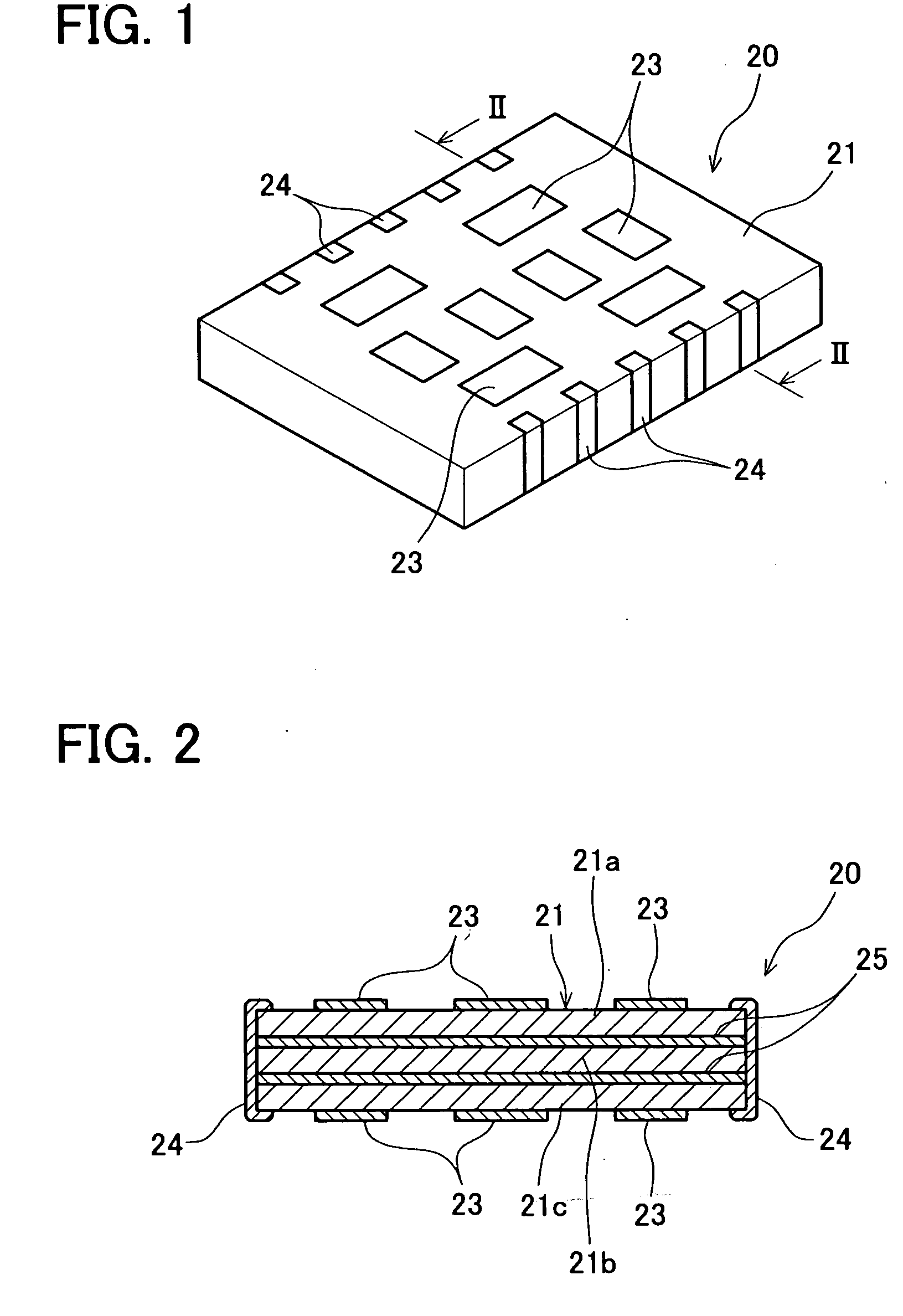

Ceramic electronic component and production method therefor

InactiveUS20040070915A1Quality improvementImprove electrical characteristicsLayered productsSemiconductor/solid-state device detailsOrganic compoundElectron

A ceramic electronic component (20) having surface conductor films (23) and side-surface conductor films (24) excellent in burning shrinkage, bonding strength, solder heat resistance, solder wettability and the like. A method of producing a ceramic electronic component which uses a conductive paste containing as a main component Ag-based metal powder, the surface of the metal powder being coated with an organic metal compound or a metal oxide having as a constituting element any one selected from a group consisting of Al, Zr, Ti, Y, Ca, Mg and Zn, to form conductor films (23, 24 25) on a ceramic base material (21). A side-surface conductor film-forming paste differs form a surface conductor film-forming paste in that (1) the former paste has a relatively small coating amount of the organic metal compound or metal oxide and / or (2) contains either at least one kind of inorganic oxide powder as an accessory composition or a comparatively high percentage of the inorganic oxide powder.

Owner:TDK CORPARATION +1

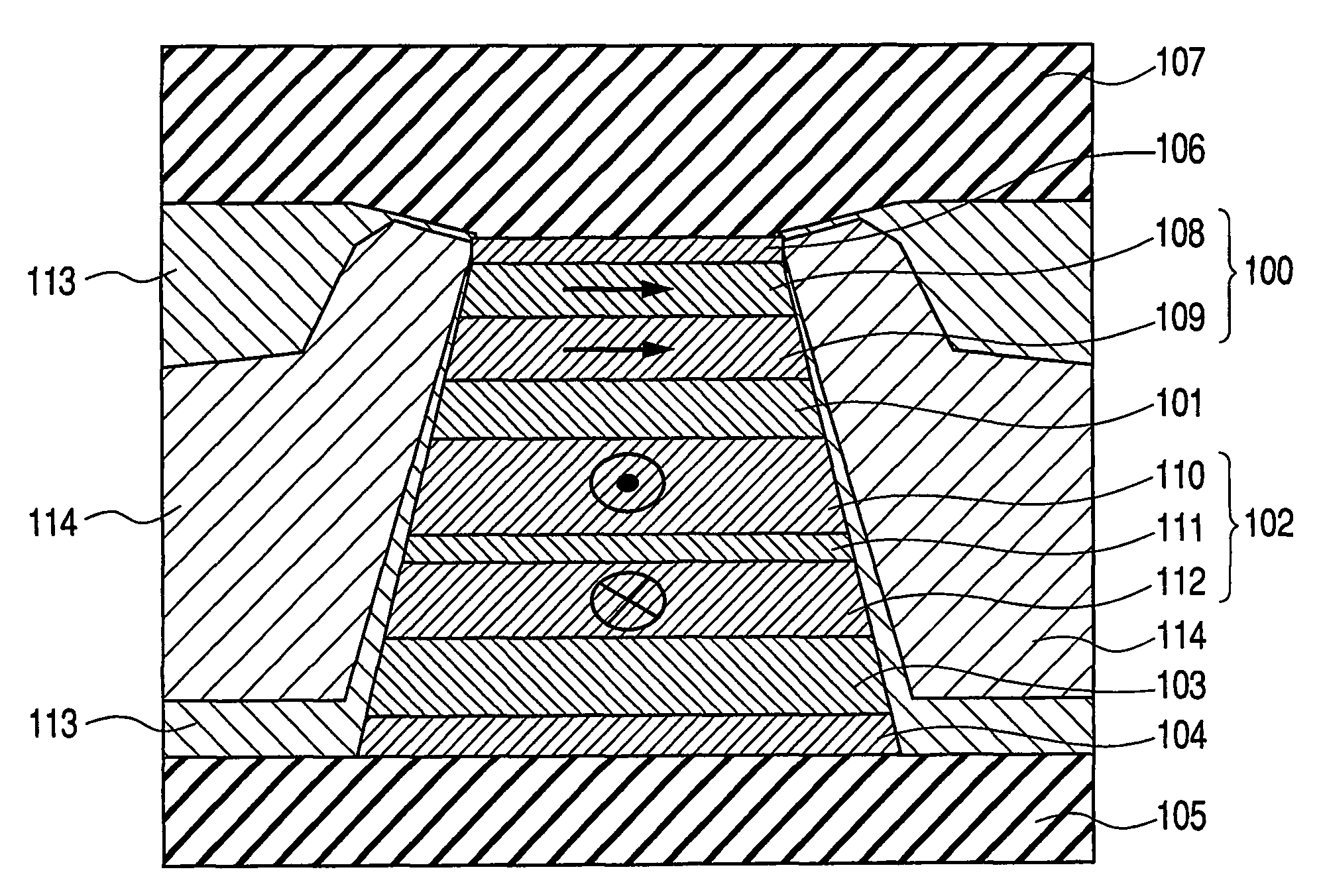

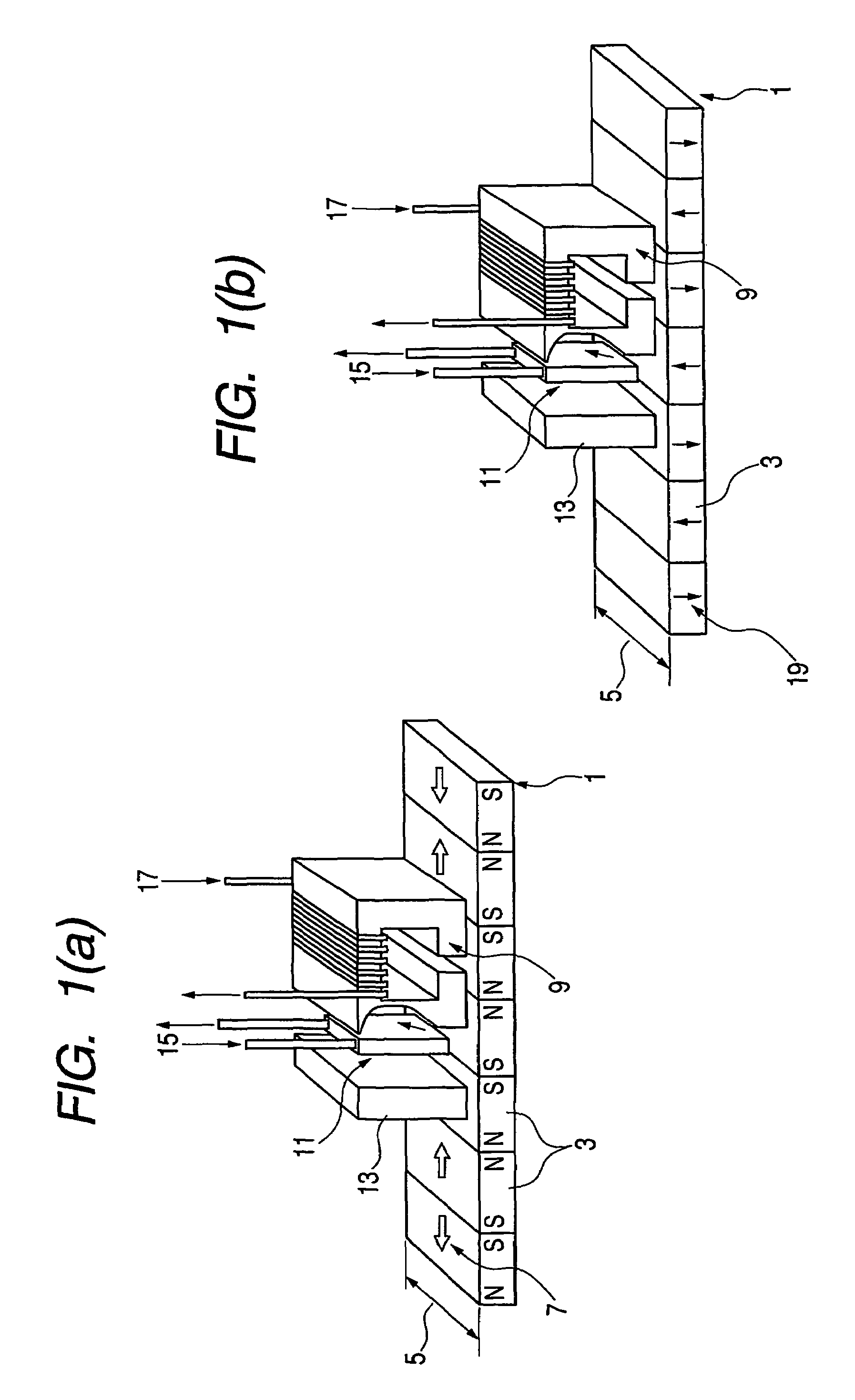

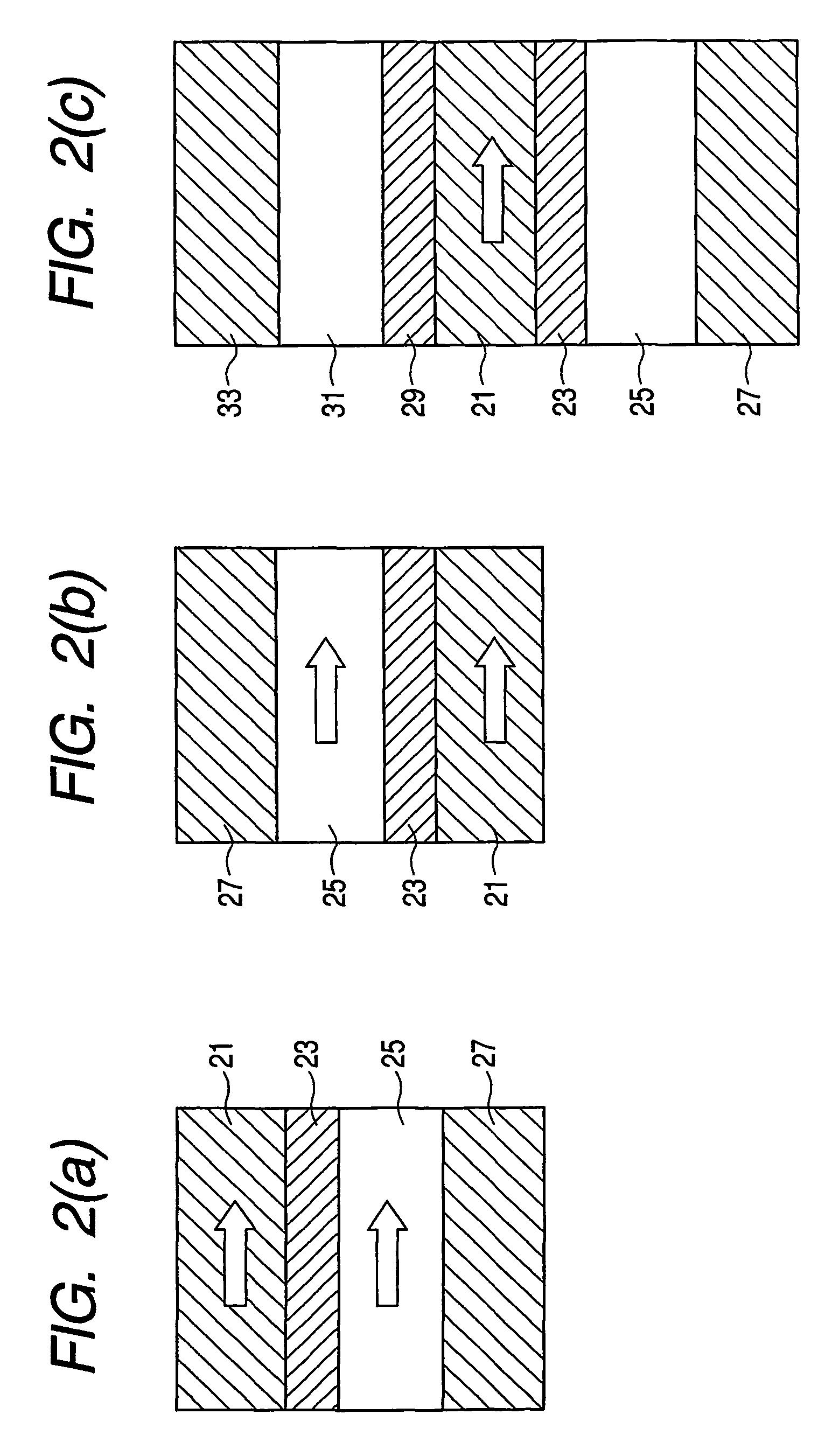

Composite free layer for stabilizing magnetoresistive head

A magnetoresistive read head includes a spin valve having at least one free layer spaced apart from at least one pinned layer by a spacer. The free layer includes a cobalt compound as a thin film including at least one of Co—X, CoFe—X and CoNi—X, where X is an element from the lanthanoid family (a 4-f element). The content of Co is higher than 80 percent, and the content of the lanthanoid element is less than 10 percent. The film may comprise the entire free layer, or be positioned adjacent to one or more conventional free layer films. The pinned layer is a conventional single layer, or a synthetic multi-layered structure having a spacer between sub-layers. Because the spin valve structure has a high exchange stiffness and damping factor, spin transfer effect is reduced and a high-speed dynamic response is provided.

Owner:TDK CORPARATION

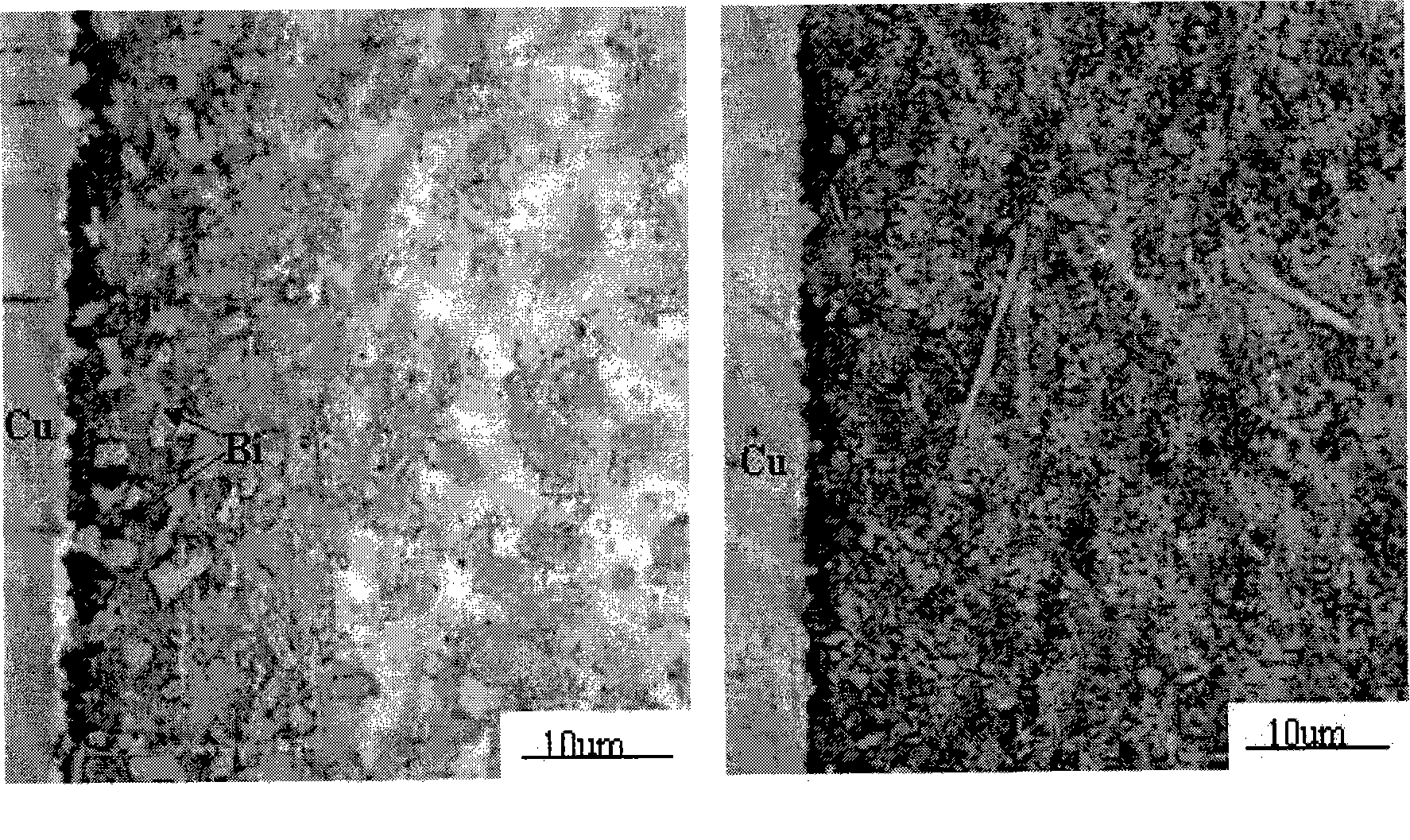

Copper alloy and sliding bearing having improved seizure resistance

InactiveUS6254701B1Improved seizure resistanceMaintain corrosion resistanceBearing componentsSolid state diffusion coatingSolid solutionMetal

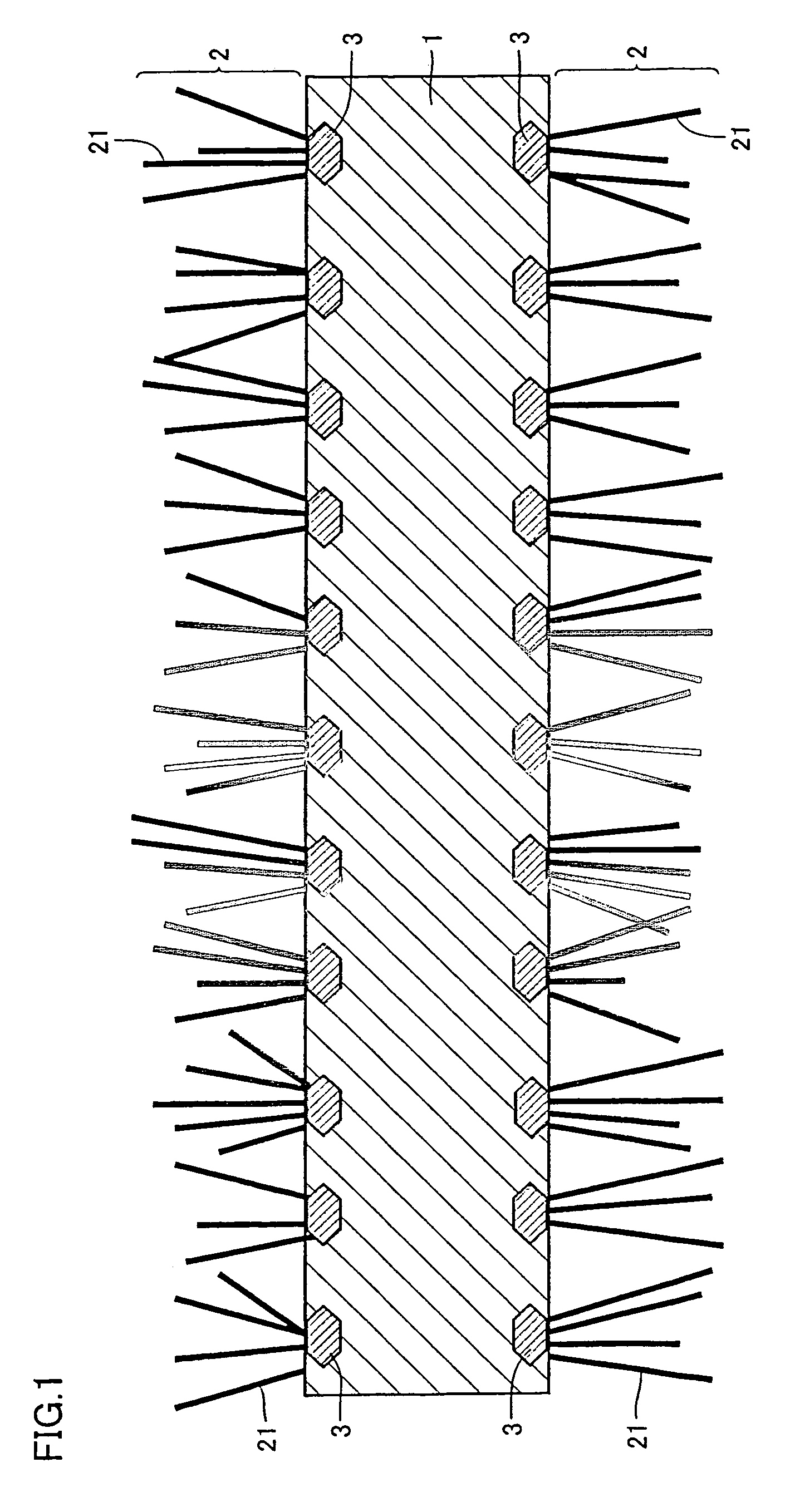

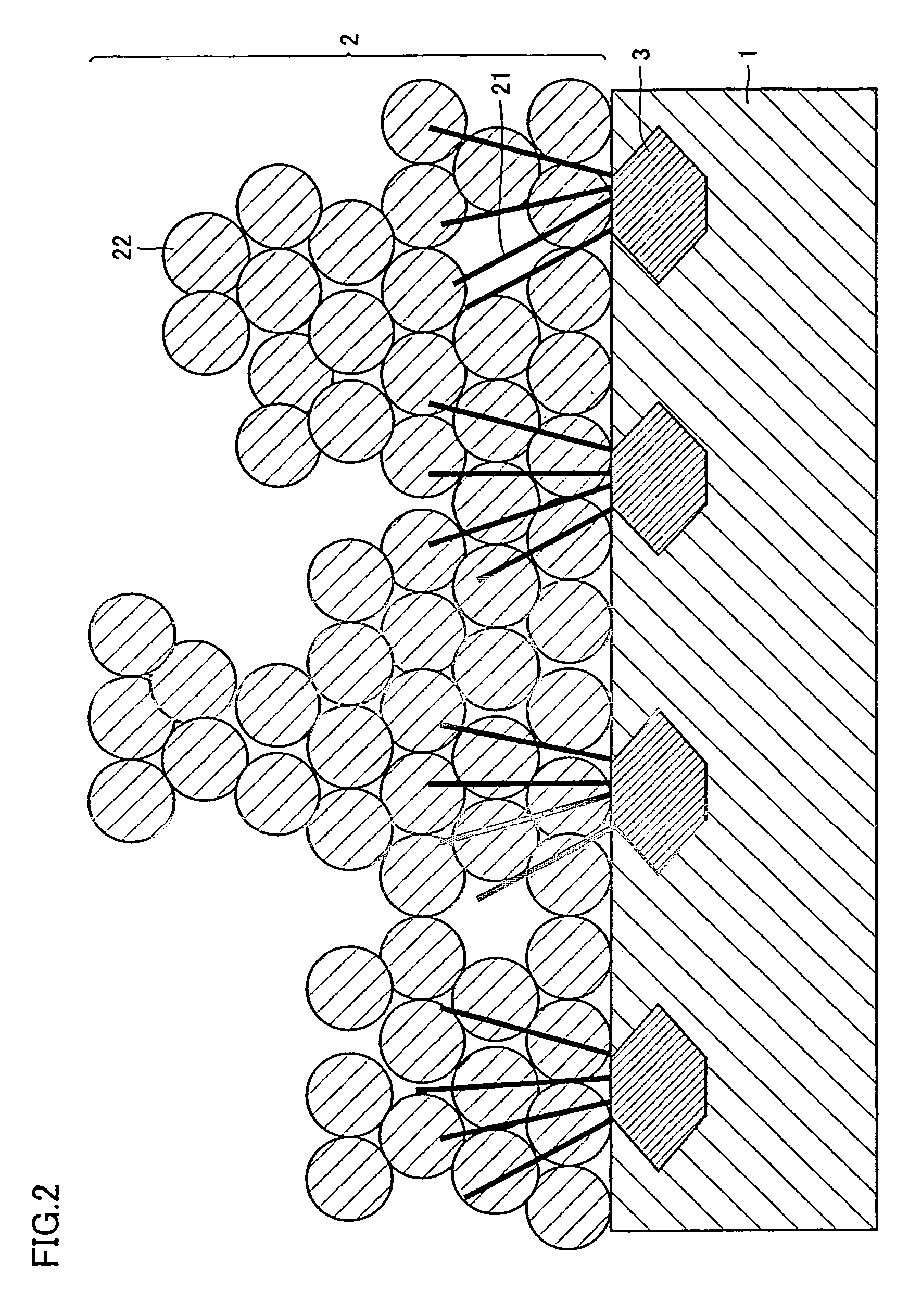

A sliding bearing having improved seizure resistance has the following structure.(a) A bearing layer (2). It comprises a copper alloy containing in a Cu matrix Ag, Sn, Sb, In, Mn, Fe, Bi, Zn, Ni and / or Cr.(b) A fisrst sub-layer (3) of the bearing layer (2). It (3) contains concentrated element, hexagonal compound or eutectic of said element(s).(c) A second sub-layer (2a) in which said element in essential solid-solution state.(d) Metal backing (1).

Owner:LUCENT TECH INC +1

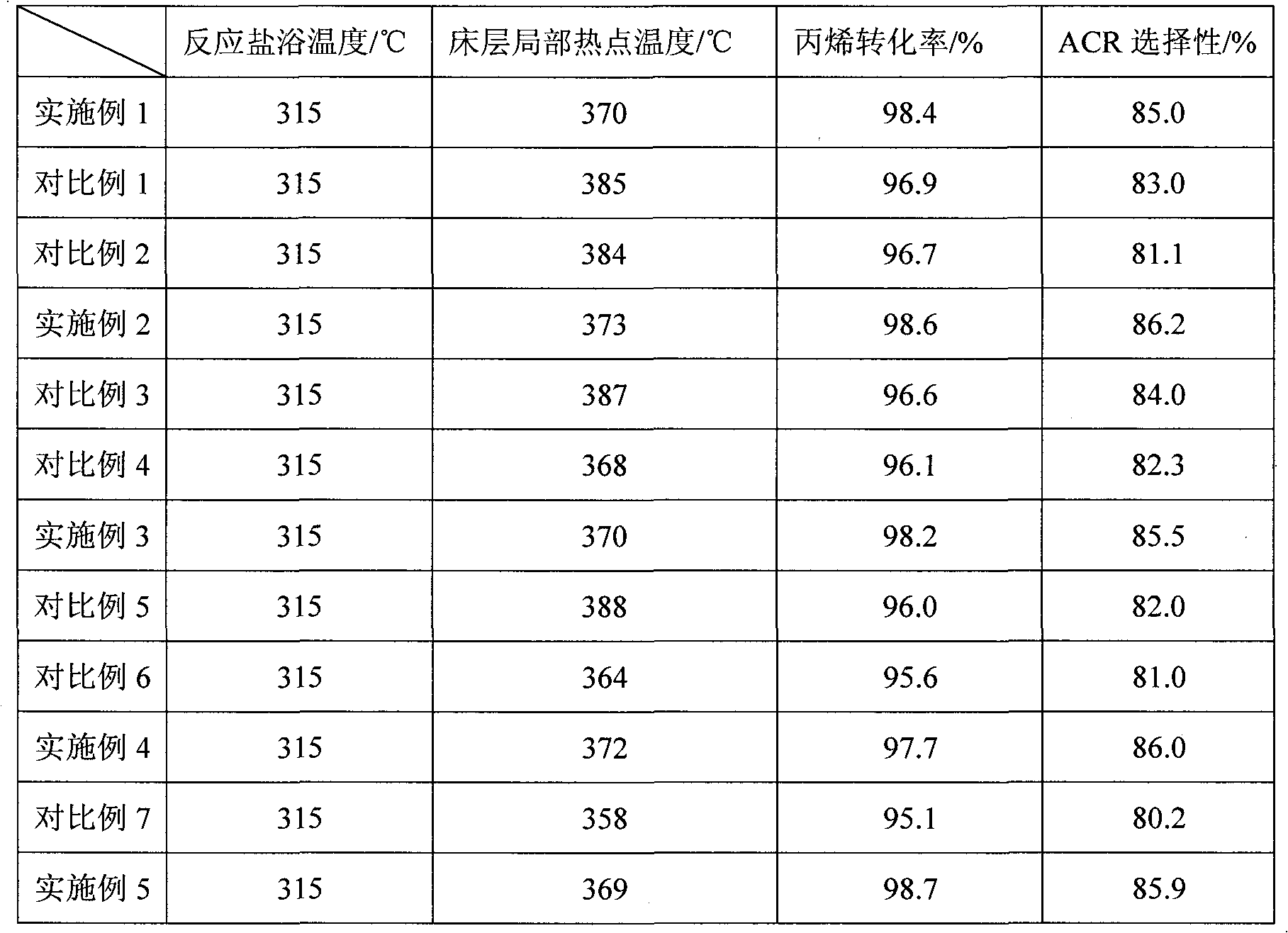

Multilayer composite metal oxide catalyst and preparation method thereof

ActiveCN102247862AHigh reactivityHigh selectivityOrganic compound preparationCarbonyl compound preparationAlkaline earth metalCerium

The invention relates to a multilayer composite metal oxide catalyst. The multilayer composite metal oxide catalyst has the general formula as follows: Mo[a]Bi[b]Ni[c]Cs[d]Cu[e]Ti[f]A[g]B[h]C[i]O[j], wherein Mo is molybdenum, Bi is bismuth, Ni is nickel, Cs is cesium, Cu is copper, and Ti is titanium; A is at least one element selected from arsenic, tellurium, manganese, cerium, niobium, zirconium, rubidium, cadmium and germanium; B is at least one element selected from cobalt, boron, strontium, tantalum, alkali metal and alkaline earth metal; C is at least one element selected from vanadium, stannum, gallium, zinc, ferrum, tungsten and stibium; and O is oxygen. The composite metal oxide catalyst has a multilayer structure in which the concentrations of all the elements are reduced progressively from a matrix at the inner layer to the outer layer. The catalyst provided by the invention can effectively reduce the local heat accumulation of single pipe reactors and inhibit the formation of hot spots, and has the characteristics of high reactivity and selectivity and long service life.

Owner:PETROCHINA CO LTD

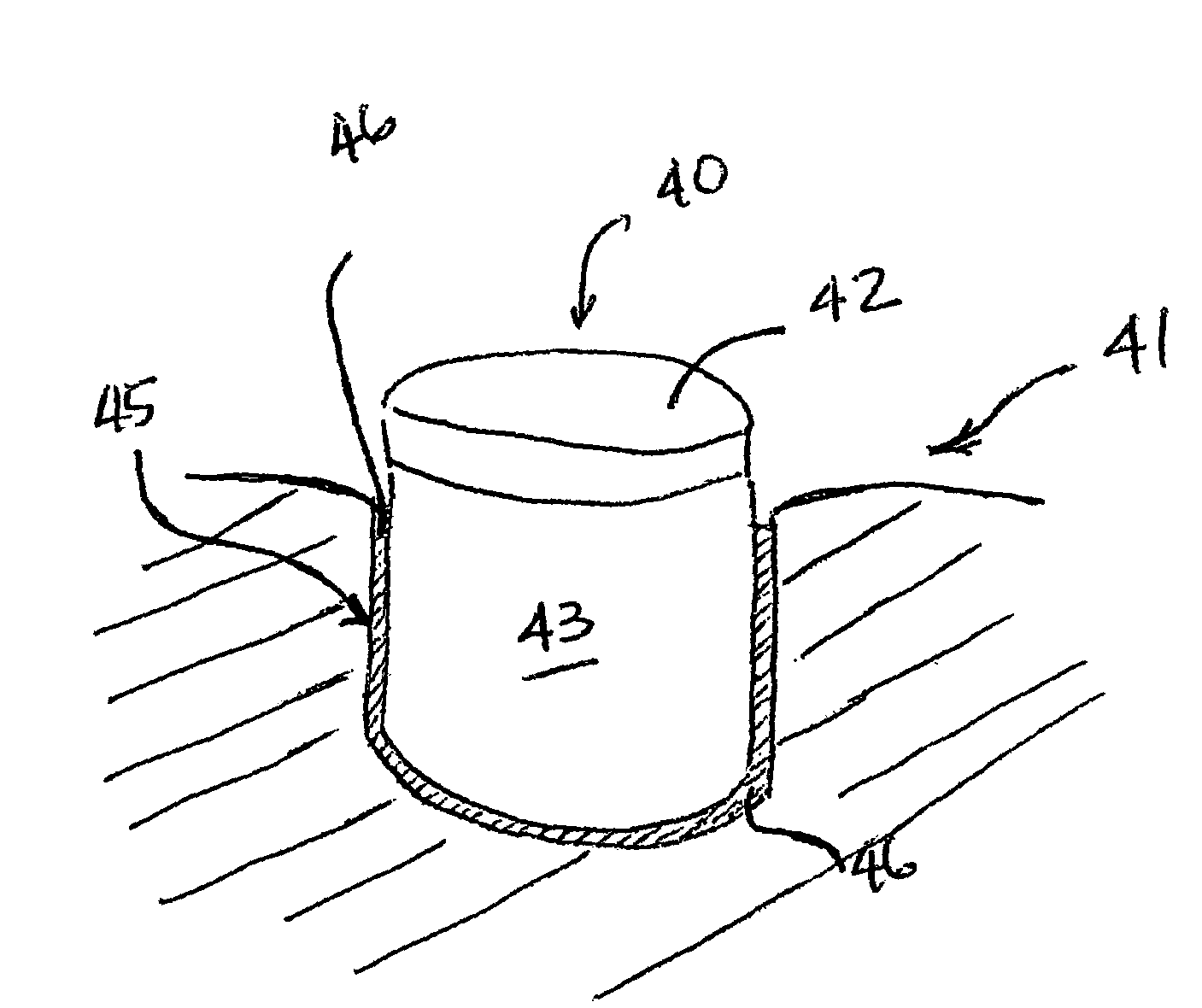

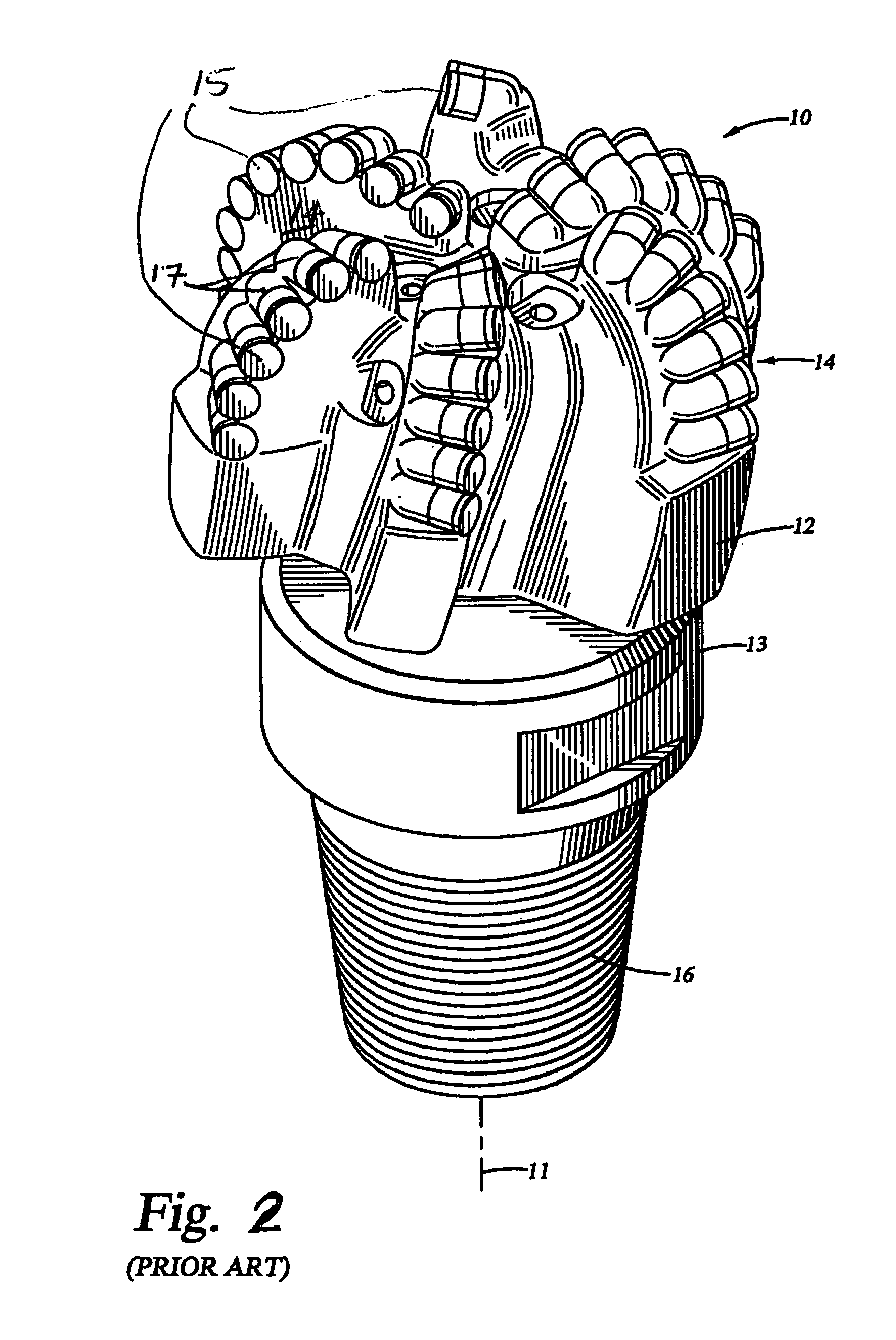

Braze alloys

An improved braze alloy is microalloyed to include about 0.0005 wt % to about 0.5 wt % of at least one aggressively surface acting element selected from tellurium (Te), selenium (Se), antimony (Sb), bismuth (Bi), and gallium (Ga), or any combination thereof. The braze alloys may include at least about 30% by weight of at least one base metal selected from the group of silver (Ag), copper (Cu), gold (Au), nickel (Ni), or aluminum (Al). In one example, a silver braze alloy suitable for brazing a cutter to a drill bit body is microalloyed to improve a characteristic of the braze material.

Owner:SMITH INT INC

Nano silver-tin oxide electric contact and its prepn

InactiveCN1417817AImprove plasticityImprove conductivityContact materialsMetal/alloy conductorsRare earthTitanium oxide

The present invention belongs to metal-based composite material technology. The electric contact material consists of Ag 70-97 wt%, nanometer tin oxide 3-22 wt% and RE elements 0.1-8 wt%. The electric contact is produced through the processes of preparation of zine oxide or titanium oxide doped nanometer tin oxide, mixing metal oxide powder, pressing the mixture to form, sintering, extruding, drawing wire and forming into rivet type or stripe contact. The pressure in pressing the mixture to form is 150-400 MPa and the sintering temperature is 800-900 deg.c. The electric contact can be used inelectric appliance, instrument and switch.

Owner:TIANJIN UNIV

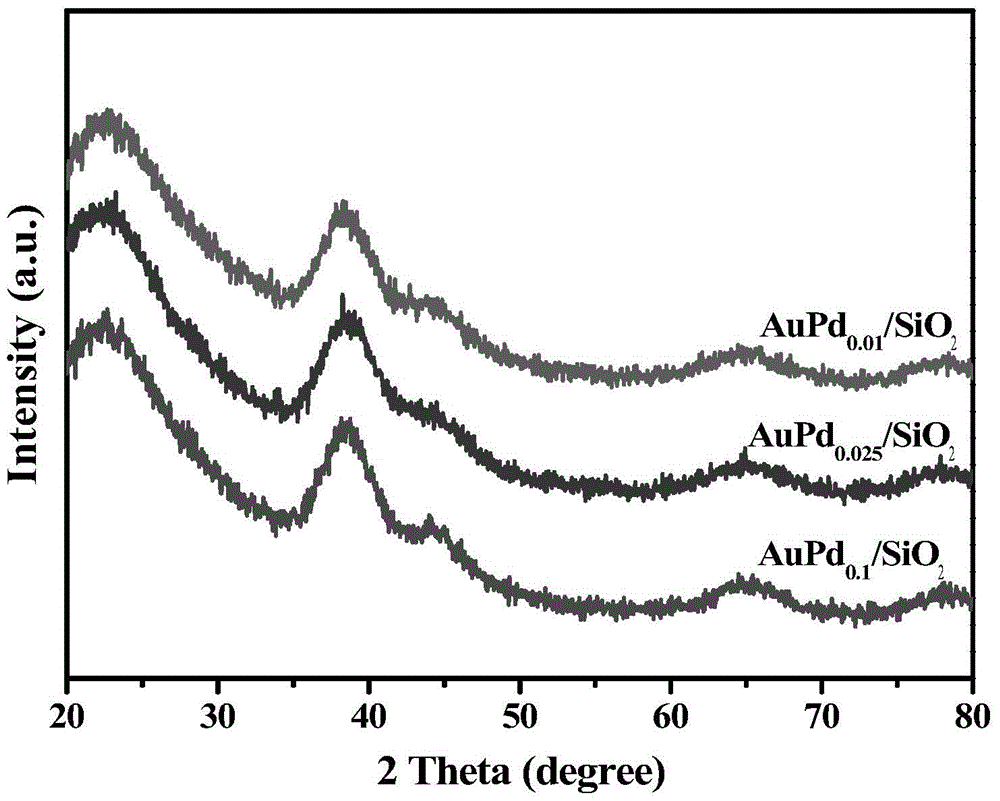

Alloy single atom catalyst for selective hydrogenation of alkyne

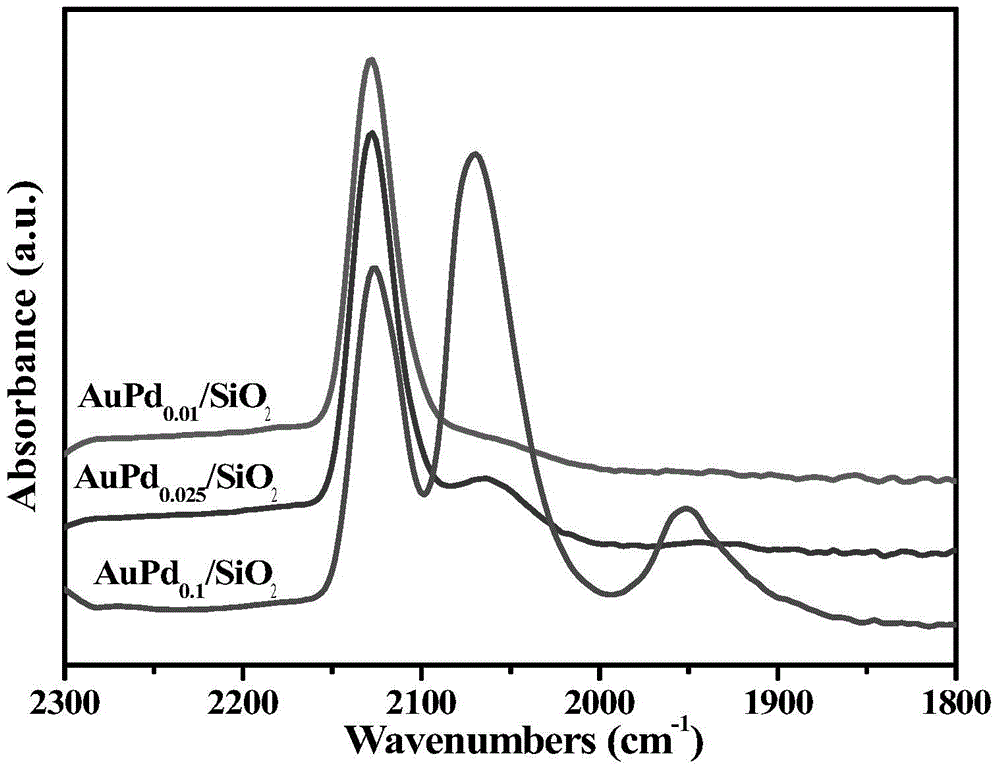

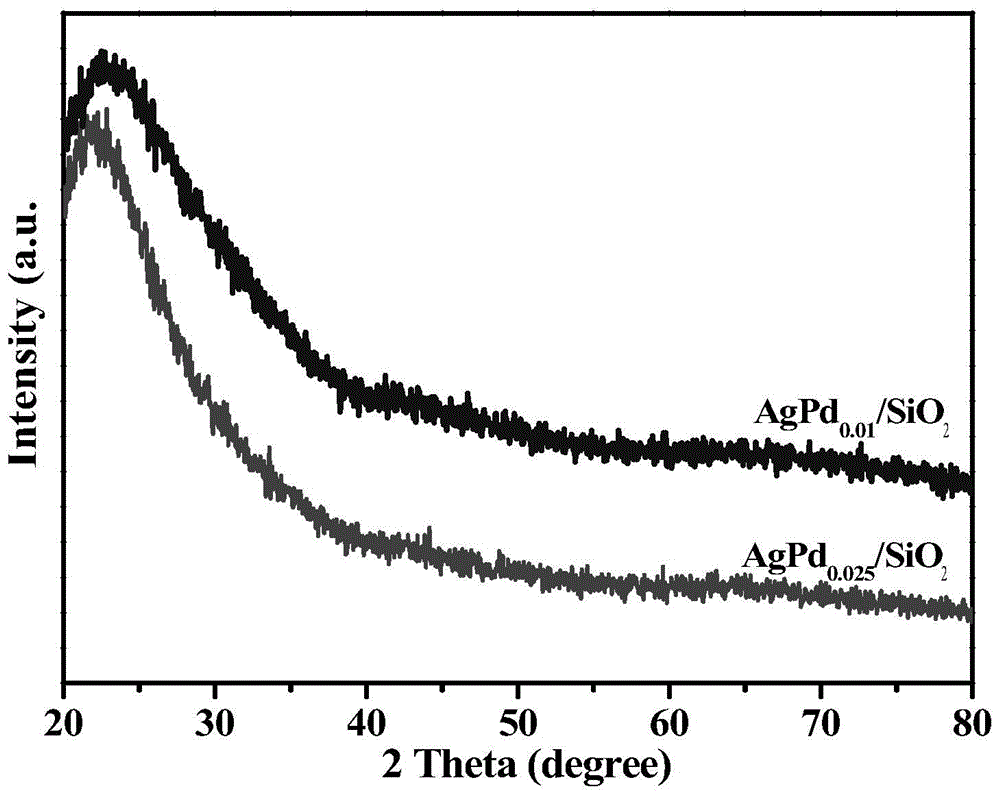

ActiveCN104588006AEfficient use ofLess side effectsHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsAlloy catalystAlloy

The present invention relates to a palladium-containing alloy single atom catalyst for selective hydrogenation of alkyne. According to the catalyst, an inert oxide SiO2 is adopted as a carrier, Pd and one or two or more than two materials selected from metal elements in group IB or Group VIII excluding Pd are combined to prepare the supported palladium-containing alloy catalyst so as to make the Pd be in the complete or partial single atom distribution state, wherein the Pd accounts for 0.002-1% of the weight of the carrier, and the content of other metal elements accounts for 0.2-8% of the weight of the carrier. The palladium-containing alloy single atom catalyst has characteristics of high catalytic hydrogenation activity, high ethylene selectivity and the like, and has the good reaction catalysis performance in the reaction for preparing ethylene gas to eliminate trace acetylene through petroleum cracking under the condition close to the industrial condition.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS7018696B2Sufficient chemicalSufficient thermalLayered productsVacuum evaporation coatingManganeseHigh reflectivity

A silver-based alloy thin film is provided for the highly reflective or semi-reflective coating layer of optical discs. Elements that can be added to silver to produce useful silver alloys include zinc, aluminum, copper, manganese, germanium, yttrium, bismuth, scandium, and cobalt. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

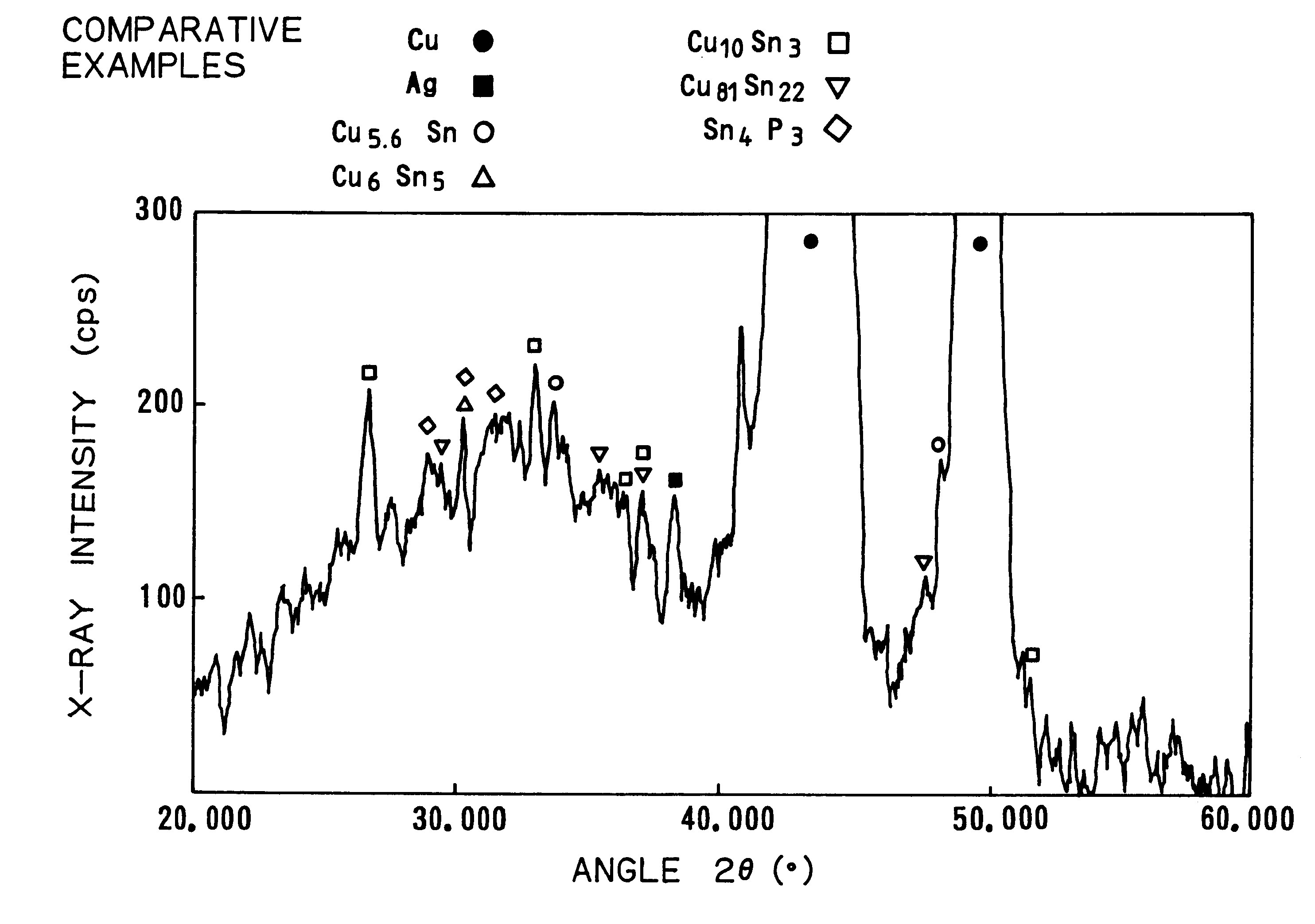

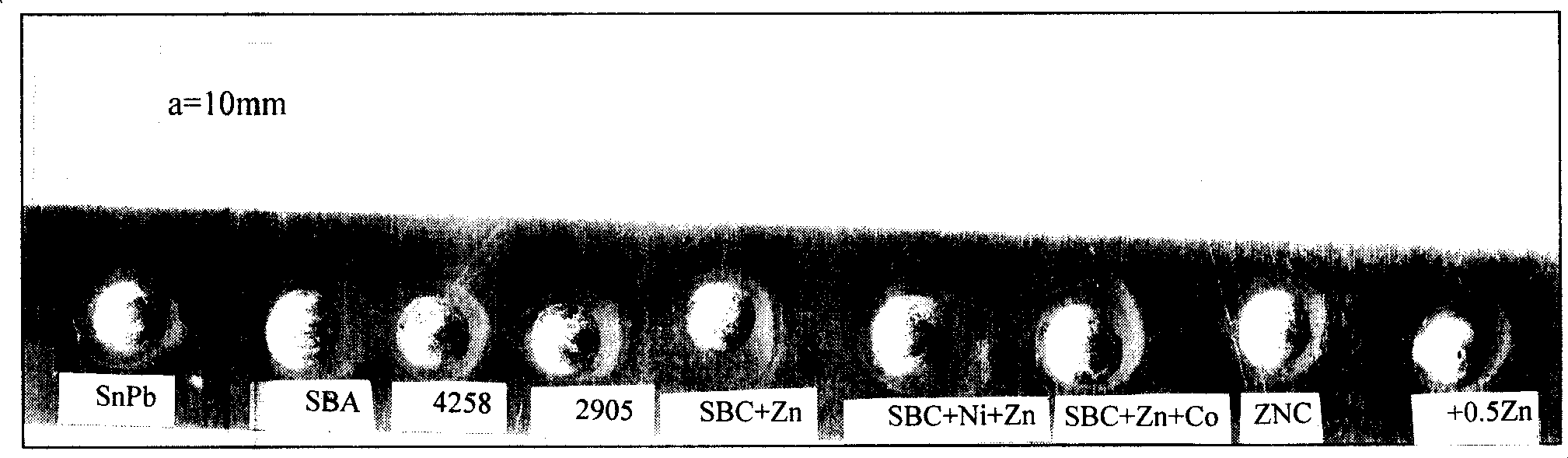

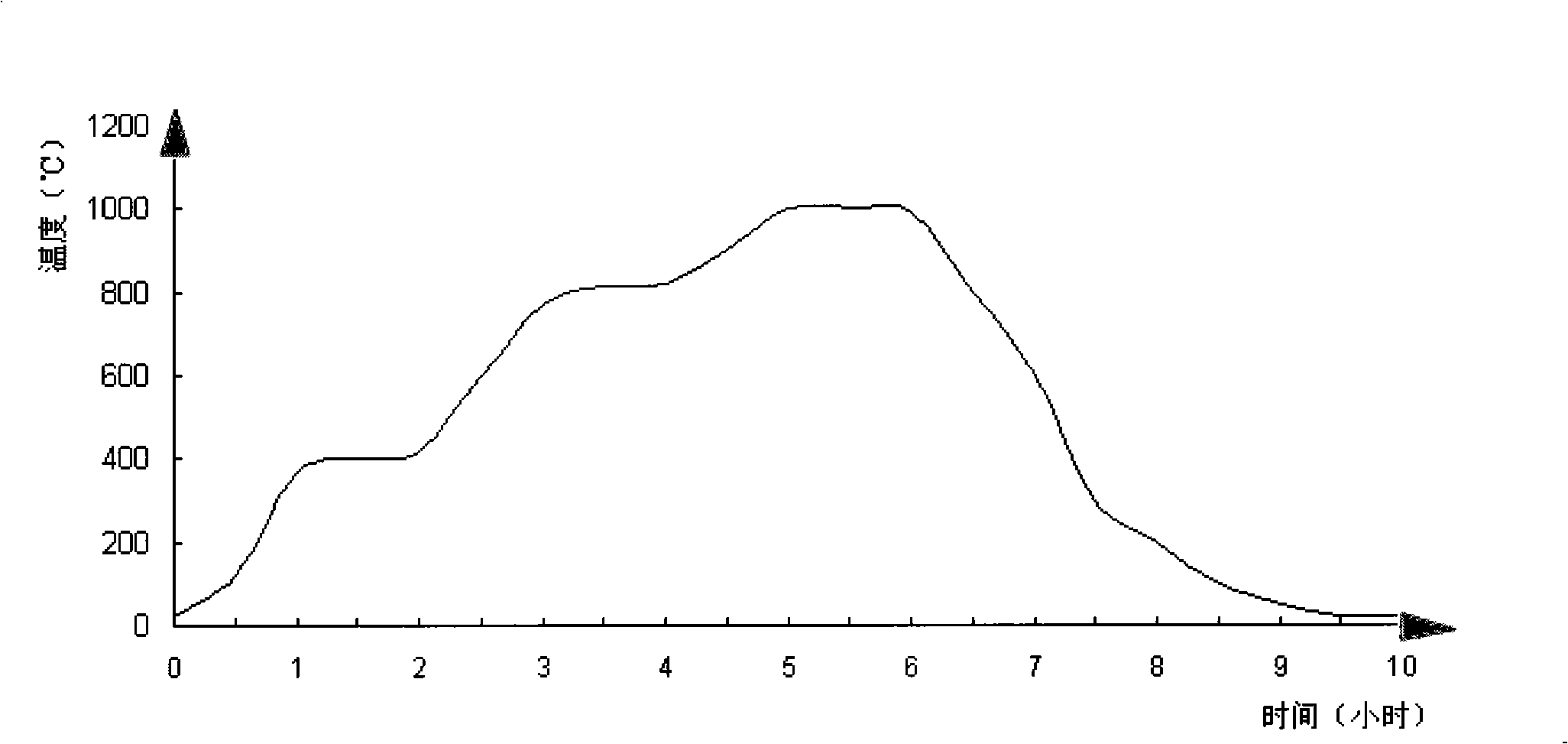

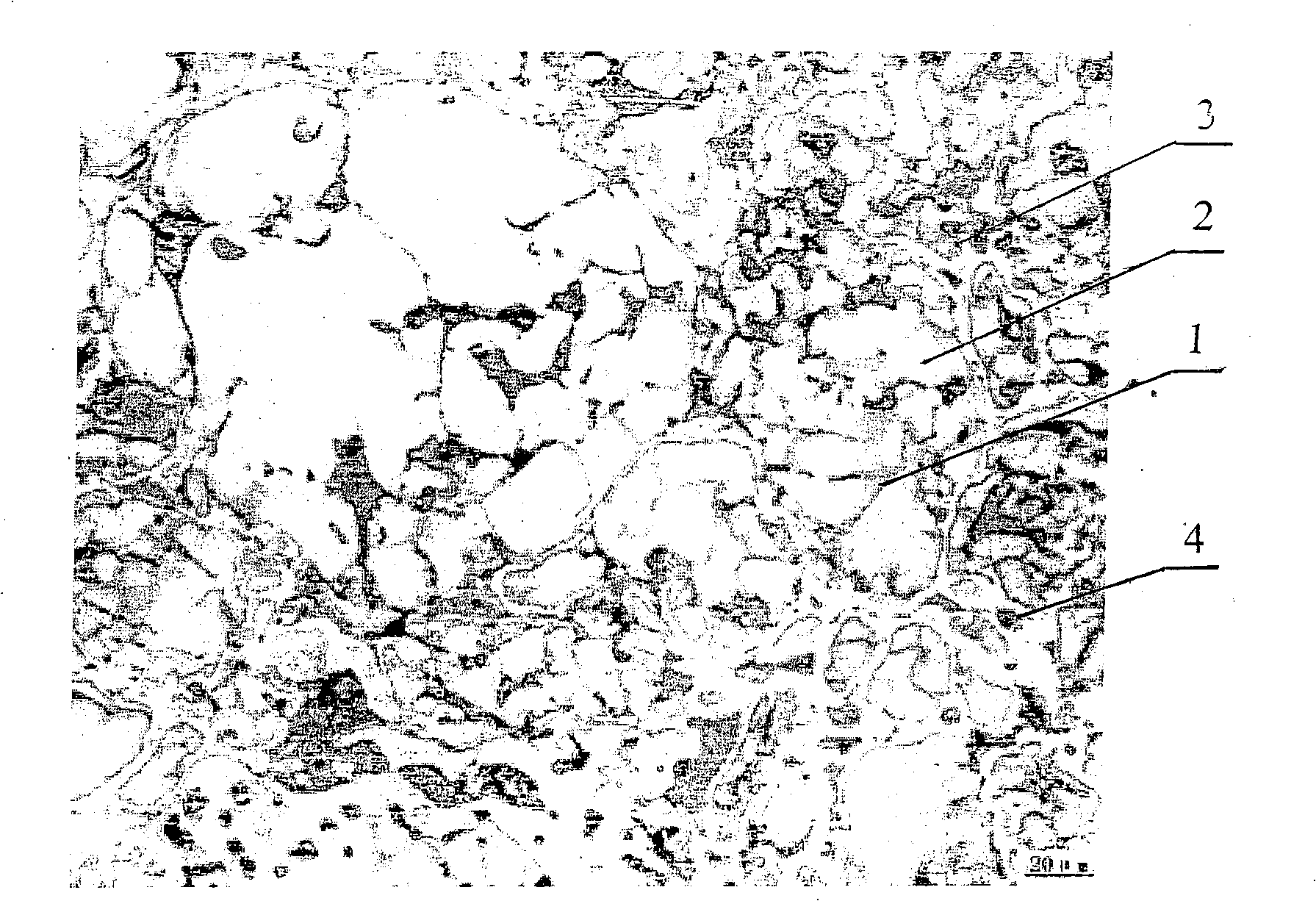

Tin bismuth cuprum series leadless solder and preparation method thereof

ActiveCN101380700ALow Sn contentReduce heat impact damageWelding/cutting media/materialsSoldering mediaCopperMechanical property

The invention relates to a tin-bismuth-copper series lead-free solder and a manufacture method thereof. Counted by weight percentage, the invention is characterized by including 29 minus or plus 1 percent of Bi, 0.5 minus or plus 0.1 percent of Cu, equal to or more than 0.005 percent and equal to or less than 0.5 percent of Zn; the rest is tin. The solder has a higher reliability; the solidifying segregation of the element Bi is remarkably restrained; the tissues of the welding points are uniform and thin; no pure-Bi layers appear on a welding interface; the IMC (compound between metals) stability of the interface is improved; the interface has excellent technique property, mechanical property and using reliability. The tin-bismuth-copper series lead-free solder can be widely applied to the low-temperature encapsulation occasion and the multilevel encapsulation occasion of an electric product.

Owner:BEIJING COMPO ADVANCED TECH

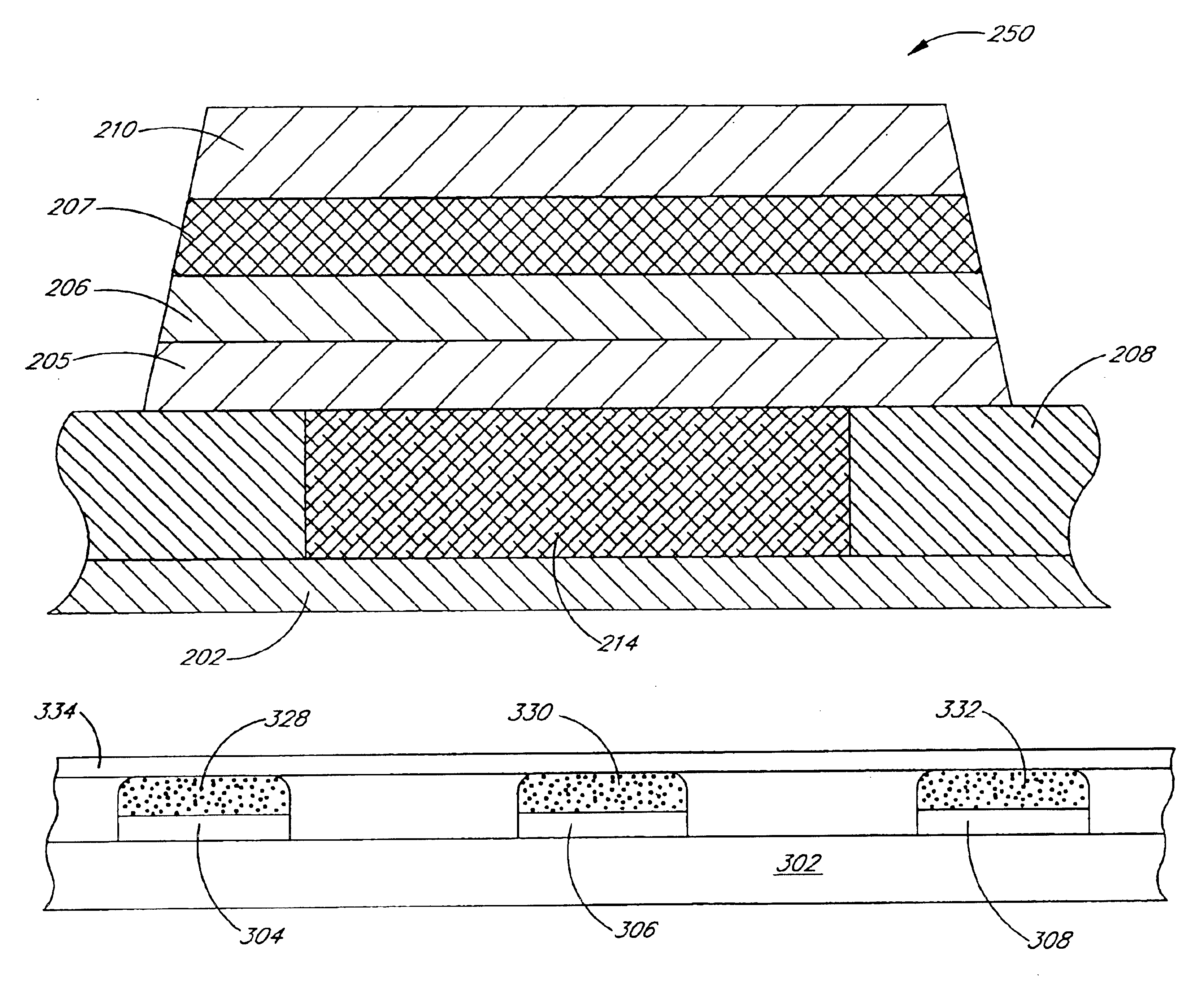

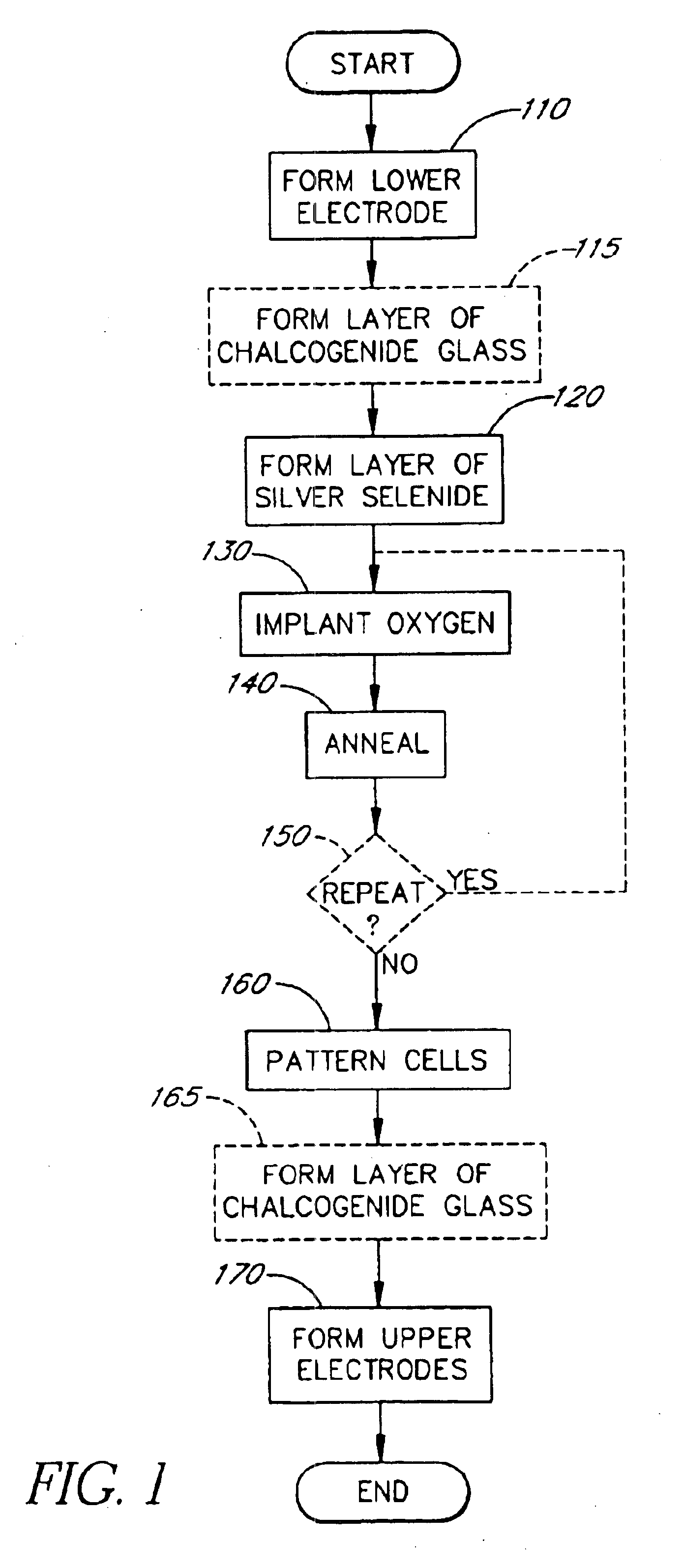

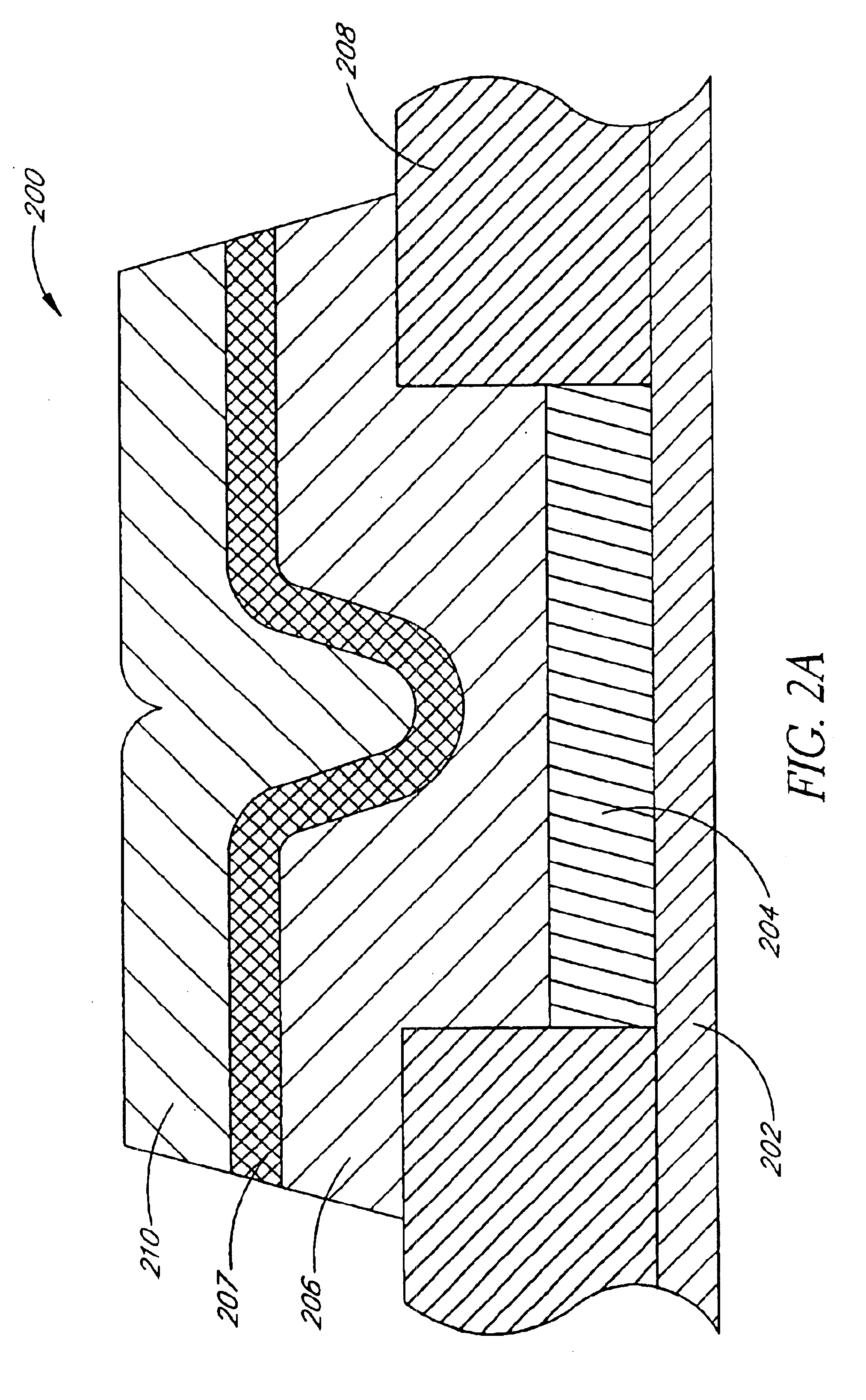

Methods to form a memory cell with metal-rich metal chalcogenide

InactiveUS6867114B2Improve uniformityEasy to controlSolid-state devicesSemiconductor/solid-state device manufacturingSulfurMetal chalcogenides

The invention relates to the fabrication of a resistance variable material cell or programmable metallization cell. The processes described herein can form a metal-rich metal chalcogenide, such as, for example, silver-rich silver selenide. Advantageously, the processes can form the metal-rich metal chalcogenide without the use of photodoping techniques and without direct deposition of the metal. For example, the process can remove selenium from silver selenide. One embodiment of the process implants oxygen to silver selenide to form selenium oxide. The selenium oxide is then removed by annealing, which results in silver-rich silver selenide. Advantageously, the processes can dope silver into a variety of materials, including non-transparent materials, with relatively high uniformity and with relatively precise control.

Owner:MICRON TECH INC

Multi-element heat-resistant aluminum alloy material with high strength and preparation method thereof

ActiveUS20120152414A1Improve mechanical propertiesImprove corrosion resistanceTransportation and packagingMetal-working apparatusHeat resistanceUltimate tensile strength

A heat-resistant aluminum alloy material with high strength and preparation method thereof are provided. The aluminum alloy material comprises (by weight %): Cu: 1.0˜10.0, Mn: 0.05˜1.5, Cd: 0.01˜0.5, Ti: 0.01˜0.5%, B: 0.01˜0.2 or C: 0.0001˜0.15, Zr: 0.01˜1.0, R: 0.001˜3 or (R1+R2): 0.001˜3, RE: 0.05˜5, and balance Al:, wherein, R, R1, and R2 include Be, Co, Cr, Li, Mo, Nb, Ni, W. The Al alloy has the advantages of narrow quasi-solid phases temperature range of alloys, low hot cracking liability during casting improved high temperature strength and high heat resistance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

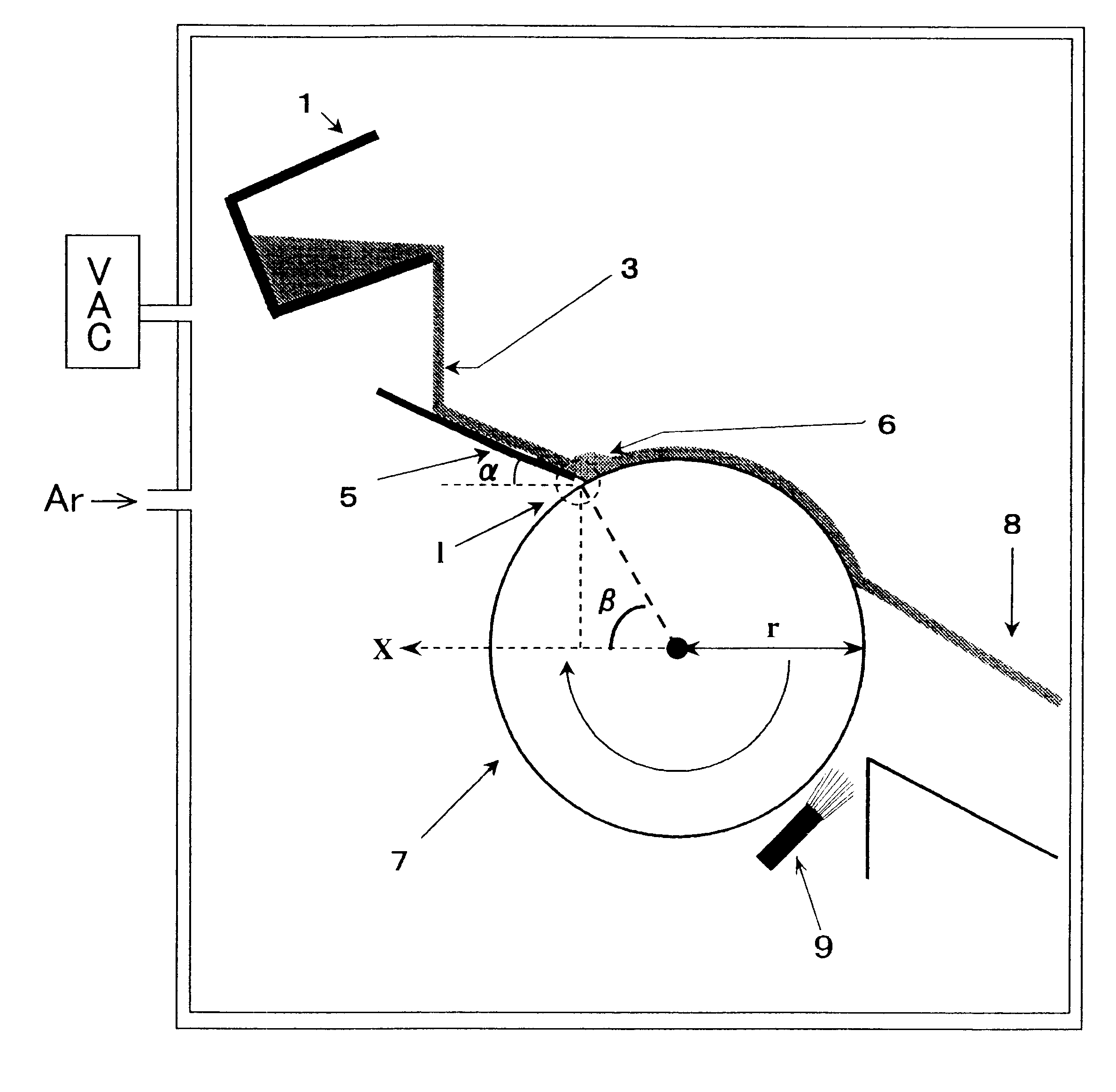

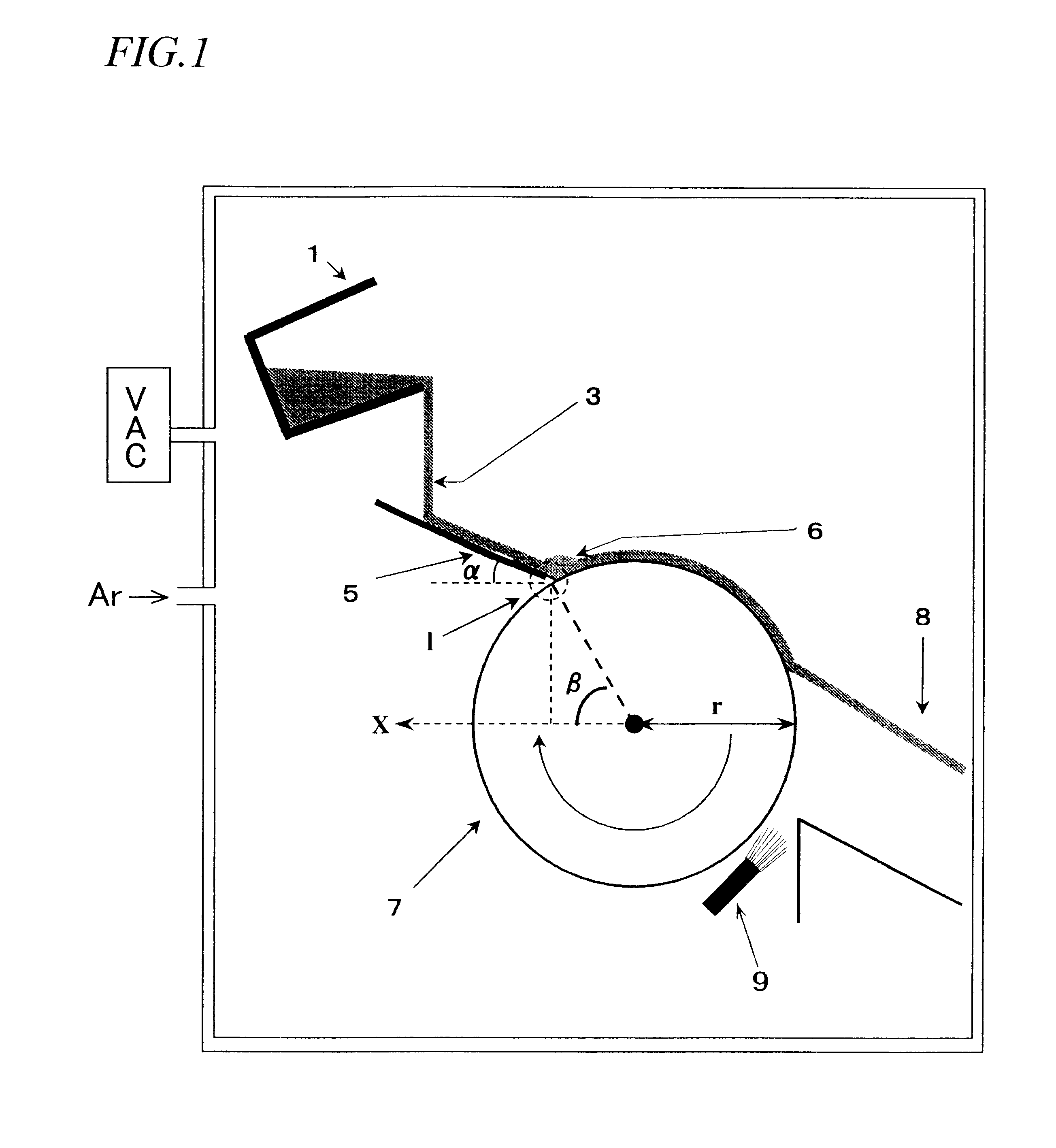

Method for preparing carbon-wrapped iron-cobalt nano wave-absorbing material

InactiveCN101567224AGood microwave absorptionImprove oxidation resistanceScreening apparatusPlasma techniqueOxidation resistantNanometre

The invention provides a method for preparing a carbon-wrapped iron-cobalt nano composite material with broad band and strong absorption. The composite material is prepared by adopting the technology that plasmas is generated by arc discharge of a negative electrode and a positive electrode under working gas, wherein the working gas is argon gas, simultaneously organic substances which can provide carbon elements and do not introduce impurities except C, H and O are added, the negative electrode is made of metals with high melting point and volatile difficulty such as tungsten and the like, and a target material for the positive electrode is iron-cobalt alloy, wherein the iron element accounts for 10 to 90 percent of alloy atomic. The carbon-wrapped iron-cobalt nano wave-absorbing material prepared by the method is a nano capsule formed by wrapping carbon outside the nano-scale iron-cobalt alloy; on one hand, a carbon shell layer is used as an oxidation resistant layer to increase the stability of a nano compound; and on the other hand, the carbon shell layer is used as a dielectric material and compounded with a magnetic iron-cobalt inner core so that the wave-absorbing property of the wave-absorbing material is superior to most classical ferrite and other most nano compound wave-absorbing materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

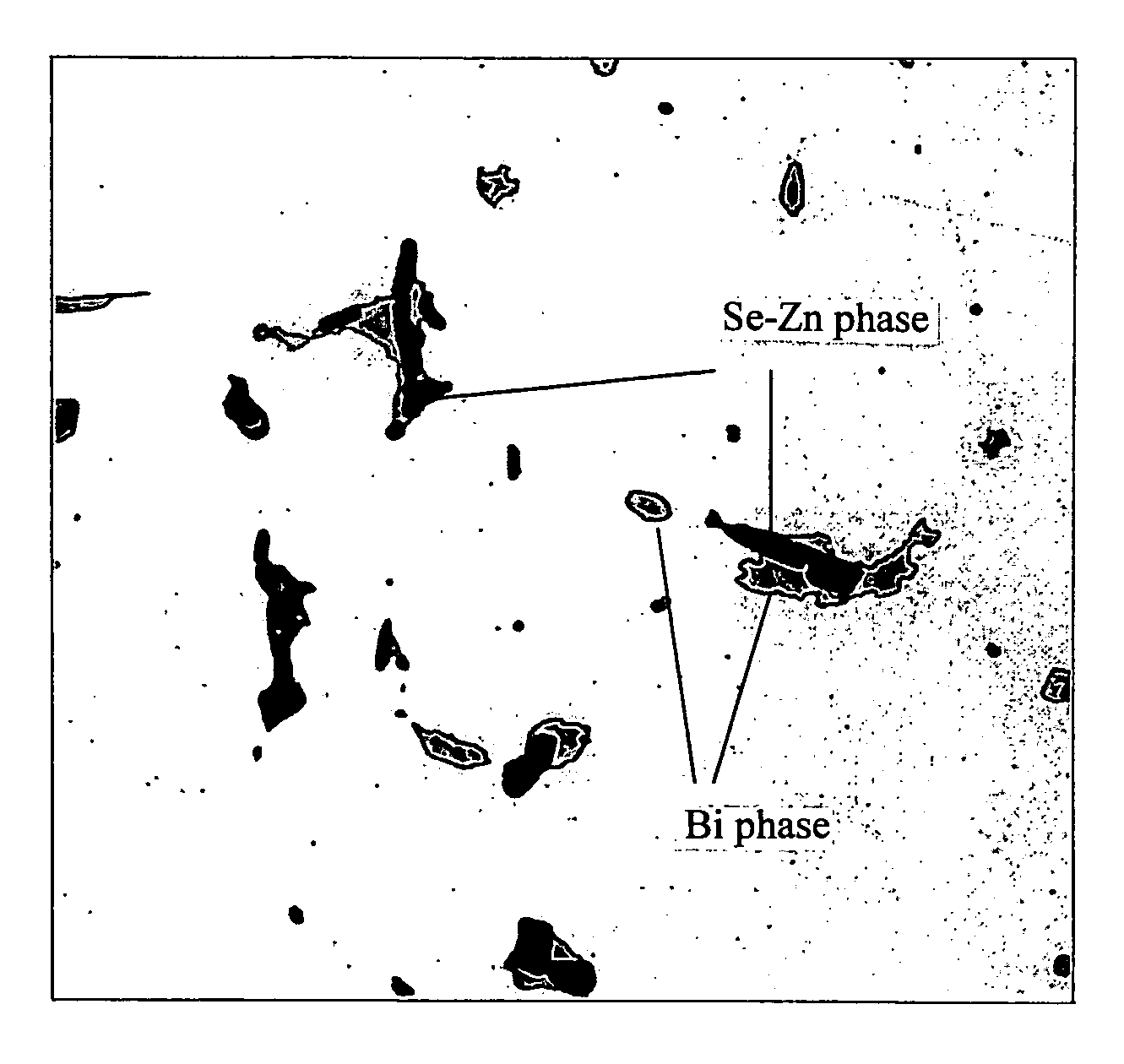

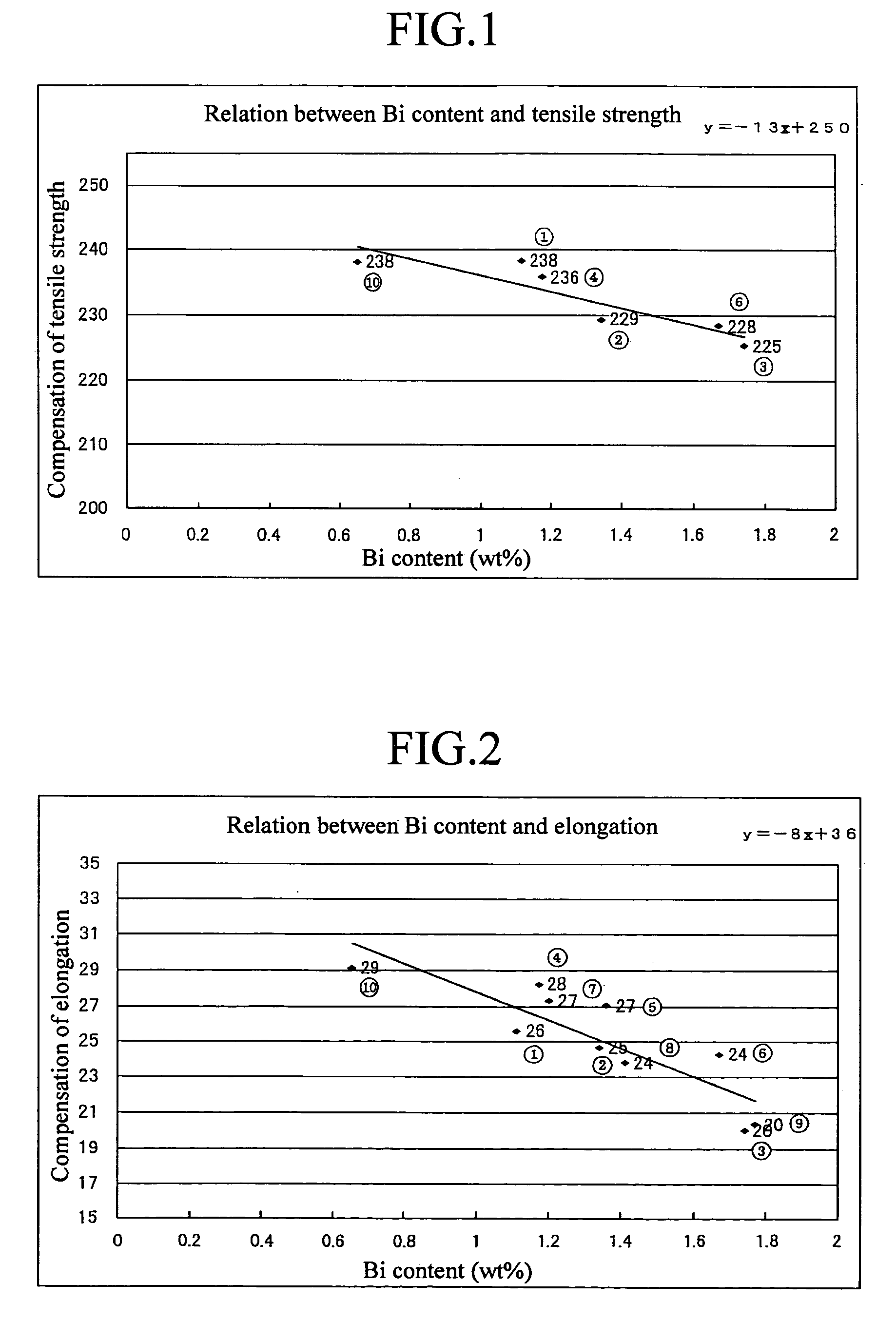

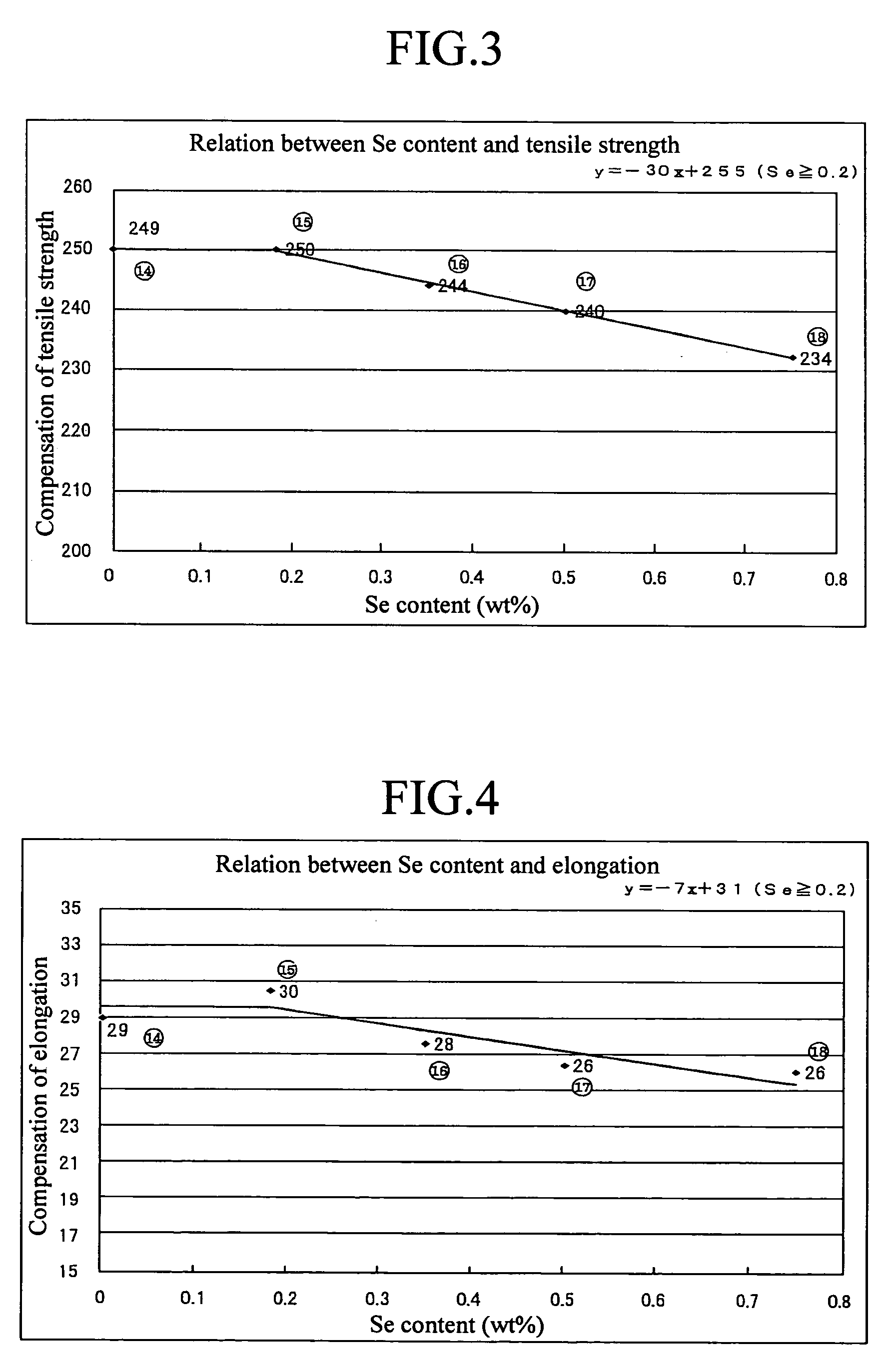

Copper base alloy, and cast ingot and parts to be contacted with liquid

By exactly comprehending the true properties of the rare elements (such as Bi and Se) which are alternative components for Pb, the alloy is enabled to secure machinability equal to the bronze alloy (CAC406) generally used hitherto and acquire mechanical properties at least equal to the CAC406 as well in spite of a decrease in the content of the rare elements (such as Bi and Se) in the alloy. Further, it is possible to suppress the occurrence of casting defects by elucidating the unresolved influence of the decrease of the alternative components (such as Bi and Se) for Pb on the wholesomeness of a casting. Moreover, it is possible, by decreasing the rare elements, to produce a copper-based alloy containing rare elements at a low cost and to provide a cast ingot and a liquid-contacting part each using the alloy. The copper-based alloy, and the cast ingot and liquid-contacting part each using the alloy individually contain at least 2.8 to 5.0 wt % of Sn, 0.4 to 3.0 wt % of Bi and satisfying 0<Se≦0.35 wt % to enable securing prescribed machinability and wholesomeness of a casting and exalt mechanical properties thereof.

Owner:KITZ CORP

Nickel-chromium-cobalt-molybdenum heat resisting alloy and pipe manufacturing process thereof

The invention provides a nickel-chromium-cobalt-molybdenum heat resisting alloy and a pipe manufacturing process thereof and belongs to the technical field of the heat-resisting alloys. The alloy comprises the following chemical components in percentage by weight: 21-23% of Cr, 0.05%-0.07% of C, less than or equal to 0.3% of Mn, 11-13% of Co, 6.0-9.0% of Mo, 0.3-0.5% of Ti, 0.8-1.3% of Al, 0.1-1.0% of W, 0.002-0.005% of B, 0.03-0.15% of Zr, 0.2-0.6% of Nb+V and 0.01-0.05% of Nb, less than or equal to 0.15% of Cu, less than 0.008% of P, less than 0.002% of S, less than or equal to 0.015% of N, 0.005-0.02% of Mg, less than or equal to 0.01% of Ca, less than or equal to 0.01% of As, less than or equal to 0.07% of Pb, less than or equal to 0.001% of Bi and the balance of nickel and inevitable impurity elements. The nickel-chromium-cobalt-molybdenum heat resisting alloy has the advantages that the room-temperature mechanical properties, the high-temperature mechanical properties, the low cycle fatigue properties and the durability of a large-diameter thick-wall boiler pipe produced from the nickel-chromium-cobalt-molybdenum heat resisting alloy are all over ASME standard requirements and the technical requirements of CCA617 alloys; the formulation of HAZ liquation cracks and stress relaxation cracks is greatly reduced, and the HAZ long term rupture strength and the tenacity after long term aging both are excellent.

Owner:CENT IRON & STEEL RES INST

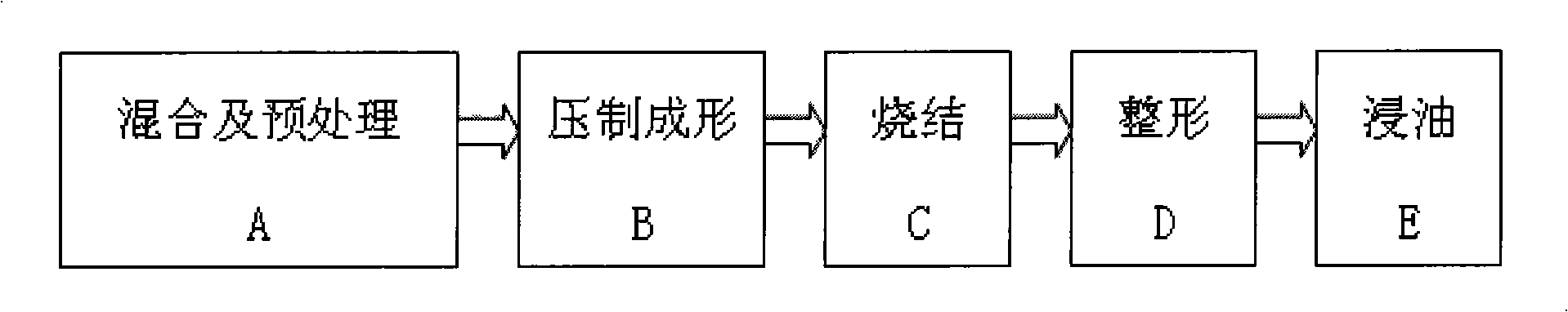

Powder metallurgy rare earth copper coated ferroalloy oil-retaining bearing and manufacturing method thereof

InactiveCN101407889AMeet environmental protection requirementsExtended service lifeTurbinesOther manufacturing equipments/toolsManufacturing cost reductionRare earth

The invention discloses a powder metallurgy rare-earth copper-clad iron alloy oil-impregnated bearing and a manufacturing method thereof. Accounted by percentage, the bearing consists of the following compositions by percentage: 18 to 22 percent of Cu, 0.2 to 1.0 percent of graphite, 0.3 to 0.8 percent of La or Ce and the residual quantity of Fe and unavoidable impurities. The bearing is made by the procedures of mixing, low temperature diffusion treatment, pressing, sintering and the like of a mixture formed by copper-clad iron powder, powder of the element La or Ce and the residual quantity of Fe and unavoidable impurities according to certain mixture ratios. The bearing uses the iron powder for substituting most of the copper powder to reduce the manufacturing cost; lead is not contained in the bearing, which meets the requirement of environmental protection; the rare earth is adopted as a catalyst for causing the copper-clad iron powder to be easily combined with other powder, and the alloy is uniformly distributed, which is beneficial for the refinement of alloy grains and leads thin through holes to be formed in the sintering body with hole connection efficiency being more than 95 percent. The mechanical property of the bearing is better than technical standards of oil-impregnated bearings sintered by copper-clad iron powder and 6-6-3 bronze powder.

Owner:JIANGSU YINGQIU GRP CO LTD

Method for preparing copper and nickel alloy seamless copper tube

InactiveCN101058142AOptimize structure sizeImprove plastic deformation abilityRoll mill control devicesFurnace typesElectrolysisCupronickel

The invention relates to a copper nickel seamless copper tube with 92. 9-93. 6% copper and 6. 4-7. 1% nickel. It takes electrolytic copper and nickel to a low frequency electric oven to heat to 1320-1340deg.C, casting into solid ingot which is heated to 650-750deg.C for heat piercing to get the surface smooth ingot to heat to 650-750deg.C for squeezing to gross blank tube which is extended and peeled for cold reeling, to get the size of the product after annealing. Through calibration and rectification, cleaning and annealing, the product is inspected and put to stock. The content for nickel is 6. 4-7. 1%. It is better in processing feature due to the low nickel and better in corrosion resistant features than copper due to the content of nickel. It is also low in cost.

Owner:江阴和宏精工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com