Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1738 results about "Scandium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scandium is a chemical element with the symbol Sc and atomic number 21. A silvery-white metallic d-block element, it has historically been classified as a rare-earth element, together with yttrium and the lanthanides. It was discovered in 1879 by spectral analysis of the minerals euxenite and gadolinite from Scandinavia.

Phosphors containing boron and metals of Group IIIA and IIIB

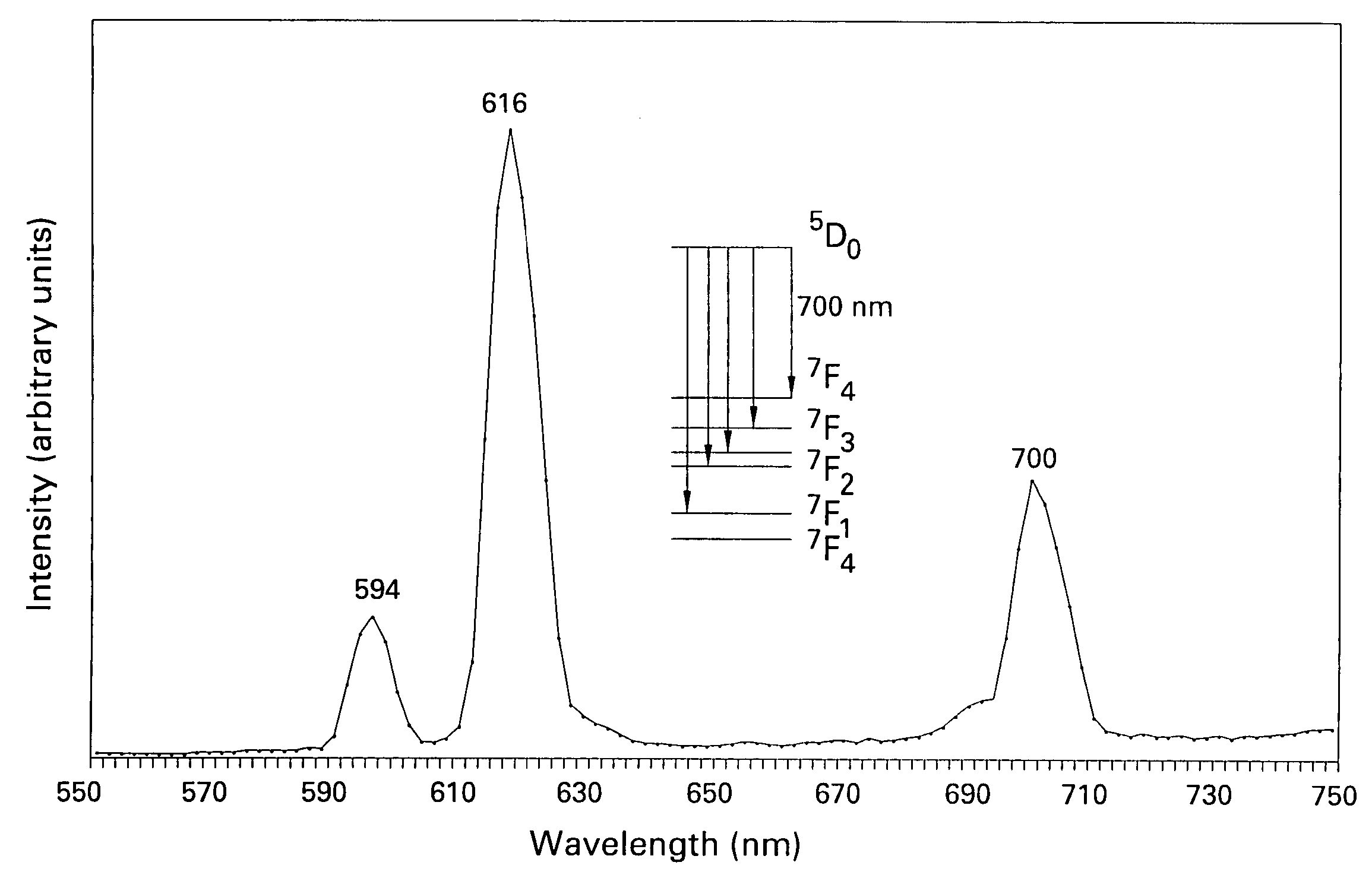

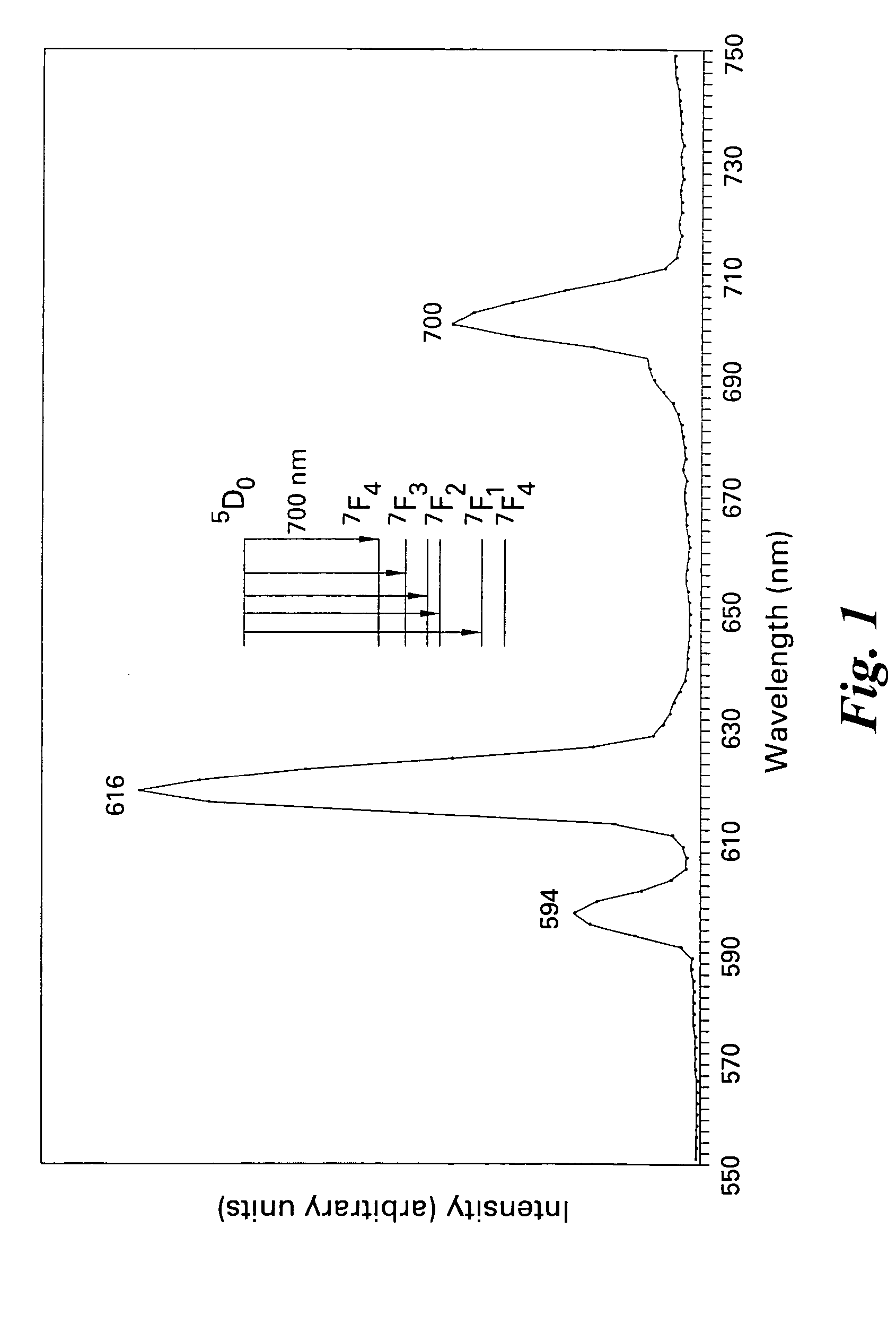

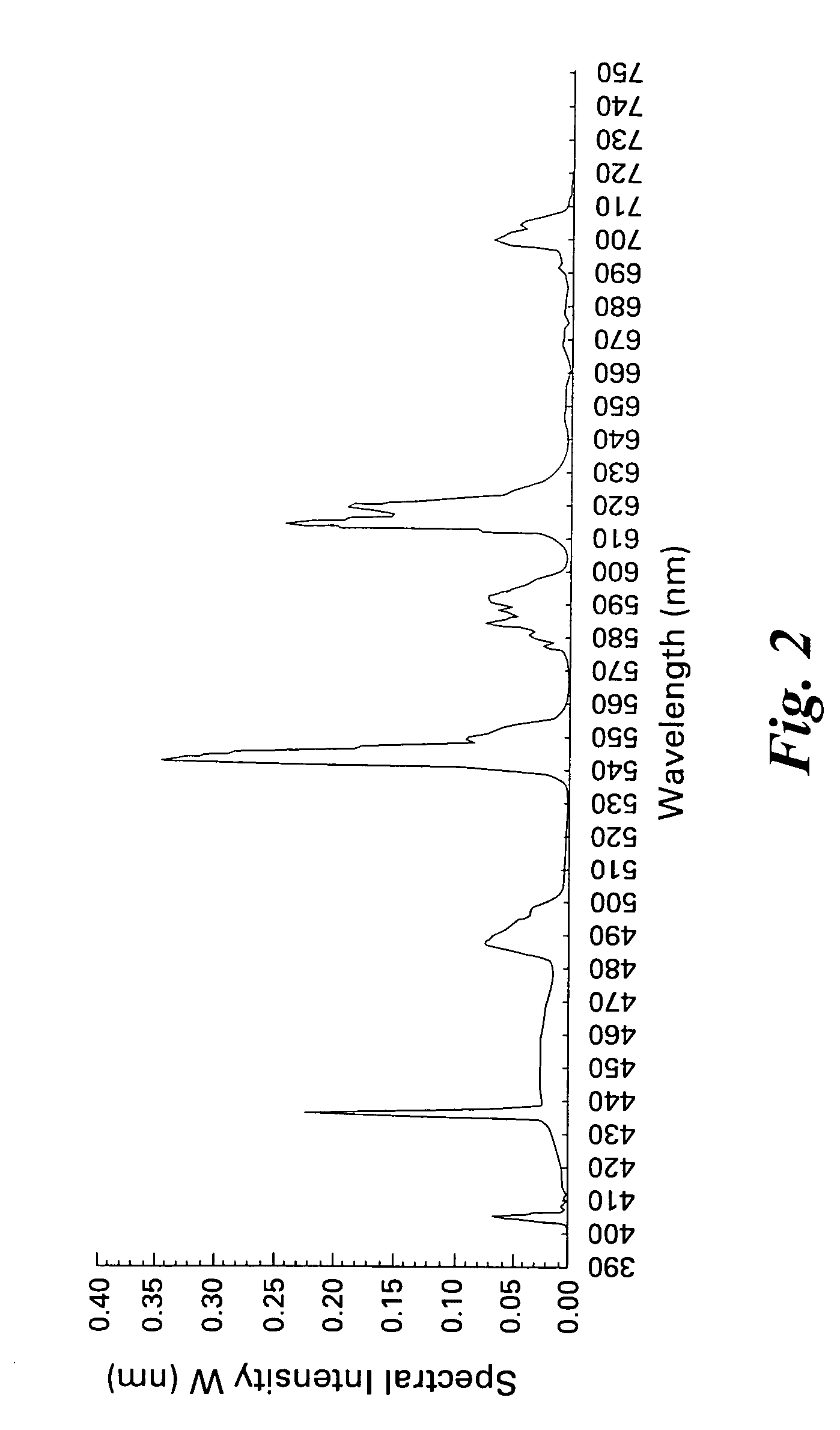

A phosphor comprises: (a) at least a first metal selected from the group consisting of yttrium and elements of lanthanide series other than europium; (b) at least a second metal selected from the group consisting of aluminum, gallium, indium, and scandium; (c) boron; and (d) europium. The phosphor is used in light source that comprises a UV radiation source to convert UV radiation to visible light.

Owner:GENERAL ELECTRIC CO

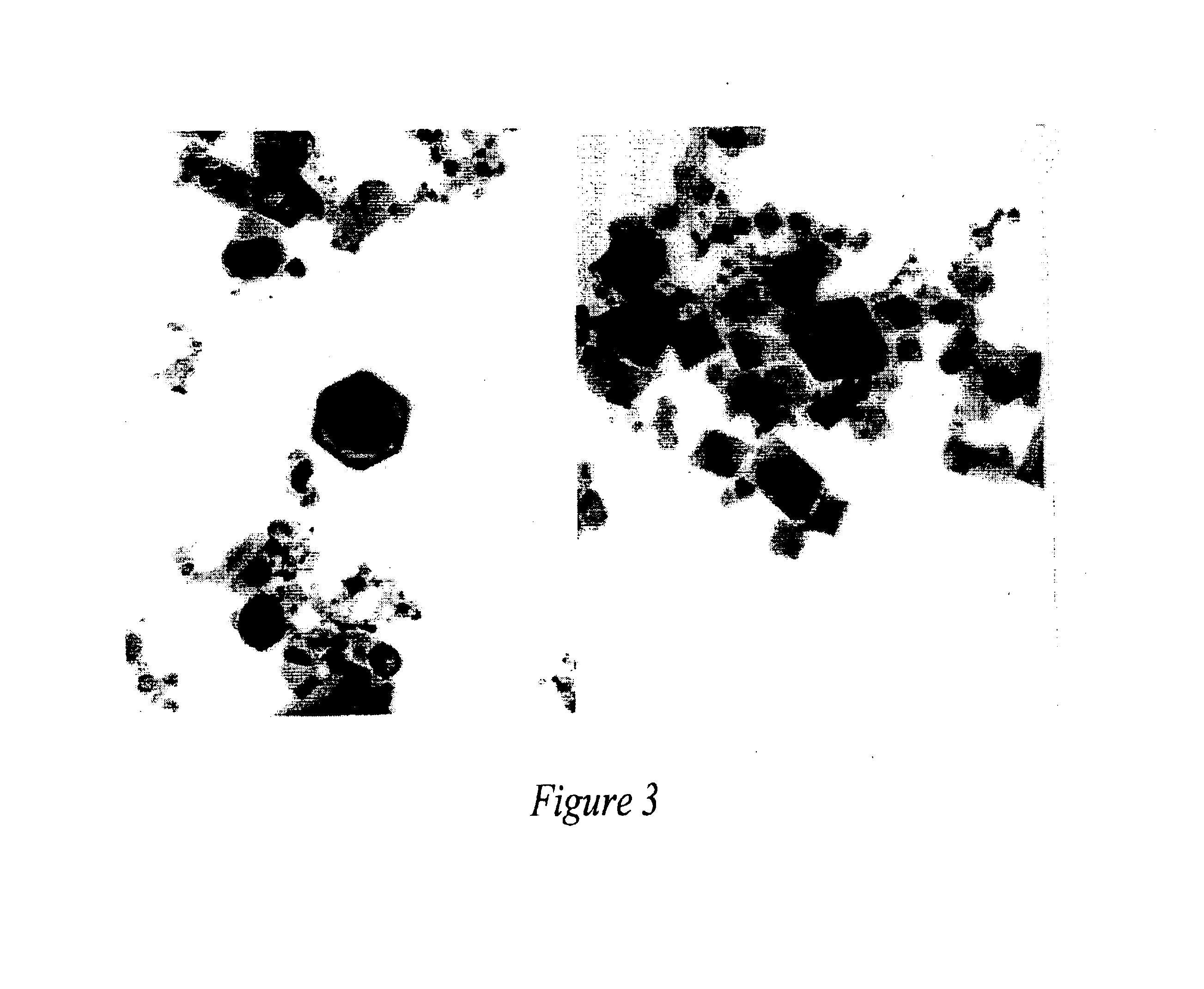

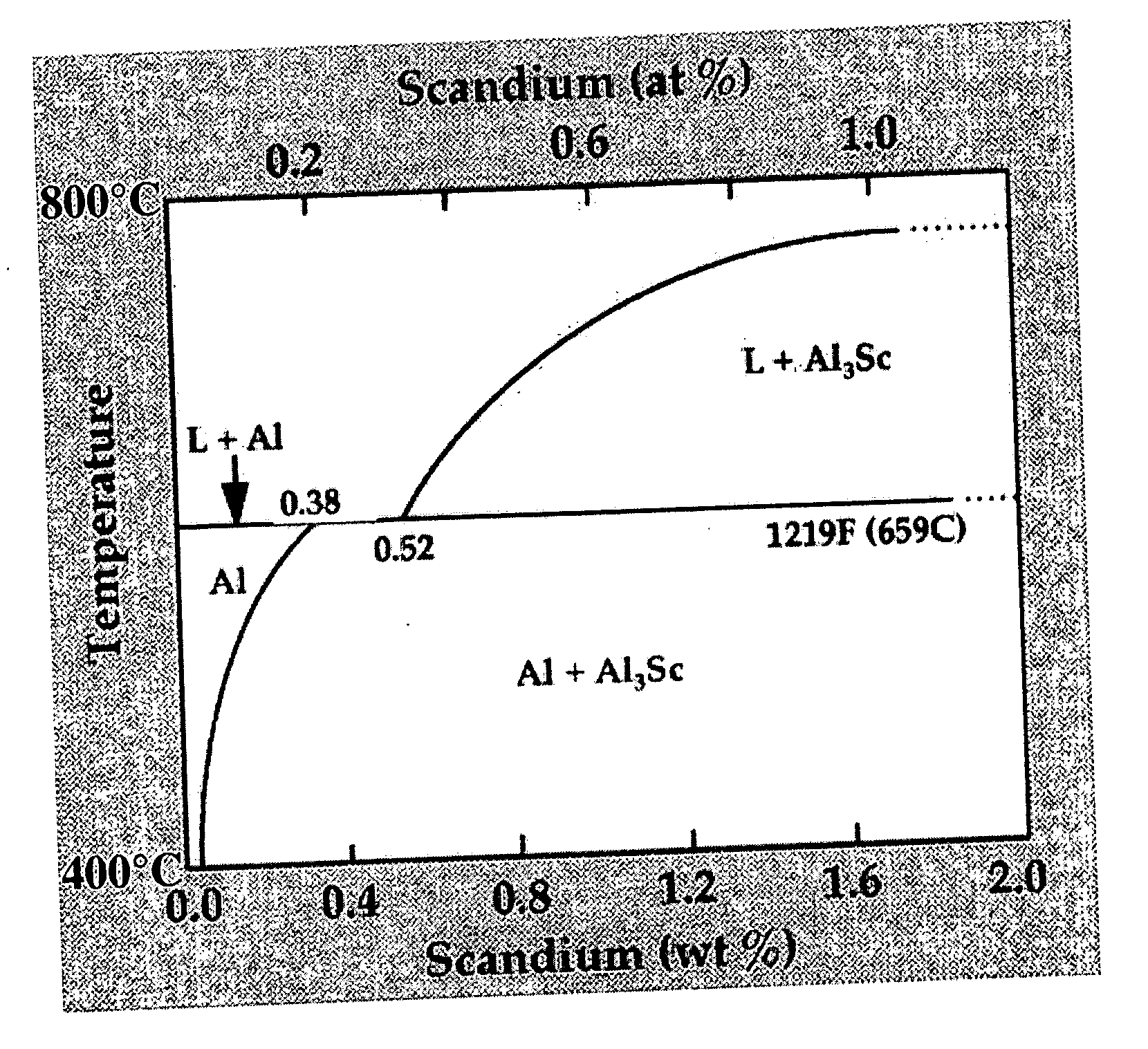

Inorganic dopants, inks and related nanotechnology

InactiveUS6849109B2Facilitated DiffusionLower transition temperatureSelenium/tellurium compundsCell electrodesIndiumCerium

Ink compositions with modified properties result from using a powder size below 100 nanometers. Colored inks are illustrated. Nanoscale coated, uncoated, whisker inorganic fillers are included. The pigment nanopowders taught comprise one or more elements from the group actinium, aluminum, antimony, arsenic, barium, beryllium, bismuth, cadmuim, calcium, cerium, cesium, chalcogenide, cobalt, copper, dysprosium, erbium, europium, gadolinium, gallium, gold, hafnium, hydrogen, indium, iridium, iron, lanthanum, lithium, magnesium, manganese, mendelevium, mercury, molybdenum, neodymium, neptunium, nickel, niobium, nitrogen, oxygen, osmium, palladium, platinum, potassium, praseodymium, promethium, protactinium, rhenium, rubidium, scandium, silver, sodium, strontium, tantalum, terbium, thallium, thorium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

Owner:PPG IND OHIO INC

Al-Cu-Li-Mg-Ag-Mn-Zr alloy for use as structural members requiring high strength and high fracture toughness

An improved aluminum lithium alloy comprising 0.1 to 2.5 wt. % Li, 2.5 to 5.5 wt. % Cu, 0.2 to 1.0 wt. % Mg, 0.2 to 0.8 wt. % Ag, 0.2 to 0.8 wt. % Mn, up to 0.4 wt. % Zr or other grain refiner such as chromium, titanium, hafnium, scandium or vanadium, the balance aluminum. The present alloy exhibits an improved combination of strength and fracture toughness, over any thickness range. The present invention is further directed to methods for preparing and using Al—Li alloys as well as to products comprising the same.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD

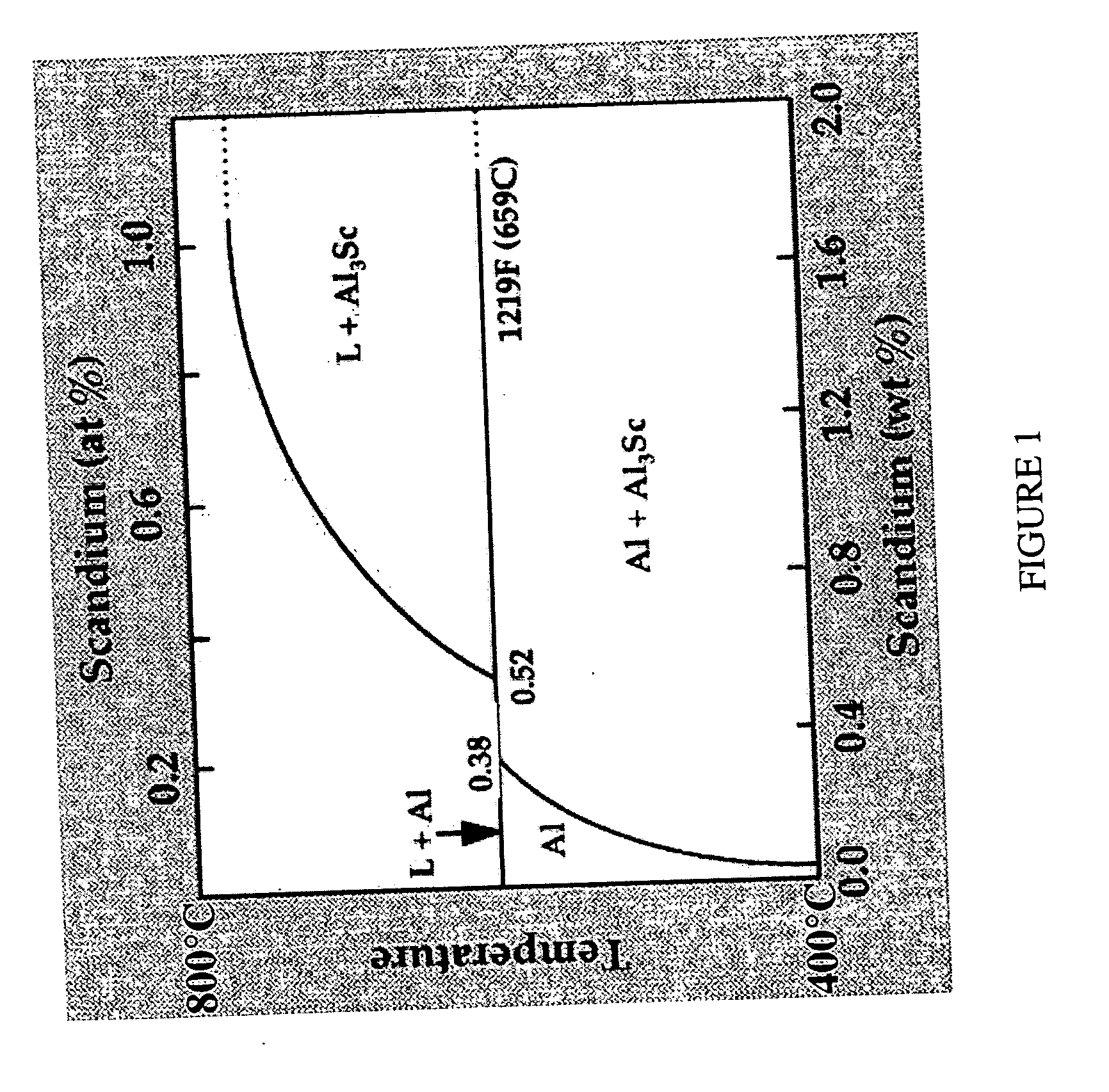

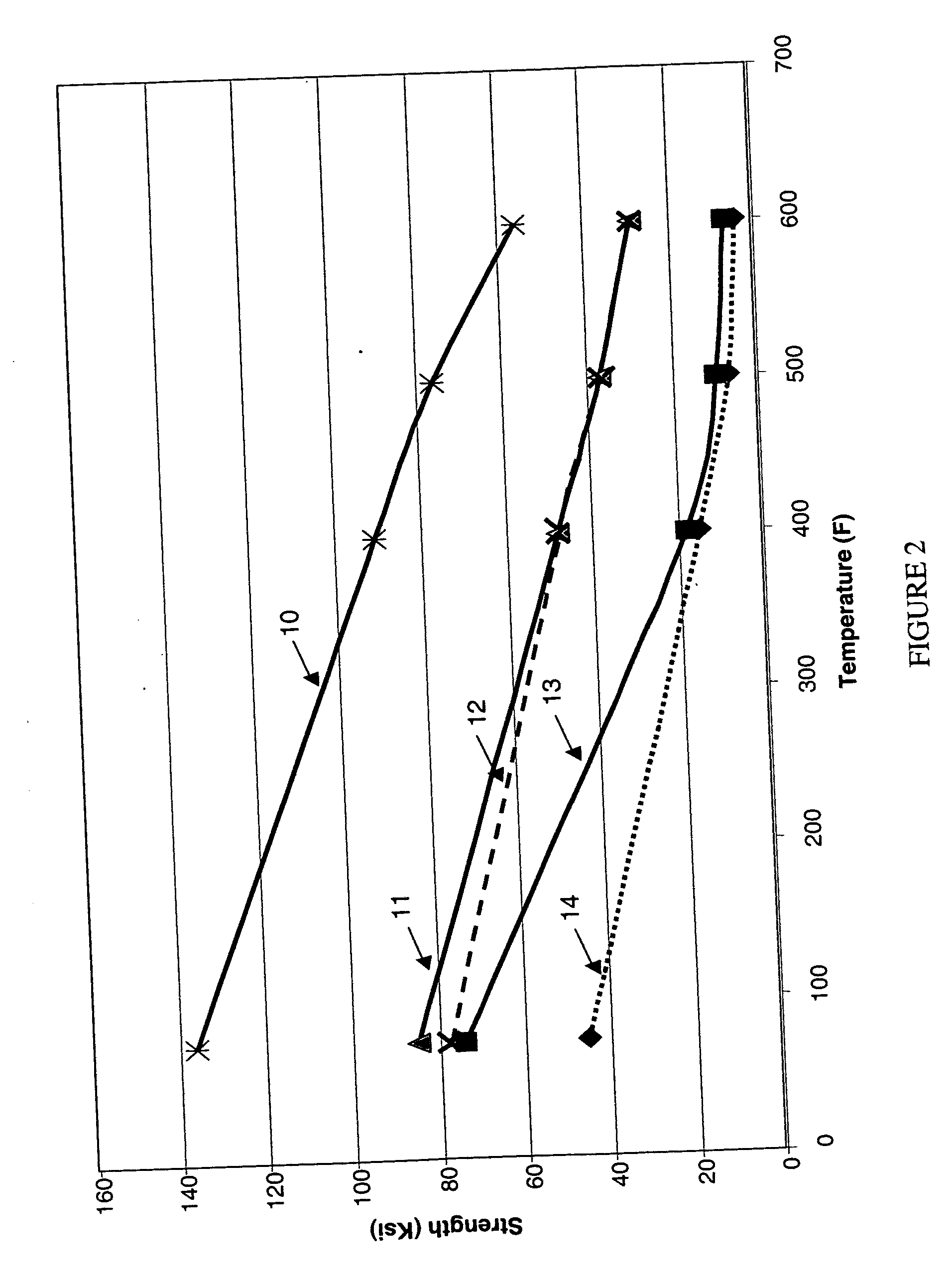

High temperature aluminum alloys

High temperature aluminum alloys that can be used at temperatures from about −420° F. (−251° C.) up to about 650° F. (343° C.) are described herein. These alloys comprise aluminum; scandium; at least one of nickel, iron, chromium, manganese and cobalt; and at least one of zirconium, gadolinium, hafnium, yttrium, niobium and vanadiuim. These alloys comprise an aluminum solid solution matrix and a mixture of various dispersoids. These alloys are substantially free of magnesium.

Owner:RTX CORP

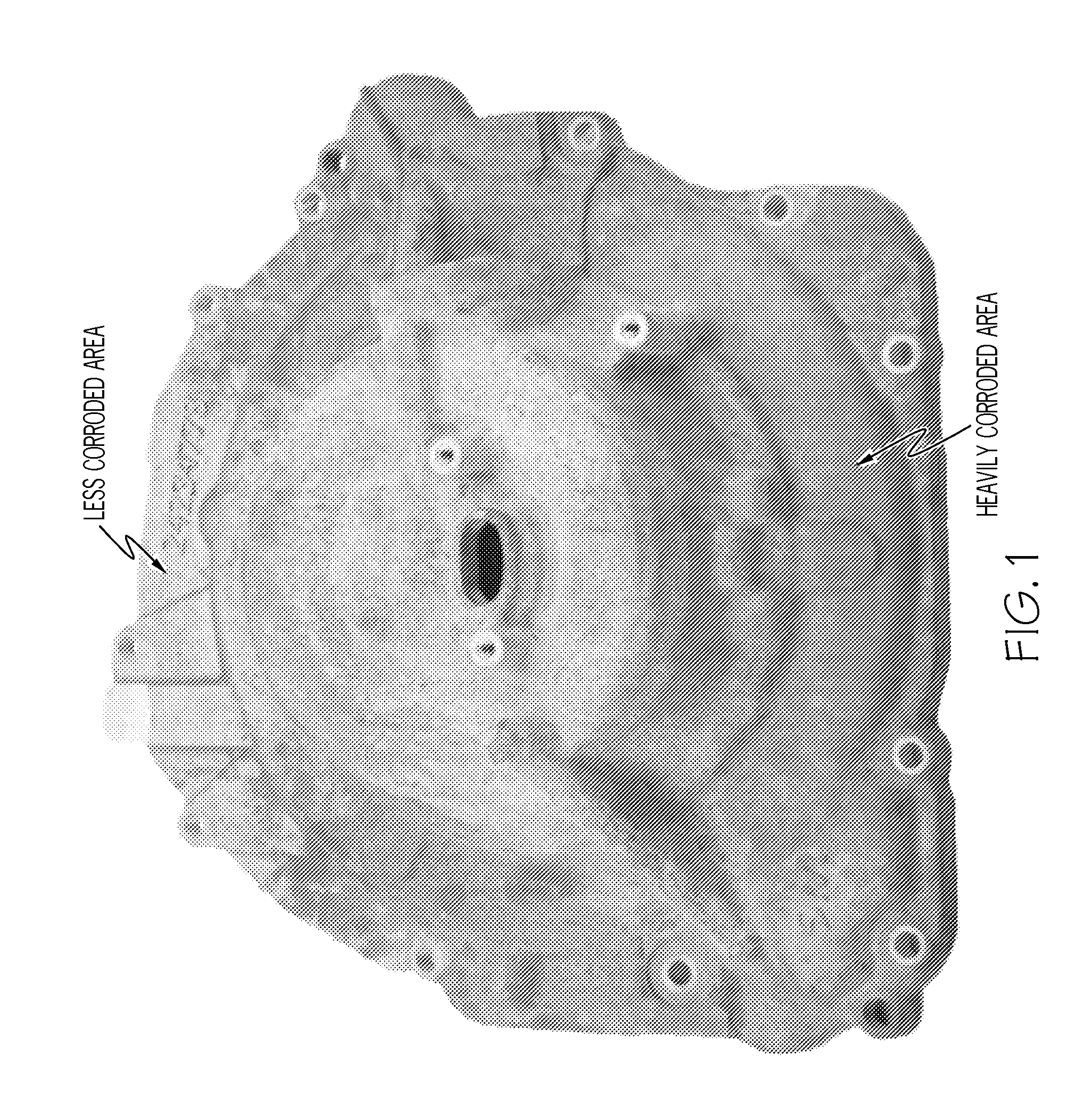

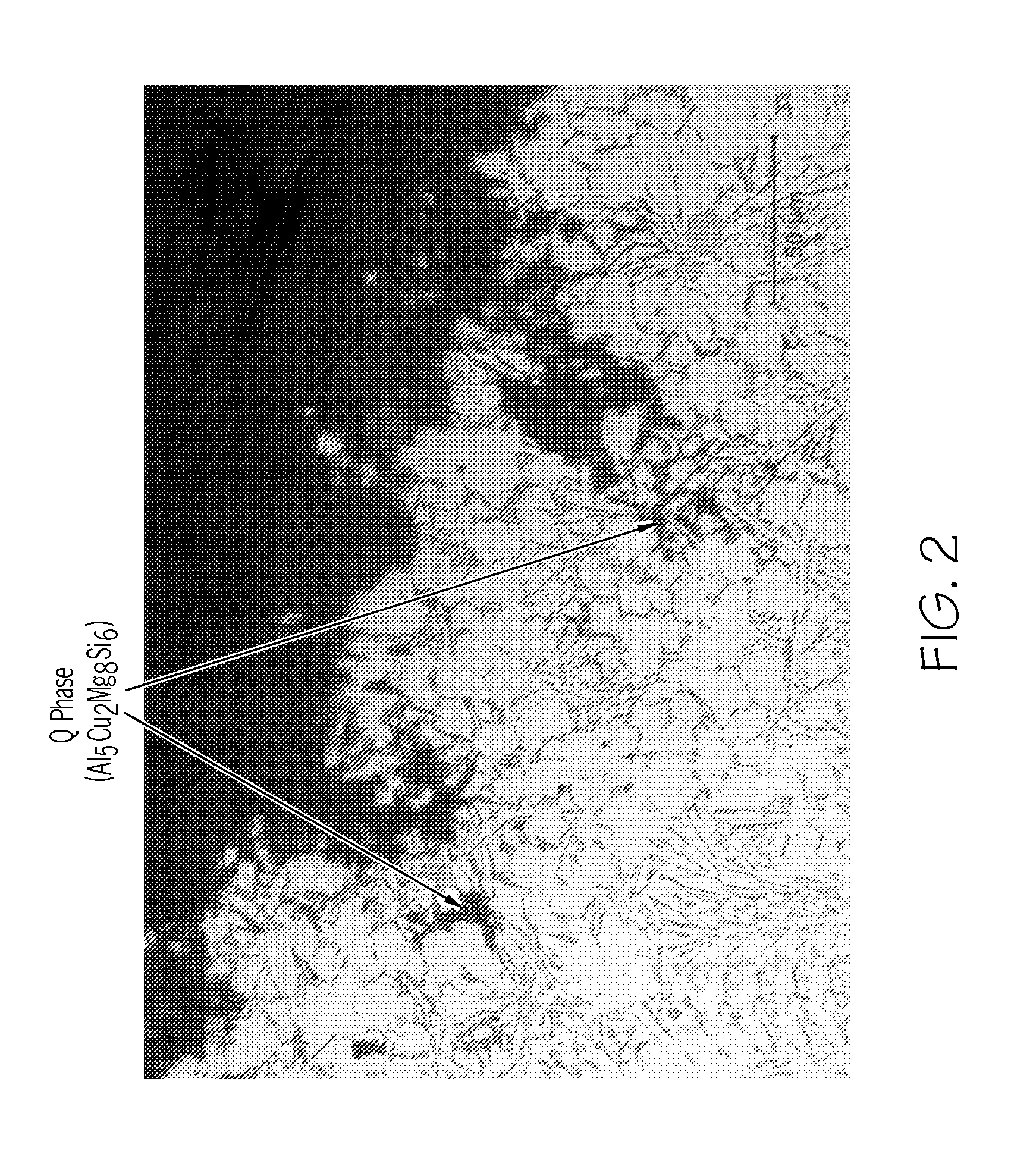

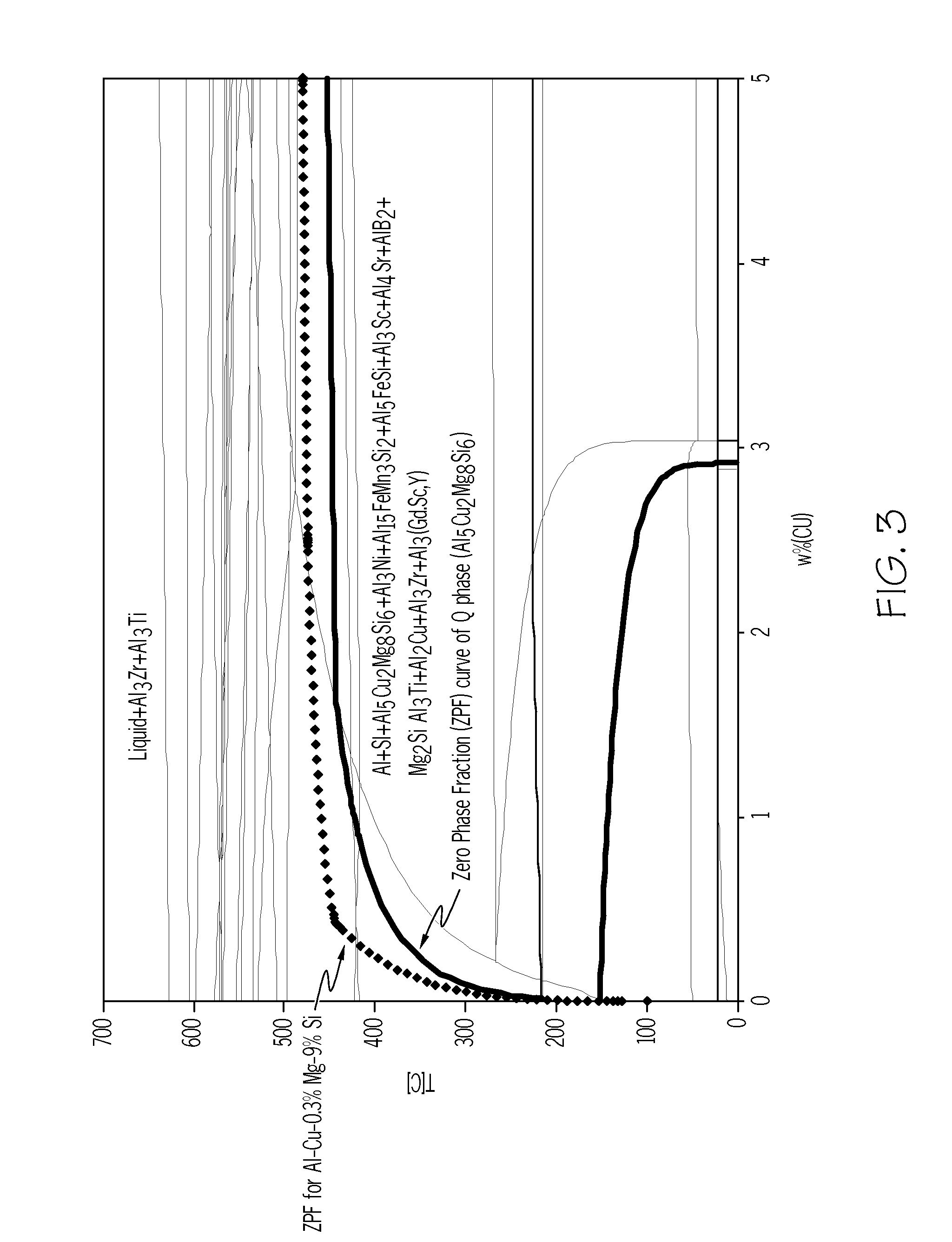

Cast aluminum alloys

ActiveUS20120000578A1Improve mechanical propertiesImprove corrosion resistanceAngiosperms/flowering plantsRare-earth elementIndium

Aluminum alloys having improved properties are provided. The alloy includes about 0 to 2 wt % rare earth elements, about 0.5 to about 14 wt % silicon, about 0.25 to about 2.0 wt % copper, about 0.1 to about 3.0 wt % nickel, approximately 0.1 to 1.0% iron, about 0.1 to about 2.0 wt % zinc, about 0.1 to about 1.0 wt % magnesium, 0 to about 1.0 wt % silver, about 0.01 to about 0.2 wt % strontium, 0 to about 1.0 wt % scandium, 0 to about 1.0 wt % manganese, 0 to about 0.5 wt % calcium, 0 to about 0.5 wt % germanium, 0 to about 0.5 wt % tin, 0 to about 0.5 wt % cobalt, 0 to about 0.2 wt % titanium, 0 to about 0.1 wt % boron, 0 to about 0.2 wt % zirconium, 0 to 0.5% yttrium, 0 to about 0.3 wt % cadmium, 0 to about 0.3 wt % chromium, 0 to about 0.5 wt % indium, and the balance aluminum. Methods of making cast aluminum parts are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

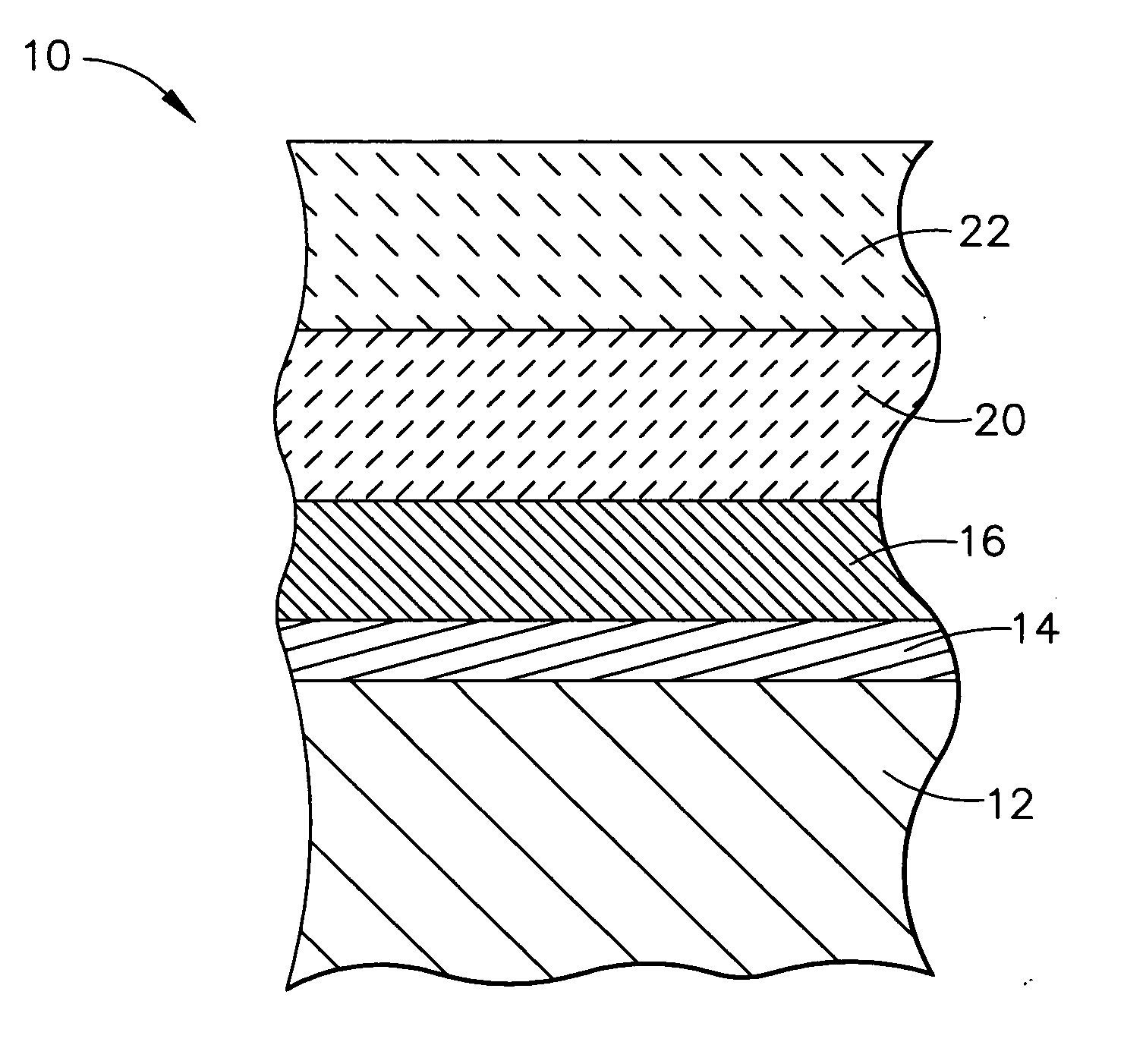

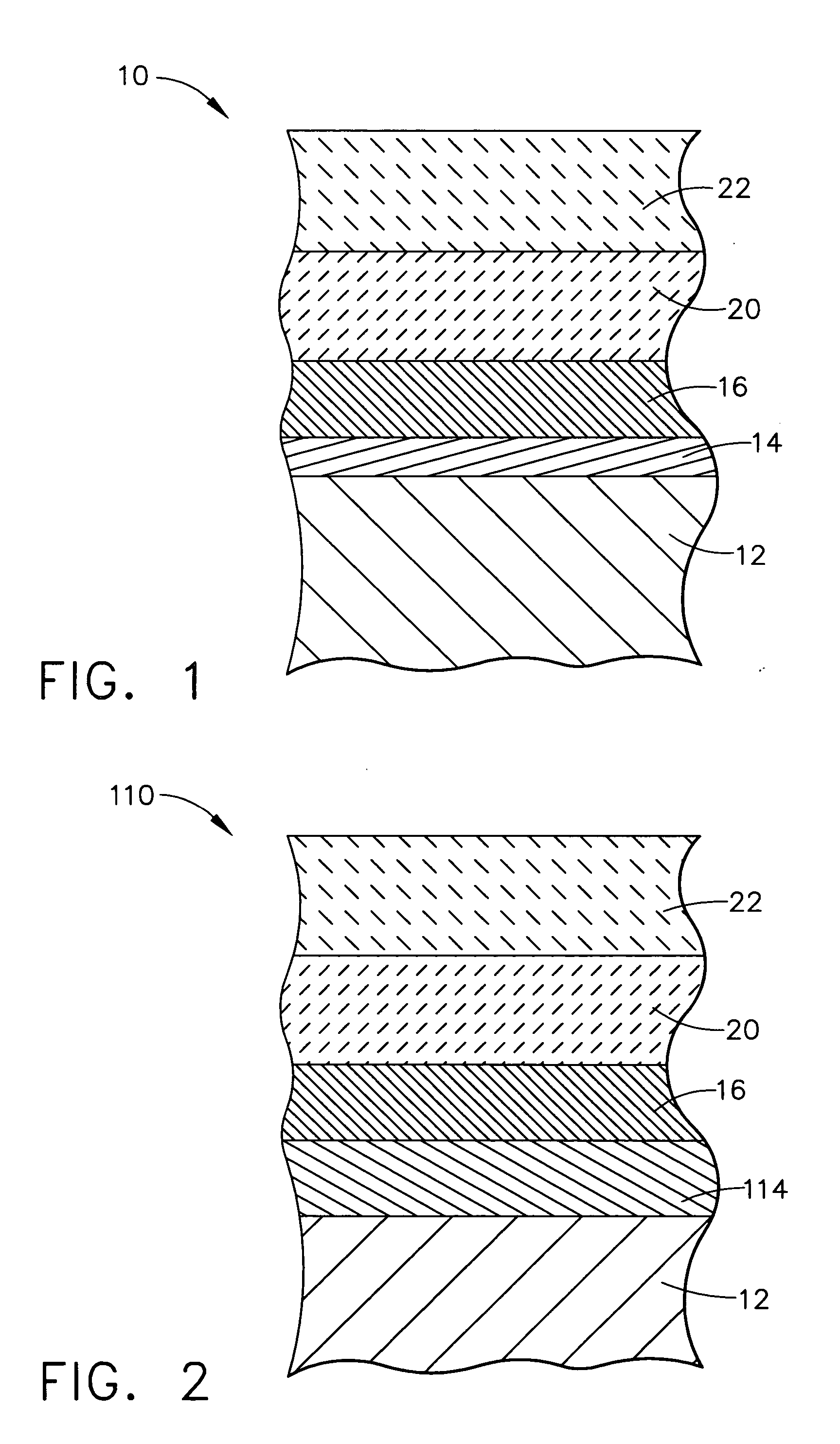

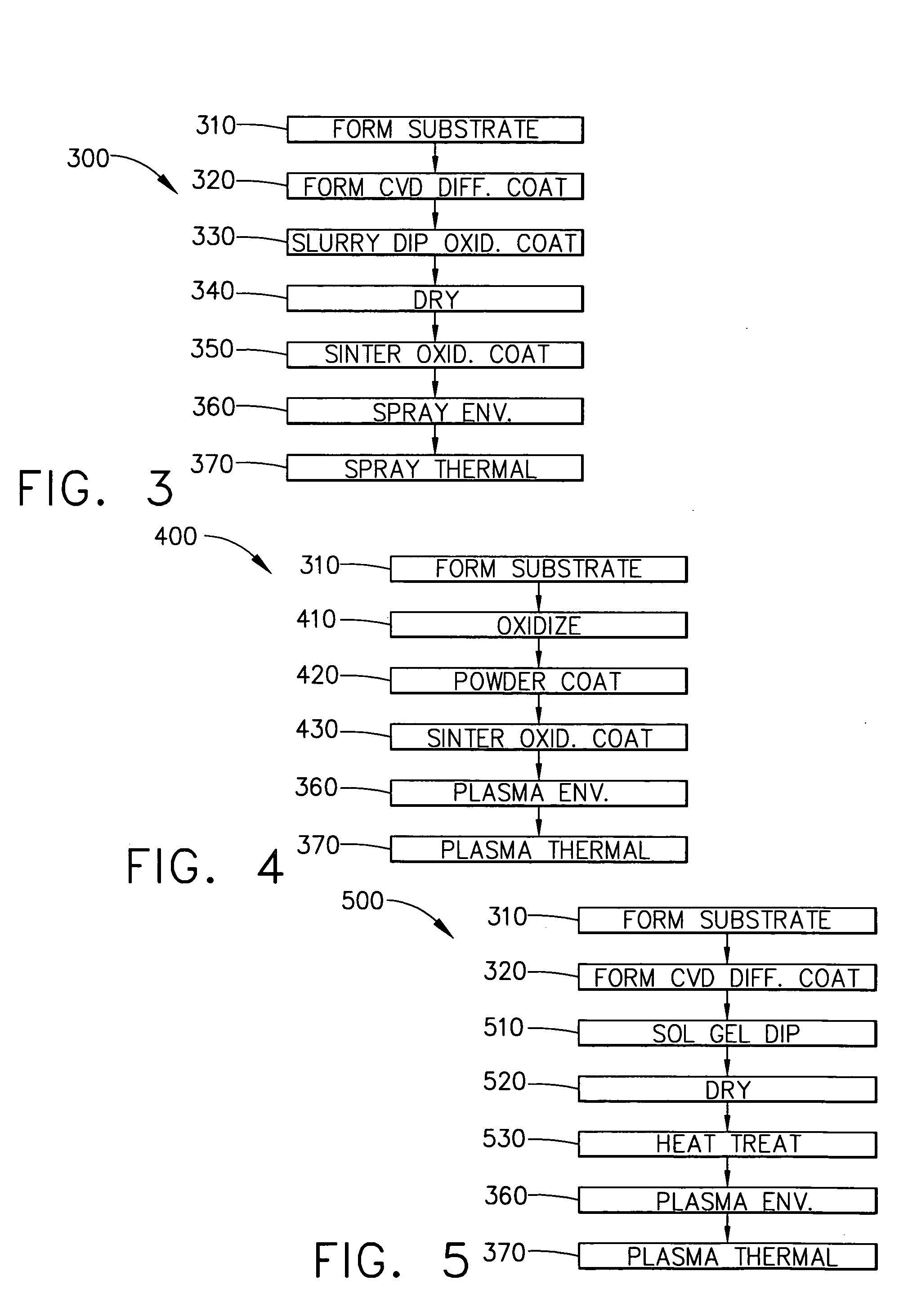

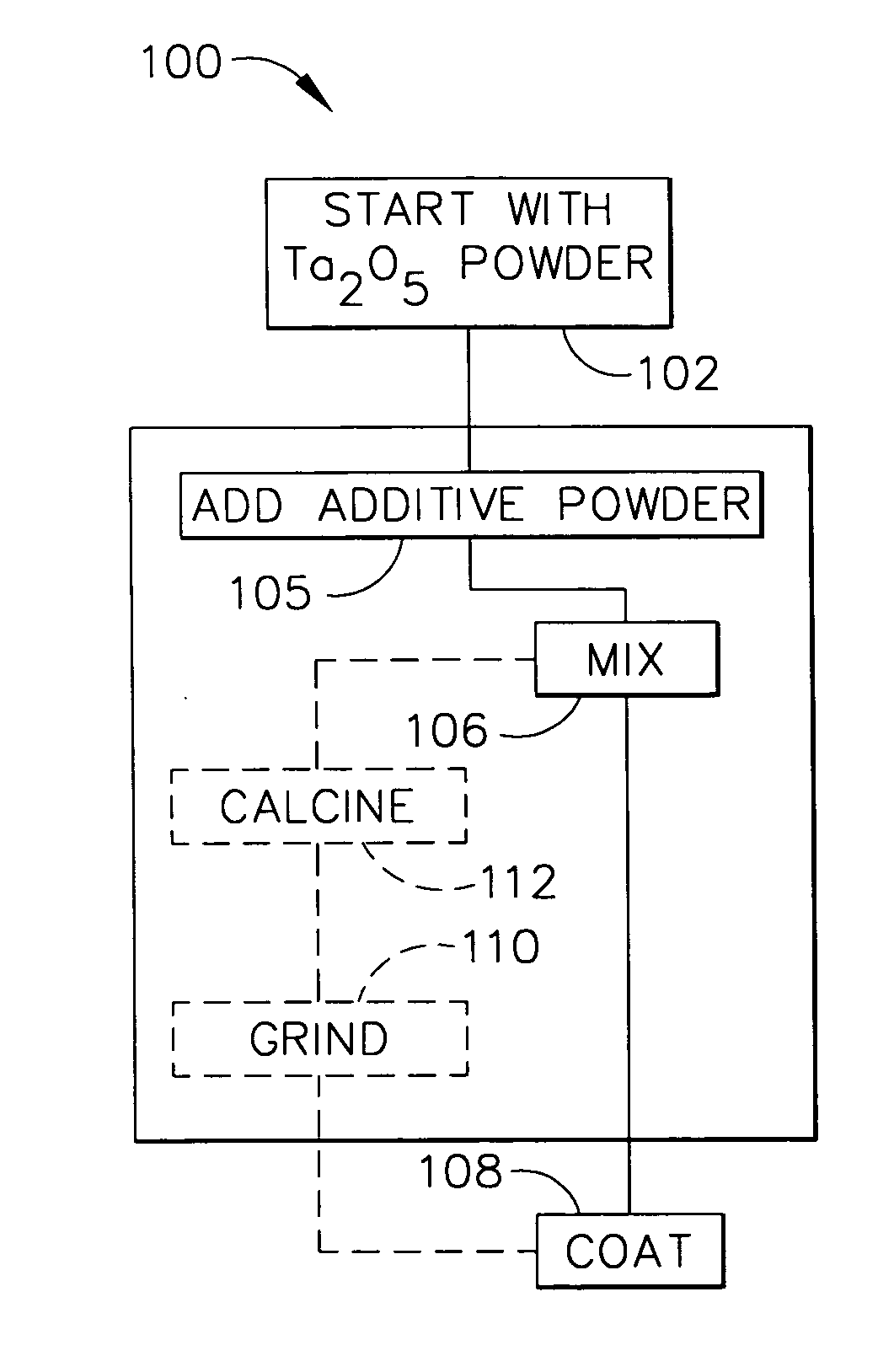

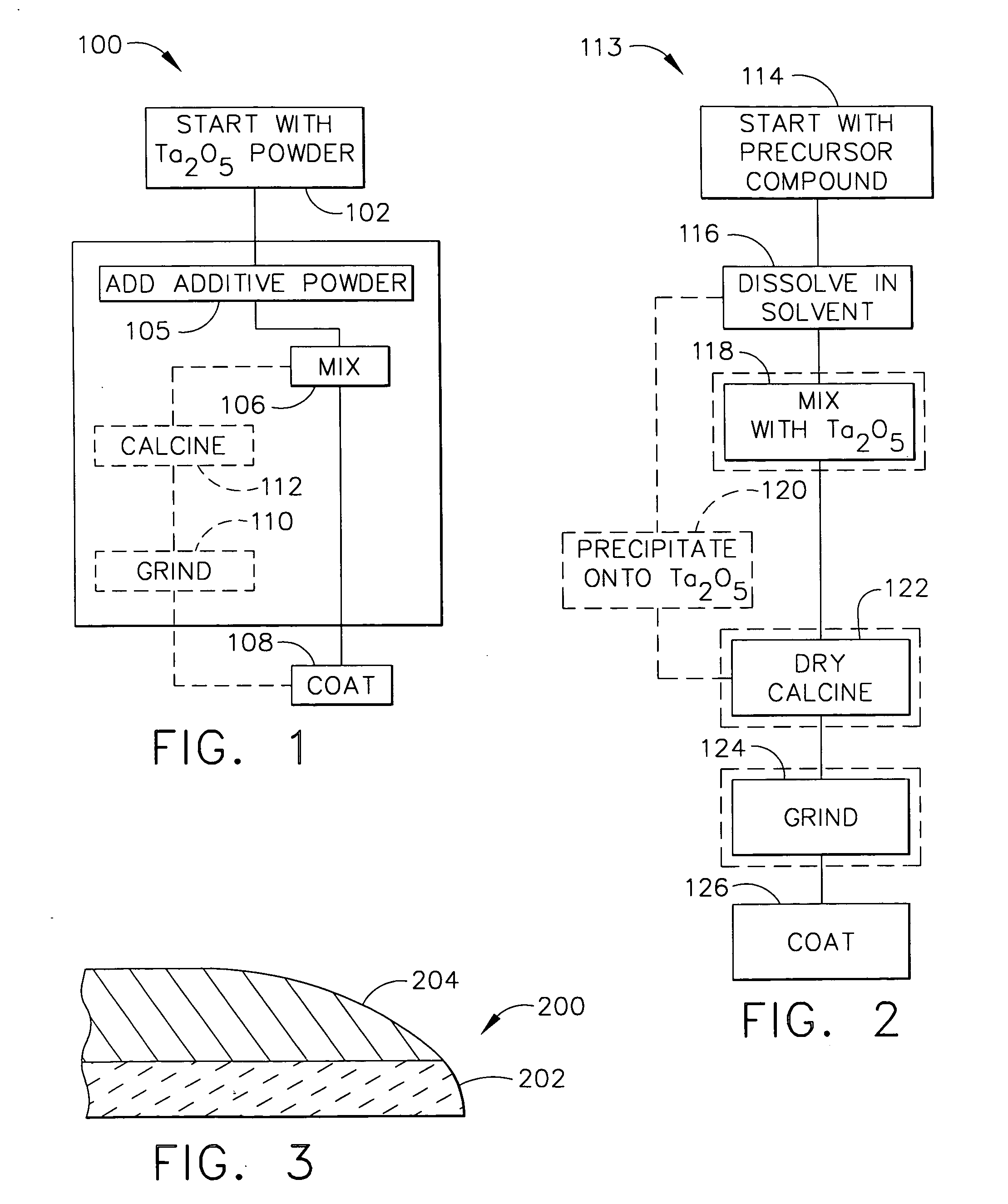

Oxidation barrier coatings for silicon based ceramics

ActiveUS20050112381A1Avoid Explosion HazardsContinuous combustion chamberBlade accessoriesElectron beam physical vapor depositionGas phase

A protective barrier coating system including a diffusion barrier coating and an oxidation barrier coating and method for use in protecting silicon-based ceramic turbine engine components. A complete barrier coating system includes a thermal barrier coating of stabilized zirconia and an environmental barrier coating of an alloyed tantalum oxide. The oxidation barrier coating includes a layer of metallic silicates formed on a substrate of silicon nitride or silicon carbide to be protected. The oxidation barrier coating can include silicates of scandium, ytterbia or yttrium. The oxidation barrier coating may also include an inner layer of Si2ON2 between the diffusion barrier and the metallic silicate layer. The oxidation barrier coating can be applied to the substrate by spraying, slurry dipping and sintering, by a sol-gel process followed by sintering, by plasma spray, or by electron beam-physical vapor deposition. The diffusion layer of essentially pure Si3N4 can be applied to the substrate to prevent the migration of damaging cations from the protective layers to the substrate and is preferably formed by chemical vapor deposition. A method for protecting silicon based substrates can comprise a step of forming an oxidation barrier coating on a substrate, where a step of forming the oxidation barrier includes a step of sintering the oxidation barrier and substrate in a wet gas containing hydrogen.

Owner:HONEYWELL INT INC

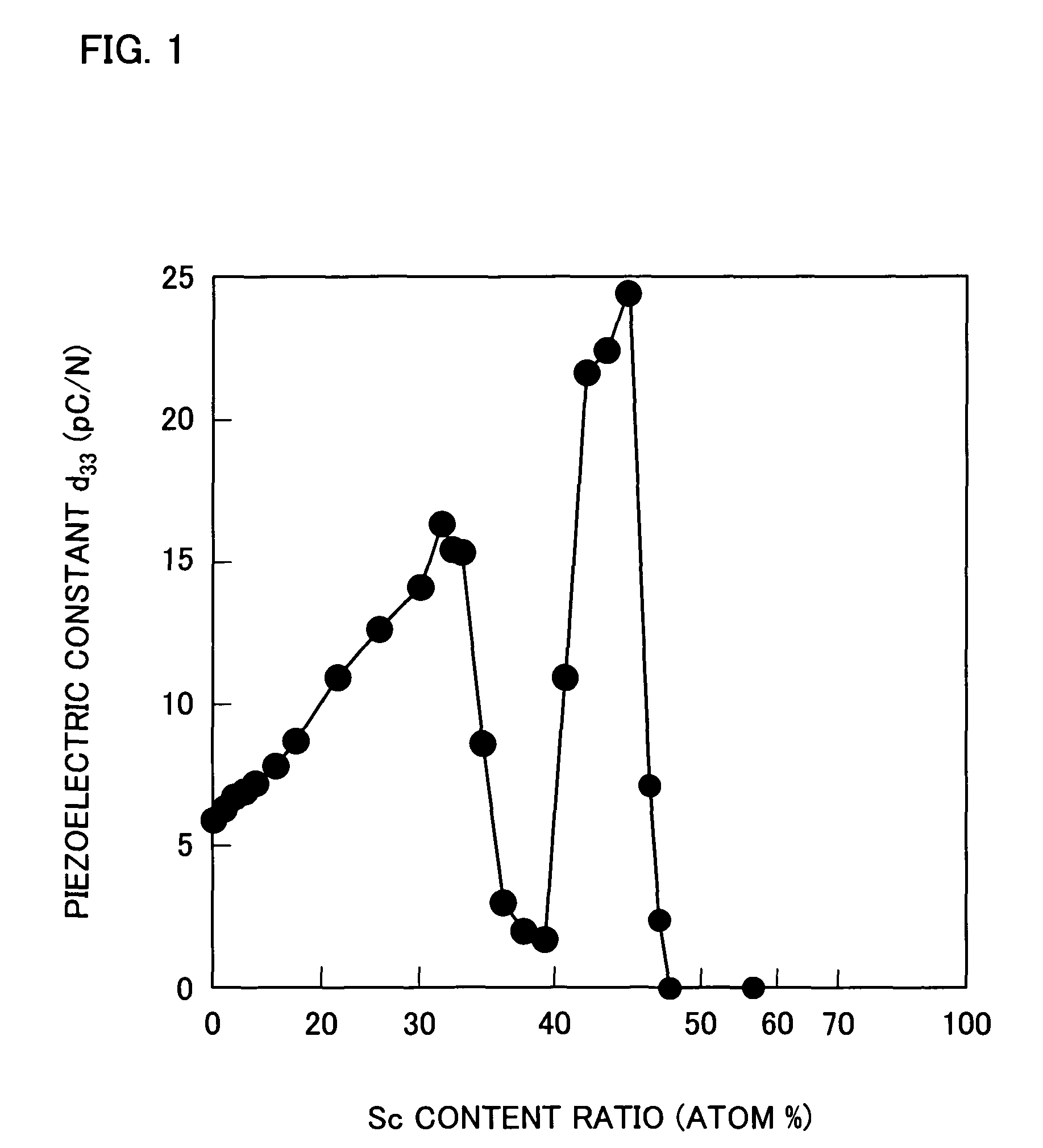

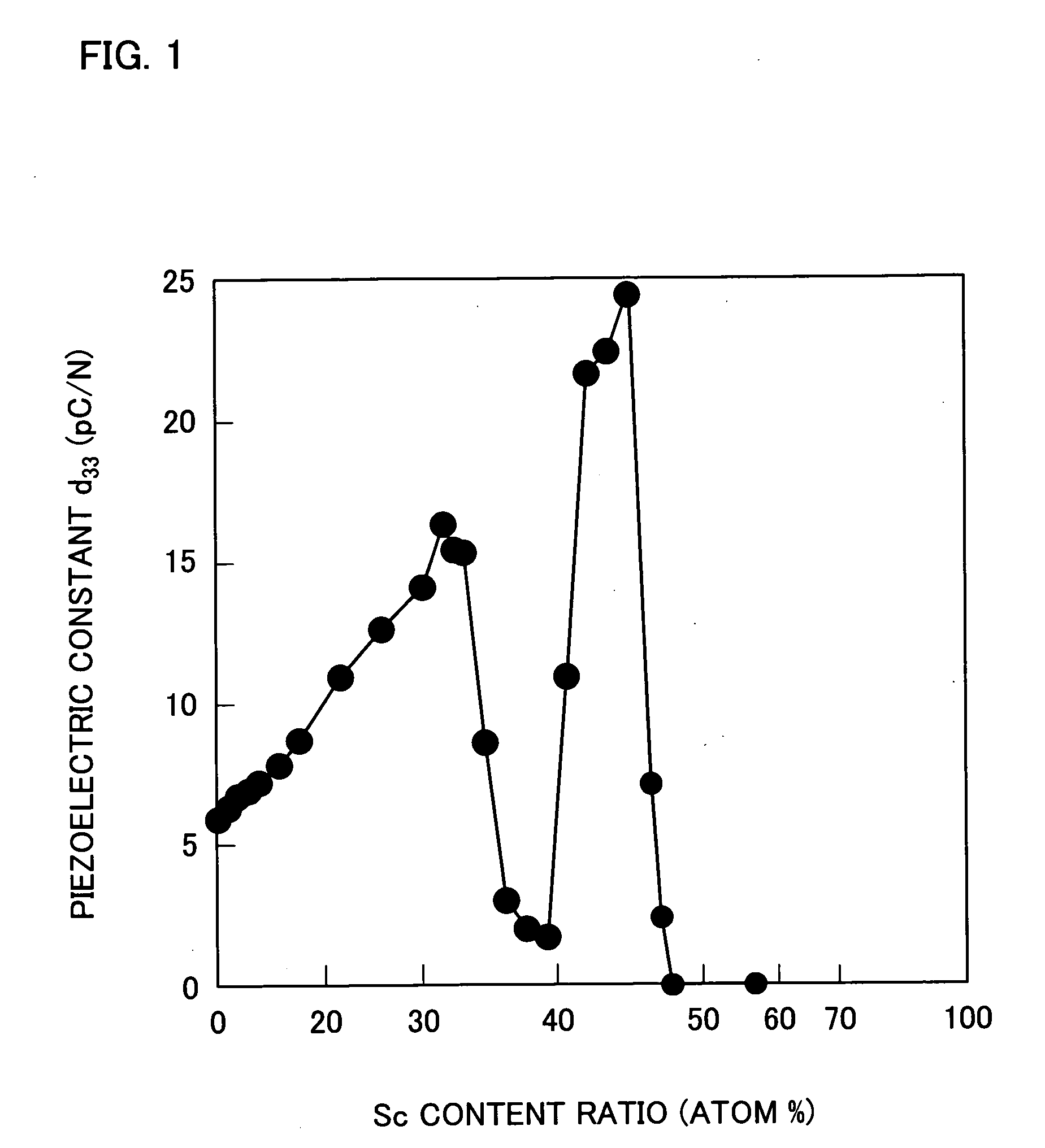

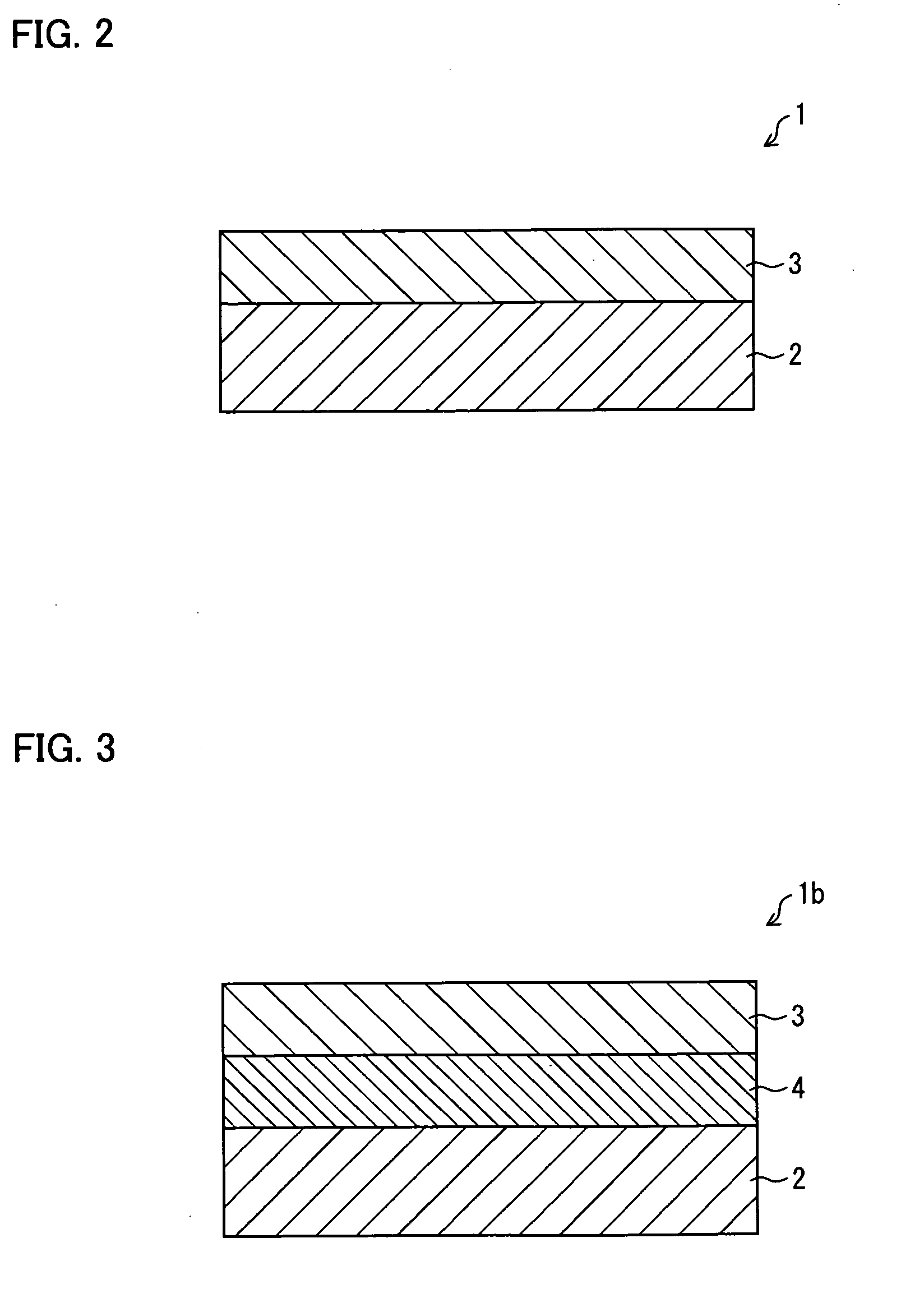

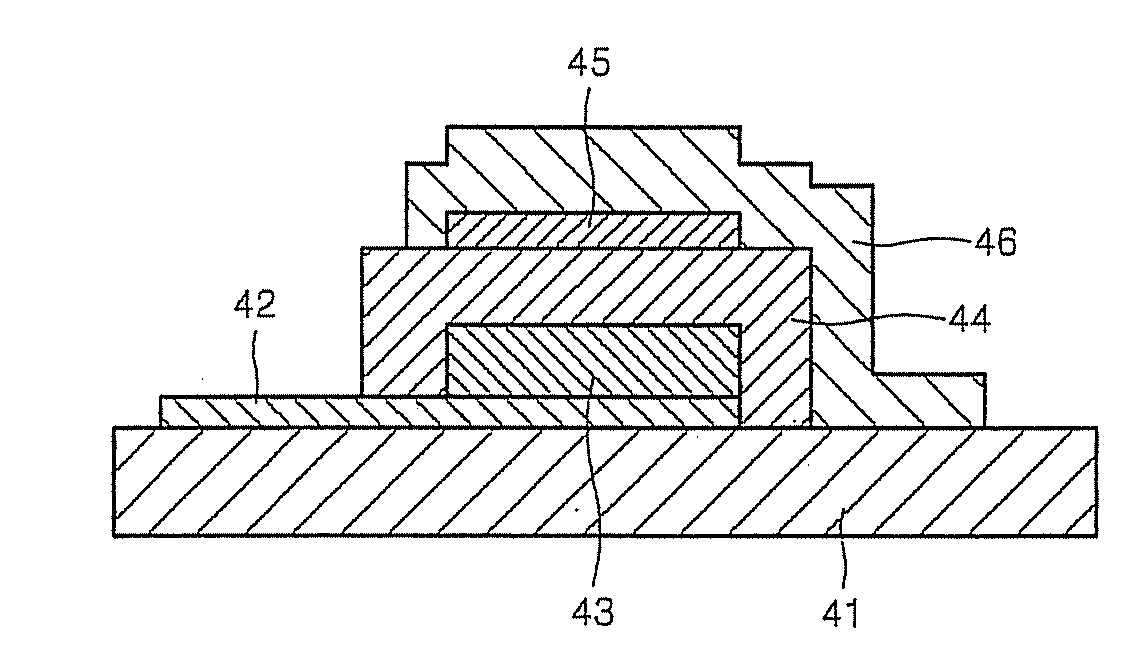

Piezoelectric thin film, piezoelectric material, and fabrication method of piezoelectric thin film and piezoelectric material, and piezoelectric resonator, actuator element, and physical sensor using piezoelectric thin film

ActiveUS7758979B2Improved piezoelectric responsePiezoelectric response of the aluminum nitride thin film that contains scandium can be further improvedImpedence networksNatural mineral layered productsActuatorTemperature coefficient

A piezoelectric thin film of the present invention includes an aluminum nitride thin film that contains scandium. A content ratio of scandium in the aluminum nitride thin film is 0.5 atom % to 50 atom % on the assumption that a total amount of the number of scandium atoms and the number of aluminum atoms is 100 atom %. According to this arrangement, the piezoelectric thin film of the present invention can improve a piezoelectric response while keeping characteristics of elastic wave propagation speed, Q value, and frequency-temperature coefficient that the aluminum nitride thin film has.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Coprecipitation method for preparing ultra fine zinc oxide powder possessing high electric conductivity

ActiveCN1590302AImprove conductivityVolume resistivity is stableZinc oxides/hydroxidesIndiumGas phase

The invention relates to a preparation method for preparing nano-scale oxidized zinc powder with high conductivity. The method simultaneously drip mixed salt solution of zincic soluble salt and doping elements such as aluminum, gallium, indium, Yt, scandium, tin, germanium, silicon, as well as precipitating agent into water, to generate coprecipitation to generate doped zinc bloom precursor basic zinc carbonate in condition of controlling temperature and PH value of entire reaction system, and at last, calcining the product in mixed gas atmospheres of hydrogen gas and argon gas, doped superfine zinc bloom conductive powder material can be obtained. The powder material prepared by the invention has small particle-size, uniform grain fineness distribution, and which mean particle diameter is about 10 to 80 nanometer. The electric volume resistivity of the powder can reach 2.5*10^-3 omega.cm, thus its electro conductivity is better than the sample prepared by plasma method and gas-phase method in current market. The preparation method further enhances whiteness degree and conductivity of the oxidized zinc powder, and further reduces the cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

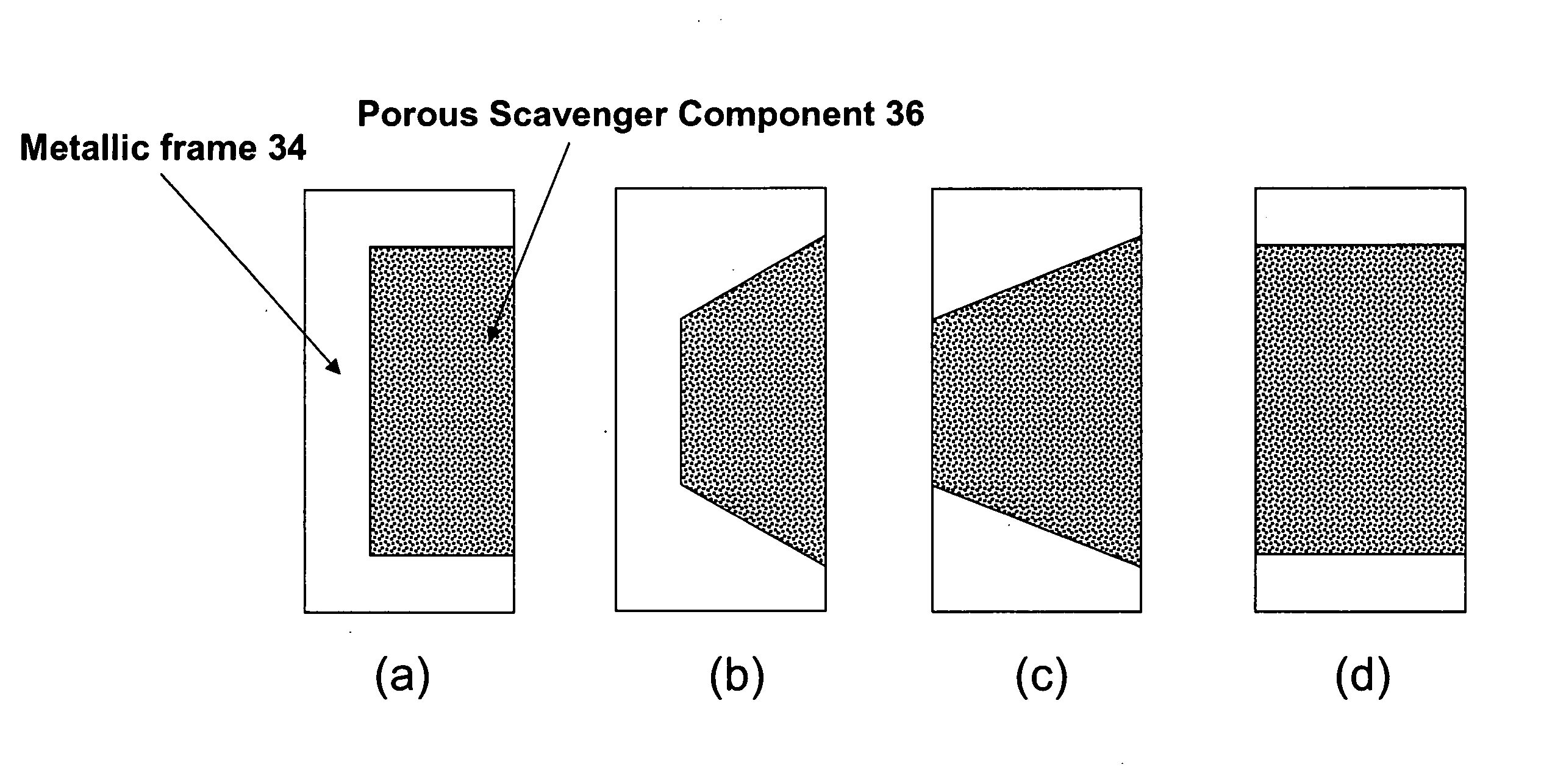

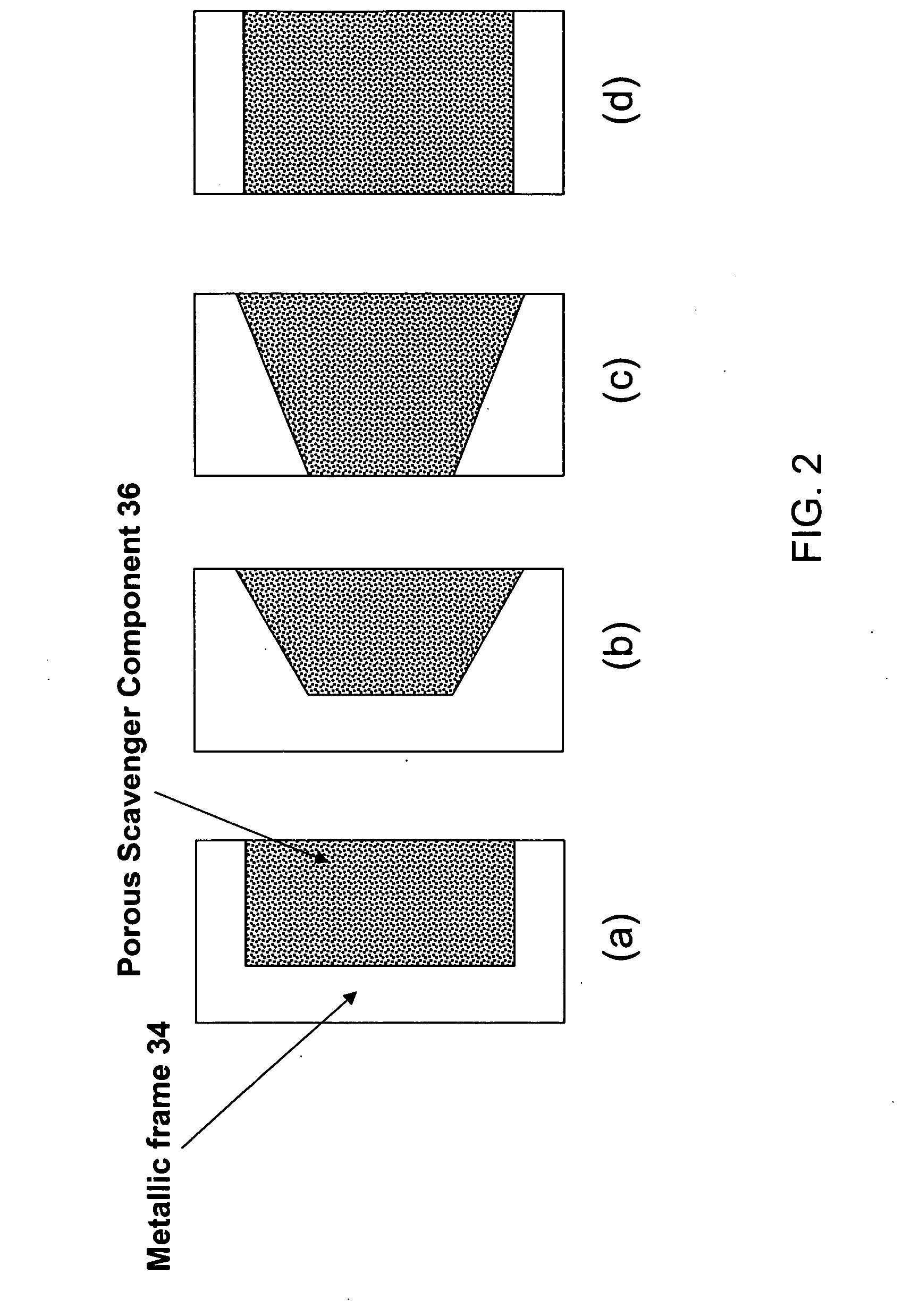

Photomask assembly incorporating a metal/scavenger pellicle frame

A photomask assembly is disclosed having a photomask substrate and a composite pellicle frame that includes both a metallic frame component and a scavenger component. The metallic frame component has a cross-sectional thickness of at least 100 micrometers in all directions, and the volume percentage of the scavenger component relative to the overall volume of the composite frame is in the range of 0.1 to 95%. The scavenger component has a gas permeability to oxygen or nitrogen greater than about 10 ml·mm / cm2·min·MPa, an average pore size between 0.001 and 10 micrometers, and a pore surface area greater than 10 m2 / g. This configuration enables the pellicle frame to have sufficient strength to withstand stresses encountered during normal use, yet also to have the capability of scavenging impurity molecules from the space adjacent to the photomask substrate. In a separate and independent feature of the invention, the scavenger component comprises at least one metal oxide selected from the group consisting of oxides of aluminum, boron, cerium, cobalt, copper, erbium, hafnium, lanthanum, neodymium, praseodymium, scandium, silicon, titanium, yttrium, zirconium, and mixtures thereof. Preferably, the metal oxide is an oxide of zirconium, yttrium, or mixtures thereof.

Owner:YAZAKI CORP

Al-zn-mg-cu alloy

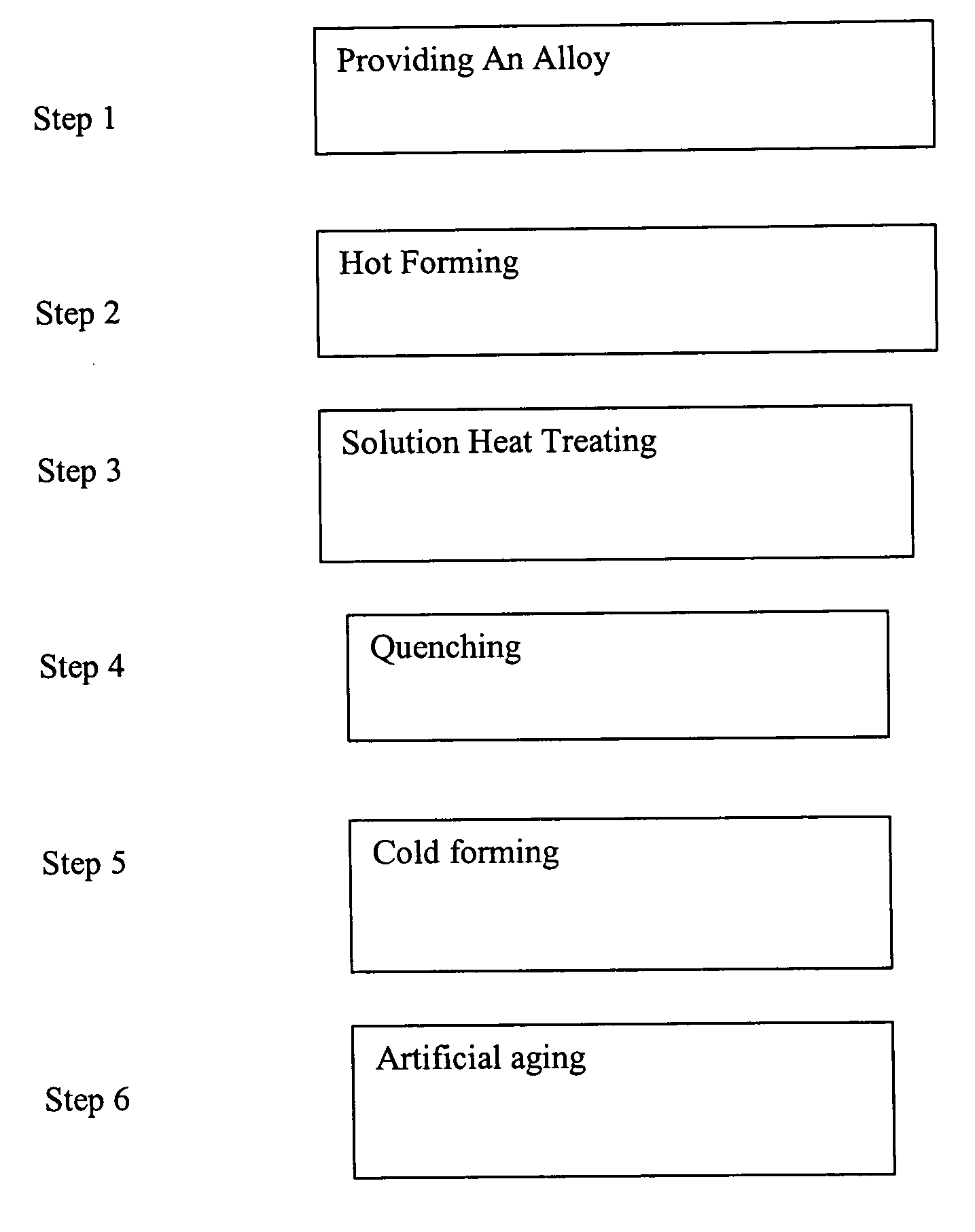

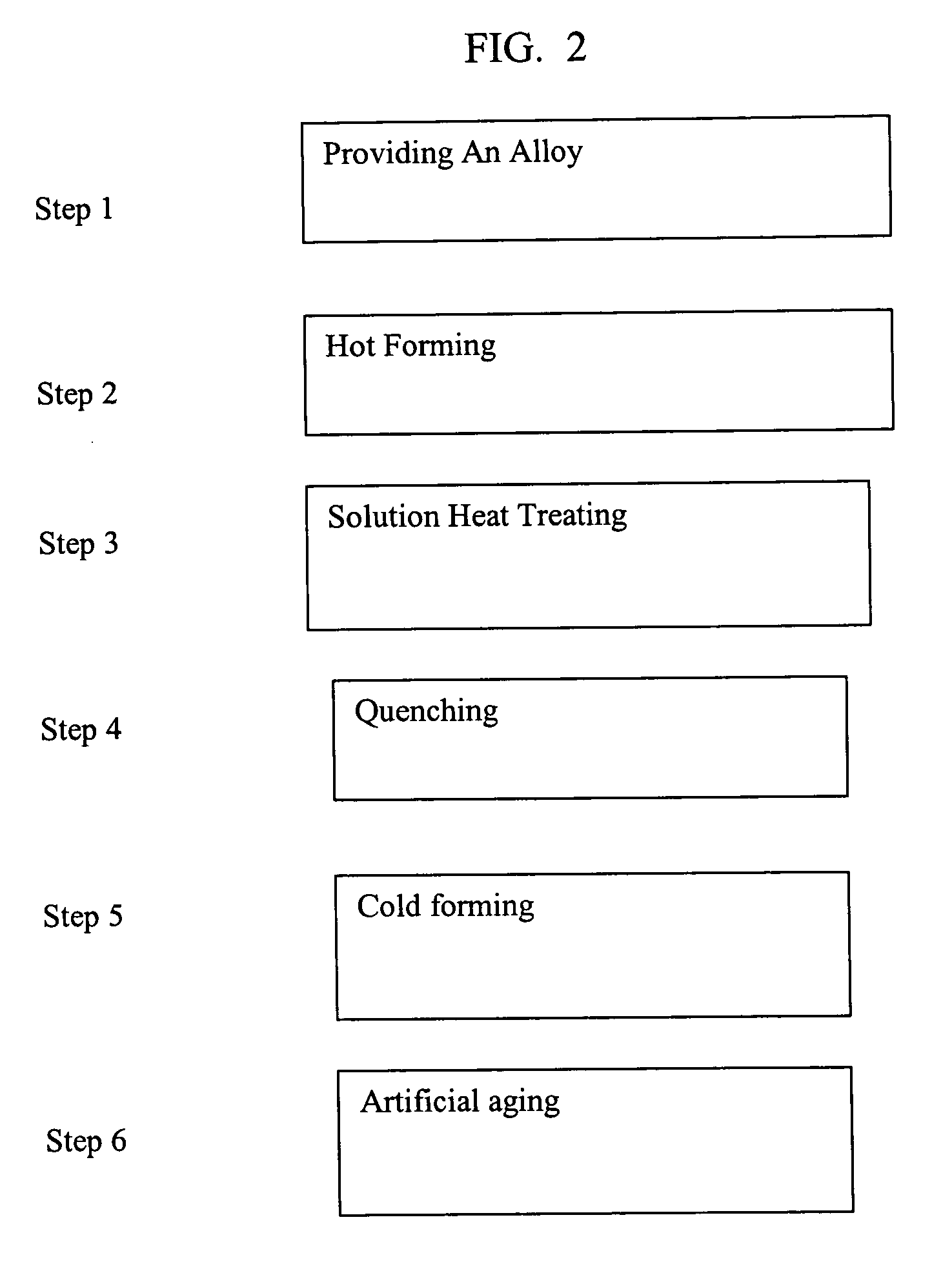

The present invention relates to an aluminum alloy product, the basic composition of the alloy is, by weight %, zinc (Zn) of about 6.5-9.5%, magnesium (Mg) of about 1.2-2.2%, copper (Cu) of about 1.0-1.9% , preferably (0.9Mg-0.6)≤Cu≤(0.9Mg+0.05), about 0~0.5% zirconium (Zr), about 0~0.7% scandium (Sc), about 0~0.4% chromium (Cr), about 0 -0.3% hafnium (Hf), about 0-0.4% titanium (Ti), about 0-0.8% manganese (Mn), balance aluminum and other incidental elements. The invention also relates to a method for the manufacture of the alloy.

Owner:NOVELIS KOBLENZ GMBH

Piezoelectric thin film, piezoelectric material, and fabrication method of piezoelectric thin film and piezoelectric material, and piezoelectric resonator, actuator element, and physical sensor using piezoelectric thin film

ActiveUS20080296529A1Improved piezoelectric responsePiezoelectric response of the aluminum nitride thin film that contains scandium can be further improvedImpedence networksPiezoelectric/electrostrictive device material selectionActuatorTemperature coefficient

A piezoelectric thin film of the present invention includes an aluminum nitride thin film that contains scandium. A content ratio of scandium in the aluminum nitride thin film is 0.5 atom % to 50 atom % on the assumption that a total amount of the number of scandium atoms and the number of aluminum atoms is 100 atom %. According to this arrangement, the piezoelectric thin film of the present invention can improve a piezoelectric response while keeping characteristics of elastic wave propagation speed, Q value, and frequency-temperature coefficient that the aluminum nitride thin film has.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

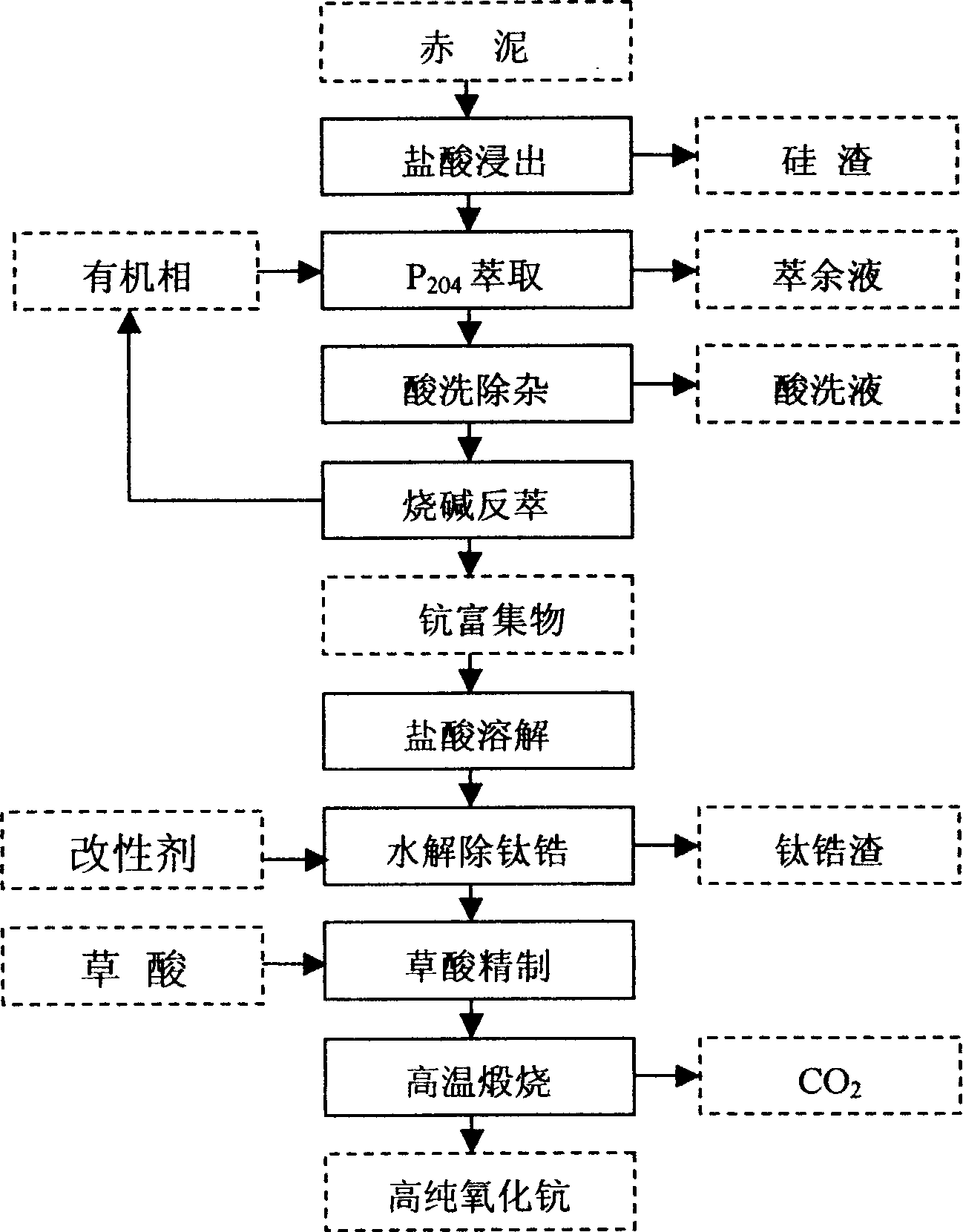

Method for extracting scandium from red mud

InactiveCN1844421AImprove protectionSimple processProcess efficiency improvementRed mudDecomposition

The invention relate to a method of extracting scandium from red mud, the method utilize the red mud that come from the process of producing aluminum oxide from alumyte, in accordance with specific characteristics of red mud, applying hydrochloric acid leach, P204 abstraction, acid-washing edulcoration, sodium-hydroxide back extraction, ammonia modifier hydrolytic decomposition zirconium and titanate in hydrochloric acid solution, oxalic acid precipitating scandium and medium temperature calcining technique, the purity of final production Sc2O3 is 99.9%. Extracting scandium from red mud change refuse into available material, save mineral resources, benefiting environmental conservation. The invention also fills up the study vacant of isolation technique in high-strength zirconium titanate and scandium.

Owner:汪友华

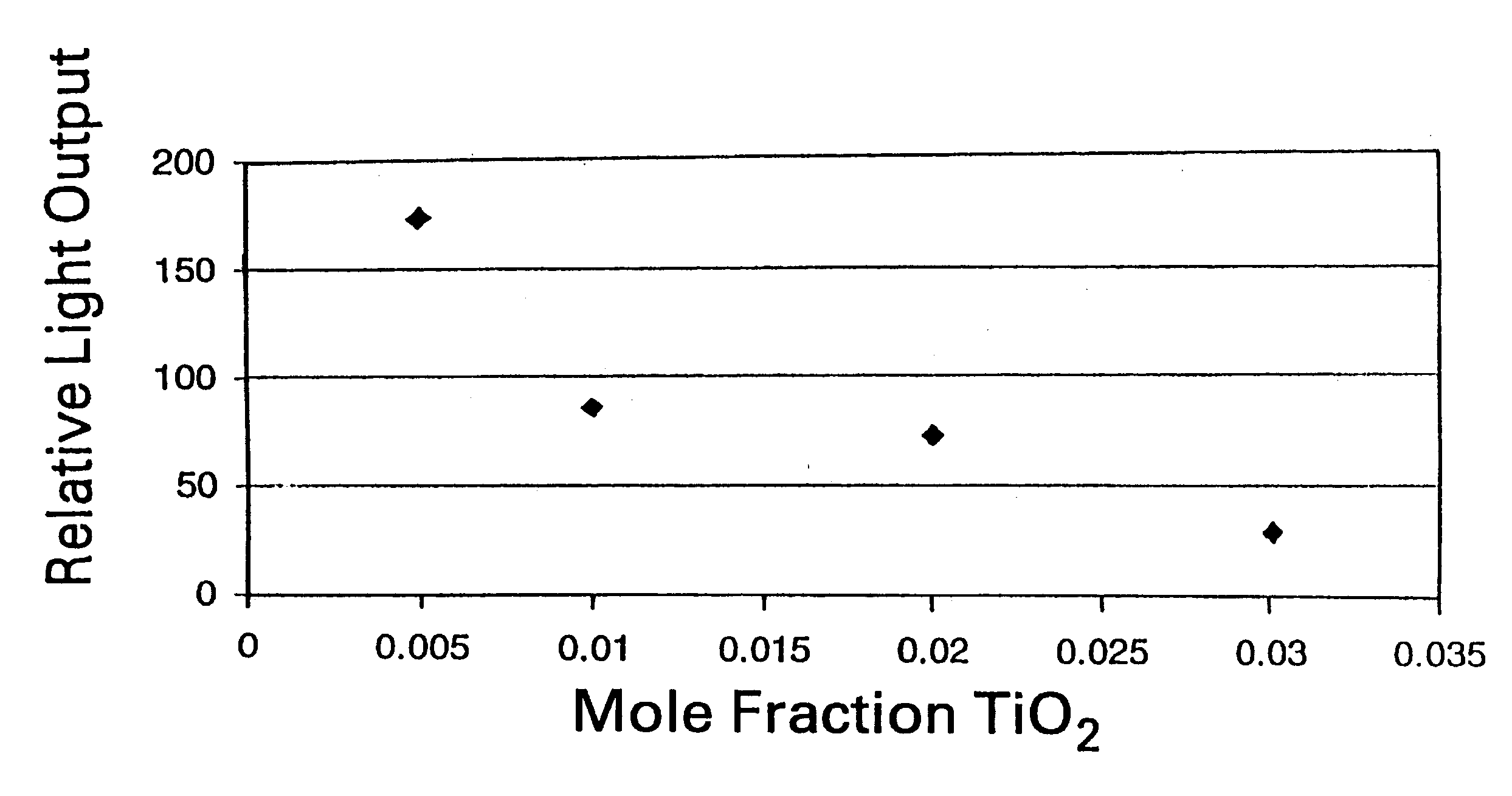

Titanium-doped hafnium oxide scintillator and method of making the same

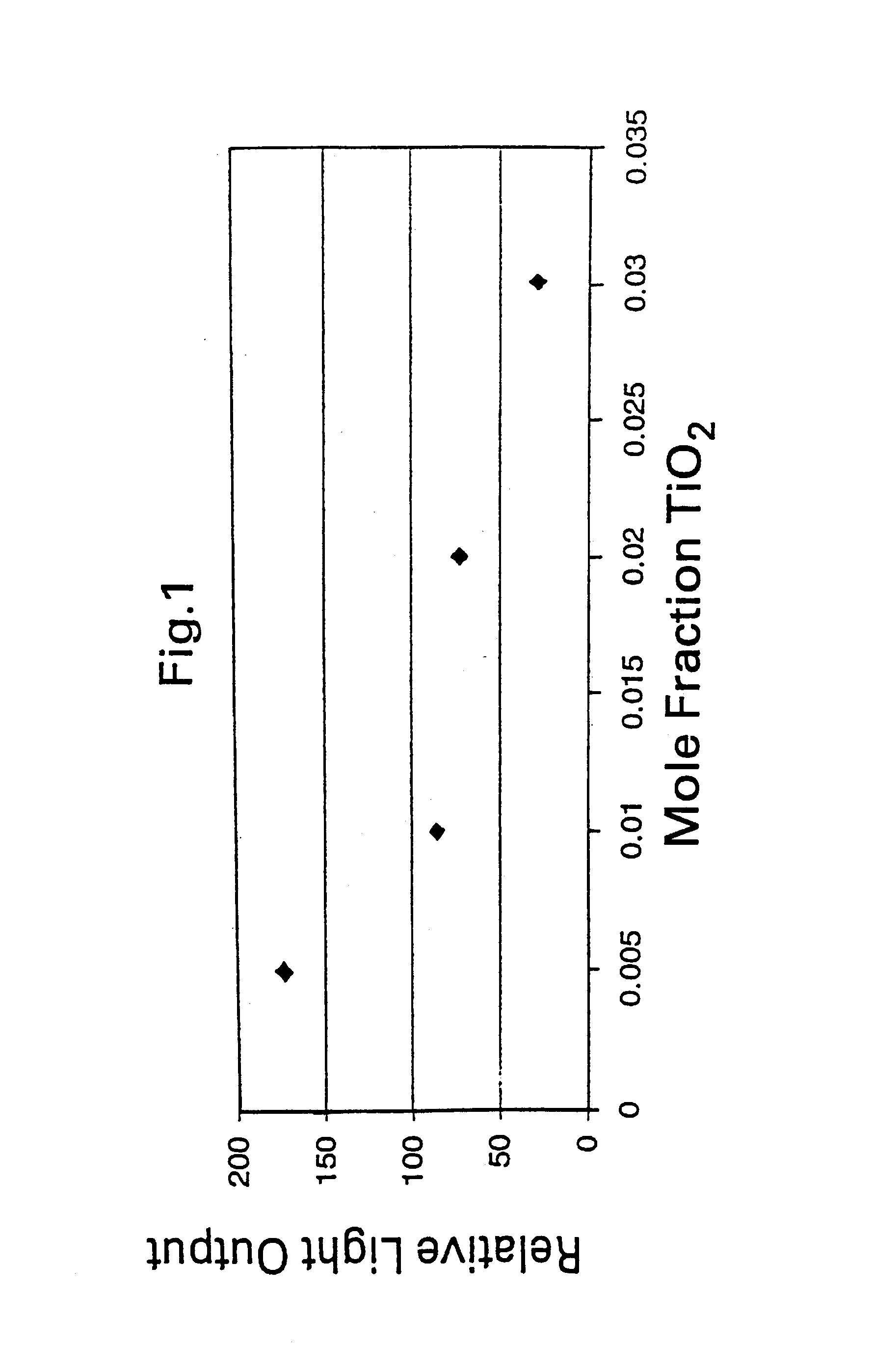

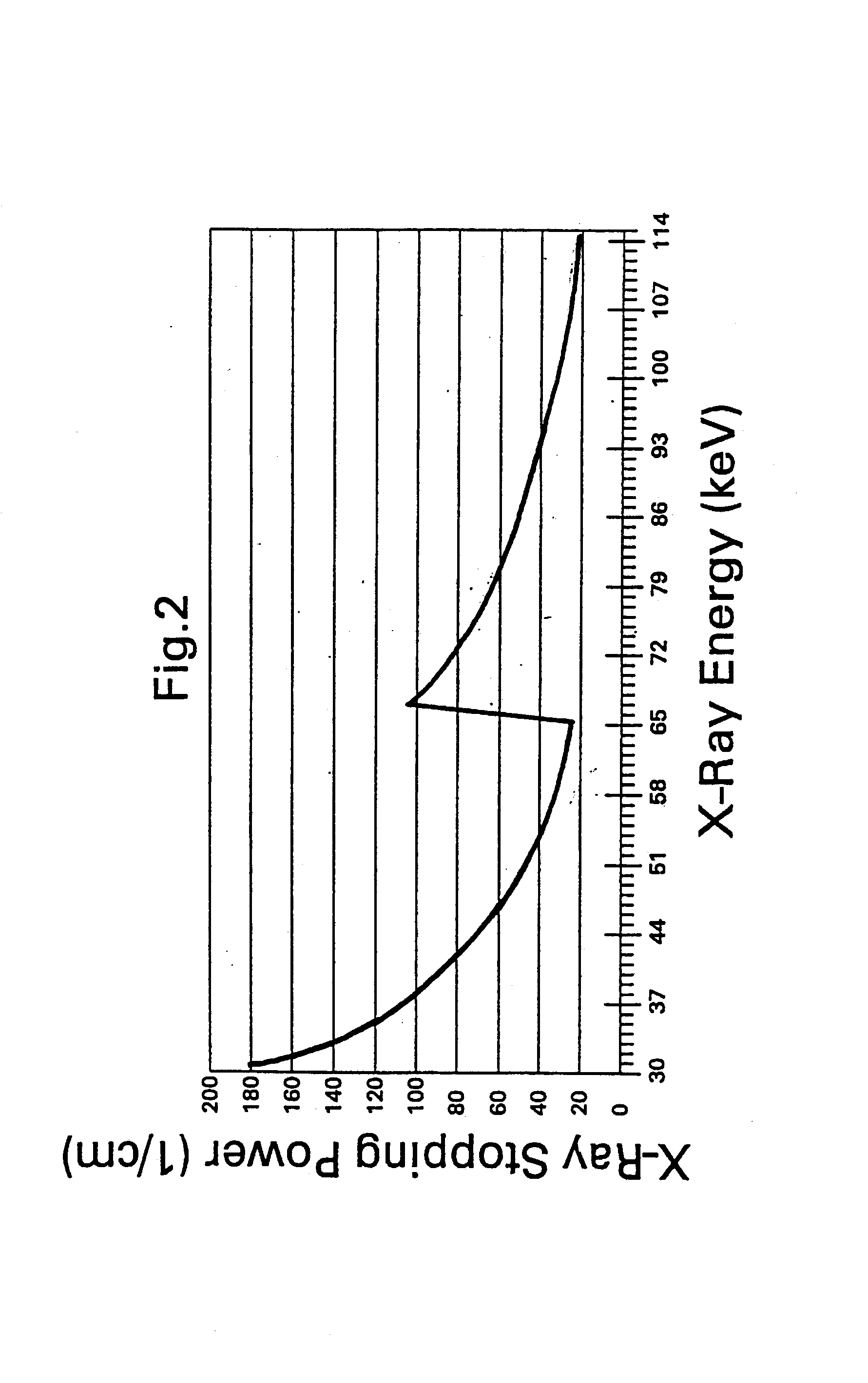

InactiveUS6858159B2Short decay timeImprove light outputMaterial analysis using wave/particle radiationRadiation/particle handlingRare earthX-ray

Hafnium oxide HfO2 scintillator compositions are doped with titanium oxide and at least an oxide of a metal selected from the group consisting of Be, Mg, and Li. The scintillator compositions can include sintering aid material such as scandium and / or tin and a rare earth metal and / or boron for improved transparency. The scintillators are characterized by high light output, reduced afterglow, short decay time, and high X-ray stopping power. The scintillators can be used as detector elements in X-ray CT systems.

Owner:GENERAL ELECTRIC CO

Method for totally extracting vanadium, gallium and scandium by using titanium dioxide hydrolysis waste acid to leach steel slag containing vanadium

InactiveCN102011010AReduce processing costsSave the cost of sulfuric acidProcess efficiency improvementSlagHydrolysis

The invention relates to a method for extracting, separating and recovering vanadium, gallium and scandium in pickle liquor by adopting a total extracting method and using titanium dioxide hydrolysis waste acid to leach steel slag containing vanadium, comprising the following steps of: mixing and stirring titanium dioxide hydrolysis waste acid and steel slag containing vanadium to obtain leaching pulp; performing solid-liquid separation for the leaching pulp, totally extracting vanadium, gallium and scandium in filtered liquor with five-category return flow, then back-extracting vanadium and gallium with five-category return flow, neutralizing with ammonium bicarbonate or ammonia water, warning up, precipitating vanadium to obtain ammonium polyvanadate, repeatedly back-extracting and precipitating vanadium for precipitating-vanadium mother liquor, and then recovering gallium; and when a back-extracting vanadium and gallium organic phase is repeatedly totally extracted and back-extracted till the content of scandium in the back-extracting vanadium and gallium organic phase is 50-1000mg, recovering scandium. The invention has the beneficial effects that waste is treated with waste, namely vanadium, gallium and scandium are recovered by using titanium dioxide hydrolysis waste acid to leach steel slag containing vanadium, and the sulfuric acid cost is saved; the method has great social and economic benefits and low production cost for producing gallium and scandium; without roasting, no waste gas is produced, and three wastes can be discharged with corresponding standards.

Owner:杨秋良 +1

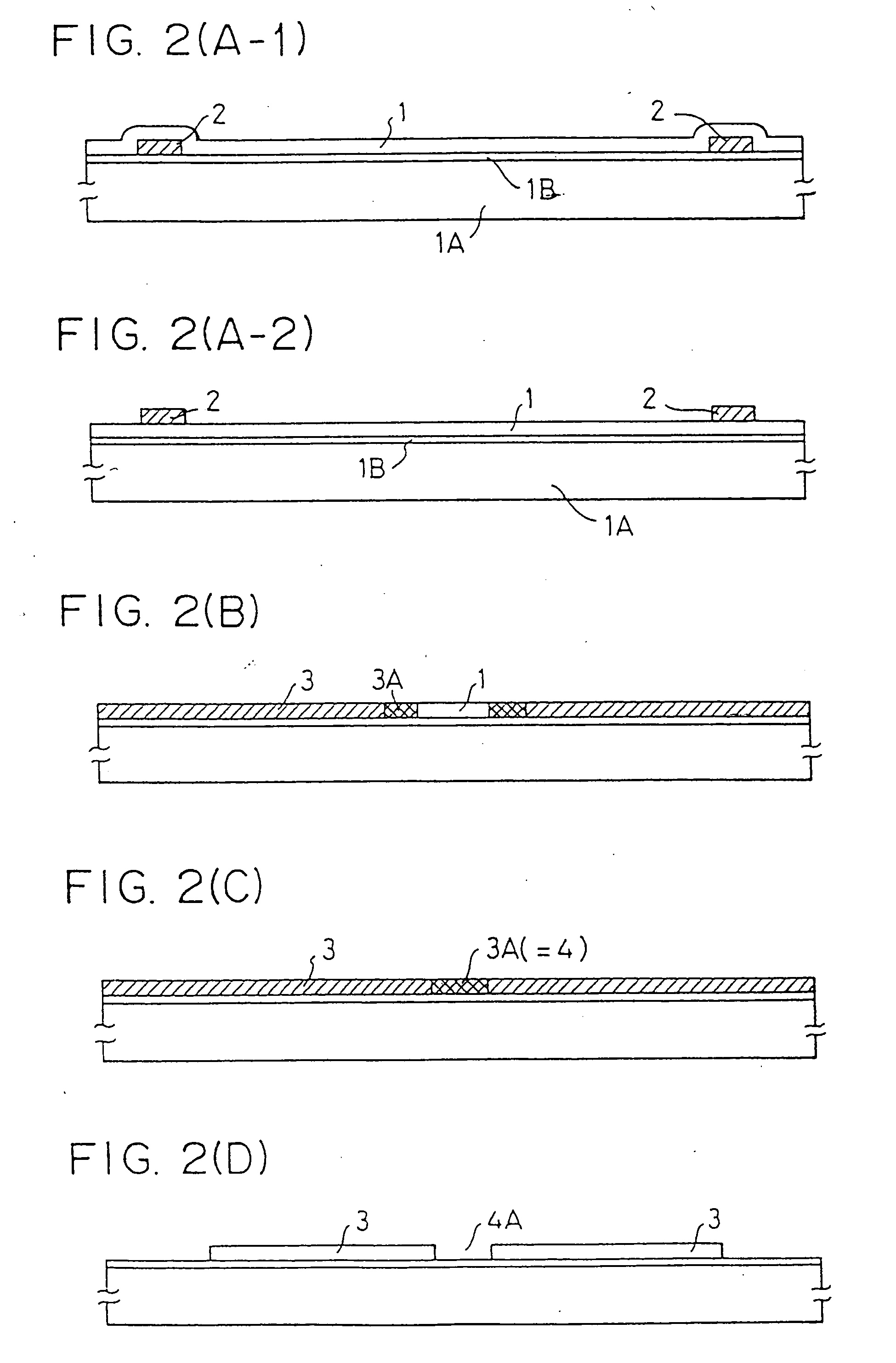

Semiconductor device and method for manufacturing the same

InactiveUS20050020006A1Small amount of resistanceImprove mobilityStatic indicating devicesSolid-state devicesIridiumManganese

A method for manufacturing a semiconductor device such as a thin film transistor using a crystal silicon film is provided. The crystal silicon film is obtained by selectively forming films, particles or clusters containing nickel, iron, cobalt, ruthenium, rhodium, paradium, osmium, iridium, platinum, scandium, titanium, vanadium, chrome, manganese, copper, zinc, gold, silver or silicide thereof in a form of island, line, stripe, dot or film on or under an amorphous silicon film and using them as a starting point, by advancing its crystallization by annealing at a temperature lower than a normal crystallization temperature of an amorphous silicon. A transistor whose leak current is low and a transistor in which a mobility is high are obtained in the same time in structuring a dynamic circuit having a thin film transistor by selectively forming a cover film on a semiconductor layer which is to become an active layer of the transistor and by thermally crystallizing it thereafter.

Owner:SEMICON ENERGY LAB CO LTD

Cast Aluminium Alloy

Cast aluminium alloys comprising 1.0-8.0% in weight magnesium (Mg), >1.0-4.0% in weight silicon (Si), 0.01-<0.5% in weight scandium (Sc), 0.005-0.2% in weight titanium (Ti), 0-0.5% in weight of at least one element or selected from the group consisting of zirconium (Zr), hafnium (Hf), molybdenum (Mo), terbium (Tb), niobium (Nb), gadolinium (Gd), erbium (Er) and vanadium (V), 0-0.8% in weight manganese (Mn), 0-0.3% in weight chromium (Cr), 0-1.0% in weight copper (Cu), 0-0.1% in weight zinc (Zn), 0-0.6% in weight iron (Fe), 0-0.004% in weight beryllium (Be), and the remainder of aluminium with further impurities to an individual maximum of 0.1% in weight and totally maximally 0.5% in weight.

Owner:EADS DEUT GMBH +1

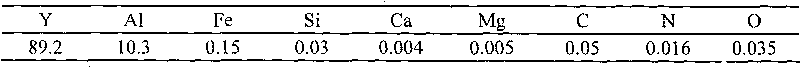

Multiple microalloying scandium-containing hydronalium welding wire and preparation method thereof

ActiveCN101380703AReduced hot cracking tendencyImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaEtchingManganese

The invention relates to a multi-element microalloyed scandium-containing aluminum-magnesium alloy series welding stick and a preparation method thereof. The components and the weight percentage of the multi-element microalloyed scandium-containing aluminum-magnesium alloy series welding stick are as follows: 4.0 to 6.0 percent of magnesium, 0 to 1.0 percent of zinc, 0.4 to 1.0 percent of manganese, 0.05 to 0.2 percent of zirconium, 0.10 to 0.40 percent of scandium, 0.10 to 0.40 percent of erbium and / or yttrium and the rest is aluminum. The Al-Mg welding stick applied by the invention has the advantages that: (1) the tissues of the welding line are uniformly thinned into spherical grains and have higher thermal stability; (2) the thermal-cracking resistance is obviously enhanced; (3) the obdurability of a welding joint is excellent; (4) the welding joint has excellent resistance for the stress etching of ocean-atmosphere; (5) a welding technique window is enlarged.

Owner:有研金属复材技术有限公司

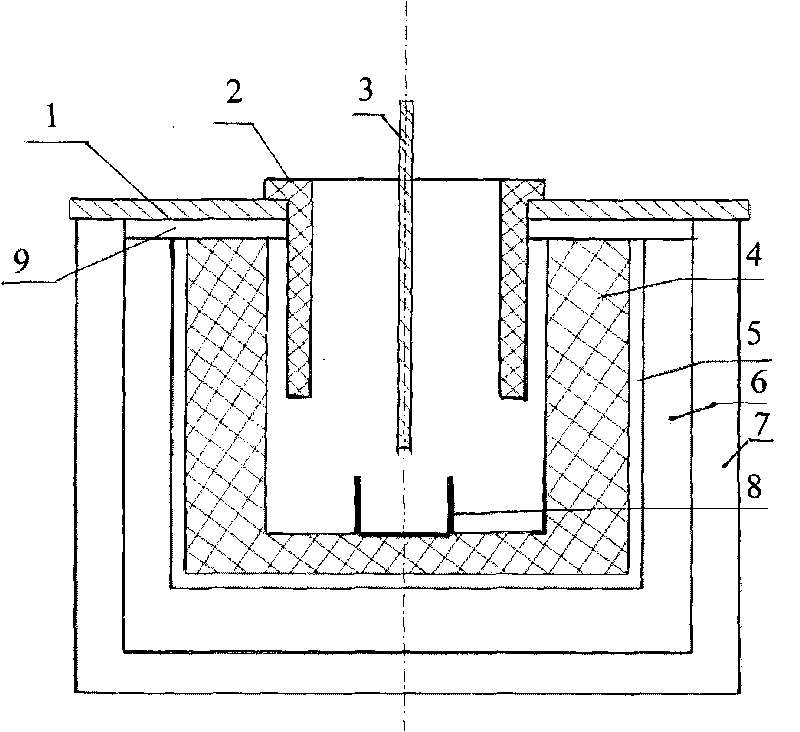

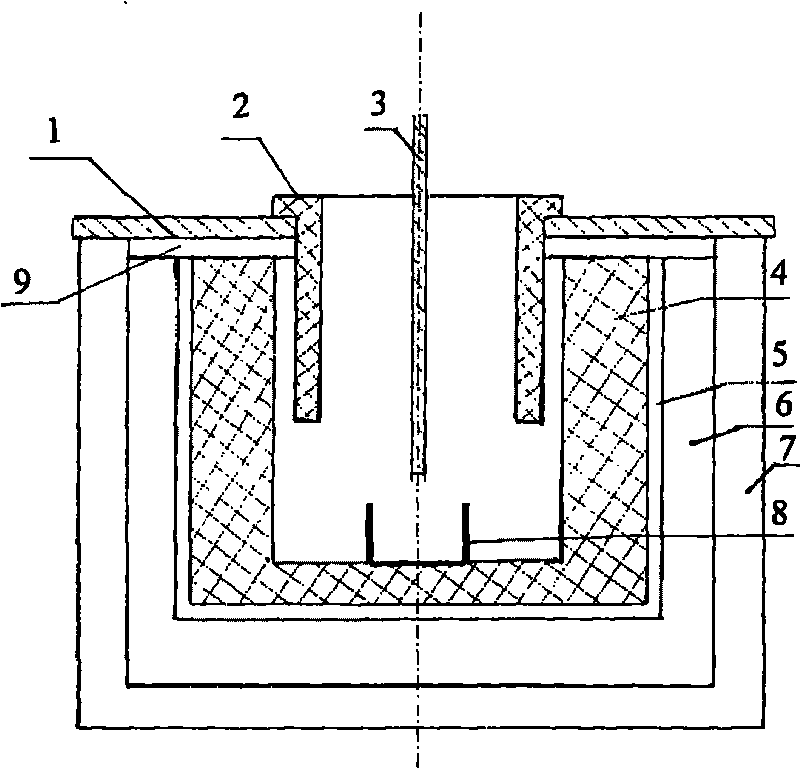

Rare earth aluminum alloy, and method and device for preparing same

The invention discloses a rare earth aluminum alloy, and a method and a device for preparing the same. The alloy contains at least one rare earth metal of lanthanum, cerium, praseodymium, neodymium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, lutetium, scandium and yttrium, the content of raw earth is 5 to 98 weight percent, and the balance is aluminum and inevitable impurities. The device for preparing the rare earth aluminum alloy is characterized in that: a) graphite serves as an electrolysis bath, a graphite plate is an anode, a tungsten bar is a cathode and a molybdenum crucible serves as a rare earth aluminum alloy receiver; b) the diameter of the tungsten bar is 30 to 55 mm; and c) the anode of the graphite consists of a plurality of graphite plates. The rare earth aluminum alloy, and the method and the device for preparing the same have the advantages that: the alloy has uniform components, little segregation and low impurity content; technology for preparing the rare earth aluminum alloy through fusion electrolysis can maximally replace a process for preparing single medium-heavy metal through metallothermic reduction, greatly reduce energy consumption and the emission of fluorine-containing tail gas and solid waste residue, improve current efficiency and metal yield and reduce the consumption of auxiliary materials and the energy consumption; and the rare earth aluminum alloys with different rare earth contents can be obtained by controlling different electrolytic temperatures and different cathode current densities.

Owner:GRIREM ADVANCED MATERIALS CO LTD

System and Method for Recovery of Scandium Values From Scandium-Containing Ores

InactiveUS20120207656A1Scandium oxides/hydroxidesProcess efficiency improvementScandiumMaterials science

Owner:SCANDIUM INT MINING

Aluminum alloy that is not sensitive to quenching, as well as method for the production of a semi-finished product therefrom

InactiveUS20060157172A1Reduce inherent stressSame and good strength propertyThin material handlingManganeseHafnium

An aluminum alloy that is not sensitive to quenching, for the production of high-strength forged pieces that are low in inherent tension, and high-strength extruded and rolled products, consisting of: 7.0-10.5 wt. % zinc, 1.0-2.5 wt. % magnesium, 0.1-1.15 wt. % copper, 0.06-0.25 wt. % zirconium, 0.02-0.15 wt. % titanium, at most 0.5 wt. % manganese, at most 0.6 wt. % silver, at most 0.10 wt. % silicon, at most 0.10 wt. % iron, at most 0.04 wt. % chrome, and at least one element selected from the group consisting of: hafnium, scandium, strontium and / or vanadium with a summary content of at most 1.0 wt. %. The alloy can also contain contaminants at proportions of at most 0.05 wt. % per element and a total proportion of at most 0.15 wt. %, wherein the remaining component includes aluminum. The sum of the alloy elements zinc and magnesium and copper is at least 9 wt. %. Furthermore, there can also be a method for the production of a high-strength semi-finished product low in inherent tension from this alloy.

Owner:OTTO FUCHS

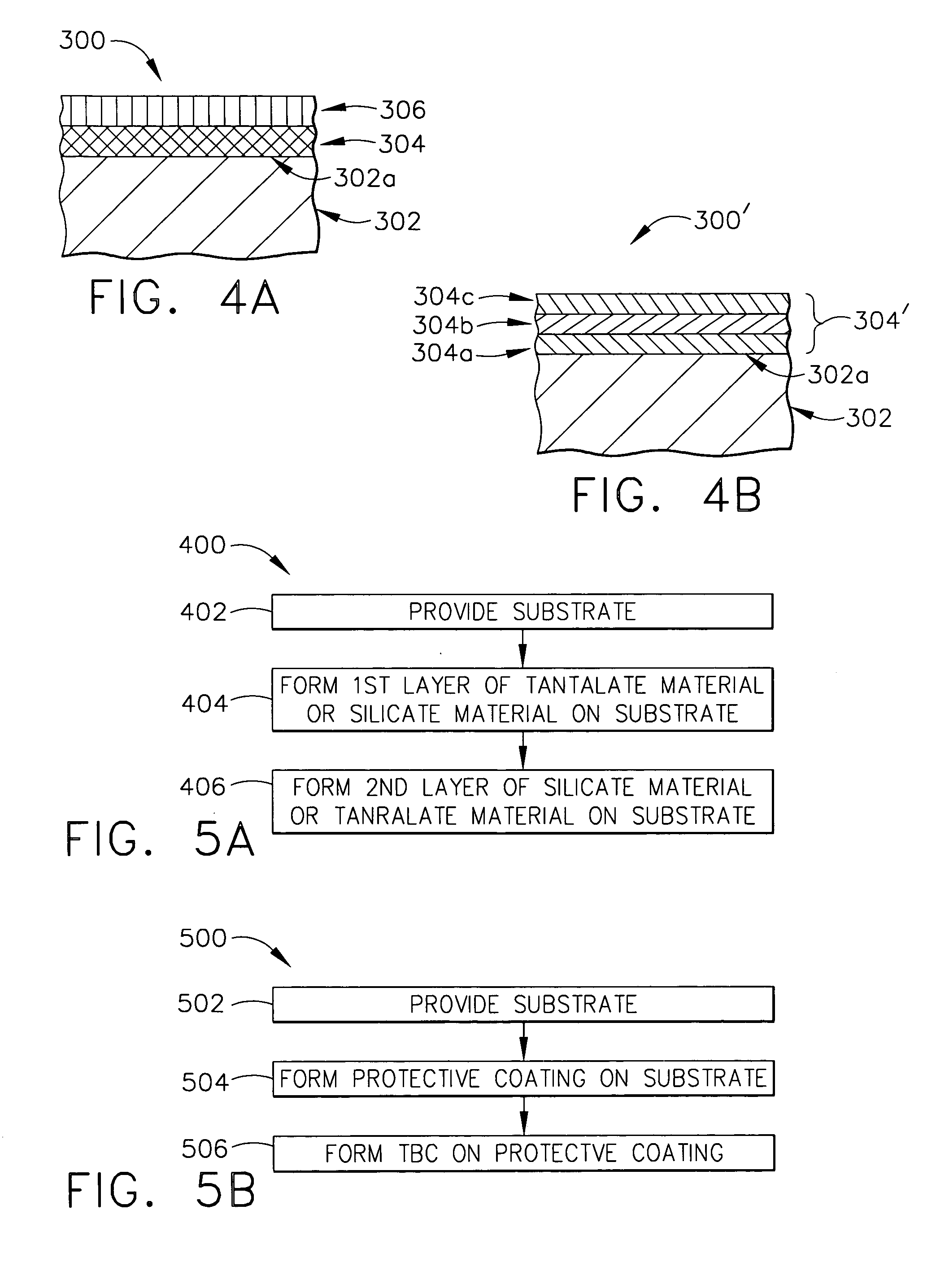

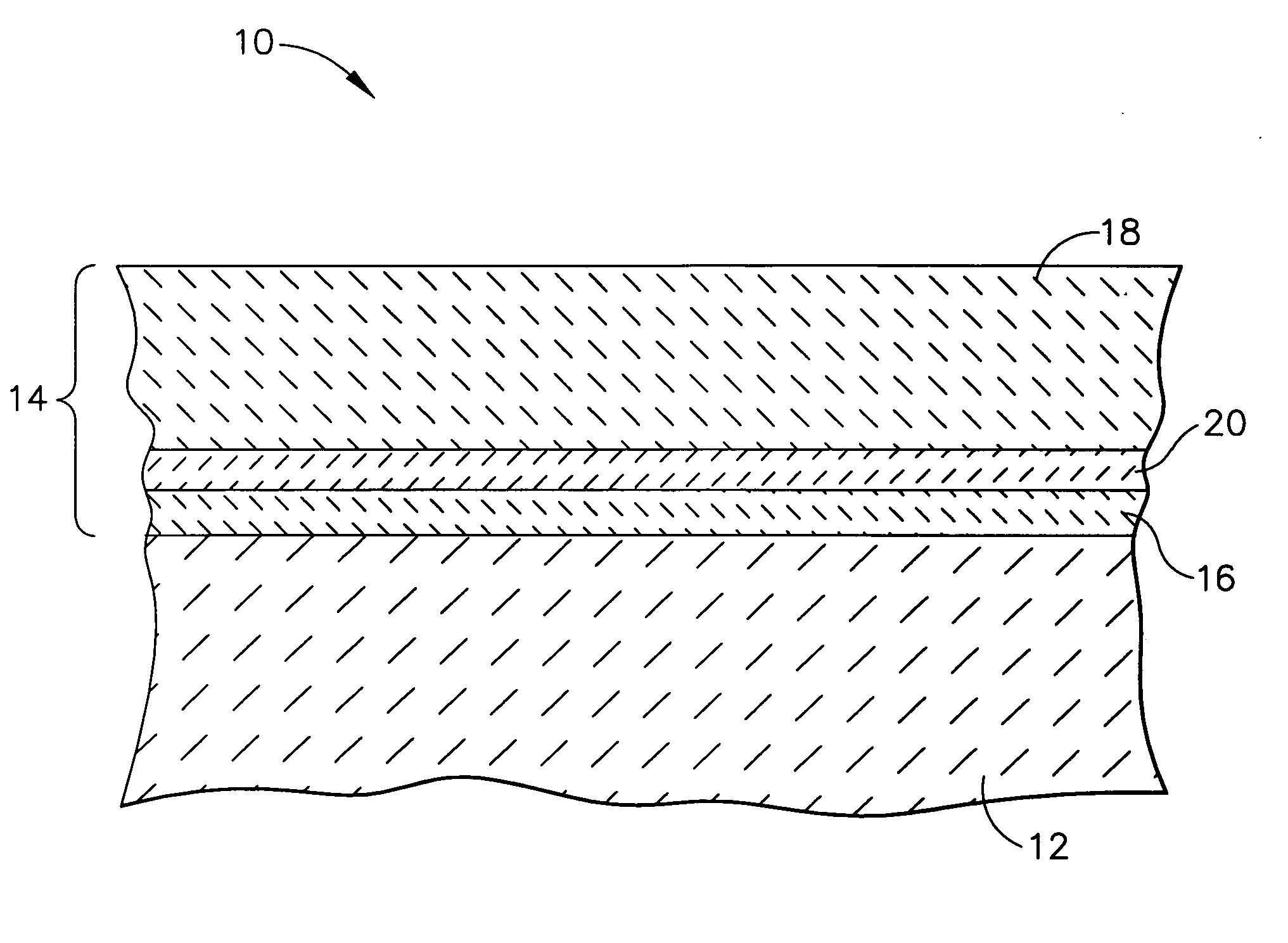

CMAS resistant thermal barrier coating

ActiveUS20070172703A1Reduce componentsReduces sand related distressMolten spray coatingBlade accessoriesIndiumCerium

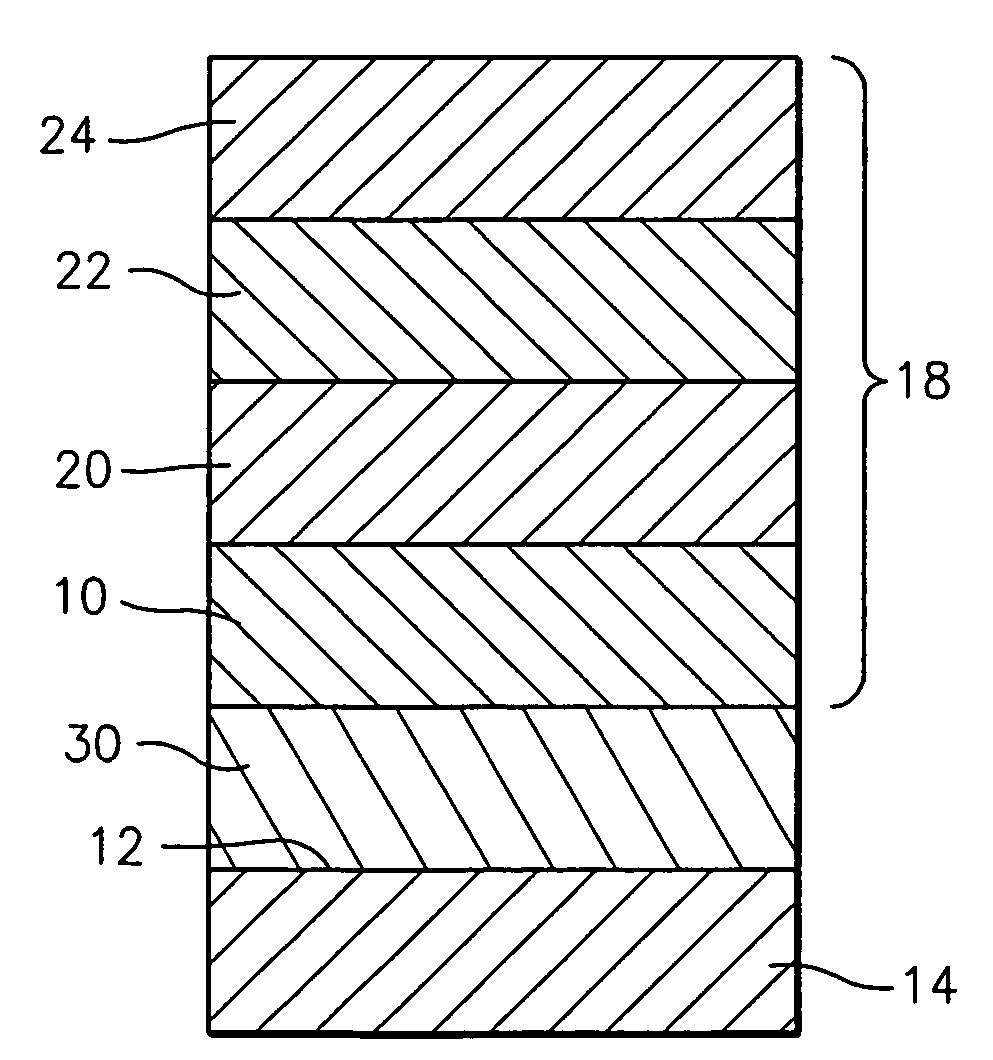

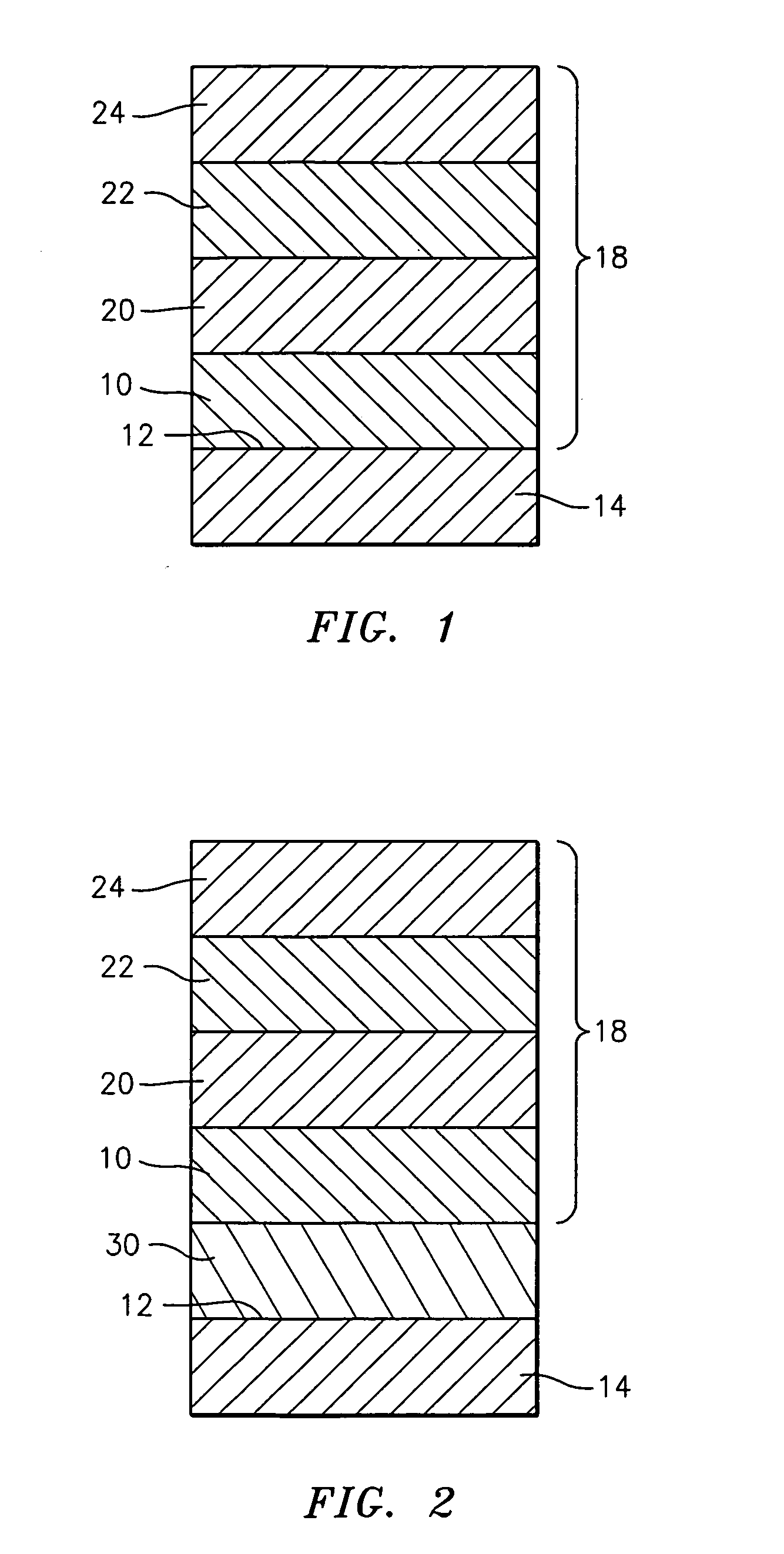

A turbine engine component is provided which has a substrate and a thermal barrier coating applied over the substrate. The thermal barrier coating comprises alternating layers of yttria-stabilized zirconia and a molten silicate resistant material. The molten silicate resistant outer layer may be formed from at least one oxide of a material selected from the group consisting of lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, scandium, indium, zirconium, hafnium, and titanium or may be formed from a gadolinia-stabilized zirconia. If desired, a metallic bond coat may be present between the substrate and the thermal barrier coating system. A method for forming the thermal barrier coating system of the present invention is described.

Owner:RTX CORP

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS7018696B2Sufficient chemicalSufficient thermalLayered productsVacuum evaporation coatingManganeseHigh reflectivity

A silver-based alloy thin film is provided for the highly reflective or semi-reflective coating layer of optical discs. Elements that can be added to silver to produce useful silver alloys include zinc, aluminum, copper, manganese, germanium, yttrium, bismuth, scandium, and cobalt. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

Protective coating for ceramic components

InactiveUS20060099358A1Envelopes/bags making machineryEfficient propulsion technologiesRare-earth elementCombustion

A protective coating for a component comprising a ceramic based substrate, and methods for protecting the component, the protective coating adapted for withstanding repeated thermal cycling. The substrate may comprise silicon nitride or silicon carbide, and the protective coating may comprise at least one tantalate of scandium, yttrium, or a rare earth element. The protective coating may further comprise one or more metal oxides. The coating protects the substrate from combustion gases in the high temperature turbine engine environment. The coating may be multi-layered and exhibits strong bonding to Si-based substrate materials and composites.

Owner:HONEYWELL INT INC

Environmental barrier coating with physical barrier layer for silicon-comprising materials

ActiveUS20060166018A1Good effectEngine manufactureMachines/enginesAlkaline earth metalCoating system

Owner:GENERAL ELECTRIC CO

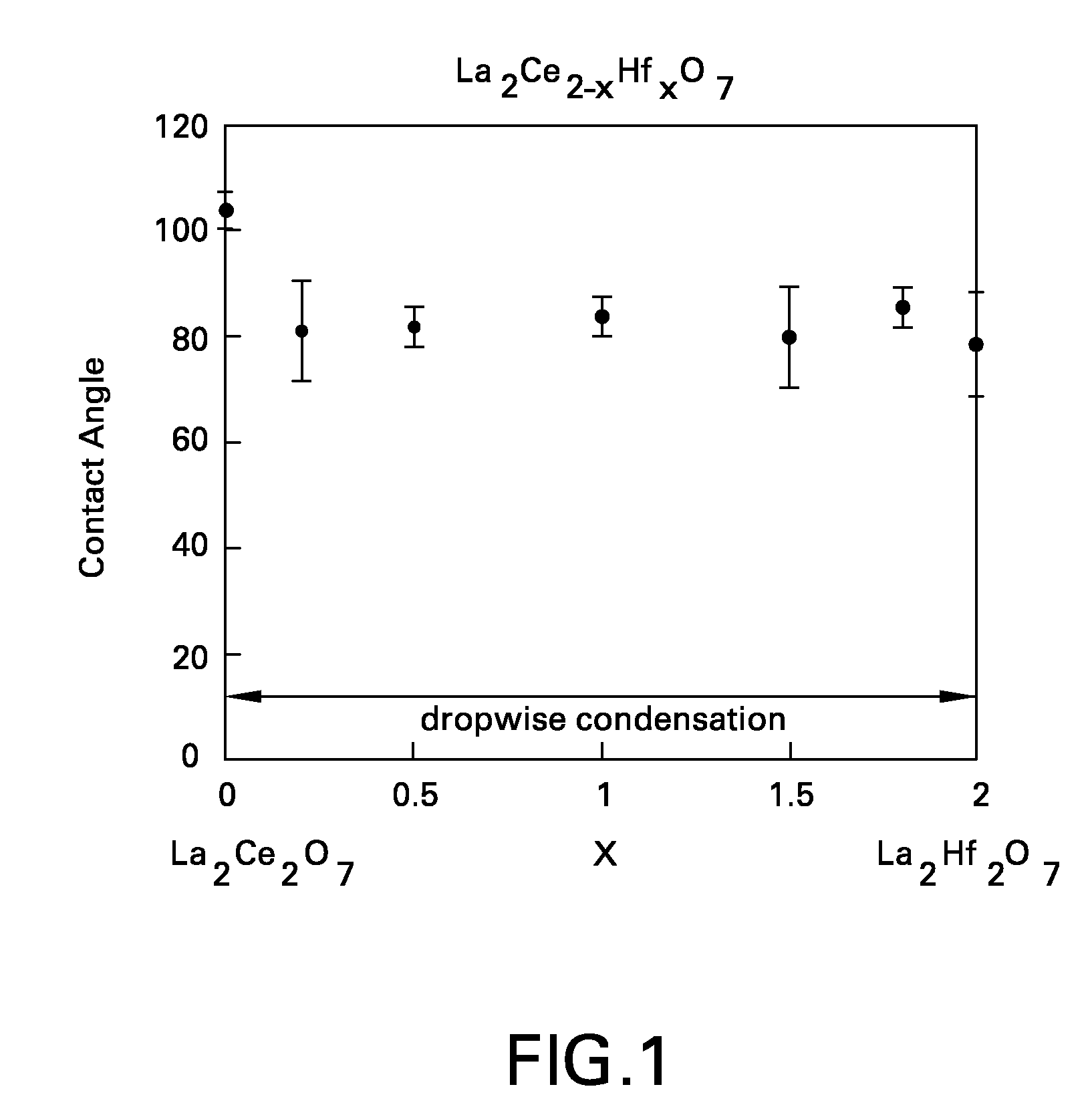

Wetting resistant materials and articles made therewith

Ceramic materials with relatively high resistance to wetting by various liquids, such as water, are presented, along with articles made with these materials, methods for making these articles and materials, and methods for protecting articles using coatings made from these materials. One particular embodiment is an article that comprises a coating having a surface connected porosity content of up to about 5 percent by volume. The coating comprises a material that comprises a primary oxide and a secondary oxide, wherein (i) the primary oxide comprises a cation selected from the group consisting of cerium, praseodymium, terbium, and hafnium, and (ii) the secondary oxide comprises a cation selected from the group consisting of the rare earth elements, yttrium, and scandium.

Owner:GENERAL ELECTRIC CO

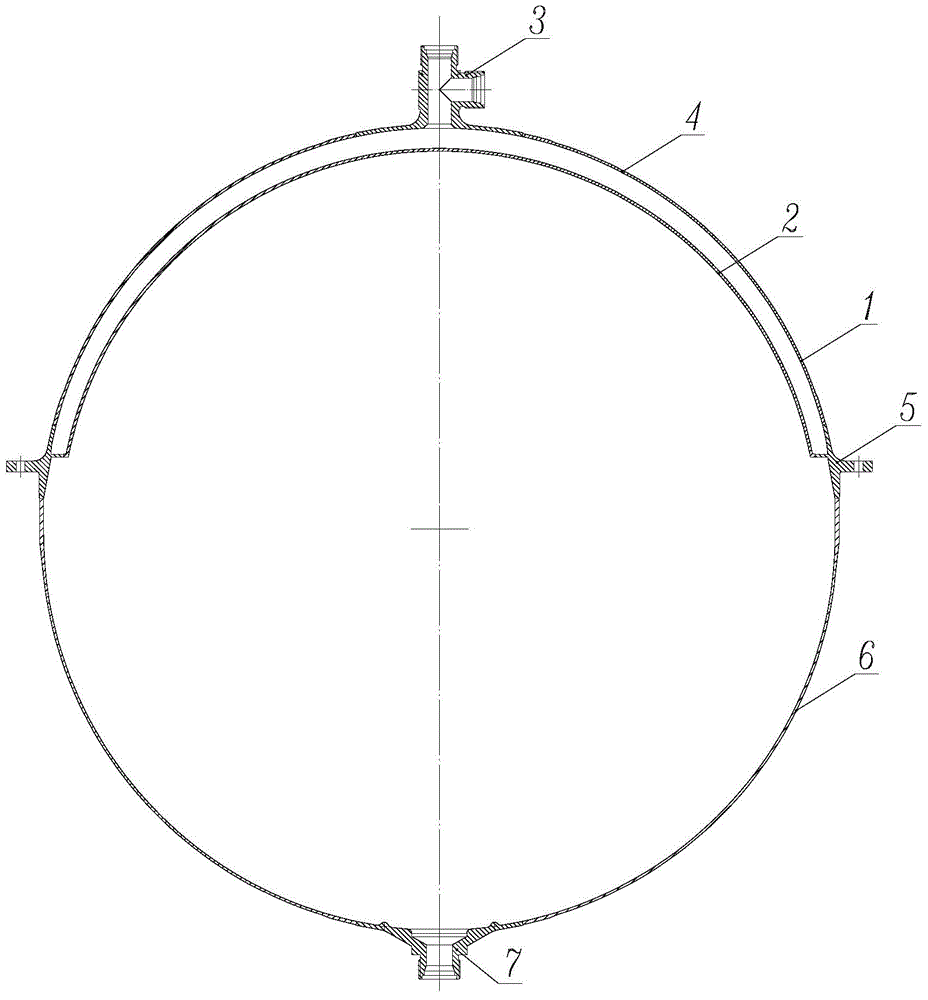

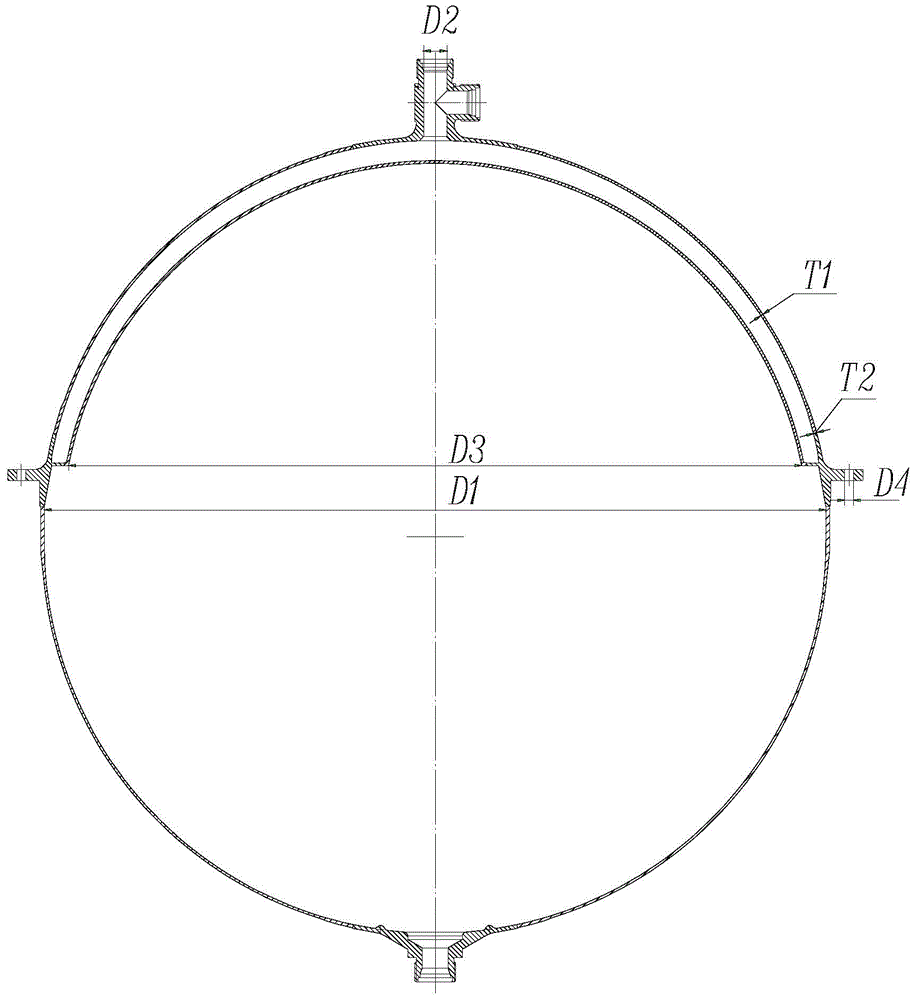

Metal propellant storage tank for spaceflight and manufacturing method thereof

ActiveCN104648696ASolve lightweight design problemsImprove performanceCosmonautic propulsion system apparatusRocket engine plantsButt jointSpaceflight

The invention provides a metal propellant storage tank for spaceflight. The metal propellant storage tank for the spaceflight comprises a shell 1 and a metal diaphragm 2. The shell comprises a gas circuit joint 3, an upper semisphere 4, a connecting ring 5, a lower semisphere 6 and a liquid circuit joint 7, wherein the upper semisphere 4 and the lower semisphere 6 are connected through the connecting ring 5, the gas circuit joint 3 is connected with the upper semisphere 4, the liquid circuit joint 7 is connected with the lower semisphere 6, and the metal diaphragm 2 is in butt joint with the connecting ring 5. The overall shell 1 is made of the scandium aluminum magnesium alloy materials whose brand type is 5B70. The metal diaphragm 2 is made of pure aluminum. The invention further provides a manufacturing method of the metal propellant storage tank for the spaceflight. The metal propellant storage tank for the spaceflight solves the problems that the propellant storage tank is large in quality and low in structural efficiency, realizes the light design of the propellant storage tank, effectively reduces the weight of the storage tank, and greatly reduces the launch cost of a vehicle.

Owner:SHANGHAI INST OF SPACE PROPULSION

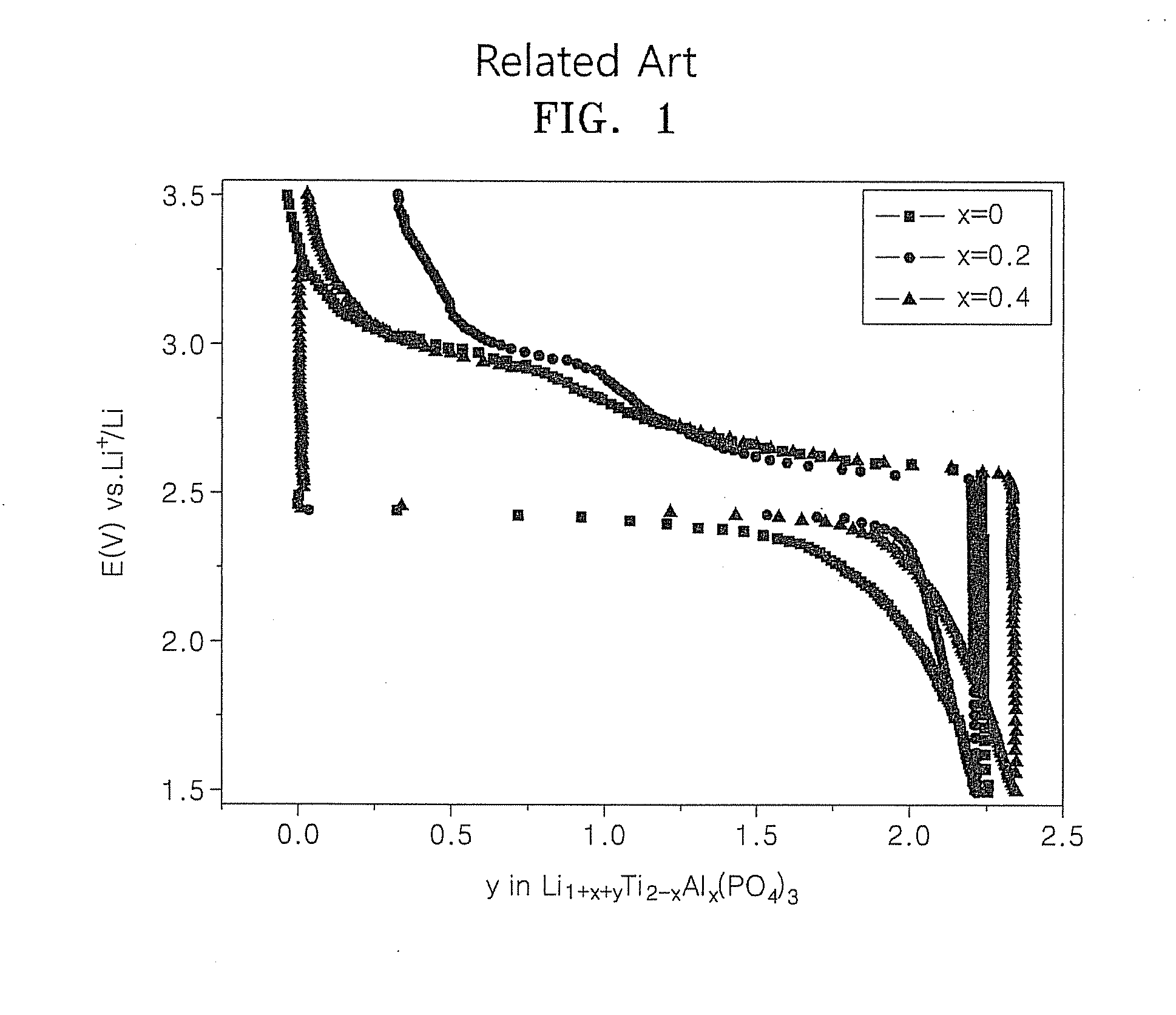

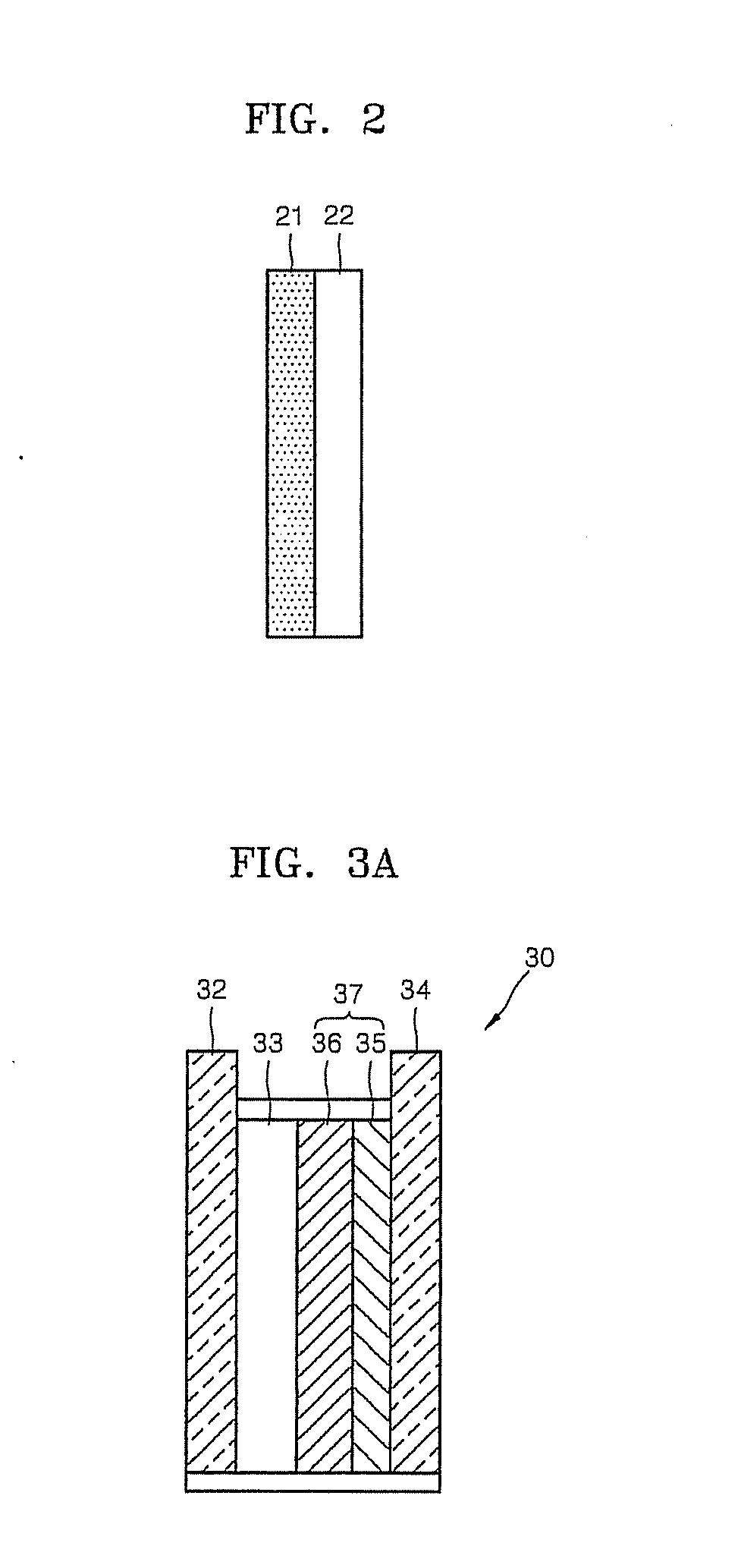

Protected anode and lithium air battery and all-solid battery including protected anode

ActiveUS20130149616A1Improve stabilityFuel and primary cellsAlkaline accumulatorsIndiumLithium–air battery

A protected anode including an anode including a lithium titanium oxide; and a protective layer including a compound represented by Formula 1 below, a lithium air battery including the same, and an all-solid battery including the protected anode:Li1+XMXA2−XSiYP3−YO12 <Formula 1>wherein M may be at least one of aluminum (Al), iron (Fe), indium (In), scandium (Sc), or chromium (Cr),A may be at least one of germanium (Ge), tin (Sn), hafnium (Hf), and zirconium (Zr),0≦X≦1, and0≦Y≦1.

Owner:SAMSUNG ELECTRONICS CO LTD +1

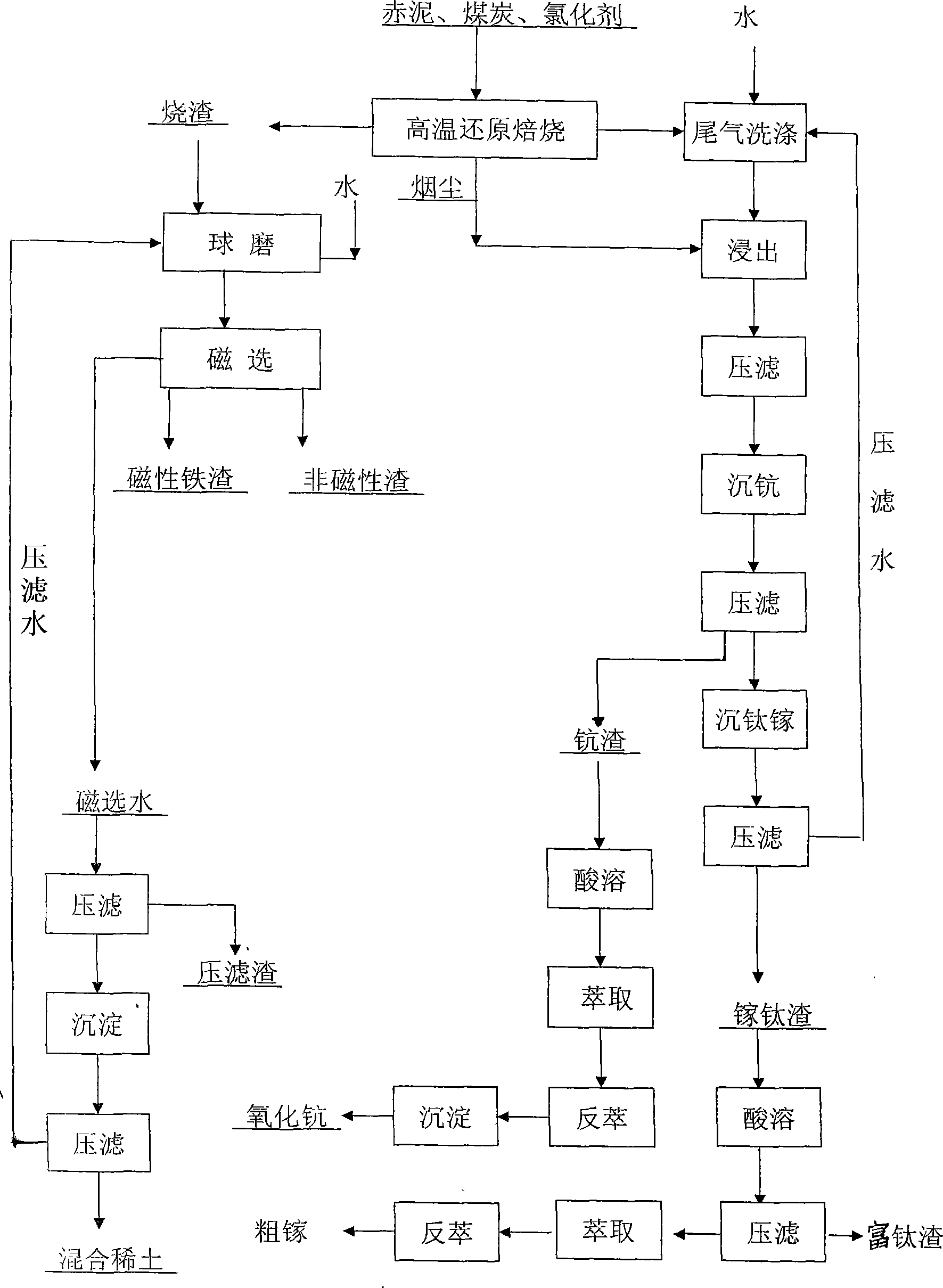

Comprehensive utilization method for red mud

InactiveCN101463426APromote environmental protectionGood benefitSolid waste managementProcess efficiency improvementWash waterRed mud

The invention discloses a method for comprehensively utilizing red mud, comprising the following steps: chloridizing roasting, namely roasting the mixture of the red mud, coal and calcium chloride; cinder treatment, namely obtaining magnetic iron slag and non-magnetic slag after magnetic separation is carried out to levigated cinder, and then separating the magnetic iron slag and non-magnetic slag; adding calcined soda or oxalic acid after levigation liquid and wash water are rich in mischmetal due to cyclic use, and then precipitating mischmetal slag; treatment of dry dust and circulation liquid, namely, after dry powder for roasting dust collection is collected, mixing the dry powder with scouring water which is used for tail gas circulation and then leaching soluble ScCl3 and GaCl3; after filter pressing, precipitating scandium by adding oxalic acid crystal in filtrate; carrying out filter pressing again, precipitating gallium and Ti(OH)4 by adding ammonia into the filtrate, dissolving obtained gallium-titanium slag with acid and then using P2O4 extractant to extract the gallium; and using extractant to extract the scandium after scandium precipitate is dissolved by acid, carrying out precipitation again by adopting back-extraction acid dissolving, and obtaining Sc2O3 by means of roasting. The method can realize recovery of valuable metals from the red mud, and secondary residual slag is totally used for building material production; and the method has environment protection effects and economic benefits, plays an important role in the development of recycling economy and is applicable to enterprises generating red mud.

Owner:张钦

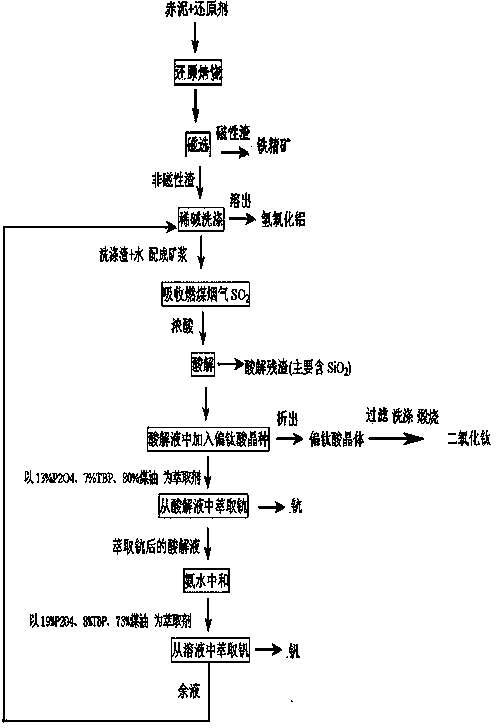

Method for comprehensively recycling such valuable metals as iron, aluminum, scandium, titanium, vanadium and the like in red mud

ActiveCN103898330AEfficient separationSolve the problem of too much acid consumptionProcess efficiency improvementRed mudTitanium

The invention provides a method for comprehensively recycling such valuable metals as iron, aluminum, scandium, titanium, vanadium and the like in red mud. The method can not only be used for recycling such elements with higher contents in the red mud as iron, aluminum, silicon and the like, but also can be used for comprehensively recycling and extracting valuable metals with relatively lower contents such as titanium, vanadium, scandium and the like, effective elements in the red mud can almost completely utilized in high efficiency, the entire process flow achieves zero emission of the red mud, thereby meeting the requirements of energy saving and environmental protection, and no new pollution is generated in the entire process flow.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

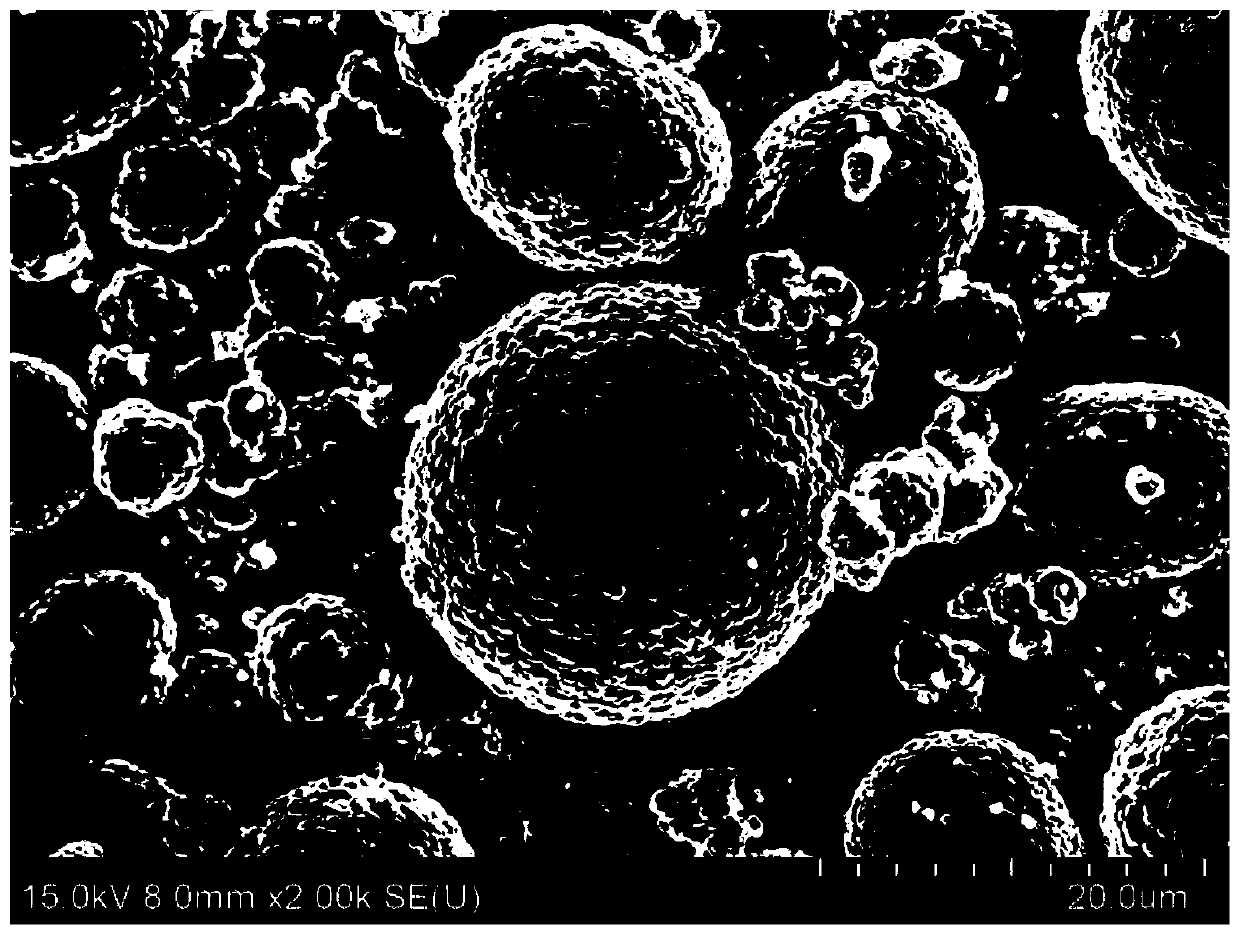

High-compaction and high-stability high-nickel cathode material and preparation method thereof, and lithium ion battery

ActiveCN110010889AImprove powder compactionIncrease the ultimate compaction densitySecondary cellsPositive electrodesHigh energyCerium

The invention discloses a high-compaction and high-stability high-nickel cathode material and a preparation method thereof, and a lithium ion battery. The high-nickel cathode material comprises a basematerial and a coating layer coating the surface of the base material, the base material is a compound as shown in the formula I: LinNixMyO2, wherein in the formula I, 0.98<n<=1.20, 0.50<x<1.00, 0.00<y<1.00, and 0.00<x+y<=1.00; the base material is consisted of a large-particle substrate and a small-particle substrate; and M is at least one selected from a group consisting of lithium, manganese,aluminum, molybdenum, chromium, vanadium, lanthanum, scandium, cerium, niobium, molybdenum, cobalt, magnesium, zirconium, strontium, yttrium, barium, titanium, fluorine, silicon, boron and phosphorus.The cathode material prepared by the invention has low residual alkali, uniform primary particle coating, primary particle pressure resistance and difficult breakage, so that the prepared lithium ionbattery has high energy density, lower internal resistance and excellent rate capability, safety performance and cycle performance.

Owner:GUIZHOU RONGBAI LITHIUM BATTERY MATERIAL CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com