Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1492 results about "Terbium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Terbium is a chemical element with the symbol Tb and atomic number 65. It is a silvery-white, rare earth metal that is malleable, ductile, and soft enough to be cut with a knife. The ninth member of the lanthanide series, terbium is a fairly electropositive metal that reacts with water, evolving hydrogen gas. Terbium is never found in nature as a free element, but it is contained in many minerals, including cerite, gadolinite, monazite, xenotime, and euxenite.

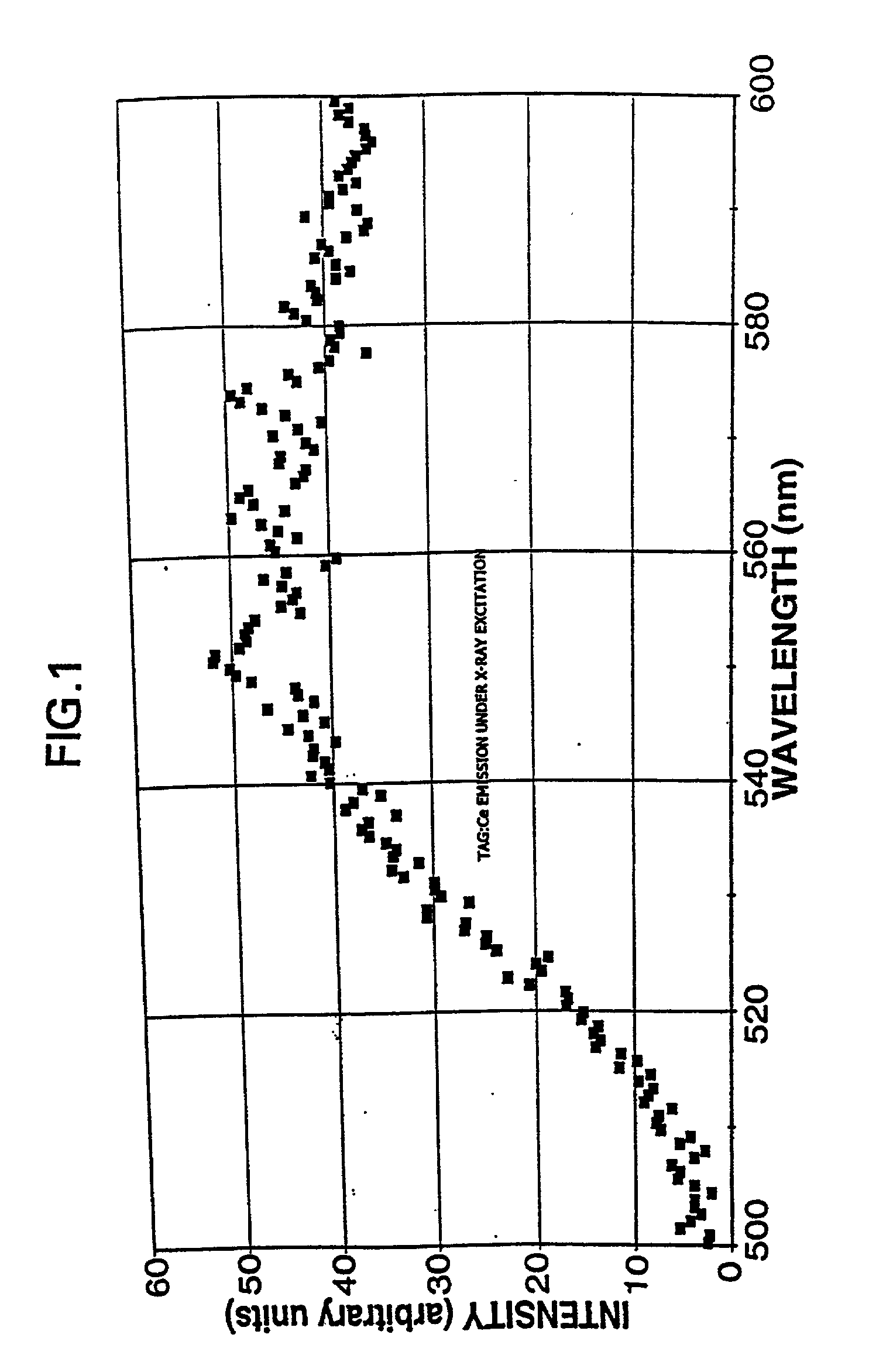

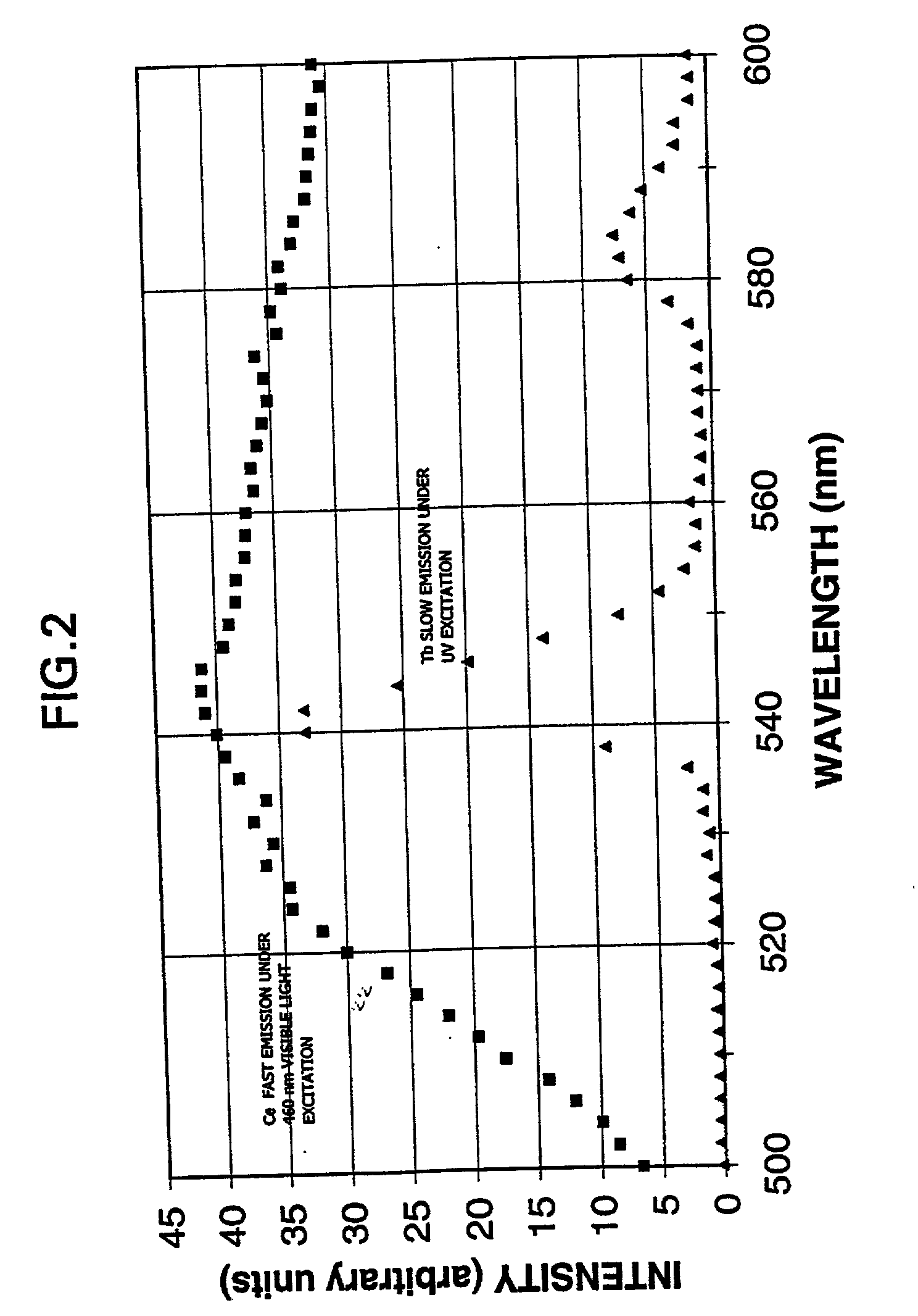

Broad-spectrum terbium-containing garnet phosphors and white-light sources incorporating the same

InactiveUS6596195B2Discharge tube luminescnet screensElectroluminescent light sourcesPlanckian locusRare earth

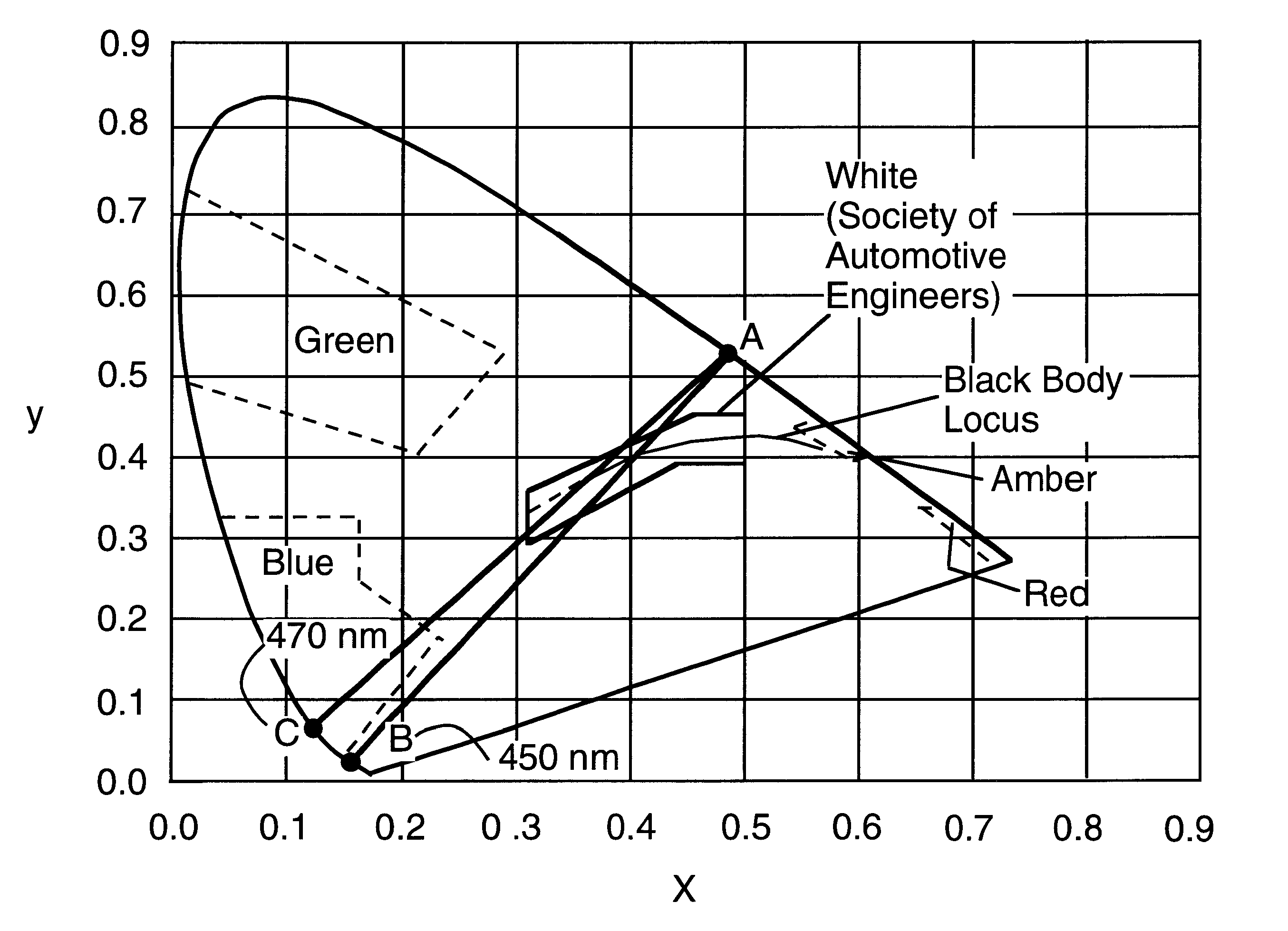

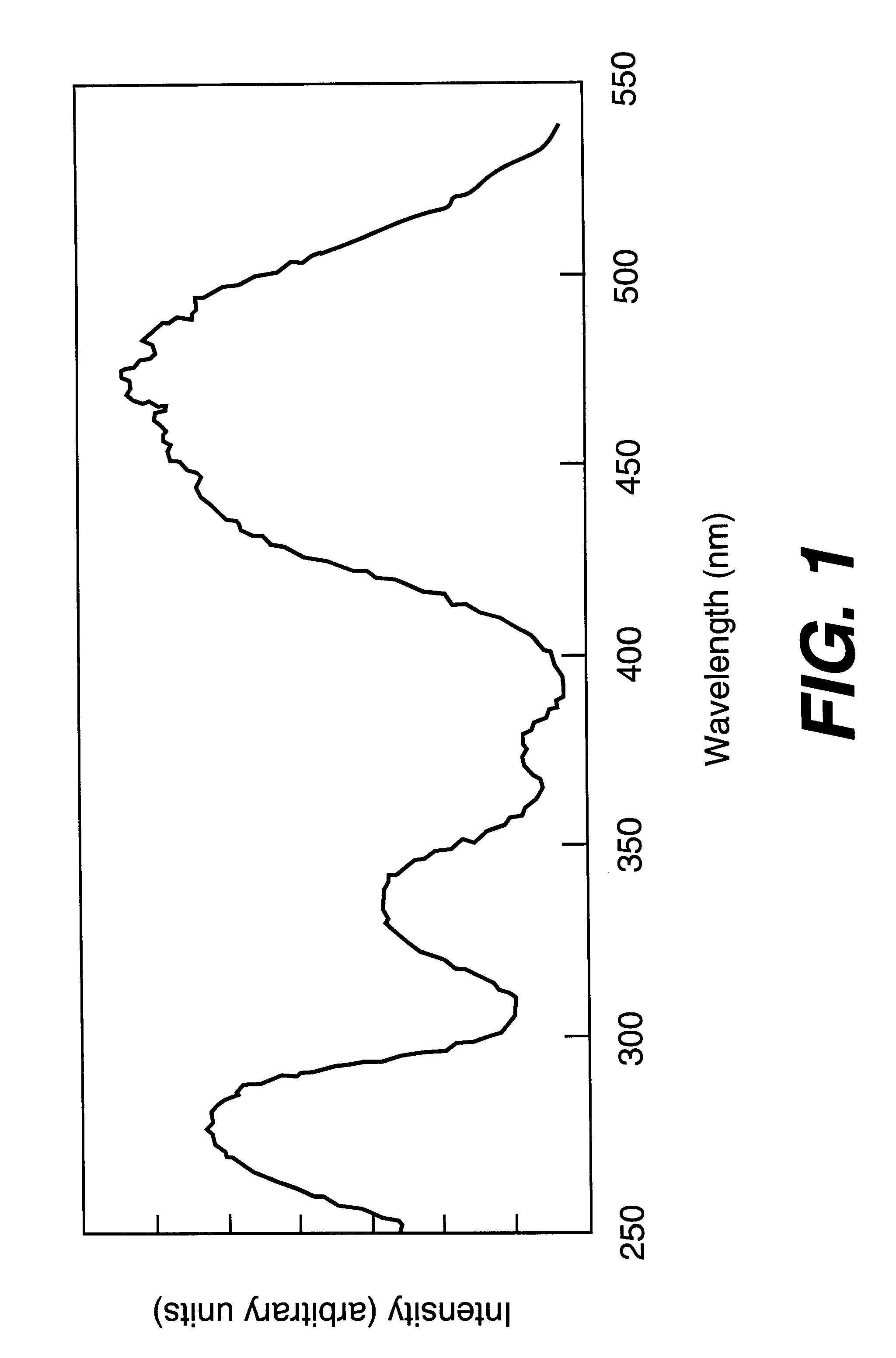

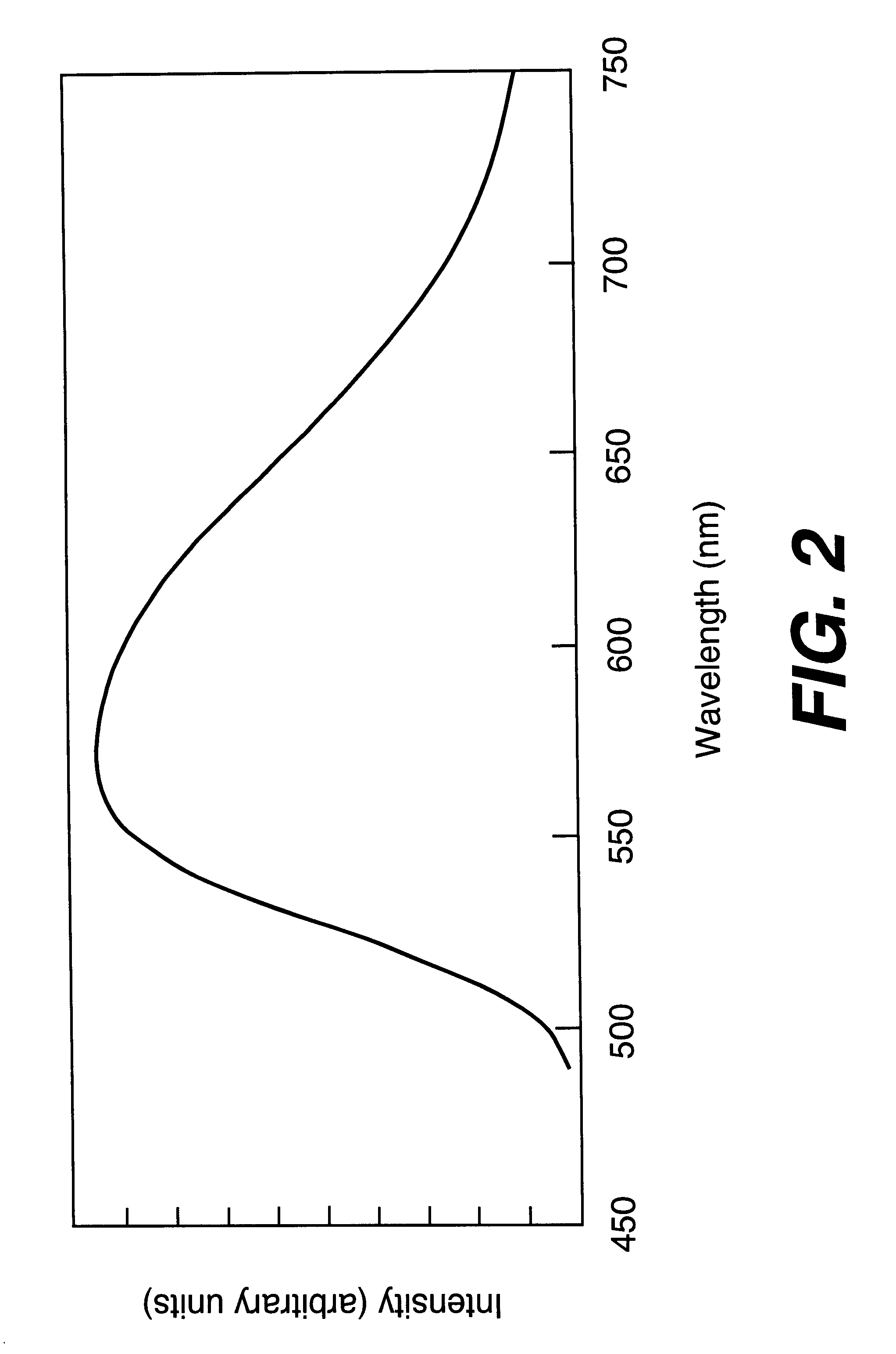

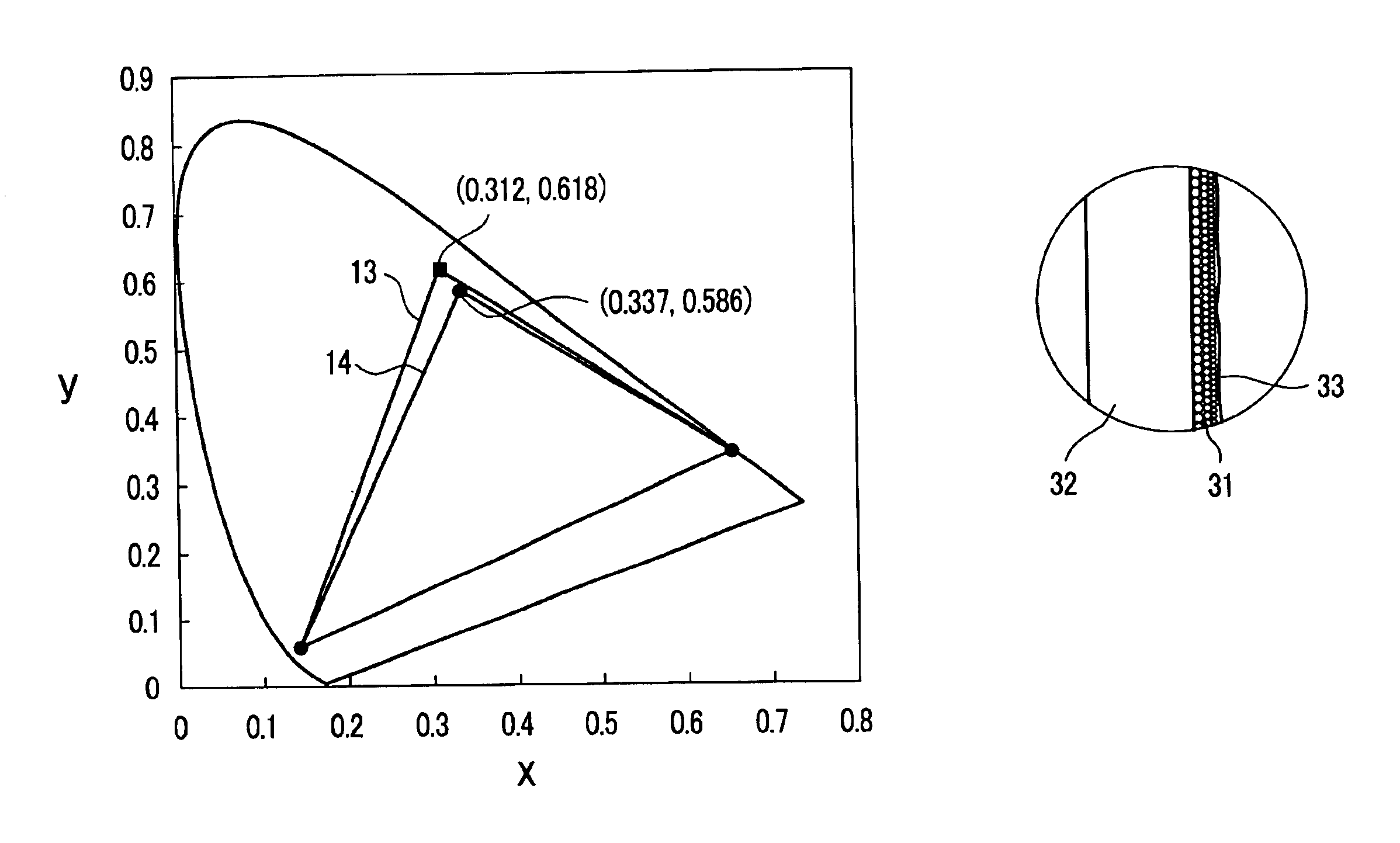

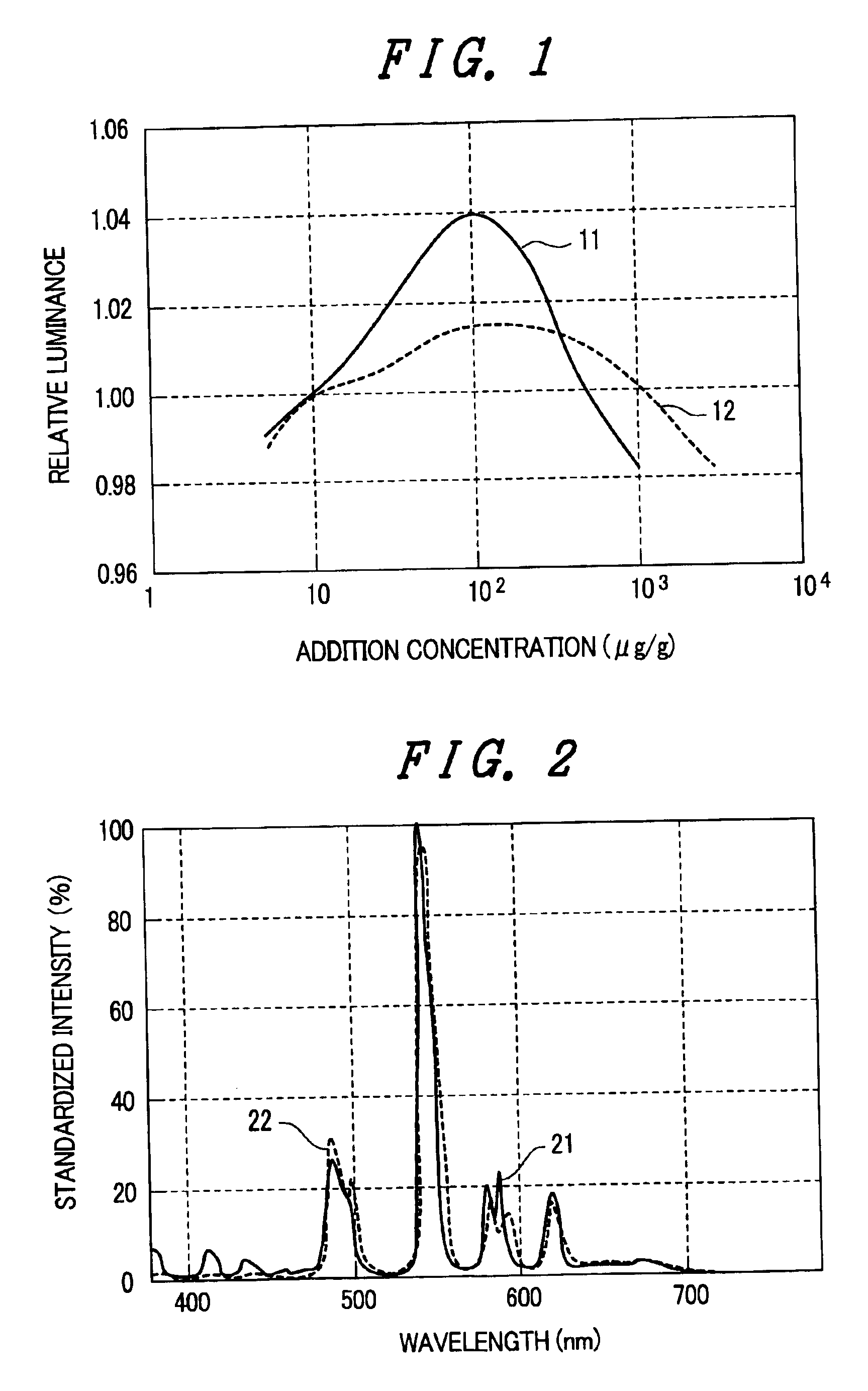

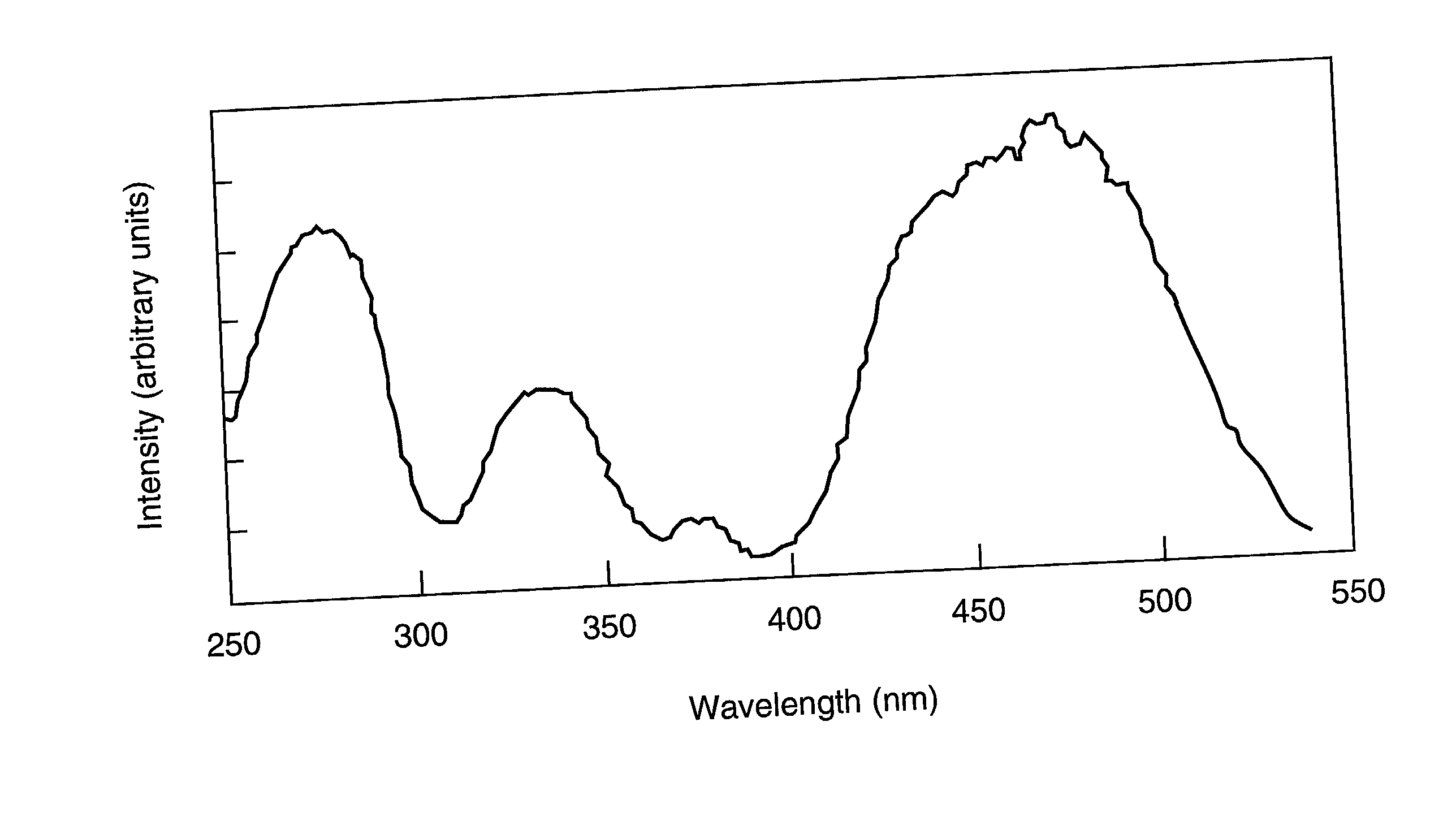

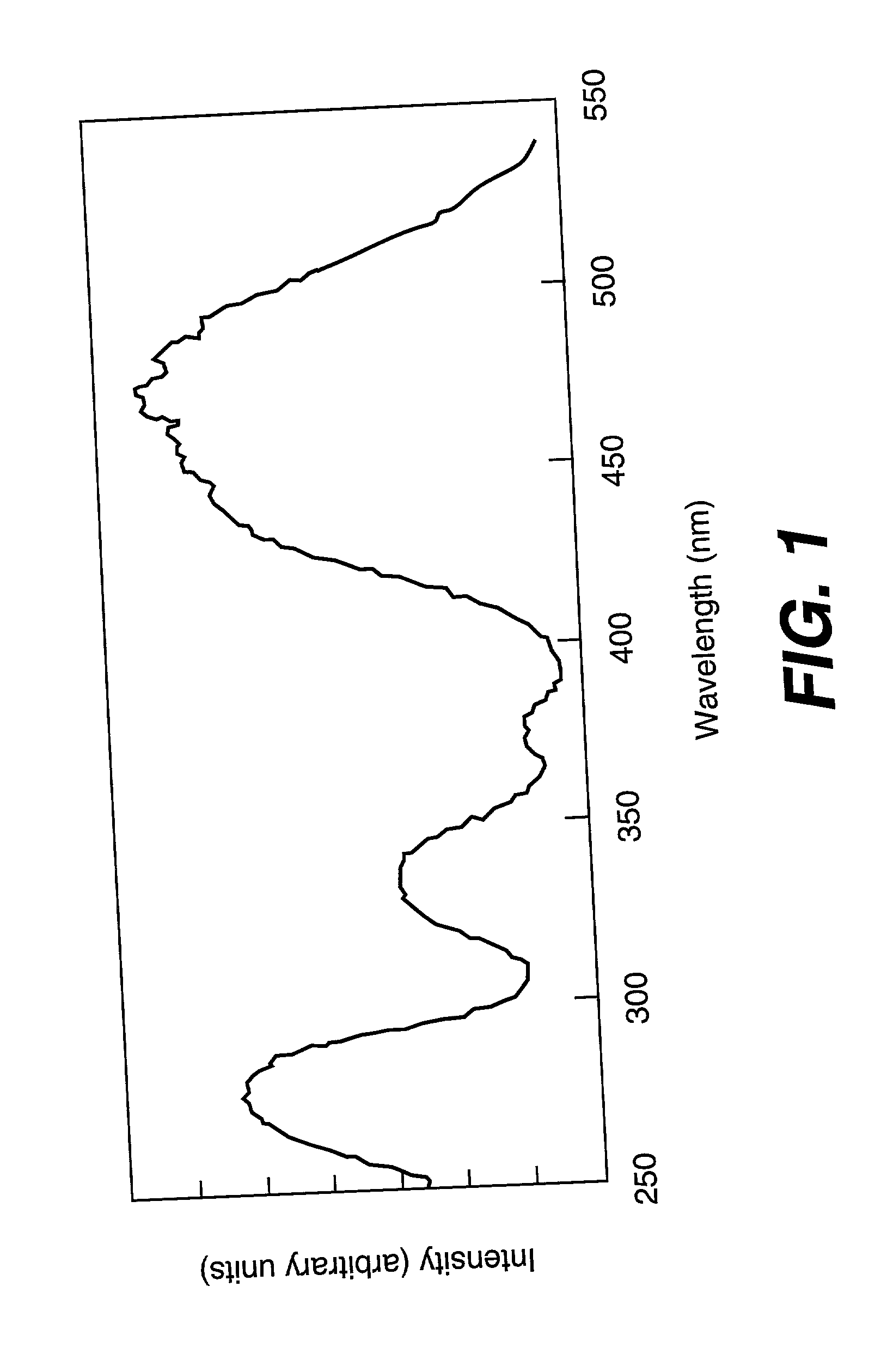

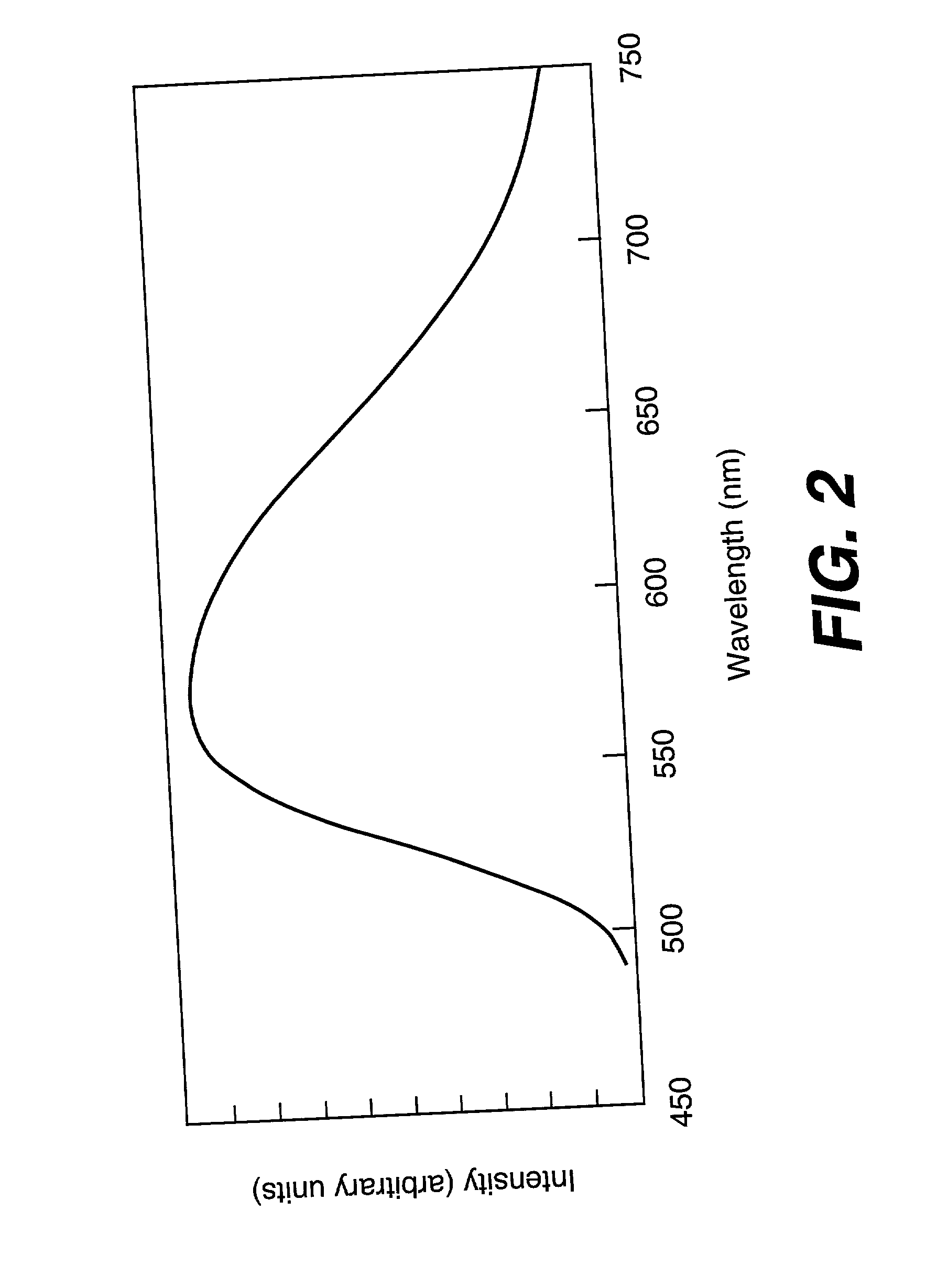

A rare earth-activated terbium-containing garnet phosphor is capable of absorbing radiation in the range from near UV to blue and emitting a broad spectrum of visible light in the range from about 490 nm to about 770 nm. The emission of the phosphor under an excitation at 450 nm exhibits a peak in the range of maximum sensitivity of the human eye. A light source combining a UV / blue LED and this phosphor can provide a white light that is on or near the Planckian locus and may be useful for general illumination.

Owner:GE LIGHTING SOLUTIONS LLC

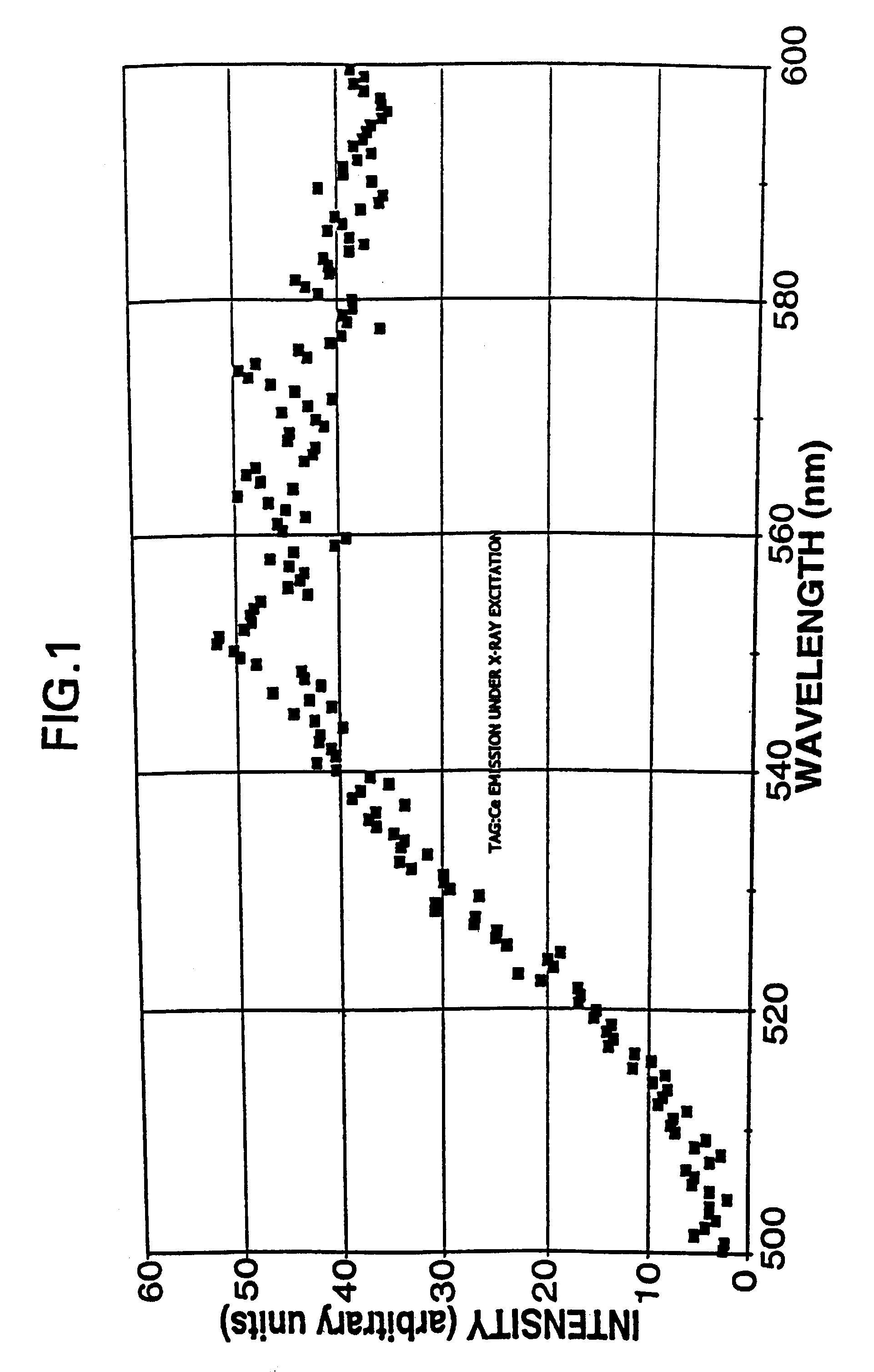

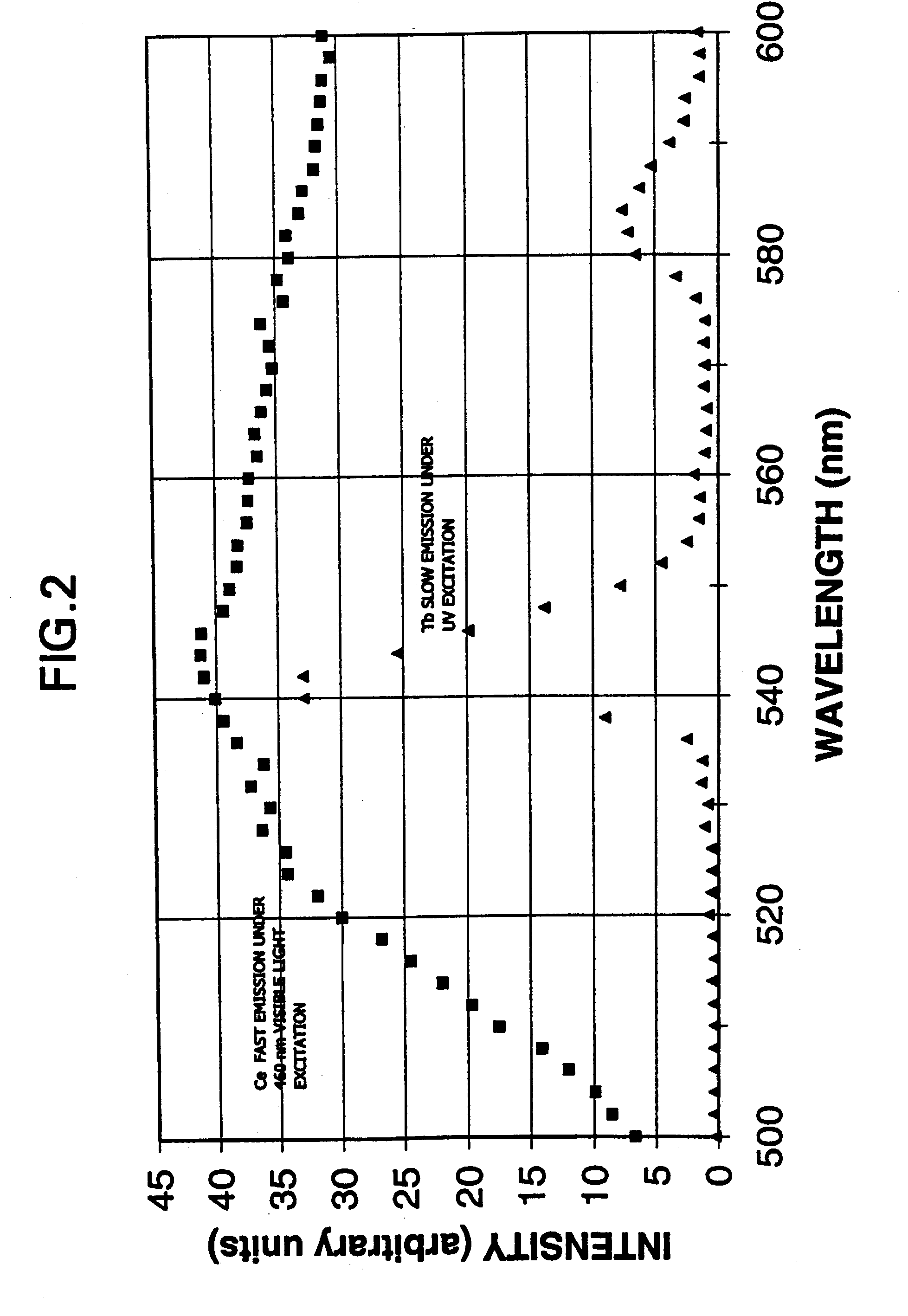

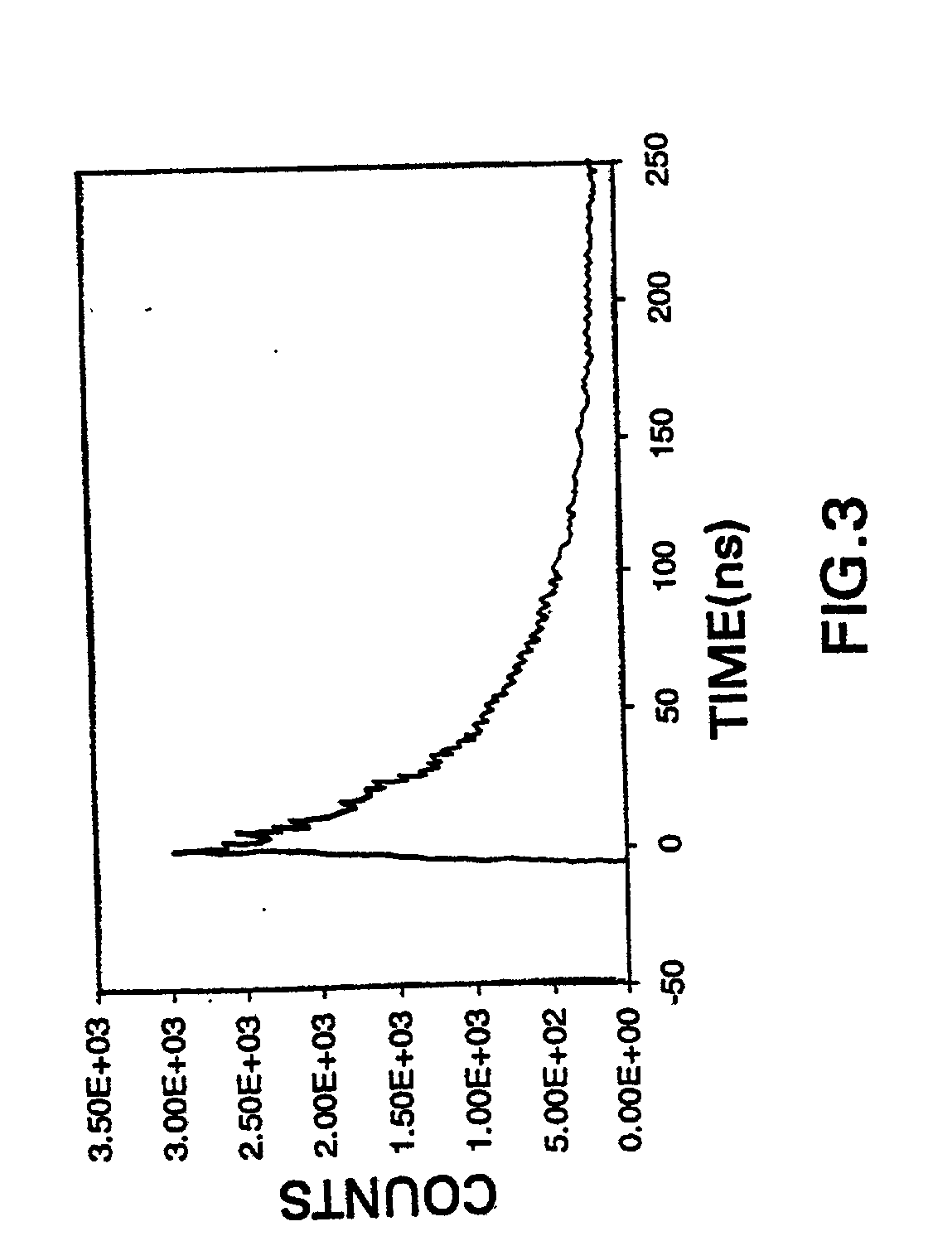

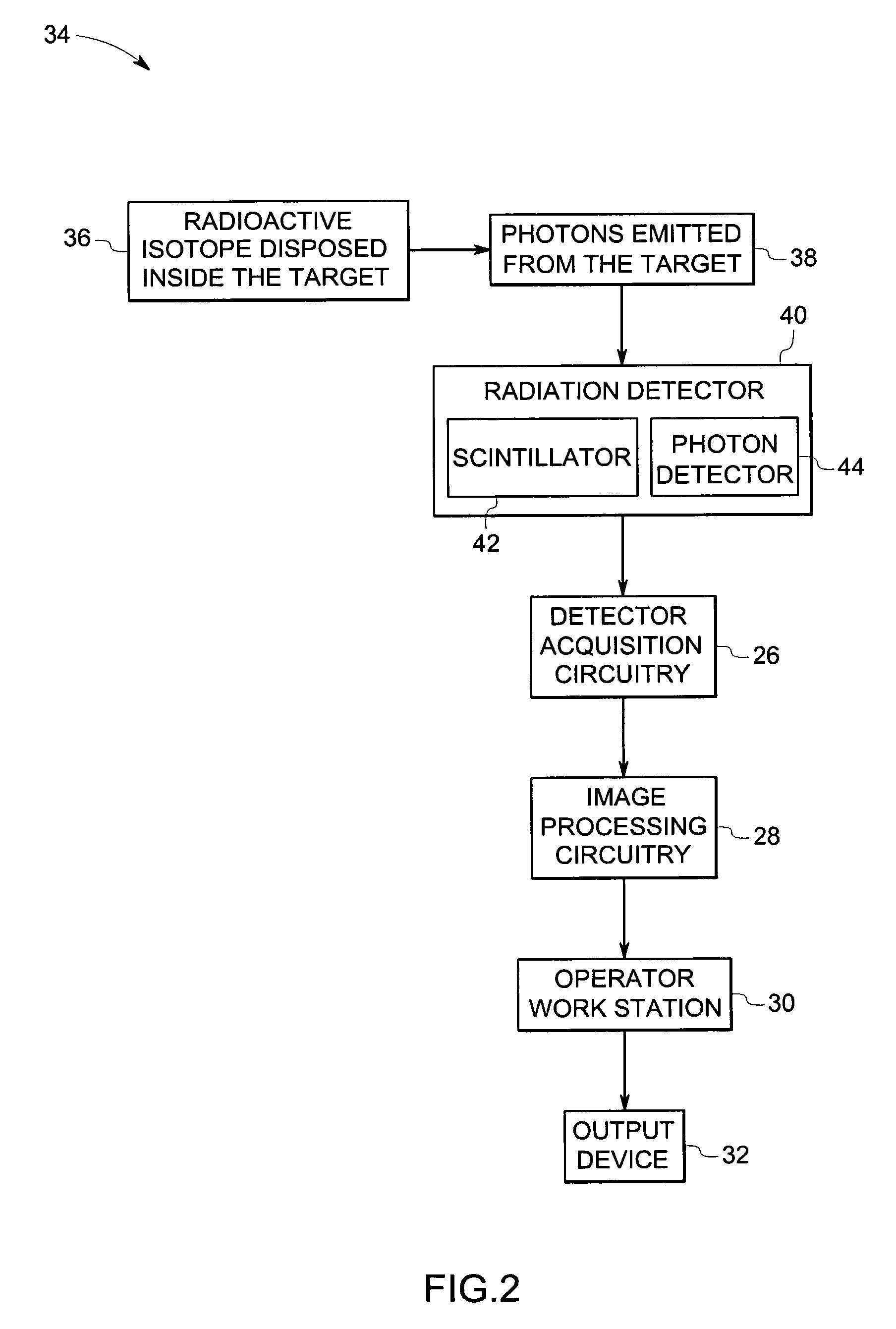

Terbium- or lutetium - containing garnet phosphors and scintillators for detection of high-energy radiation

InactiveUS6630077B2Improve light outputShort decay timePolycrystalline material growthMaterial analysis using wave/particle radiationLutetiumHigh energy

Owner:GENERAL ELECTRIC CO

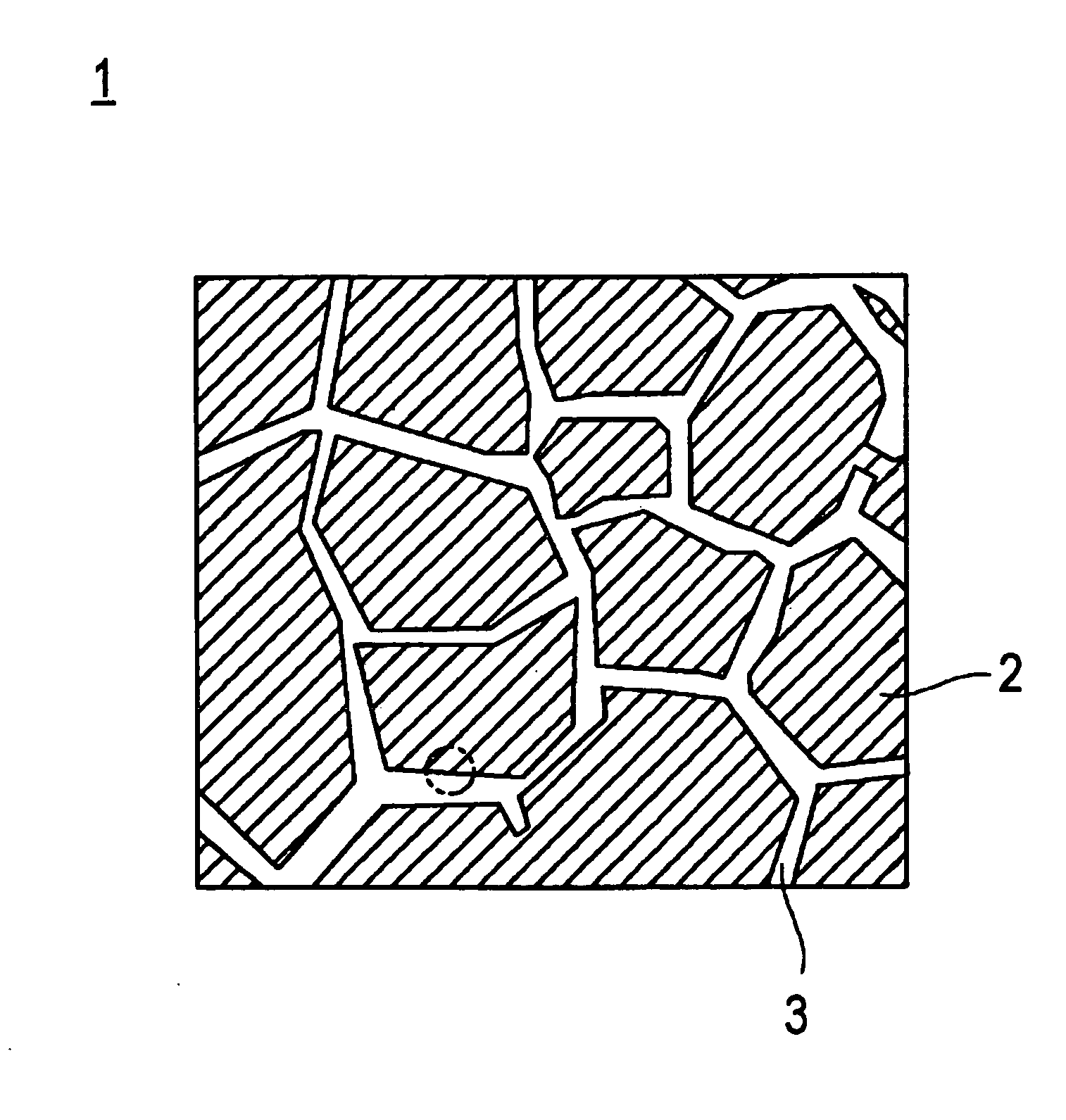

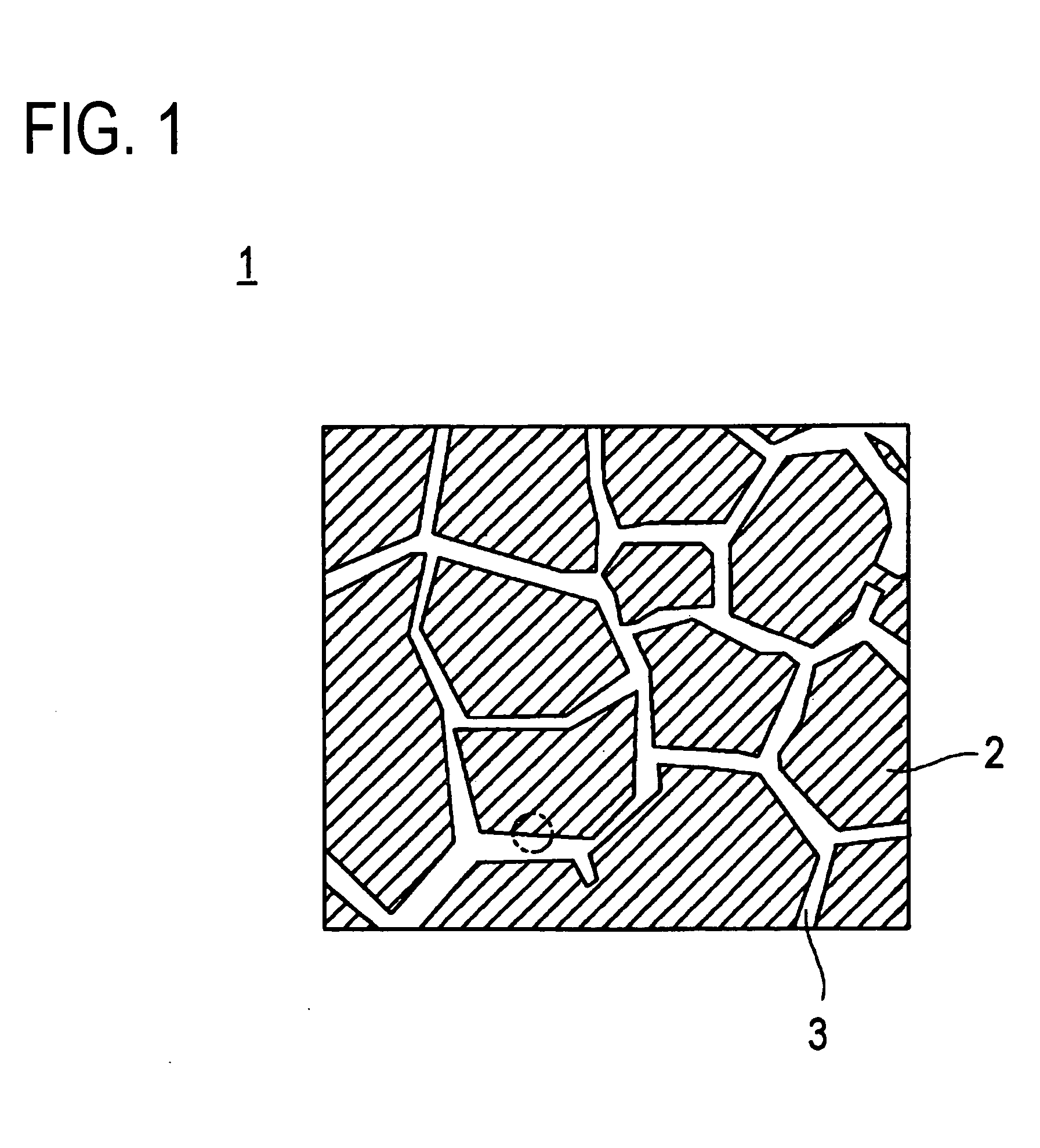

Rare earth magnet and method therefor

InactiveUS20050133117A1Increase resistanceReduced characteristicsMagnetic circuit rotating partsInorganic material magnetismEddy currentRare-earth magnet

A rare earth magnet includes rare earth magnet particles; and amorphous and / or crystalline terbium oxide present at the boundary of the rare earth magnet particles and represented by the formula: TbOn, wherein 1.5<n≦2. The rare earth magnet prevents decrease eddy current effectively.

Owner:NISSAN MOTOR CO LTD

Thermal protective coating for ceramic surfaces

ActiveUS6921431B2Extended shelf lifeConvenience to workFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

Thermal protective coating for ceramic surfaces

ActiveUS20050051057A1Extend working lifeReduce surface temperatureFireproof paintsOther chemical processesColloidal silicaSodium Bentonite

A coating admixture, method of coating and substrates coated thereby, wherein the coating contains colloidal silica, colloidal alumina, or combinations thereof; a filler such as silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides, copper chromium oxides, cerium oxides, terbium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide is also added.

Owner:WESSEX

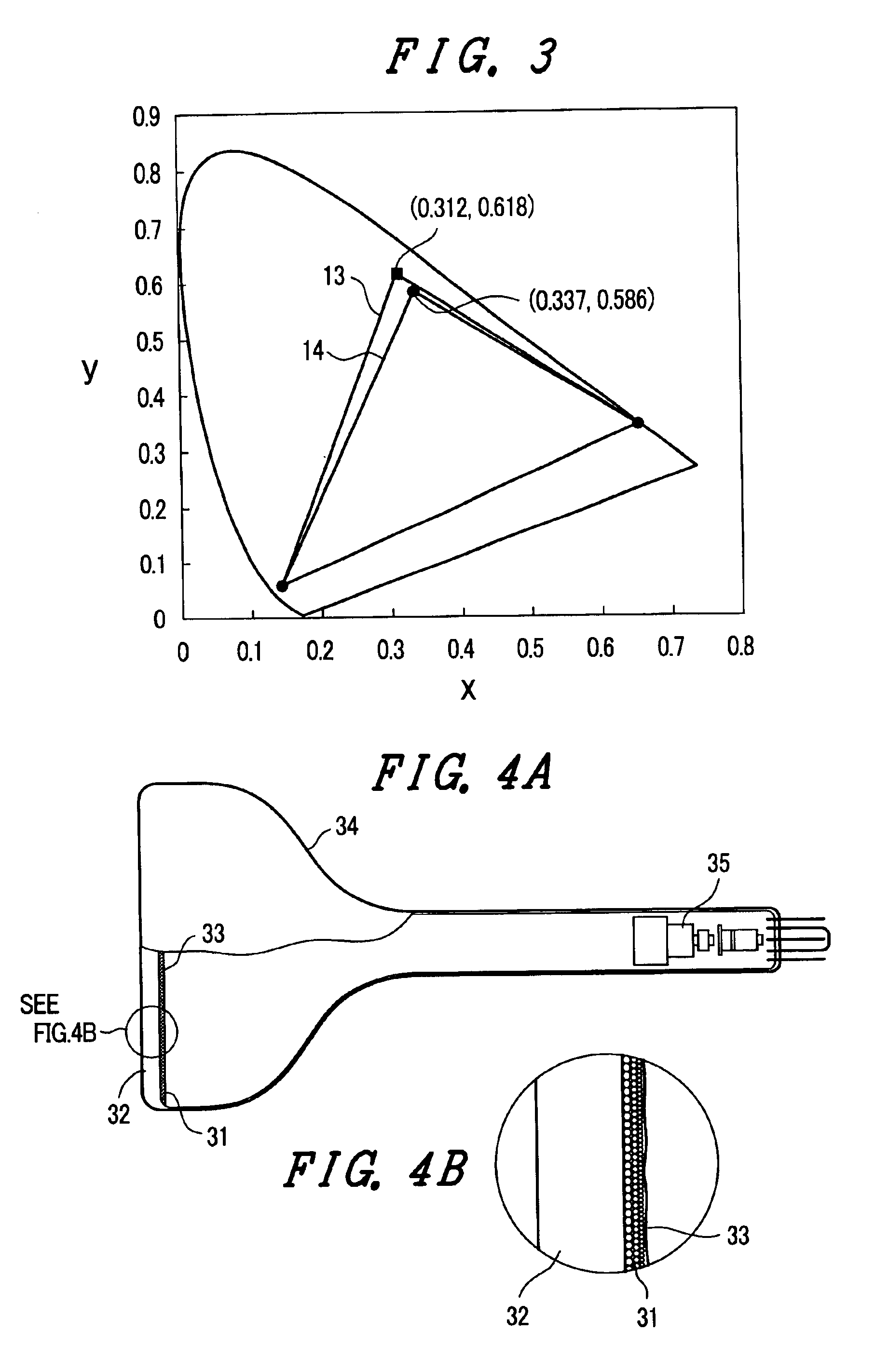

Display device

ActiveUS6940221B2Reduce harmImprove extinctionDischarge tube luminescnet screensLamp detailsRare-earth elementFluorescence

The present invention can further enhance the light emission characteristics of phosphor excited by the irradiation of electron beams of high density. In a cathode ray tube including a phosphor film, a faceplate panel which constitutes a screen, an aluminum vapor-deposited film, a funnel and an electron gun, phosphor which constitutes the phosphor film applied to the faceplate panel is constituted of a terbium activated phosphor which is produced by substituting a portion of yttrium (Y) in base material crystals which contain zinc (Zn), yttrium (Y), silicon (Si) and oxygen (O) as main constitutional elements with terbium ion (Tb3+) and a trace amount of rare earth element ion is added to the terbium activated phosphor.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Broad-spectrum terbium-containing garnet phosphors and white-light sources incorporating the same

InactiveUS20020195587A1Increase contactImprove uniformityDischarge tube luminescnet screensLamp detailsPlanckian locusRare earth

A rare earth-activated terbium-containing garnet phosphor is capable of absorbing radiation in the range from near UV to blue and emitting a broad spectrum of visible light in the range from about 490 nm to about 770 nm. The emission of the phosphor under an excitation at 450 nm exhibits a peak in the range of maximum sensitivity of the human eye. A light source combining a UV / blue LED and this phosphor can provide a white light that is on or near the Planckian locus and may be useful for general illumination.

Owner:GE LIGHTING SOLUTIONS LLC

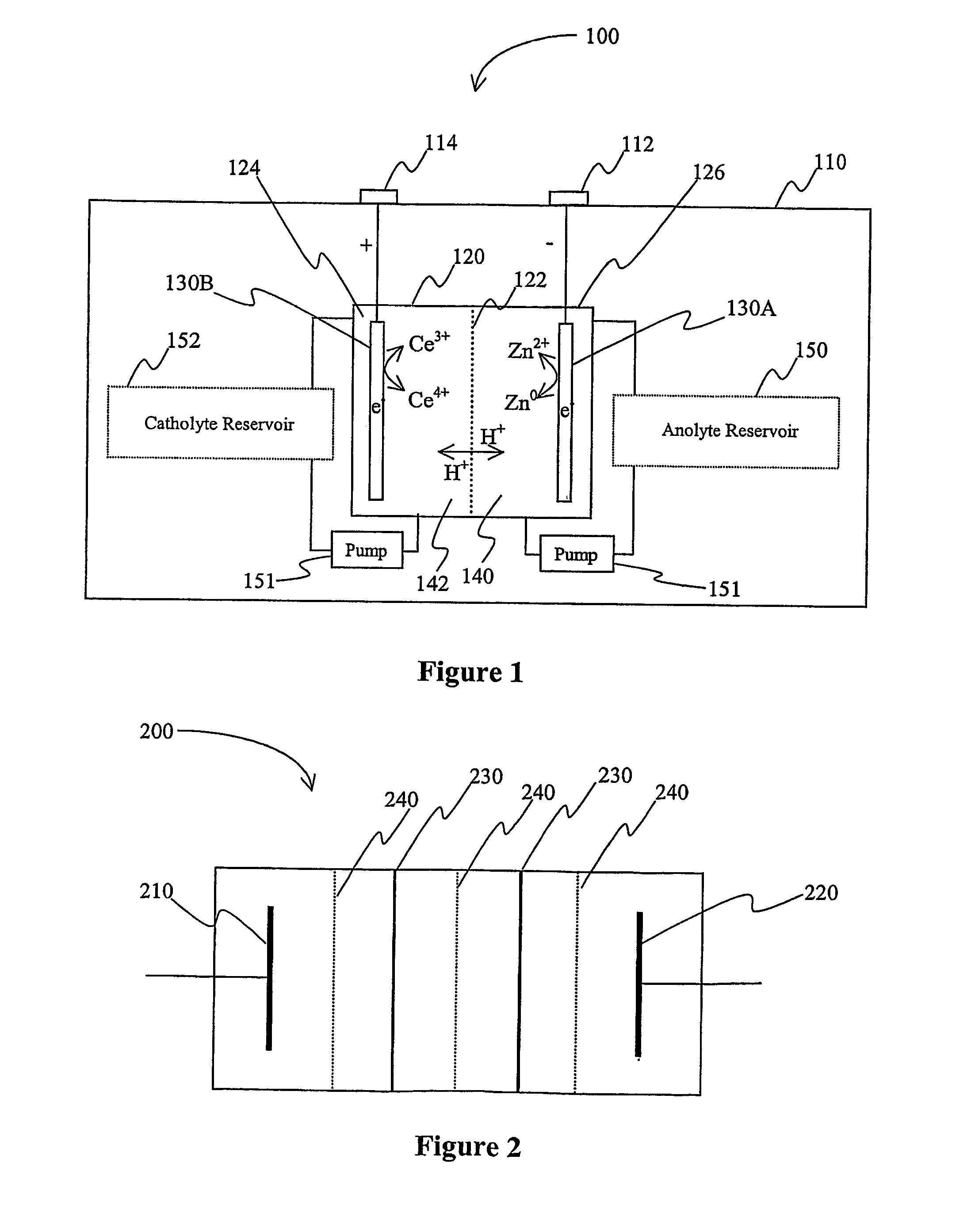

Lanthanide batteries

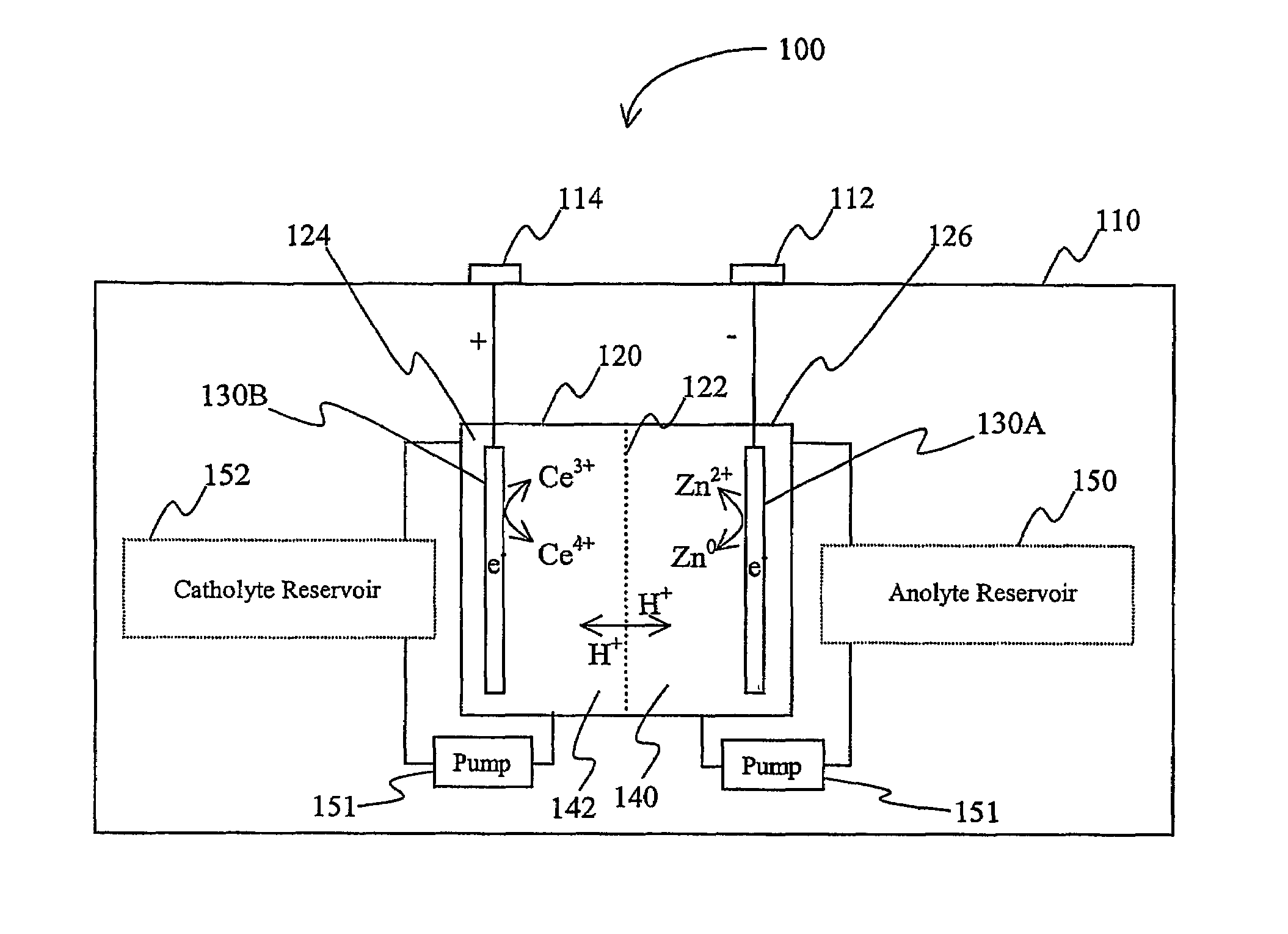

InactiveUS7252905B2Wide capacity rangeLarge capacityAlkaline accumulatorsSolid electrolyte cellsLanthanideCerium

A battery (100) comprises an electrolyte in which a lanthanide and zinc form a redox pair. Preferred electrolytes are acid electrolytes, and most preferably comprise methane sulfonic acid, and it is further contemplated that suitable electrolytes may include at least two lanthanides. Contemplated lanthanides include cerium, praseodymium, neodymium, terbium, and dysprosium, and further contemplate lanthanides are samarium, europium, thulium and ytterbium.

Owner:PLURION LTD

Method for preparing heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet

ActiveCN101521069AImprove coercive forceNot easily oxidizedInorganic material magnetismRare-earth elementDehydrogenation

The invention discloses a method for preparing a heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet, which belongs to the technical field of magnetic materials. The prior preparation method improves the coercive force and the temperature stability of magnets by adding heavy rare earth elements, namely terbium or dysprosium into master alloy, but the method can cause the residual magnetism of the magnets, the reduction of magnetic energy product and the increase of manufacturing cost. The method adopts heavy rare earth terbium hydride and dysprosium hydride nano-powder doping technology to prepare the sintered NdFeB permanent magnet with high coercive force and excellent magnetic property. The method comprises the following steps: preparing NdFeB powder by a rapidly solidified flake process and a hydrogen decrepitation process; preparing the terbium hydride or the dysprosium hydride nano-powder by physical vapor deposition technology; mixing the two powders, and performing magnetic field orientation and press forming; and performing dehydrogenation treatment, sintering and heat treatment on a green compact at different temperatures, and obtaining the sintered magnet. The coercive force of the magnet prepared by the method is higher than that of the prior sintered magnet with the same ingredients; and compared with the sintered magnet with the equivalent coercive force, the proportion of the terbium and dysprosium needed by the magnet prepared by the method is remarkably reduced.

Owner:BEIJING UNIV OF TECH

Ceramic bonding composition, method of making, and article of manufacture incorporating the same

A ceramic bonding composition comprises a first oxide and at least a second oxide having a formula of Me2O3; wherein the first oxide is selected from the group consisting of aluminum oxide, scandium oxide, and combinations thereof; Me is selected from the group consisting of yttrium, lanthanum, cerium, praseodymium, neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium, and combinations thereof. The ceramic bonding composition can further comprise silica. An article of manufacture comprising at least two members attached together with the ceramic bonding composition.

Owner:GENERAL ELECTRIC CO

Cast Aluminium Alloy

Cast aluminium alloys comprising 1.0-8.0% in weight magnesium (Mg), >1.0-4.0% in weight silicon (Si), 0.01-<0.5% in weight scandium (Sc), 0.005-0.2% in weight titanium (Ti), 0-0.5% in weight of at least one element or selected from the group consisting of zirconium (Zr), hafnium (Hf), molybdenum (Mo), terbium (Tb), niobium (Nb), gadolinium (Gd), erbium (Er) and vanadium (V), 0-0.8% in weight manganese (Mn), 0-0.3% in weight chromium (Cr), 0-1.0% in weight copper (Cu), 0-0.1% in weight zinc (Zn), 0-0.6% in weight iron (Fe), 0-0.004% in weight beryllium (Be), and the remainder of aluminium with further impurities to an individual maximum of 0.1% in weight and totally maximally 0.5% in weight.

Owner:EADS DEUT GMBH +1

Rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and preparation method thereof

ActiveCN103123839AReduce production and sales balancePromote the balance of production and salesInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementCost Controls

The invention discloses a rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and a preparation method of the rare earth permanent magnet produced by applying abundant rare earth Ce. Based on a double-alloy process, main phase alloy formula uses Ce to partly replace neodymium (Nd), an optimized composition design enables a main alloy to form Ce2Fe14B phase and Nd2Fe14B phase to a greatest extent, and therefore high intrinsic magnetic property is guaranteed. A brand new crystal boundary phase is prepared by a crystal boundary reconstitution technology, and high integral magnetic property and corrosion resistant property are guaranteed, and meanwhile a nanometer powder crystal modification method is supplemented, a micro organization structure of a magnet is optimized, crystal boundary distribution is improved, and the magnetic property and the corrosion resistant property are further improved. By applying abundant rare earth cerium, cost is effectively reduced, and meanwhile balance between production and marketing is promoted. Praseodymium (Pr), Nd, and the like are chosen to form a hard magnetic shell layer of a main phase boundary in a composition design of crystal phase auxiliary alloy at the same time, compared high price heavy rare earth elements of dysprosium (Dy) and terbium (Tb) with the elements, and cost control can be further achieved.

Owner:ZHEJIANG UNIV +1

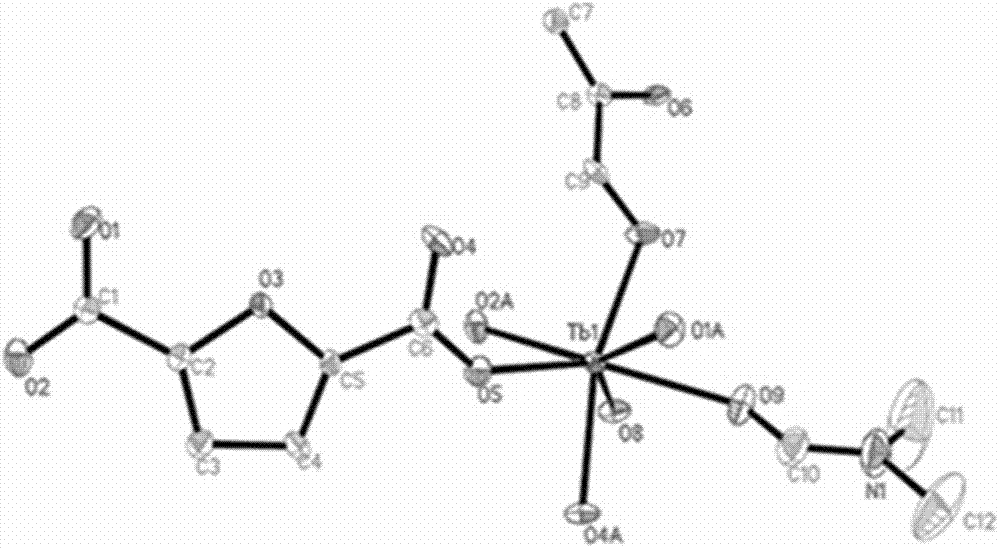

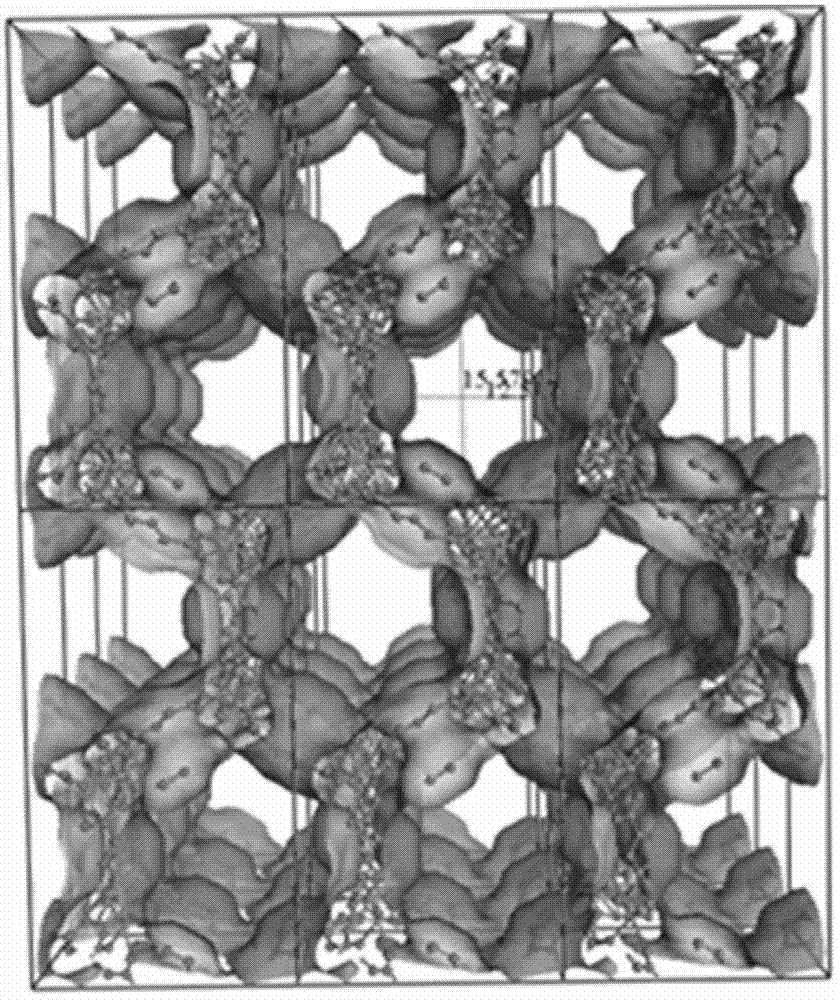

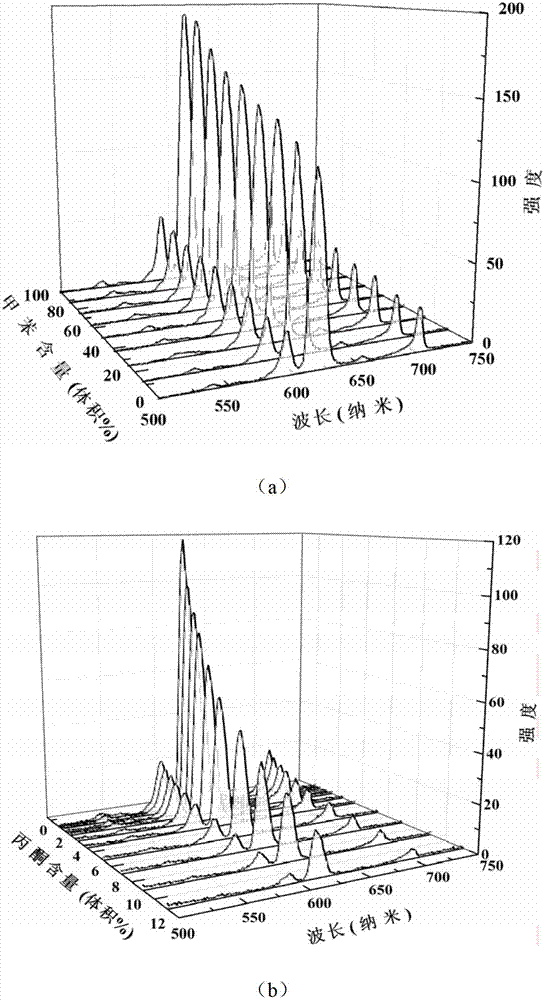

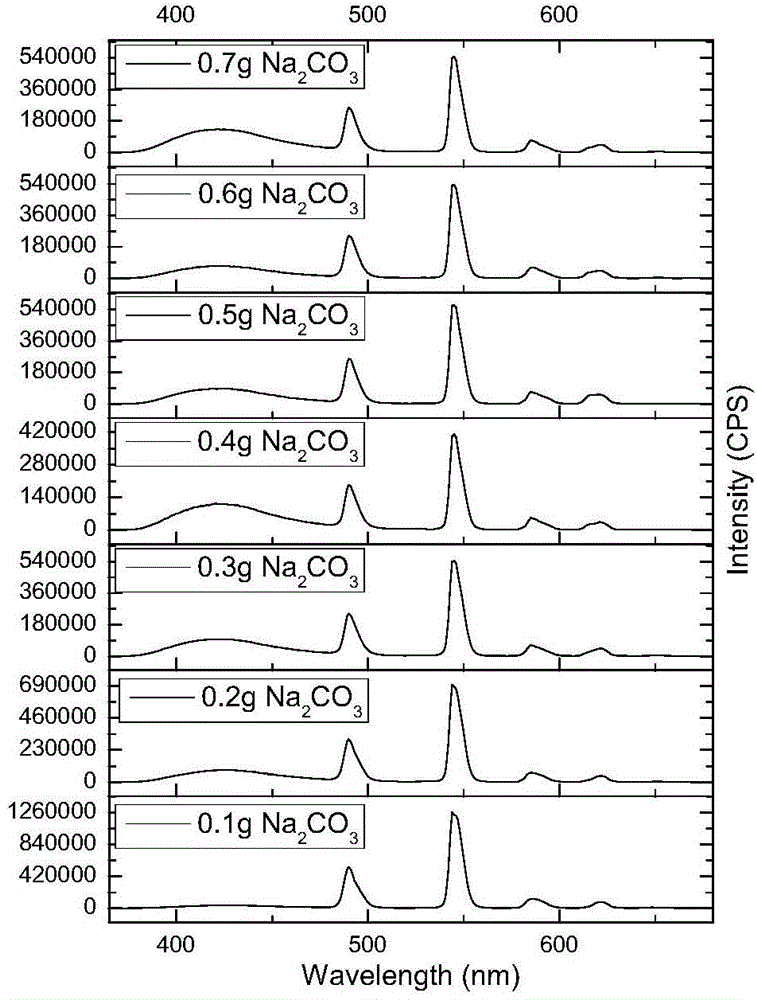

Multifunctional rare earth metal-organic framework and preparation method thereof

InactiveCN102757453ANovel structureSensitive recognitionCarbon compoundsOther chemical processesCooking & bakingN dimethylformamide

The invention relates to a multifunctional rare earth metal-organic framework of which the chemical formula is {[Ln(FDA)1.5(DMF)].DMF}n, wherein Ln is Eu or Tb, the FDA is furyl-2,5-dicarboxylic acid, and the DMF is N,N-dimethylformamide; and the rare earth metal framework structure has an Eu<3+> / Tb<3+> ion in a coordination environment, and forms a three-dimensional framework structure containing one-dimensional honeycomb channels. The preparation method comprises the following steps: by using europium nitrate hexahydrate or terbium nitrate hexahydrate as a metal salt, H2FDA as a ligand and DMF as a solvent, stirring the mixed solution, baking, separating and washing the solid to obtain the multifunctional rare earth metal-organic framework. The multifunctional rare earth metal-organic framework provided by the invention has an fluorescent identification function on cancerigenic organic solvents, such as methylbenzene, benzene and acetone, has excellent selective adsorptivity for gas and high acting force with H2, contains high adsorptive enthalpy, and thus, is a multifunctional novel-structure microporous MOF (metal-organic framework) material.

Owner:NANKAI UNIV

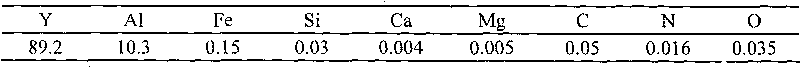

Rare earth aluminum alloy, and method and device for preparing same

The invention discloses a rare earth aluminum alloy, and a method and a device for preparing the same. The alloy contains at least one rare earth metal of lanthanum, cerium, praseodymium, neodymium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, lutetium, scandium and yttrium, the content of raw earth is 5 to 98 weight percent, and the balance is aluminum and inevitable impurities. The device for preparing the rare earth aluminum alloy is characterized in that: a) graphite serves as an electrolysis bath, a graphite plate is an anode, a tungsten bar is a cathode and a molybdenum crucible serves as a rare earth aluminum alloy receiver; b) the diameter of the tungsten bar is 30 to 55 mm; and c) the anode of the graphite consists of a plurality of graphite plates. The rare earth aluminum alloy, and the method and the device for preparing the same have the advantages that: the alloy has uniform components, little segregation and low impurity content; technology for preparing the rare earth aluminum alloy through fusion electrolysis can maximally replace a process for preparing single medium-heavy metal through metallothermic reduction, greatly reduce energy consumption and the emission of fluorine-containing tail gas and solid waste residue, improve current efficiency and metal yield and reduce the consumption of auxiliary materials and the energy consumption; and the rare earth aluminum alloys with different rare earth contents can be obtained by controlling different electrolytic temperatures and different cathode current densities.

Owner:GRIREM ADVANCED MATERIALS CO LTD

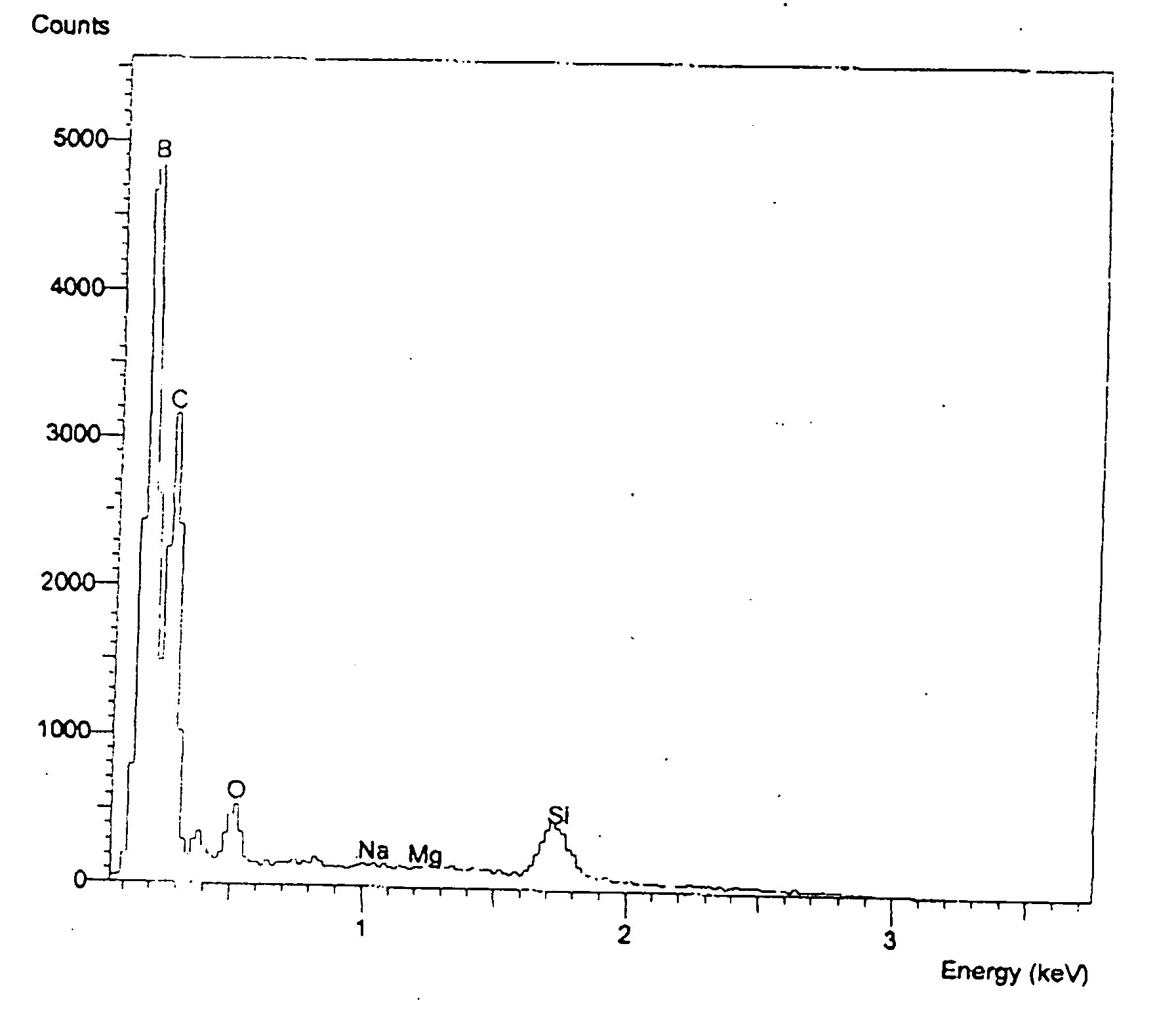

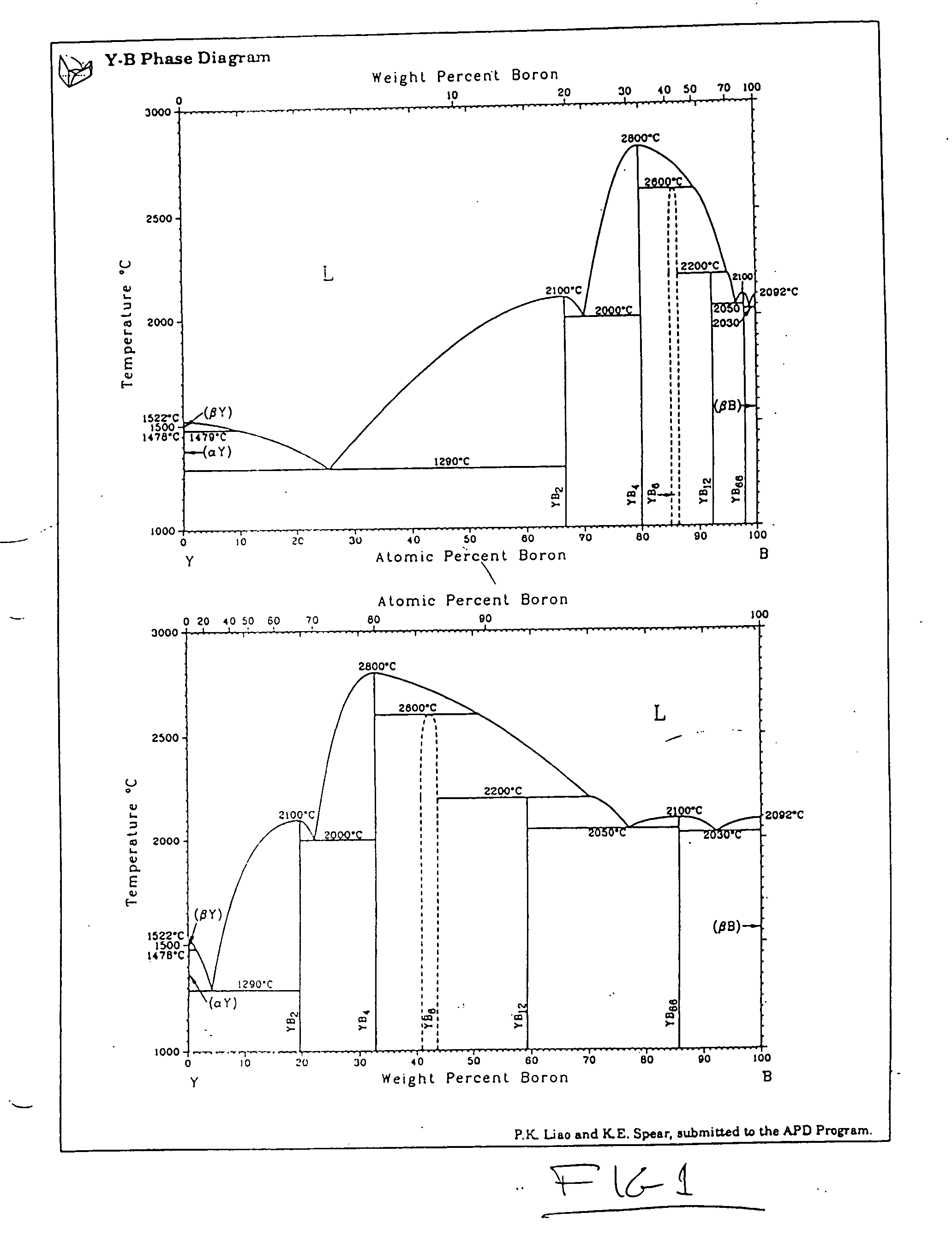

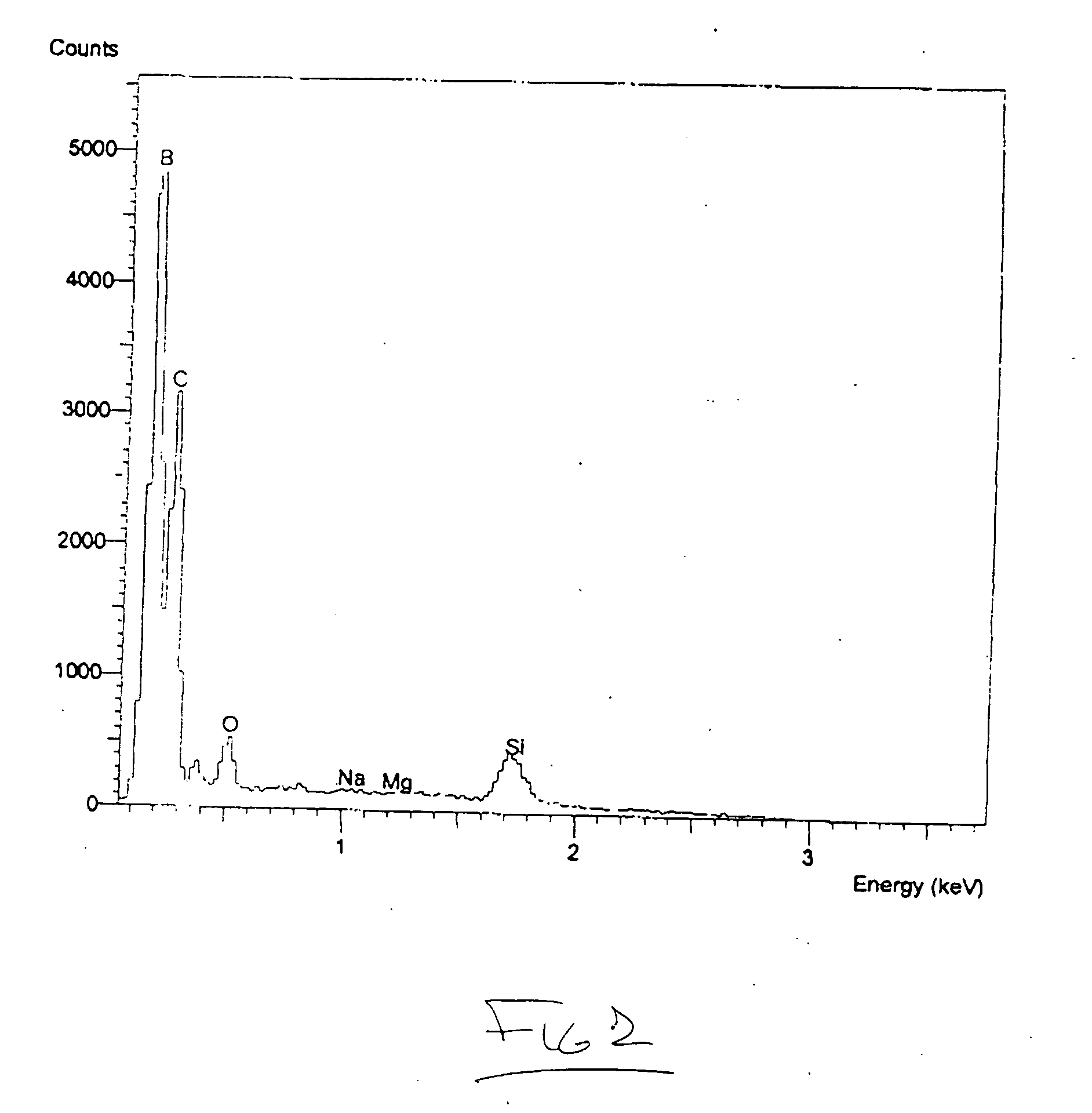

Method for depositing boron-rich coatings

InactiveUS20050208218A1Not readyReduce usageSpark gapsLiquid surface applicatorsLutetiumControl manner

A method is disclosed for coating substantially pure boron or highly boron-rich borides in a controlled manner. Such a method of coating of boron has a variety of applications, including surface chemical and wear protection, neutron absorption, prevention of impurity emission from heated filaments and ion beams, elimination of metal dust from vacuum systems, boridizing, boron cluster emission, and reactive chemistry. Borides with a boron-to-metal ratio of 20 or more are known to exist and may be used as a feedstock for substantially pure boron coatings for deposition processes requiring feedstock electrical conductivity, and / or enhanced reactivity. While most metal borides coincidentally produce significant metal vapor as a by-product, certain borides of yttrium, holmium, erbium, thulium, terbium, gadolinium, and lutetium have been identified as capable of producing substantially pure boron vapor.

Owner:IBADEX

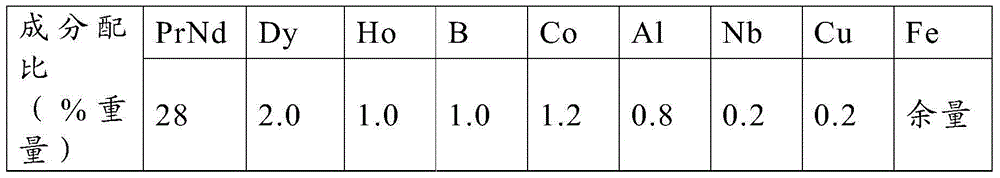

NdFeB magnet and preparation method thereof

ActiveCN104064346AReduce usageImprove intrinsic coercive forceInductances/transformers/magnets manufactureMagnetic materialsHolmiumGranularity

The invention relates to an NdFeB magnet and belongs to the technical field of rare earth magnetic materials. The NdFeB magnet is prepared by sintering a mixture of main phase alloy powder with the granularity of 2-5 <Mu>m, heavy rare earth alloy powder with the granularity of 1-2 <Mu>m and superfine powder with the granularity of 0.1-1.5 <Mu>m, which are mixed at the mass percents of 85-99.8, 0.1-10 and 0.1-5 respectively, the heavy rare earth alloy is one or more of dysprosium hydride and dysprosium-ferrum hydride compound, a holmium hydride and holmium-ferrum hydride compound and terbium hydride and terbium-ferrum hydride compound. The invention further provides a preparation method of the NdFeB magnet. According to the invention, 10-40 percent of heavy rare earth is saved, and the intrinsic coercive field of the NdFeB magnet is increased greatly without reducing the effect of residual magnetism.

Owner:宁波同创强磁材料有限公司

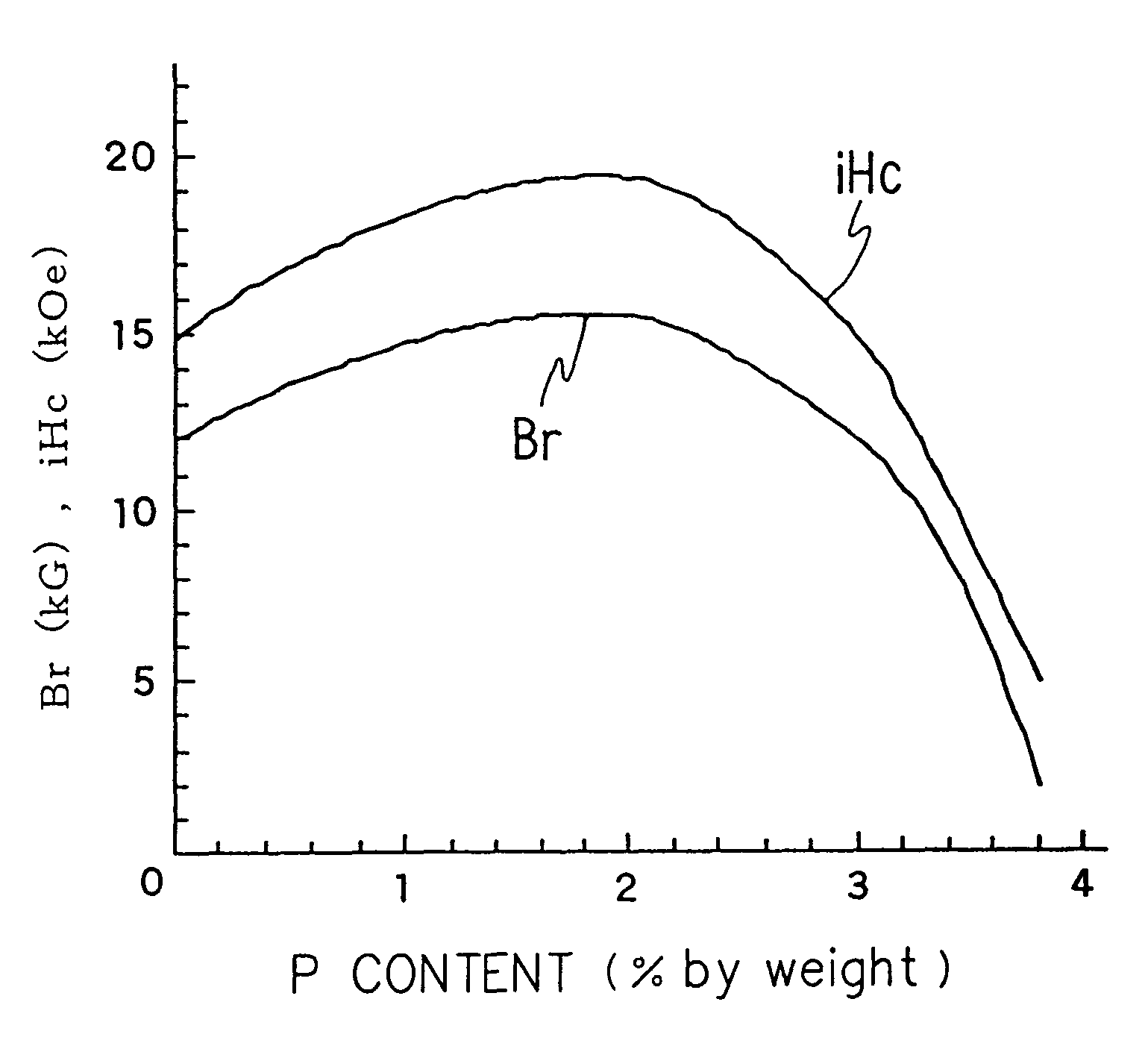

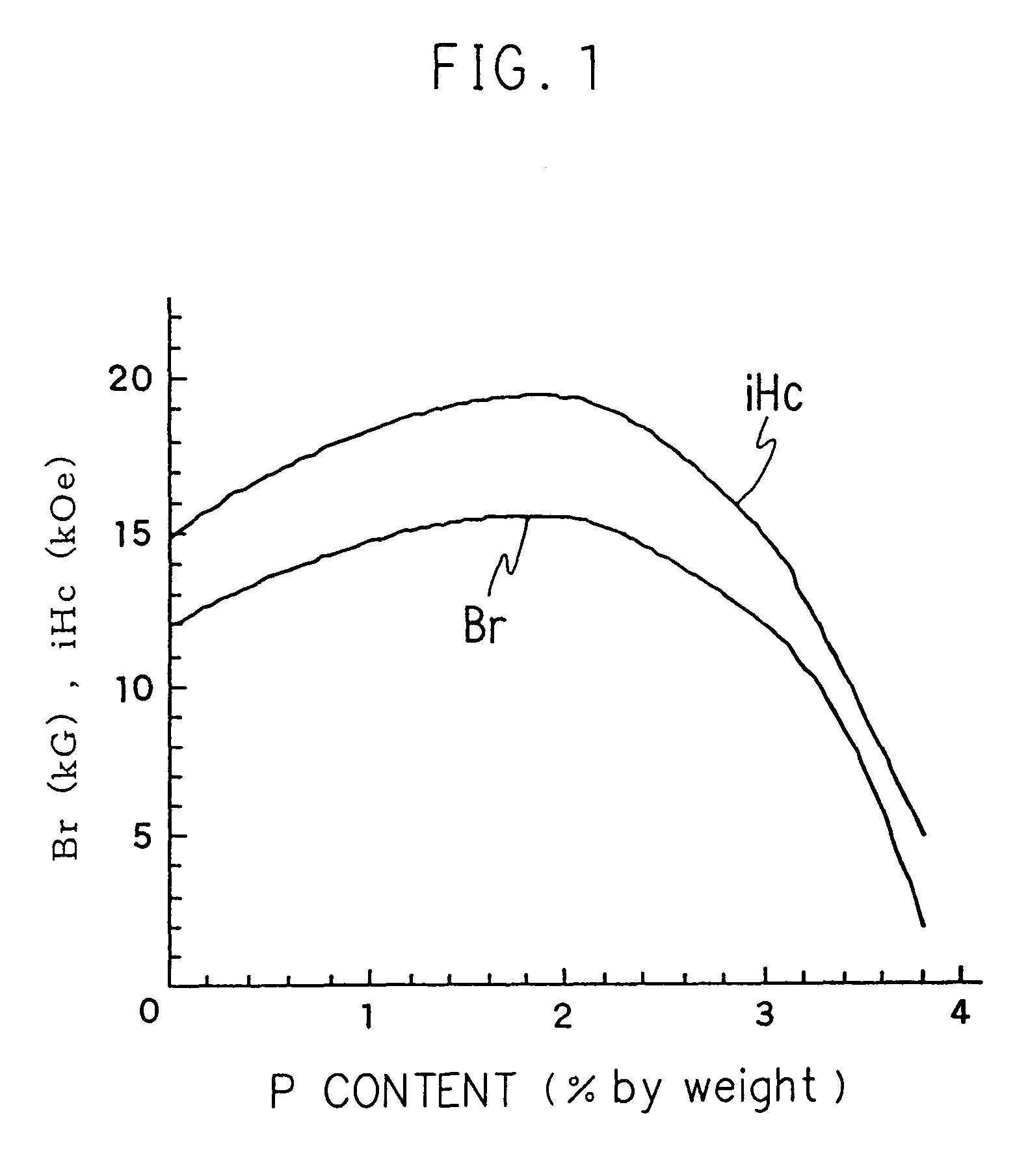

Rare earth element permanent magnet material

A material for a rare earth permanent magnet having a high magnetic coercive force and a high residual magnetic flux density. 28 to 35% by weight of at least one rare earth element selected from the group consisting of neodymium, praseodymium, dysprosium, terbium, and holmium, 0.9 to 1.3% by weight of boron, 0.25 to 3% by weight of phosphorus, iron, and inevitable impurities. It can further comprise 0.1 to 3.6% by weight of cobalt and 0.02 to 0.25% by weight of copper.

Owner:MITSUBISHI ELECTRIC CORP

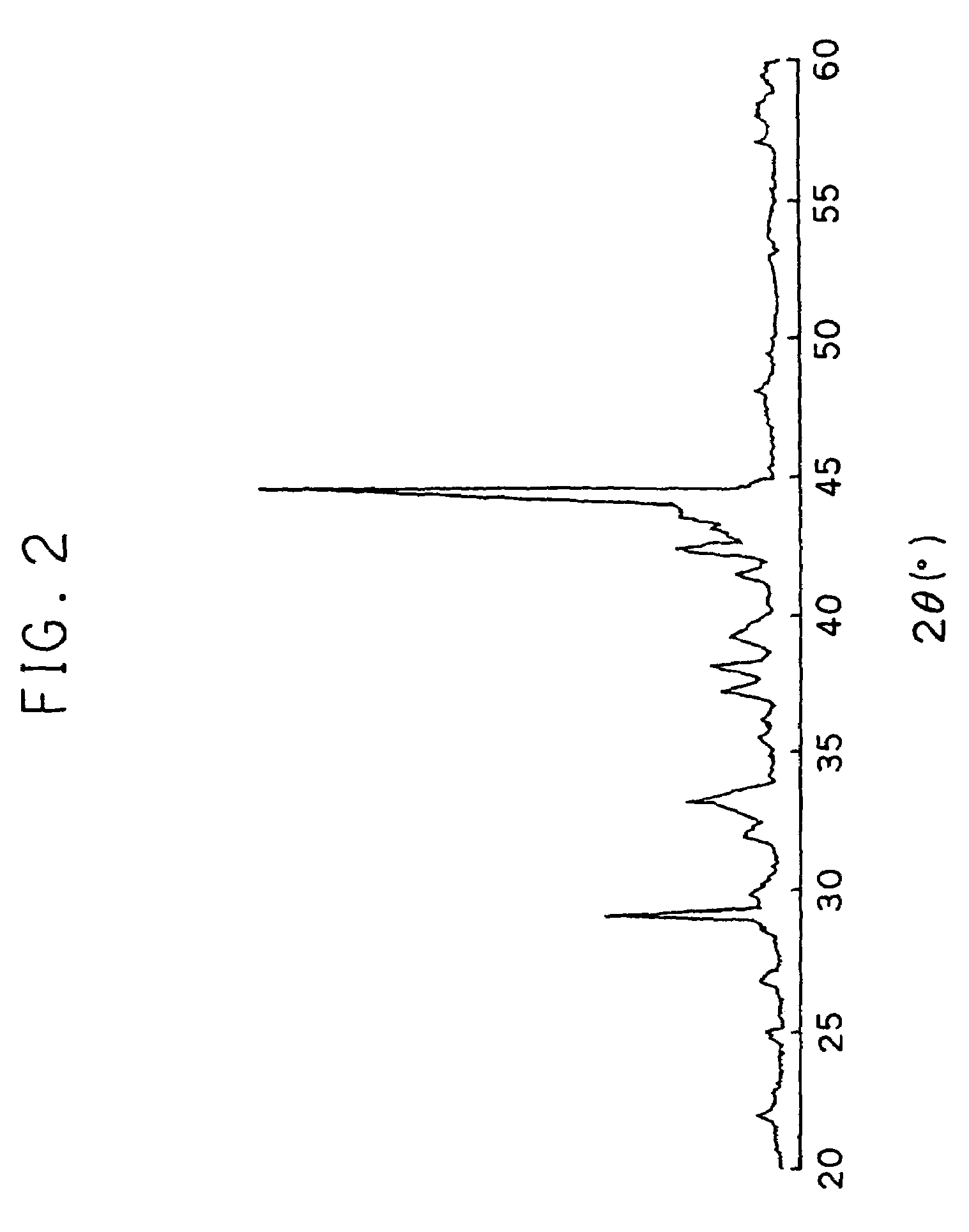

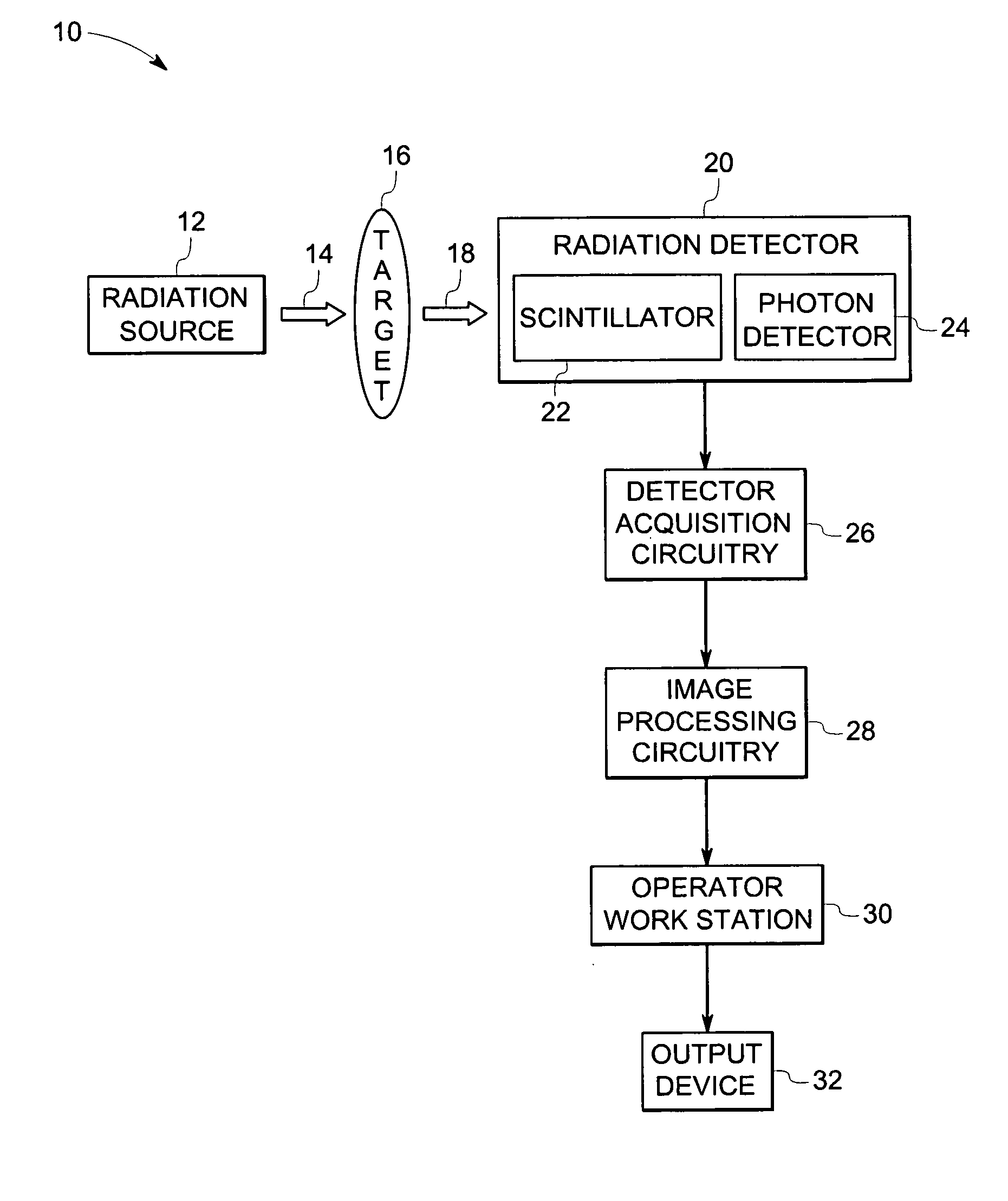

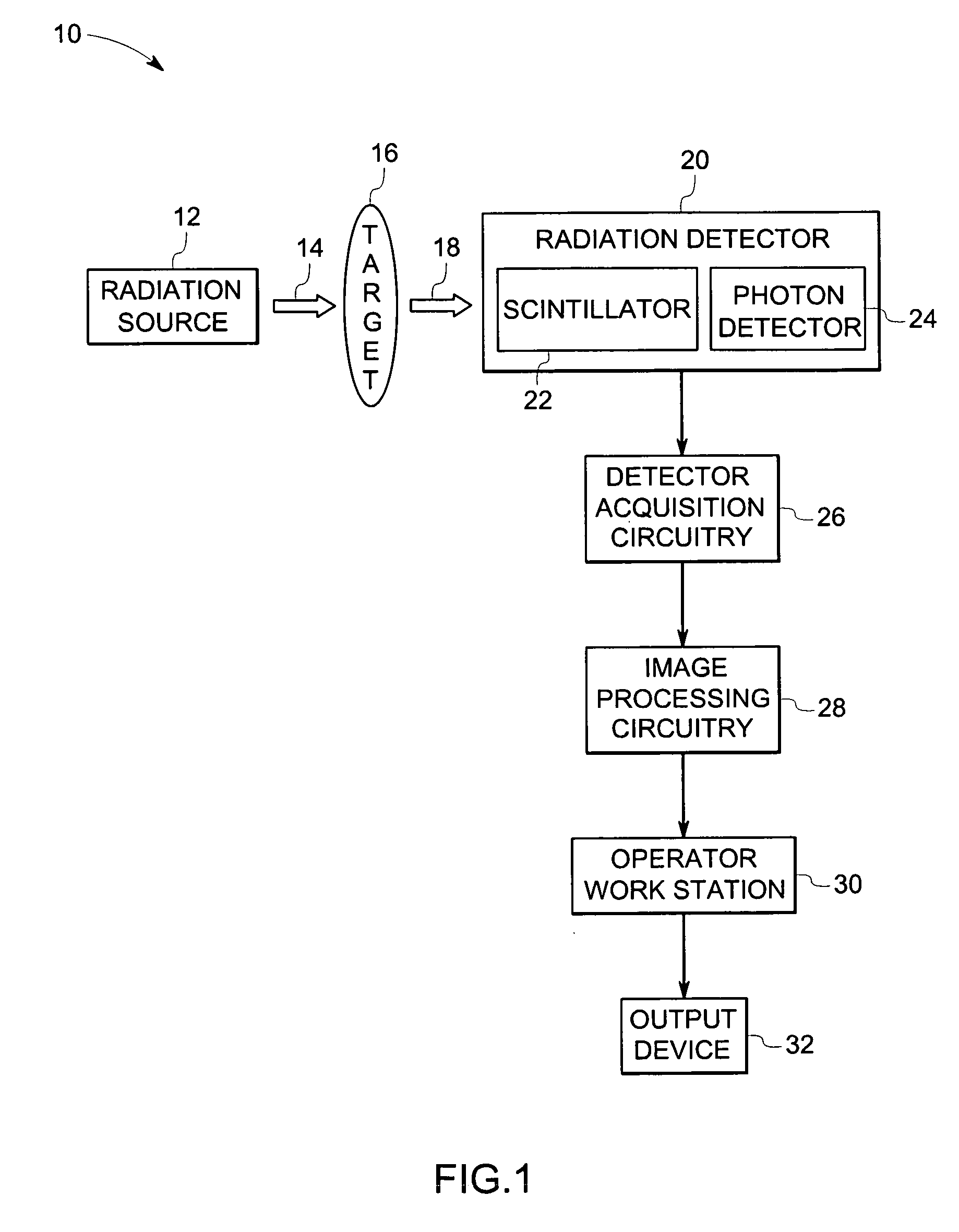

Terbium- or lutetium - containing garnet phosphors and scintillators for detection of high-energy radiation

InactiveUS20030075706A1Improve light outputShort decay timePolycrystalline material growthMaterial analysis using wave/particle radiationLutetiumHigh energy

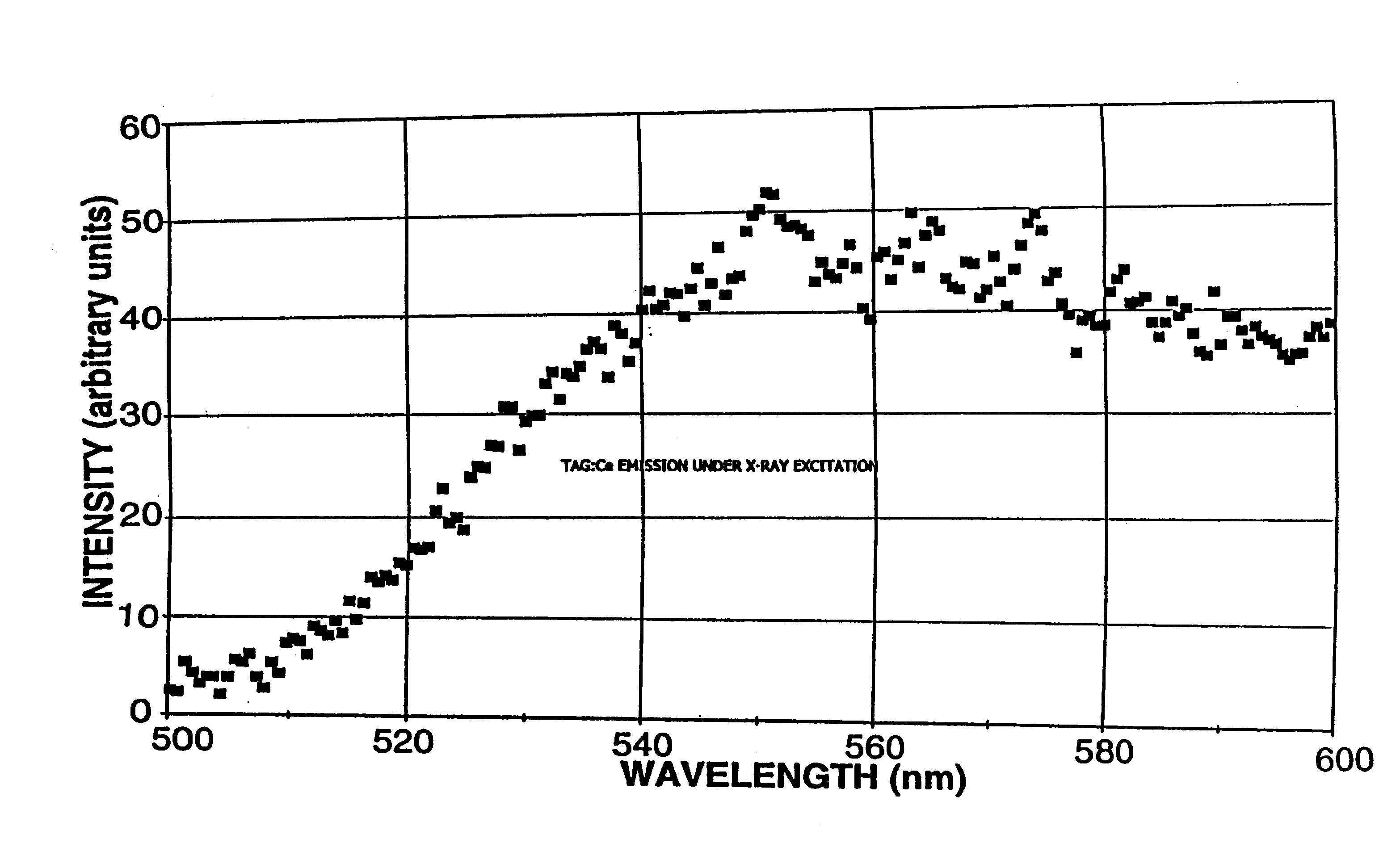

Scintillator compositions having a garnet crystal structure useful for the detection of high-energy radiation, such as X, beta, and gamma radiation, contain (1) at least one of terbium and lutetium; (2) at least one rare earth metal; and (3) at least one of Al, Ga, and In. Terbium or lutetium may be partially substituted with Y, La, Gd, and Yb. In particular, the scintillator composition contains both terbium and lutetium. The scintillators are characterized by high light output, reduced afterglow, short decay time, and high X-ray stopping power.

Owner:GENERAL ELECTRIC CO

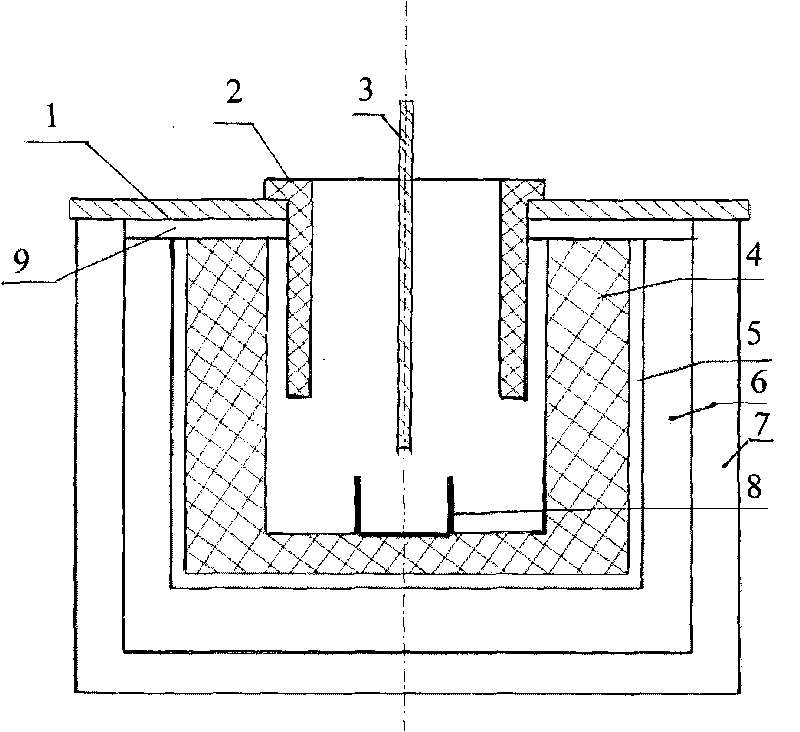

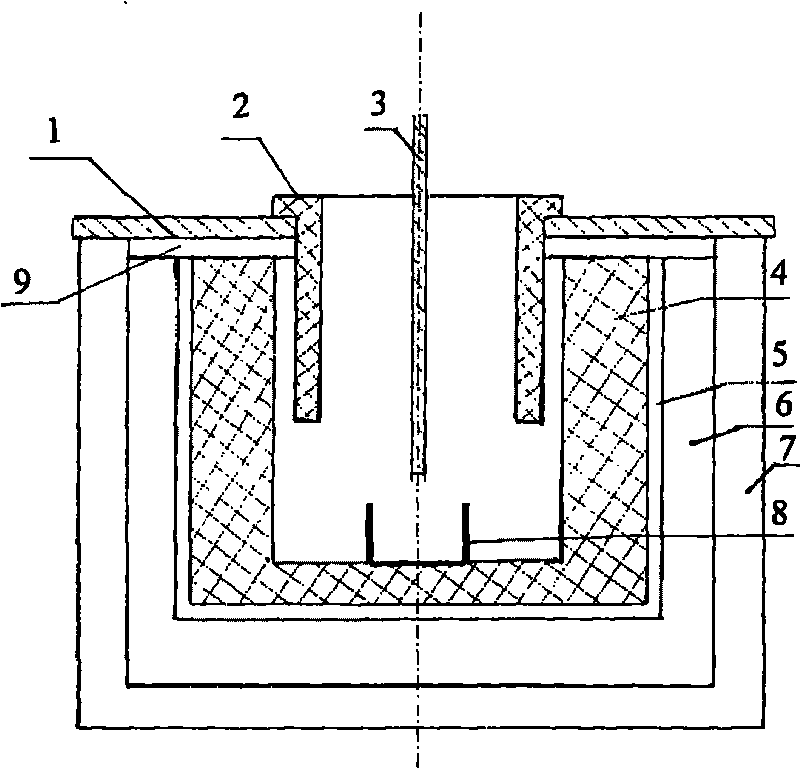

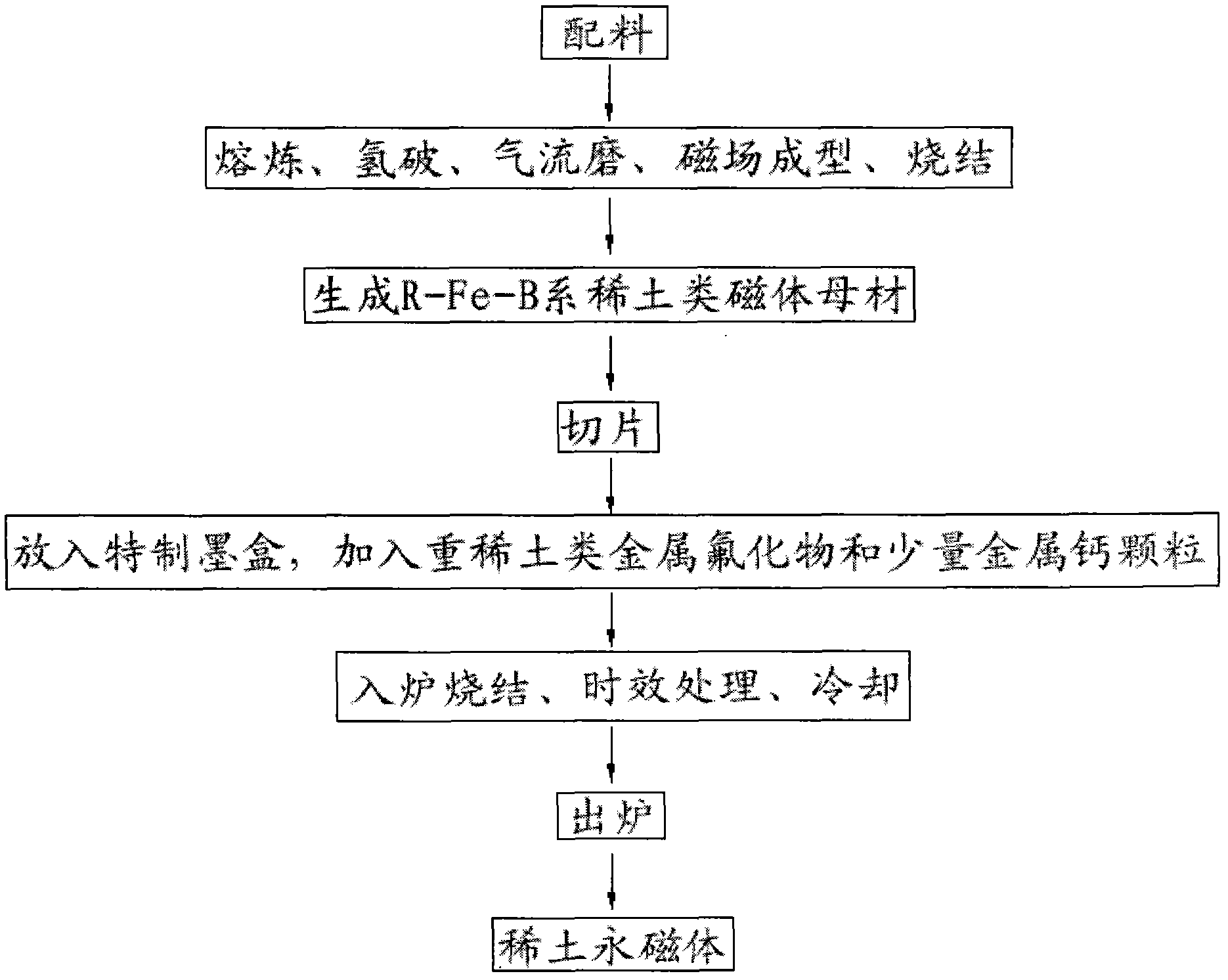

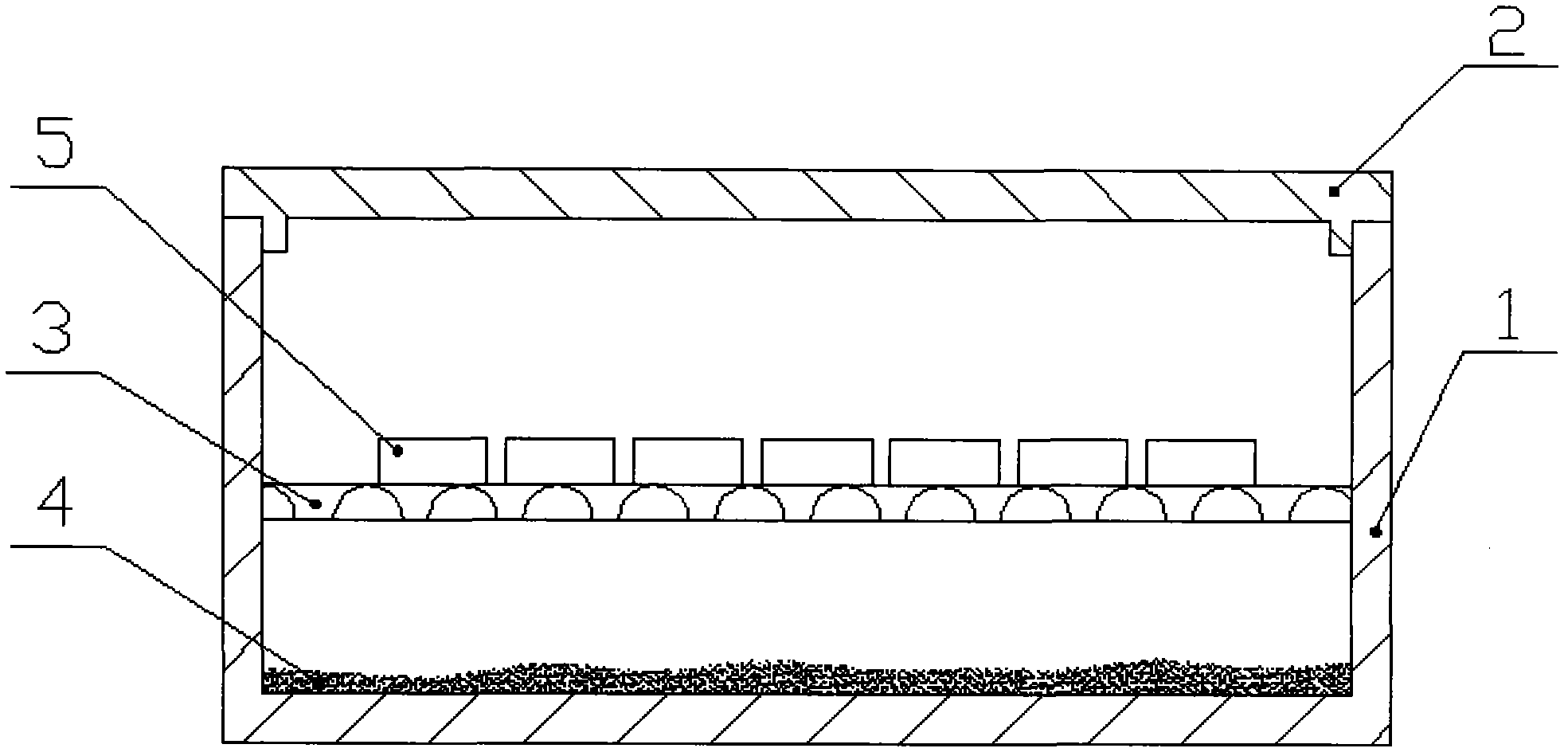

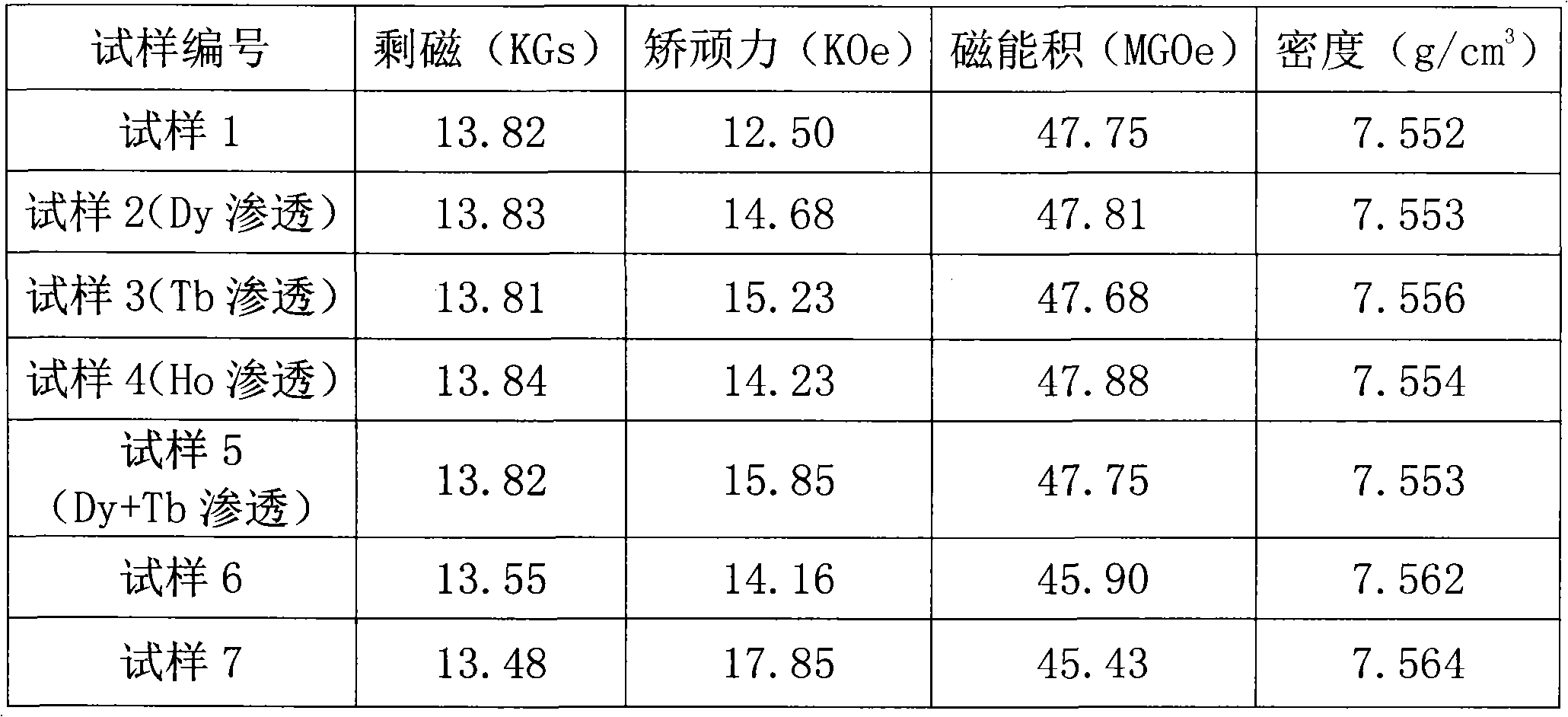

Method for preparing rare-earth permanent magnets by infiltration process and graphite box utilized in method

InactiveCN102568806AReduce manufacturing costReduce usagePermanent magnetsSolid state diffusion coatingRare earthMaterials science

Disclosed are a method for preparing rare-earth permanent magnets by the infiltration process and a graphite box utilized in the method. The method includes: preparing base materials of R (rare earth)-Fe (ferrum)-B (boron) rear earth magnets by prepared raw materials which are subjected to smelting, hydrogen decrepitation, magnetic field forming, sintering and the like; cutting the base material into slices with the thickness ranging from 2mm to 10mm; placing the slices into a specially-made graphite box and placing heavy rare earth type metal fluoride and a few of metal calcium particles into the bottom of the graphite box; sintering the graphite box in a sintering furnace, inflating air into the sintering furnace to cool the temperature to be lower than 60 DEG C, finally ageing magnets, then inflating Ar gas into the sintering furnace to cool the temperature to be lower than 60 DEG C after ageing, and finally obtaining the rare-earth permanent magnets. Elements including Dy (dysprosium), Tb (terbium), Ho (holmium) and the like are infiltrated into the crystal boundary of the R-Fe-B to prepare high-coercivity rare-earth permanent magnets by means of infiltration process, usage of heavy rare earth metal can be greatly reduced, and production cost of magnets can be effectively reduced. Additionally, the method for preparing rare-earth permanent magnets by the infiltration process is simple in operation and suitable for batch production.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

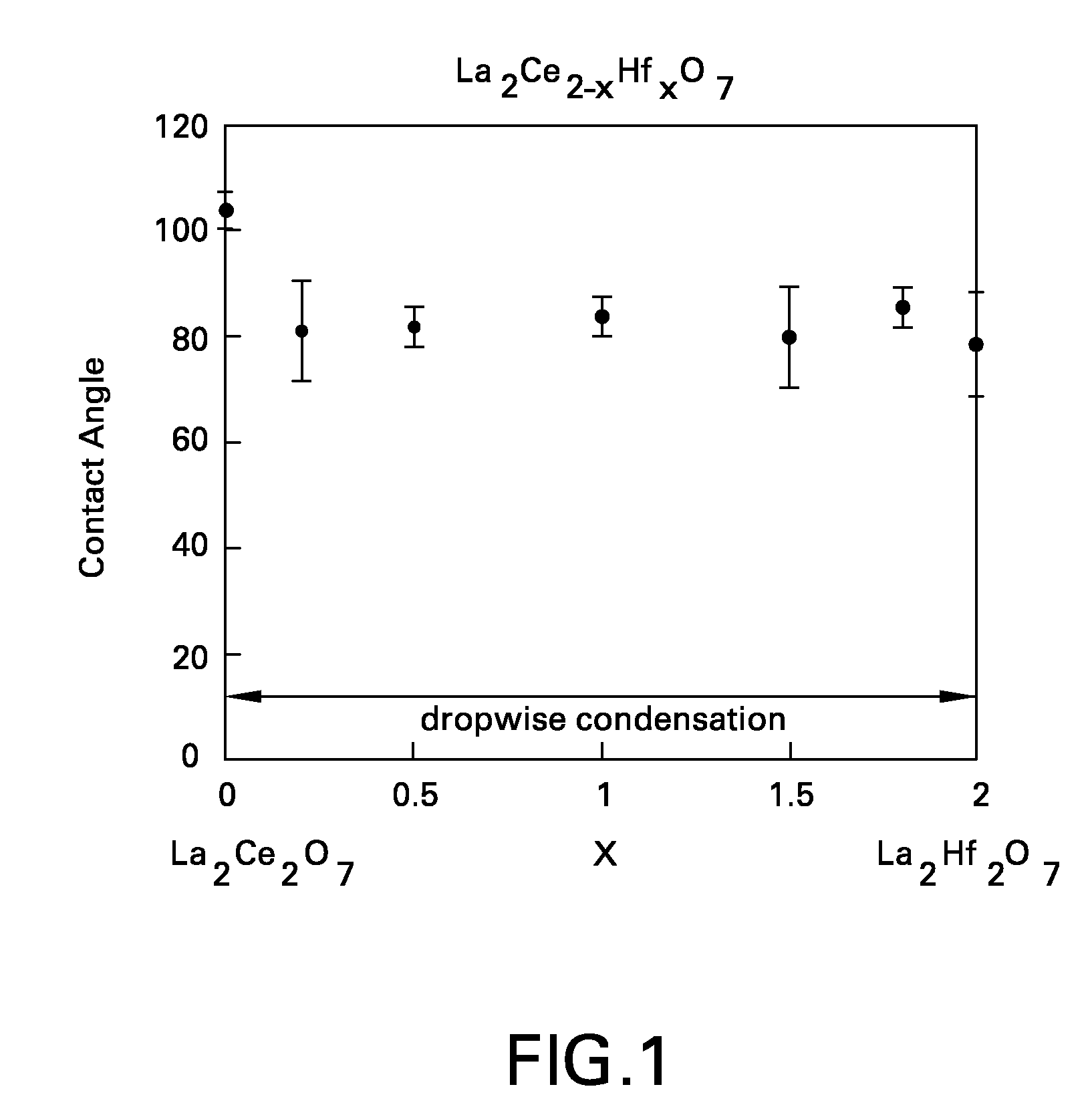

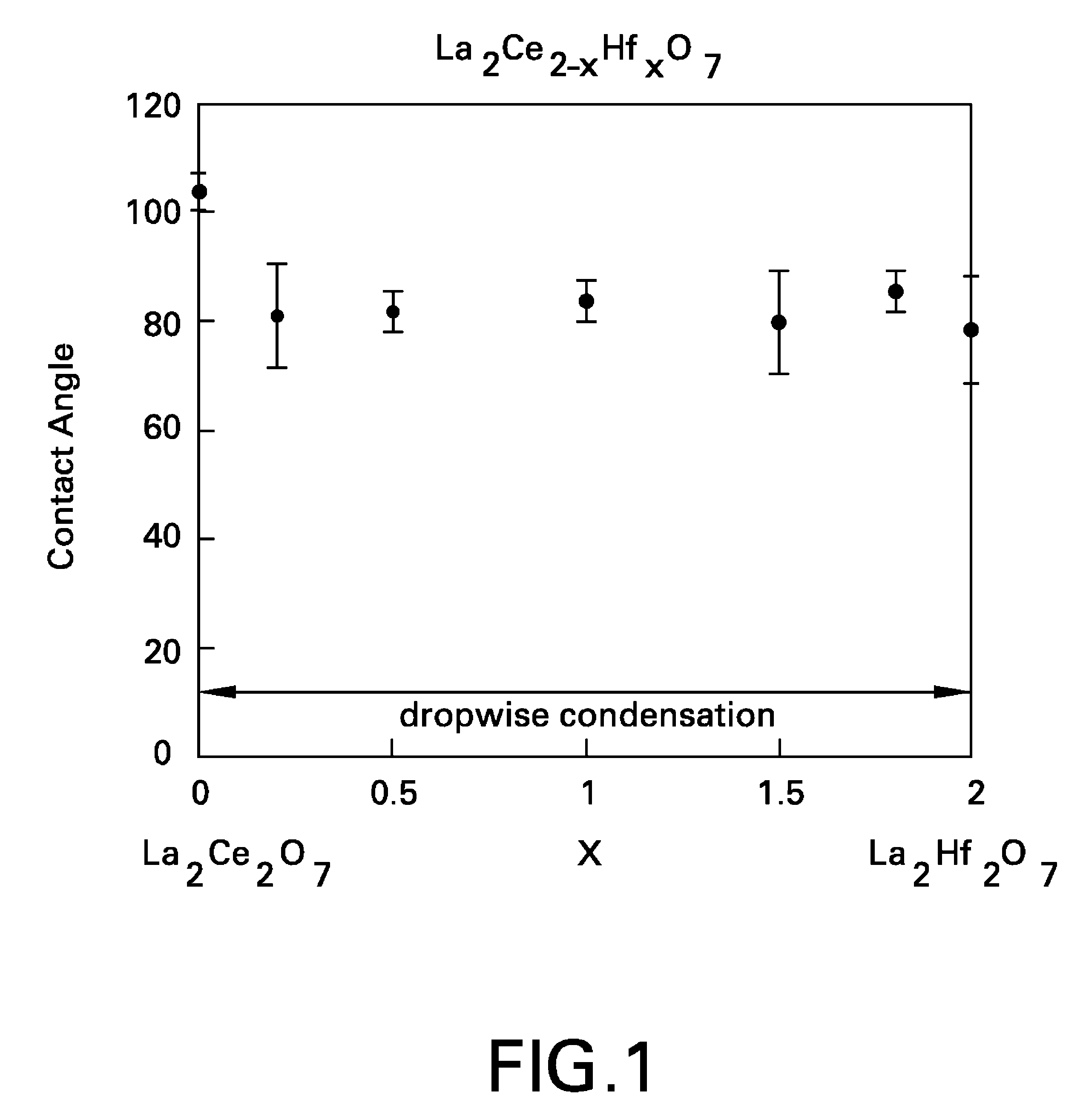

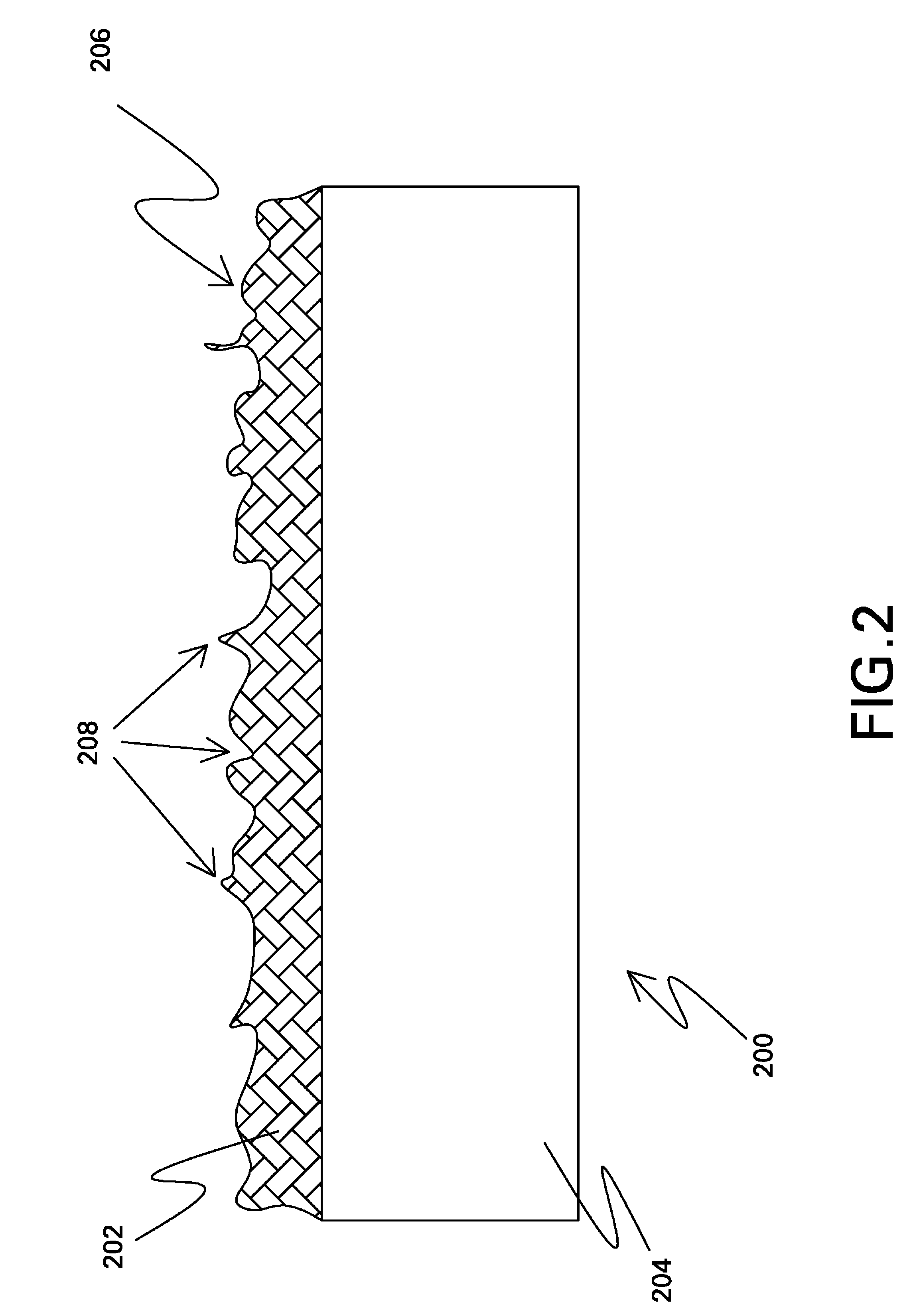

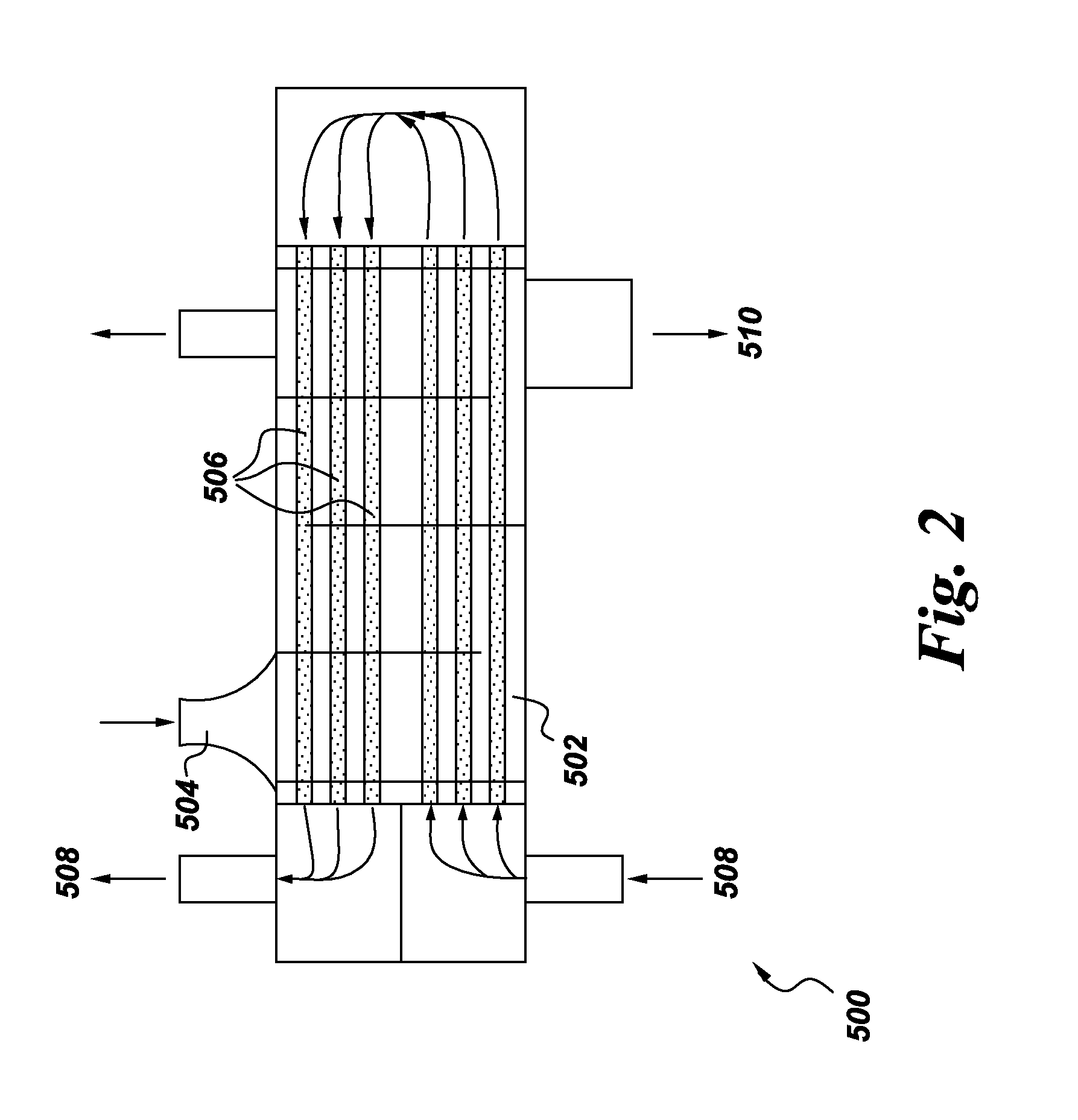

Wetting resistant materials and articles made therewith

Ceramic materials with relatively high resistance to wetting by various liquids, such as water, are presented, along with articles made with these materials, methods for making these articles and materials, and methods for protecting articles using coatings made from these materials. One particular embodiment is an article that comprises a coating having a surface connected porosity content of up to about 5 percent by volume. The coating comprises a material that comprises a primary oxide and a secondary oxide, wherein (i) the primary oxide comprises a cation selected from the group consisting of cerium, praseodymium, terbium, and hafnium, and (ii) the secondary oxide comprises a cation selected from the group consisting of the rare earth elements, yttrium, and scandium.

Owner:GENERAL ELECTRIC CO

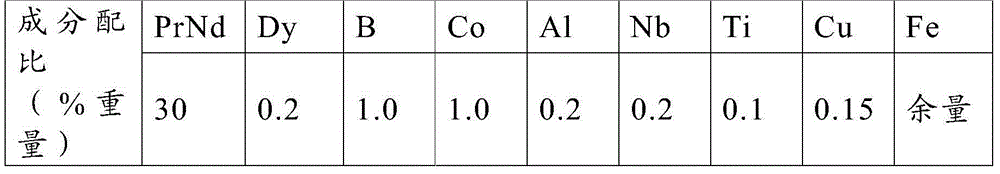

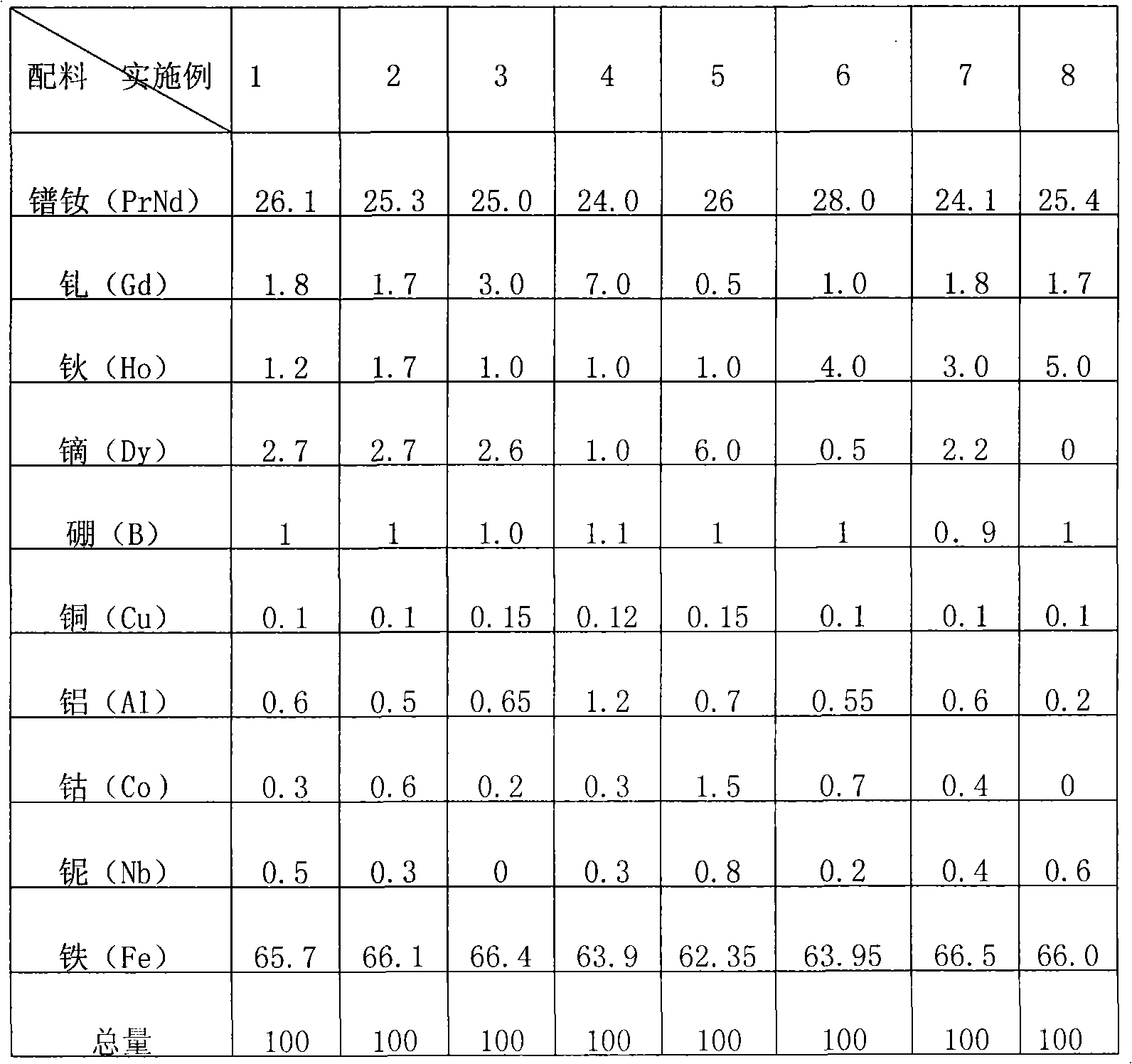

Neodymium iron boron permanent magnet for motor and manufacturing method thereof

ActiveCN101409121AReduce manufacturing costLow costInductances/transformers/magnets manufactureMagnetic materialsNiobiumMaterials science

The invention discloses an NdFeB permanent magnet used for NdFe motors and a manufacture method thereof. The magnet comprises the following components by weight: 24-28 percent of PrNd, 0.5-7 percent of Gd, 1-5 percent of Ho, 0-6 percent of Dy, 0.9-1.1 percent of B, 0.1-0.15 percent of Cu, 0.2-1.2 percent of Al, 62.35-66.5 percent of Fe, 0.2-1.5 percent of Co and 0.2-0.8 percent of Nb. The magnet is manufactured through the procedures of mixing, melting, milling, forming, sintering and grinding processing. Through the use of cheap gadolinium and holmium instead of expensive praseodymium, neodymium, dysprosium and terbium for the production of high-performance NdFeB permanent magnet, the invention can greatly reduce production cost and the product has high magnetic property and strong market competitiveness.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

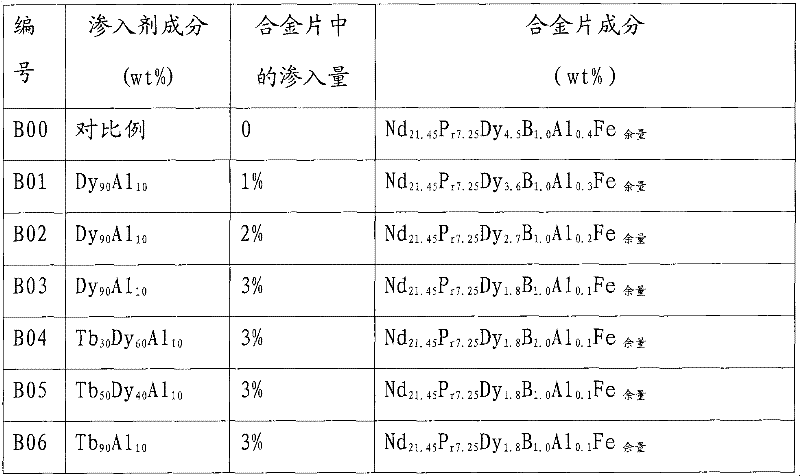

High-performance sintered neodymium-iron-boron (Nd-Fe-B) rare-earth permanent magnet material and manufacturing method thereof

ActiveCN102347126AReduce dosageProtect scarce resourcesTransportation and packagingMetal-working apparatusRare-earth elementCobalt

The invention discloses a high-performance sintered neodymium-iron-boron (Nd-Fe-B) rare-earth permanent magnet material and a manufacturing method thereof. The manufacturing method comprises the following steps: firstly, casting R-iron-boron-aluminum (R-Fe-B-Al) into a rapidly solidified alloy plate (R represents one and / or several of rare-earth elements containing Nd) by adopting a vacuum rapid solidifying process, then, coating a metal penetrant comprising the component Ra-Al or Ra-Al-X [the Ra represents dysprosium (Dy) and / or terbium (Tb), and the X represents one or several of cobalt, copper, gallium and zirconium (Co, Cu, Ga and Zr) elements] to the surface of the alloy plate, and heating to enable the metal penetrant to penetrate into the crystal boundary of the rapidly solidified alloy plate. A replacement reaction happens between the Ra in the penetrant entering the crystal boundary of the rapidly solidified alloy plate and the Nd and / or praseodymium (Pr) in the main phase of the alloy plate to form an Rh2(Fe, Al)14B phase with high content of the Dy and / or the Tb (the Rh represents that the content of the Dy and / or the Tb is higher than that of the Dy and / or the Tb in the R), and the positions of part of Fe atoms are replaced by Al atoms to encircle the double-main phase structure of an R2Fe14B phase. The high-performance sintered neodymium-iron-boron (Nd-Fe-B) rare-earth permanent magnet material disclosed by the invention is capable of effectively improving a coercive force and obviously reducing the use level of rare earth, and simultaneously, is also capable of improving the corrosion resistance of a magnet.

Owner:SHENYANG GENERAL MAGNETIC

Preparation method for zirconium-contained rare-earth composite oxide

ActiveCN102417352AExpand industrial applicationsHigh surface areaCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsChemical industryCalcium bicarbonate

The invention relates to a preparation method for a zirconium-contained rare-earth composite oxide. At a certain ratio, rare earth (cerium, yttrium, praseodymium or terbium) is mixed with zirconium to burden, or rare earth (cerium, yttrium, praseodymium or terbium) and zirconium are mixed with at least one of other metal ions (aluminum, barium, magnesium, strontium, titanium, manganese, ferrum, copper and hafnium) to burden. A magnesium bicarbonate or / and calcium bicarbonate aqueous solution prepared from raw materials of magnesium or / and calcium minerals or oxides and hydroxides by at least one working procedure of roasting, digesting, mixing size, carbonizing and the like can serve as a precipitator to carry out precipitation so as to obtain at least one of rare earth and zirconium composite carbonate and subcarbonate, and the at least one of rare earth and zirconium composite carbonate and subcarbonate is further roasted to obtain a zirconium-contained rare-earth composite oxide product. In the preparation method, cheap calcium or / and magnesium minerals or low-purity oxides and hydroxides can serve as initial raw materials to replace common chemical industry precipitators, such as ammonia water, ammonium bicarbonate, sodium carbonate, sodium hydroxide and the like, substances, such as magnesium, calcium, carbon dioxide and the like can be effectively circulated and utilized so as to greatly lower the production cost of the zirconium-contained rare-earth composite oxide, such as ceria-zirconia, yttrium zirconium, praseodymium zirconium, terbium zirconium and the like. In addition, in the production technology disclosed by the invention, no ammonia nitrogen wastewater, high-salinity wastewater and the like are generated, carbon dioxide greenhouse gas emission amount is reduced, the preparation technology is environmentally-friendly, and environment pollution is avoided.

Owner:GRIREM ADVANCED MATERIALS CO LTD

High-density scintillators for imaging system and method of making same

InactiveUS20060219927A1Material analysis using wave/particle radiationRadiation/particle handlingAlkaline earth metalCerium

A scintillator composition comprising a garnet represented by (M1-x-yNxAy)3(Al5-a-bCaDb)O12, where M comprises yttrium, or terbium, or gadolinium, or holmium, or erbium, or thulium, or ytterbium, or lutetium, or combinations thereof, where N comprises additives including a lanthanide, or an alkali metal, or an alkaline earth metal, or combinations thereof, where A comprises a suitable activator ion including cerium, or europium, or praseodymium, or terbium, or ytterbium, or combinations thereof, where C or D comprises lithium, or magnesium, or gallium, or an element from group IIIa, or IVa, or Va, or IIId transition metal, or IVd transition metal, or combinations thereof, where x ranges from about 0 to about 0.90, y ranges from about 0.0005 to about 0.30, and a sum of a and b ranges from about 0 to 2.0.

Owner:GENERAL ELECTRIC CO

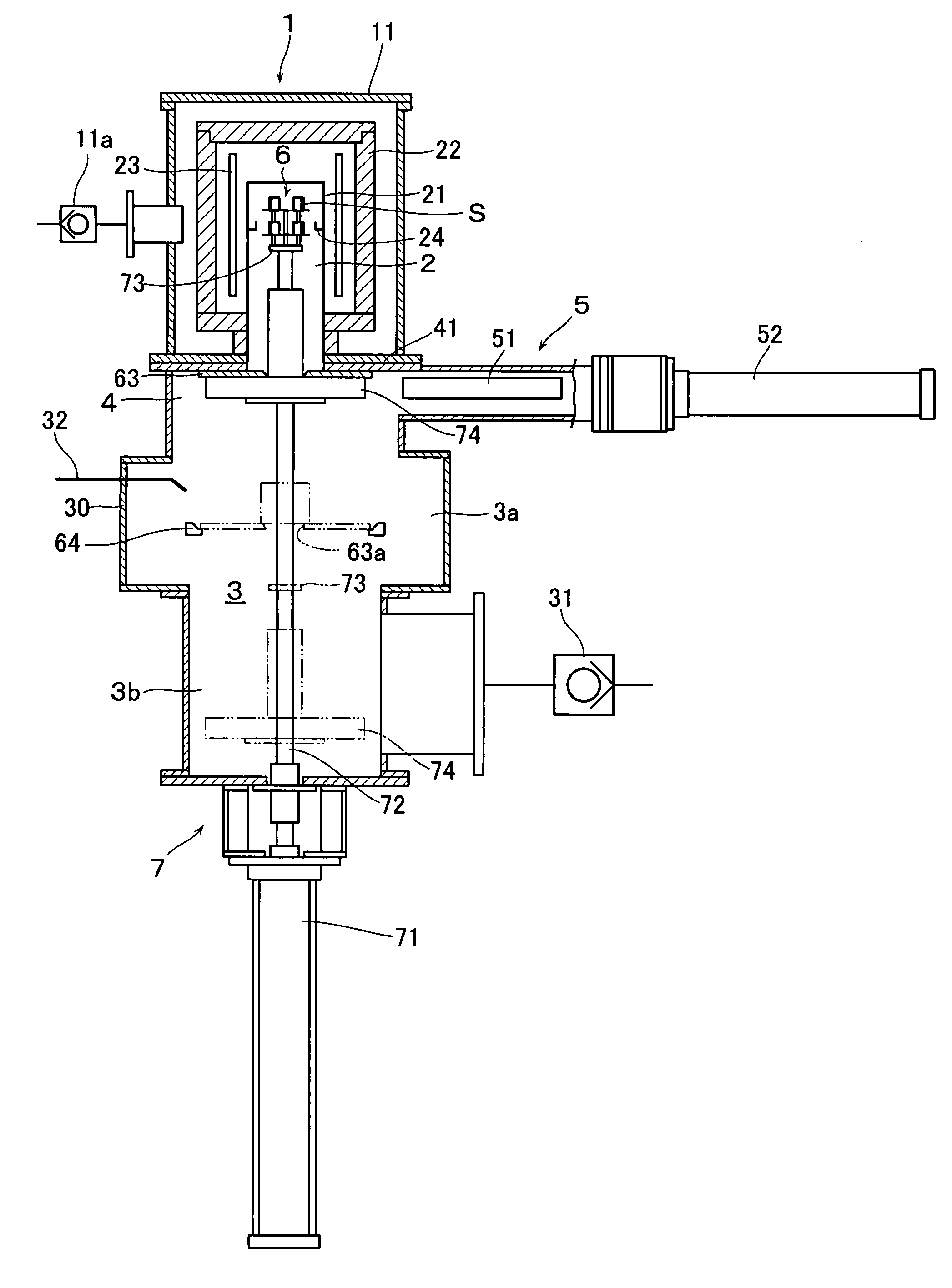

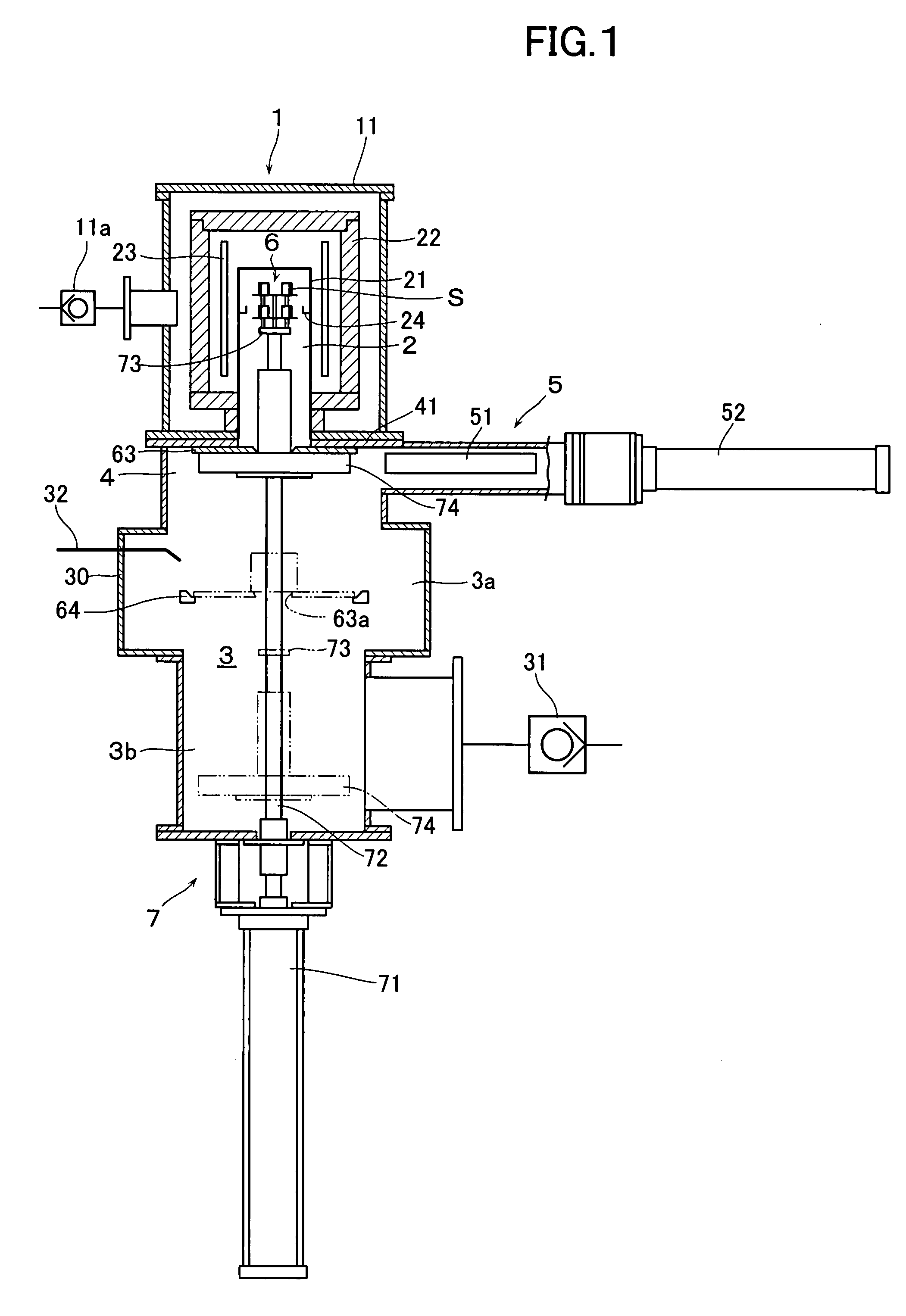

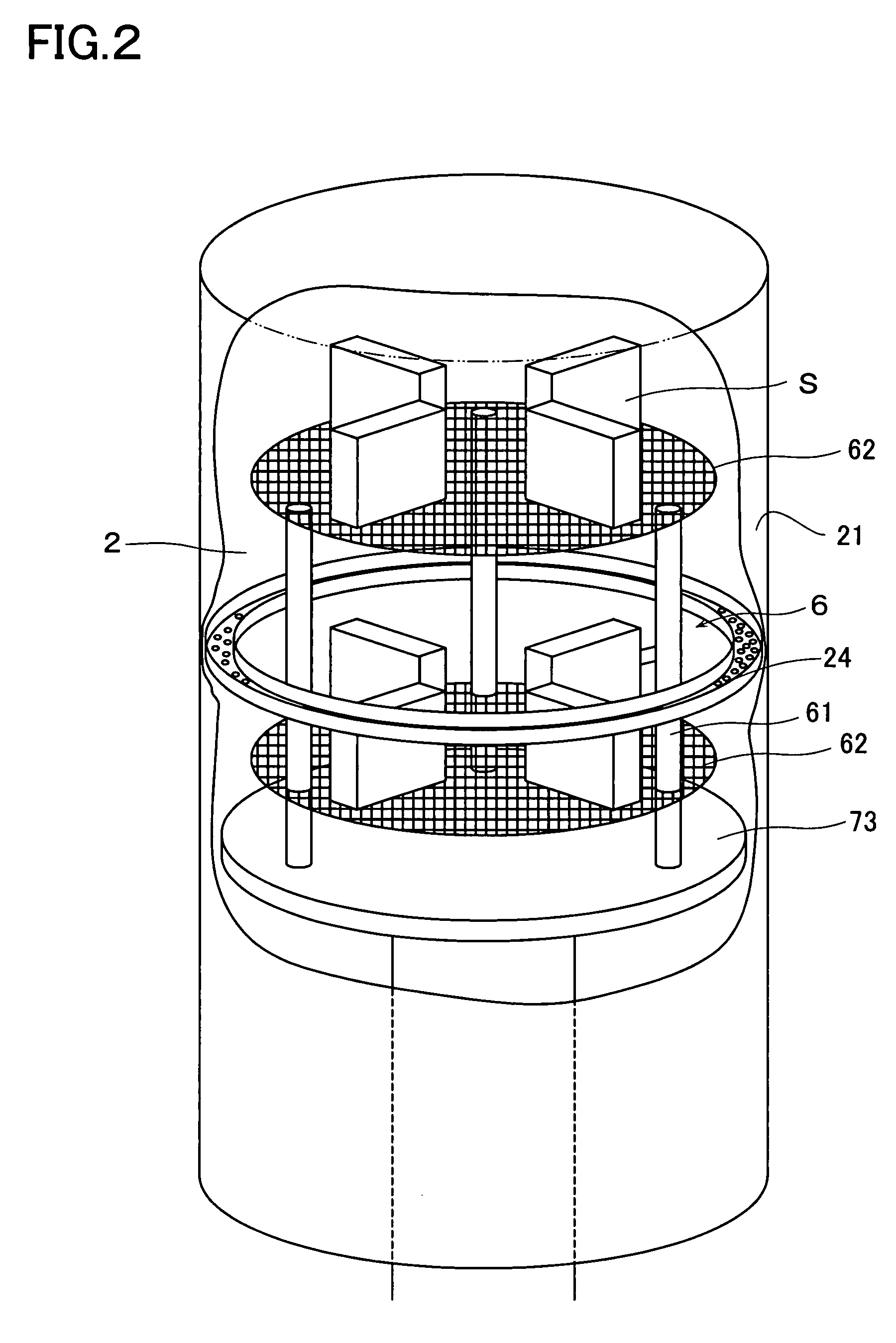

Coating Method and Apparatus, a Permanent Magnet, and Manufacturing Method Thereof

InactiveUS20080257716A1Improve productivityLow costCellsVacuum evaporation coatingHigh rateRare earth

A film is formed at a high rate on the surface of an iron-boron-rare-earth-metal magnet having a given shape, while effectively using dysprosium or terbium as a film-forming material. Thus, productivity is improved and a permanent magnet can be produced at low cost. A permanent magnet is produced through a film formation step in which a film of dysprosium is formed on the surface of an iron-boron-rare-earth-metal magnet of a given shape and a diffusion step in which the magnet coated is subjected to a heat treatment at a given temperature to cause the dysprosium deposited on the surface to diffuse into the grain boundary phase of the magnet. The film formation step comprises: a first step in which a treating chamber where this film formation is performed is heated to vaporize dysprosium which has been disposed in this treating chamber and thereby form a dysprosium vapor atmosphere having a given vapor pressure in the treating chamber; and a second step in which a magnet kept at a temperature lower than the internal temperature of the treating chamber is introduced into this treating chamber and the dysprosium is selectively deposited on the magnet surface based on a temperature difference between the treating chamber and the magnet until the magnet temperature reaches a given value.

Owner:ULVAC INC

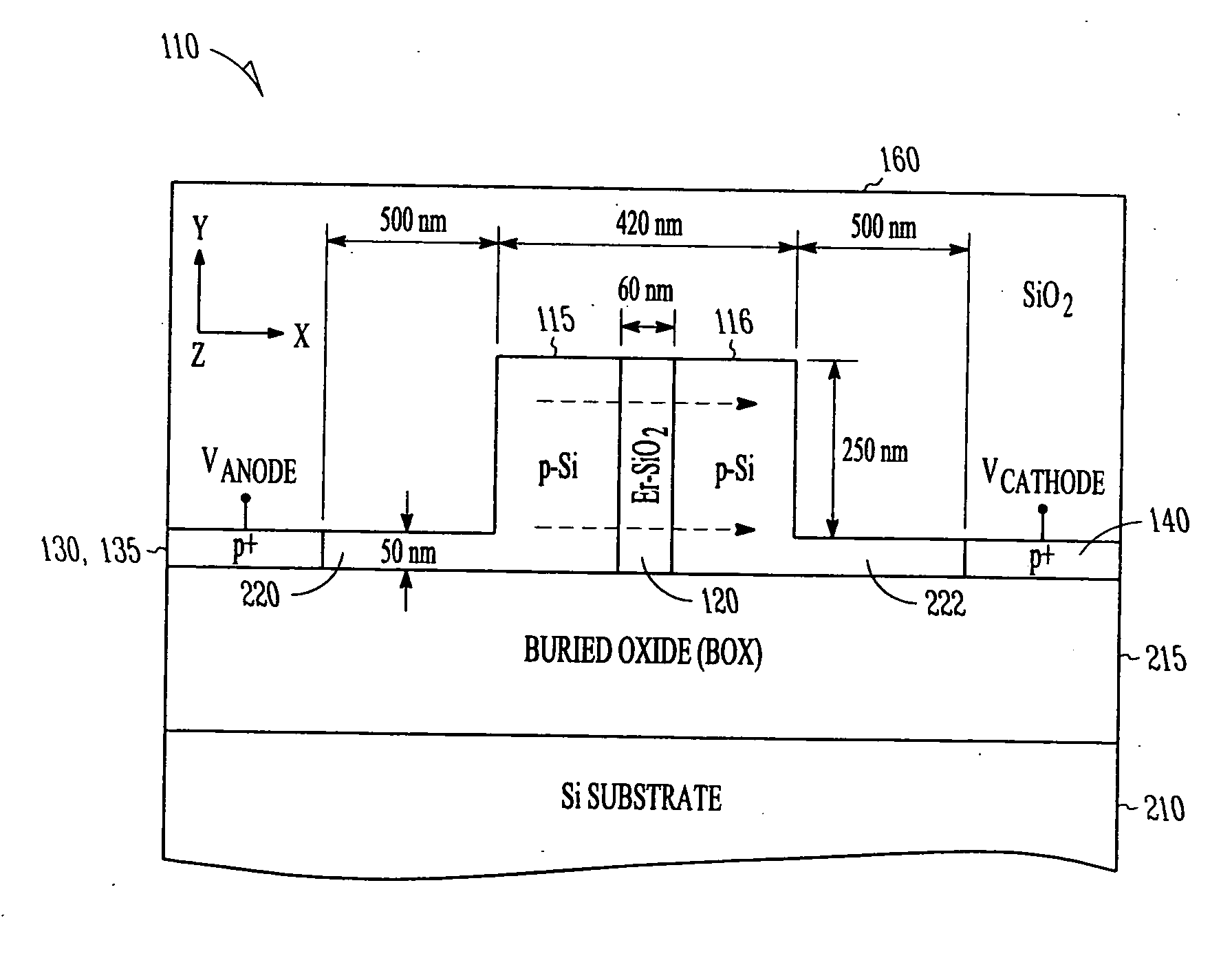

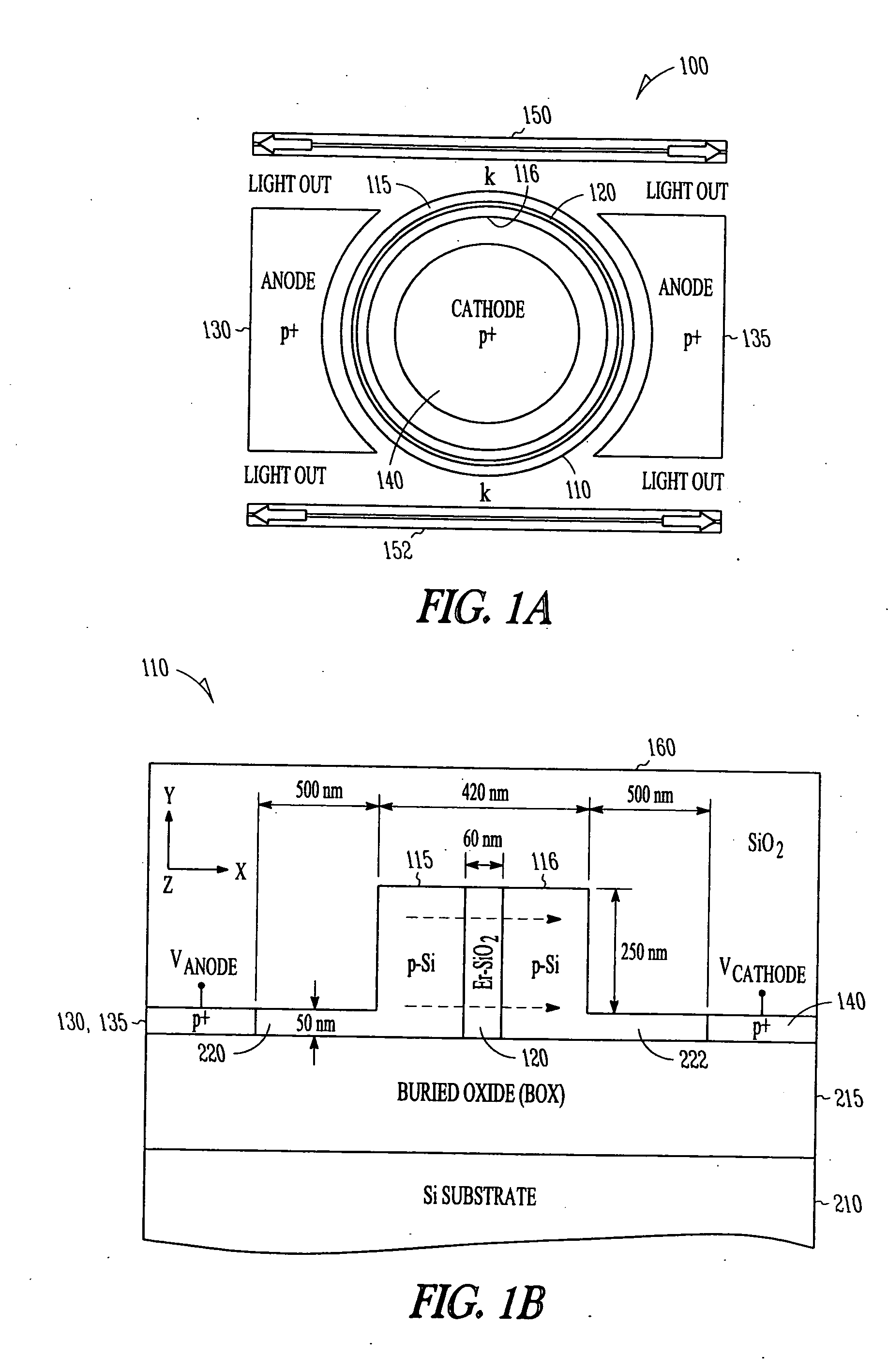

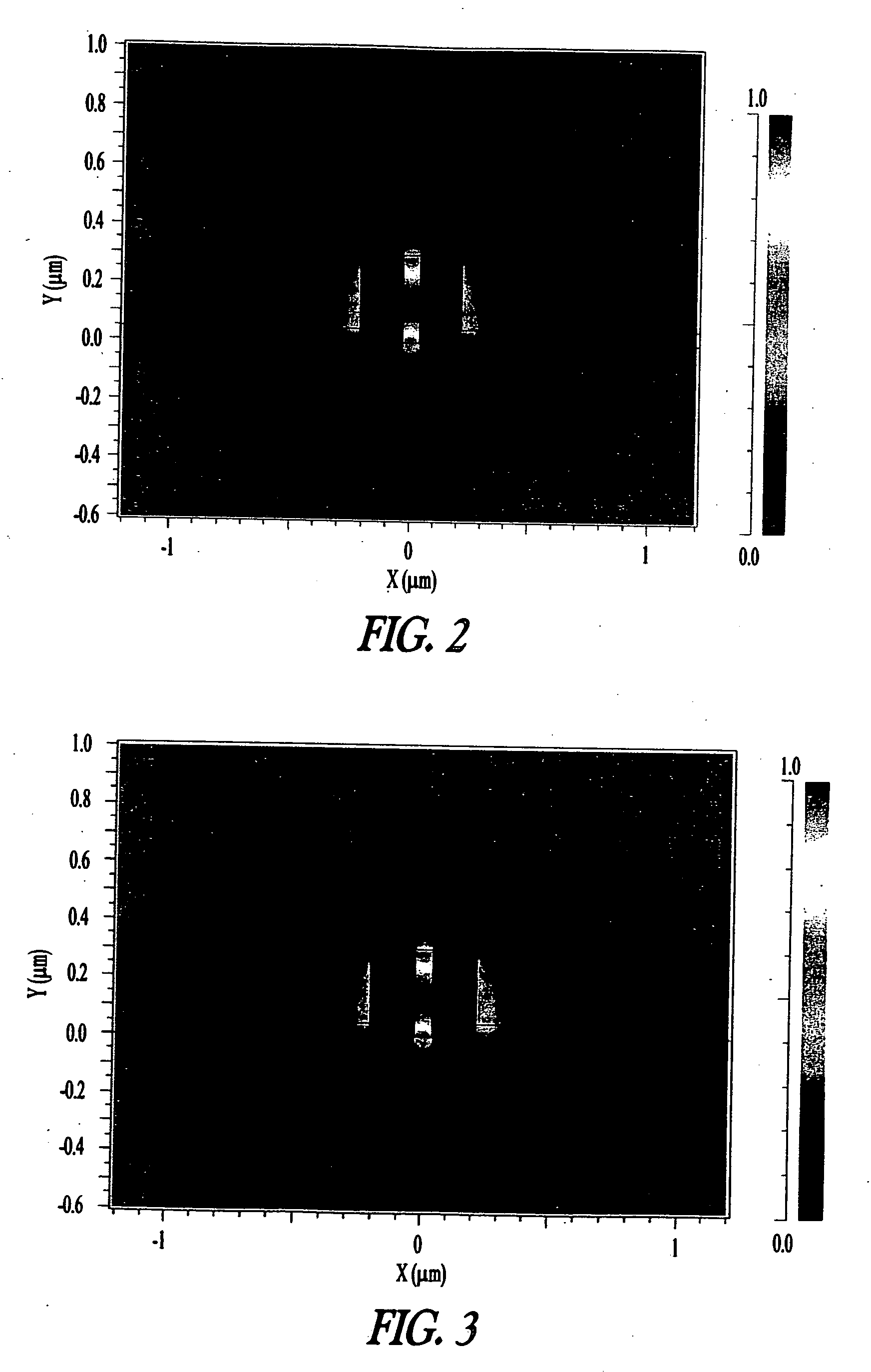

Light emitting slot-waveguide device

An electroluminescent material slot waveguide generates light in response to current injection. In one embodiment, the waveguide is formed as part of an optical resonator, such as ring resonator waveguide or distributed Bragg reflector with an anode and cathode for electrical stimulation. A compact, electrically-driven resonant cavity light emitting devices (RCLED) for Si microphotonics may be formed. Several different rare-earth ions, such as erbium, terbium and ytterbium, can be used to dope SiO2 in order to emit light at different wavelengths.

Owner:CORNELL RES FOUNDATION INC

Wetting resistant materials and articles made therewith

Ceramic materials with relatively high resistance to wetting by various liquids, such as water, are presented, along with articles made with these materials, methods for making these articles and materials, and methods for protecting articles using coatings made from these materials. One particular embodiment is an article that comprises a coating having a surface connected porosity content of up to about 5 percent by volume. The coating comprises a material that comprises a primary oxide and a secondary oxide, wherein (i) the primary oxide comprises a cation selected from the group consisting of cerium, praseodymium, terbium, and hafnium, and (ii) the secondary oxide comprises a cation selected from the group consisting of the rare earth elements, yttrium, and scandium. The material is transparent to electromagnetic radiation of at least one type selected from the group consisting of ultraviolet radiation, visible light, and infrared radiation.

Owner:GENERAL ELECTRIC CO

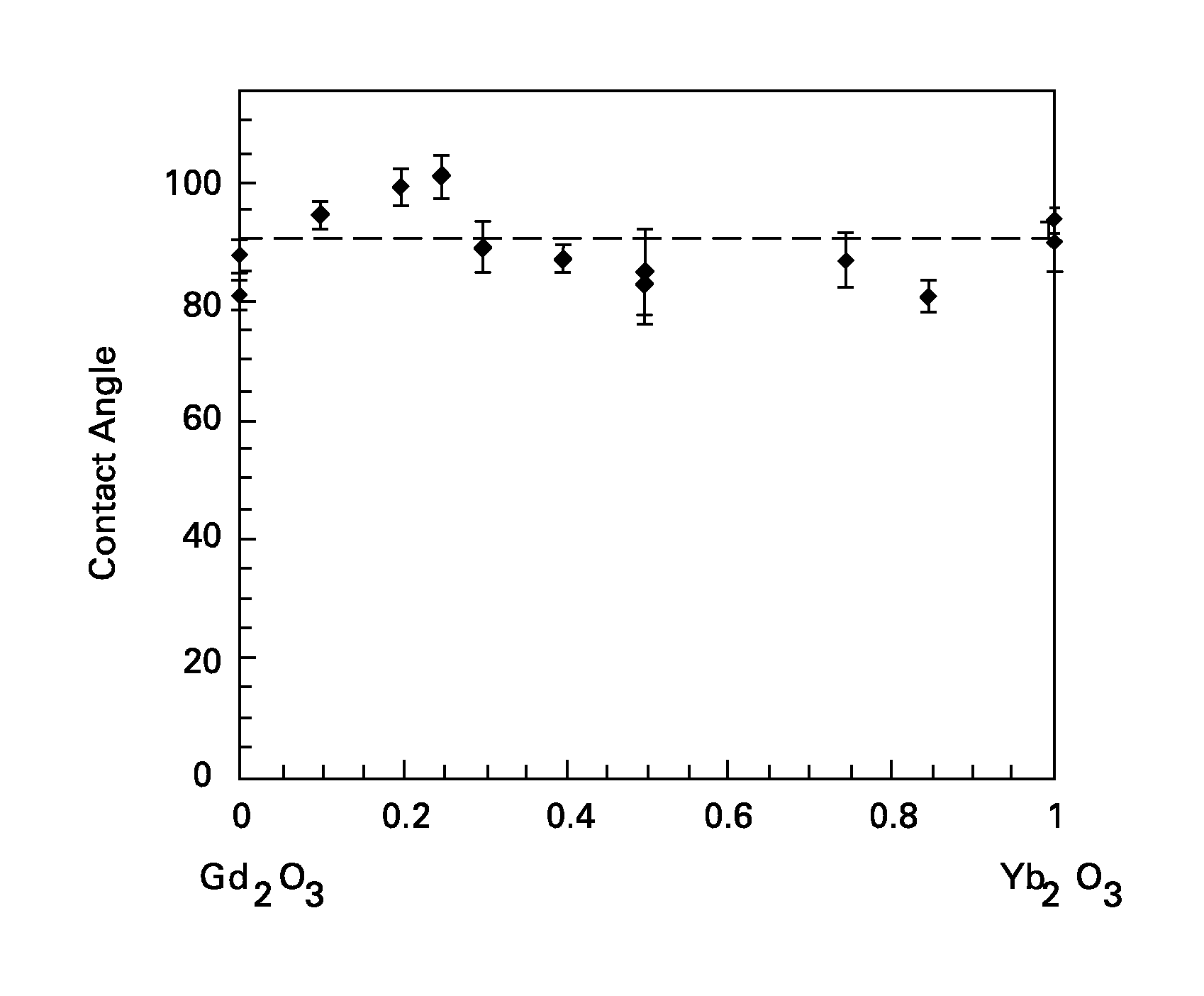

Wetting resistant materials and articles made therewith

Ceramic materials with relatively high resistance to wetting by various liquids, such as water, are presented, along with articles made with these materials. The oxide materials described herein as a class typically contain one or more of ytterbia (Yb2O3) and europia (Eu2O3). The oxides may further contain other additives, such as oxides of gadolinium (Gd), samarium (Sm), dysprosium (Dy), or terbium (Tb). In certain embodiments the oxide, in addition to the ytterbia and / or europia, further comprises lanthanum (La), praseodymium (Pr), or neodymium (Nd).

Owner:GENERAL ELECTRIC CO

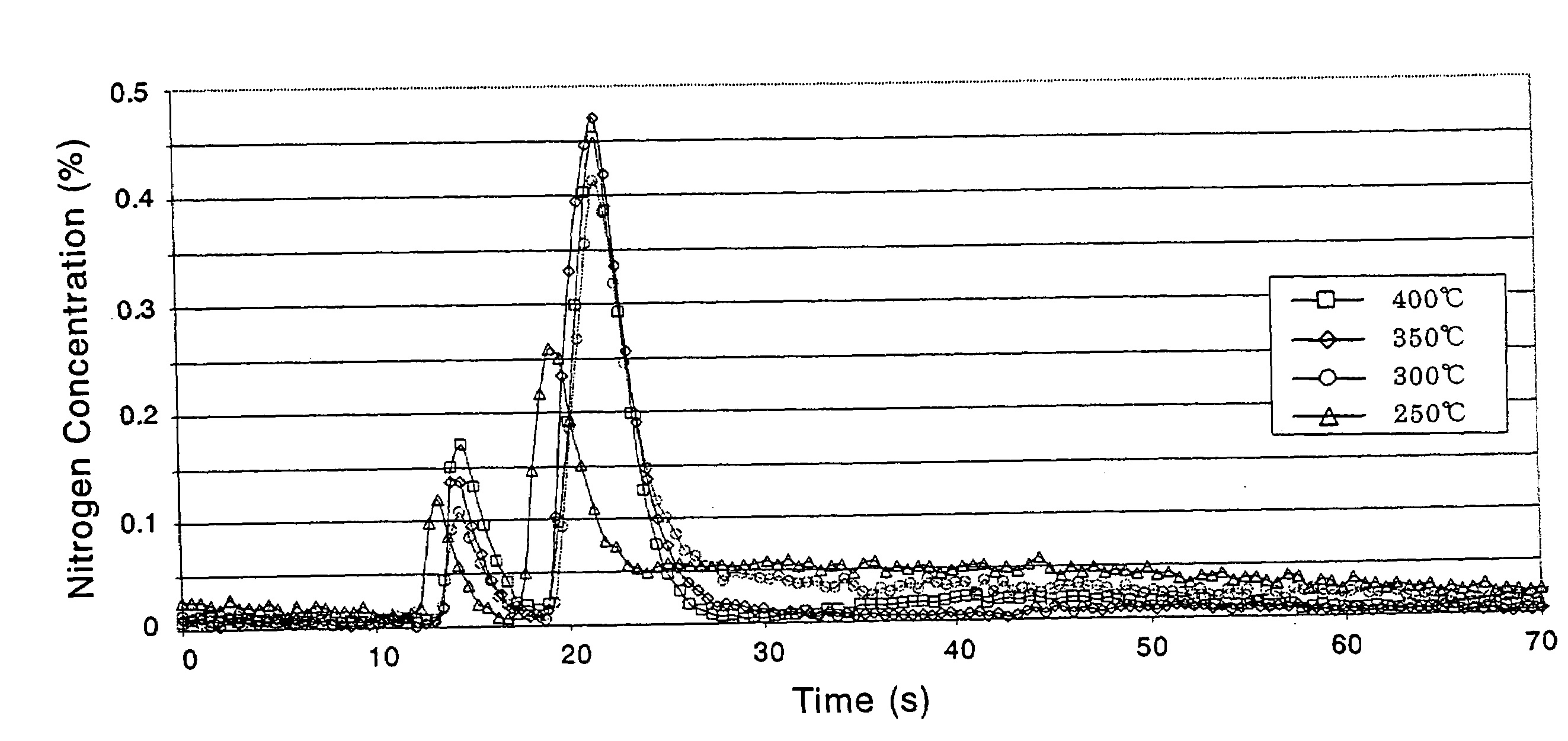

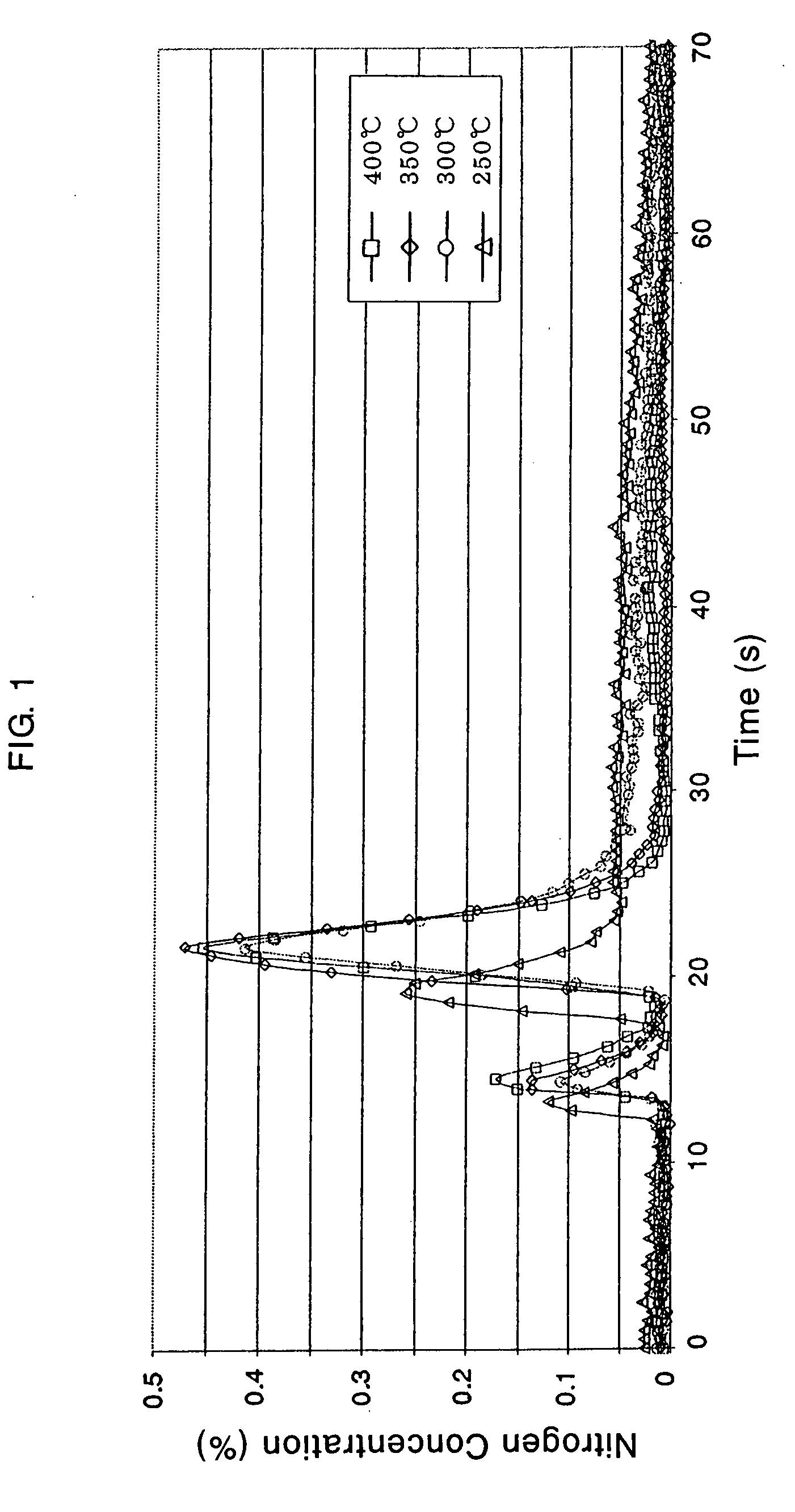

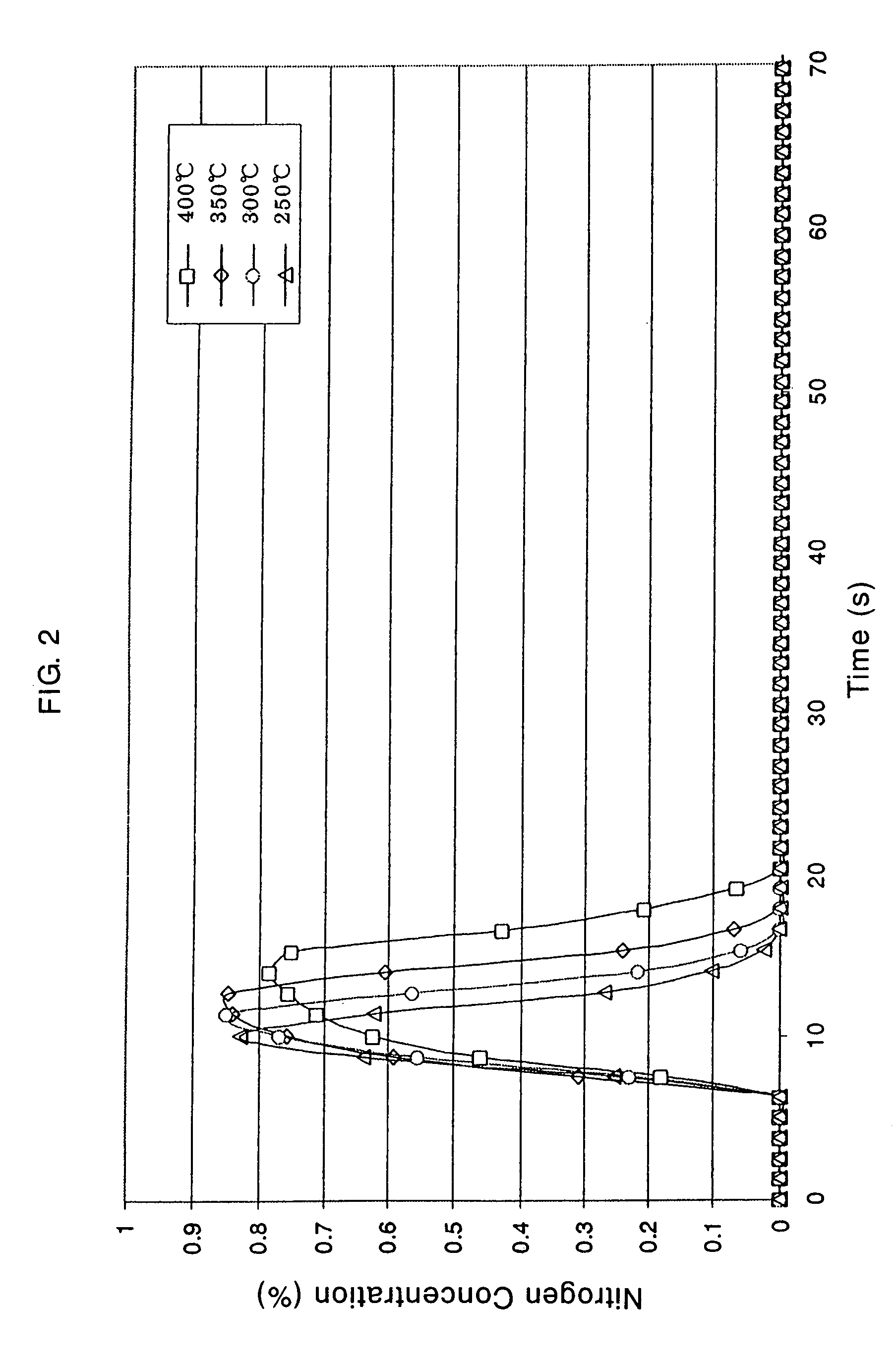

Catalyst and Catalyst Structure for Reduction of Nitrogen Oxides, and Method for Catalytic Reduction of Nitrogen Oxides

InactiveUS20090084090A1Increased durabilityNo deteriorationGas treatmentMolecular sieve catalystsCobaltPt element

The invention provides a catalyst and a catalyst structure for catalytic reduction of nitrogen oxides contained in exhaust gas wherein fuel is supplied and subjected to combustion under periodic rich / lean conditions and the resulting exhaust gases are brought into contact therewith, which catalyst comprises:an outer catalyst layer comprising an outer catalyst component A which comprises at least one selected from a solid acid, and a solid acid supporting oxides and / or ions of at least one element selected from vanadium, tungsten, molybdenum, copper, iron, cobalt, nickel and manganese, andan inner catalyst layer comprising an inner catalyst component which comprises at least one noble metal catalyst component B selected from platinum, rhodium, palladium and an oxide thereof and a catalyst component C comprising ceria or praseodymium oxide or a mixture of oxides and / or a composite oxide of at least two elements selected from cerium, zirconium, praseodymium, neodymium, terbium, samarium, gadolinium and lanthanum. The invention further provides a method for catalytic reduction of nitrogen oxides by contacting the nitrogen oxides with the catalyst.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS +1

Rare earth terbium complex and preparation method thereof

ActiveCN104789213AImprove adsorption capacityReduced number of ligandsLuminescent compositionsRare earthSolvent

The invention discloses a preparation method of a composite rare earth complex, which comprises the steps of weighing an inorganic alkaline matter, adding a polar solvent, performing dispersion, adding rare earth salt and ligand, performing a reaction under stirring, performing filtering, obtaining the composite rare earth complex, optionally performing drying, and obtaining the composite rare earth complex. According to the method, the composite rare earth complex is successfully synthesized and extracted in the polar solvent by using the inorganic alkaline matter for a rare earth binary complex which is difficultly deposited in the polar solvent, so that the difficult-to-deposit rare earth binary complex is effectively deposited out, and the cost of a rare earth fluorescent material is lowered.

Owner:河南索顿新材料有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com