NdFeB magnet and preparation method thereof

A technology of neodymium iron boron and magnets, which is applied in the field of rare earth magnetic materials, can solve the problems of formula cost increase and resource waste, and achieve the effects of obvious intrinsic coercive force, resource saving, and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Production of 48H products:

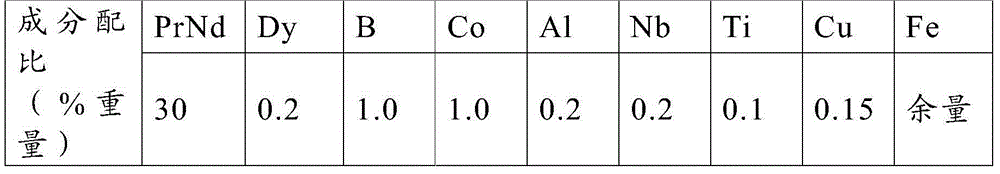

[0030] The composition ratio of the main phase alloy:

[0031]

[0032] S1. Put the ferrodysprosium hydride into the hydrogen crushing furnace for hydrogen crushing. After the ferrodysprosium has completely absorbed hydrogen, the temperature is raised to 550-600°C for dehydrogenation for 6-9 hours. 1-2μm heavy rare earth alloy powder, ready for use;

[0033] S2. Weigh the raw materials of the main phase alloy according to the above formula, mix them directly and put them into the vacuum quick-setting furnace. When the vacuum belt furnace is evacuated to 0.4Pa, start heating and melting. When the material in the furnace turns red, fill it with Argon, and heat up to 1450°C for smelting until the raw materials are completely melted, pouring after refining for 10 minutes, and when the flakes are lower than 80°C, the main phase alloy flakes are placed in the hydrogen crushing furnace, and then poured into the hydrogen crushing furnace Intro...

Embodiment 2

[0045] Production of 35UH products:

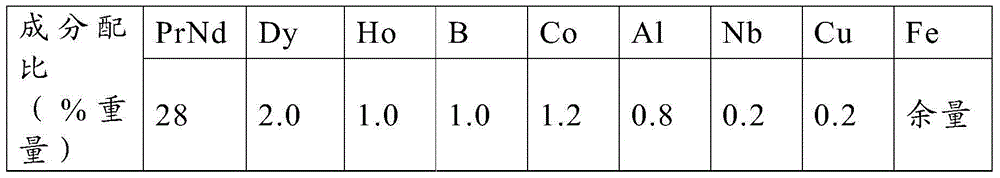

[0046] The composition ratio of the main phase alloy:

[0047]

[0048] S1. Put dysprosium ferrohydride and holmium ferrohydride into a hydrogen crushing furnace for hydrogen crushing. After the dysprosium ferrohydride has completely absorbed hydrogen, heat up to 550-600°C for dehydrogenation for 6-9 hours. After the dehydrogenation is complete, use a jet mill Make the heavy rare earth alloy powder with a particle size of 1-2 μm, and take the heavy rare earth alloy powder containing 0.5% dysprosium iron hydride and 0.5% holmium iron hydride for use;

[0049] S2. Weigh the raw materials of the main phase alloy according to the above formula, mix them directly and put them into the vacuum quick-setting furnace. When the vacuum belt furnace is evacuated to 0.4Pa, start heating and melting. When the material in the furnace turns red, fill it with Argon, and heat up to 1450°C for smelting until the raw materials are completely melted, pouri...

Embodiment 3

[0061] Production of 33EH products:

[0062] The composition ratio of the main phase alloy:

[0063]

[0064] S1. Put dysprosium ferrohydride and holmium ferrohydride into a hydrogen crushing furnace for hydrogen crushing. After the dysprosium ferrohydride completely absorbs hydrogen, raise the temperature to 550-600°C for dehydrogenation for 6-9 hours. Use jet mill after complete dehydrogenation Make a heavy rare earth alloy powder with a particle size of 1-2 μm, and take the heavy rare earth alloy powder containing 2.5% dysprosium iron hydride and 0.5% holmium iron hydride for use;

[0065] S2. Weigh the raw materials of the main phase alloy according to the above formula, mix them directly and put them into the vacuum quick-setting furnace. When the vacuum belt furnace is evacuated to 0.4Pa, start heating and melting. When the material in the furnace turns red, fill it with Argon, and heat up to 1470°C for smelting until the raw materials are completely melted, pouring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com