Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4109 results about "Neodymium iron boron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neodymium Iron Boron (NdFeB) Magnets. Neodymium Iron Boron magnets are a type of rare earth alloy that typically has two atoms of Neodymium (Nd), 14 atoms of Iron (Fe), and one atom of Boron (B) as its primary elements, hence their chemical composition Nd 2Fe 14B, which is commonly abbreviated as NdFeB.

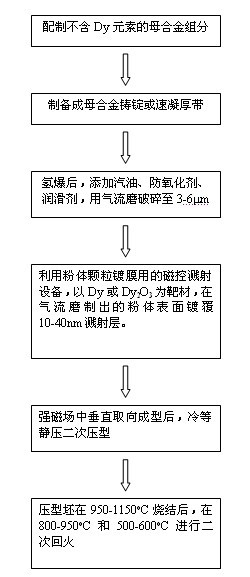

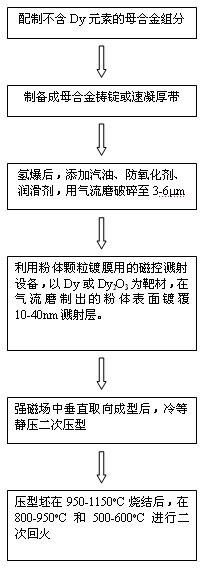

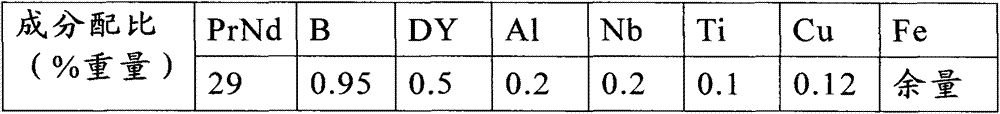

A preparation method of high-performance sintered NdFeB with low dysprosium content

The invention discloses a method for preparing sintered NdFeB with low dysprosium (Dy) content and high performance; the method comprises the following steps of: sputtering and plating the Dy element on the surface of jet mill powder by using the powder plate technology based on magnetron sputtering on the basis of preparing NdFeB powder, and then sufficiently dispersing the Dy element to micron-sized NdFeB crystal particles by dispersing the Dy element at high temperature in the sintering and tempering process, thereby achieving the effect of improving magnetic performance of the sintered NdFeB. Compared with the introduction of the Dy element in the proportioning process of the prior art, the method disclosed by the invention has the advantages: the low dysprosium content and high performance is limited in the nano-size by adopting the physical gas-phase deposition, the consumption quantity of the Dy element during the production process is controlled effectively and the preparationof sintered NdFeB with low dysprosium content and high performance is realized. Compared with the sintered NdFeB of the same components prepared by the traditional casting and powder metallurgy process, both the intrinsic coercivity and the maximum magnetic energy product of the sintered NdFeB rare-earth permanent magnetic material obtained according to the invention are improved obviously; compared with the sintered NdFeB with the same performance prepared by the traditional casting and powder metallurgy process, the dosage of the dysprosium element is reduced remarkably. The method can be widely applicable to producing and manufacturing sintered NdFeB with high performance.

Owner:NANJING UNIV OF SCI & TECH +1

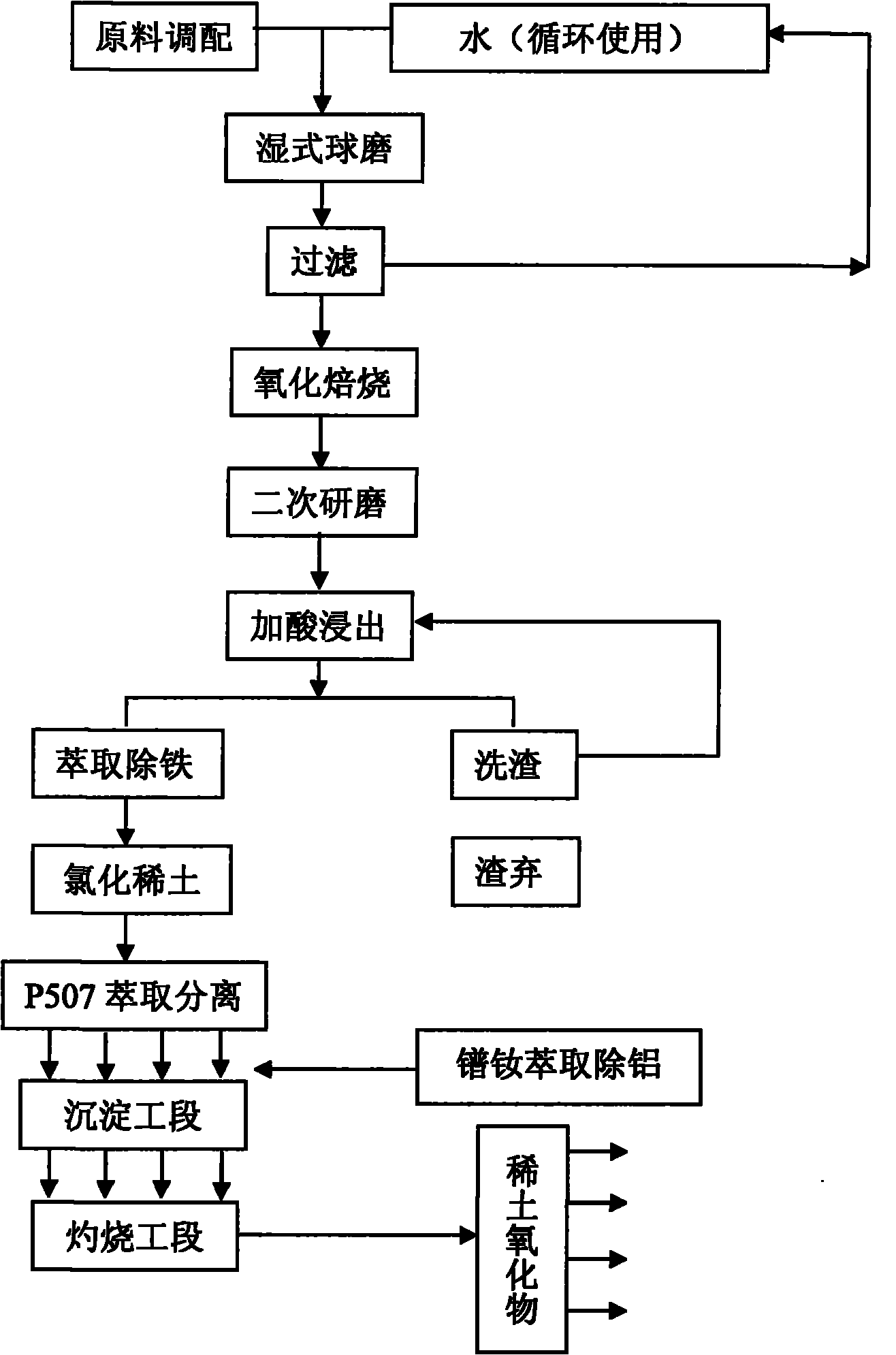

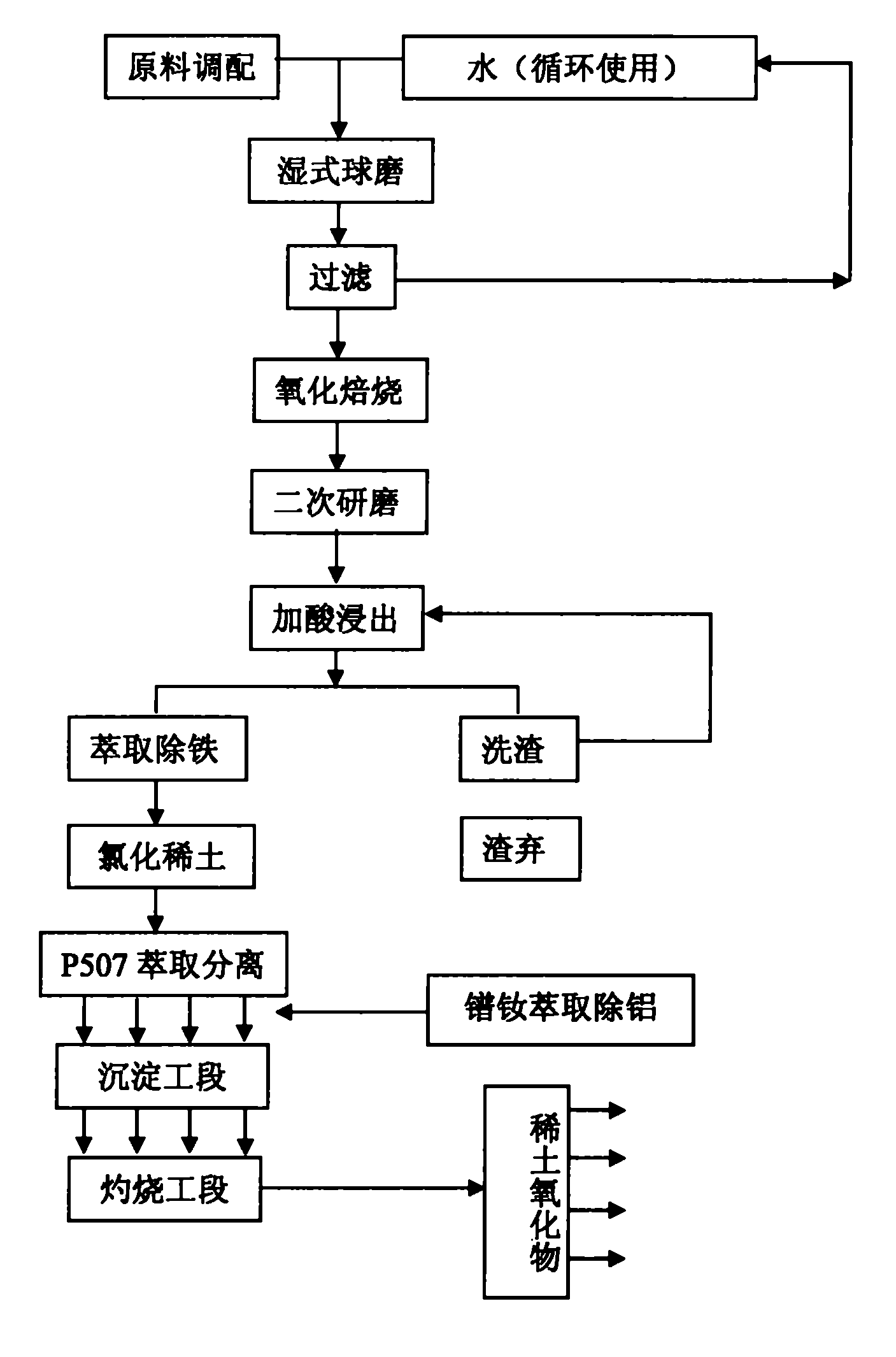

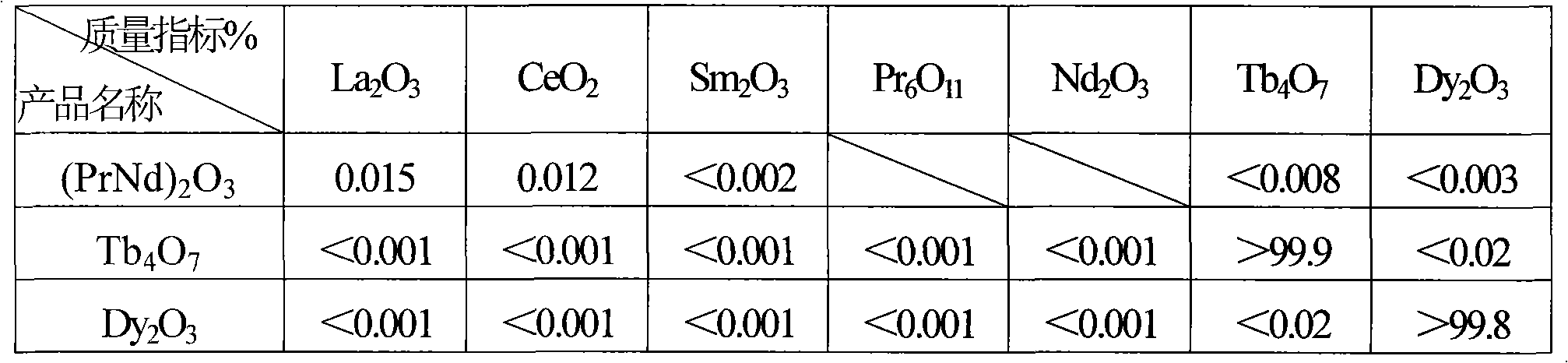

Method for recovering rare earth elements from neodymium-iron-boron wastes

InactiveCN102011020AHigh recovery rateImprove use valueProcess efficiency improvementMischmetalRare-earth element

The invention discloses a method for recovering rare earth elements from neodymium-iron-boron wastes, which comprises the steps of: mixing the neodymium-iron-boron wastes with water and then grinding; oxidizing the ground neodymium-iron-boron wastes; carrying out the secondary grinding for oxidation products; leaching by adding acid; separating solid from liquid; extracting to remove iron; chloridizing rare earth; separating the rare earth by extraction; extracting to remove aluminum; sedimenting; and firing. The method applied to recovery of the rare earth has the beneficial effects that the rare earth recovery rate is increased by 5-8%; the use value of the recovered rare earth is improved so that the production cost of further processing is reduced; the problem of puree fused salt in the electrolysis of single rare earth is solved, and the electrolytic efficiency of the rare earth metal during electrolysis is improved and energy consumption is effectively reduced; and the contents of non rare earth metals, such as C, S, O and the like are reduced.

Owner:BAOTOU XIJUN RARE EARTH

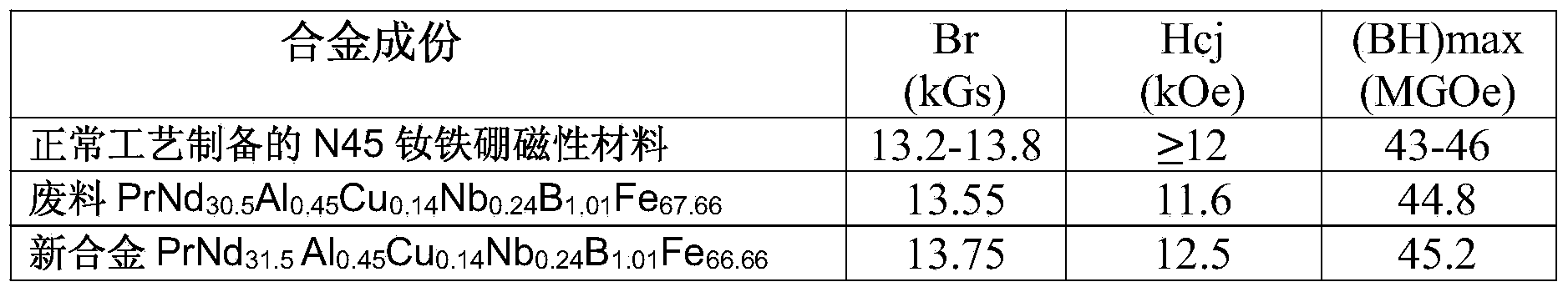

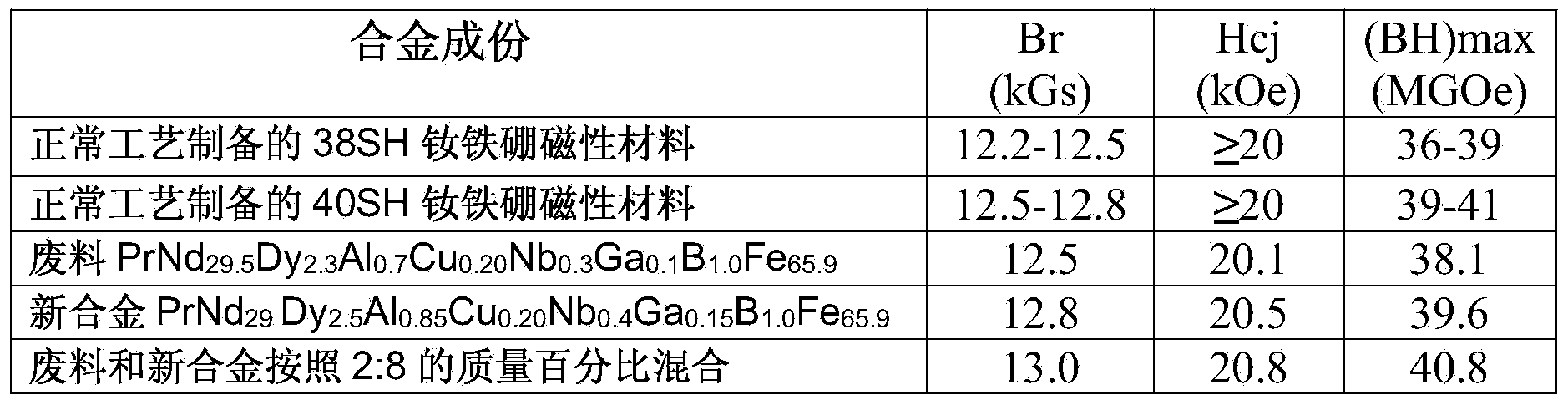

Method for preparing neodymium iron boron through regenerating waste material containing neodymium, iron and boron

ActiveCN103866127AFully absorb hydrogenImprove recycling ratesMagnetic materialsProcess efficiency improvementMetallurgyEconomic benefits

The invention provides a method for preparing neodymium iron boron through regenerating a waste material containing neodymium, iron and boron. The method comprises steps of (1) preprocessing the waste material; (2) correcting the components of the waste material; (3) crushing by hydrogen; (4) preparing into powder; (5) molding under a magnetic field; and (6) vacuum sintering. The method fully uses the waste material recycled in a production process, has high recovery rate of the waste material, can produce high performance product, has a simple and controllable flow, has high operability, uses no strong acid and strong base polluting the environment, is environment-friendly and energy-saving, and has high social and economic benefits.

Owner:CHINALCO JINYUAN RARE EARTH

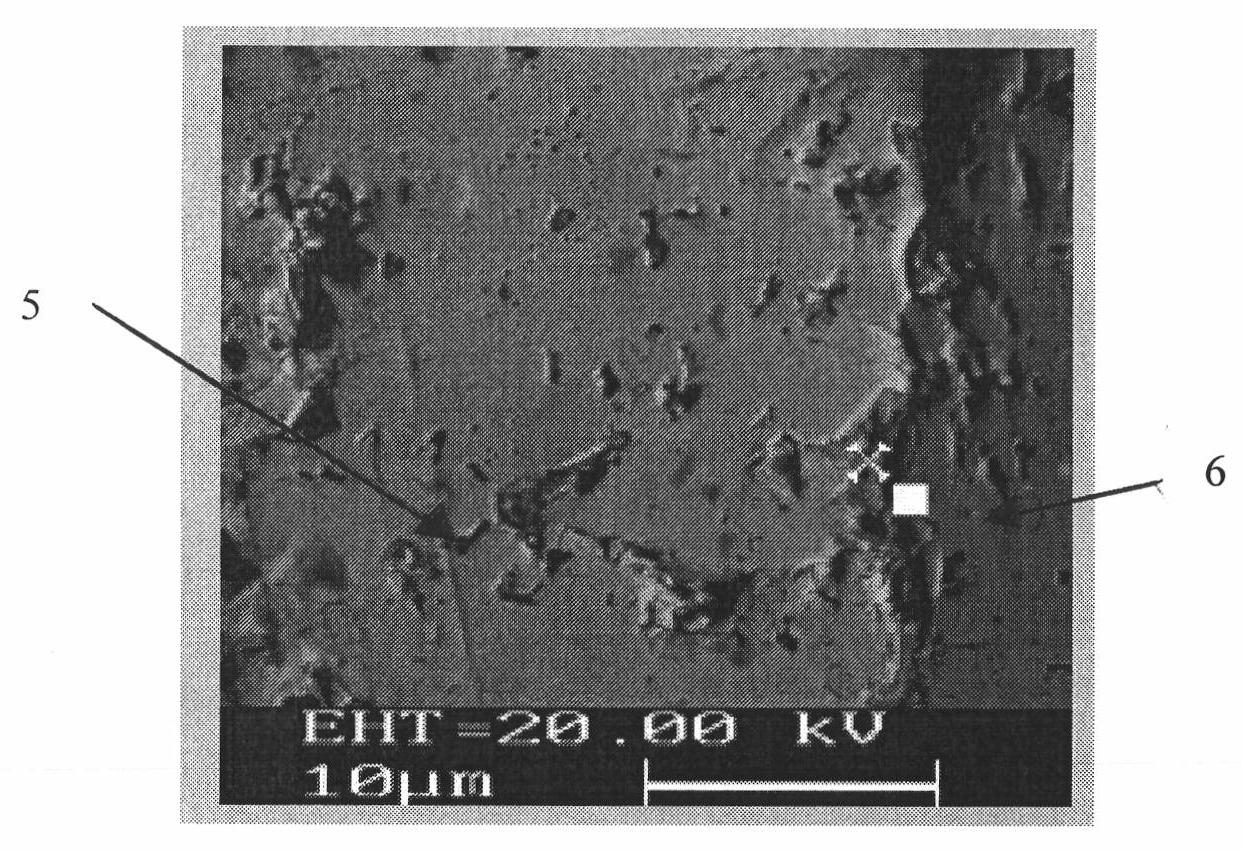

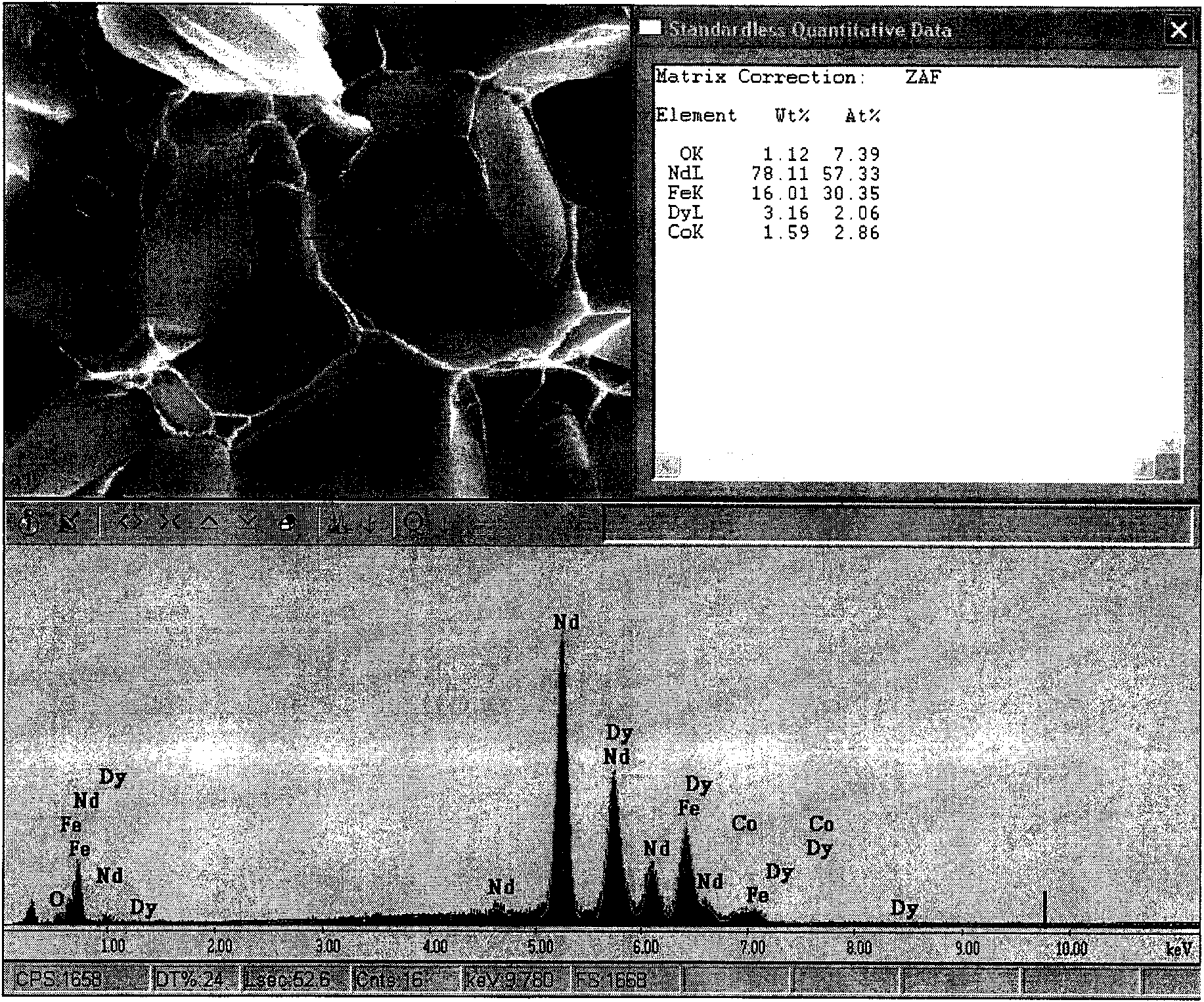

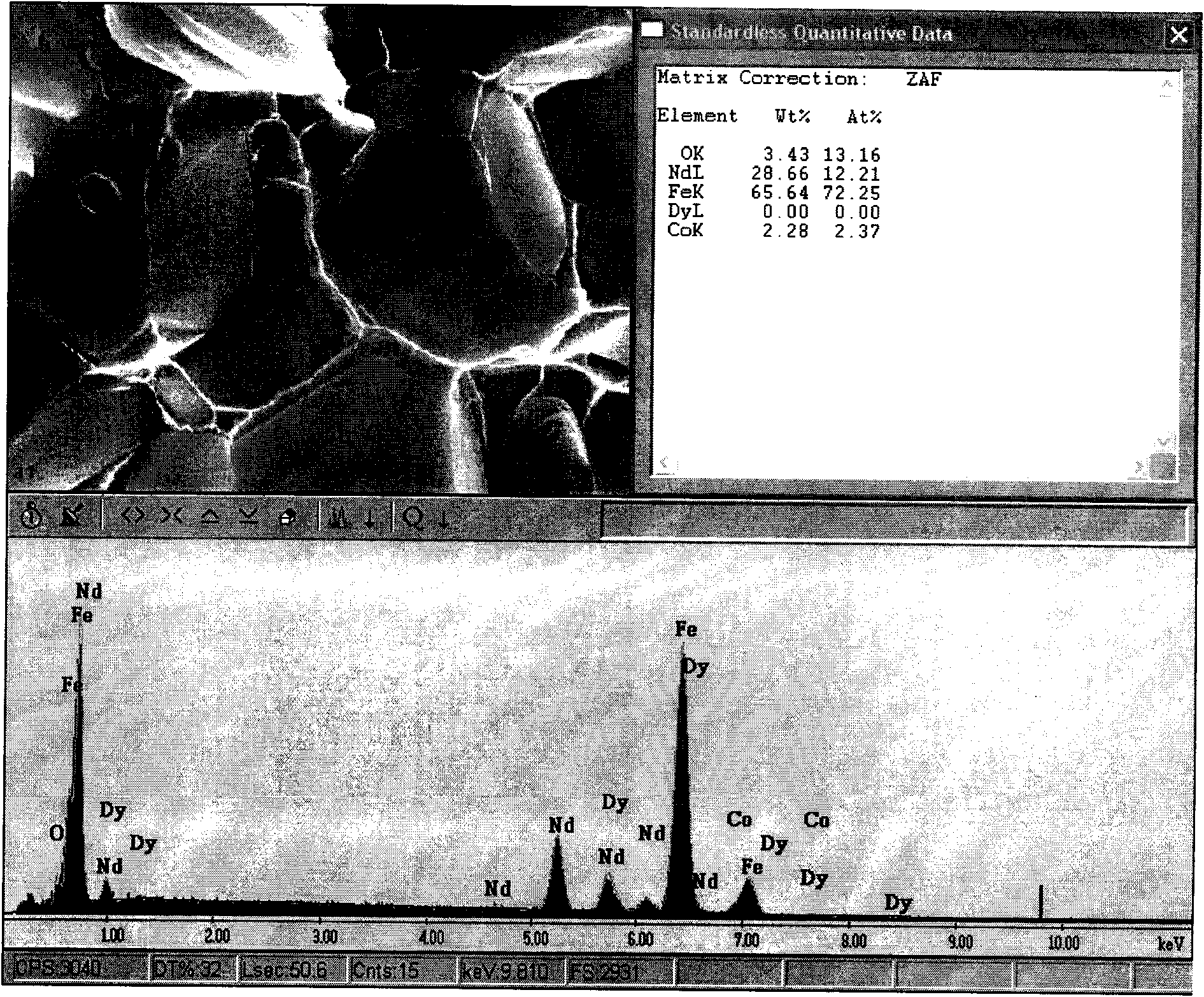

High-coercivity and high-stability neodymium iron boron magnet and preparation method based on crystal boundary reconstruction

ActiveCN103106991AImprove organizationImprove distributionPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementAlloy

The invention discloses a high-coercivity and high-stability neodymium iron boron magnet and a preparation method based on crystal boundary reconstruction. The preparation method comprises the steps of separating design and preparation of main alloy and crystal boundary phase alloy powder, nano-modification of crystal boundary phase, powder mixing, magnetic field profiling, isostatic pressing, sintering and thermal treatment. According to the high-coercivity and high-stability neodymium iron boron magnet and the preparation method is based on crystal boundary reconstruction and combines with a rich heavy rear earth novel crystal boundary phase and nano-modification technology, namely the rich heavy rare earth novel crystal boundary phase is redesigned and synthesized, in the process of magnetic sintering and tempering, magnetic hardening is achieved through spread of the heavy rare earth element to the boundary layers of the principle phase crystal grain, and thus a high-coercivity magnetic is prepared under the condition that no or less heavy rear earth is added in the principle phase. Meanwhile the distribution of the crystal boundary and the form of the crystal grain boundary are optimized through a nano-modification method, a pinning domain wall restrains counter magnetic field nucleation and crystal grain growth, and thus high coercivity and high stability of the neodymium iron boron is achieved. The high-coercivity and high-stability neodymium iron boron magnet and preparation method based on crystal boundary reconstruction is simple in process, low in cost and suitable for large-scale volume production.

Owner:ZHEJIANG UNIV

Water-based cutting fluid used for processing neodymium-iron-boron material slices and application method thereof

ActiveCN102311860AGuaranteed lubrication effectGuaranteed anti-rust performanceLubricant compositionSolubilityWater based

The invention discloses a water-based cutting fluid used for processing neodymium-iron-boron material slices and an application method thereof. The cutting fluid comprises the following components in parts by weight: organic amine, organic acid, water-soluble phosphate, polyether, antirust corrosion inhibitor, dispersing agent and surfactant, antiseptic bactericide, anti-hard-water agent, defoaming agent, auxiliary agent and water, wherein environmentally-friendly lubricating agent, extreme-pressure agent and antirust agent are reasonably matched in the cutting fluid disclosed by the invention, thus the lubricating property, extreme pressure property and antirust property of the cutting fluid are guaranteed; organic base, organic acid and special auxiliary agent are reasonably matched, thus the corrosion dissolution phenomenon of the cutting fluid to adhesive is greatly weakened; the dispersing agent and the surfactant are used for reducing surface tension of solution, thus permeability and settlement performance of the cutting fluid are enhanced; pH value of a final product is 7.5-8.5; and solubility of the cutting fluid to adhesive used for binding neodymium-iron-boron material in a processing cycle is extremely low, and the condition that product processing accuracy error is large or a tool is damaged as the adhesive is dissolved by the cutting fluid can not be caused.

Owner:AMER TECH CO LTD

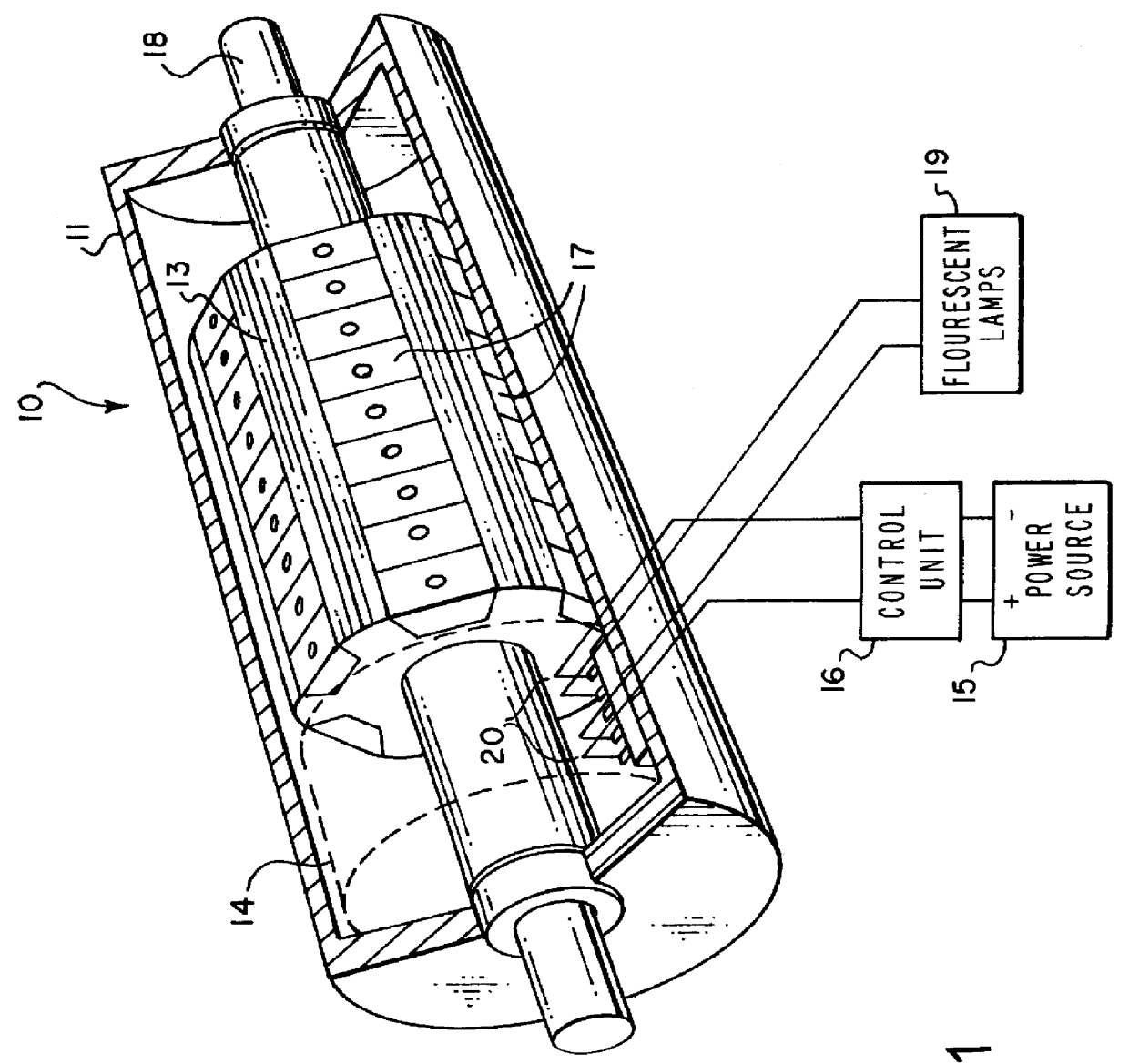

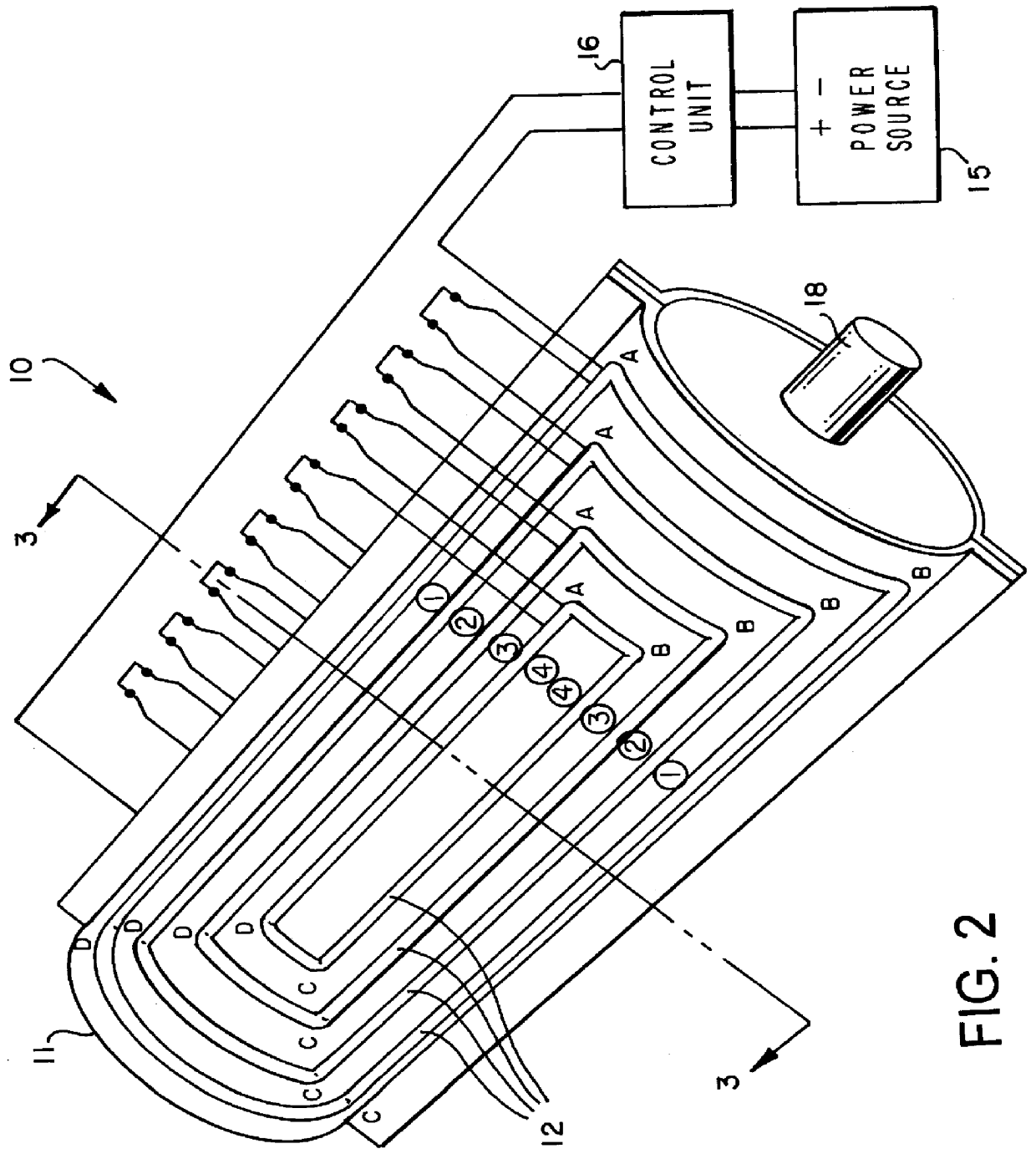

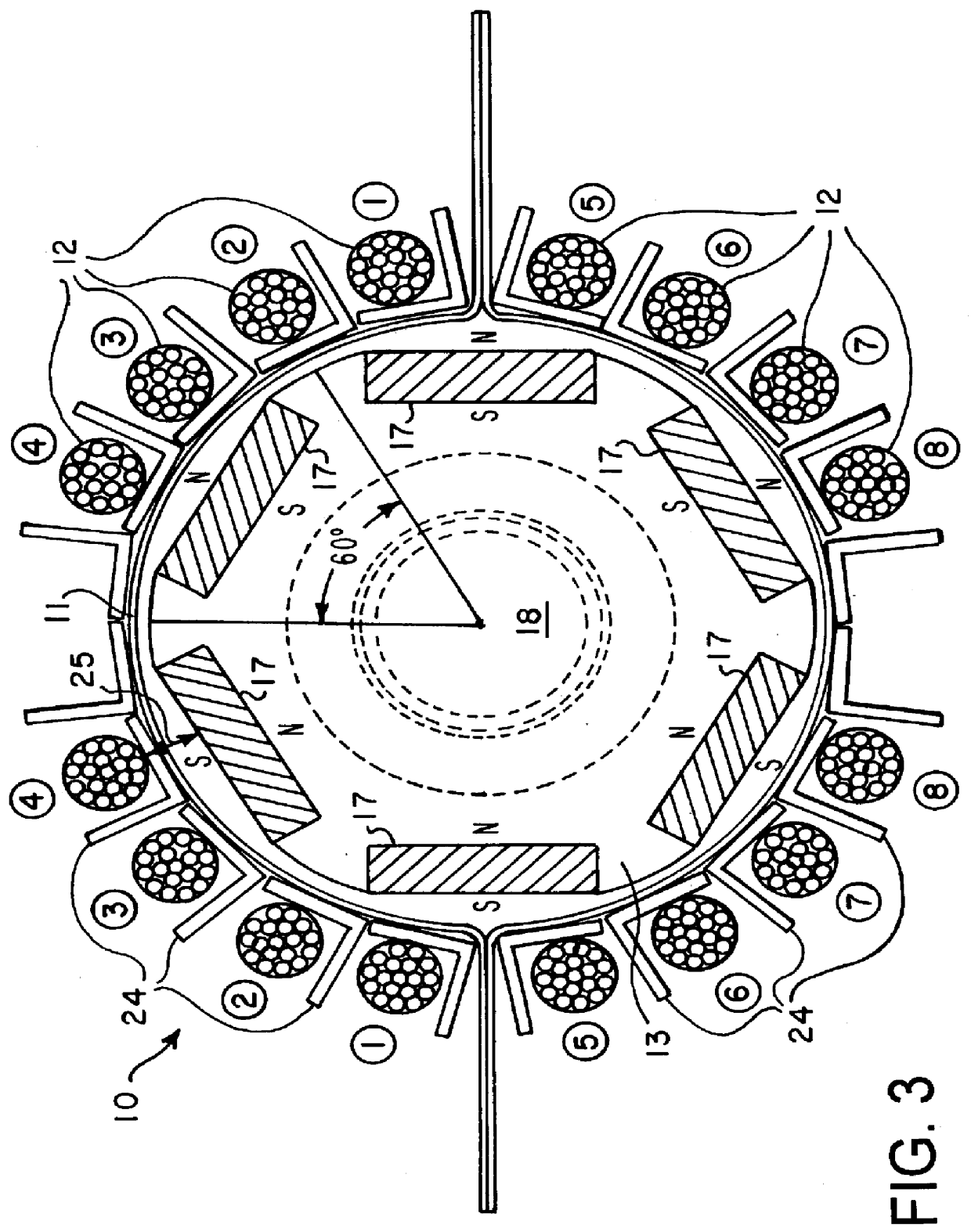

High efficiency electro-mechanical energy conversion device

An Electro-Mechanical Energy Conversion (EMEC) device and a method of electro-magnetically converting electrical energy to mechanical energy and electrical energy. The EMEC device comprises a stator; a rotor; a direct current power source; a commutator, and flourescent lamps acting as a non-linear, capacitive, voltage-limiting load. Four armature coils of a first magnetic polarity are concentrically mounted on a first side of the outer surface of a non-magnetic cylindrical stator casing, and four armature coils of an opposite polarity are concentrically mounted on an opposite side of the stator casing. Each coil is wound with an average of 6,650 turns of 34 AWG gauge teflon-coated wire. The rotor is constructed of non-magnetic material, and is rotationally mounted in the stator casing. A plurality of neodymium iron-boron permanent magnets are circumferentially mounted on the rotor. The magnets on a first side of the rotor are mounted with a first outward polarity, and the magnets on an opposite side of the rotor are mounted with an opposite outward polarity. The power source is connected to the coils and produces an output of 0-5,000 volts at 30 to 40 milliamperes maximum. The flourescent lamps are connected to the coils for rapidly dumping magnetic energy from the coils when the polarity is reversed. The commutator reverses the polarity of the first and second coils every 180 DEG of rotor rotation, and guides the magnetic energy from the coils to the load.

Owner:EMEC ENERGY L L C

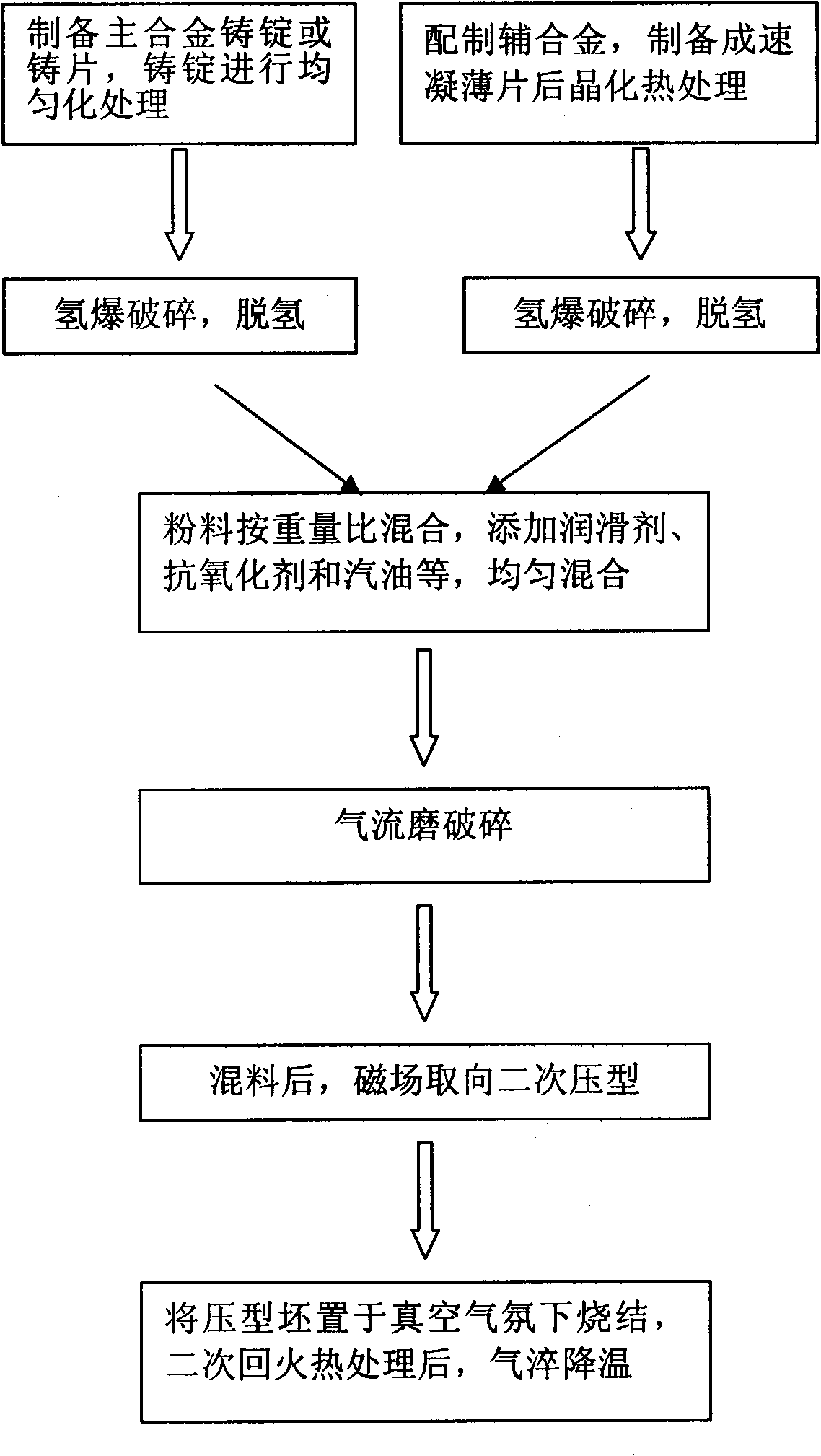

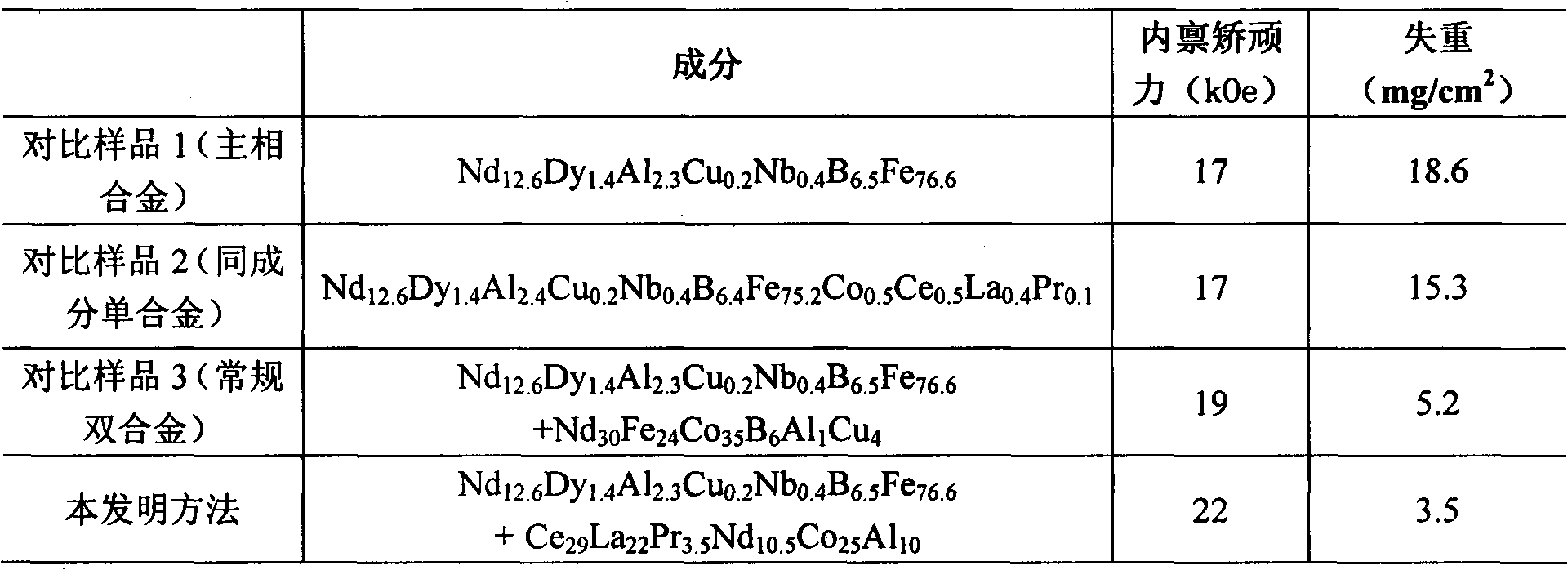

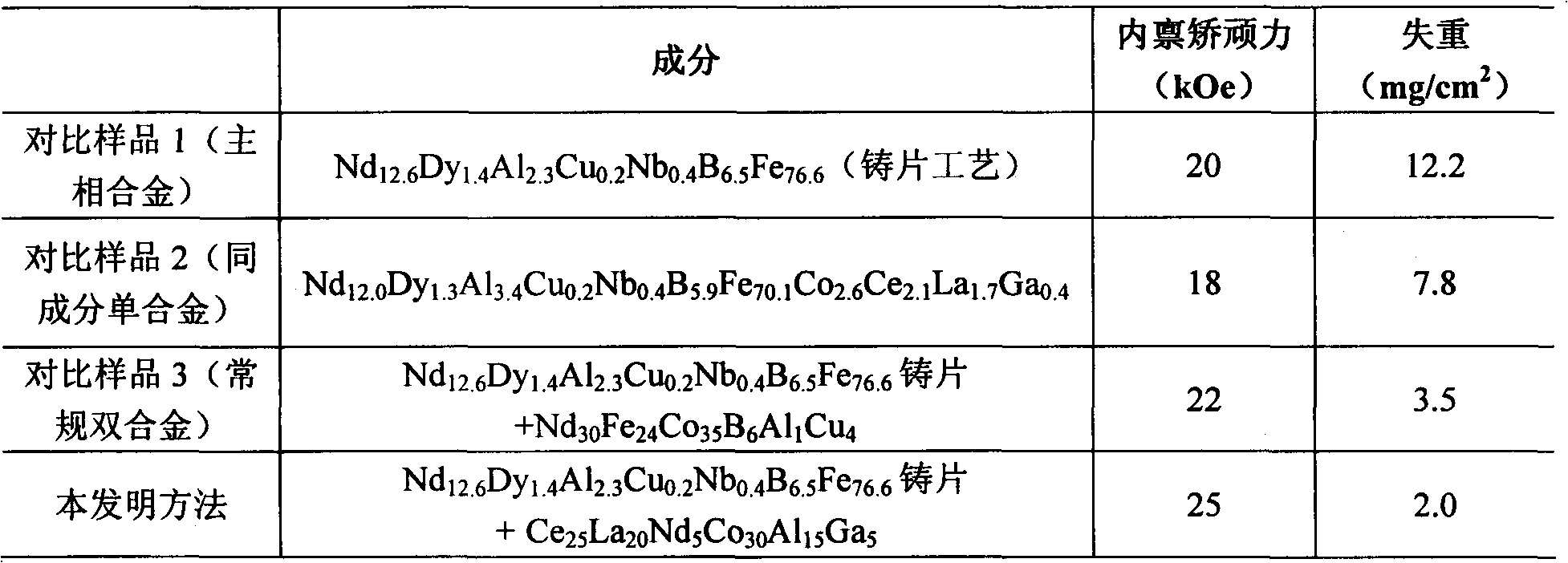

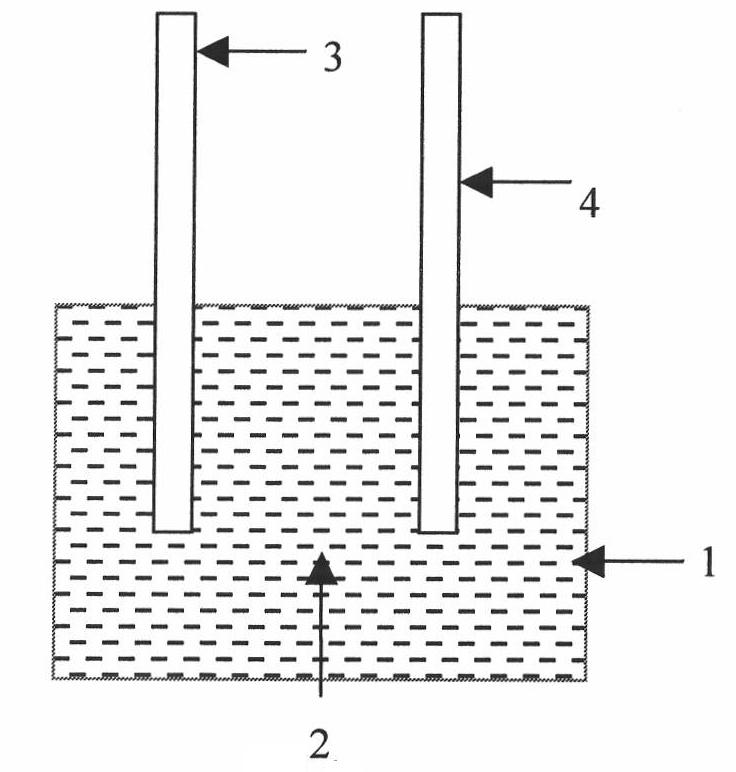

Sintered neodymium-iron-boron preparation method capable of improving intrinsic coercivity and anticorrosive performance

ActiveCN102220538ALow cooling rate requirementsEnhanced Amorphous Formation AbilityInorganic material magnetismAlloyGas quenching

The invention discloses a sintered neodymium-iron-boron preparation method capable of improving intrinsic coercivity and anticorrosive performance. On the basis of a double-alloy preparation process, Ce-enriched multicomponent rare-based alloy with high amorphous forming ability is used as an auxiliary alloy, and the decrystallizatoin of crystal boundary phase structure is realized by gas quenching cooling in a sintering tempering process. In the invention, the intrinsic coercivity is obviously improved, the anticorrosive weight loss is greatly reduced, the magnetic performance and anticorrosive performance are high, and the method can be widely used in the field of production of high-performance anticorrosive sintered neodymium-iron-boron material.

Owner:NANJING UNIV OF SCI & TECH +1

Method for grain boundary adulterated by oxide or nitride to improve the NdFeB permanent magnetic material performance

InactiveCN101055779AImprove magnetismIncrease working temperatureInductances/transformers/magnets manufactureMagnetic materialsRare earthGrain boundary

The invention relates to a method of a rare earth material technic field for adding an oxide in a grain boundary or increasing an Nd-Fe-B permanent magnetic material performance by a nitride, the method comprises: (1) preparing an Nd-Fe-B ingot casting alloy by an ingot casting process or preparing an Nd-Fe-B alloy rapid hardening thin sheet by a rapid hardening thin sheet process, (2) performing rough-cracking on the alloy and grinding the alloy to powder by an air flow; (3) adding oxide or nitride powder and evenly mixing; (4) directional press-forming the mixed power in a magnetic field, isostatic cool pressing a blank after being directional press-forming; (5) putting the blank into a high vacuum fritting furnace, producing a magnet by fritting and tempering. The Nd-Fe-B permanent magnetic material has a chemical formula of NdaFe100-a-b-cBbMc, atom percents are: 12<=a<=24, 5.5<=b<=7, 0<=c<=7; M is one or more of elements Dy, Tb, Co, Ga, Al, Cu. The fritted Nd-Fe-B prepared in the invention has better magnetic performance and corrosion resistance than the magnet produced without adding the oxide or the nitride.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of neodymium iron boron magnet

ActiveCN102103916AReduce usageUniformity controllableInductances/transformers/magnets manufactureMagnetic materialsRare earthImpurity

A preparation method of neodymium iron boron magnet is disclosed. The composition general formula of the magnet provided by the invention is R1R2FeMB, wherein R1 is at least one element selected from the group consisting of Nd, Pr, La, Ce, Sm, Sc, Y and Eu, having a content of 23 to 35 wt%; R2 is at least one element selected from the group consisting of Tb, Dy, Gd, and Ho, having a content of 0.1 to 5 wt%; M represents transition group metal with the exception of Fe, having the content of 0.01 to 5 wt%; B represents simple substance boron, having the content of 0.8 to 1.2 wt%; the balance isFe and the other inevitable impurities. The preparation method of neodymium iron boron magnet provided by the invention works in such a manner that: one or more elements in the R2 are plated to the surface of the magnet, the metal R2 is diffused into the interior of the magnet by primary high temperature heat treatment, and imbalance organization and internal stress brought by the high temperature treatment are eliminated through secondary low temperature tempering. Low temperature molten salt electrodeposition method is employed to plate films. The present invention is advantageous in greatly improving the production efficiency, reducing the dosage of the heavy rare earth during preparation process of magnet, saving rare earth resource, and obtaining high coercivity without reducing remanent magnetism and magnetic energy product of a magnet.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for preparing corrosion-resistant sintered neodymium iron boron (NdFeB) magnet

InactiveCN101958171AStrong resistance to electrochemical corrosionReduce weightlessnessInductances/transformers/magnets manufactureMagnetic materialsWeightlessnessRare earth

The invention discloses a method for preparing a corrosion-resistant sintered neodymium iron boron (NdFeB) magnet. In the method, an intergranular phase optimized design is used as a starting point on the basis of preparation technology of a double-alloy method, the high-cobalt content rare earth cobalt-based alloy which does not contain iron and boron is selected as an auxiliary alloy, and the melting point of the auxiliary alloy is ensured to be lower than 1,050 DEG C through component control so as to meet the liquid-phase sintering effect. By measuring the weightlessness condition of the material placed in an environment of the temperature of 120 DEG C, two atmosphere and 100 percent of humidity for 96 hours, results show that the weightlessness of the prepared sintered NdFeB magnet is only less than 1 / 3 of that of the sintered NdFeB magnet prepared by a single-alloy method and a conventional double-alloy method, and the sintered NdFeB magnet has excellent corrosion resistance. The method for preparing the corrosion-resistant sintered NdFeB magnet can be widely applied in the field of production of high-performance sintered NdFeB magnets.

Owner:WUXI NANLIGONG TECH DEV +2

Flexible binding neodymium ferroboron magnet and manufacturing method thereof

InactiveCN1624824AIncrease productivityLow costPolyureas/polyurethane adhesivesInorganic material magnetismMixed approachMagnetic powder

The invention relates to a flexible bond ndfeb magnet. It is uniformly in proportion mixed by the processed rubber binding agent, ndfeb magnetic powder, and processing agent. The mixture method is adopted banbury mixing, roll mixing, pudding process or screw milling. Then the uniformly mixed rubber material is formed to magnet with certain thickness by rolling and plate pressing. Its each composition weight content is that the ndfeb magnetic powder is from eighty seven percent to ninety seven percent; the modified rubber binding agent is from one percent to eight percent; the processing agent is from zero to five percent. The advantages are high production efficiency, low cost and flexibility and elasticity.

Owner:GUANGZHOU GOLDEN SOUTH MAGNETIC MATERIAL

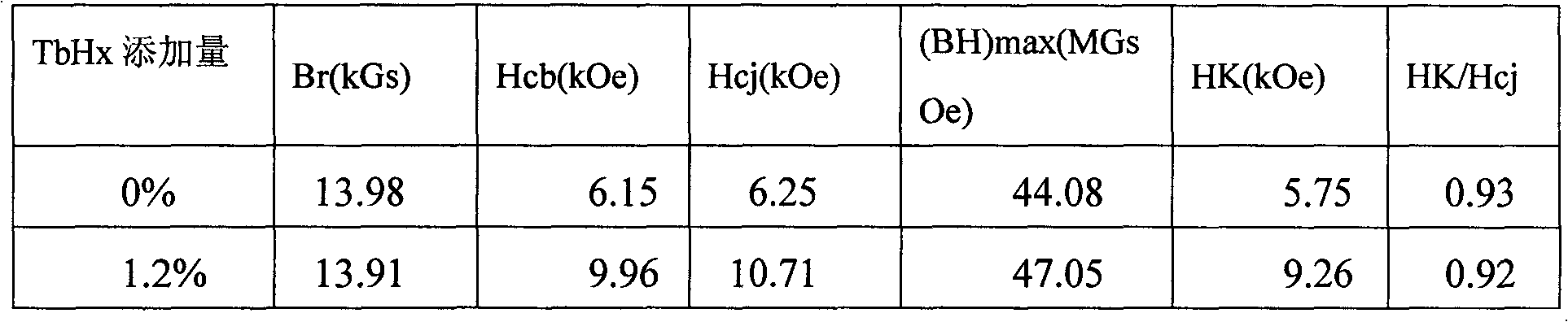

Method for improving coercive force of sintered neodymium ferrum boron (NdFeB)

ActiveCN101996721AEasily brokenTake advantage ofInorganic material magnetismInductances/transformers/magnets manufactureFully developedRare earth

The invention relates to a method for improving coercive force of sintered neodymium ferrum boron (NdFeB) by adding rare earth hydride in a grain boundary phase, which is characterized in that a rare earth or a rare earth mixed hydride is adopted as a grain boundary phase to be added into a NdFeB principal phase alloy to achieve the purpose of improving the coercive force of the sintered NdFeB. The invention provides a process for improving coercive force by adding less amount of rare earth hydride. According to the invention, the distribution of added elements in the grain boundary is controlled, the adverse effect of some alloy elements to the principle phase is avoided, and the improvement potential of the NdFeB magnet property is fully developed.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

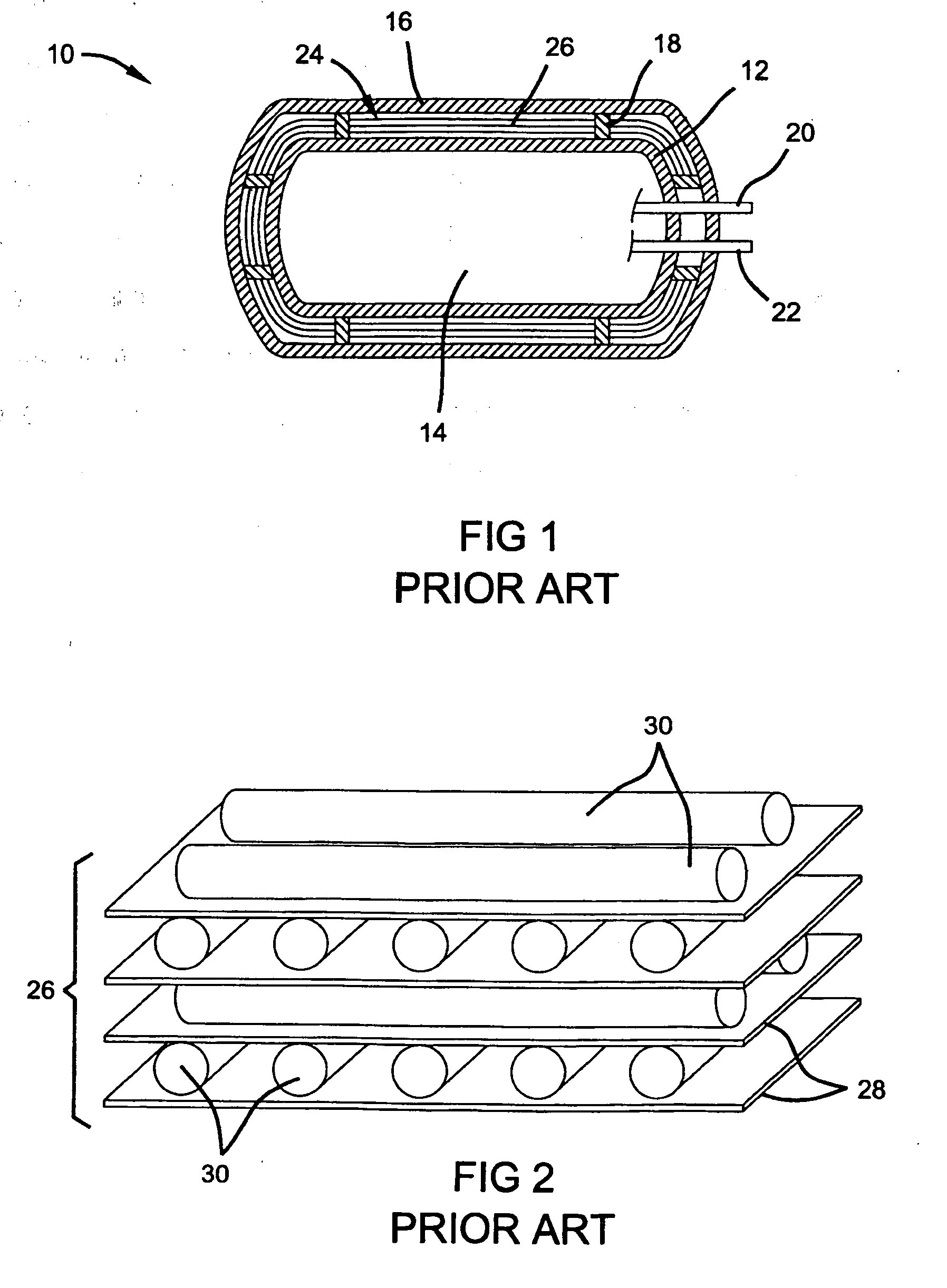

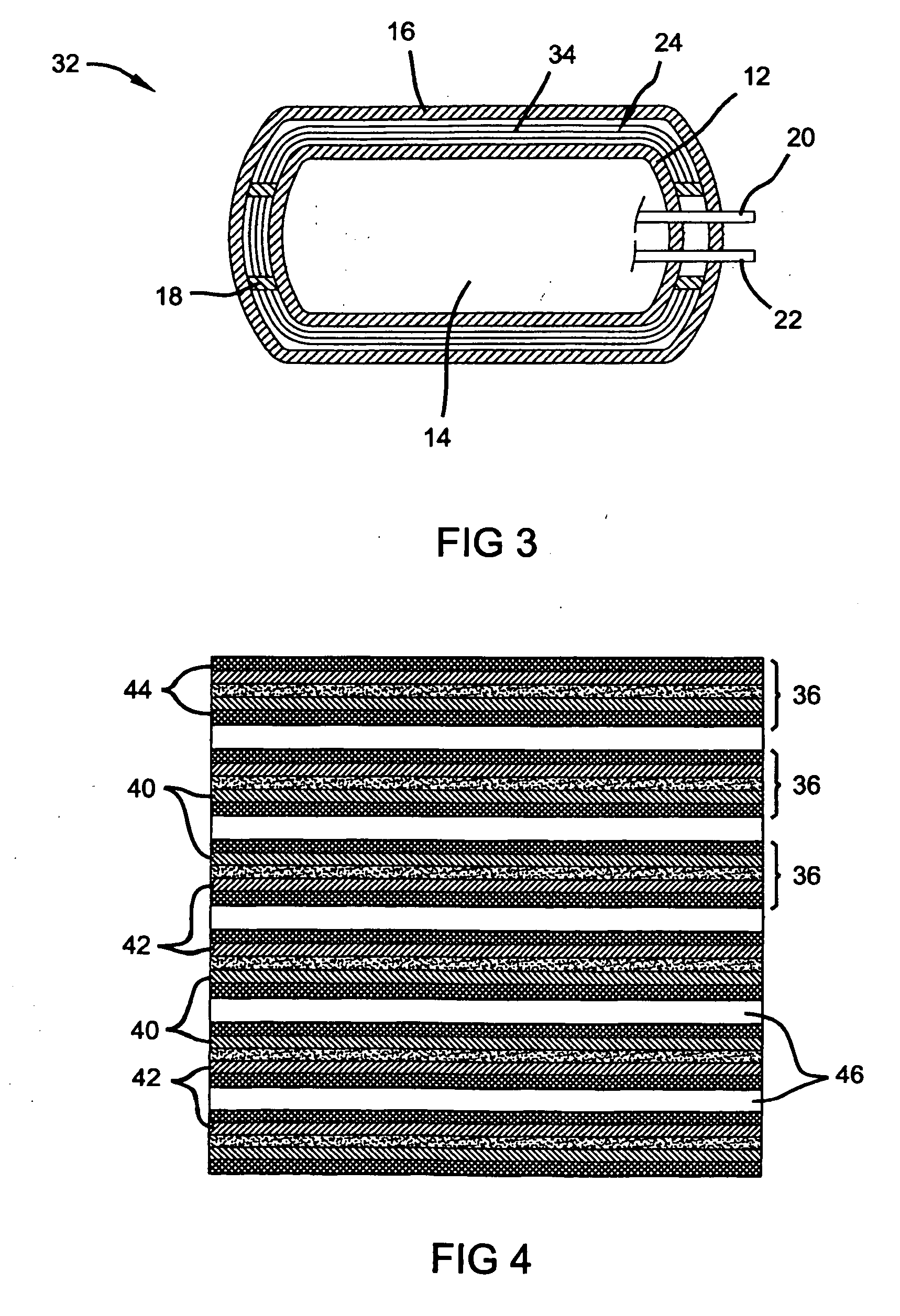

Insulation for cryogenic tanks

InactiveUS20060196876A1Domestic cooling apparatusLighting and heating apparatusMetal foilMagnetic poles

A magnetic multi-layer insulation system for a cryogenic storage tank. The system includes multiple layers of insulation comprising a carrier support structure disposed between a first major surface of a magnetic material defining a north pole facing away from the carrier support structure, and a second and opposite major surface of a magnetic material defining a south pole facing away from the carrier support structure. A reflective surface, or metal foil, is disposed adjacent the magnetic poles to deflect radiation. The layers are repelled from one another without the use of spacers. In various embodiments, the magnetic material is a permanent magnet selected from the group consisting of Samarium-Cobalt, Alnico, Neodymium-Iron-Boron, an alloy of the Lanthanide group of elements, and mixtures and alloys thereof.

Owner:GM GLOBAL TECH OPERATIONS LLC

Surface protection of neodymium iron boron permanent-magnet material

ActiveCN101029389AImprove bindingUniform surfaceMetallic material coating processesTectorial membraneBoron

A surface protection technology of neodymium-ferrous-boron permanent magnetic material is carried out by grinding for neodymium-ferrous-boron permanent magnetic material, degreasing while removing oil, removing rust while acid cleaning, activating acid liquid, putting it into black liquid or blue liquid, chemically coating and forming into blue-black or dark blue protection film. It has excellent combination and anti-corrosion performances.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

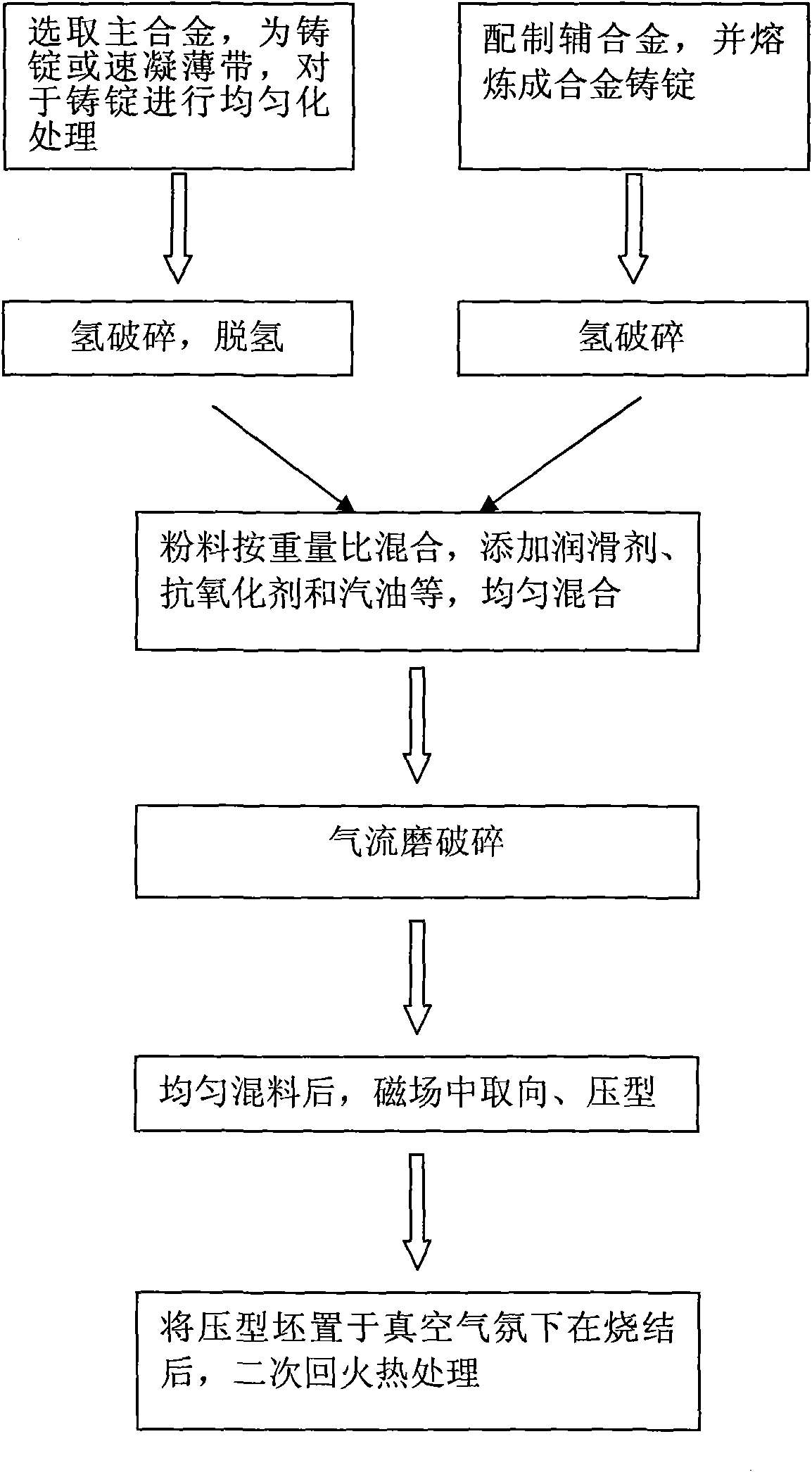

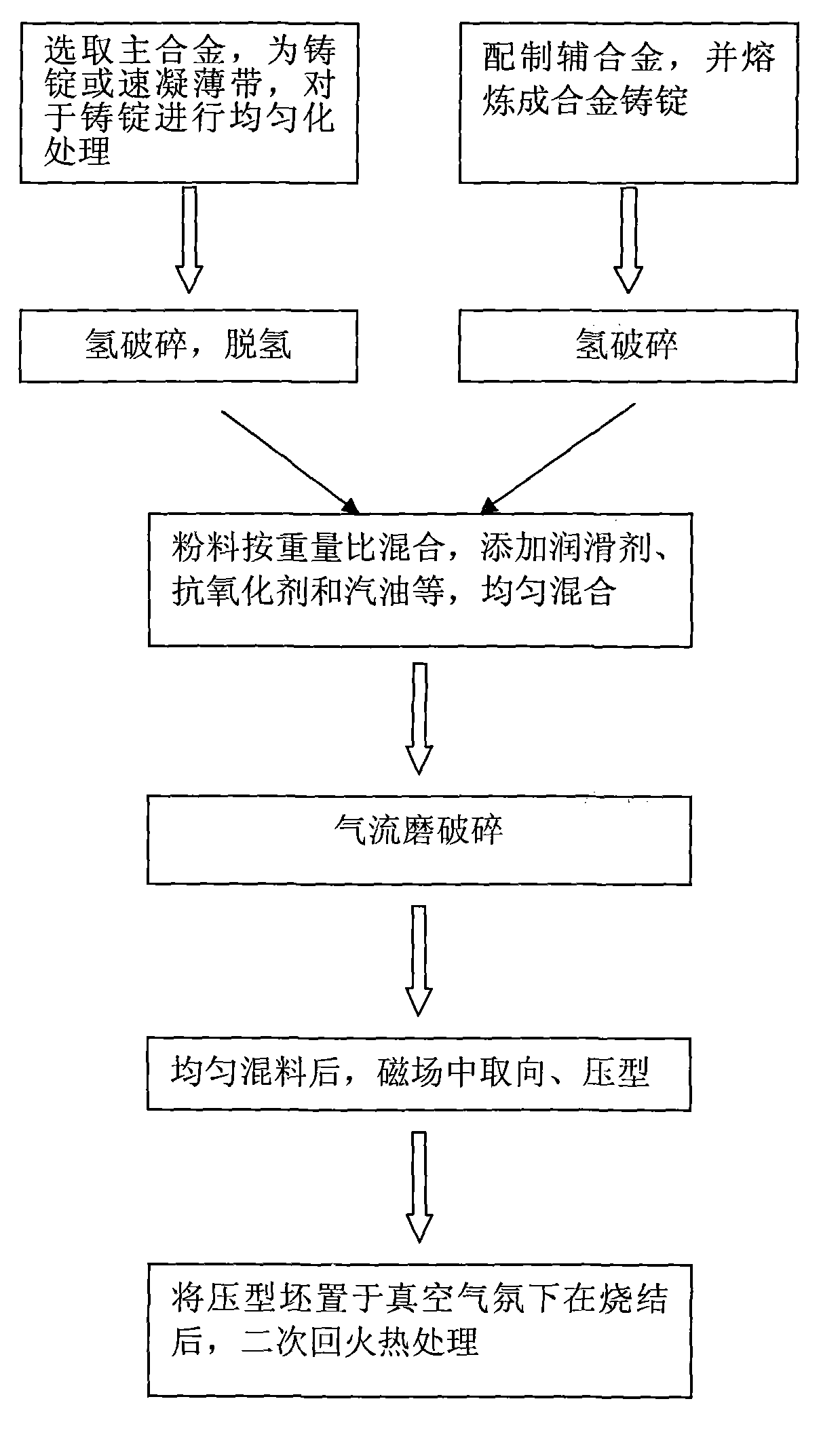

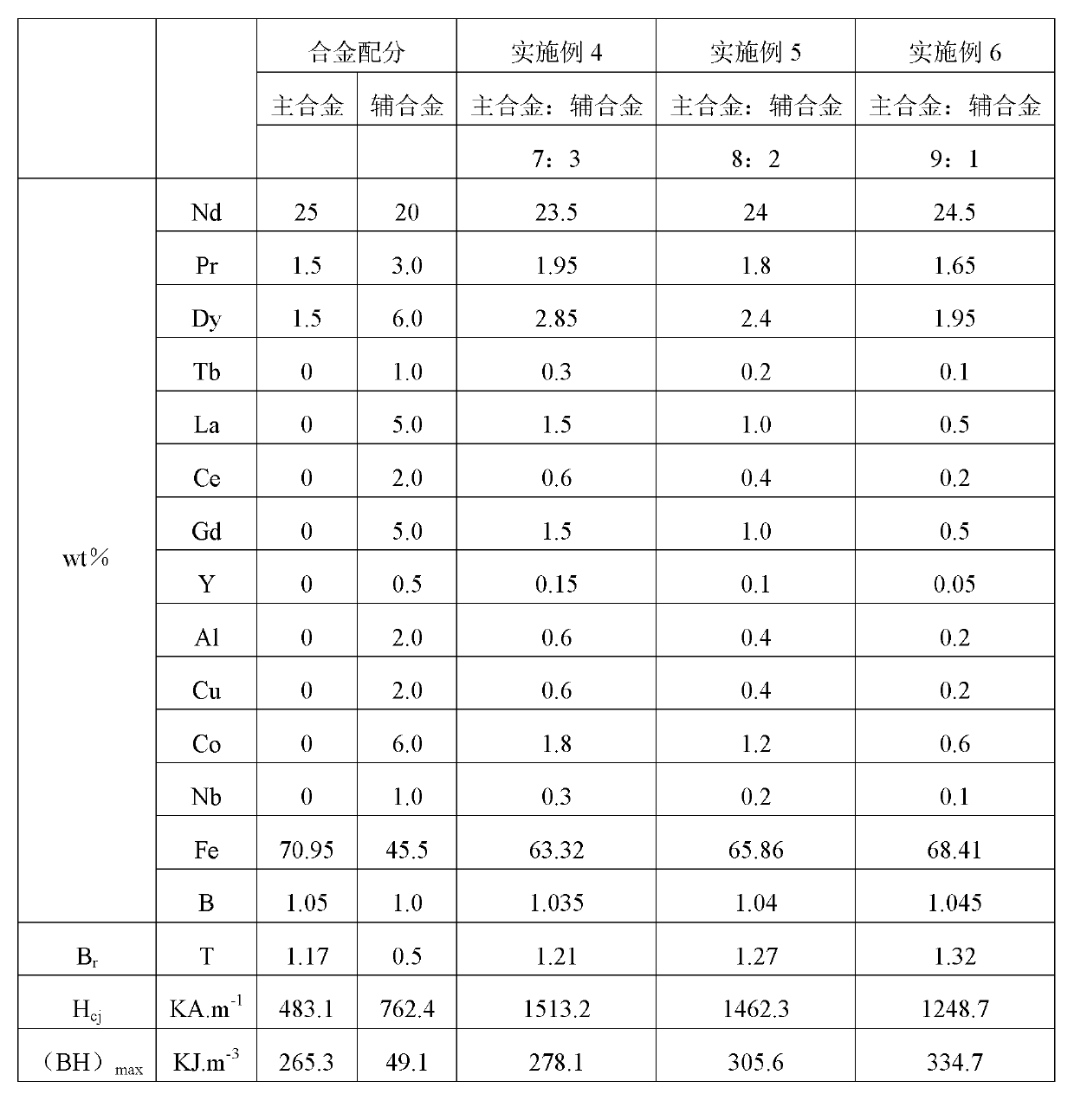

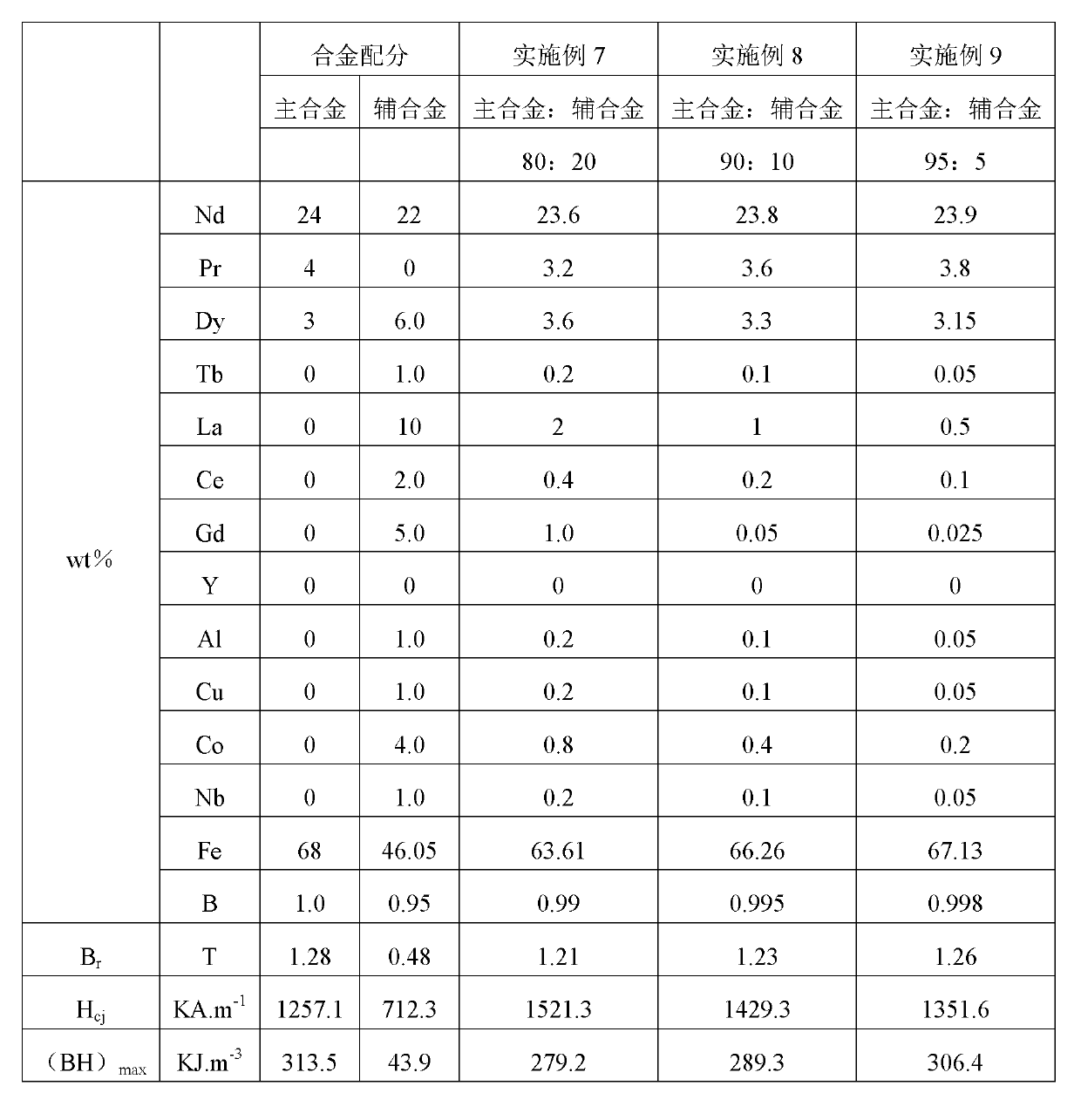

Method for preparing neodymium-iron-boron material through main-auxiliary alloy method

InactiveCN103103442AExpand the borderImprove coercive forceMagnetic materialsRare-earth elementAlloy

The invention relates to a method for preparing a neodymium-iron-boron permanent magnet material through a main-auxiliary alloy method. The method is characterized in that raw materials for preparing the neodymium-iron-boron permanent magnet material consists of a main alloy and an auxiliary alloy, wherein the main alloy comprises the component of RexFe(100-x-z)Bz, and Re is a rare earth element and contains at least one of Nd or Pr; the auxiliary alloy is ReaFe100-a-yMyBb, Re is one or more of La, Ce, Y, Dy, Pr and Gd, and M is one or more of addition elements including Al, Go, Cu, Nb and Ga; the main alloy is mixed in a ratio of u:(100-u), wherein u is a weight percentage and is more than or equal to 70 and less than 100; and the main alloy and the auxiliary alloy with corresponding components are prepared according to component requirements, and then a neodymium-iron-boron alloy is prepared through the steps of smelting, crushing, molding, sintering and tempering processes. The method has the advantages of reducing the material cost and improving the coercive force of a magnet on the premise that the magnetic performance of the neodymium-iron-boron permanent magnet material is not influenced.

Owner:BAOTOU RES INST OF RARE EARTHS

NdFeB magnet and preparation method thereof

ActiveCN104064346AReduce usageImprove intrinsic coercive forceInductances/transformers/magnets manufactureMagnetic materialsHolmiumGranularity

The invention relates to an NdFeB magnet and belongs to the technical field of rare earth magnetic materials. The NdFeB magnet is prepared by sintering a mixture of main phase alloy powder with the granularity of 2-5 <Mu>m, heavy rare earth alloy powder with the granularity of 1-2 <Mu>m and superfine powder with the granularity of 0.1-1.5 <Mu>m, which are mixed at the mass percents of 85-99.8, 0.1-10 and 0.1-5 respectively, the heavy rare earth alloy is one or more of dysprosium hydride and dysprosium-ferrum hydride compound, a holmium hydride and holmium-ferrum hydride compound and terbium hydride and terbium-ferrum hydride compound. The invention further provides a preparation method of the NdFeB magnet. According to the invention, 10-40 percent of heavy rare earth is saved, and the intrinsic coercive field of the NdFeB magnet is increased greatly without reducing the effect of residual magnetism.

Owner:宁波同创强磁材料有限公司

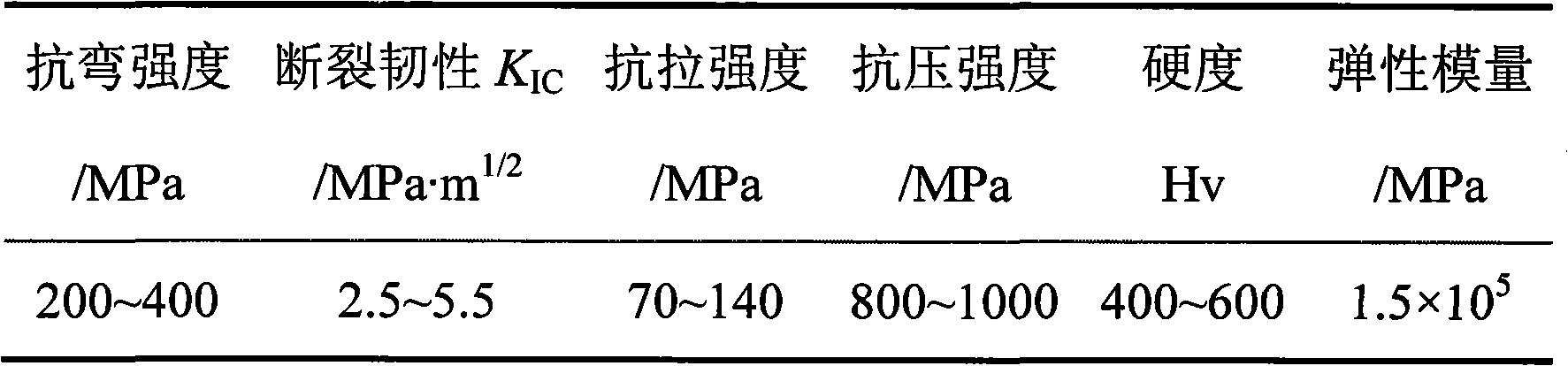

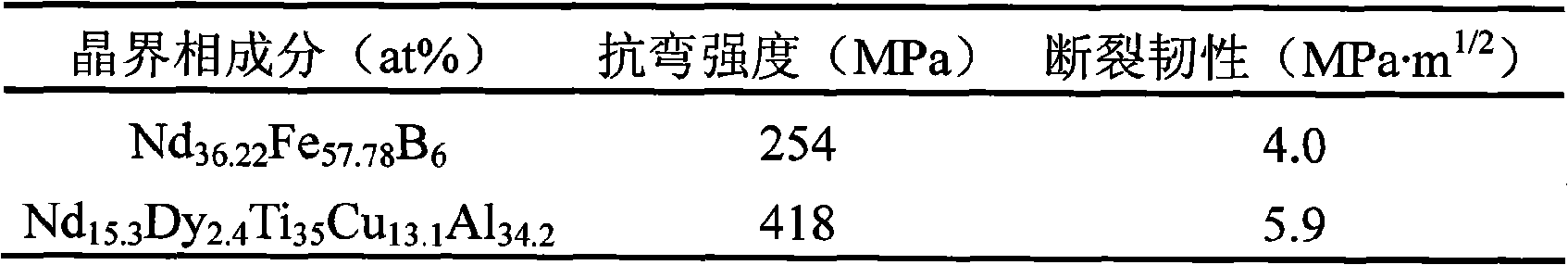

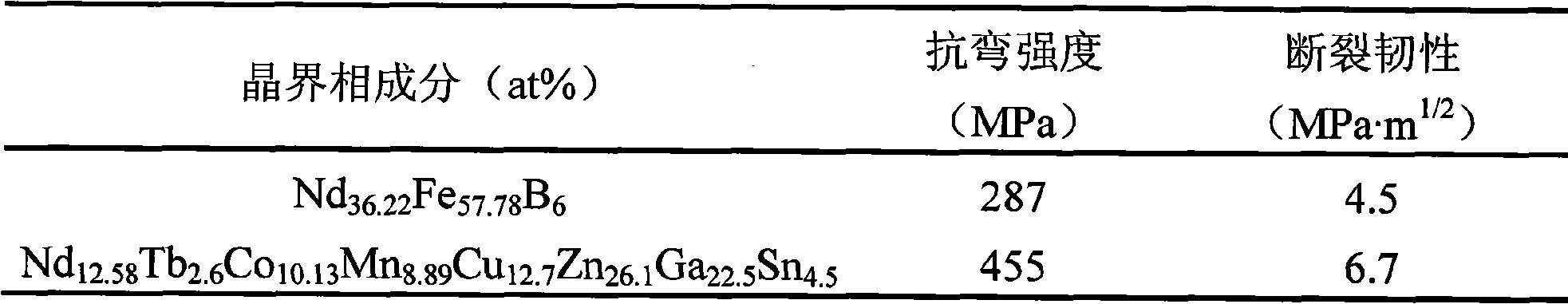

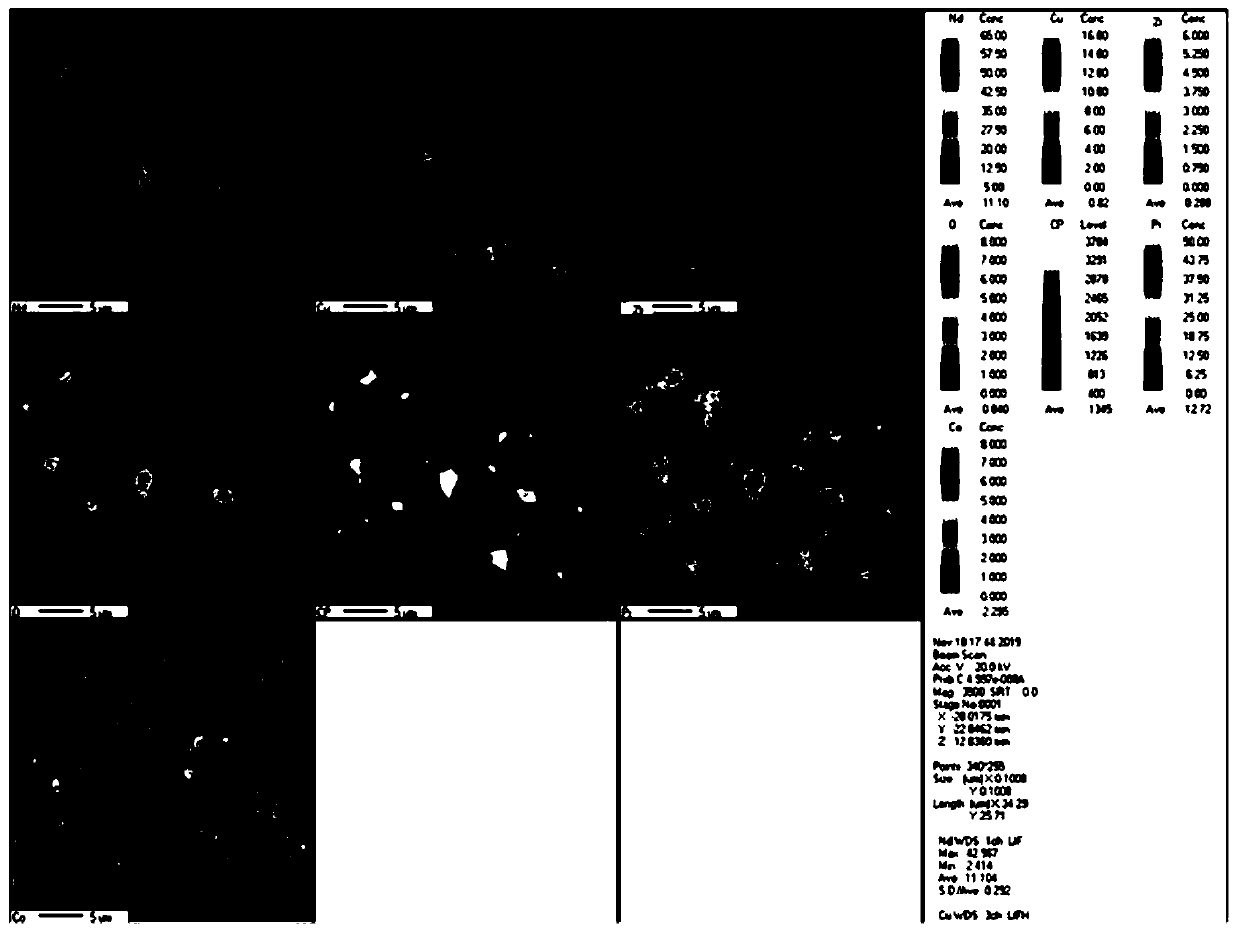

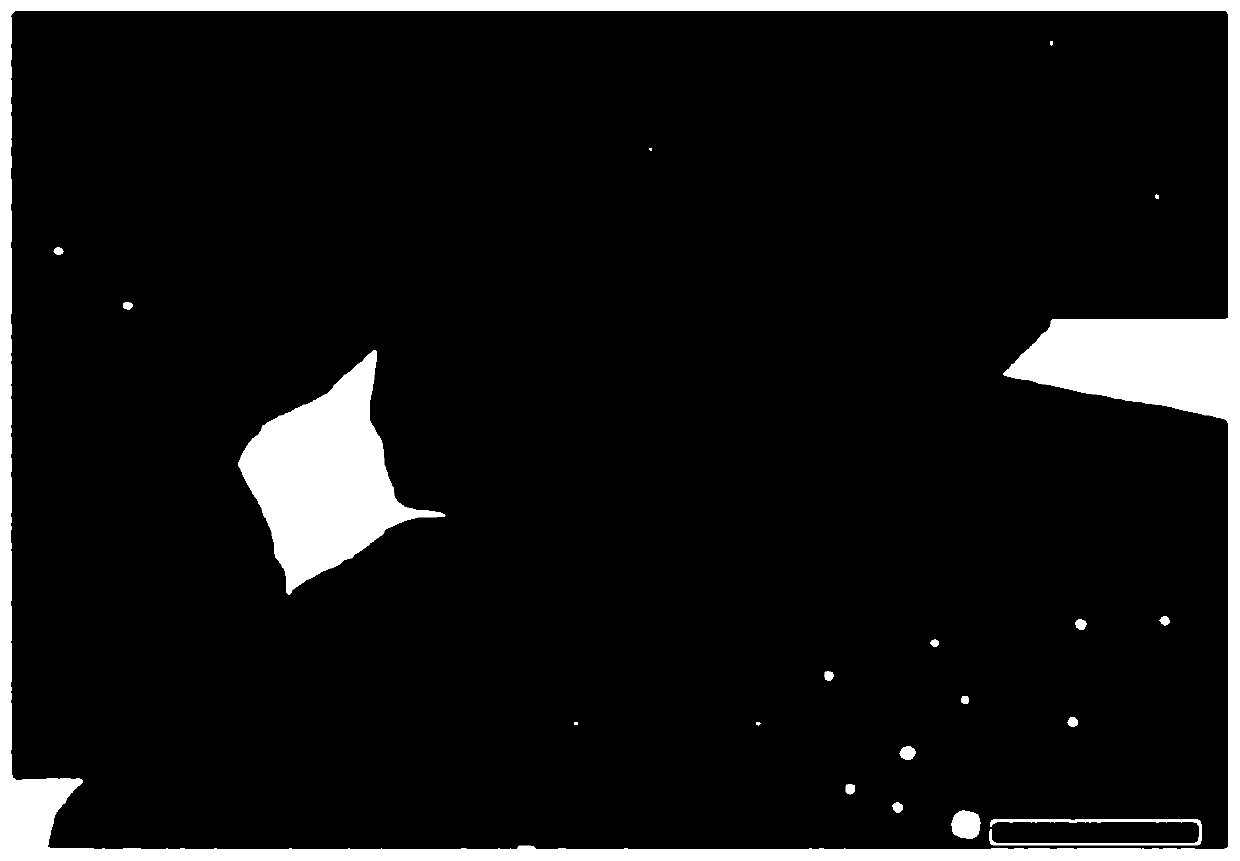

High-strength tenacity agglomeration neodymium-iron-boron magnet reconstructed by crystal boundary phase and preparation method thereof

InactiveCN101325109AImprove toughnessLow melting pointMagnetic materialsSintered magnetsGrain boundary

The invention discloses a high-obdurability Nd-Fe-B sintered magnet reconstructed by the grain boundary phase and the preparation method thereof. The Nd-Fe-B sintered magnet comprises the component of NdeFe100-e-f-gBfMg, wherein, e is more than or equal to 6 and less than or equal to 24, f is more than or equal to 5.3 and less than or equal to 6.4, and g is more than or equal to 0.01 and less than or equal to 6, and M is one or more elements of Dy, Tb, Pr, Sm, Ce, Yb, Co, Ni, Mn, Nb, Ta, Zr, Si, Ti, Mo, Ag, Au, Mg, Cu, Al, Zn, Ga, Bi, Sn and In; the preparation method comprises the following steps: main phase alloy and grain boundary phase alloy are respectively prepared into powder, and then the powder is intensively mixed; the mixed powder is pressed into the molded blank in the magnetic field; and the sintered magnet is obtained in a high-vacuum sintering oven. Through the restruction of the grain boundary phase component, the solution grain boundary phase alloy with low smelting point and high strength ductility is achieved, the obdurability of the grain boundary phase is enhanced on the basis that the magnetic property is guaranteed, thereby the high ductility of the magnet is enhanced, and the process is simple, the cost is low, and the magnet is suitable for the mass production, thereby the double-alloy method combined with the grain boundary restruction can be used for preparing the Nd-Fe-B sintered magnet with high obdurability.

Owner:ZHEJIANG UNIV +1

Treating method for improving performance of sintered NdFeB (neodymium iron boron) materials

InactiveCN104681225AInorganic material magnetismSolid state diffusion coatingAdditive ingredientHeat treated

The invention discloses a treating method for improving performance of sintered NdFeB (neodymium iron boron) materials and belongs to the field of sintered NdFeB (neodymium iron boron) magnet preparing. By means of post-changing of a microstructure and ingredients of a sintered NdFeB magnet, coercive force of the sintered NdFeB magnet is increased. The treating method includes the steps of forming a coating layer comprising one of or a combination of a variety of Dy, Tb, Ho, Al and Ga on the surface of the sintered NdFeB magnet, and heating the sintered NdFeB magnet up to the temperature lower than the sintering temperature of a base material of the magnet so as to perform tempering heat treatment. According to the treating method, one of or more of the Dy, the Tb, the Ho, the Al and the Ga in the coating layer are diffused to the crystal boundary position inside the base material of the magnet, so that the microstructure and partial ingredients of the magnet are improved, and the coercive force of the sintered NdFeB magnet is increased.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Neodymium-iron-boron permanent-magnet material and preparation method thereof

InactiveCN102903471ARemanence unchangedMagnetic energy product constantMagnetic materialsMetallurgyNeodymium iron boron

The invention provides a neodymium-iron-boron permanent-magnet material of which the composition is disclosed as the following formula: R1xR2yFe100-x-y-z-u-v-p-q-w-cCozBuGavNbpAlqMwOc, wherein R1 is selected from Pr and / or Nd; R2 contains Ho, contains at least one of Dy and Tb, and contains or does not contain Gd; 5wt%<=y<=12wt%; and M is selected from one or more of Zr, Cu, Sn, Mo, V, W, Si, Hf and Ti. The invention also provides a preparation method of the neodymium-iron-boron permanent-magnet material. The preparation method provided by the invention can lower the cost on the premise of keeping the magnetic properties of the neodymium-iron-boron permanent-magnet material basically unchanged.

Owner:BYD CO LTD

Neodymium-iron-boron magnet material and raw material composition thereof, and preparation method and application of neodymium-iron-boron magnet material

ActiveCN110828089AImprove remanenceImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMetallurgy

The invention discloses a neodymium-iron-boron magnet material and a raw material composition thereof, and a preparation method and application of a neodymium-iron-boron magnet material. The raw material composition of the neodymium-iron-boron magnet material is prepared from the following components in percentage by mass: 29.5-32% of R' which is a rare earth element and comprises Pr and Nd, wherein Pr>=17.15%; Cu being not less than 0.35%; 0.9-1.2% of B; and Fe: 64-69.2%, wherein the percentage refers to the mass percentage of the total mass of the raw material composition of the neodymium-iron-boron magnet material. According to the neodymium-iron-boron magnet material disclosed by the invention, the residual magnetism and the coercive force of the obtained neodymium-iron-boron magnet material are still relatively high under the condition that heavy rare earth elements are not added.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

Anisotropic nanocrystal complex-phase compact block neodymium-iron-boron permanent-magnet material and preparation method thereof

ActiveCN102496437AAchieving macroscopic anisotropyAchieve anisotropyInductances/transformers/magnets manufactureMagnetic materialsState of artMagnetic phase

The invention relates to an anisotropic nanocrystal complex-phase compact block neodymium-iron-boron permanent-magnet material which is characterized by comprising a nanocrystal-structure hard magnetic phase and a soft magnetic phase, wherein the hard magnetic phase is a (Nd,R)2Fe17B phase, and R is selected from at least one of La, Ce, Pr, Gd, Tb and Dy; and the soft magnetic phase is at least one of alpha-Fe alpha-FeCo or Fe3B. The invention also discloses a preparation method of the permanent-magnet material. Compared with the prior art, the permanent-magnet material has the following advantages: due to the introduction of the soft magnetic phase, the coercive force of the nano complex-phase magnet is far lower than that of the single hard magnetic phase magnet, and the liquid phase is diffused into the nano complex-phase magnet and positioned at the grain boundary, thereby obviously enhancing the coercive force of the magnet.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of particle-enhanced organic anticorrosive coating on surface of neodymium-iron-boron permanent magnet material

InactiveCN102443834AMagnetic has no effectExtended service lifeElectrophoretic coatingsEpoxyMicro nano

The invention relates to a preparation method of a particle-enhanced organic anticorrosive coating on the surface of a neodymium-iron-boron permanent magnet material, and specifically relates to a cathode electrophoresis coating method of the particle-enhanced organic anticorrosive coating on the surface of the neodymium-iron-boron permanent magnet material. According to the invention, first, the surface of the neodymium-iron-boron permanent magnet material is polished; the surface of the neodymium-iron-boron permanent magnet material is subject to degreasing, rust removing by acid cleaning, surface phosphorizing, cathode electrophoresis coating and high-temperature curing, such that a particle-enhanced organic matter coating is formed on the surface of the neodymium-iron-boron permanent magnet material. According to the coating provided by the invention, epoxy resin, acrylic acid and polyurethane are adopted as substrates; micro-nano titanium oxide particles, alumina particles, graphite particles, aluminum particles and the like are adopted as enhancing phases, such that a composite organic coating can be prepared. The coating causes no influence on the inherent magnetic performance of the magnet. The coating has a good bonding force with the magnet, and has a good caking property with bonding glue. The coating is also advantaged in uniform thickness, smooth surface, high corrosion resistance, and low preparation cost.

Owner:NANCHANG HANGKONG UNIVERSITY

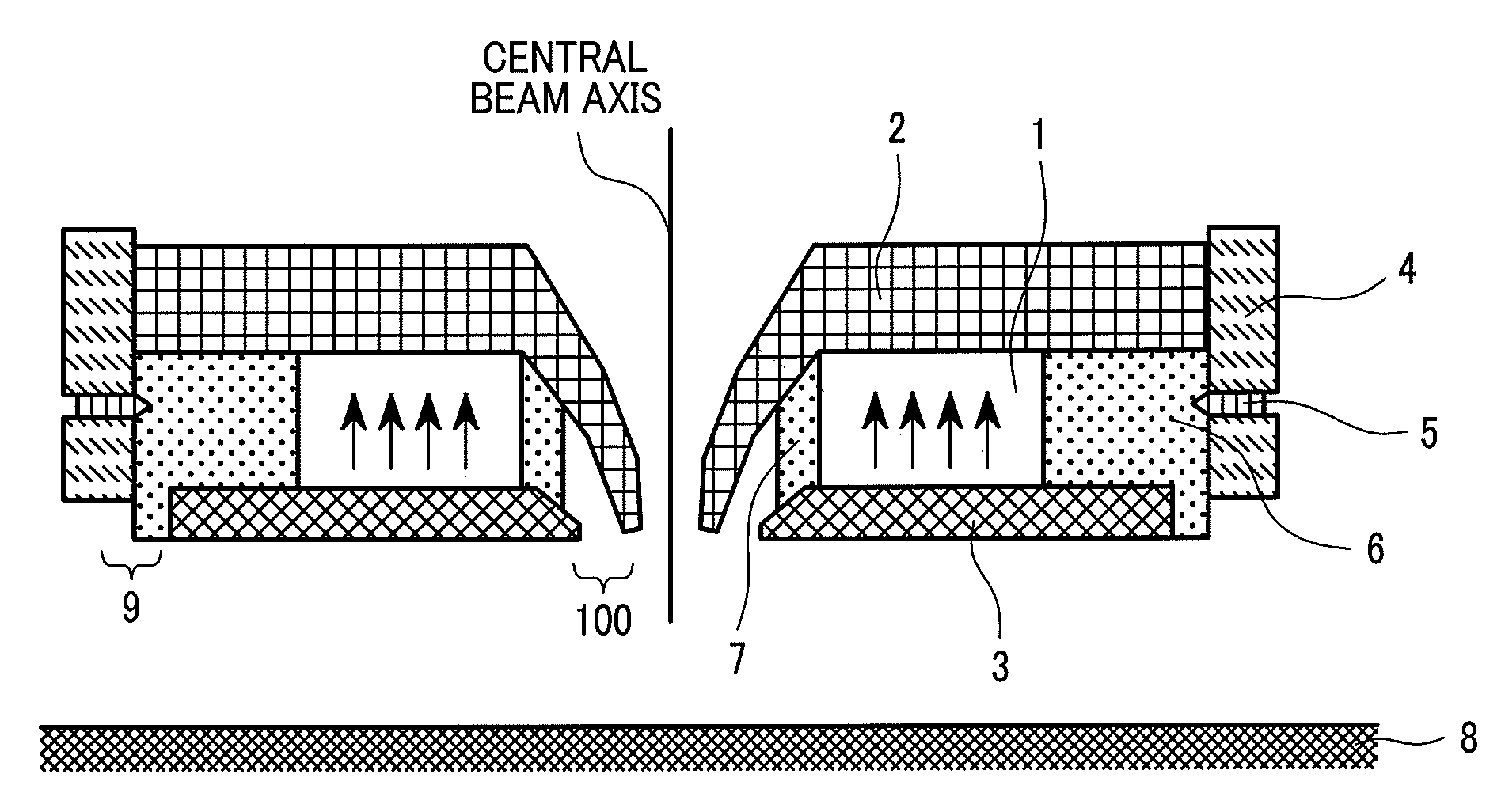

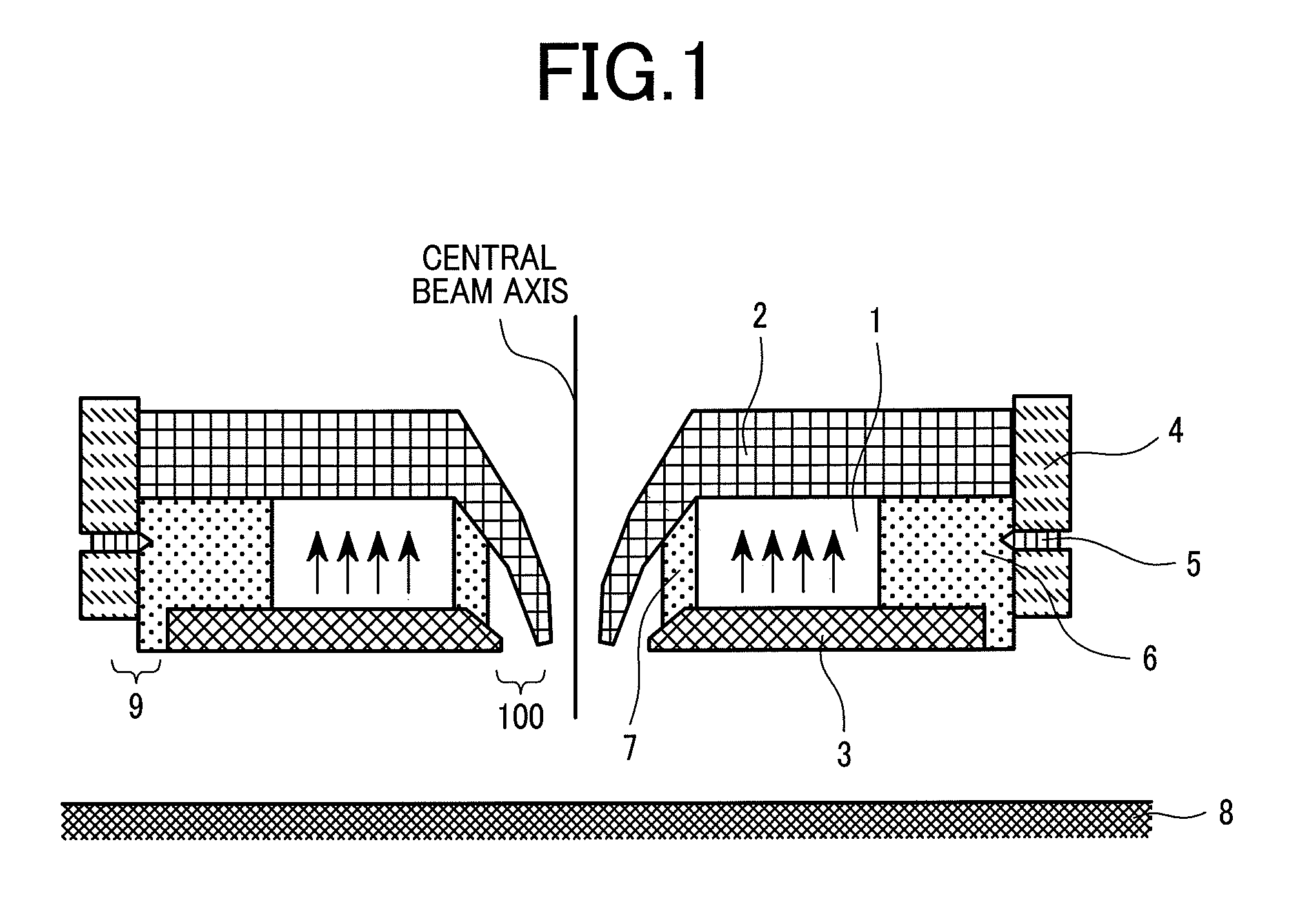

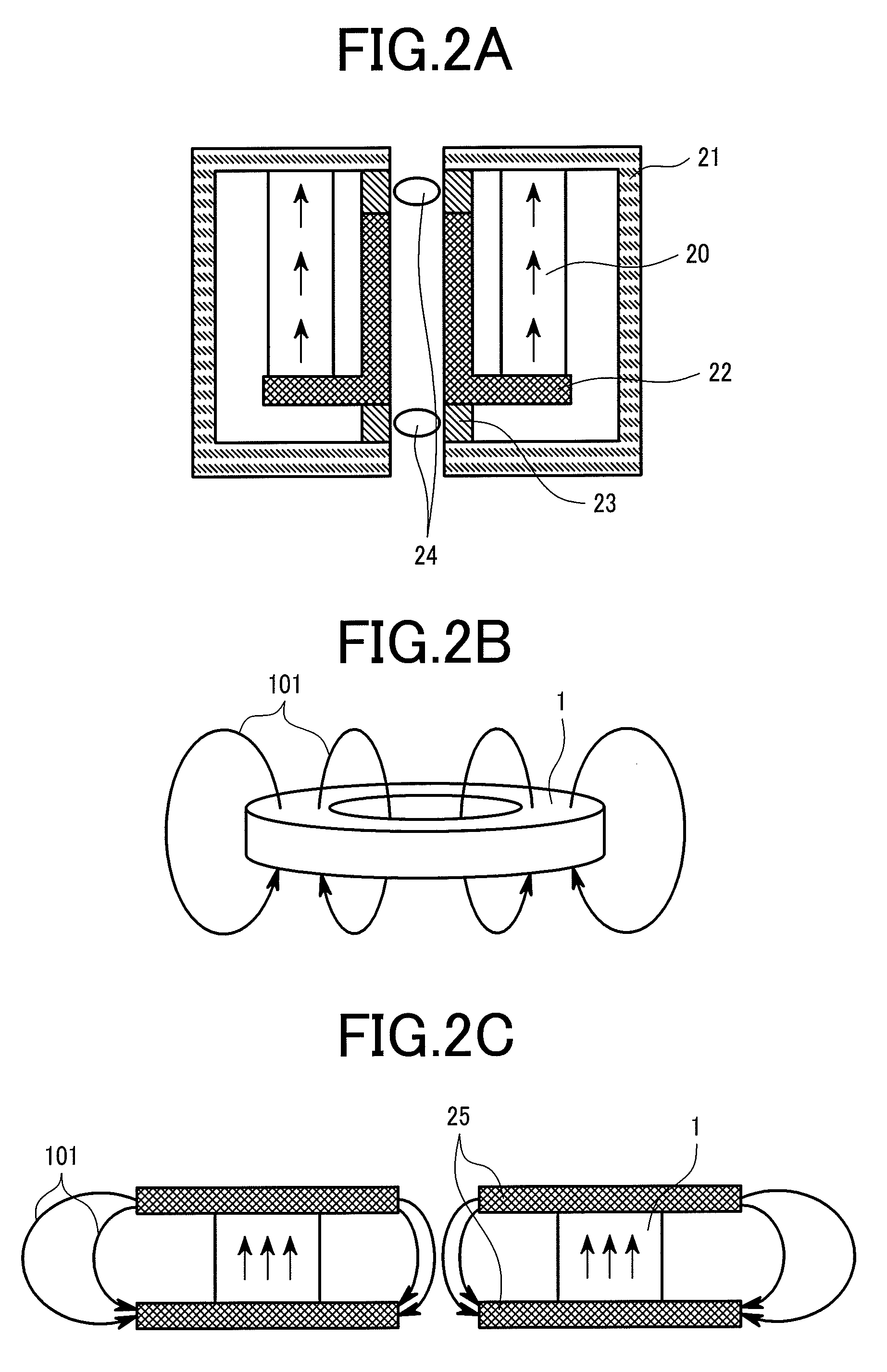

Electron Lens and Charged Particle Beam Apparatus

InactiveUS20080067396A1High resolutionSmall aberrationElectric discharge tubesMaterial analysis by optical meansRare earthMagnetic poles

The present invention provides a compact electron lens causing little aberration, and a charged particle beam apparatus such as a scanning electron microscope that is super compact and offers a high resolution. An upper magnetic pole and a sample-side magnetic pole are magnetically coupled to the respective poles of a permanent magnet that is made of a highly strong magnetic material such as a rare-earth cobalt system or a neodymium-iron-boron system, that is axially symmetrical, and that has a hole in the center thereof. An inner gap is created on the side of a center axis. Thus, a magnetic lens is formed axially. Moreover, a semi-stationary magnetic path that shields an outside magnetic field and has the magnetic reluctance thereof regulated is disposed outside. The sample-side magnetic pole and magnetic path defines a region where magnetic reluctance is the highest outside the permanent magnet. A space defined by the permanent magnet, upper magnetic pole, sample-die magnetic pole, and semi-stationary magnetic path is filled with a filling made of a non-magnetic material. Thus, an objective lens is constructed.

Owner:HITACHI HIGH-TECH CORP

Method for preparing high performance sintered neodymium-iron-boron air stream millby hydrogenation

InactiveCN101051544AImprove powder output efficiencyIncrease the coercive force of the magnetInorganic material magnetismNitrogen gasCrusher

The method includes steps: (1) using casting technique to produce ingot of Nd-Fe-B alloy, or using quick hardening technique to produce quick hardening slices; (2) using hydrogen explosion technique or crusher to crash alloy of ingot or quick hardening slices into coarse powder; (3) through airflow grinding machine to produce fine powder from coarse powder; and mixed compressed gas from nitrogen and hydrogen is adopted by the airflow grinding machine; (4) mixing fine powder, gasoline, and antioxidant evenly by blender so as to obtain mixed powder; (5) molded blanks are pressed from mixed powder under 1.2-2.0T magnetic field; (6) molded blanks are sintered inside high vacuum sintering furnace at deg.C 1050-1120 for 2-4h; and through temper of heat treatment 2-4h at deg.C 500-650 so as to produce sintered magnet. Comparing with traditional technique, the invention produces magnet with high coercive force, and fine powder in high efficiency, is suitable to batch production.

Owner:ZHEJIANG UNIV +1

High-performance neodymium-iron-boron magnet and preparation method thereof

ActiveCN103093914AImprove performanceIncrease profitPermanent magnetsInductances/transformers/magnets manufactureRare earthMixed materials

The invention discloses a high-performance neodymium-iron-boron magnet and a preparation method of the high-performance neodymium-iron-boron magnet. The high-performance neodymium-iron-boron magnet and the preparation method of the high-performance neodymium-iron-boron magnet solve the problems that an existing neodymium-iron-boron magnet is low in performance, low in waste material utilization rate and the like. The neodymium-iron-boron magnet is prepared by mixed materials composed of neodymium-iron-boron waste materials and rich rare earth alloy through sintering craft, mass percentage of the neodymium-iron-boron waste materials in the mixed materials is 70% to 99%, and the mass percentage of the rich rare earth alloy in the mixed materials is 1% to 30%. The performance of the neodymium-iron-boron magnet comprises: residual magnetism (Br) >=11.9 kGs, intrinsic coercivity (Hcjj) >=15 kOe, coercivity (Hcb) >=11.2 kOe, magnetic energy product ((BH) max) is from 34.8 MGOe to 48.0 MGOe, and rectangularity (HK / Hcj) is from 0.92 to 0.98. The preparation method of the high-performance neodymium-iron-boron magnet comprises: the neodymium-iron-boron waste materials are smelted; neodymium-iron-boron waste material powders are prepared; mixture is prepared; the neodymium-iron-boron magnet is molded; and the neodymium-iron-boron magnet is sintered. The neodymium-iron-boron magnet has the advantages of being high in performance, simple in preparation method and high in waste material utilization rate.

Owner:宁波同创强磁材料有限公司

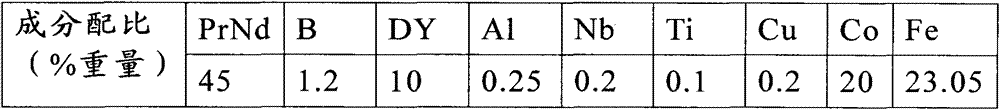

Sintered neodymium-iron-boron magnethigh cost performance and high corrosion resistancepreparation method thereof

InactiveCN101740190AMake up for the loss of magnetic propertiesImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureHydrogenRare earth

The invention relates a neodymium-iron-boron magnetpreparation method thereof, and belongs to the field of rare earth permanent magnet materials, in particular to the sintered neodymium-iron-boron magnethigh cost performance and high corrosion resistance, and the preparation method thereof. In the sintered neodymium-iron-boron magnethigh cost performance and the high corrosion resistance, the molecular formula of a neodymium-iron-boron magnet alloy material has the following general formula: (PrNd) aMbBcFe (100-a-b-c). The neodymium-iron-boron magnet is prepared by the steps of grinding, hydrogen blistering processing, grinding, mixing, molding and sintering. Through the preparation method, magnets having high the cost performance and the high corrosion resistance can be prepared; the technical process is easy to control; and the method is suitable for batch production.

Owner:MIANYANG WESTMAG MAGNETISM & ELECTRICITY CO LTD

Method for preparing high-coercivity sintered Nd-Fe-B permanent magnet

ActiveCN103839670AMaximize resource efficiencyResource efficiency is stableElectrolytic coatingsInductances/transformers/magnets manufactureAlloySolid matter

The invention discloses a method for preparing a high-coercivity sintered Nd-Fe-B permanent magnet. The method includes the following steps that firstly, the vacuum rapid hardening technology is used for preparing Nd-Fe-B alloy magnetic material blank; secondly, chamfering, cleaning, washing, surface modifying and washing are sequentially performed on the blank; thirdly, a processed permanent magnet is placed to a nickel / heavy rare earth composite coating for being electroplated; fourthly, a sintered Nd-Fe-B magnetic material is placed into a vacuum heat treatment furnace to receive heat treatment. With the technology of compositing heavy rare earth on a nickel-plate, heavy rare earth solid matter can be effectively utilized, and maximum benefits of rare earth resources are achieved. Meanwhile, it is ensured that the proportion of the content of the heavy rare earth in the nickel-plate is stable, volatile matter which is prone to decomposition does not exist in the nickel-plate in subsequent heat treatment to pollute a vacuum heat treatment system, a production device with infiltration of the heavy rare earth can be stable continuously, the application range of a technology is wider, and the method can be popularized and applied in an enterprise more easily.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

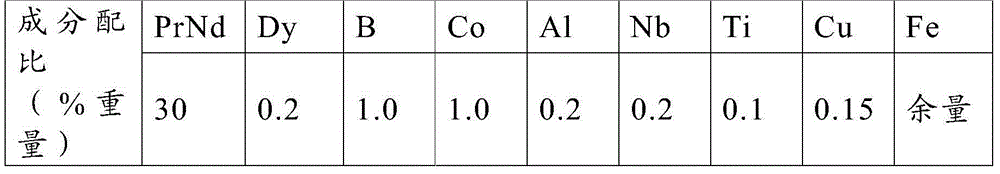

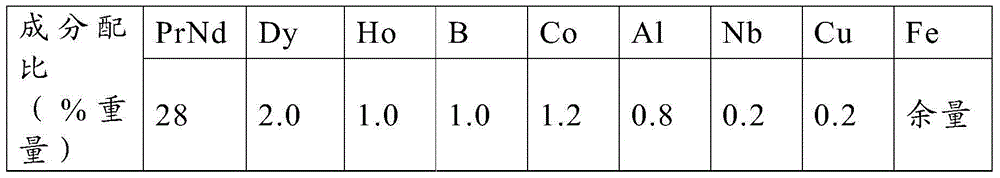

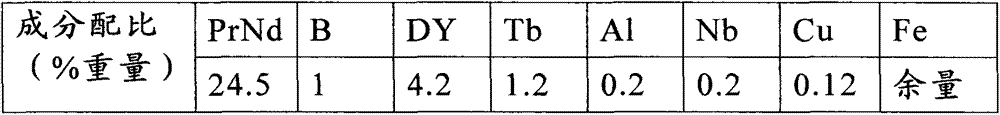

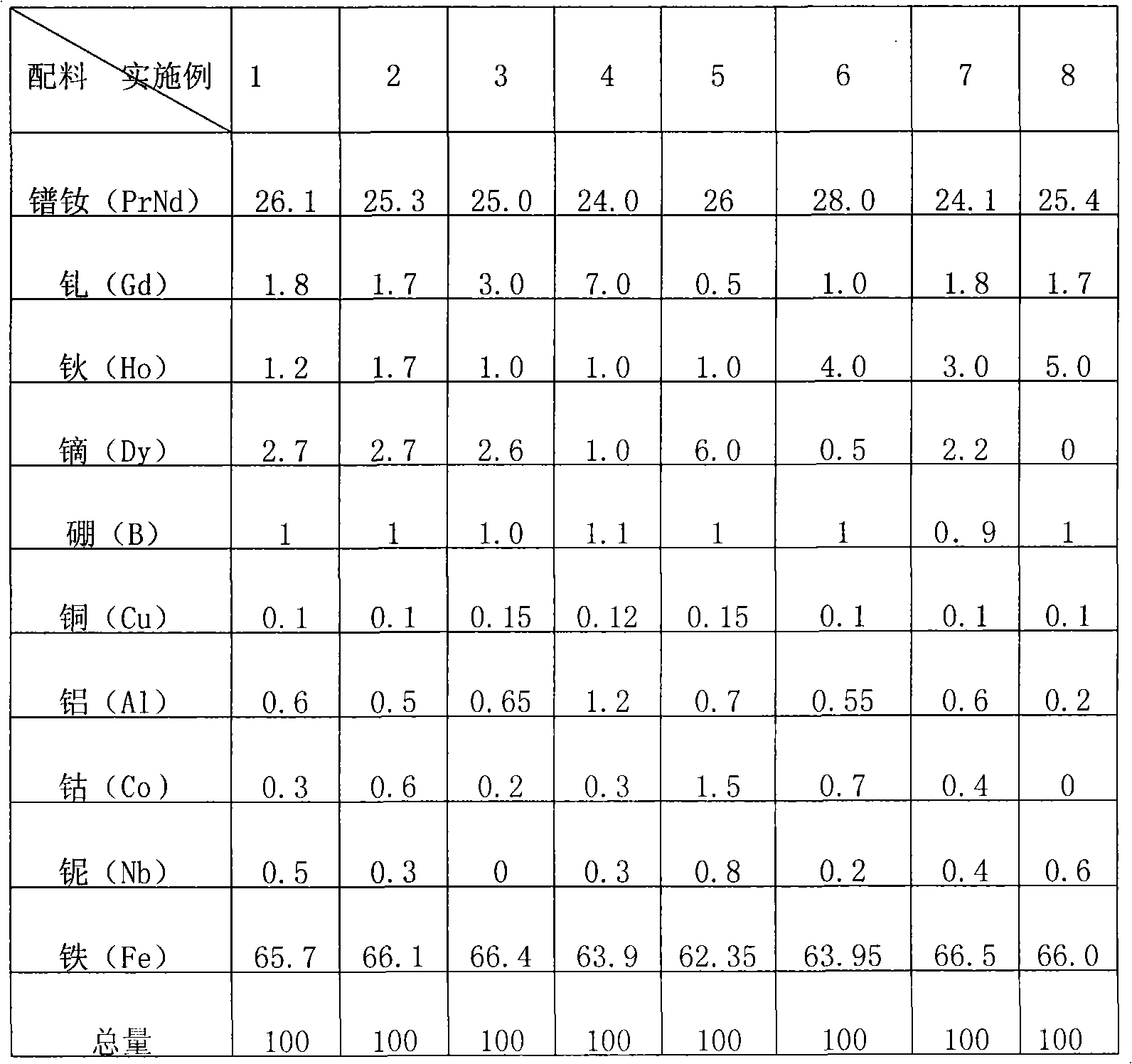

Neodymium iron boron permanent magnet for motor and manufacturing method thereof

ActiveCN101409121AReduce manufacturing costLow costInductances/transformers/magnets manufactureMagnetic materialsNiobiumMaterials science

The invention discloses an NdFeB permanent magnet used for NdFe motors and a manufacture method thereof. The magnet comprises the following components by weight: 24-28 percent of PrNd, 0.5-7 percent of Gd, 1-5 percent of Ho, 0-6 percent of Dy, 0.9-1.1 percent of B, 0.1-0.15 percent of Cu, 0.2-1.2 percent of Al, 62.35-66.5 percent of Fe, 0.2-1.5 percent of Co and 0.2-0.8 percent of Nb. The magnet is manufactured through the procedures of mixing, melting, milling, forming, sintering and grinding processing. Through the use of cheap gadolinium and holmium instead of expensive praseodymium, neodymium, dysprosium and terbium for the production of high-performance NdFeB permanent magnet, the invention can greatly reduce production cost and the product has high magnetic property and strong market competitiveness.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

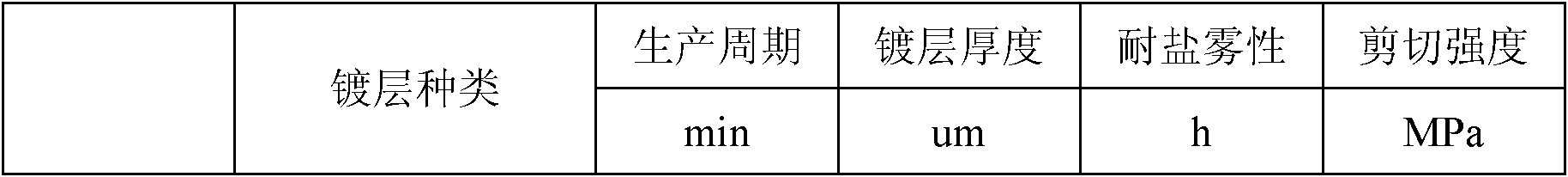

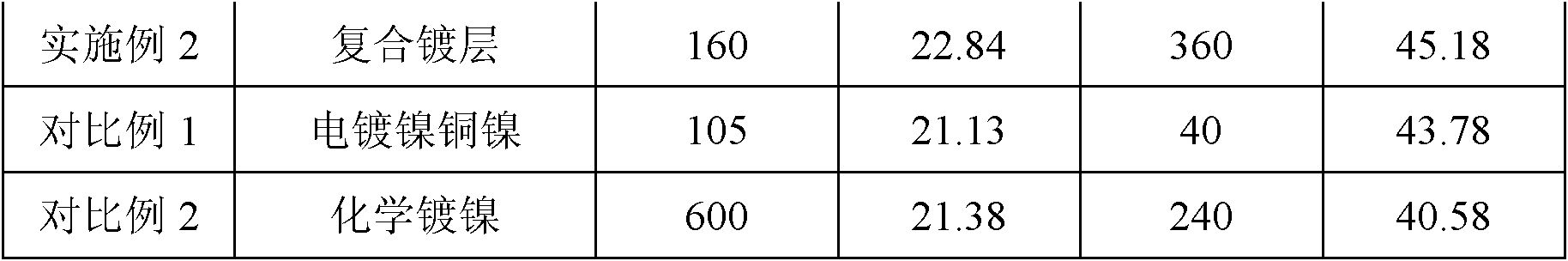

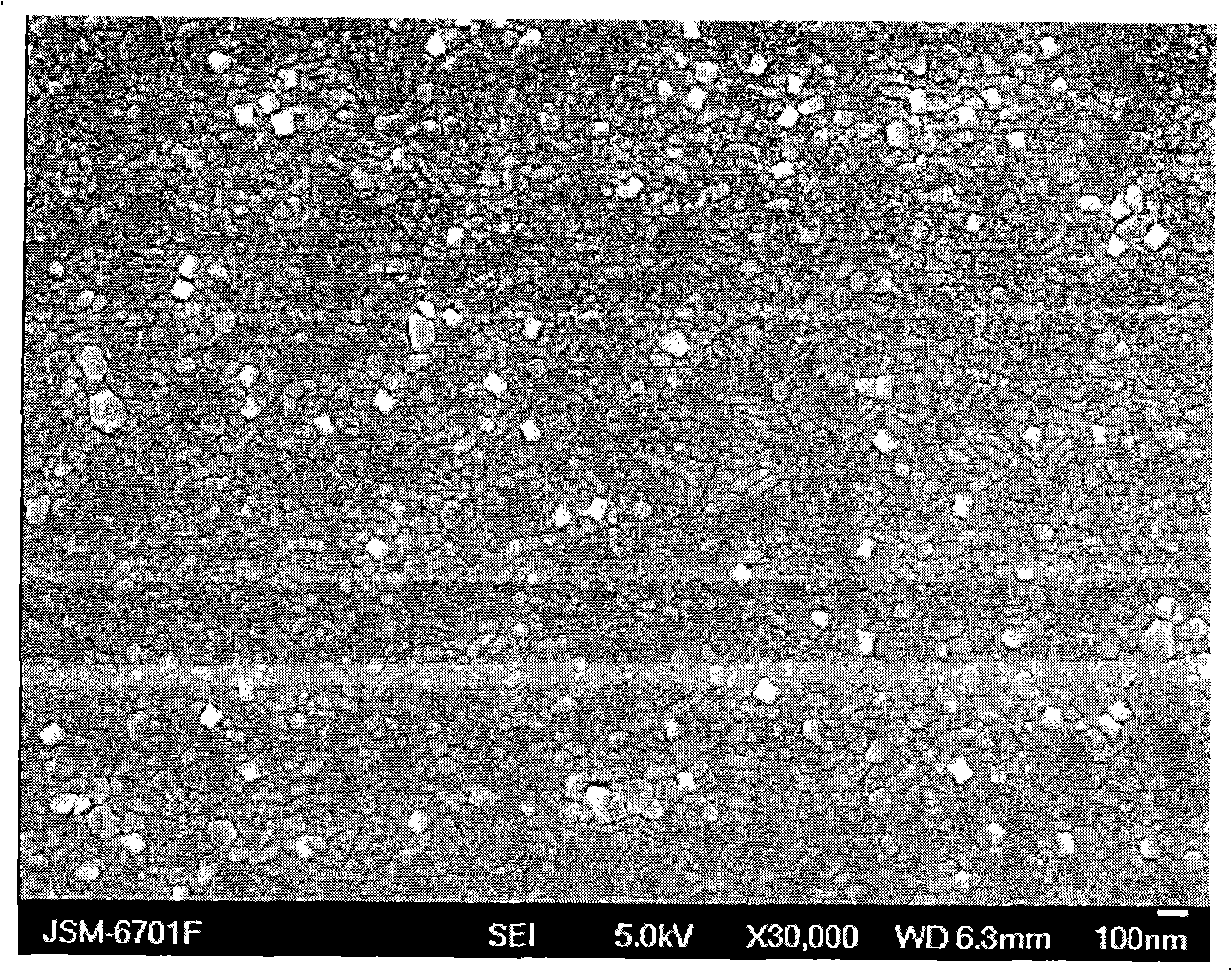

Electroplating and chemical plating composite protecting process for NdFeB permanent magnet and NdFeB permanent magnet with composite protective layer

InactiveCN102108511AImprove corrosion resistanceReduce porosityPermanent magnetsLiquid/solution decomposition chemical coatingChemical platingPre treatment

The invention provides an electroplating and chemical plating composite protecting process for an NdFeB permanent magnet and the NdFeB permanent magnet with a composite protective layer, relating to the surface treatment protecting process for the NdFeB permanent magnet. The invention aims at providing the NdFeB permanent magnet electroplating and chemical plating composite protecting process and the NdFeB permanent magnet with the composite protective layer with high production efficiency and good corrosion resistance. The electroplating and chemical plating composite protecting process for the NdFeB permanent magnet comprises the following steps: (1) pre-treatment: the NdFeB permanent magnet is subjected to oil removal, dust removal and surface activation; (2) electroplating: the surface of the NdFeB permanent magnet is electroplated; (3) transitional treatment: the electroplated NdFeB permanent magnet is subjected to water cleaning and surface activation; (4) chemical plating: nickel is plated chemically outside the electroplating layer of the NdFeB permanent magnet; and (5) post-treatment: the chemically plated NdFeB permanent magnet is subjected to water cleaning, surface adjustment and drying.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

Method of manufacturing vacuum composite film coating on surface of neodymium iron boron magnet

InactiveCN101403093AAvoid the disadvantages of brittlenessImprove anti-corrosion performanceVacuum evaporation coatingSputtering coatingComposite filmChemical plating

The invention relates to the technical filed of vacuum plating, in particular to a preparation method for conducting vacuum compound plating on the surface of a neodymium iron boron magnet, which is characterized in that the preparation method comprises the following steps: A. pre-treatment, the mixed liquor of washing liquid and purified water is used for conducting oil removal and parting medium washing to the magnet surface in an ultrasonic wave cleaner; B. ion cleaning and activation, the pre-treated neodymium iron boron magnet which is dried at 80-100 DEG C for 5-10 minutes undergoes bombardment activation of a glow plasma in vacuum environment, so as to increase surface activation energy; and C. vacuum plating, vacuum plating treatment is conducted to the neodymium iron boron magnet washed by ions in a vacuum chamber, and a metal plating is prepared on the surface. The deposited metal film on the surface of the neodymium iron boron magnet has the advantages of good stability, high bonding force and tightness, stronger anti-corrosion performance in cold and hot alternation environment. Furthermore, in the physical vapor deposition plating process, the plating thickness is affected much less by the magnet workpiece corner than in electroplating and chemical plating, and the pollution problem is avoided in the preparation process.

Owner:兰州大成科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com