High-performance neodymium-iron-boron magnet and preparation method thereof

A neodymium-iron-boron, high-performance technology, applied in the field of rare earth magnetic materials, can solve the problems of poor performance of neodymium-iron-boron magnets, low utilization rate, difficult to meet high-demand applications, etc. The effect of organization and improvement of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Use NdFeB waste to produce 48M products:

[0030] Smelting NdFeB waste: directly mix 600kg NdFeB waste and put it into a vacuum quick-setting furnace. When the air in the furnace is evacuated to a vacuum of 0.4Pa, the heating and smelting is started. When the material in the furnace turns red, fill it with argon gas and heat it to 1450°C for smelting until the NdFeB waste is completely melted. After refining for 10 minutes, it is poured into a spun sheet, and the spun sheet is released when the temperature of the spun sheet is lower than 80°C.

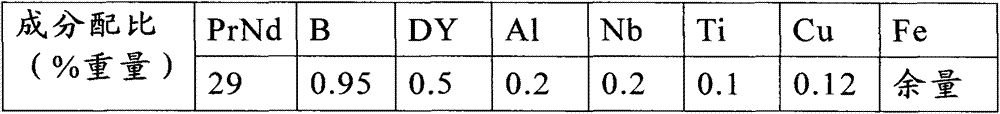

[0031] Preparation of neodymium iron boron waste powder: the prepared spun sheet was subjected to ICP composition test, and the composition test results are shown in Table 1. After determining the composition, place the splinter in a hydrogen crusher, and pass hydrogen into the hydrogen crusher. After the product has completely absorbed hydrogen, the product is heated to 550°C for dehydrogenation for 6 hours. After the dehydrogenati...

Embodiment 2

[0047] Use NdFeB waste to produce 35EH products:

[0048] Smelting NdFeB waste: directly mix 600Kg of NdFeB waste and put it into a vacuum quick-setting furnace. When the air in the furnace is evacuated to a vacuum of 0.4Pa, heating and smelting are started. When the material in the furnace turns red, fill it with argon and heat it to 1480°C for smelting until the NdFeB waste is completely melted. After refining for 10 minutes, it is poured into a spun sheet, and the spun sheet is released when the temperature of the spun sheet is lower than 80℃.

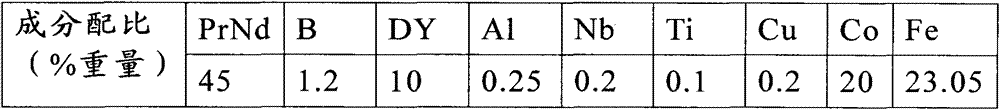

[0049] Preparation of neodymium iron boron waste powder: the prepared spin film was subjected to ICP composition test, and the composition test results are shown in Table 3. After measuring the composition, place the spun sheet in a hydrogen crusher, and pass hydrogen into the hydrogen breaker. After the product completely absorbs hydrogen, it is heated to 580°C for dehydrogenation for 8 hours, and the oxygen content of the spun sheet a...

Embodiment 3

[0065] Use NdFeB waste to produce 42SH products:

[0066] Smelting NdFeB waste: directly mix 600Kg of NdFeB waste and put it into a vacuum quick-setting furnace. When the air in the furnace is evacuated to a vacuum of 0.4Pa, heating and smelting are started. When the material in the furnace turns red, fill it with argon gas and heat it to 1460°C for smelting until the NdFeB waste is completely melted. After refining for 10 minutes, it is poured into a spun sheet, and the spun sheet is released when the temperature is lower than 80°C.

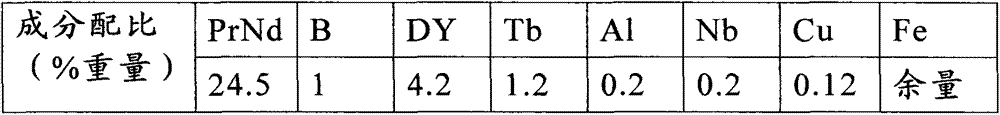

[0067] Preparation of neodymium iron boron waste powder: the prepared spun sheet was subjected to ICP composition test, and the composition test results are shown in Table 5. After determining the composition, place the splinters in a hydrogen crusher, and pass hydrogen into the hydrogen crusher. After the product has completely absorbed hydrogen, it is heated to 600°C for 9 hours to dehydrogenate. After the dehydrogenation is completed, the splinte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Residual magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com